Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10509results about How to "Reduce width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

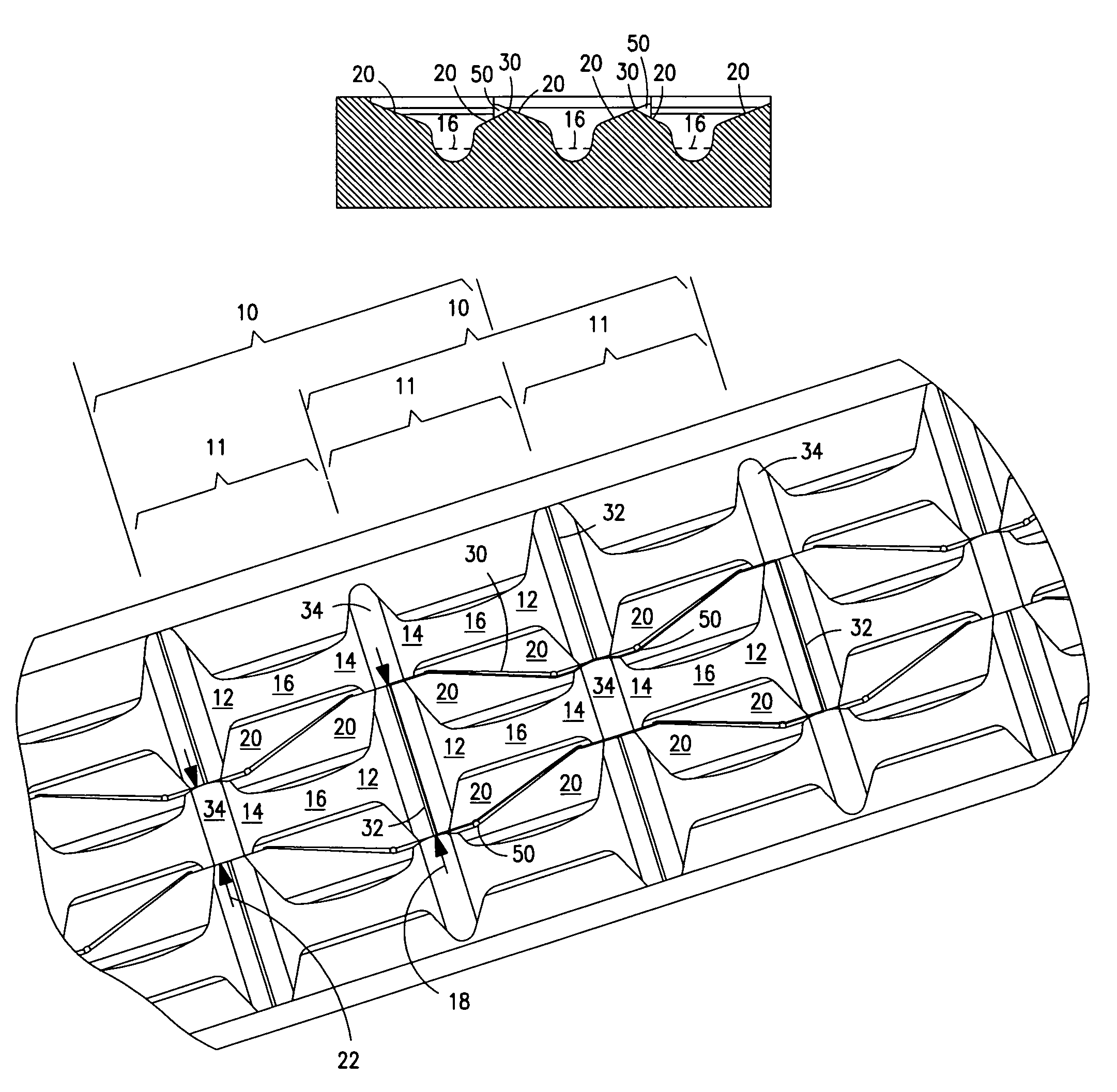

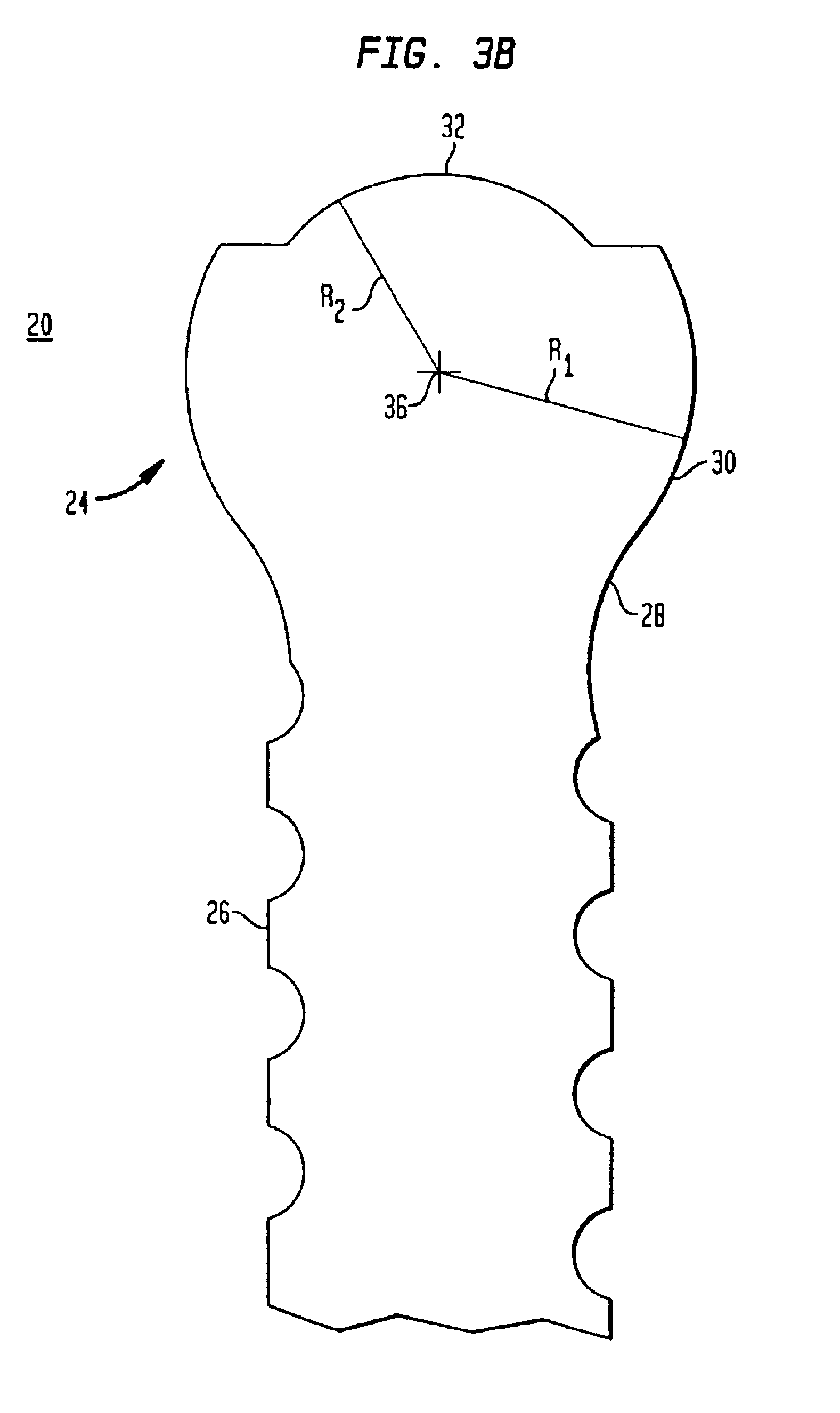

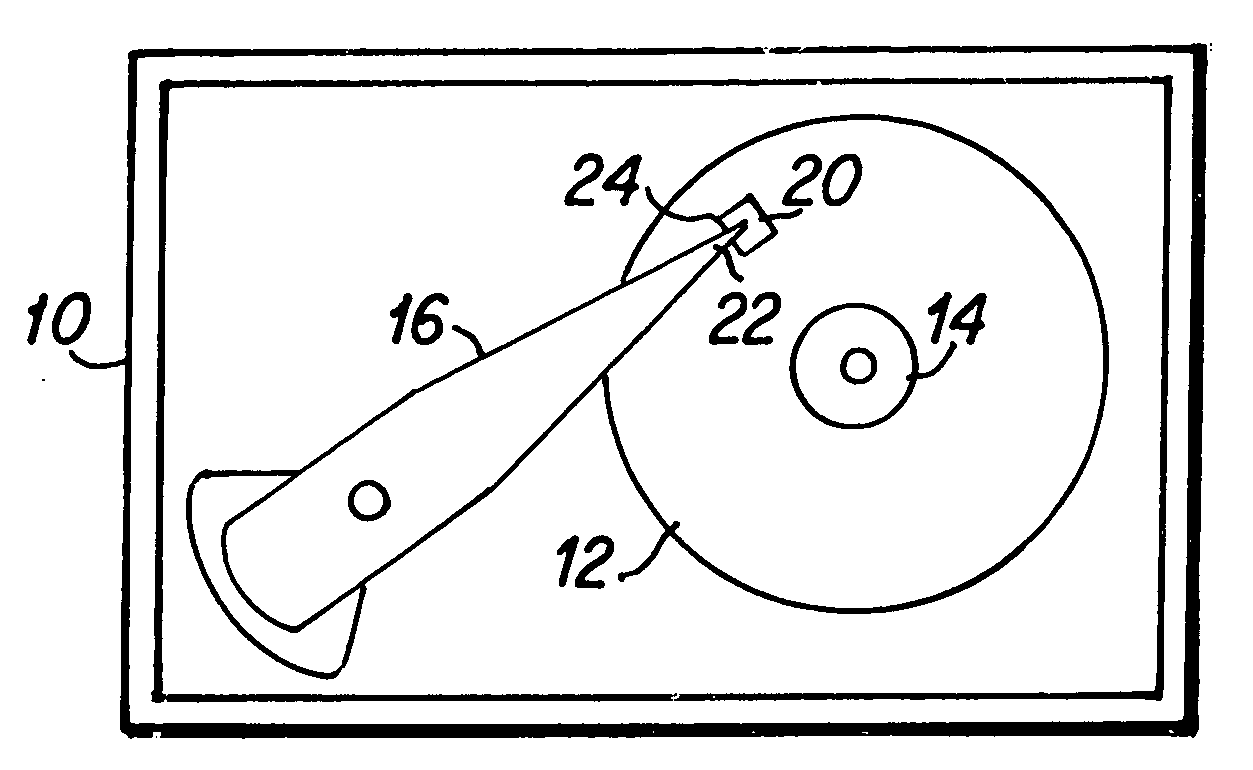

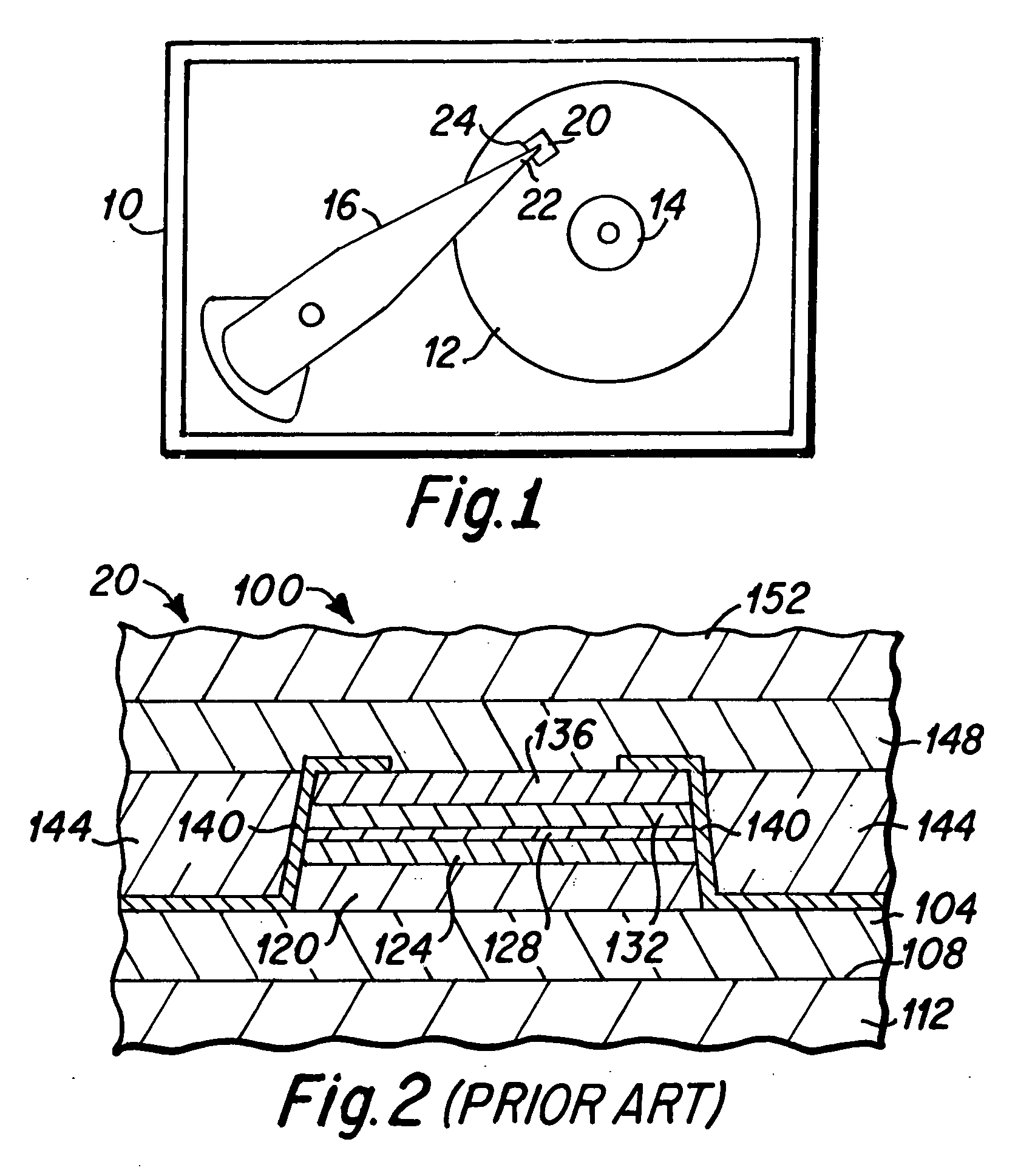

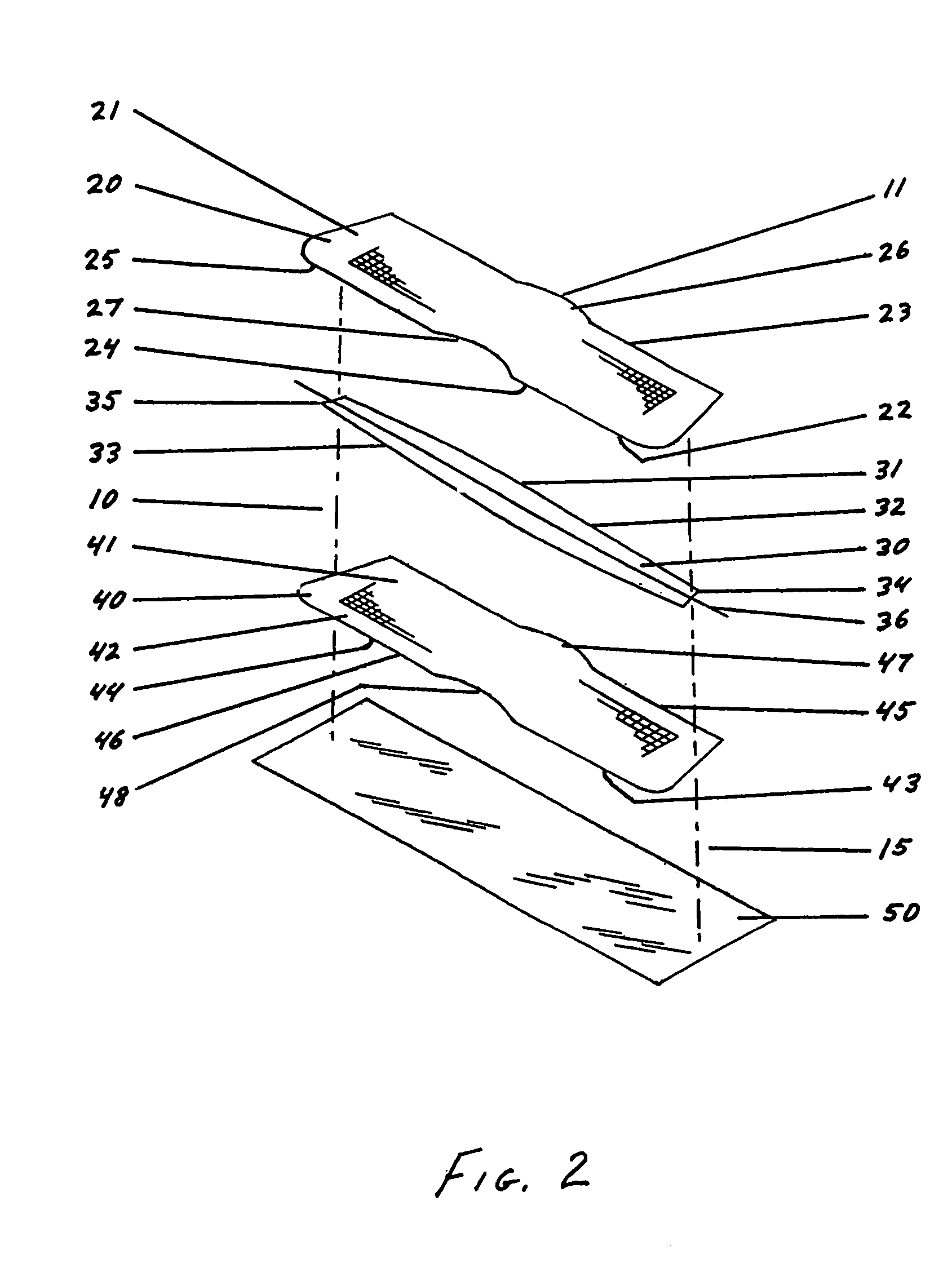

Surgical stapler anvil with nested staple forming pockets

InactiveUS6953138B1Increased lateral widthLittle lateral spaceSuture equipmentsStapling toolsMirror imageBiomedical engineering

A surgical stapler anvil provides an expanded leg-receiving target area for a staple forming pocket in a compact staggered array by narrowing the lateral width of the leg-clinching portion of a laterally adjacent pocket. Advantageously, the lateral spacing between adjacent rows of staple forming pockets can remain small, while the leg-receiving target area for laterally adjacent rows of pockets is significantly expanded. The staple forming pockets include two mirror image leg-forming cups. The cups are longitudinally aligned with their respective ascending leg clinching portions adjoining in the center of the pocket. Laterally spaced guide surfaces extend upwardly and outwardly from the clinching surface at the bottom of the cup to define an expanded leg-receiving target area at the distal ends of the pocket. Substantially planar laterally outward portions of the guide surface intersect with the guide surface of a laterally adjacent pocket to form a non-linear ridge.

Owner:DWORAK FR W

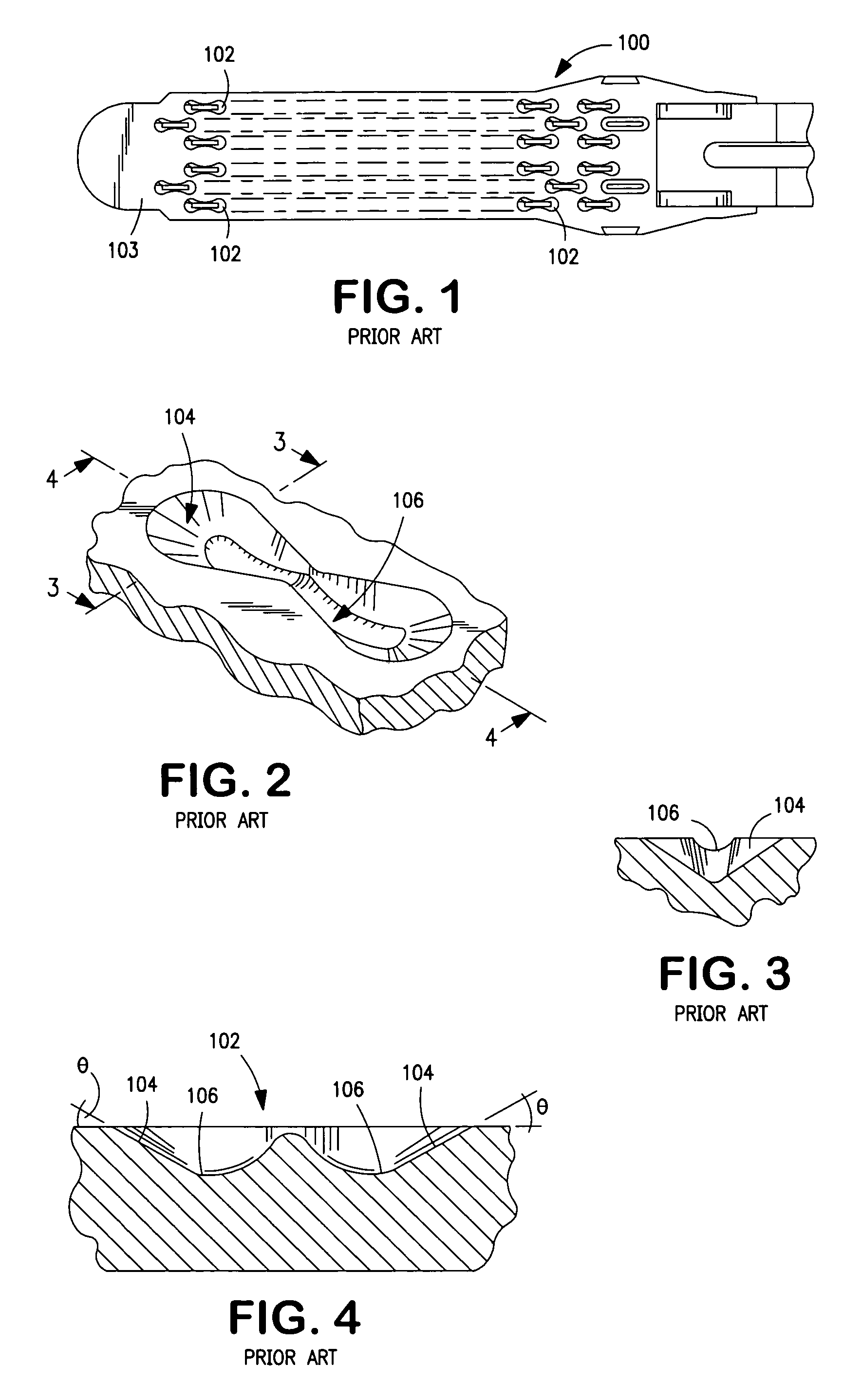

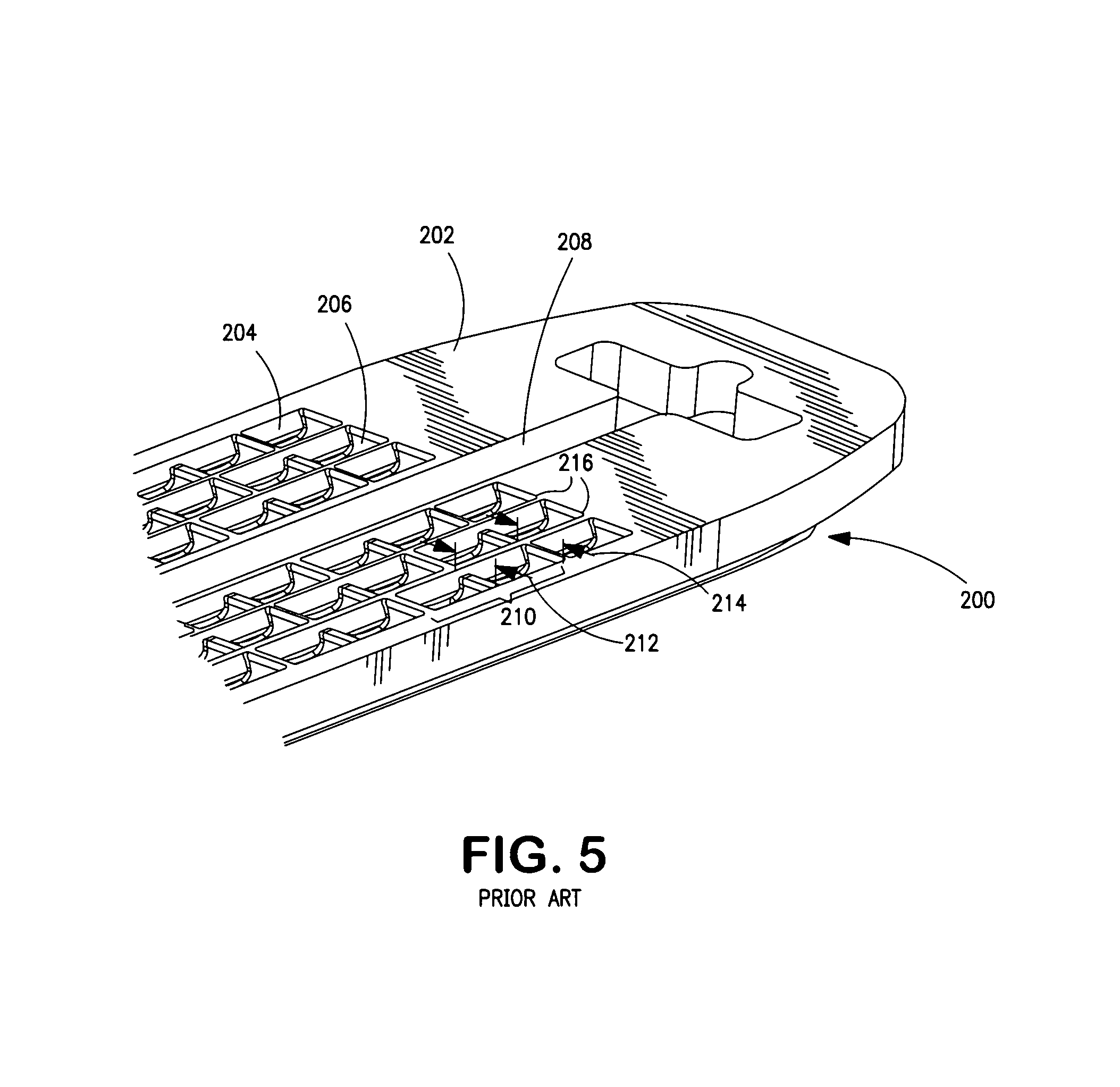

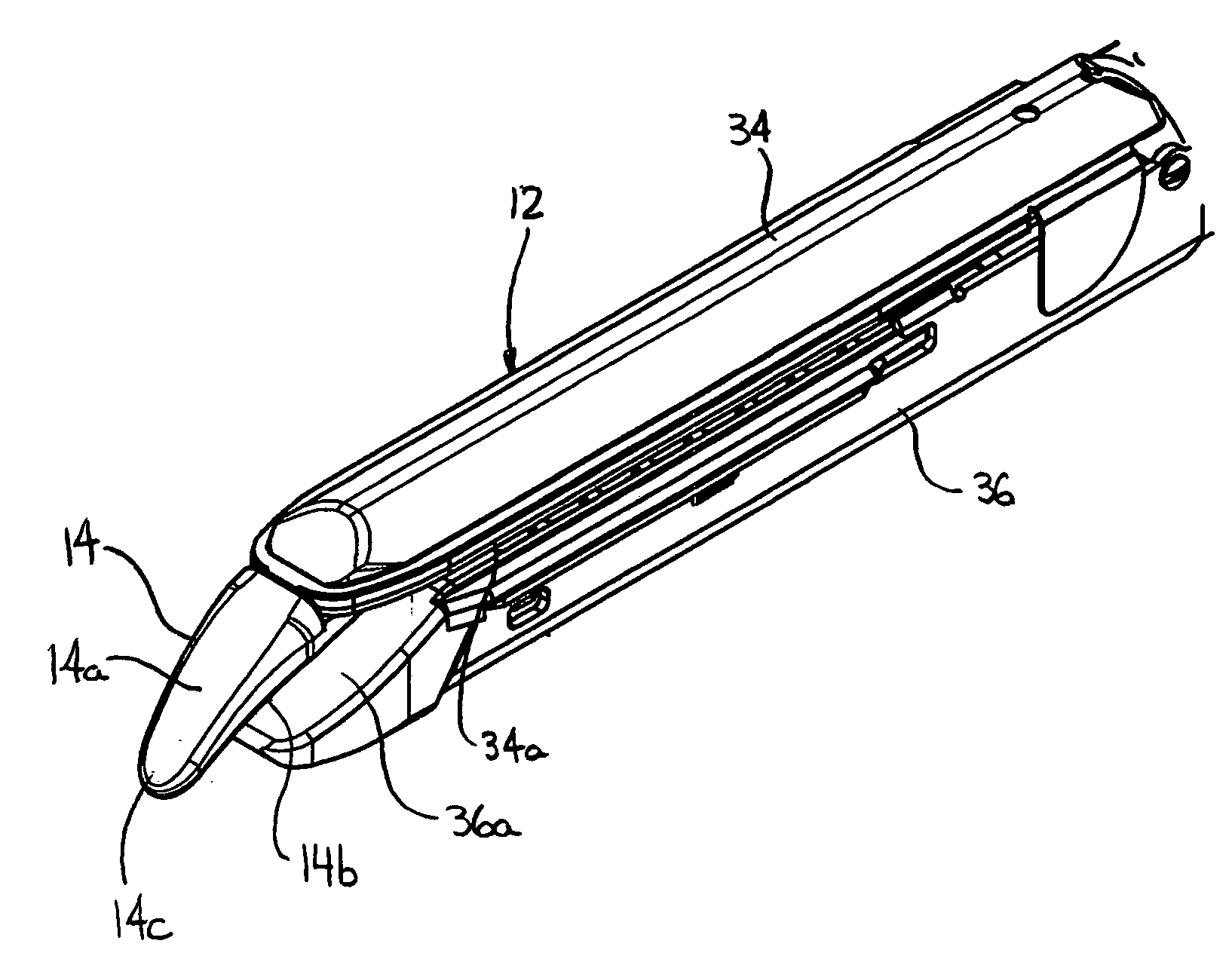

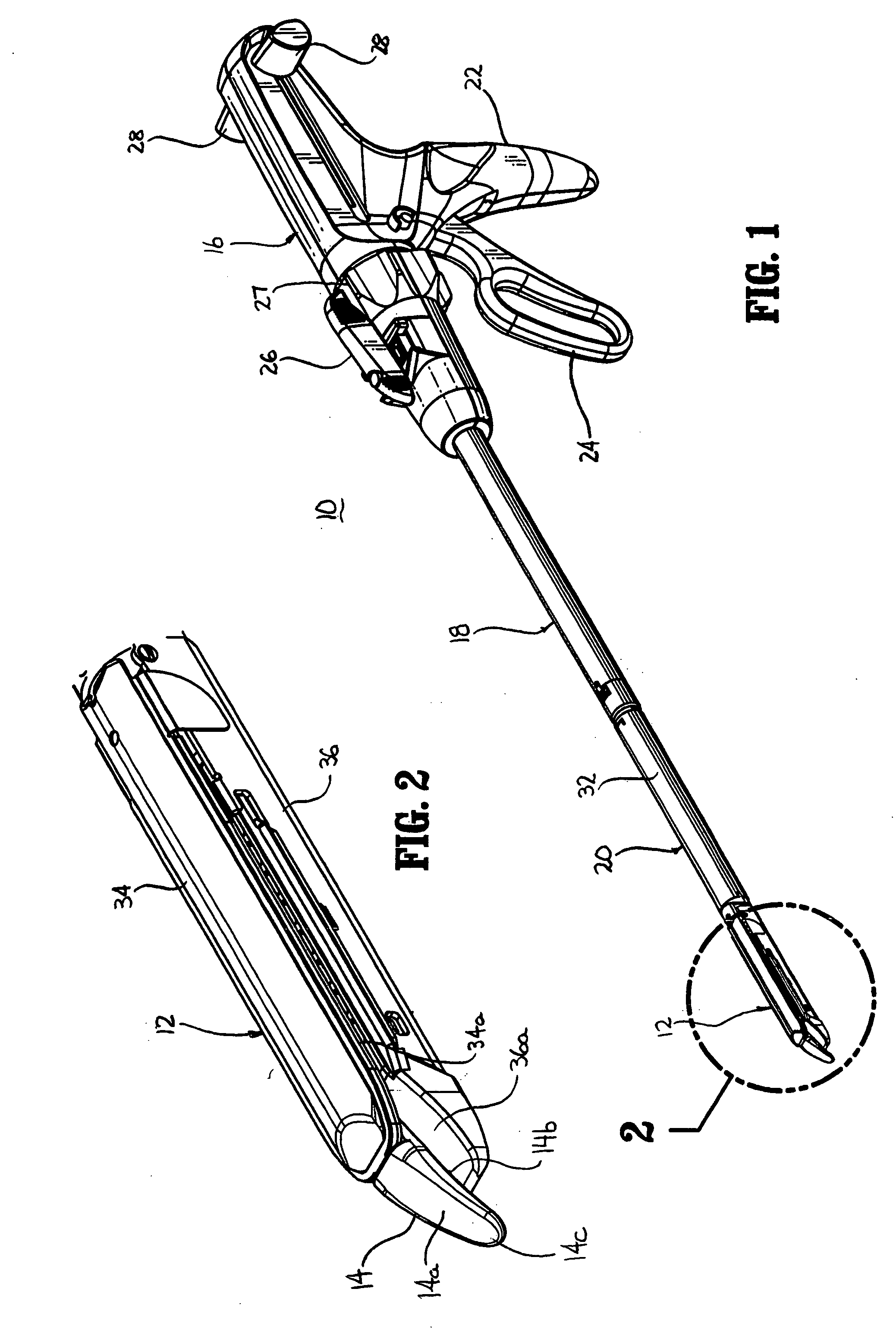

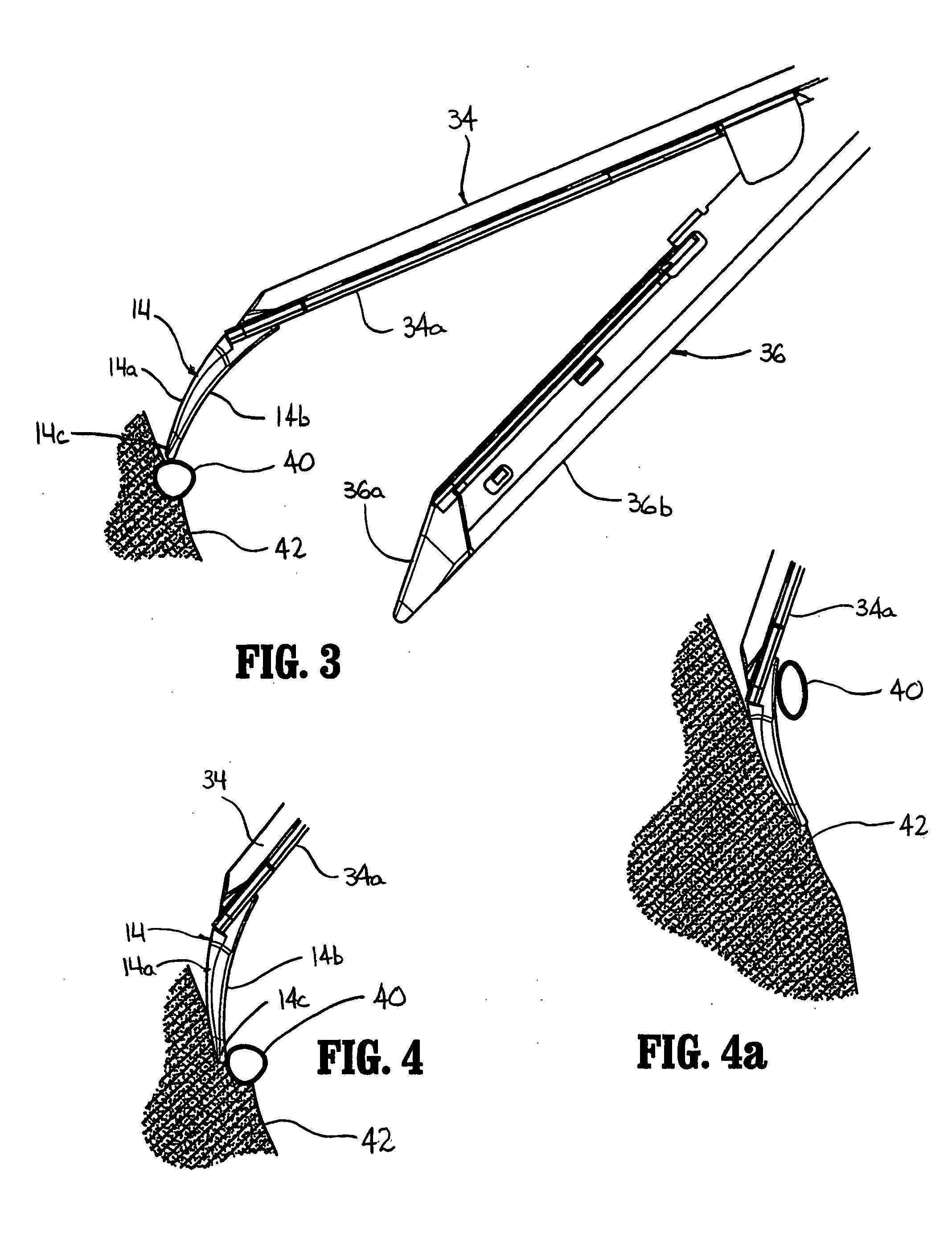

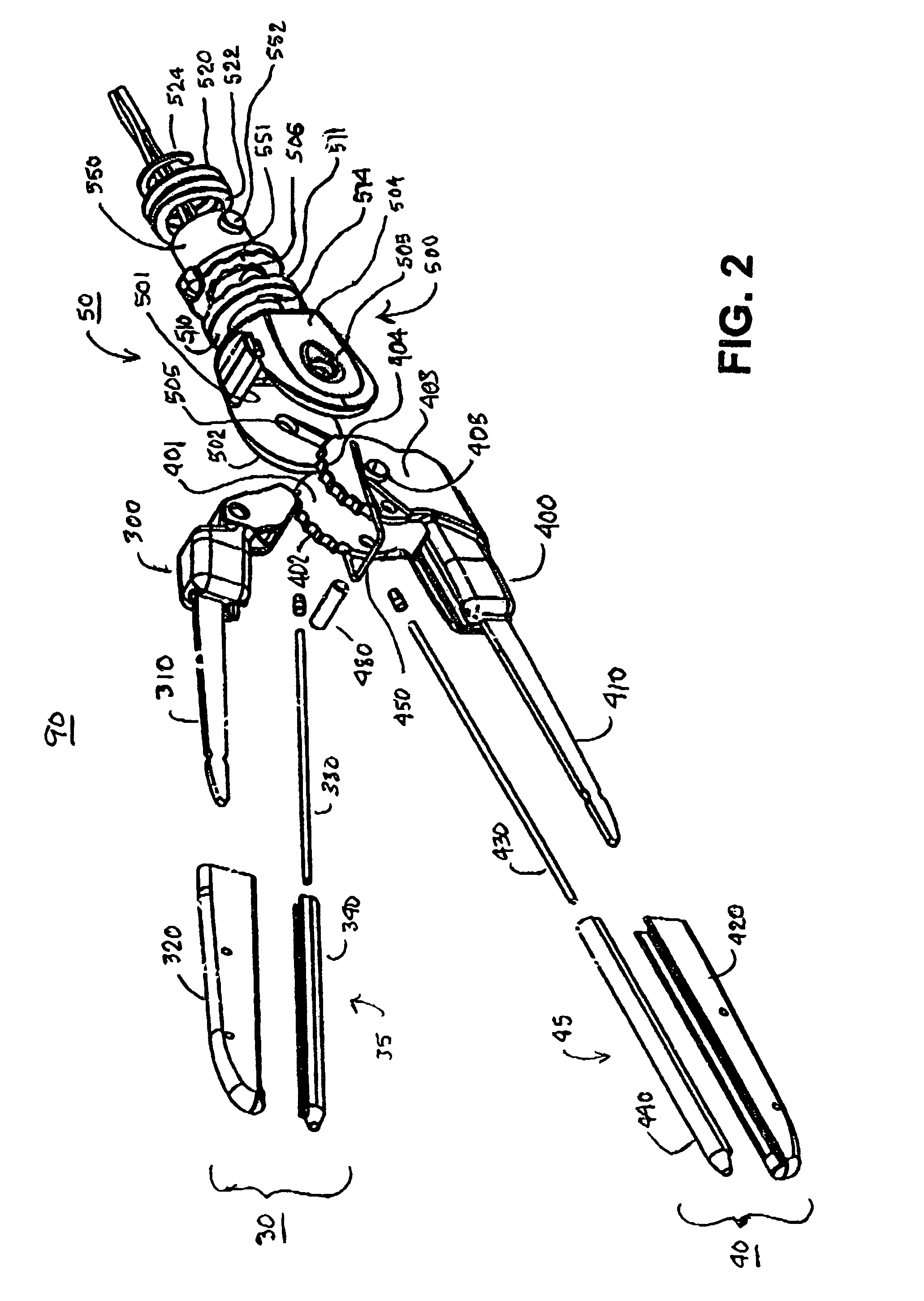

Surgical stapling device with dissecting tip

InactiveUS20050216055A1Prevent snaggingAvoid pullingSuture equipmentsStapling toolsActuatorSurgical department

A dissecting tip is provided for use with a surgical stapler or instrument. In one embodiment, the dissecting tip is secured to the end effector of the surgical instrument, e.g., to the cartridge assembly. The dissecting tip extends distally from the end effector and is configured to dissect or separate target tissue from certain tissue, e.g., adherent, connective, joined or other tissue.

