Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

735 results about "Radial surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As with the radial contour, certain features of the radial surface are simplified to ease the problem of registration. The angle between radials in a slice is kept constant, and slices themselves are evenly spaced. It is also assumed that each radial will intersect the surface only once.

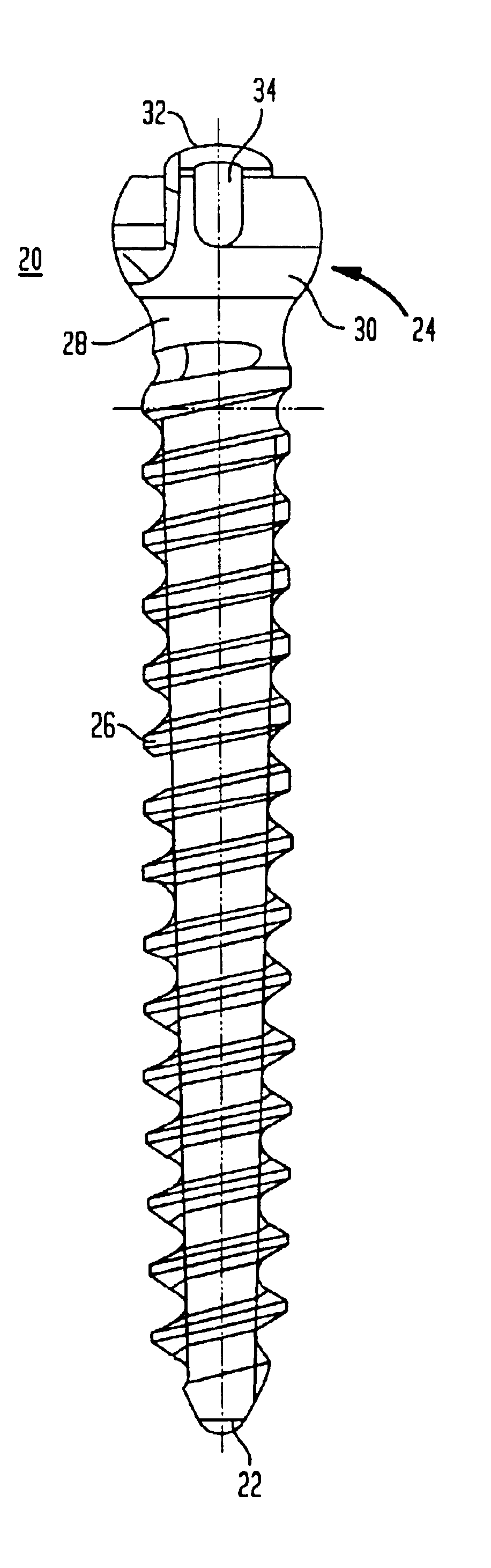

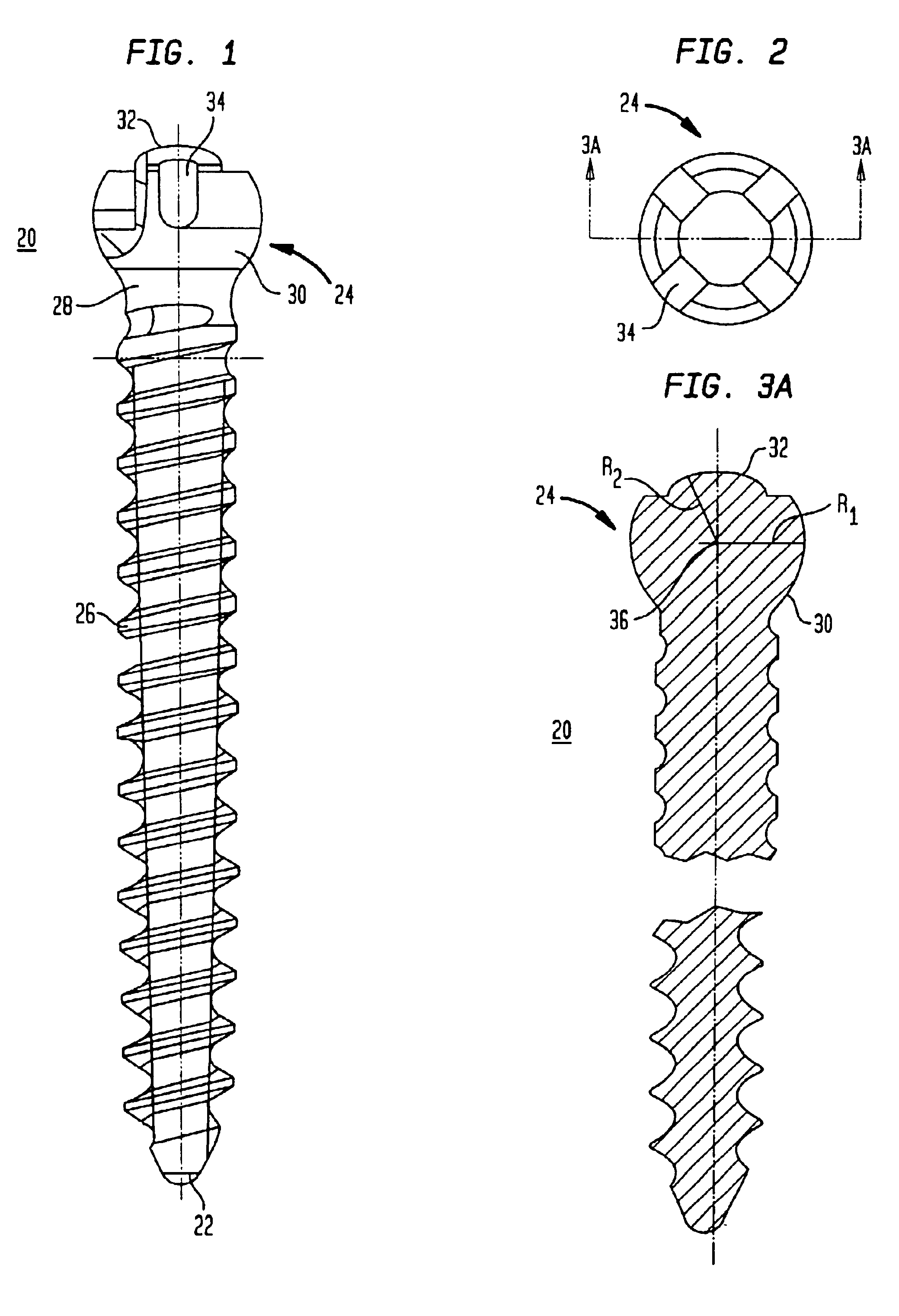

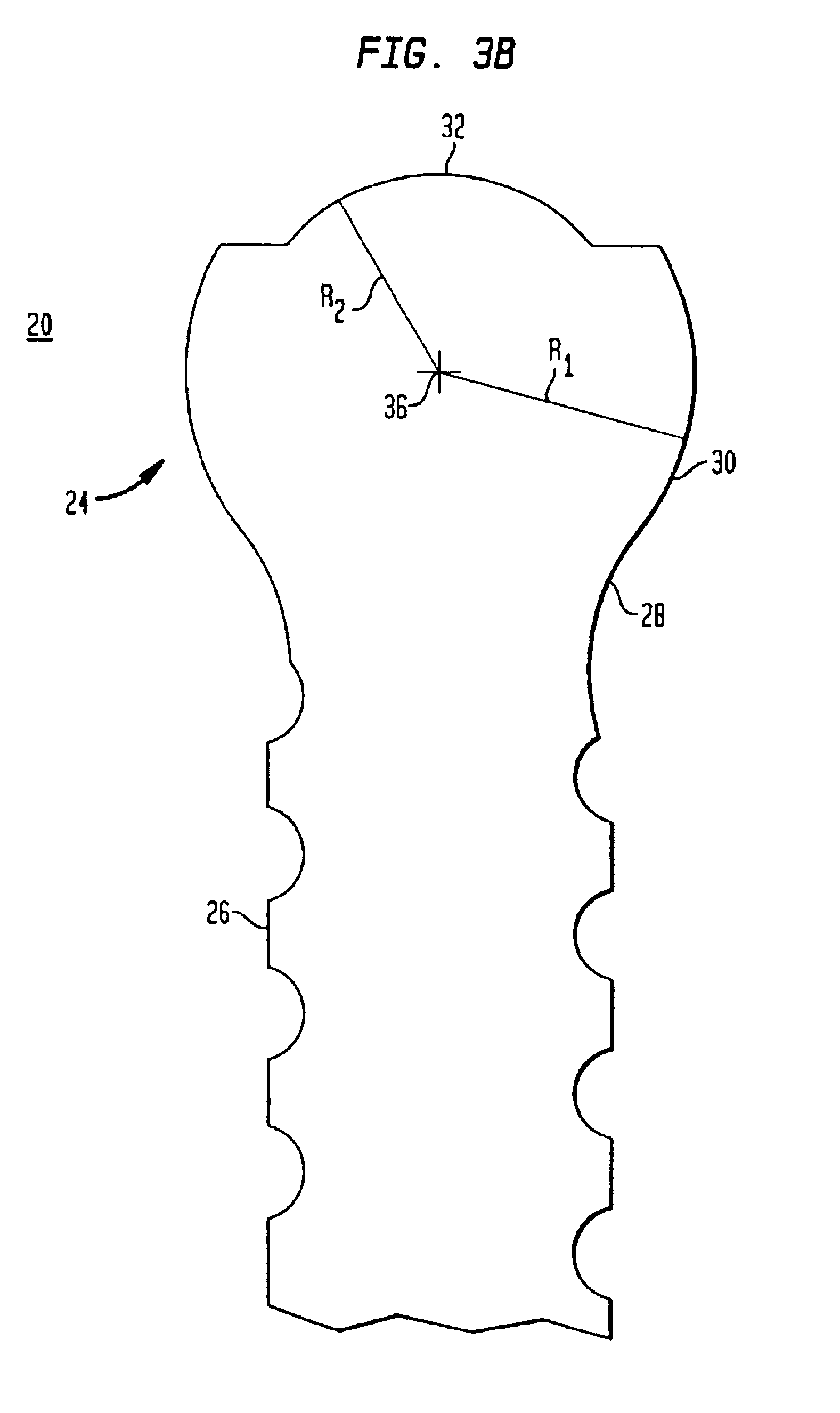

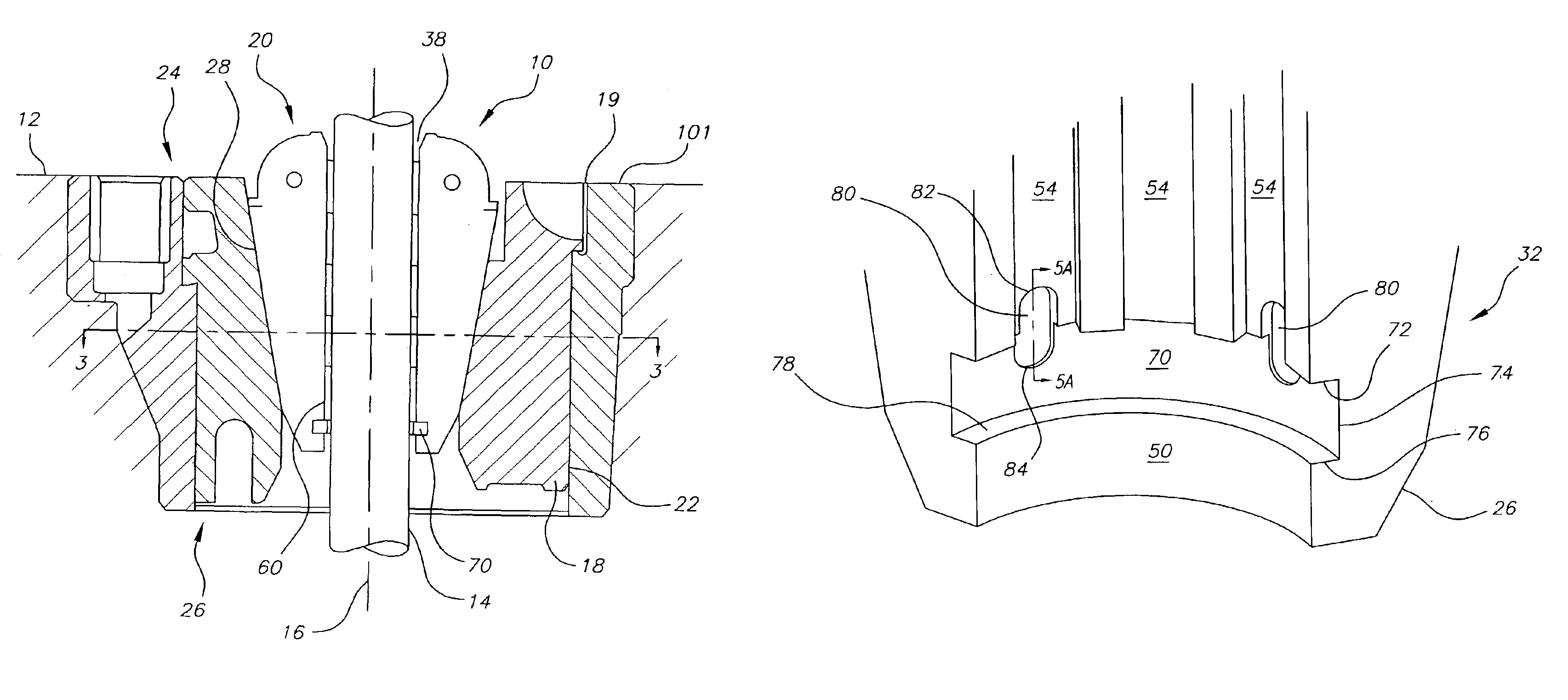

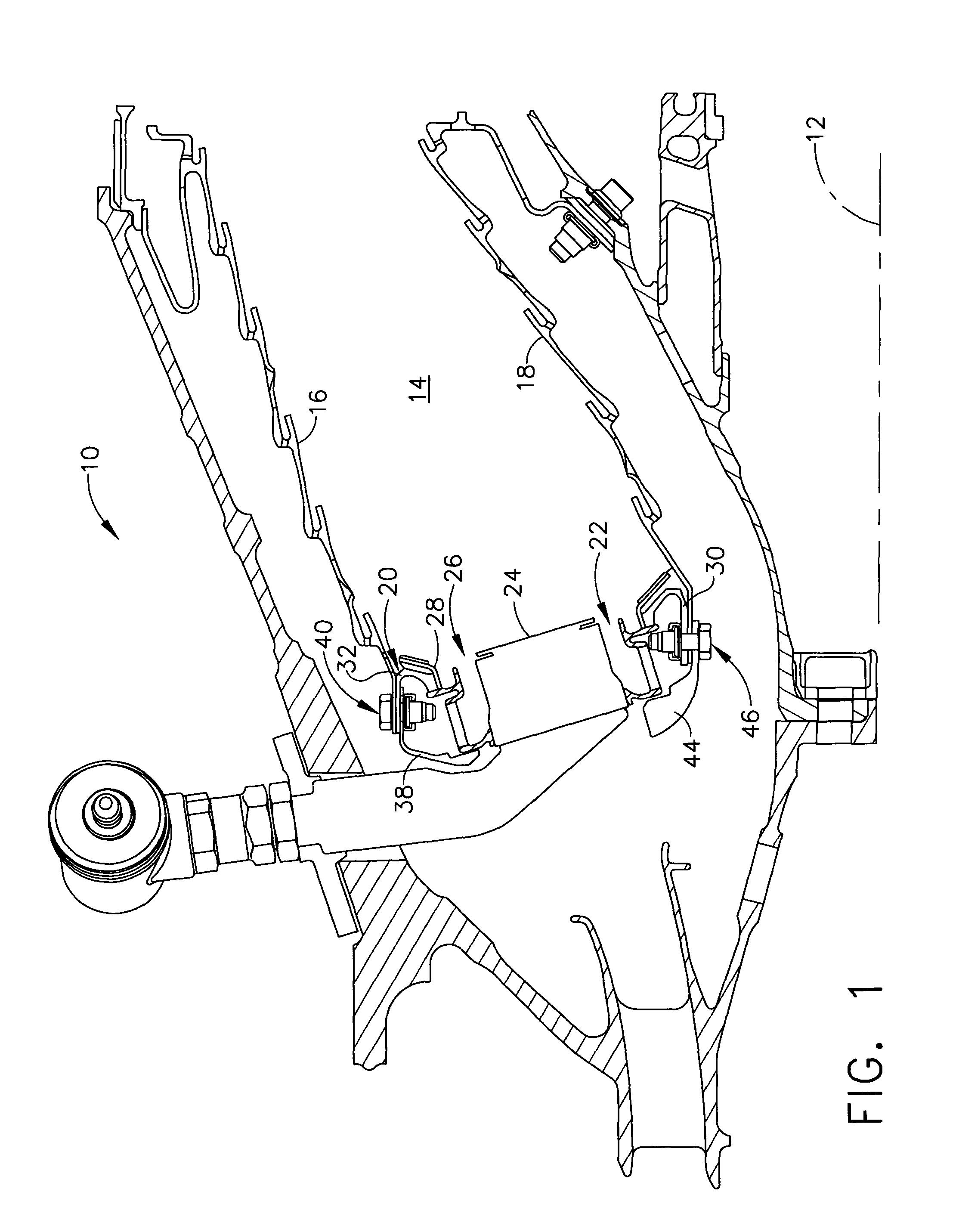

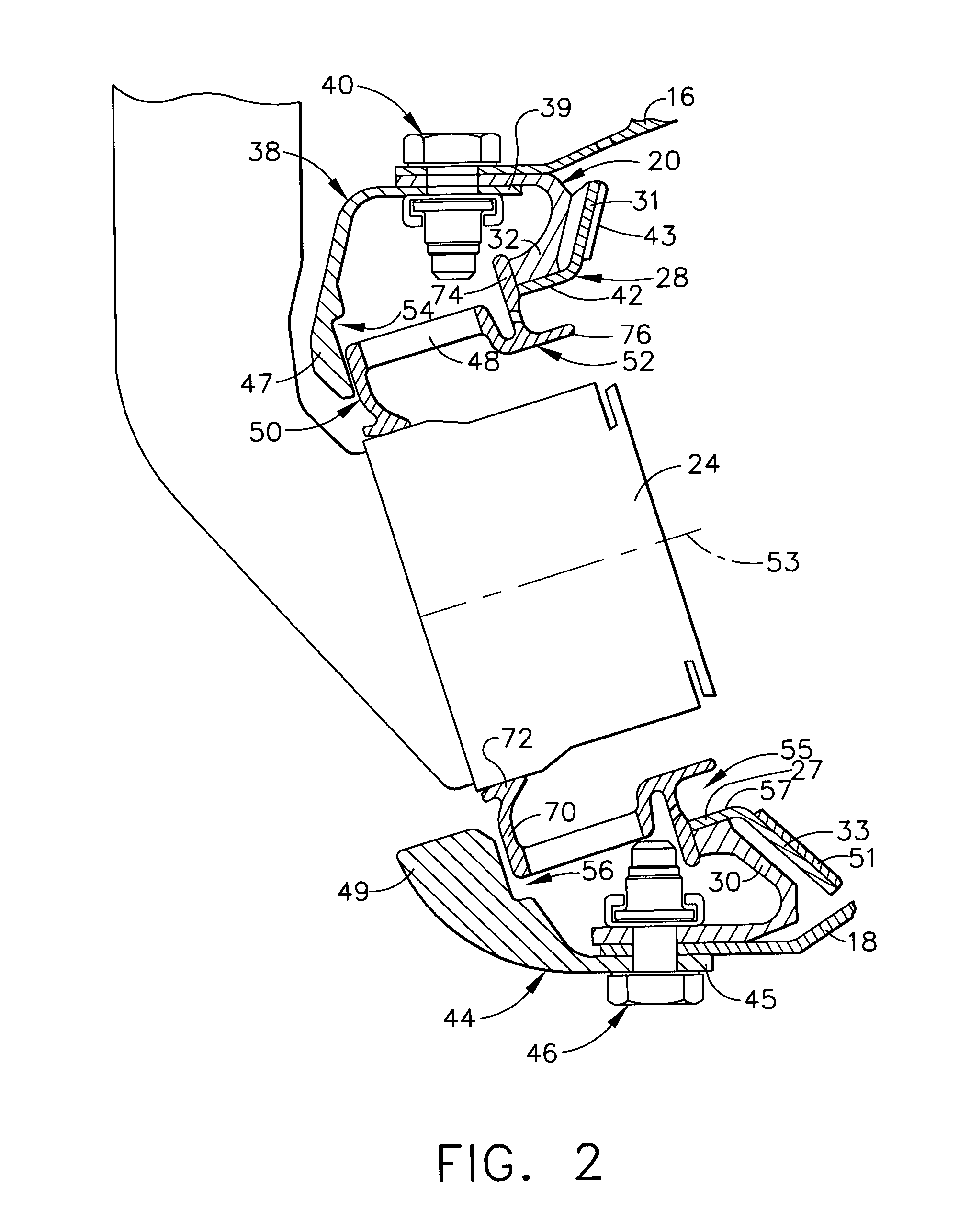

Pedicle screw assembly and methods therefor

InactiveUS6858030B2Improve compactnessLow profileInternal osteosythesisJoint implantsCouplingEngineering

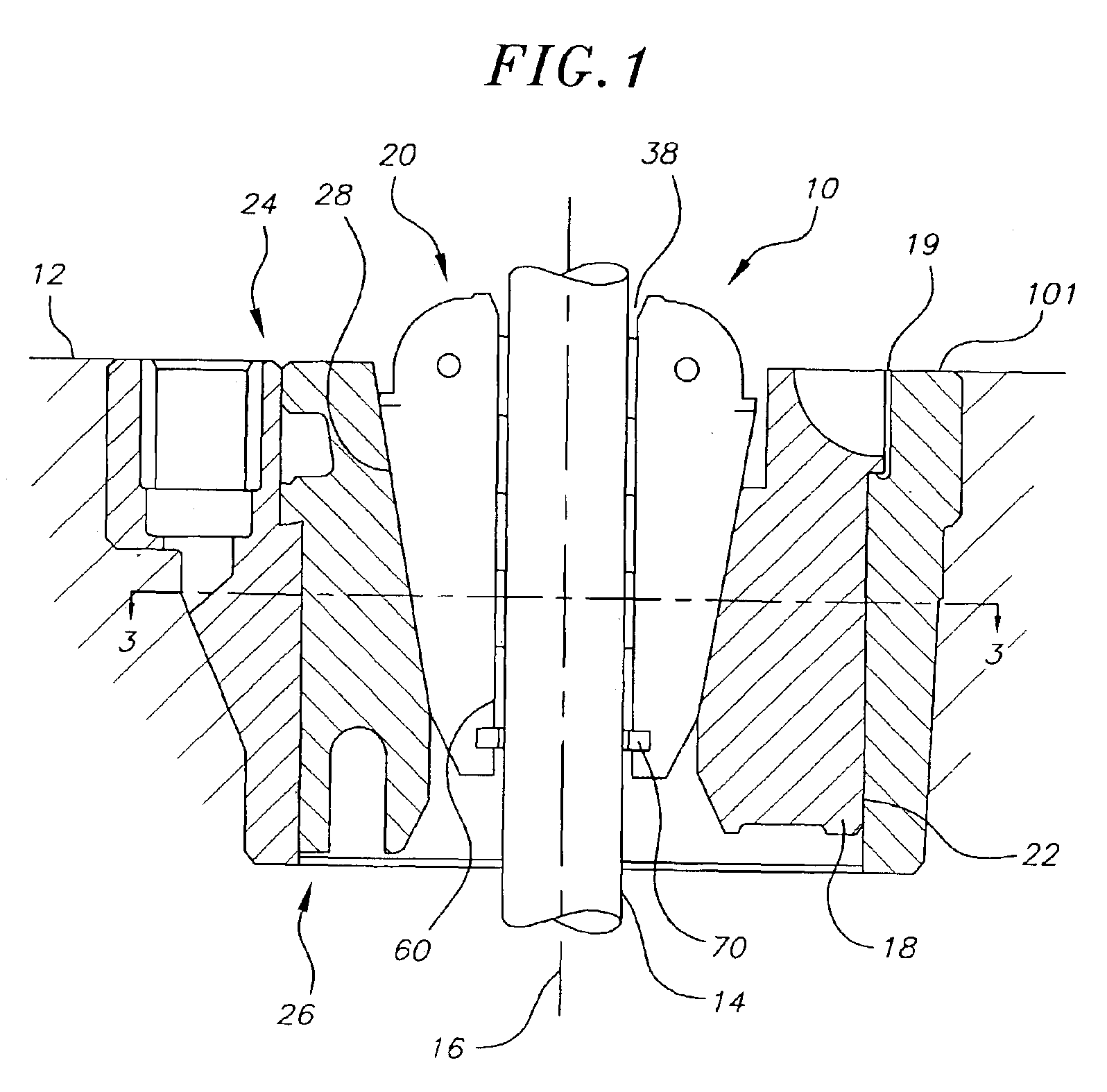

A method for stabilizing a spine includes providing a coupling element having upper and lower ends, a rod receiving opening adapted to receive an elongated stabilizing rod, a bore extending through the lower end and a conical-shaped seat surrounding the bore adjacent the lower end; providing a fastener having upper and lower ends, a head having a radial surface, and at least one anchoring element between the lower end of the fastener and the head; assembling the fastener with the coupling element so that the lower end of the fastener passes through the bore of the coupling element and the radial surface of the head engages the conical-shaped seat. The method also includes anchoring the fastener to bone; moving the coupling element relative to the fastener for capturing the elongated stabilizing rod in the rod receiving opening; and urging the captured stabilizing rod toward the head of the fastener so that the rod contacts the head and forces the radial surface of the head against the conical-shaped seat of the coupling element for locking the coupling element from further movement relative to the fastener.

