Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1617results about How to "Not easy to scratch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

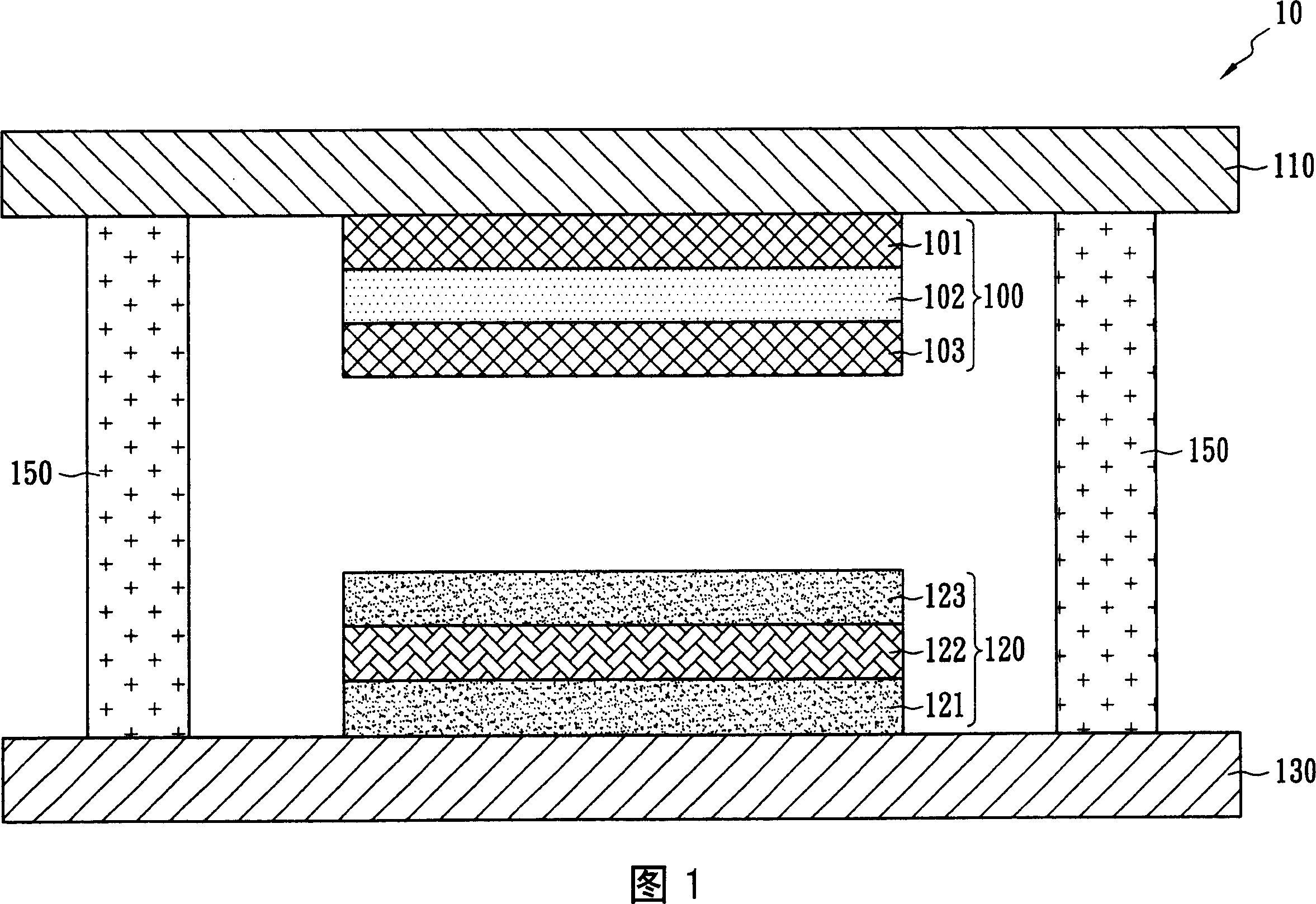

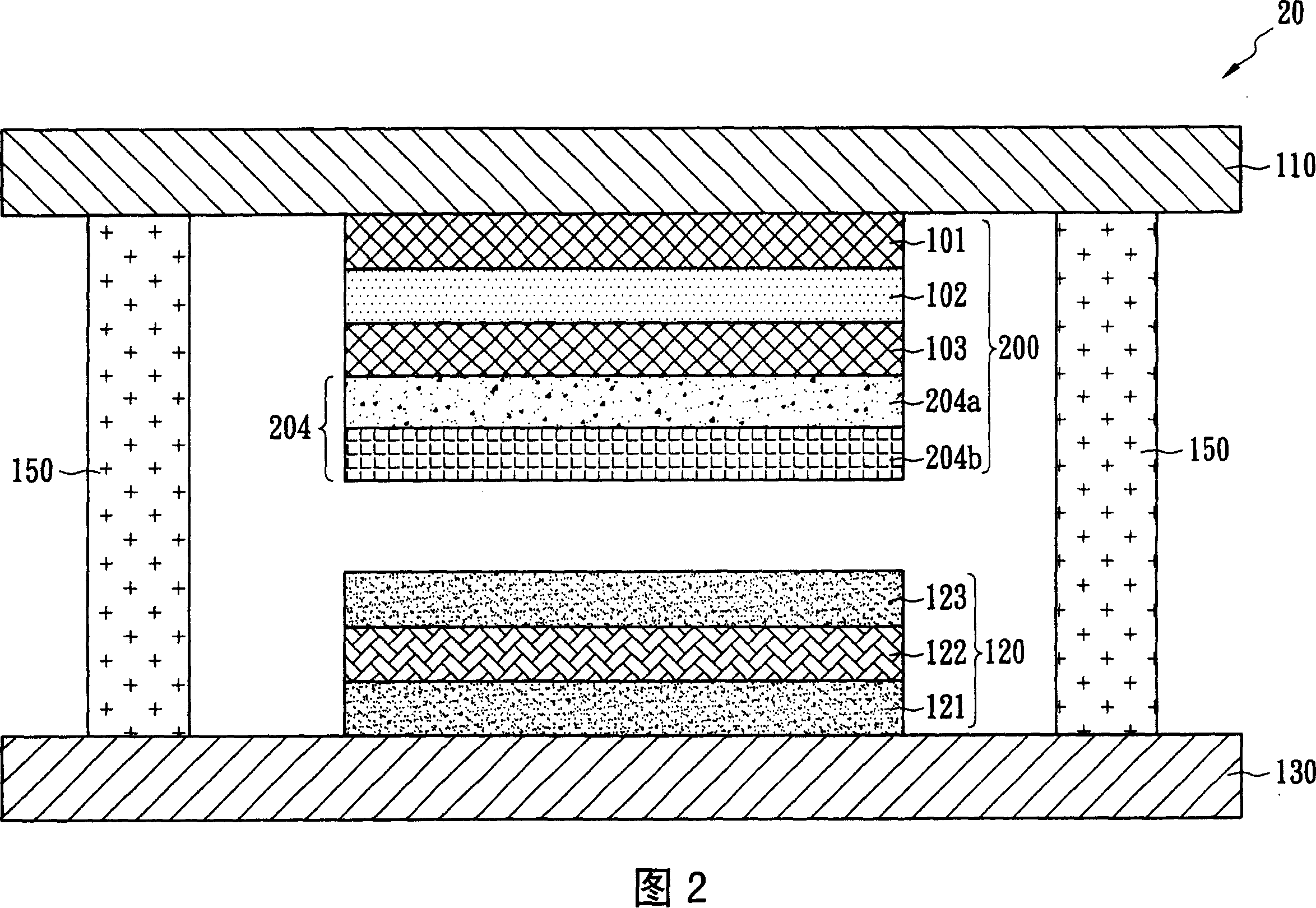

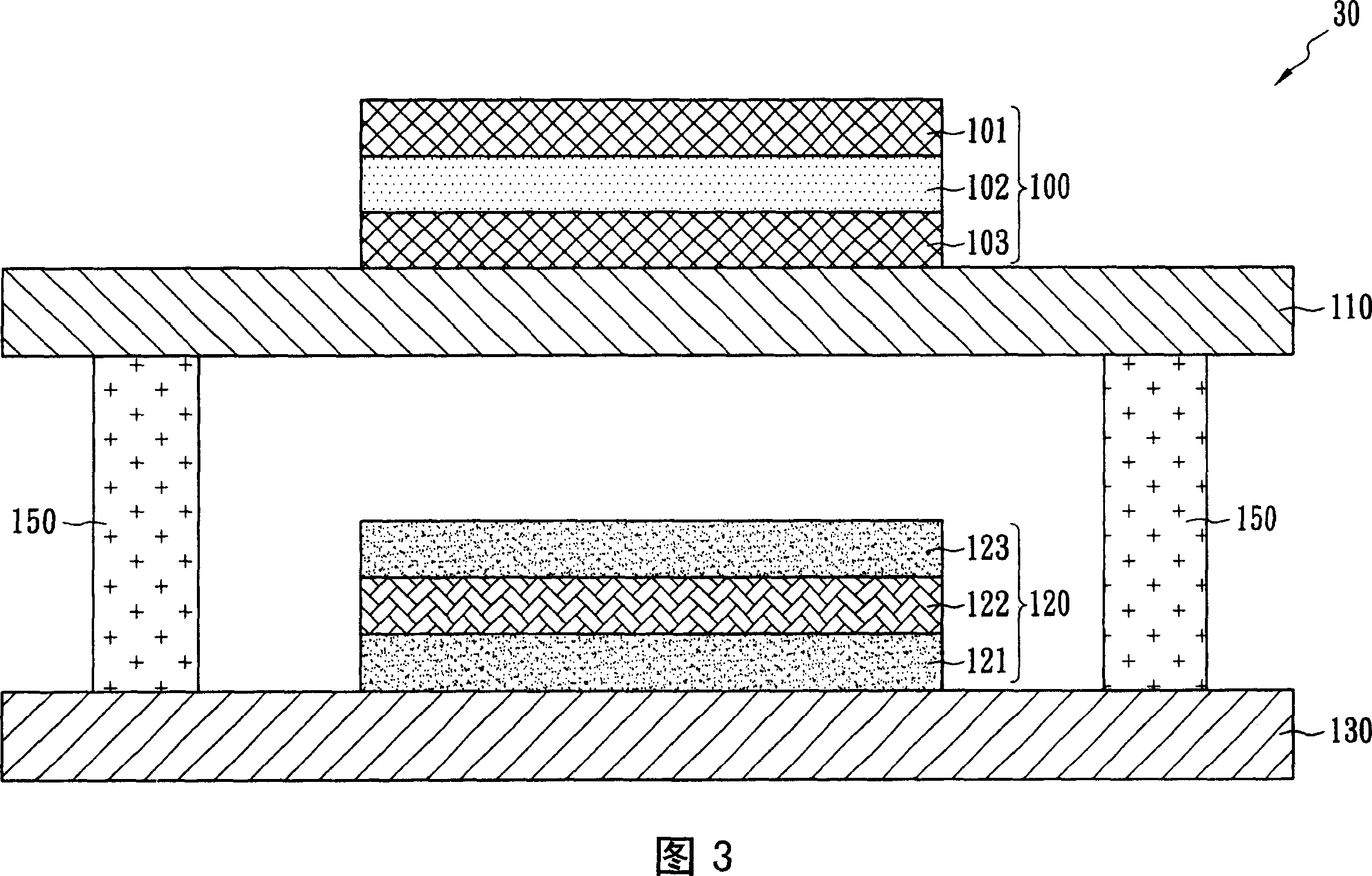

Upper shining type organic shining diode transparent touch screen

InactiveCN101059738AGood light transmissionHigh sensitivityInput/output processes for data processingBaseboardEngineering

The invention discloses an upward lighting transparent touch screen with organic light emitting diode, wherein the screen comprises a baseboard, an upper cover plate, an organic light emitting diode display element, a capacitor touch controller, and a seal layer. The diode is laminated on the baseboard, the controller is laminated on the upper cover plate, and the seal layer is combined with the baseboard and the upper cover plate to seal the diode and the controller between the baseboard and the upper cover plate. The controller forms a first transparent conductive layer, an insulation layer, a second transparent conductive layer and an electromagnetic shield layer on the upper cover plate, while the shield layer can effectively reduce the electric field interface between the diode and the controller. The invention can accurately and sensitively sense touch operation, with wide application in screens.

Owner:RITDISPLAY

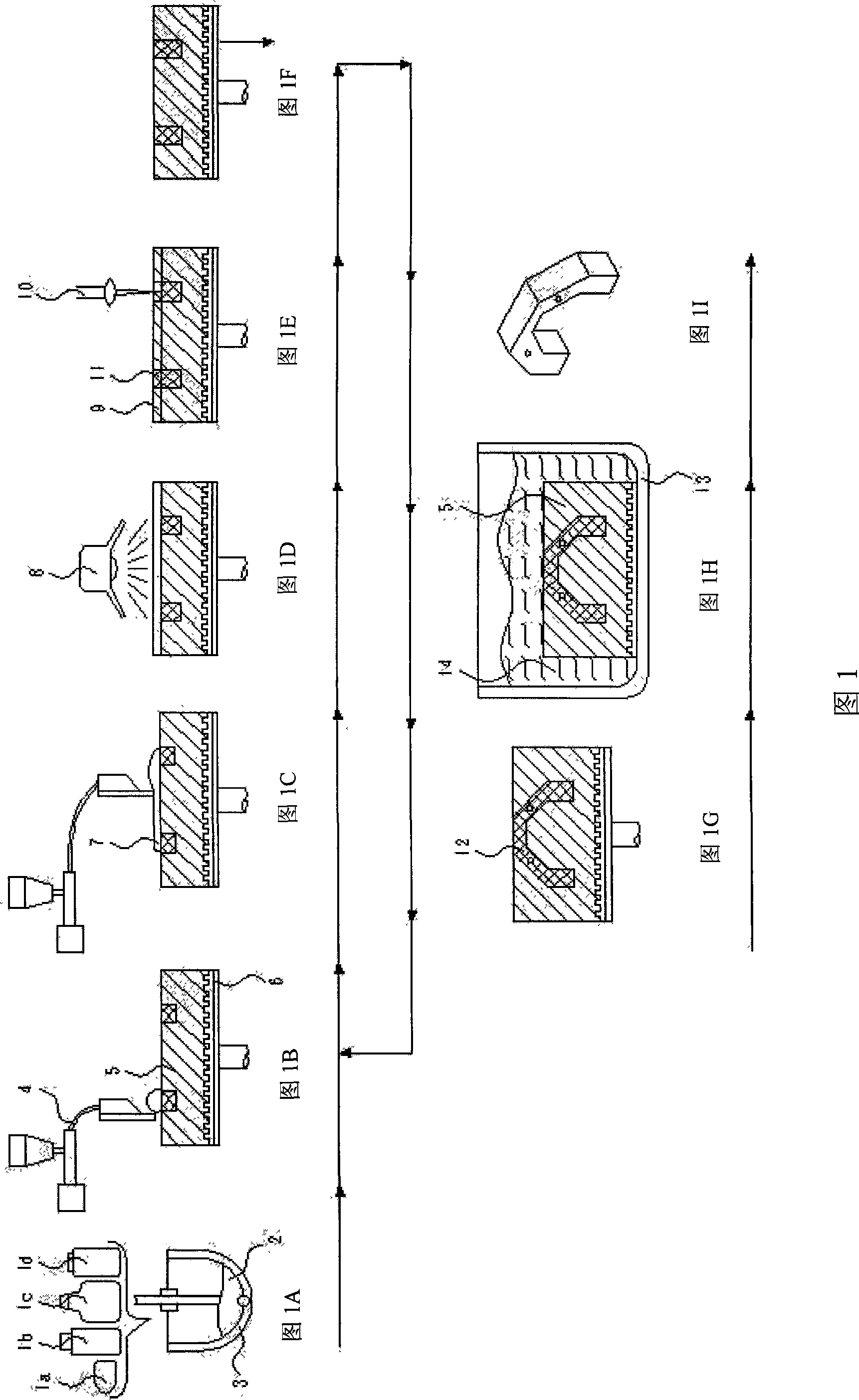

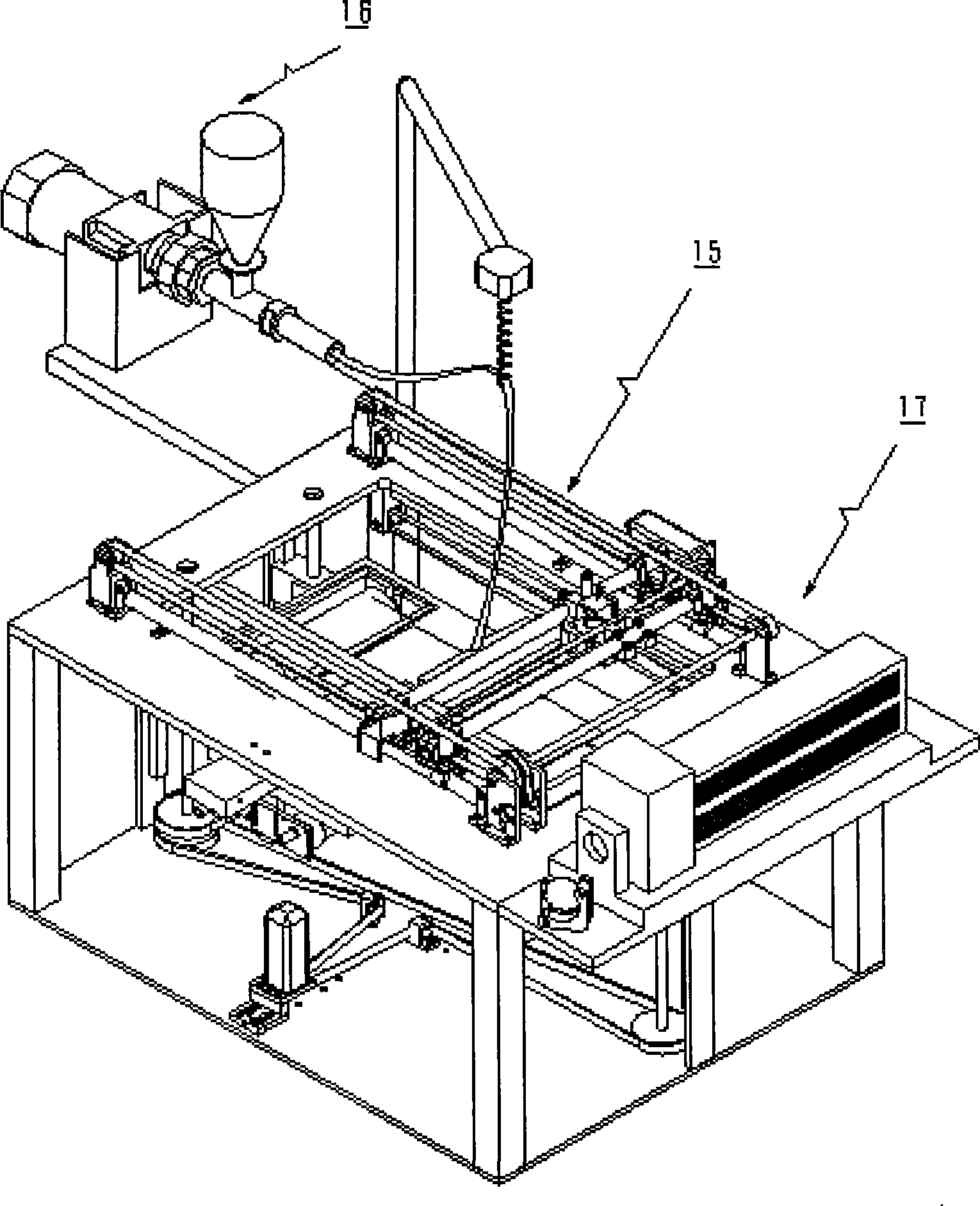

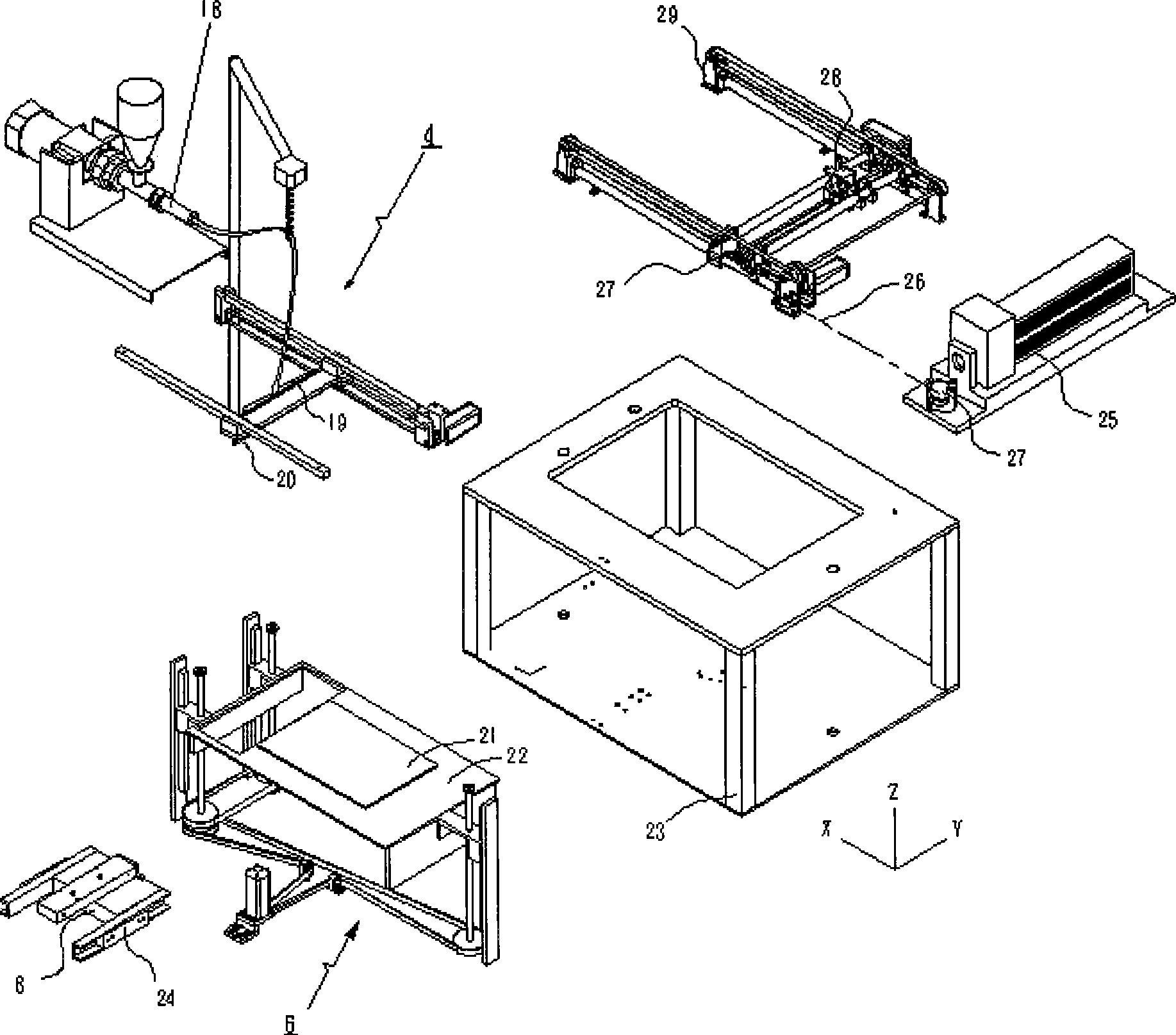

Manufacture method and device of three-dimensional workpiece

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

Skin cleaning article

InactiveCN101427990ASoftIncrease elasticityCosmetic preparationsToilet preparationsBranSURFACTANT BLEND

The invention relates to a skin cleansing product. Mill offals are added to the cleansing product, and comprise components by the following contents (weight percentages): 0.01% to 99% of water, 0.01% to 99% of surfactant and 0.01% to 30% of mill offals. Mill offals are adopted as the abradant and the massage particles of the skin cleansing product, and compared with the prior art, the skin cleansing product has the advantages that the utilization value of the mill offals is increased; the mill offals originate from natural plants, are soft in texture, and have the advantages of environment protection, naturalness and temperateness; and simultaneously, the nutrient components in the mill offals of plants serve the functions of nutrient caring and nourishing.

