Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1854 results about "Metal grid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

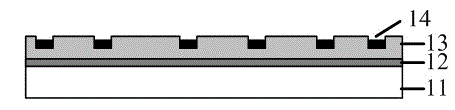

Metal grid conducting layer and touch panel equipped with the conducting layer

InactiveCN102722279AImprove adhesionImprove bond firmnessElectrical connection printed elementsInput/output processes for data processingFilling materialsConductive materials

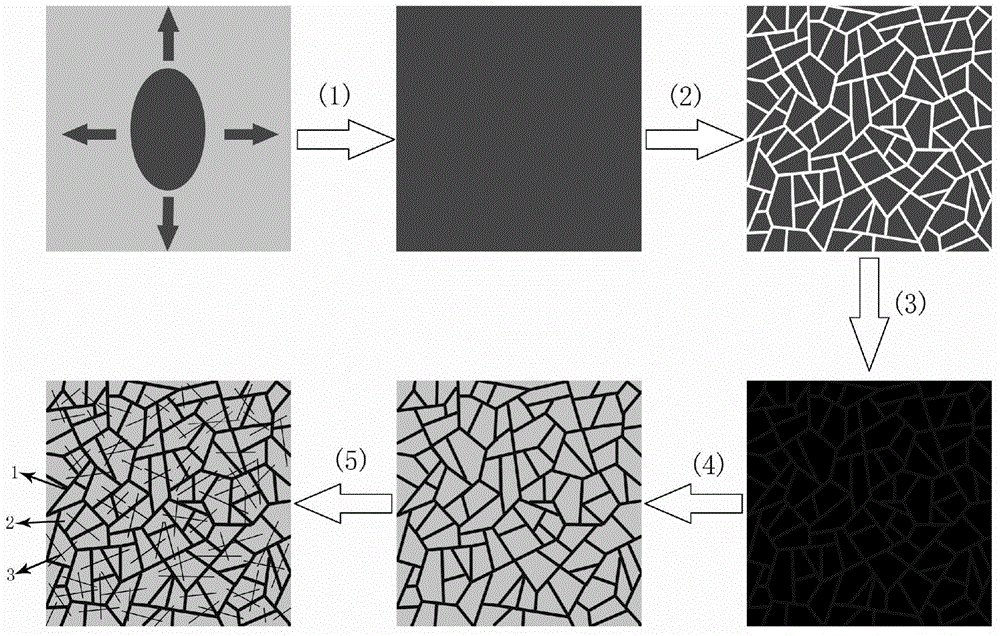

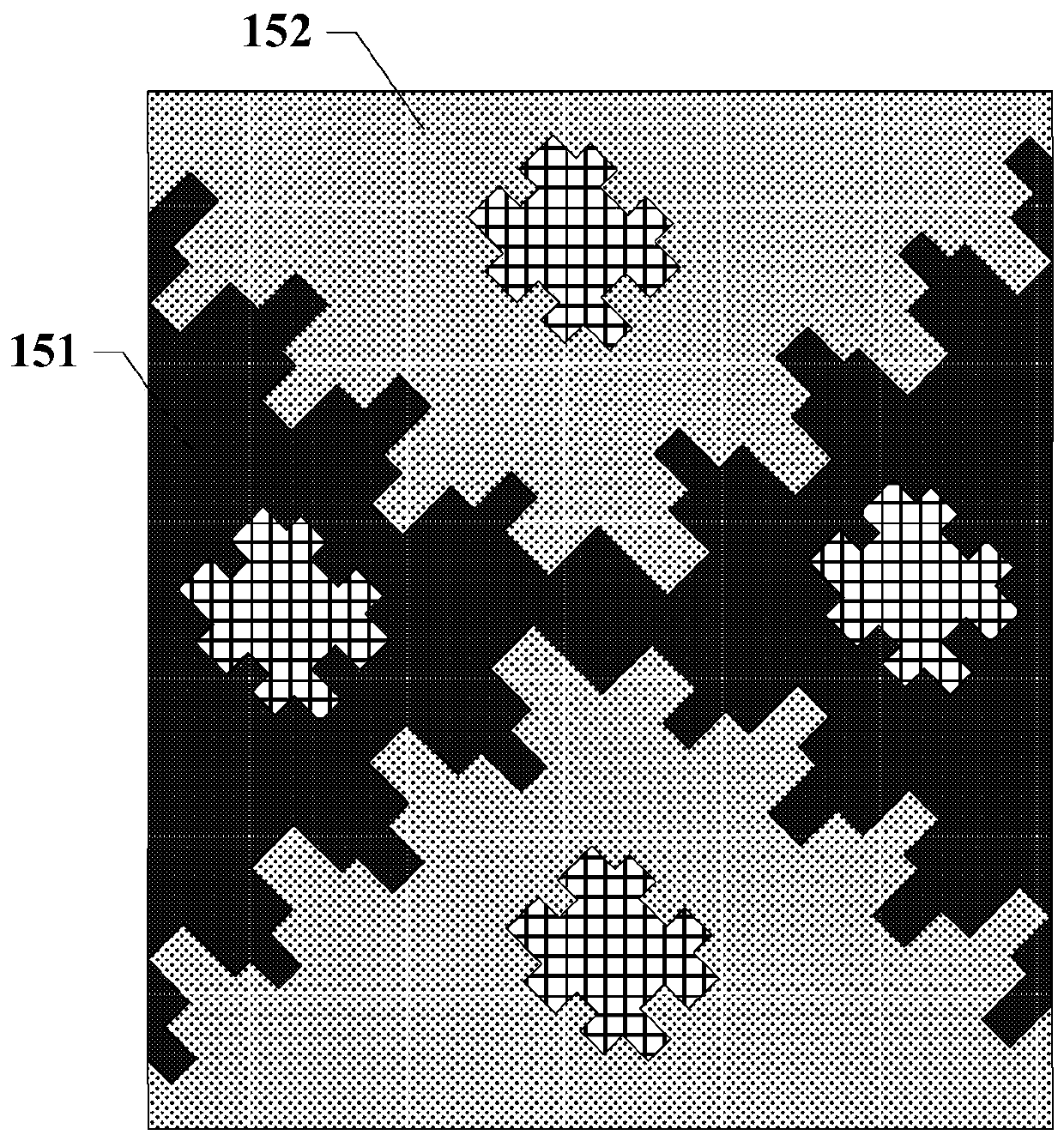

The invention relates to a metal grid conducting layer and a touch panel equipped with the conducting layer. Surface of the conducting layer comprises a transparent electrode area and an electrode lead area, wherein the transparent electrode area is equipped with random metal grids in irregular shapes, and the electrode lead area is equipped with metal grids in regular shapes. Grid lines of the transparent electrode area are evenly distributed in each angular direction. Said grids are filled into grooves. In the transparent electrode area of the invention, grids are adopted so that conductive filling materials are more evenly filled in the grooves and are better connected with external conductive materials. In addition, the transparent electrode composed of irregular grids would no longer generate moire fringes.

Owner:NANCHANG O FILM TECH CO LTD

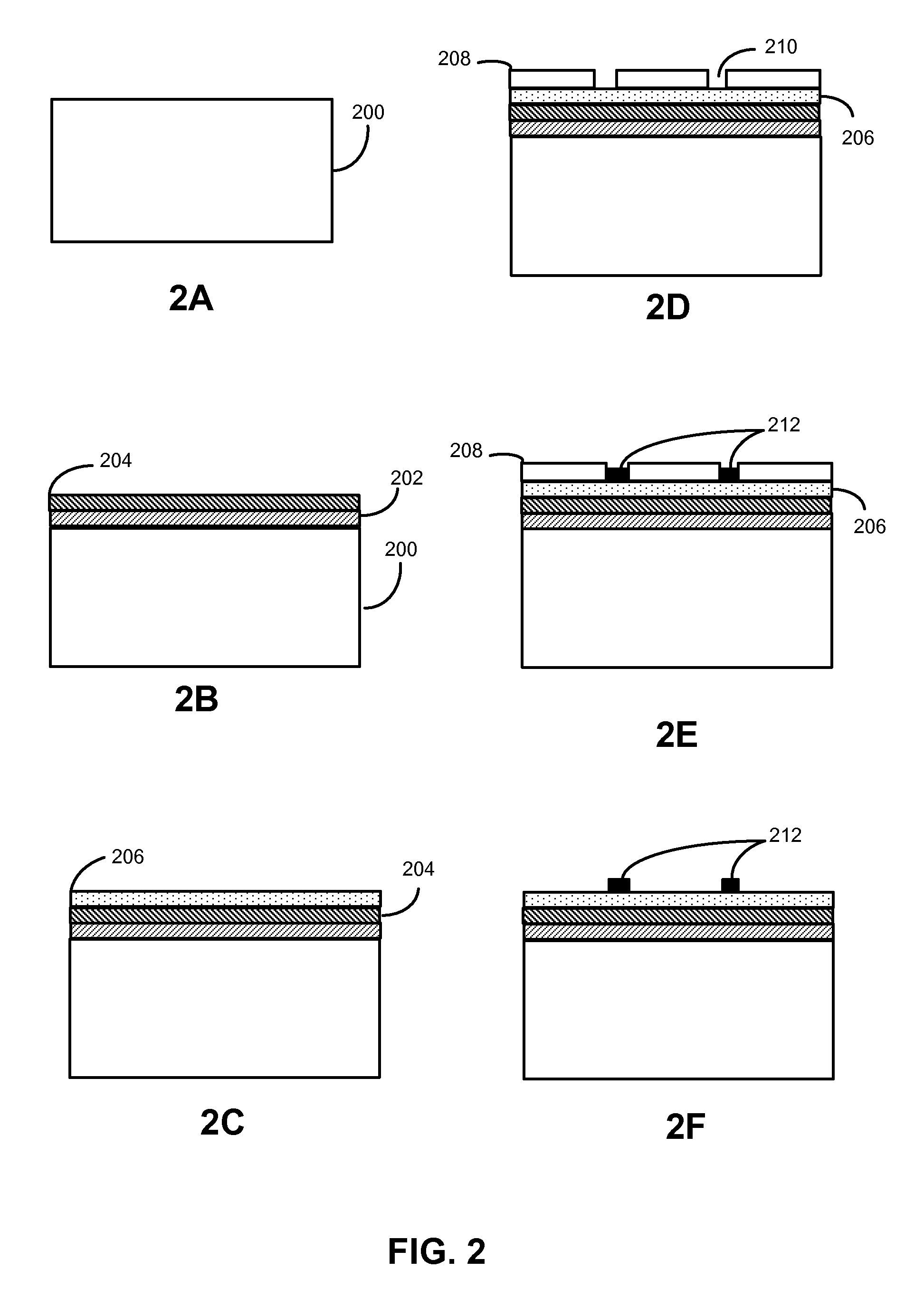

Solar cell with electroplated metal grid

ActiveUS20120060911A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationSemiconductor structureAdhesive

One embodiment of the present invention provides a method for fabricating solar cells. During operation, an anti-reflection layer is deposited on top of a semiconductor structure to form a photovoltaic structure, and a front-side electrode grid comprising a metal stack is formed on top of the photovoltaic structure. The metal stack comprises a metal-adhesive layer comprising Ti or Ta, and a conducting layer comprising Cu or Ag situated above the metal-adhesive layer.

Owner:TESLA INC

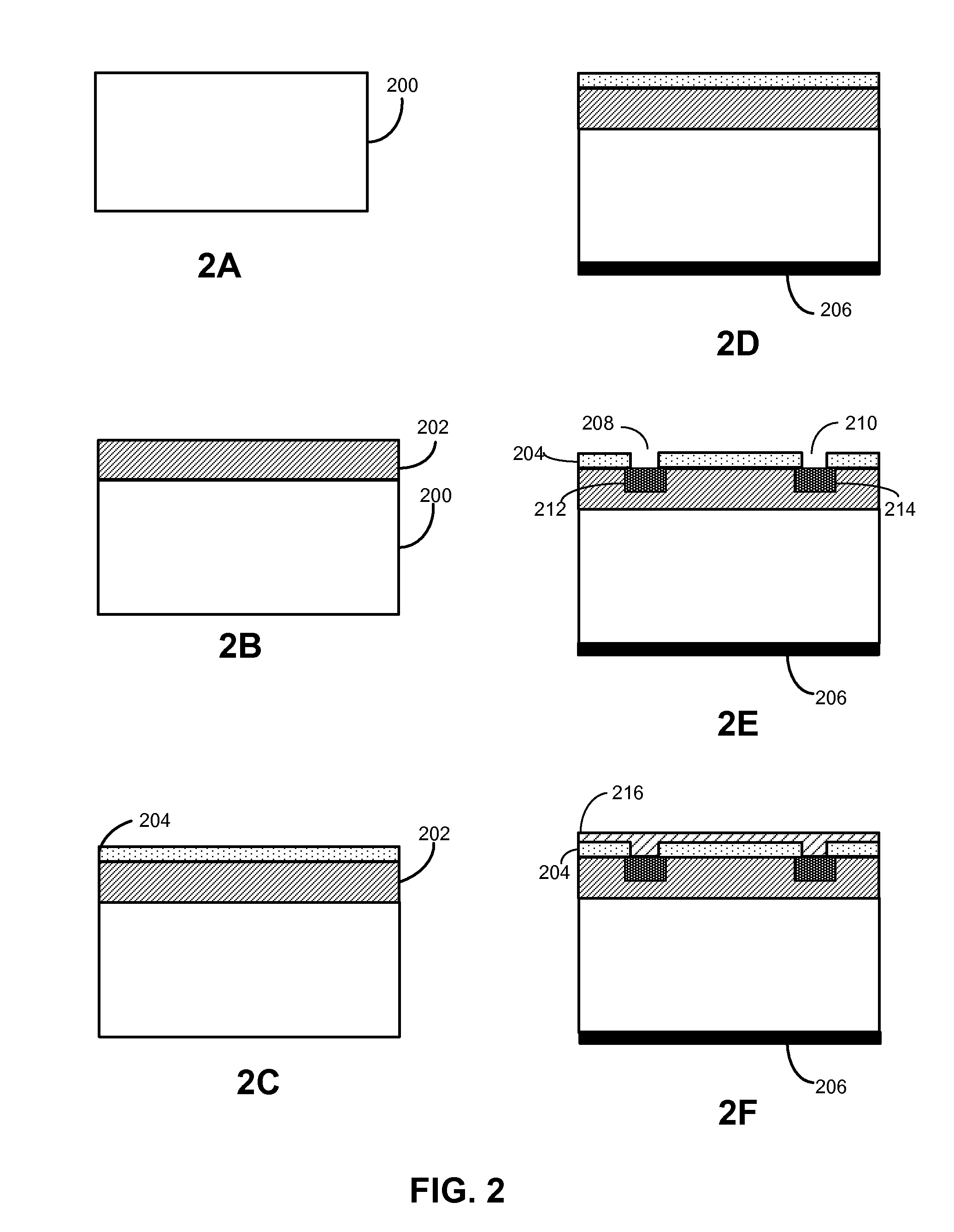

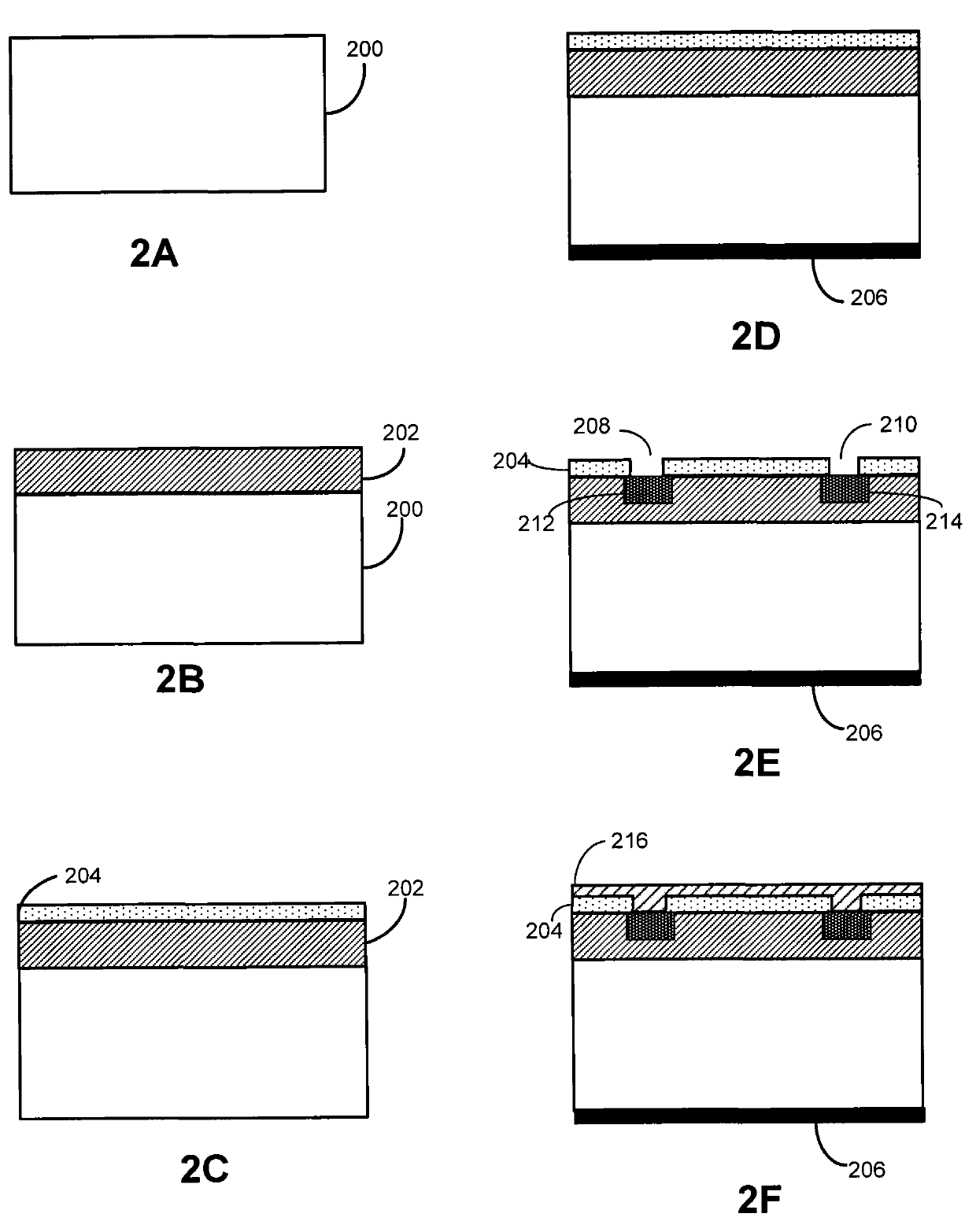

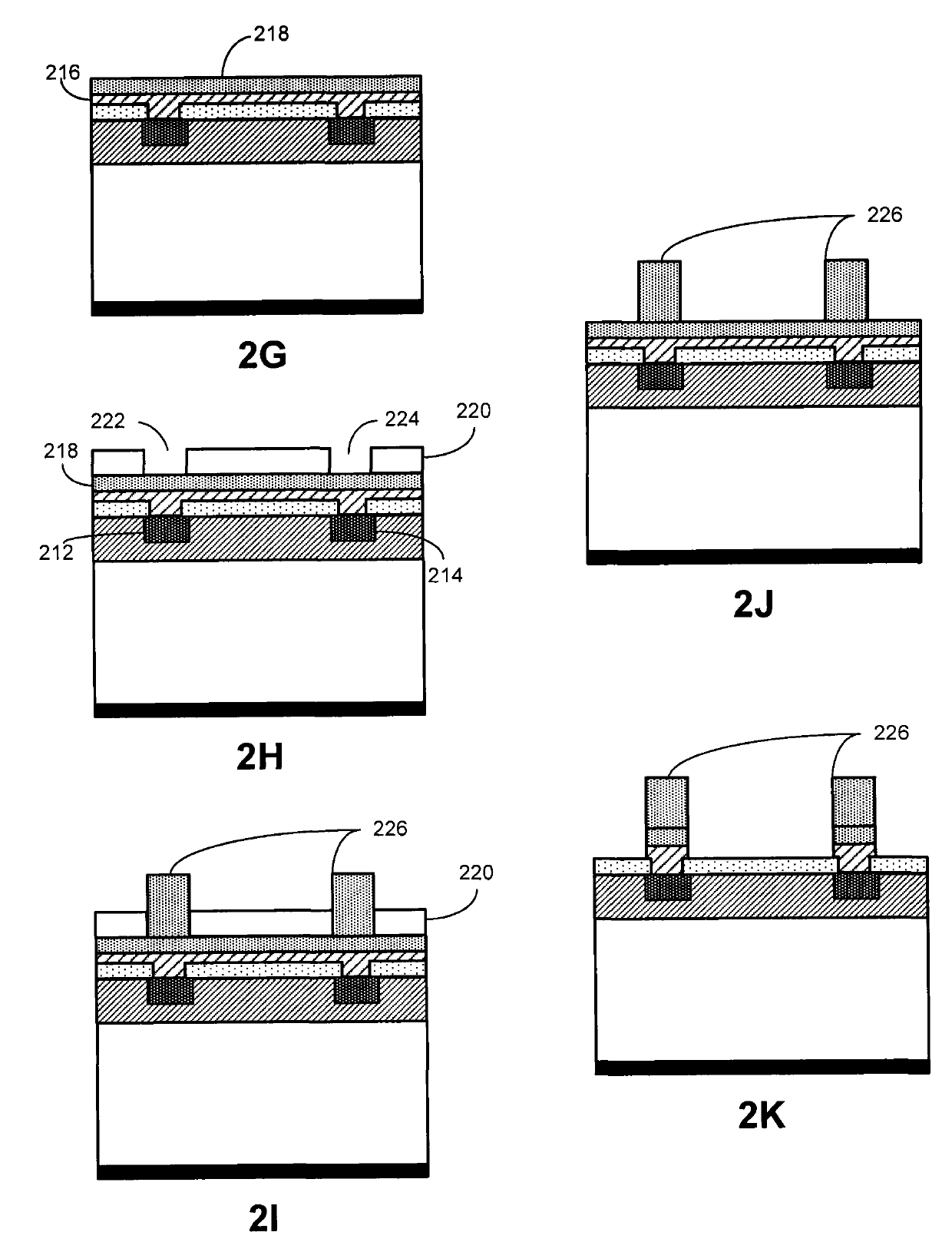

Solar cell with metal grid fabricated by electroplating

InactiveUS20110277825A1Less resistivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationSolar cellElectroplating

One embodiment of the present invention provides a solar cell. The solar cell includes a photovoltaic structure, a transparent-conductive-oxide (TCO) layer situated above the photovoltaic structure, and a front-side metal grid situated above the TCO layer. The TCO layer is in contact with the front surface of the photovoltaic structure. The metal grid includes at least one of: Cu and Ni.

Owner:SOLARCITY

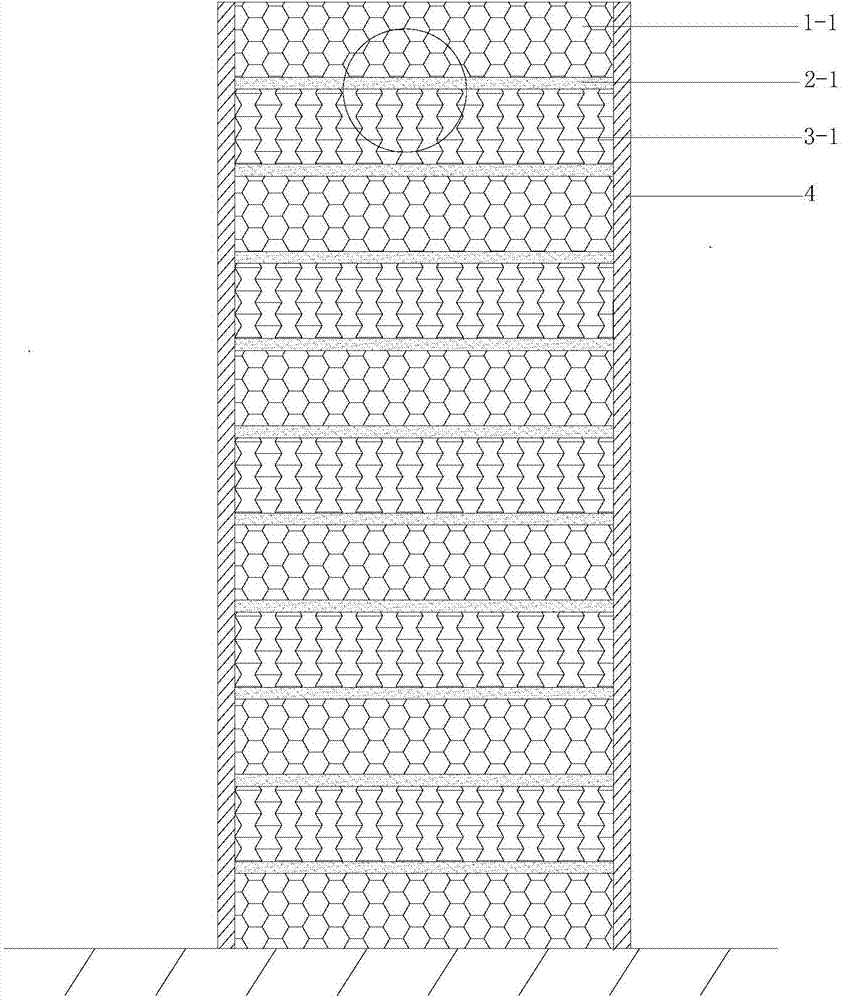

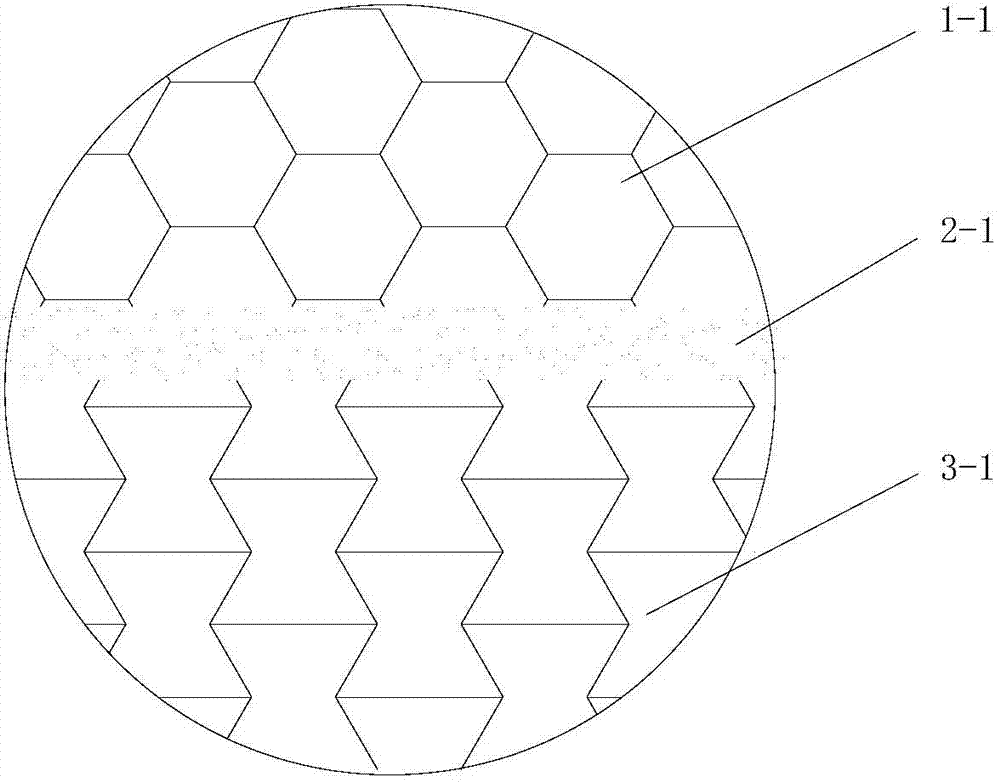

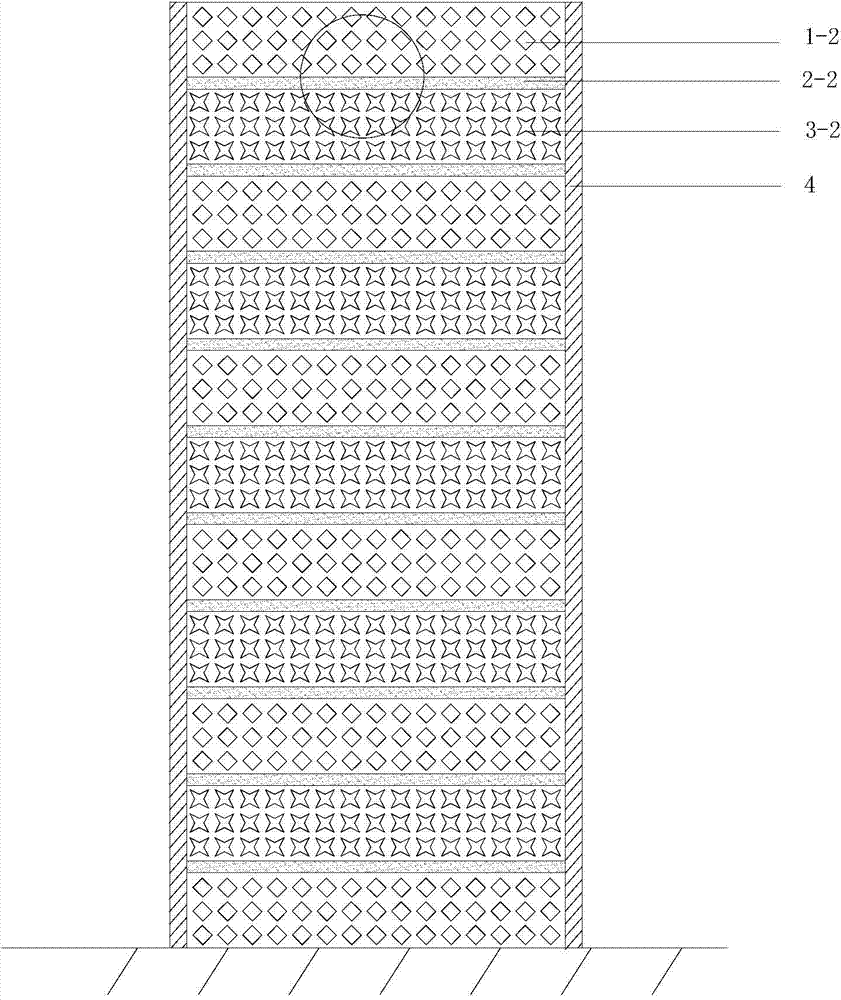

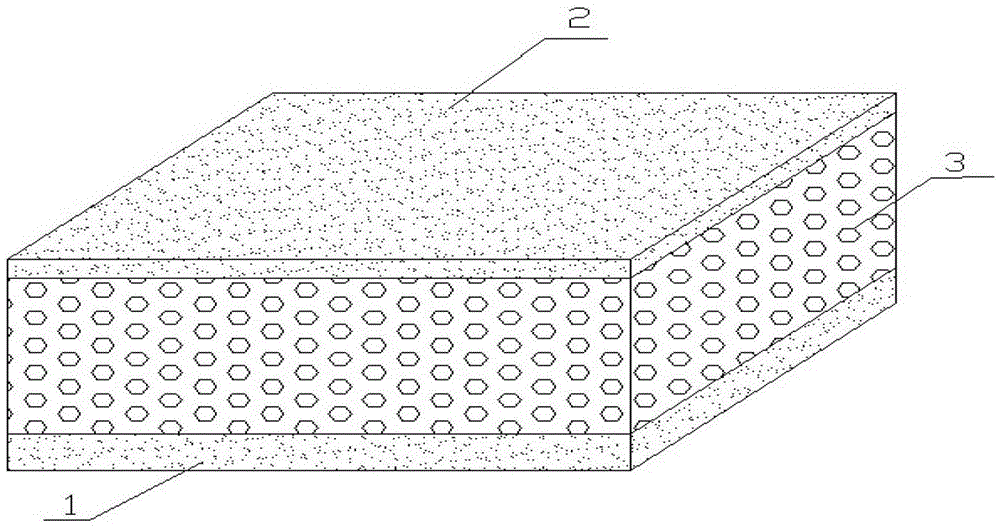

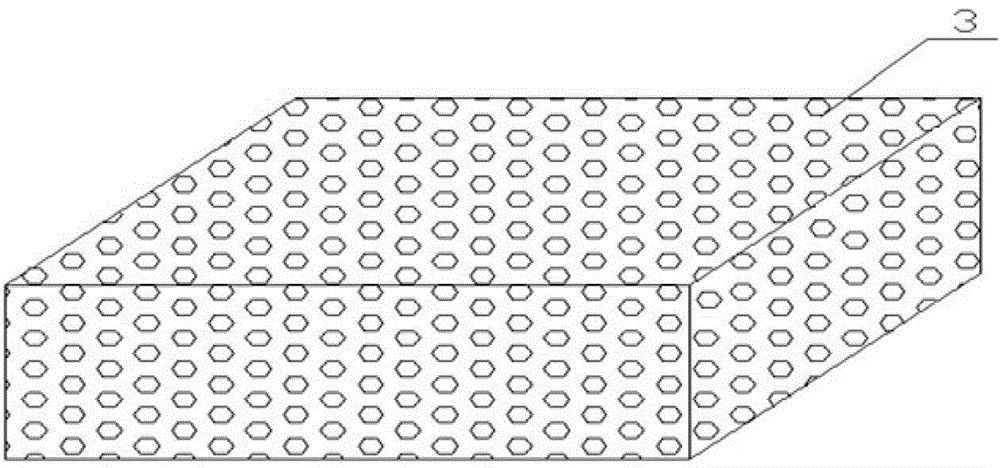

Buffering and energy absorbing structure

ActiveCN104763772ADeformation stableEnsure safetySpringsNon-rotating vibration suppressionHoneycombPeak value

The invention discloses a buffering and energy absorbing structure. The buffering and energy absorbing structure comprises a housing. The buffering and energy absorbing structure is a multi-layer metal grid structure or porous bubble structure filled in the housing; the metal grid structures or porous bubble structures of adjacent layers are lengthways alternatively overlapped in positive and negative poisson ratio; the metal grid structure in the positive poisson ratio is composed of a three-dimensional honeycomb grid structured formed by array type regular hexagonal pore grids; the metal grid structure in the negative poisson ratio is composed of a three-dimensional stretching and expanding grid structure formed by array type concave angle pore grids; the meshes of the porous bubble structure in the positive poisson ratio are of an array type rhombus structure; the meshes of the porous bubble structure in the negative rhombus structure are of an array type four-star shaped structure. Compared with the traditional buffering and energy absorbing structure, the buffering and energy absorbing structure can effectively reduce the peak value of the impact force, so that the whole energy absorbing process is stable, and as a result, the energy absorbing efficiency of the structure can be increased.

