Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1825results about "Engine of arcuate-engagement type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

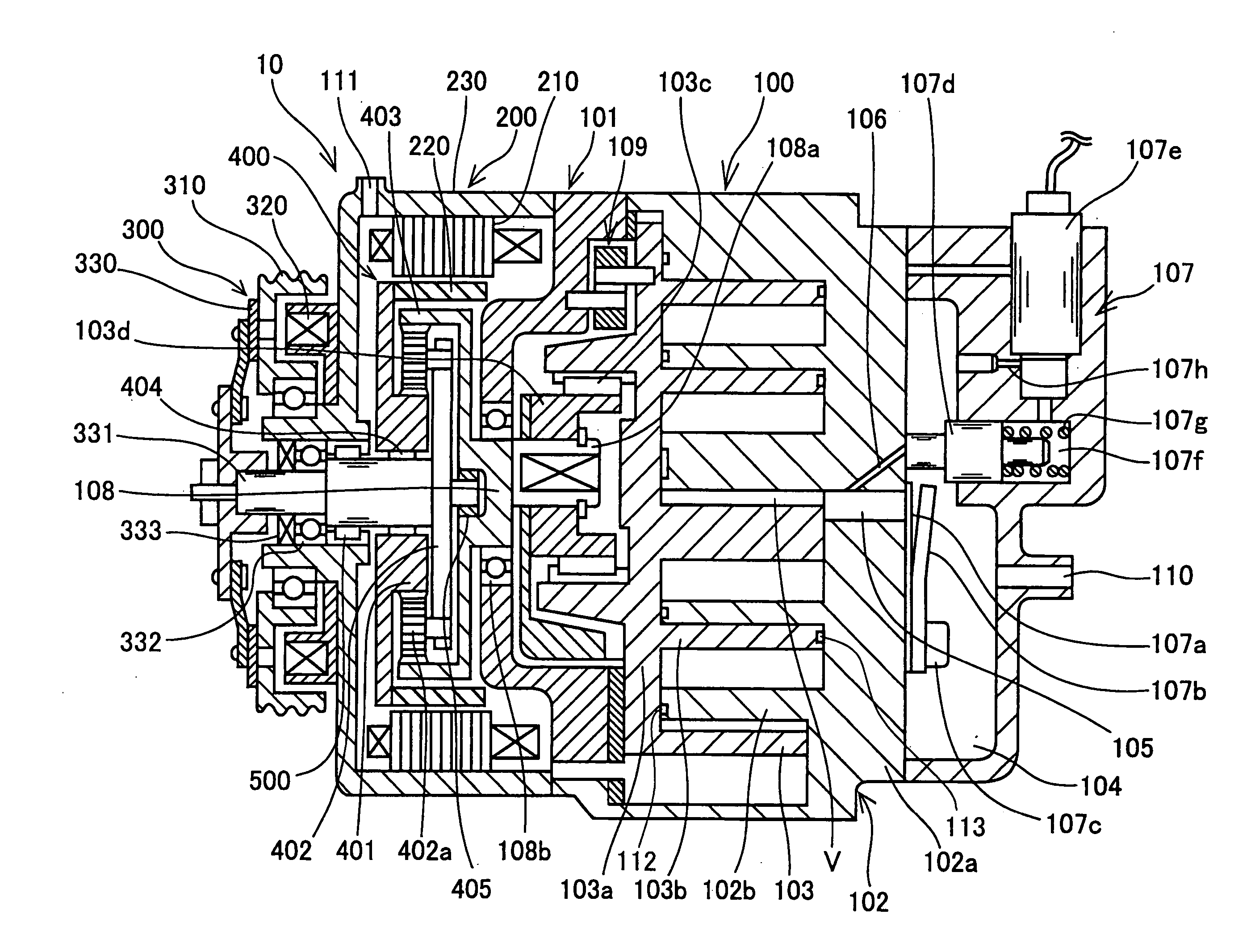

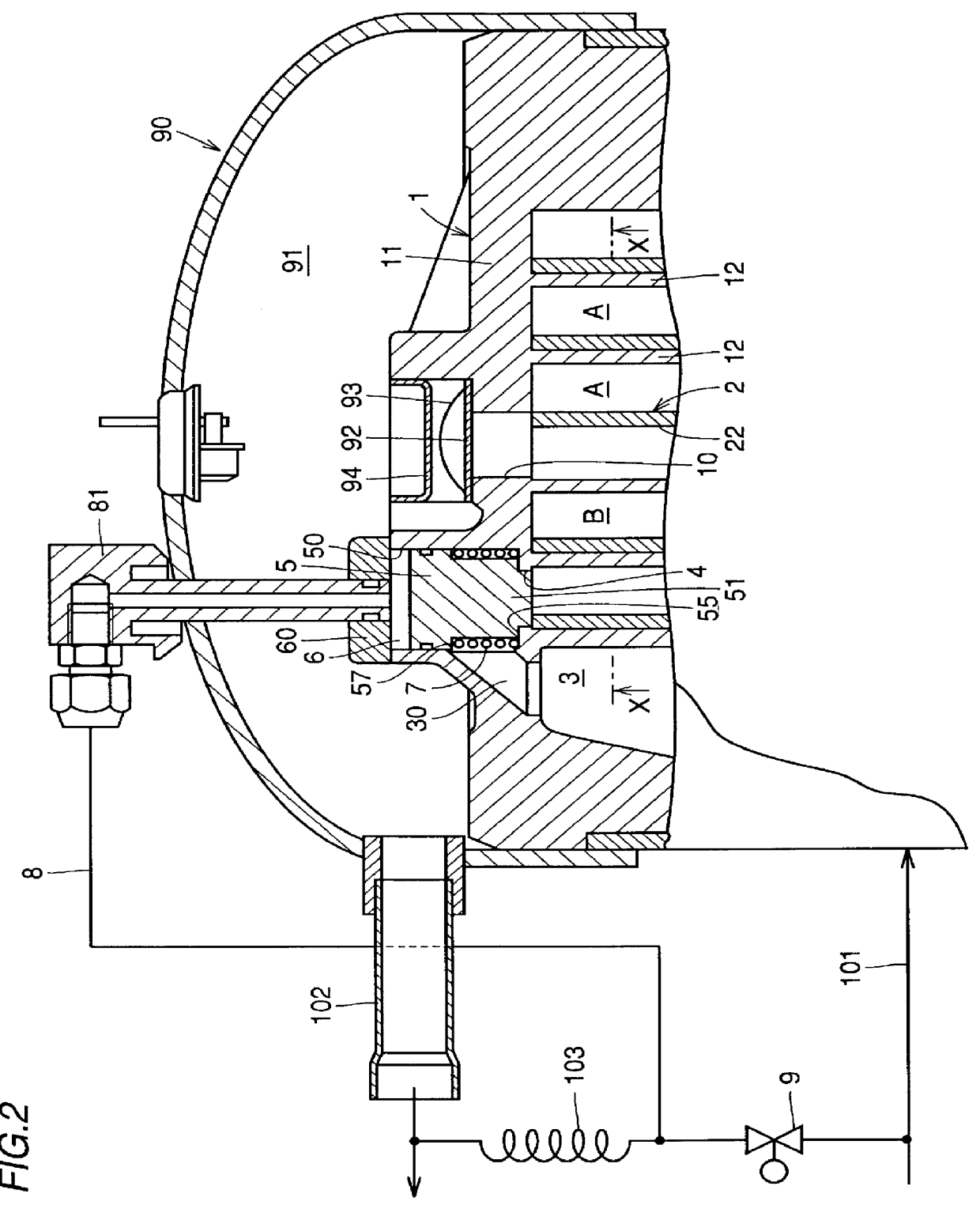

Compressor

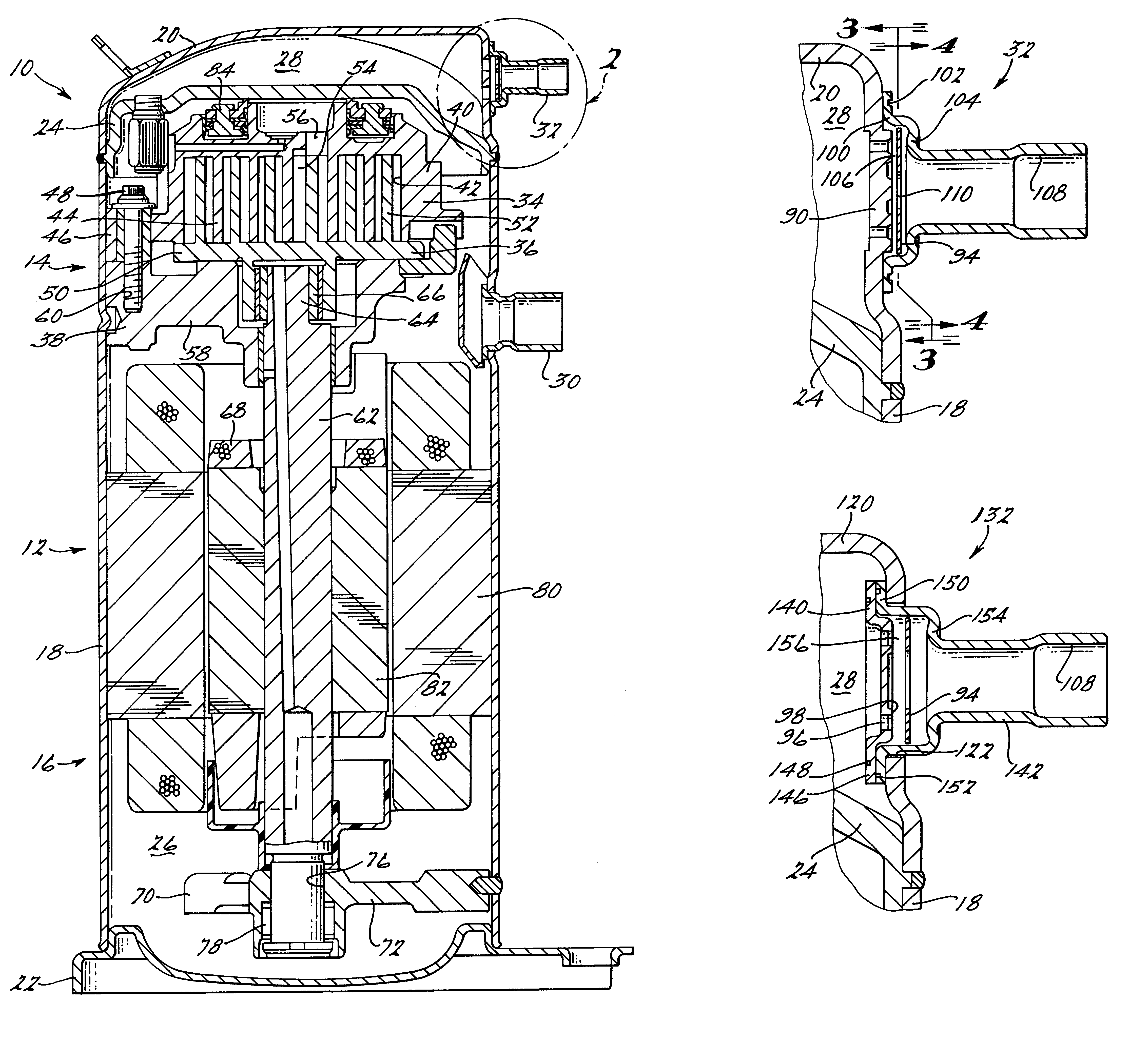

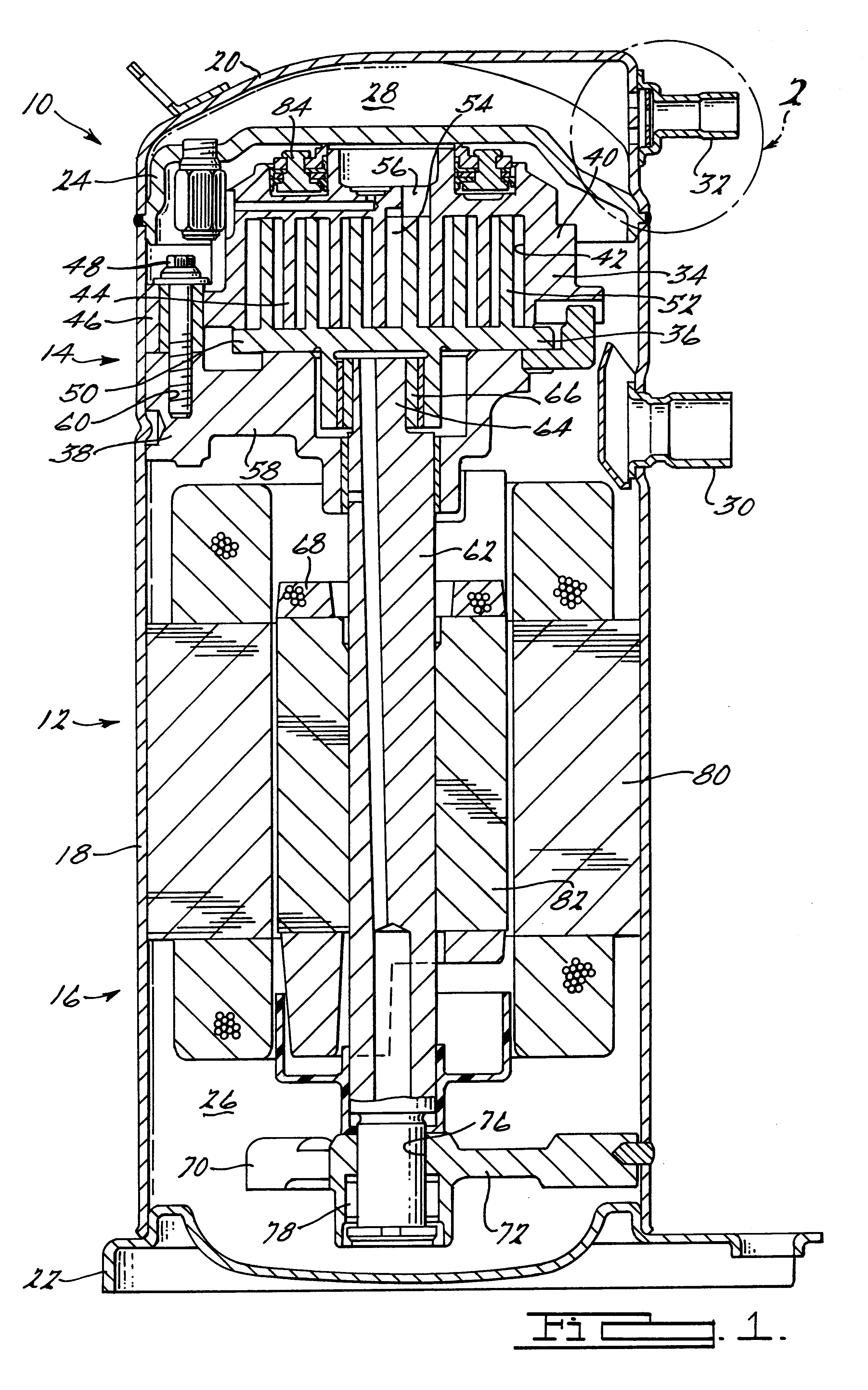

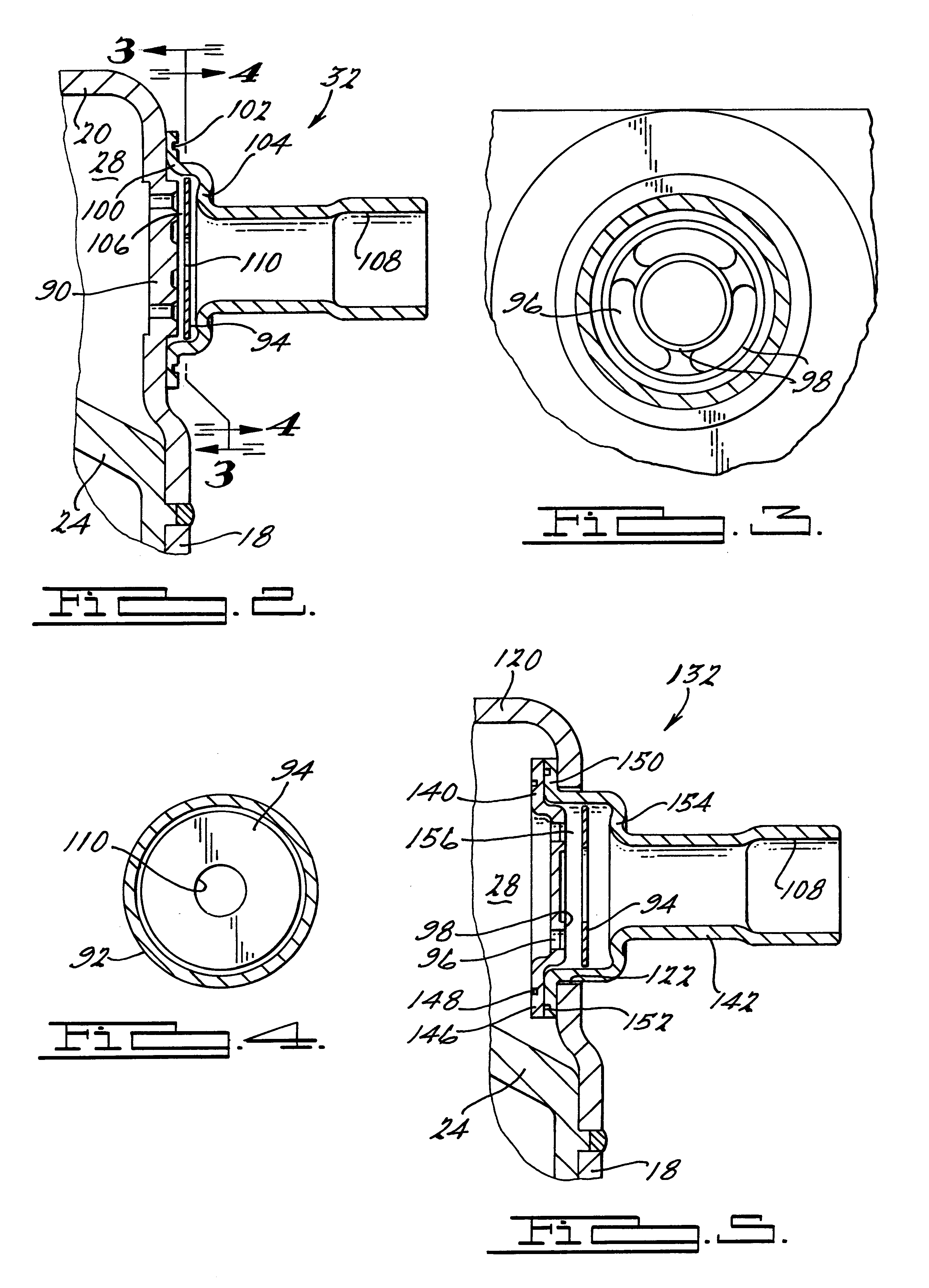

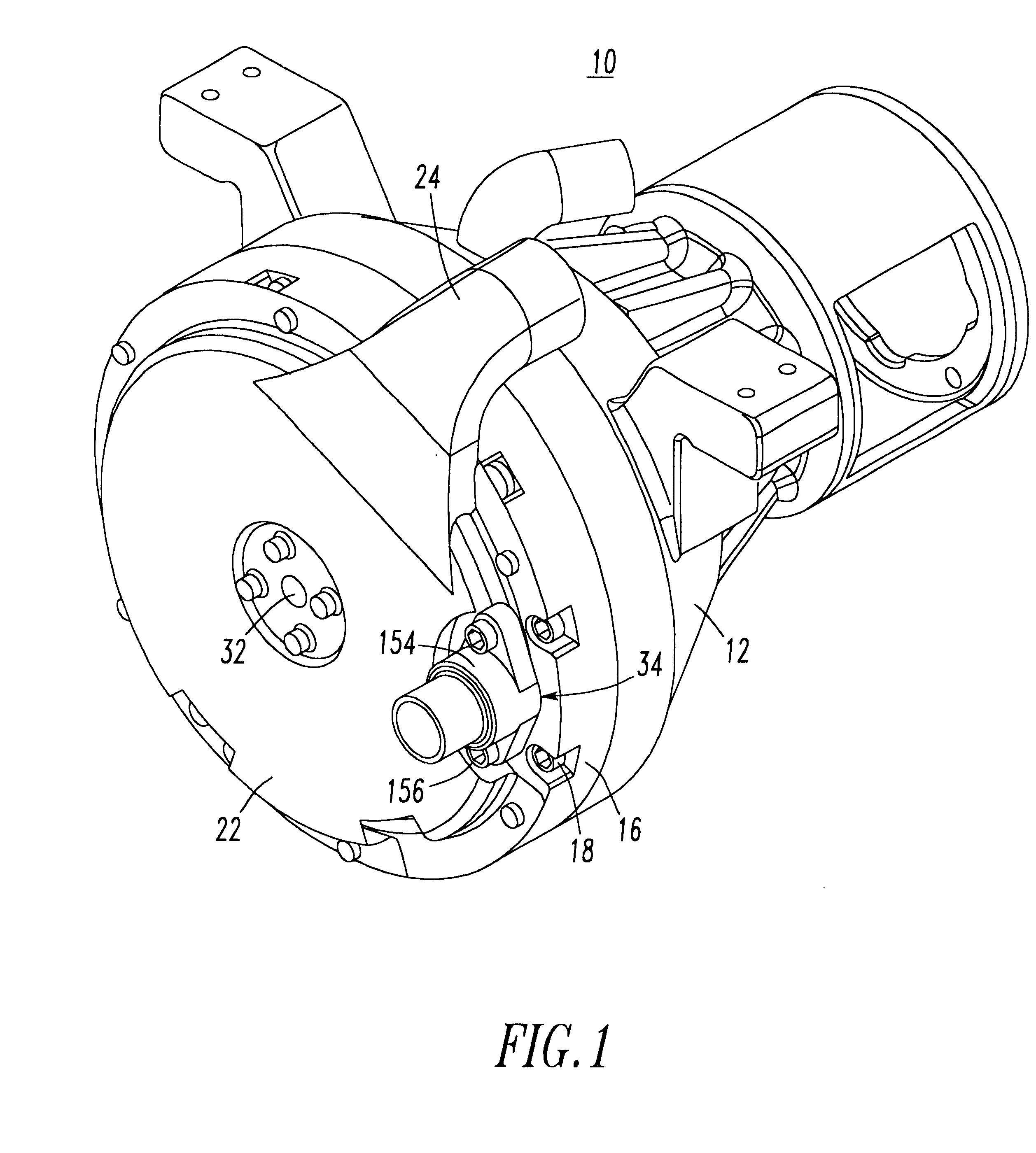

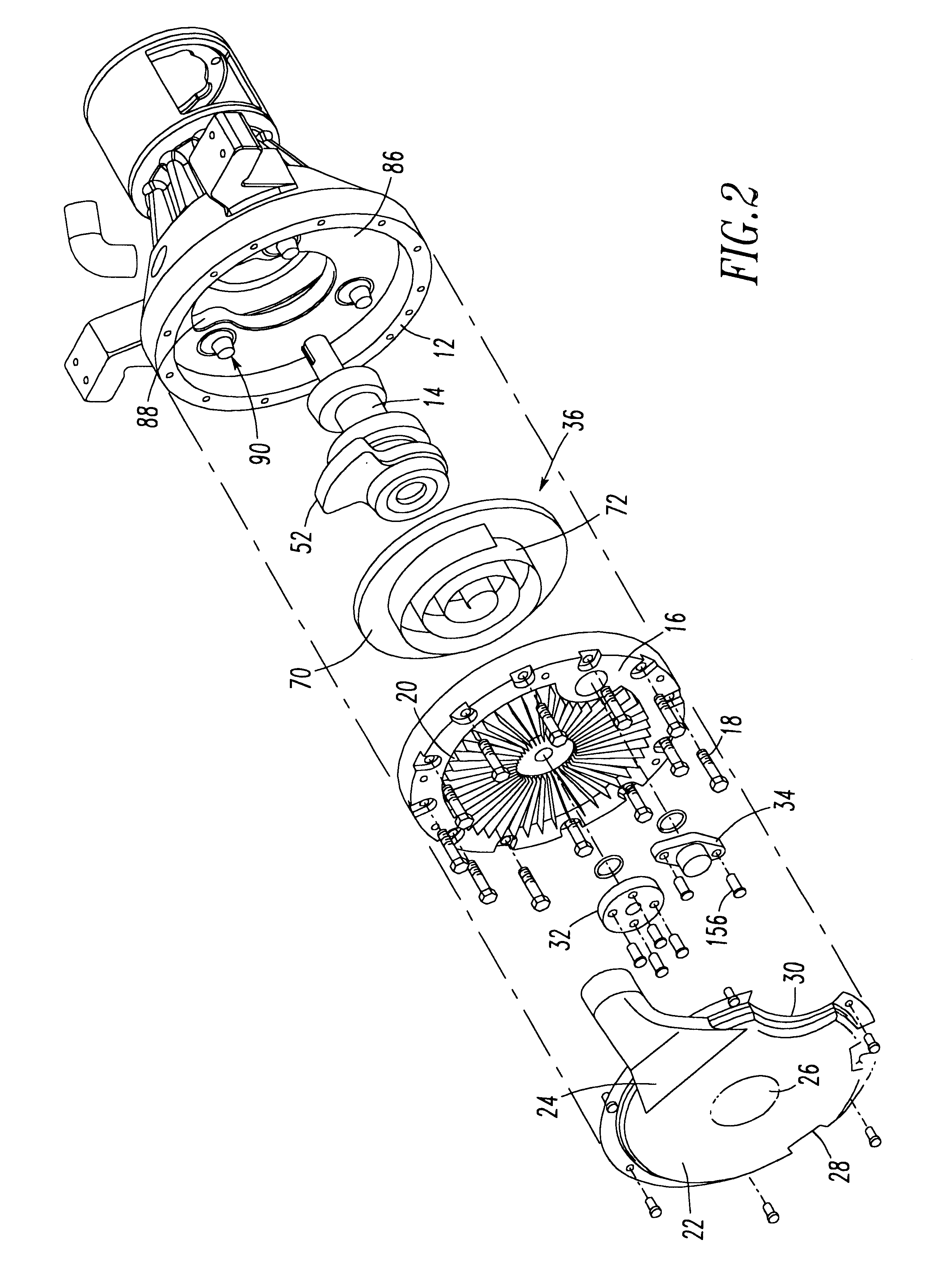

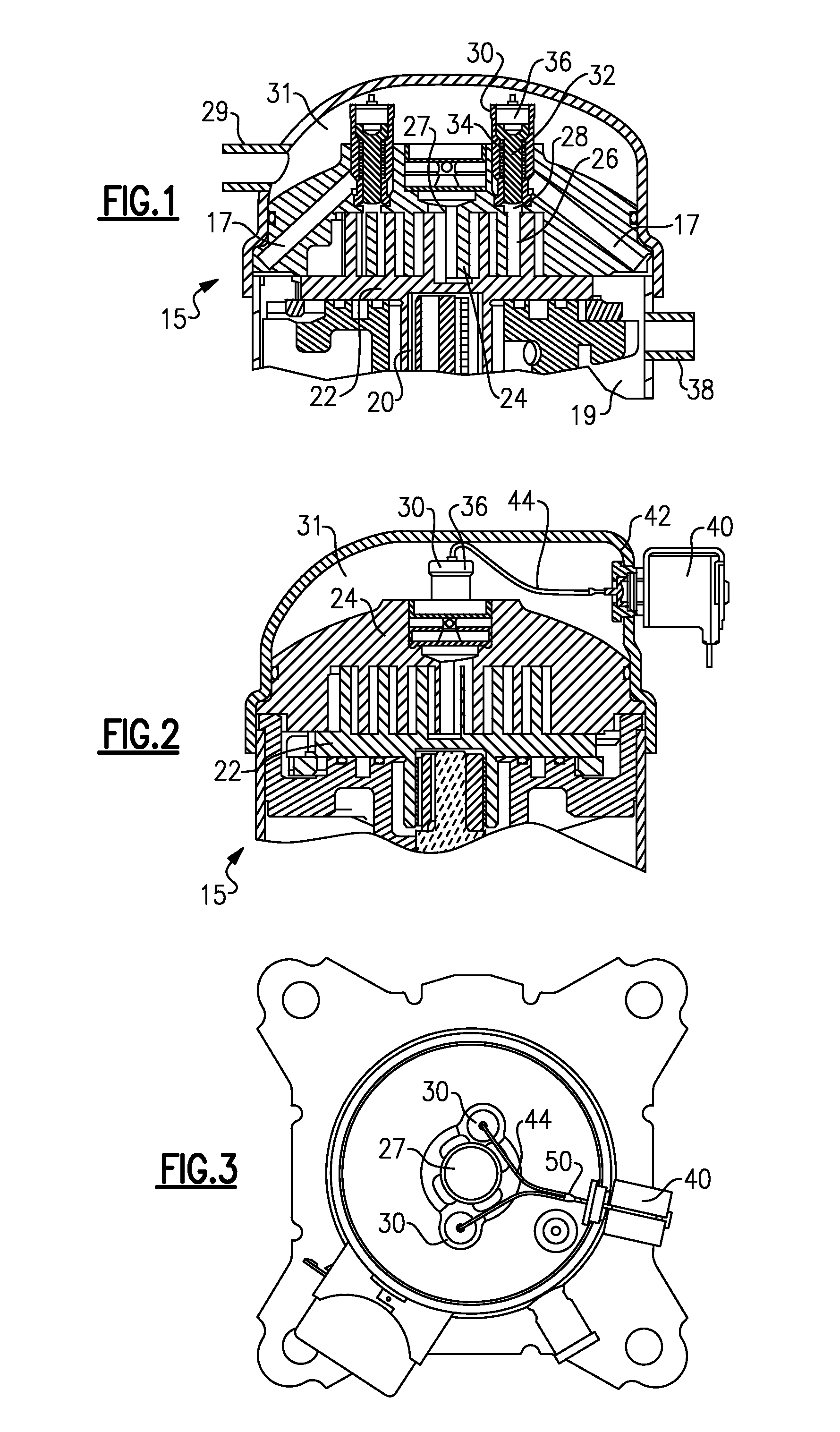

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

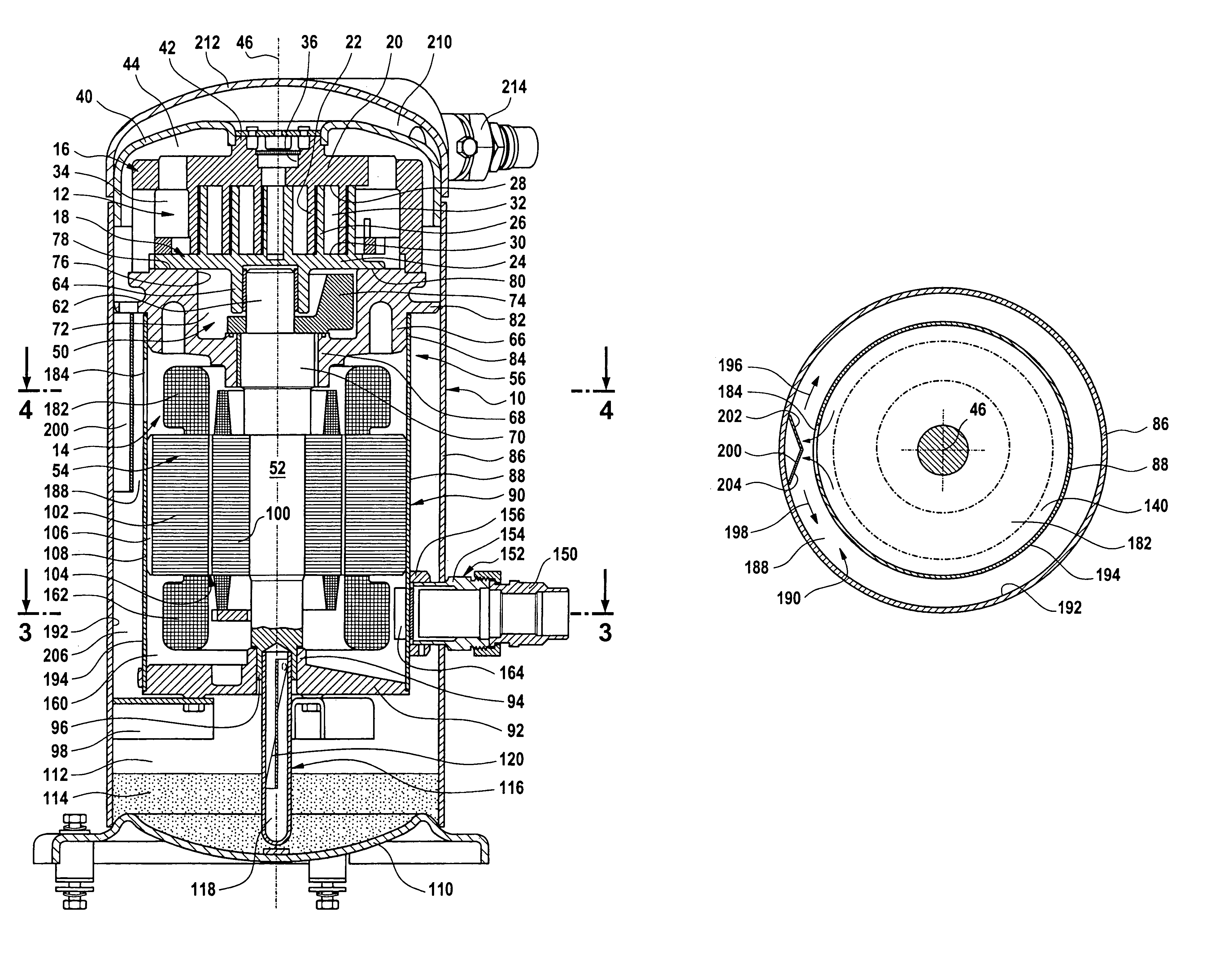

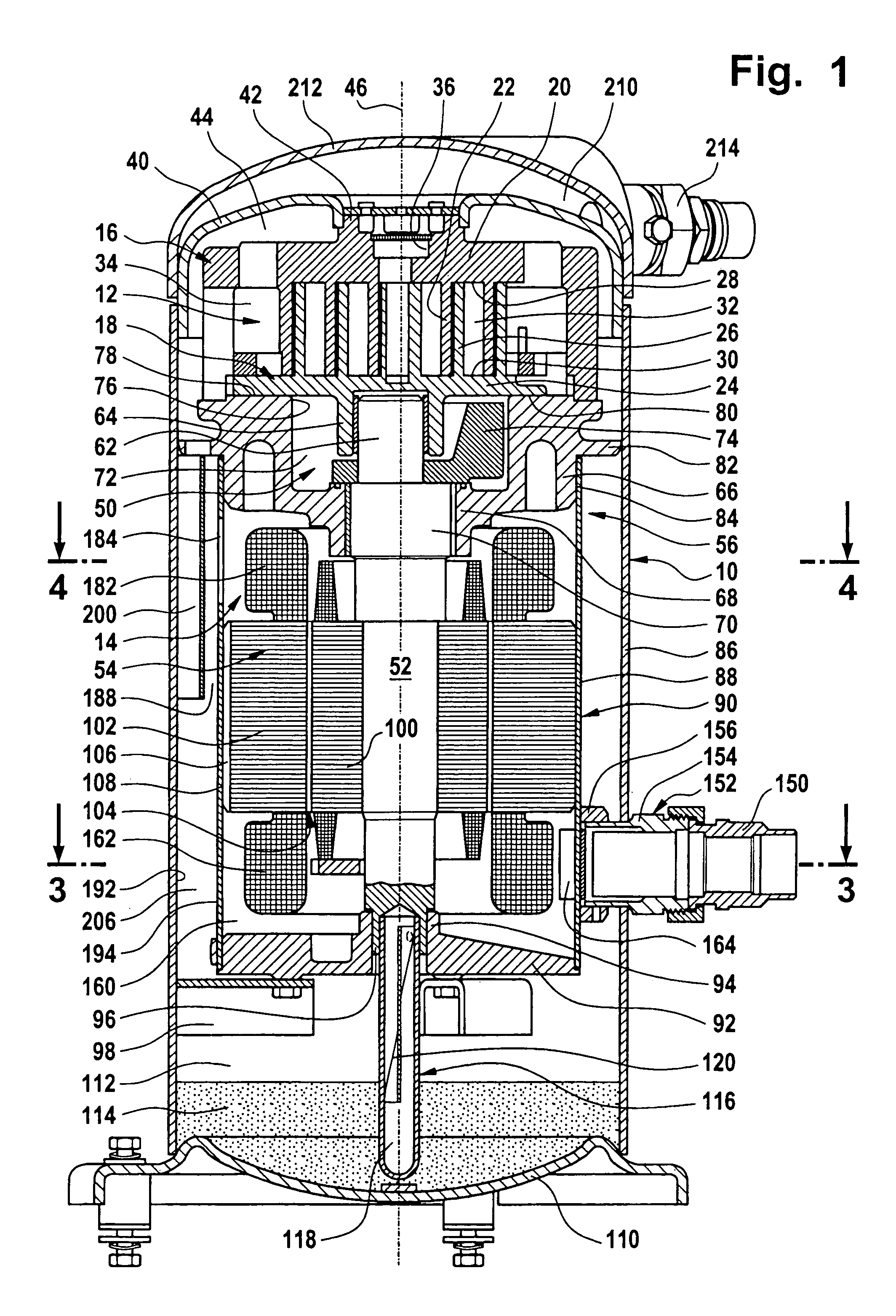

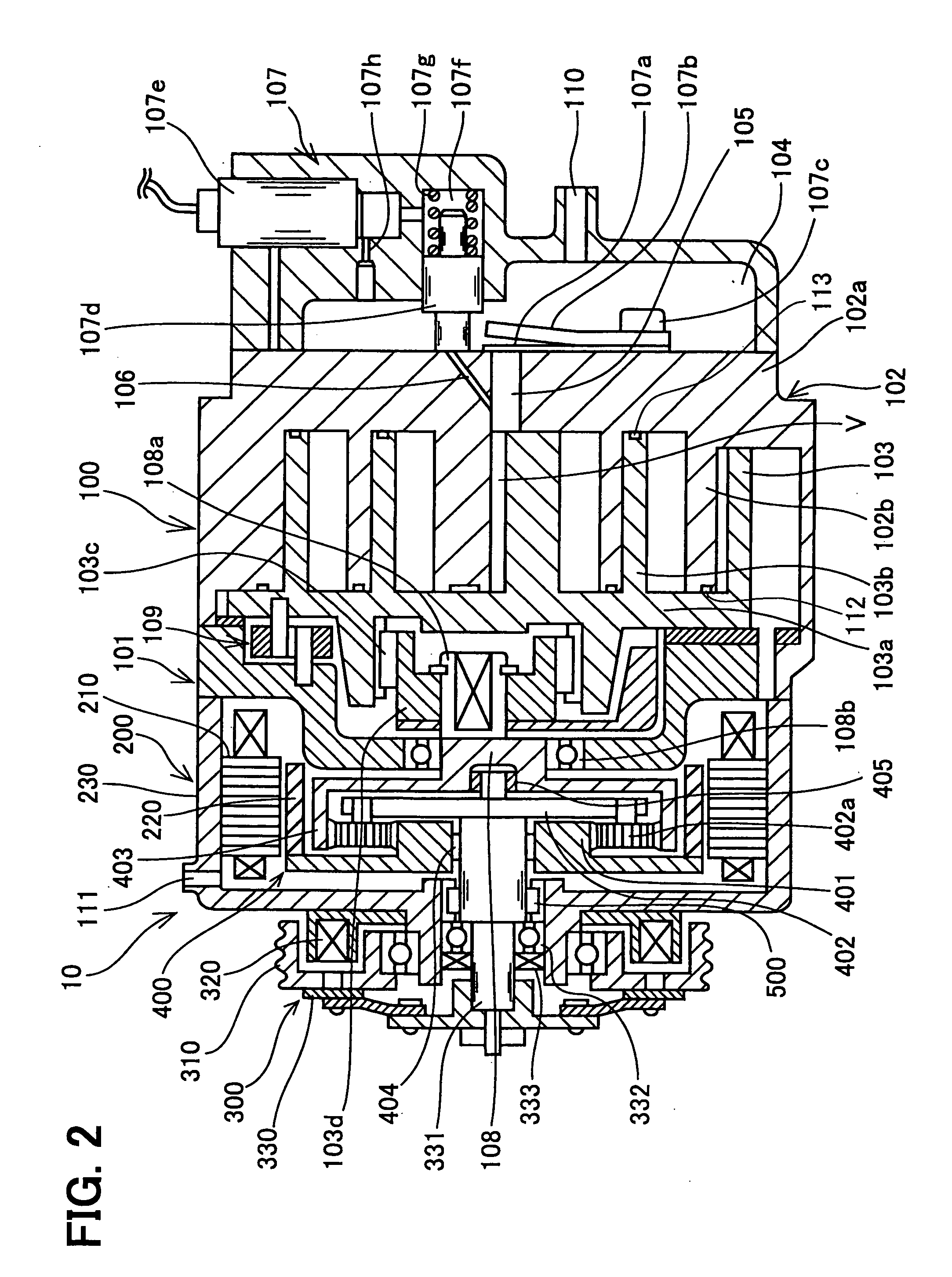

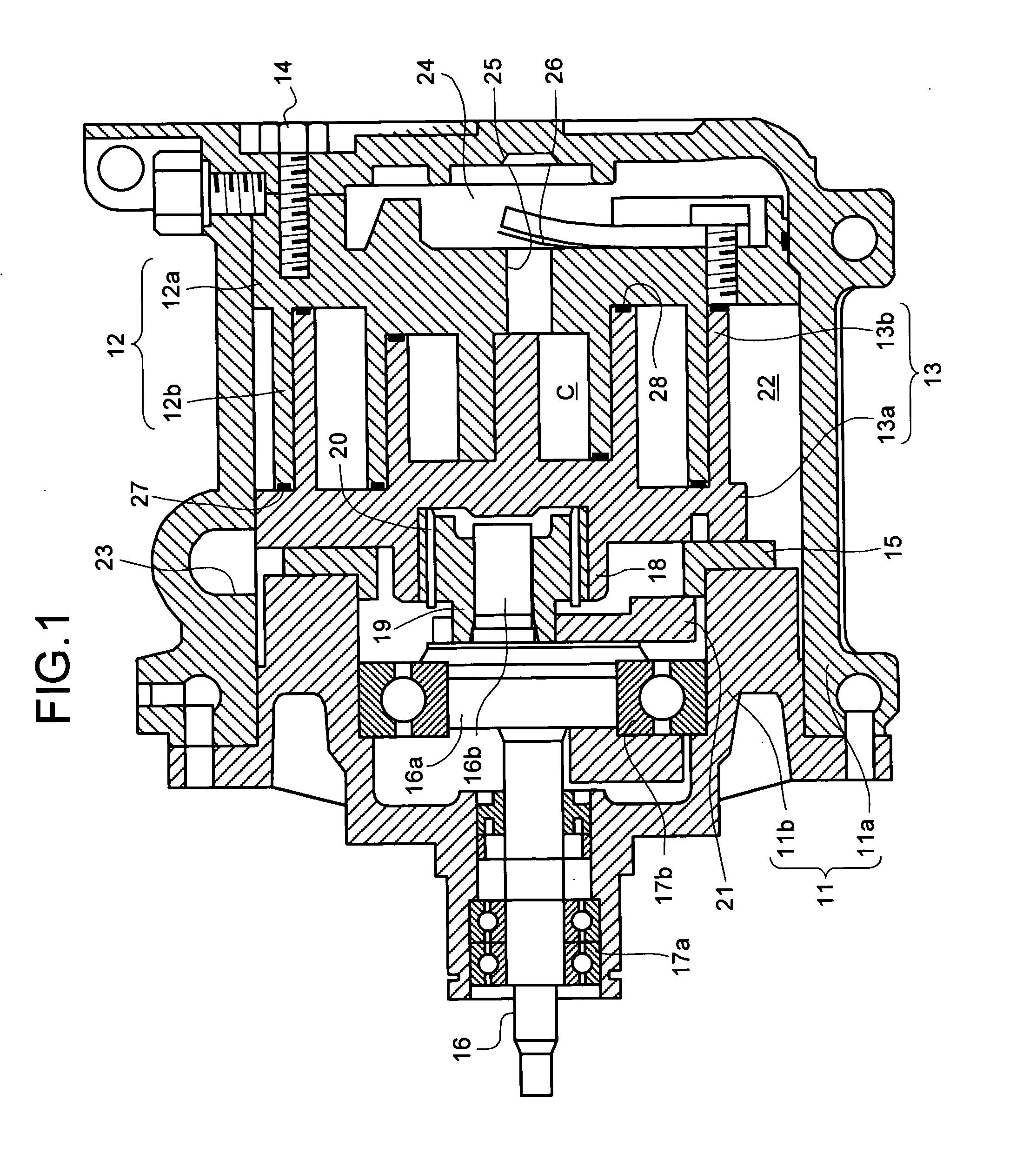

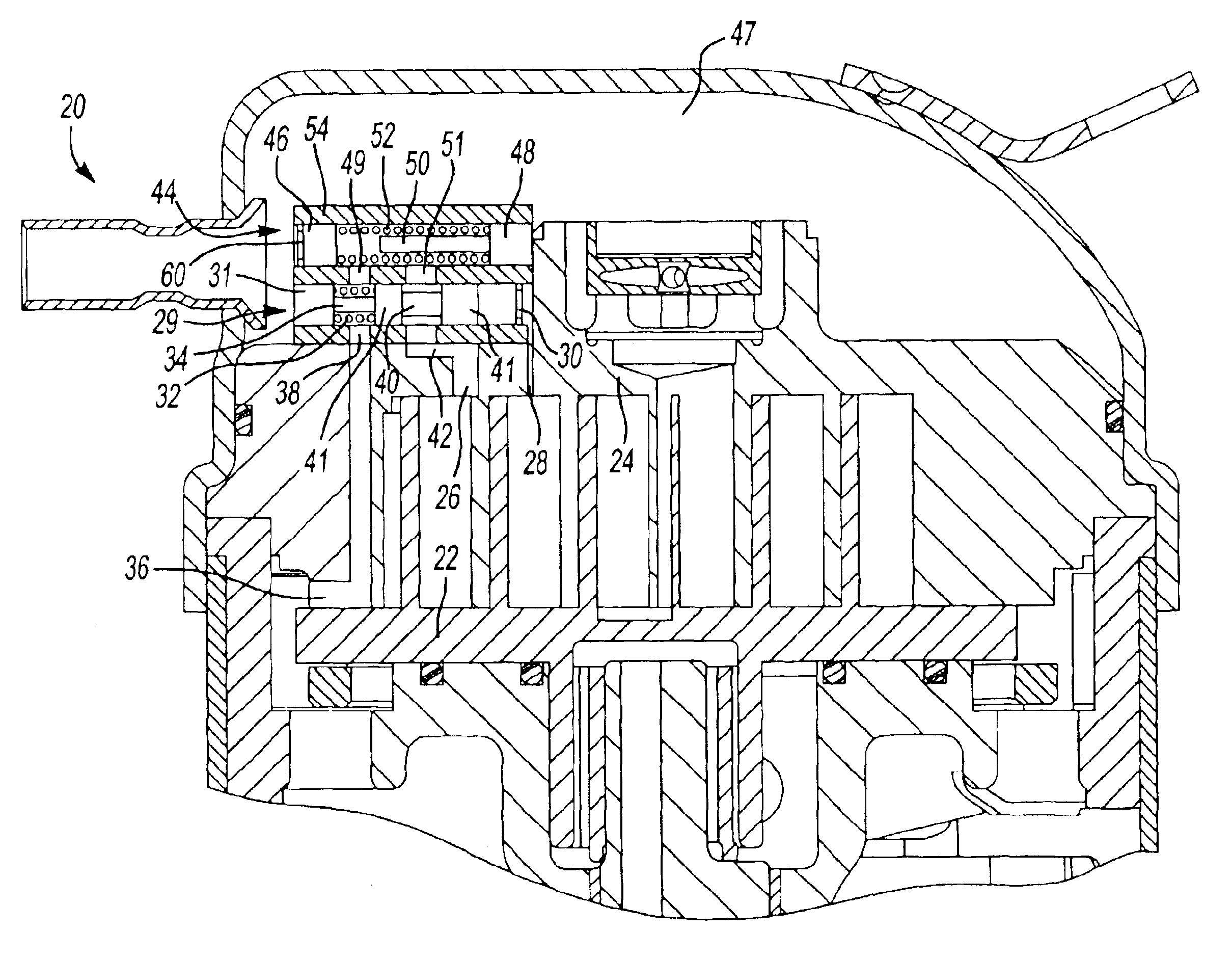

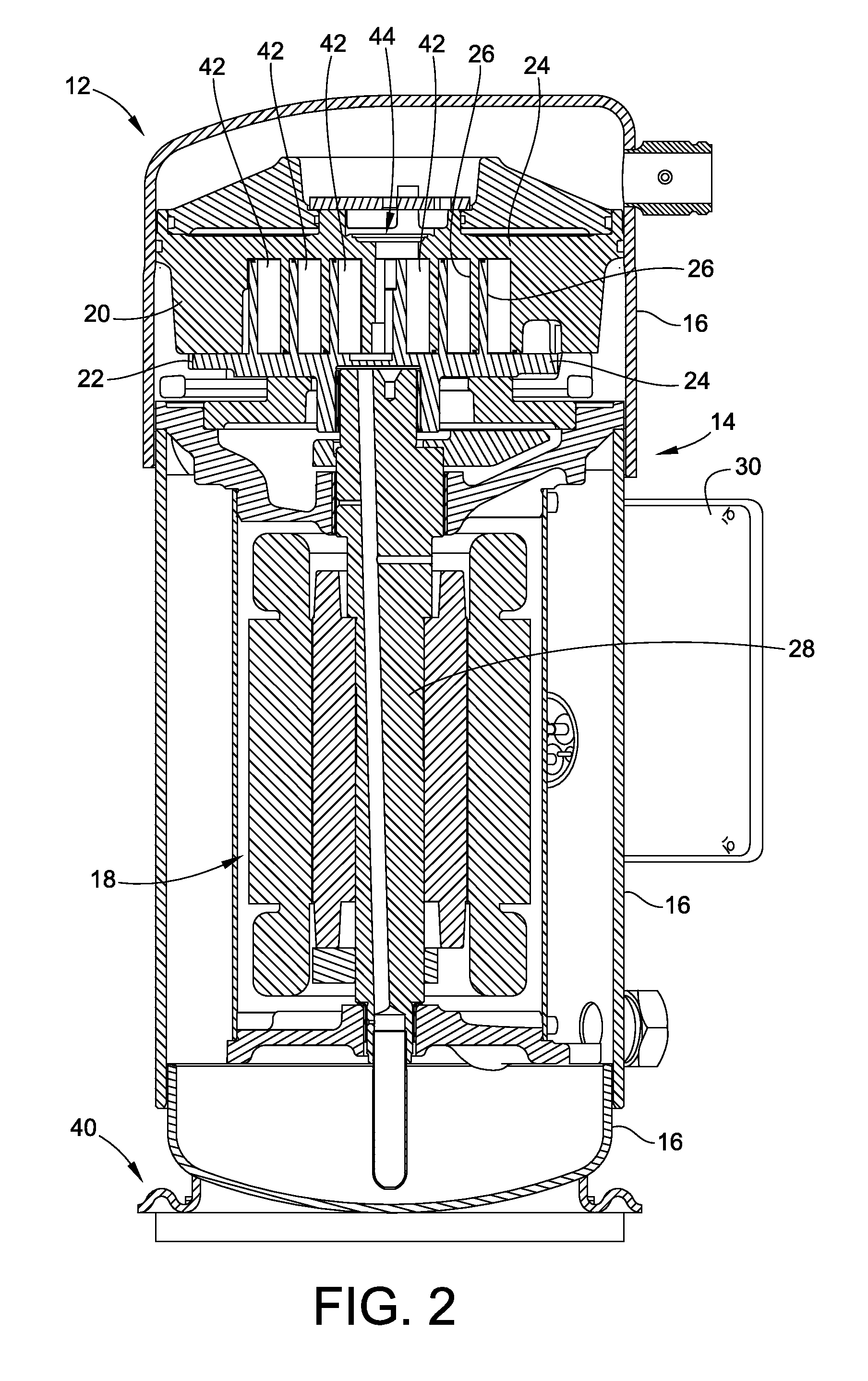

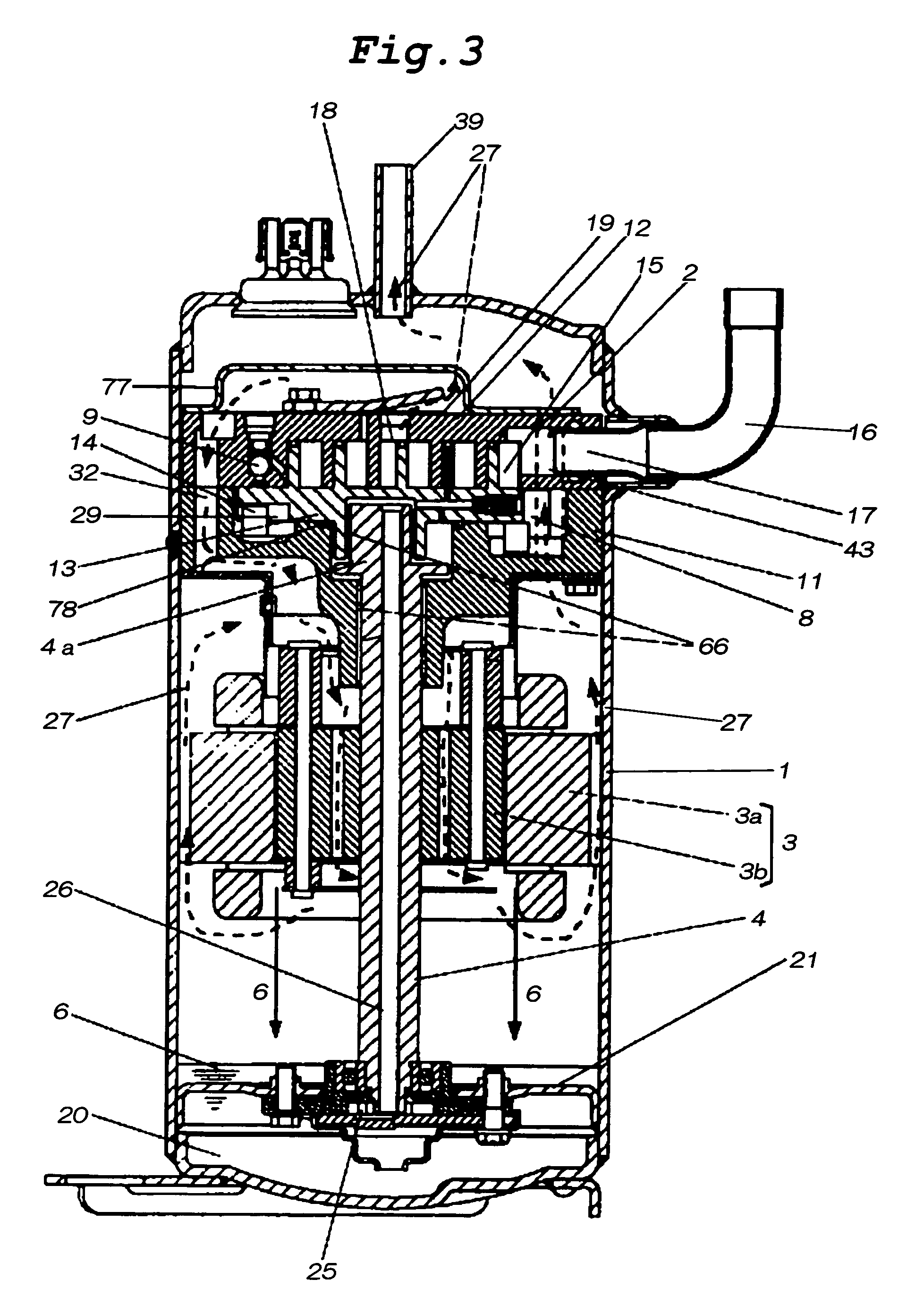

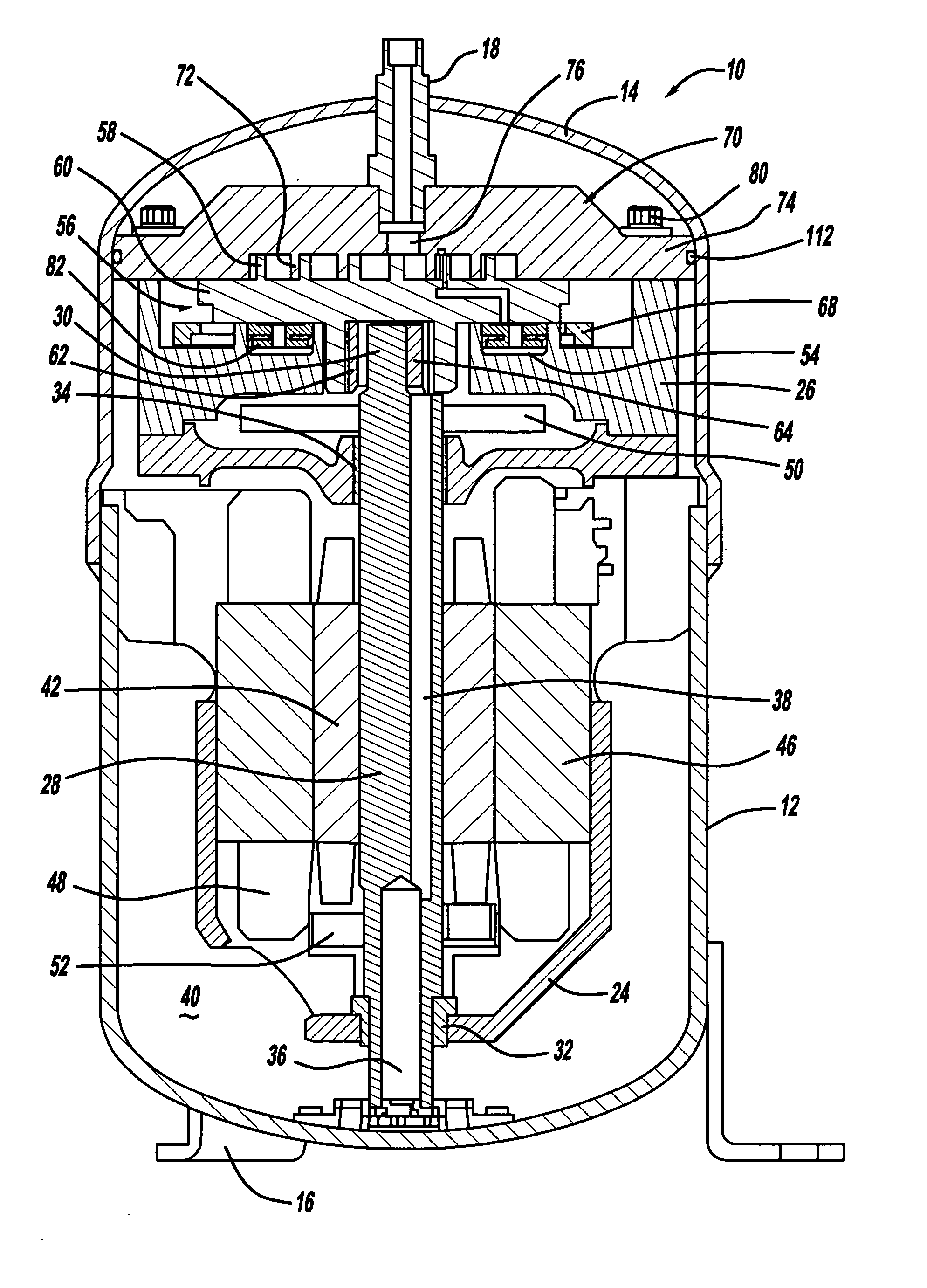

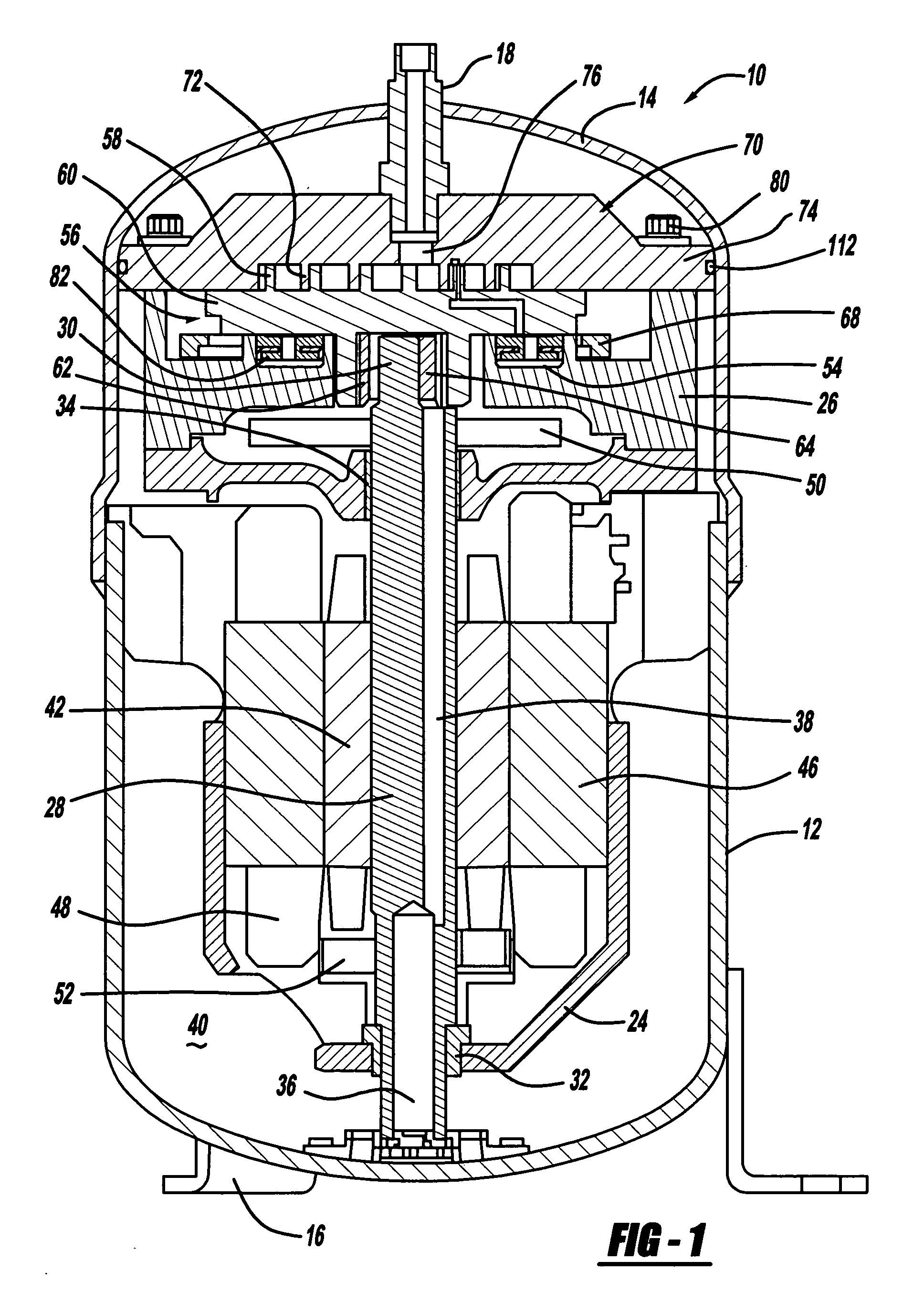

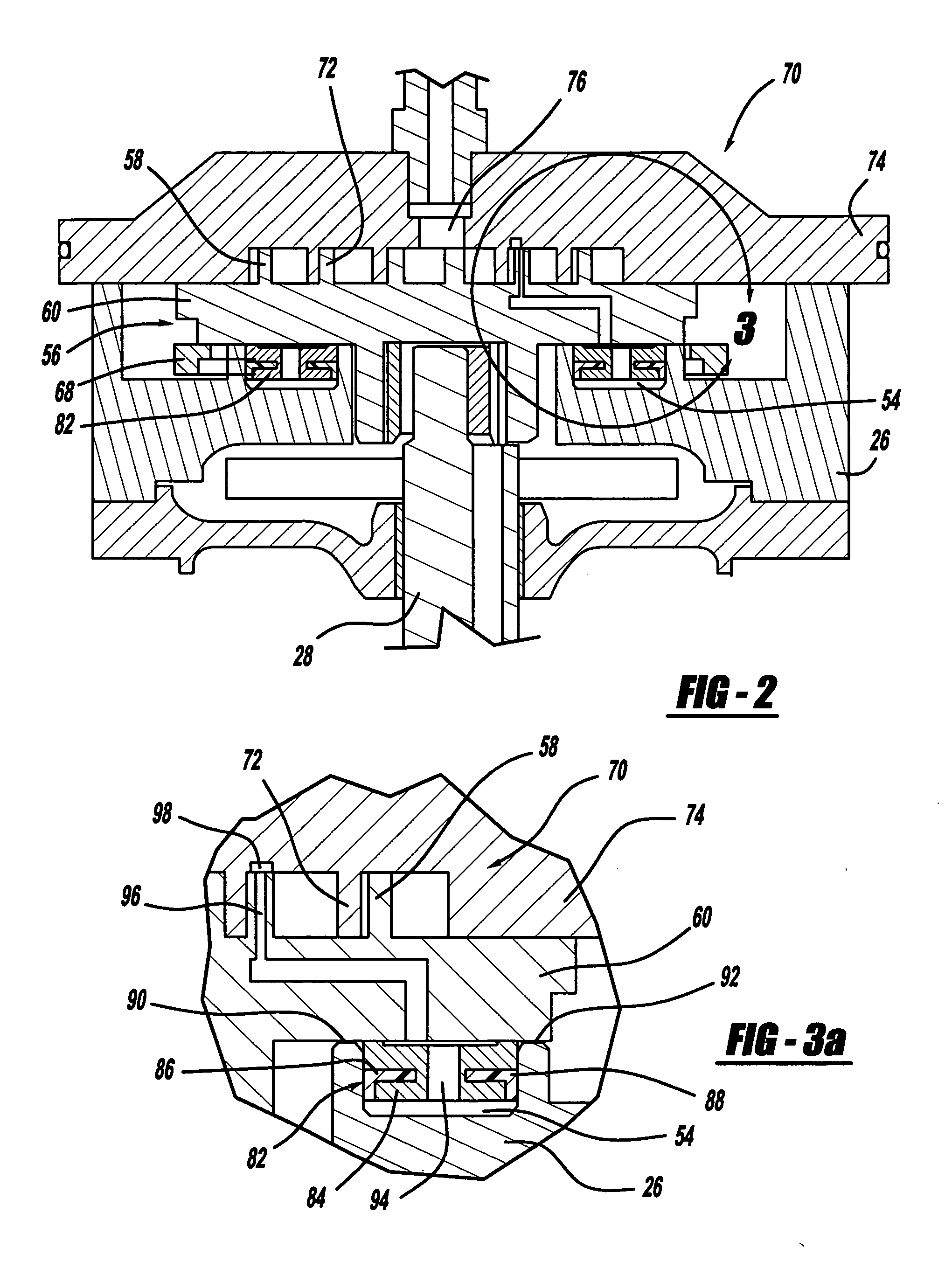

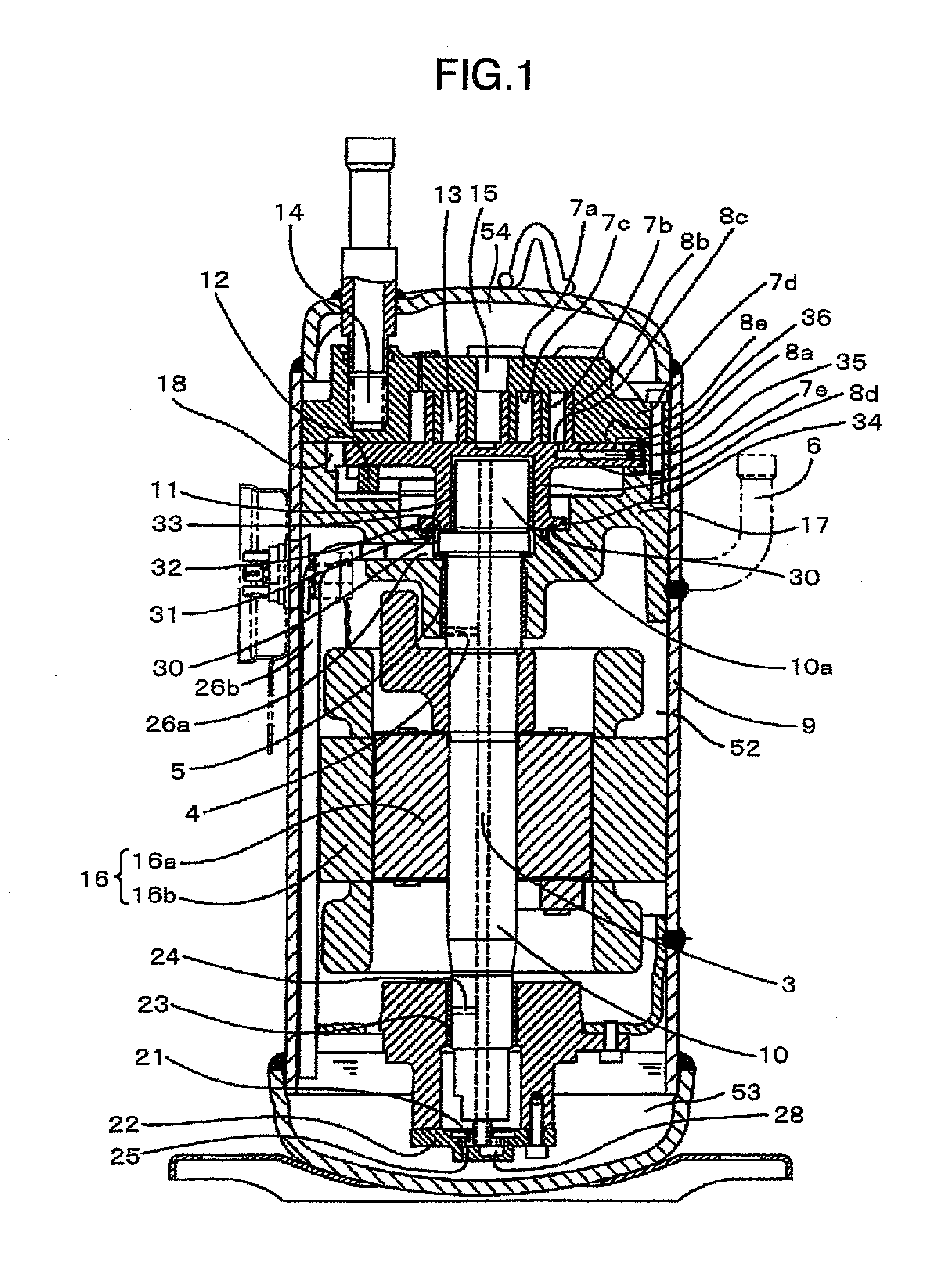

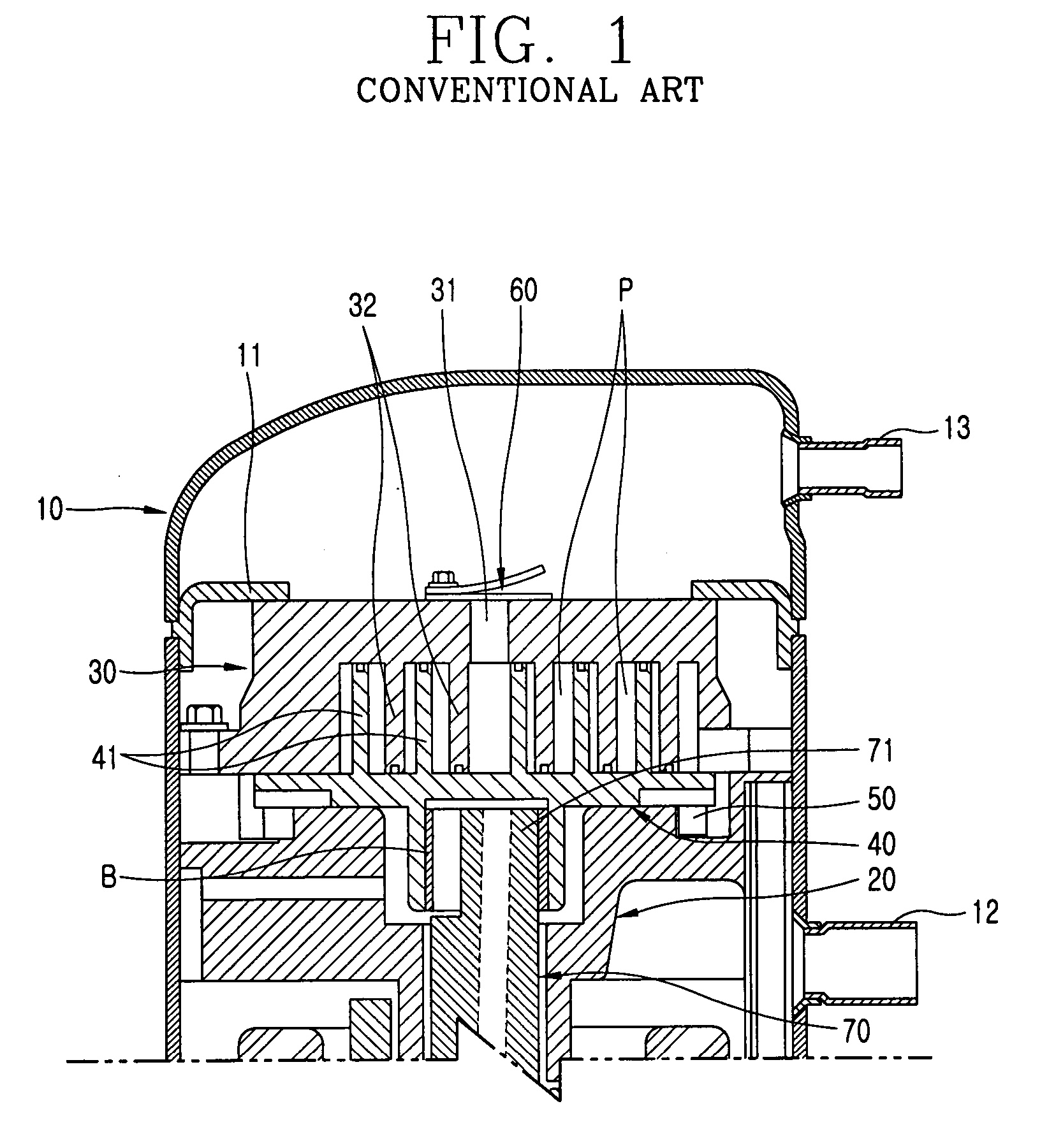