Owner:上海蔻漫生物科技有限公司 +2

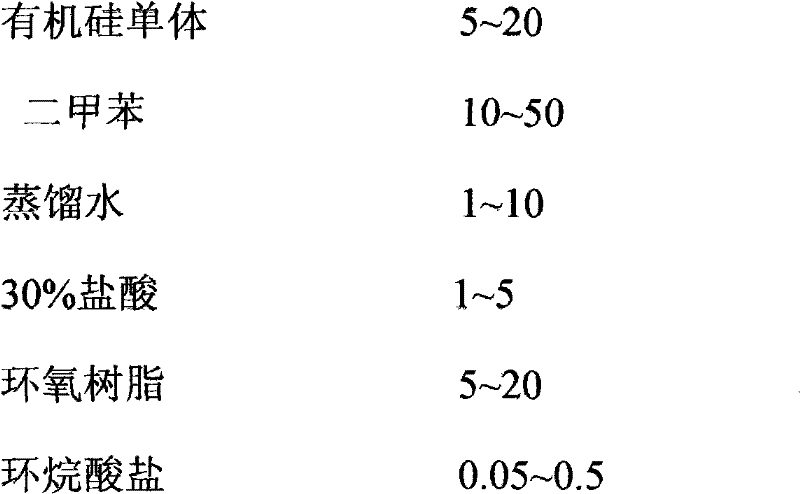

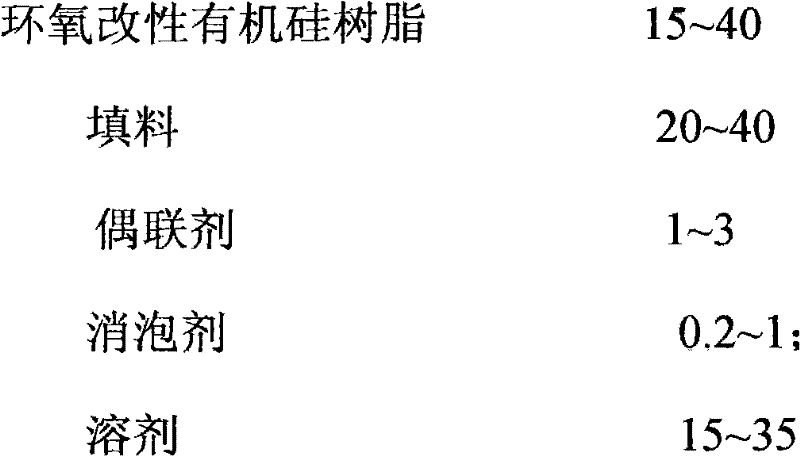

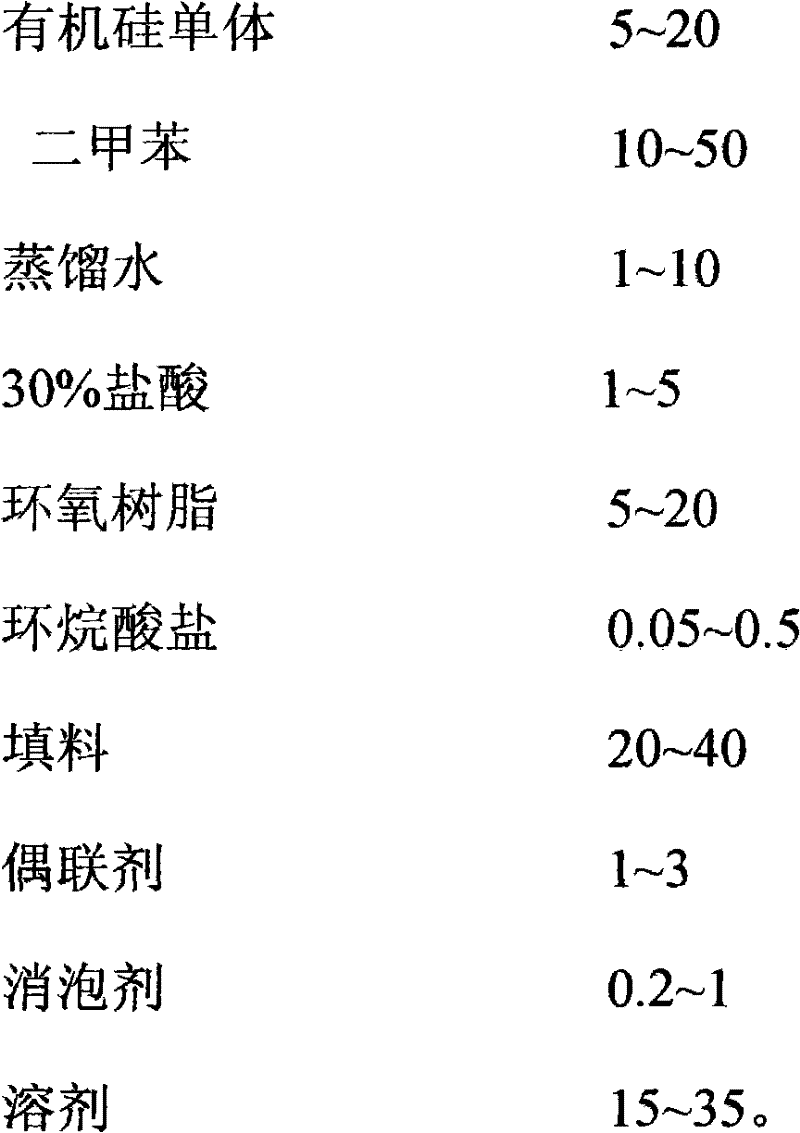

Preparation method of epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating and its products

The invention provides a preparation method of an epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating, comprising the following steps: preparing raw materials; synthesizing an organosilicon pre-polymer; synthesizing an epoxy-modified organosilicon resin; and preparing the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating. The invention also provided the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating prepared by the method. The coating is composed by the epoxy modified organosilicon resin, fillers, a coupling agent and solvents. The coating prepared by the method in the invention takes account of insulation, thermal-conductivity, and high-temperature resistance at the same time, has coating adhesion of first level, hardness of 5H, a breakdown voltage of 1800V / 0.5mA, 2 seconds, a heat transfer coefficient of larger than 100W / (m<2>.K), and no obviously changed coating at a temperature of 250 DEG C for 24 hours, therefore the coating can be widely used in various industrial equipment and household appliances.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN +2

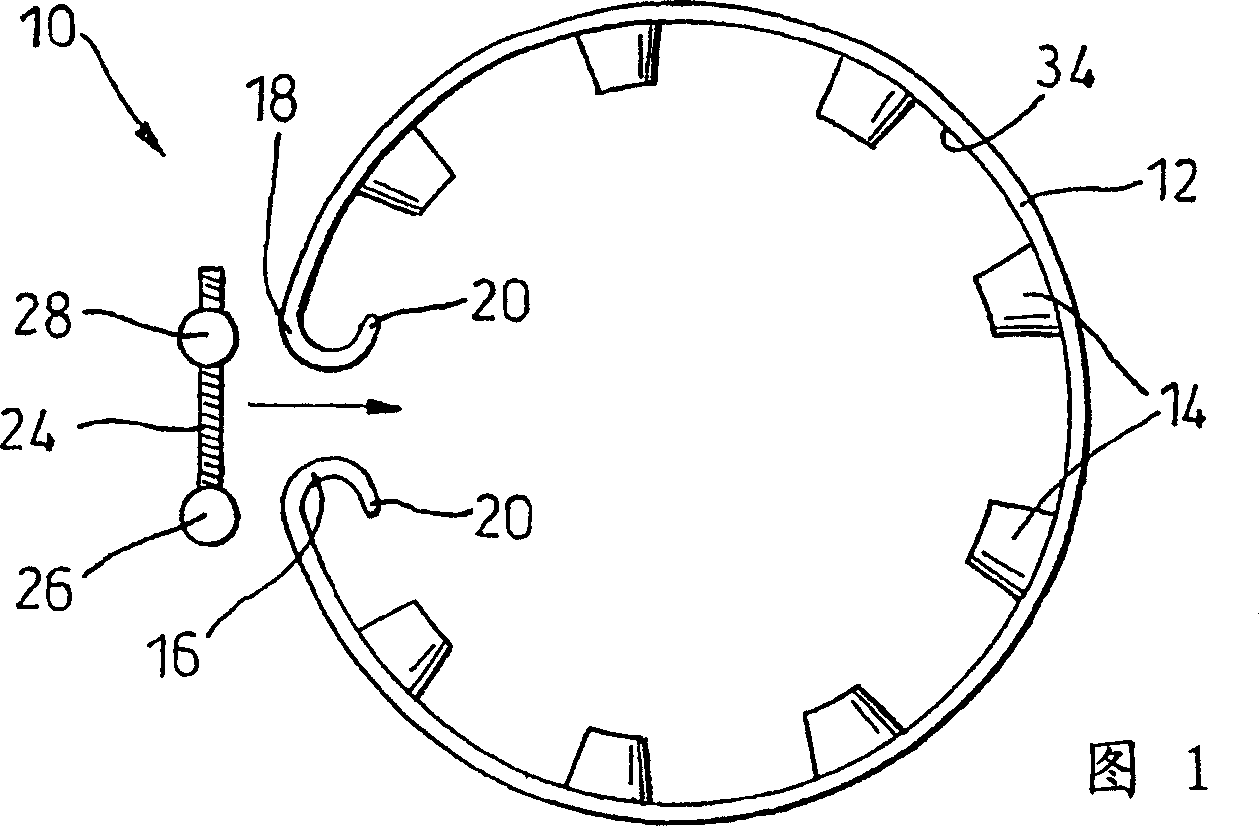

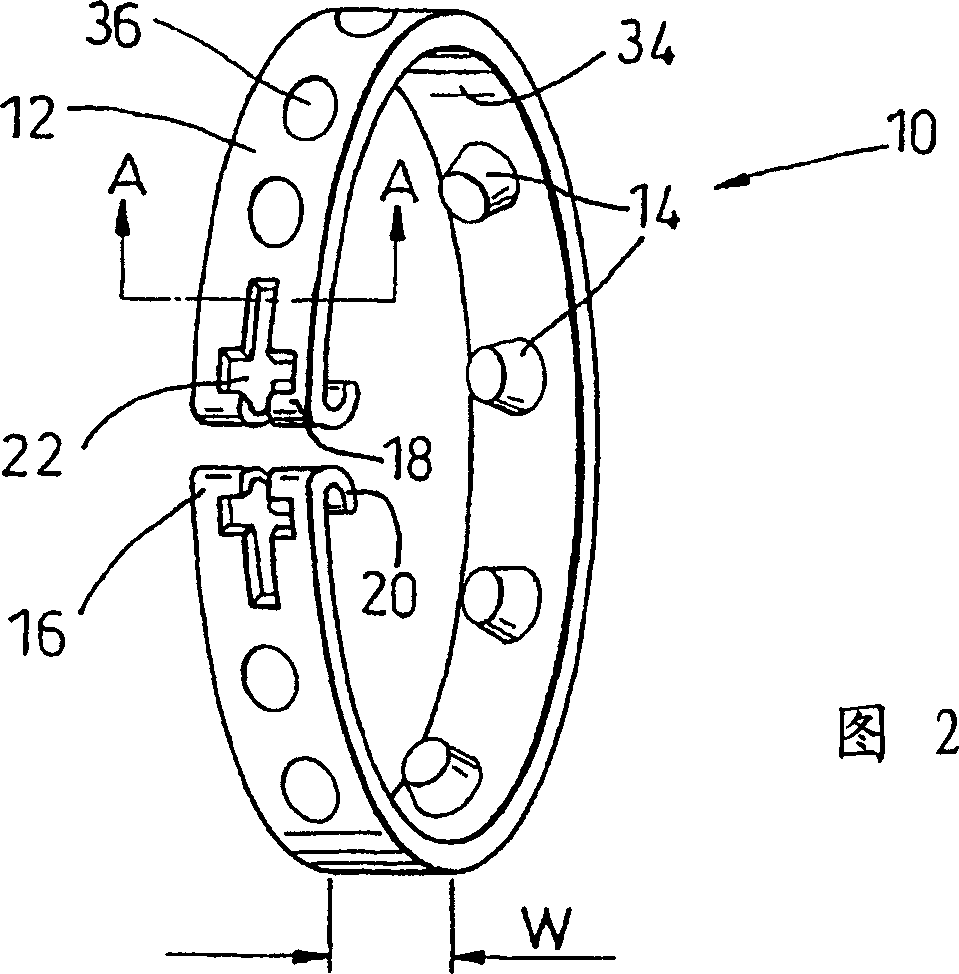

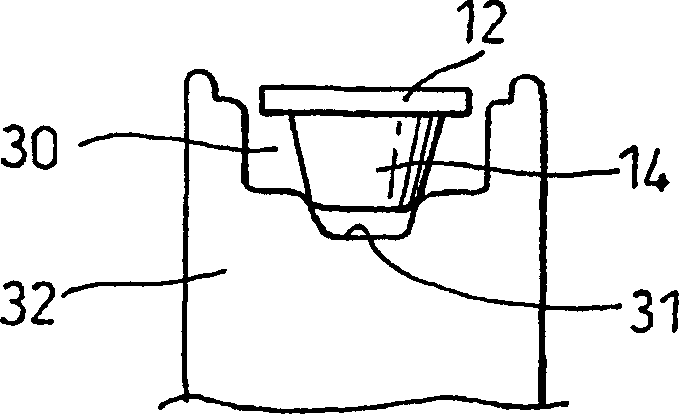

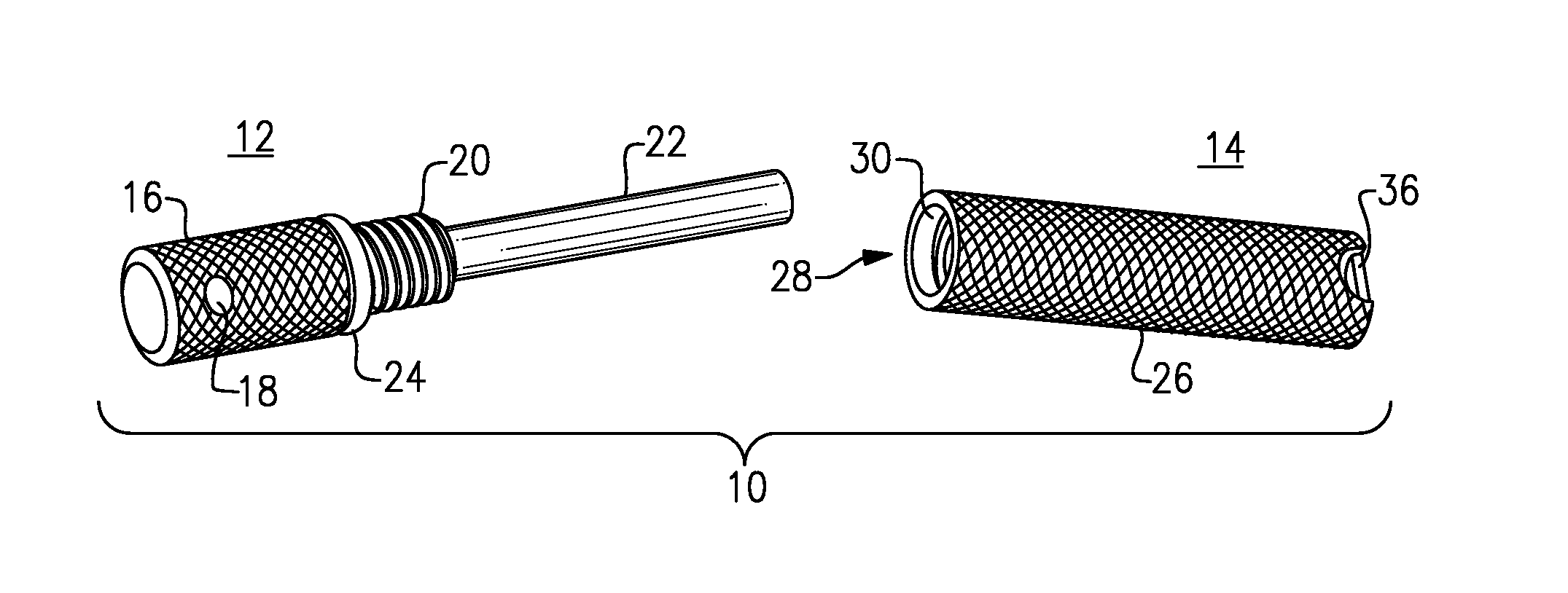

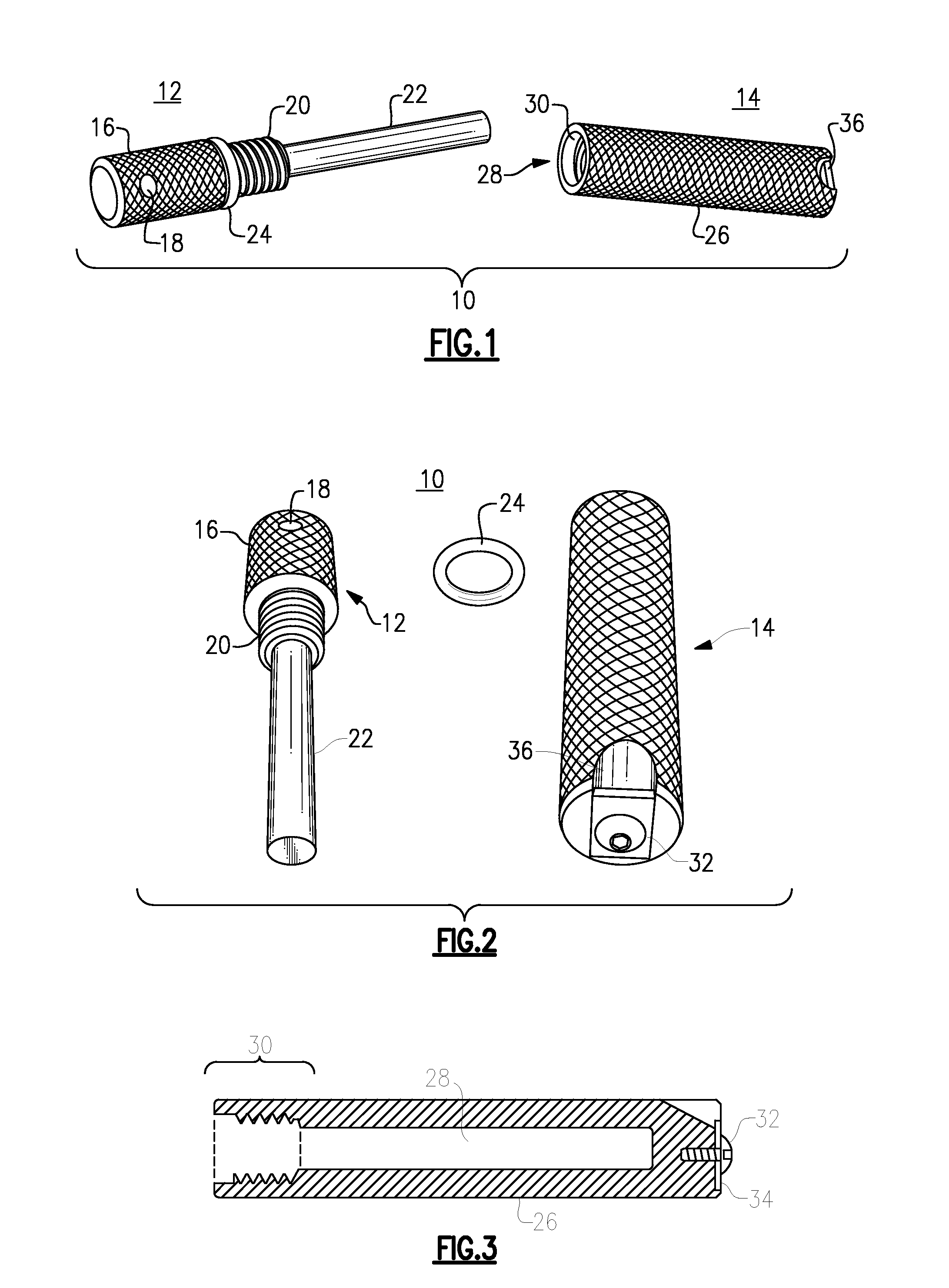

Band device for a wheel rim

An assembly ( 10 ) for location around a wheel rim ( 32 ) includes an annular support band ( 12 ) being formed of a relatively inextensible material. The support band ( 12 ) is split at at least one circumferential location to define a pair of opposed ends ( 16, 18 ). Adjustment bolt ( 24 ) is operably connected to the opposed ends ( 16, 18 ) for enabling adjustment of the diameter of the support band ( 12 ), and feet ( 14 ) depend from the radially inner face ( 34 ) of the support band ( 12 ). The feet ( 14 ) are formed from a relatively non-compressible material and, in use, are seated upon the wheel rim ( 32 ) to maintain the support band ( 12 ) in a spaced apart relationship with the wheel rim ( 32 ). The assembly may be adapted for use as a runflat assembly or as a beadlock assembly.