Owner:STRYKER SPINE

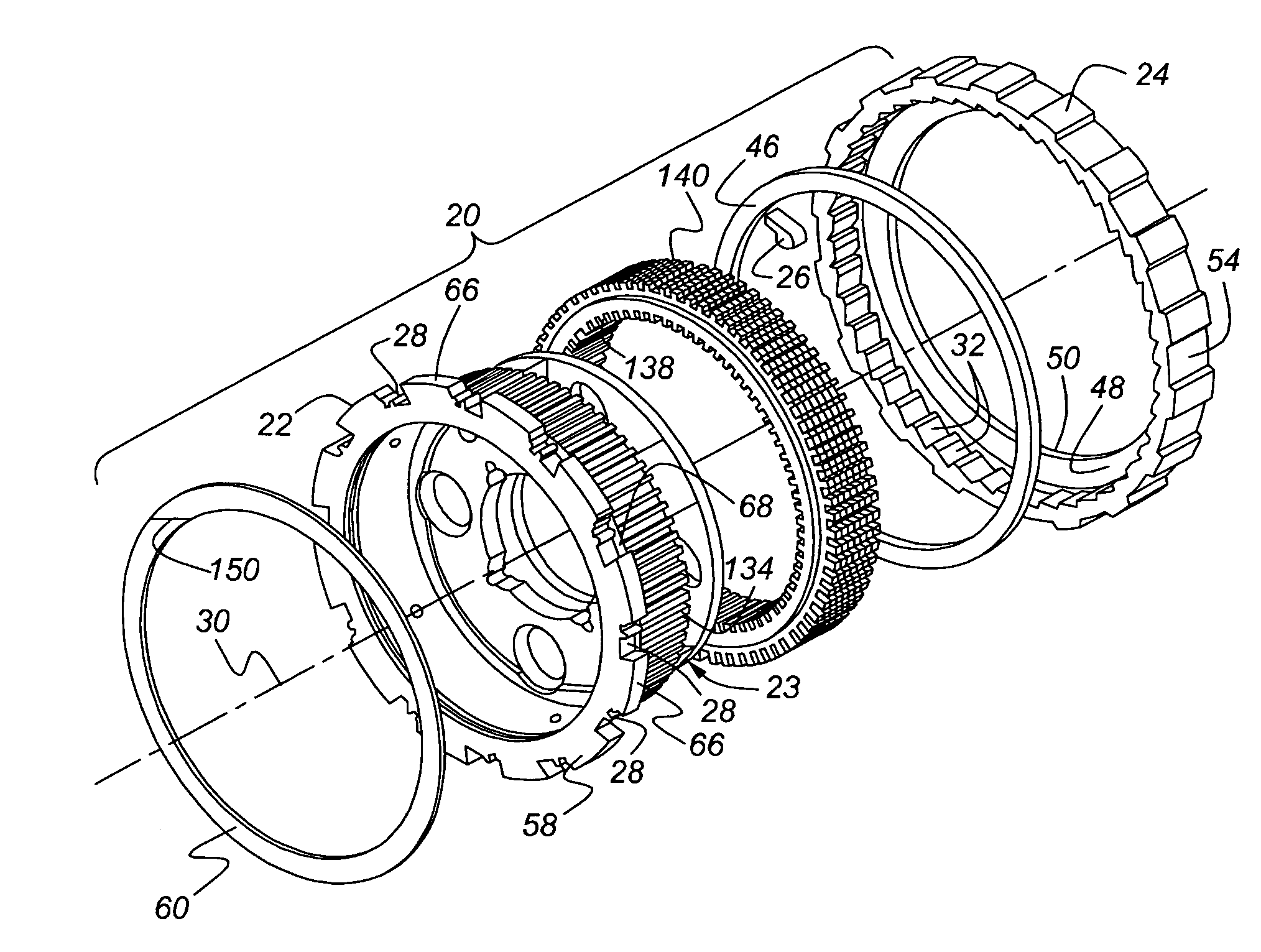

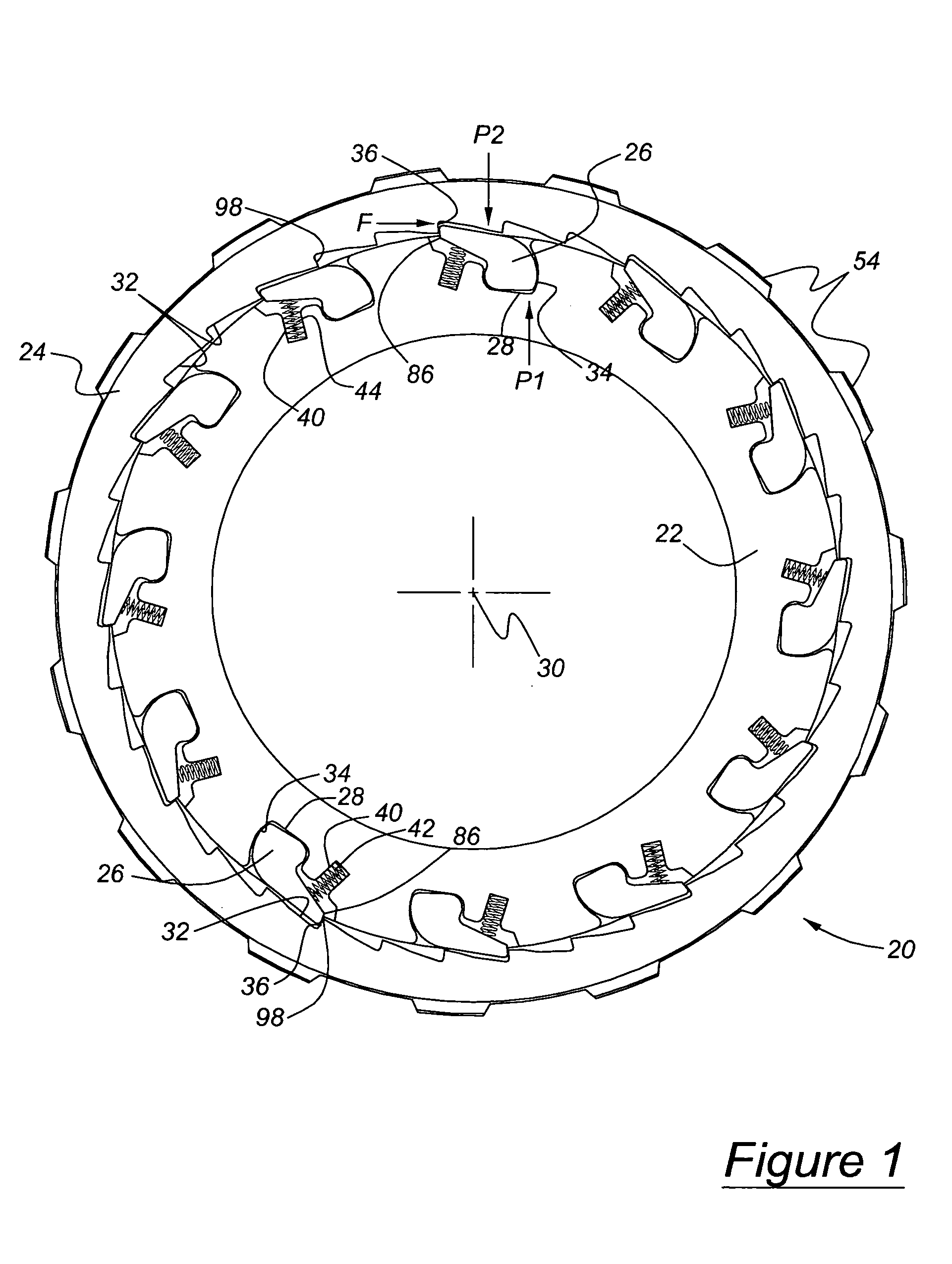

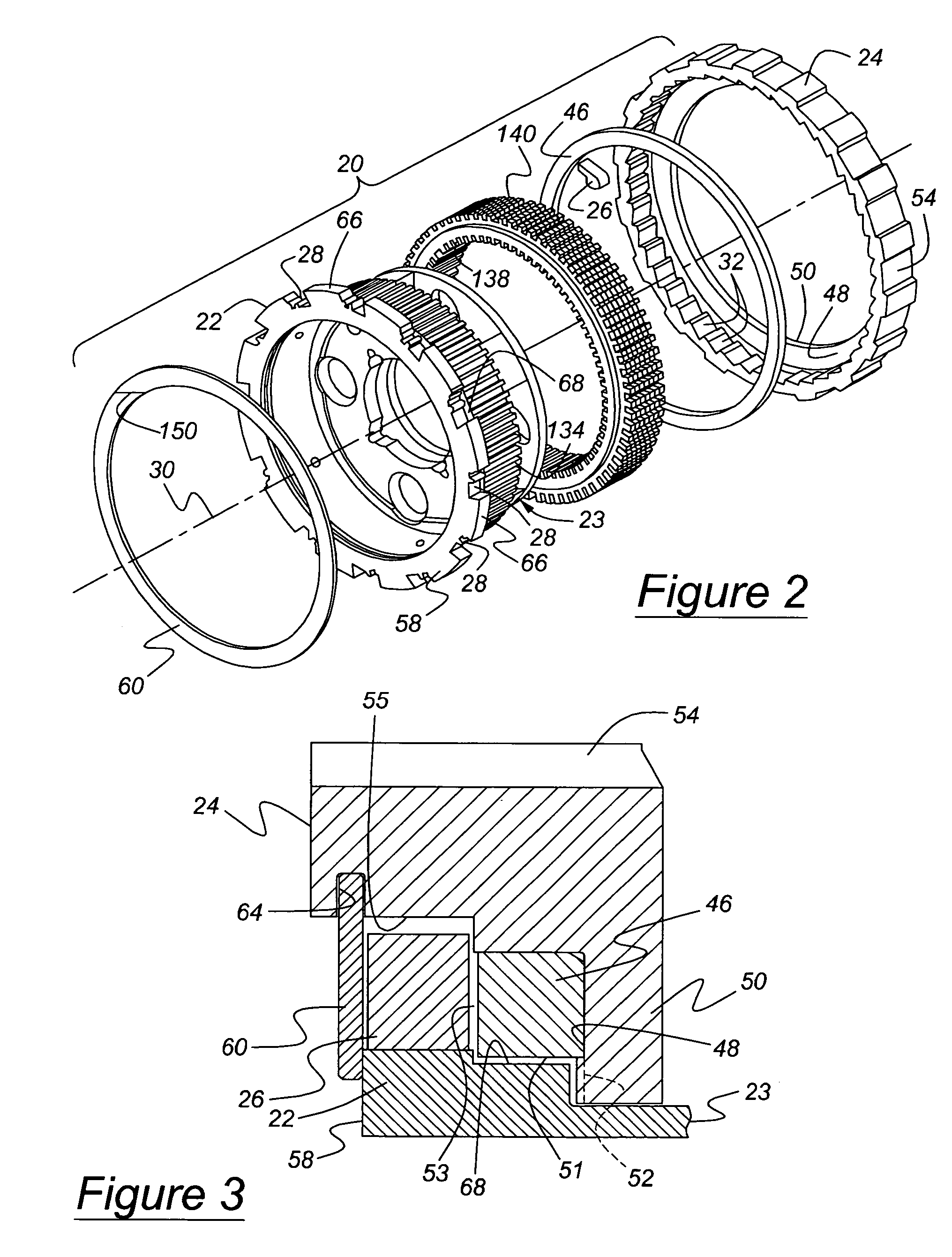

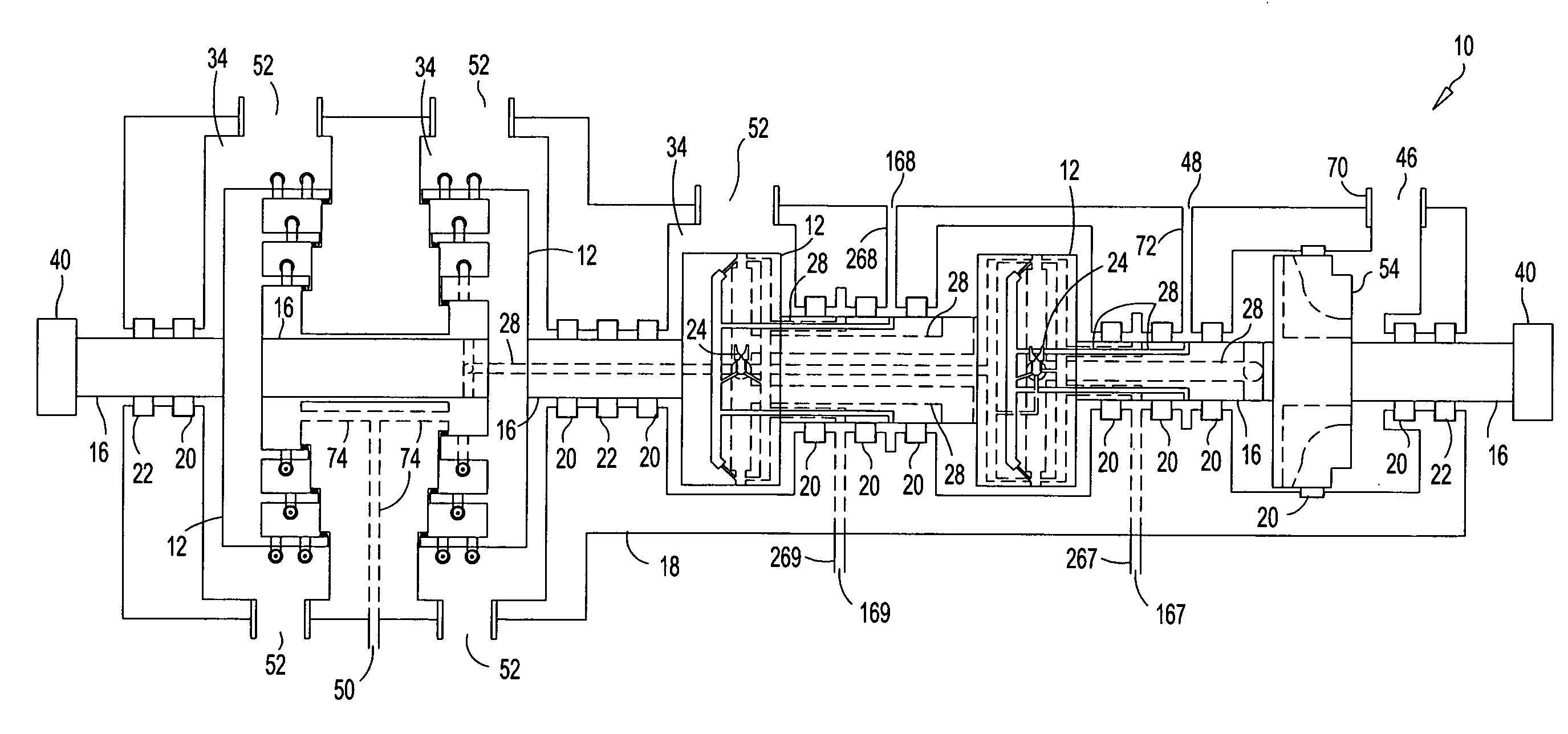

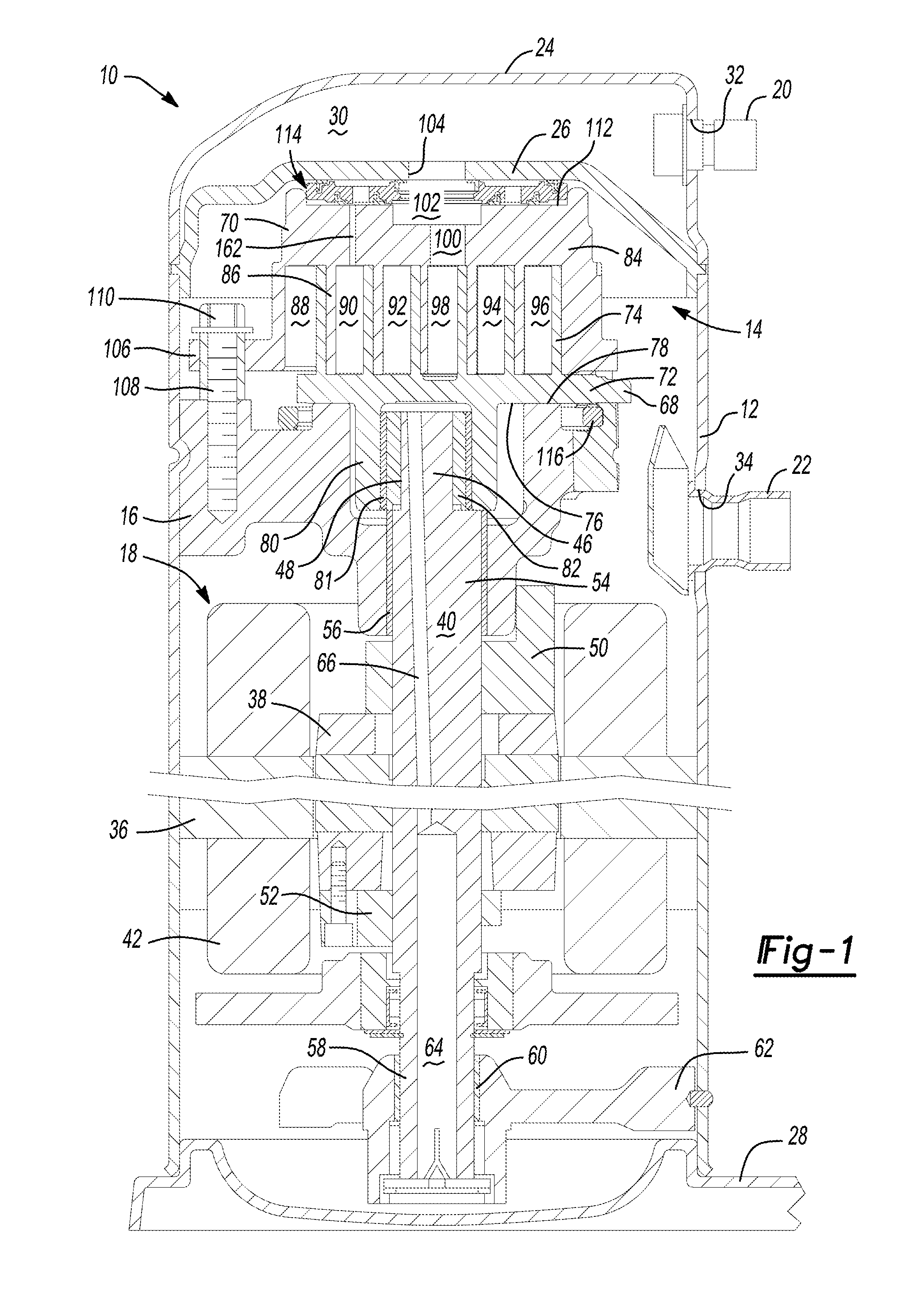

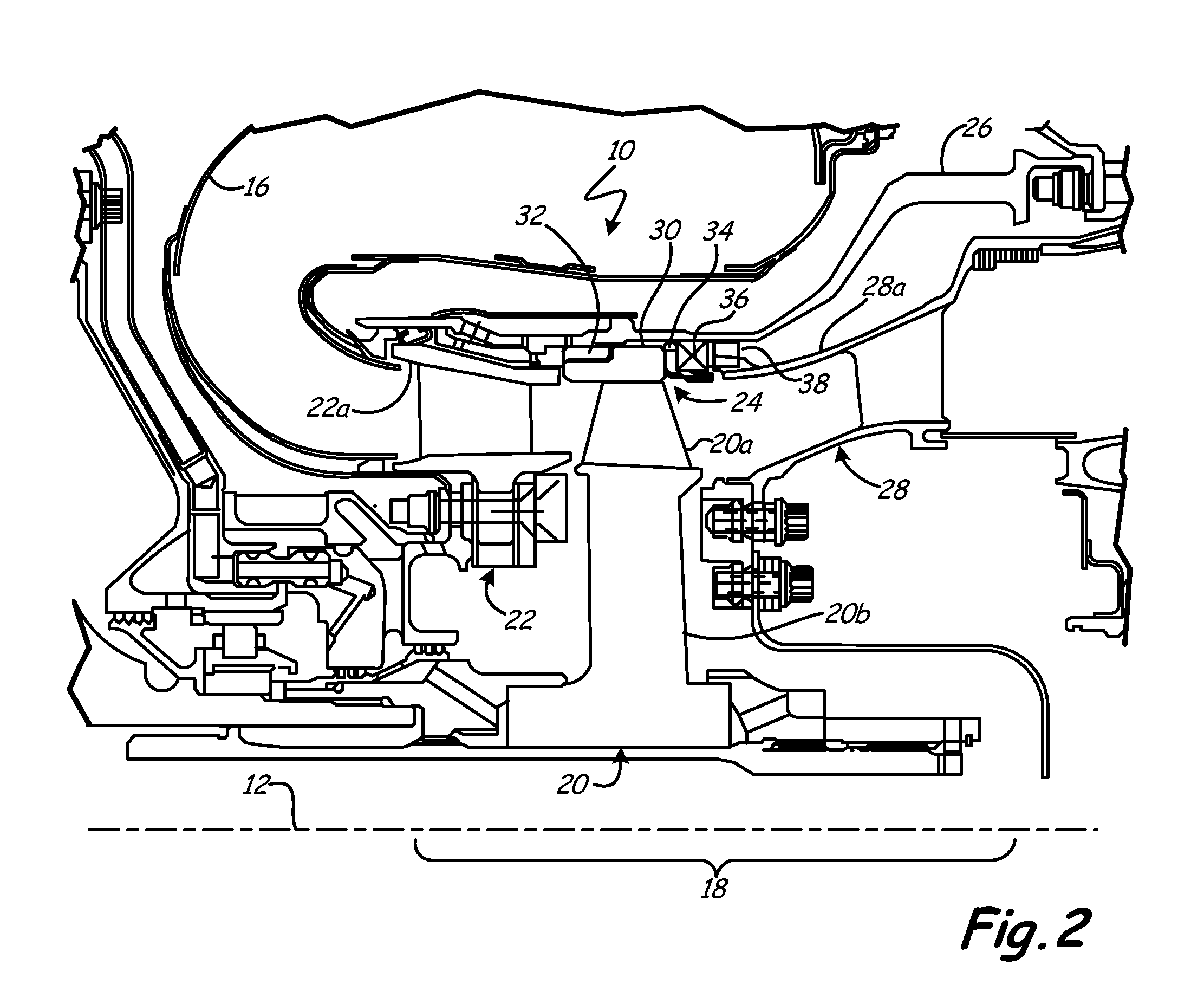

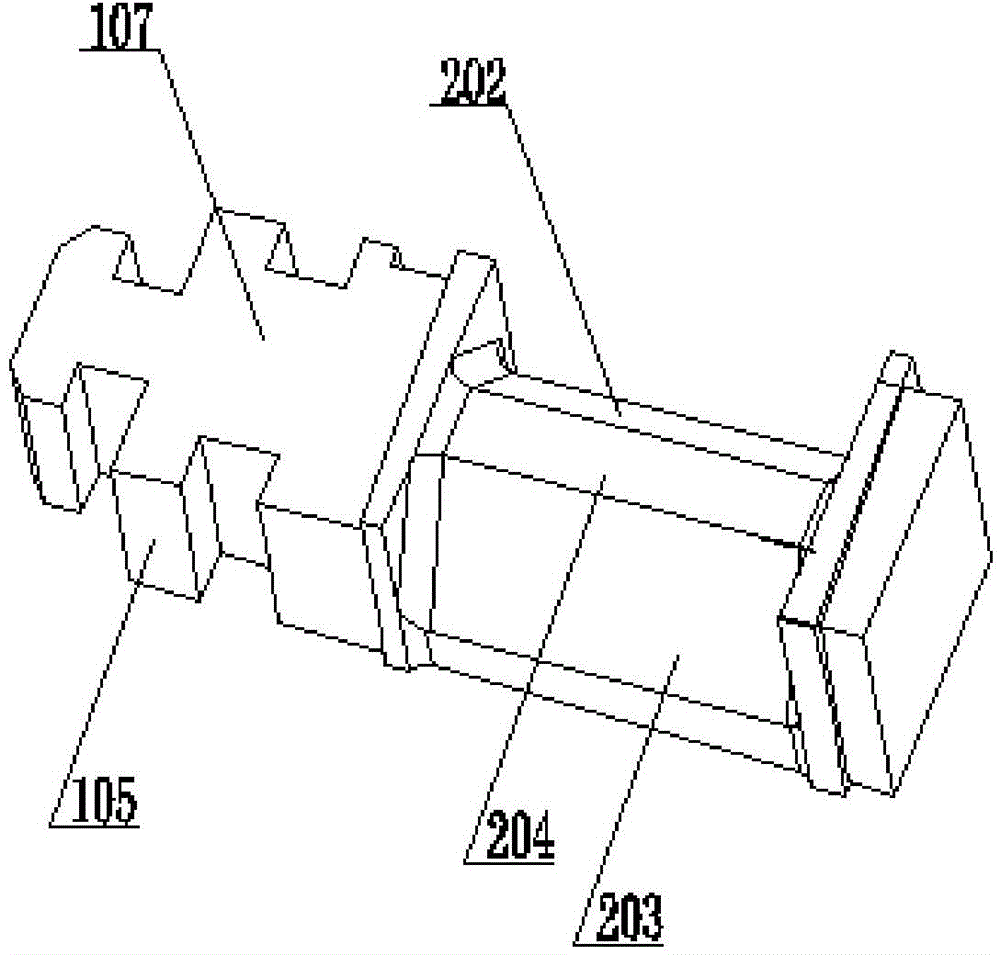

Automatic transmission carrier assembly including an overrunning brake

ActiveUS7223198B2Well formedEliminate needToothed gearingsGearing detailsAutomatic transmissionEngineering

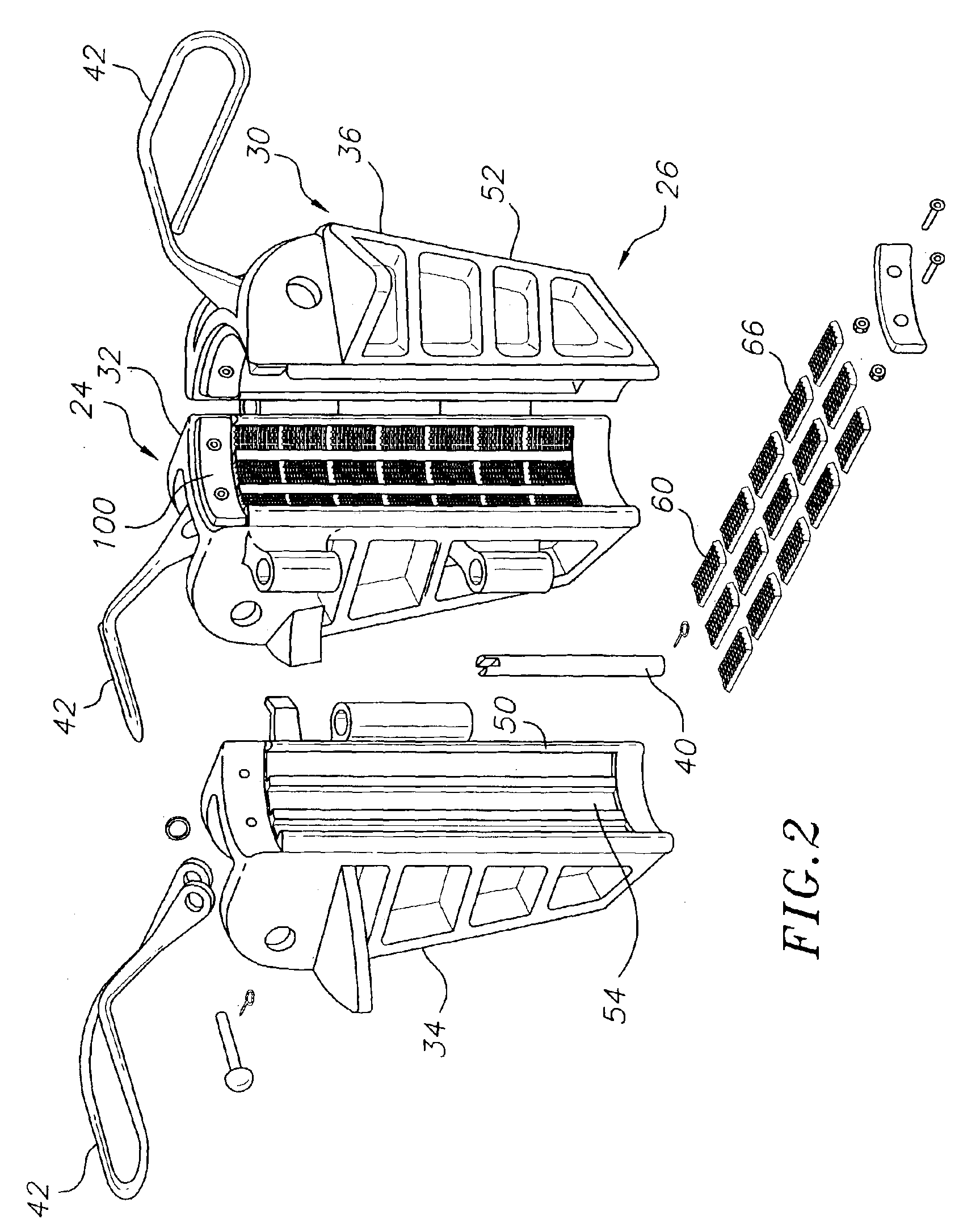

A carrier assembly for a planetary gearset of a transmission includes a pinion carrier, a one-way brake having a rocker ring integral with the carrier and having multiple pockets mutually spaced about an axis and located on an outer radial surface of the carrier. A cam ring includes multiple notches angularly spaced about the axis and facing the rocker ring. A rocker, located in each pocket, pivots about a pivot center to engage the cam ring, and a spring urges each rocker to pivot toward engagement with the cam ring. A hydraulically actuated friction brake secured to the carrier alternately holds the carrier against rotation relative to a housing and permits the carrier to rotate.

Owner:FORD GLOBAL TECH LLC

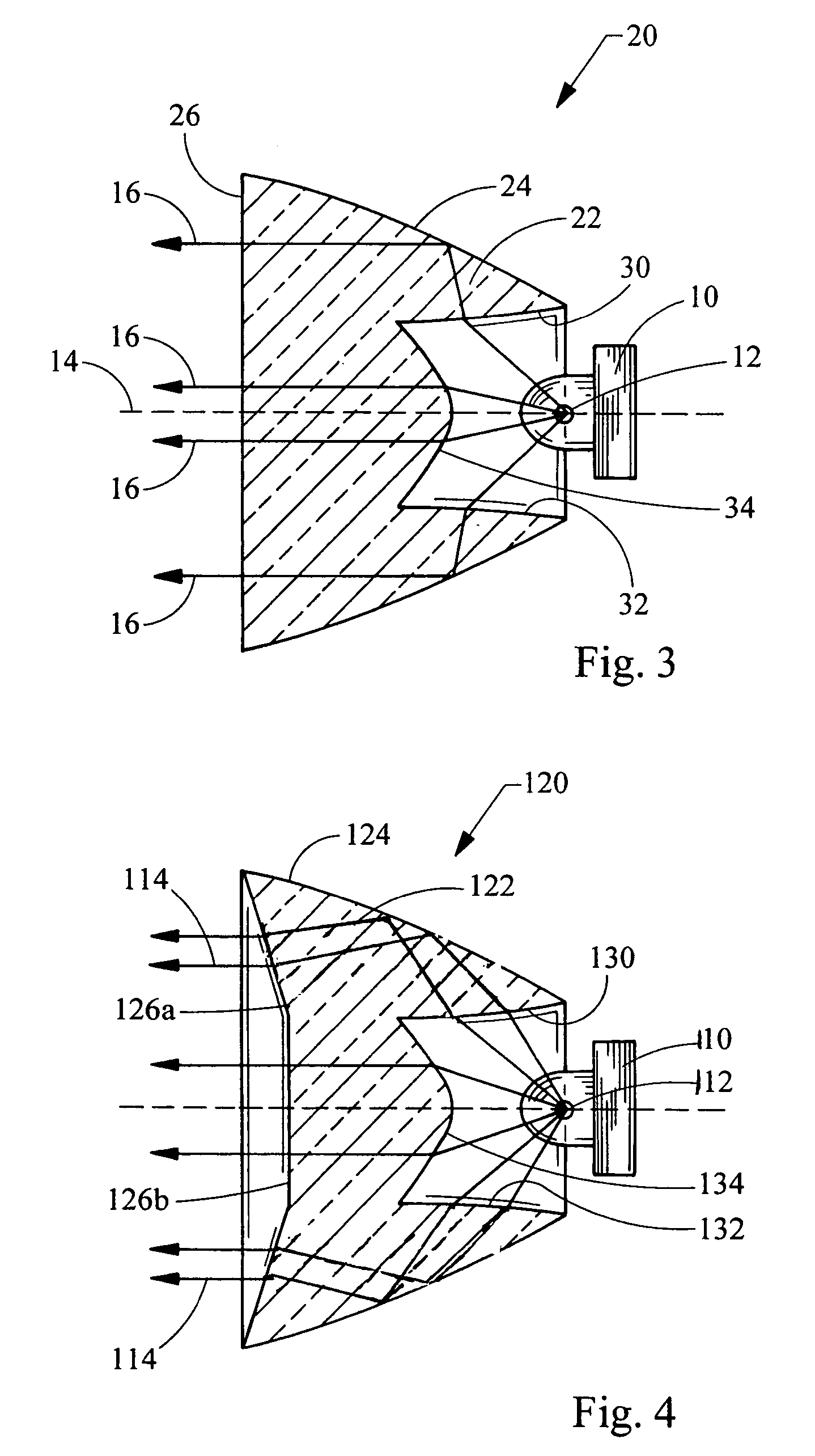

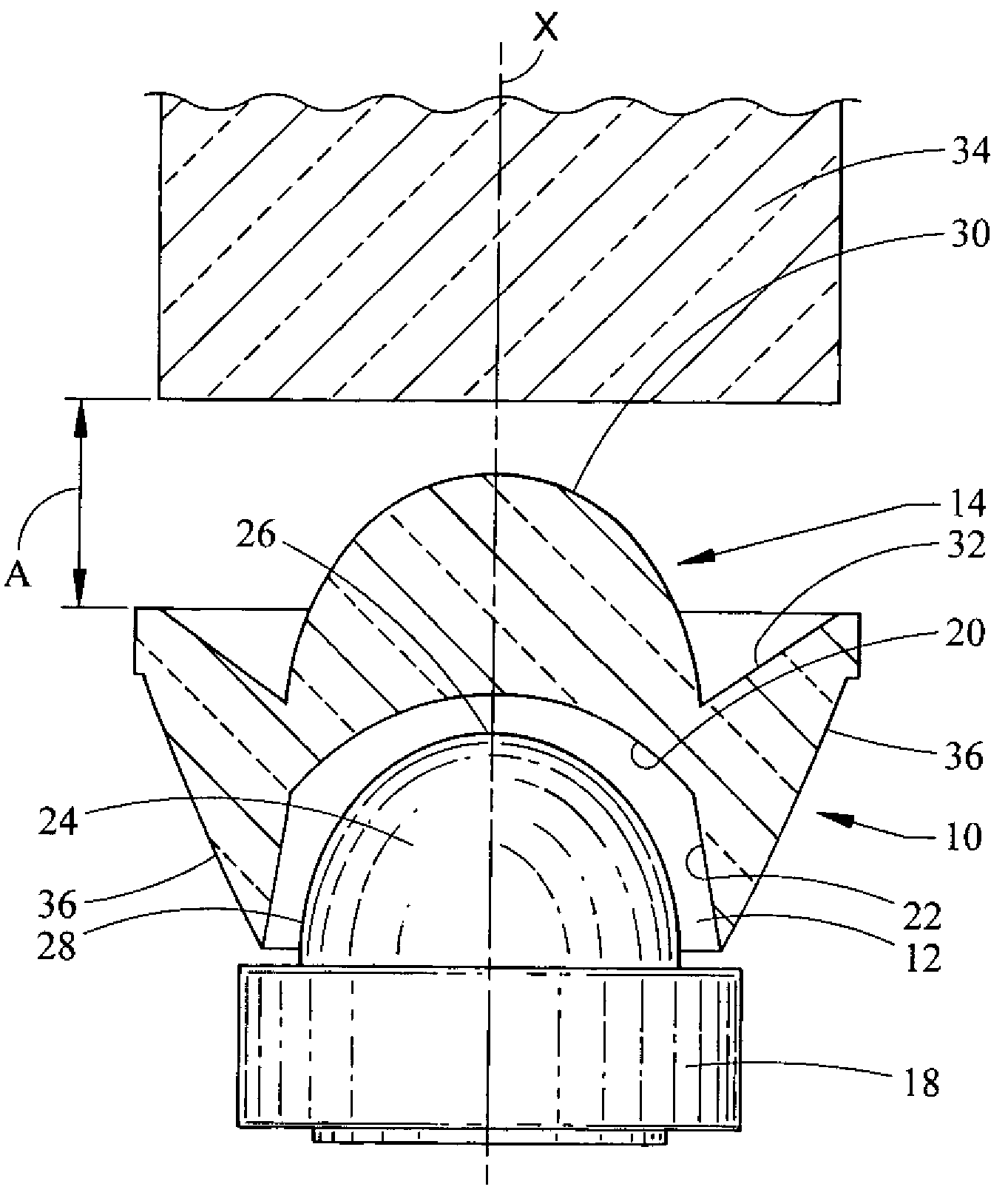

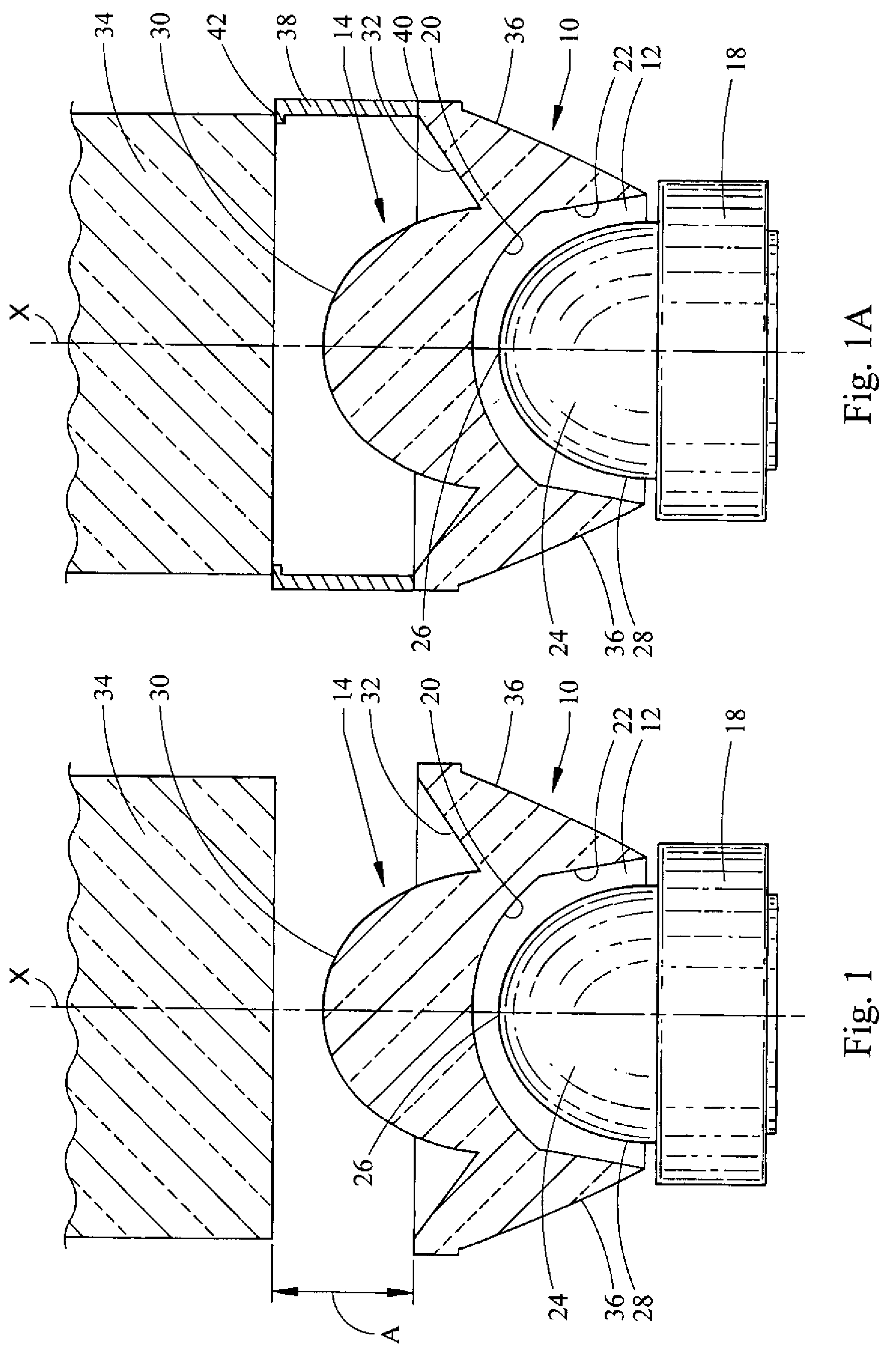

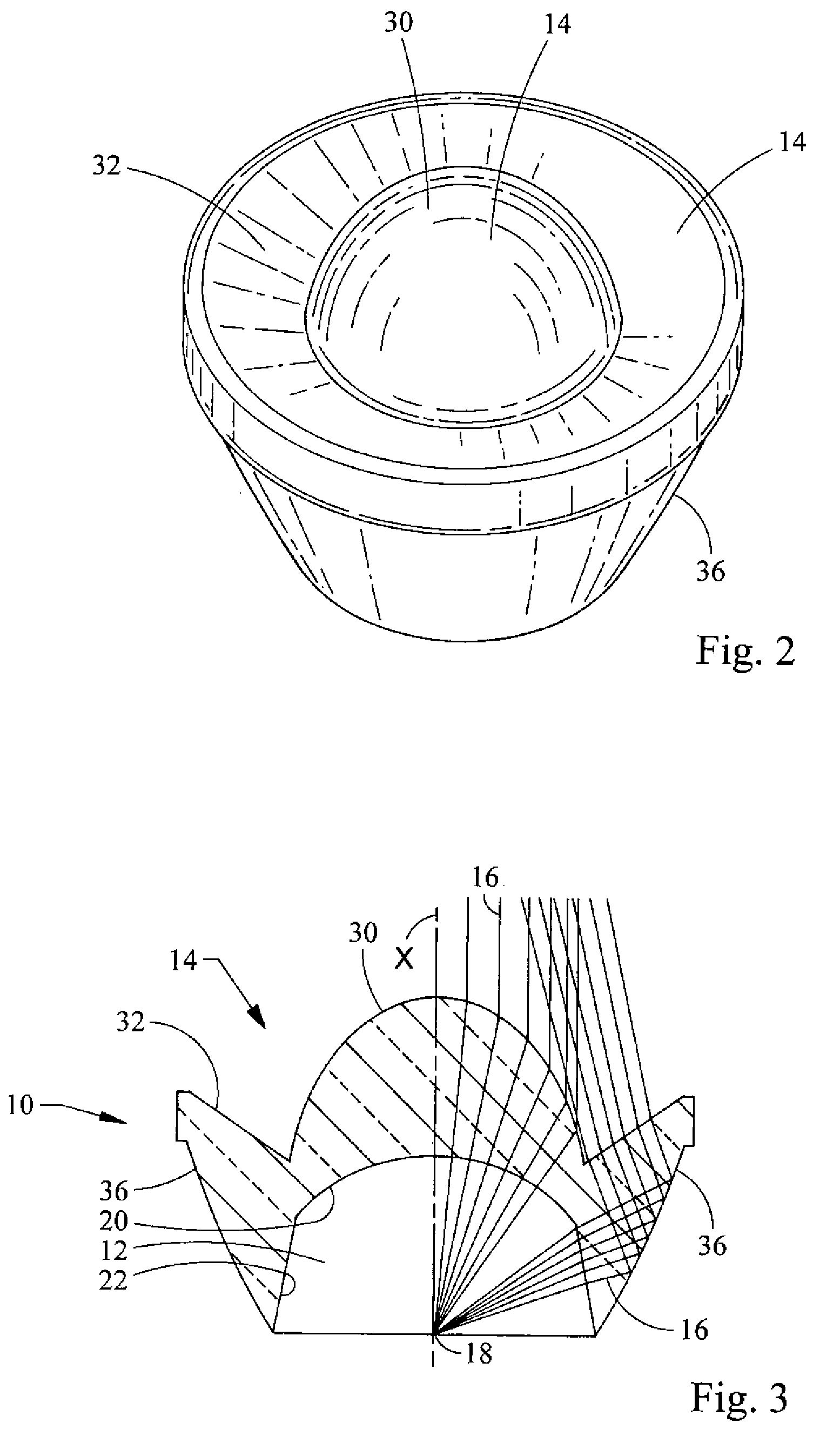

Near field lens having reduced size

A near field lens for an automotive light assembly which has a reduced thickness. Generally, the near field lens includes a main body of light transmitting material. A pocket is formed in the main body for receiving light from a light source. The pocket is defined by an inner radially facing surface and an inner axially facing surface. The inner radially facing surface is structured to reduce the thickness of the lens.

