Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21872results about "Welding/cutting media/materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

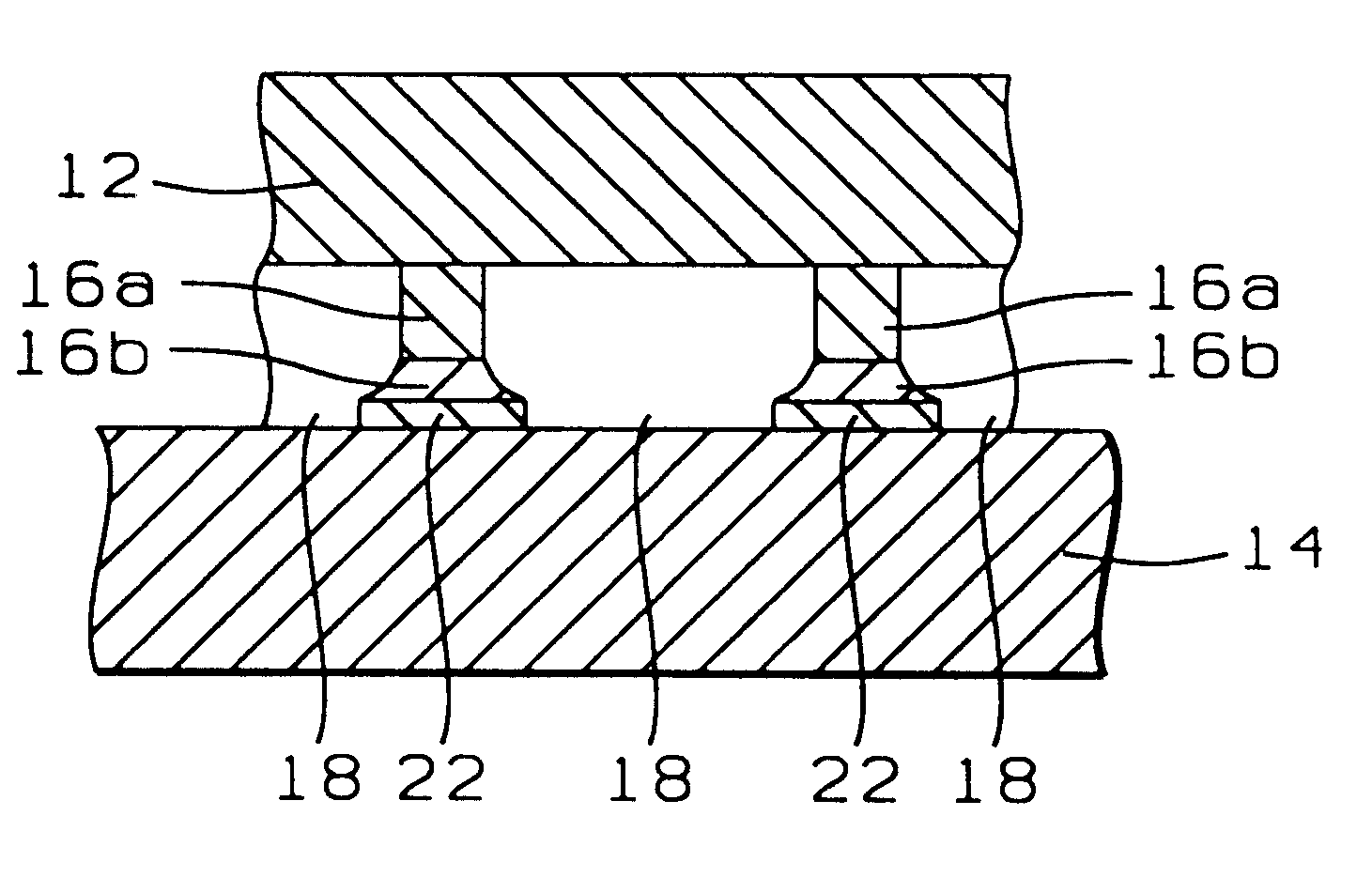

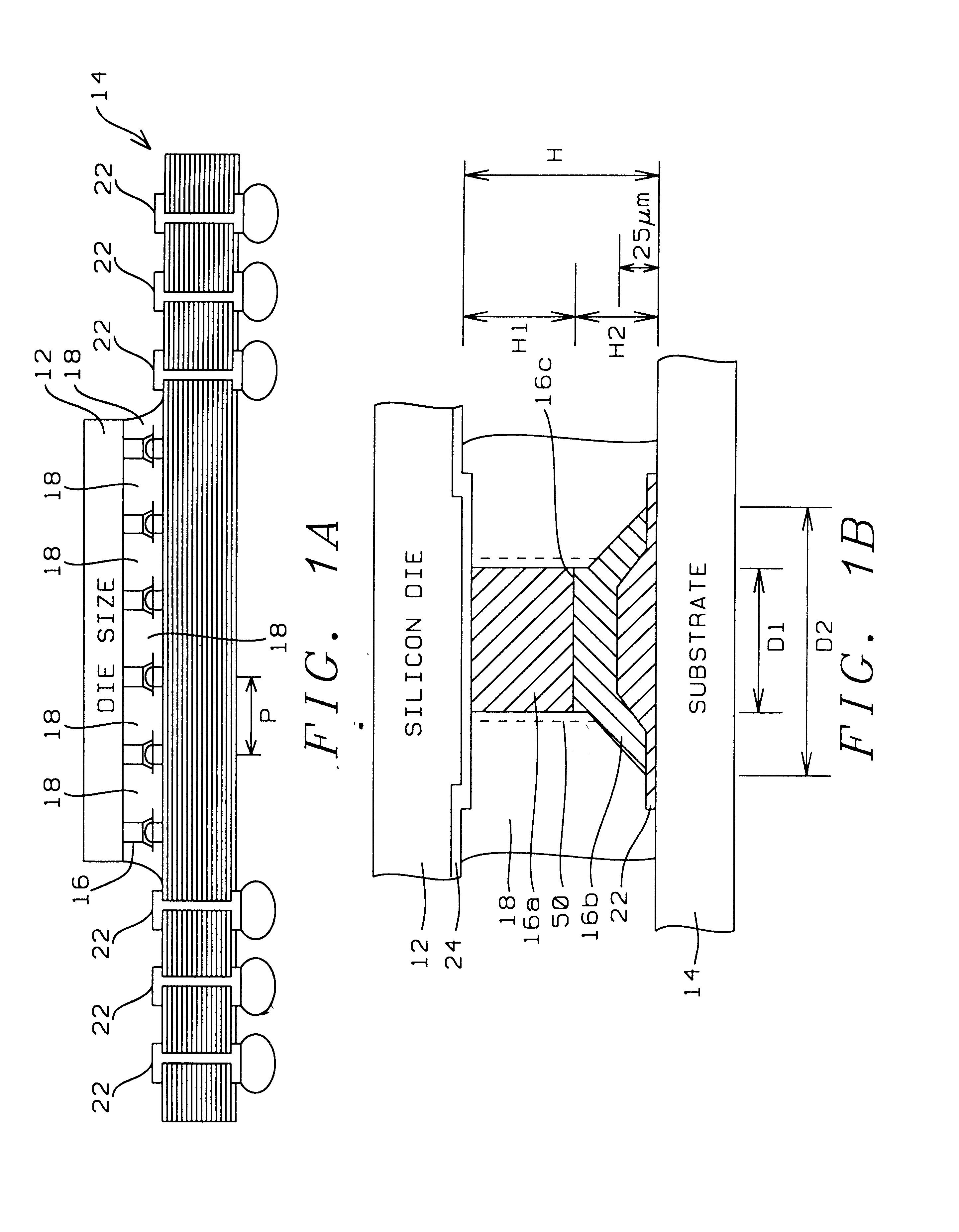

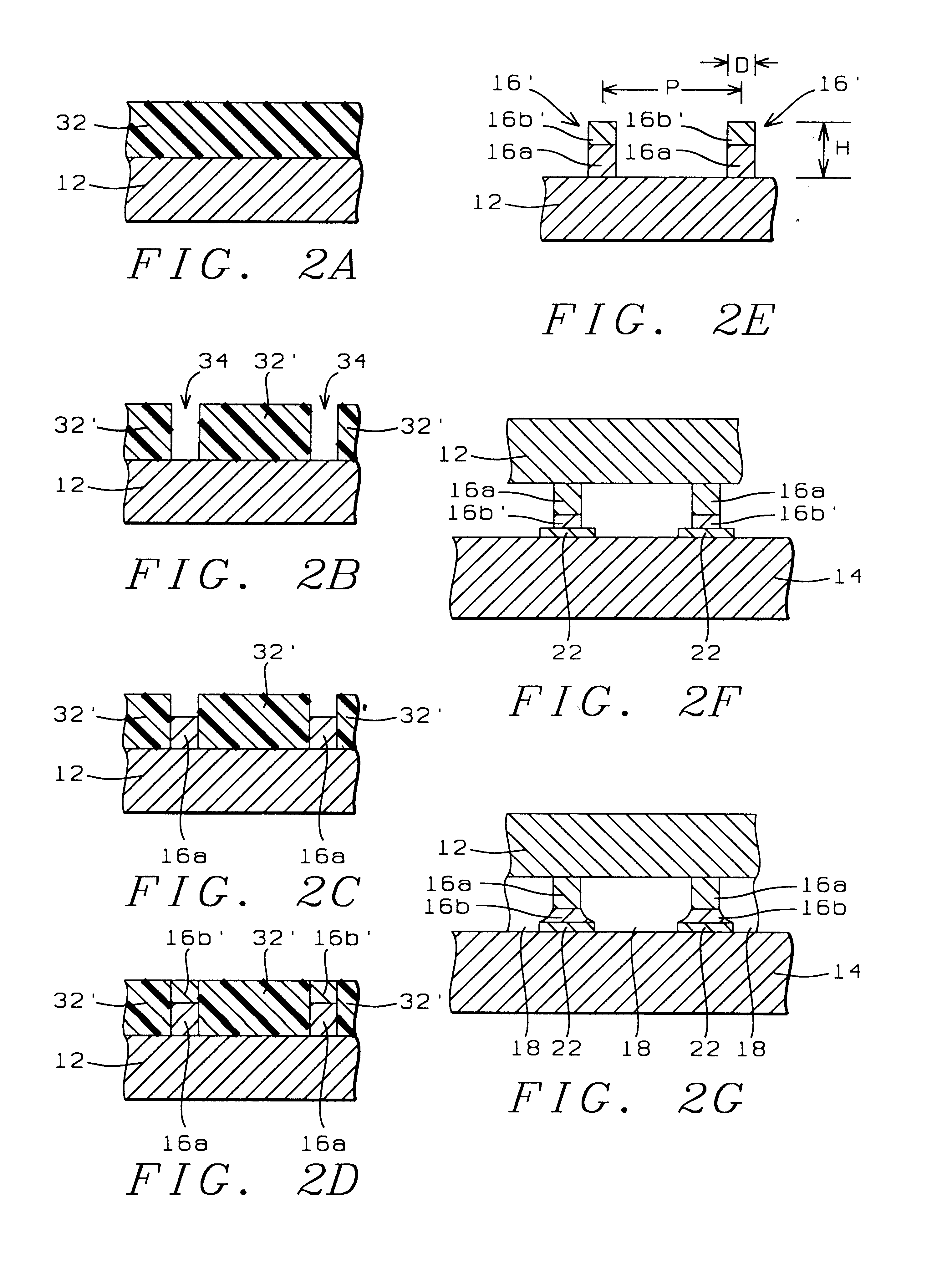

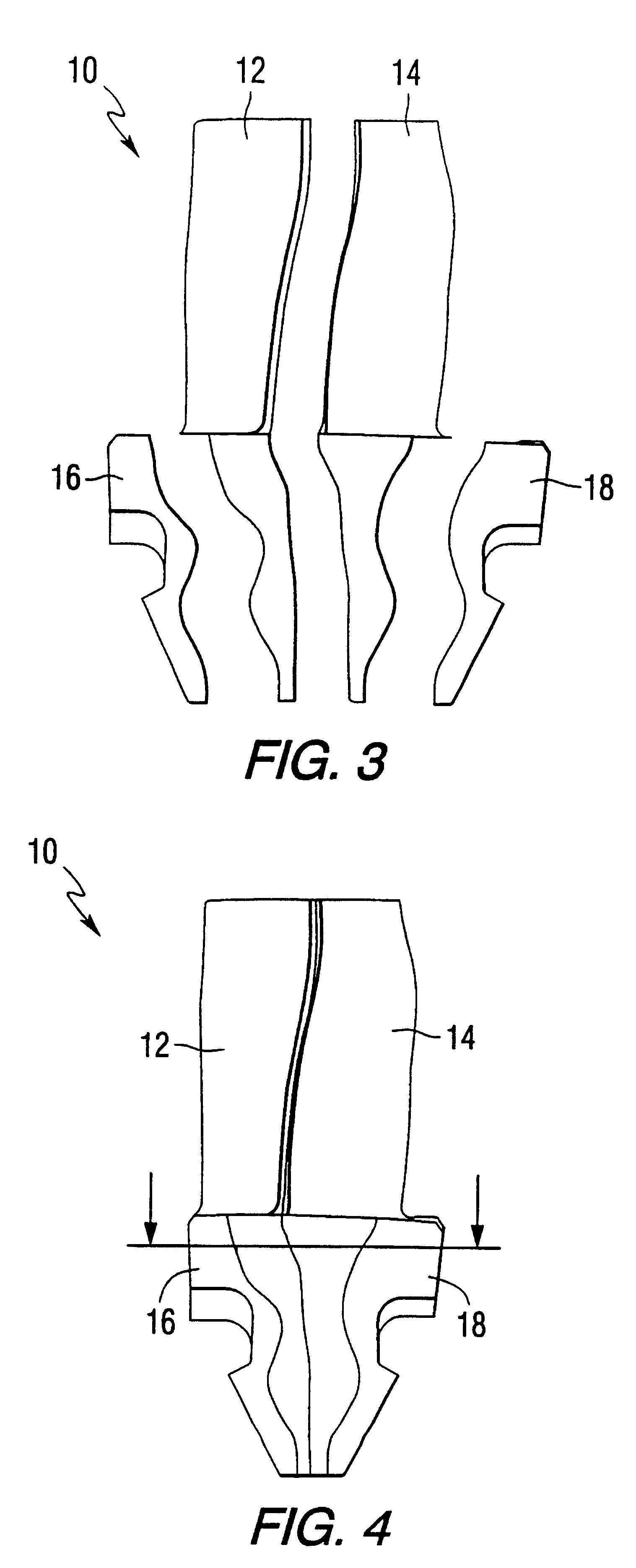

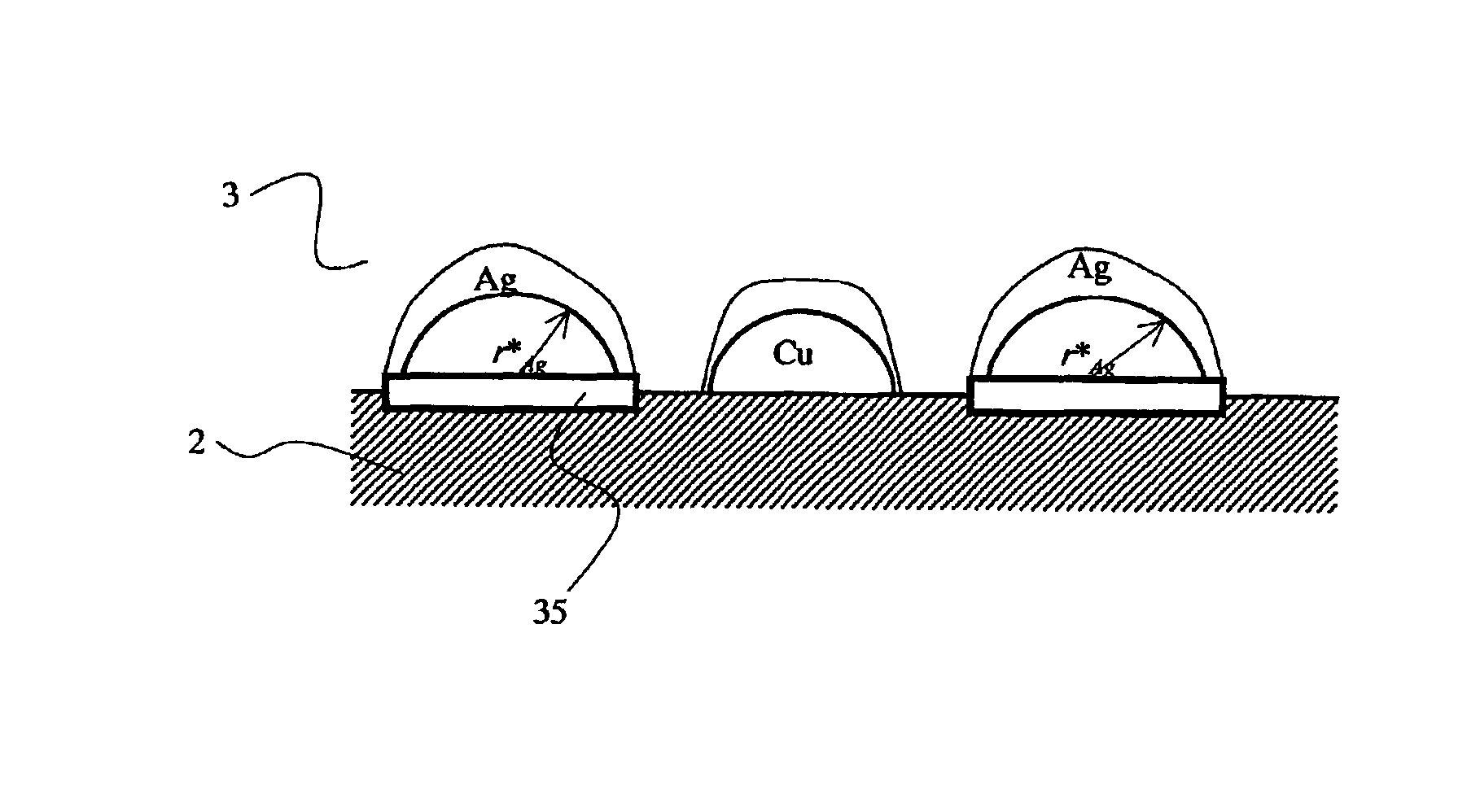

Pillar connections for semiconductor chips and method of manufacture

InactiveUS6578754B1Reduce chanceInduced in connectionSemiconductor/solid-state device detailsSolid-state devicesFlip chip interconnectSemiconductor chip

A flip chip interconnect system comprises and elongated pillar comprising two elongated portions, one portion including copper and another portion including solder. The portion including copper is in contact with the semiconductor chip and has a length preferably of more than 55 microns to reduce the effect of .alpha. particles from the solder from affecting electronic devices on the chip. The total length of the pillar is preferably in the range of 80 to 120 microns.

Owner:ADVANPAK SOLUTIONS PTE

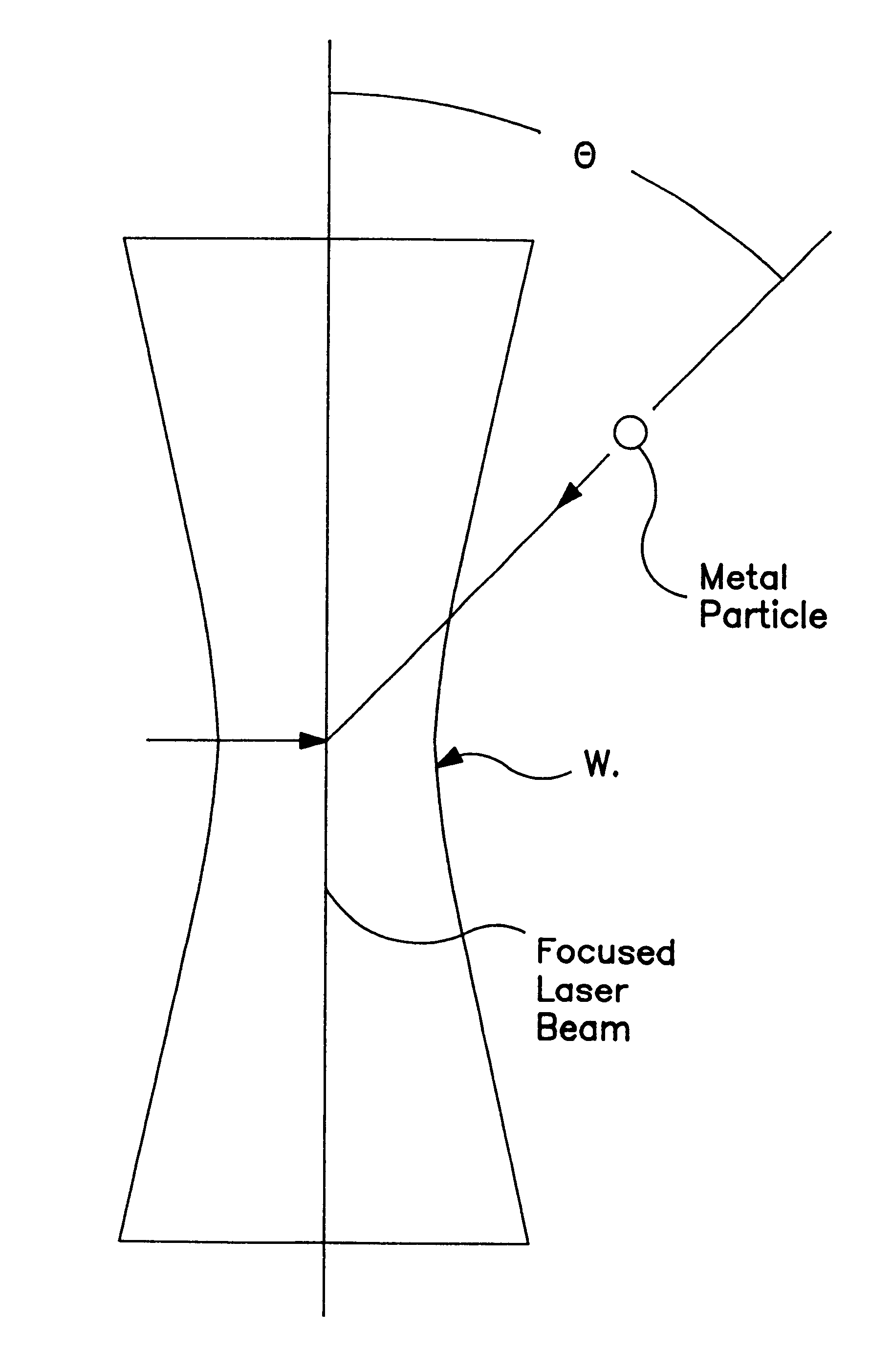

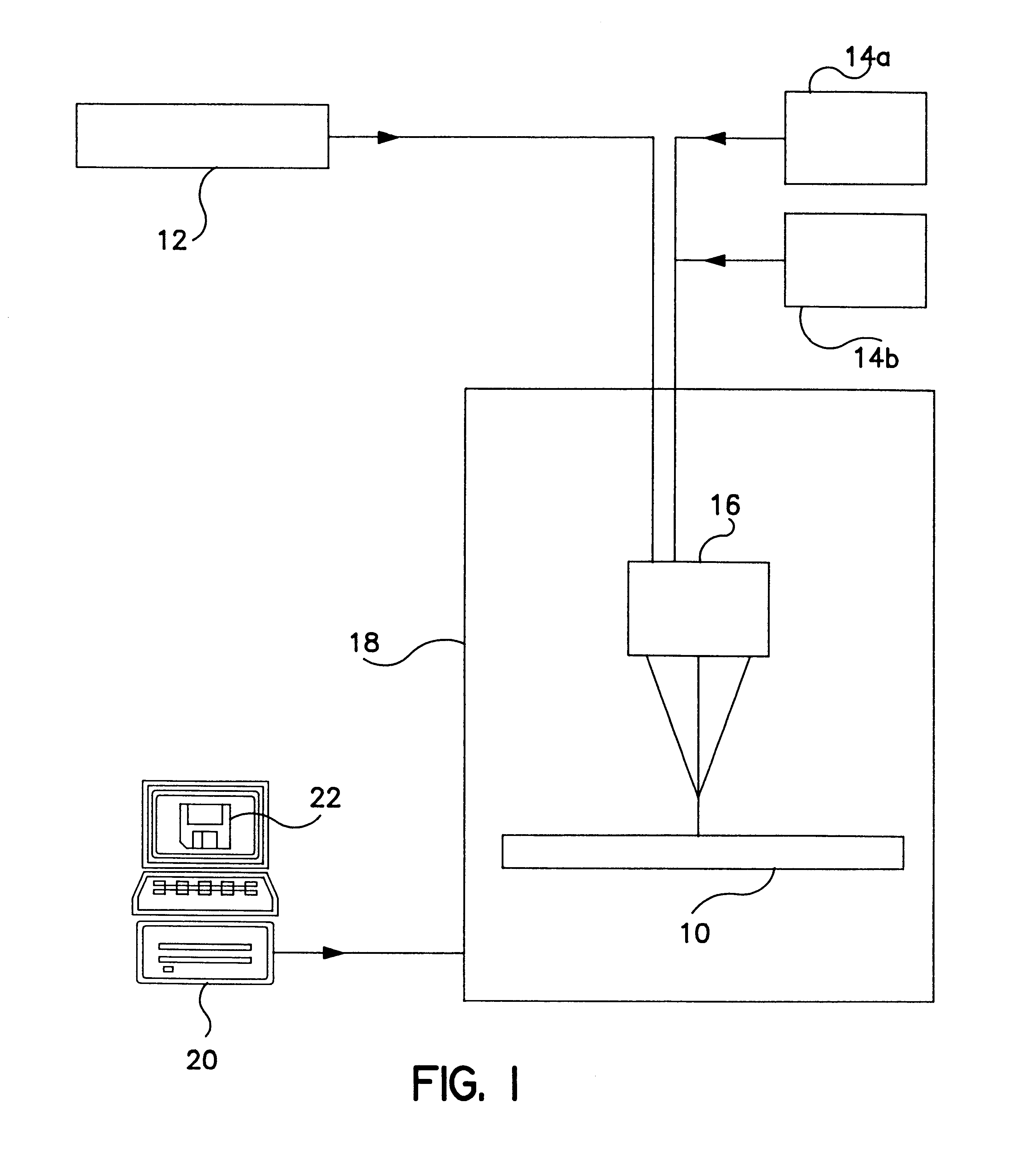

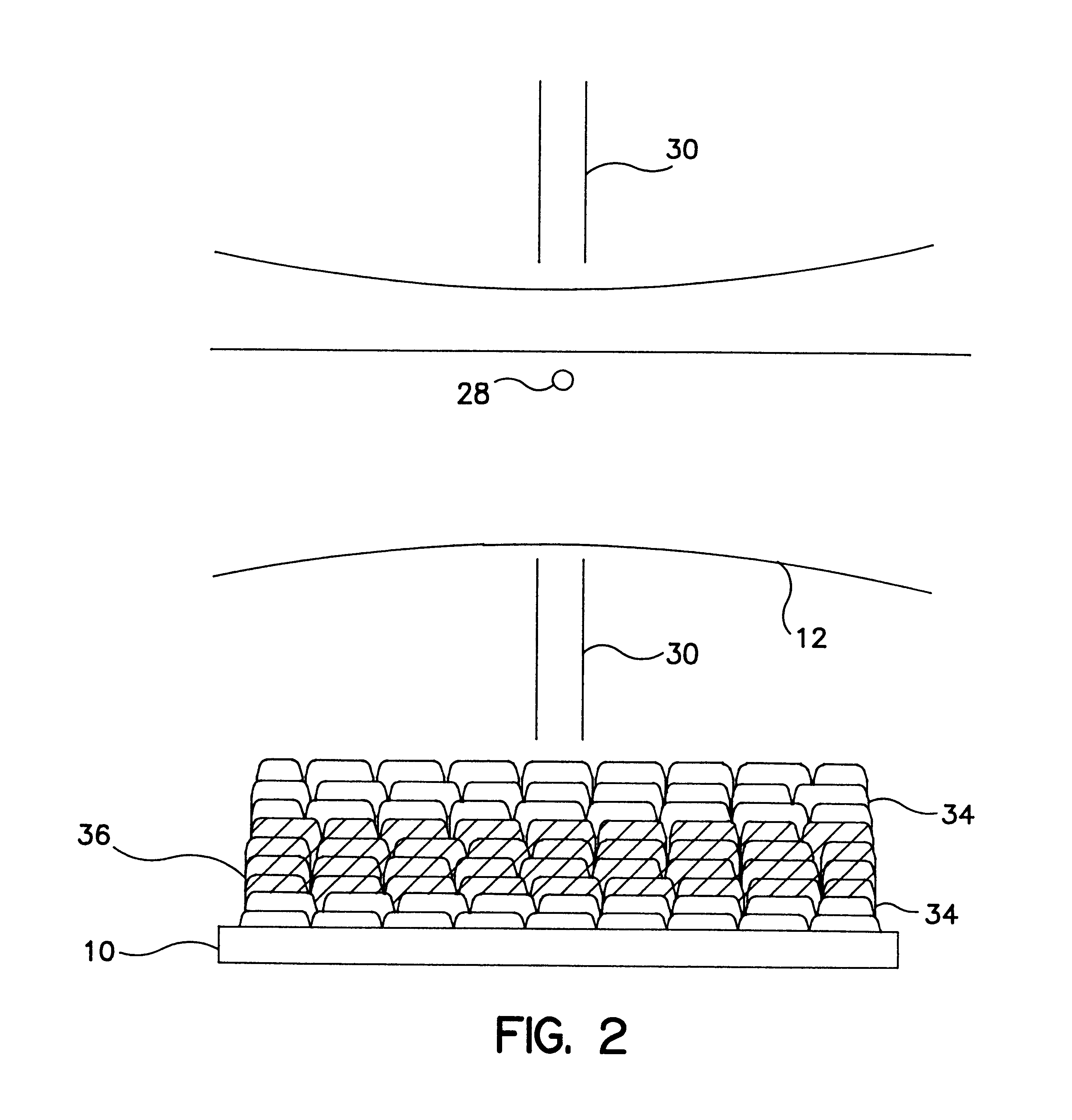

Precision spray processes for direct write electronic components

InactiveUS6251488B1Keep for a long timeIncrease probabilityMolten spray coatingVacuum evaporation coatingElectrical resistance and conductanceElectronic component

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

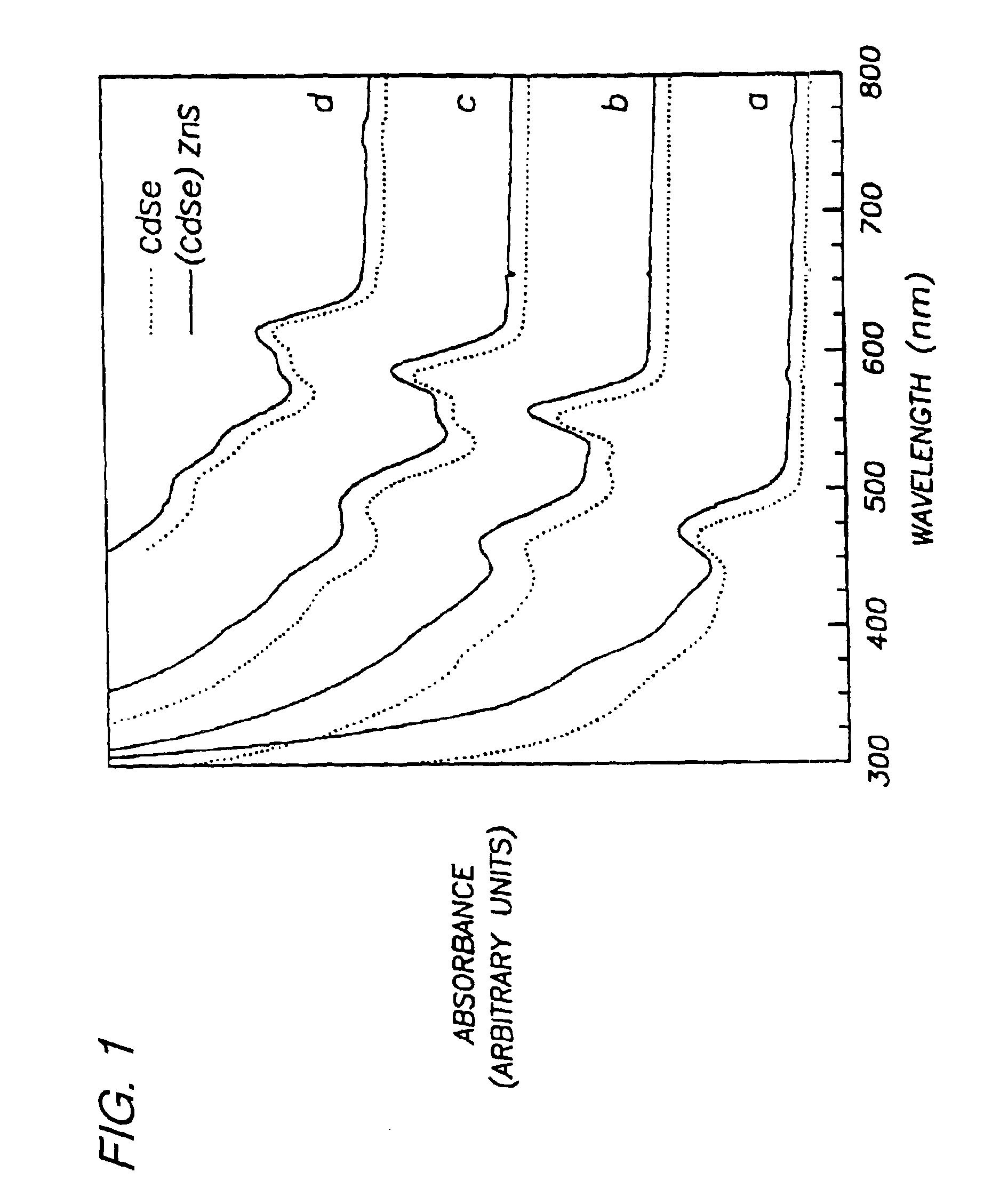

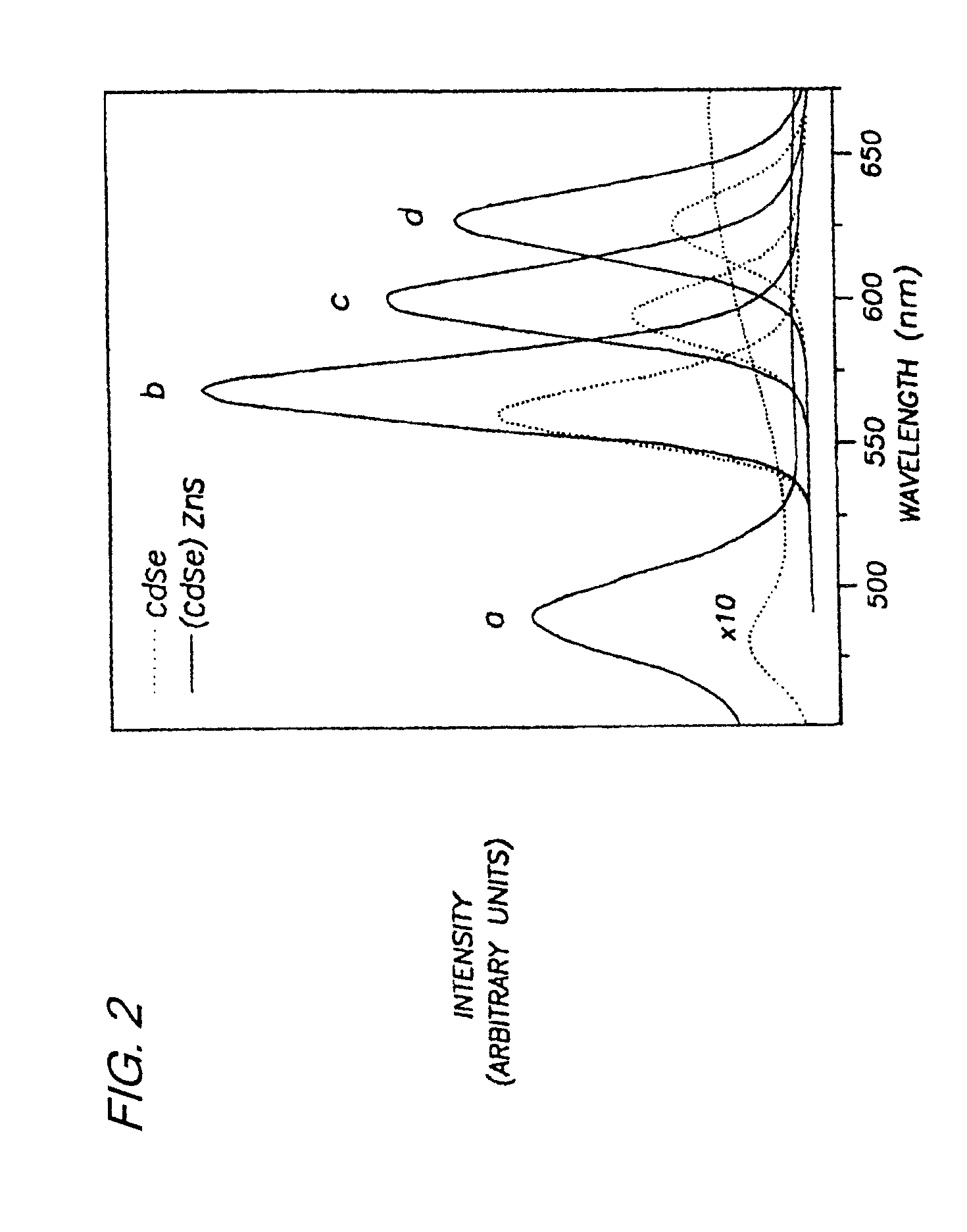

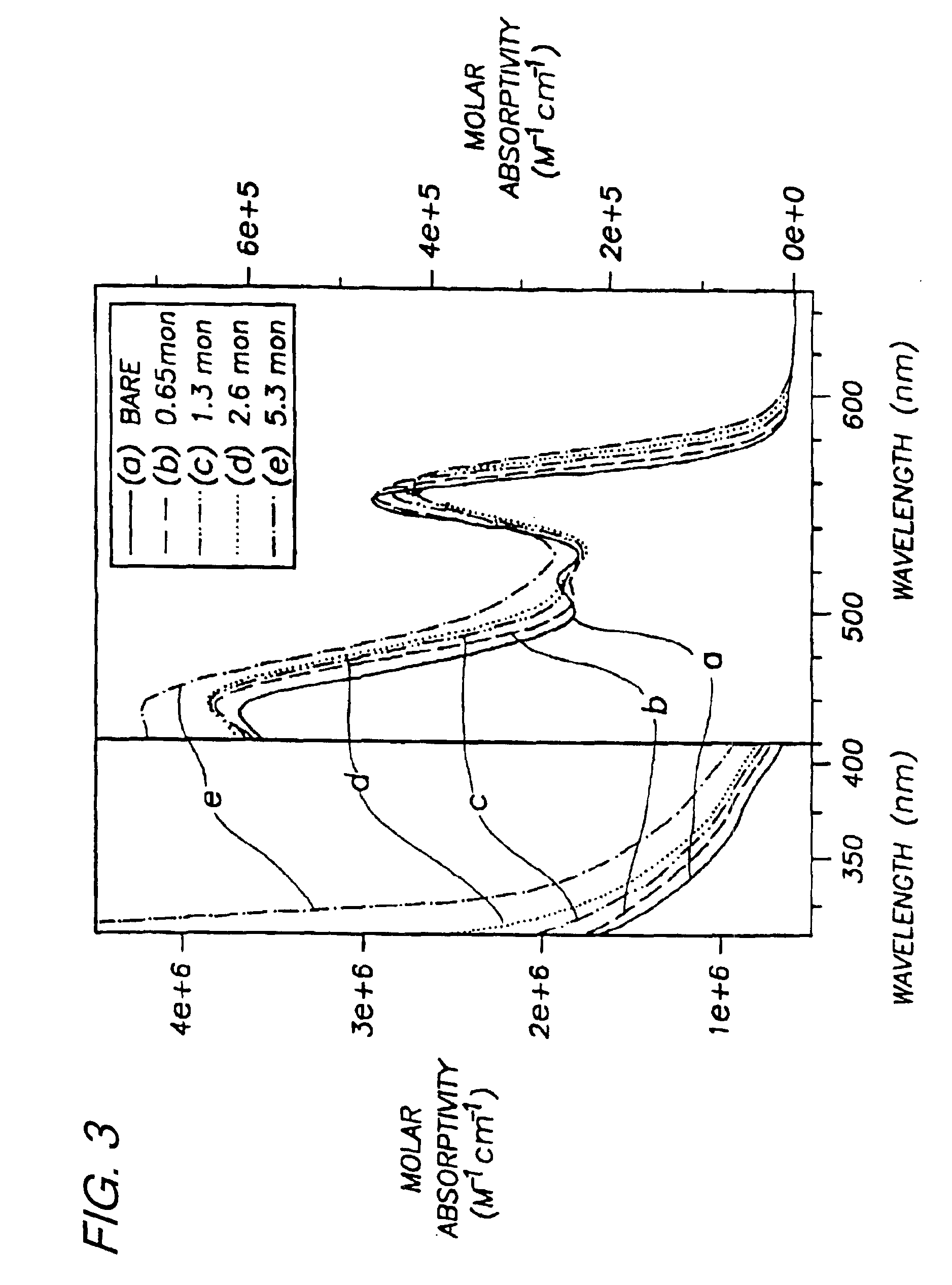

Highly luminescent color selective nanocrystalline materials

InactiveUS6861155B2Improve coordinationMaterial nanotechnologyFrom normal temperature solutionsQuantum yieldPhotoluminescence

A coated nanocrystal capable of light emission includes a substantially monodisperse nanoparticle selected from the group consisting of CdX, where x=S, Se, Te and an overcoating of ZnY, where Y=S, Se, uniformly deposited thereon, said coated nanoparticle characterized in that when irradiated the particles exhibit photoluminescence in a narrow spectral range of no greater than about 60 nm, and most preferably 40 nm, at full width half max (FWHM). The particle size of the nanocrystallite core is in the range of about 20 Å to about 125 Å, with a deviation of less than 10% in the core. The coated nanocrystal exhibits photoluminescence having quantum yields of greater than 30%.

