Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1029 results about "Rotary engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

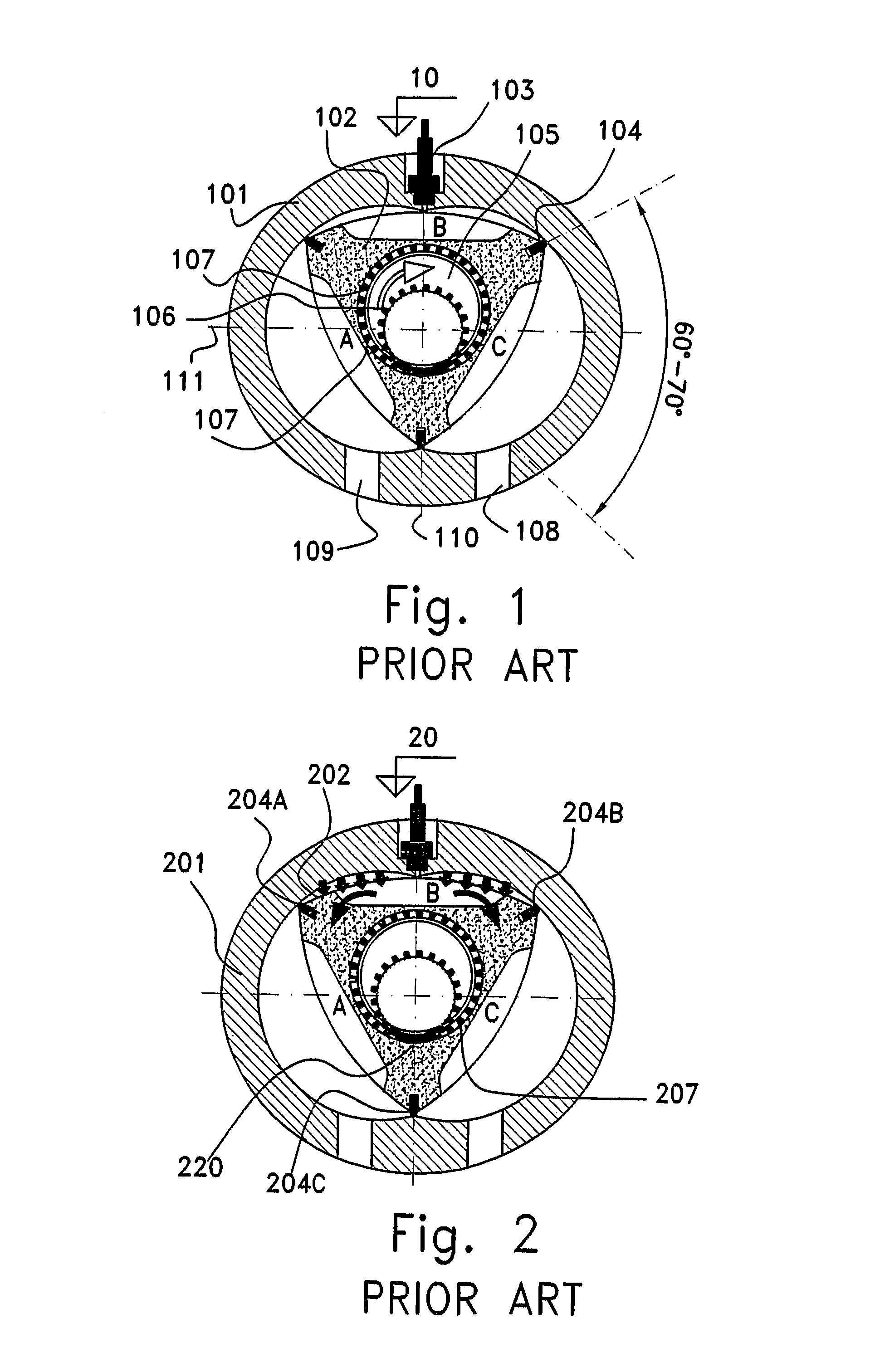

The rotary engine was an early type of internal combustion engine, usually designed with an odd number of cylinders per row in a radial configuration, in which the crankshaft remained stationary in operation, with the entire crankcase and its attached cylinders rotating around it as a unit. Its main application was in aviation, although it also saw use before its primary aviation role, in a few early motorcycles and automobiles.

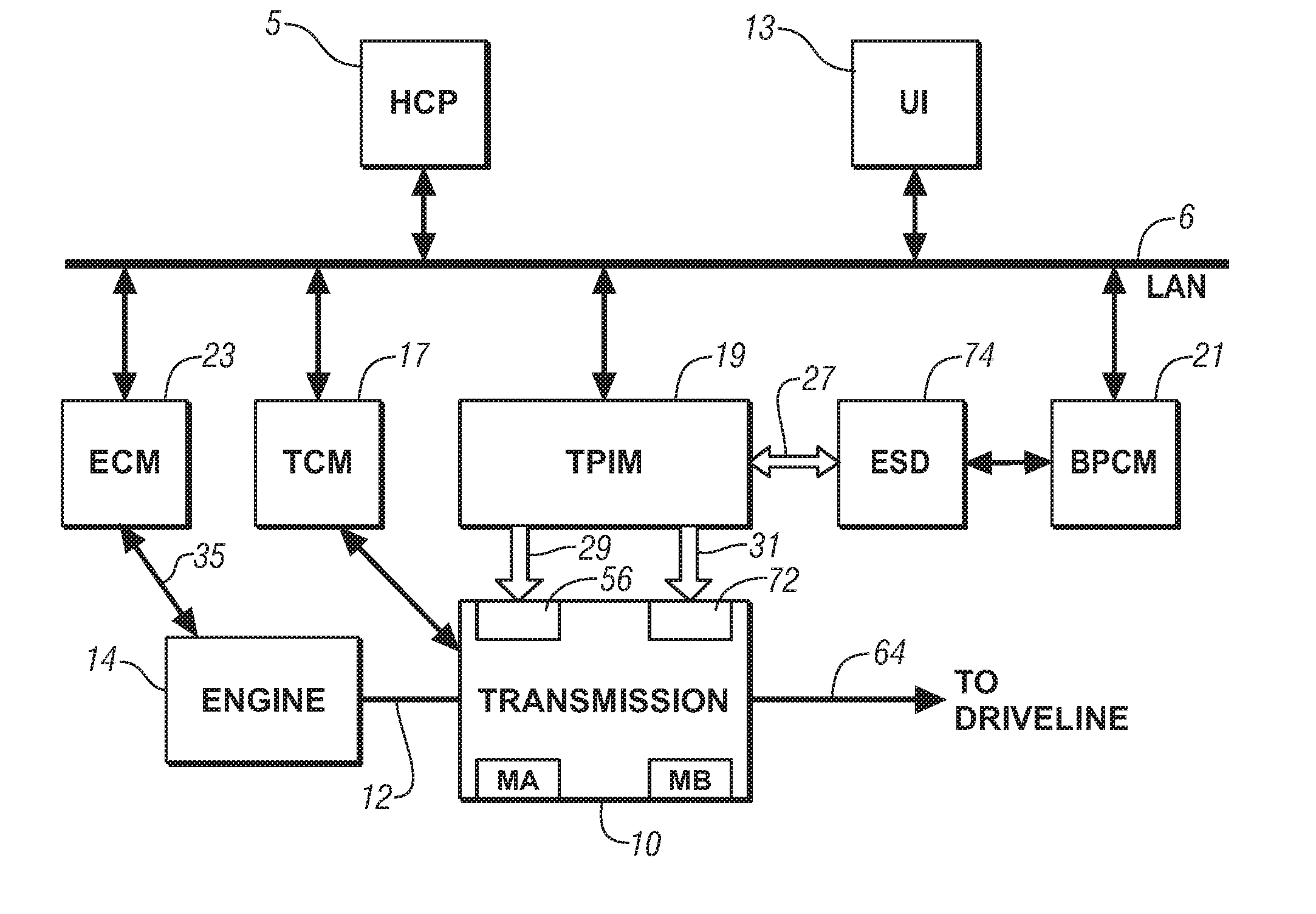

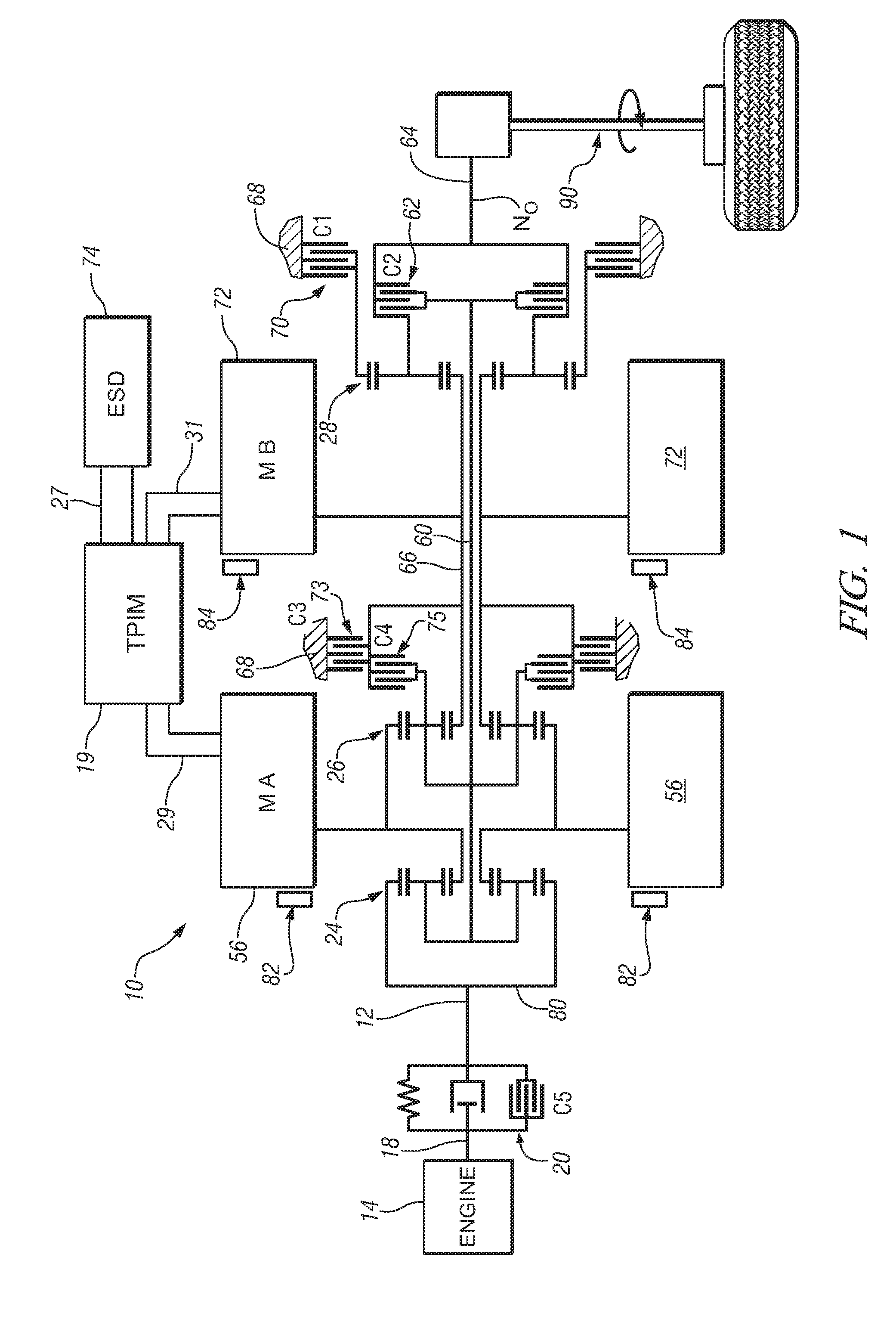

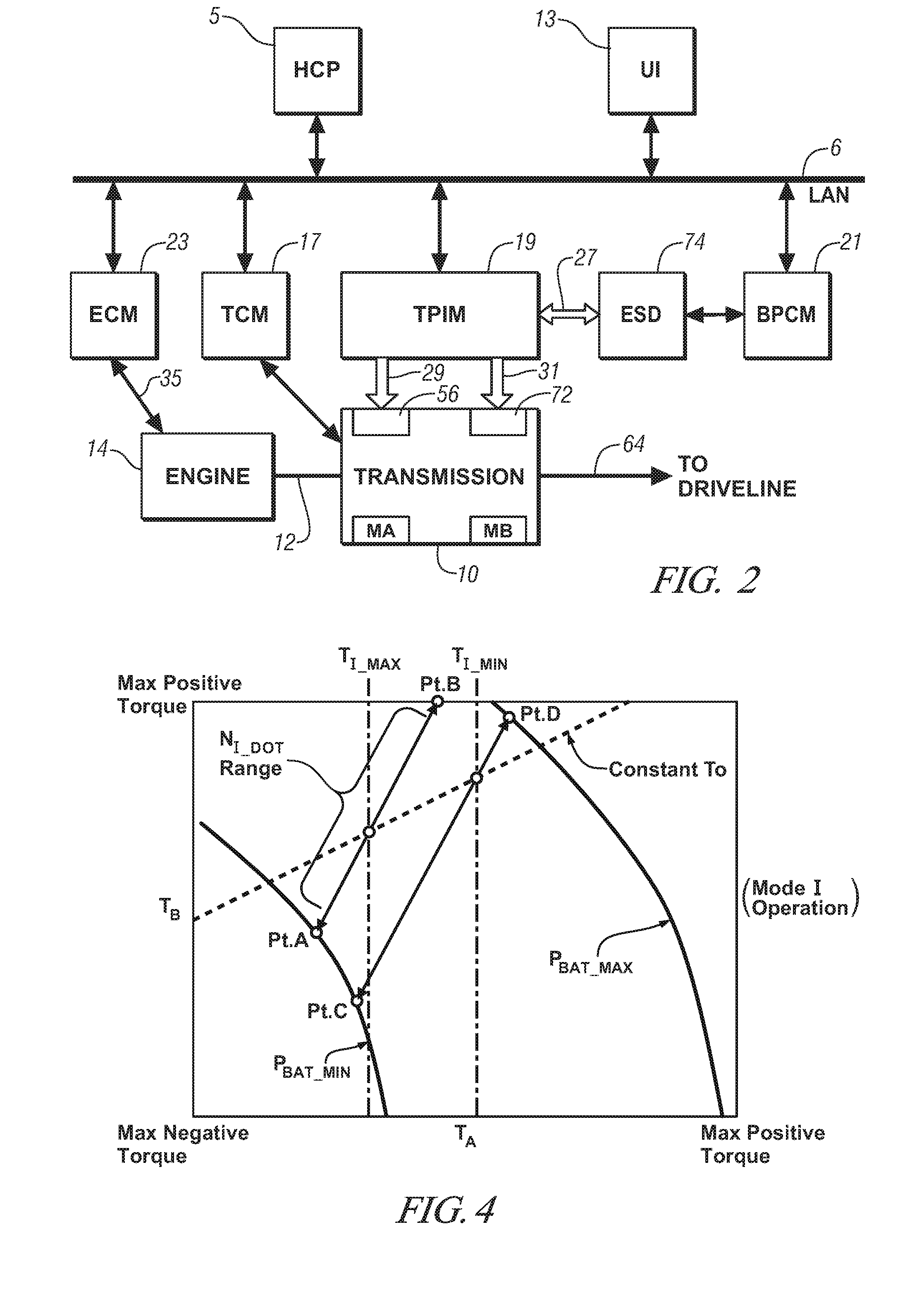

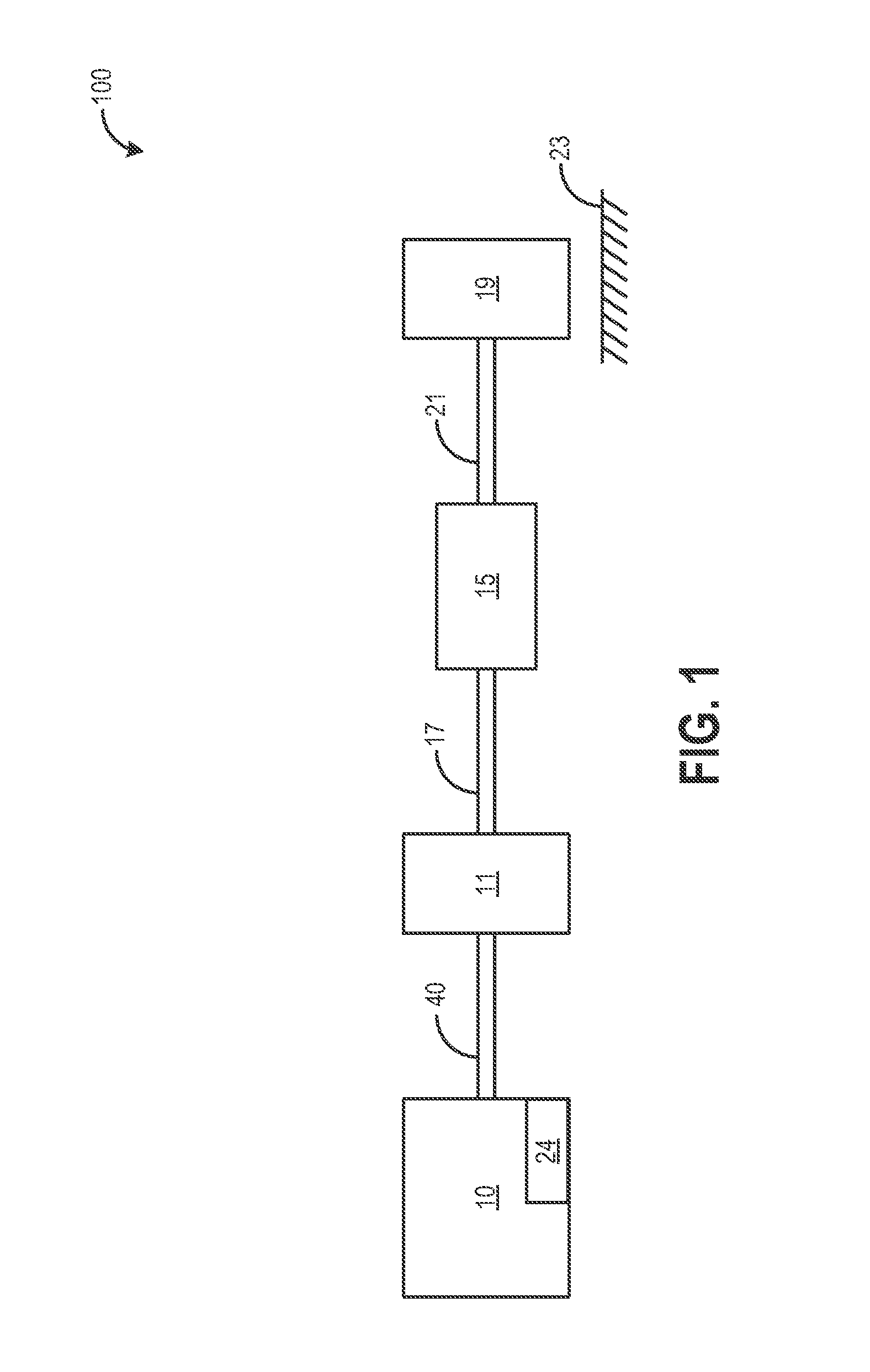

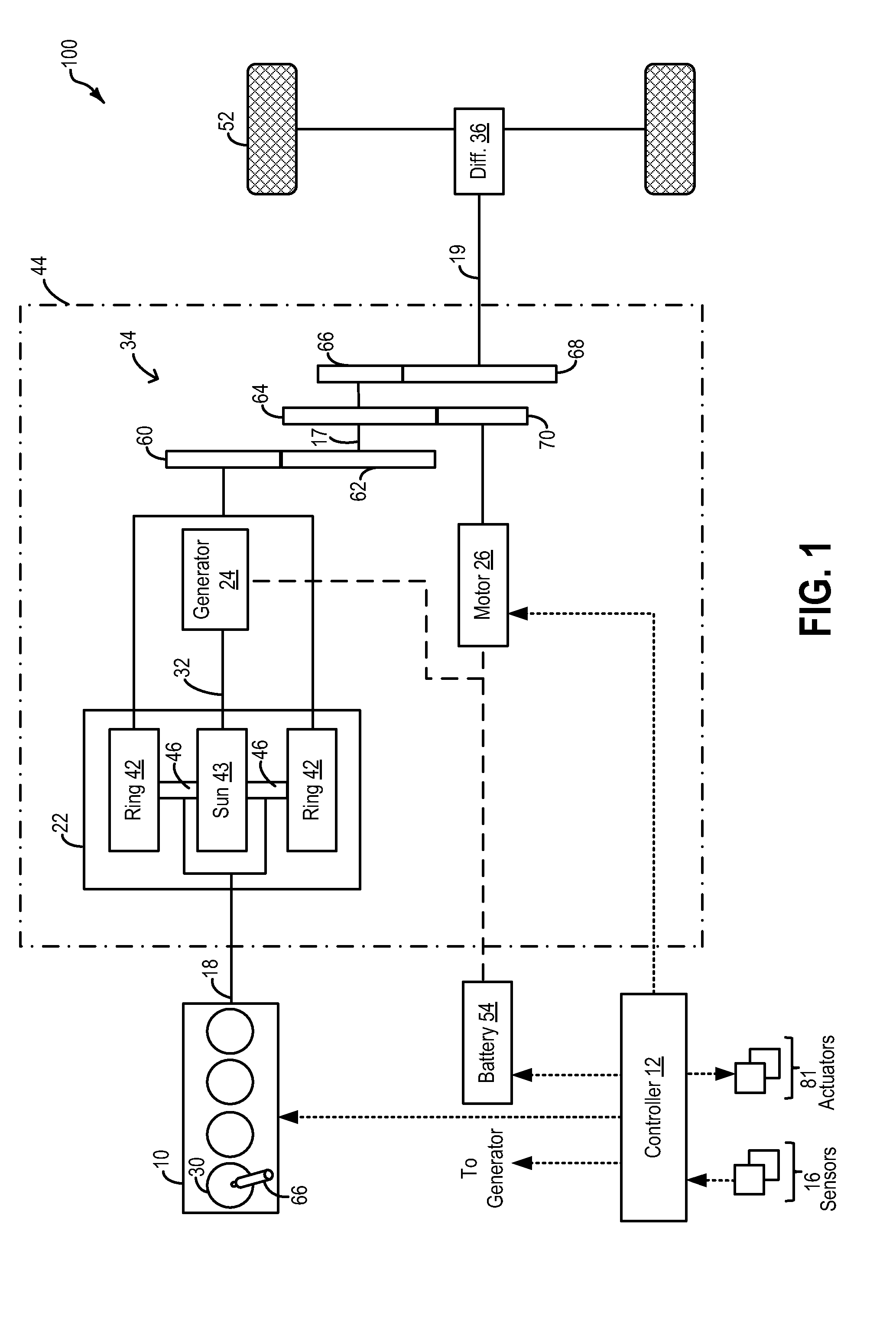

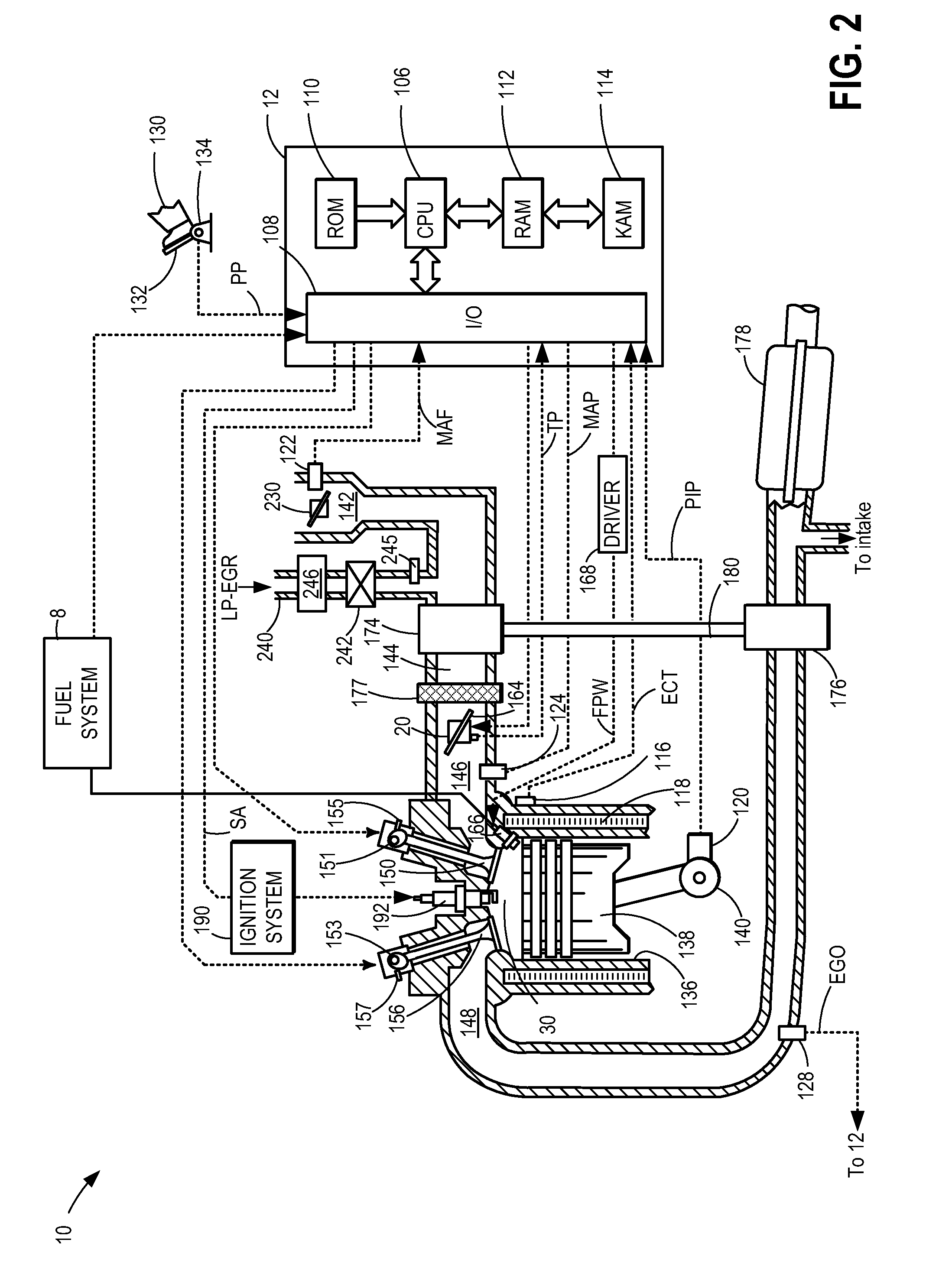

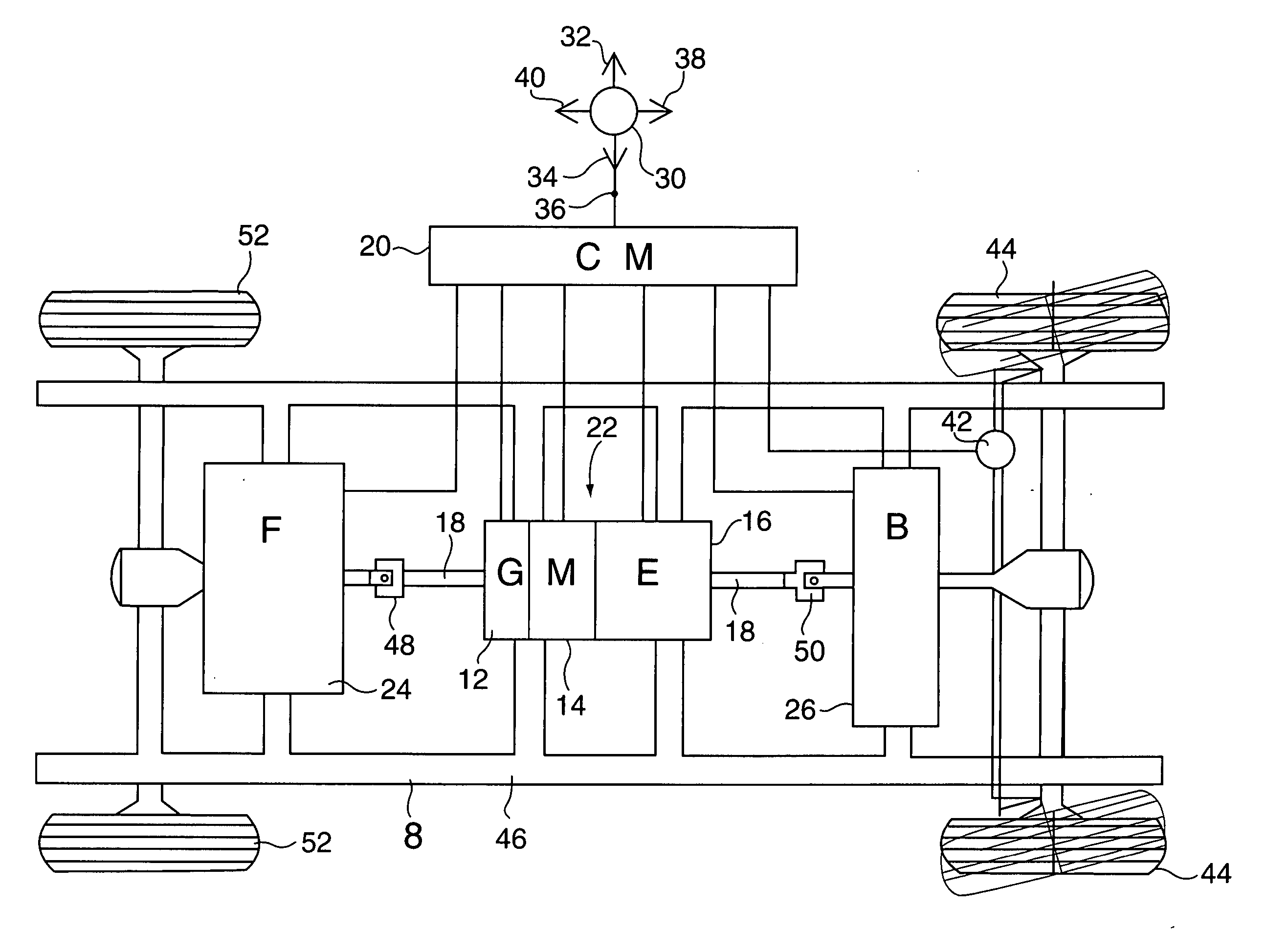

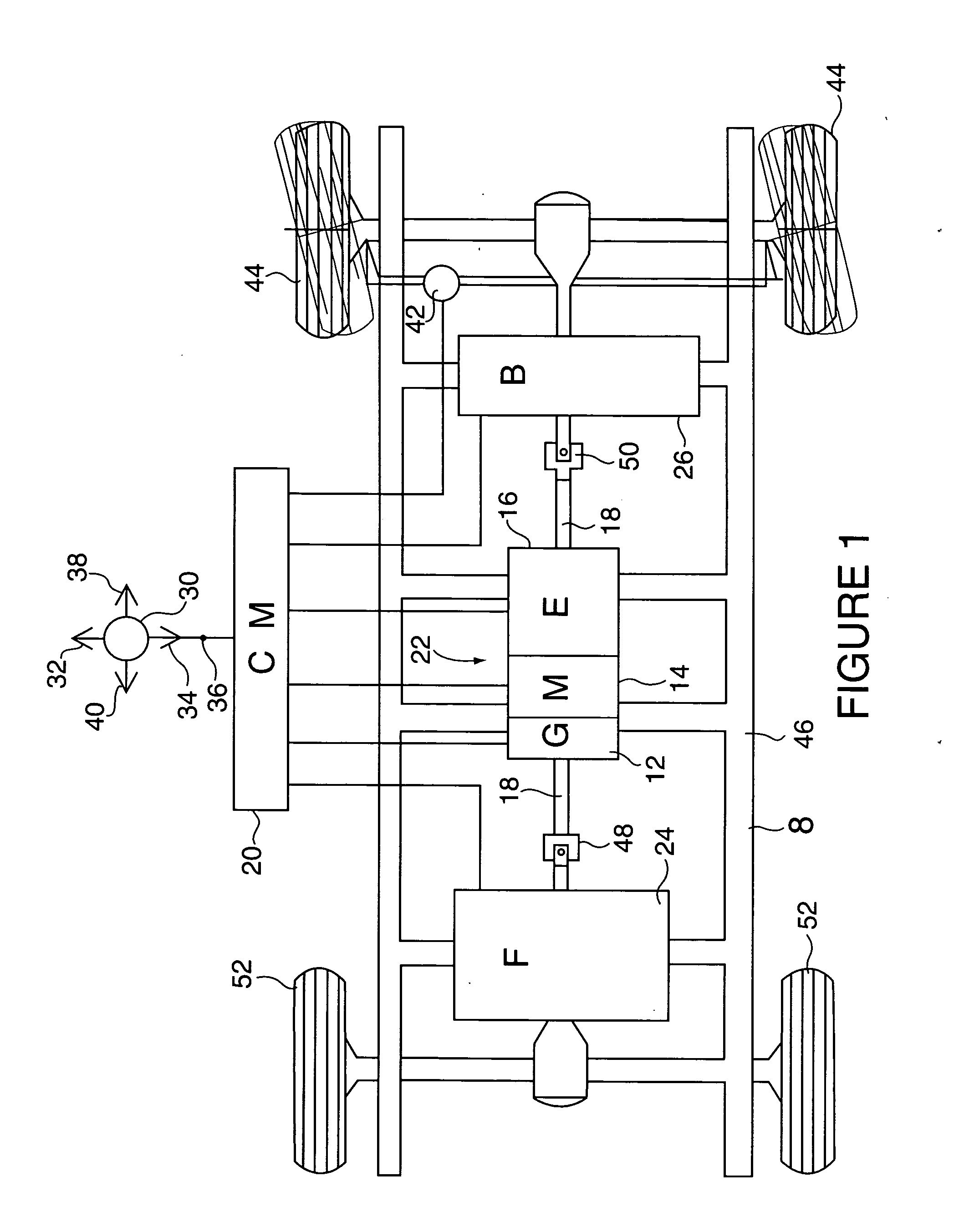

Method and apparatus to control engine restart for a hybrid powertrain system

ActiveUS20080275624A1Accurately determineAccurate pressureInternal combustion piston enginesDigital data processing detailsRotary engineInternal combustion engine

There is provided a control scheme for restarting an internal combustion engine of a hybrid powertrain during ongoing vehicle operation. The method comprises generating a torque output from an electrical machine to rotate the engine, and determining an engine crank torque. The torque output from the electrical machine is selectively controlled based upon the engine crank torque. The engine is fired when rotational speed of the engine exceeds a threshold. An engine torque simulation model accurately determines engine compression pressures in real-time to accommodate changes in engine operating conditions, based upon present engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

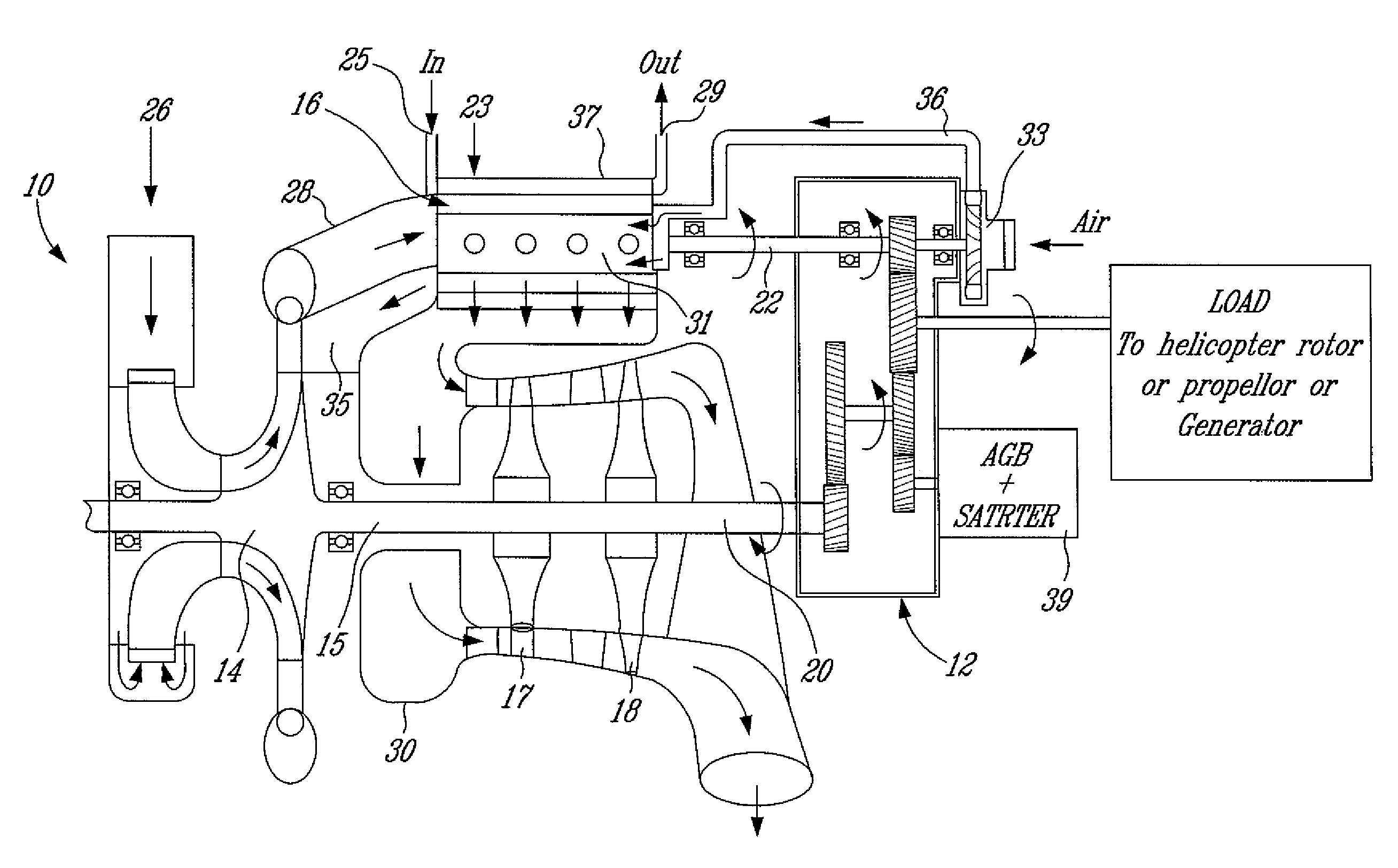

Low volumetric compression ratio integrated turbo-compound rotary engine

ActiveUS7775044B2Reduce the compression ratioImprove thermal efficiencyGas turbine plantsEfficient propulsion technologiesAir cycleRotary engine

