Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3240results about "Connections effected by permanent deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

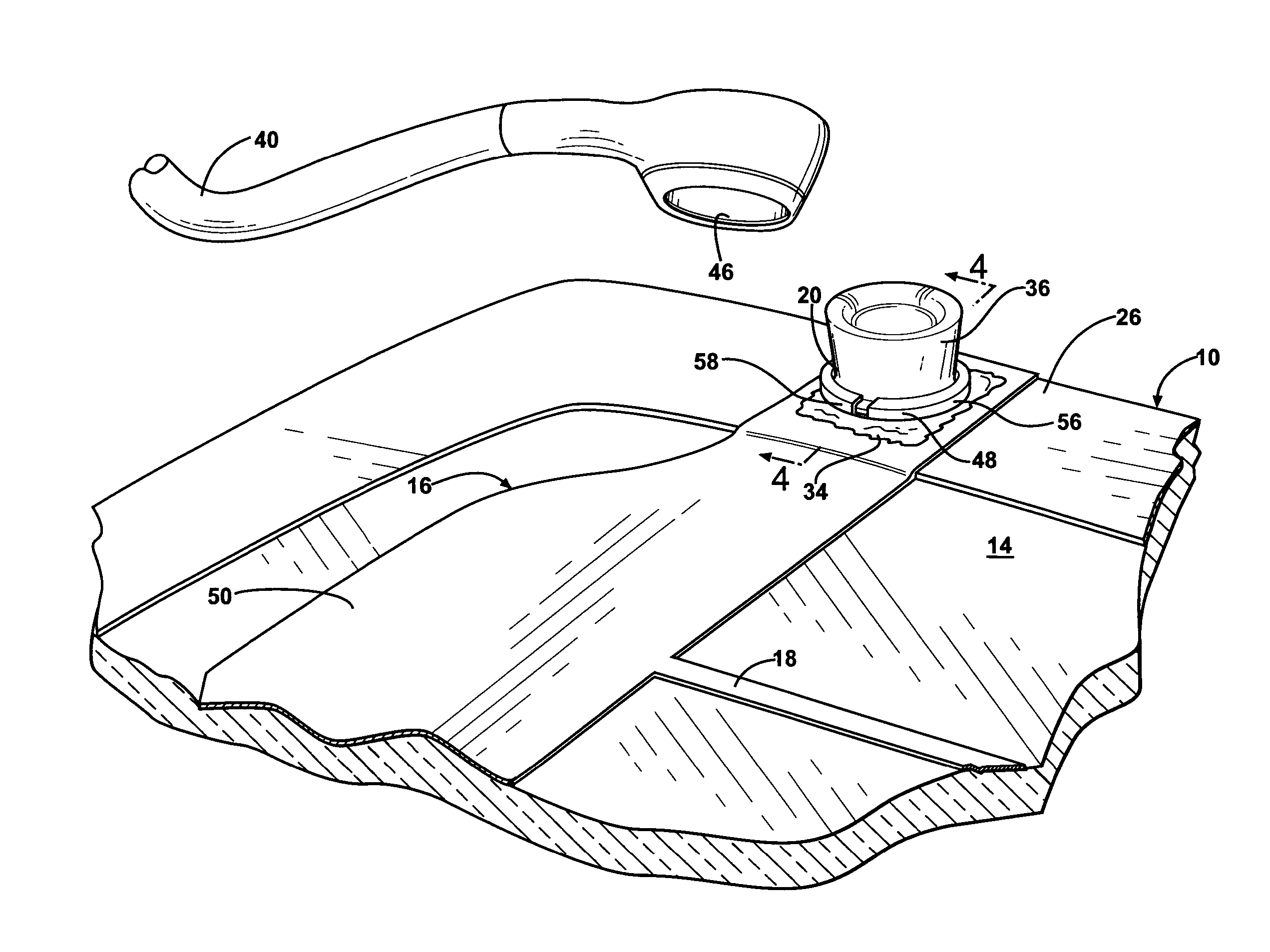

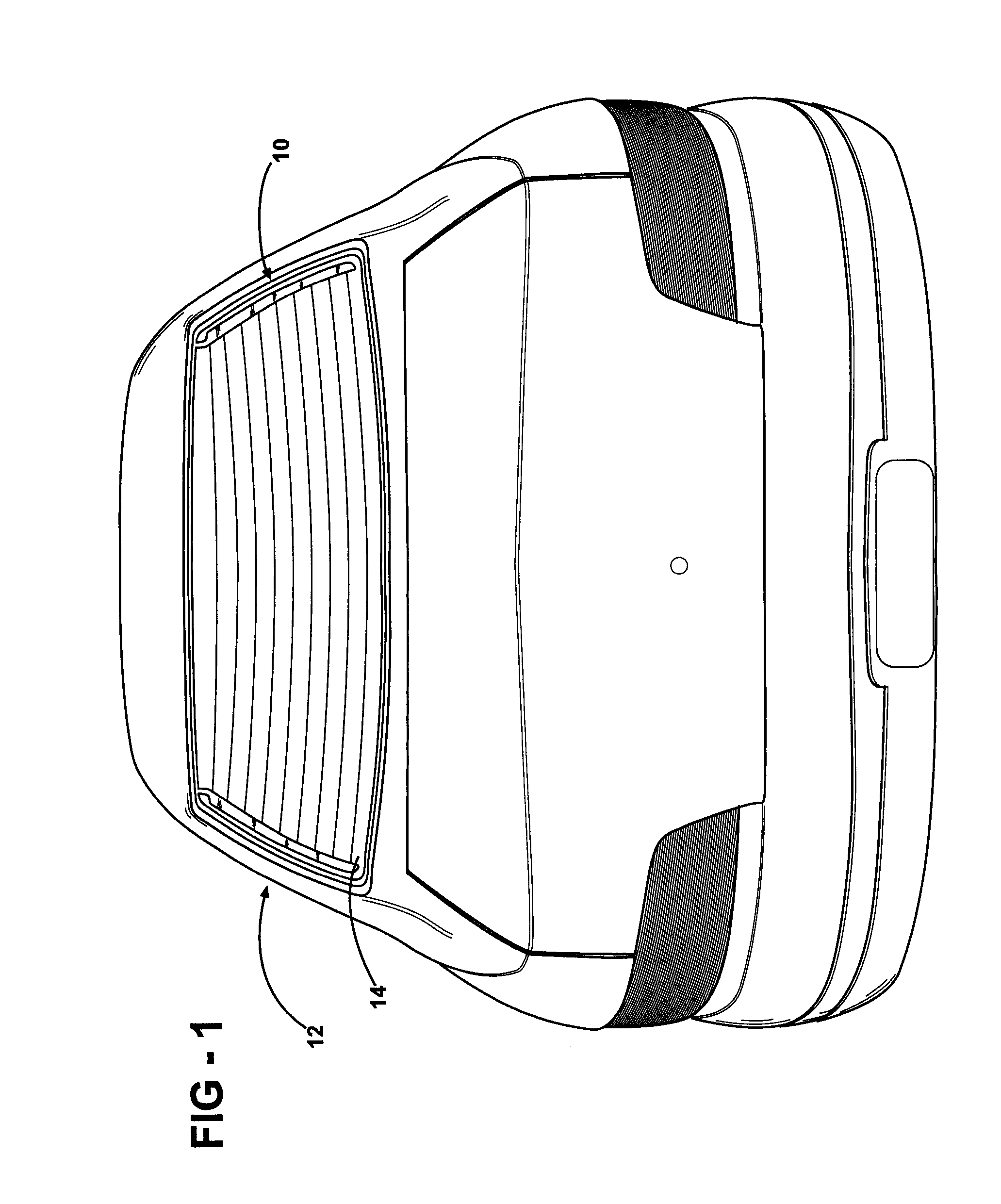

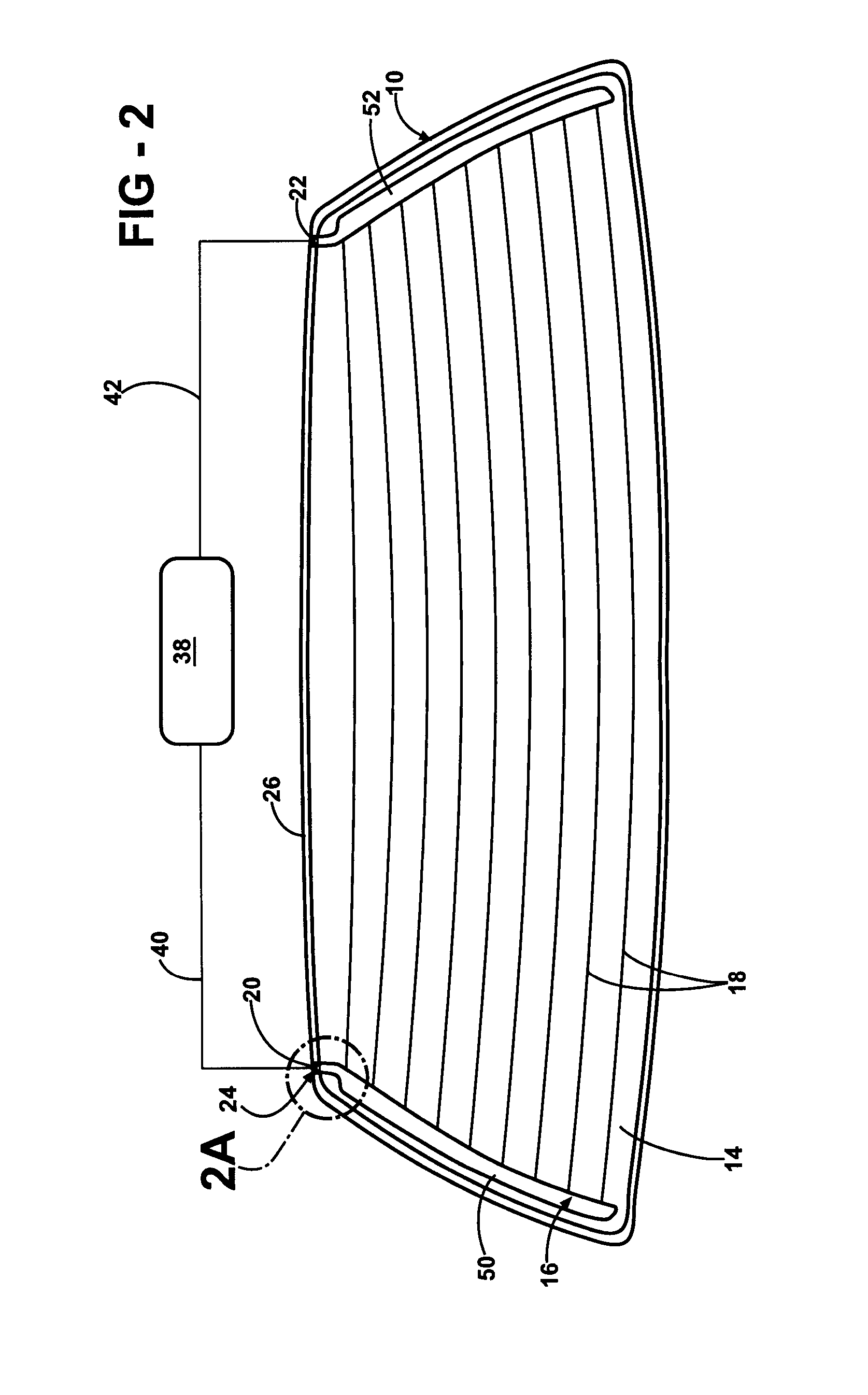

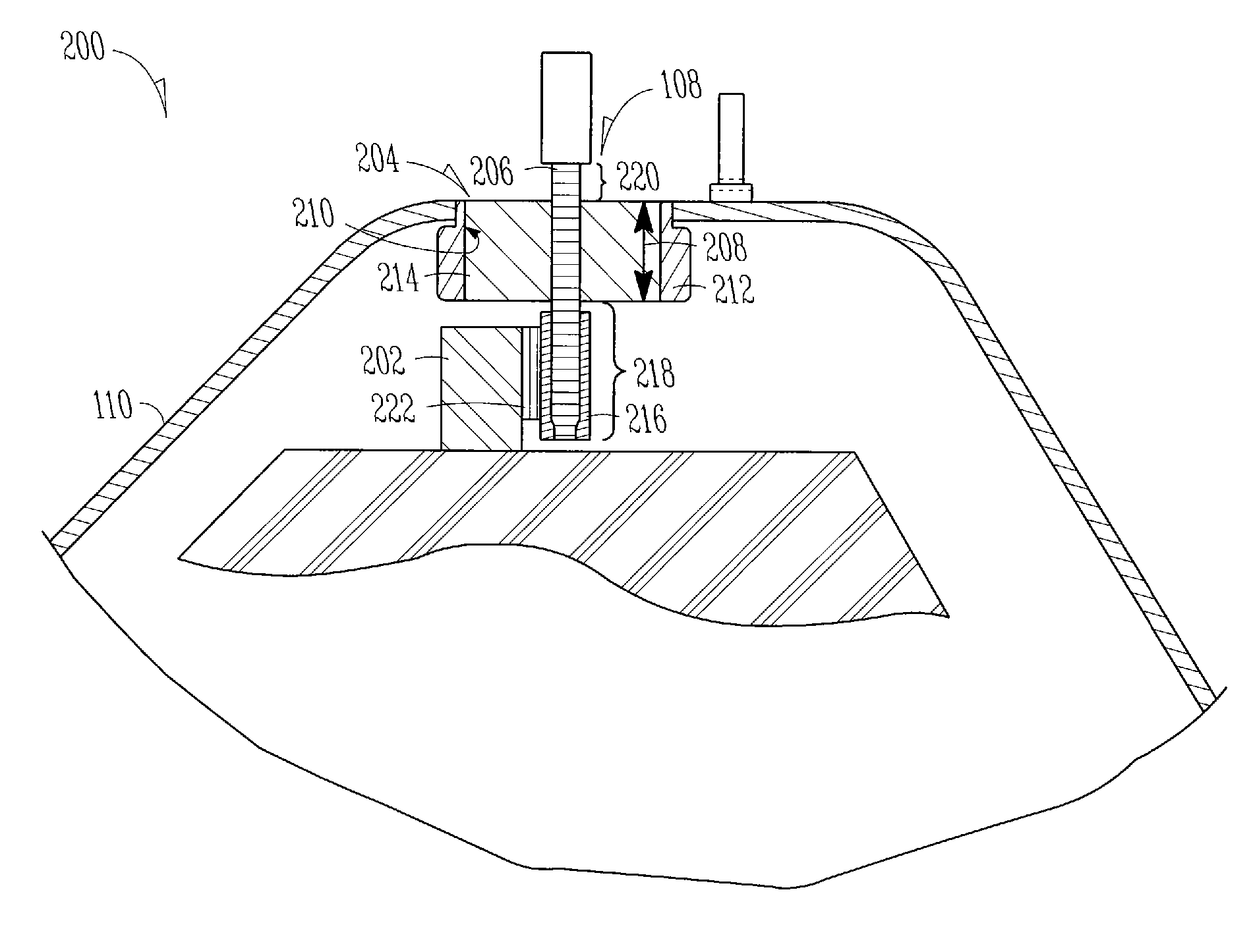

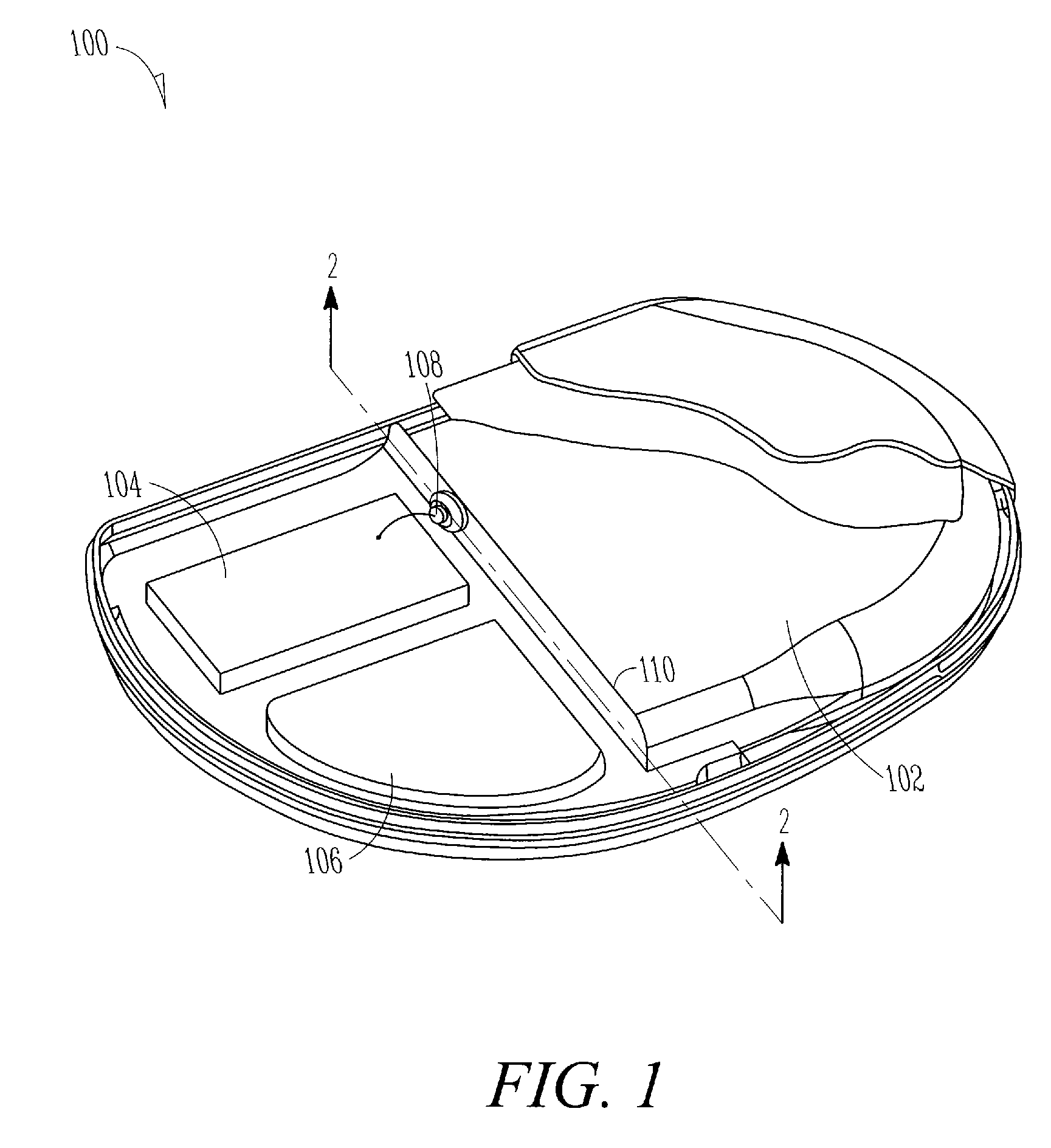

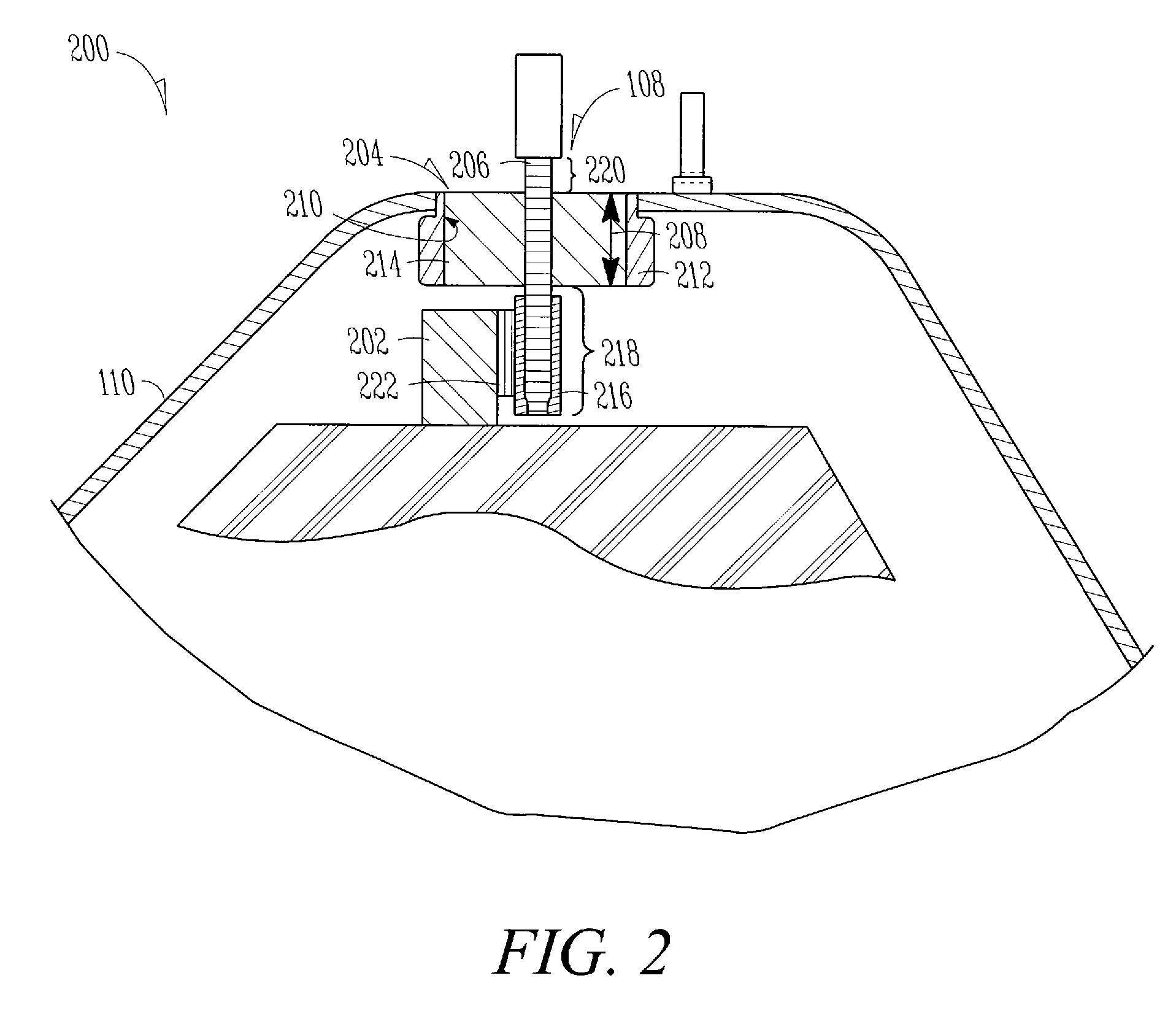

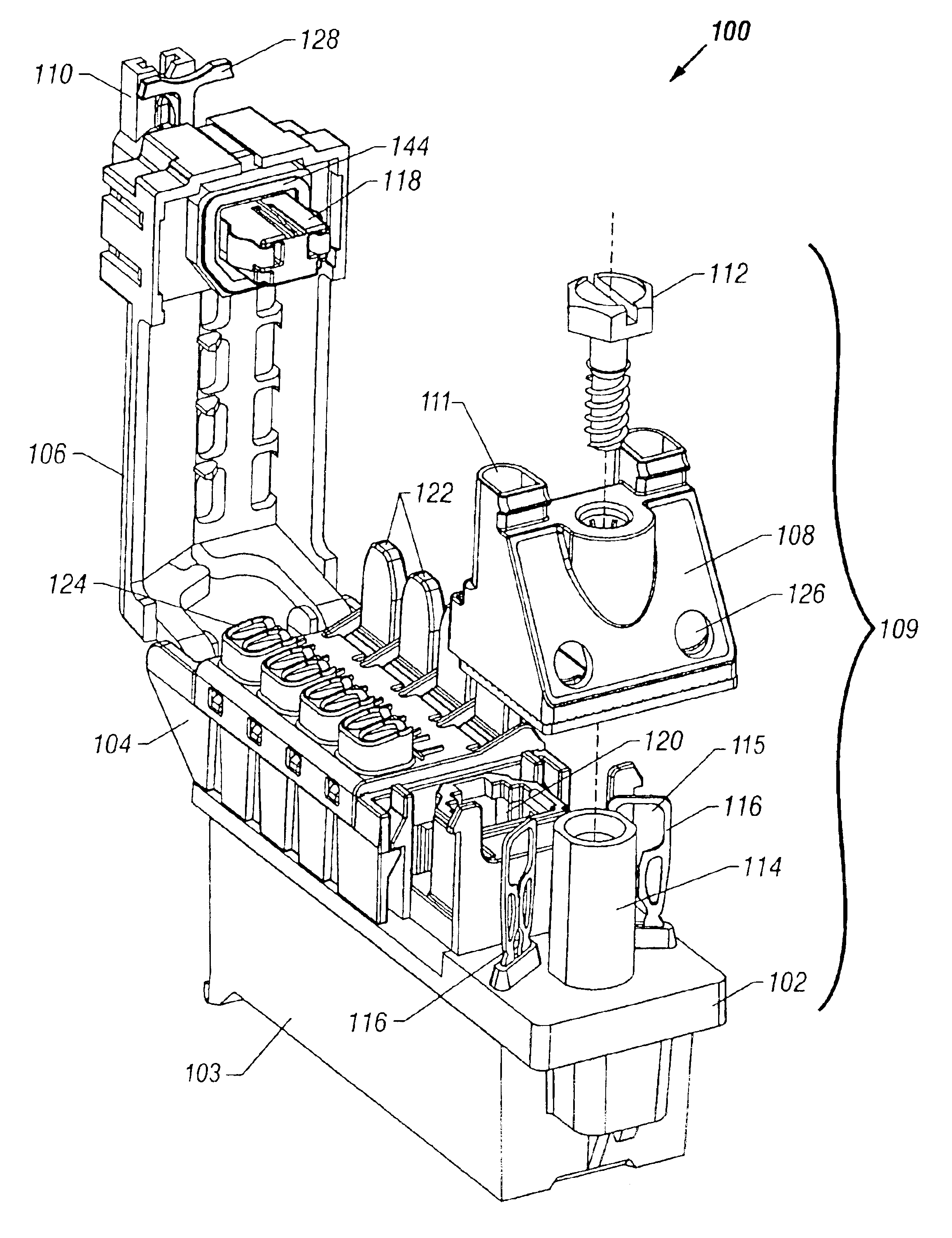

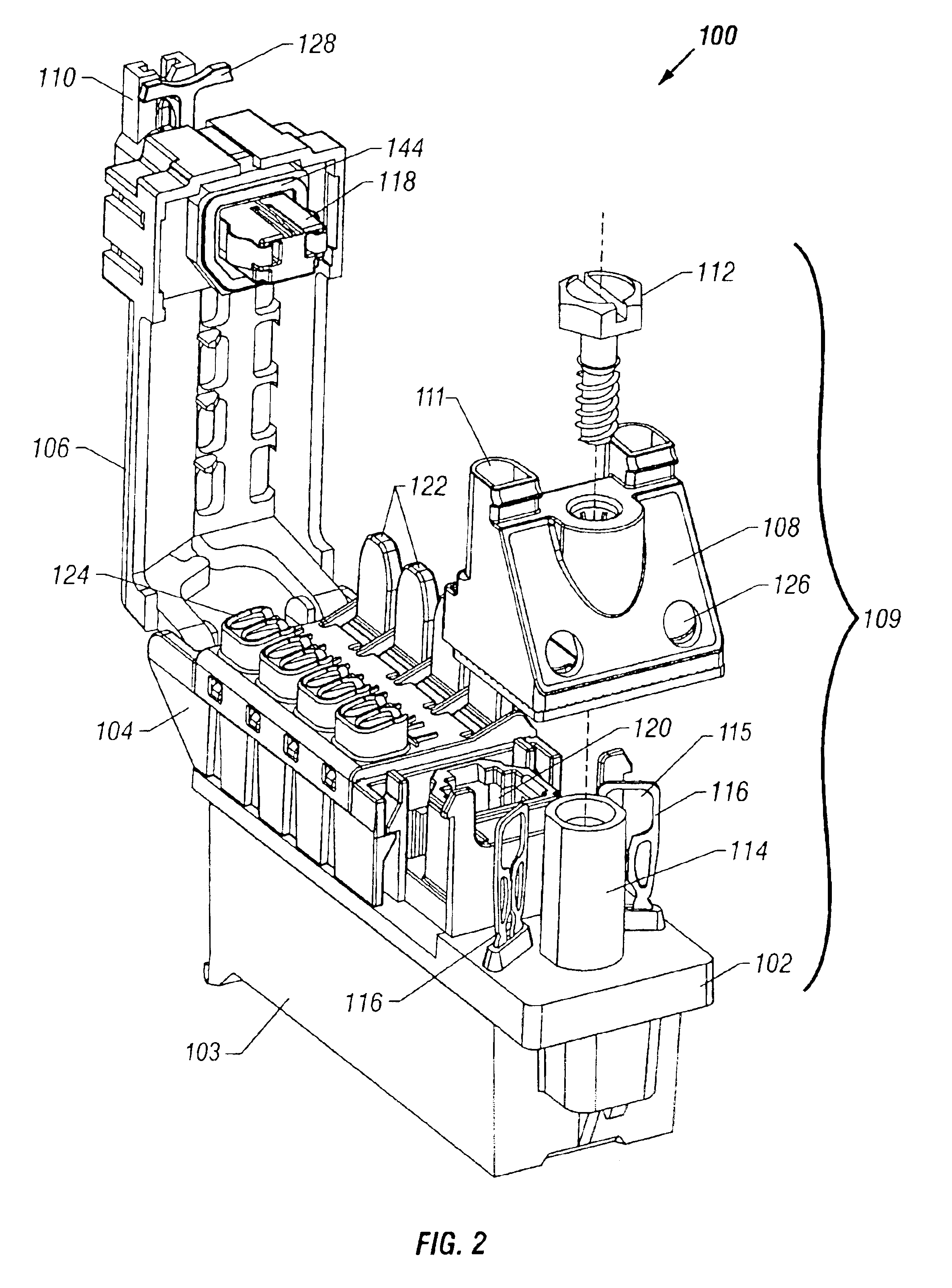

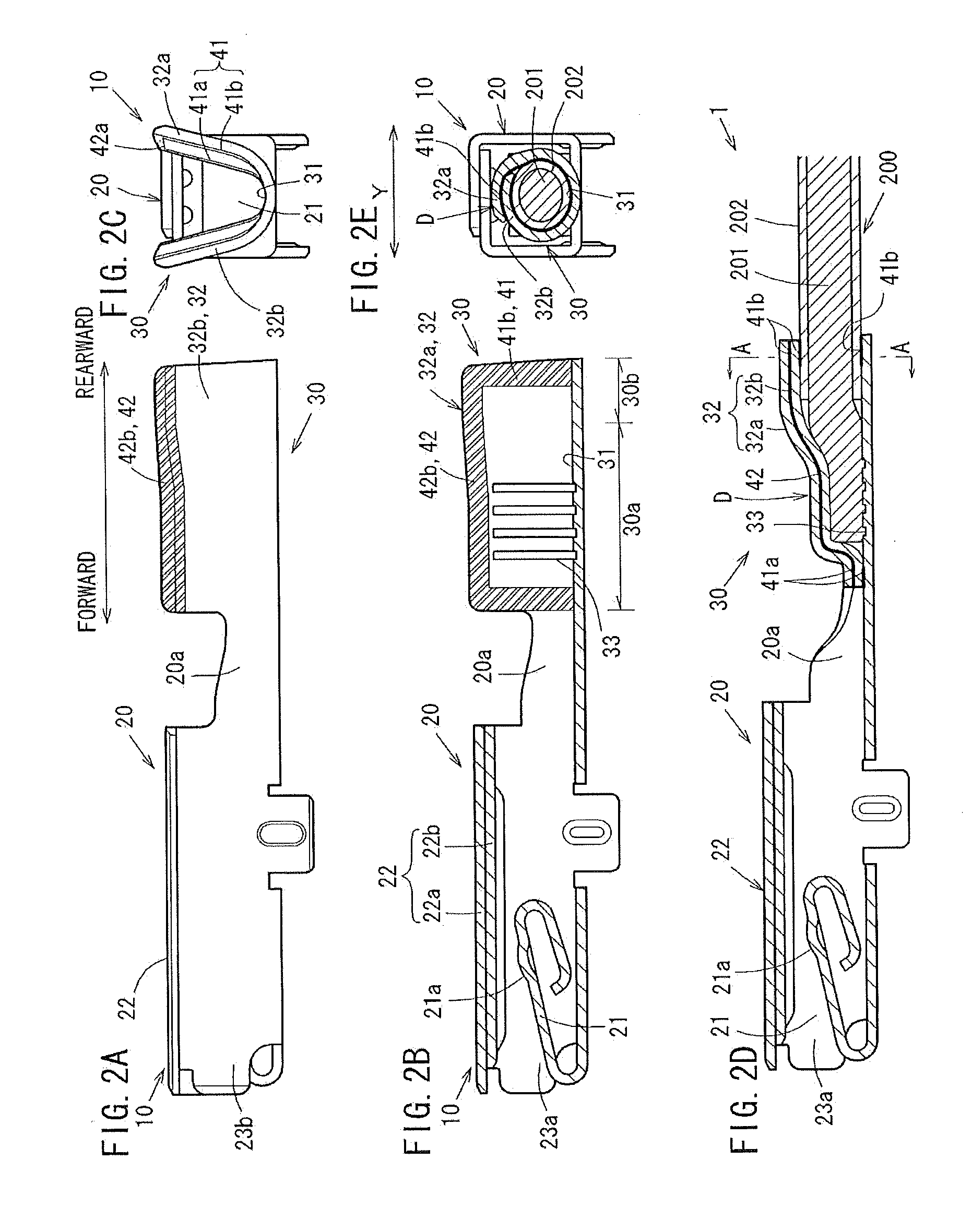

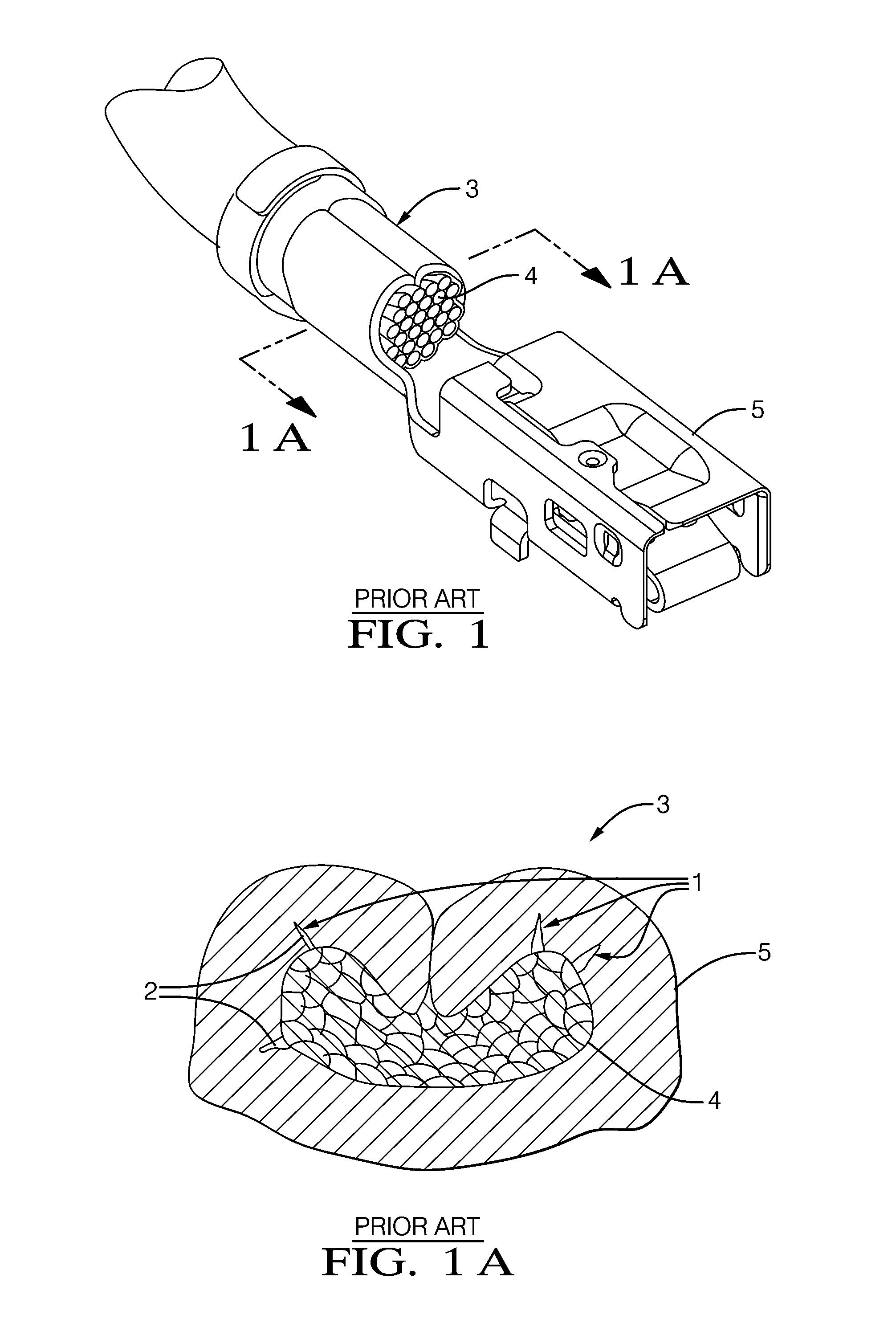

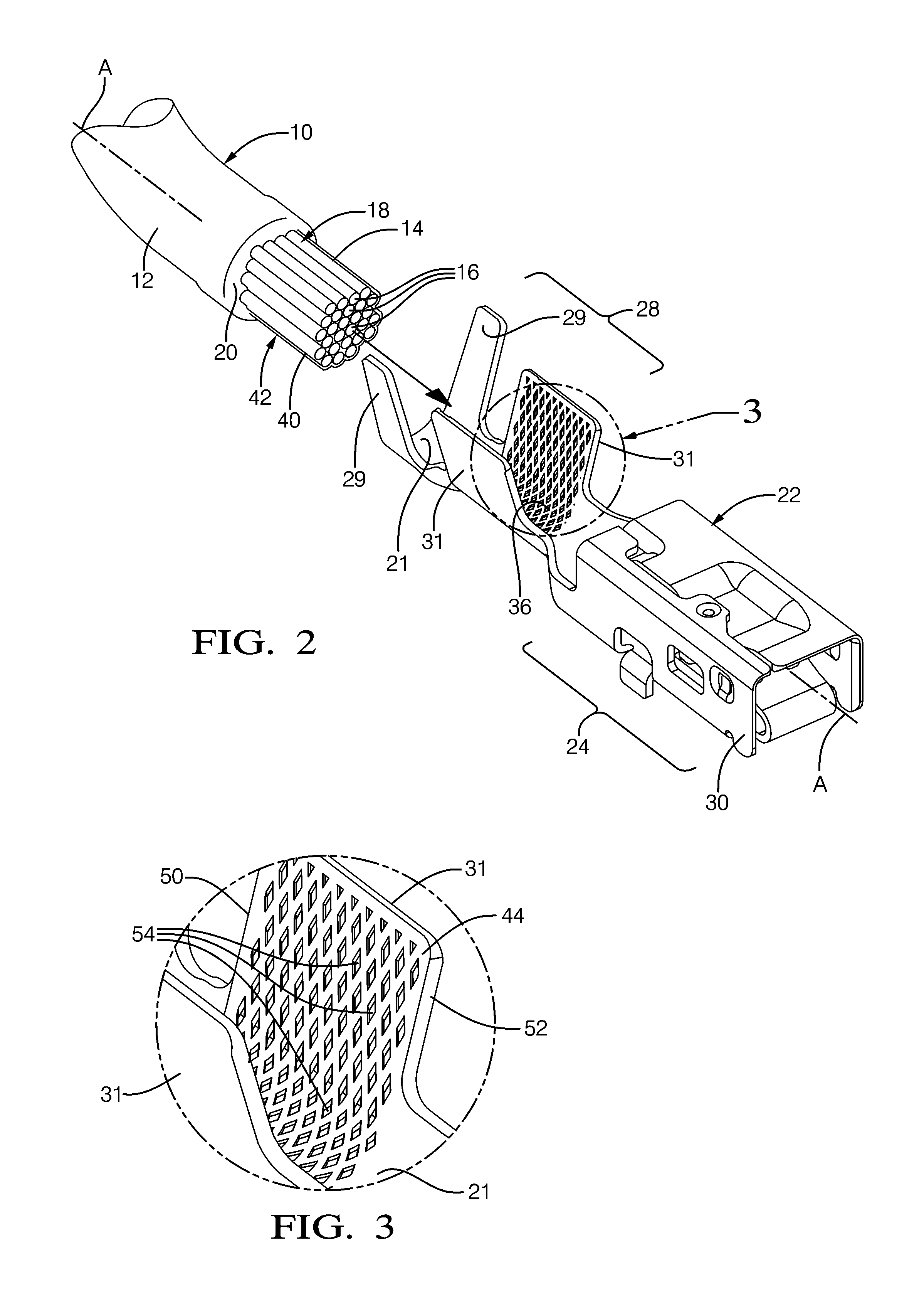

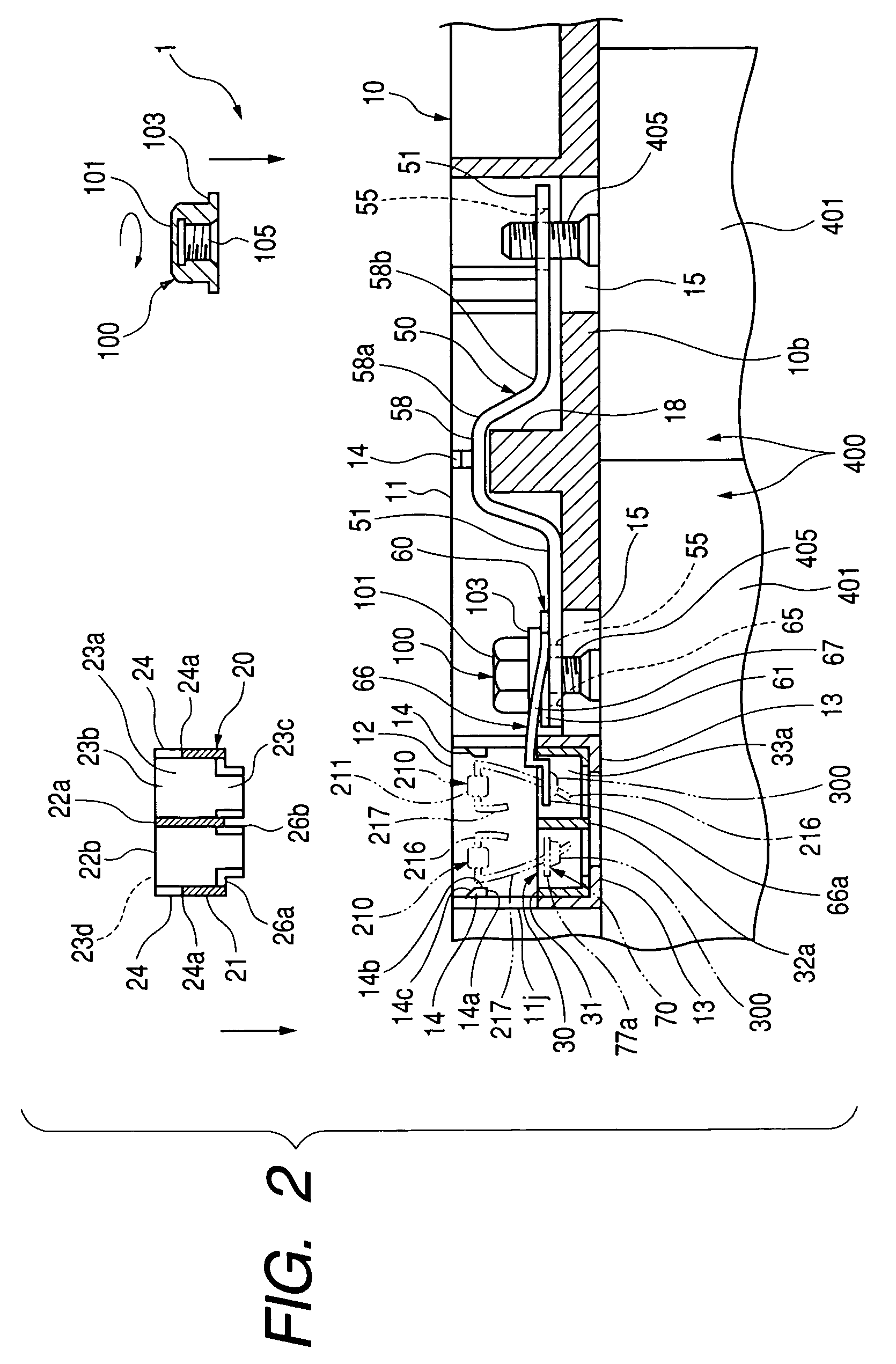

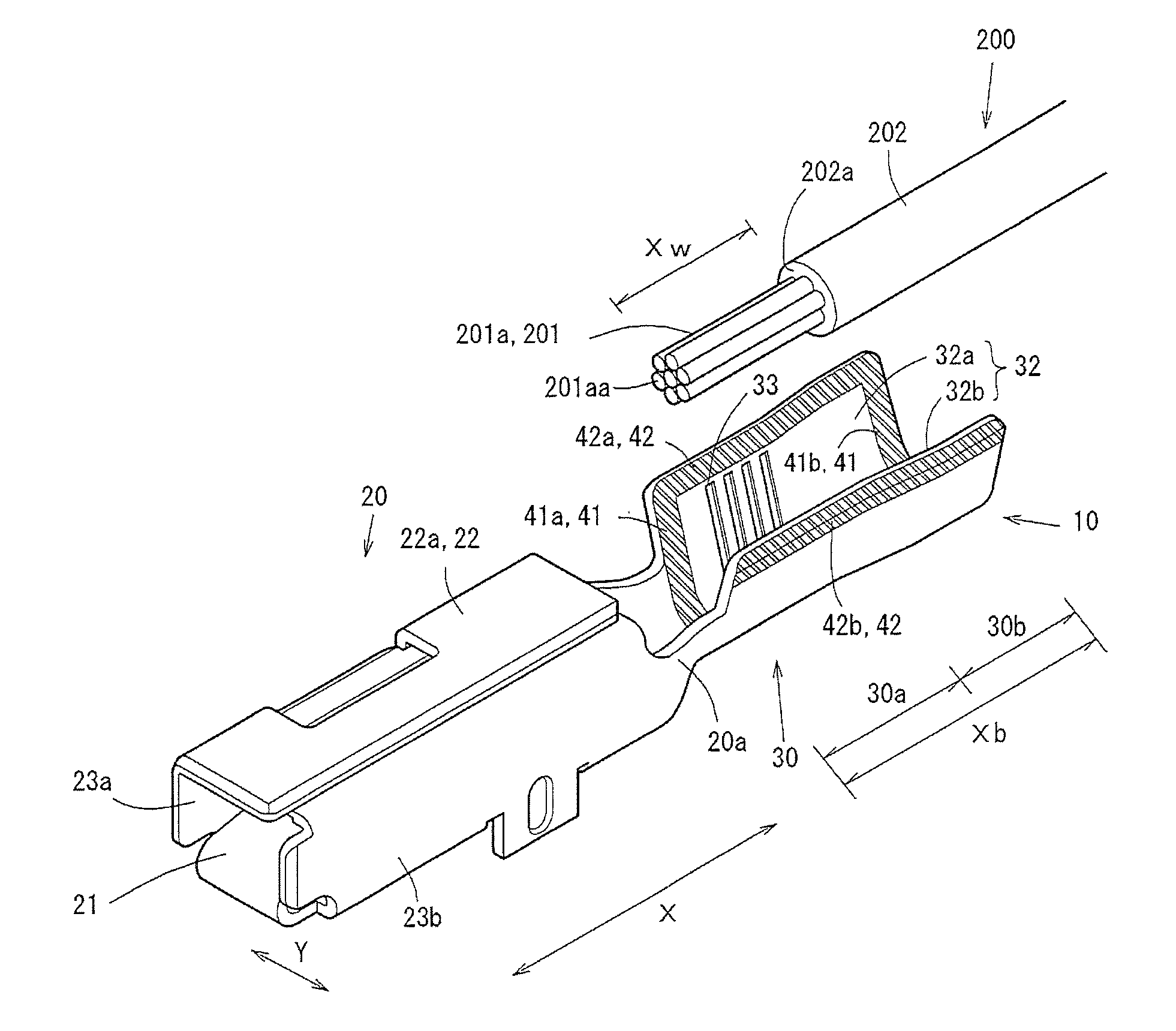

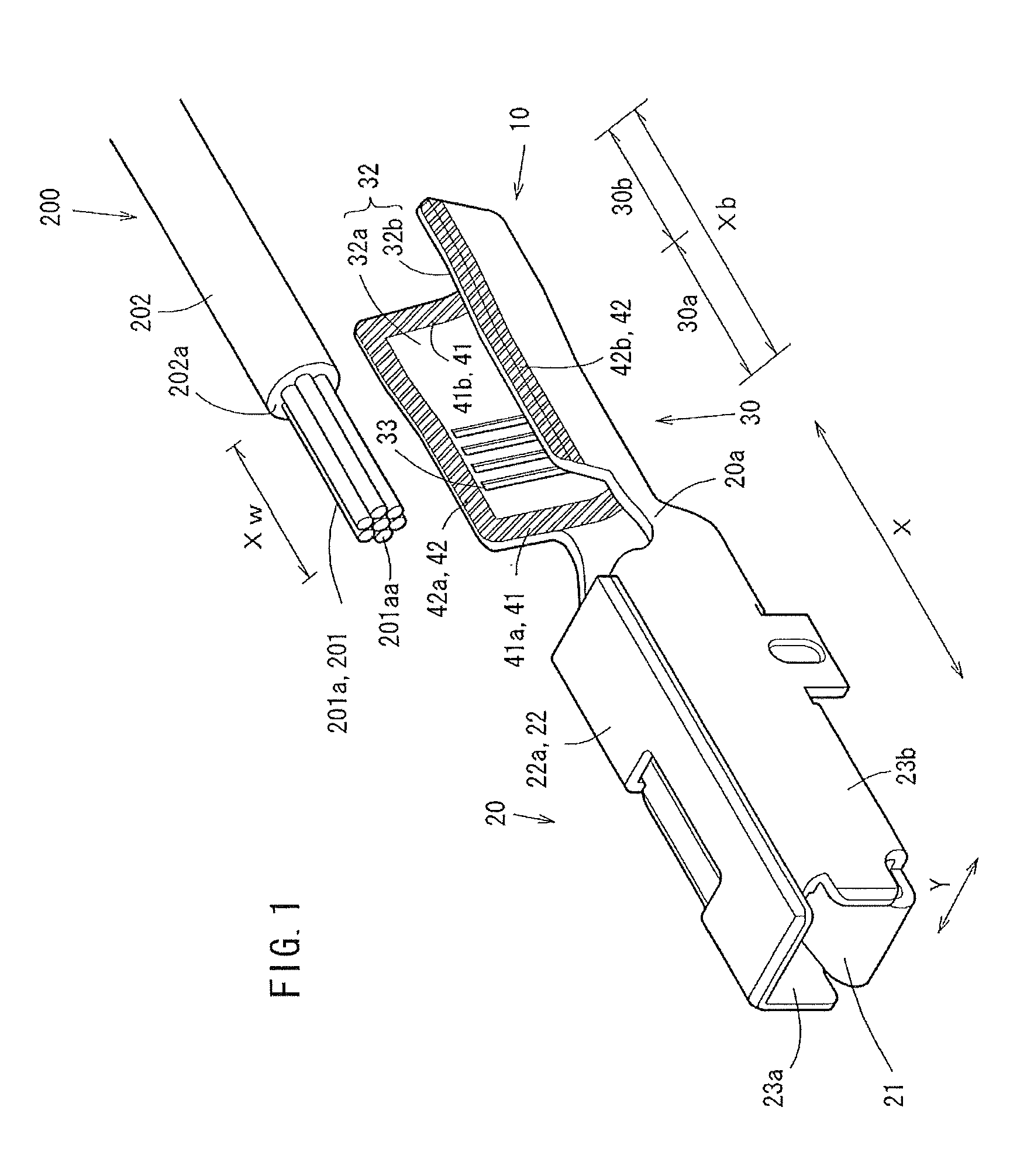

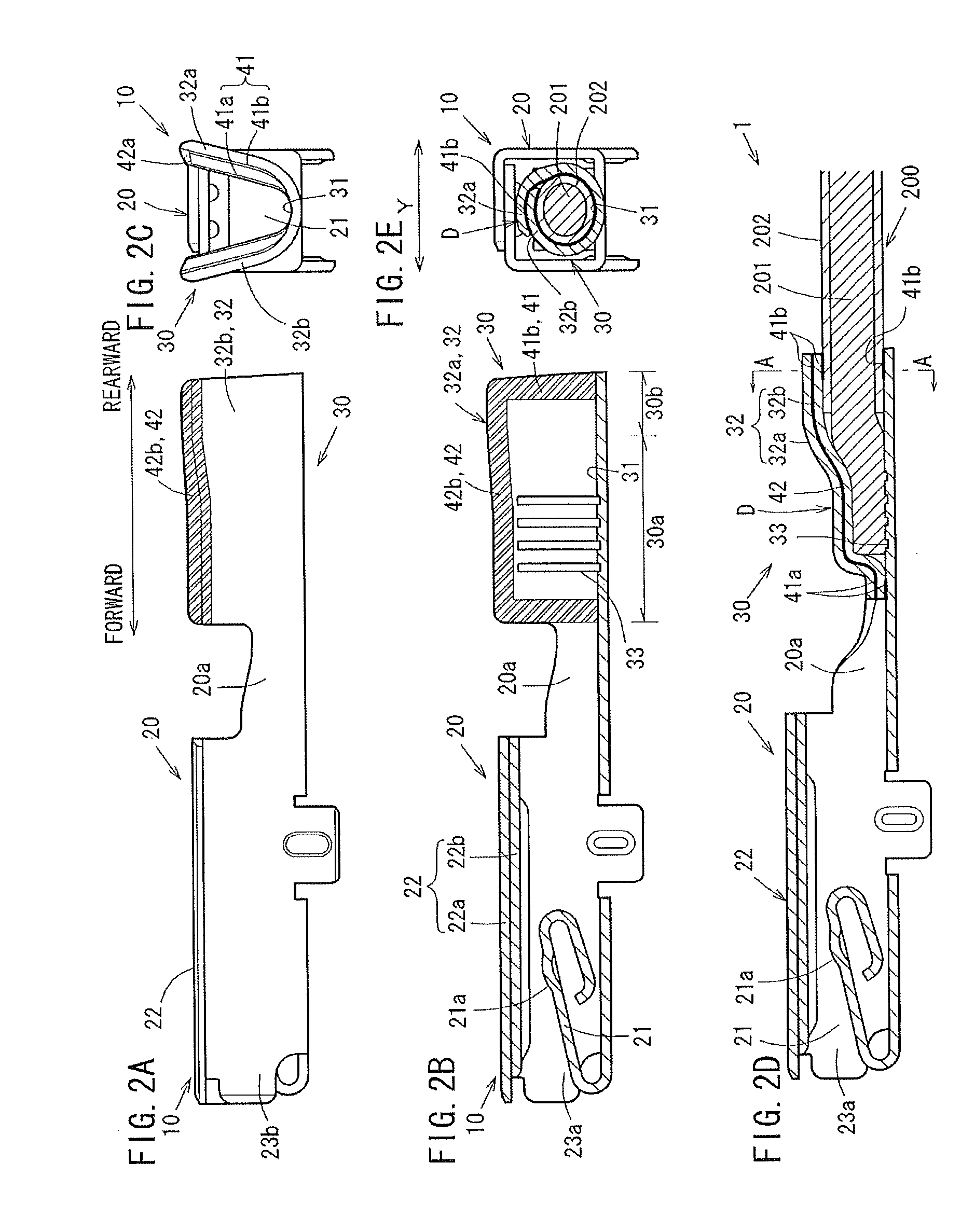

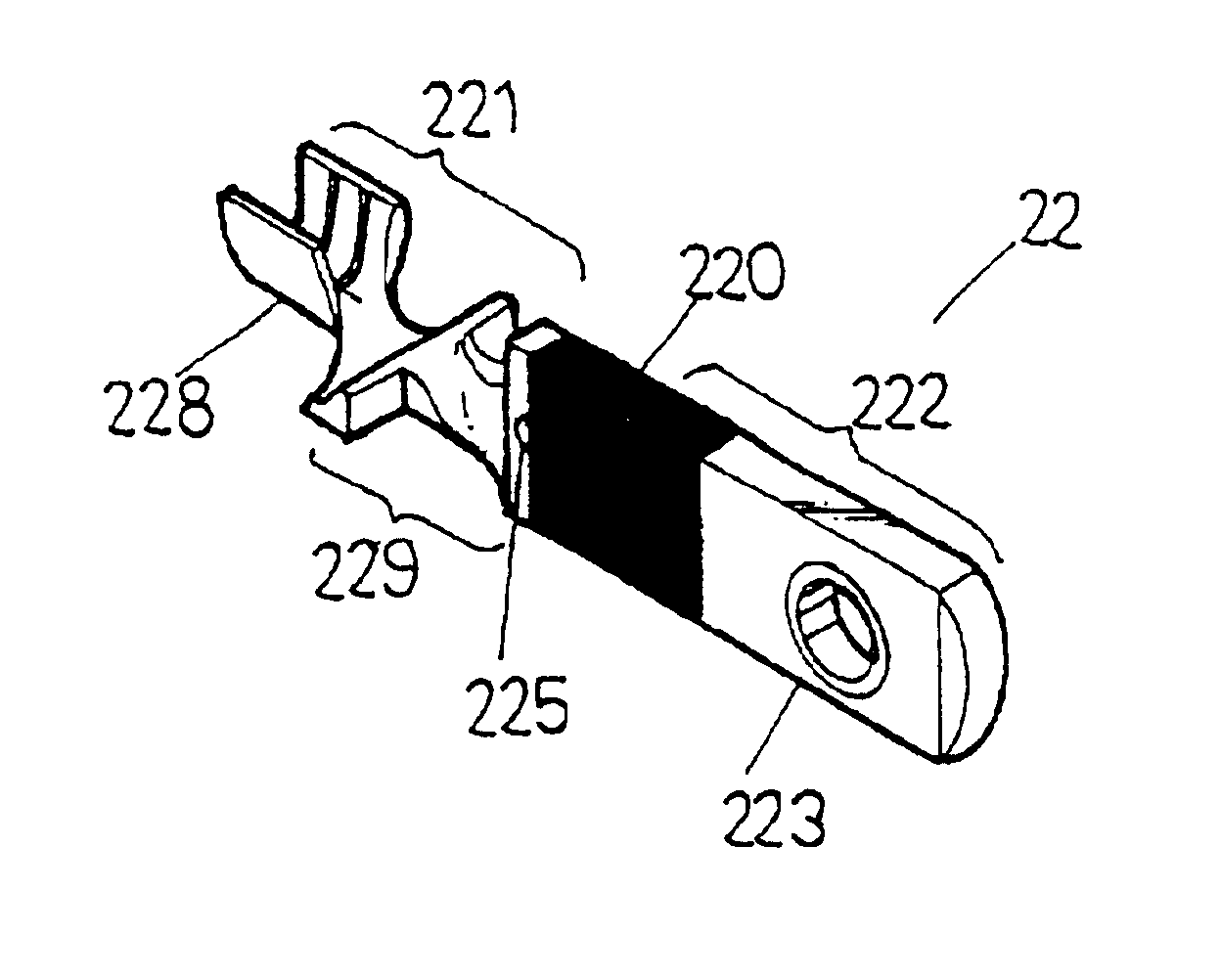

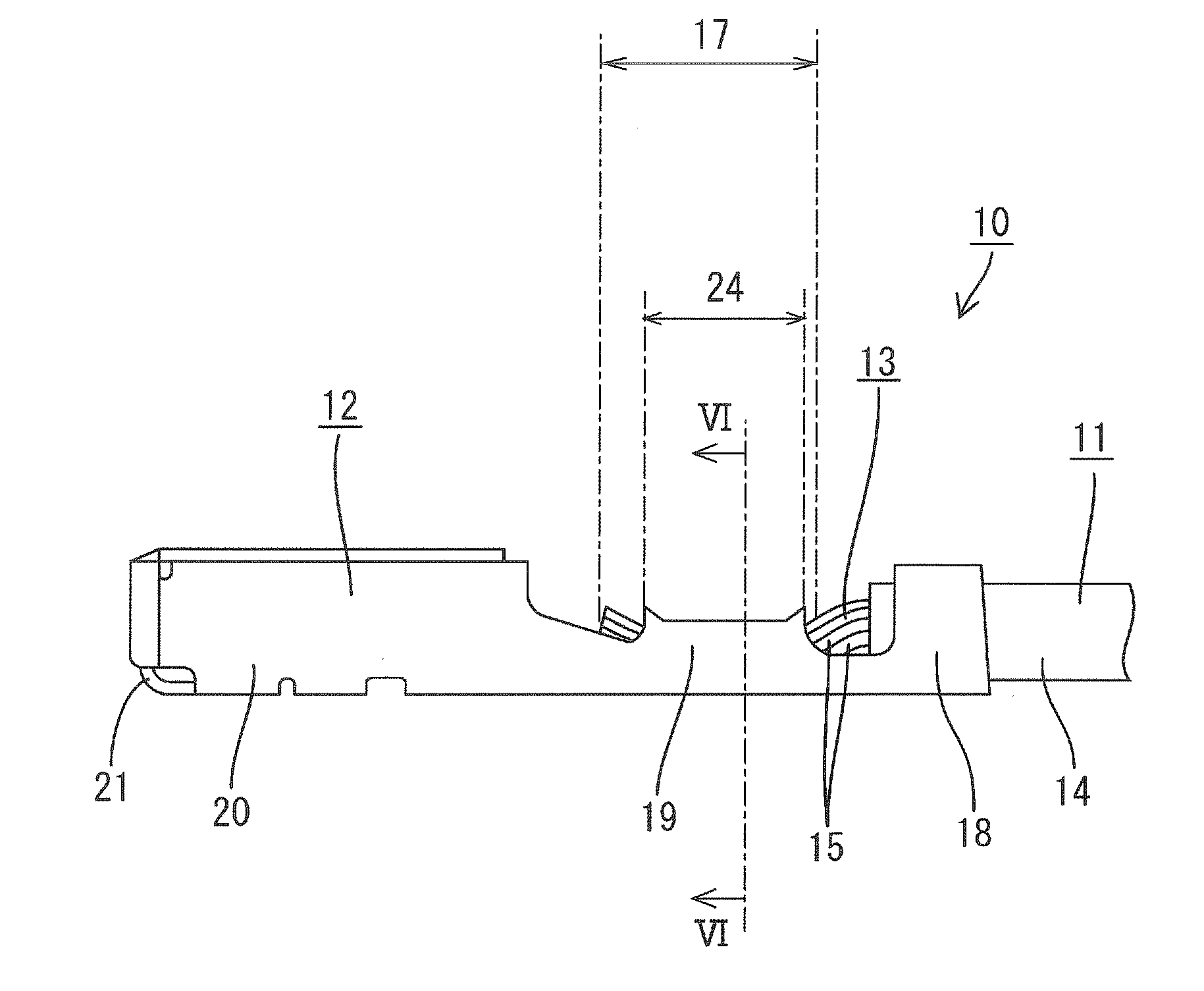

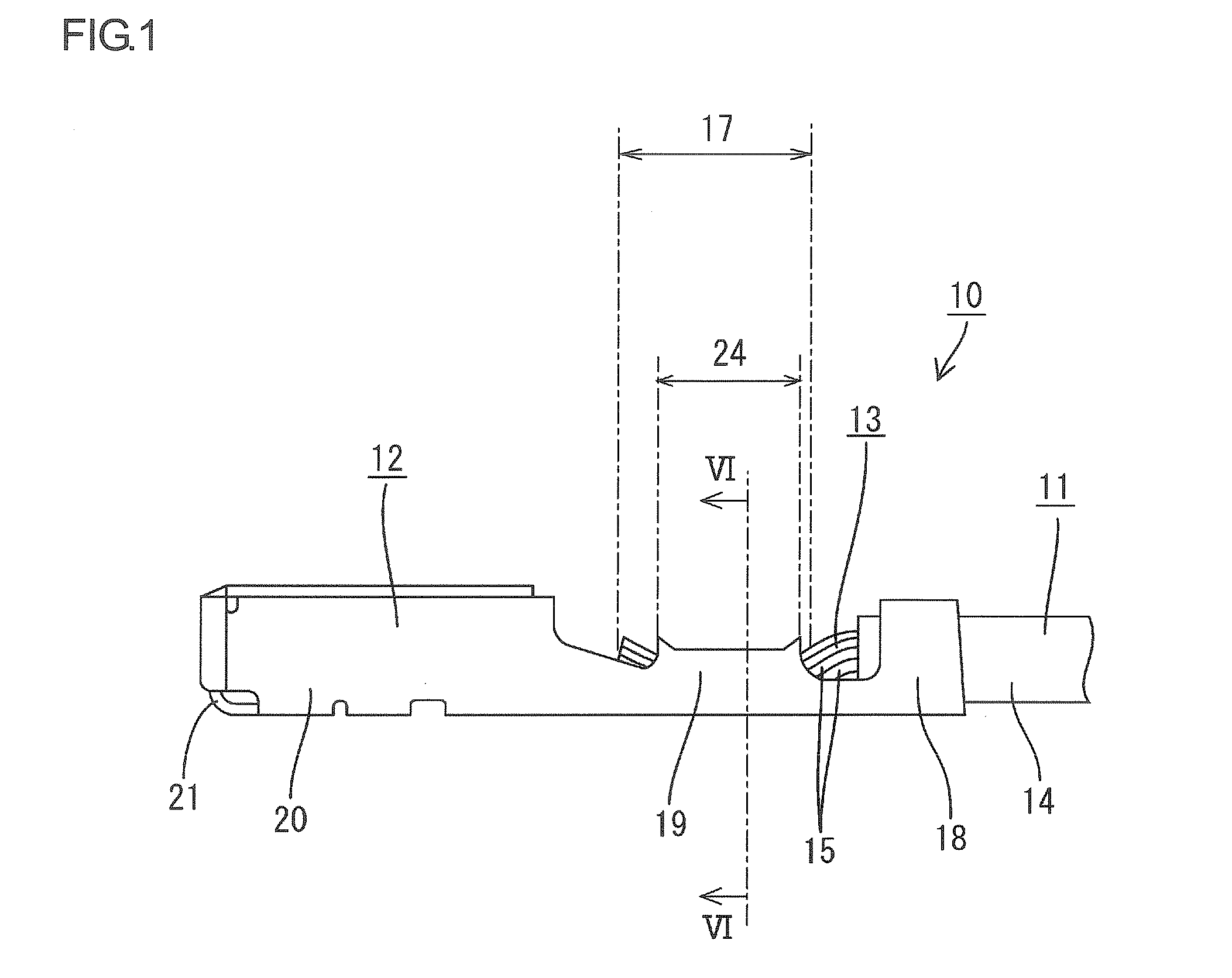

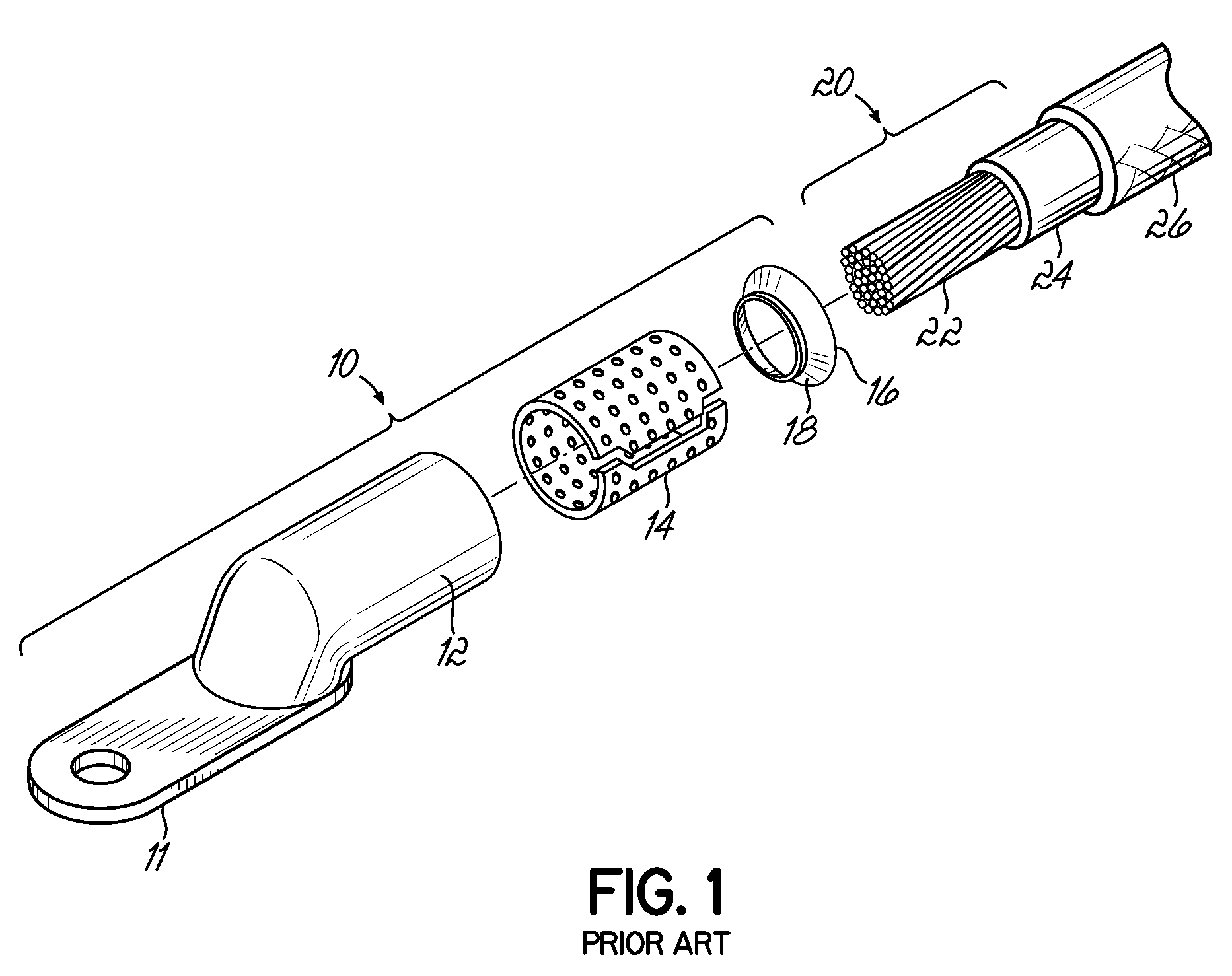

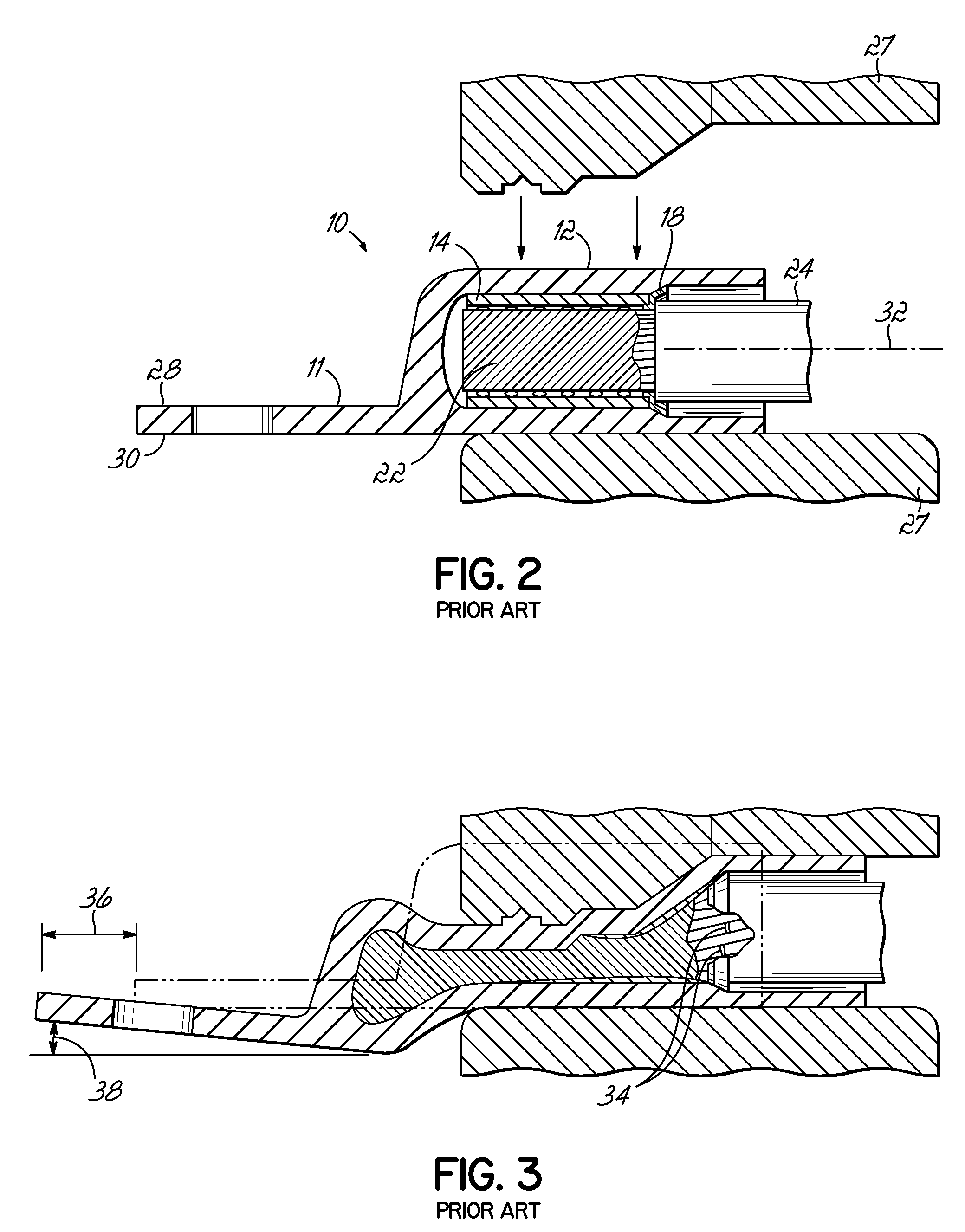

Electrical Connector For A Window Pane Of A Vehicle

InactiveUS20070224842A1Reduce stress concentrationMinimizes mechanical stressElectric discharge tubesSoldered/welded conductive connectionsElectrical conductorCoupling

A window pane has a substrate formed from glass and includes an electrical device including an electrical conductor. An electrical connector is operatively connected to and in electrical communication with the conductor for transferring electrical energy to the conductor. An electrical connector is bonded to the electrical conductor and has a first interacting portion. A terminal is disposed adjacent to the electrical connector and has a second interacting portion for interacting with the first interacting portion to mechanically couple the electrical connector