Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4197 results about "Bushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electric power, a bushing is an insulated device that allows an electrical conductor to pass safely through a grounded conducting barrier such as the case of a transformer or circuit breaker. Bushings are typically made from porcelain; though other insulating materials are also possible, generally porcelain is used.

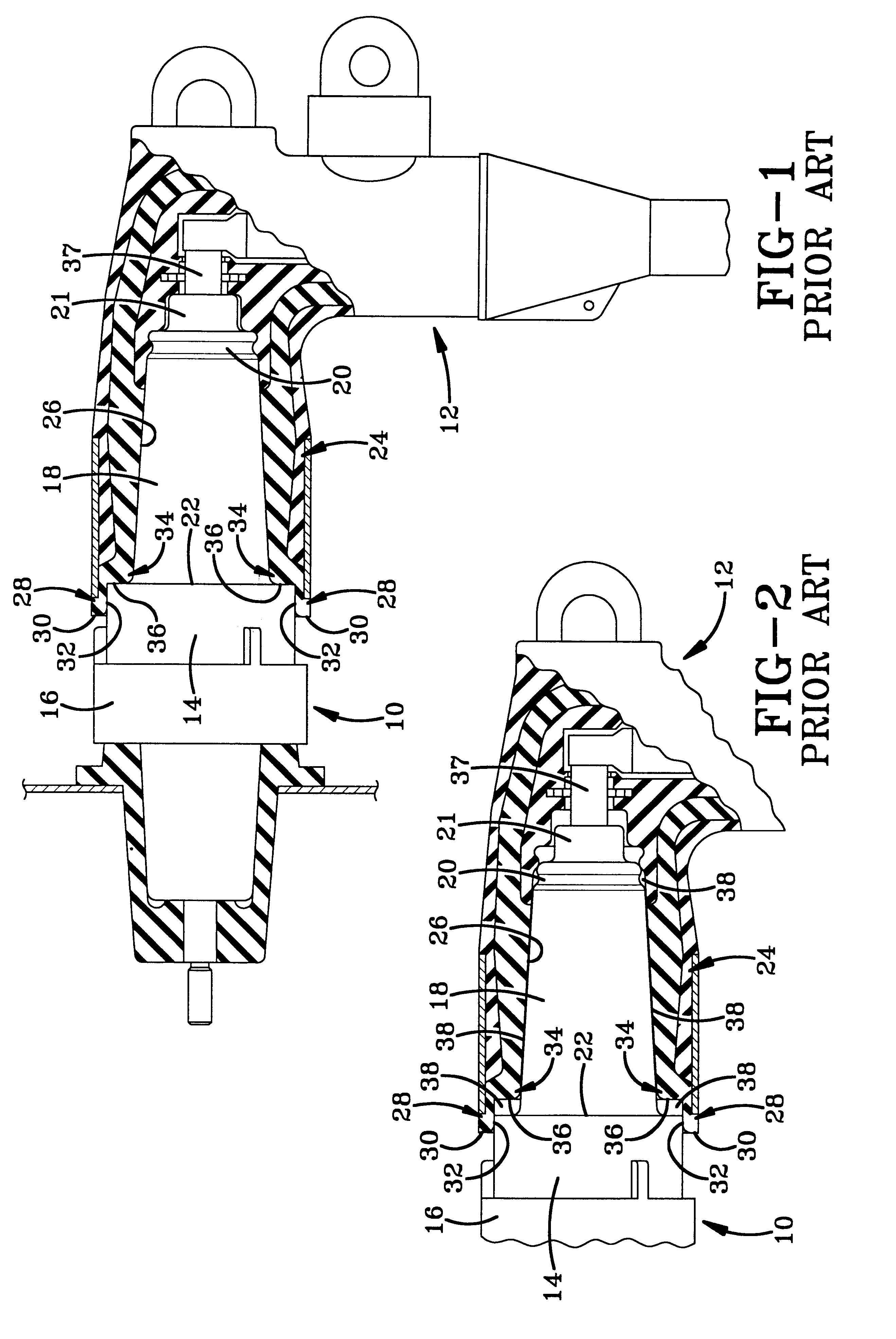

Anti-flashover ring for a bushing insert

InactiveUS6213799B1Avoid flashoverSimple and effective and inexpensiveCouplings bases/casesEngineeringElectrical probe

The anti-flashover ring of the present invention includes a substantially cylindrical body having an outer surface with a plurality of passageways thereon. Each of the passageways pass from one of the sidewalls through the body to the other of the sidewalls of the ring. The passageways function to provide fluid communication between the atmosphere surrounding an accessory product such as a bushing insert and the interior of a connector mounted thereon when the connector is being pulled off the bushing insert. The fluid communication prevents a vacuum from forming between the connector and the bushing insert that can lead to a flashover between an electrical probe in the connector and a ground shield of the bushing insert. The anti-flashover ring is also configured to provide an indication to the operator installing the connector of when the connector is fully installed on the bushing insert. Such indication is provided by providing the ring with a width that is equal to length of the lip of the connector when the connector is fully installed. As such, the operator installing the connector continues to push on the connector until the end of the lip aligns with the end of the ring.

Owner:HUBBELL INC

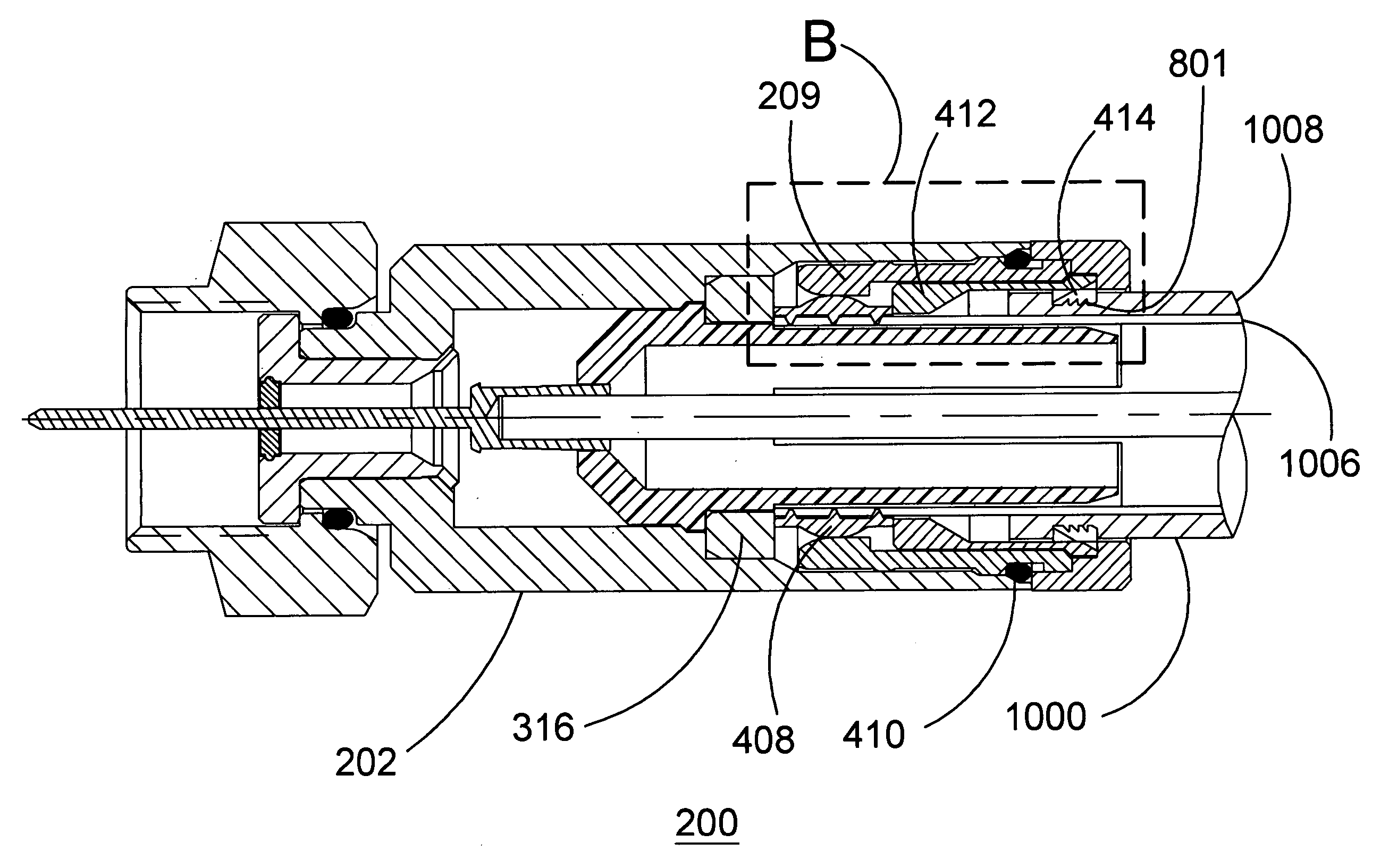

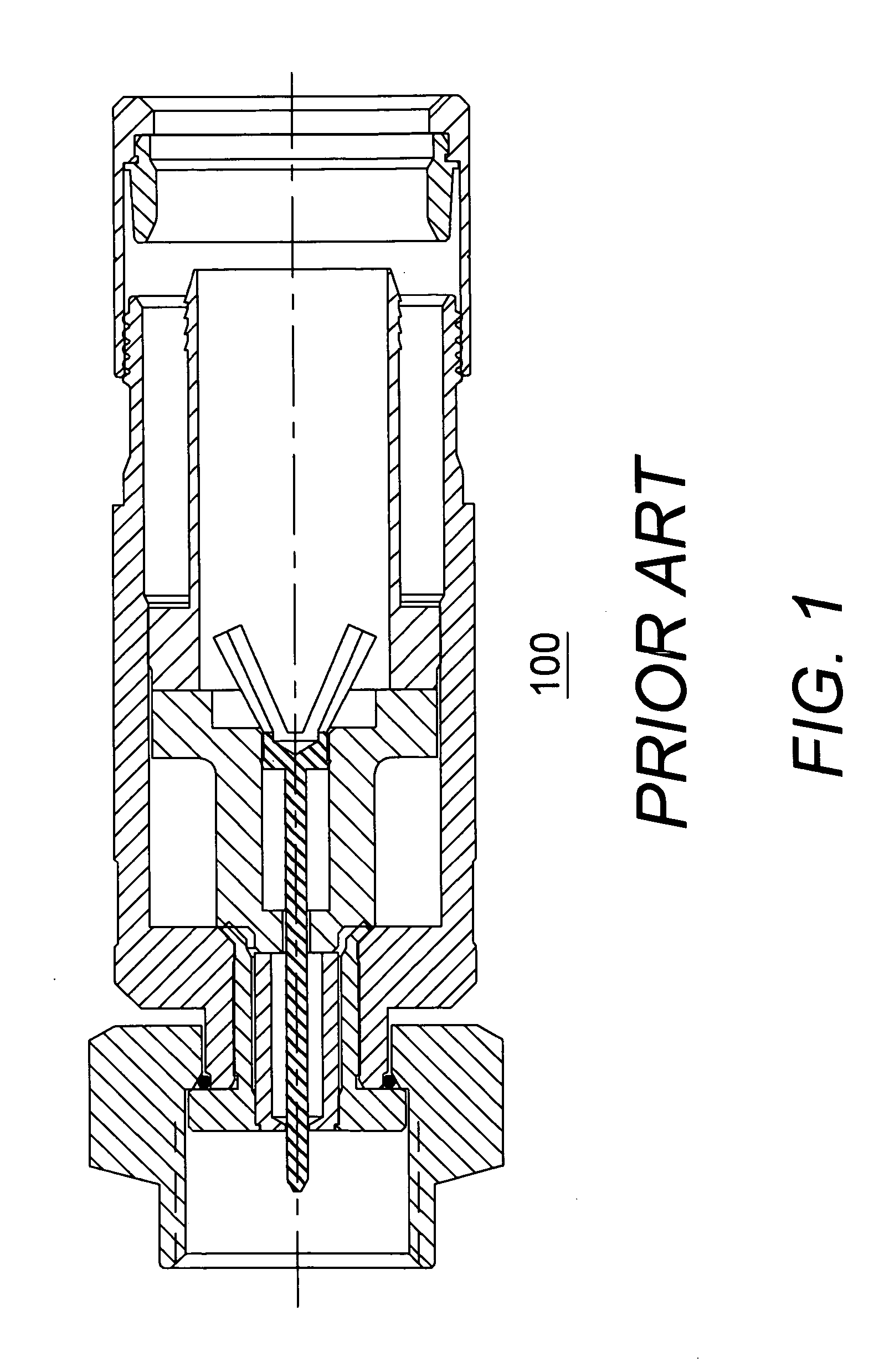

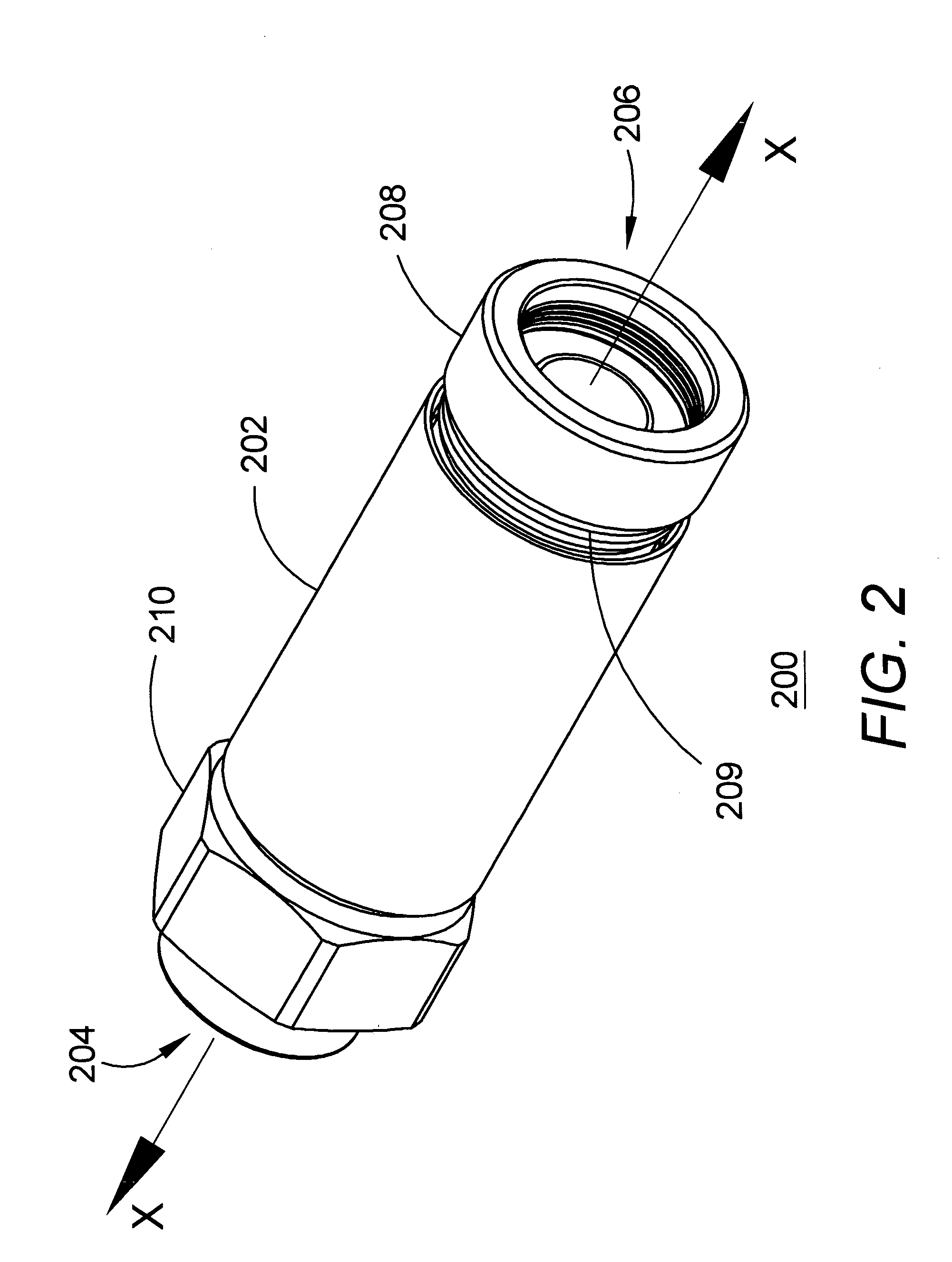

Hardline coaxial cable connector

InactiveUS7108547B2Easy to compressElectrically conductive connectionsTwo pole connectionsElectrical conductorCoaxial cable

Owner:CORNING OPTICAL COMM LLC

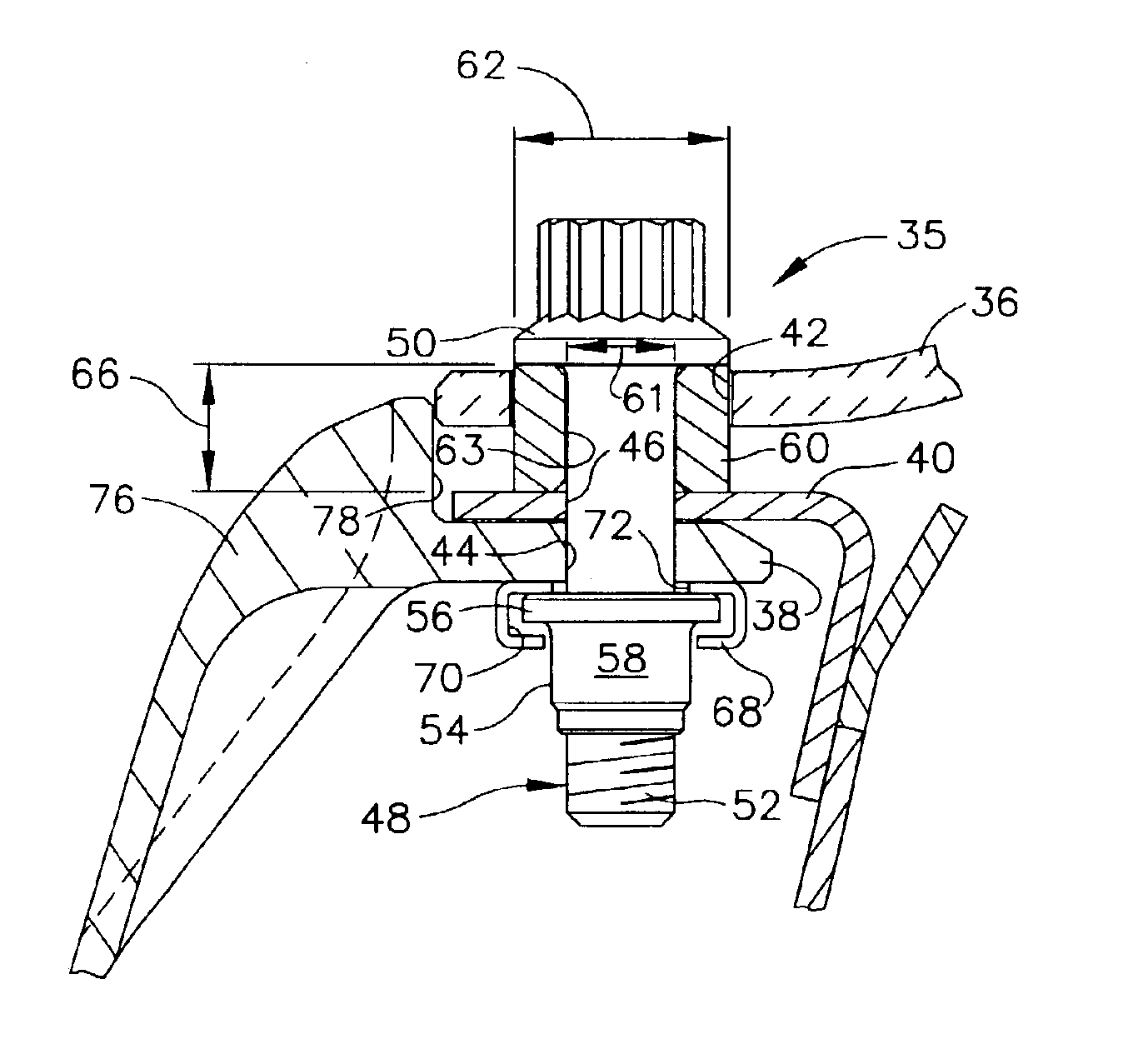

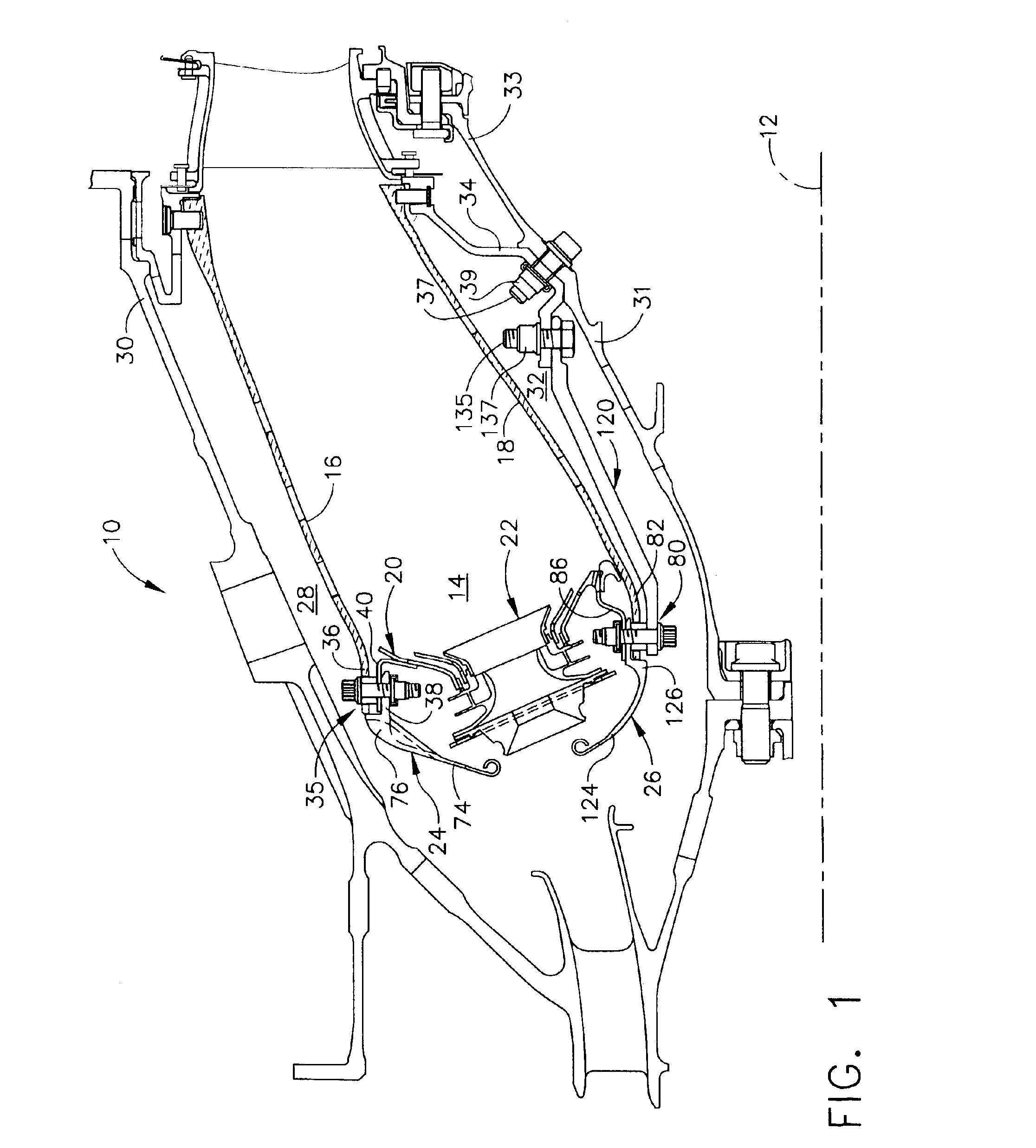

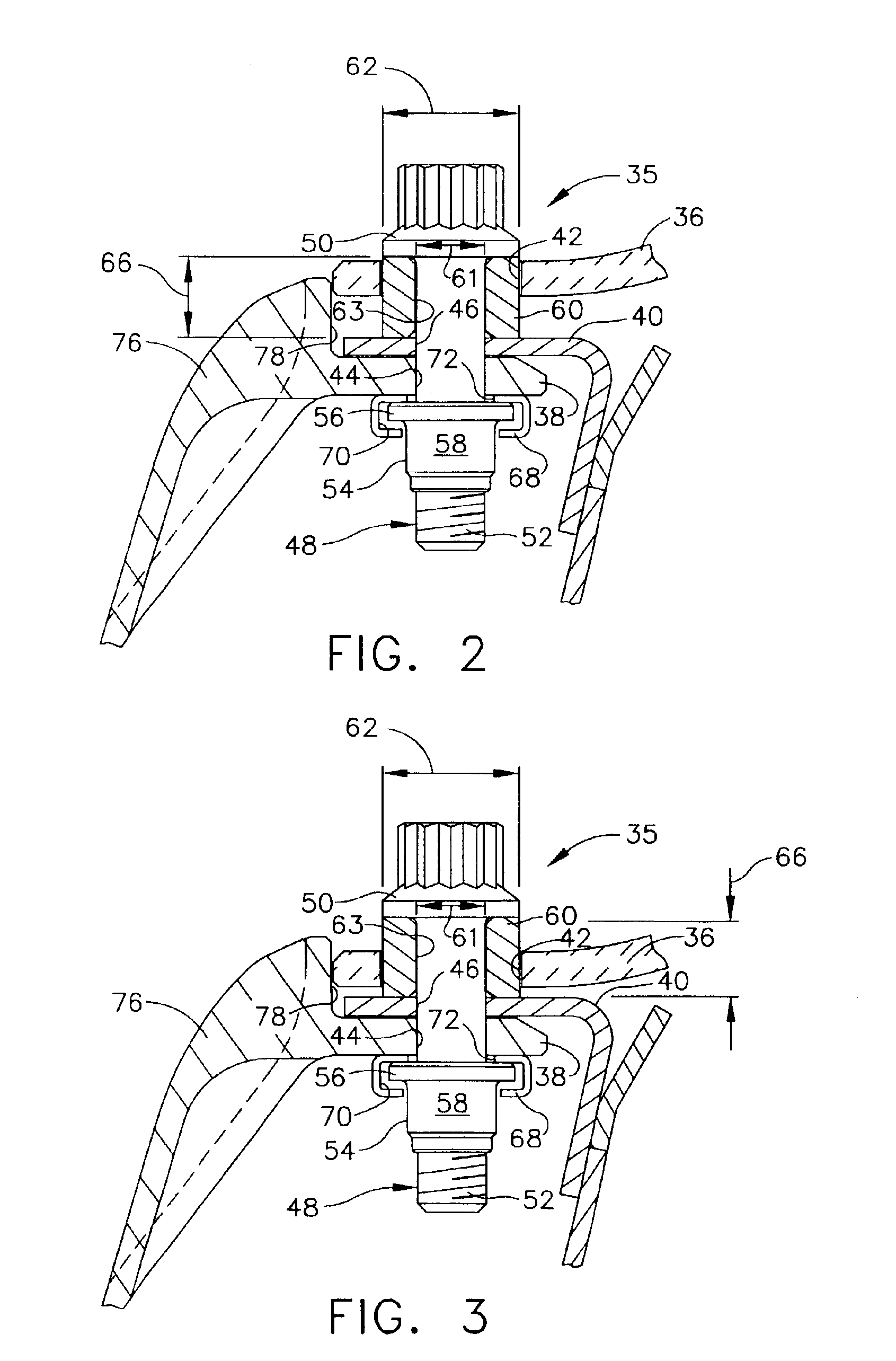

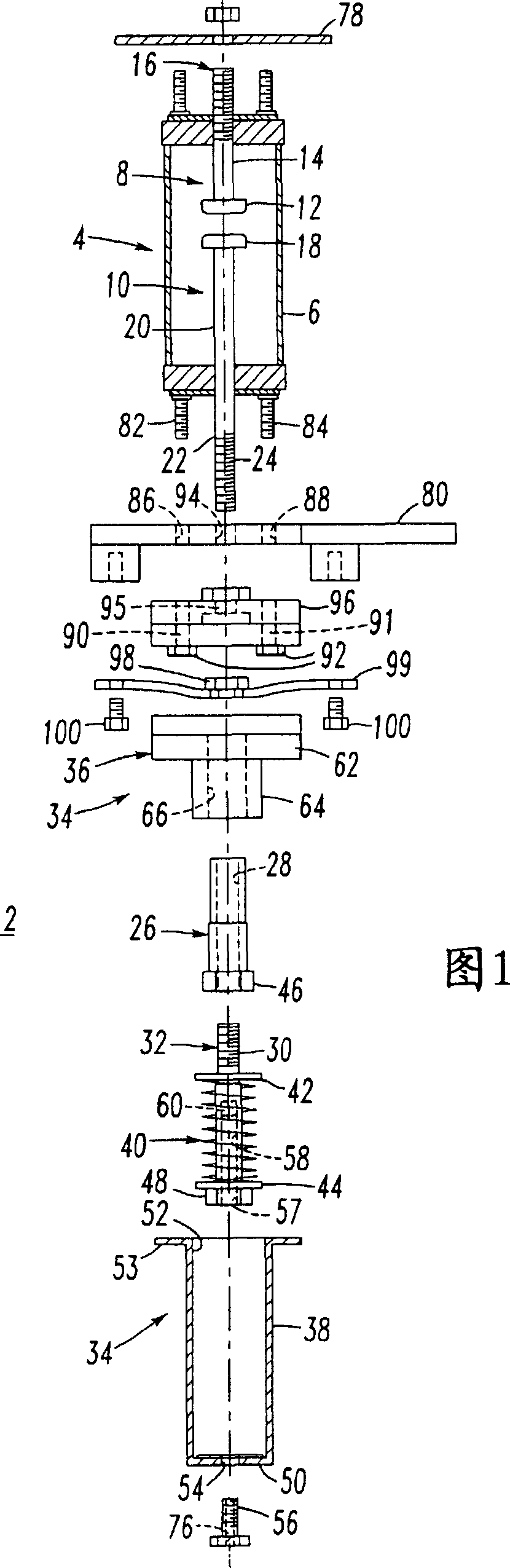

Mounting assembly for the forward end of a ceramic matrix composite liner in a gas turbine engine combustor

InactiveUS6904757B2Low thermal expansionContinuous combustion chamberGas turbine plantsCombustorEngineering

A mounting assembly for a forward end of a liner in a combustor of a gas turbine engine including a dome and a cowl, wherein a longitudinal centerline axis extends through the gas turbine engine. The mounting assembly includes a pin member extending through each one of a plurality of circumferentially spaced openings formed in the forward end of the liner, an aft portion of the cowl, and a portion of the dome, with each pin member including a head portion at one end thereof. A nut is adjustably connected to an end of each pin member opposite the head portion. A bushing is located on each pin member at a position intermediate the head portion and the nut, wherein the openings in the liner forward end are sized to fit around the bushings. In this way, the cowl aft portion and the dome portion are fixedly connected together between the bushing and the nut so that the bushings are able to slide radially through the openings in the liner forward end as the cowl and the dome experience thermal growth greater than the liner.

