Preparation methods of electromagnetic shielding film and electromagnetic shielding window

A technology of electromagnetic shielding film and electromagnetic shielding window, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, photoengraving process of pattern surface, etc. The effect of surface resistance and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

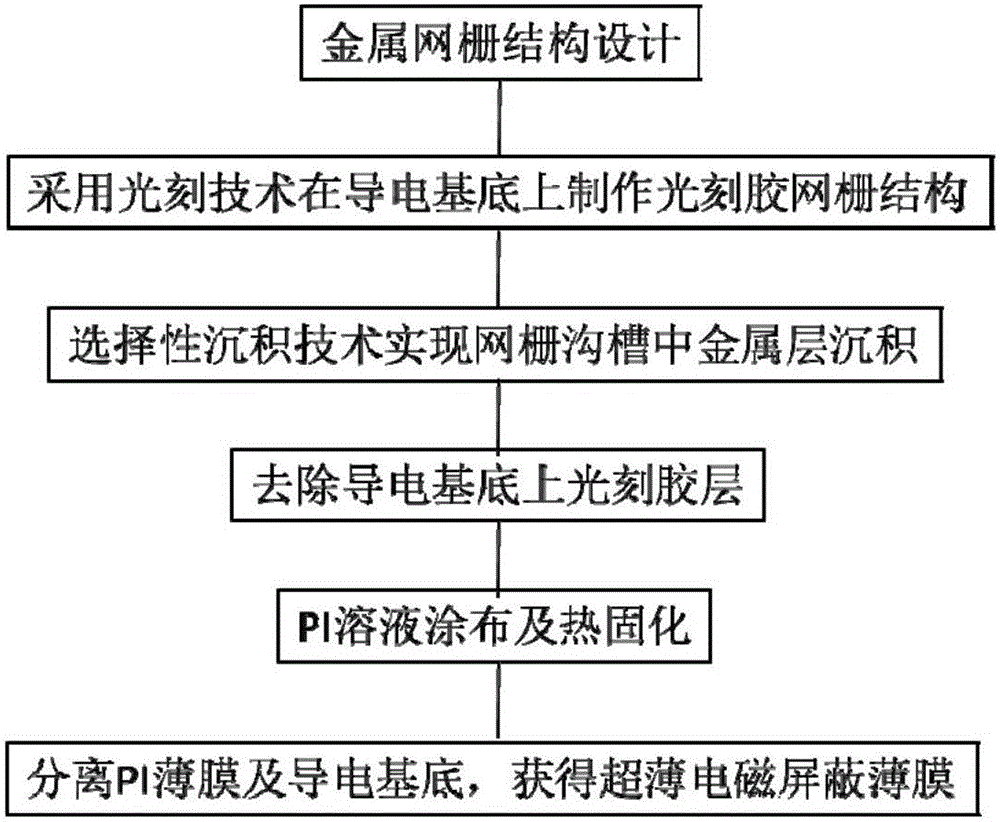

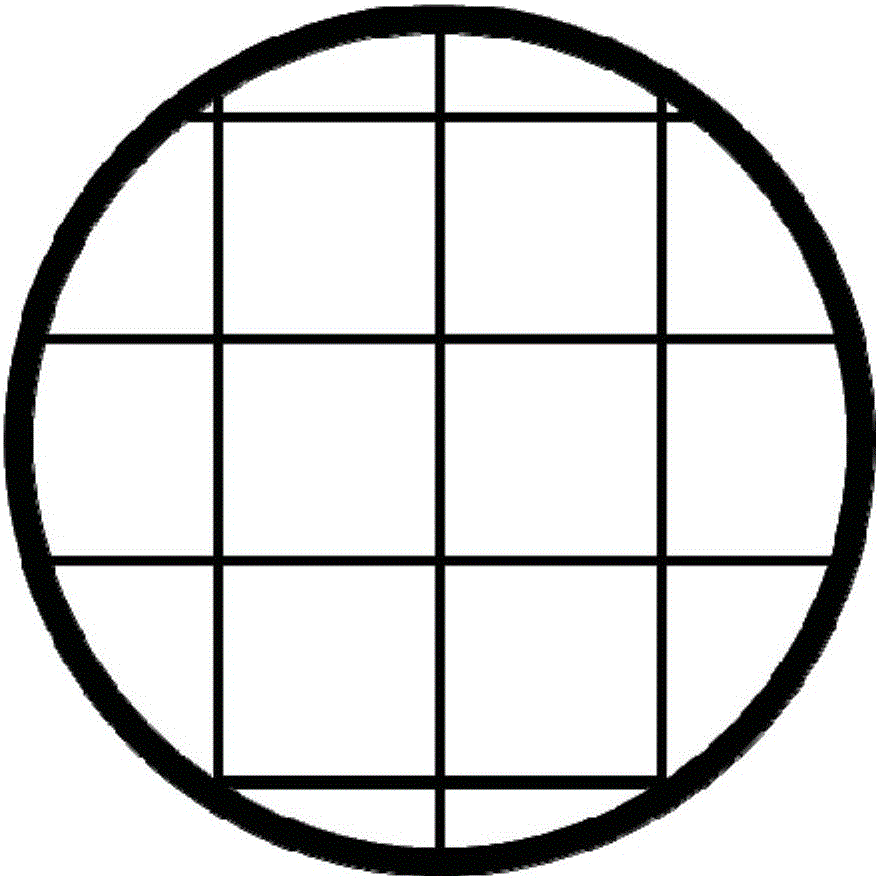

[0056] Embodiment 1: Ultra-thin metal grid electromagnetic shielding film. Production process such as figure 1 As shown, firstly, according to the requirement of shielding effectiveness, design the arrangement of the metal grid structure, which can be hexagonal, square, rectangular, parallelogram, triangular, etc. periodic arrangement, or arbitrary multi-deformation arrangement, etc., the grid structure Line width (300nm-10μm), grid spacing (1-500μm) and other parameters, and then patterned on the conductive substrate coated with photoresist by patterning (laser direct writing, ultraviolet exposure, electron beam exposure, etc.) technology grid structure. The patterned conductive substrate is placed on the cathode of the electrodeposition tank, and the metal material (nickel, copper, gold, aluminum, silver, etc.) to be deposited is placed on the anode. Using the selective depositability of electrodeposition, the metal on the anode is gradually deposited on the cathode by cati...

Embodiment 2

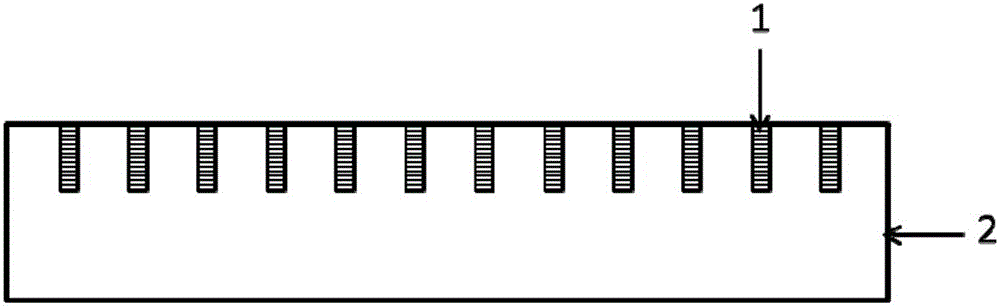