and the terminal. The substrate has a first coefficient of thermal expansion and the connector has a second coefficient of thermal expansion. A difference between the first and second coefficients of thermal expansion is equal to or less than 5×10−6 / ° C. Due to the mechanical coupling between the connector and the terminal, the terminal and connector are less prone to bending, breakage, or delamination than conventional connector structures.

Owner:AGC AUTOMOTIVE AMERICAS

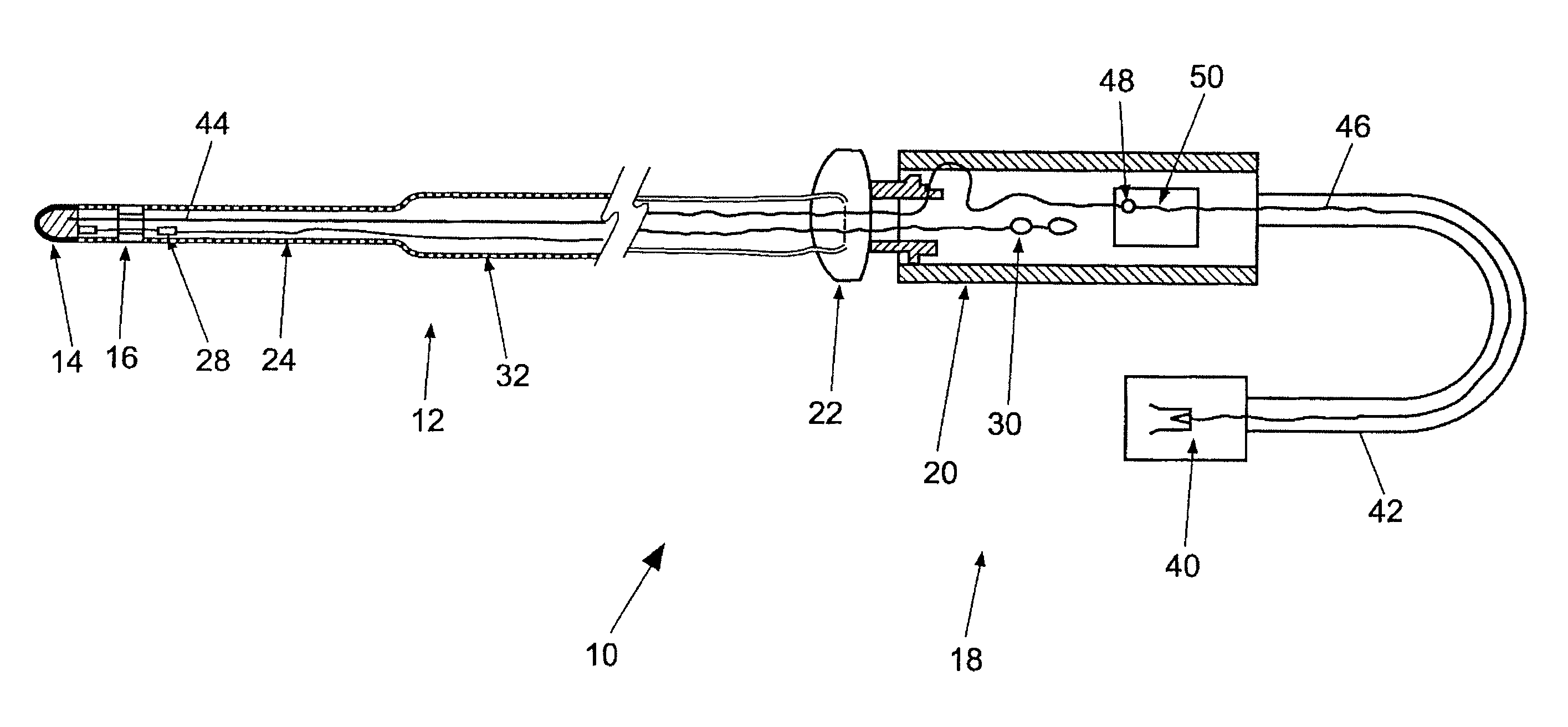

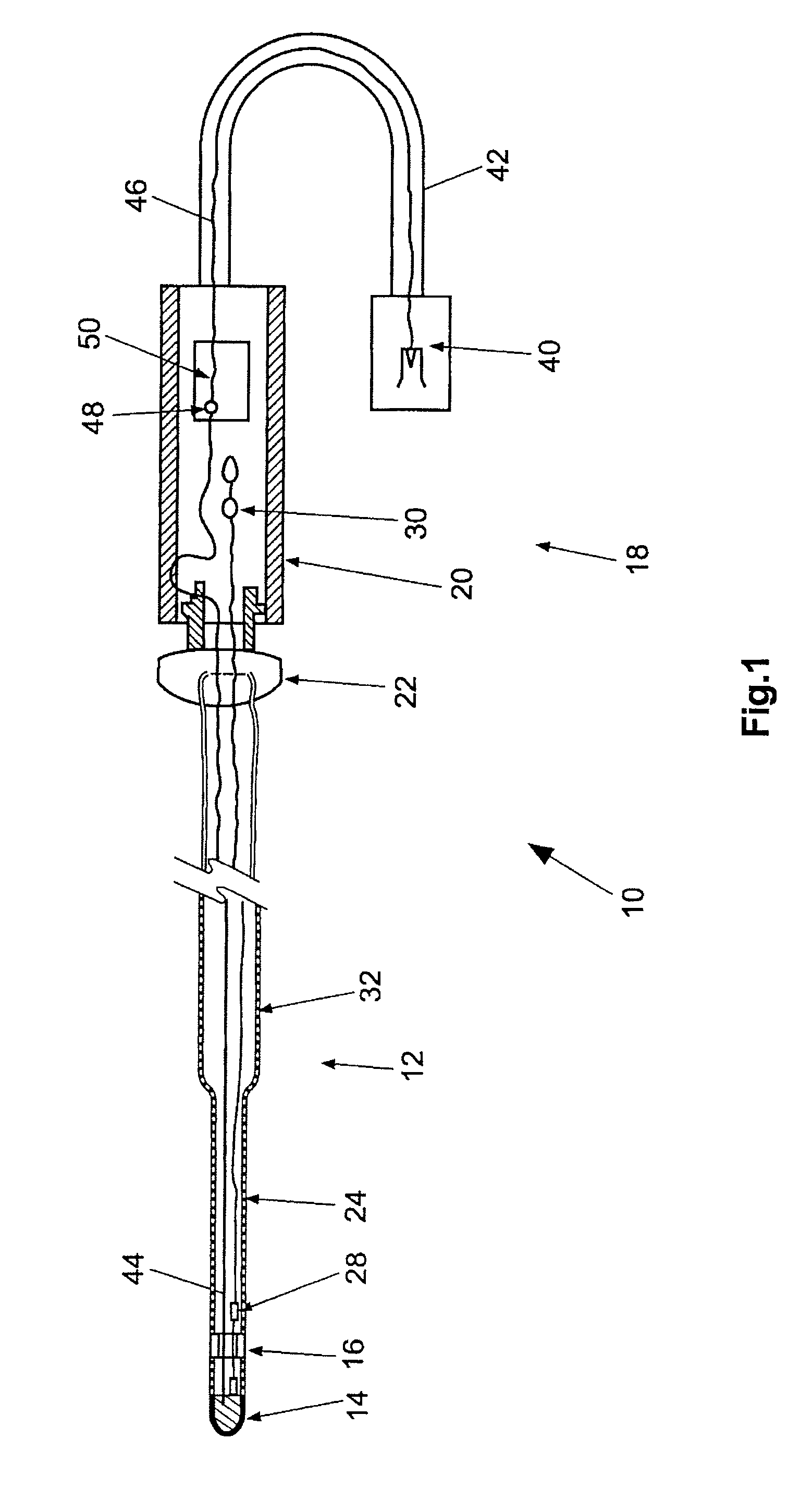

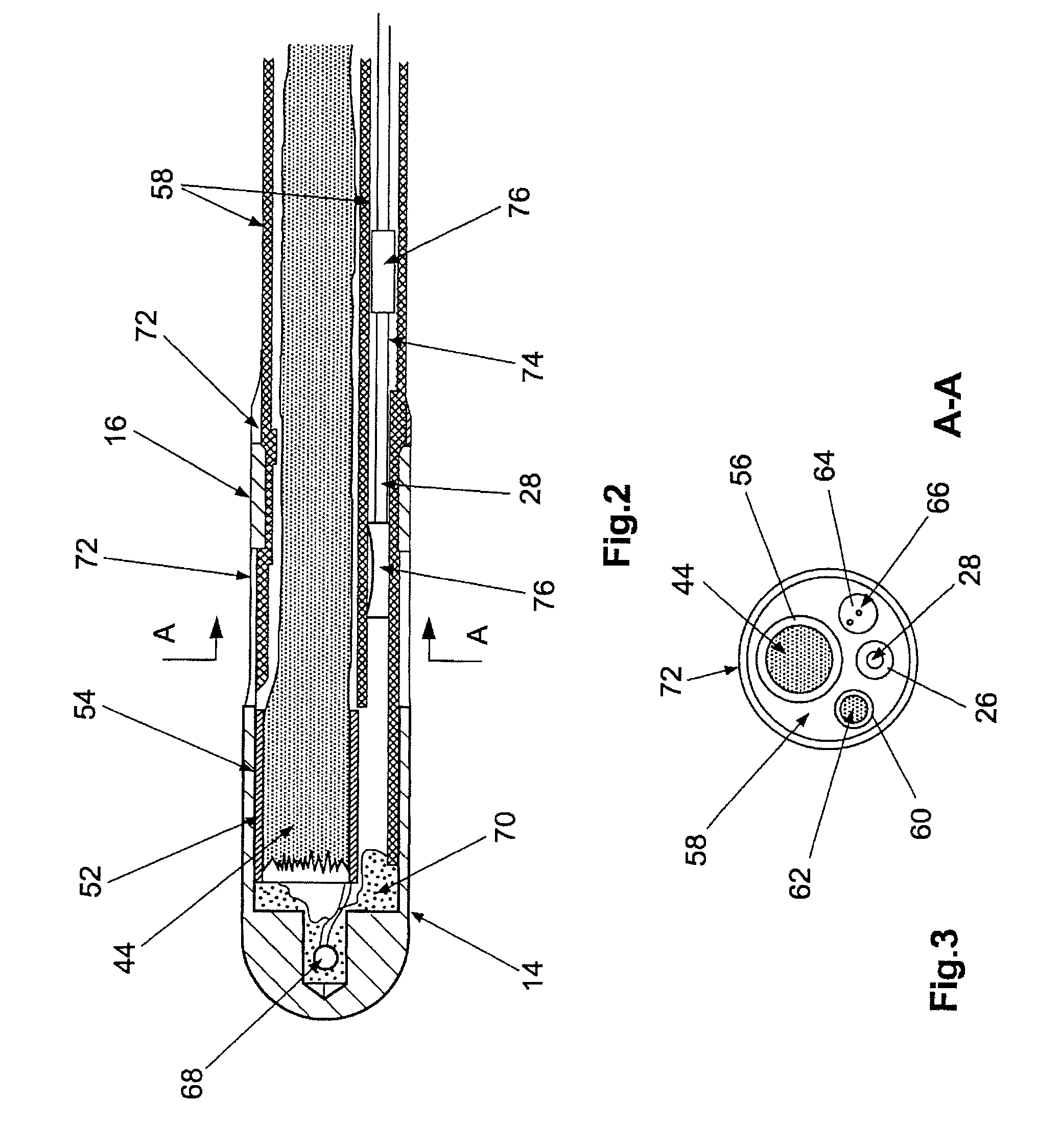

Electrode catheter for the electrotherapy of cardiac tissue

InactiveUS7896873B2Avoid tissue damageTransvascular endocardial electrodesDiagnostic recording/measuringElectrical conductorCatheter device

The present invention relates to an electrode catheter for defibrillation, mapping or ablation of cardiac tissue. Said catheter comprises a terminal (40) on the proximal end of the electrode catheter and one or more sensing and / or treatment electrodes (14, 16) that are situated on or in the vicinity of the distal end of the electrode catheter, in addition to at least one electric conductor (44, 62), which is used to electrically connect a respective sensing or treatment electrode to the terminal. The electric conductor (44, 62) is composed of carbon and the electrode catheter is configured to be suitable for us as part of magnetic resonance tomography and for connection to electrophysiotherapy equipment. Said catheter comprises at least one defibrillation electrode, or at least one sensing electrode (14, 16) for the recording and evaluation of cardiac tissue potentials, or at least one treatment electrode (14) for delivering high-frequency currents for ablation purposes.