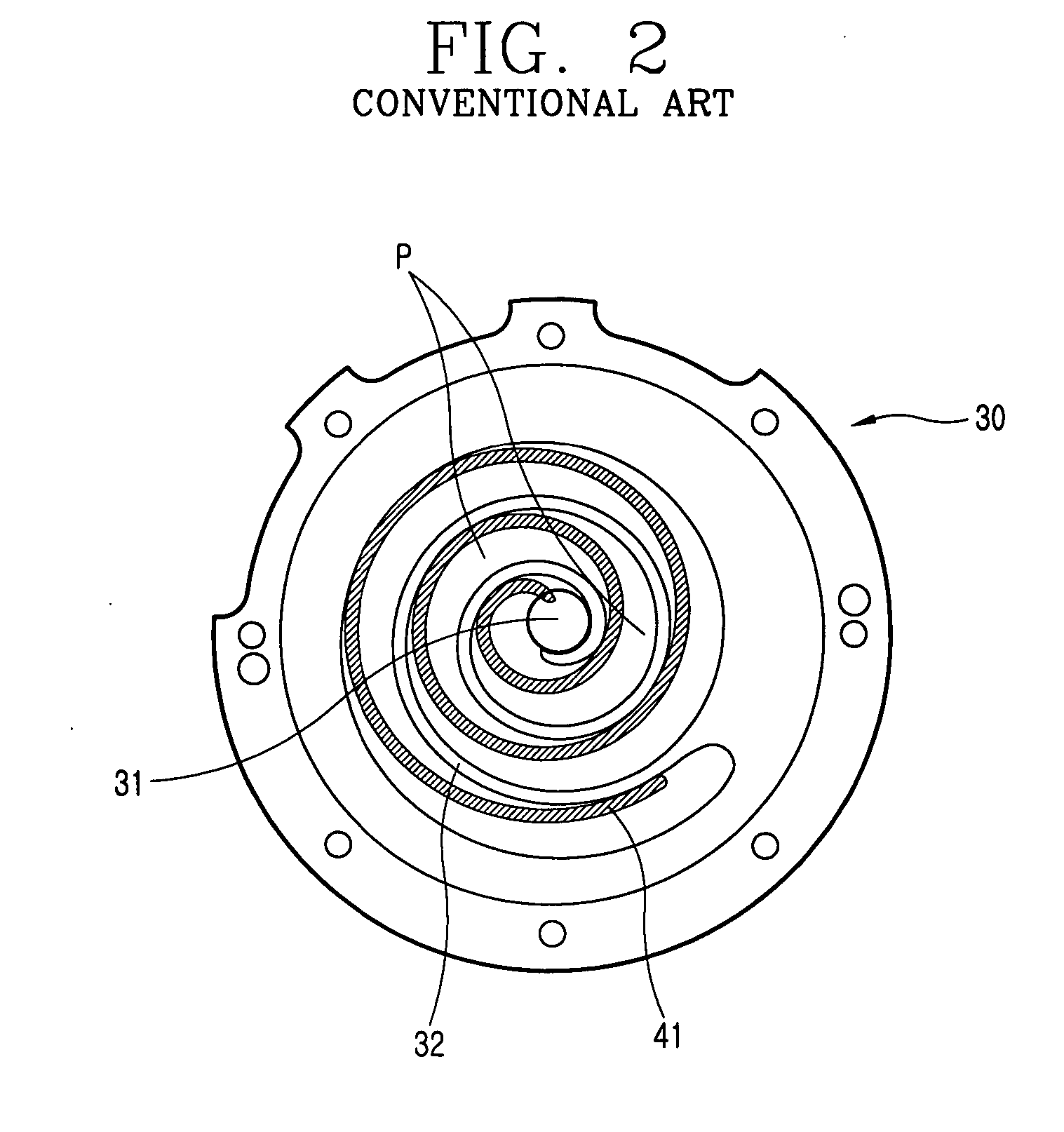

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

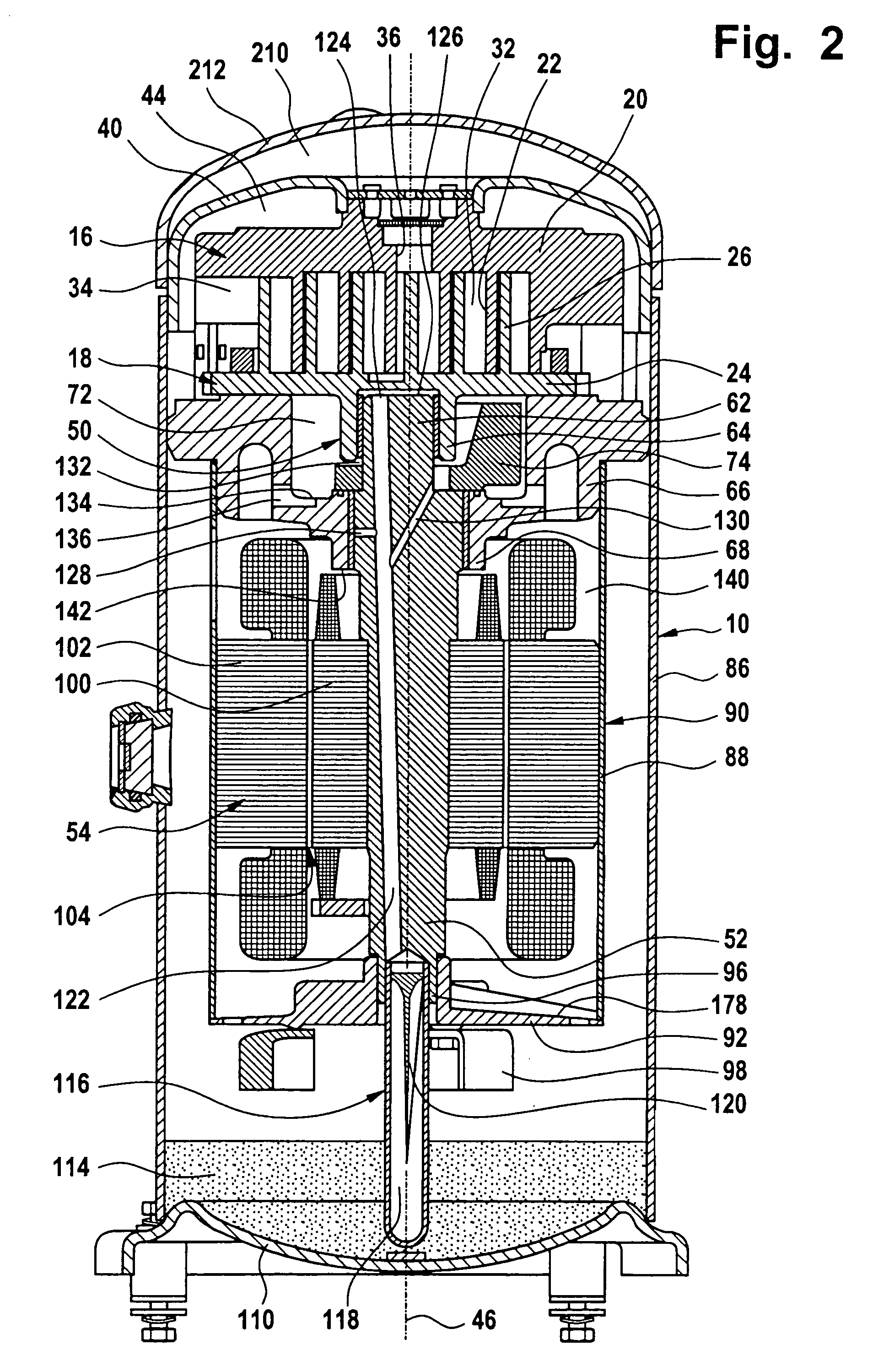

Low emission energy source

Owner:BRIGHTSOURCE ENERGY

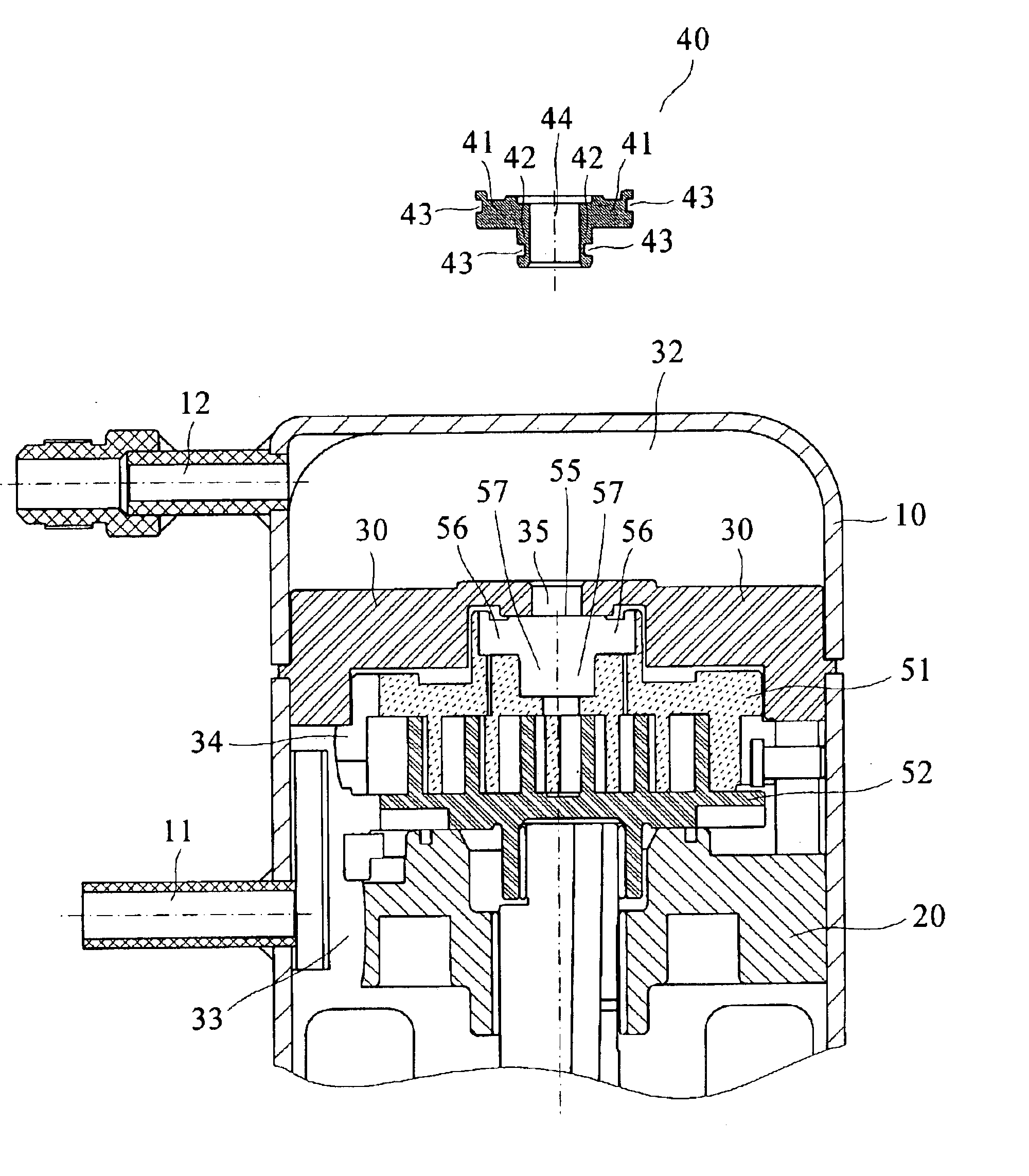

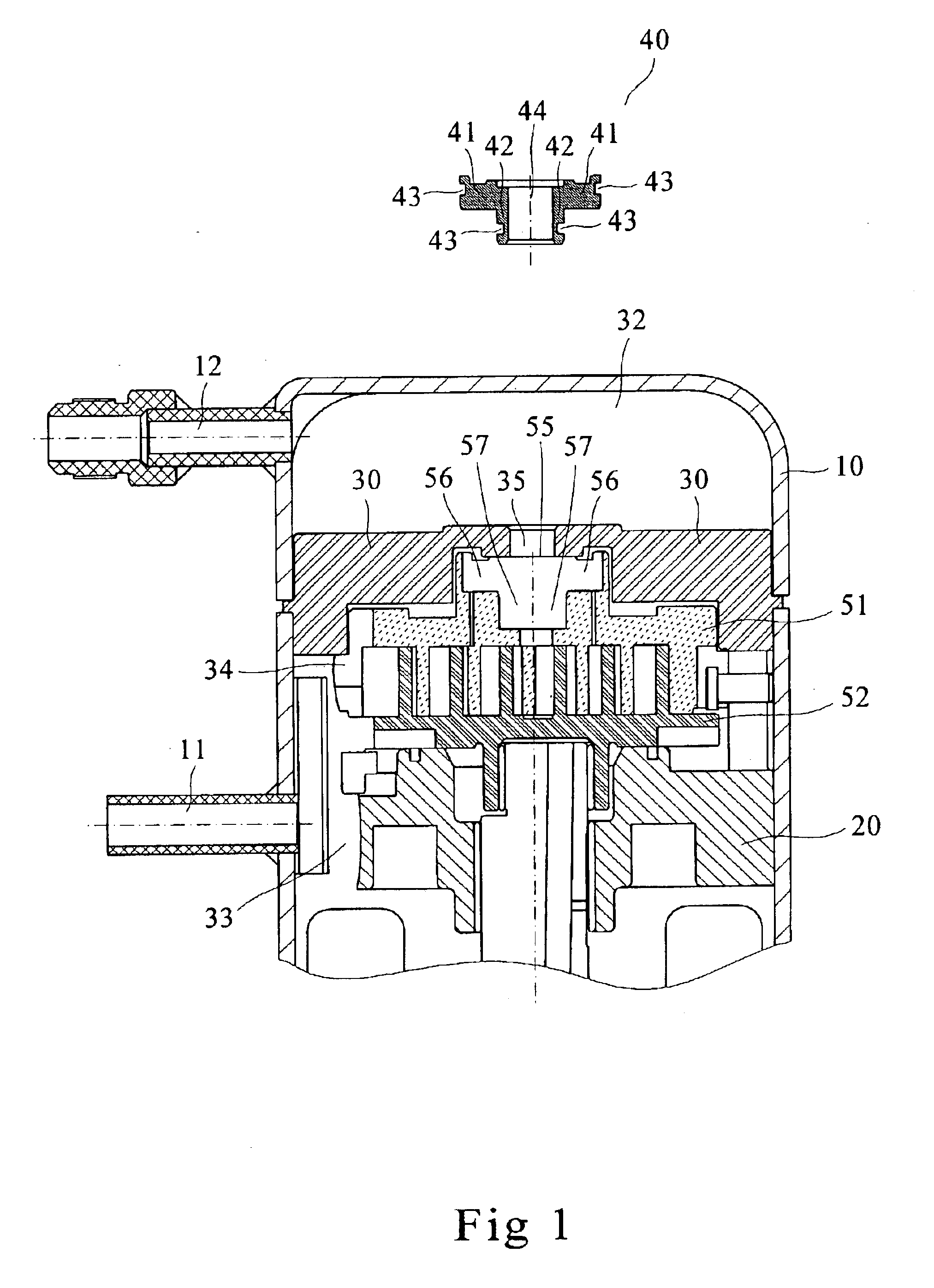

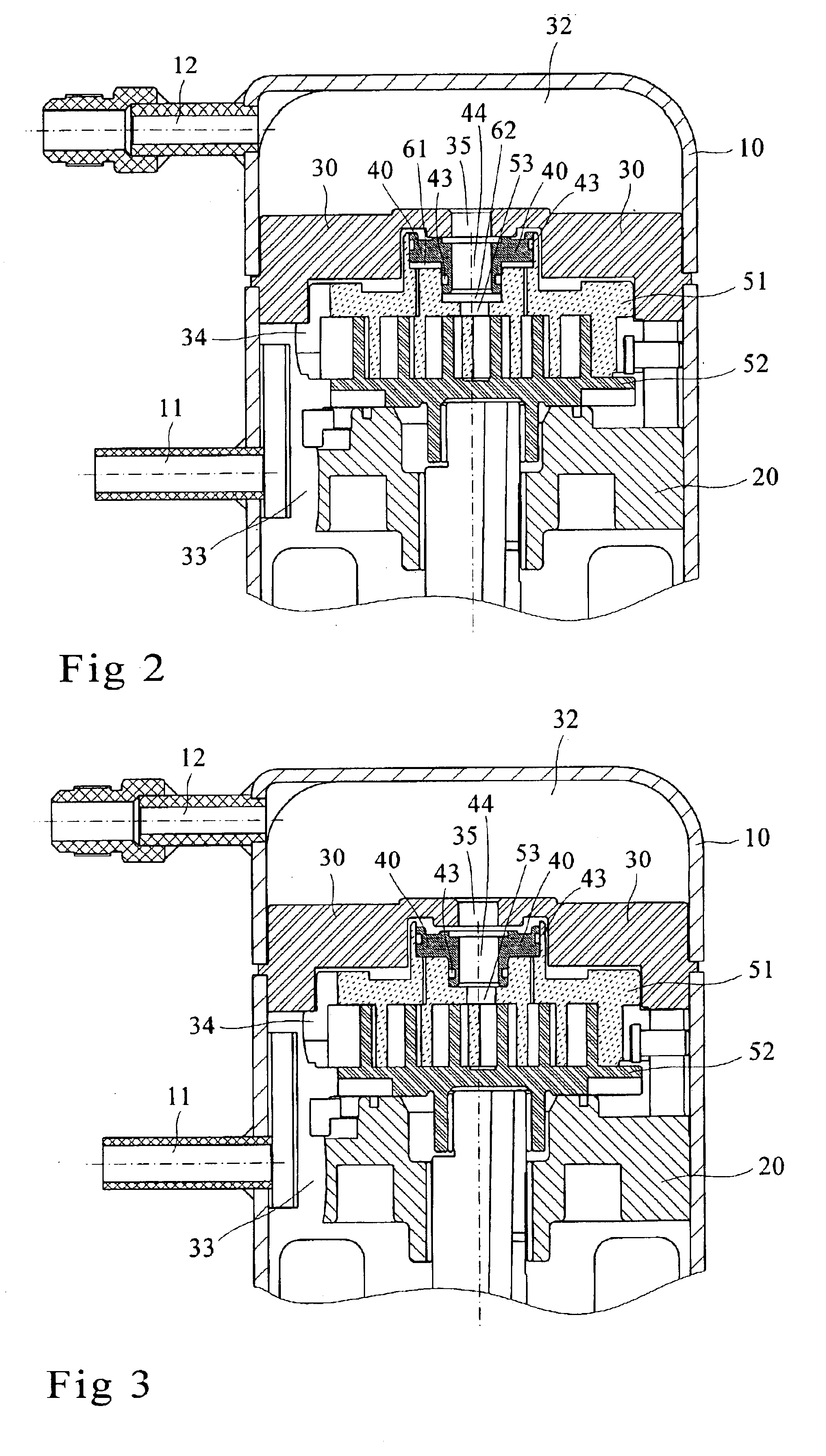

Fluid machine

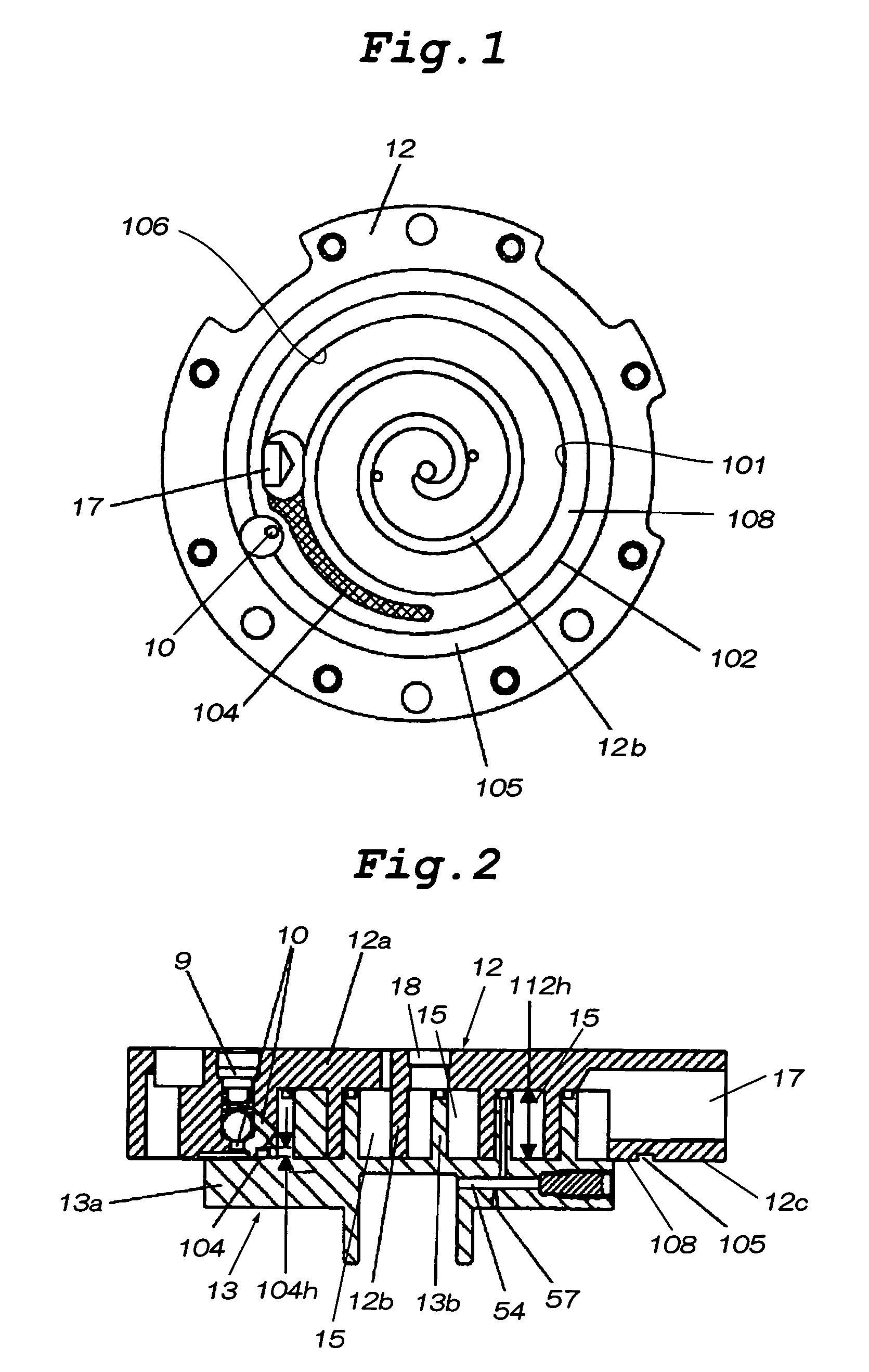

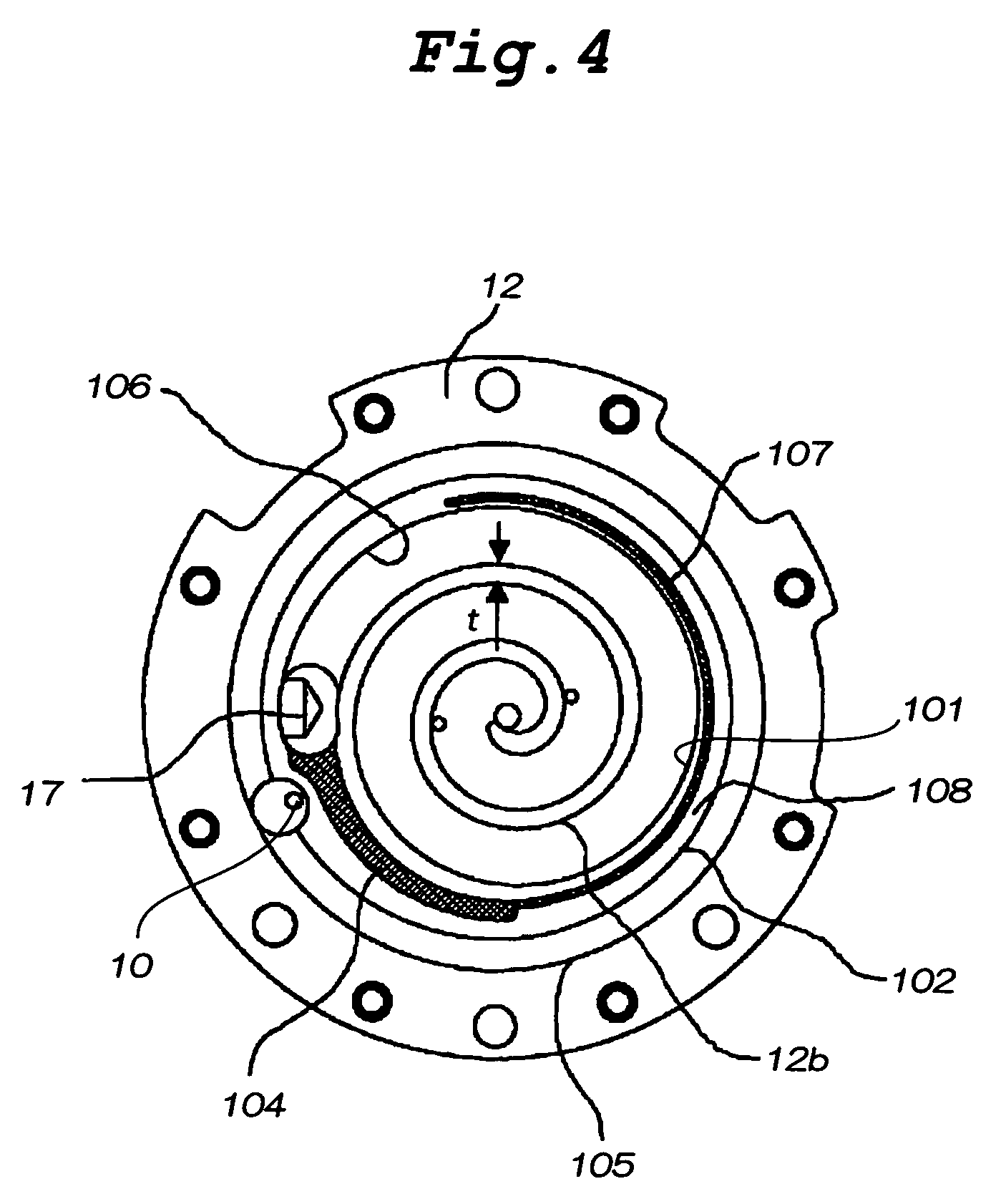

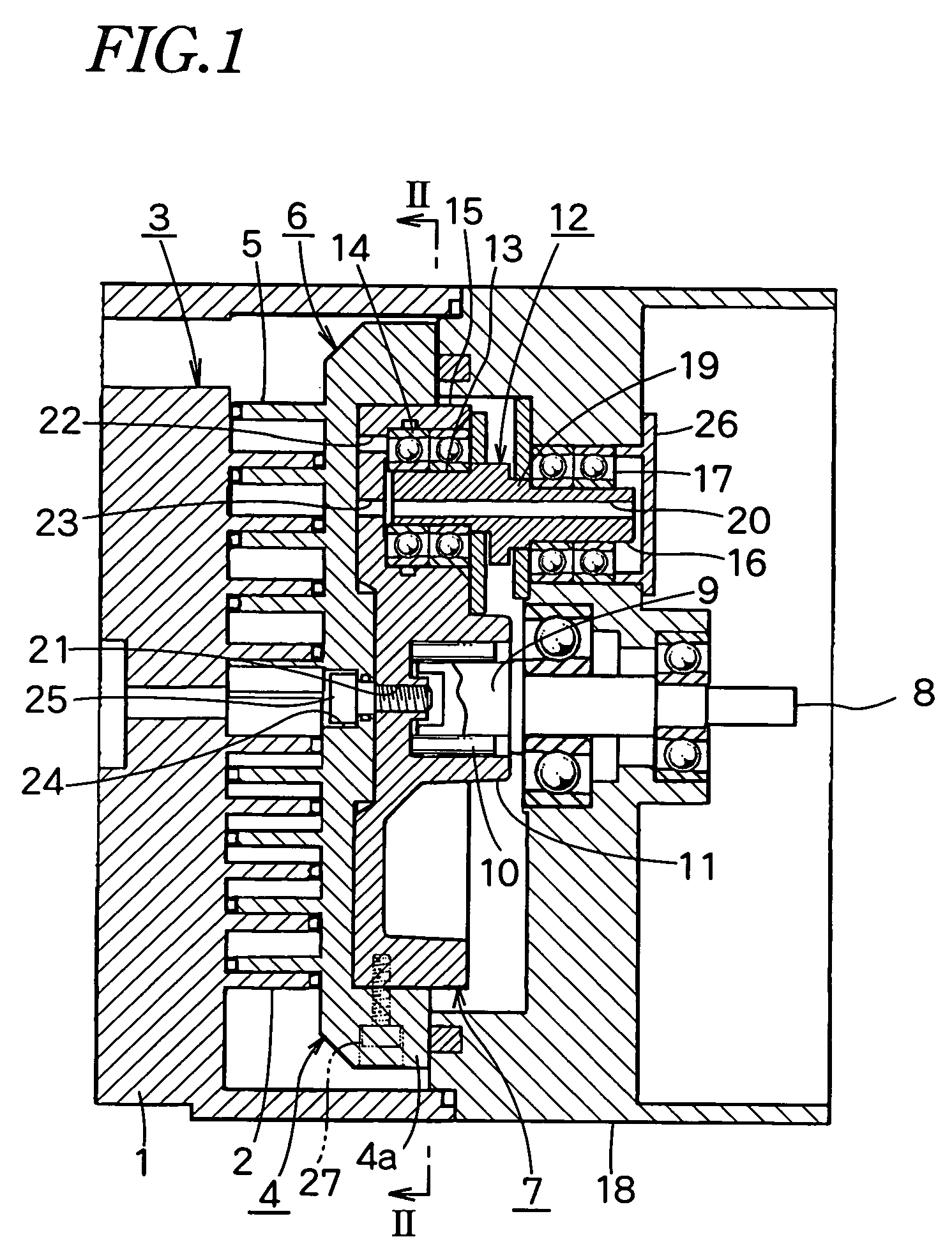

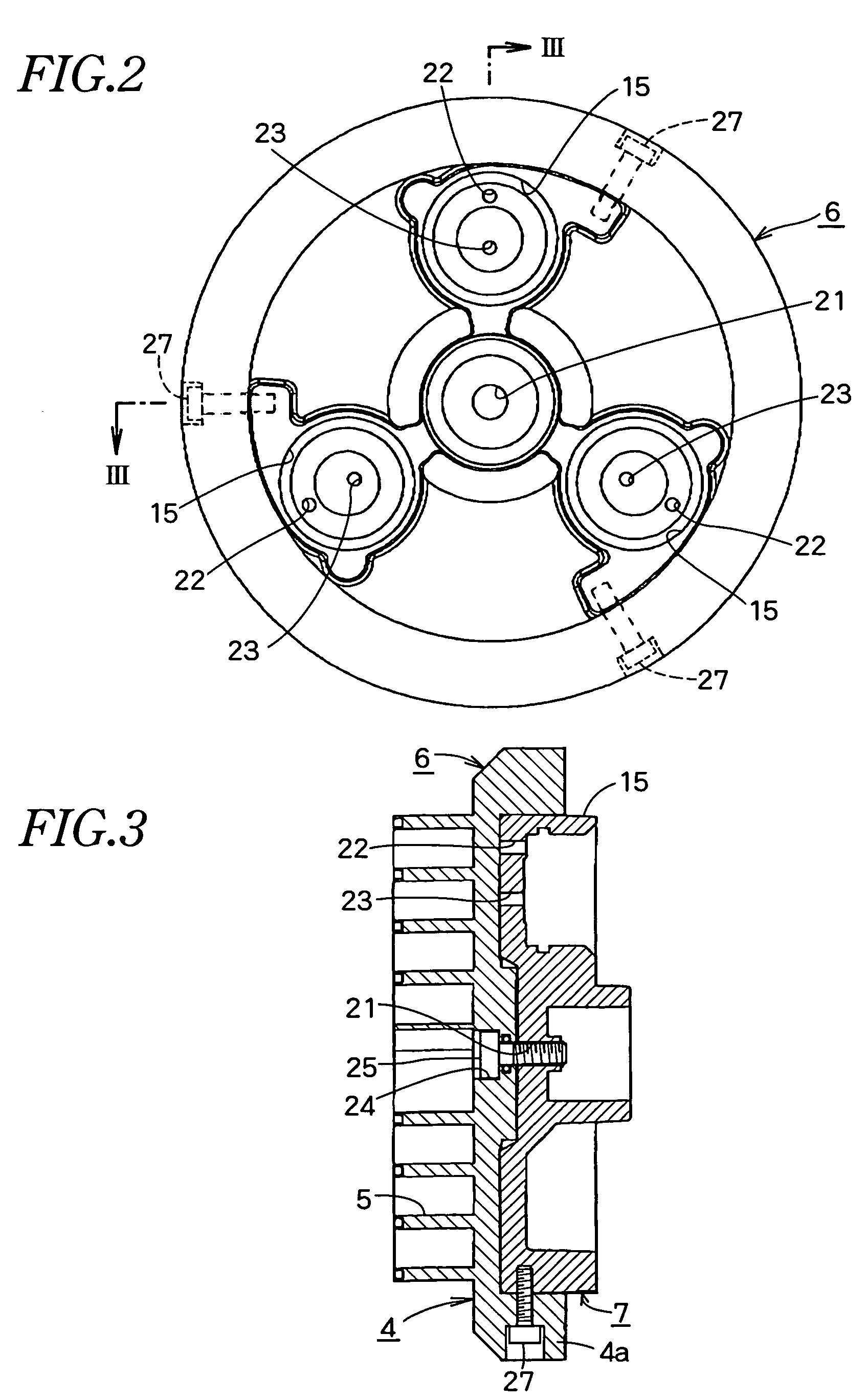

InactiveUS20050214148A1Improve sealingSmall sizeCompressorEngine of arcuate-engagement typeEngineeringSliding contact

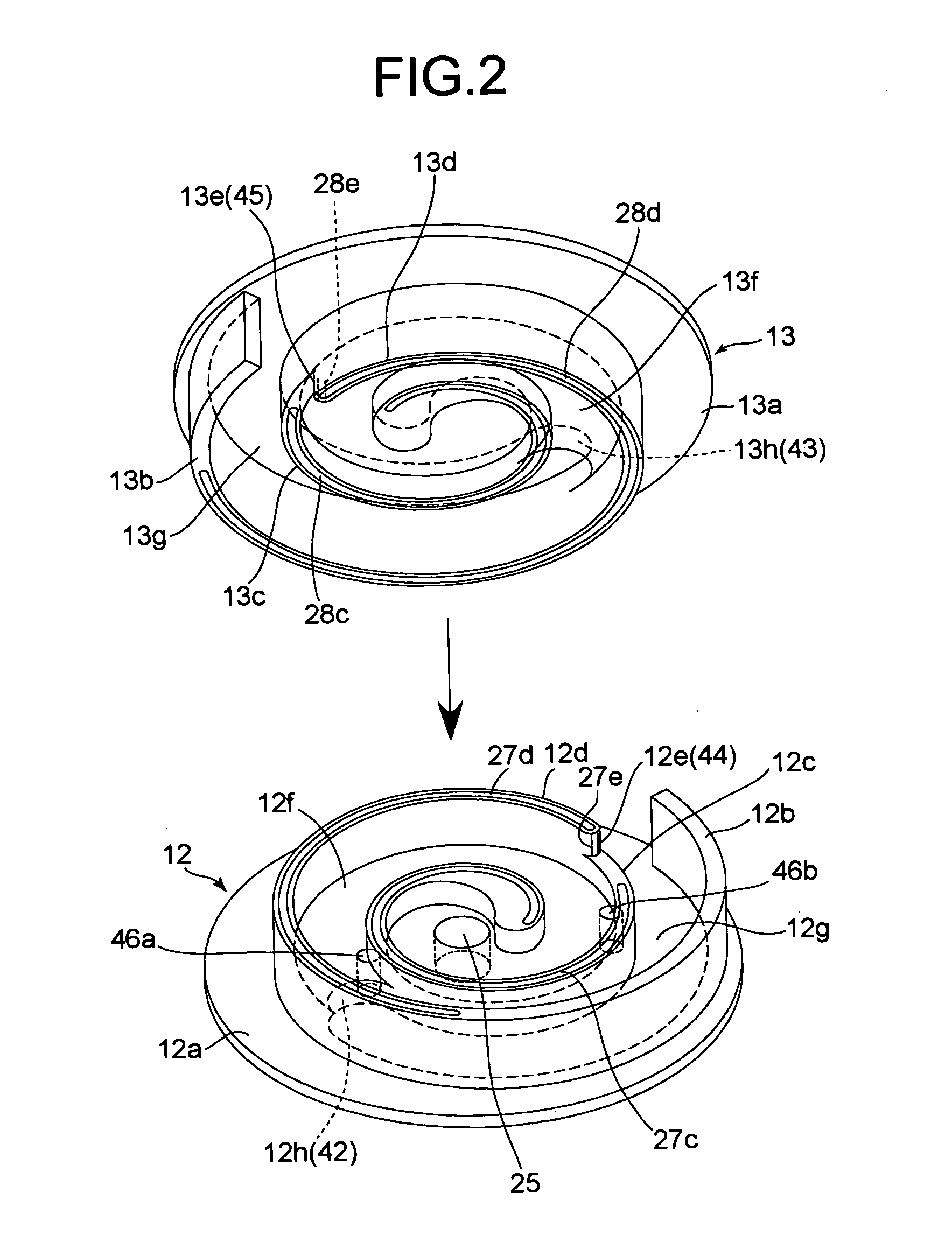

An outer end of a seal element for a fixed scroll is extended to a position close to an end of an inside spiral wall of the fixed scroll, and an outwardly extended portion is formed at an outer periphery of a disc-shaped base plate of a movable scroll, so that a bottom surface of the movable scroll is always kept in a sliding contact entirely with the seal element during the orbital movement of the movable