Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1056 results about "Selective laser sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to Selective Laser Melting (SLM); the two are instantiations of the same concept but differ in technical details. Selective laser melting (SLM) uses a comparable concept, but in SLM the material is fully melted rather than sintered, allowing different properties (crystal structure, porosity, and so on). SLS (as well as the other mentioned AM techniques) is a relatively new technology that so far has mainly been used for rapid prototyping and for low-volume production of component parts. Production roles are expanding as the commercialization of AM technology improves.

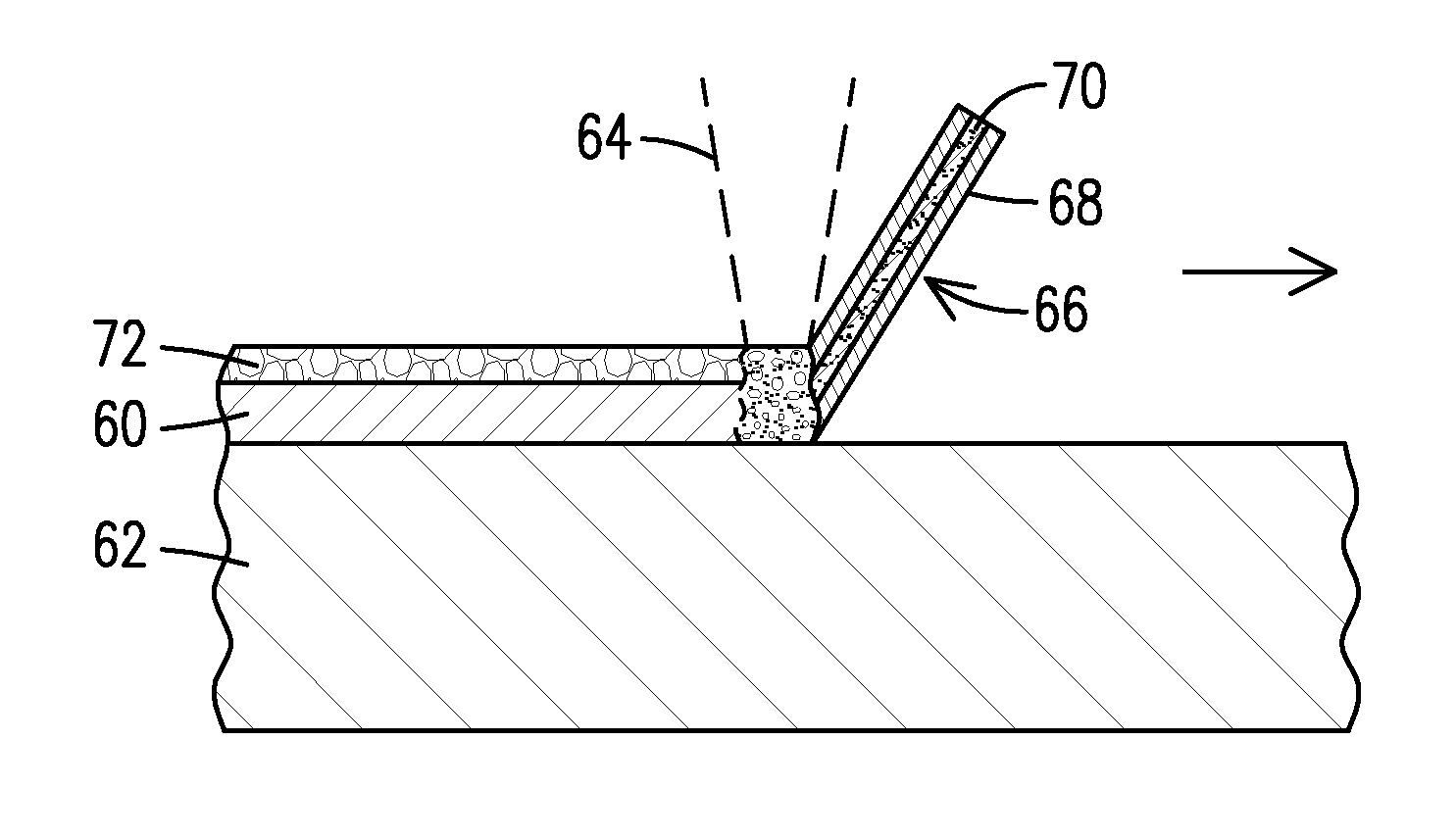

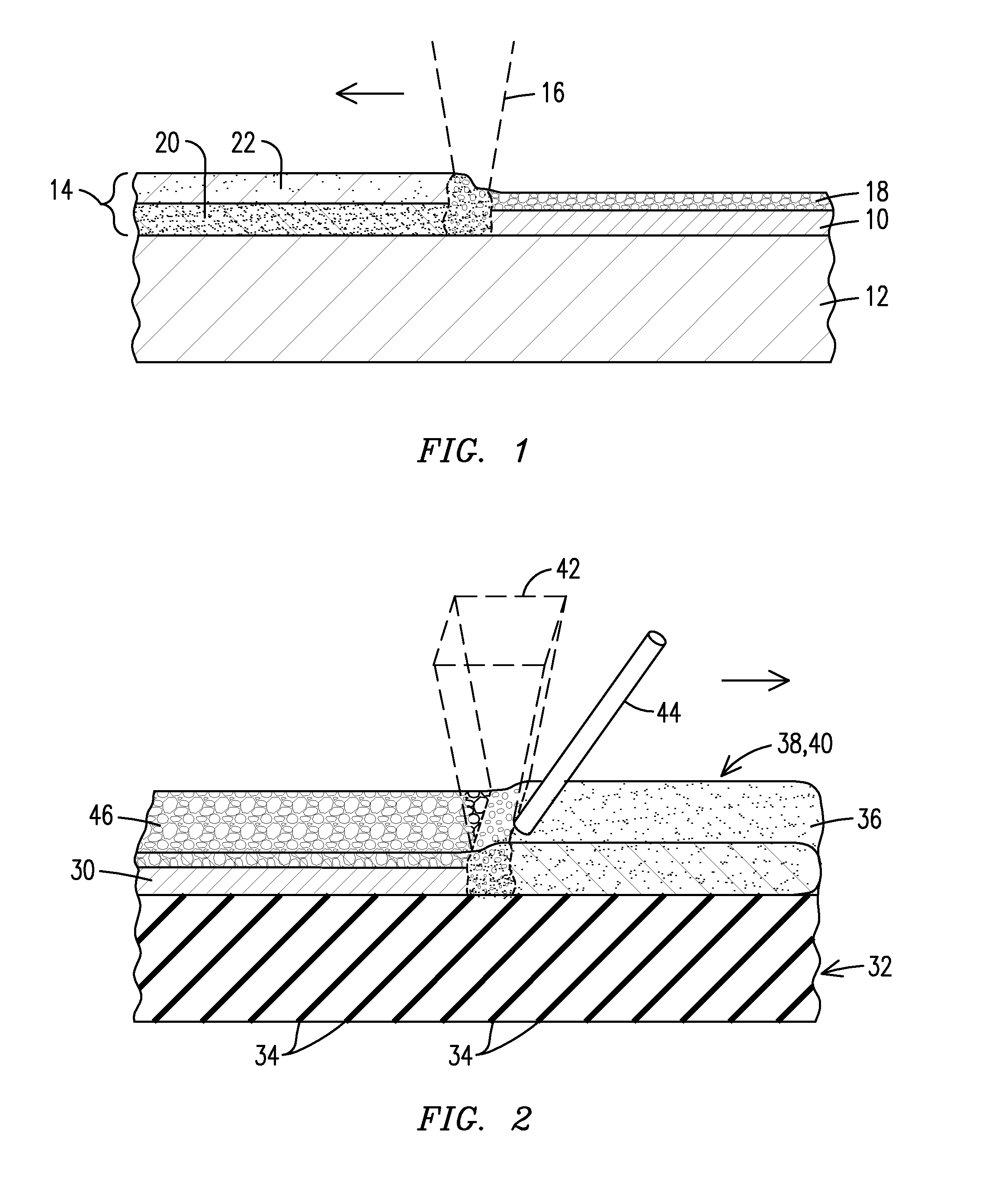

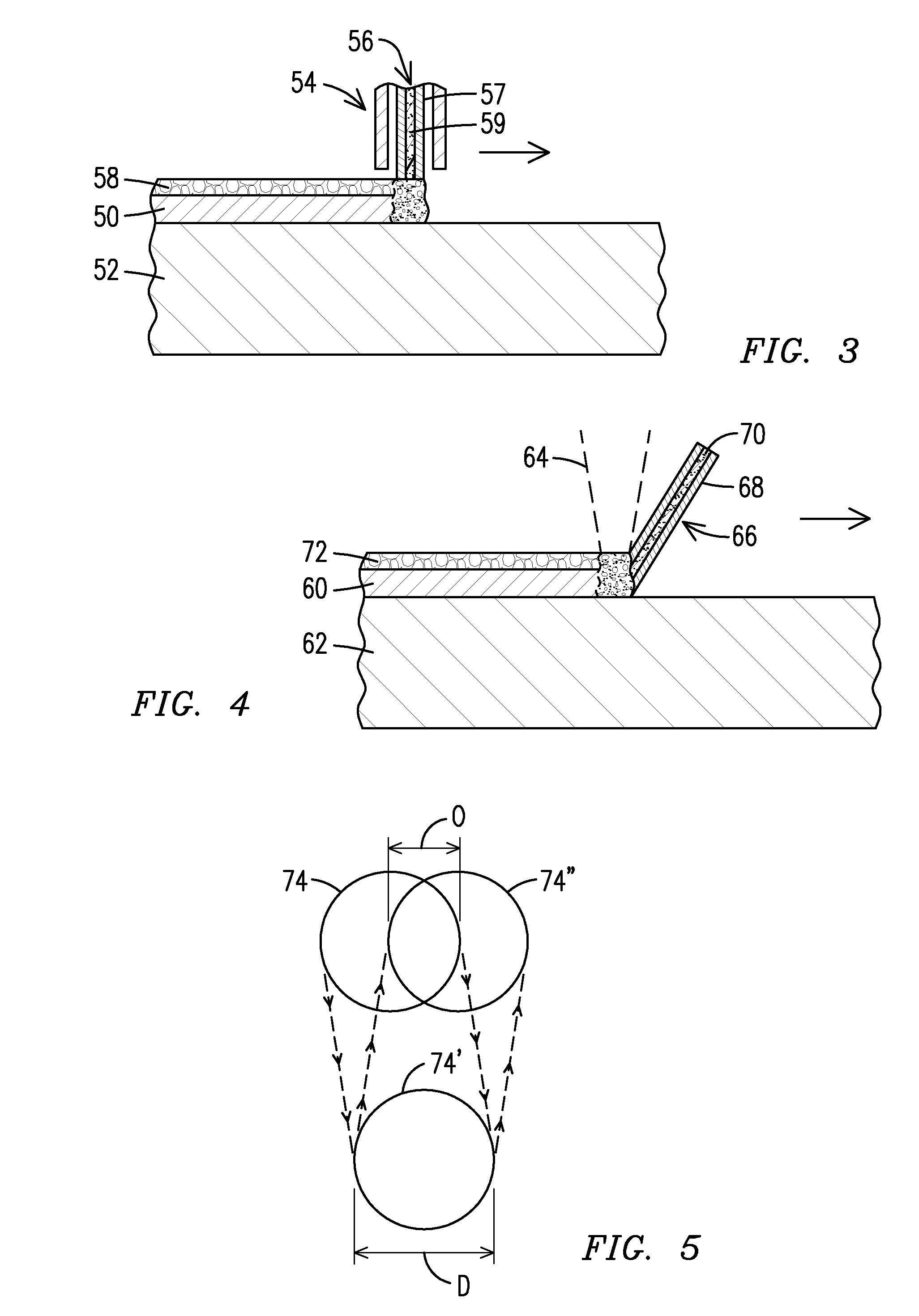

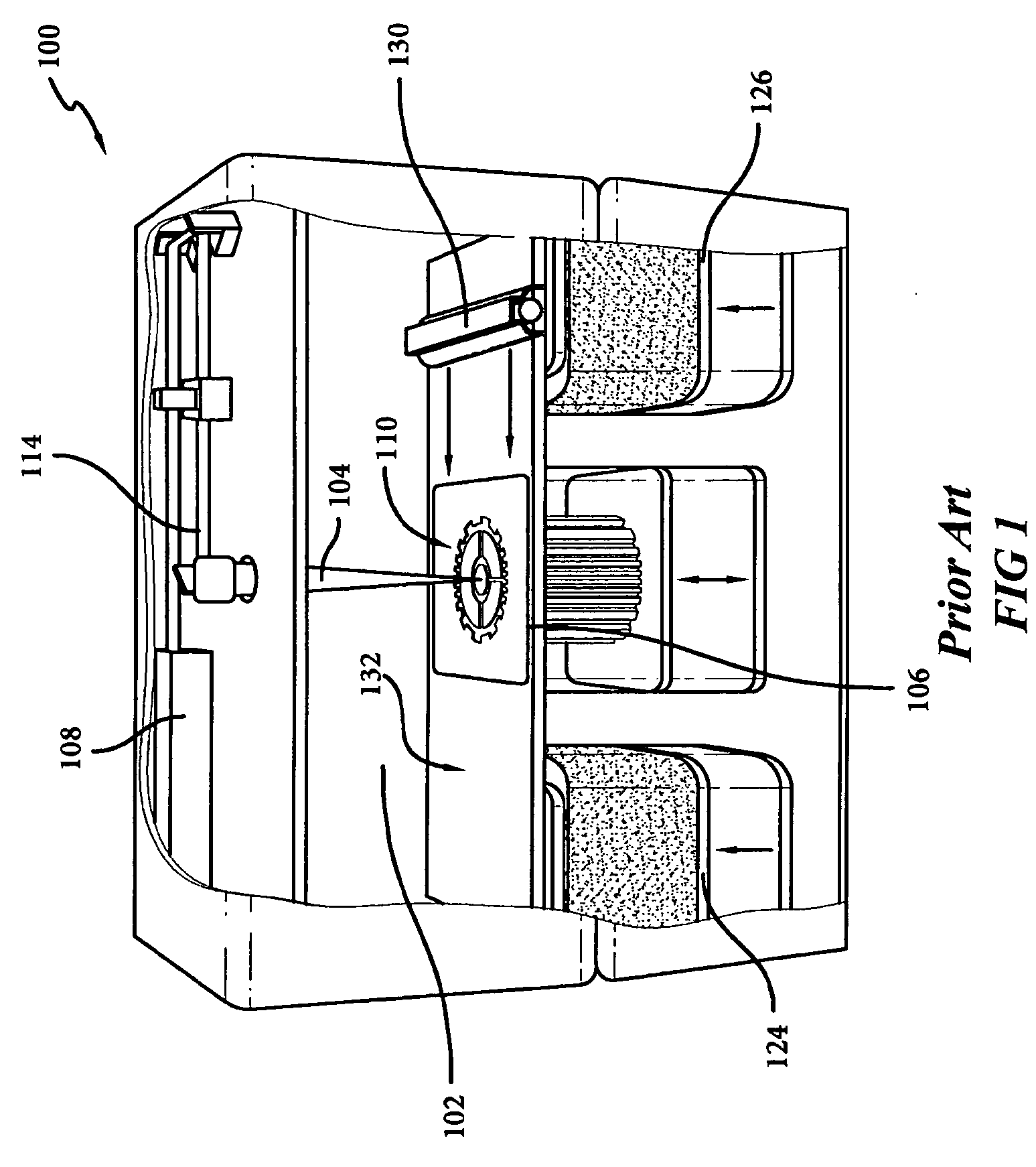

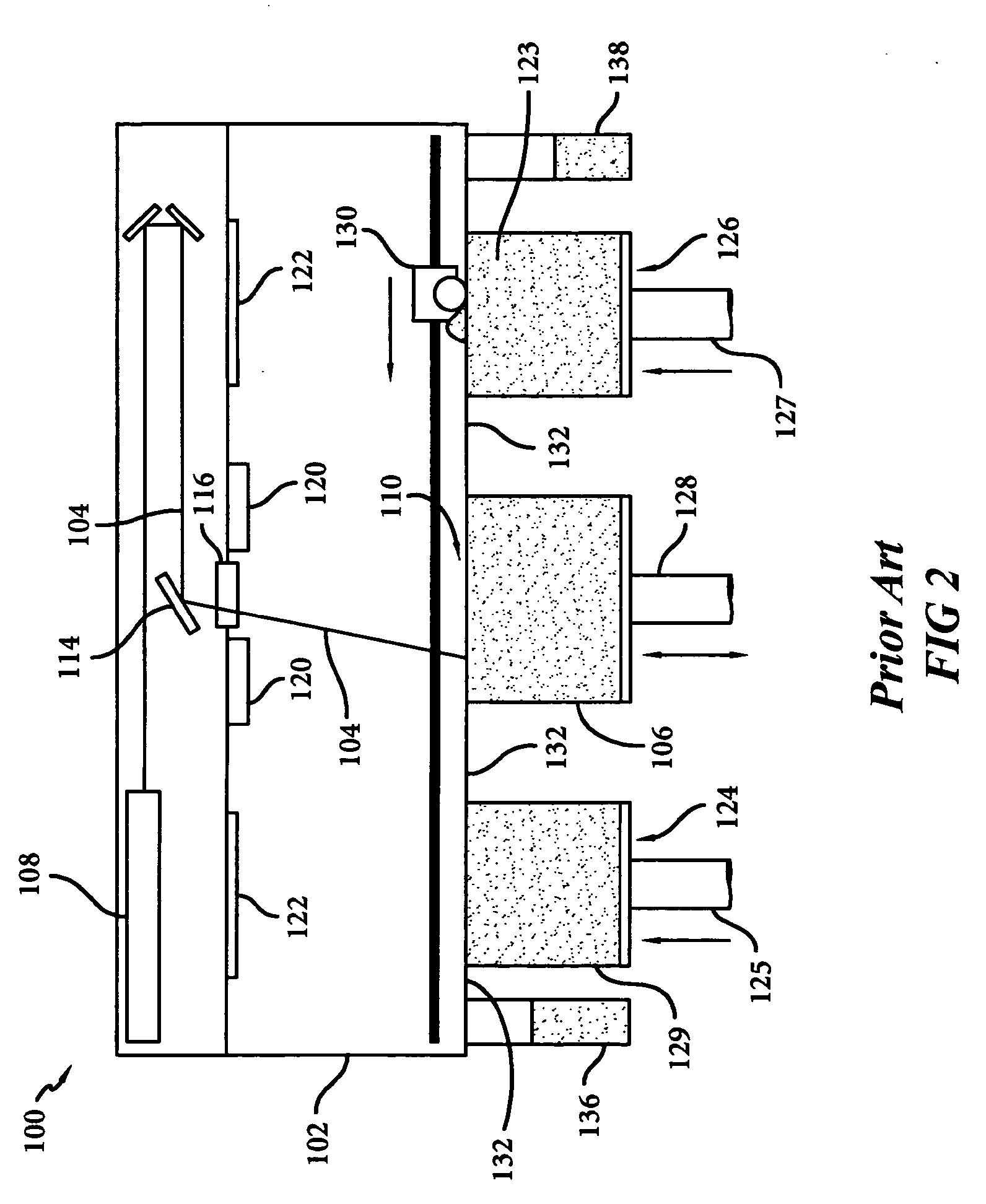

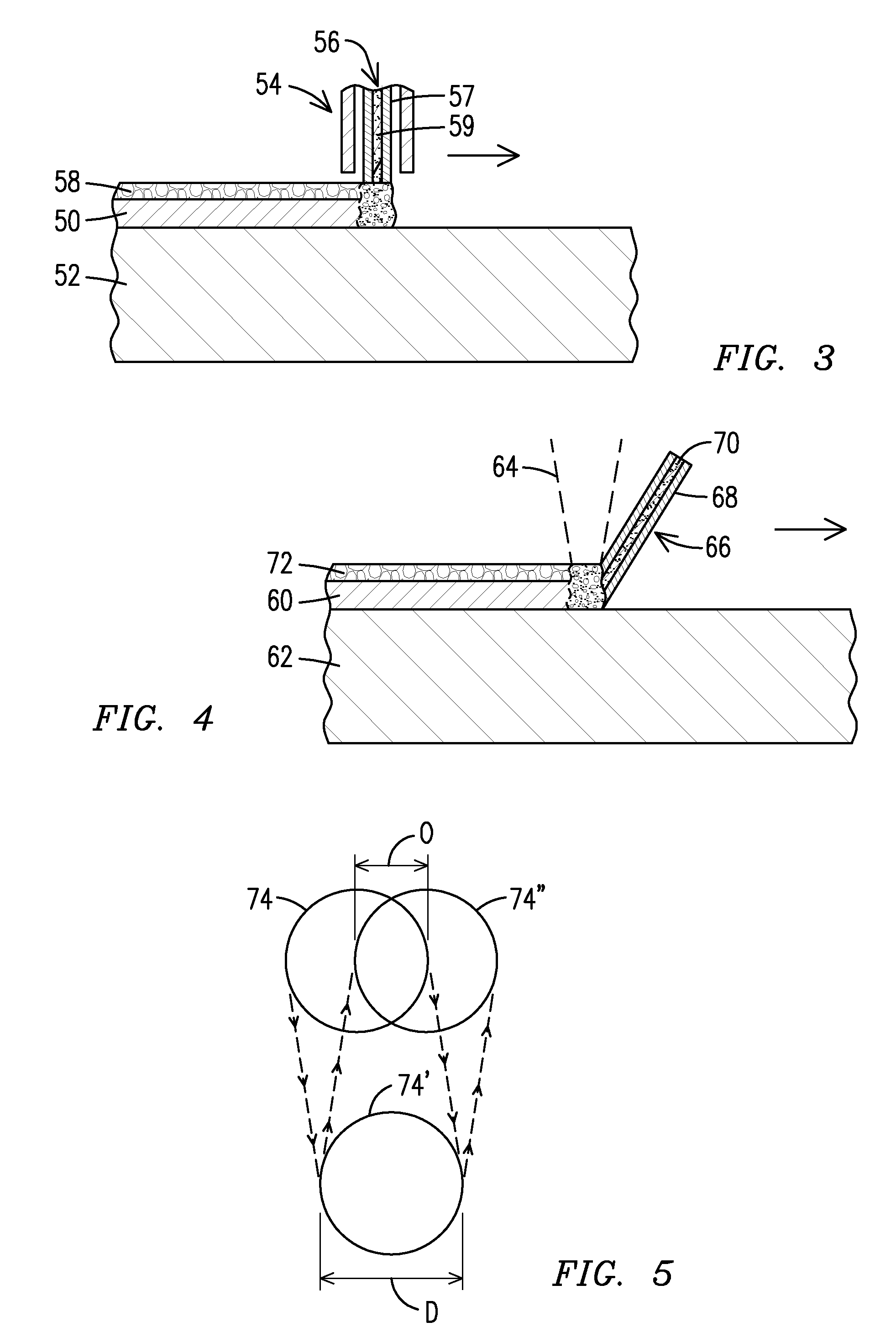

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

Laser sinter powder with a metal salt and a fatty acid derivative, process for its production, and moldings produced from this laser sinter powder

InactiveUS20050027050A1Improve the immunityMaintain good propertiesAdditive manufacturing apparatusFibre treatmentSelective laser sinteringPolyamide

The present invention relates to a sinter powder composed of polyamide which also comprises metal salts of weak acids, in particular metal carbonates, and fatty acid derivatives, in particular fatty acid esters or fatty acid amides, to a process for laser sintering, and also to moldings produced from this sinter powder. The moldings formed using the powder of the invention have marked advantages in appearance and in surface finish when compared with conventional products, especially when recyclability in the selective laser sintering (SLS) process is taken into account. Moldings produced from recycled sinter powder of the invention moreover also have markedly improved mechanical properties when compared with moldings based on recycled conventional nylon-12 powders, in particular in terms of modulus of elasticity and tensile strain at break. These moldings also have a density approaching that of injection moldings.

Owner:EVONIK DEGUSSA GMBH

Laser-produced implants

ActiveUS8350186B2Additive manufacturing apparatusJoint implantsSelective laser sinteringPlastic surgery

A method of producing an orthopedic implant including the steps of building a flat open model of at least a portion of an implant. The flat open model may be built using a selective laser sinter process. The flat open model preferably includes at least one groove along either a first surface or a second surface of the model. Next a force may be applied to the flat open model at predetermined locations to thereby cause the model to bend and assume a shape similar to a desired result. The now bent model may be resurfaced by either applying additional material such that the bent flat open model assumes the shape of a desired implant or the bent open model may be snap fit to an additional element.