Owner:MASSACHUSETTS INST OF TECH

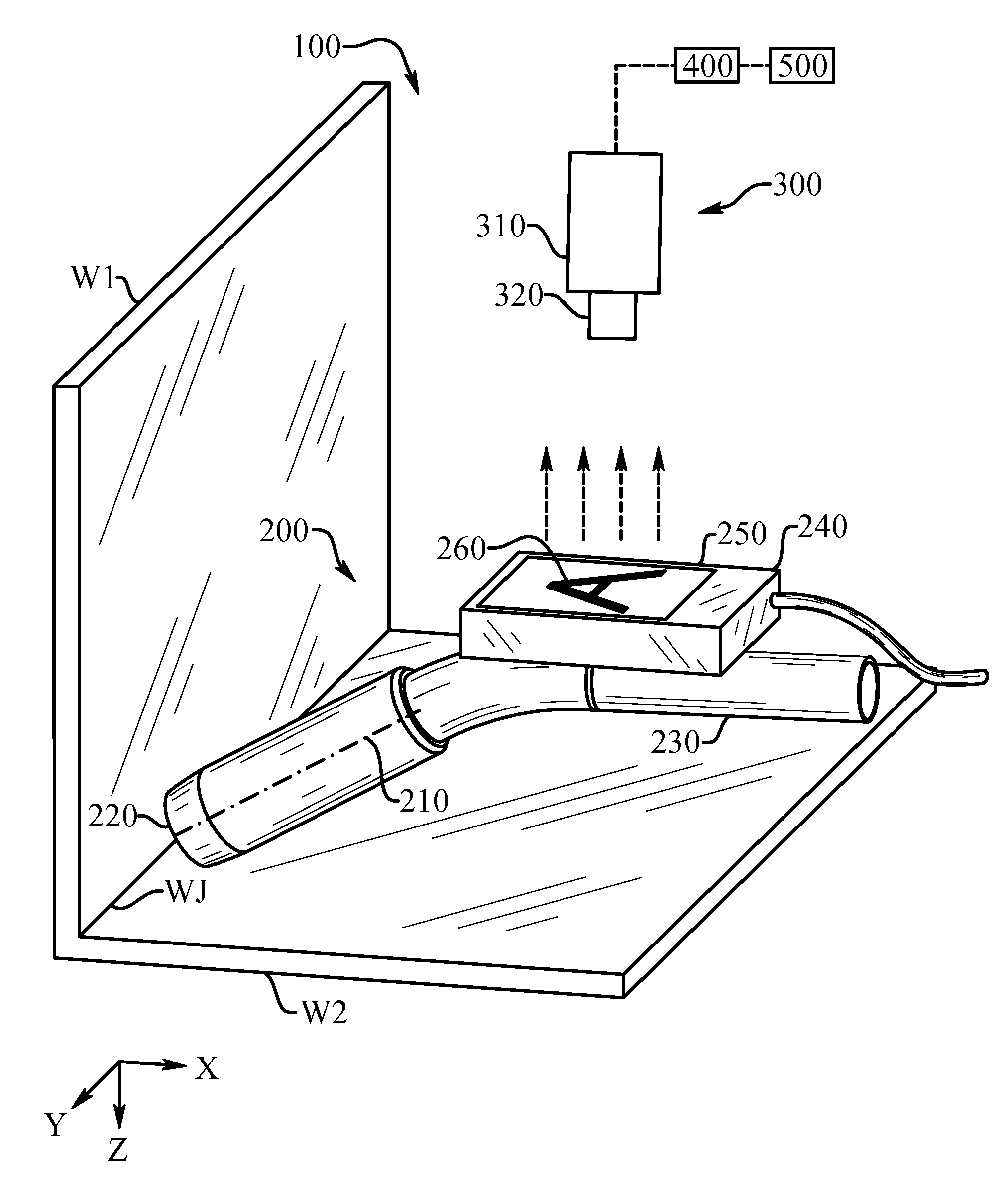

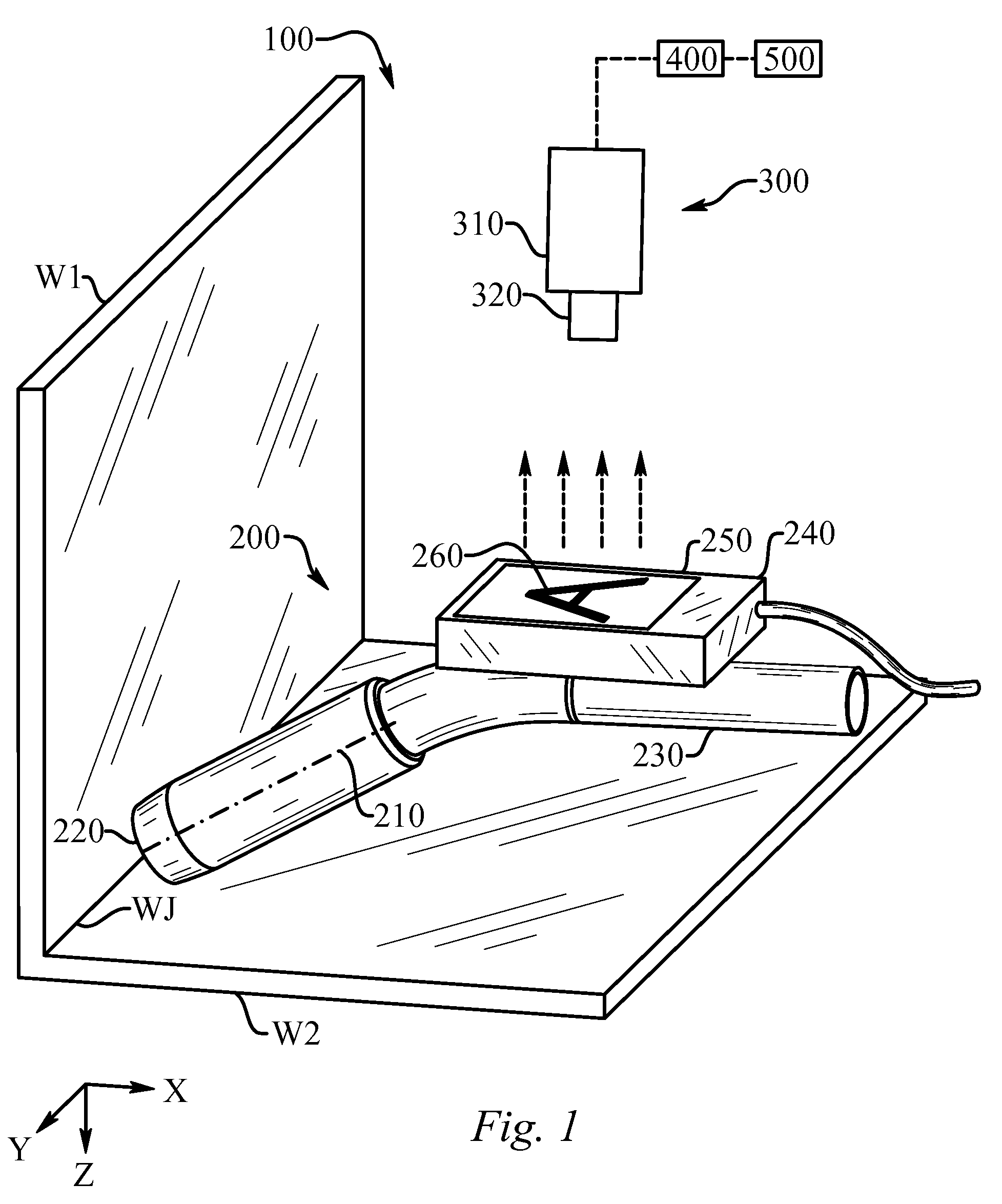

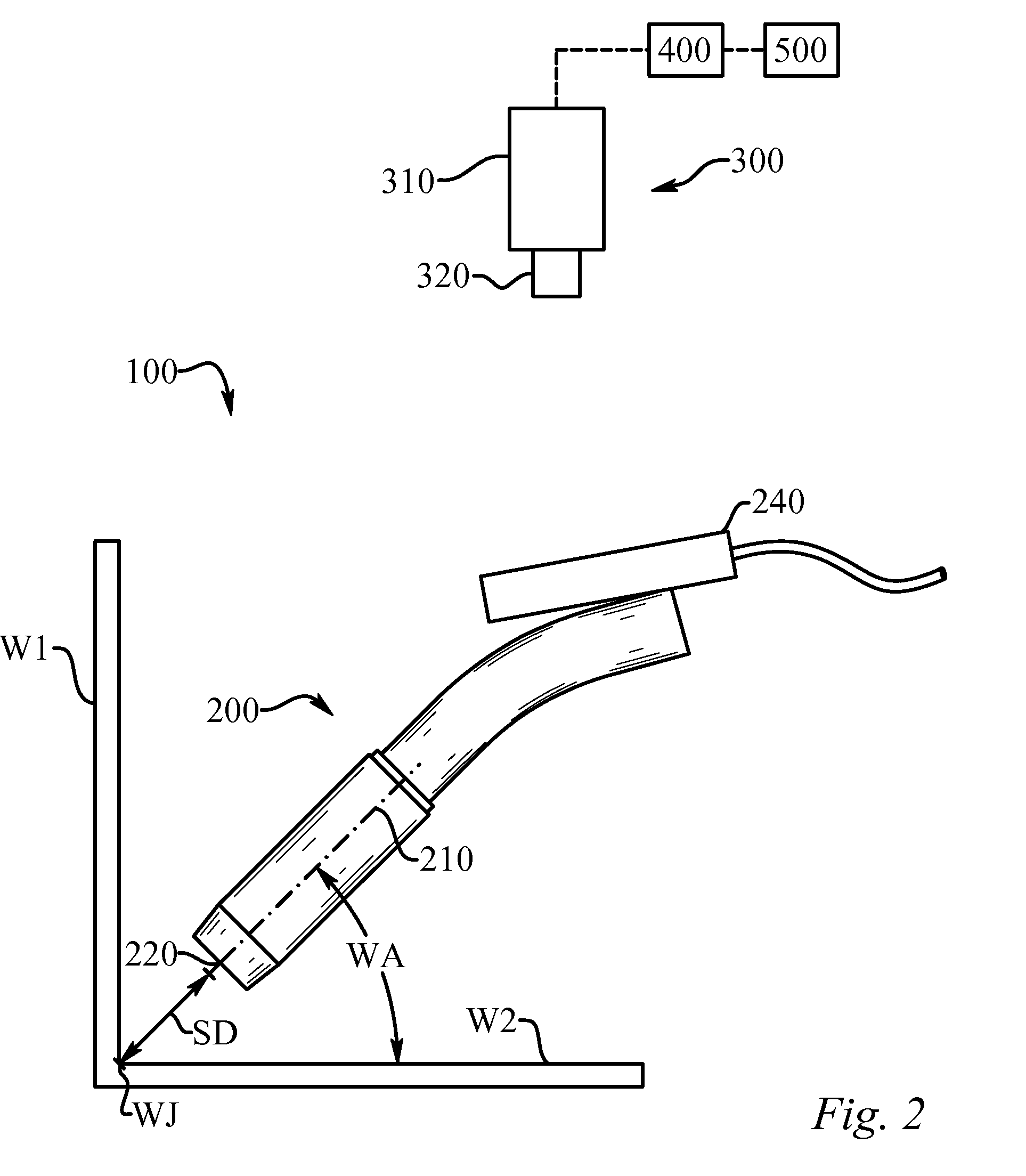

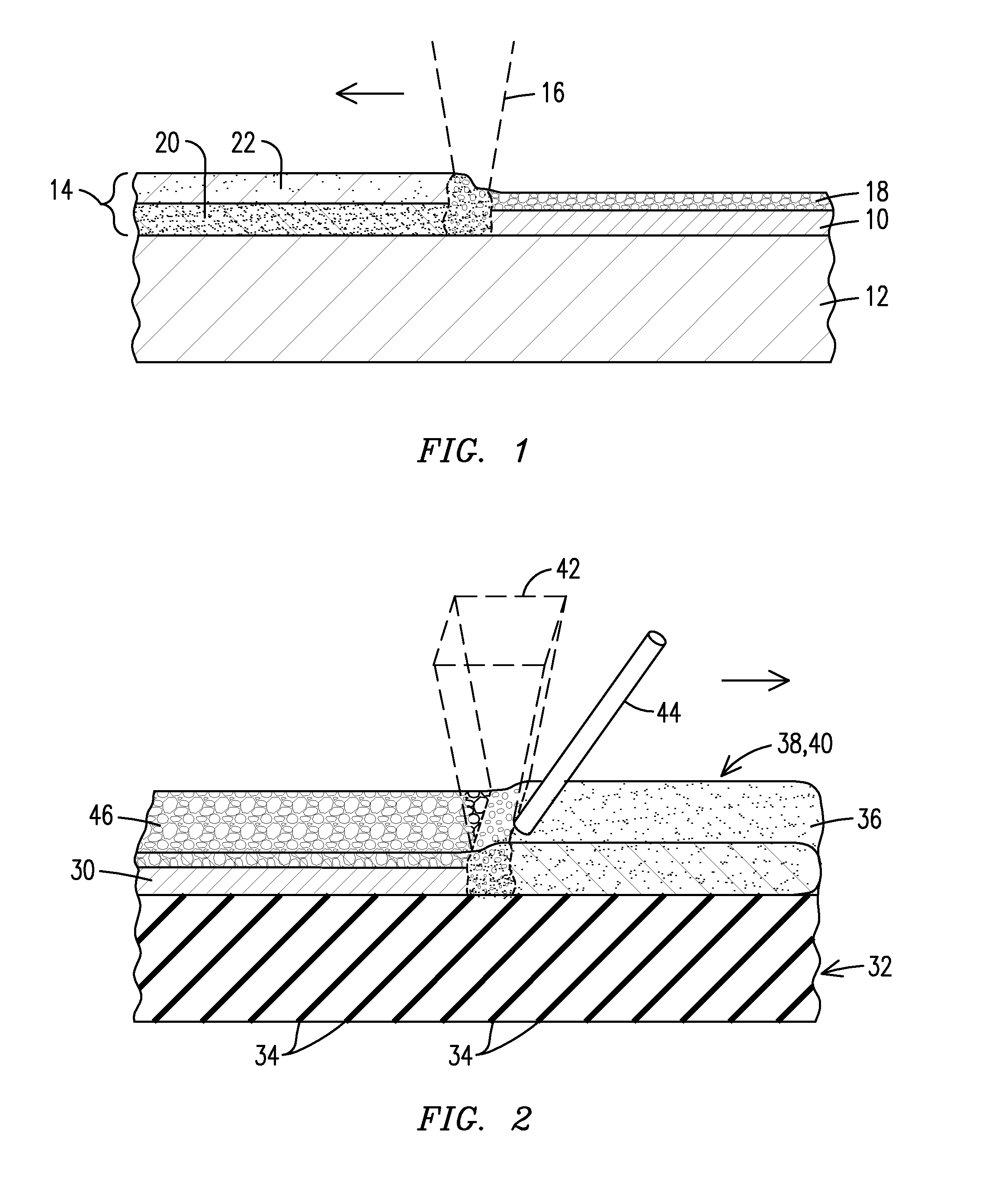

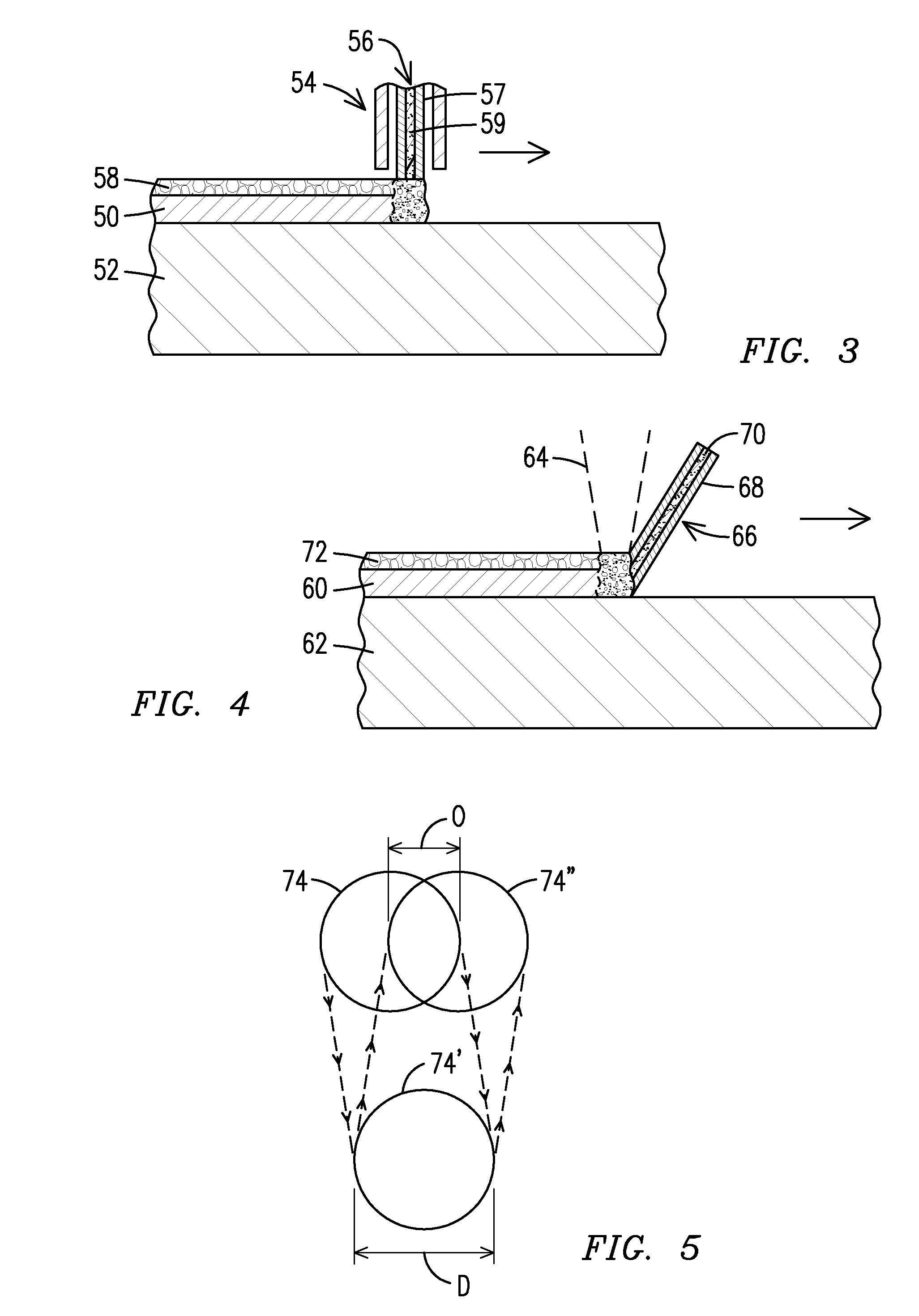

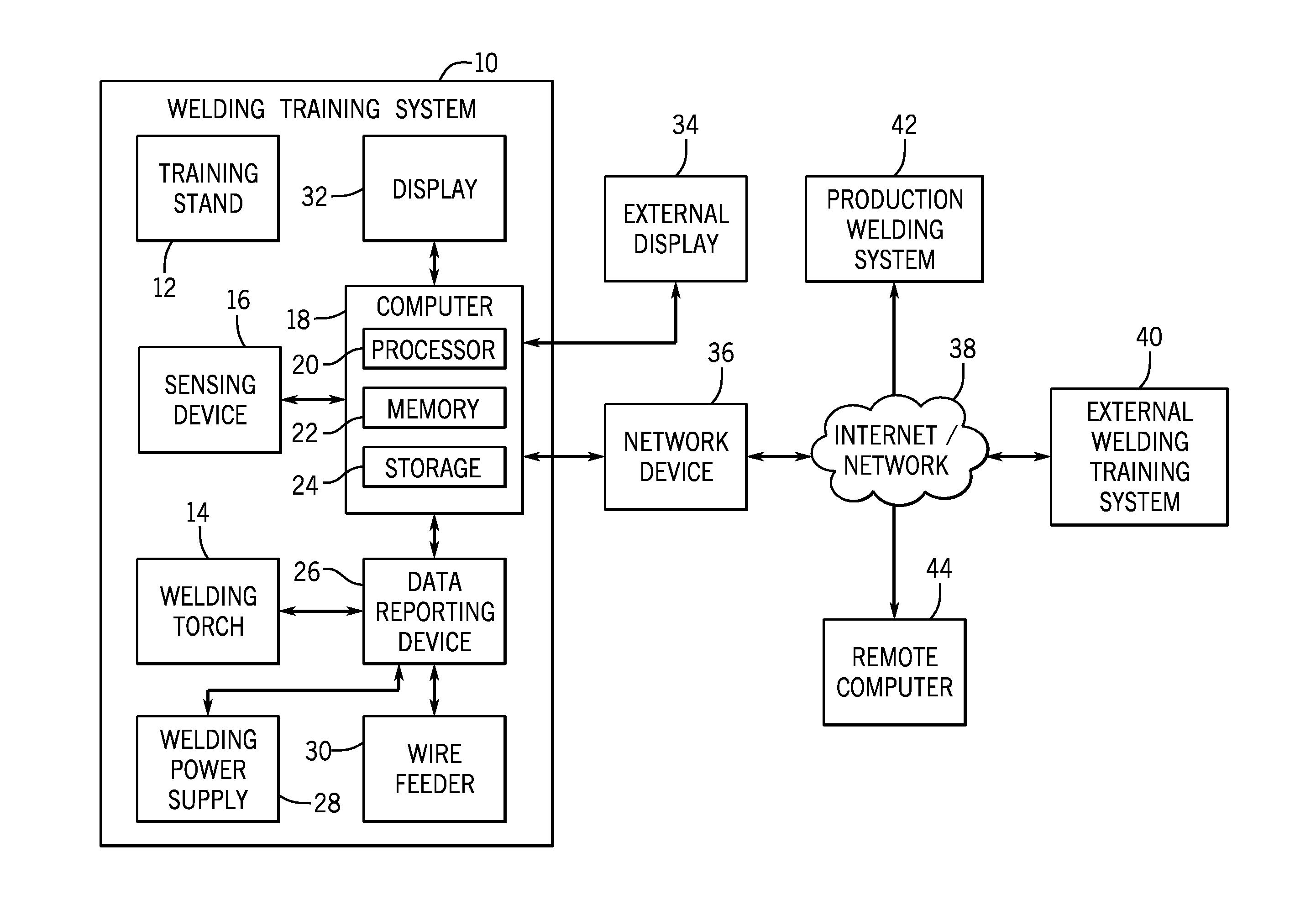

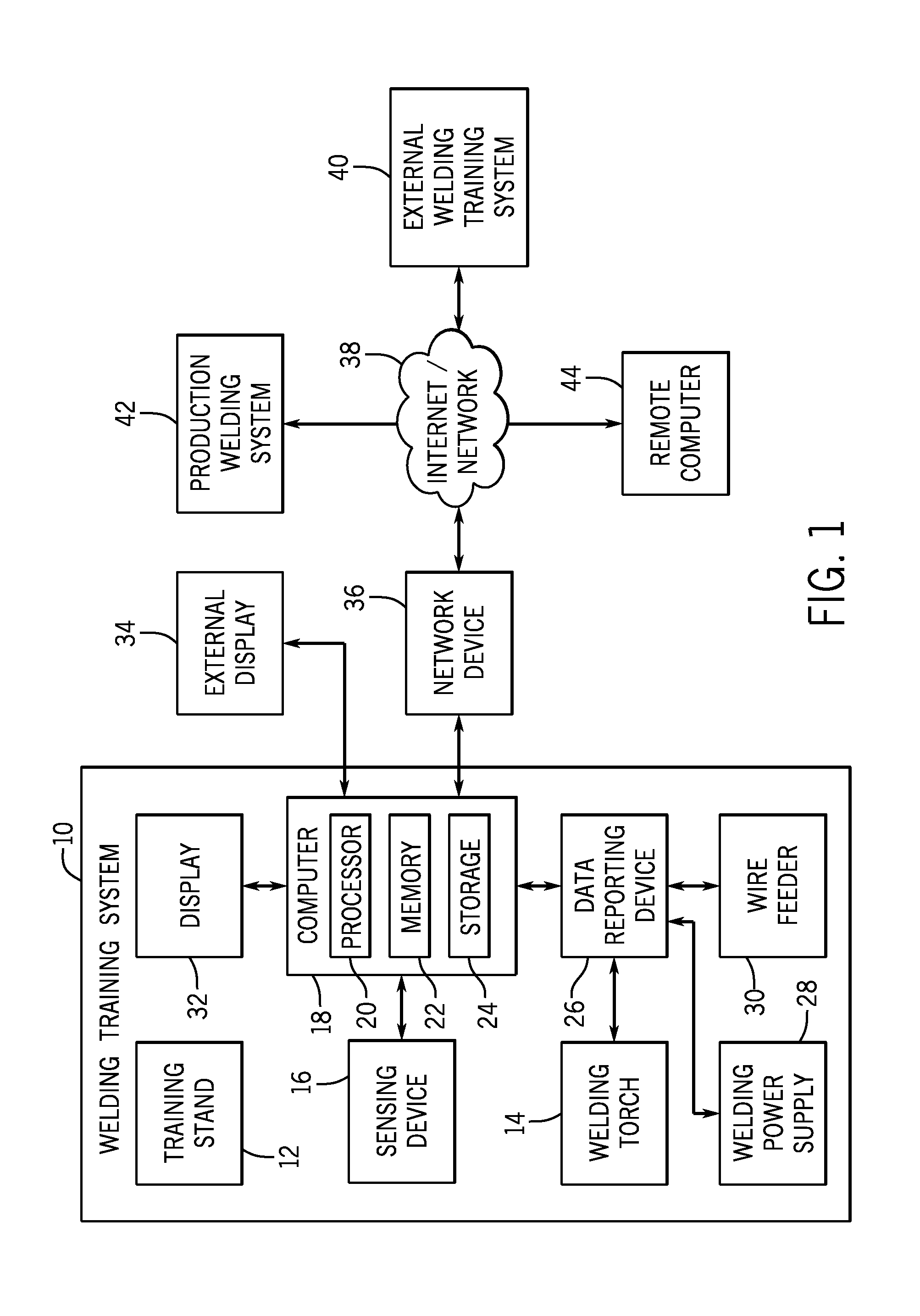

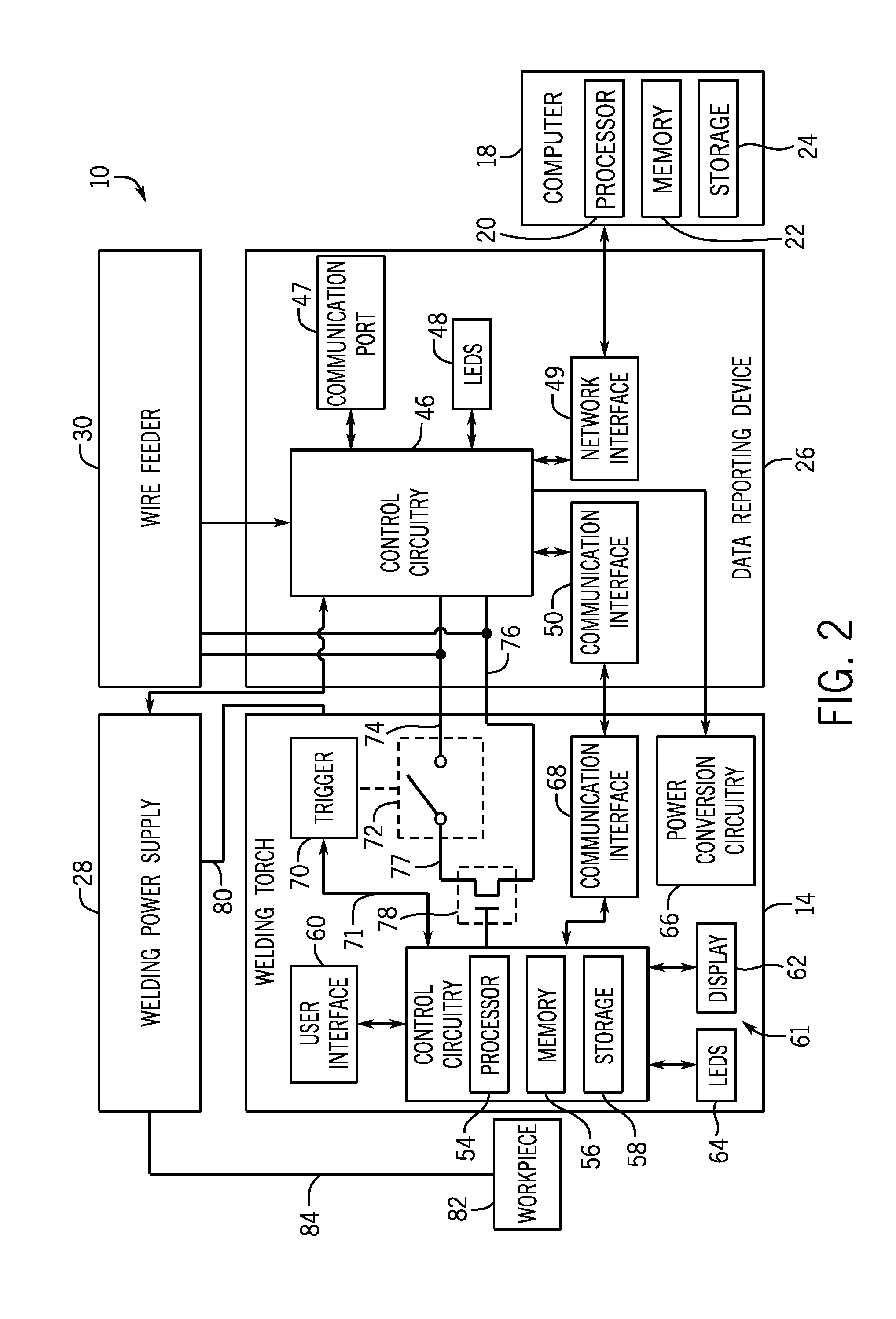

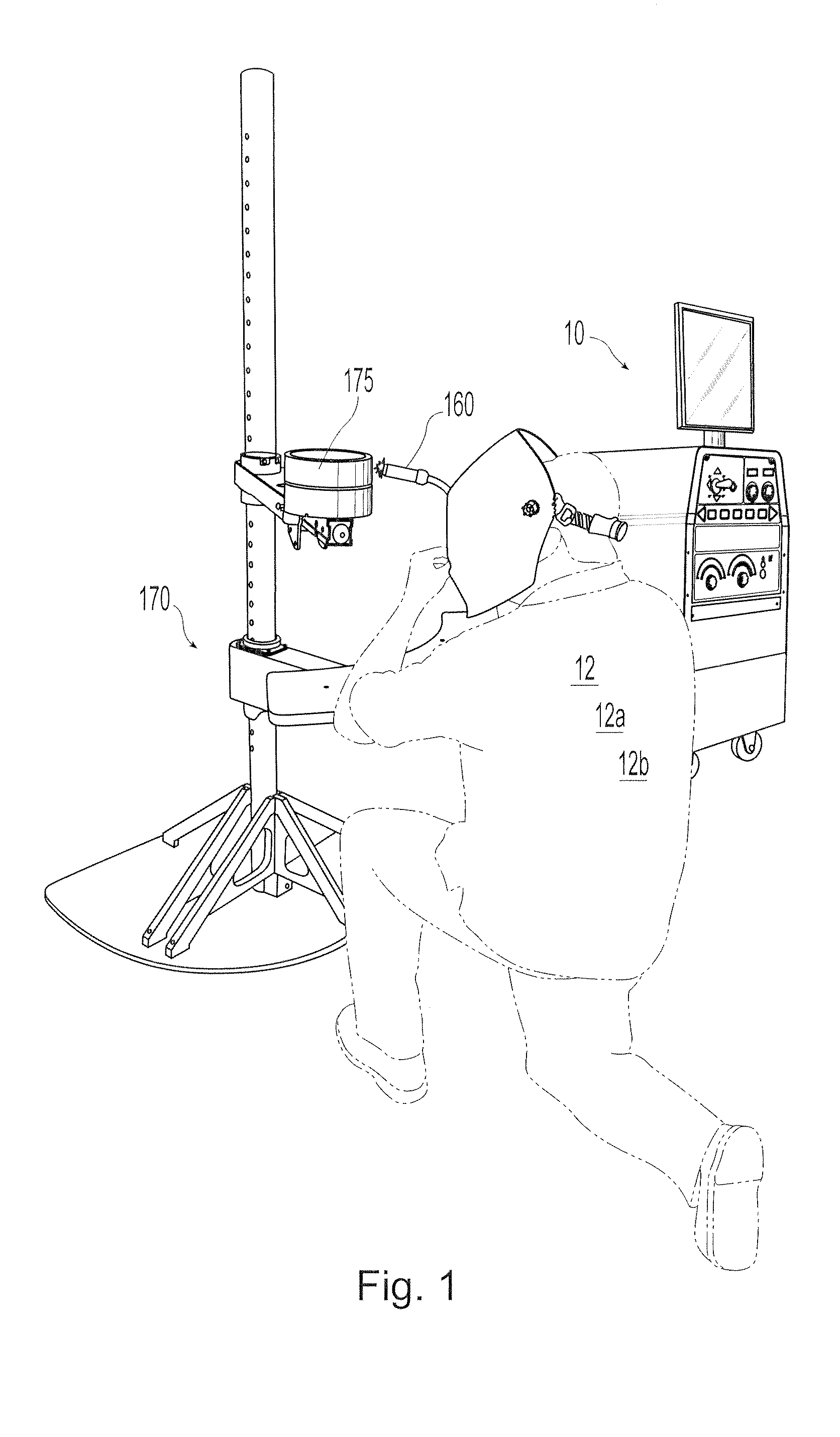

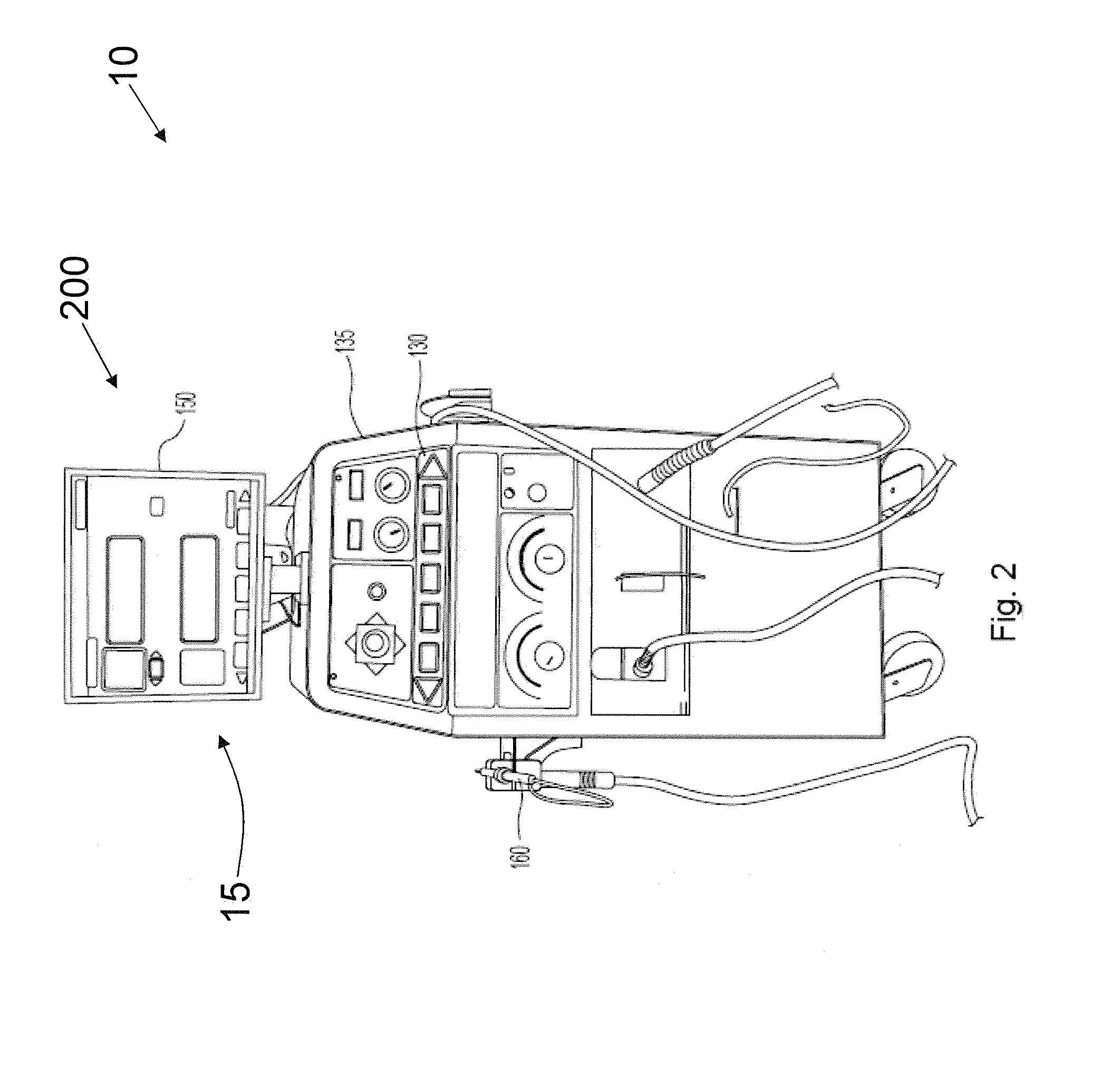

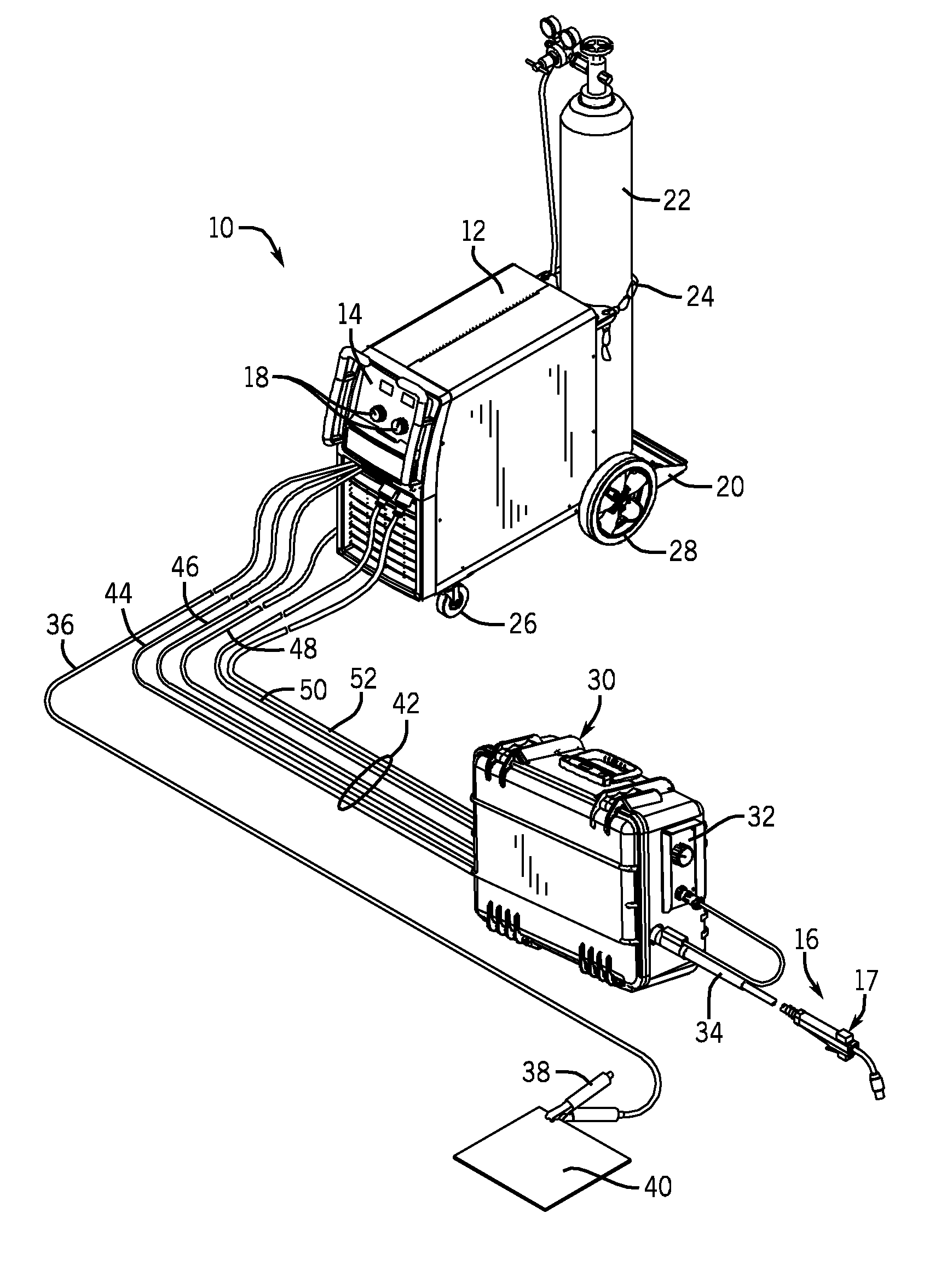

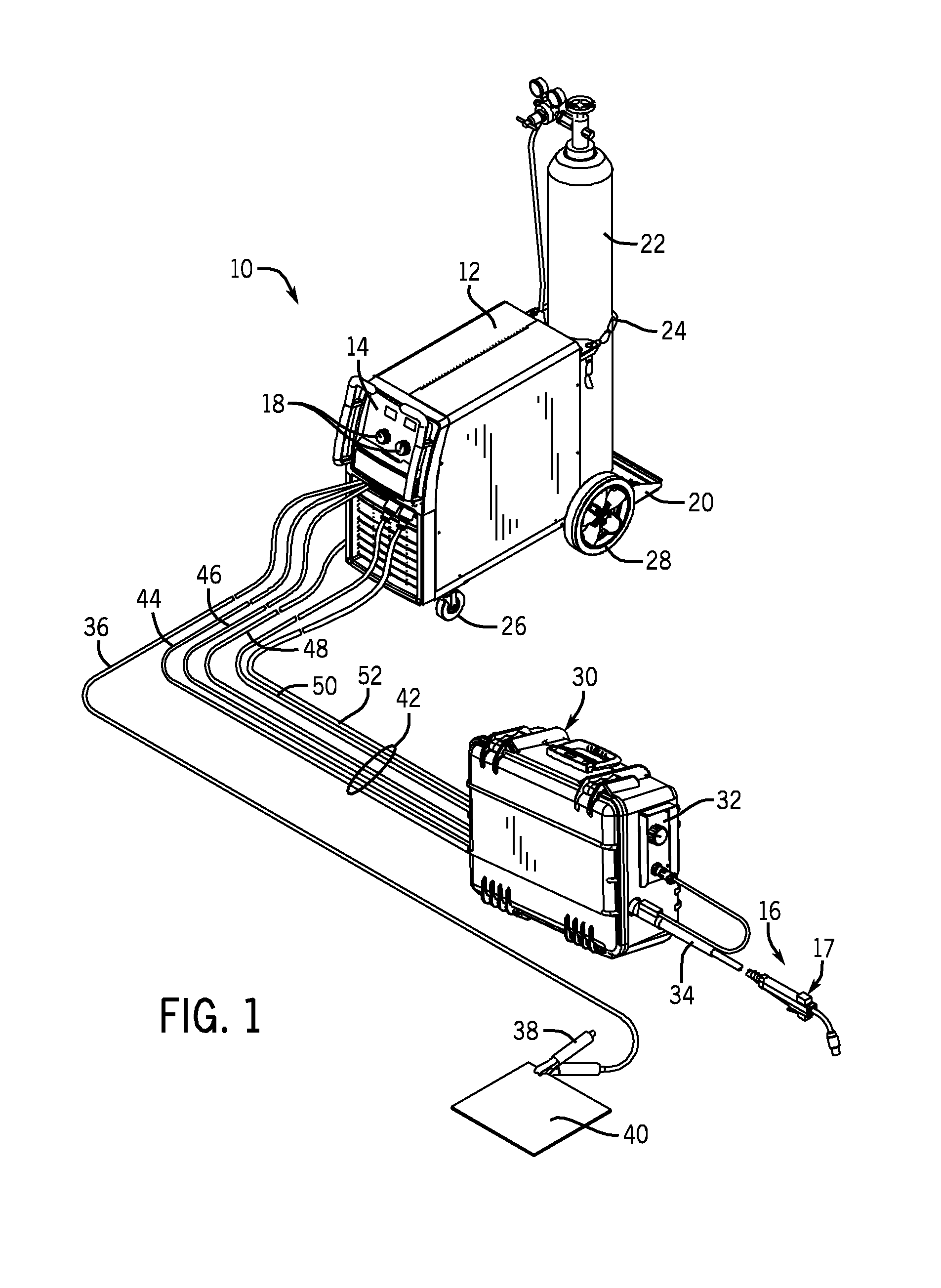

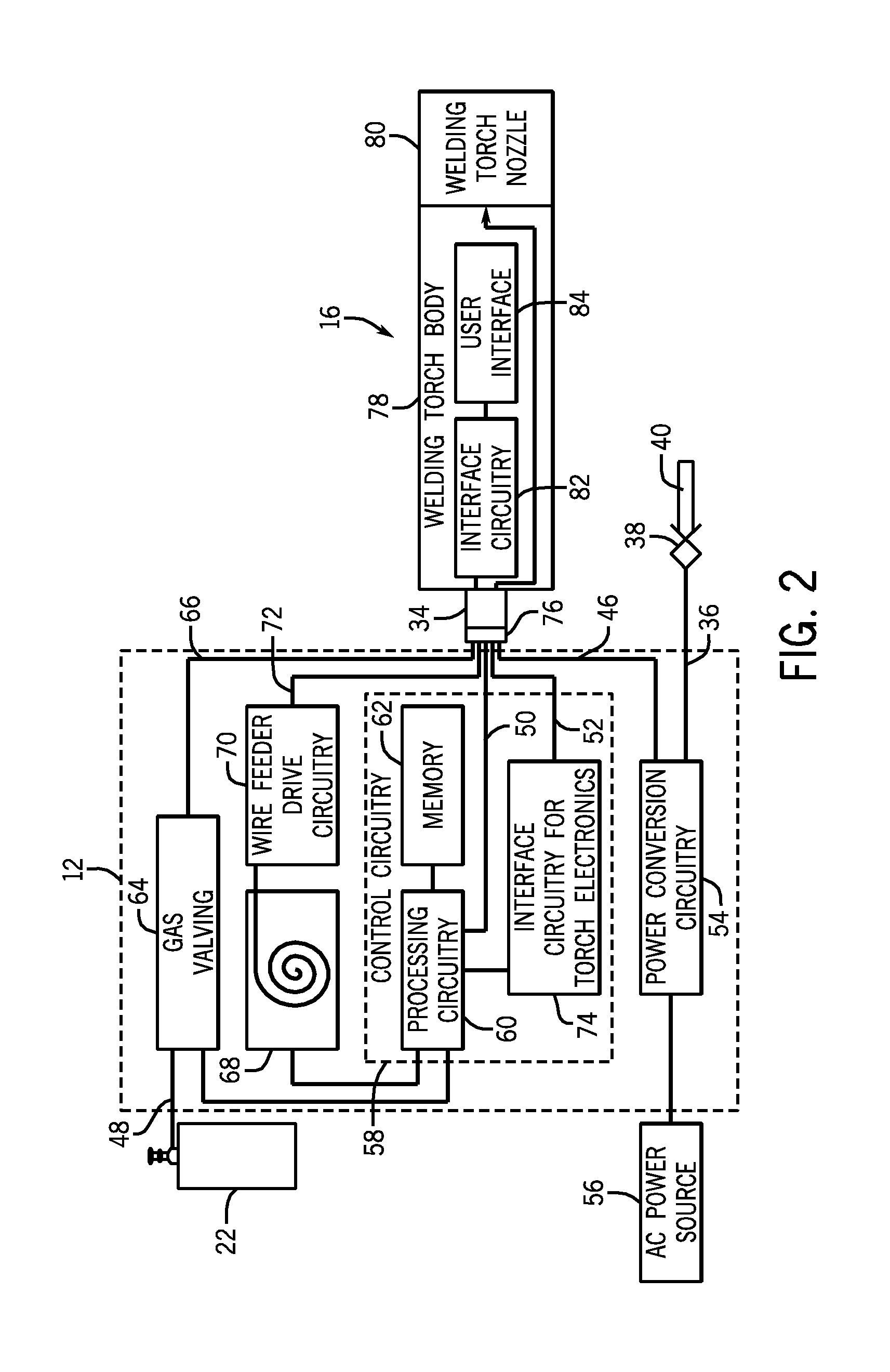

Method and system for monitoring and characterizing the creation of a manual weld

InactiveUS20110006047A1Good conditionOvercomes shortcomingEducational modelsWelding/cutting media/materialsDisplay deviceEngineering

A method and system for monitoring and characterizing the creation of a manual weld is disclosed. The system generally includes a welding gun having a target, an imaging system, a processor, and a display. During the creation of a manual weld, the imaging system captures a plurality of images of the target. The processor analyzes the plurality of images of the target to calculate a plurality of position and orientation characteristics associated with the manipulation of the welding gun during the welding process. The display illustrates at least one of the plurality of position and orientation characteristics to provide feedback regarding the creation of the weld. In one embodiment, the disclosed method and system may be utilized as a tool for training welders.

Owner:LINCOLN GLOBAL INC

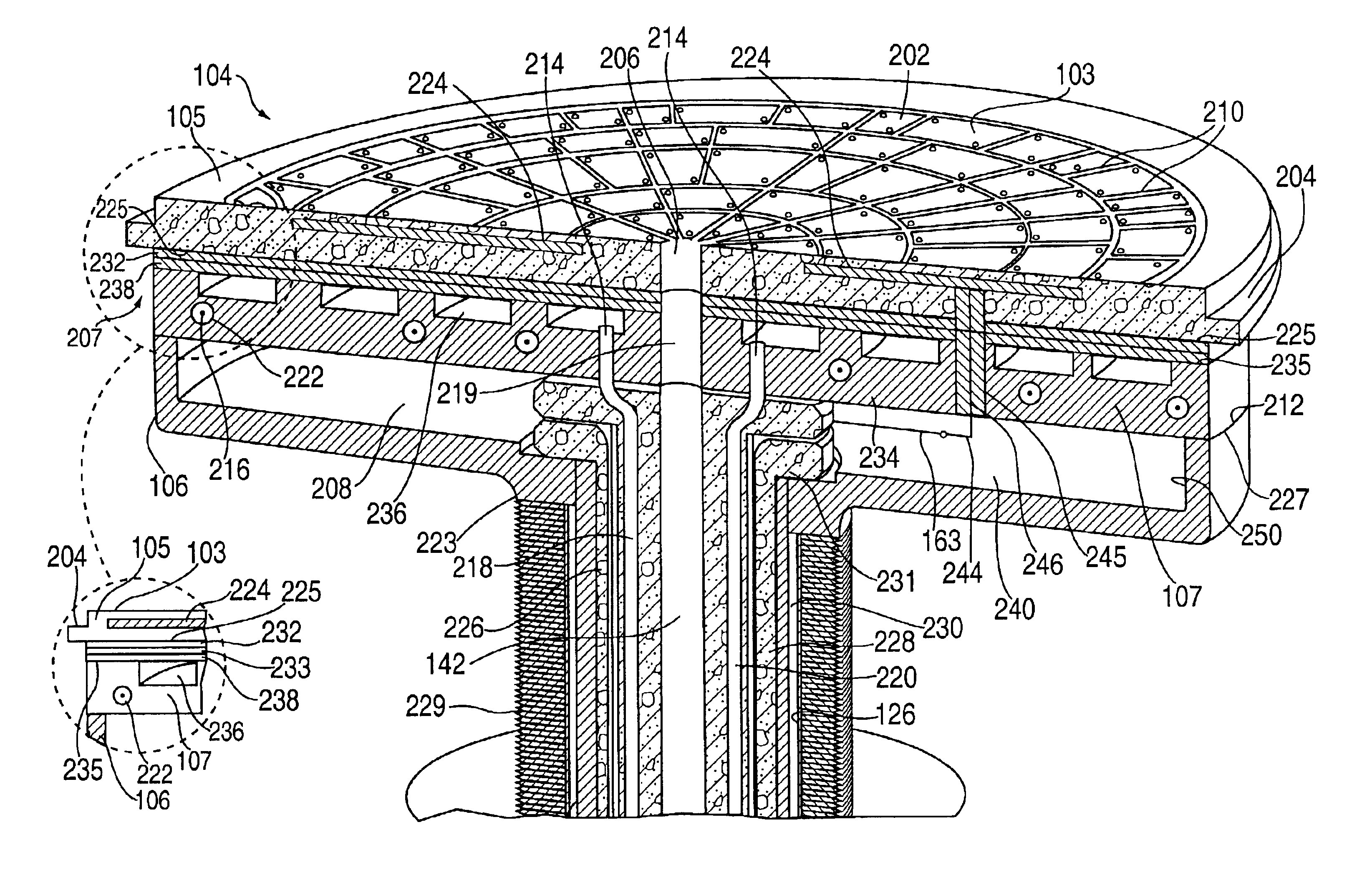

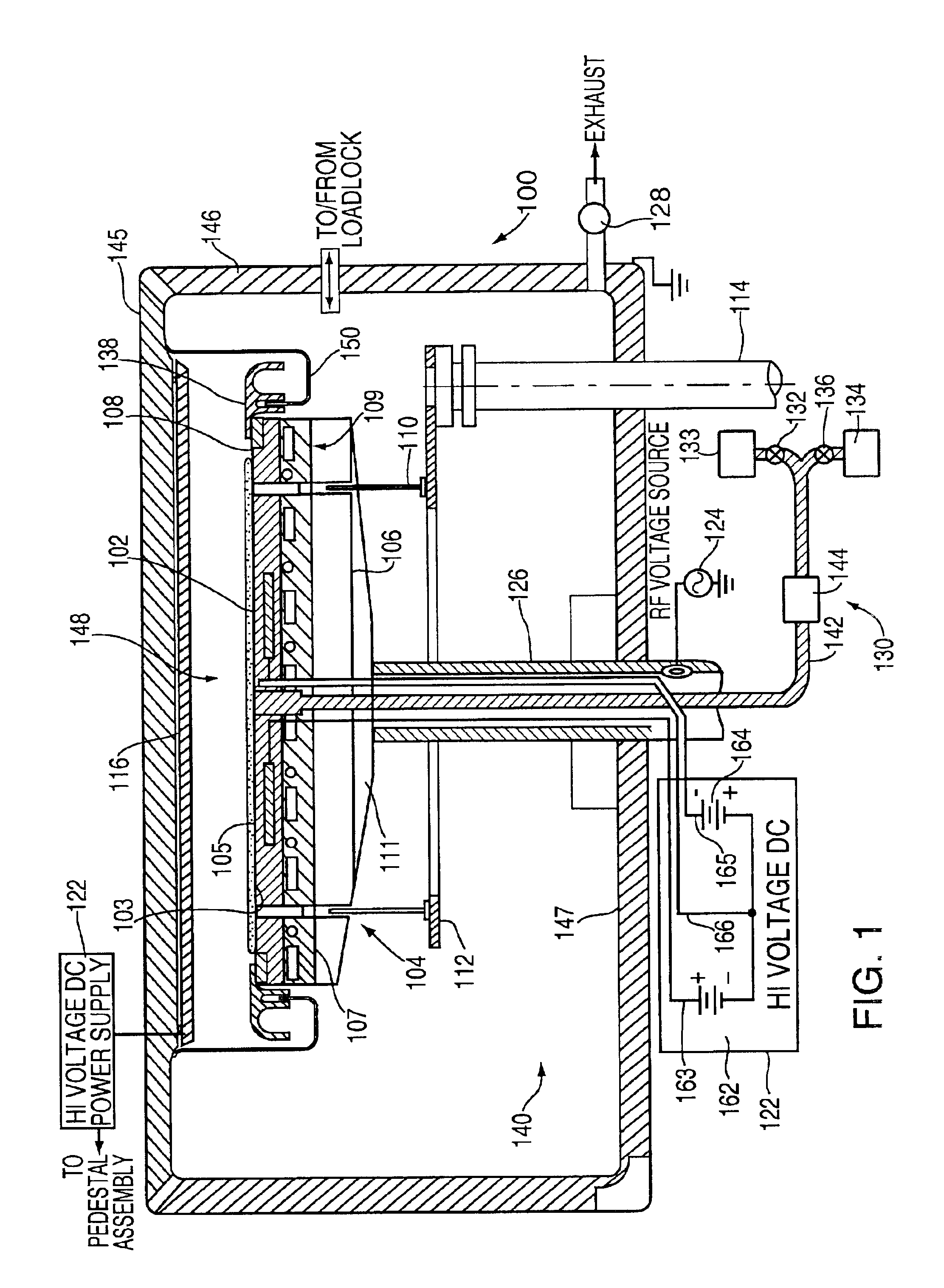

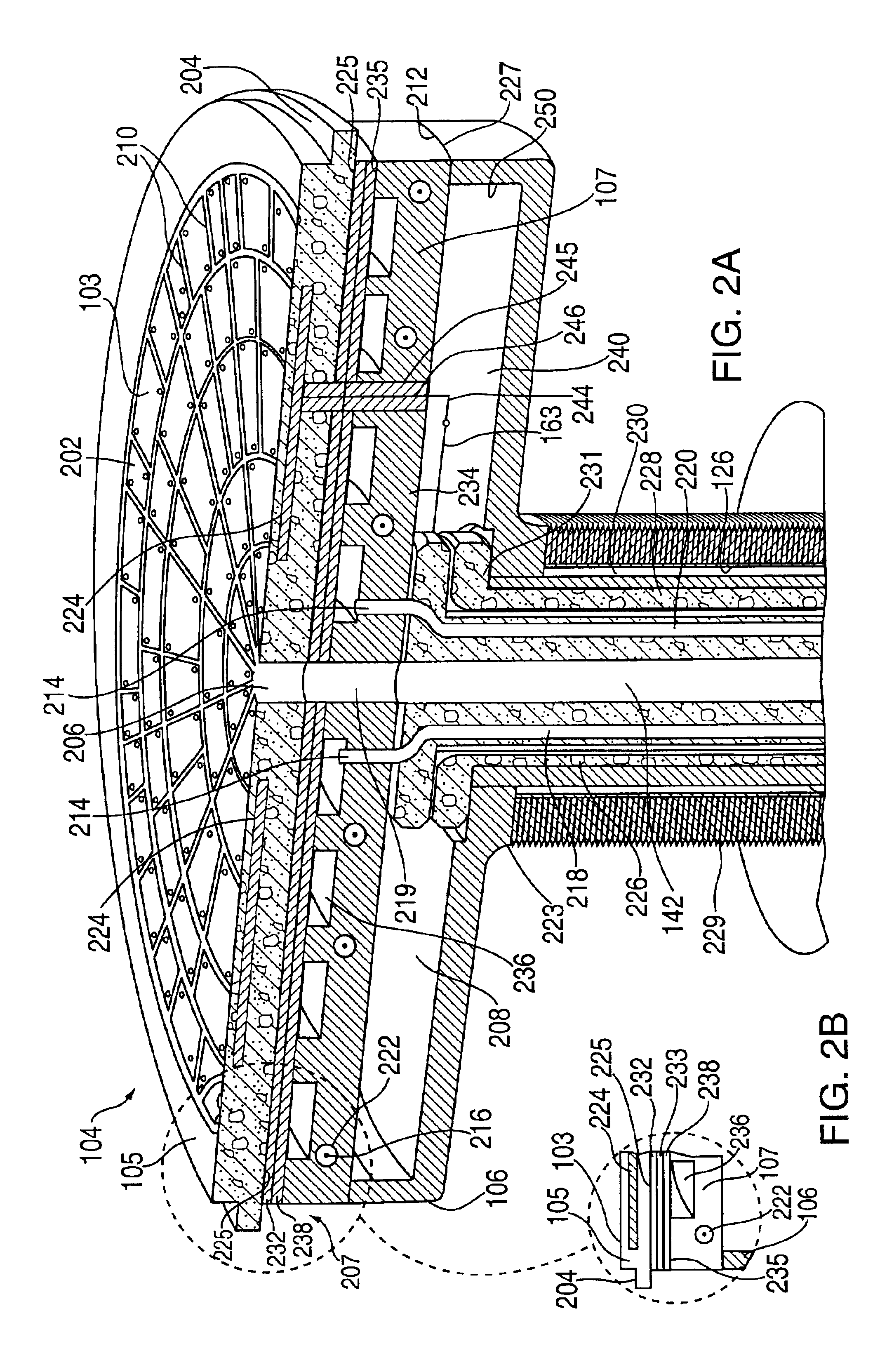

Full area temperature controlled electrostatic chuck and method of fabricating same

InactiveUS6853533B2Liquid surface applicatorsLighting and heating apparatusTemperature controlMetallurgy

A semiconductor wafer support assembly and method of fabricating the same are provided. In one embodiment, the method and resulting assembly include attaching a pedestal joining-ring to a bottom surface of a ceramic puck. Low temperature brazing a composite cooling plate structure to the bottom surface of the ceramic puck, where the pedestal joining-ring circumscribes the composite cooling plate structure. Thereafter, a pedestal is electron-beam welded to the pedestal joining-ring.