Owner:GENERAL ELECTRIC CO

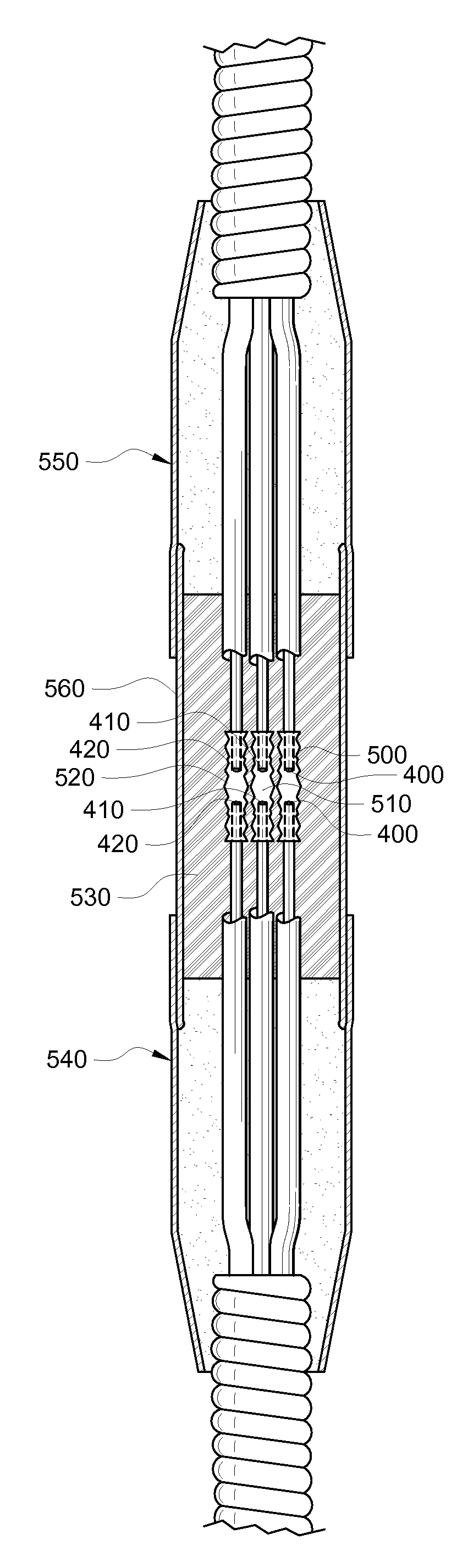

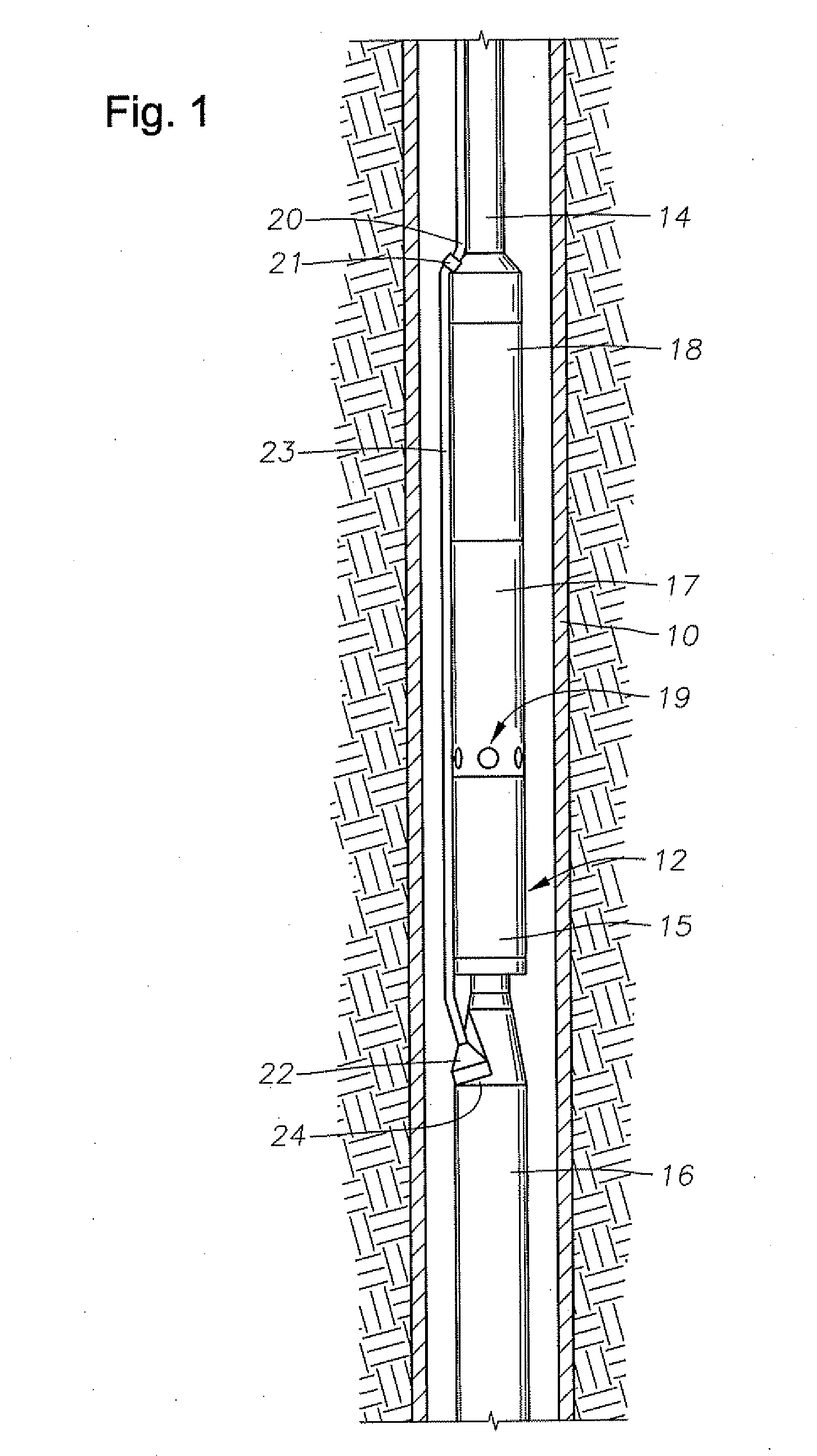

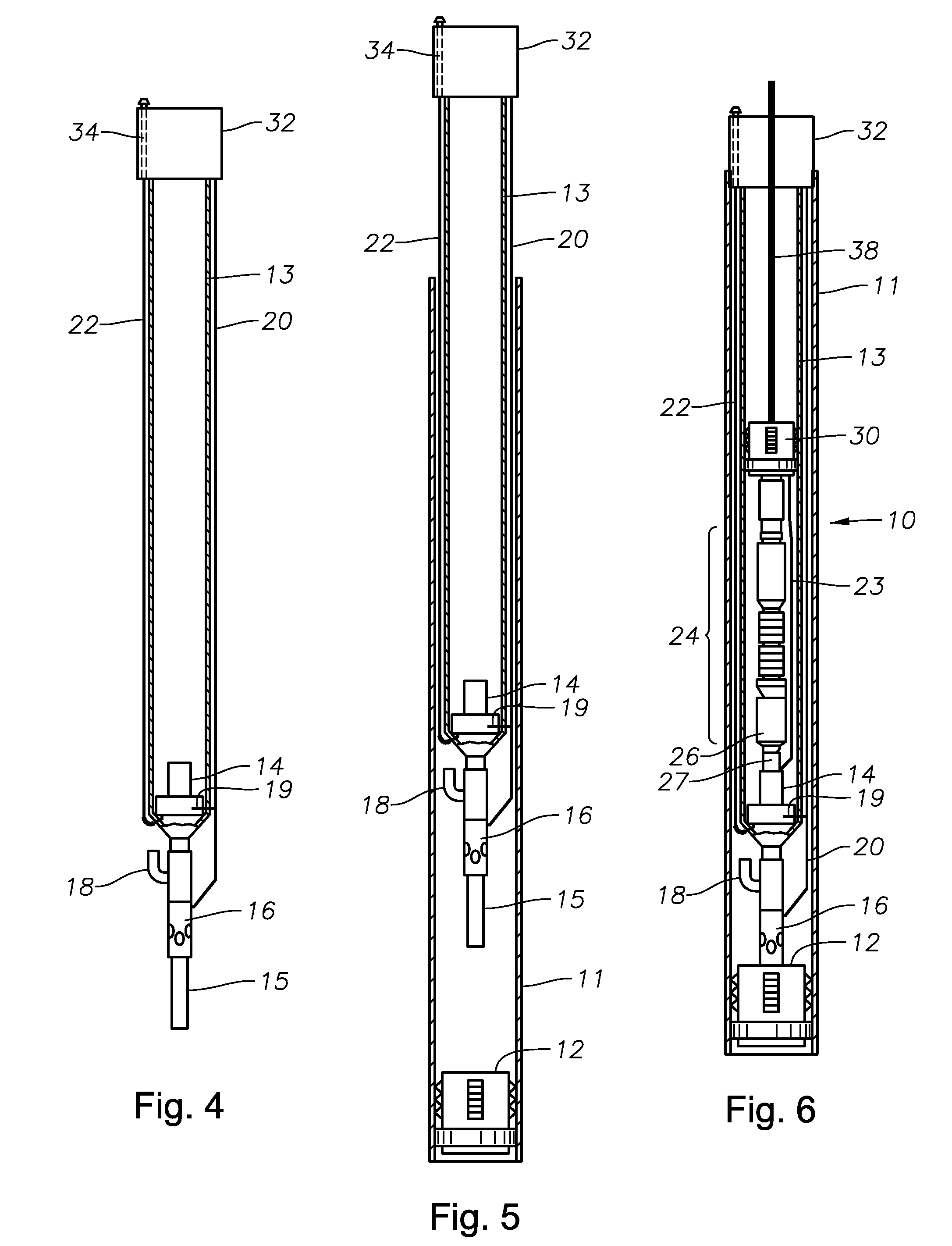

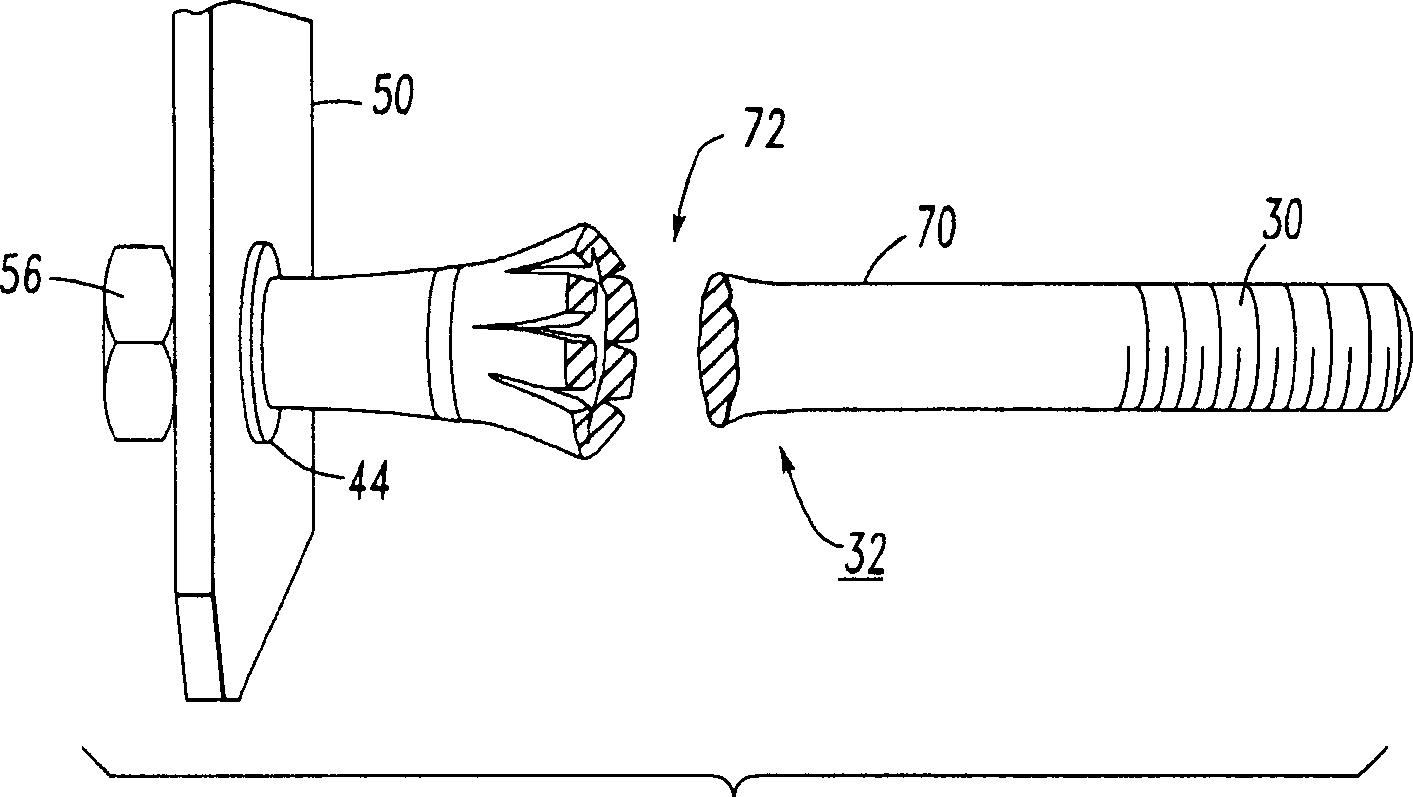

Splice for down hole electrical submersible pump cable

ActiveUS7405358B2Overcome problemsCoupling device detailsConnections effected by permanent deformationElectricityEngineering

A splicing system that establishes an electrical union between two segments of power cable having internal conductor wires. The splicing system is resistant to electrical failures and the harsh environment existing in subterranean environments during all phases of the hydrocarbon extraction process. The splicing arrangements comprise a protective housing, insulating sleeve and crimp splice working in cooperation to create a sealed power cable connection.

Owner:QUICK CONNECTORS

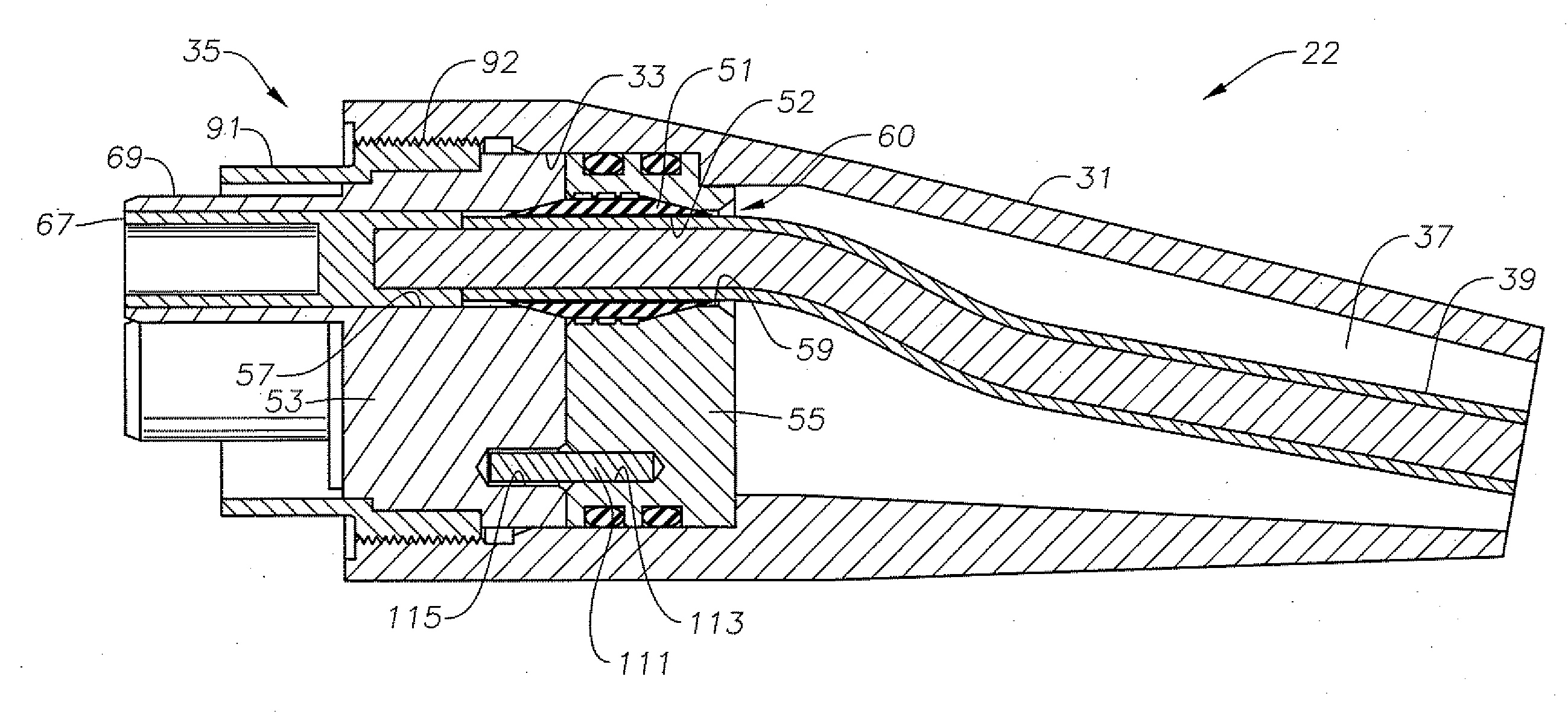

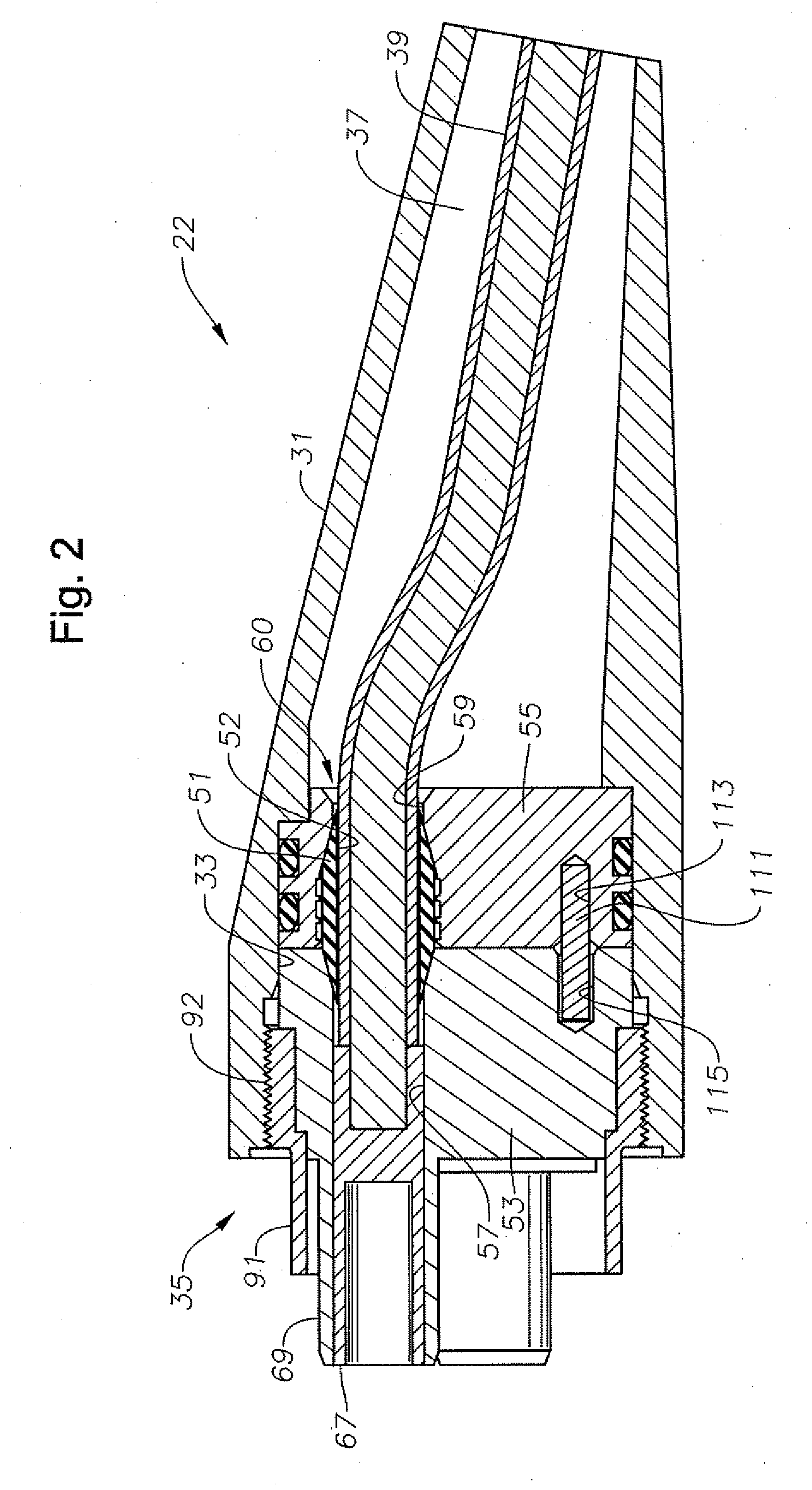

Apparatus and methods of sealing and fastening pothead to power cable

ActiveUS20120100737A1Prevent pressure buildupEasy to fixSecuring/insulating coupling contact membersDustproof/splashproof/drip-proof/waterproof/flameproof connectionPower cablePothead

Apparatus of components and methods for connecting and sealing a pothead to an electrical cable used in an oil well environment, are provided. Electrical leads are anchored in insulating members retained within the pothead. The leads inserted into passages formed through the insulating members each having an elliptically shaped portion. Channels are formed along the surface of the passages and along the circumference of the elliptically shaped portions. Boot seals are provided in the elliptically shaped portions and circumscribe the electrical leads. A hydrocarbon-based liquid is applied to the boot seals to cause them to swell and occupy the space between the leads and the insulators, including the channels.