Owner:VASCOMED GMBH

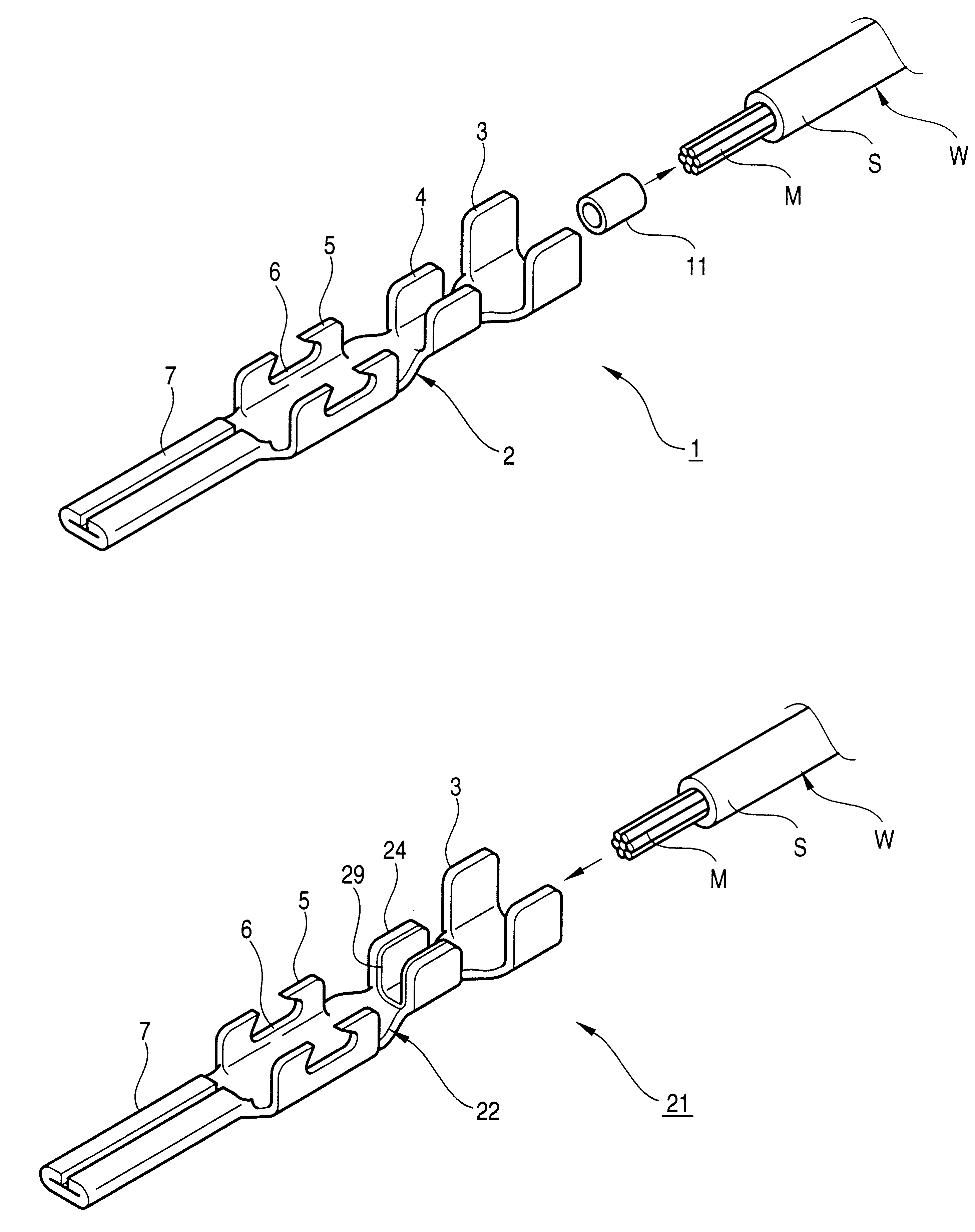

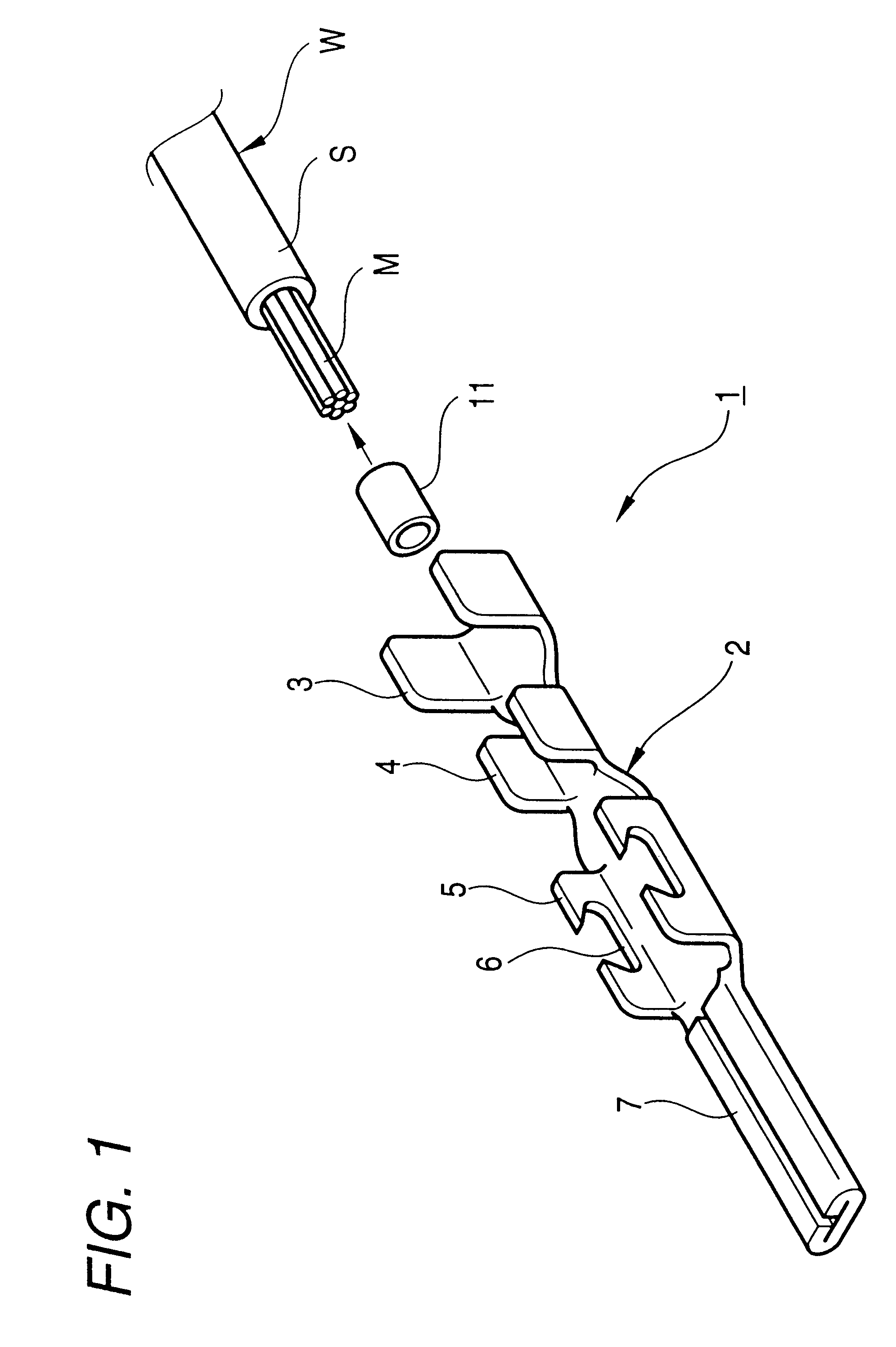

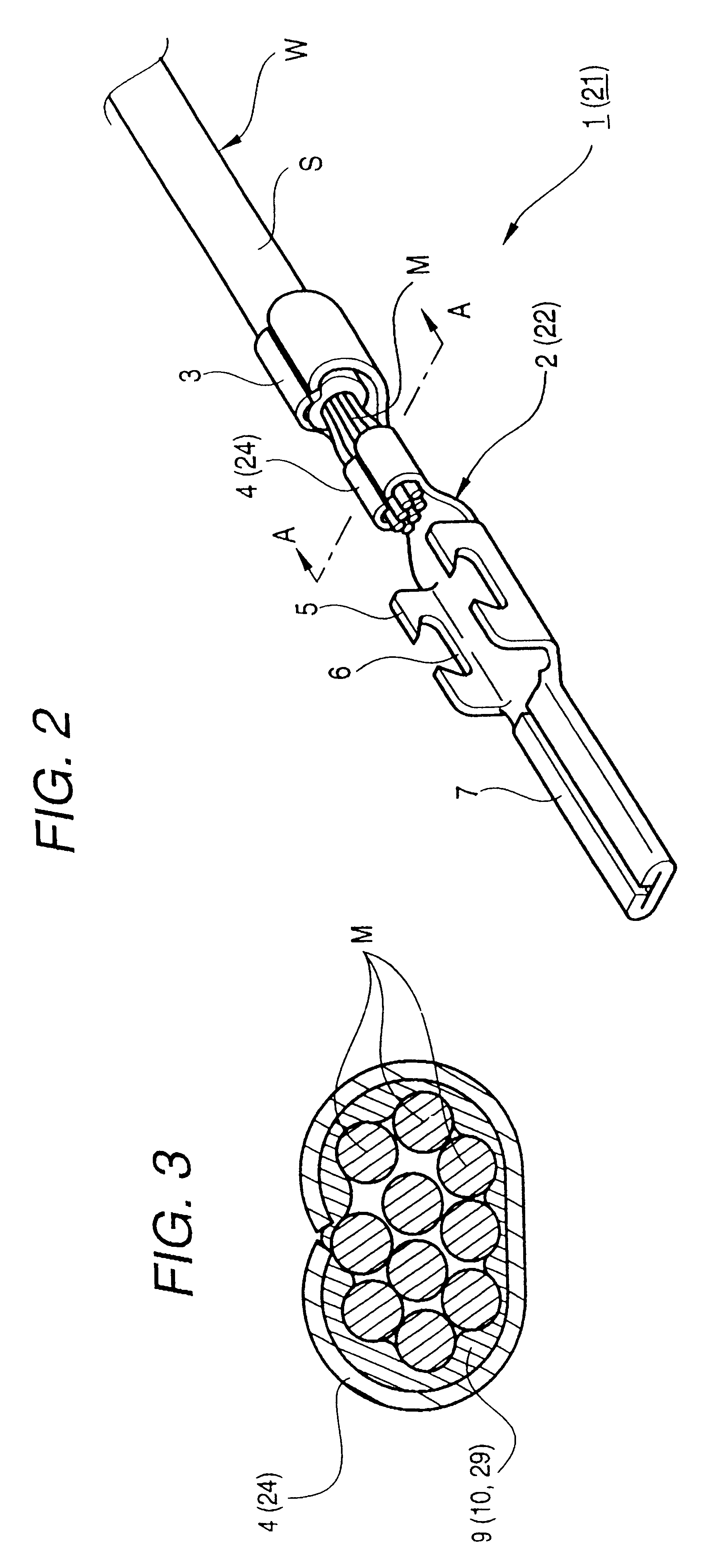

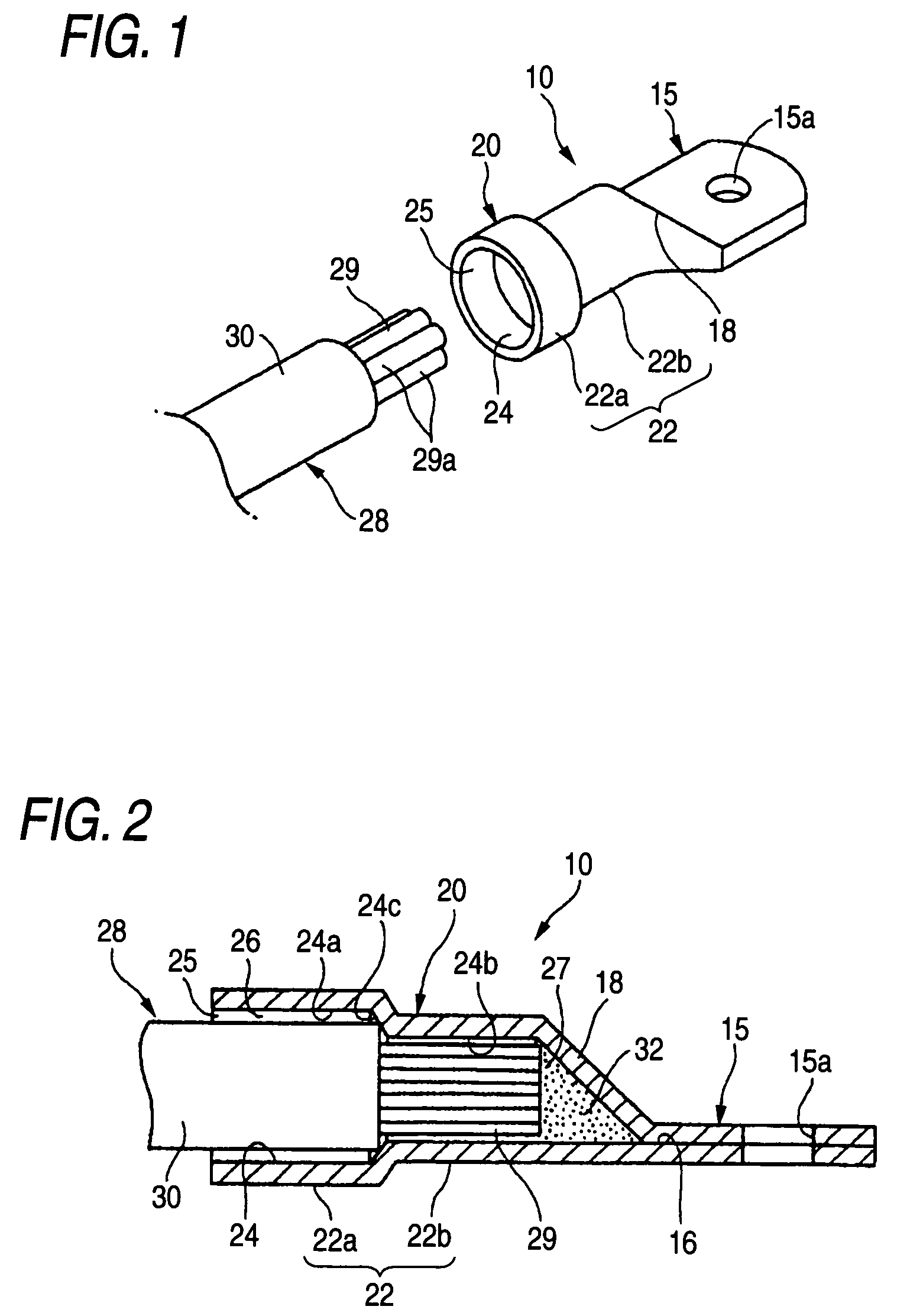

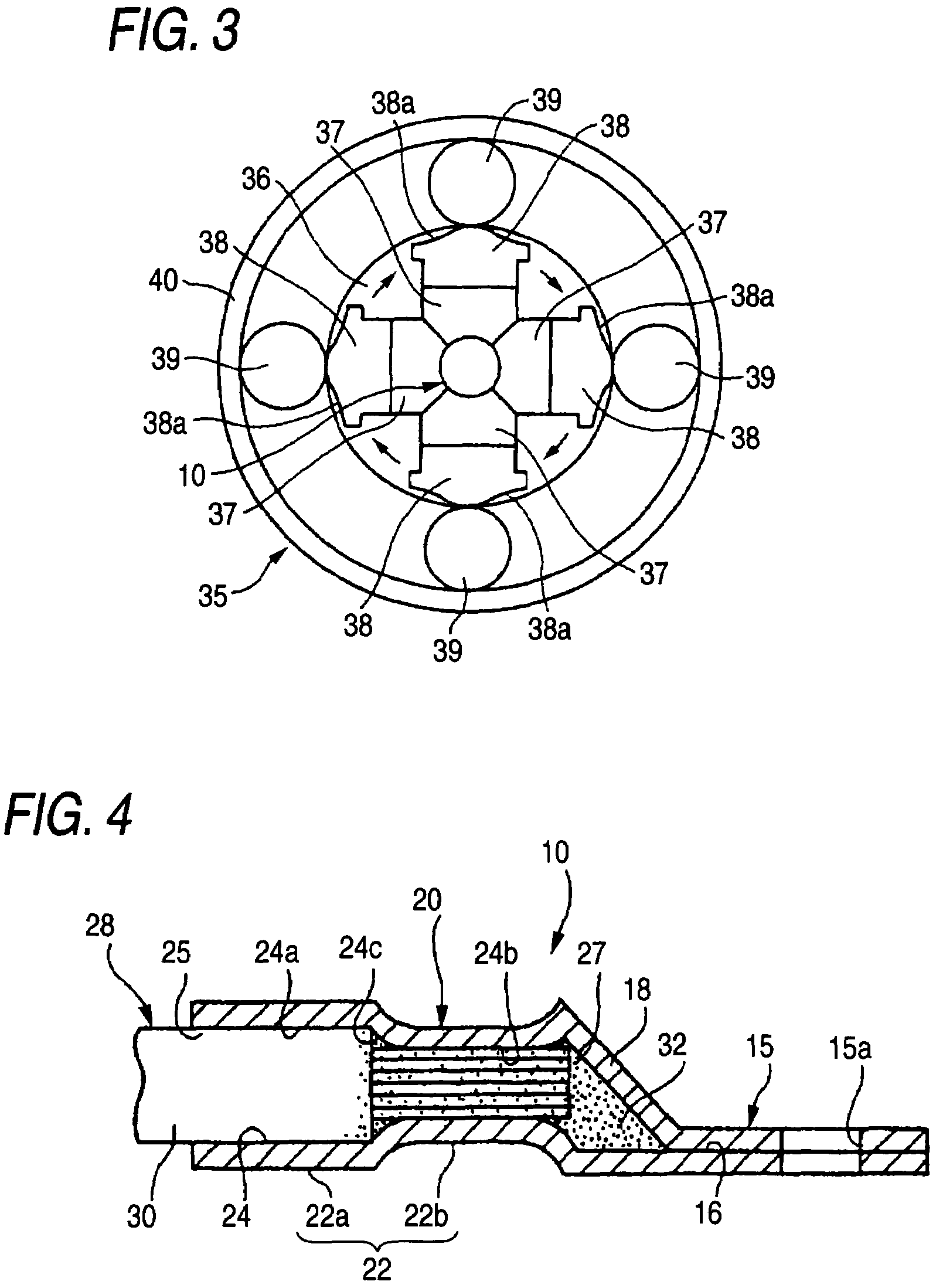

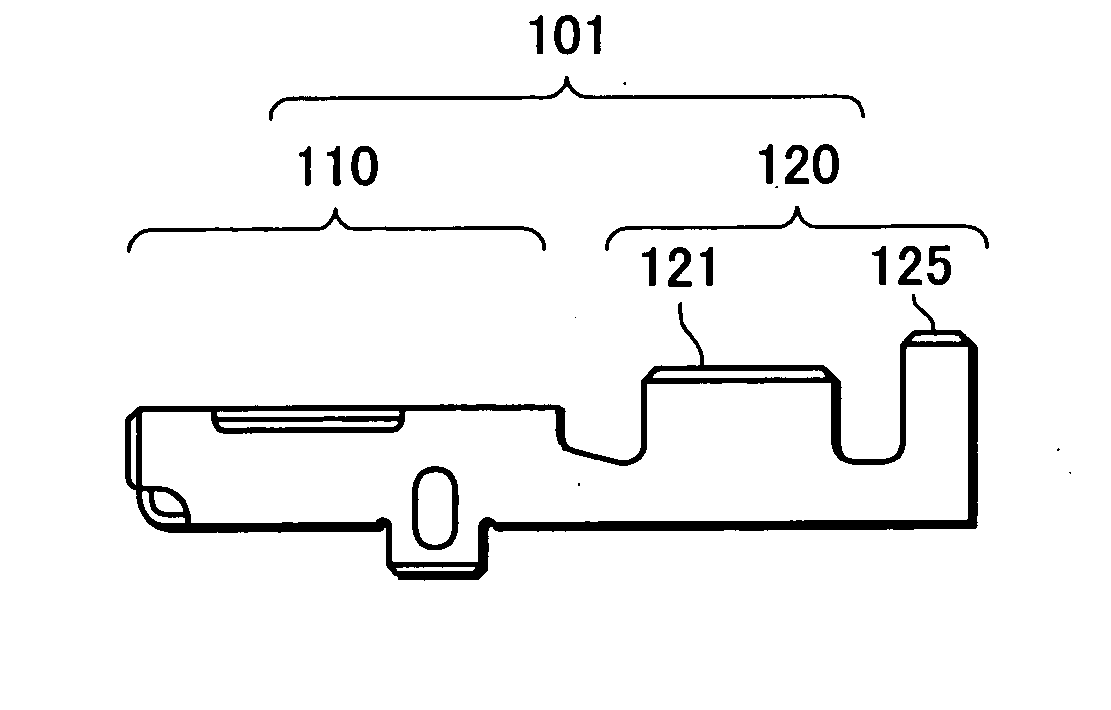

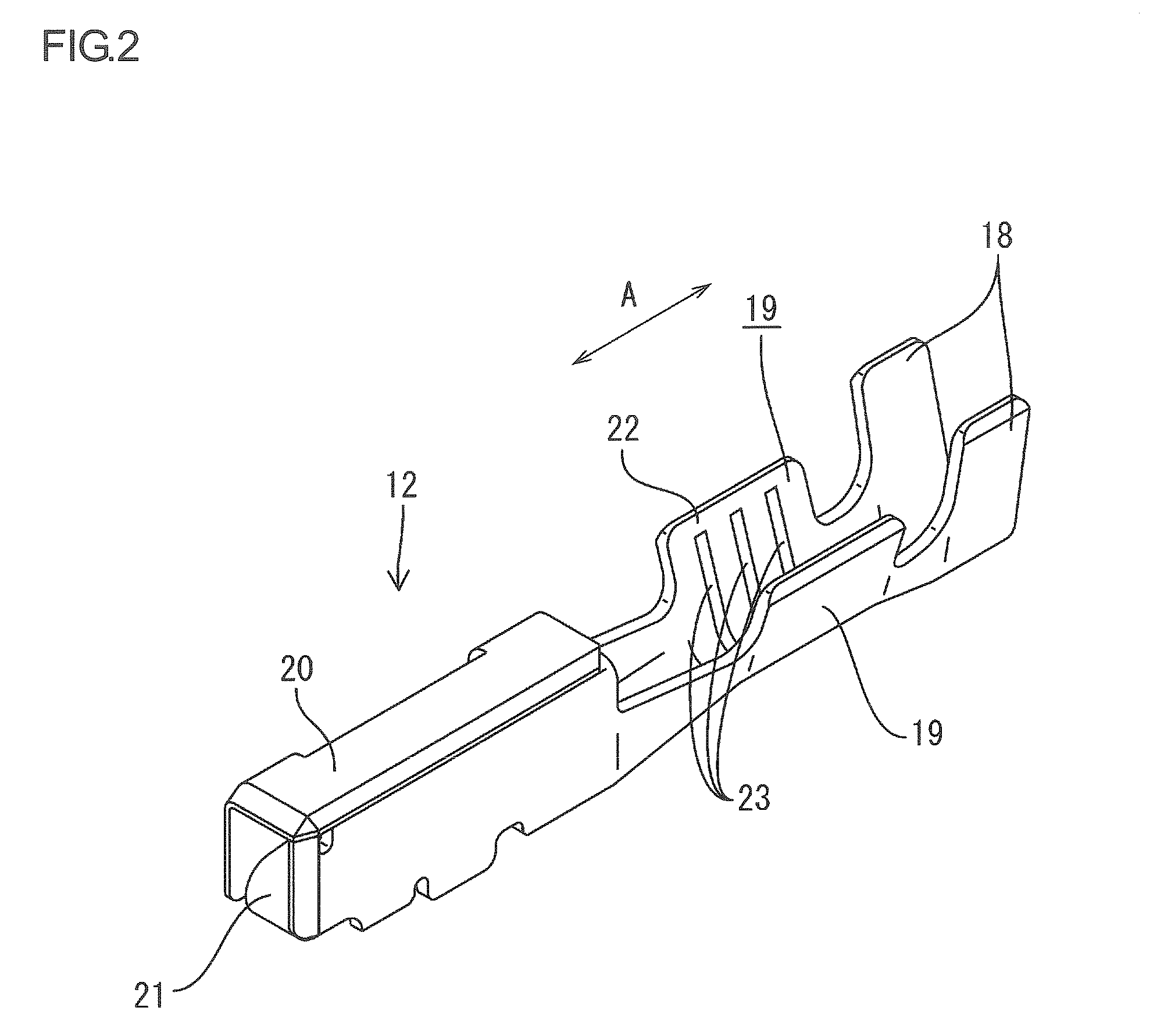

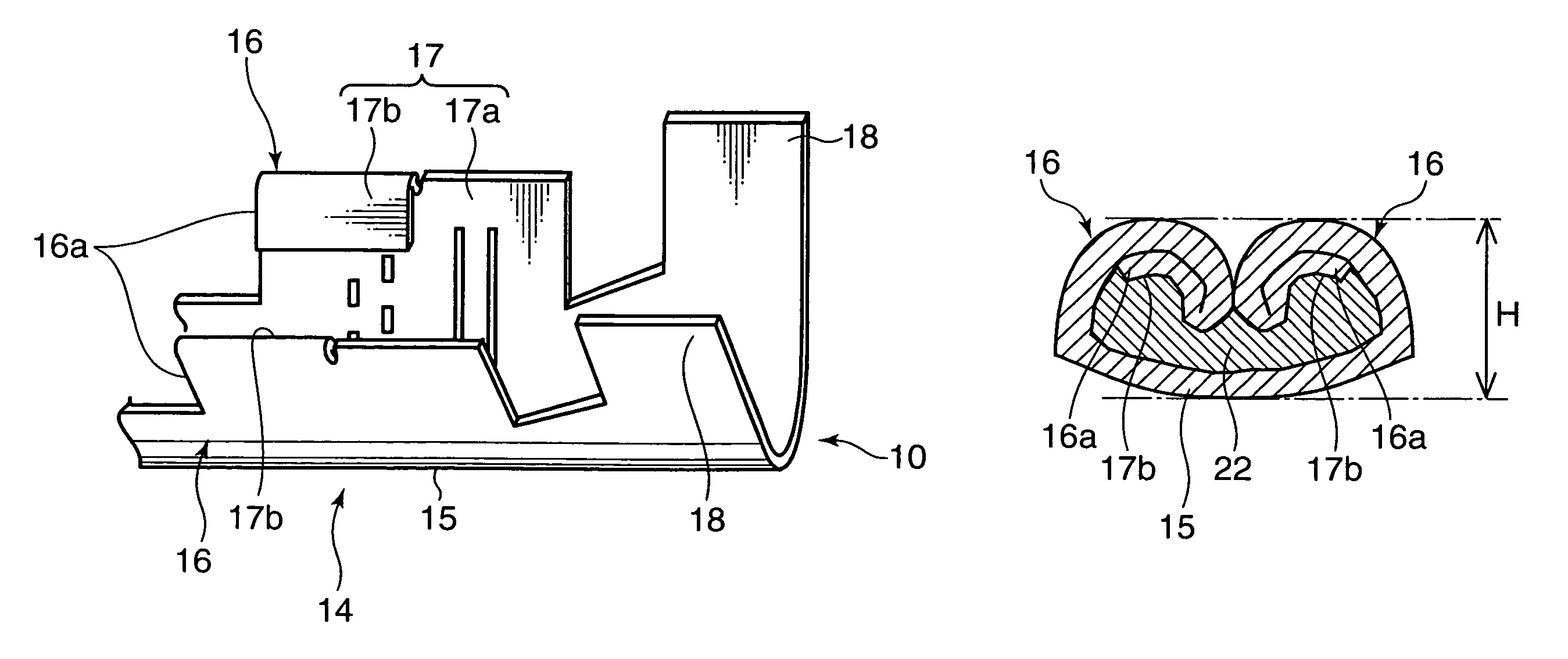

Method of and structure for connecting electric wire and connecting terminal

InactiveUS6334798B1Soldered/welded conductive connectionsConnections effected by permanent deformationElectrical conductorEngineering

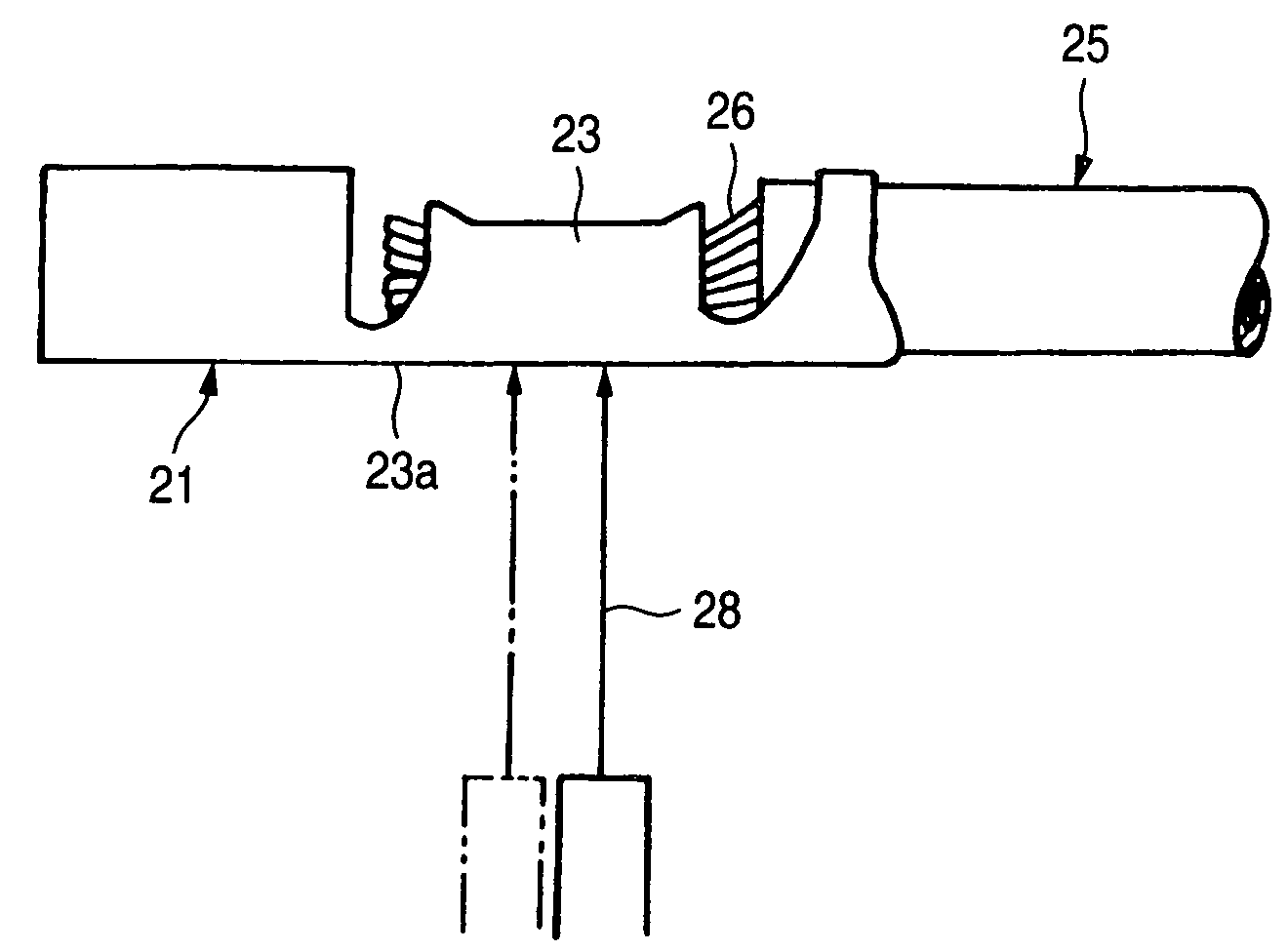

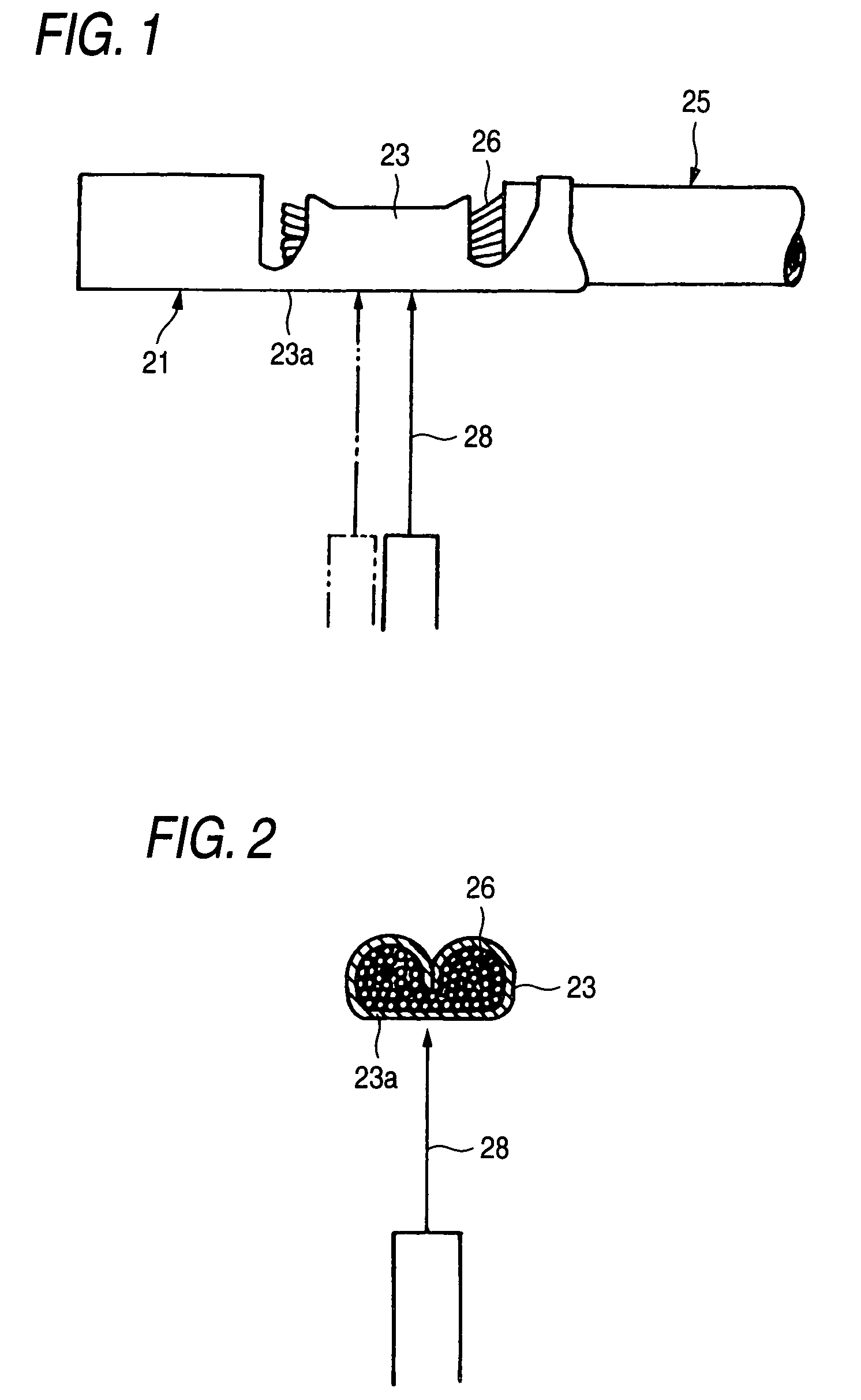

In a structure 21 for connecting an electric wire and a connecting terminal in the invention, a ductile metal film 29 is formed in advance on an inner surface of a conductor caulking portion 24 of a crimp terminal 22 by such as plating, vacuum deposition, or adhesion. Then, the conductor caulking portion 24 in the rear portion of the crimp terminal 22 is caulked onto core wire portions M in a state of being stripped and extended in the axial direction from an end of a sheathed wire W to thereby establish connection. Subsequently, the metal film 29 is fused on heating. Accordingly, the ductile metal film 29 enters gaps between the inner surface of the conductor caulking portion 24 and the core wire portions M and between adjacent ones of the core wire portions M by the caulking stress. Hence, the area of contact between the conductor caulking portion 24 and the core wire portions M via the metal film 29 increases, and conductivity improves, thereby making it possible to suppress heat generation.