Owner:SOUTH CHINA UNIV OF TECH

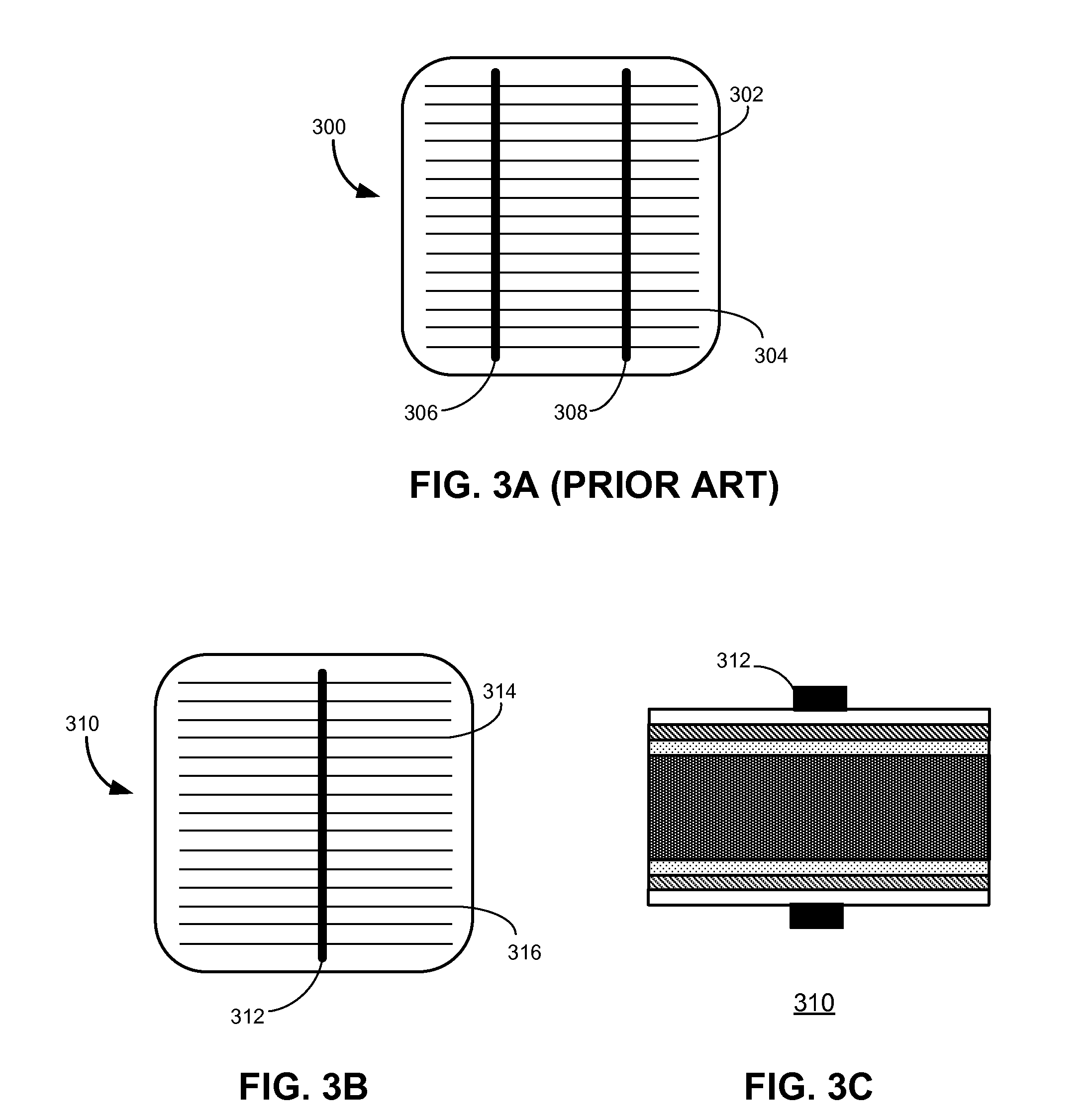

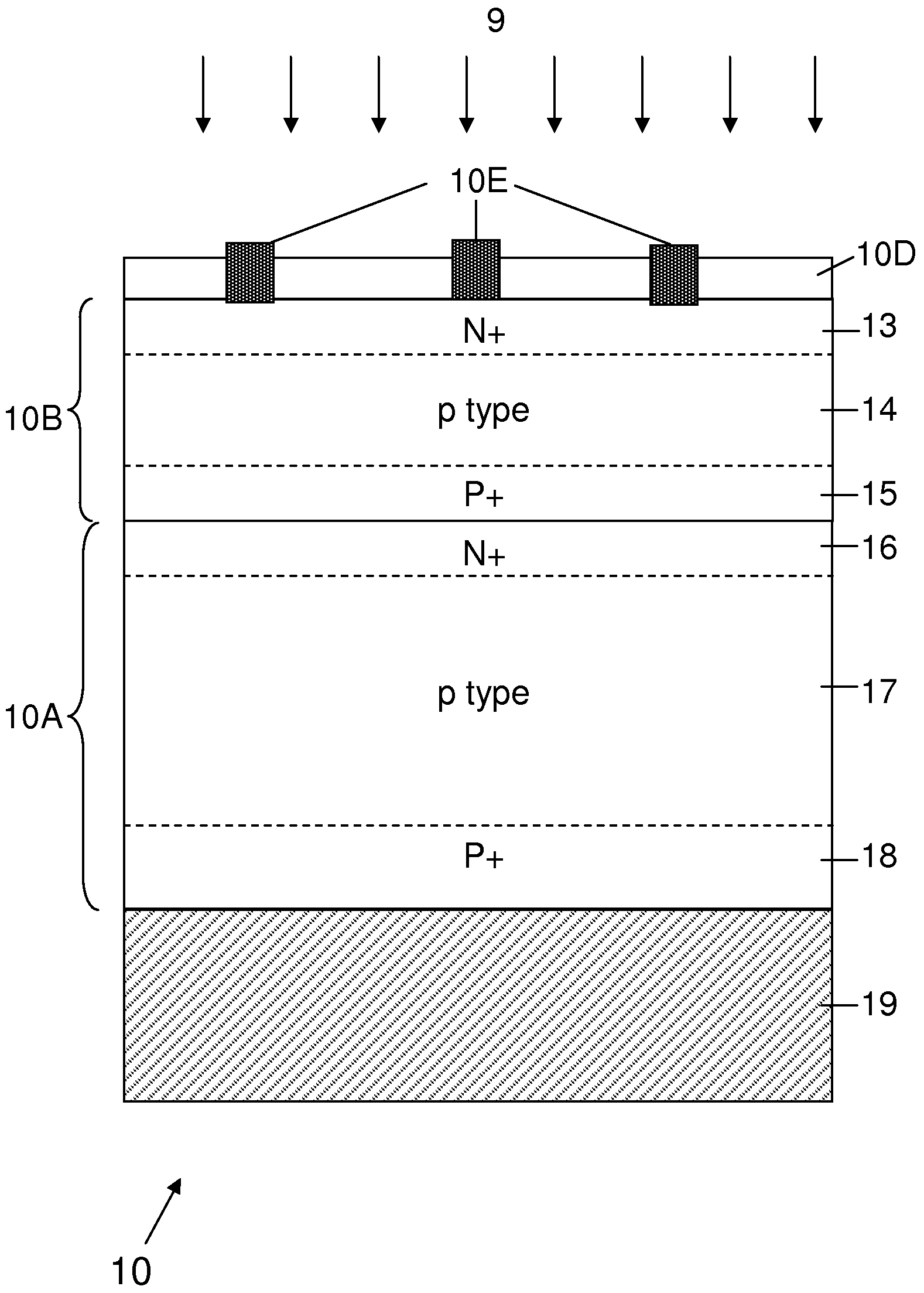

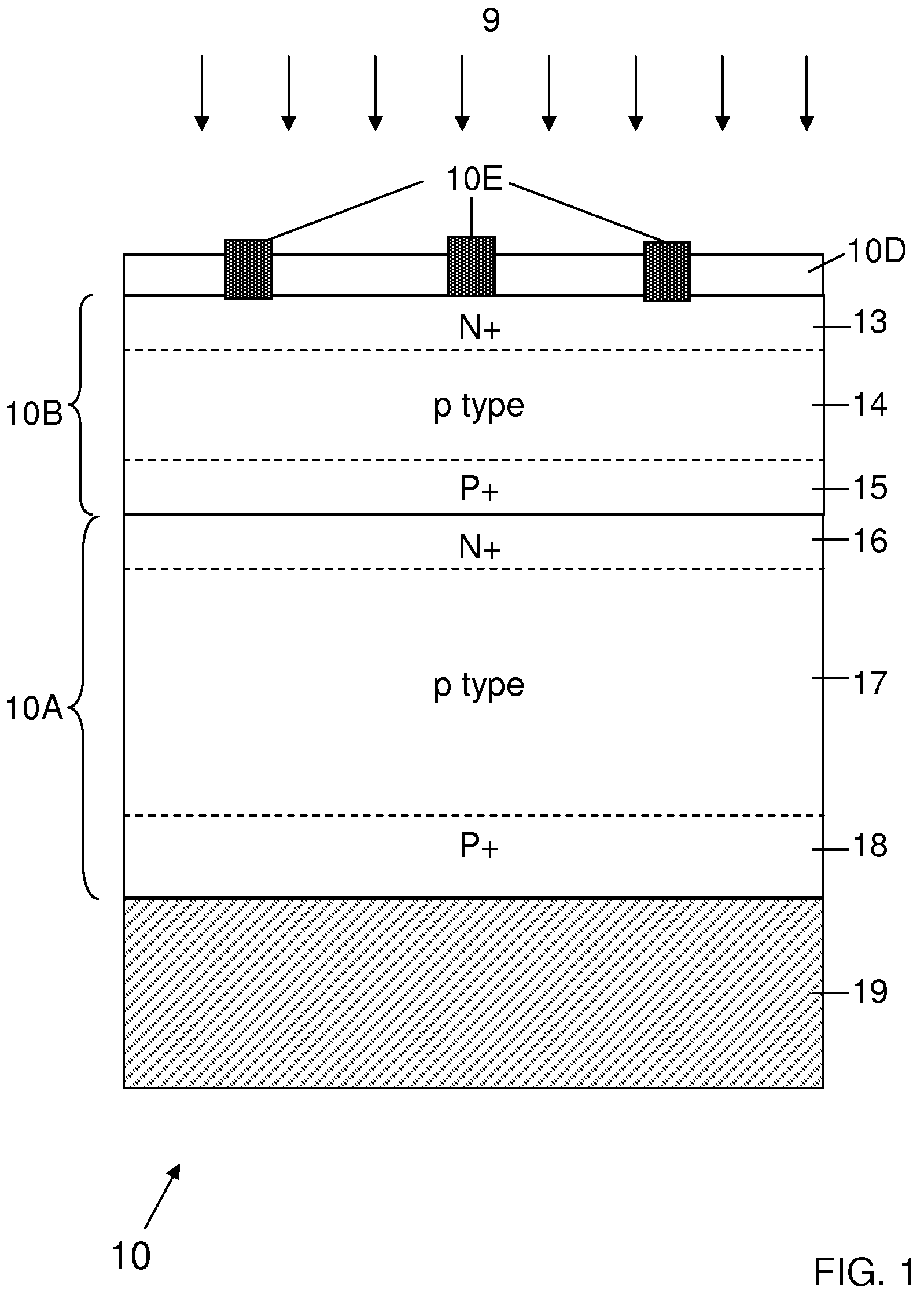

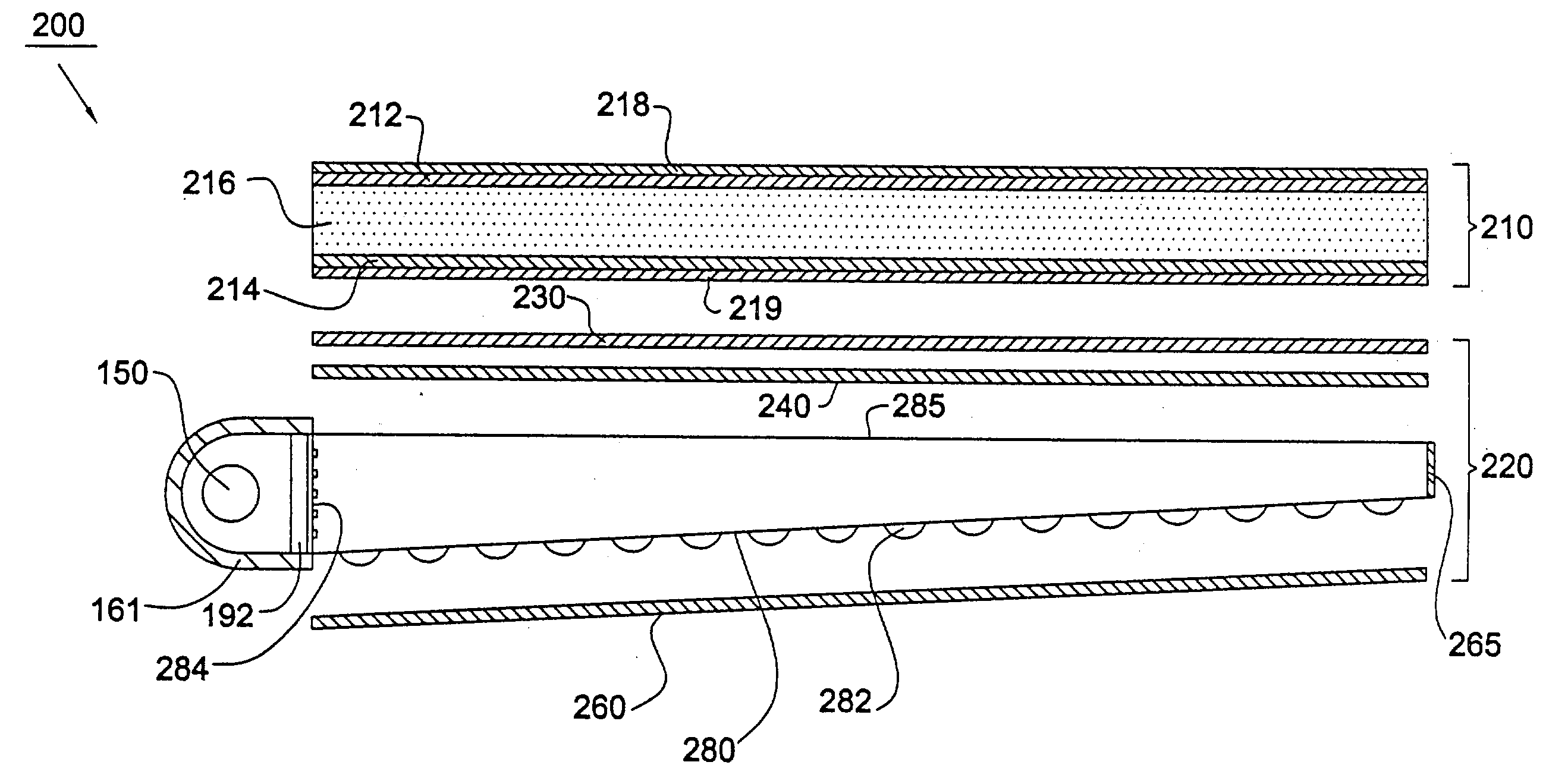

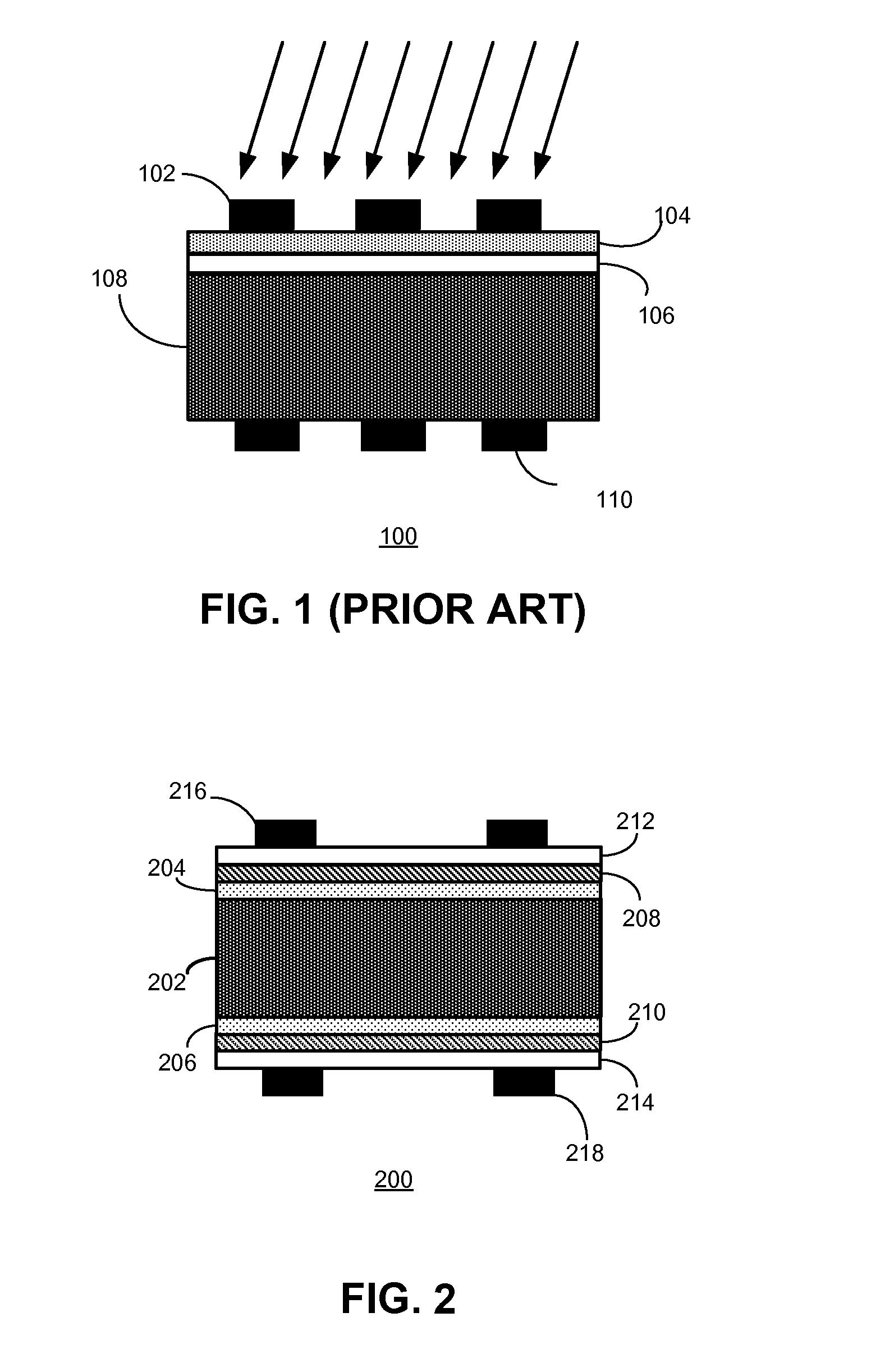

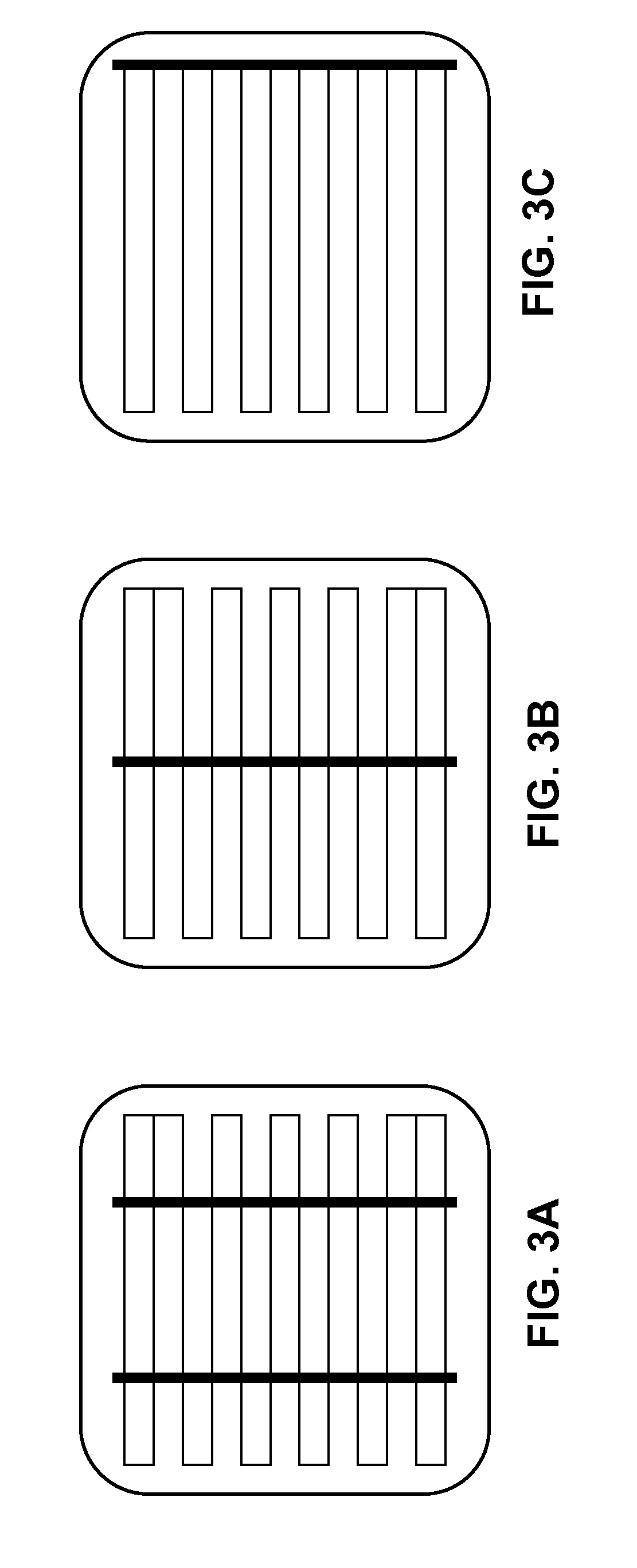

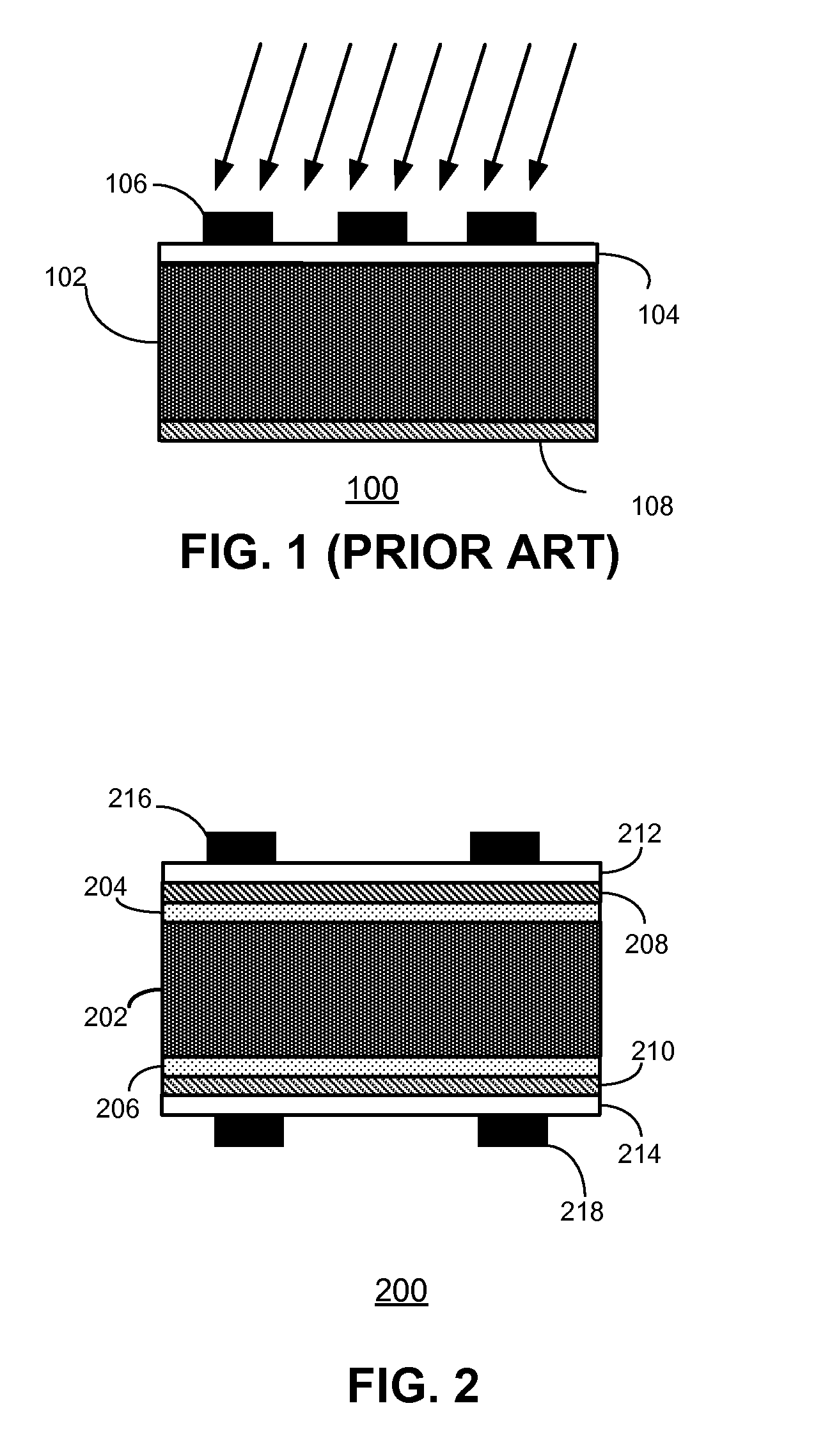

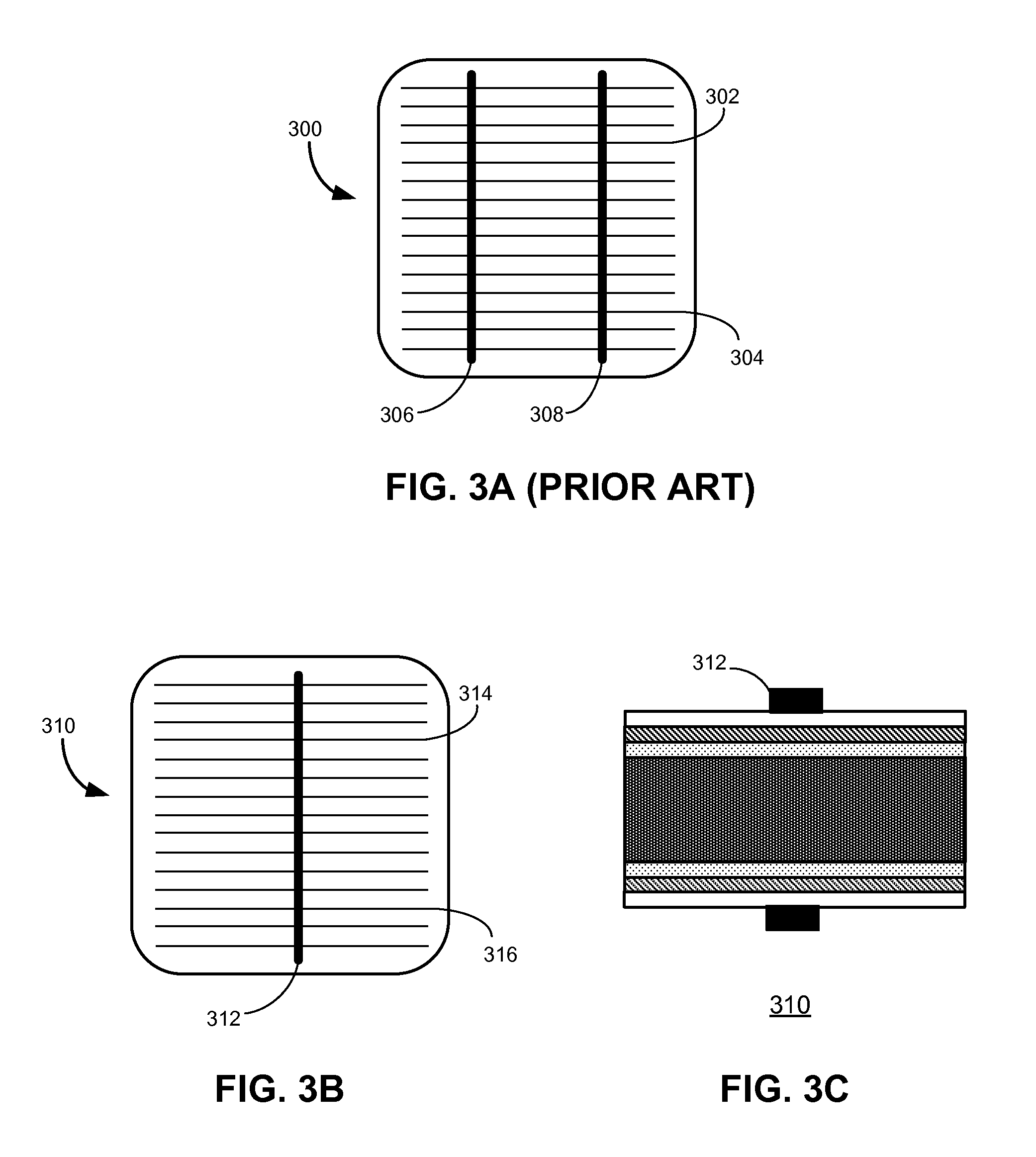

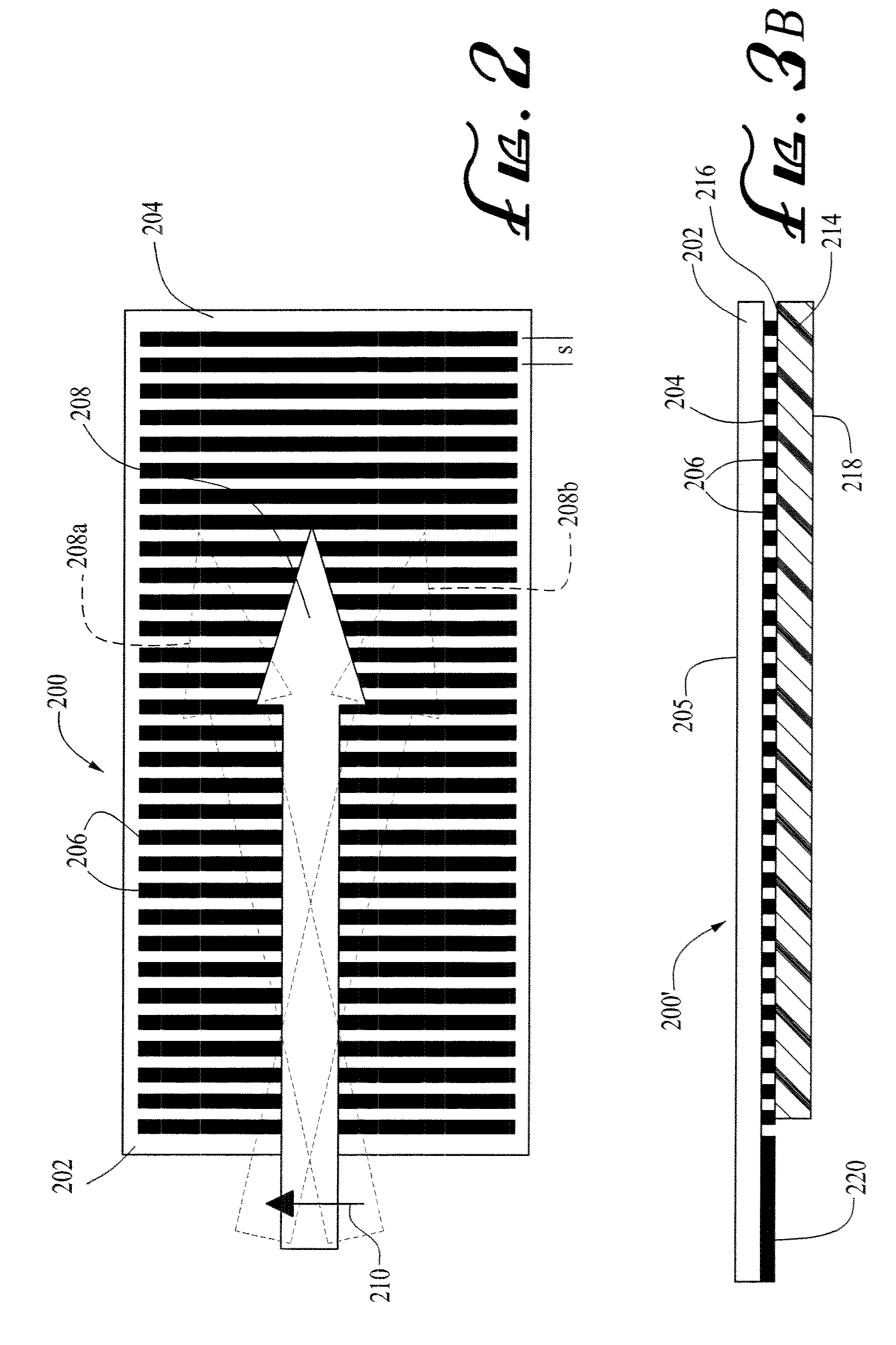

Module fabrication of solar cells with low resistivity electrodes

ActiveUS20140196768A1Facilitating cell-level MPPTPV power plantsPhotovoltaic energy generationPhysicsMetal grid

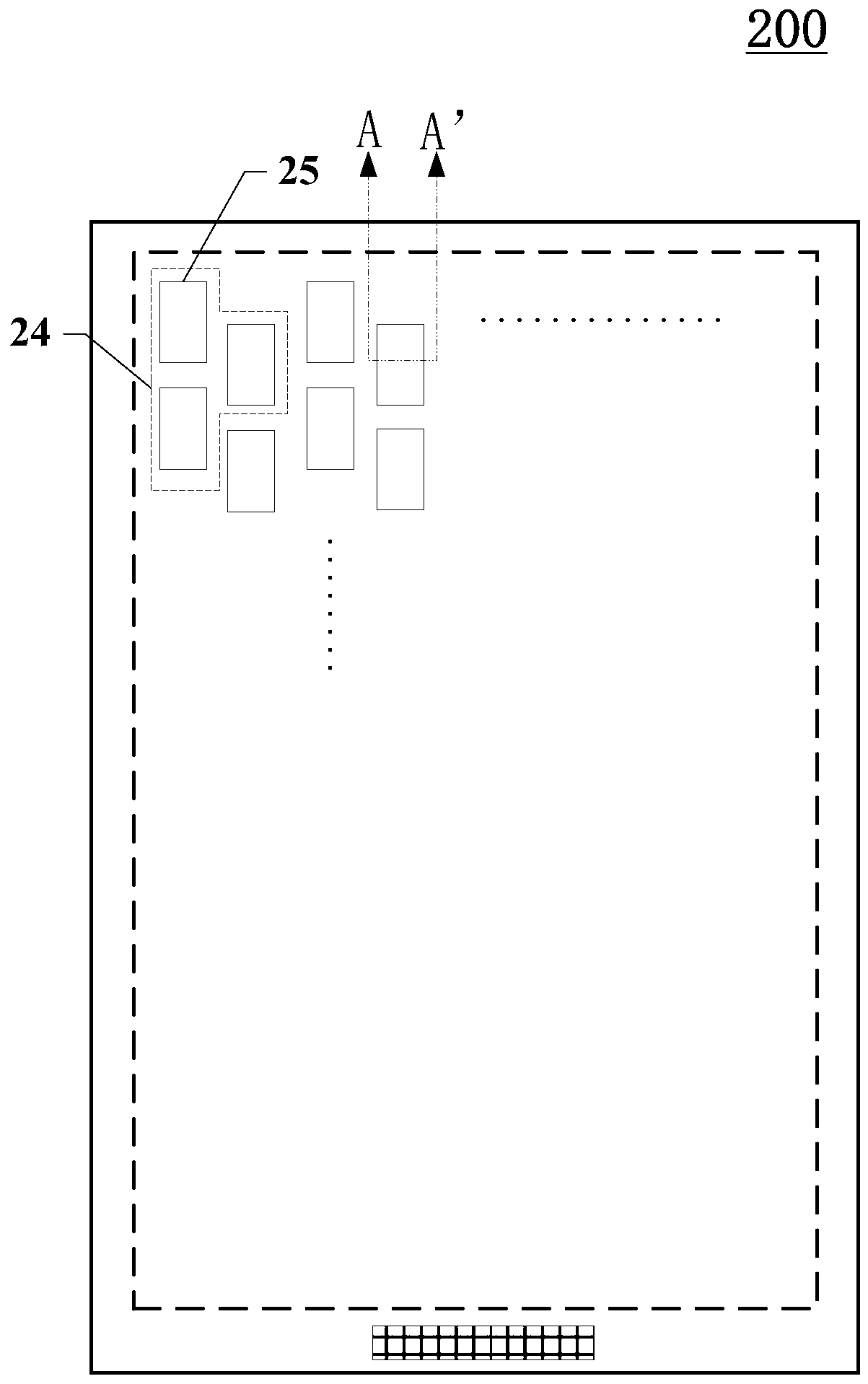

One embodiment of the present invention provides a solar module. The solar module includes a front-side cover, a back-side cover, and a plurality of solar cells situated between the front- and back-side covers. A respective solar cell includes a multi-layer semiconductor structure, a front-side electrode situated above the multi-layer semiconductor structure, and a back-side electrode situated below the multi-layer semiconductor structure. Each of the front-side and the back-side electrodes comprises a metal grid. A respective metal grid comprises a plurality of finger lines and a single busbar coupled to the finger lines. The single busbar is configured to collect current from the finger lines.

Owner:TESLA INC

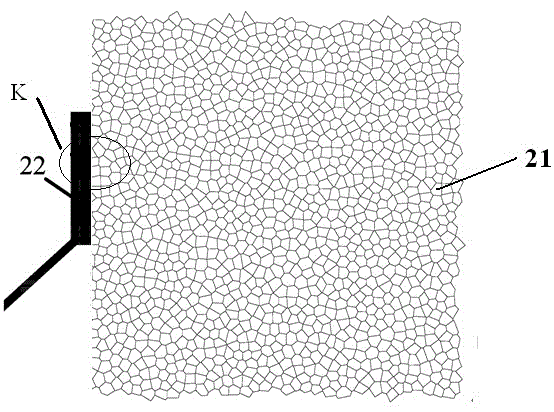

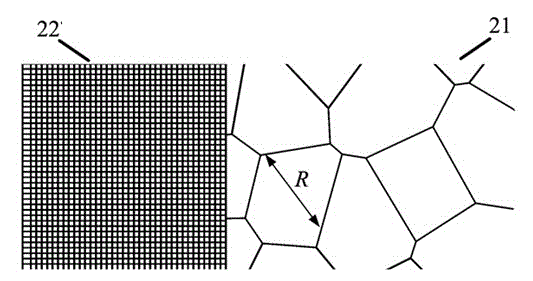

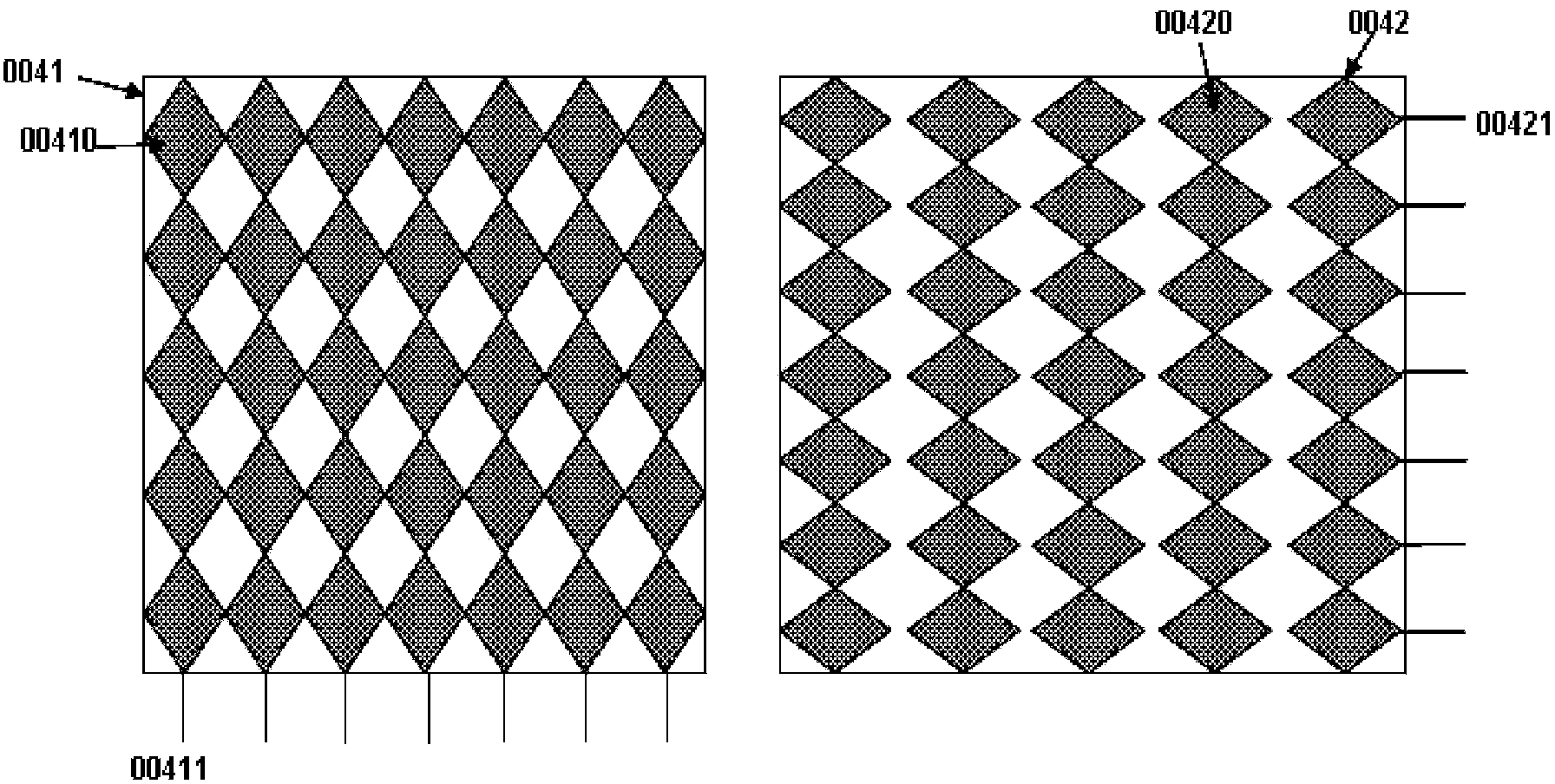

Transparent conducting film with anisotropic conductivity

ActiveCN102930922AHigh light transmittanceConstant conductivityConductive layers on insulating-supportsCircuit optical detailsComputer moduleTransmittance