Owner:BAKER HUGHES INC

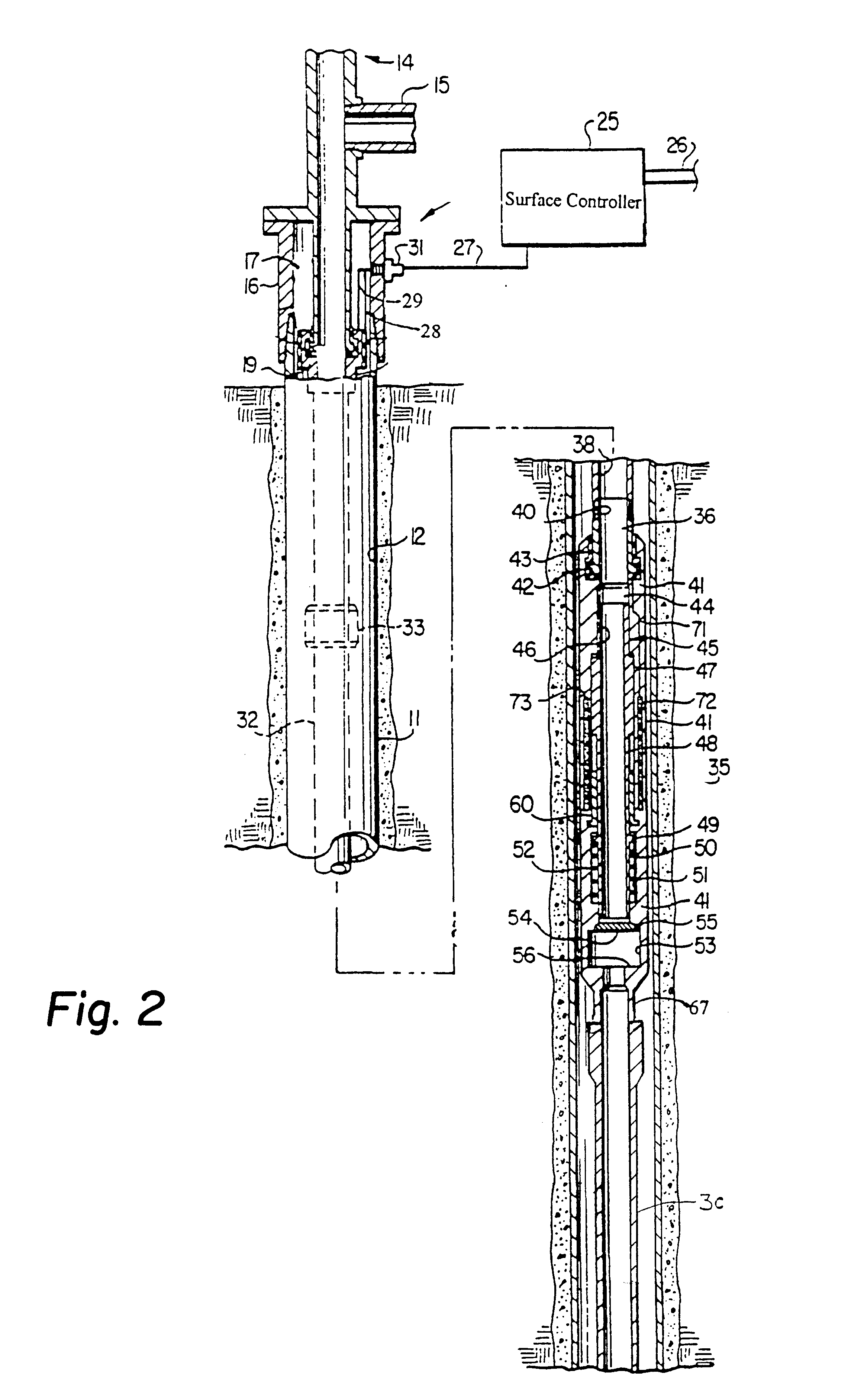

Deep-set subsurface safety valve assembly

An apparatus and method for use in a cased well having a production tubing assembly installed in the well and terminating with a connection mechanism at a subterranean location. The apparatus and method utilizes a spoolable tubular assembly for installation extending into the well to the connection mechanism wherein the tubular assembly has a plurality of conductors formed connected to electrically operable valve, sensors and tubing latch in the tubular assembly. In the method the assembly is spooled into the well with the tubing latch being operated from outside the well through the tubing conductors to selectively connect and disconnect the assembly from the connector mechanism. Operating the salve and sensors from outside the well when the assembly is installed. The assembly tubing is preferably made of a non-conductive, and preferably composite material that enclosed at least one, and preferably a plurality of electrical conductors.

Owner:HALLIBURTON ENERGY SERVICES INC

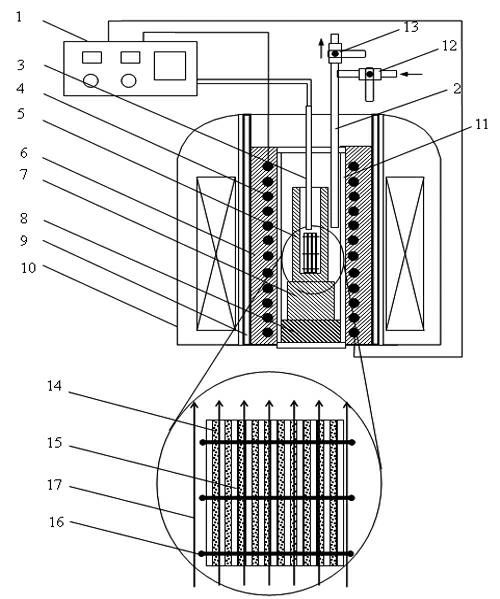

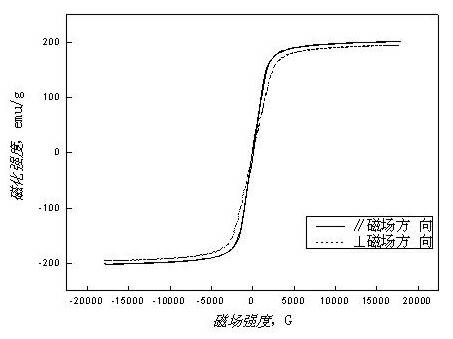

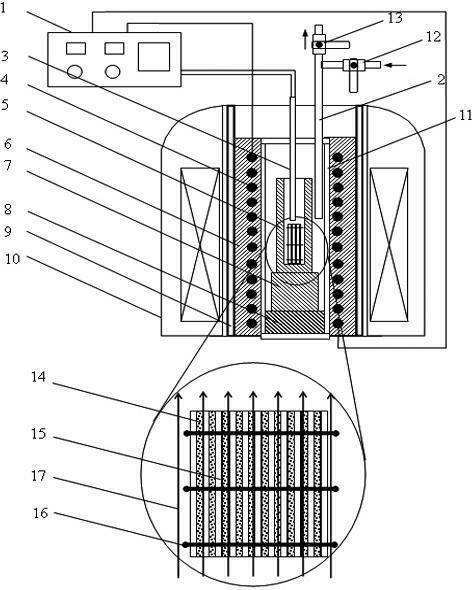

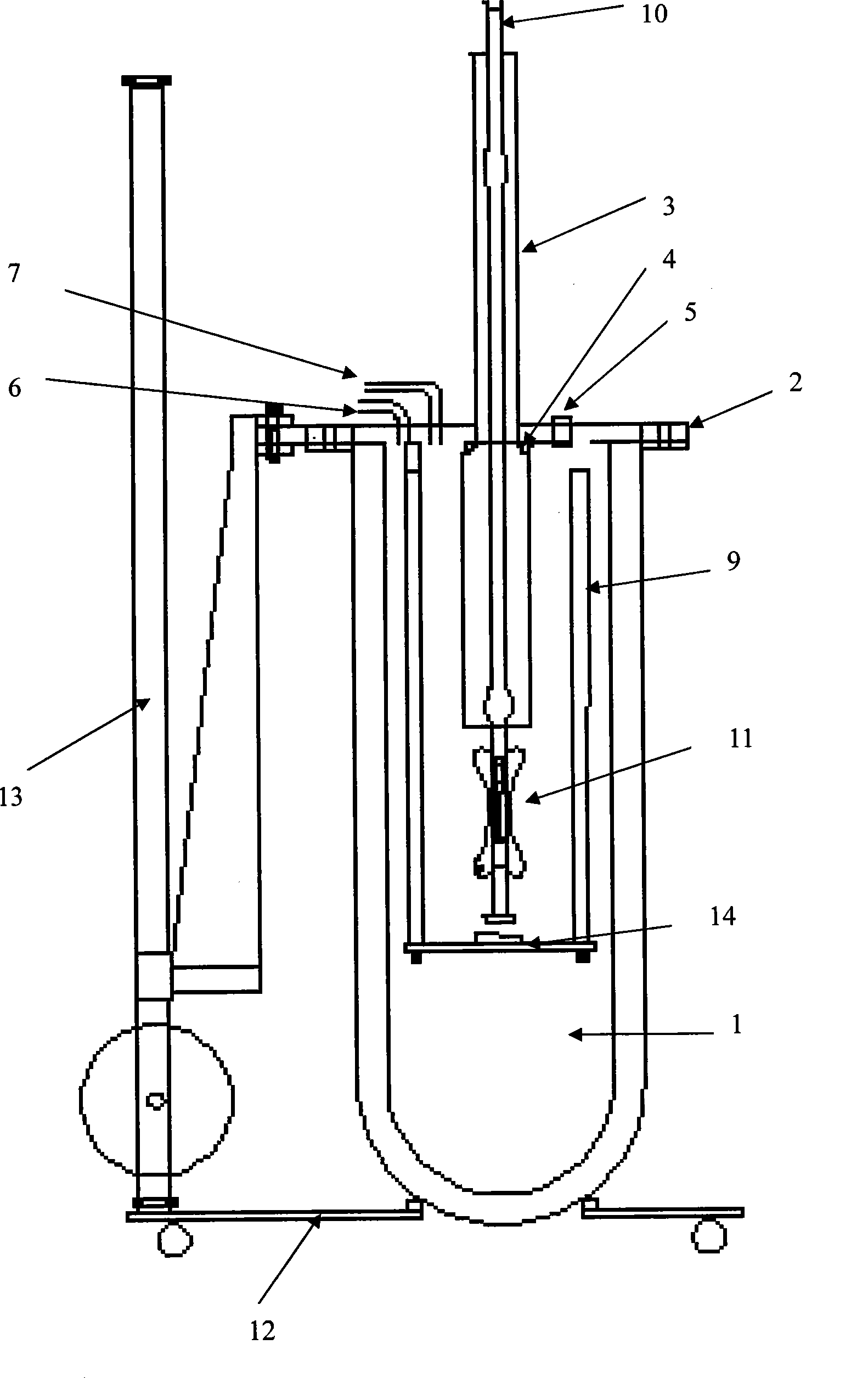

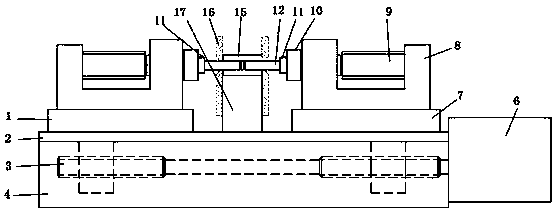

Method and device for preparing high-silicon silicon steel sheet in static magnetic field with powder sintering method

ActiveCN102658367AAccurate control of silicon contentHigh densityInorganic material magnetismInlet valveExhaust pipe

The invention relates to a method and device for preparing a silicon steel sheet in a static magnetic field with a powder sintering method. The specific process of the method consists of the following steps of: mixing Fe-Si powder; rolling into a plate blank; and sintering a Fe-6.5 weight percent Si green compact in a static magnetic field. In the method, 6.5 percent by weight of Si high-silicon steel with high density is obtained by using the influence of the magnetic field on the sintering densification and orientation process of a Fe-6.5 weight percent Si powder green compact, and an easily-magnetized axis is oriented along the magnetic field. An atmosphere / vacuum sintering device in a static magnetic field consists of a temperature control device, an exhaust pipe, a thermocouple, a heating element, a corundum crucible, a refractory fiber, a support block, a heat insulating block, a water-cooled bush, a static magnetic field generating device, a sealed corundum pipe, an inert gas inlet valve, a vacuum pumping valve, a Fe-6.5weight percent Si green compact, a thin corundum plate interlayer and a fixing molybdenum wire. The 6.5 percent Si silicon steel sheet prepared with the method has the advantages of near net molding, superior magnetic property, high orientation degree and the like, and has a remarkable industrial application prospect.

Owner:SHANGHAI UNIV

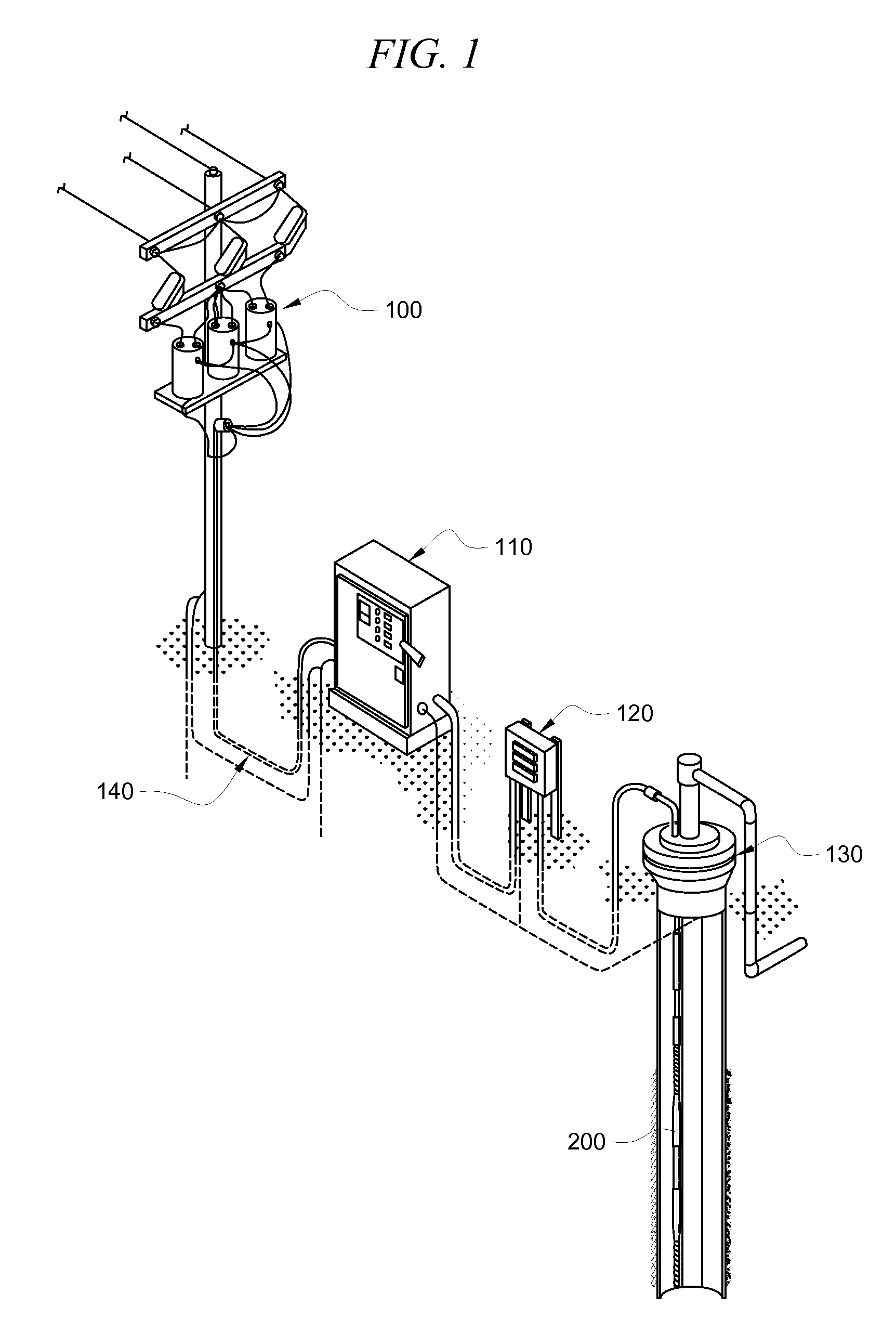

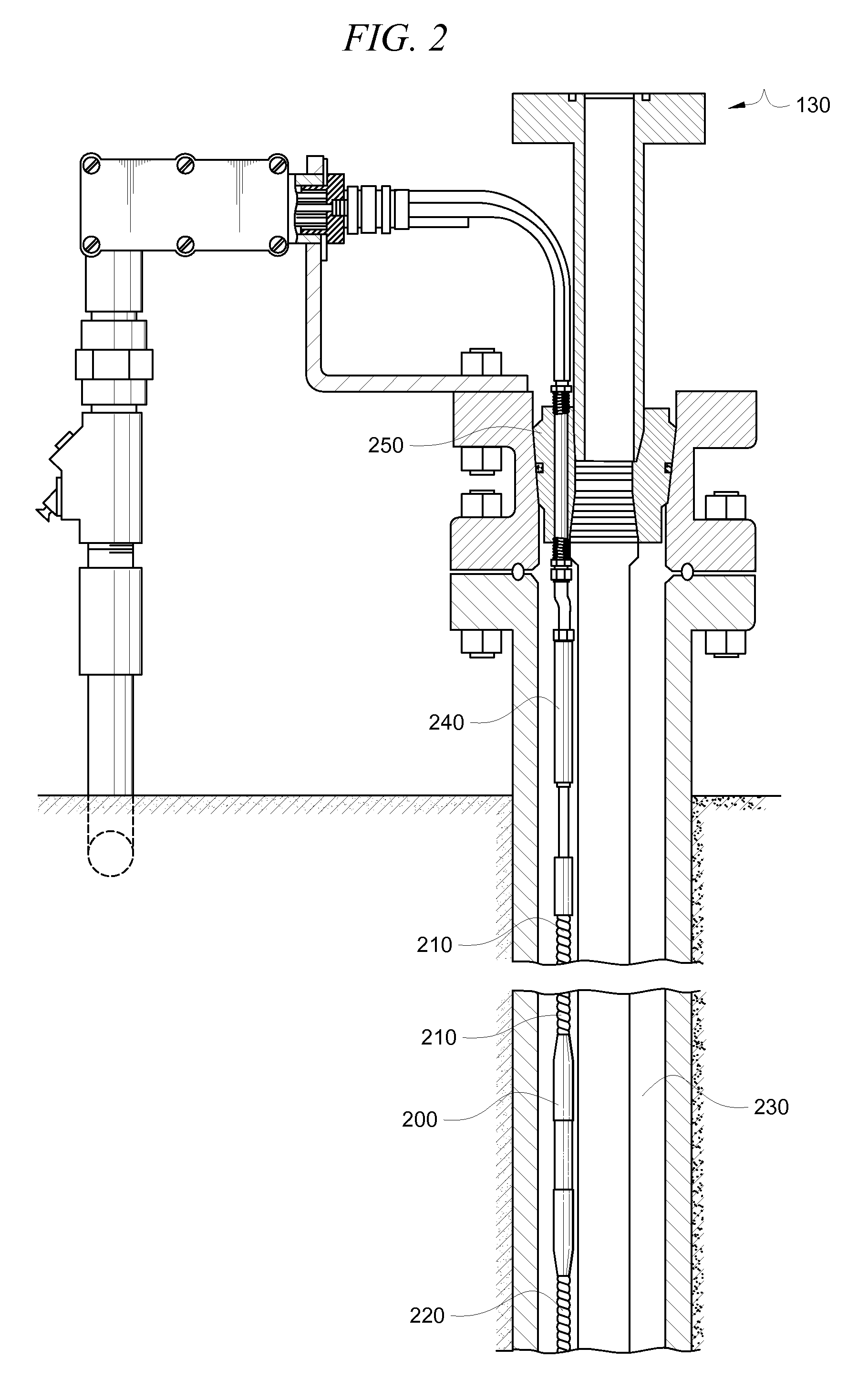

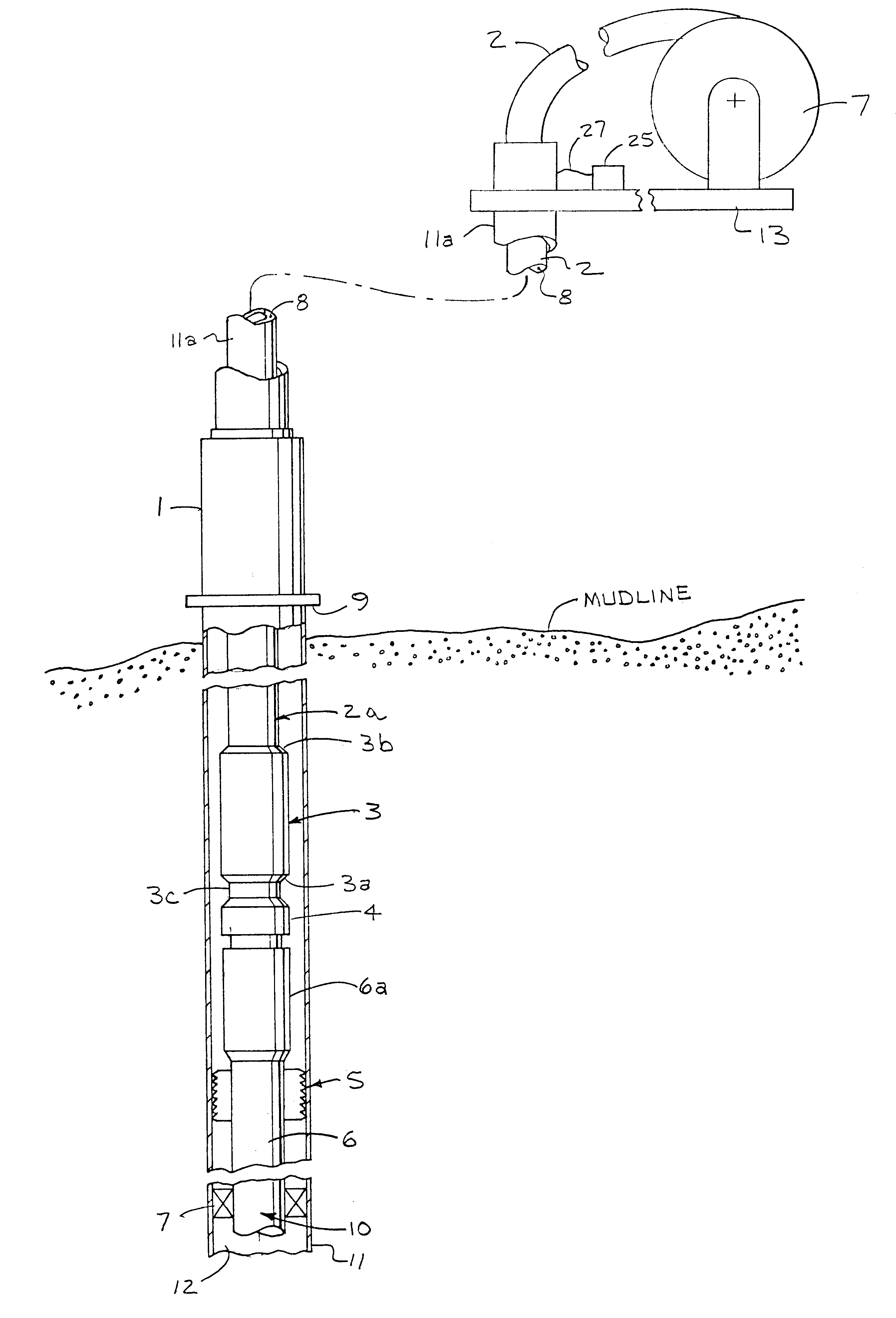

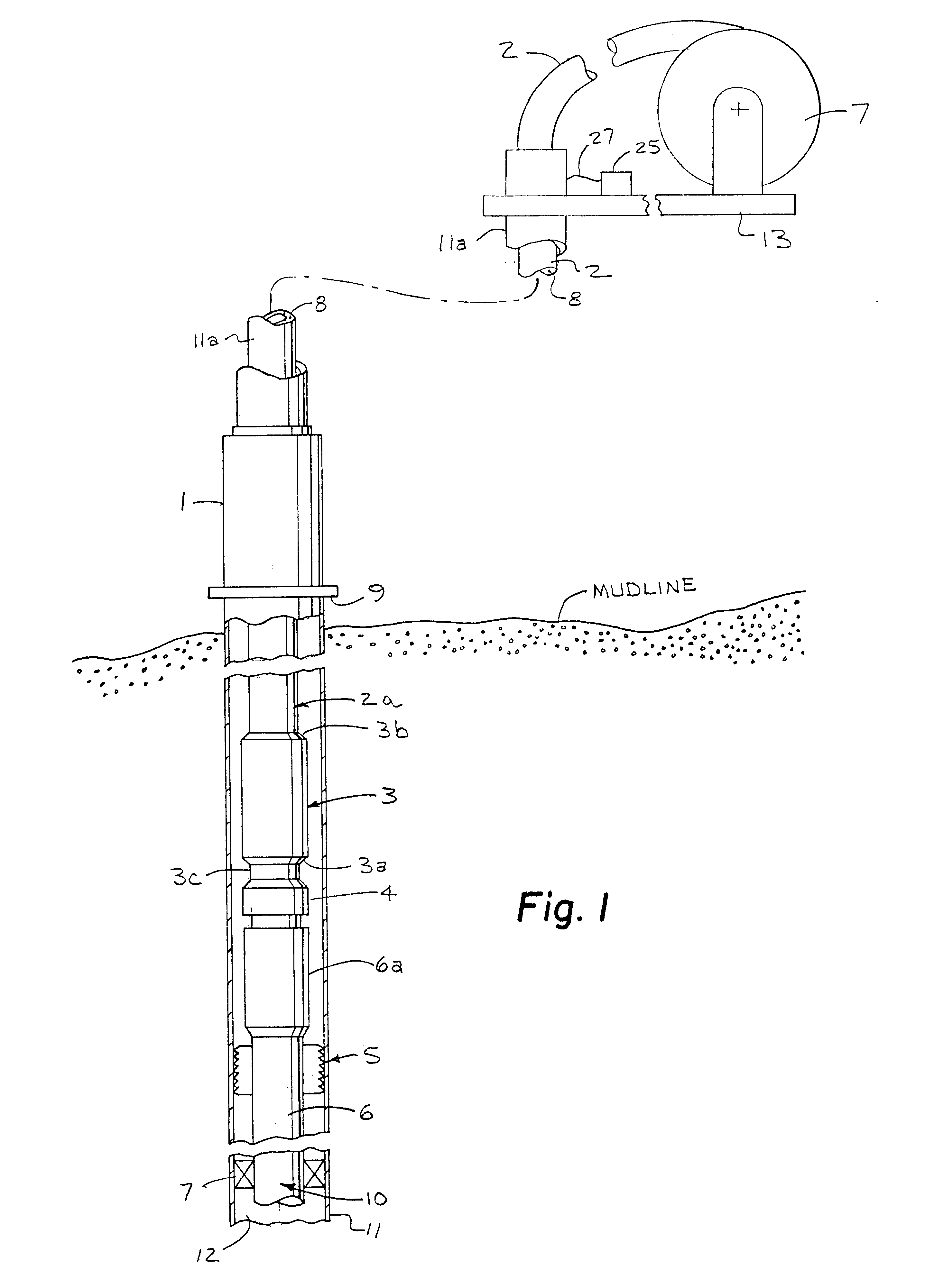

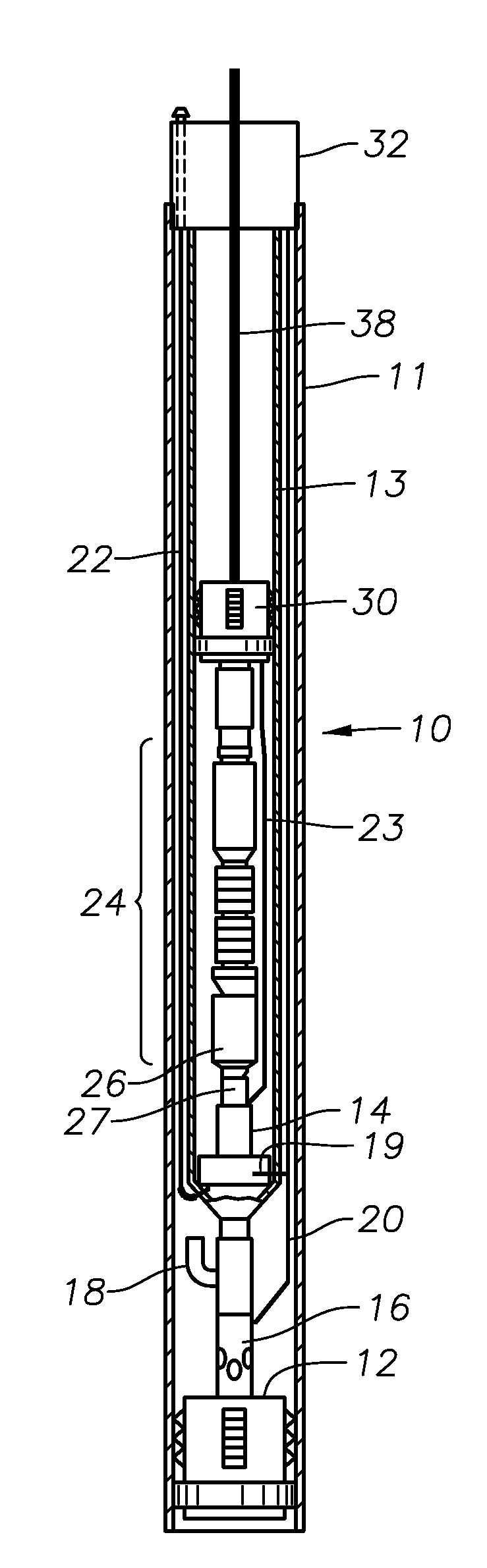

In-well rigless esp

ActiveUS20100206577A1Reduce the overall diameterReduce installation costsFluid removalSealing/packingSaline waterWell drilling

An in-well ESP string that can be installed or retrieved with a wireline instead of a rig. The ESP is combined with a motor and a hydraulic valve to pump formation fluid from a well to the surface. A wet connector is used to facilitate electrical and hydraulic connections. The ESP system is disposed within a tubing string located within the casing of a well. The hydraulic valve controls the flow of formation fluid to the ESP, opening to allow formation fluid to flow to the ESP, and closing to shut off production. When the valve is closed, the ESP may be cleaned with brine introduced via a flow port in the valve. This cleaning operation allows the ESP string to be to retrieved in an environmentally friendly manner. In addition, the wireline installation and retrieval is significantly less costly and less complicated than currently possible with a rig.