Owner:VARROC LIGHTING SYST SRO

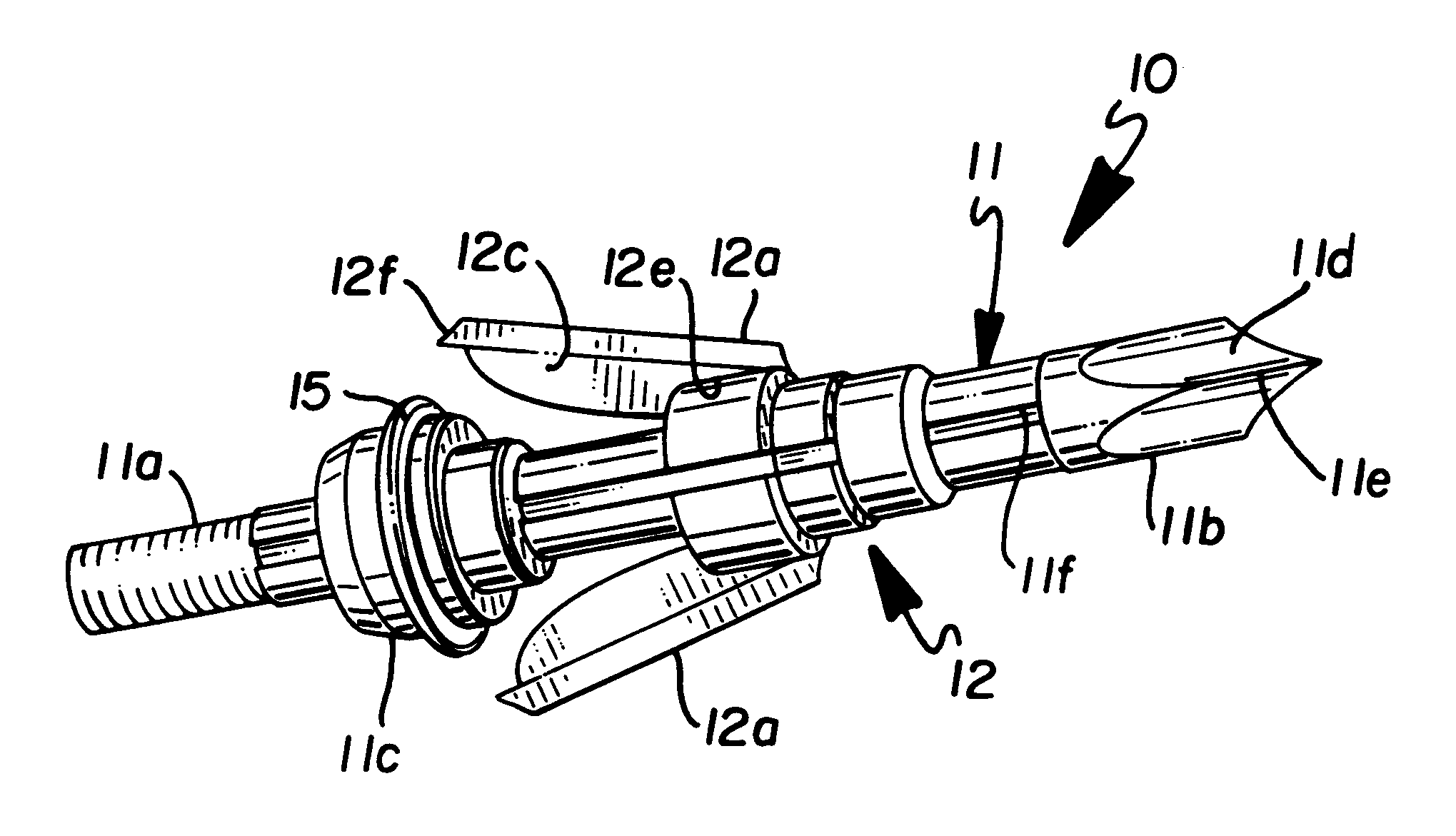

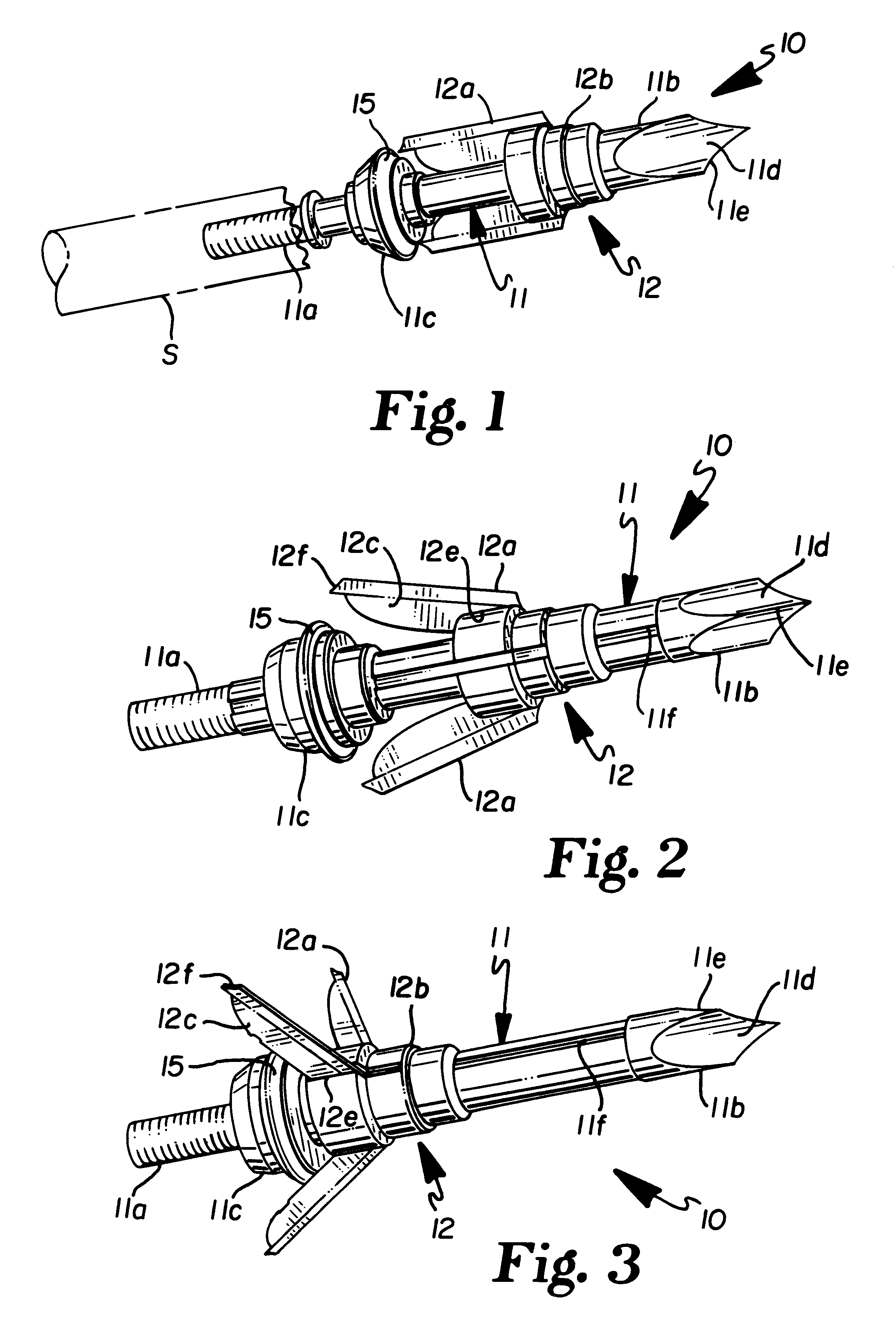

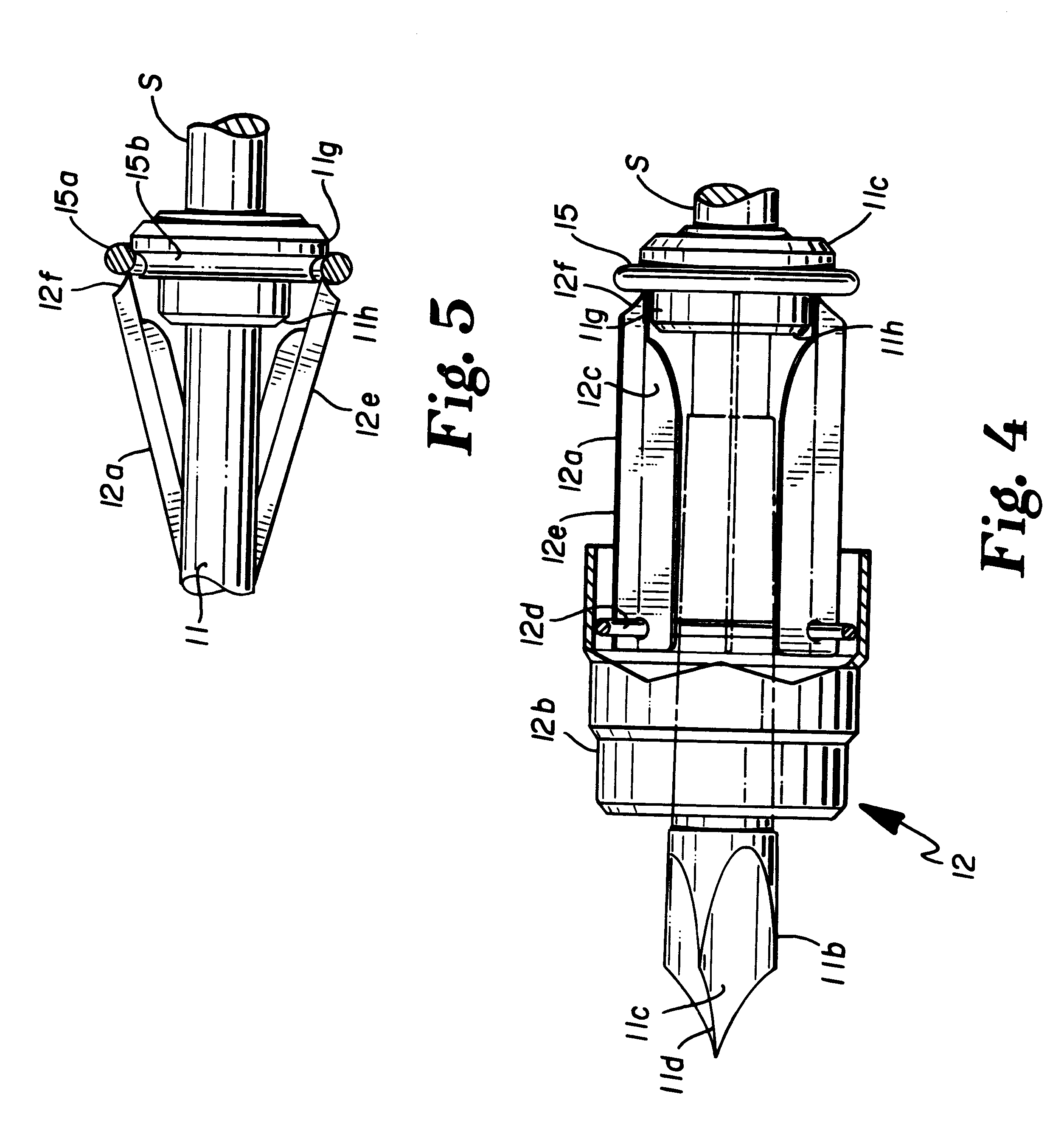

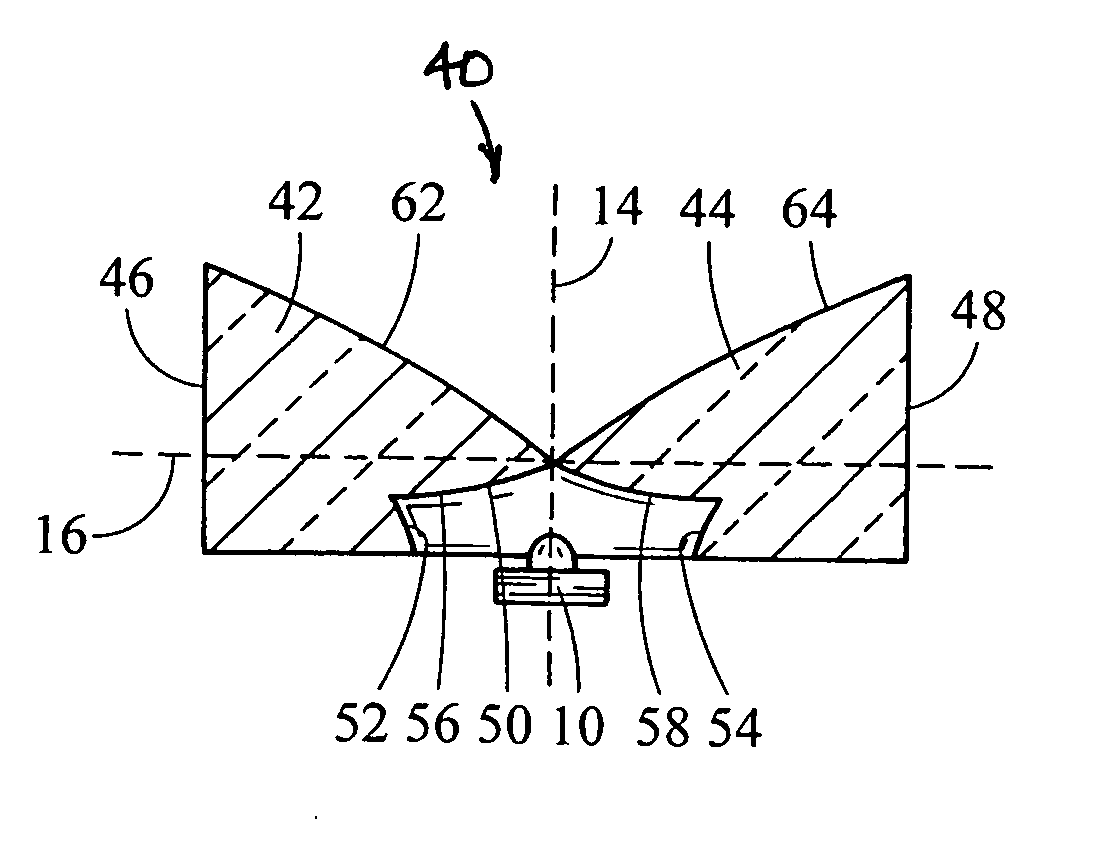

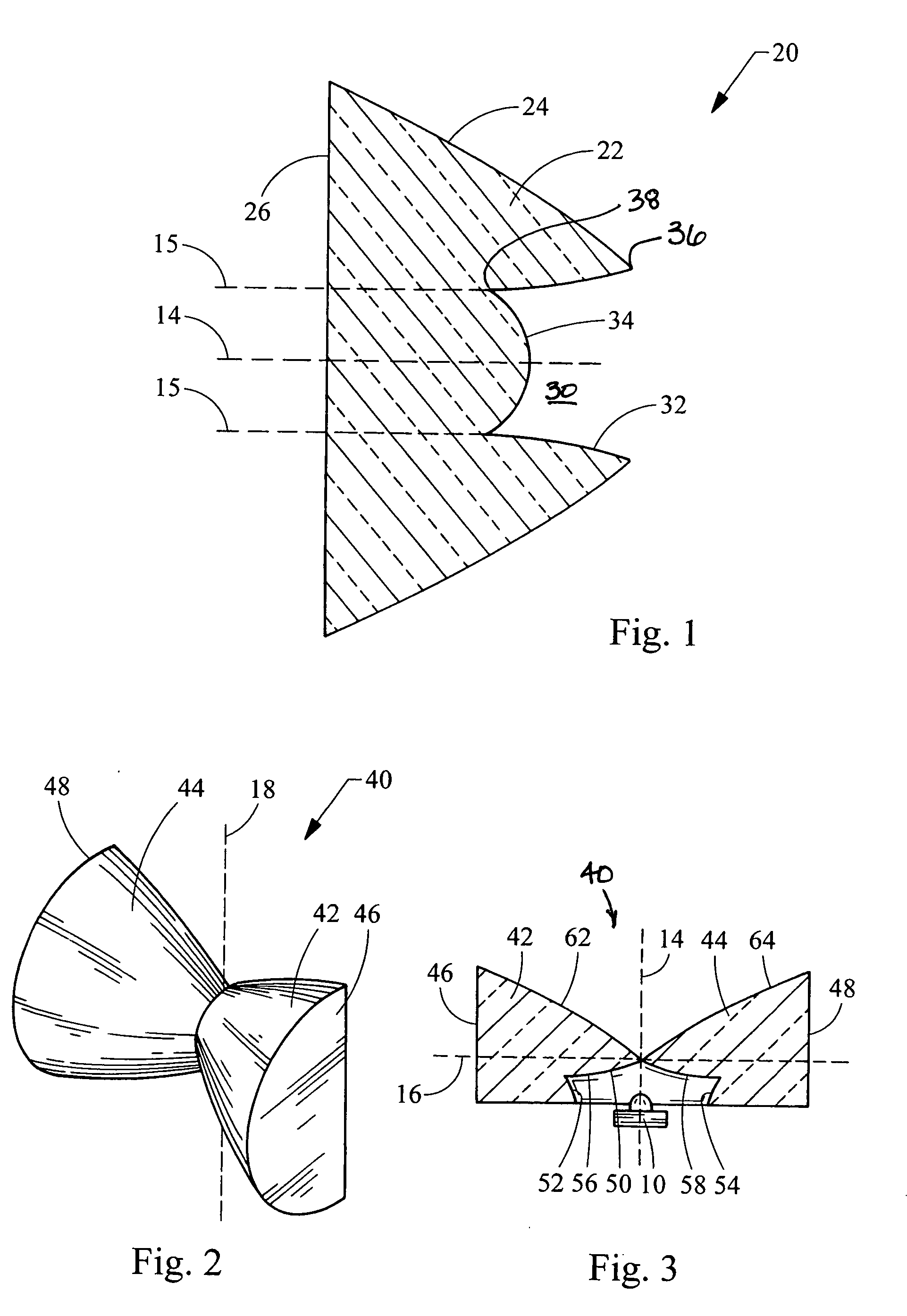

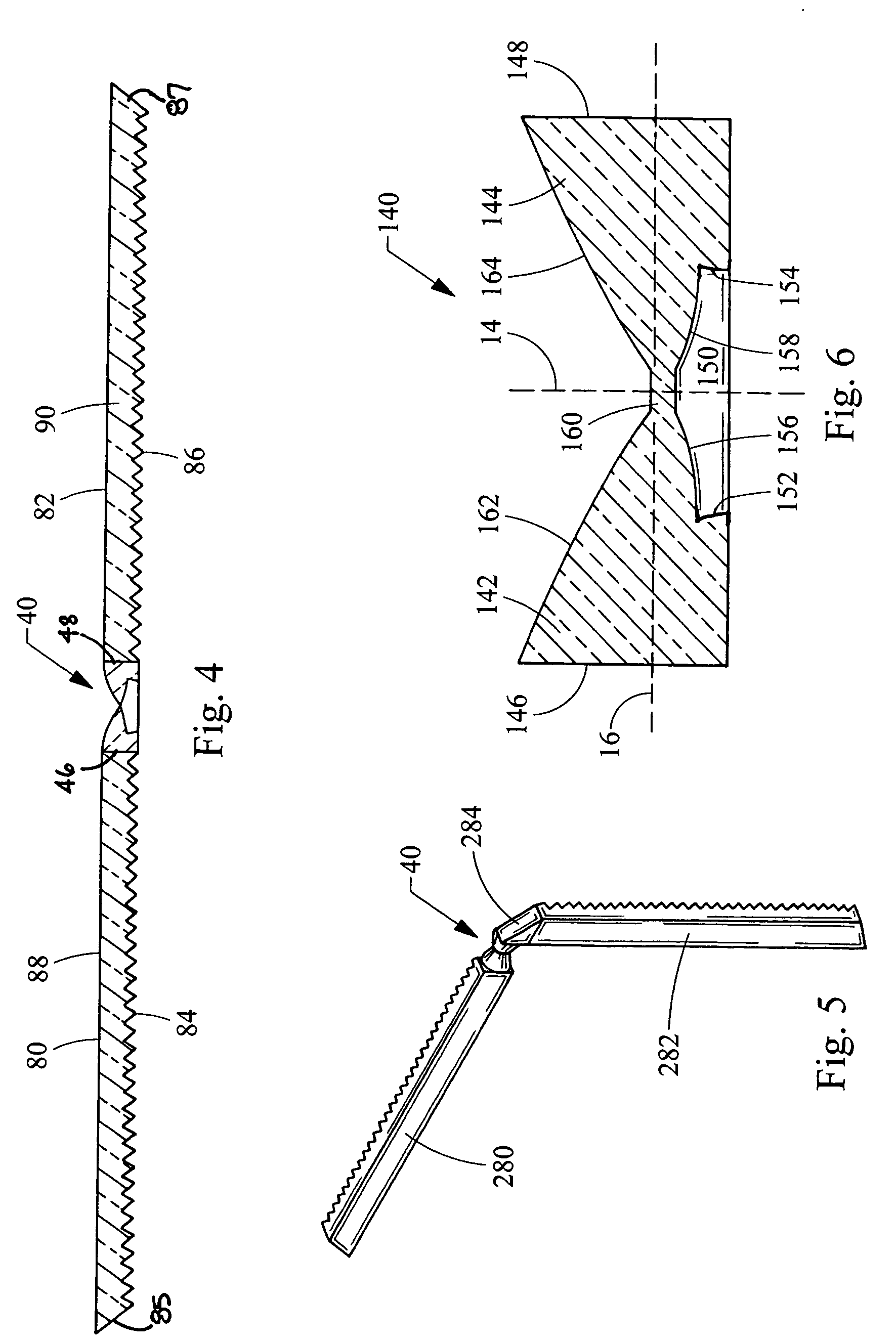

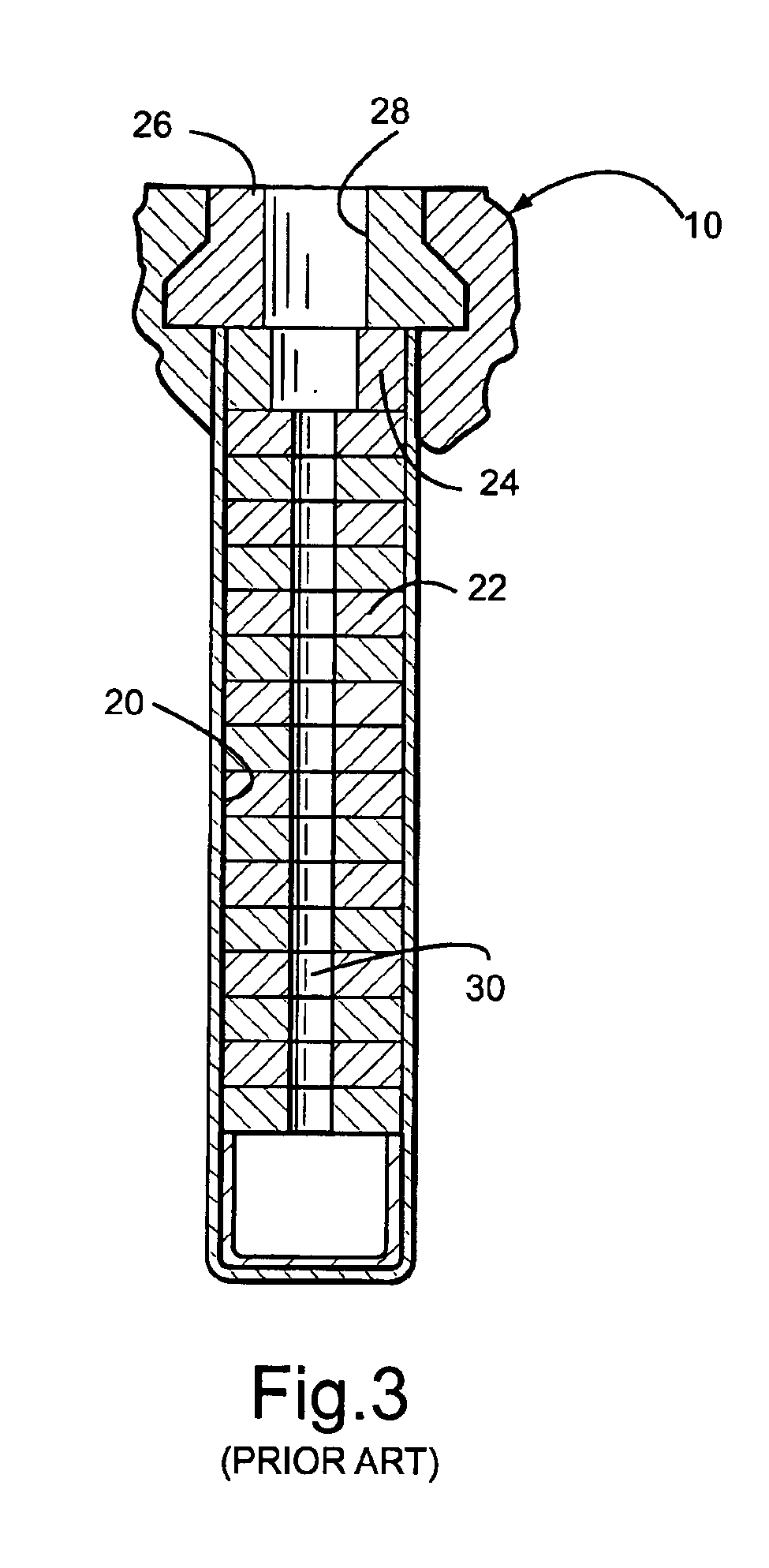

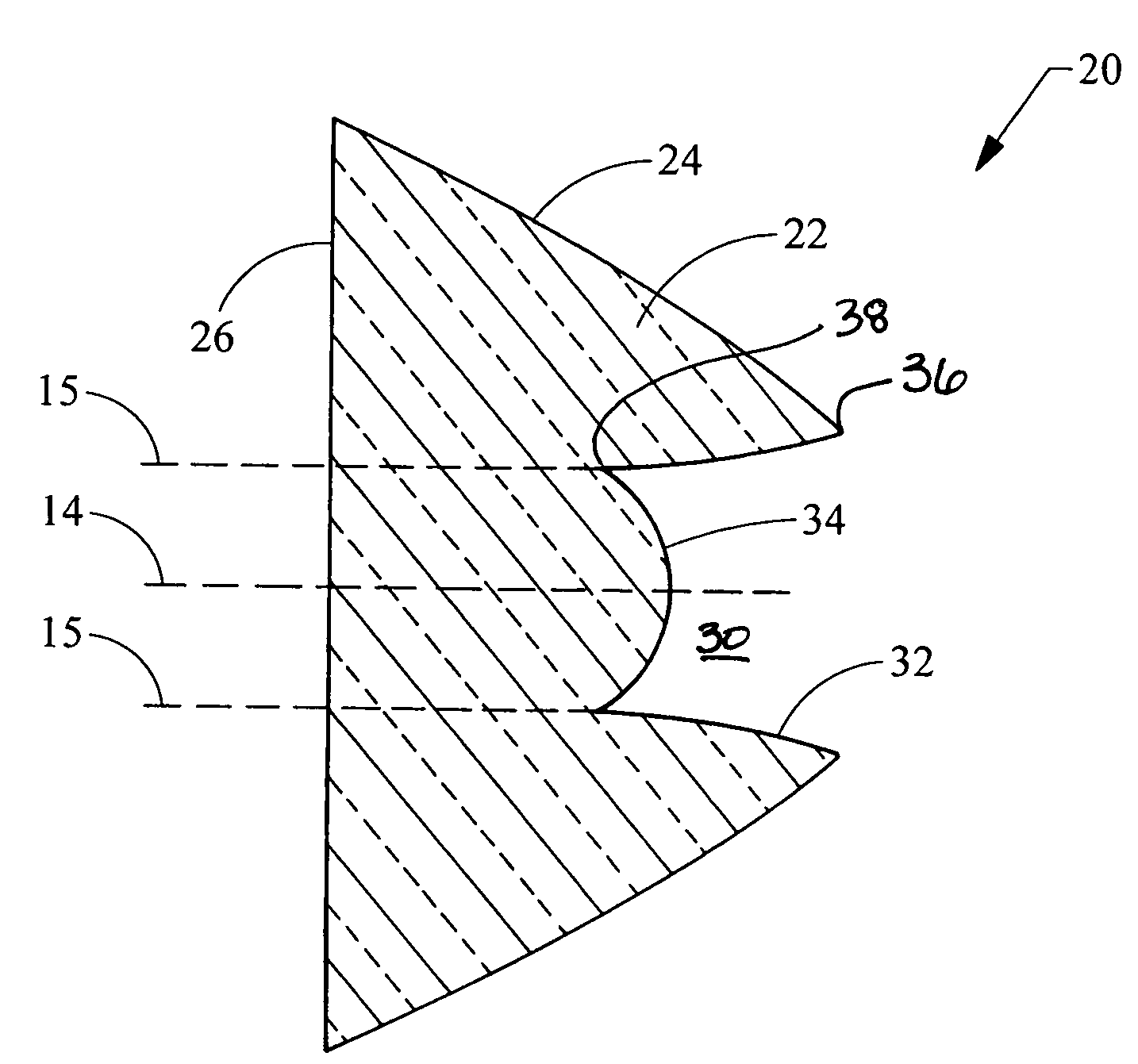

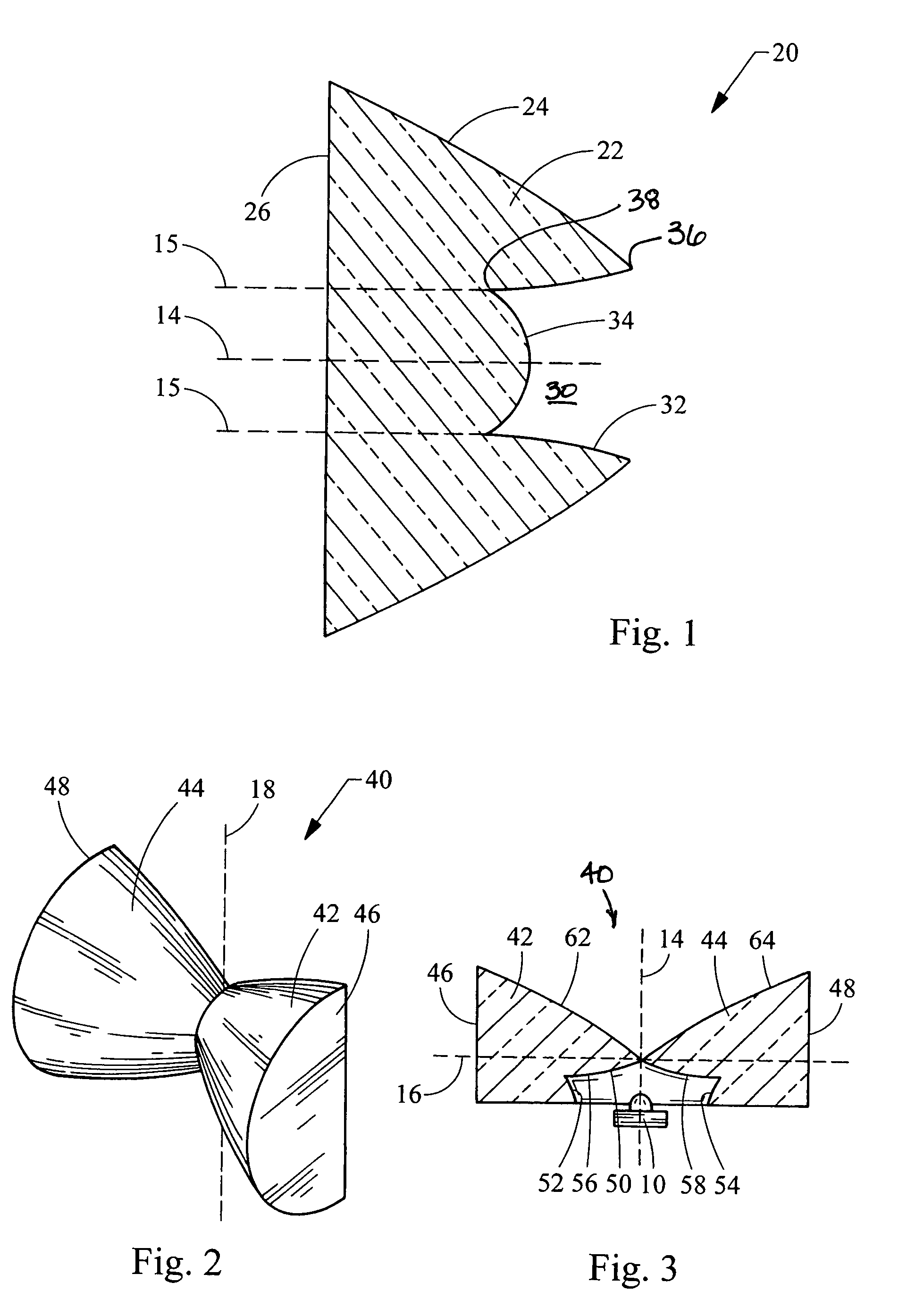

Sliding body expanding broadhead

InactiveUS6200237B1Promote repairEasy to replaceAmmunition projectilesThrow gamesCamMechanical engineering

An expanding or expandable broadhead tip for arrows wherein a sliding body is provided to carry the blades of the arrow and allow for rotation of the blades to an expanded position. When in folded or inflight position, the rearmost ends of the blades rest on a radial surface of a stationary or positionable stop having a camming front surface and which are held in such position by a retainer. When the tip strikes an object, the sliding body moves rearwardly causing the ends of the blades to override the hold down force of the retainer and as rearward motion continues, the blades are cammed outwardly by the camming front of the stop.