Owner:PRATT & WHITNEY CANADA CORP

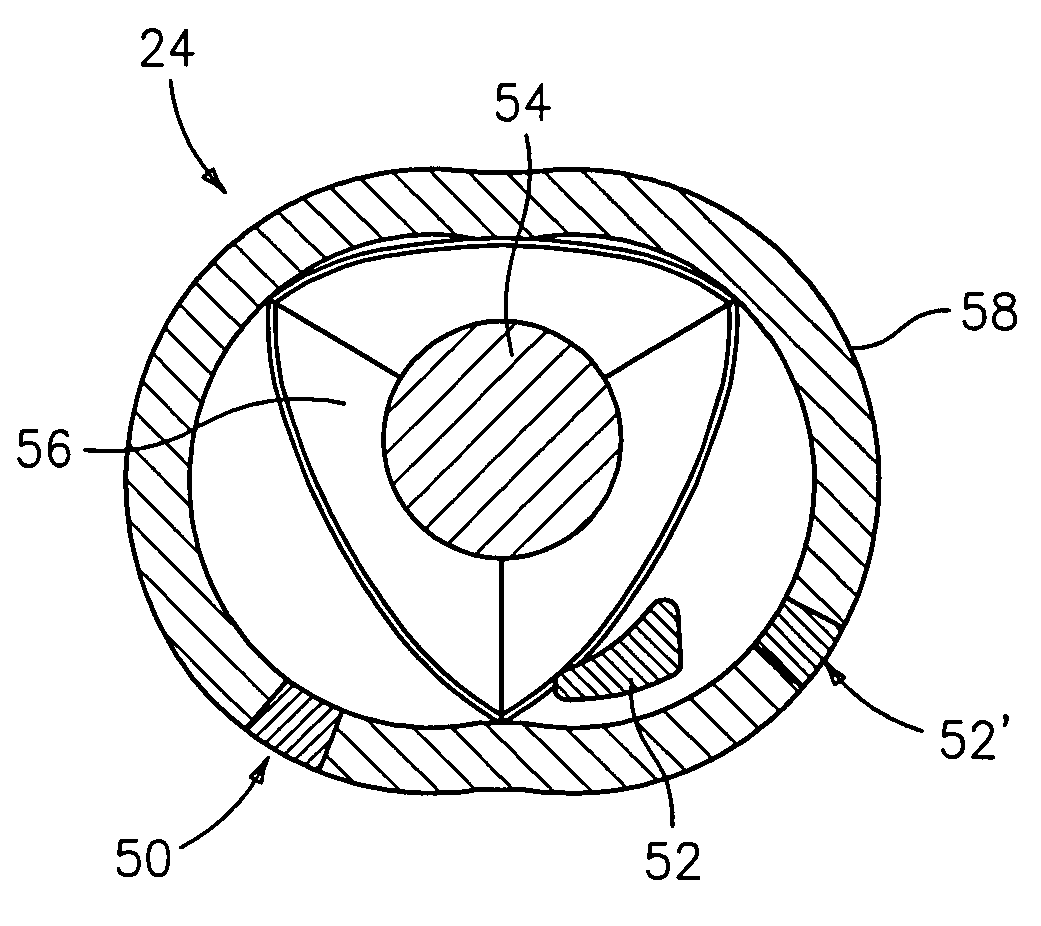

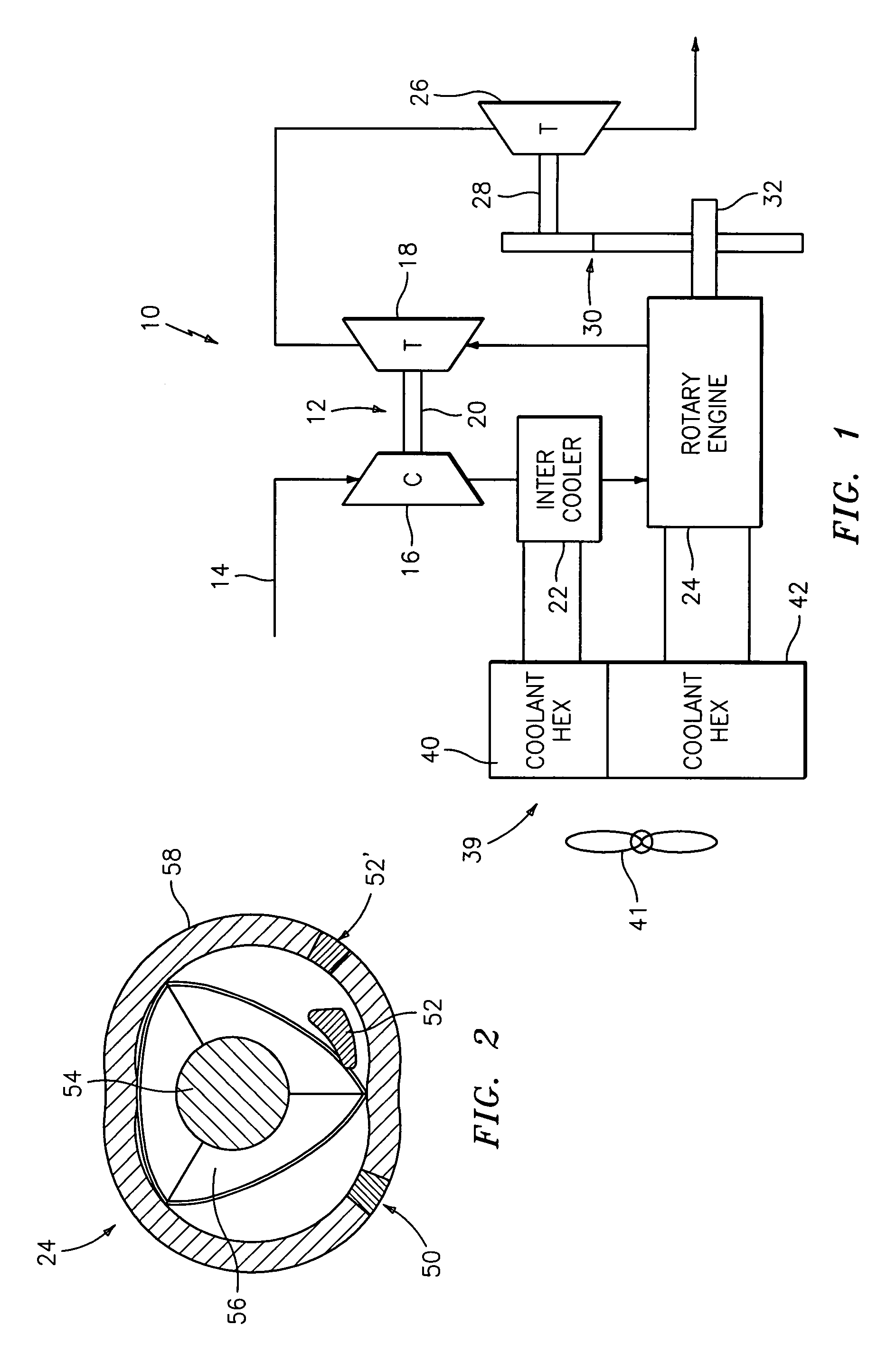

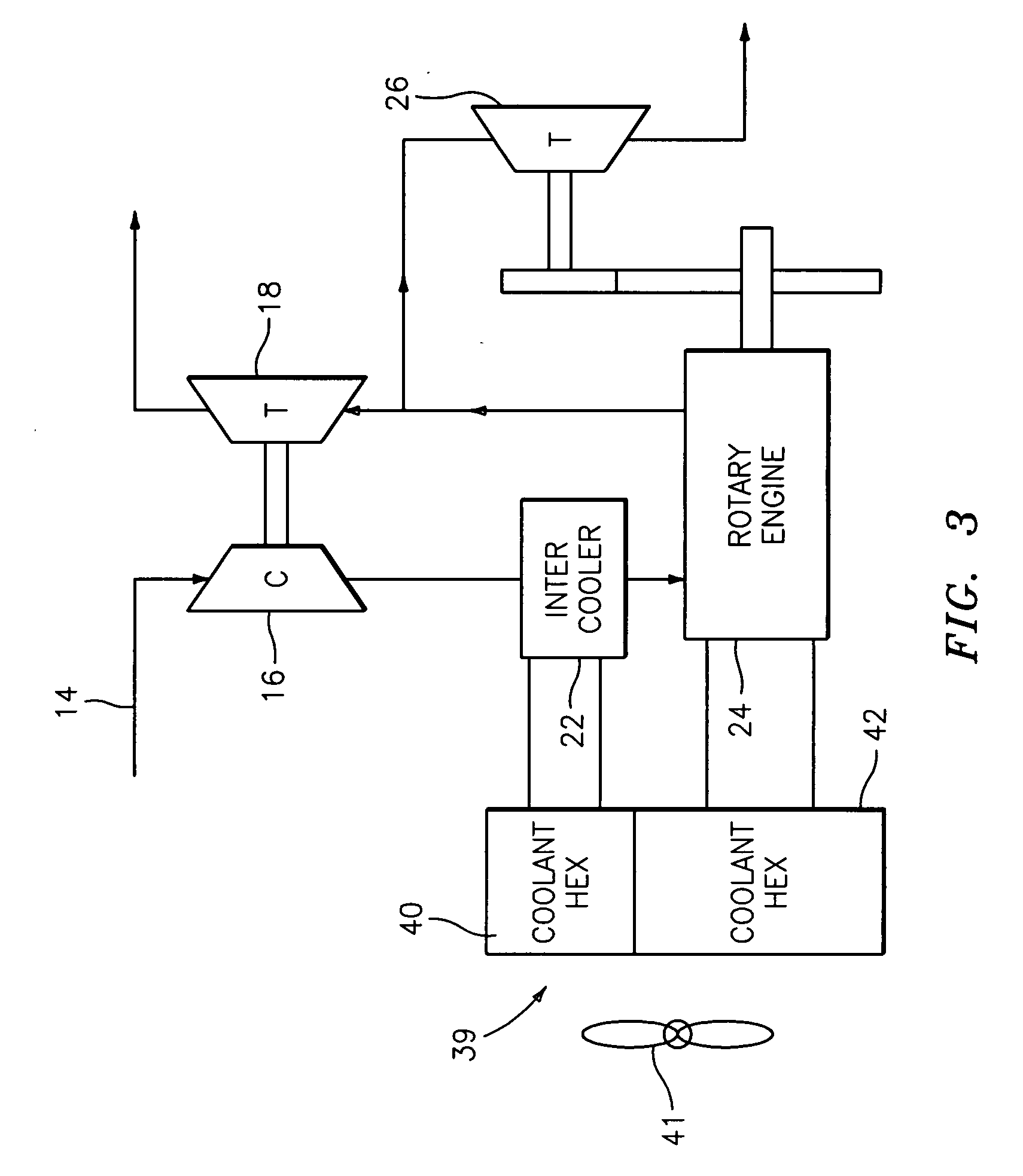

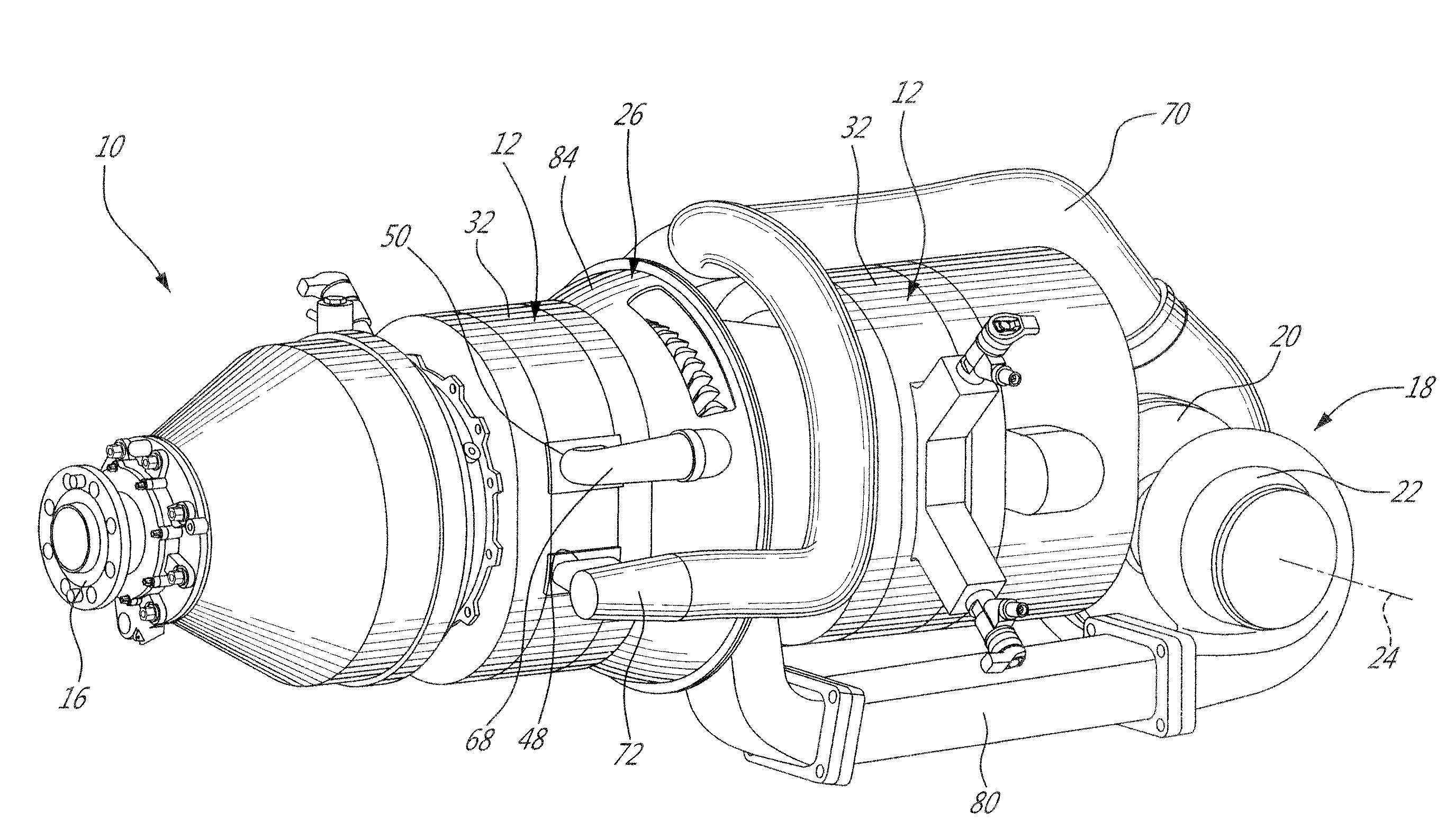

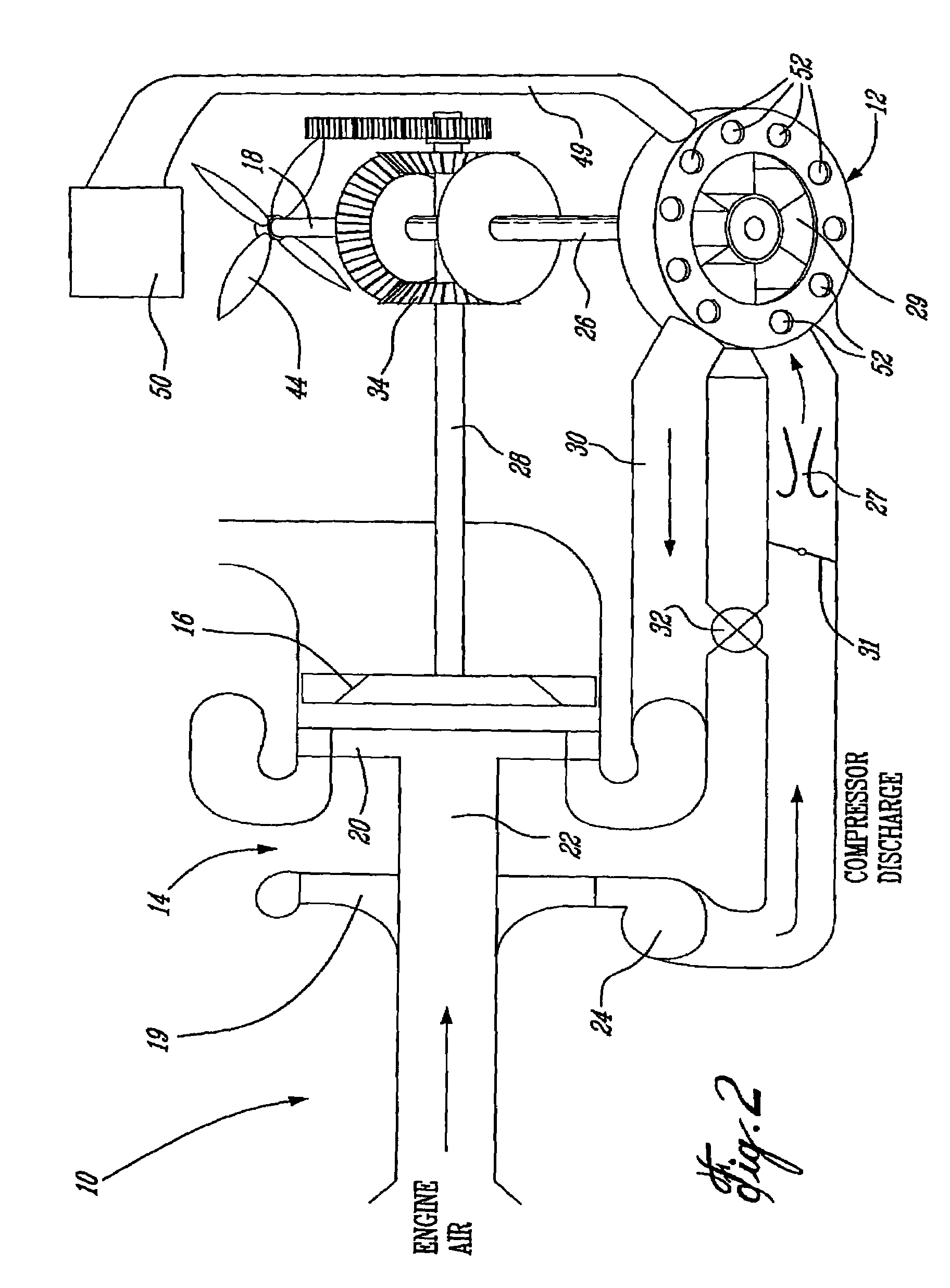

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

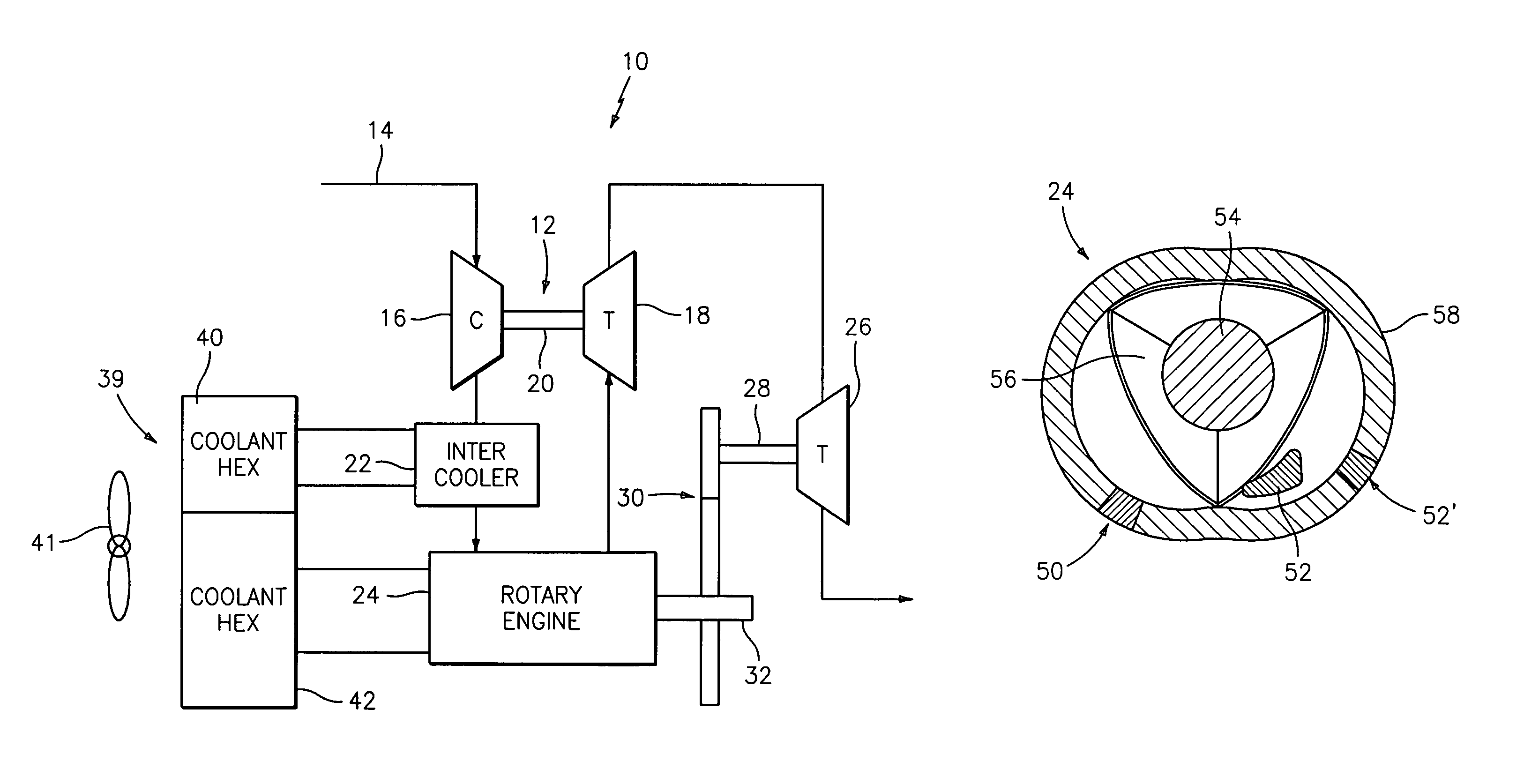

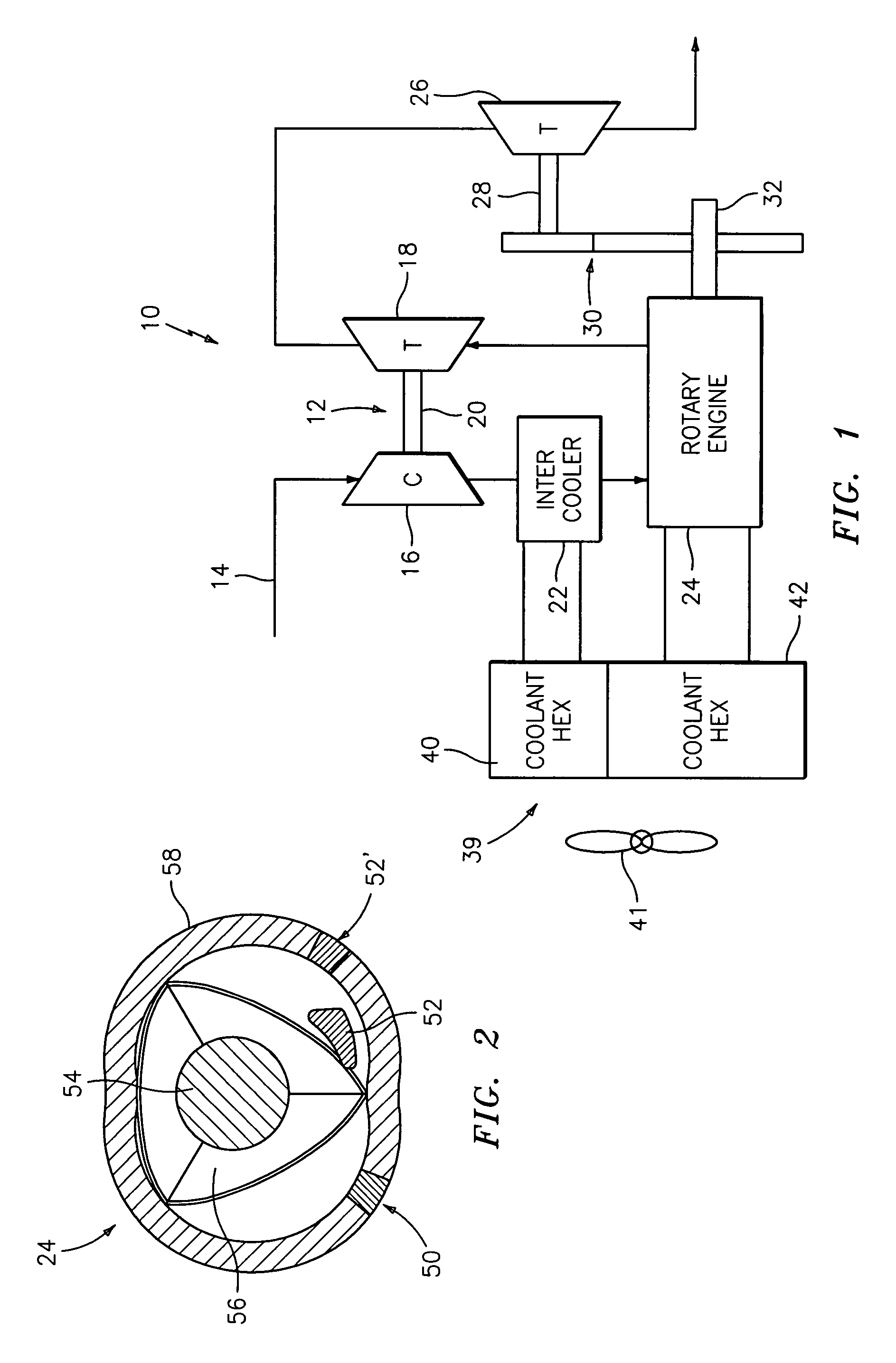

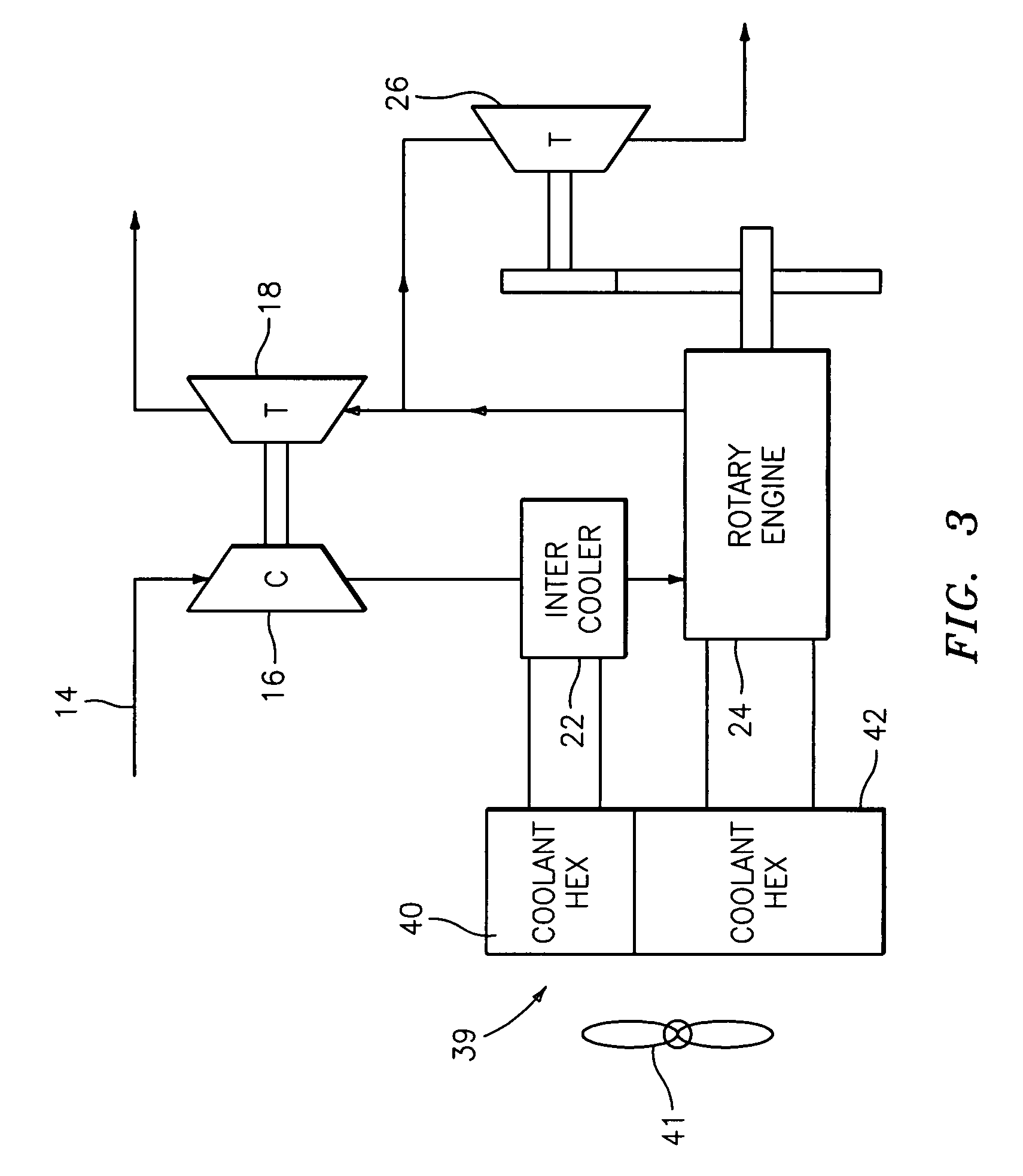

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

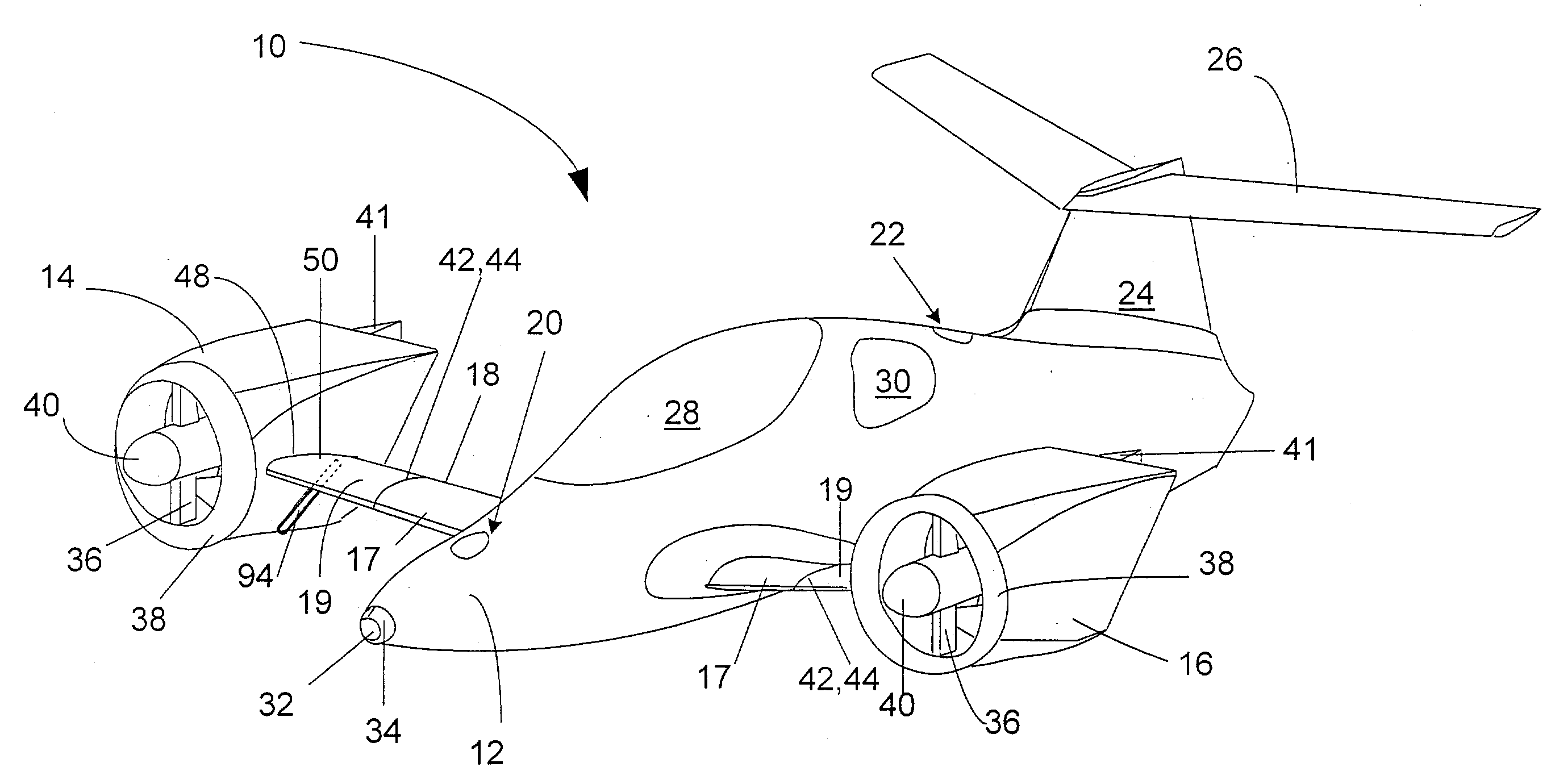

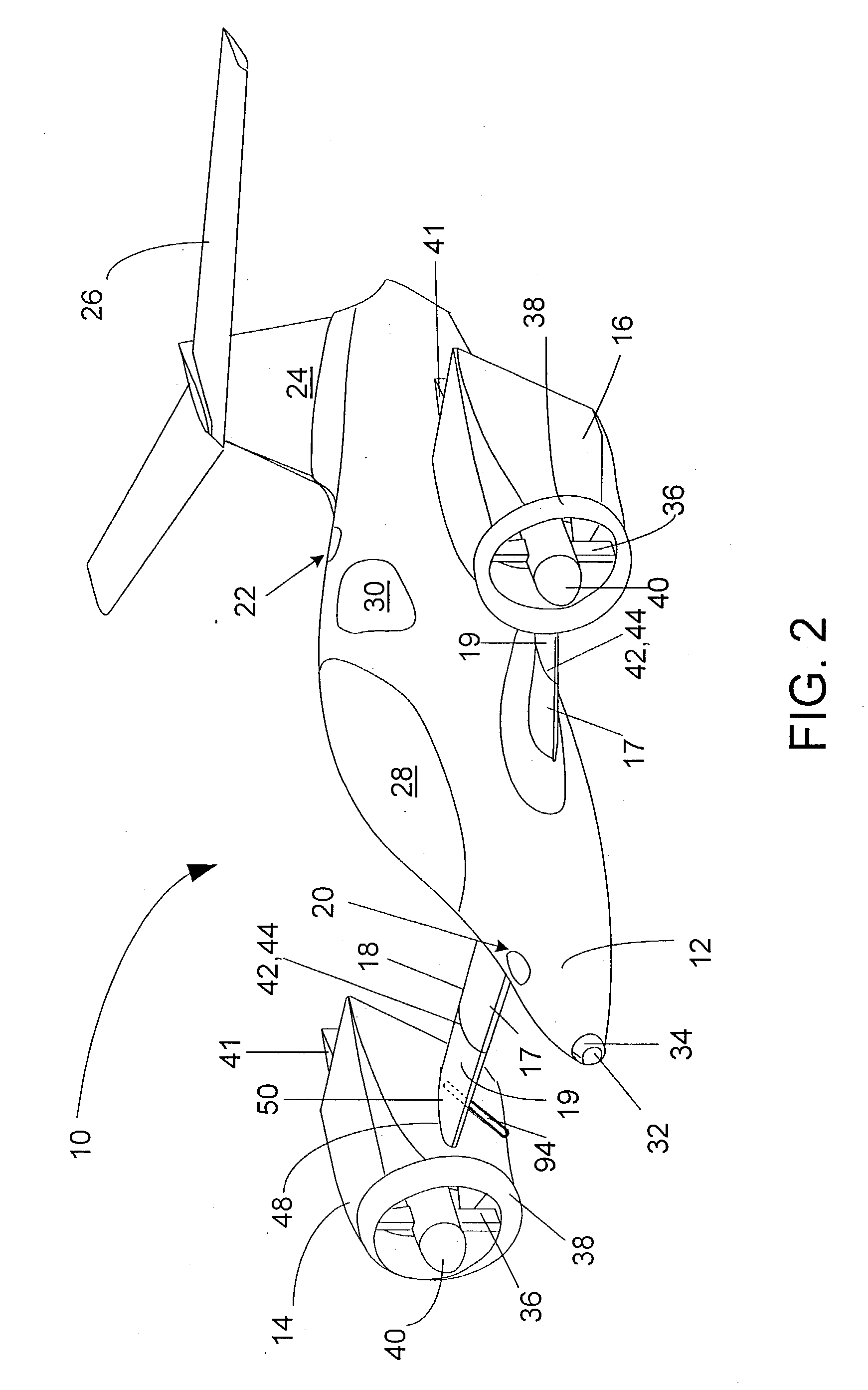

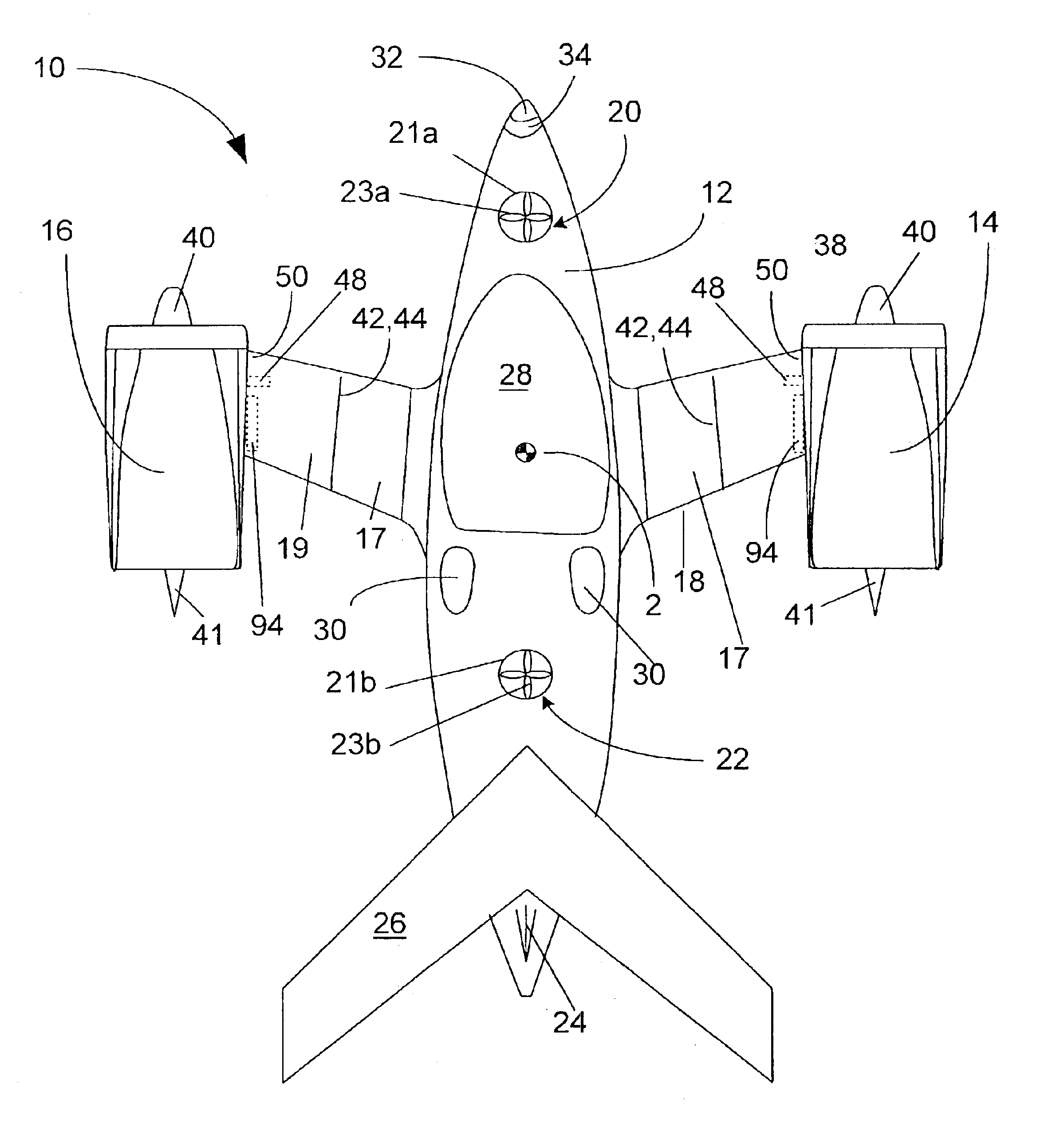

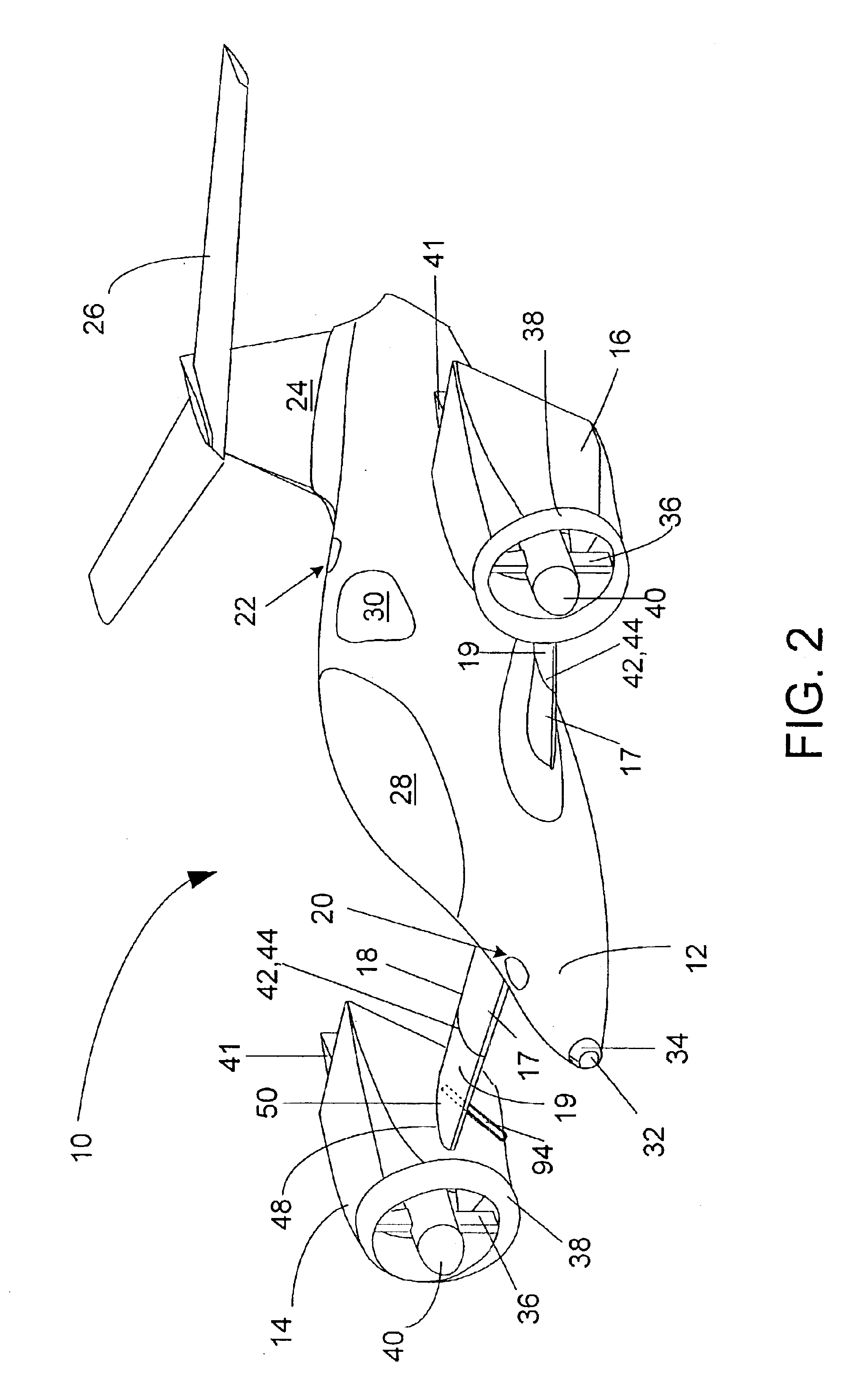

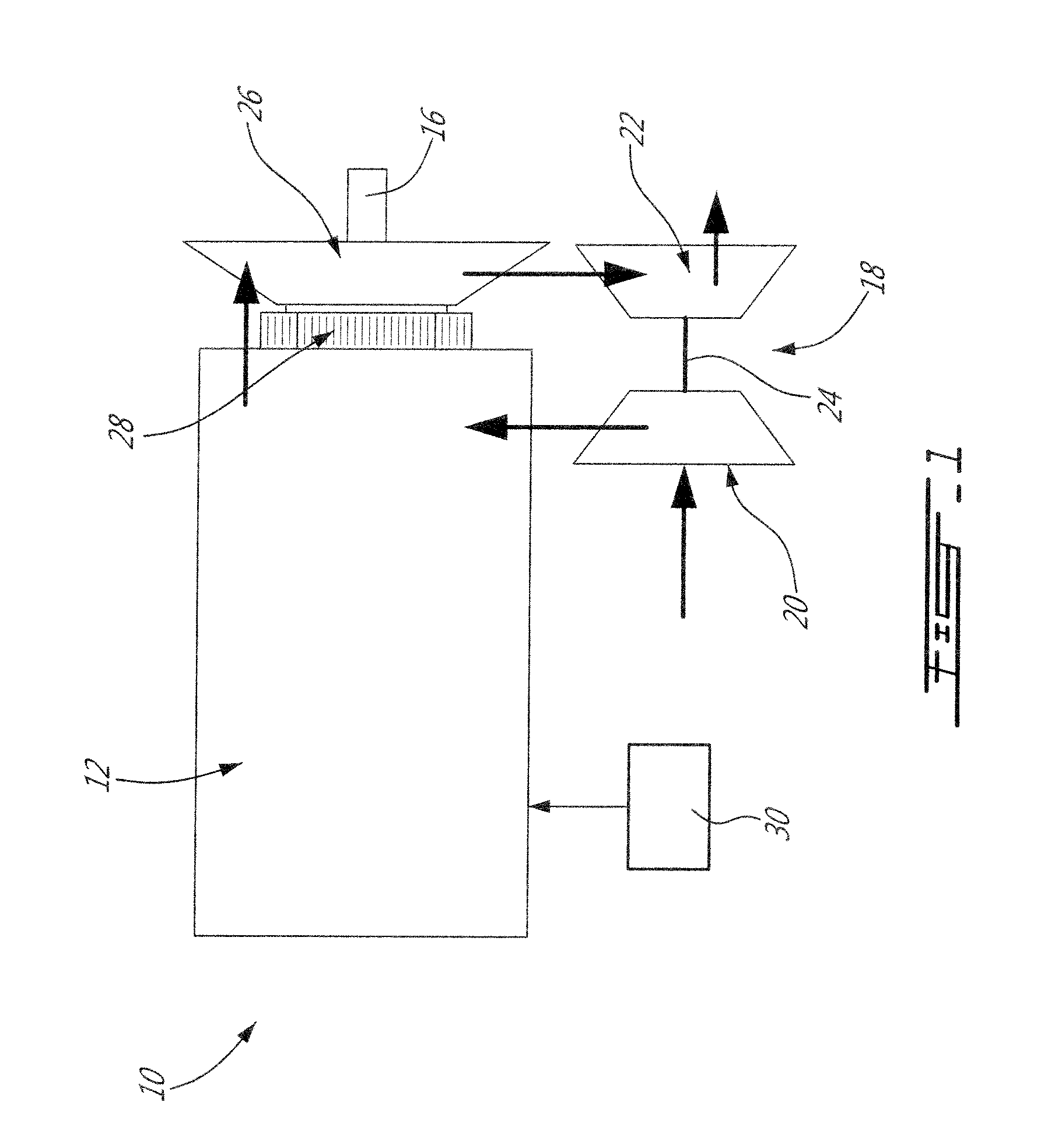

Vertical take-off and landing vehicles

A VTOL vehicle including a fuselage with two foldable wings, two tiltable nacelles attached to the wings, a vertical stabilizer, a horizontal stabilizer, and two auxiliary thrusters. Each nacelle contains a system of vanes located at the rear opening thereof, and actuators are provided for extending and retracting the vanes in conjunction with nacelle tilting mechanisms to deflect the airflow over a predetermined range of angles from the horizontal. Each nacelle also contains two rotary engines, each of which directly drives a fan. The fans face each other and operate in counter-rotating directions at the same rotational speed. An alternative embodiment includes two additional nacelles attached to the fuselage instead of having the auxiliary thrusters. A redundant computerized flight control system maintains stability of the vehicle as it transitions from one flight mode to another.