Owner:UNIV OF LIVERPOOL +2

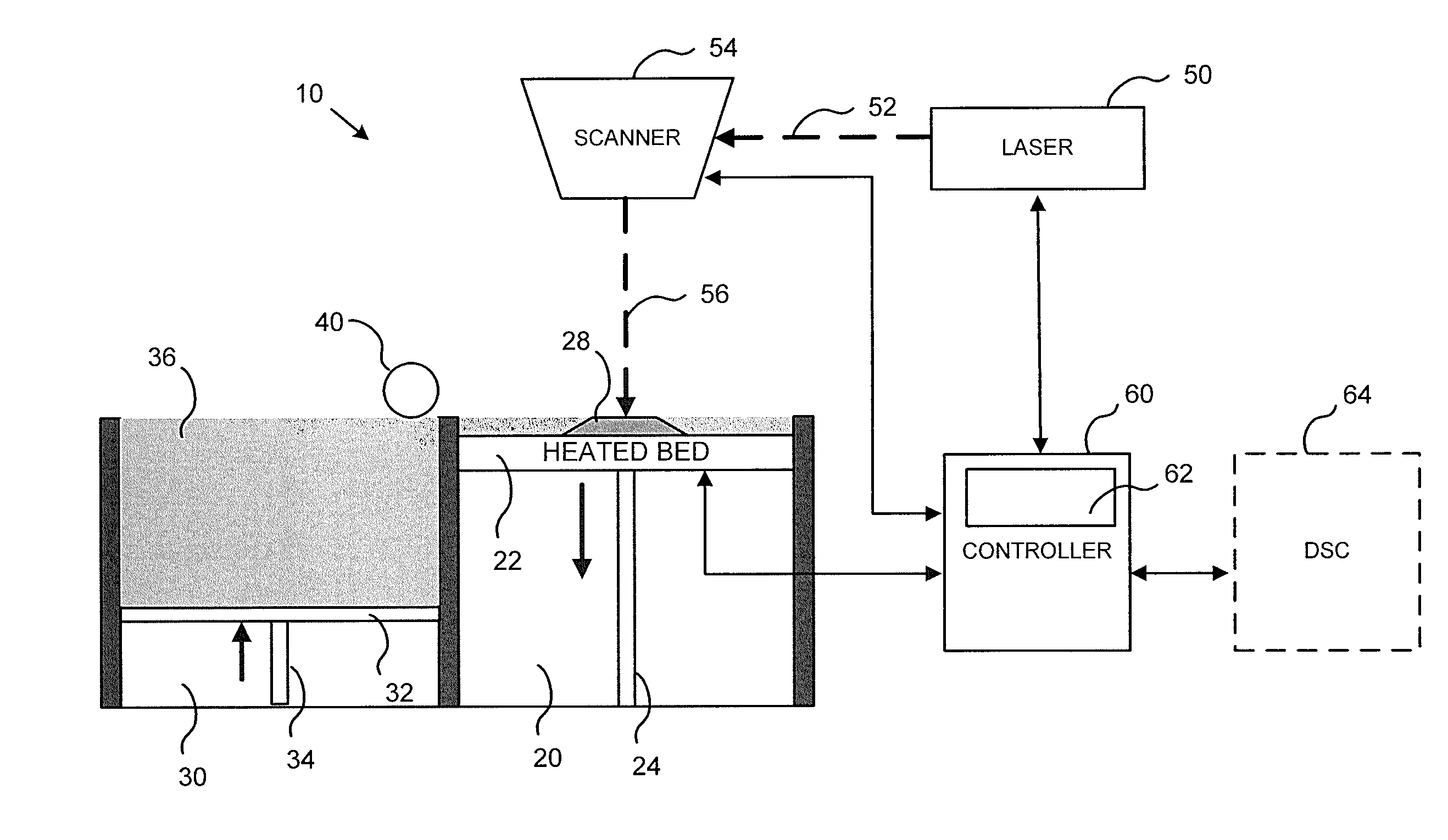

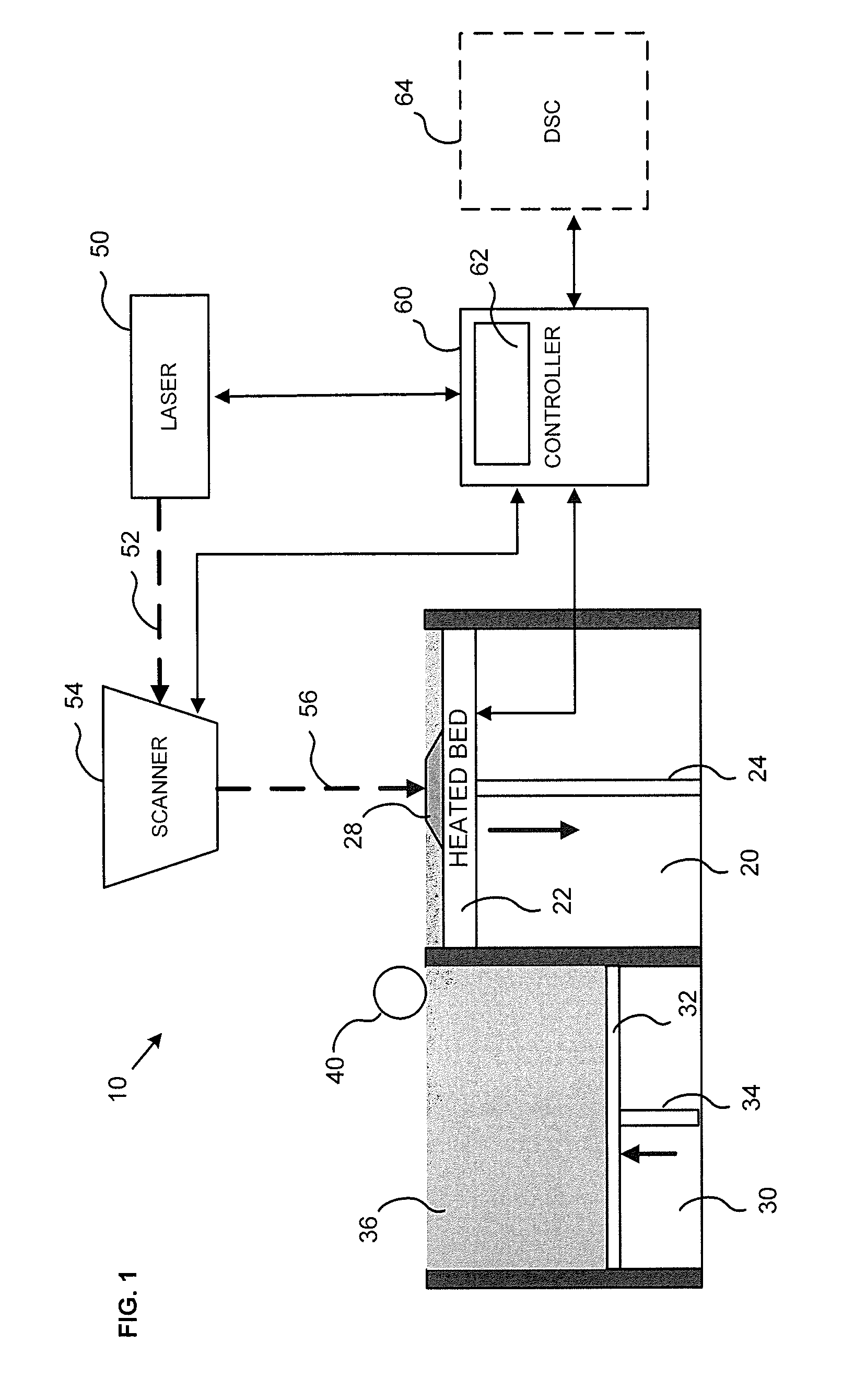

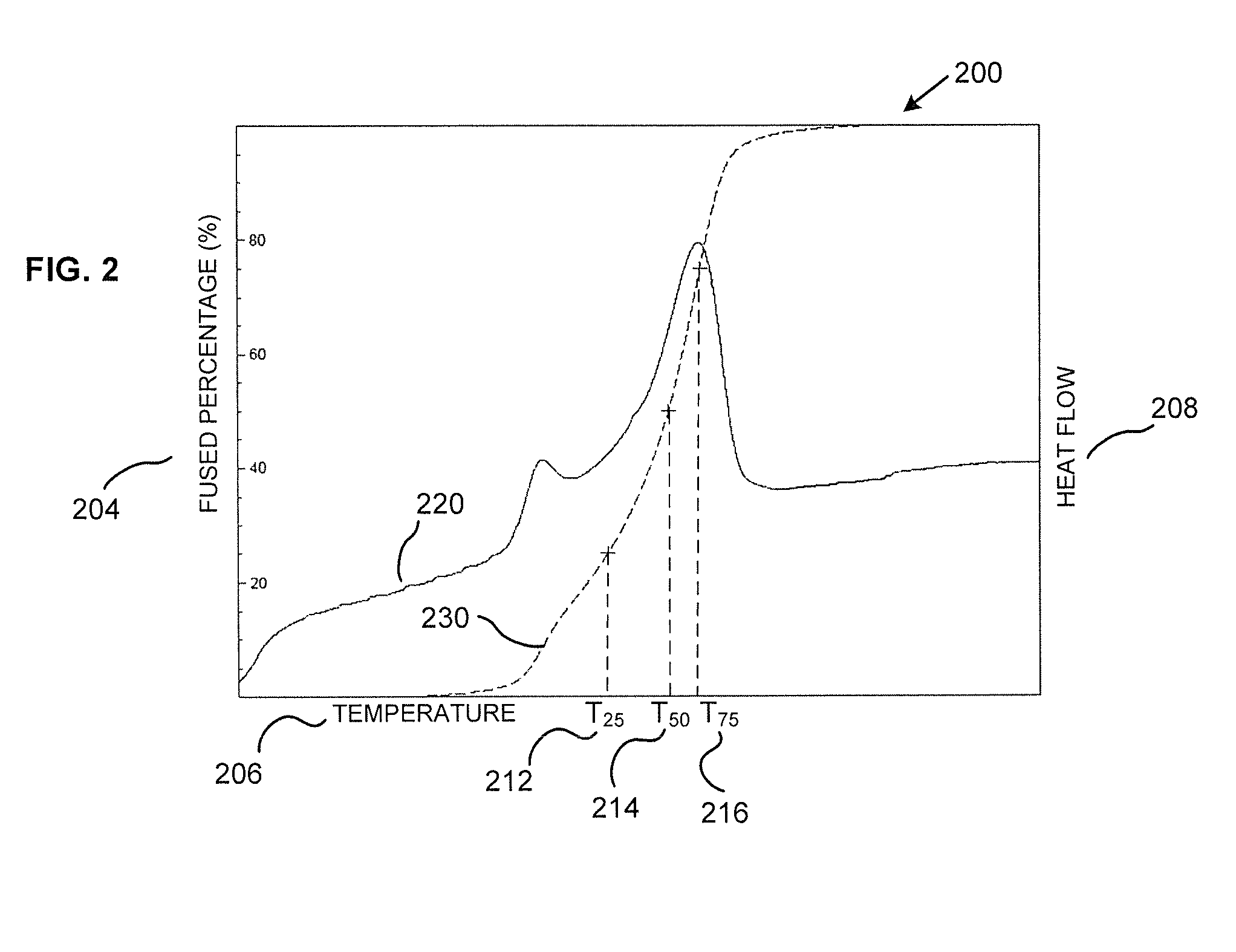

Method For Analytically Determining SLS Bed Temperatures

ActiveUS20150061195A1Avoid problemsThermometer detailsThermometers using material expansion/contactionSelective laser sinteringMaterials science

A method for determining a bed temperature setpoint for use with a powder in a selective laser sintering machine is disclosed. The method includes the step of providing a powder comprising a polymer for use in a selective laser sintering machine. The method further includes the step of determining a ratio of a liquid portion of the powder to a solid portion of the powder as a function of temperature within a temperature range. A bed temperature setpoint is selected in the temperature range corresponding to a desired ratio of the liquid portion of the powder to the solid portion of the powder. A temperature of a bed of a selective laser sintering machine is set to the selected bed temperature setpoint, and a part is built from the powder using the selective laser sintering machine.

