Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

400 results about "Peel force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The peel strength is the measure of the average force to part two bonded materials like tape, labels, textile or plastic films. The strength is calculated during a peel test at a constant speed rate by divided the average force required during the test by the unit width of the bonded samples.

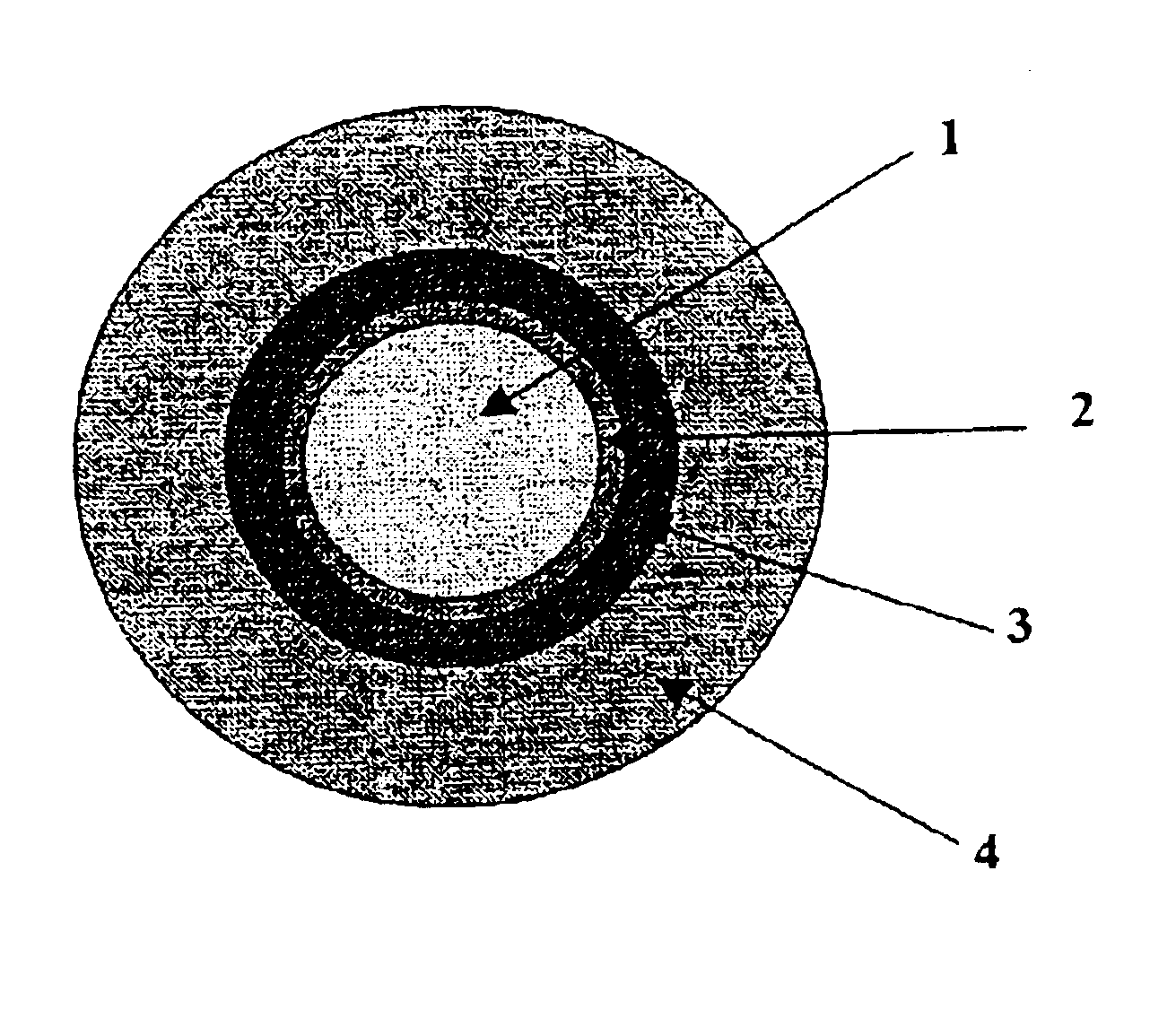

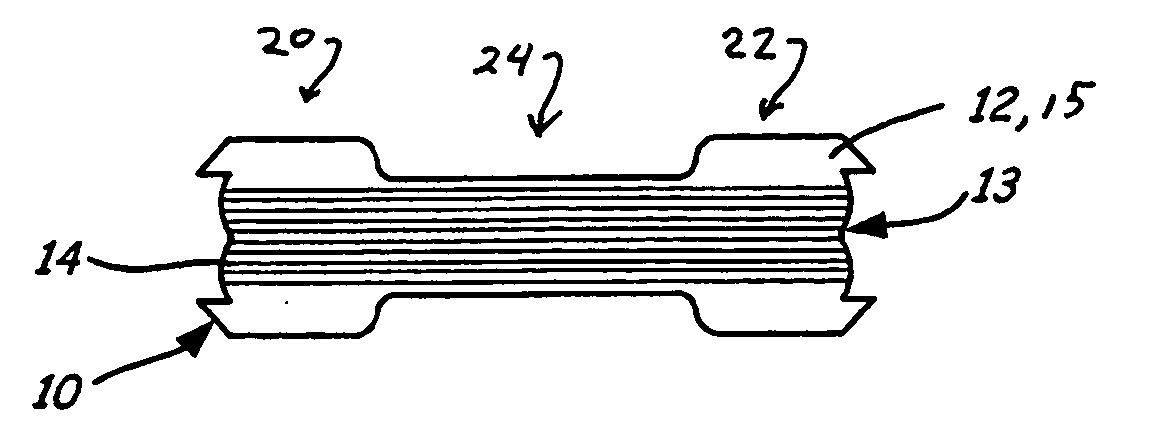

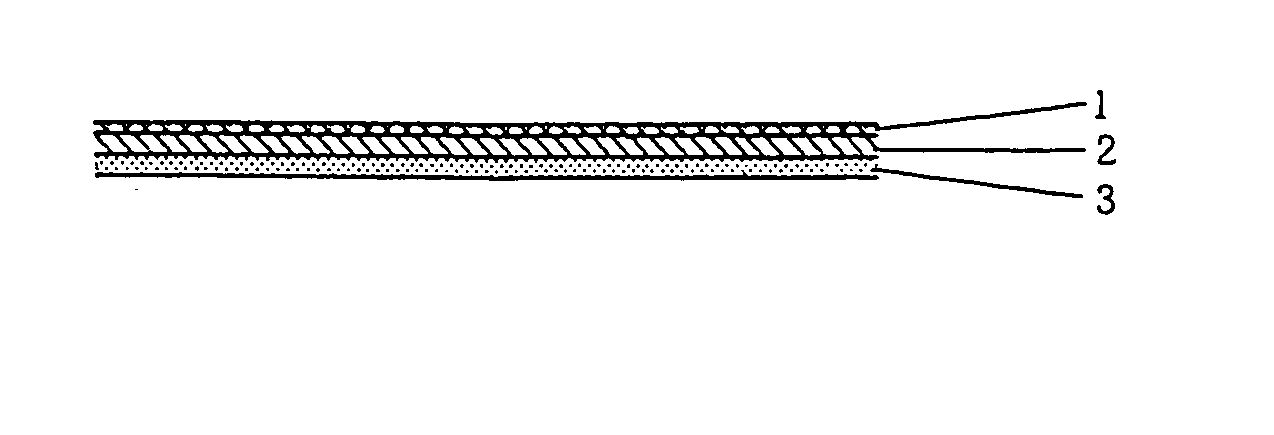

Polymeric optical conductors

InactiveUS6766091B2Glass optical fibreOptical fibre with graded refractive index core/claddingFiberZero shear viscosity