Owner:MOLLER INT

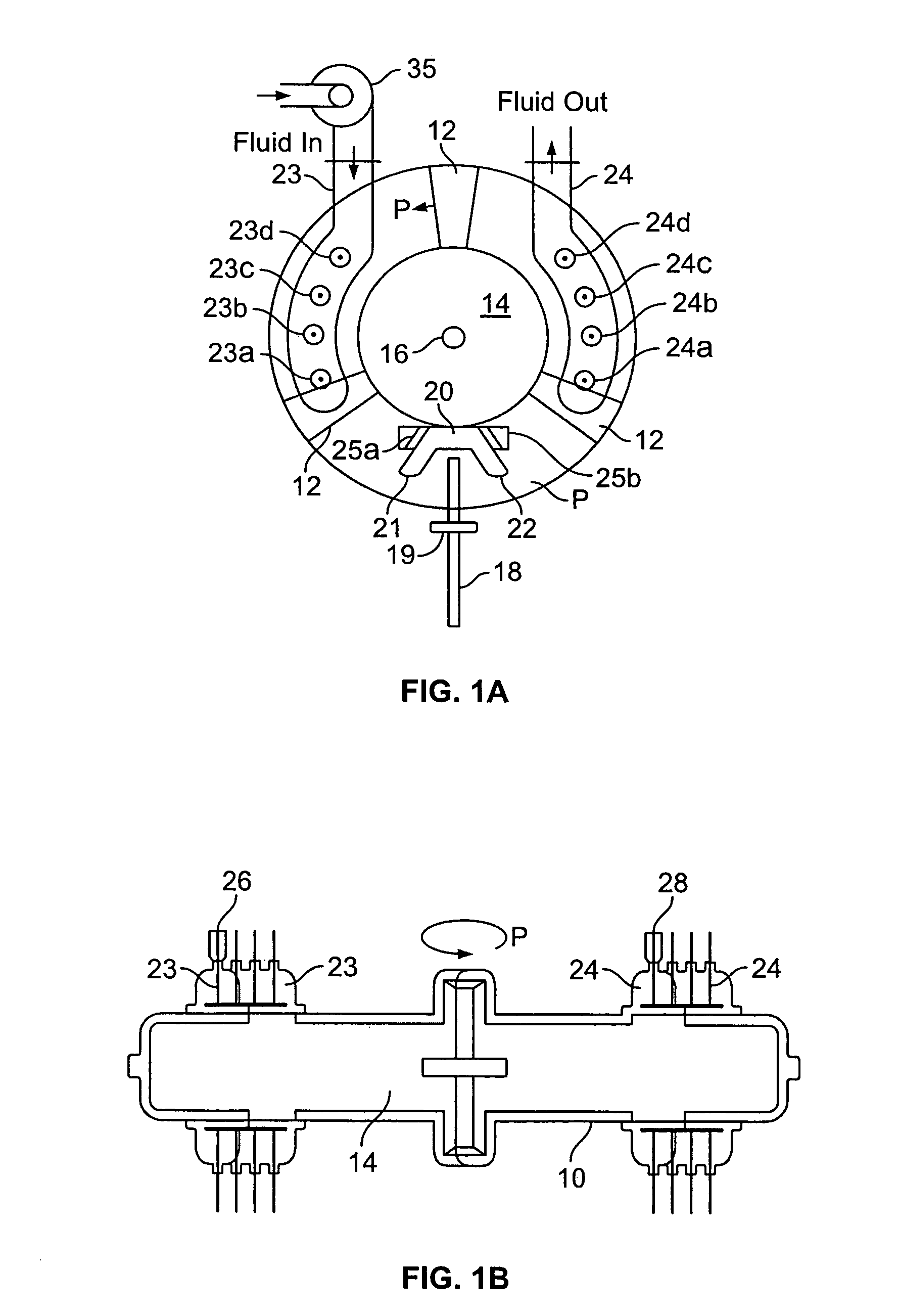

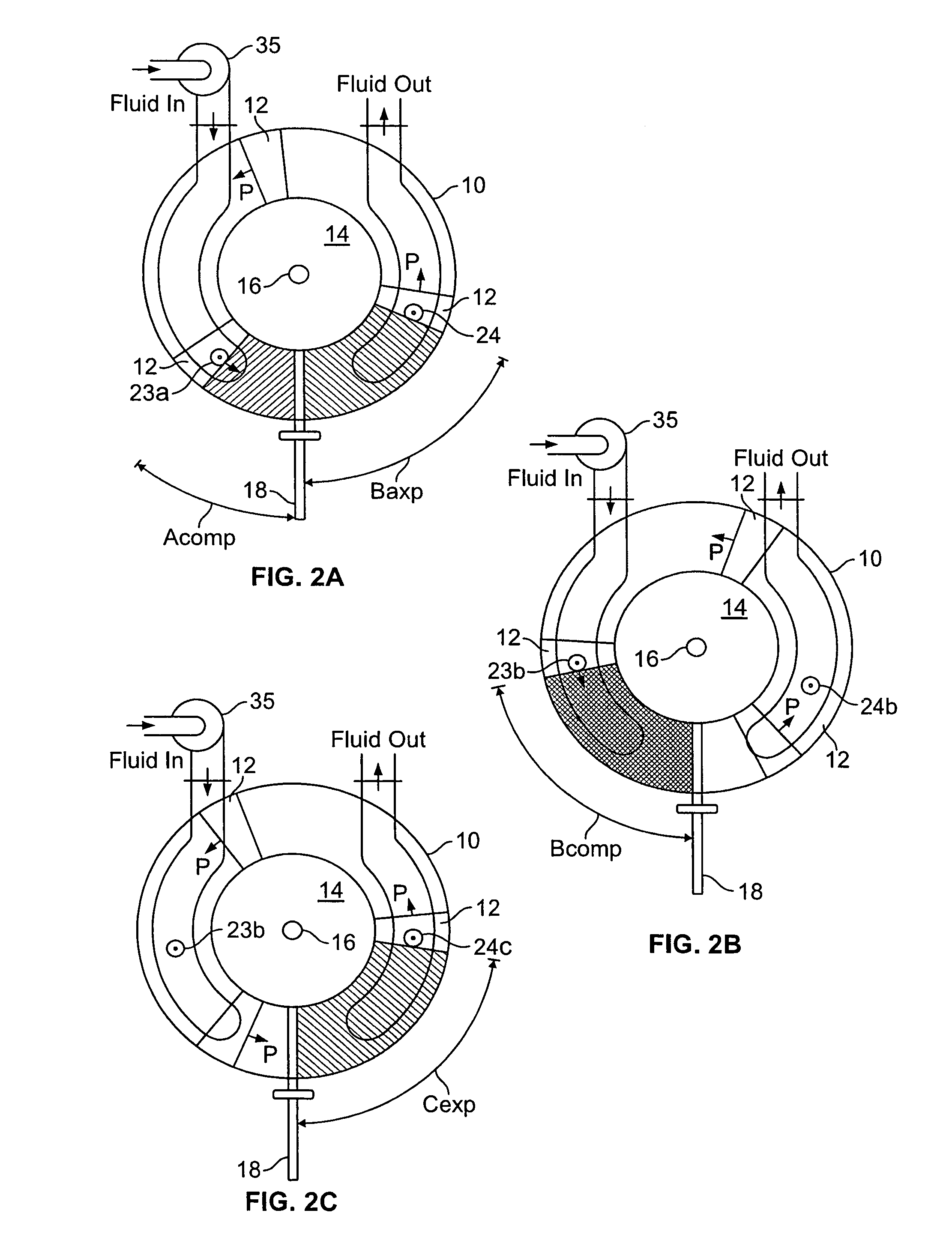

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

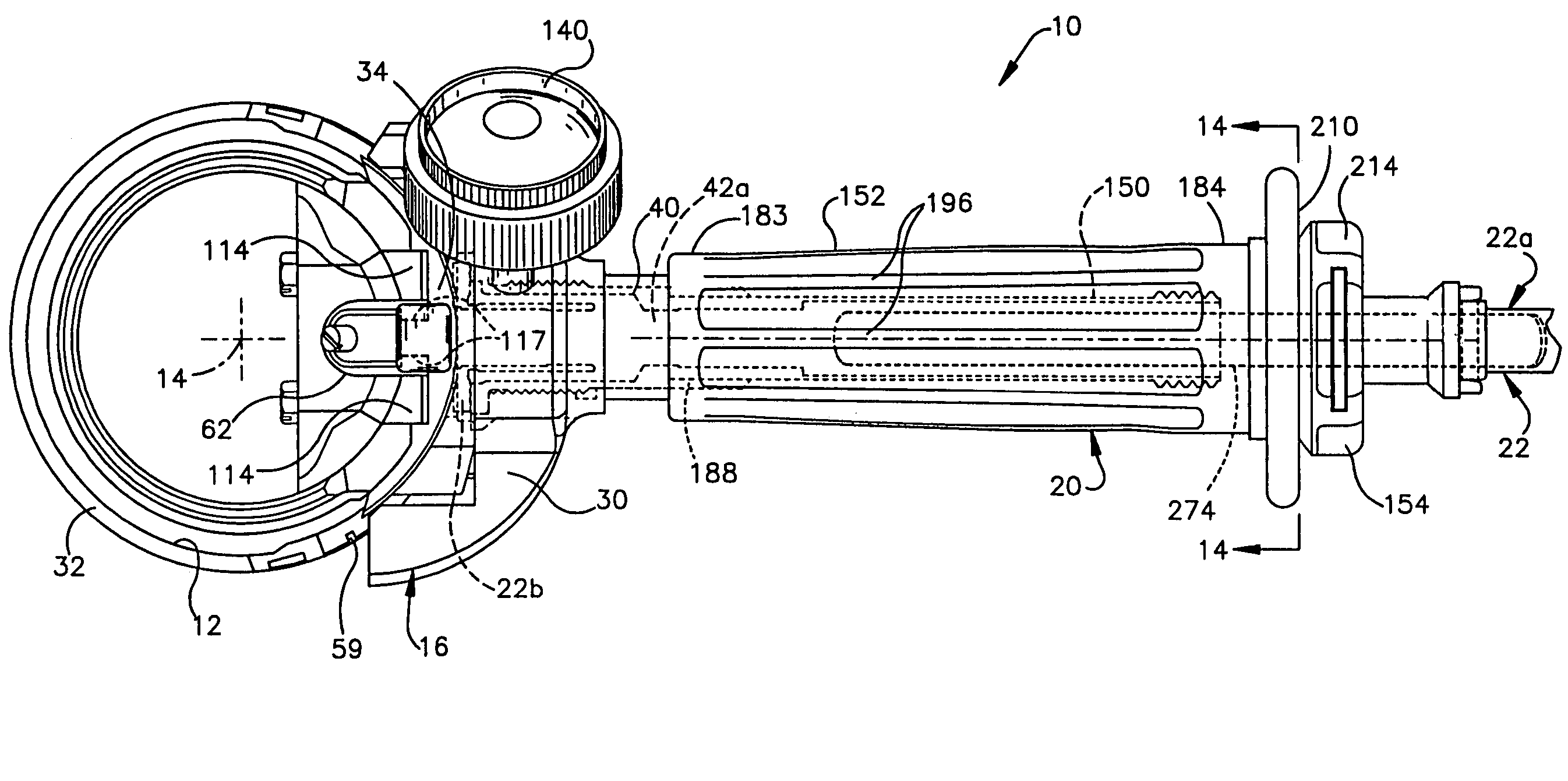

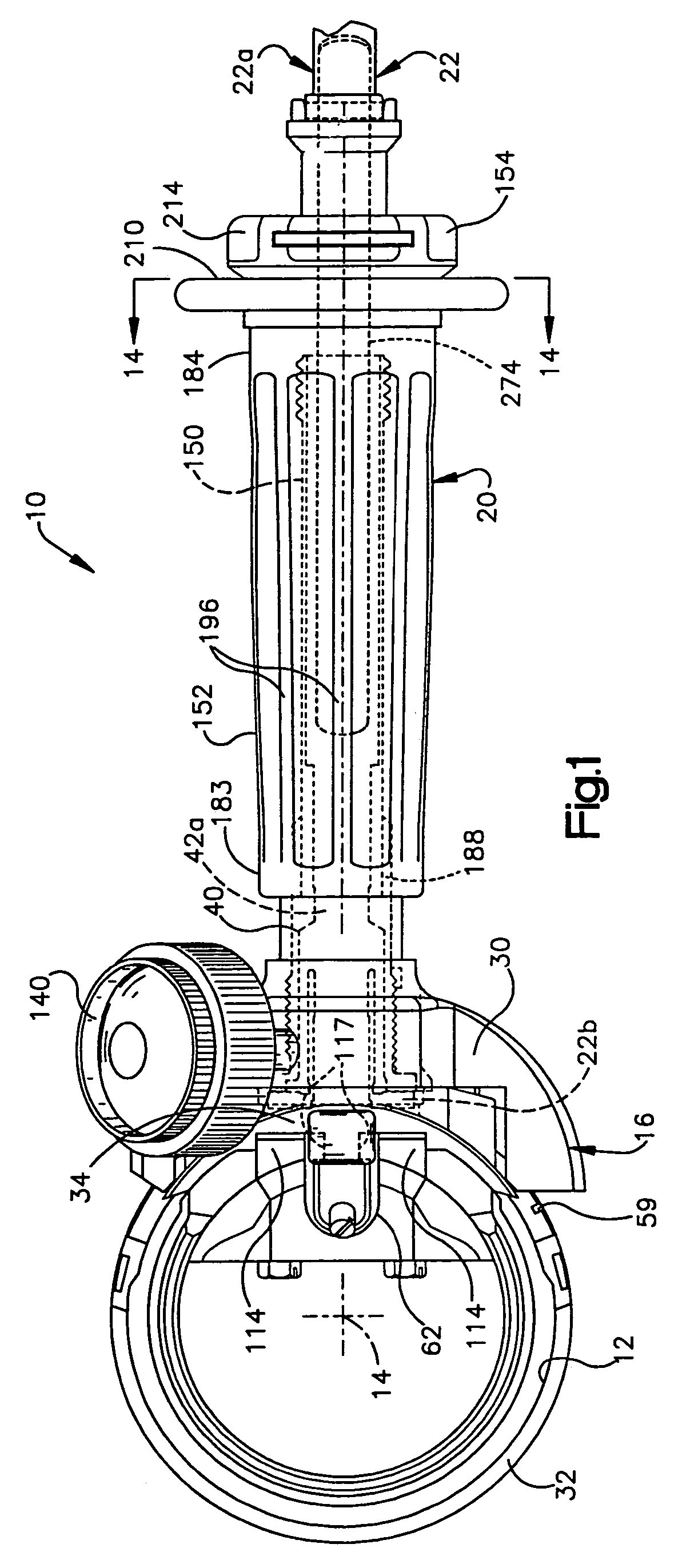

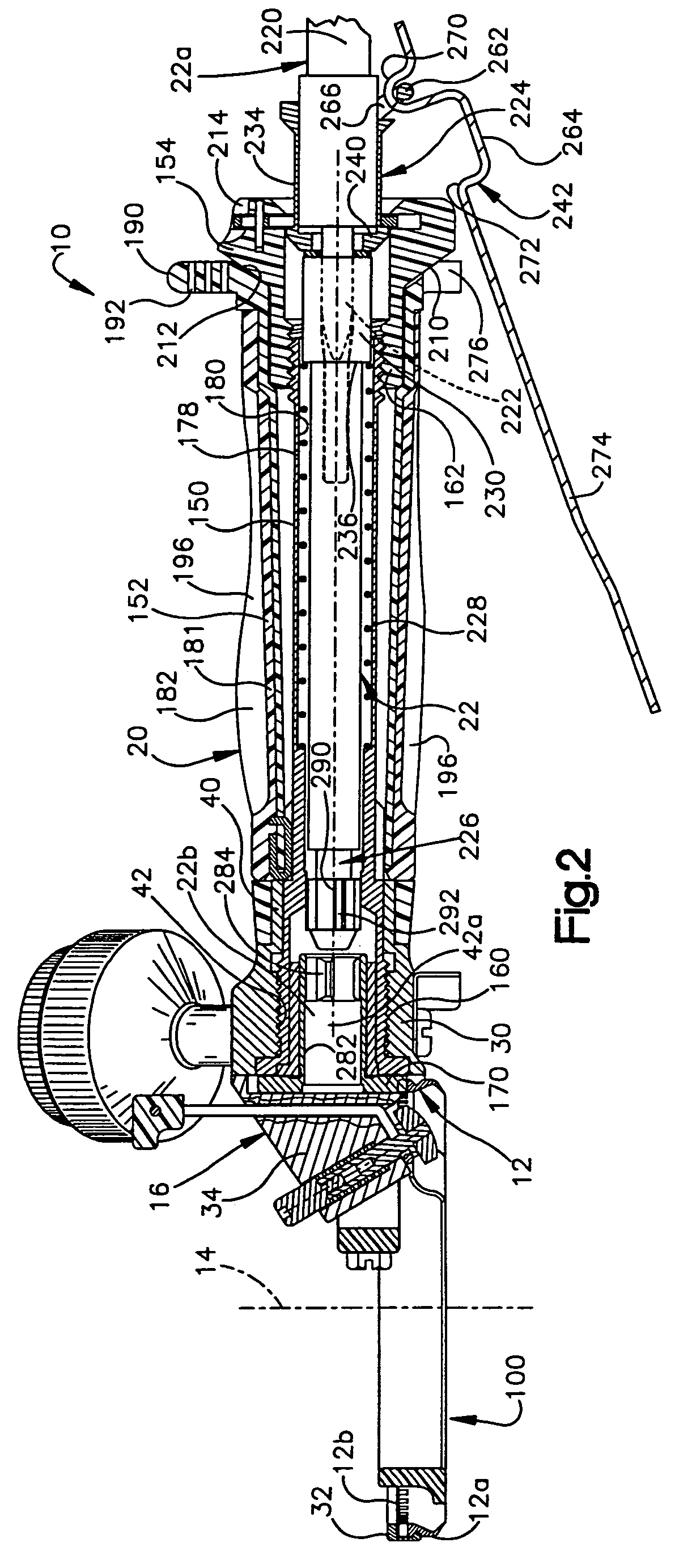

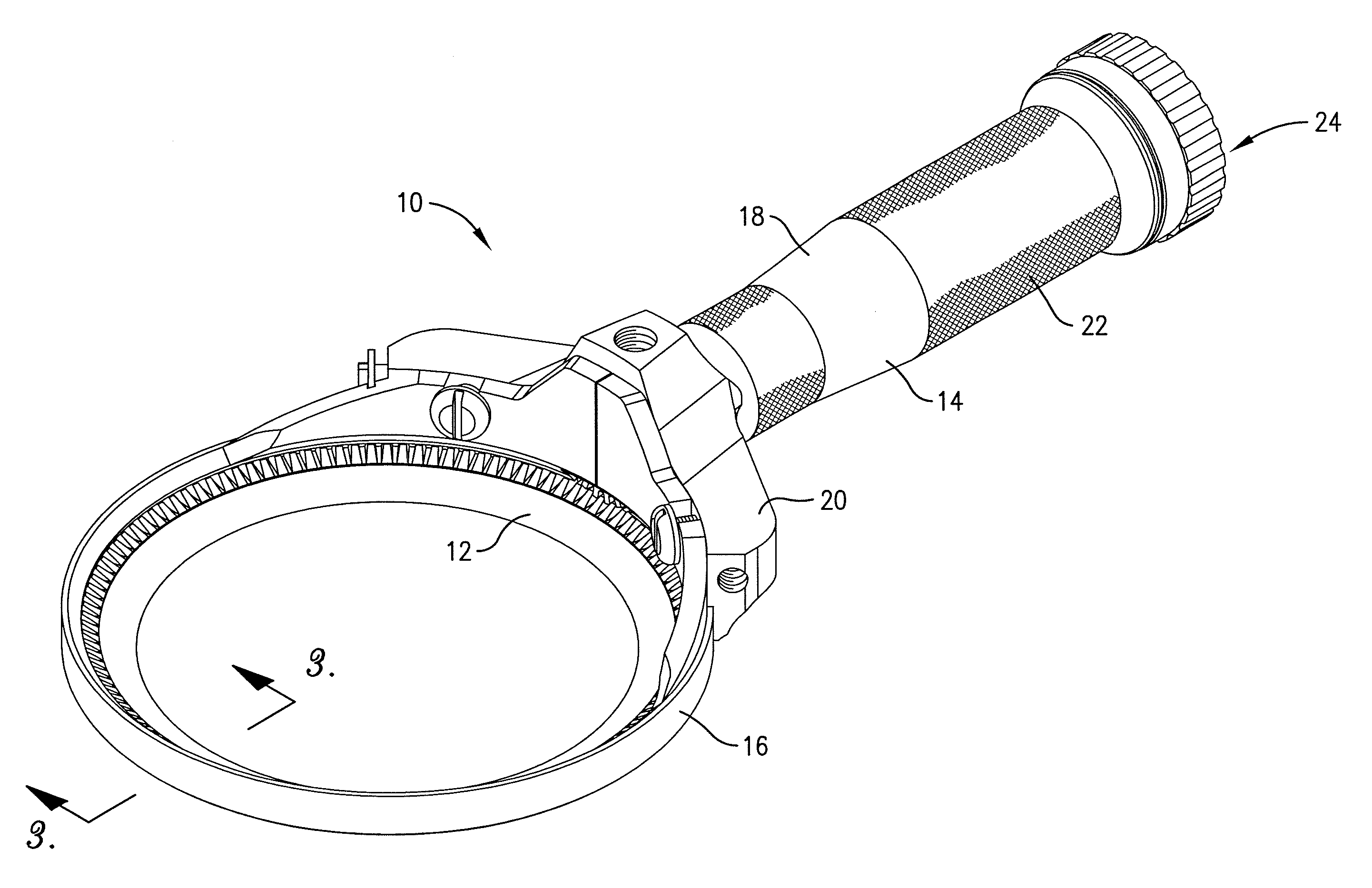

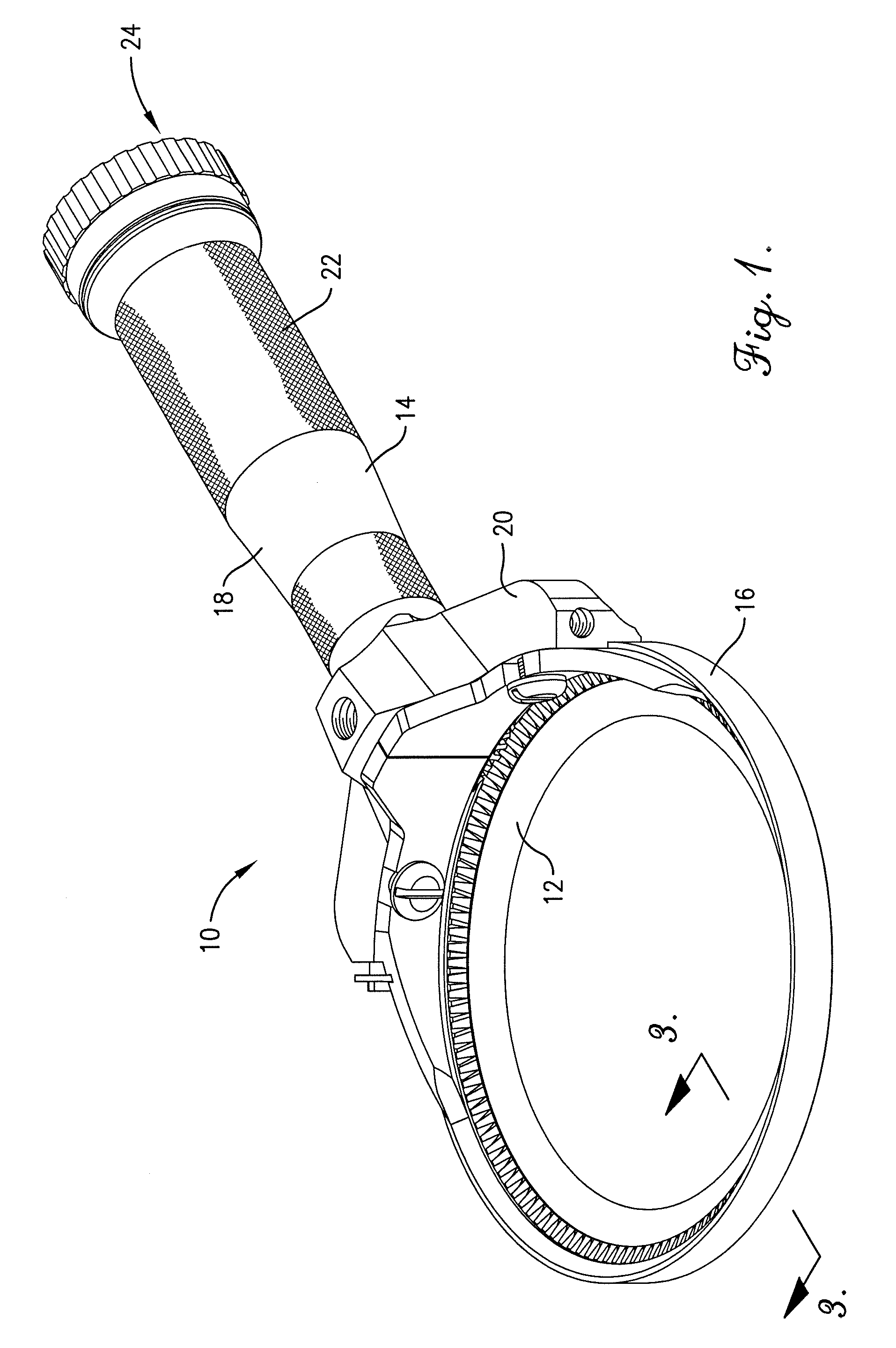

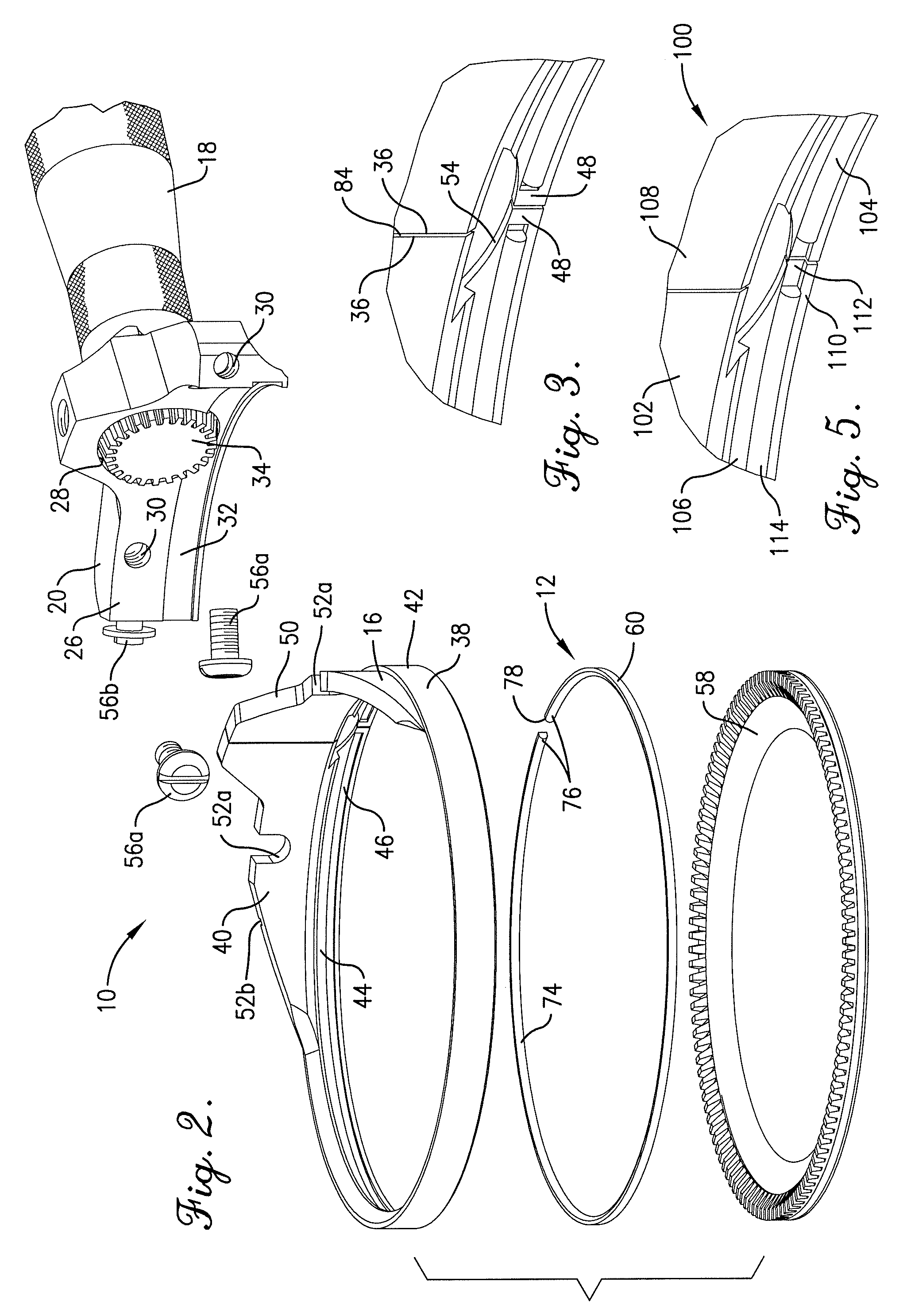

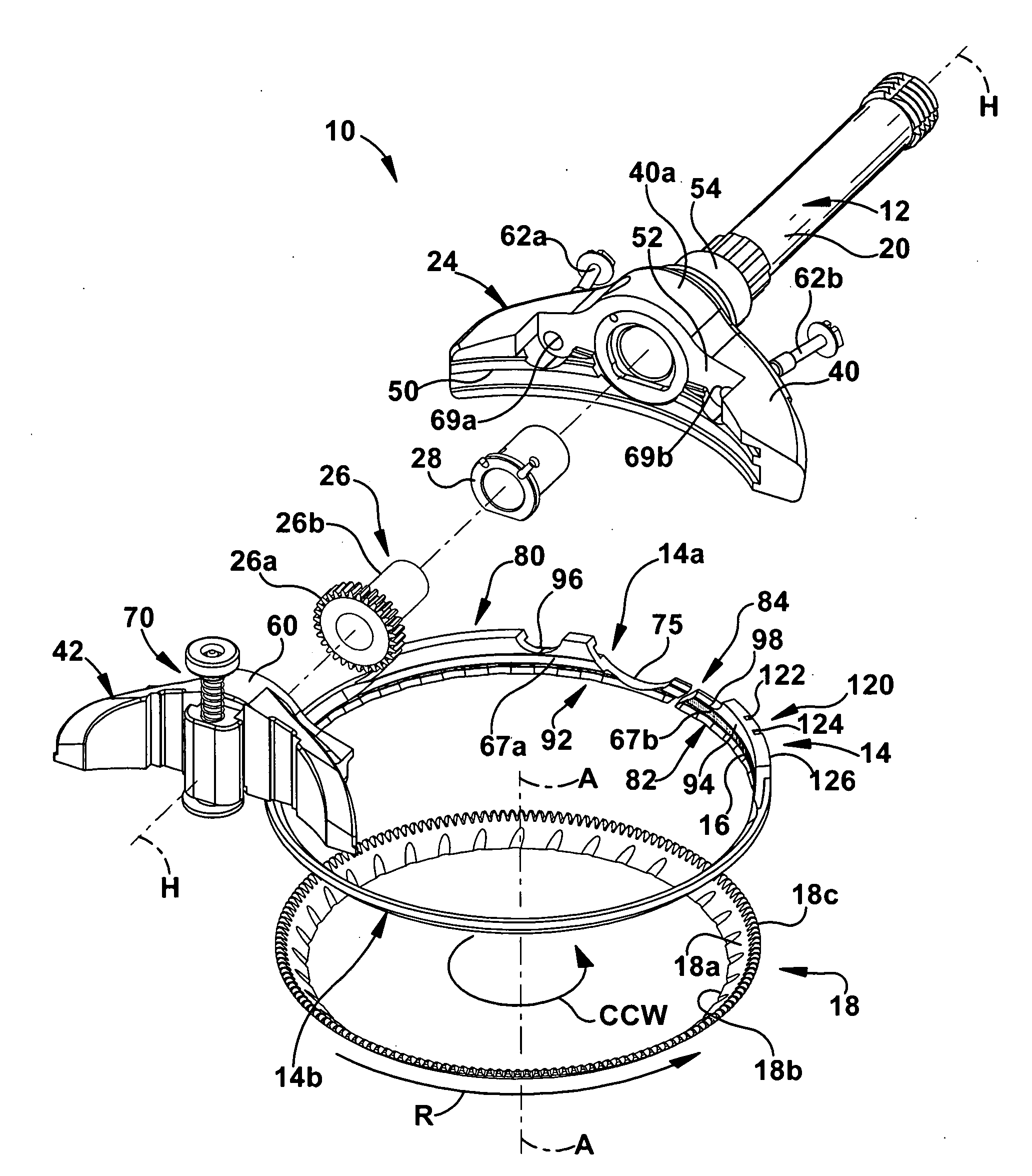

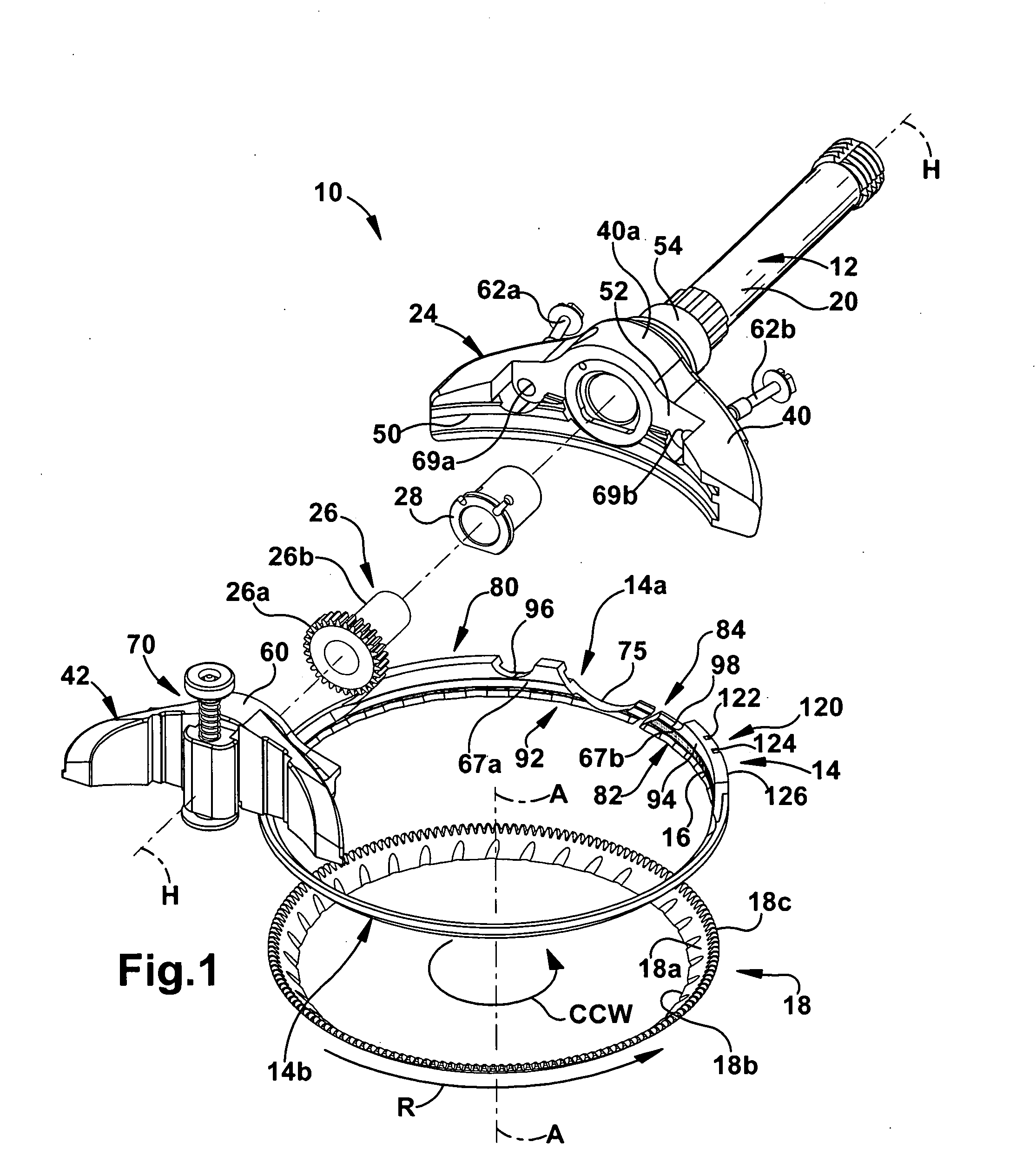

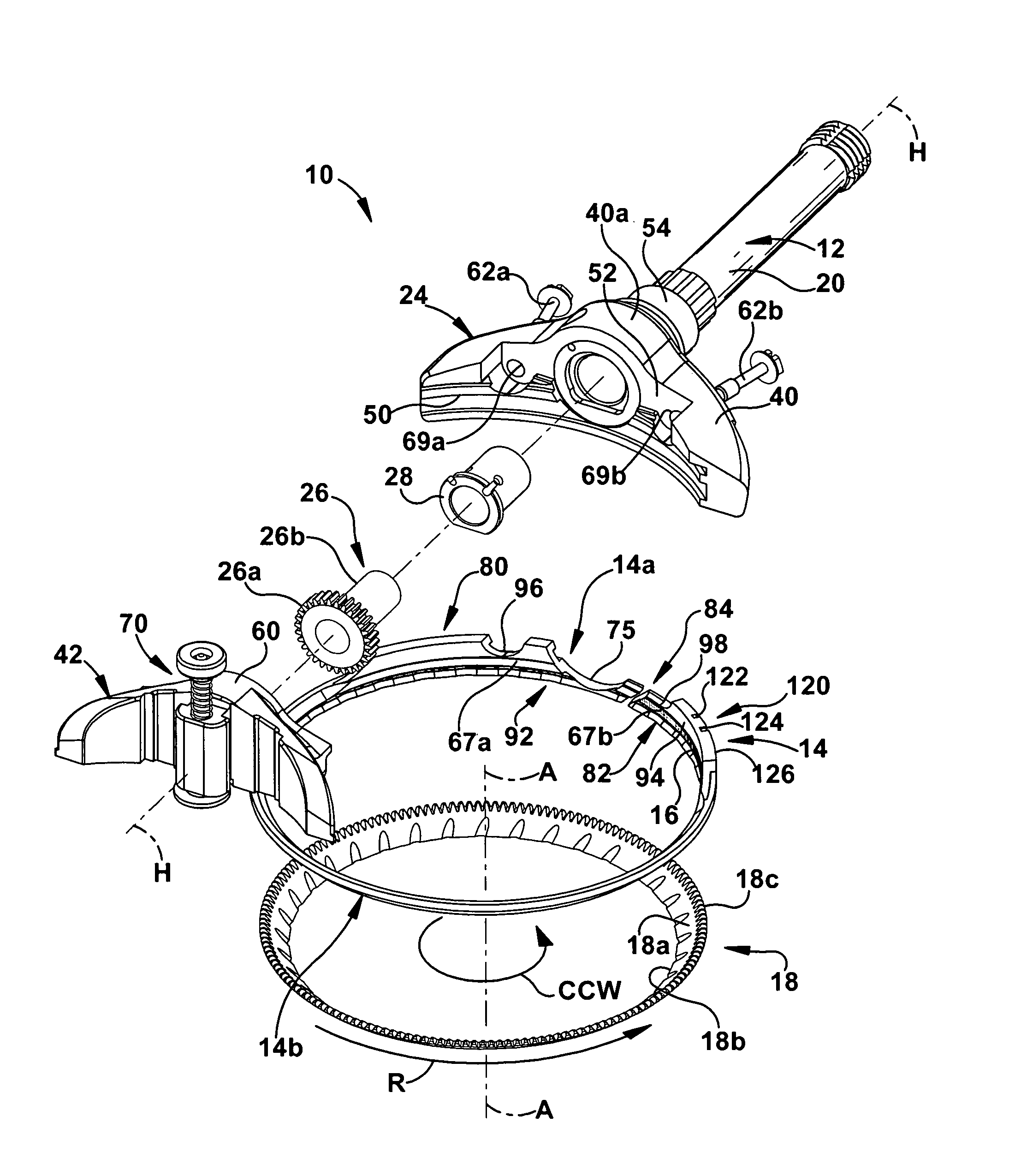

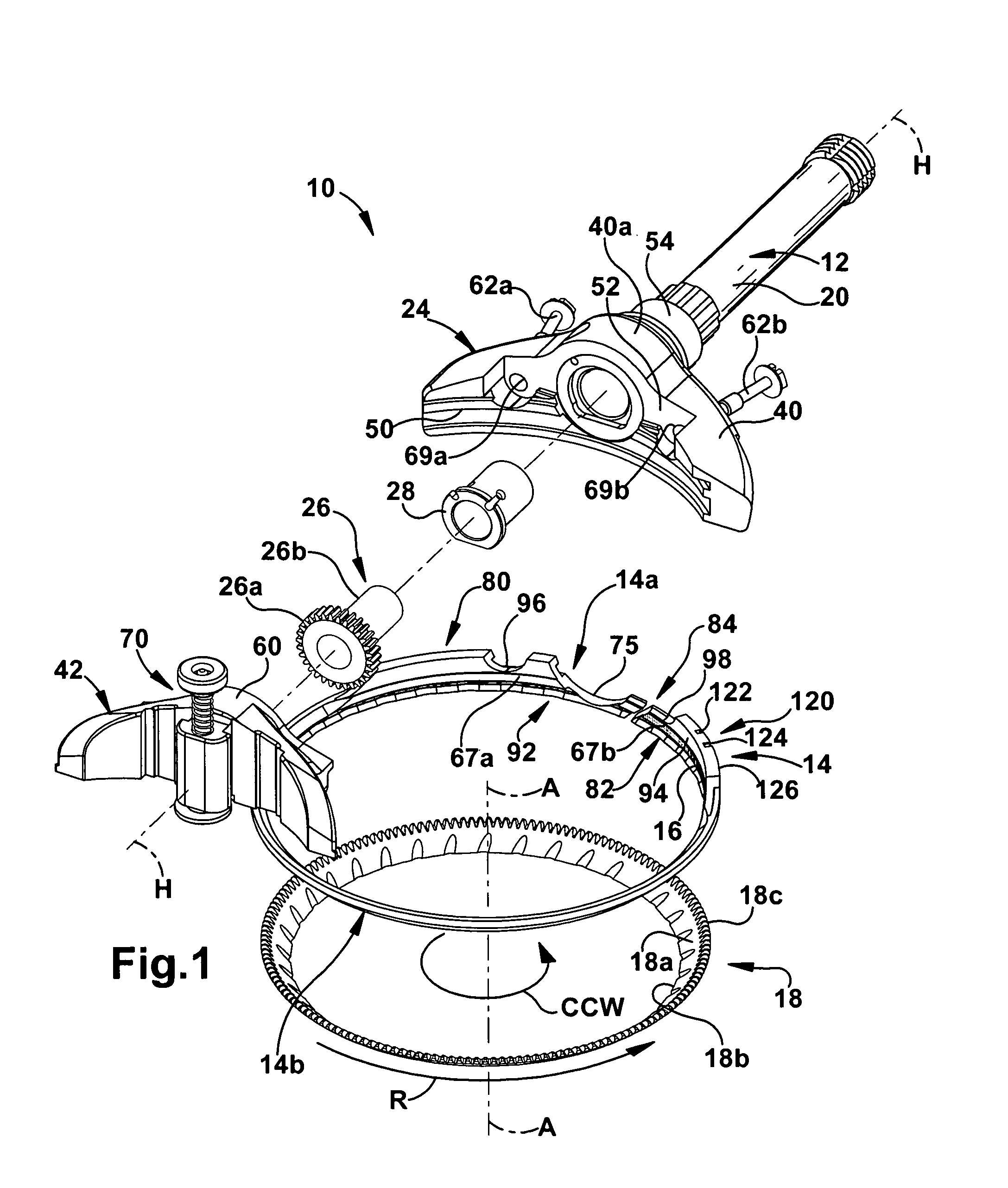

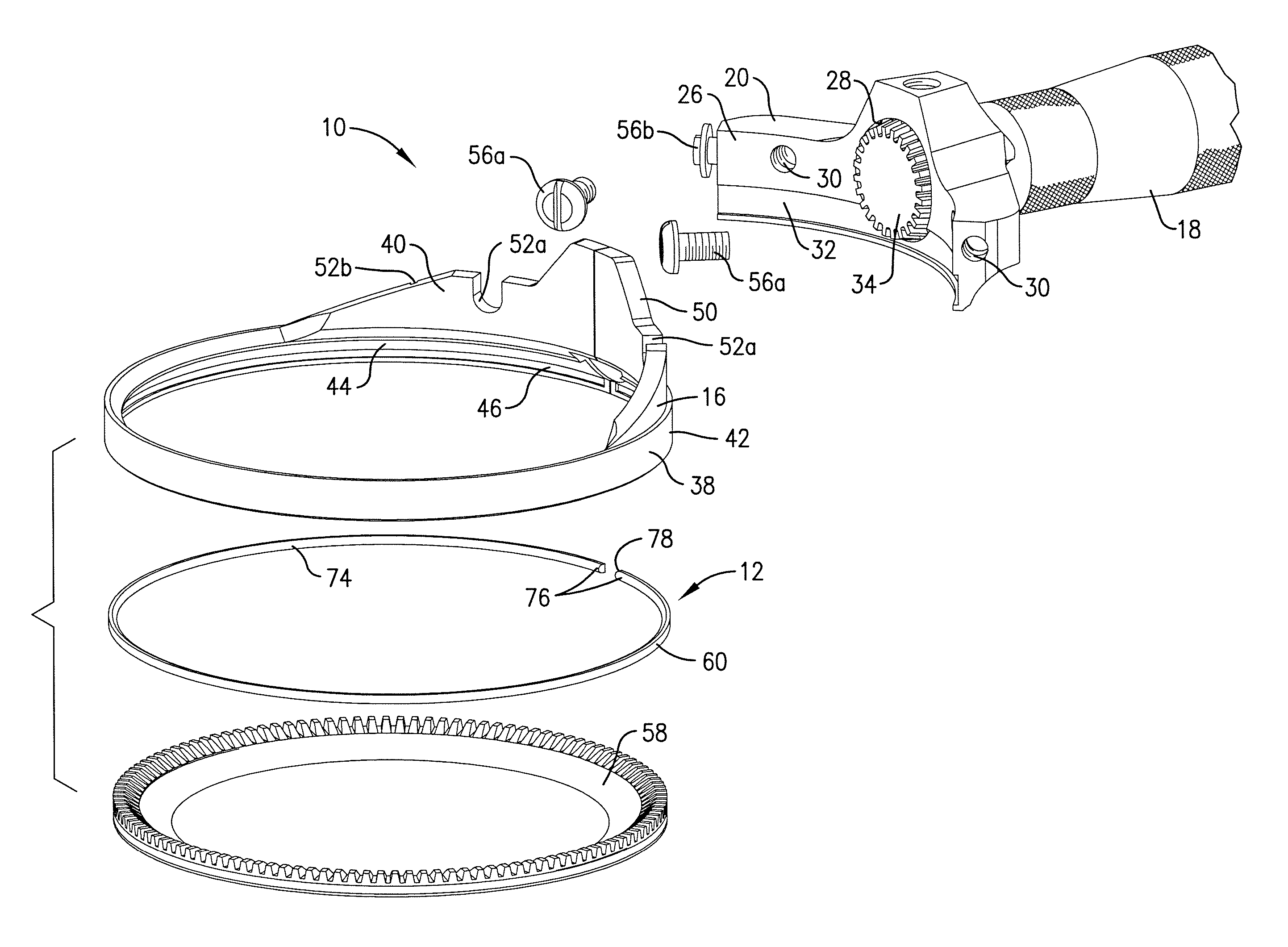

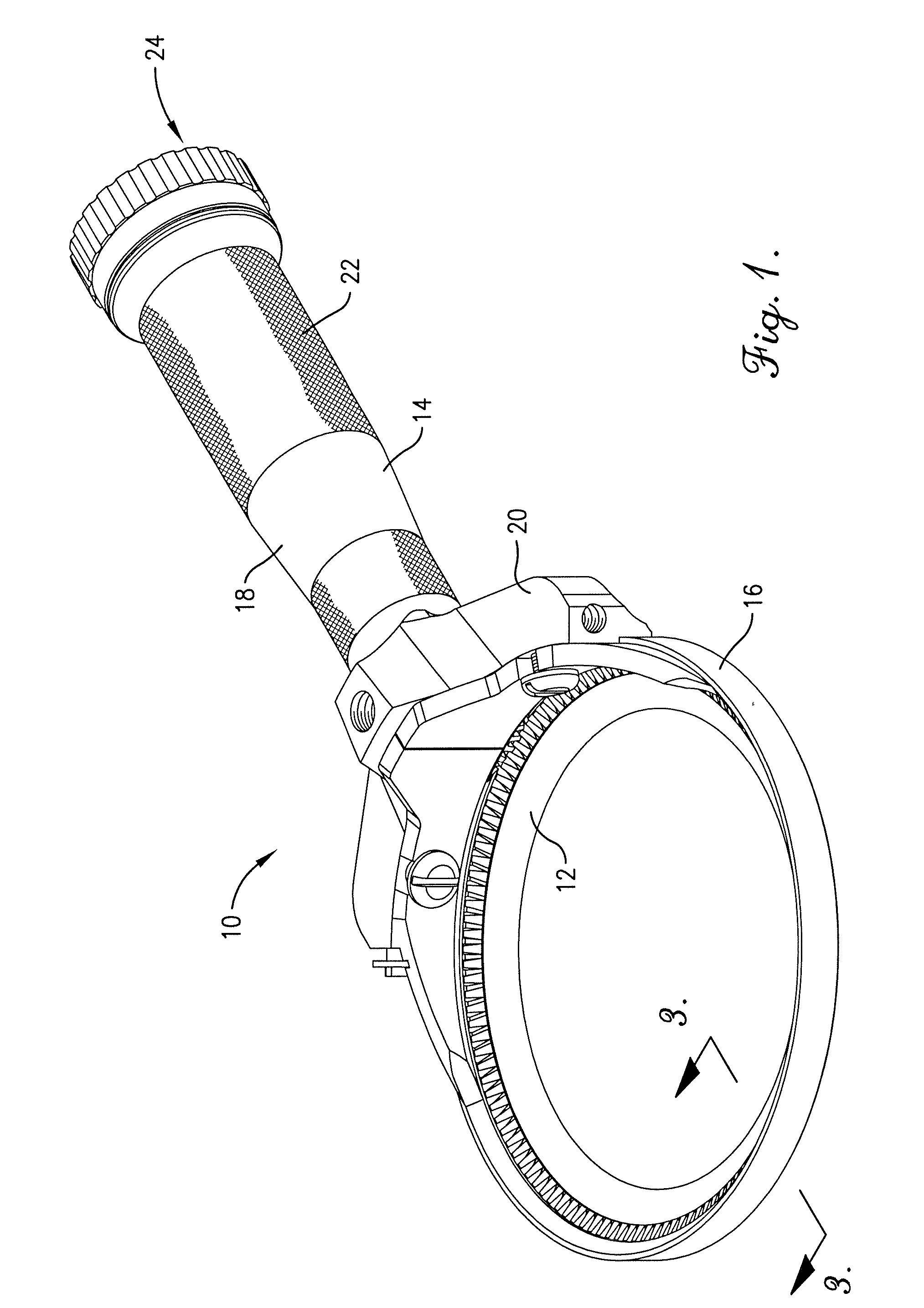

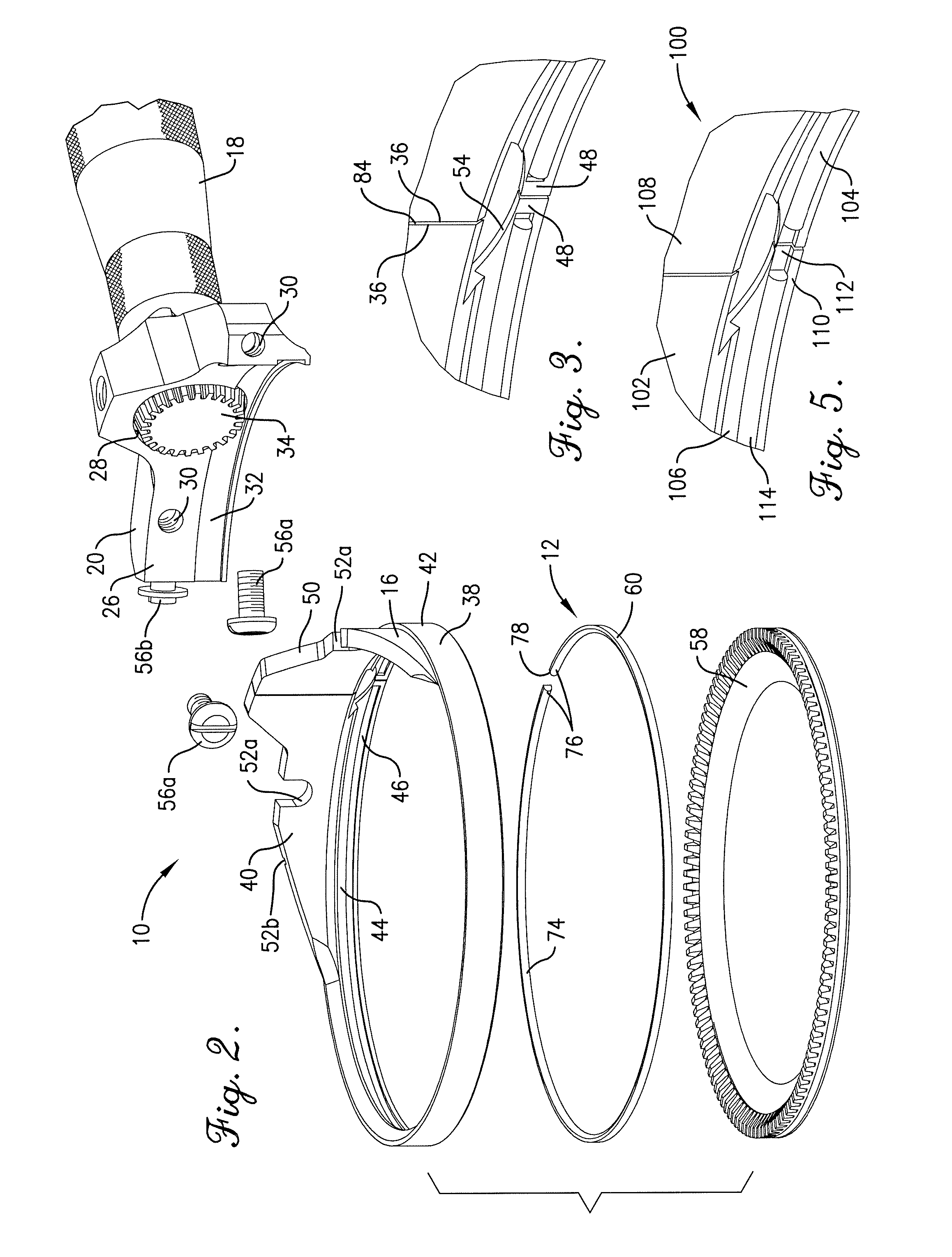

Power operated rotary knife

InactiveUS6978548B2Easy accessMetal working apparatusMetal-working hand toolsRotary engineEngineering

A rotary knife comprising, an annular blade having a central axis, a blade supporting head assembly supporting the blade for rotation about the axis, a manually grippable handle assembly connected to the head assembly, and a flex shaft drive transmission for driving the blade about the axis. The handle assembly comprises a core, a hand grip surrounding the core, and a connector unit that secures the hand grip to the core. The core has a first end region rigidly fixed with respect to the head assembly and a second end region spaced from the head assembly. The core defines a drive transmission guiding channel leading toward the blade. The hand grip has a first end region proximal the blade support assembly and a second end region proximal the second core end region. The connector detachably secures the hand grip in fixed relationship with the core. The connector engages the second end regions and is detachable for enabling hand grip removal and replacement.

Owner:BETTCHER INDUSTRIES

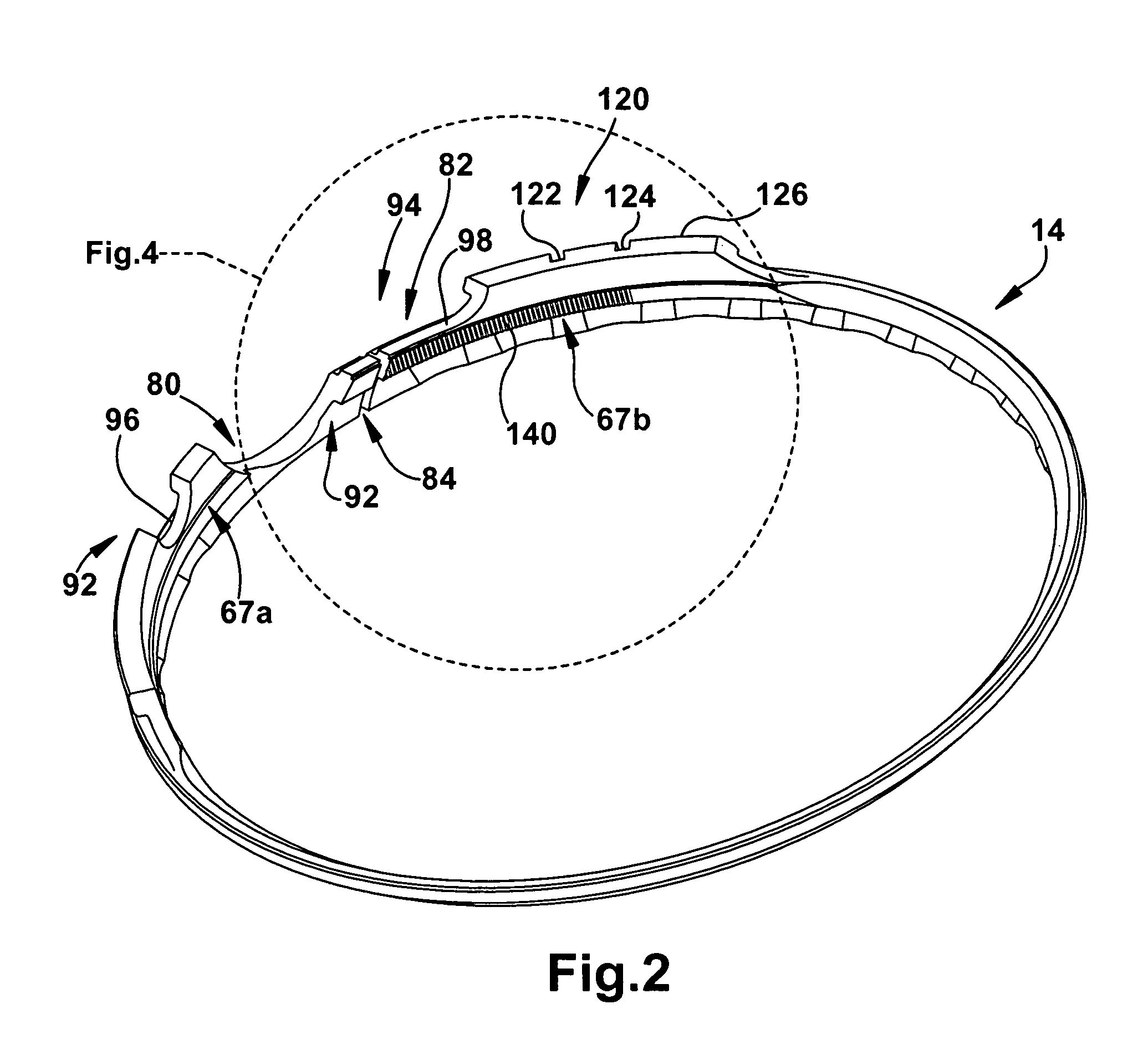

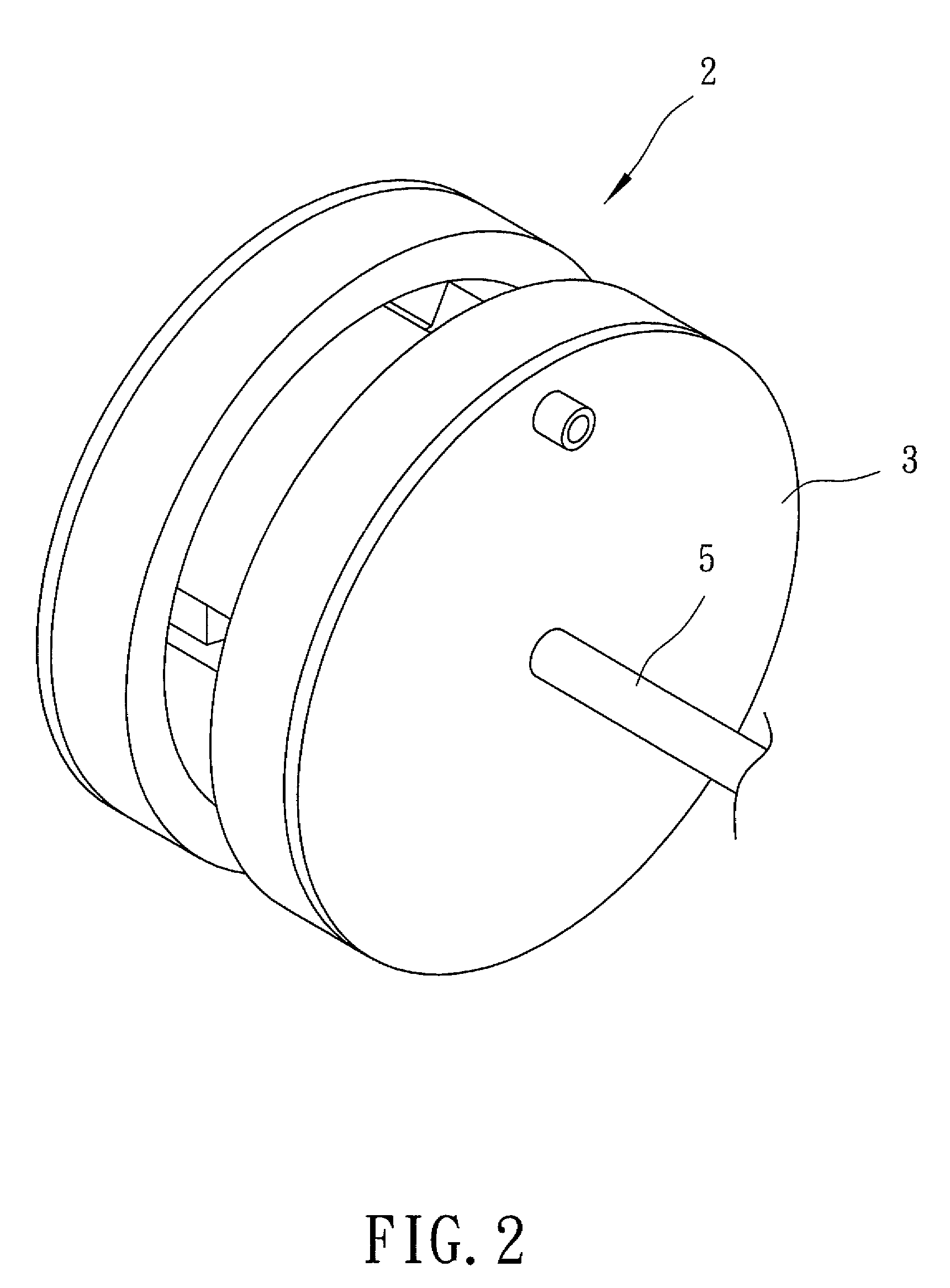

Rotary knife with blade bushing