Owner:TYCO HEALTHCARE GRP LP

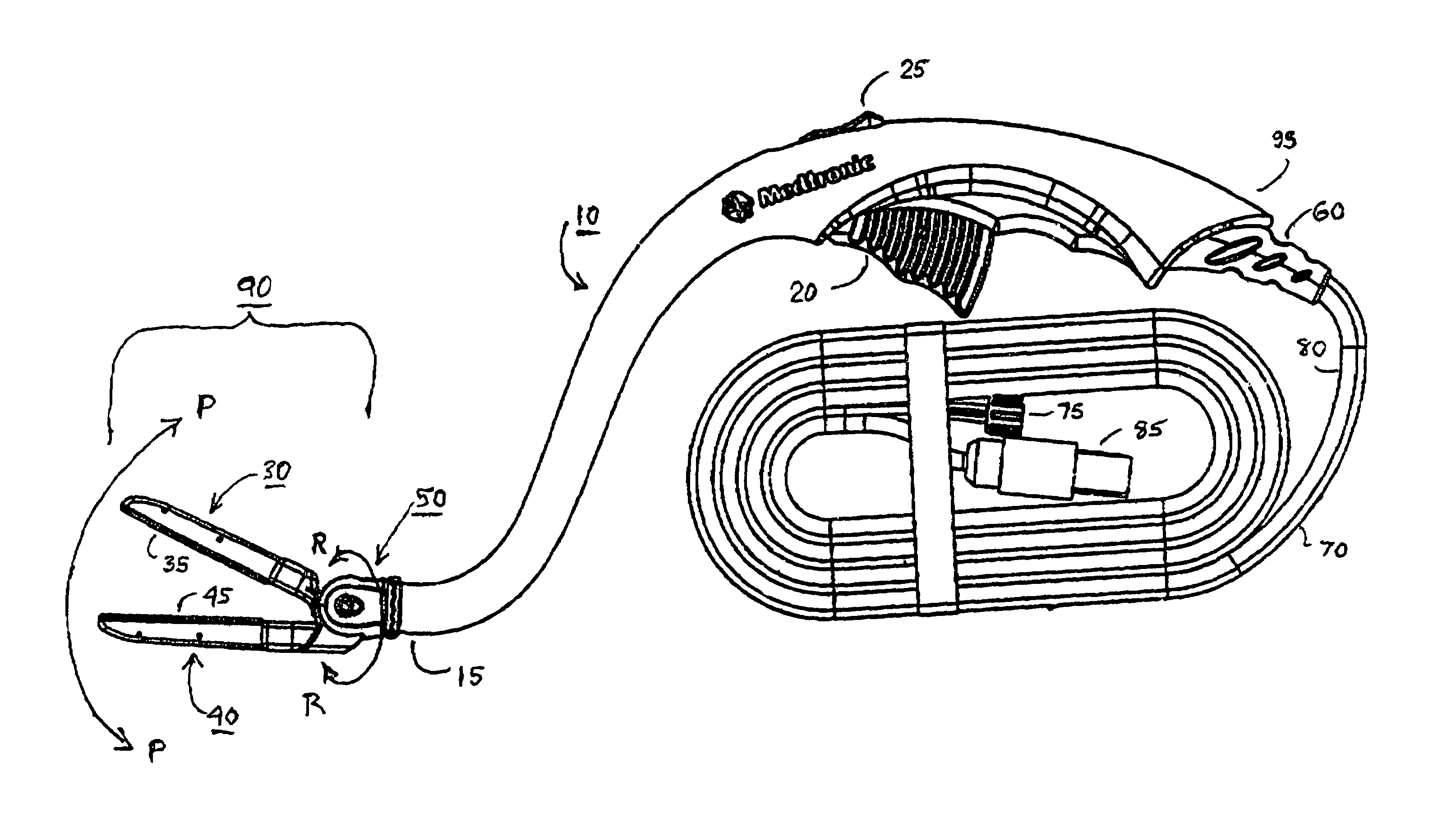

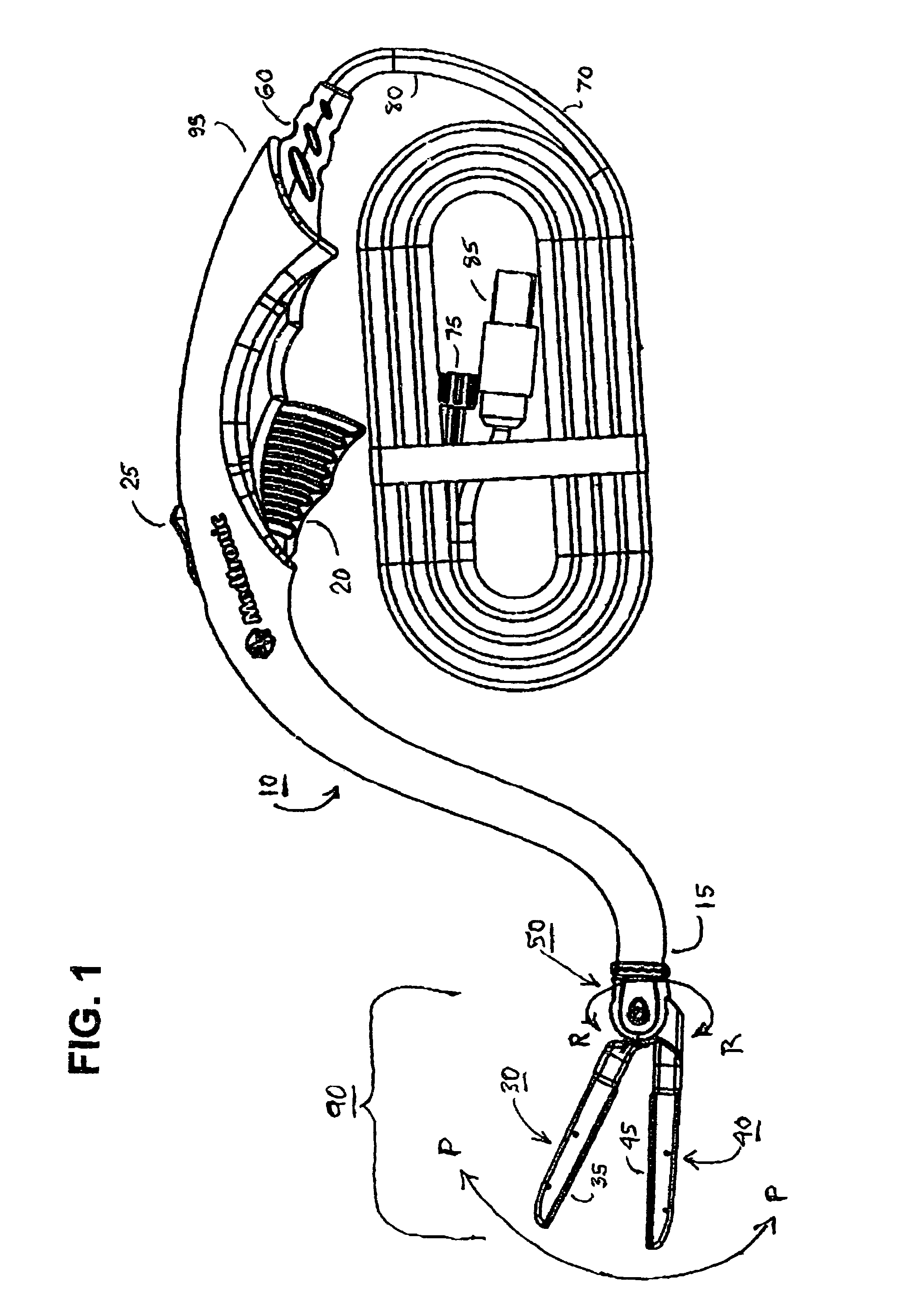

Electrosurgical hemostat

InactiveUS7083620B2Reduce usageImprove performanceCatheterSurgical instruments for heatingDetentEffective treatment

A hemostat-type device for ablative treatment of tissue, particularly for treatment of atrial fibrillation, is constructed with features that provide easy and effective treatment. A swiveling head assembly can allow the jaws to be adjusted in pitch and roll. Malleable jaws can permit curved lesion shapes. A locking detent can secure the jaws in a closed position during the procedure. An illuminated indicator provides confirmation that the device is operating. A fluid delivery system simplifies irrigated ablation procedures.

Owner:MEDTRONIC INC

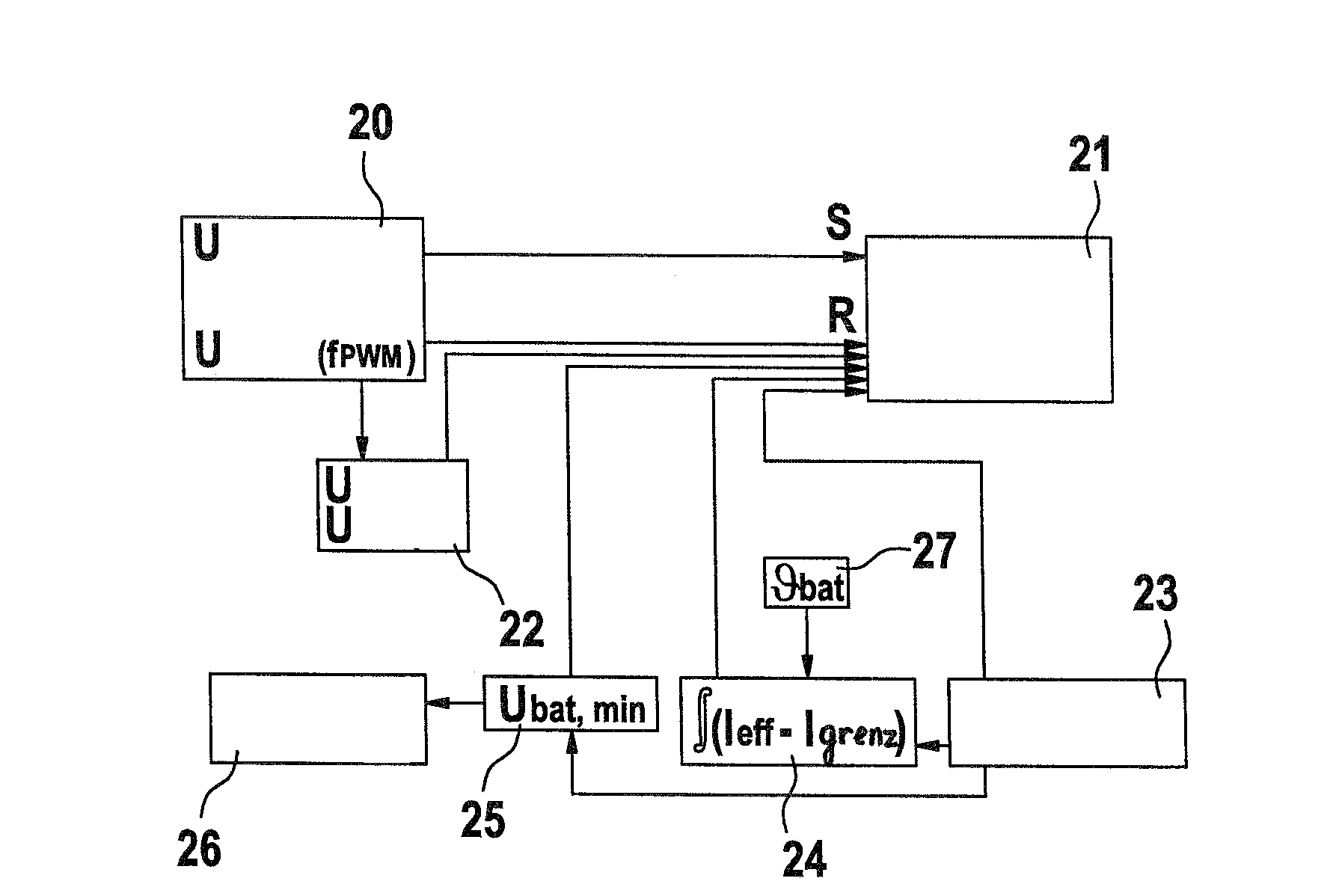

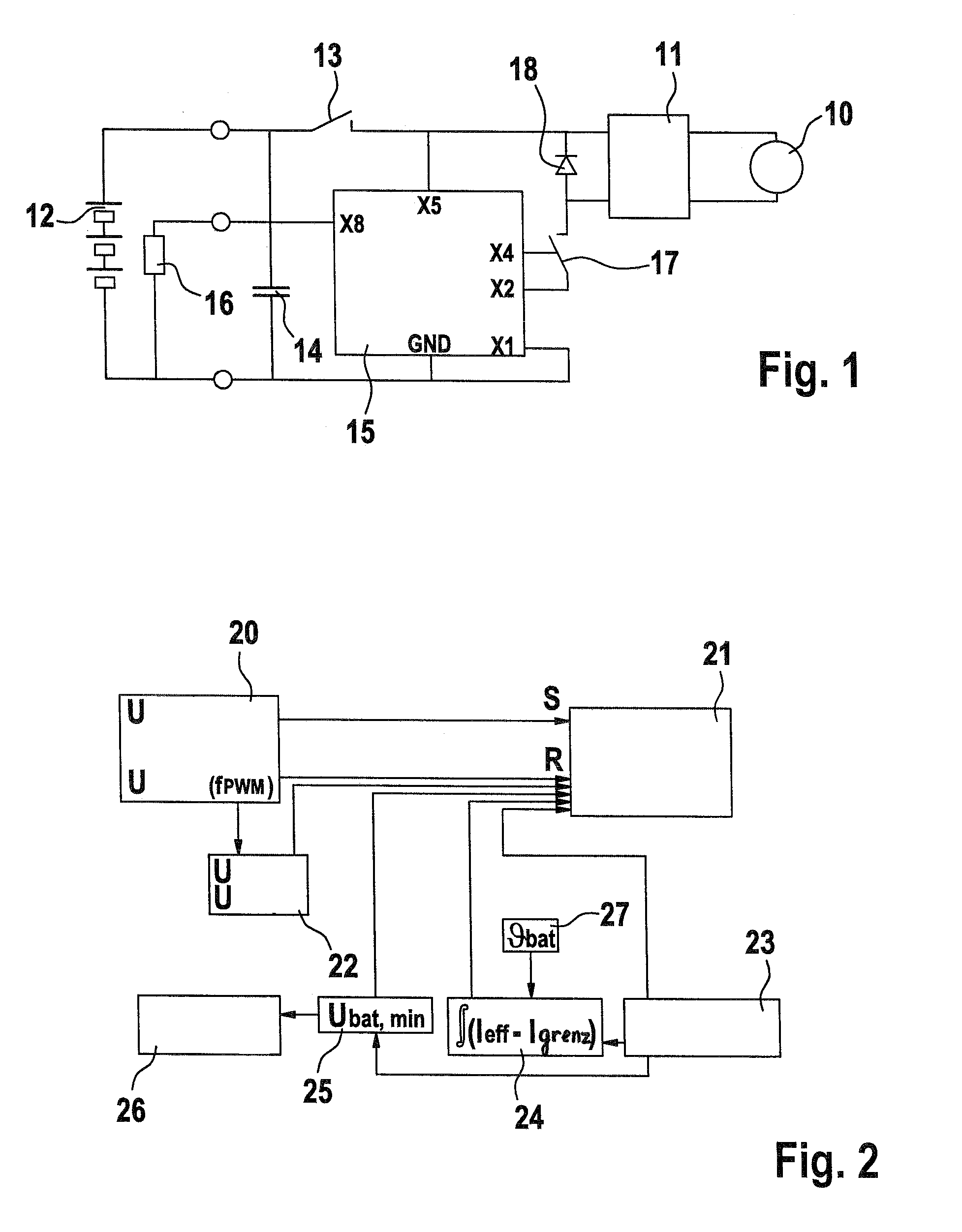

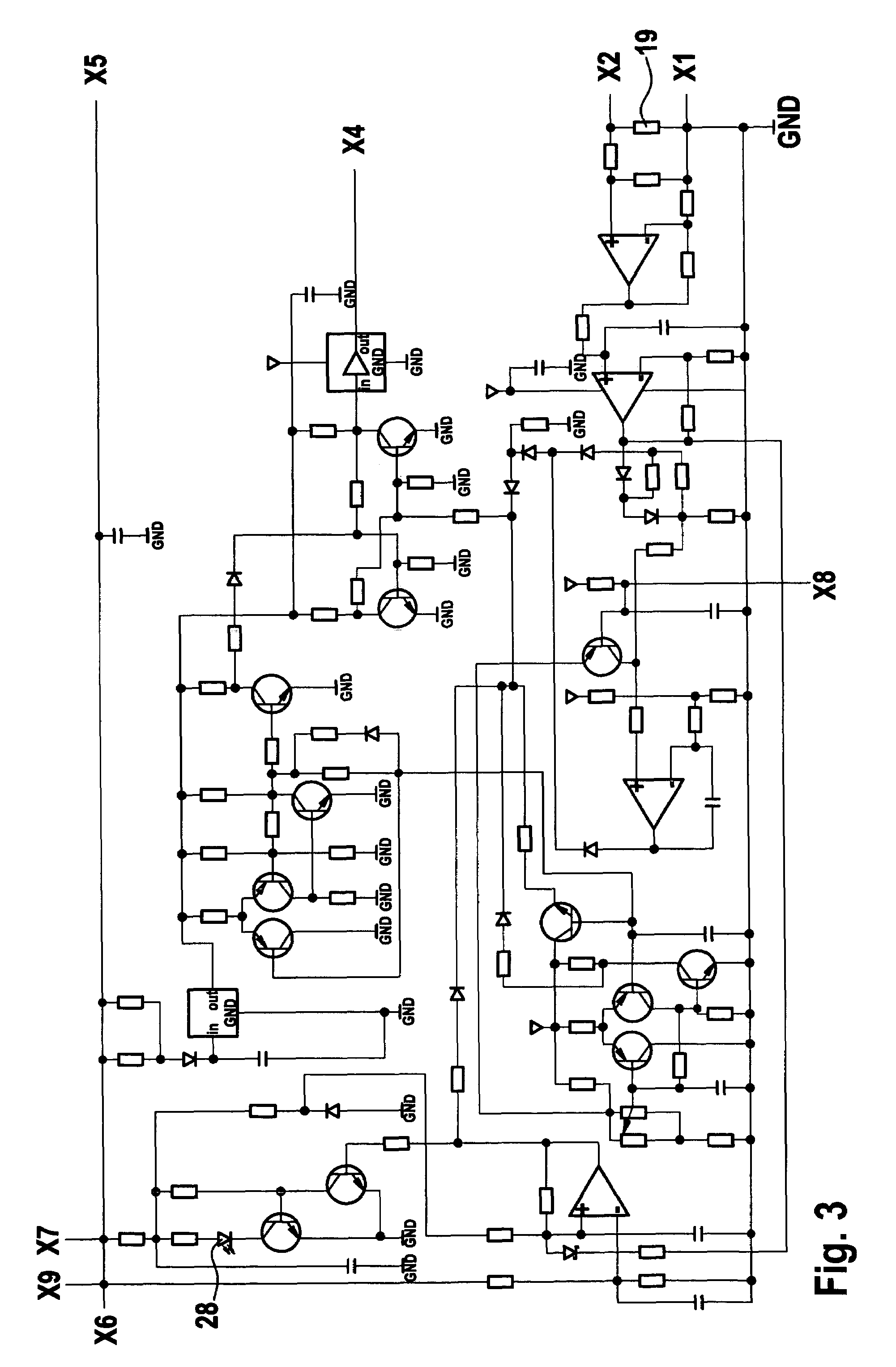

Method for operating a power tool

ActiveUS7336048B2Maintain good propertiesReduce widthTemperatue controlEmergency protective arrangements for automatic disconnectionMOSFETElectricity

In a method for operating a power tool with an energy accumulator, in particular a rechargeable energy accumulator, which supplies power to an electric drive motor, a clock frequency is generated by an electronic unit, with which a gate of a MOSFET—which supplies operating voltage to the drive motor—is switched on with each cycle, and a switching-off of the MOSFET is carried out within one cycle using different signals, as a function of operating parameters.