The invention discloses a transparent conducting film with anisotropic conductivity. The transparent conducting film is suitable for a touch screen, and comprises a first transparent conducing film and a second transparent conducting film, wherein the first transparent conducting film and the second transparent conducting film are embedded metal grid transparent conducting films; in the first transparent conducting film, the probability density of grid metal lines the line slopes of which are close to X axis is larger than the probability density of grid metal lines the line slopes of which are close to Y axis; and in the second transparent conducting film, the probability density of grid metal lines the line slopes of which are close to Y axis is larger than the probability density of grid metal lines the line slopes of which are close to X axis. The transparent conducting film module can ensure constant conductivity while increasing the light transmittance.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

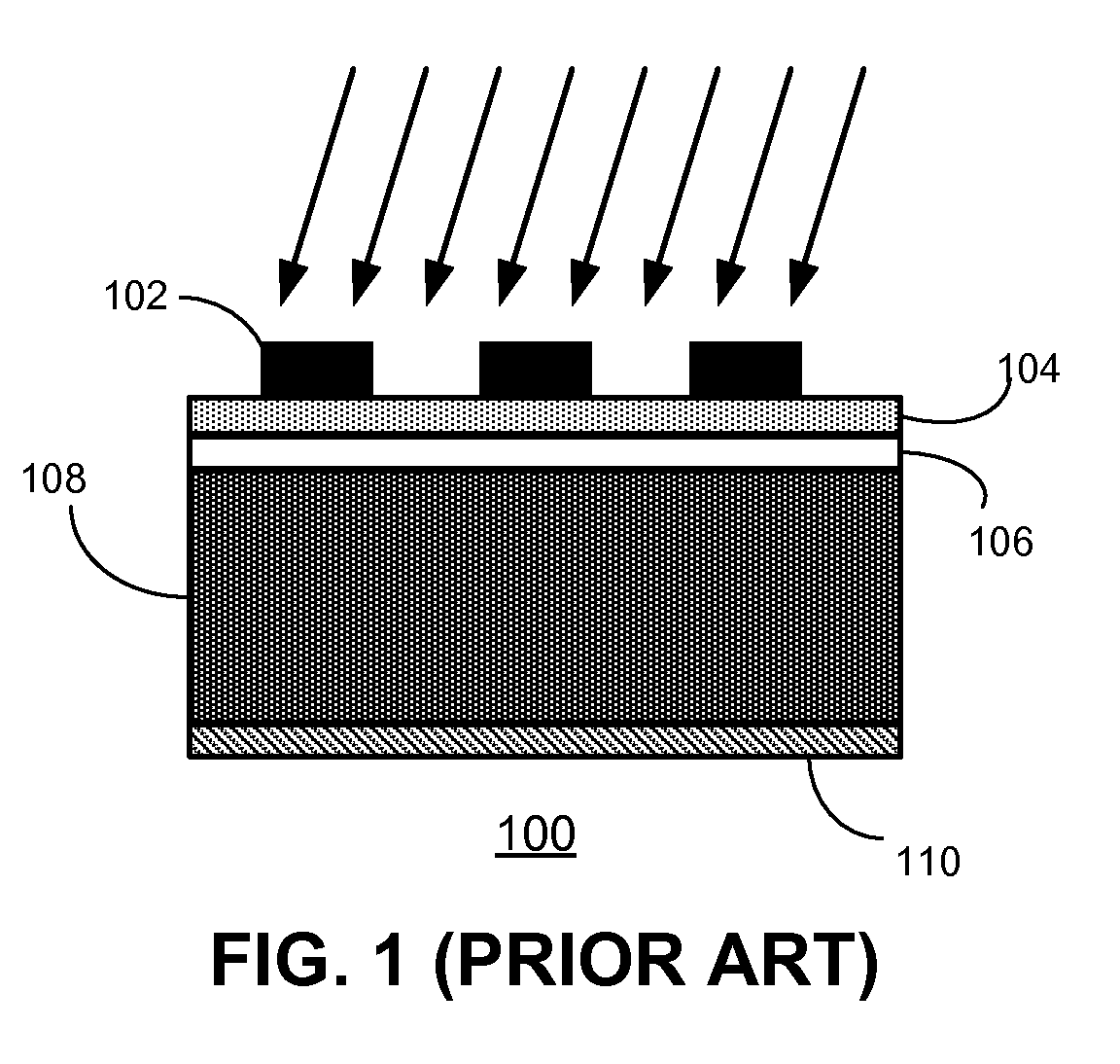

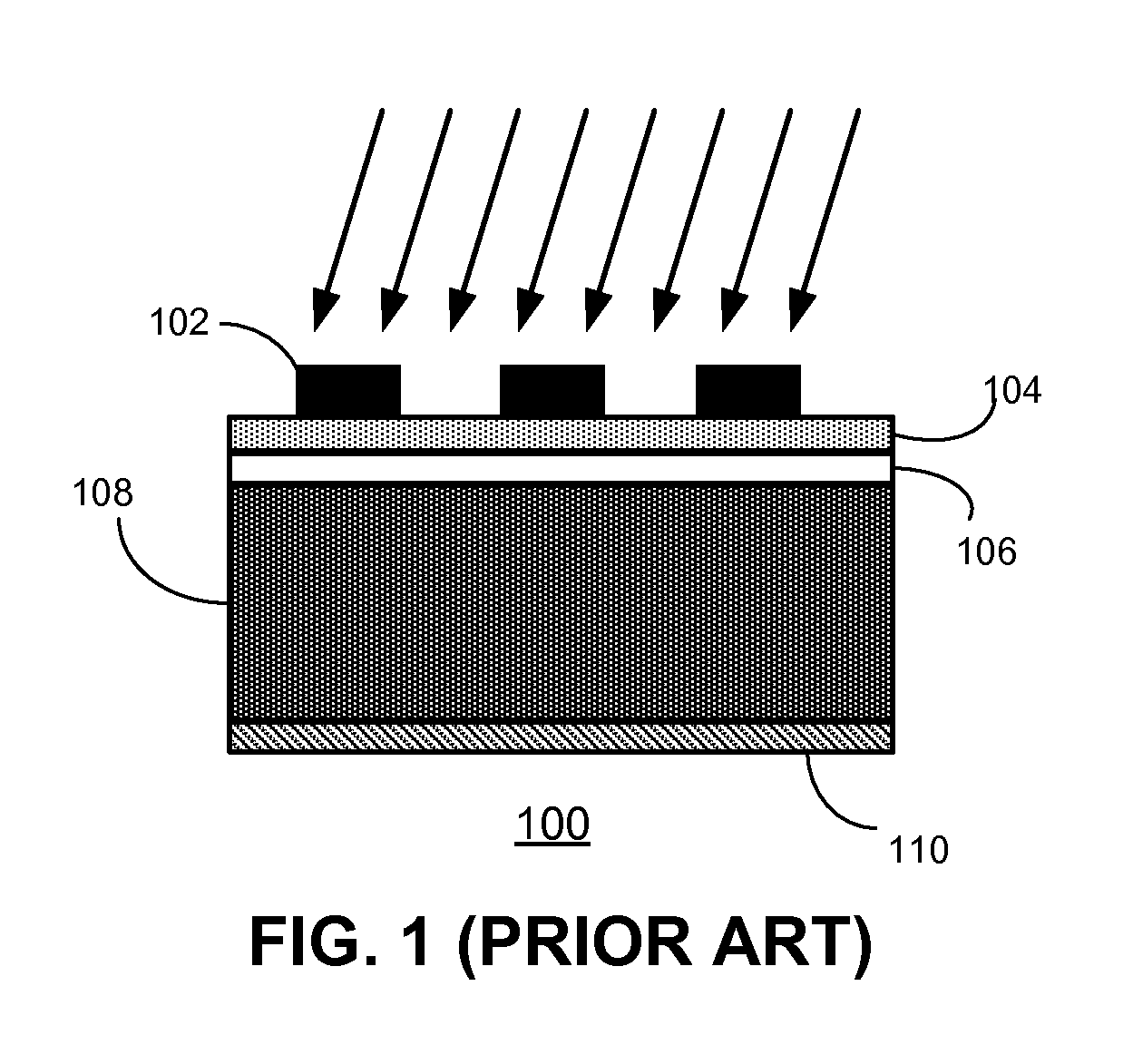

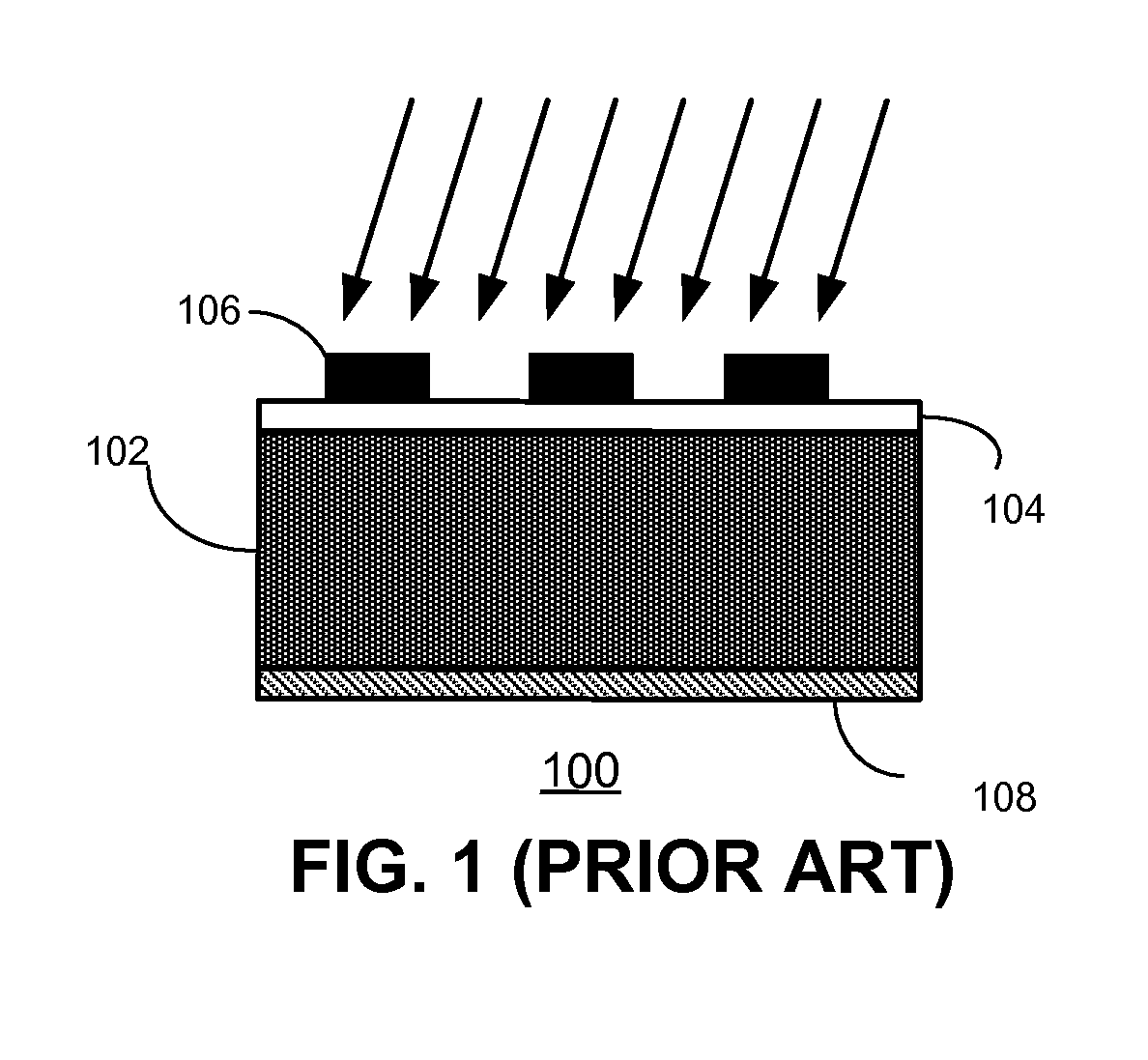

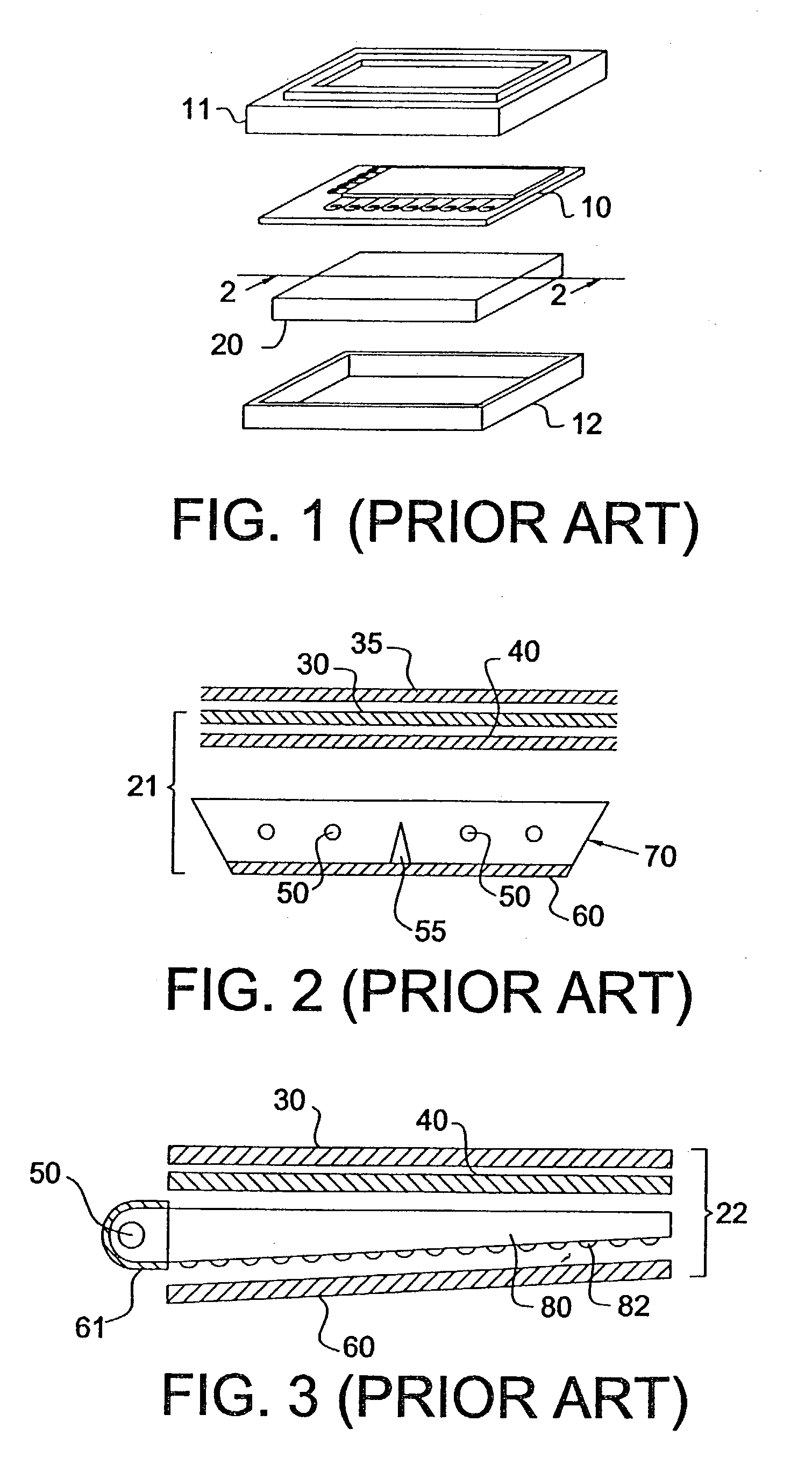

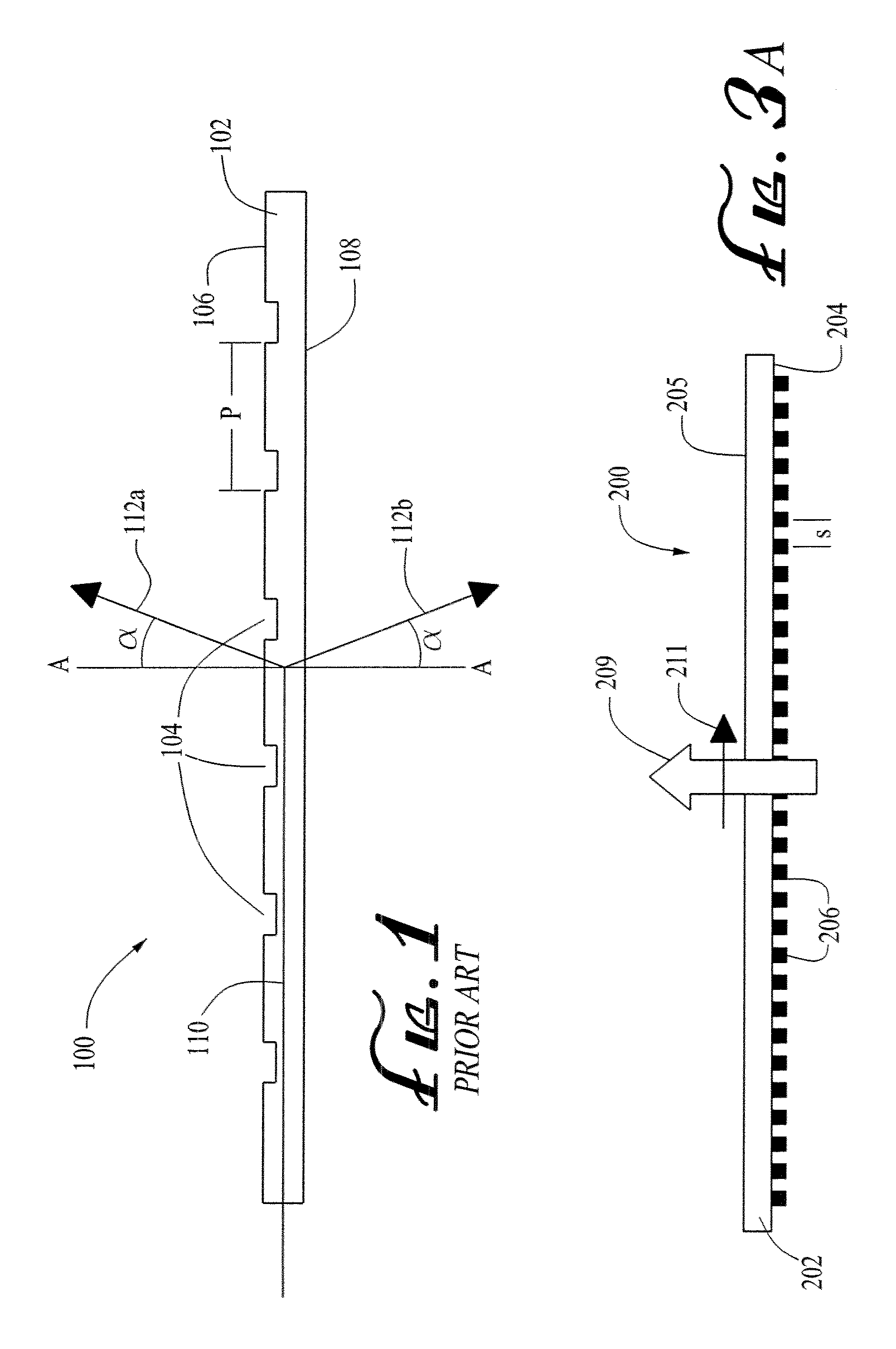

Solar cell with shade-free front electrode

InactiveUS20110277816A1PV power plantsSemiconductor/solid-state device manufacturingMetal gridOhmic contact

One embodiment of the present invention provides a solar cell with shade-free front electrode. The solar cell includes a photovoltaic body, a front-side ohmic contact layer situated above the photovoltaic body, a back-side ohmic contact layer situated below the photovoltaic body, a front-side electrode situated above the front-side ohmic contact layer, and a back-side electrode situated below the back-side ohmic contact layer. The front-side electrode includes a plurality of parallel metal grid lines, and the surface of at least one metal grid line is curved, thereby allowing incident light hitting the curved surface to be reflected downward and absorbed by the solar cell surface adjacent to the metal grid line.