Owner:蒂龙爆胎保护有限公司

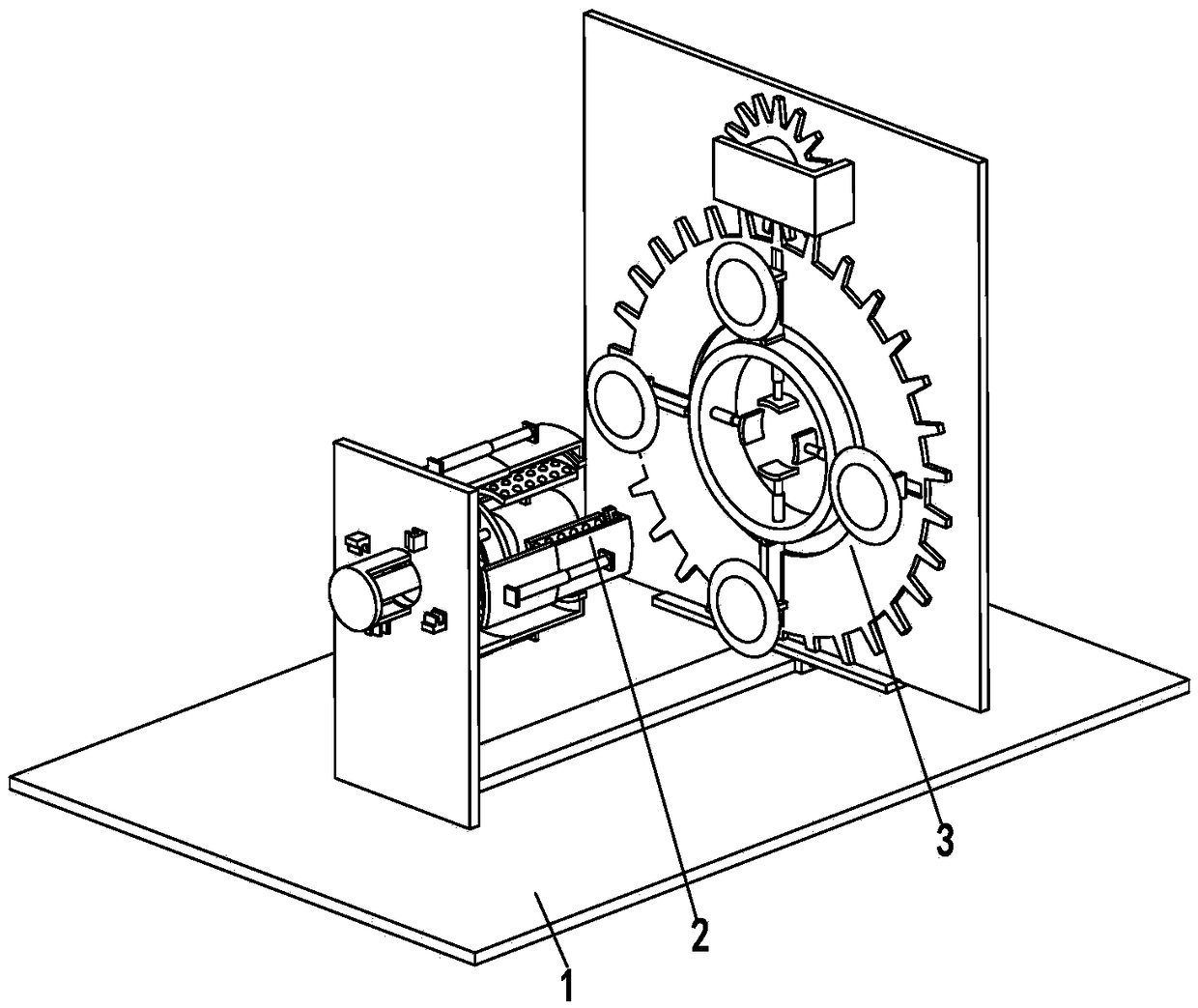

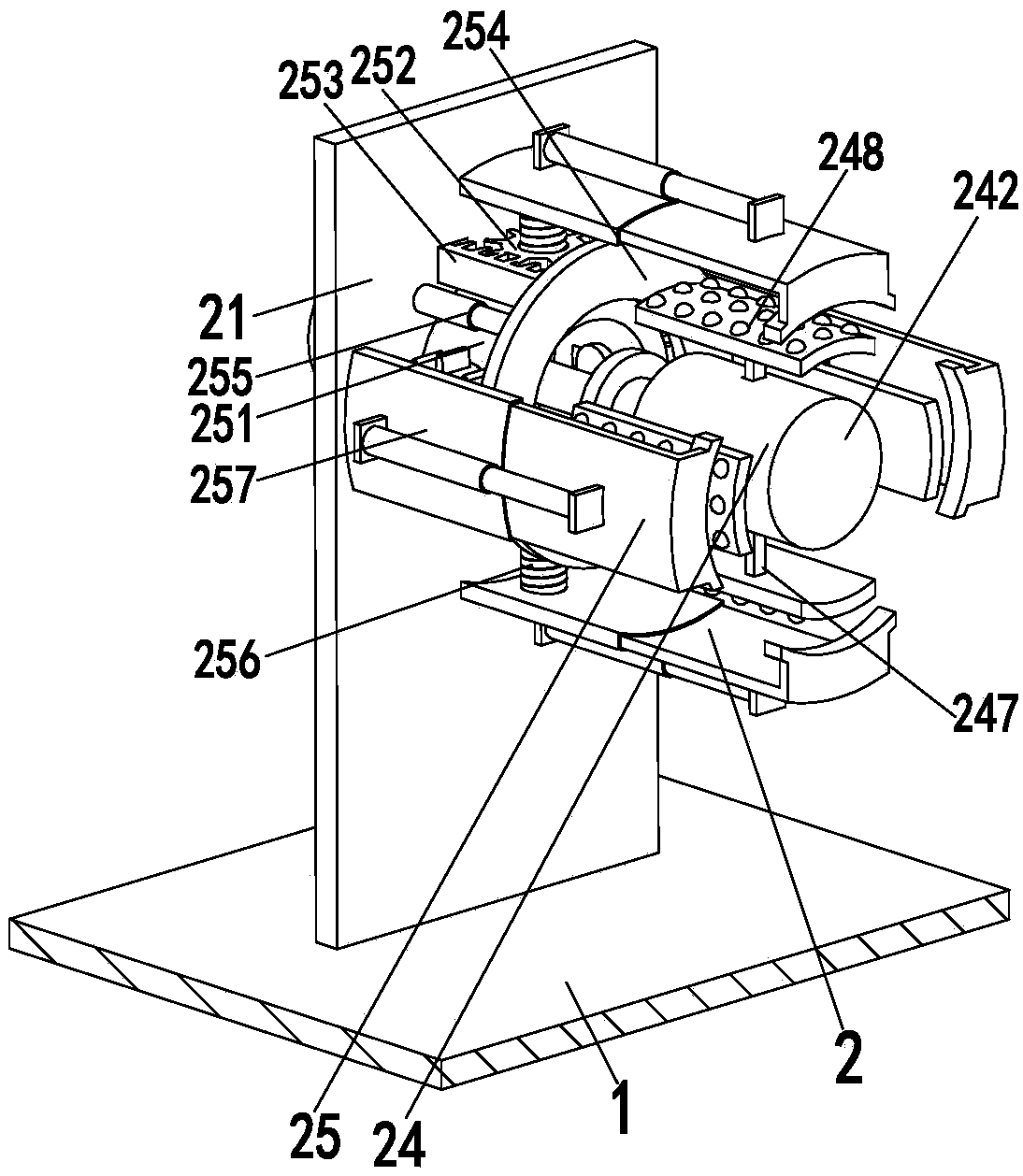

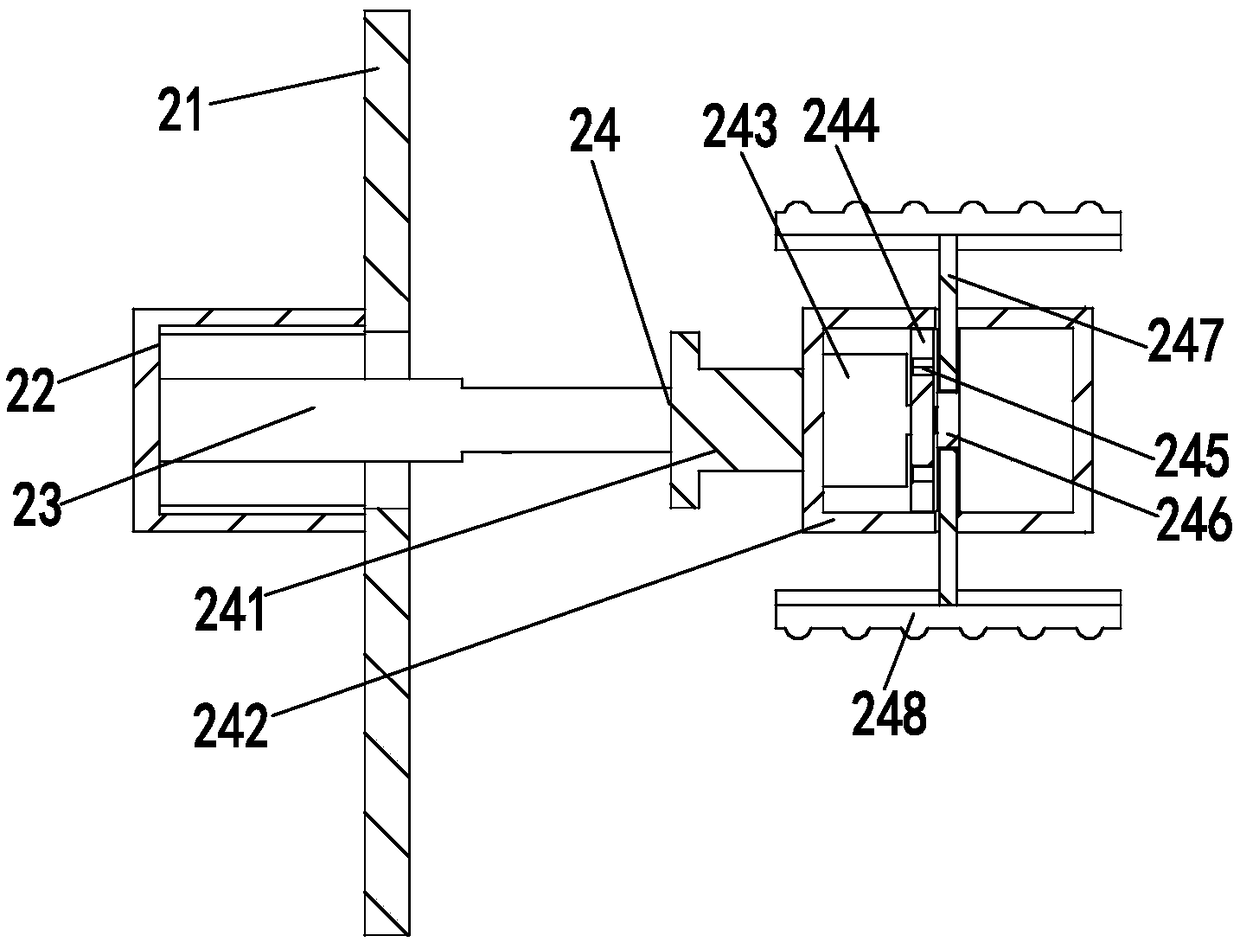

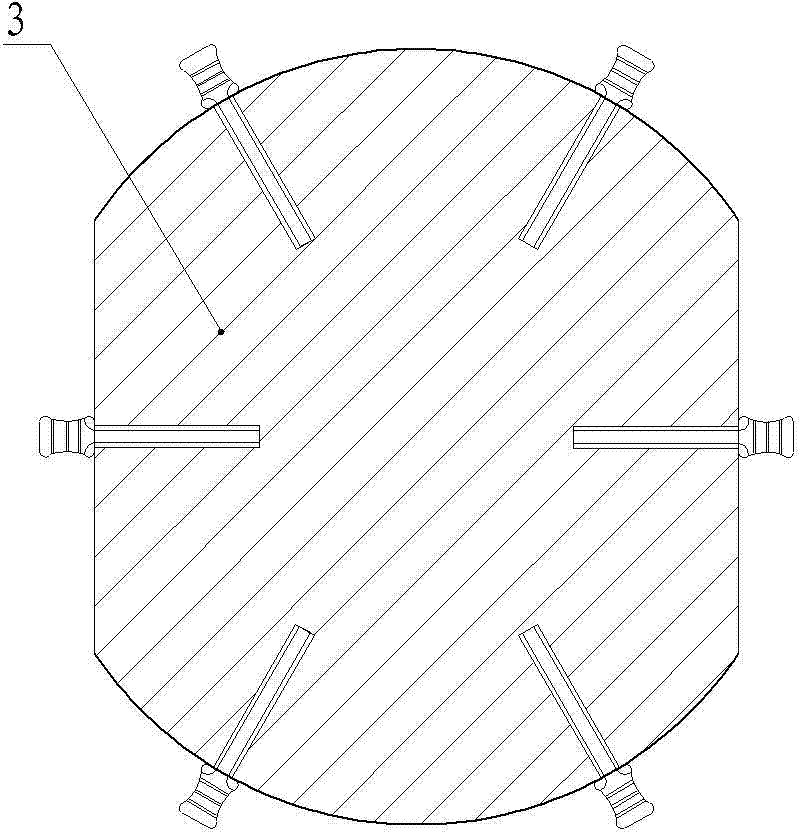

Automatic rubber hose cutting equipment and automatic rubber hose cutting technology

ActiveCN109227674ARealize automatic cuttingNot easy to scratchMetal working apparatusGear wheelFixed frame

The invention relates to automatic rubber hose cutting equipment and an automatic rubber hose cutting technology. The automatic rubber hose cutting equipment comprises a bottom plate, a supporting device and a cutting device, and the supporting device and the cutting device are sequentially installed on the bottom plate from left to right; the supporting device comprises a fixing plate, a fixed frame, a movable air cylinder, an inner wall supporting mechanism and an outer wall supporting mechanism; the cutting device comprises a linear guide rail, an electric sliding block, a working plate, aworking gear, a driving gear, a driving motor, a rotating ring, a rotating gear, a rotating motor, a supporting air cylinder, a supporting plate, a rotating rod, a sliding frame, a mounting frame, a cutting motor and a cutting blade. The invention further provides a using method of the automatic rubber hose cutting equipment. The equipment and the technology can solve the problems that in an existing rubber hose cutting process, the labor cost is high, the working efficiency is low, the cutting surface is not smooth, safety hidden hazards exist and the surface of a rubber hose is easily scratched, and the function of automatically cutting the rubber hose can be achieved.

Owner:中金液压胶管股份有限公司

Directly sprayed polypropylene material and preparation method thereof

The invention relates to a directly sprayed polypropylene material and a preparation method thereof. The polypropylene material is prepared with the following materials: polypropylene, second component high polymer material, compatilizer, filler, lubricating agent and antioxidant. The preparation method includes the following steps: (1) the materials are weighed according to a ratio, and are uniformly mixed in a high-speed mixer at a high speed for 5 to 10 minutes; (2) the mixed material is added in a double-screw extruder, melted, extruded and granulated. The polypropylene material has high rigidity and good sprayability, cannot be easily scratched and chipped and cannot easily leave traces, and moreover, the preparation method has the advantages of simple technique, convenient operationand low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

Curing nanometer building paint from fluoride carbon resin at normal temperature and production thereof

InactiveCN1712470AUnique performanceUnique excellent performanceCoatingsUltravioletFluorocarbon Resins

A cured nanometer resin fluorinated carbon building coating at normal temperature and its production are disclosed. The process is carried out by using tin catalyst, and adding into wetting disperser, anti-bubbling agent, curing agent, anti-settling agent, ultraviolet absorber and coloring pigment. It achieves long anti-aging time, better water-proof and anti-fouling ability, and higher hardness of coating.