Owner:OUT RAGE

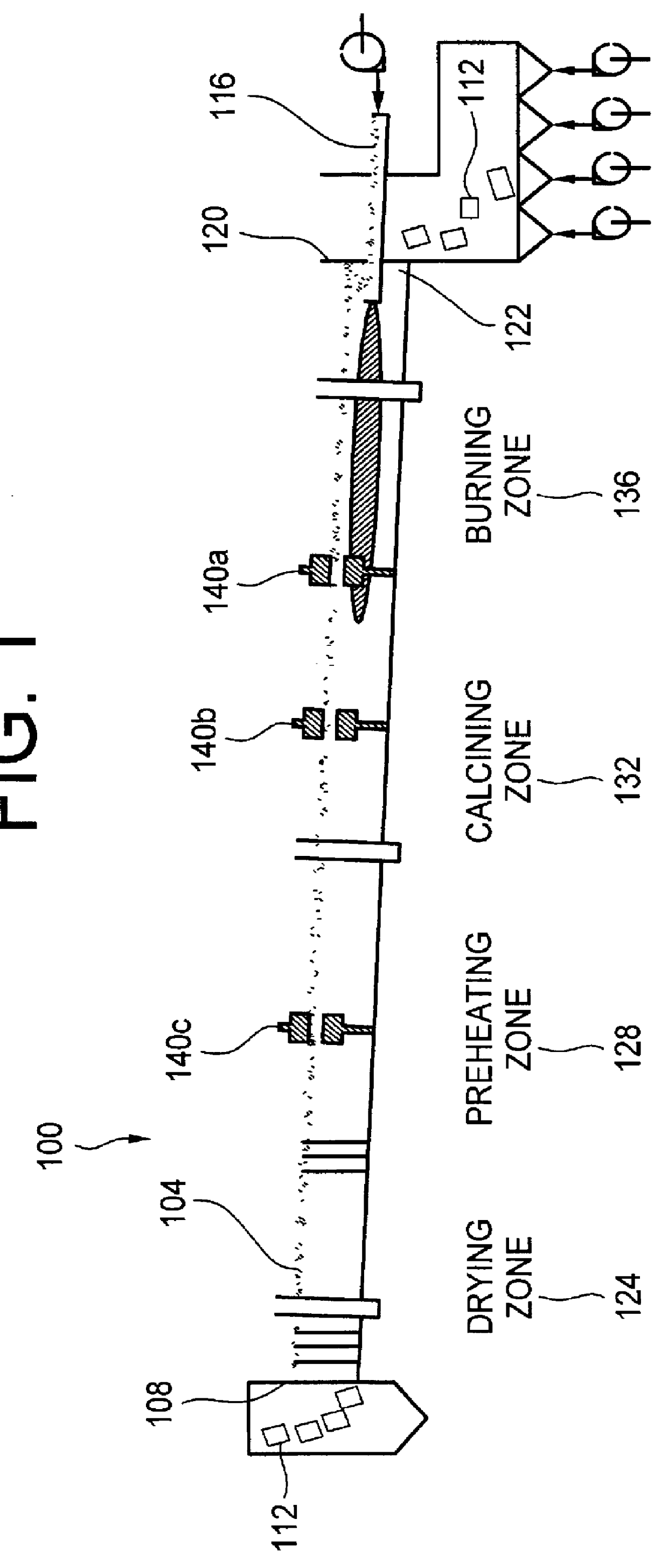

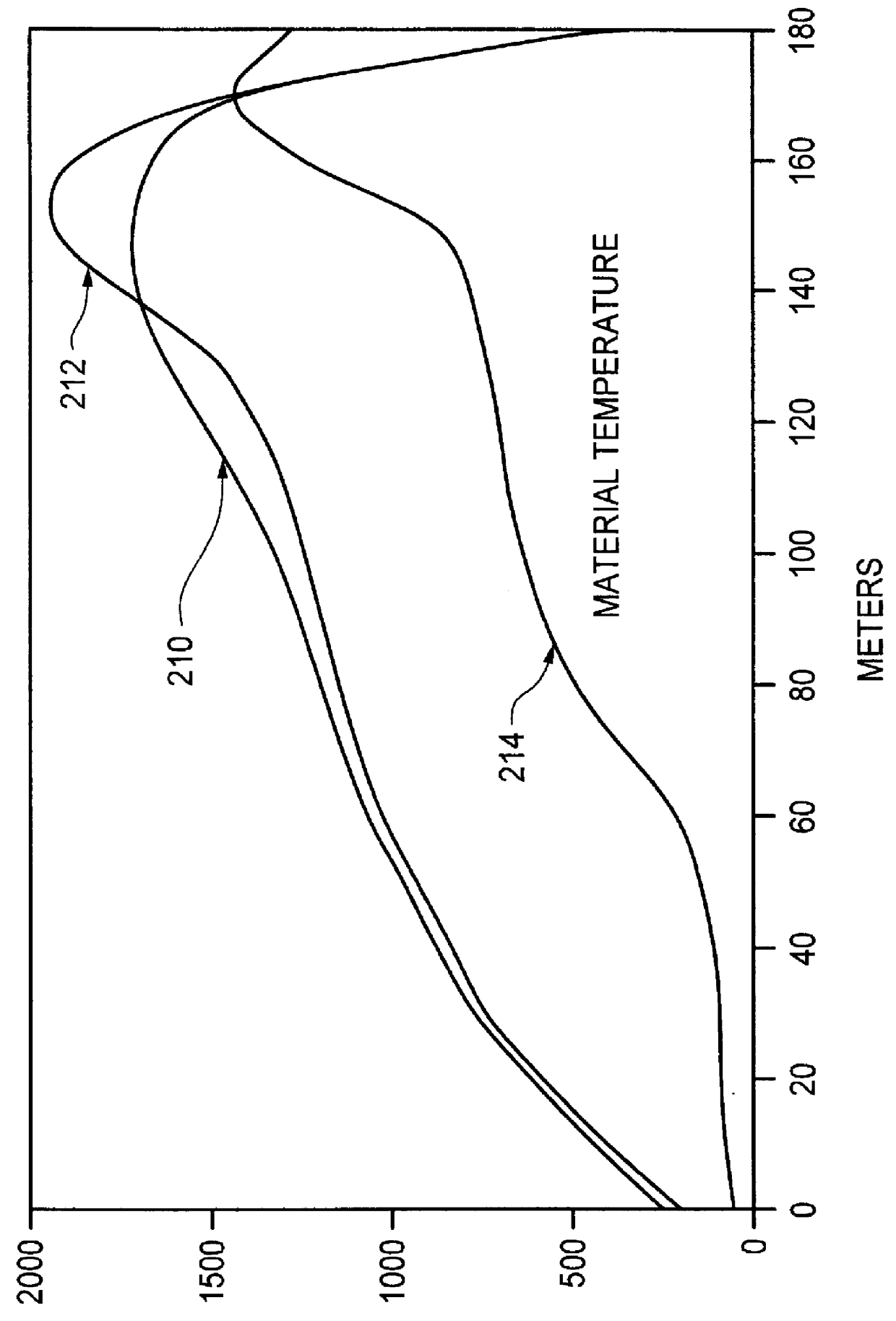

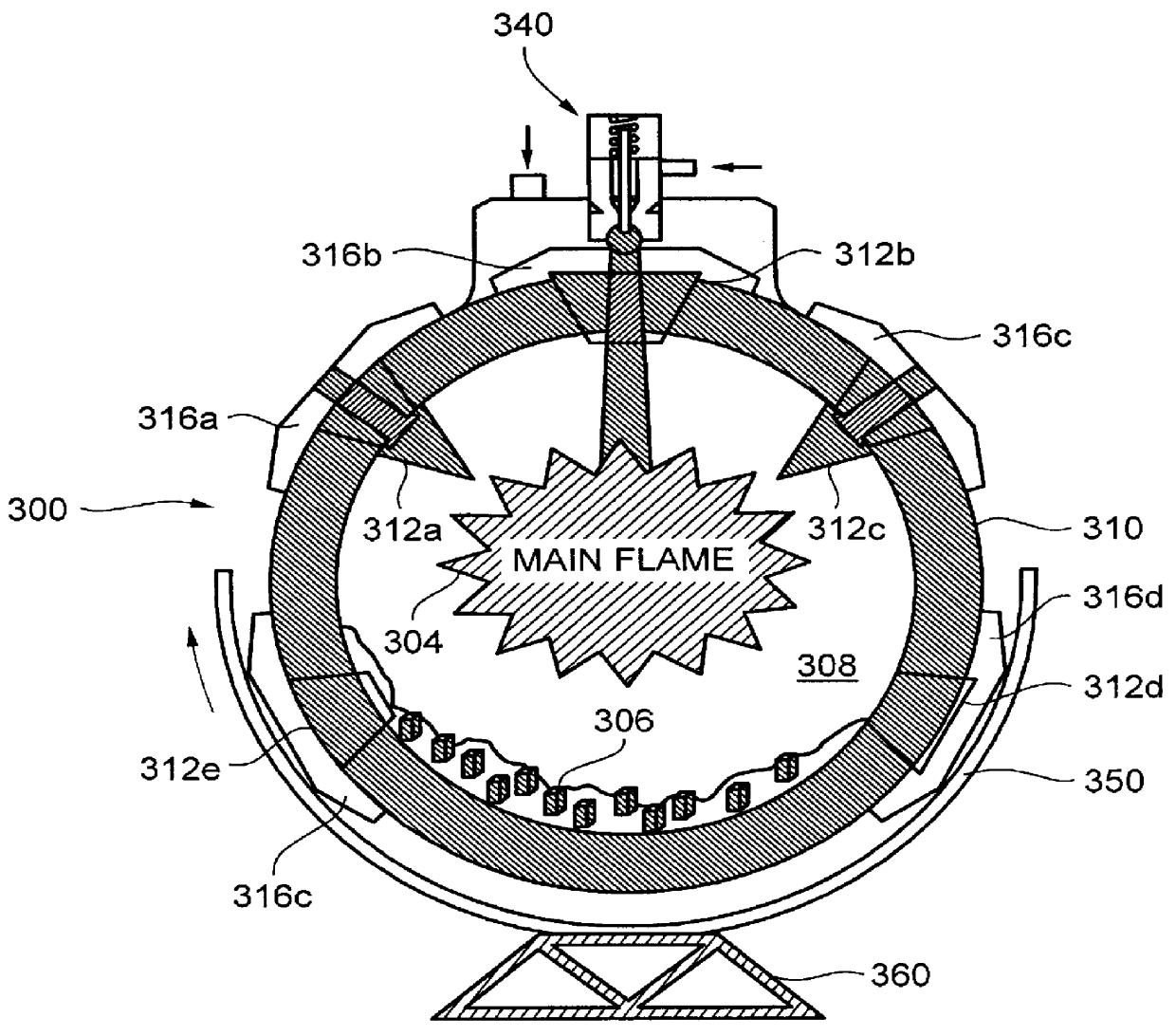

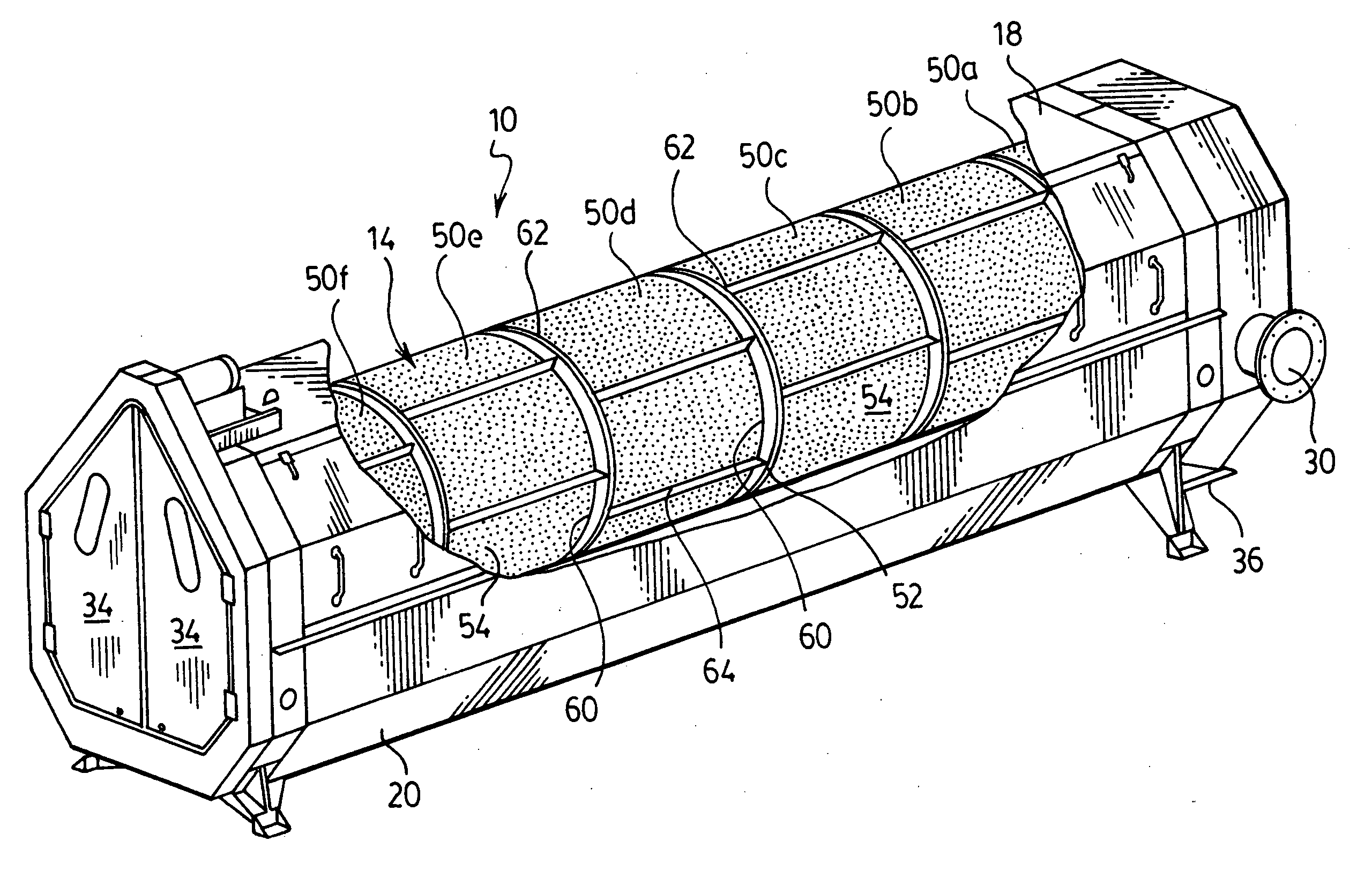

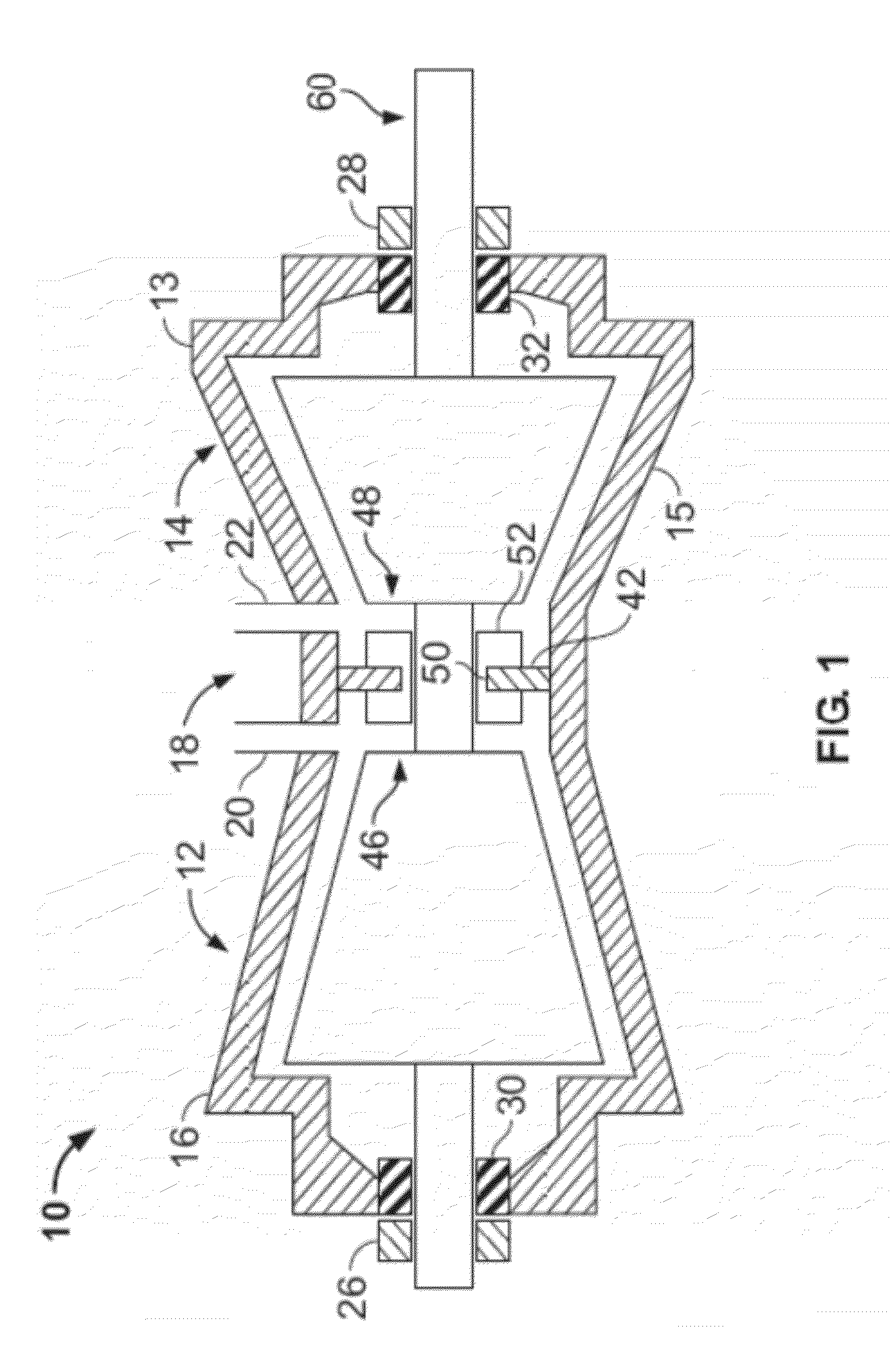

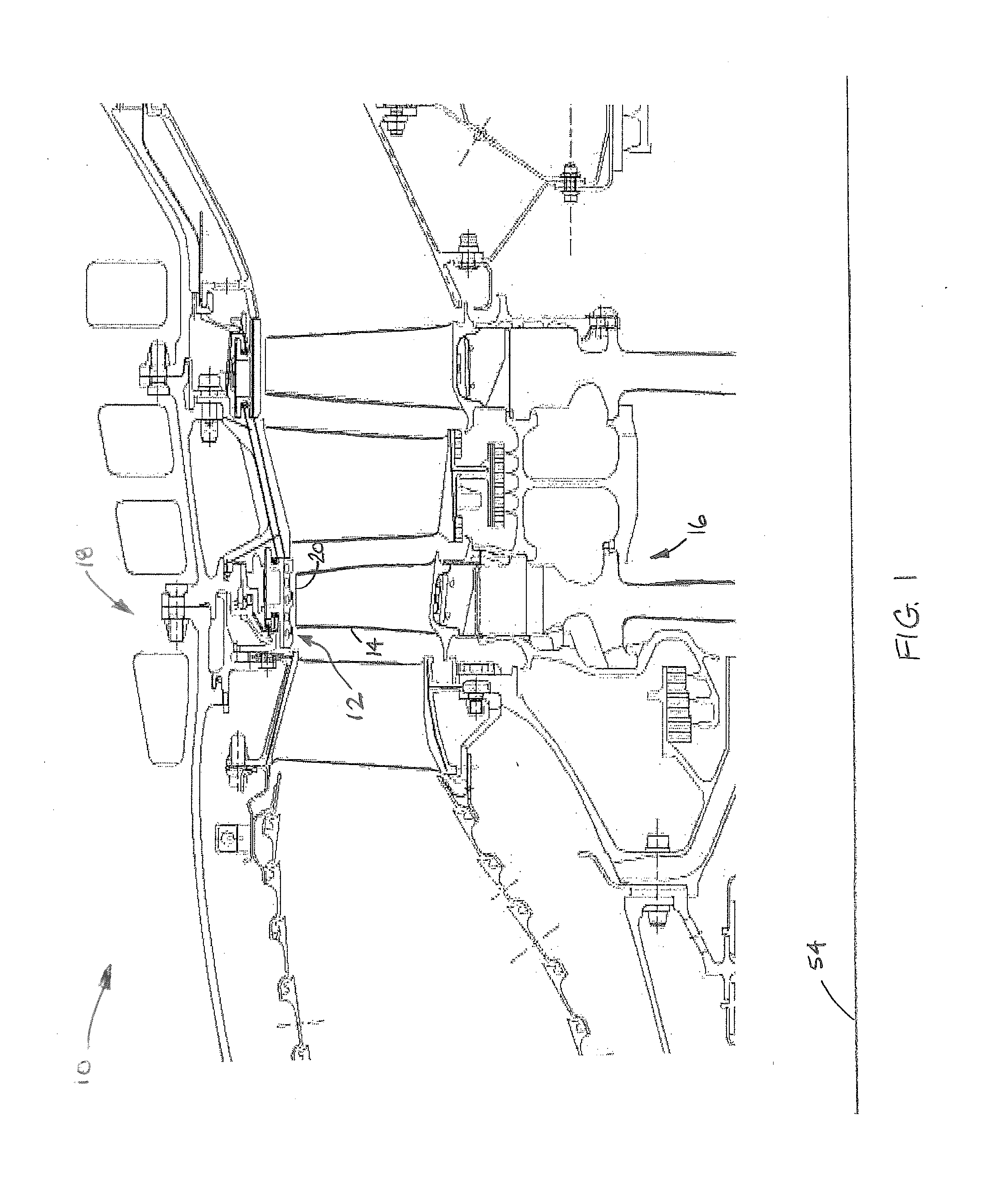

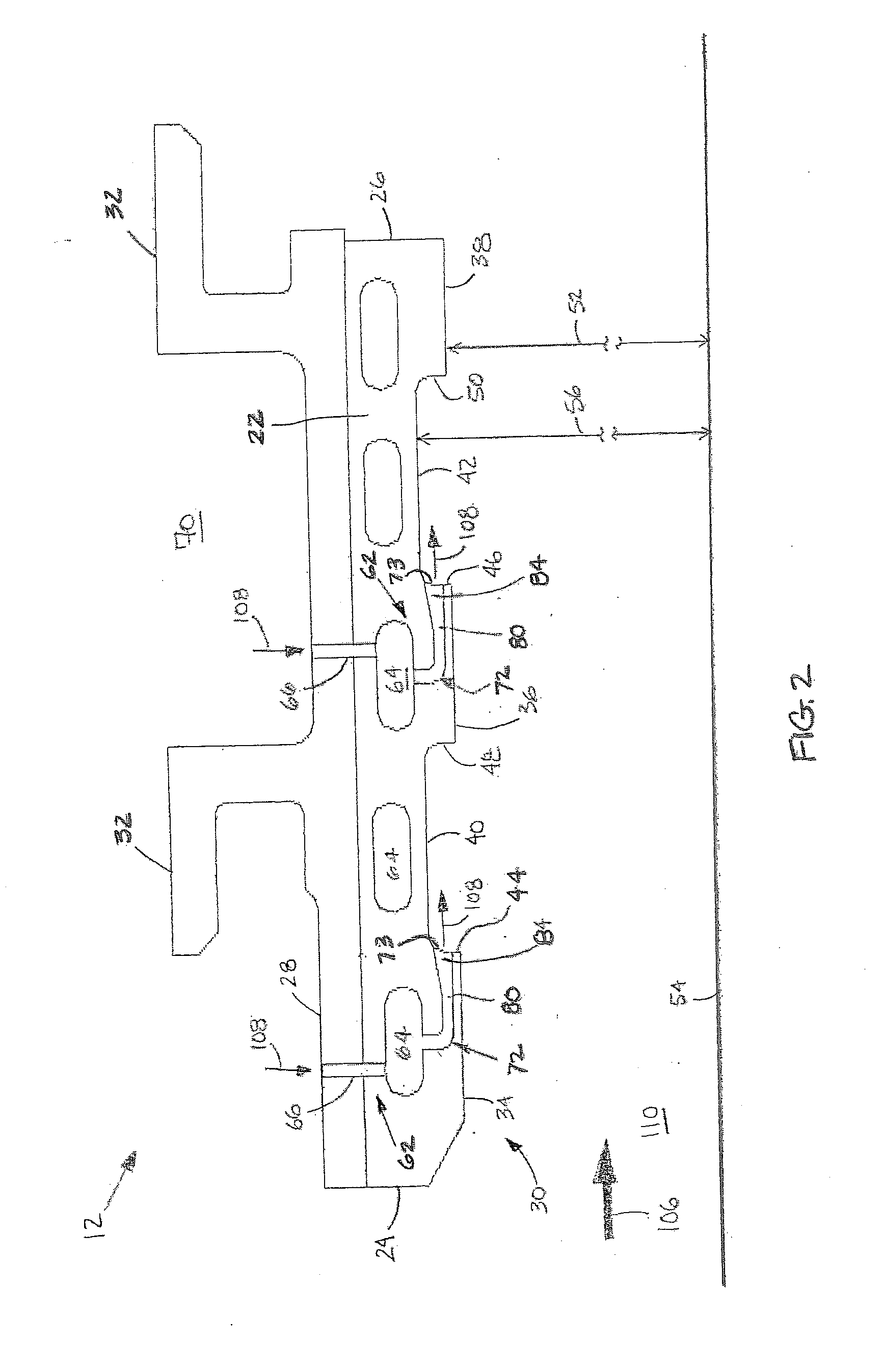

System and method for oxidant injection in rotary kilns

InactiveUS6116896AOperating means/releasing devices for valvesMuffle furnacesInjection portEngineering

A system and method for increasing the amount of oxygen in a kiln chamber is disclosed. The radial surface of a rotatable kiln is provided with at least one oxidant injection port extending through the radial surface into the kiln chamber. A cam is connected to the radial surface adjacent the oxidant injection port. A valve assembly including a valve chamber in fluid communication with an oxidant supply is mounted adjacent the kiln substantially in fixed spatial relation with the rotatable kiln body. The valve assembly includes a follower member adapted to contact a surface to the cam to actuate the valve assembly. Rotation of the kiln body brings the cam into contact with the follower member, thereby actuating the oxidant injection assembly, and injecting oxidant through the injection port into the kiln chamber.

Owner:LAIR LIQUIDE SOCITE ANONYME POUR LETUD & LEXPL DES PROCEDES GEORCLAUDE +1

Multi-Piece Packing Element Containment System

InactiveUS20090255690A1Preventing and minimizing extrusionAvoid squeezingFluid removalSealing/packingEngineeringMechanical engineering

Methods and devices for retaining a packer element in a set condition within a wellbore and for preventing or minimizing extrusion of the packer element after setting. A packer device includes a plurality of deformable packer elements which radially surround a packer mandrel. One or more of the packer elements is contained against axial extrusion using a packer containment system. The packer containment system includes a flexible metal backup ring, which partially encases the packer element by substantially covering at least one axial side and a portion of the exterior radial surface of the packer element. The packer containment system also includes a plurality of annular support rings, or “petal rings” which have petal-shaped radial protuberances with slots between them.

Owner:BAKER HUGHES INC

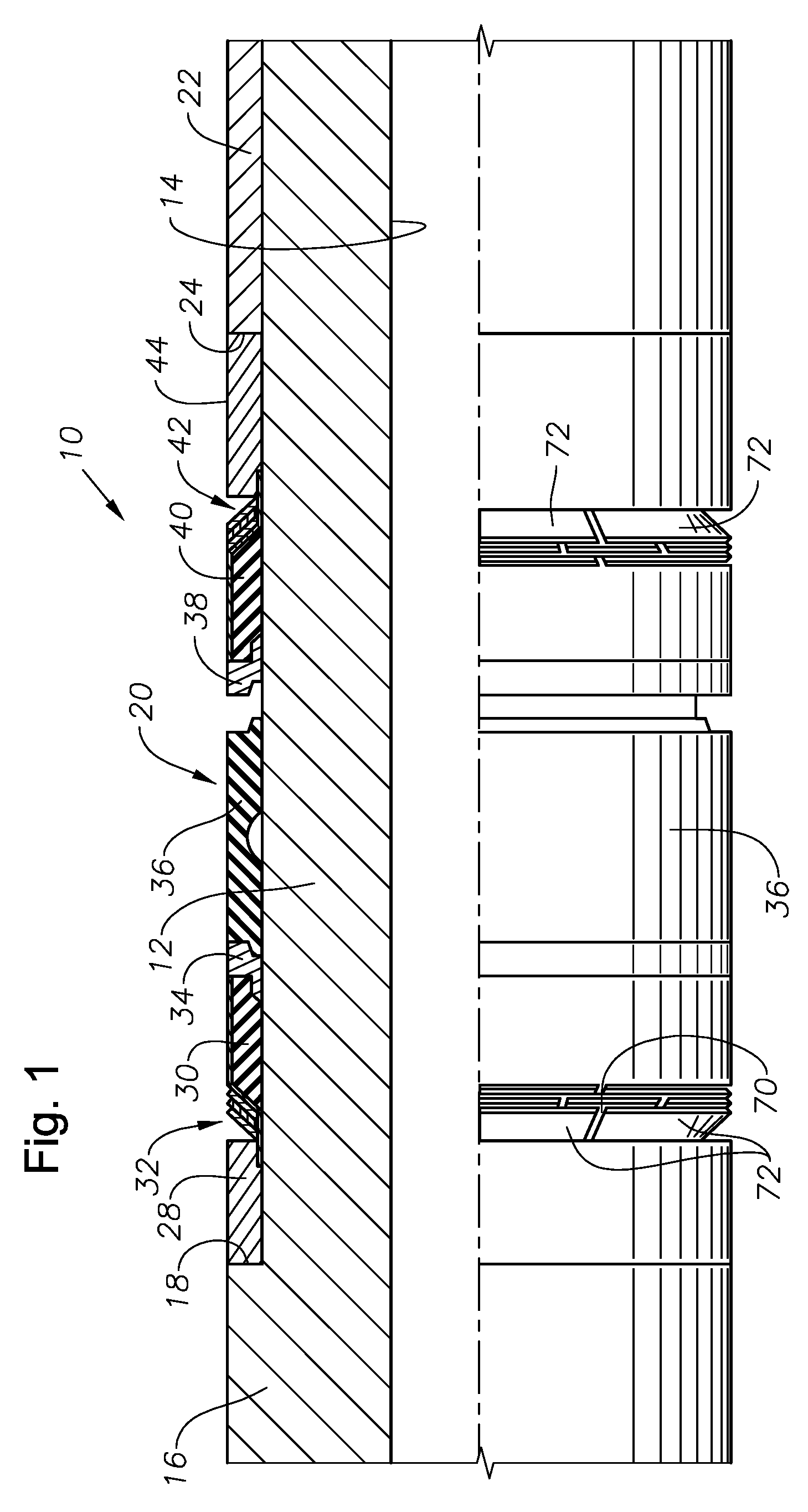

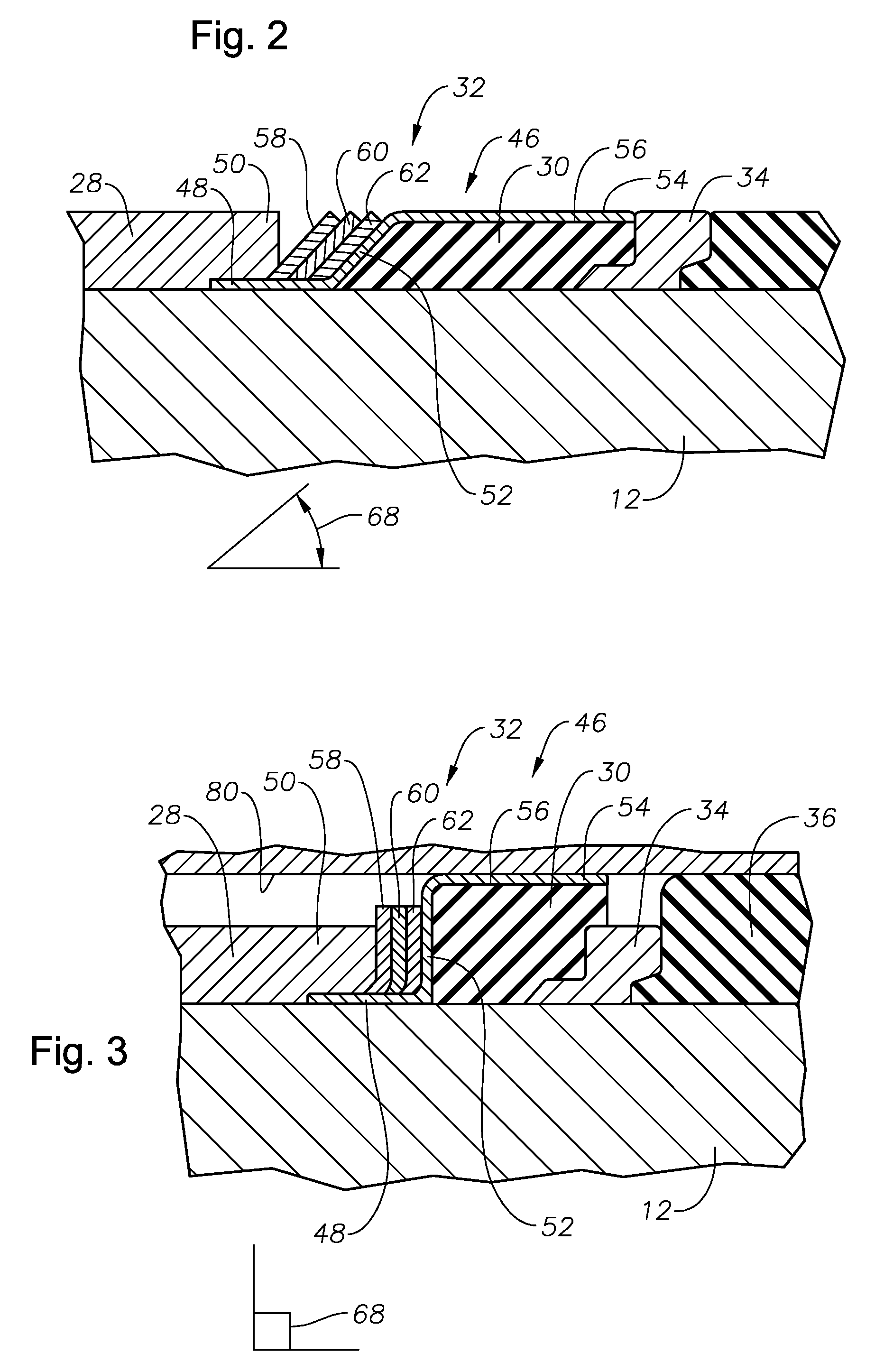

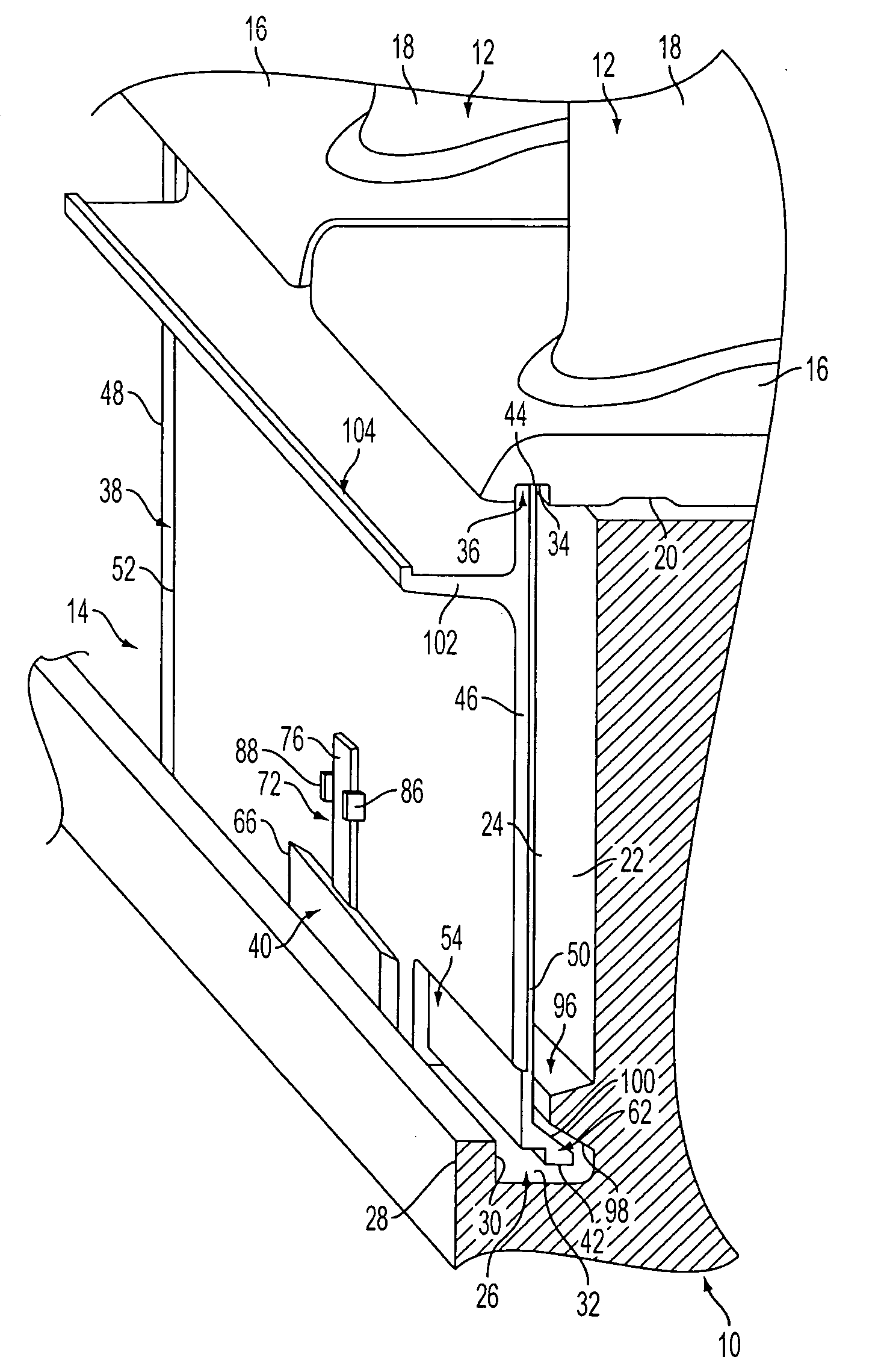

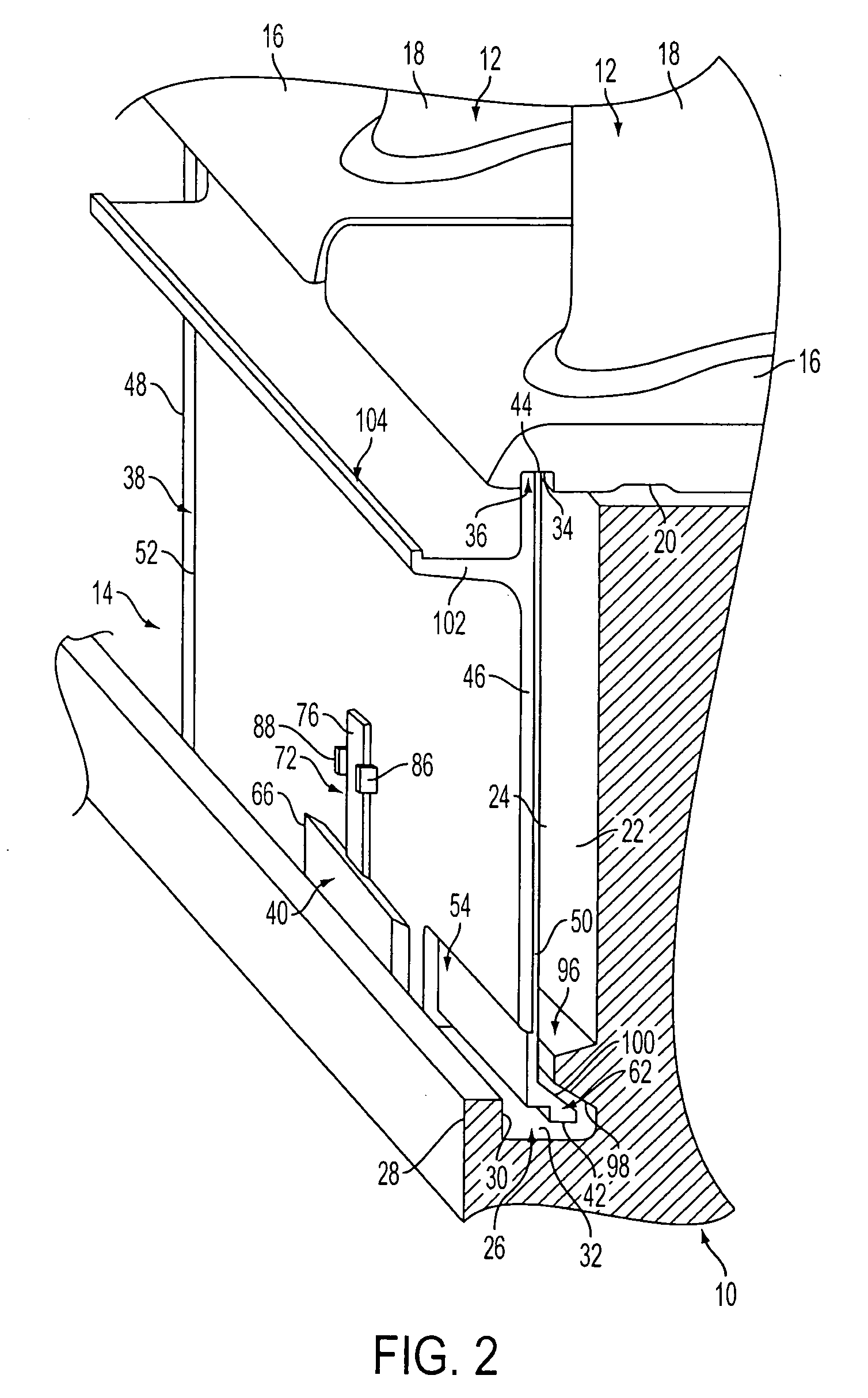

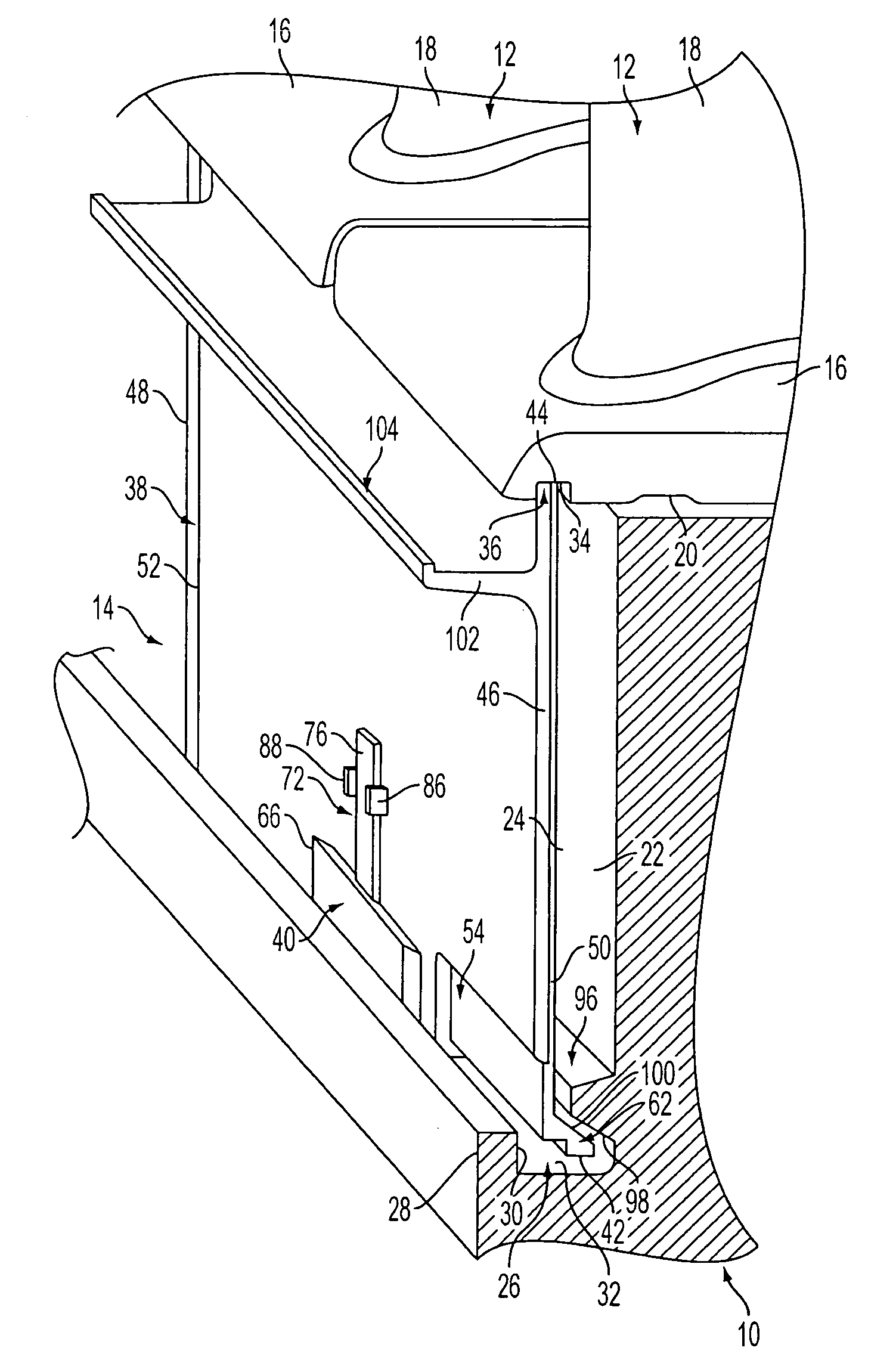

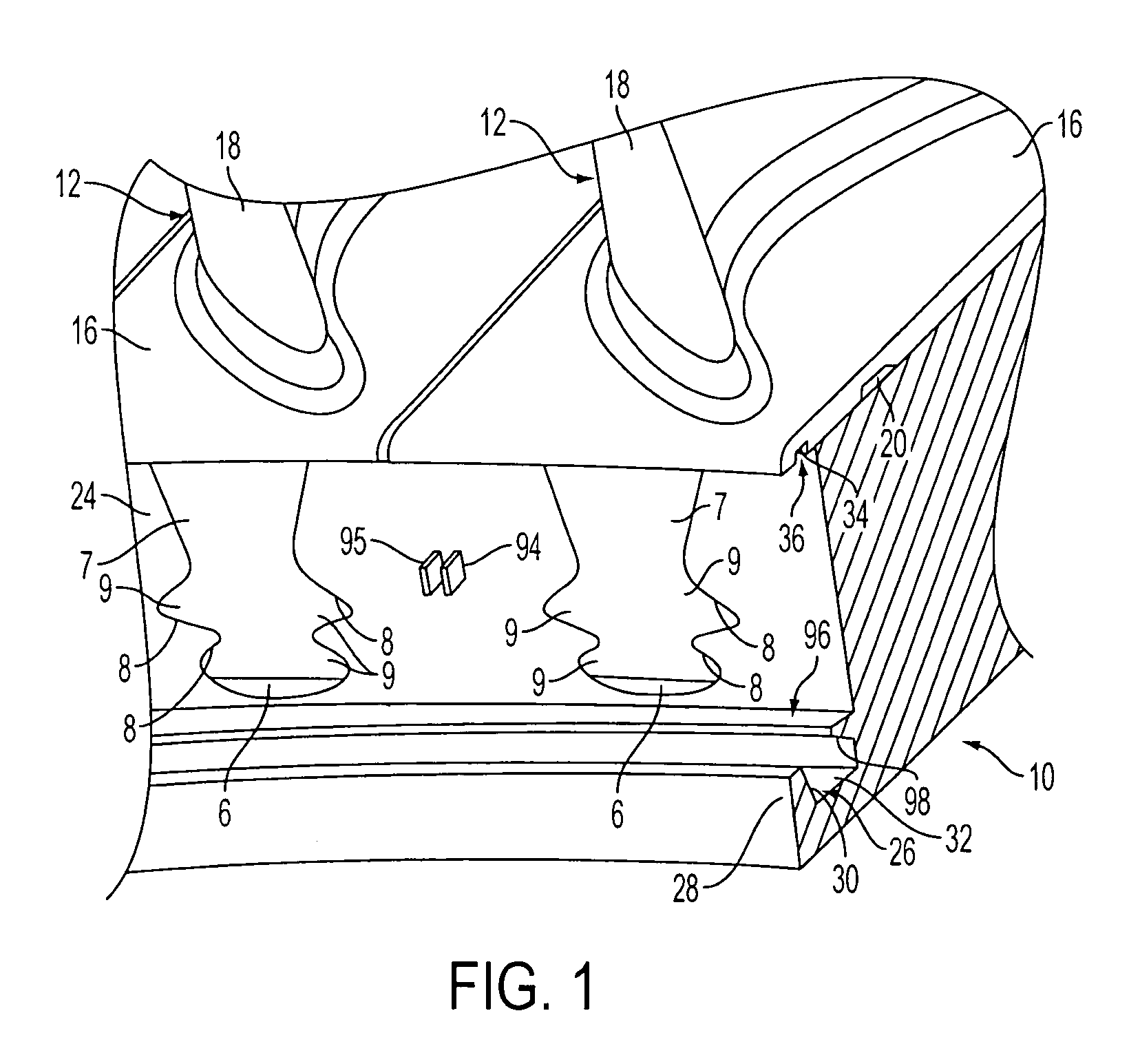

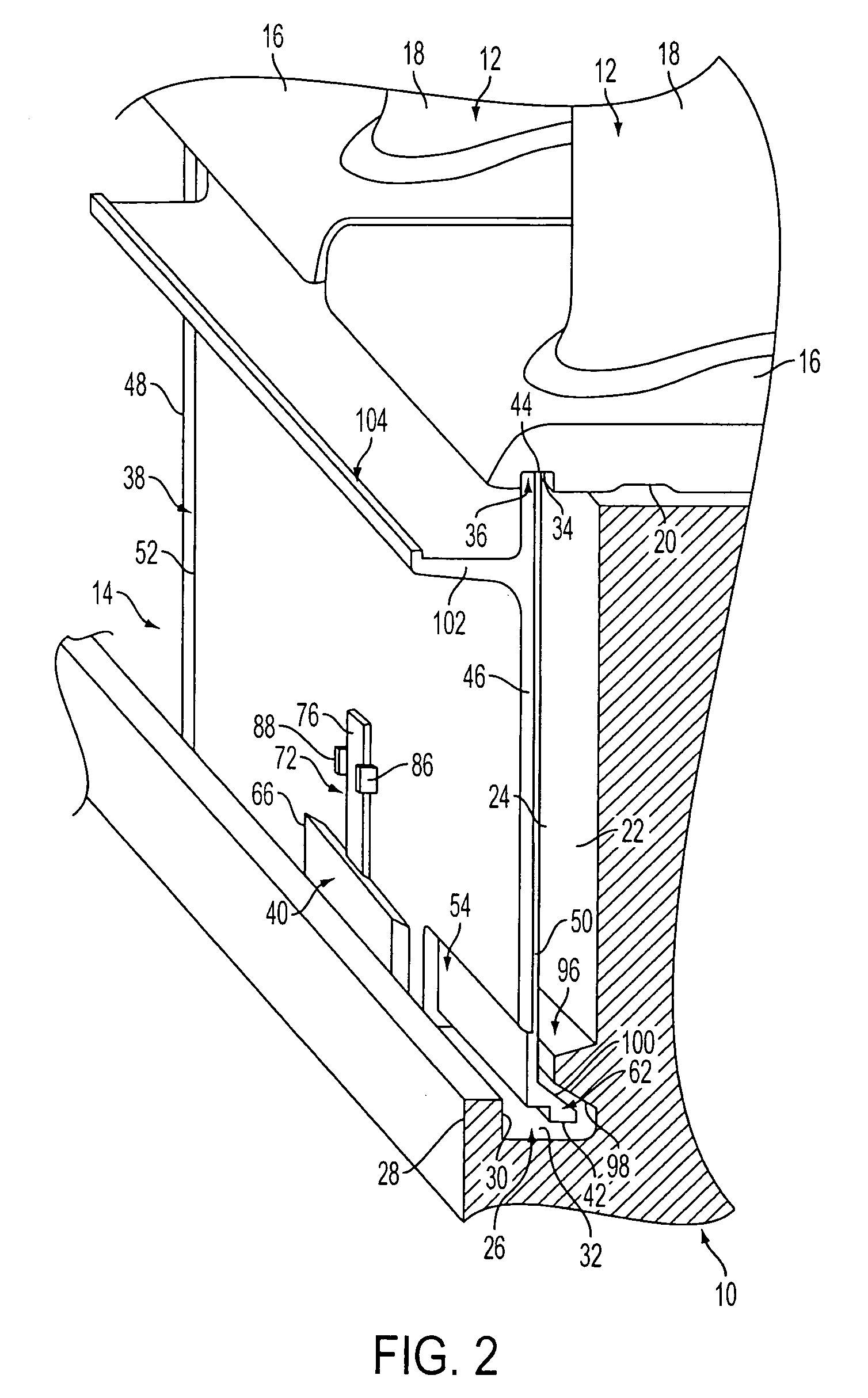

Turbine seal plate locking system

A seal plate assembly is provided in a rotor disc for a turbine engine. The seal plate assembly includes a radially extending flange on the disc and an annular groove defined between a radial surface on the flange and a face of the disc. An annular outer surface extends axially in facing relationship to an annular inner surface of the groove. A plate structure is supported between the inner and outer surfaces, and a lock structure is provided for holding the plate structure in place. The lock structure includes an axial leg that is adapted to be located between an inner edge of the plate structure and the inner surface of the groove, and the lock structure further includes a radial leg that is adapted to be located between the radial surface on the flange and an outwardly facing surface of the plate structure.

Owner:SIEMENS ENERGY INC

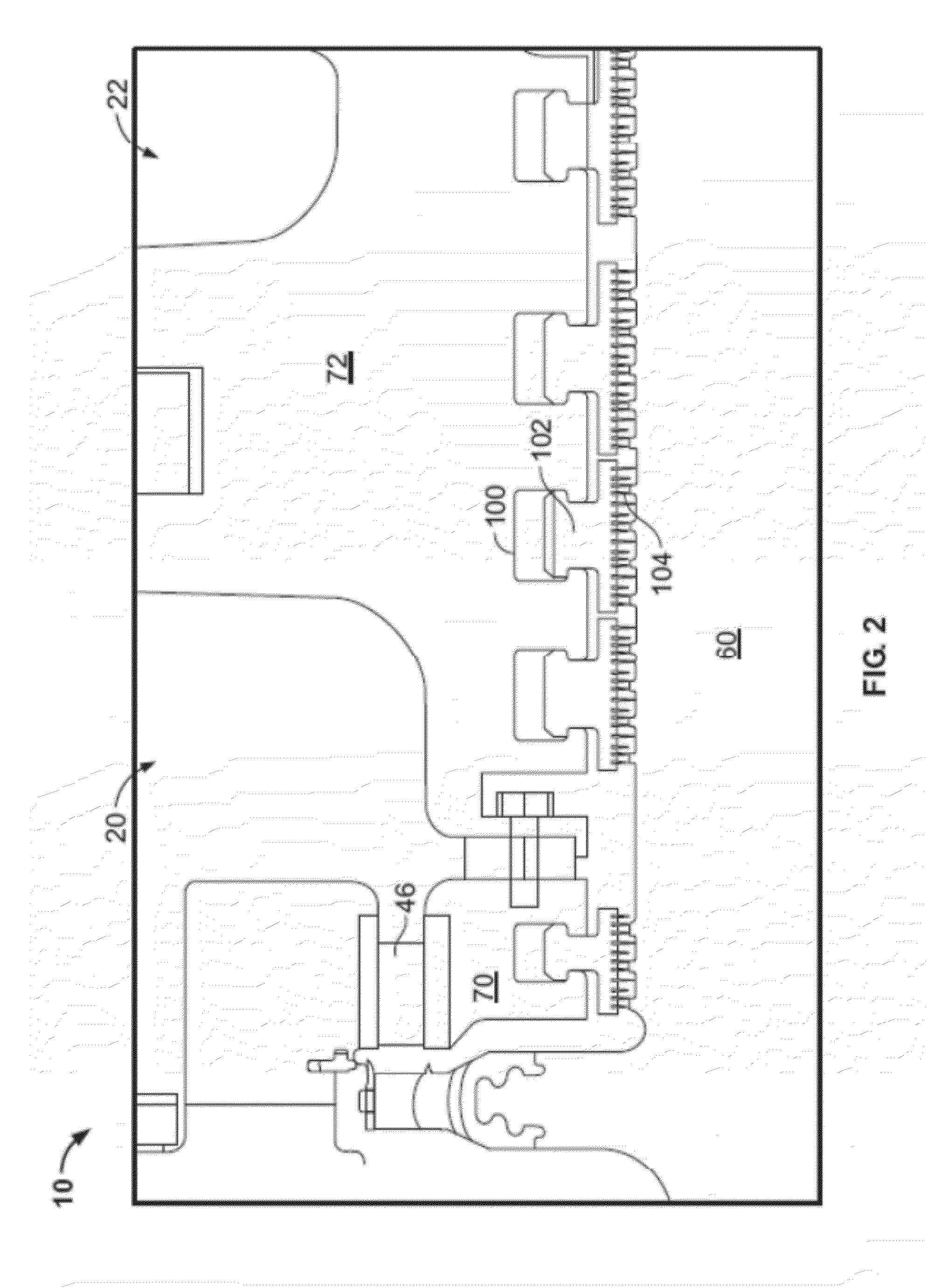

Turbine Engine

ActiveUS20110173991A1Easy dischargeLow costBlade accessoriesGas turbine plantsRadial surfaceMultiple stages

A multiple-fluid, multiple-substance, multiple-phase, multiple-pressure, multiple-temperature, multiple-stage turbine engine. In preferred embodiments, one or more fluids are supplied by passageways in the turbine shaft or supplied by non-shaft passageways, or both, through rotor passageways to multiple-phase, multiple-fluid, multiple-substance nozzles affixed to one or more perimeters, radial surfaces, axial surfaces, and / or curved or slanted surfaces of the turbine rotor assemblies. The multiple perimeters, radial surfaces, axial surfaces, and / or curved or slanted surfaces of the turbine rotor assemblies are preferably configured and located for multiple inlet and exit velocities of the nozzles, multiple inlet and exit pressures of the nozzles, or combinations thereof. The one or more fluids entering the turbine may each be a substance of single phase, or a substance of multiple phases, or a mix of the single-phase and / or multiple-phase conditions for two or more entrance fluids.