Owner:HEXCEL

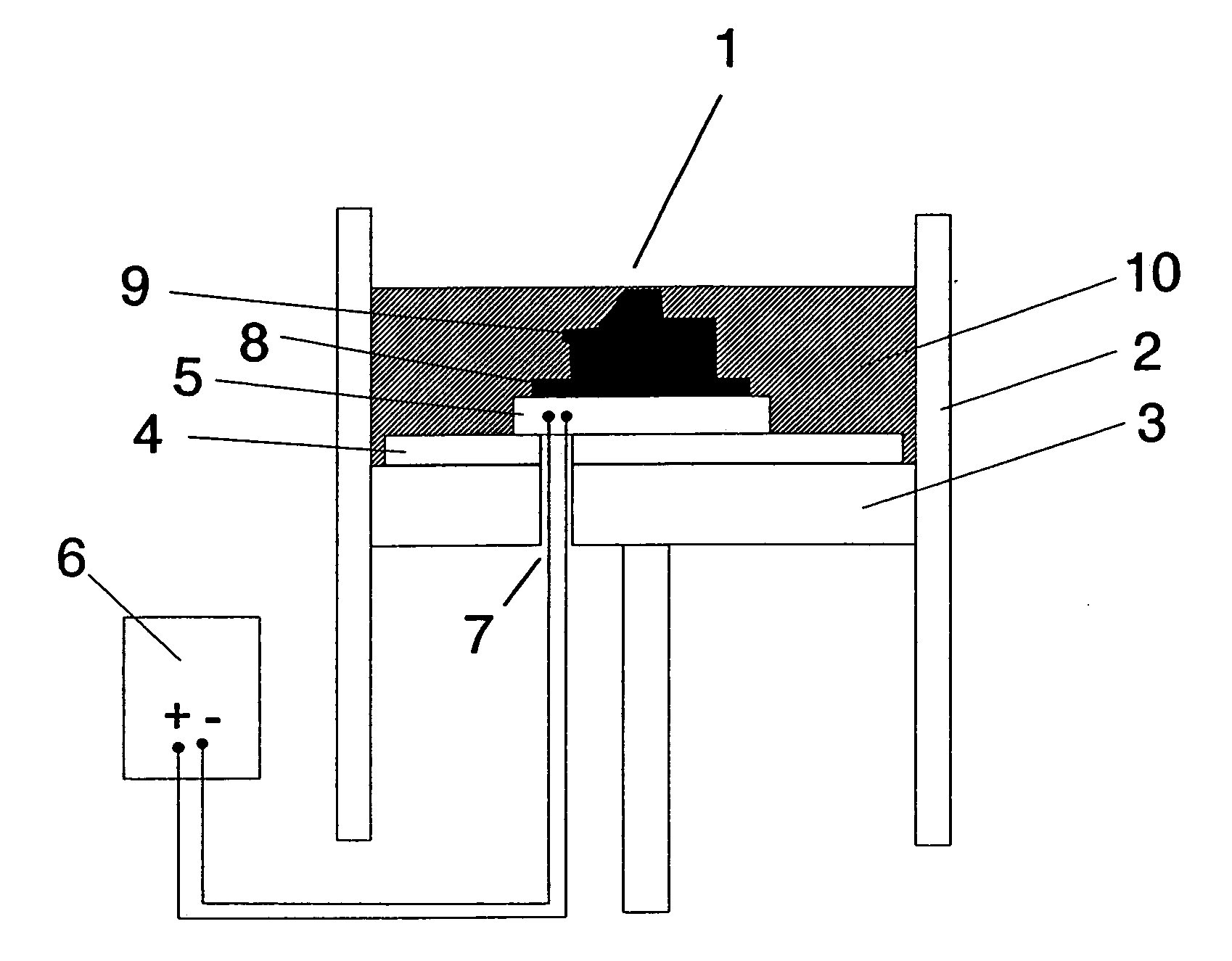

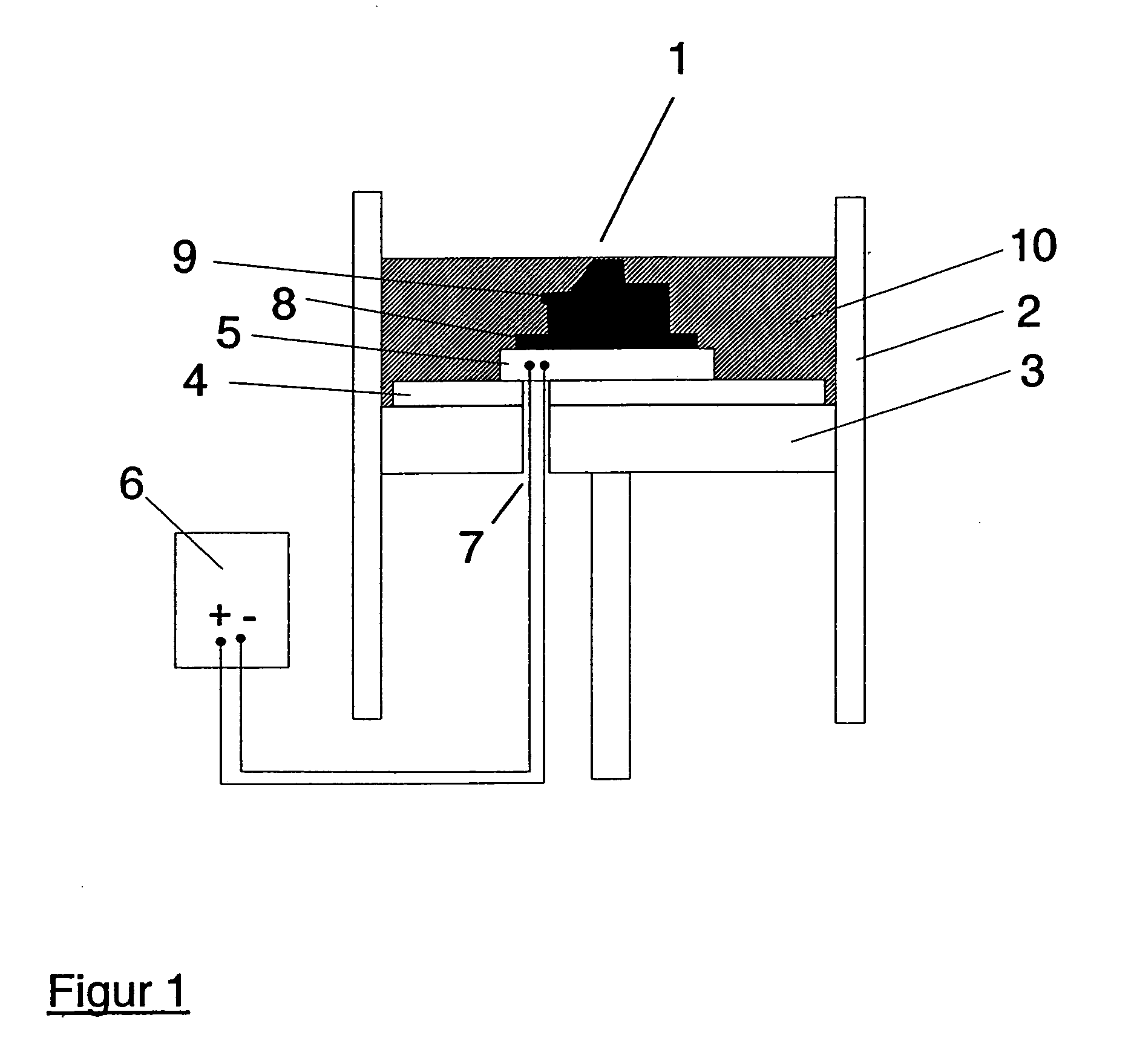

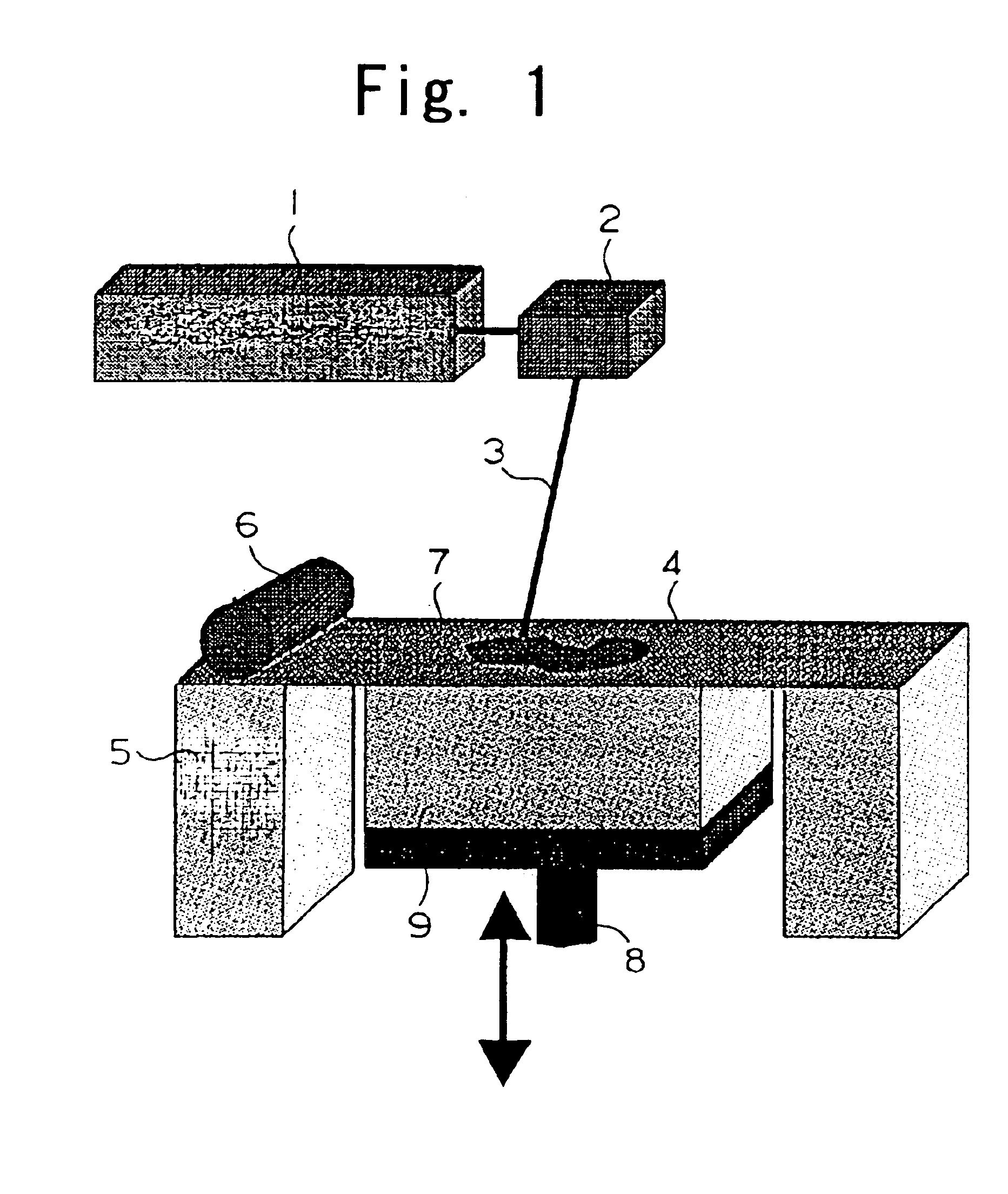

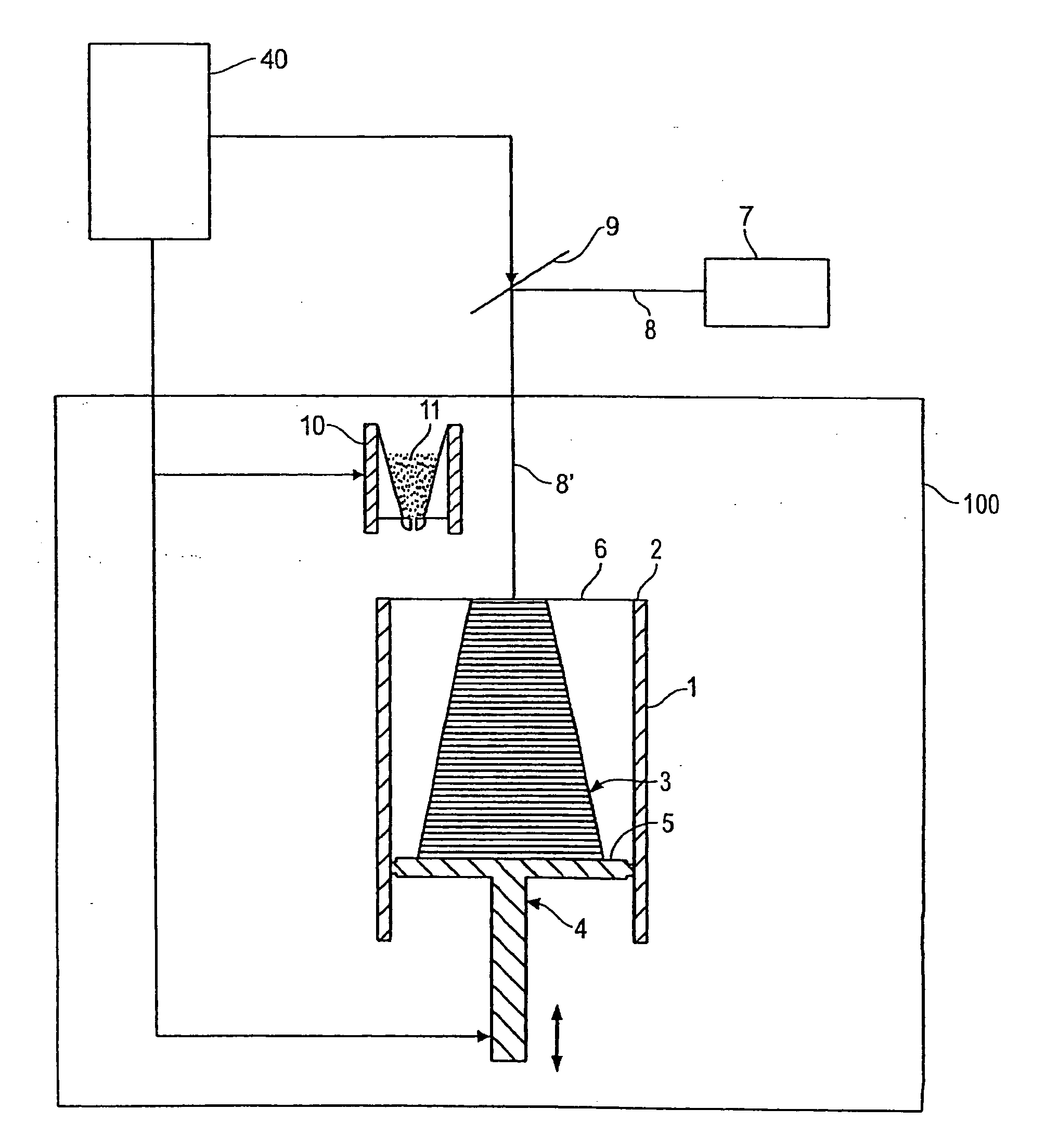

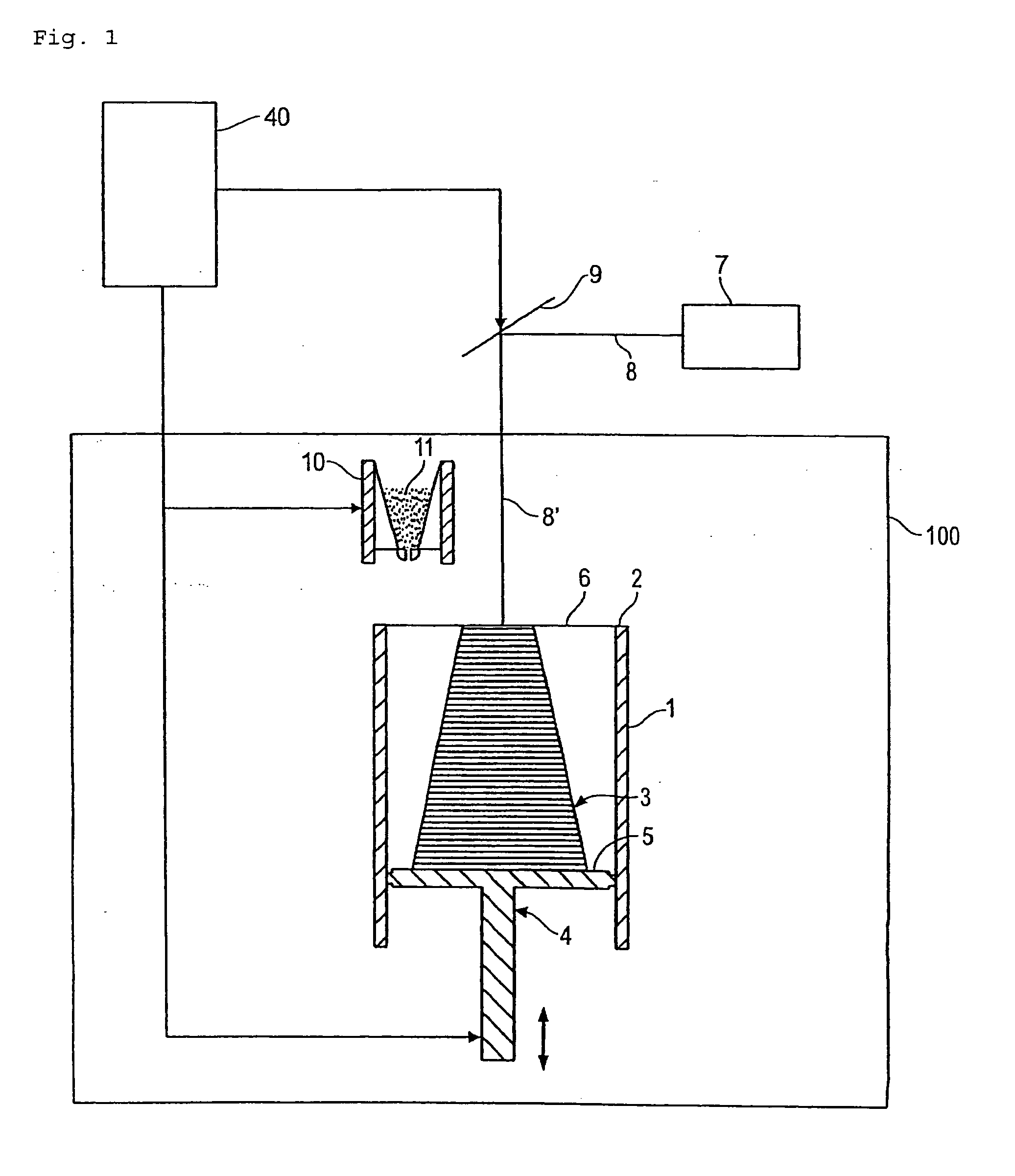

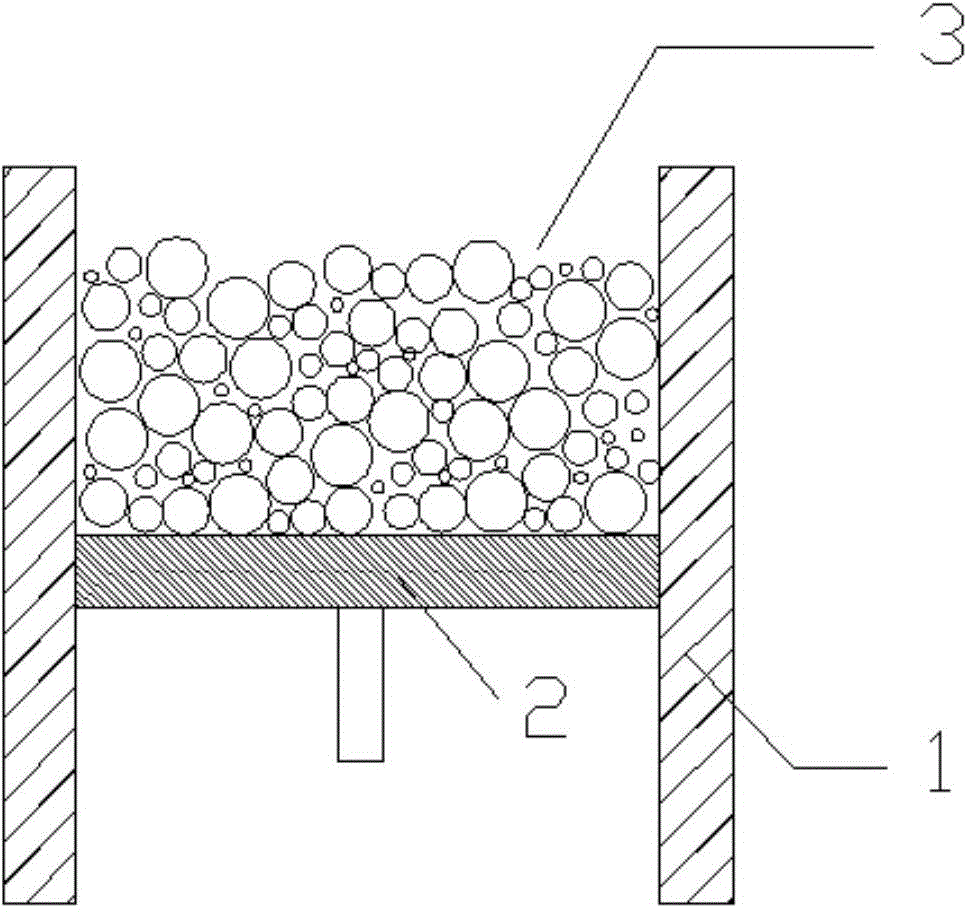

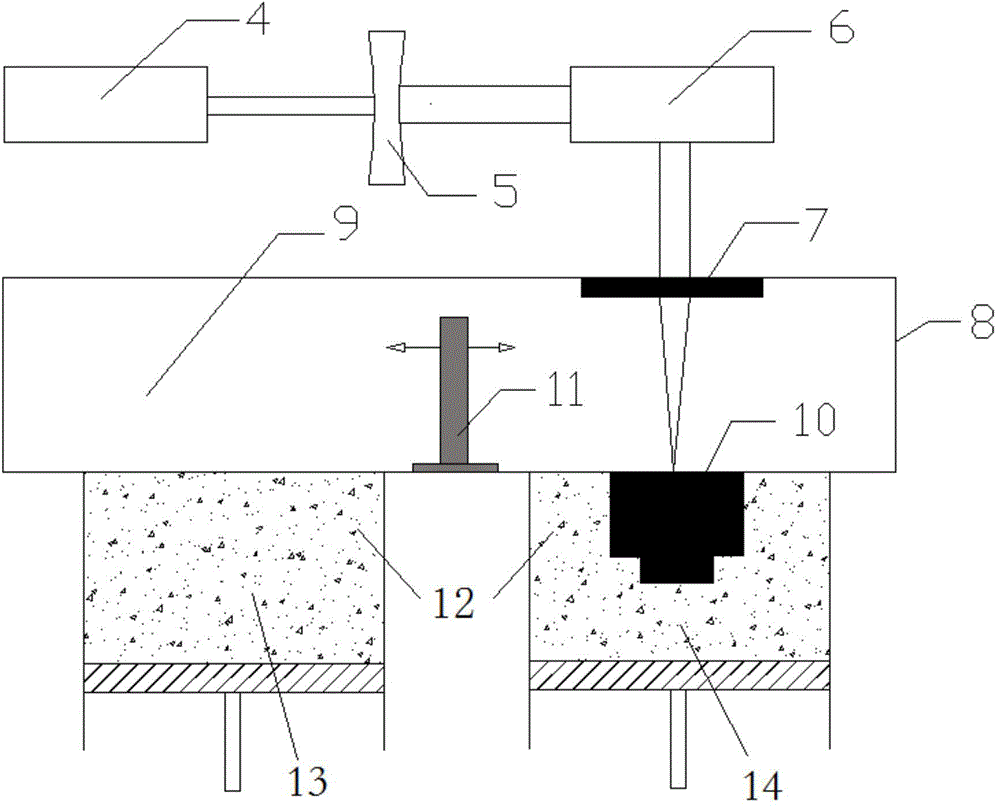

Method and device for the selective laser sintering of metallic substances

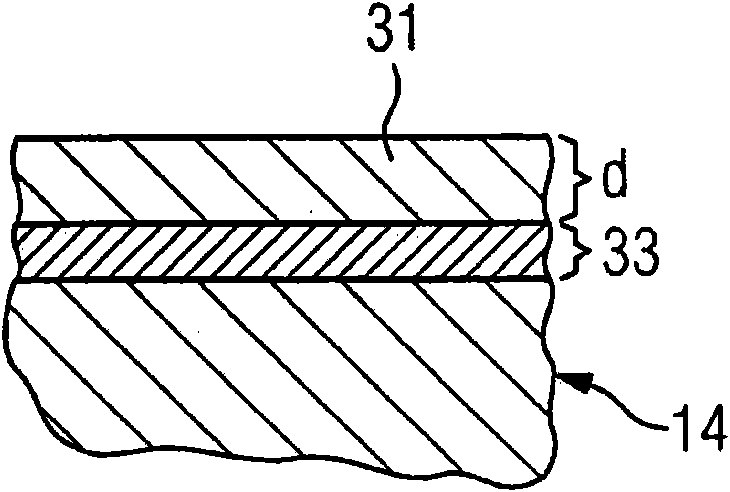

InactiveUS20040056022A1Additive manufacturing apparatusRadiation applicationsSelective laser sinteringInsulation layer

The present invention relates to a device and a method for the selective laser sintering of metallic substances. The construction volume of the device is delimited by side walls (2) and by a construction platform (3), which is adjustable in height, for building up a component (9). A heating plate (5) is placed on the construction platform (3) at a distance from the side walls (2) or is integrated in the surface of the construction platform (3). The heating plate (5) is designed and thermally insulated from the construction platform (3) by an insulation layer (4) in such a manner that it reaches temperatures of at least 500° C. during heating operation. With the device and the corresponding method, metallic components are maintained at temperatures above 500° C. during the building up process thereby reducing the danger of tensions or cracking in the component.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

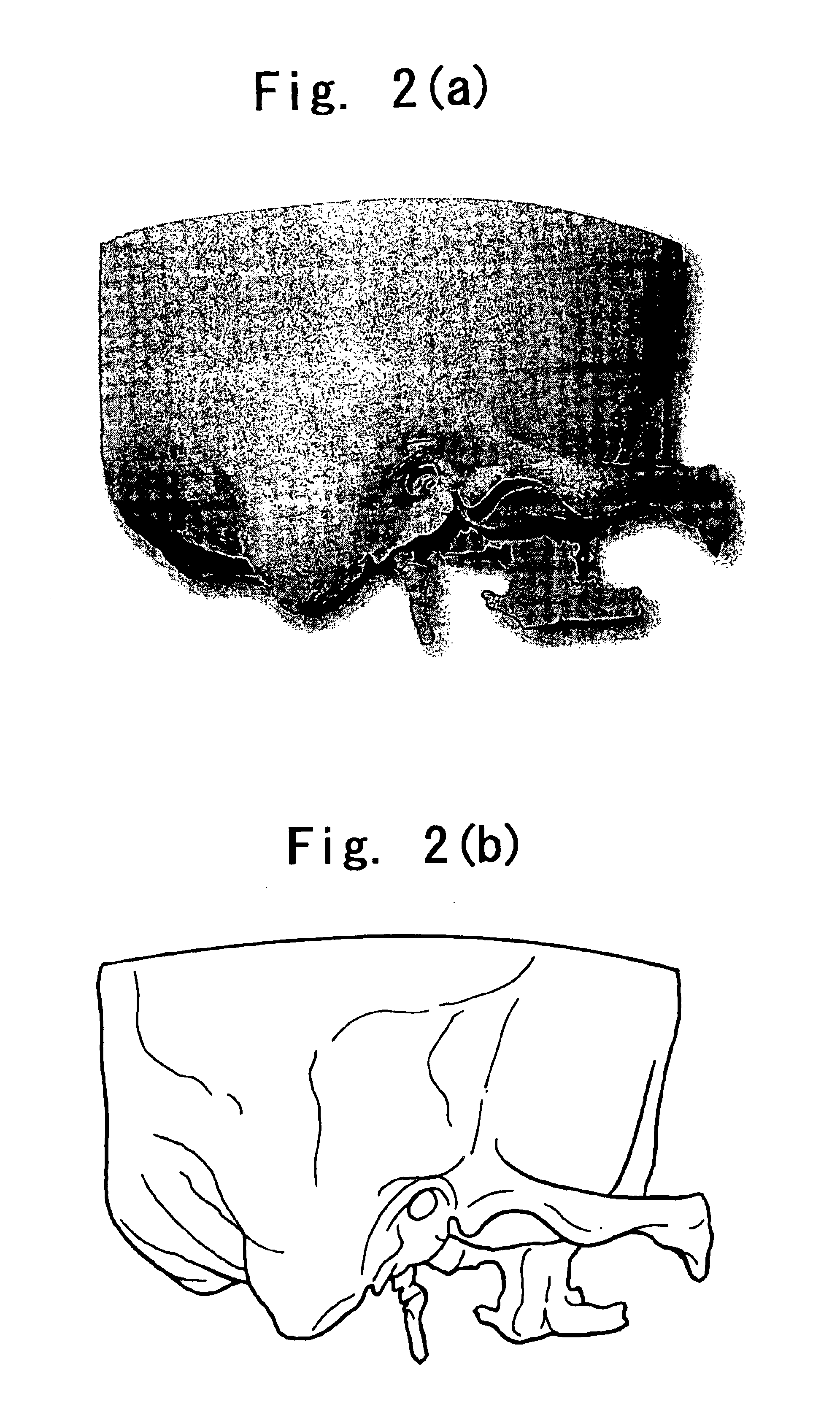

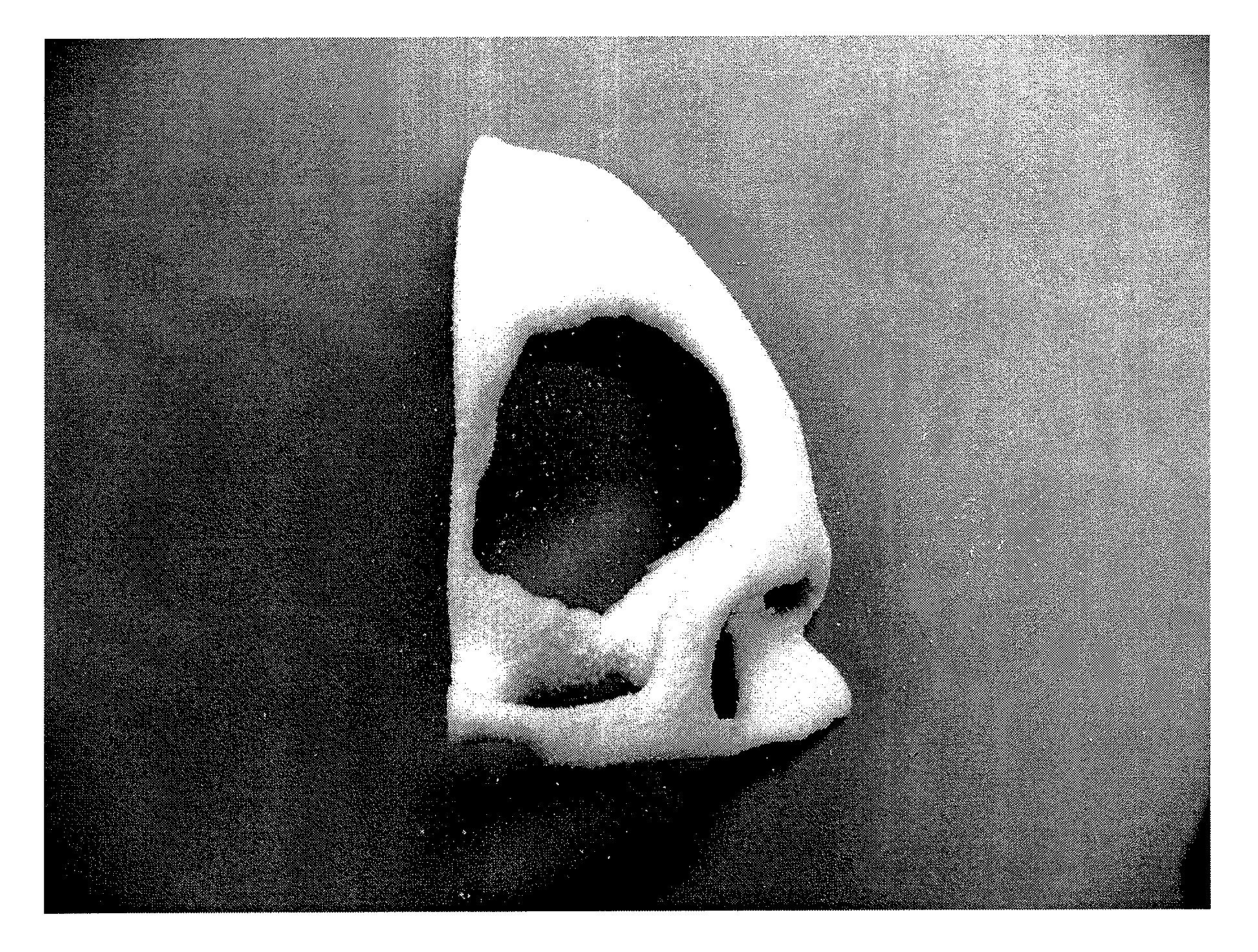

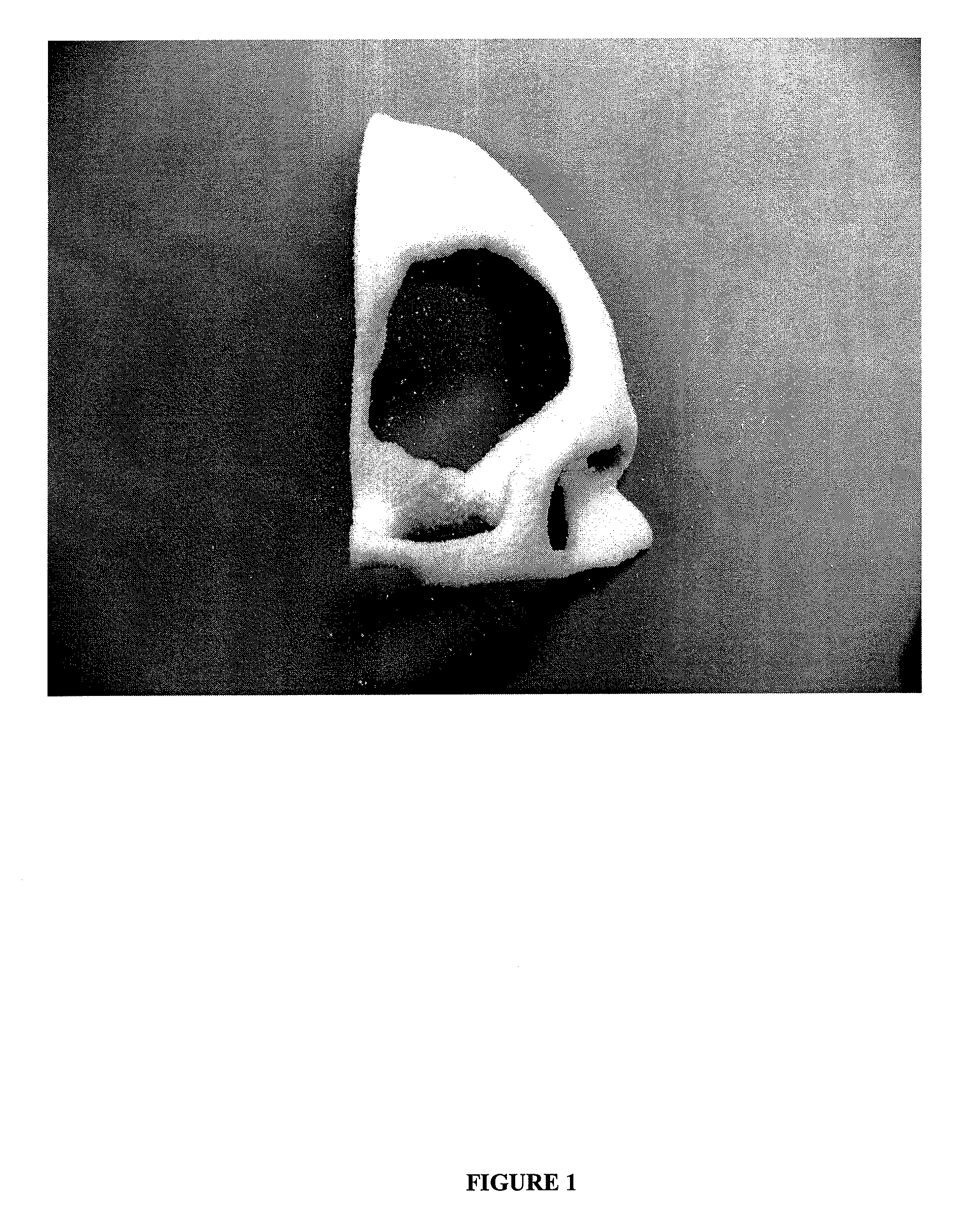

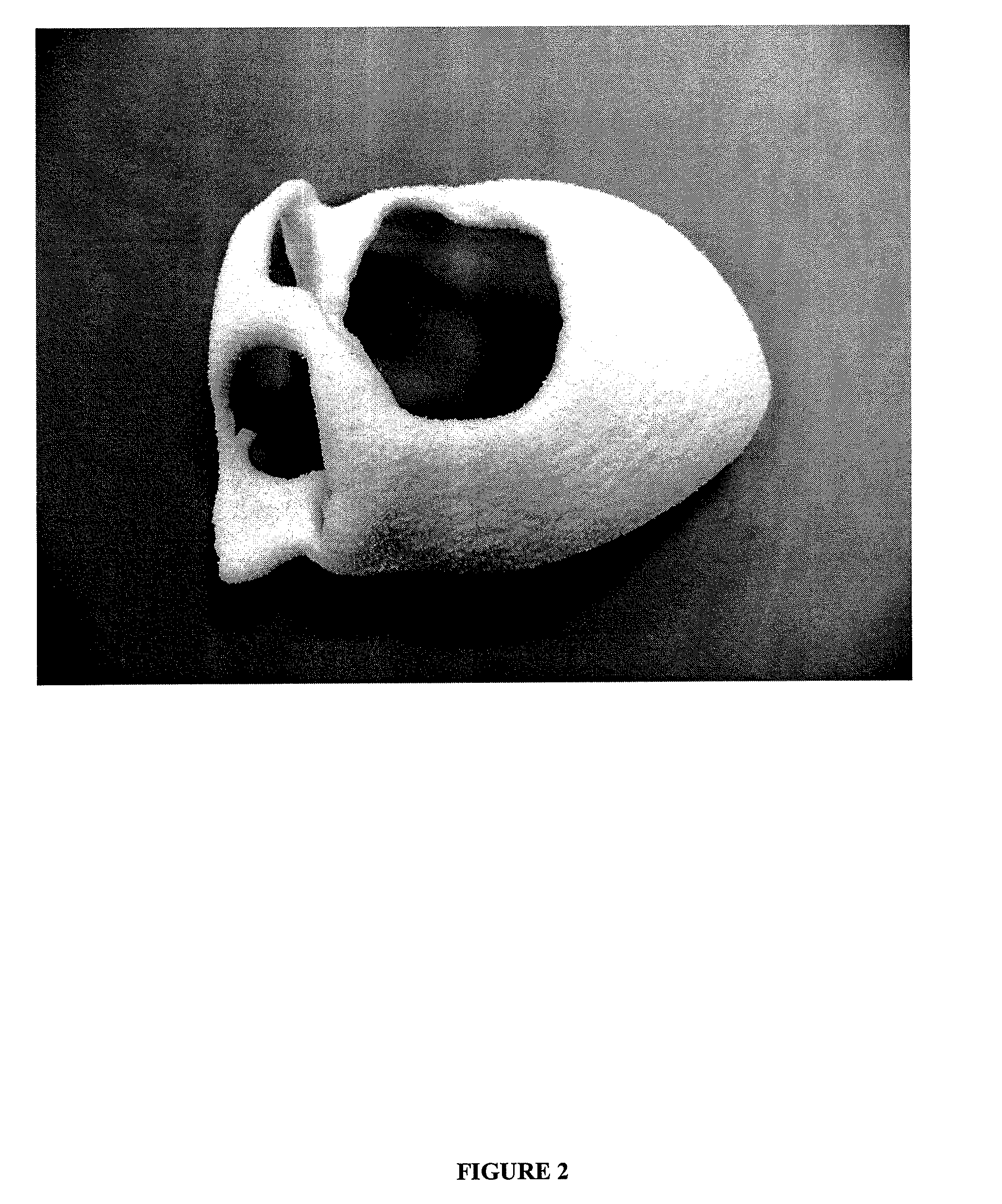

Process for producing an artificial bone model and an artificial bone model produced by the process

ActiveUS6932610B2Improve skillsEasy to getAdditive manufacturing apparatusPharmaceutical delivery mechanismHuman bodySurgical operation

A process for producing an artificial bone model in accordance with the selective laser sintering process which comprises extending a powder material for sintering comprising 30 to 90 parts by weight of powder of a synthetic resin and 10 to 70% by weight of an inorganic filler to form a thin layer and irradiating a portion of the thin layer having the shape formed based on tomograpic information of a natural bone with laser light so that the irradiated portion of the thin layer is sintered. The extension of the powder material for sintering to form the thin layer and the irradiation of the thin layer with laser light for sintering are conducted repeatedly. The artificial bone model can three-dimensionally reproduce steric shapes of natural bones such as bones in the human body precisely and accurately and exhibits the property for cutting closely similar to that of natural bones. The artificial bone model can be used for educational training or for studying a plan for curing before a surgical operation.