A powered rotary knife includes a handle, a blade housing, an annular blade, and a blade bushing for rotatably mounting the blade within the housing. The blade housing includes an inner groove that is operable to receive the blade bushing therein. The blade housing and blade bushing are split in order to expand and receive the blade. The blade includes an outer groove that is also operable to receive the blade bushing. Thus, the blade bushing is spaced between the blade housing and blade and rotatably secures the blade within the blade housing.

Owner:HANTOVER

Vertical take-off and landing vehicles

Owner:MOLLER INT

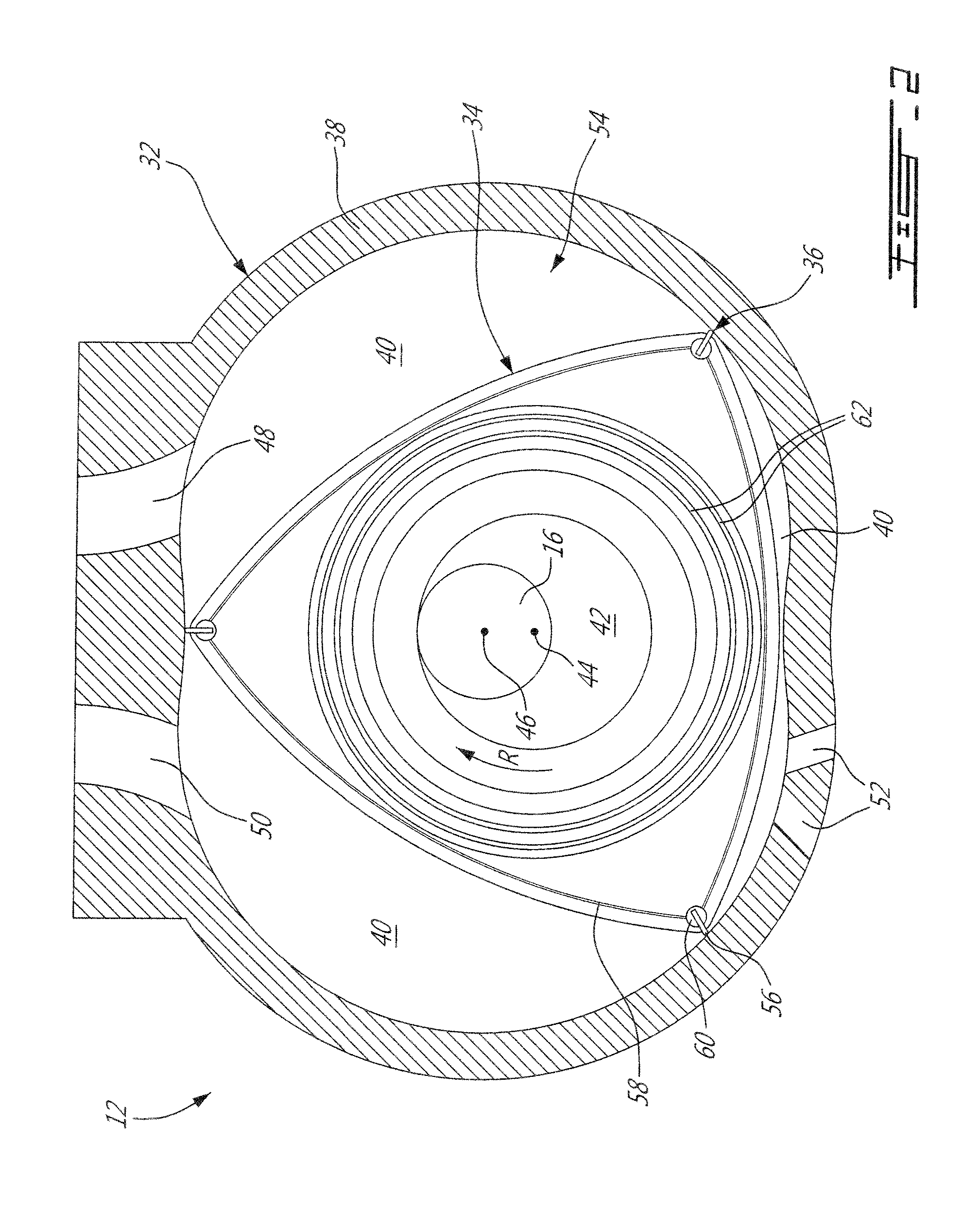

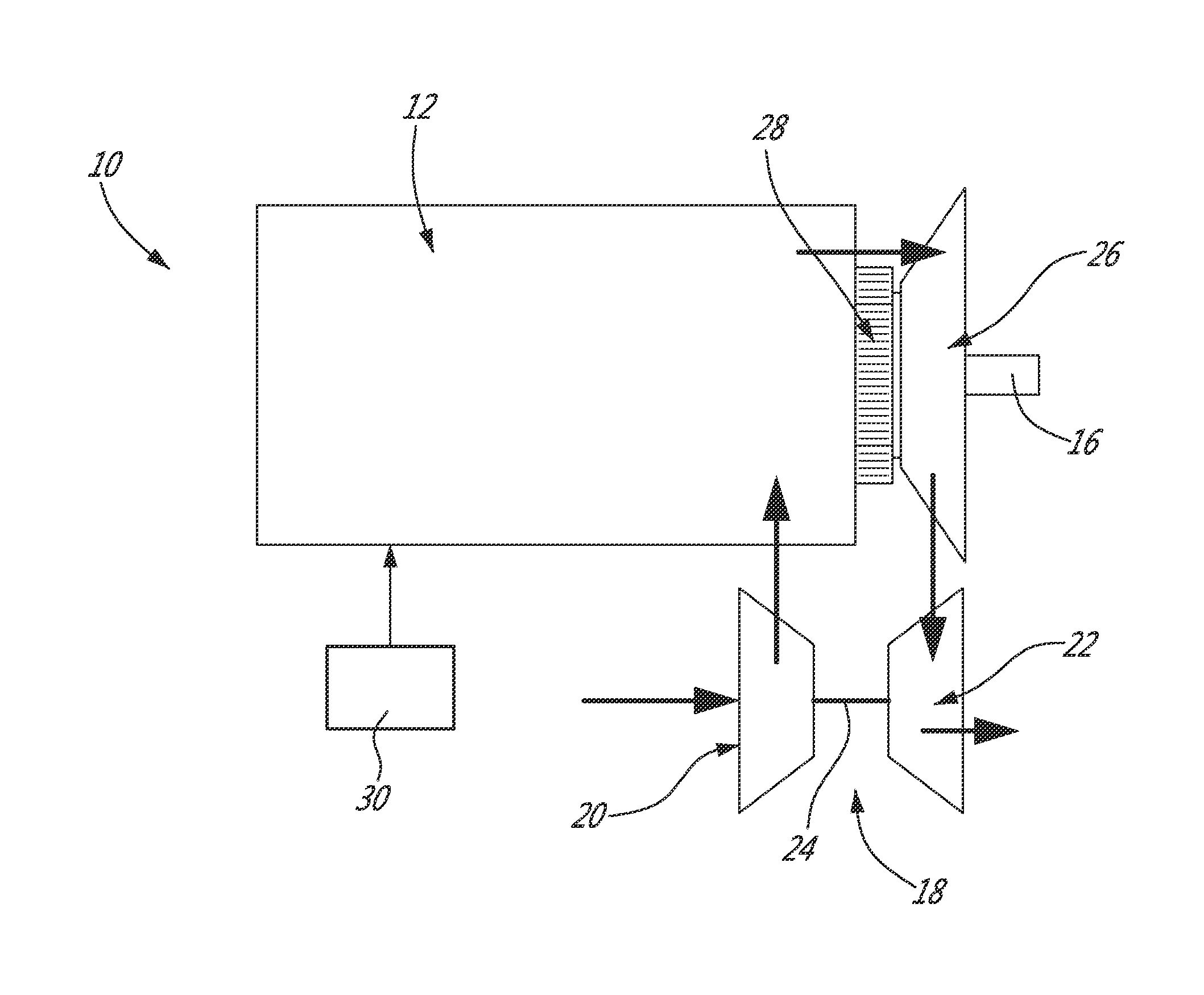

Compound cycle rotary engine

ActiveUS20090007882A1Reduce fuel consumptionHigh power to weightInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

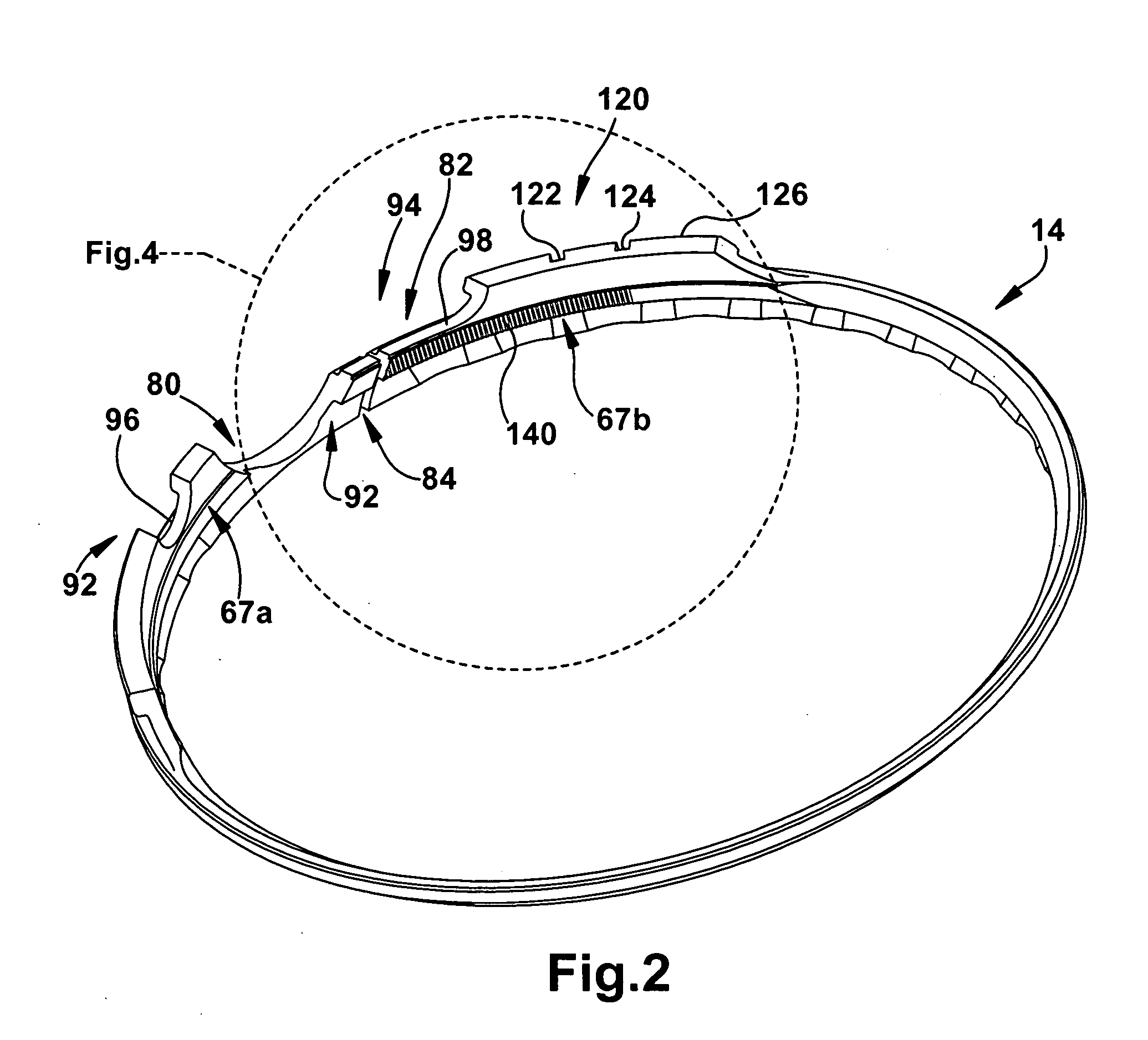

Split blade housing for power operated rotary knife

ActiveUS20080098605A1Easy to disassembleIncrease the diameterMetal working apparatusRotary engineEngineering

A split blade housing adapted to support an annular knife blade for rotation in a power operated rotary knife. The blade housing includes a mounting section and a body section extending from the mounting section and forming a ring. The mounting section of the split blade housing is adapted to be mounted to a handle assembly of the rotary knife and includes a recess providing clearance for a pinion gear that extends from the handle assembly to engage and drive the knife blade. The split blade housing includes an annular groove for rotatably supporting the knife blade, the groove defining a rotational plane of the knife blade. The split blade housing includes a split defining first and second end portions adjacent the split to facilitate removal of the knife blade from the housing. The housing split is peripherally offset from the mounting section recess and the split is transverse with respect to a center vertical axis of the blade housing.