Owner:APPLIED MATERIALS INC

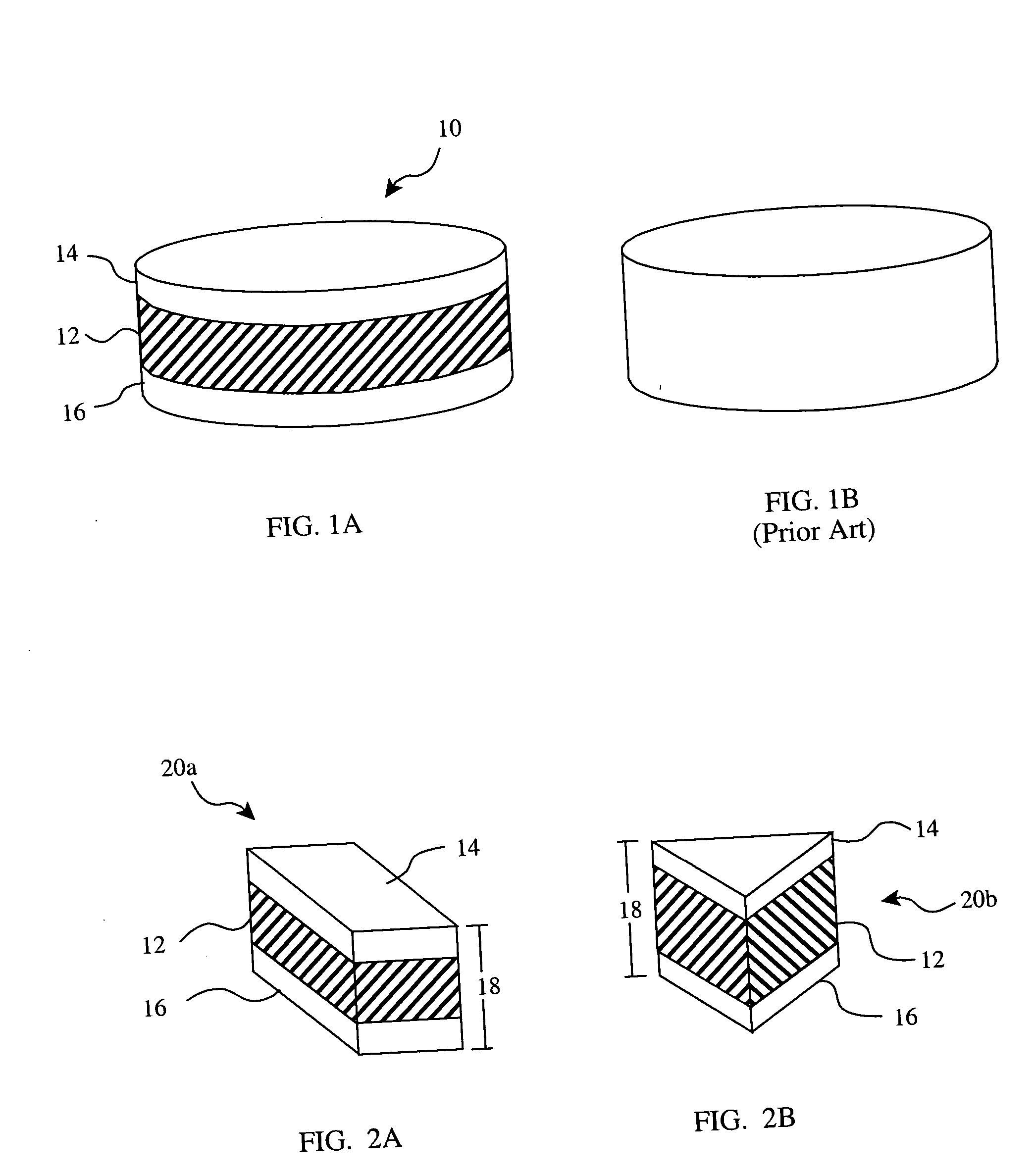

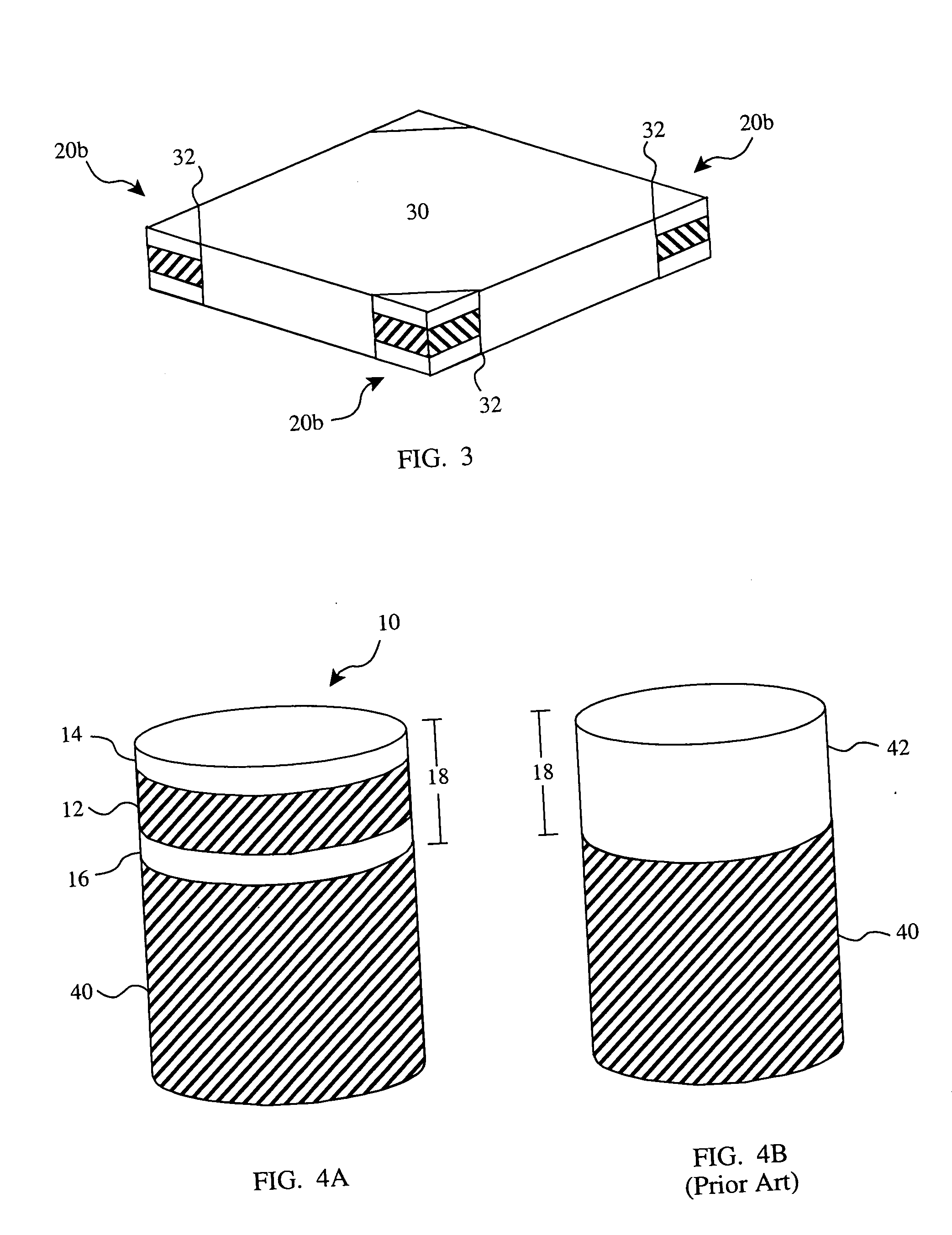

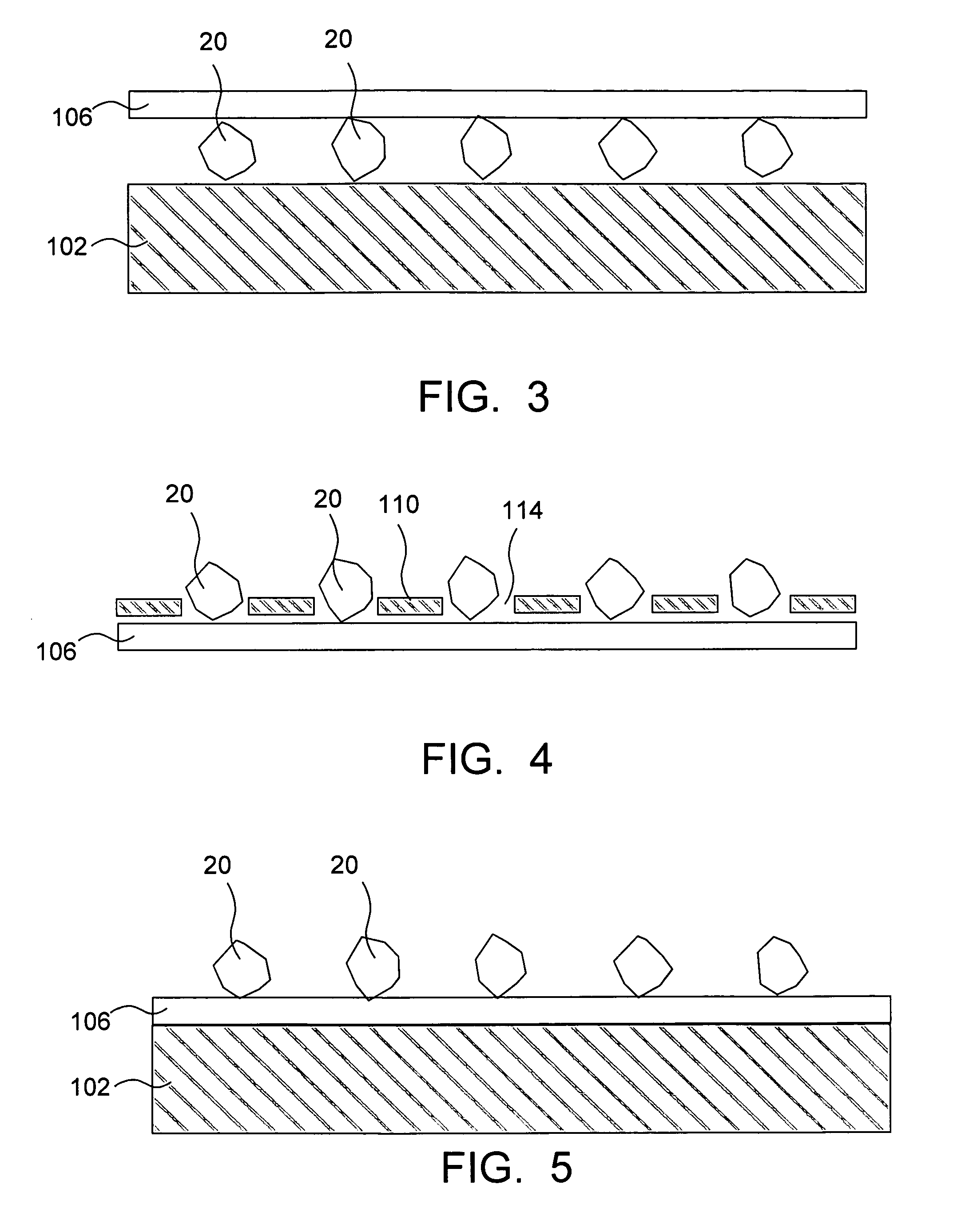

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

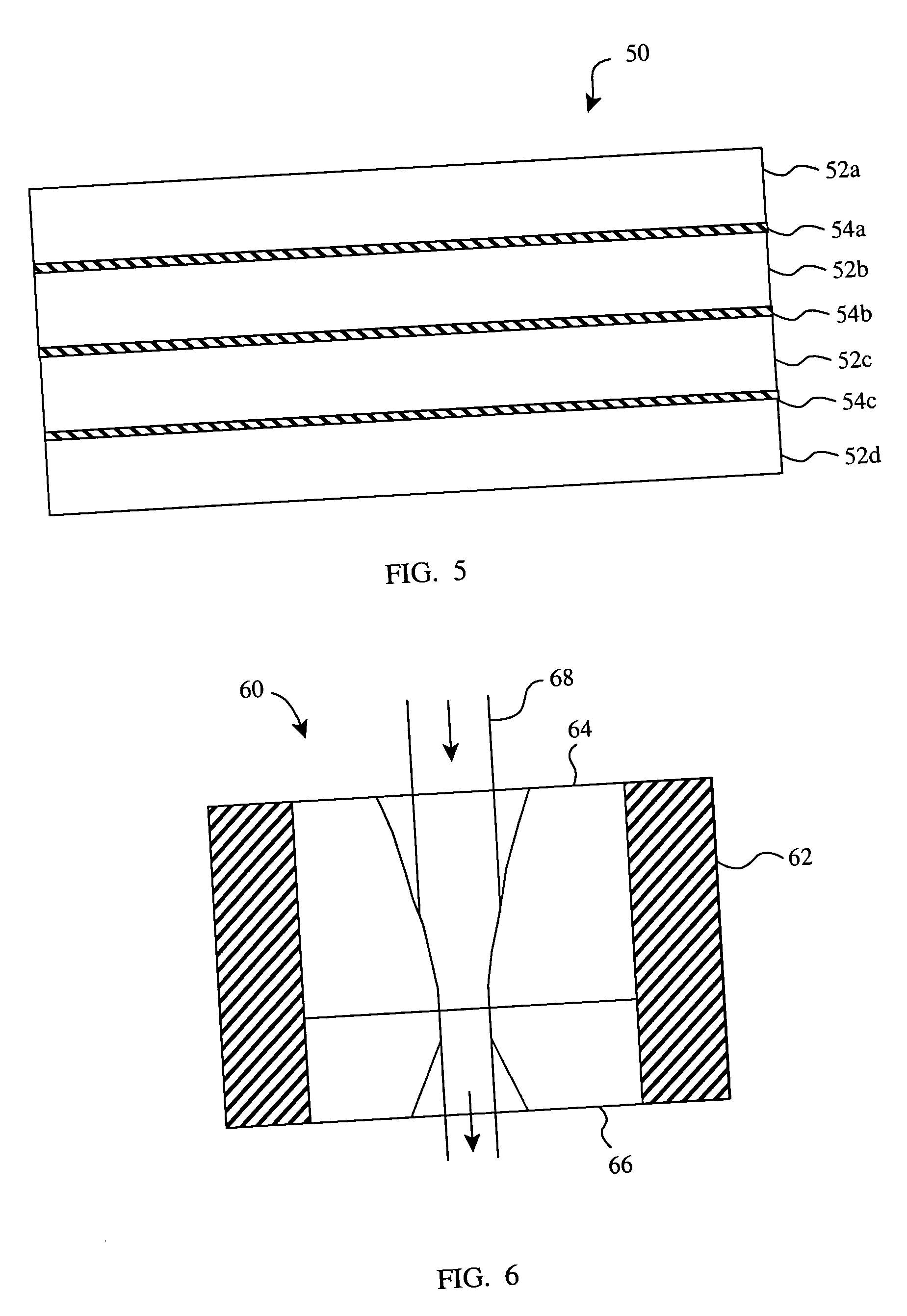

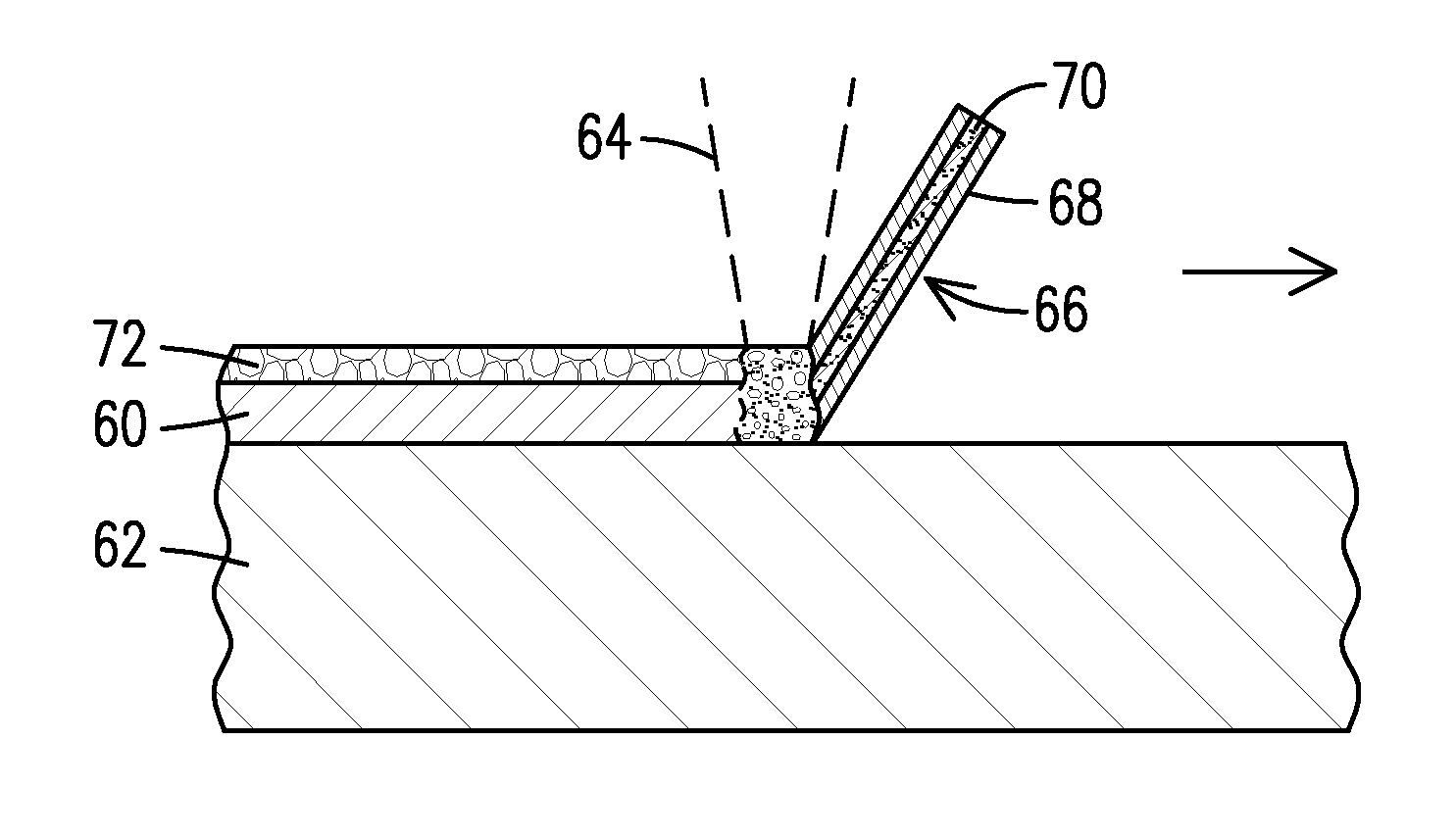

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

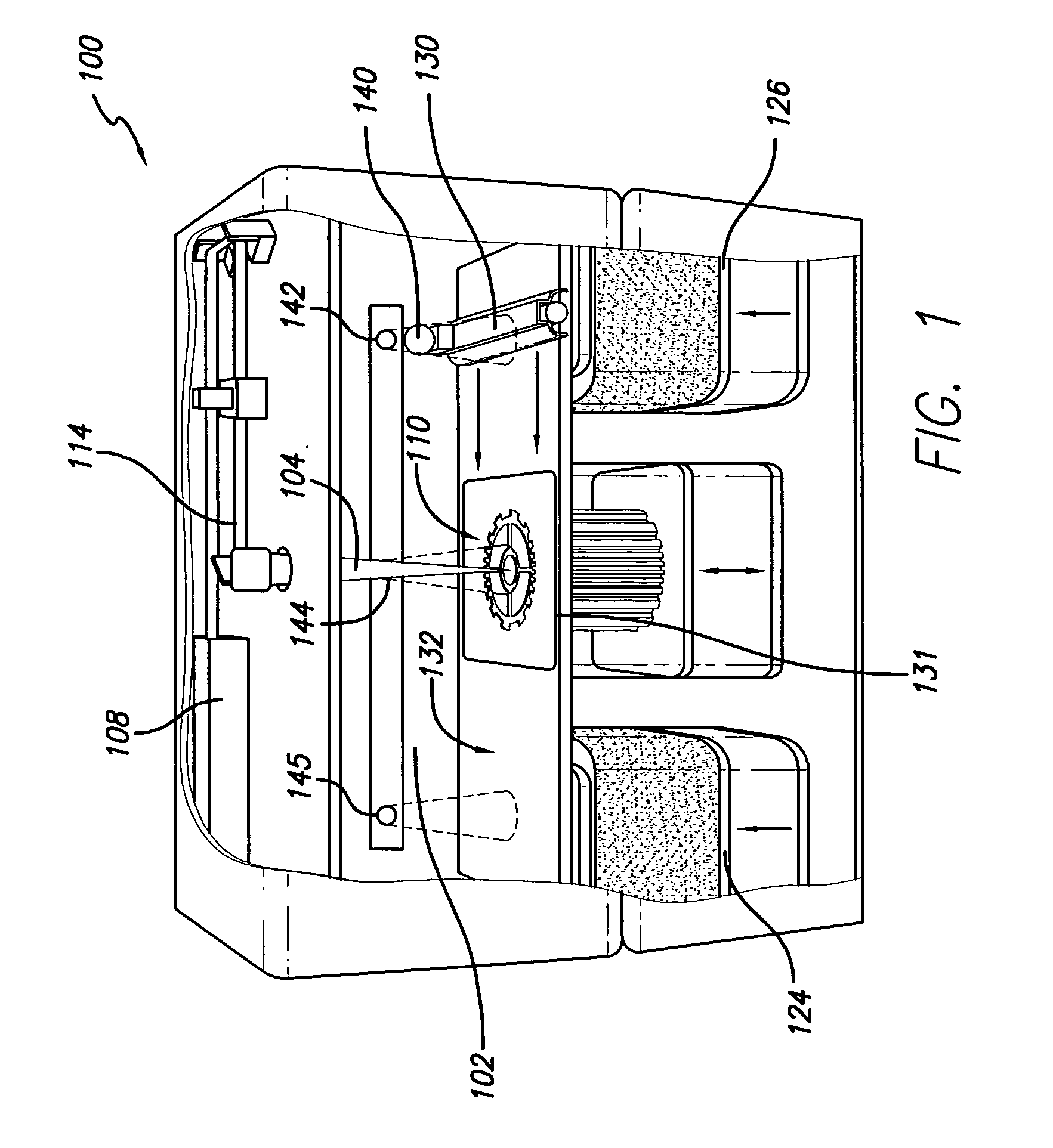

Welding training systems and devices

A welding tool includes a first handle and a second handle. The welding tool also includes a torch nozzle holder configured to hold a nozzle of a welding torch therein, and to block the nozzle from extending therethrough. The welding tool includes a blade assembly positioned a predetermined distance from the torch nozzle holder. The blade assembly is configured to cut welding wire extending through the blade assembly to calibrate wire stickout from the welding torch to the predetermined distance.

Owner:ILLINOIS TOOL WORKS INC

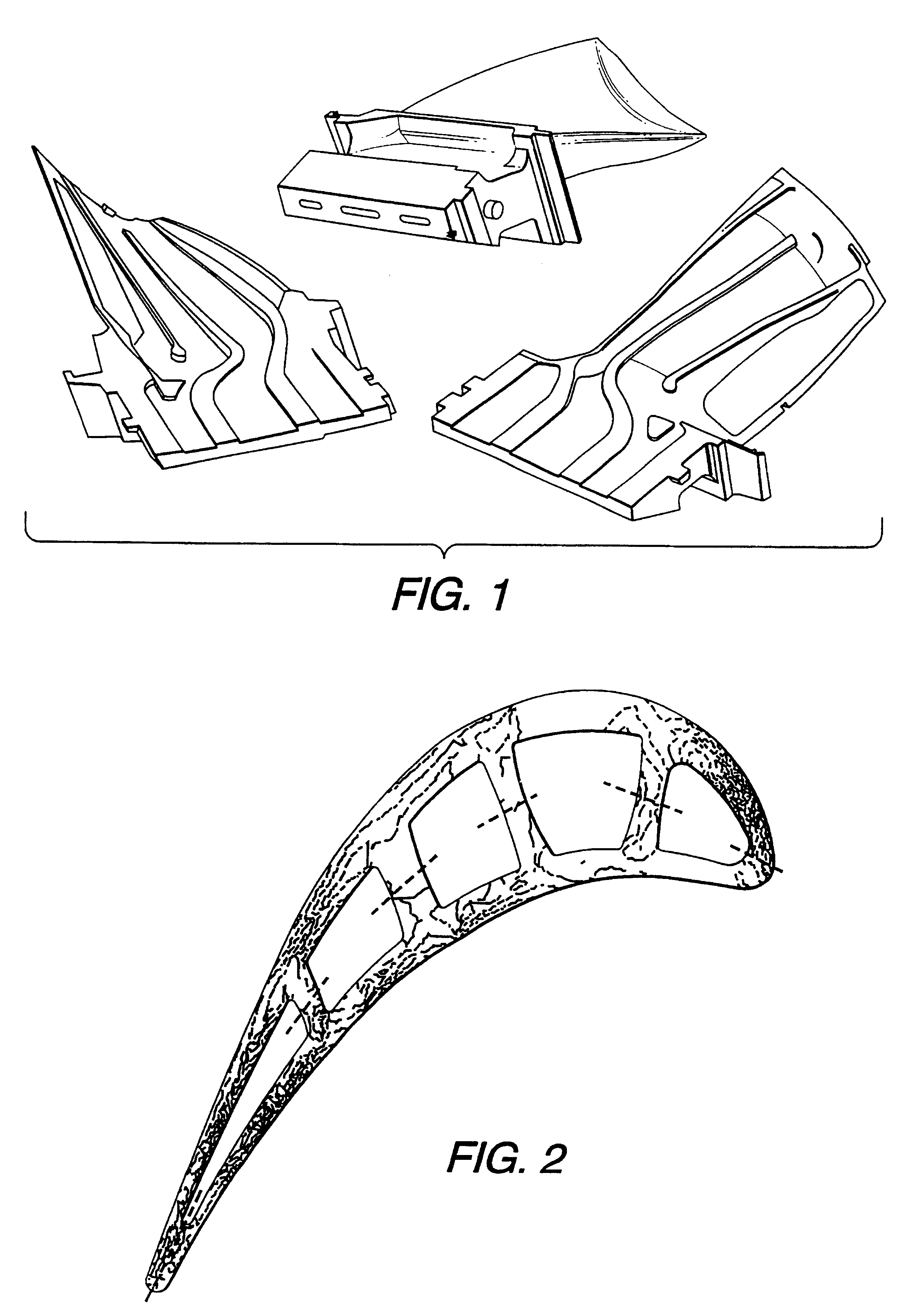

Turbine blades made from multiple single crystal cast superalloy segments

InactiveUS6331217B1Improve bindingQuality improvementPropellersFrom frozen solutionsTurbine bladeSingle crystal

Large gas turbine blades made from separate cast segments of superalloys are disclosed. The turbine blade is designed such that bond lines between adjacent segments are placed in low stress regions of the blade. The cast superalloy segments of the blades are aligned and fitted together with specified tolerances. The turbine blade segments are then joined by transient liquid phase bonding, followed by a controlled heat treatment which produces the desired microstructure in the bond region. The method allows for the production of large, high quality turbine blades by joining small, high quality cast superalloy sections, in comparison with prior attempts to cast large turbine blades as single pieces which have produced very low yields and high individual component costs.

Owner:SIEMENS ENERGY INC

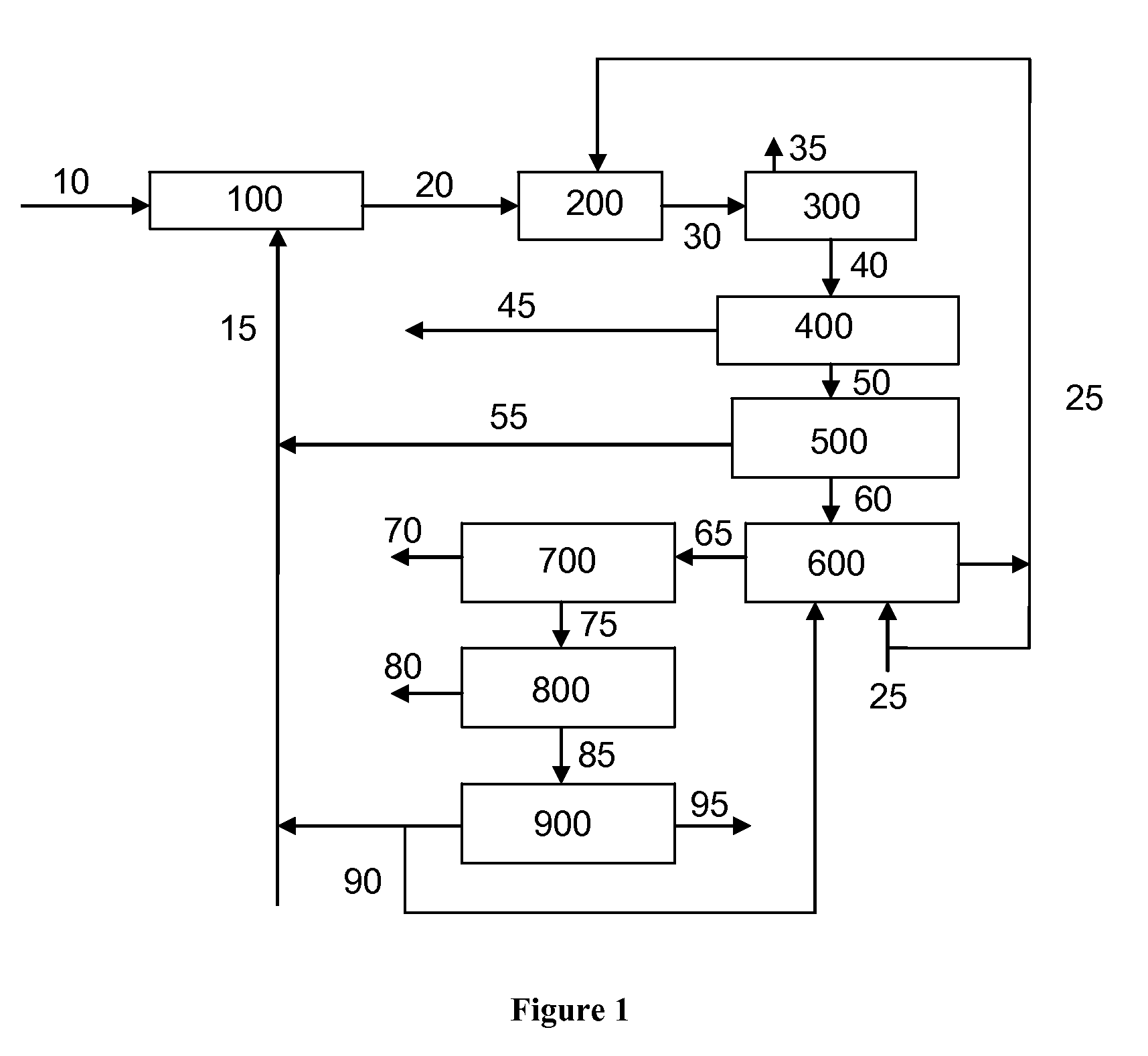

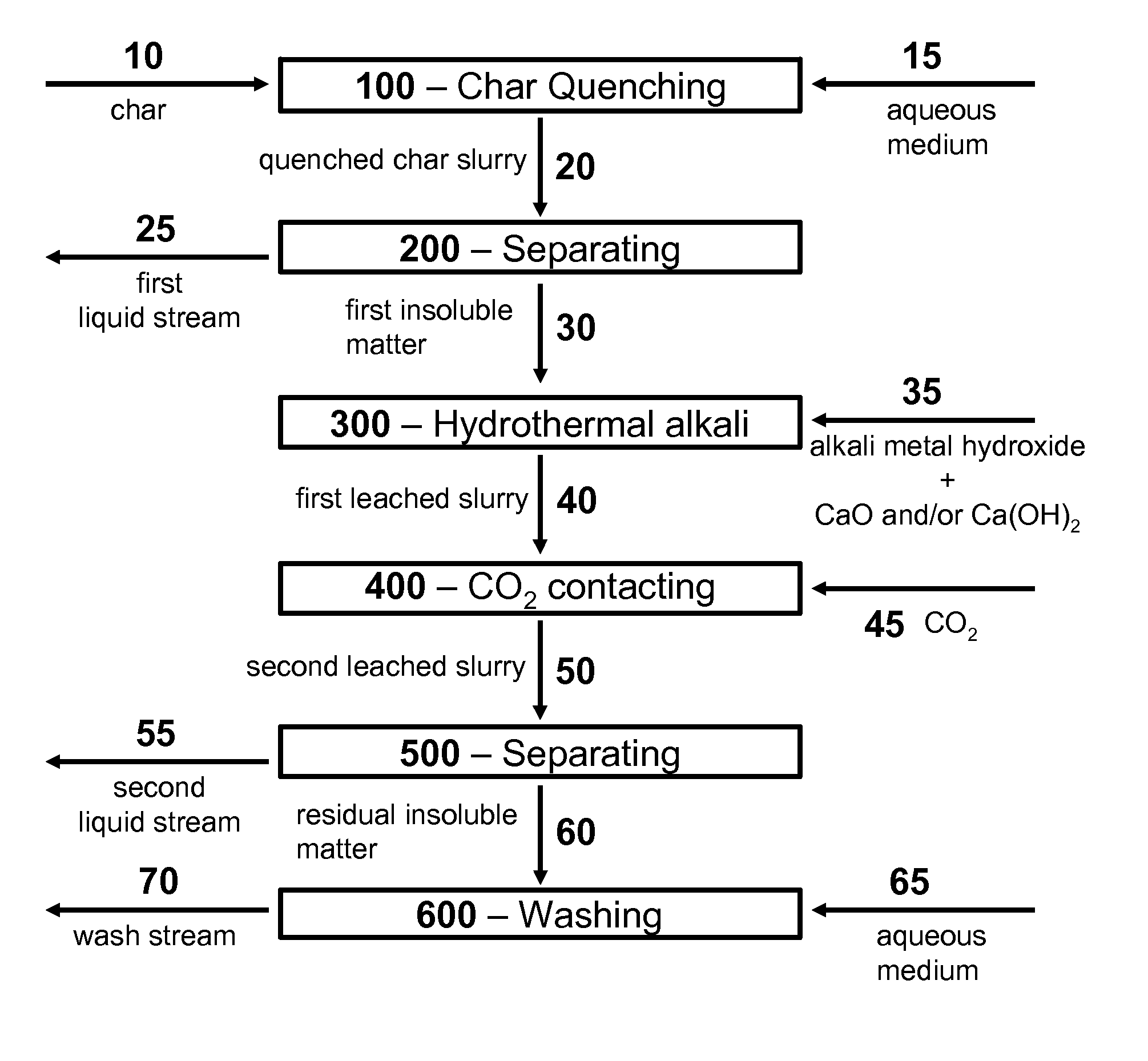

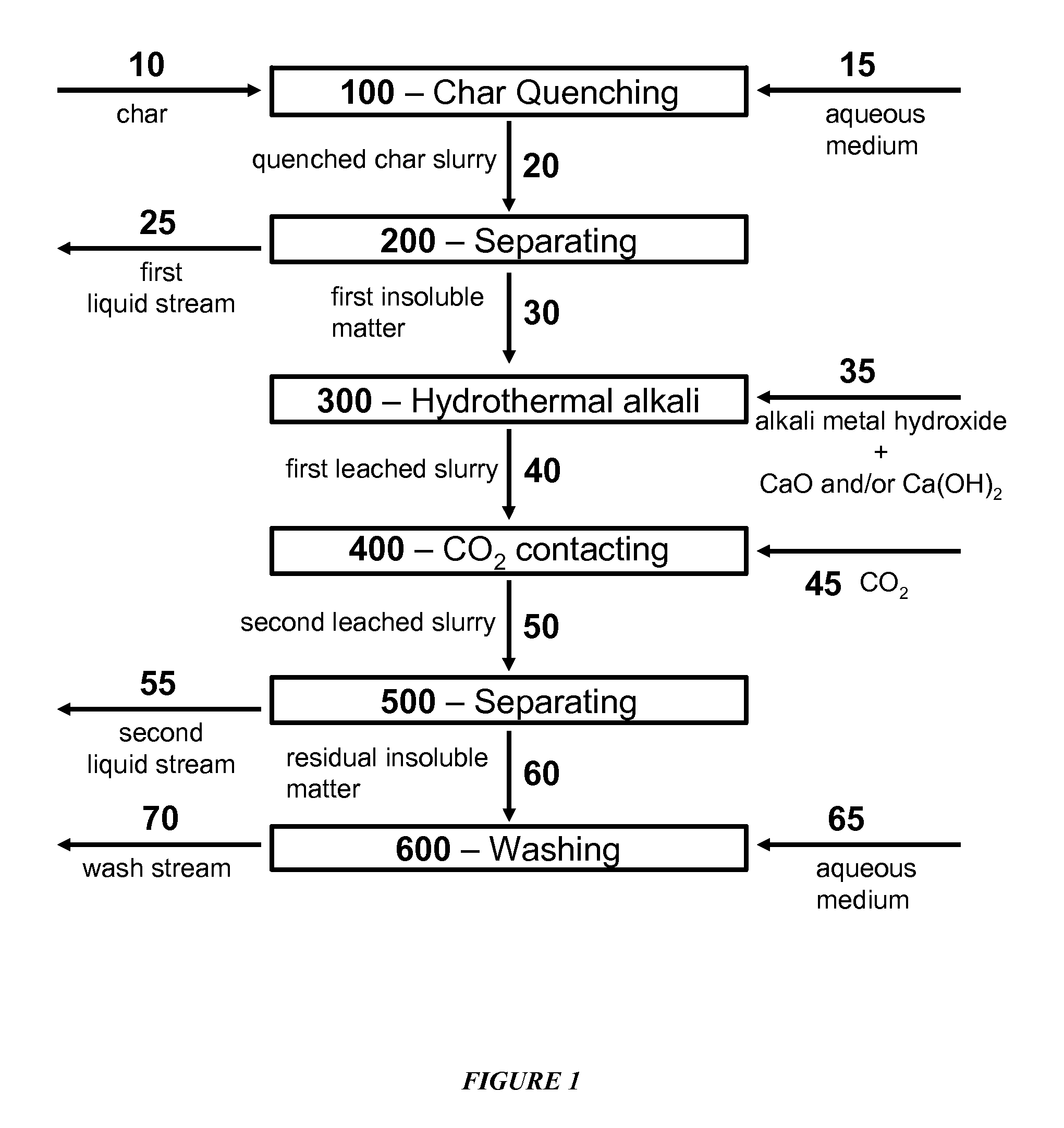

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Process with Recovery of Alkali Metal from Char

InactiveUS20090165383A1Quantity minimizationGaseous fuelsGasification processes detailsPhysical chemistryAlkali metal

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

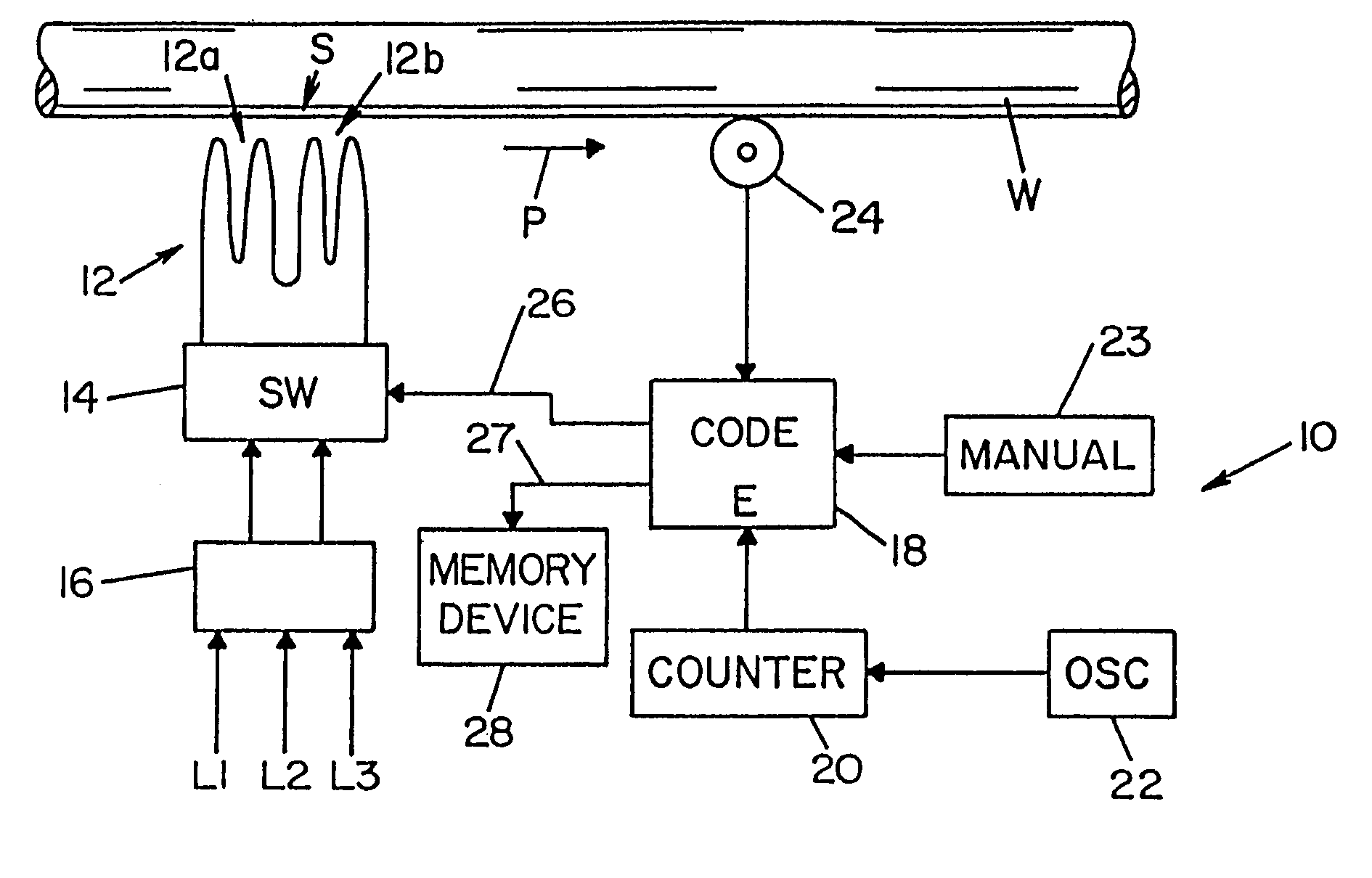

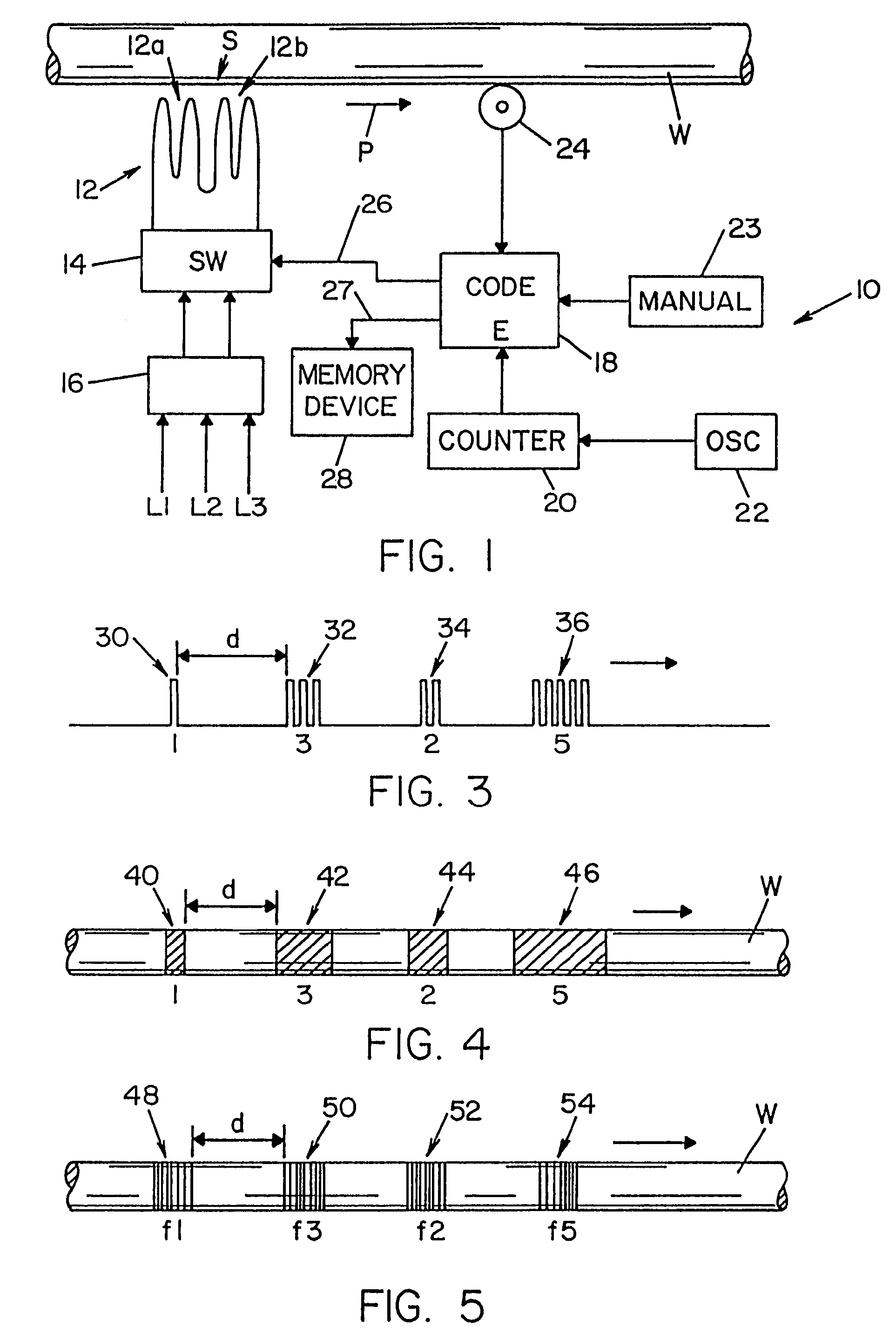

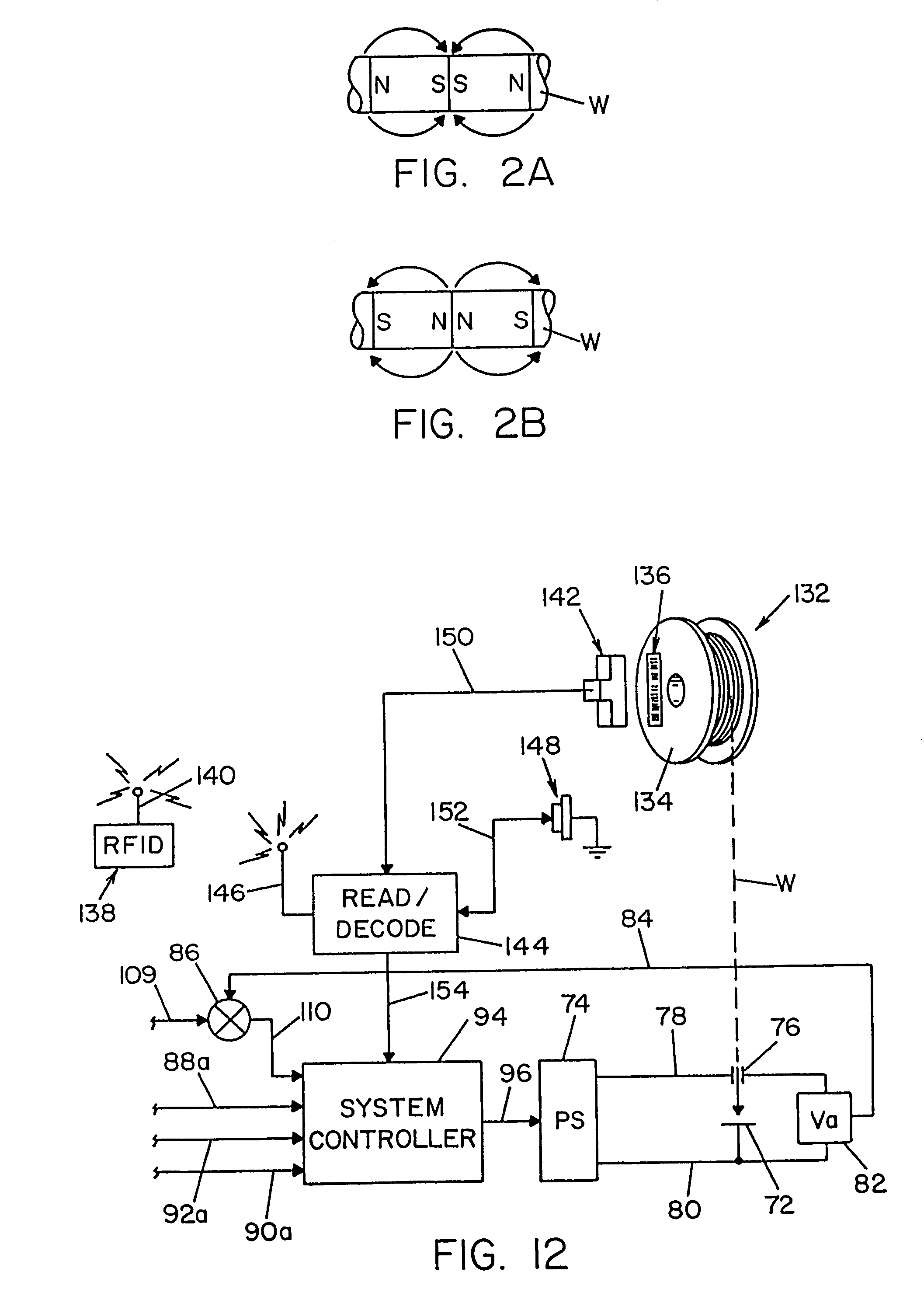

Coded welding consumable

InactiveUS7032814B2Quality improvementImprove welding efficiencyArc welding apparatusCo-operative working arrangementsCarbon Dioxide / HeliumShielding gas

Information pertaining to characteristics of consumables such as metal welding electrode wire and shielding gas and which characteristics are useful in connection with adjusting welding parameters in an arc welding process and / or selecting between operating modes in a welding system are encoded on welding wire and / or on other memory components such as bar code labels and tags, RFID cards and tags, IC cards, and Touch Memory buttons, and the memory device is scanned prior to and / or at the point of use of the welding wire or shielding gas for enabling tracking of product distribution, manual and / or automatic selection of an operating mode for the welding system, manual and / or automatic adjustment of welding parameters in a given operating mode, consumables inventory, and the like.