Owner:ONO +1

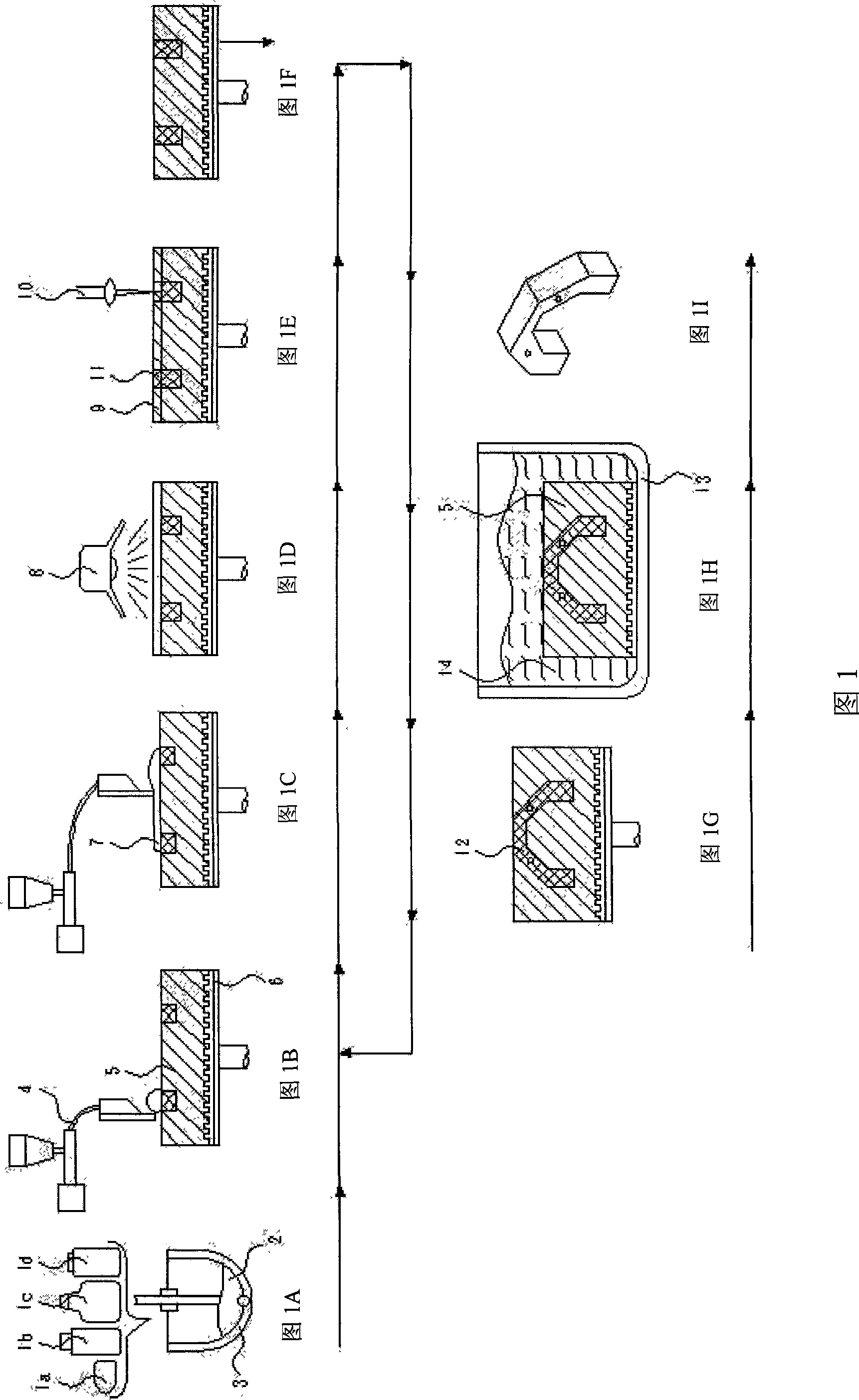

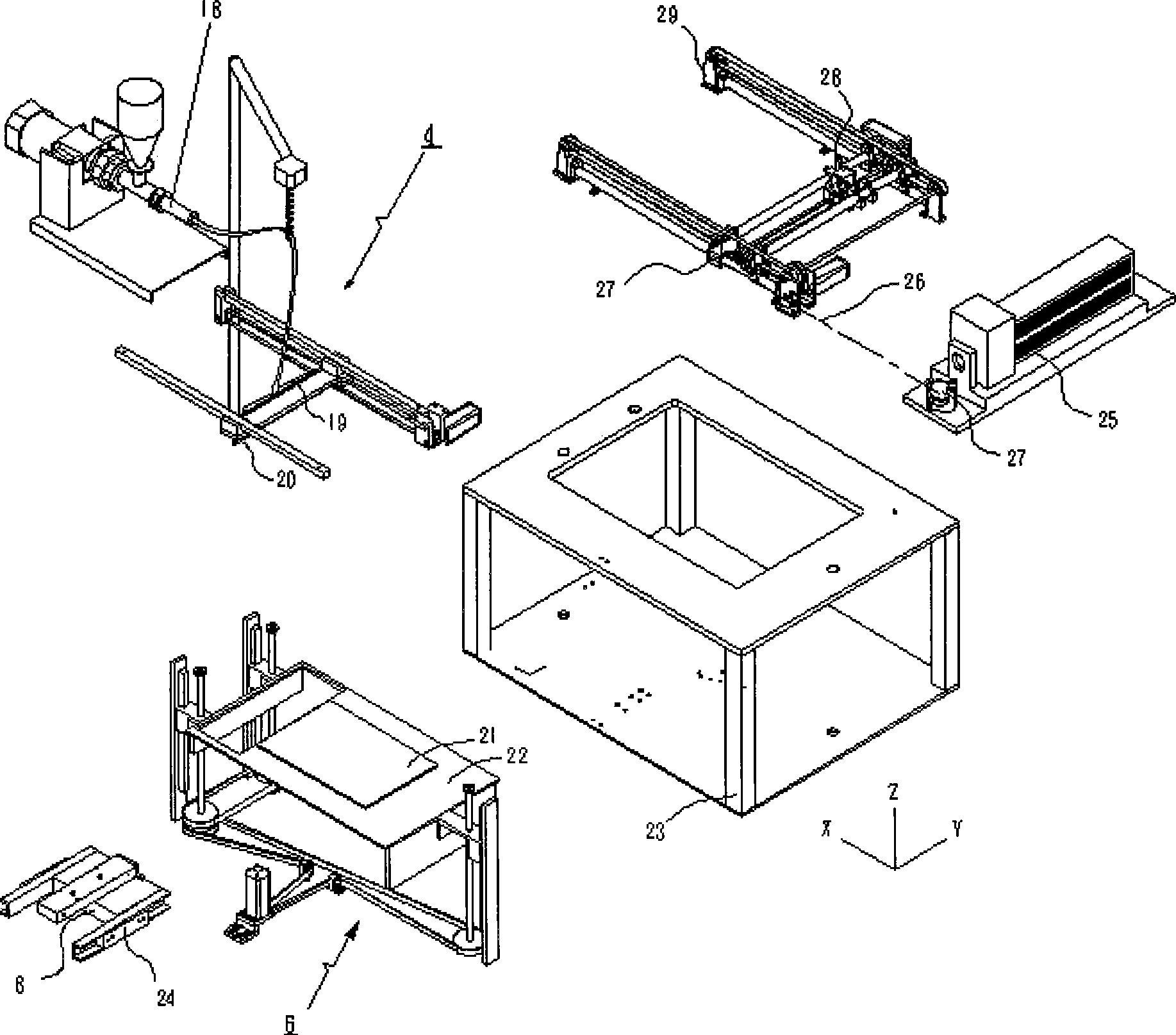

Manufacture method and device of three-dimensional workpiece

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

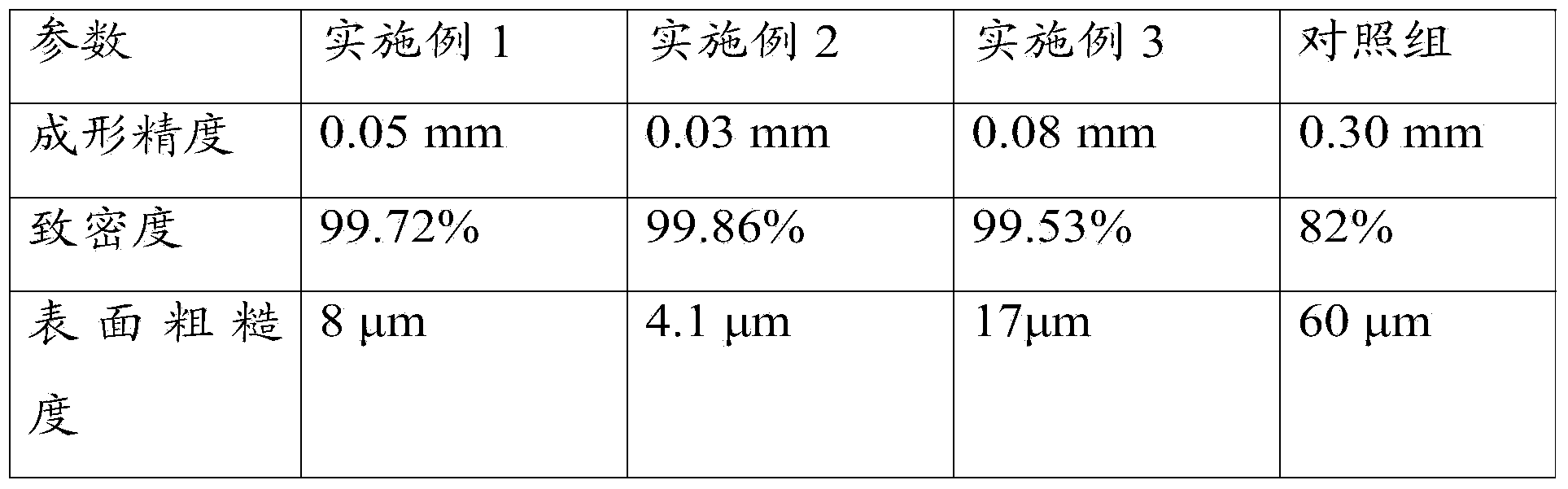

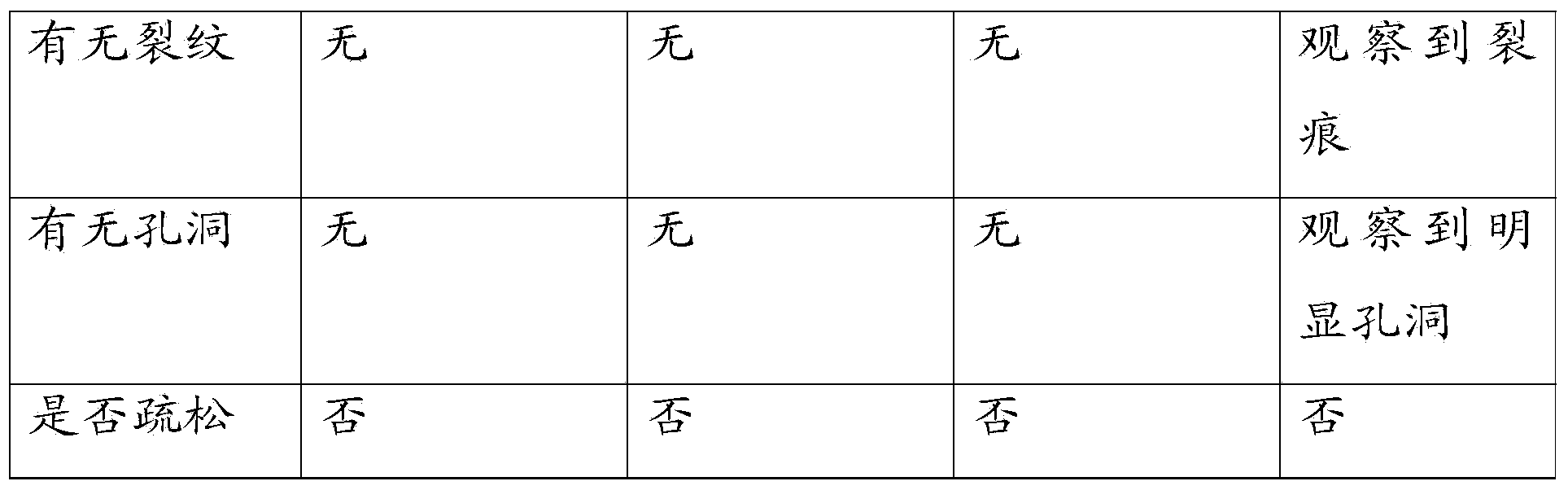

Method for producing titanium alloy artware by adopting selective laser melting

ActiveCN104259459AHigh precisionImprove forming qualityIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to the field of material preparation, in particular to a method for producing titanium alloy artware by adopting selective laser melting. The method includes the steps: creating two-dimensional slicing data of a part structure to be produced and importing the two-dimensional slicing data into a metal powder laser melting system; setting processing technological parameters of the metal powder laser melting system; taking titanium alloy powder and spreading the titanium alloy powder on the metal powder laser melting system, and sequentially performing laser melting, powder sieving, heat treatment, wire cutting, cleaning, sand blasting, polishing and the like under the protection of inert gas to obtain the titanium alloy artware. According to the method, specific titanium alloy types and specification parameters are selected, and the processing technological parameters of the metal powder laser melting system are optimized for multiple times, so that the produced titanium alloy artware is high in precision, stable in shaping quality, small in distortion, excellent in mechanical property and good in surface smoothness through follow-up processing and has great artistic value.

Owner:飞而康快速制造科技有限责任公司

Selective Laser Sintering Powder Recycle System

ActiveUS20090169664A1Good blendingReduce powder lossFlow mixersTransportation and packagingSelective laser sinteringMetallurgy

A method and apparatus for forming three-dimensional objects by laser sintering that includes the use of dense phase pneumatic conveying to internally recycle overflow powder, and to thoroughly blend overflow, recovered and virgin powder to provide a consistent powder feed mix to a laser sintering machine. Overflow powder from the laser sintering machine is recovered and recycled back into the laser sintering machine for reuse. The approach results in a compact and reliable powder recycle system with complete blending and minimum attrition to the handled powder.

Owner:3D SYST INC

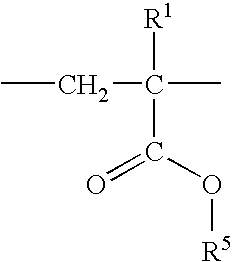

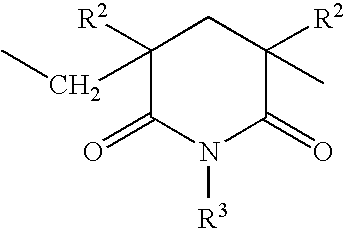

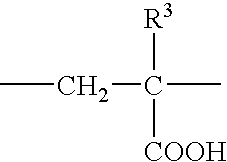

Selective sintering of structurally modified polymers

ActiveUS20090295042A1Improve mechanical propertiesSpeed up the processAdditive manufacturing apparatusLiquid surface applicatorsSelective laser sinteringPolymer science

A three-dimensional object is manufactured by selective sintering by means of electromagnetic radiation, wherein the powder comprises a polymer or copolymer having at least one of the following structural characteristics:(i) at least one branching group in the backbone chain of the polymer or copolymer, provided that in case of the use of polyaryletherketones (PAEK) the branching group is an aromatic structural unit in the backbone chain of the polymer or copolymer;(ii) modification of at least one end group of the backbone chain of the polymer or copolymer;(iii) at least one bulky group within the backbone chain of the polymer of copolymer, provided that in case of the use of polyaryletherketones (PAEK) the bulky group is not selected from the group consisting of phenylene, biphenylene, naphthalene and CH2— or isopropylidene-linked aromatics;(iv) at least one aromatic group non-linearly linking the backbone chain.

Owner:EOS ELECTRO OPTICAL SYST

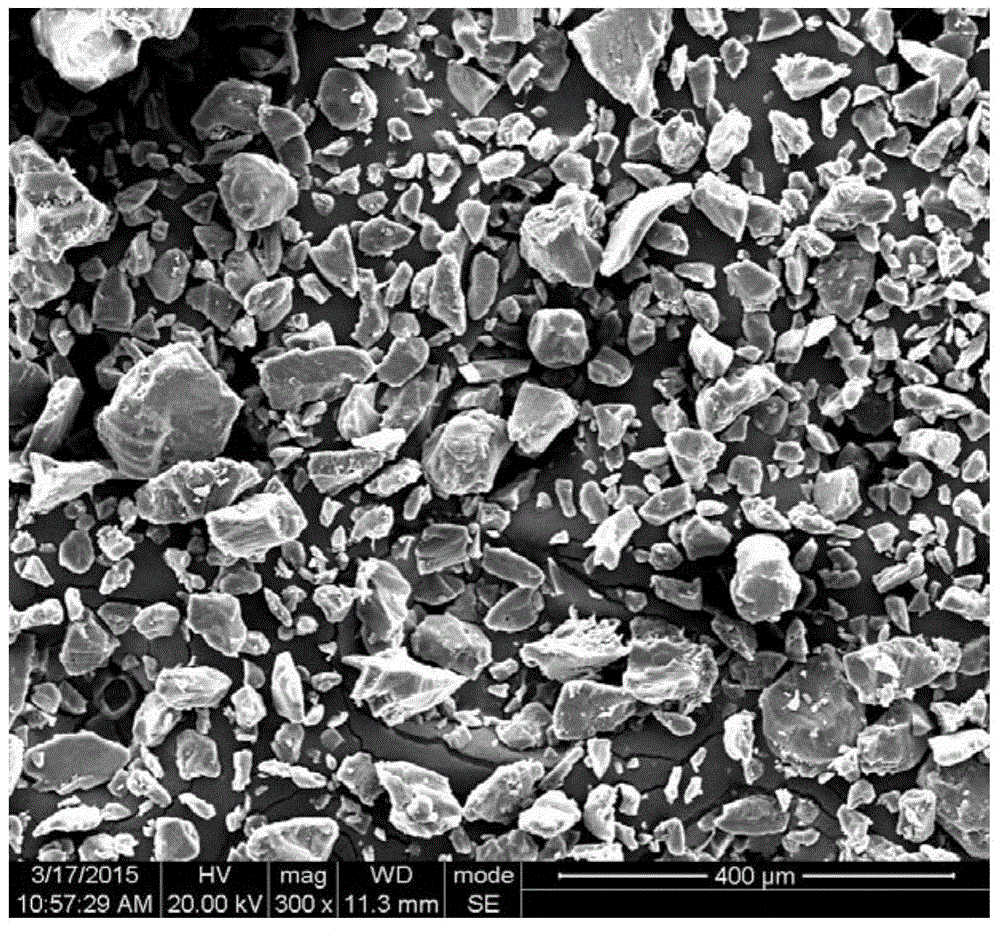

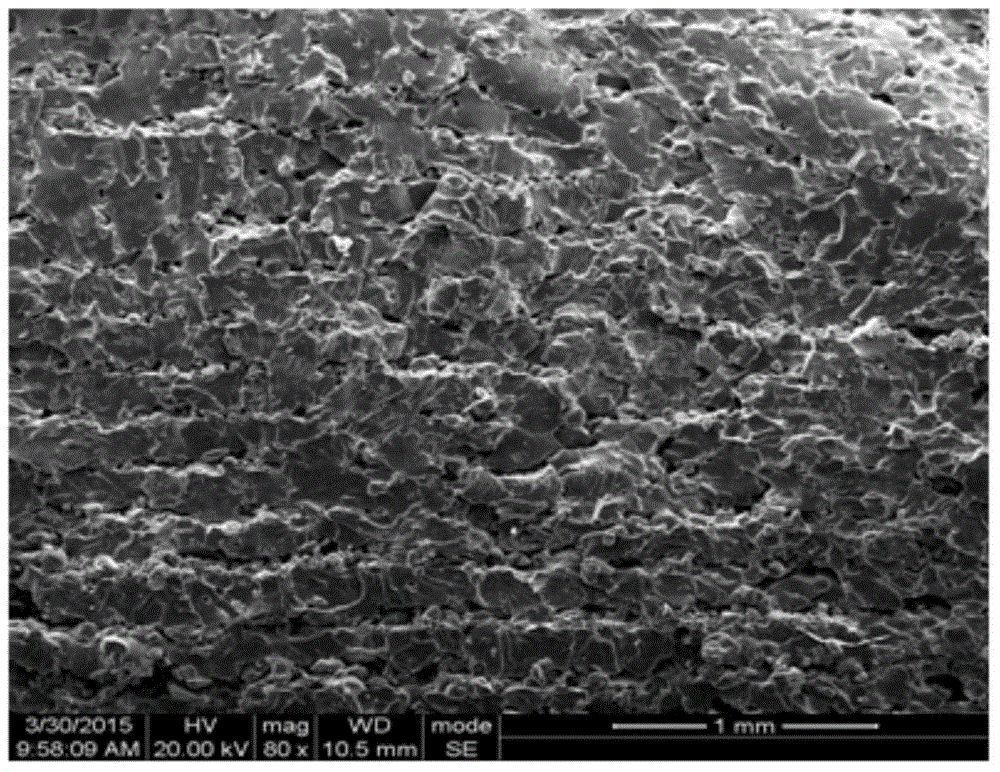

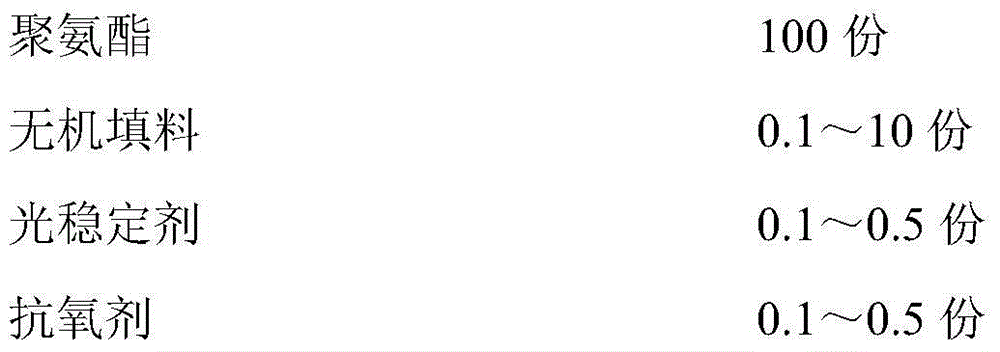

Polyurethane composite material for 3D printing, and preparation method and application thereof

InactiveCN104910609AImproved laser sintering performanceImprove mechanical propertiesAdditive manufacturing apparatusSelective laser sinteringPolymer science

The invention discloses a polyurethane composite material for 3D printing, and a preparation method and application thereof. The invention is characterized in that the polyurethane composite material is prepared from the following initial raw materials in parts by weight: 100 parts of polyurethane, 0.1-10 parts of inorganic filler, 0.1-0.5 part of light stabilizer and 0.1-0.5 part of antioxidant. The preparation method comprises the following steps: evenly mixing 100 parts of polyurethane, 0.1-10 parts of inorganic filler, 0.1-0.5 part of light stabilizer and 0.1-0.5 part of antioxidant, and preparing power to obtain the composite material, wherein the average particle size of the composite material powder is 10-100 mu m. The product can be prepared by a 3D printing technique, such as selective laser sintering. The polyurethane has favorable flexibility; and the introduced inorganic filler improves the 3D printing performance of the polyurethane, so that the product has excellent mechanical properties. The tensile strength of the product prepared from the material by laser sintering can reach 20.12 MPa, and the elongation at break can reach 511.12%.

Owner:SICHUAN UNIV

Metal 3D printing product production method by means of low-power laser sintering

InactiveCN103769586ACeramic shaping apparatusIncreasing energy efficiencySelective laser sinteringAdhesive

The invention discloses a metal 3D printing product production method by means of low-power laser sintering. According to the metal 3D printing product production method, metal powder materials and thermoplastic molding adhesives are adopted to prepare a low-melting-point 3D metal printing raw material mixture; due to the fact that the thin-layer thermoplastic adhesives are formed on the surfaces of metal powder particles, low-power (smaller than 50 W) selective laser sintering or electron beam sintering 3D printer is used, the metal powder materials are stacked to be molded through surface layer thermoplastic adhesive low-temperature melting-cooling adhesive solidification, then metal part product green bodies can be printed through the prepared metal powder raw materials, the molded adhesives in the part green bodies are removed through thermal debinding or chemocatalysis debinding or other technologies, high-temperature sintering is conducted on the green bodies without the molded adhesives through a vacuum sintering method or an atmosphere protection sintering method, and alloying compact high-performance complex metal part products are produced. The metal 3D printing product production method by means of low-power laser sintering has the advantage that the 3D printing device and technology for producing the metal parts are low in cost.