scroll. A thickness of the outwardly extended portion formed at the outer periphery of the disc-shaped base plate is made smaller than that of the disc-shaped base plate, so that the weight of the fluid machine can be smaller.

Owner:NIPPON SOKEN +1

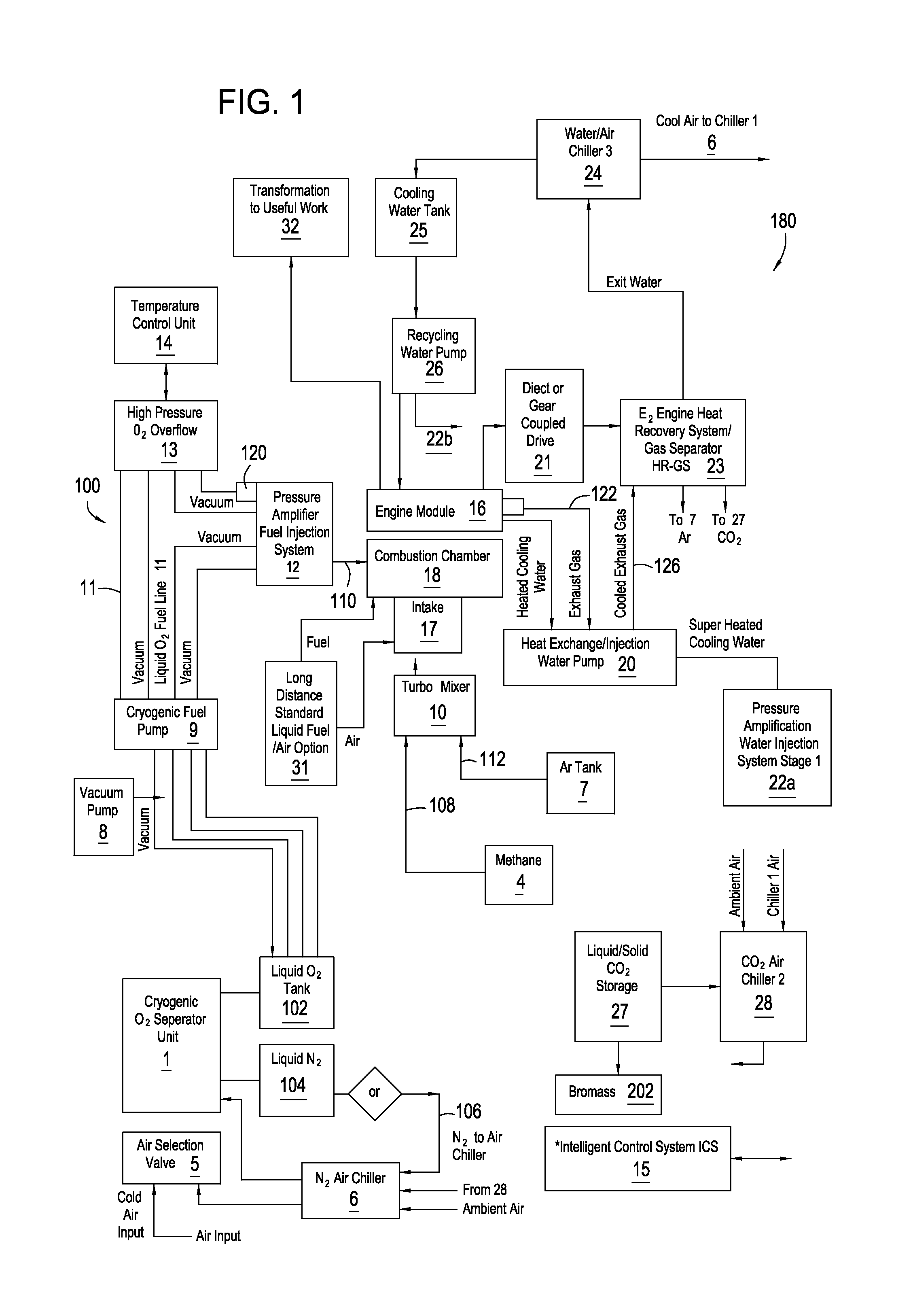

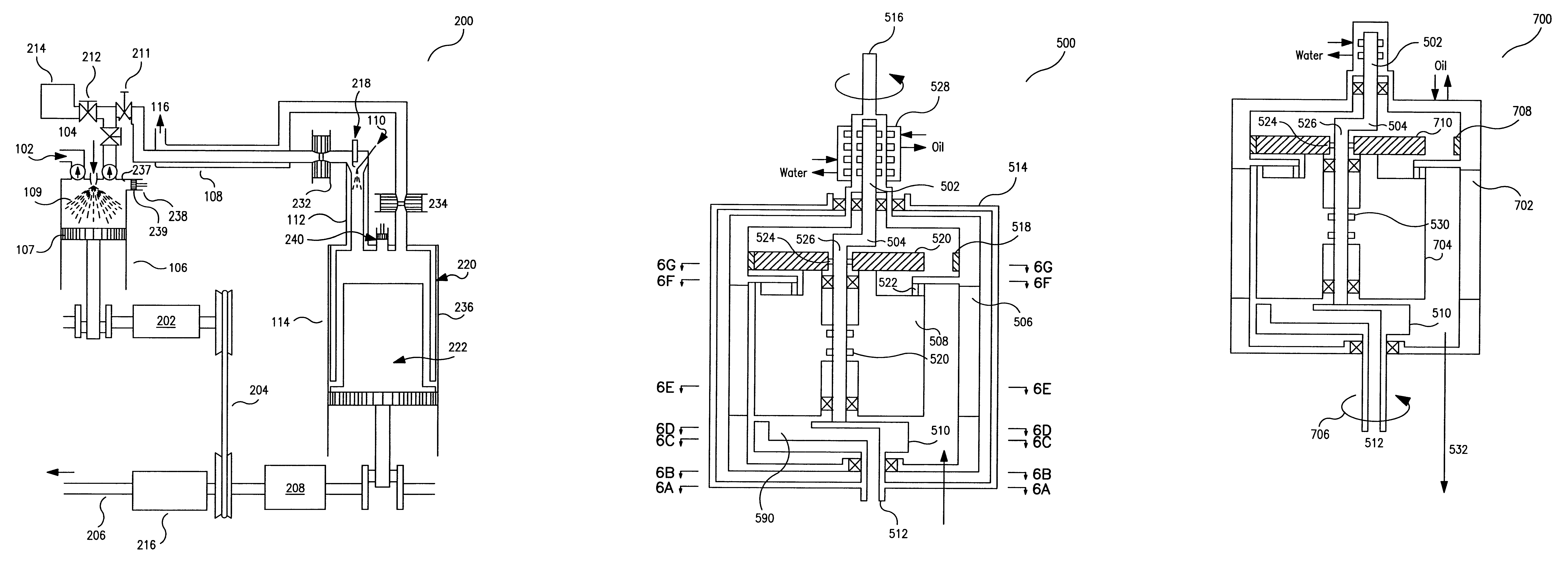

Quasi-isothermal Brayton Cycle engine

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

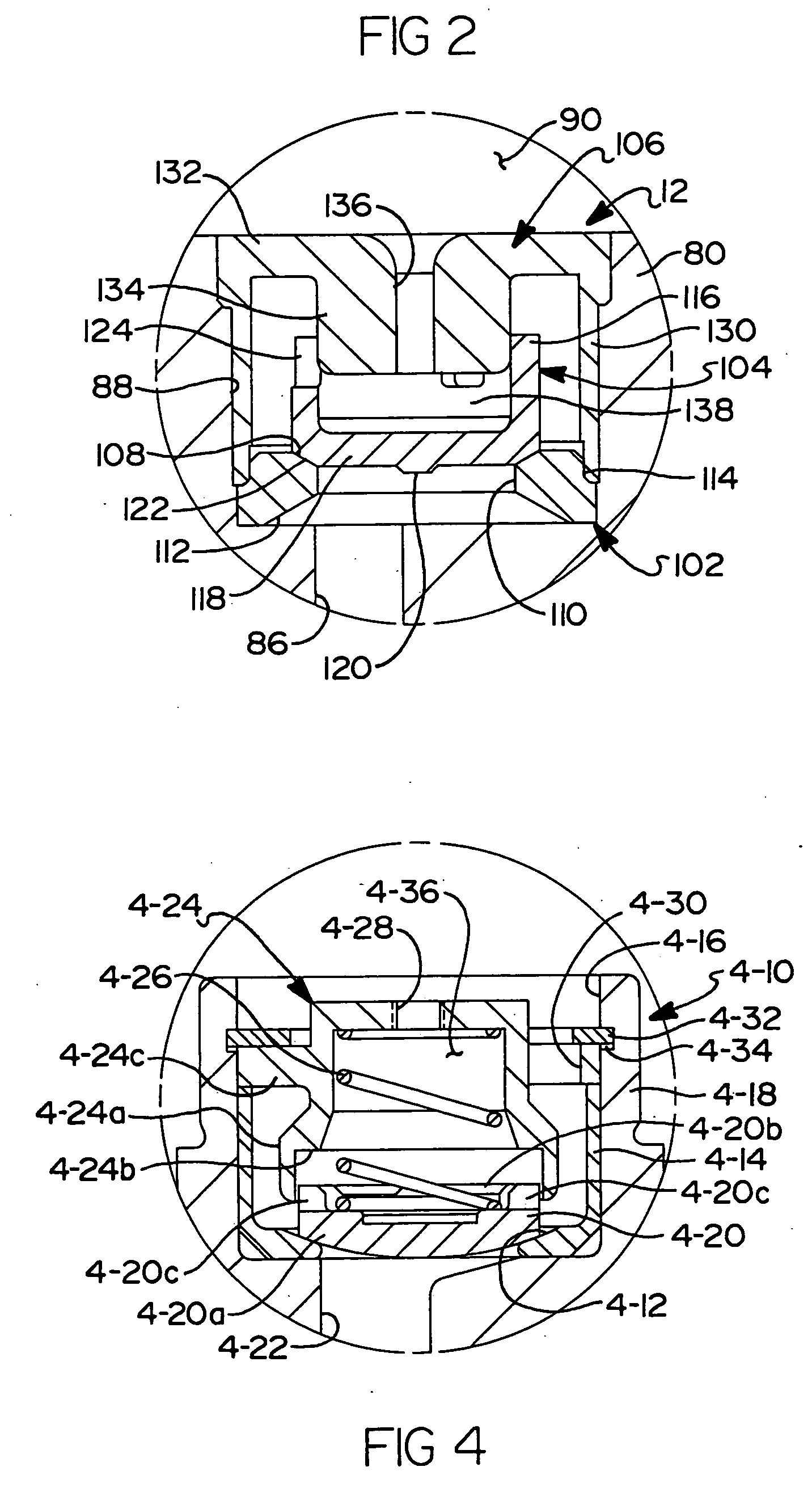

Discharge valve

InactiveUS6171084B1Easy to operateRaise the possibilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringValve seat

A compressor assembly includes a shell which defines a discharge chamber. A discharge valve assembly is attached to the shell in communication with the discharge chamber. The discharge valve assembly includes a stamped or coined valve seat, a drawn tubular element and a stamped valve member. The stamping, drawing and coining operations used to manufacture the discharge valve assembly significantly reduce the manufacturing costs for the discharge valve assembly.