Owner:ROBERT BOSCH GMBH

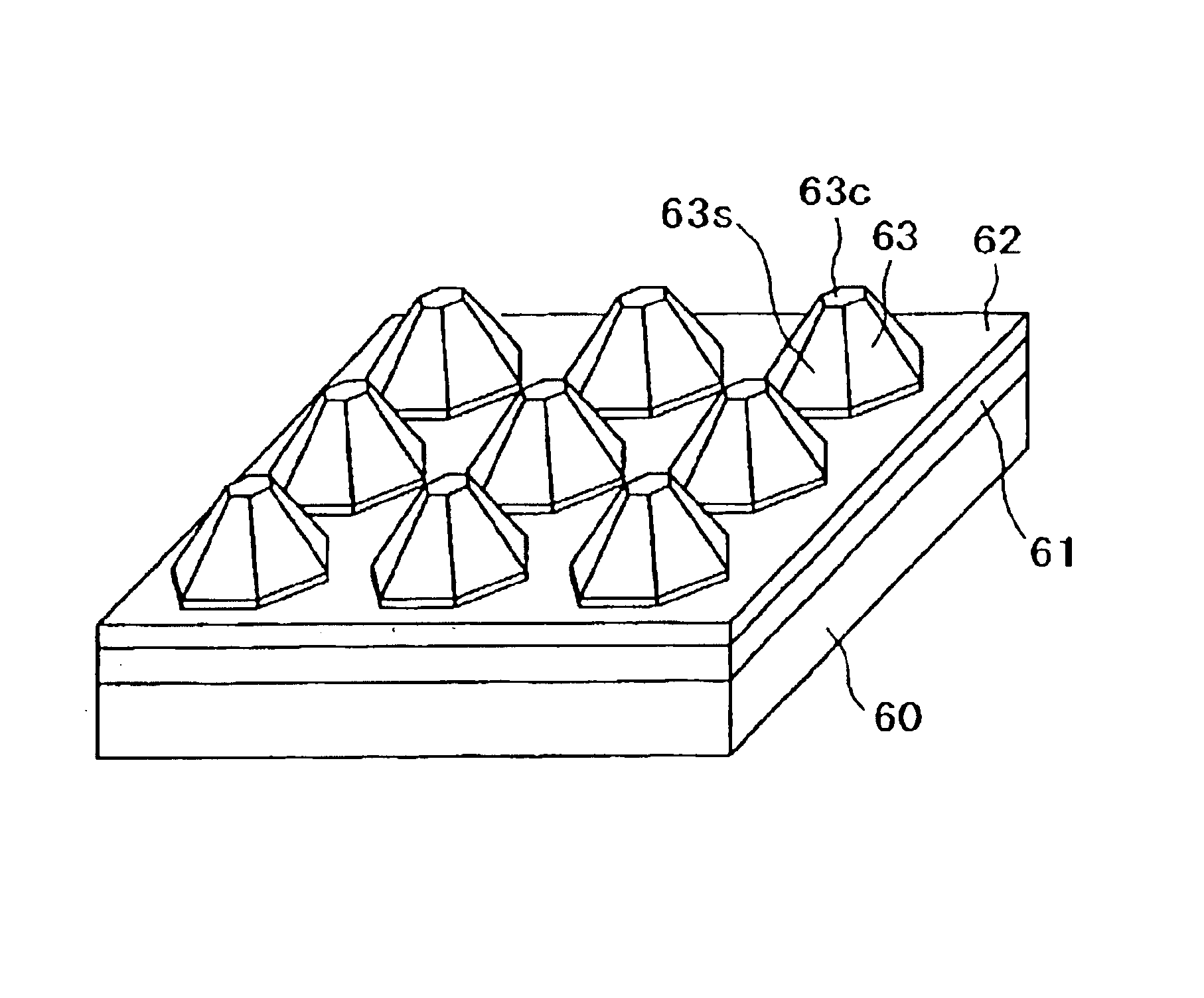

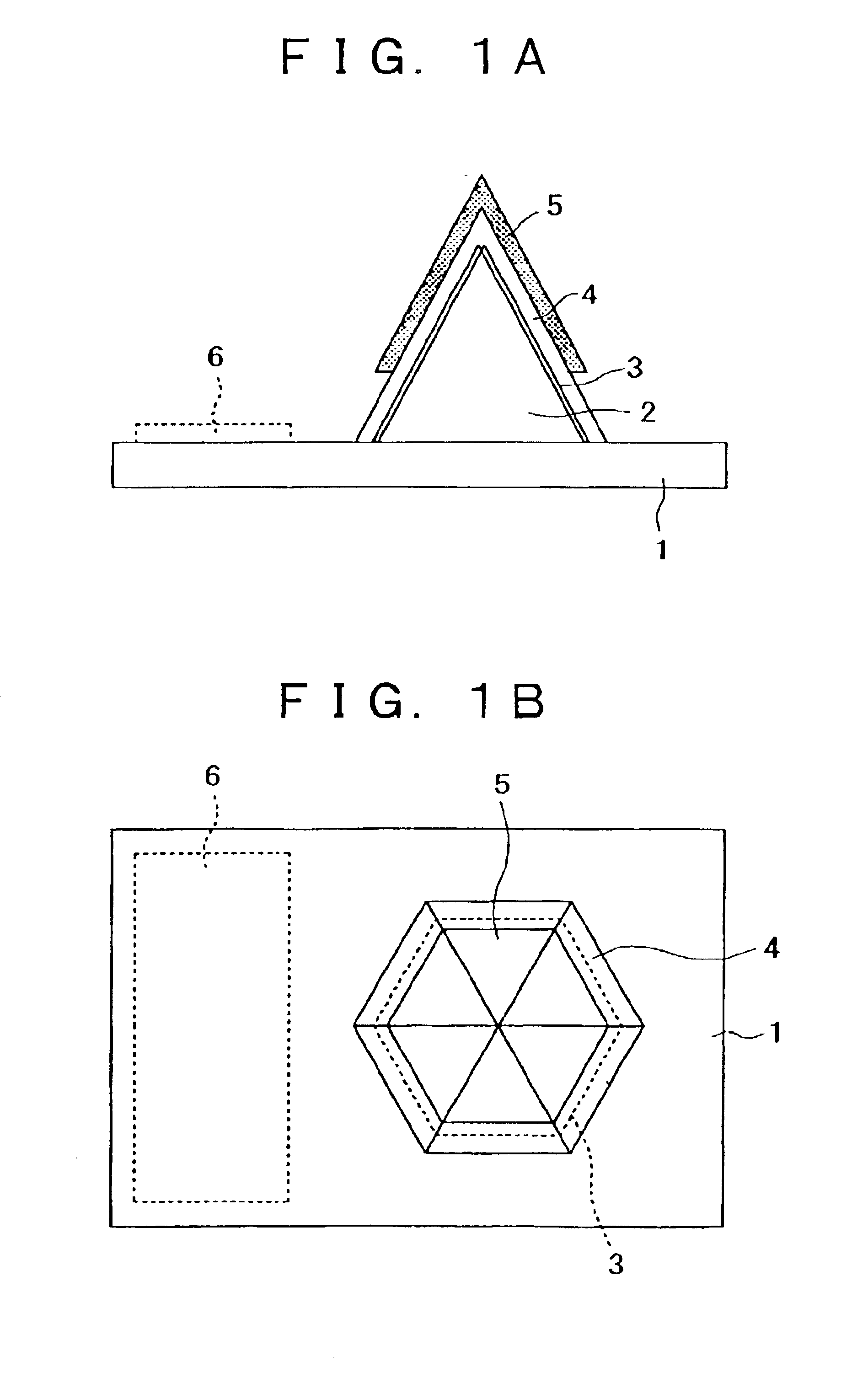

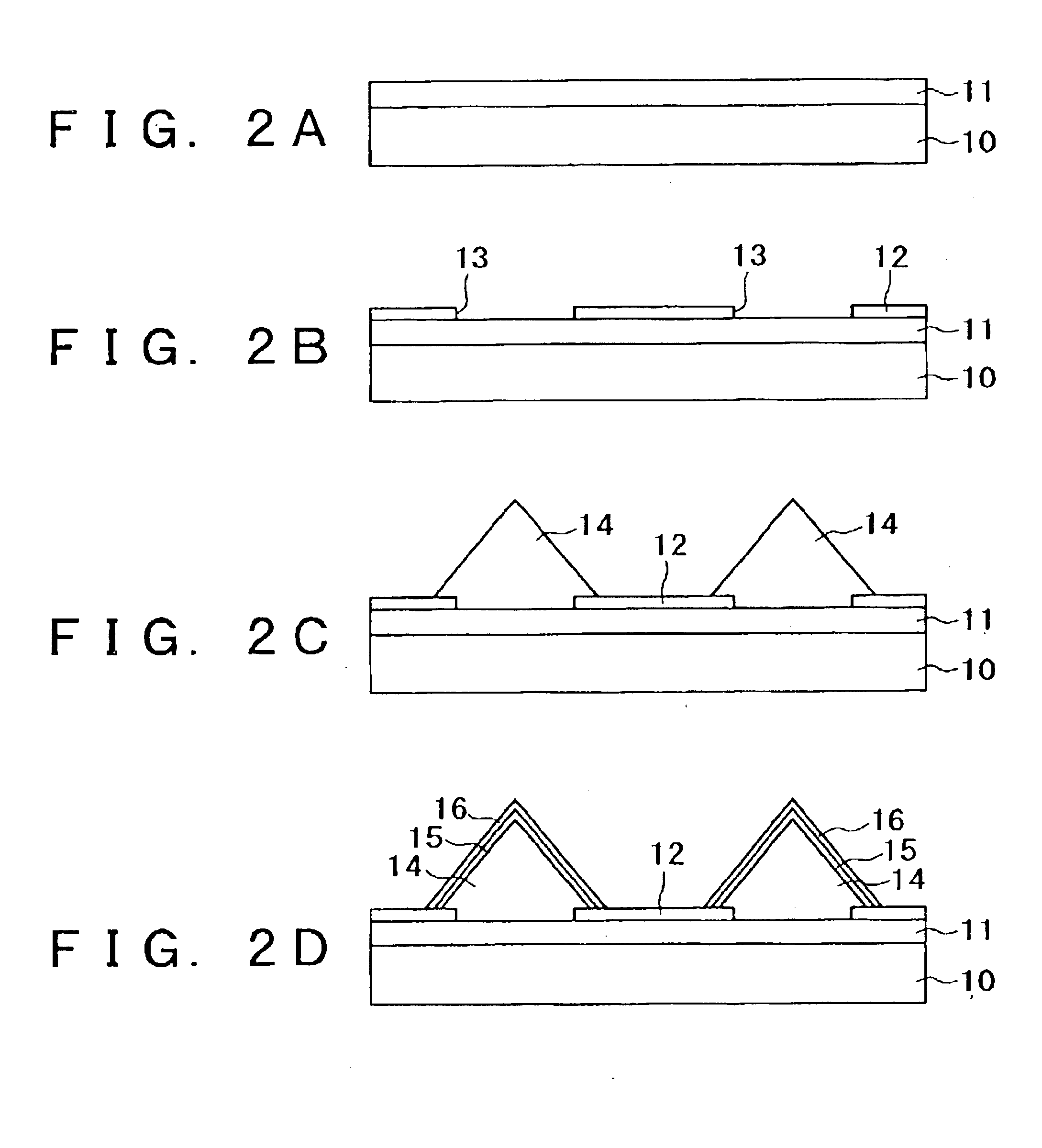

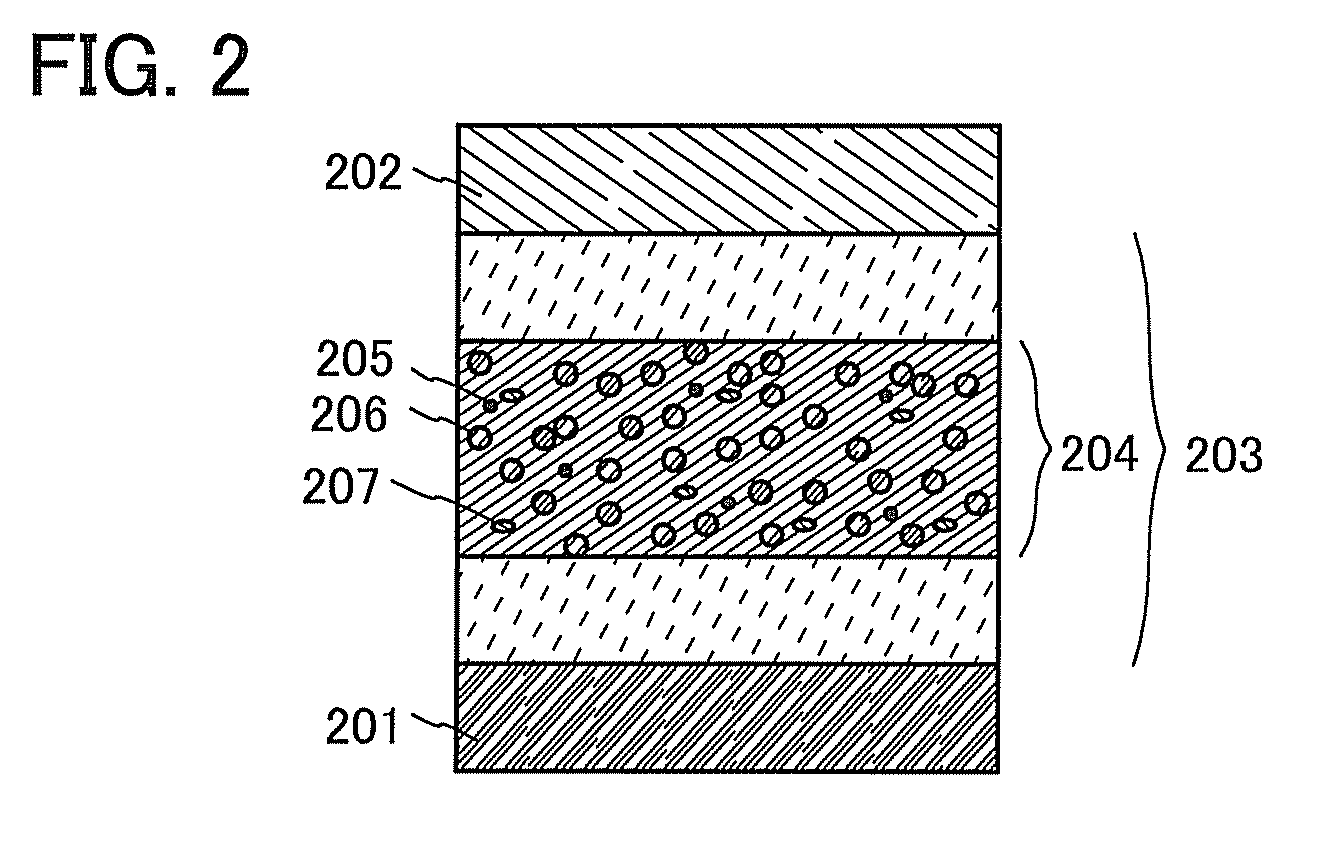

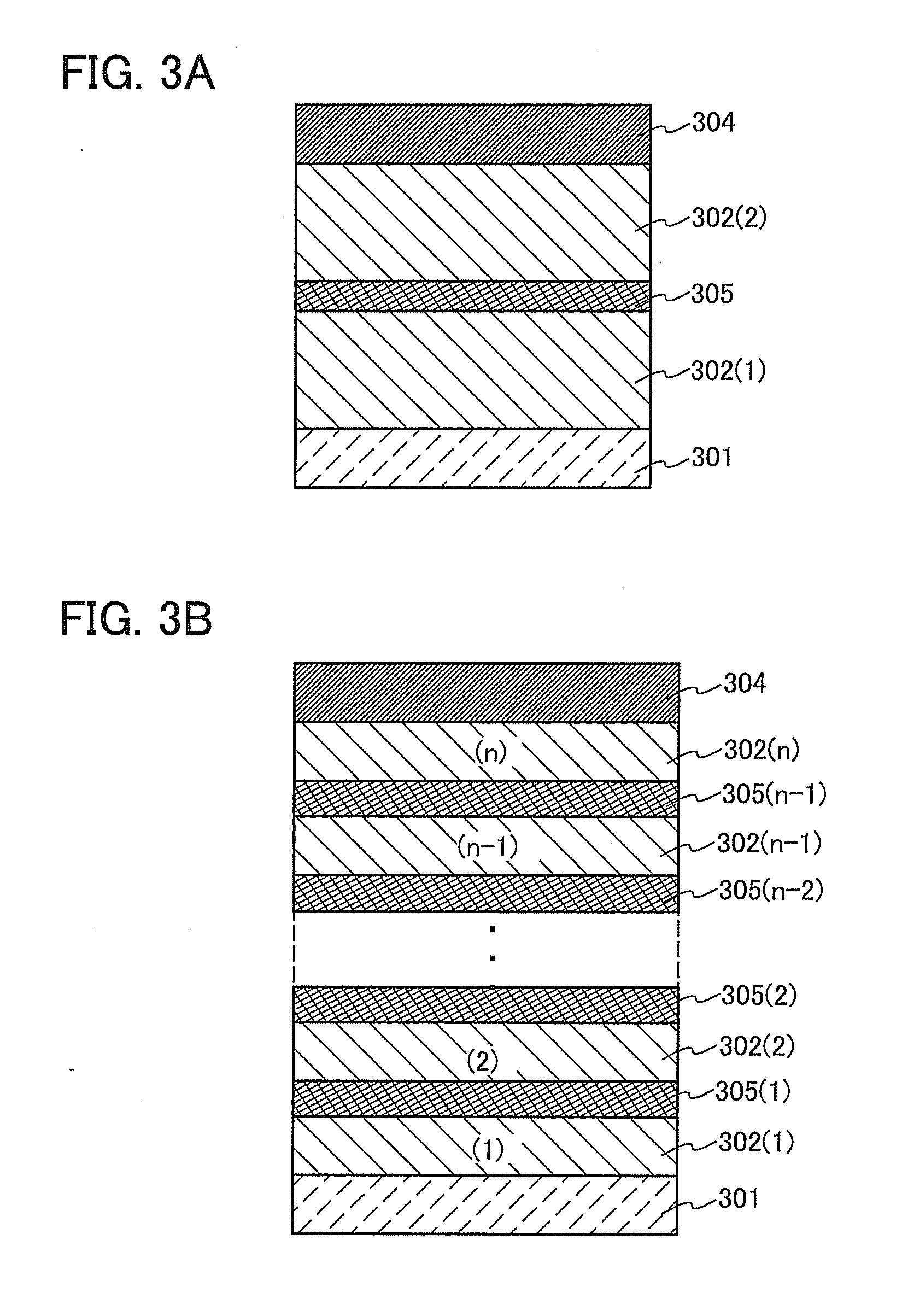

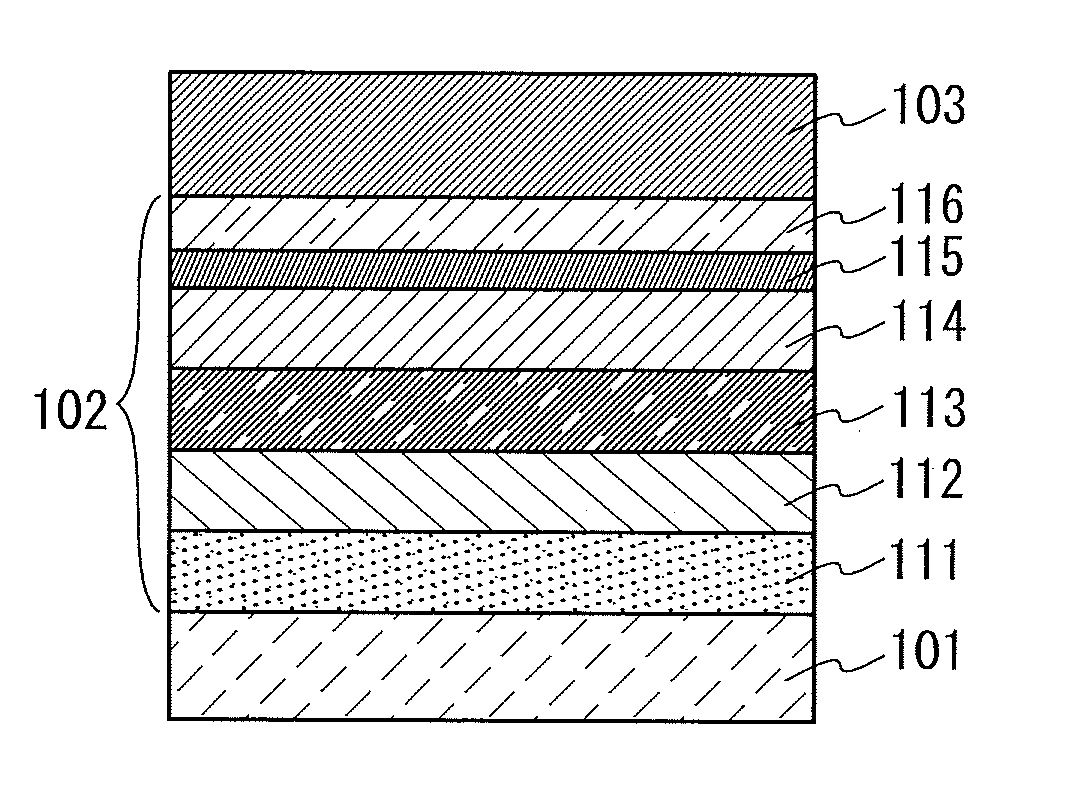

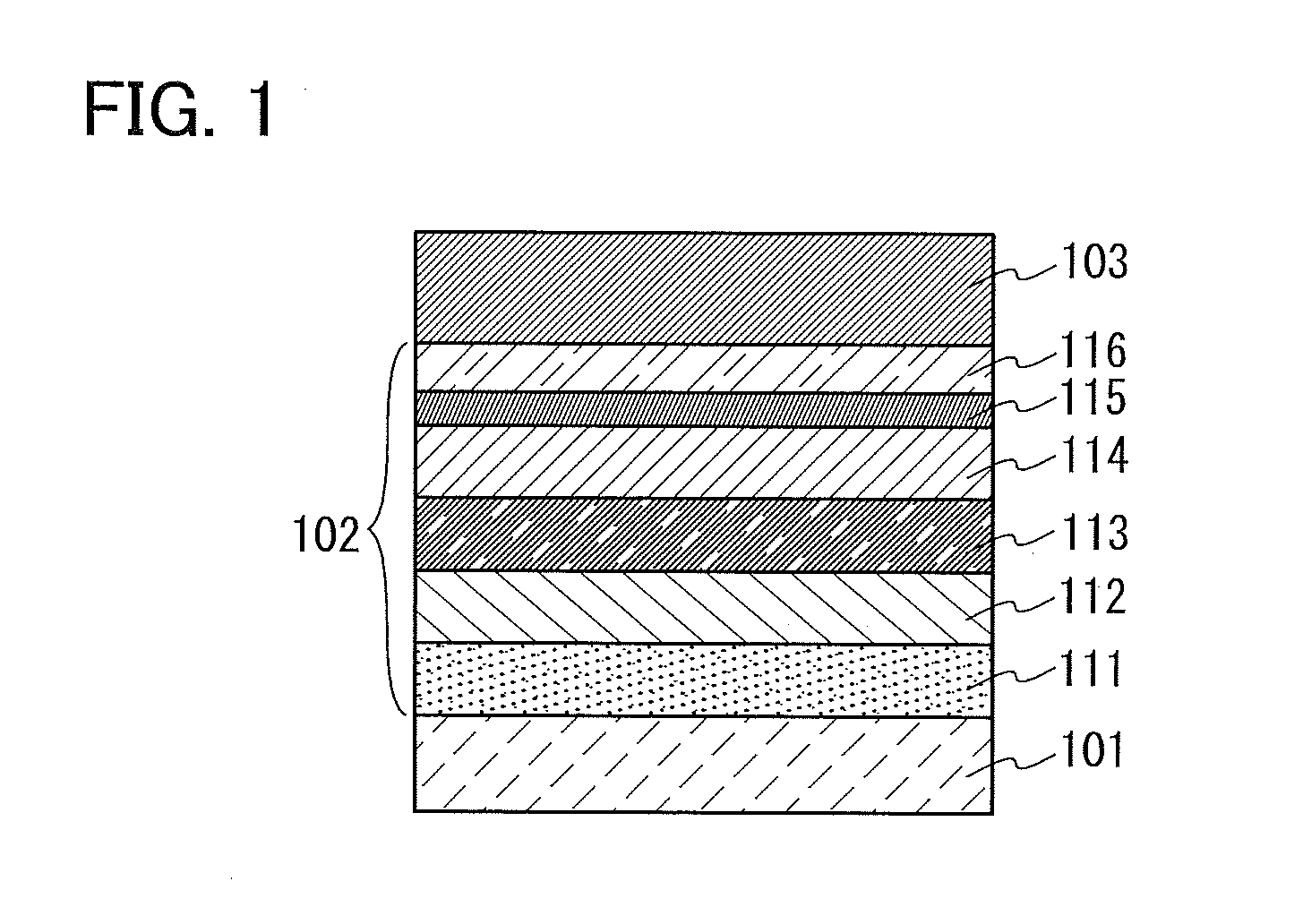

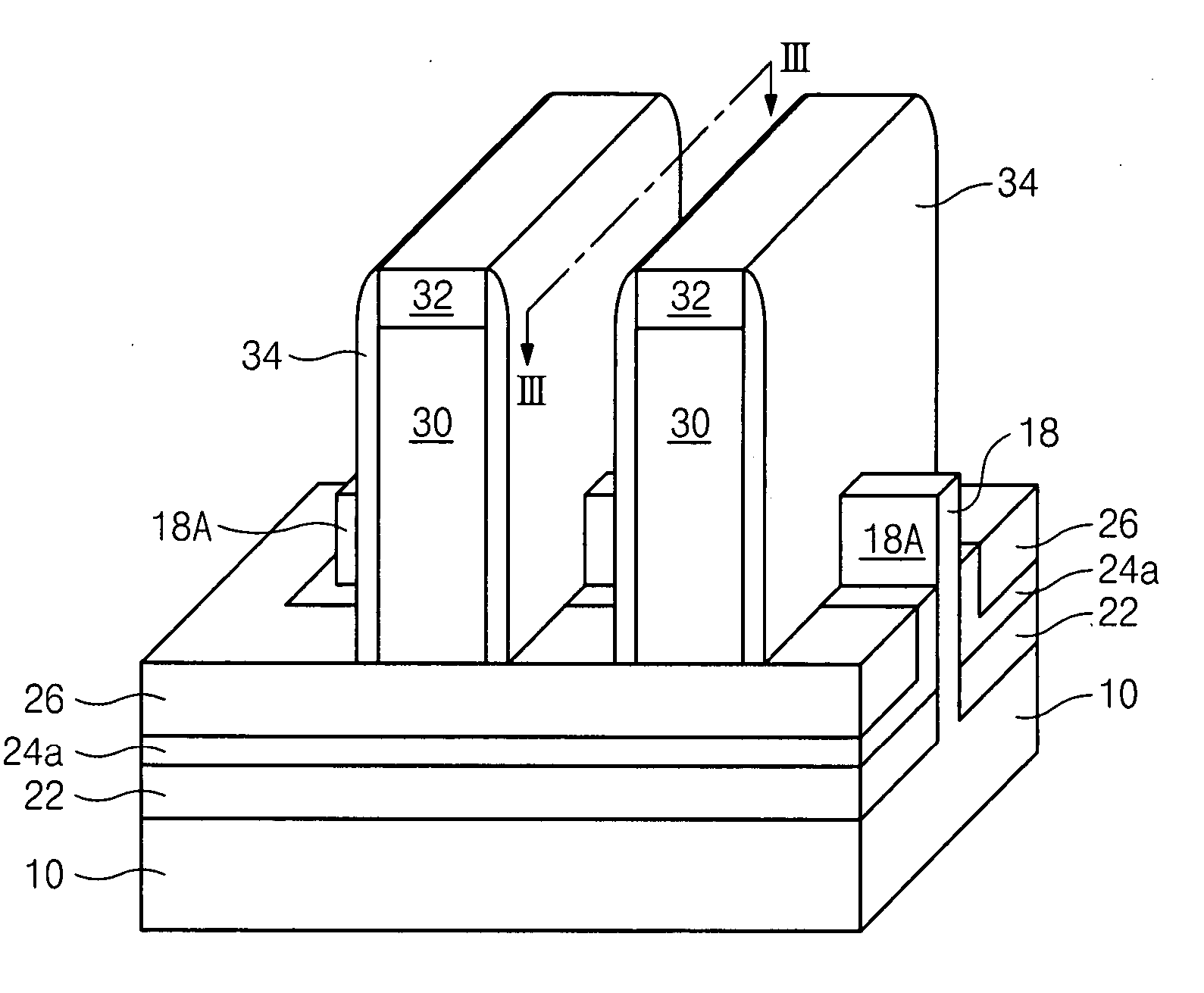

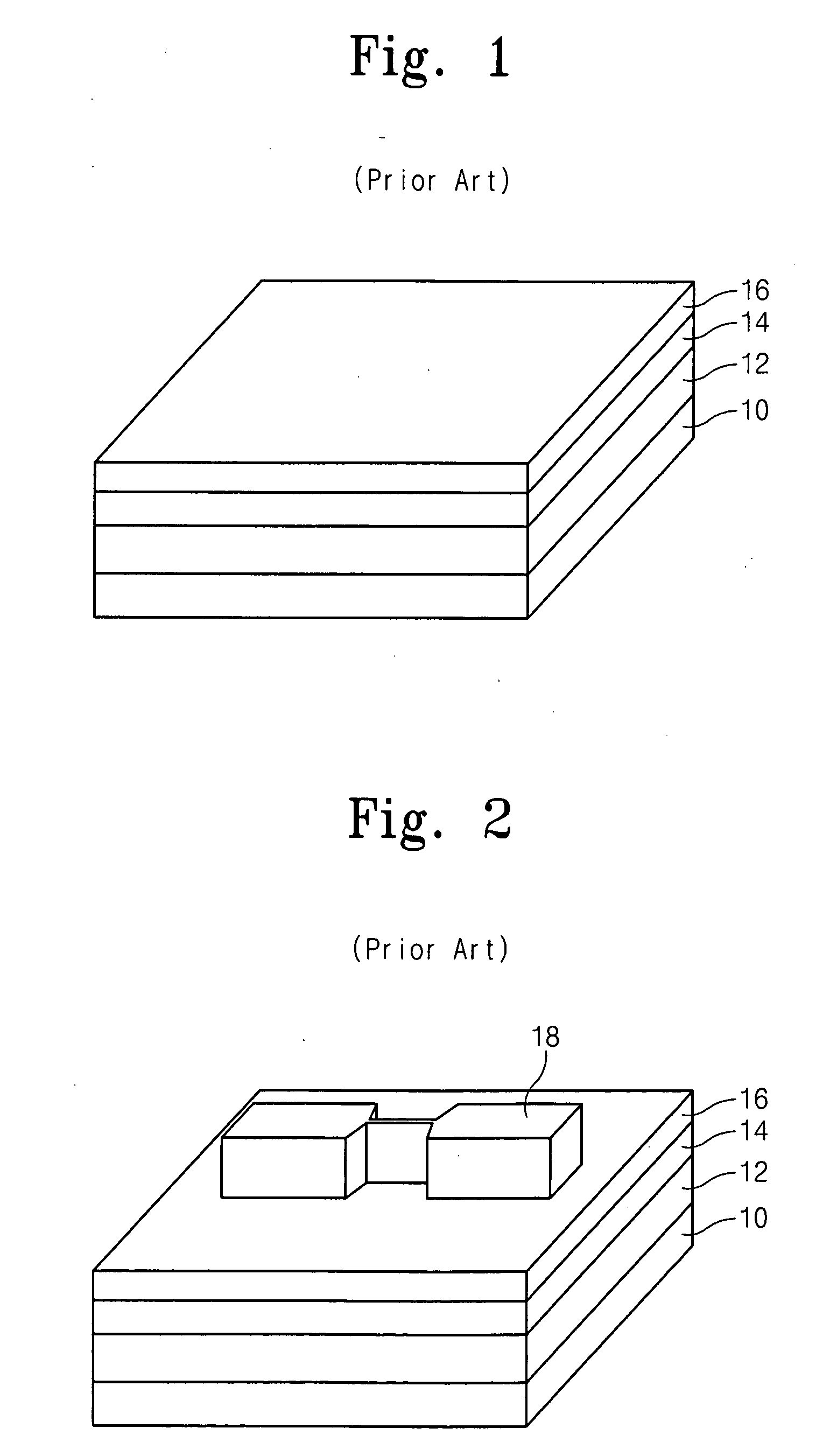

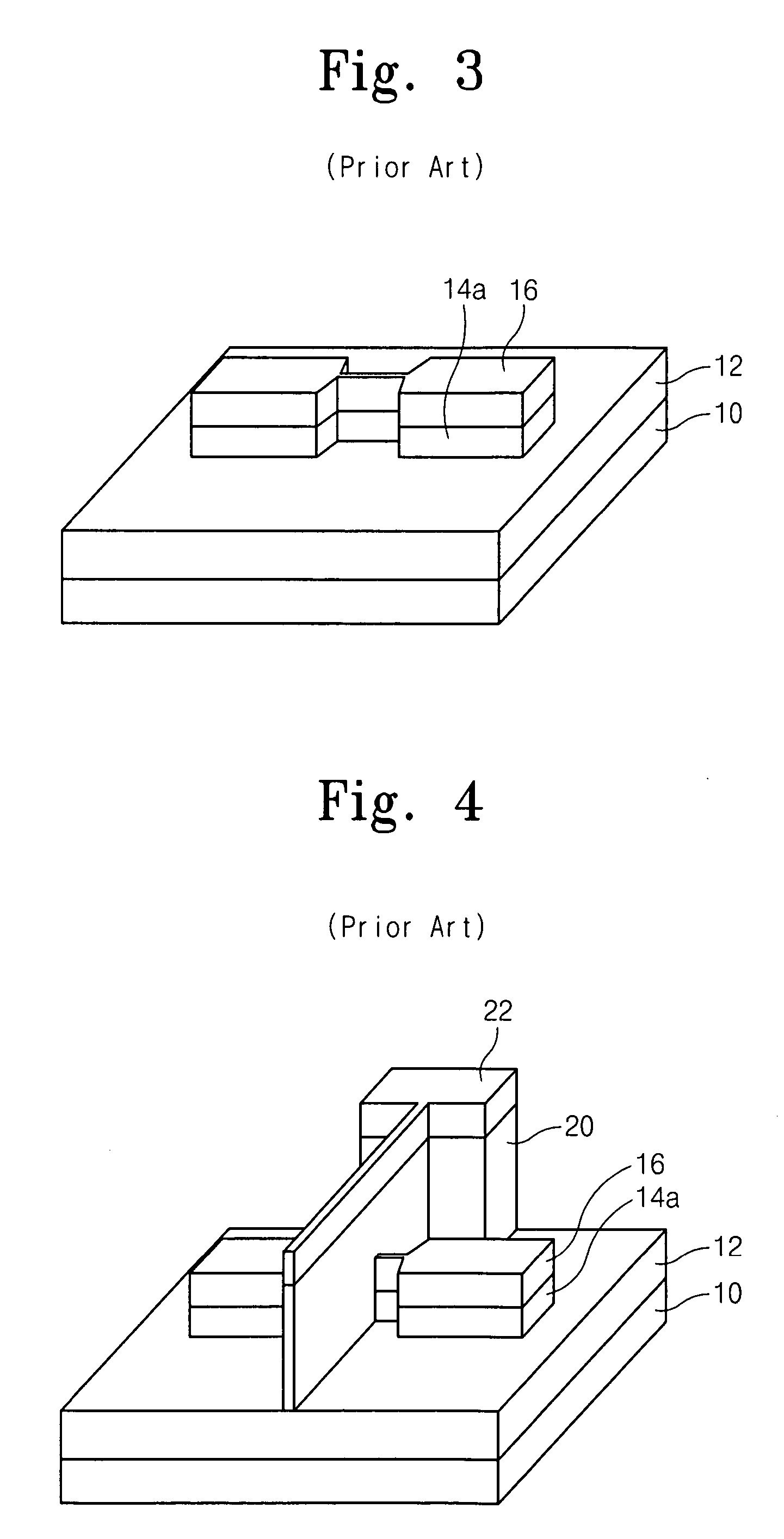

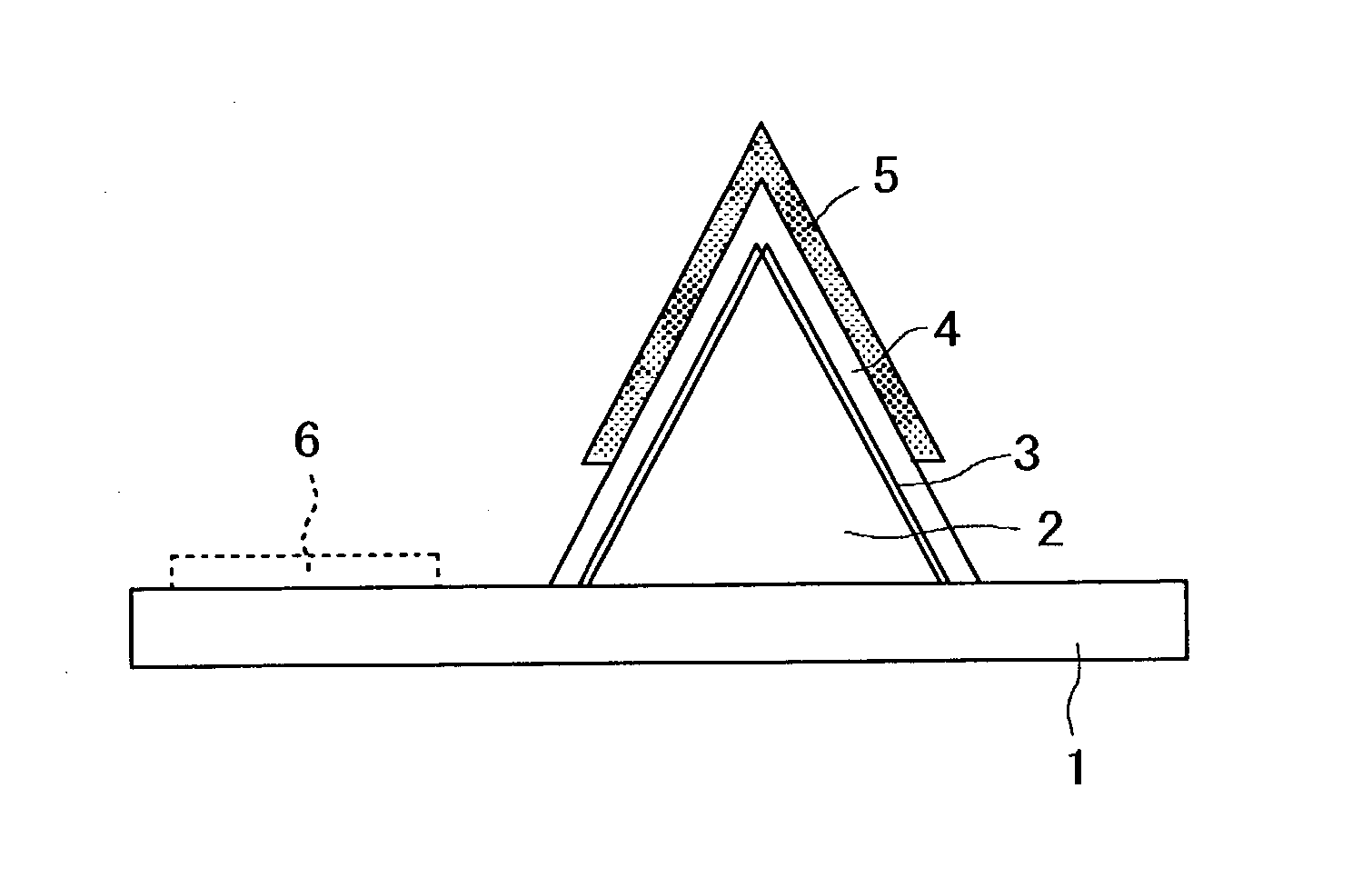

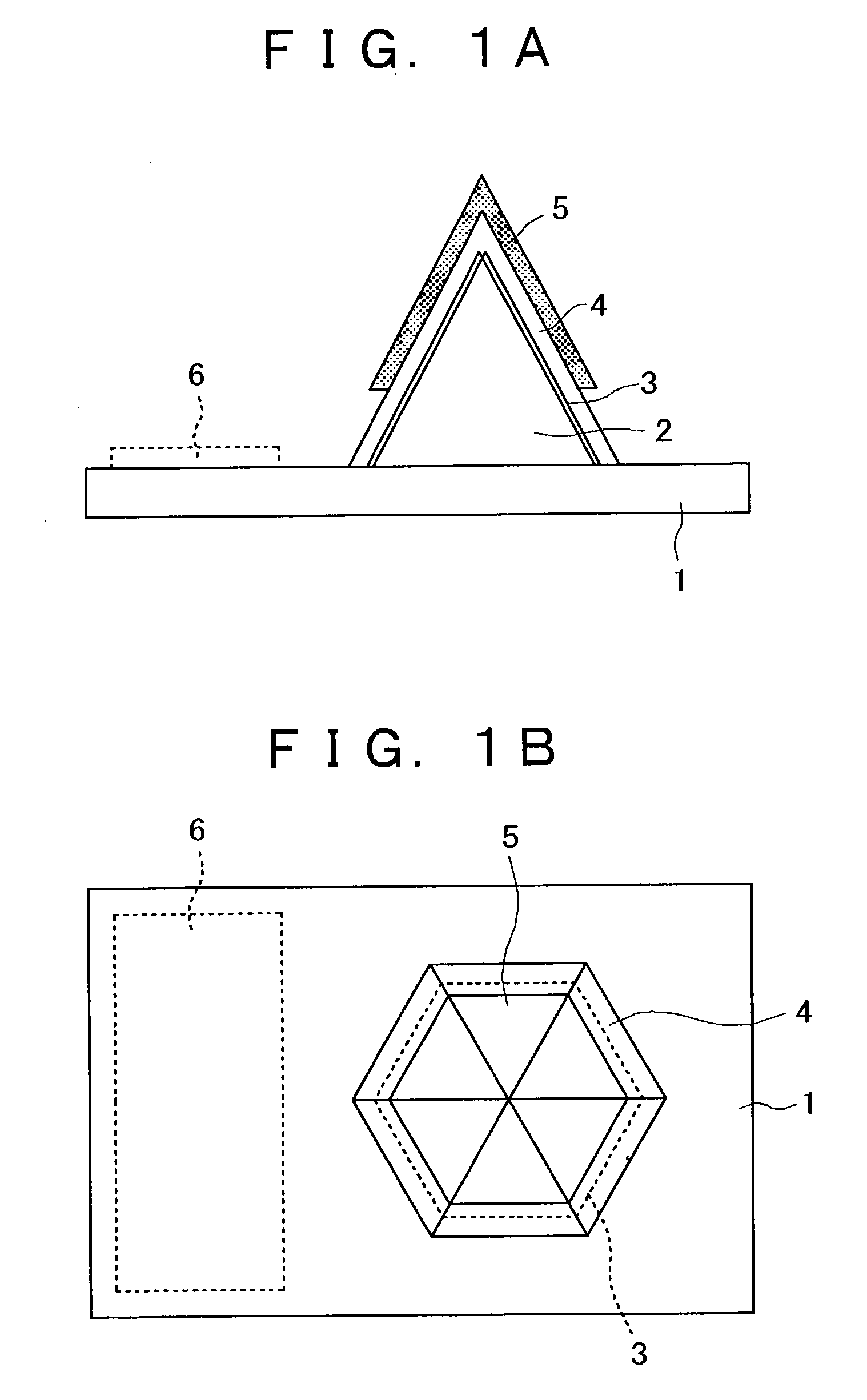

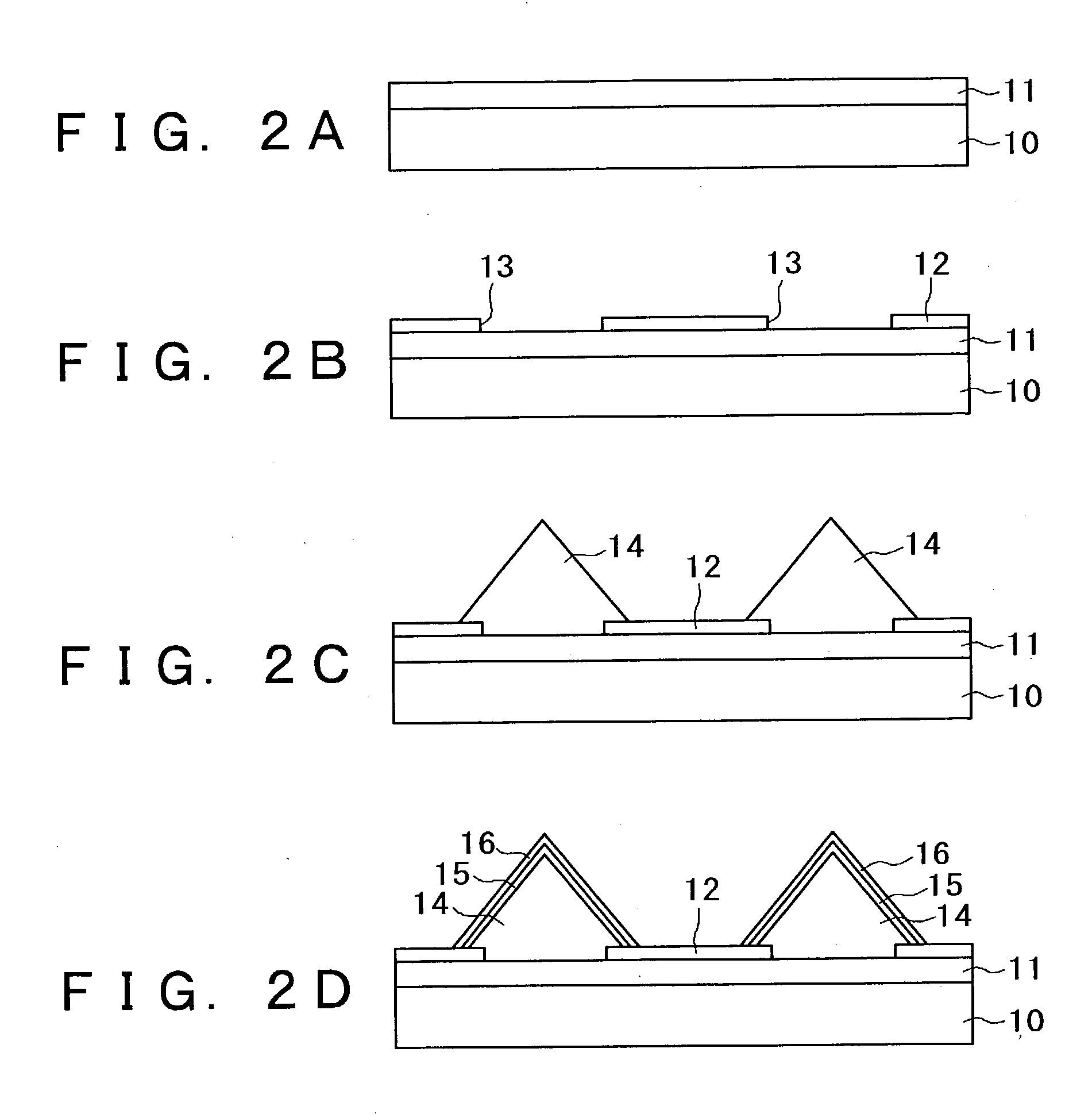

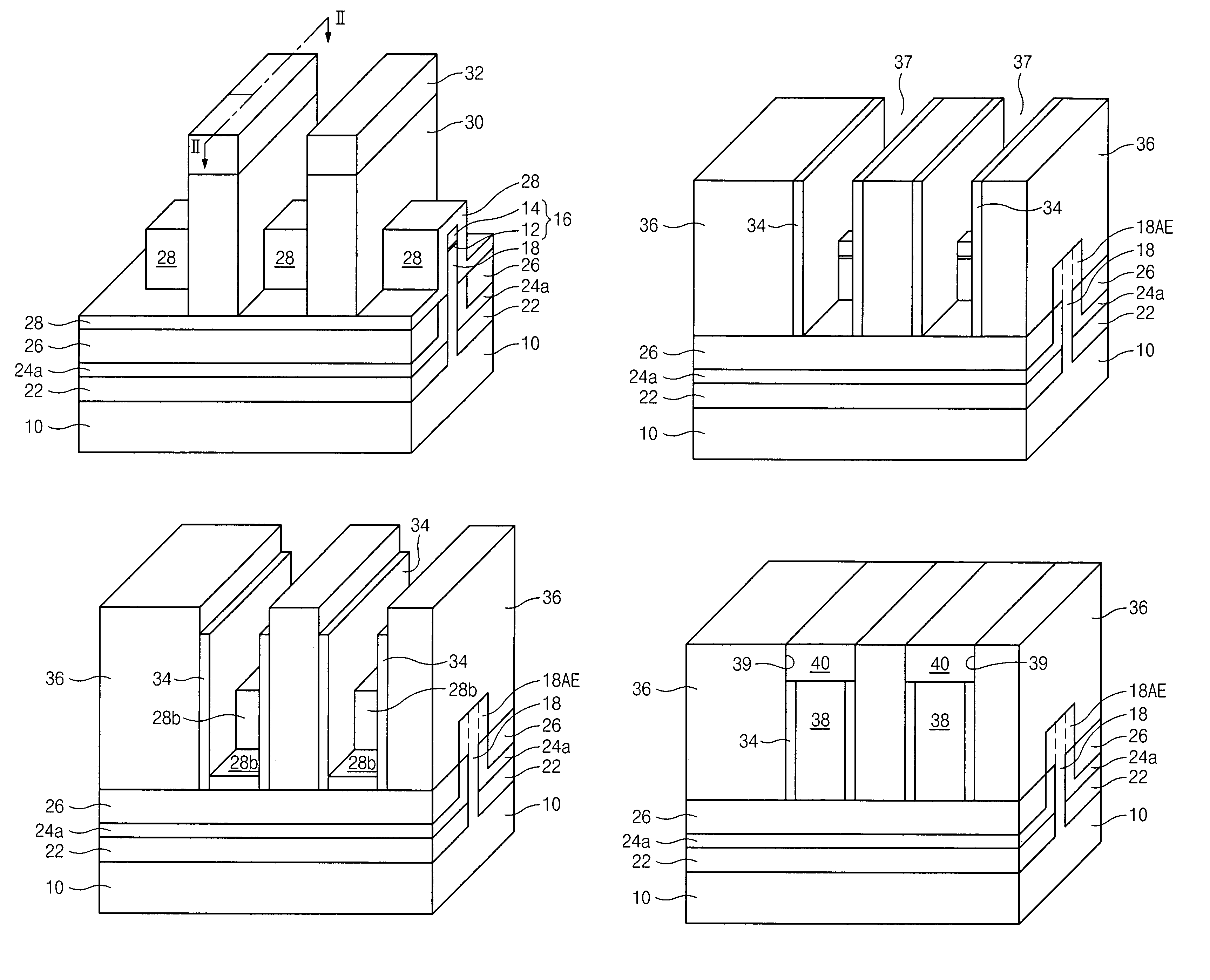

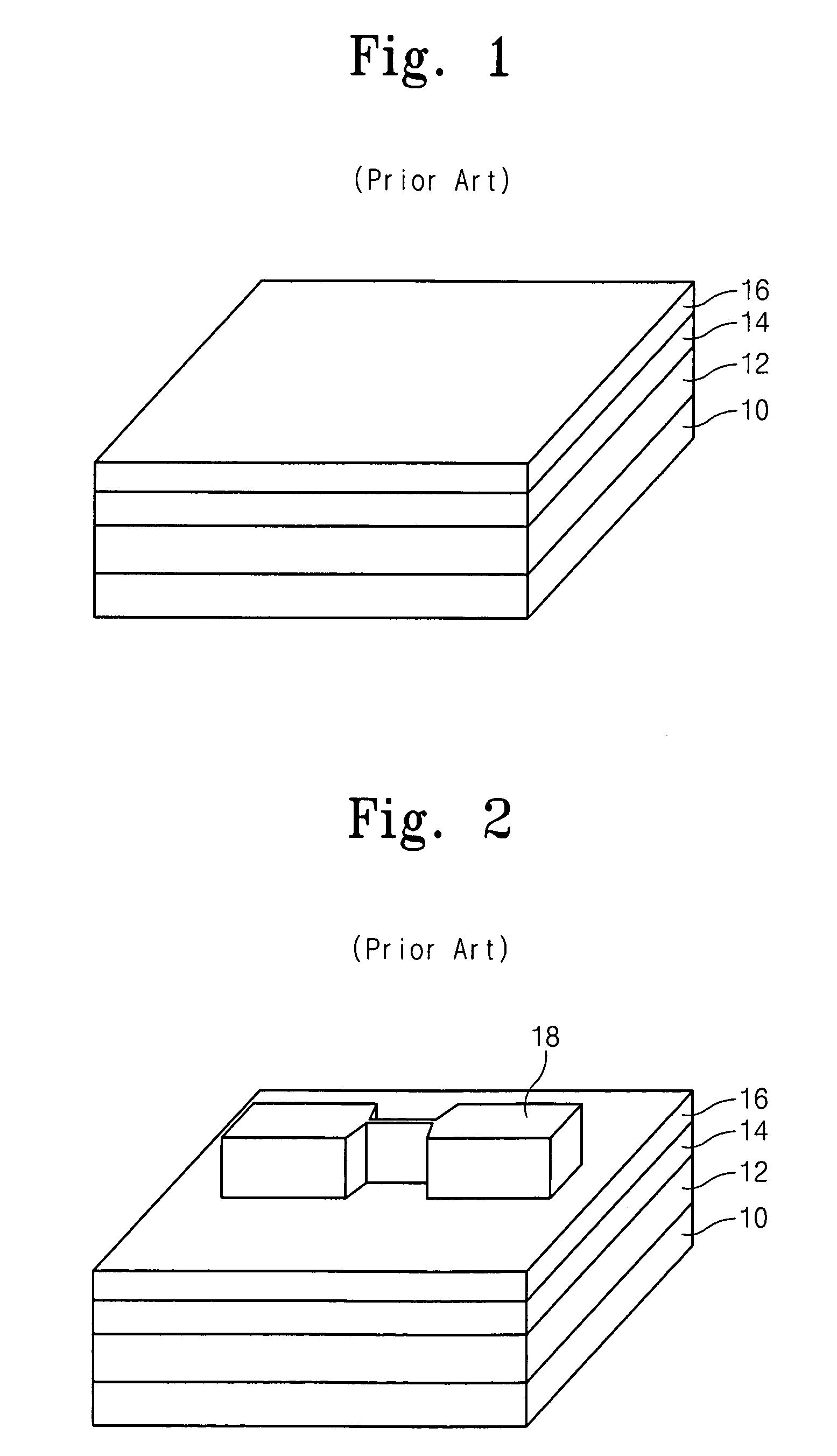

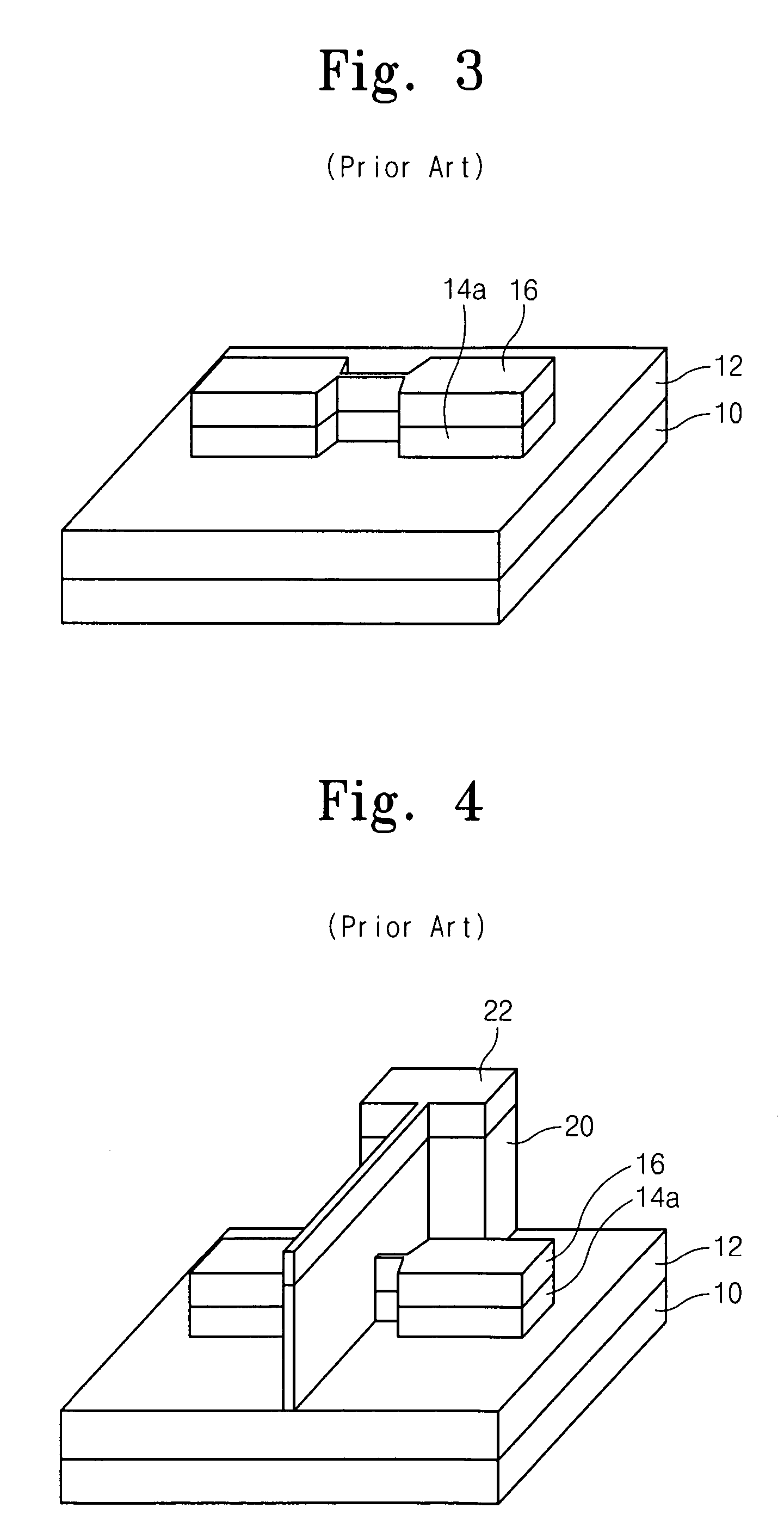

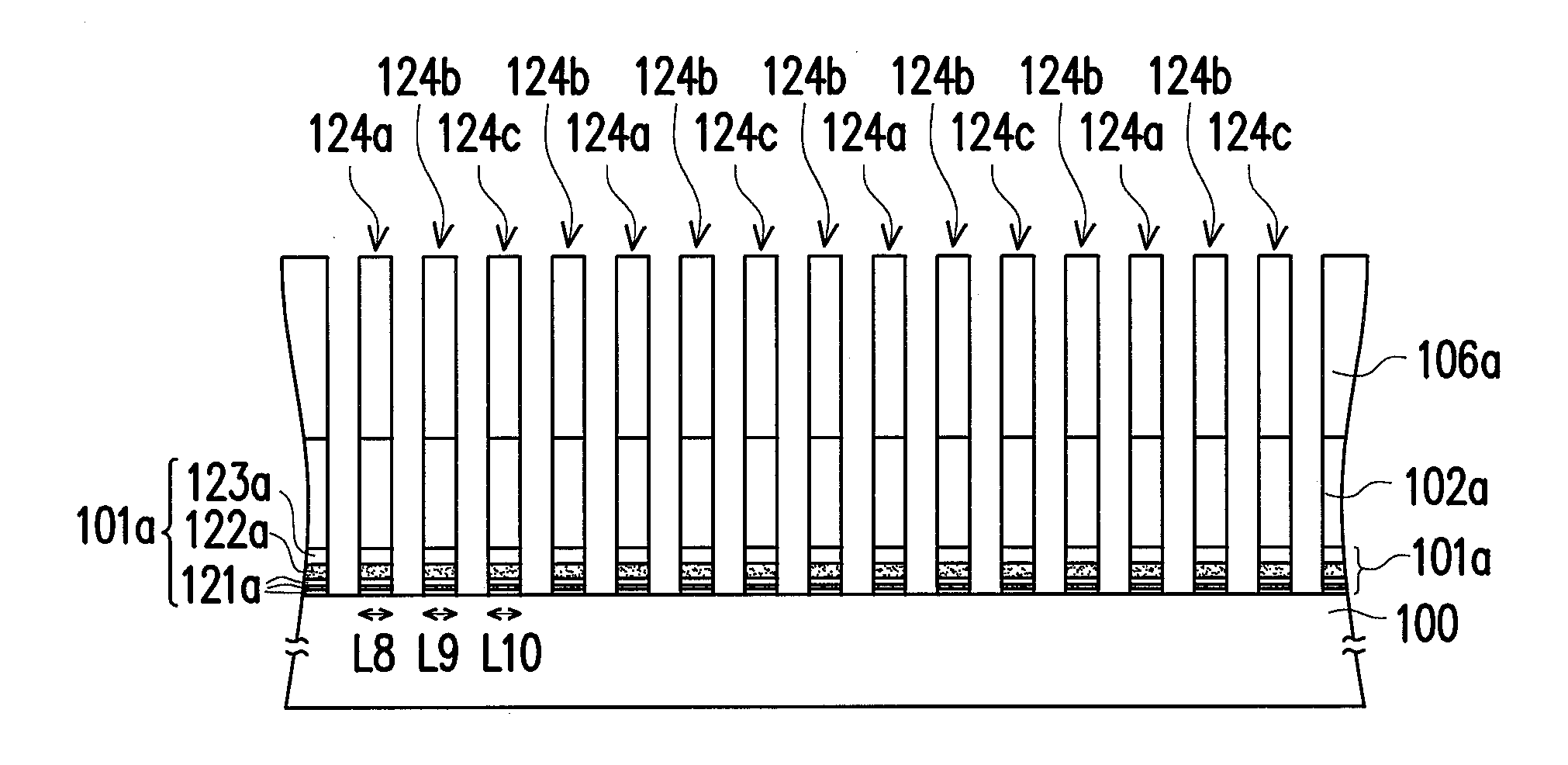

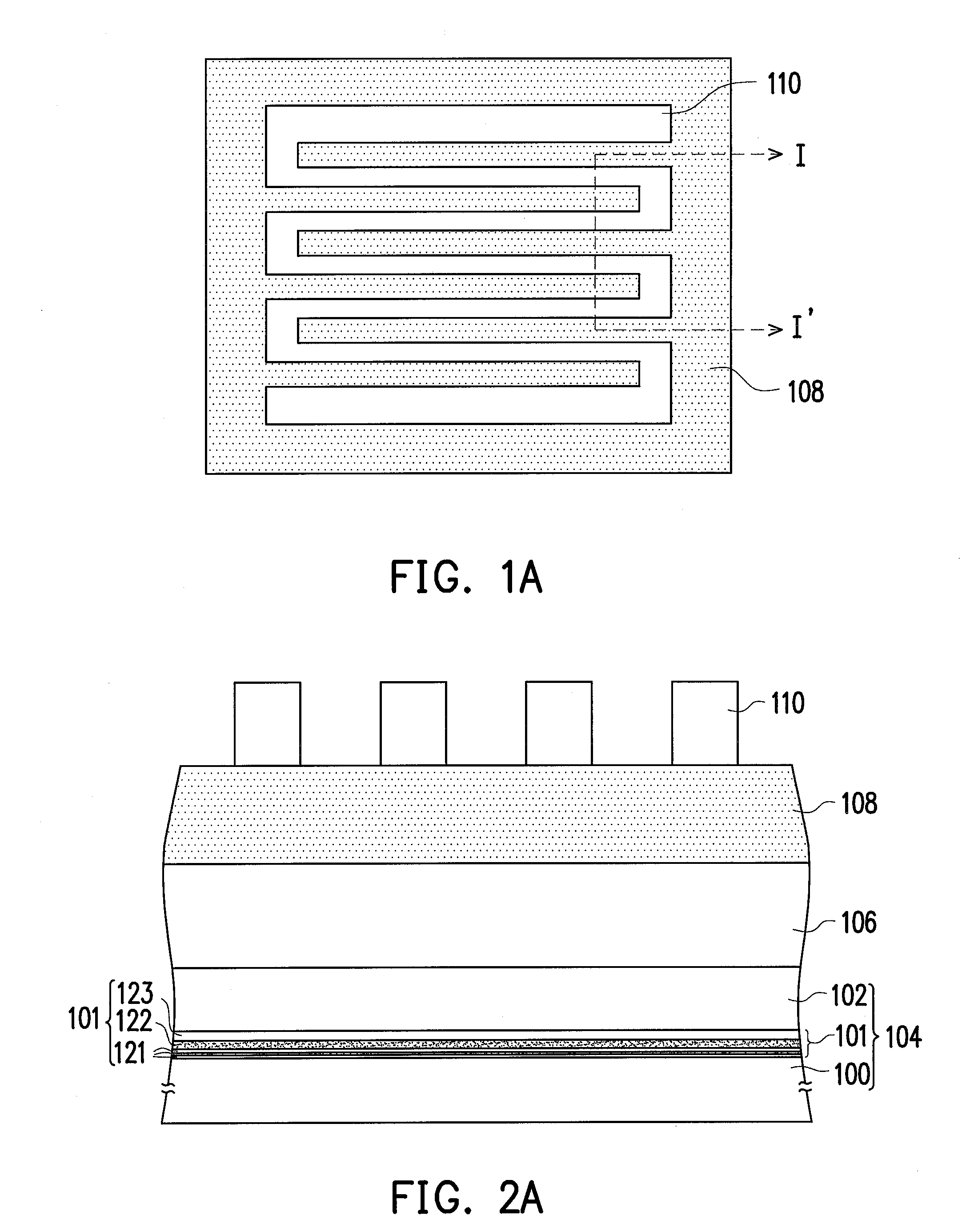

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS6858081B2Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

Organometallic Complex, Light-Emitting Element, Light-Emitting Device, Electronic Device, and Lighting Device

ActiveUS20130165653A1Improve emission efficiencyHigh color purityGroup 5/15 element organic compoundsGroup 3/13 element organic compoundsNitrogenKetone

As a novel substance having a novel skeleton, an organometallic complex with high emission efficiency which achieves improved color purity by a reduction of half width of an emission spectrum is provided. One embodiment of the present invention is an organometallic complex in which a β-diketone and a six-membered heteroaromatic ring including two or more nitrogen atoms inclusive of a nitrogen atom that is a coordinating atom are ligands. In General Formula (G1), X represents a substituted or unsubstituted six-membered heteroaromatic ring including two or more nitrogen atoms inclusive of a nitrogen atom that is a coordinating atom. Further, R1 to R4 each represent a substituted or unsubstituted alkyl group having 1 to 6 carbon atoms.