Owner:BAKER HUGHES INC

Hot extrusion forming process of half-shaft casings and special device

InactiveCN101690965AShorten molding timeImprove efficiencyForging/hammering/pressing machinesPunchingForming processes

The invention discloses a hot extrusion forming process of half-shaft casings, comprising the following steps: 1) selecting proper round steel according to design products and heating the round steel to 1100-1250 DEG C, 2) carrying out forward extrusion and upsetting, 3) carrying out backward extrusion and positioning, 4) carrying out shallow punching and performing, and 5) carrying out deep punching, finish forging and forming. The invention also discloses a special device for implementing the hot extrusion forming process, comprising upsetting tools, positioning tools, tools for shallow punching and performing and tools for deep punching, finish forging and forming, which are arranged from left to right in sequence. The process has four stations. Each station has enough cooling and lubricating time. Not only can the special device not be deformed after long-term use and the workpieces can not have the problem that inner hole inclination leads to inner and outer coaxiality difference, but also the special device is protected to reduce damage while the capacity is increased.

Owner:济南中森机械制造有限公司

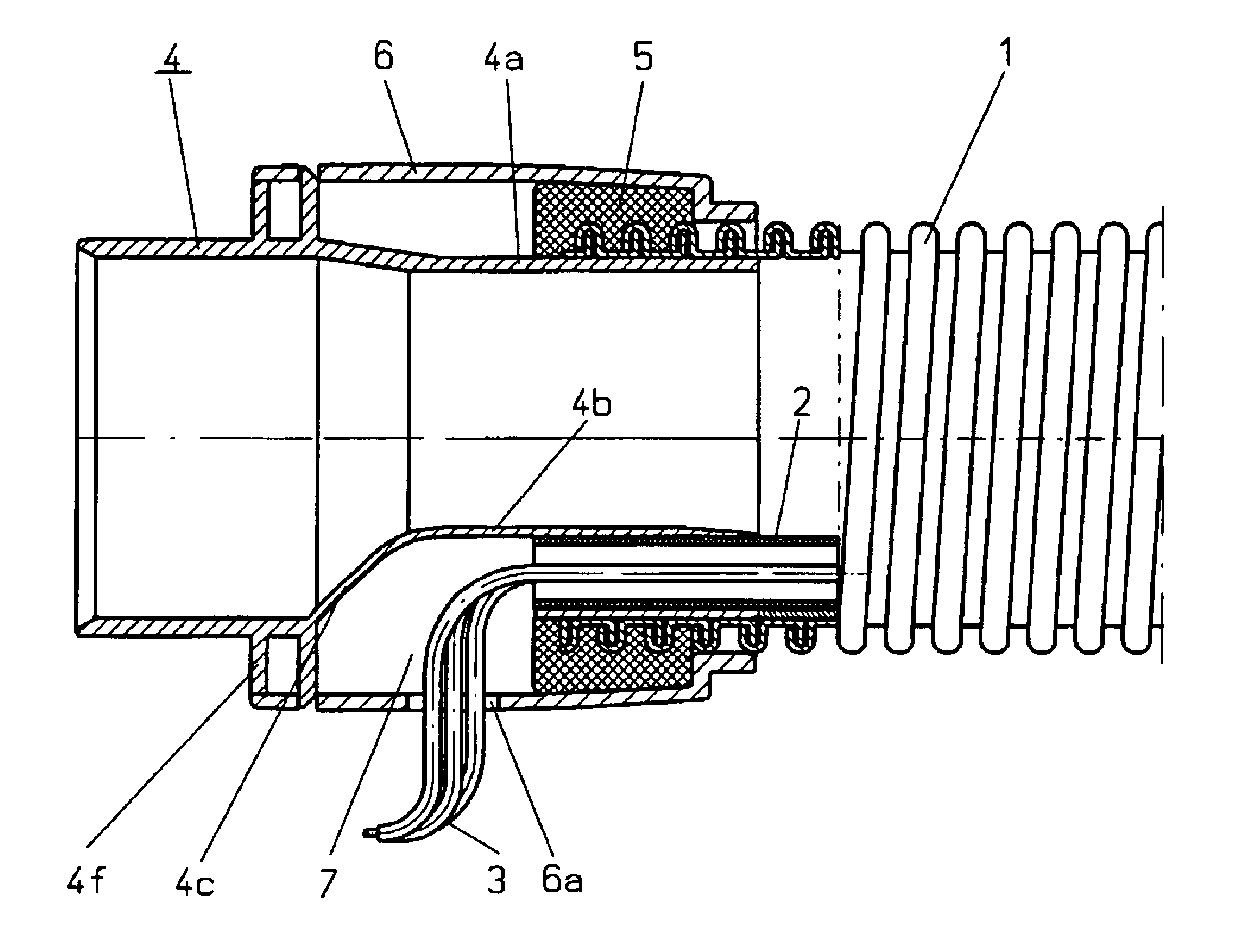

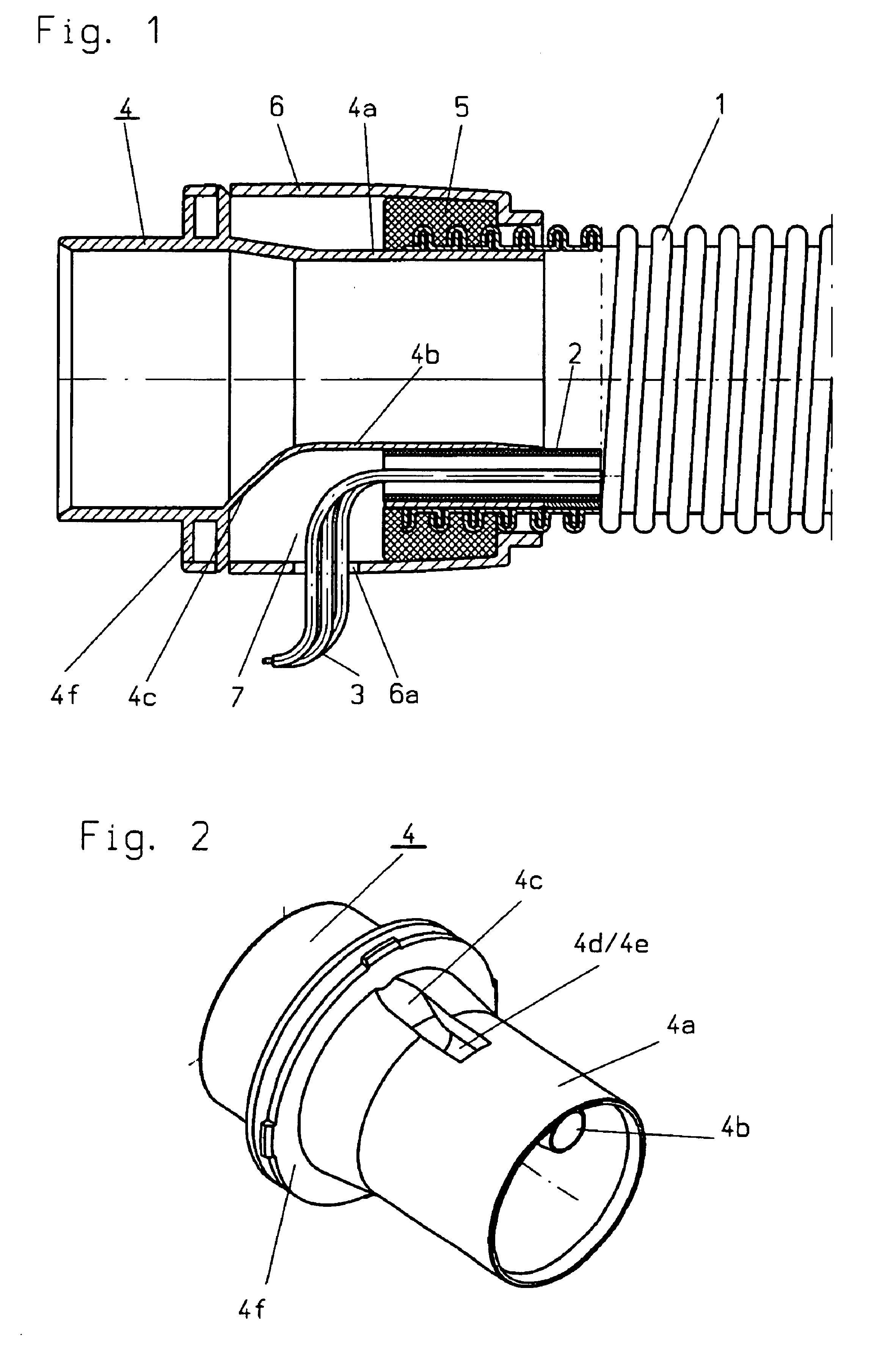

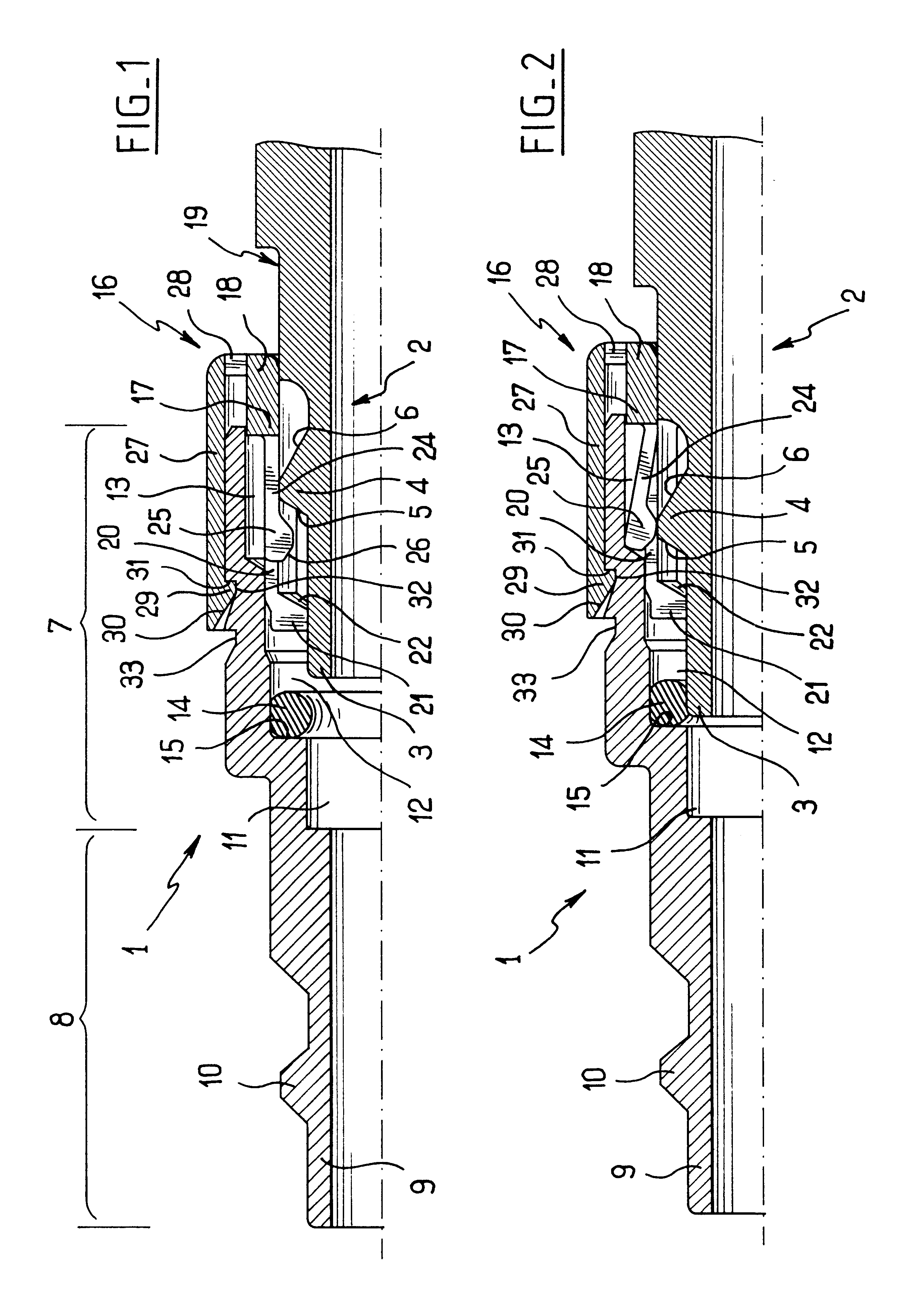

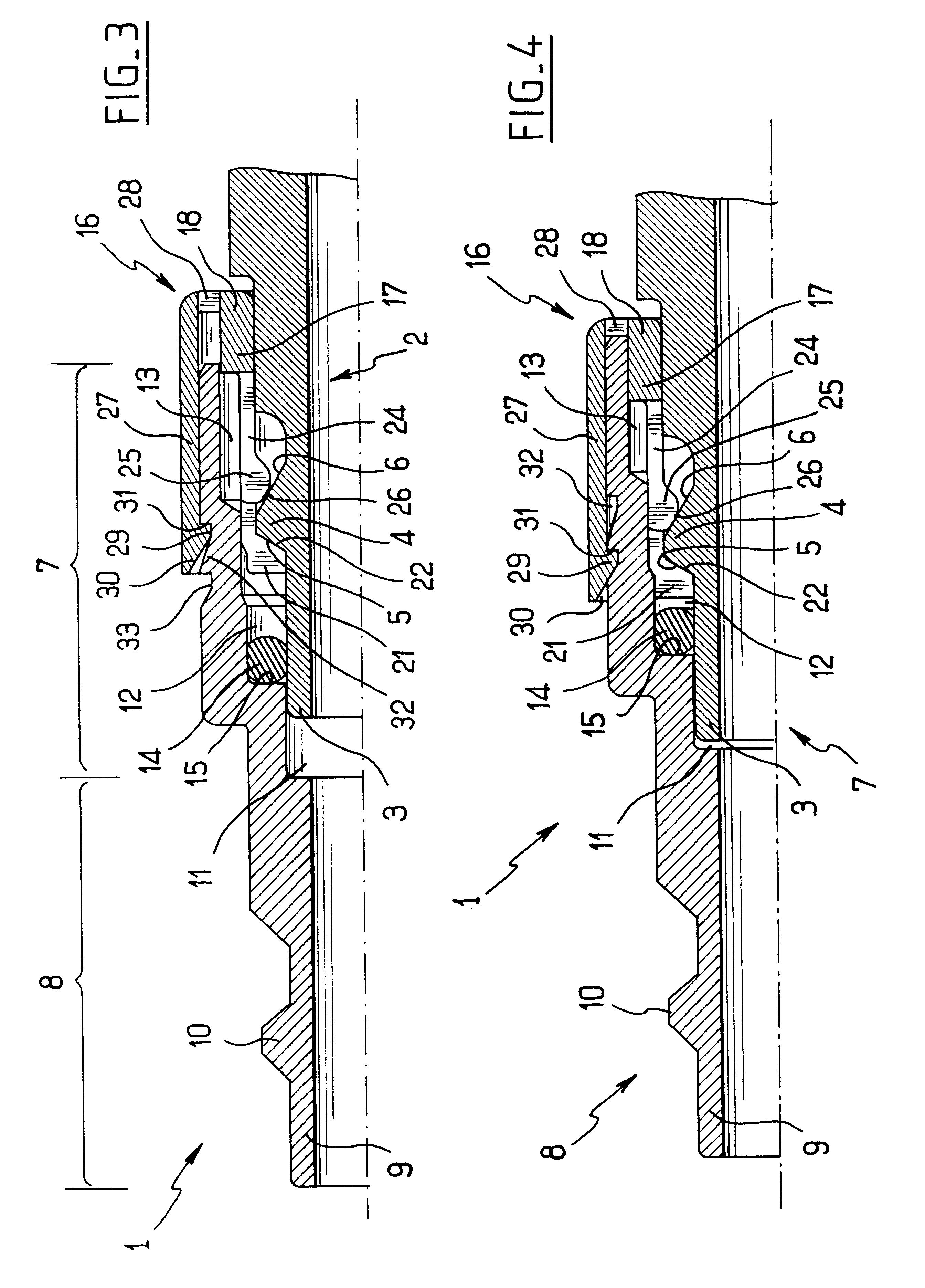

Vacuum cleaner hose with a connection sleeve

InactiveUS6722904B2Avoid seal failureSuction hosesInsulated cablesElectrical conductorVacuum cleaner

A vacuum cleaner hose with a connection sleeve includes a hose (1) having an inner wall, a protective envelope (2) for electrical conductors (3) attached at an inner wall of the hose (1), a rear connection part (4a) formed at a connection sleeve (4) and engaging partially into the hose (1), a receiver (4b) extending from the rearward end of the connection sleeve (4) and formed for an insertion of a coordinated end of the protective envelope (2), wherein an end of the receiver (4b) is disposed opposite to an end for insertion and is closed. The receiver (4b) is formed as a tube molded to the inner jacket face of the rear connection part (4). The tube exhibits a first recess (4d) directed rearwardly from the closed end of the tube.

Owner:TRUPLAST KUNST STOFFTECHNIK GMBH

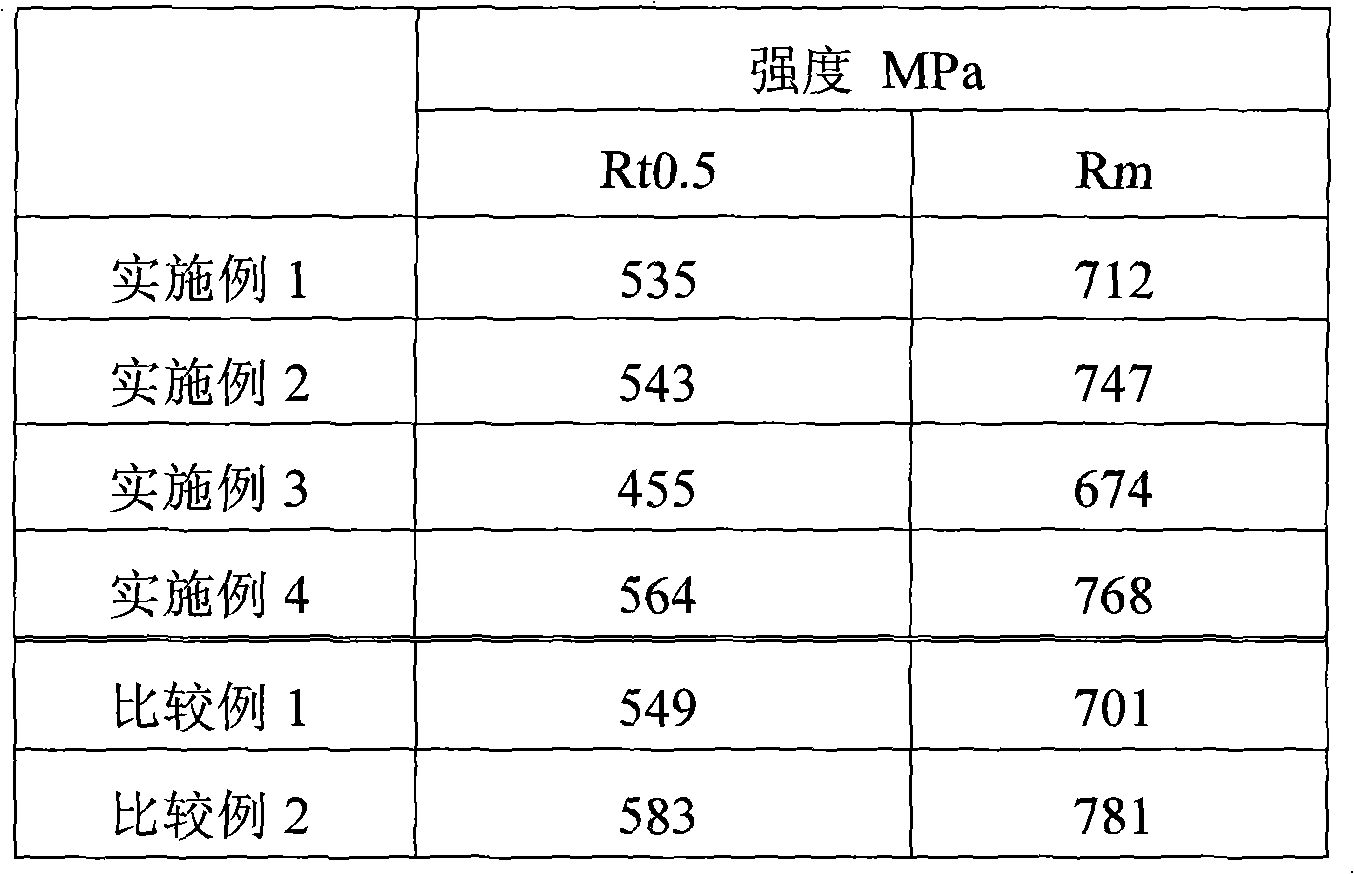

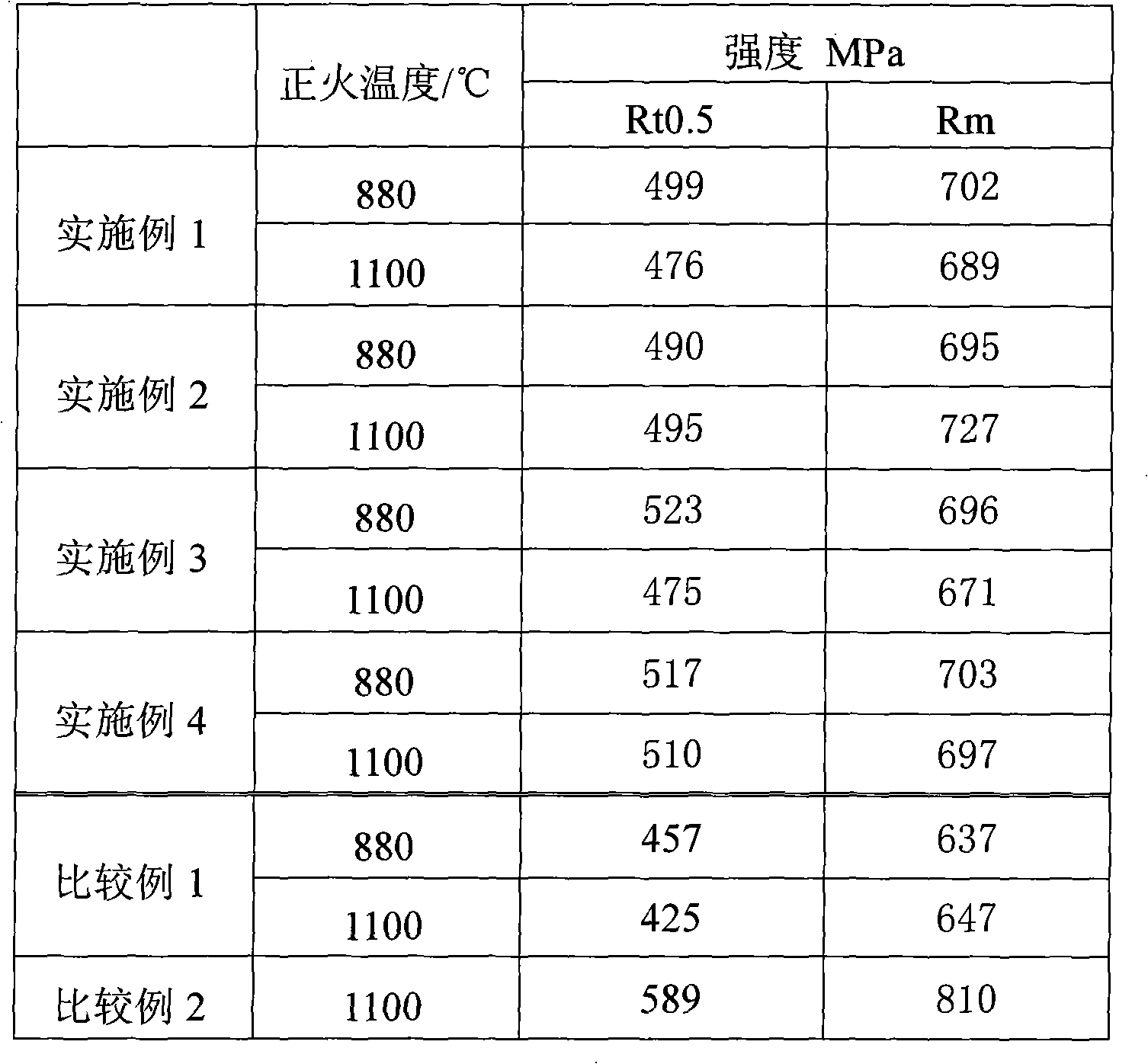

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654AHigh strengthImprove toughnessFurnace typesProcess efficiency improvementWeld seamElectric resistance welding

The invention relates to a steel used for straight seam electric resistance welding petroleum casing and a casing manufacturing method, which is applied to a straight seam electric resistance welding petroleum casing used for an oil and gas well in petroleum and gas industry. The steel used for the straight seam electric resistance welding petroleum casing comprises the following components in percentage by mass: 0.15-0.28% of C, 1.0-1.6% of Mn, 0.2-0.4% of Si, 0. 02-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, 0.001-0.005% of Ca and the balance of Fe. The preparation method comprises the steps of: preparing hot-rolled plate coils, producing straight seam electric resistance welding steel pipes by the hot-rolled plate coils, carrying out welding seam normalization or overall normalization on the welded steel pipes, straightening and cutting the normalized or tempered welded steel pipes into pipe segments with the length of 10-12m, and processing API standard screw threads. The invention has the advantages that the steel has good strength and toughness, the welding seam has no defect, and the properties of the steel are uniform with those of mother material. The yield strength is greater than or equal to 380-760MPa, the tensile strength is greater than or equal to 520-865MPa, the elongation is greater than or equal to 20%, and the impact energy of a room-temperature transverse full-size V-shaped notch is greater than or equal to 40J.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