Owner:王利民

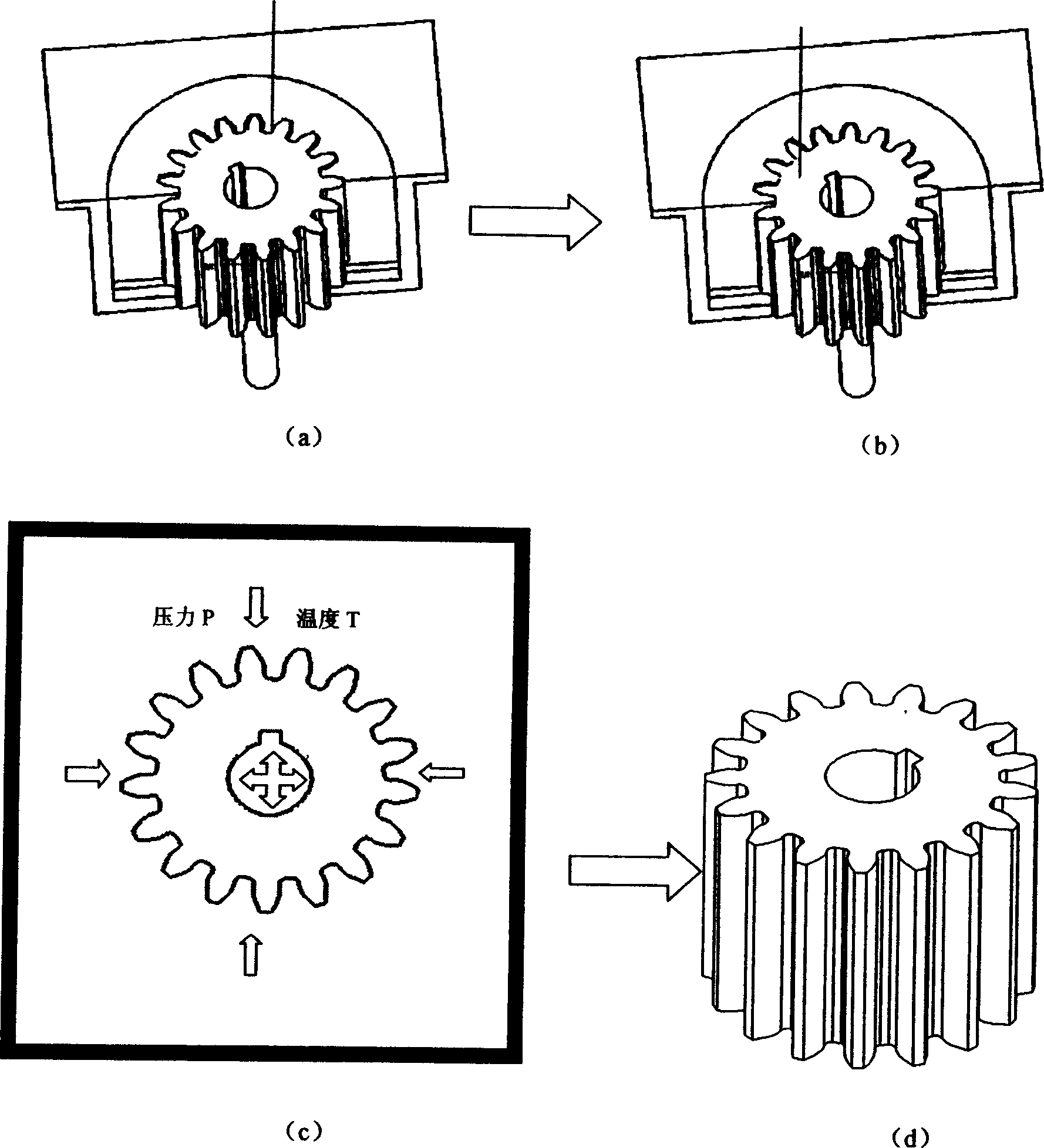

Method for near-purification formation of parts

InactiveCN1861296AEnsure existenceAvoid pollutionIncreasing energy efficiencySelective laser meltingSelective laser sintering

A technology for manufacturing a part by proximal forming method includes such steps as inputting the 3D model of a part to a fast SLM or SLS machine, vacuumizing the shaping chamber of SLM or SLS machine, using laser to scan the metal powder outside the boundary for smelting it, scan the metal powder inside the boundary to form mesh structure, forming a compact shell sealed part, and HIP processing.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing nylon powder for selective laser sintering

The invention provides a method for preparing nylon powder for selective laser sintering. The method is used for preparing nylon powder materials by steps of heat treatment, powder preparation in a solvent method, addition of an appropriate addition agent and the like, wherein the nylon powder materials have excellent performances and can be effectively applied to a selective laser sintering (SLS for short) process for preparing SLS pieces. The method has simple and convenient process, is environmental friendly and is easy to implement.

Owner:HUNAN FARSOON HIGH TECH CO LTD

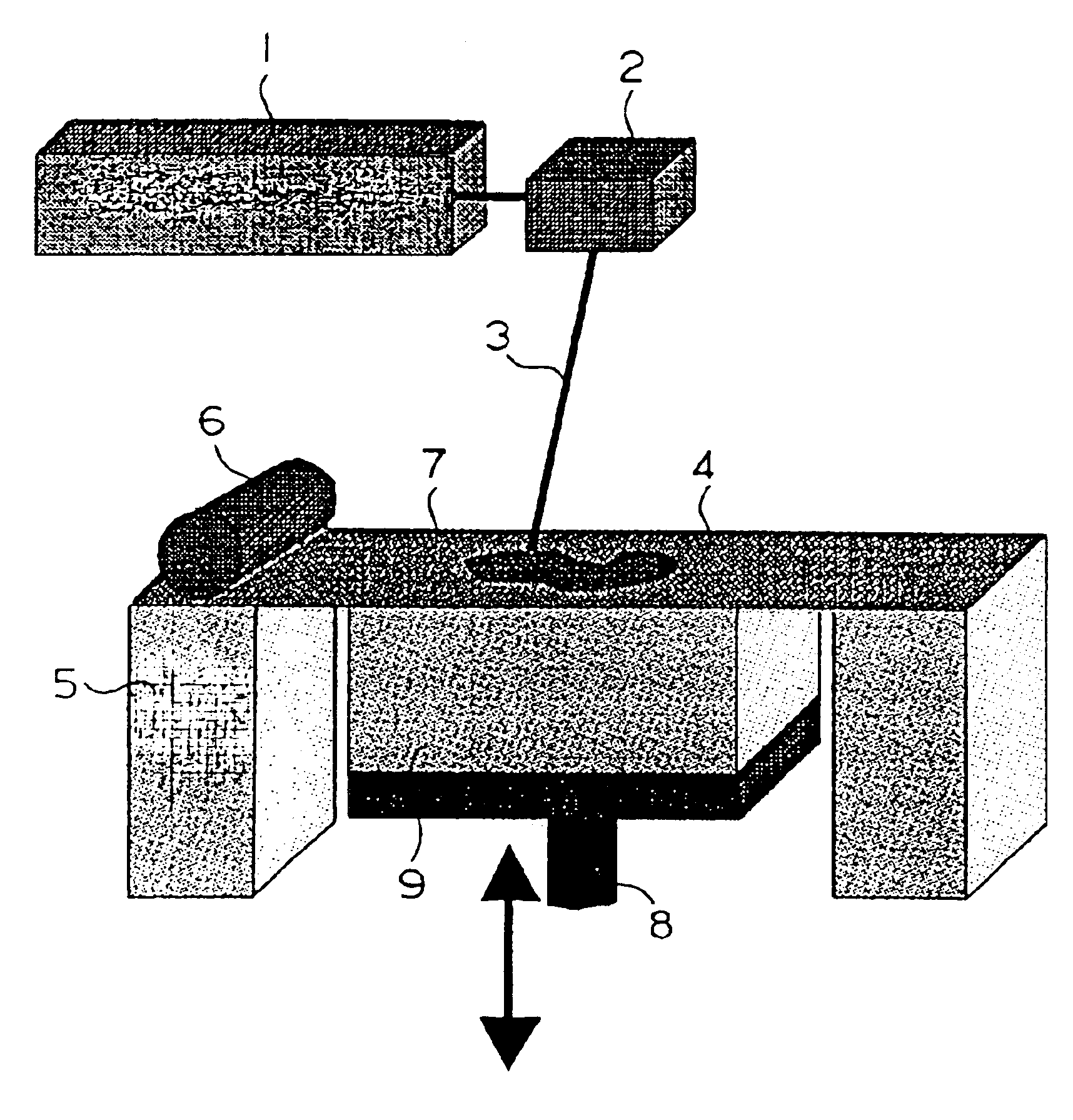

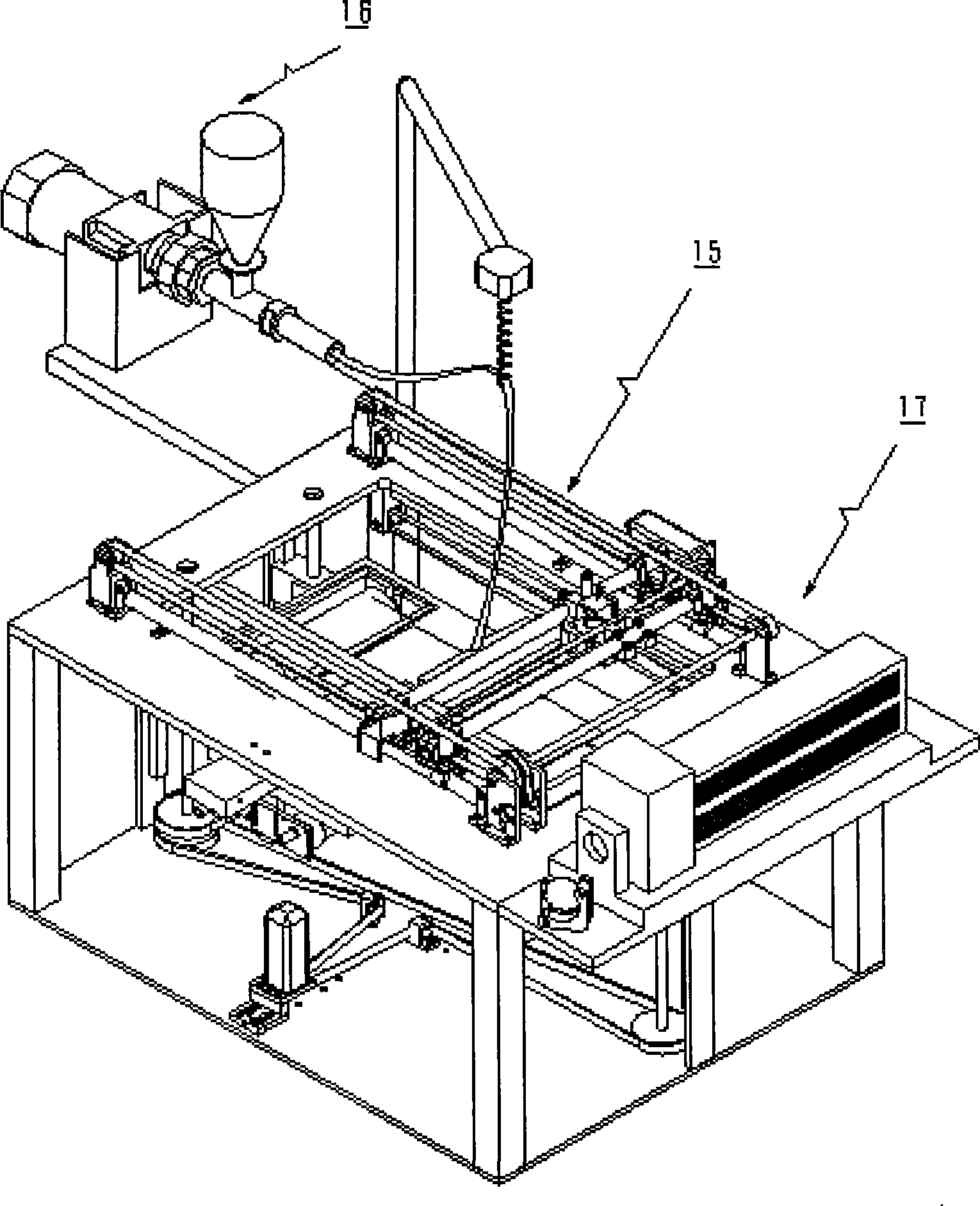

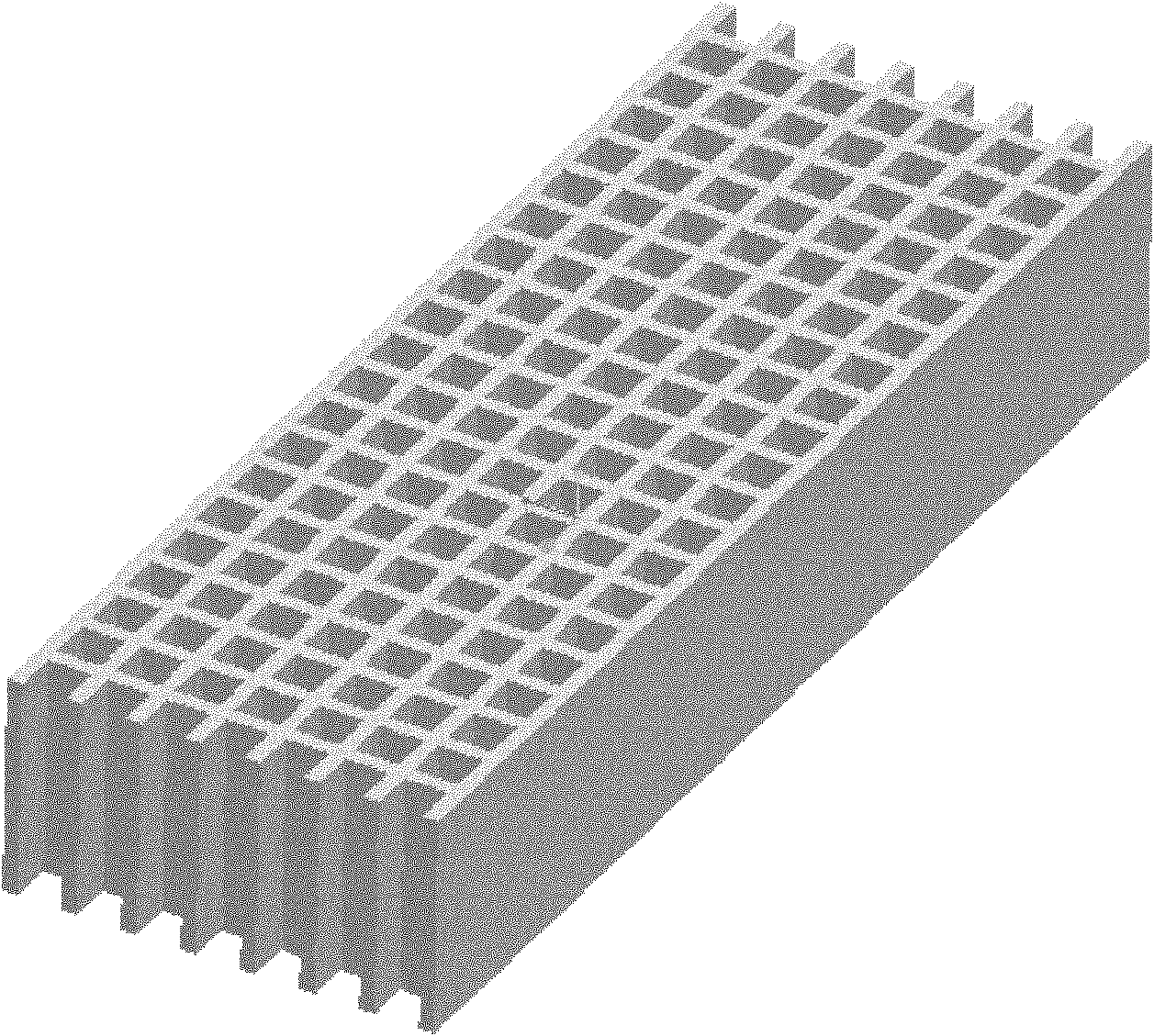

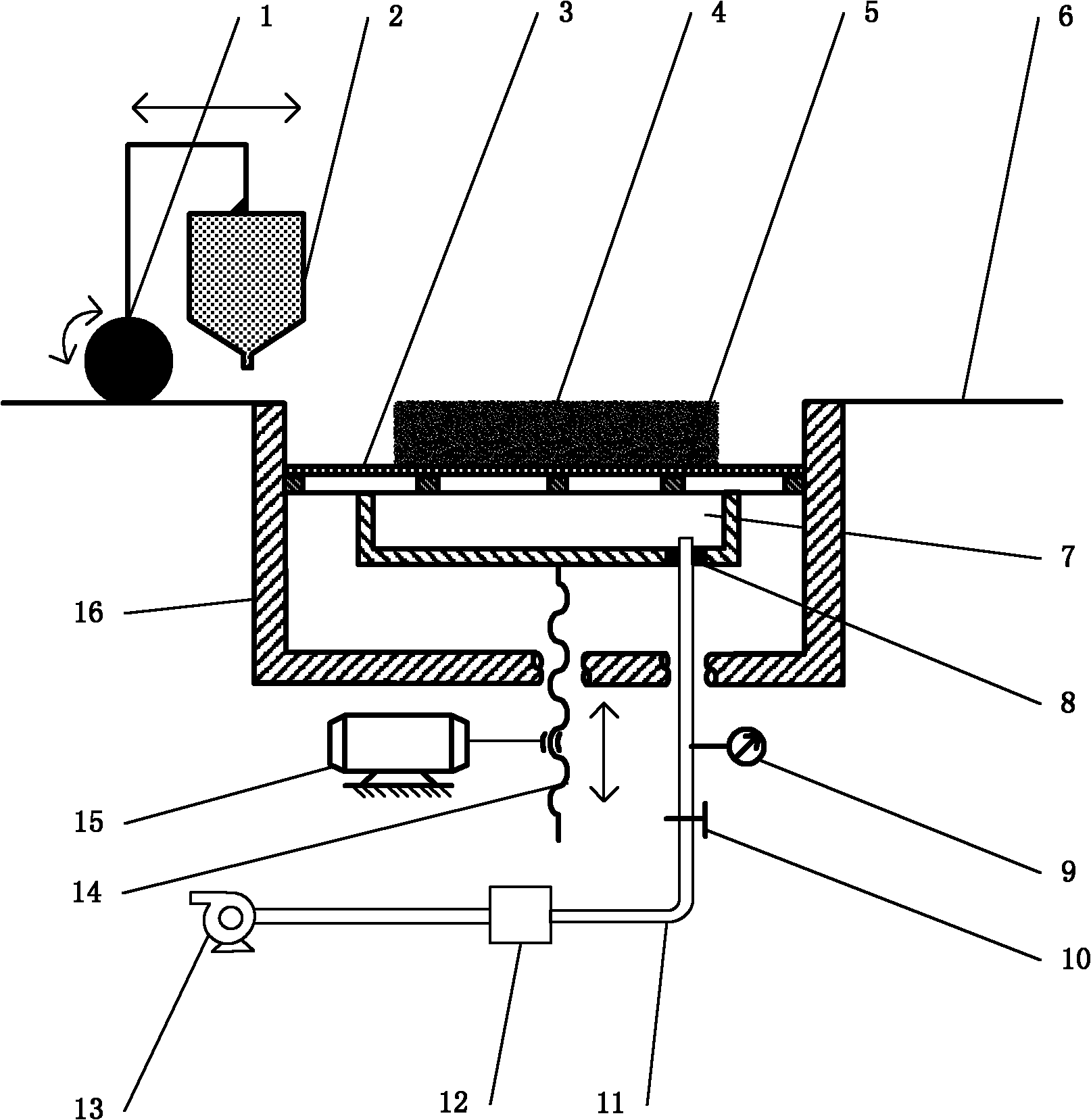

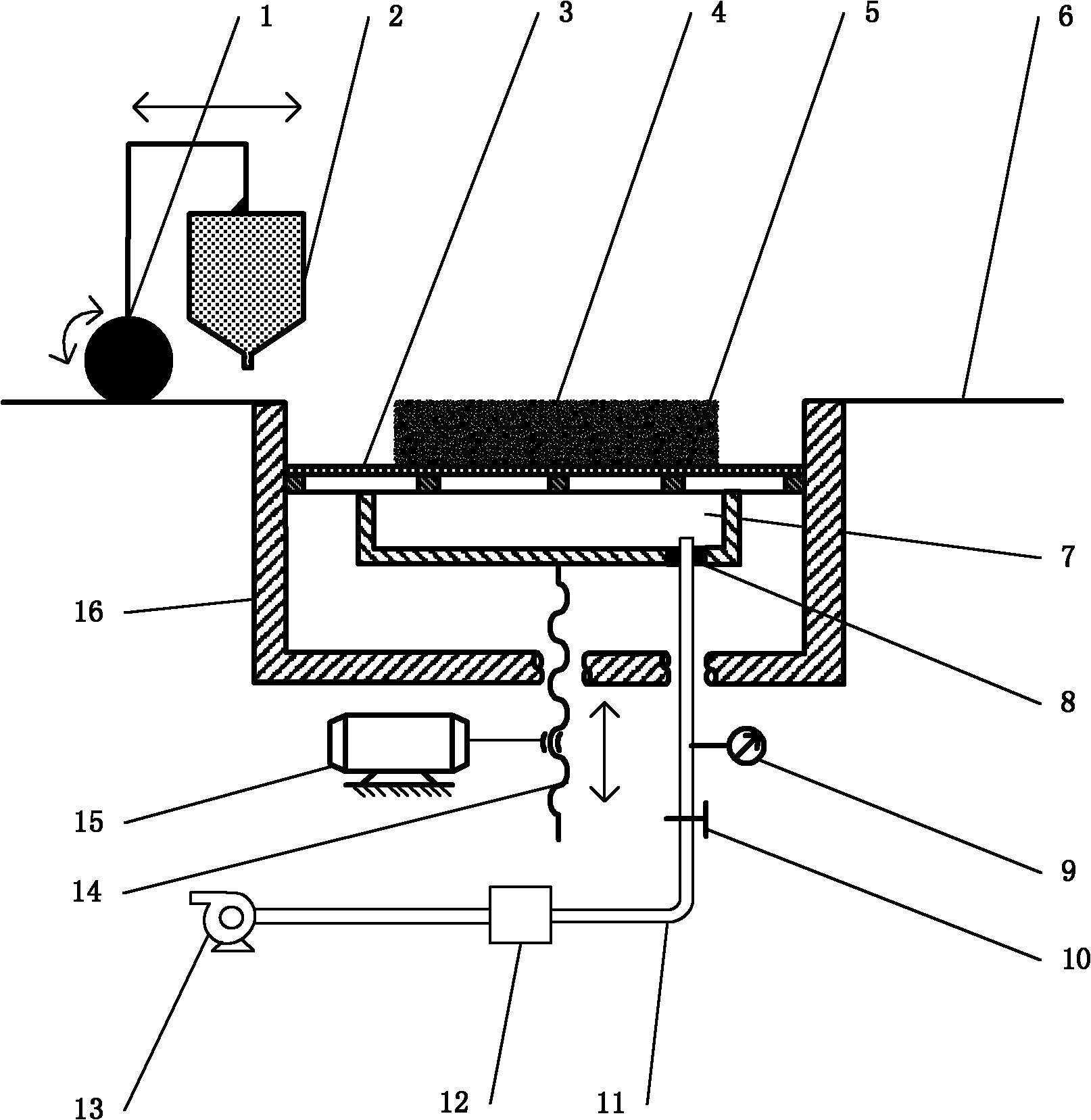

Negative pressure-based device and method for manufacturing porous textures by laser sintering and quick molding

InactiveCN102029389AFast molding speedGuaranteed porosityIncreasing energy efficiencySelective laser sinteringReciprocating motion

The invention relates to a negative pressure-based device and a negative pressure-based method for manufacturing porous textures by laser sintering and quick molding. The device comprises an X-Y workbench, wherein a pair of guide rails is arranged on the workbench, and the guide rails have a powder spreading roller and a power spreading groove which can move reciprocally along the guide rails; the X-Y workbench is provided with a molding tank, and a molding workbench capable of moving vertically is arranged in the molding tank; the molding workbench consists of a screen with holes distributed densely and a carriage, and a negative pressure chamber is formed on the lower surface of the molding workbench; the bottom end of the negative pressure chamber is connected with a screw and a servo motor in turn; an absorption tube is communicated with the negative pressure chamber through an opening; and the other end of the absorption tube is connected with a filter and a vacuum pump in turn. In the invention, based on a negative pressure absorption principle, powder which is not sintered on each layer is removed and recycled through an absorption tube; and through layer-by-layer absorption, the powder which is not sintered and solidified is cleaned completely, while the sintered and solidified powder is continuously stacked and overlaid to form parts, so that the manufacturing of the porous texture with an aperture of less than 1mm is realized through selective laser sintering and quick molding.

Owner:NANJING HONNY 3 DIMENSIONAL TECH

Laser-sintering powder with PMMI, PMMA, and/or PMMI-PMMA copolymers, process for its preparation, and moldings produced from this laser-sintering powder

InactiveUS7135525B2High resolutionFlat surfacePretreated surfacesGlass/slag layered productsSelective laser sinteringNylon 12

The present invention relates to a sinter powder composed of polyamide which also comprises PMMI, PMMA, or copolymers with PMMI, in particular PMMI-PMMA copolymers, to the use of this sinter powder for laser-sintering, and also to moldings produced from this sinter powder. The moldings made from the powder of the invention have marked advantages over conventional products in their appearance and in their surface quality, especially as far as roughness and dimensional stability during selective laser sintering (SLS) are concerned. In addition, moldings produced from the sinter powder of the invention also have better mechanical properties than moldings based on conventional nylon-12 powders, in particular in terms of modulus of elasticity and tensile strength. These moldings also have a density close to that of injection moldings.

Owner:EVONIK DEGUSSA GMBH

Method of preparing organization bracket performing selectivity laser sintering by using macromolecule microsphere

InactiveCN101138651AParticle size controllableHigh forming precisionBone implantSelective laser sinteringPolymer science

The present invention discloses a manufacture method of a tissue frame, which conducts the selective laser sintering by the polymer micro spheres. The method comprises the following steps. The polymer material dissolved in the solvent is dropped in the dispersant under stirring status at a uniform speed. The polymer micro spheres are obtained after cleaning, ultrasound dispersion and freezing preparation. The mixing powder is obtained after mixing the polymer micro spheres with a pore-foaming agent. A three-dimensional model of the frame is designed by the computer assistant software. The mixing powder is formed by the selective laser sintering according to the three-dimensional model; therefore the frame is produced. The polymer micro spheres produced by the method in the present invention have regular shapes and adjustable particle diameter. The method is simple and practical. The mechanical property of the frame after forming is excellent. The horizontal movement between the layers is small and the forming accuracy is high.