Owner:BETTCHER INDUSTRIES

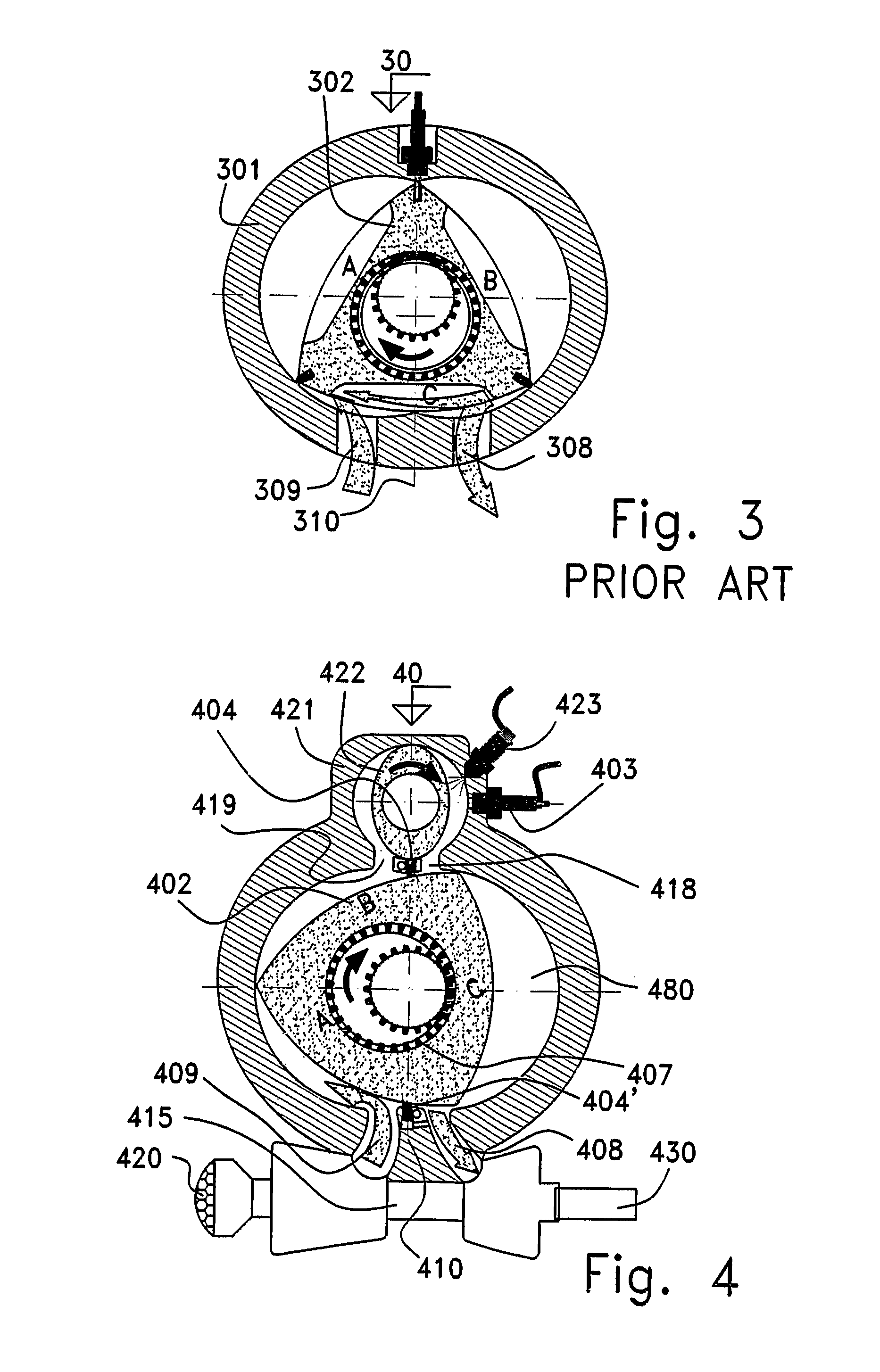

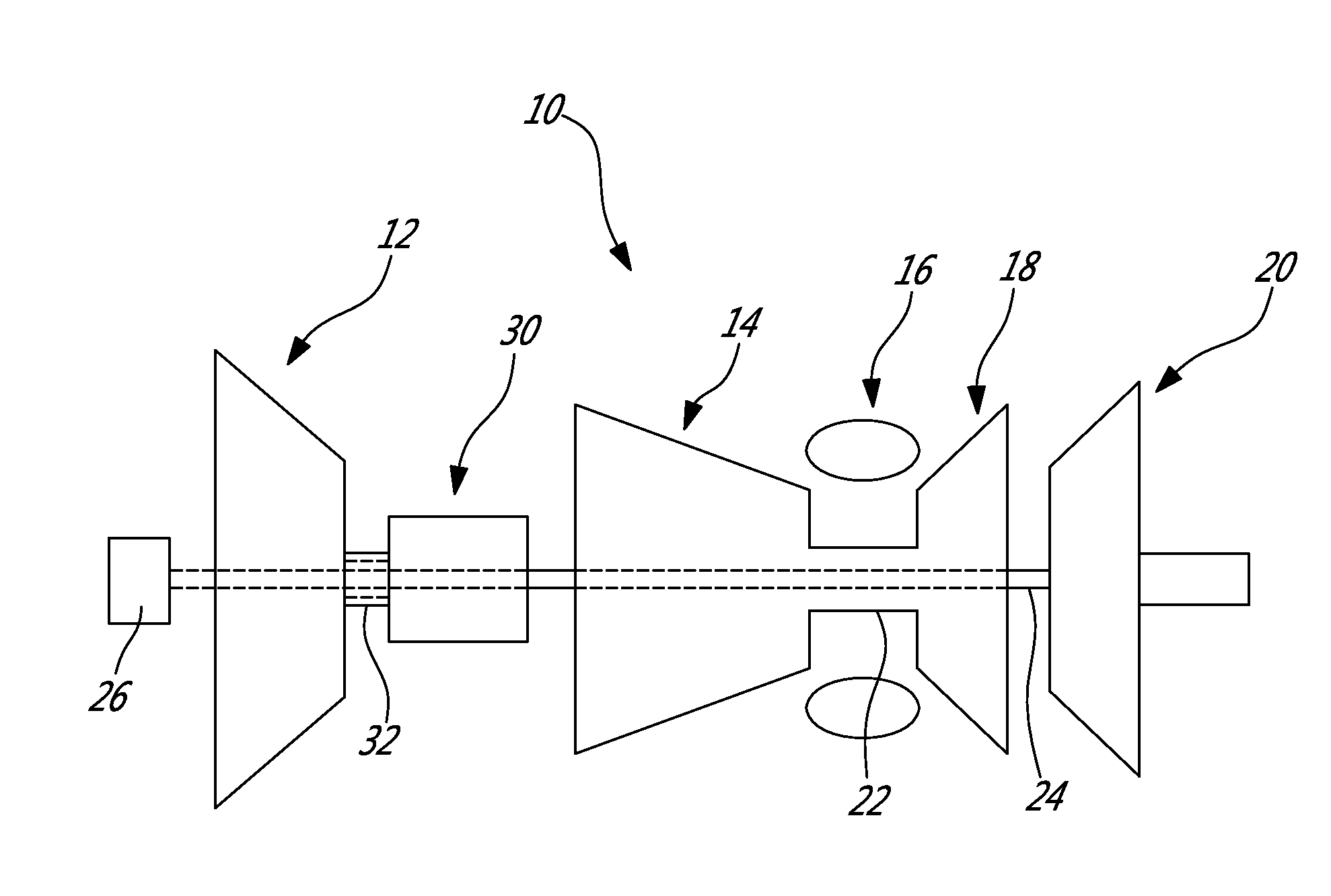

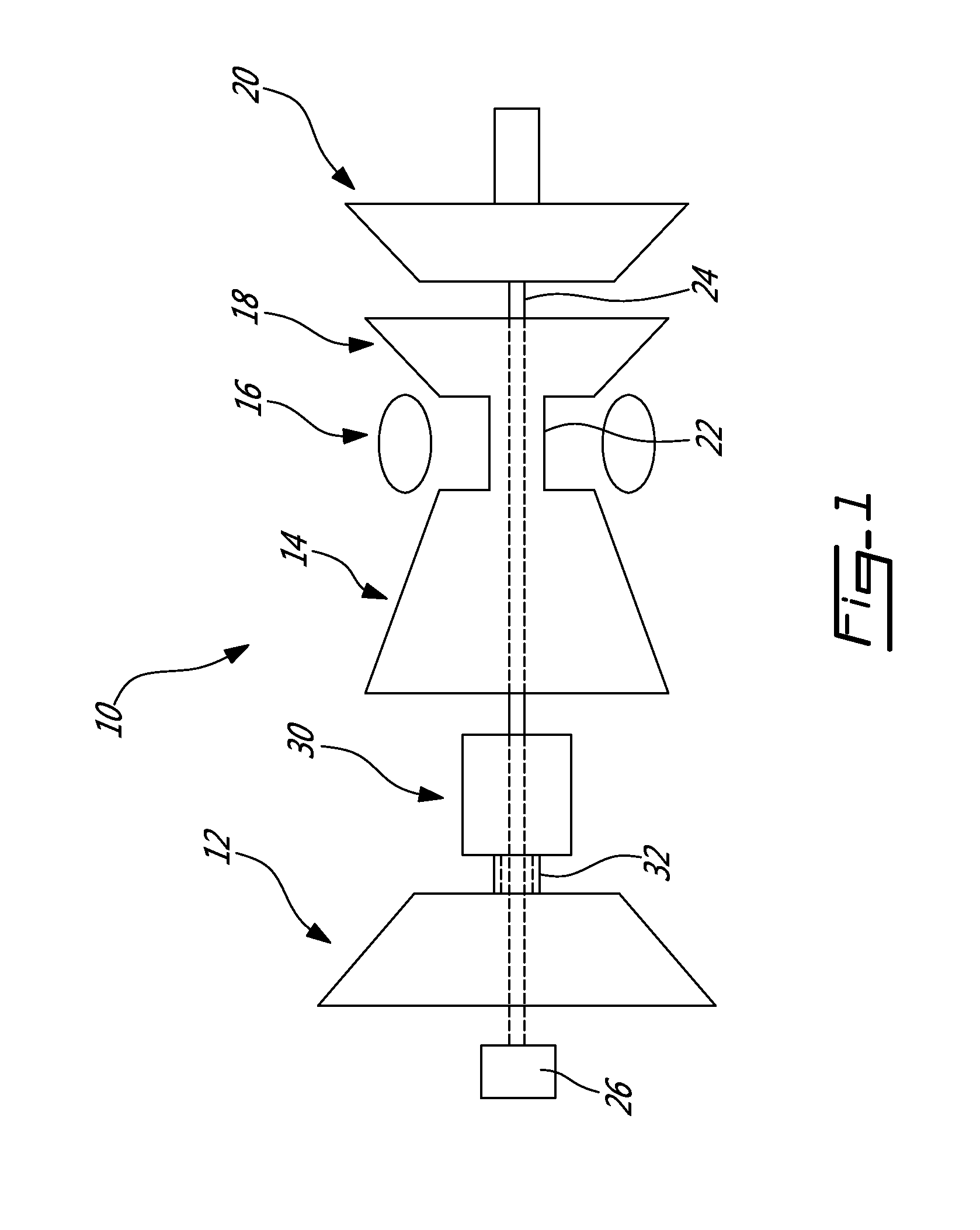

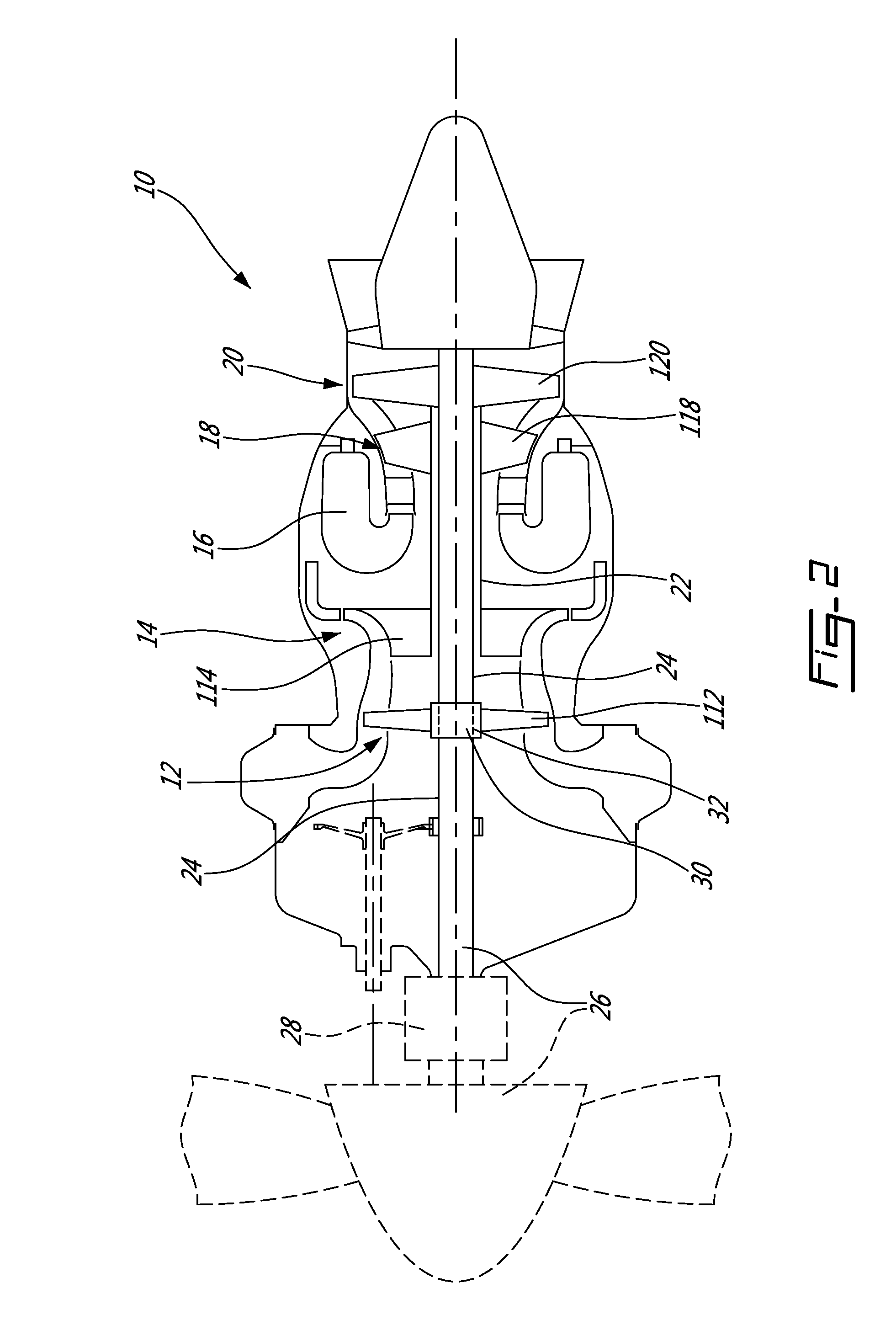

Compound cycle engine

ActiveUS20140020381A1Internal combustion piston enginesWorking fluid for enginesExternal combustion engineTurbocharger

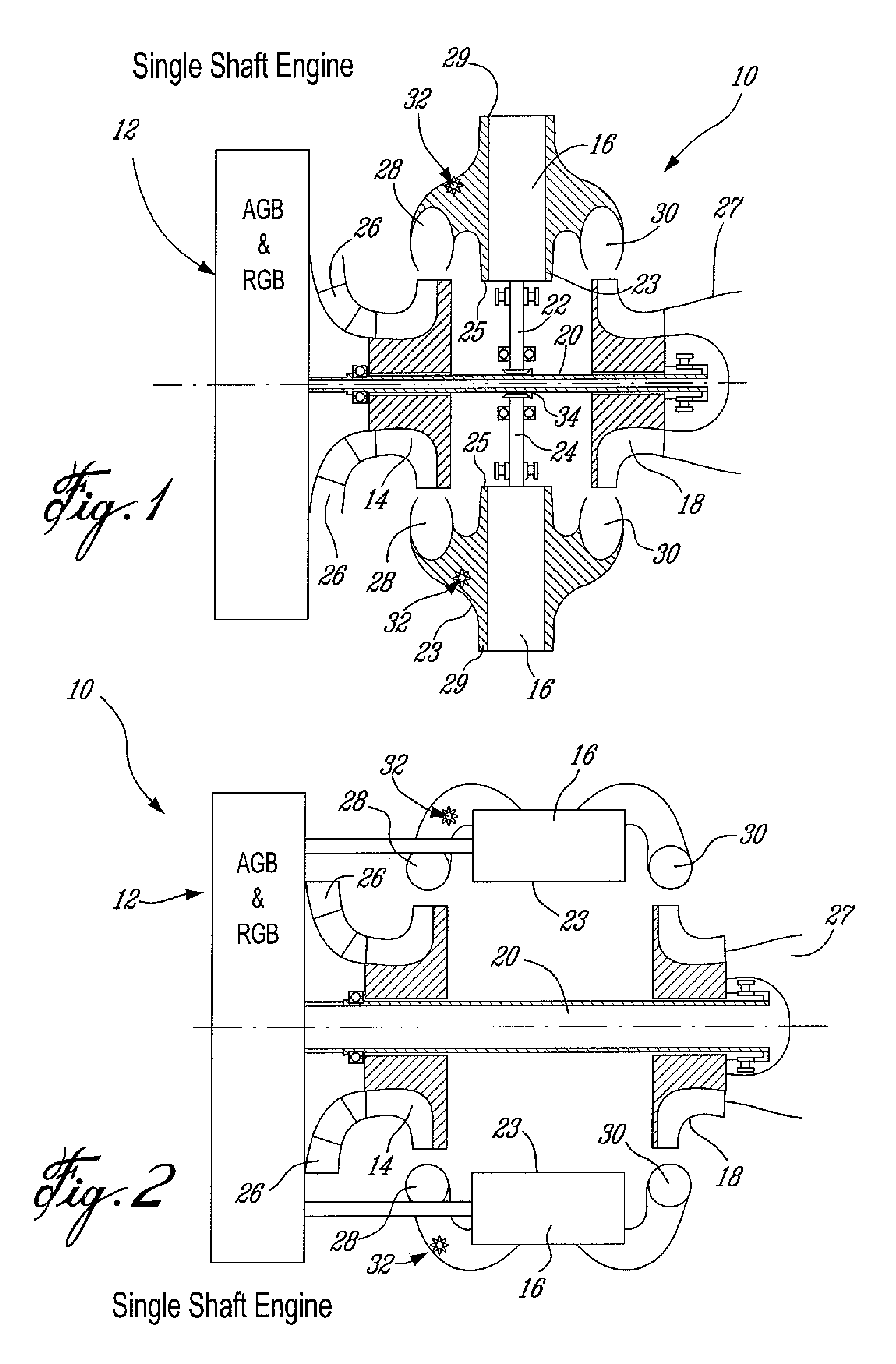

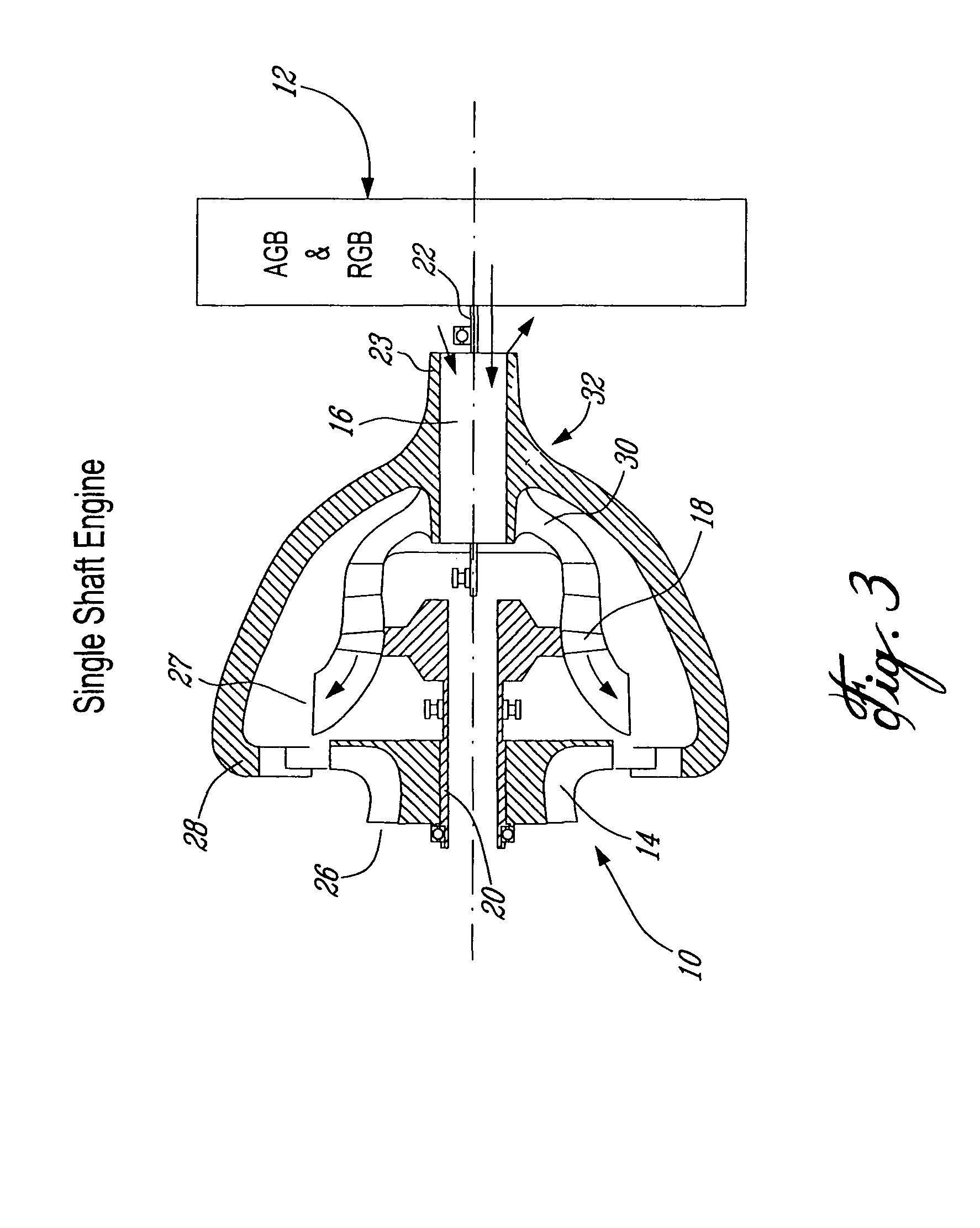

A compound cycle engine having an output shaft; at least two rotary units each defining an internal combustion engine, a velocity turbine, and a turbocharger is discussed. The velocity turbine includes a rotor in driving engagement with the output shaft between two of the rotary units. The exhaust port of each rotary unit is in fluid communication with the flowpath of the velocity turbine upstream of its rotor. The outlet of the compressor of the turbocharger is in fluid communication with the inlet port of each rotary unit. The inlet of the pressure turbine of the turbocharger is in fluid communication with the flowpath of the velocity turbine downstream of its rotor. A method of compounding at least two rotary engines is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Compound cycle engine

ActiveUS20150275756A1Internal combustion piston enginesPump componentsTurbochargerExternal combustion engine

A compound cycle engine having an output shaft; at least two rotary units each defining an internal combustion engine, a first stage turbine, and a turbocharger is discussed. The first stage turbine includes a rotor in driving engagement with the output shaft between two of the rotary units. The exhaust port of each rotary unit is in fluid communication with the flowpath of the first stage turbine upstream of its rotor. The outlet of the compressor of the turbocharger is in fluid communication with the inlet port of each rotary unit. The inlet of the second stage turbine of the turbocharger is in fluid communication with the flowpath of the first stage turbine downstream of its rotor. The first stage turbine has a lower reaction ratio than that of the second stage turbine. A method of compounding at least two rotary engines is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

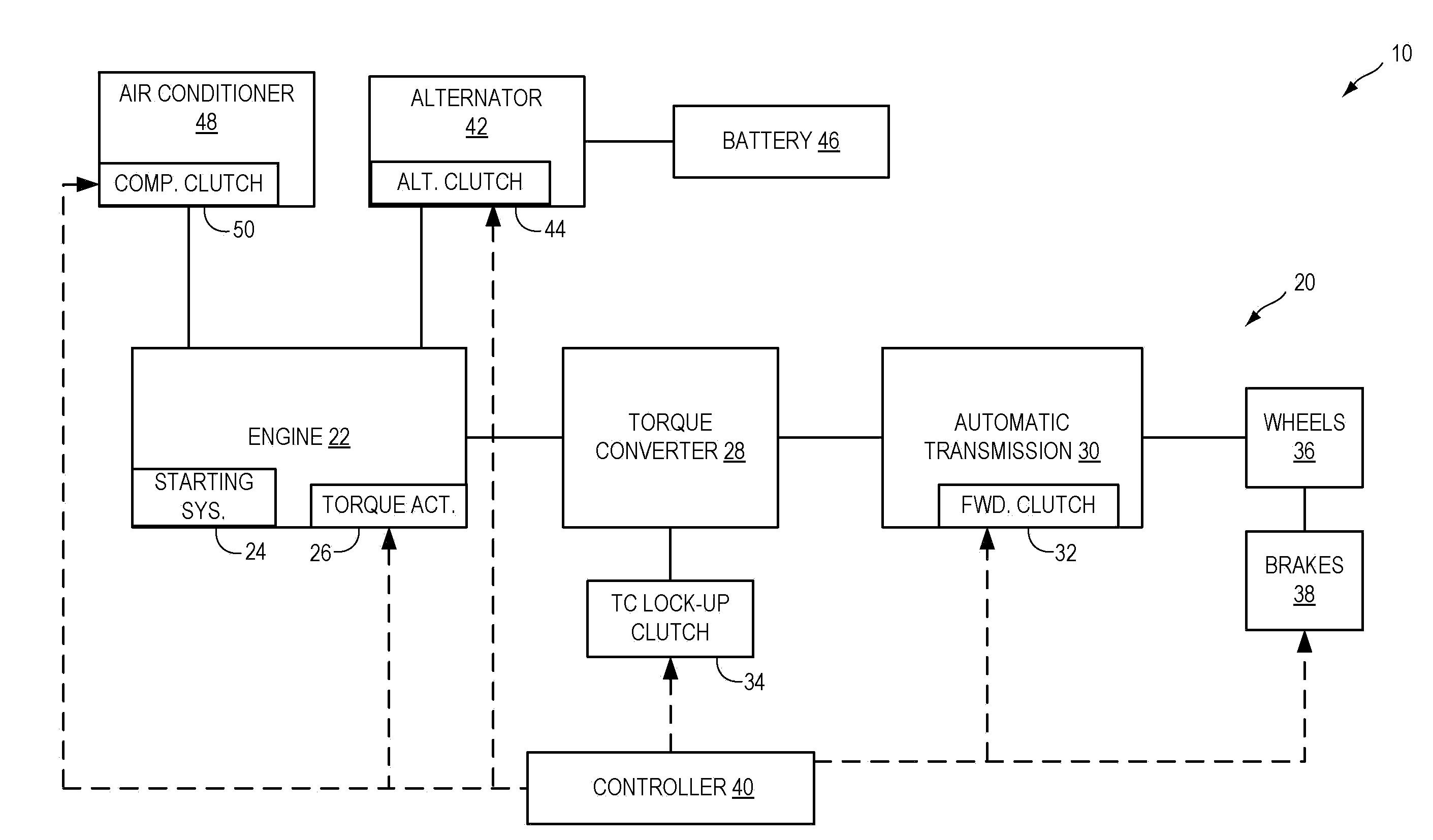

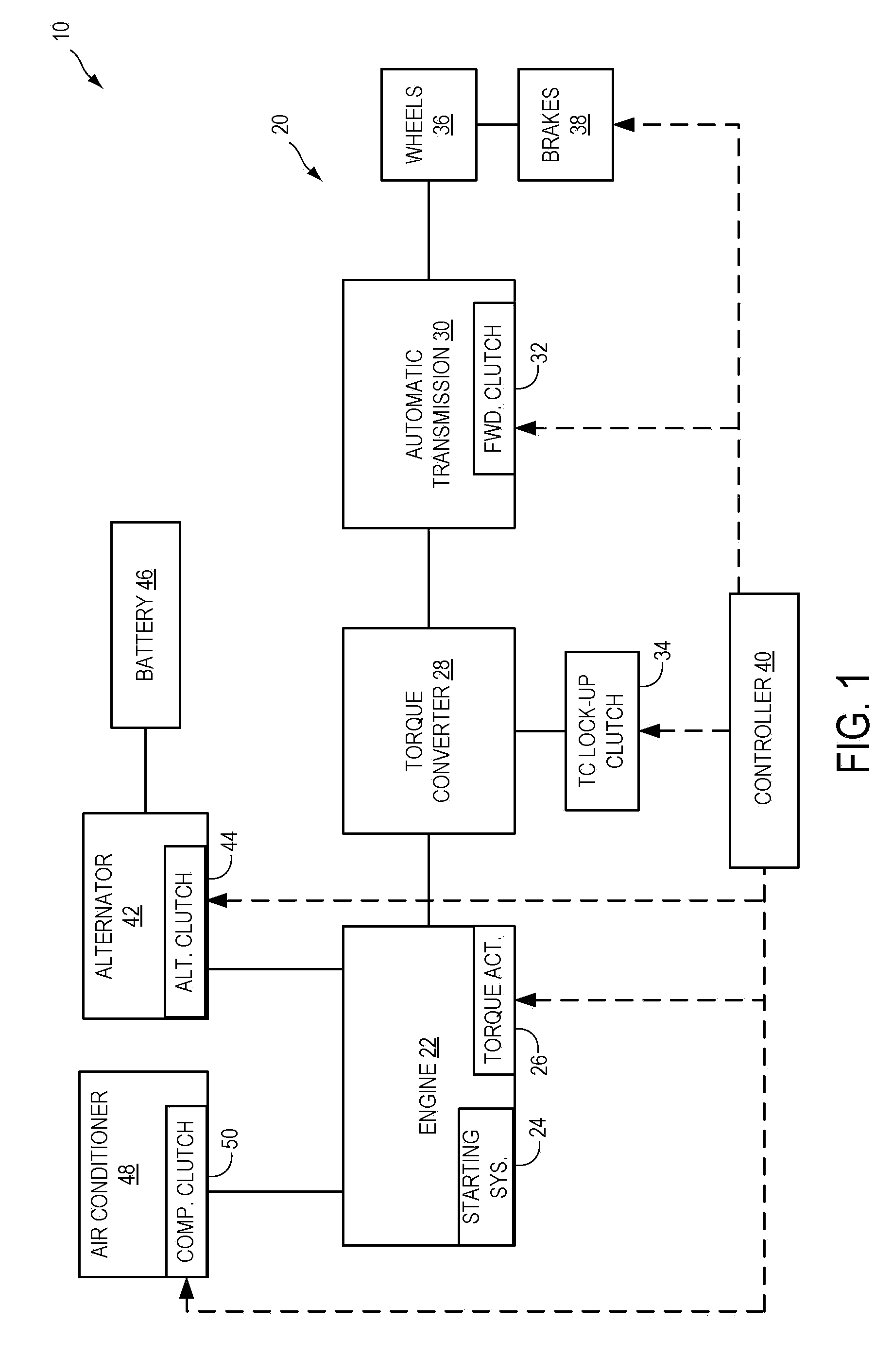

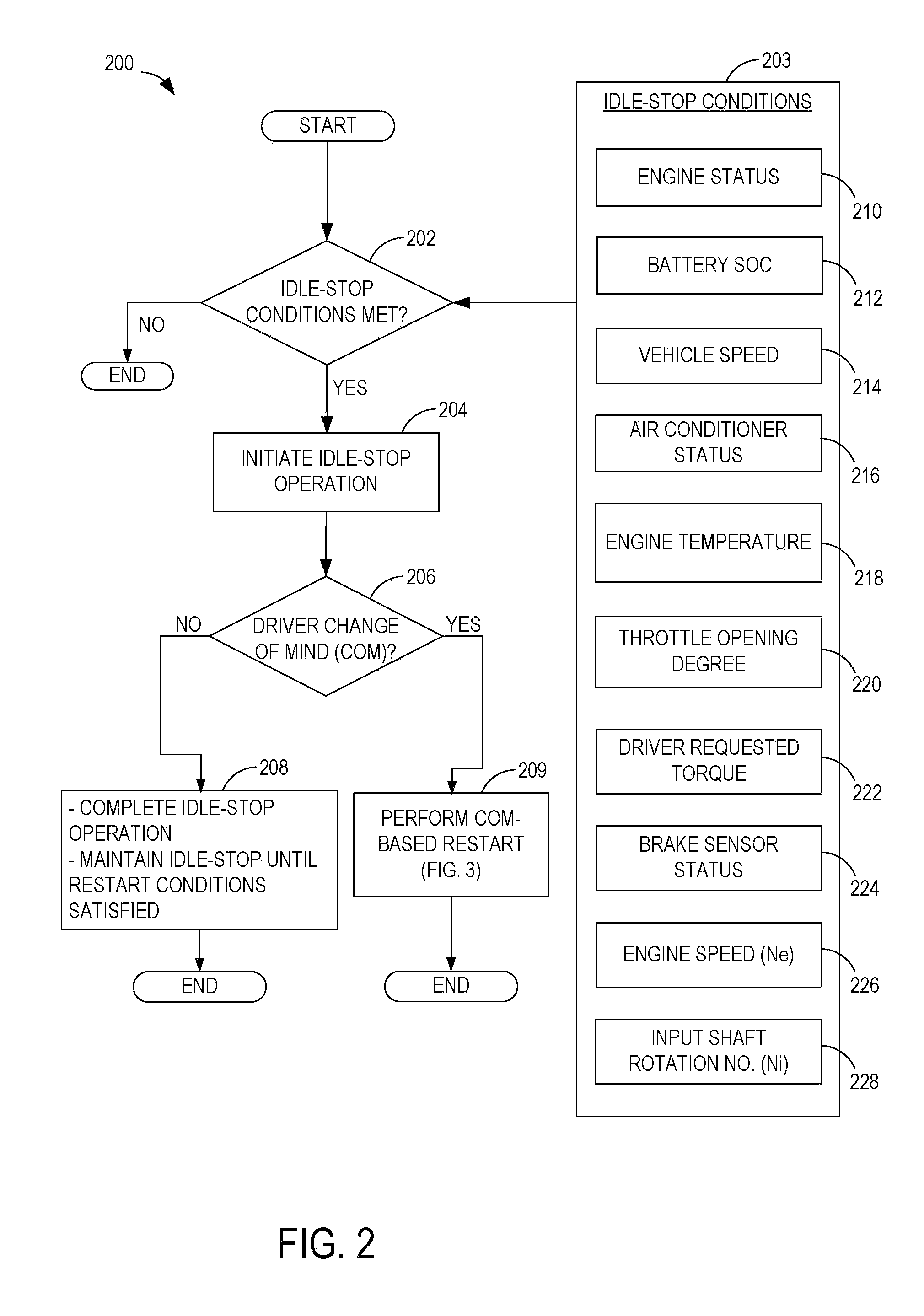

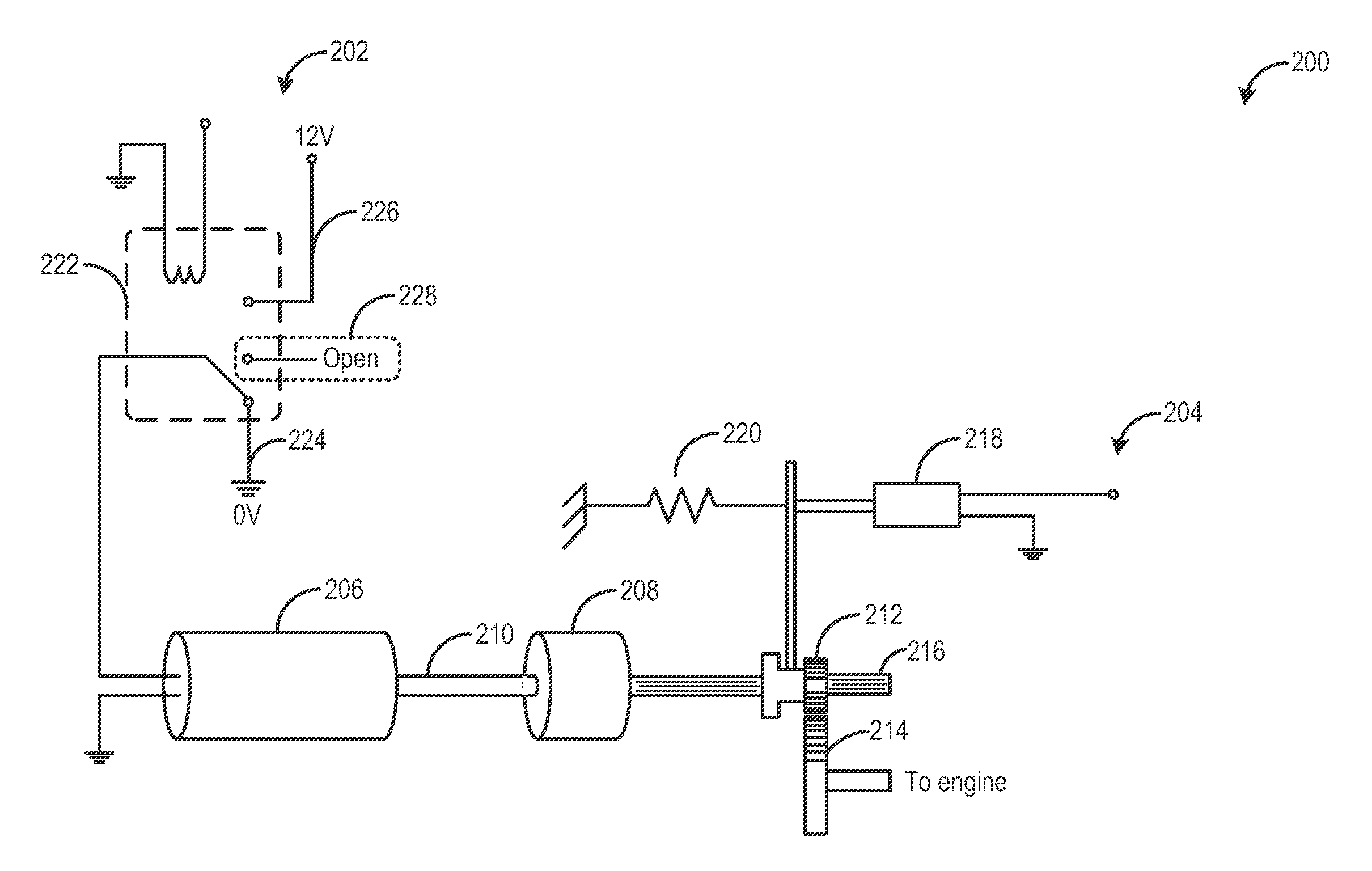

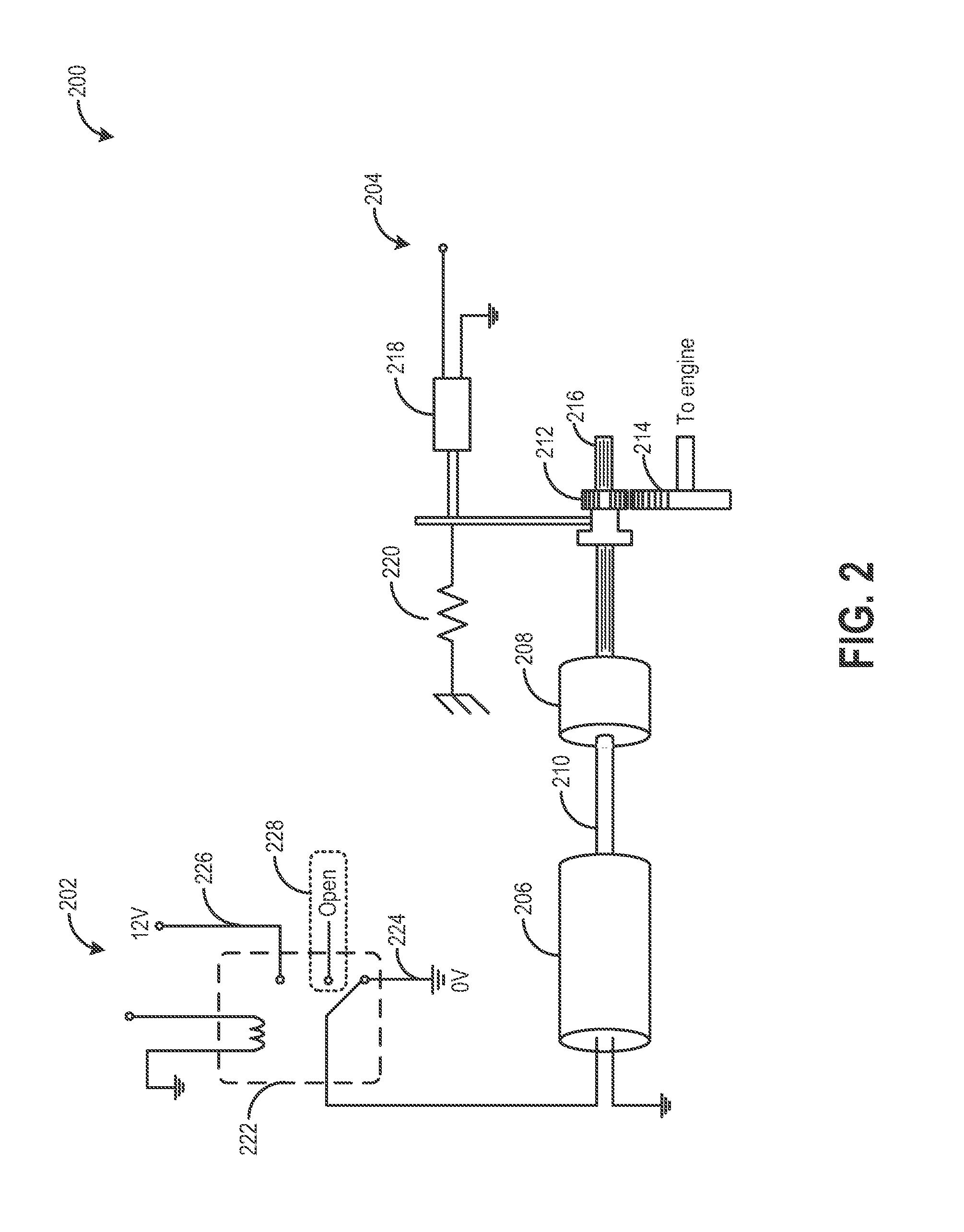

Methods and systems for assisted direct start control

ActiveUS20100174473A1Reduce exhaust emissionsSave fuelAnalogue computers for vehiclesPower operated startersBrake torqueRotary engine

Method and systems are provided for controlling a vehicle system including an engine that is selectively deactivated during engine idle-stop conditions. One example method comprises, adjusting a brake torque applied to a deactivated rotating engine after an engine restart request, the brake torque applied to slow the engine to at least a predetermined threshold speed without stopping the engine, and engaging a starter to the still rotating engine to increase the engine speed and restart the engine.