Owner:宁波艾利特科技发展有限公司

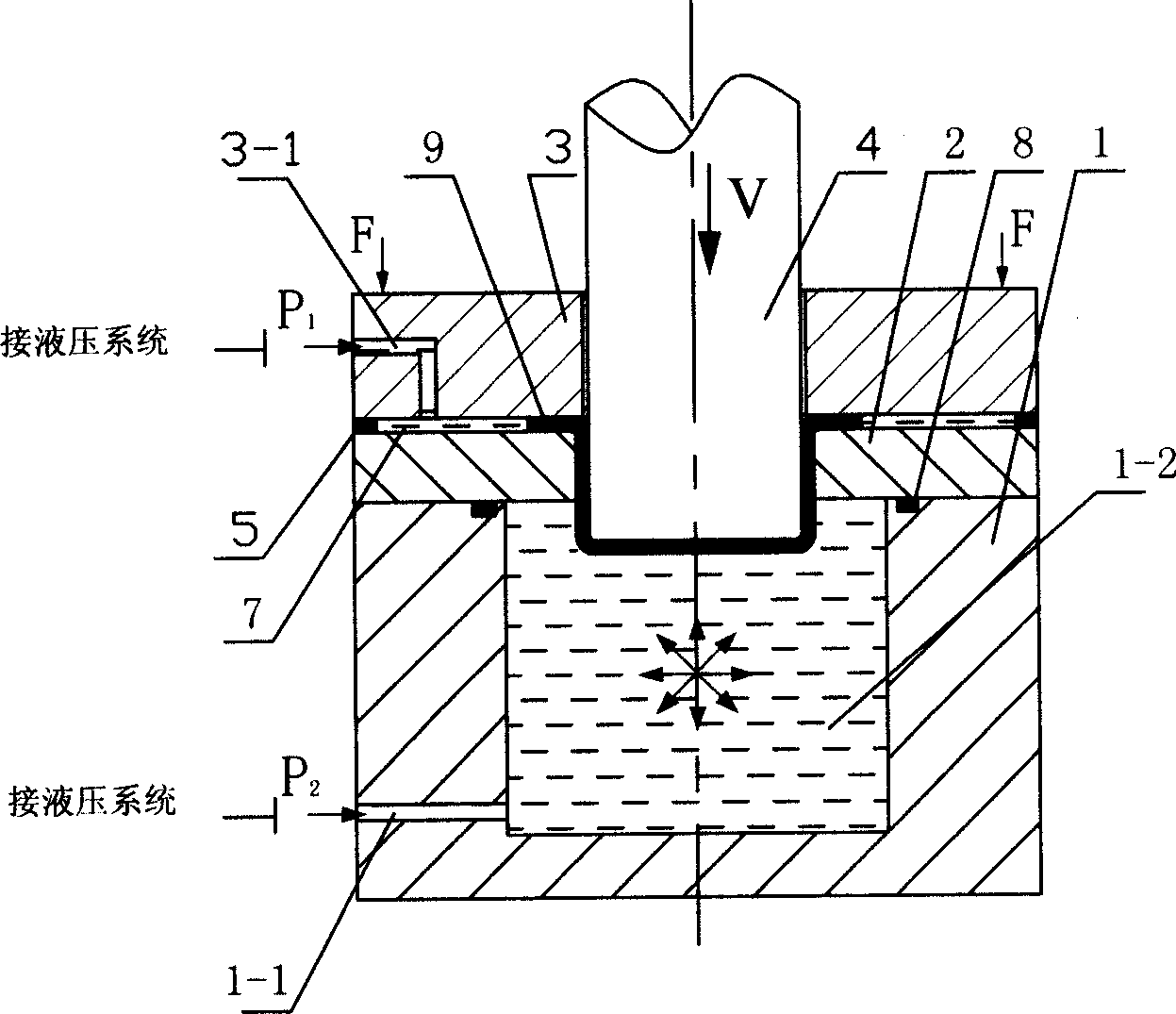

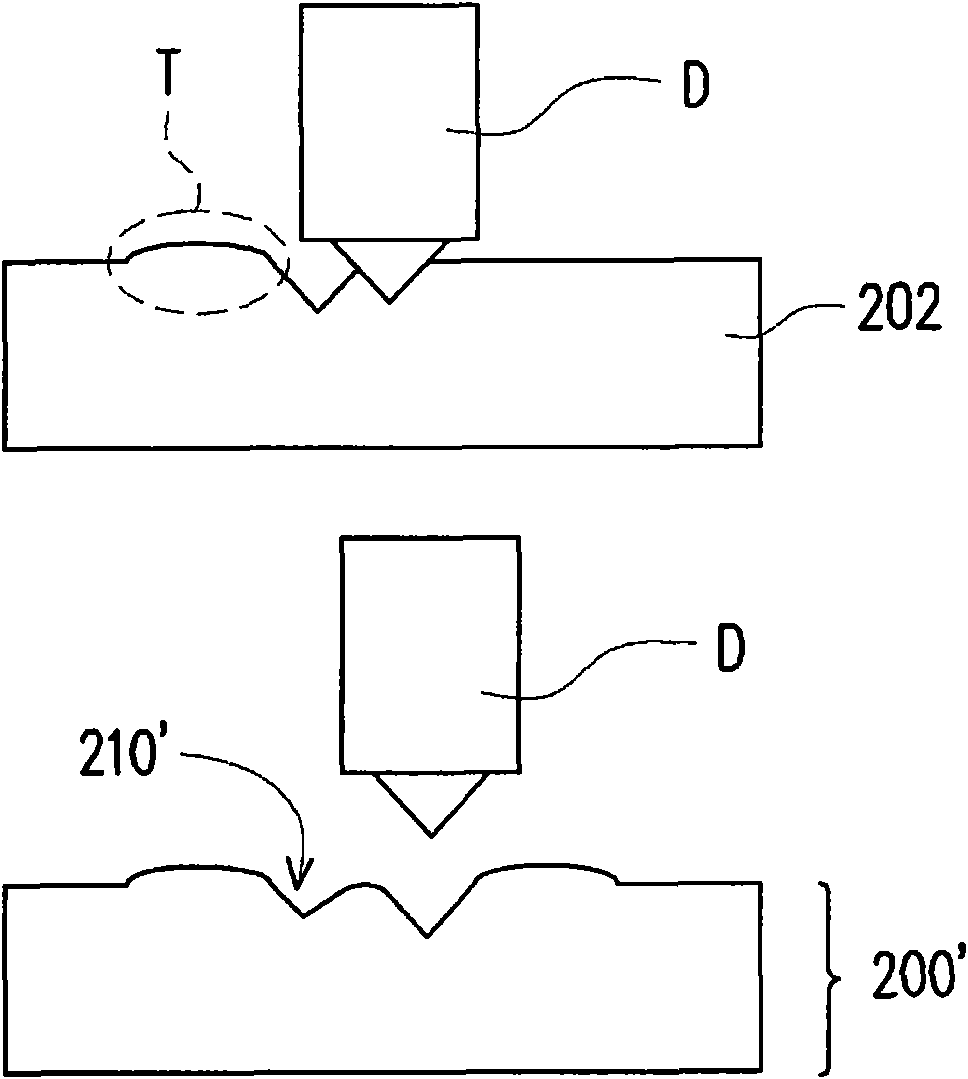

Procesing equipment capable of improving plate part formation limitation and method therefor

Owner:HARBIN INST OF TECH

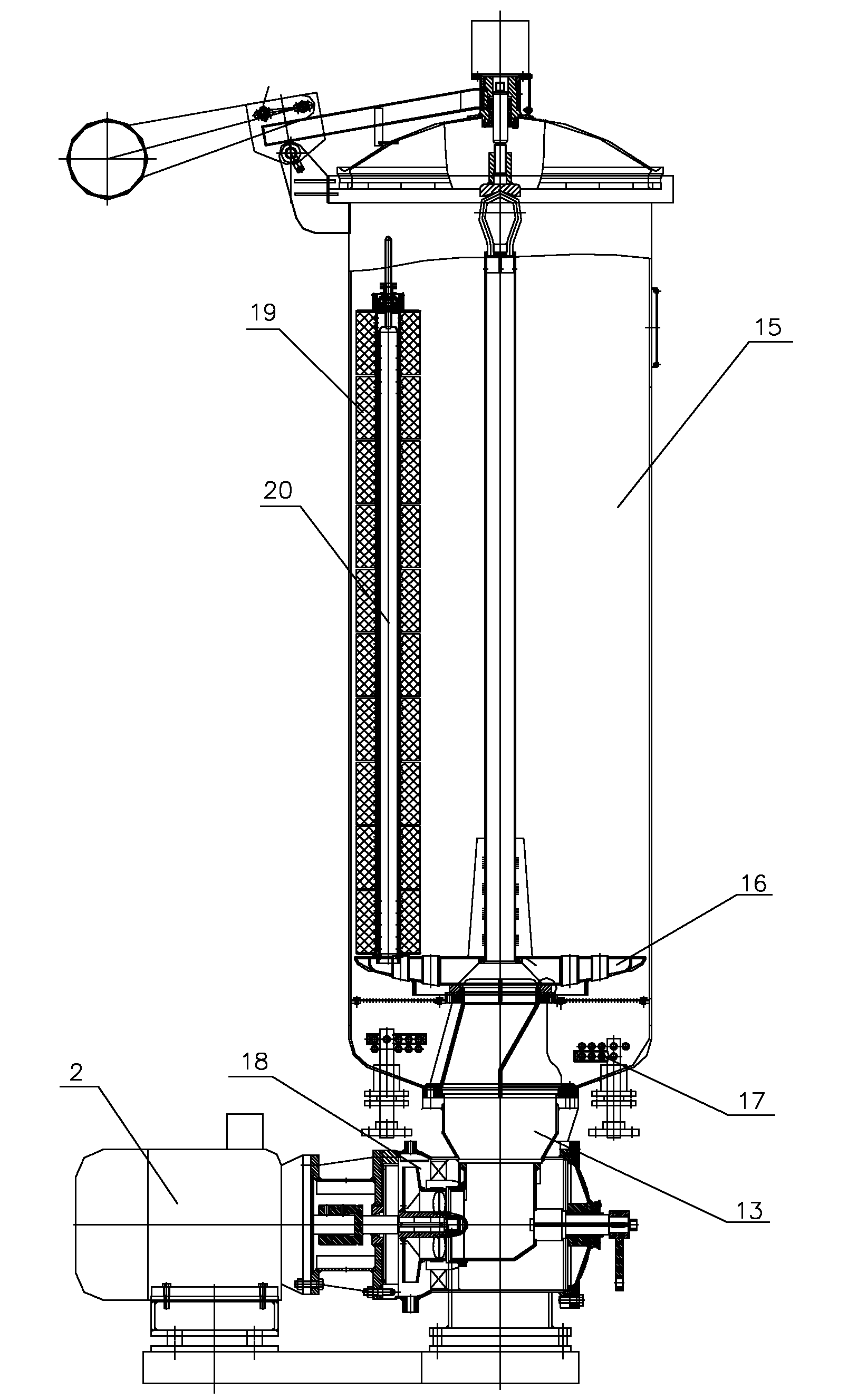

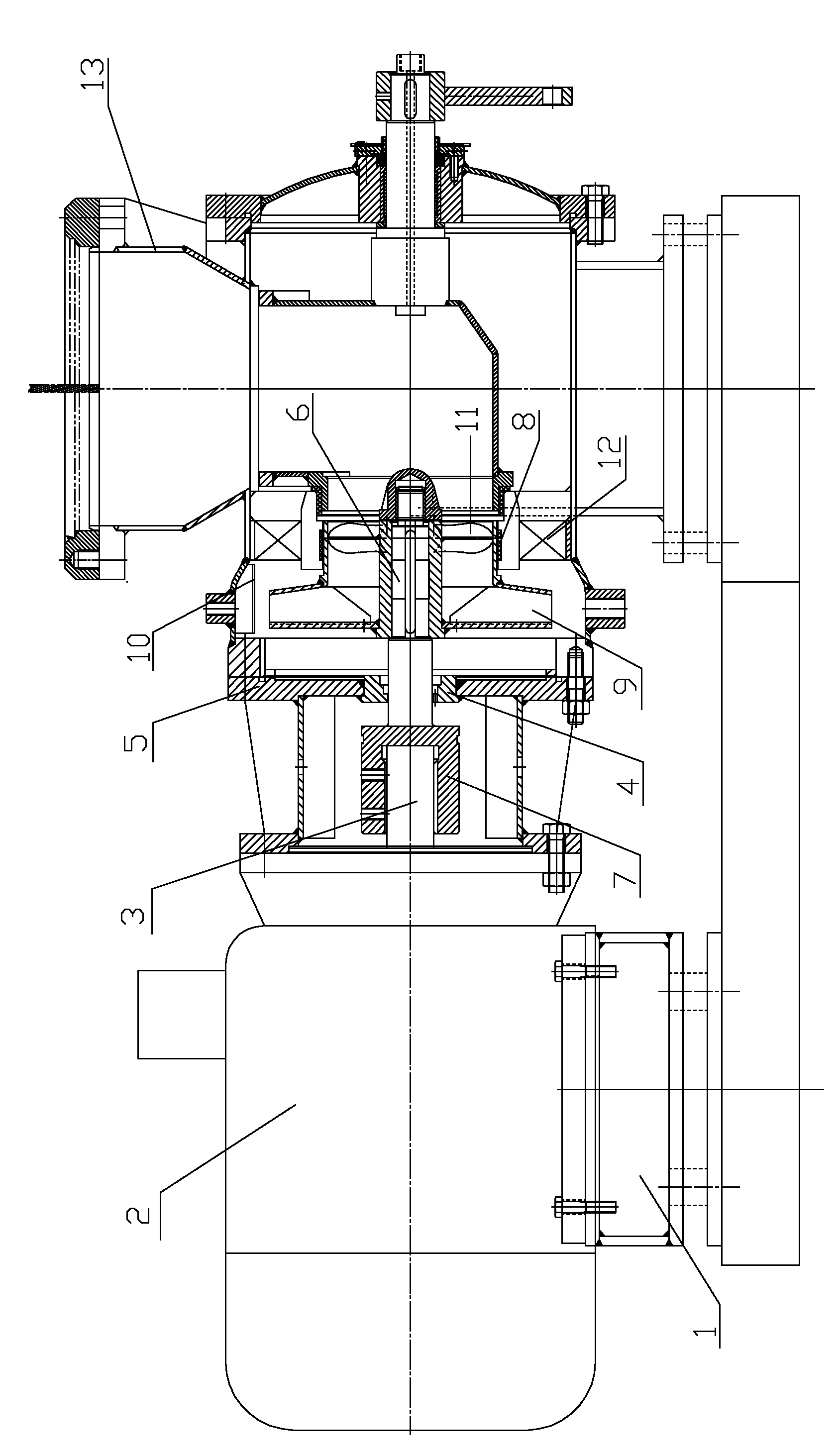

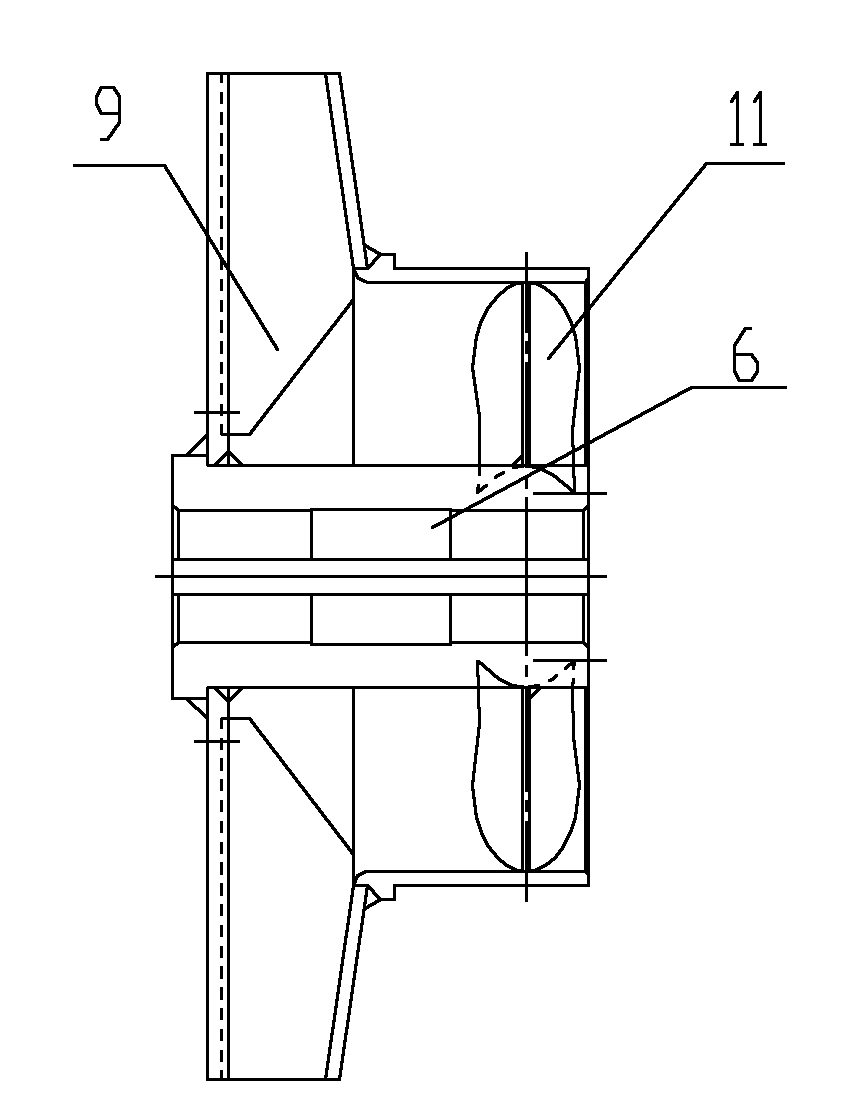

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

Survival tool fire starter with mischmetal flint rod

Owner:THE FOUNTAIN HEAD GROUP INC

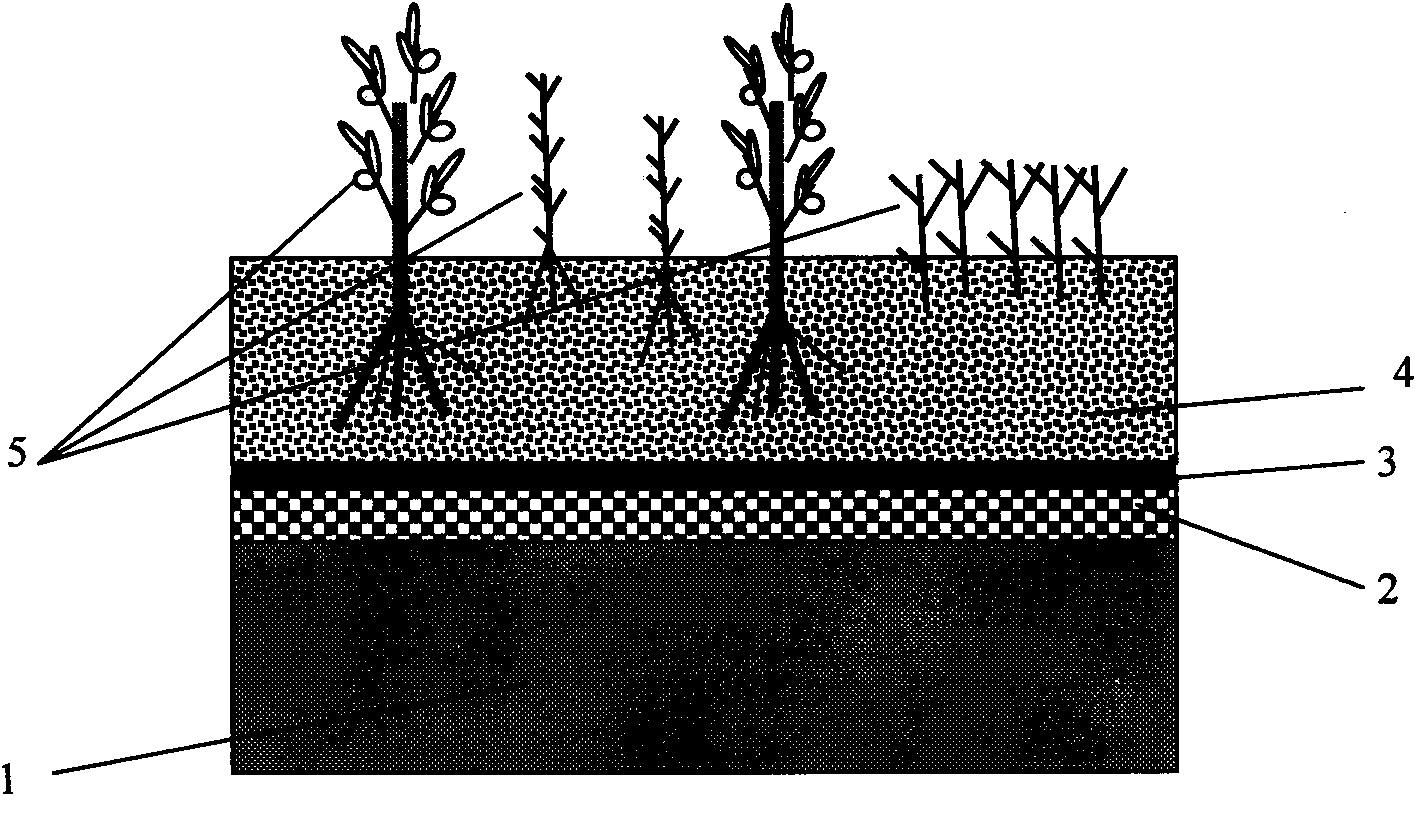

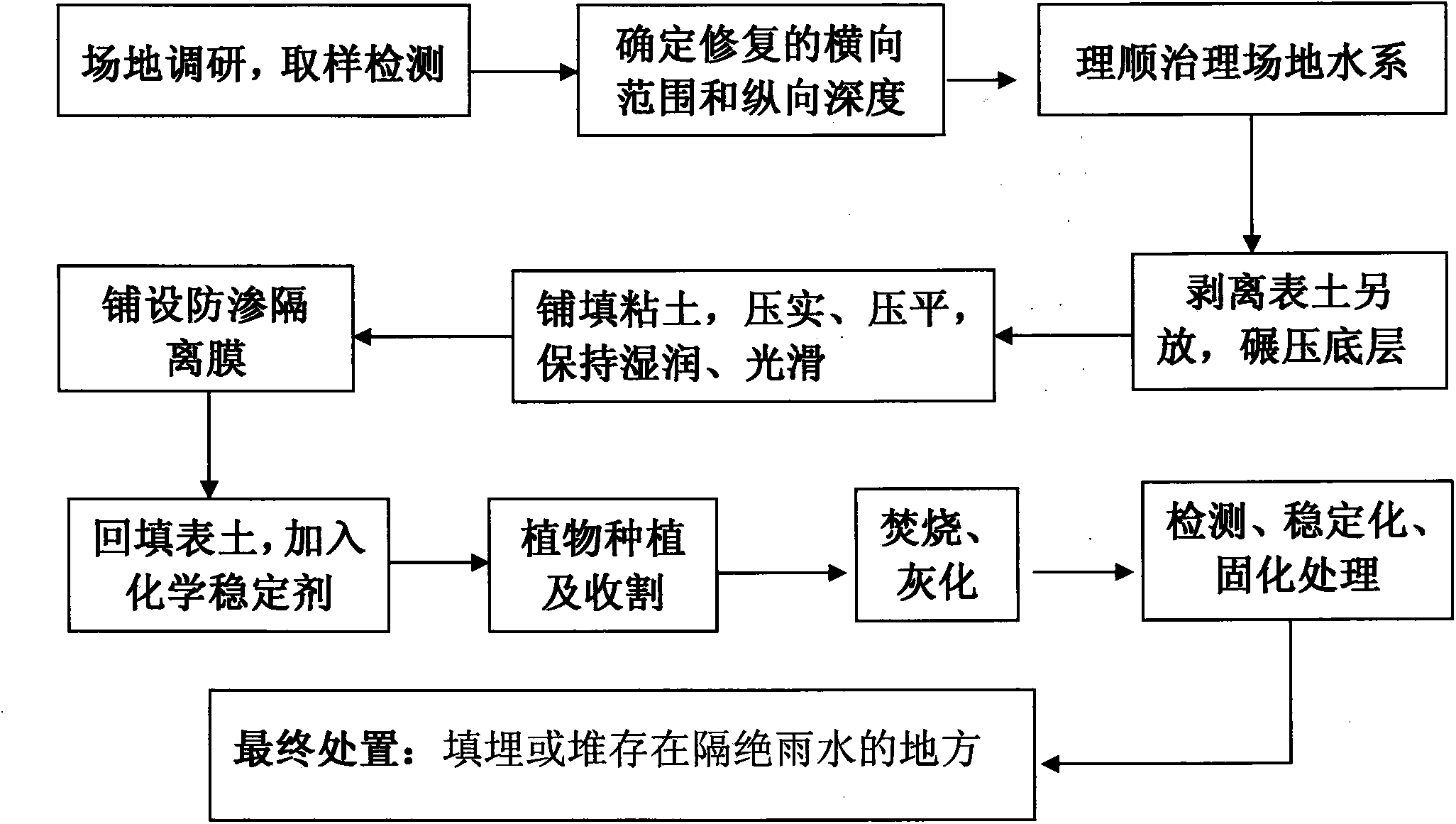

Method for treating farmland soil polluted by cadmium

ActiveCN103817145ASpeed up the reaction processImprove the effect of chemical stabilizationContaminated soil reclamationAshingSoil science

The invention provides a method for treating farmland soil polluted by cadmium. The method integrates technical measurements such as seepage-proofing isolation, chemical stabilizing treatment, phytoremediation and the like, and comprises technical steps as follows: sampling detection, repairing range determination, dredging of river systems, surface soil stripping, bottom layer grinding, clay pavement, laying of a seepage-proofing isolating membrane, surface soil backfilling, addition of a chemical stabilizing agent, plant planting and harvesting, incineration and ashing, ash content stabilizing and curing treatment, terminal treatment and the like. The method for treating the farmland soil polluted by cadmium has the advantages of on-site treatment, simple process, convenience in construction, instant effect, high efficiency, low cost and the like, and is wide in popularization and application prospect.