Owner:HUAZHONG UNIV OF SCI & TECH

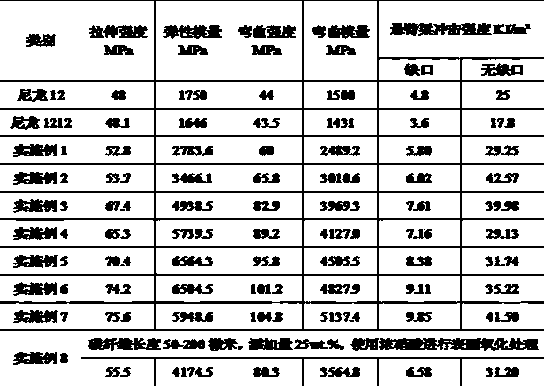

Carbon fiber reinforced resin powder material for selective laser sintering

The invention relates to a carbon fiber reinforced resin powder material for selective laser sintering (SLS). The powder material comprises 48-88 parts by mass of resin powder, 10-50 parts by mass of carbon fibers, 0.5-1.2 parts by mass of antioxidants, 0.2-1 part by mass of flow promoting agent and 0.2-0.6 parts by mass of dispersant per 100 parts by mass of the reinforced material. The carbon fiber reinforced resin powder material for selective laser sintering is obtained by configuring the each component sequentially according to a certain process. The strength and modulus of SLS molded parts made of the resin powder material disclosed by the invention, compared with SLS molded parts made of the matrix resin material, are greatly enhanced and the requirements on the mechanical performance of the molded parts directly as end products can be met better.

Owner:HUNAN FARSOON HIGH TECH CO LTD

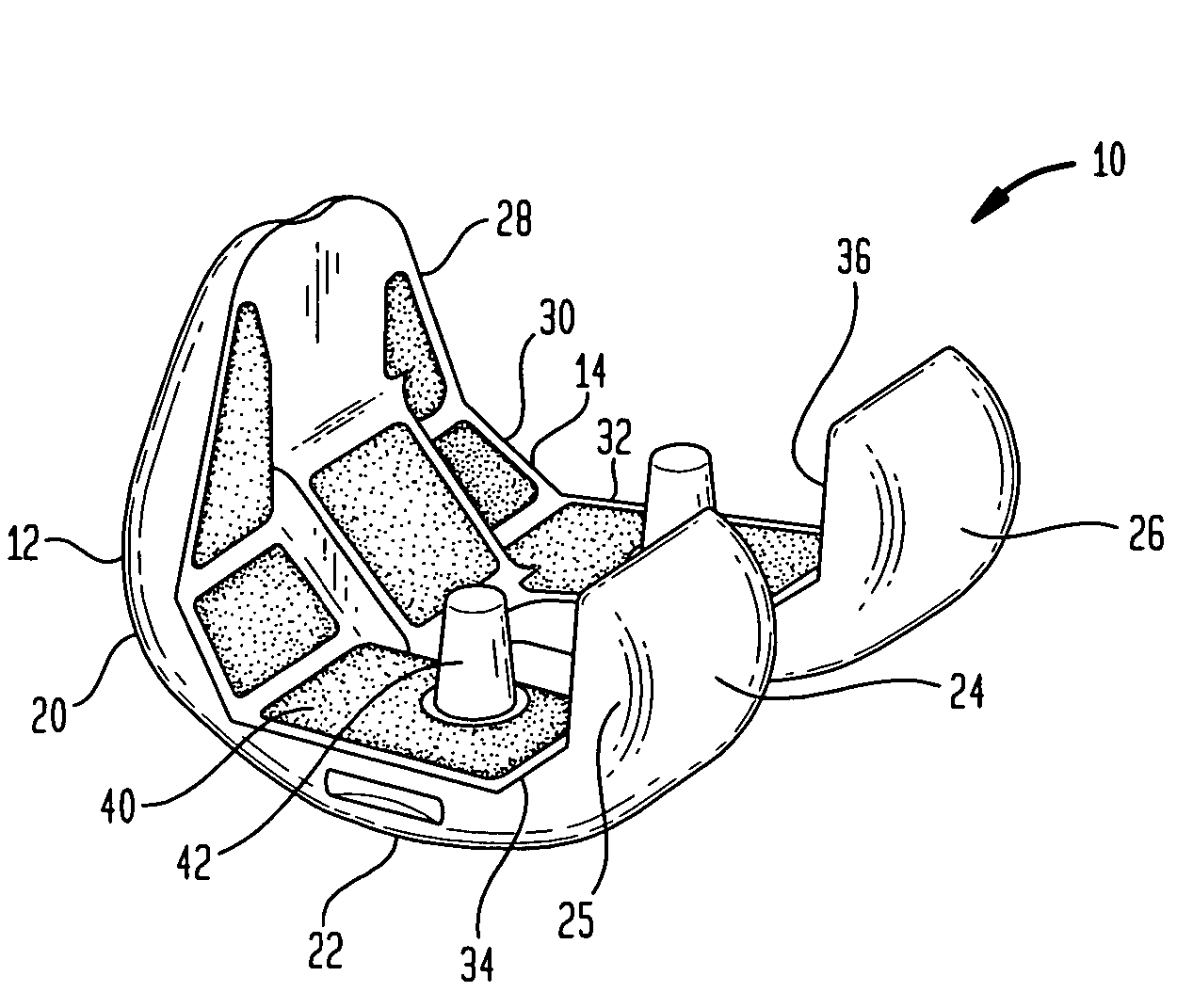

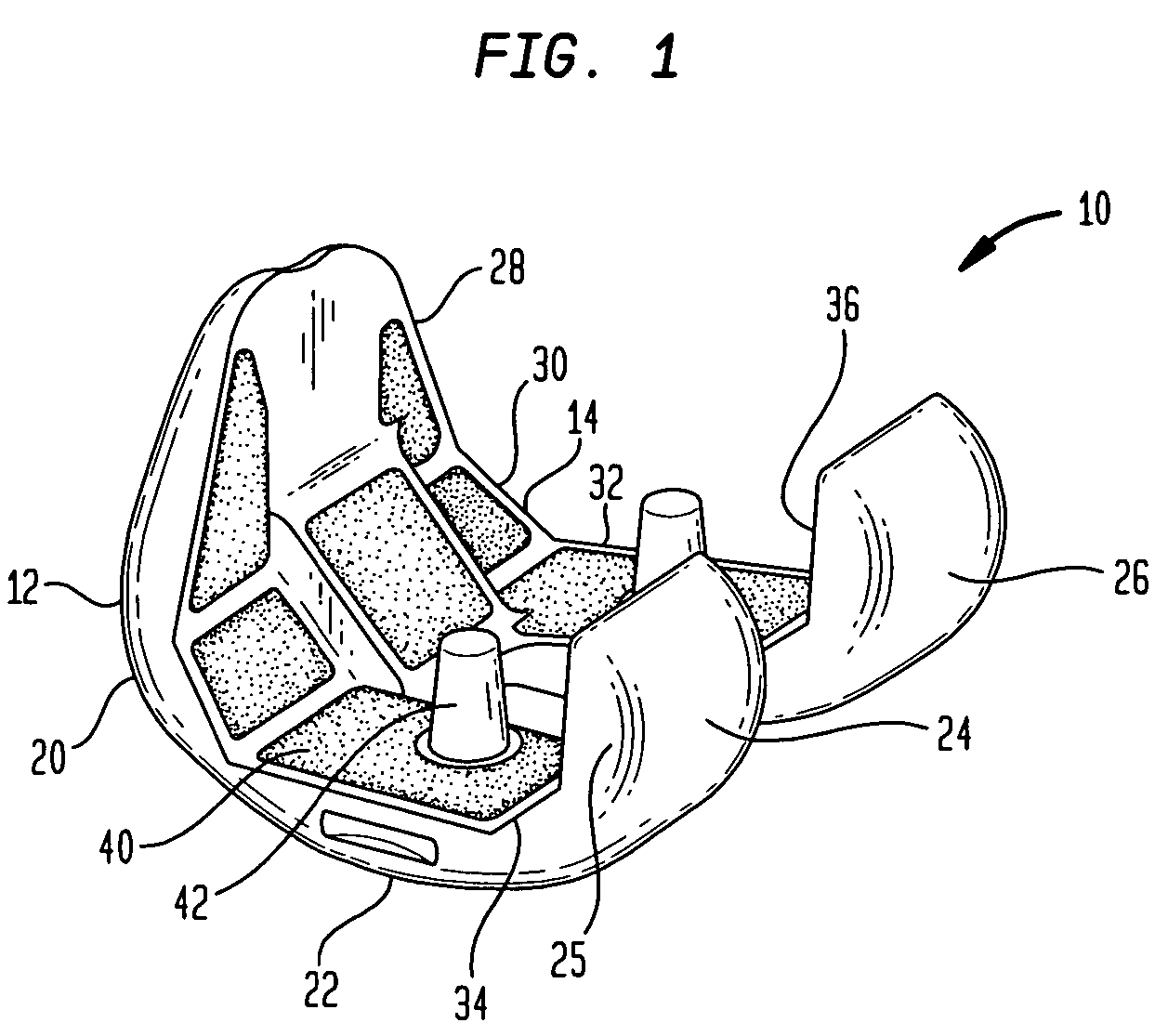

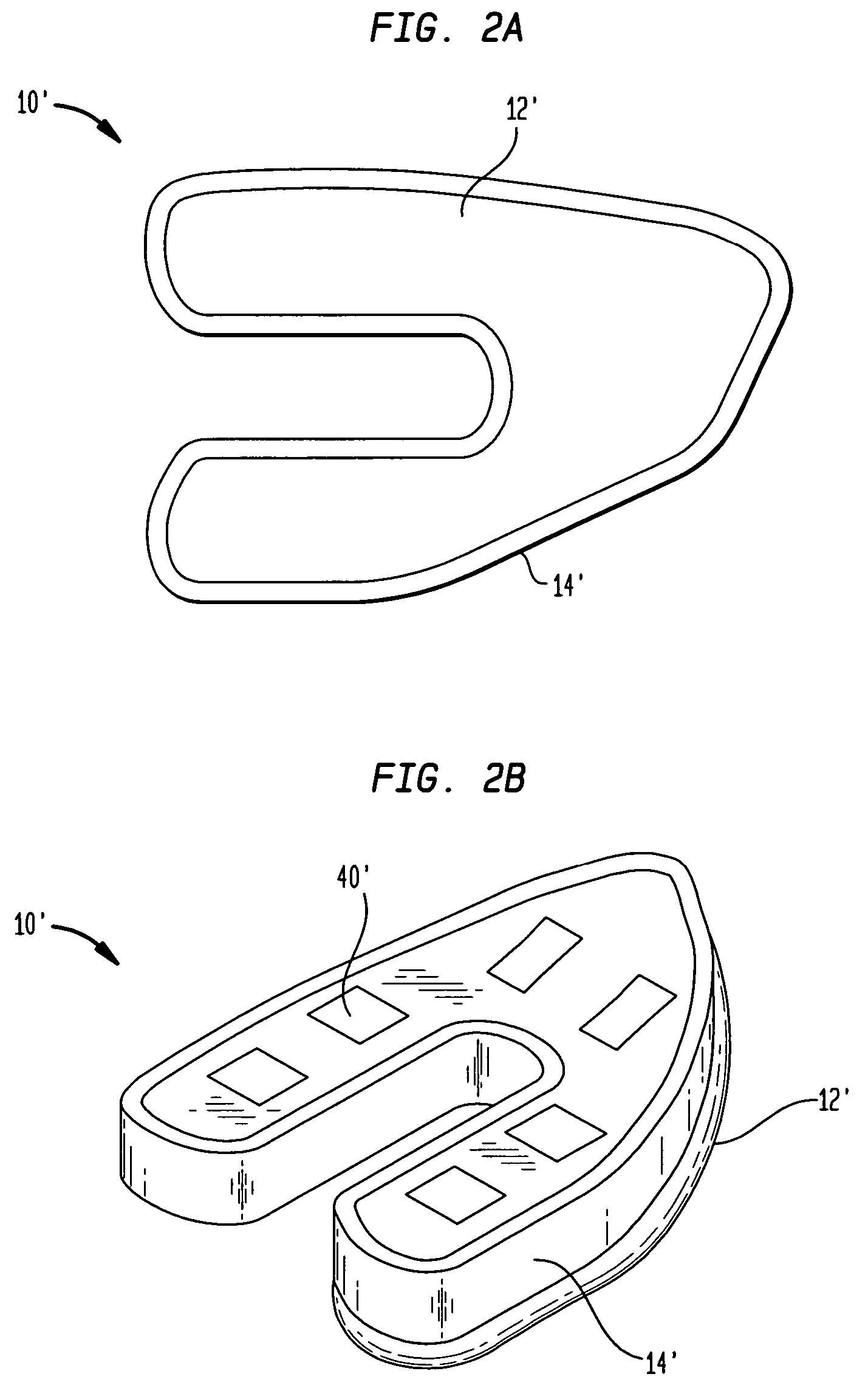

Built-in attachment device using selective laser sintering

ActiveUS20070051704A1Low profileSave spaceAdditive manufacturing apparatusAdditive manufacturing with solidsSelective laser sinteringLithographic artist

A method of assembling a first part and a second part. The method may comprise the step of integrally forming an attachment device and a first part. For example, the attachment device may be a nut plate operative to retain a nut therein, and the first part may be an air duct. The nut plate and the air duct may be integrally formed via selective laser sintering or stereo lithography such that the nut plate is an integral feature of the air duct. A nut may be retained in the nut plate, and a mating bolt may engage the nut to attach the air duct (i.e., the first part) to the second part.

Owner:NORTHROP GRUMMAN SYST CORP

Preparation method of polyamide powder used for selective laser sintering

Owner:HUNAN FARSOON HIGH TECH CO LTD

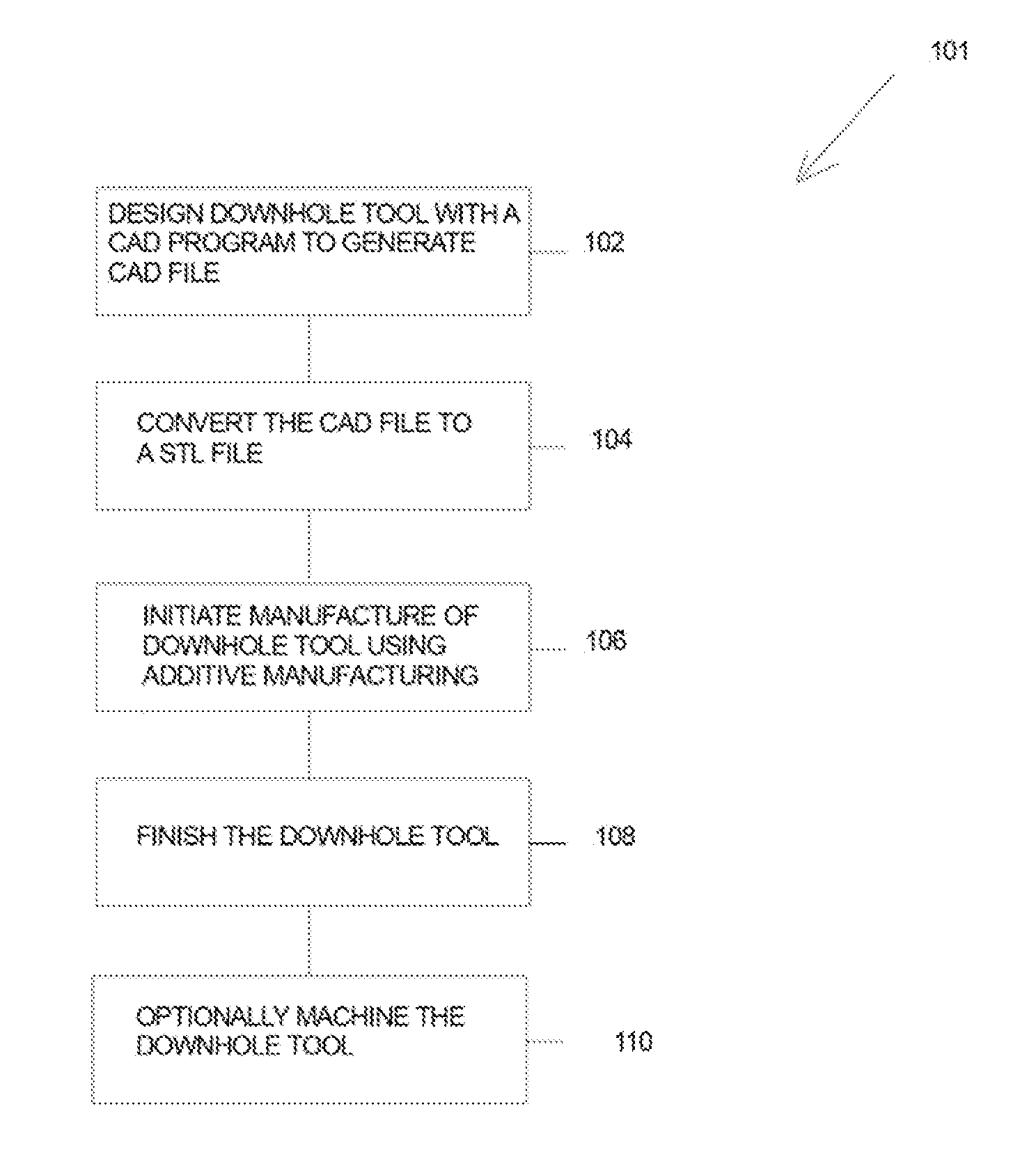

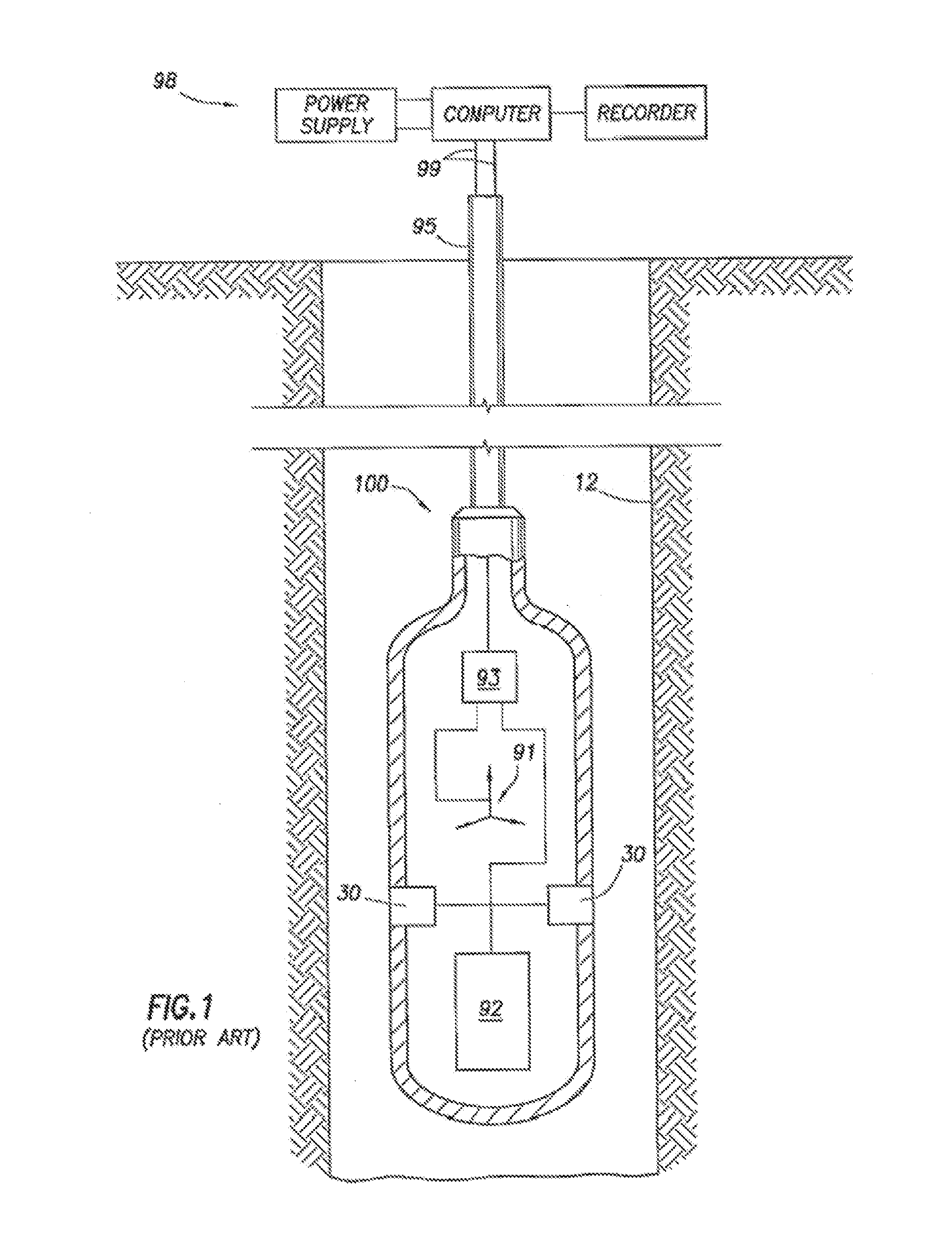

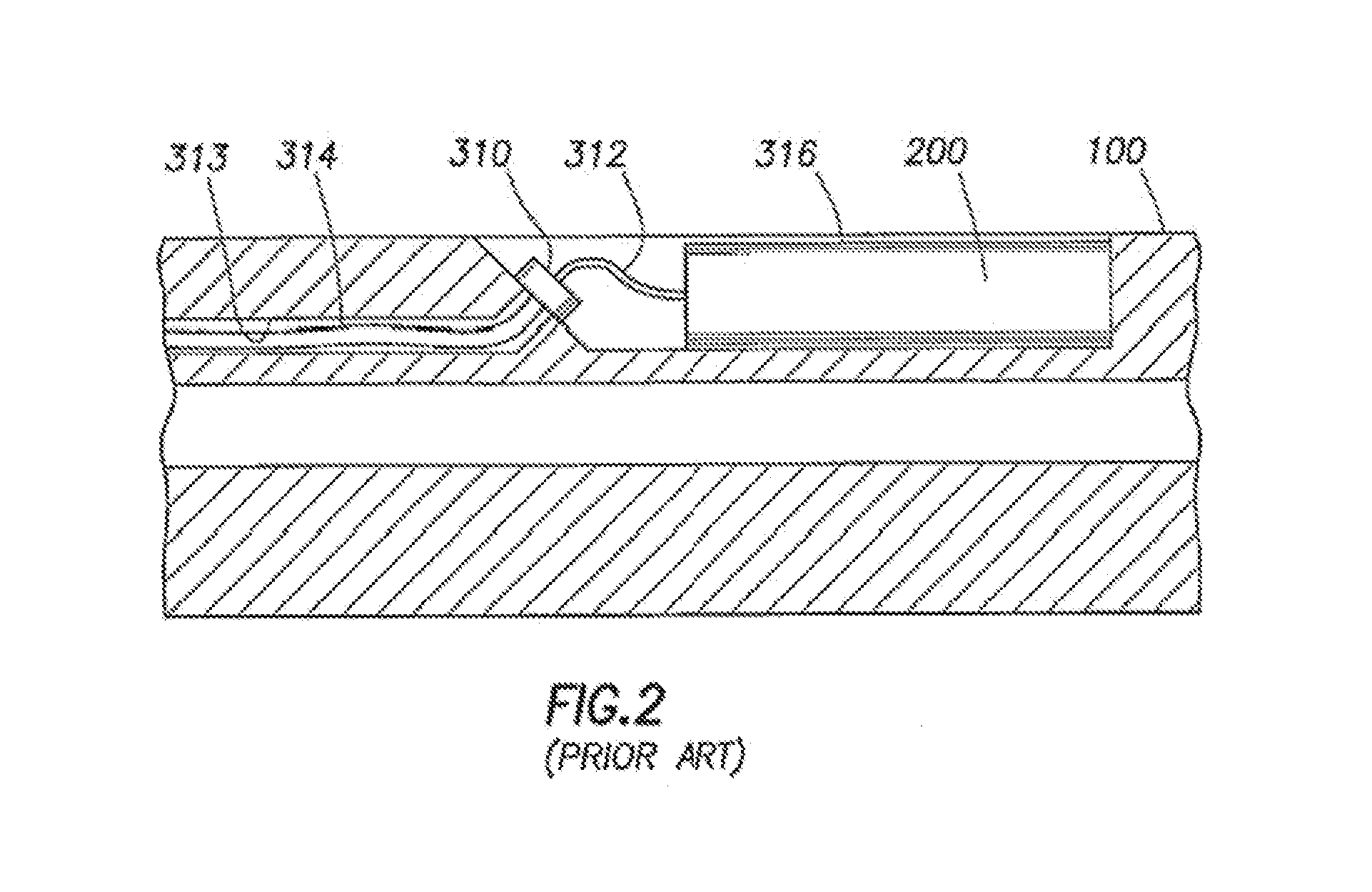

Addititve manufacturing of components for downhole wireline, tubing and drill pipe conveyed tools

InactiveUS20130310961A1Additive manufacturing apparatusIncreasing energy efficiencyDirect metal laser sinteringSelective laser sintering

Additive manufacturing may be used to manufacture components of downhole tools conveyed by downhole wireline, tubing, drill pipe and / or the like. A method in accordance with one or more aspects of the disclosure uses starting materials to incorporate one or more feedthroughs, passages, channels, chambers and the like in a downhole tool structure during the formation of the structure. A CAD may be made and then converted to a STL file, and then stereo lithography, selective laser sintering, fused deposition modeling, direct metal laser sintering and / or electron beam melting may be used to form the downhole tool. Subtractive manufacturing may be performed on the downhole tool after the downhole tool is formed by additive manufacturing.