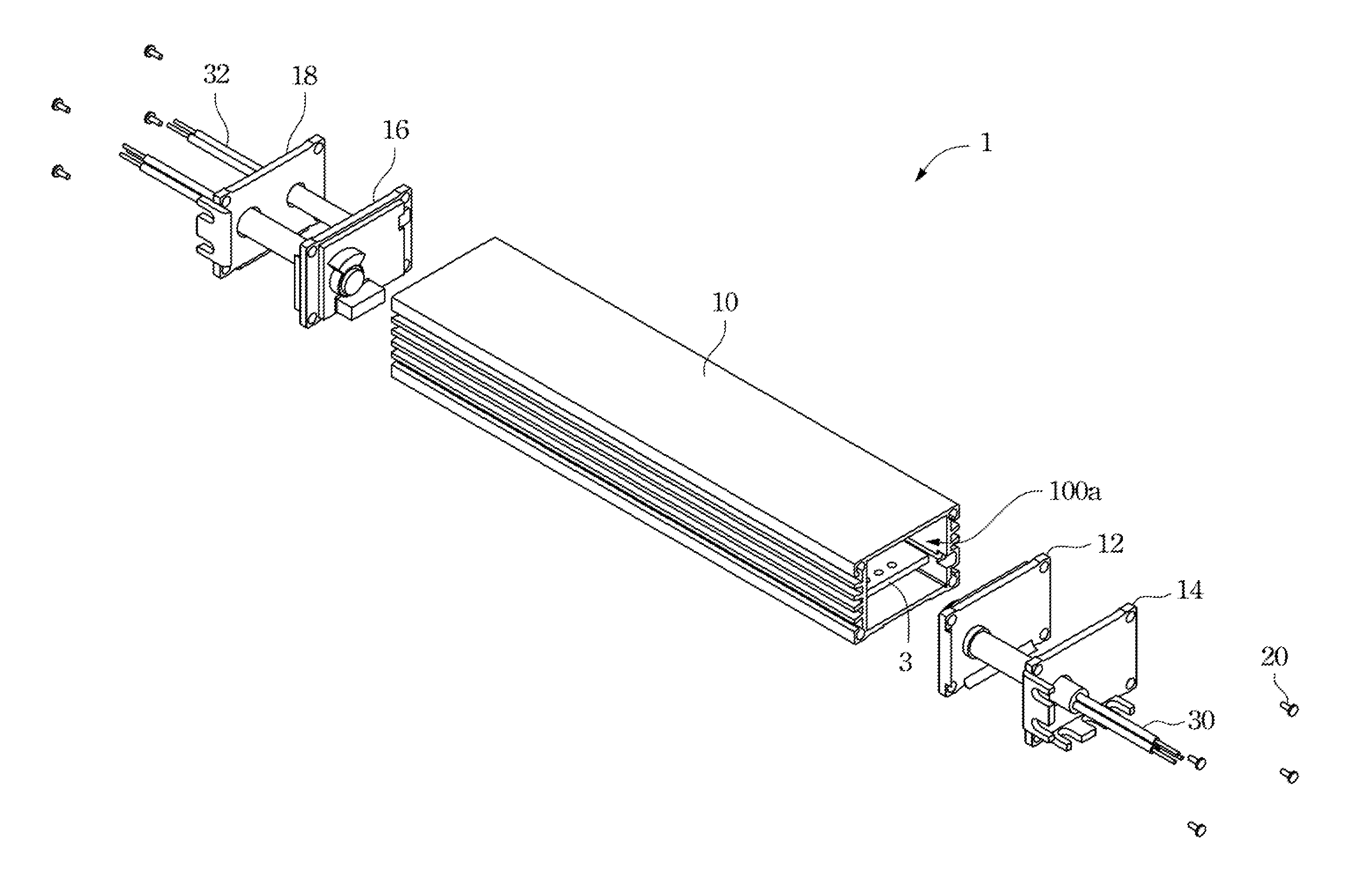

External structure of outdoor electronic apparatus

An external structure of an outdoor electronic apparatus for packaging a circuit board having a power line is provided. The external structure includes a housing having an opening and a waterproof gasket. The waterproof gasket includes a main body, a platform portion, a first protrusion, and a bushing portion. The main body covers the opening. The platform portion, located at the inner side of the main body, extends into the housing from the opening. The platform portion seals the opening and tightly fits with the housing. The first protrusion is located on the platform portion for abutting against the circuit board. The bushing portion, located at the outer side of the main body, has a channel. The channel passes through the main body and the platform portion and can be passed through by the power line. The bushing portion and the power line tightly fit to each other.

Owner:DELTA ELECTRONICS INC

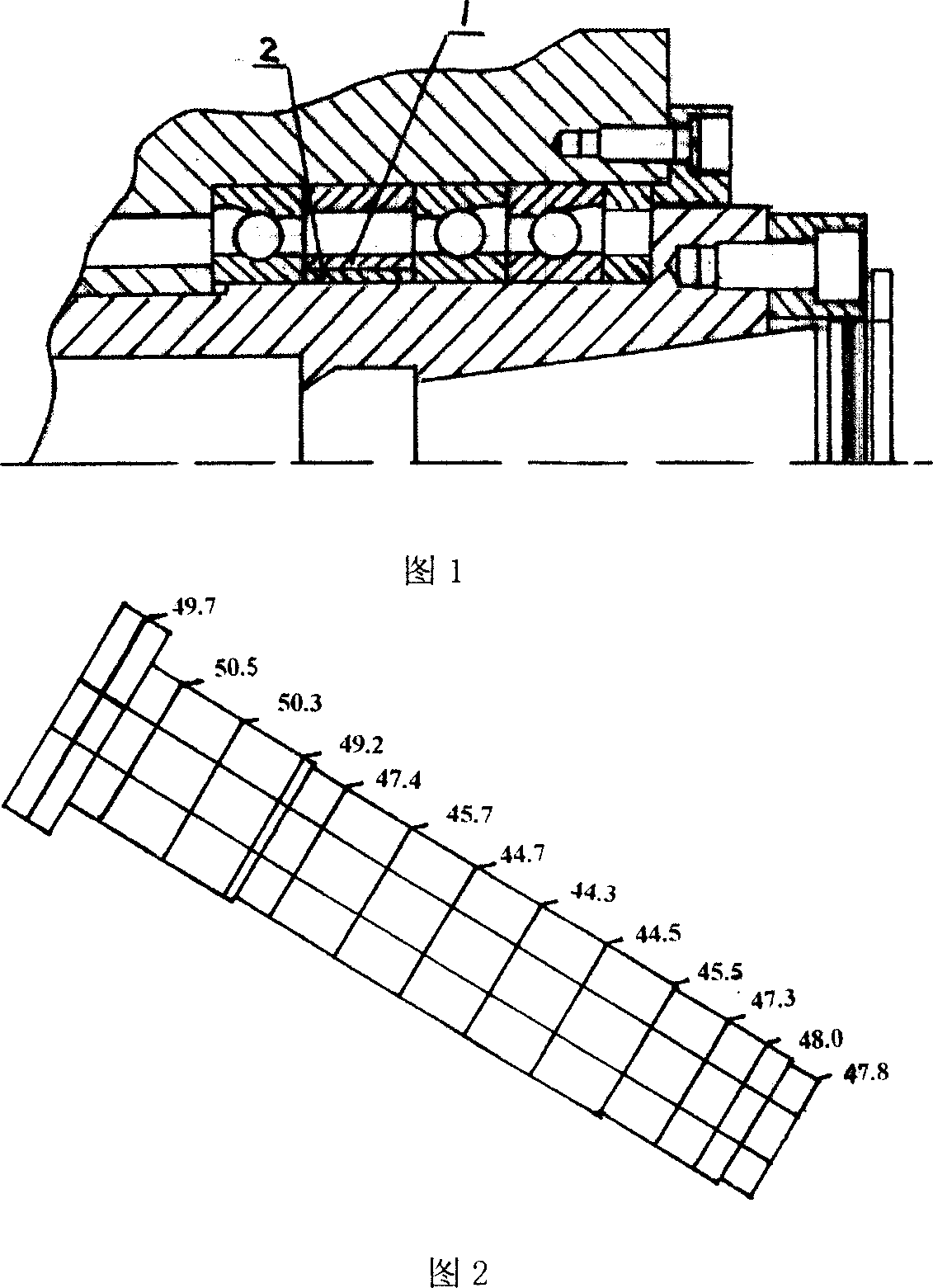

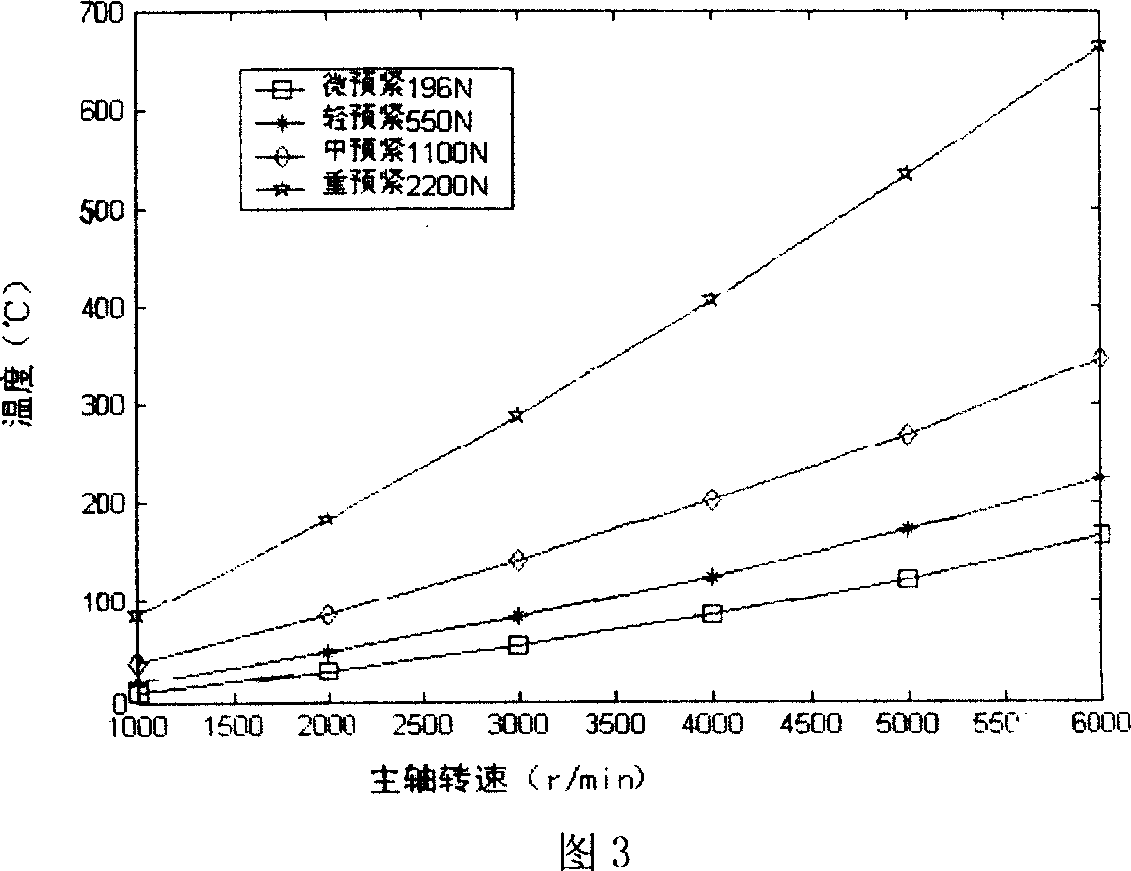

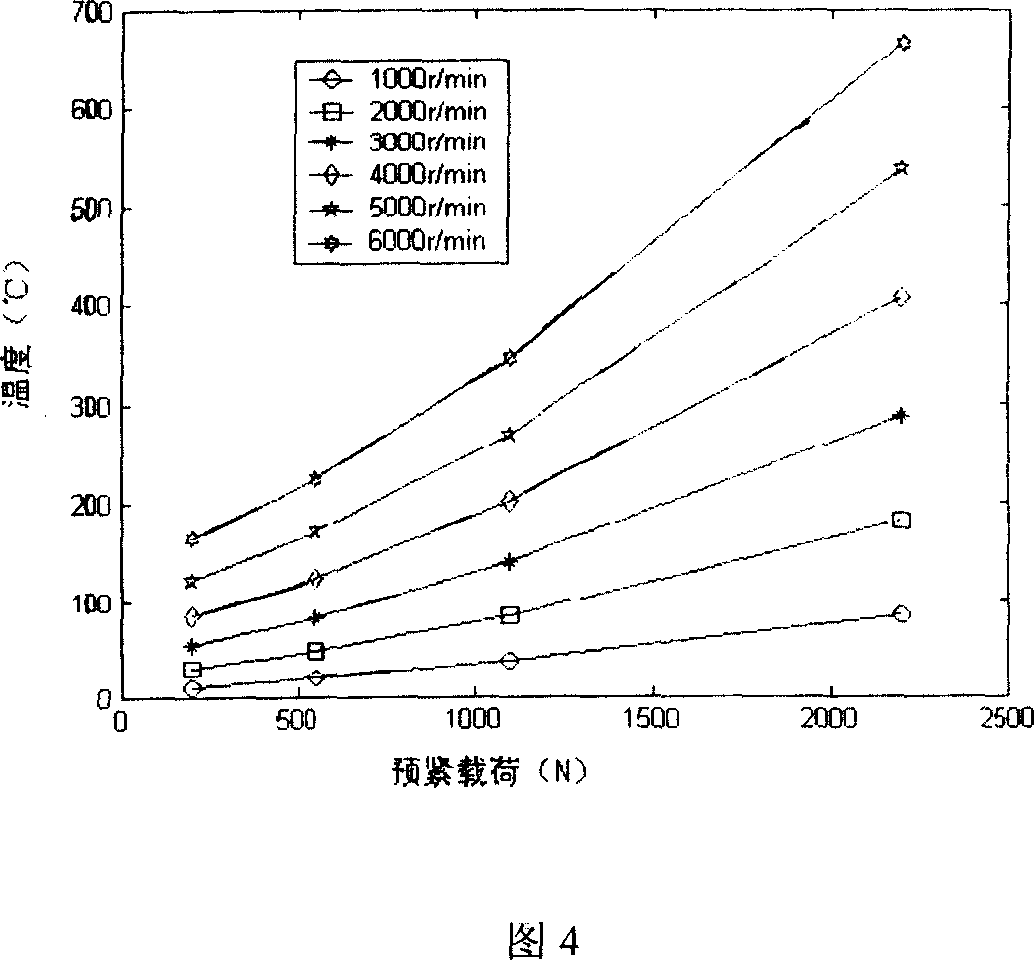

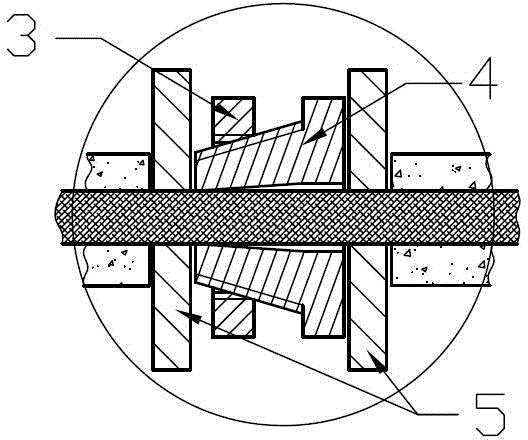

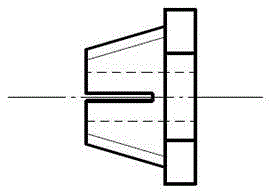

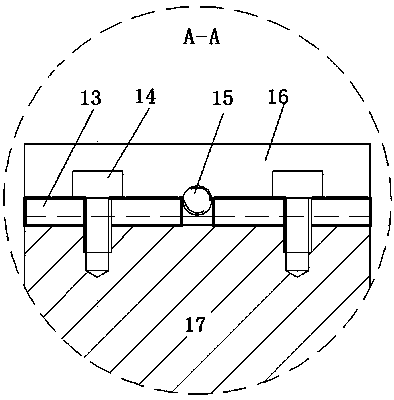

Method of regulating bearing pretightening force using heat characteristics of metal material and its device

InactiveCN1948775AAdjust the preloadEffective adjustment of preloadMilling equipment detailsBearing unit rigid supportMetallic materialsEngineering

The inventive method consists in: modeling for thermal analysis of heating and temperature rise of the main shaft, using a cylindrical-coordinate system for the temperature distribution of the axially symmetric structure and determining the boundary condition; calculating friction heat and power loss of front and back bearings of main shaft in a state of different speeds and different pretightening forces; determining the relation of axial shifting of the bearing with the pretightening forces; according to the above calculated data, choosing material for making double-layer bushing and making length different double-layer bushing size of the sleeve because the extension volume of the bushing heat expansion depends on the length of the sleeve.

Owner:北京机械工业学院

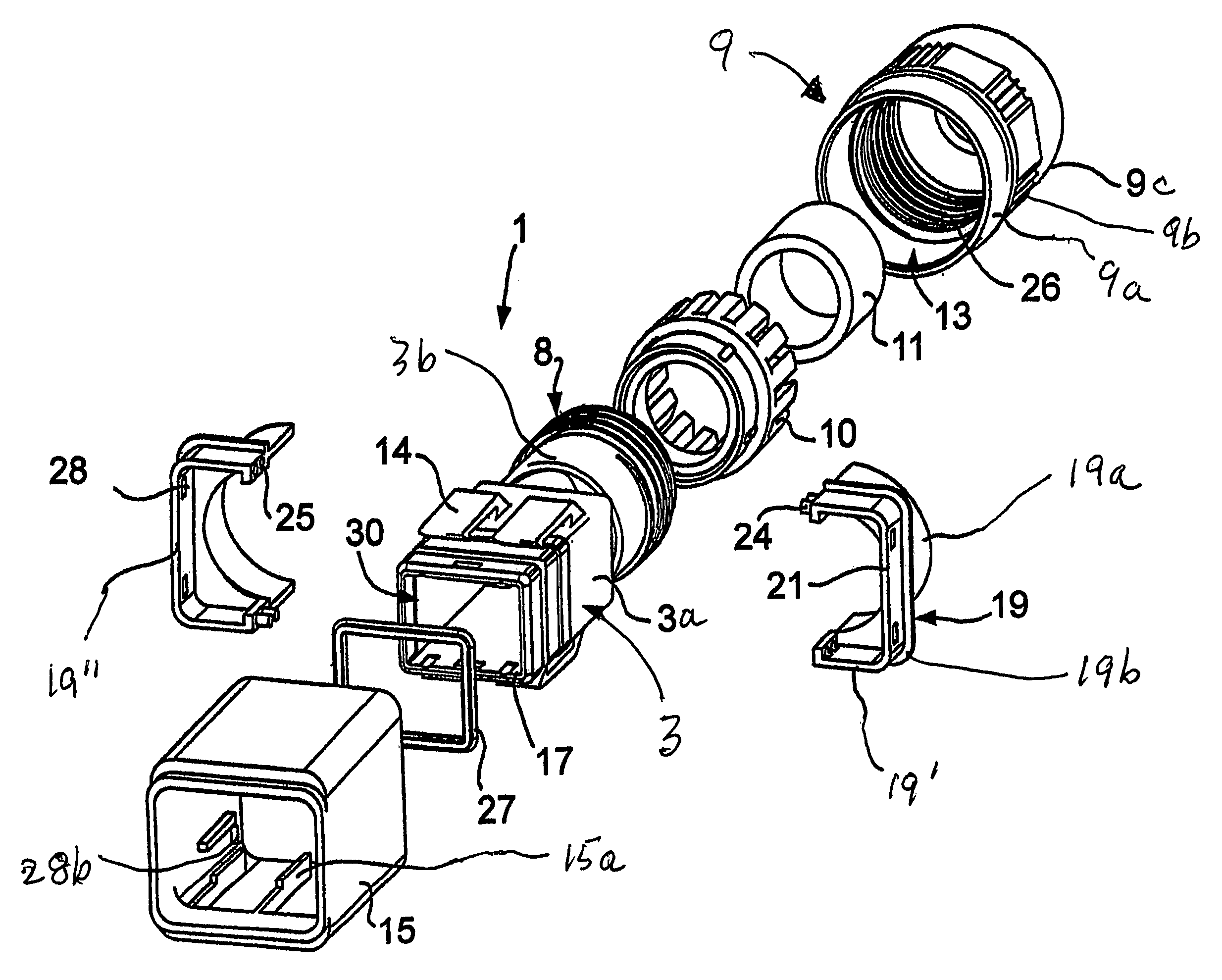

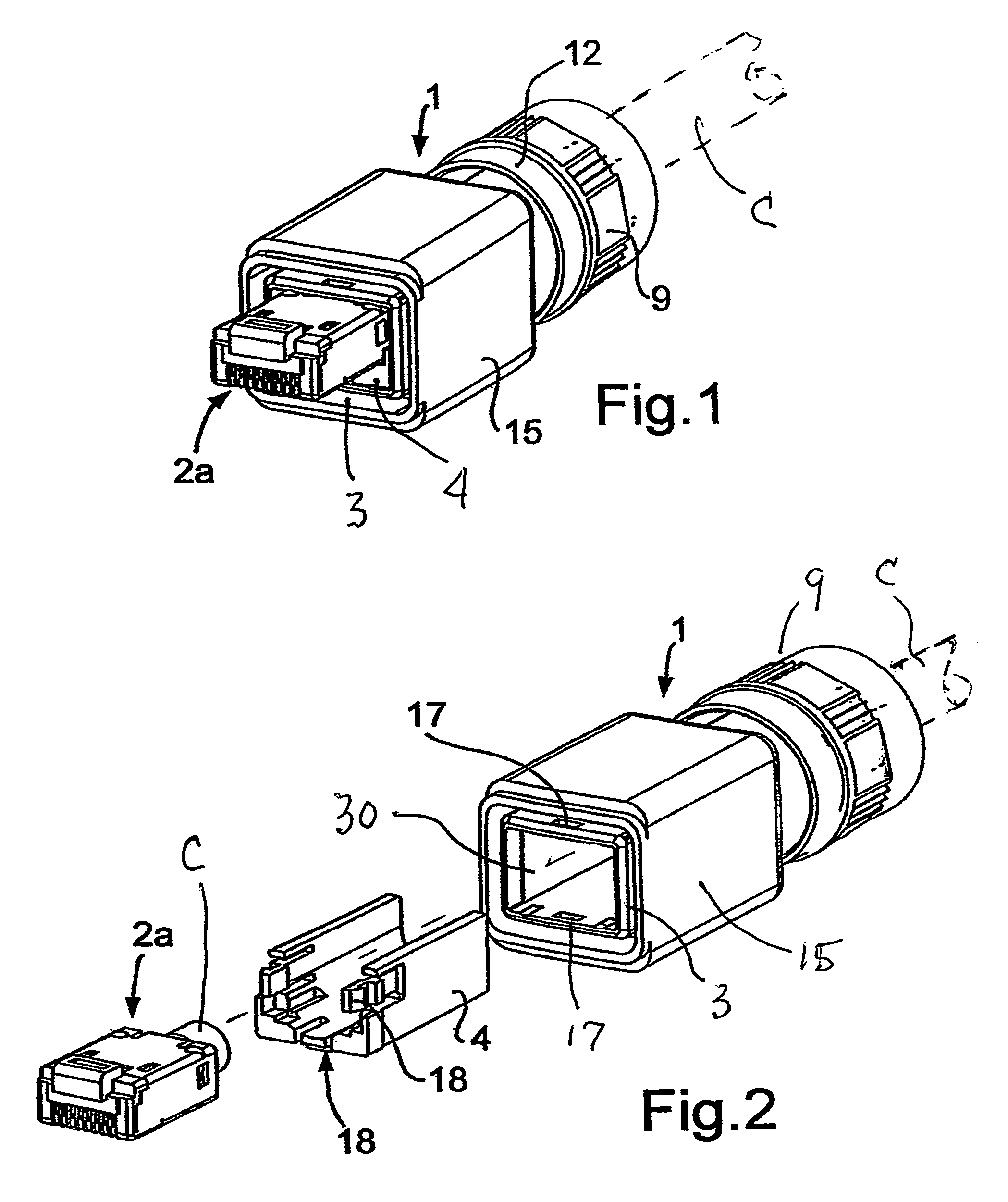

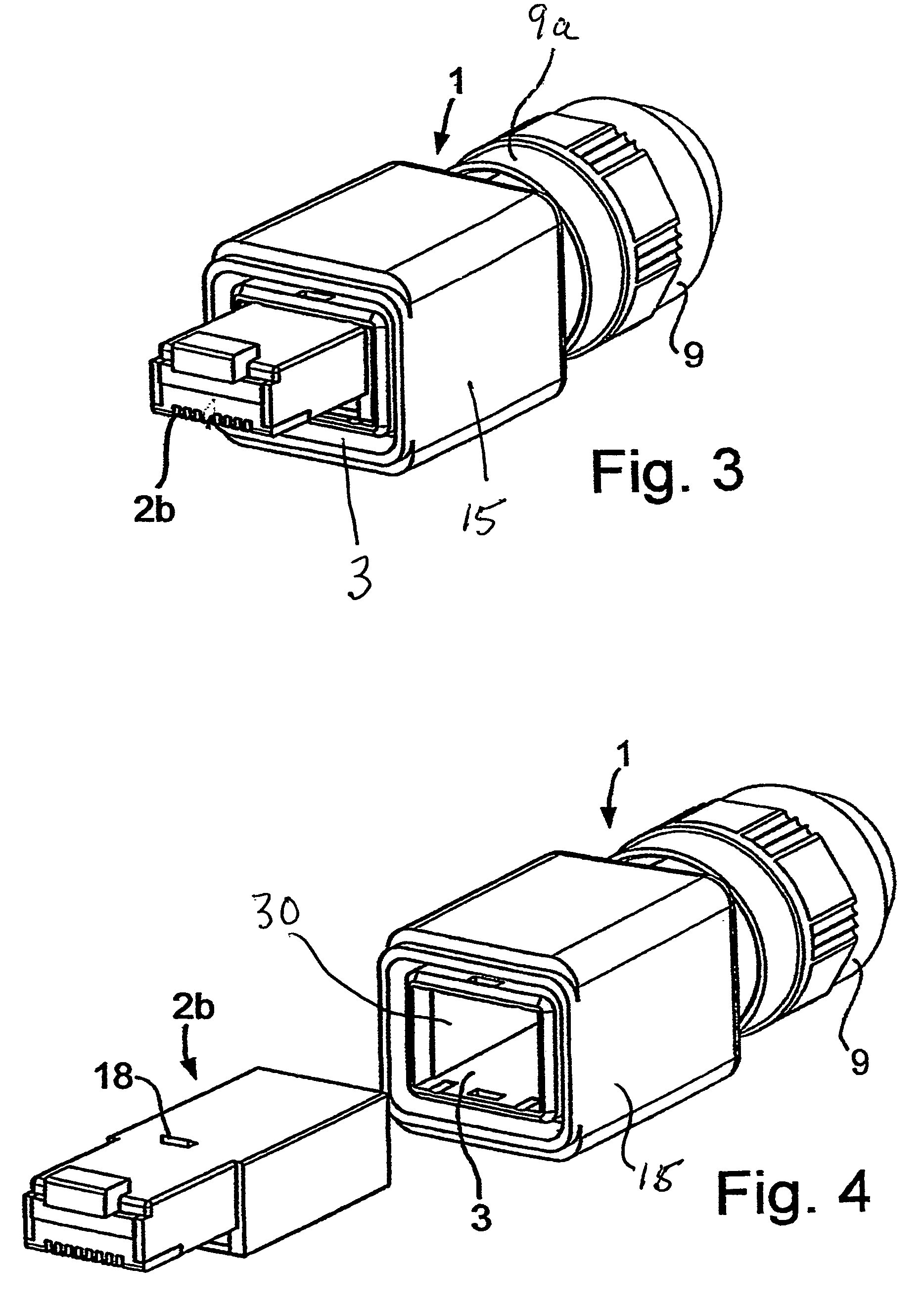

Adapter for attaching an insertion device to a cable fitting

InactiveUS7367832B2High degreeEasy to insertEngagement/disengagement of coupling partsTwo-part coupling devicesInsertion deviceElectric cables

Owner:WEIDMULLER INTERFACE GMBH & CO KG

High-temperature superconductive cable insulation electrical characteristic test device

ActiveCN101387672ABreakdown field strengthEasy to useElectrical testingMachines/enginesHigh-temperature superconductivityThermal insulation

The invention provides a ultra-high temperature superconductive cable insulation electric character tester, comprising a low temperature pressure thermal insulation controller provided with a cover board, a hole at the center of the cover board, an insulation sleeve penetrating through the hole, a vacuum connector mounted on the cover board, a connecting tube for filling liquid nitrogen and a connecting tube for adding pressure which are mounted on the cover board, a test electrode in the low temperature pressure insulation container, and a conductive bar in the insulation sleeve, of which the upper end is connected with high voltage and the lower end is connected with the high voltage end of the test electrode. The ultra-high temperature superconductive cable insulation electric character tester can improve the electric property of the insulation material of a high temperature superconductive cable, under low temperature liquid nitrogen temperature, having simple operation.