Owner:SOLARCITY

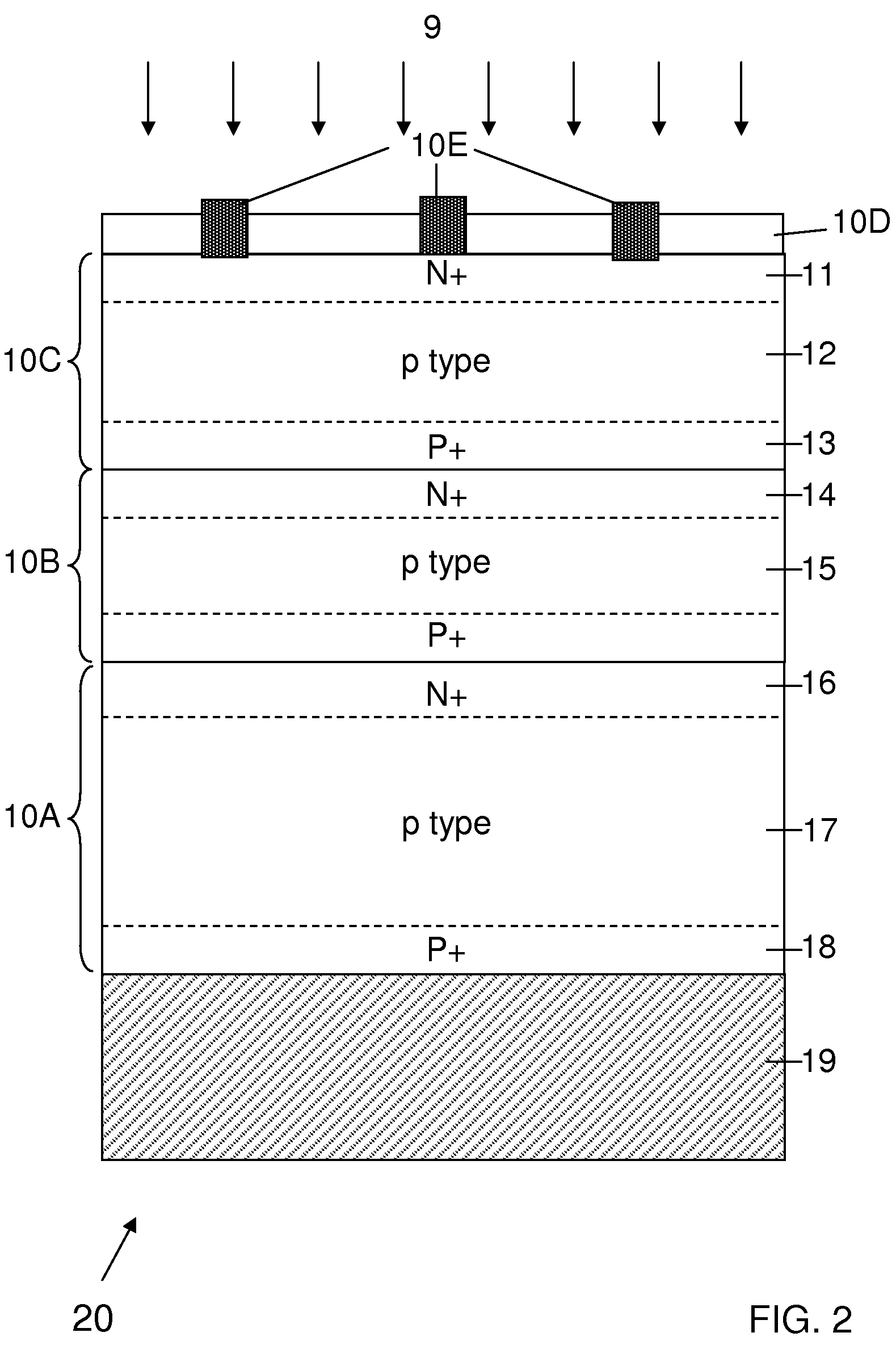

Tandem nanofilm solar cells joined by wafer bonding

An energy conversion device comprises at least two thin film photovoltaic cells fabricated separately and joined by wafer bonding. The cells are arranged in a hierarchical stack of decreasing order of their energy bandgap from top to bottom. Each of the thin film cells has a thickness in the range from about 0.5 μm to about 10 μm. The photovoltaic cell stack is mounted upon a thick substrate composed of a material selected from silicon, glass, quartz, silica, alumina, ceramic, metal, graphite, and plastic. Each of the interfaces between the cells comprises a structure selected from a tunnel junction, a heterojunction, a transparent conducting oxide, and an alloying metal grid; and the top surface and / or the lower surface of the energy conversion device may contain light-trapping means.

Owner:IBM CORP

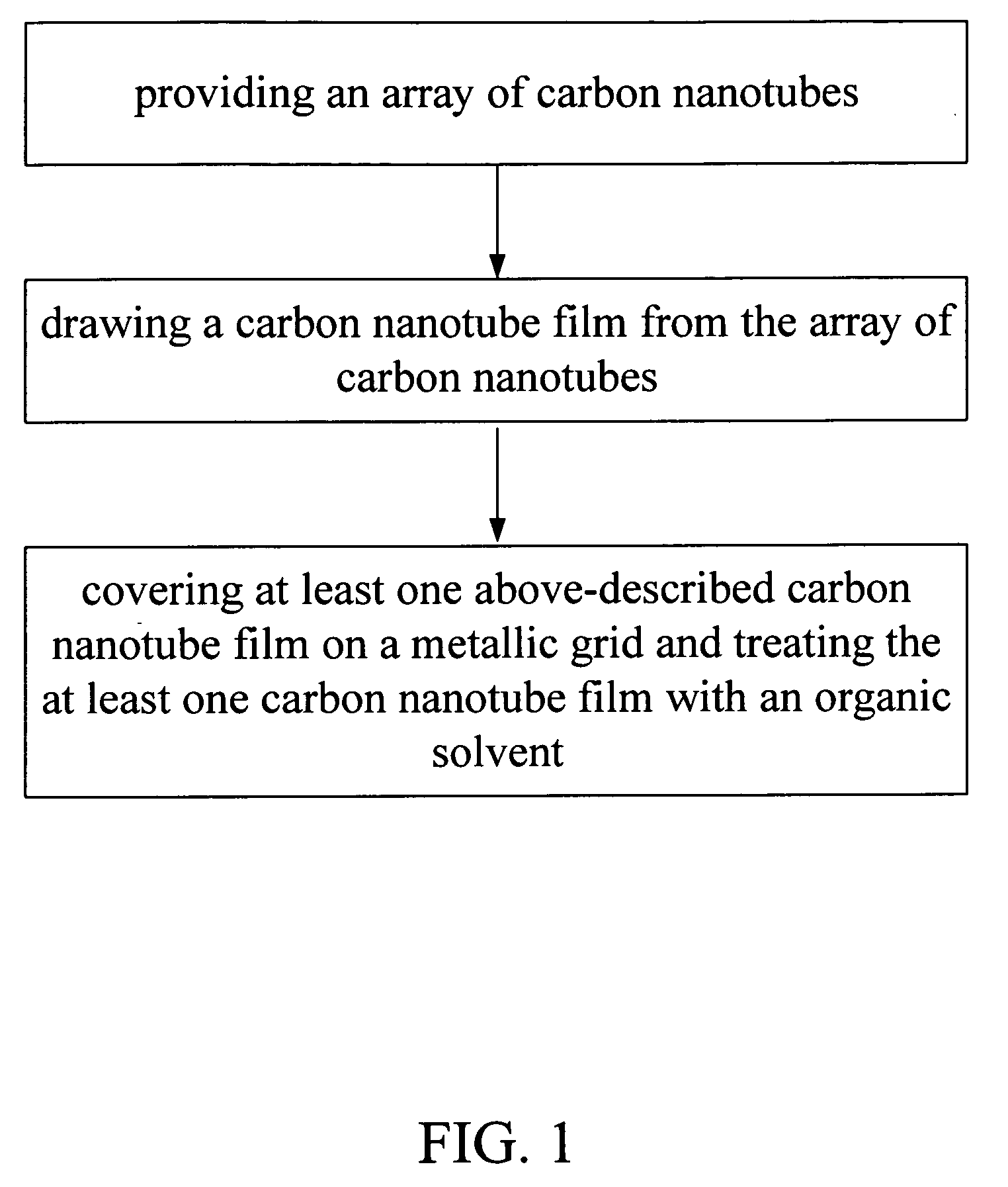

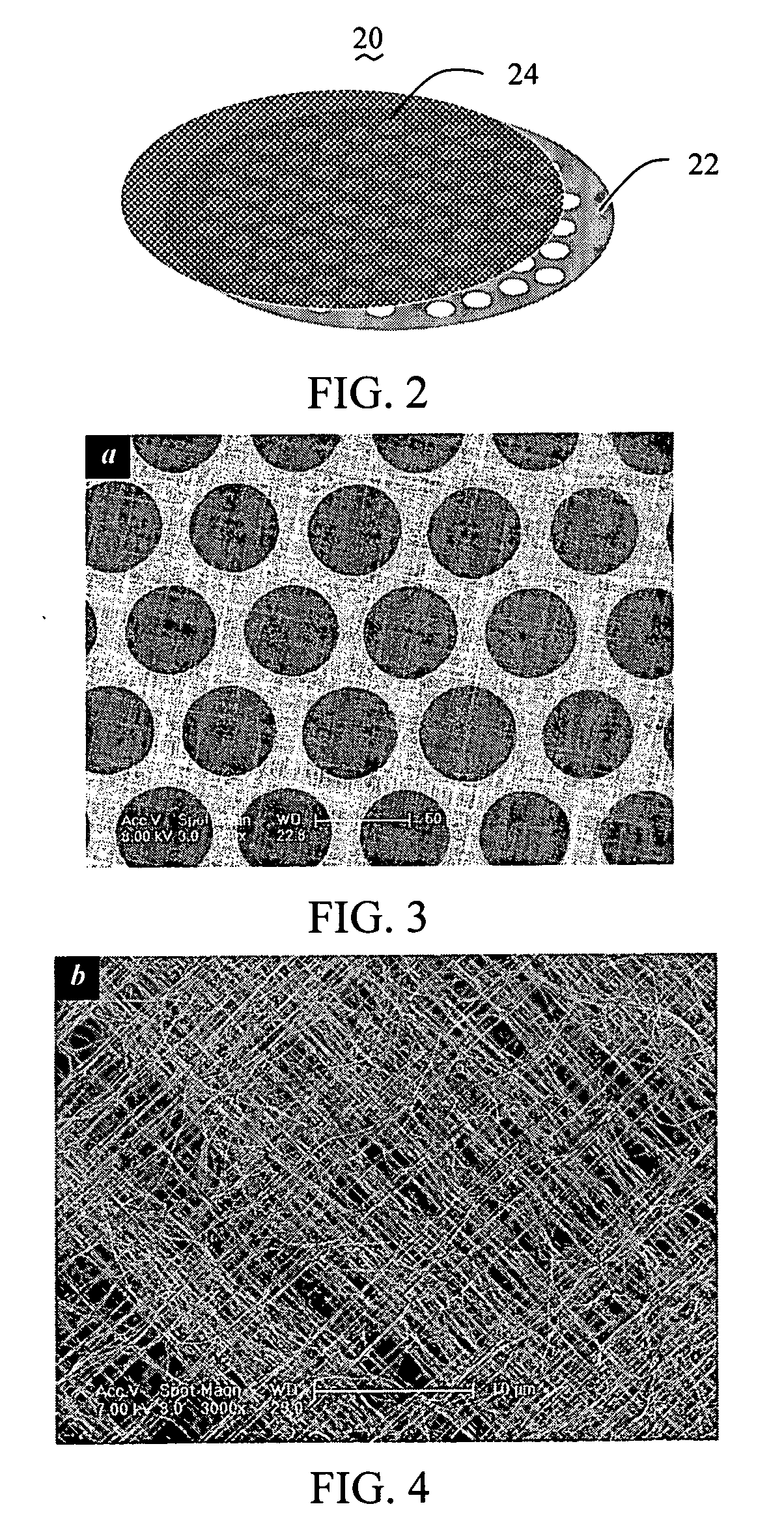

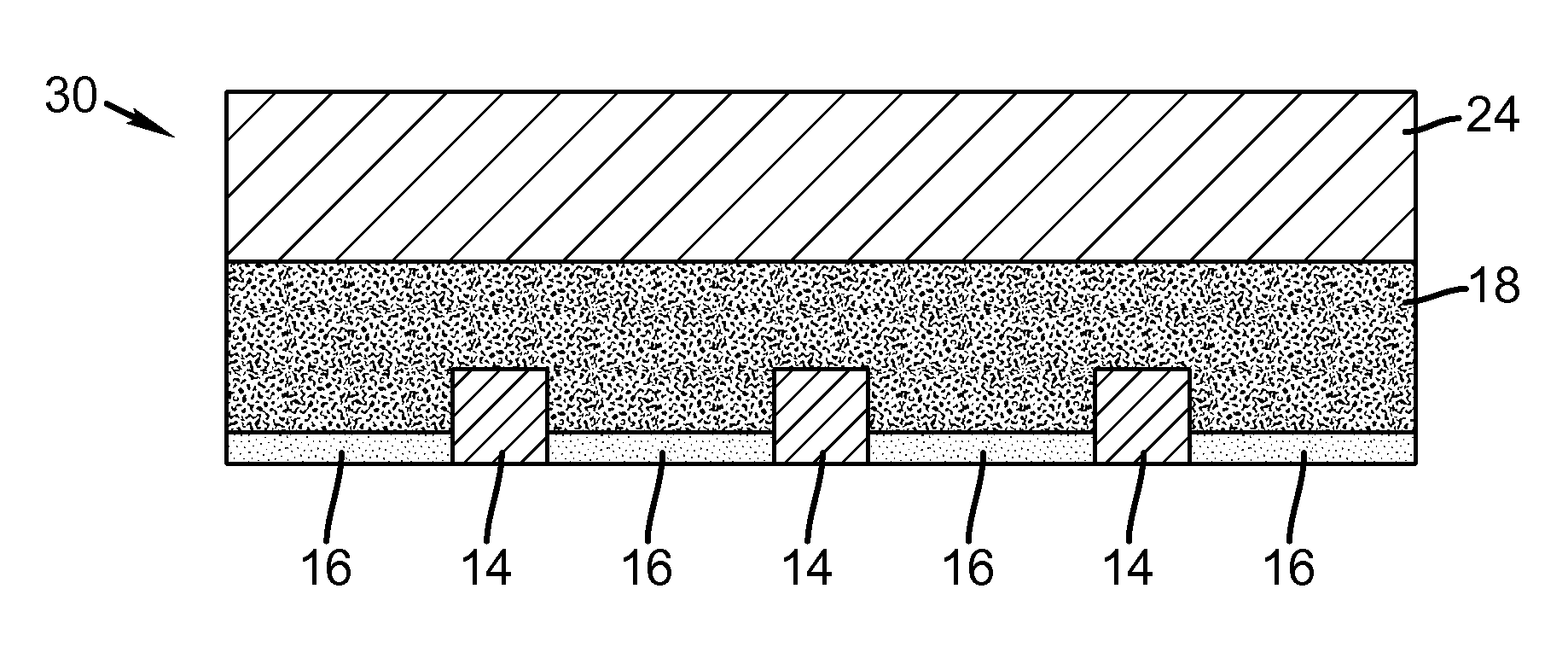

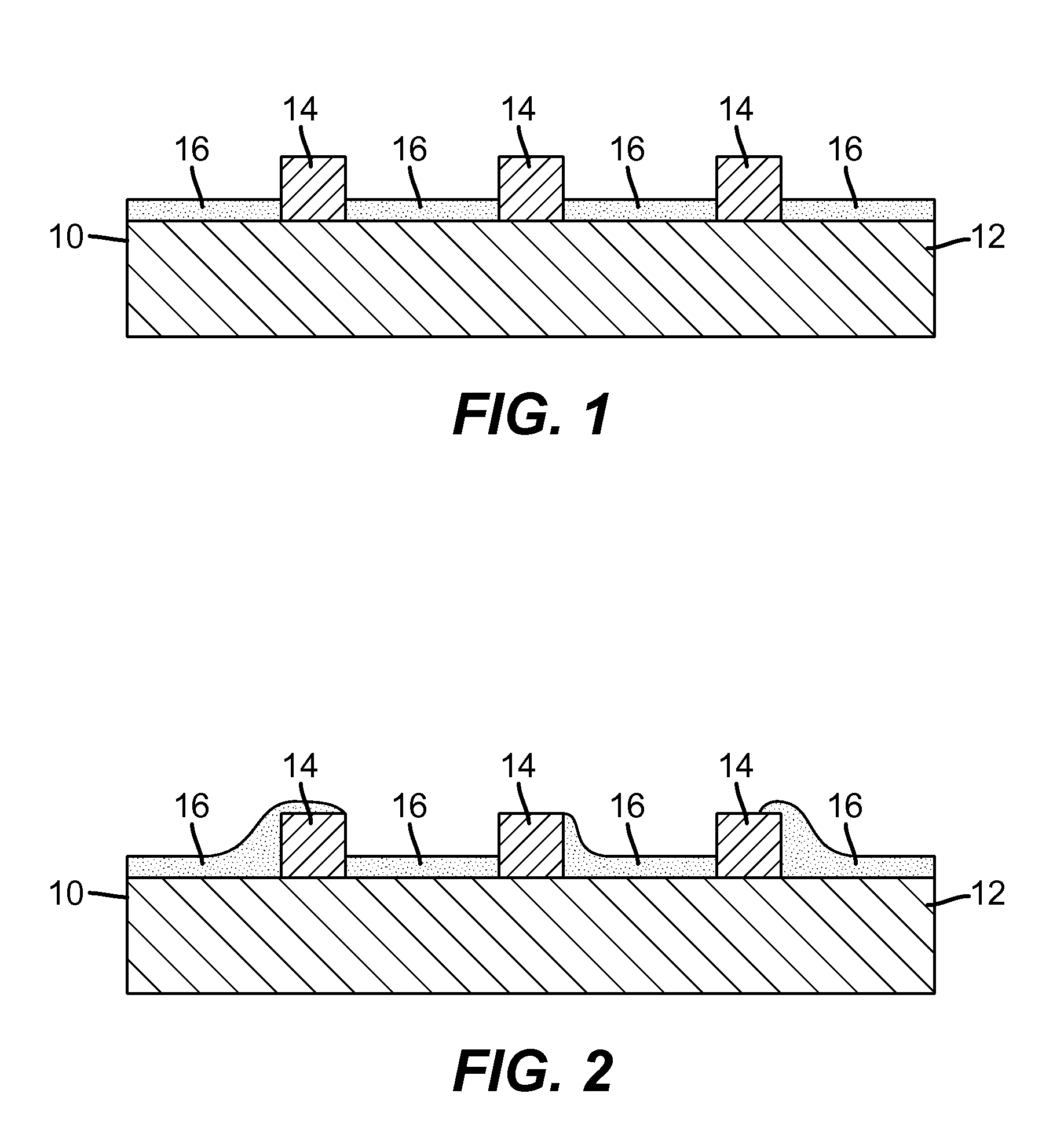

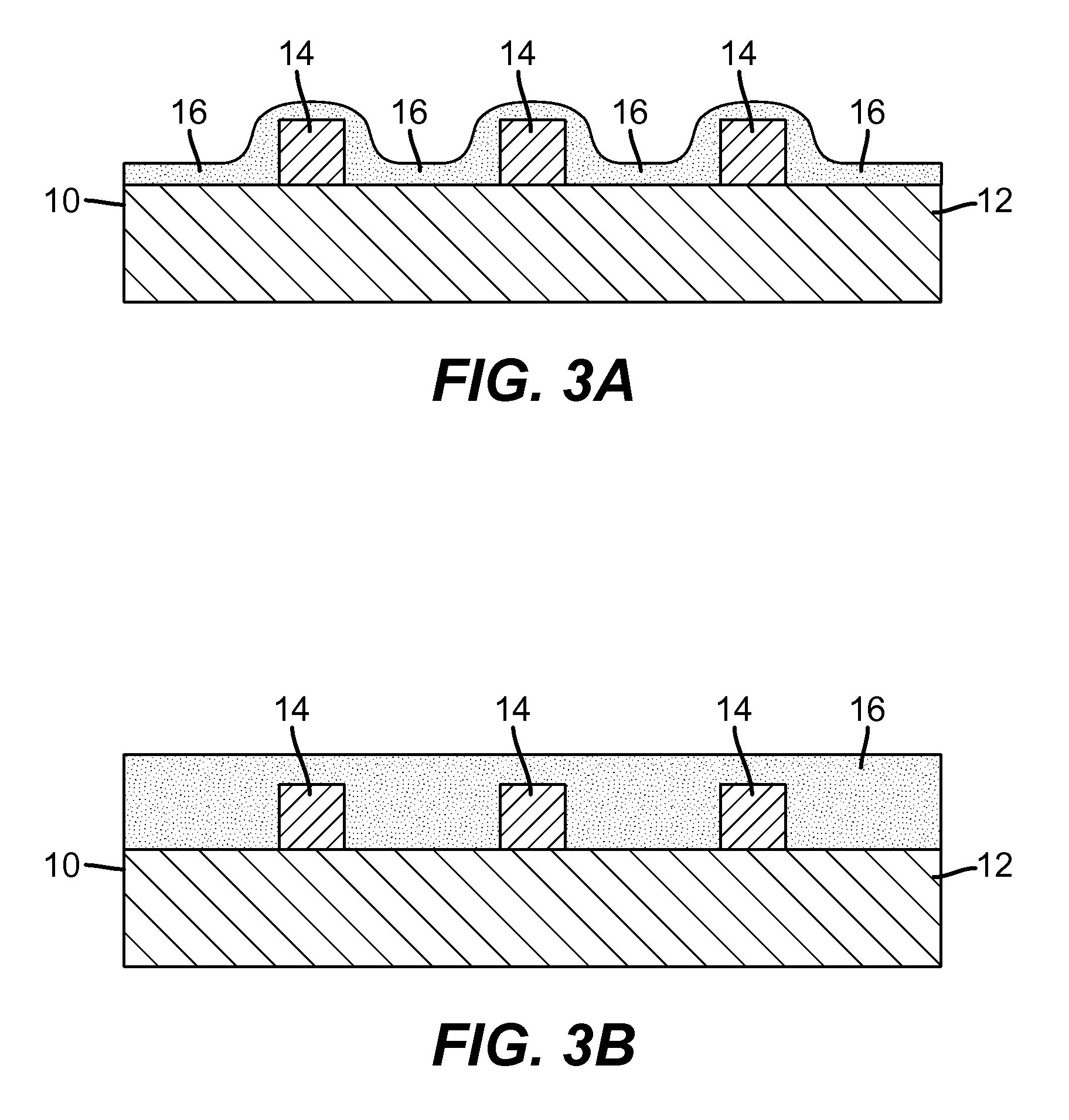

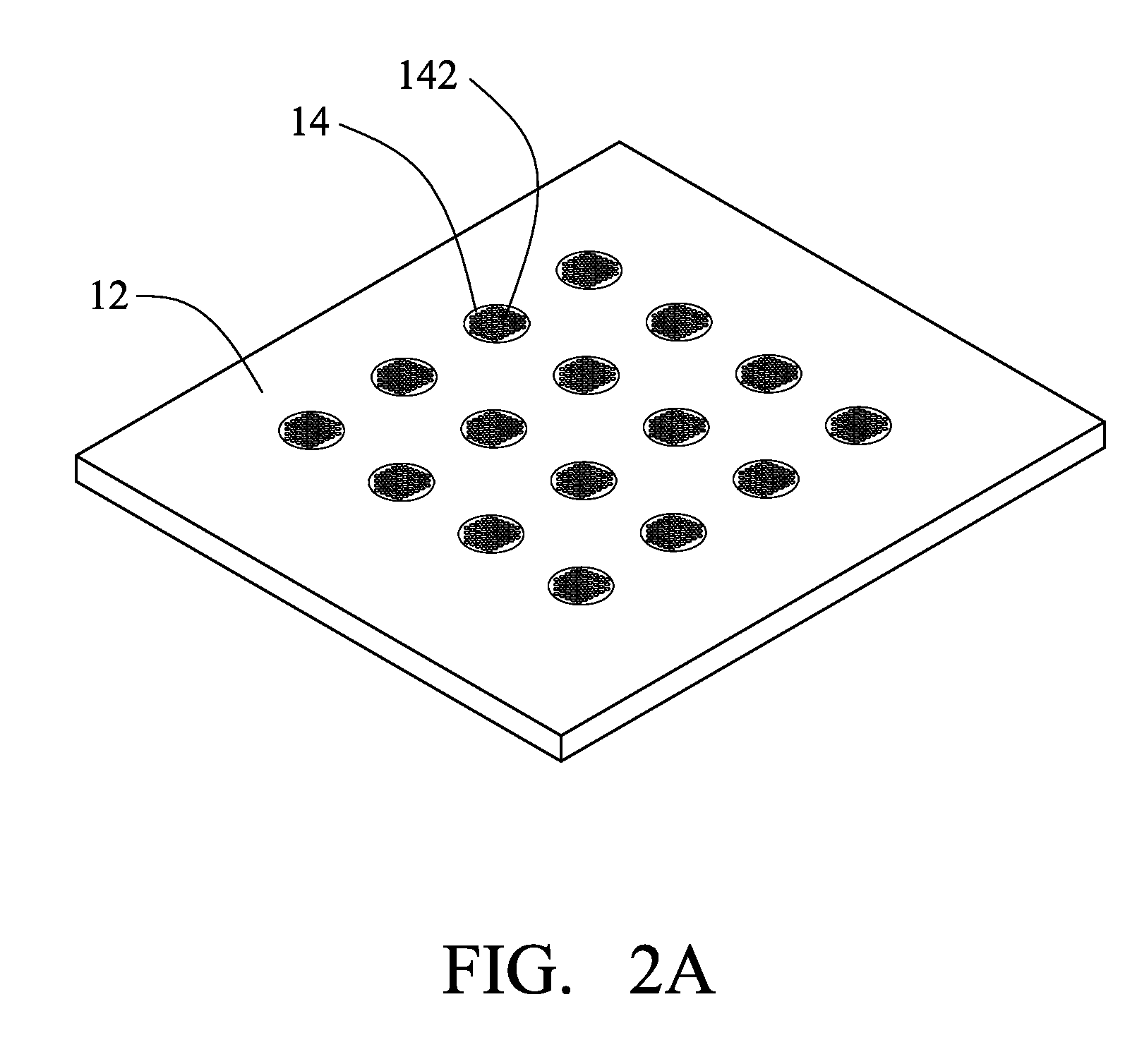

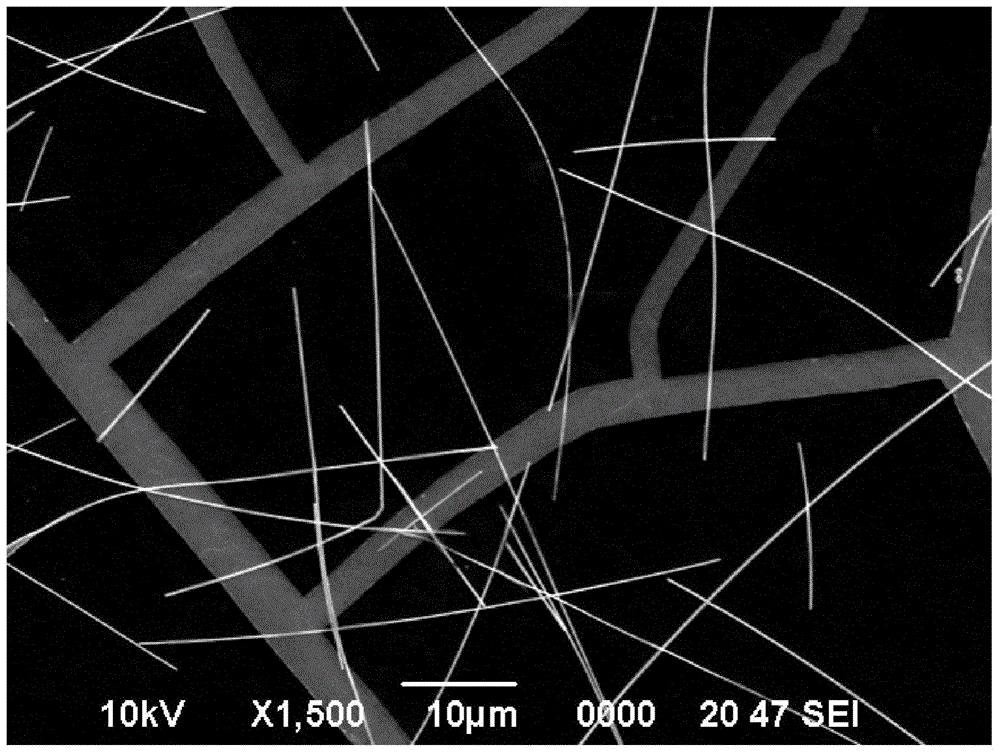

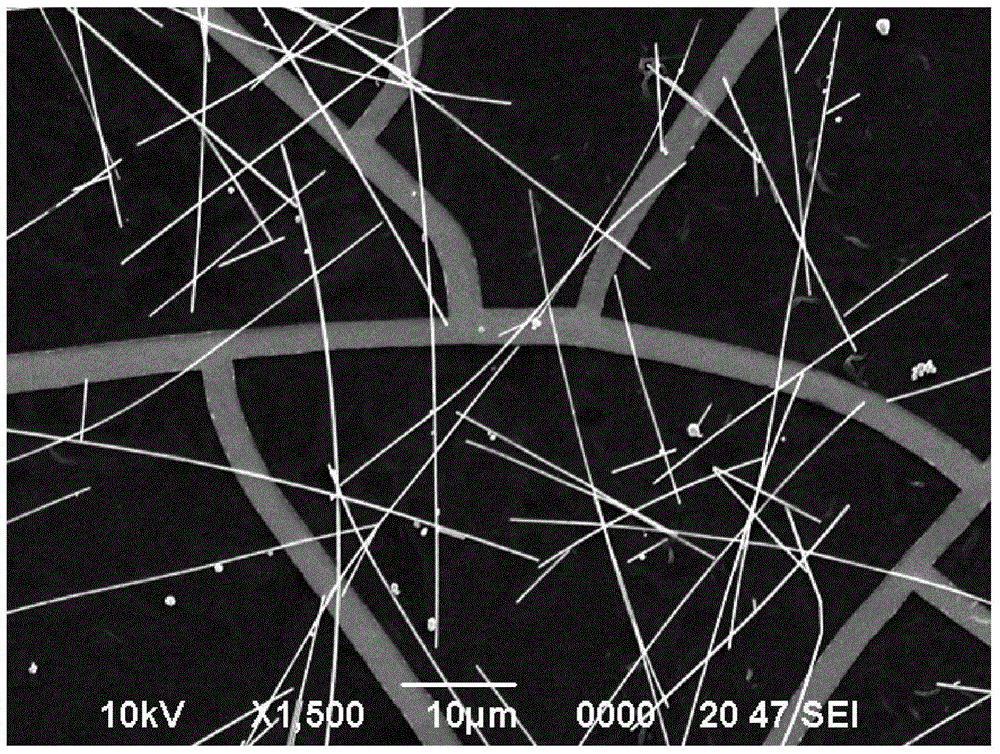

Transmission electron microscope micro-grid and method for making the same

ActiveUS20080237464A1Material analysis using wave/particle radiationWave amplification devicesOrganic solventCarbon nanotube

A transmission electron microscope (TEM) micro-grid includes a metallic grid and a carbon nanotube film structure covered thereon. A method for making a TEM micro-grid includes the steps of: (a) providing an array of carbon nanotubes, quite suitably, providing a super-aligned array of carbon nanotubes; (b) drawing a carbon nanotube film from the array of carbon nanotubes; (c) covering the carbon nanotube film on a metallic grid, and treating the carbon nanotube film and the metallic grid with an organic solvent.