Owner:FORD GLOBAL TECH LLC

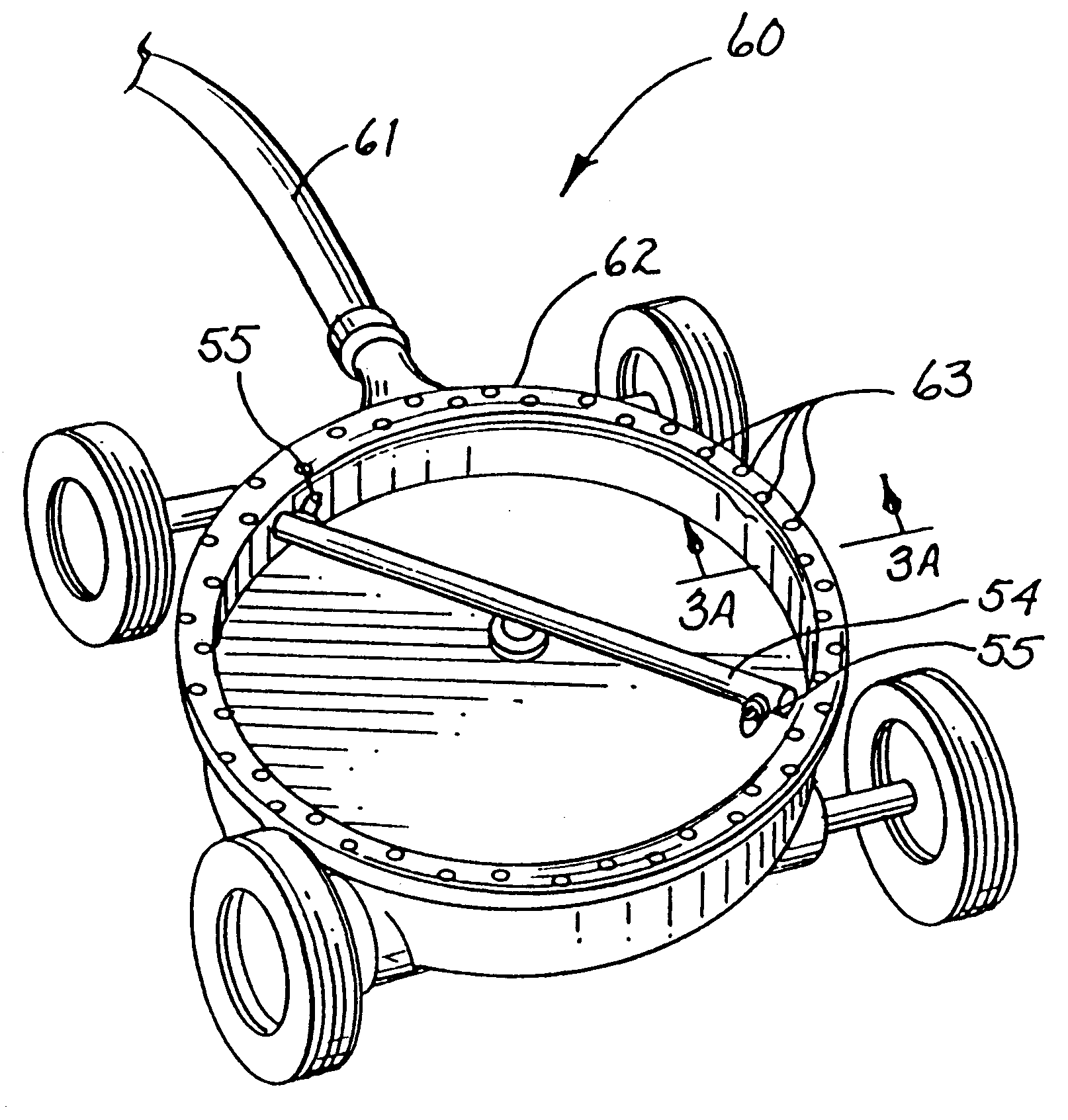

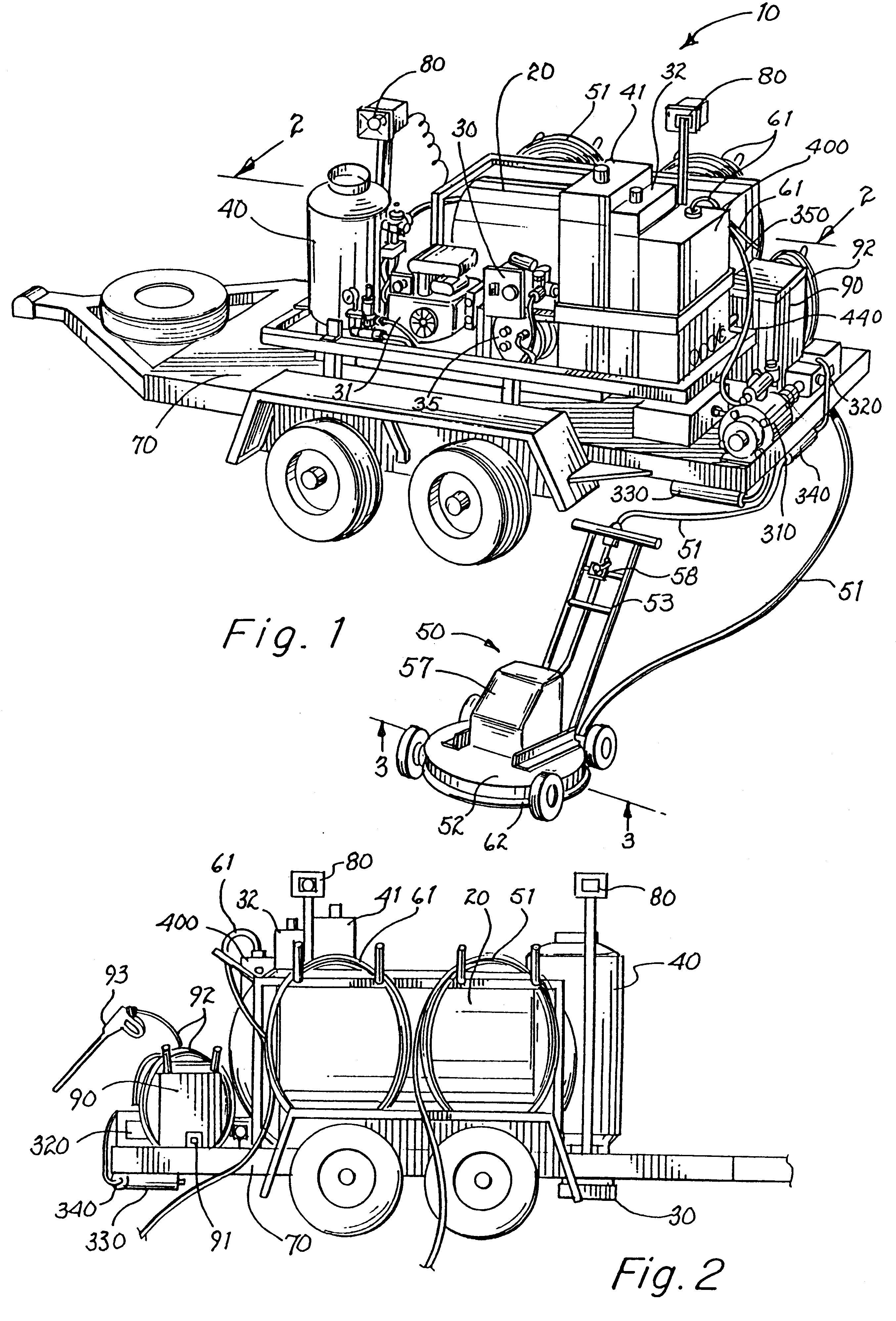

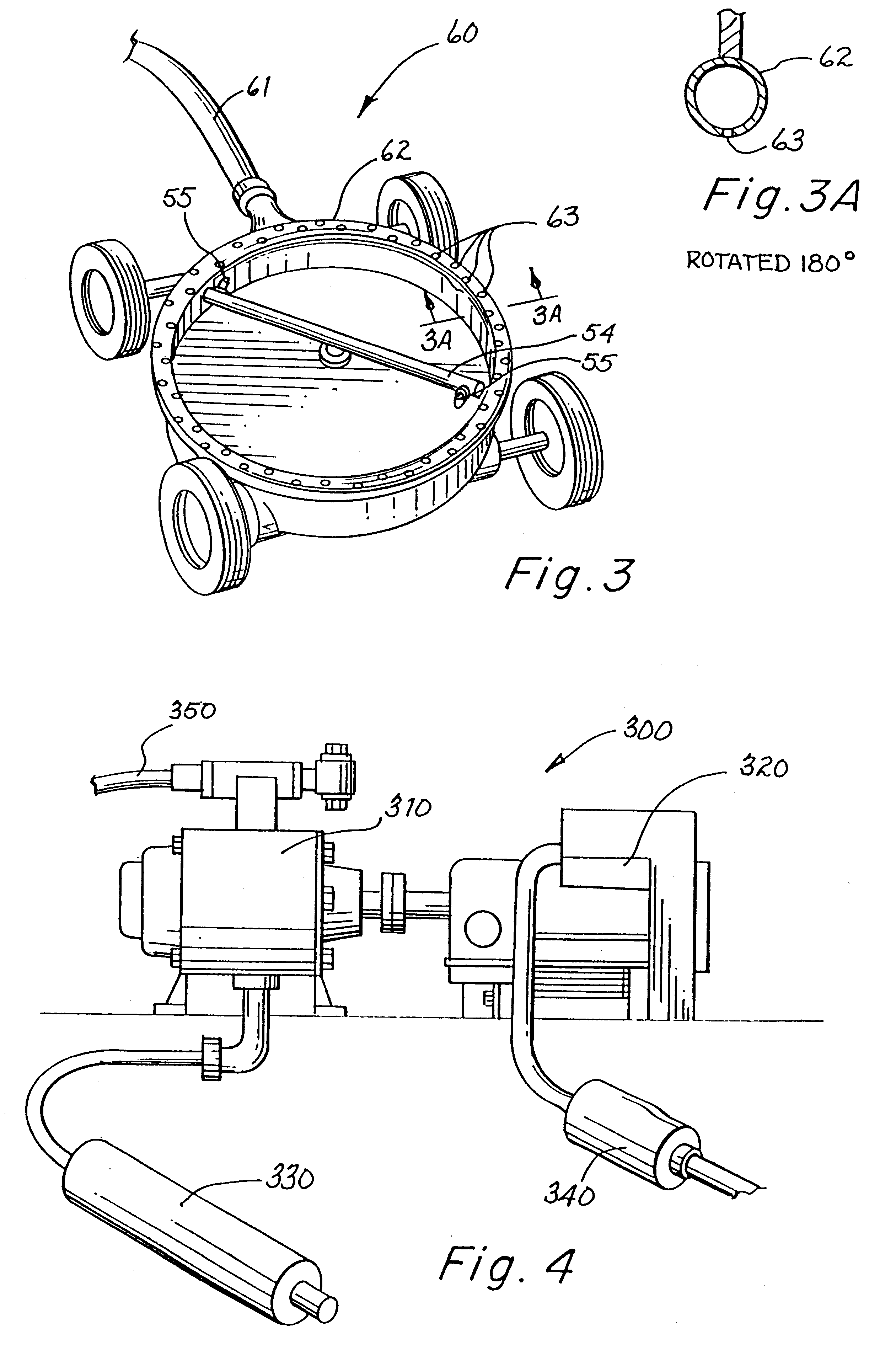

Mobile cyclonic power wash system with water reclamation and rotary union

A cyclonic power wash system uses high pressure, high temperature water for selectively cleaning large, flat, concrete or asphalt surfaces. The sprayed water is reclaimed by vacuuming it through holes in the bottom of a reclamation ring attached to the underside of the mobile cyclone sprayer, filtering the vacuumed water and returning it to a storage tank for re-use by the system. The filtration tank initially filters out large matter in an inlet trough and smaller matter in a plurality of cascading chambers. A rotary union in the sprayer prevents the water, passing from the inlet of the rotary union to the discharge thereof, from leaking through or around a seal formed by pressing together a pair of hard, durable sealing surfaces, for example, silicon carbide, one of which is non-rotatably slidingly received in an upper recess of the union's fixed housing and the other, affixed to a spindle rotatably received and retained in a lower recess of the housing. The sliding fit interface of the non-rotatable seal face in the upper recessed housing is sealed by an o-ring supported at its inner bore by extended portions adjacent the central bores of the members between which it is sandwiched. Upward and rotational forces are applied to the spindle in reaction to the water exiting from nozzles affixed to a spray bar attached to the spindle.

Owner:NILFISK ADVANCE TECH

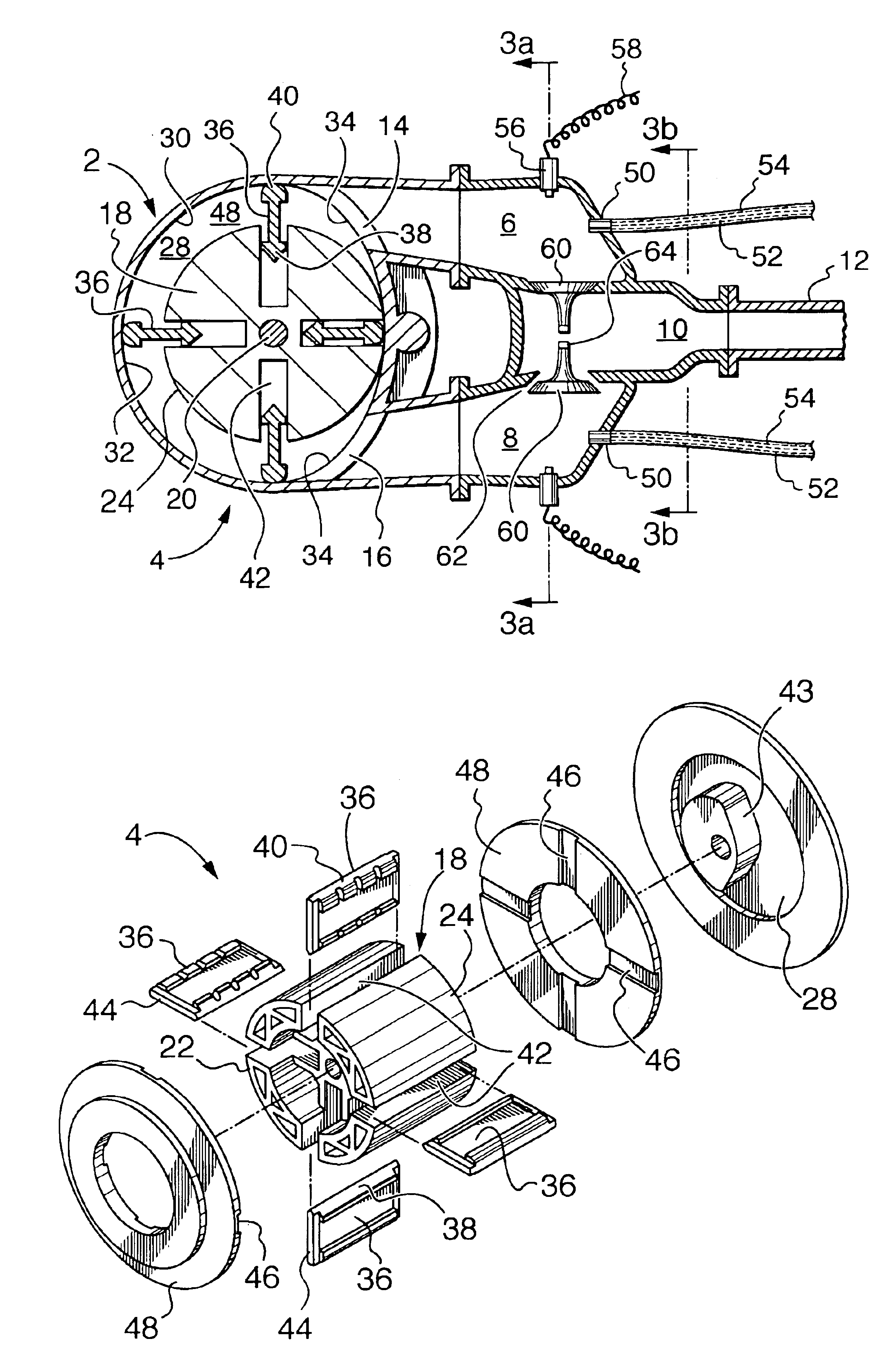

Radial engine power system

InactiveUS20070137595A1Improve efficiencyInternal combustion piston enginesEngines with rotating cylindersFlywheel effectEngineering

A power plant utilizing a radial rotary engine and incorporating onboard energy storage. The engine is of the type utilized in pre-World War I aircraft, but with certain modifications. The energy storage system exploits the flywheel effect inherent in these engines and optionally also includes auxiliary energy storage in other forms, such as compressed air or electrical. Using a continuously variable transmission enables advantageous use of engine inertia in a coast down mode of driving.

Owner:GREENWELL GARY A

Methods and systems for assisted direct start control

ActiveUS20110132308A1Reduce exhaust emissionsSave fuelElectric motor startersMachines/enginesBrake torquePower flow

Methods and systems are provided for controlling a vehicle system including an engine that is selectively deactivated during engine idle-stop conditions. One example method includes, during a first condition, engaging an engine starter, without applying a starter current, to the deactivated rotating engine after the engine speed drops below a threshold speed. The method further includes, during a second condition, engaging the starter and adjusting a starter motor switch to apply a starter braking torque to the rotating engine.

Owner:FORD GLOBAL TECH LLC

Split blade housing for power operated rotary knife

A split blade housing adapted to support an annular knife blade for rotation in a power operated rotary knife. The blade housing includes a mounting section and a body section extending from the mounting section and forming a ring. The mounting section of the split blade housing is adapted to be mounted to a handle assembly of the rotary knife and includes a recess providing clearance for a pinion gear that extends from the handle assembly to engage and drive the knife blade. The split blade housing includes an annular groove for rotatably supporting the knife blade, the groove defining a rotational plane of the knife blade. The split blade housing includes a split defining first and second end portions adjacent the split to facilitate removal of the knife blade from the housing. The housing split is peripherally offset from the mounting section recess and the split is transverse with respect to a center vertical axis of the blade housing.

Owner:BETTCHER INDUSTRIES

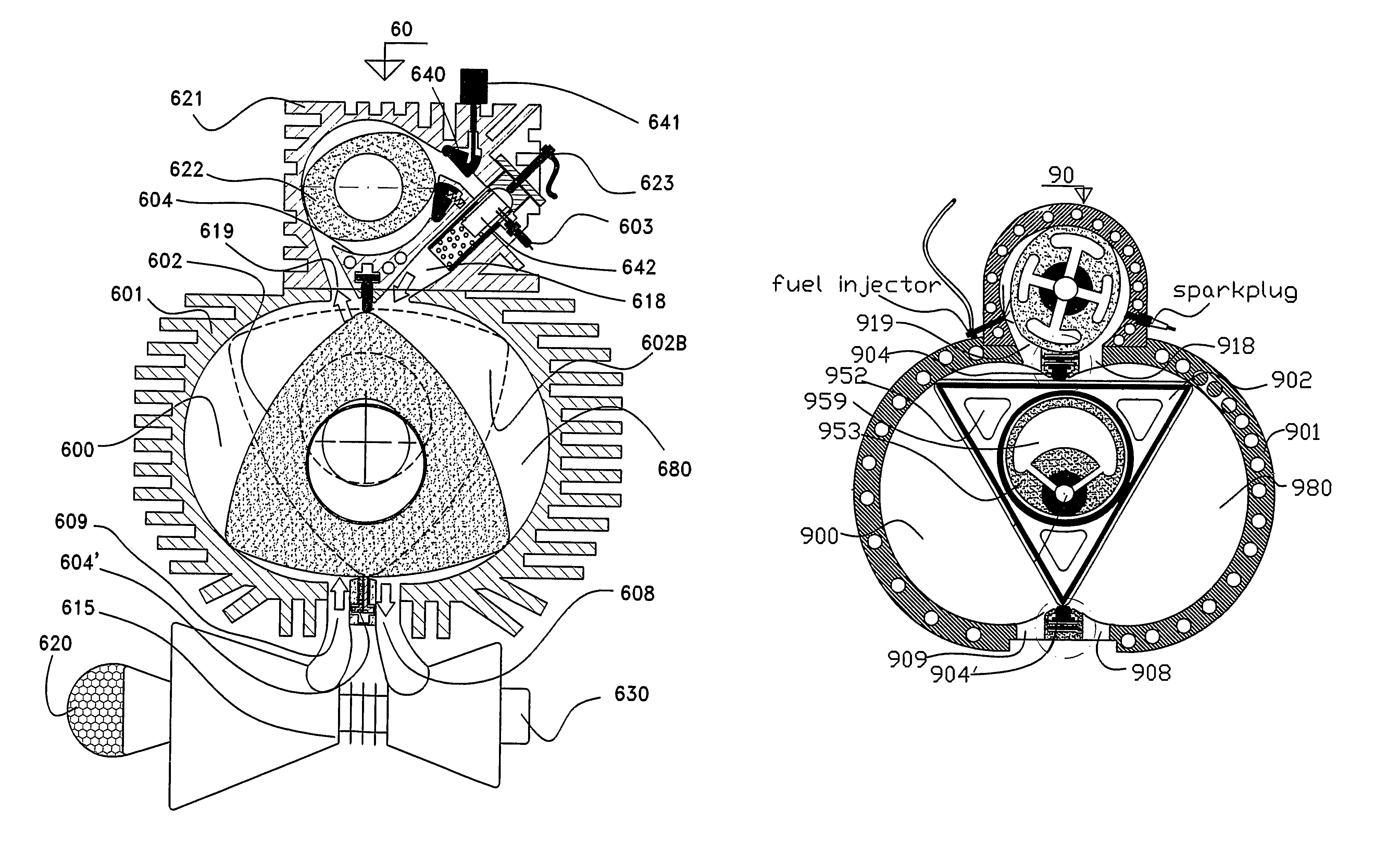

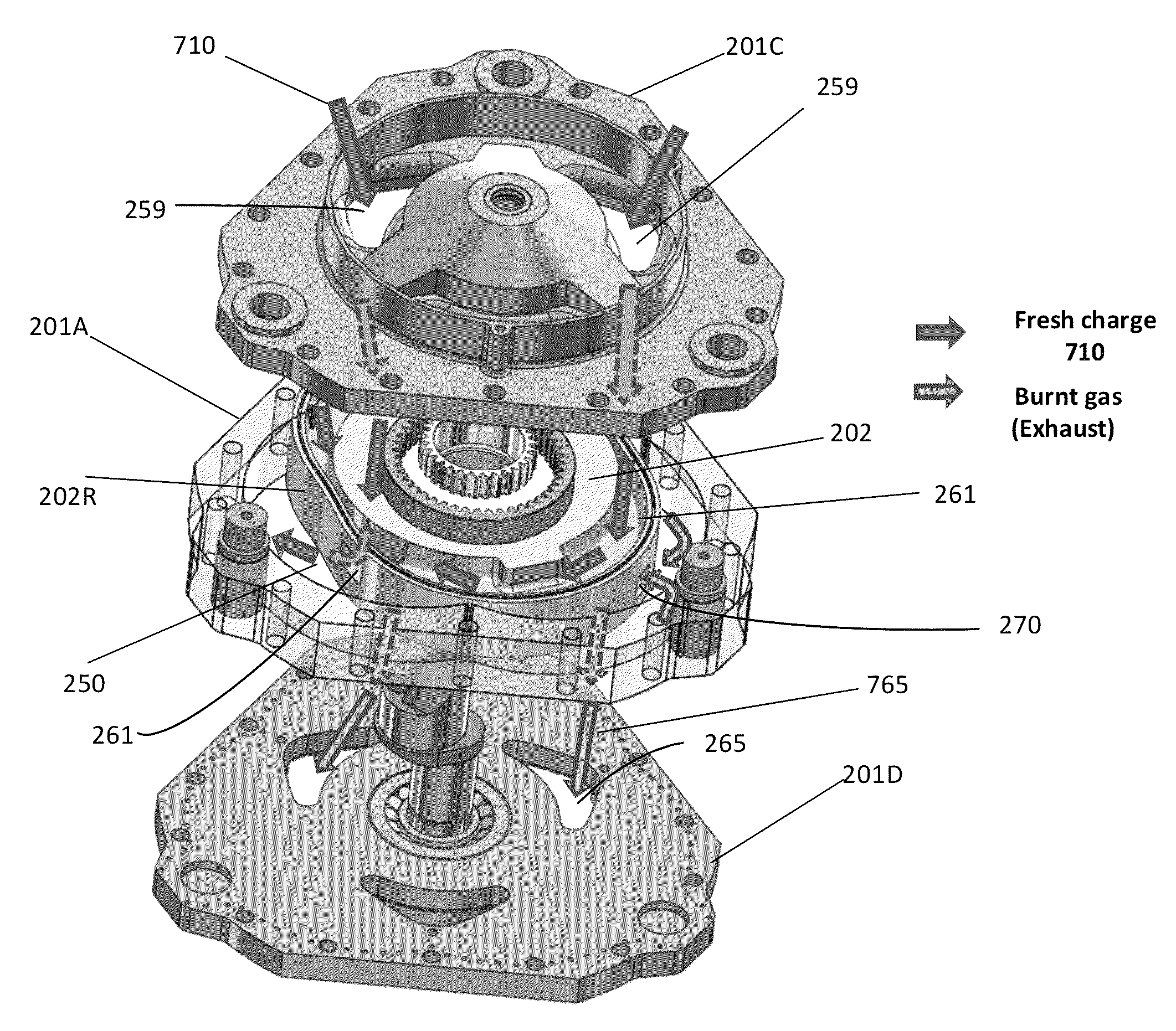

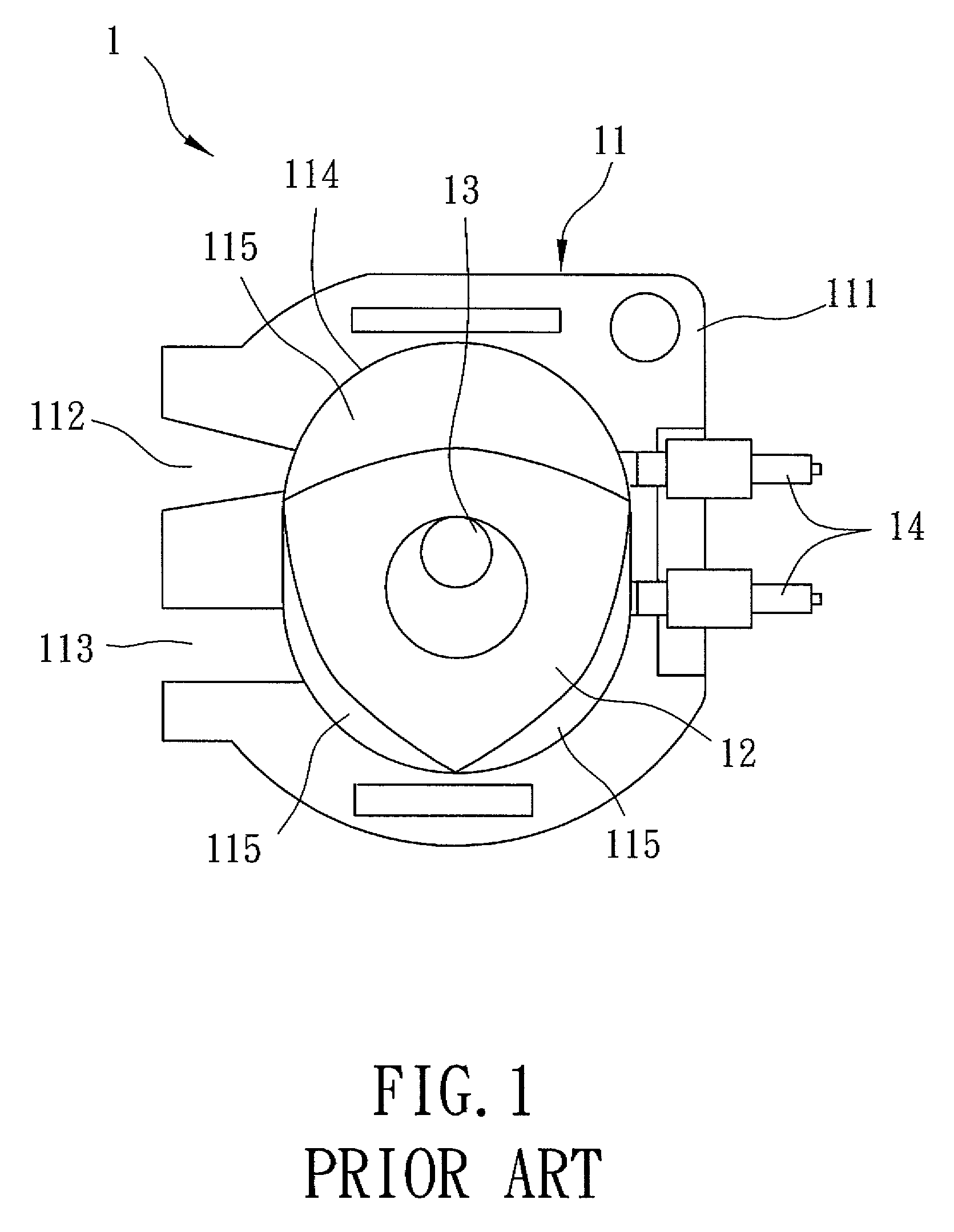

Wankel and similar rotary engines

InactiveUS8312859B2High power outputGuaranteed uptimeInternal combustion piston enginesEngine of arcuate-engagement typeCombustion chamberCompressed fluid

Owner:ROM HAIM +1

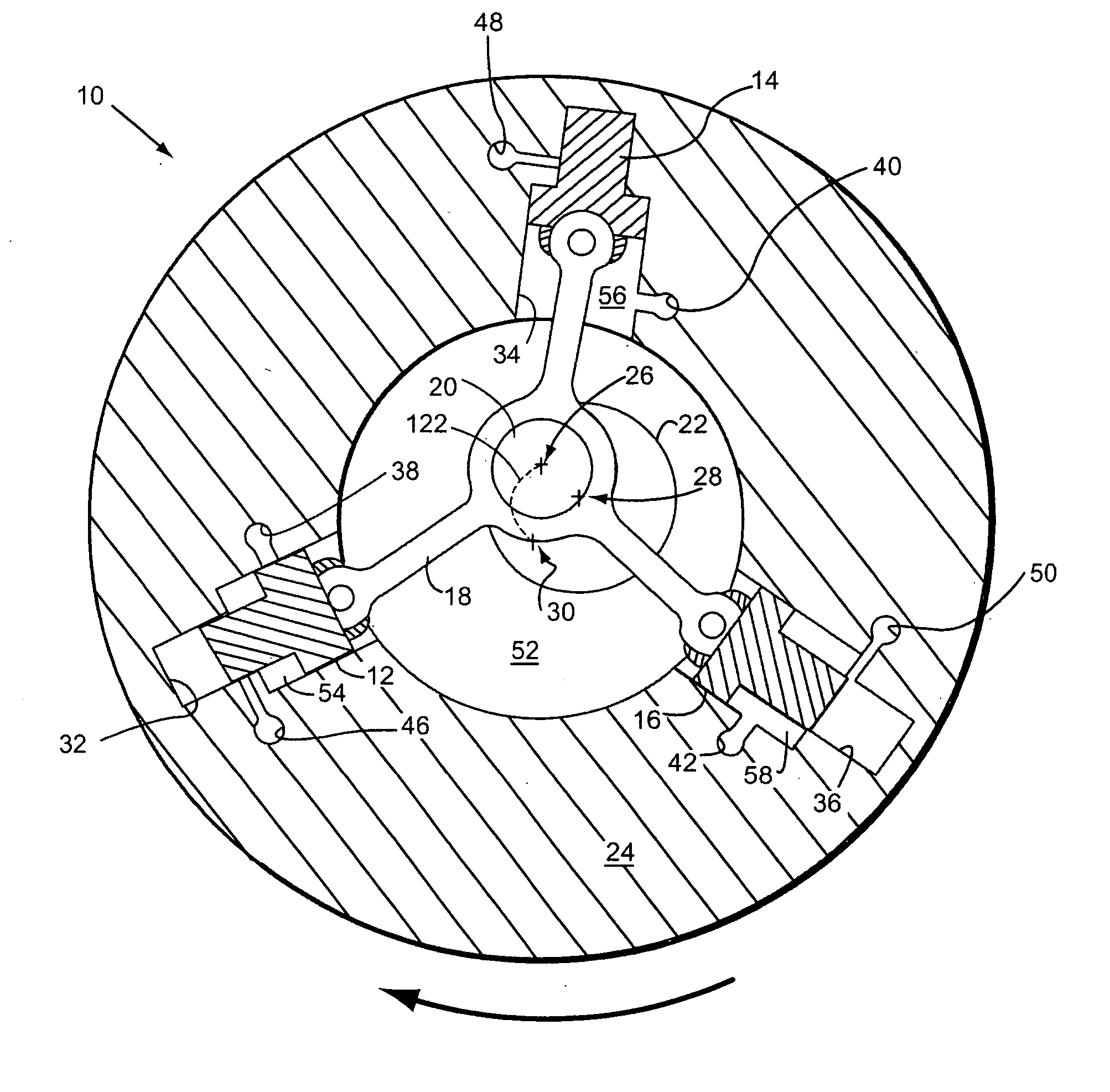

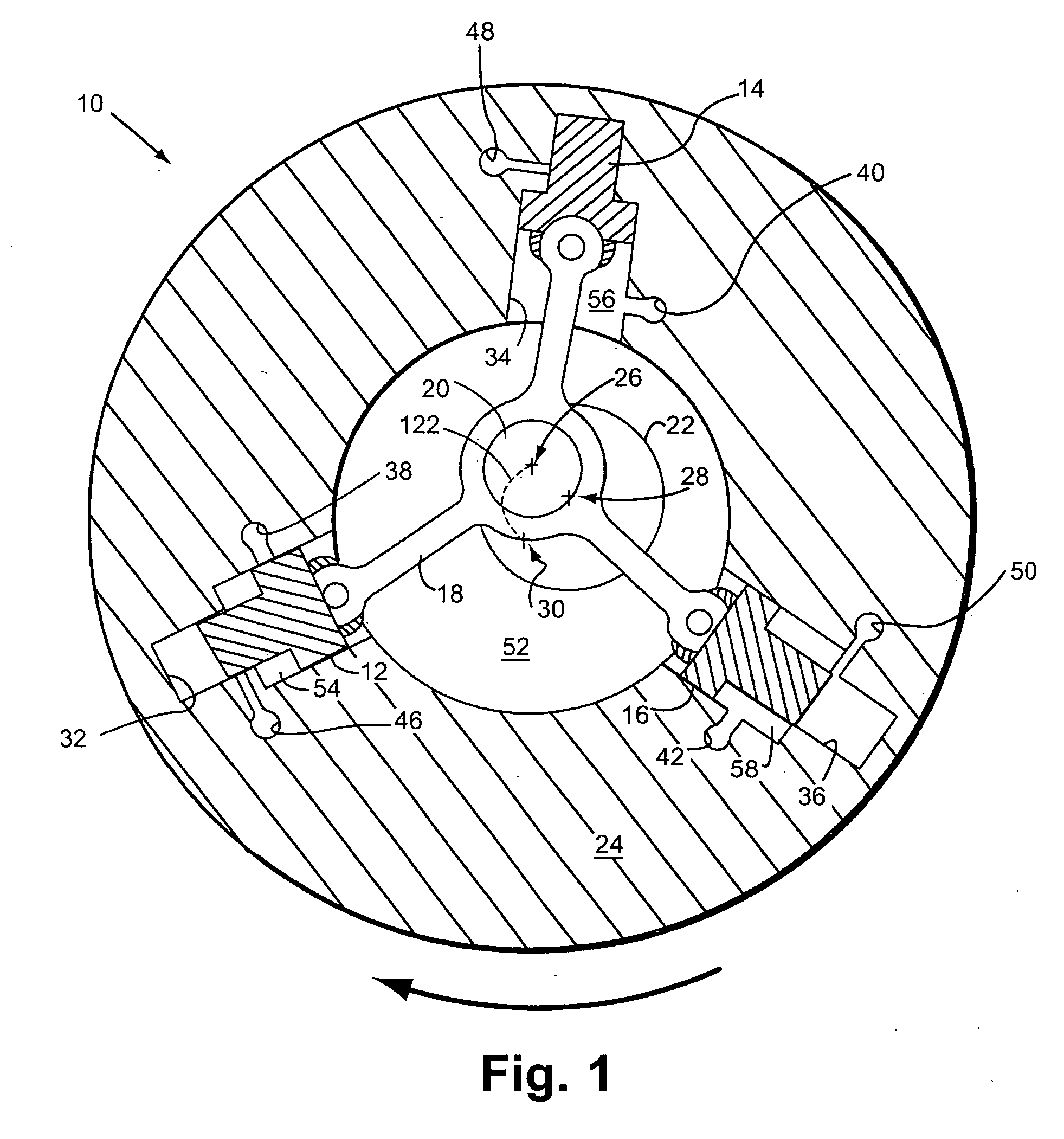

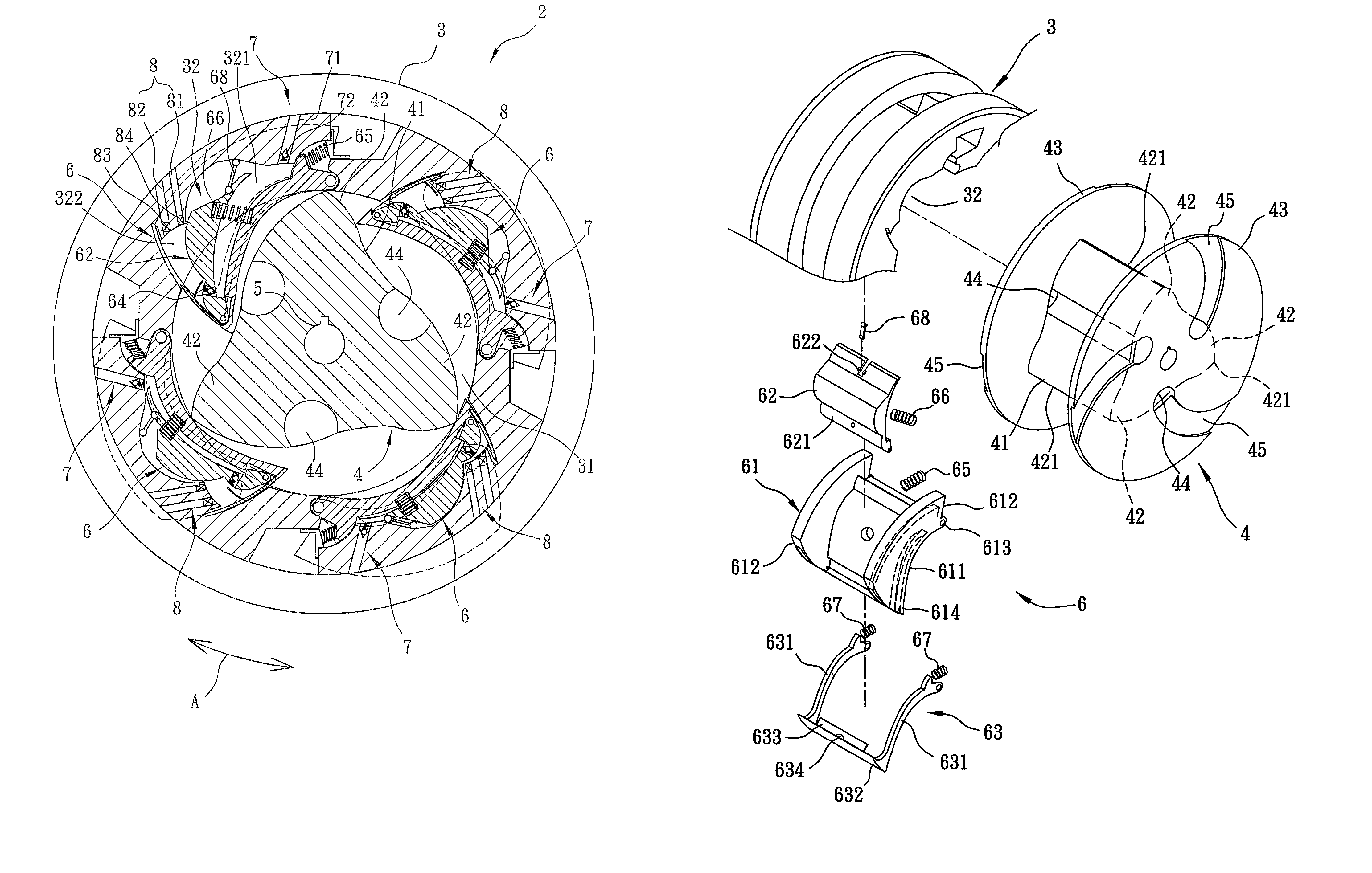

Cycloid rotor engine

ActiveUS8523546B2Internal combustion piston enginesEngine of arcuate-engagement typeRotary engineEngineering

Owner:LIQUIDPISTON INC

Gas turbine engine with transmission and method of adjusting rotational speed

A method of adjusting a rotational speed of the low pressure compressor rotor(s) of a gas turbine engine, including rotating the high pressure compressor rotor(s) with the high pressure turbine rotor(s) through the high pressure spool, rotating the low pressure turbine rotor(s) with a flow of exhaust gases from the high pressure turbine, rotating the low pressure spool with the low pressure turbine rotor(s), rotating a load of the engine with the low pressure spool, driving a rotation of the low pressure compressor rotor(s) with the low pressure spool through a variable transmission defining a variable transmission ratio between rotational speeds of the compressor rotor(s) and the low pressure spool, and adjusting the transmission ratio to obtain a desired rotational speed for the low pressure compressor rotor(s). A method of adjusting rotational speeds of a gas turbine engine and a gas turbine engine are also described.

Owner:PRATT & WHITNEY CANADA CORP

Rotary edging and burring device for metal hubs

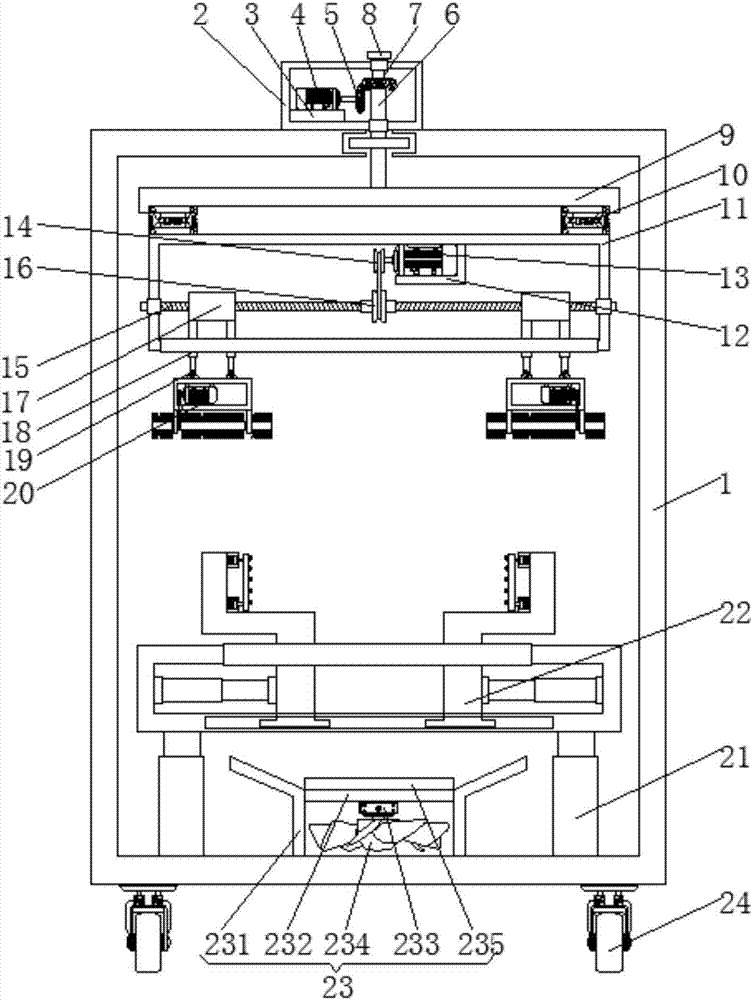

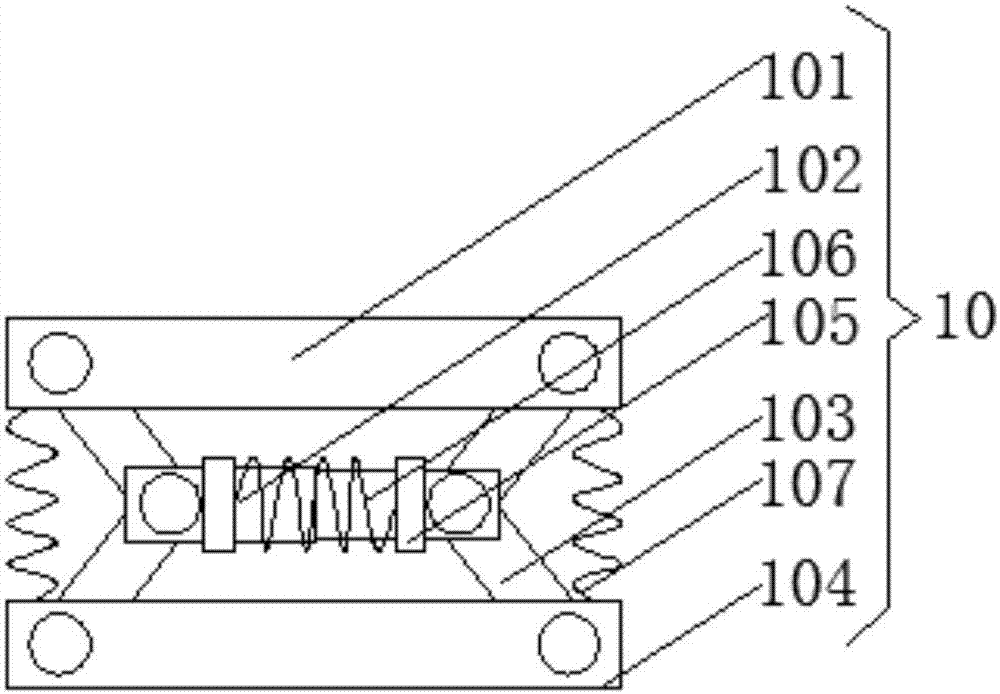

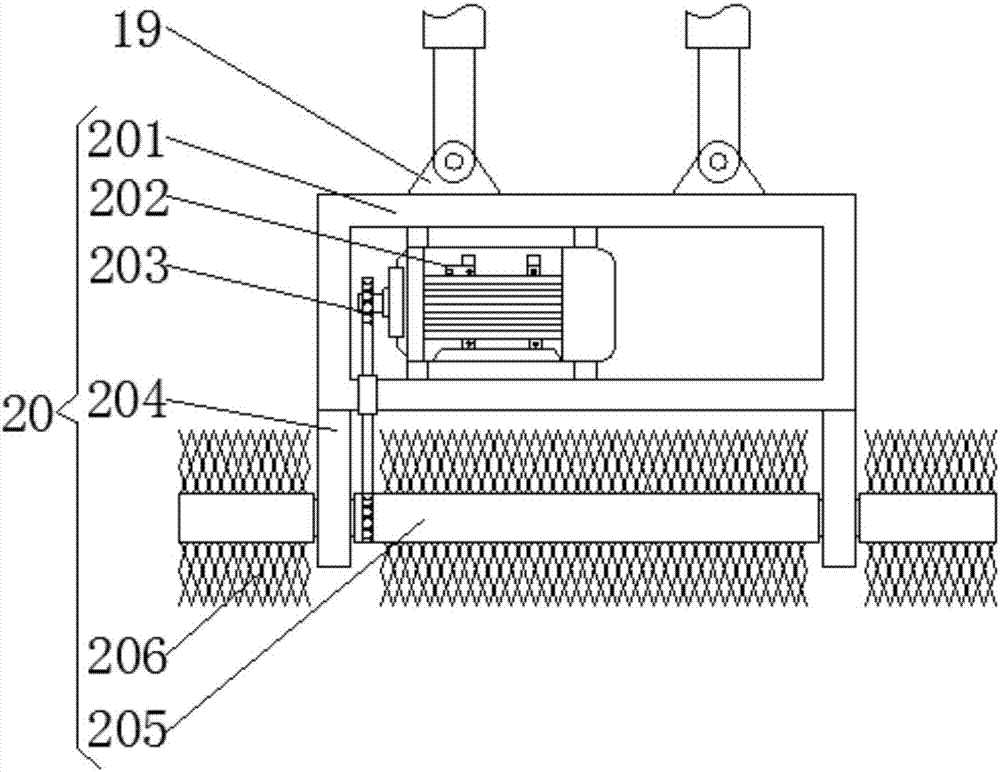

ActiveCN107350921AImprove qualityReduce workloadEdge grinding machinesGrinding drivesRotary engineArchitectural engineering

The invention discloses a rotary edging and burring device for metal hubs. The device includes a box, the center of the top of the box is fixedly connected to a protective motor box, and one side of the bottom of the inner wall of the protective motor box is fixedly connected with a first motor through a fixing plate of the first motor, wherein one end of the first motor is rotatably connected with a first oblique gear through an output shaft, a rotating shaft is rotatably connected to the bottom of the inner wall of the protective motor box and positioned on the right side of the first motor, and the middle surface of the rotating shaft is fixedly connected with a second oblique gear through a flat key. The invention relates to the technical field of metal processing equipment. The rotary edging and burring device for the metal hubs solves the problems that during the existing edging processes of the metal hubs, manual operation is required, labor intensity is high, and the dust generated during edging causes damage to the breath function of the human body, reduces workload of workers and improves working efficiency and quality of edging, and meanwhile, the application range of equipment is expanded, and the flexibility of the equipment is improved.