Owner:RECOGEN

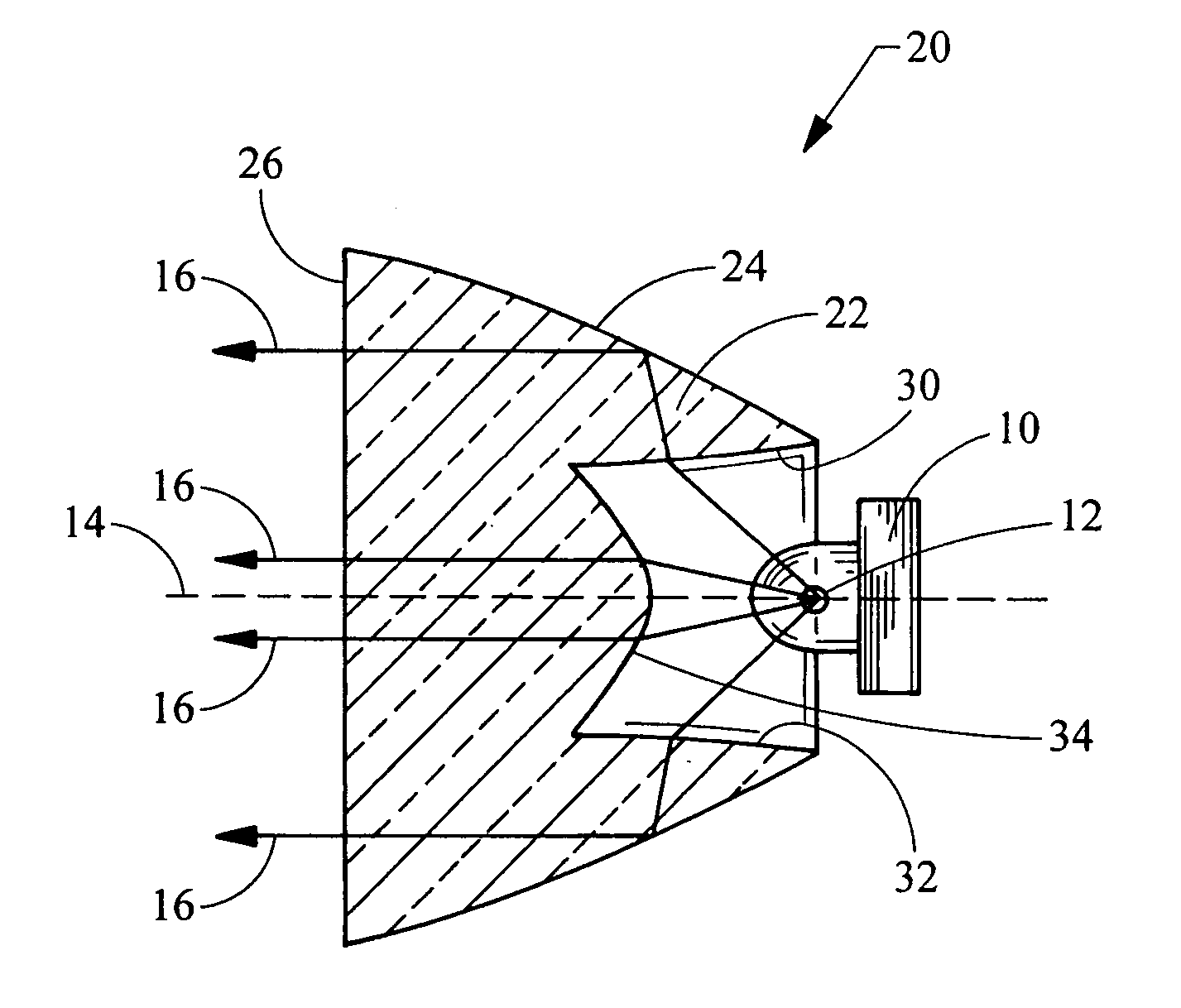

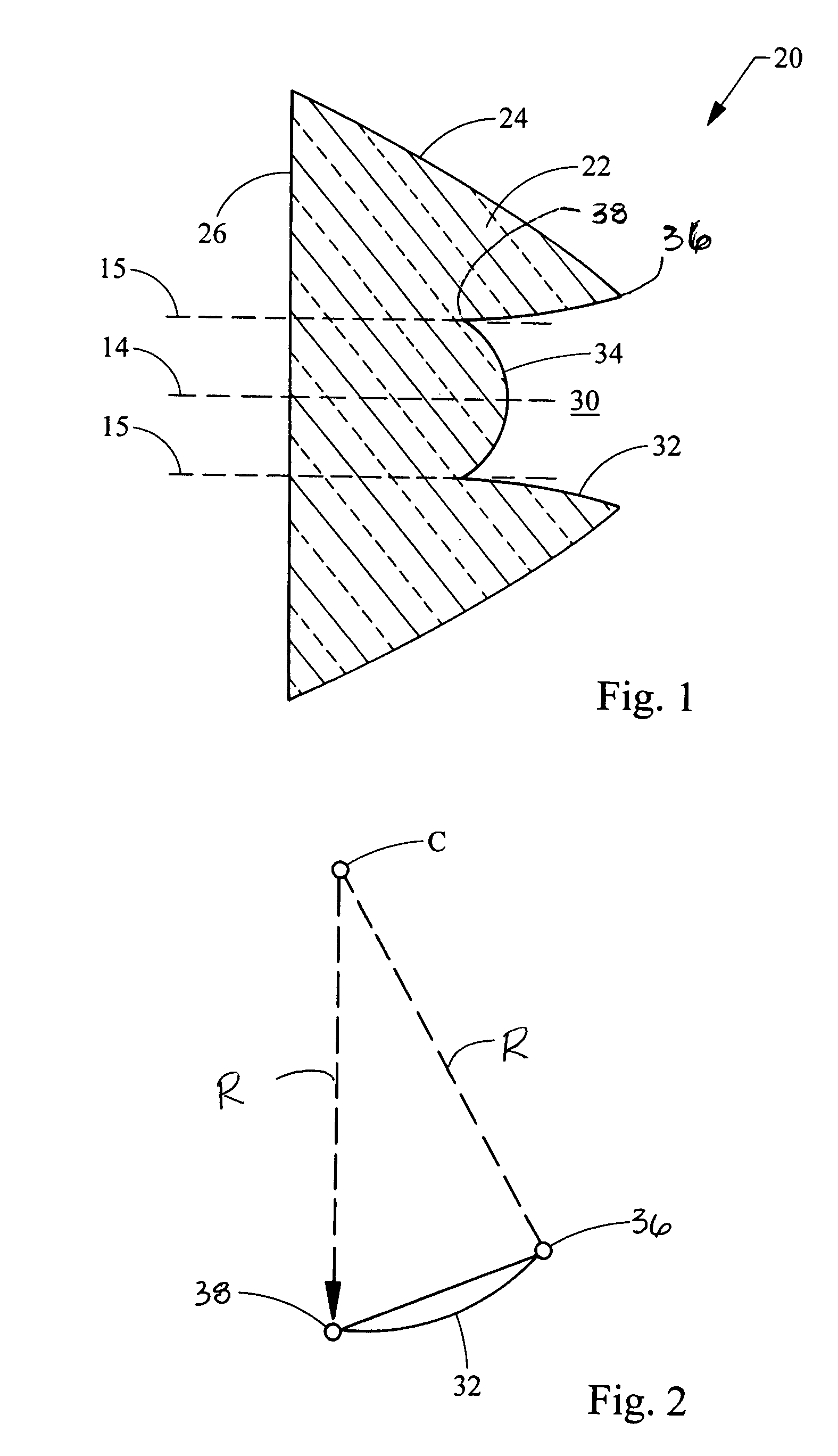

Near field lens

A lens for use with a light emitting source is provided. The lens has a main body with a light-collecting face and a light-emitting face and which defines an optical axis extending through the centers of these two faces. A pocket for receiving light from the light source is defined in the light-collecting face by an inner axially-facing surface surrounded by an inner radially-facing surface. The inner axially-facing surface is concave and has a spherical shape. The inner radially-facing surface has a non-spherical, tapered shape and extends between the axially-facing surface and an open end of the pocket. A light assembly incorporating the lens includes a light-emitting diode.

Owner:VARROC LIGHTING SYST SRO

Pipe-gripping structure having load rings

A rotary slip for supporting a drill string having a plurality of slip segments connected to define an opening for insertion of the drill string, wherein each slip segment comprises a head region, a toe region, and an inner radial surface axially extending between the head and toe regions, and wherein the inner radial surface of each slip segment comprises a circumferential groove. A plurality of axially aligned drill string gripping inserts are attached to each slip segment between the head region and the circumferential groove, wherein each insert comprises a gripping surface for contacting the drill string. A load ring is disposed within the circumferential groove of each slip element, the load ring comprising at least one securing element which is engaged by one of the plurality of axially aligned inserts to secure the load ring within the circumferential groove.

Owner:VARCO I P INC

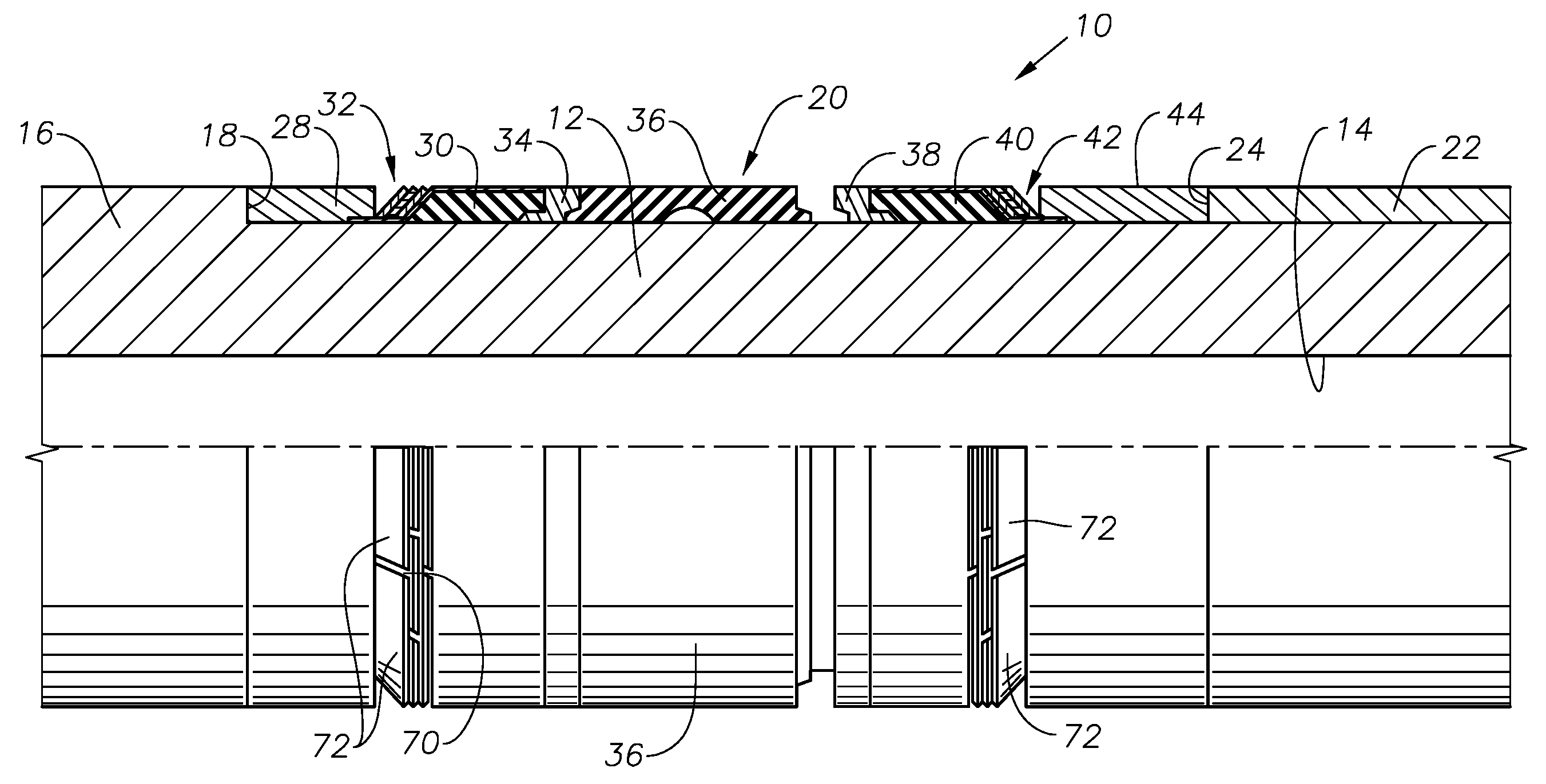

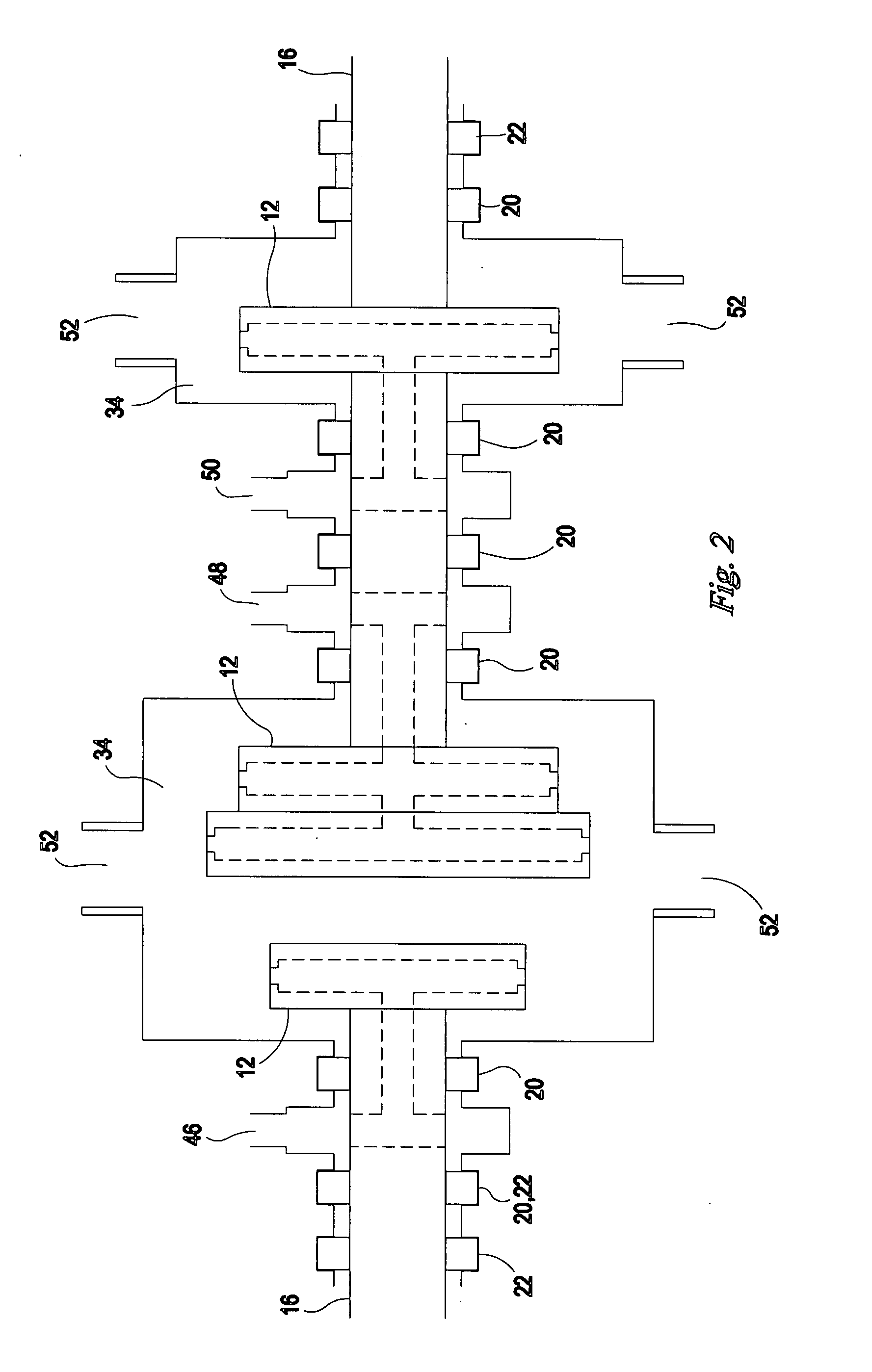

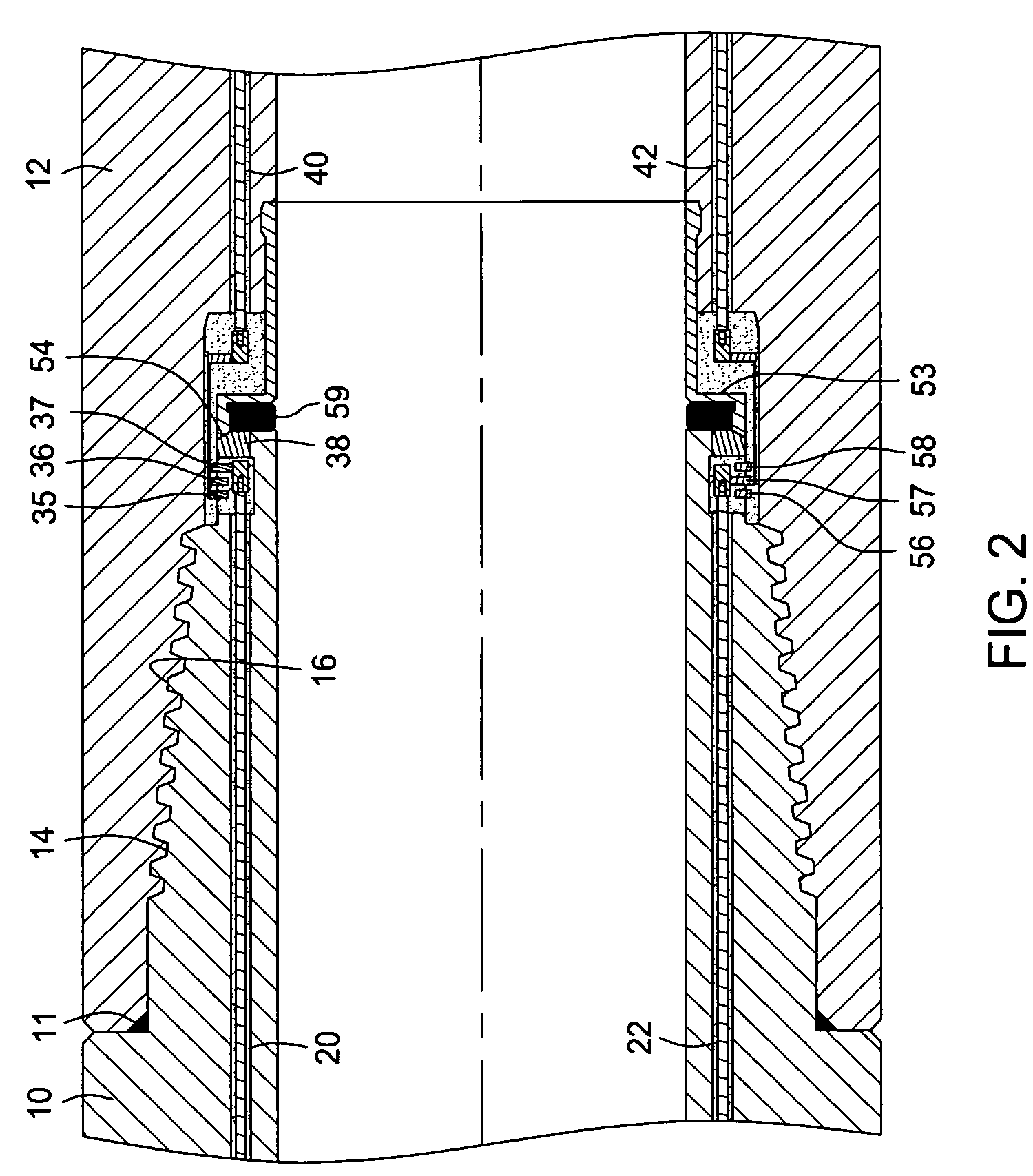

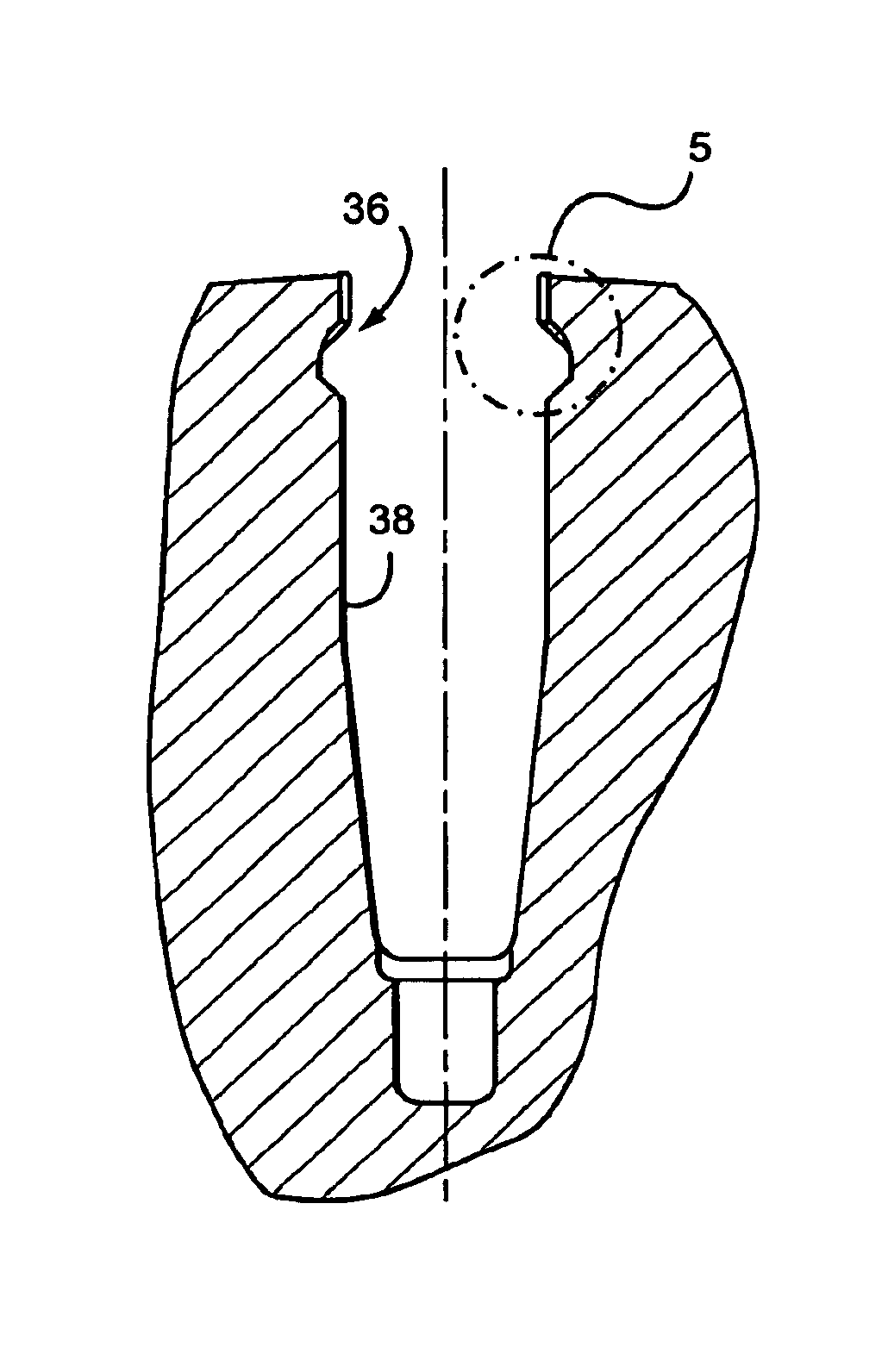

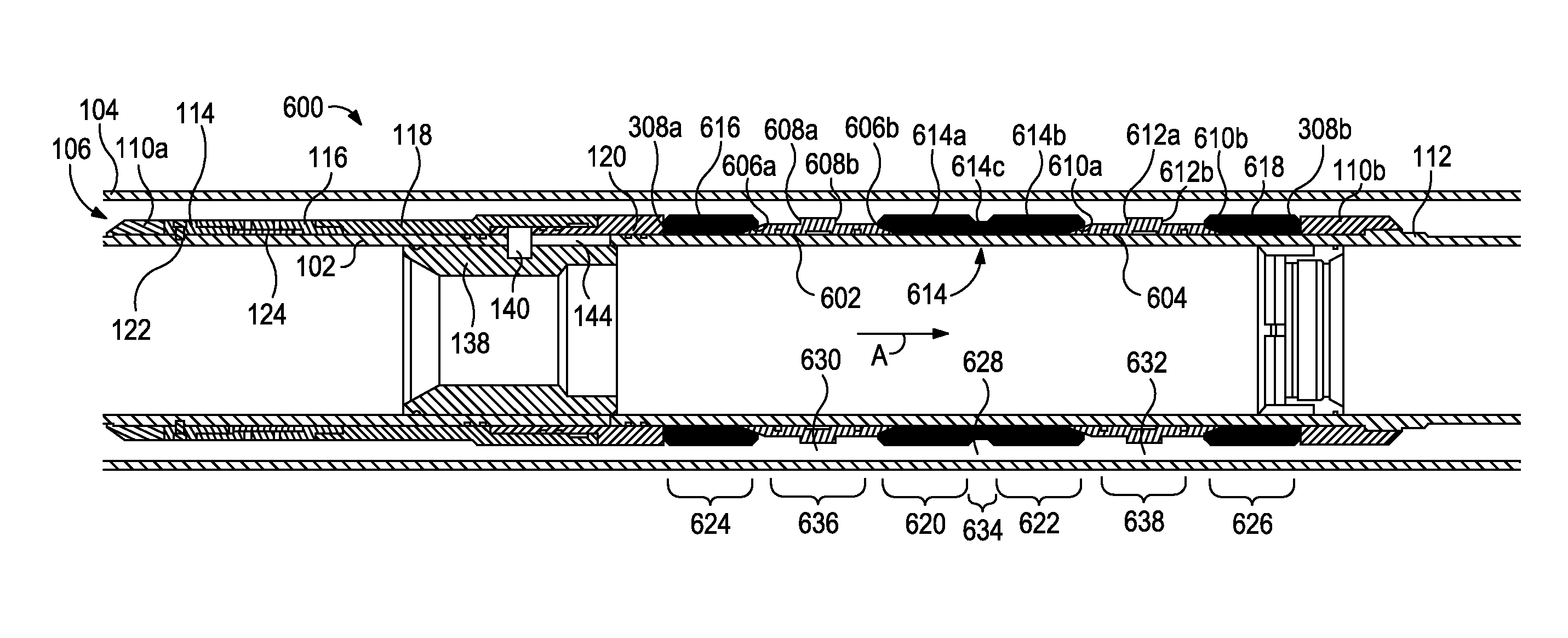

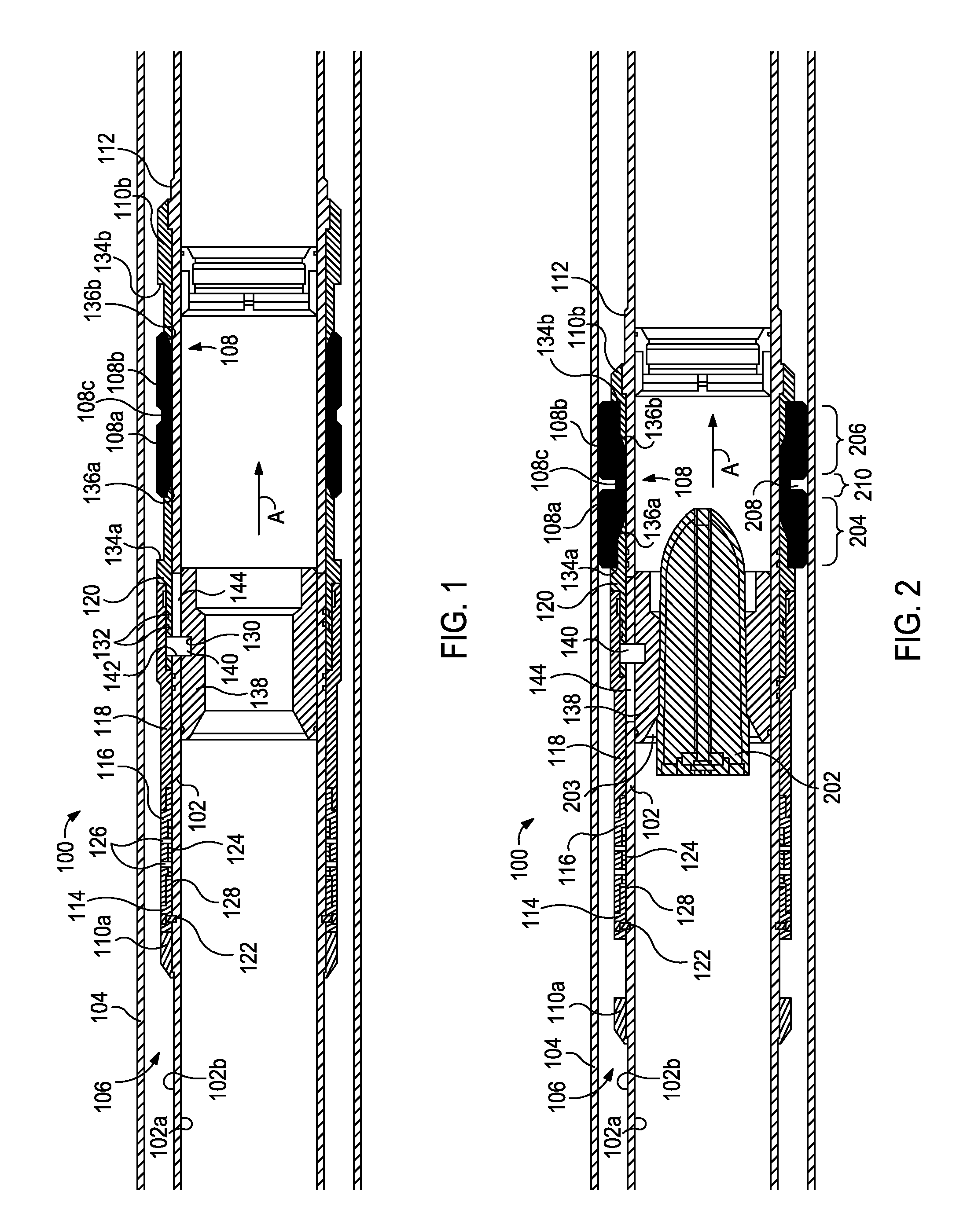

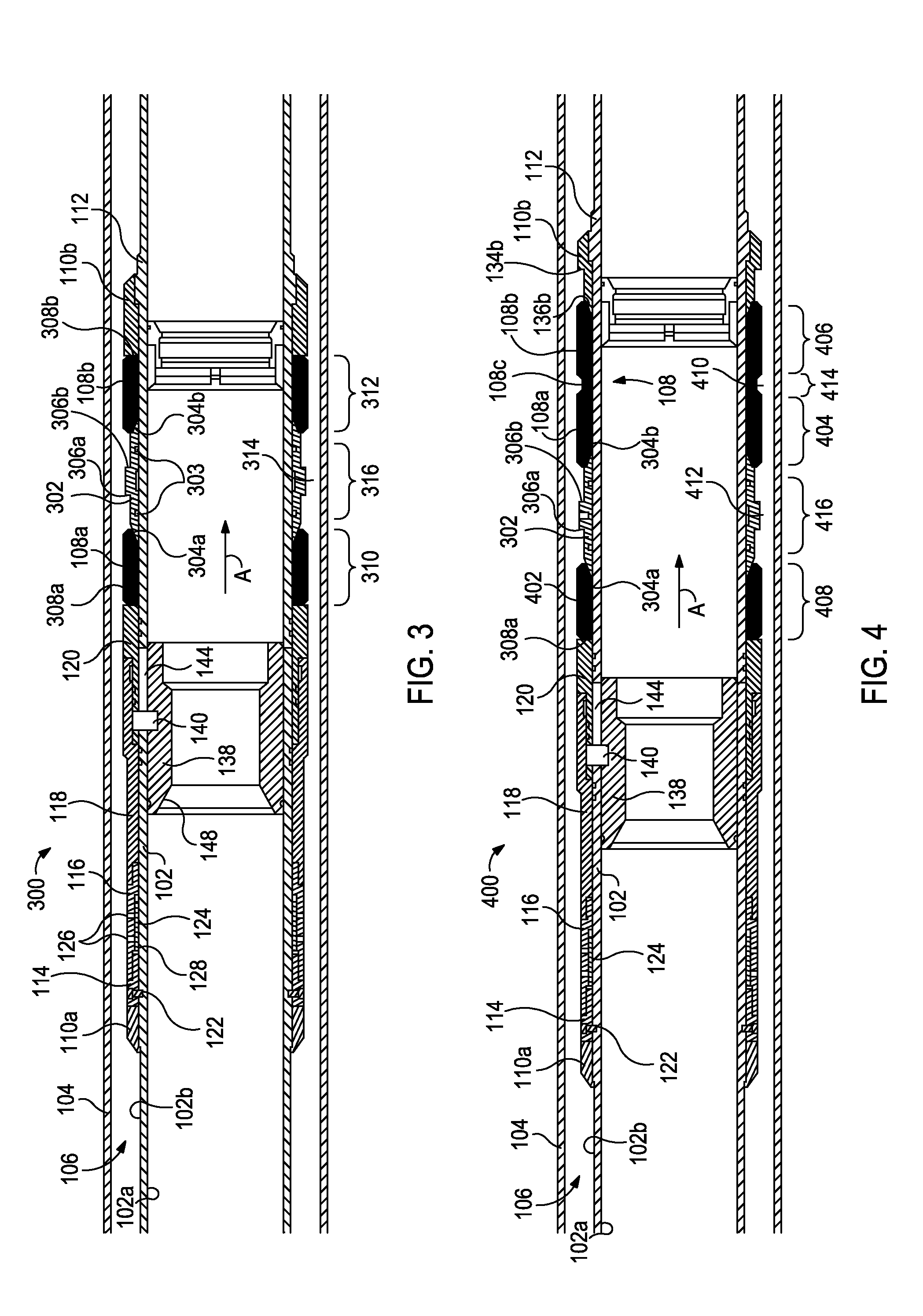

Electrical conducting system

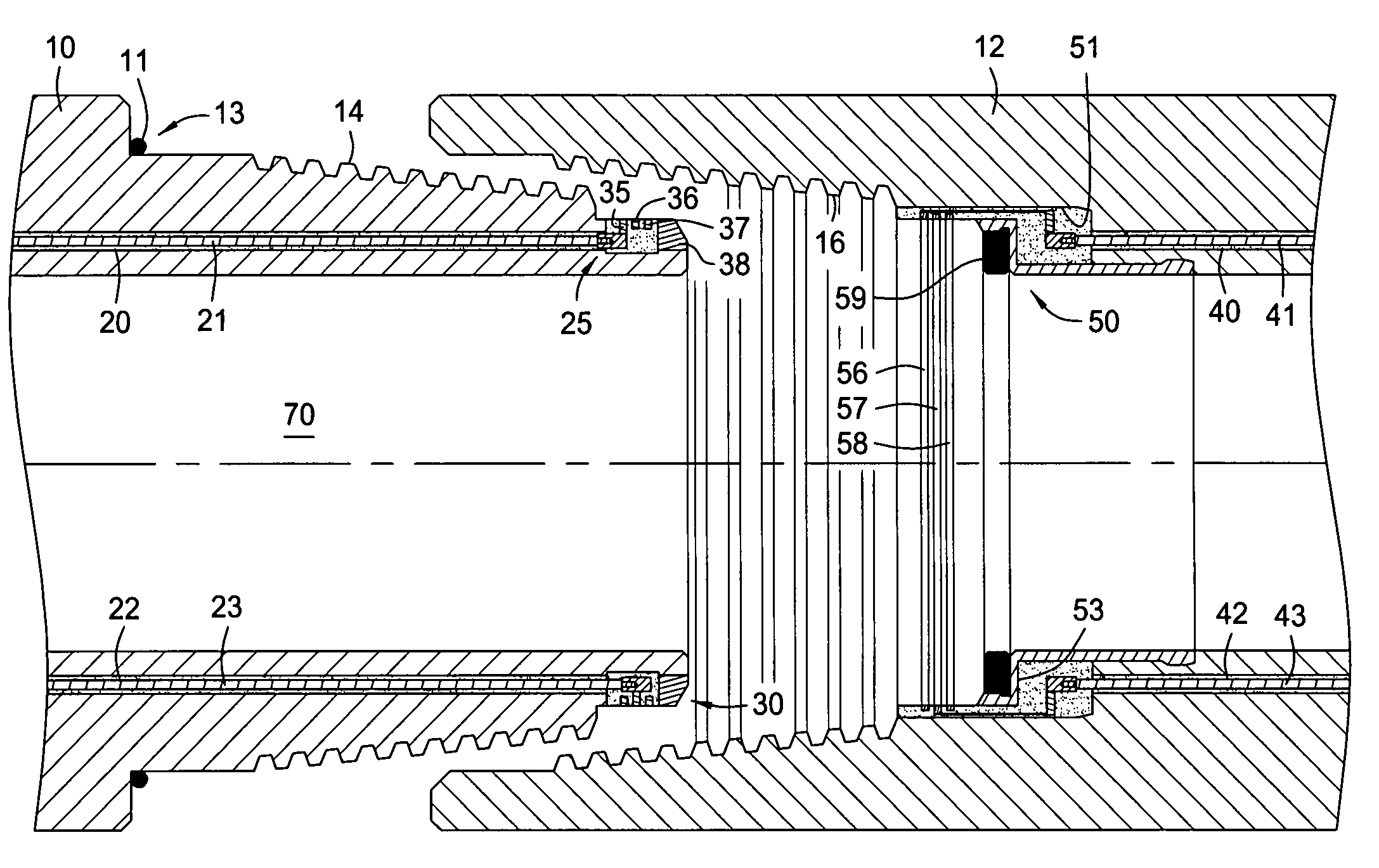

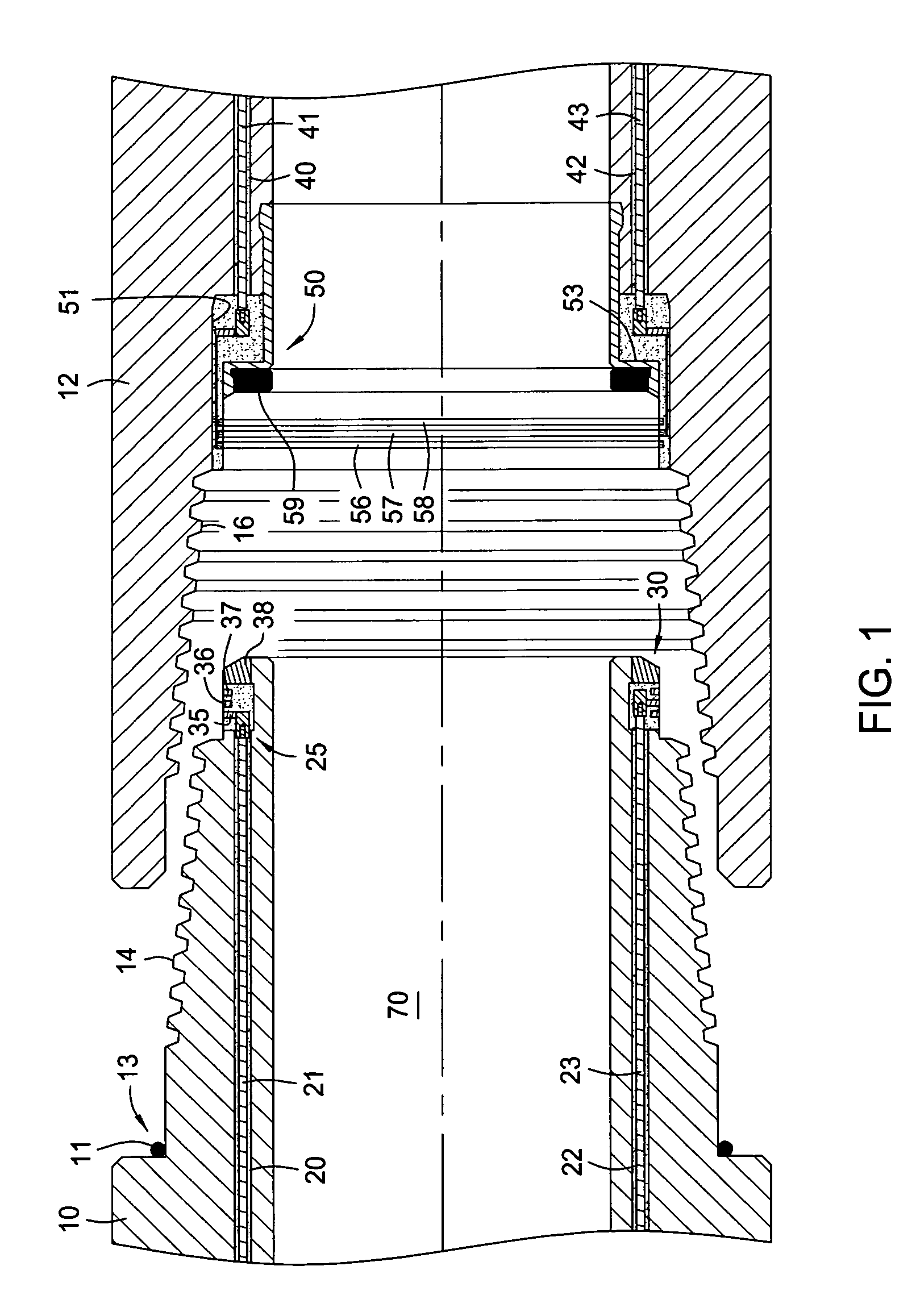

A generally tubular drill string has a conductive path over a plurality of drill pipe section (10). Each drill pipe section has a first end and a second end, and a wall, and the first end has a first radial sealing surfaces (11) and the second end has a corresponding second radial surfaces (59), such that when the first or second end of one drill pipe section is engaged with the second or first end respectively of another drill pipe section, at least one seal is formed. The drill pipe includes at least one conductor (21) disposed inside it, this conductor being connected to a first contact means at the first end and a corresponding contact means at the second end of each drill pipe section. Ingress protection means (240) are provided to protect the contact means from ingress from inside or outside of the drill pipe section. The ingress protection means comprises a sealed volume surrounding the contact means.