Owner:LINCOLN GLOBAL INC

Co-Feed of Biomass as Source of Makeup Catalysts for Catalytic Coal Gasification

Continuous processes are provided for converting a carbonaceous feedstock comprising biomass containing alkali metal, non-biomass components, and at least one gasification catalyst including an alkali metal recovered from solid char, into a plurality of gaseous products including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Particulate Compositions

ActiveUS20090229182A1Efficient use ofBiofuelsGas modification by gas mixingPtru catalystPetroleum coke

Particulate compositions are described comprising a carbonaceous material, such as petroleum coke and / or coal, treated or otherwise associated with a gasification catalyst, where the catalyst is at least in part derived from a leachate from a biomass char, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

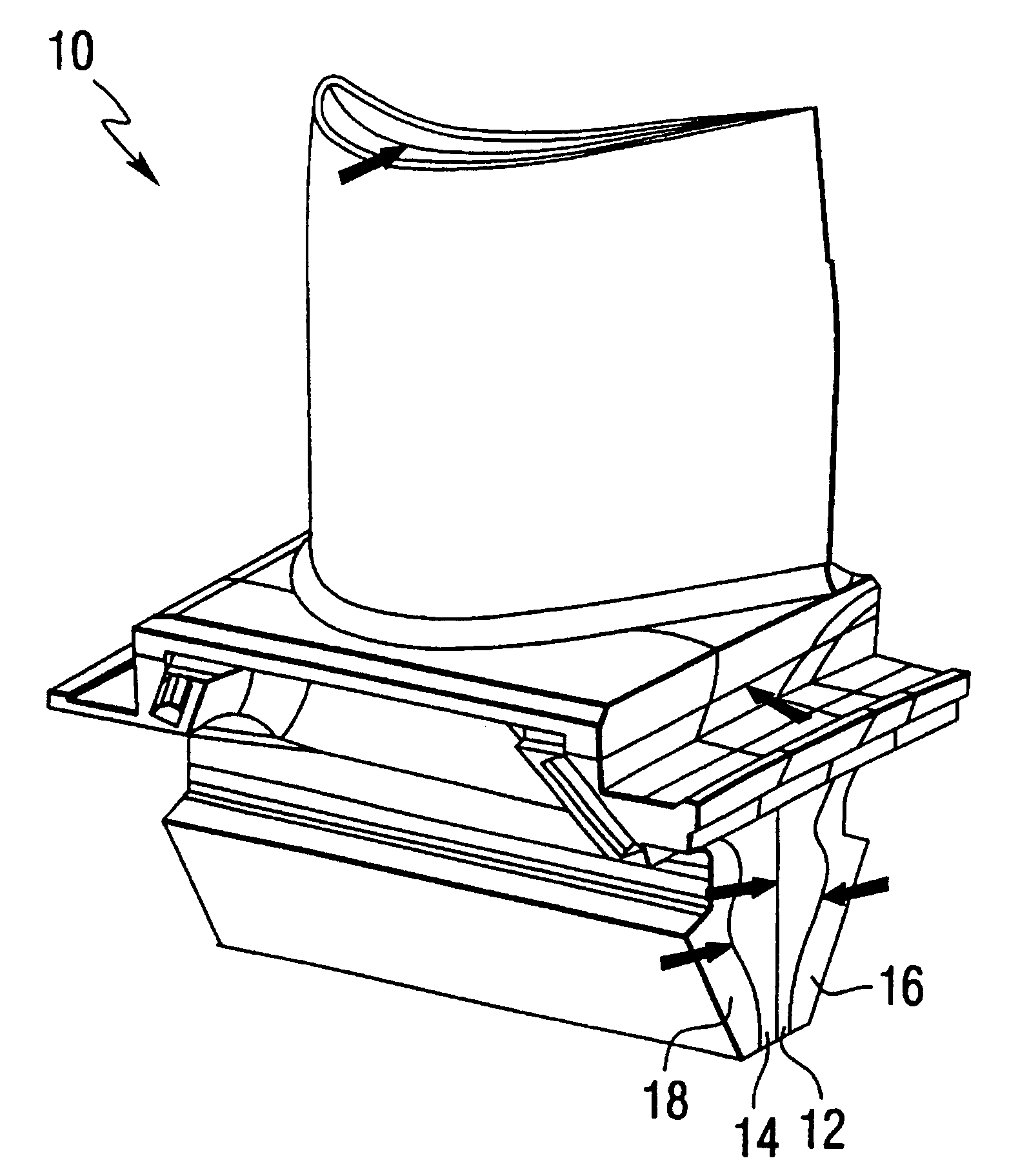

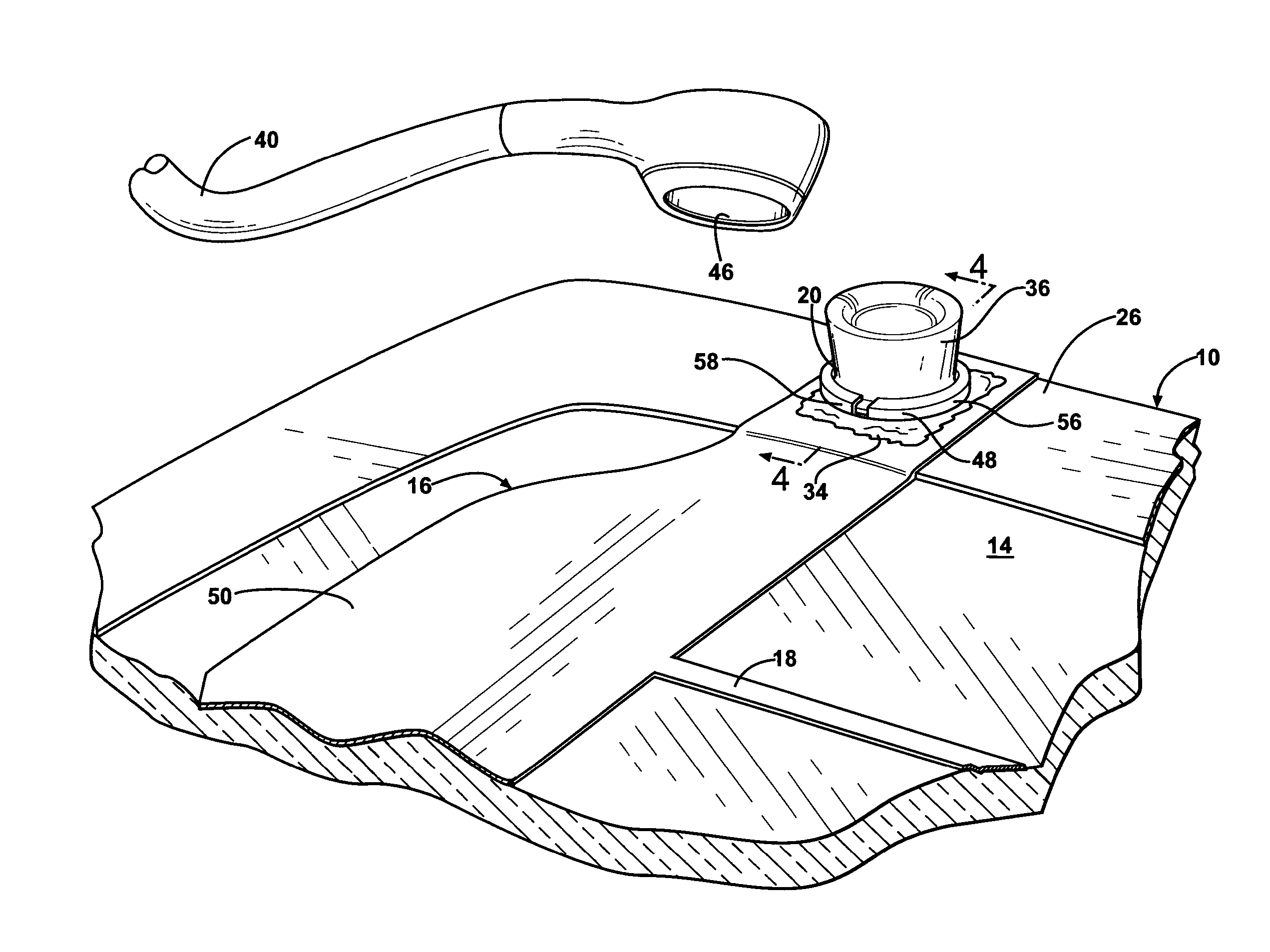

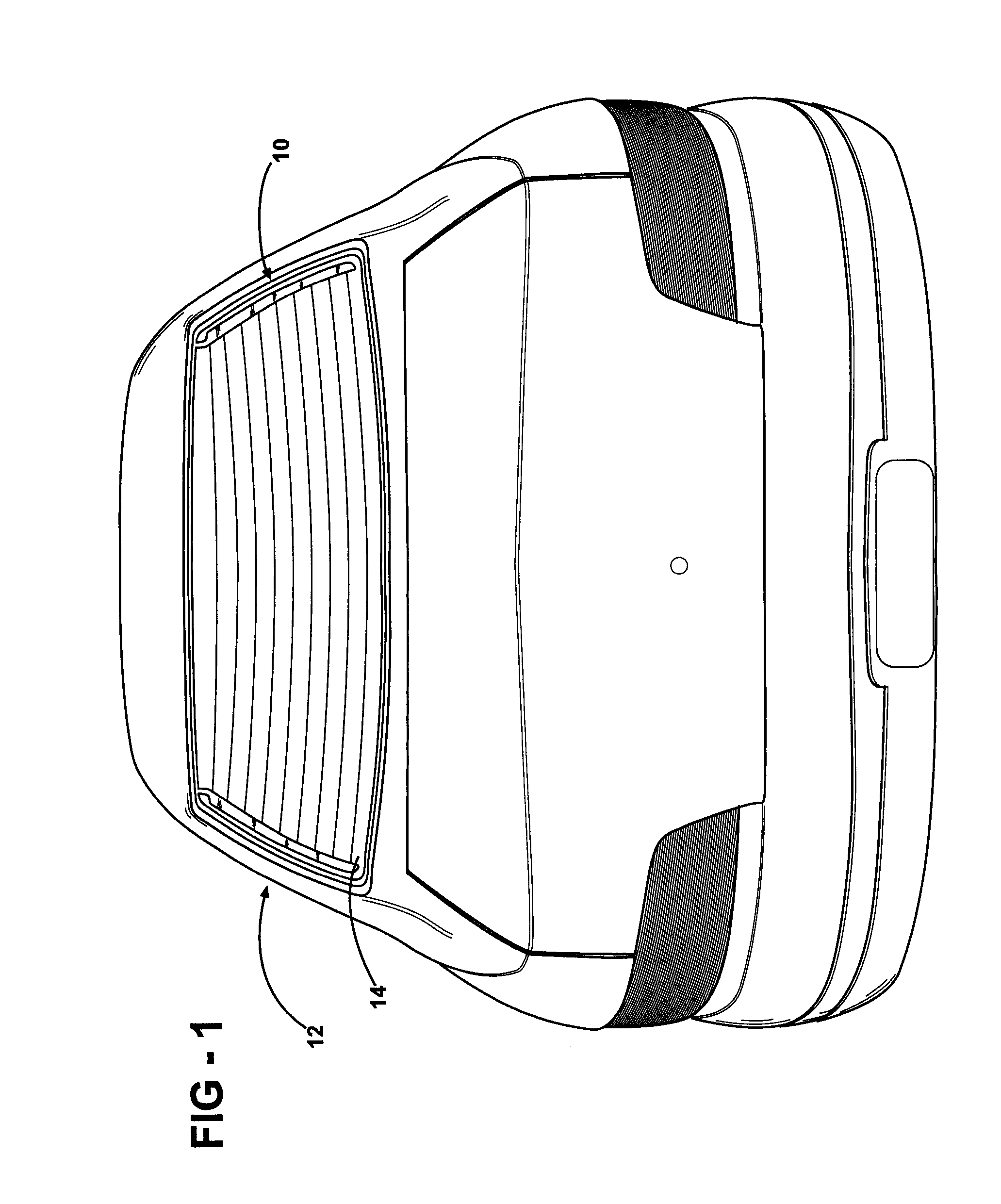

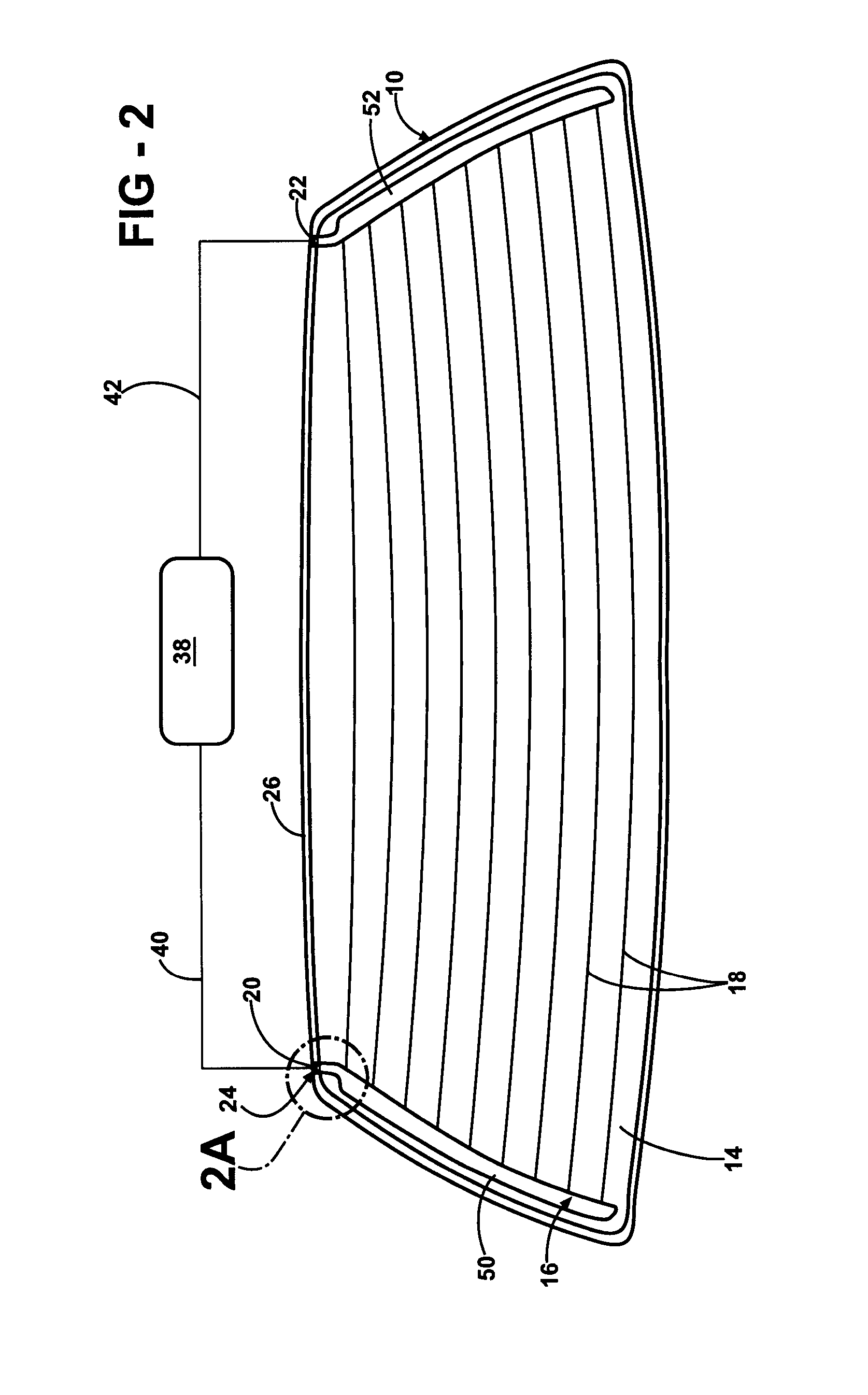

Electrical Connector For A Window Pane Of A Vehicle

InactiveUS20070224842A1Reduce stress concentrationMinimizes mechanical stressElectric discharge tubesSoldered/welded conductive connectionsElectrical conductorCoupling

A window pane has a substrate formed from glass and includes an electrical device including an electrical conductor. An electrical connector is operatively connected to and in electrical communication with the conductor for transferring electrical energy to the conductor. An electrical connector is bonded to the electrical conductor and has a first interacting portion. A terminal is disposed adjacent to the electrical connector and has a second interacting portion for interacting with the first interacting portion to mechanically couple the electrical connector and the terminal. The substrate has a first coefficient of thermal expansion and the connector has a second coefficient of thermal expansion. A difference between the first and second coefficients of thermal expansion is equal to or less than 5×10−6 / ° C. Due to the mechanical coupling between the connector and the terminal, the terminal and connector are less prone to bending, breakage, or delamination than conventional connector structures.

Owner:AGC AUTOMOTIVE AMERICAS

Brazing-filler material and method for brazing diamond

InactiveUS6889890B2Beautiful sceneryStable joint strengthLayered productsOther manufacturing equipments/toolsFilling materialsCopper

When a diamond is brazed to a metal substrate, while obtaining a stable joining strength, a joined interface of the diamond is not eroded to provide a good joint with a beautiful view. A brazing-filler material containing at least one selected from a group consisting of gold and silver, and copper as principal components, and further containing 0.001 to 5 mass % of vanadium is used. Preferably, a vanadium content is not more than 2.0 mass %, and more preferably not more than 0.5 mass %. Using this brazing-filler material, unidirectional solidification is performed from a side of diamond to form vanadium carbide in a joined interface in a shape of islands, and thereby an interface having a beautiful view with stable joining strength can be obtained. In addition, strong joining is possible also by a usual solidification method.

Owner:HOHOEMI BRAINS INC

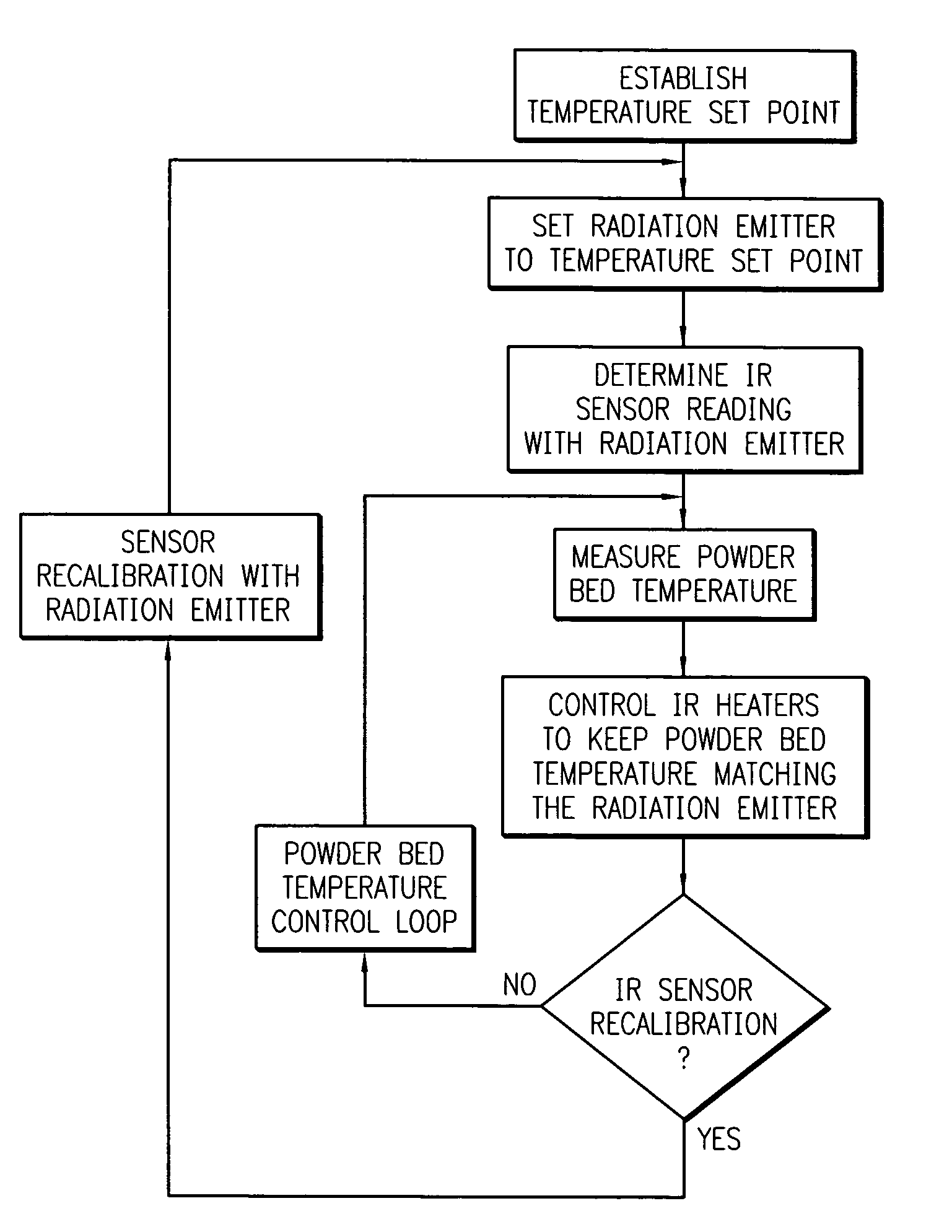

Continuous calibration of a non-contact thermal sensor for laser sintering

ActiveUS6930278B1Accurate monitoringHighly consistent mechanical propertyAdditive manufacturing apparatusIncreasing energy efficiencyAcousticsLaser

An apparatus and a method of using the apparatus wherein a radiation emitter is positioned adjacent a sensor apparatus within a process chamber in a laser sinter system that emits radiation to the sensor apparatus and a calibration apparatus receives readings from the sensor apparatus to compare temperature sensings received from the sensor apparatus with set emission signals from the radiation emitter to adjust the temperature sensings to calibrate the sensor apparatus during the forming of a three-dimensional article. The calibration is done repeatedly during the build process of the three-dimensional article.

Owner:3D SYST INC

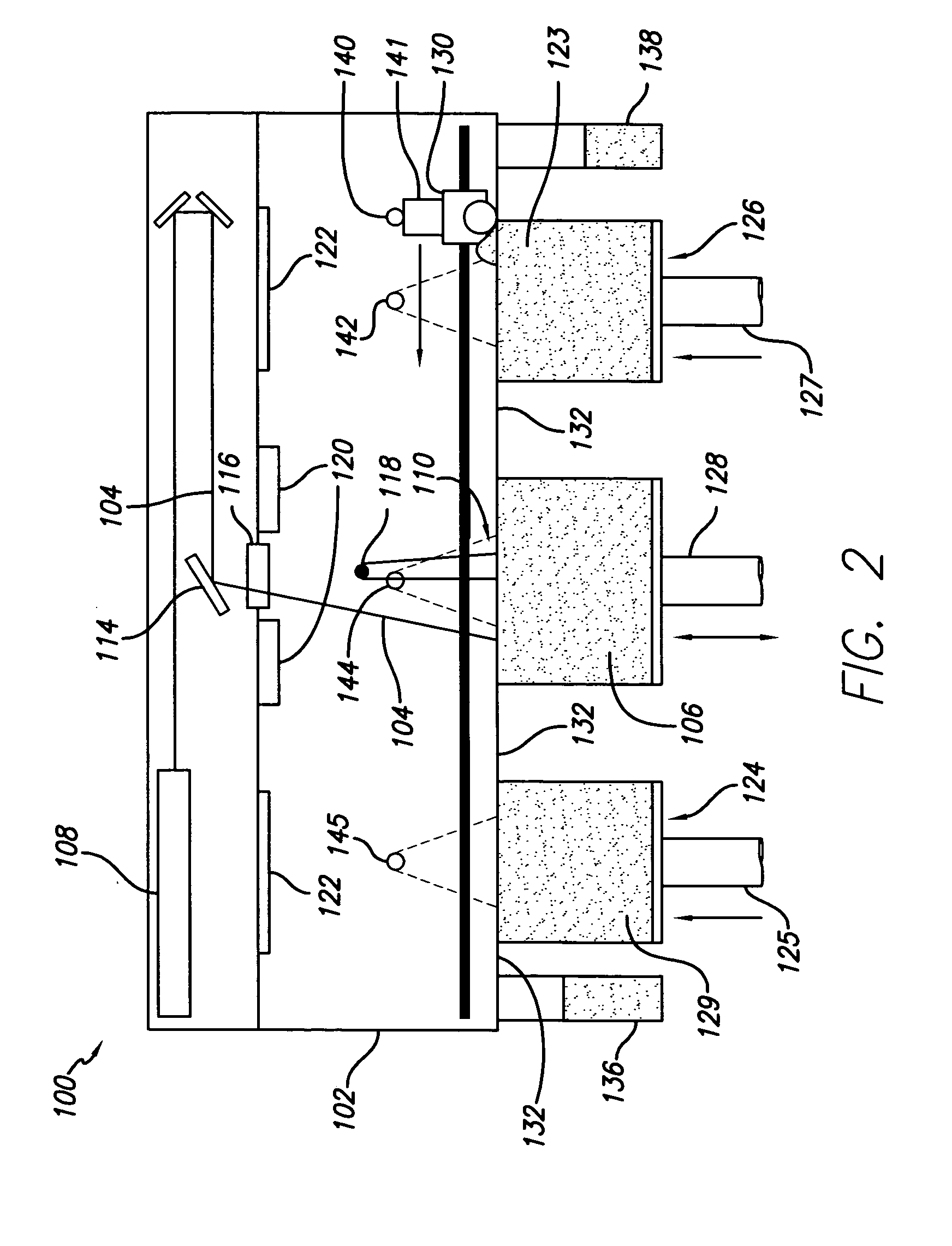

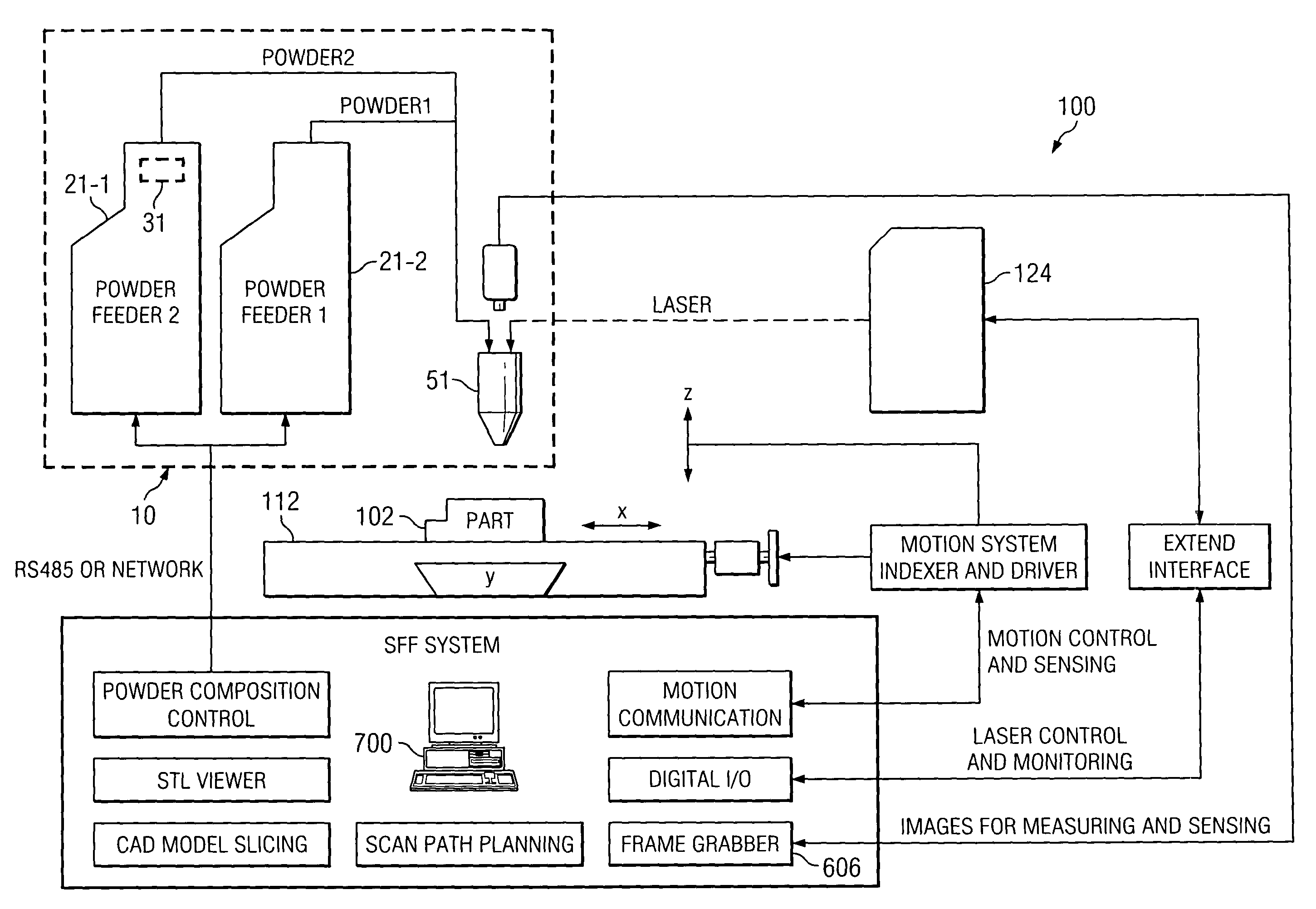

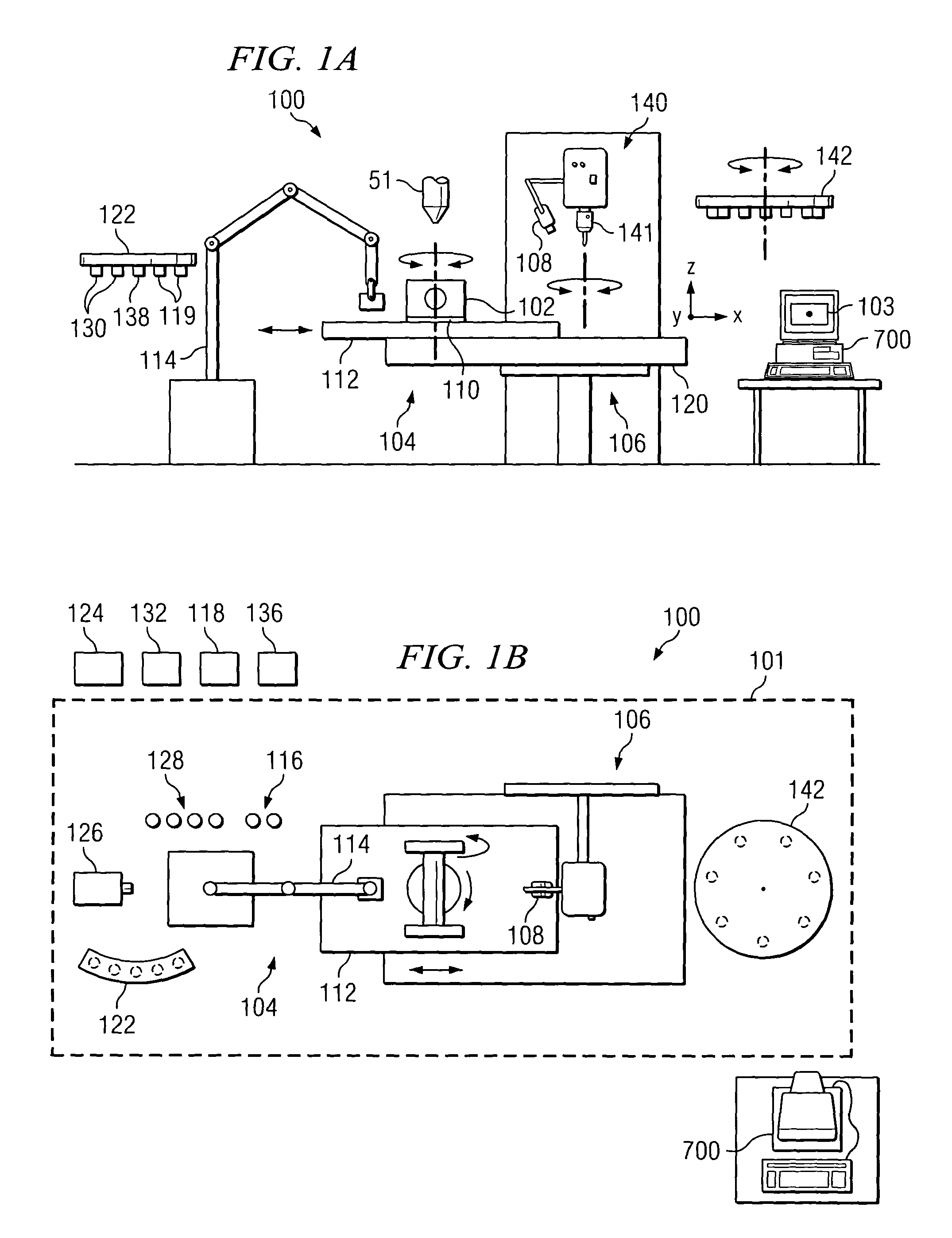

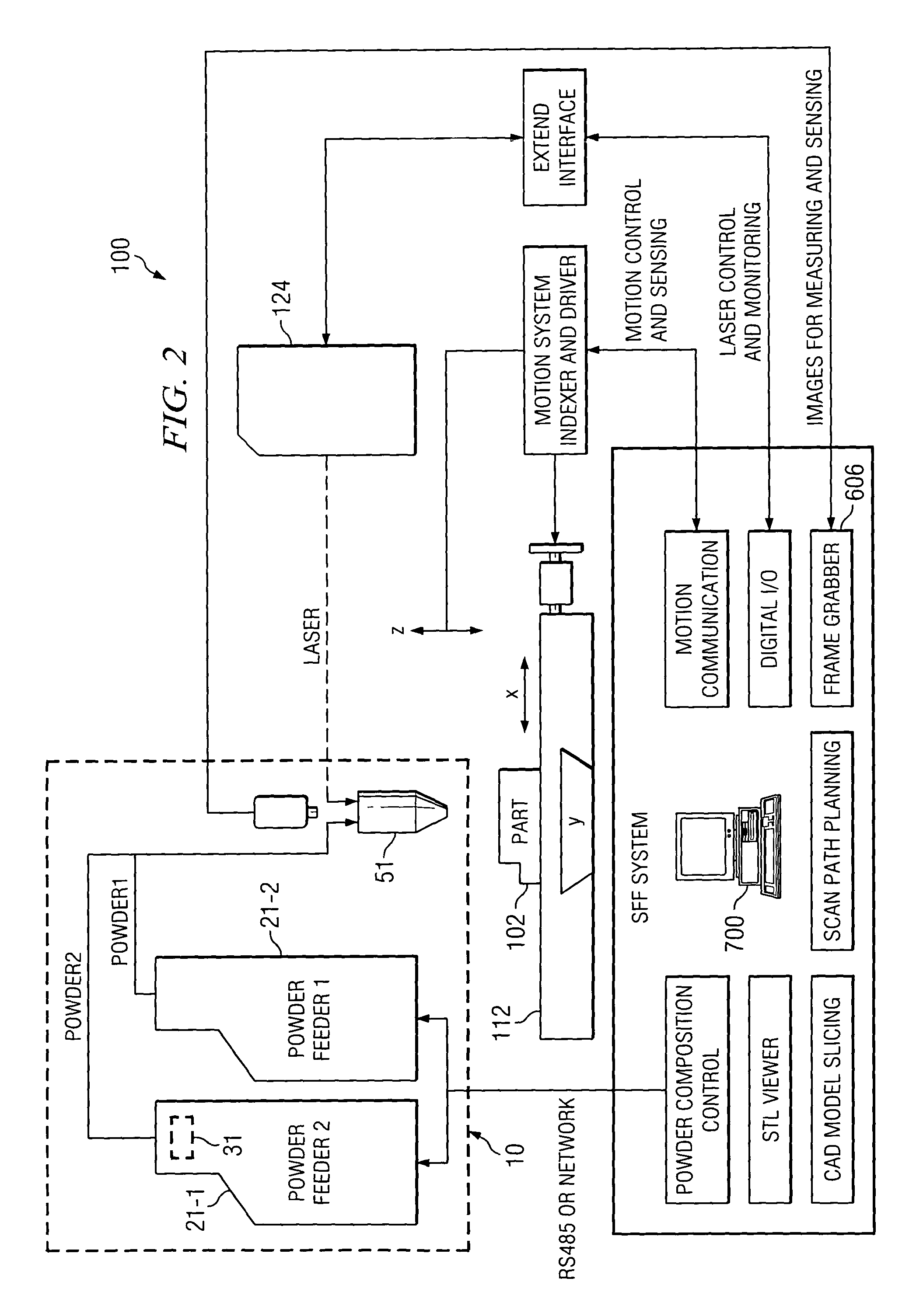

System and method for controlling the size of the molten pool in laser-based additive manufacturing

InactiveUS6995334B1High geometric accuracyEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser Nozzle

According to one embodiment of the invention, a method for controlling the size of the molten pool in a laser based additive manufacturing process includes coaxially aligning an imaging device with a laser nozzle and imaging a molten pool, created by a laser, on a substrate with the imaging device. The method further includes comparing at least one characteristic of the molten pool with a respective characteristic of a target molten pool, and adjusting, in substantially real-time, a laser power of the laser based on the comparison in order to correlate the characteristic of the molten pool with the respective characteristic of the target molten pool.