[0058] Embodiment 2, a metal grid type electromagnetic shielding film embedded in an ultraviolet curing glue. According to the manufacturing process of Embodiment 1, a metal grid structure is fabricated on a conductive substrate through a selective electrodeposition process. According to the design requirements, the line width (300nm-10μm) of the metal grid, the grid spacing (10-500μm), and the thickness of the metal deposition layer (300nm-10μm) are formed. Then, the UV-curable glue is coated on the deposited and deglued conductive substrate, and the PET film is covered thereon, and irradiated with a UV lamp. The UV-curable glue is cured after being irradiated with light, and adheres to the PET substrate3. After the PET and the conductive substrate are peeled off, the metal grid 4 is embedded in the ultraviolet curing adhesive 5 to form an electromagnetic shielding film, such as image 3 shown. The transmittance of the electromagnetic shielding film is determined by the ra...

Embodiment 3

[0060] Embodiment 3, embedded electromagnetic shielding film. According to the manufacturing process of Embodiment 1, a metal grid structure is fabricated on a conductive substrate through a selective electrodeposition process. According to the design requirements, the line width (300nm-10μm) of the metal grid, the grid spacing (10-500μm), and the thickness of the metal deposition layer (300nm-10μm) are formed. Then cover the COC film on the deposited and deglued conductive substrate, and apply a certain temperature (over the glass transition temperature of the COC film) and pressure. By hot embossing technology, the metal grid is embedded inside the COC film. After the COC film is separated from the conductive substrate, an electromagnetic shielding film embedded in the COC is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com