Owner:HON HAI PRECISION IND CO LTD +1

Article with metal grid composite and methods of preparing

ActiveUS20130004753A1Improve flatnessUniform conductionConductive layers on insulating-supportsDecorative surface effectsPolymer scienceConductive polymer

A laminate donor element can be used to transfer a composite of a metal grid and an electronically conductive polymer to a receiver sheet for use in various devices. The laminate donor element has a donor substrate, a metal grid that is disposed over only portions of the donor substrate, leaving portions of the substrate uncovered by the metal grid, and an electronically conductive polymer that covers the portions of the donor substrate that are uncovered by the metal grid. The composite of metal grid and electronically conductive polymer exhibits a peel force of less than or equal to 40 g / cm for separation from the donor substrate at room temperature. The resulting article has a substrate on which a reverse composite of the metal grid and electronically conductive polymer is disposed, which article can be incorporated into various devices.

Owner:EASTMAN KODAK CO

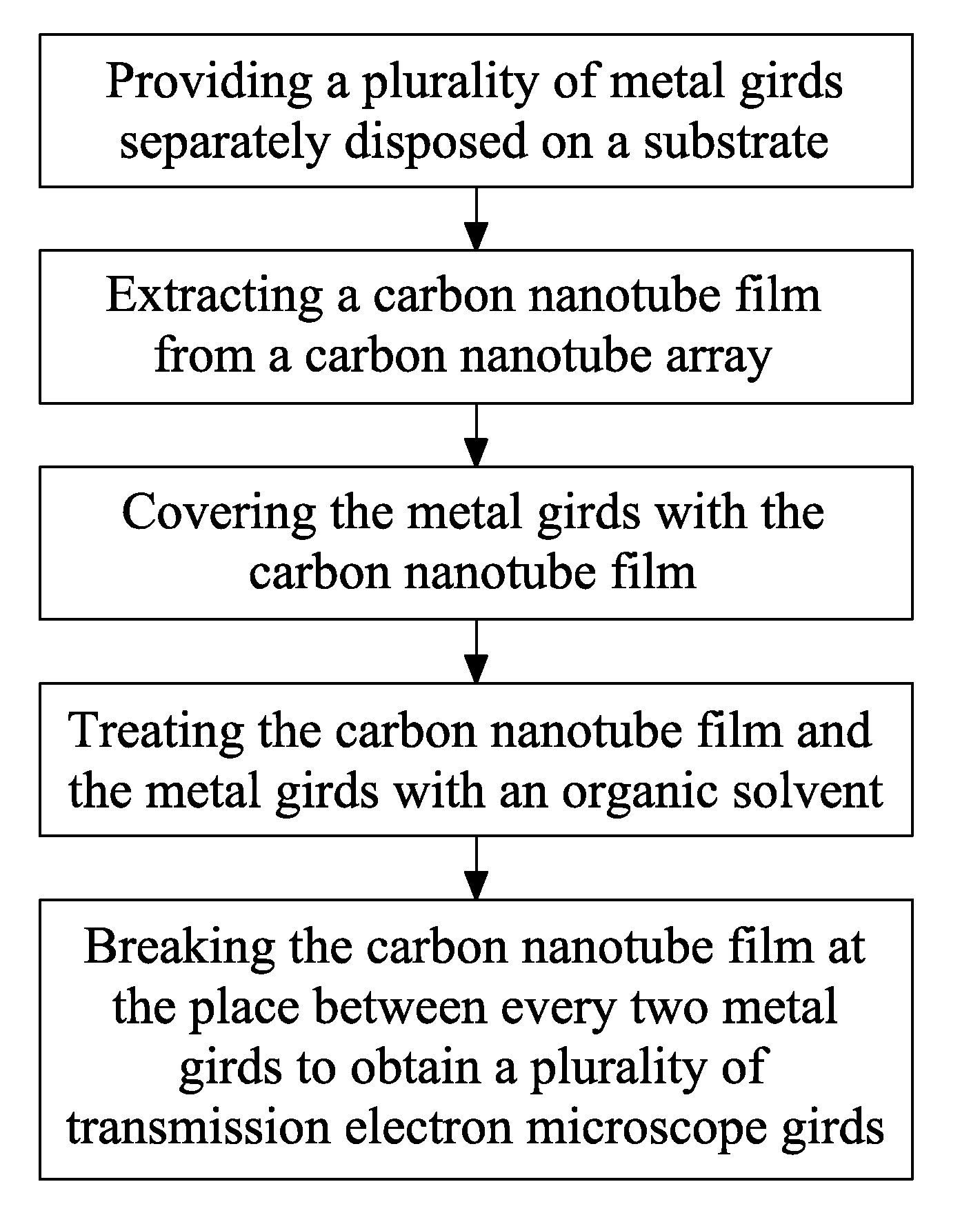

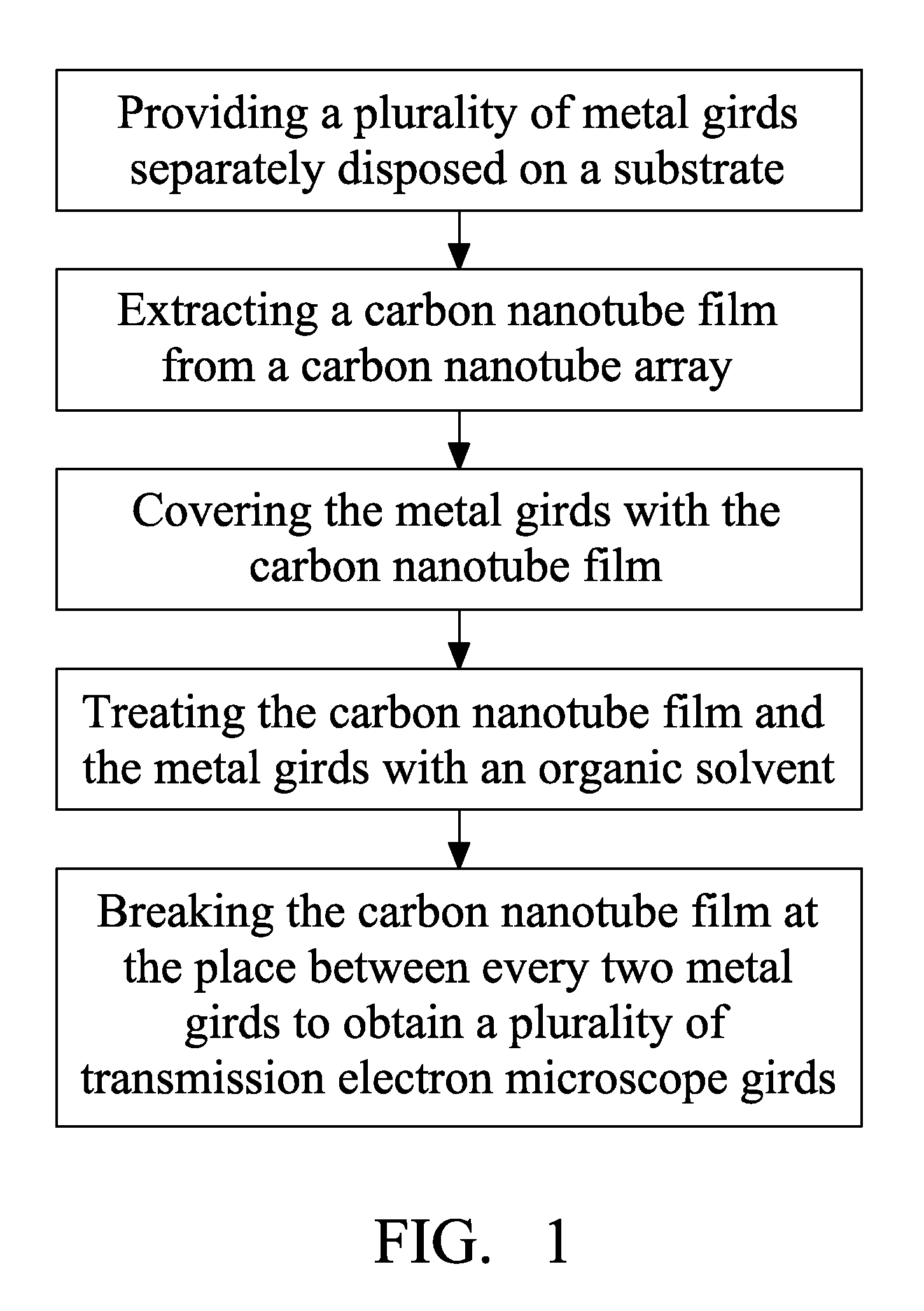

Method for making transmission electron microscope grid

ActiveUS20090317926A1High imagingElectric discharge tubesSemiconductor/solid-state device manufacturingOrganic solventCarbon nanotube

A method for making transmission electron microscope gird is provided. An array of carbon nanotubes is provided and drawing a carbon nanotube film from the array of carbon nanotubes. A substrate has a plurality of spaced metal girds attached on the substrate. The metal girds are covered with the carbon nanotube film and treating the carbon nanotube film and the metal girds with organic solvent. A transmission electron microscope (TEM) grid is obtained by removing remaining CNT film.

Owner:TSINGHUA UNIV +1

Method for preparing composite transparent conductive electrode based on metal grid and metal nano-wire

ActiveCN104681645AImprove conductivityEasy to prepareFinal product manufactureSemiconductor devicesNanowireResource consumption

The invention discloses a method for preparing a composite transparent conductive electrode based on a metal grid and a metal nano-wire. The method comprises the following steps: (1) preparing a template solution; (2) manufacturing a sacrificial layer template; (3) depositing a metal thin film; (4) removing the sacrificial layer template; (5) synthesizing the metal nano-wire; and (6) coating the metal nano-wire to prepare the composite transparent conductive electrode. The composite transparent conductive electrode prepared by the method has excellent photoelectric property and environment stability; meanwhile, the electrode in a photoelectric device can be easily in contact with other functional layers; the preparation process is simple and the resource consumption is low; the composite transparent conductive electrode is a good substitute of a traditional metal oxide electrode, and the efficiency of a solar battery can be improved and the cost is reduced.

Owner:SOUTH CHINA NORMAL UNIVERSITY

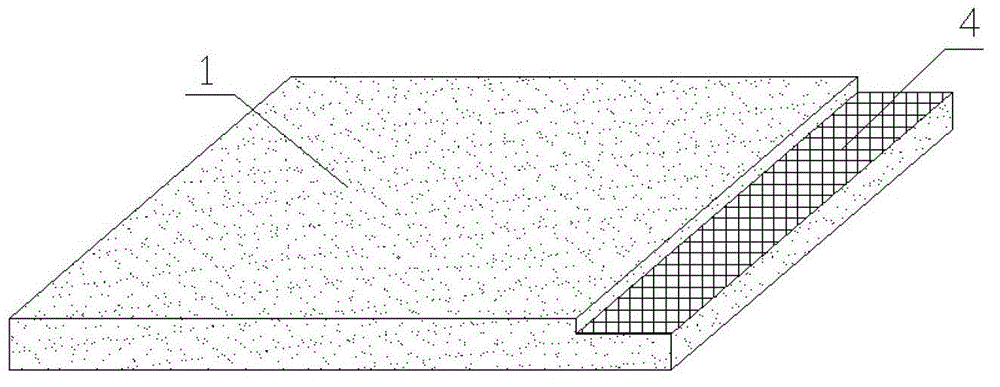

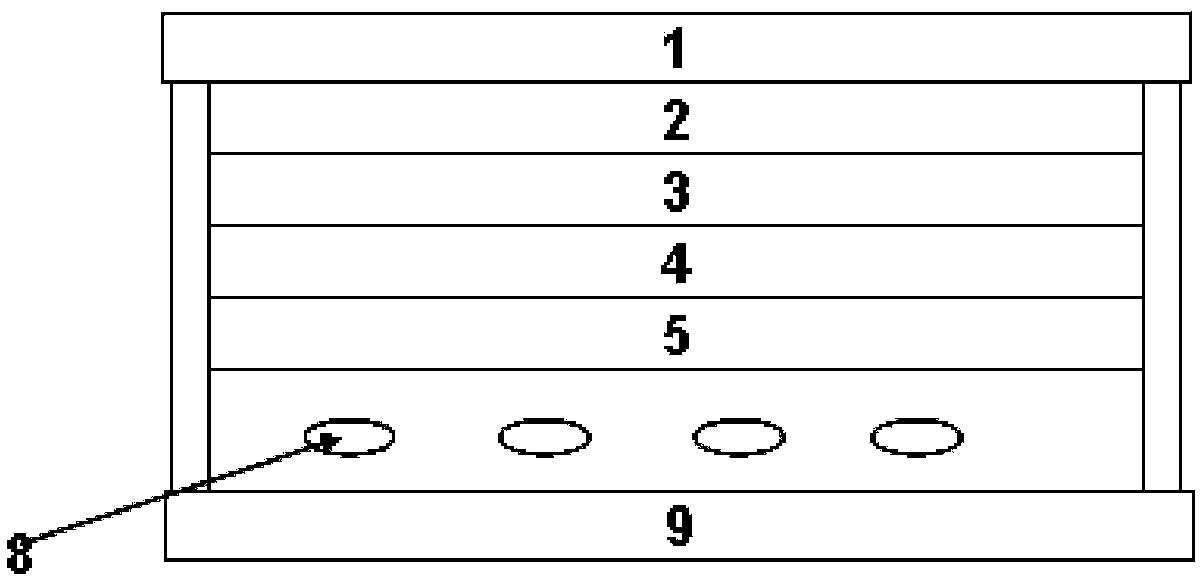

Explosion-proof heat-preservation multifunctional sheet material of foaming concrete sandwich and preparation method of material

InactiveCN102747789AWith anti-knock abilityStrong anti-knock abilityHeat proofingWater-setting substance layered productFoam concreteUltimate tensile strength

The invention discloses an explosion-proof heat-preservation multifunctional sheet material of a foaming concrete sandwich and a preparation method of the material. The sheet material comprises an outer wall heat-preservation sheet material core body; and explosion-proof light mortar outer protection plates are respectively spliced on the surfaces of the two sides of the outer wall heat-preservation sheet material core body. The explosion-proof heat-preservation multifunctional sheet material of the foaming concrete sandwich has stronger explosion-proof capability and can be used for protecting the safety and stability of a main body structure of a building under the effect of protecting an explosive load; and the heat-preservation, heat-insulation, fireproof, environmentally-friendly performances and the like of the explosion-proof heat-preservation multifunctional sheet material are better than those of like products. The method comprises the following steps of: A, preparing an explosion-proof and light-weight mortar outer protection plate; and B, preparing a foaming concrete core body. The heat-preservation, heat-insulation, fireproof, environmentally-friendly performances and the like of the explosion-proof heat-preservation multifunctional sheet material are better than those of like products and the construction process is simple. Panels on the two sides of the explosion-proof heat-preservation multifunctional sheet material of the foaming concrete sandwich are made of high-strength and light-weight mortar and the strength of the panels is higher. When the panels are cast and molded, a metal grid reinforcing layer is additionally arranged so that the panels have stronger anti-explosion capability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

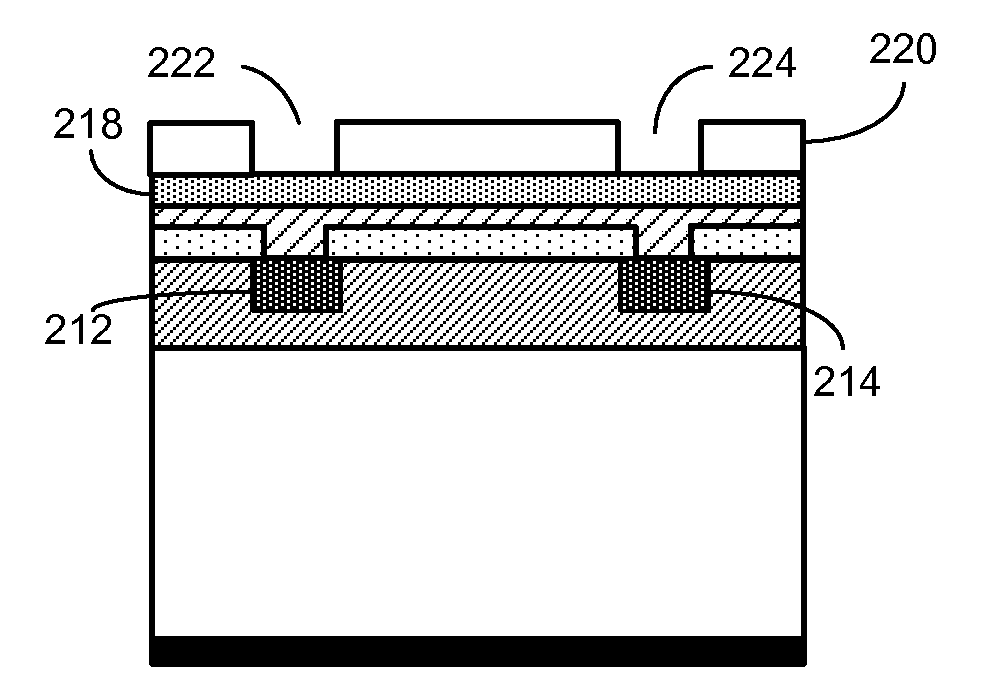

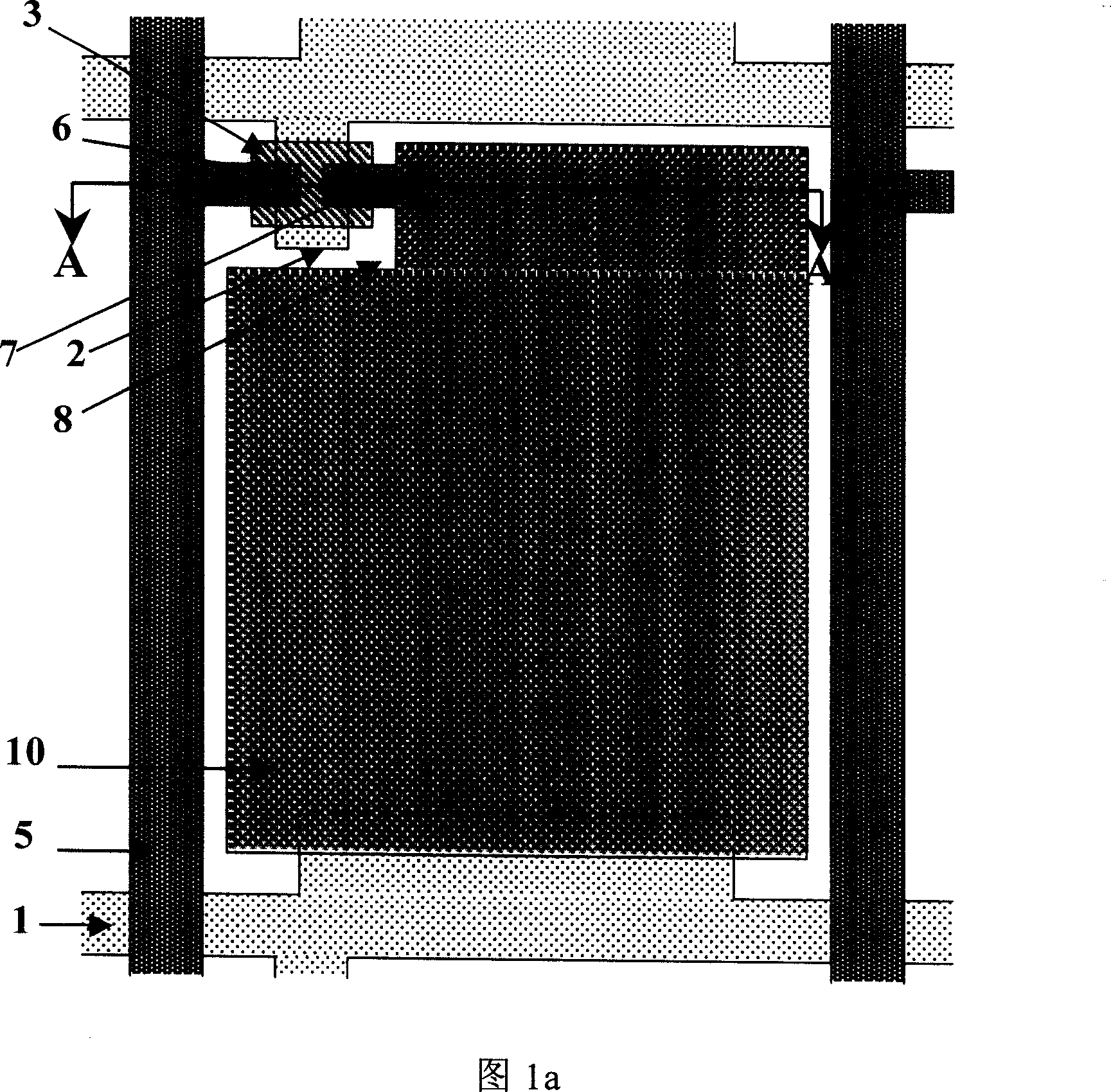

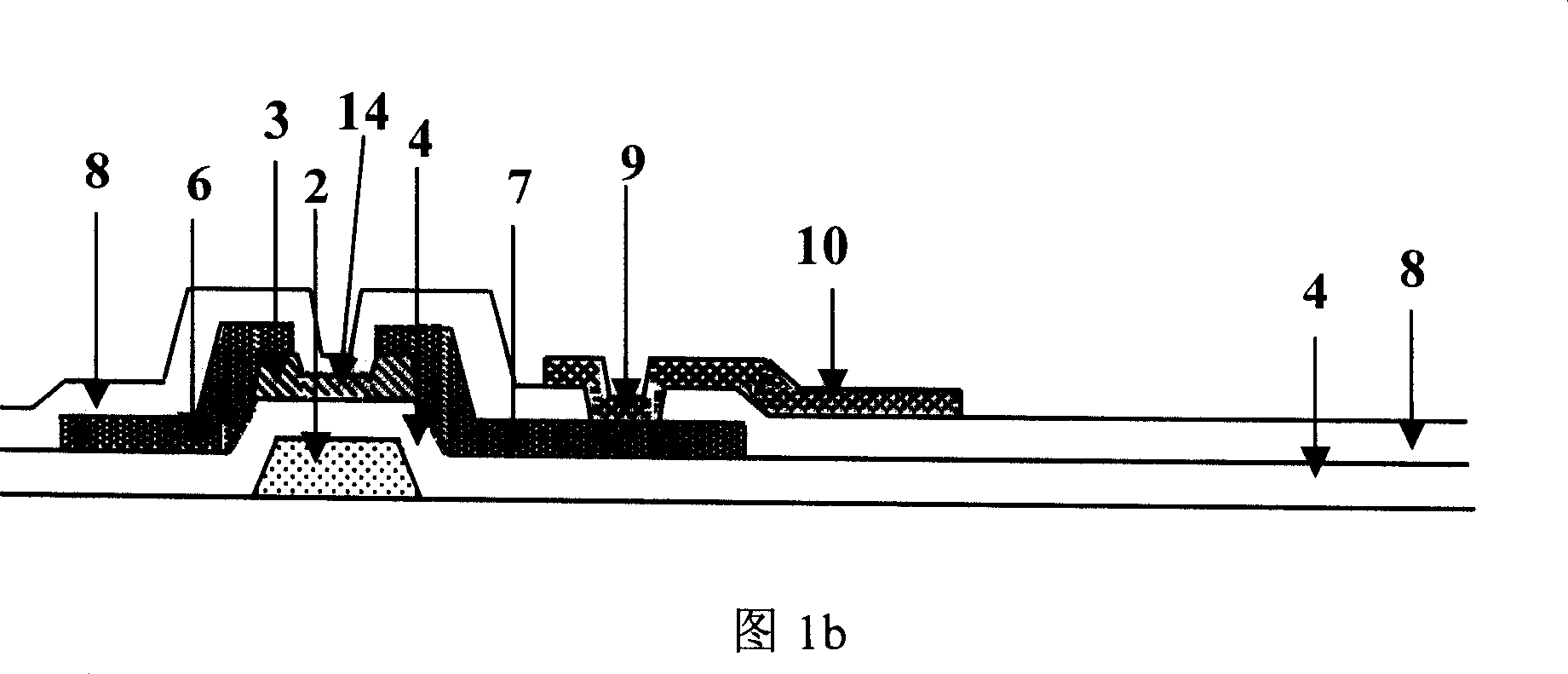

Manufacturing method for array substrate of thin film transistor LCD

ActiveCN101034262ALow costSimple manufacturing processSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusInsulation layerThin-film-transistor liquid-crystal display

The invention opens a manufacturing method of the thin film transistor liquid crystal display array substrate. Including the following steps: first, forms the first metal film on the substrate; uses the version of the first layer metal film define the design of the first metal film and to form grid scan line and grid electrode. Next, the first insulating layer, the active layer, ohmic contact layer and the second layer metal film were deposited above the metal grid in turn; The use of the second block mask, namely, a gray-first definition of the second mask layer metal film patterns, forms a source of leakage and data scanning lines; Secondly forms the active layer island and conductive thin film transistor device channel. Then it forms the second insulation film on the second metal layer. Finally, the use of the third block mask, that is the second block of gray-definition version of the second mask layer insulation film, forms a second layer insulation film designs, makes some part of the second layer and the second layer of metal insulation layer exposed, and the other part was the protection of light-sensitive materials. Here a transparent conductive film deposits on it, and then removes light sensitive materials and their attachment -the electro-conductive film, finally forms the design of the electric conduction thin film.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