Owner:EMERSON CLIMATE TECH INC

Scroll compressor

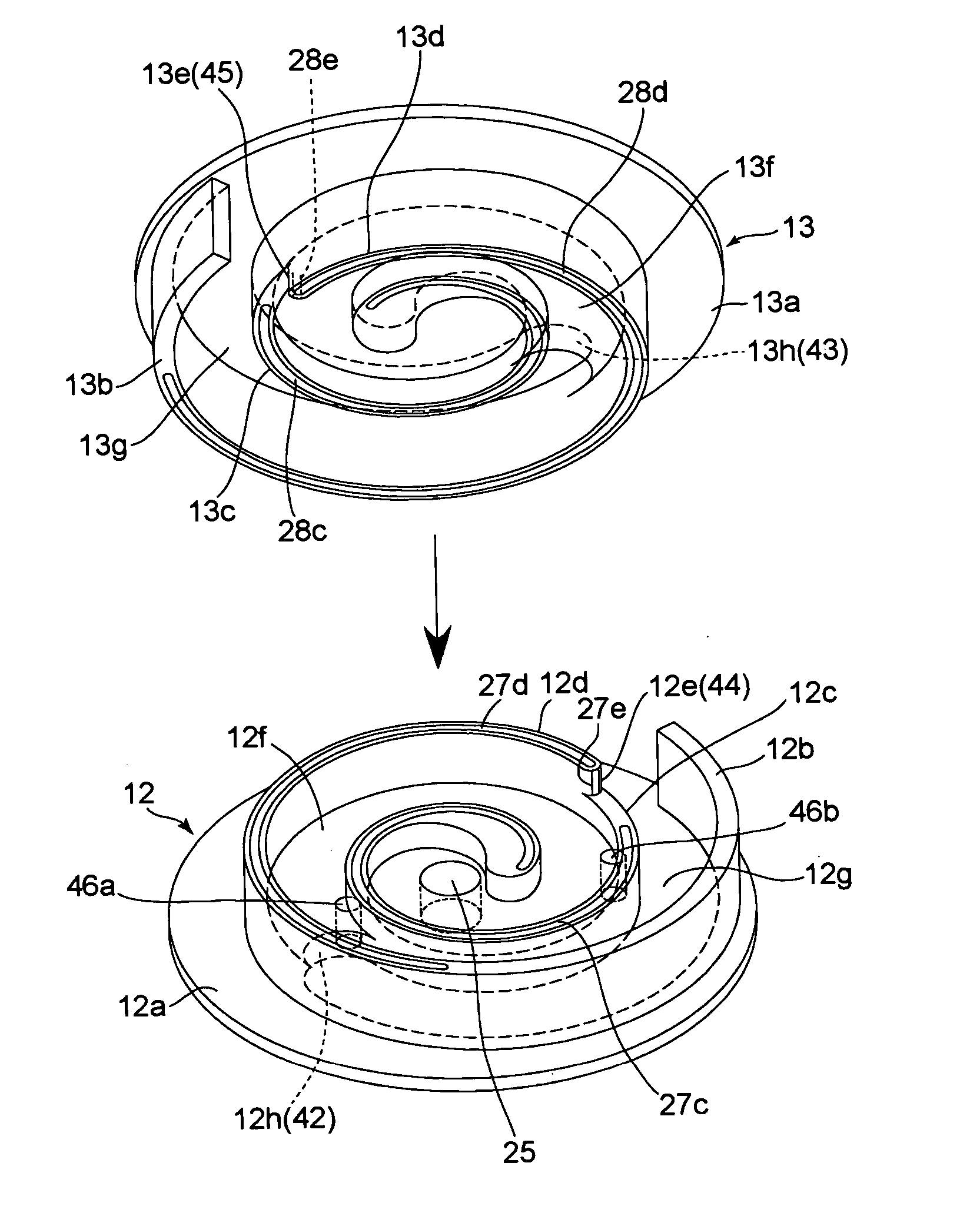

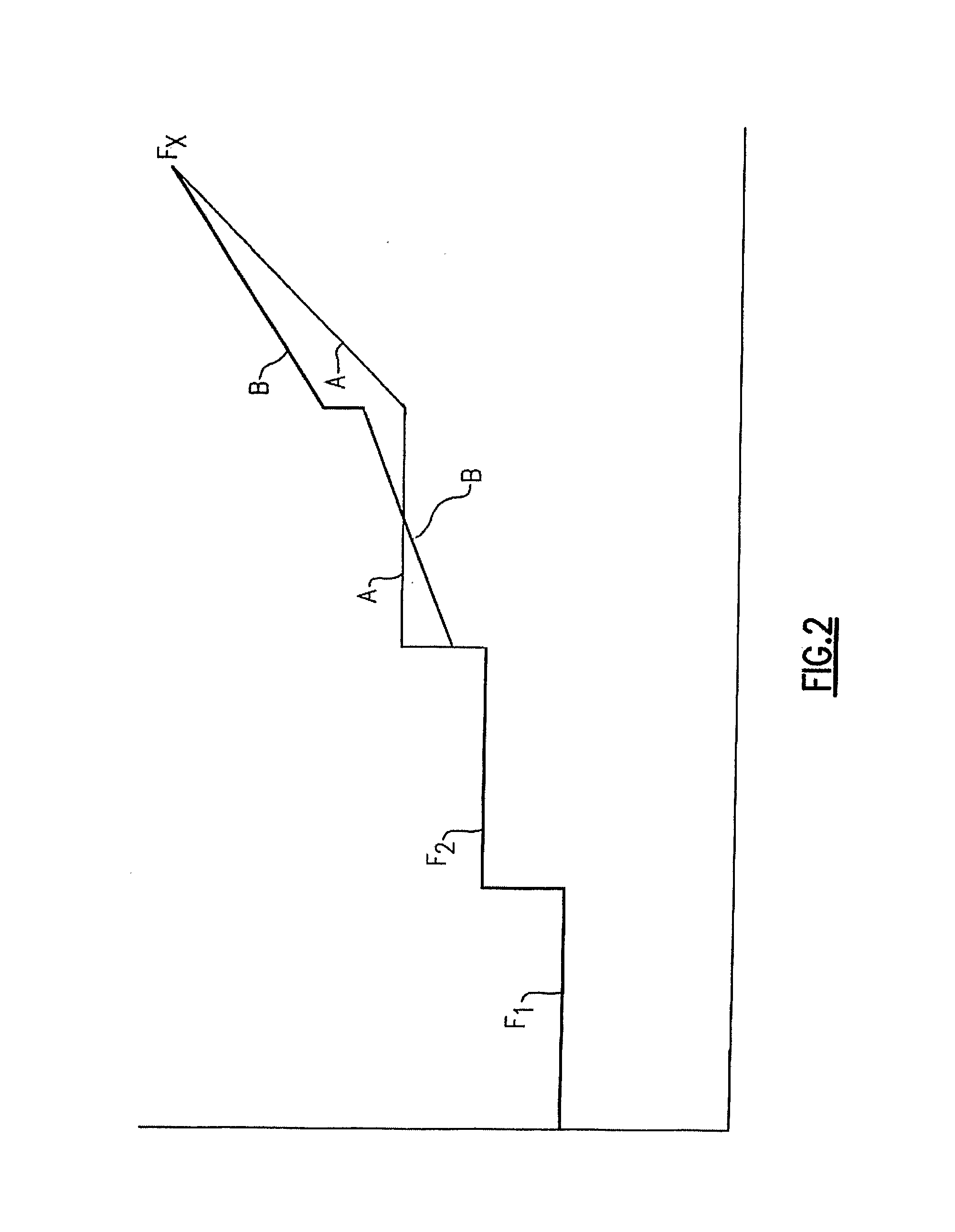

InactiveUS20050053507A1Reduced compression lossEngine of arcuate-engagement typeOscillating piston enginesEngineeringHelix

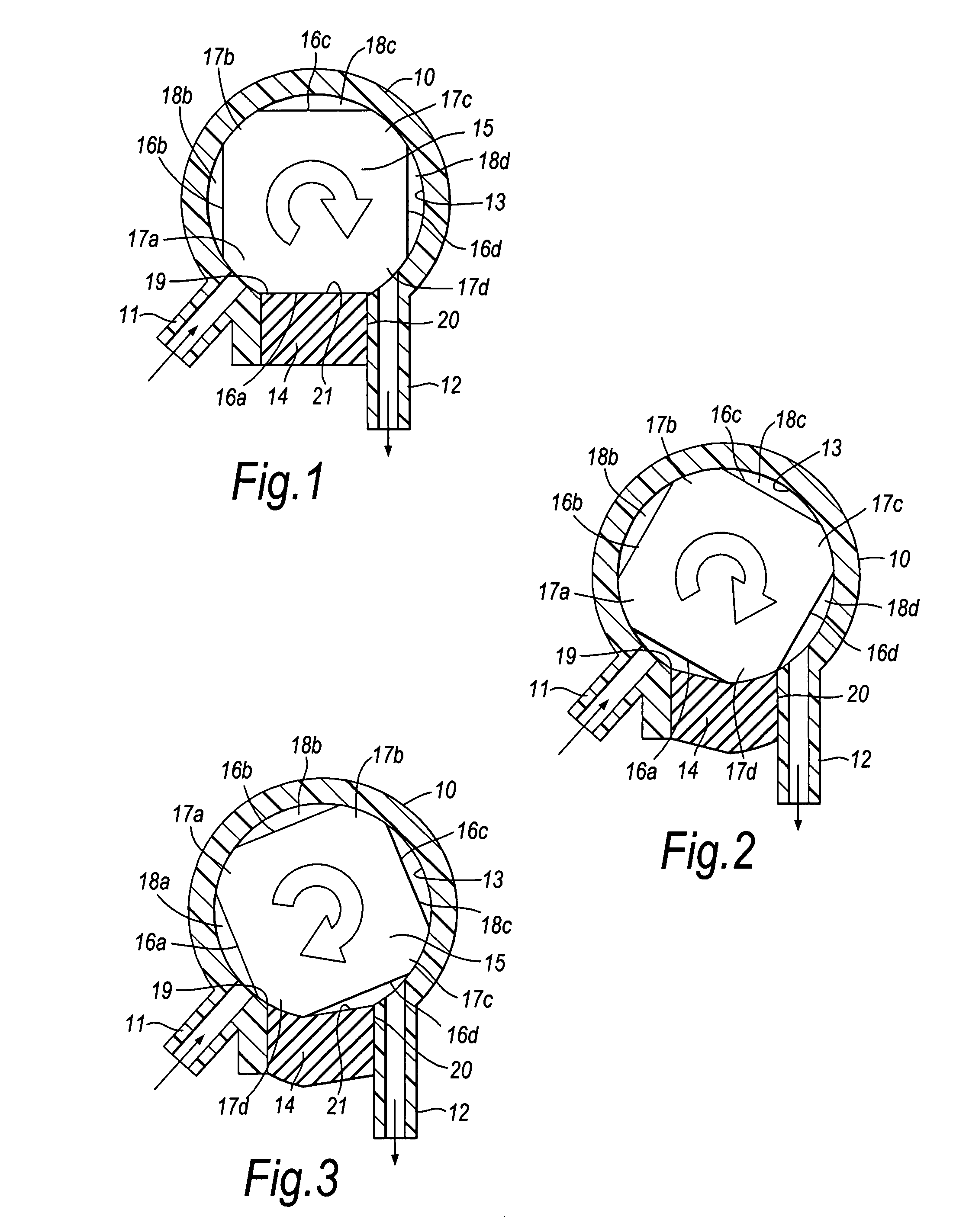

A scroll compressor includes a first scroll and a second scroll. The first scroll has a step portion that separates an elevated portion and a recessed portion of a surface of the first scroll. A spiral wall of the second scroll has a step that separates an elevated portion and a recessed portion of the wall. A first bypass hole is provided in the elevated portion of the surface of the first scroll. A second bypass hole is provided in the recessed portion of the surface of the first scroll. The second bypass hole is within 360 degrees toward a center of the spiral of the first scroll from an outer end of the spiral. The first bypass hole is within 360 degrees from the second bypass hole toward the center of the spiral.

Owner:MITSUBISHI HEAVY IND LTD

Pump with conveying chamber formed in outer rotor surface

ActiveUS7674100B2Avoid flowEngine of arcuate-engagement typeRotary piston pumpsMechanical engineeringMedical treatment

Owner:QUANTEX ARC LTD

Two-step self-modulating scroll compressor

InactiveUS6884042B2Pump componentsEngine of arcuate-engagement typePressure differenceElectrical and Electronics engineering

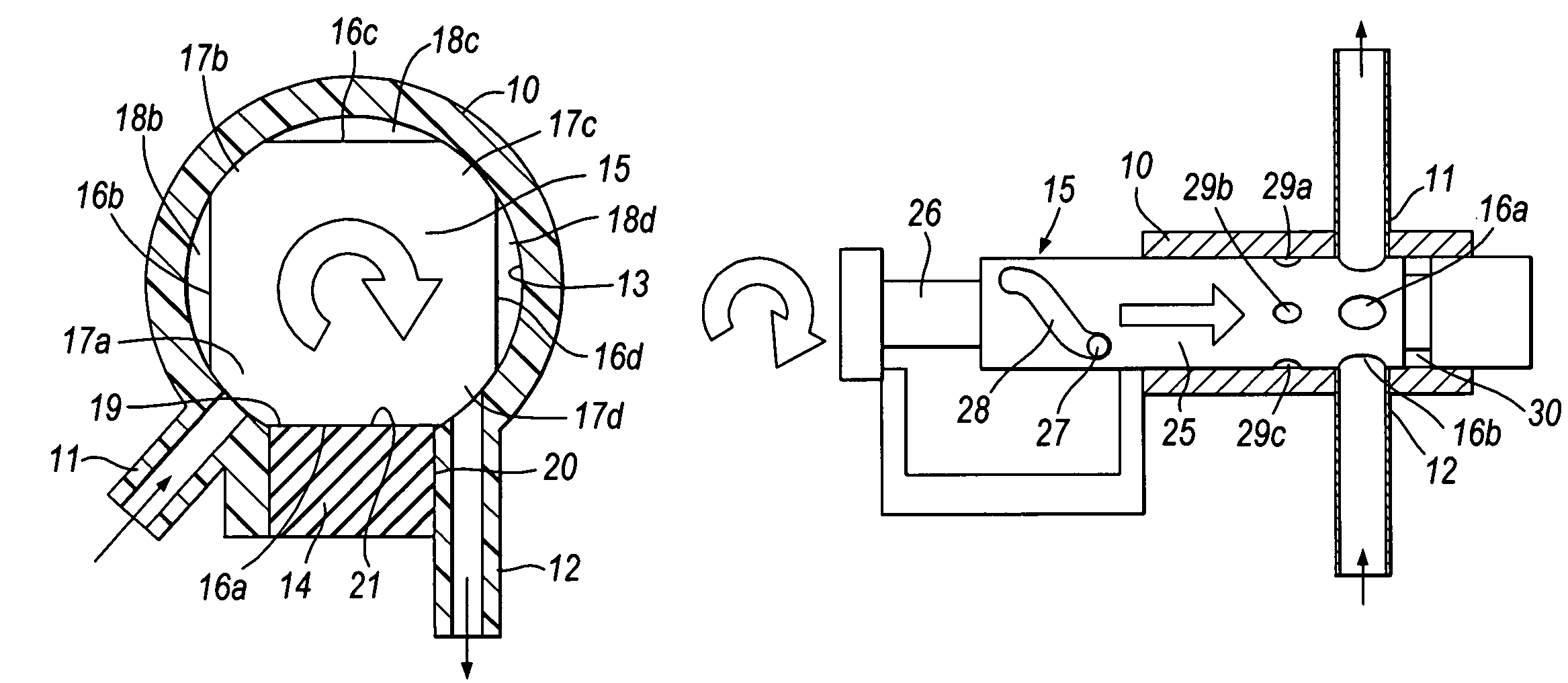

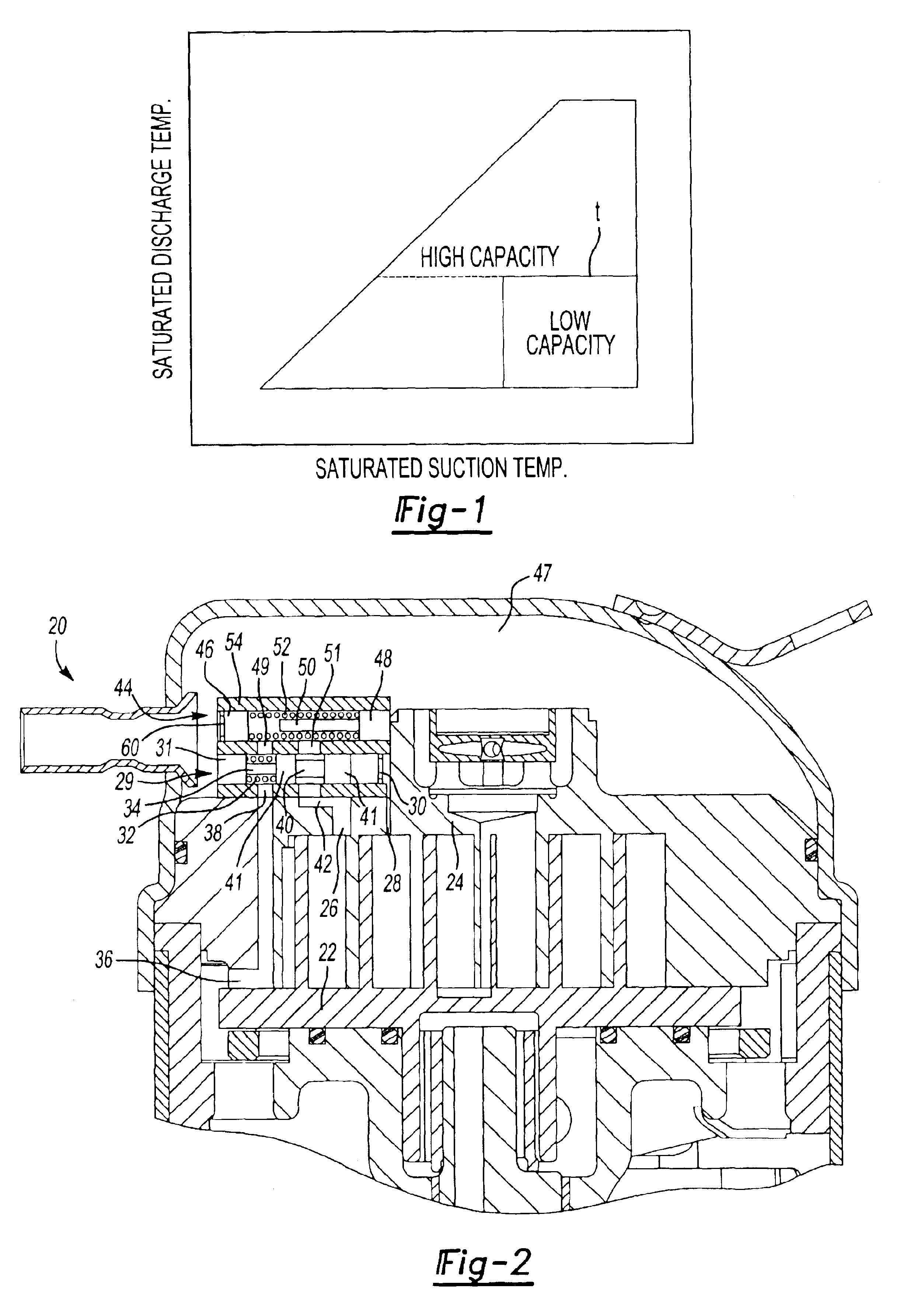

A self-modulating scroll compressor includes a pair of valves. A first valve moves to a low capacity position when the pressure differential is below a predetermined amount. A second valve moves to a low capacity position when the suction pressure is above a predetermined amount. Low capacity operation will only occur when both valves are open. The present invention thus provides a scroll compressor design with the ability to self-modulate and control the conditions under which low capacity operation occurs based upon two criteria.

Owner:SCROLL TECH

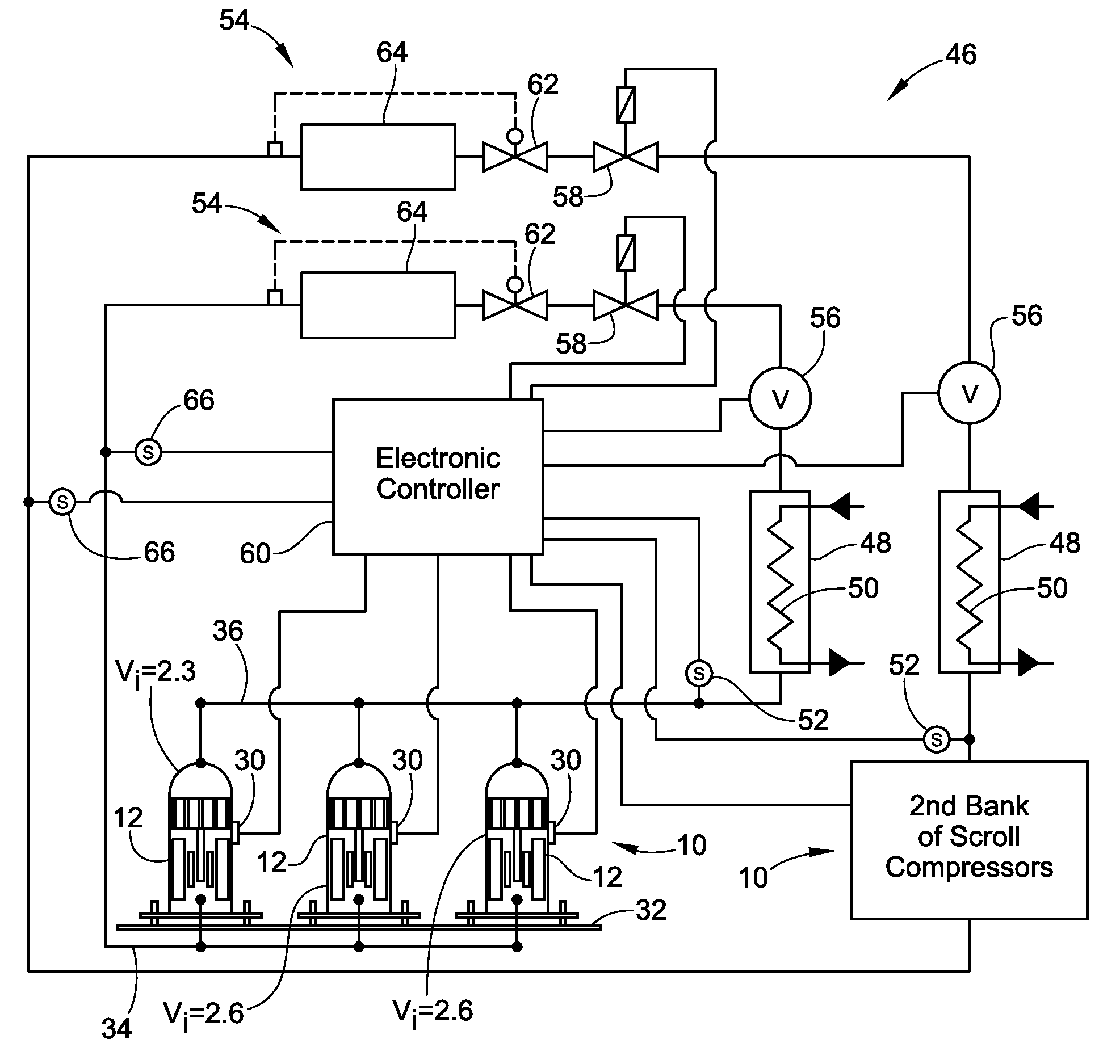

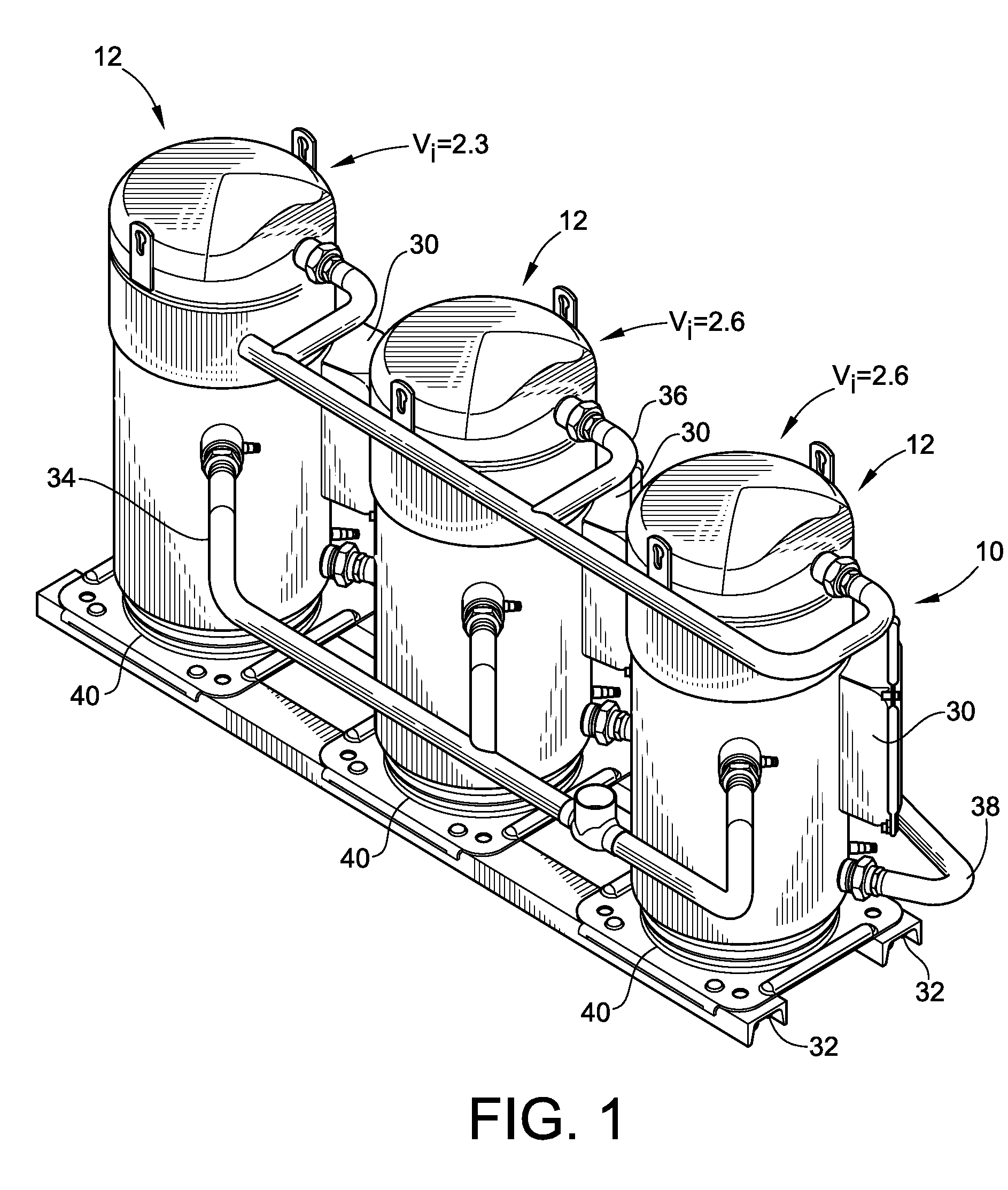

Scroll Compressors with Different Volume Indexes and Systems and Methods for Same

InactiveUS20100186433A1Improve efficiencyRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringScroll compressor

Owner:BITZER KUEHLMASCHINENBAU GMBH

Scroll machine with stepped sleeve guide

ActiveUS20050201883A1Improve reliability and durabilitySlow downEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

An axial complaint mounting system for a scroll machine positions the centroid reaction of the mounting system toward the top of a mounting bore extending through the axial compliant scroll member. The mounting system defines a first clearance located near the top of the mounting bore and a second clearance located near the bottom of the mounting bore. The positioning of the centroid reaction for the mounting system is accomplished by designing the second clearance larger than the first clearance.

Owner:COPELAND LP

Scroll compressor having an annular recess located outside an annular seal portion and another recess communicating with suction port of fixed scroll

ActiveUS7229261B2Reduce back pressureSliding loss can be reducedEngine of arcuate-engagement typeOscillating piston enginesEngineeringSliding contact

A surface of a fixed scroll which is opposed to a end plate of an orbiting scroll existing outside of a lap of the fixed scroll is formed with: a substantially annular seal portion which extends such as to have an outer wall surface of the fixed scroll outwardly extending from an inner wall surface of outermost periphery of the lap substantially along the inner wall surface, and which comes into slide contact with the end plate of the orbiting scroll; a substantially annular recess located outside of the substantially annular seal portion; and a recess which is brought into communication with an intake port of the fixed scroll independently from the substantially annular recess. With this, back pressure of the orbiting scroll is increased, and turning-over phenomenon of the orbiting scroll can be suppressed.