Owner:SEMICON ENERGY LAB CO LTD

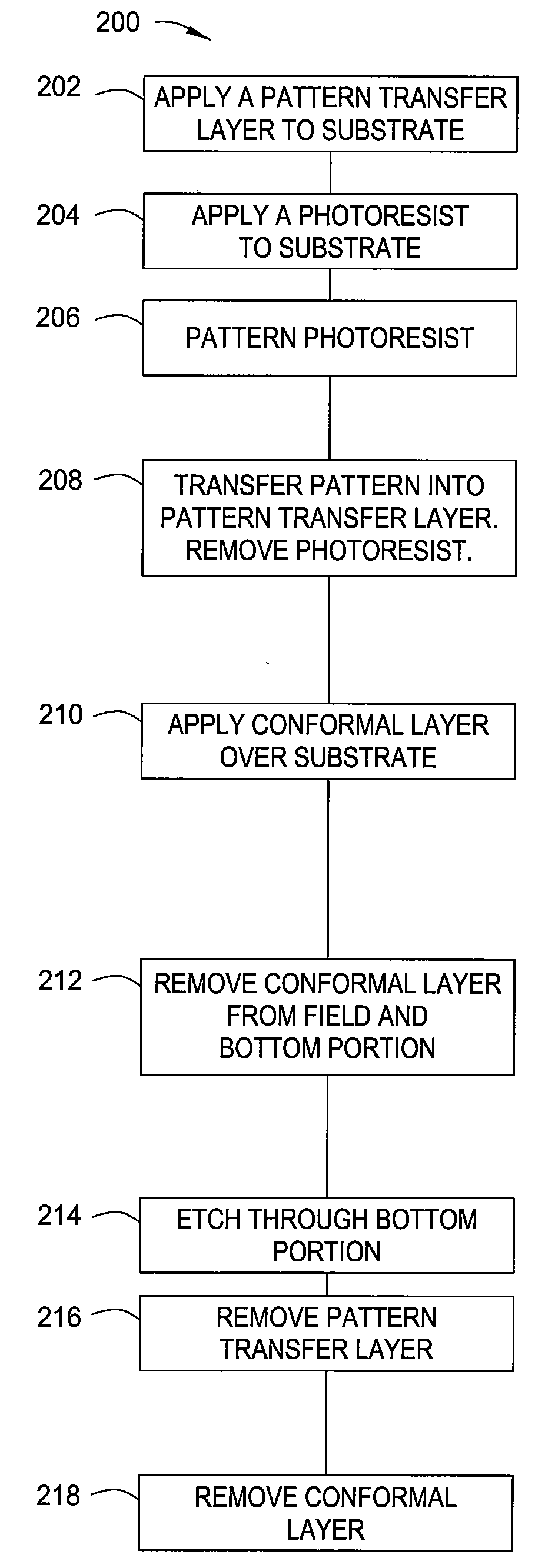

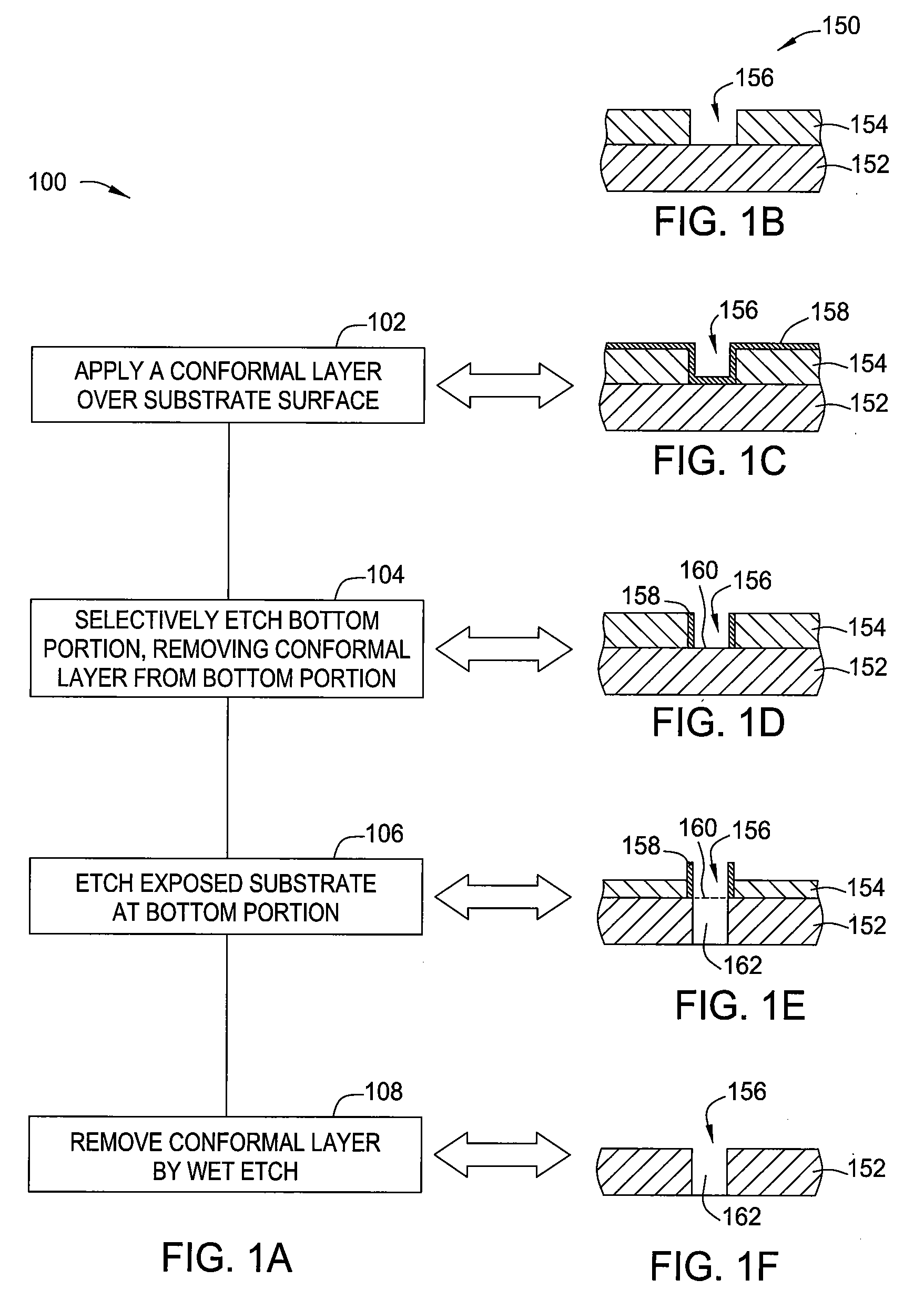

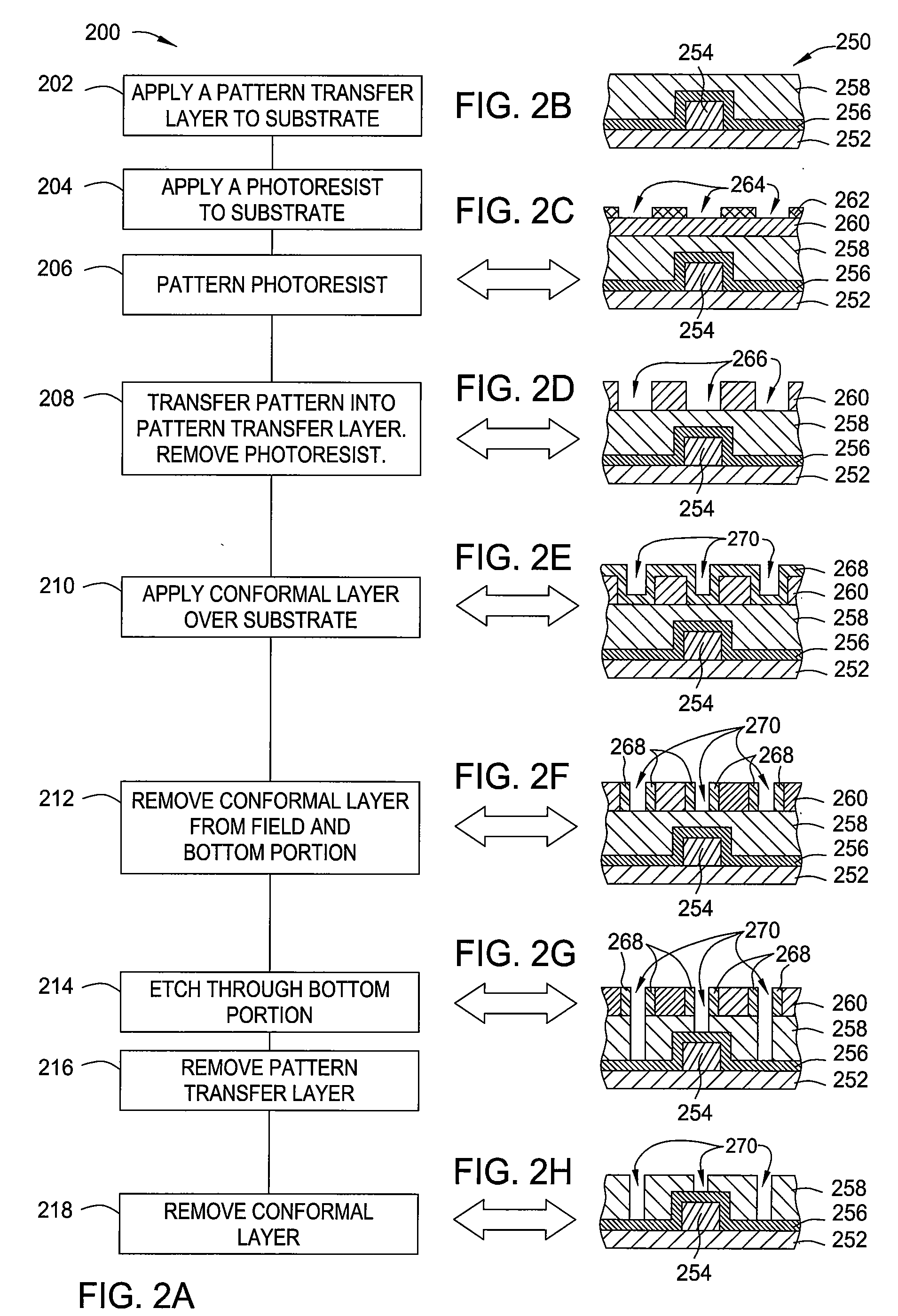

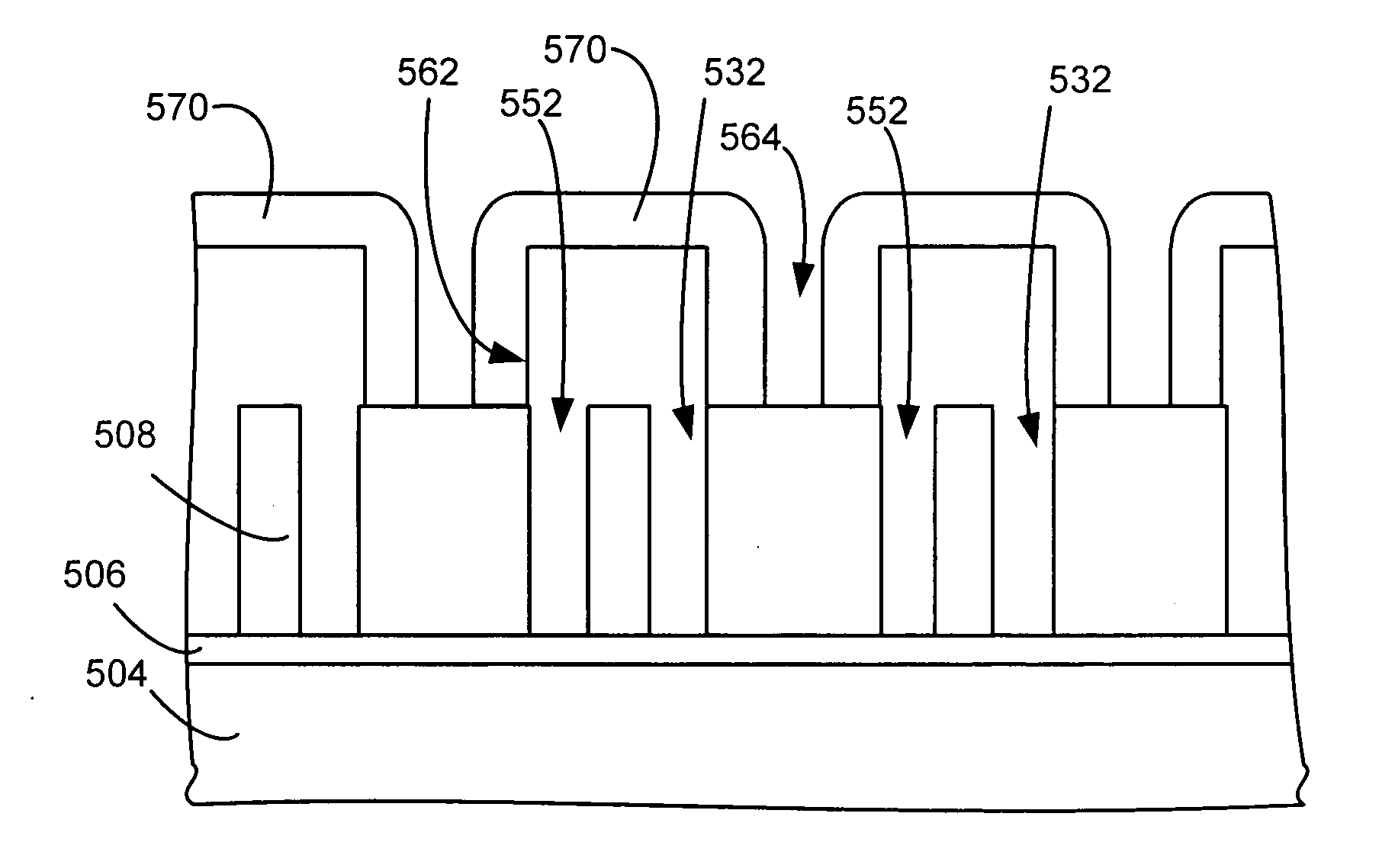

Method for critical dimension shrink using conformal pecvd films

InactiveUS20090286402A1Critical dimension reductionGood step coverageSemiconductor/solid-state device manufacturingLithographic artistAnisotropic etching

A method and apparatus for forming narrow vias in a substrate is provided. A pattern recess is etched into a substrate by conventional lithography. A thin conformal layer is formed over the surface of the substrate, including the sidewalls and bottom of the pattern recess. The thickness of the conformal layer reduces the effective width of the pattern recess. The conformal layer is removed from the bottom of the pattern recess by anisotropic etching to expose the substrate beneath. The substrate is then etched using the conformal layer covering the sidewalls of the pattern recess as a mask. The conformal layer is then removed using a wet etchant.

Owner:APPLIED MATERIALS INC

Organometallic Complex, Light-Emitting Element, Light-Emitting Device, Electronic Device, and Lighting Device

InactiveUS20140246656A1Improve efficiencyHigh sublimabilityGroup 5/15 element organic compoundsSolid-state devicesHydrogenEmission efficiency

As a novel substance having a novel skeleton, an organometallic complex having high emission efficiency and improved color purity is provided. The color purity is improved by reducing the half width of an emission spectrum. The organometallic complex is represented by General Formula (G1). In General Formula (G1), at least one of R1 to R4 represents a substituted or unsubstituted alkyl group having 1 to 4 carbon atoms, and the others each independently represent hydrogen or a substituted or unsubstituted alkyl group having 1 to 4 carbon atoms. Note that the case where all of R1 to R4 represent alkyl groups each having 1 carbon atom is excluded. Further, R5 to R9 each independently represent hydrogen or a substituted or unsubstituted alkyl group having 1 to 6 carbon atoms.

Owner:SEMICON ENERGY LAB CO LTD

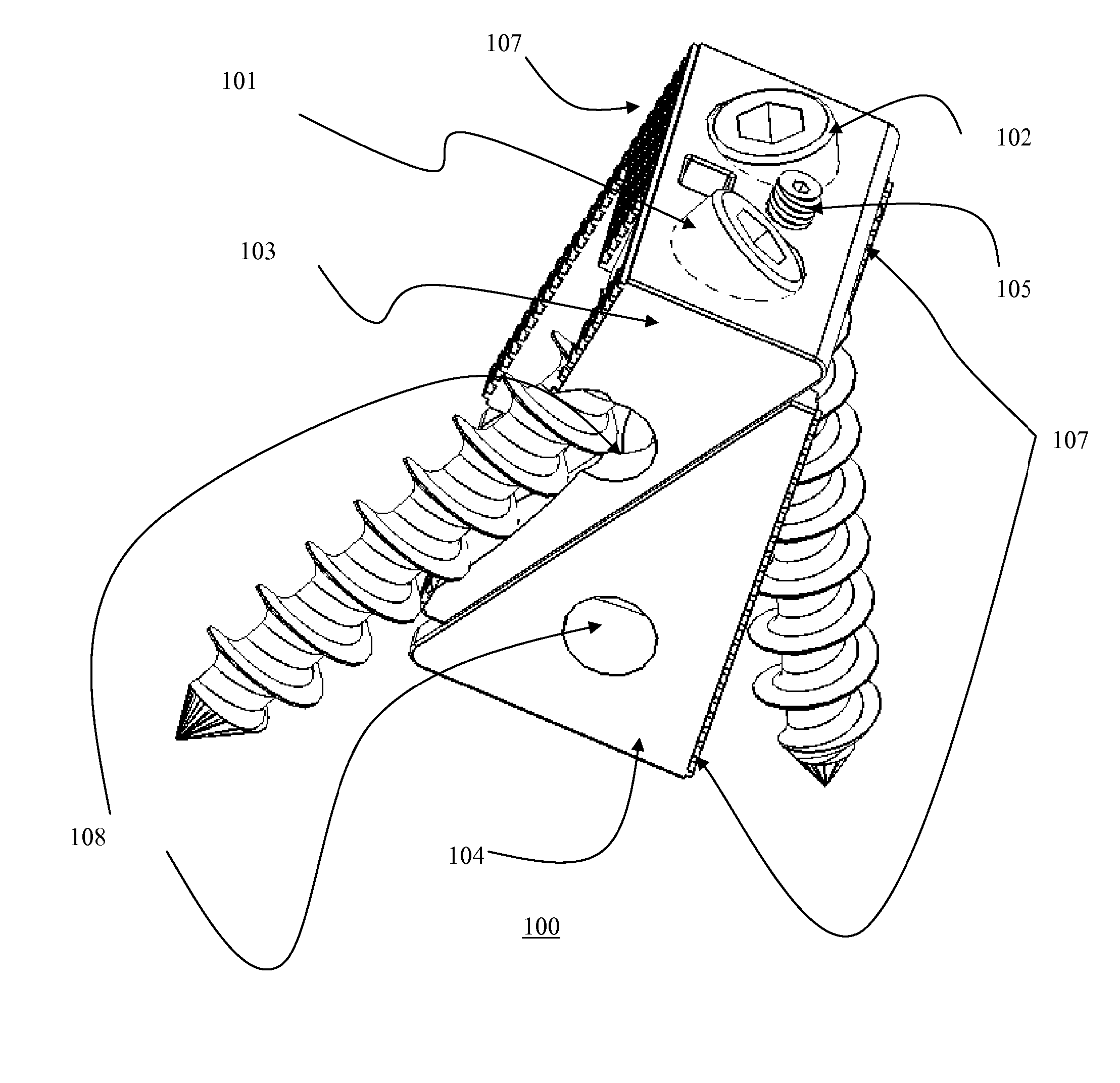

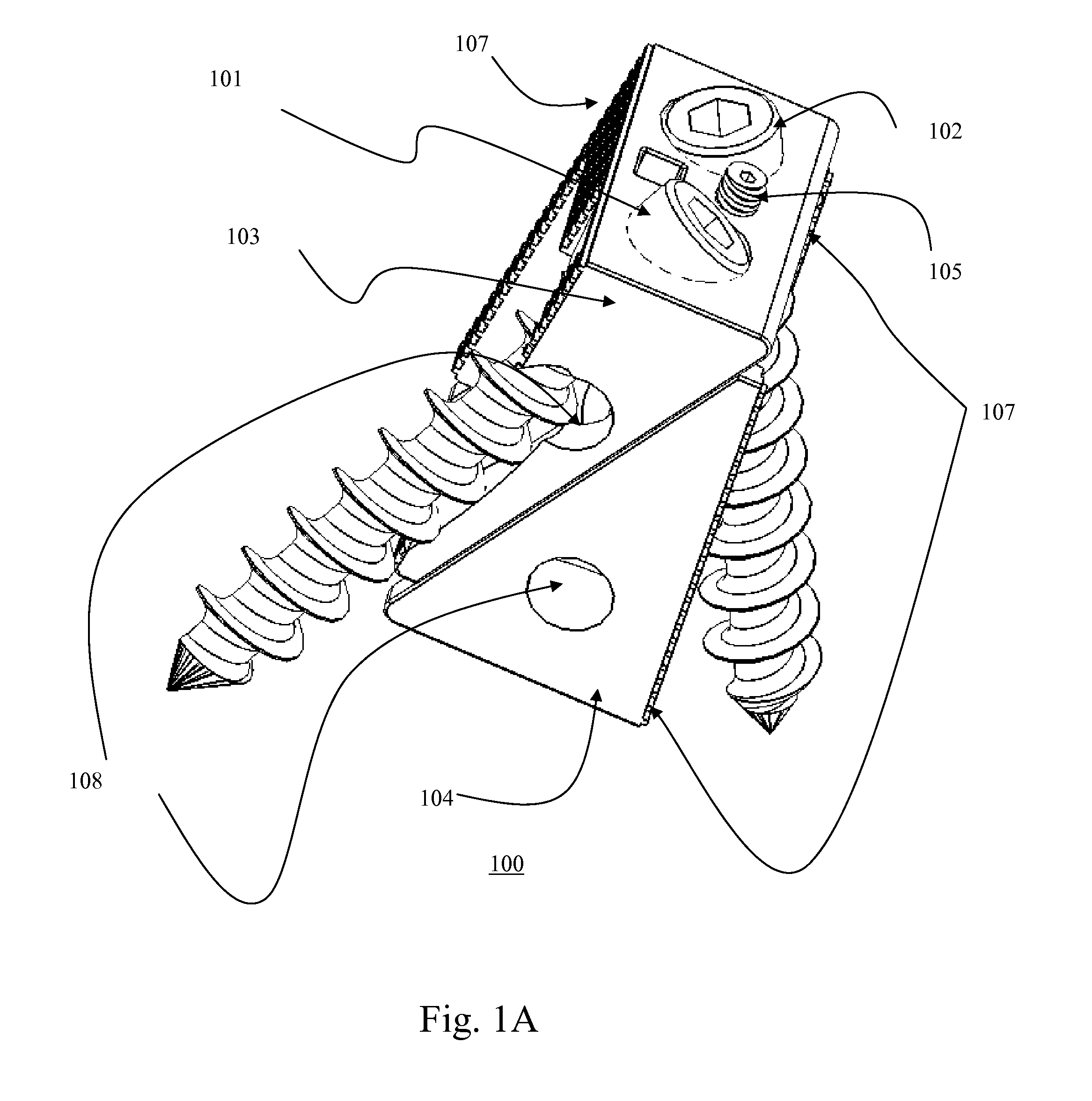

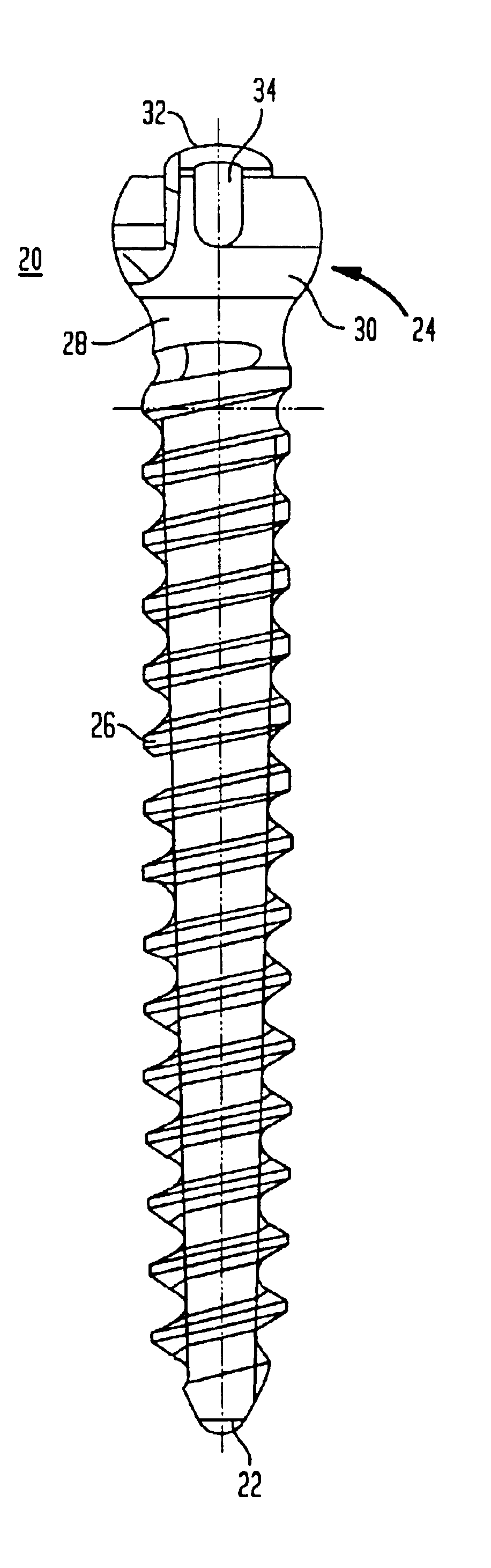

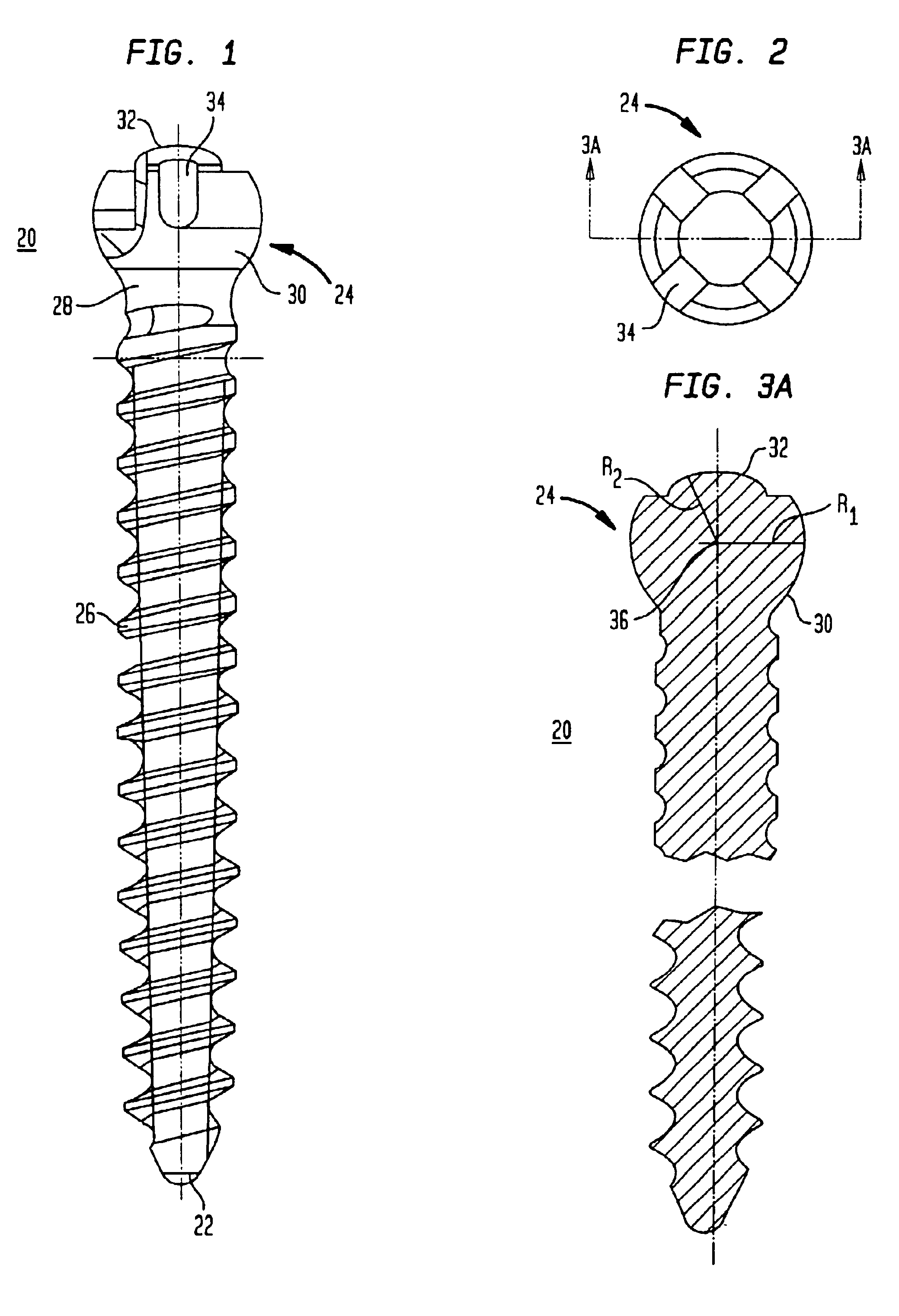

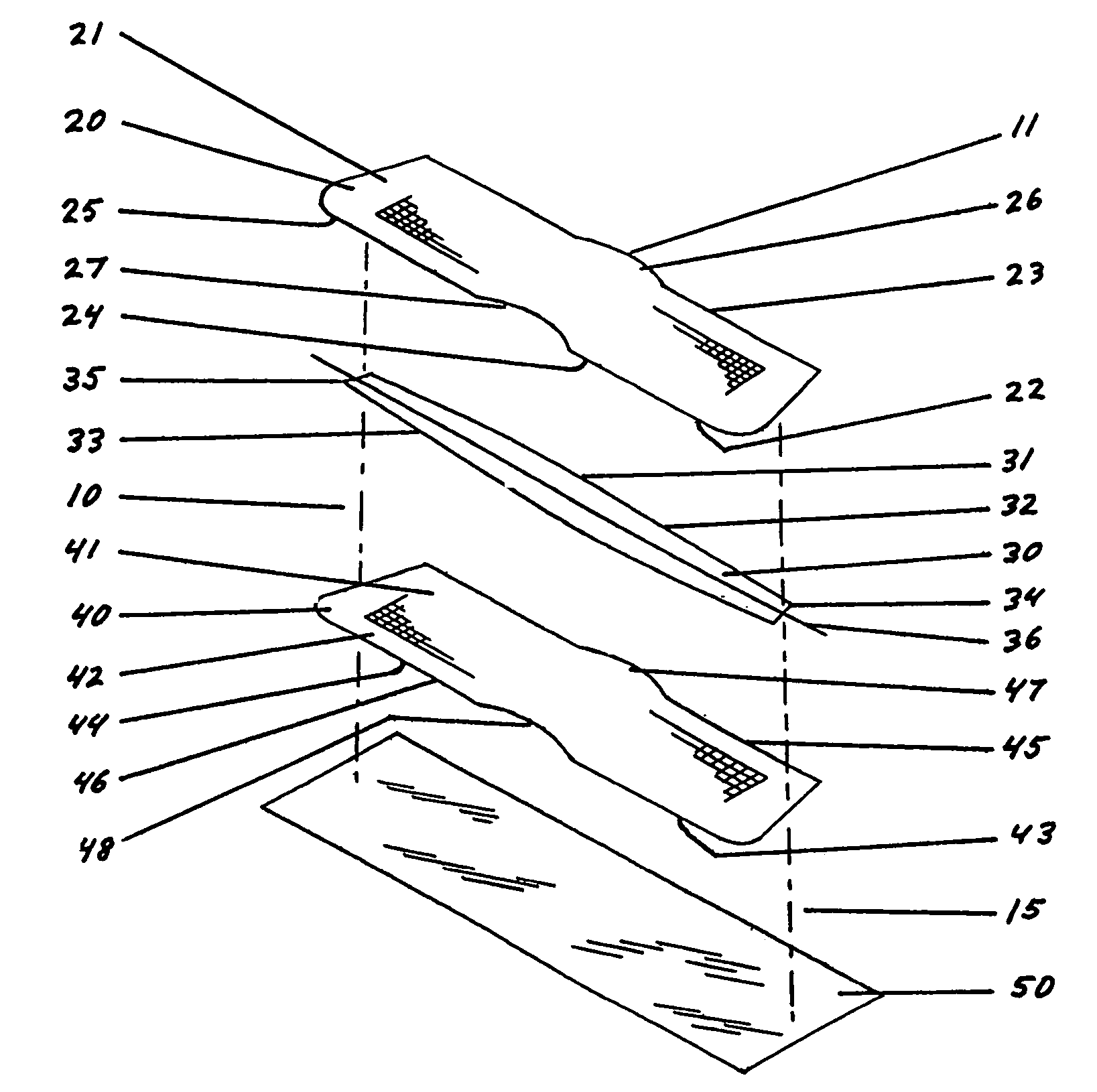

Bi-directional fixating transvertebral body screws and posterior cervical and lumbar interarticulating joint calibrated stapling devices for spinal fusion

ActiveUS20080033440A1Reduce widthAvoid excessive retractionInternal osteosythesisBone implantBones fusionLumbar vertebrae

A self-drilling bone fusion screw apparatus is disclosed which includes at least first and second sliding boxes. A first screw member having a tapered end and a threaded body is disposed within the first sliding box, and a second screw member having a tapered end and a threaded body disposed within the second sliding box. An adjuster adjusts the height of the sliding boxes. The screw members are screwed into vertebral bodies in order to fuse the vertebral bodies together. A plurality of the self-drilling bone fusion screw apparatuses may be attached together and / or integrated via a plate or cage. Also disclosed is a cervical facet staple that includes a curved staple base and at least two prongs attached to the bottom surface of the curved staple base.