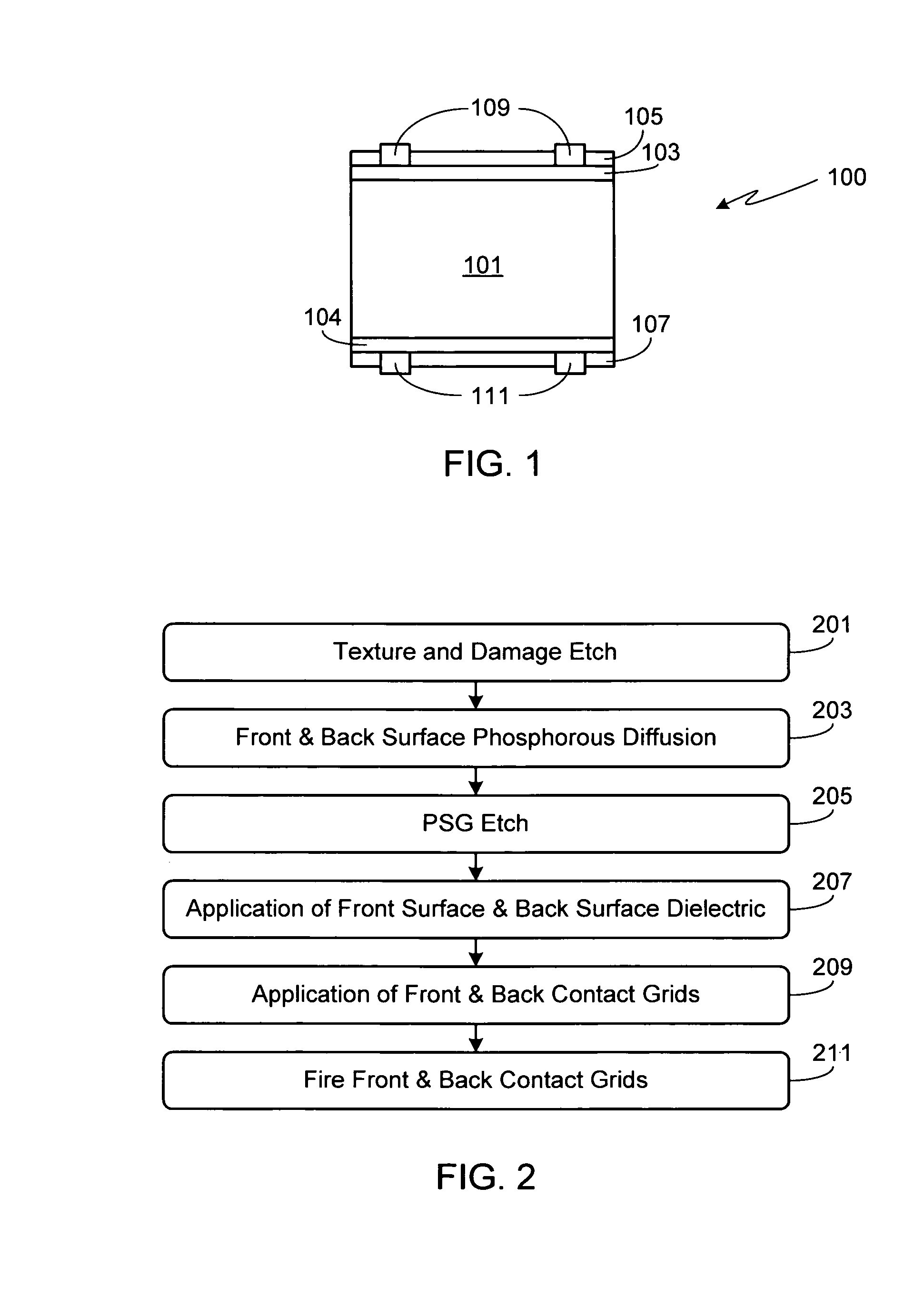

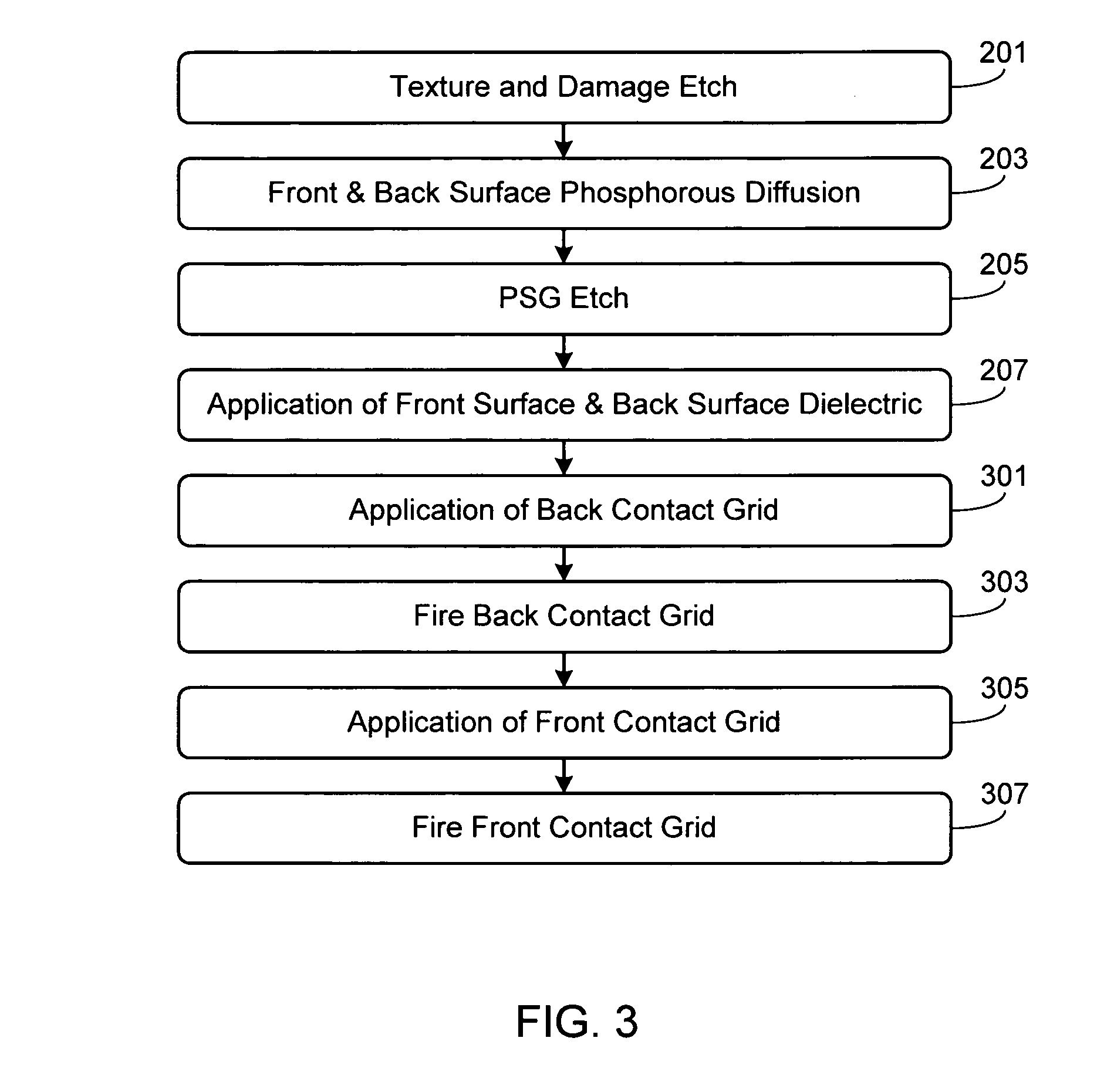

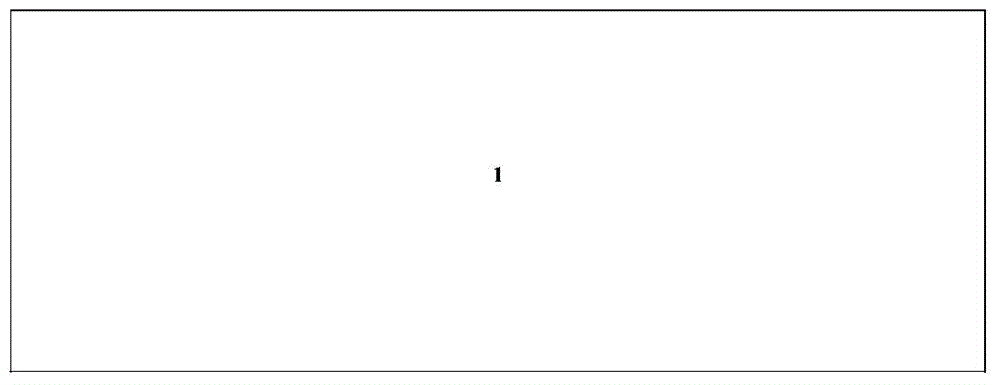

Bifacial solar cells with overlaid back grid surface

InactiveUS20100275983A1Simple manufacturing processReduce manufacturing costFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingEngineering

A simplified manufacturing process and the resultant bifacial solar cell (BSC) are provided, the simplified manufacturing process reducing manufacturing costs. The BSC includes an active region located on the front surface of the substrate, formed for example by a phosphorous diffusion step. After removing the PSG, assuming phosphorous diffusion, and isolating the front junction, dielectric layers are deposited on the front and back surfaces. Contact grids are formed, for example by screen printing. Prior to depositing the back surface dielectric, a metal grid may be applied to the back surface, the back surface contact grid registered to, and alloyed to, the metal grid during contact firing.

Owner:SUNNUVELLIR SLHF +1

Three-dimensional semiconductor device and manufacturing method thereof

ActiveCN104022121AImprove reliabilityImprove control characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETVertical channel

The invention discloses a three-dimensional semiconductor device comprising a plurality of memory unit transistors and a plurality of selection transistors, wherein the plurality of memory unit transistors are at least partially overlapped in the vertical direction; each selection transistor comprises a first drain electrode distributed along the vertical direction, an active region, a common source electrode formed in a substrate and a metal grid electrode distributed around the active region; each memory unit transistor comprises a channel layer distributed vertical to the surface of the substrate, wherein a plurality of interlayer insulating layers and a plurality of grid electrode stacking structures are alternately stacked along the side wall of the channel layer, and a second drain electrode is located at the top of the channel layer; the channel layer is electrically connected with the first drain electrode. According to the three-dimensional semiconductor device and a manufacturing method thereof disclosed by the invention, multi-grid MOSFETs (Metal-Oxide-Semiconductor Field Effect Transistors) are formed below memory unit string stacks comprising vertical channels so as to be used as the selection transistors, thus the threshold voltage control characteristic of the grid electrode is improved, the off-state leakage current is reduced, the over-etching for the substrate is avoided, and the reliability of the device is effectively improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Polarized light source device and back light module for liquid crystal display

InactiveUS20040080926A1Measurement apparatus componentsOperating tablesLiquid-crystal displayLight source

A polarized light source device comprises a light source, a reflector, a transparent substrate, an antireflection layer, and a plurality of metal grid wires. The reflector surrounds the light source for reflecting the light, and has an opening for emitting the light. The transparent substrate is disposed at the opening. The antireflection layer is disposed on the transparent substrate. The metal grid wires are disposed on the antireflection layer for transmitting the light with a predetermined polarization therethrough.

Owner:HANNSTAR DISPLAY CORPORATION

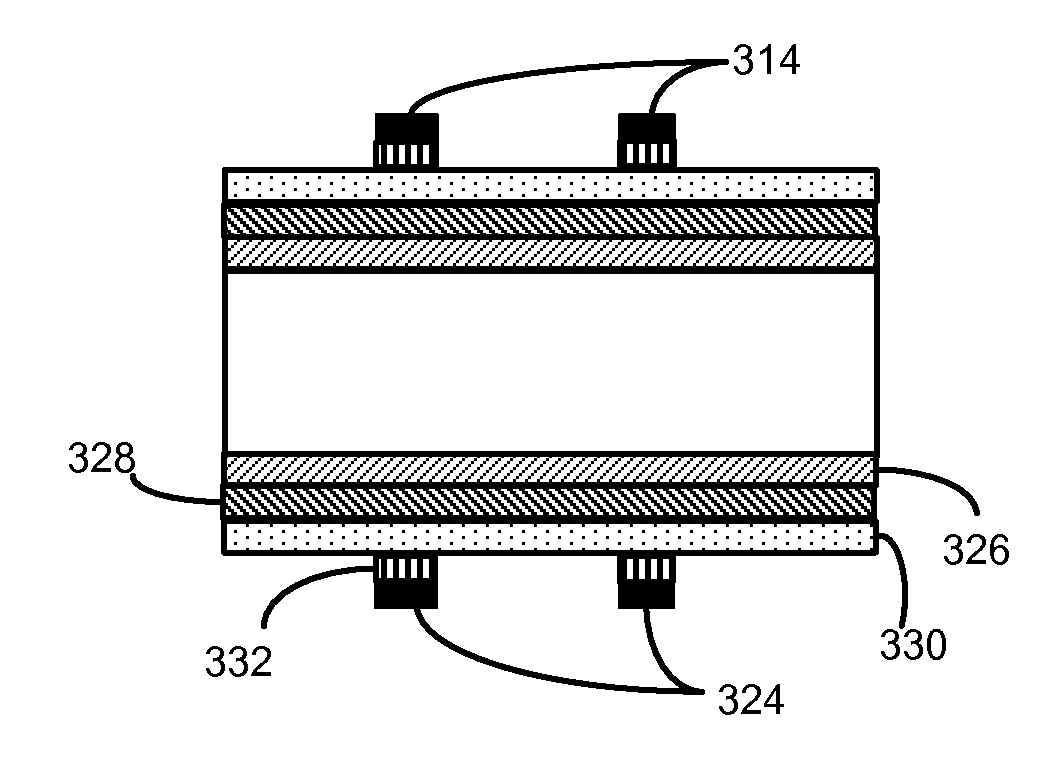

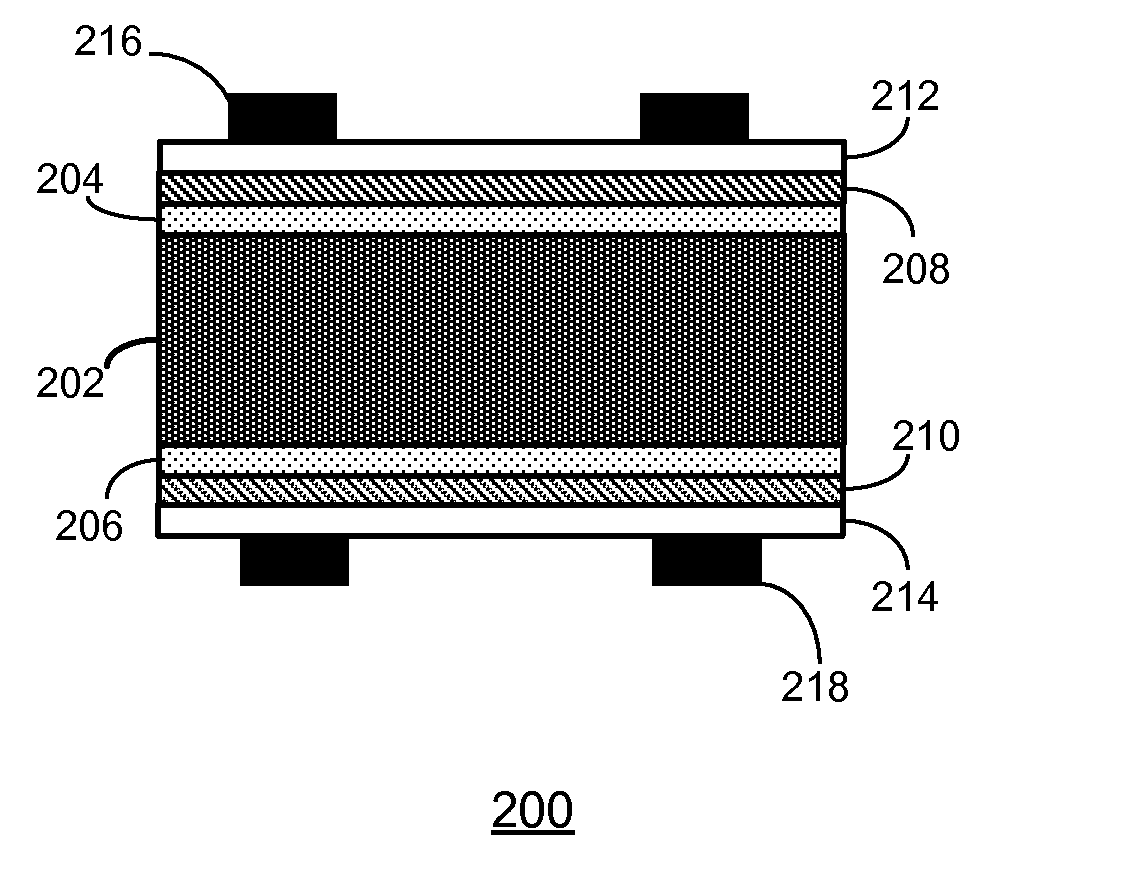

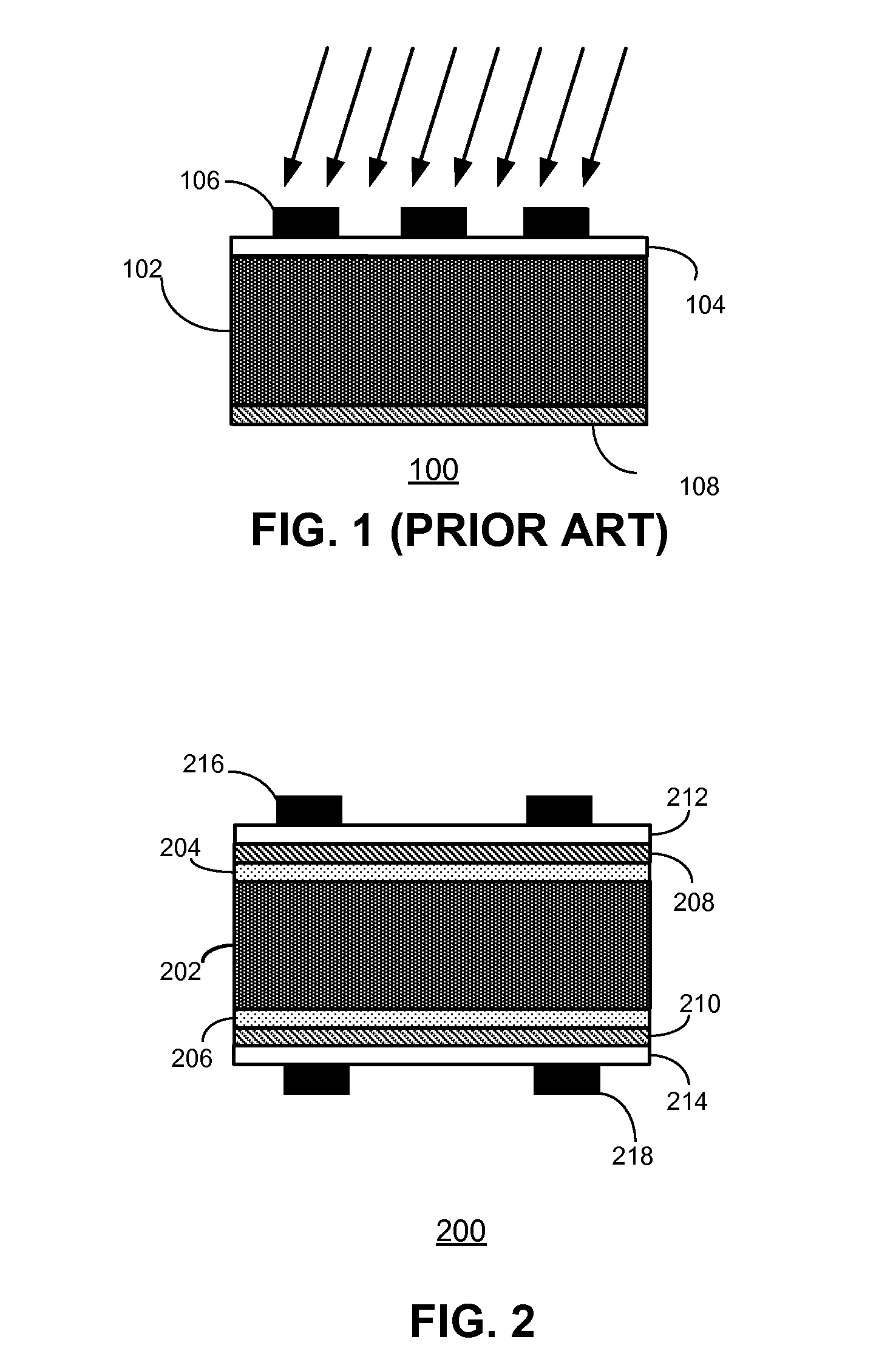

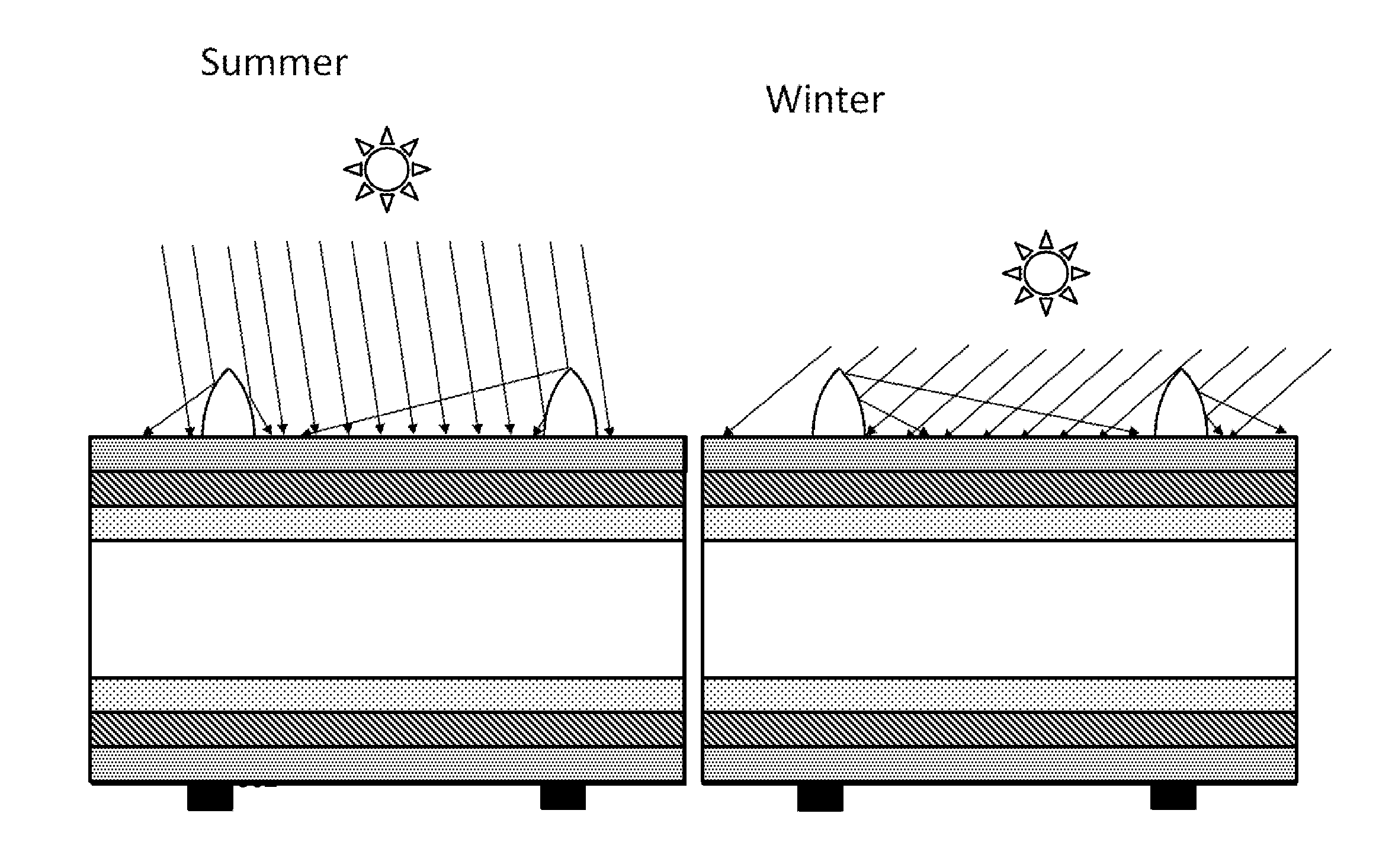

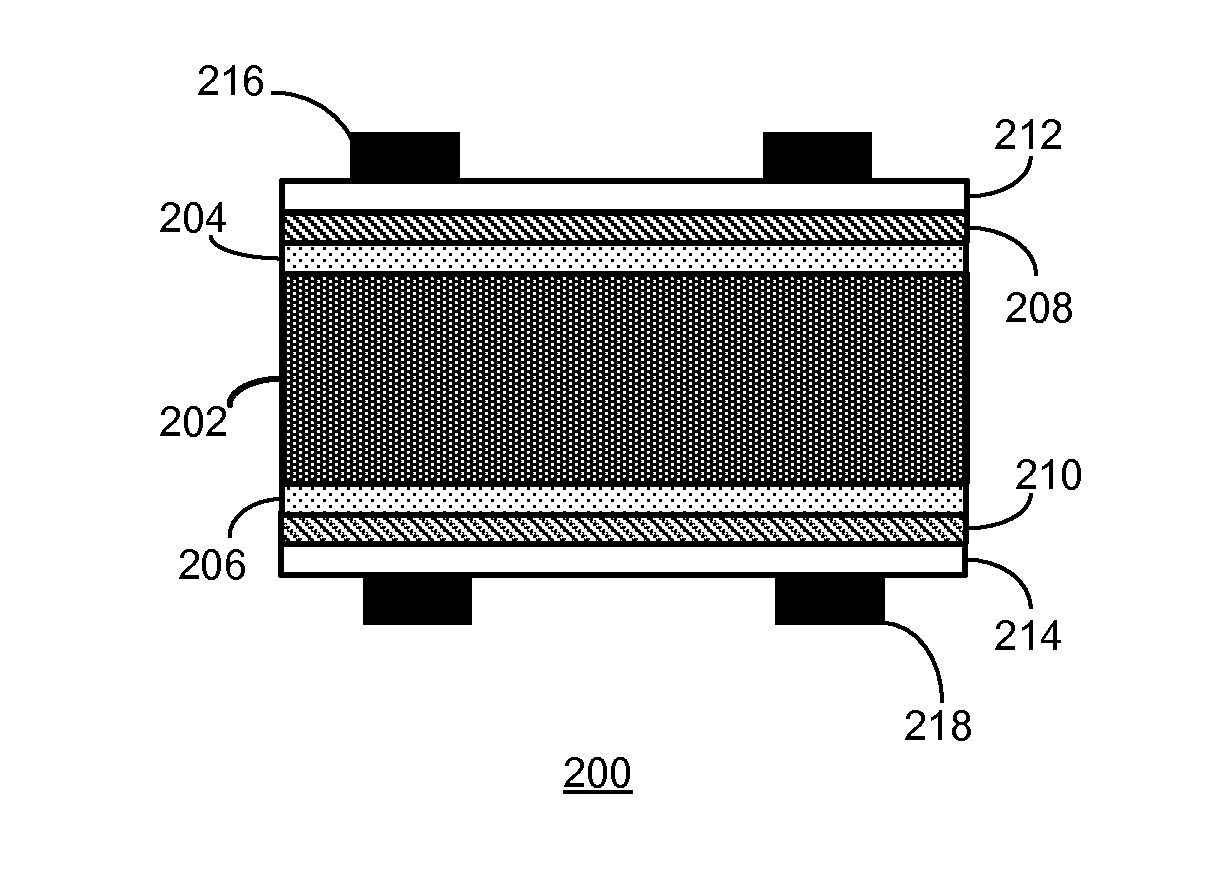

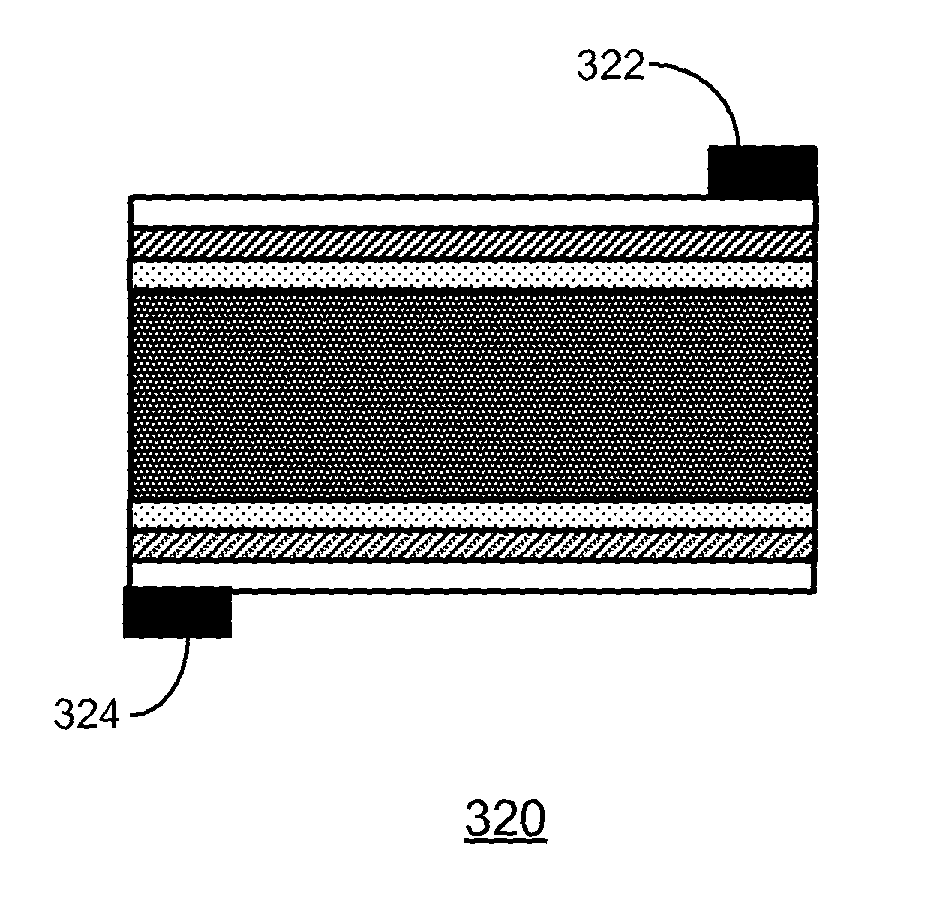

Bifacial photovoltaic module using heterojunction solar cells

One embodiment of the present invention provides a bifacial solar panel. The bifacial solar panel includes a first transparent cover on a first side of the solar panel, a second transparent cover on a second side of the solar panel, a plurality of solar cells sandwiched between the first cover and the second cover, and one or more lead wires for outputting power generated by the solar panel. The lead wires are positioned on an edge of the solar panel without shading the first and second sides of the solar panel. A respective solar cell comprises a photovoltaic structure, a first metal grid on the first side of the photovoltaic structure, which allows the solar cell to absorb light from the first side, and a second metal grid on the second side of the photovoltaic structure, which allows the solar cell to absorb light from the second side.

Owner:TESLA INC

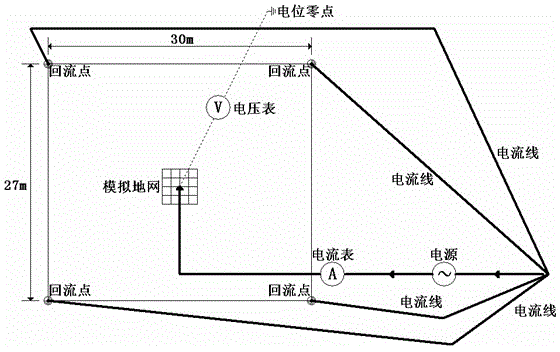

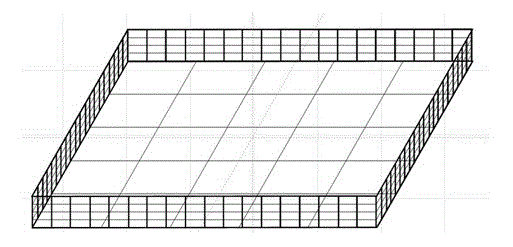

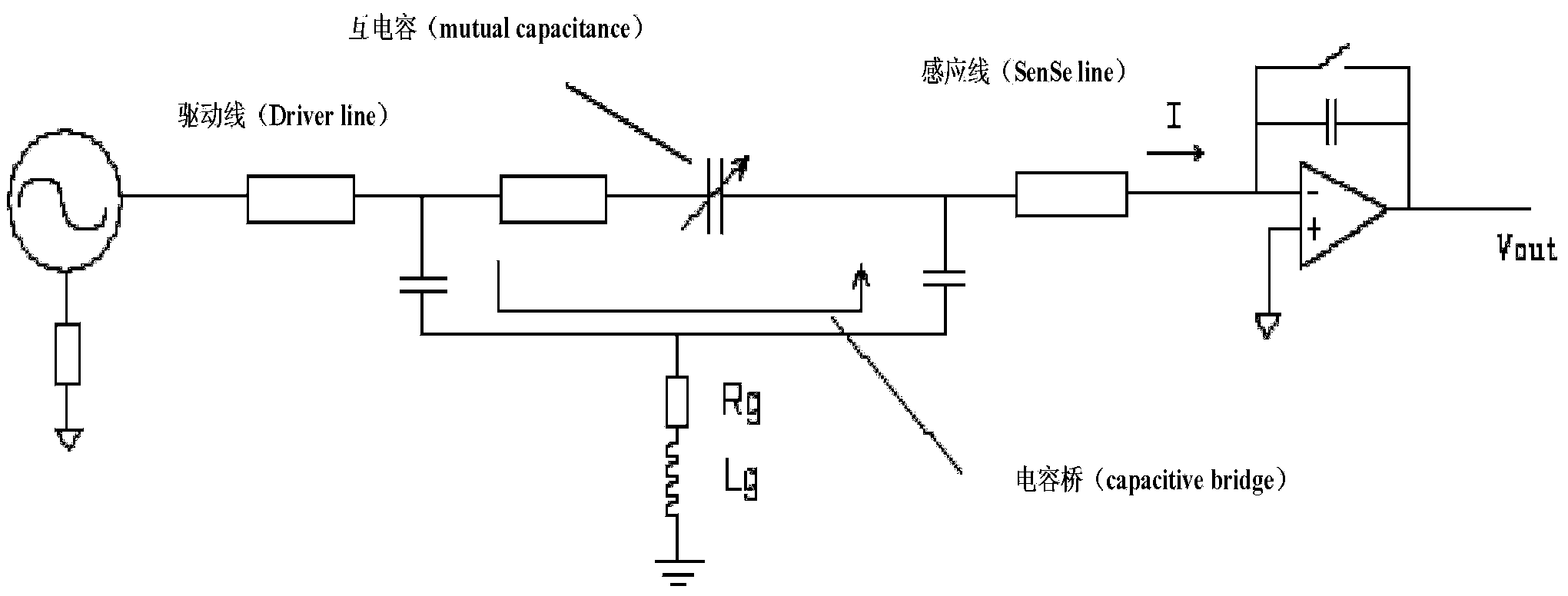

Simulation experiment device and method of alternating current, direct current and impact performance of large earth screen

The invention provides a simulation experiment device and a method of alternating current, direct current and impact performance of a large earth screen. The device mainly comprises a rectangular simulated slot, an earth screen model equivalently reduced, an alternating and direct current experimental power supply, an impact current generator and a precise positioning system, and is characterized in that metal grids are laid on four walls and the bottom inside the rectangular simulated slot, so as to form a mesh backflow electrode; a liquid medium is injected into the slot; the earth screen model is designed and manufactured according to the experimental objective and content; the precise positioning system comprises an electrically controlled traveling crane and a total station; and the electric potential in any position in the rectangular simulated slot is convenient to measure at a fixed point through the coordination work of the electrically controlled traveling crane and the total station. The simulation experiment device and the method can meet the experimental research on direct current, power frequency and impact grounding properties of the large earth screen, can also be extensively applied to the fields, such as the experimental research of influence on aquatic organism and metal pipelines by an alternating and direct current system and corrosive property, and the like, and have the advantages of simplicity in operation, large power capacity, durability, flexibility and diversity in refitment and the like.