Owner:PANASONIC CORP

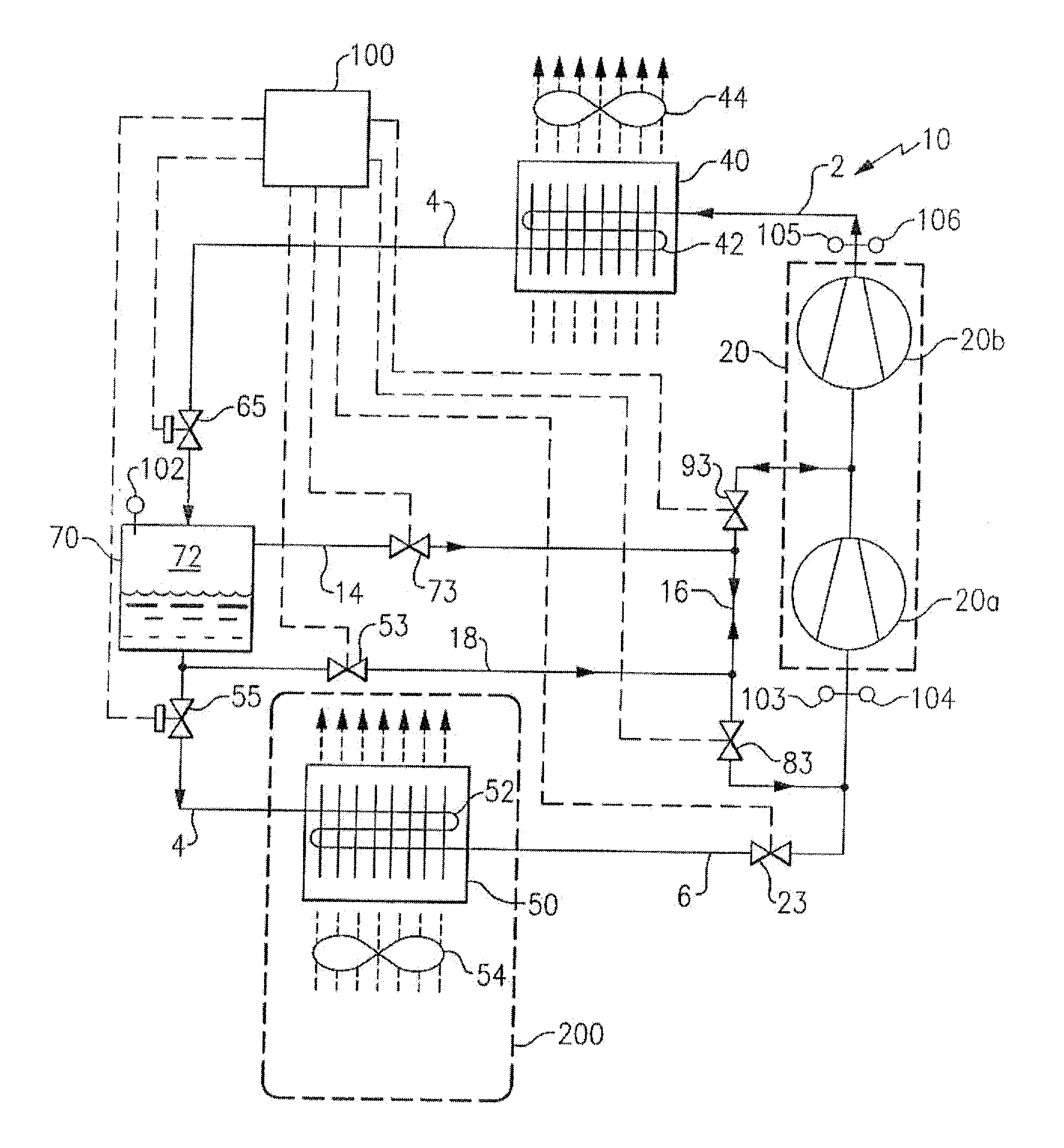

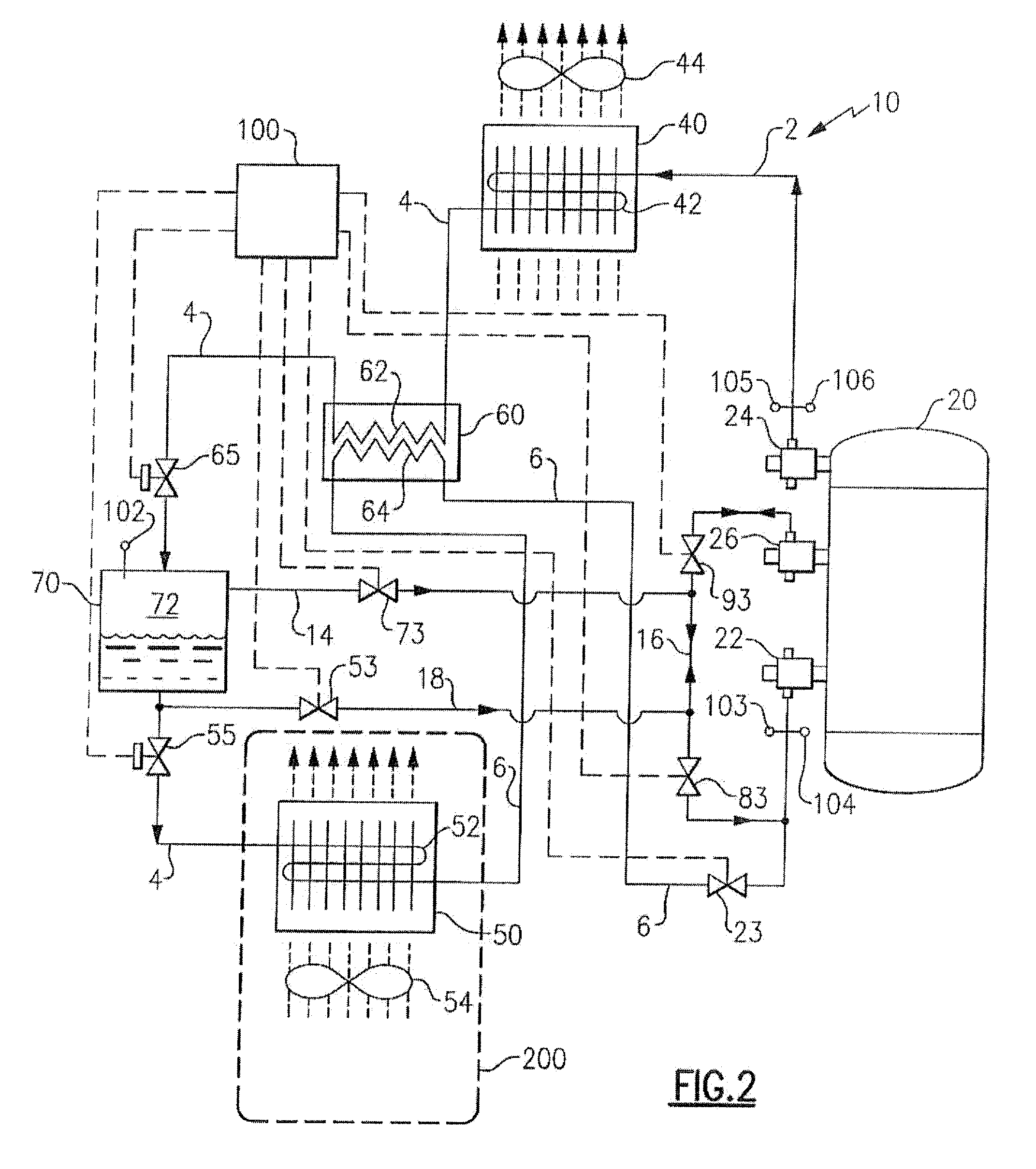

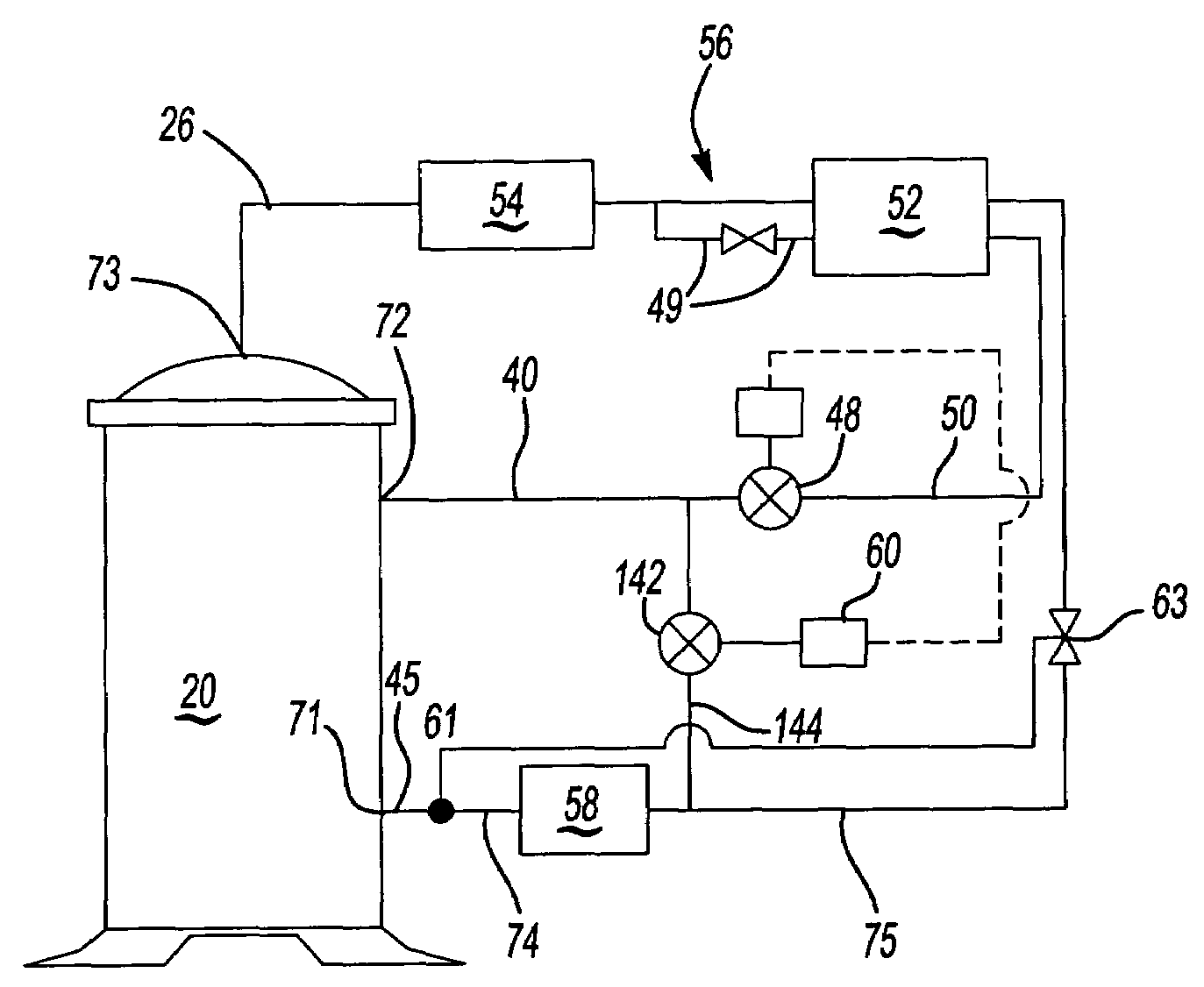

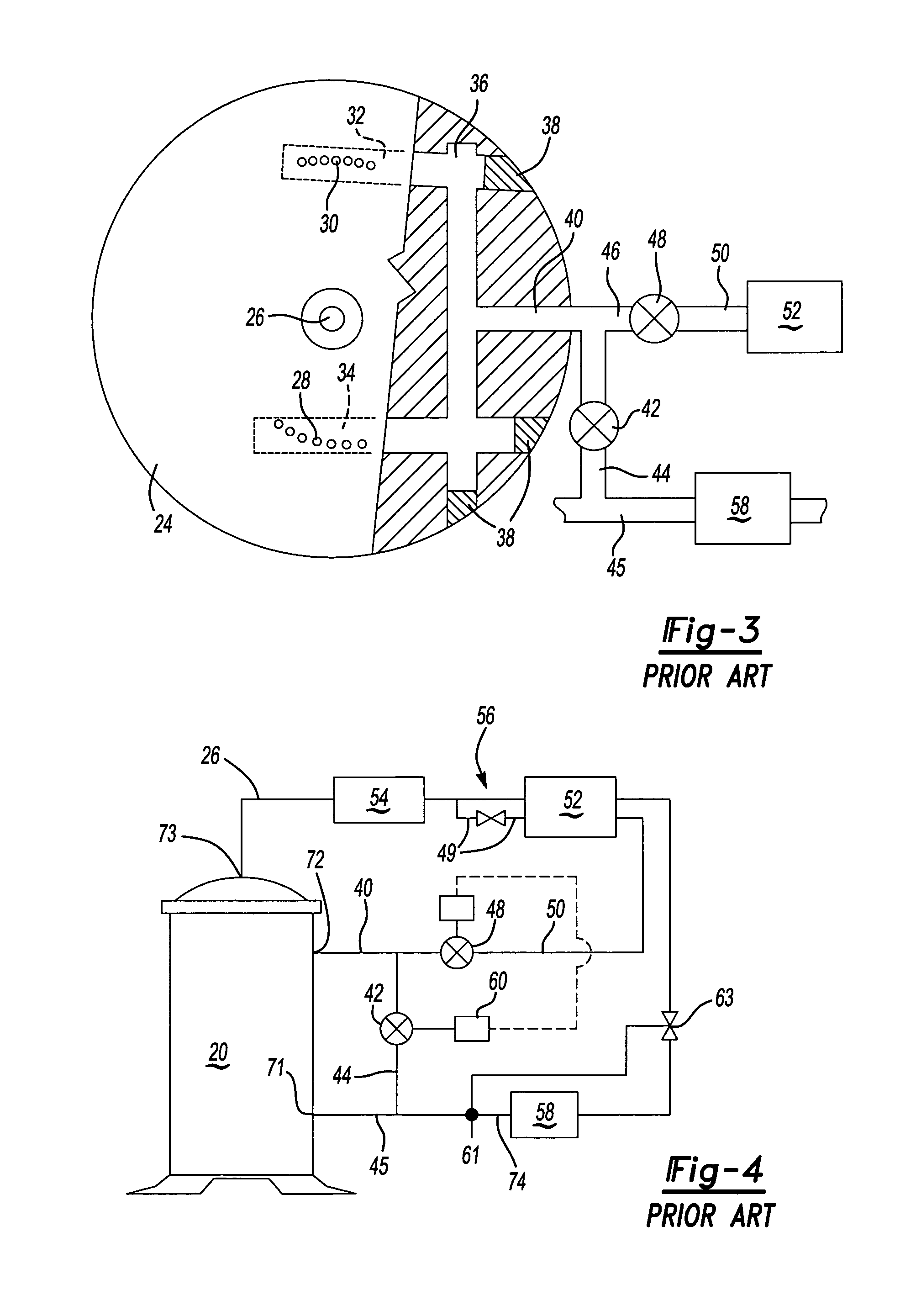

Refrigerant vapor compression system and method of transcritical operation

A refrigerant vapor compression system includes a flash tank economizer defining a separation chamber is disposed in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit in operative association with and upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit in operative association and upstream of the flash tank economizer. A refrigerant vapor injection line establishes refrigerant flow communication between an upper portion of the separation chamber and an intermediate pressure stage of the system's compression device and a suction pressure portion of the refrigerant circuit. A refrigerant liquid injection line establishes refrigerant flow communication between a lower portion of said separation chamber and an intermediate pressure stage of the compression device and a suction pressure portion of the refrigerant circuit.

Owner:CARRIER CORP

Scroll compressor with capacity modulation

ActiveUS7547202B2Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeActuatorCompression member

A scroll compressor may include a shell, a compression mechanism, and a sealing apparatus. The compression mechanism may be contained within the shell and include a compression member. The compression member may include an aperture extending radially there a surface. The sealing apparatus may be contained within the shell and include a first seal member and an actuator. The first seal member may be pivotally supported relative the compression member and may be movable from a first position wherein a sealing portion of the first seal member is in a sealing engagement with the surface and a second position wherein the sealing portion of the first seal member is displaced radially outwardly from the surface. The actuator may be engaged with the first seal member and configured to displace the first seal member from the first position to the second position.

Owner:COPELAND LP

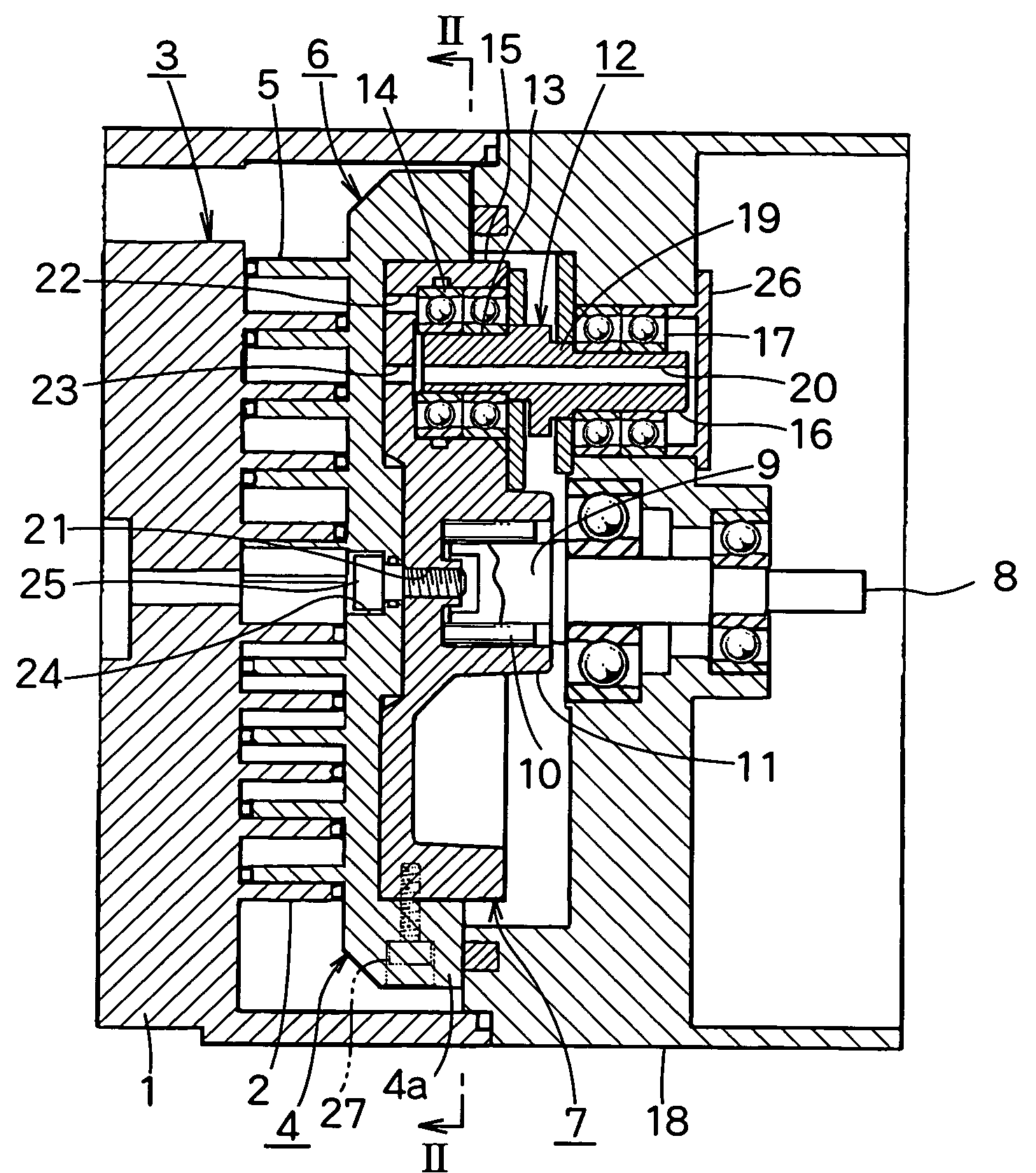

Load-regulating device for scroll type compressors

InactiveUS6913448B2Quickly build up pressurePrevent leakageEngine of arcuate-engagement typeOscillating piston enginesEngineeringLoad regulation

A load-regulating device for scroll type compressors comprising a compressor housing, a bracket body, a partition block, a gliding block, a pair of scrolls and a plurality of air chambers, wherein the gliding block being coupled with the pair of scrolls for defining a plurality of air chambers on the scrolls, the pressure variation in the air chambers is then utilized for causing the motion of the gliding block, enabling the compressor to cause the gliding block by means of the pressure variation to motion upwardly as the compressor is actuated, and preventing the fluid in the high-pressure chamber from leaking towards the low-pressure chamber, thus allowing the compressors to quickly build up the pressure; the gliding block is caused by the pressure variation to motion downwardly at times when the compression ratio is excessively high, so as to relieve part of the load, thus improving the performance and reliability of the compressors.

Owner:IND TECH RES INST

Scroll compressor

InactiveUS20070092390A1Improve sealingImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringScroll compressor

A scroll compressor has a fluid pressure biasing system for both the orbiting scroll member and the non-orbiting scroll member. The biasing system can utilize a pressurized gas from the pocket of the scroll compressor or it can utilize an external pressurized oil source. In an additional embodiment, a hydrostatic bearing is located between the orbiting scroll member and the non-orbiting scroll member.

Owner:EMERSON CLIMATE TECH INC

Oiless rotary scroll air compressor air inlet valve

InactiveUS6336797B1Reduce manufacturing costGuaranteed uptimeEngine of arcuate-engagement typeOscillating piston enginesPistonValve stem

An air inlet valve assembly for a rotary scroll compressor is disclosed. The rotary scroll compressor includes stationary and orbiting scroll elements which are intermeshed and nested to form at least one spiraling compression pocket therebetween, a drive mechanism drives the orbiting scroll element in an orbit about the stationary scroll element, and an anti-rotation bearing device maintains the orbiting scroll element substantially non-rotational with respect to the stationary scroll element. The air inlet valve assembly supplies an uncompressed gas (e.g., ambient air) to the compression apparatus and prevents backward rotation of the orbiting scroll element when power to the drive mechanism is terminated. The air inlet valve assembly includes a valve piston positioned within an air intake channel leading to the suction region of the rotary scroll compressor, the valve piston having a first position blocking the air intake channel and a second position unblocking the air intake channel. A valve stem member is connected to a valve housing, the valve housing enclosed a valve cavity wherein the valve piston is located, the valve piston coacts with a valve seat formed on the valve housing, and stop surfaces are provided on the valve piston and the valve stem to limit movement of the valve piston toward the suction region of the rotary scroll compressor.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

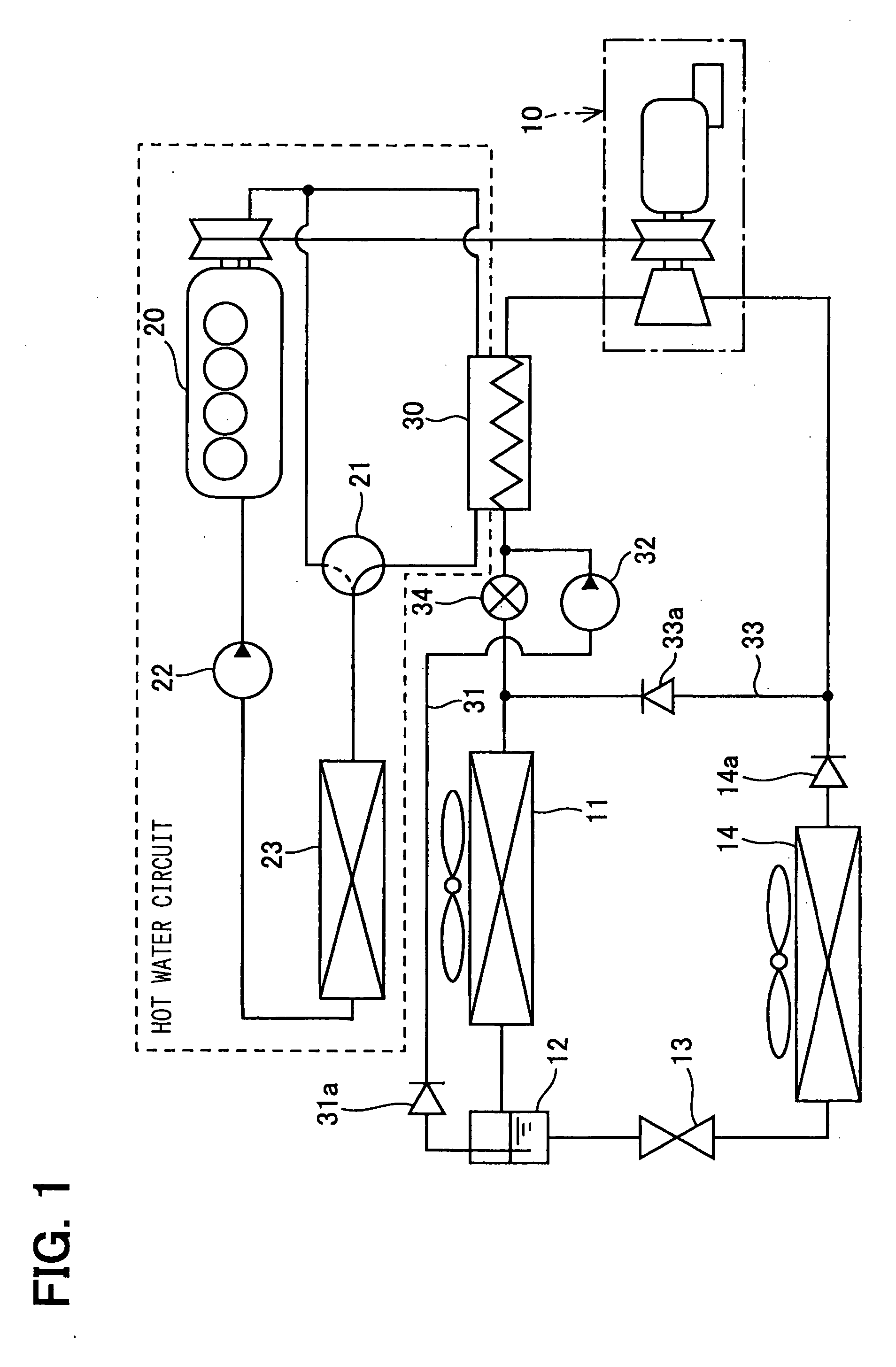

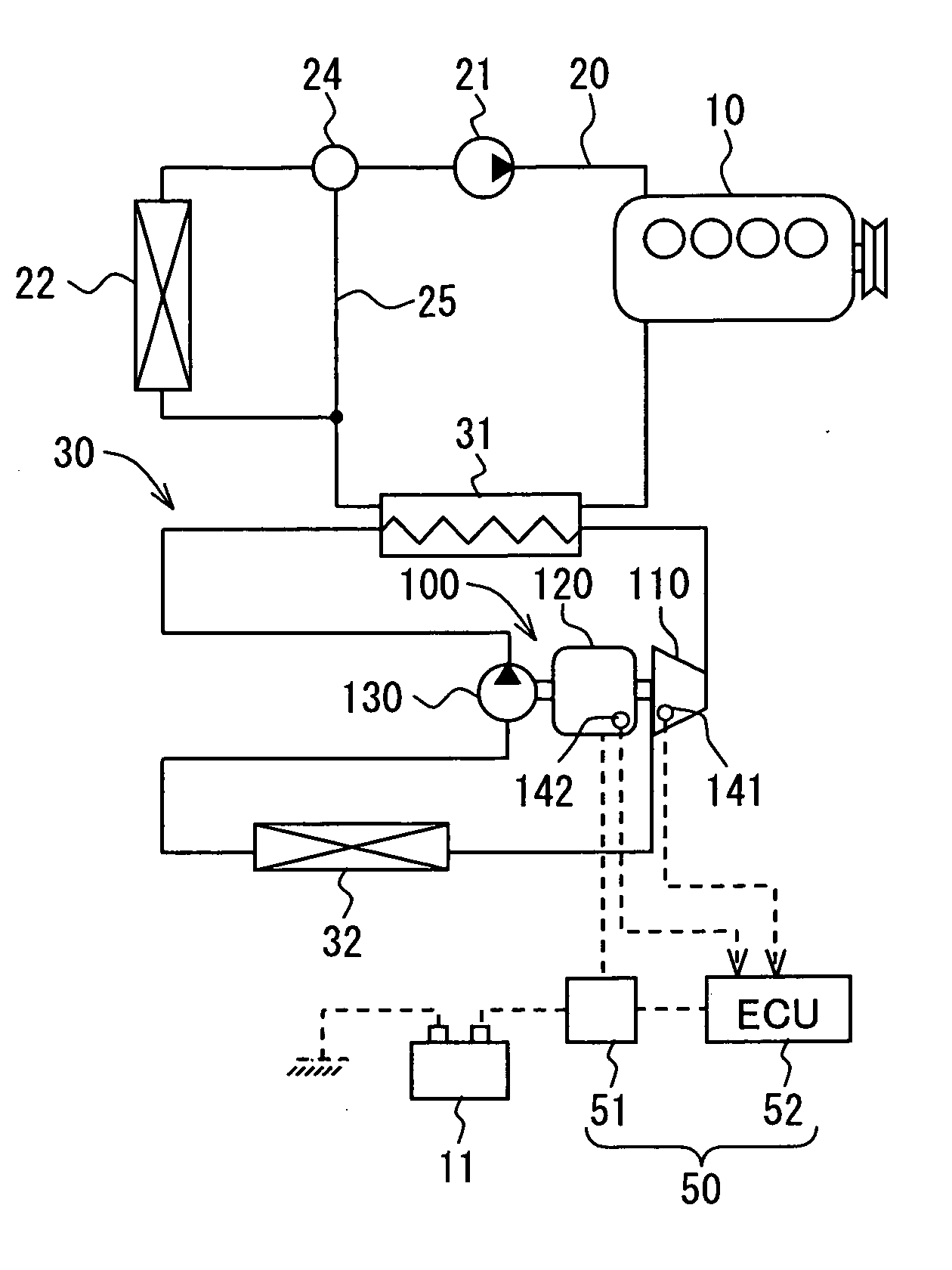

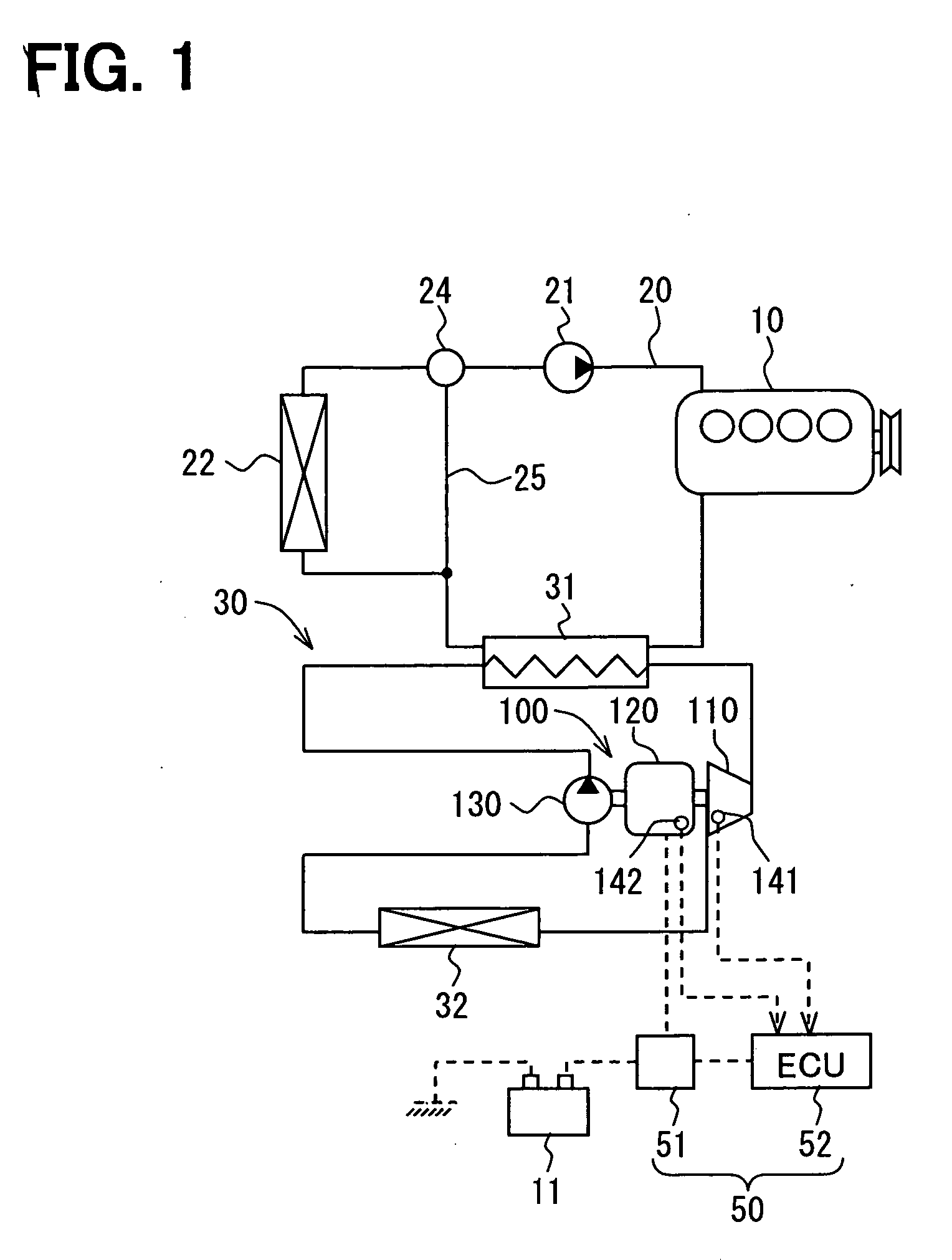

Fluid machine for Rankine cycle

InactiveUS20070175212A1Easily equalizedSafely and surely stopLiquid degasificationEngine of arcuate-engagement typeWorking fluidGas phase

It is an object to provide a fluid machine, which is simple in structure and in which lubricating oil containing smaller amount of the working fluid is supplied to sliding portions of an expansion device. The fluid machine has the expansion device for generating a driving force by expansion of the working fluid, which contains the lubricating oil and is heated to a gas phase condition. The fluid machine further has an electric power generating device driven by the driving force of the expansion device and generating electric power. An oil pooling portion is formed in a fluid passage, through which the working fluid discharged from the expansion device flows, such that the lubricating oil contained in the working fluid is brought into contact with at least one of sliding portions of the expansion device and the electric power generating device. And a heating unit is provided to heat the working fluid in the oil pooling portion.

Owner:DENSO CORP +1

Scroll compressor

InactiveUS20100111741A1Improve performanceImprove reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringBack pressure

A scroll compressor comprises a fixed scroll, an orbiting scroll engaged with the fixed scroll to form a compression chamber therebetween, a back pressure chamber arranged at a back side of an end plate of the orbiting scroll, a back pressure hole formed in the end plate of the orbiting scroll to form a fluidal communication between the compression chamber and the back pressure chamber, and a release valve mechanism for discharging the fluid from the compression chamber to the discharge space when a pressure in the compression chamber is higher than the pressure in the discharge space, wherein the back pressure hole and the release flow path are arranged to prevent both of the fluidal communication and the another fluidal communication from being formed simultaneously.

Owner:HITACHI APPLIANCES INC

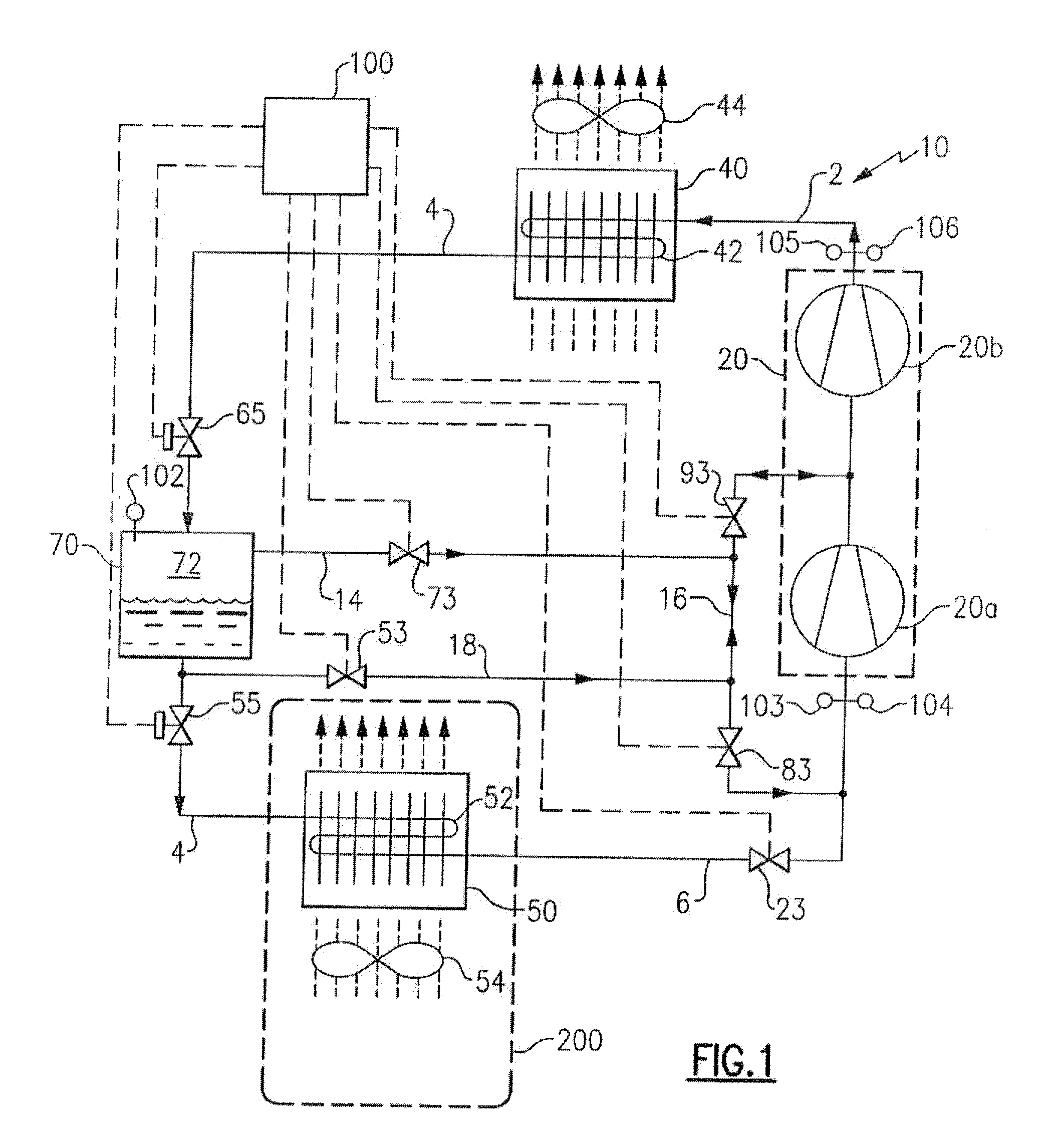

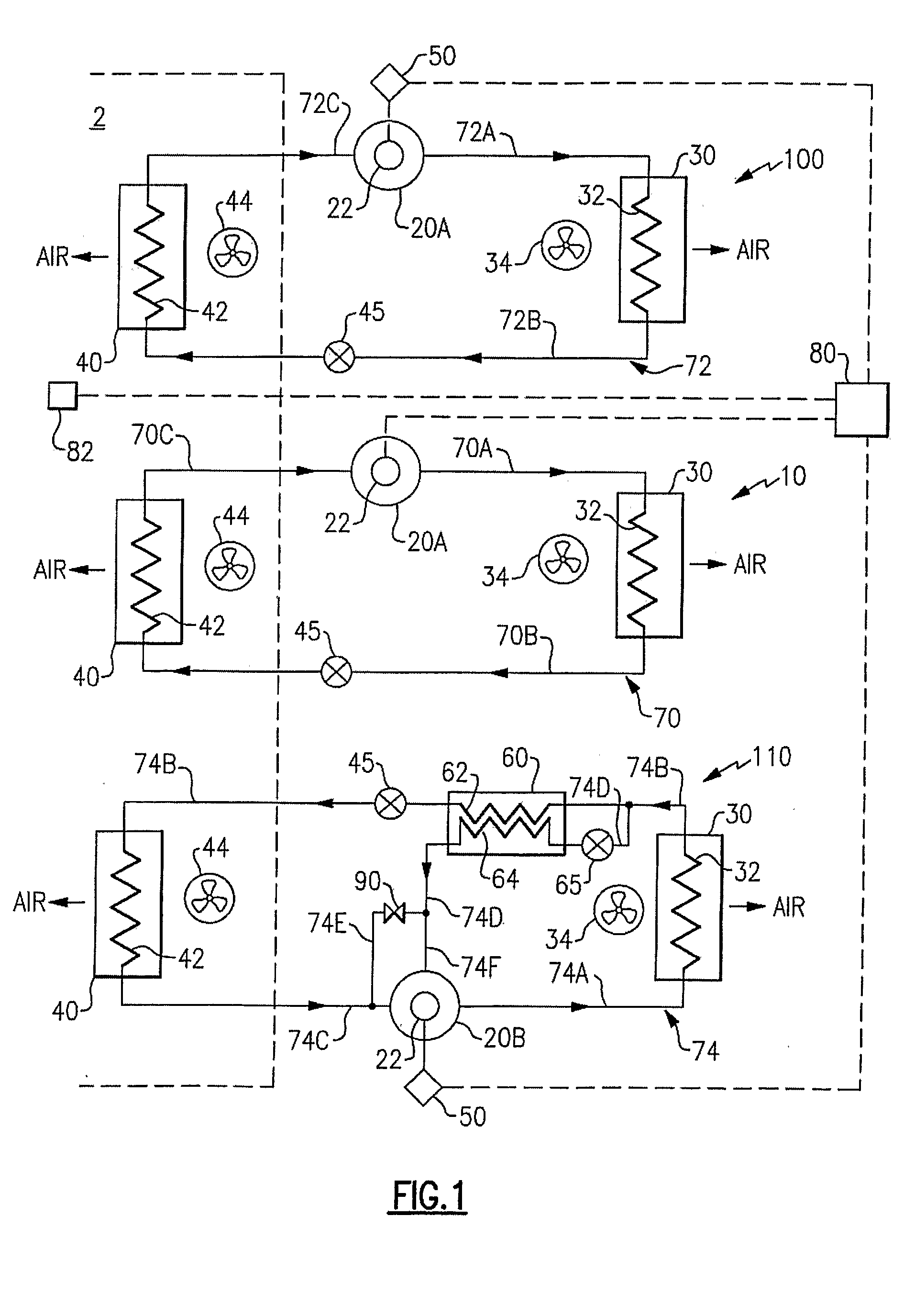

Variable Capacity Multiple Circuit Air Conditioning System

InactiveUS20080307813A1Engine of arcuate-engagement typeTemperatue controlEngineeringAir conditioning

A refrigerant vapor compression system for conditioning air within a climate controlled space has multiple refrigerant circuits including at least one refrigerant circuit having a fixed capacity and at least one refrigerant circuit having a variable capacity. Each refrigerant circuit includes a compressor, a condenser, an expansion device and an evaporator connected in refrigerant circulation flow communication. The compressor associated with each fixed capacity refrigerant circuit is a fixed speed compressor and the compressor associated with each variable capacity refrigerant circuit is a variable speed compressor. A controller is provided for controlling the speed of the variable speed compressor to adjust the refrigeration capacity of the variable capacity refrigerant circuit and thereby adjust the overall capacity of the system to match the cooling demands.