Owner:SHENZHEN WANXINDA ECOLOGICAL ENVIRONMENT CO LTD

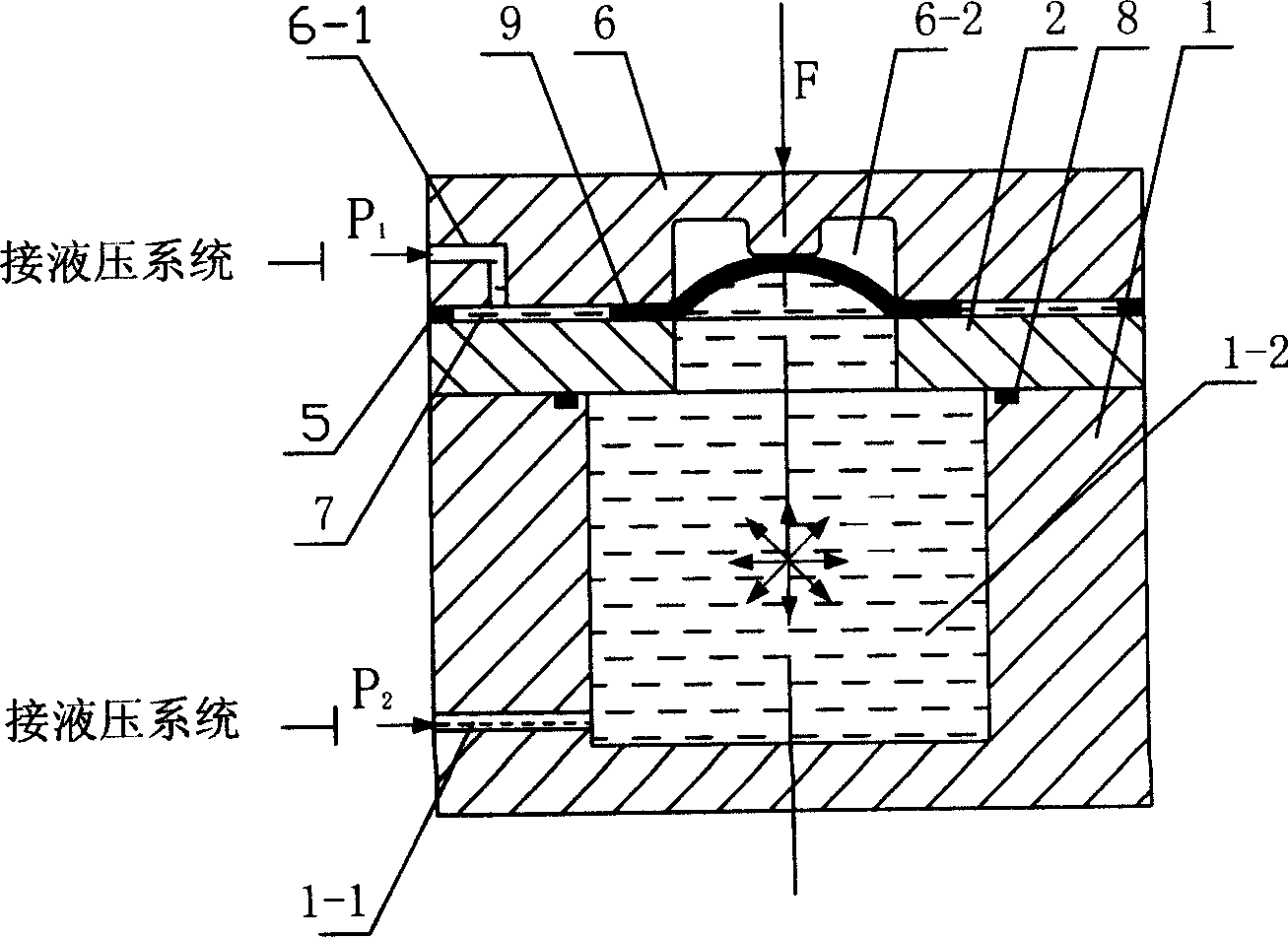

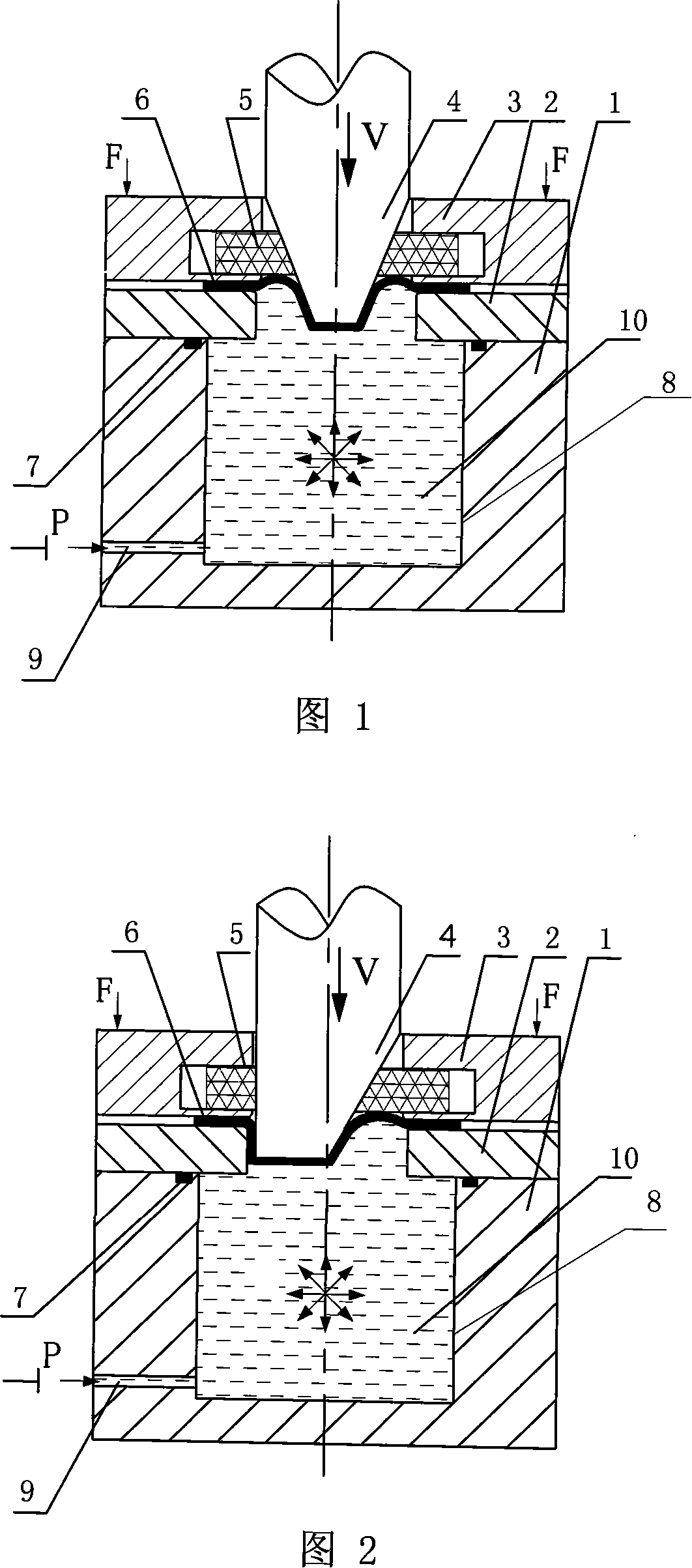

Device for preventing suspension area from breaking while taper piece filling liquid and drawing deep forming and forming method

InactiveCN101147940AReduce frictionReduce friction, so that the surface of the billet is fully protectedShaping toolsEngineeringMechanical engineering

The present invention relates to a conical component forming device capable of preventing floating zone from being broken when the conical component is formed by adopting liquid-charging and drawing process and its forming method. Said conical component forming device is characterized by that its rigid edge-pressing ring is set over a concave die, in said rigid edge-pressing ring interior a recessed groove is cut, a flexible supporting ring is placed in the recessed groove interior, said concave die is placed on the fluid medium cavity, and its liquid-injecting hole is connected with its hydraulic system. Its forming method includes the following steps; (1), making the liquid-injecting hole on the cavity body be communicated with the hydraulic system; (2), placing a plate blank on the concave die; (3), making the rigid edge-pressing ring be moved downwards and apply edge-pressing force; and (4), making convex die be downwards moved until the plate blank is drawn into the concave die interior with the convex die so as to obtain a formed conical component.

Owner:HARBIN INST OF TECH

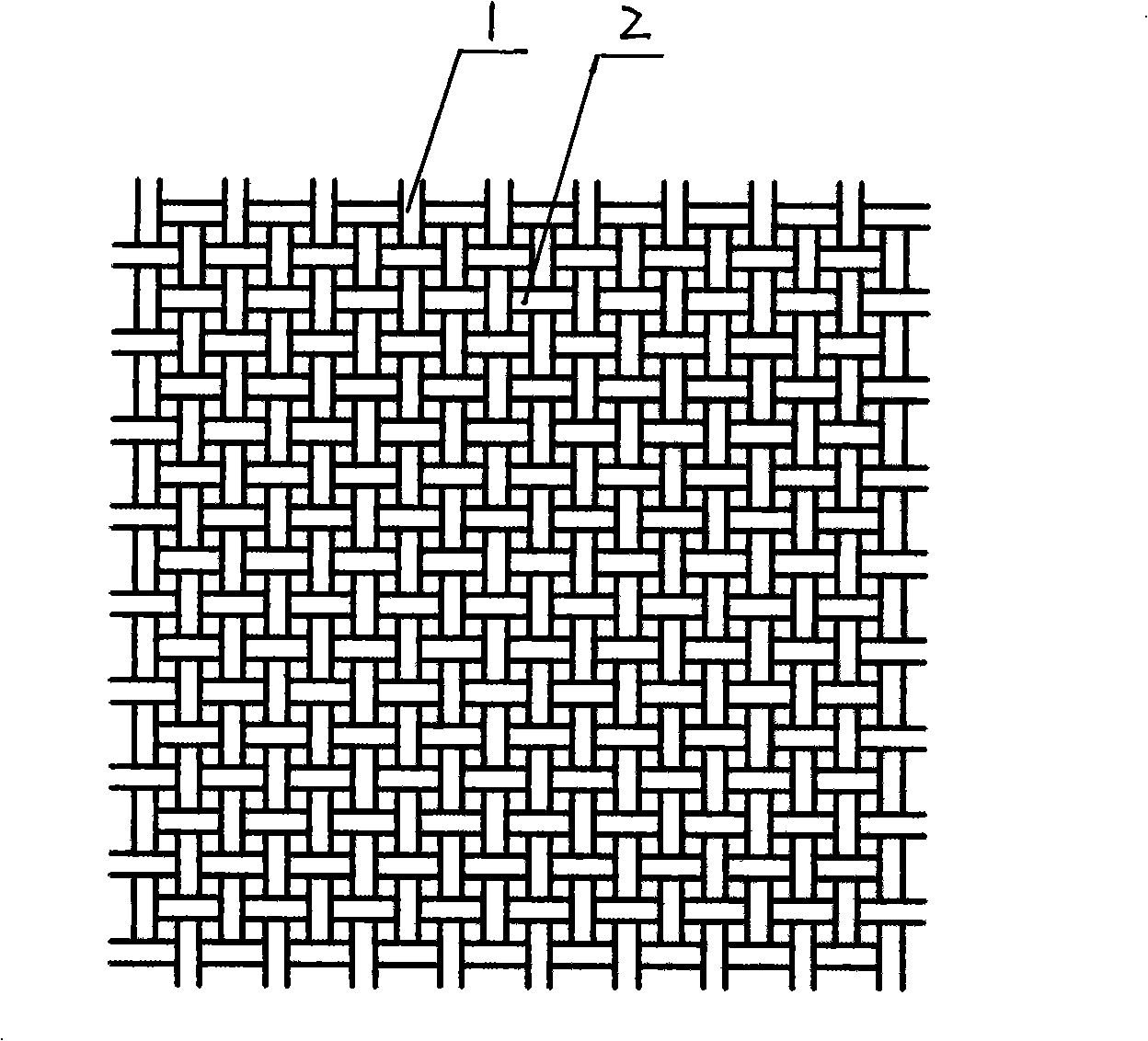

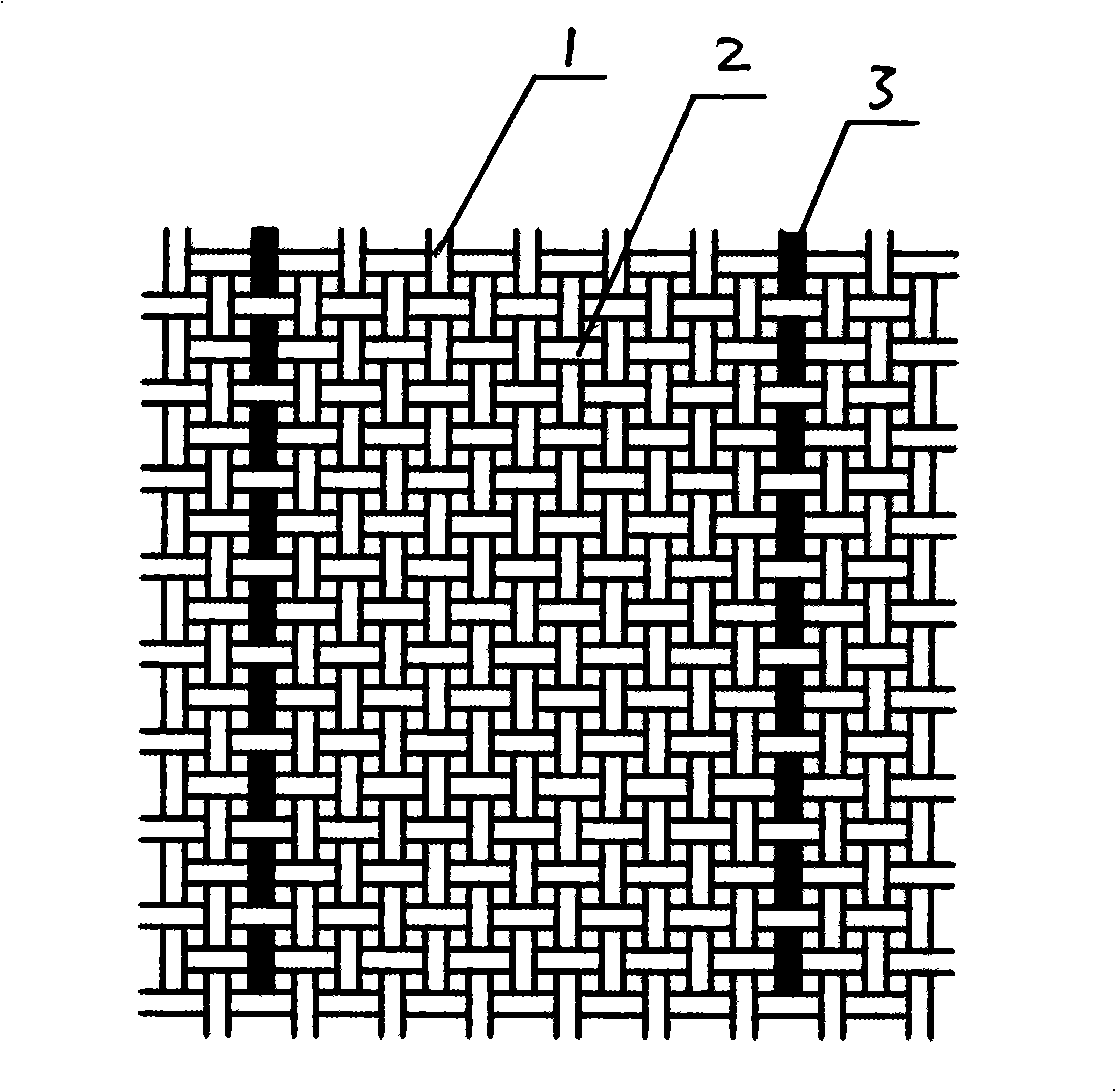

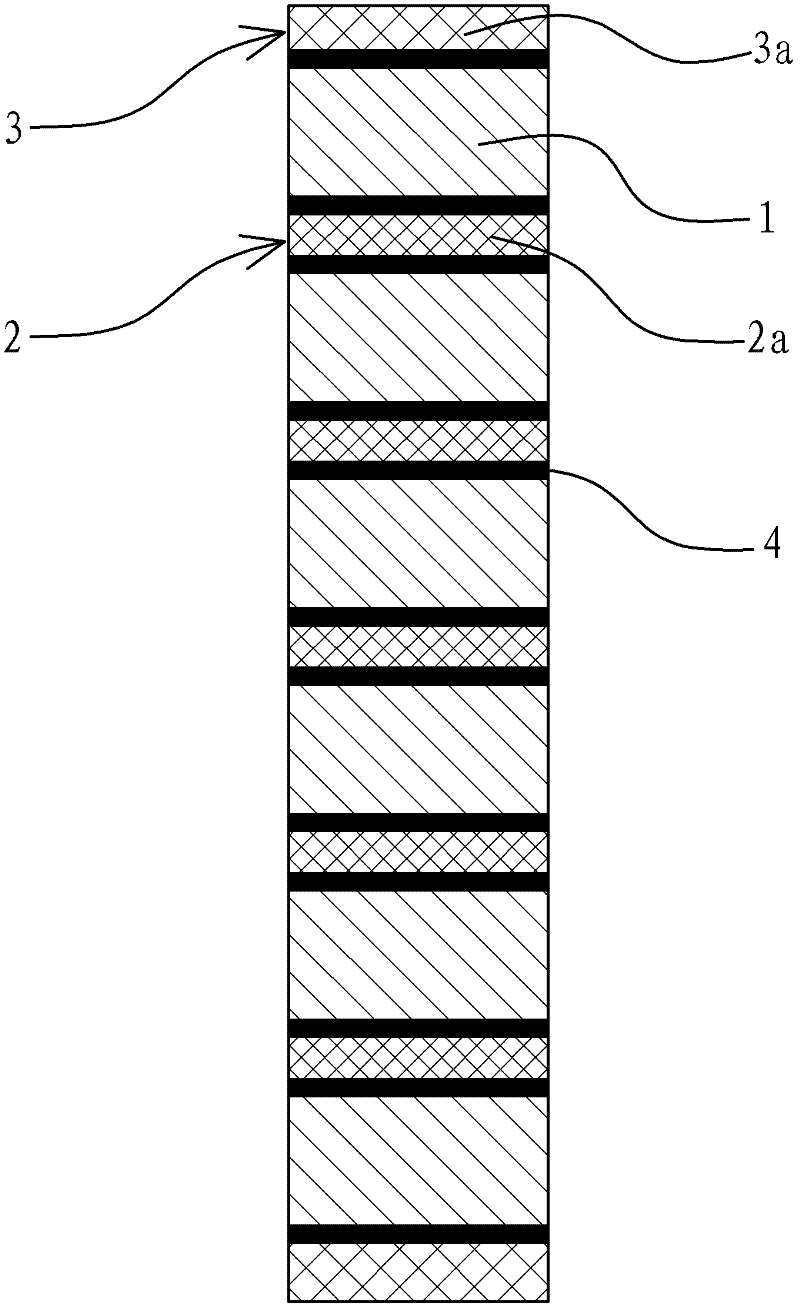

High strength coating cloth for tarpaulin of goods train and preparation thereof

InactiveCN101338522AHigh transparencyImprove thermal stabilityRailway componentsNon-woven fabricsEngineeringLow shrinkage

The invention discloses coated cloth with high strength for railway wagon tarp and making method thereof. The coating cloth includes high-strength and low-shrinkage terylene continuous filament yarn base cloth and PVC coating agent coated on the base cloth. The method comprises employing 800D-1300D high-strength and low-shrinkage terylene continuous filament yarns as warp yarn and weft yarn, or warp yarn, weft yarn and reinforced rib to make the base cloth; making base material and facing material of the PVC coating agent by PVC paste resin, plasticizer, temperature depressing plasticizer, stabilizer, flame retardant, stuffing, aging resistance agent, milew-proof agent and dye; evenly coating the base material on two sides of the base cloth with vertical coating method, and dyeing; coating one layer of facing material on vertically-coated two sides of the cloth by horizontal coating method, and tentering, plasticizing, drying, then performing surface treatment to make the coated cloth with high strength special for railway wagon tarp. The product of the invention has advantages of good stability, high strength, light weight, aging resistance, water-proof, dirt-proof, milew-proof, flame-proof, splite-proof performances, good weathering resistance and stripping performance. The method of the invention is simple, use and operation are convenient.