Owner:SHANGHAI INT SUPERCONDUCTION TECH CO LTD

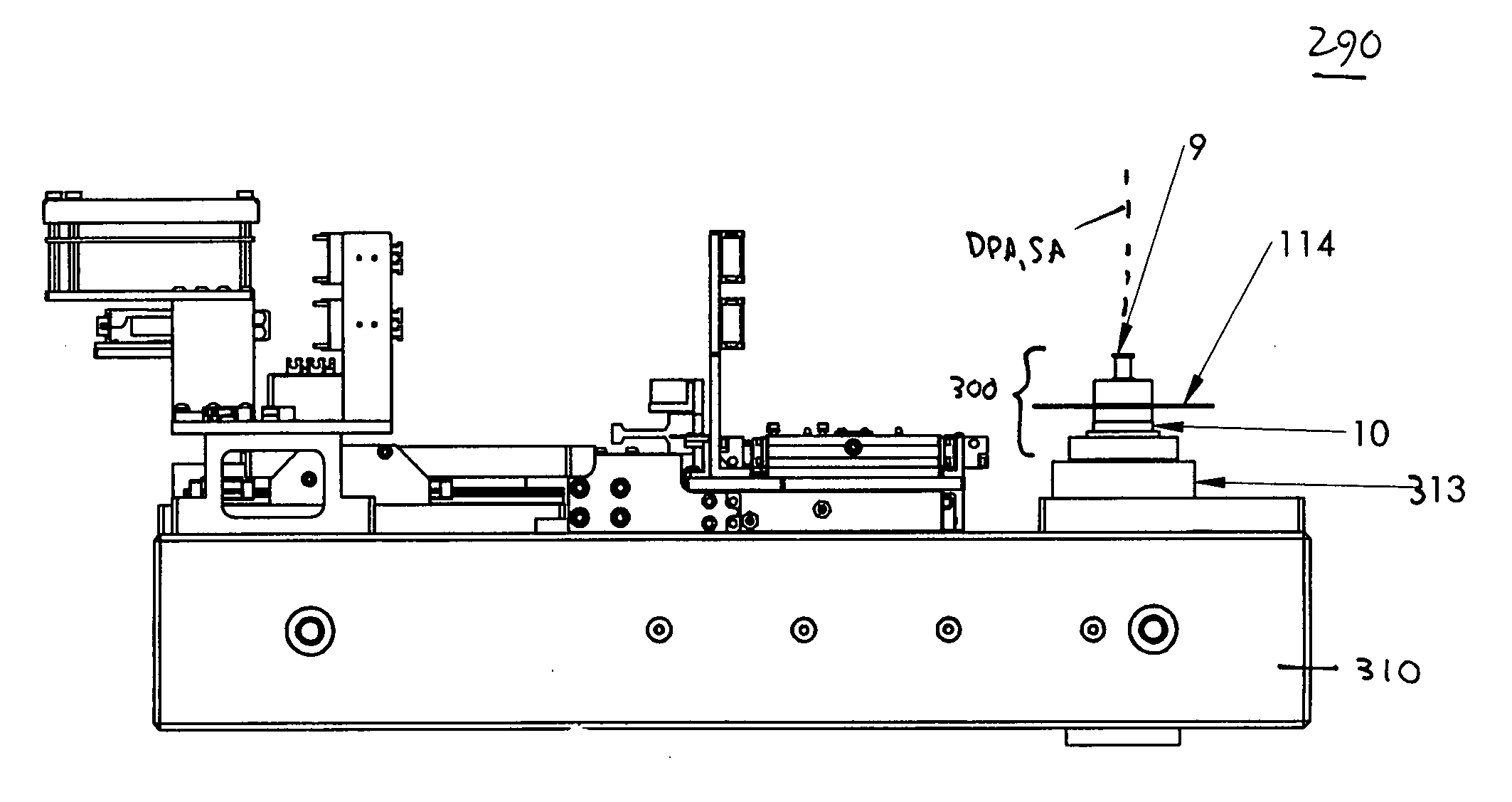

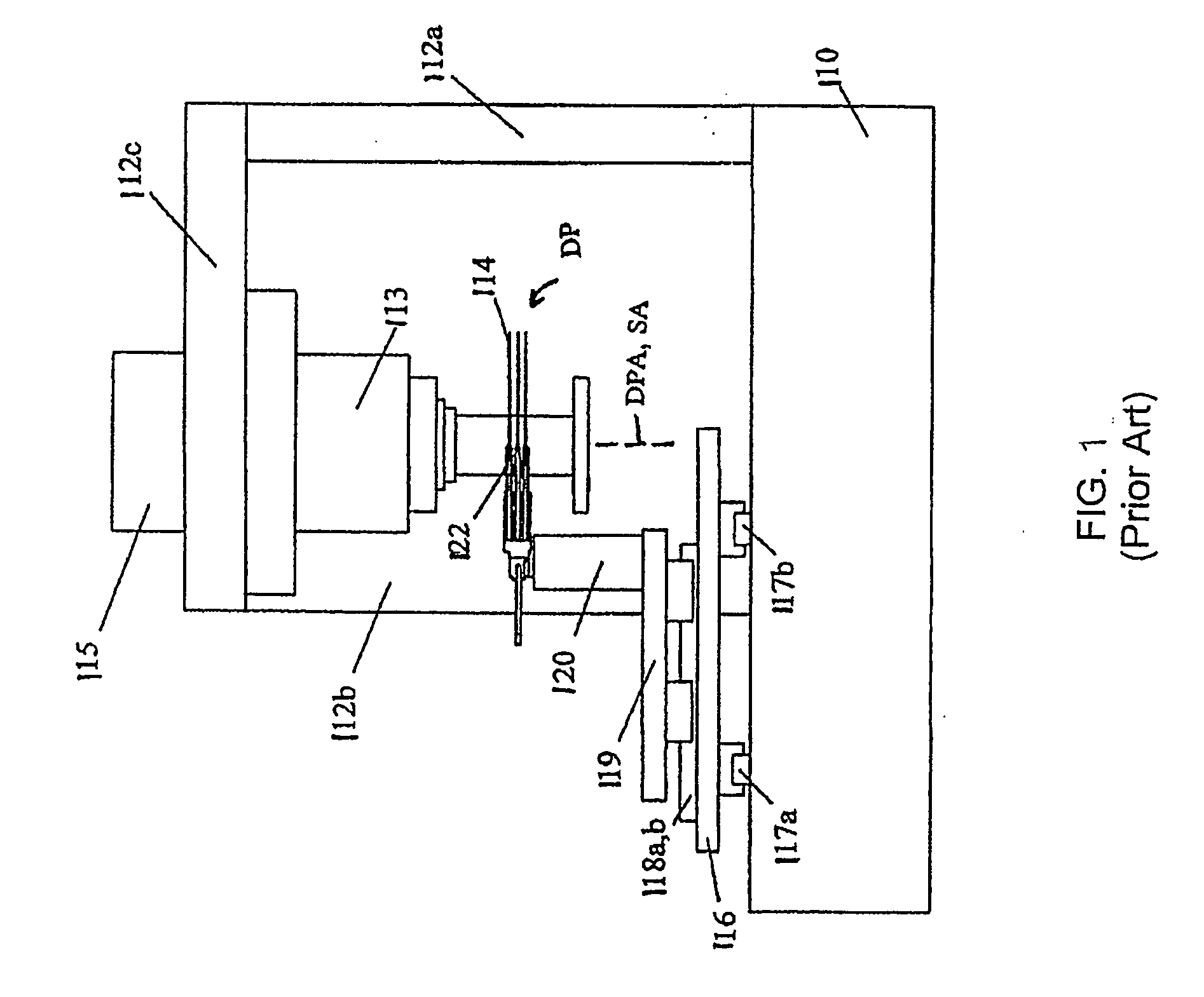

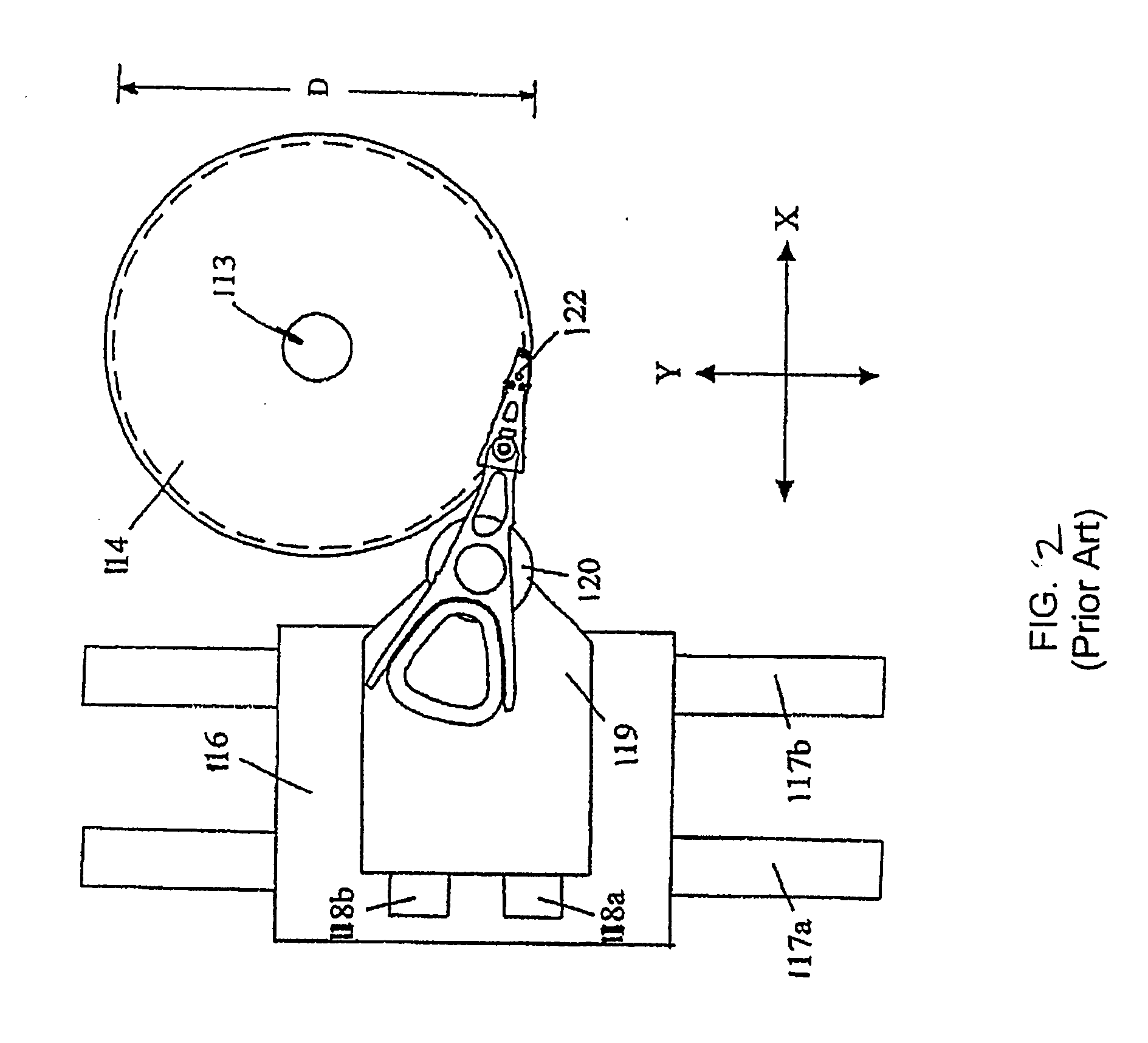

Vacuum chuck spinstand for testing magnetic heads and disks

InactiveUS20070018640A1Quickly and accurately centerQuickly removeMagnetic property measurementsRecord information storagePistonMagnetic disks

A spinstand having a vacuum chuck clamping mechanism for securing magnetic discs includes a cap (9) and a base (10). A disk-to-be-clamped is held between the cap (9) and the base (10). Vacuum, applied through a port (4) in a mounting screw (12) of the base, provides the clamping force. The vacuum is held constant using a circumferential seal (27) on a piston (2) of the cap, which extends into a cylindrical countering bushing (3) extending from the base. In one form, the cap (9) is centered about a spin axis (SA) extending through the base (10), using a hardened pin (1) extending from the cap and a locating bushing (19) affixed to the base. When the cap (9) is inserted into the base (10), the pin (1) prevents a piston (2) in the cap from contacting the inside walls / sealing surface (11) of the centering bushing (3) of the base. To remove the cap, positive air pressure is applied to the air passage (4), collapsing the seal (27), and forcing the cap (9) out of the base (10) without causing wear on the seal (27) or the sealing surface (11) of the centering bushing (3).

Owner:GUZIK TECHN ENTERPRISES

Leadless and free-cutting phosphorus-brass alloy and manufacturing method thereof

The invention provides a lead-free cutting-free alloy and a preparation method thereof. The components (weight percentage) of the alloy are: more than 97.0 but not equal to 99.5 of (copper + zinc), more than 35.0 of zinc, 0.4-1.6 of phosphor and 0.005-0.6 of at least two other elements selected from aluminum, silicon, antimony, stannum, lanthanon, titanium and boron, the balance being zinc and impurities, wherein, the zinc content is more than 35.0 (weight percentage). The invention also provides a preparation method for the lead-free cutting-free high phosphor brass alloy. The alloy of the invention has excellent machinability, castibility, welding property, dezincification corrosion resisting property, formability and mechanical property, and is particularly suitable for forged pieces and low-pressure cast castings needing cutting processing, grinding processing (polish), welding and plating, such as hydrants, valve bodies and bushings in a water supply system.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

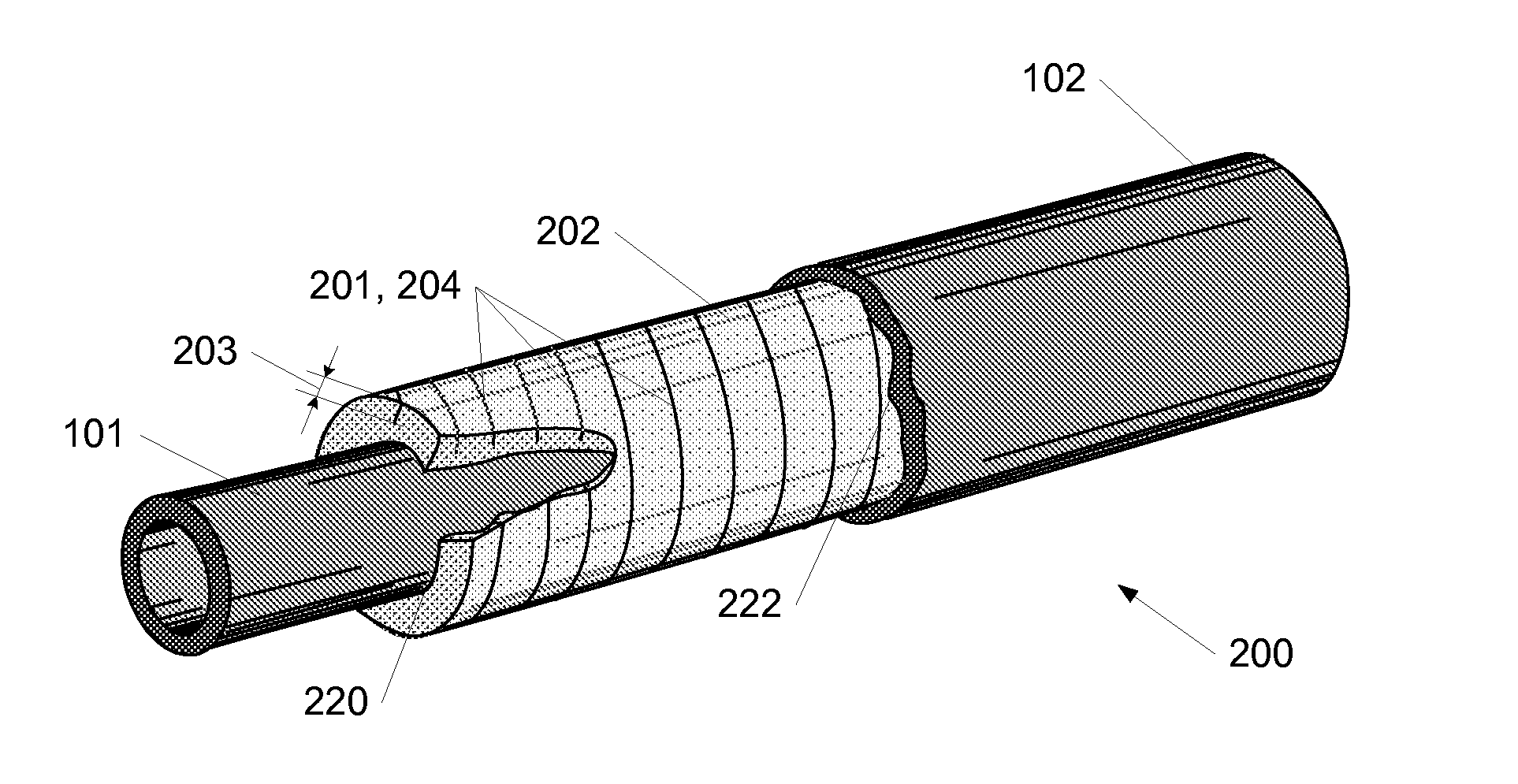

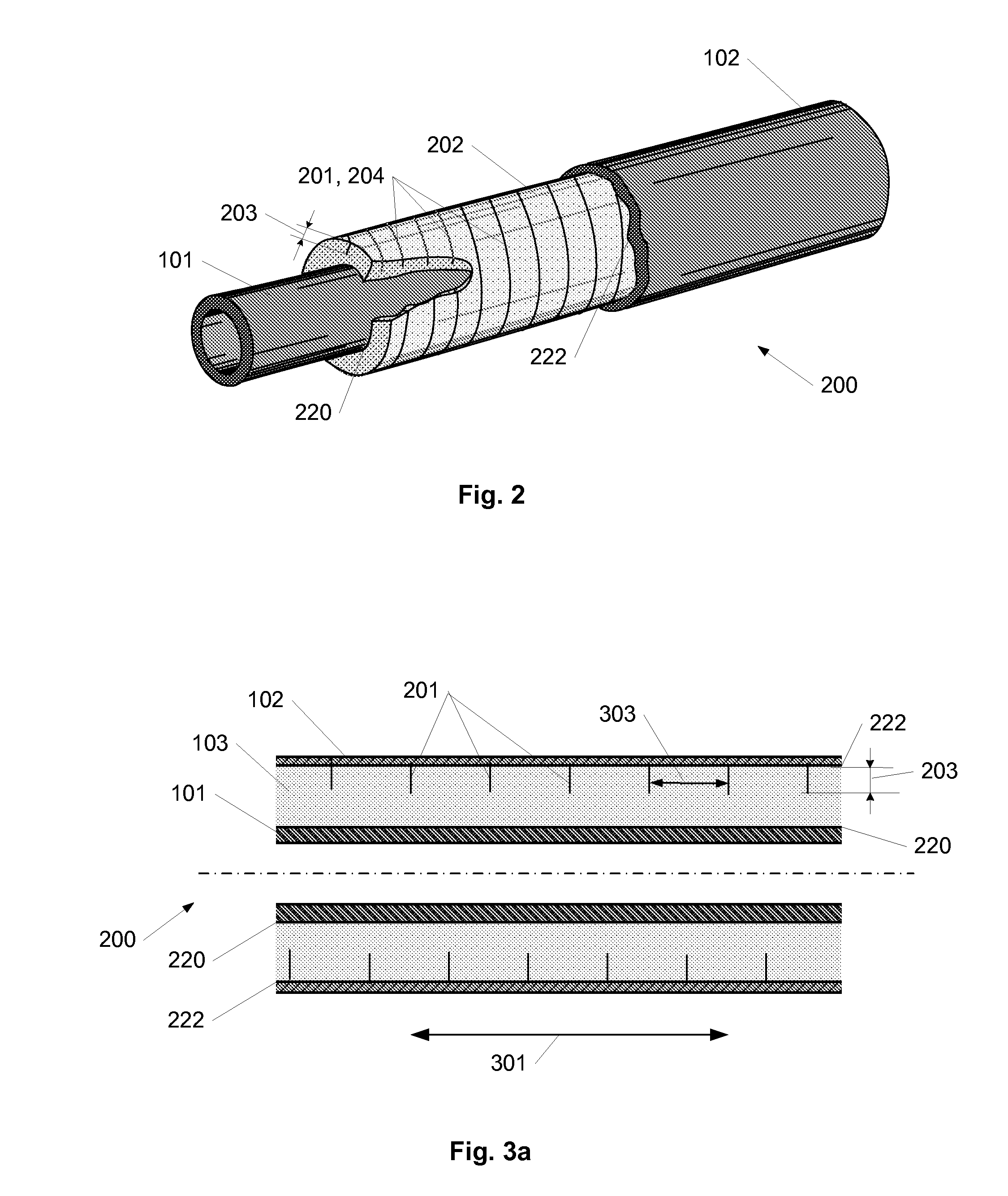

Bendable Pre-Insulated Pipeline Assembly

ActiveUS20100260551A1Improve bending performanceFaster and less involved method of installationPipe laying and repairThermal insulationThermal insulationEngineering

This invention relates to a pipeline assembly especially for offshore installation comprising an inner carrier pipe, a casing and at least one closed-cell and / or solid thermal insulation material layer placed in between the casing and the inner carrier pipe, and the at least one insulation layer being directly or indirectly bonded to at least the casing and the inner carrier pipe. The pipeline assembly has improved bending properties which is achieved as the insulation material layer comprises at least one slit substantially transversely to the longitudinal direction of the pipeline assembly. The slit can be applied as a helical or circumferential cut, enabling the pipeline assembly to be rolled onto a reel or spool which greatly improves the pipeline assembly installation process. Methods of improving the bending properties of such a pipeline assembly are also described.

Owner:LOGSTOR

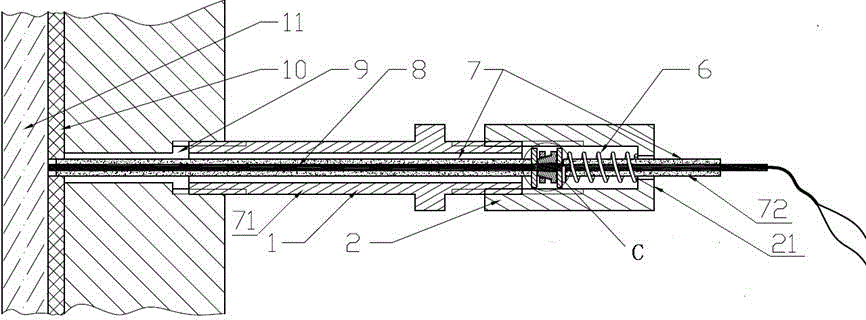

Thermocouple insulation locator, mounting method thereof and wall temperature measuring device

InactiveCN104089715AAvoid damagePrecise positioningThermometer detailsThermometers using electric/magnetic elementsMeasurement deviceArchitectural engineering

The invention discloses a thermocouple insulation locator, a mounting method of the locator and a wall temperature measuring device. The thermocouple insulation locator comprises a self-tightness locating bolt fixed to a thermal coupler, a locating nut connected to the self-tightness locating bolt, a first insulation casing pipe, a second insulation casing pipe, a locating guide pipe and a pushing and pressing nut, wherein the first insulation casing pipe and the second insulation casing pipe are arranged on the two sides of the self-tightness locating bolt and are arranged on the thermal coupler in a sleeved mode, the first insulation casing pipe is sleeved with the locating guide pipe, and the pushing and pressing nut is arranged on the second insulation casing pipe in a sleeved mode and is in threaded connection with the rear end of the locating guide pipe. An end cover is arranged at the rear end of the pushing and pressing nut, and insulation blocking pieces are arranged between the self-tightness locating bolt and the two insulation casing pipes, a pushing and pressing spring is arranged between the insulation blocking piece at the rear end of the self-tightness locating bolt and the end cover arranged at the rear end of the self-tightness locating bolt in a sleeved mode, and the second insulation casing pipe is sleeved with the pushing and pressing spring. According to the thermocouple insulation locator, the thermal coupler can be precisely located to the measuring point, it is ensured that the thermal coupler is insulated from other components except a measured device, and small vibration and migration of the measured device in the channel direction of the thermal coupler can be borne.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