Owner:MOSKOWITZ FAMILY LLC

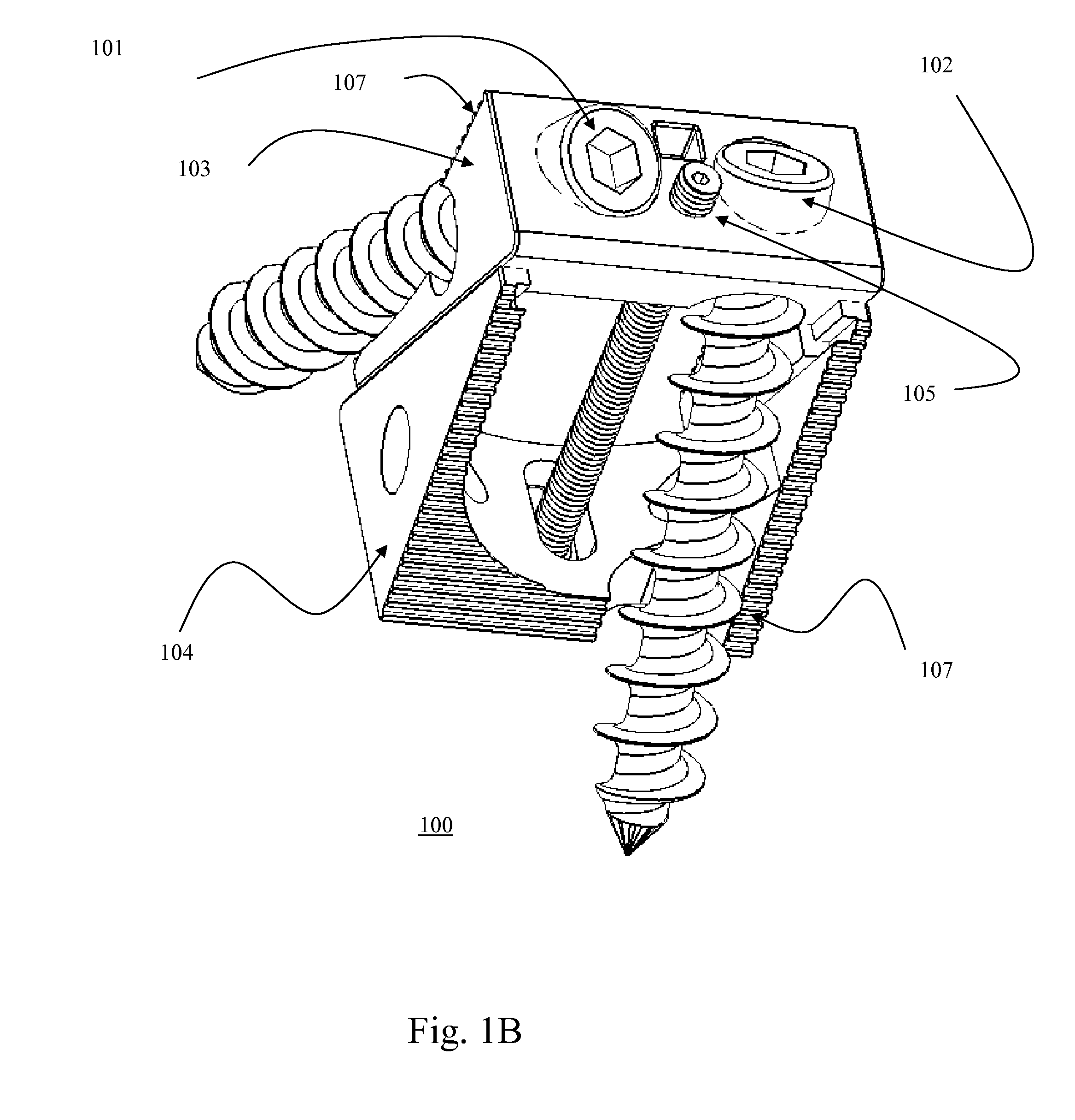

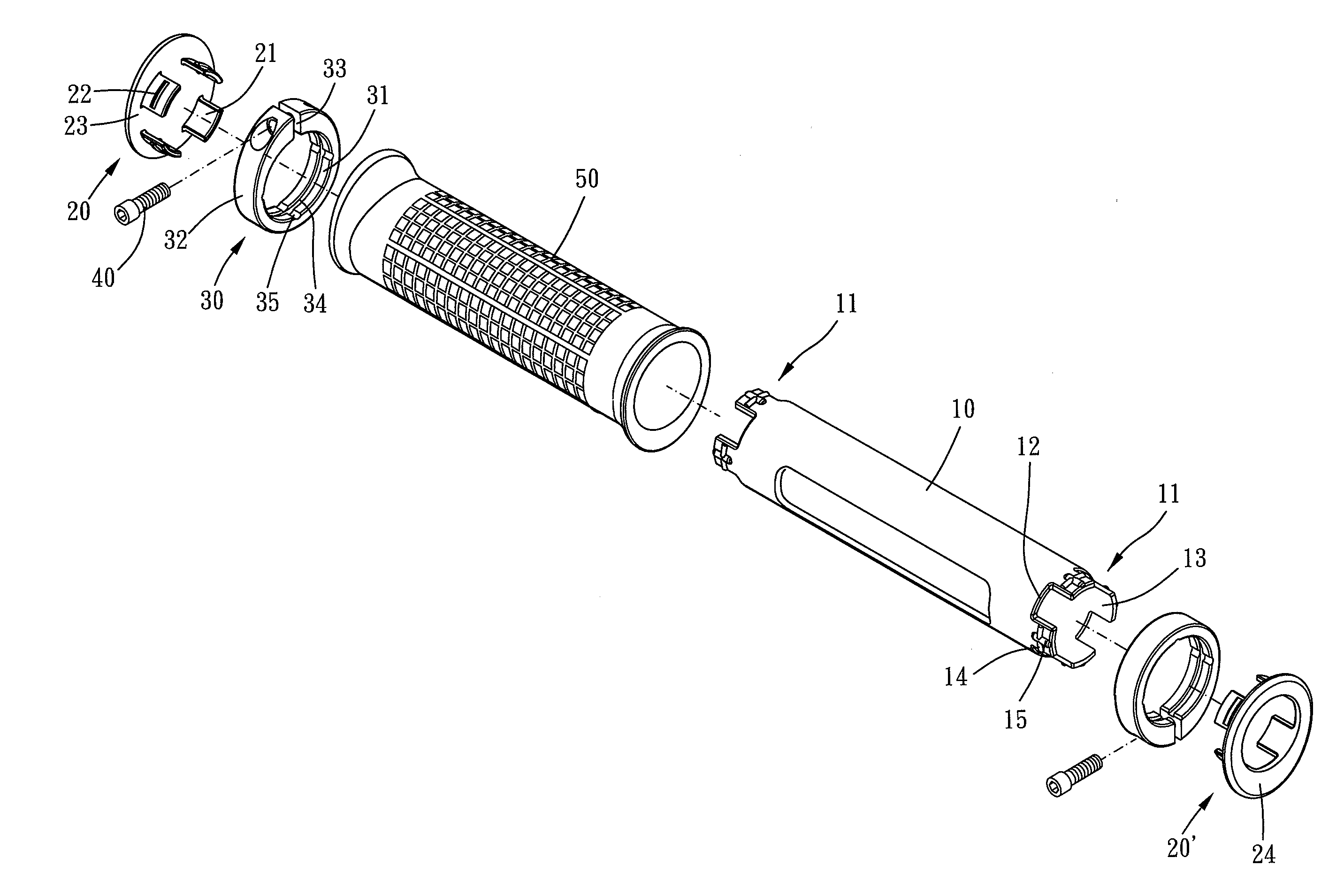

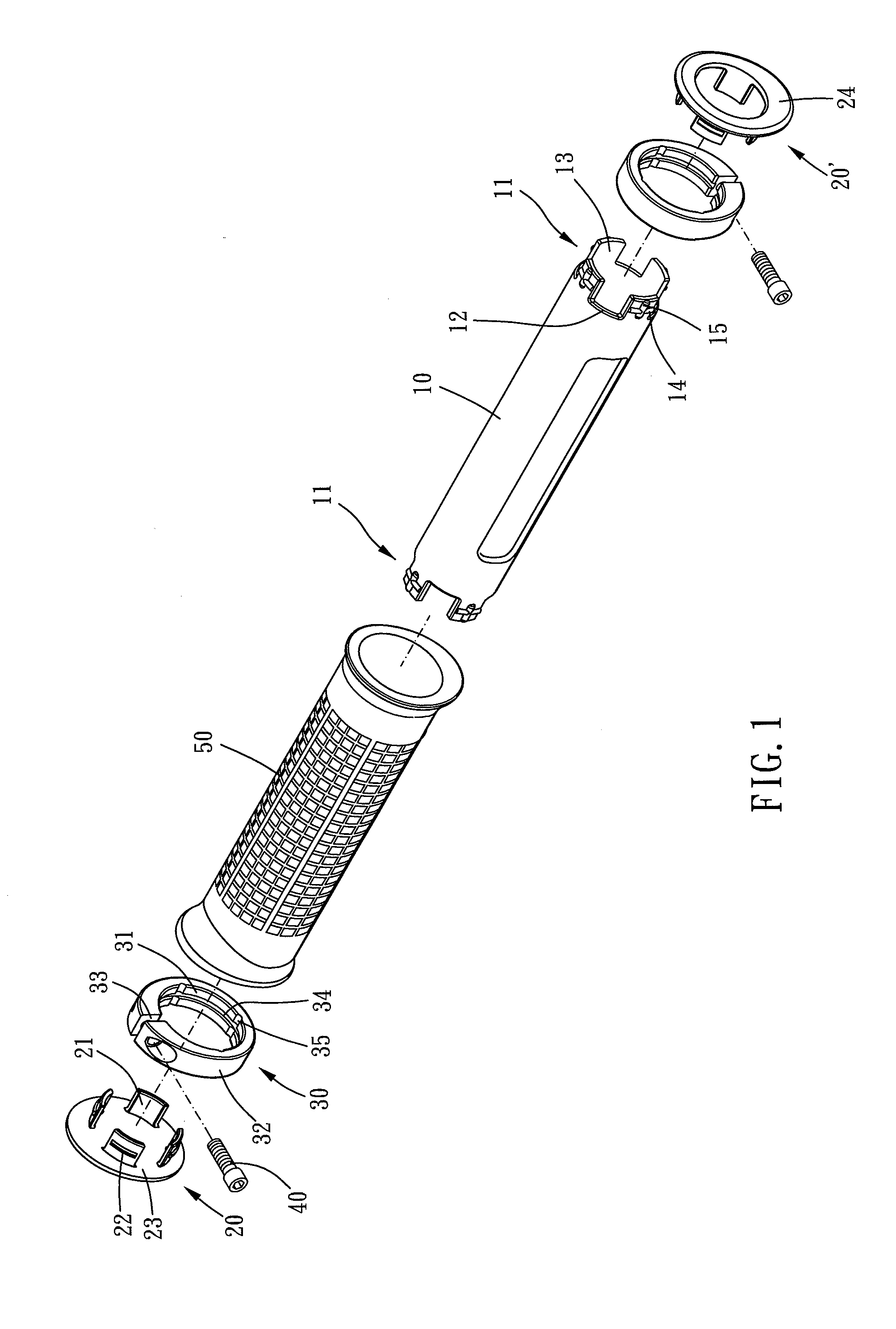

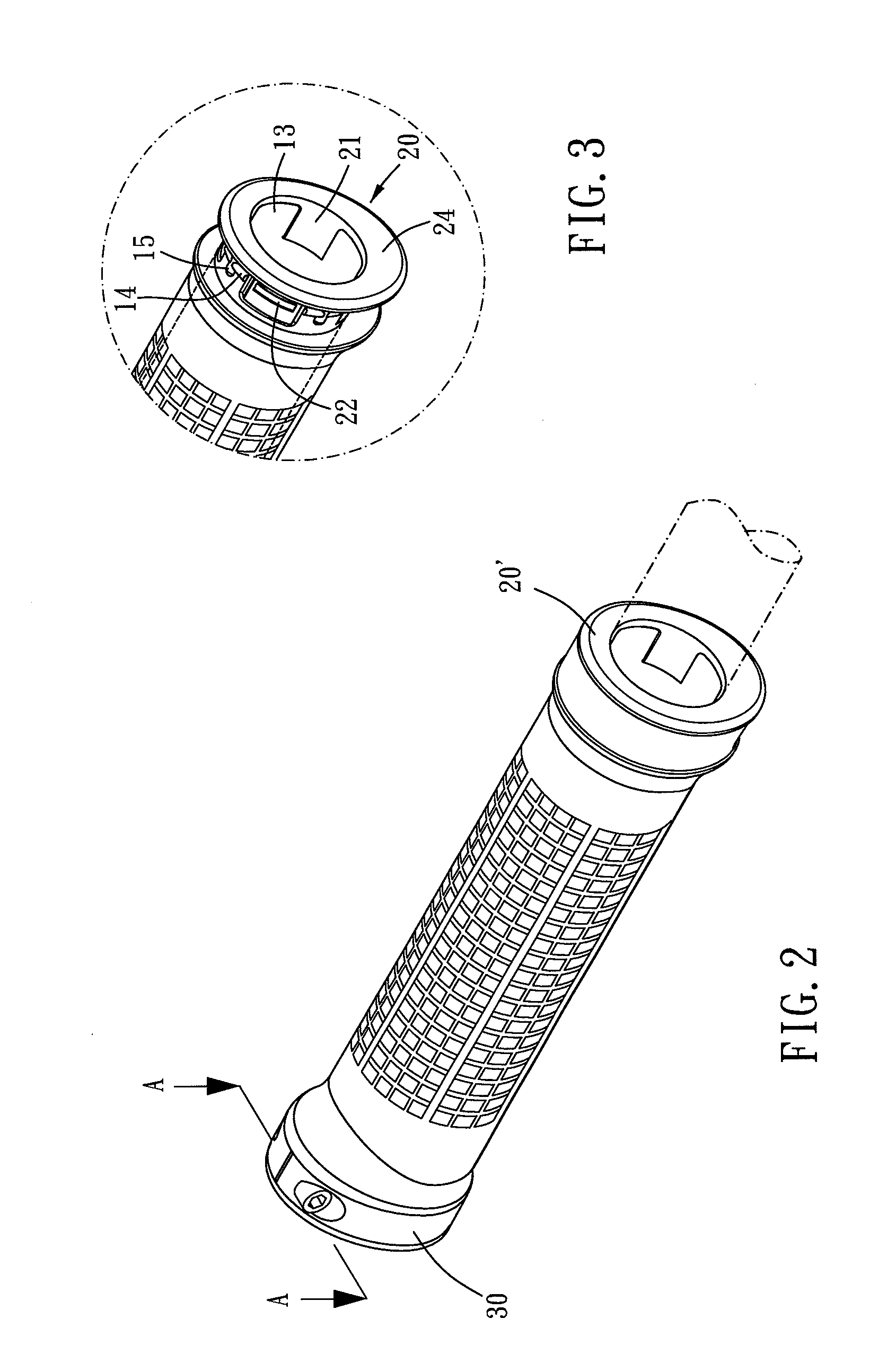

Handlebar grip assembly

InactiveUS20120073400A1Reduce widthMechanical apparatusSteering deviceMechanical engineeringEngineering

A handlebar grip assembly of the present invention includes a sleeve, two covers and two clamps. The sleeve has two clamping ends which defines several axial grooves. A first clamping piece is defined between any two adjacent grooves. The first clamping piece is formed with an axial rib and a first lateral rib which crosses through the axial rib. The cover has several second clamping pieces which is adapted for being inserted in the grooves. The second clamping piece is formed with a second lateral rib. The first lateral ribs and the second lateral ribs are coplanar arranged. The clamp has an inner surface which is formed with an annular recess and several axial recesses. The annular recess is adapted for the first lateral ribs and the second lateral ribs to be received therein. The axial recesses are adapted for the axial ribs to be received therein.

Owner:WANG JOHN

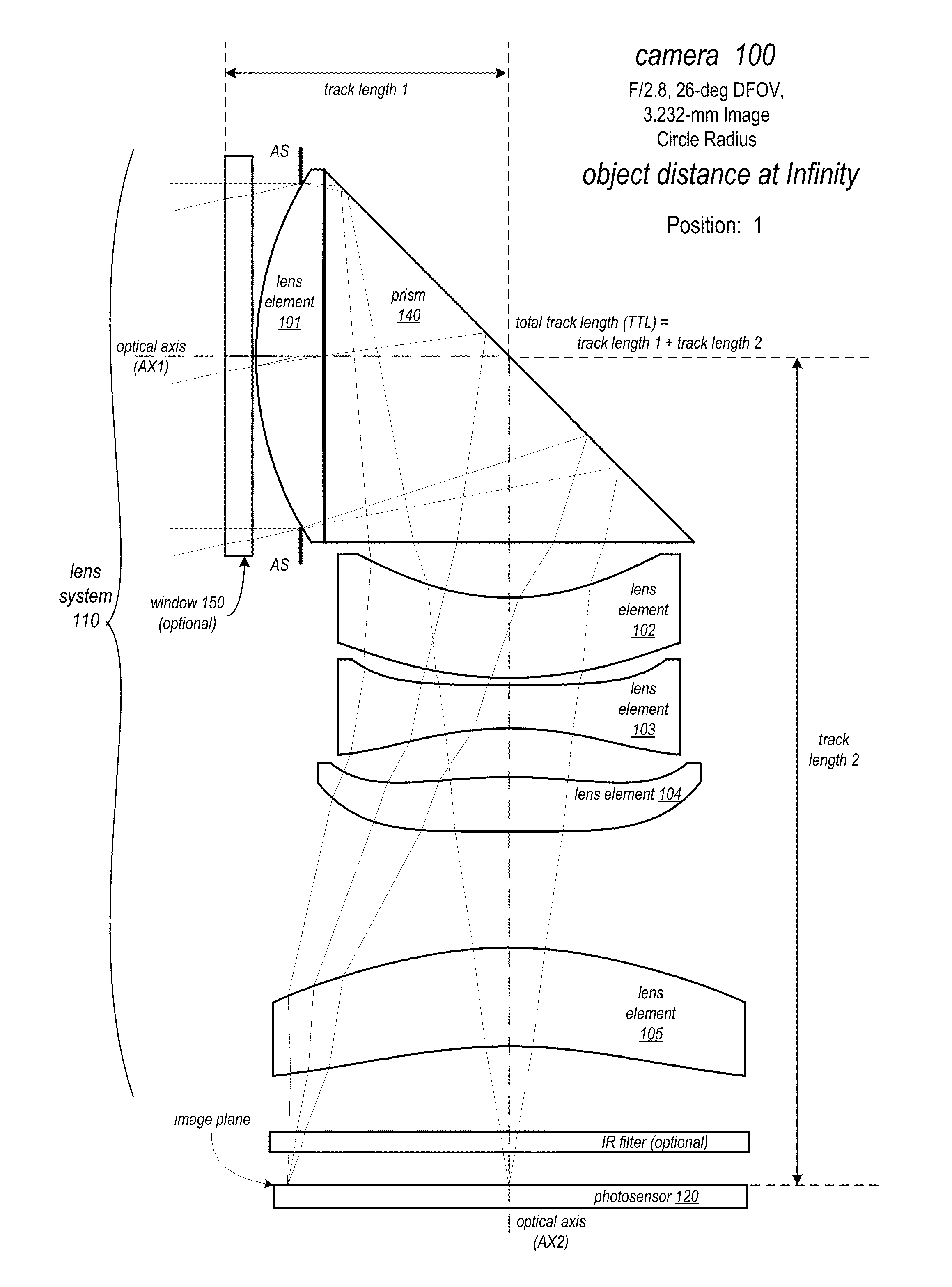

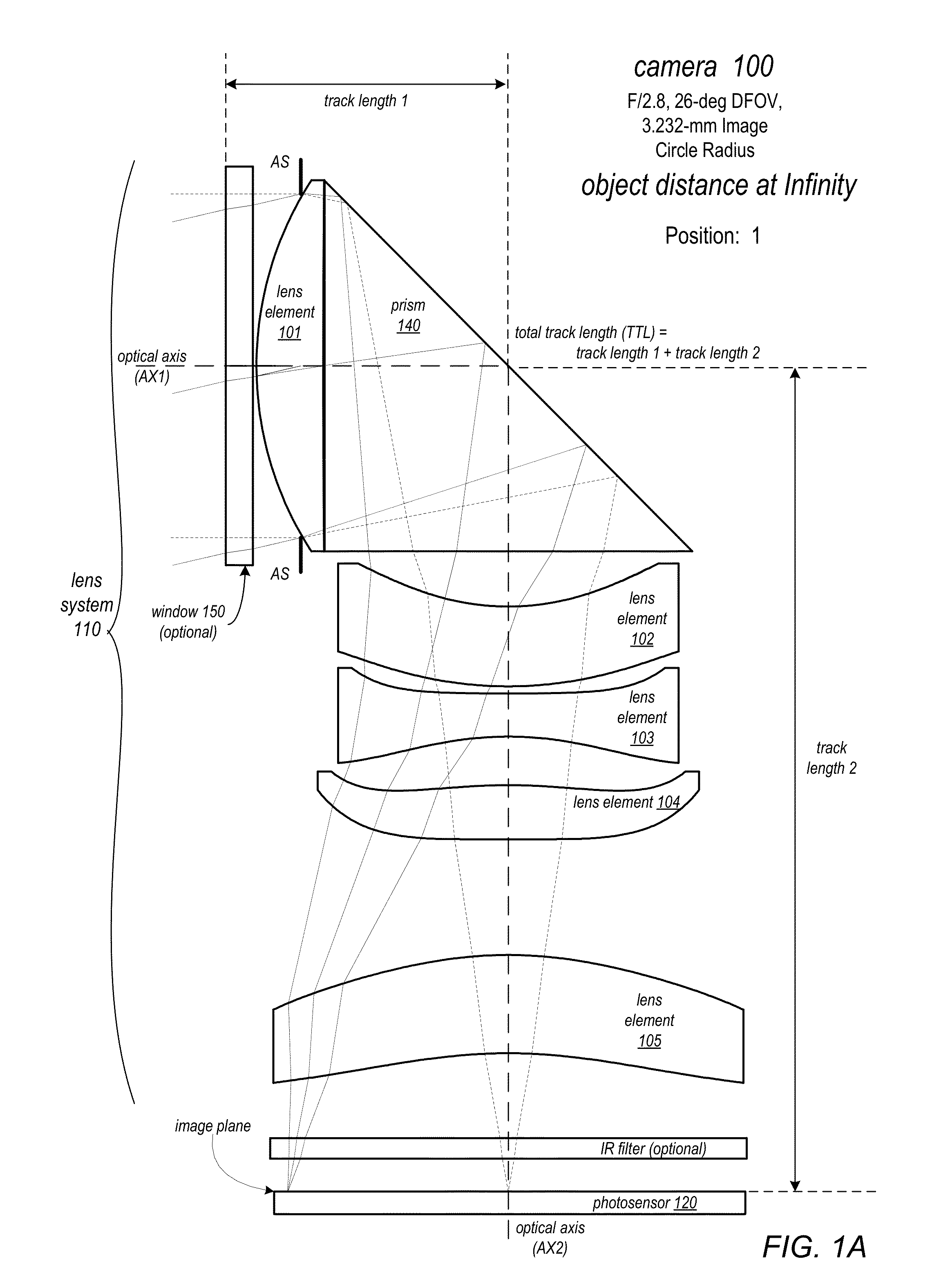

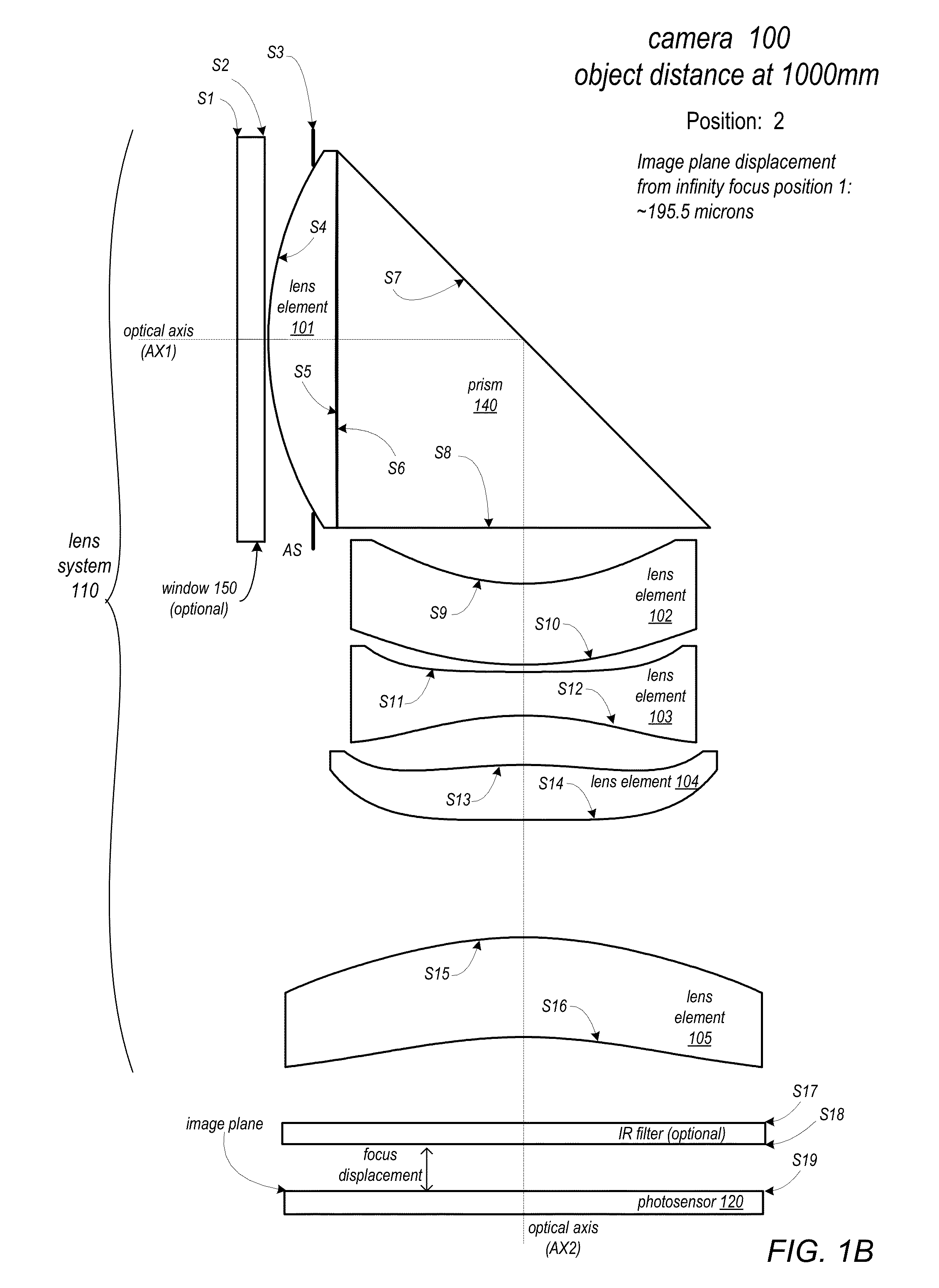

Folded camera lens systems

ActiveUS20150253647A1Well-corrected and balanced minimal residual aberrationReduce track lengthTelevision system detailsColor television detailsCamera lensImage resolution

A folded lens system may include multiple lenses with refractive power and a light path folding element. Light entering the camera through lens(es) on a first optical path or axis is refracted to the folding element, which changes direction of the light onto a second optical path or axis with lens(es) that refract the light to form an image plane at a photosensor. At least one of the object side and image side surfaces of at least one of the lens elements may be aspheric. Total track length (TTL) of the lens system may be 16.0 mm or less. The lens system may be configured so that the telephoto ration |TTL / f| is greater than 1.0. Materials, radii of curvature, shapes, sizes, spacing, and aspheric coefficients of the optical elements may be selected to achieve quality optical performance and high image resolution in a small form factor camera.

Owner:APPLE INC

Methods for fabricating fin field effect transistors using a protective layer to reduce etching damage

A method of forming a fin field effect transistor on a semiconductor substrate includes forming a vertical fin protruding from the substrate. A buffer oxide liner is formed on a top surface and on sidewalls of the fin. A trench is then formed on the substrate, where at least a portion of the fin protrudes from a bottom surface of the trench. The trench may be formed by forming a dummy gate on at least a portion of the fin, forming an insulation layer on the fin surrounding the dummy gate, and then removing the dummy gate to expose the at least a portion of the fin, such that the trench is surrounded by the insulation layer. The buffer oxide liner is then removed from the protruding portion of the fin, and a gate is formed in the trench on the protruding portion of the fin.

Owner:SAMSUNG ELECTRONICS CO LTD

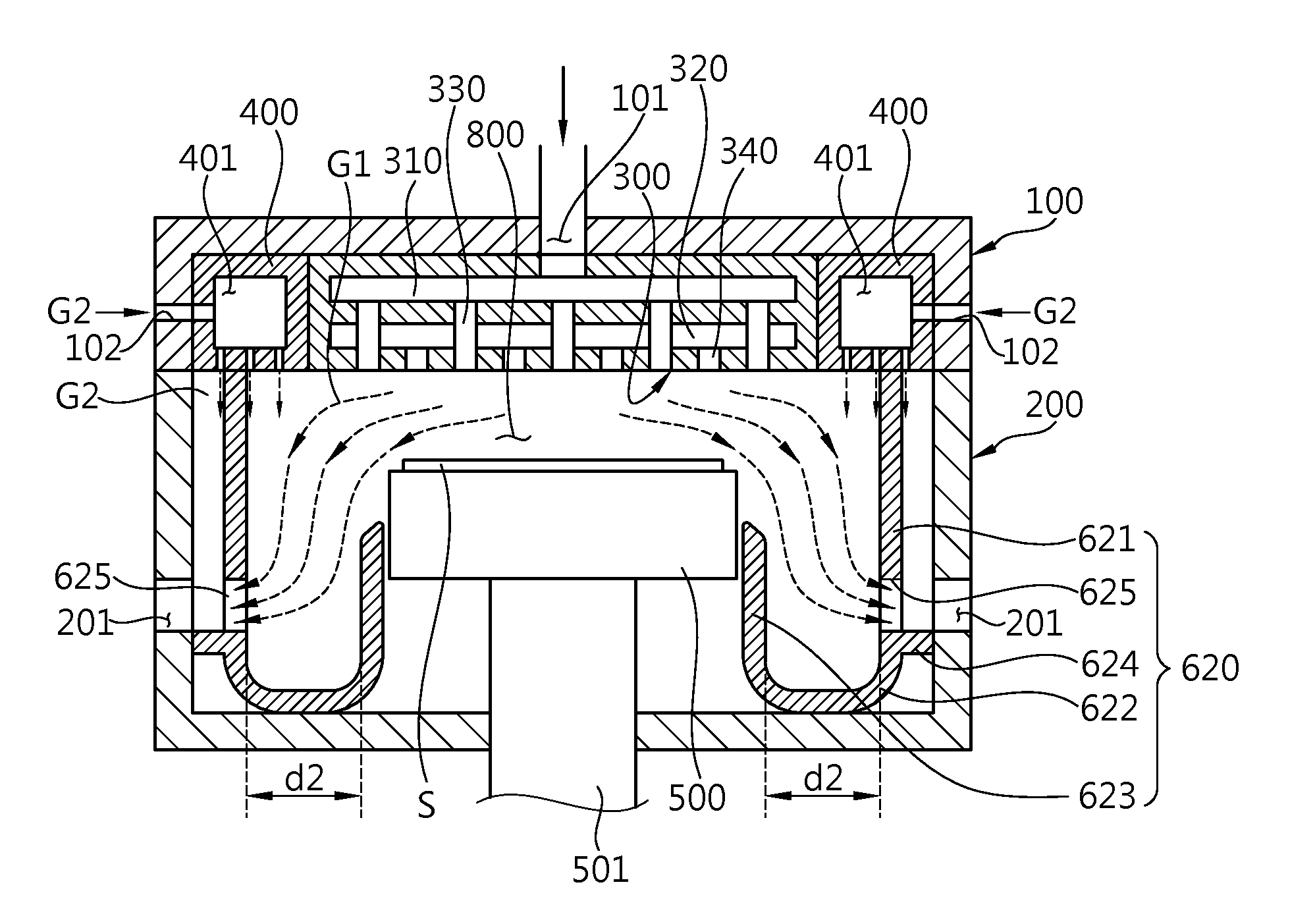

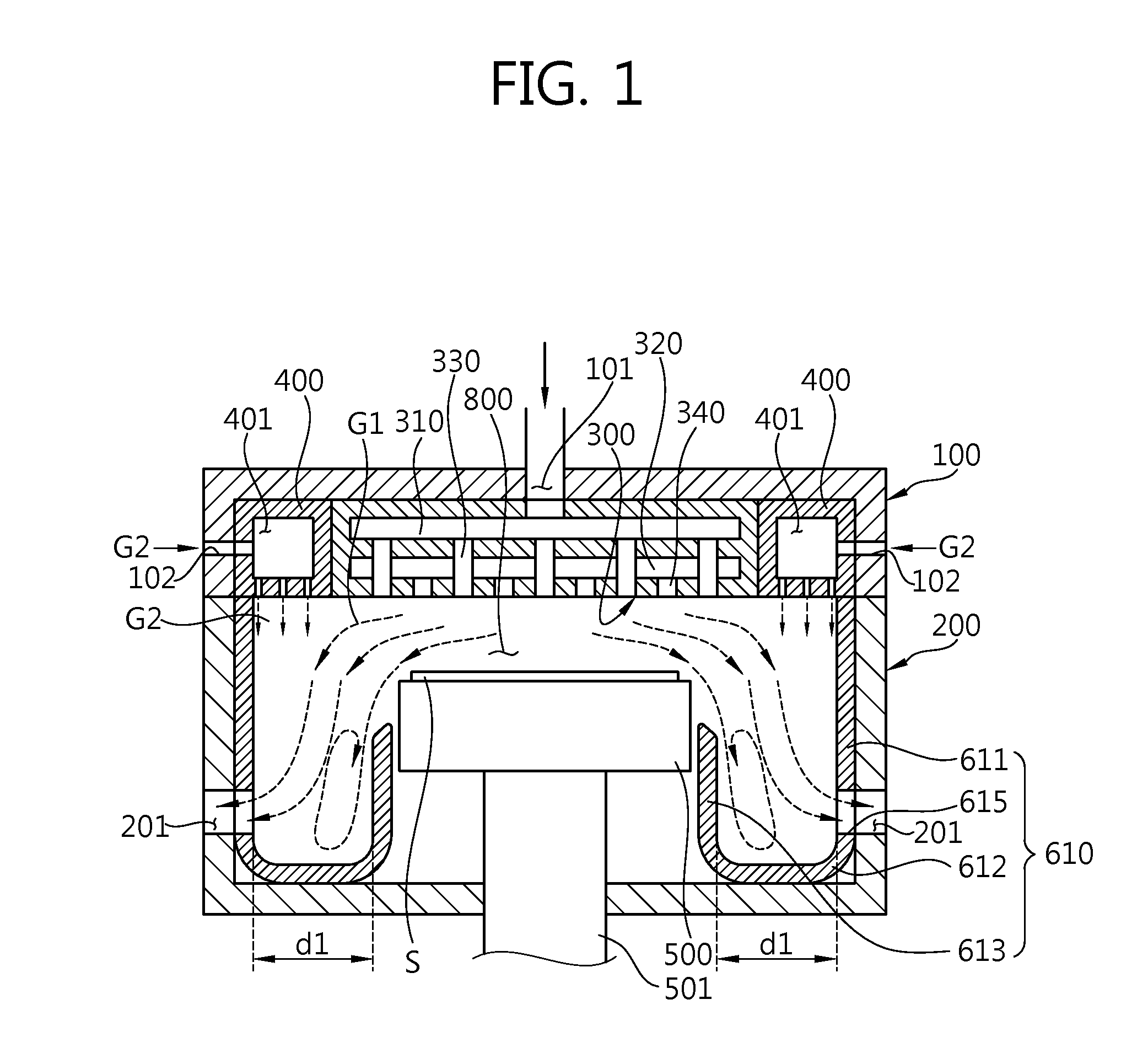

Chemical vapor deposition apparatus capable of controlling discharging fluid flow path in reaction chamber

InactiveUS8876974B2Reduce widthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorGas phase

A chemical vapor deposition apparatus is equipped to control the width of a gas discharge path between a susceptor and an inner surface of a chamber without having to resort to redesign and remanufacturing of the apparatus. The chemical vapor deposition apparatus includes: a chamber; a susceptor positioned inside the chamber and on which a substrate can be loaded; a shower head injecting a processing gas toward the substrate; and a guide unit detachably installed inside the chamber to guide the processing gas such that the processing gas injected from the shower head is discharged through a chamber hole formed in the chamber.

Owner:LIGADP

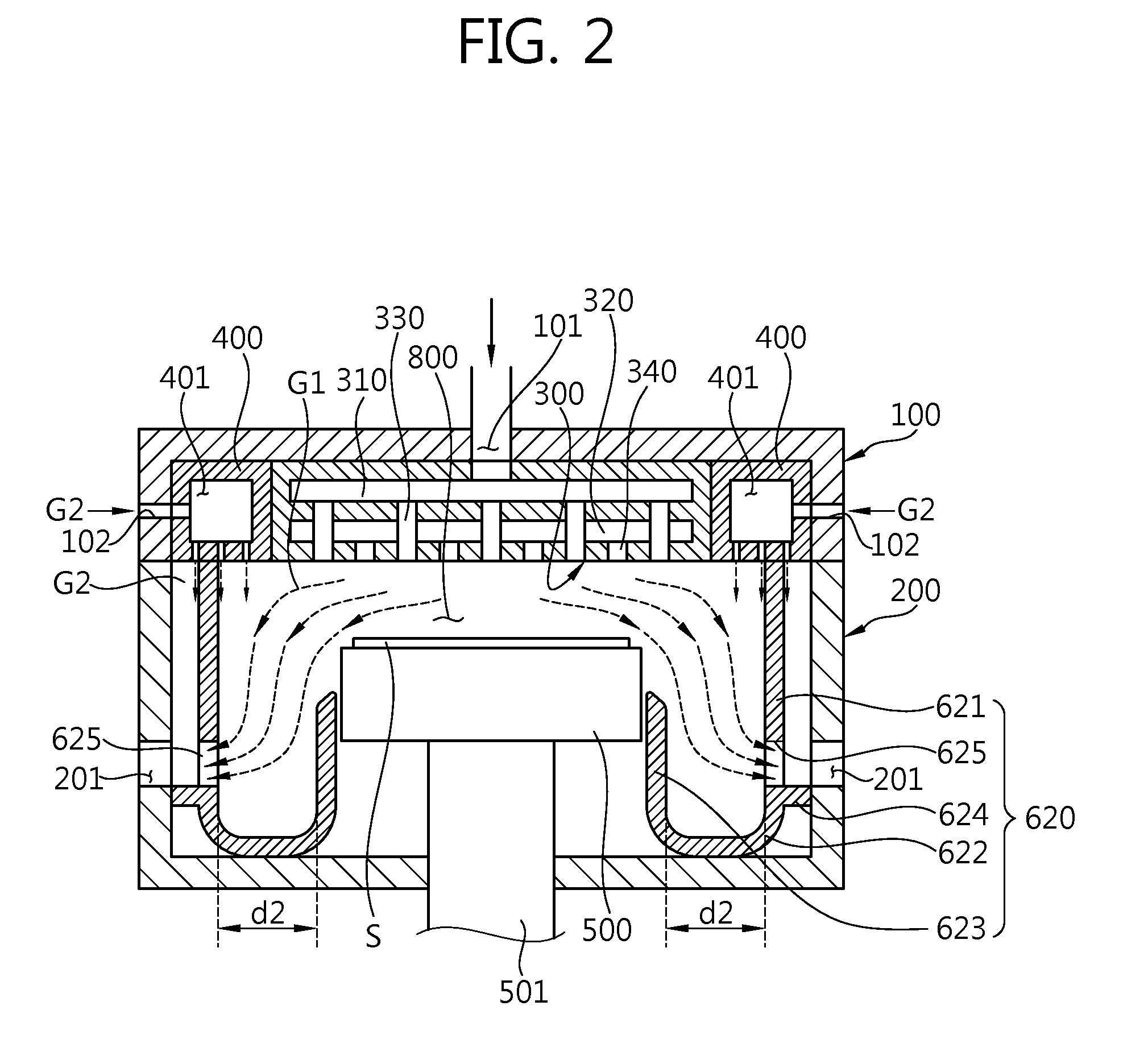

Pedicle screw assembly and methods therefor

InactiveUS6858030B2Improve compactnessLow profileInternal osteosythesisJoint implantsCouplingEngineering

A method for stabilizing a spine includes providing a coupling element having upper and lower ends, a rod receiving opening adapted to receive an elongated stabilizing rod, a bore extending through the lower end and a conical-shaped seat surrounding the bore adjacent the lower end; providing a fastener having upper and lower ends, a head having a radial surface, and at least one anchoring element between the lower end of the fastener and the head; assembling the fastener with the coupling element so that the lower end of the fastener passes through the bore of the coupling element and the radial surface of the head engages the conical-shaped seat. The method also includes anchoring the fastener to bone; moving the coupling element relative to the fastener for capturing the elongated stabilizing rod in the rod receiving opening; and urging the captured stabilizing rod toward the head of the fastener so that the rod contacts the head and forces the radial surface of the head against the conical-shaped seat of the coupling element for locking the coupling element from further movement relative to the fastener.

Owner:STRYKER SPINE

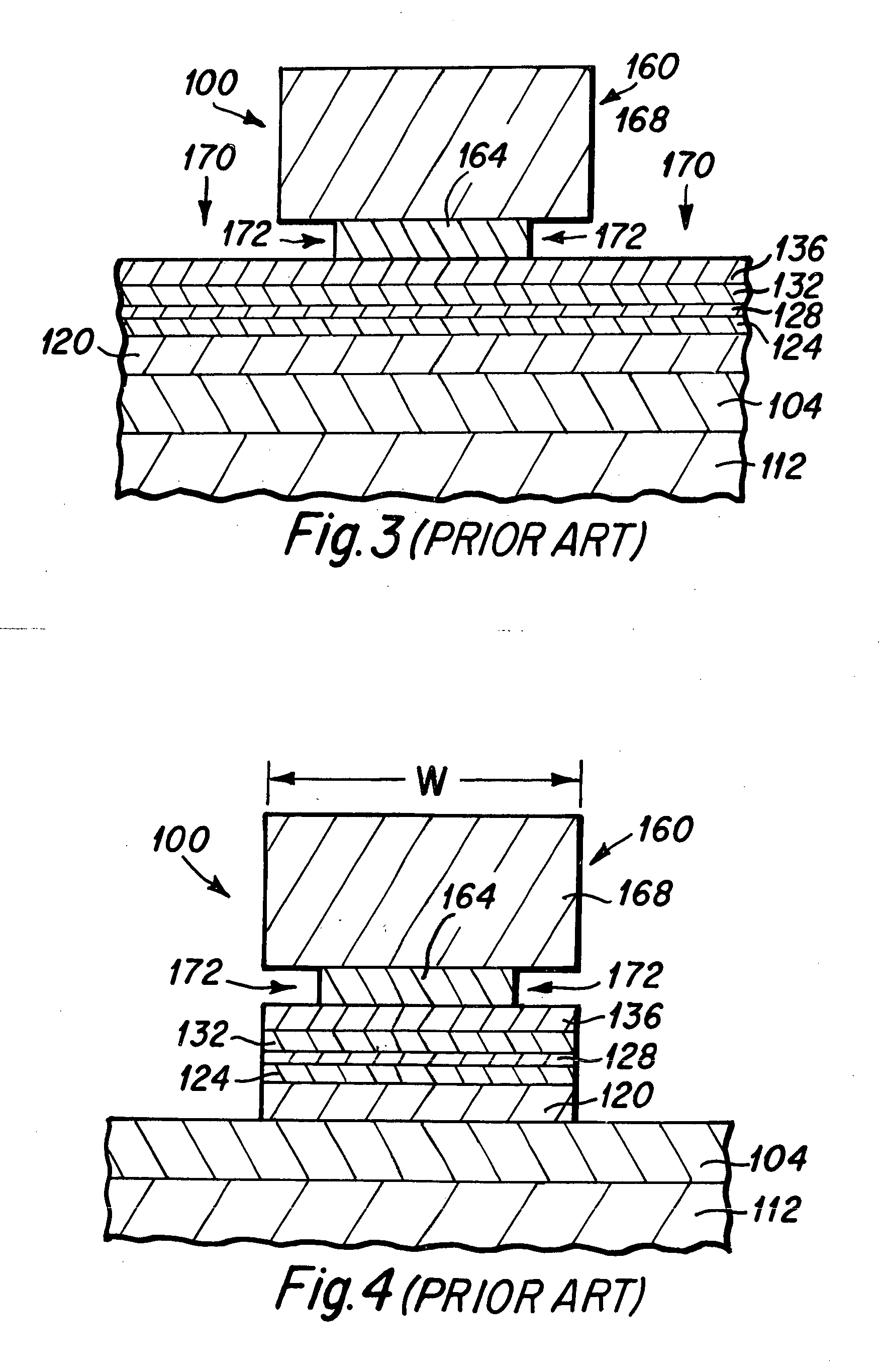

Method to fabricate side shields for a magnetic sensor

InactiveUS20060256482A1Reduce widthElectrical transducersDecorative surface effectsInsulation layerCompound (substance)

A method for fabricating magnetic side shields for an MR sensor of a magnetic head. Following the deposition of MR sensor layers, a first DLC layer is deposited. Milling mask layers are then deposited, and outer portions of the milling mask layers are removed such that a remaining central portion of the milling mask layers is formed having straight sidewalls and no undercuts. Outer portions of the sensor layers are then removed such that a relatively thick remaining central portion of the milling mask resides above the remaining sensor layers. A thin electrical insulation layer is deposited, followed by the deposition of magnetic side shields. A second DLC layer is deposited and the remaining mask layers are then removed utilizing a chemical mechanical polishing (CMP) liftoff step. Thereafter, the first DLC layer and the second DLC layer are removed and a second magnetic shield layer is then fabricated thereabove.