Owner:河北路篷塑胶有限公司 +1

Sand pattern powder coating for aluminum profiles as well as preparation method and application thereof

InactiveCN102775888AFeel smoothNot easy to scratchPowdery paintsPolyester coatingsSodium BentoniteRoom temperature

The invention belongs to the technical field of new materials and discloses a sand pattern powder coating for aluminum profiles as well as a preparation method and application thereof. The coating is prepared from the following raw materials in percentage by weight: 50-60% of saturated carboxyl polyester resin, 3.7-4.5% of triglycidyl isocyanurate, 17-27% of titanium dioxide, 13-20% of precipitated barium sulfate, 0.2-1.5% of bentonite, 0.2-0.7% of sand pattern agent, 0.3% of carbon black, 0.1-0.2% of pink and 0.1-0.2% of phthalocyanine blue. The preparation method comprises the following steps of: putting the raw materials into a mixing cylinder and premixing the raw materials; carrying out melt extrusion on the premixed raw materials and then pressing the materials into flakes; cooling the flakes to room temperature, crushing the flakes and then carrying out fine crushing; and screening the finely crushed materials to obtain the product.

Owner:广东华江粉末科技有限公司

Curable composition and sealing method

ActiveUS20090025870A1Increase resistanceWithout deteriorating sealing performanceImpression capsLamination ancillary operationsMeth-Silanes

An object of the present invention is to provide a curable composition excellent in on-site formability, excellent in heat resistance, chemical resistance and oil resistance, and low in compression set. The invention relates to a curable composition comprising (a) a vinyl-based polymer containing at least one (meth)acryloyl group in a molecule thereof and having a number average molecular weight of 500 to 1,000,000, (b) an ethylenic unsaturated group-containing compound, (c) a thixotropic property-imparting agent, (d) fumed silica surface-treated with a (meth)acryloyl group-containing silane and (e) a photopolymerization initiator.

Owner:THREEBOND FINE CHEM CO LTD

Nanometer composite powder zinc impregnation processing method

ActiveCN1730727AMeeting Corrosion Protection NeedsDoes not affect mechanical propertiesHeat inorganic powder coatingCooling downZinc

The invention provides a process for nanometer composite powder zinc impregnation processing method, which comprises metal member pretreatment, powder zinc impregnation processing and metal member post-treatment. The powder zinc impregnation processing comprises formulation of nano composite powder zinc impregnation agent, a zinc impregnation procedure and a cooling down separation process.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +4

Condenser type touch screen

InactiveCN101464761AUniform base colorImprove visual effectsInput/output processes for data processingTransmittanceMembrane surface

The invention relates to a capacitive touch screen, which comprises a substrate, and a film layer arranged on side of the substrate membrane surface. A black film is arranged around an atmospheric surface for shielding metal routings around the substrate in the film layer; a protective layer is arranged on the black film; the metal routings in the shielding film are arranged through a the atmospheric surface, so as to avoid a transparent cover plate used on one side of the atmospheric surface of the substrate, improve the transmittance of a touch-control screen panel, reduce the reflectivity of the film layer, enable the whole background of a touch-control screen to be even, improve the visual effect, enable the contrast of the touch-control screen to be improved, and reduce the working efficiency of the back light; the protective layer is arranged on the black film, so as to enable the atmospheric surface to be smooth, and protect the touch-control screen from being scratched when a finger touches the touch-control screen.

Owner:深圳市伟光导电膜有限公司

Ultrathin glass corner machining method and special computerized numerical control (CNC) cutter

InactiveCN102350661AImproved efficiency in processing glassNot easy to scratchEdge grinding machinesAbrasion apparatusMachining processGlass sheet

The invention provides an ultrathin glass corner machining method and a special computerized numerical control (CNC) cutter, and belongs to the technical field of glass machining. The method solves the problems that the conventional single ultrathin glass can only be subjected to single-piece and single-side chamfer machining and the machining efficiency is relatively low. The ultrathin glass corner machining method mainly comprises the following steps of: taking glass sheets, superposing the glass sheets, arranging a protective layer, curing a spacing layer, arranging the special CNC cutter for simultaneously machining corners of each glass sheet in superposed rectangular blocky glasses, and performing corner grinding on each glass sheet in the superposed rectangular block glasses by a CNC machining technology. By the method, polishing is not needed after machining, the glass machining efficiency is improved exponentially, shape and chamfer machining is performed on the superposed glass sheets, the surface of the single glass sheet is not easily scratched in the machining process, the product has good consistency, the qualification rate of the product is improved, and the machining efficiency is obviously improved.

Owner:ZHEJIANG XINGXING TECH CO LTD

Substrate carrier

InactiveCN101670942AReduce usageNot easy to fall offSolid-state devicesSemiconductor/solid-state device manufacturingDrive shaftDrive motor

The invention discloses a substrate carrier which is suitable for substrate transferring in a vacuum cavity; the substrate carrier comprises a base, a transmission component, a driving motor and a substrate holder; a groove is arranged on the substrate holder for bearing the substrate, rails are arranged at two sides of the base in parallel, a first rolling wheel is pivoted on the substrate holderand is contacted with the rails; the transmission component comprises a rack and a plurality of gears, the central part of the gear is extended outwards to form a gear transmission shaft, and the gear transmission shaft penetrates through the base in a pivoting way, at least one gear transmission shaft of the gear is connected with the driving motor, and the rack is fixedly connected with the substrate holder and is meshed with the gear, and the driving motor drives the gear which drives the substrate holder to slide along the rails. The substrate carrier is particularly suitable for substrate transferring in vacuum environment, and the transferring process is safe and has accurate location.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

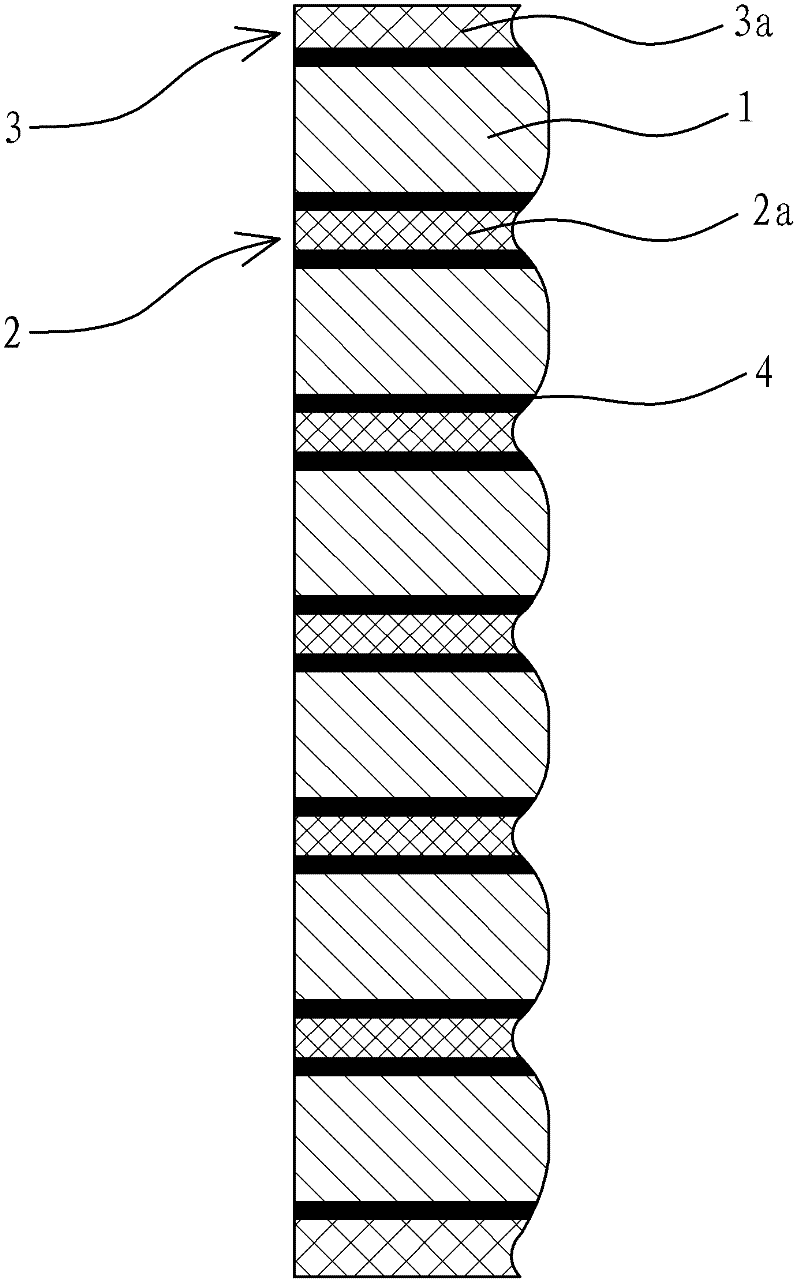

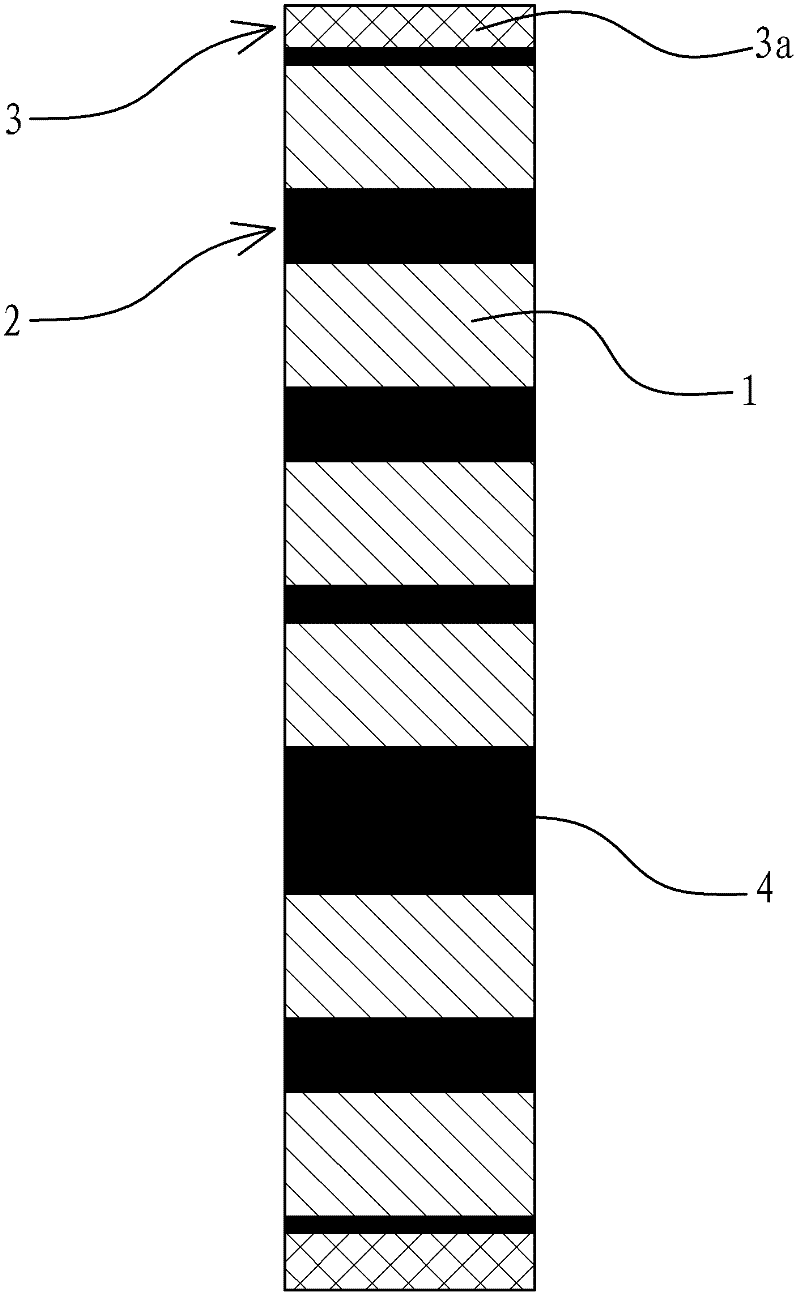

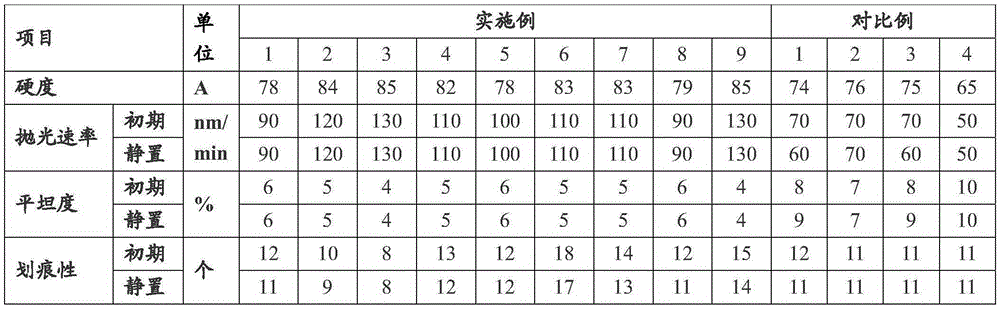

Composite polishing pad and preparation method thereof

ActiveCN105415168AReduce hair sheddingGood surface smoothnessGrinding devicesLapping toolsElastomerPolymer science

The invention discloses a preparation method of a composite polishing pad. The preparation method comprises the following steps that (1) non-woven fabric is preprocessed, specifically, (a) the non-woven fabric is put into a drying oven for flattening, (b) the flattened non-woven fabric is immersed into a glue solution and then is taken out after being infiltrated sufficiently, and a non-woven fabric substrate material is obtained; (2) a polymer solution is prepared, specifically, (I) a macromolecular elastomer is dissolved into a solvent, and a macromolecular elastomer solution is prepared; (II) polymer particles are added into the macromolecular elastomer solution, and the polymer solution is obtained; (3) the non-woven fabric is made into a pad, specifically, the non-woven fabric substrate material is infiltrated into the polymer solution and then is taken out after being infiltrated sufficiently, and unnecessary solutions on the surface of the non-woven fabric substrate material are scraped off; the non-woven fabric substrate material is immersed into coagulating bath for consolidation forming and then put into pure water for rinsing and finally dried to the constant weight, and an original polishing pad is obtained; and (4) the polishing pad is formed, specifically, after the surface of the original polishing pad is polished, cut and rubberized, and the finished polishing pad is obtained. By means of the preparation method, the composite polishing pad has a large polishing rate, and moreover the flatness of a polished object is good.

Owner:河南惠强新能源材料科技股份有限公司

Polishing liquid for grinding and polishing lithium niobate optical wafer

InactiveCN1858131AEasy to break awayIncrease viscosityOptical surface grinding machinesAqueous dispersionsLithiumLiquid viscosity

The present invention discloses polishing liquid for grinding and polishing optical lithium niobate wafer. The polishing liquid consists of silica sol 30-90 vol%, organic amine alkali 1-10 vol%, inorganic alkali 1-5 vol%, activator 0.5-5 vol%, chelating agent FA / O 0.5-5 vol%, and deionized water for the rest. Under CMP and high pH condition, lithium is formed into stable complex and water soluble niobate to raise polishing efficiency and surface quality. The present invention has organic alkali and lithium niobate surface matter to form soluble amine salt easy to separate from the reaction surface, and this avoids the increase in the abrasive granularity and polishing liquid viscosity to ensure no scoring, high flatness and no adsorbate.

Owner:HEBEI UNIV OF TECH

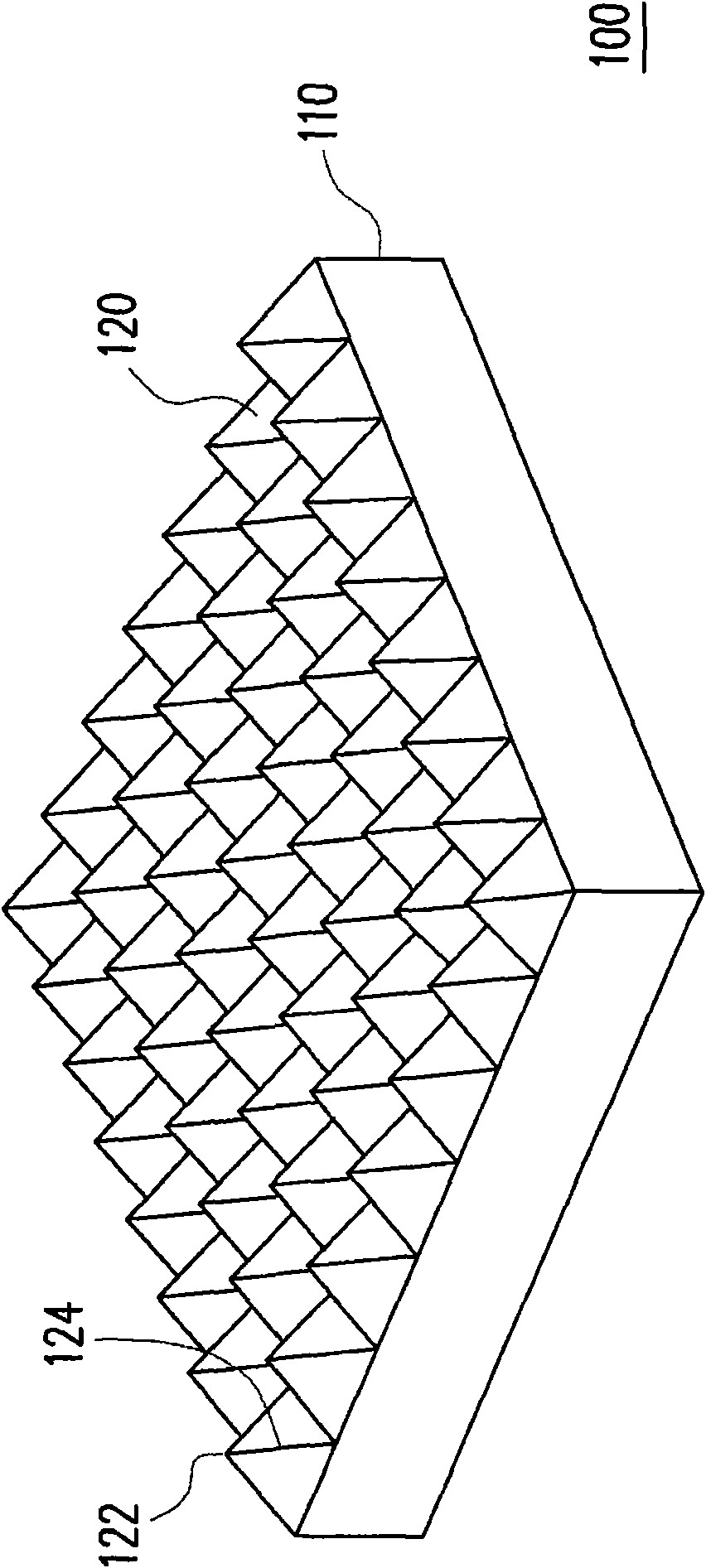

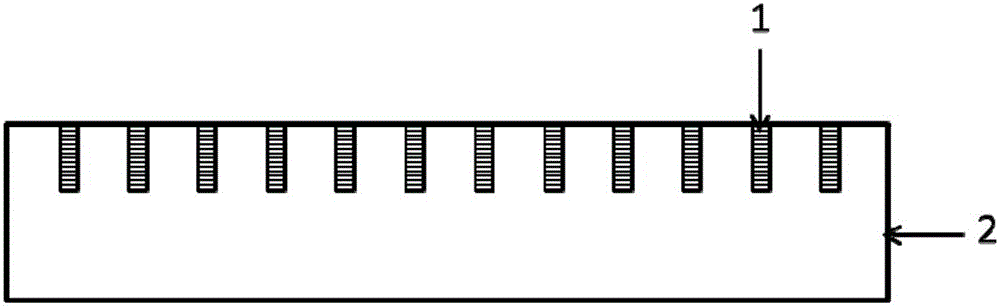

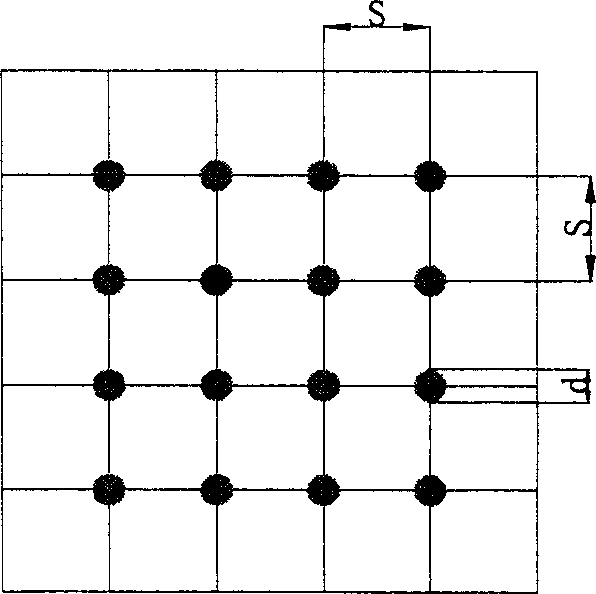

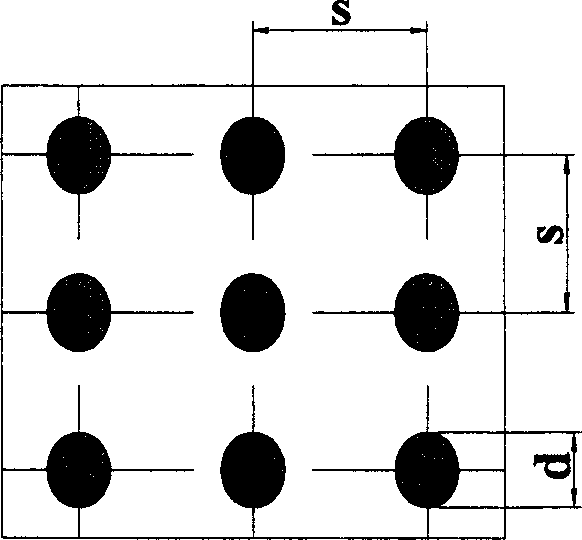

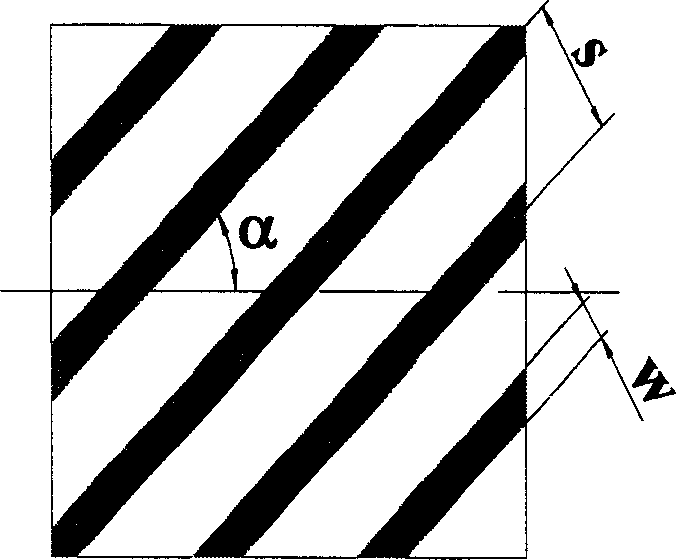

Manufacturing method of light source module, optical plate, and master mould and sub-mould of the optical plate

