Manufacture method and device of three-dimensional workpiece

A manufacturing method and technology of workpieces, applied in the field of manufacturing and equipment of three-dimensional workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limited to these descriptions. For those of ordinary skill in the technical field of the present invention, without departing from the concept of the present invention, some simple deduction or replacement can be made, which should be regarded as belonging to the protection scope of the present invention.

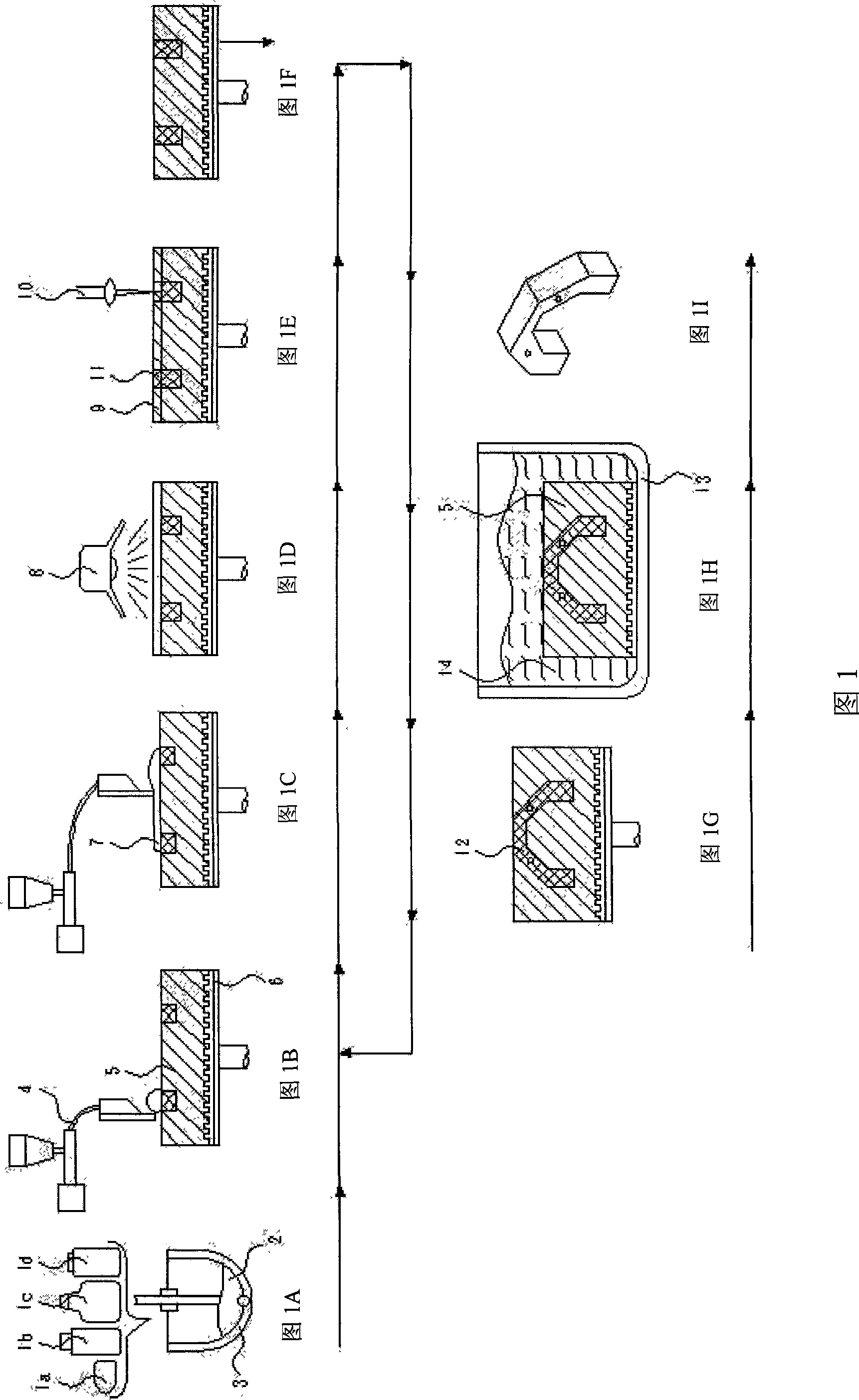

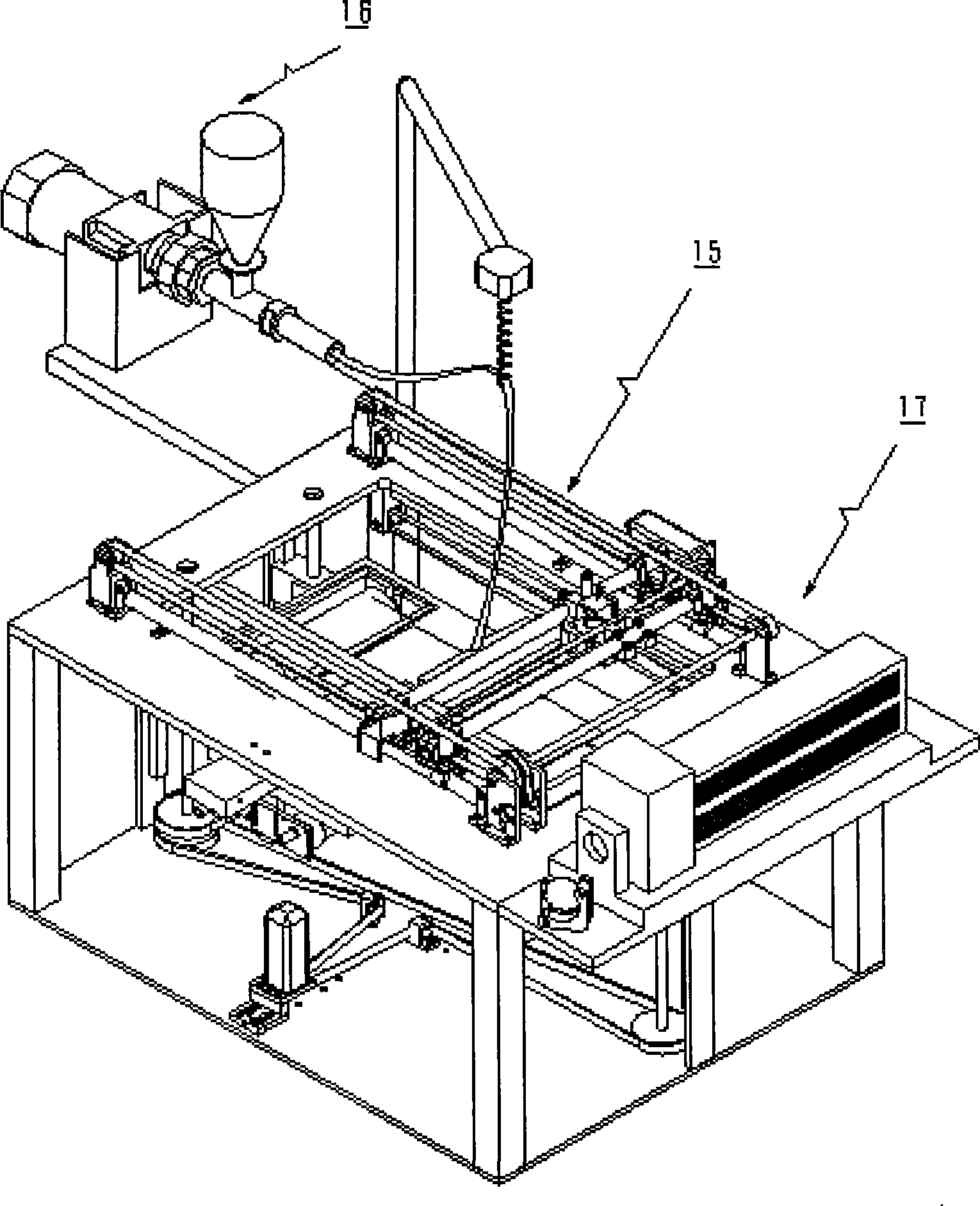

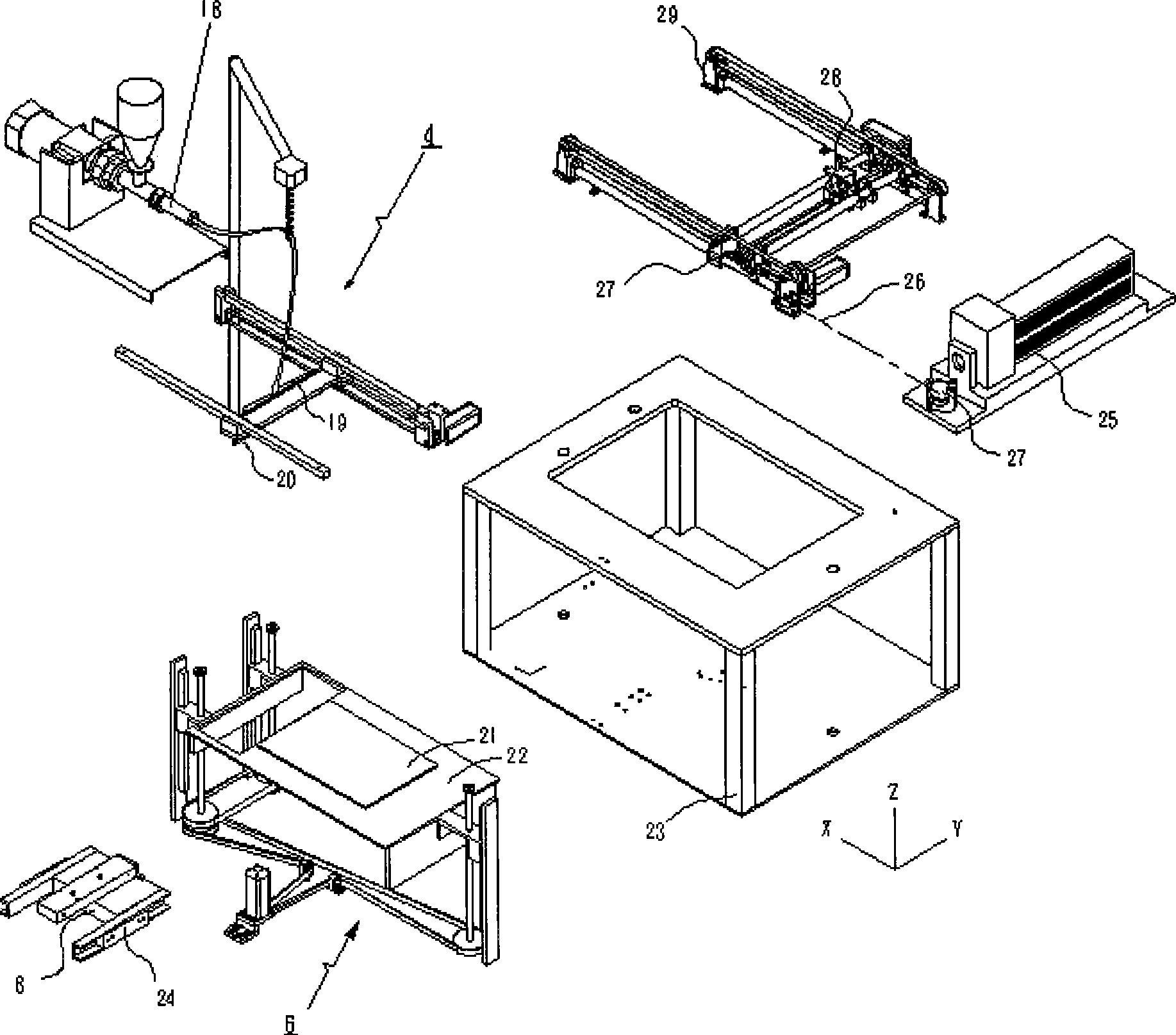

[0064] figure 1- image 3 Explanation of main component symbols

[0065] 1a, powder; 1b, solvent; 1c, organic adhesive; 1d, additive; 2, slurry; 3, stirring device; 4, laying thin layer device; 5, green block; 6, workbench; 7, slurry Thin layer; 8. Heater; 9. Green thin layer; 10. Energy beam; 11. Workpiece thin layer; 12. Workpiece; 13. Green body removal container; 14. Disintegrant; 15. Rapid prototyping machine; 16 17. Energy beam sintering equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com