Owner:SOUTHERN METHODIST UNIVERSITY

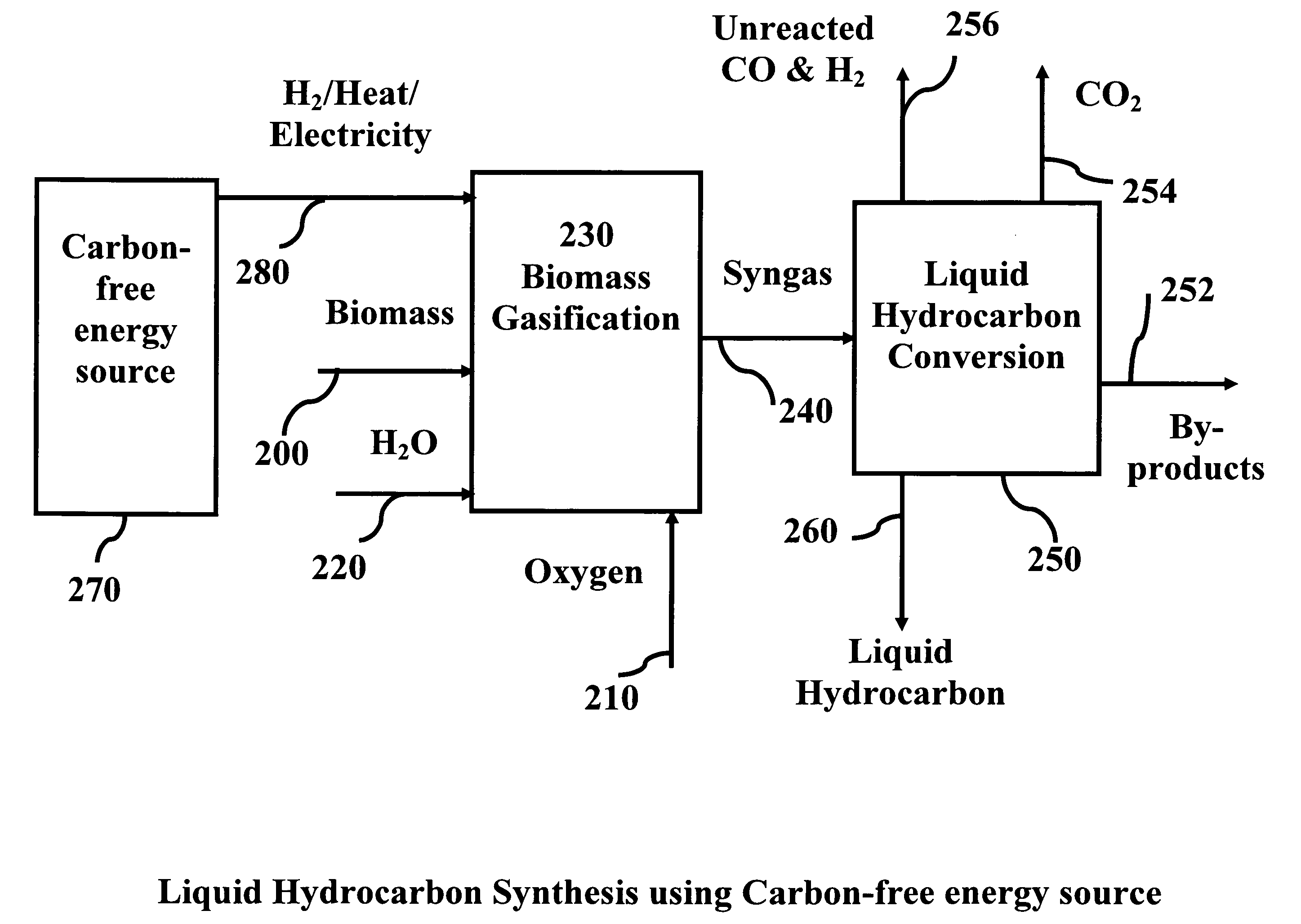

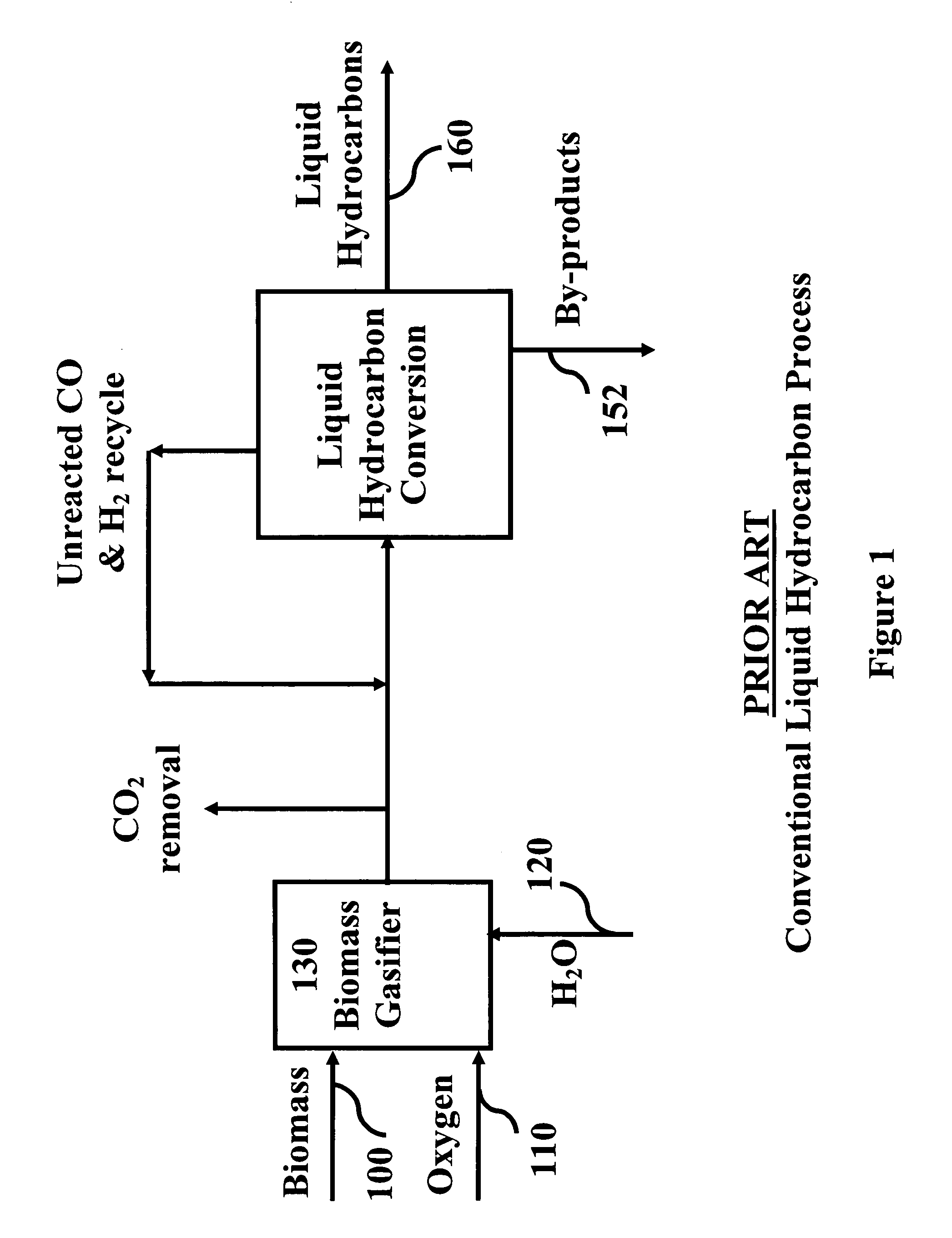

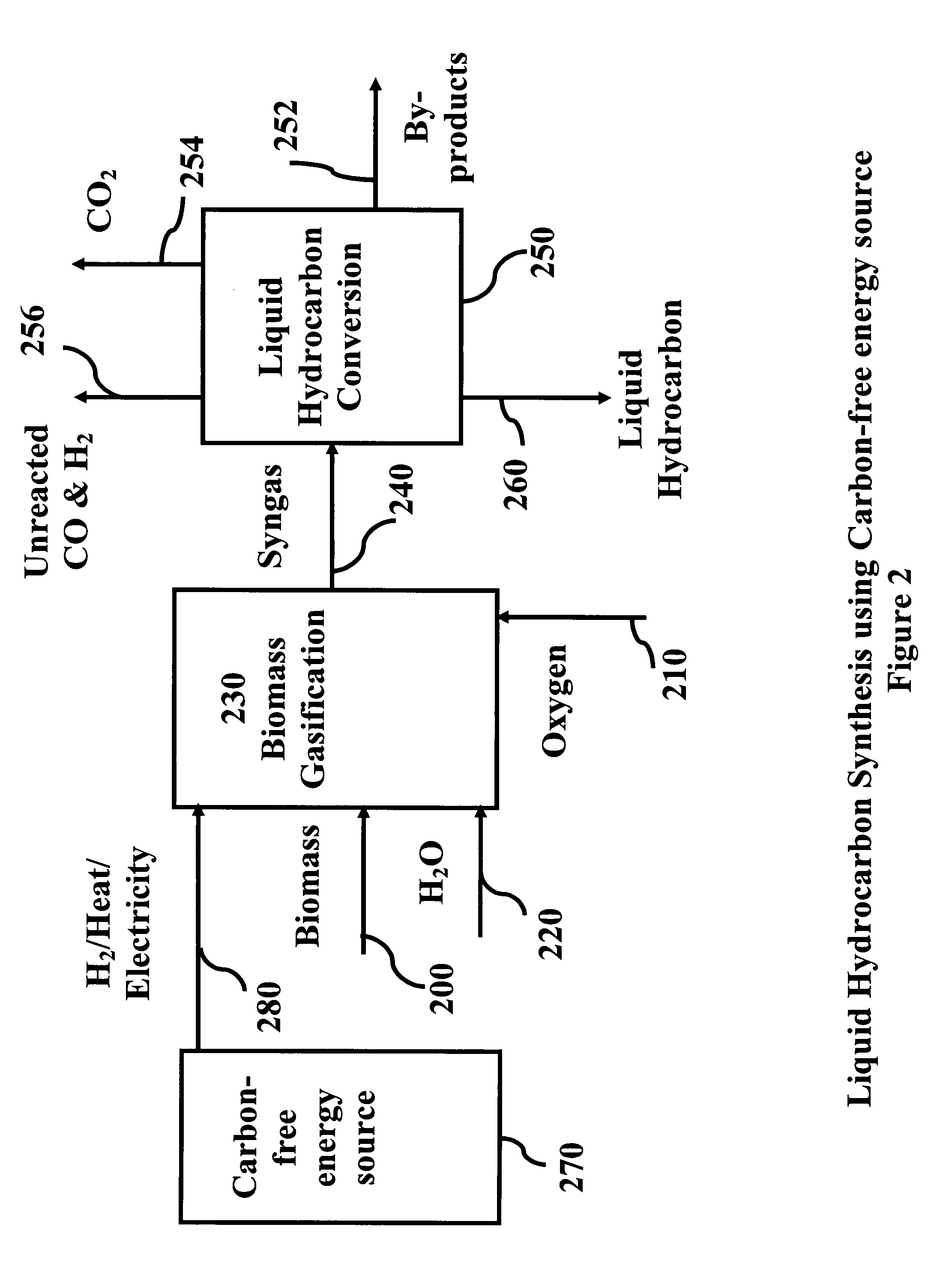

System and process for producing synthetic liquid hydrocarbon

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

Virtual reality pipe welding simulator

A simulator facilitates virtual welding activity of pipe and open root weld joints. The simulator may include a logic processor based system operable to execute coded instructions for generating an interactive welding environment that emulates welding activity on a section of virtual pipe having at least one virtual weld joint. It also includes a display connected to the logic processor based system for visually depicting the interactive welding environment, wherein the display depicts the section of virtual pipe. A mock welding tool is provided for performing virtual welding activity on the at least one weld joint in real time where one or more sensors are adapted to track movement of the input device in real time for communicating data about the movement of the input device to the logic processor based system.