Owner:YAZAKI CORP

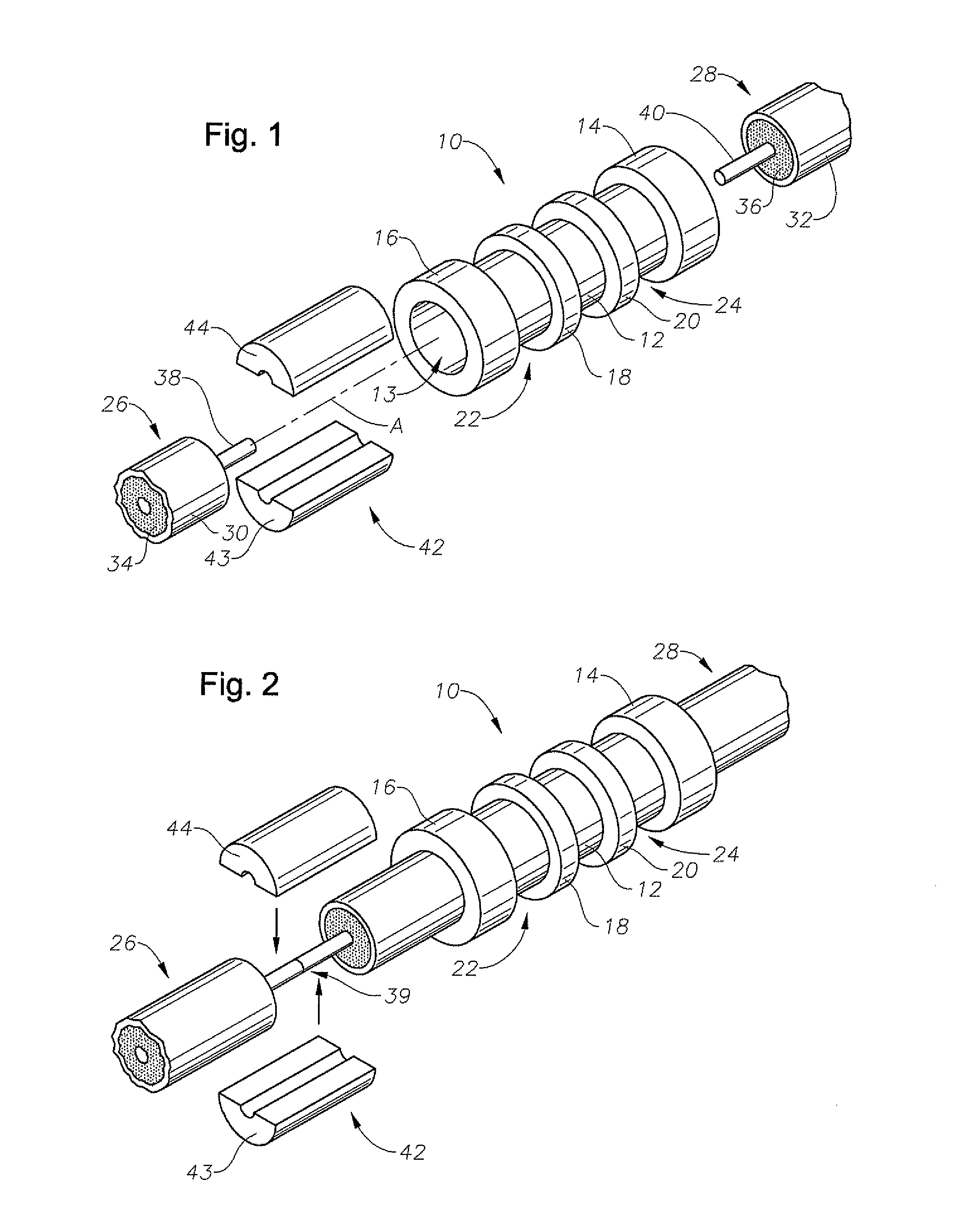

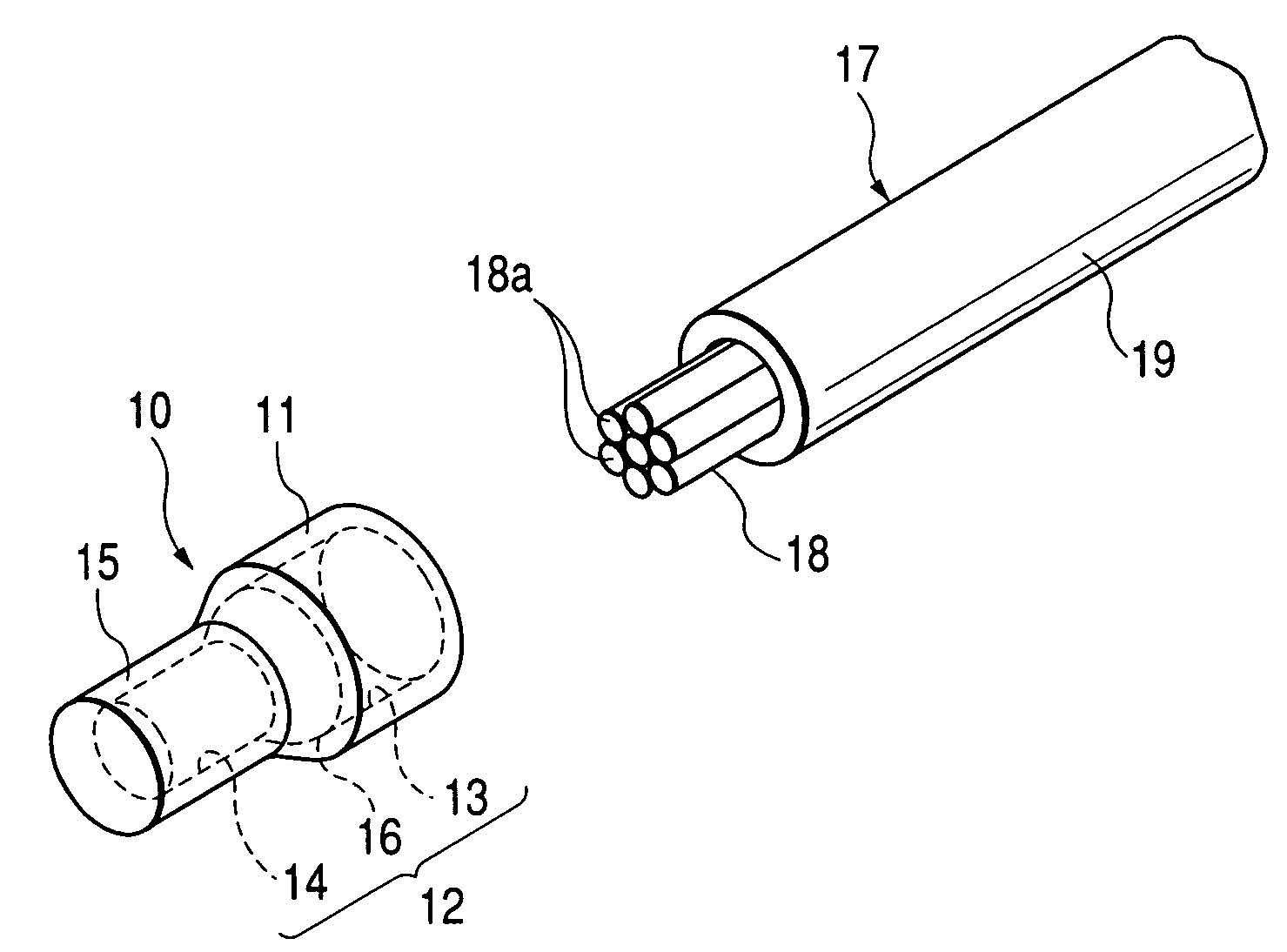

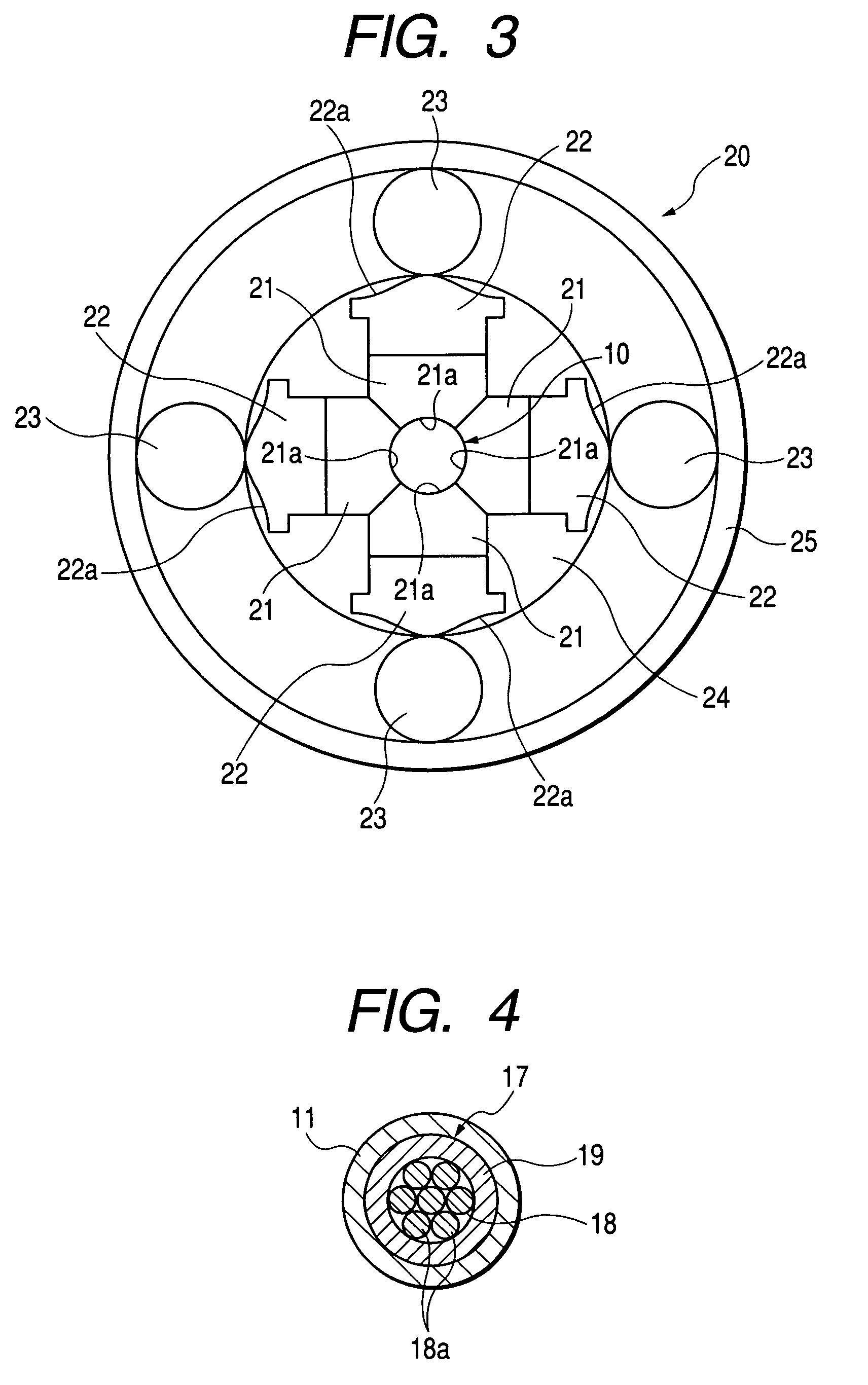

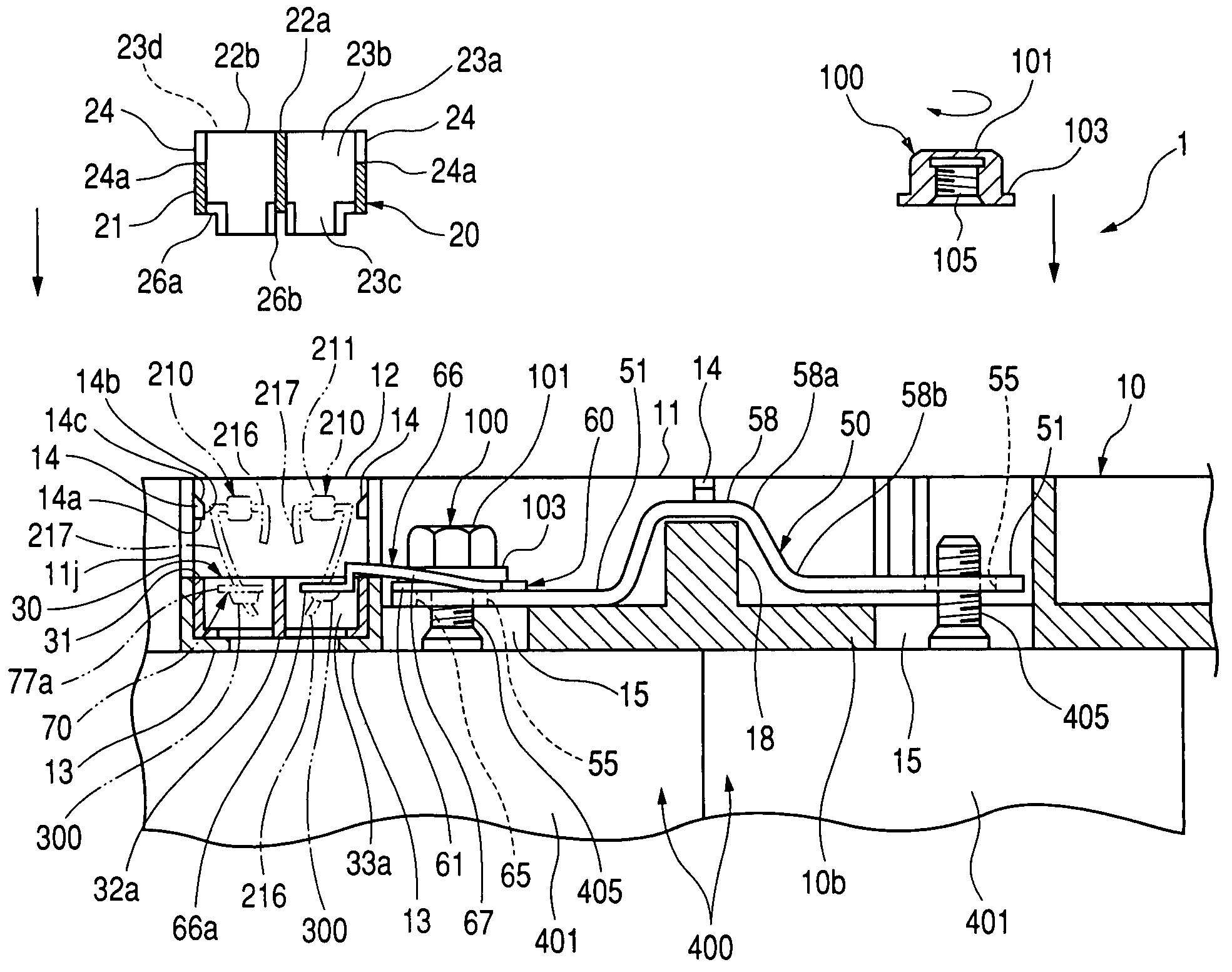

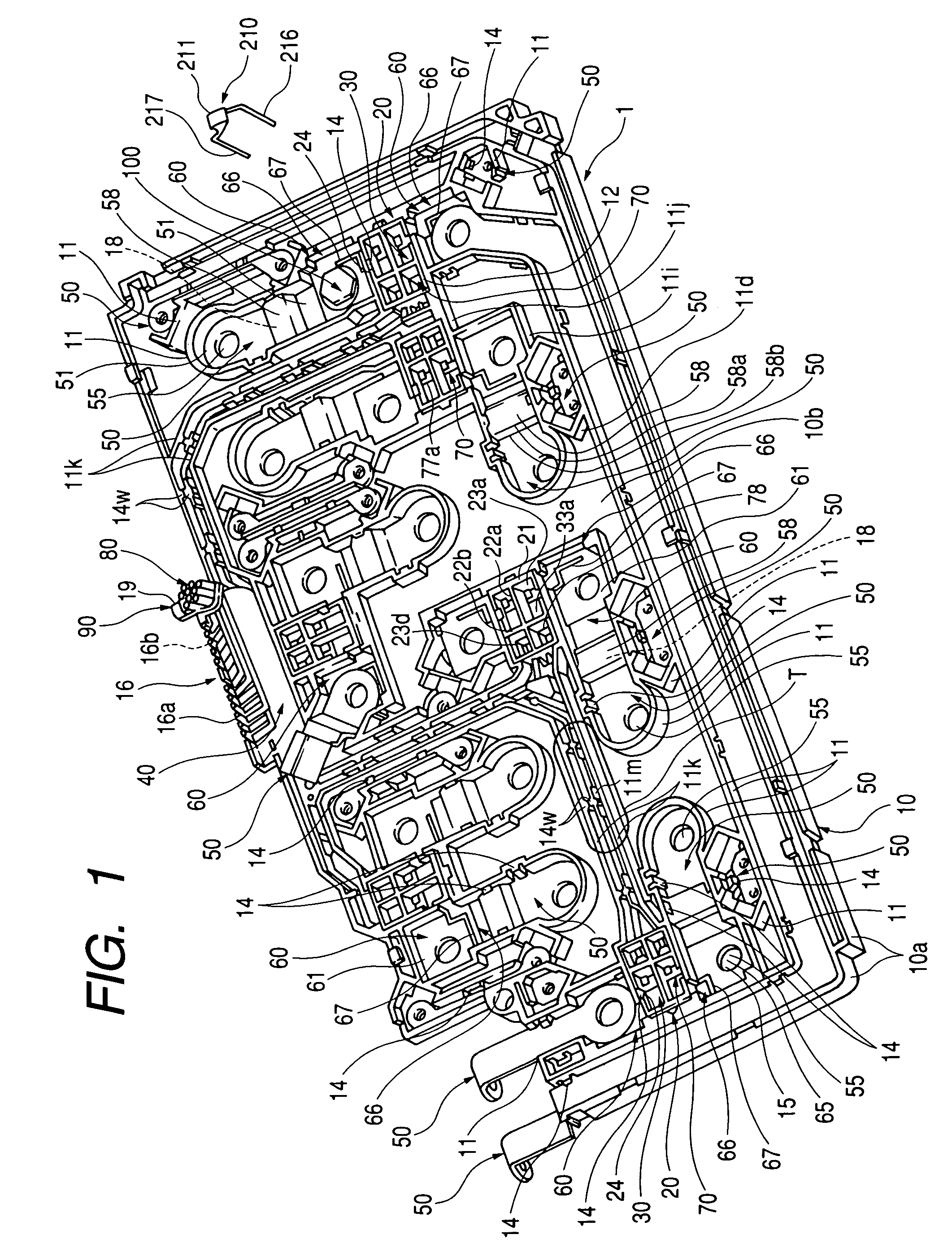

Mineral insulated metal sheathed cable connector and method of forming the connector

InactiveUS7622677B2Coupling device detailsConnections effected by permanent deformationElectrical elementMetal

A connection for a mineral insulated metal sheathed cable, wherein the connection employs a compression fitting. The connection may make up two or more mineral insulated metal sheathed cables wherein one or more of the cables may be secured with a compression fitting. The connection may splice together two individual cables, or a cable to an electrical element.

Owner:ACCUTRU INT

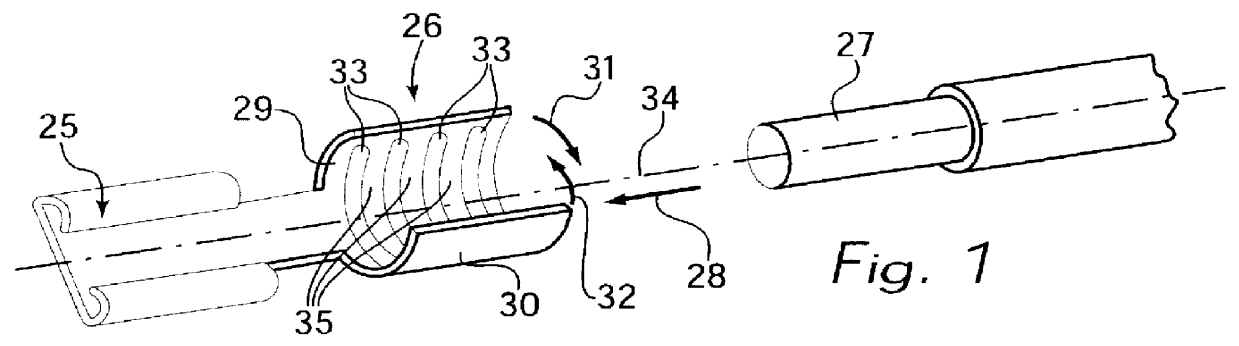

Method of connecting terminal and electric wire

ActiveUS7174633B2Few partsLow costPrinted circuit assemblingElectrically conductive adhesive connectionsEpoxyElectricity

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

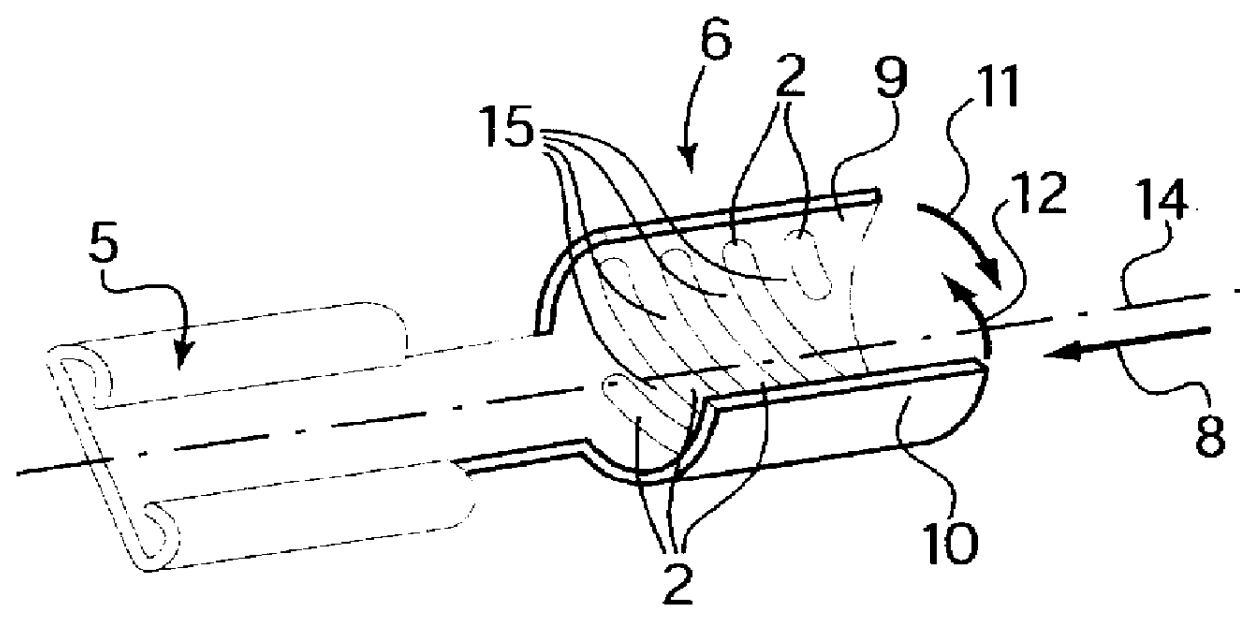

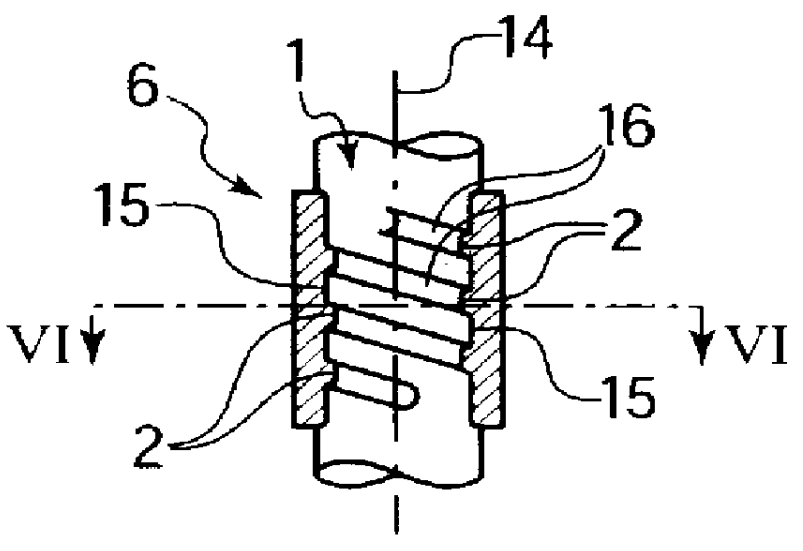

Contact element with crimp section

InactiveUS6056605ACoupling device detailsConnections effected by permanent deformationElectrical conductorEngineering

PCT No. PCT / DE96 / 01684 Sec. 371 Date Jun. 24, 1998 Sec. 102(e) Date Jun. 24, 1998 PCT Filed Sep. 9, 1996 PCT Pub. No. WO97 / 16867 PCT Pub. Date May 9, 1997To reduce the risk of breakage and yet ensure good electric and thermal conductivity, pull-off strength and long service life of the connection, when connecting a contact element to a conductor (1) by crimping, the inner surface of the crimp section (6), in contact with the conductor (1), is provided with deformations that are grooves (2) and ribs running crosswise and obliquely to the longitudinal axis of the conductor (1).

Owner:ROBERT BOSCH GMBH

Feedthrough assembly including sleeve and methods related thereto

InactiveUS7561917B2Heart defibrillatorsSoldered/welded conductive connectionsElectrical conductorBiomedical engineering

Owner:CARDIAC PACEMAKERS INC

Sealed terminating device

InactiveUS6839428B2Interconnection arrangementsElectric discharge tubesTerminal equipmentEngineering

A terminating device for interconnecting service provider wiring with subscriber wiring includes a base, a customer bridge, a removable cover and insulation displacement contacts for terminating the service provider wiring and the subscriber wiring. The insulation displacement contacts for the subscriber wiring are housed within the customer bridge and terminate the subscriber wiring by moving an actuating arm from a disconnected position to a connected position. The insulation displacement contacts for the service provider wiring terminate the service provider wiring by moving a stuffer from a disconnected position to a connected position. The cover includes a locking slide having a movable clasp for deterring unauthorized access to the customer bridge, while permitting authorized access. A plug on the cover and a jack on the base each have a resilient seal that telescope together to effectively seal test contacts located within the jack when the plug is inserted into the jack.

Owner:CORNING OPTICAL COMM LLC

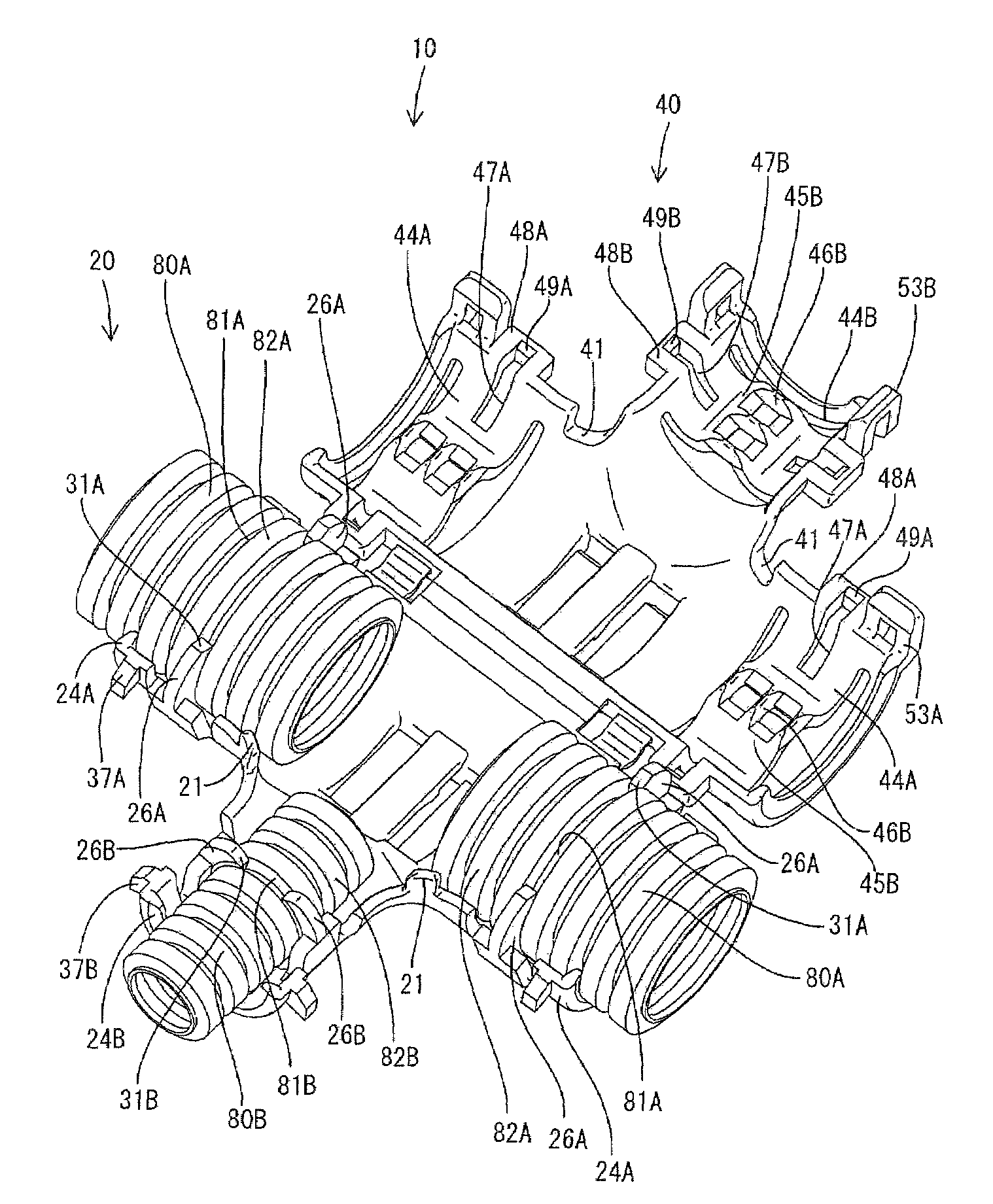

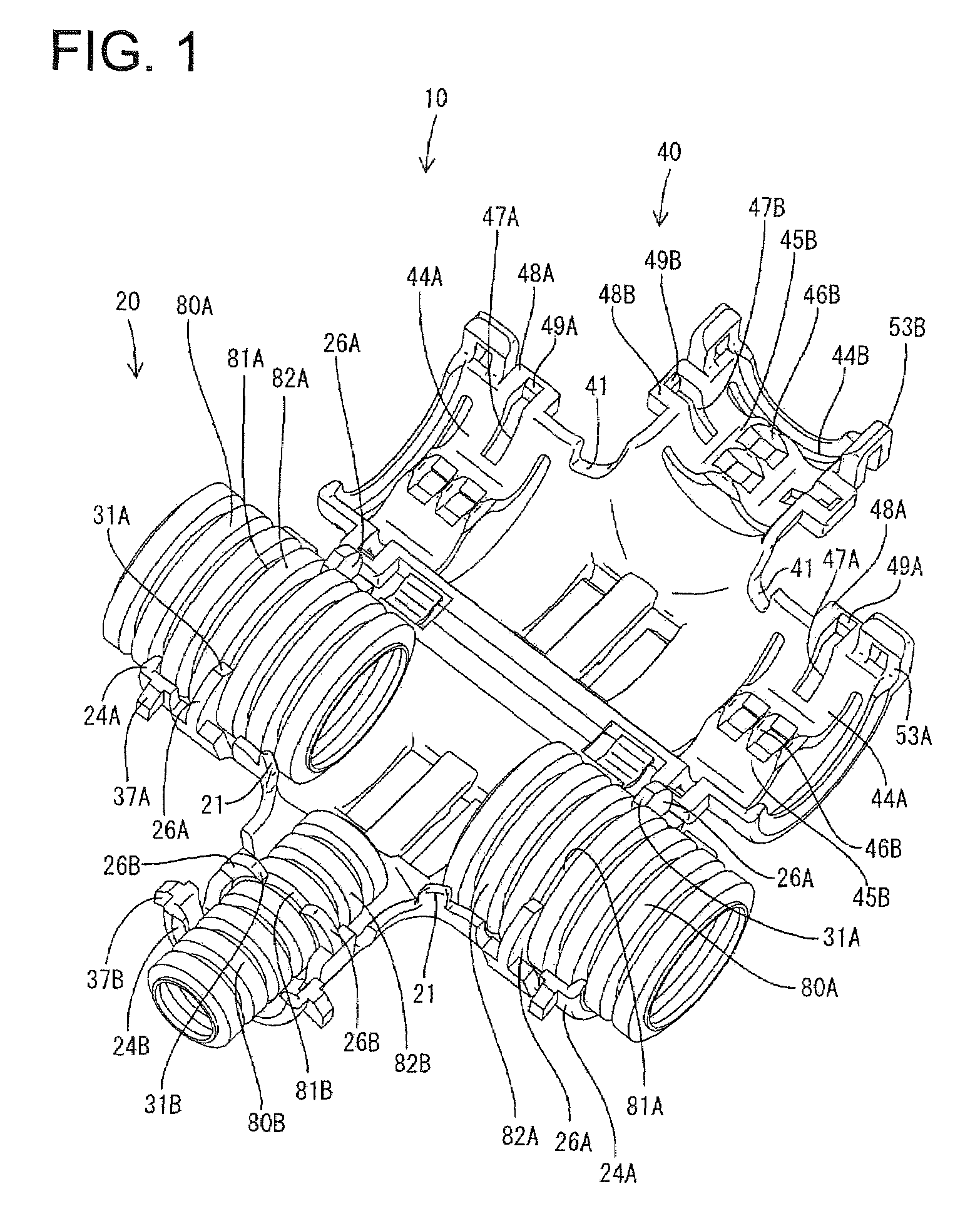

Electric connector for shielded cable, a connector body thereof and a method of producing the electric connector

InactiveUS6652296B2Firmly connectedImpedance stabilityContact member assembly/disassemblySecuring/insulating coupling contact membersShielded cableElectrical conductor