Owner:WESTERN DIGITAL TECH INC

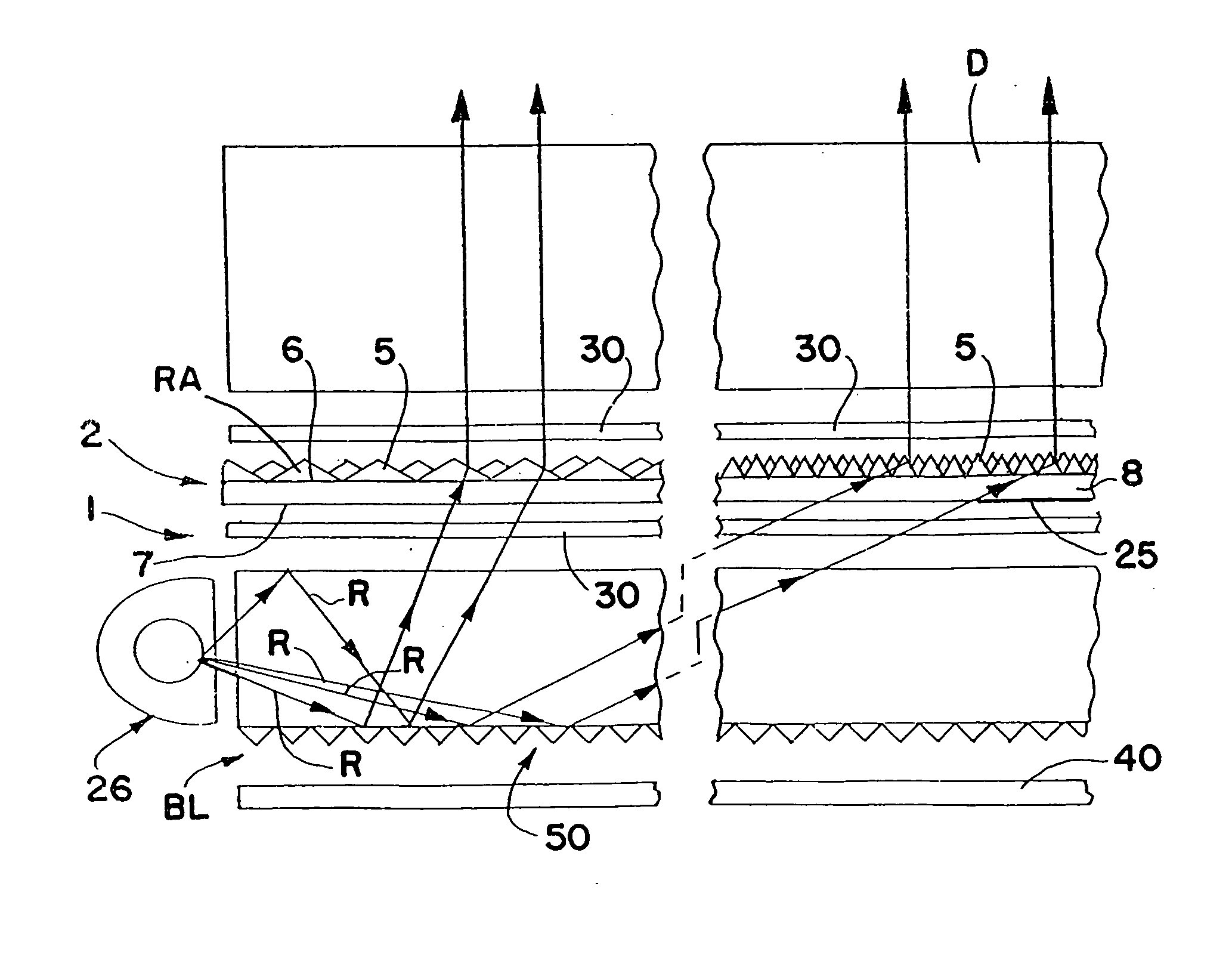

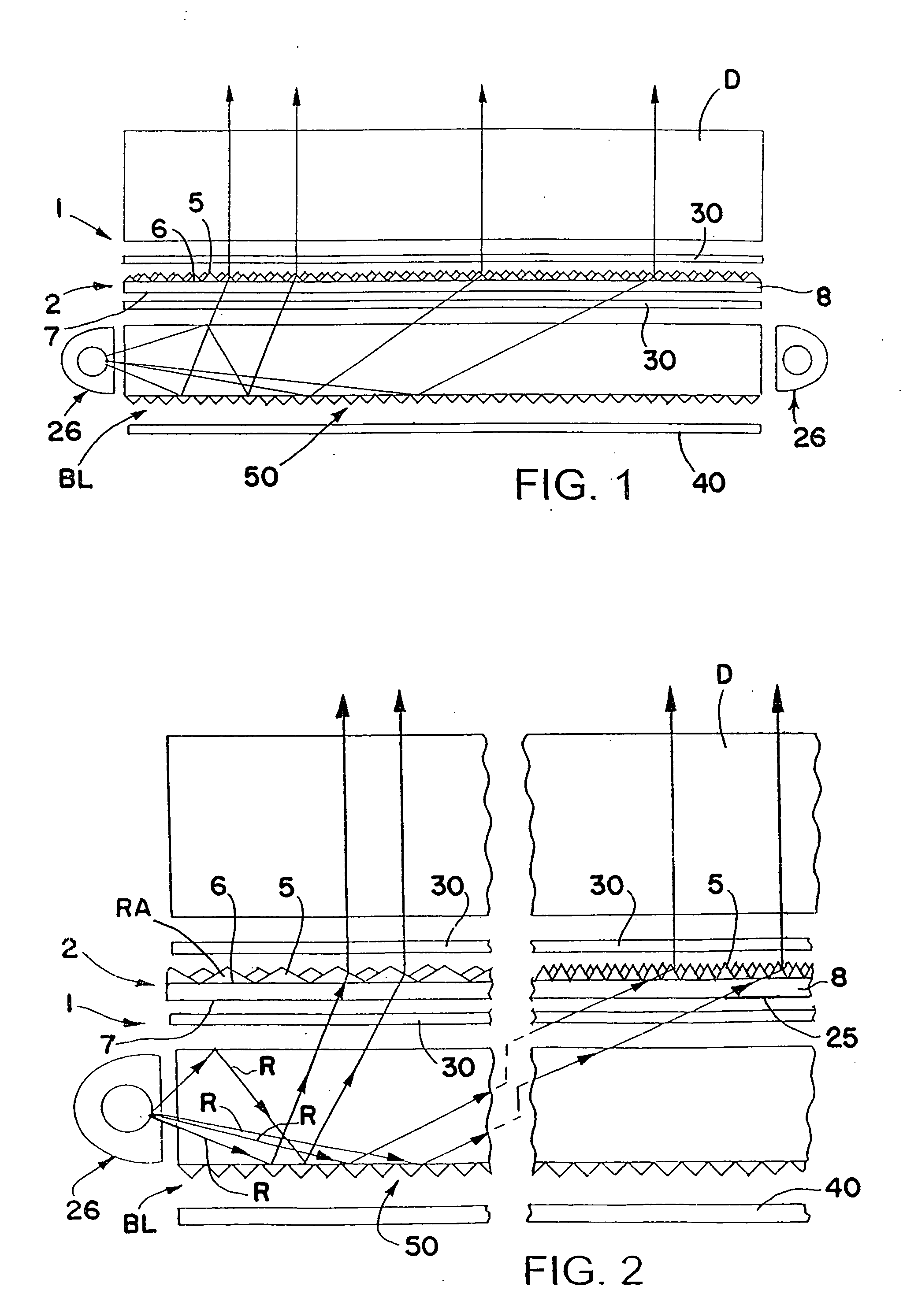

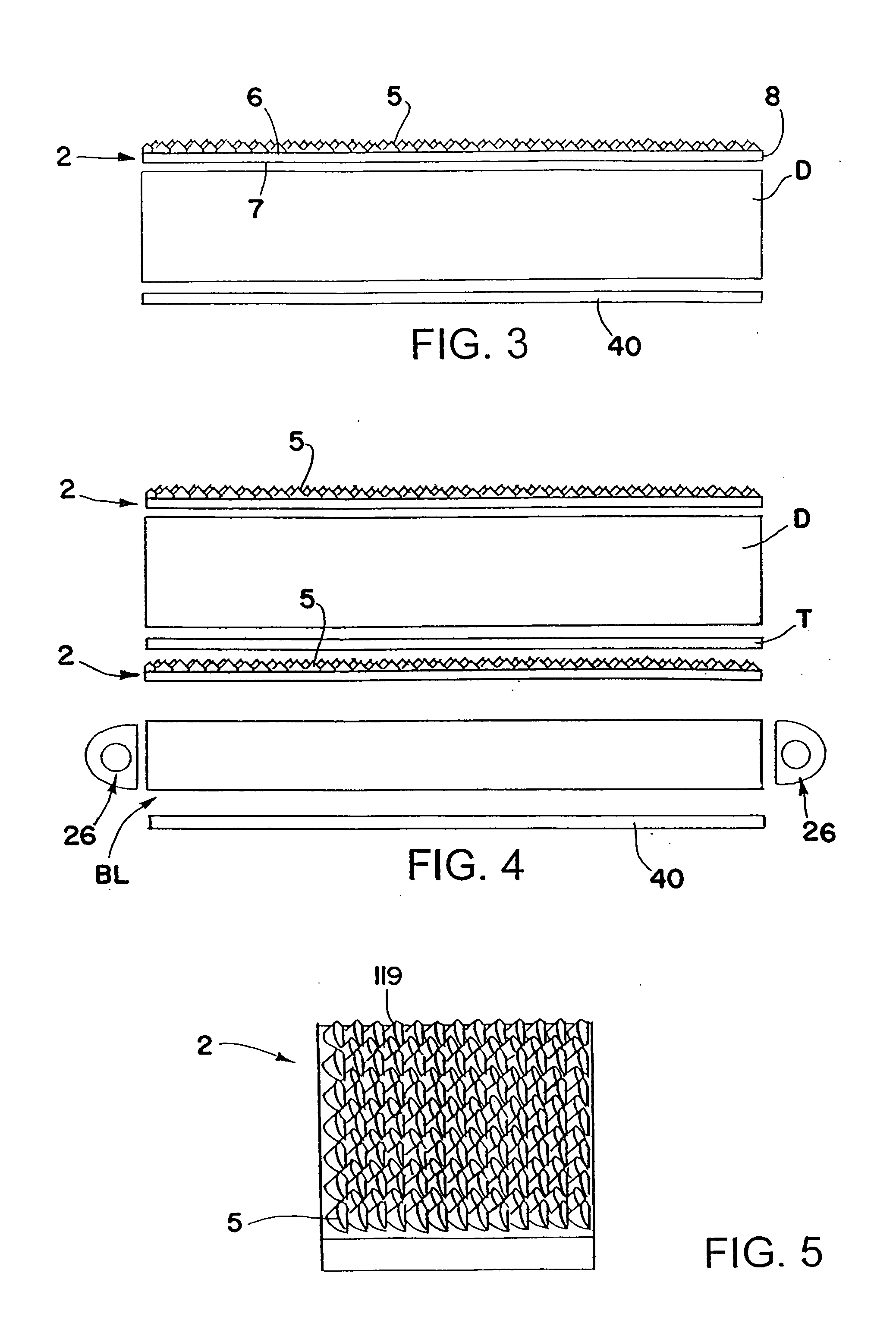

Methods of cutting or forming cavities in a substrate for use in making optical films, components or wave guides

InactiveUS20050024849A1Small in in lengthSmall in widthMechanical apparatusFlat articlesEngineeringRidge

The methods involve using a tool to cut or form multiple optical element shaped cavities in a surface of a substrate without rotating the tool or substrate during the cutting or forming process. At least some of the cavities are cut or formed to have at least two surfaces that come together to form a ridge and that are quite small relative to the length and width of the substrate. Thereafter the substrate is used to form optical films, components or wave guides having multiple optical elements on at least one surface corresponding to the cavities in the substrate.

Owner:SOLID STATE OPTO

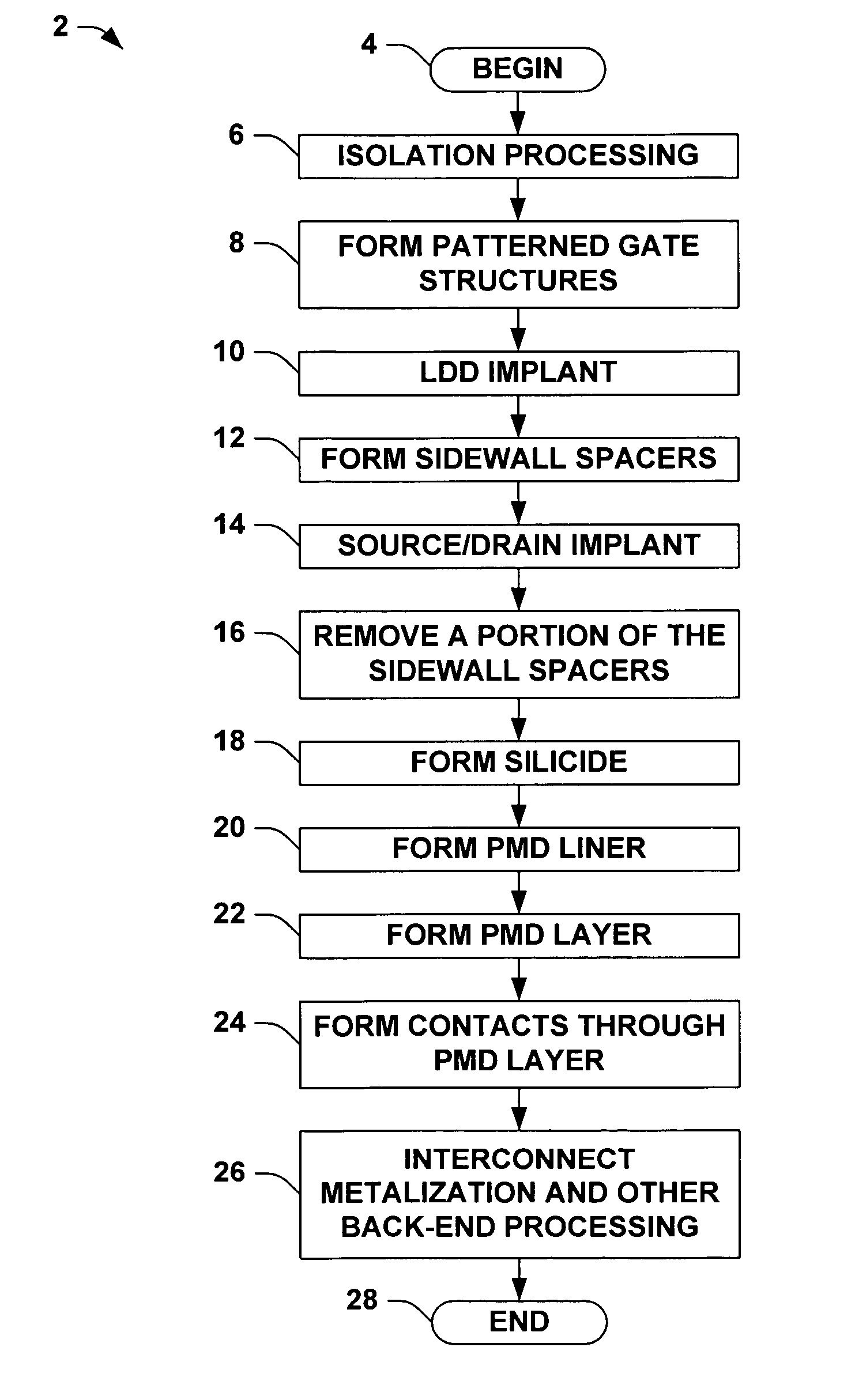

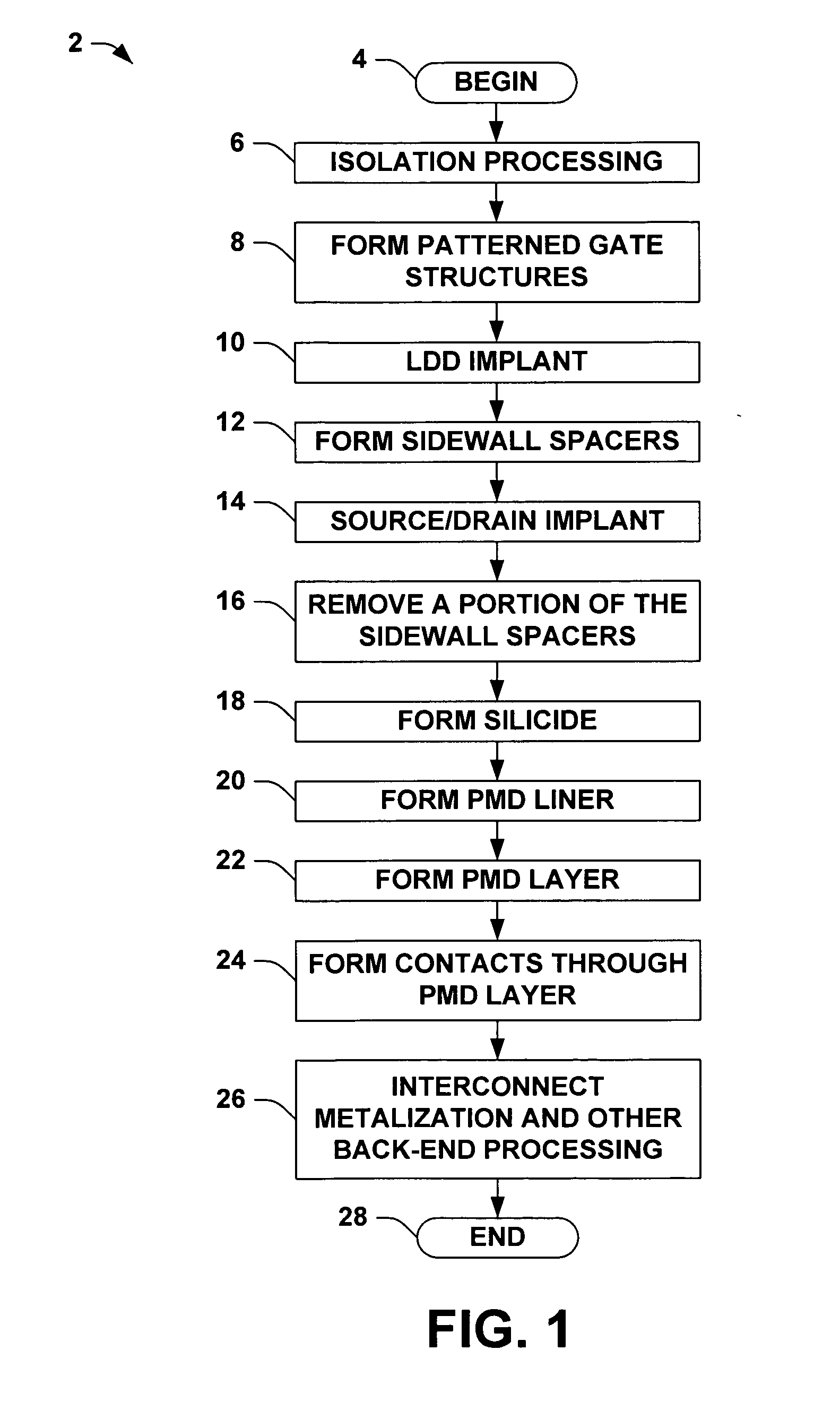

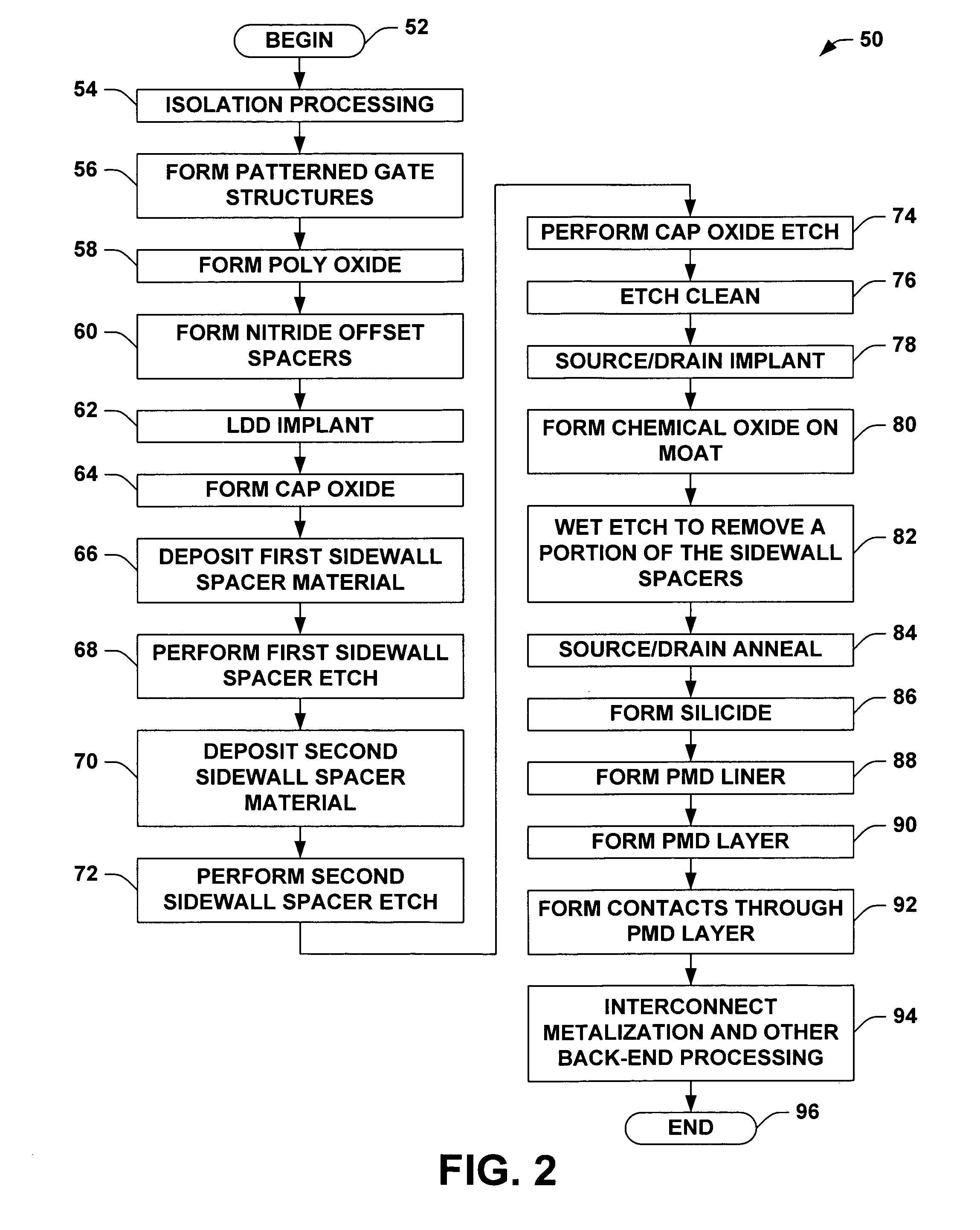

Transistor fabrication methods using dual sidewall spacers

ActiveUS20060019456A1Increase pressureIncrease contact resistanceTransistorSemiconductor/solid-state device manufacturingTransistorElectrical and Electronics engineering

Methods (50) are presented for transistor fabrication, in which first and second sidewall spacers (120a, 120b) are formed laterally outward from a gate structure (114), after which a source / drain region (116) is implanted. The method (50) further comprises removing all or a portion of the second sidewall spacer (120b) after implanting the source / drain region (116), where the remaining sidewall spacer (120a) is narrower following the source / drain implant to improve source / drain contact resistance and PMD gap fill, and to facilitate inducing stress in the transistor channel.

Owner:TEXAS INSTR INC

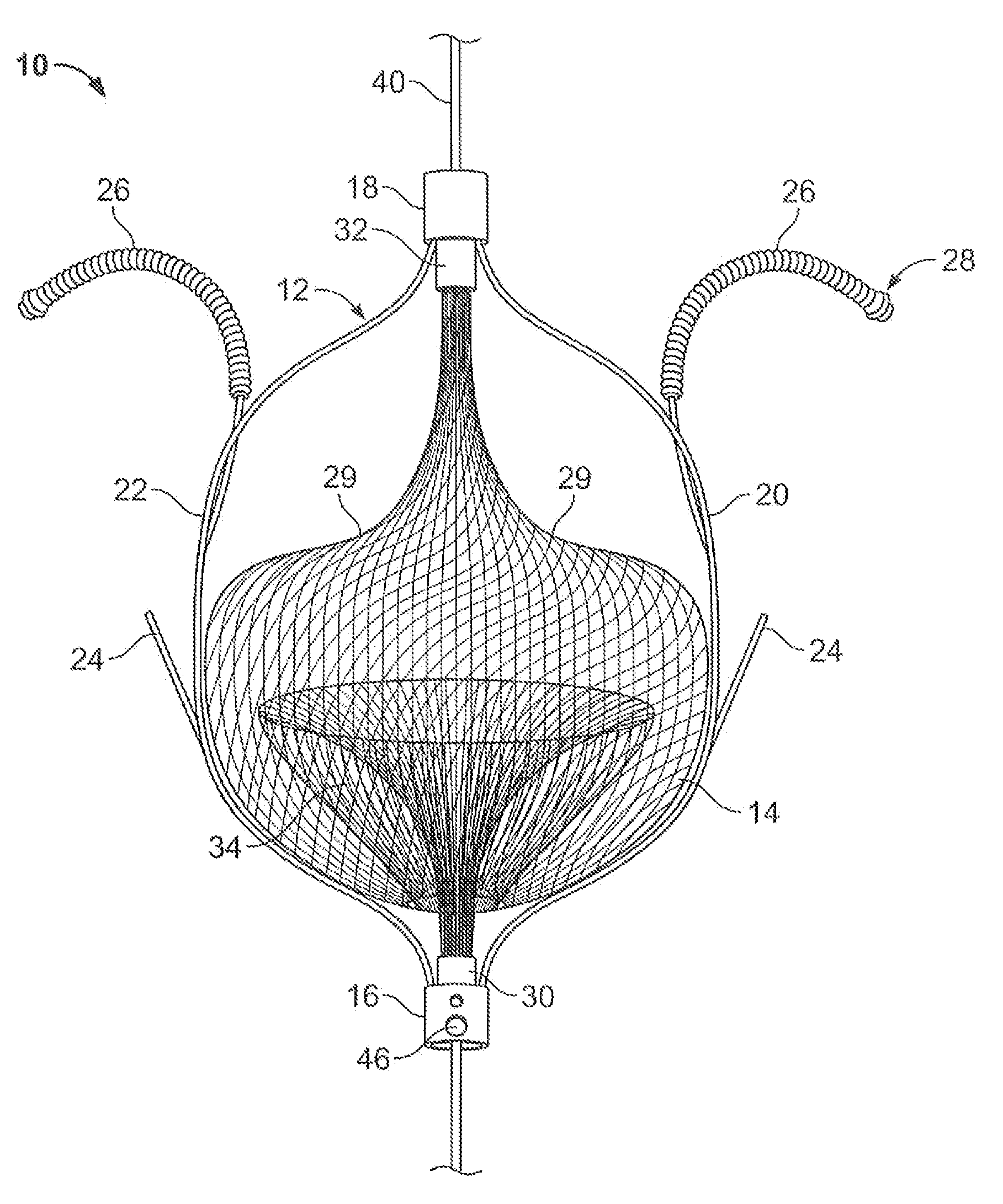

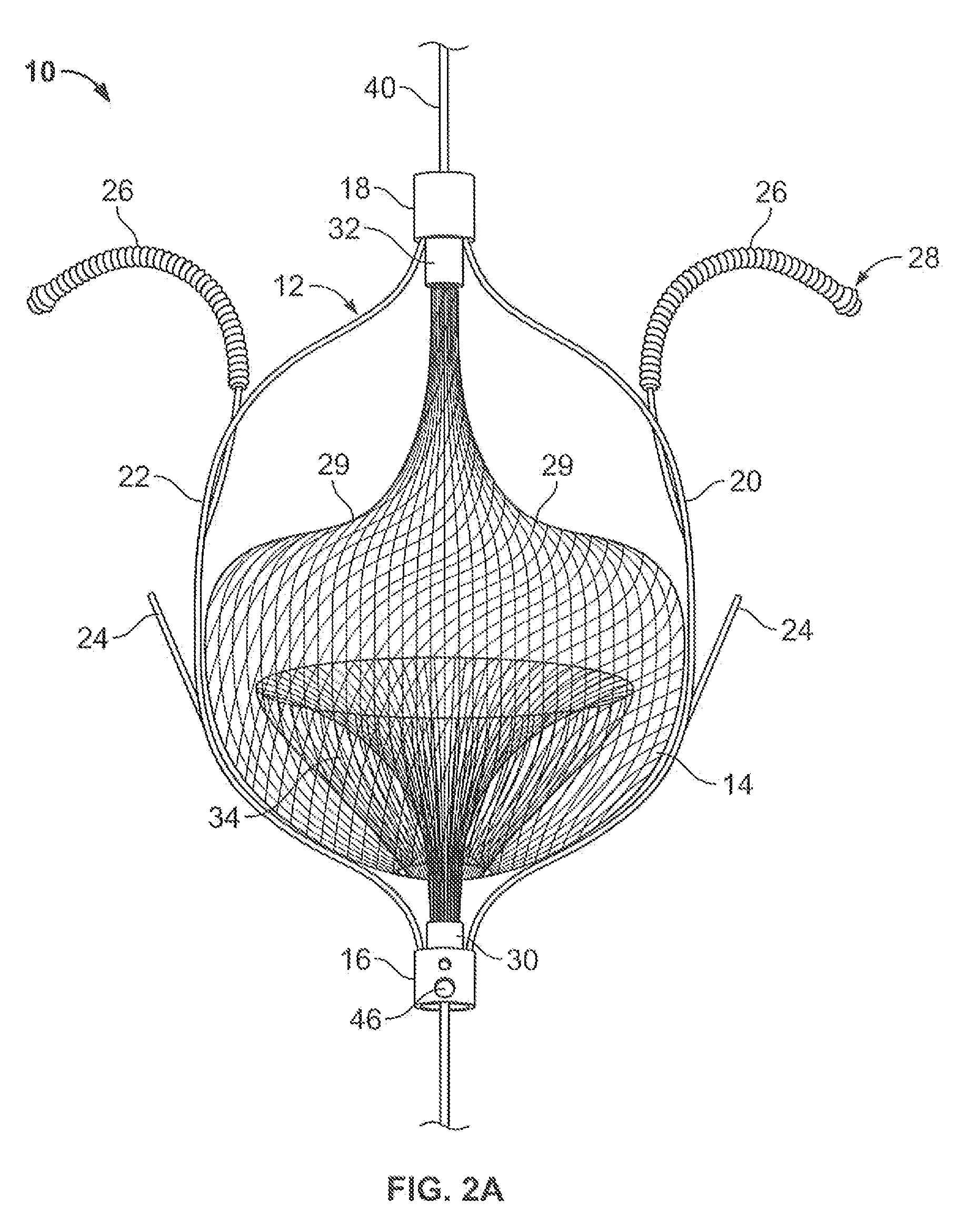

Mechanical tissue device and method

InactiveUS20080119886A1Rigid enoughLength of device being increasedDilatorsOcculdersVeinVenous blood

The present invention relates generally to a device and method for preventing the undesired passage of emboli from a venous blood pool to an arterial blood pool. The invention relates especially to a device and method for treating certain cardiac defects, especially patent foramen ovales and other septal defects, through the use of an embolic filtering device capable of instantaneously deterring the passage of emboli from the moment of implantation. The device consists of a frame, and a braided mesh of sufficient dimensions to prevent passage of emboli through the mesh. The device is preferably composed of shape memory allow, such as Nitinol, which conforms to the shape and dimension of the defect to be treated.

Owner:SEPTRX

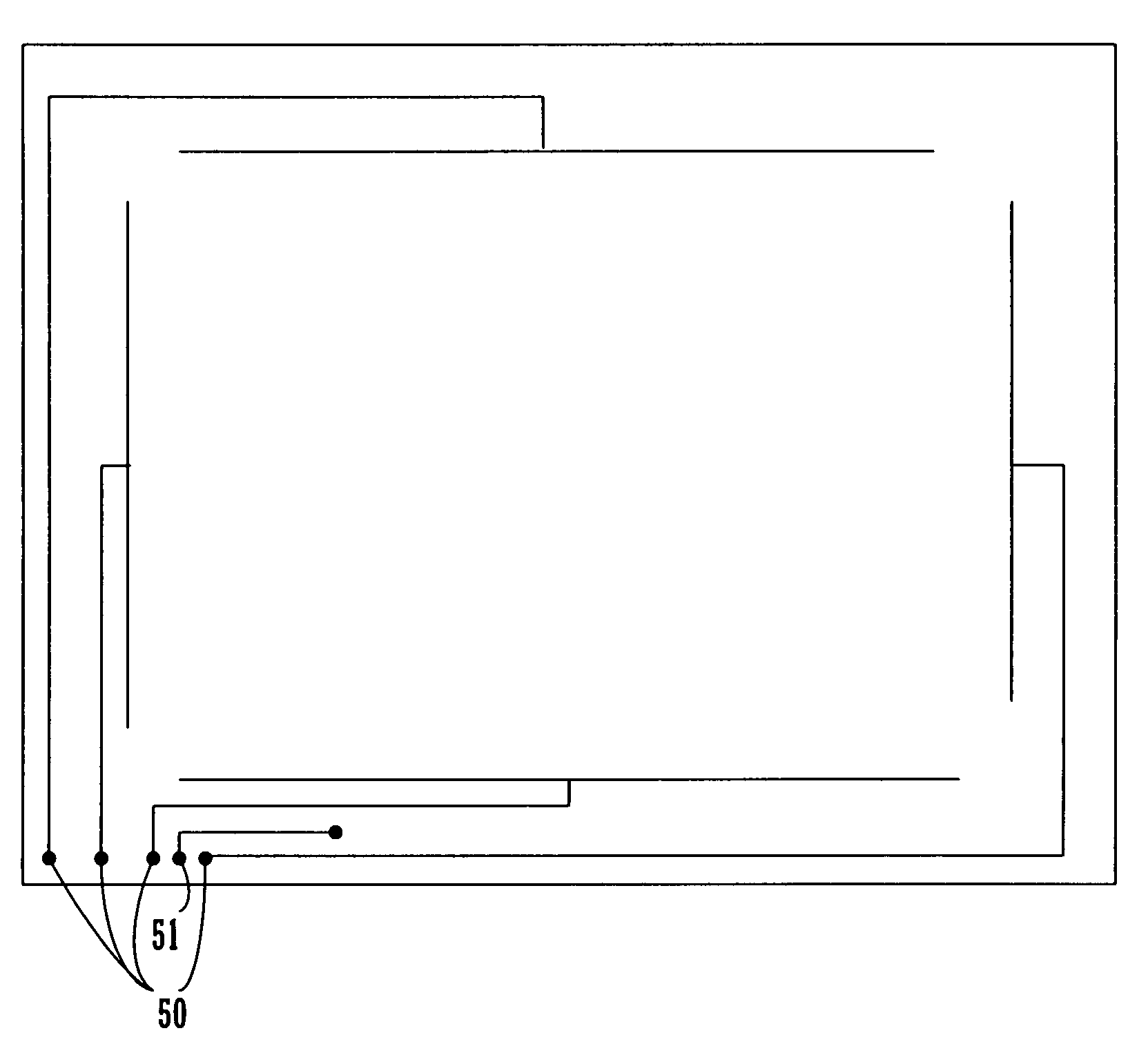

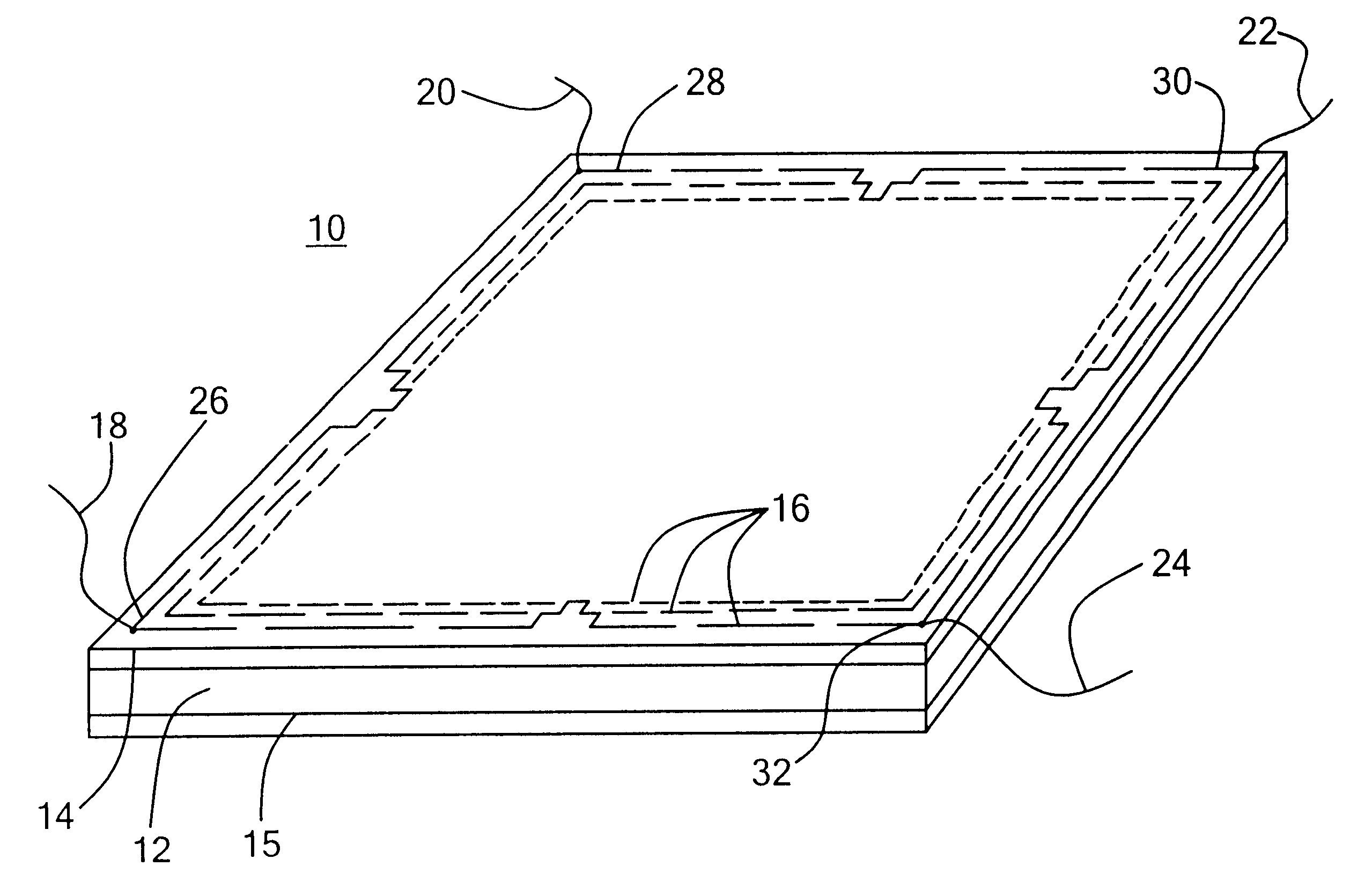

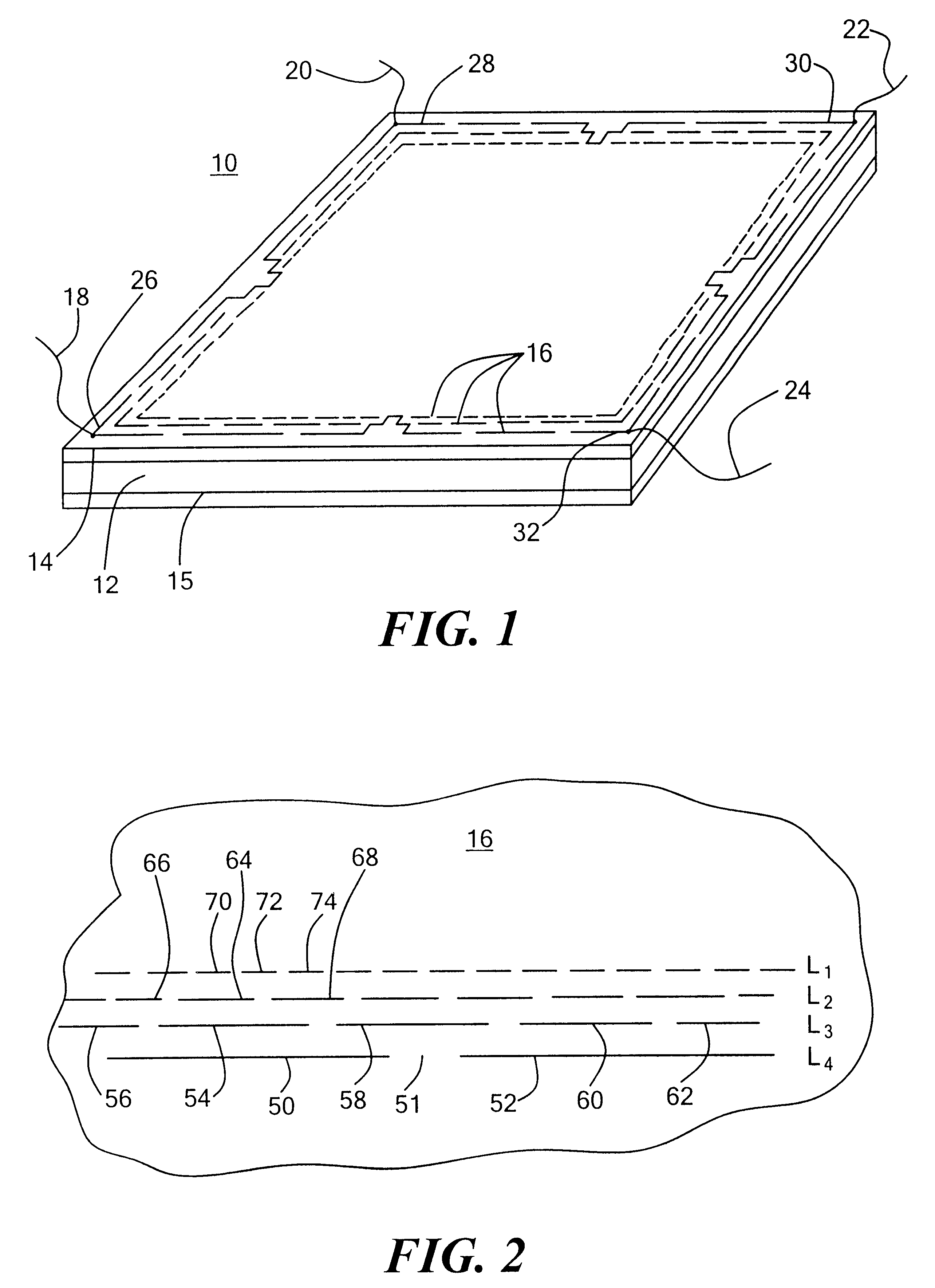

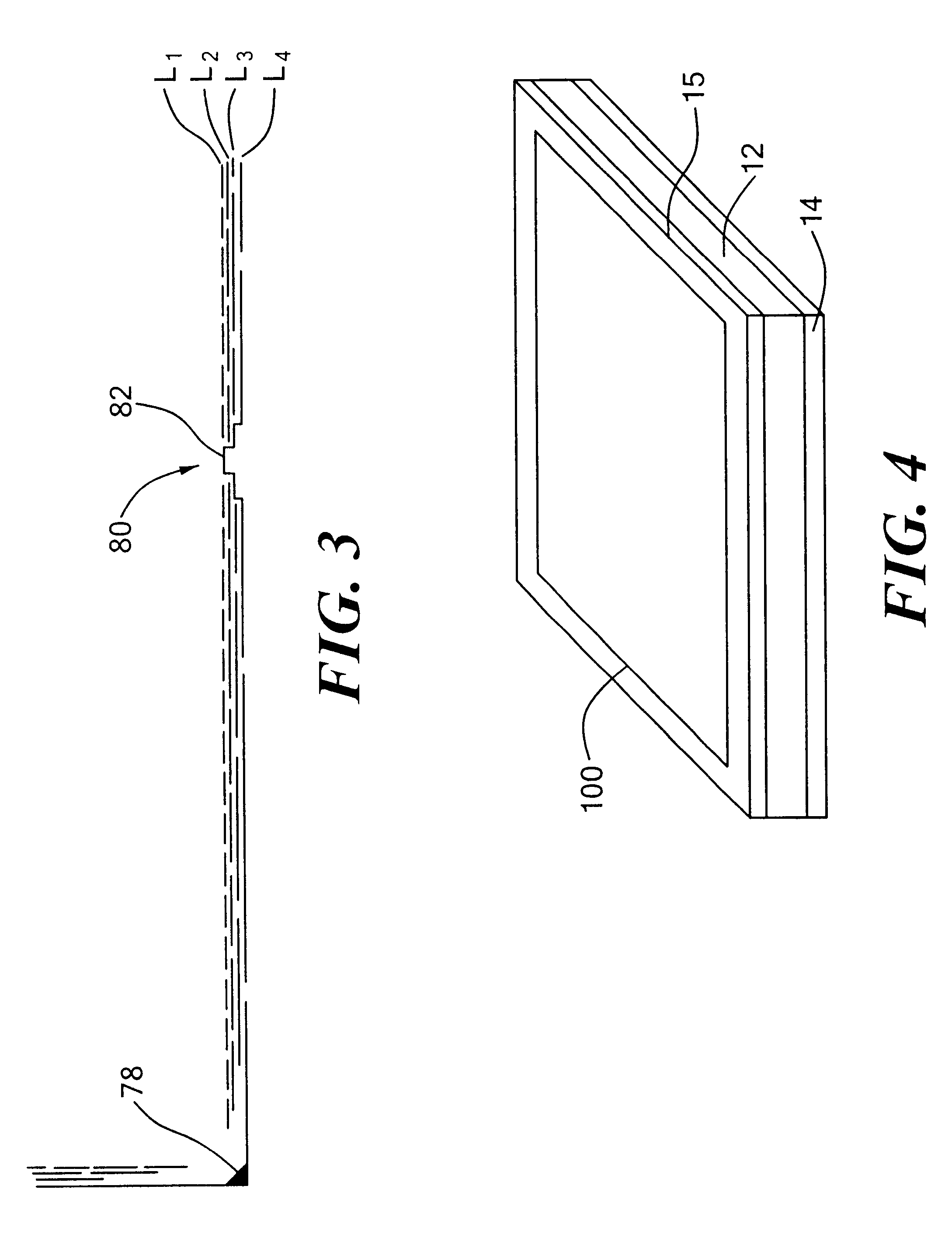

Compact integrated touch panel display for a handheld device

InactiveUS6965375B1Minimizing length of busReduction in size of handheldTransmission systemsCathode-ray tube indicatorsFlexible circuitsElectrical connection

A handheld device with a compact integrated touch panel is disclosed. A handheld device incorporating a touch panel display requiring electrical connections is reduced in size by incorporating electrical pathways within the support structure of the touch panel display, obviating the need for a flex circuit extension from the touch panel display for connection to the handheld device. A further reduction in size is obtained by providing an inherent visually homogeneous perimeter for the touch panel display by matching the colors of the conductive and dielectric materials, thereby eliminating the need for a bezel.