Owner:绍兴兴裕门窗有限公司

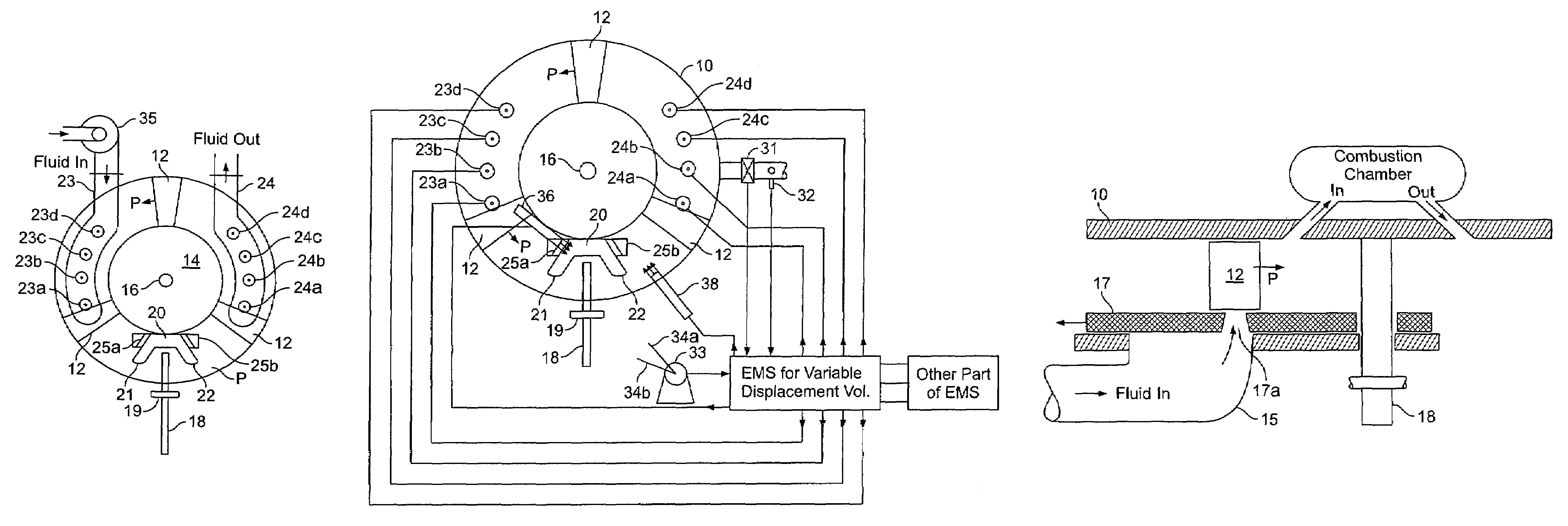

Toroidal engine with variable displacement volume

InactiveUS7341041B2Increase consumptionImprove efficiencyInternal combustion piston enginesOscillating piston enginesRotary engineEngine management

A novel rotary engine of the kind having a toroidal cylinder and a set of pistons on a rotating circular piston assembly provides instantaneous adjustment of the displacement volume of the engine by varying the intake and expansion stroke length on the circular path of the pistons through the opening and closing of valves into the engine cylinder under the control of an engine management system responsive to the speed / load conditions of the engine and the throttle position.

Owner:VGT TECH

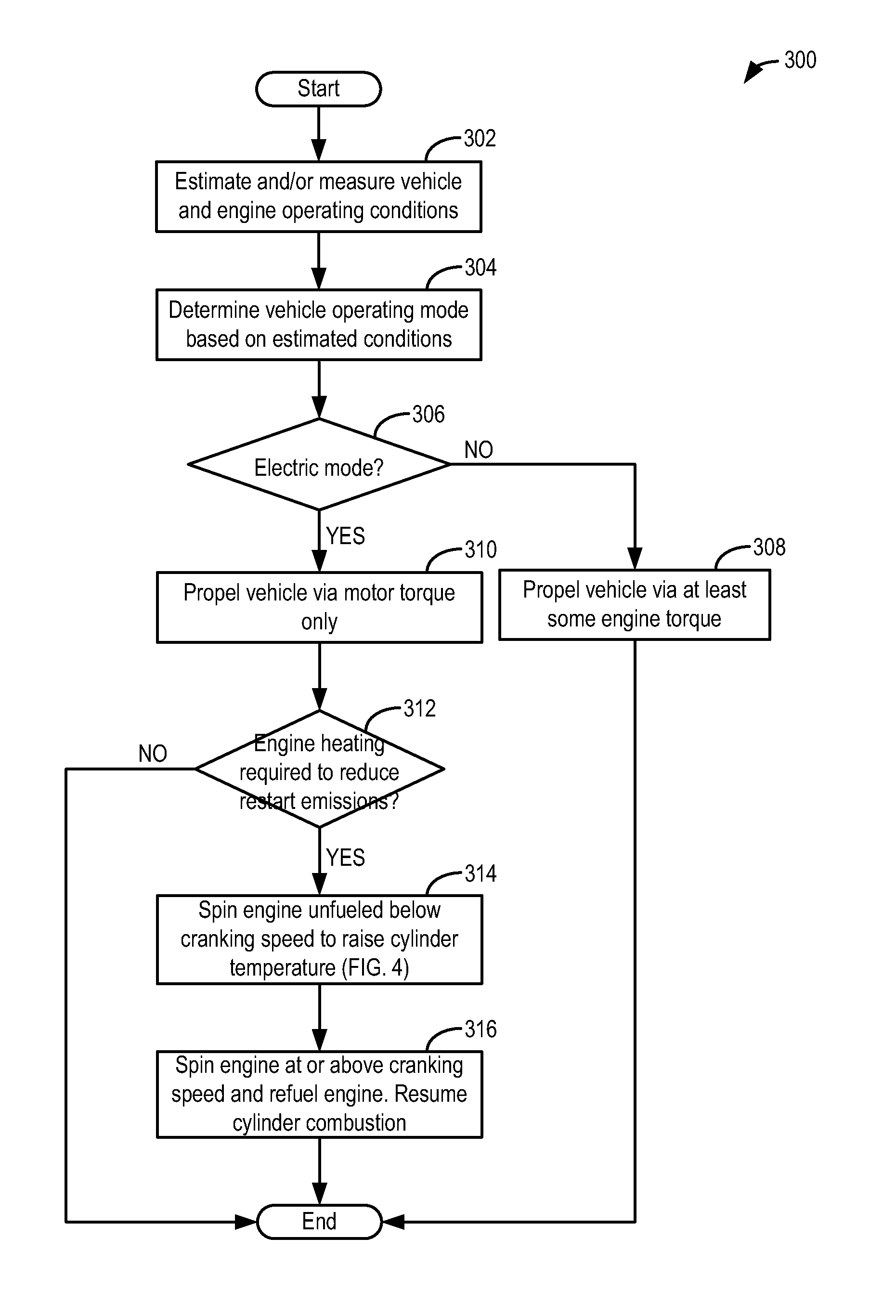

Method and system for engine control

ActiveUS9346451B2Improve cooling effectImprove fuel efficiencyHybrid vehiclesEngine controllersParticulatesRotary engine

Methods and systems are provided for slowly rotating an engine, unfueled, via a motor prior to an imminent engine restart to heat the engine. By rotating the engine so that heat generated in the compression stroke of a cylinder can be transferred to cylinder walls, thereby expediting engine warm-up. By warming the engine before a restart, particulate emissions generated during an engine cold-start due to direct injection of fuel can be reduced.

Owner:FORD GLOBAL TECH LLC

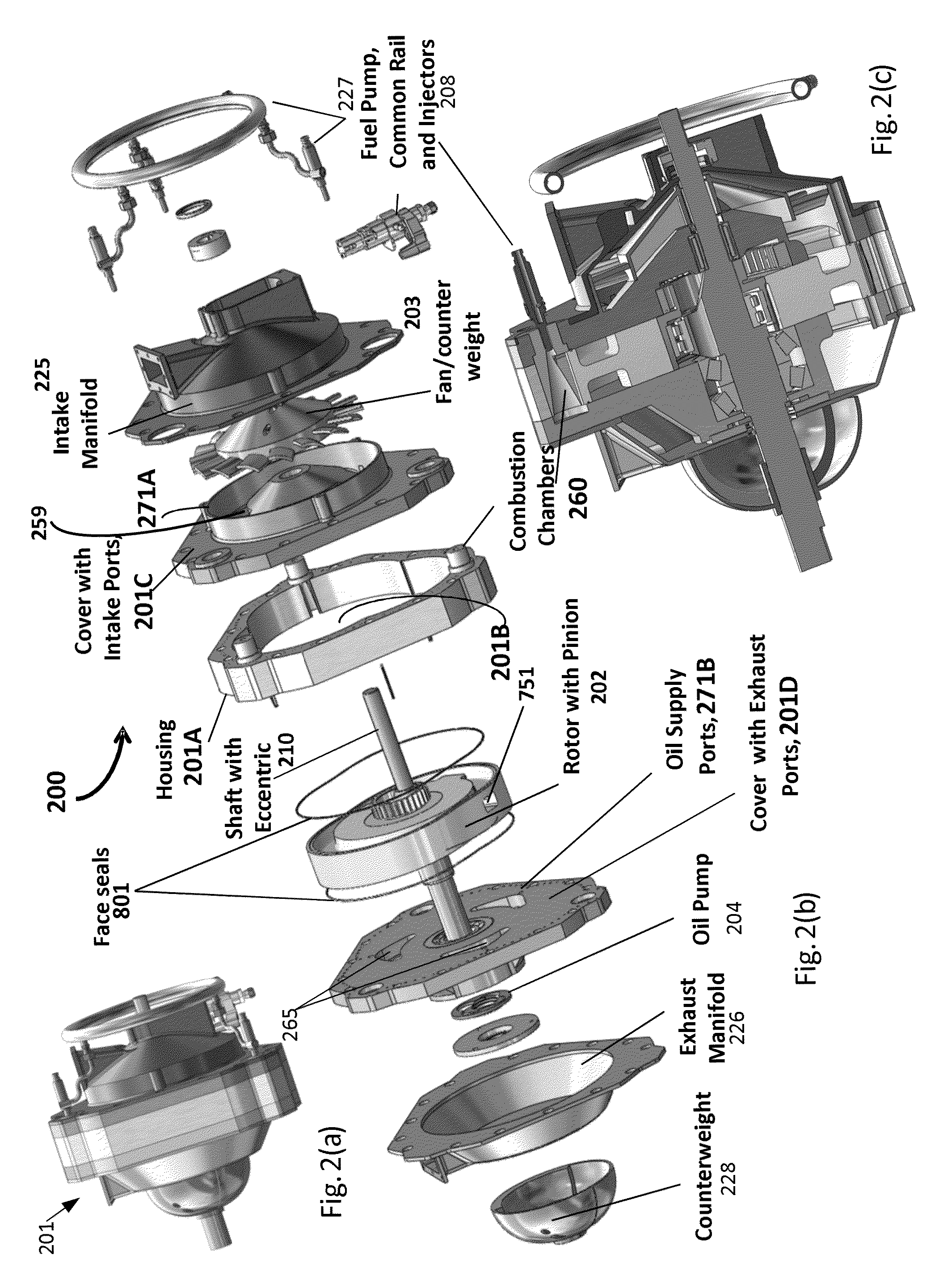

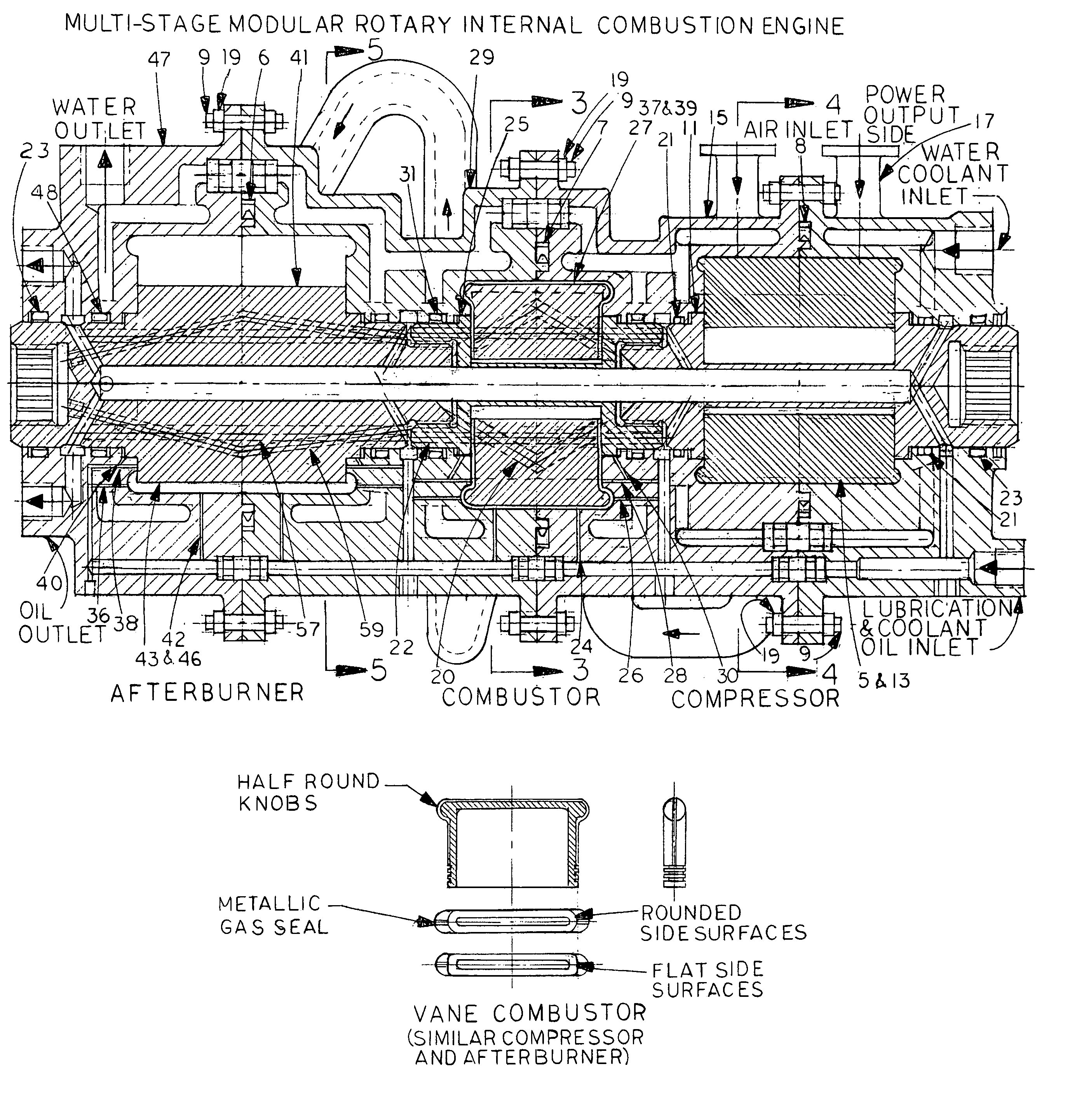

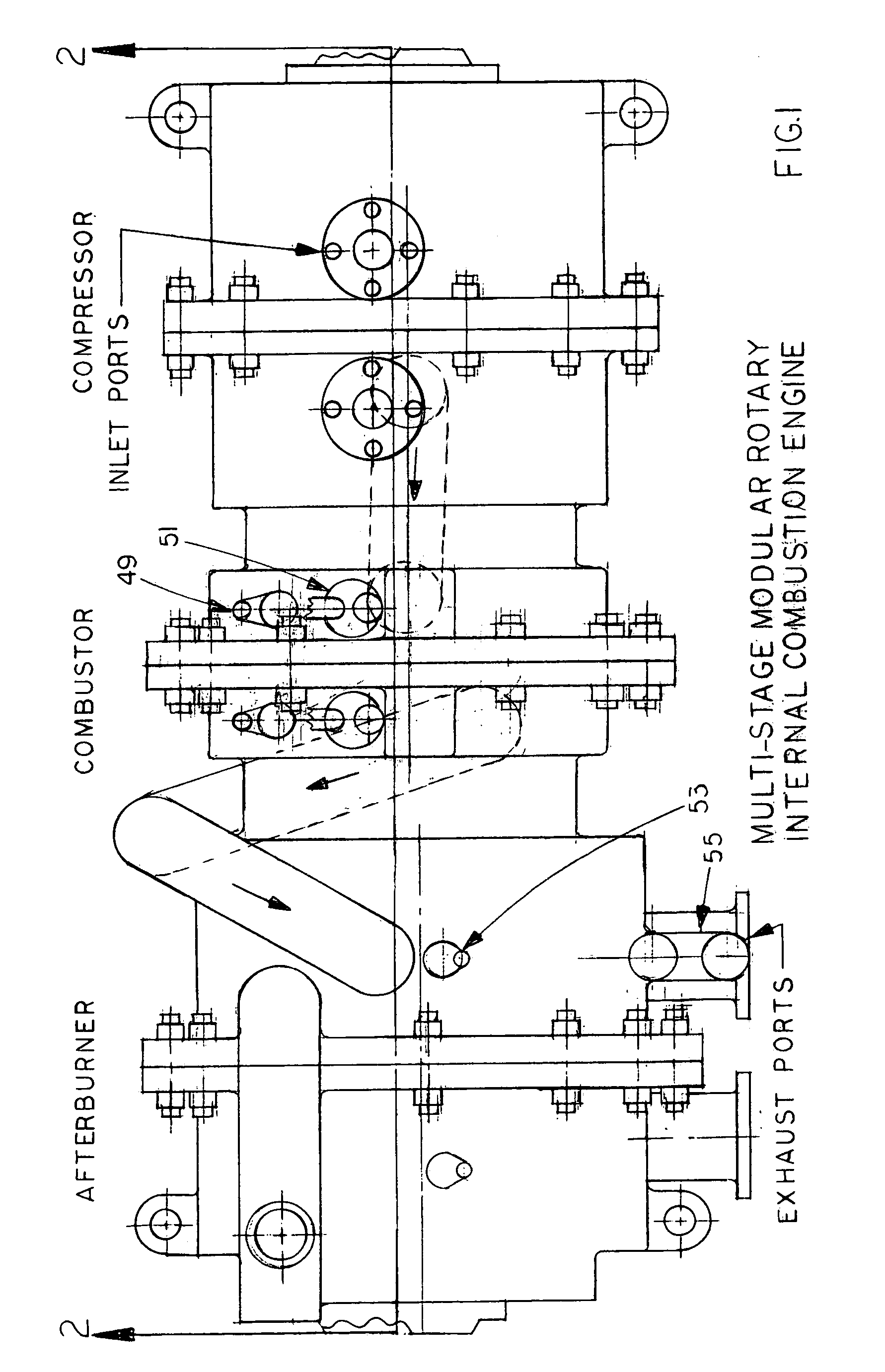

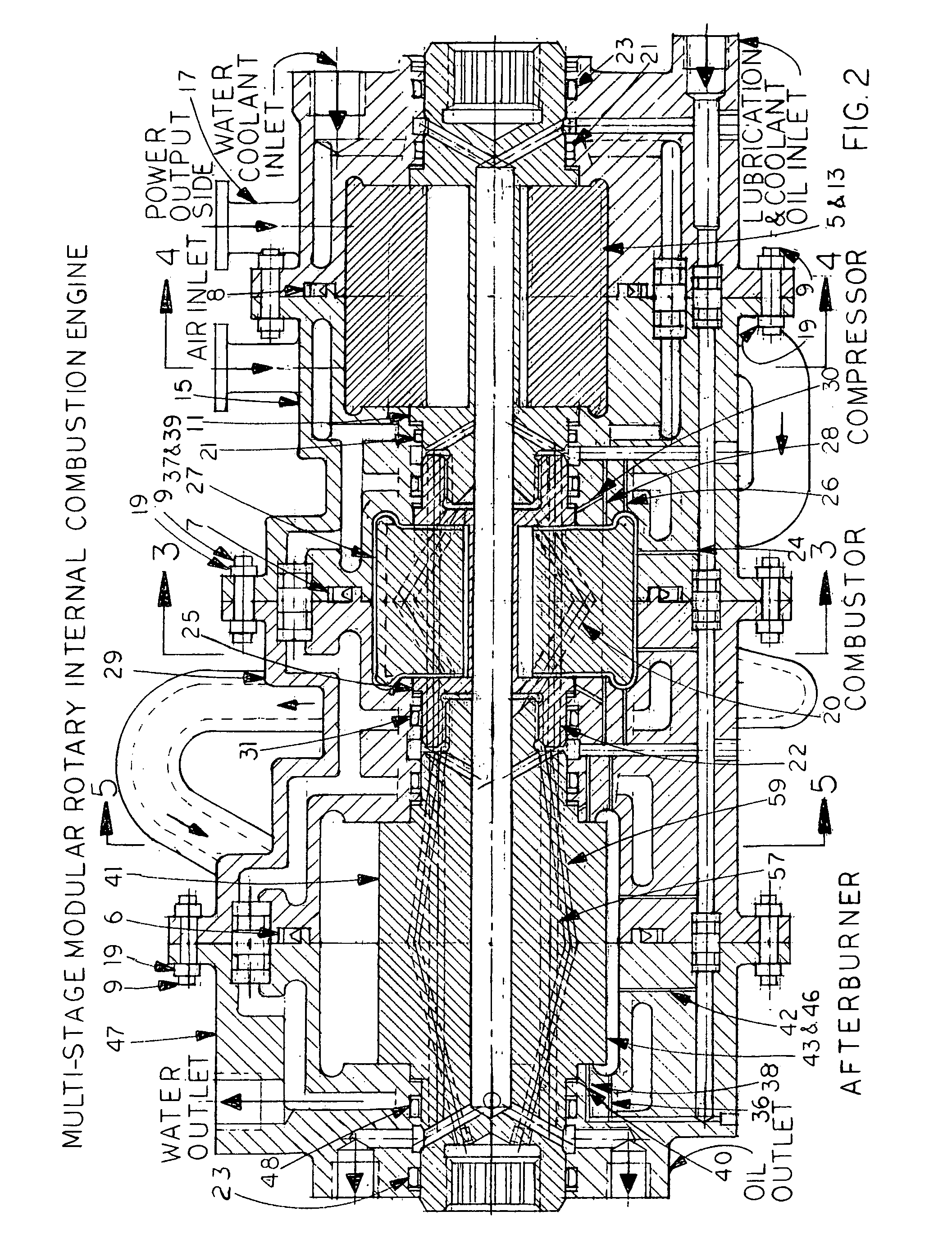

Multi-stage modular rotary internal combustion engine

ActiveUS7117839B2Easy constructionRobust designInternal combustion piston enginesOscillating piston enginesCombustorThree stage

A three-stage internal combustion rotary engine, comprised of: a compressor feeding compressed air to a combustor for compression, fuel injection, combustion, and expansion of gases which rotate the rotor. The combustor rotor generates torque and drives the compressor and afterburner rotors simultaneously. The afterburner receives the combusted gases and scavenged air from the combustor for secondary combustion and expels the exhaust gases. Each unit consists of a housing joined together on a common axis and a rotor with a shaft mounted in an eccentric position of the housing side-walls. The shafts are interconnected by splines. The rotors have radial blind slots which contain slidable, movable vanes fitted with half-round knobs on opposite sides, aligned with the top surface and fit in the hemispherical grooves on the interior side-walls of the housing. This maintains a permanent contact with the interior housing periphery, regardless of gas pressures and rotating speed.