Owner:JST MFG CO LTD

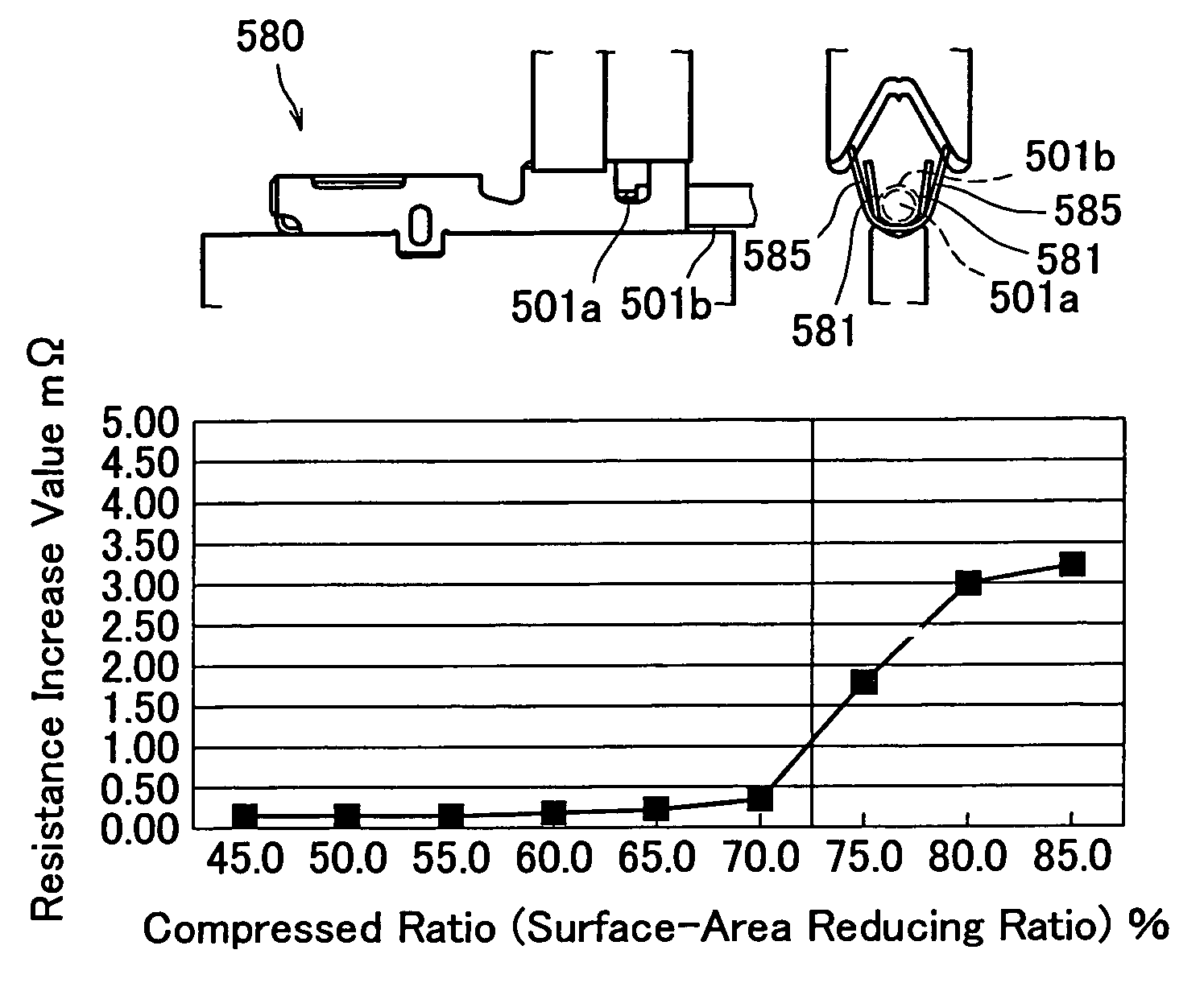

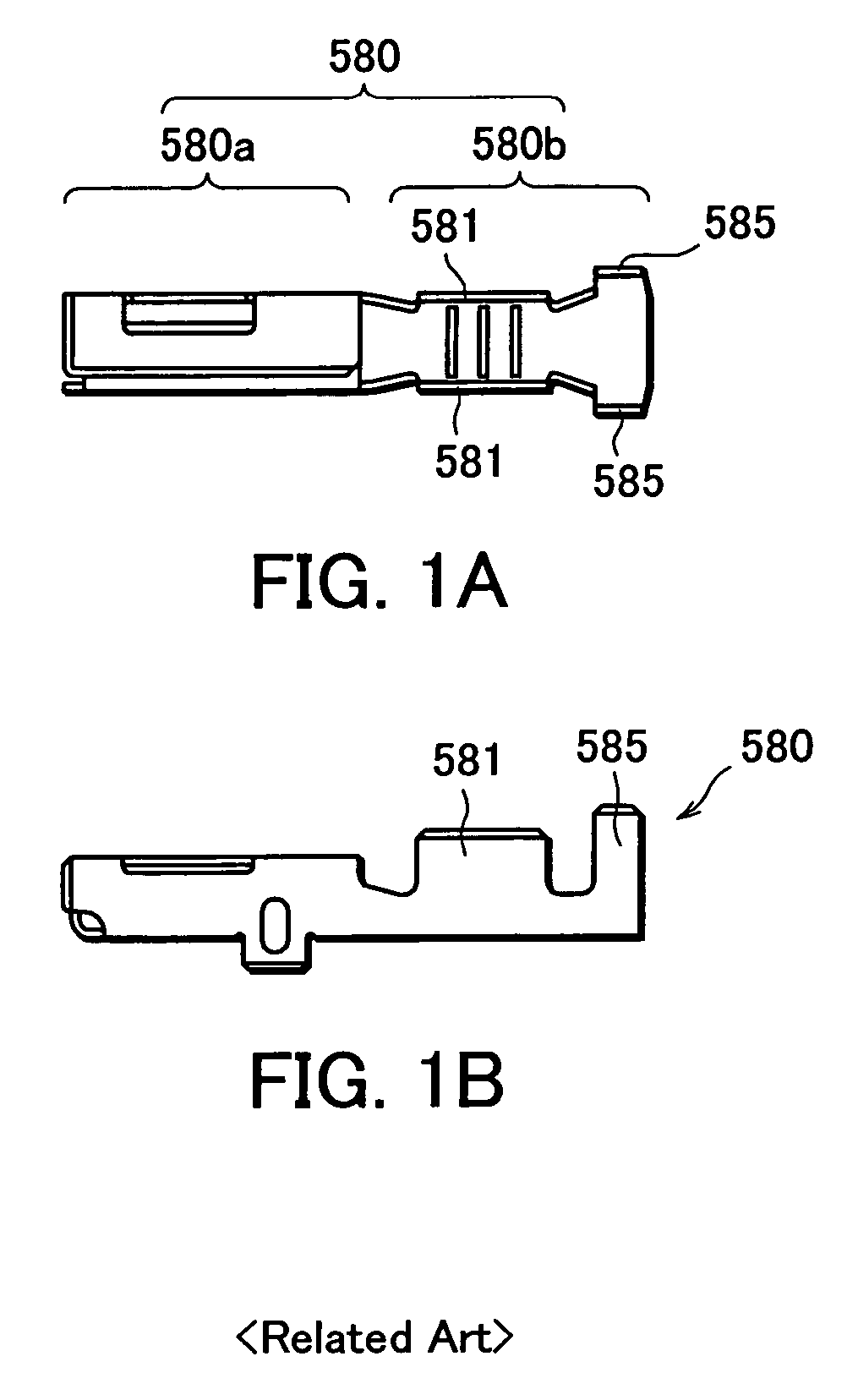

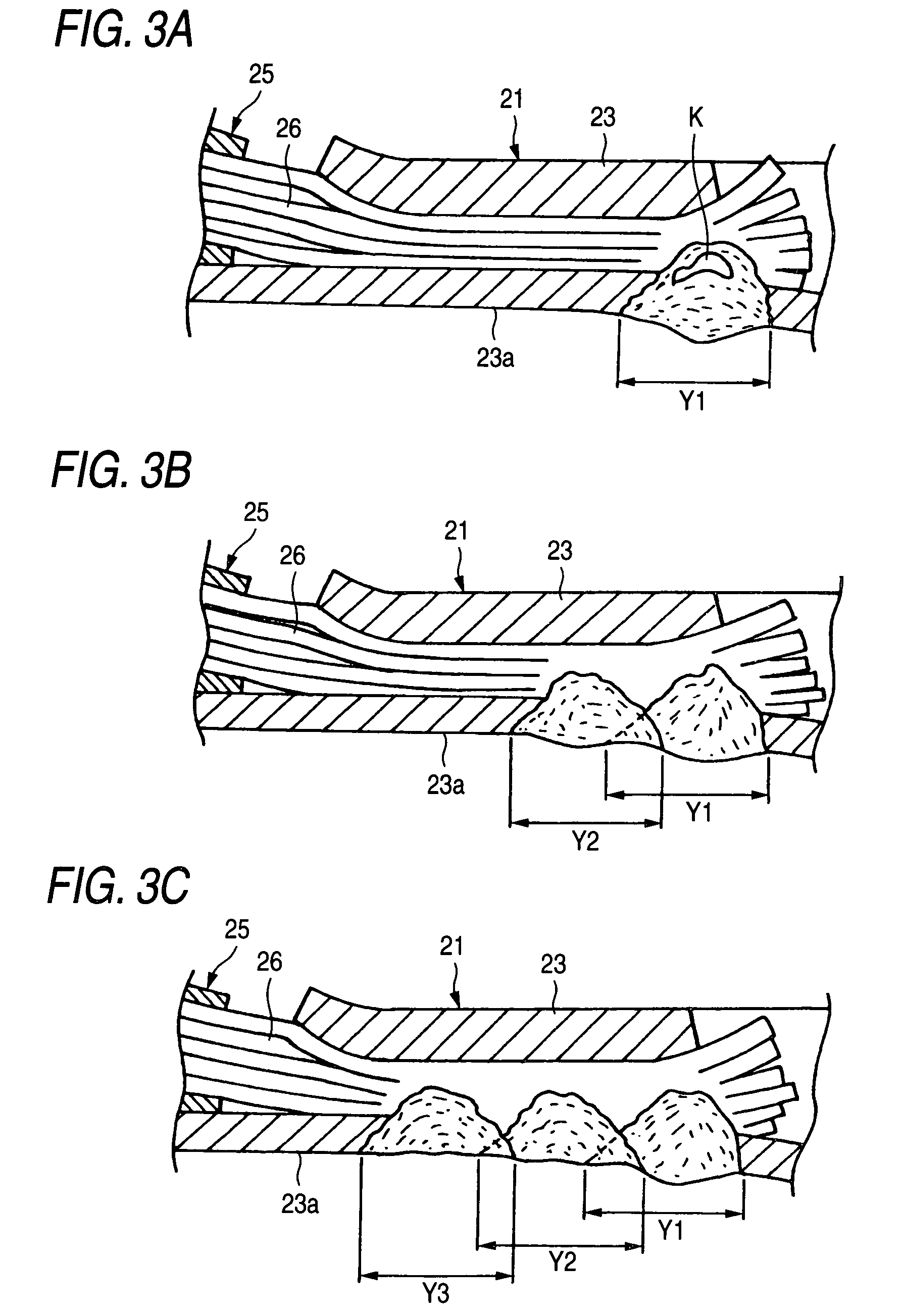

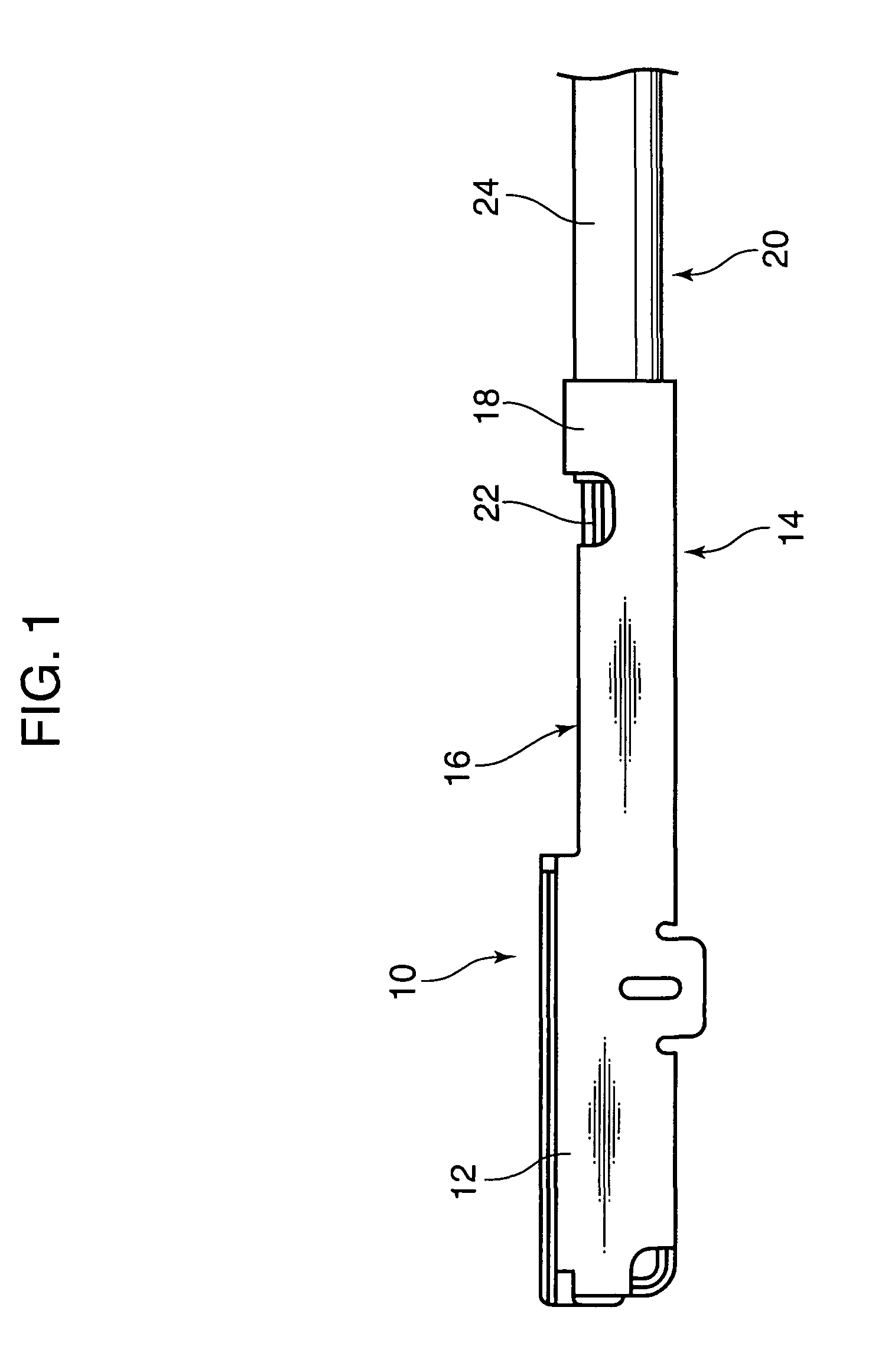

Terminal crimping structure and terminal crimping method onto aluminum electric-wire and producing method of aluminum electric-wire with terminal

ActiveUS7306495B2Maintenance characteristicSufficient electric conducting propertyLine/current collector detailsConnections effected by permanent deformationElectrical conductorEngineering

A terminal crimping structure onto aluminum electric-wire, for crimping a terminal onto an aluminum electric-wire including: an electrical conductor part comprising numerous strands; and a coating part coated on the . electrical conductor part; wherein the terminal has a wire barrel to be crimped onto the electrical conductor part of the aluminum electric-wire; and wherein the compressed ratio of the aluminum electric-wire's conductor part by the wire barrel is within a range of 50 to 70%, in terms of the ratio of (cross-sectional area of aluminum electric-wire's conductor part at crimped portion) / (cross-sectional area of aluminum electric-wire's conductor part before crimping).

Owner:FURUKAWA ELECTRIC CO LTD

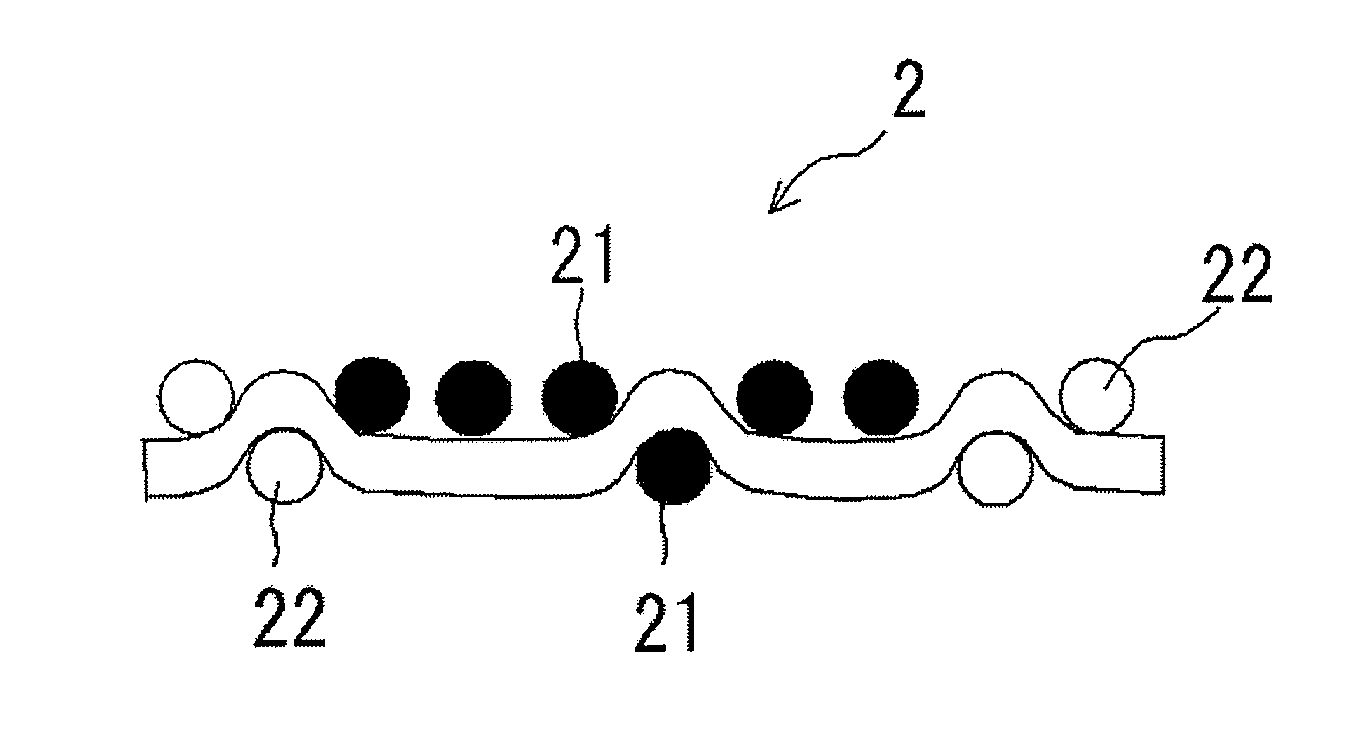

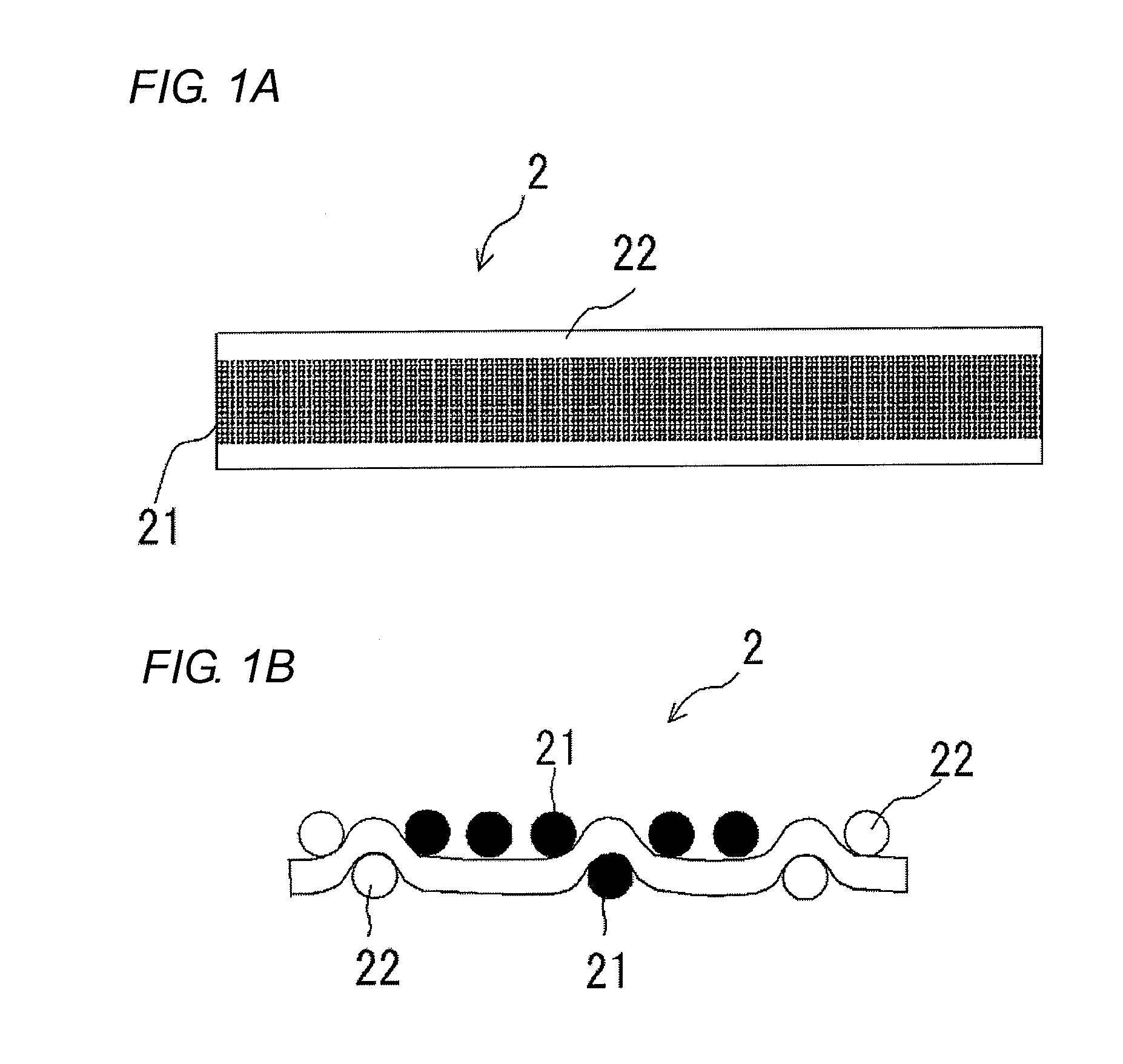

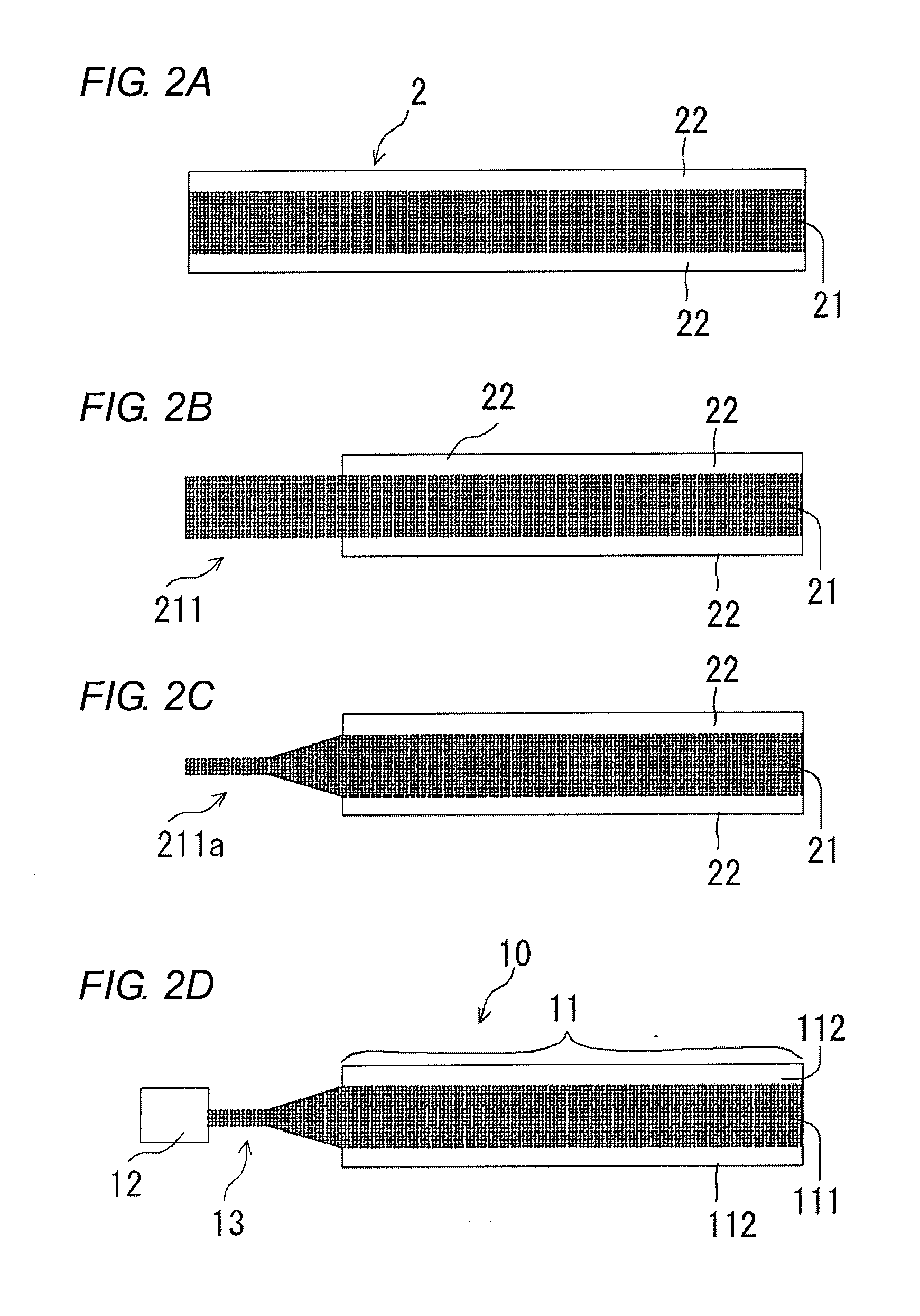

Connection member, method of manufacturing the same and connection structure

InactiveUS20120156926A1Easy to implementReduce in quantityLine/current collector detailsCarpetsBand shapeElectrical and Electronics engineering