InactiveCN101571246AAvoid damageGood light extraction efficiencyMechanical apparatusElectric lightingComputer moduleEngineering

The invention discloses a manufacturing method of a light source module, an optical plate, and a master mould and a sub-mould of the optical plate. The optical plate comprises a substrate, a plurality of first microstructures, a plurality of second microstructures and a plurality of third microstructures. The substrate has a first area, a second area and a third area, and the second area is between the first area and the third area. A plurality of the first microstructures are arranged on a surface of the substrate in the first area at a predetermined spacing. A plurality of the second microstructures are arranged on the surface of the substrate in the second area. A plurality of the second microstructures have paired mutual connection at least, and a connection and the surface of the substrate are coplanar. A plurality of the third microstructures are arranged on the surface of the substrate in the third area, and a plurality of the third microstructures have paired partial superposition at least; wherein, the first microstructures, the second microstructures and the third microstructures have circular arc-shaped tips respectively. The method can help prevent moire generation, provide uniform and concentrated beams and be used for manufacturing a concaved microstructure mould and a convex microstructure mould with circular arc-shaped tips, and the optical plate with high light extraction efficiency.

Owner:AU OPTRONICS CORP

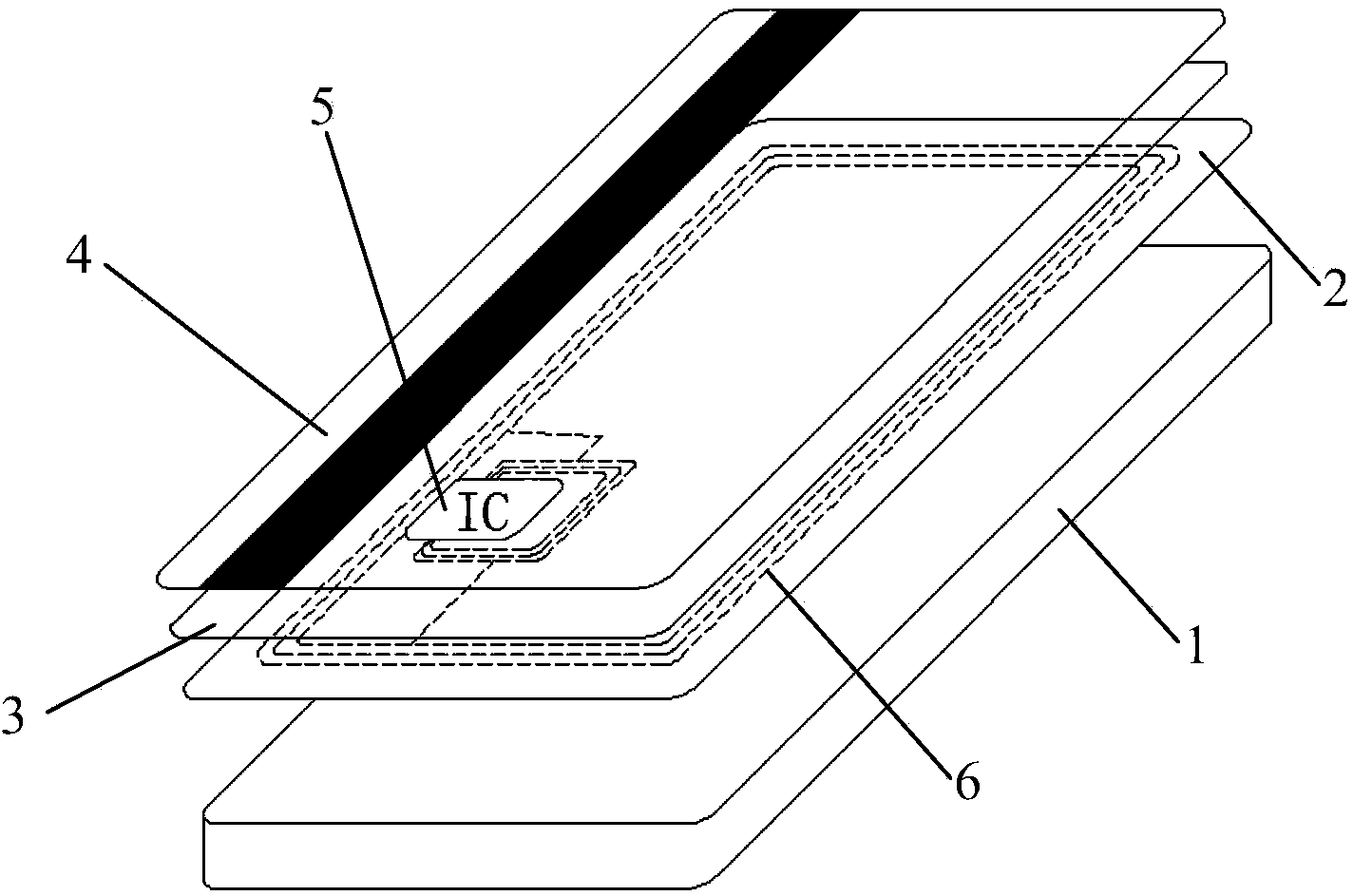

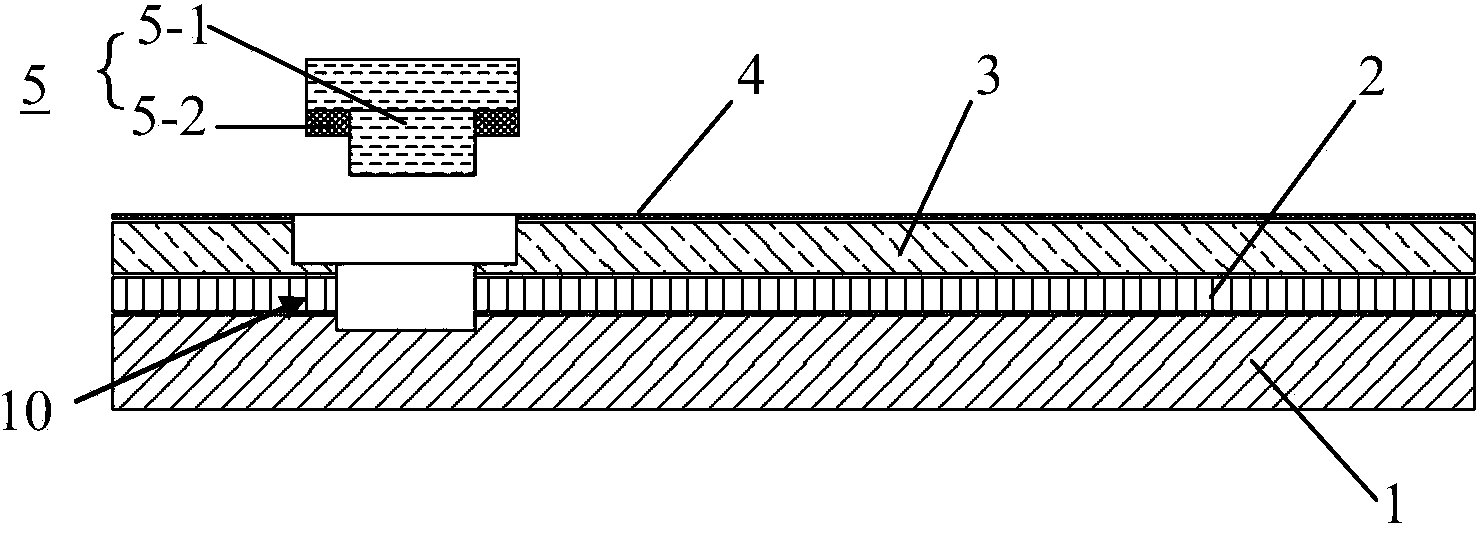

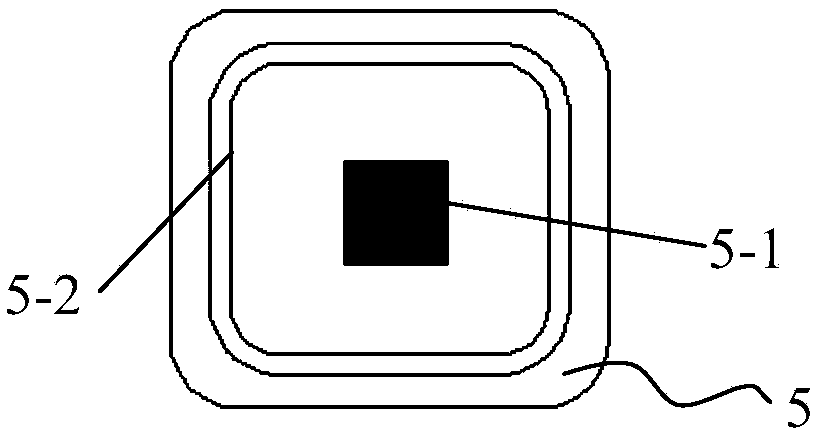

Double-interface metal intelligent chip card and manufacture method

ActiveCN104166870AImprove the anti-electromagnetic interference characteristicsExchangeRecord carriers used with machinesElectricityElectromagnetic coupling

The invention discloses a double-interface metal intelligent chip card and a manufacture method. The double-interface metal intelligent chip card comprises a metal card body. The metal card body is provided with an interlayer, a printing sheet layer and a transparent protection layer which are positioned on the metal card body. The metal card body, the interlayer, the printing sheet layer and the transparent protective layer constitute a card base for the intelligent chip card. The base card is provided with a concave cavity for containing an IC module; the metal card body is a wave-absorption material metal card body; the interlayer is provided with an induction antenna; the IC module comprises a chip and a coupling micro antenna which is electrically connected to the chip; and the IC module can perform the information exchange between the chip and a reader through electromagnetic coupling between the coupling micro antenna and the induction antenna and the electromagnetic coupling between the induction antenna and the induction coil of the reader. The invention solves the technical problem that the metal card hardly realizes double-interface chip clamping contact type function and a non-contact type communication function at the same time, and provides a new double-interface IC metal card which is good in touching, has metal texture and can realize a double-interface transaction function.

Owner:GOLDPAC GRP LTD

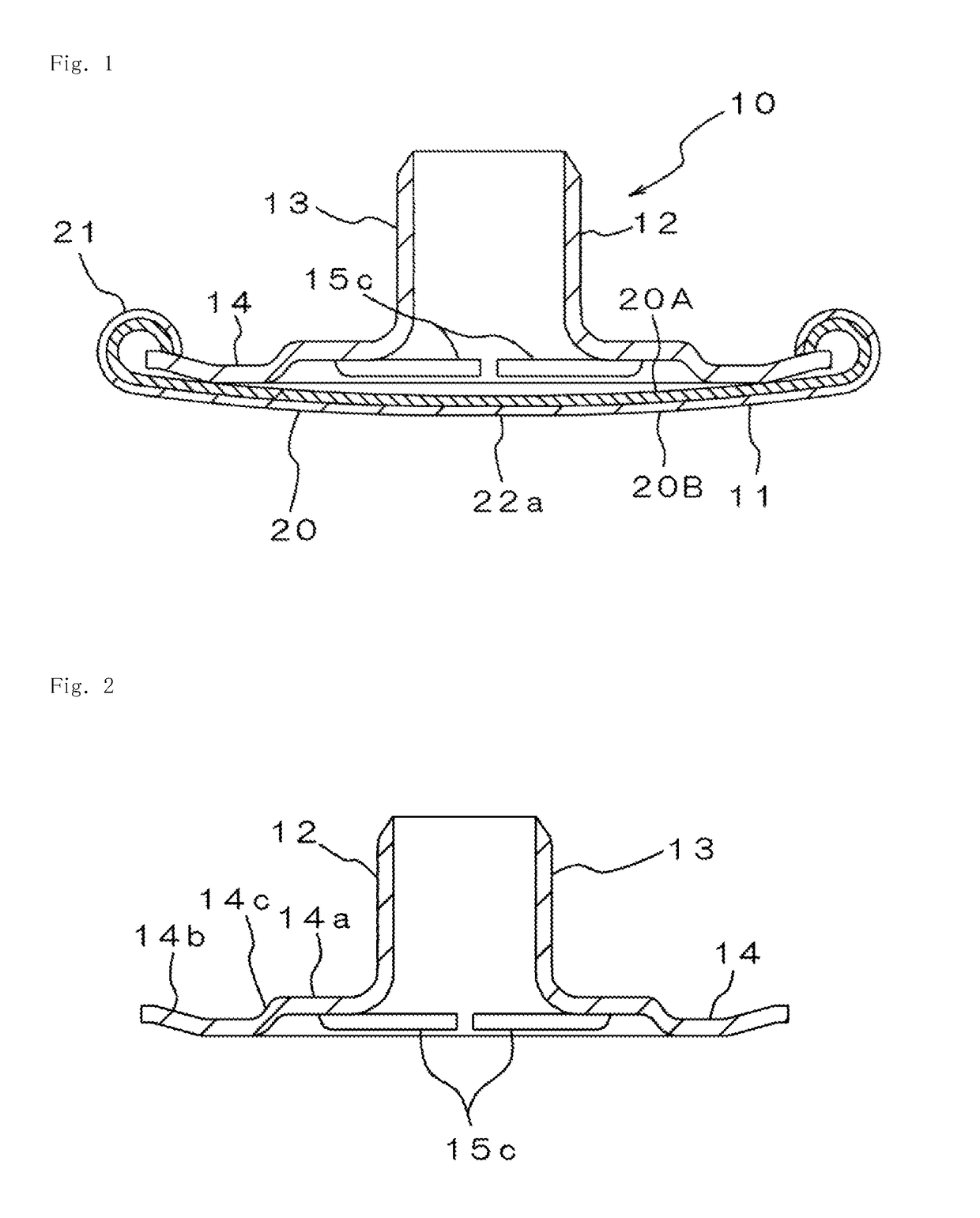

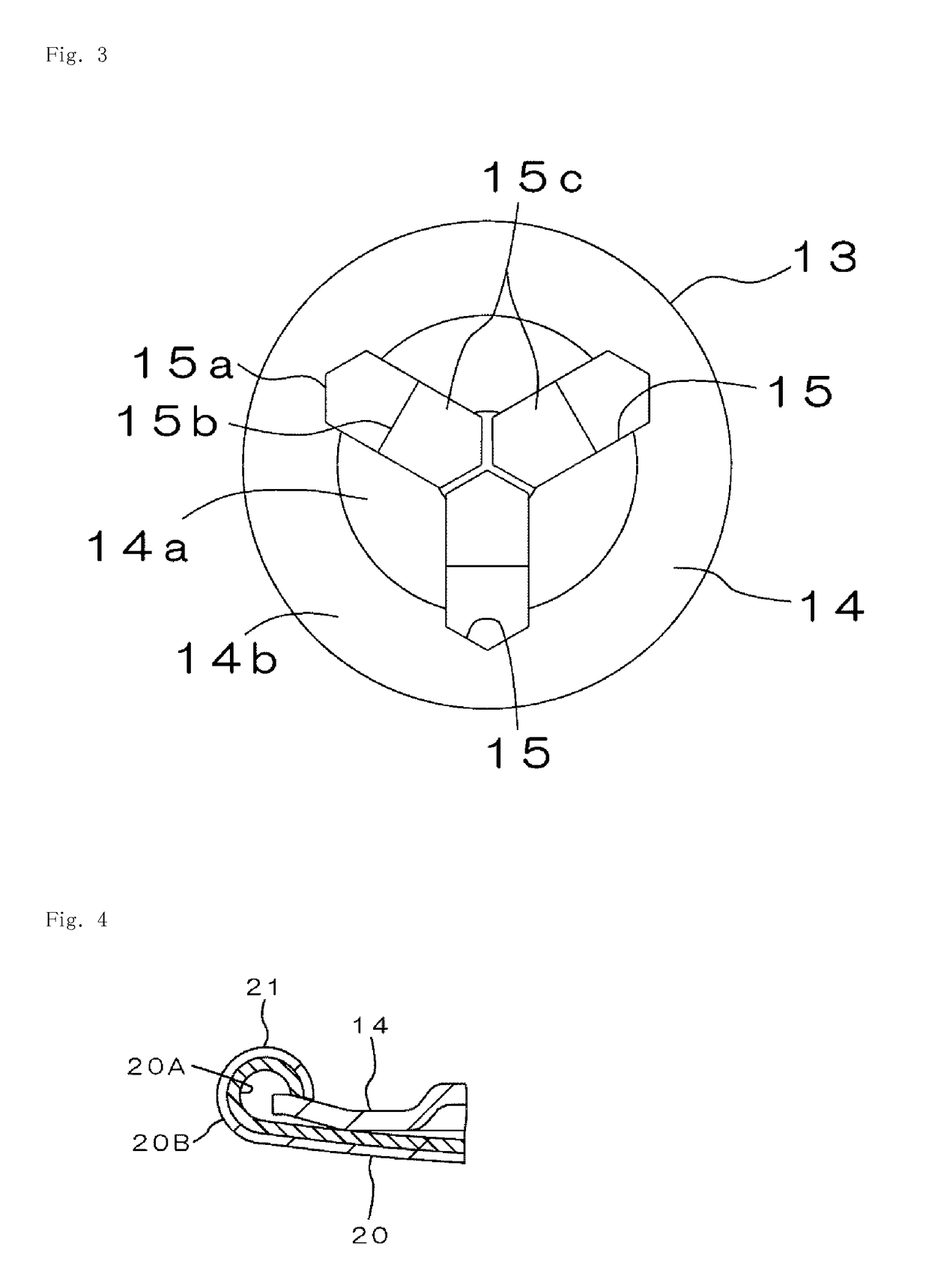

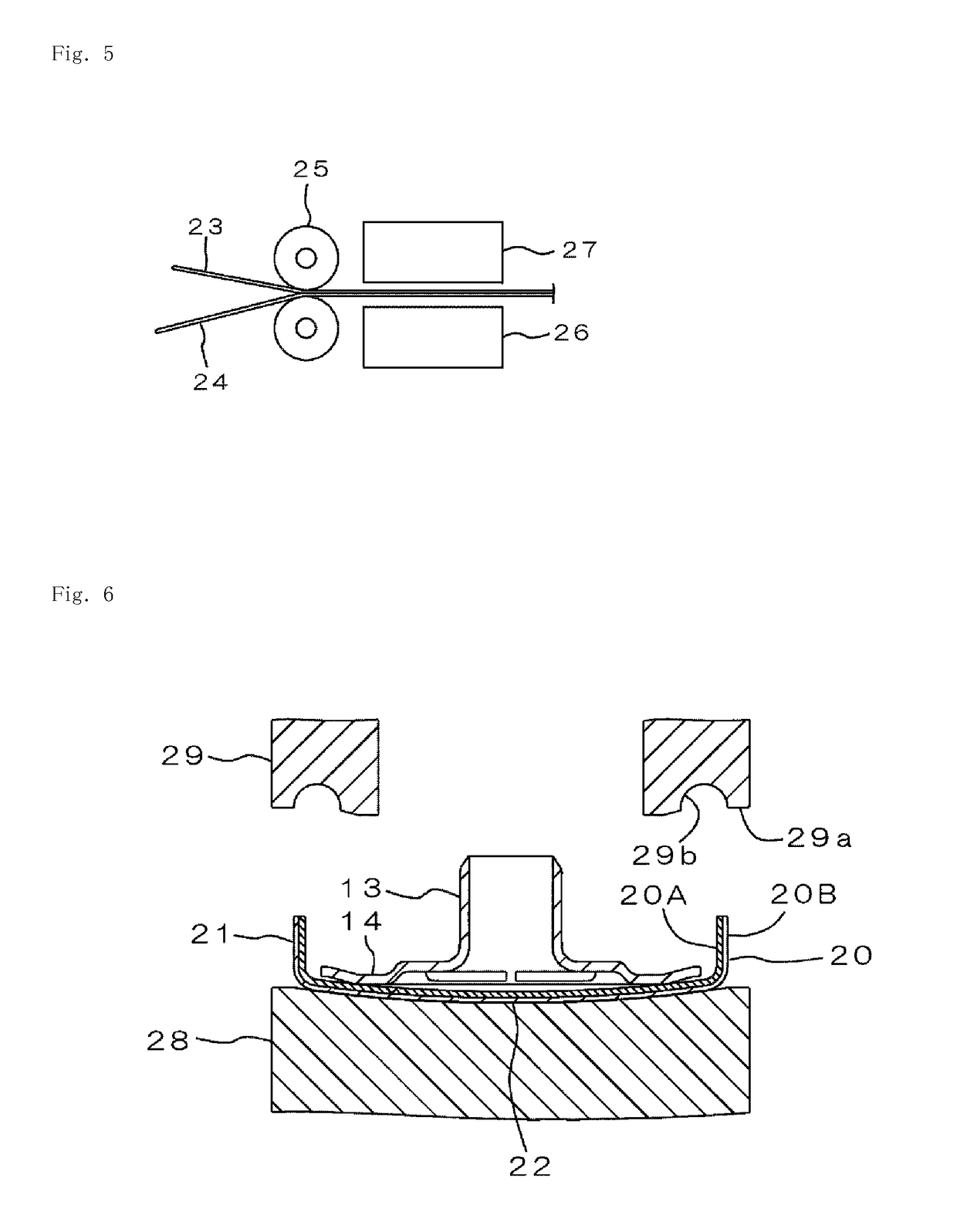

Cap, button group and method for forming button group

ActiveUS10159312B2Cost advantagePrevent rotationSnap fastenersClothes buttonsHardnessUltimate tensile strength

Owner:YKK CORP

Lifting tool for mounting large-size machine tools

The invention discloses a lifting tool for mounting large-size machine tools and relates to the technical field of mechanical equipment manufacture. The lifting tool comprises a lifting part and a plug-in mounting part inserted into a lifting object, wherein the lifting part is connected with the plug-in mounting part into a whole, and provided with a plurality of circular grooves. The lifting tool can solve the problems that when the large-size machine tools and accessories of the large-size machine tools are lifted, the lifting tool is poor in lifting flexibility, inconvenient to use and low in efficiency and scratches surfaces of lifted objects easily, a steel rope is broken easily, and a safety accident is even caused.