Owner:CHINA ELECTRIC POWER RES INST +2

Embedded type touch control display device

ActiveCN103901650ALower resistanceReduce parasitic capacitanceStatic indicating devicesNon-linear opticsControl layerDisplay device

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

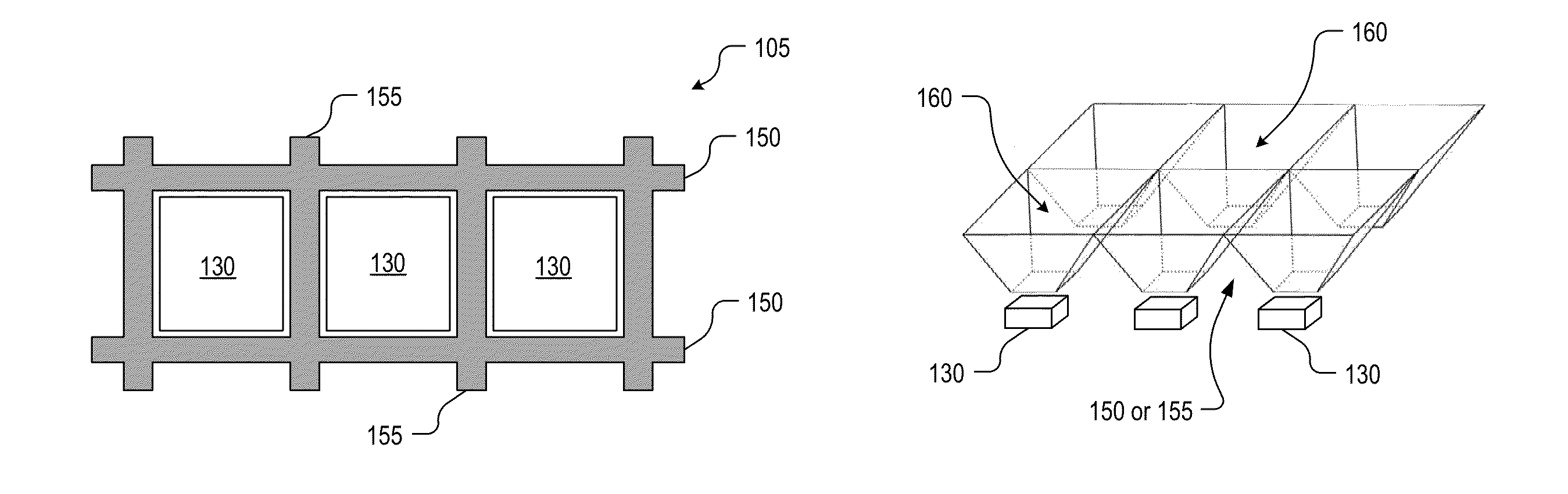

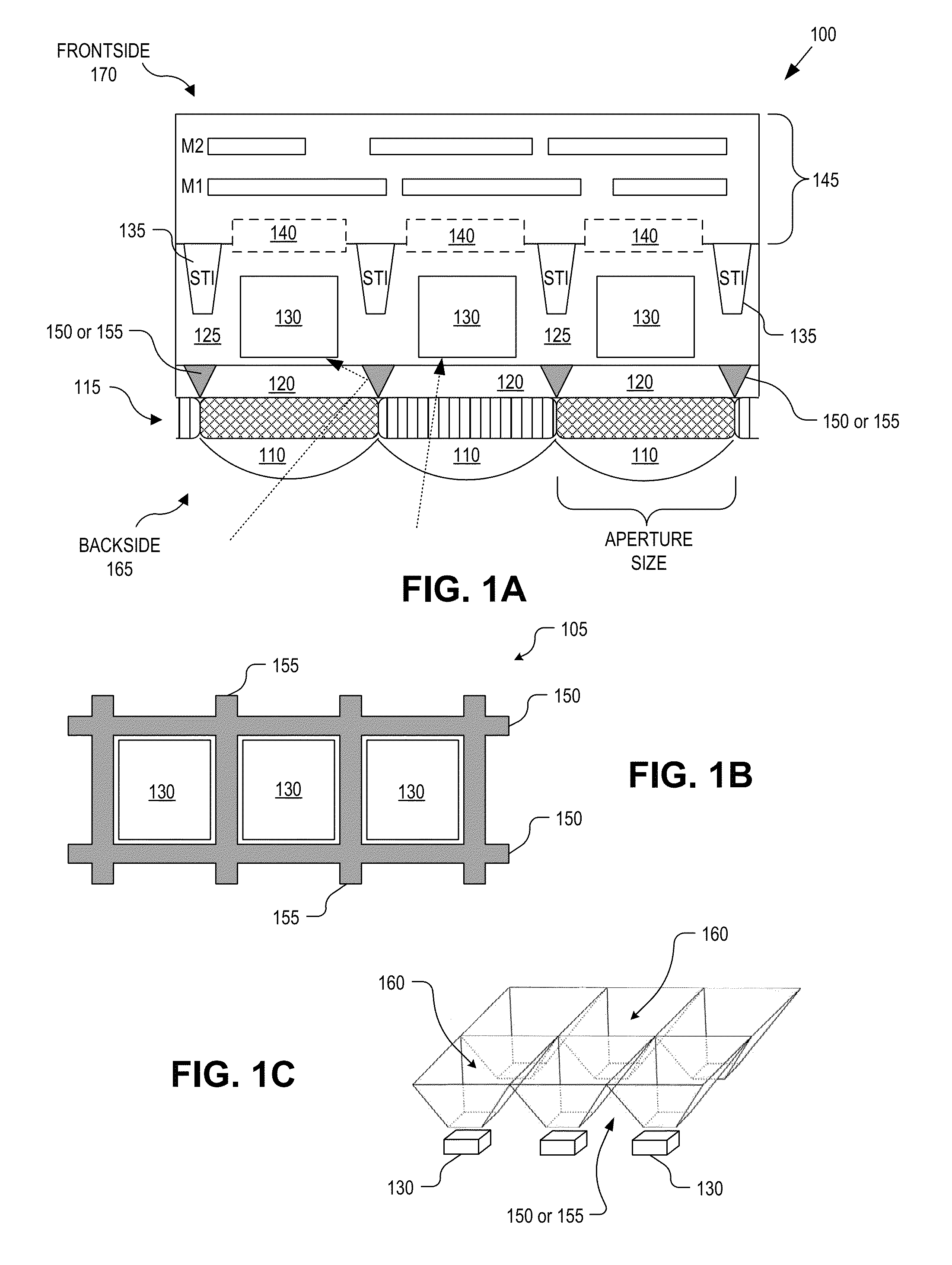

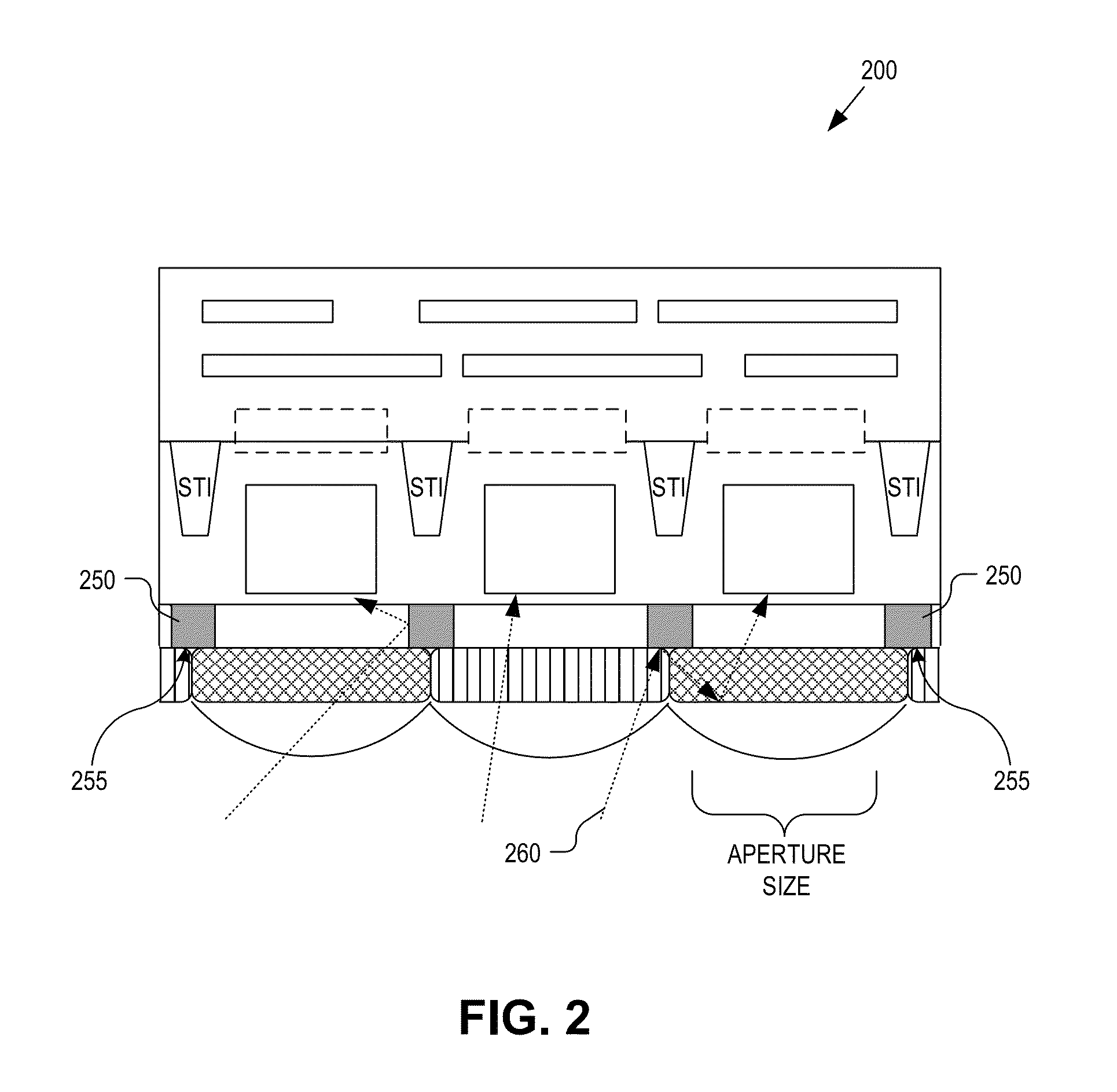

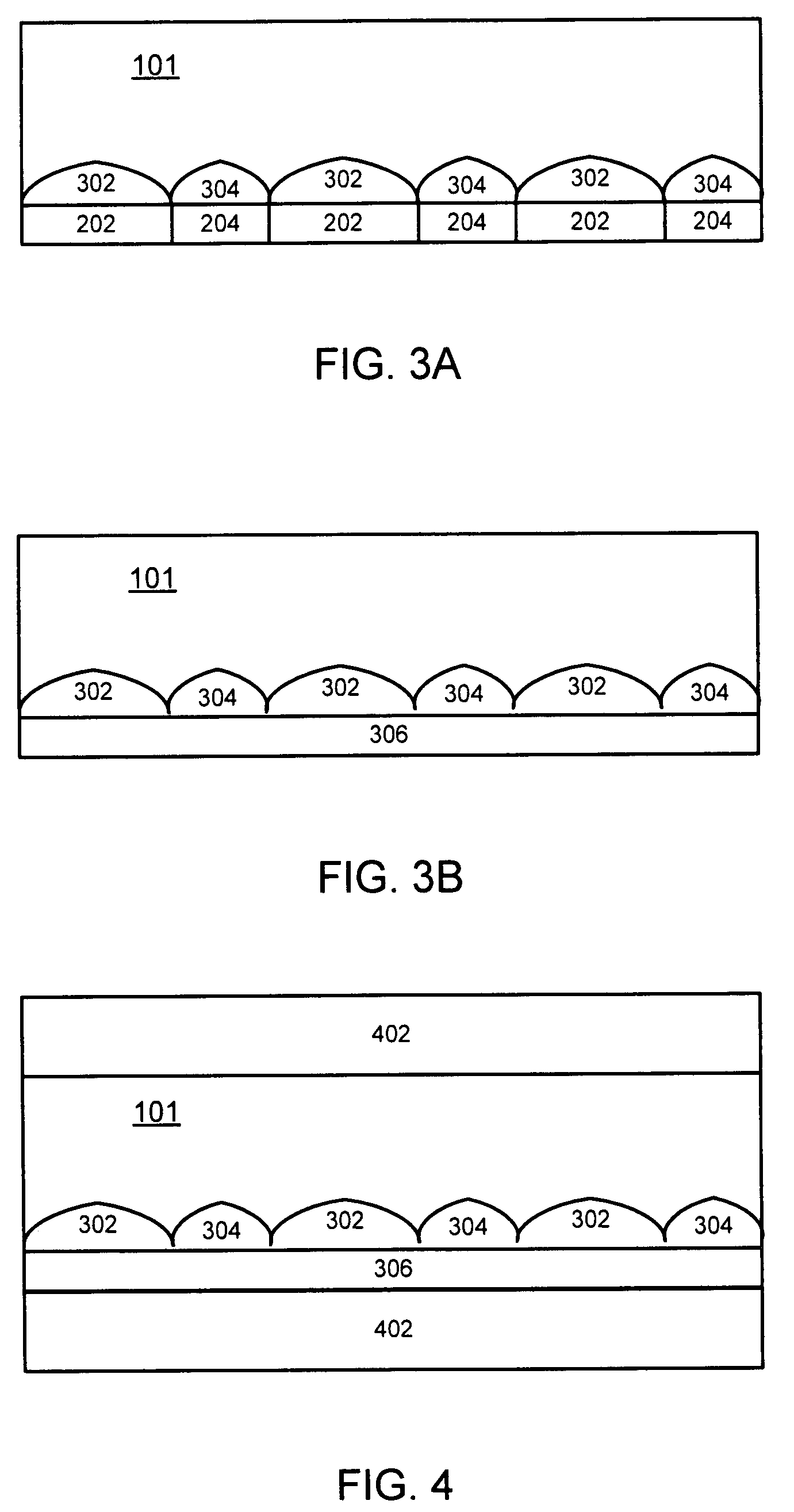

Image sensor having metal grid with a triangular cross-section

ActiveUS8530266B1Semiconductor/solid-state device detailsSolid-state devicesLight sensitiveMetal grid

A backside illuminated image sensor includes a substrate layer having a frontside and a backside. An array of photosensitive pixels is disposed within the substrate layer and is sensitive to light incident through the backside of the substrate layer. A metal grid is disposed over the backside of the substrate layer. The metal grid surrounds each of the photosensitive pixels and defines optical apertures for receiving the light into the photosensitive pixels through the backside. The metal grid includes intersecting wires each having a triangular cross-section. A material layer surrounds the metal grid.

Owner:OMNIVISION TECH INC

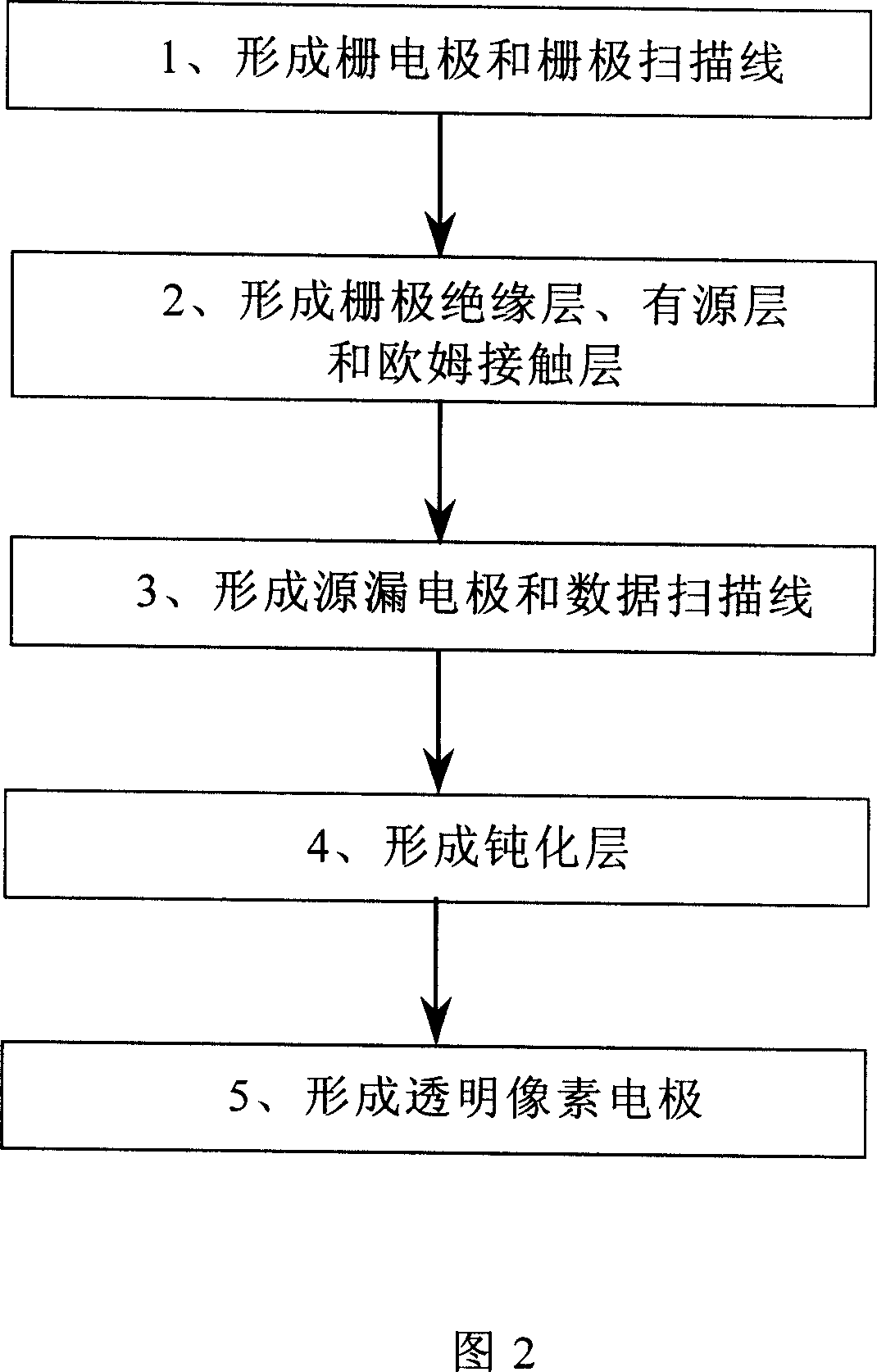

Module fabrication of solar cells with low resistivity electrodes

ActiveUS9412884B2Reliable electrical connectionFacilitating cell-level MPPTPhotovoltaicsPhotovoltaic energy generationPower flowSemiconductor structure

One embodiment of the present invention provides a solar module. The solar module includes a front-side cover, a back-side cover, and a plurality of solar cells situated between the front- and back-side covers. A respective solar cell includes a multi-layer semiconductor structure, a front-side electrode situated above the multi-layer semiconductor structure, and a back-side electrode situated below the multi-layer semiconductor structure. Each of the front-side and the back-side electrodes comprises a metal grid. A respective metal grid comprises a plurality of finger lines and a single busbar coupled to the finger lines. The single busbar is configured to collect current from the finger lines.

Owner:TESLA INC

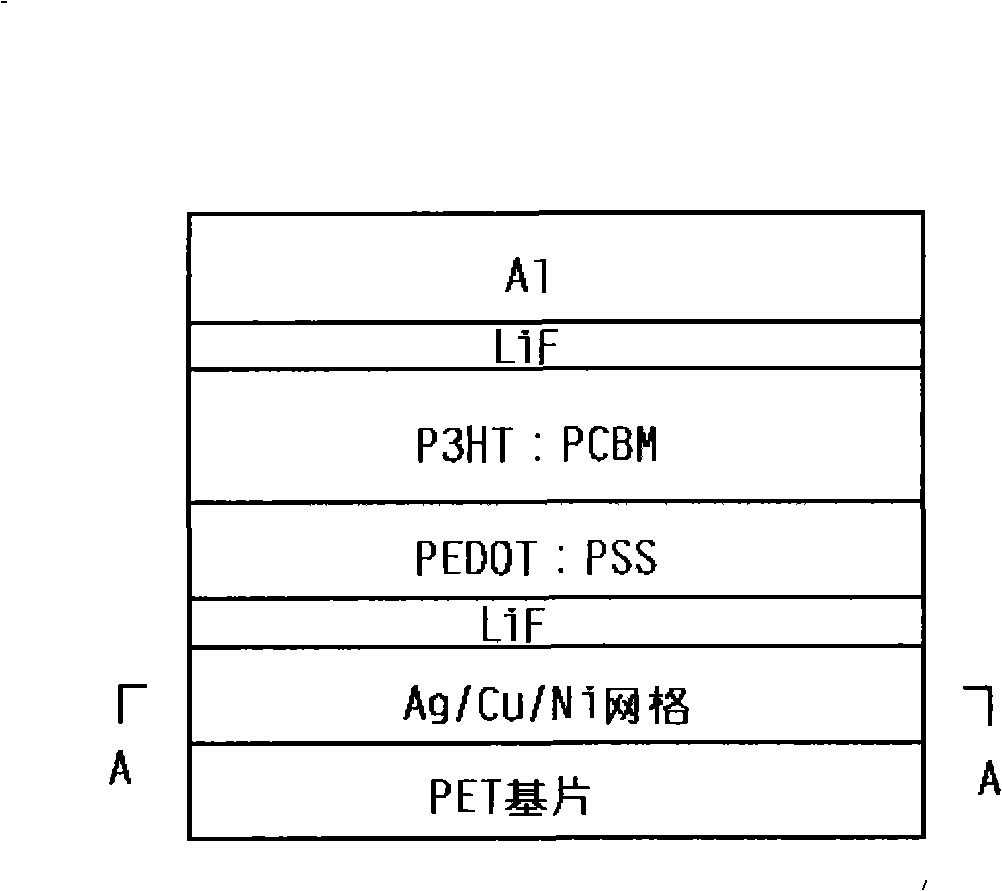

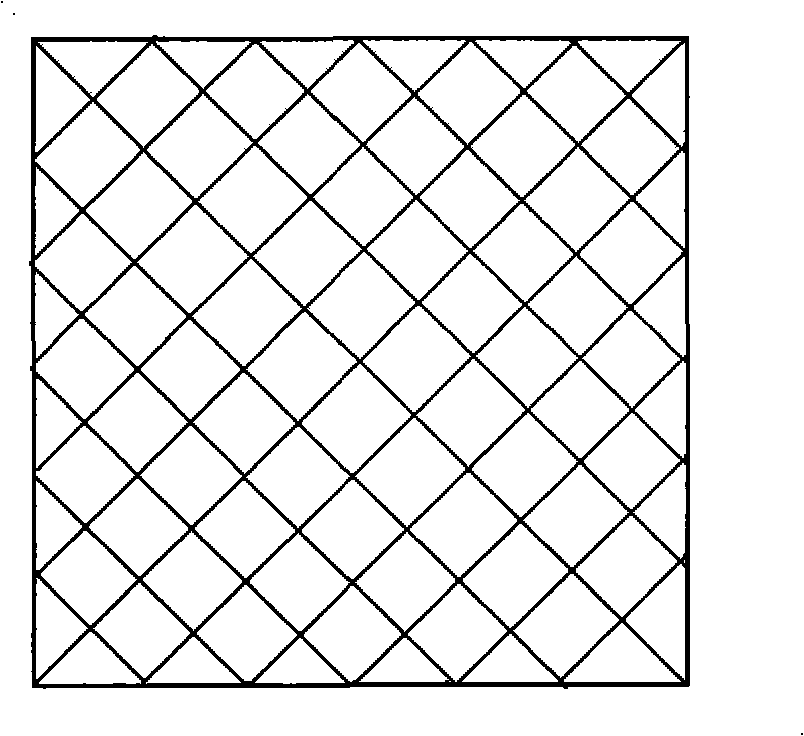

Flexible polymer solar battery of anode layer of metal grid and preparation method

InactiveCN101540371AImprove balanceImprove performanceVacuum evaporation coatingSolid-state devicesHole transport layerSolar battery

The invention relates to a flexible polymer solar battery of an anode layer of a metal grid, which comprises a flexible substrate, an anode layer, a hole transport layer, an active layer, an electron transfer layer and an Al electrode cathode and is characterized in that the anode layer is made from one or more of composition metal wire grid materials of Ag, Cu, and Ni. In the solar battery, a silver, copper and nickel (Ag: Cu: Ni) metal grid / LiF combined electrode is used as the anode; compared with the battery prepared by a common flexible substrate ITO electrode, the flexible solar battery prepared by taking P3HT / PCB as the active layer can show up better performance; after a layer of lithium fluoride (LiF) layer with the thickness of 2nm is added between the Ag: Cu: Ni metal grid and the polythiophene derivative doped polystyrolsulfon acid (PEDOT: PSS) layer, the film formation of PEDOT: PSS on the surface of the anode is improved, the balance between the hole and the electron transport is enhanced, and compared with the battery with the common flexible substrate ITO electrodes, the energy conversion efficiency is obviously improved.

Owner:HEBEI UNIVERSITY

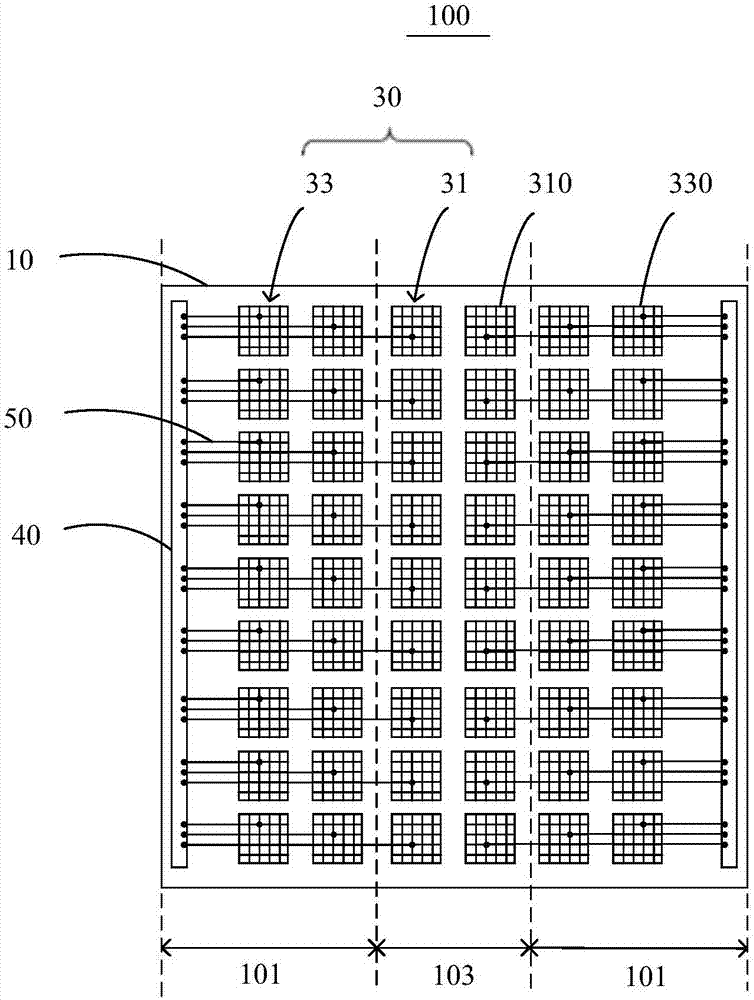

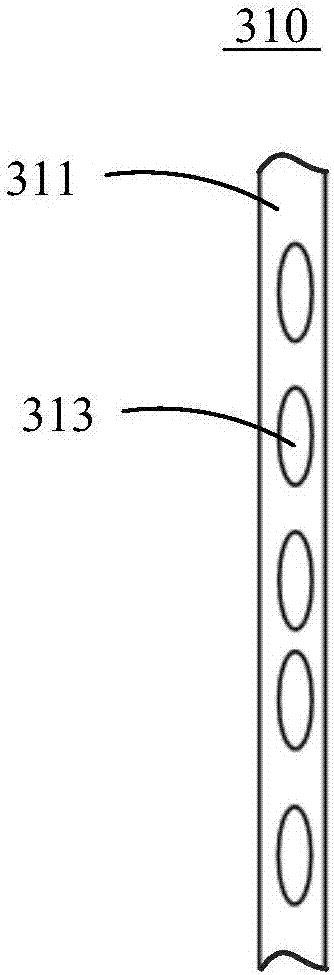

Display panel and display device

ActiveCN110034168AImprove the display effectUniform display brightnessSolid-state devicesPhotovoltaic energy generationElectricityControl layer

The invention discloses a display panel and a display device, and relates to the technical field of display. The display panel comprises a display layer and a touch control layer which are arranged ina stacked mode, and at least one first touch control electrode, wherein the display layer comprises a plurality of pixel units formed by a plurality of sub-pixels; the touch control layer comprises across-bridge layer, an insulating layer and a touch control metal layer; the touch control metal layer comprises a plurality of metal grid units, and the metal grid units are arranged corresponding to the pixel units; and the first touch control electrode comprises a plurality of metal grid units, and every two adjacent metal grid units are electrically connected through a connecting lead. The first touch control electrode is divided into a plurality of mutually-disconnected metal grid units on the touch control metal layer, so that the edge position and the interior of the first touch control electrode are subjected to the same disconnection treatment, and therefore the possibility that the display effect is poor due to uneven disconnection density or different positions can be lowered,and the display effect of the display panel is further improved; and meanwhile, the fingerprint identification under an optical screen is highly facilitated.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

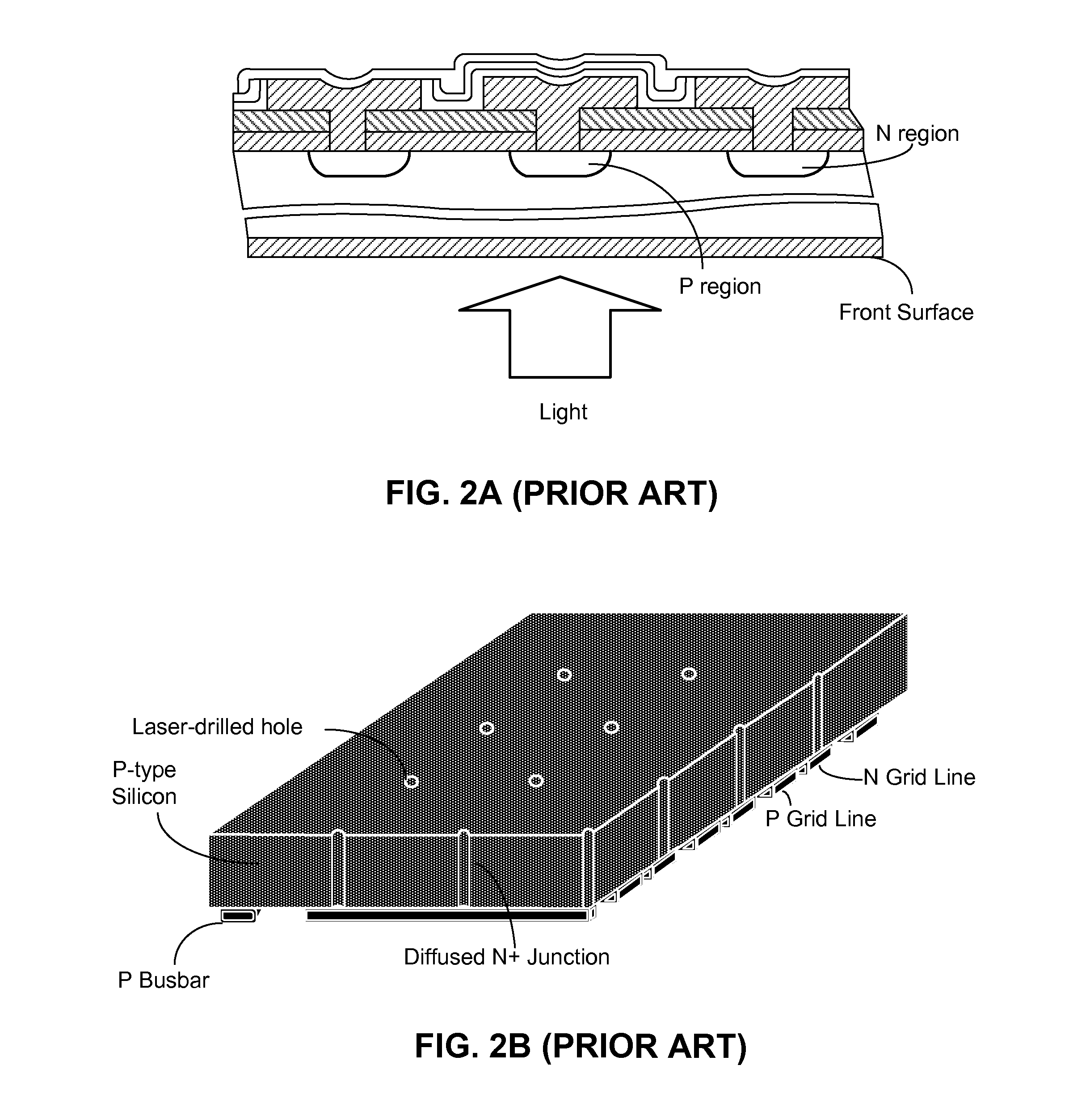

Oxynitride passivation of solar cell

InactiveUS20080251121A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationMetal gridSolar cell

One embodiment relates to a structure for a solar cell. The structure includes a silicon substrate with P-type and N-type active diffusion regions therein. An oxynitride passivation layer is included at least over the P-type and N-type active diffusion regions. The structure further includes contact openings through the oxynitride passivation layer to the P-type and N-type active diffusion regions, and metal grid lines which selectively contact the P-type and N-type active diffusion regions by way of the contact openings. Another embodiment relates to a method of fabricating a solar cell. Other embodiments, aspects and features are also disclosed.