Owner:CARRIER CORP

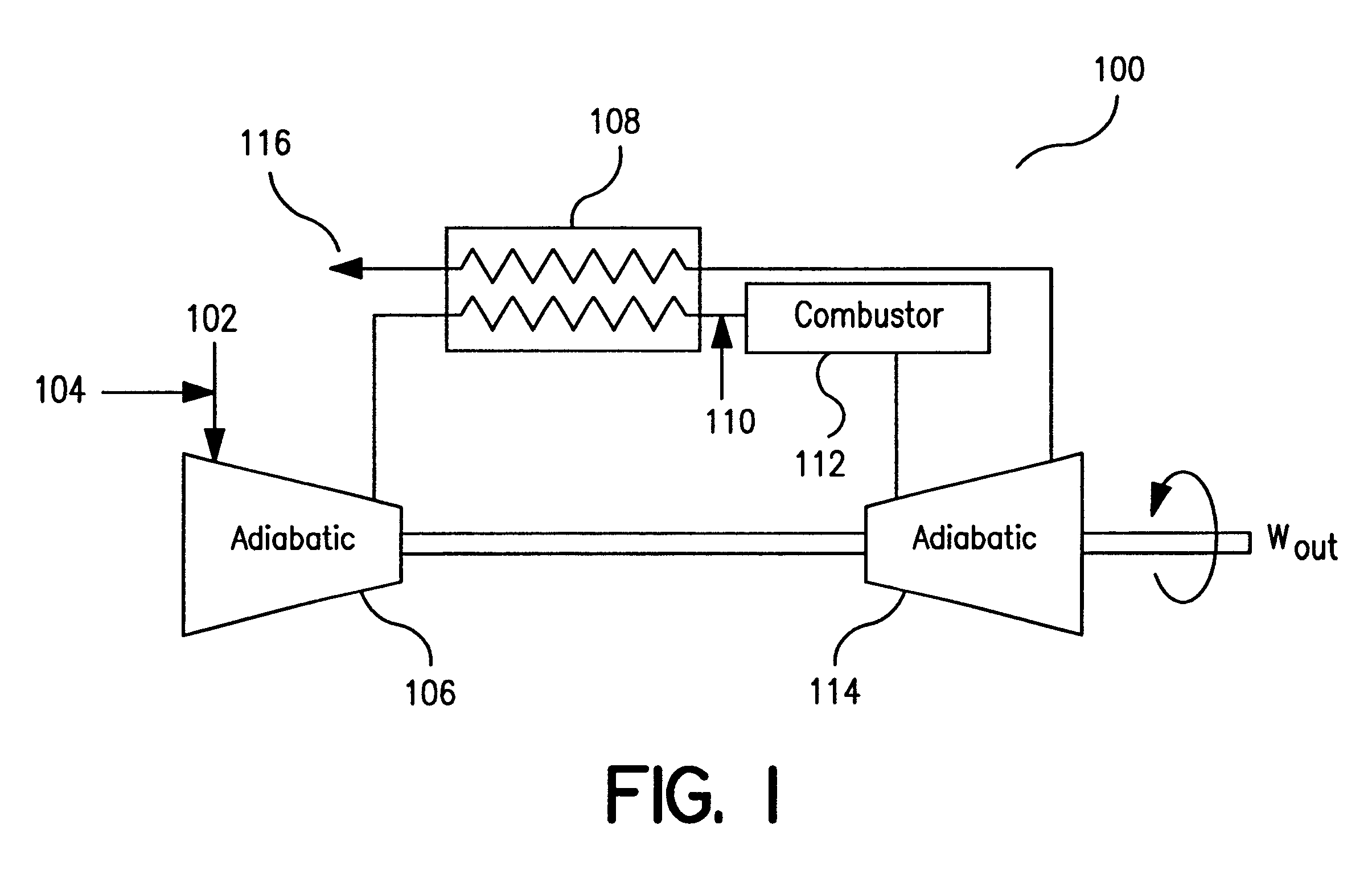

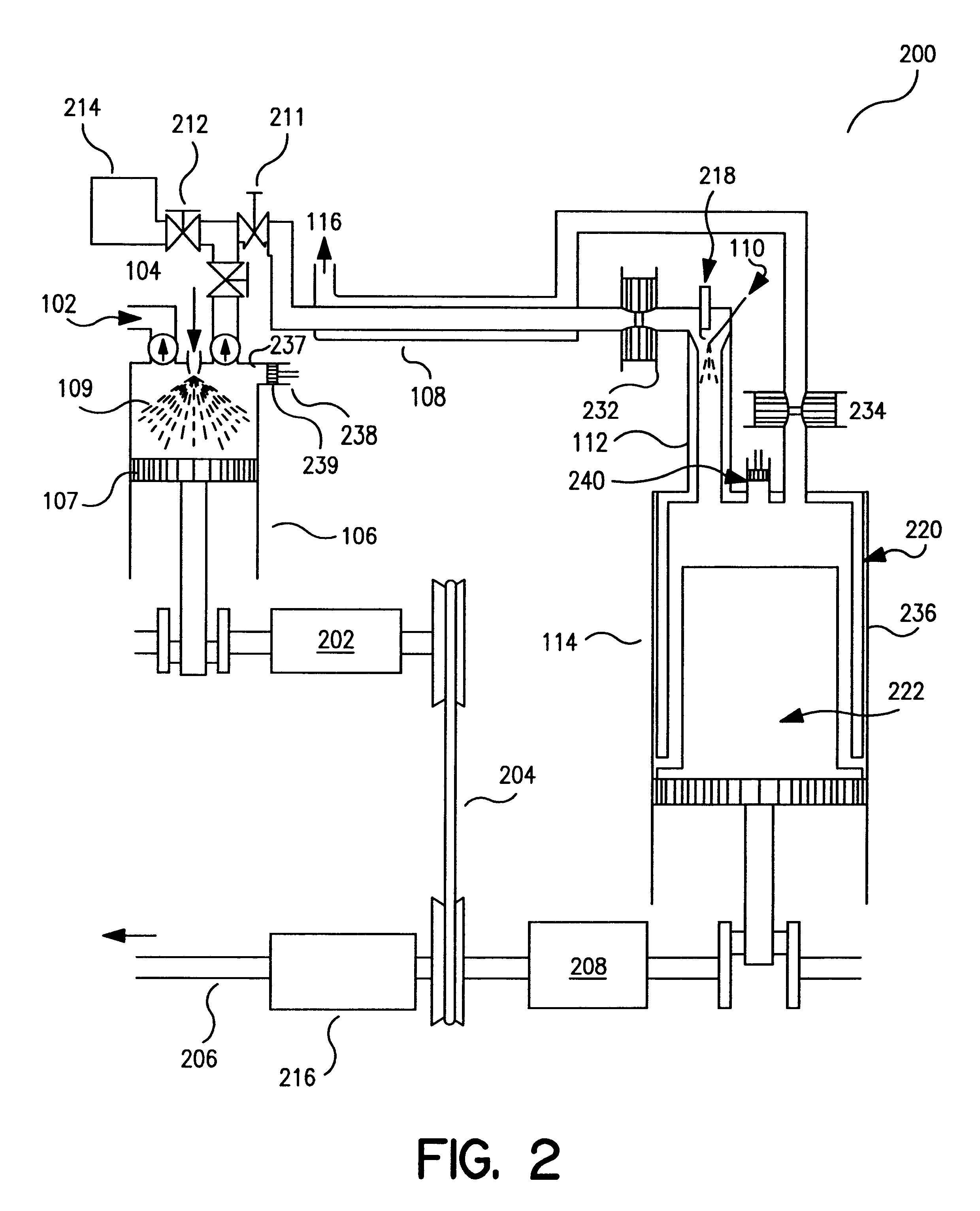

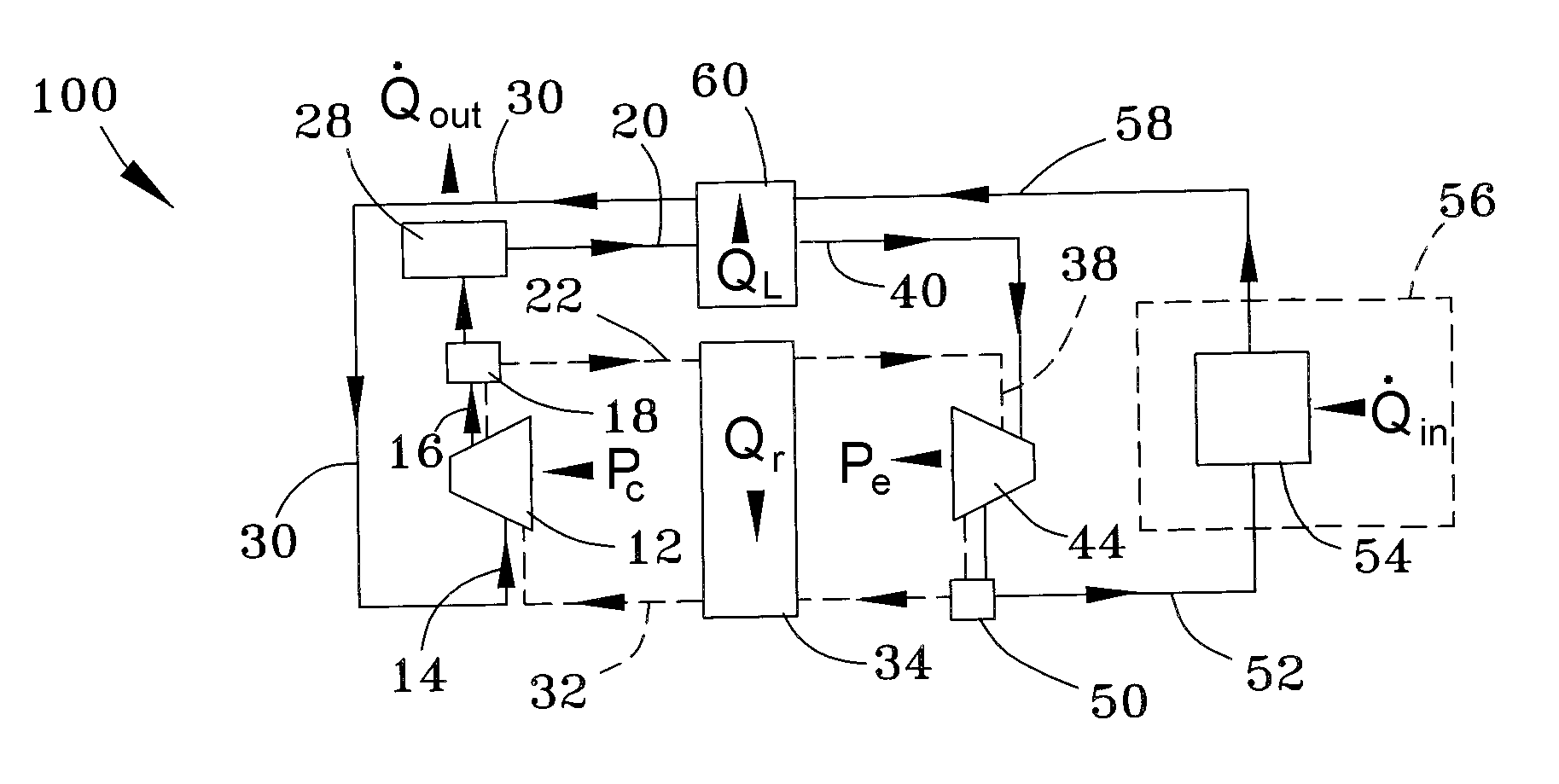

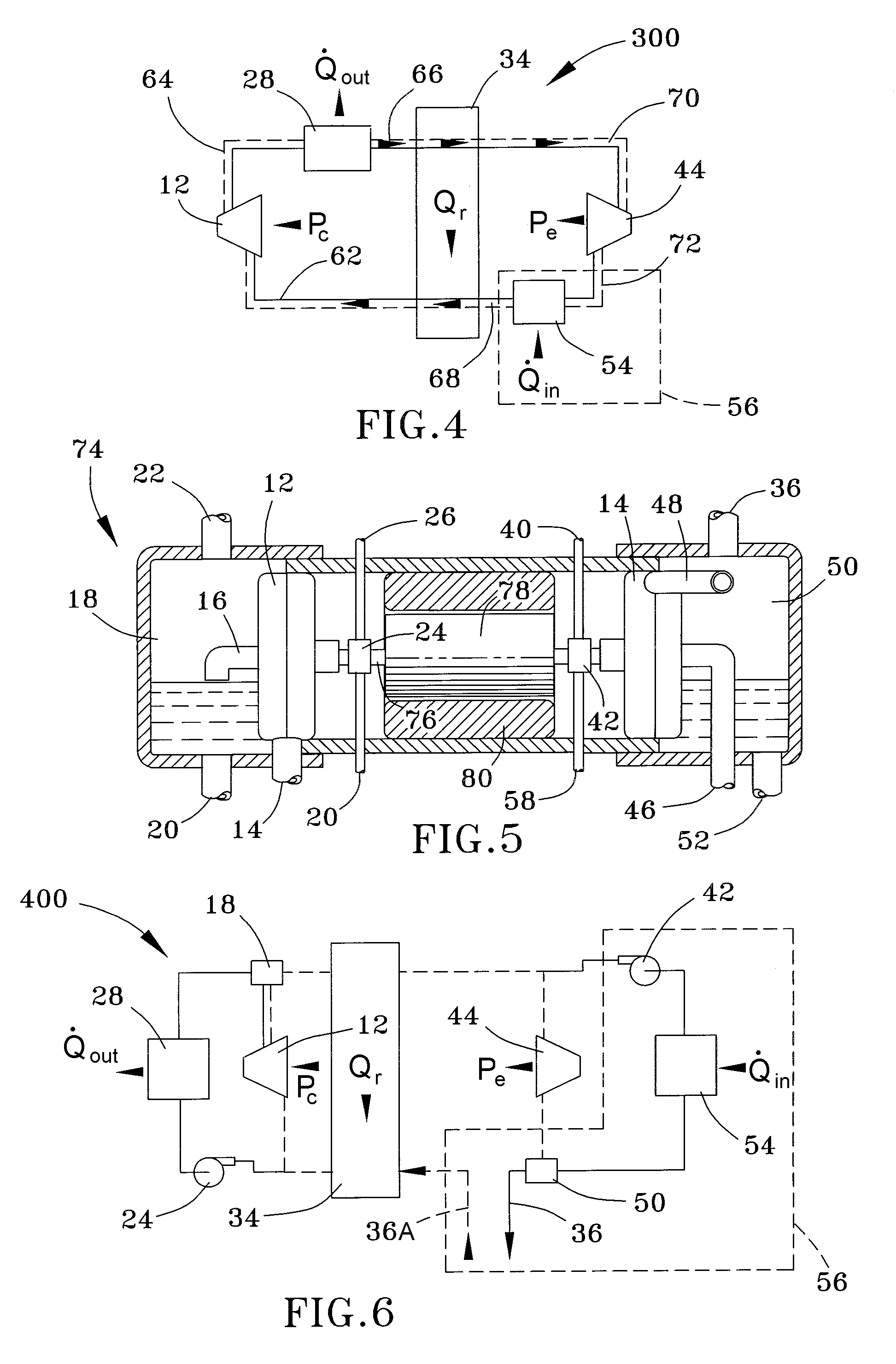

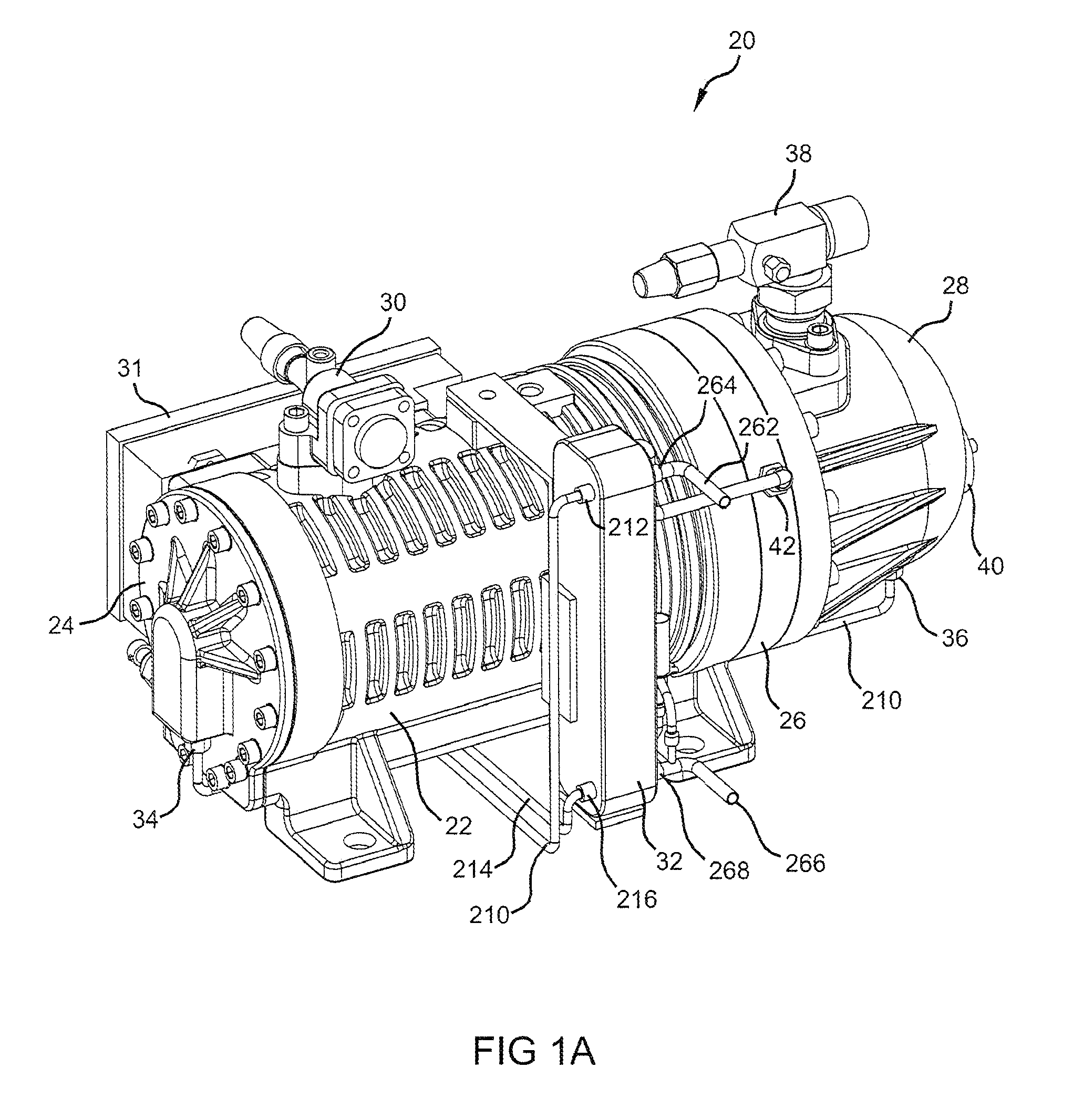

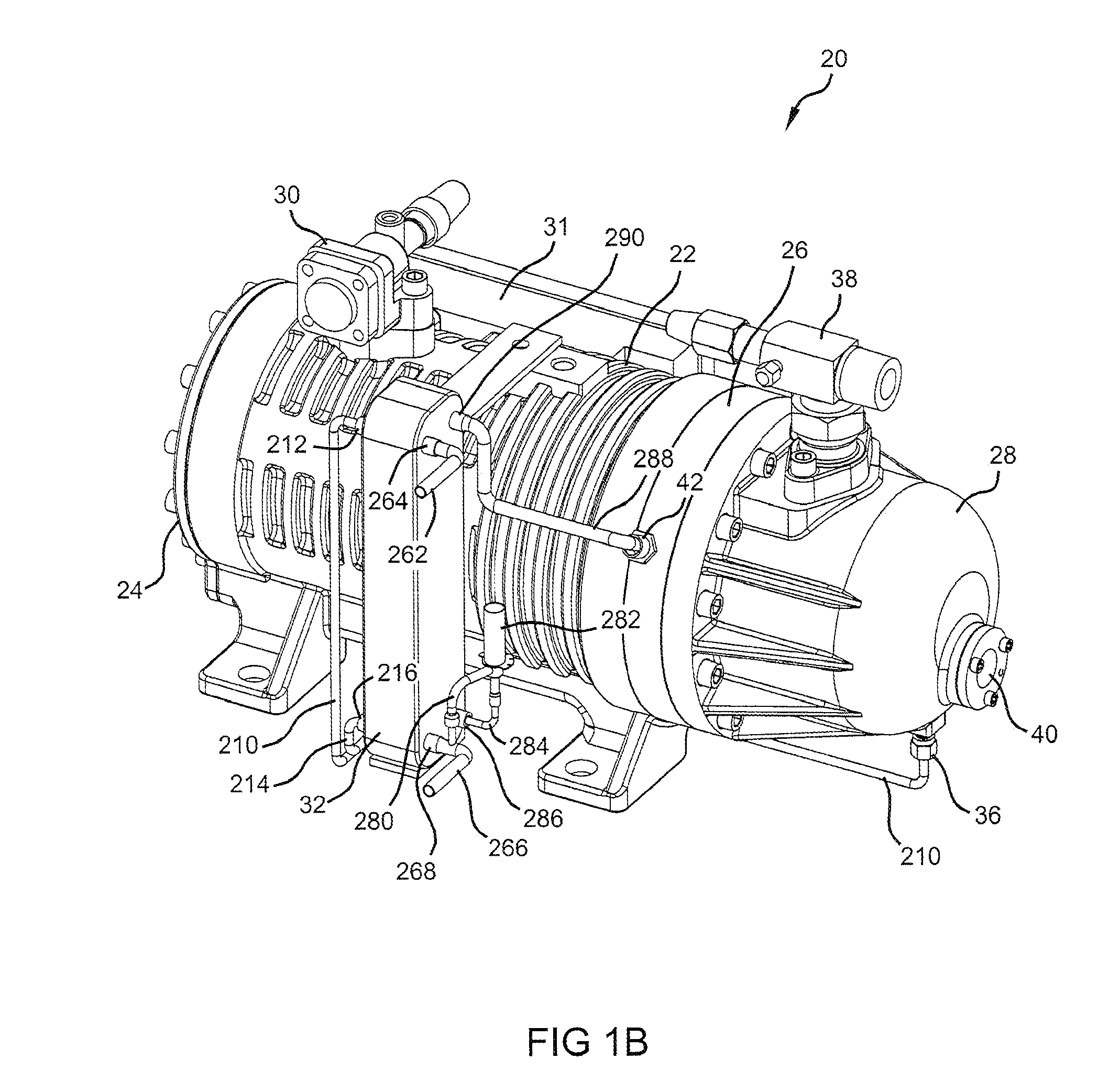

Thermodynamic systems operating with near-isothermal compression and expansion cycles

InactiveUS20070074533A1Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleEngineering

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

Discharge valve system of scroll compressor

ActiveUS20060099098A1Minimize the numberMaximize discharge amountEngine of arcuate-engagement typeOscillating piston enginesDischarge efficiencyProduction rate

A discharge valve system of a scroll compressor comprises: a fixed scroll having a discharge hole and discharge bypass holes; a discharge valve assembly mounted at the fixed scroll, for opening and closing the discharge hole by a pressure difference; and an integral bypass valve assembly mounted at the fixed scroll, for opening and closing the bypass holes and interworking the discharge valve assembly. According to this, a discharge amount of gas is maximized in a low pressure ration driving of the scroll compressor thereby to enhance a discharge efficiency. Also, the number of components is greatly reduced thus to reduce a fabrication cost. Also, the number of assembly processes is greatly reduced thereby to enhance an assembly productivity.

Owner:LG ELECTRONICS INC

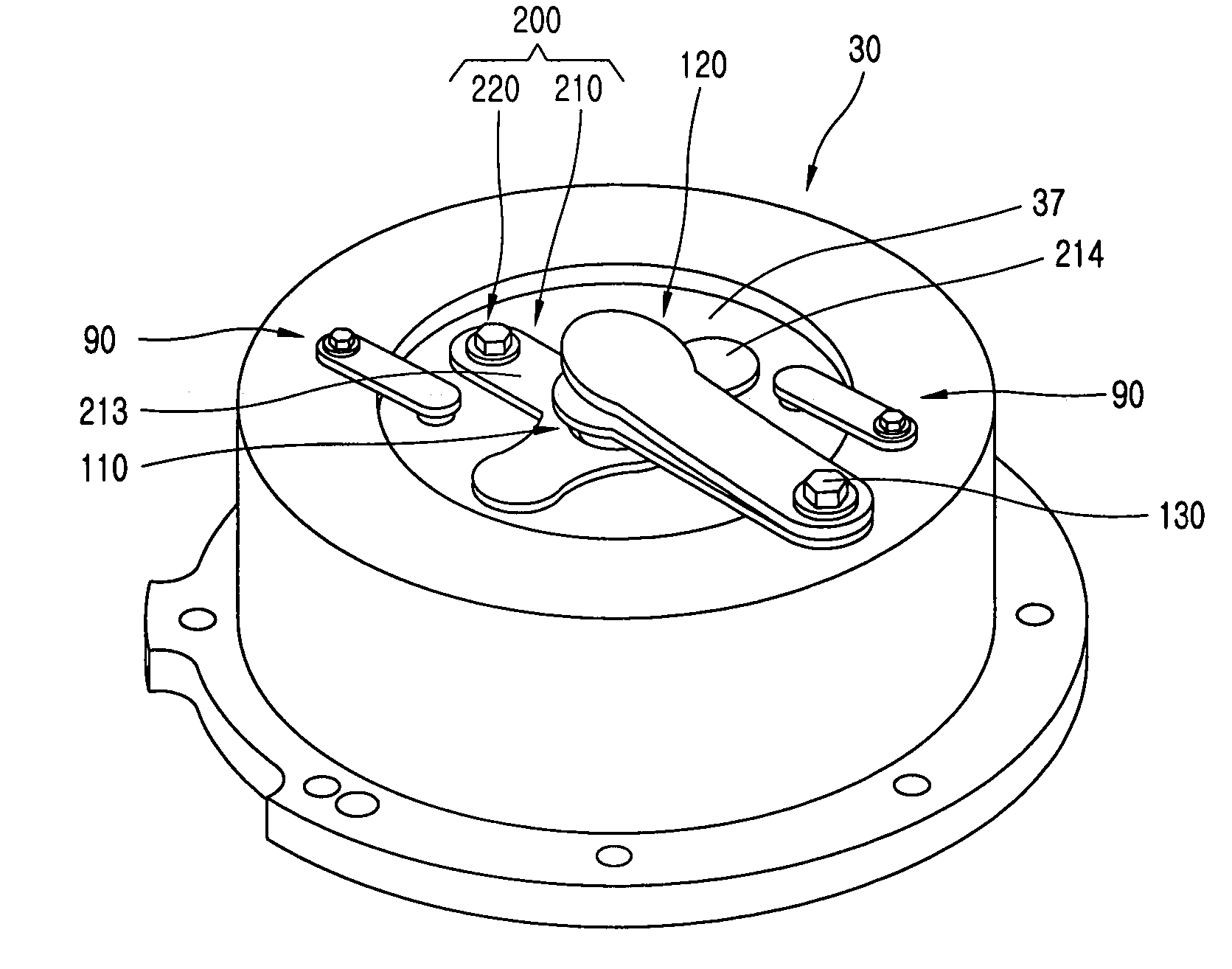

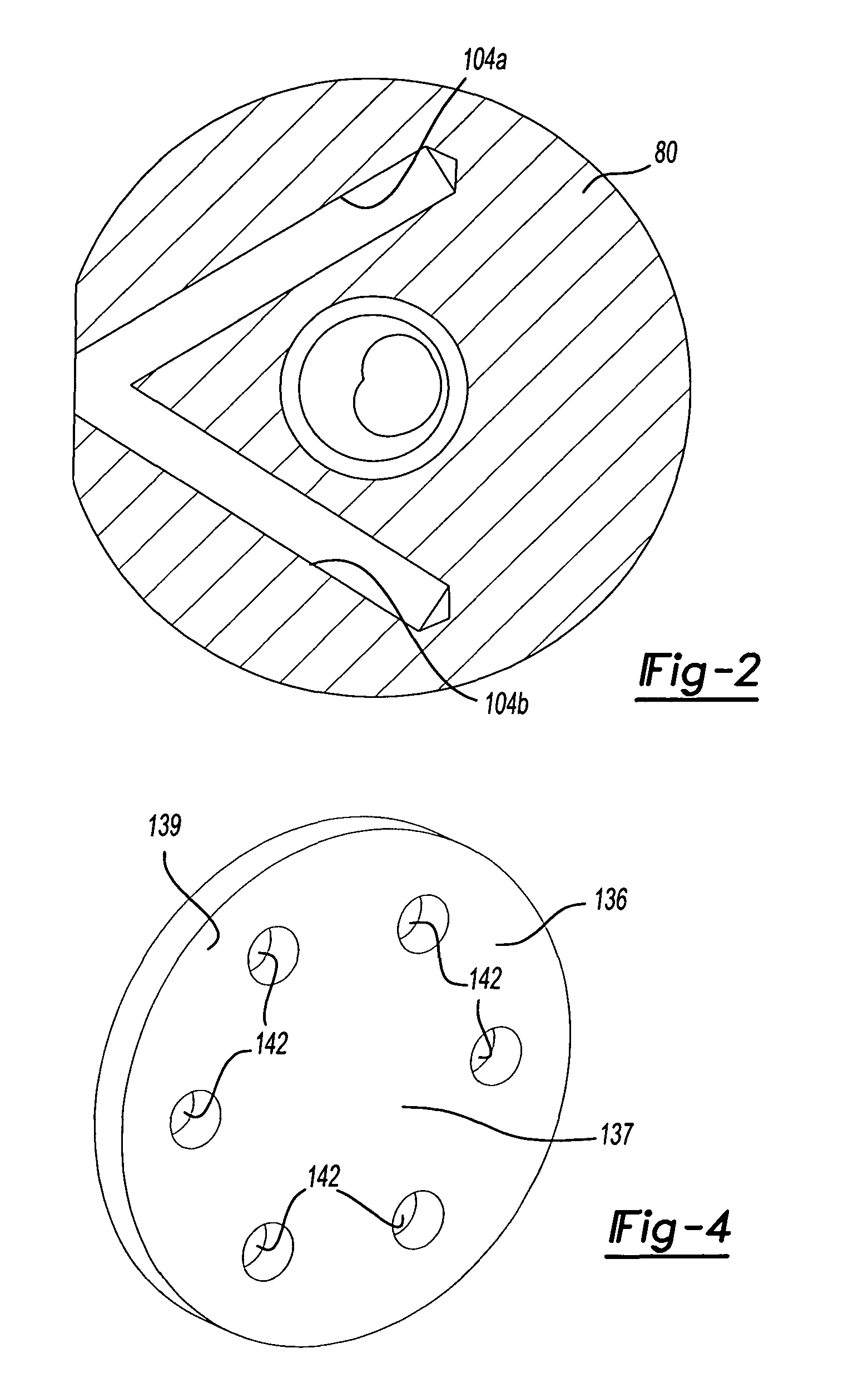

Scroll fluid machine having oil-supply holes being formed through a reinforcement bearing plate on a rear surface of the orbiting scroll

InactiveUS7404706B2Increase supplyEngine of arcuate-engagement typeOscillating piston enginesEngineeringOil supply

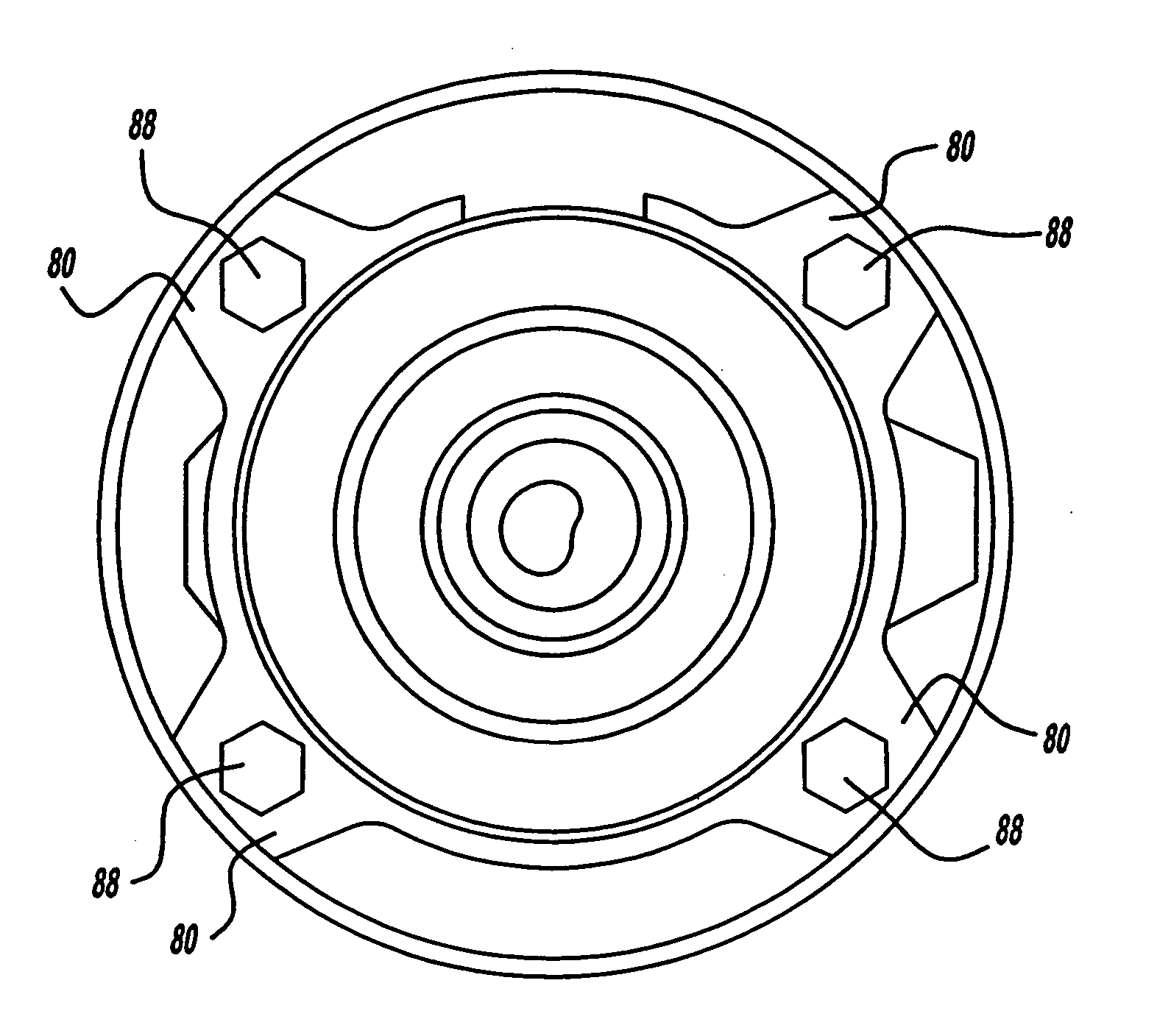

A scroll fluid machine comprises a fixed scroll, an orbiting scroll and a plurality of self-rotation preventing device for preventing the orbiting scroll from rotating on its own axis. On the rear surface of the orbiting scroll, a reinforcement bearing plate is fixed with a central bolt and an outer circumferential bolt. A follower of the self-rotation preventing device is provided in the reinforcement bearing plate. An oil-supply hole is formed through the reinforcement bearing plate to supply oil to the follower.

Owner:ANEST IWATA CORP

Compressor with unloader valve between economizer line and evaporator inlet

InactiveUS6883341B1Simplifies compressor replacementIncrease oil flowEngine of arcuate-engagement typeOscillating piston enginesEngineeringRefrigerant

A compressor has an economizer injection line communicating into the compressor compression chambers. An unloader valve selectively communicates the economizer injection line back to a point upstream of the evaporator. When the compressor is run in unloaded mode, partially compressed refrigerant is thus returned to a point upstream of the evaporator. In unloaded mode, this results in a higher refrigerant mass flow through the evaporator, as compared to prior art where the bypassed refrigerant was returned downstream of the evaporator. This increases system efficiency by more effectively returning oil which otherwise might be left in the evaporator back to the compressor. Also, the amount of refrigerant superheat entering the compressor in unloaded operation is reduced as compared to the prior art compressor systems, wherein the bypassed refrigerant is returned directly to the compressor suction line. Reduced refrigerant superheat increases system efficiency, improves motor performance and reduces compressor discharge temperature.

Owner:CARRIER CORP

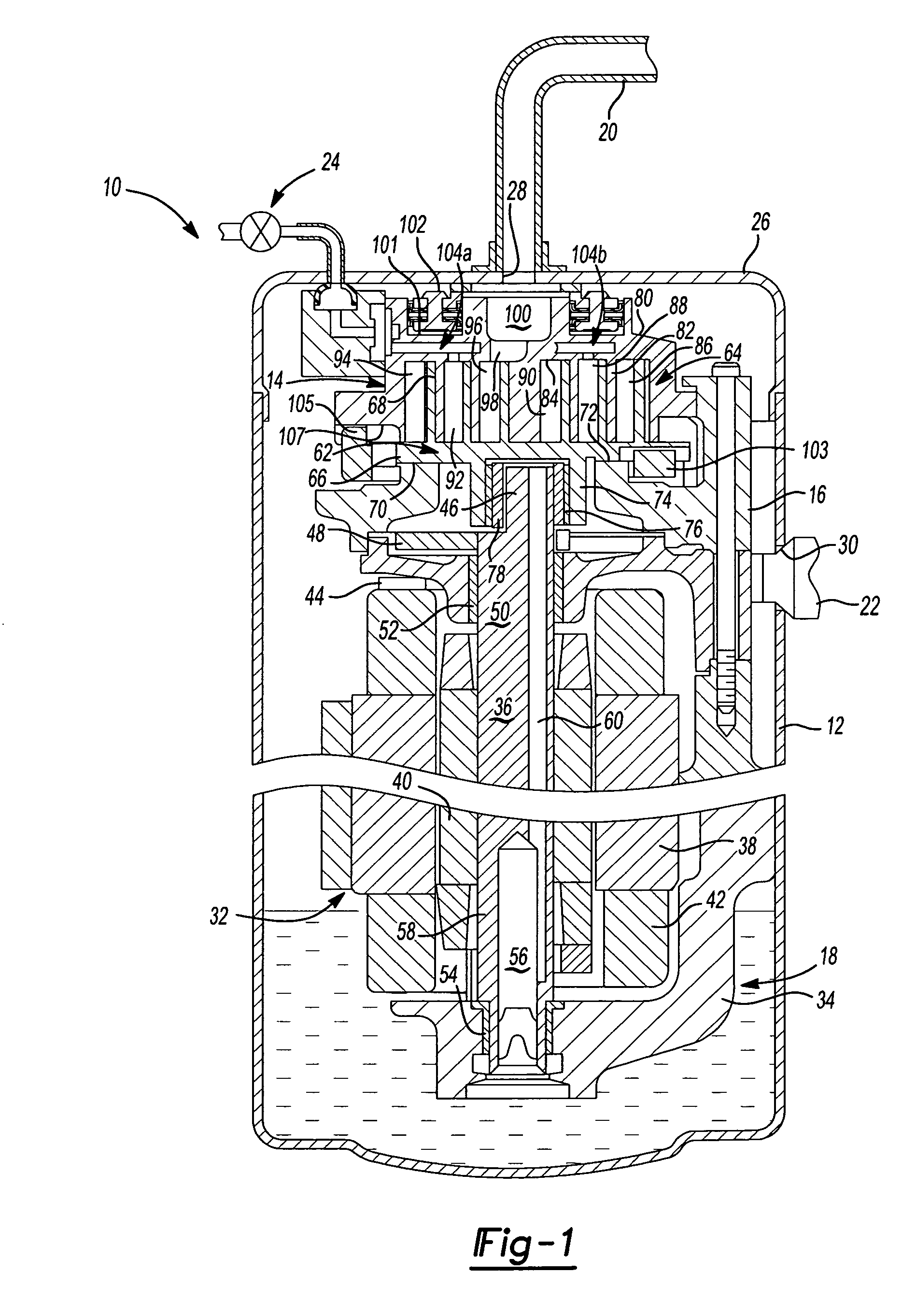

Vapor injection system for a scroll compressor

ActiveUS7771178B2Increase capacityImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInjection deviceScroll compressor

A compressor may include a shell, a compression mechanism, a motor, and a vapor injection system. The compression mechanism may be contained within in the shell and include a non-orbiting scroll axially displaceably mounted to the shell. The non-orbiting scroll may have an exterior portion, an interior portion, and a vapor injection passage extending therethrough from the exterior portion to the interior portion. The motor may be contained within the shell and may be drivingly coupled to the compression mechanism. The vapor injection system may include a vapor injection device, a vapor injection fitting, and a vapor injection valve. The vapor injection fitting may be in communication with the vapor injection device and the vapor injection passage. The vapor injection valve may be disposed between the shell and the interior of the non-orbiting scroll.