Owner:柳州金盛重型数控机床有限责任公司

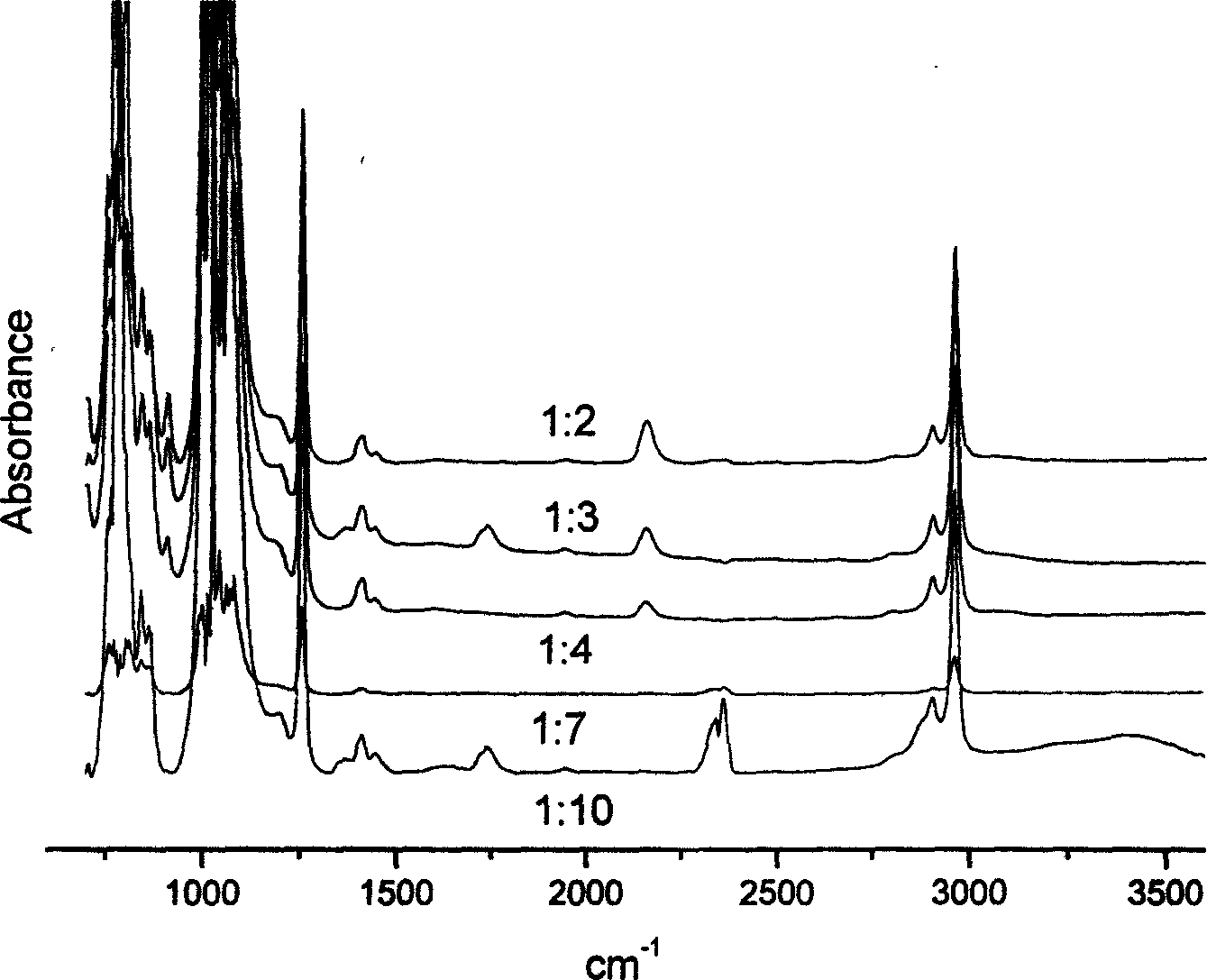

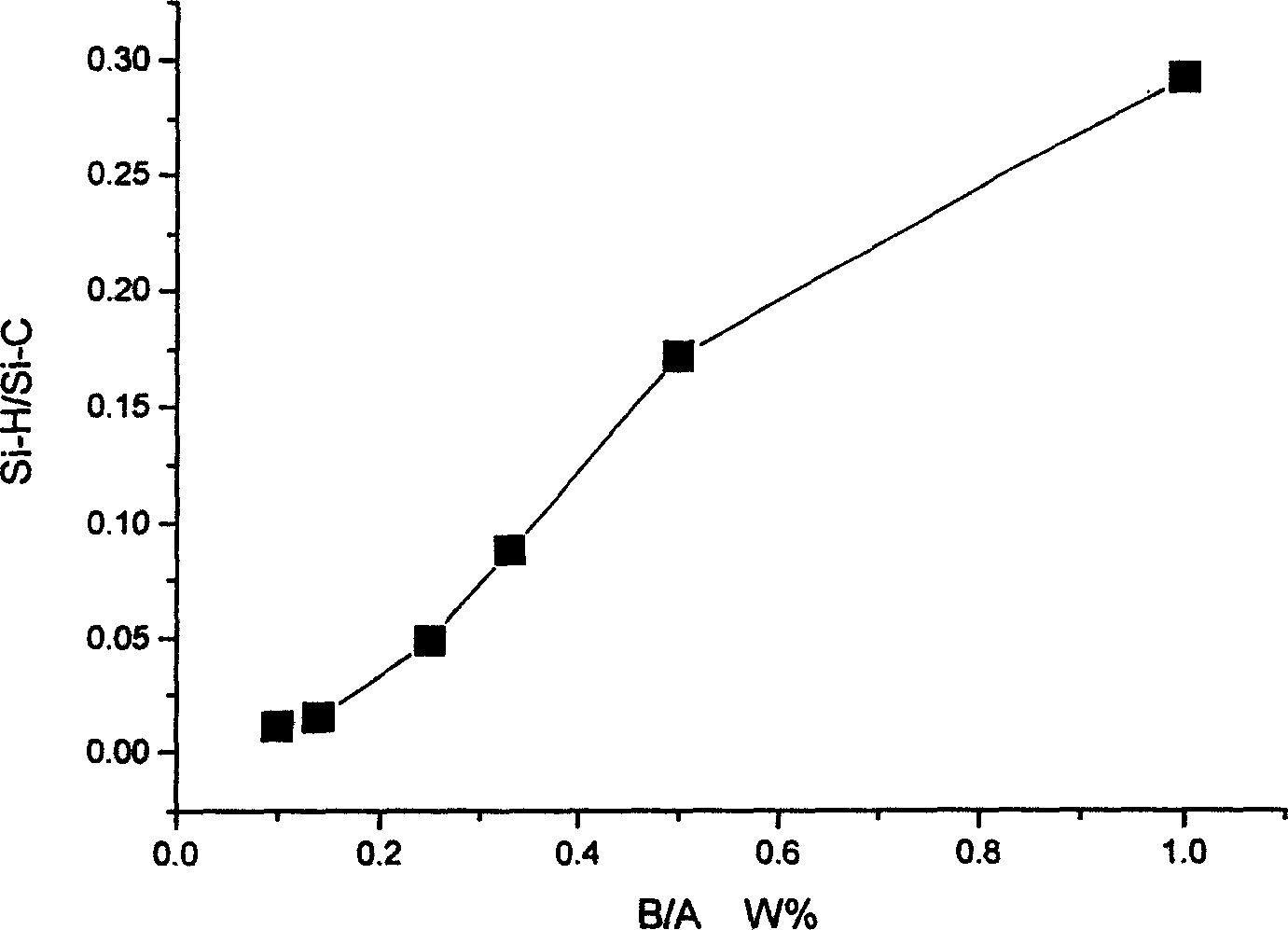

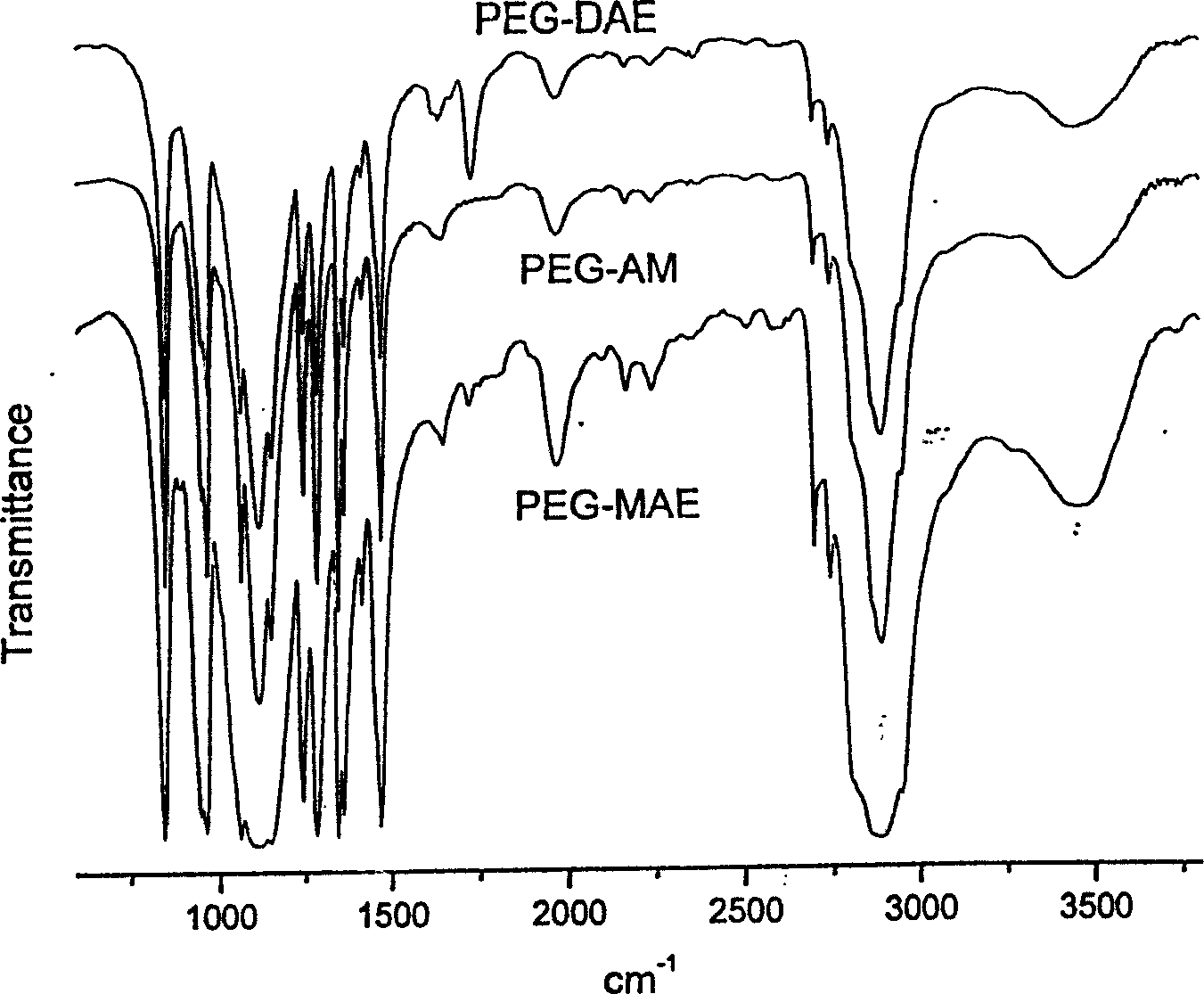

Silicone rubber with permanent hydrophilic property on surface, preparing method and use thereof

InactiveCN1583834AImprove breathabilityGood optical performanceOptical partsPolymer sciencePolyethylene glycol

A silicone rubber with durable hydrophilic surface is produced by reacting hydro-silicon bonds in surface with polyethylene glycol monoallyl ether, alpha-allyl-omiga-methyl-polyethylene clycol or polyethylene glycoldiqallyl ether to form polyglycol modified silicone rubber with Si-C covalent bonds. The average value of molecular weights is 1000 - 8000. The surface modified PDMS is improved in compactness, uniform and stability of hydrophilic layer with polyglycol derivatives combined with silicone rubber. The surface does not adsorb protein and is of perfect biocompatible, so that it can be used in bio-medical purposes, eg, lenses of contact spectacles. Its manufacture and uses are related here.

Owner:NANJING UNIV

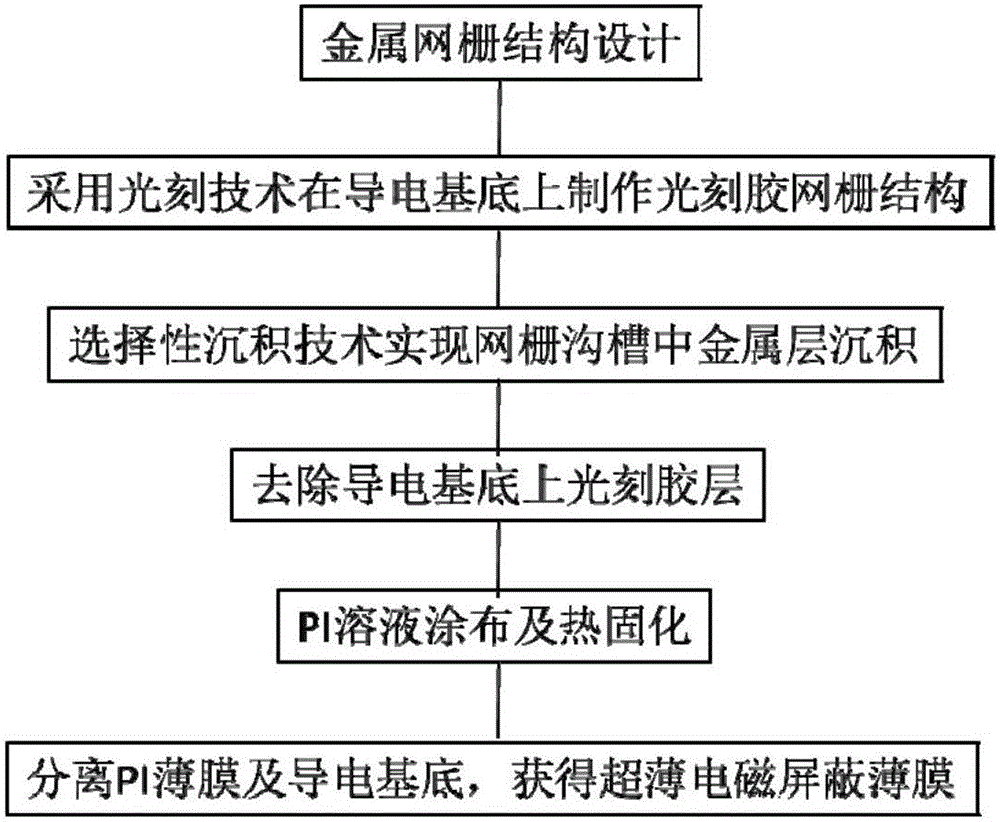

Preparation methods of electromagnetic shielding film and electromagnetic shielding window

InactiveCN106061218AGood light transmissionImprove shielding effectMagnetic/electric field screeningPhotosensitive material processingLithographic artistSurface mounting

The invention discloses a preparation method of an electromagnetic shielding film. The method comprises the steps of 1), coating photoresist on a conductive substrate, and forming a pattern structure on the conductive substrate through a lithography technology; 2), growing a metal layer in the pattern structure through a selective electro-deposition technology, thereby forming a metal pattern structure; and 3), embedding the metal pattern structure in a flexible base material through an embossing technology, thereby forming the electromagnetic shielding film. The invention also discloses a preparation method of an electromagnetic shielding window. The methods have the advantages of high transparency and high temperature resistance. According to the methods, demands of an optical window for high shielding performance, high imaging quality and high temperature resistance of the electromagnetic shielding film can be satisfied. The demand of flexible electronics for bending performance of the electromagnetic shielding film can be satisfied. The demand of surface mounting of a complex structure for ultrathin property of the shielding film can be satisfied.

Owner:SUZHOU UNIV +1

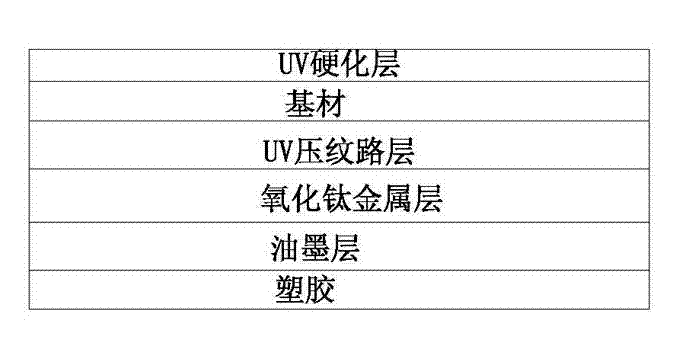

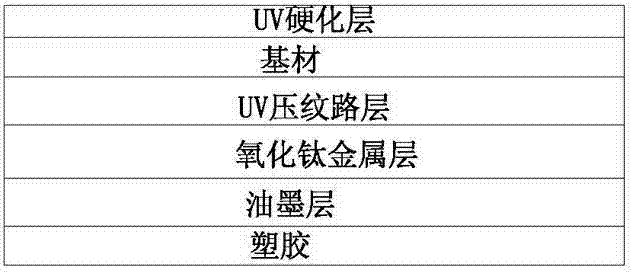

Treatment process of injecting product in mold

The invention discloses a treatment process of injecting a product in a mold, which comprises the following steps: (1) coating UV finish on one surface of a base material, curing to form a UV hardened layer; (2) coating the UV finish on the other surface of the base material, performing die casting on the UV finish to obtain lines, curing the base material in a curing furnace to form a UV line layer; (3) performing vacuum sputtering of a titanium oxide metal layer on the UV line layer, wherein the light transmittance of the titanium oxide metal layer is 75-80%; (4) printing an ink layer on the titanium oxide metal layer; (5) punching the base material with the printed ink layer to form a sheet material; (6) putting the punched sheet material in a corresponding injection mold to perform injection molding so as to obtain a finished product. The product processed by the treatment process of injecting a product in a mold of the invention has diamond cutting effect with high angularity and high stereoscopic impression, has high wear resistance, and is applicable to mobile phones, panel personal computers, and products with other structures.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Braking drum with bionic non-smooth surface

InactiveCN1644950AIncrease coefficient of frictionImprove wear resistanceBraking drumsRough surfaceEngineering

A drum break with bionic rough surface characters high friction index, anti-wear, anti-heat fatigue. On the surface of the drum break distribute knaggy units of height 0.15-0.5 mm in parallel or net. The structure and chemical components of the knaggy units increase the ability of anti-friction and anti-heat fatigue of the drum break. The structure of the knaggy units changes a surface friction to point friction therefore reduce wearniess of the drum break. The life this knagg drum break is 1.5-3 times of that of same material in smooth.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com