Owner:QUALCOMM INC

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS20030140846A1Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

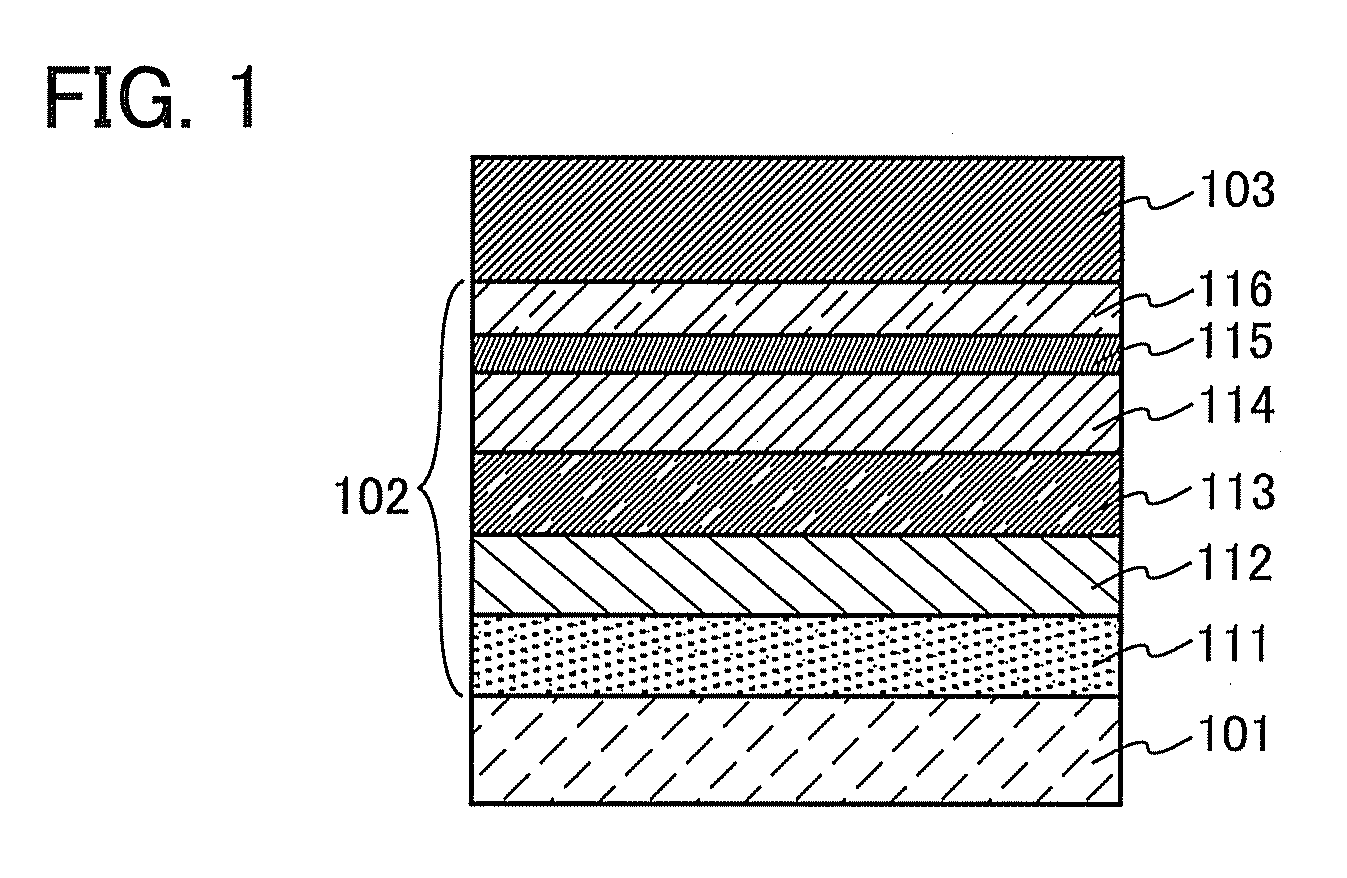

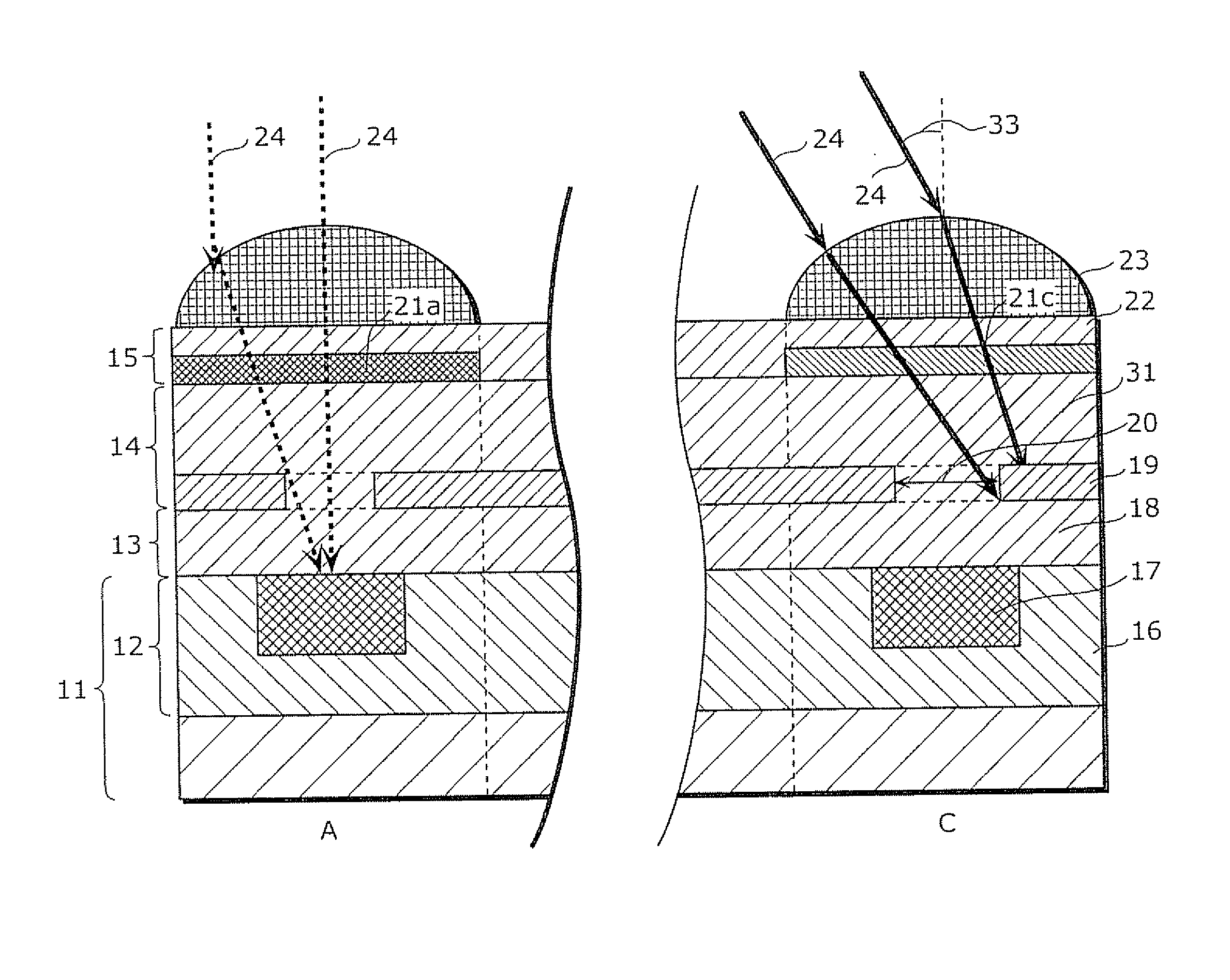

Solid-state image sensor and manufacturing method thereof

ActiveUS20060278948A1Small aperture widthLight-condensing efficiencySolid-state devicesRadiation controlled devicesRefractive indexPhotoelectric conversion

An object of the present invention is to provide a small solid-state image sensor which realizes significant improvement in sensitivity. The solid-state image sensor of the present invention includes a semiconductor substrate in which photoelectric conversion units are formed, a light-blocking film which is formed above the semiconductor substrate and has apertures formed so as to be positioned above respective photoelectric conversion units, and a high refractive index layer formed in the apertures. Here, each aperture has a smaller aperture width than a maximum wavelength in a wavelength of light in a vacuum converted from a wavelength of the light entering the photoelectric conversion unit through the apertures, and the high refractive index is made of a high refractive index material having a refractive index which allows transmission of light having the maximum wavelength through the aperture.

Owner:PANASONIC CORP

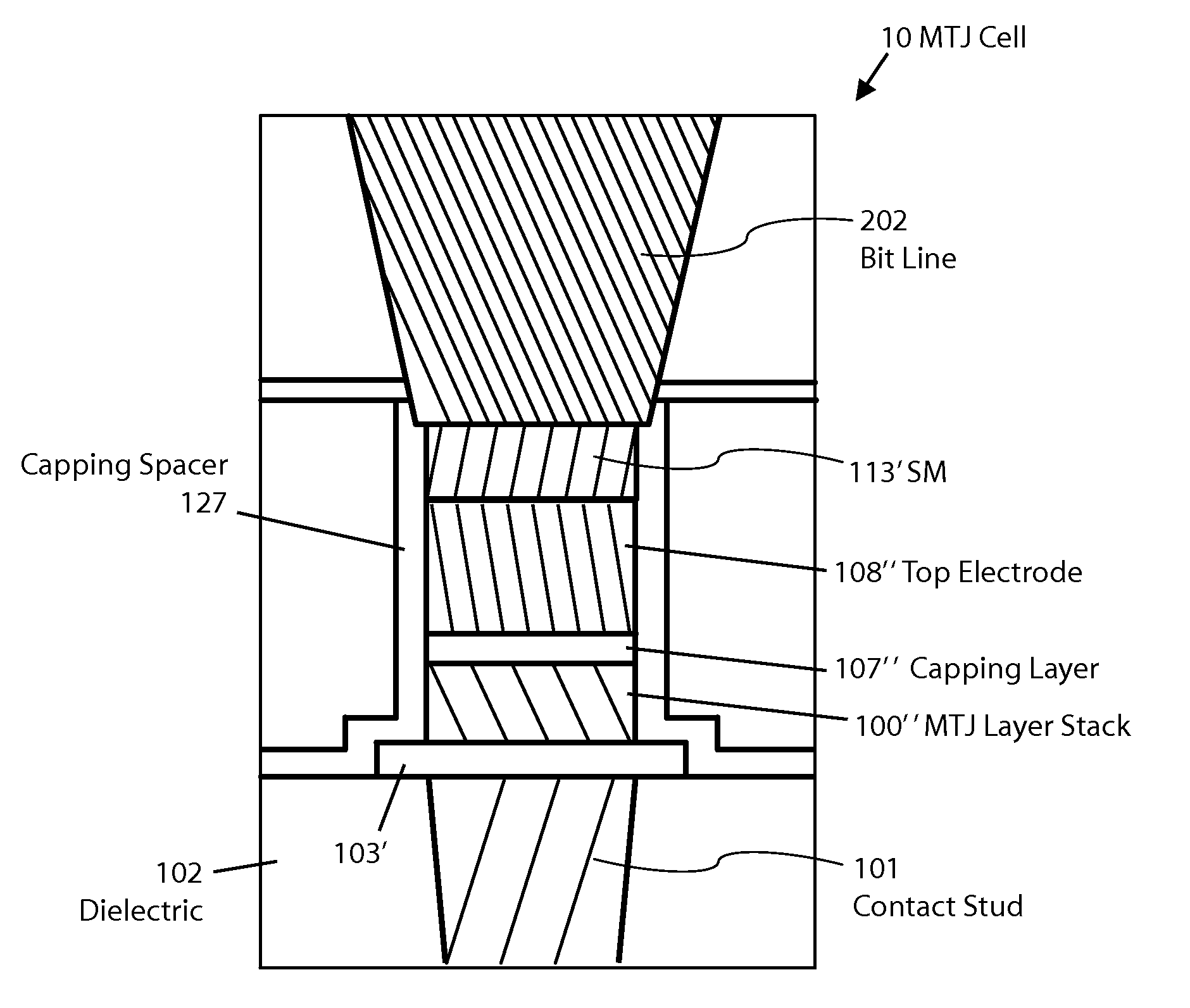

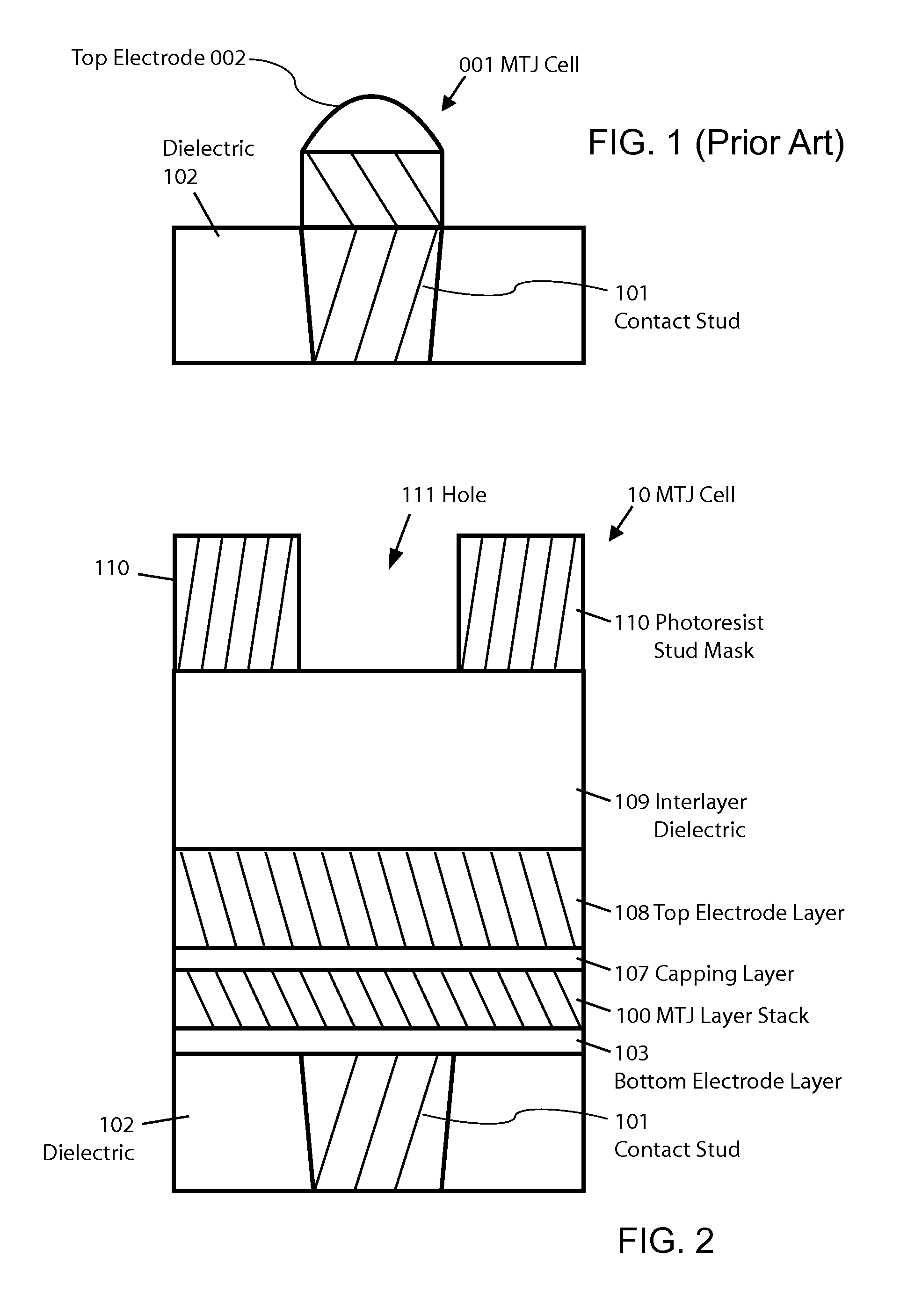

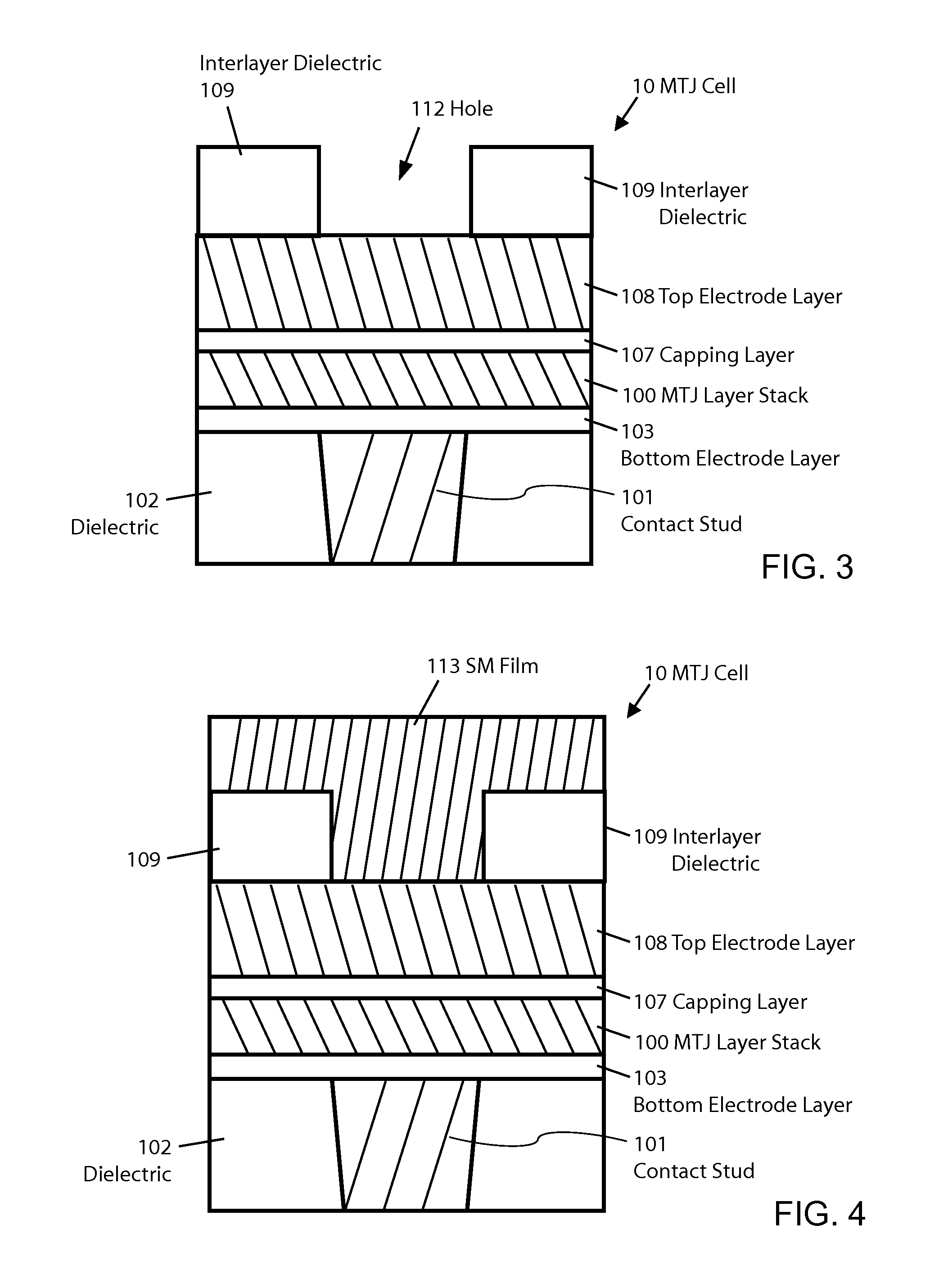

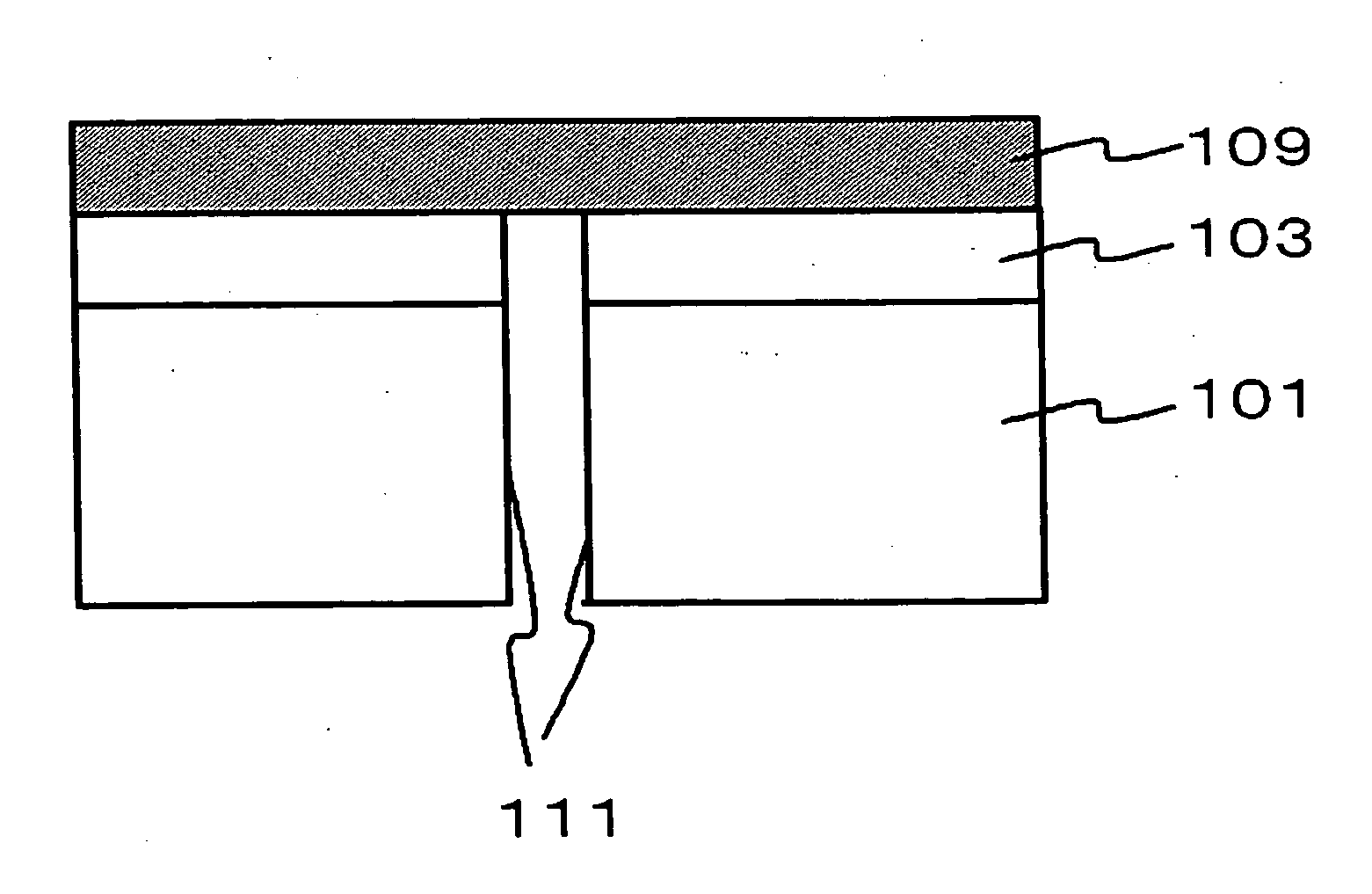

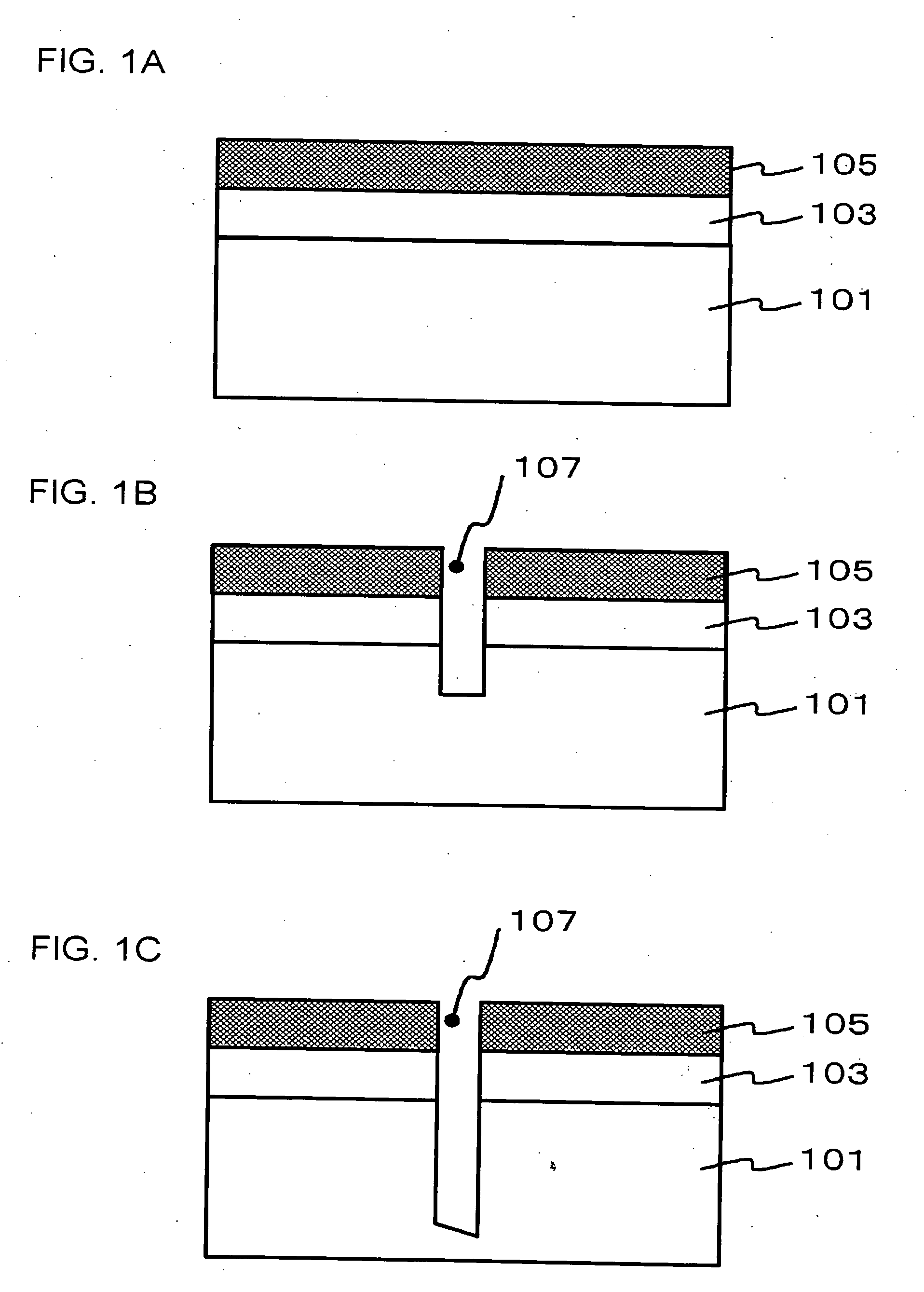

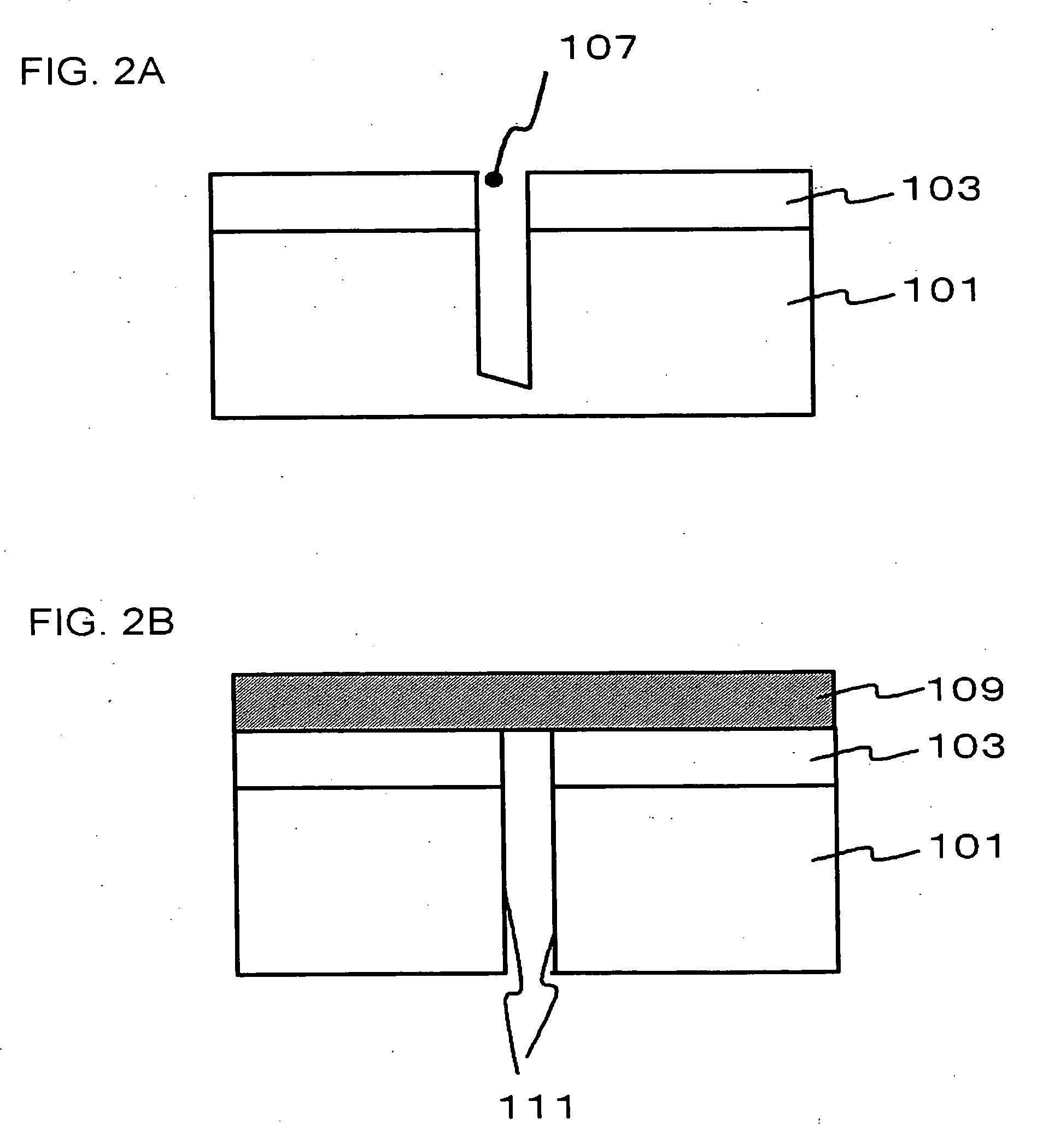

MTJ MRAM with stud patterning

ActiveUS8772888B2Reduce widthImprove errorMagnetic-field-controlled resistorsSolid-state devicesEtchingConductive materials

Owner:AVALANCHE TECH

Method for manufacturing semiconductor device

InactiveUS20060205182A1Reduce widthRate of the processing for providing the trenched portion can beSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDevice form

A method of dicing a semiconductor wafer includes providing an interconnect layer providing a protective film on the interconnect layer on the side of a device-forming surface of a silicon wafer, irradiating the protective film with a laser beam to provide a trenched portion that extends through the interconnect layer from the protective film and reaches to an inside of the silicon wafer, removing a portion of the silicon wafer selectively in a depth direction from a bottom of the trenched portion, after irradiating with the laser beam to provide the trenched portion and dividing the silicon wafer along the portion where the trenched portion is provided into respective pieces of the silicon wafer, after removing a portion of the silicon wafer 101 selectively in the depth direction.

Owner:NEC ELECTRONICS CORP

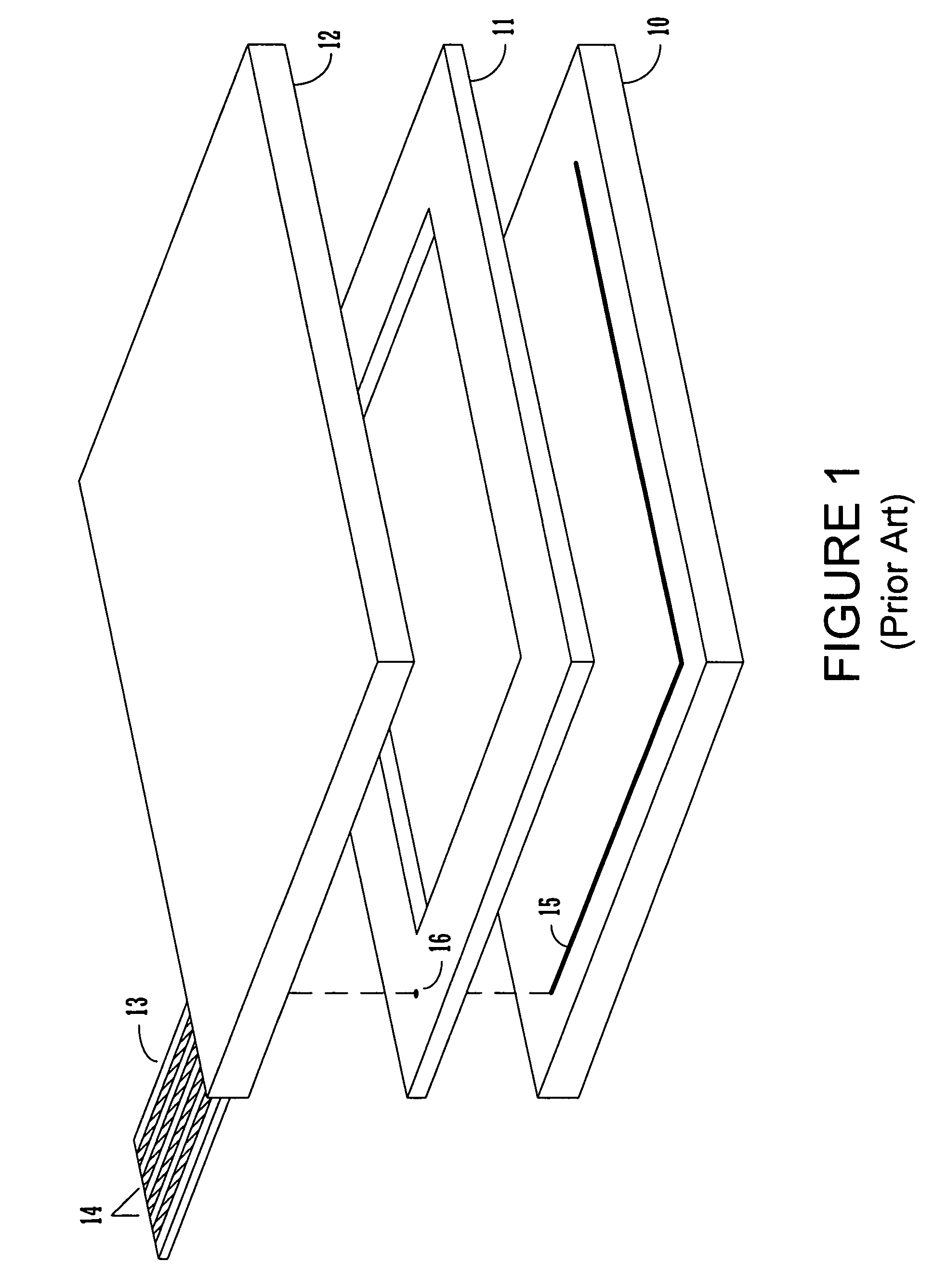

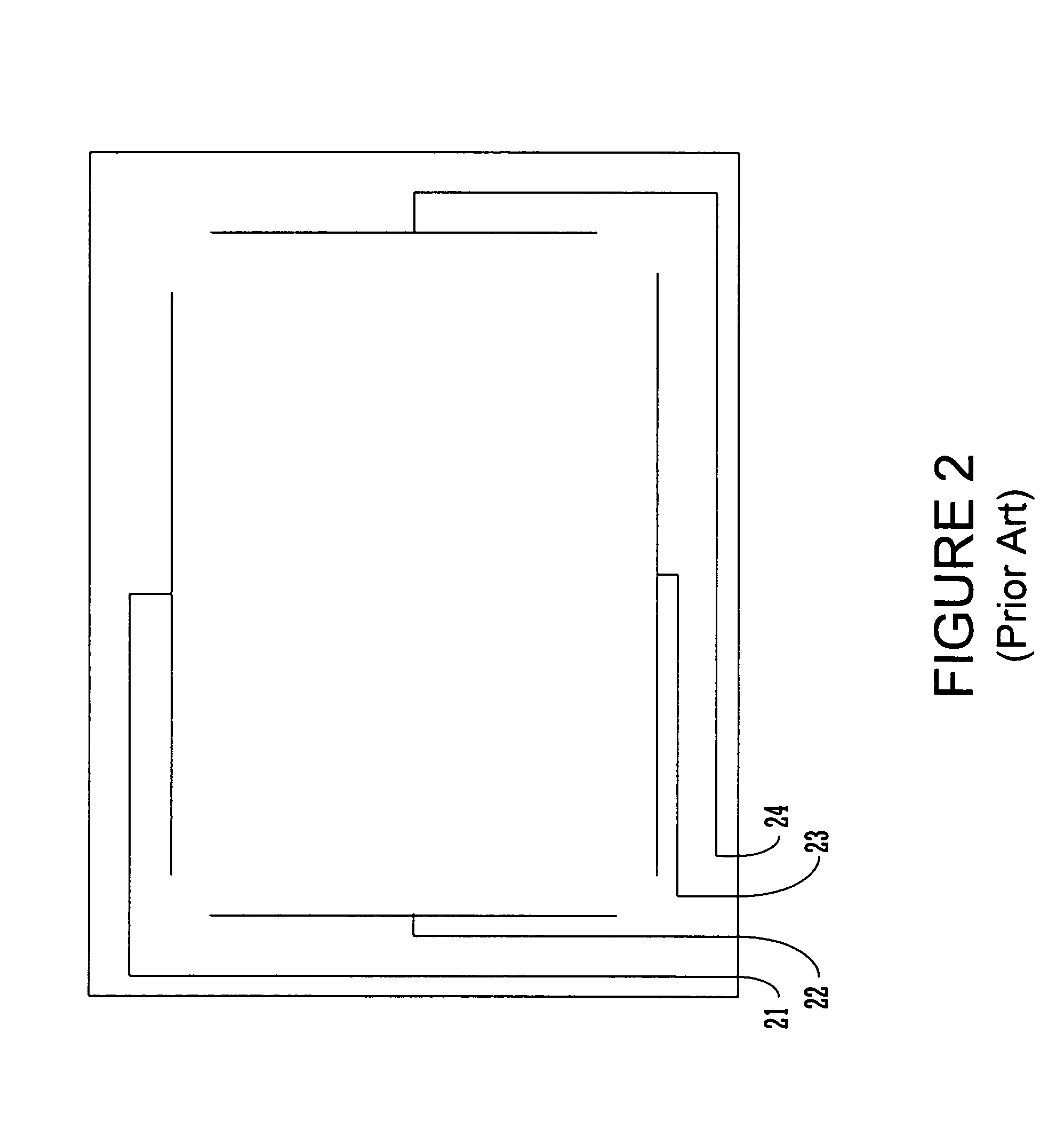

Touch panel with improved linear response and minimal border width electrode pattern

InactiveUS6549193B1Good linear responseMinimum border width edge electrode patternCathode-ray tube indicatorsInput/output processes for data processingElectrical resistance and conductanceTouchscreen

A touch screen panel including an insulative substrate; a resistive layer disposed on the insulative substrate; and a plurality of spaced conductive segments on the resistive layer along the border thereof. The conductive segments are disposed in rows, and every row has at least two segments which face at least a portion of three segments in the next inner row for optimizing the linearity of the touch screen panel and at the same time reducing the space occupied on the touch screen panel by the conductive segments.