Owner:COPELAND LP

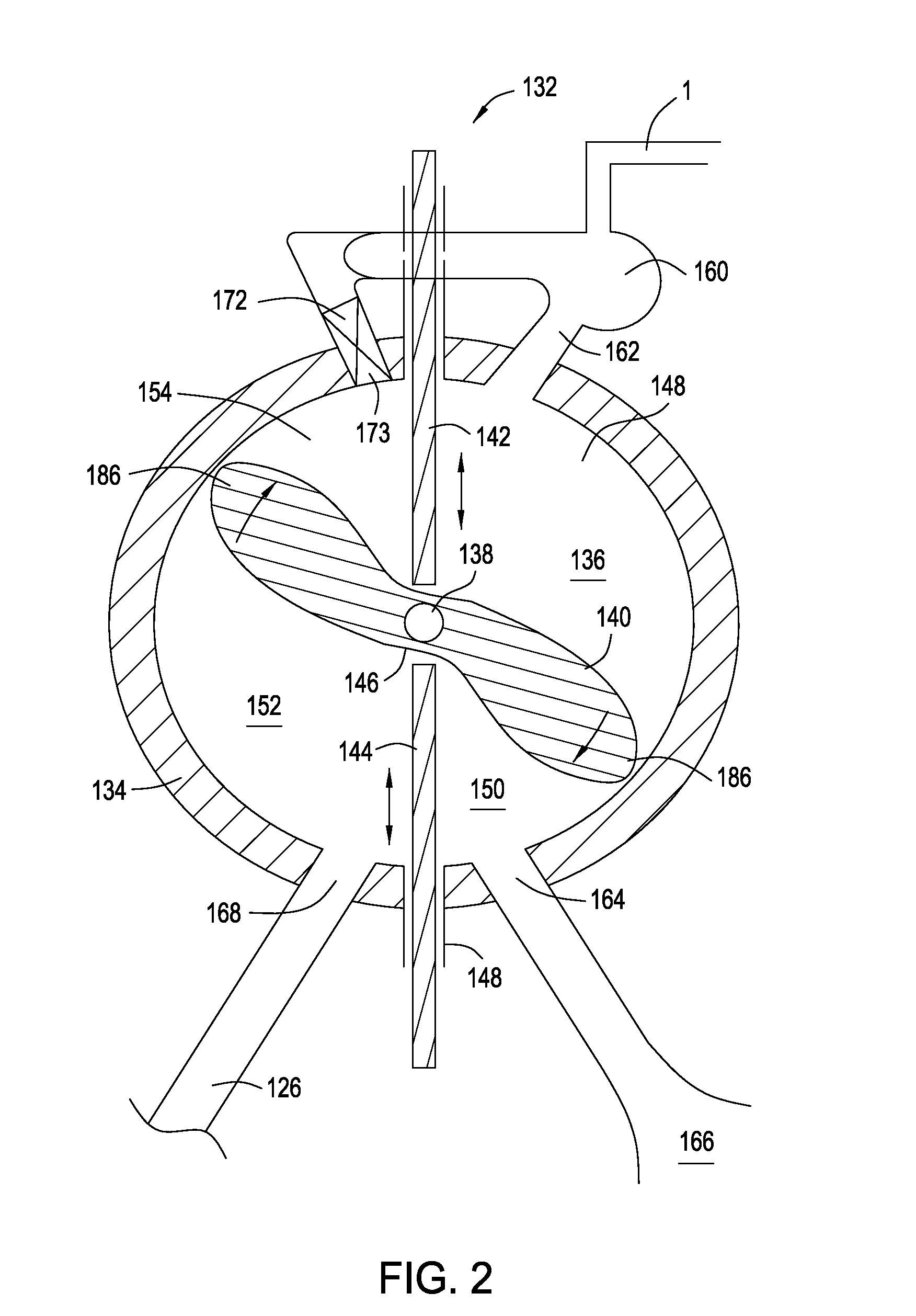

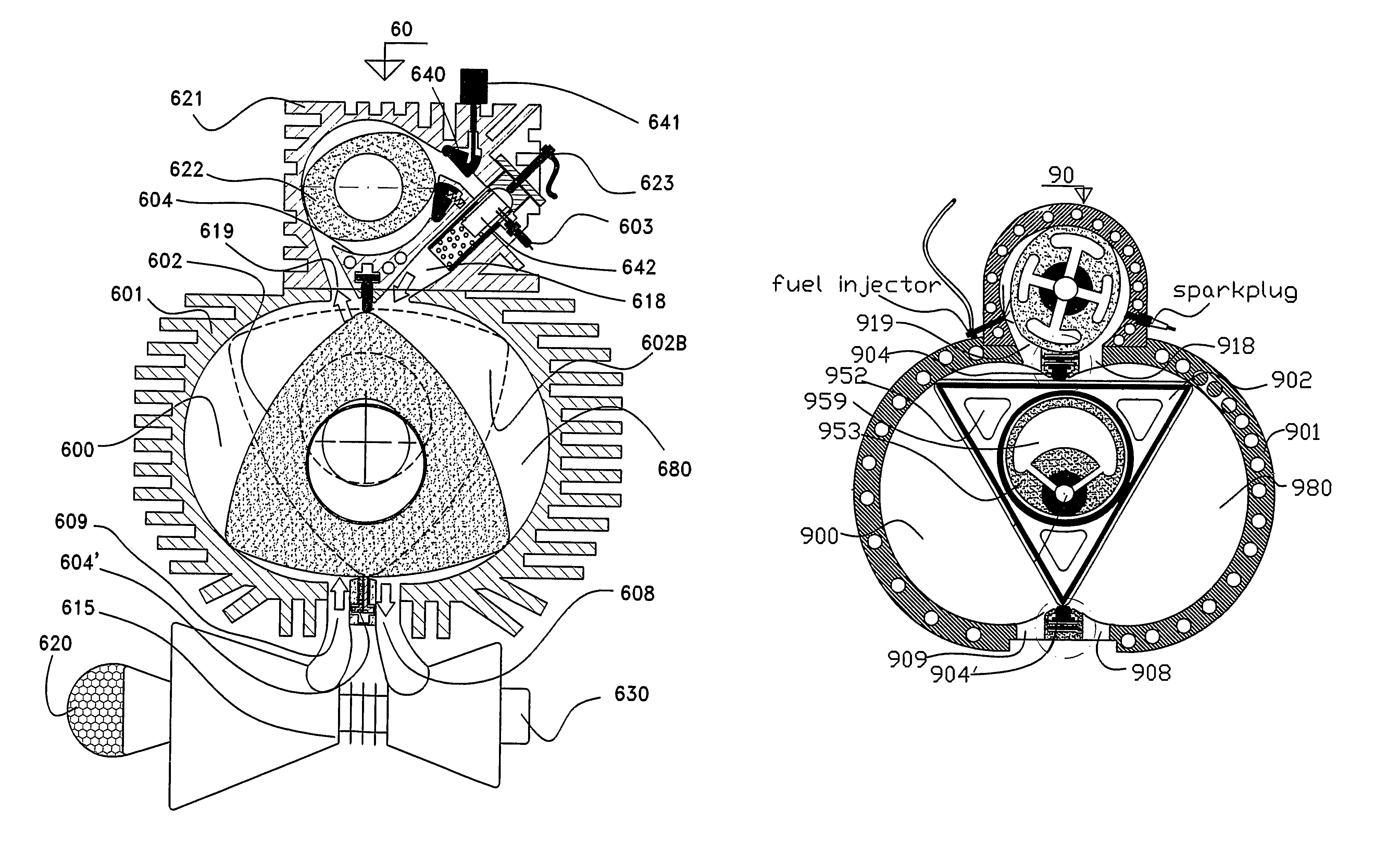

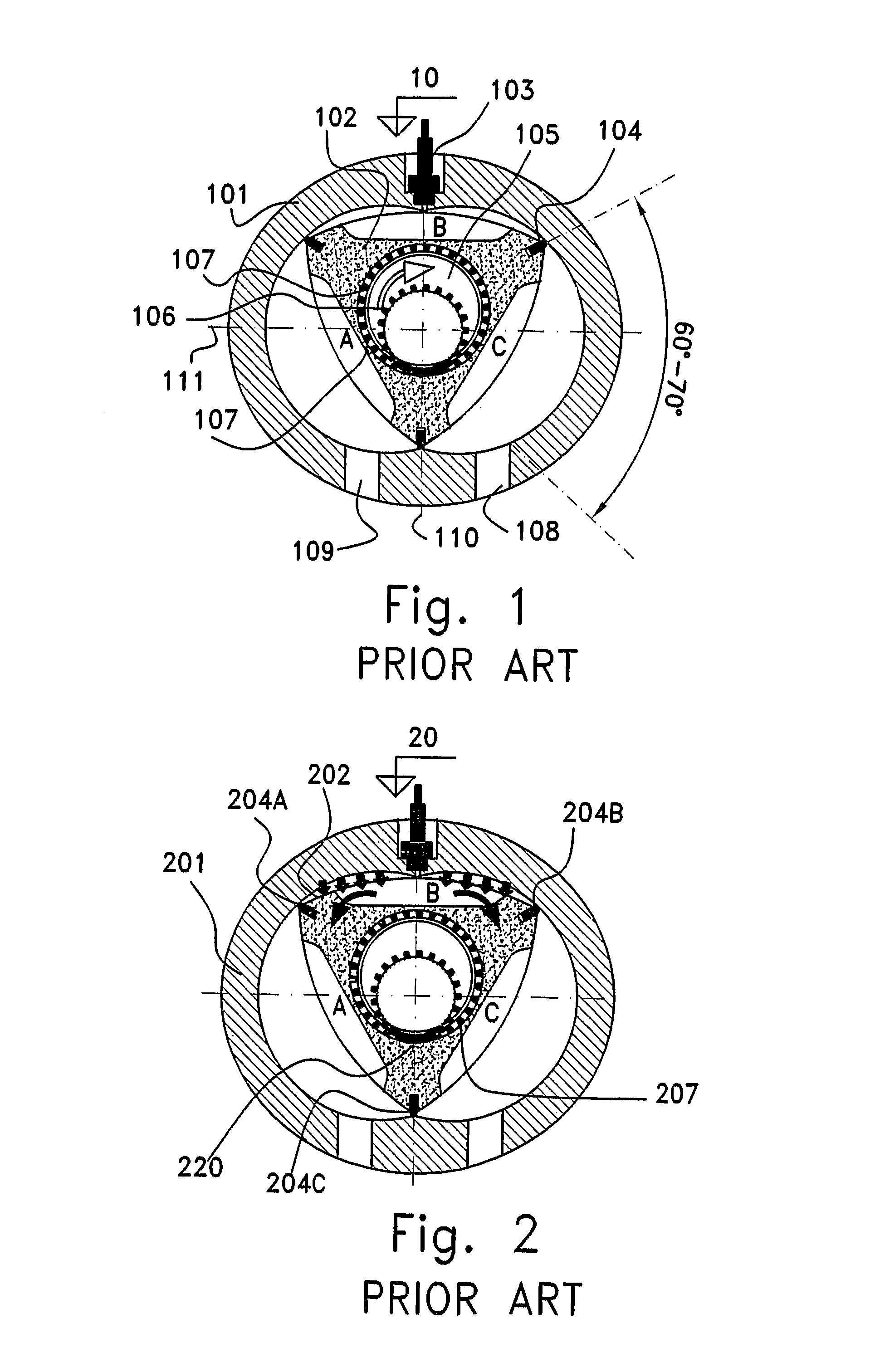

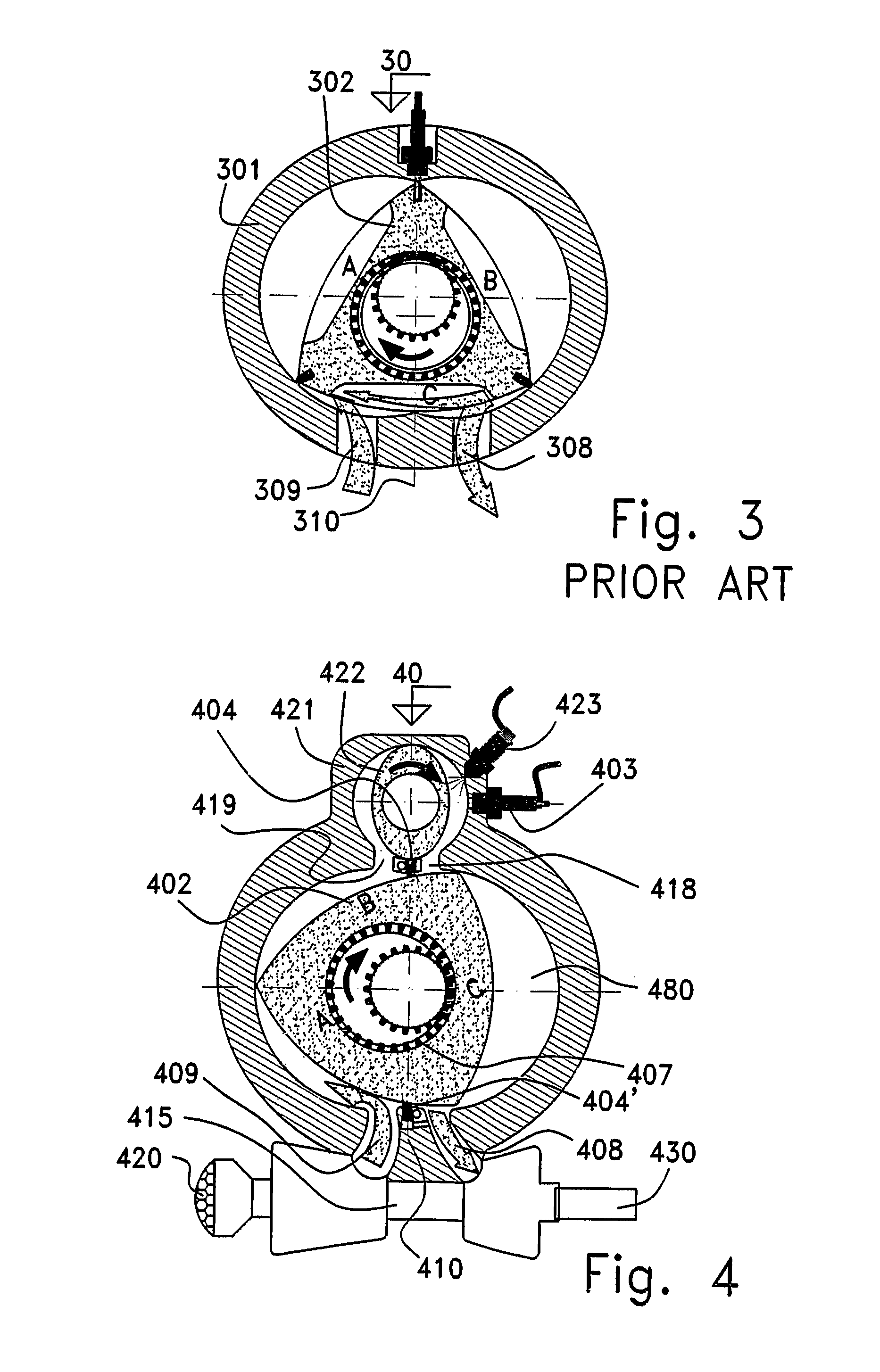

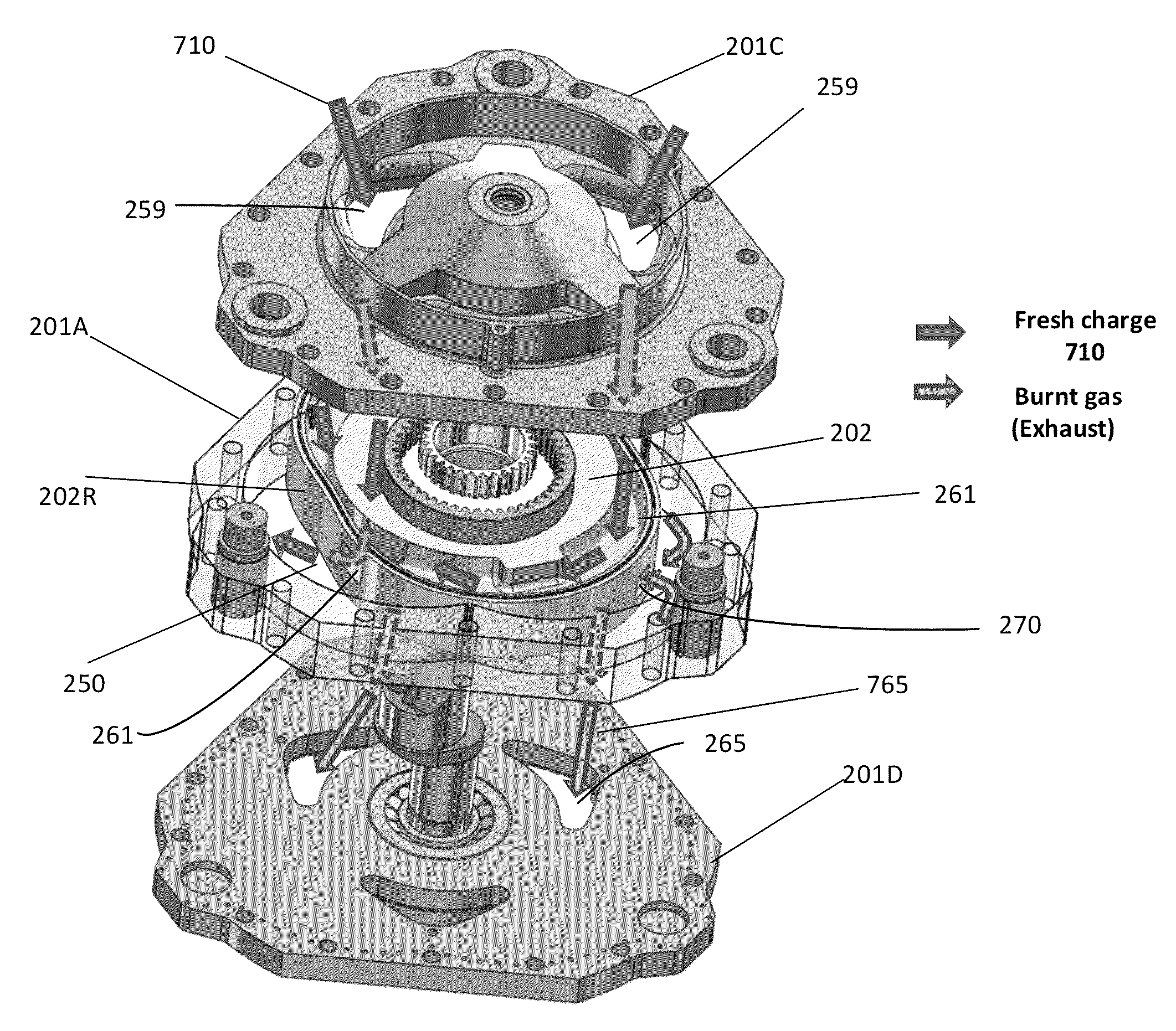

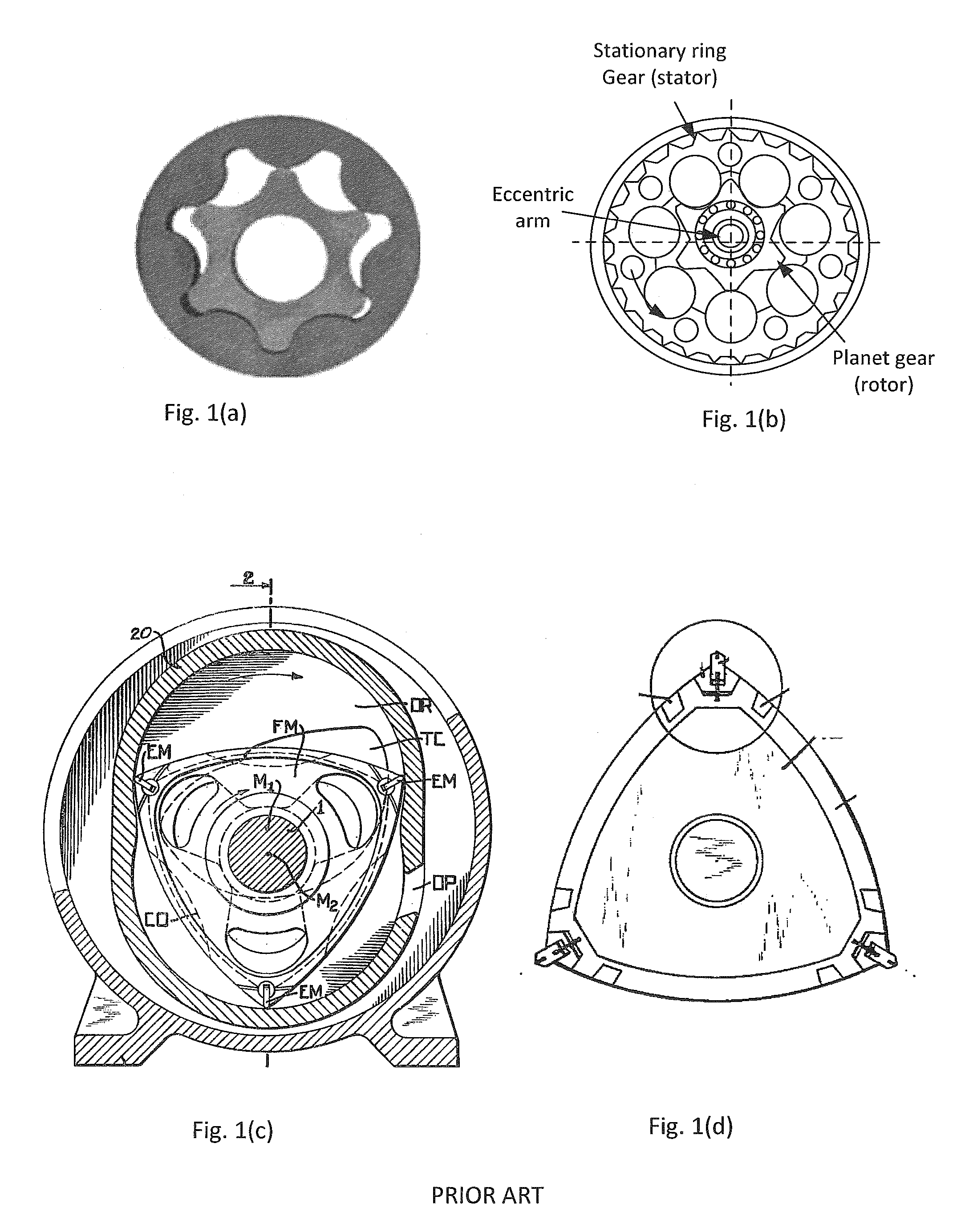

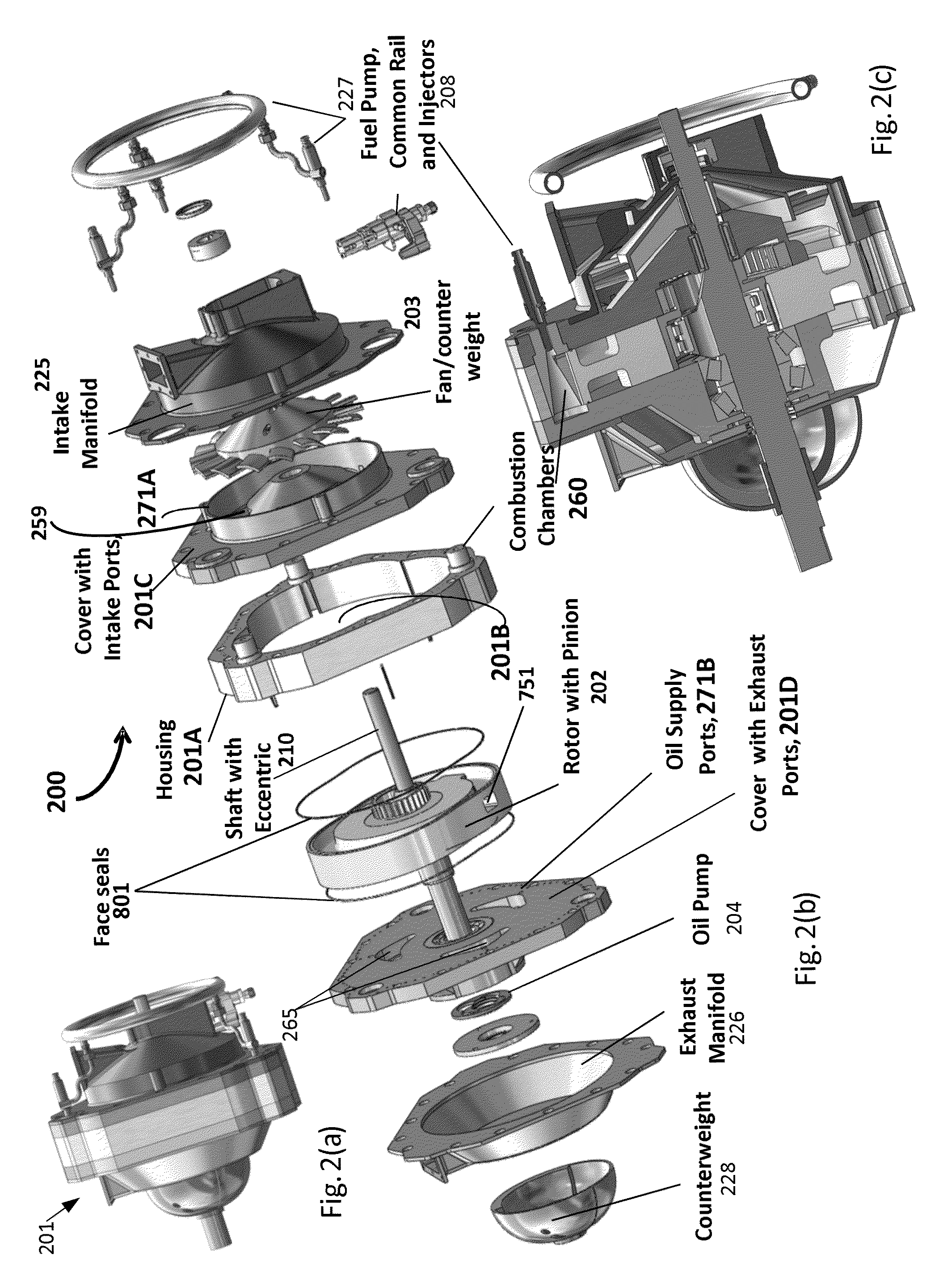

Wankel and similar rotary engines

InactiveUS8312859B2High power outputGuaranteed uptimeInternal combustion piston enginesEngine of arcuate-engagement typeCombustion chamberCompressed fluid

Owner:ROM HAIM +1

Scroll machine

ActiveUS20060233657A1Quantity minimizationMinimize volume of compressedEngine of arcuate-engagement typeOscillating piston enginesCounter rotationVALVE PORT

A discharge valve assembly is provided for preventing reverse rotation of a scroll compressor. The discharge valve assembly includes a cup-shaped valve member slidably engaged with a central post of a retainer member. The cup-shaped valve member includes notches in communication between the central post of the retainer and the sidewalls of the cup-shaped valve member.

Owner:COPELAND LP

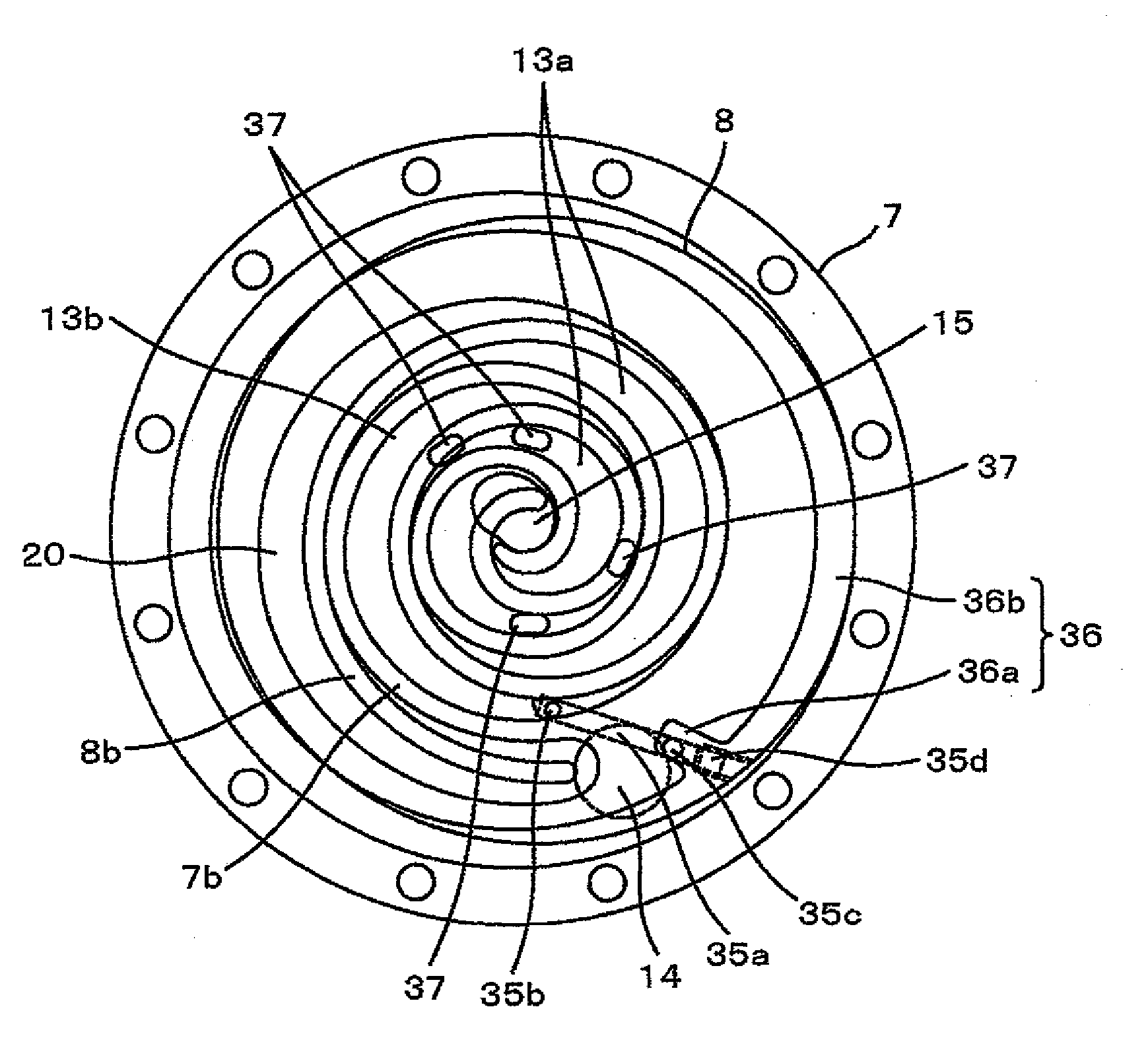

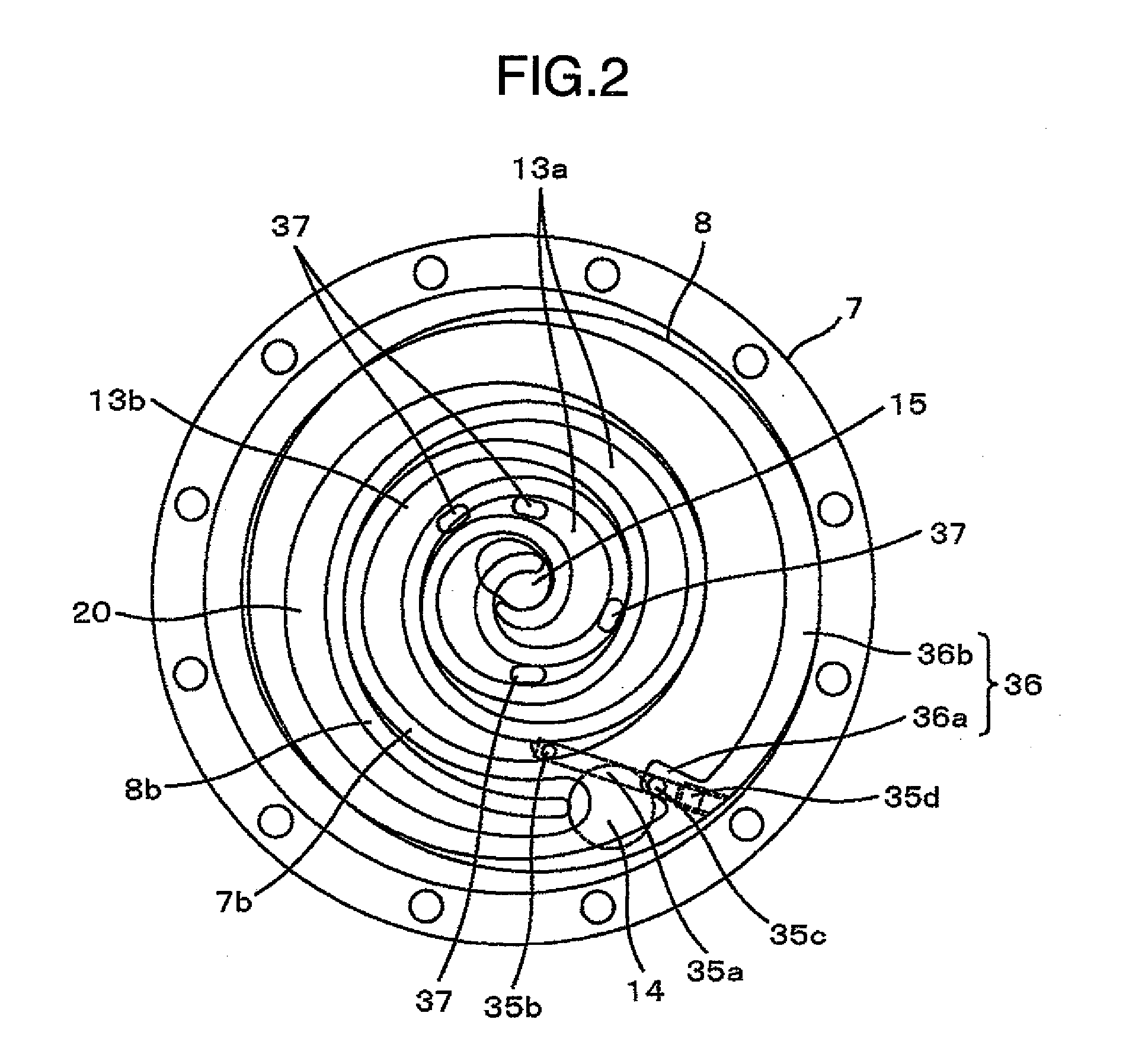

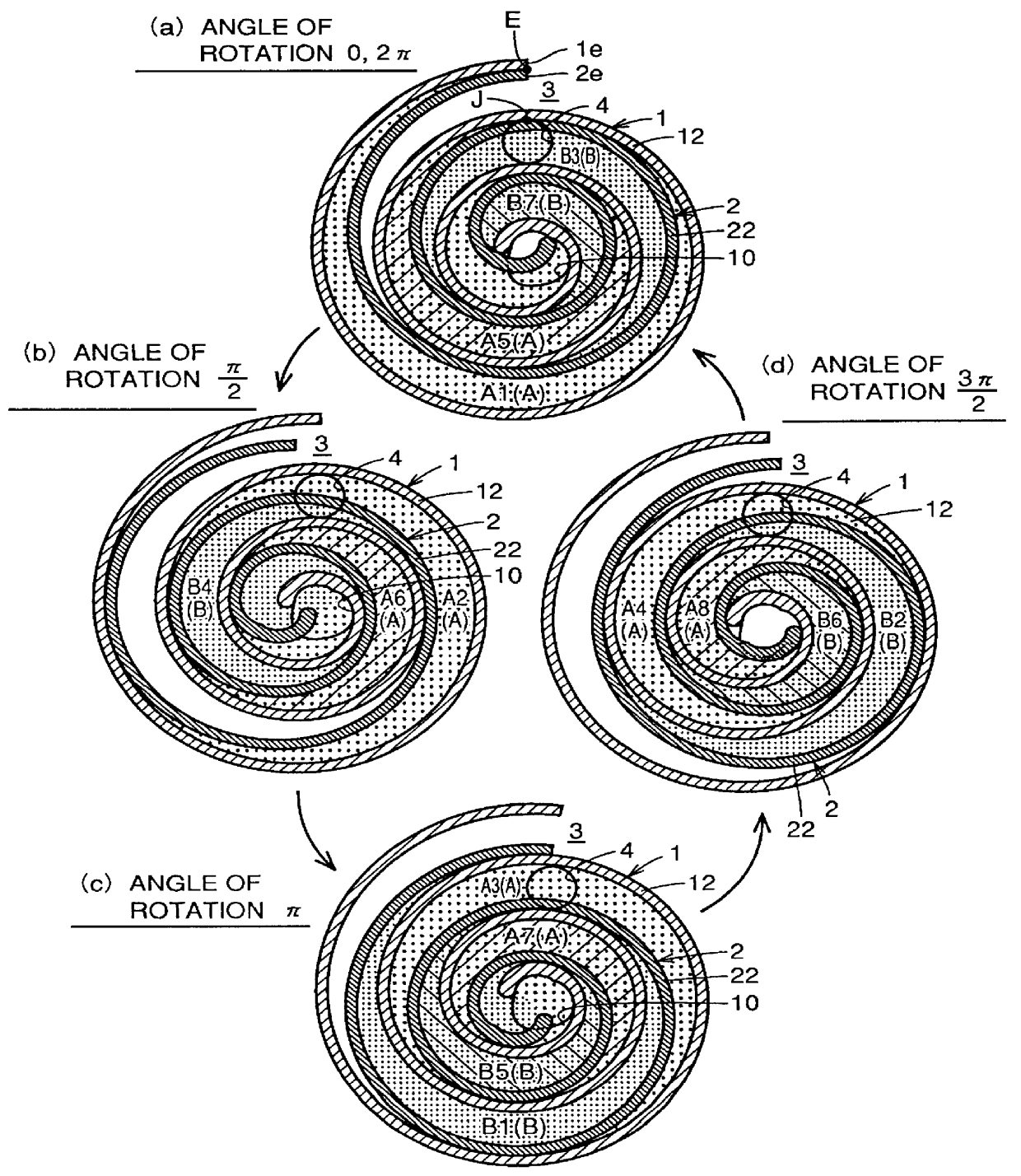

Scroll type fluid machine

InactiveUS6139287AOperating means/releasing devices for valvesEngine of arcuate-engagement typeSpiral bladeEngineering

PCT No. PCT / JP97 / 02013 Sec. 371 Date Nov. 3, 1998 Sec. 102(e) Date Nov. 3, 1998 PCT Filed Jun. 11, 1997 PCT Pub. No. WO98 / 57066 PCT Pub. Date Dec. 17, 1998A scroll type fluid machine having a bypass hole structure for capacity control is disclosed. The scroll type fluid machine comprises a first scroll having a first spiral blade, and a second scroll having a second spiral blade. A first fluid working chamber is formed between an inner surface of the first spiral blade, and a second scroll having a second spiral blade. A first fluid working chamber is formed between an inner surface of the first spiral blade and an outer surface of the second spiral blade, and a second fluid working chamber is formed between an outer surface of the first spiral blade and an inner surface of the second spiral blade. A winding end of the first spiral blade is extended so that the first fluid working chamber and the second fluid working chamber open and close with respect to a single low-pressure port. A common bypass hole making the first and second fluid working chambers communicate with the low-pressure port in common is provided.

Owner:DAIKIN IND LTD

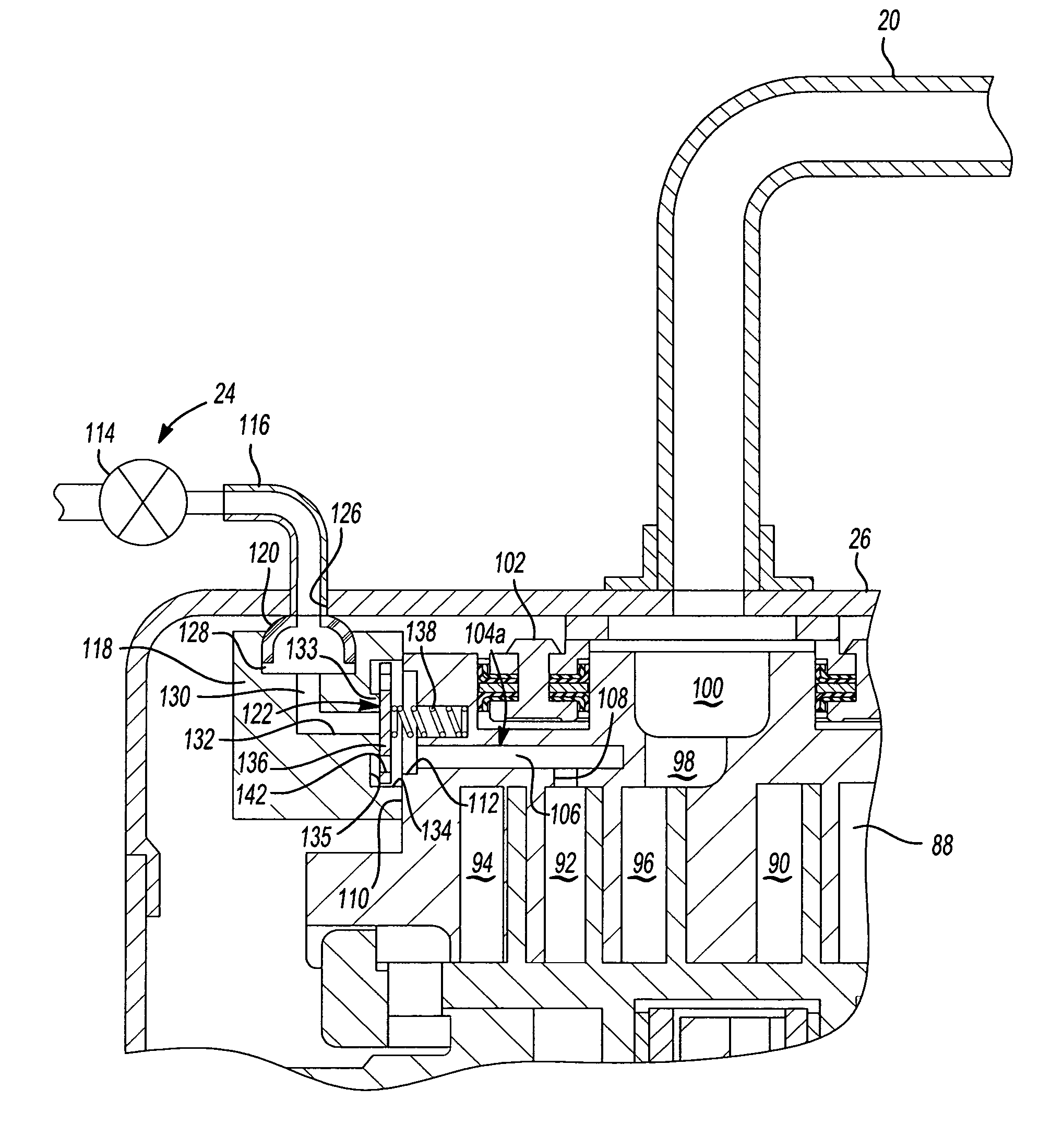

Scroll compressor capacity modulation with hybrid solenoid and fluid control

InactiveUS20110135509A1Control movementRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeReducing capacityFluid control

A scroll compressor includes a compressor shell having first and second scroll members. The scroll members each have a base and a generally spiral wrap extending from its base. The generally spiral wraps of the first and second scroll members interfit to define compression chambers. A shaft causes the second scroll member to orbit relative to the first scroll member. At least one bypass port is formed in a base of one scroll member, and communicates with at least one of the compression chambers. The bypass port communicates with a passage leading to a suction pressure chamber within the compressor shell. A solenoid valve is movable between a reduced capacity position and a full capacity position, and selectively supplies a pressurized fluid to a fluid valve associated with the bypass port, such that movement of the solenoid can control whether the bypass port is open or closed.