Owner:SUNPOWER CORPORATION

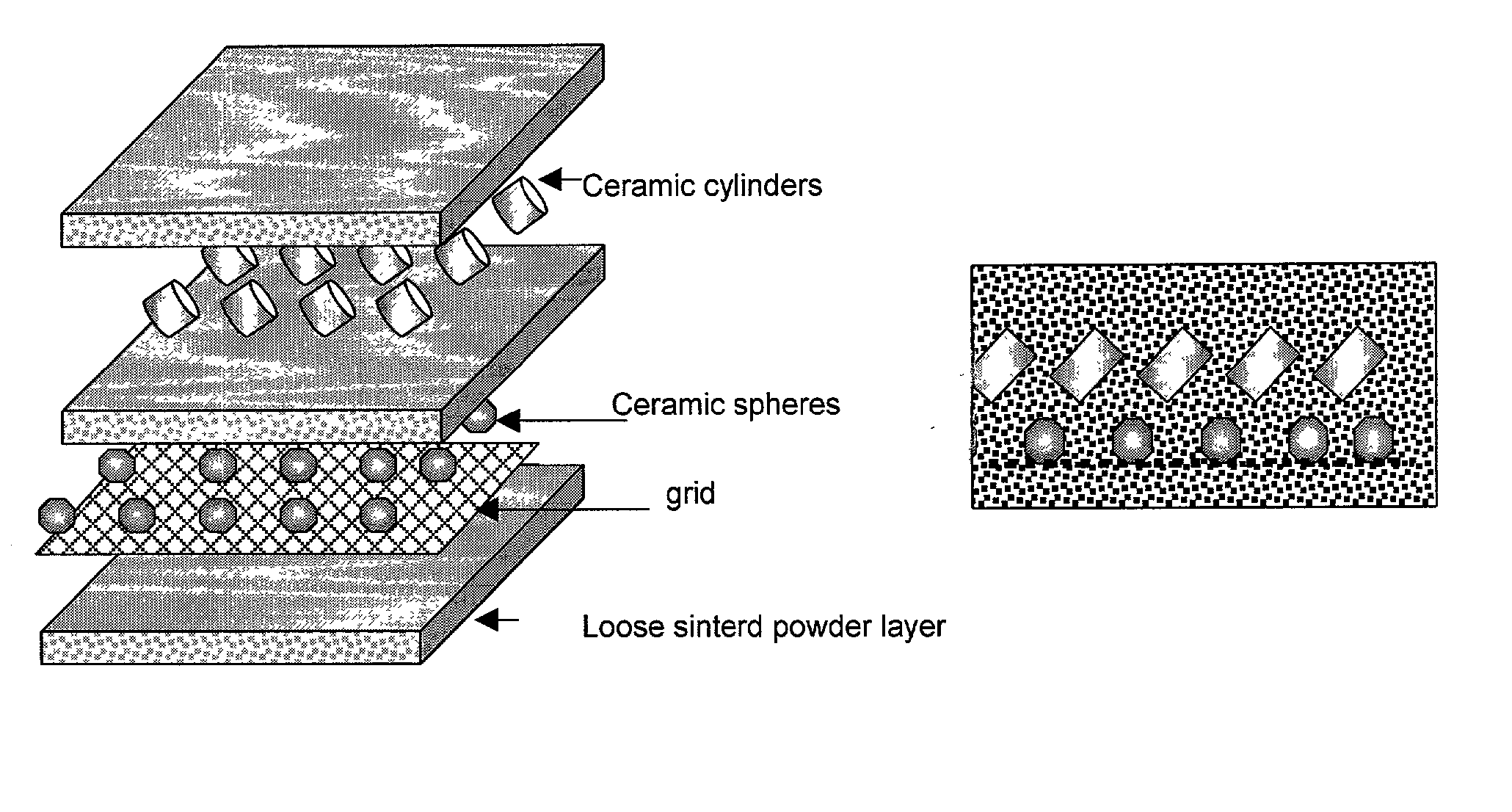

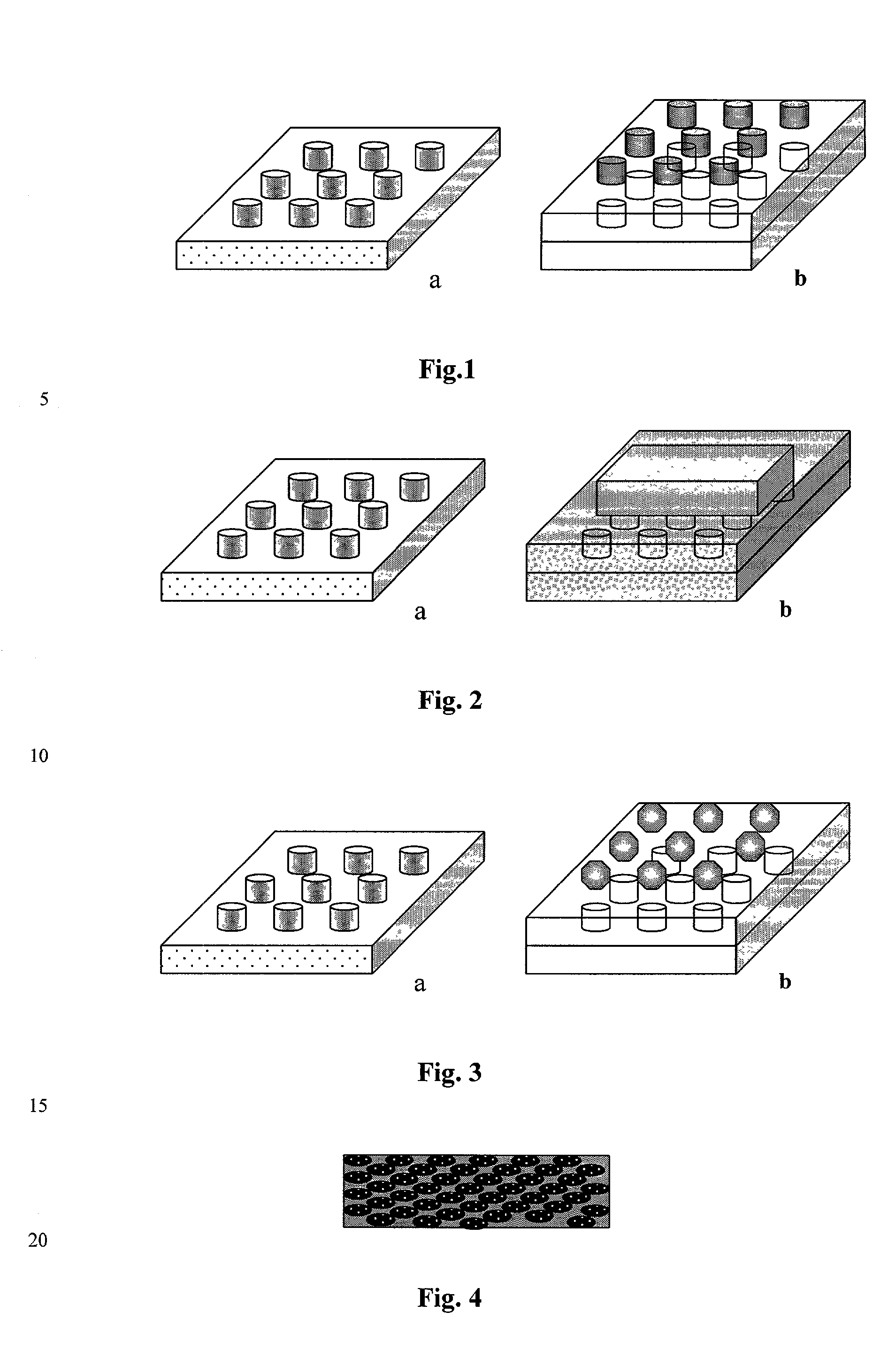

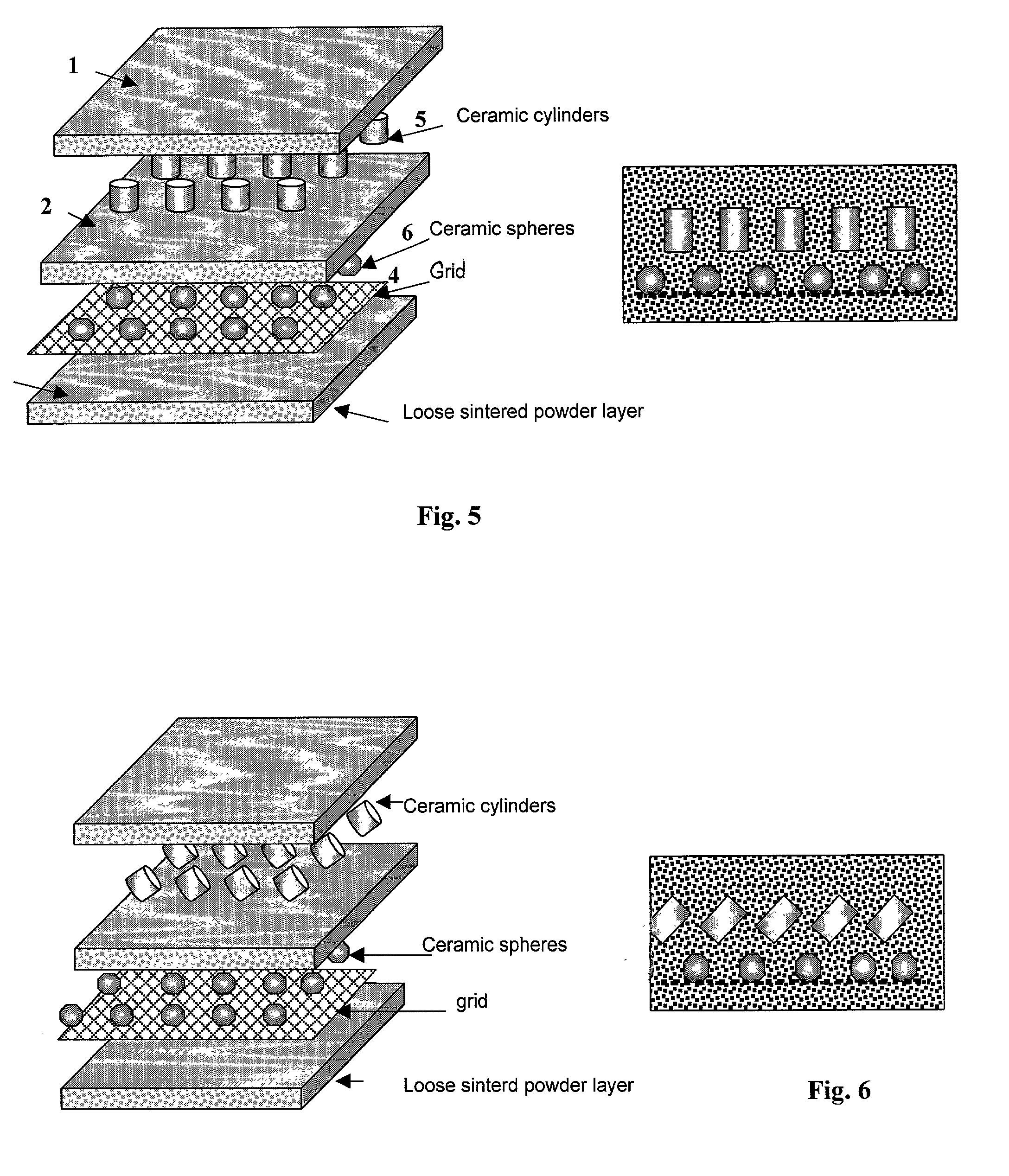

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS20030161750A1Stop crack propagationPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityGeometric pattern

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing. The positioning of the ceramic inserts in Ti-based powder is carried out by using a metal grid aiding the placement of inserts in a predetermined geometric pattern, and said grid becomes the integral part of the macrocomposite material. The technology is suitable for the manufacture of flat or shaped metal matrix macrocomposites having improved ductility and impact energy absorption such as lightweight bulletproof plates and sheets for airplane, helicopter, and automotive applications.

Owner:ADVANCED MATERIALS PRODS

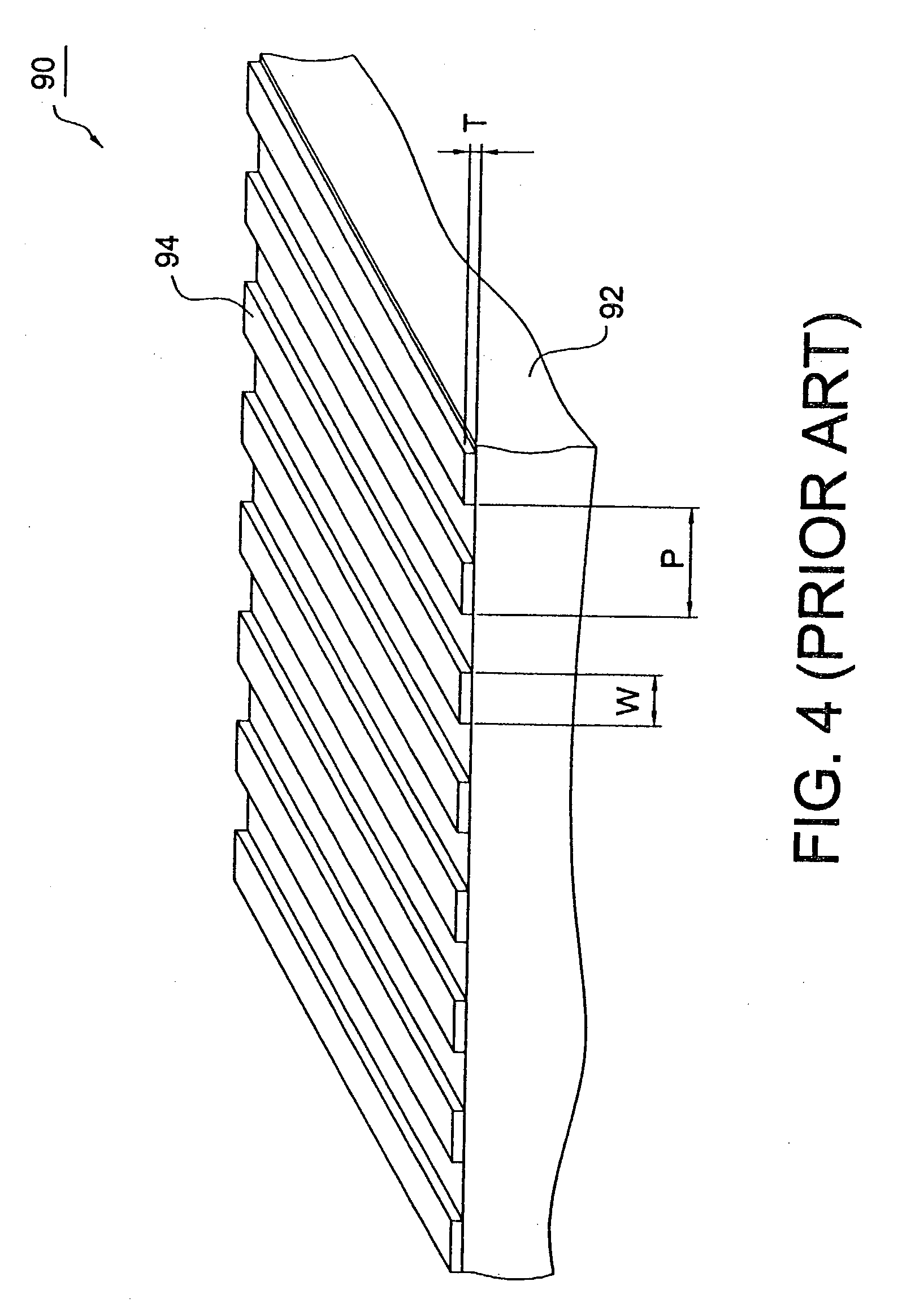

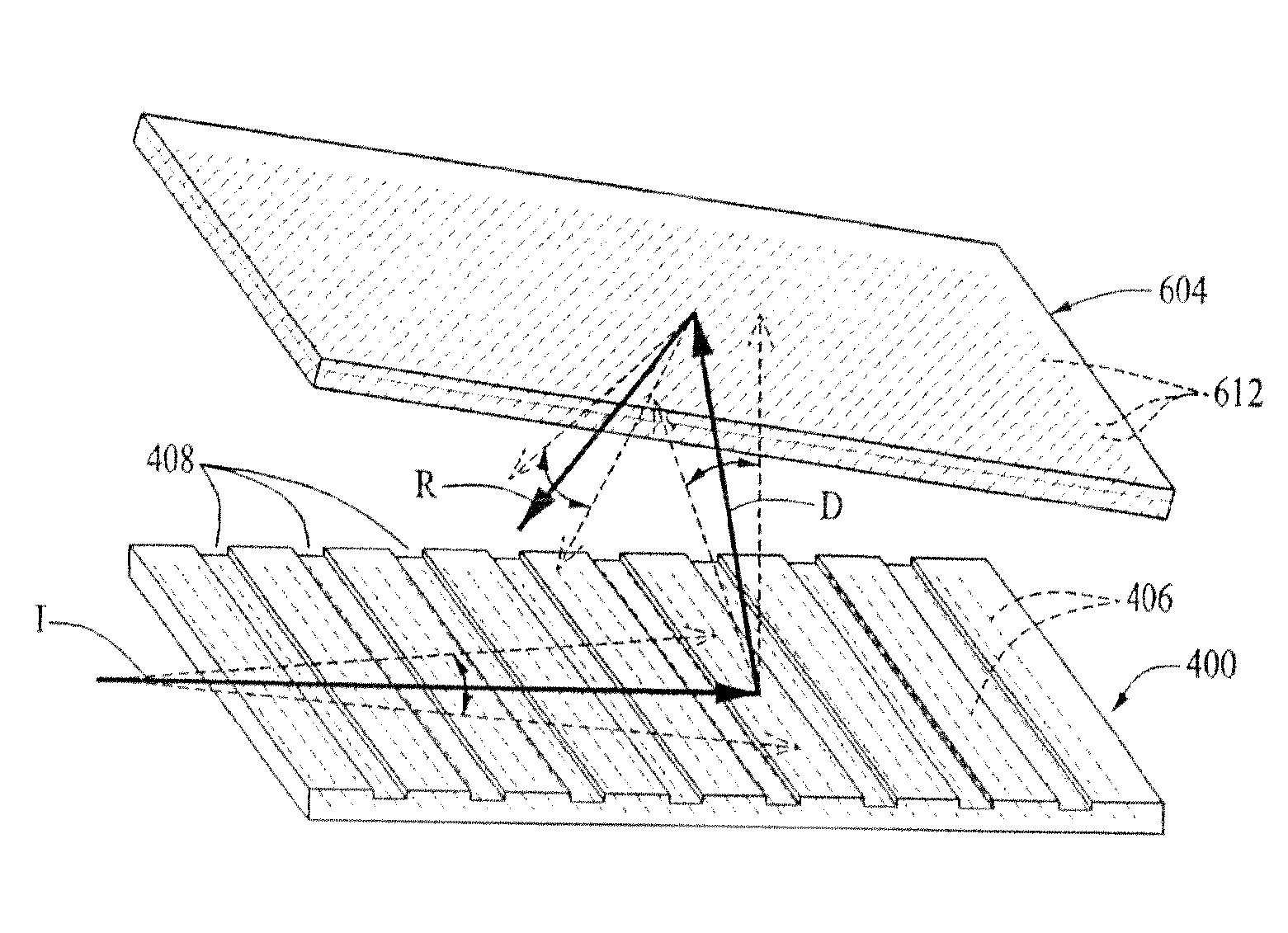

Planar dielectric waveguide with metal grid for antenna applications

A waveguide includes a dielectric substrate having first and second opposed surfaces defining a longitudinal wave propagation path therebetween; and a conductive grid on the first surface of the substrate and comprising a plurality of substantially parallel metal strips, each defining an axis. The grid renders the first surface of the substrate opaque to a longitudinal electromagnetic wave propagating along the longitudinal wave propagation path and polarized in a direction substantially parallel to the axes of the strips. The grid allows the first surface of the substrate to be transparent to a transverse electromagnetic wave having a transverse propagation path that intersects the first and second surfaces of the substrate and having a polarization in a direction substantially normal to the plurality of metal strips. A diffraction grating on the second surface allows the waveguide to function as an antenna element that may be employed in a beam-steering antenna system.

Owner:SIERRA NEVADA CORP

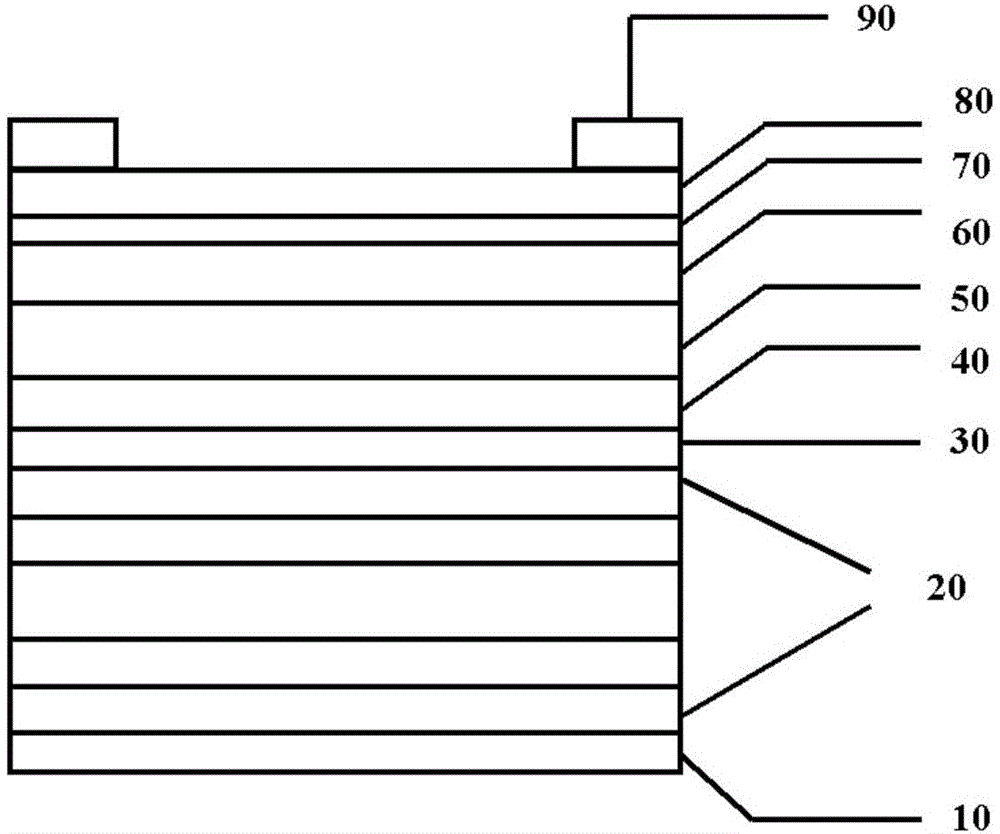

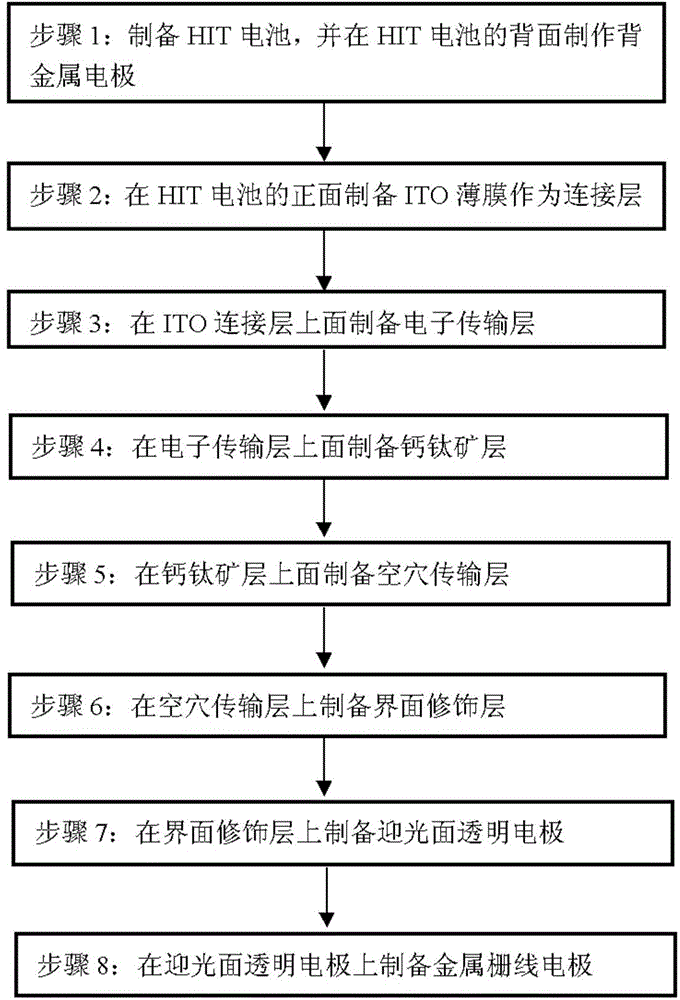

Laminated solar battery based on perovskite battery and HIT battery and manufacturing method

InactiveCN104979474AImprove photoelectric conversion efficiencyBroad absorption spectrumFinal product manufactureSolid-state devicesLight energyEngineering

A laminated solar battery based on a perovskite battery and an HIT battery comprises a back metal electrode; the HIT battery which is manufactured on the back metal electrode; an ITO connection layer which is manufactured on the HIT battery; an electron transporting layer which is manufactured on the ITO connection layer; a perovskite active absorption layer which is manufactured on the electron transporting layer; a hole transporting layer which is manufactured on the perovskite active absorption layer; an interface modification layer which is manufactured on the hole transporting layer; a light facing surface transparent electrode which is manufactured on the interface modification layer; and a metal grid line electrode which is manufactured on the light facing surface transparent electrode, wherein the metal grid line electrode is located on the two sides of the center on the light facing surface transparent electrode. With the adoption of the laminated solar battery based on the perovskite battery and the HIT battery, the absorption spectrum can be expanded and light energy is converted into electric energy to the greatest extent, so that the photoelectric conversion efficiency of the perovskite solar battery is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Solar cell with electroplated metal grid

ActiveCN102403371APhotovoltaic energy generationSemiconductor devicesSemiconductor structureAdhesive

The present invention relates to a solar cell with an electroplated metal grid. One embodiment of the present invention provides a method for fabricating solar cells. During operation, an anti-reflection layer is deposited on top of a semiconductor structure to form a photovoltaic structure, and a front-side electrode grid comprising a metal stack is formed on top of the photovoltaic structure. The metal stack comprises a metal-adhesive layer comprising Ti or Ta, and a conducting layer comprising Cu or Ag situated above the metal-adhesive layer.

Owner:TESLA INC

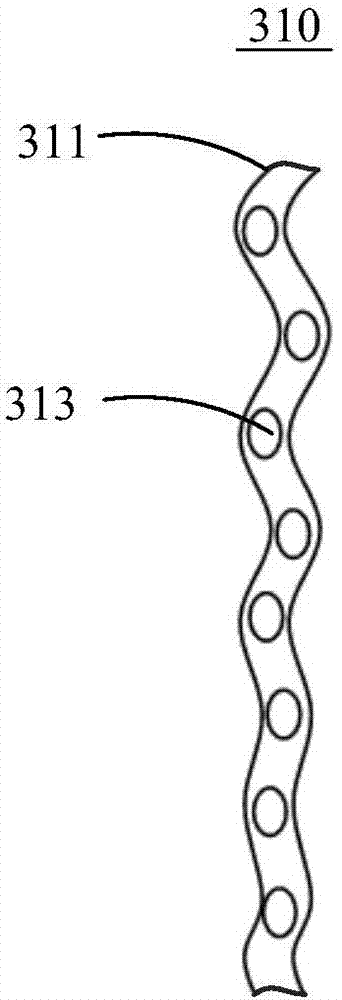

Flexible touch panel, touch display screen and touch display device

ActiveCN107977116AReduce bending stressReduced risk of breakageInput/output processes for data processingDisplay deviceComputer science

The invention provides a flexible touch panel. The flexible touch panel is divided into at least two non-bending regions and bending regions connecting every two adjacent non-bending regions. The flexible touch panel comprises a metal grid layer, wherein the metal grid layer comprises multiple independent first touch electrode units formed through patterning of first metal grids, the first touch electrode units are distributed at intervals corresponding to the bending regions, and each first metal grid is an electric lead with multiple hollowed-out patterns. Through the flexible touch panel, bending stress borne by the first touch electrode units can be reduced when the bending regions are bent, and therefore the risk of cracking of the first metal grids during bending is lowered. The invention furthermore provides a touch display screen provided with the flexible touch panel and a touch display device provided with the flexible touch panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com