Owner:SCHLUMBERGER TECH CORP

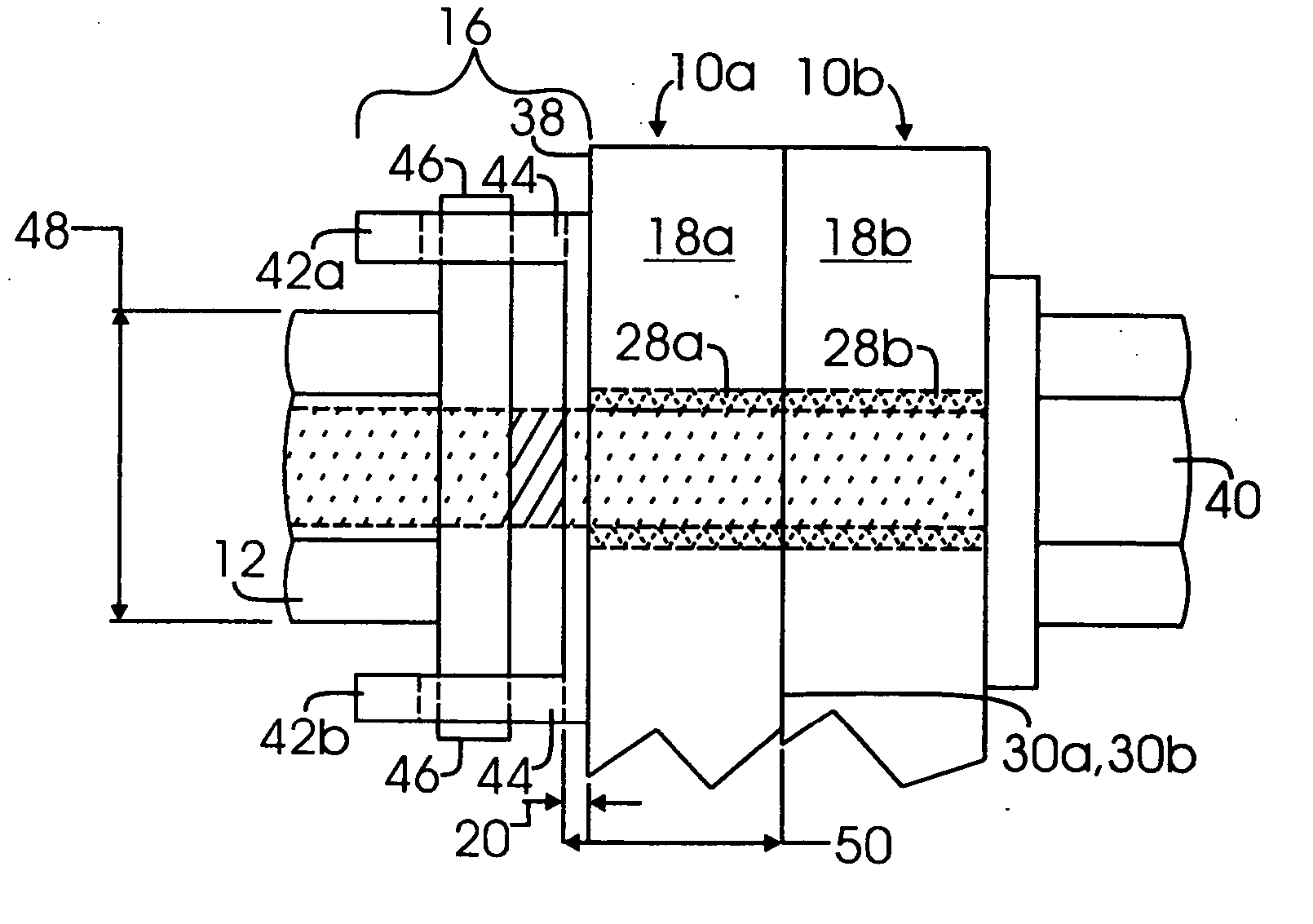

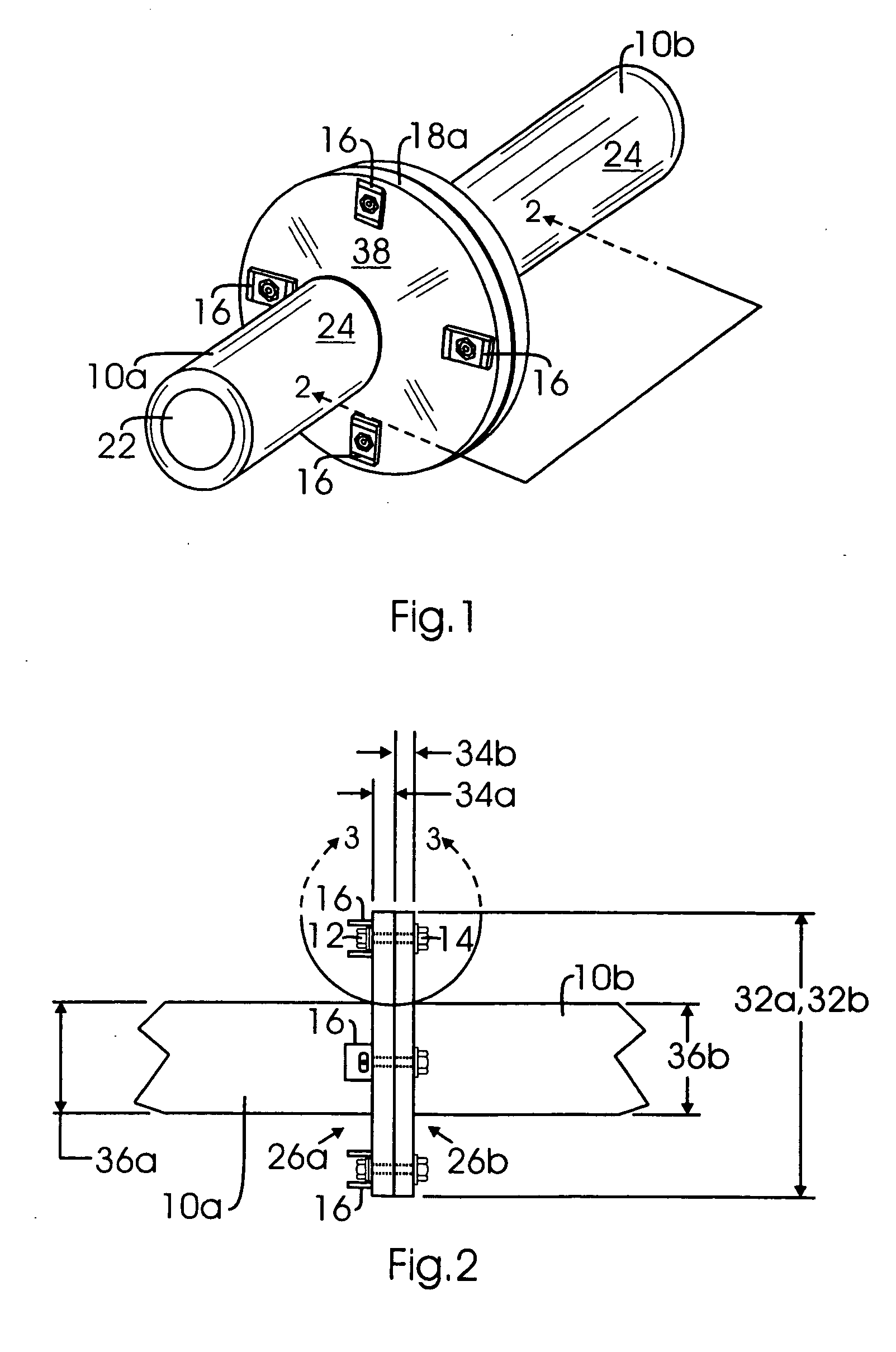

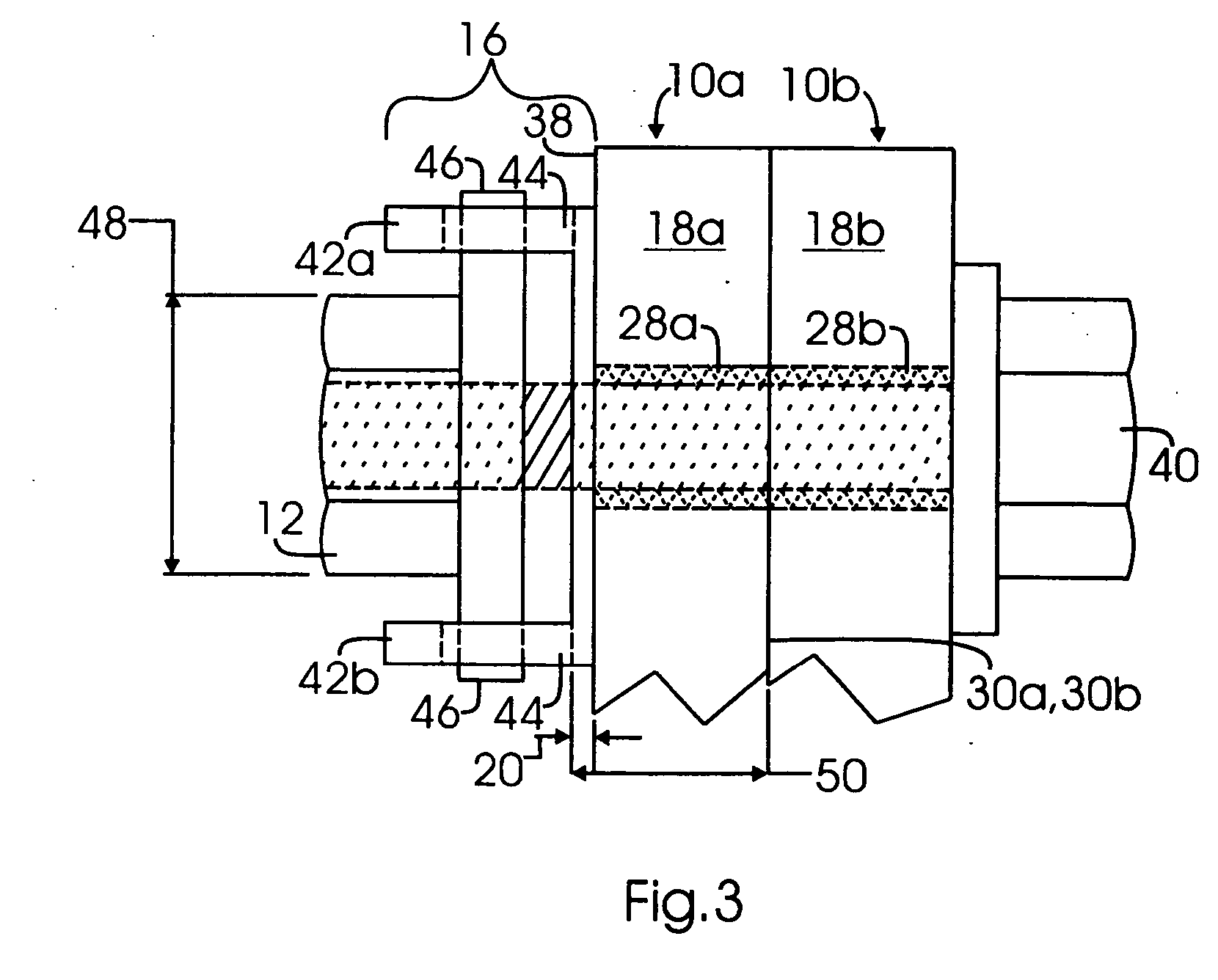

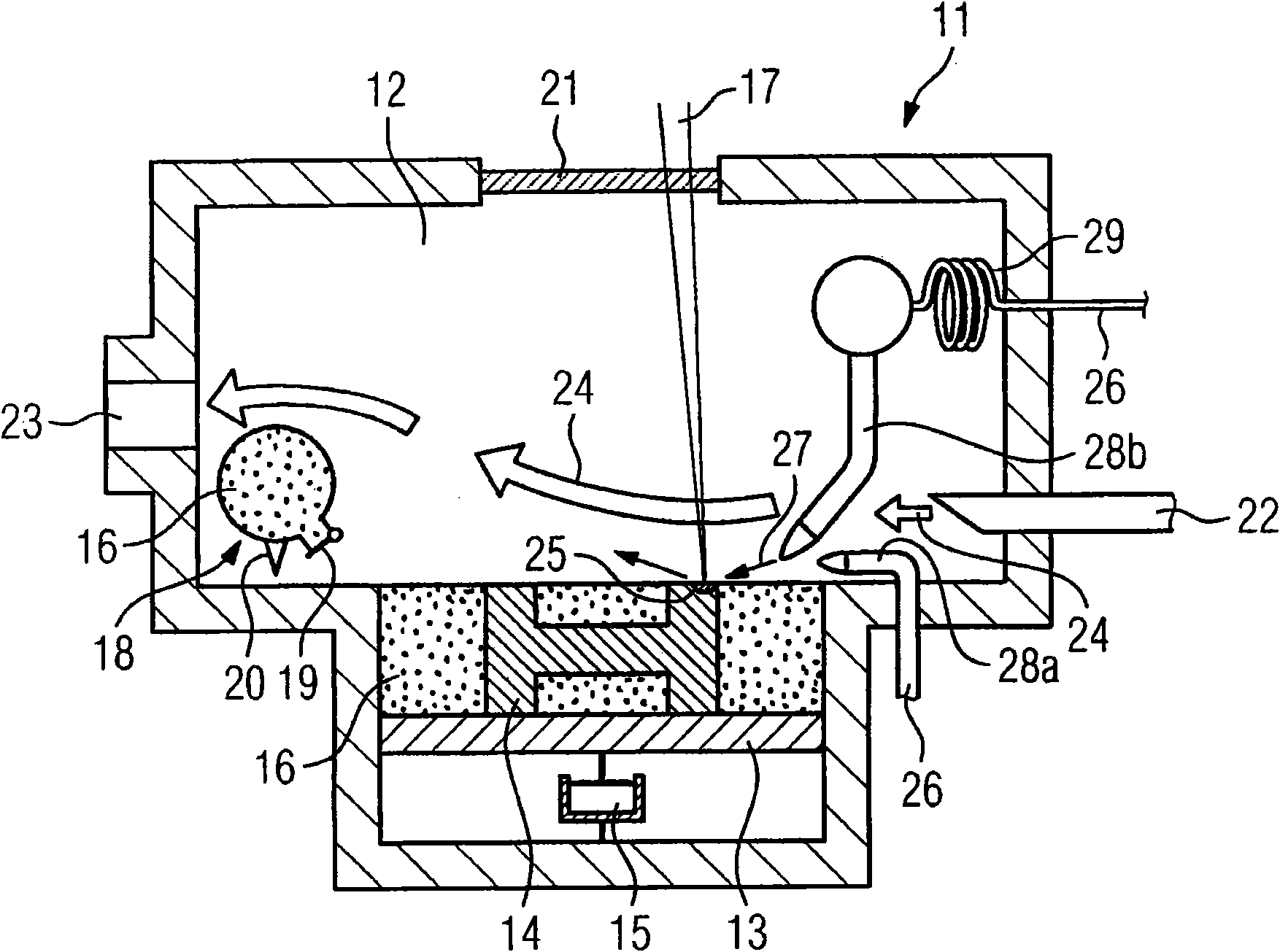

Method for producing a component through selective laser melting and process chamber suitable therefor

InactiveCN102076456AReduce consumptionEasy to introduceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to a method for producing a component through selective laser melting and to a process chamber (11) for carrying out the method. According to the invention, the selective laser melting by way of a laser (17) is also used for producing coating areas (25) of the component (14) being produced, said coating areas having a composition that differs from the composition of the powder. This is accomplished by intermittently introducing a reactive gas (27) that reacts with the powder material or that produces a material on the component (14) from precursors present in the reactive gas. In the process chamber according to the invention, an additional feed line (28a, 28b) is provided for introducing reactive gas, said feed line permitting the feeding of the reactive gas if possible close to the laser (17).

Owner:SIEMENS AG

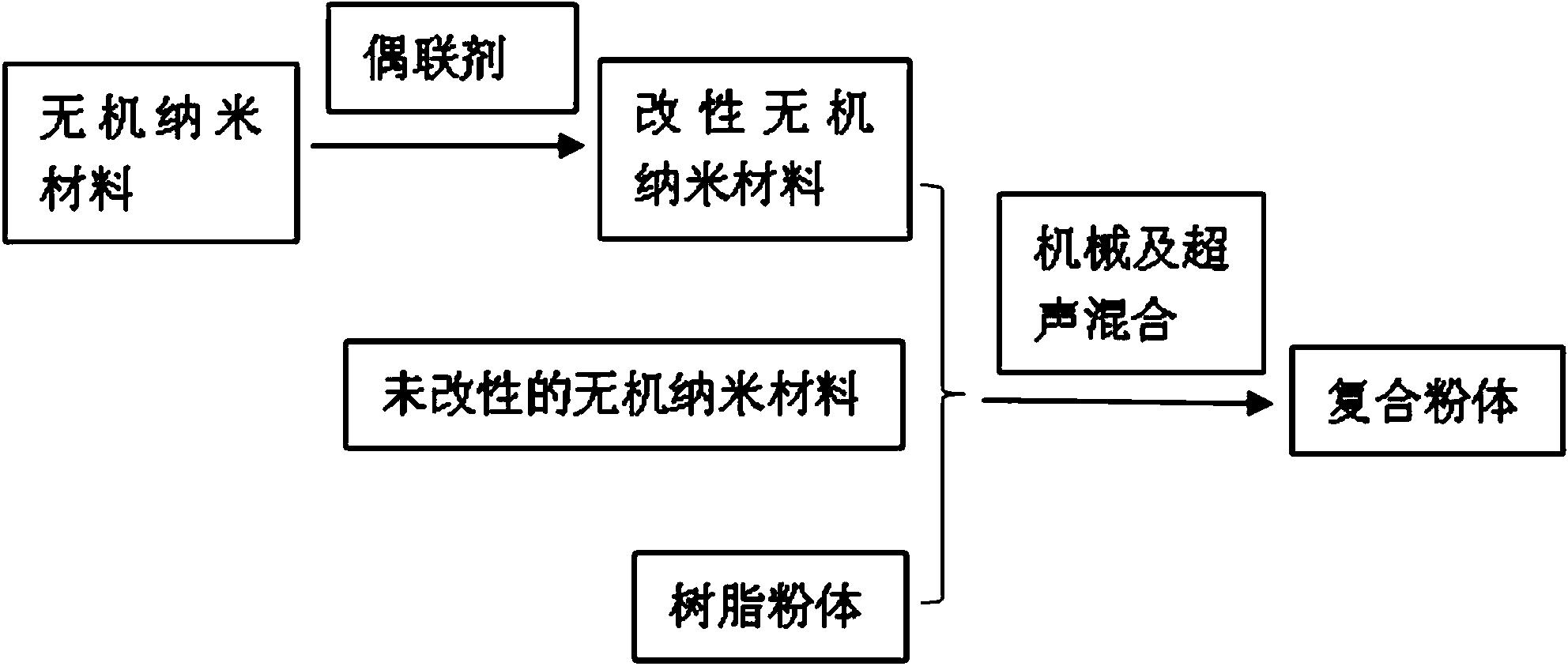

High-fluidity powder material for selective laser sintering

InactiveCN104140668AImprove liquidityUnique Surface Interface EffectApparent densitySelective laser sintering

The invention discloses a high-fluidity powder material for selective laser sintering. The high-fluidity powder material comprises a plastic powder body and inorganic nanometer materials, wherein the diameter of the plastic powder body ranges from 40 micrometers to 150 micrometers, the weight of the inorganic nanometer materials accounts for 0.01% to 5% of the total weight of the high-fluidity powder material, and the inorganic nanometer materials are surface-modified inorganic nanometer particles or unmodified inorganic nanometer materials. According to high-fluidity powder material for selective laser sintering, a small number of modified or unmodified inorganic nanometer materials are added into the plastic powder body, due to the fact that the nanometer materials are special in structure, are in the unstable thermodynamics status and have the unique surface interface effect, the fluidity of the powder body and the apparent density of the powder body can be remarkably enhanced, and the high-fluidity powder material is more suitable for SLS sintering. According to the high-fluidity powder material for selective laser sintering, no special requirements for types of plastic powder bodies exist, and the application range is wide.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

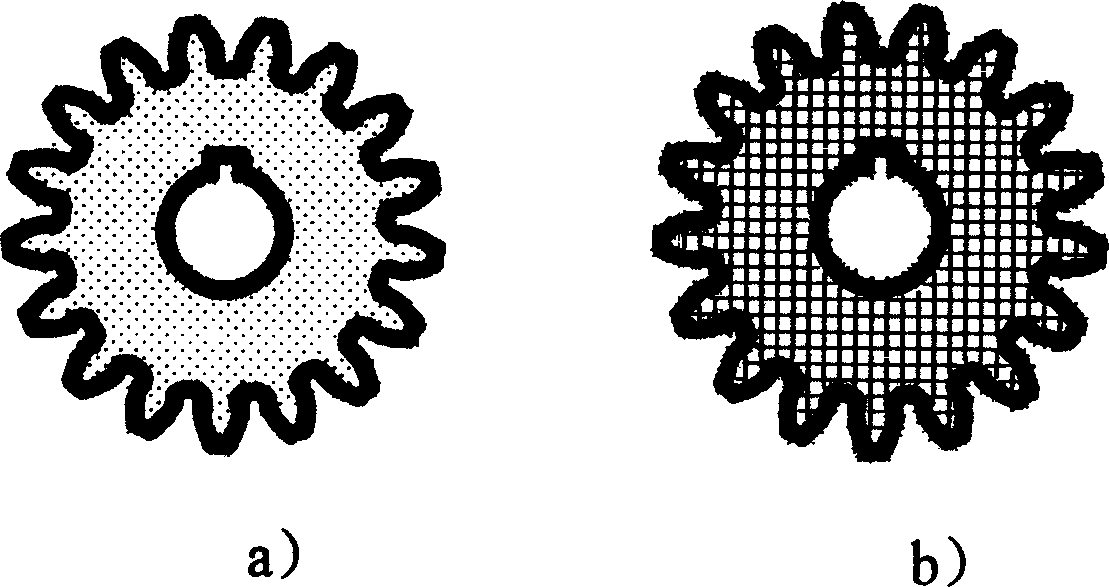

3D (Three Dimensional) forming method for large-sized porous amorphous alloy part of complex shape

ActiveCN104399978ASolve difficult-to-machine defectsOvercoming the Deficiencies of Difficult ChoicesSelective laser sinteringAlloy

The invention discloses a 3D (Three Dimensional) forming method for a large-sized porous amorphous alloy part of a complex shape. The method comprises the following steps: preparing amorphous alloy powder through mechanical alloying pulverization in combination with plasma spherizing or atomization; then sintering metal powder by using selective laser so as to prepare the large-sized porous amorphous alloy part with the complex shape. The method has the advantages that the problems such as small critical dimension of amorphous alloy formed by a water quenching method and a copper mold casting method and difficulty in selection of a pore forming agent are solved, the 3D preparation and forming of the large-sized porous amorphous alloy part are realized, the part with the complex shape can be prepared, the defect of difficulty in machining of the amorphous alloy material is overcome, the amorphous alloy part of the porous structure can be conveniently formed, the pore size and the volume fraction can be flexibly adjusted, and the method has the advantages of raw material saving, high efficiency, low cost and the like and is suitable for industrialized preparation of the amorphous alloy part.