Owner:LINCOLN GLOBAL INC

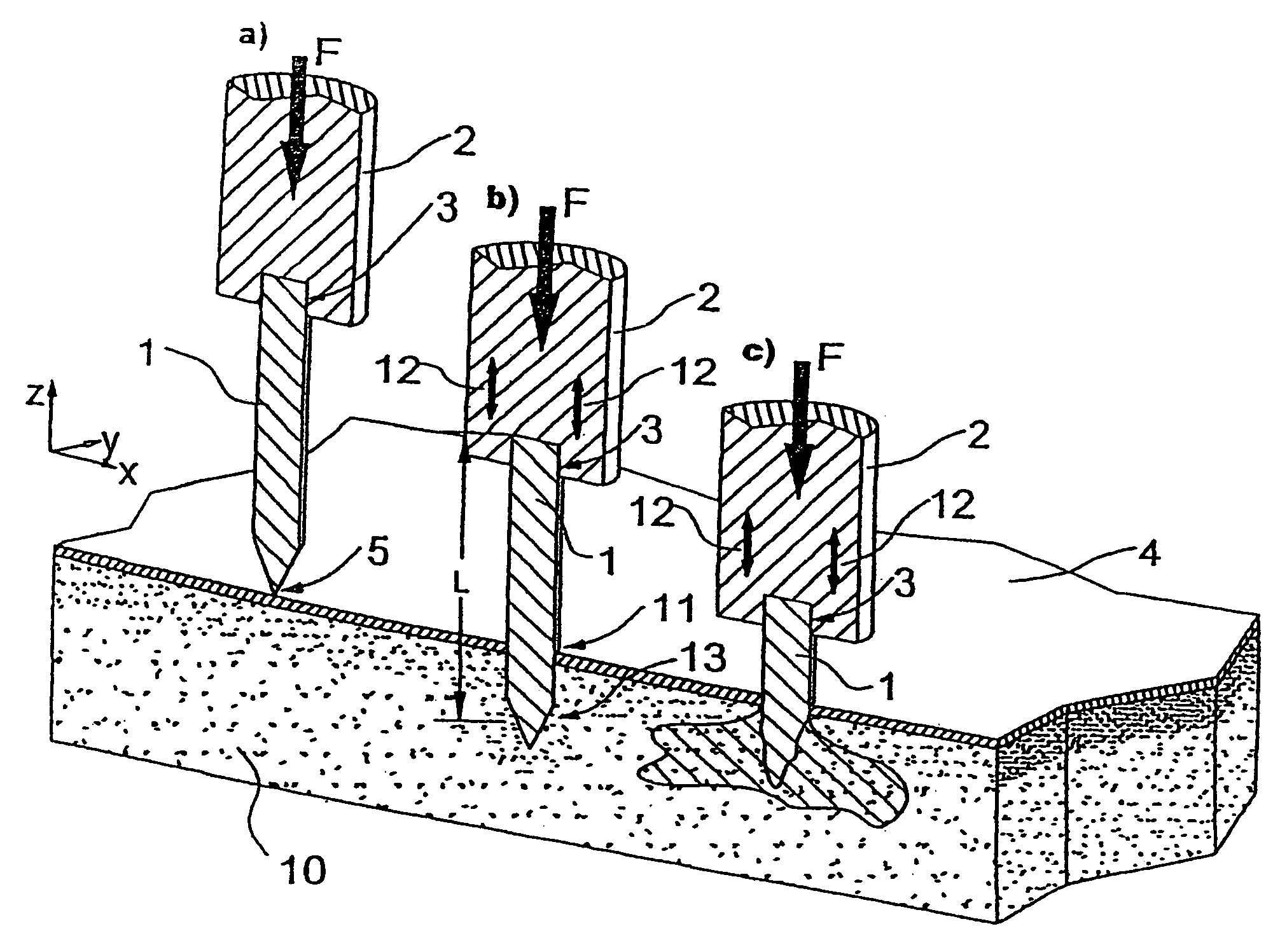

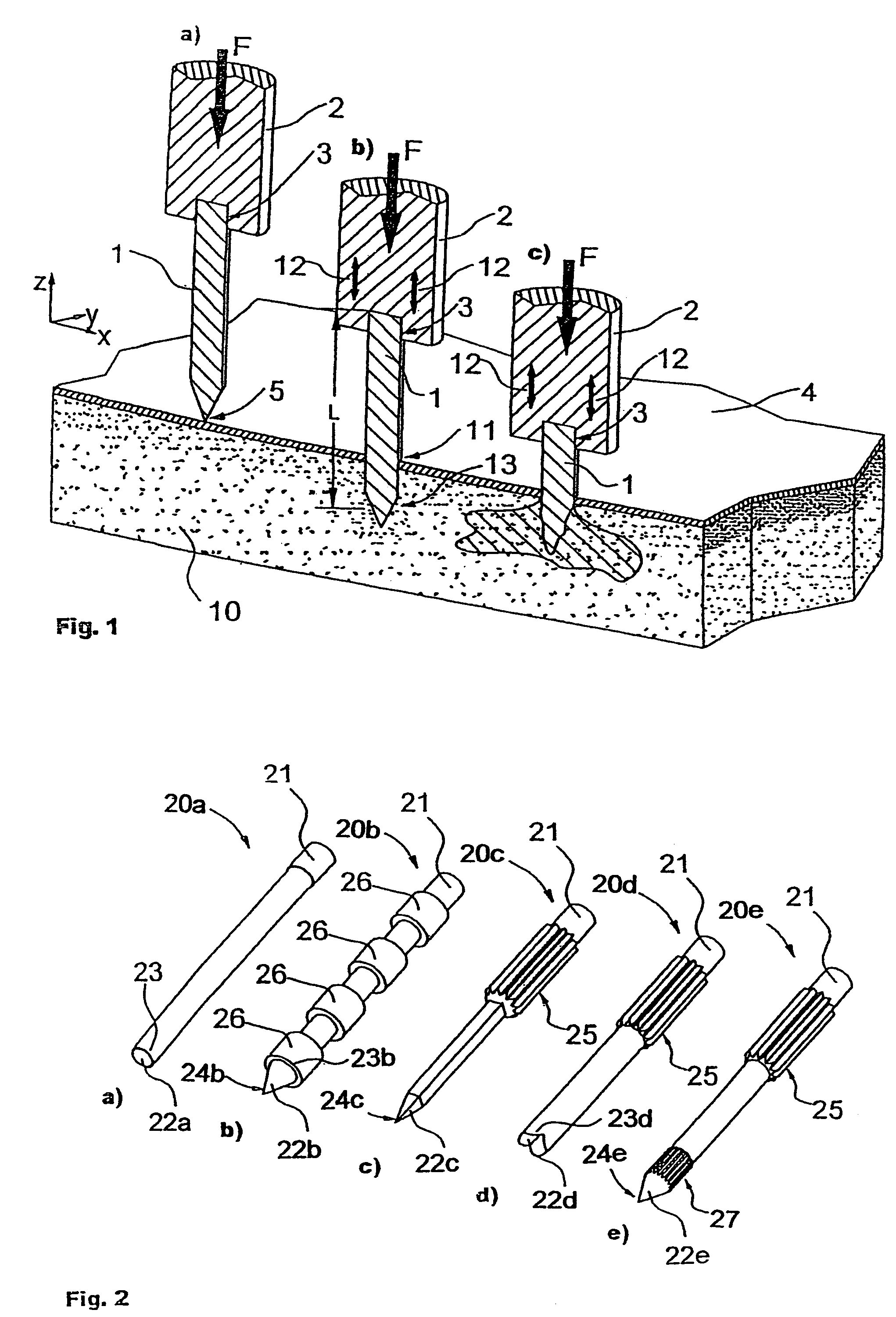

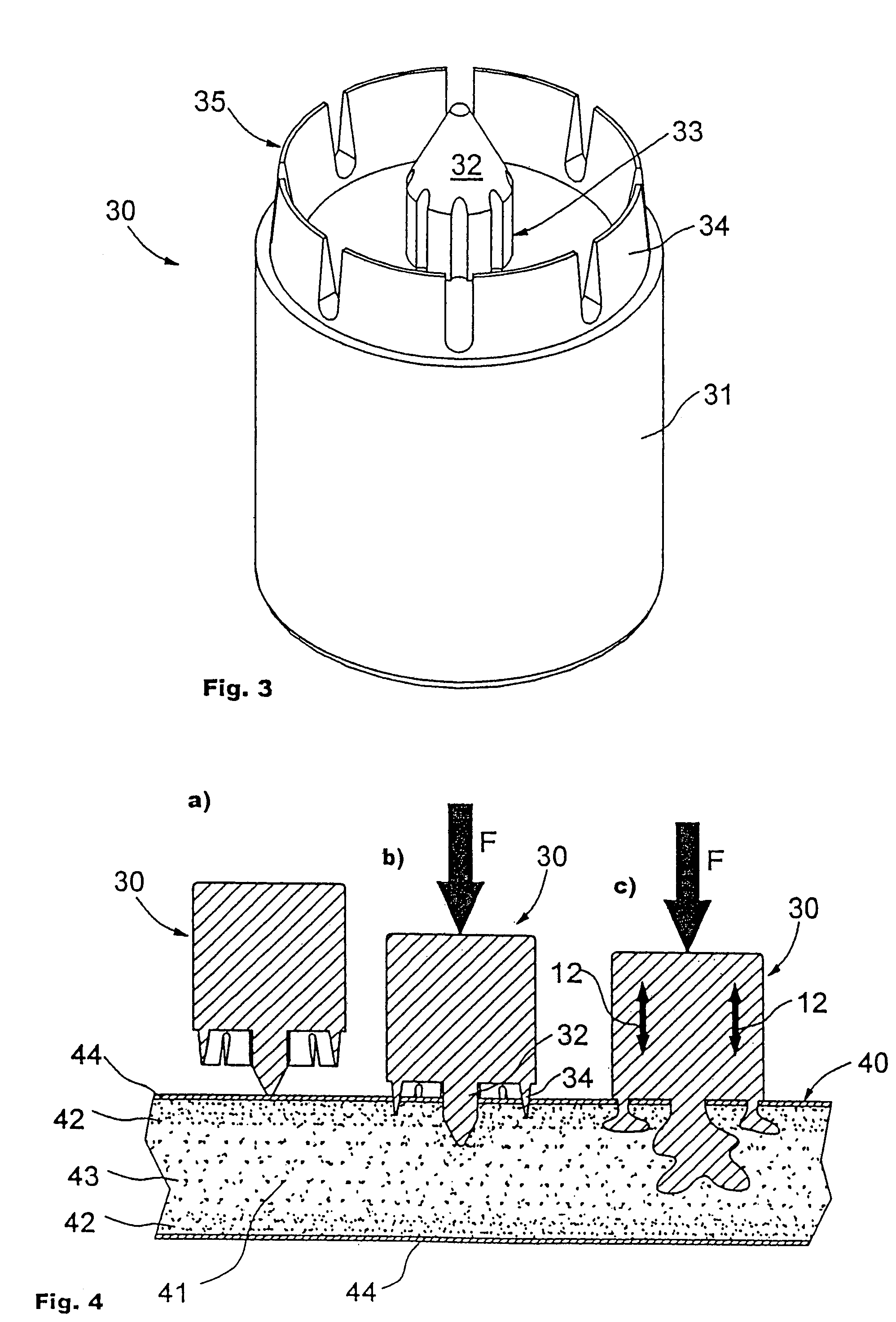

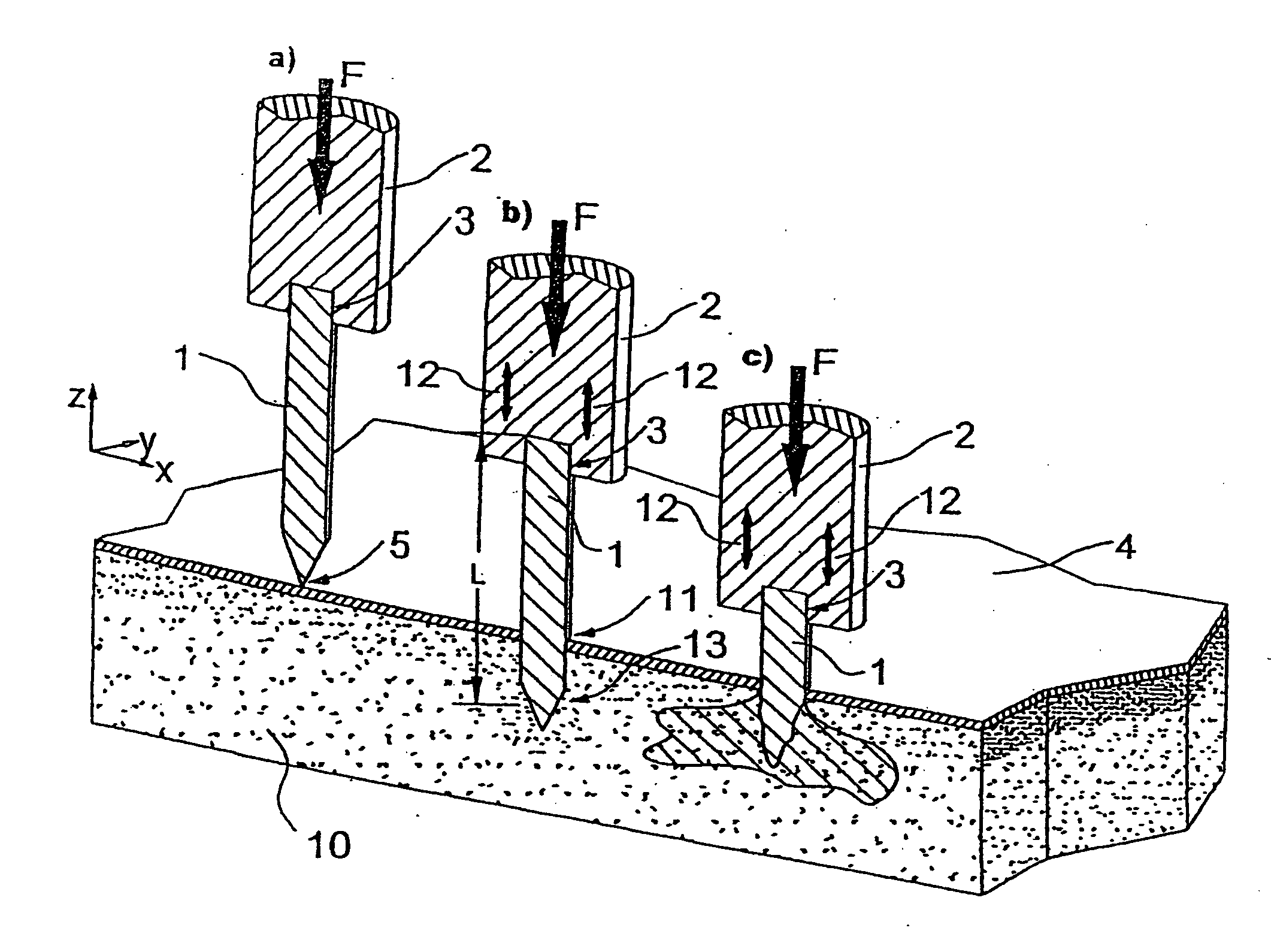

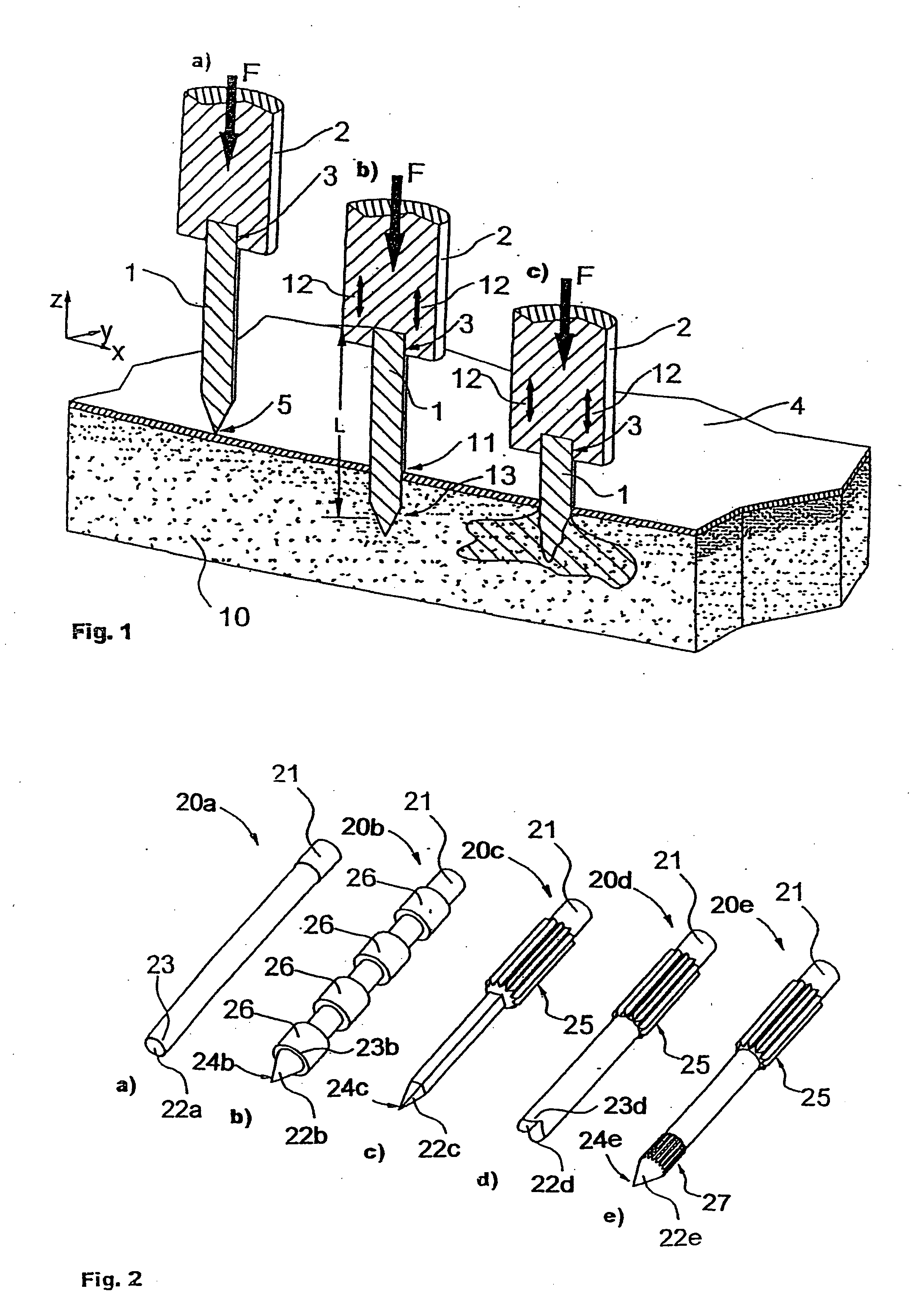

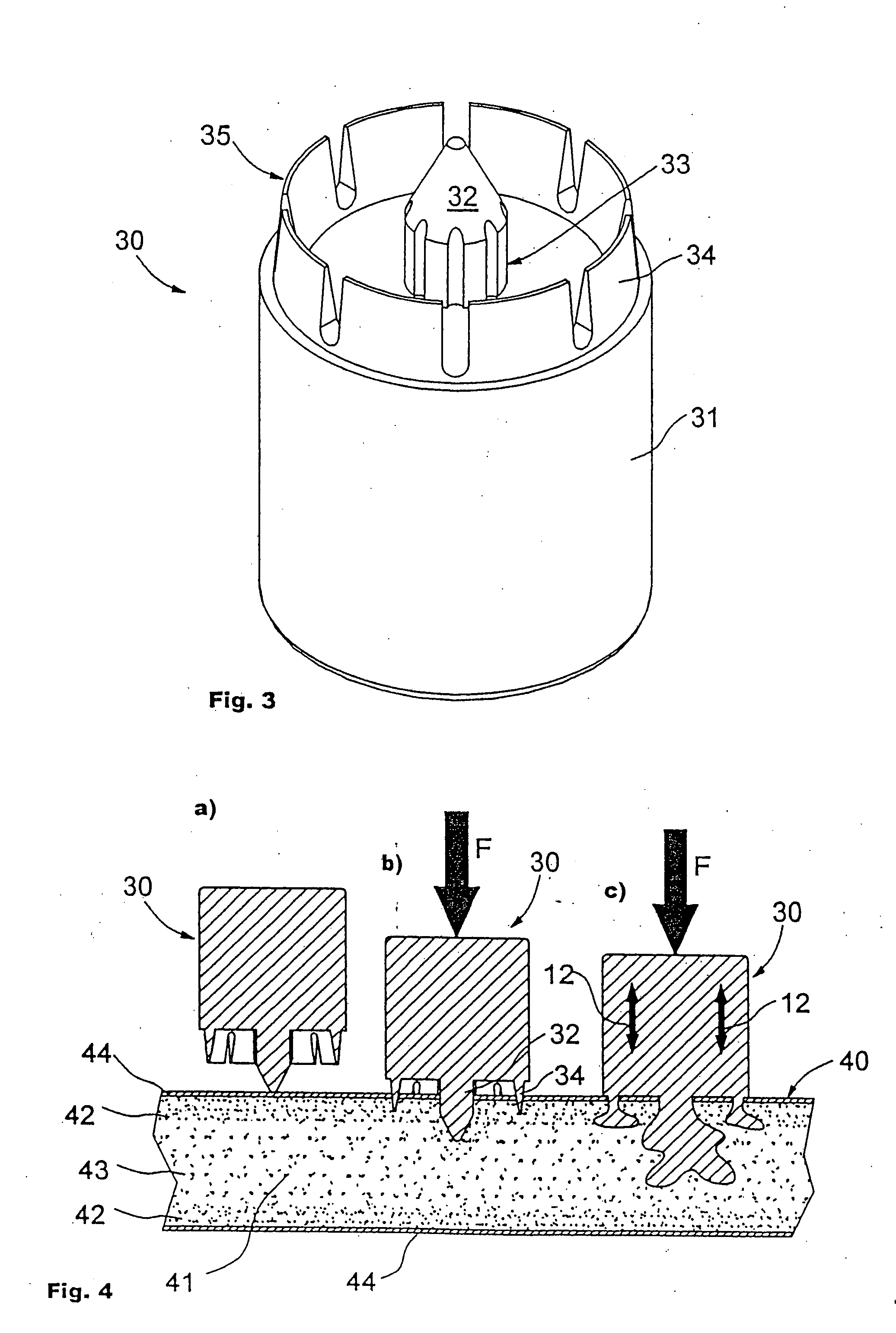

Integral joining

InactiveUS7160405B2Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

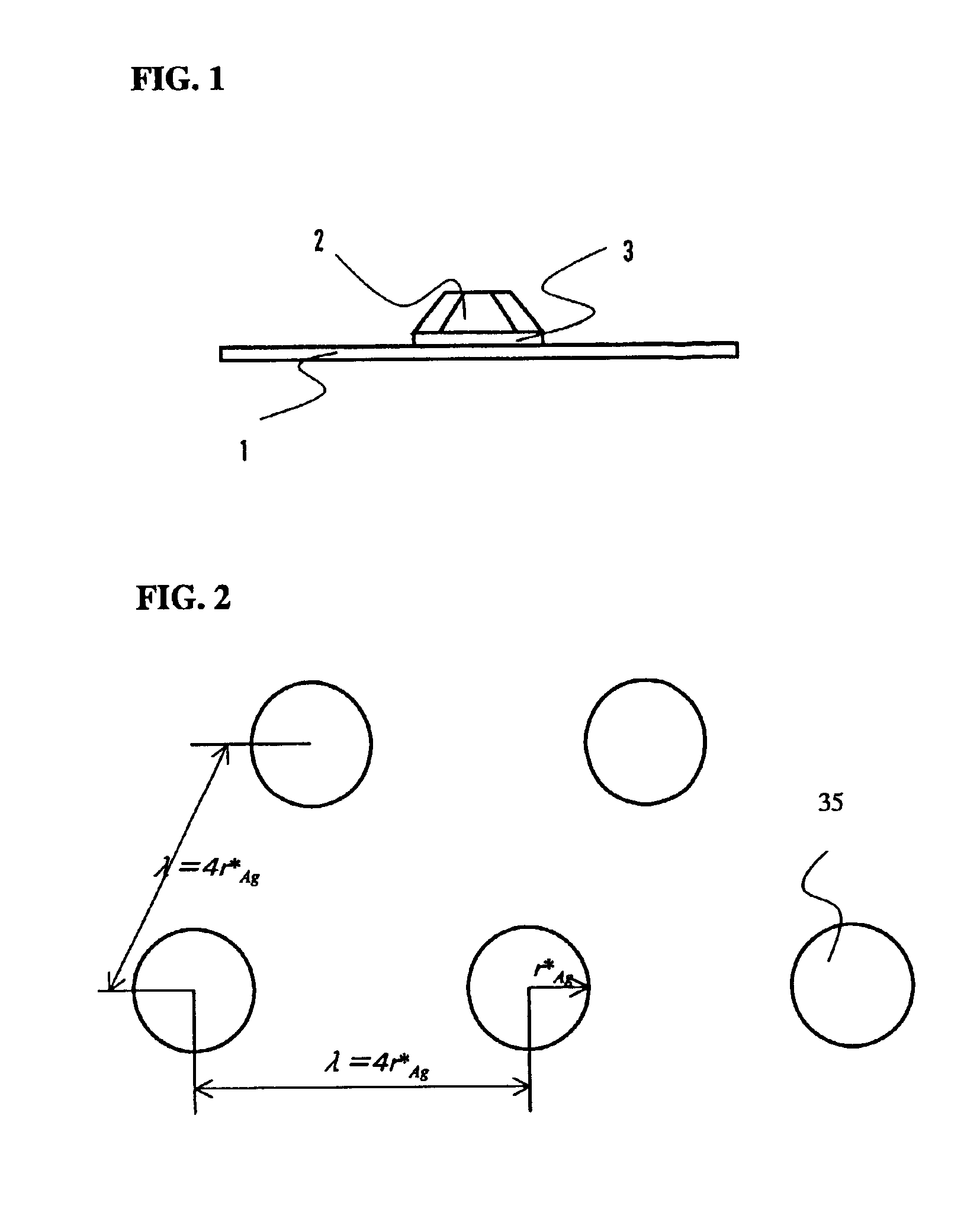

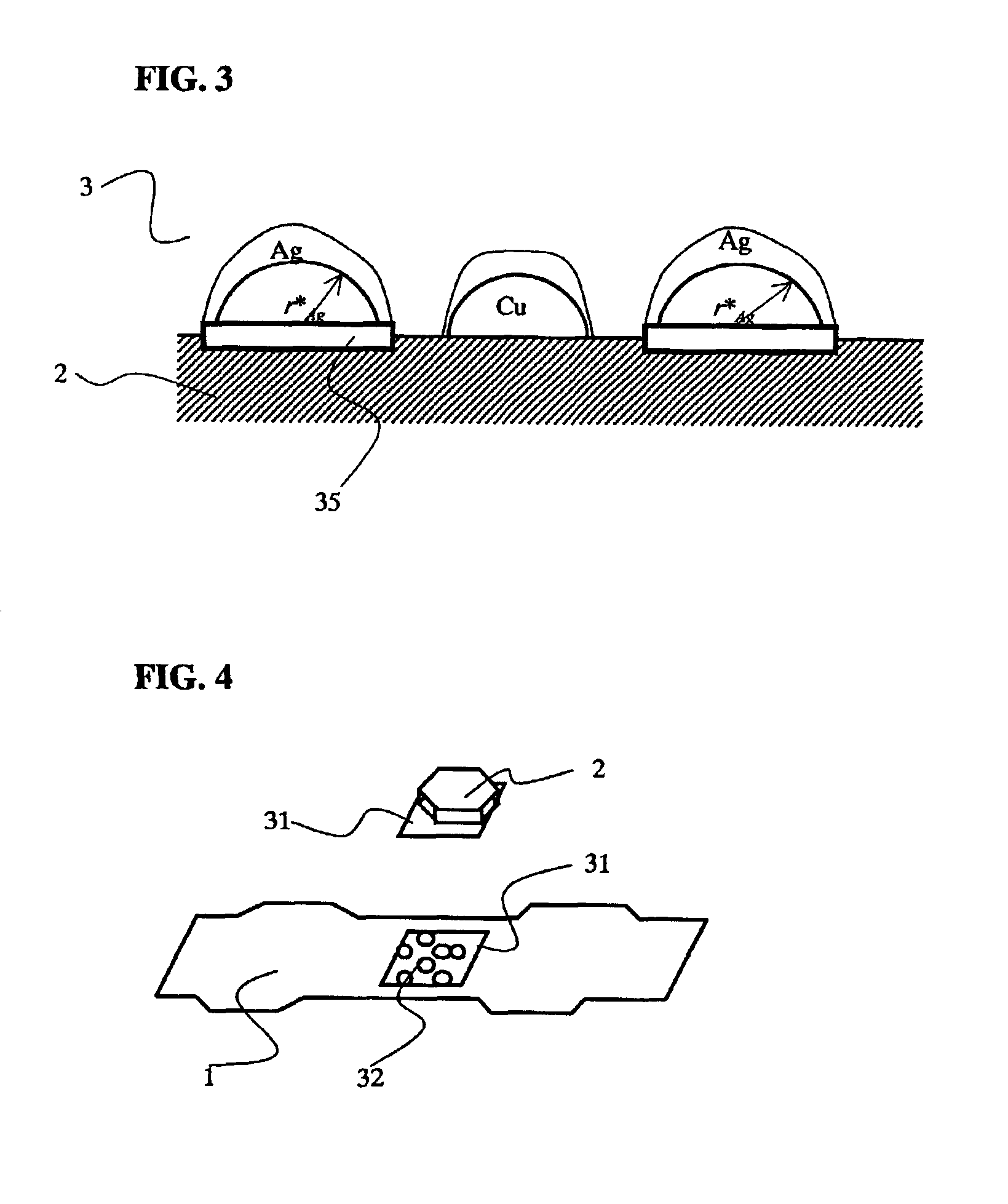

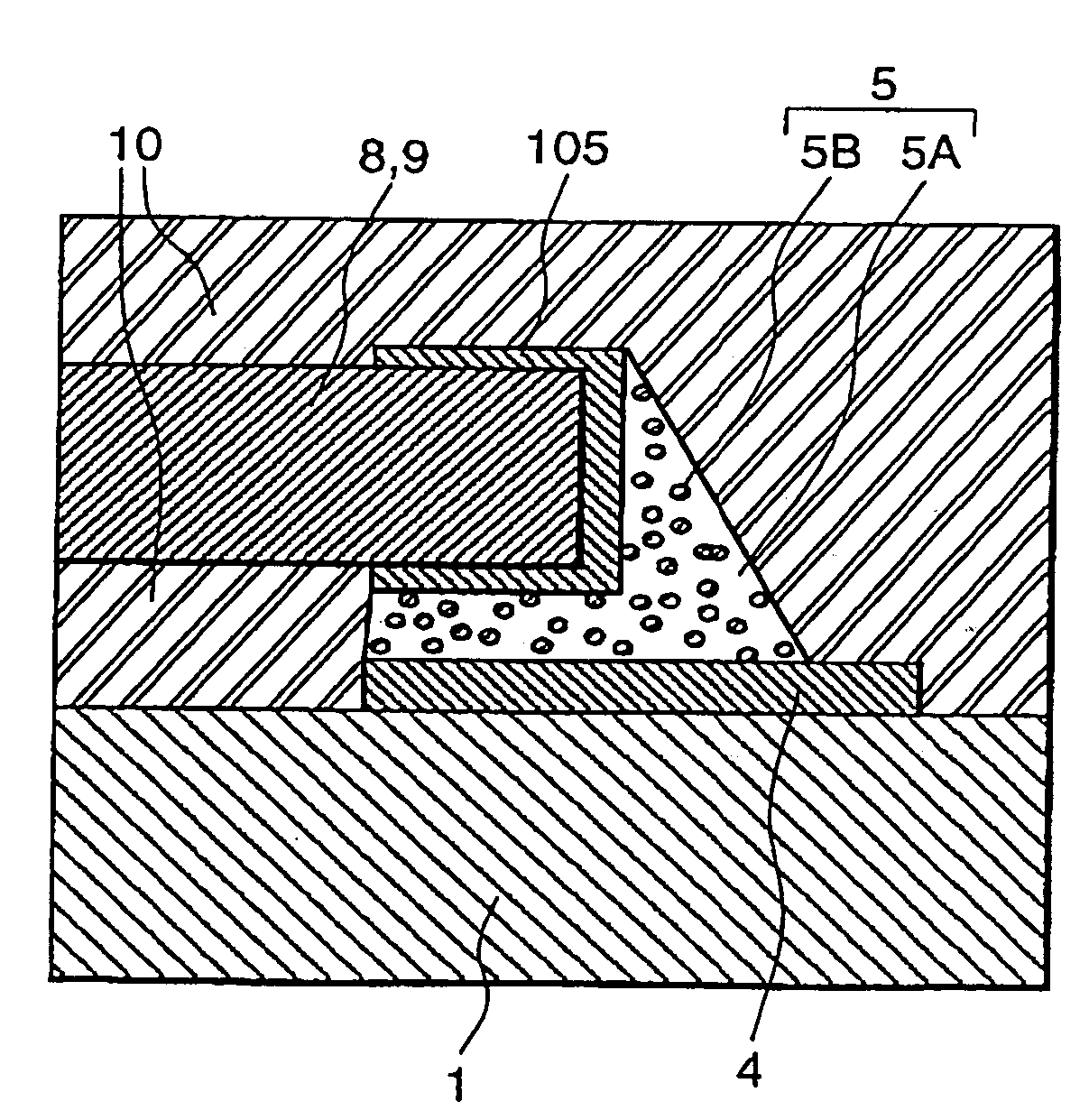

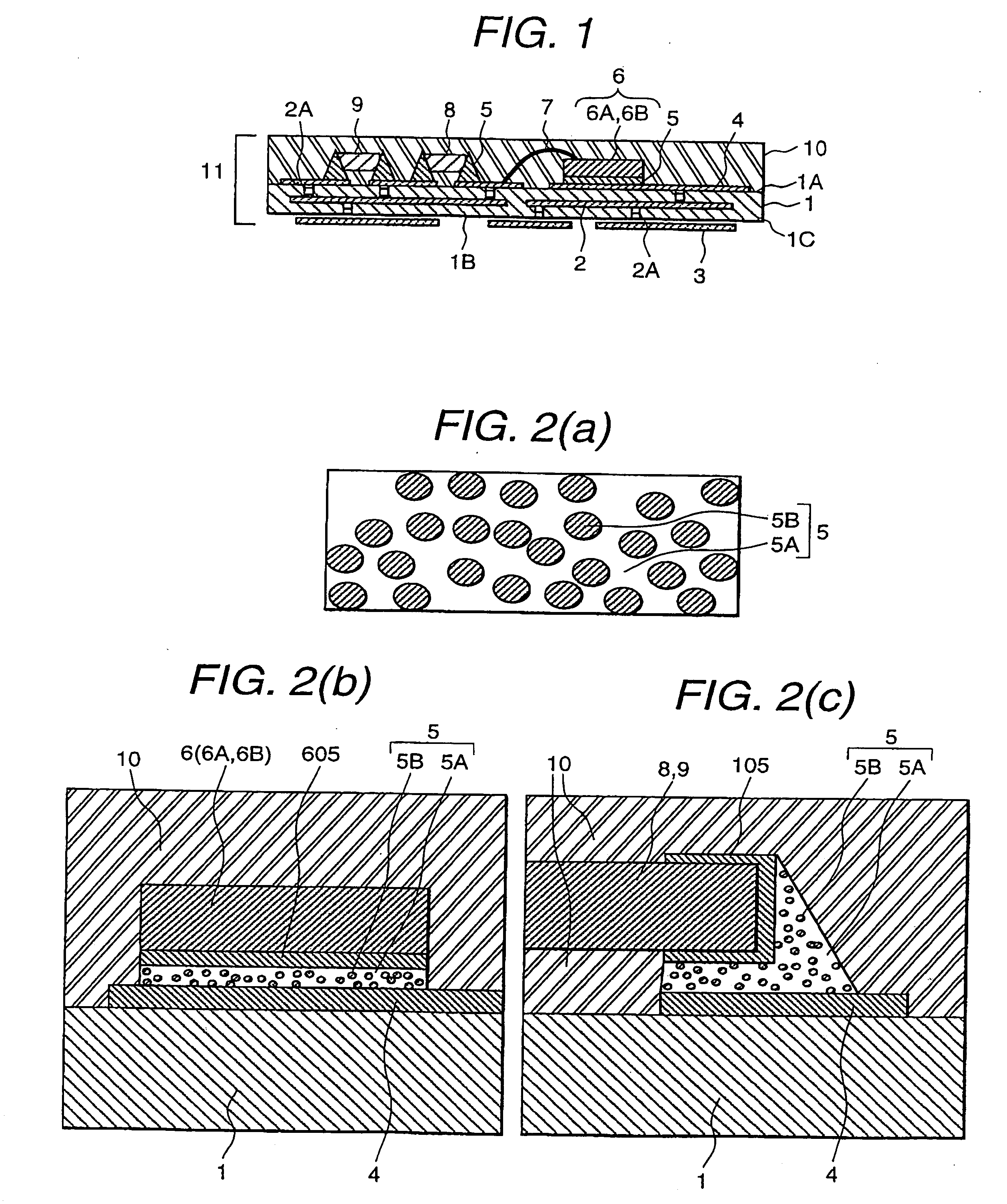

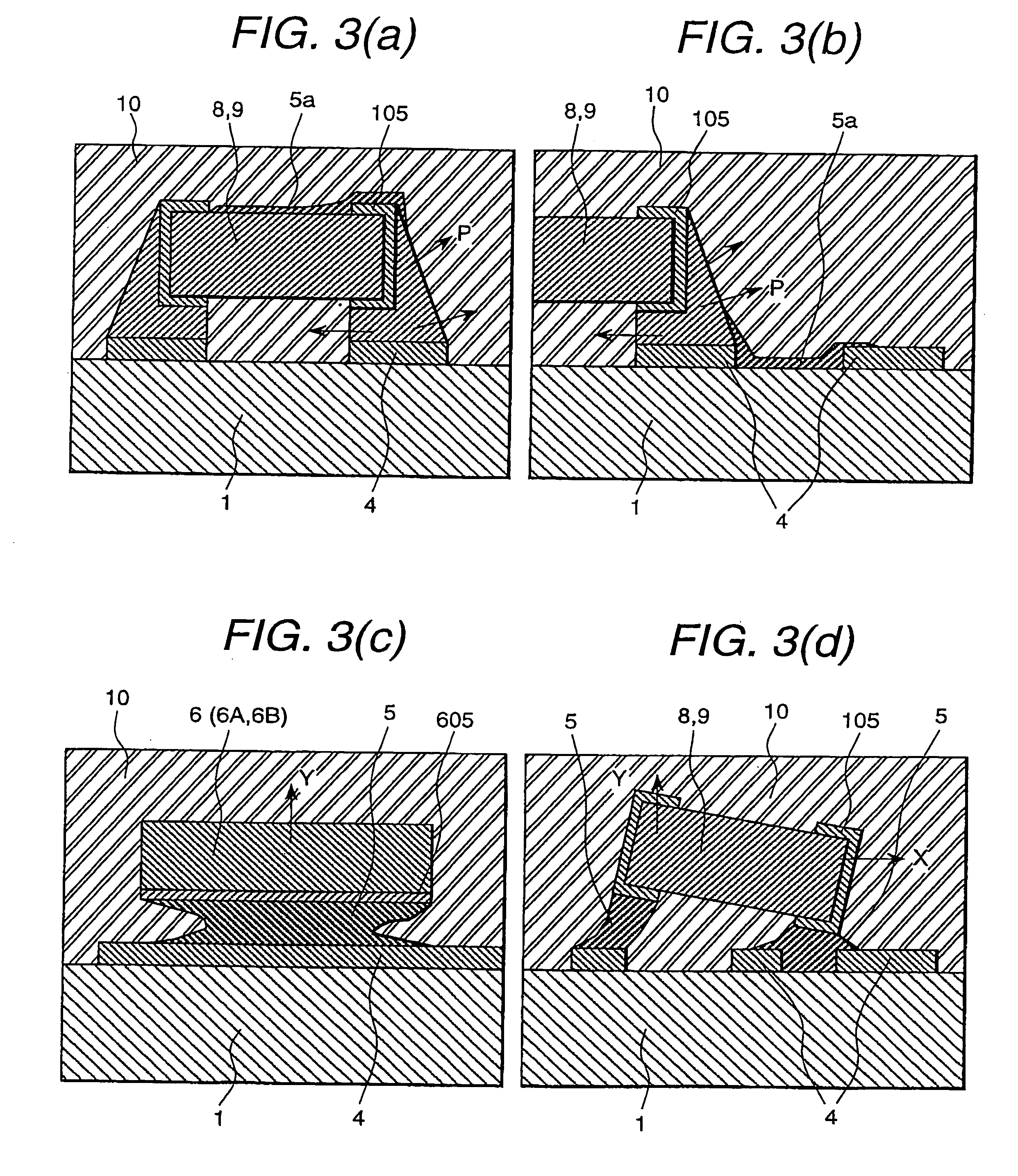

Semiconductor device structural body and electronic device

InactiveUS20050029666A1Prevent outflowPrinted circuit assemblingFinal product manufactureDevice materialMetal powder

A semiconductor device, in which a solder layer bonding chip parts and wiring members are enclosed with the resin layer, and the solder layer is comprised of a compound body in which metal powder is distributed in the matrix metal, is disclosed. When a semiconductor device in which the chip parts are installed in the wiring member with the solders, the soldering part is sealed with the resin is mounted secondly on the external wiring member, the outflow of the solders and the short circuit due to the outflow, the disconnections, and the displacement of the chip parts can be prevented.

Owner:HITACHI LTD +1

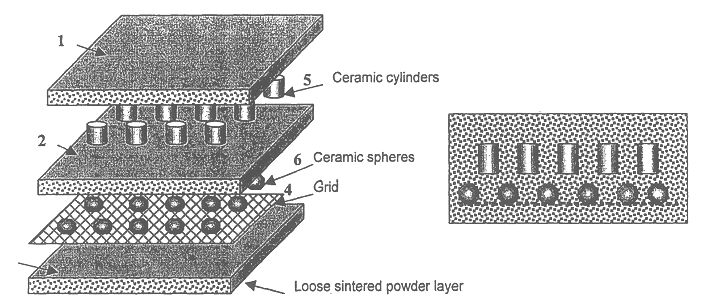