Owner:TOYOTA BOSHOKU KK

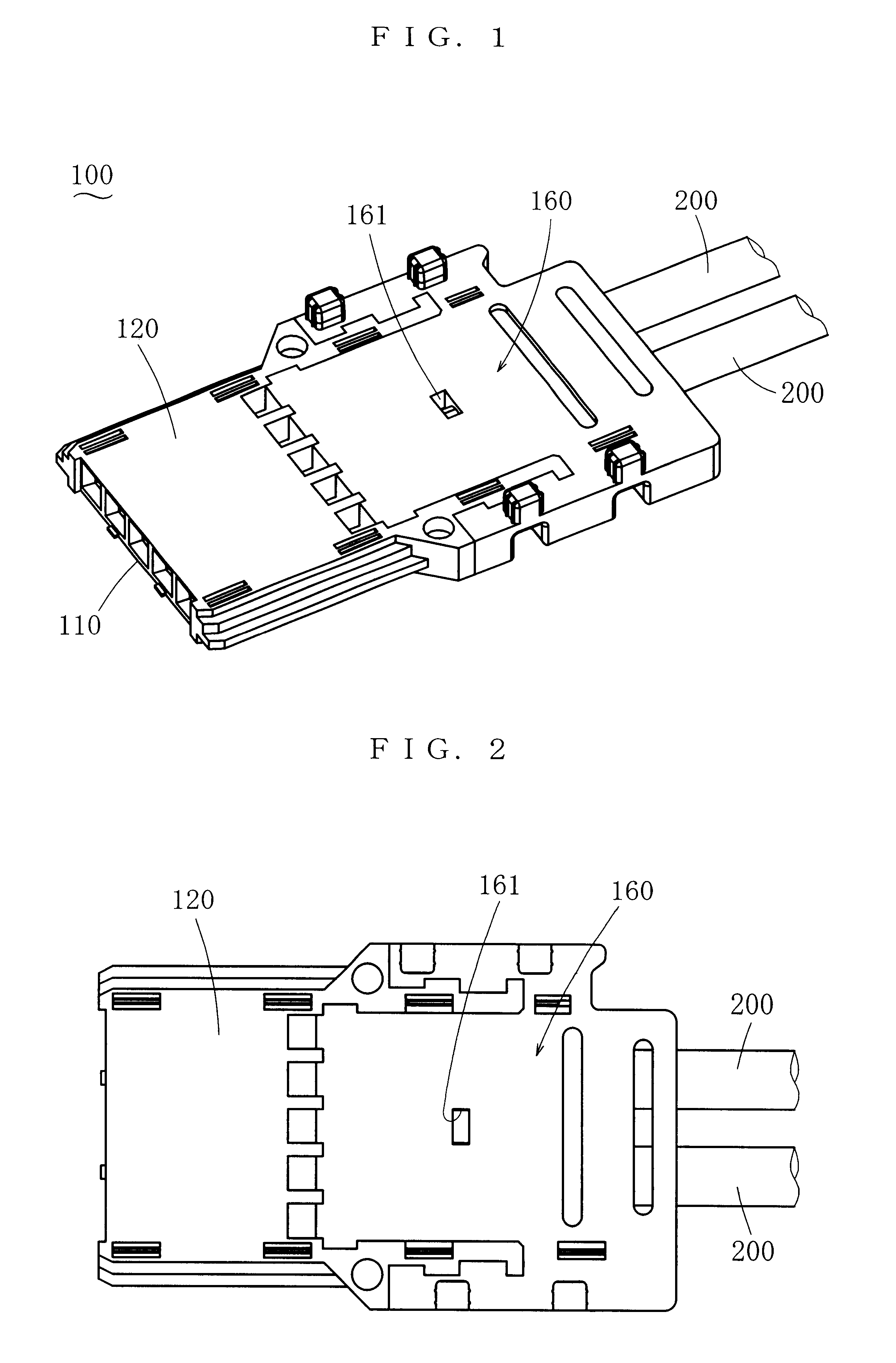

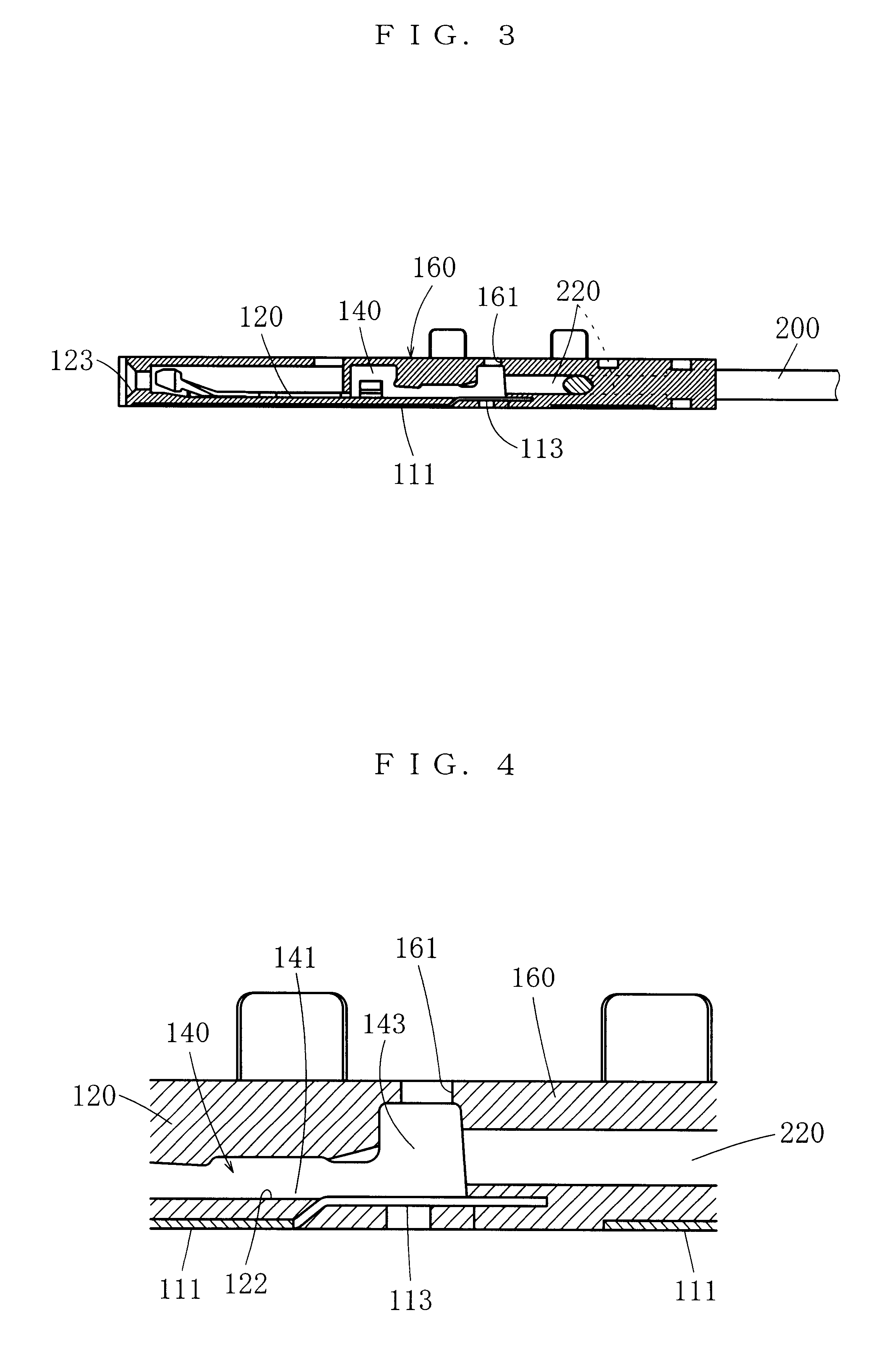

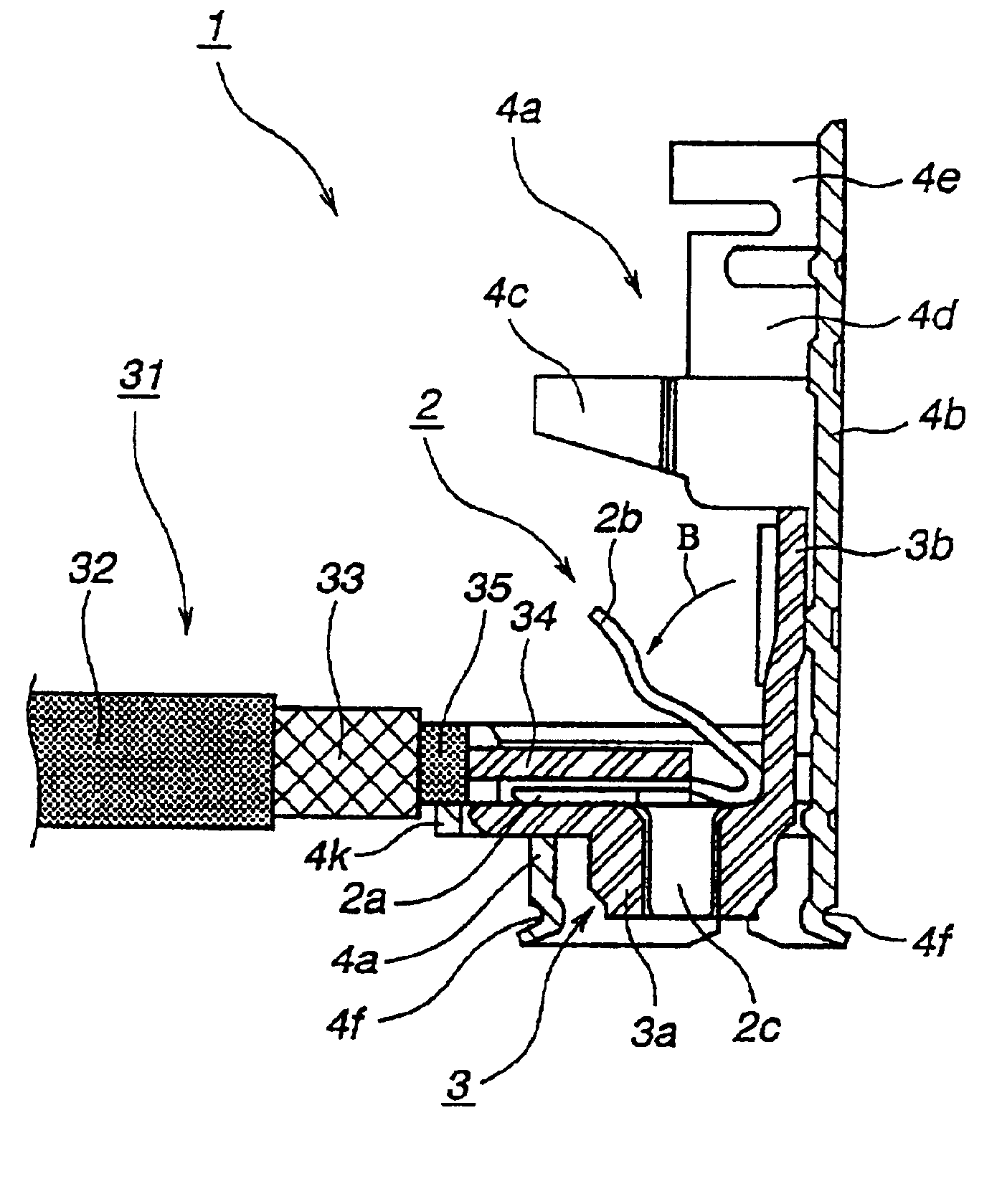

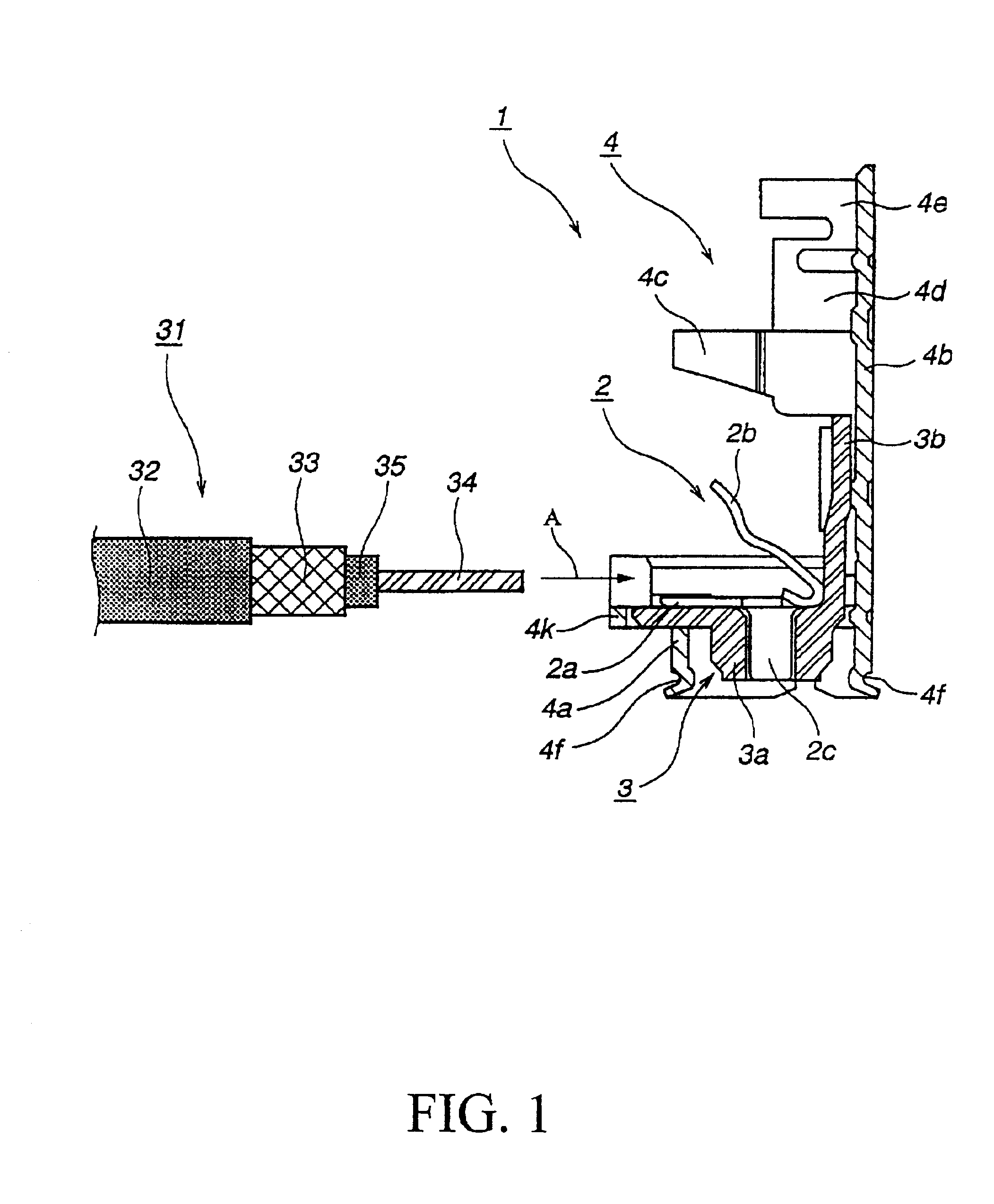

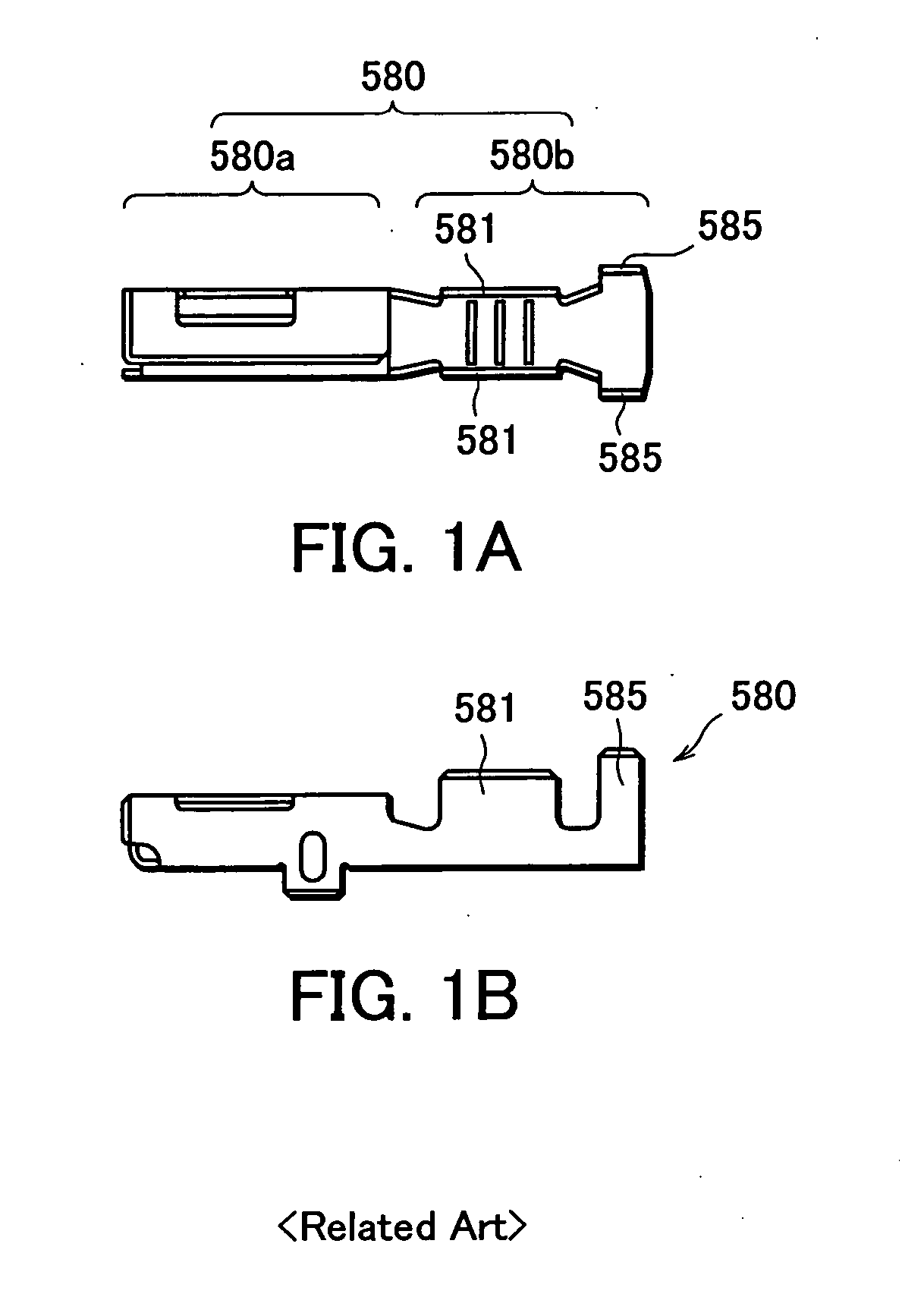

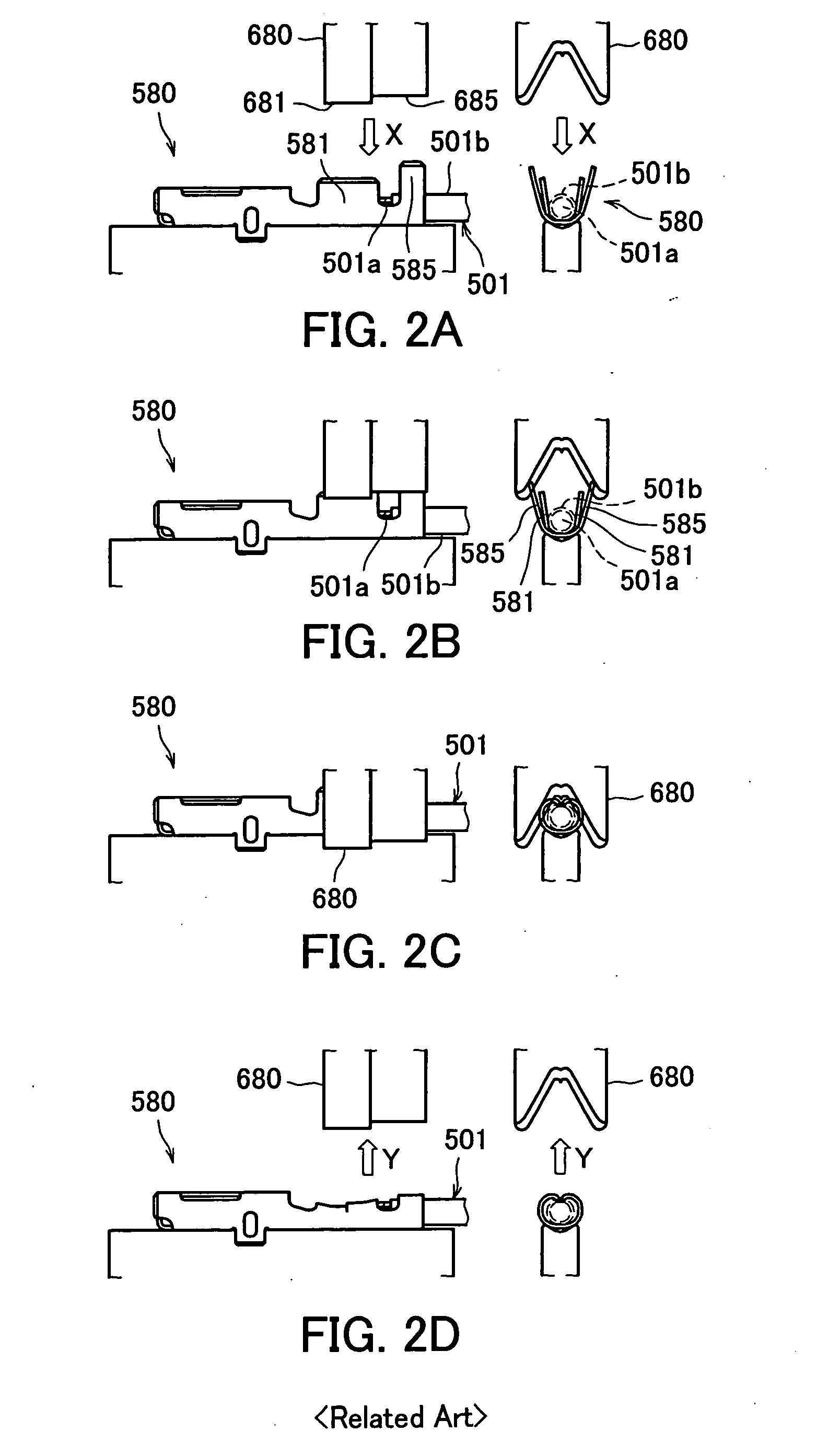

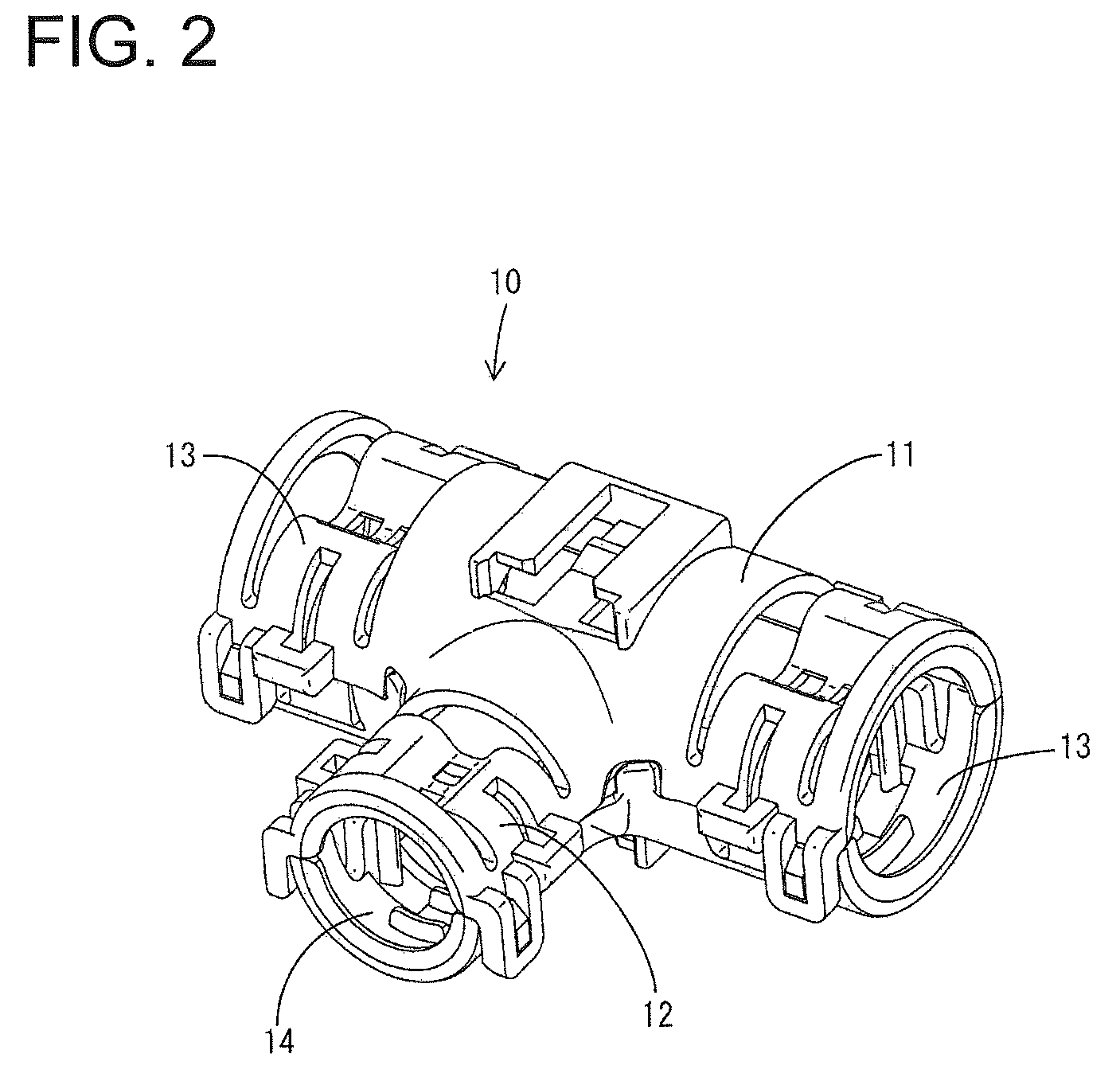

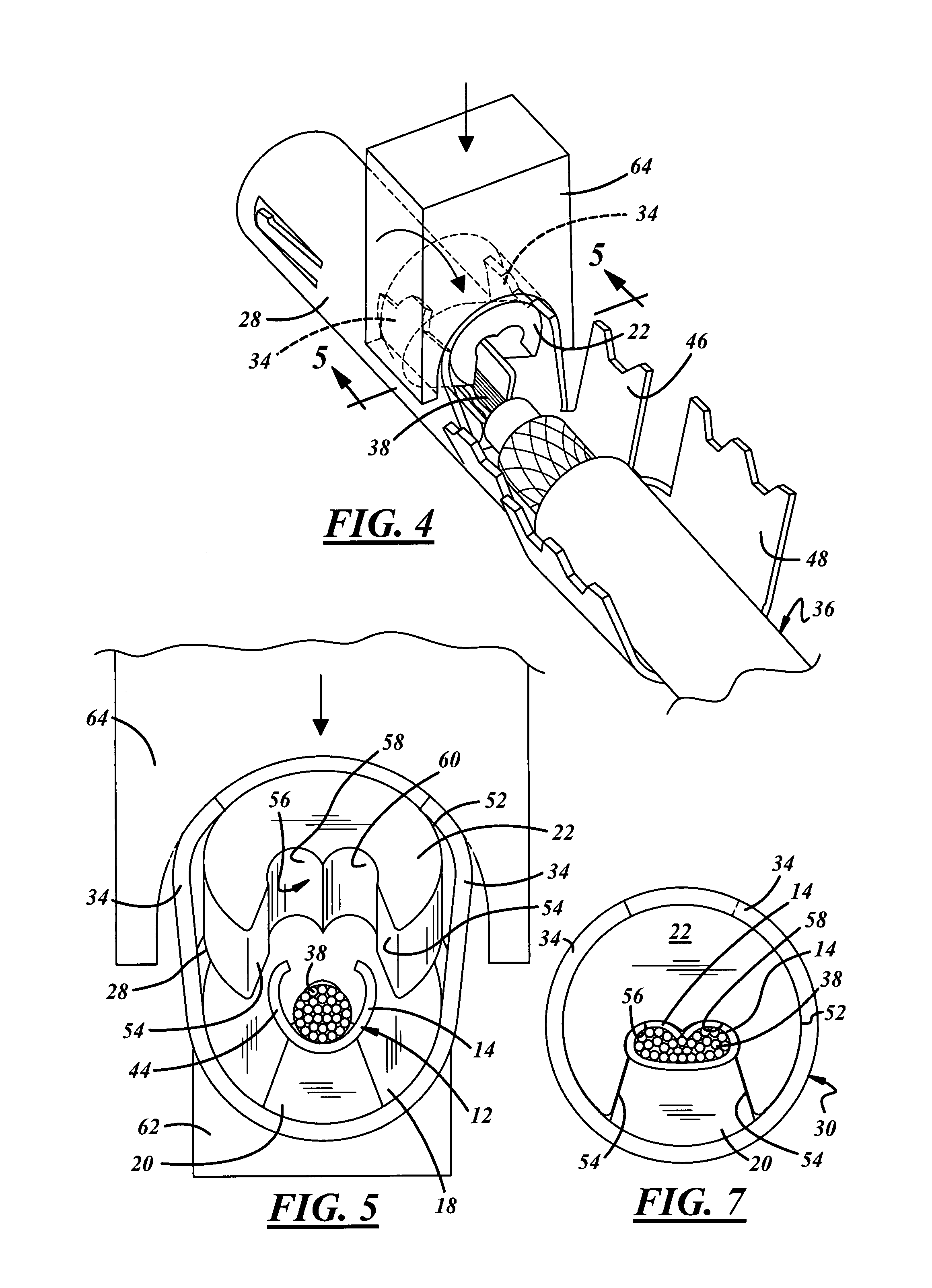

Coaxial cable connector

InactiveUS6790082B2Two pole connectionsConnections effected by permanent deformationCoaxial cableElectrical conductor

A coaxial cable connector 1 including a connection terminal (2) to be connected to an internal conductor (34) of a coaxial cable 31 and a metal shell (4) for supporting the connection terminal (2) via an insulating member 3 establishes electrical connection between the internal conductor (34) of the coaxial cable (31) and the connection terminal (2) by bending the connection terminal (2) according to the respective bending forces of the shell (4) and the insulating member (3) and making such connection terminal (2) retain the internal conductor (34) of the coaxial cable (31).

Owner:DAIICHI SEIKO CO LTD

Crimp terminal, connection structural body and connector

ActiveUS20130095708A1Vehicle connectorsDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical conductorEngineering

A crimp terminal includes barrel pieces respectively on both of two sides in a width direction thereof. The barrel pieces are included in a pressure-bonding section for pressure-bonding an exposed part of an electric wire conductor of an insulated wire. The insulated wire includes the electric wire conductor and an insulating cover for covering an outer circumference of the electric wire conductor, and the exposed part is a part of the electric wire conductor which is exposed from a tip of the cover by a predetermined length. The barrel pieces have a length in a longitudinal direction which is longer than the length of the exposed part of the electric wire conductor. The pressure-bonding section pressure-bonds, by the barrel pieces, a continuous part from a tip of the electric wire conductor to a position rear to the tip of the cover.