Owner:WEATHERFORD TECH HLDG LLC

Side emitting near field lens

A near field lens for an automotive light assembly which has a reduced thickness. Generally, the near field lens includes a main body of light transmitting material. A pocket is formed in the main body for receiving light from a light source. The pocket is defined by an inner radially facing surface and an inner axially facing surface. The inner radially facing surface is structured to reduce the thickness of the lens.

Owner:VARROC LIGHTING SYST

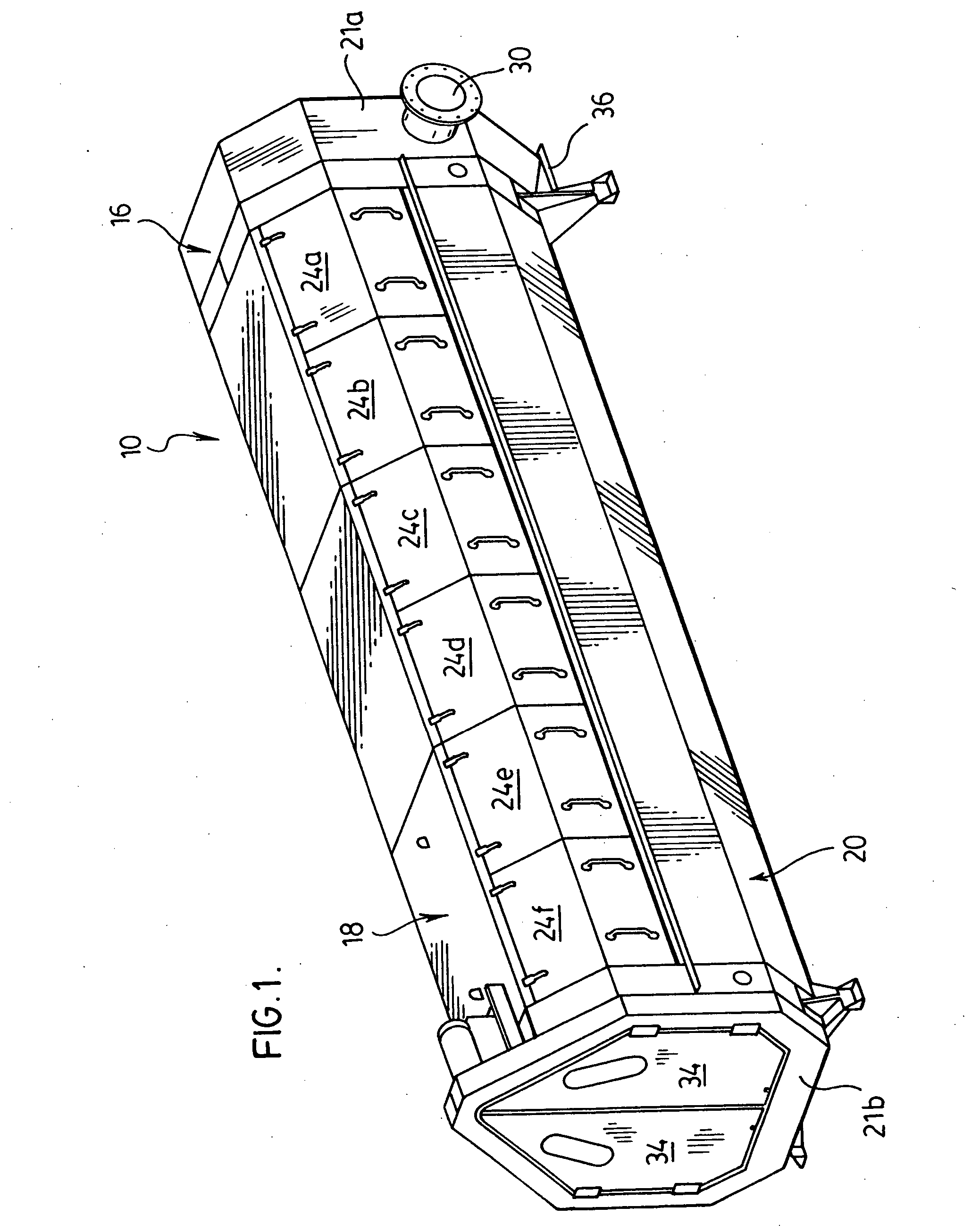

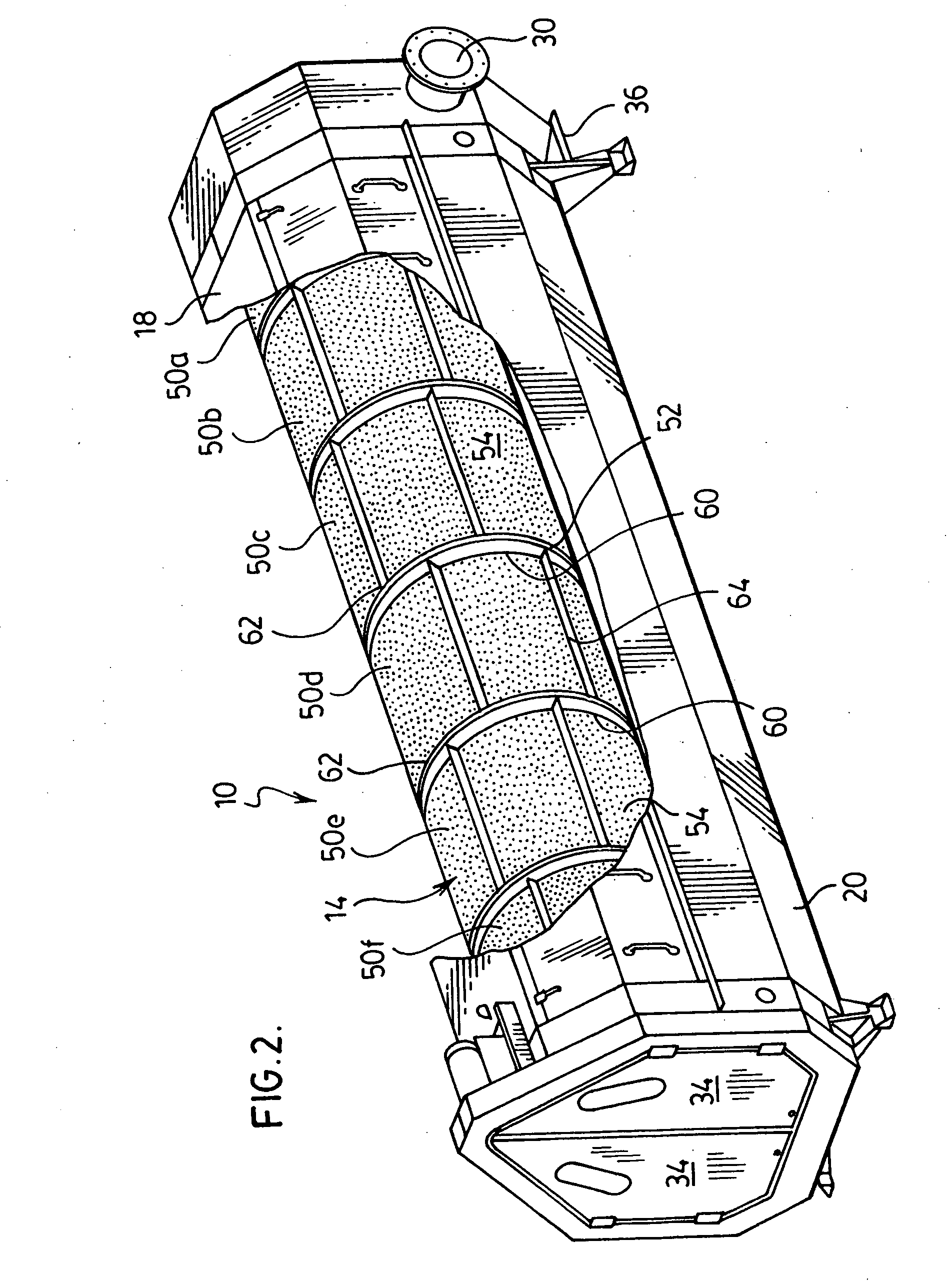

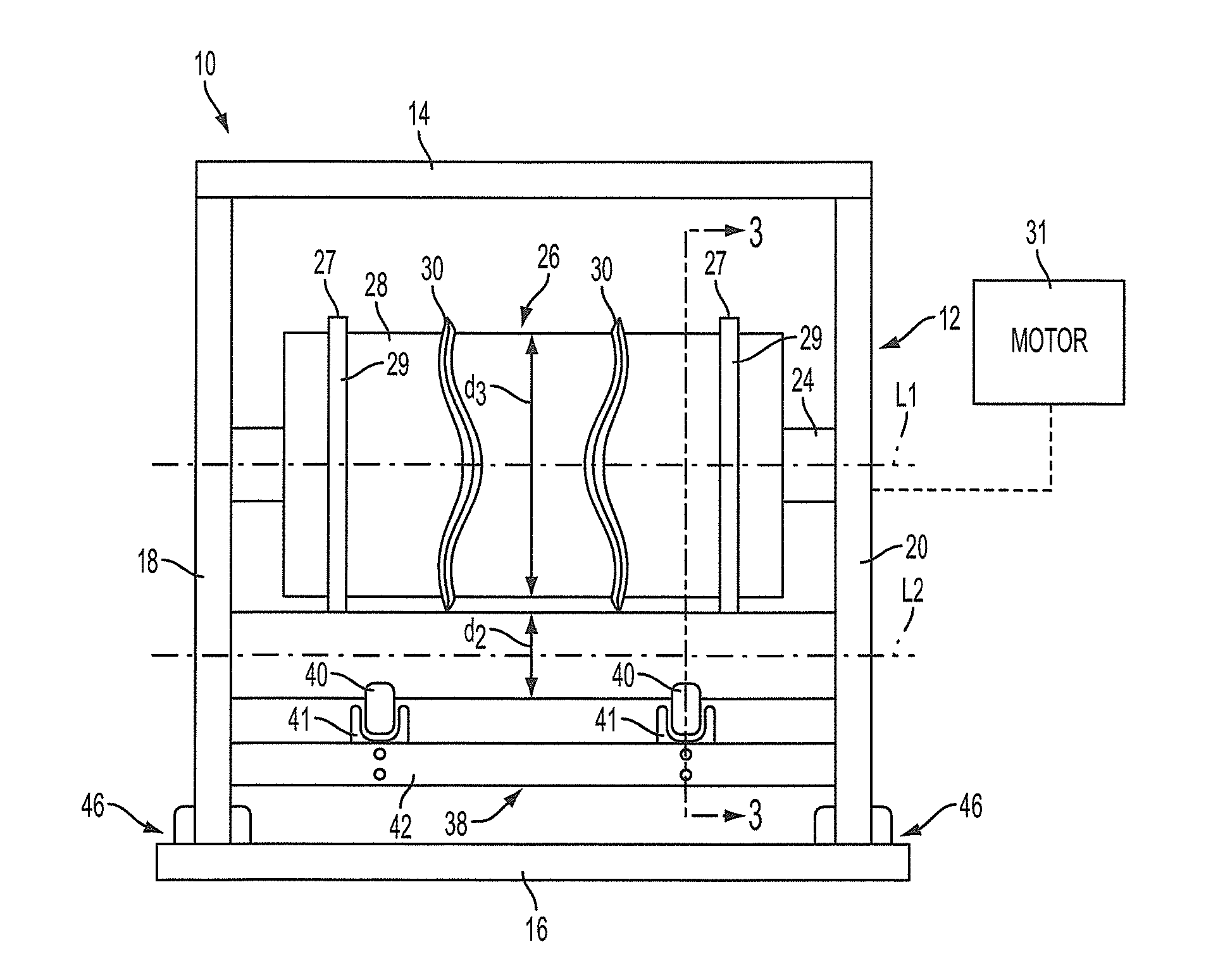

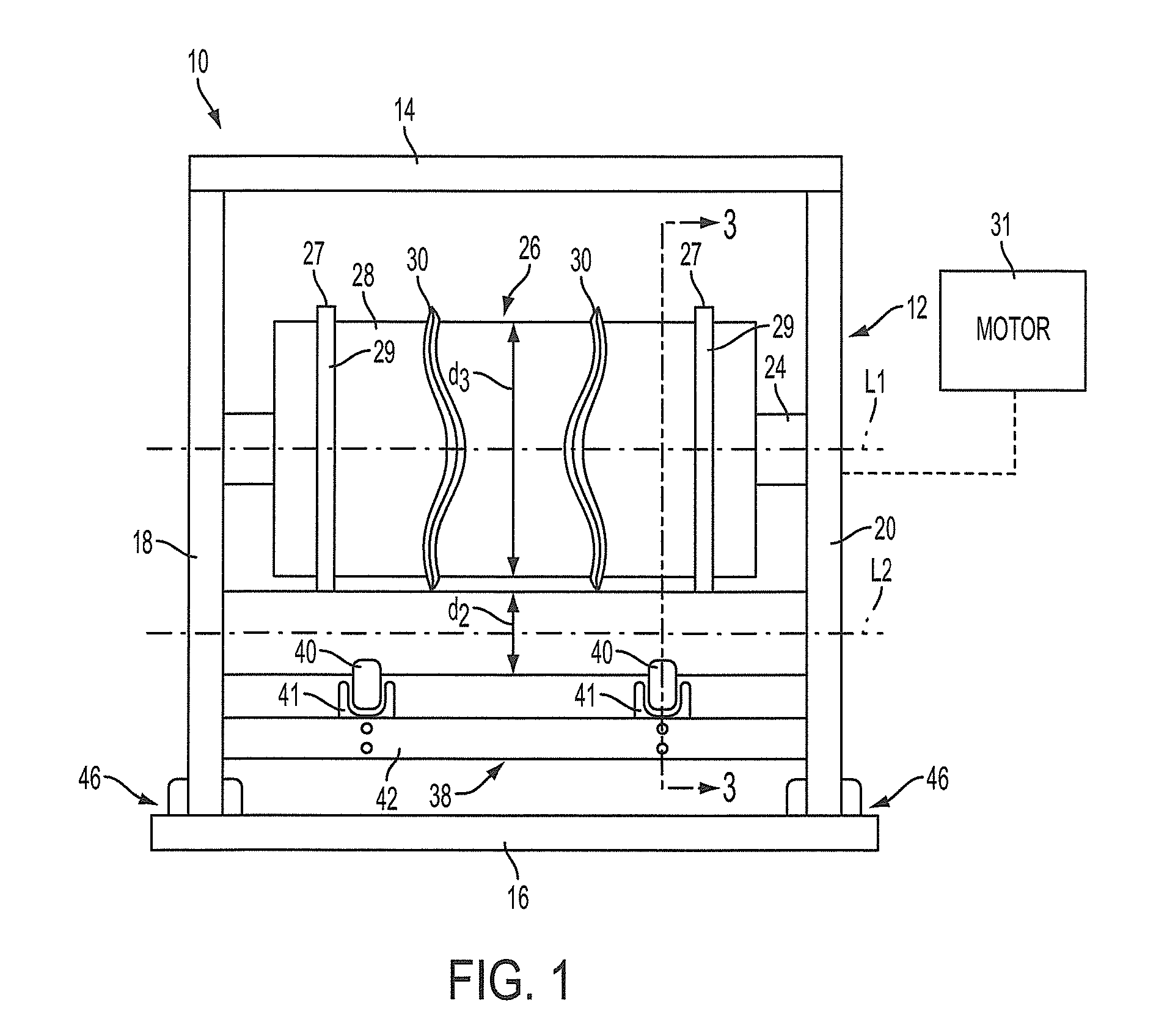

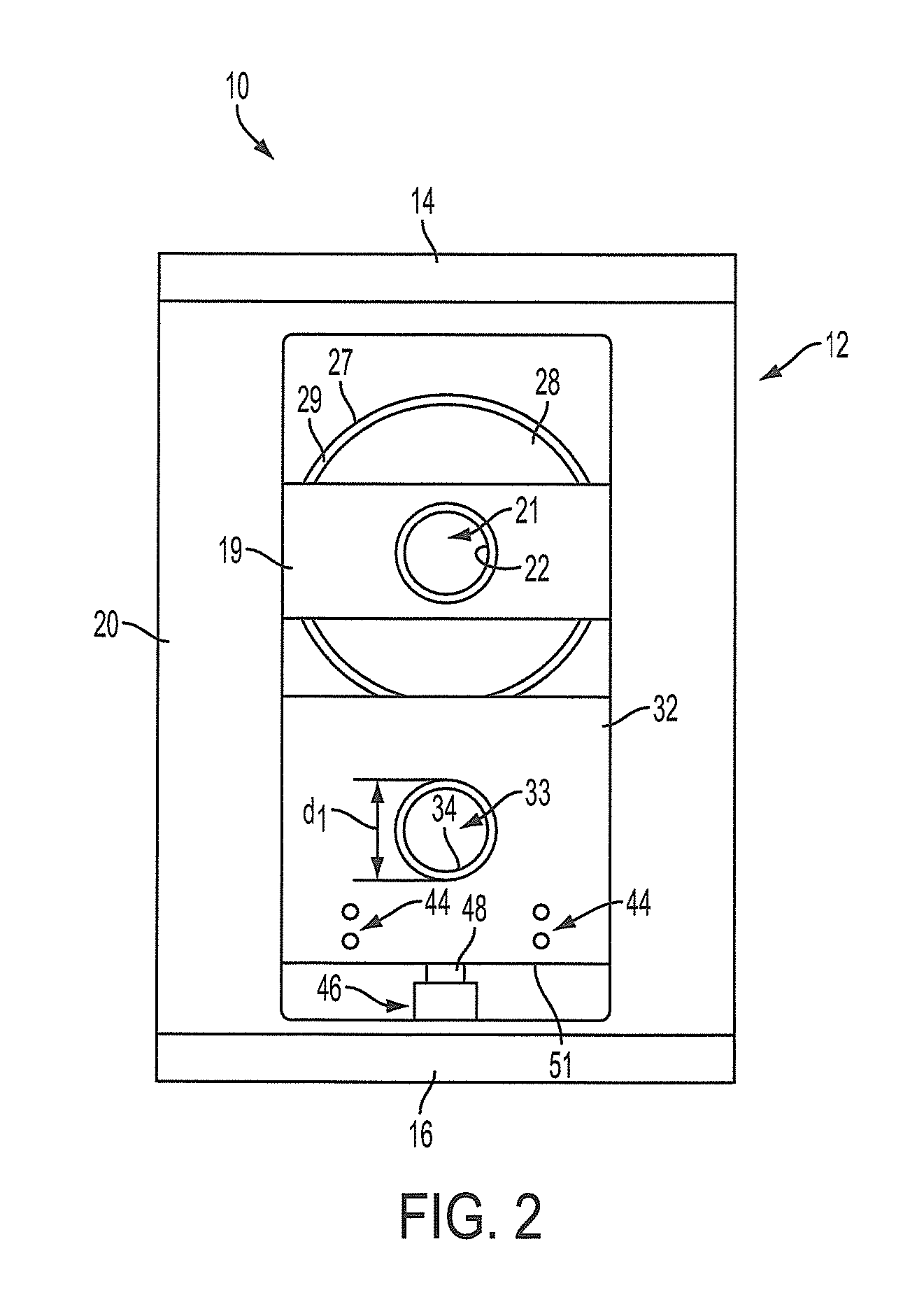

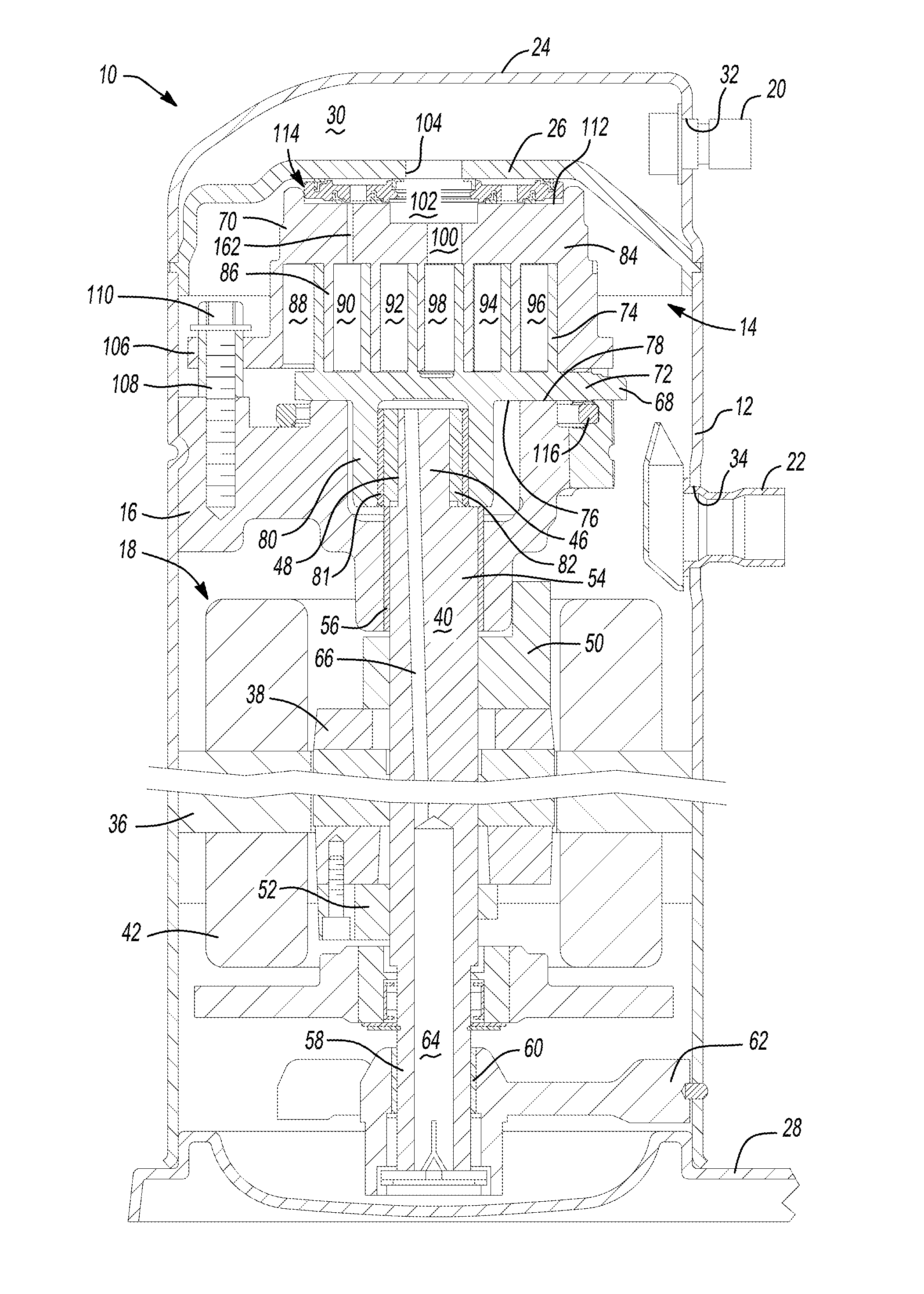

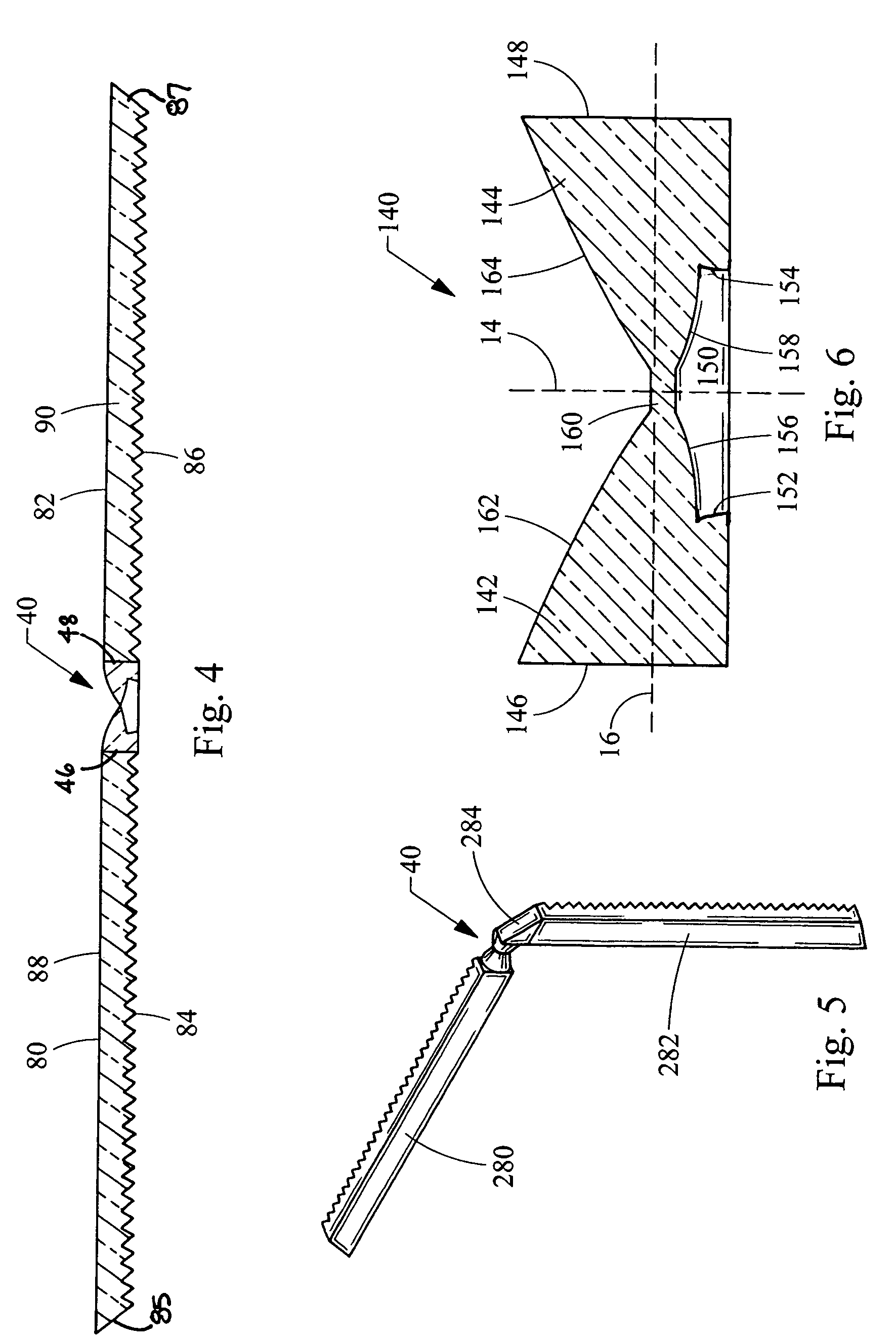

Method and apparatus for screening kaolin

InactiveUS20070074998A1Easy to customizeSimplified access to and replacementSievingScreeningMechanical engineeringRadial surface

Owner:LANGNER HERBERT GUNTHER JOACHIM

Turbine engine seals

A seal is provided for preventing axial leakage through a radial gap between a stationary structure and a rotating structure. The radial gap is defined by an inner radial surface opposing an outer radial surface across the radial gap. The seal includes at least one land disposed on one of the inner radial surface and outer radial surface. At least one first tooth and at least one second tooth project from the other of the radial surfaces. The second tooth is shorter than the first tooth. At least one of the first tooth and second tooth, is configured to extend at an angle upstream. This angle is defined between a radial surface from which the first or second tooth projects and an upstream surface of the same tooth. The angle is less than or equal to about 80 degrees.

Owner:GENERAL ELECTRIC CO

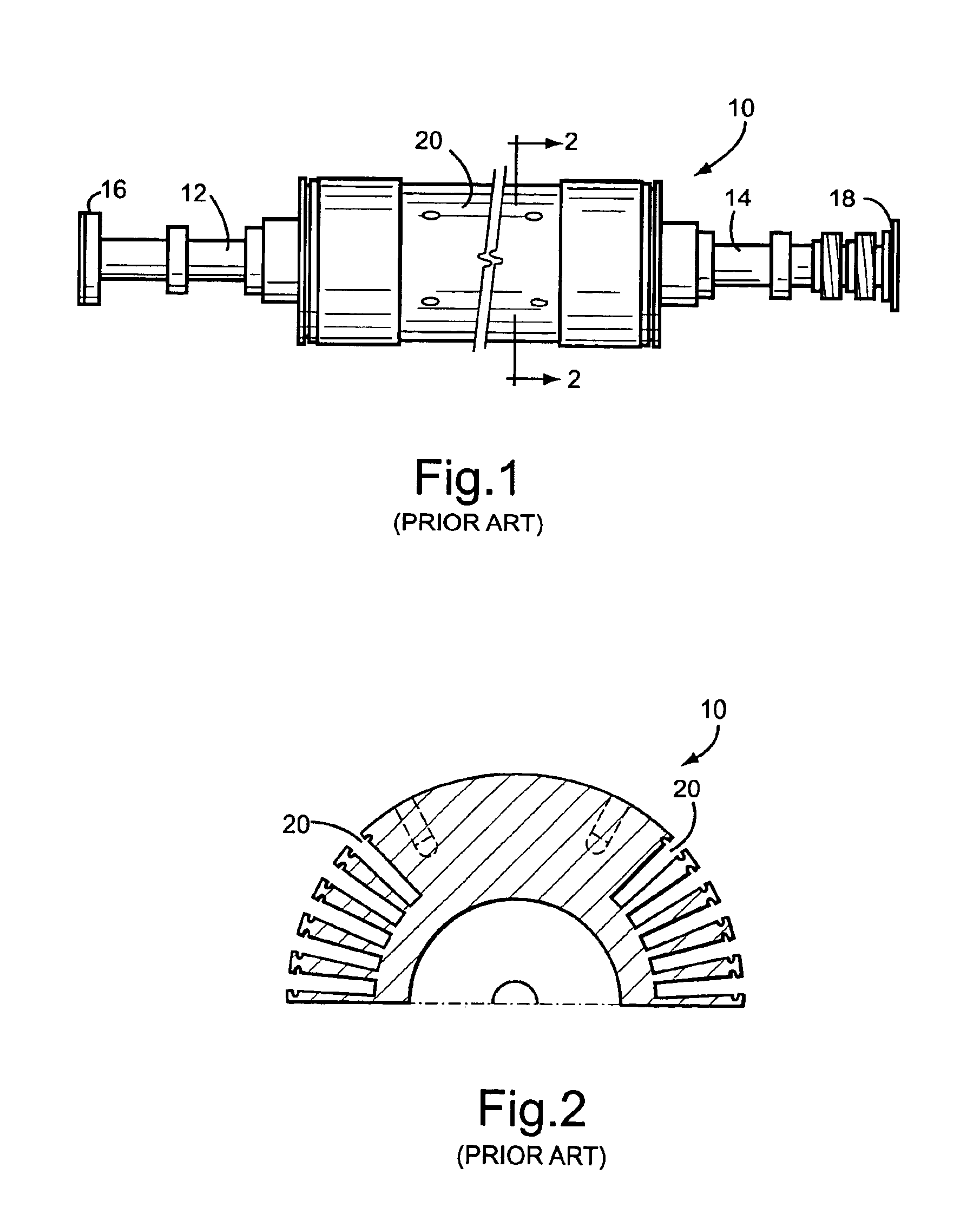

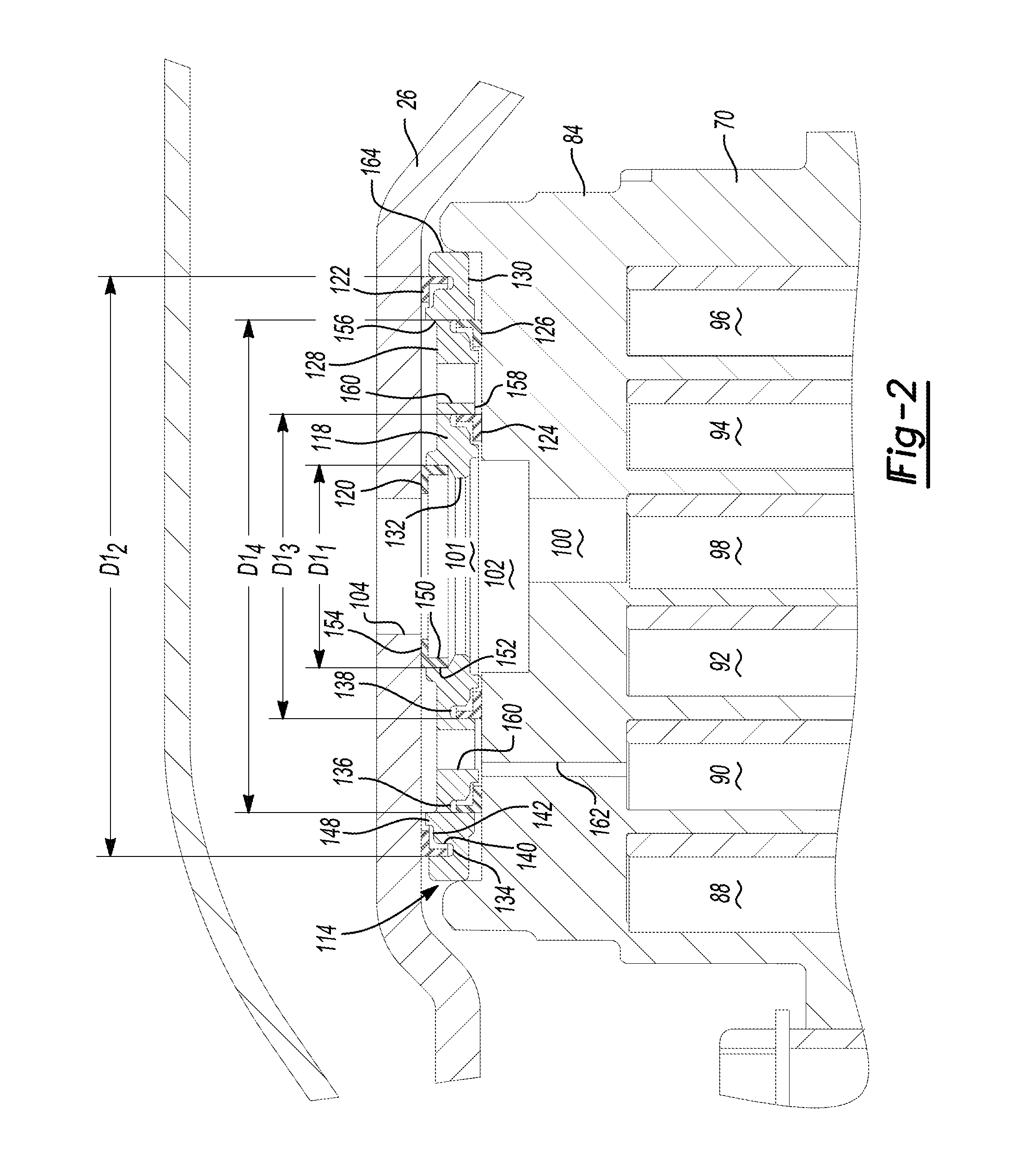

Field assembly for a motor and method of making same

InactiveUS7038343B2Prevent movementGood for scrollingMagnetic circuit rotating partsMagnetic circuit stationary partsPower toolRadial surface

A cylindrical magnet ring assembly having a cylinder magnet flux ring (102) formed with a plurality of inwardly projecting anchors (108); a plurality of permanent magnets (104), wherein the magnet can be formed with step portions (112) in the inner radial surface; a molded plastic member (106) being molded around the magnets and anchors to secure the magnets to a surface of the cylinder flux ring. There are several variations of the embodiments of the invention. Few embodiments are the following: in one aspect of the invention, magnets are inserted into magnet molded around an assembly ring (806) and the molded plastic secures the assembly ring to the flux ring; in another aspect, there are two assembly rings, a first assembly ring (is inserted into the one side of the cylinder flux ring then the second assembly ring is inserted into the other side of the cylinder flux ring and mated to the first assembly ring, after that the molded plastic secures the two assembly rings. The foregoing cylindrical magnet ring assembly is used in a stator of a motor which is used in a power tool.

Owner:BLACK & DECKER INC

Generator rotor fretting fatigue crack repair

InactiveUS6849972B1Reduces the low and high cycle fatigue life of the rotorReduces low and high cycle fatigue lifeWindingsMagnetic circuit rotating partsFrettingClassical mechanics

A method of repairing a crack in at least one side of a dovetail portion of a generator rotor coil slot wall, the dovetail portion having received at least two axially adjacent steel wedges and including at least a radial entry surface, an inwardly tapered surface and an intermediate radial surface, the method comprising a) machining a groove at least partly along the inwardly tapered surface to remove damaged material from the coil slot wall; and b) replacing the at least two axially adjacent steel wedges.