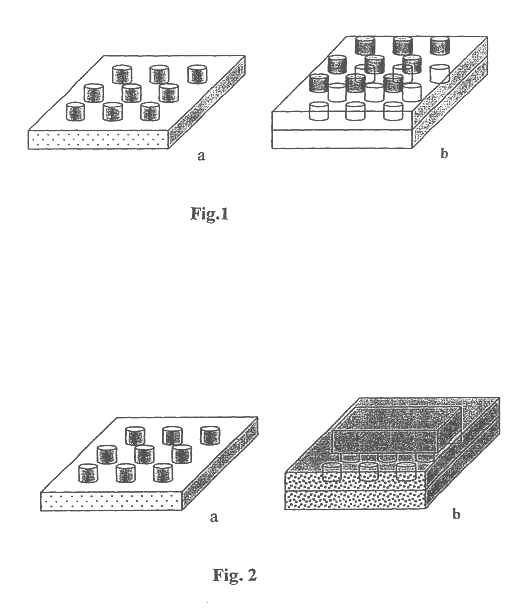

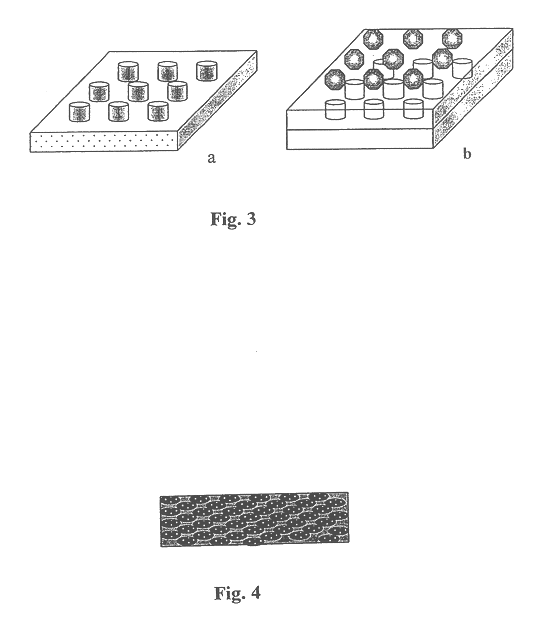

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

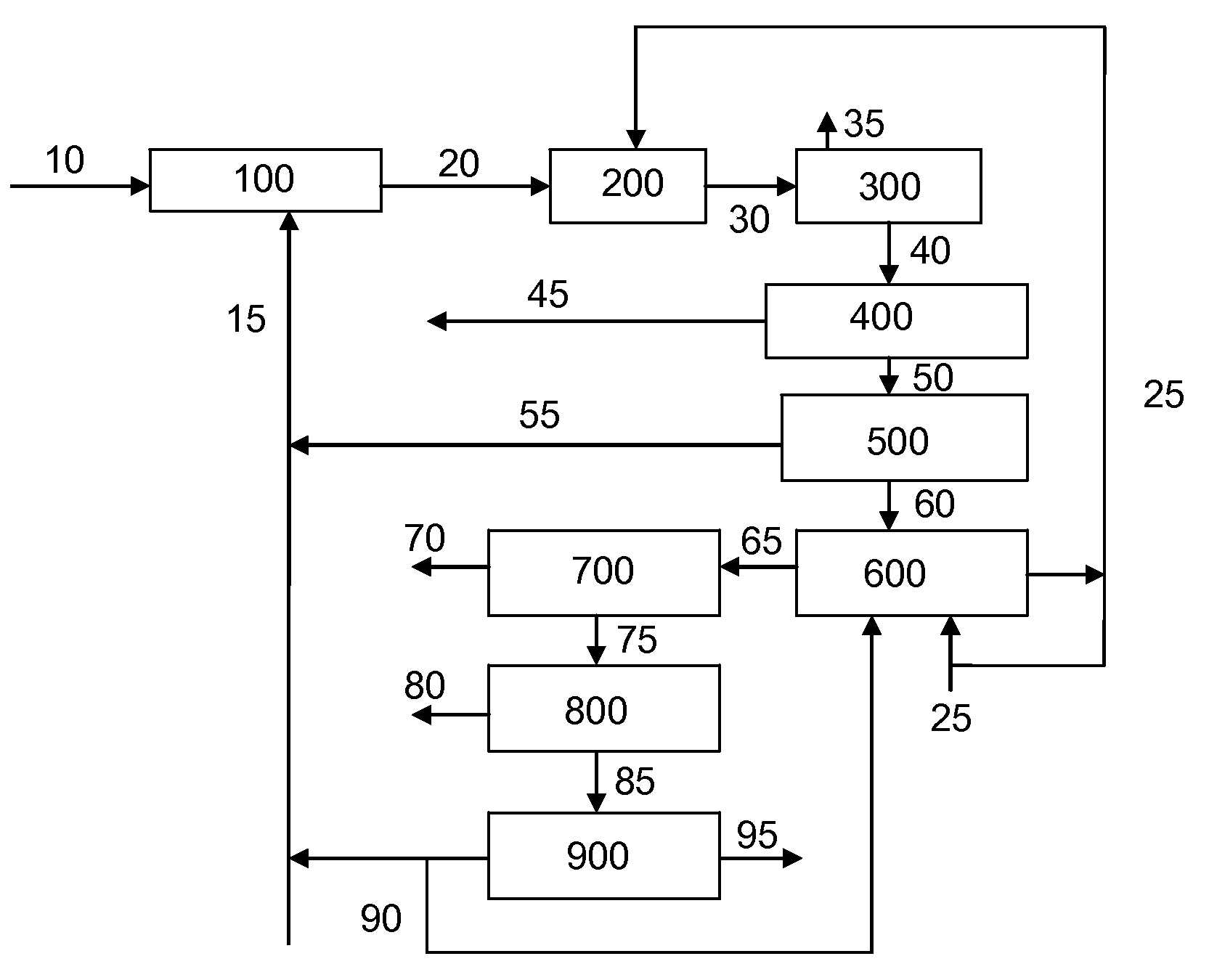

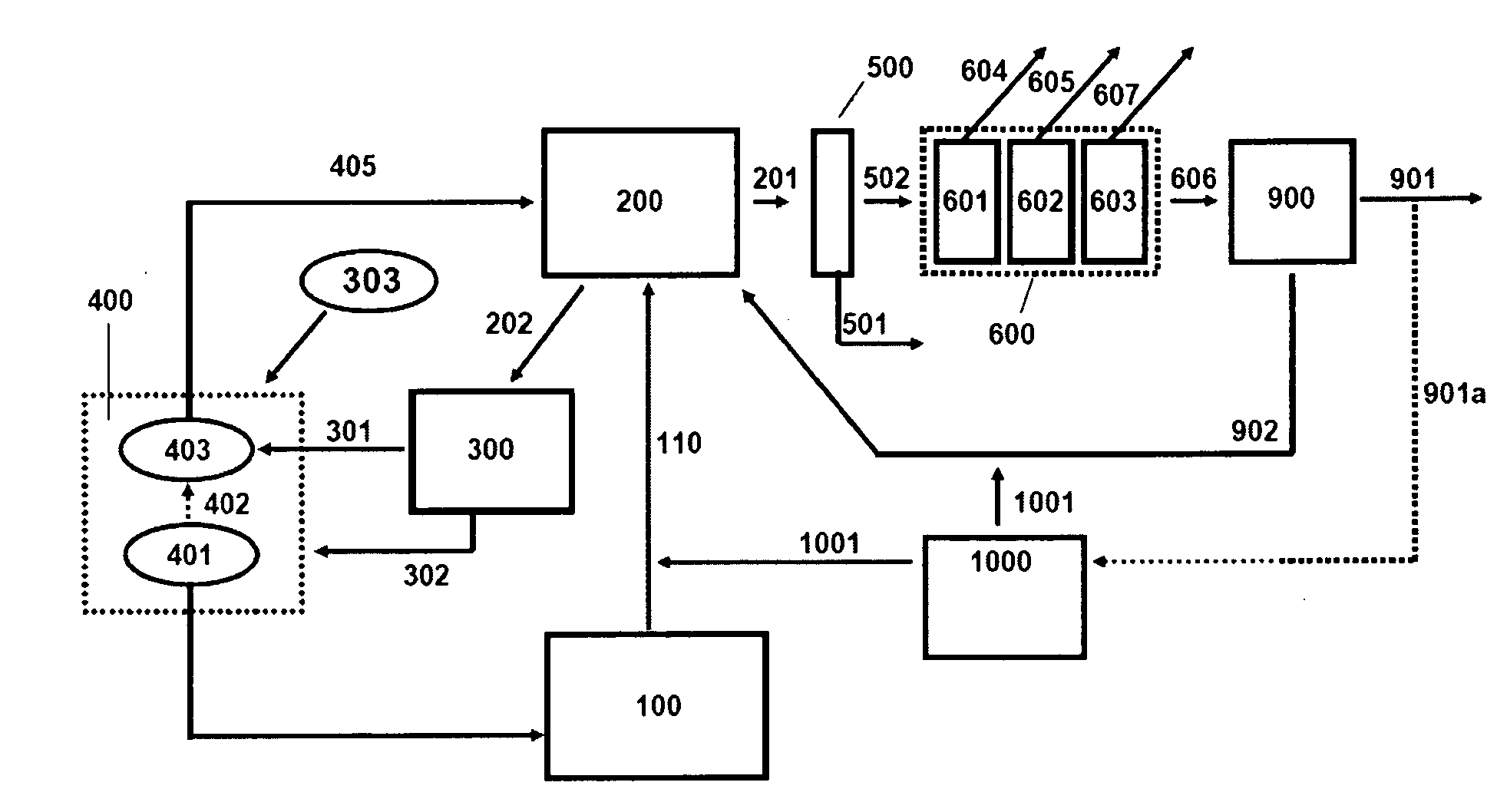

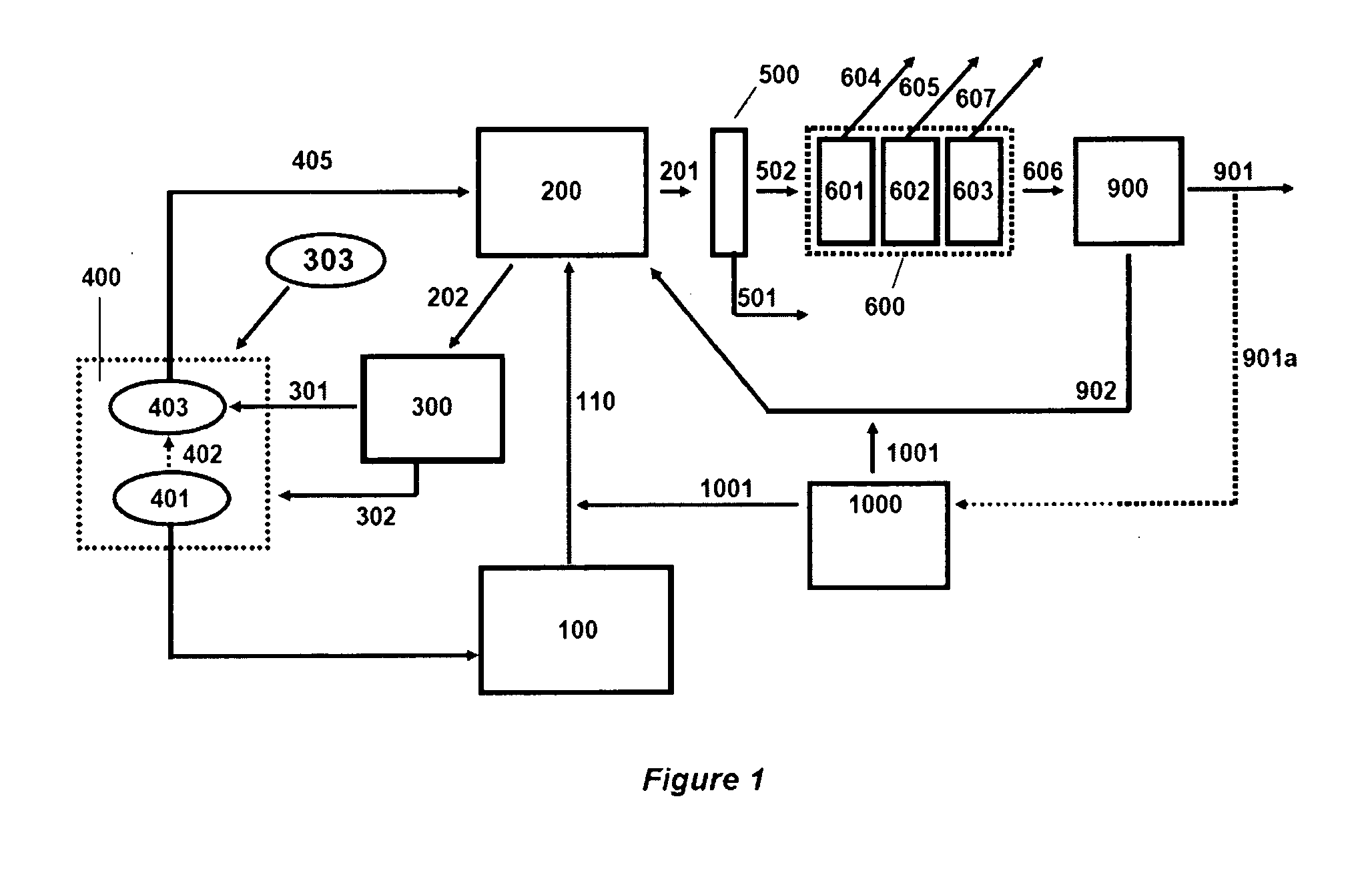

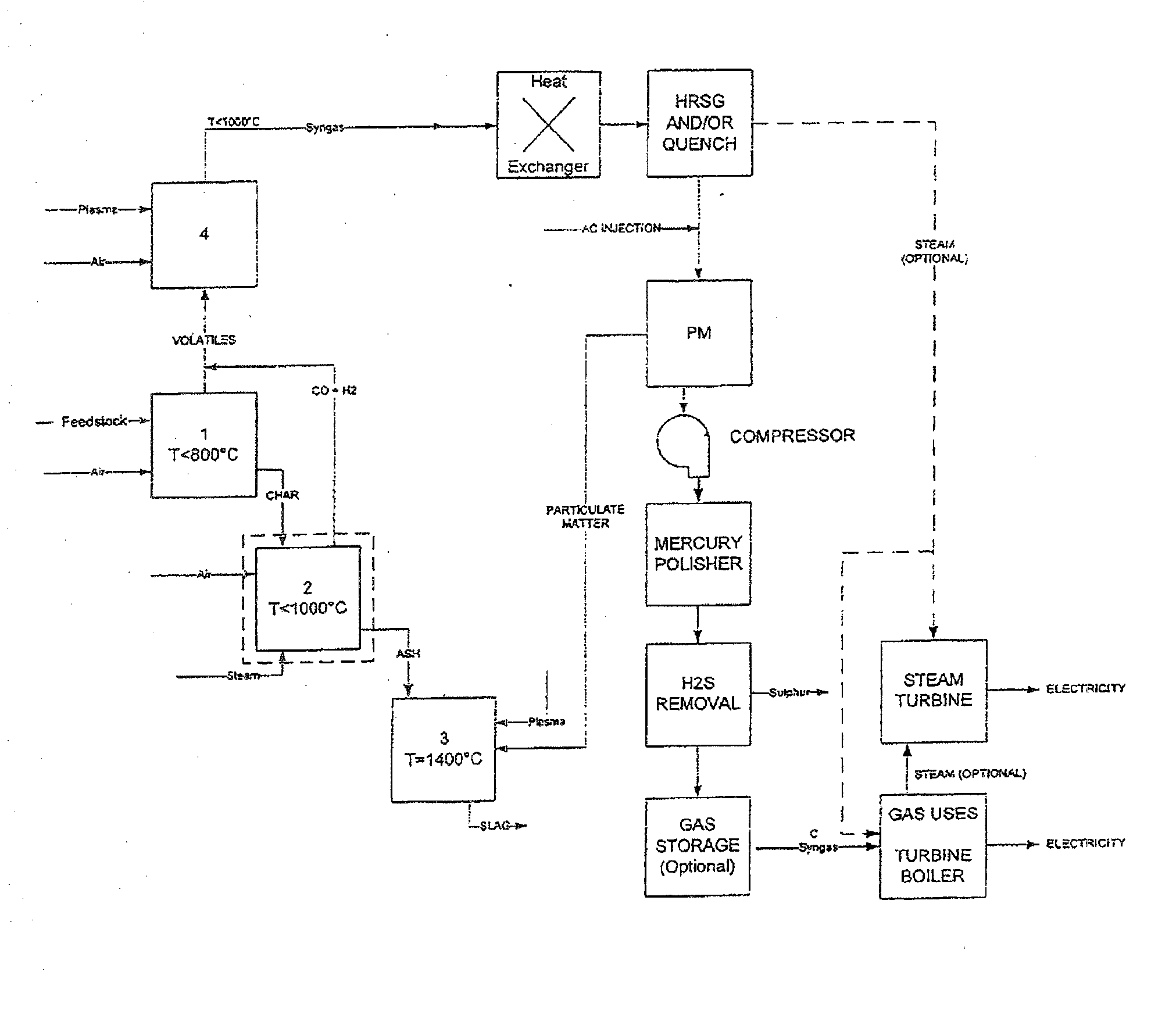

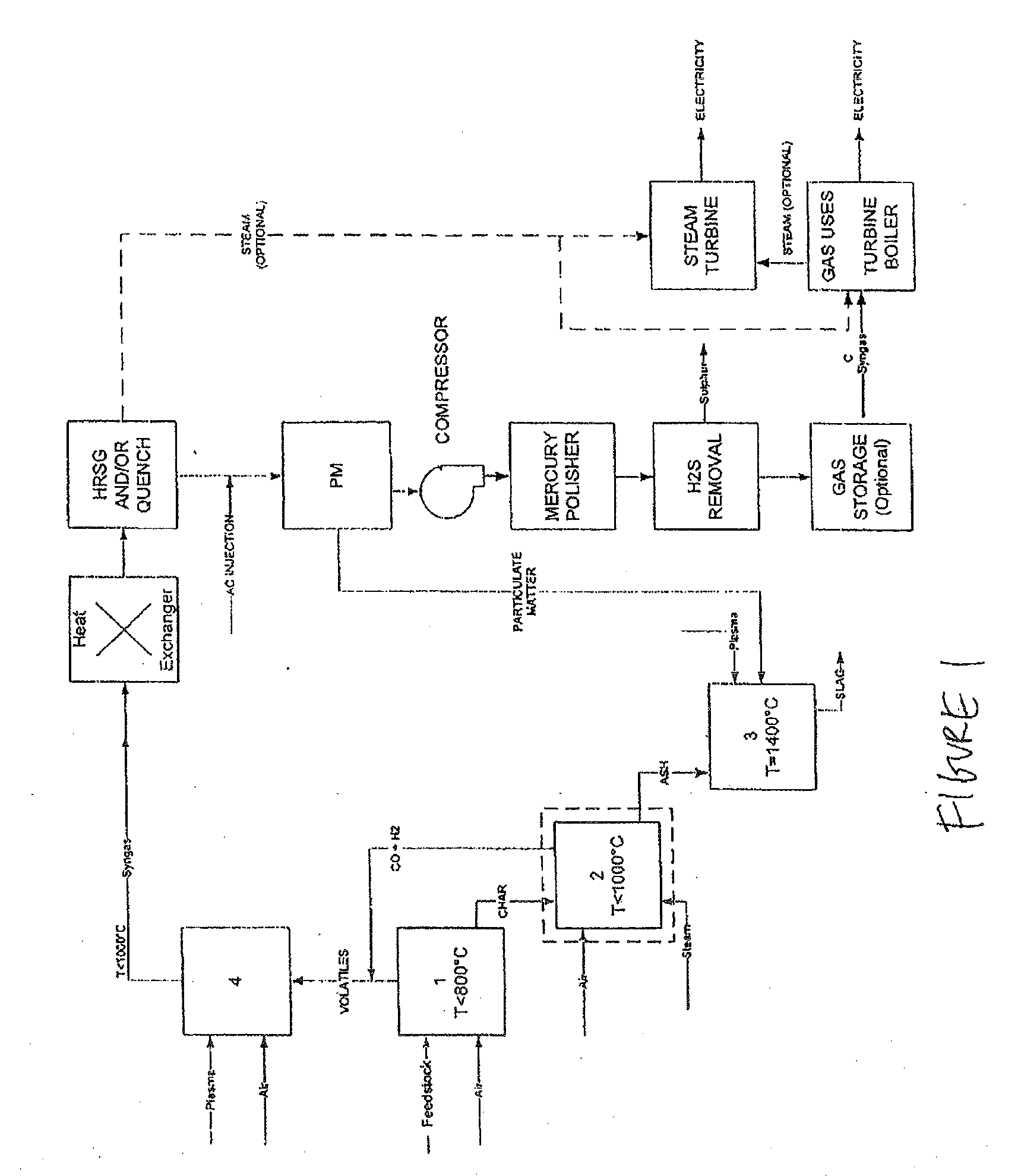

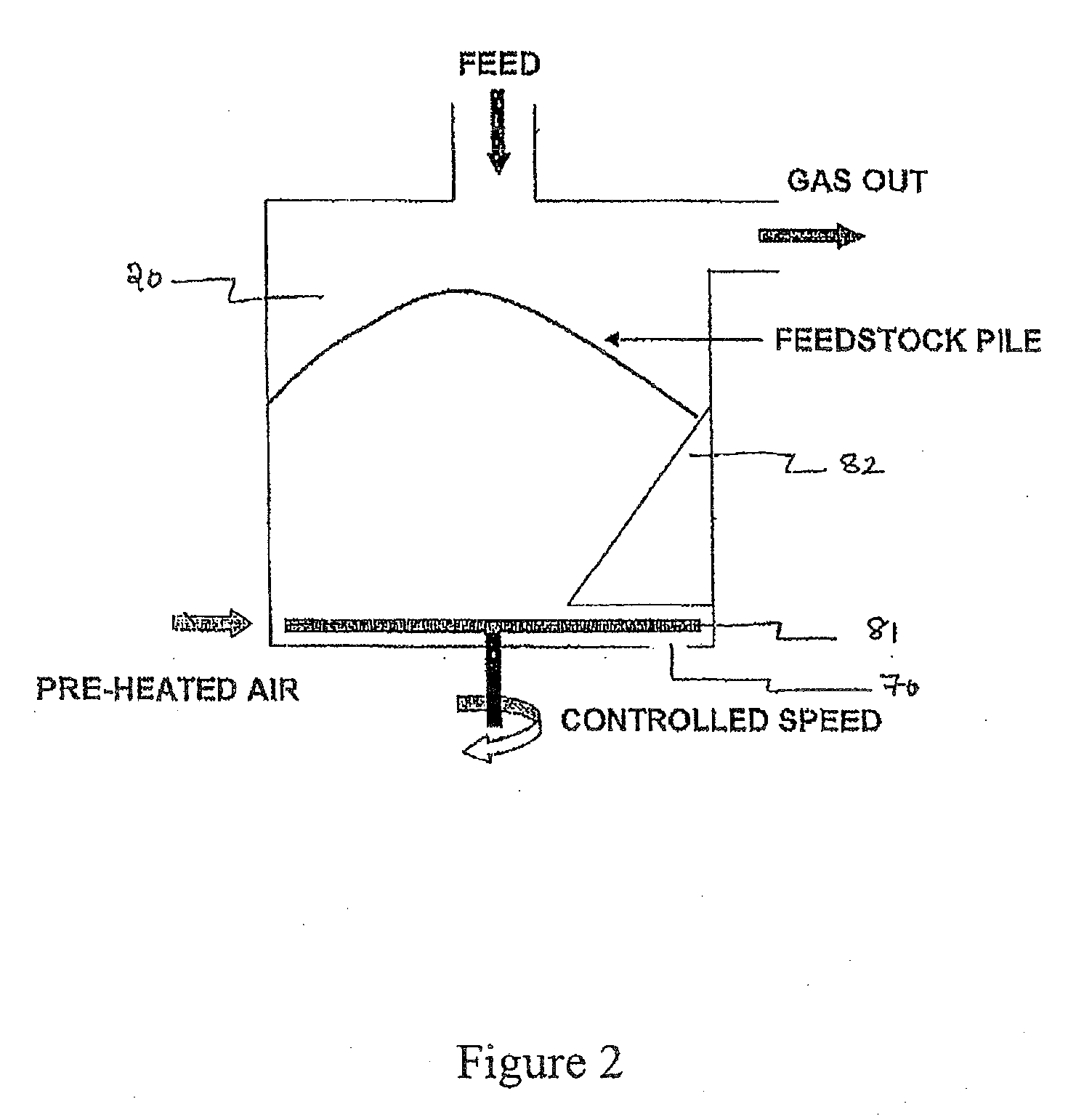

Gasification system with processed feedstock/char conversion and gas reformulation

ActiveUS20110036014A1Gasifier mechanical detailsEnergy based wastewater treatmentVitrificationSyngas

The invention provides a system designed for the complete conversion of carbonaceous feedstock into syngas and slag. The system comprises a primary chamber for the volatilization of feedstock generating a primary chamber gas (an offgas); a secondary chamber for the further conversion of processed feedstock to a secondary chamber gas (a syngas) and a residue; a gas-reformulating zone for processing gas generated within one or more of the chambers; and a melting chamber for vitrifying residue. The primary chamber comprises direct or indirect feedstock additive capabilities in order to adjust the carbon content of the feedstock. The system also comprises a control system for use with the gasification system to monitor and regulate the different stages of the process to ensure the efficient and complete conversion of the carbonaceous feedstock into a syngas product.