Owner:3M INNOVATIVE PROPERTIES CO

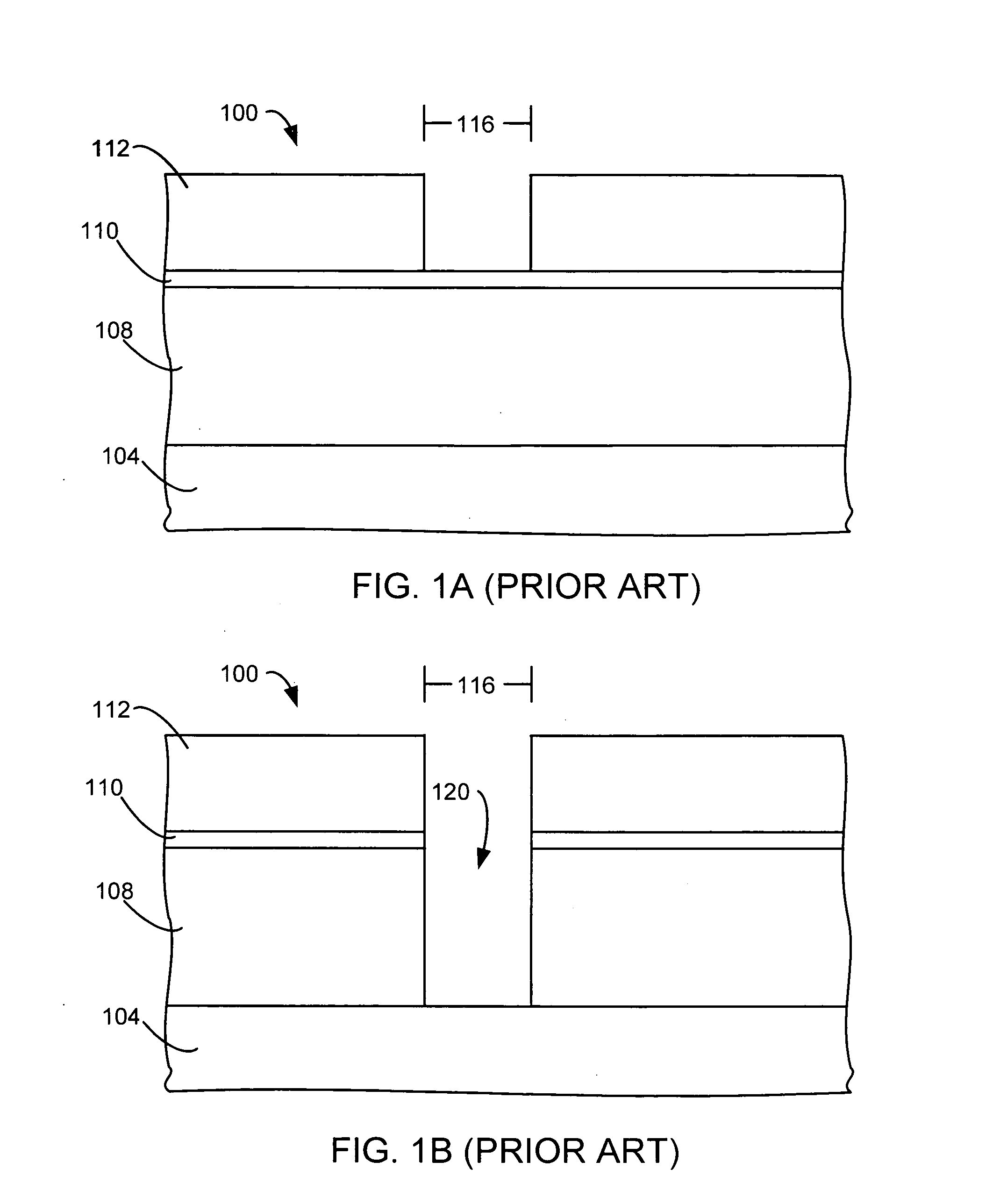

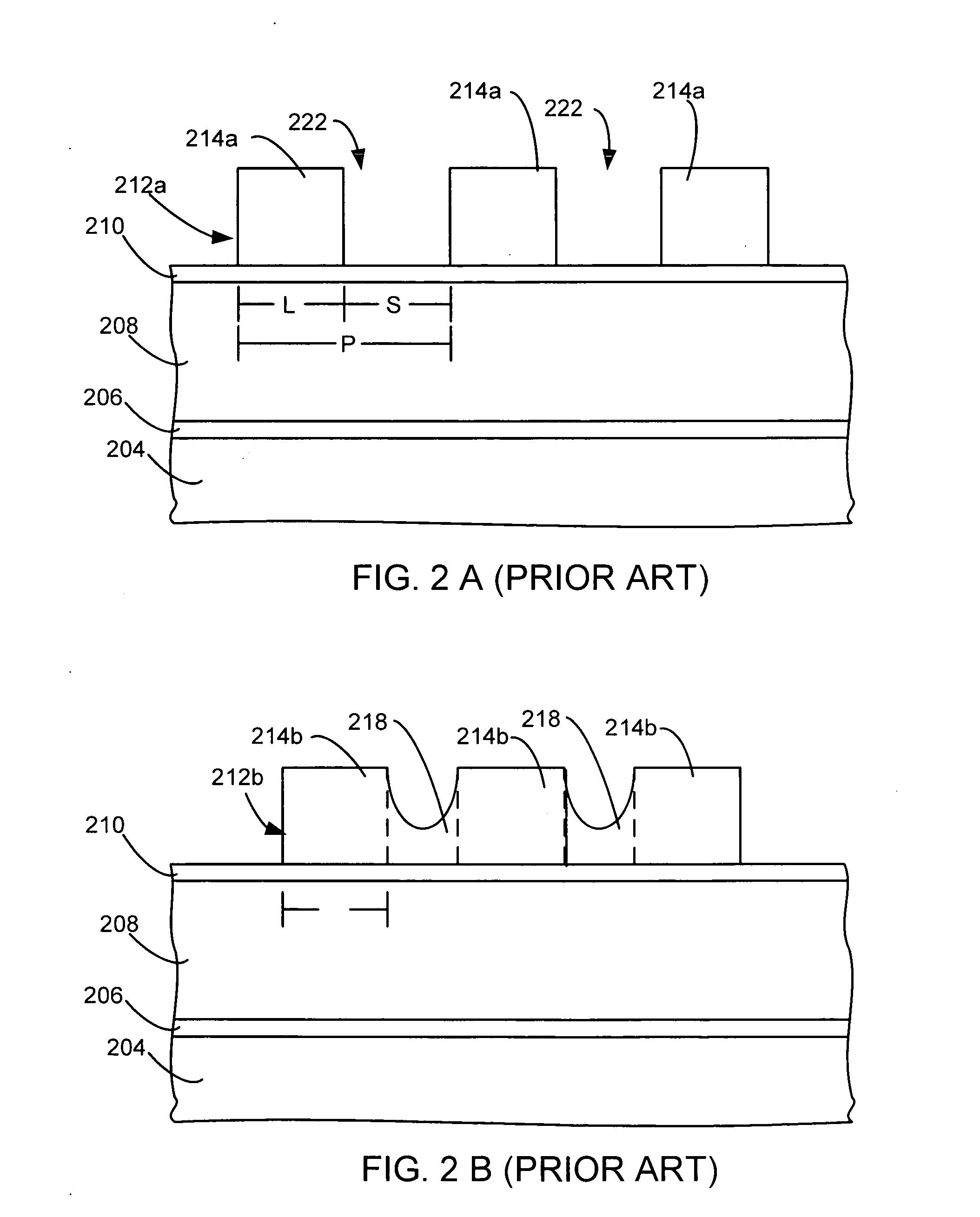

Reduction of feature critical dimensions using multiple masks

InactiveUS20060172540A1Reduce widthReduce space widthSemiconductor/solid-state device manufacturingCritical dimensionComputer science

A method for forming features in an etch layer is provided. A first mask is formed over the etch layer wherein the first mask defines a plurality of spaces with widths. A sidewall layer is formed over the first mask. Features are etched into the etch layer through the sidewall layer, wherein the features have widths that are smaller than the widths of the spaces defined by the first mask. The mask and sidewall layer are removed. An additional mask is formed over the etch layer wherein the additional mask defines a plurality of spaces with widths. A sidewall layer is formed over the additional mask. Features are etched into the etch layer through the sidewall layer, wherein the widths that are smaller than the widths of the spaces defined by the first mask. The mask and sidewall layer are removed.

Owner:LAM RES CORP

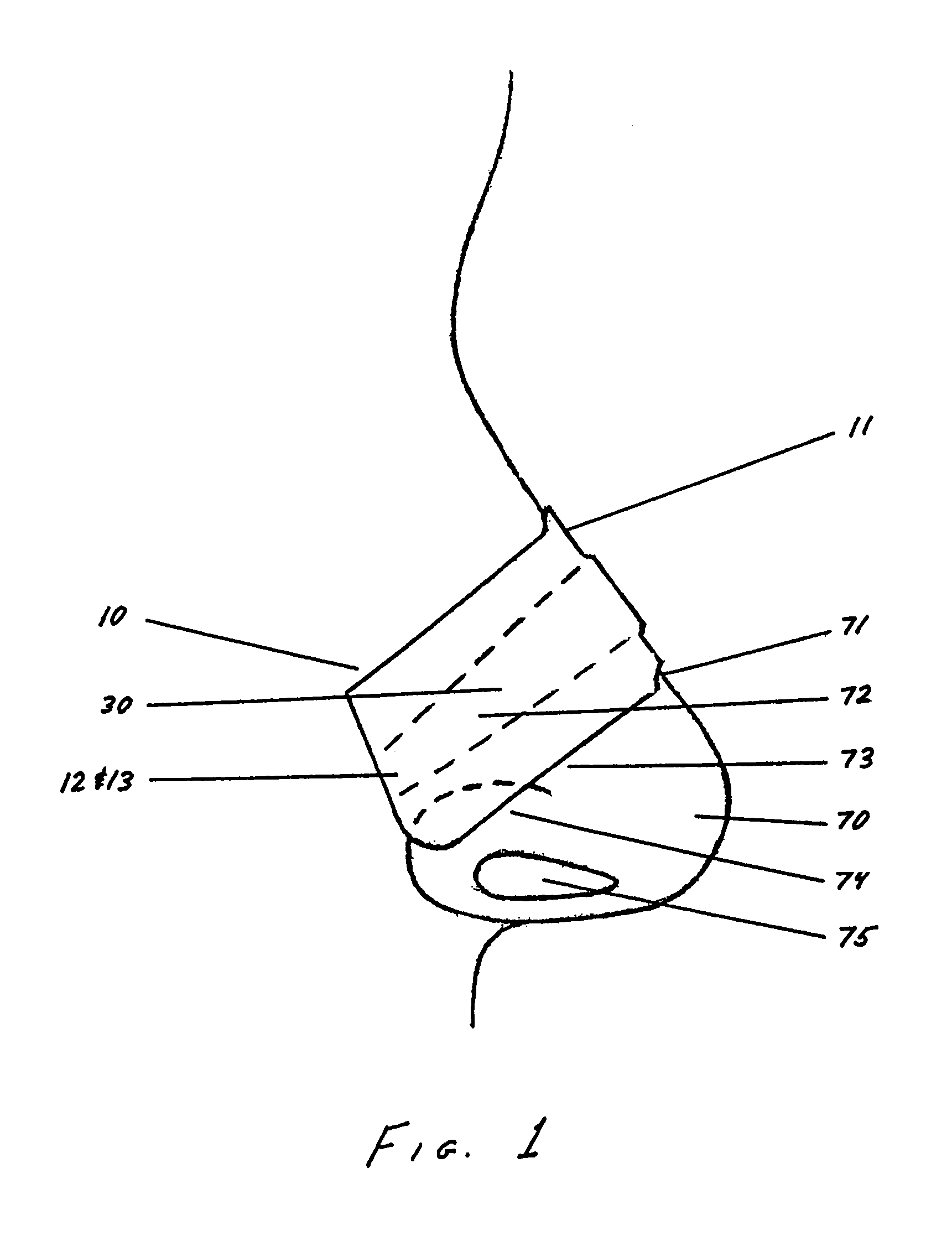

Nasal strip with variable spring rate

A nasal dilator capable of introducing separating stresses in nasal outer wall tissues has a truss of a single body with a resilient member secured therein and a pair of spaced-apart end surfaces which, when forced toward one another from initial positions to substantially reduce direct spacing therebetween by a spacing reducing force external to said truss, results in restoring forces in the truss tending to return to the original direct spacing between the end surfaces. A resilient member, which is symmetrical with respect to a centerline of the truss that is perpendicular to the long axis of the truss, has a spring rate which continuously diminishes from the centerline to the end surfaces. An adhesive on the end surfaces adhesively engages exposed surfaces of nasal outer wall tissues sufficiently to keep the truss attached to the nasal wall surfaces while subjecting them to the restoring forces.

Owner:INFINITE FINANCIAL SOLUTIONS

Methods for fabricating fin field effect transistors using a protective layer to reduce etching damage

A method of forming a fin field effect transistor on a semiconductor substrate includes forming a vertical fin protruding from the substrate. A buffer oxide liner is formed on a top surface and on sidewalls of the fin. A trench is then formed on the substrate, where at least a portion of the fin protrudes from a bottom surface of the trench. The trench may be formed by forming a dummy gate on at least a portion of the fin, forming an insulation layer on the fin surrounding the dummy gate, and then removing the dummy gate to expose the at least a portion of the fin, such that the trench is surrounded by the insulation layer. The buffer oxide liner is then removed from the protruding portion of the fin, and a gate is formed in the trench on the protruding portion of the fin.

Owner:SAMSUNG ELECTRONICS CO LTD

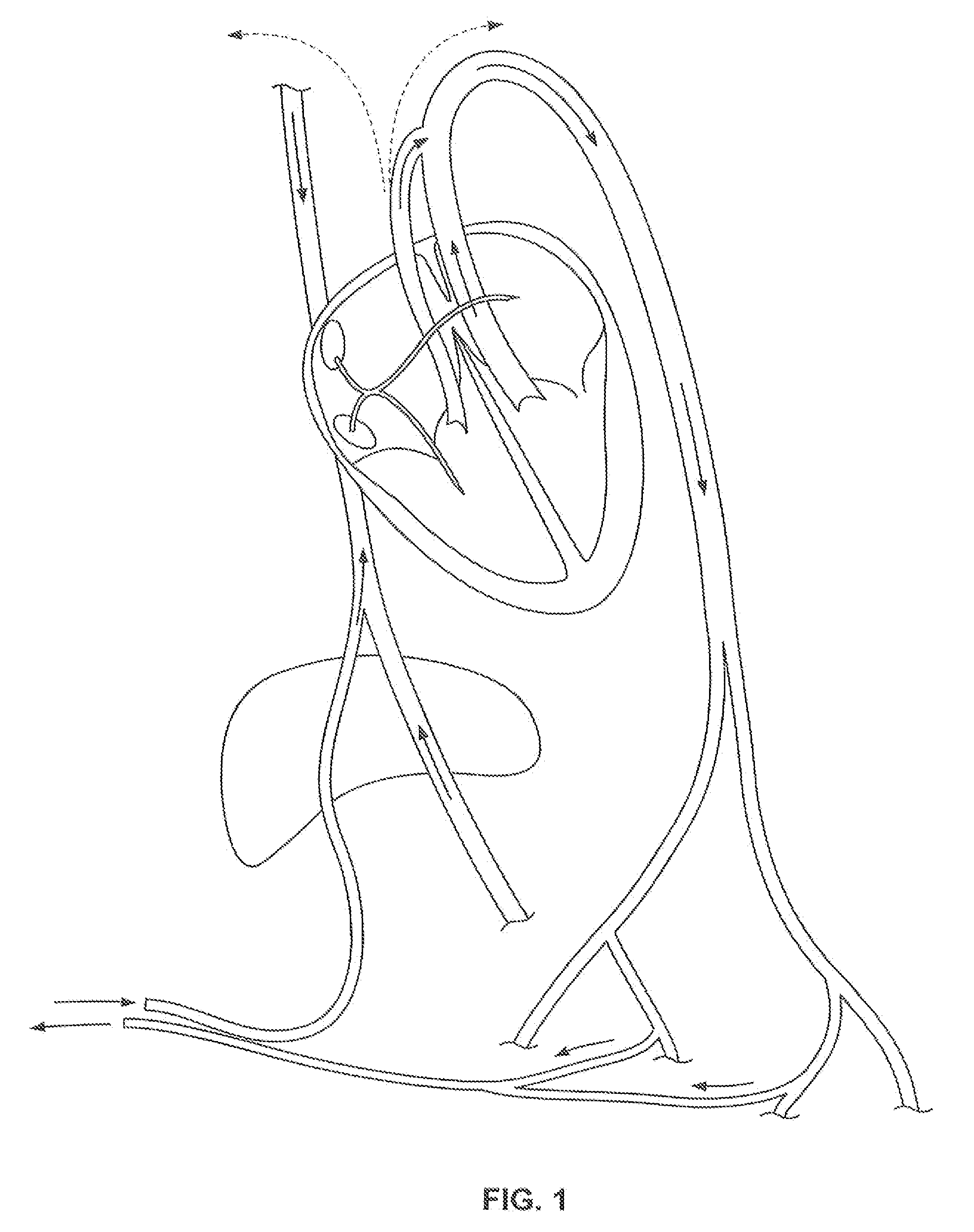

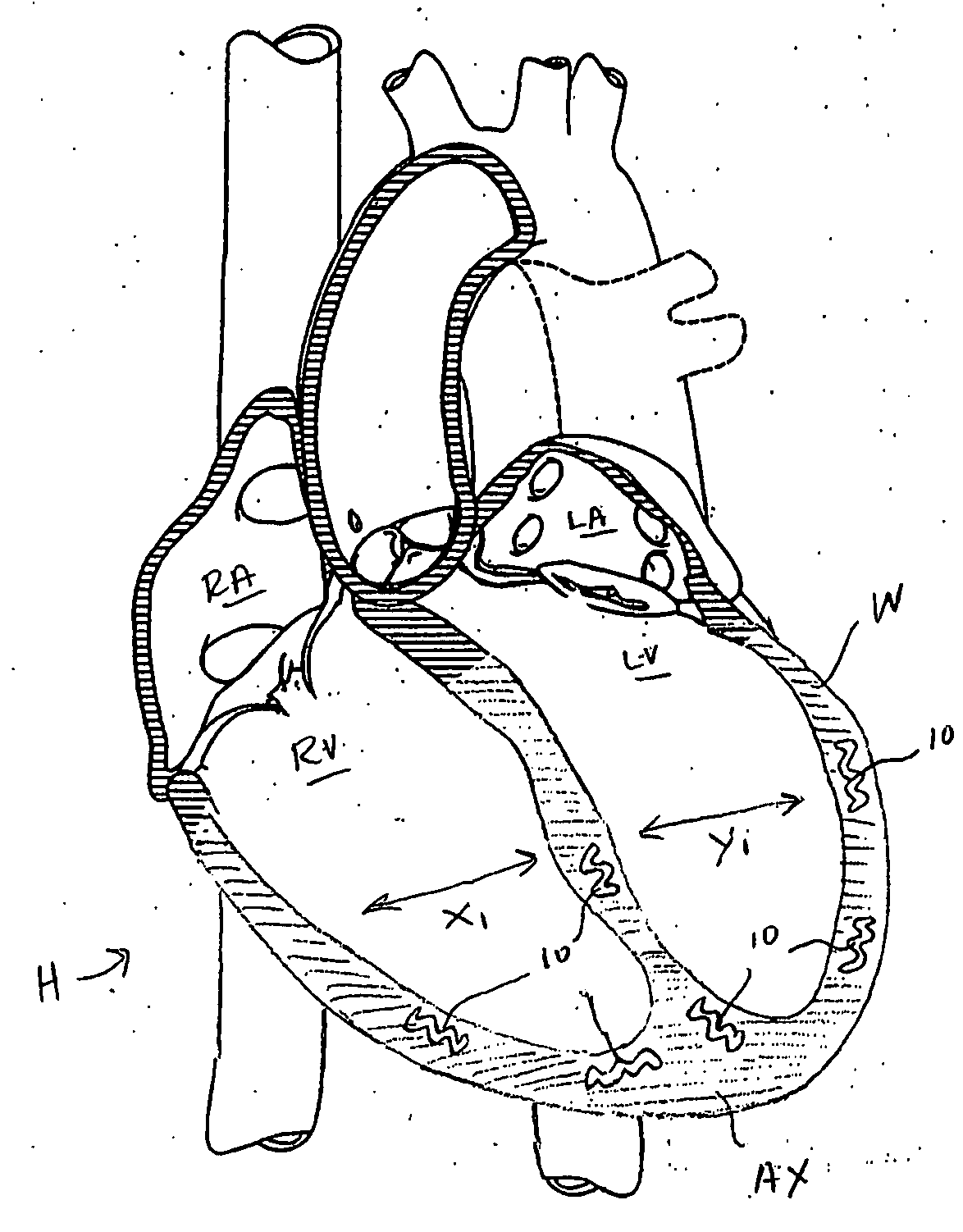

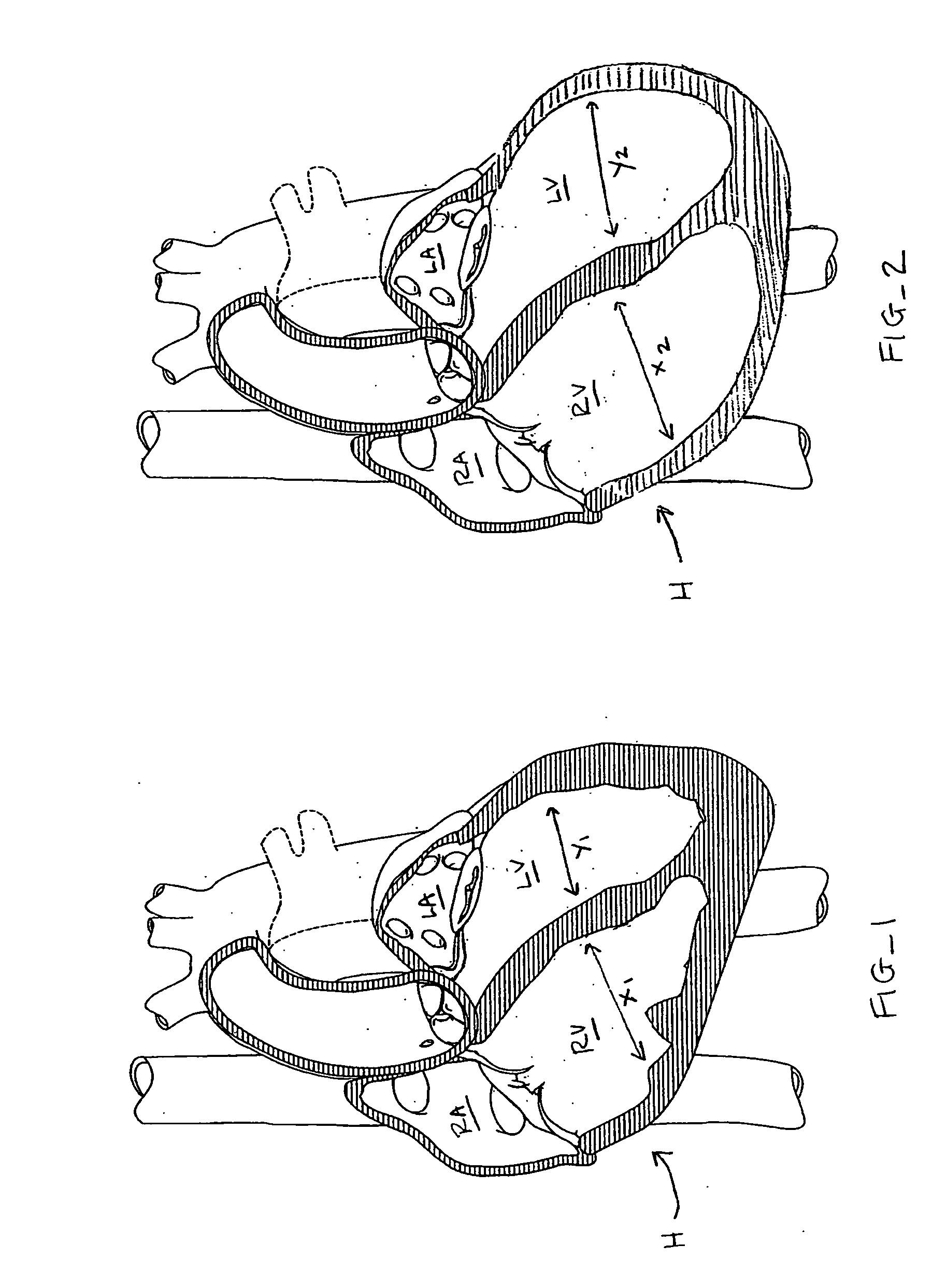

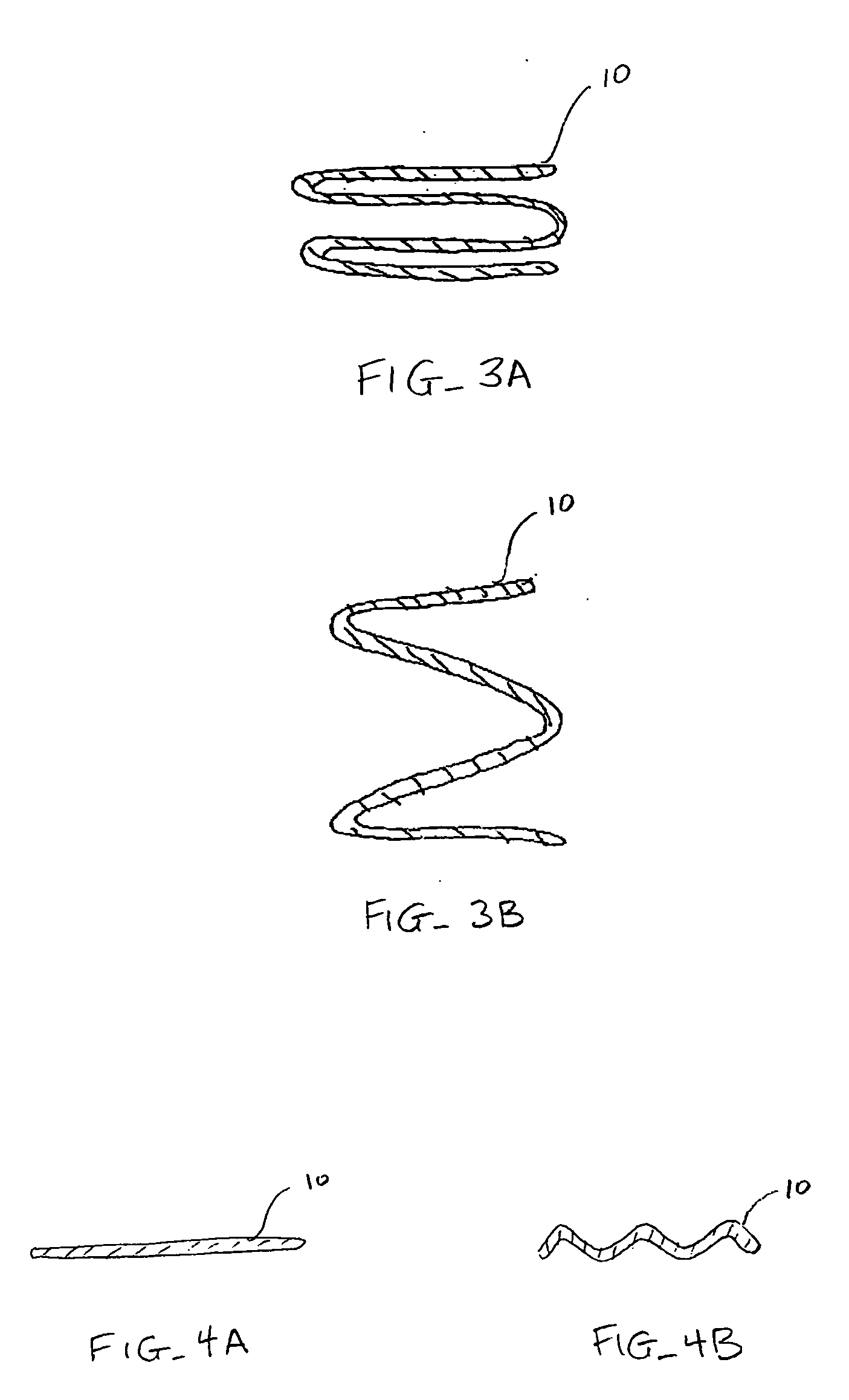

Shape memory devices and methods for reshaping heart anatomy

InactiveUS20060015002A1Improve shrinkageReduce widthSuture equipmentsSurgical needlesCardiac surfaceHeart anatomy

Systems, methods and devices are provided for treating heart failure patients suffering from various levels of heart dilation. Such heart dilation is treated by reshaping the heart anatomy with the use of shape memory elements. Such reshaping changes the geometry of portions of the heart, particularly the right or left ventricles, to increase contractibility of the ventricles thereby increasing the stroke volume which in turn increases the cardiac output of the heart. The shape memory elements have an original shape and at least one memory shape. The elements are implanted within the heart tissue or attached externally and / or internally to a surface of the heart when in the original shape. The elements are then activated to transition from the original shape to one of the at least one memory shapes. Transitioning of the elements cause the associated heart tissue areas to readjust position, such as to decrease the width of the ventricles. Such repositioning is maintained over time by the elements, allowing the damaging effects of heart dilation to slow in progression or reverse.

Owner:MICARDIA CORP

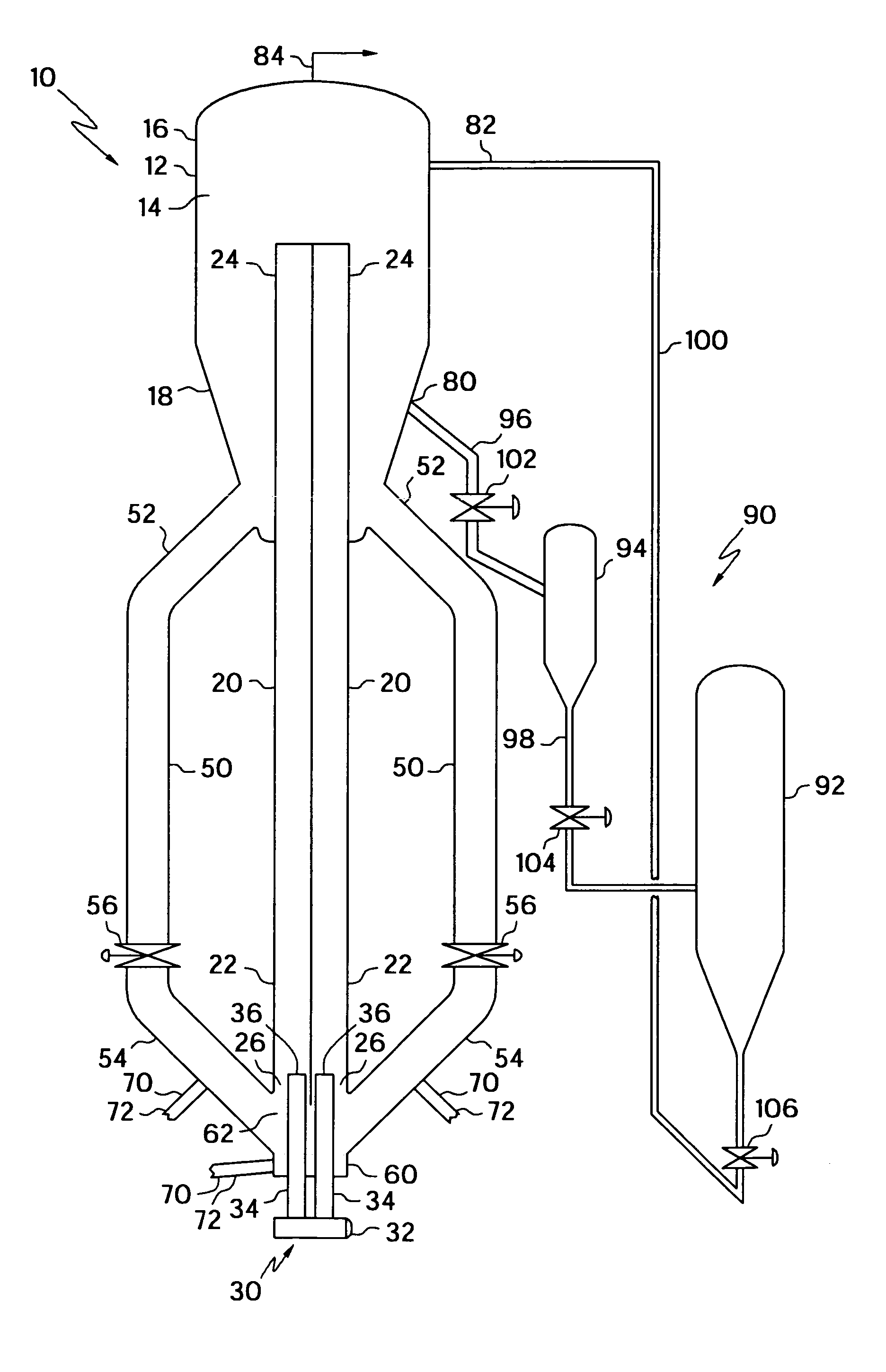

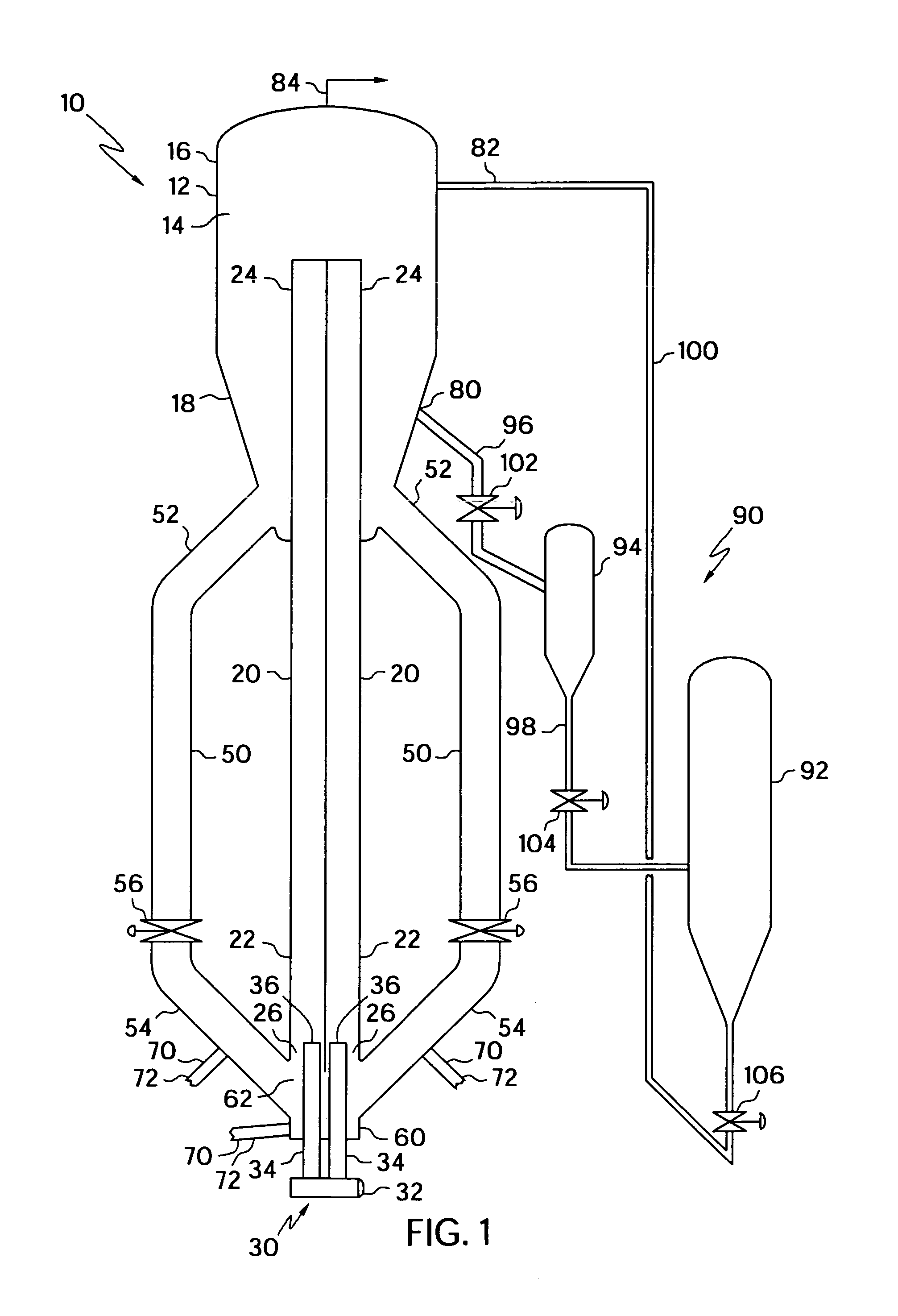

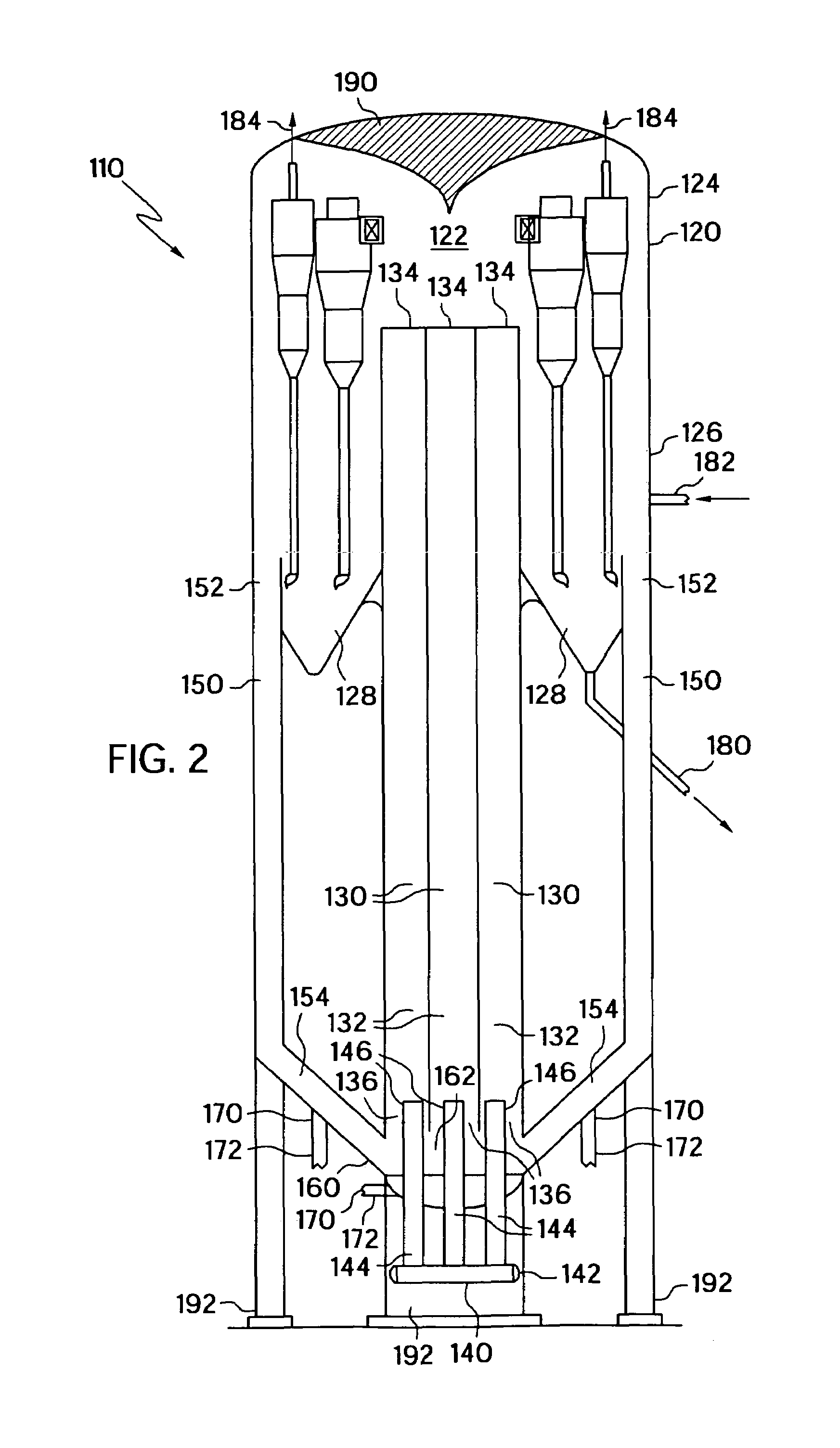

Multiple riser reactor

InactiveUS7102050B1Reduce the overall diameterReduce widthCatalytic crackingOrganic chemistry methodsHydrocarbonChemistry

The present invention is directed to a hydrocarbon conversion apparatus. The apparatus comprises the following: a plurality of riser reactors, each of the riser reactors having a first end into which a catalyst can be fed and a second end through which the catalyst can exit the riser reactor; a separation zone into which the second ends of the riser reactors extend, the separation zone being provided to separate the catalyst from products of a reaction conducted in the hydrocarbon conversion apparatus; and at least one catalyst return in fluid communication with the separation zone and the first ends of the riser reactors, the catalyst return being provided to transfer the catalyst from the separation zone to the first ends of the riser reactors.

Owner:EXXONMOBIL CHEM PAT INC

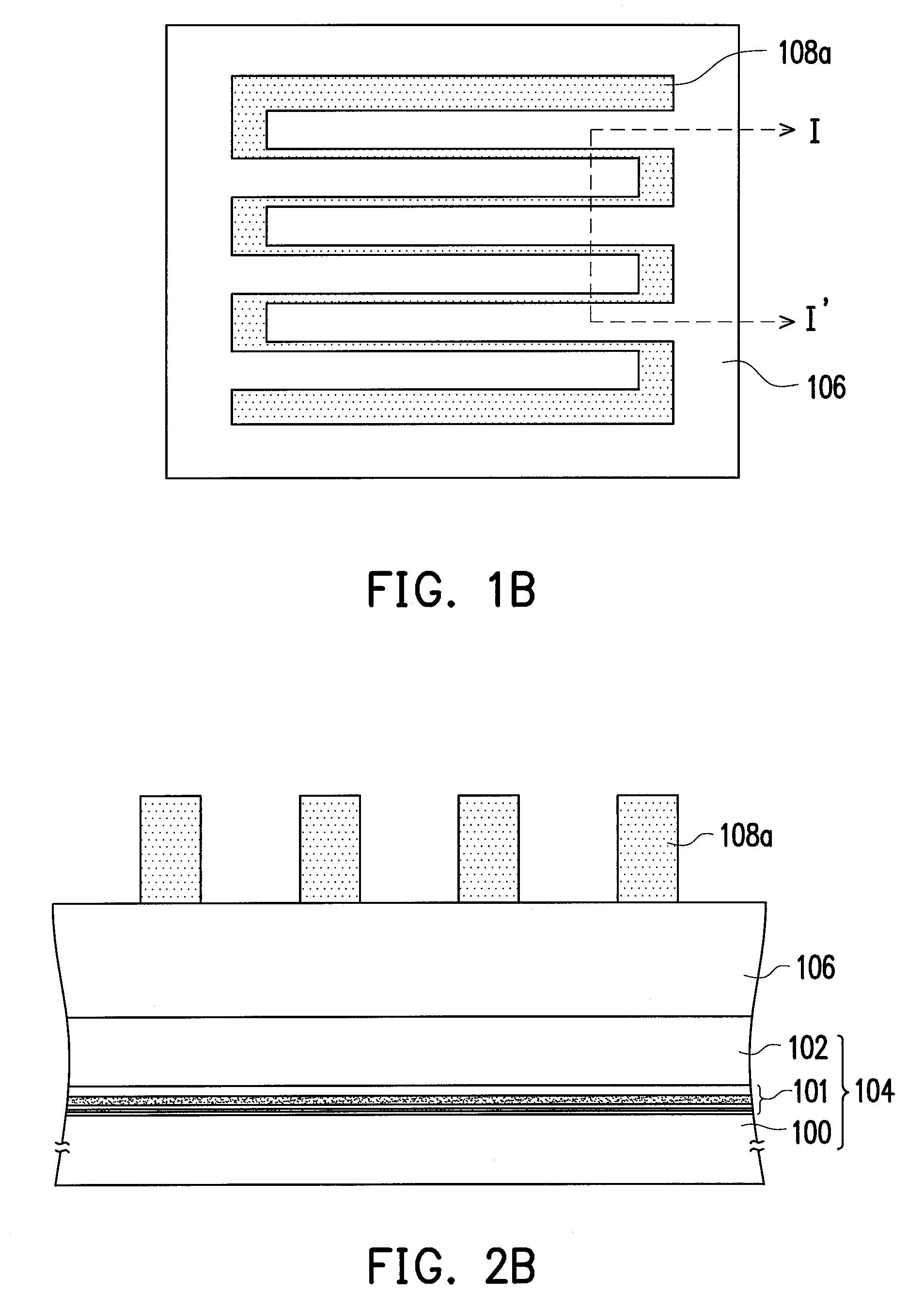

Patterning method and integrated circuit structure

ActiveUS20100258913A1Reduce widthThe implementation process is simpleSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuitEngineering

A patterning method is provided. First, a mask layer and a plurality of first transfer patterns are sequentially formed on a target layer. Thereafter, a plurality of second patterns is formed in the gaps between the first transfer patterns. Afterwards, a plurality of third transfer patterns is formed, wherein each of the third transfer patterns is in a gap between a first transfer pattern and a second transfer pattern adjacent to the first transfer pattern. A portion of the mask layer is then removed, using the first transfer patterns, the second transfer patterns and third transfer patterns as a mask, so as to form a patterned mask layer. Further, a portion of the target layer is removed using the patterned mask layer as a mask.

Owner:MACRONIX INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com