Owner:GENERAL ELECTRIC CO

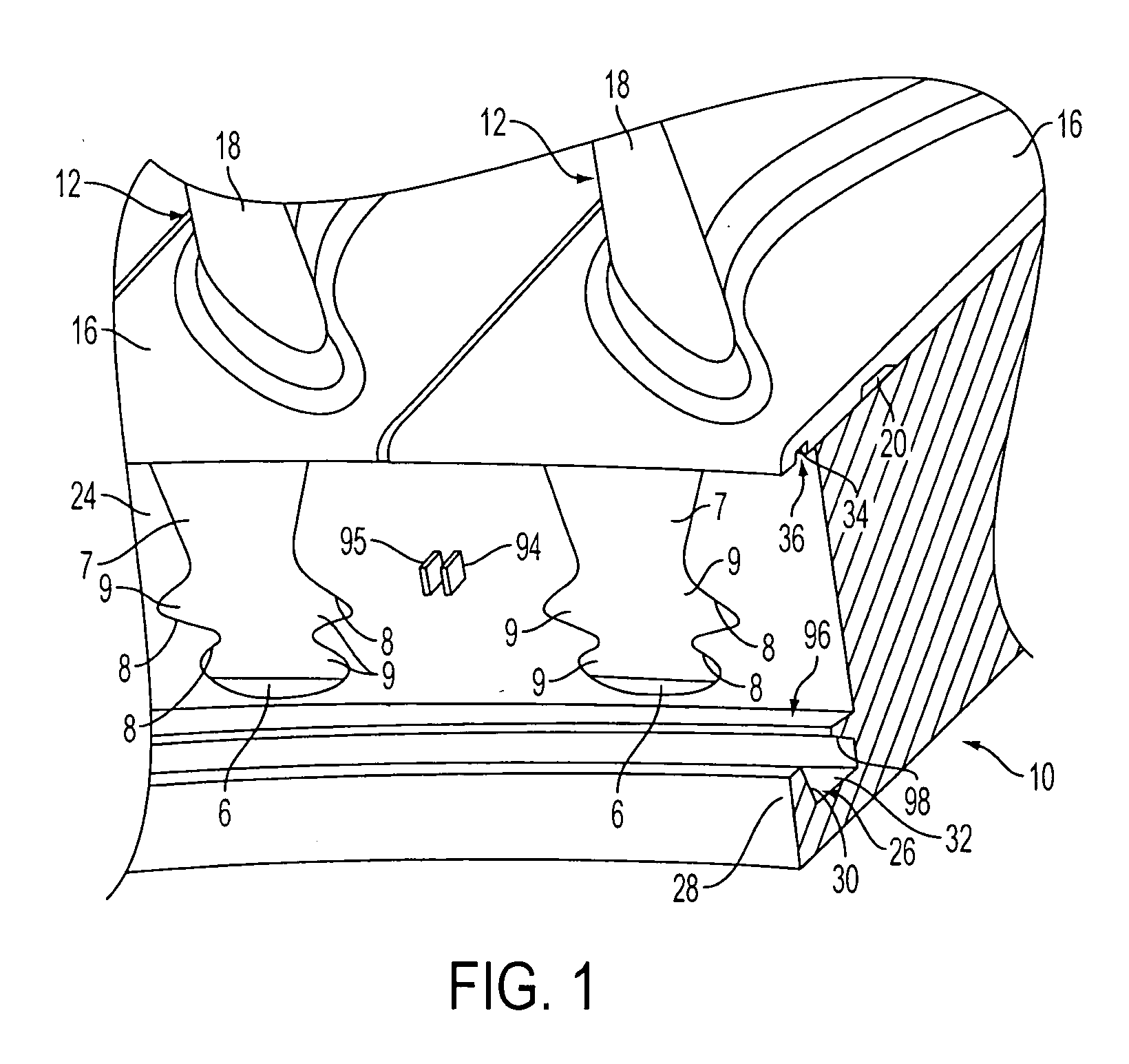

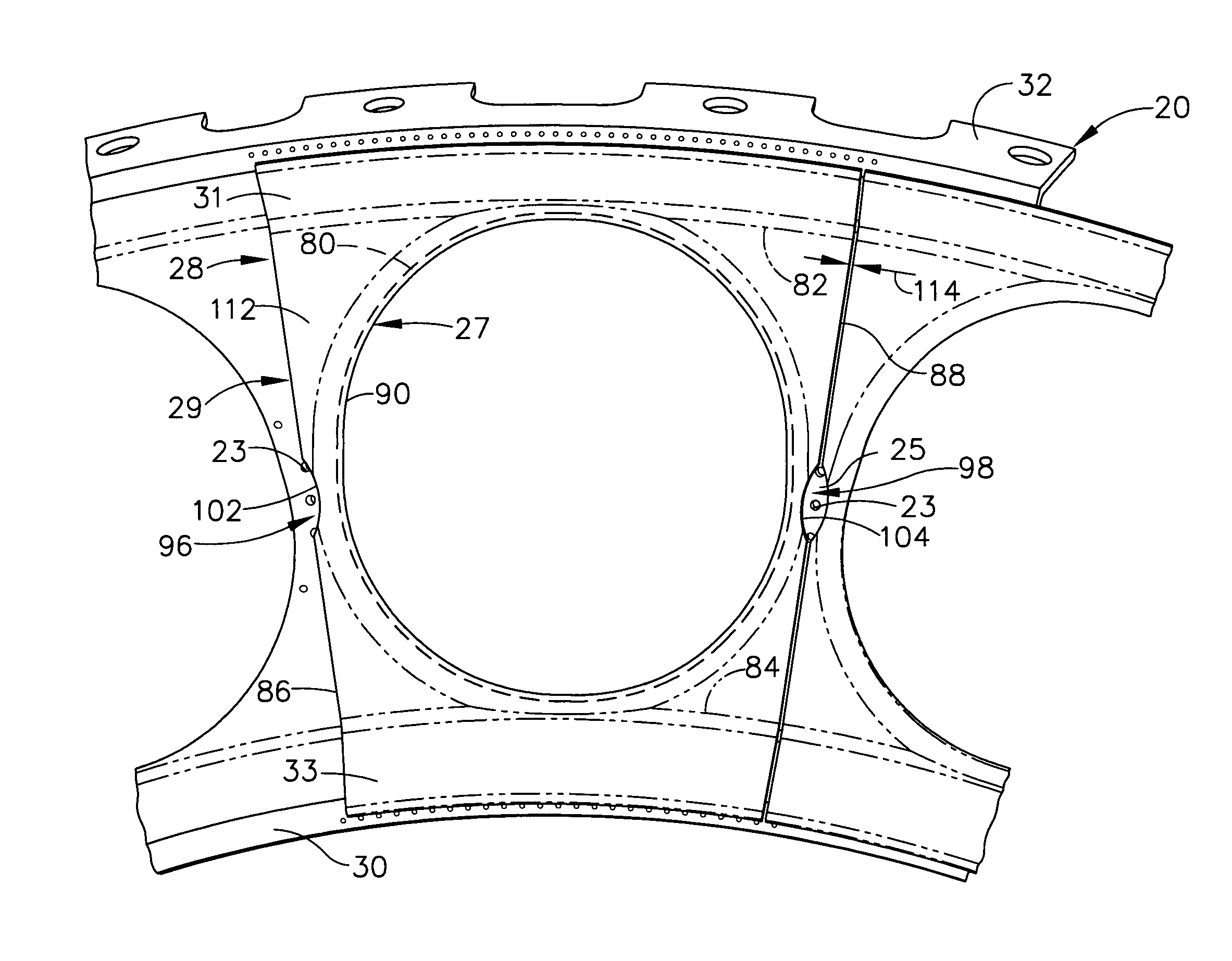

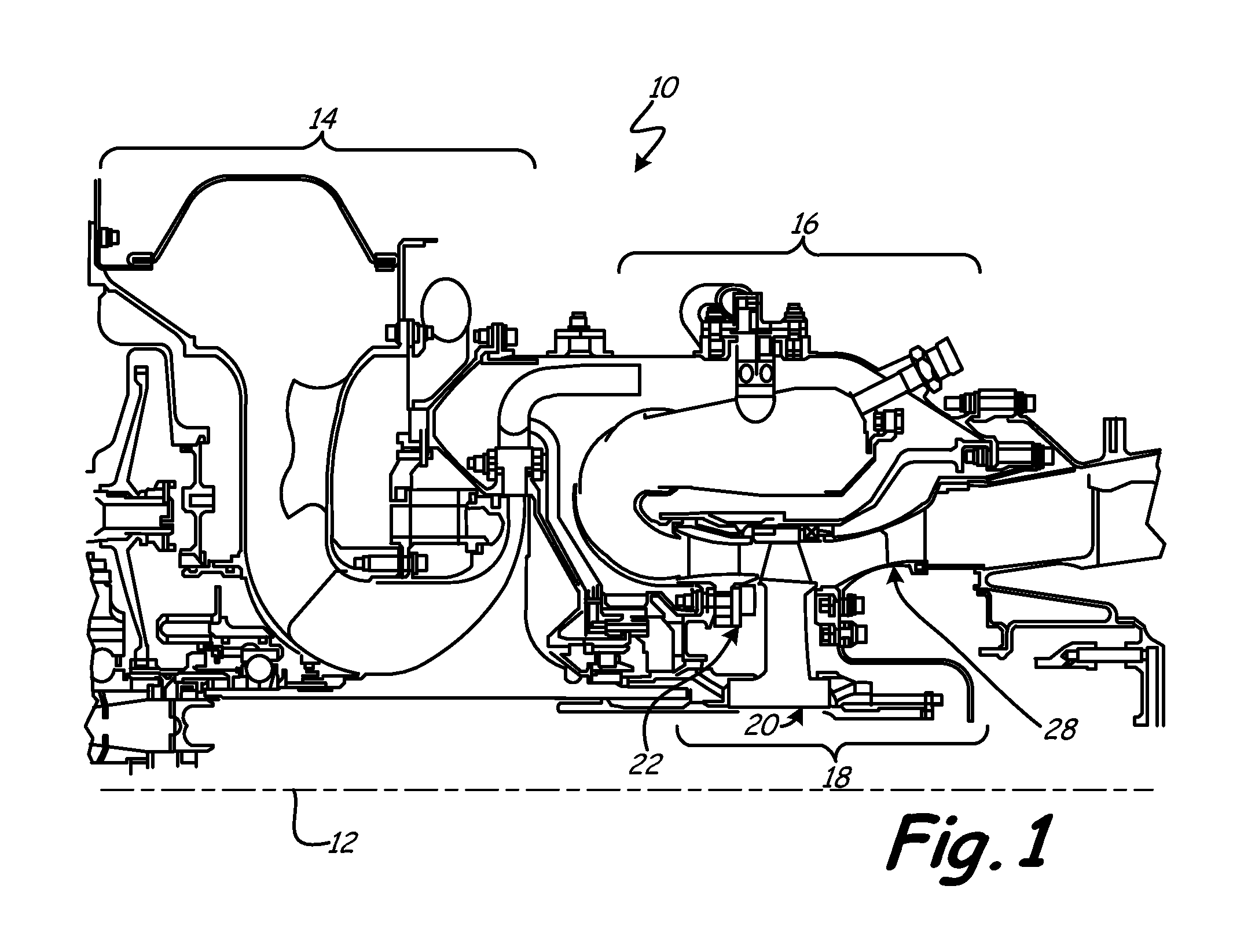

Combustor dome assembly of a gas turbine engine having improved deflector plates

ActiveUS7121095B2Relieve pressureContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A combustor dome assembly for a gas turbine engine having a longitudinal centerline axis extending therethrough, including: an annular dome plate having an inner portion, an outer portion, a forward surface, and a plurality of circumferentially spaced openings formed therein, wherein a radial section defined between each of the openings includes a cooling trough formed therein; an outer cowl connected to the dome plate outer portion at a downstream end thereof; an inner cowl connected to the dome plate inner portion at a downstream end thereof; and, a deflector plate connected to and positioned aft of each opening in the dome plate. Each deflector plate further includes: an annular section at an upstream end thereof having a forward end, an aft end, an inner surface and an outer surface; a substantially planar flange connected to the aft end of the annular section, the planar flange including an outer circumferential surface, an inner circumferential surface, a first radial surface, a second radial surface, and an opening therein sized to the inner surface of the annular section so as to form opposing radial sections; a first flange connected to the outer circumferential surface of the planar flange at a predetermined angle thereto; and, a second flange connected to the inner circumferential surface of the planar flange at a predetermined angle thereto. The first and second radial sections of the deflector plate planar flange are configured so at least a portion of the dome plate cooling trough is in flow communication with a combustion chamber downstream of said dome plate.

Owner:GENERAL ELECTRIC CO

Anvil Roll System and Method

A rotary cutting apparatus comprising a frame and a die roll defining a first longitudinal axis and comprising a cutting member. The die roll is rotatably connected with the frame and configured to rotate about the first longitudinal axis. The rotary cutting apparatus further comprises a bearer ring connected with the die roll and an anvil roll defining a second longitudinal axis and comprising an outer radial surface. The anvil roll is rotatably connected with the frame and is configured to rotate about the second longitudinal axis. The bearer ring of the die roll is in contact with the outer radial surface. The anvil roll may be supported by at least one cam follower. The anvil roll may be axially removable from the frame via lateral translation along the second longitudinal axis.

Owner:THE PROCTER & GAMBLE COMPANY

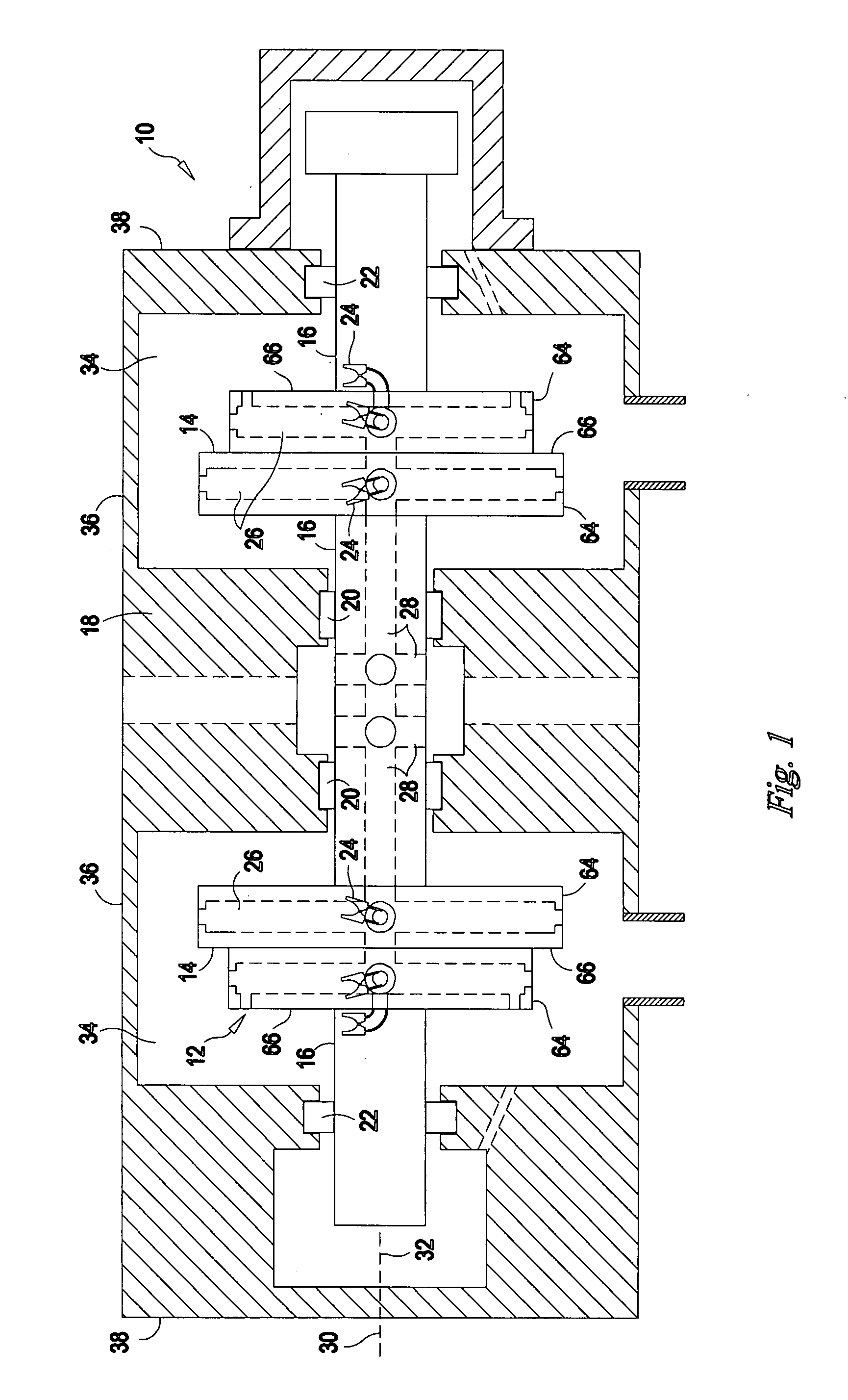

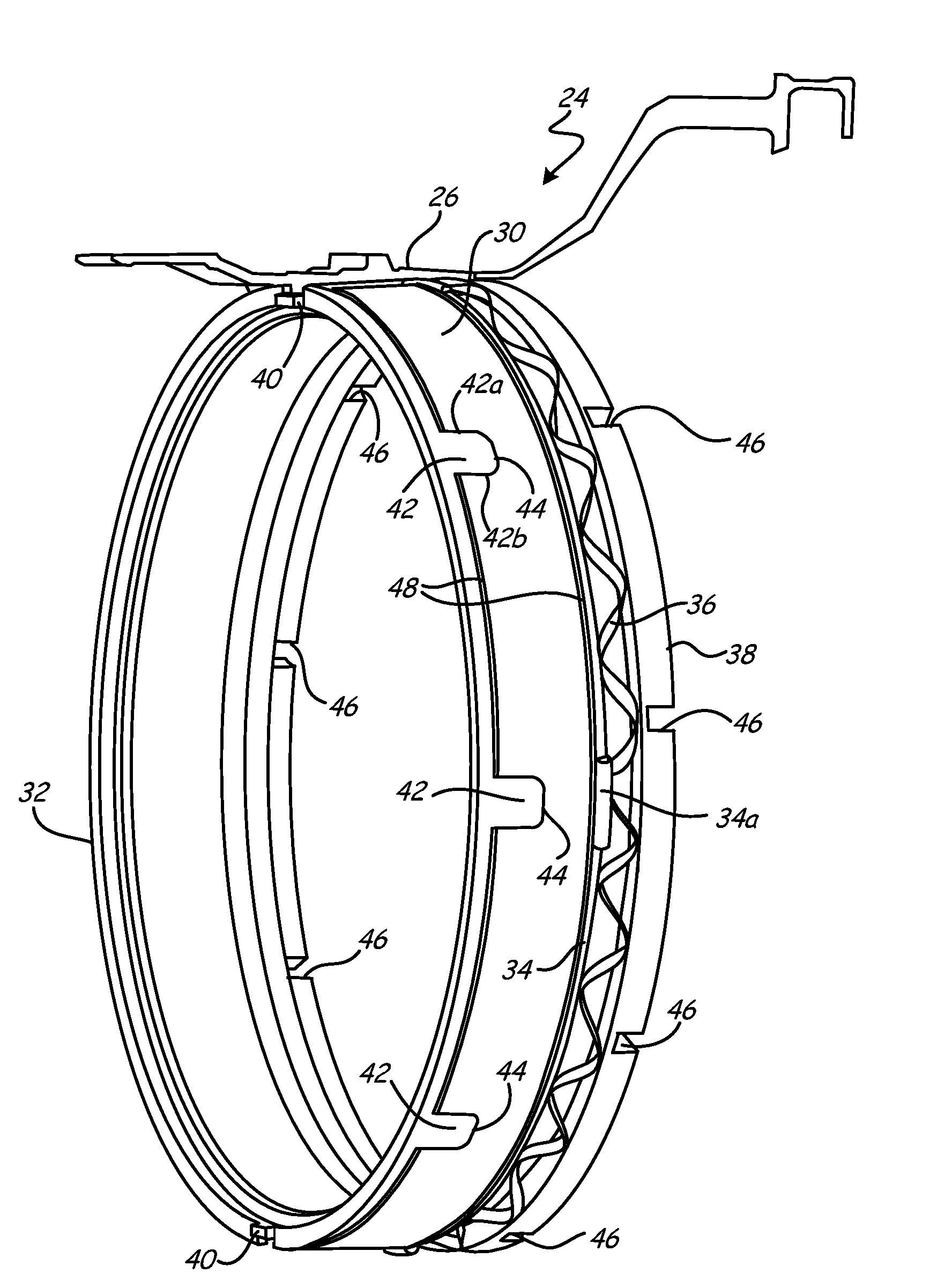

Scroll machine

ActiveUS20110293456A1Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringDischarge pressure

A compressor includes a shell, a compression mechanism, and an axial biasing system. The shell defines a first passage forming a first discharge passage. The compression mechanism includes first and second scroll members meshingly engaged with one another and forming a series of compression pockets. The first scroll member includes a second discharge passage. The axial biasing system includes a biasing member having first and second surfaces generally opposite one another. The first surface includes a first radial surface area exposed to an intermediate pressure from one of the compression pockets and a second radial surface area exposed to a discharge pressure. The second surface includes a third radial surface area exposed to the intermediate pressure. The biasing member is axially displaceable between first and second positions. The biasing member axially engages the first scroll member when in the first position.

Owner:COPELAND LP

Ceramic turbine shroud support

A turbine shroud includes a ceramic shroud ring configured to surround a plurality of turbine rotor blades, a plurality of slots circumferentially distributed around the ceramic shroud ring, a forward metallic support ring, a plurality of tabs attached to a forward edge of the forward metallic support ring configured to engage a turbine support case, and a plurality of tabs attached to an aft edge of the forward metallic support ring received by the slots of the ceramic shroud ring. Only two axially extending radial surfaces of each of the tabs attached to the aft edge of the forward metallic support ring are configured to contact the slots of the ceramic shroud ring.

Owner:RTX CORP

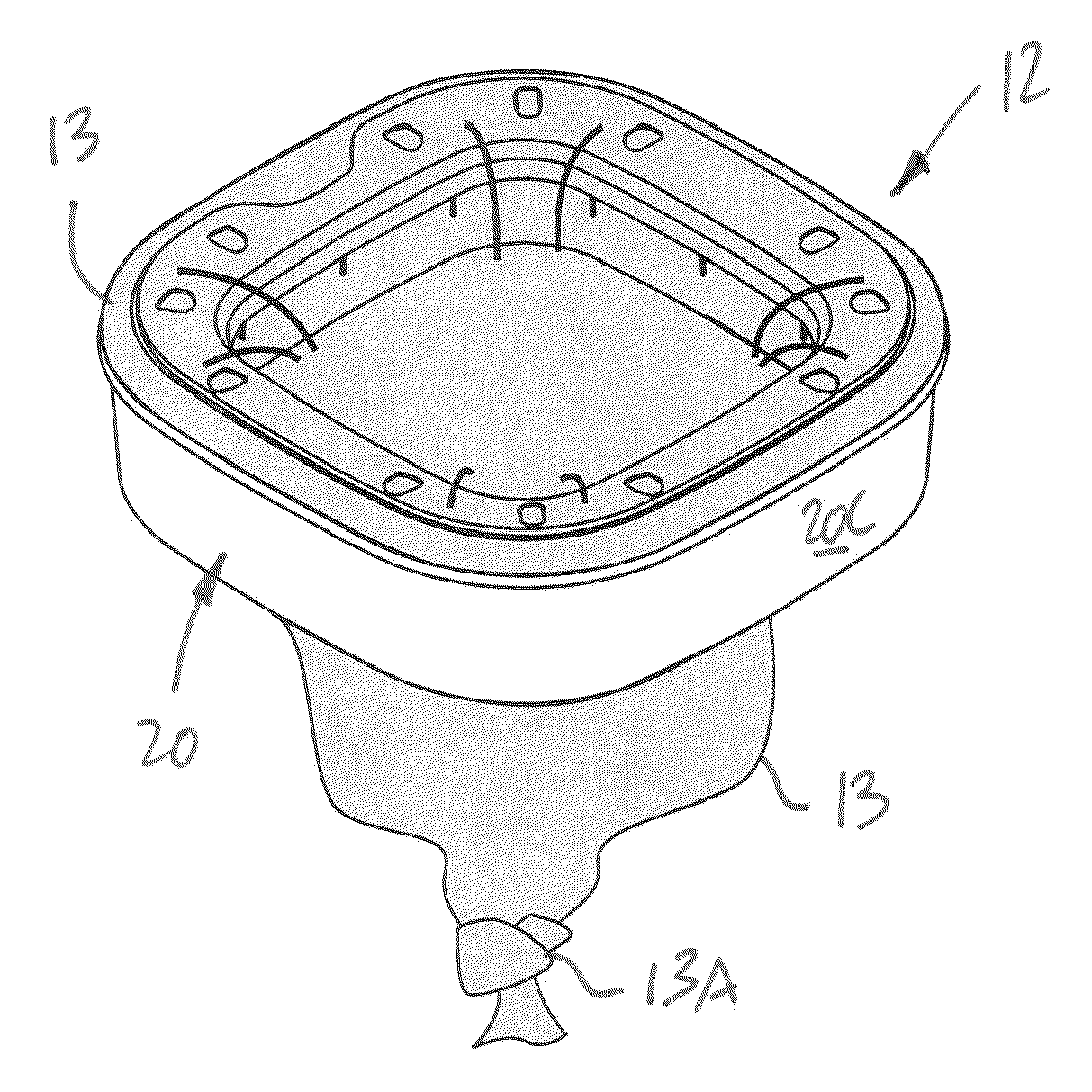

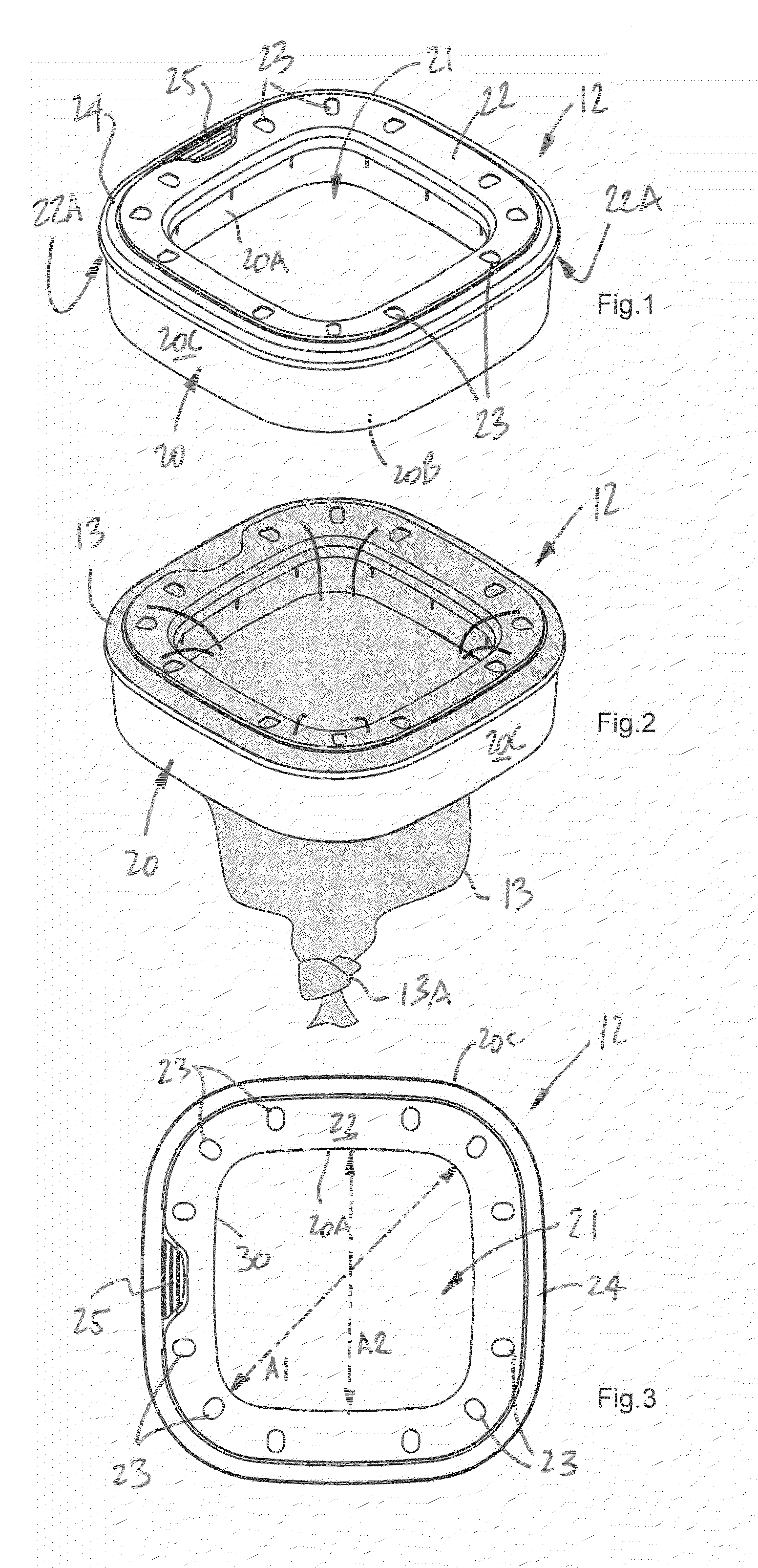

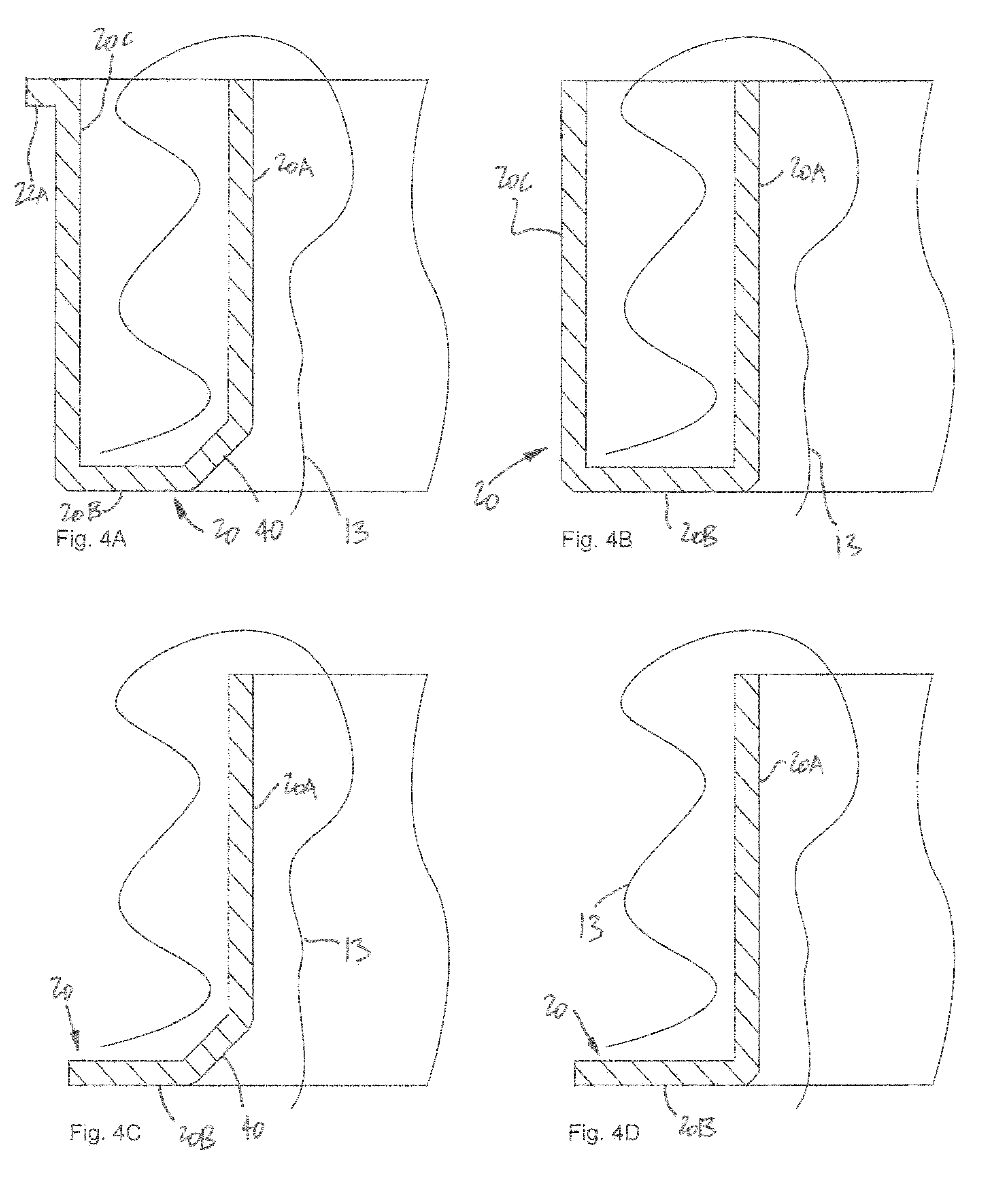

Film-dispensing cassette and rimmed bag for waste-disposal unit

A film-supporting device is used with a waste-disposal unit. The device comprises an annular body. The annular body has an annular wall. The inward radial surface of the wall defines a central opening of the body. The outline of the central opening in a transverse plane of the device has variable diametrical dimensions with a first diameter of greater dimension than the second diameter. The outline has two of the first diameter of generally equal dimension and two of the second diameter of generally equal dimension. The device has tubular film about an outward radial surface of the annular body. A free annular end is dispensed outwardly from the annular wall. The free annular end is closed to form a bag. The opening of the bag is accessible through the central opening and is of optimized shape via the central opening for the disposal of waste. A method for disposing of waste on a scooping tool is also provided.

Owner:MONITEUSNGELCARE

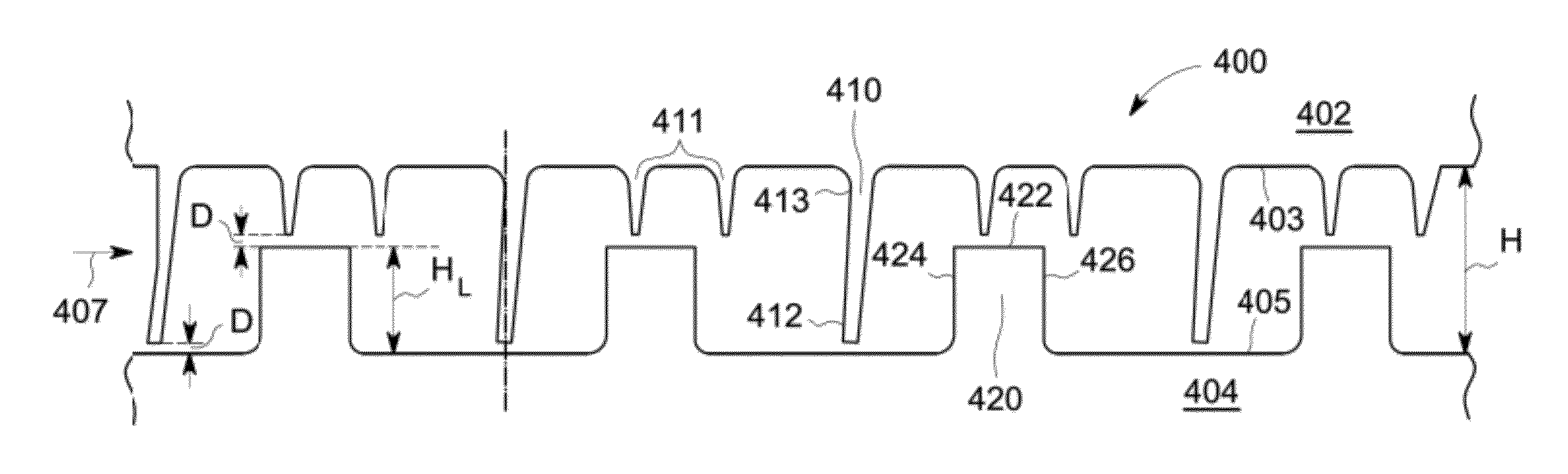

Multiple Ramp Compression Packer

Systems and methods for remotely setting a downhole device. The system includes a base pipe having inner and outer radial surfaces and defining one or more pressure ports extending between the inner and outer radial surfaces. An internal sleeve is arranged against the inner radial surface and slidable between a closed position, where the internal sleeve covers the one or more pressure ports, and an open position, where the one or more pressure ports are exposed to an interior of the base pipe. A trigger housing is disposed about the base pipe and defines an atmospheric chamber in fluid communication with the one or more pressure ports. A piston port cover is disposed within the atmospheric chamber and moveable between blocking and exposed positions. A wellbore device is used to engage and move the internal sleeve into the open position by applying predetermined axial force to the internal sleeve.

Owner:HALLIBURTON ENERGY SERVICES INC

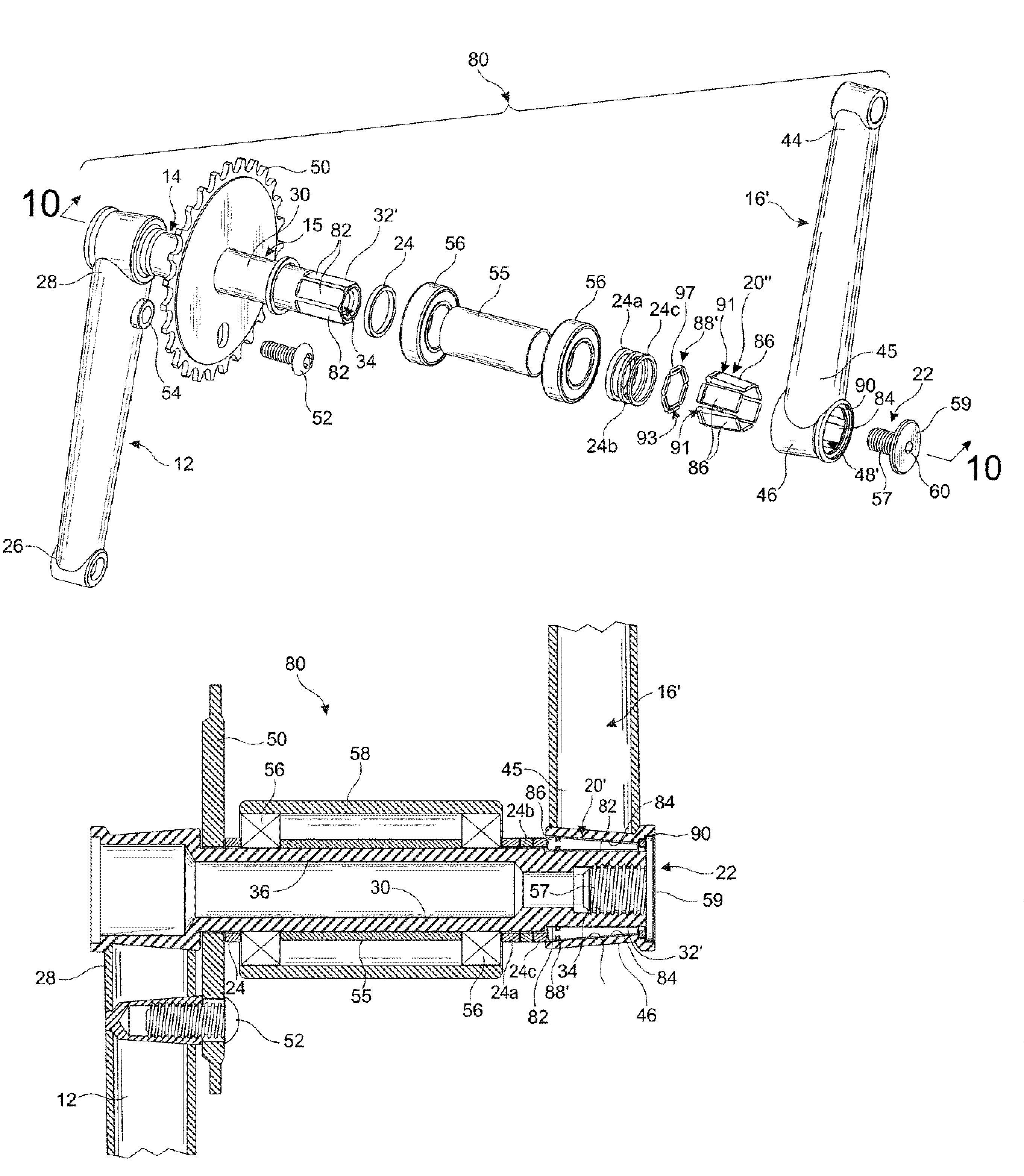

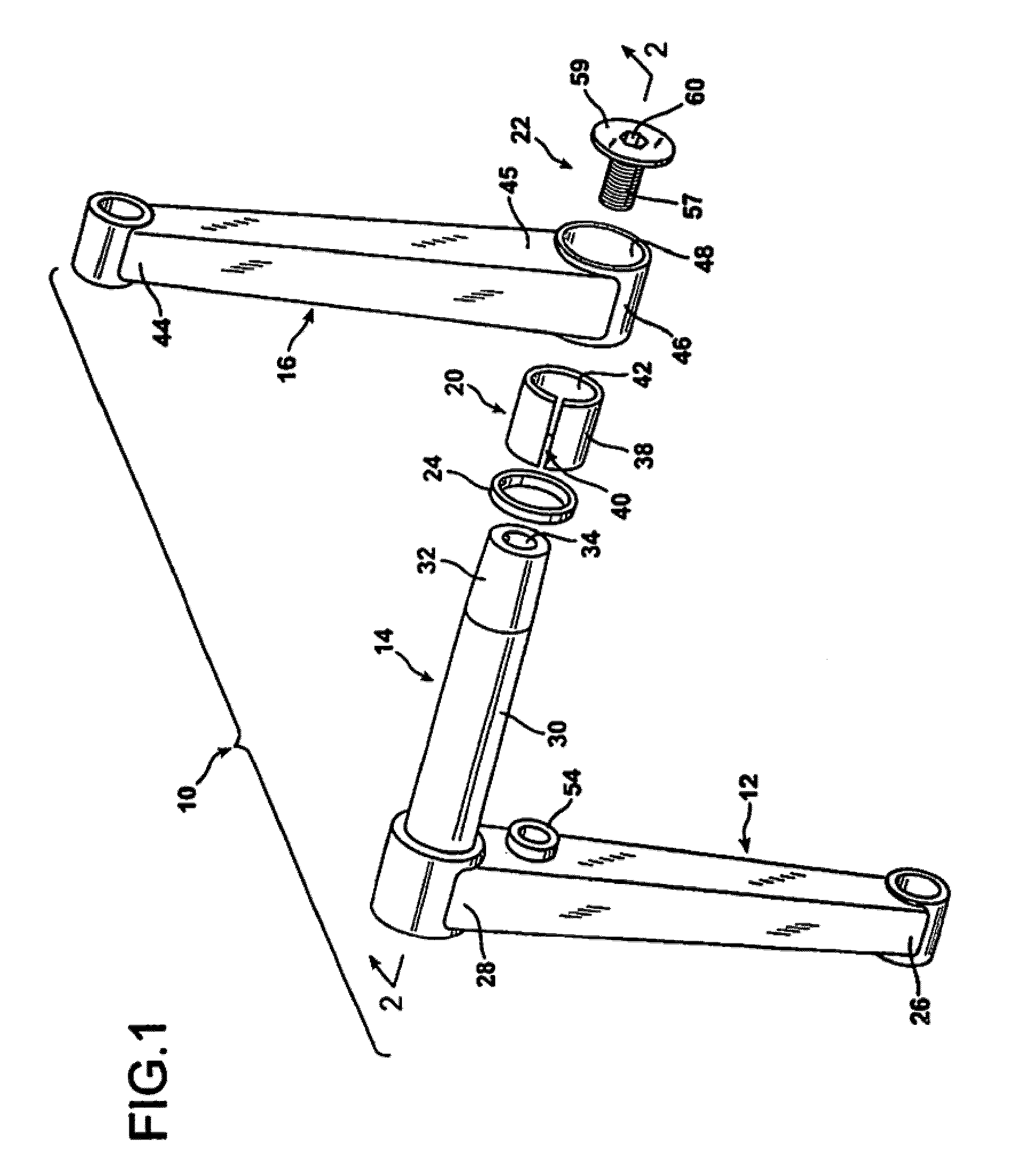

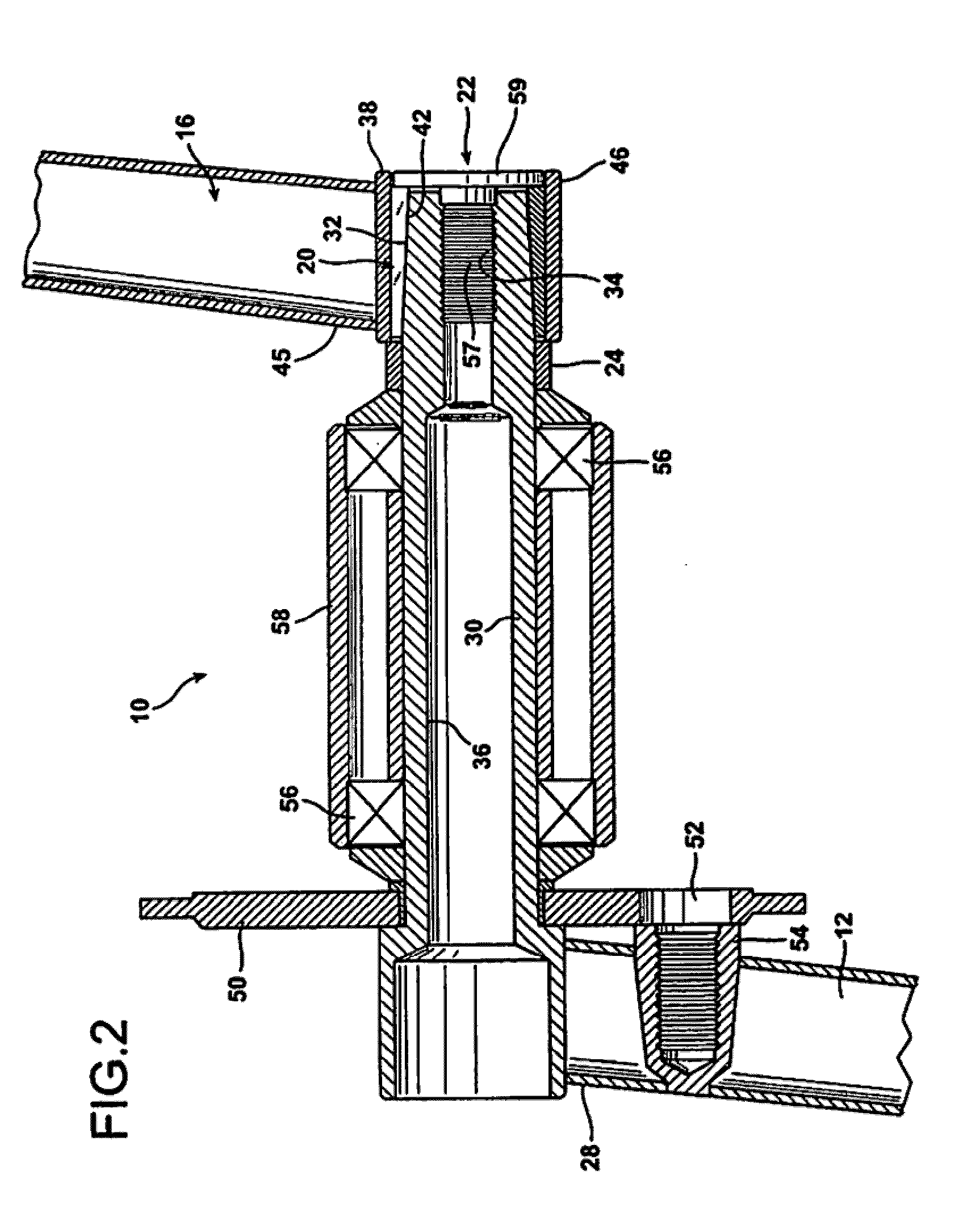

Bicycle Crank Assembly

InactiveUS20100064845A1Maintain strengthConsiderable amount of weightMechanical apparatusVehicle cranksCouplingSprocket

A bicycle sprocket crank assembly is comprised of first and second crank arms joined to a spindle. One of the crank arms and the spindle may be fabricated as a unitary structure, or both cranks arms may be formed as separate structures and joined together. In either case the spindle has at least a first coupling end with an internally tapped axial bore defined therein and the second crank arm forms at least a first socket at its axle end. At least a first wedging sleeve is provided and is disposed about the first coupling end of the spindle. The first wedging sleeve conforms to the shapes of both the first coupling end of the spindle and the hollow cavity in the first socket. Either the coupling end of the spindle or the hollow cavity is axially tapered, and the wedging sleeve is tapered to match so that as the first socket is drawn onto the first coupling end of the spindle, the wedging sleeve is increasingly forced in between the inner radial surface of the hollow cavity of the socket and the outer radial surface of the coupling end of the spindle. The wedging sleeves may be interconnected by flexible, elastic straps to allow each individual shim to move independently of the other.