Owner:PLASCO CONVERSION TECH INC

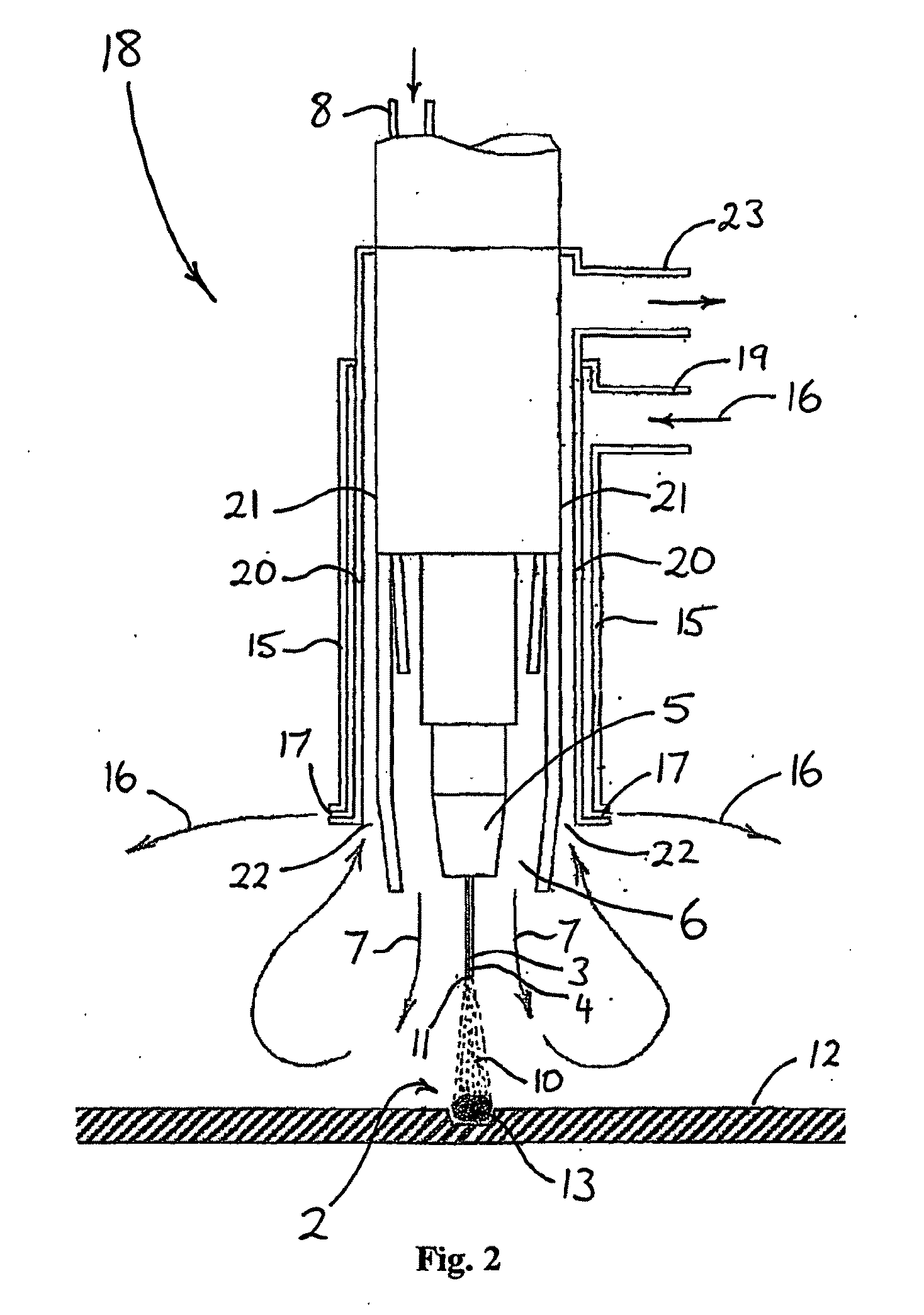

Apparatus and method for welding

InactiveUS20100276396A1Improve smoke extraction efficiencyFine-tune fume extraction efficiencyShielding gas supply/evacuation devicesDirt cleaningShielding gasCarbon Dioxide / Helium

The present invention relates to arc welding torch and a method of extracting fume gas from a welding site. The torch comprises a metal electrode and at least one shield gas port adapted to direct a shield gas curtain around the metal electrode and a welding site. At least one shroud gas port is spaced radially outward from the shield gas port and adapted to impart to an exiting shroud gas a radially outward component of velocity. Fume gas is preferably extracted from a position radially intermediate the shield gas curtain and the shroud gas curtain.

Owner:COOPER PAUL +2

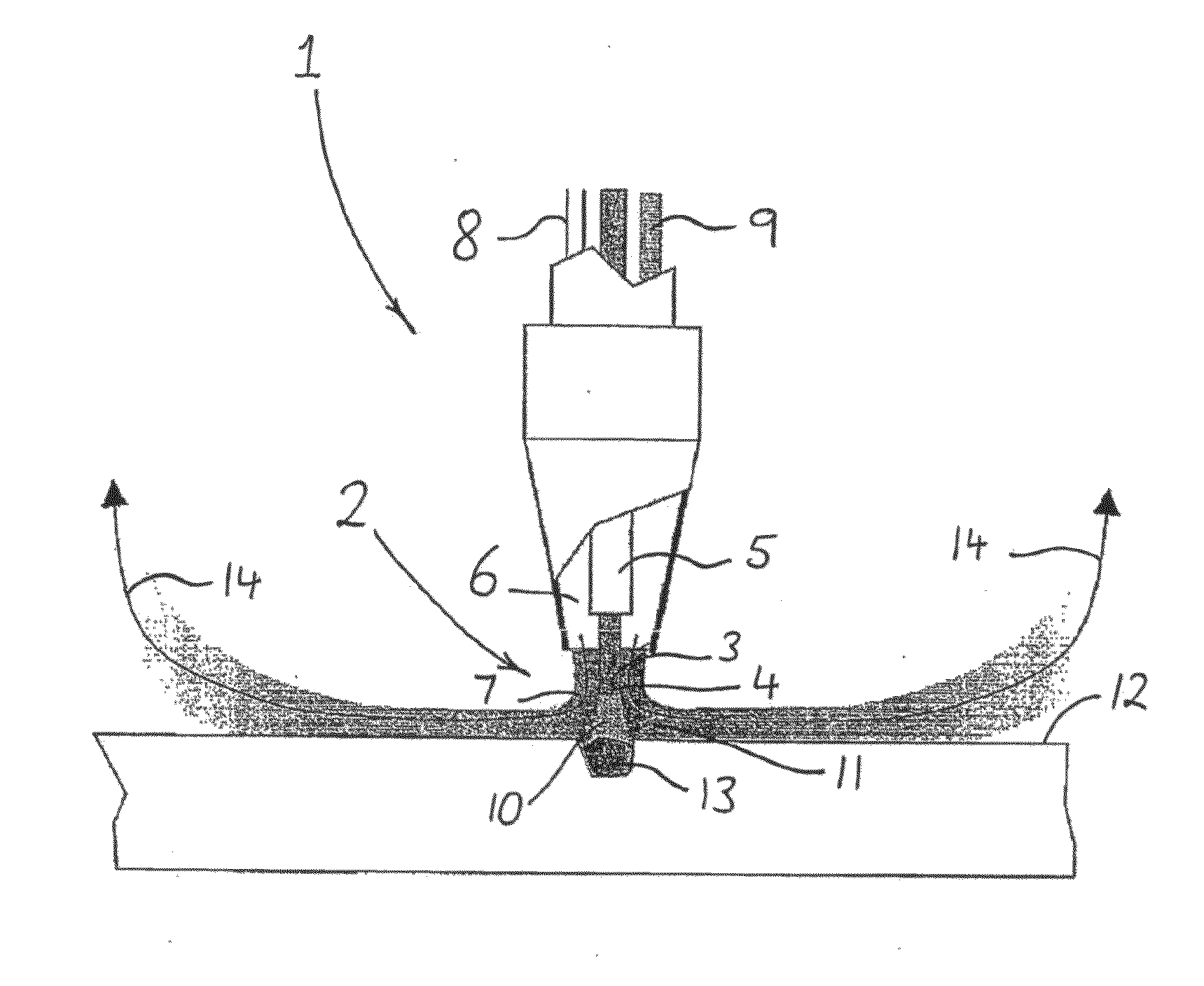

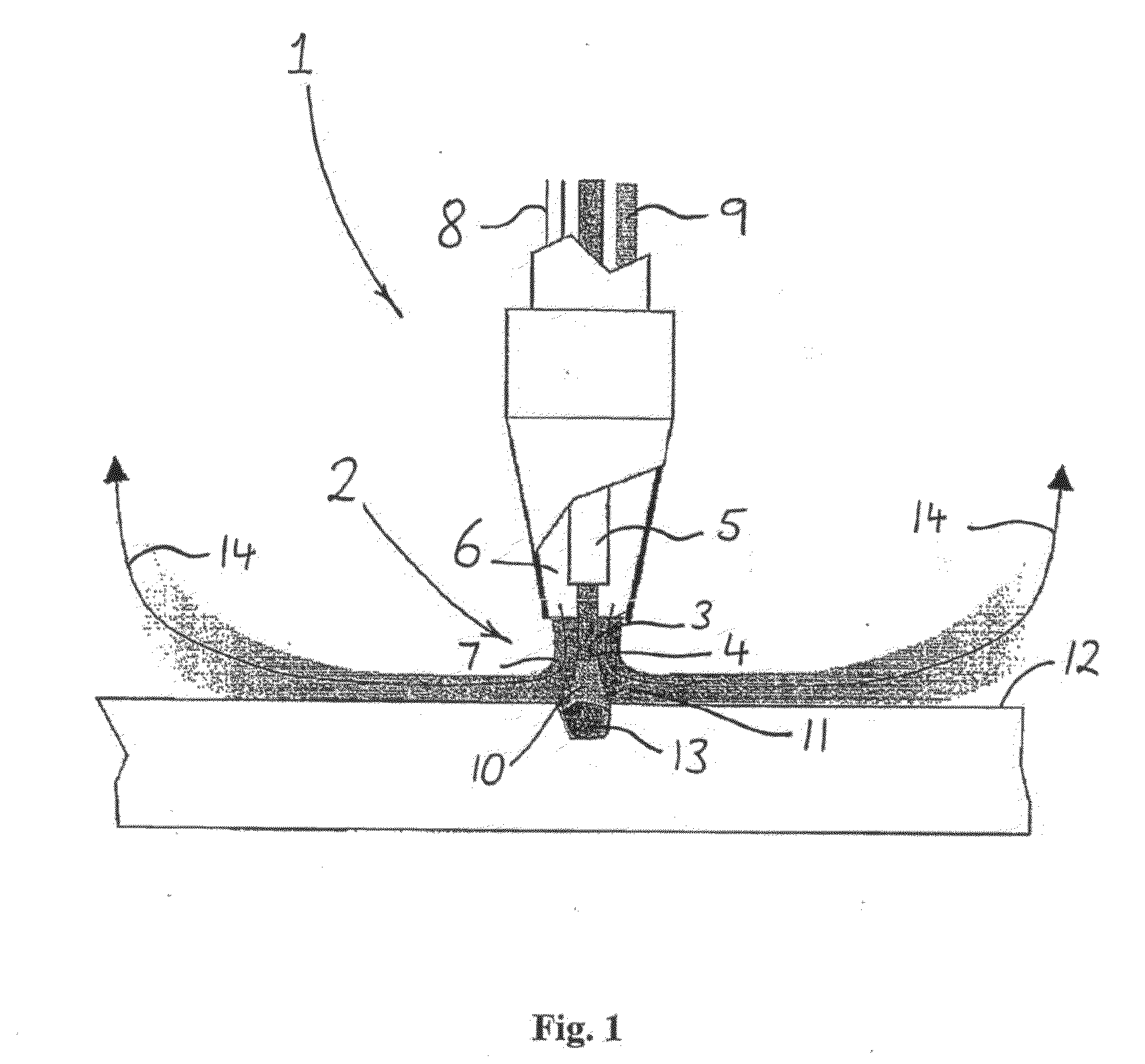

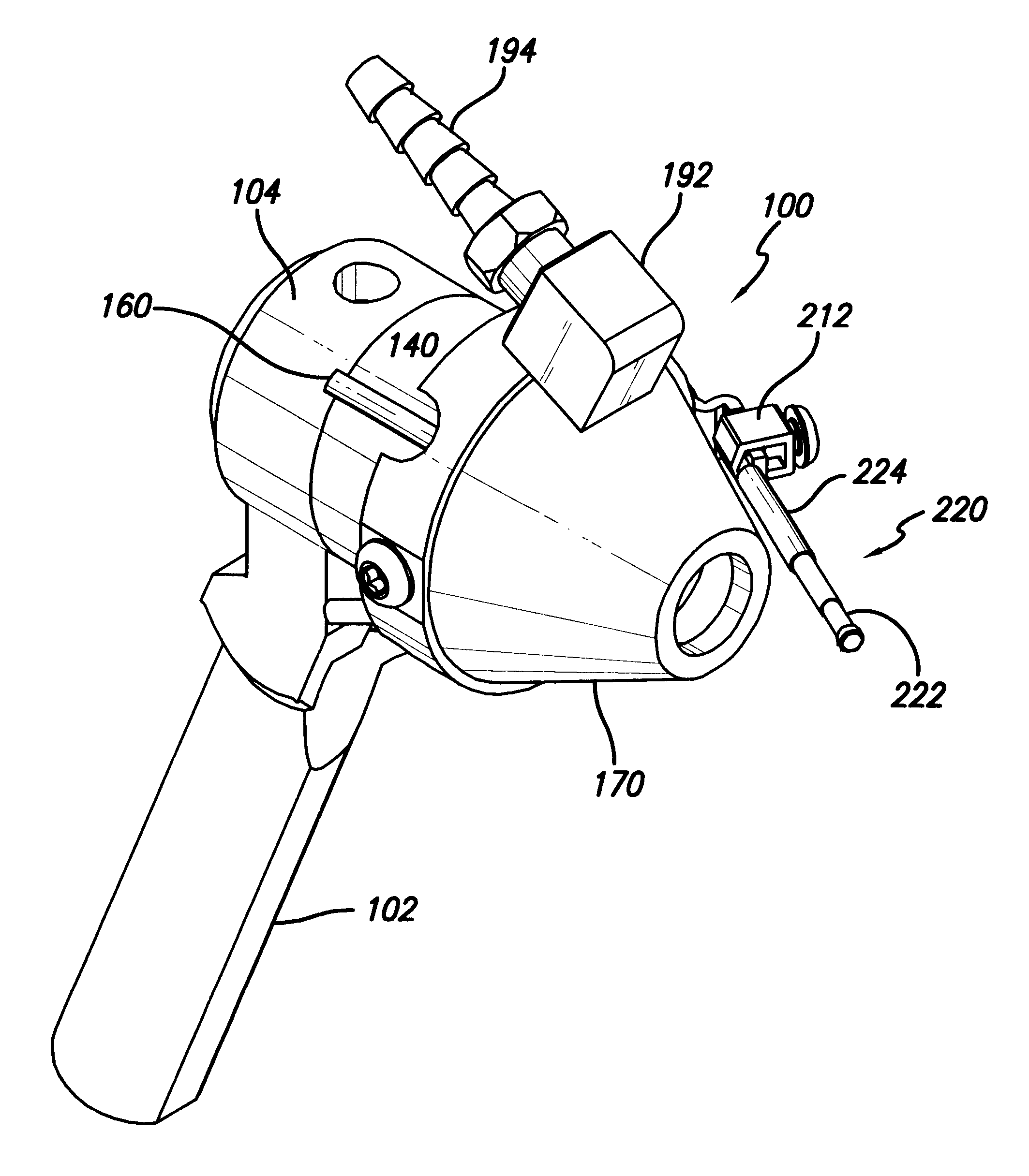

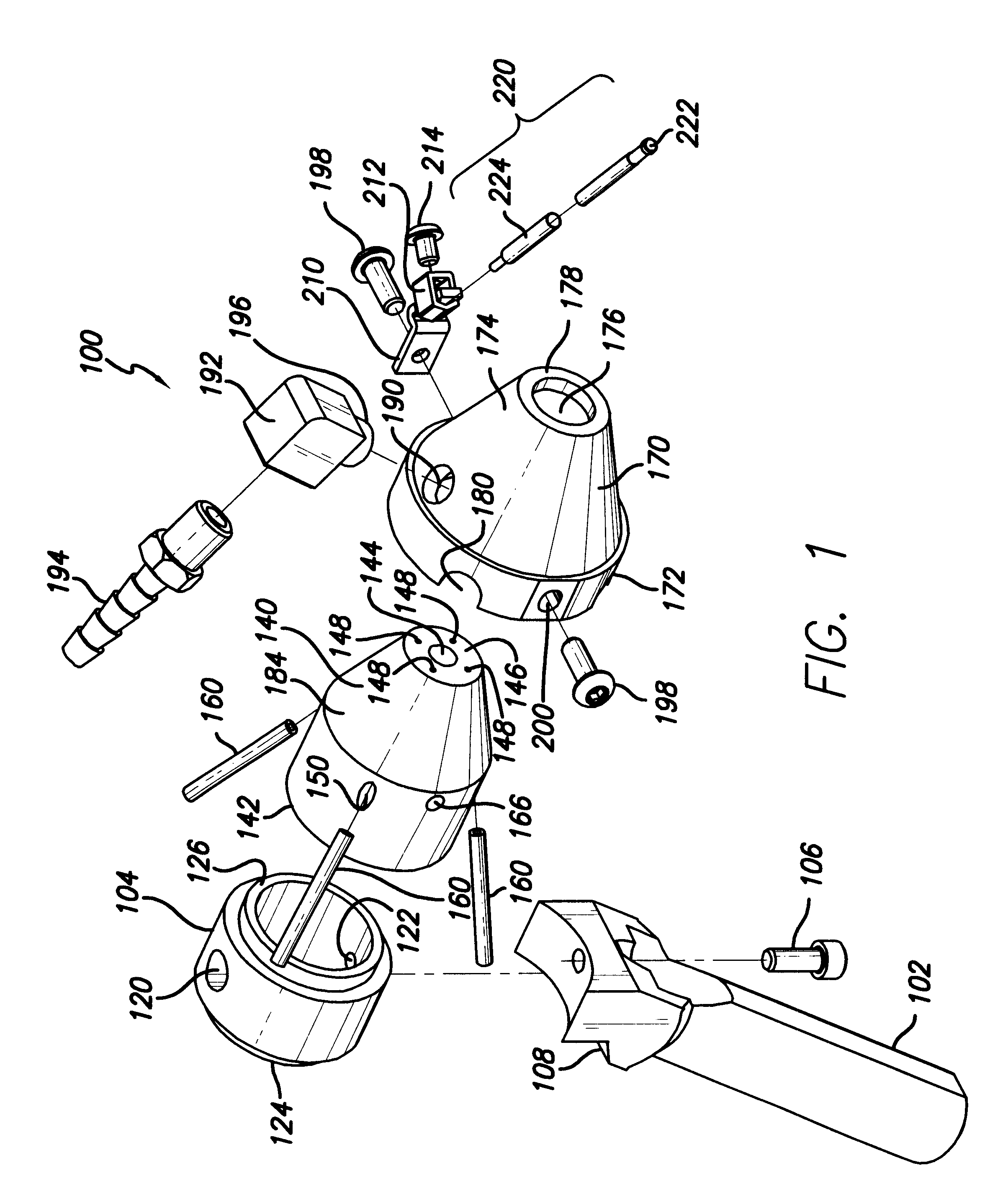

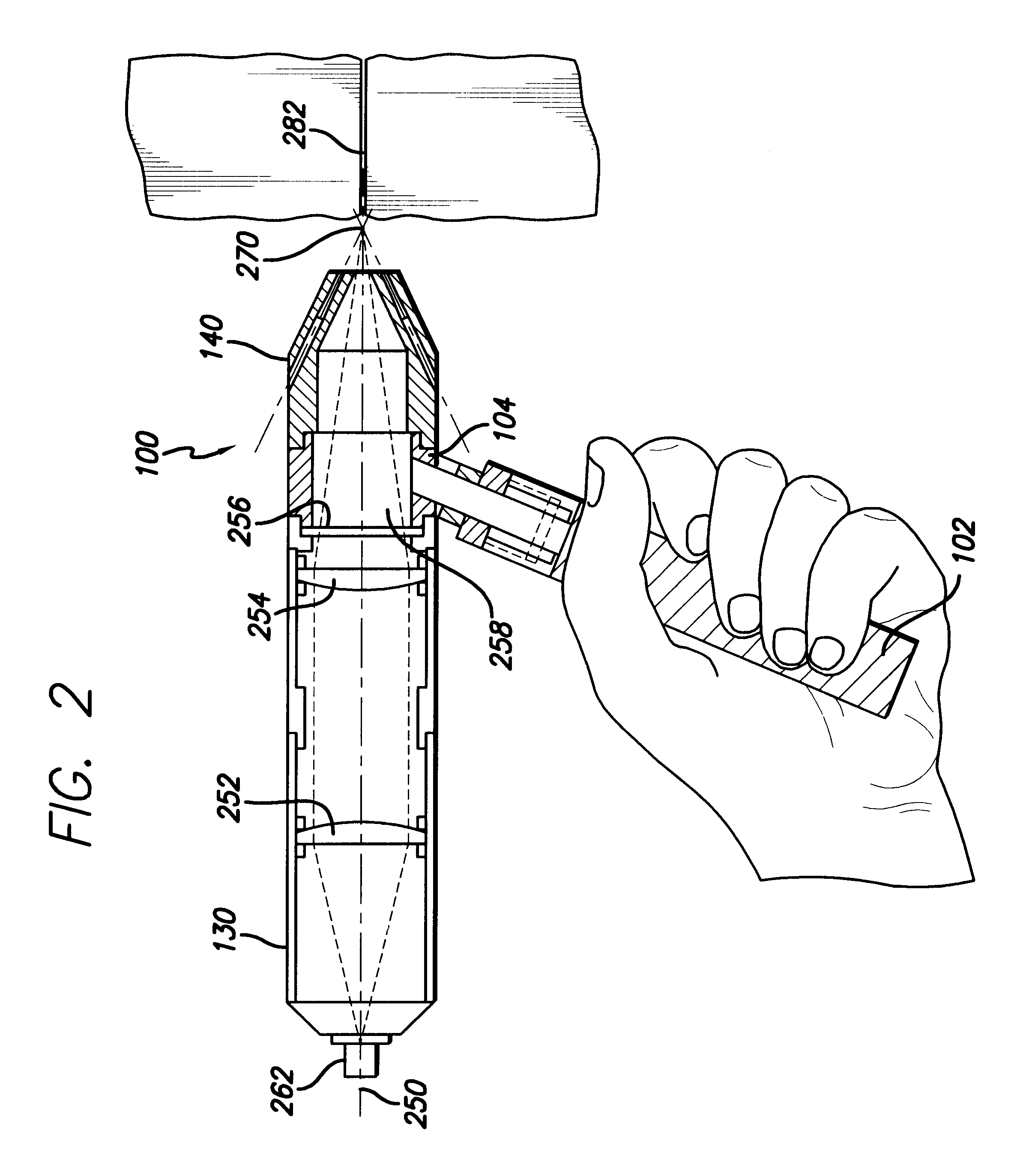

Hand held powder-fed laser fusion welding torch

A novel and inventive hand held powder-fed laser fusion welding torch providing manual flexibility for laser welding with powder-fed material. The hand held laser includes a body, handle, and nozzle assembly. The nozzle may be shrouded by a cover that is slightly spaced apart from the nozzle. The gap between the two may provide space through which inert gas may flow. Laser light from a remote source shines through the nozzle's central aperture. The nozzle aperture may be circumscribed by powder channel outlets aligned upon a working focal point coincident with the laser beam to treat a workpiece. A proximity sensor may enable selective welding torch operation according to the presence of a workpiece.

Owner:HONEYWELL INT INC

Integral joining

InactiveUS20050126680A1Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

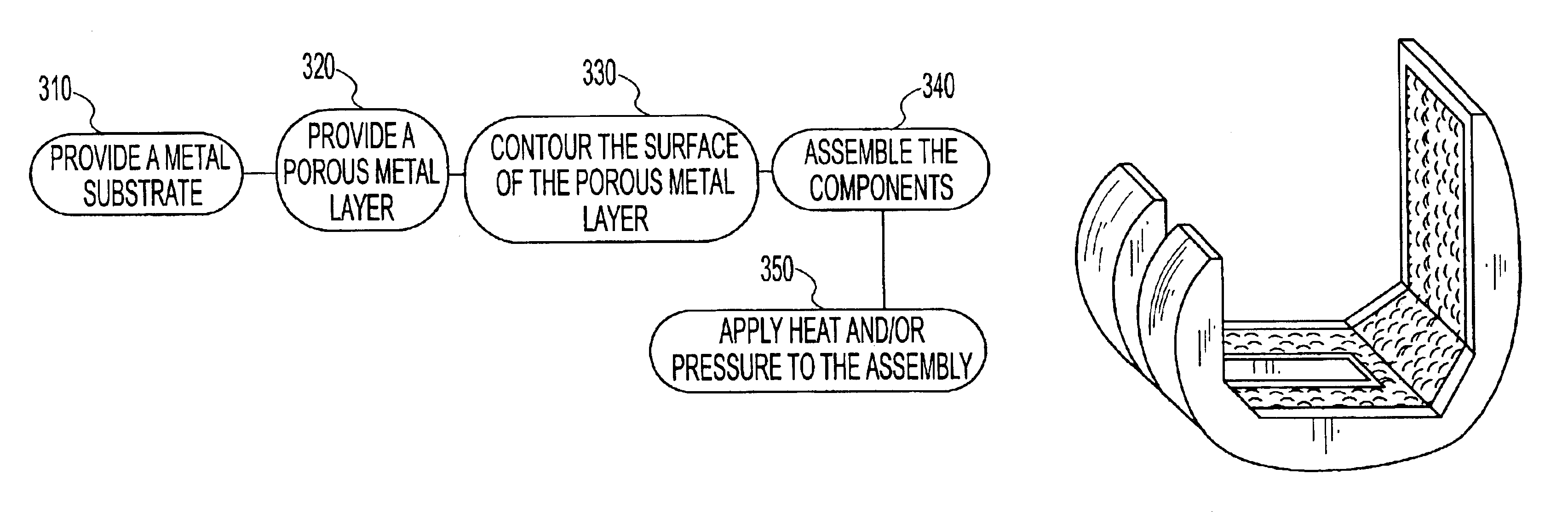

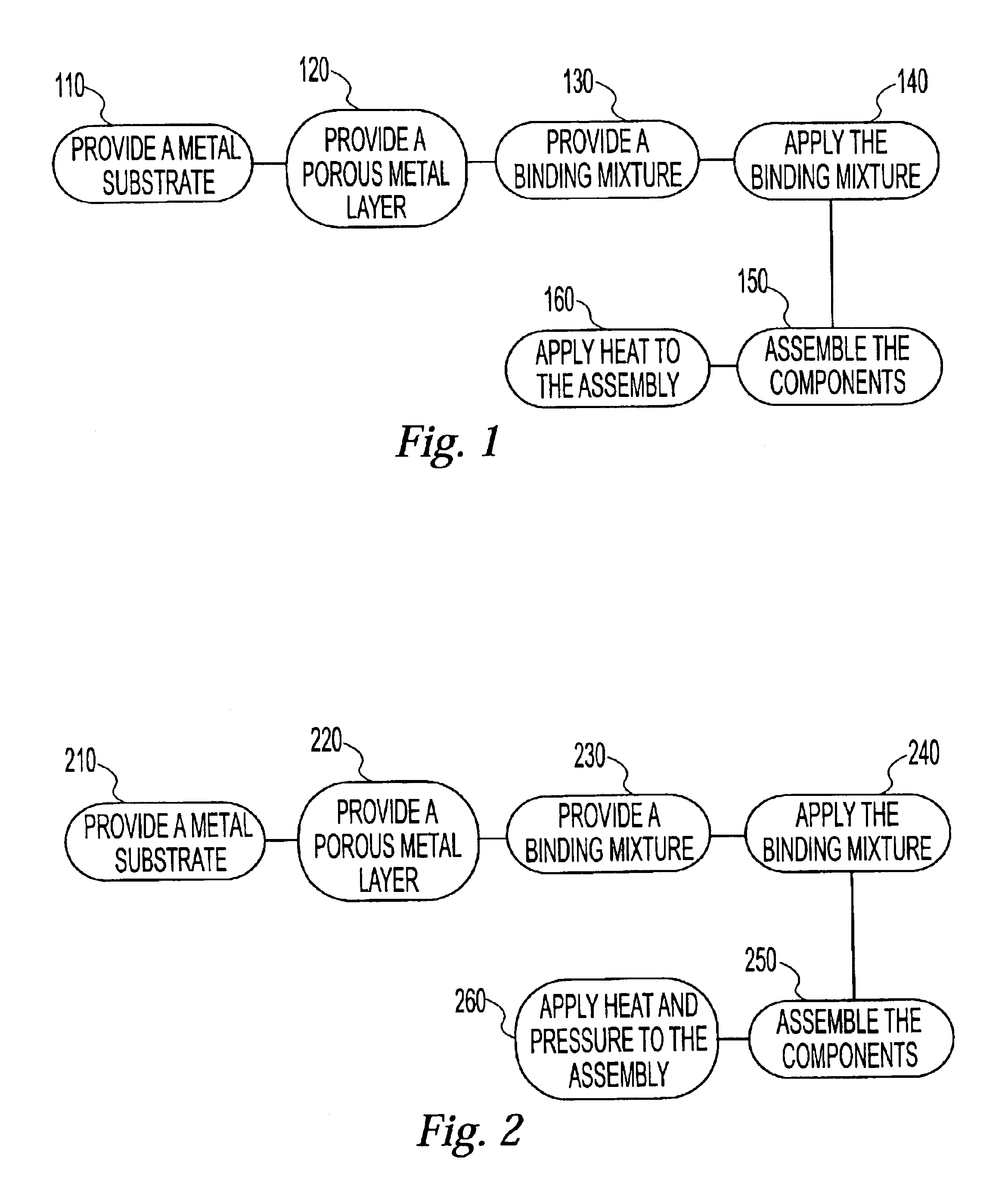

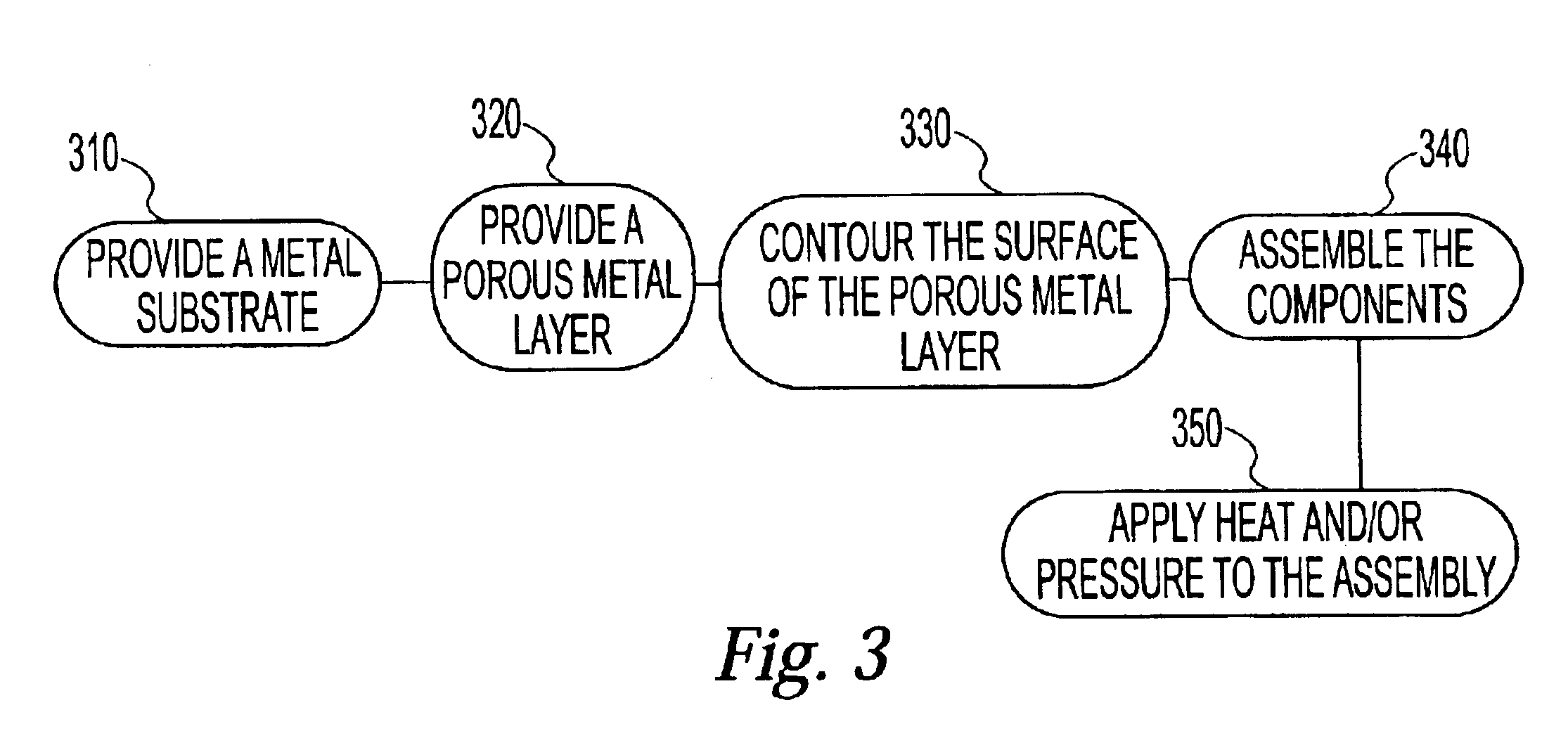

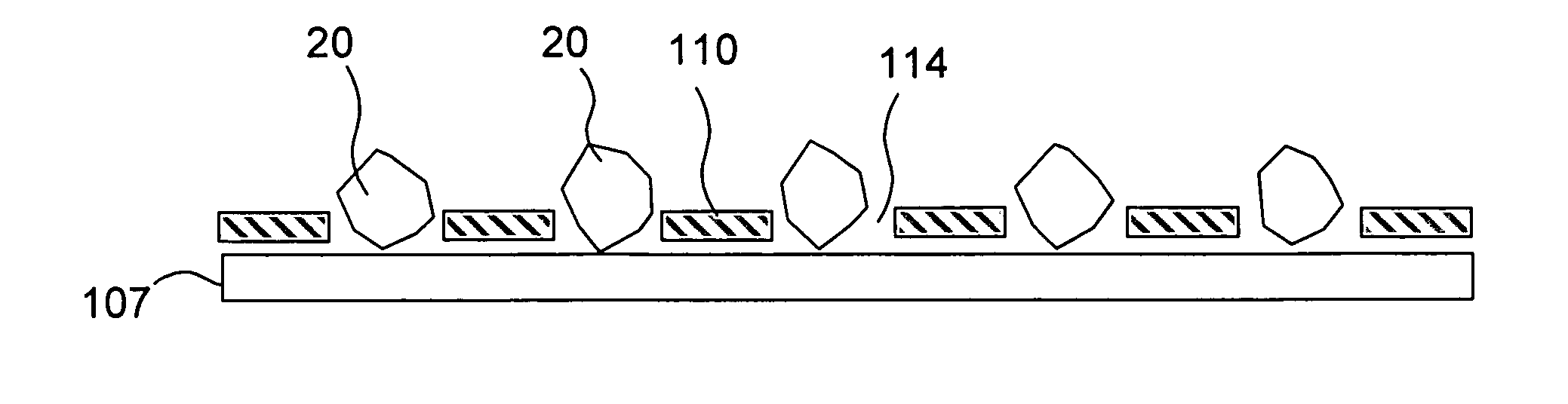

Method for attaching a porous metal layer to a metal substrate

InactiveUS6945448B2Increase resistanceHigh strengthImpression capsPretreated surfacesPorous layerSurgical implant

A method for attaching a porous metal layer to a dense metal substrate, wherein the method is particularly useful in forming orthopedic implants such as femoral knee components or acetabular cups. The method, in one embodiment thereof, comprises providing a structured porous layer; providing a dense metal substrate; providing a binding mixture; applying the binding mixture to the exterior of the substrate; placing the porous layer against the substrate such that the binding mixture is disposed there between forming an assembly; and heat treating the assembly to metallurgically bond the porous layer to the substrate.

Owner:ZIMMER TECH INC

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

Welding device with integral user interface

InactiveUS20110220616A1Arc welding apparatusWelding/cutting media/materialsGraphical user interfaceWelding power supply

Welding torch assemblies including a torch body having a user interface module integrally formed therewith, a welding nozzle, and a torch lead assembly are provided. The user interface module may enable a user to control one or more parameters of a welding operation. The welding nozzle may be coupled to a first end of the torch body. The torch lead assembly may be coupled to a second end of the torch body opposite the first end and may include a weld power lead and a weld control lead.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com