Owner:HORSTIN ABRAHAM H

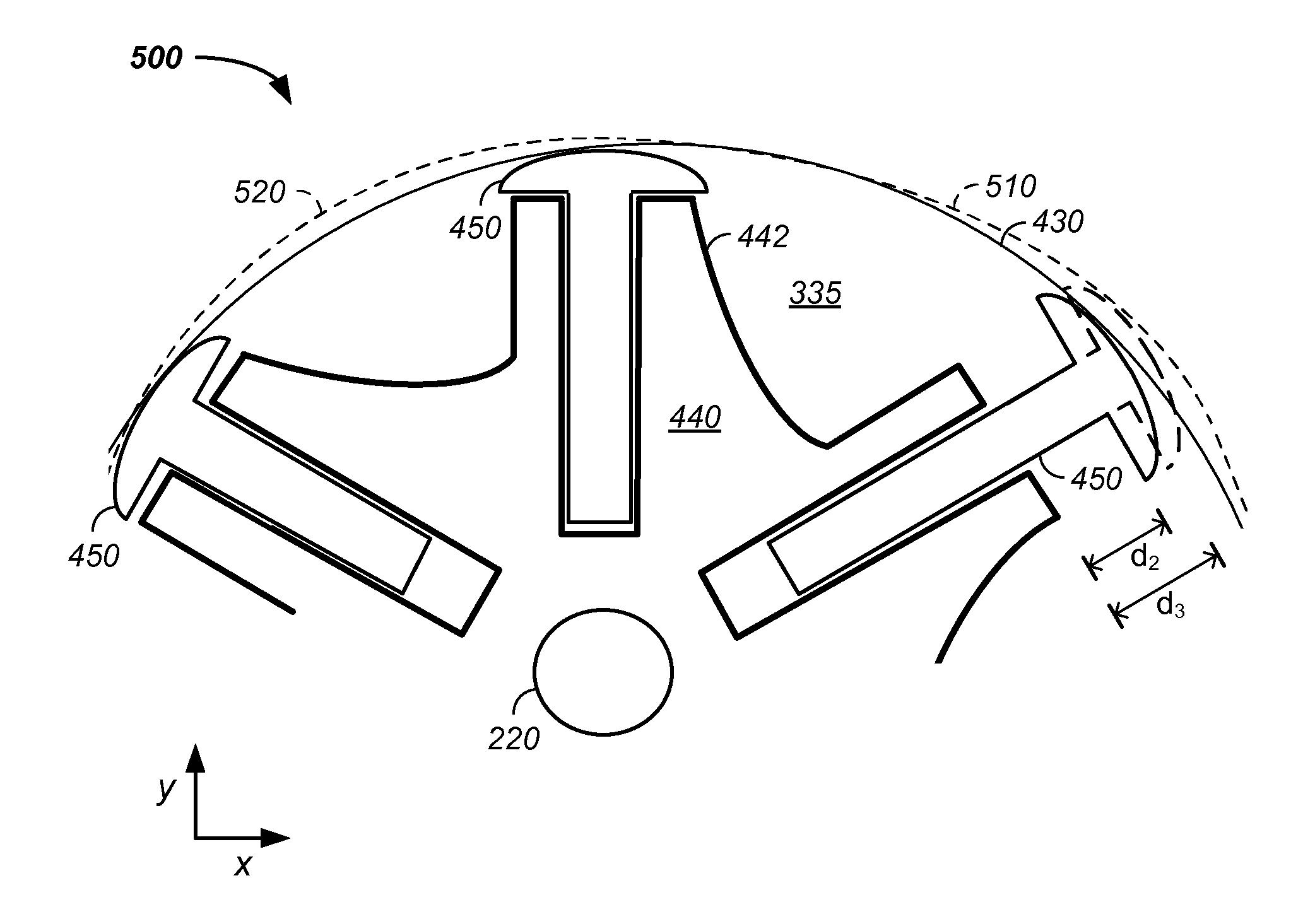

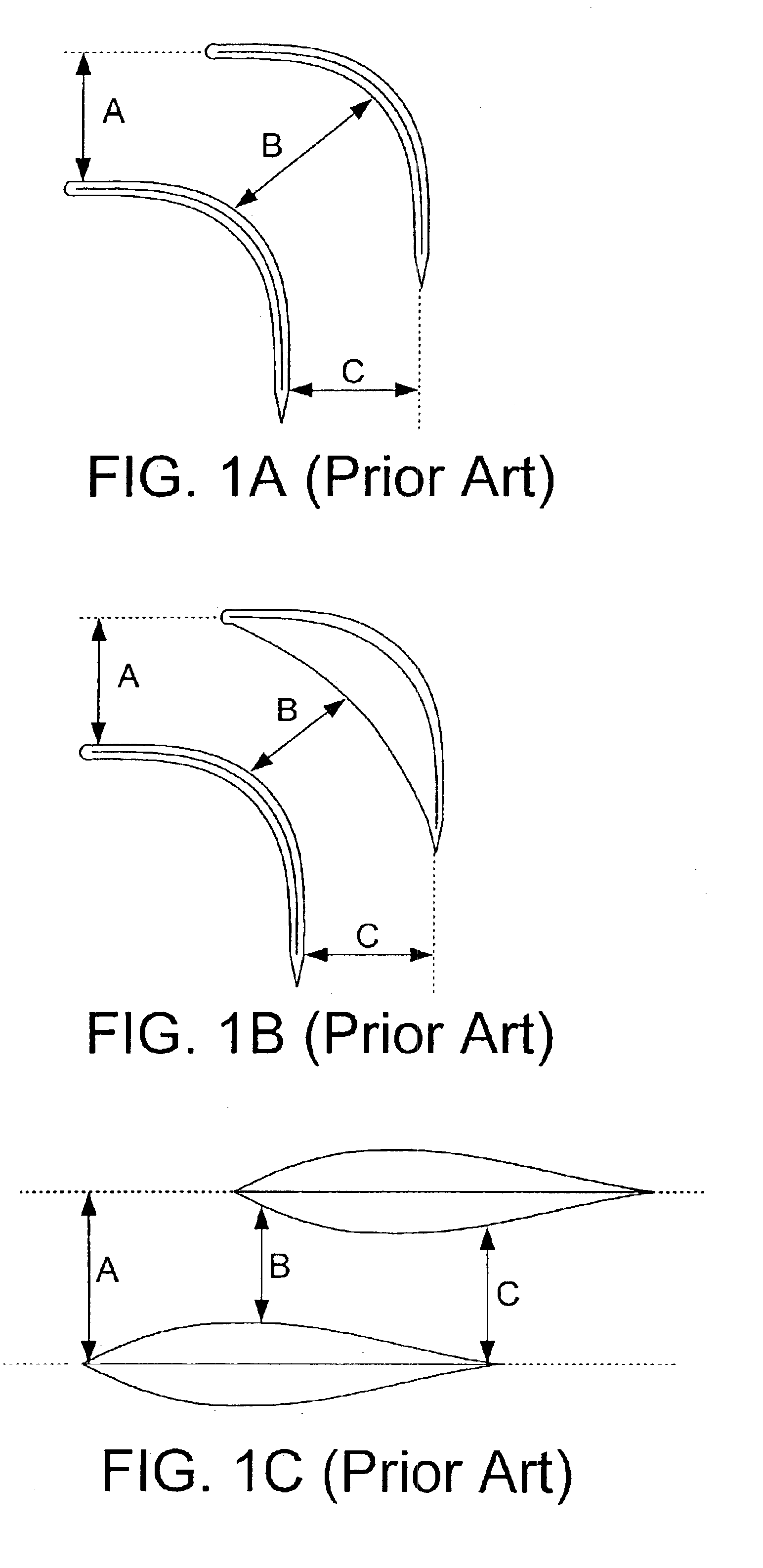

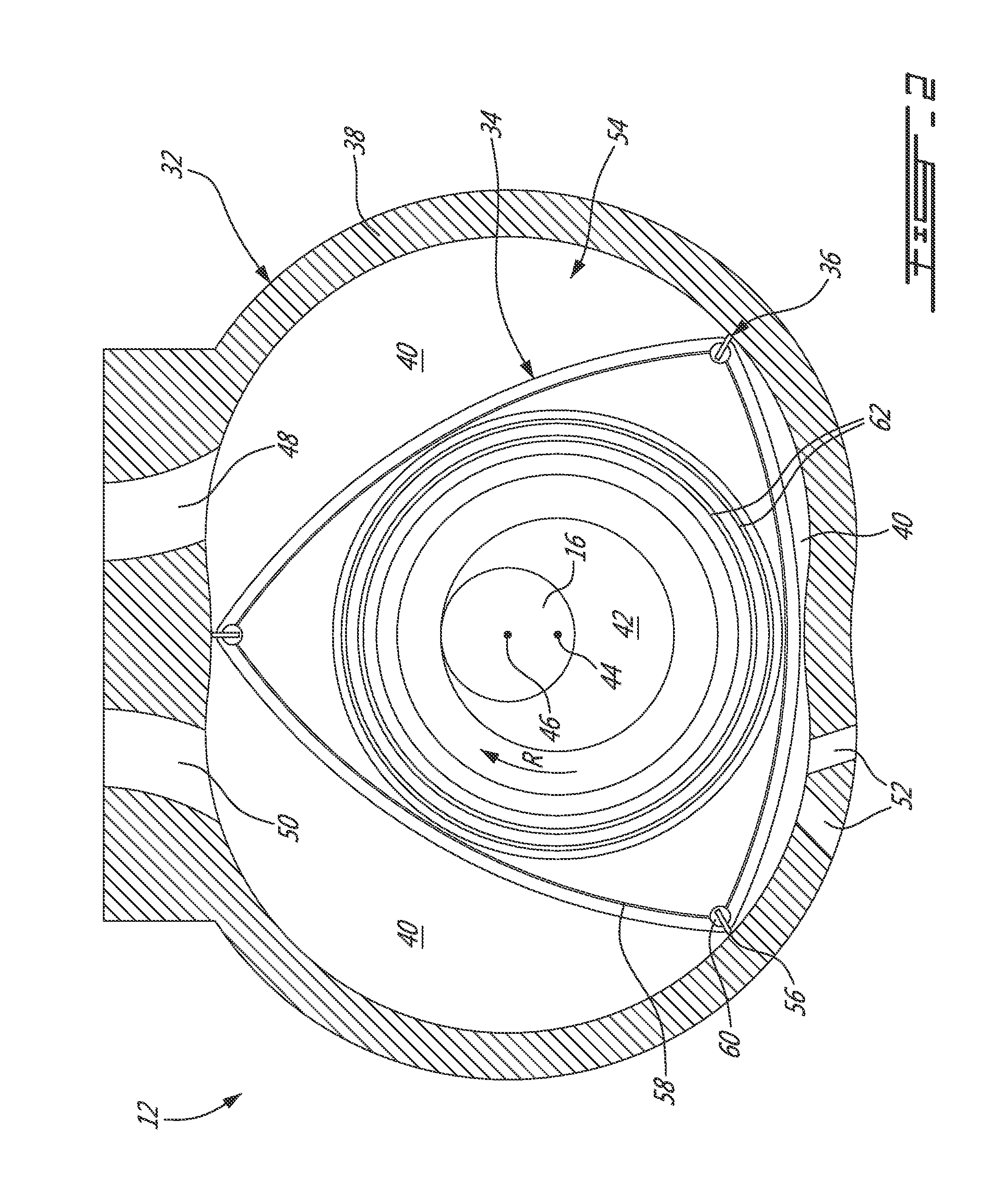

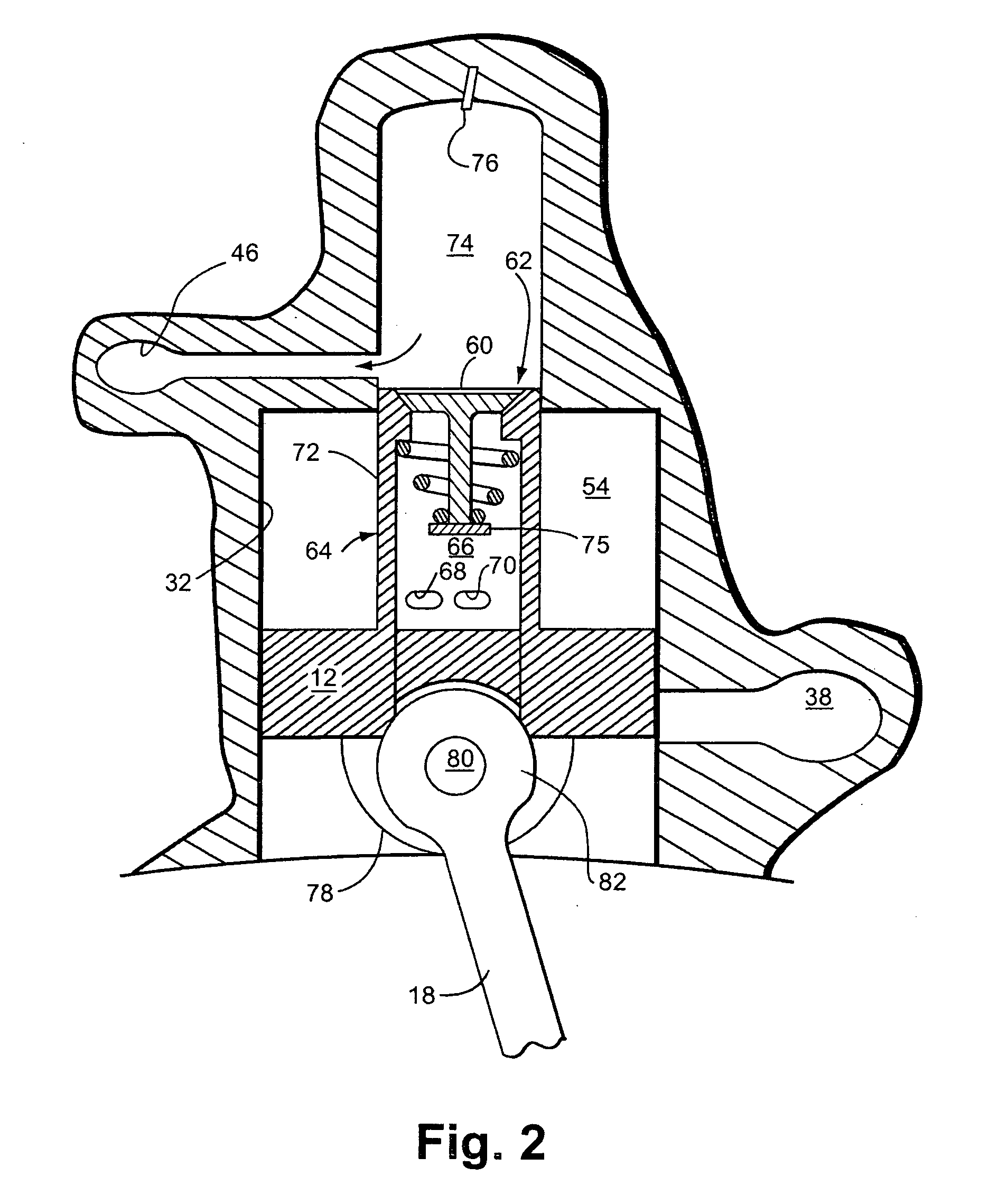

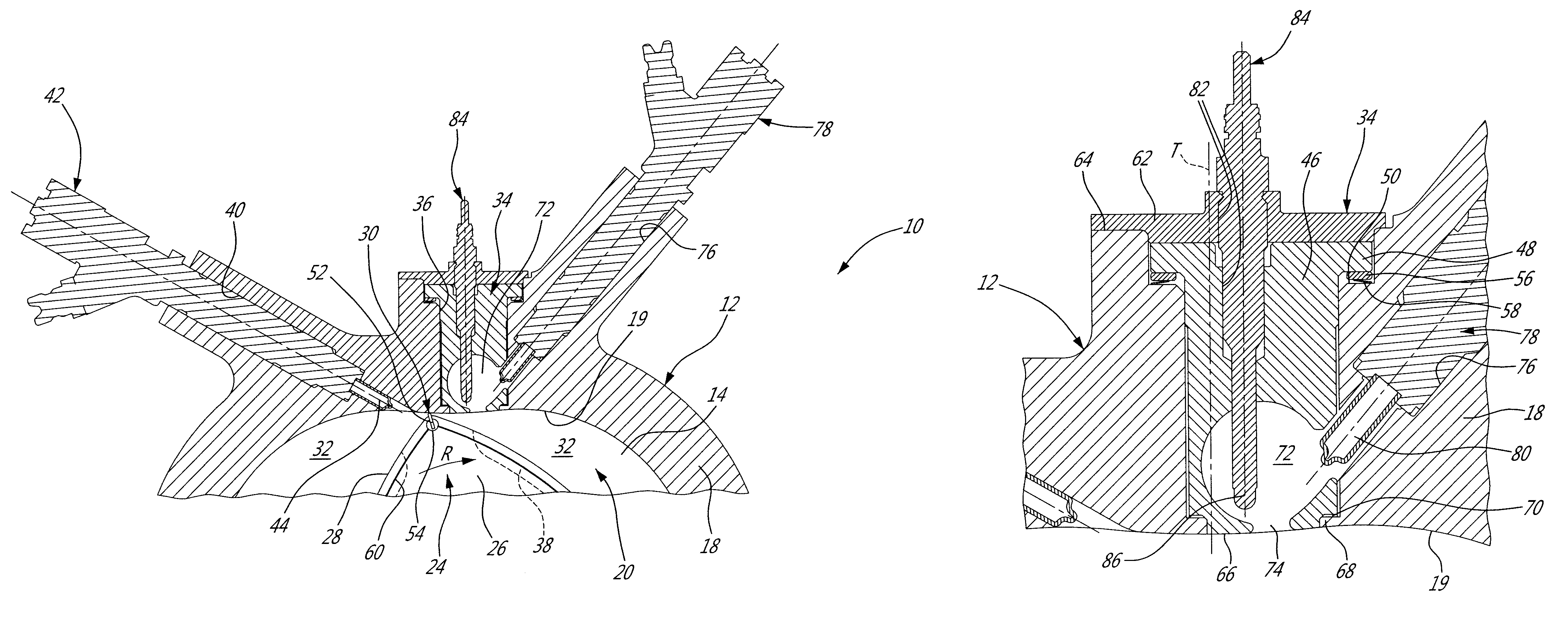

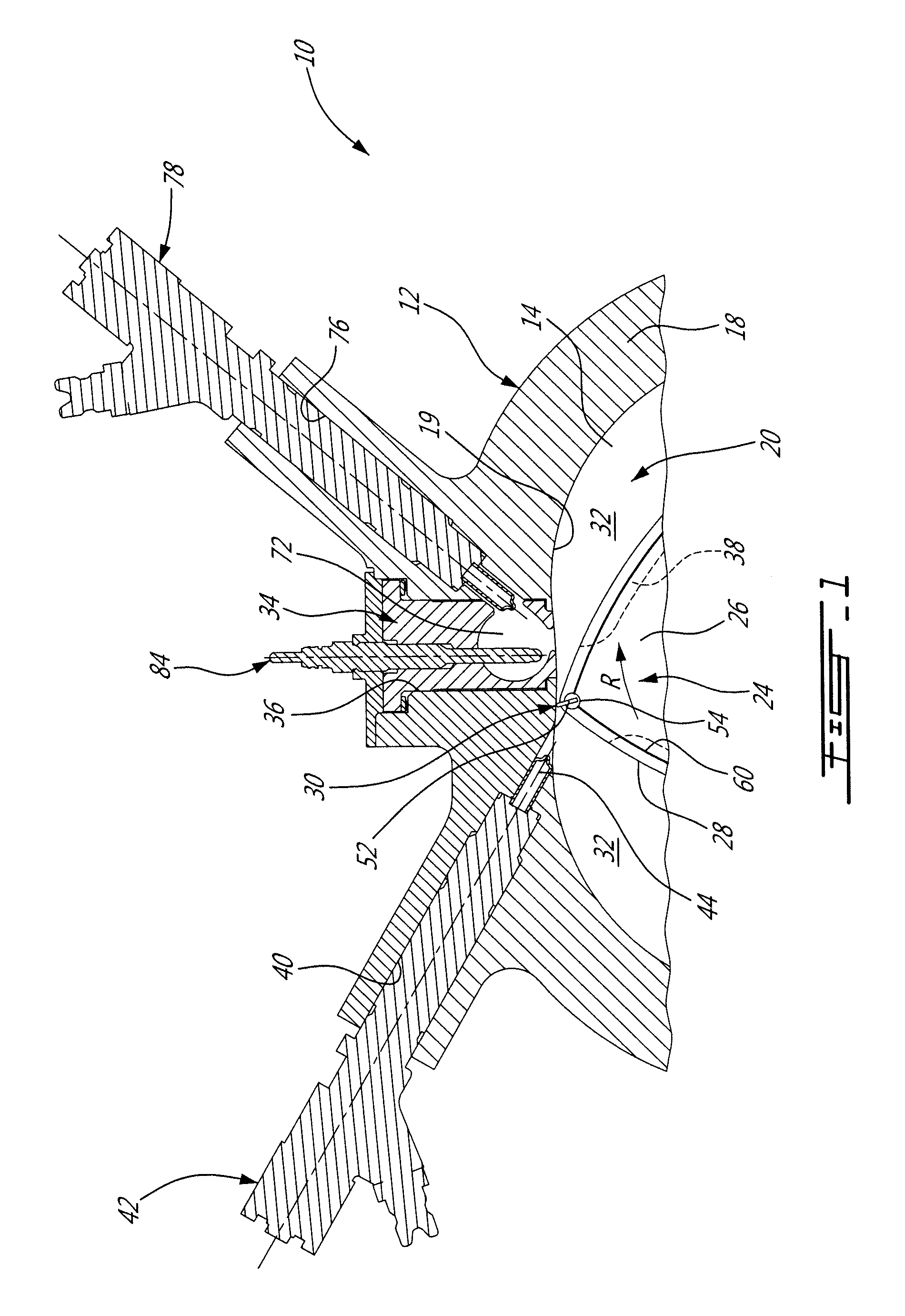

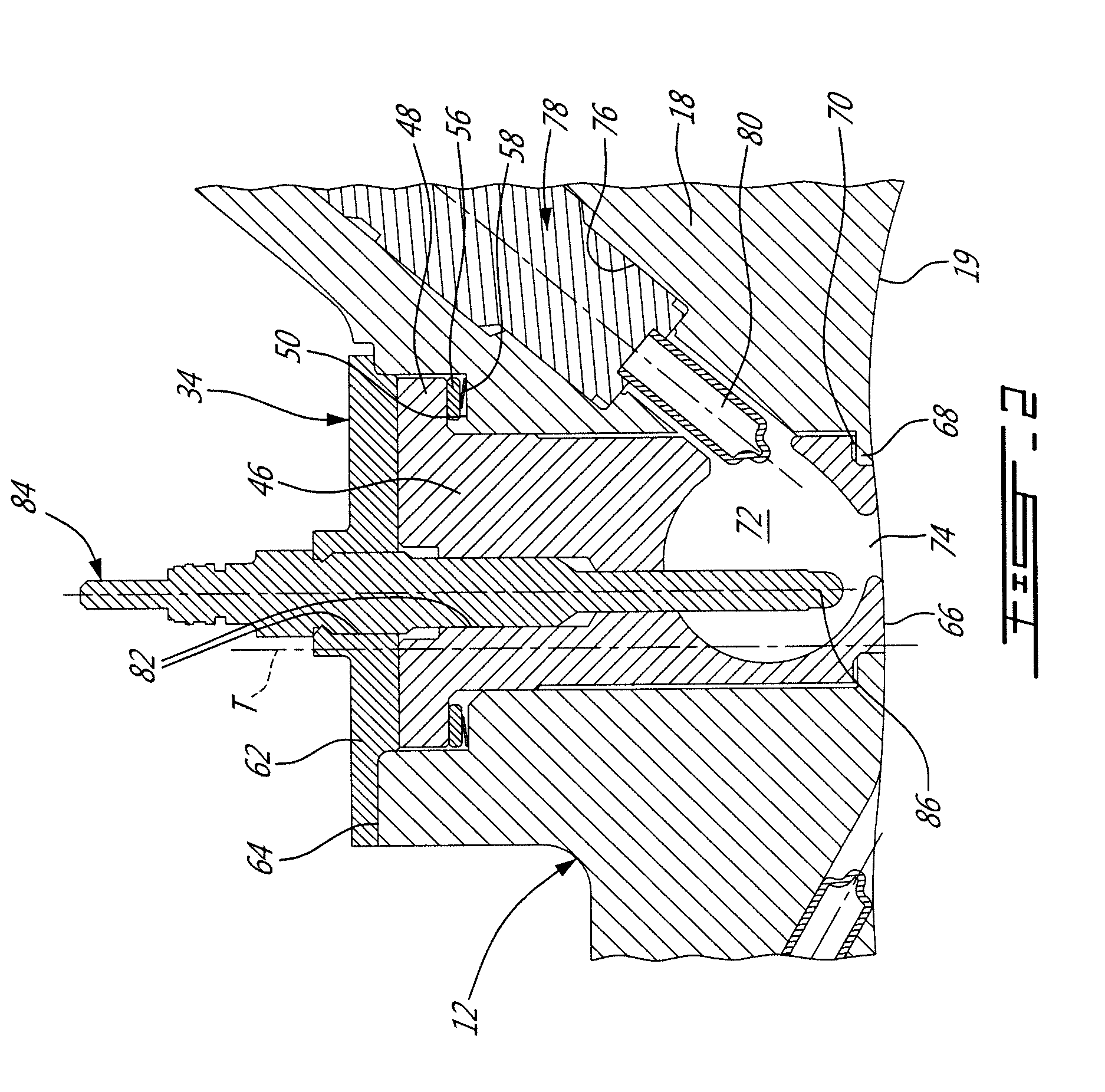

Rotary internal combustion engine with pilot subchamber

ActiveUS9528434B1Internal combustion piston enginesCombination enginesHeat resistanceExternal combustion engine

A non-Wankel rotary engine having an insert in the peripheral wall of the outer body, the insert being made of a material having a greater heat resistance than that of the peripheral wall, having a subchamber defined therein and having an inner surface bordering the cavity, the subchamber communicating with the cavity through at least one opening defined in the inner surface and having a shape forming a reduced cross-section adjacent the opening, a pilot fuel injector having a tip received in the subchamber, an ignition element having a tip received in the subchamber, and a main fuel injector extending through the housing and having a tip communicating with the cavity at a location spaced apart from the insert.

Owner:PRATT & WHITNEY CANADA CORP

Rotary engine with improved hybrid features

InactiveUS20050224263A1Easy to operateImprove sealingGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingSteering wheelExternal combustion engine

A hybrid engine including an electric motor, a rotary internal combustion engine, and an electric generator incorporating a clutch and translator unit to drive the generator at a ratio greater than 1:1 during vehicle slowing and at a 1:1 ratio rate at other times in providing increased braking and fuel efficiency—along with a programmable central control module and vertical control lever in effectuating steering and vehicle operation without the use of a steering wheel or foot gas and brake pedals.

Owner:VASILANTONE MICHAEL M

Rotary engine with vanes rotatable by compressed gas injected thereon

InactiveUS7845332B2Guaranteed uptimeInternal combustion piston enginesOscillating piston enginesCombustionWork cycle

Owner:WANG SERN BEAN

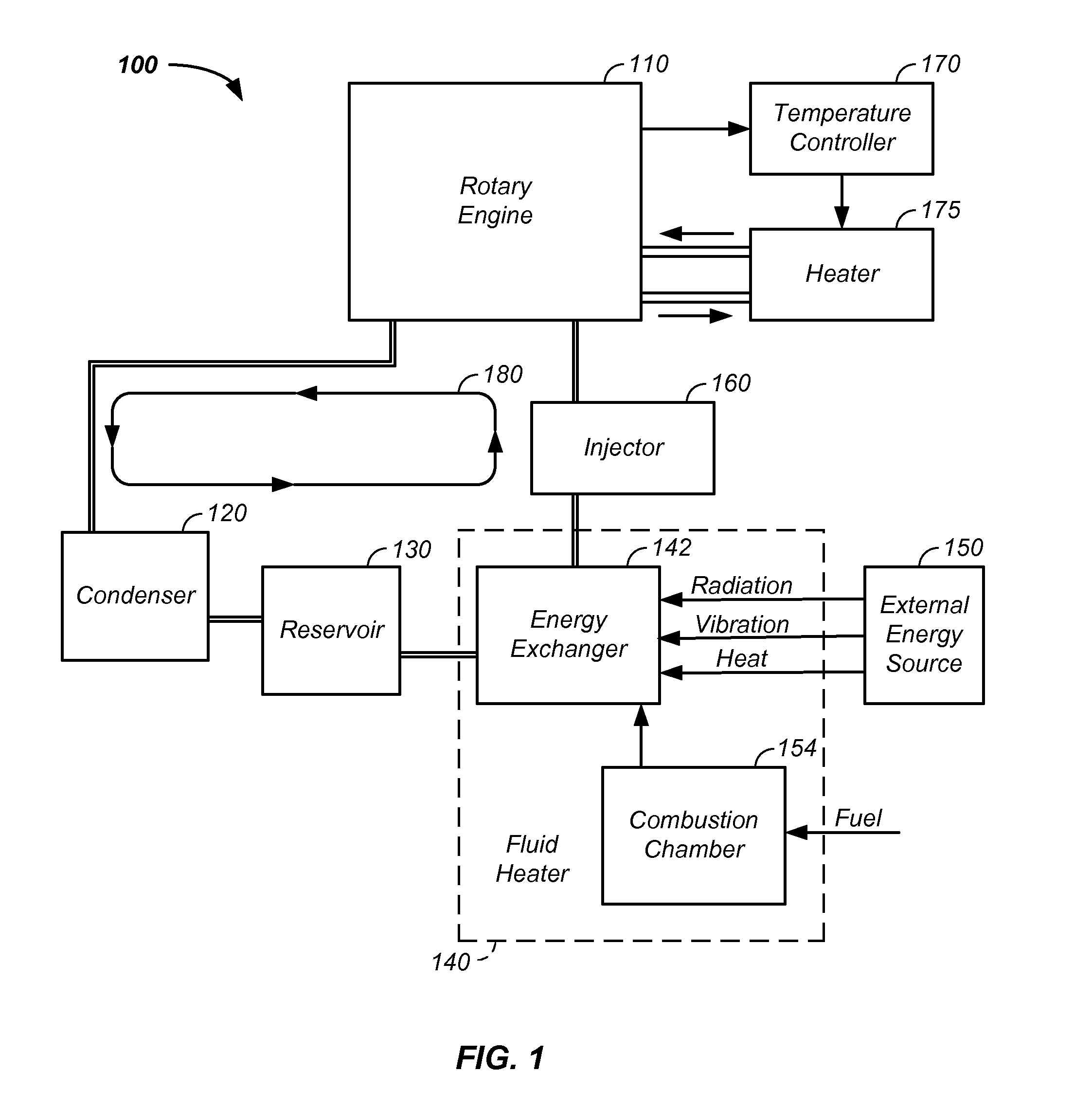

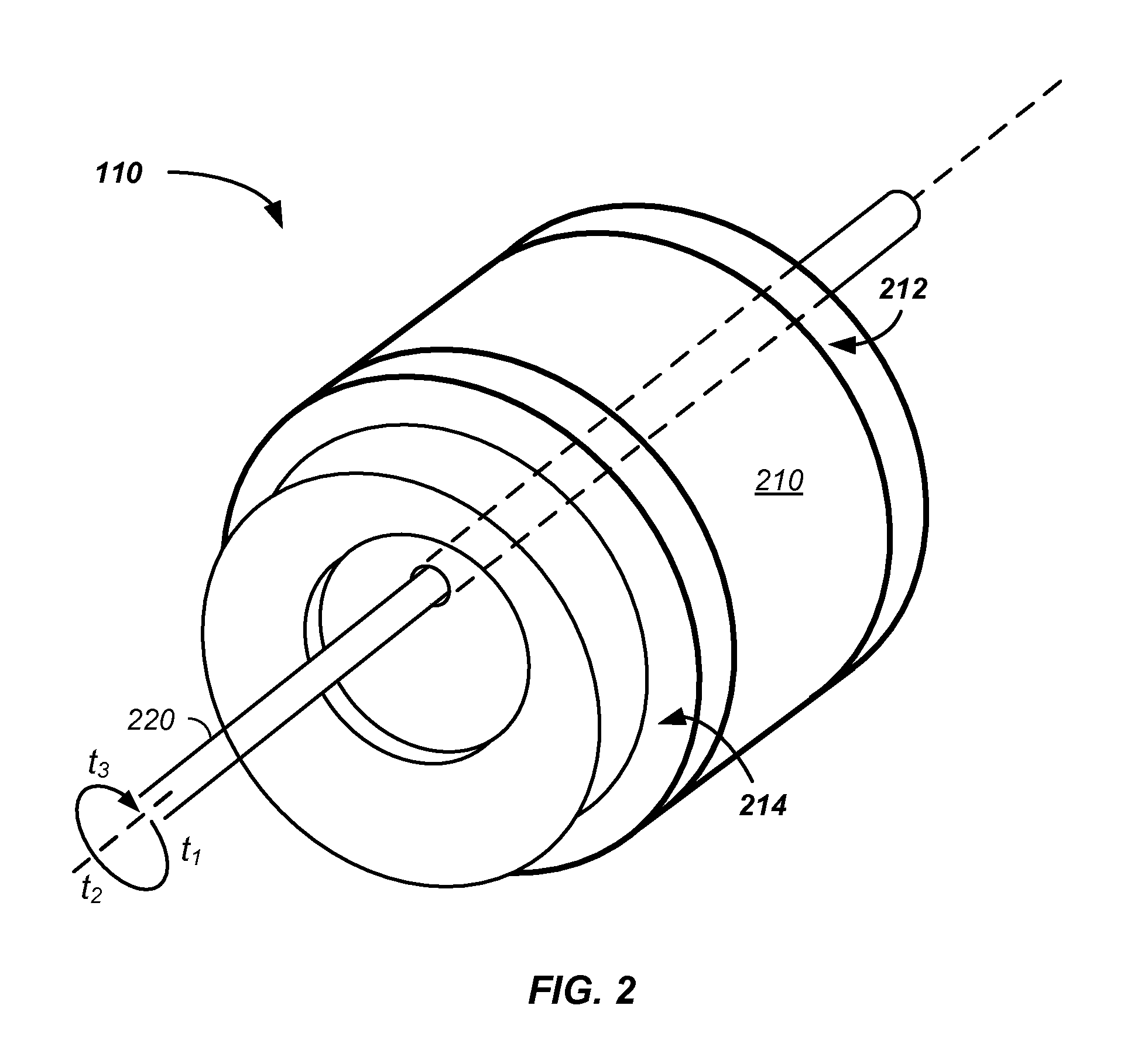

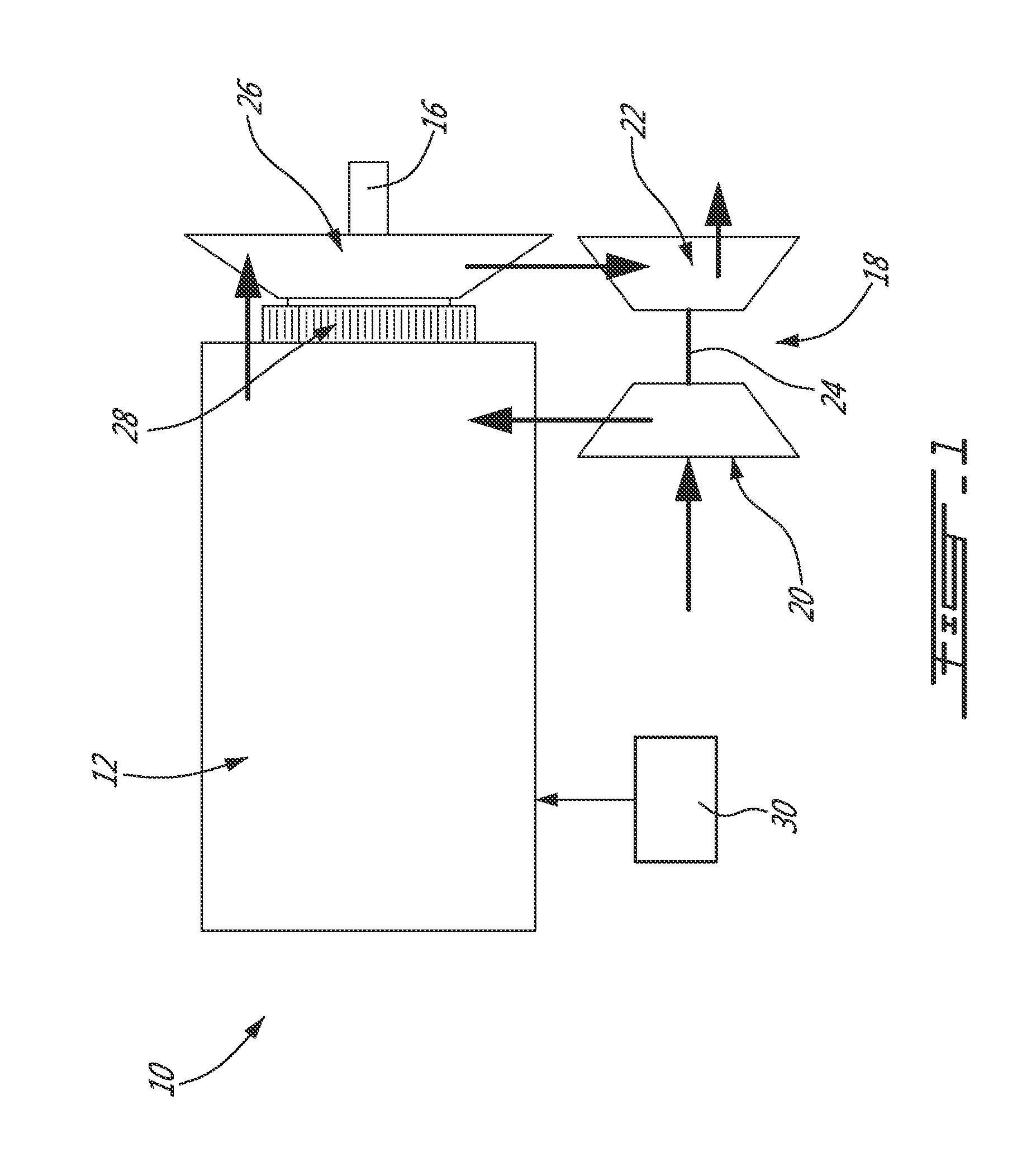

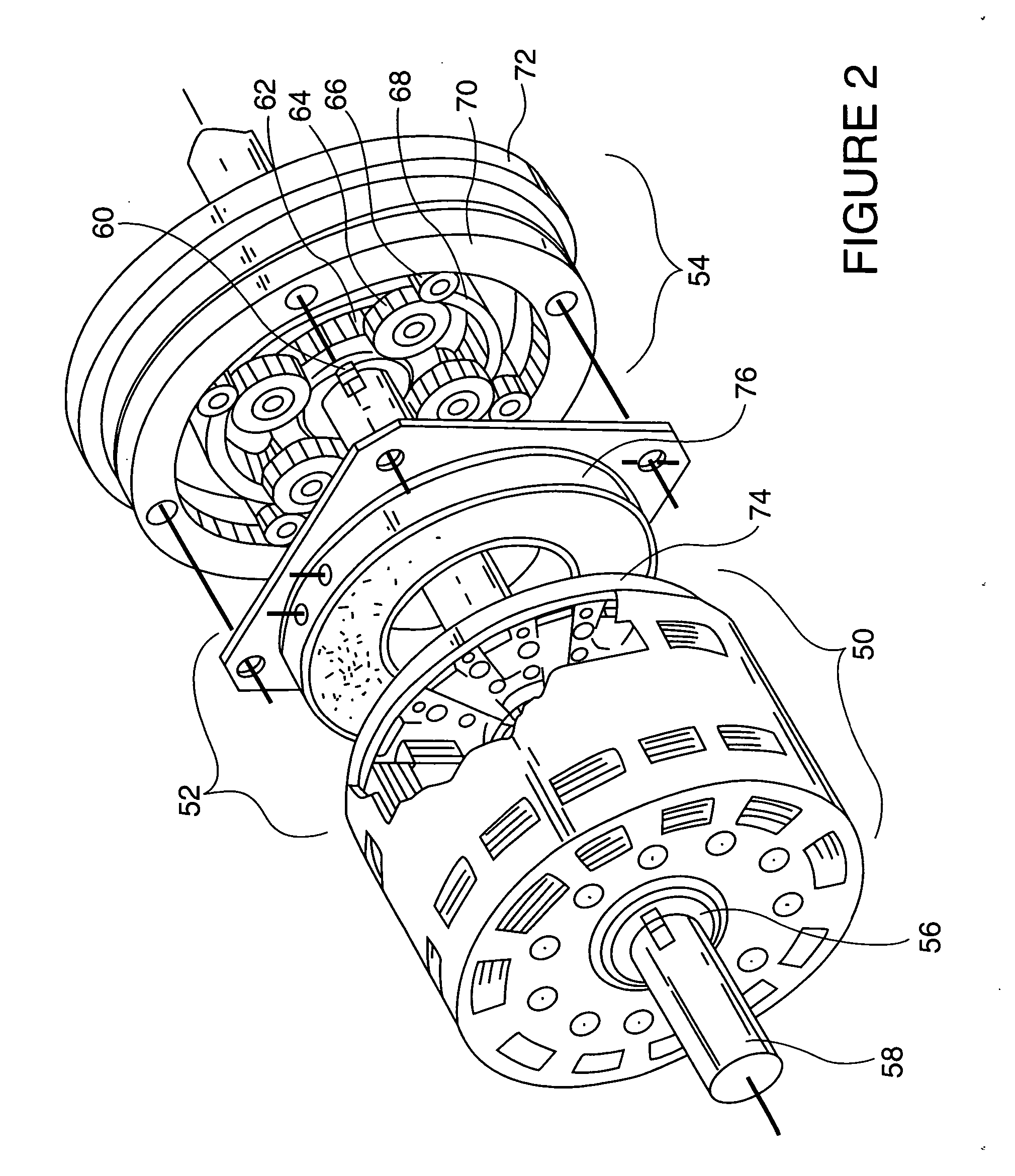

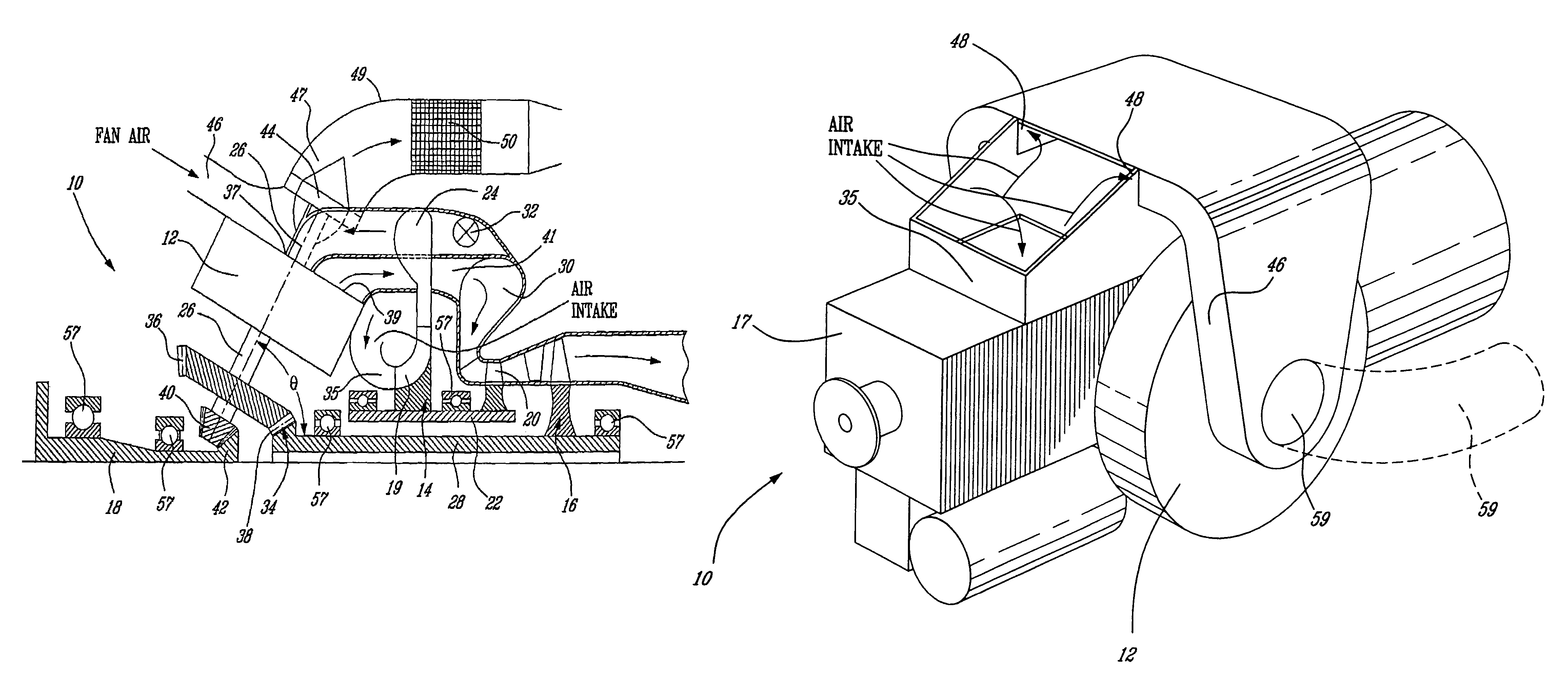

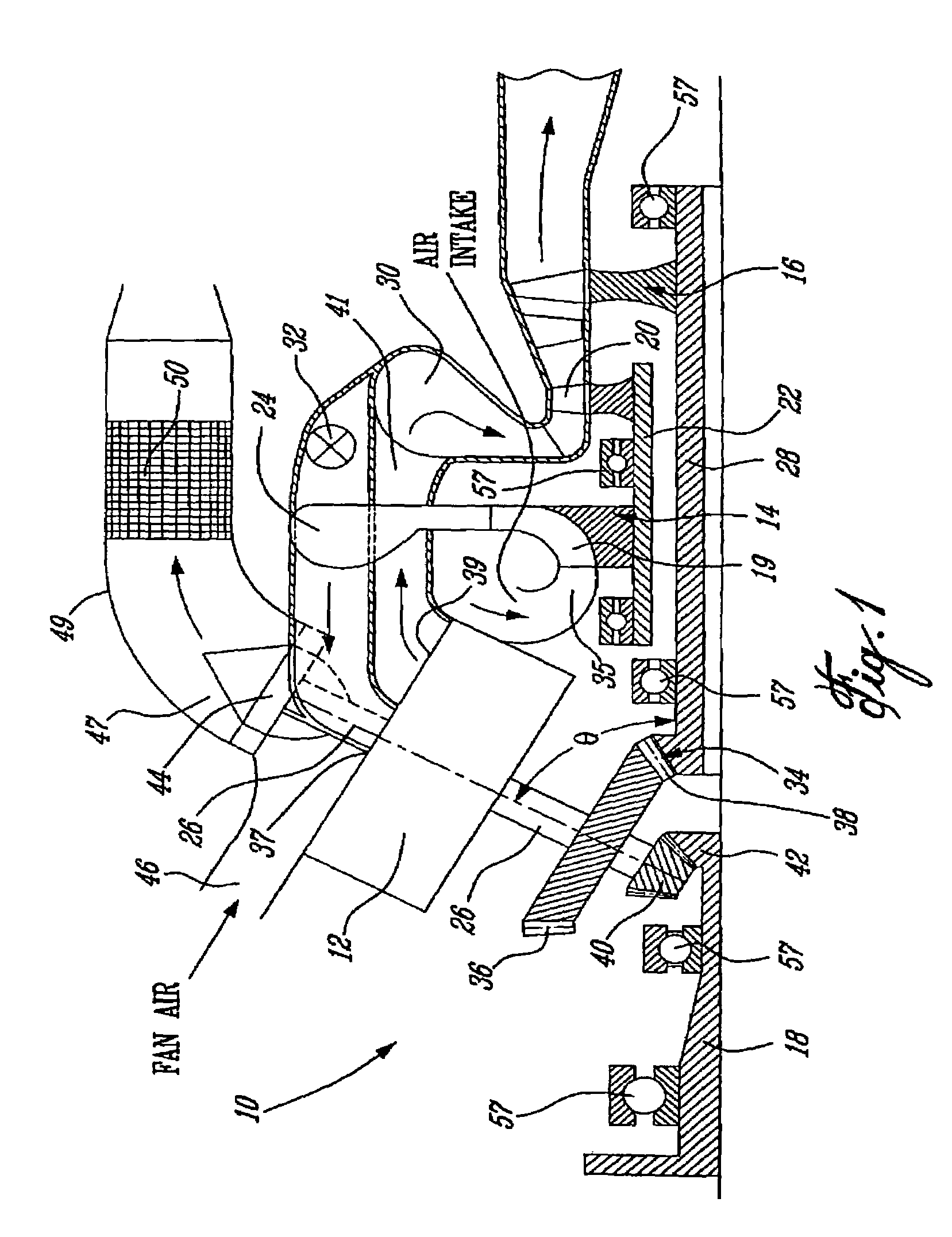

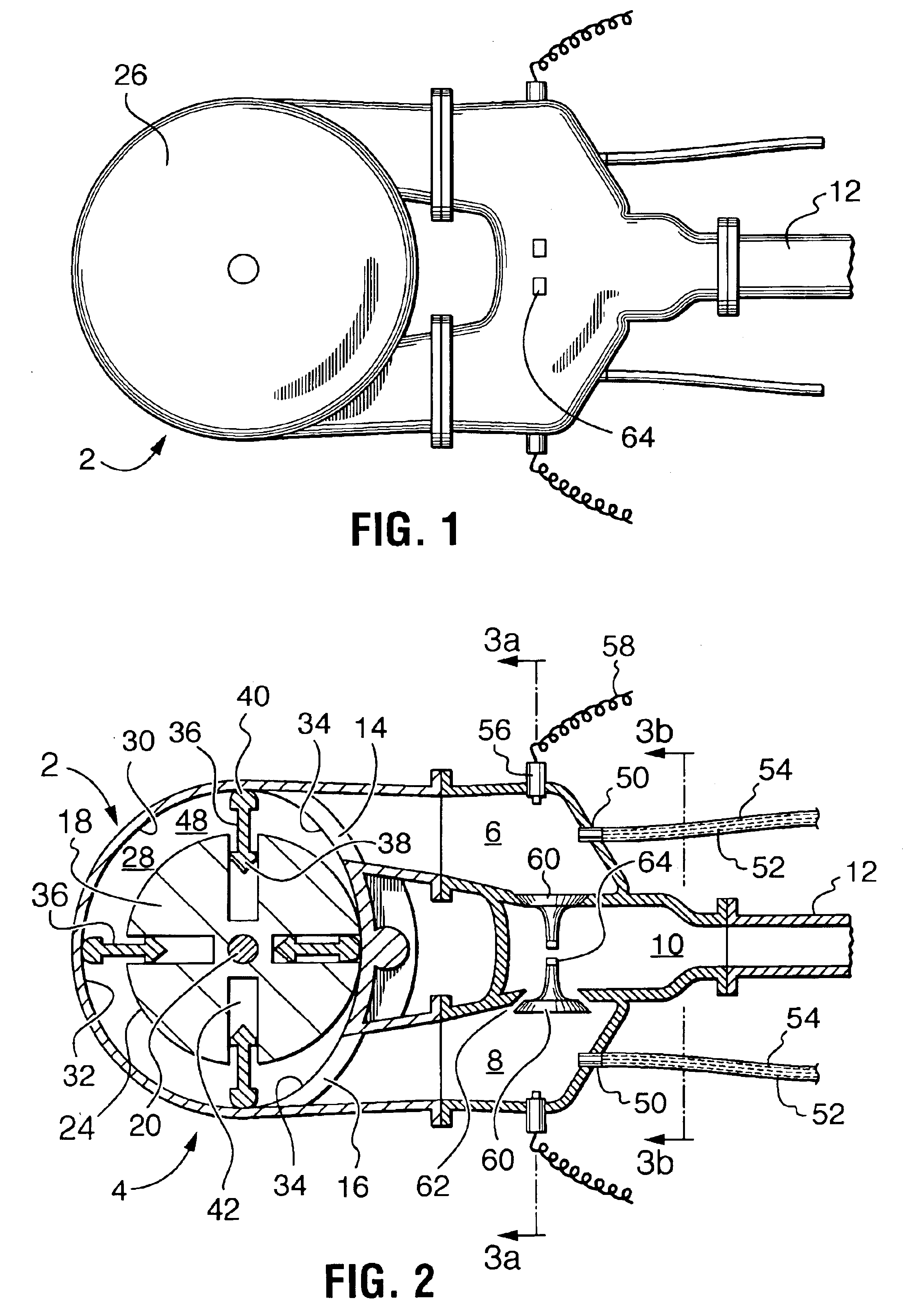

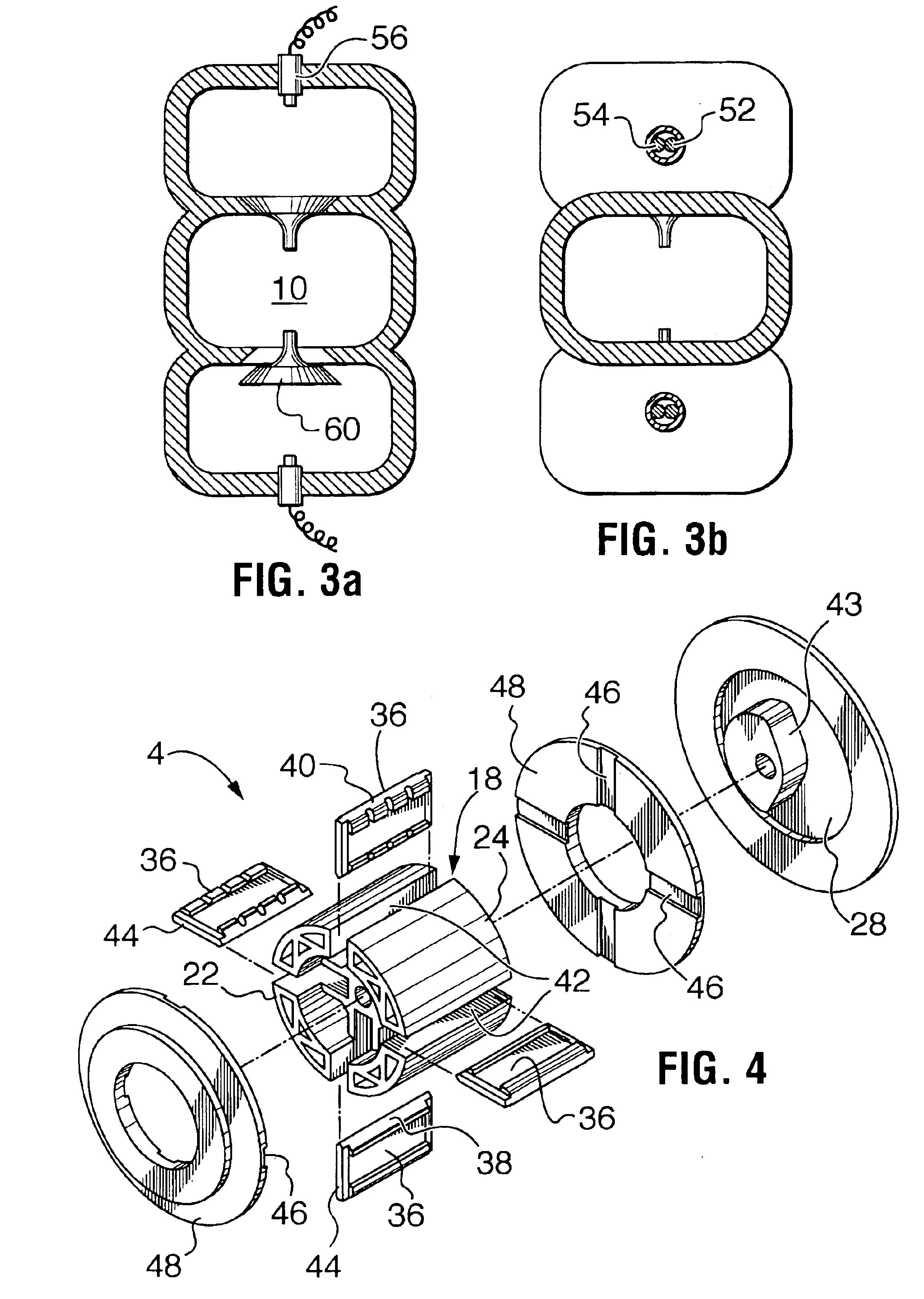

Integral cooling system for rotary engine

ActiveUS7412831B2The process is compact and efficientDomestic stoves or rangesInternal combustion piston enginesCombustionRotary engine

A rotary combustion engine (12) with a self-cooling system comprises a heat exchanging interface for discharging excess heat from the rotary combustion engine (12), and a direct drive fan (44) integrated on the rotary engine output shaft (26) for providing a flow of forced air over the heat exchanging interface.

Owner:PRATT & WHITNEY CANADA CORP

Rotary knife with blade bushing

A powered rotary knife includes a handle, a blade housing, an annular blade, and a blade bushing for rotatably mounting the blade within the housing. The blade housing includes an inner groove that is operable to receive the blade bushing therein. The blade housing and blade bushing are split in order to expand and receive the blade. The blade includes an outer groove that is also operable to receive the blade bushing. Thus, the blade bushing is spaced between the blade housing and blade and rotatably secures the blade within the blade housing.

Owner:HANTOVER

Combustion and exhaust heads for fluid turbine engines

InactiveUS6799549B1Simpler and economical to manufactureLess componentsInternal combustion piston enginesOscillating piston enginesCombustion chamberExhaust valve

An internal combustion rotary engine which includes a housing encased rotor having: cam actuated inwardly and outwardly extending vanes, a combustion chamber communicating with a fluid inlet port to the vanes within the housing, and an exhaust chamber communicating with the fluid outlet port from the vanes of the housing, air and fuel injectors associated with the combustion chamber for delivery of an air and fuel mixture to the combustion chamber, and igniter means associated with the combustion chamber for igniting air and fuel mixture within that chamber. Controls are provided to properly control the sequence of air and fuel injection, fuel ignition and exhaust valve opening and closing during operation of the engine to provide simpler and more economical rotary engine.

Owner:1564330 ONTARIO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com