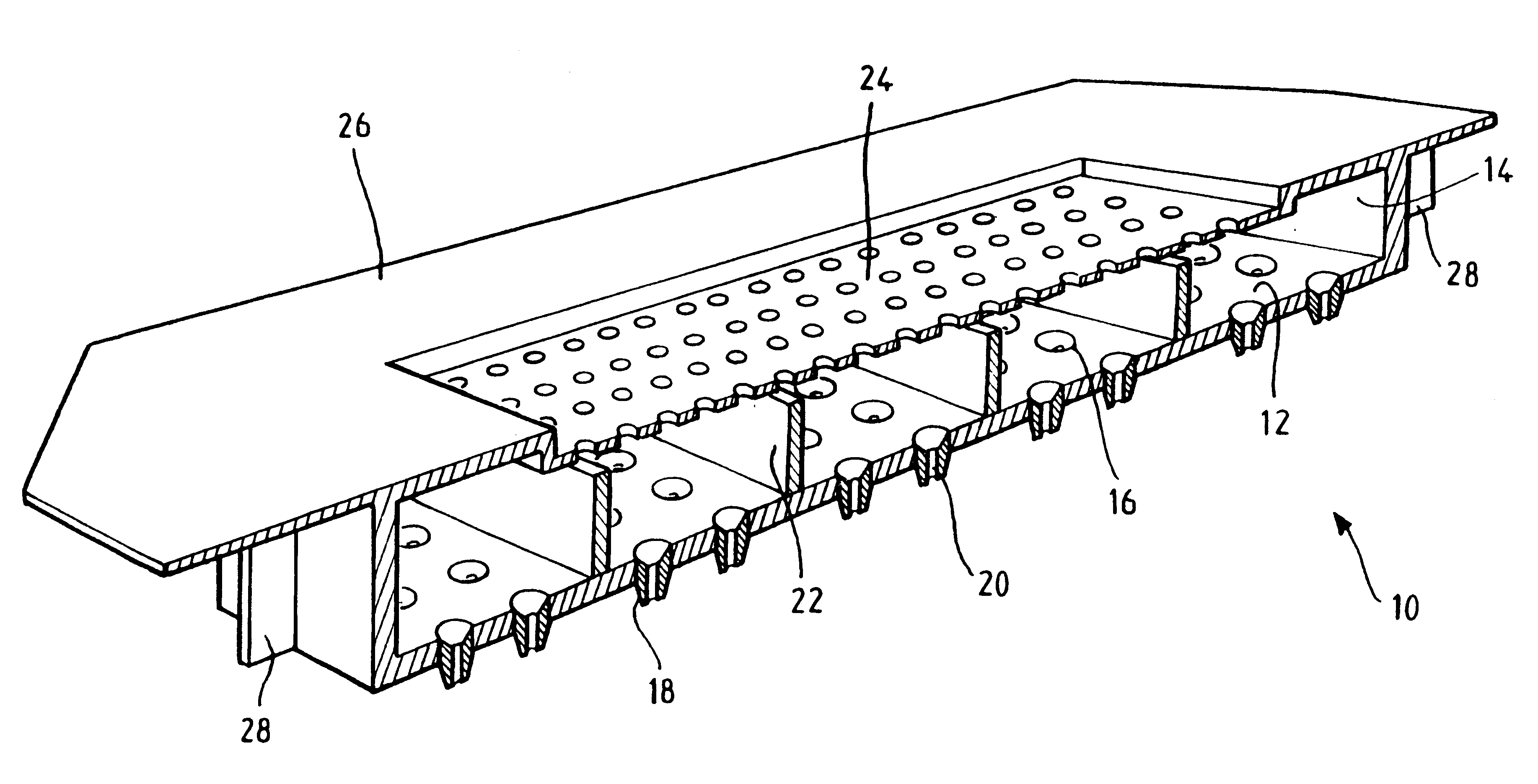

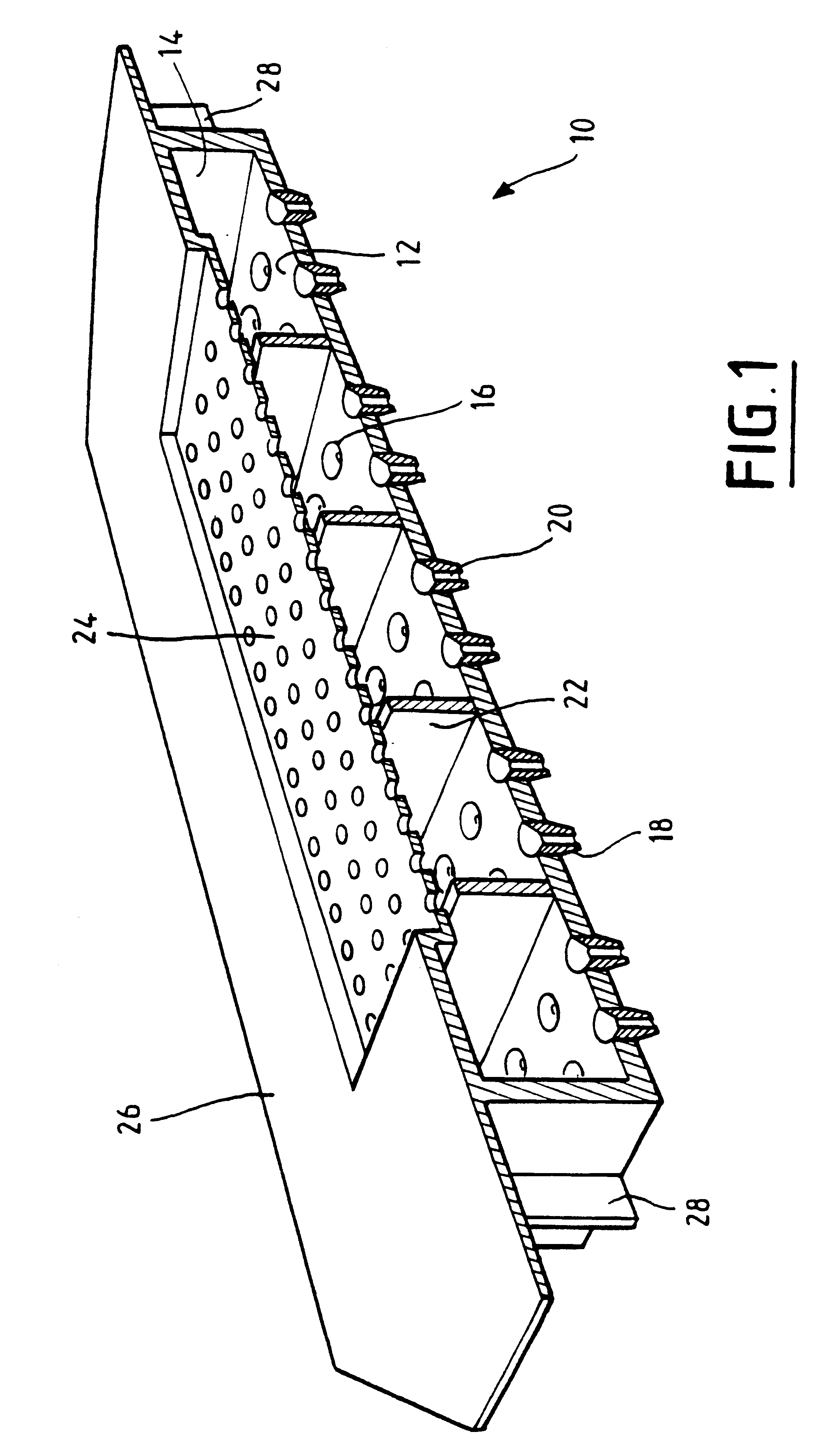

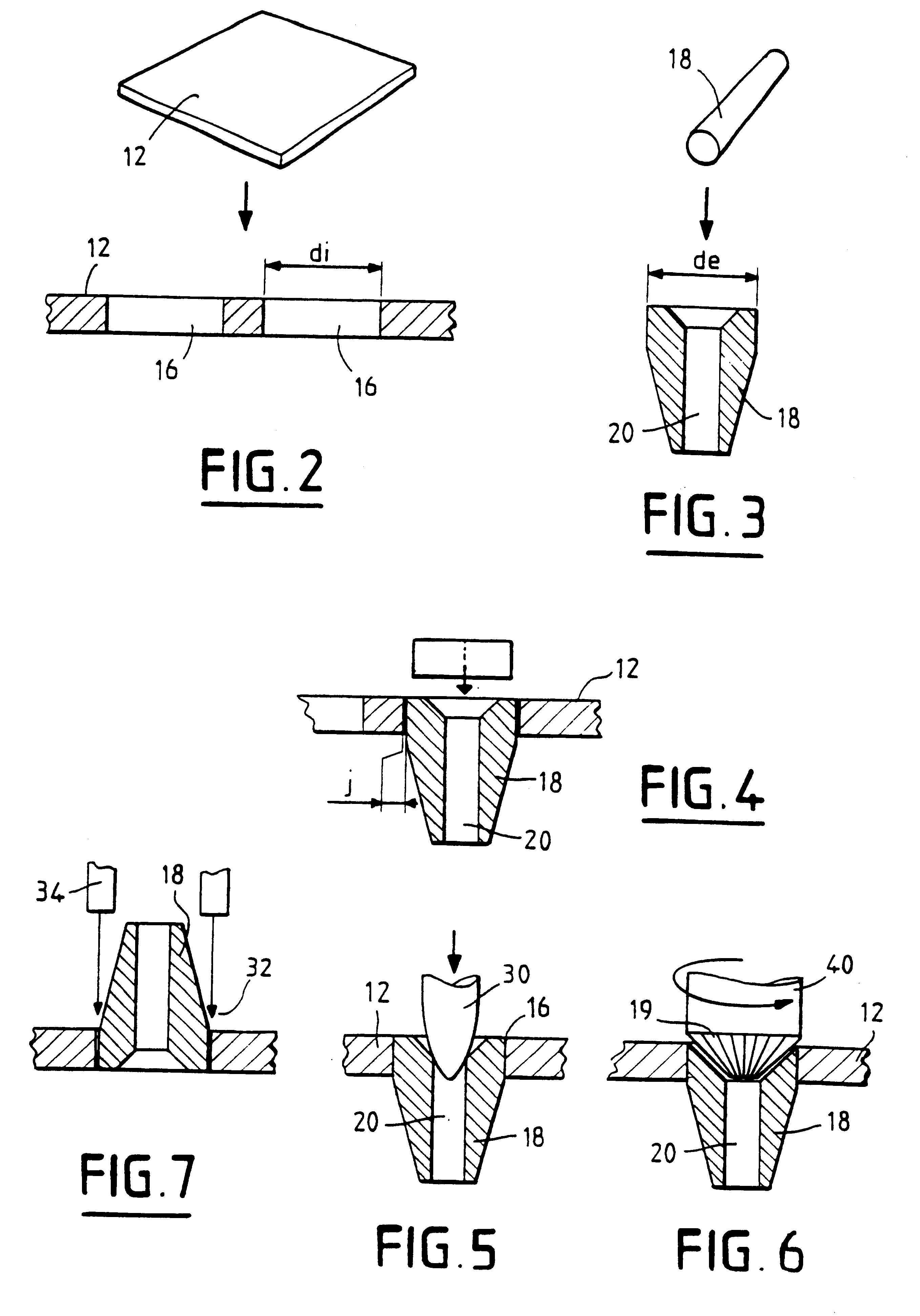

Bushing base with mounted nozzles

The invention relates to a method of manufacturing a bushing baseplate, and to a bushing baseplate. The bushing baseplate is characterized in that it comprises tips (18) constituted by hollow tubular elements of outside diameter slightly smaller than the inside diameter of holes (16) in the plate (12) forming the bushing baseplate, which tips are subjected to a step of being expanded radially relative to their axes. The method is simpler and less expensive.

Owner:ENGELHARD CLAL SAS

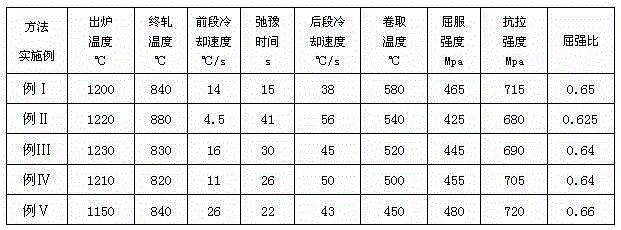

Normalized steel for resistance welding petroleum case pipe with low yield ratio, resistance welding casing tube and its manufacturing method

ActiveCN101270438ASimple processStable mechanical propertiesDrilling rodsTemperature control devicePetroleumCalcium

The invention provides an air hardening steel for oil casing with low yield ratio electrical resistance welding (ERW), an oil casing with low yield ratio electrical resistance welding which is made of the air hardening steel and a preparation method of oil casing. The components of the air hardening steel for oil casing with low yield ratio electrical resistance welding (ERW) in weight percent comprises: 0.19 to 0.29 percent of Carbon, 0.1 to 0.4 percent of Silicon, 1.0 to 1.3 percent of Manganese, less than or equal to 0.015 percent of Phosphorus, smaller than 0.008 percent of Sulfur, 0.002 to 0.04 percent of Aluminum, 0.001 to 0.01 percent of Calcium, 0.08 to 0.14 percent of Vanadium, the remaining part is Ferrum and other inevitable purities. The air hardening steel of the chemical proportion is adopted, continuously casted to form blank, the normalizing heat treatment is carried out for the entire casing after ERW of casing, and then the oil casing with low yield ratio electrical resistance welding of the invention is fabricated out. The yield strength of the oil casing is between 379 to 552 Megapascal, the tensile strength is greater than or equal to 655 Megapascal, and the oil casing has the moderate carbon equivalent and the stable mechanical property of the entire casing.

Owner:BAOSHAN IRON & STEEL CO LTD

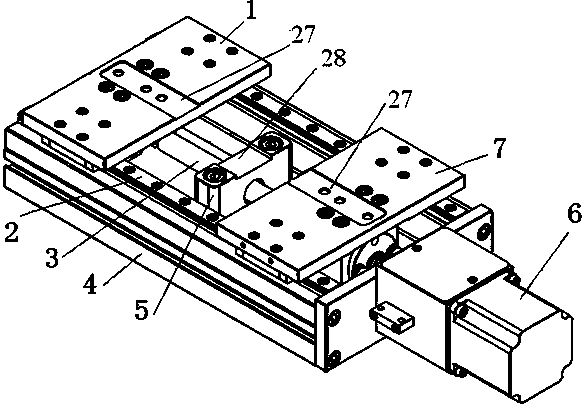

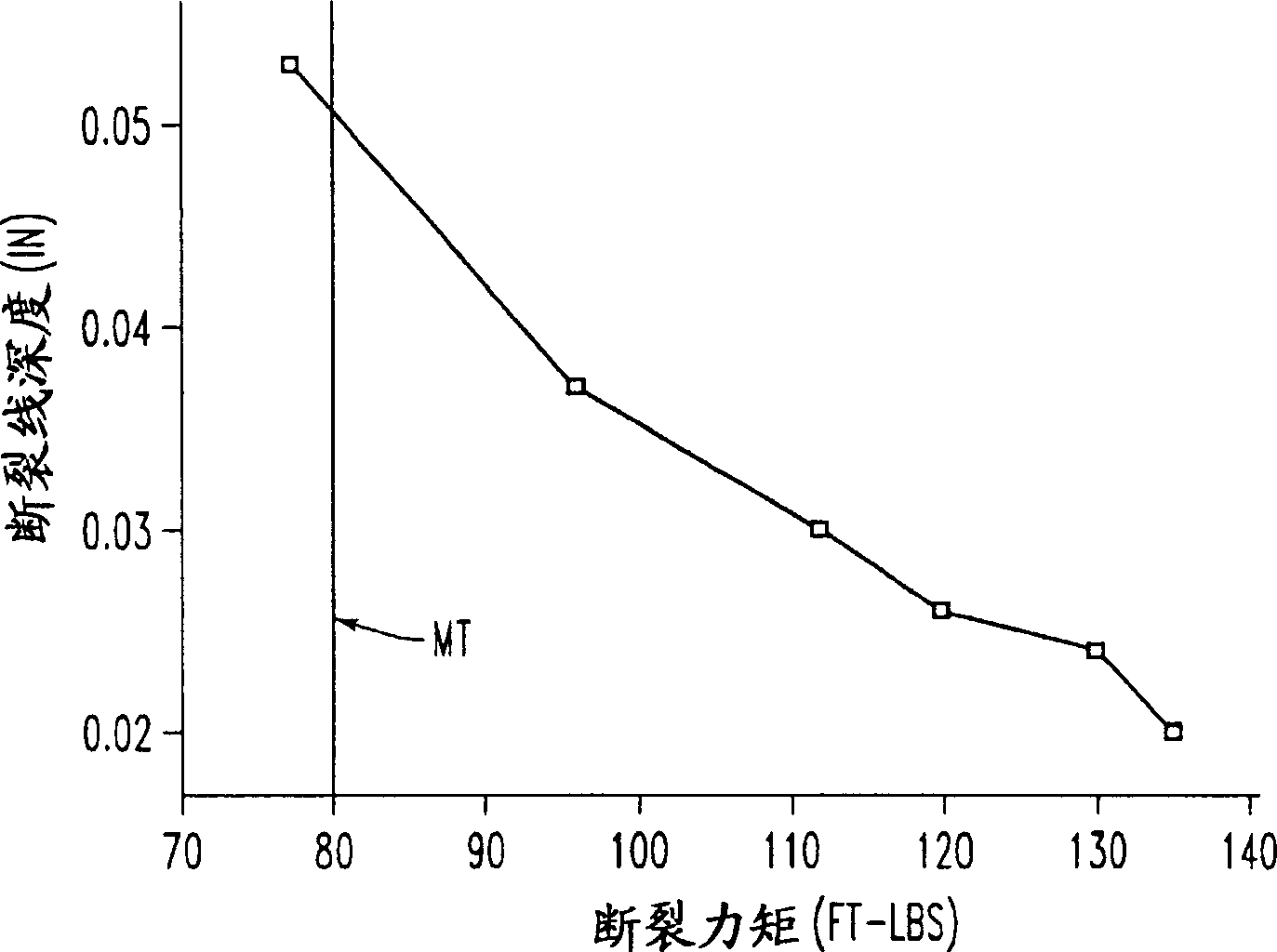

Drawing force detector and test method thereof

InactiveCN104111134AImprove test accuracyReduce biasMachine part testingApparatus for force/torque/work measurementReciprocating motionElectric machinery

The invention discloses a bidirectional drawing force detector for a precise bushing and a test method of the detector. The drawing force detector includes a pedestal, a slide rail arranged on the pedestal, a double-end leading screw, left and right sliding tables mounted on the leading screw, a stepping motor arranged at one end part of the leading screw, a clamp supporting seat arranged in a middle part of the pedestal, and a clamp arranged on the clamp supporting seat and used for fixing a ceramic bushing sample, the left and right sliding tables are fixedly equipped with two oppositely arranged detection heads, each detection head comprises a detection insertion core, a connecting part and a force sensor, the stepping motor can drive the double-end leading screw and drive the detection heads on the left and right sliding tables to perform centering insertion and pulling drawing force detection movement on the ceramic bushing workpiece on the clamp. The equipment is high in precision and small in vibration, a return reset limit switch of the stepping motor is arranged, deviation of the detection heads on the sliding tables in reciprocating motion is reduced, test precision of the drawing force detector is improved, and the drawing force detector can serve as an instrument for calibration of an automatic detection machine.

Owner:SHENZHEN POLYTECHNIC

Tool for metal plugging or sealing of casing

ActiveUS20180148991A1Great amount of materialImprove sealingSurveySolid-state devicesEngineeringMaterial Perforation

Owner:CONOCOPHILLIPS CO

Steel for expandable casing for oil well and manufacturing method thereof

ActiveCN101812631APerformanceAvoid easy crackingTemperature control deviceFurnace typesNumerical controlAlloy

The invention discloses steel for an expandable casing for an oil well and a manufacturing method thereof, and the manufacturing method is applied to preparing the expandable casing for the oil well for petroleum and gas industrial oil. The steel alloy material of the expandable casing for the oil well comprises the following components in percentage by weight: 0.08 to 0.2 percent of C, 1 to 2 percent of Mn, 0.15 to 0.35 percent of Si, 0.02 to 0.06 percent of Al, less than or equal to 0.01 percent of P, less than or equal to 0.05 percent of S, less than or equal to 0.08 percent of N, 0.001 to 0.005 percent of Ca, and the balance of Fe. The method for preparing the expandable casing for the oil well comprises the following steps of: preparing hot rolled steel coils; producing straight seam resistance welded steel pipes by using the hot rolled steel coils; normalizing welding lines after welding; and finally, cutting into welded steel pipes, and machining API standard threads or special threads at two ends of each welded steel pipe by using a numerical control machine. The steel for the expandable casing for the oil well has the advantages of excellent comprehensive performance such as expansion deformation capacity, intensity, toughness, and the like, no defect of the welding lines and uniform and consistent performance with base metals.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