Owner:BEARCORP

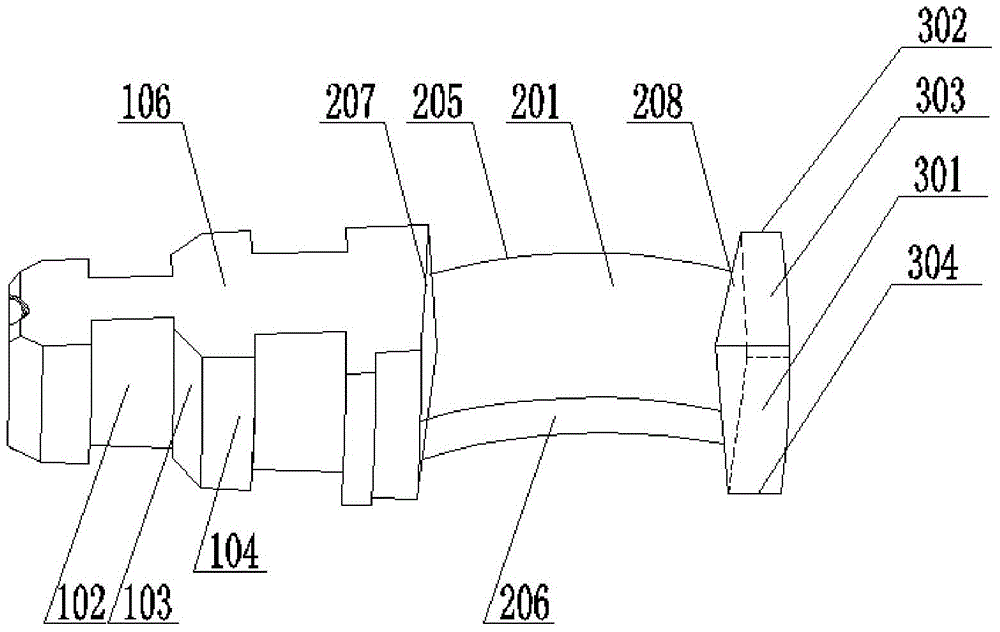

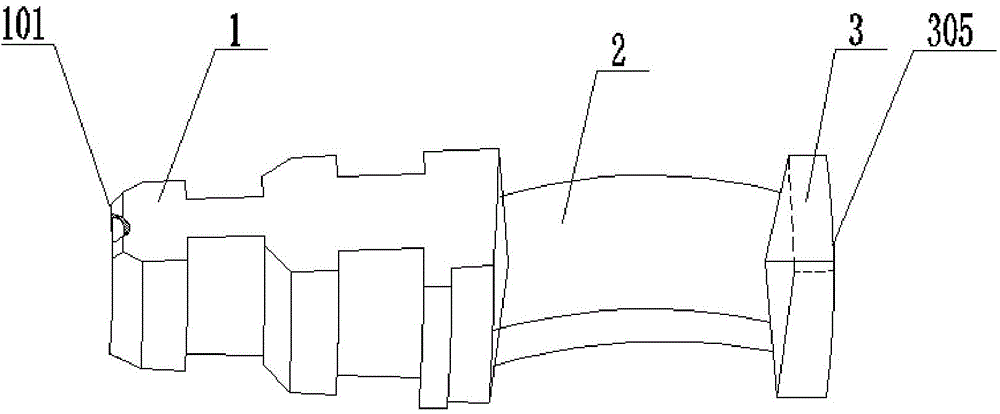

Machining process of axial-flow type turbine blade

The invention discloses a machining process of an axial-flow type turbine blade. The machining process of the axial-flow type turbine blade comprises the following steps that two side faces are machined on a square blank stock through an end face end mill on an ordinary milling machine through two process of rough milling and finish milling, another two side faces are machined with the two machined side faces as base planes, and then the two end faces are machined through the end face end mill; a steam outlet side face is machined on one side face through two process of rough milling and finish milling, the position, close to the steam outlet side face, of the blade root end face is marked as C, a face which forms an acute angle with the steam outlet side face and is adjacent to the steam outlet side face is marked as N and is the inner radial surface, and the other three side faces are machined to be a parallelogram through rough milling and finish milling; central holes are drilled in the blade root end face and the blade crown end face; the blade type is roughly milled through the end face end mill, the blade root is roughly milled, and finally the blade crown is roughly milled; then the blade is installed on a five-axis numerical control machining center for alignment and is machined in a finish mode; a process head at the blade root end face is roughly sawn through a sawing machine; the turbine blade is detected according to the requirements of a drawing.

Owner:南京赛达科技有限公司

Turbine seal plate locking system

A seal plate assembly is provided in a rotor disc for a turbine engine. The seal plate assembly includes a radially extending flange on the disc and an annular groove defined between a radial surface on the flange and a face of the disc. An annular outer surface extends axially in facing relationship to an annular inner surface of the groove. A plate structure is supported between the inner and outer surfaces, and a lock structure is provided for holding the plate structure in place. The lock structure includes an axial leg that is adapted to be located between an inner edge of the plate structure and the inner surface of the groove, and the lock structure further includes a radial leg that is adapted to be located between the radial surface on the flange and an outwardly facing surface of the plate structure.

Owner:SIEMENS ENERGY INC

Side emitting near field lens

A near field lens for an automotive light assembly which has a reduced thickness. Generally, the near field lens includes a main body of light transmitting material. A pocket is formed in the main body for receiving light from a light source. The pocket is defined by an inner radially facing surface and an inner axially facing surface. The inner radially facing surface is structured to reduce the thickness of the lens.

Owner:VARROC LIGHTING SYST SRO

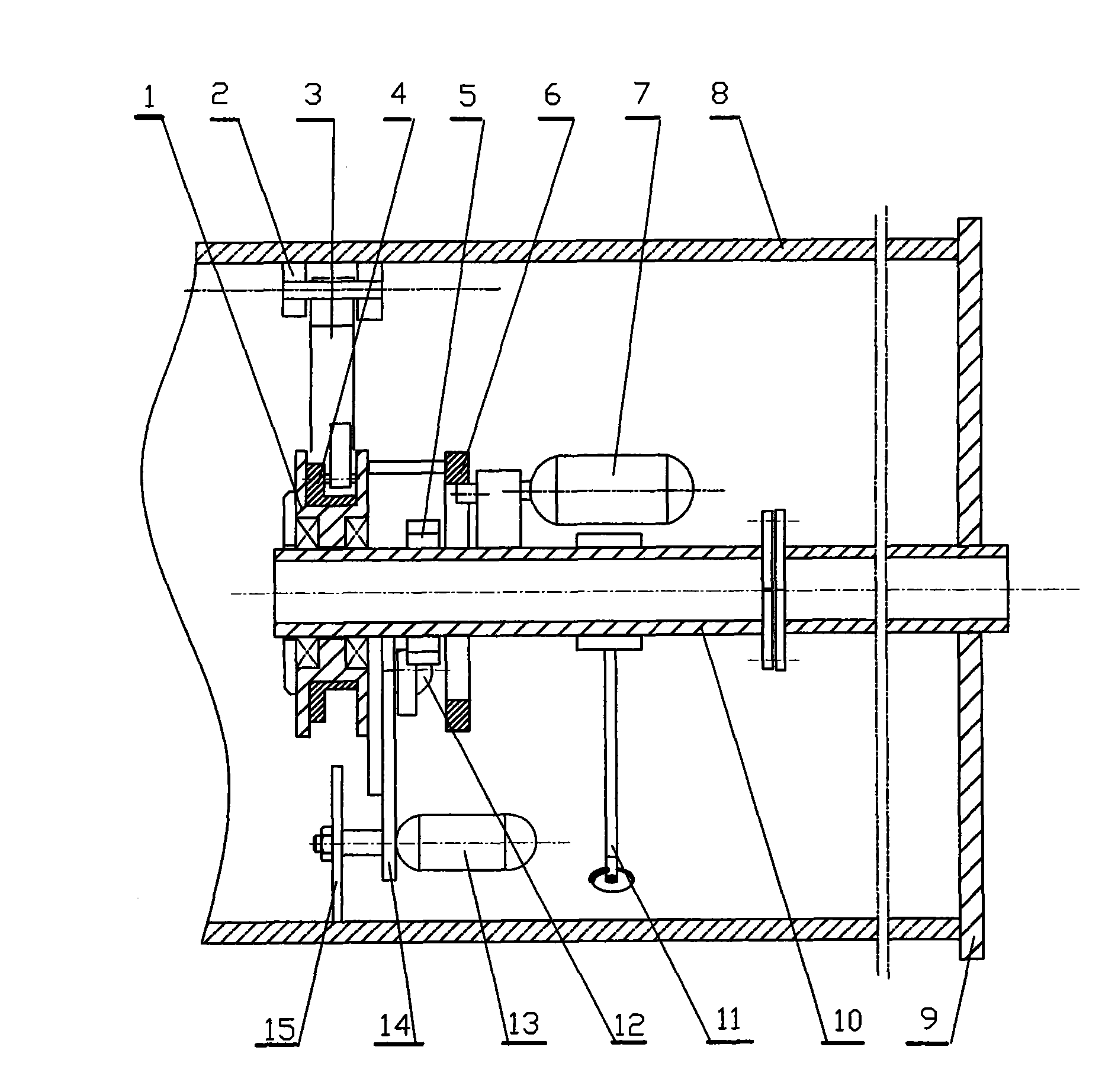

Cutting device and method

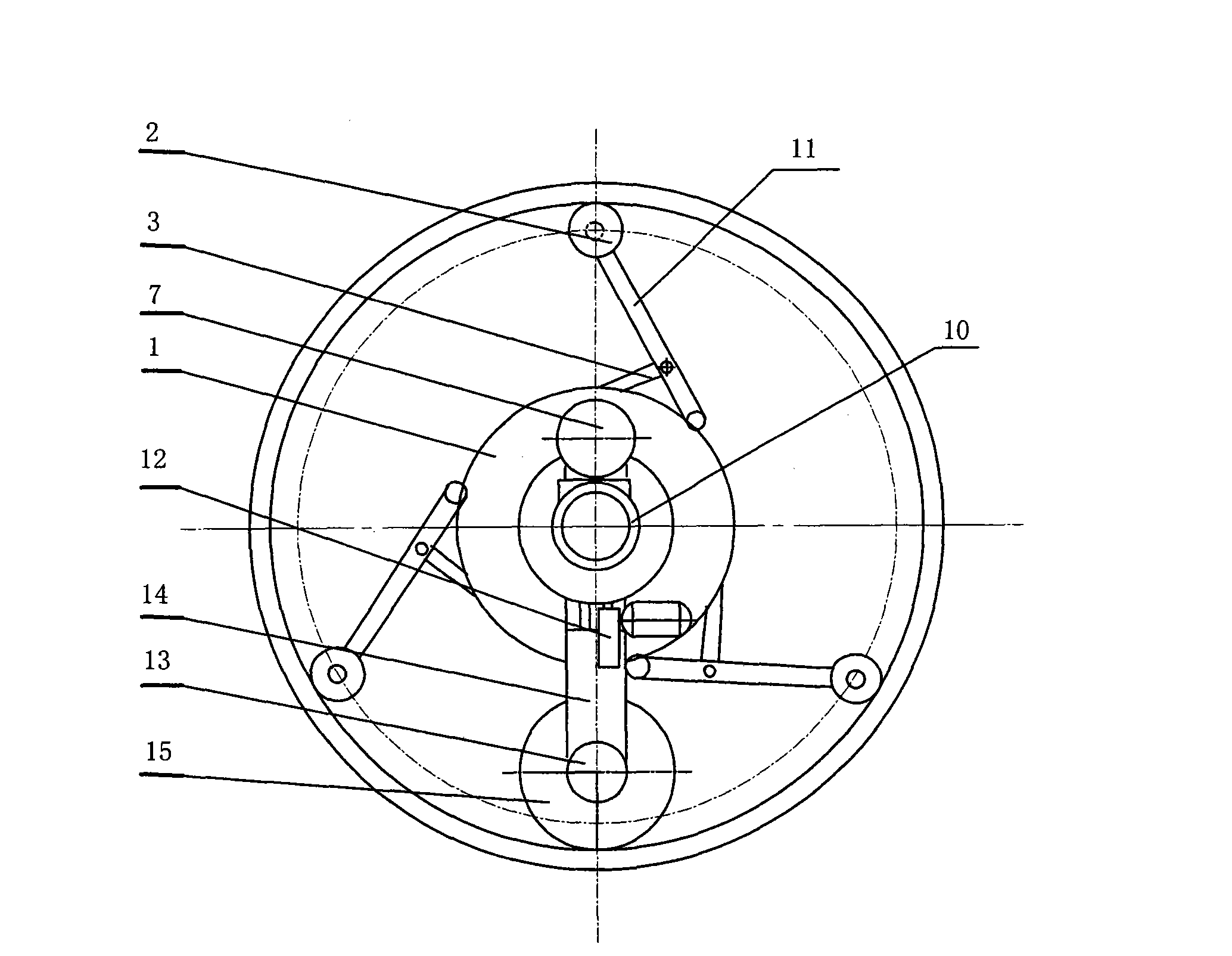

InactiveCN101491848AImprove construction efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMechanical equipmentGrinding wheel

The invention relates to a cutting machine and a cutting method for mechanical equipment, and is designed aiming at the fact that cleaning of a long section of a pile foundation of the prior building engineering is realized by implementing cutting from the periphery of a steel pipe pile, so that the construction efficiency is reduced. The design key points of the invention comprise that: the cutting machine is arranged inside the steel pipe pile, and the extending depth is adjusted through a central pipe and a fixed plate; the central pipe is fixedly connected with a plane of the steel pipe pile; a rotary platform component which is connected with the radial surface is connected with a rotary disc, a positioning wheel extending mechanism and a positioning wheel component; an output shaft of a rotary motor is connected with a gear component, an electrically conductive sliding block component and the rotary disc; a control motor is connected with a telescopic planker; a cutting motor is connected with the telescopic planker and a grinding wheel; the radial surface of the central pipe is connected with the positioning wheel extending mechanism and an auxiliary wheel carrier which provides a driving force for the grinding wheel; and the high speed rotational grinding wheel forms a circle of cutting line along the inner wall of the steel pipe pile so as to complete cutting of the steel pipe pile which is a section higher from the inside diameter to the outside diameter. The cutting machine and the cutting method solve the technical problems of cutting of the steel pipe pile and are particularly suitable for project cleaning of a complete stage of the pile foundation.

Owner:NINGBO CONSTR ENG GROUP

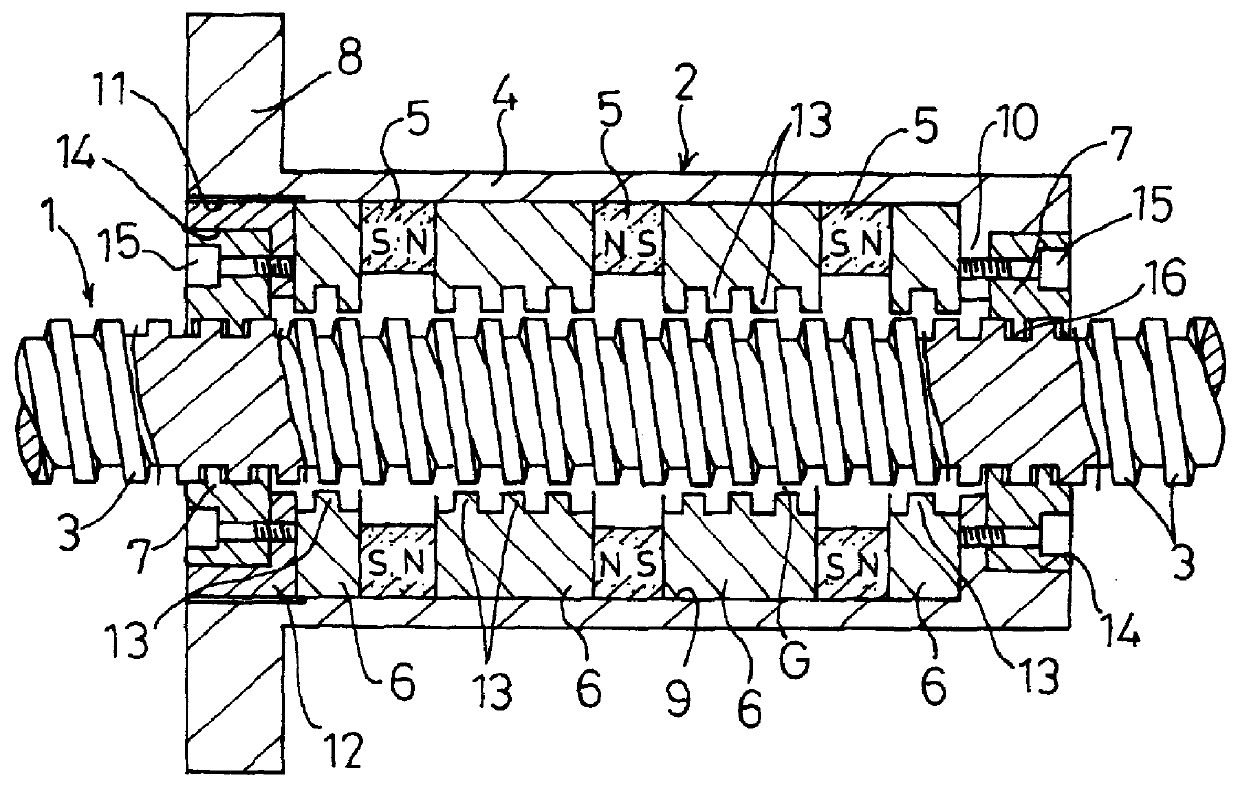

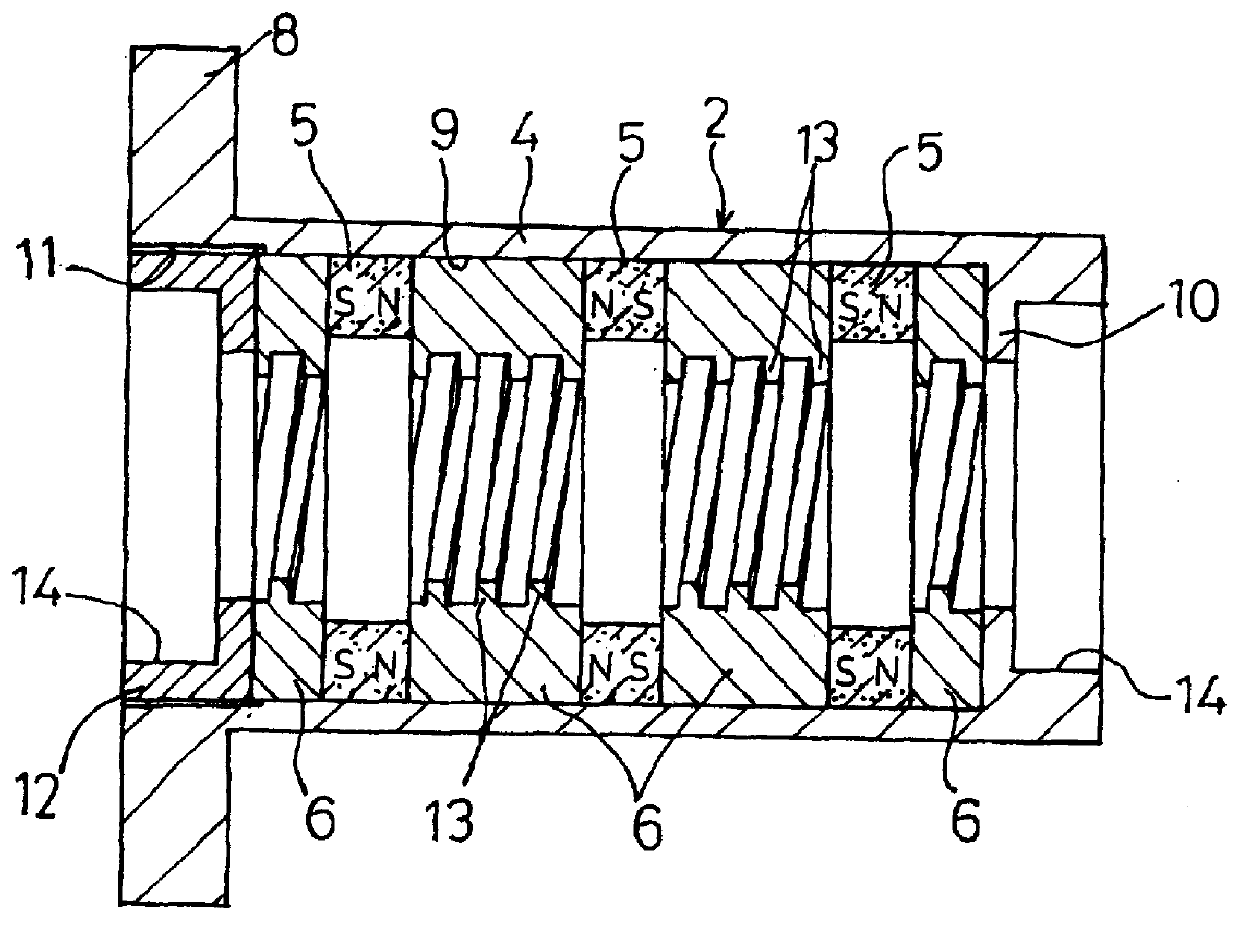

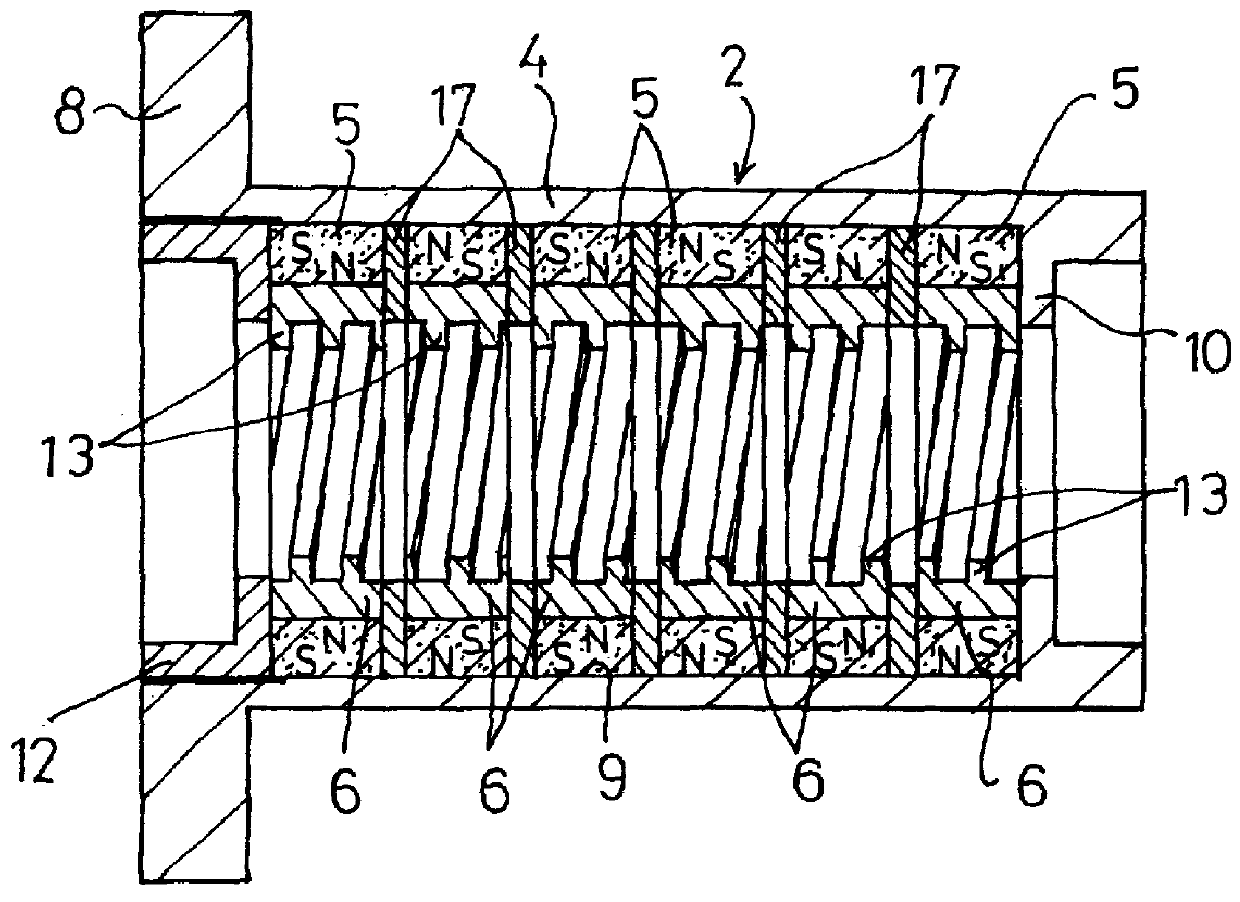

Magnetic screw

InactiveUS6111491AHigh efficiency of magnetic couplingIncrease axial thrust forceElectromagnets without armaturesPermanent magnetsElectrical polarityRadial surface

A magnetic screw having a screw shaft of magnetic material having thread crests formed on the outer peripheral surface thereof, and a magnetic nut fitted on the outer periphery of the screw shaft. The magnetic nut includes annular permanent magnets magnetized with magnetic poles of opposite polarities on opposed sides, and annular yokes disposed such that the annular yokes are magnetically coupled with the magnetic poles of the magnets. The inner peripheral surfaces of the yokes are provided with thread crests corresponding with the thread crests of the screw shaft with a minute gap G defined therebetween such that magnetic circuits are formed between the screw shaft and the magnets through the thread crests of the screw shaft. The magnets are magnetized on their inner and outer radial surfaces with magnetic poles of opposite polarities, and the yokes are fitted in the magnets.

Owner:KOYO MASCH IND CO LTD +1

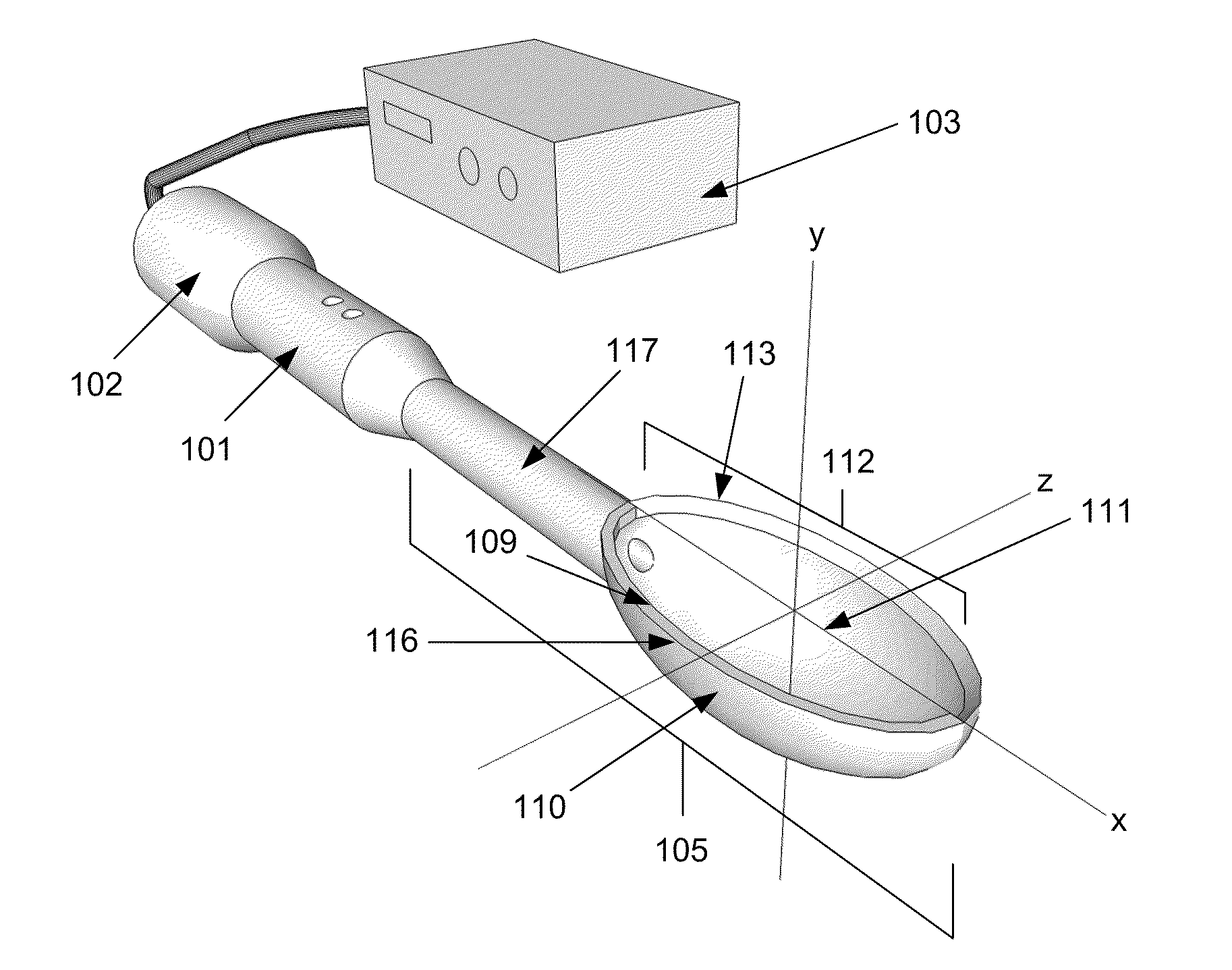

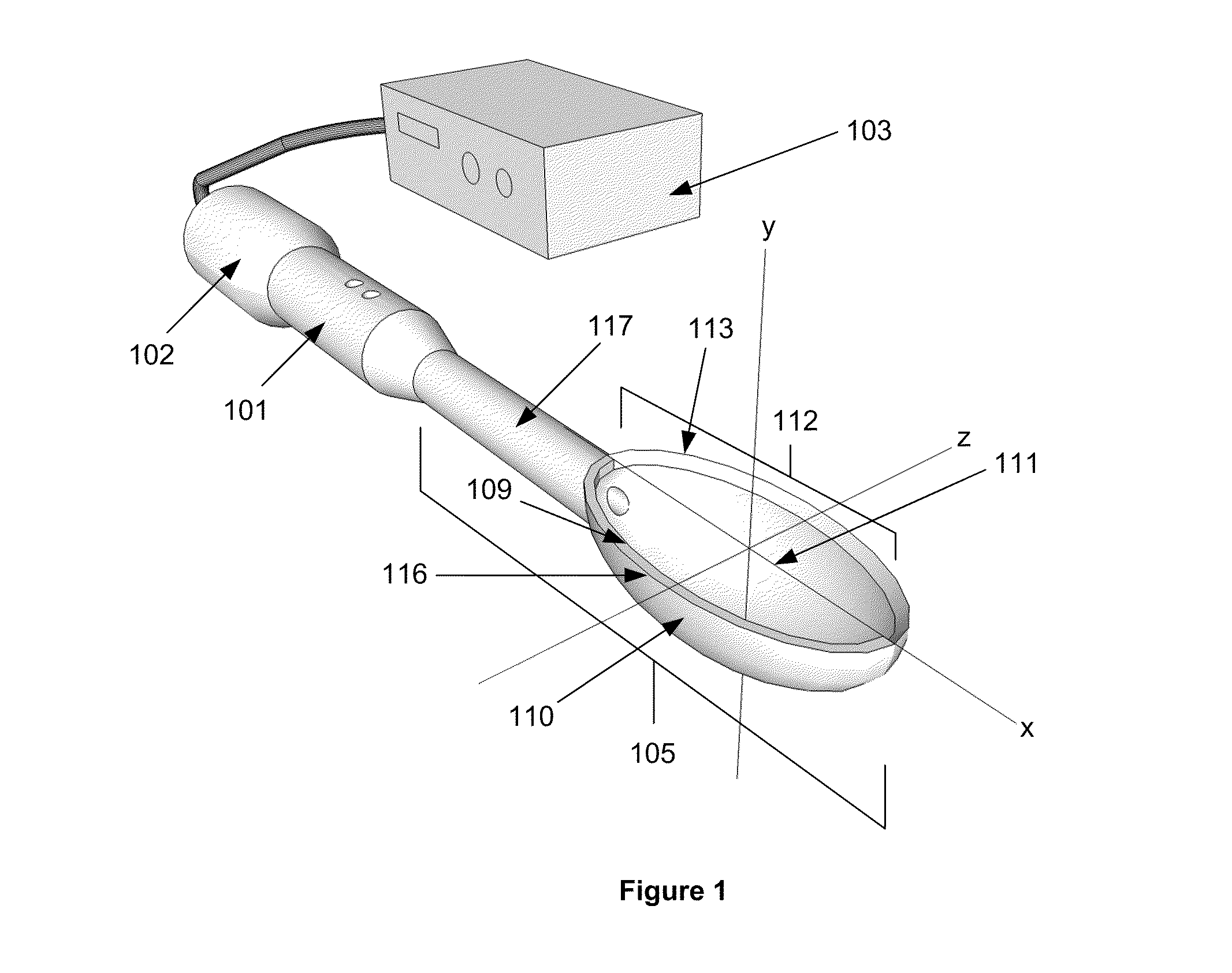

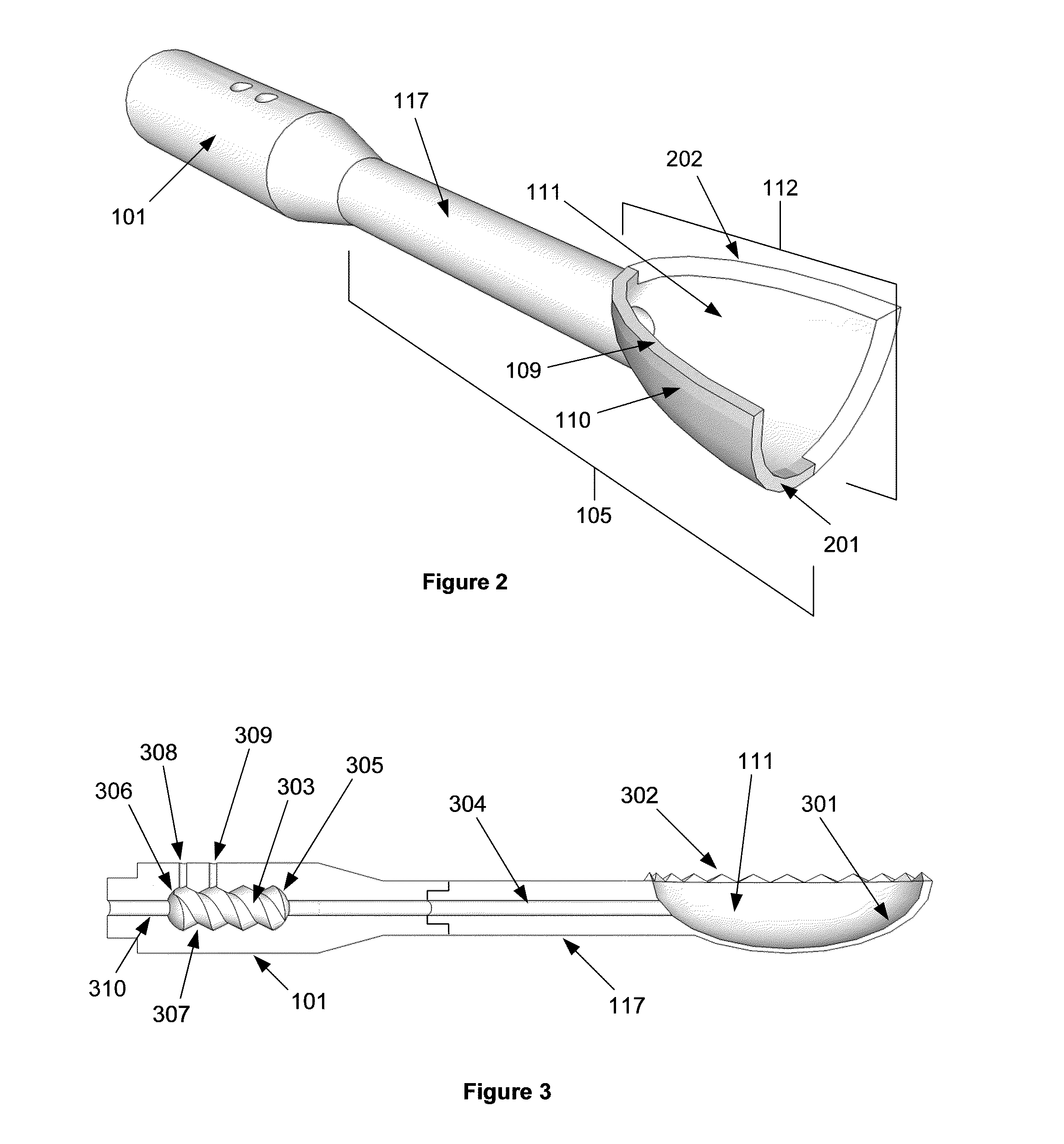

Apparatus for creating a therapeutic solution and debridement with ultrasound energy

InactiveUS20110160624A1Reduce sensitivityImprove usabilityUltrasound therapyChiropractic devicesSonificationMedicine

An ultrasound surgical apparatus is provided. The apparatus is constructed from a tip mechanically coupled to an ultrasound horn containing an internal chamber. The horn is mechanical coupled to an ultrasound transducer driven by a generator. The ultrasound tip possesses at least one radial surface, a cavity, or some other form of a hollowed out area, within at least one of the radial surfaces, and a sharpened cutting member at the opening of the cavity. The horn contains an internal chamber enabling the creation of therapeutic solution that may serve as or be incorporated into a coupling medium delivered to the cavity of the tip.

Owner:BACOUSTICS LLC

Blade outer seal for a gas turbine engine

A blade outer air seal for a gas turbine engine is provided. The blade outer air seal includes a body having an outer radial surface, an inner radial surface, and a plurality of cooling air apertures. The body extends between a forward edge and an aft edge. The inner radial surface includes at least one first seal section, at least one second seal section, and a riser extending radially between the first seal section and the second seal section. Each of the plurality of cooling air apertures extends between the outer radial surface and the riser, and each cooling air aperture has an exit configured to direct cooling air substantially parallel to the second seal section of the inner radial surface.

Owner:RAYTHEON TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com