Owner:DANFOSS SCROLL TECH

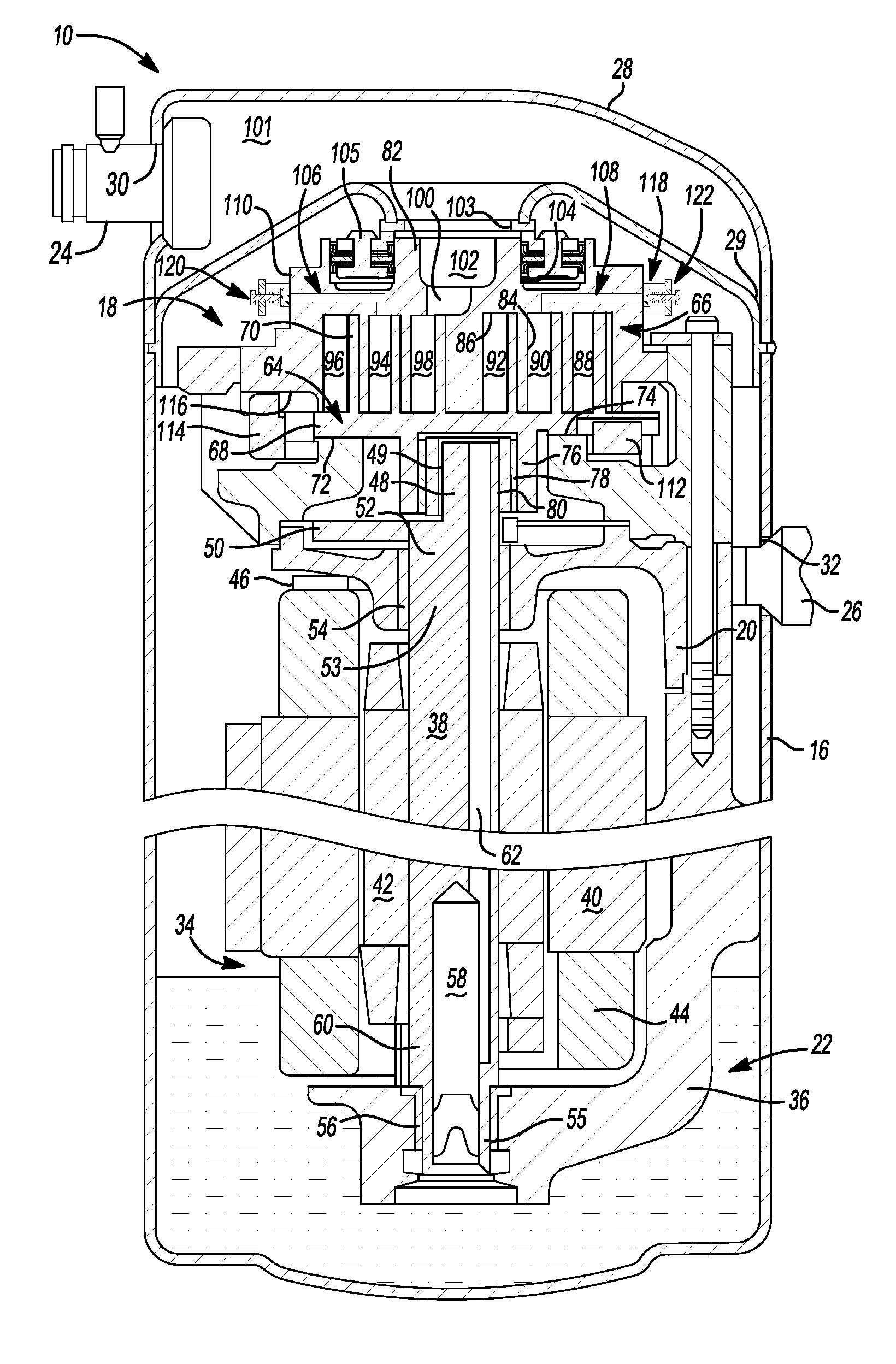

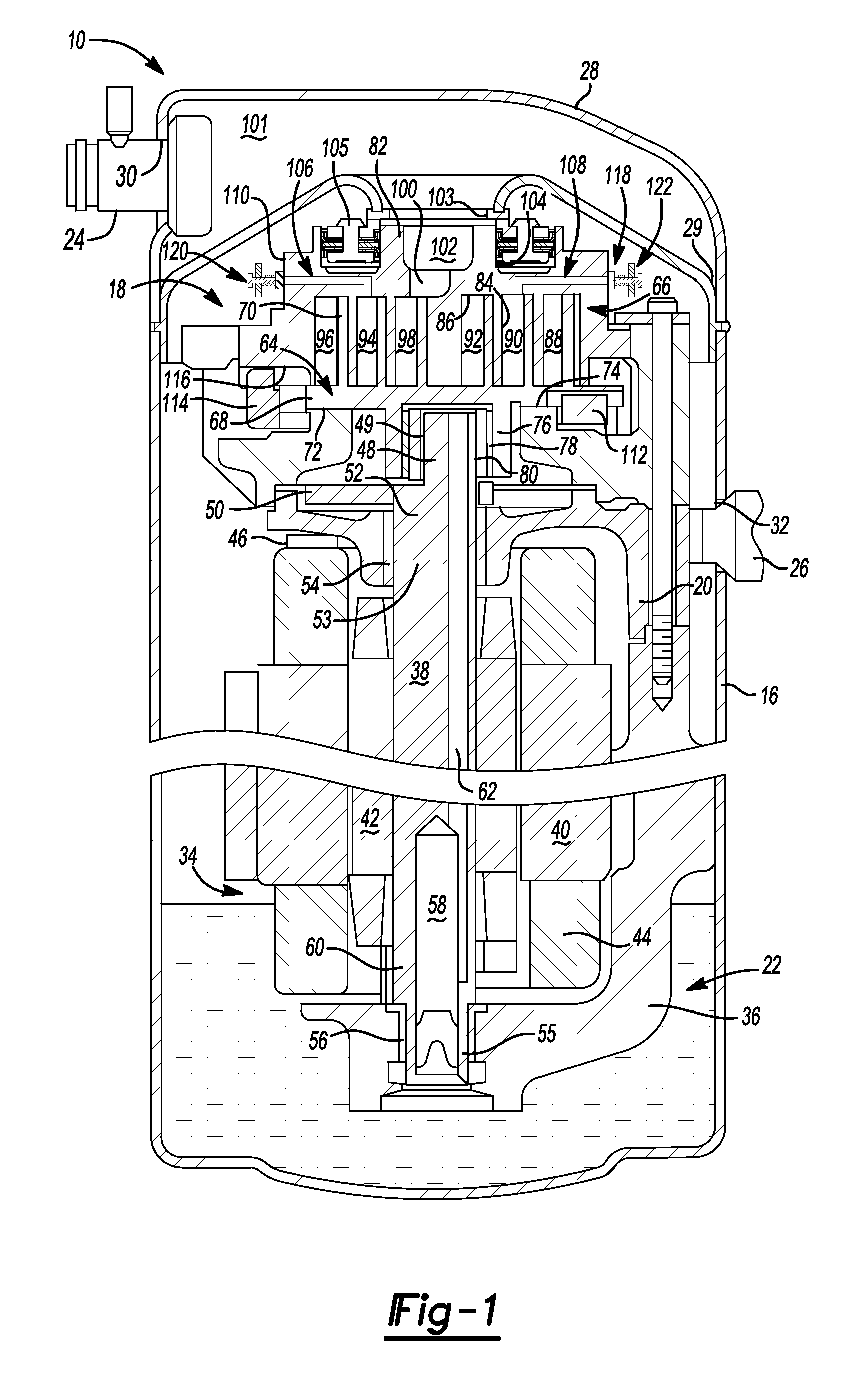

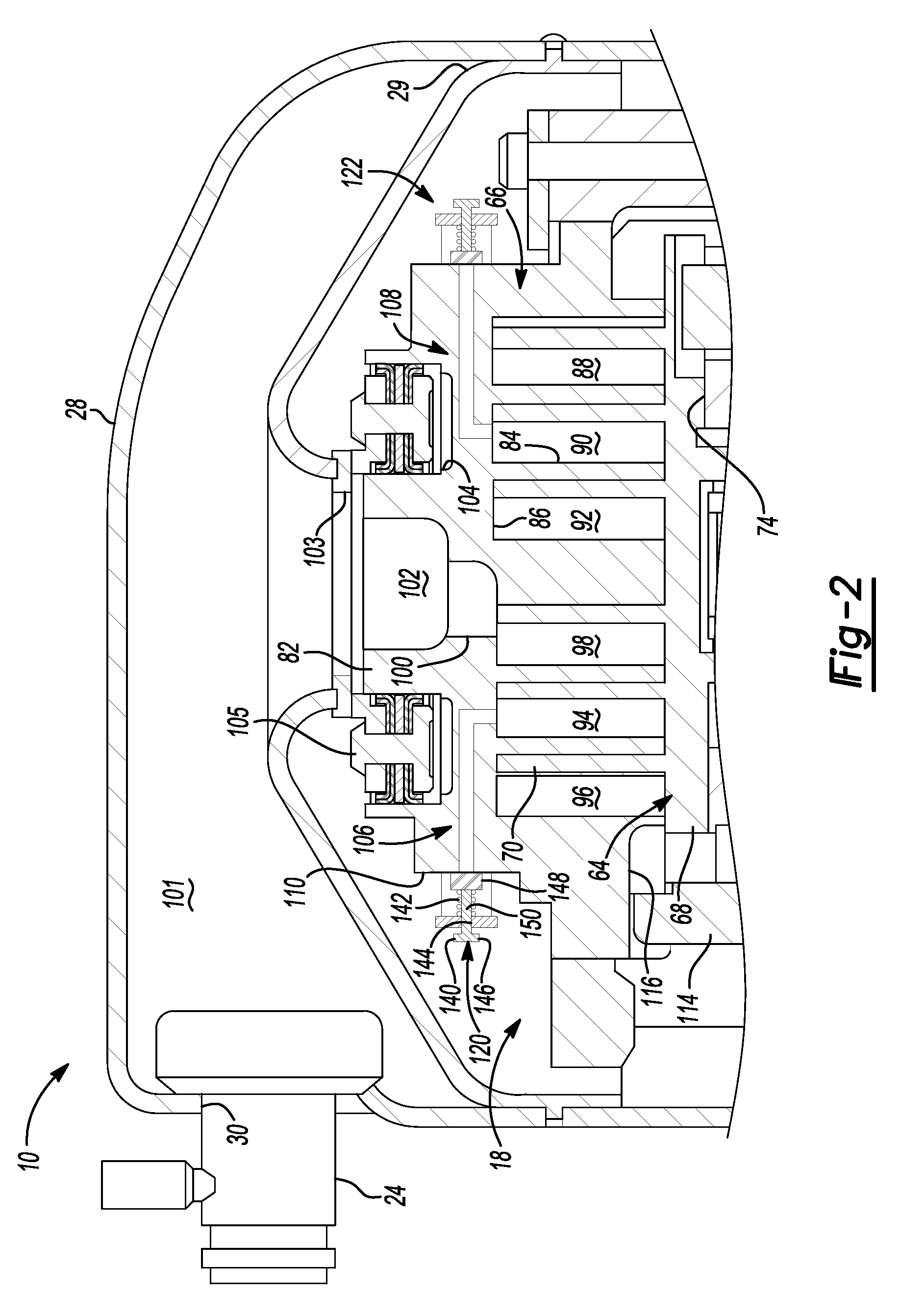

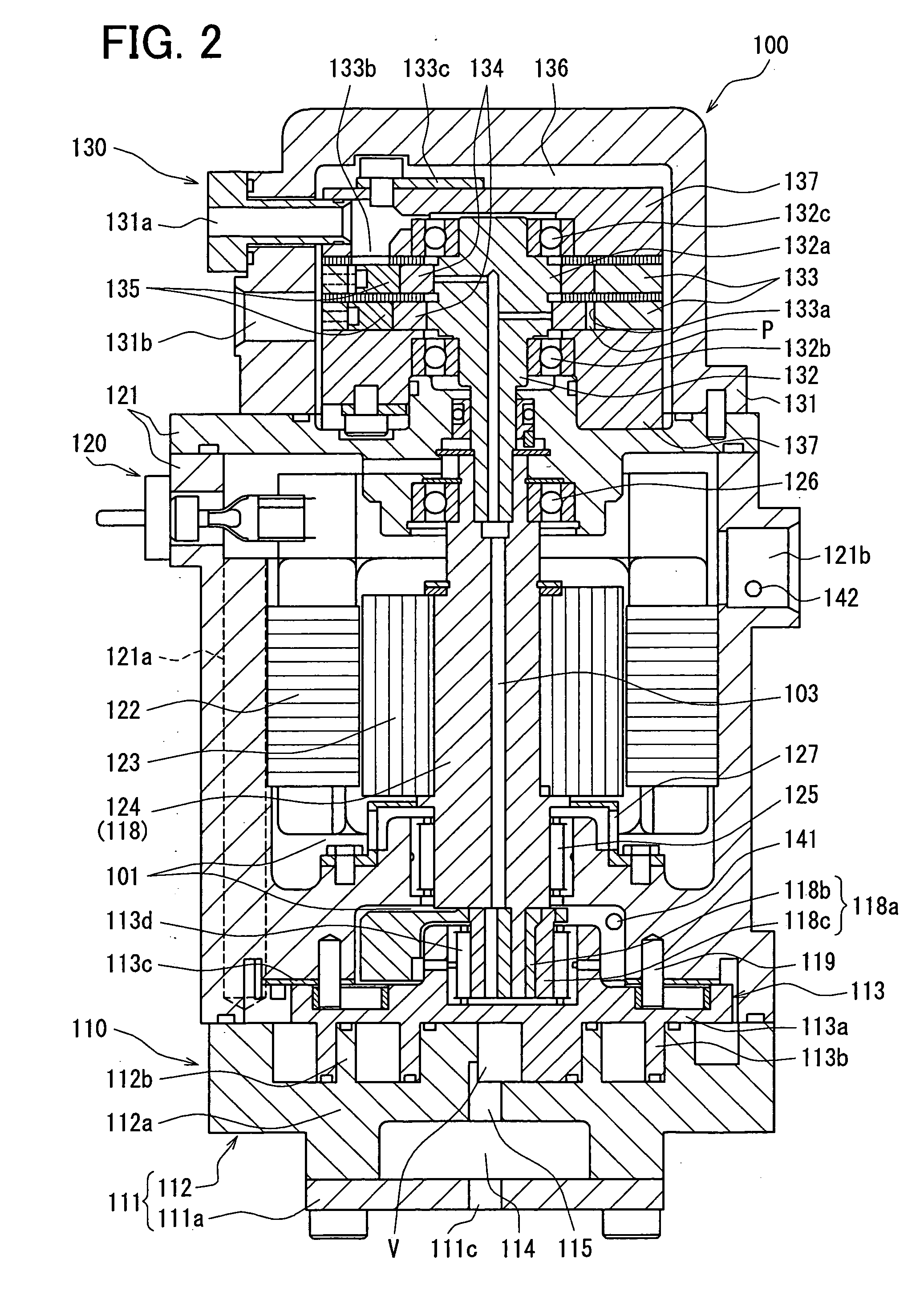

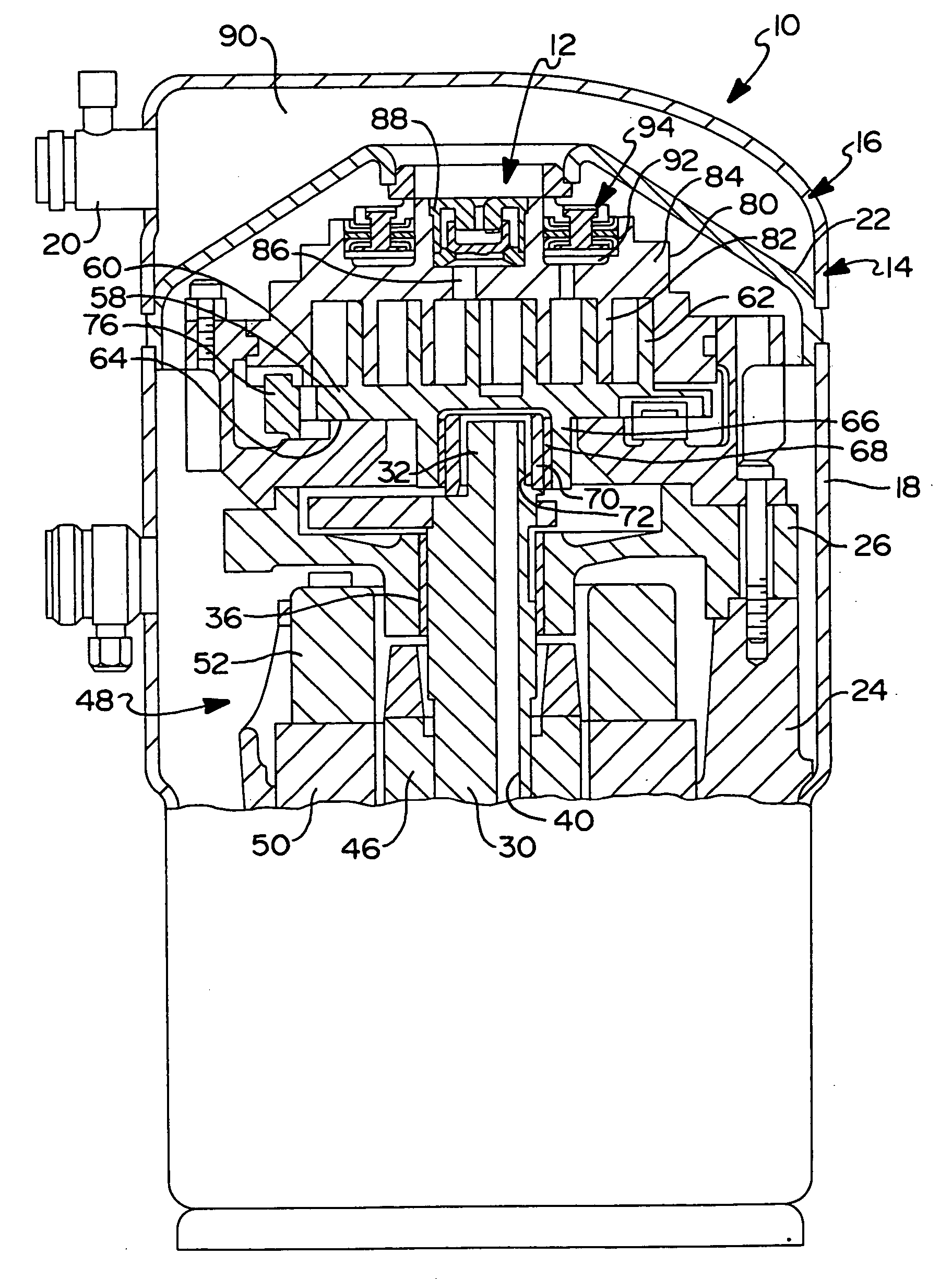

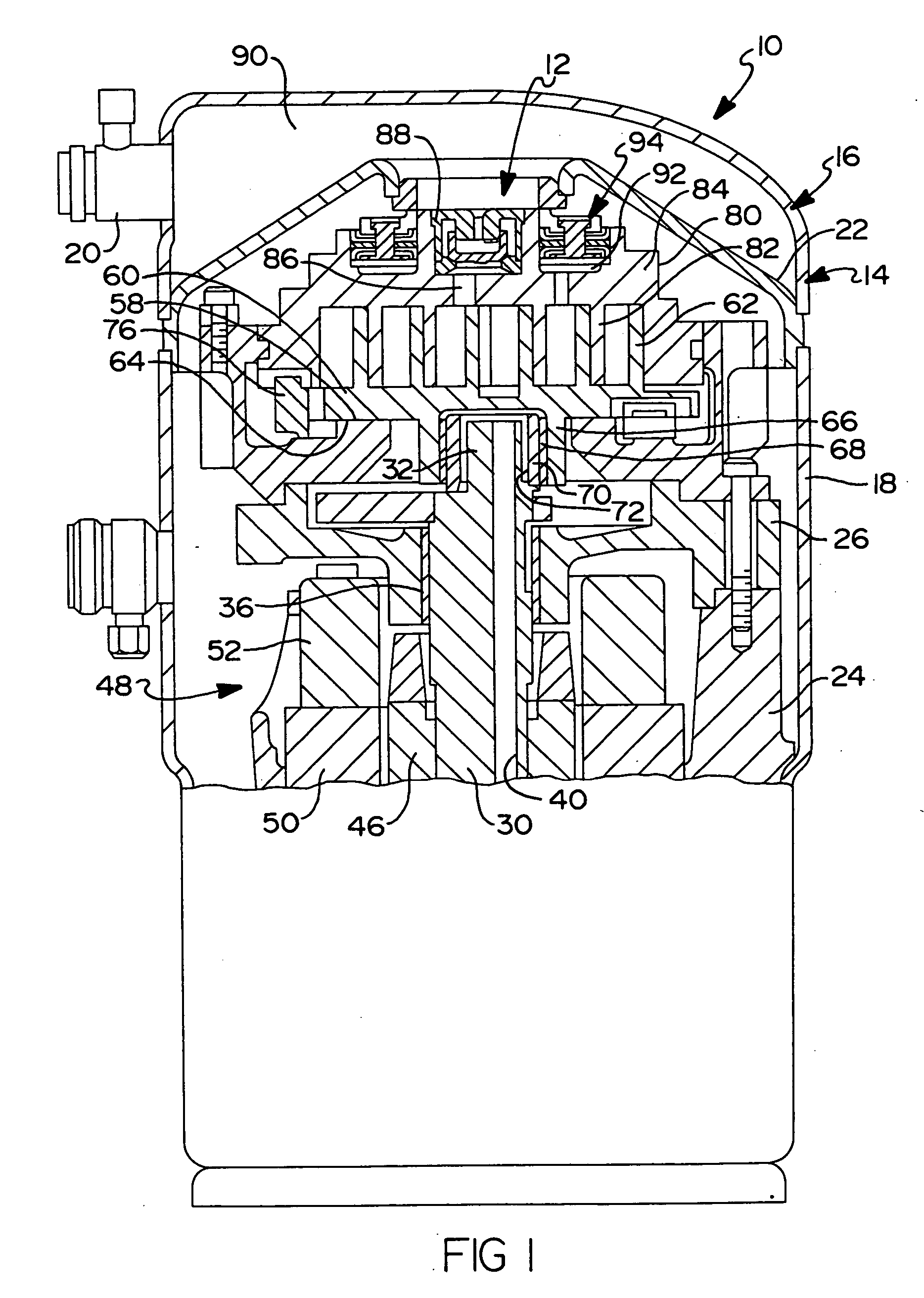

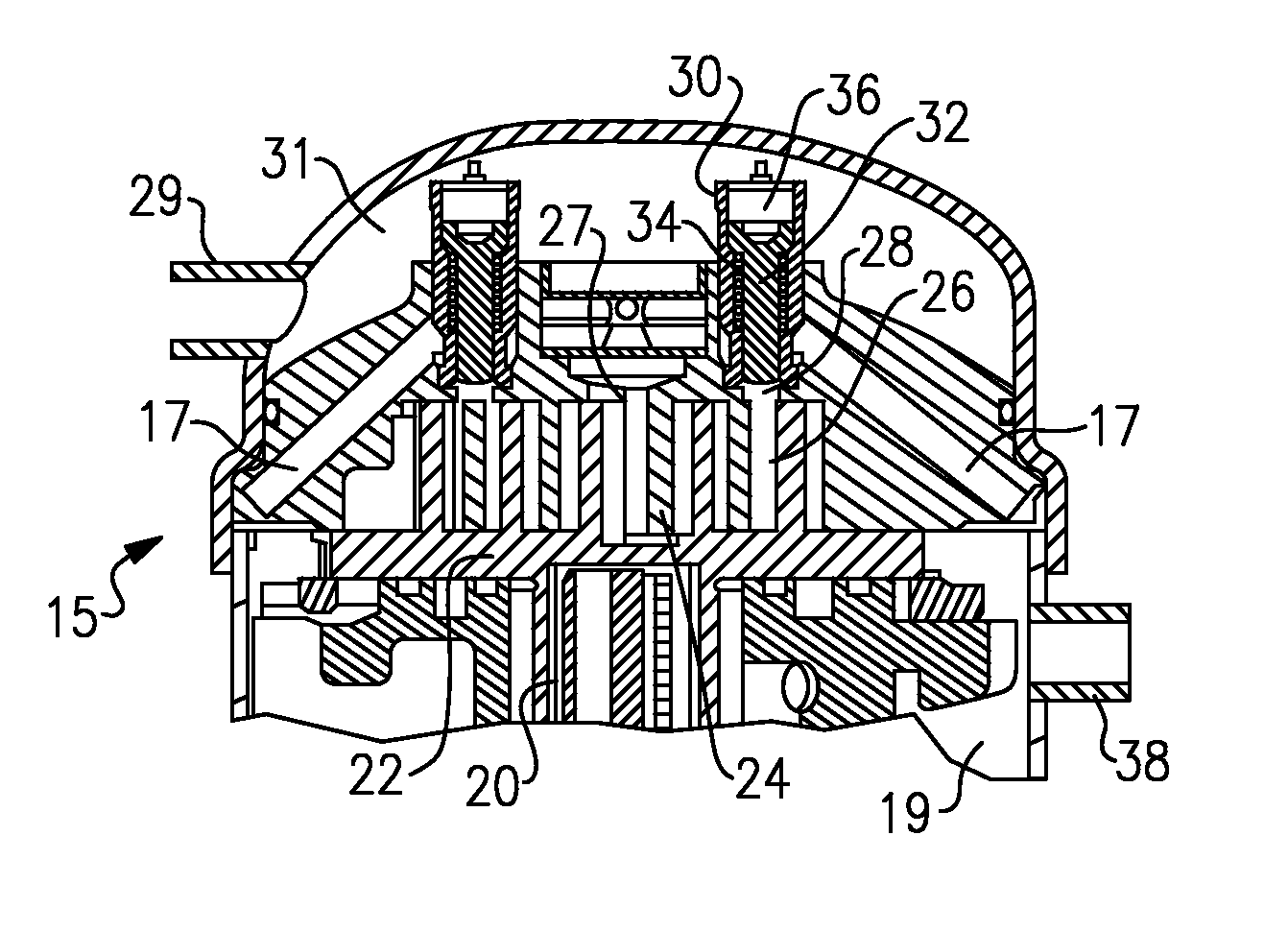

Compressor and oil-cooling system

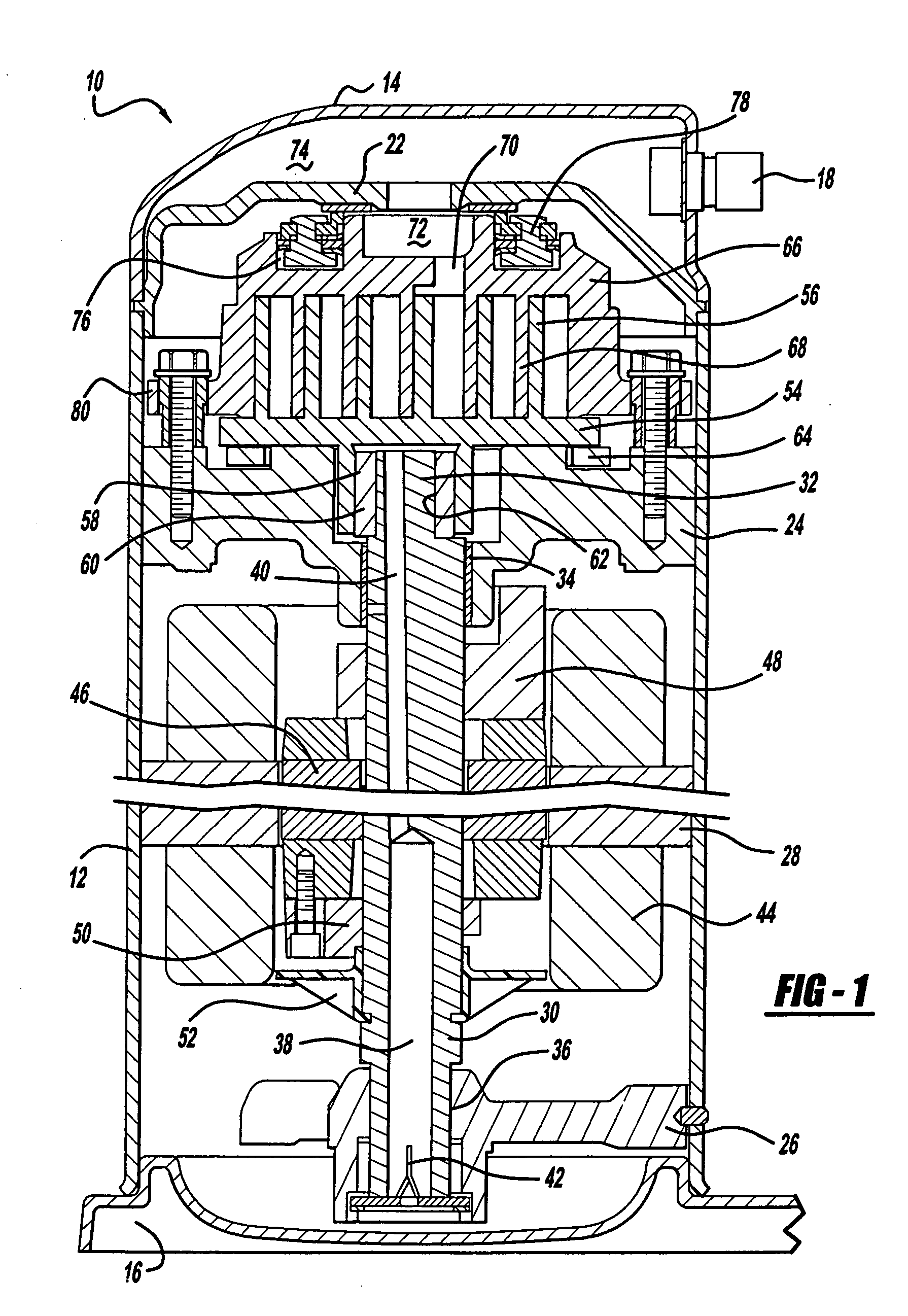

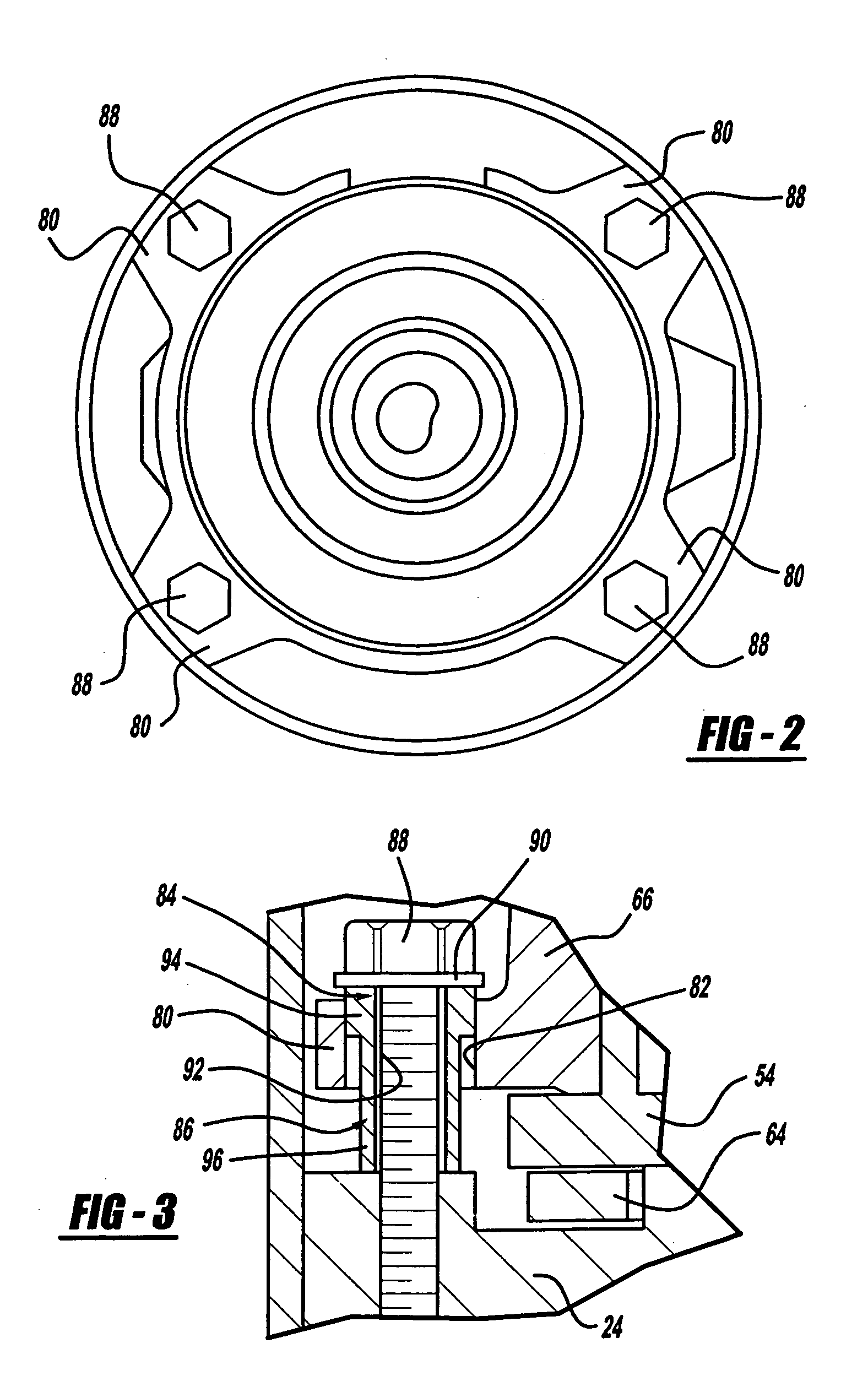

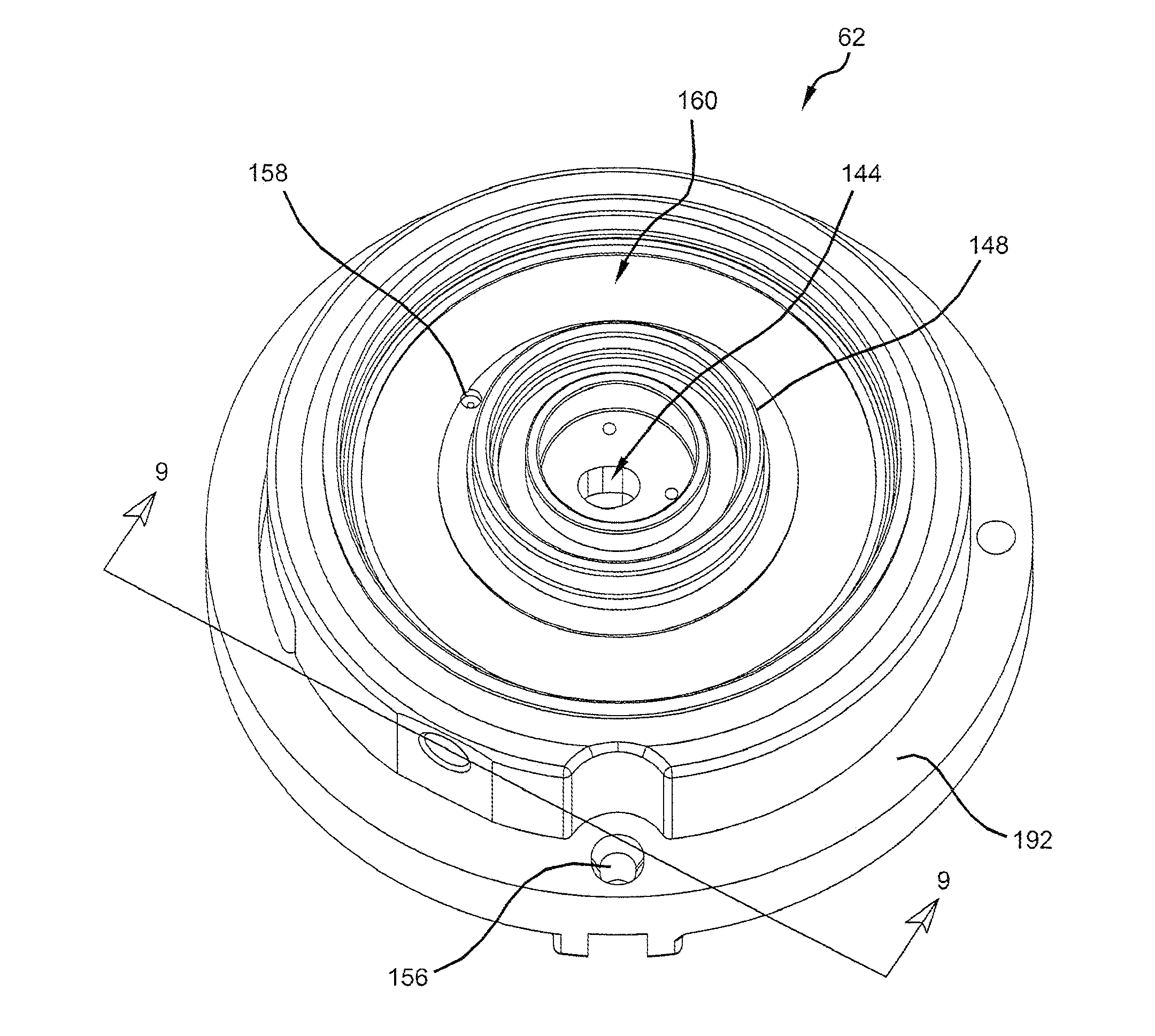

ActiveUS20100307173A1Reduce suction superheatImproving compressor volumetric efficiencyCompressorRotary/oscillating piston combinations for elastic fluidsWorking fluidEngineering

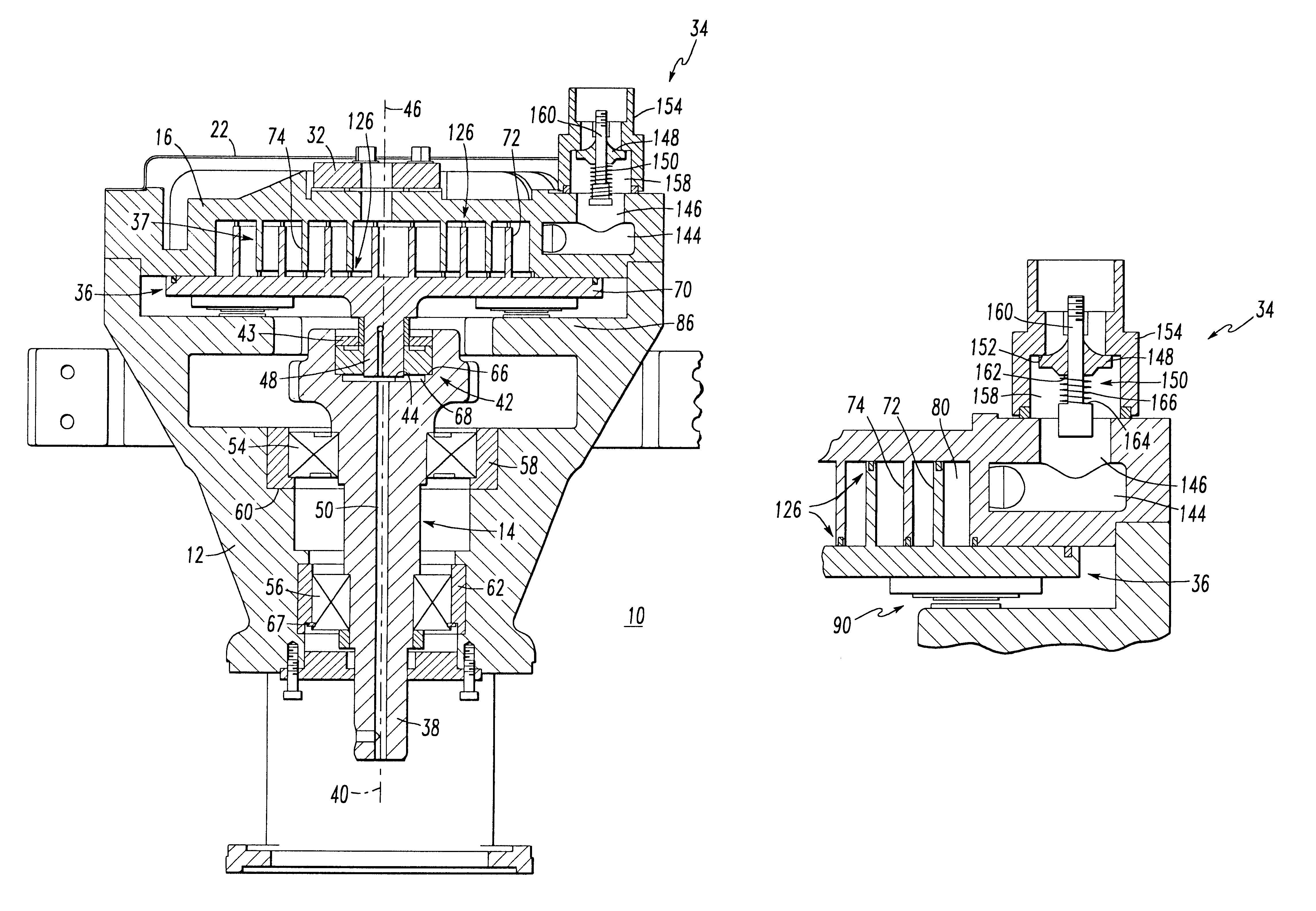

An external heat exchanger is used to transfer heat from a compressor lubricant to an expanded working fluid, thereby cooling the lubricant. The heat exchanger may also be used to sub-cool condensed working fluid with the same flow of expanded working fluid. A horizontal scroll-type compressor includes an intermediate lubricant sump between a main bearing support and a scroll member. A counterweight on the crankshaft can travel through the lubricant in the intermediate sump to splash the lubricant around. A horizontal scroll-type compressor can include multiple machined surfaces that are utilized to precisely center and align components of the compressor.

Owner:COPELAND LP

Cycloid rotor engine

ActiveUS8523546B2Internal combustion piston enginesEngine of arcuate-engagement typeRotary engineEngineering

Owner:LIQUIDPISTON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com