Owner:FURUKAWA ELECTRIC CO LTD +1

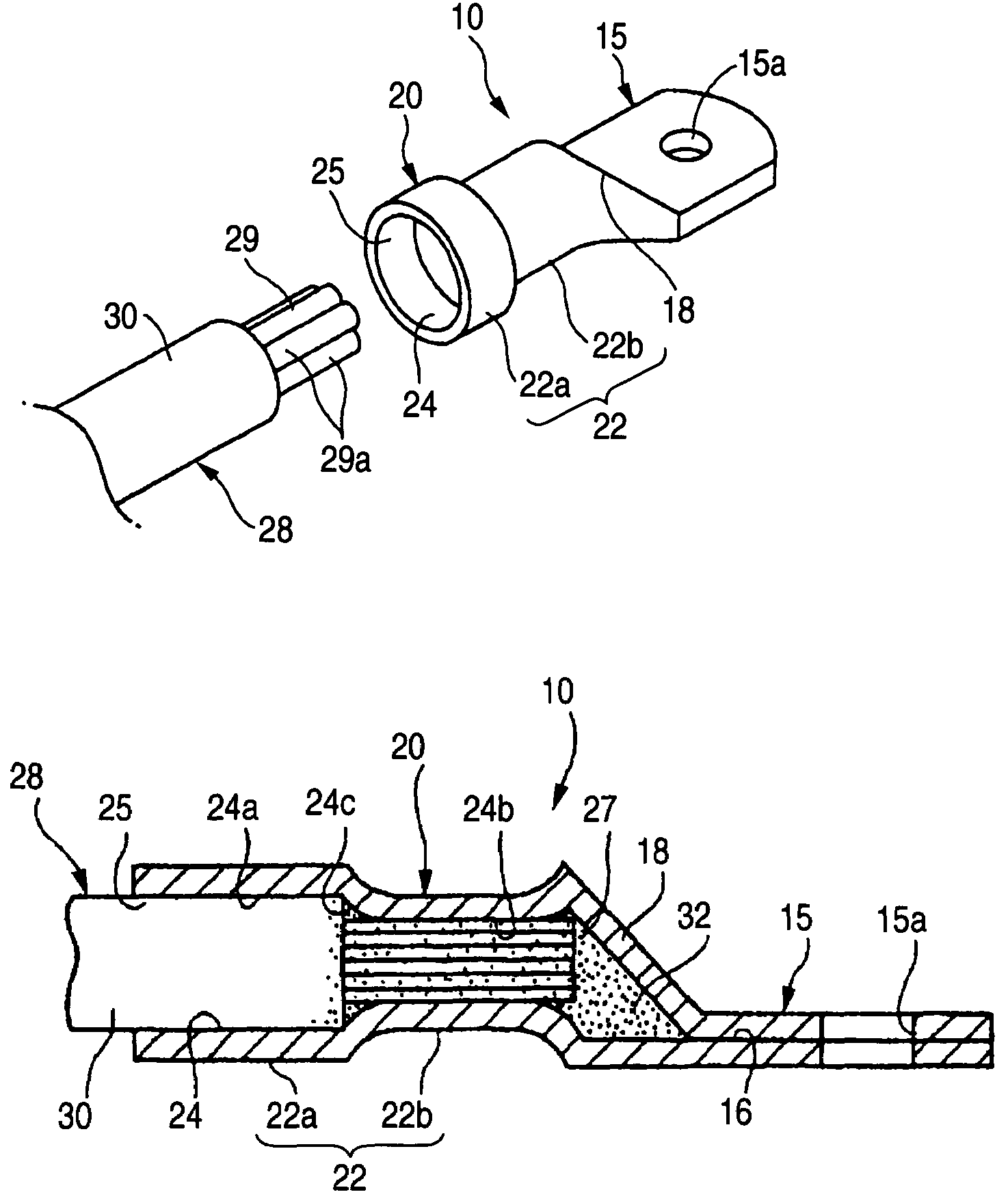

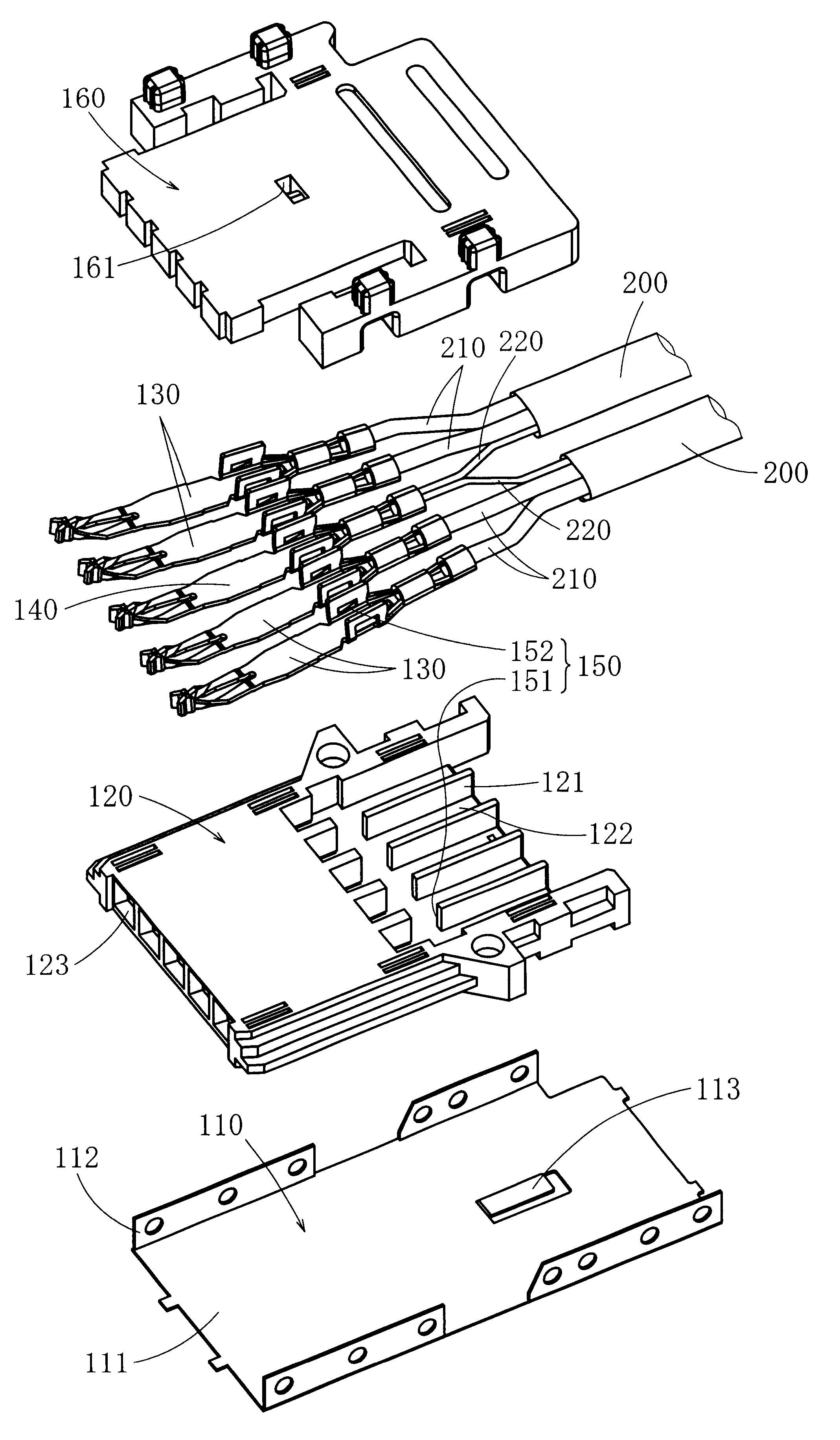

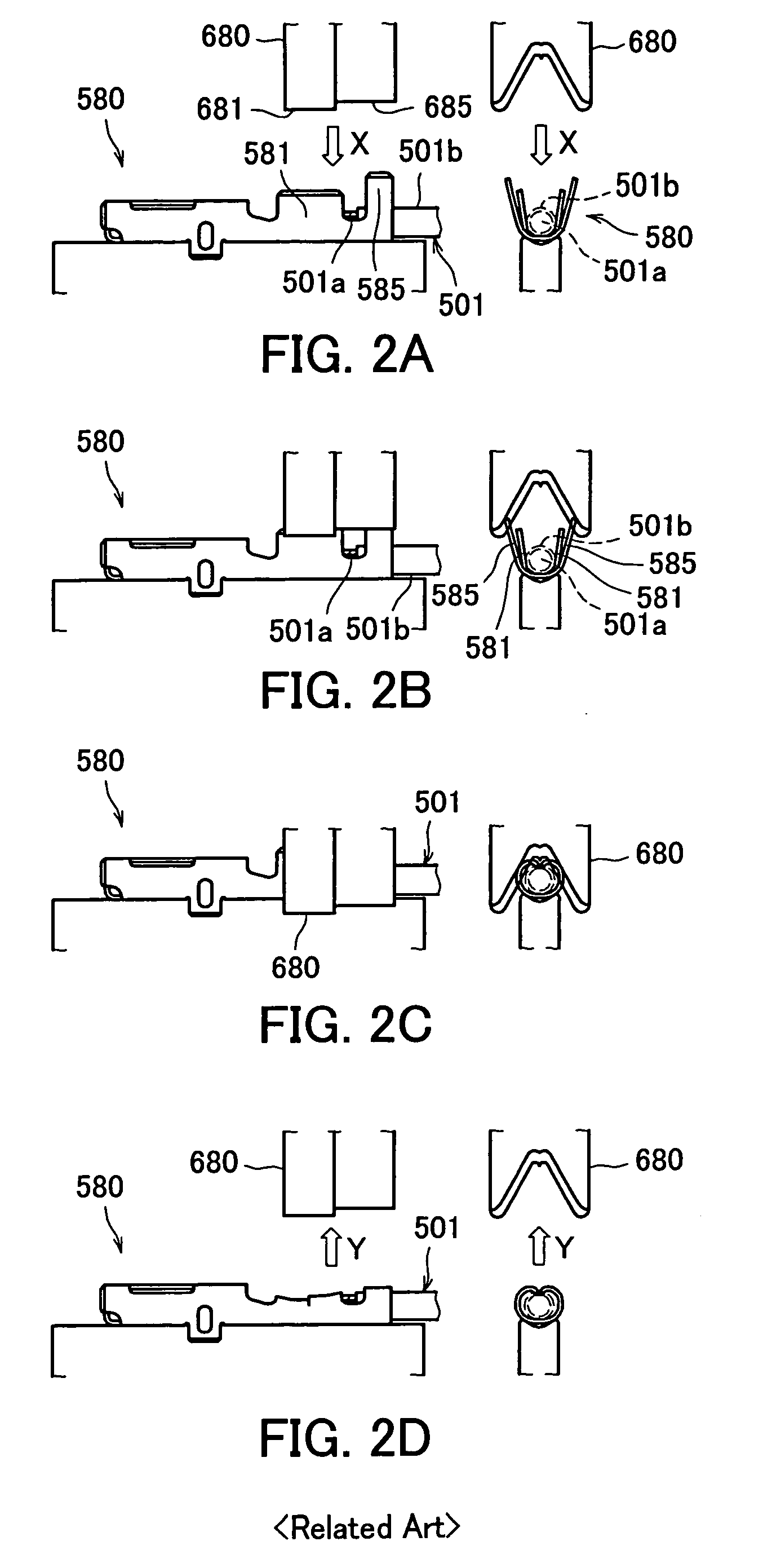

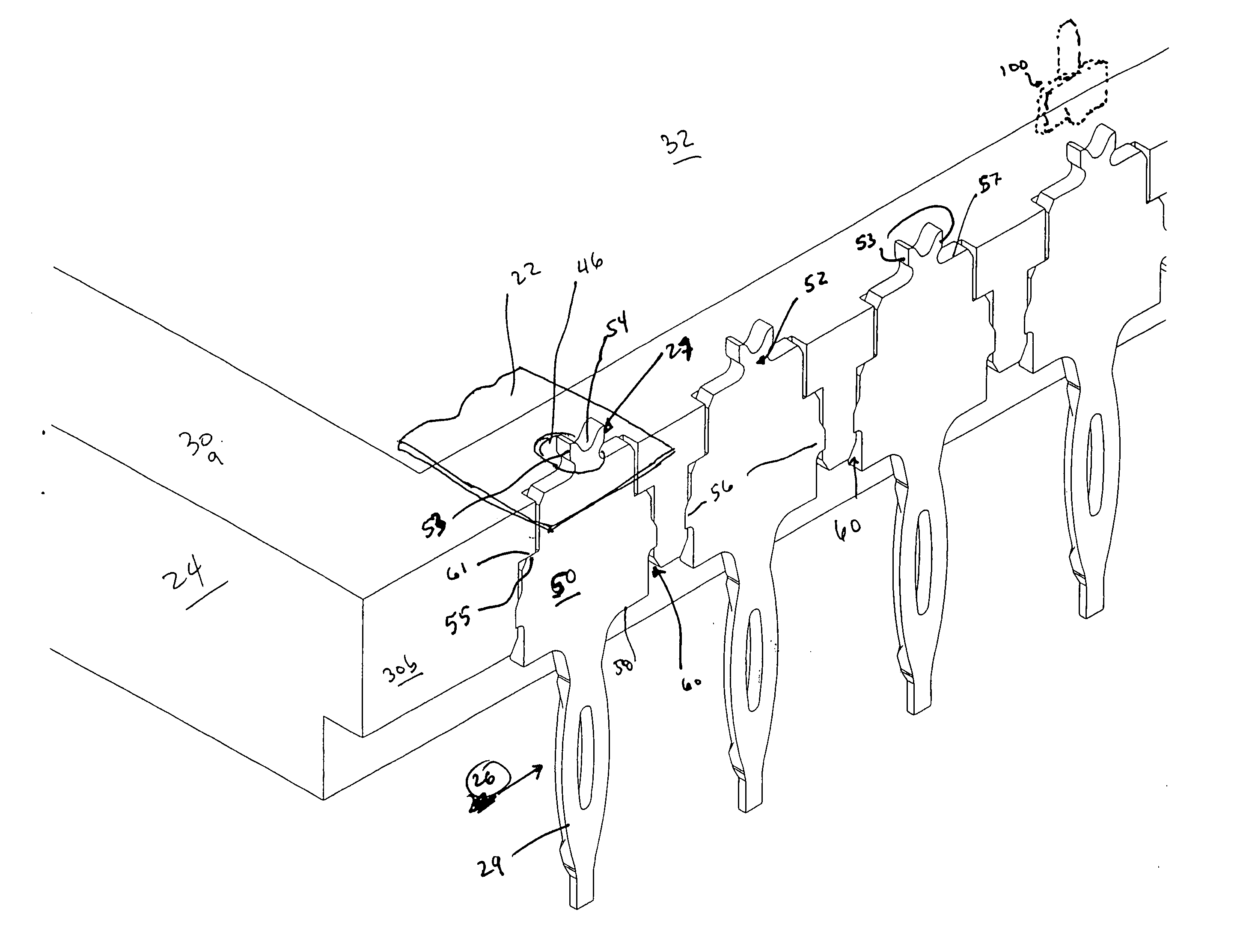

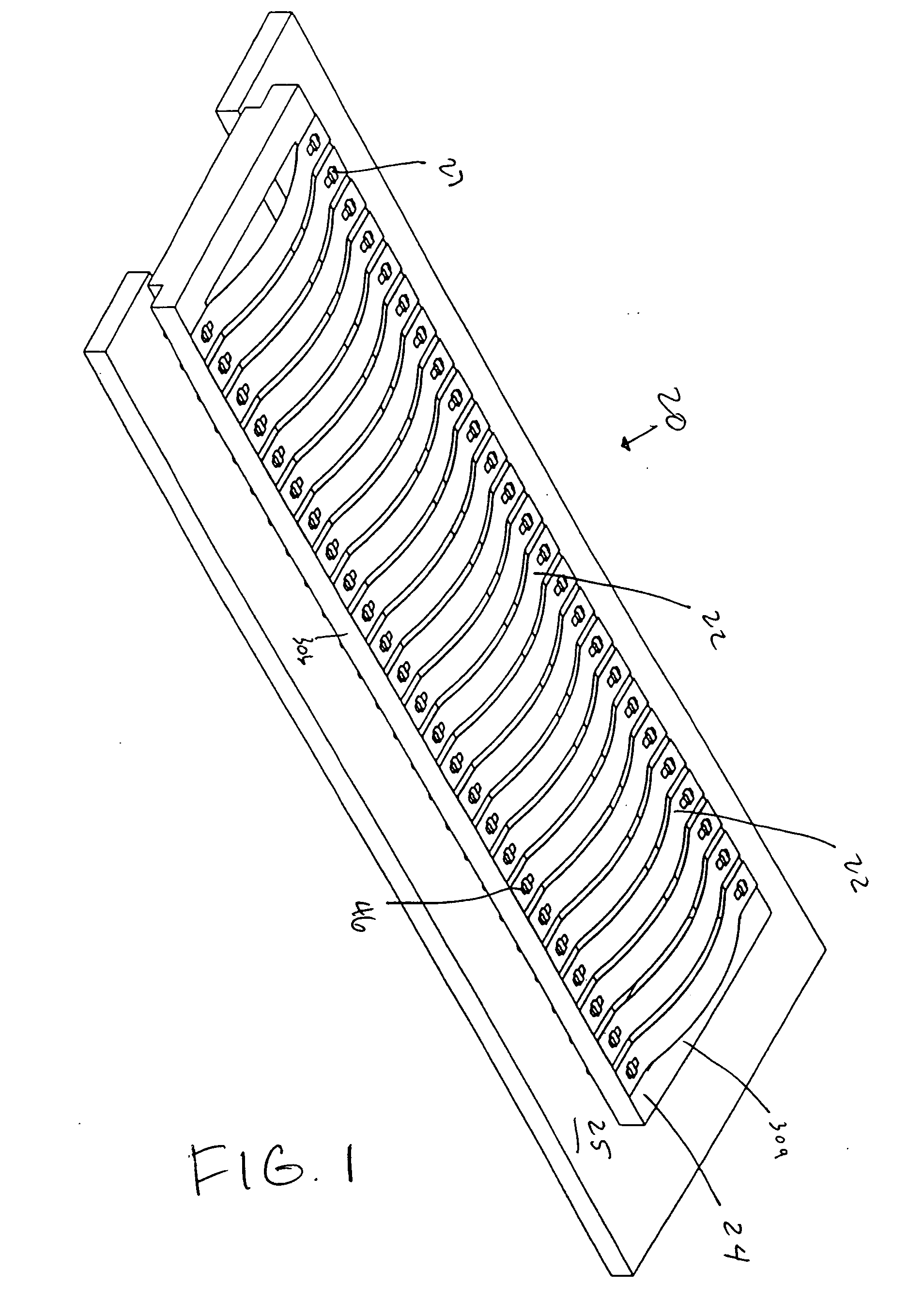

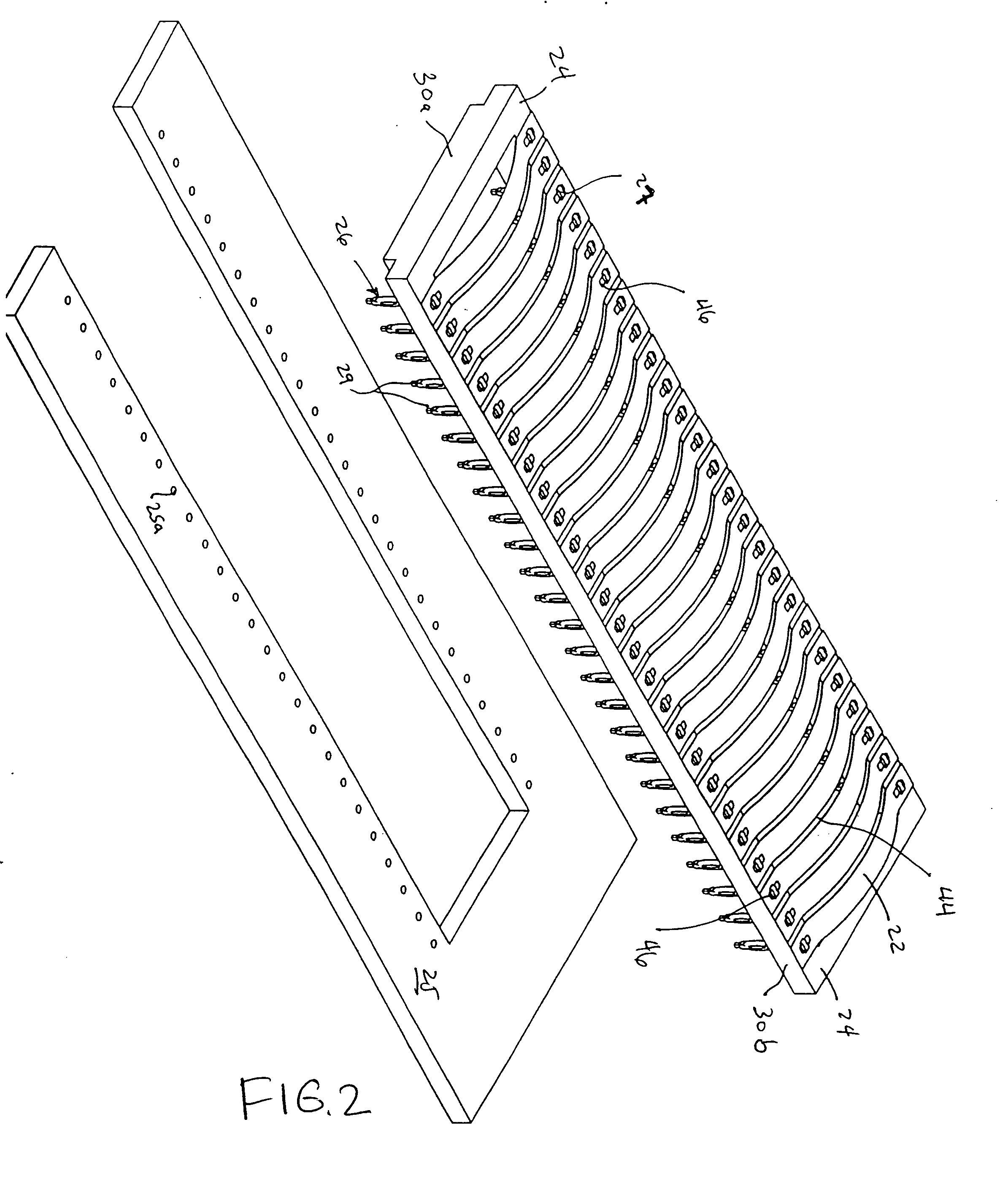

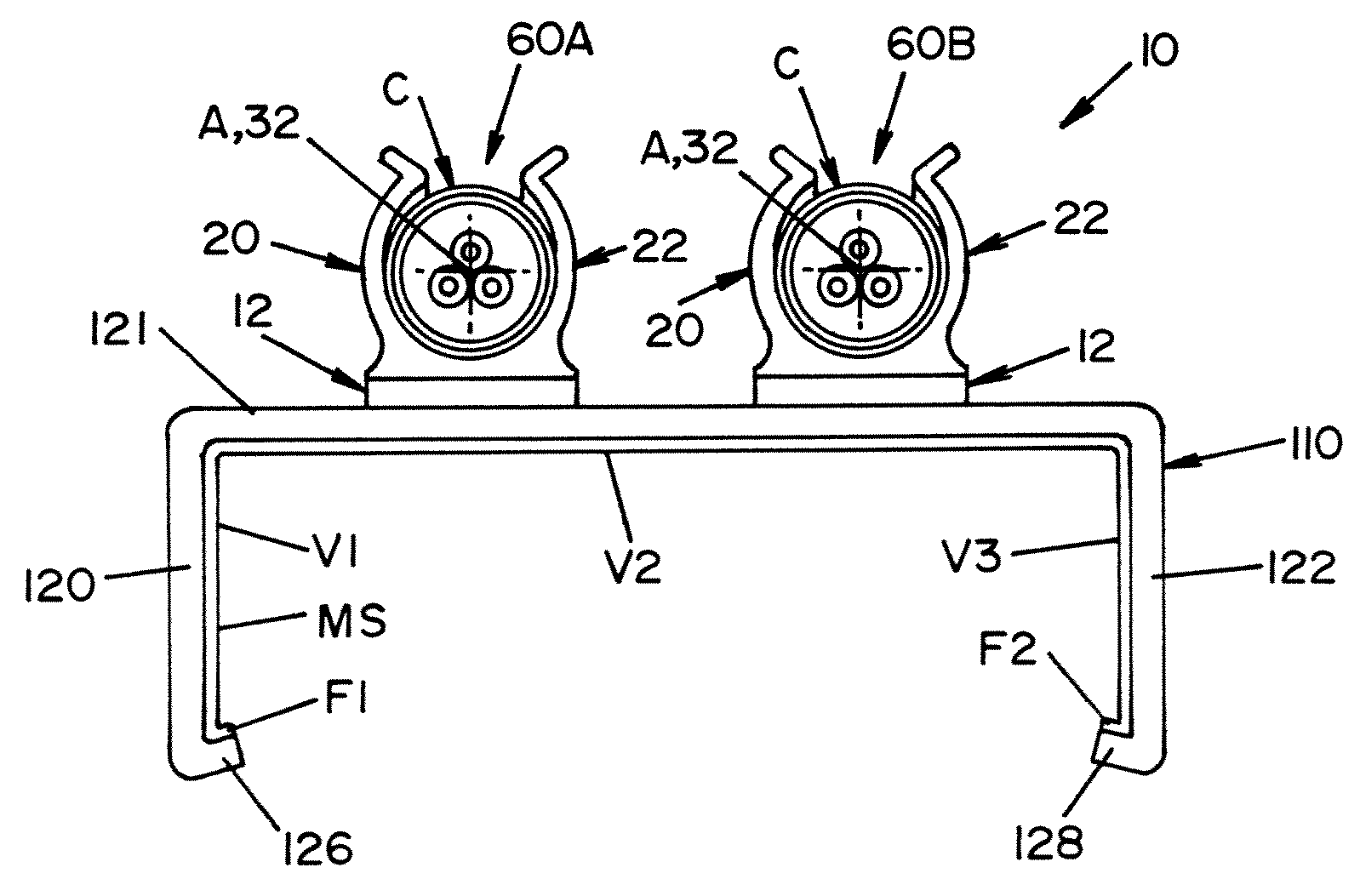

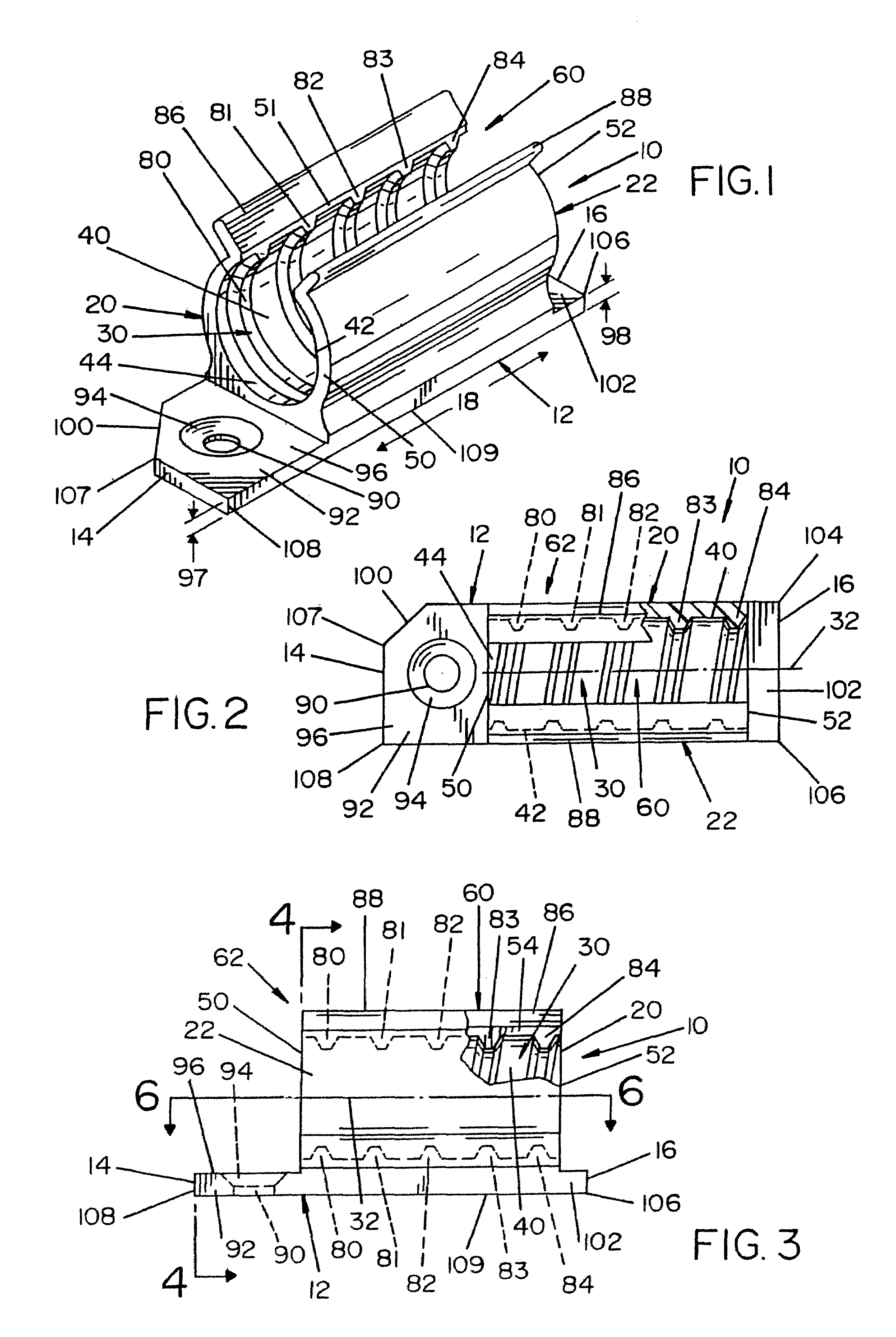

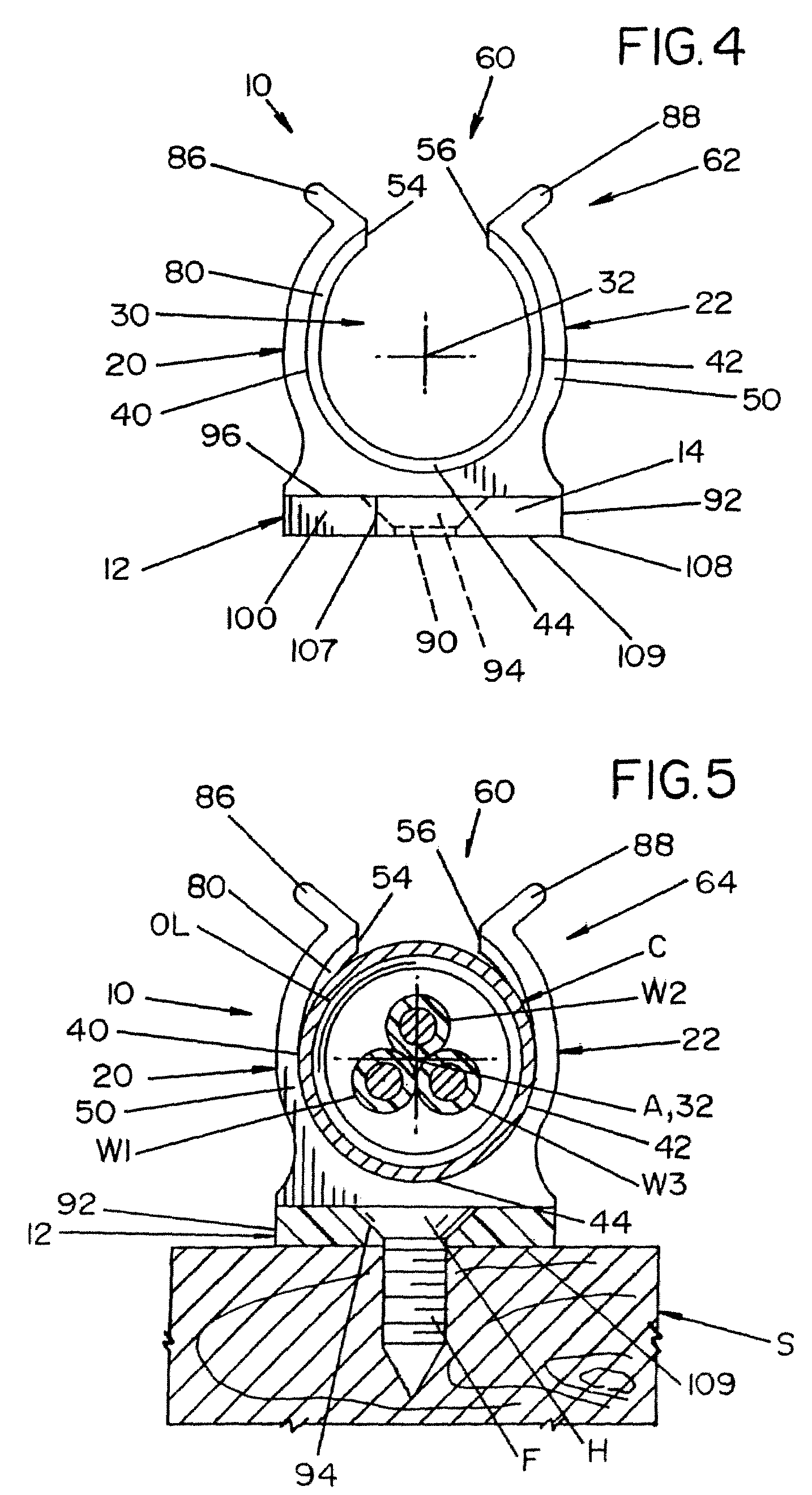

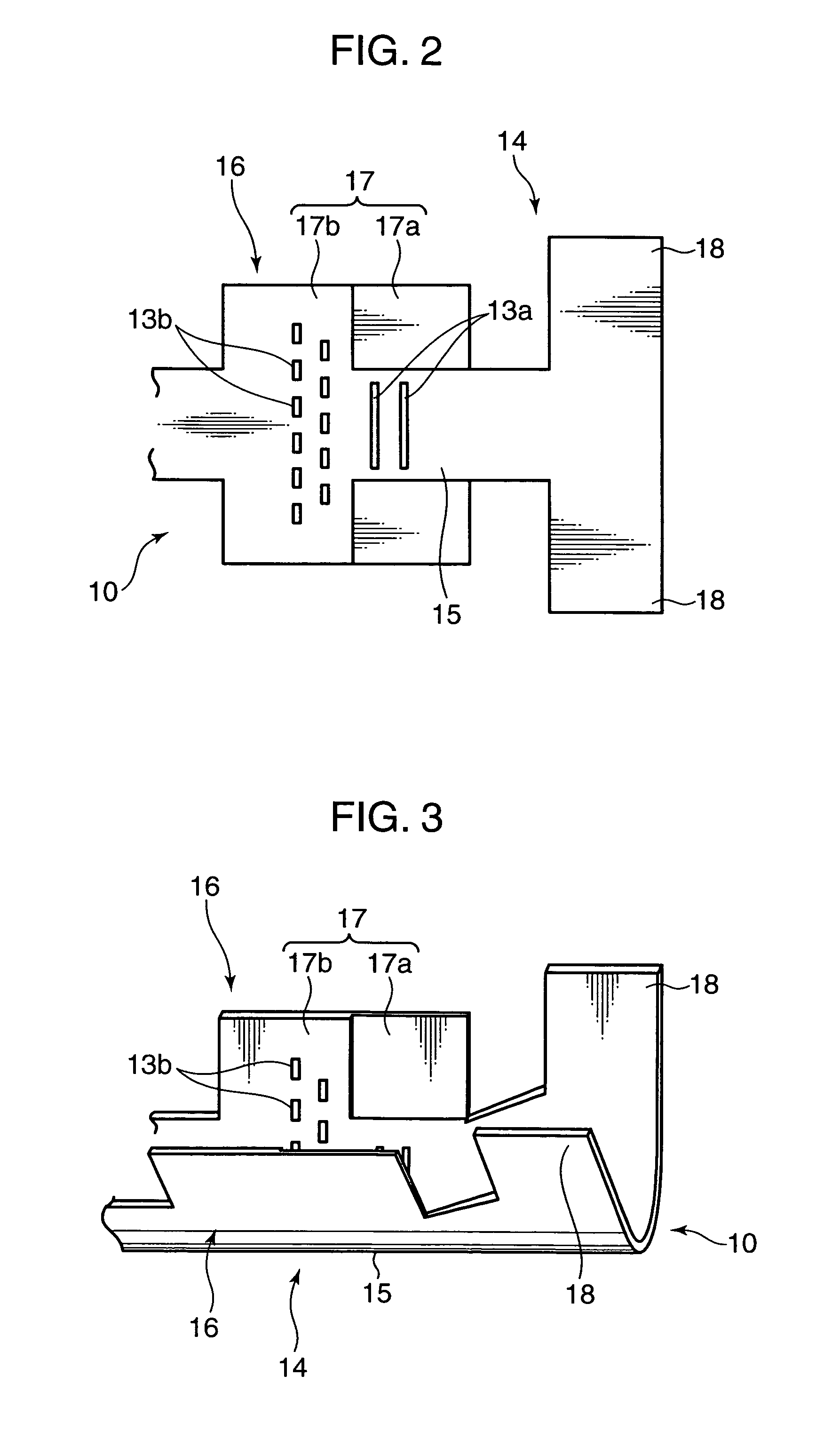

Heating element connector assembly with press-fit terminals

ActiveUS20070155255A1Easy constructionLow costHeater elementsSecuring/insulating coupling contact membersEngineeringHeating element

An improved heating element connector assembly includes an insulative, rectangular frame with a central opening and a plurality of conductive terminals which are press fit into openings in the frame. The terminals are spaced apart from each other lengthwise of two opposing sidewalls of the frame, and pairs of terminals are aligned with each other between the two sidewalls. A plurality of conductive strips extend across the frame opening to interconnect the pairs of terminals together. The terminals include compliant pin tail portions for receipt by corresponding holes formed in a circuit board of the assembly and deformable head portions for crimping onto the conductive strips.

Owner:ALEXZA PHARMA INC

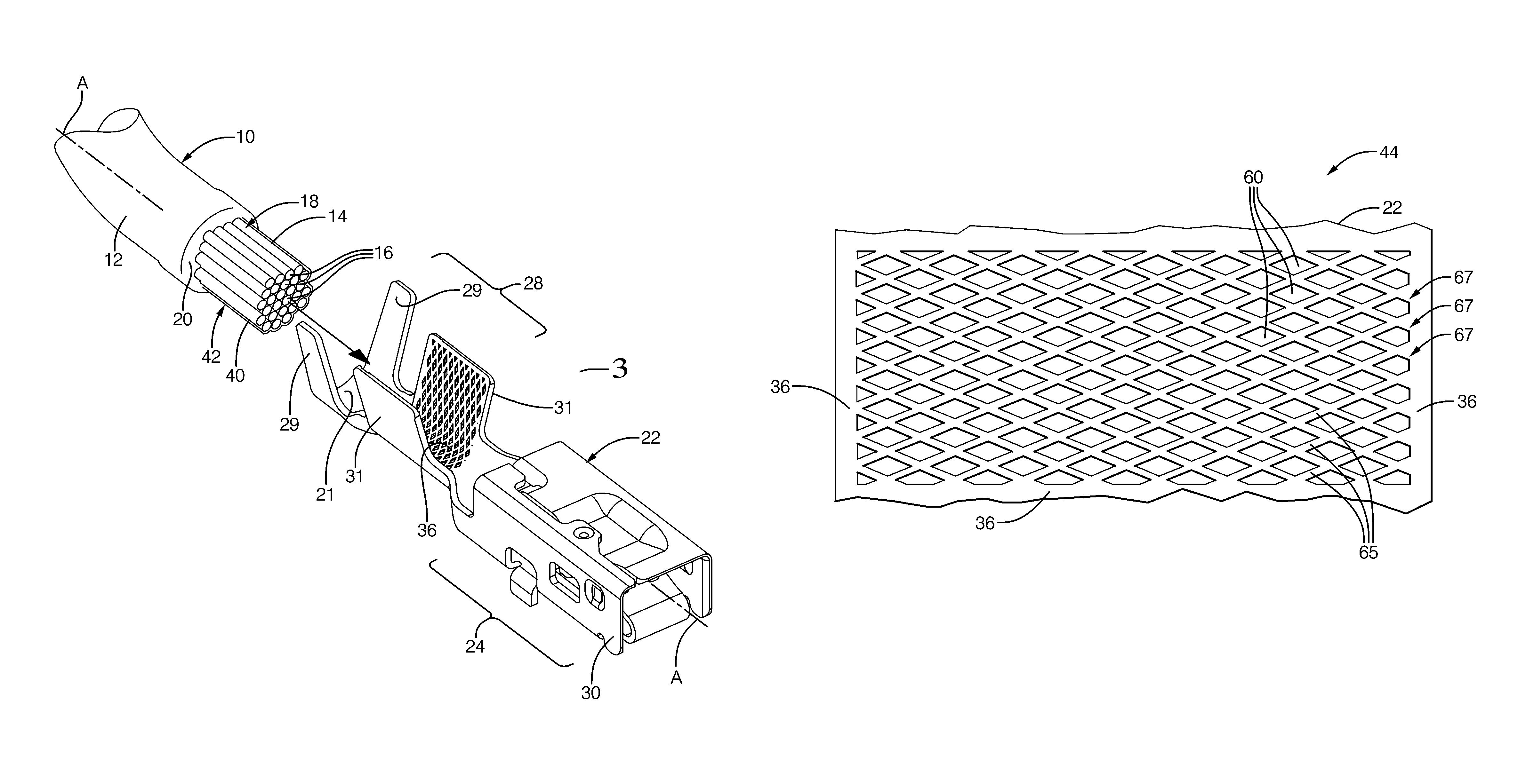

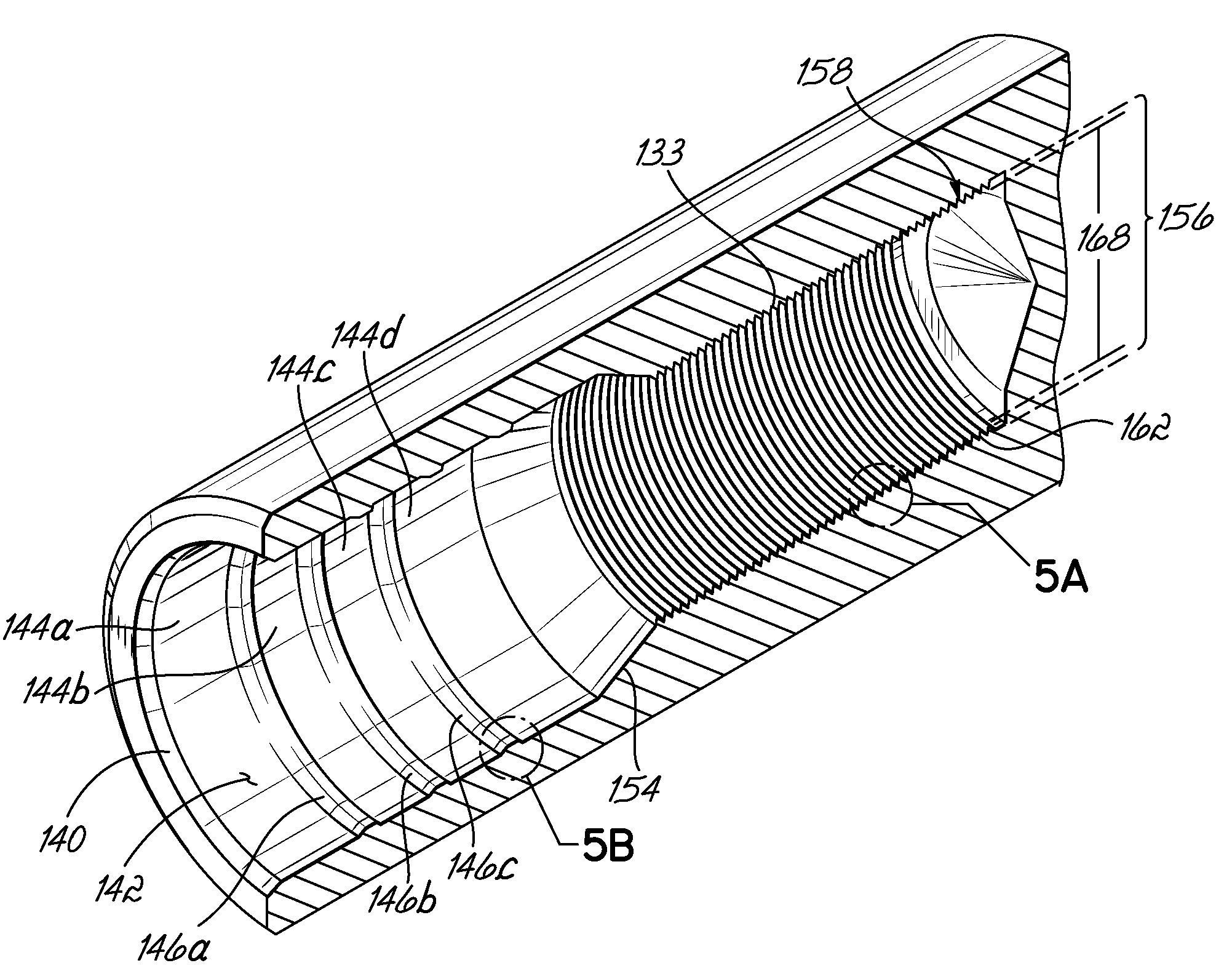

Electrical contact having knurl pattern with recessed rhombic elements that each have an axial minor distance

An electrical contact includes a knurl pattern disposed along at least a portion of an interior surface of the electrical contact. The portion receives a lead of a wire cable along a longitudinal axis and is attached thereto to form a crimp connection. The knurl pattern includes a plurality of recessed elements and each recessed element has a rhombus shape that includes inner corners. An orientation of a first pair of opposing, generally axial inner corners define an axial minor distance therebetween and an orientation of a second pair of opposing, inner corners define a major distance therebetween. The axial minor distance is less than the major distance. The recessed elements of the knurl pattern are especially suitable for engagement with an aluminum wire cable to form the crimp connection. A wire assembly that includes the crimp connection is associated with a cable harness disposed in a motorized vehicle.

Owner:APTIV TECH LTD

Clip

ActiveUS7608782B2Easily and quickly securedEasy to buildPipe supportsCoupling device detailsEngineering

Owner:HILL DOUGLAS C

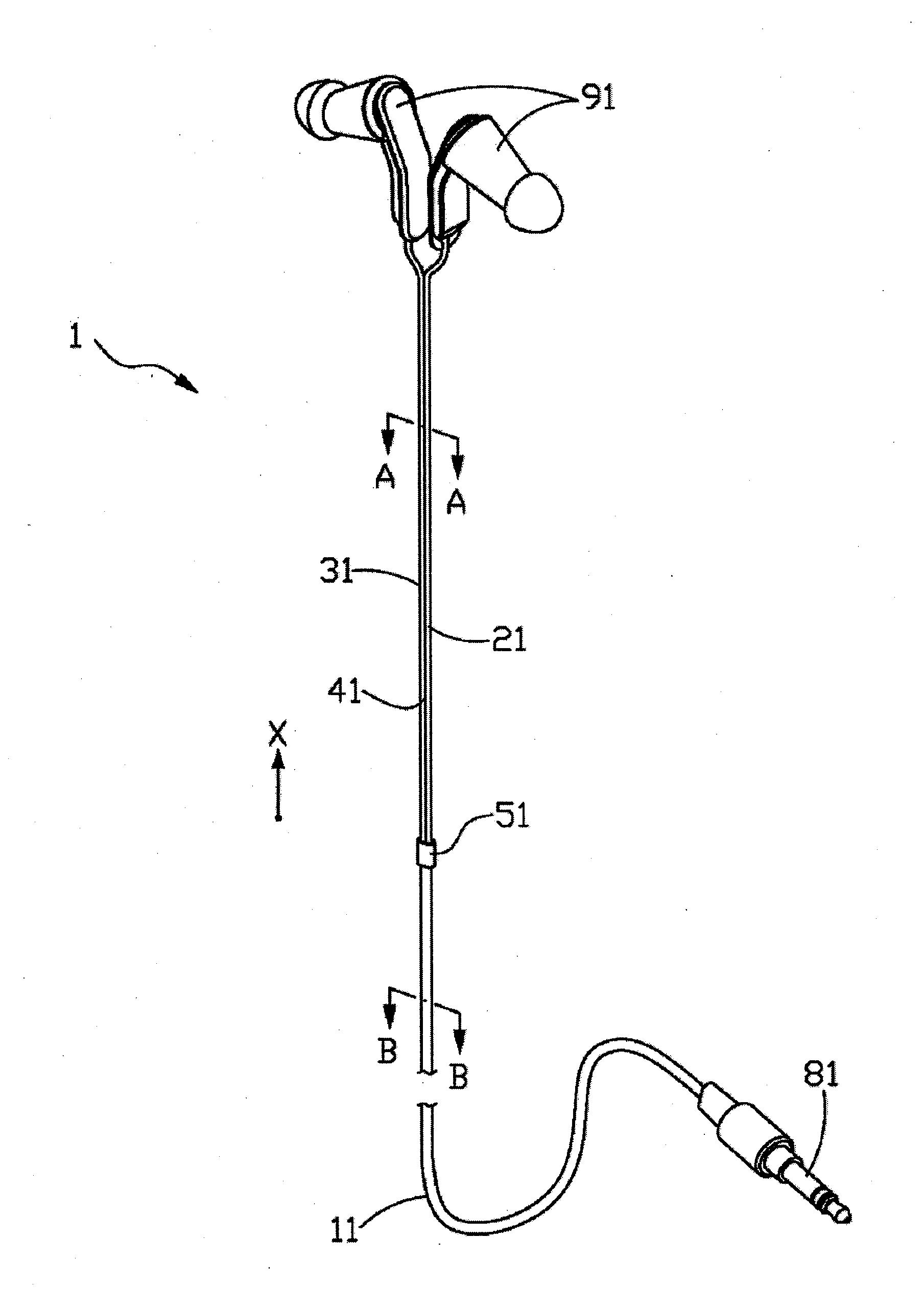

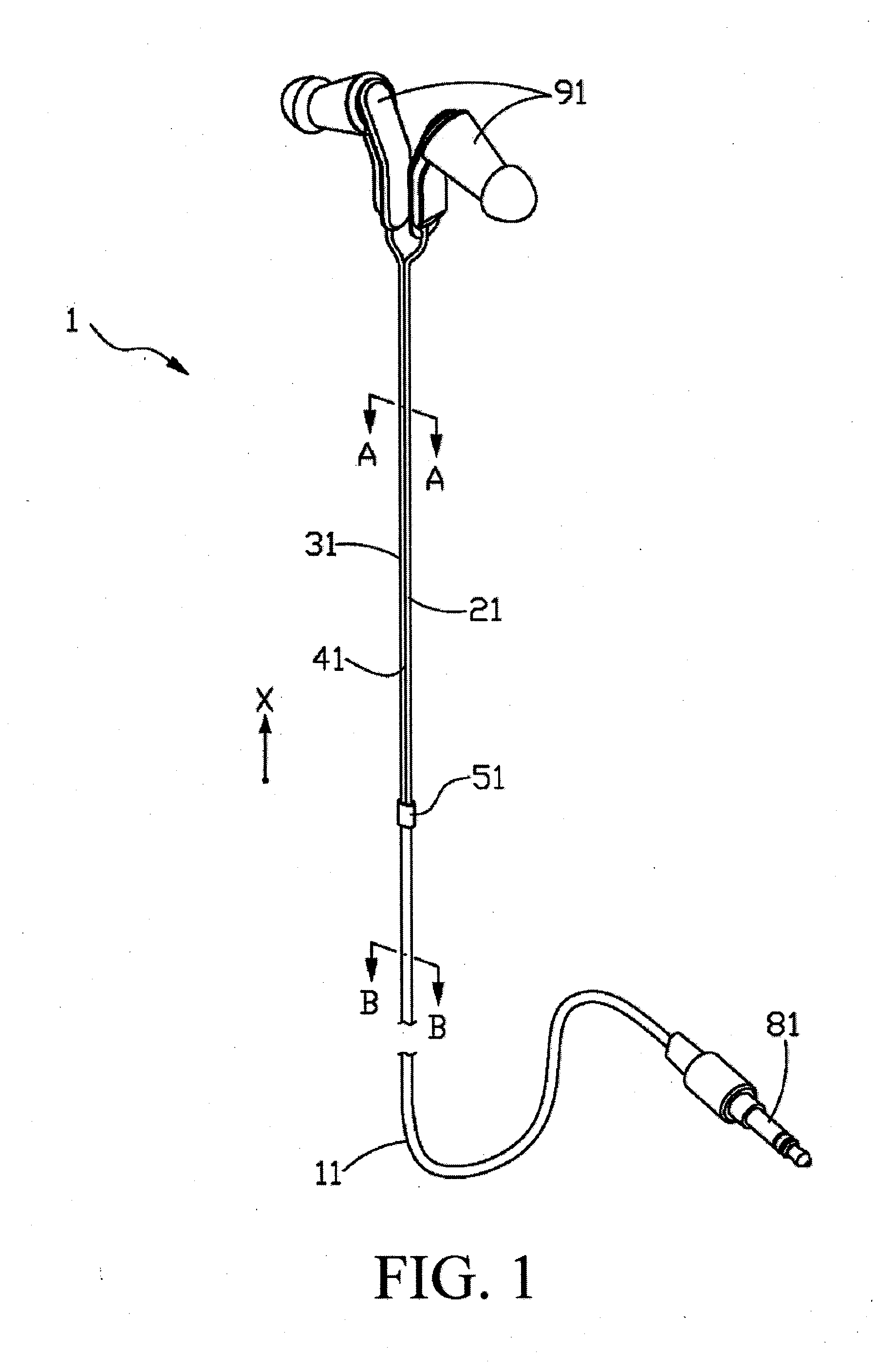

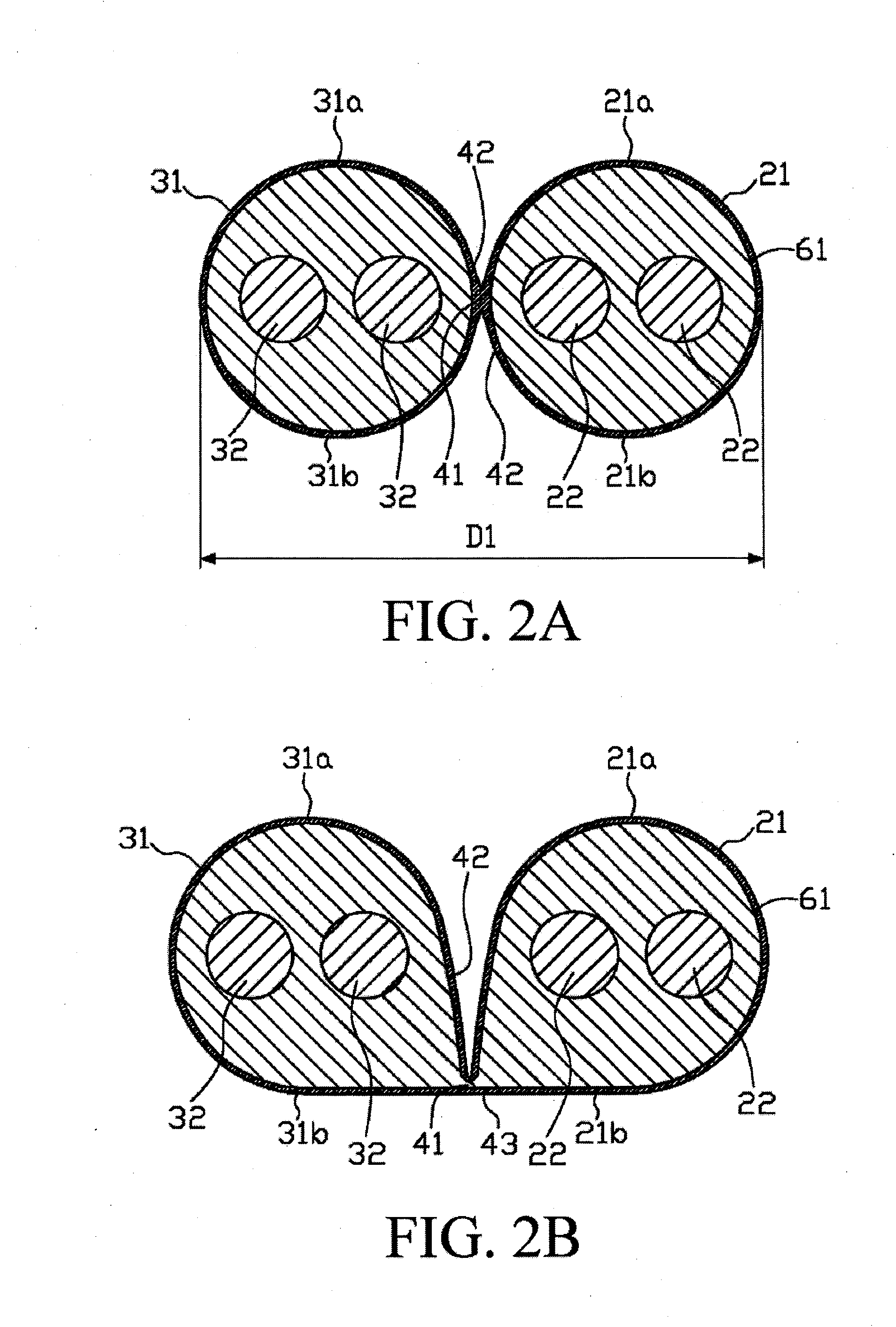

Earphone cable structure

InactiveUS20140138150A1Reduce weightImproving impedanceHeadphones for stereophonic communicationCommunication cablesEngineeringHeadphones

An earphone cable structure includes a first connection sleeve, a primary cable, a first branch cable, a second branch cable and a thin-type bridging section. The first connection sleeve includes a first end and a second end. The primary cable is connected to the first end, and includes first core lines and second core lines. The first branch cable is connected to the second end, and includes third core lines connected to the first core lines. The second branch cable is connected to the second end, and includes fourth core lines connected to the second core lines. The axial cross-sectional width of the primary cable is equal to the axial cross-sectional width of the first branch cable plus that of the second branch cable. The thin-type bridging section is connected between the first branch cable and the second branch cable.

Owner:JETVOX ACOUSTIC

Terminal crimping structure and terminal crimping method onto aluminum electric-wire and producing method of alminum electric-wire with terminal

ActiveUS20050026515A1Close contactMaintenance characteristicLine/current collector detailsConnections effected by permanent deformationElectrical conductorEngineering

A terminal crimping structure onto aluminum electric-wire, for crimping a terminal onto an aluminum electric-wire including: an electrical conductor part comprising numerous strands; and a coating part coated on the . electrical conductor part; wherein the terminal has a wire barrel to be crimped onto the electrical conductor part of the aluminum electric-wire; and wherein the compressed ratio of the aluminum electric-wire's conductor part by the wire barrel is within a range of 50 to 70%, in terms of the ratio of (cross-sectional area of aluminum electric-wire's conductor part at crimped portion) / (cross-sectional area of aluminum electric-wire's conductor part before crimping).

Owner:FURUKAWA ELECTRIC CO LTD

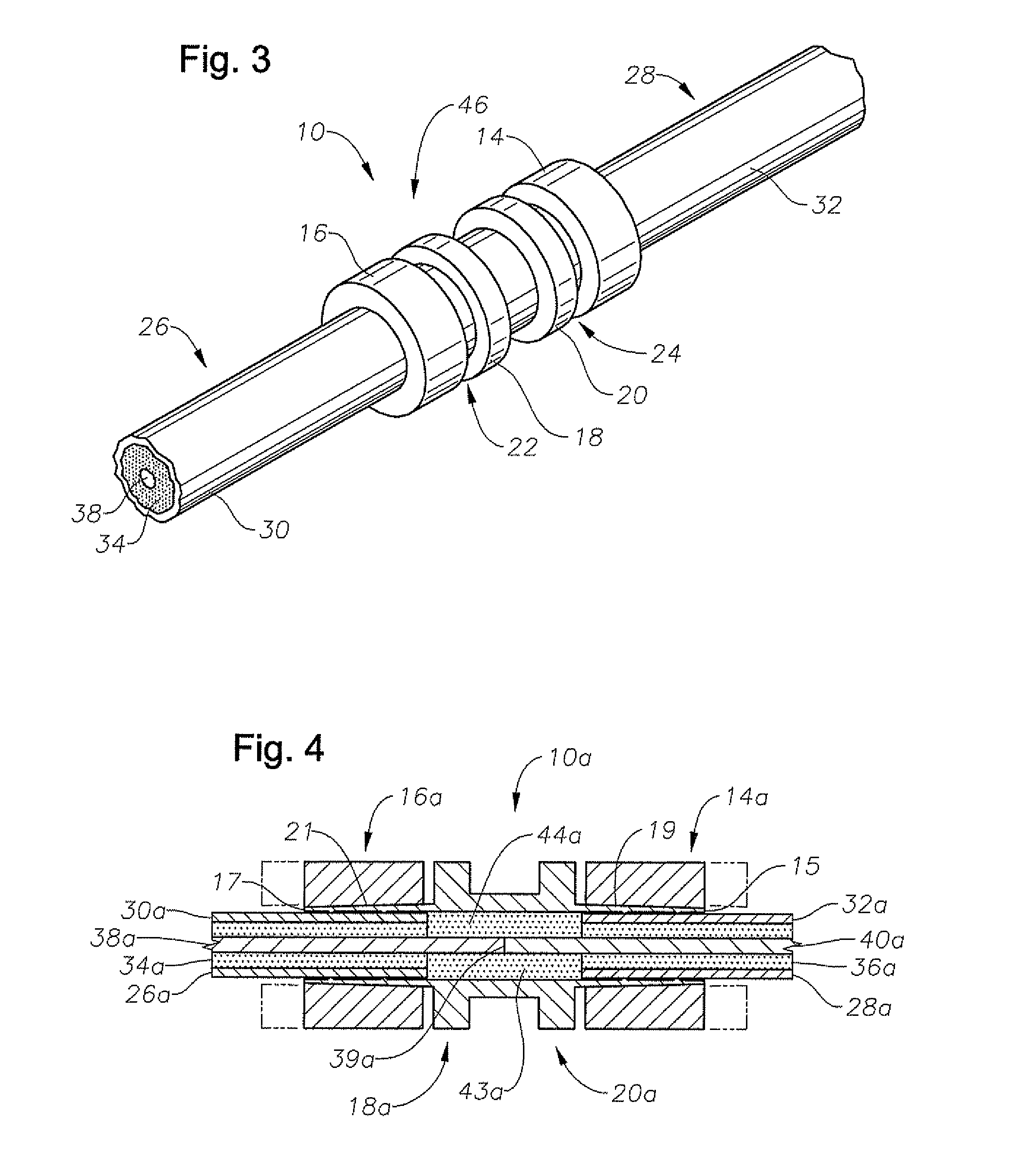

Method of connecting wire and terminal fitting

InactiveUS7374466B2Treatment effectAvoid damageSoldered/welded conductive connectionsCoupling contact membersElectric wireElectrical and Electronics engineering

A method of connecting a terminal fitting and an electric wire, includes the steps of: providing a terminal fitting; providing an electric wire in which a core wire is covered with an insulating sheath; providing a conductive connecting member formed with an insertion hole; inserting the electric wire into the insertion hole of the connecting member; compressing the connecting member radially inwardly so as to caulk an inserted portion of the electric wire uniformly over a whole periphery thereof; and welding the connecting member and the terminal fitting by applying ultrasonic wave.

Owner:YAZAKI CORP

Battery connecting plate, and attachment structure of the same

ActiveUS7077704B2Easily and accurately mountedSize toleranceVehicle connectorsElectric discharge tubesEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP +1

Protector

InactiveUS7581564B2Avoid lateral displacementAvoid longitudinal displacementSleeve/socket jointsInsulated cablesEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

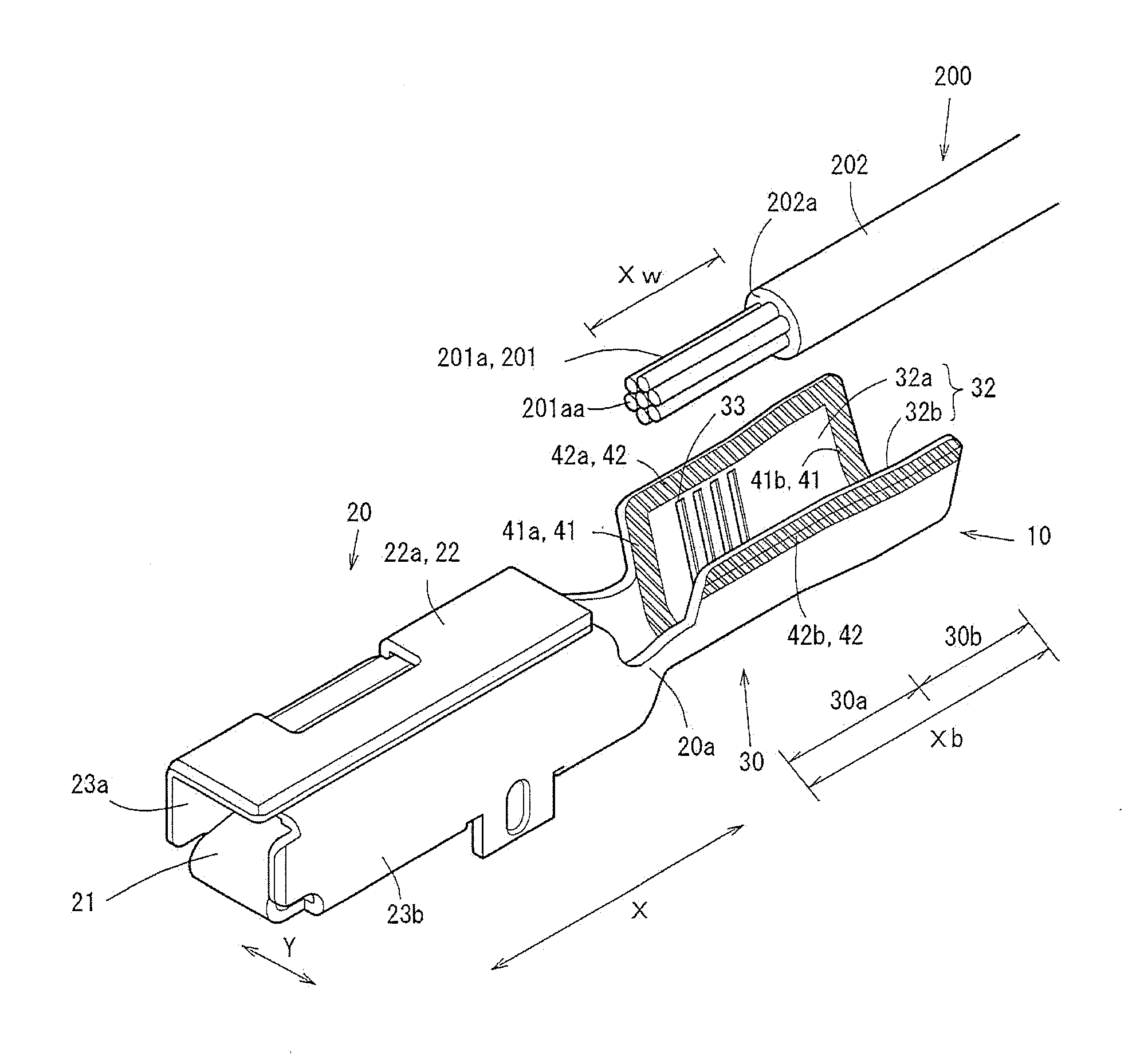

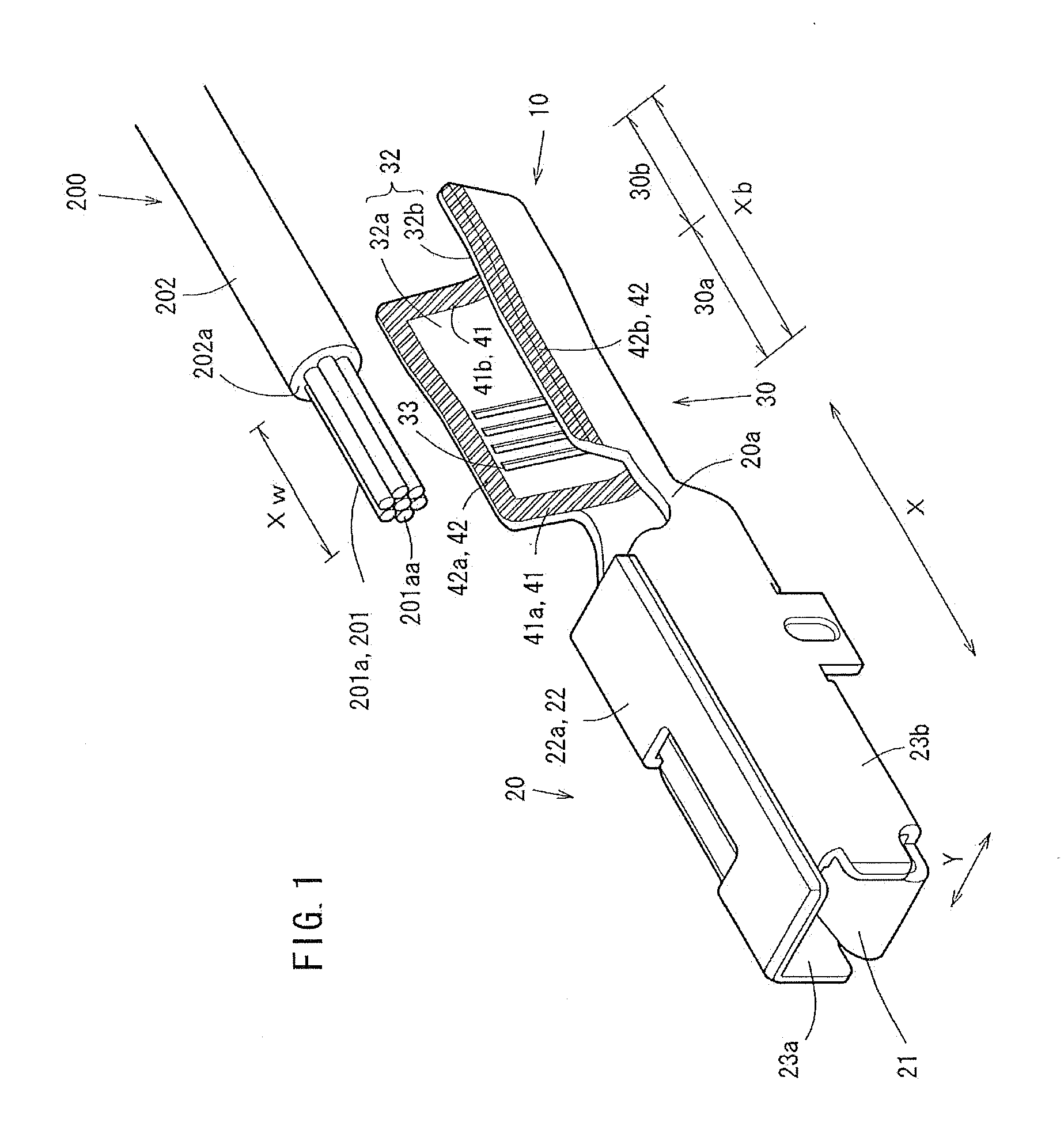

Crimp terminal, connection structural body and connector

ActiveUS8974258B2Vehicle connectorsDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical conductorEngineering

A crimp terminal includes barrel pieces respectively on both of two sides in a width direction thereof. The barrel pieces are included in a pressure-bonding section for pressure-bonding an exposed part of an electric wire conductor of an insulated wire. The insulated wire includes the electric wire conductor and an insulating cover for covering an outer circumference of the electric wire conductor, and the exposed part is a part of the electric wire conductor which is exposed from a tip of the cover by a predetermined length. The barrel pieces have a length in a longitudinal direction which is longer than the length of the exposed part of the electric wire conductor. The pressure-bonding section pressure-bonds, by the barrel pieces, a continuous part from a tip of the electric wire conductor to a position rear to the tip of the cover.