Owner:SOUTH CHINA UNIV OF TECH

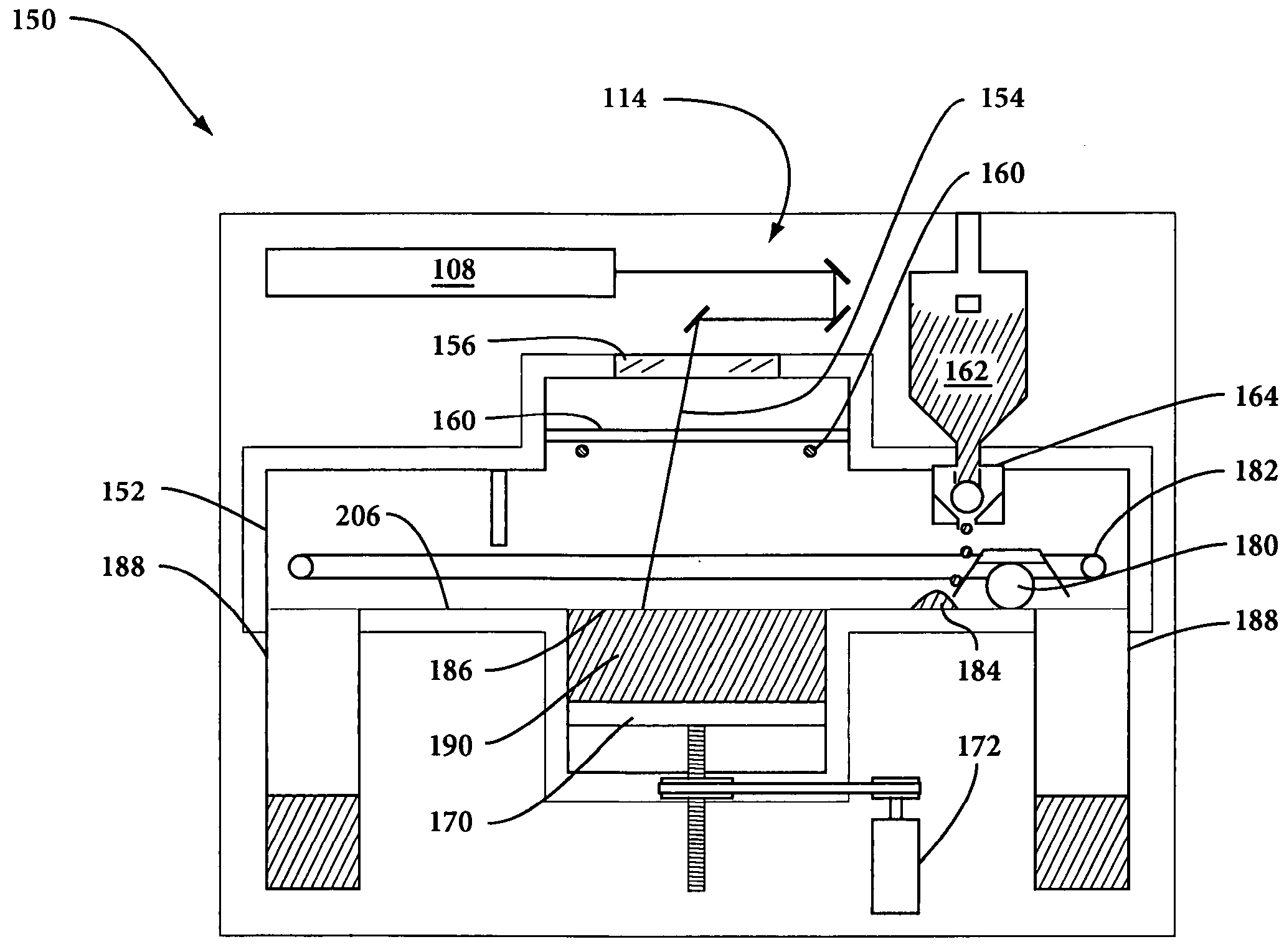

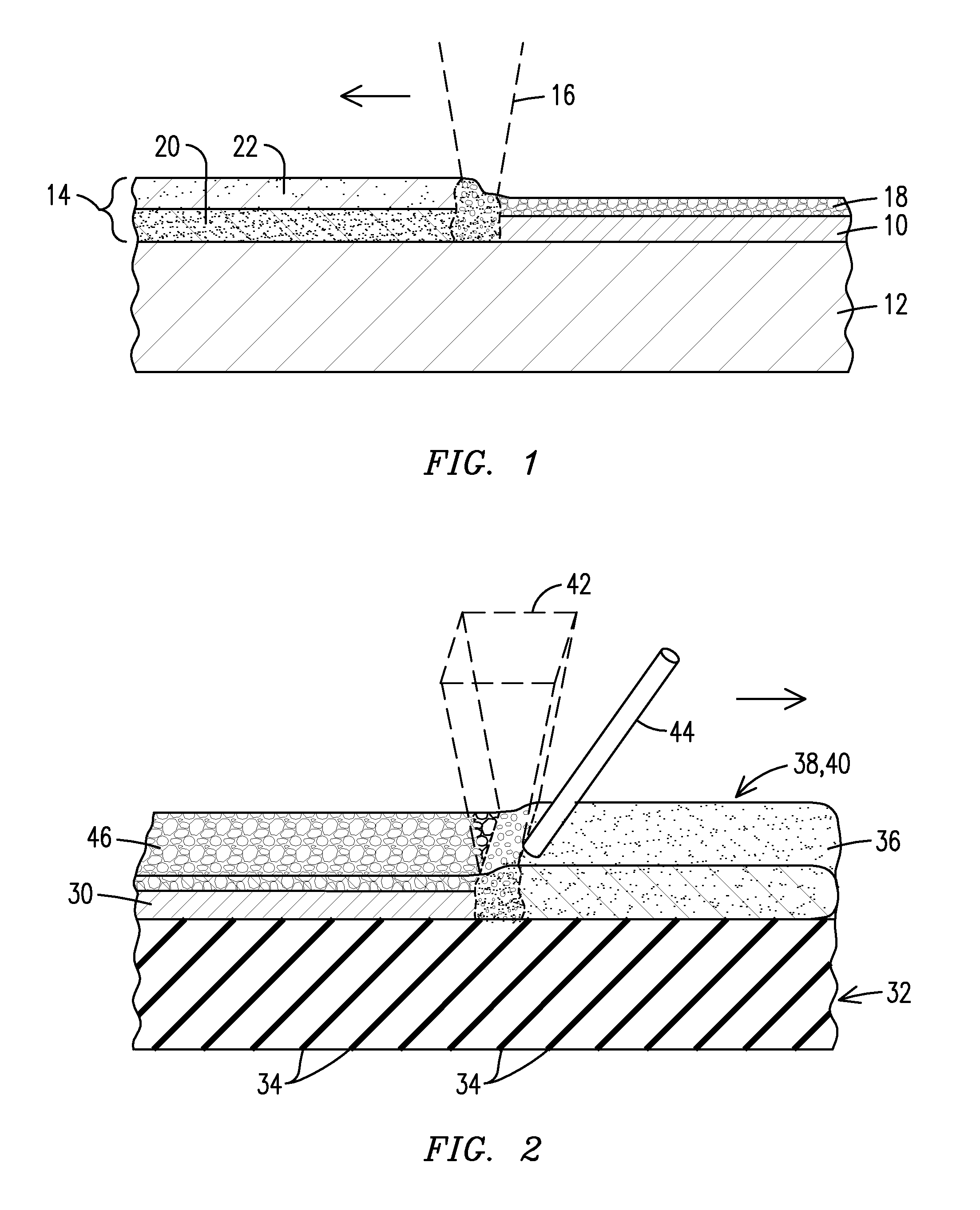

Selective laser melting / sintering using powdered flux

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

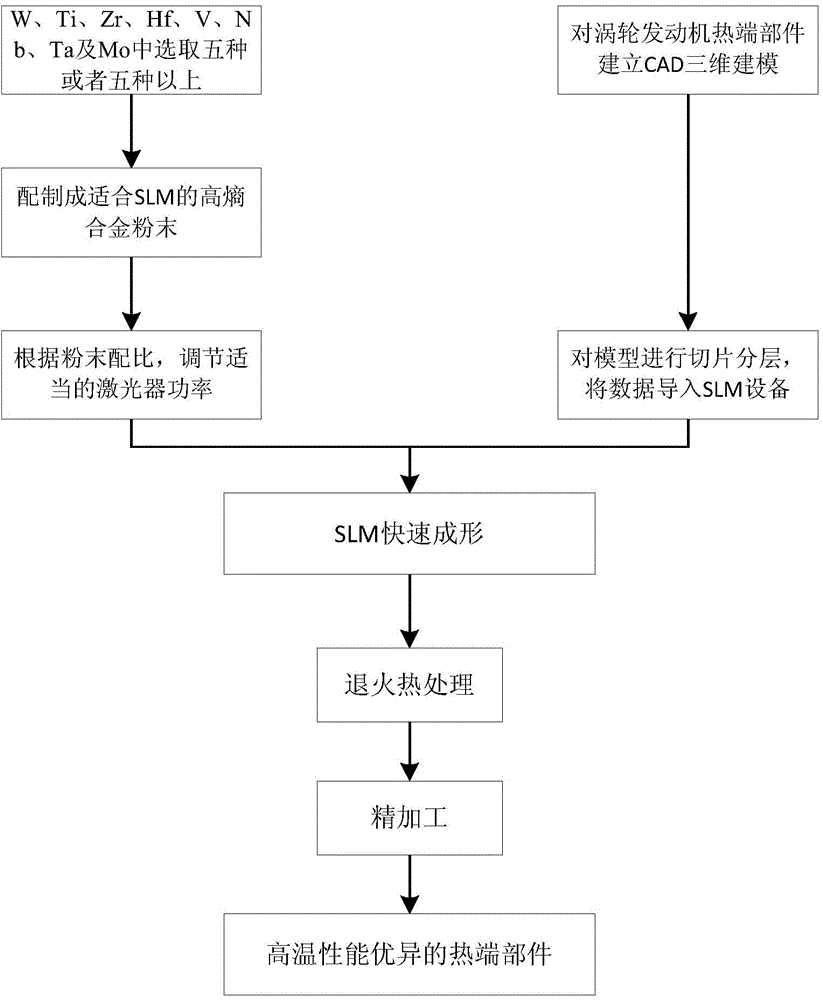

High-entropy alloy hot-end part manufacturing method of turbine engine on basis of selective laser melting

ActiveCN104308153AMeet the requirements of gas temperature to form a large thrustSatisfy the requirement of increasing the gas temperature to form a large thrustTurbinesIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a high-entropy alloy hot-end part manufacturing method of a turbine engine on the basis of selective laser melting and belongs to the technical field of manufacture of hot-end parts of the turbine engine. The high-entropy alloy hot-end part manufacturing method includes firstly selecting five or more of eight kinds of high-melting metal powder of tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum, and mixing the powder uniformly according to a certain mole ratio to obtain high-entropy alloy powder; setting up a three-dimensional solid model of a hot-end part of the turbine engine, slicing and layering by software to obtain profile data of various sections, and importing the data into a quick forming device; quickly forming a hot-end part blank of the turbine engine by the SLM technology; thermally treating and finely processing the blank to obtain the high-temperature high-entropy alloy hot-end part of the turbine engine. The formed hot-end part of the turbine engine has high compactness and excellent high temperature performance, has high forming accuracy and surface accuracy and can be quickly and accurately manufactured.

Owner:XI AN JIAOTONG UNIV

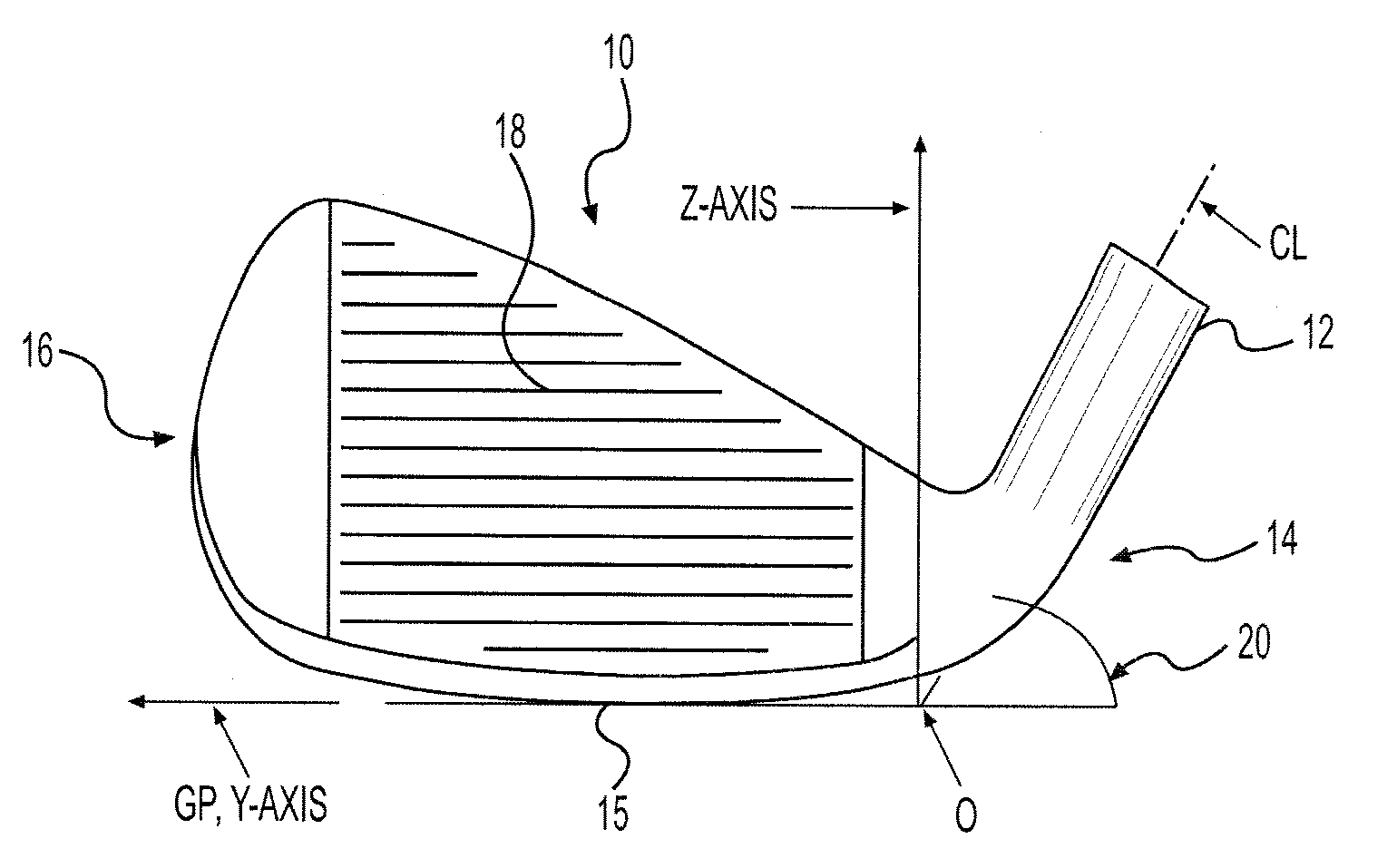

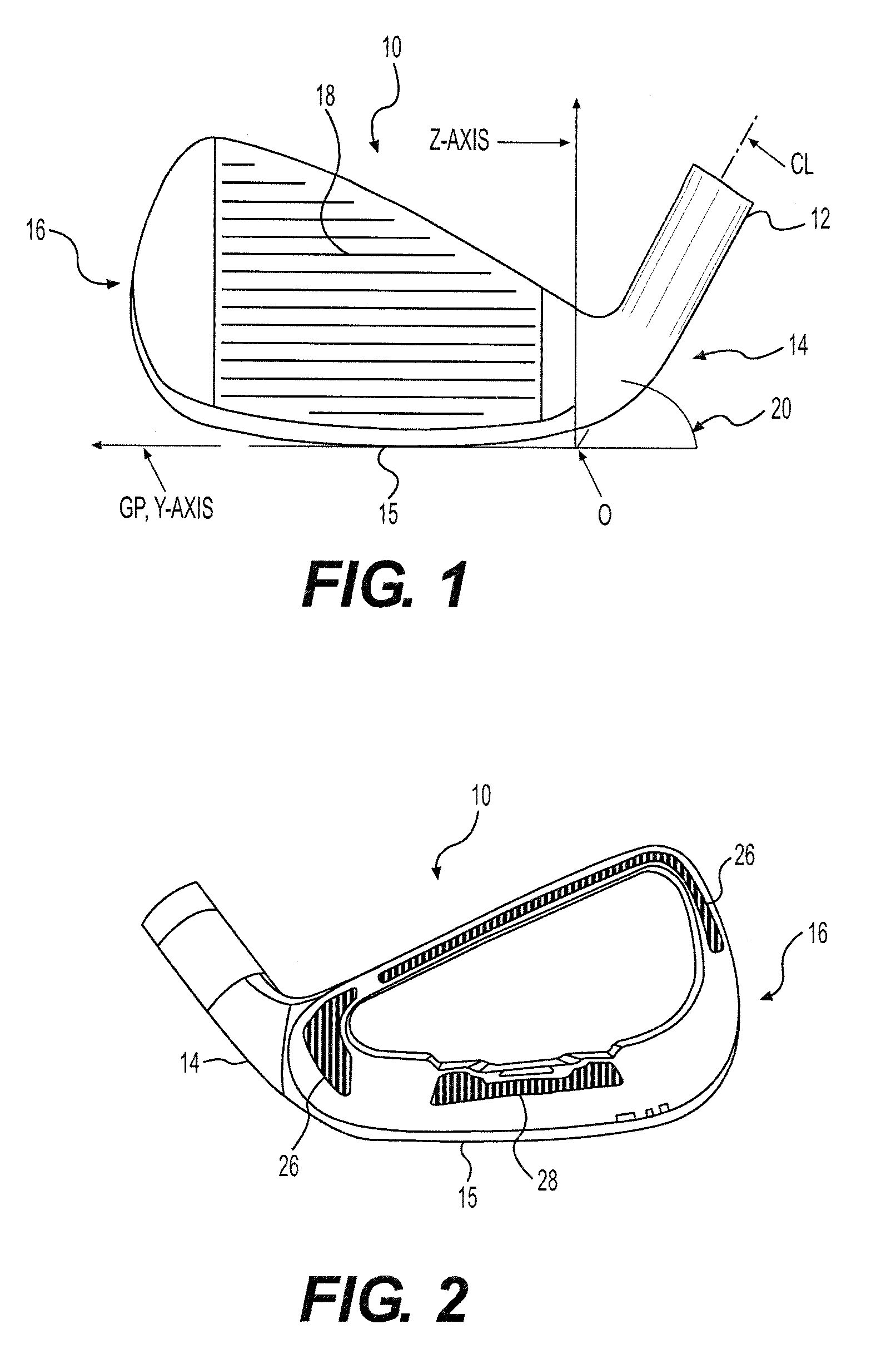

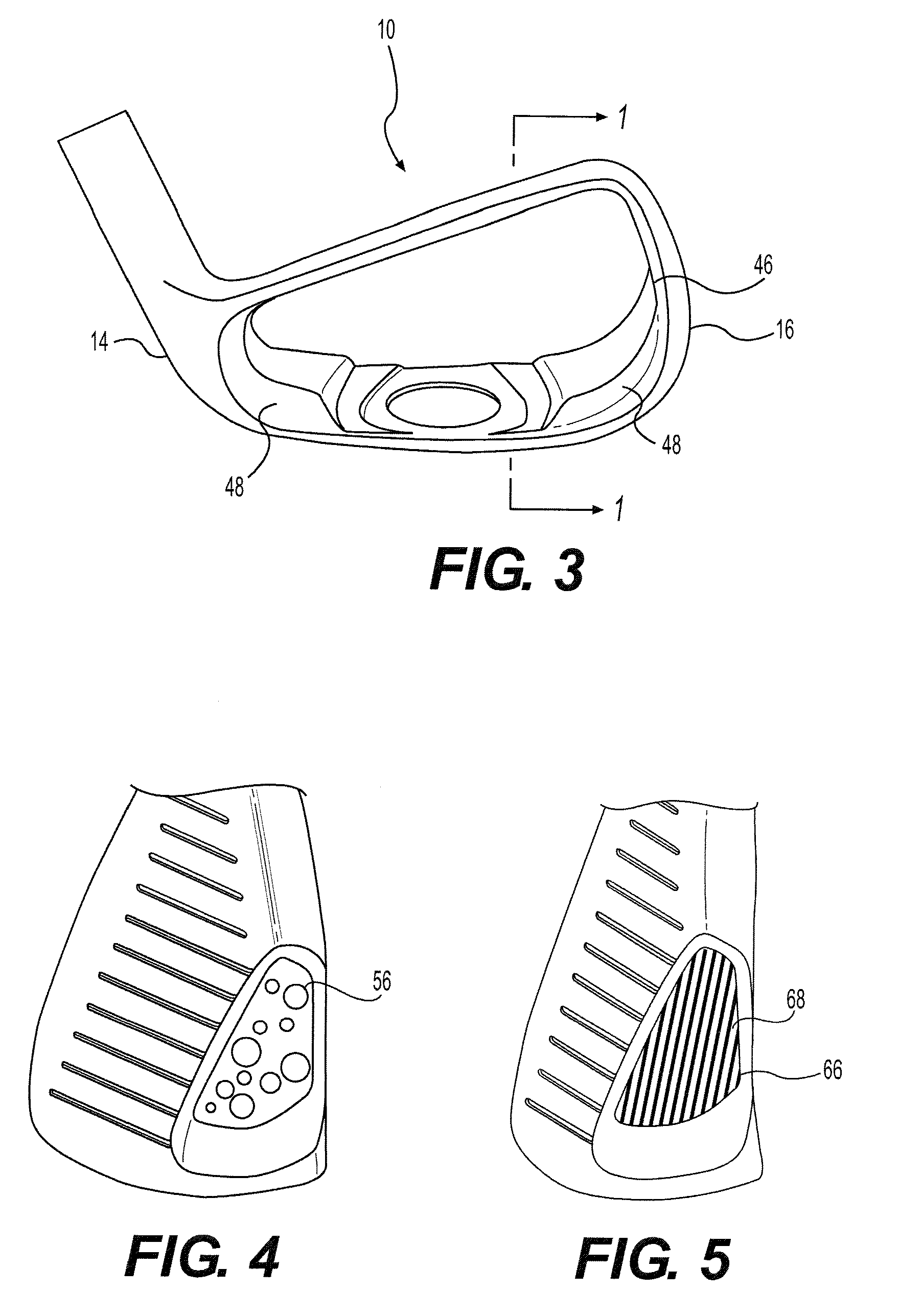

Method of making golf clubs

ActiveUS20100298065A1Additive manufacturing apparatusIncreasing energy efficiencySelective laser meltingPorosity

A method for making golf club heads includes using direct metal laser sintering (DMLS), selective laser melting (SLM) and other computer controlled high energy sintering or melting techniques to form club heads with customized user parameters. The powdered metals can be selected by type and quantity to achieve a desired density or weight distribution. Club heads made by these techniques are characterized by having customized parameters chosen for individual golfers. By sintering powdered metal to form areas of different porosity, club heads with desired weight distributions can be achieved.

Owner:COBRA GOLF

Porous laser sintered articles

Owner:ORTHOVITA INC

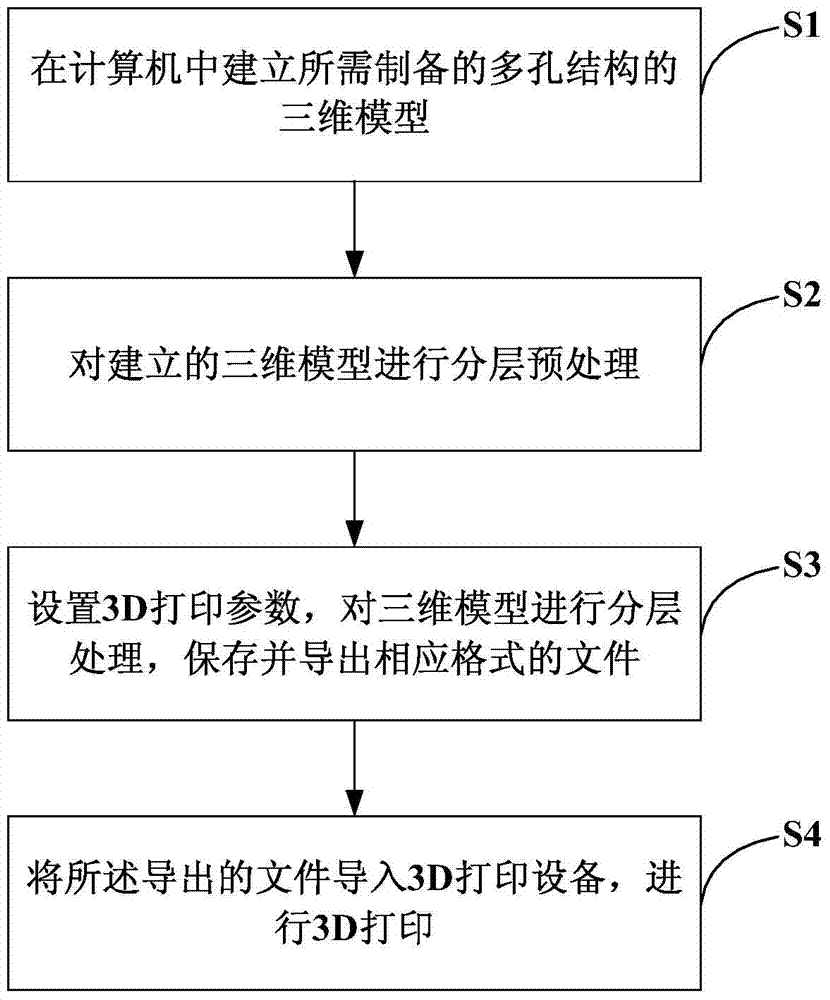

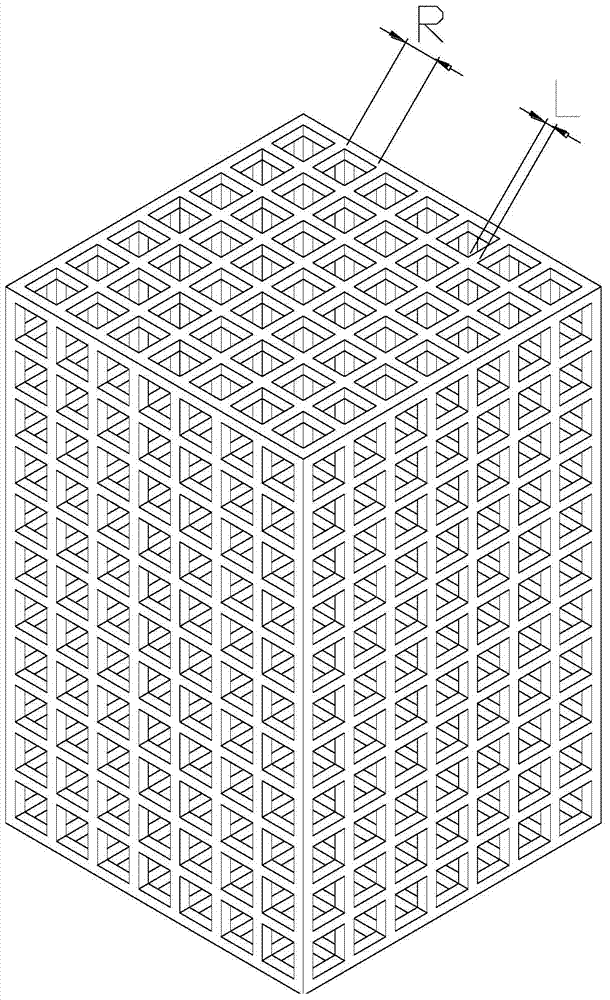

Method for manufacturing pure titanium porous structure through selective laser melting

ActiveCN103495731AOvercome stabilityOvercome the disadvantages of single shapeSelective laser meltingSelective laser sintering

The invention provides a method for manufacturing a pure titanium porous structure through selective laser melting. The method for manufacturing the pure titanium porous structure through selective laser melting comprises the following steps that firstly, a three-dimensional model of the porous structure to be manufactured is built in a computer; secondly, hierarchical preprocessing is conducted on the built three-dimensional model; thirdly, 3D printing parameters are set, hierarchical processing is conducted on the three-dimensional mode, and a file of a corresponding format is saved and exported; fourthly, the exported file is imported into 3D printing equipment, and 3D printing is conducted. According to the method for manufacturing the pure titanium porous structure through selective laser melting, metal parts with various macro-structure porous structures can be manufactured according to actual requirements, one-time forming is realized, the shortcomings of unstable mechanical properties and a simplex shape caused by a traditional processing method are overcome, and processing efficiency and economic benefit are improved.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Powder material for selective laser sintering and preparation method thereof

InactiveCN105985632AHigh sphericitySimple preparation processCoatingsSelective laser sinteringAntioxidant

The invention discloses a powder material for selective laser sintering and a preparation method thereof. The powder material is composed of, by weight, 10-90 parts of resin matrix, 5-90 parts of filler, 0.1-5 parts of coupling agent, 0.1-5 parts of dispersant, 0.1-5 parts of compatibilizer, 0.1-8 parts of flow promoting agent, 0.01-3 parts of antioxidant, 0.05-2 parts of light absorbing agent, 0.01-2 parts of lubricant and 0.05-4 parts of surfactant. The preparation method includes: treating the surface of the filler; blending raw materials; banburying the raw materials; powdering; spherifying powder; performing surface modification on the powder. Compared with the prior art, the powder material and the preparation method have the advantages that the preparation method is simple and supportive of continuous production; the preparation process is energy-saving, environment-friendly and pollution-free; resin in the powder material prepared by the method uniformly coats the surface of the filler, and the powder is high in sphericity and excellent in sintering performance.

Owner:HEFEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com