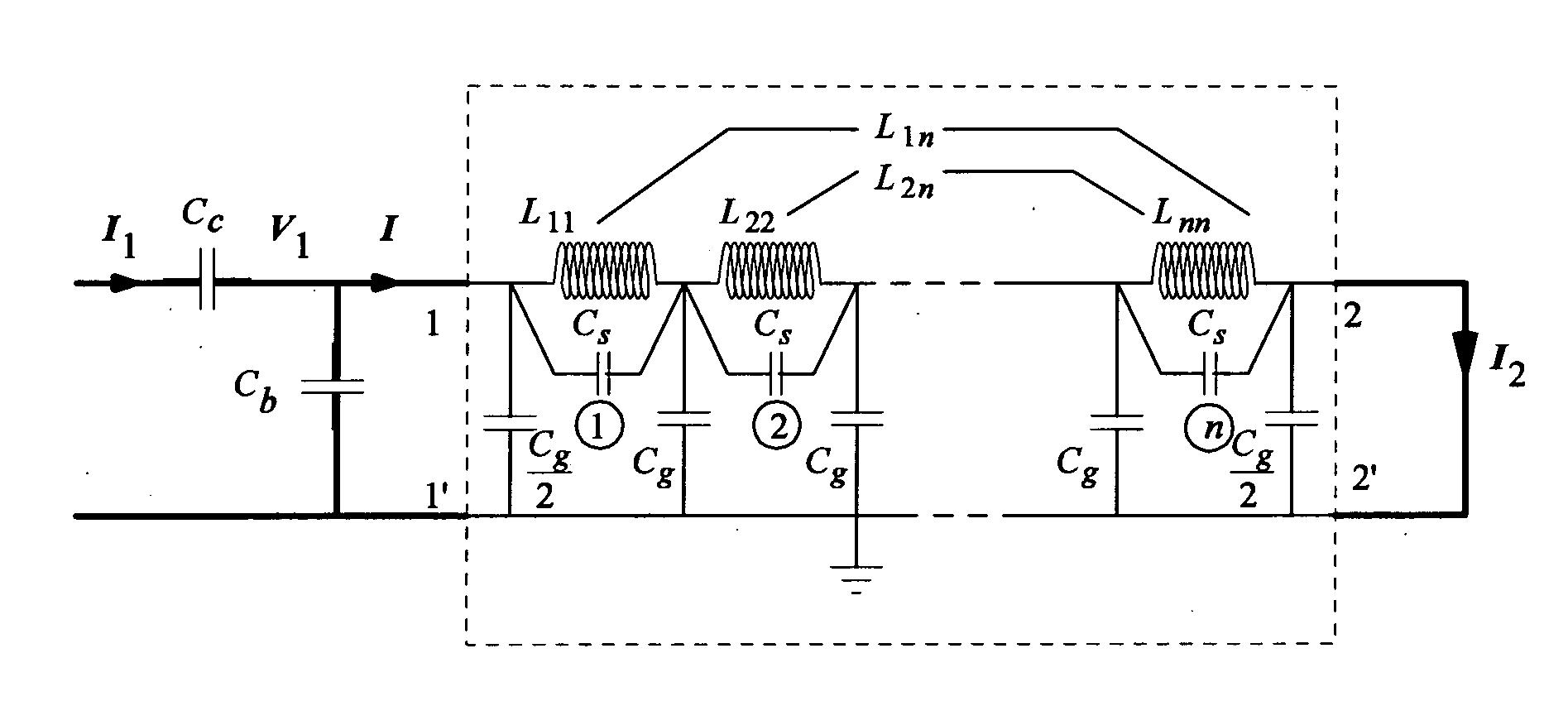

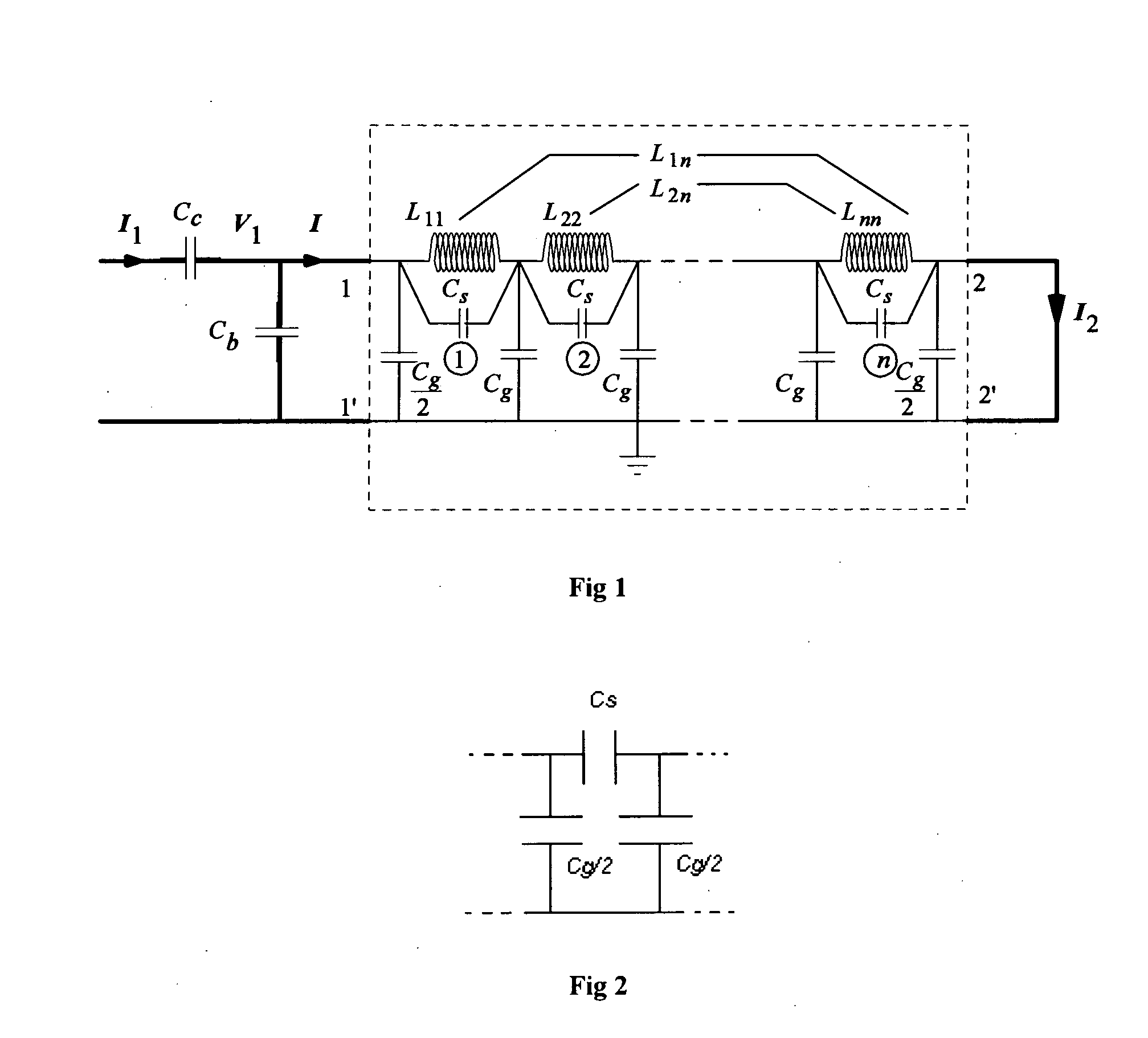

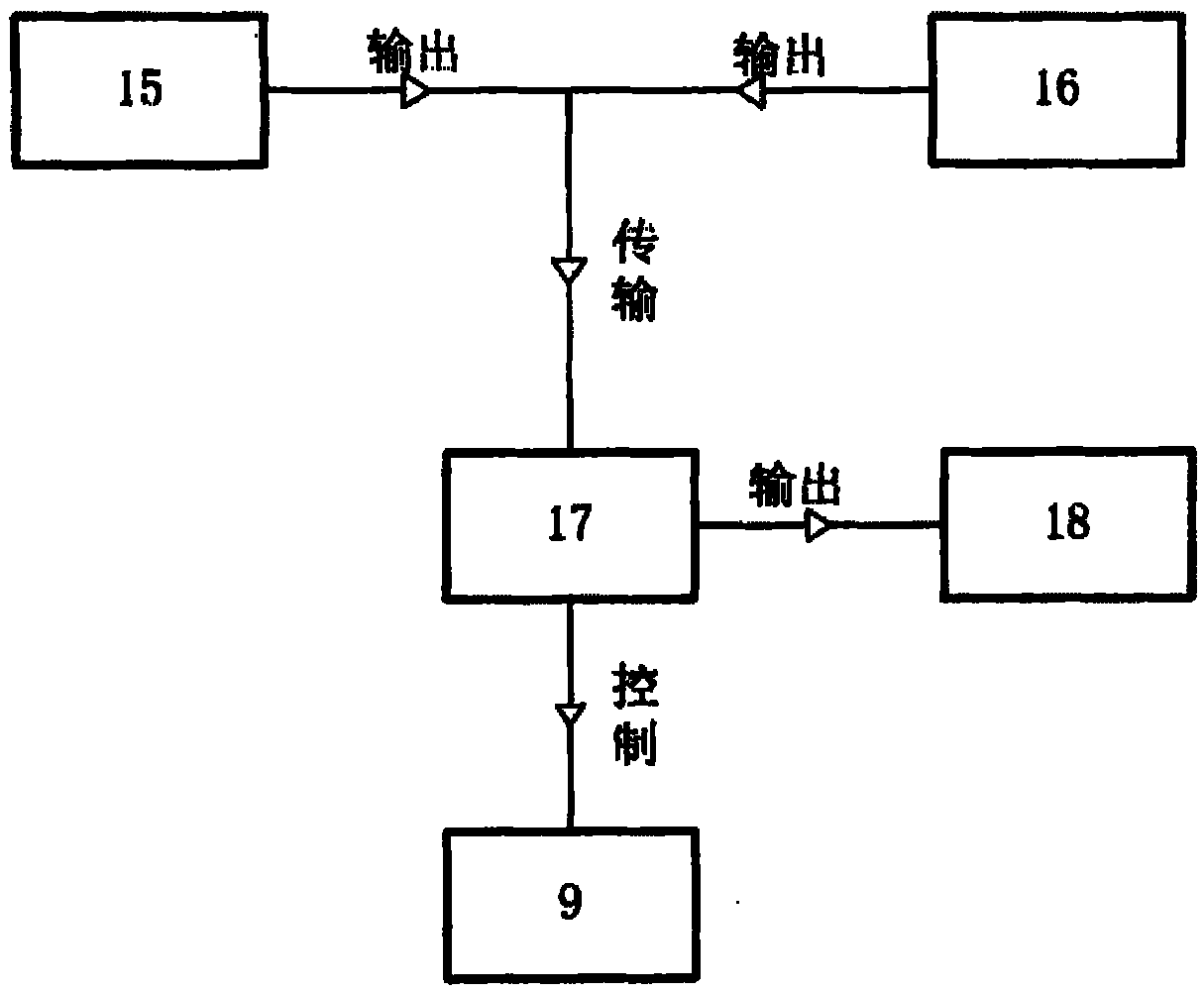

On-line diagnostic method for health monitoring of a transformer

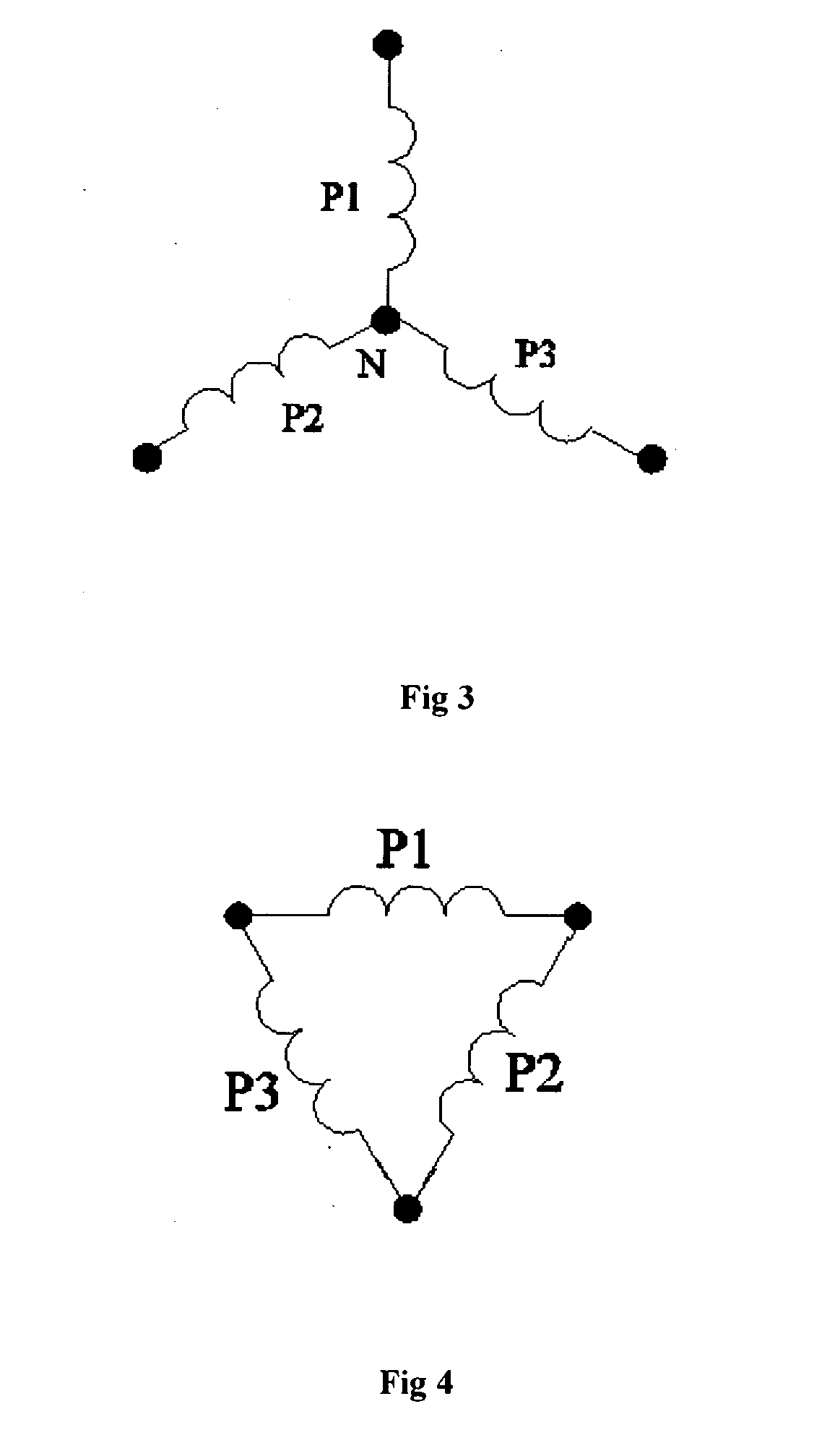

InactiveUS20120130663A1Accurate and reliable processEfficiently determinedResistance/reactance/impedenceVoltage-current phase angleCapacitanceThree-phase

An on-line diagnostic method for health monitoring of a transformer. In the case of a single phase or three phase star connected transformer deformations in the winding are determined byrepresenting the transformer winding as a lumped parameter circuit and dividing the winding into at least two sections. A first set of fingerprint values are generated to determine the location of the deformed section of the winding and the type of deformation. A second set of finger print values are generated to determine the extent of deformation of the deformed section. The location and extent of radial or axial deformation or combination of both radial and axial deformation in the winding are then determined. The change in the capacitance of the bushing of the transformer connected at the line end of the winding is also determined. The state of the insulation system of the transformer is determined by detecting partial discharge pulses in the transformer winding. The change in the dielectric characteristics of the insulation system of the transformer is detected on the basis of phase angle difference.

Owner:INDIAN INSTITUTE OF TECHNOLOGY BOMBAY

Device for connecting an end piece to an element

A coupling device for coupling an endpiece to a member, comprises a female portion for receiving the endpiece, and a bushing mounted to slide in the female portion and possessing one end projecting from the female portion and provided with at least one blocking member for blocking the bushing either in a pushed-in, locking position or pulled-back, unlocking position, and an opposite end provided both with front abutment elements for coming into abutment with an annular bead of the endpiece, and rear abutment elements for coming into abutment with the bead so that when the bushing is in its unlocking position, the rear abutment elements are movable by the annular abutment between a position in which they project towards the inside of the bushing and a retracted position, and when the bushing is in its locking position, the rear abutment elements are held in their projecting position.

Owner:LEGRIS

Hot-rolled coil plate for oil casing and manufacturing method thereof

InactiveCN102719743ARefine the grain sizeHigh strength and toughness matching performanceHeat treatment process controlLaminar coolingHardness

The invention relates to a hot-rolled coil plate for an oil casing and a manufacturing method thereof. The hot-rolled coil plate comprise, by mass percent, 0.10 to 0.21 of C, 0.10 to 0.25 of Si, 1.0 to 1.50 of Mi, 0.010 to 0.020 of Al, less than or equal to 0.020 of P, no more than 0.010 of S, 0,012 to 0.045 of Nb, 0.005 to 0.020 of Ti, and the balance Fe and inevitable impurities. The tensile strength Rm is more than or equal to 655Mpa, the yield strength Rt 0.5 is 379-552Mpa, the elongation A50% is more than or equal to 24, and the hardness HV10 is less or equal to 248. The manufacturing method includes:LF refining, the S being less than or equal to 0.004%; RH refining, subjecting the molten steel to Ca treatment; slab continuous casting, the temperature being in a range from 1527 DEG C to 1547 DEG C, and the casting speed being less than or equal to 1.2m / min; slab heating, the temperature being in a range from 1150 DEG C to 1230 DEG C; roughing mill group rolling, the final temperature being in a range from 750 DEG C to 920 DEG C; laminar cooling; and coiling. The hot-rolled coil plate for the oil casing has low yield ratio and good welding performances, and no subsequent thermal treatment is needed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

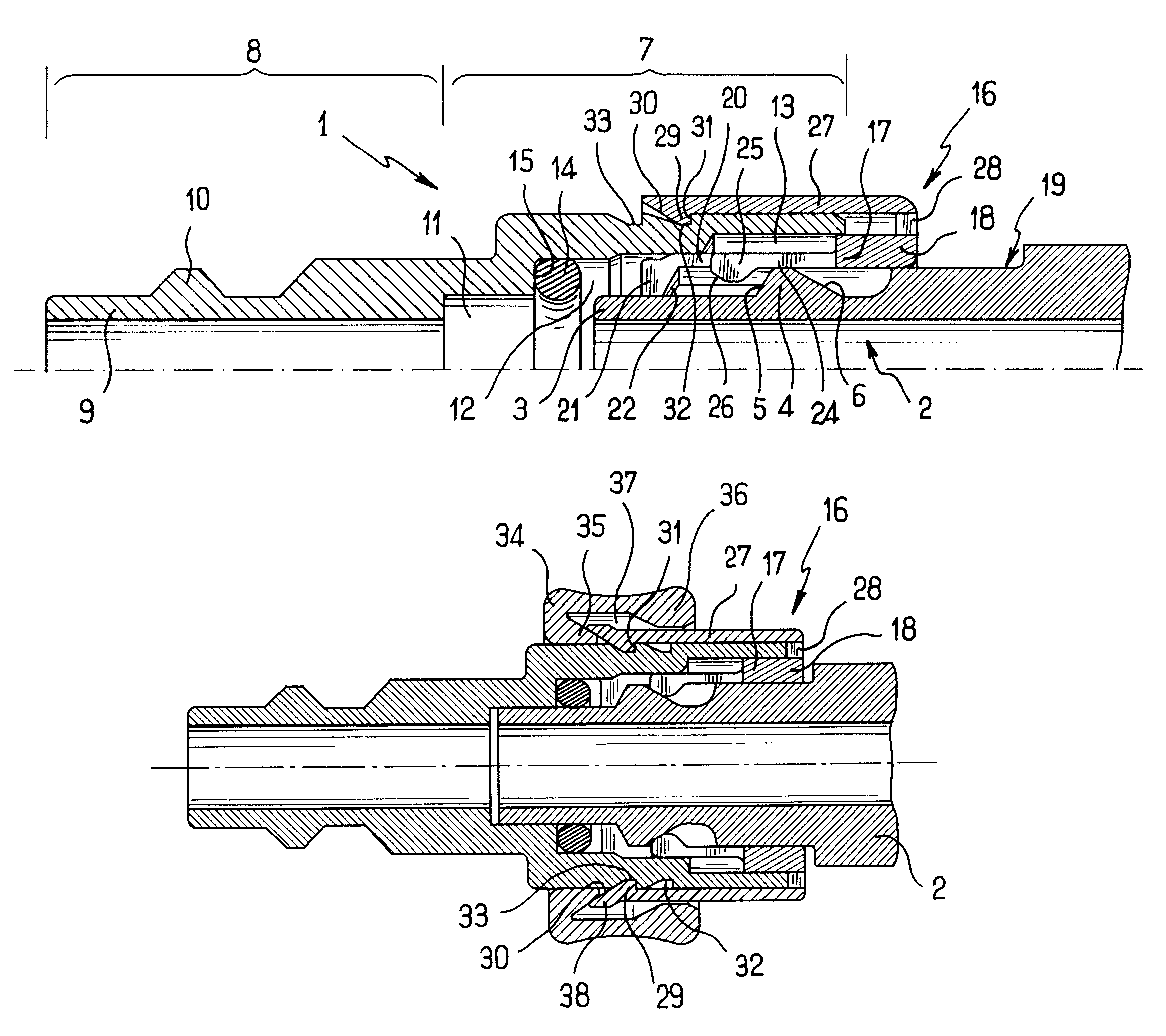

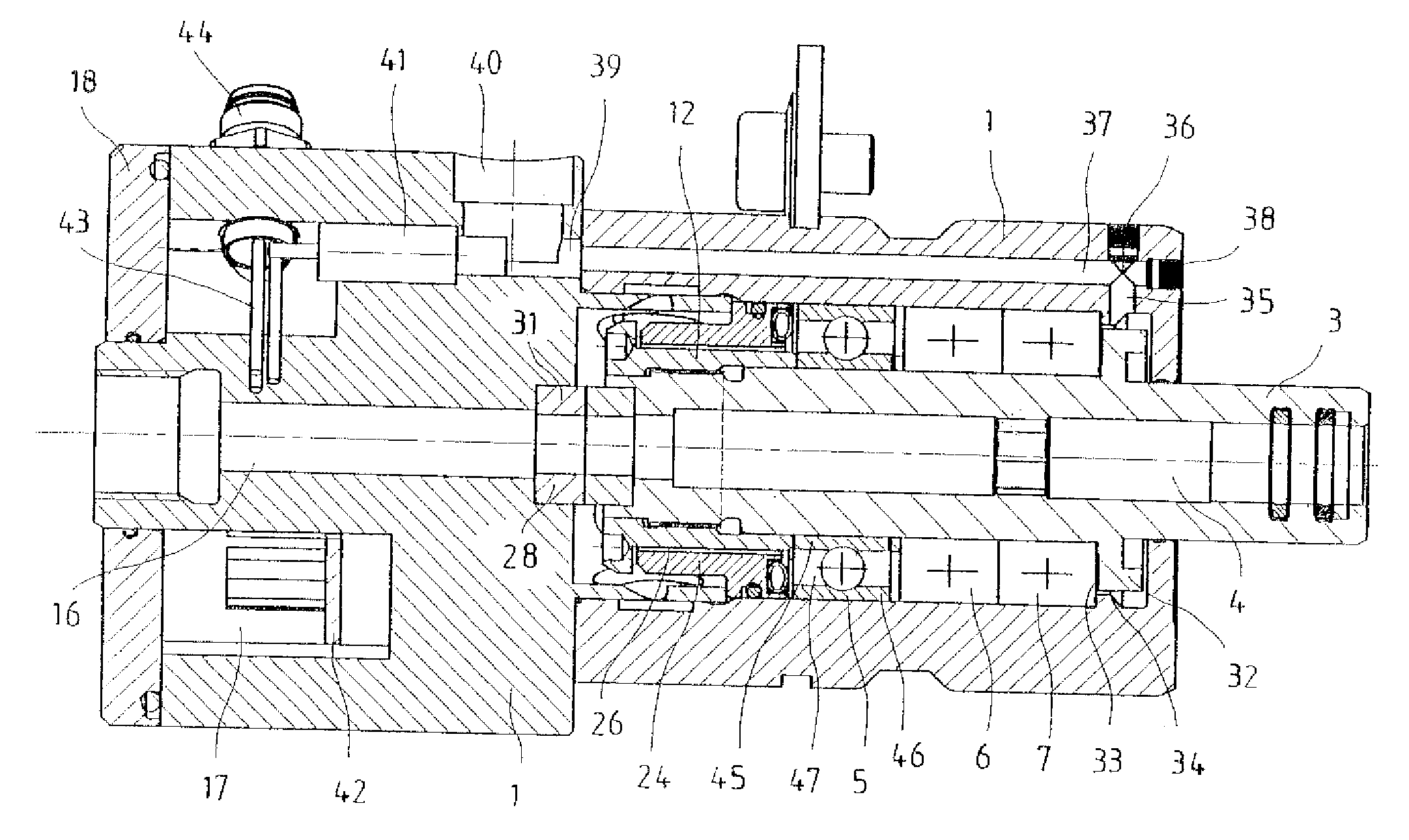

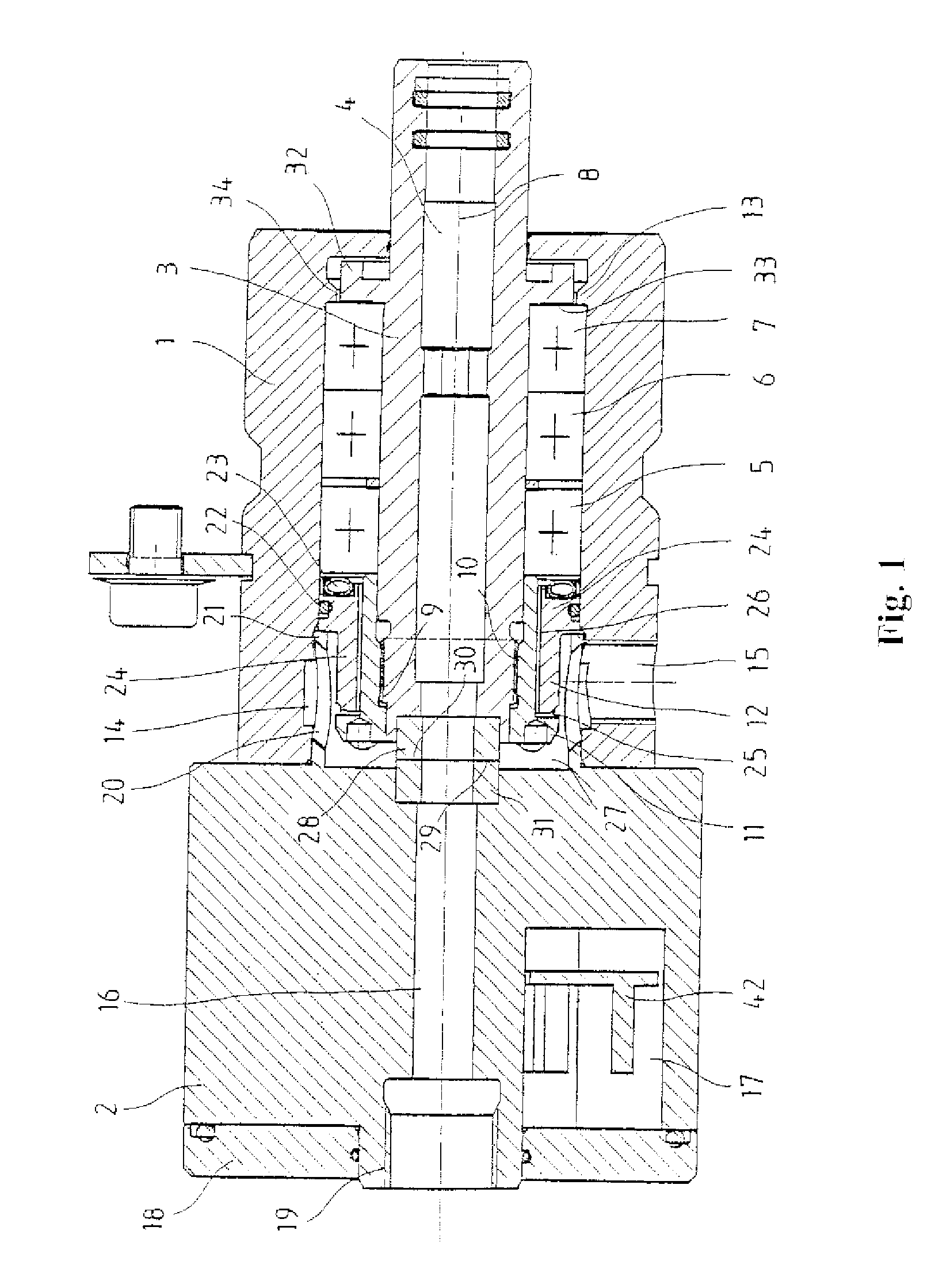

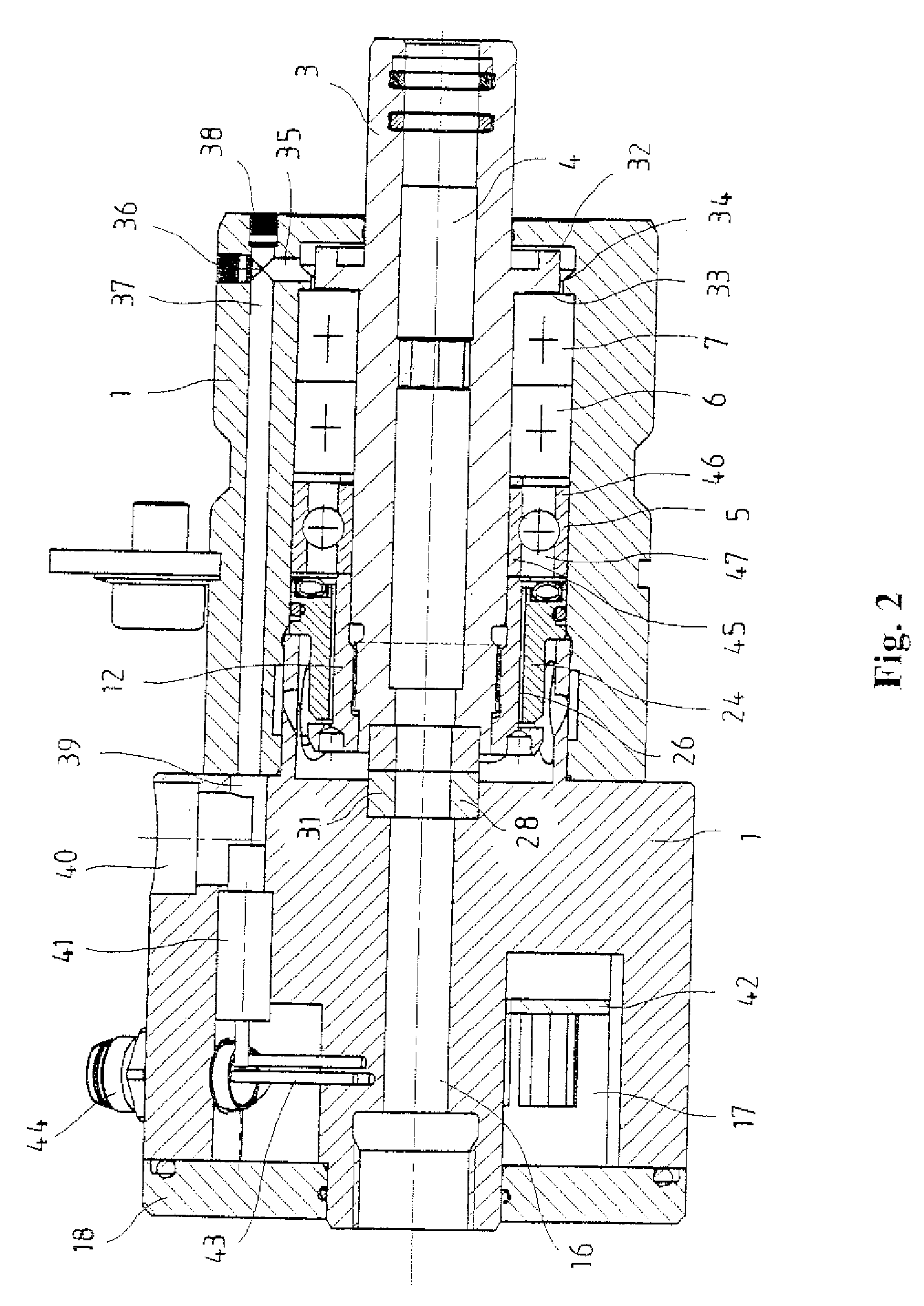

Rotary feed-through with leakage sensor

InactiveUS20070034265A1Avoid damageValve arrangementsFluid pressure sealed jointsMachine partsMachine

The invention pertains to a rotary feed-through for supplying a fluid to a rotating machine part with a hollow shaft (3) that is rotatably supported in a housing (1, 2) and has a first sliding surface (29), with a sealing bushing (31) that is arranged in a rotationally fixed fashion within the housing (1, 2) coaxial to the shaft (3) and has a second sliding surface (30) for contacting the first sliding surface (29), and with a collecting chamber (27) that is arranged within the housing (1, 2) and serves for collecting the leakage fluid escaping between the two sliding surfaces (29, 30). The leakage fluid collected within the rotary feed-through can be monitored with the aid of a detection channel (26, 33, 34, 37, 39, 47) in the housing (1, 2) that is connected to the collecting chamber (27) and contains a leakage sensor (41).

Owner:OTT JAKOB & SPANNTECHN

On-line underground temperature measurement system

ActiveCN101942990AAvoid short circuit problemsHigh strengthSurveyConstructionsThermocouple WireEngineering

The invention relates to an underground temperature measurement system. The system comprises a thermocouple, a compensating lead and a heavy hammer, wherein the compensating lead is positioned above the thermocouple, and the lower end of the compensating lead is connected with the upper end of the thermocouple; the heavy hammer is positioned below the thermocouple, connected with the lower end of the thermocouple and used for guiding the thermocouple to advance in a temperature measurement passage; and the thermocouple is a sheathed thermocouple manufactured by combined assembly of a thermocouple wire, an insulating material and a metal protective sleeve and stretching, and the length of the sheathed thermocouple corresponds to the thickness of a highest temperature interval in an underground high temperature layer to be measured. The temperature measurement system can greatly reduce the manufacturing cost of the thermocouple, effectively prolong the service life of the thermocouple and improve the automation degree of temperature measurement, and is convenient for repair and maintenance of the system per se.

Owner:ENN SCI & TECH DEV

Shorting switch and system to eliminate arcing faults in power distribution equipment

InactiveCN1672228ASwitch power arrangementsEmergency protective arrangement detailsElectricityEngineering

A shorting switch (2) includes a vacuum switch (4) having fixed and movable contact assemblies (8, 10) and a driven member (26). A spring cover tube (38) and bushing (36) mount the driven member (26) for linear movement along a path substantially parallel to a longitudinal axis of the movable contact assembly (10). The driven member (26) moves the movable contact assembly (10) between open and closed circuit positions. A compression spring (40) has a compressed state and a released state, which moves the driven member (26) and movable contact assembly (10) to the closed circuit position. A release bolt (32) has an opening (68) therein and is coupled to the driven member (26) to normally maintain the compression spring (40) in the compressed state. A charge (60) is disposed in the opening of the release bolt (32) and is actuated to fracture the release bolt and release the compression spring (40) to the released state. First and second terminals (16, 22) are respectively electrically interconnected with the fixed and movable contact assemblies (8, 10).

Owner:EATON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com