Owner:FURUKAWA ELECTRIC CO LTD +1

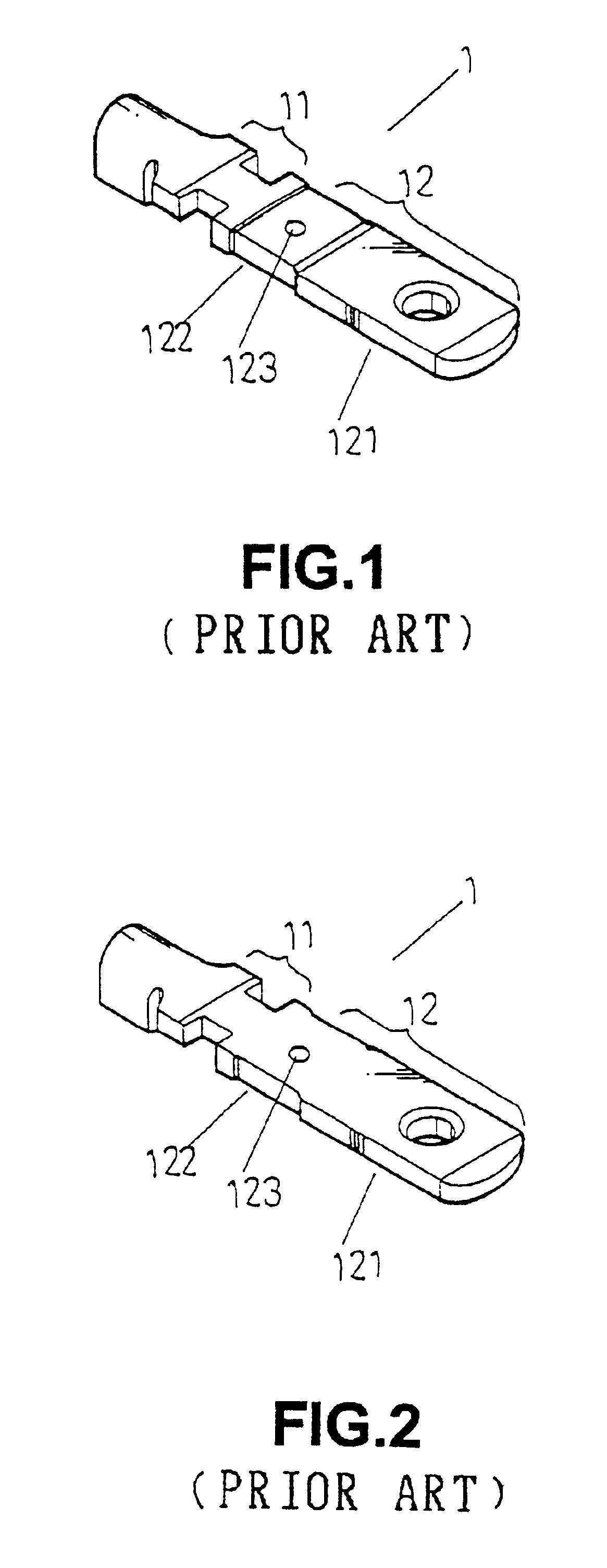

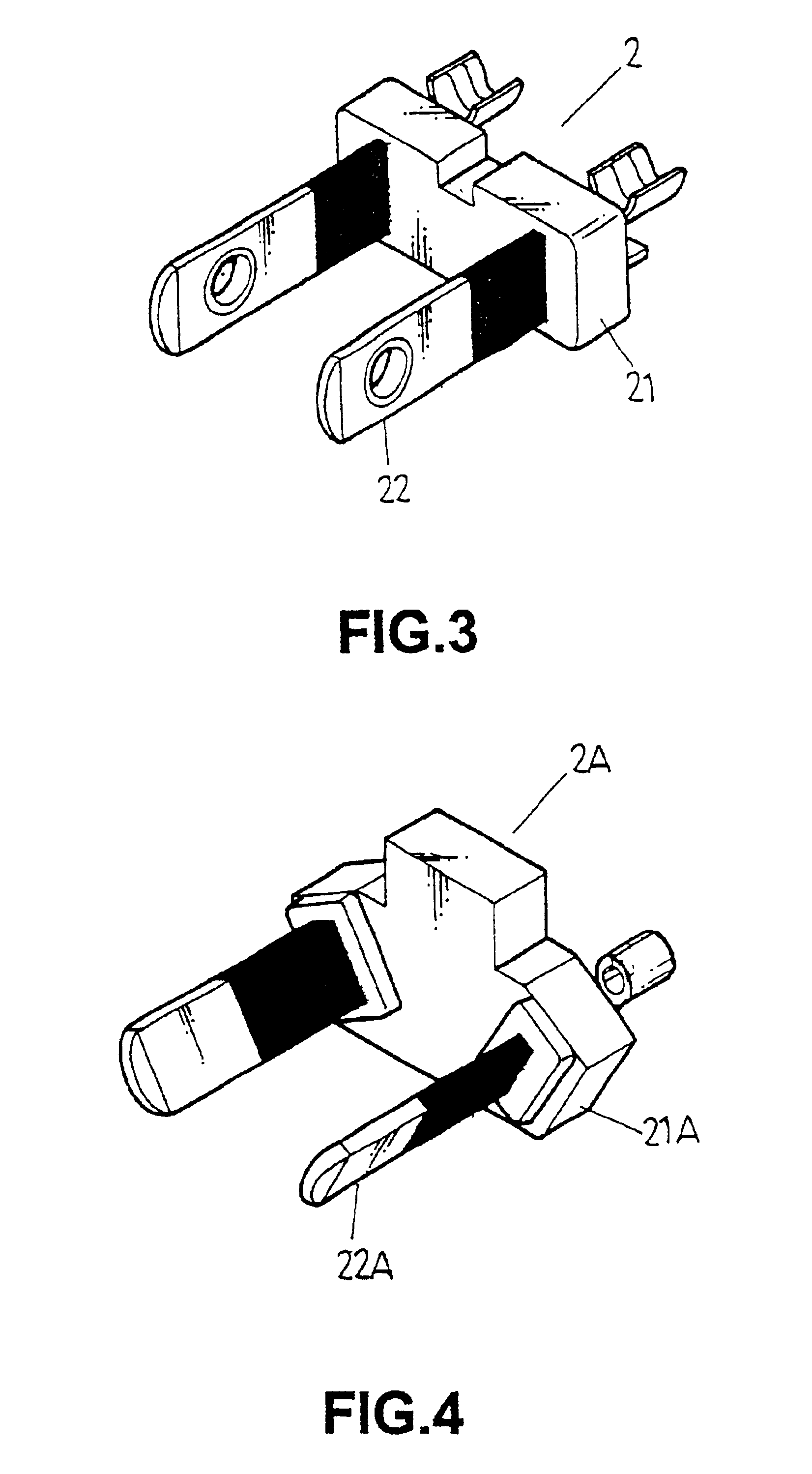

Plug inner frame with twisted blades

InactiveUS6981896B2Reduce manufacturing costRelieving strain on wire connectionTwo pole connectionsEngineeringElectric wire

Owner:GEM TERMINAL IND

Method of connecting and structure of connecting electric wire and connection terminal

InactiveUS7705265B2Easy to connectIncreasing costSoldered/welded conductive connectionsConnections effected by permanent deformationElectrical conductorIrradiation

After bringing a conductor of an electric wire into press contact to connect with a wire caulking portion of a connection terminal, the conductor and the wire caulking portion are welded to connect by irradiating laser beam to a bottom wall of the wire caulking portion. Laser irradiation is carried out intermittently by three times and the laser irradiation at the second time and thereafter which is carried out later is carried out such that during a time period in which a laser welded portion immediately previously is brought into a predetermined state of elevating temperature, portions or welded regions overlap welded regions in laser irradiation irradiated previously.

Owner:YAZAKI CORP

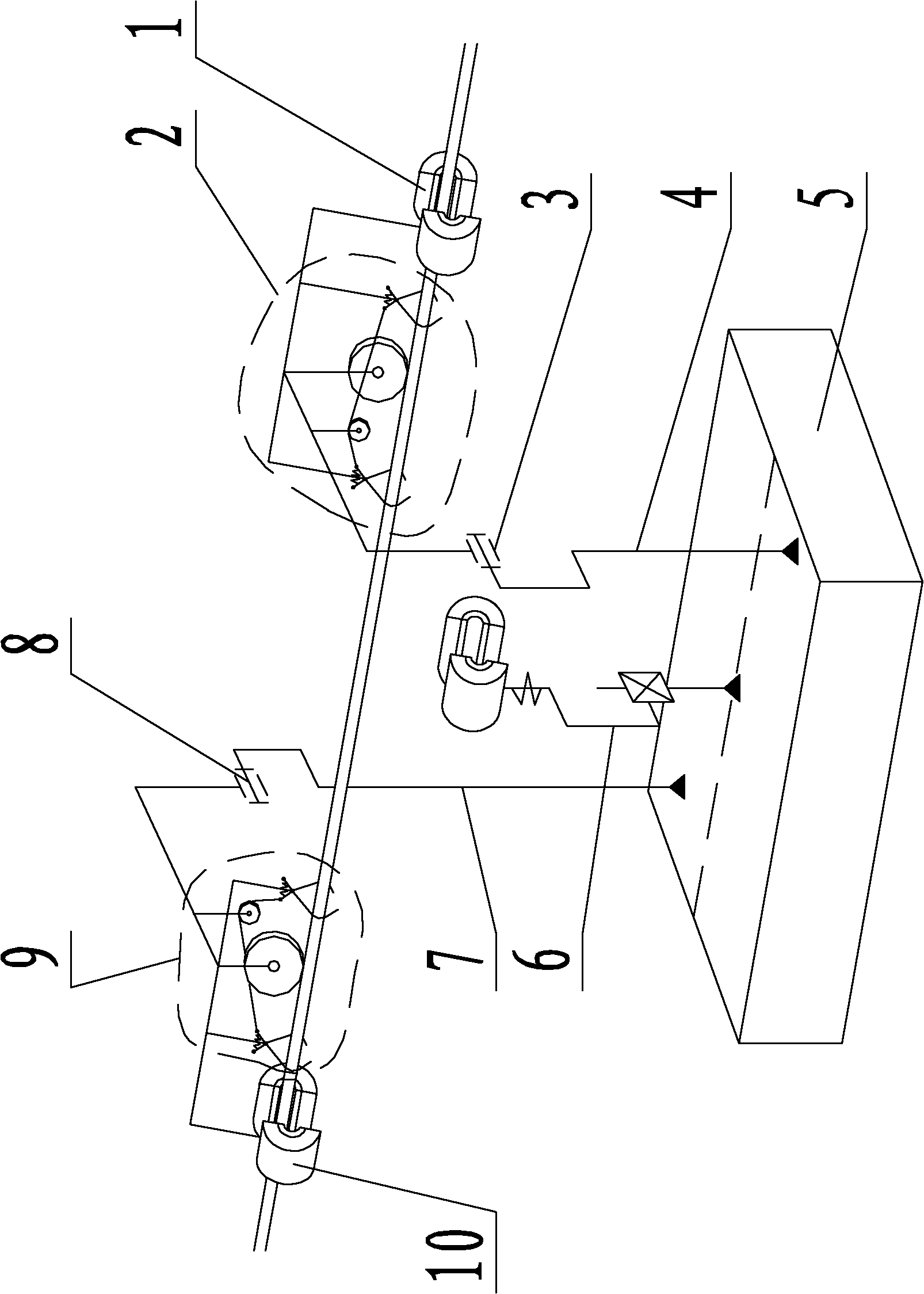

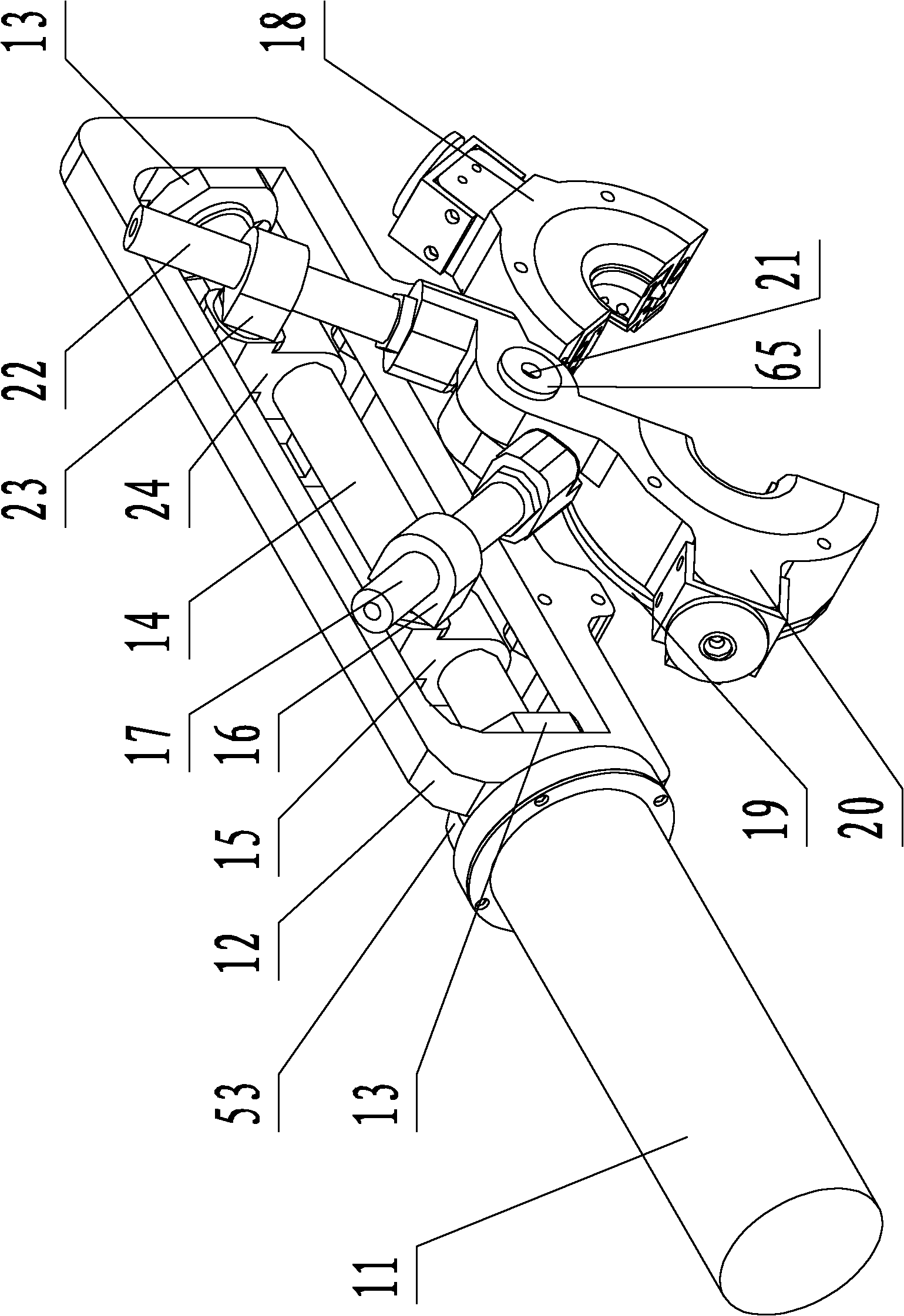

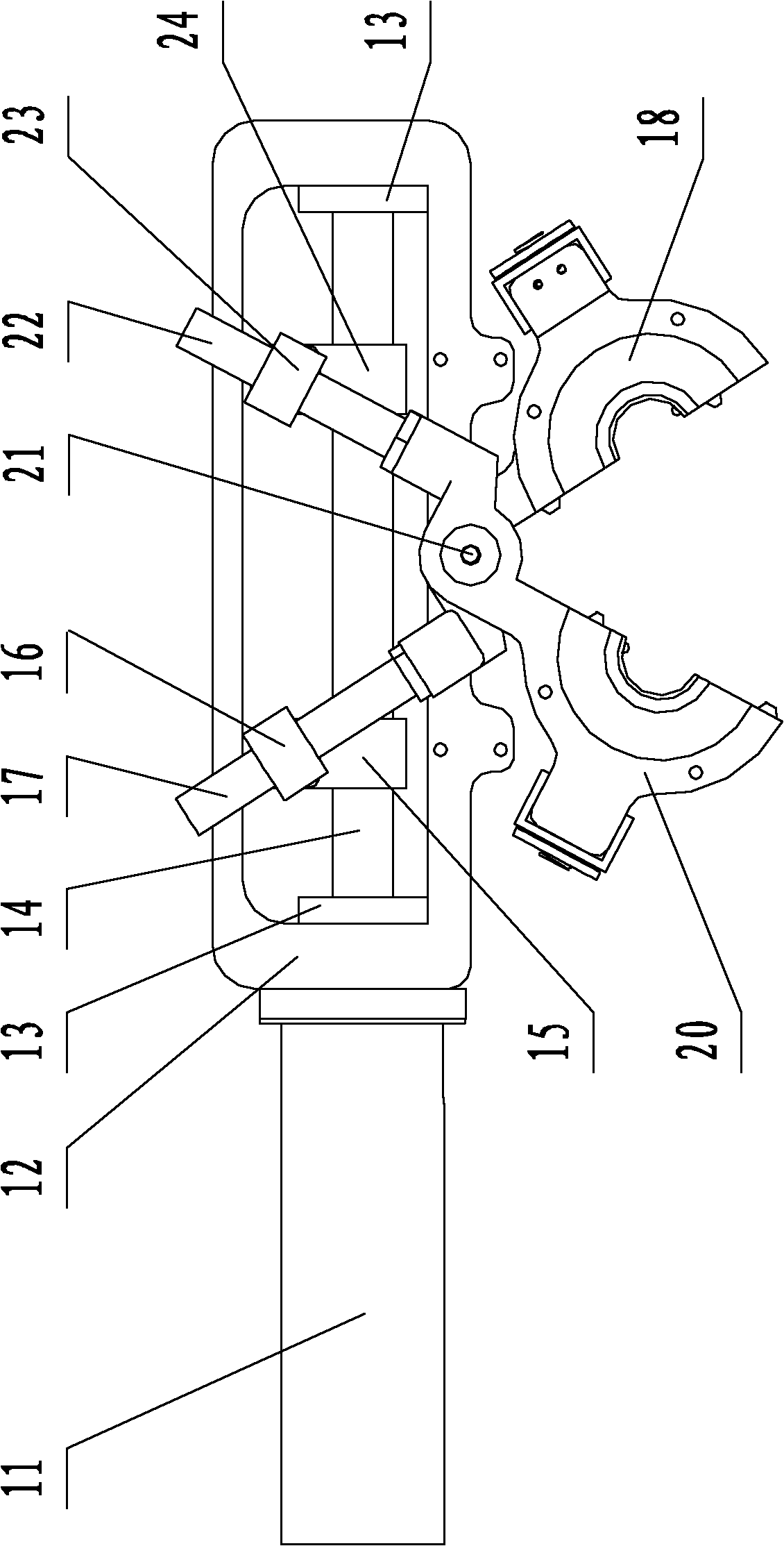

Broken strand crimping work robot mechanism of super-high-voltage power transmission line

ActiveCN102655314AThe threading process is simpleAchieve the purpose of strokingConnections effected by permanent deformationConnection formation by deformationEngineeringObstacle crossing

The invention relates to a power transmission line repairing robot and particularly relates to a broken strand crimping work robot mechanism of a super-high-voltage power transmission line. The broken strand crimping work robot mechanism comprises a front line stroking device, a front walking clamping mechanism, a front arm, an electrical equipment box body, a crimping arm, a rear arm, a rear walking clamping mechanism and a rear line stroking device, wherein one ends of the front arm and the rear arm are respectively and fixedly connected to the electrical equipment box body and the other ends of the front arm and the rear arm are hinged with the front walking clamping mechanism and the rear walking clamping mechanism; the front line stroking device and the rear line stroking device are respectively arranged on the outer sides of the front walking clamping mechanism and the rear walking clamping mechanism; one end of the crimping arm is fixedly connected with the electrical equipment box body; and the other end of the crimping arm is a crimping end and is located between the front walking clamping mechanism and the rear walking clamping mechanism. The broken strand crimping work robot mechanism has the advantages of large climbing angle, good safety protection, short obstacle crossing time, simple obstacle crossing process, simple and efficient line stroking process, small abrasion on the line and good broken strand crimping effect, improves the personal safety, reduces the labor intensity of staff and improves the efficiency.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Electric wire with terminal connector and method of manufacturing electric wire with terminal connector

InactiveUS20110094797A1Increase resistanceLower resistanceSoldered/welded connectionsConnections effected by permanent deformationUltrasonic vibrationElectric wire

An electric wire with terminal connector including an electric wire having a core wire including a plurality of wires and a female terminal connector including a wire barrel that is crimped onto the core wire exposed from the electric wire, the following steps are executed. The steps include a step of removing wire insulation covering an outer peripheral surface of the core wire to expose the core wire, a step of holding the exposed core wire with jigs provided in a pair and applying ultrasonic vibration to the core wire via the jigs, and a step of crimping the wire barrel so as to surround a part of the core wire to which the ultrasonic vibration is applied.

Owner:AUTONETWORKS TECH LTD +2

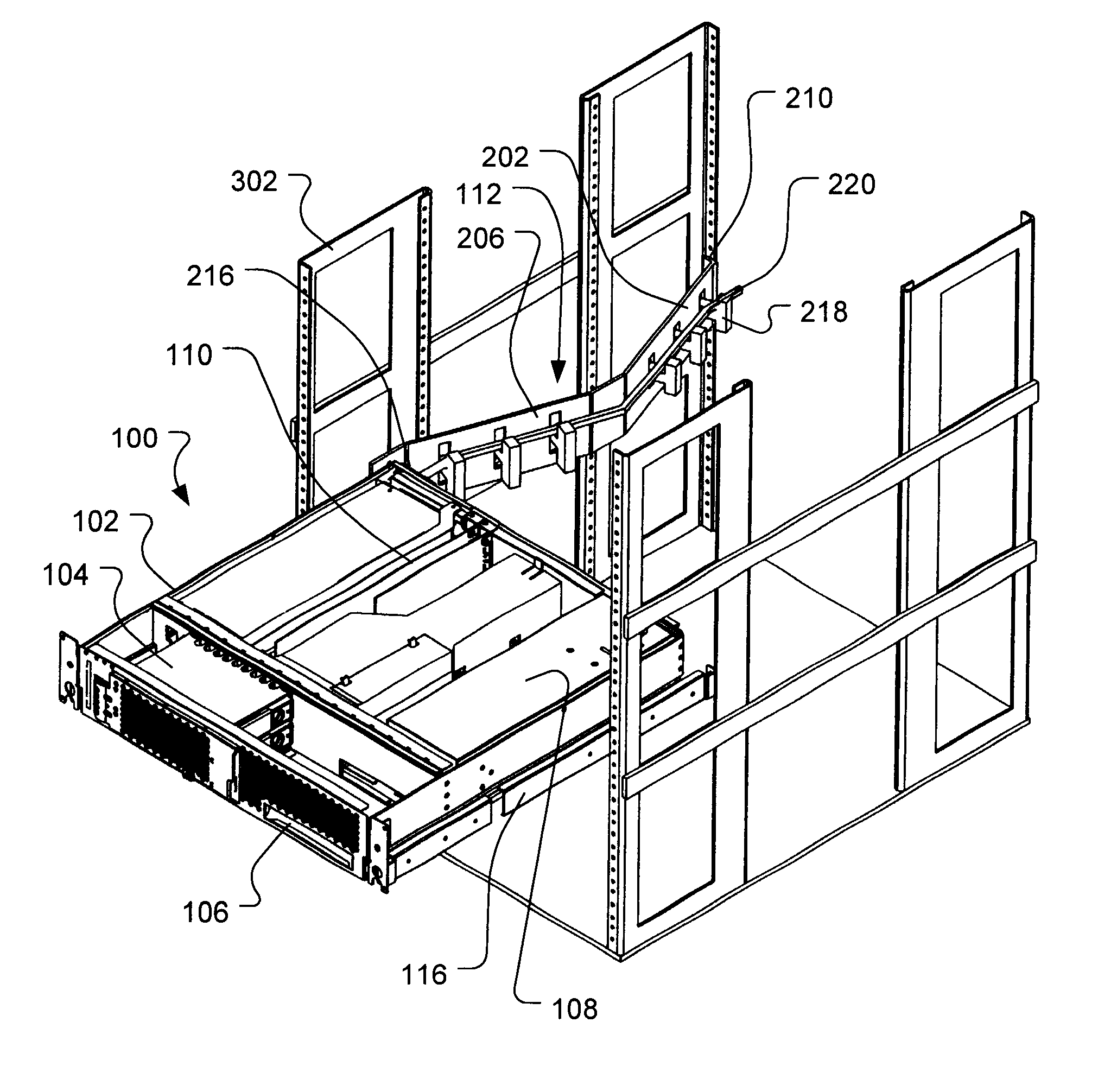

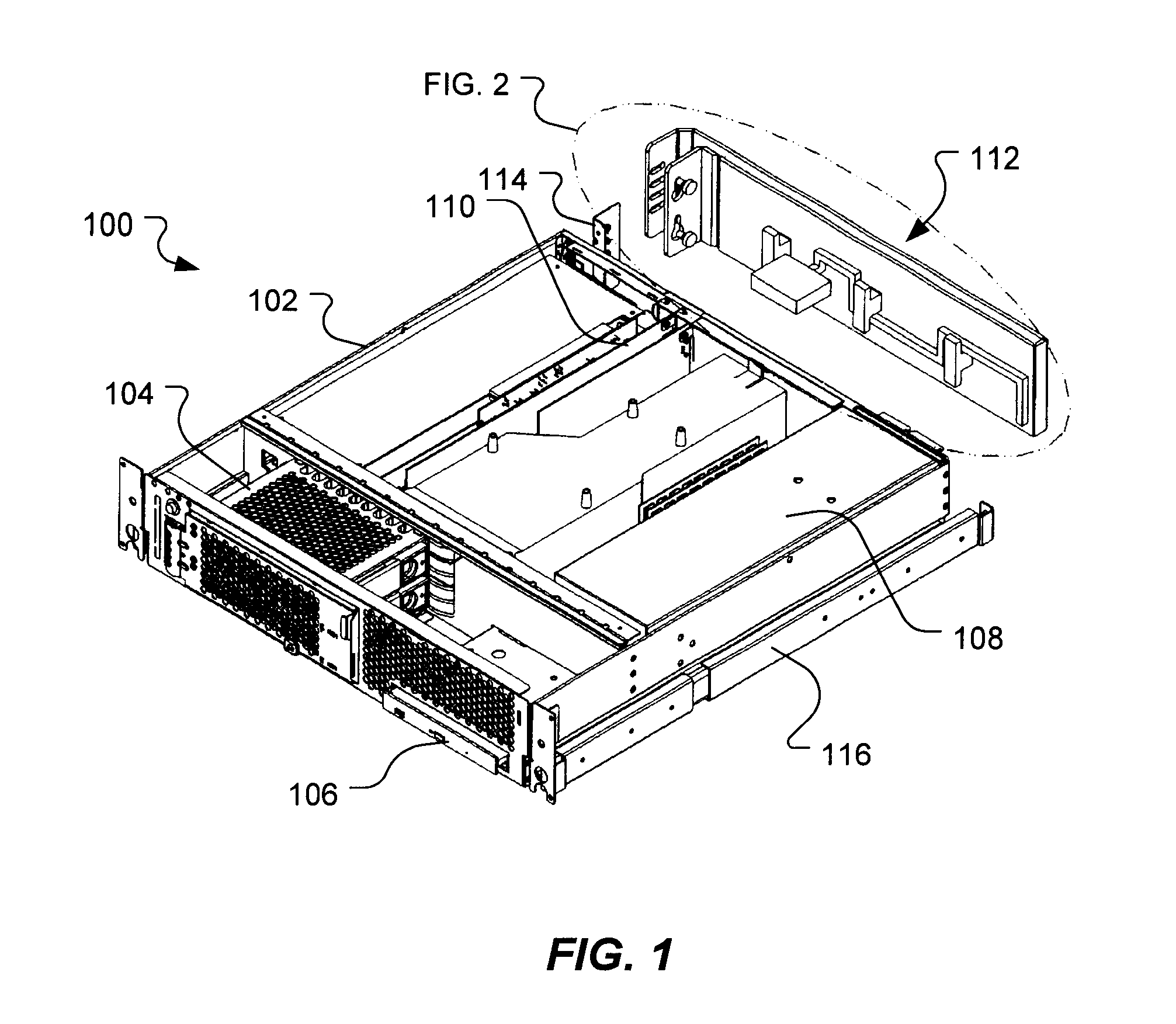

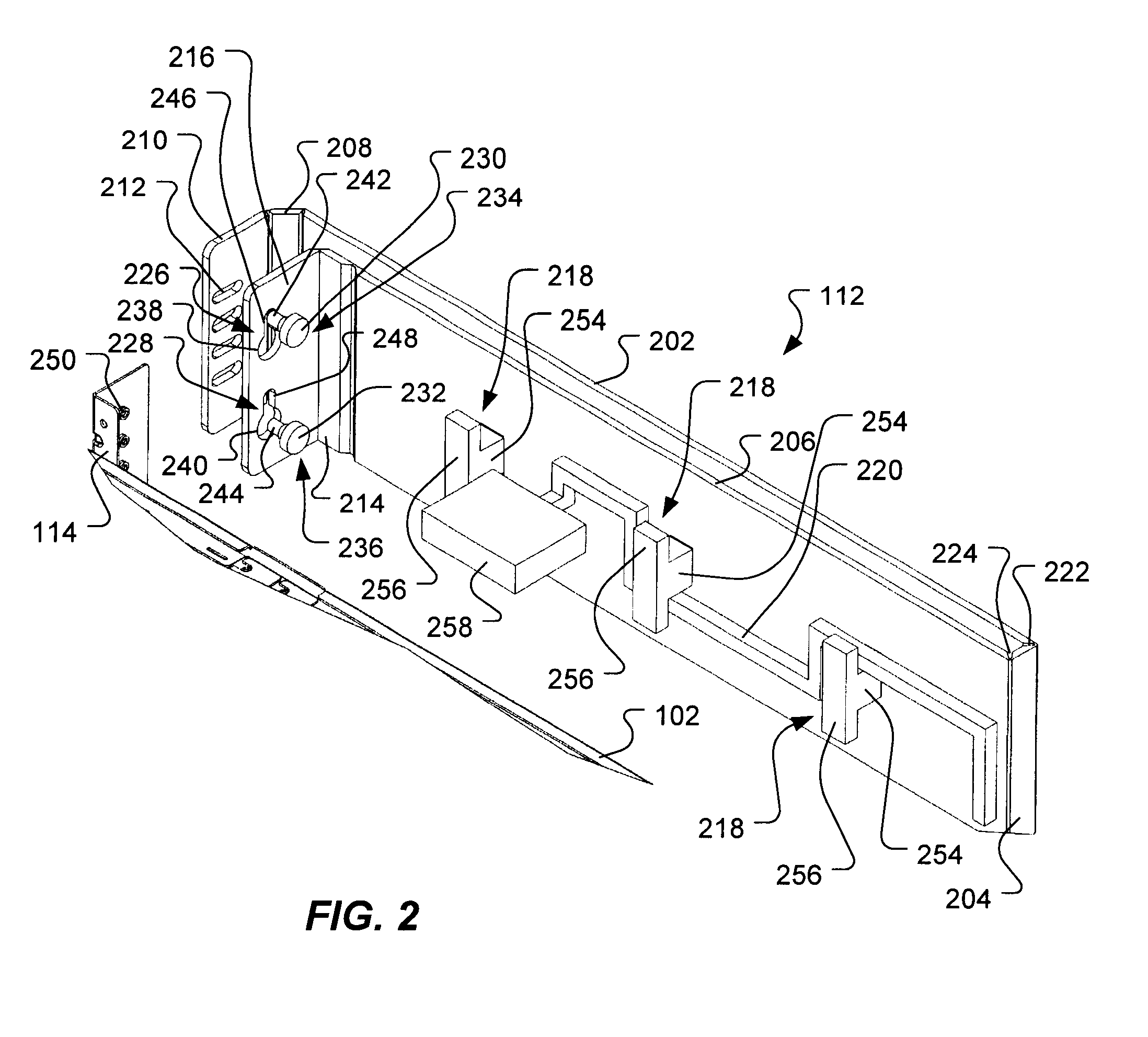

Apparatus and method for routing cables

A cable arm for a computer system includes a first leg, a second leg hingedly joined to the first leg, and an enclosure flange hingedly joined to the second leg. The cable arm further includes a rack flange, hingedly joined to the first leg, capable of being attached to a rack for holding the computer system, an enclosure bracket capable of being attached to the computer system and capable of being attached to the enclosure flange, and a hook, extending from the second leg, capable retaining a cable attached to the computer system.

Owner:ORACLE INT CORP

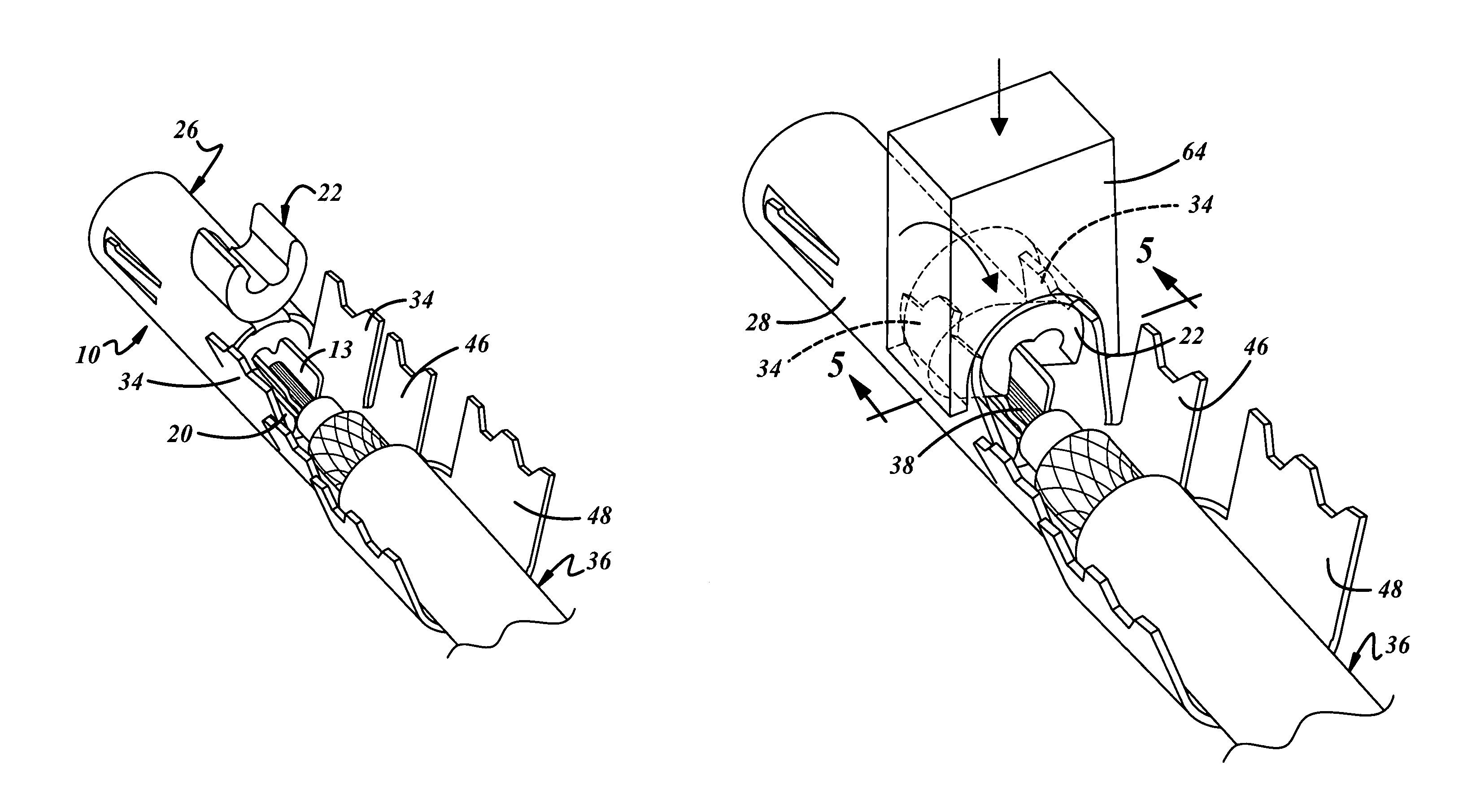

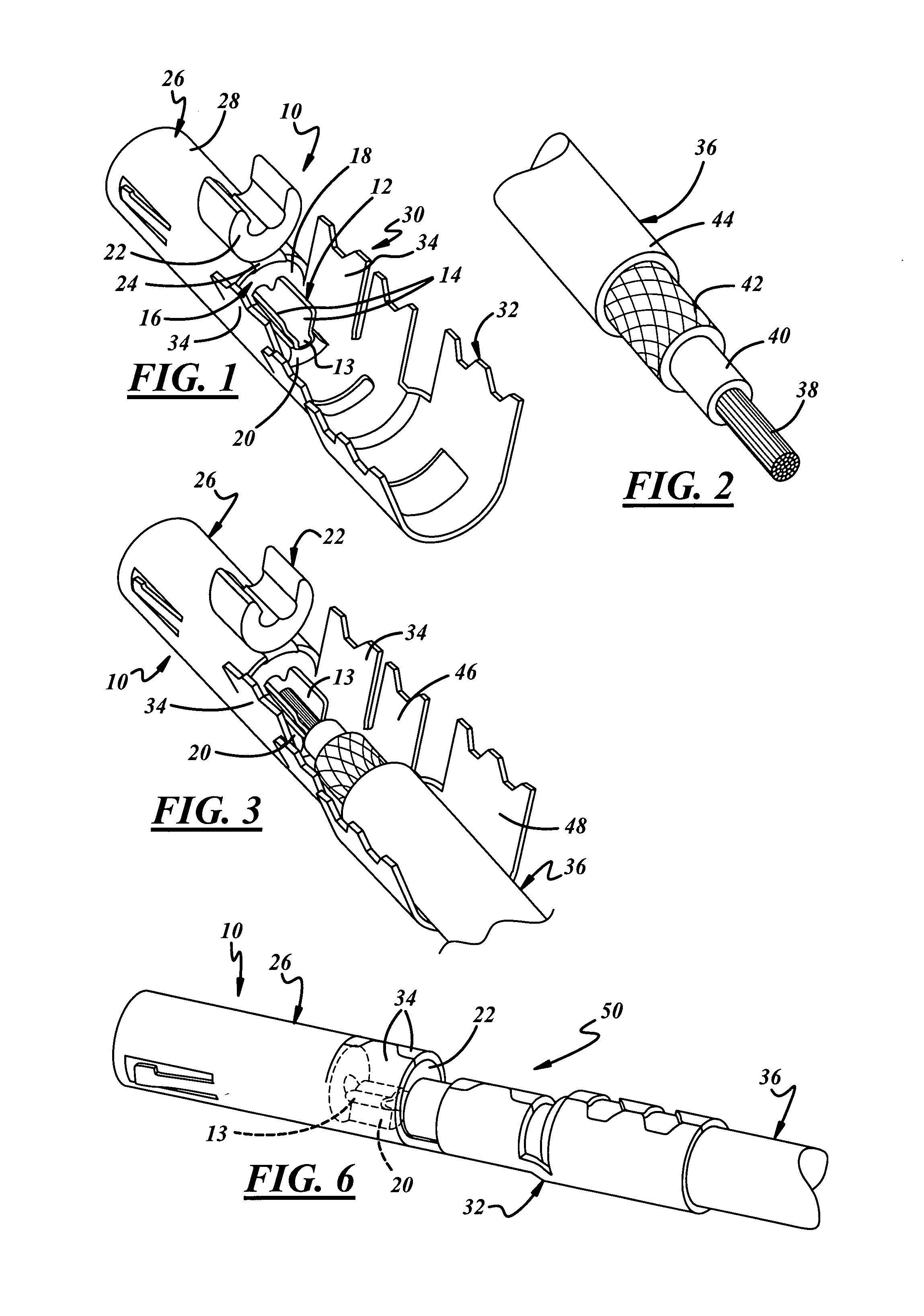

Shielded electric connector and cable assembly and method for making same

A shielded electric cable assembly comprises a shielded electric cable and a shielded electric connector that has an inner terminal, an insulator and an outer shielding terminal. The inner terminal has an attachment portion that is supported on a projecting anvil of the insulator that is disposed in an intermediate bay of the outer shielding terminal. The bay has an opening for a crimp tool that crimps the attachment portion of the inner terminal onto an exposed end of a conductive core of the shielded electric cable. The intermediate bay is closed by side wall flaps of the intermediate bay or by a closure shell. The crimp tool that may be part of the insulator.

Owner:APTIV TECH LTD

Crimp terminal, terminal-provided wire, and manufacturing method thereof

InactiveUS8221171B2Ensure mechanical strengthReduce contact resistanceLine/current collector detailsConnections effected by permanent deformationElectrical conductorEngineering

Owner:AUTONETWORKS TECH LTD +2

Terminal having integral oxide breaker

ActiveUS20100206631A1Line/current collector detailsConnections effected by permanent deformationCircuit breakerOxide

A one piece integral electrical terminal has a mount portion and a wire receiving portion. The wire receiving portion has a continuous annular interior wall having a contact portion with an integral oxide breaker especially suited to breaking through the oxide layer on aluminum wire. The wire receiving portion also has a sealing portion with at least one integral seal ring. An electrical cable is made by crimping the electrical terminal to an aluminum wire using a modified hexagonal crimp.

Owner:CARLISLE INTERCONNECT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com