An optical cable, which is flame-retardant, and has excellent adhesion of the protective covering to the fiber cladding and uniform thickness of the fiber cladding, contains a polymer optical conductor containing a fiber core; a single-layer or multi-layer fiber cladding; an inner external layer which adheres to the fiber cladding with a peel force of at least 50 N; and an outer external layer which adheres to the inner external layer with a peel force of not more than 30 N. The inner external layer contains a molding composition having a first polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, and f) mixtures thereof. The first polyamide contains at least 50 mueq / g of amino end groups. The first molding composition has a zero-shear viscosity of from 400 to 6000 Pas. The outer external layer contains a second molding composition which has the following i)-iii): i) from 20 to 95% by weight of a second polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, f) a polyetheramide of at least one of a)-e), and g) mixtures thereof, ii) from 5 to 45% by weight of a flame retardant, and iii) from 0 to 60% by weight of an impact modifier.

Owner:EVONIK DEGUSSA GMBH

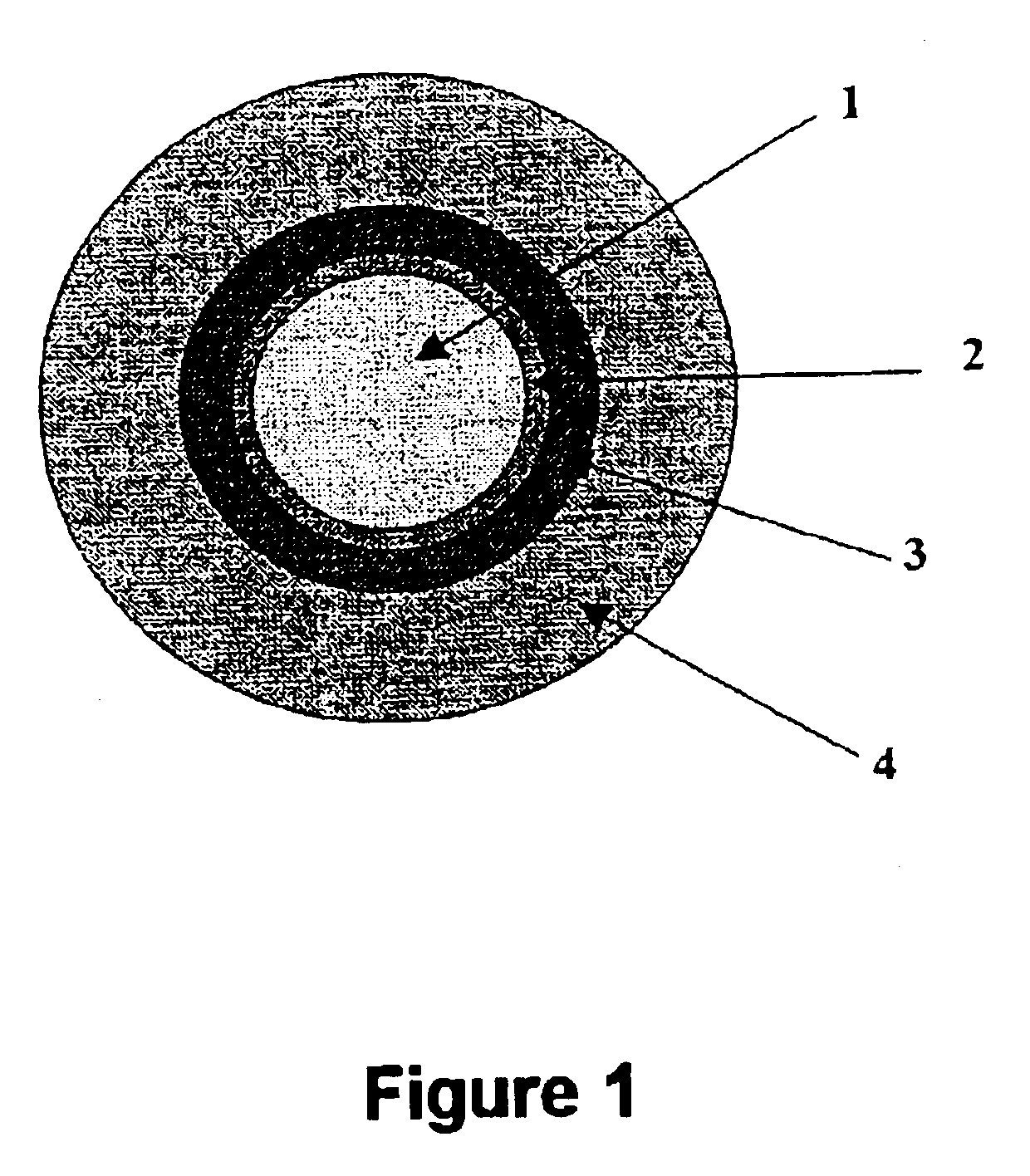

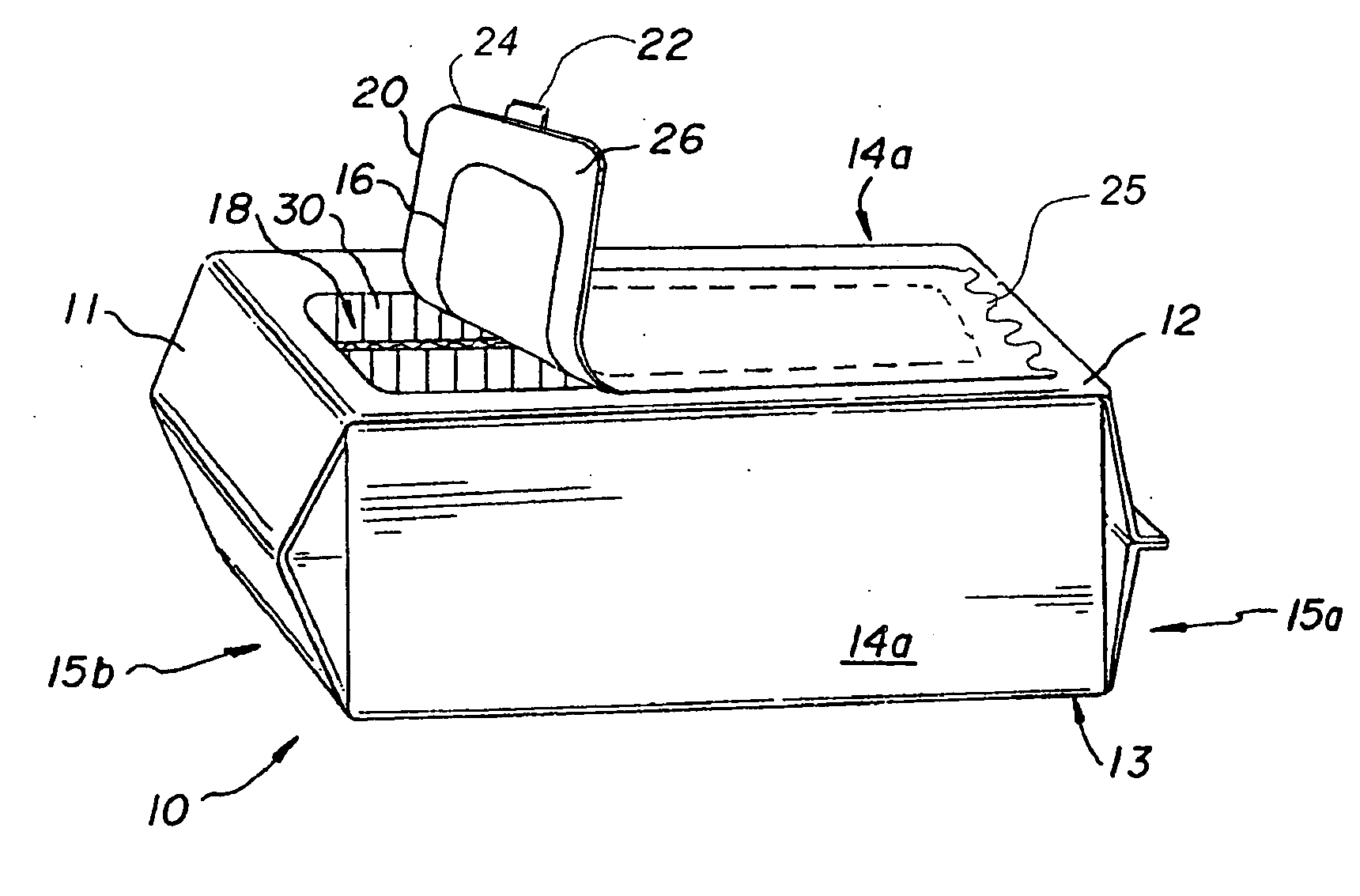

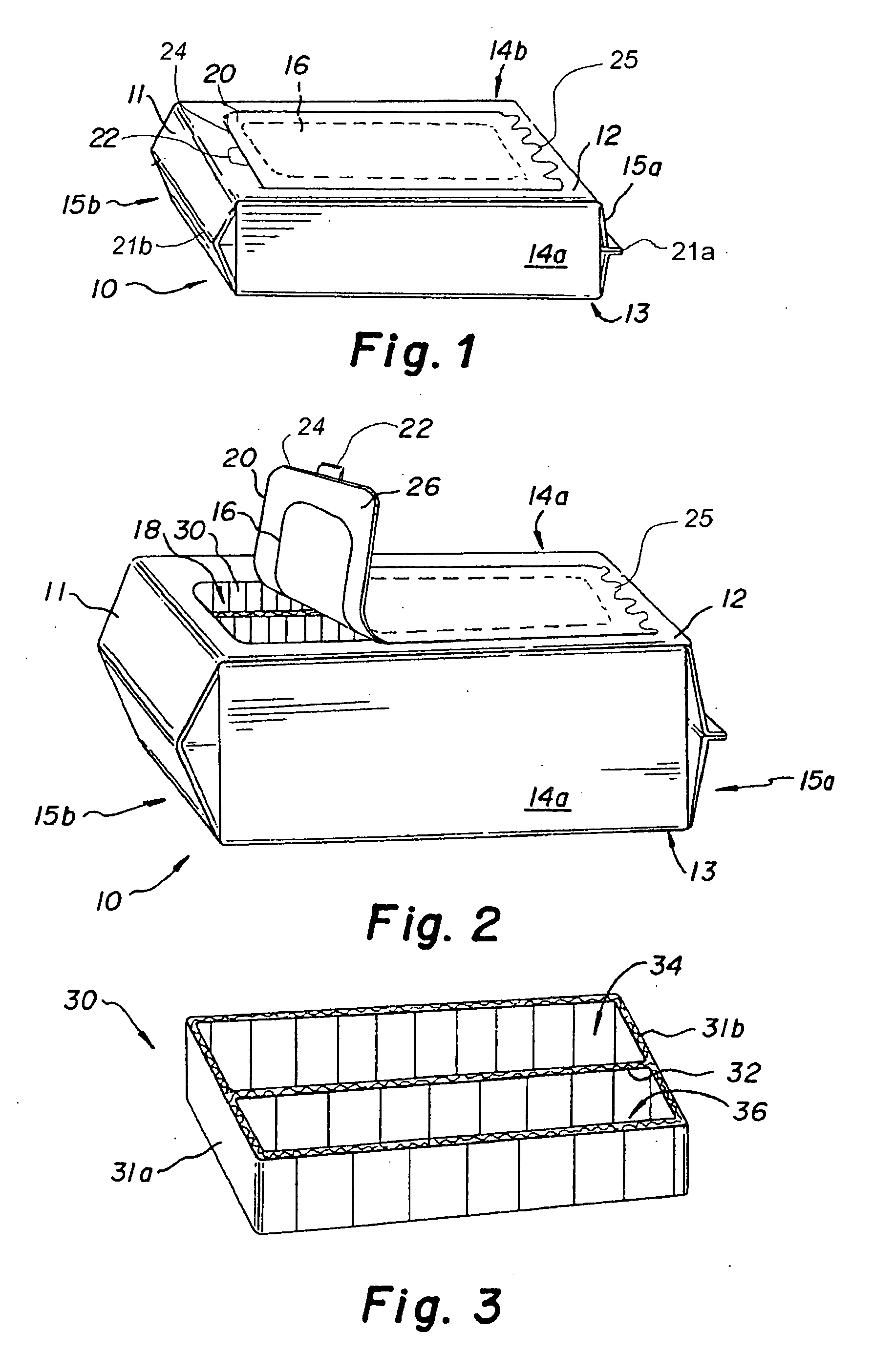

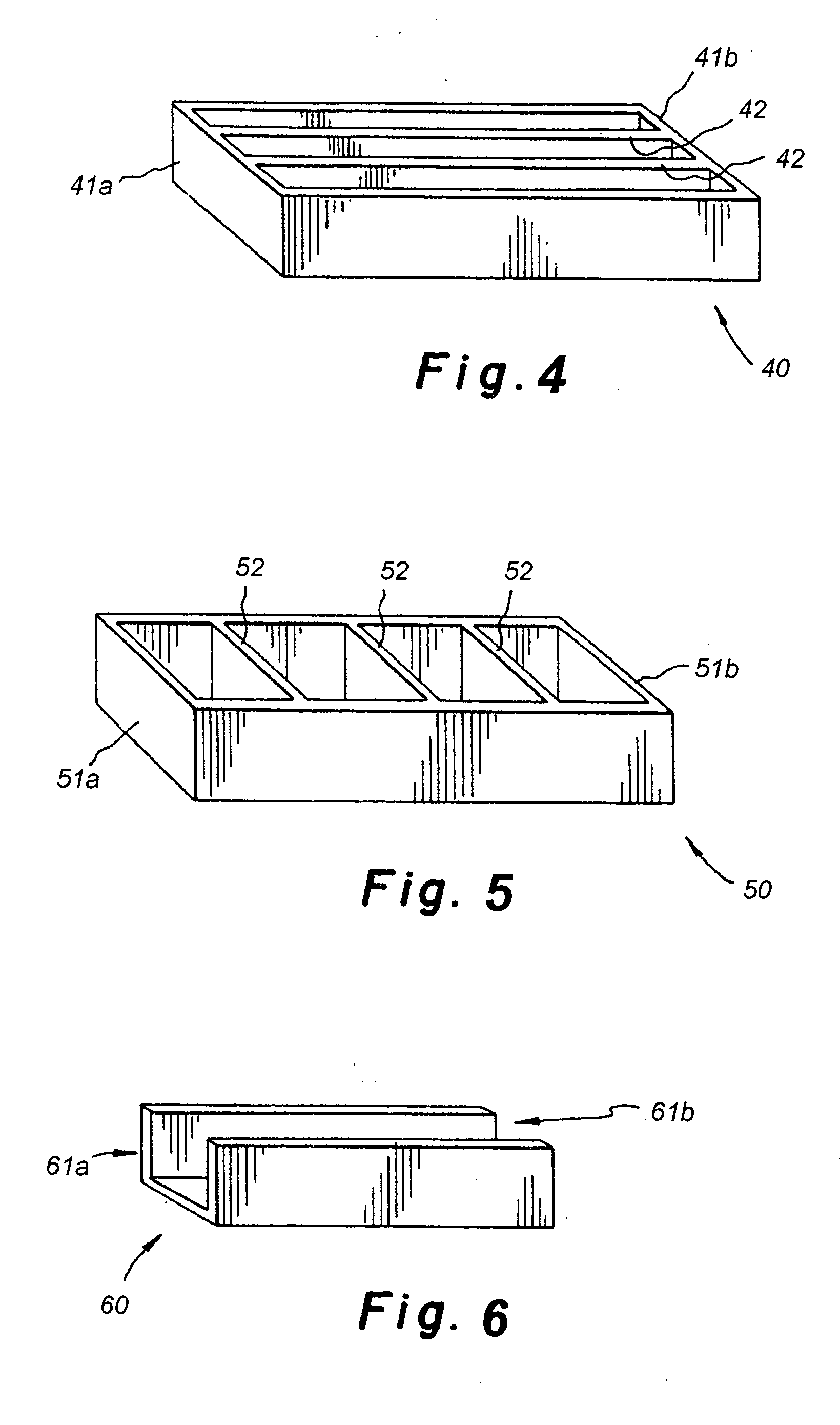

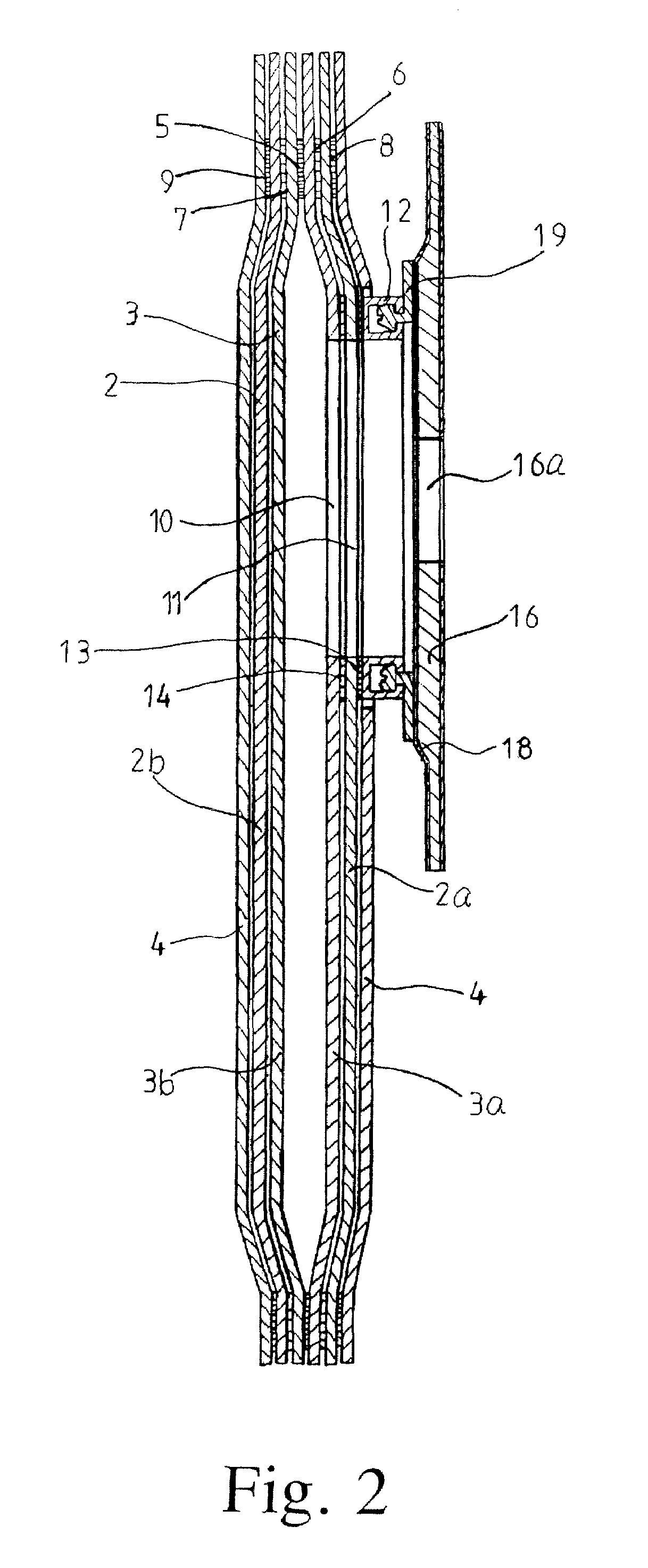

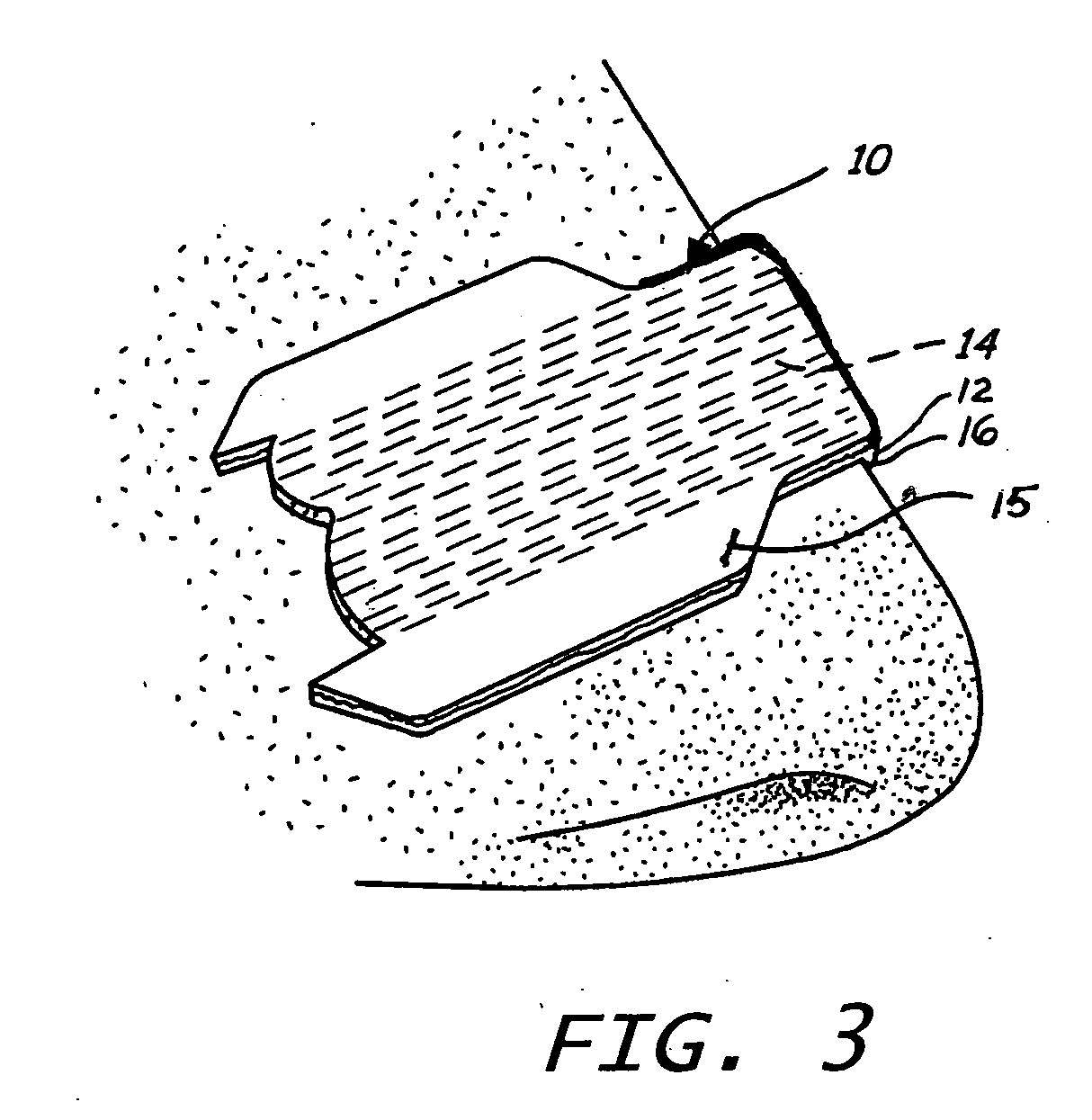

Resealable food container

InactiveUS7350688B2Reduce noiseIncrease surface areaReady-for-oven doughsFlexible coversLow noiseEngineering

A container for a food product includes a wrapper which surrounds a frame. The container can be any polygonal shape which is defined by the shape of the frame. The wrapper forms a top of the container which has an access opening. A sealing cover is adhesively sealed to the top around the opening. The sealing cover is operable to expose the access opening and reclosable against the top to seal the access opening. The sealing cover, adhesive and top surface are optimized to provide sealing characteristics of sufficiently resealing frequency, relatively low noise level during unsealing and desirable peel forces to separate the seal between the sealing cover and the top.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

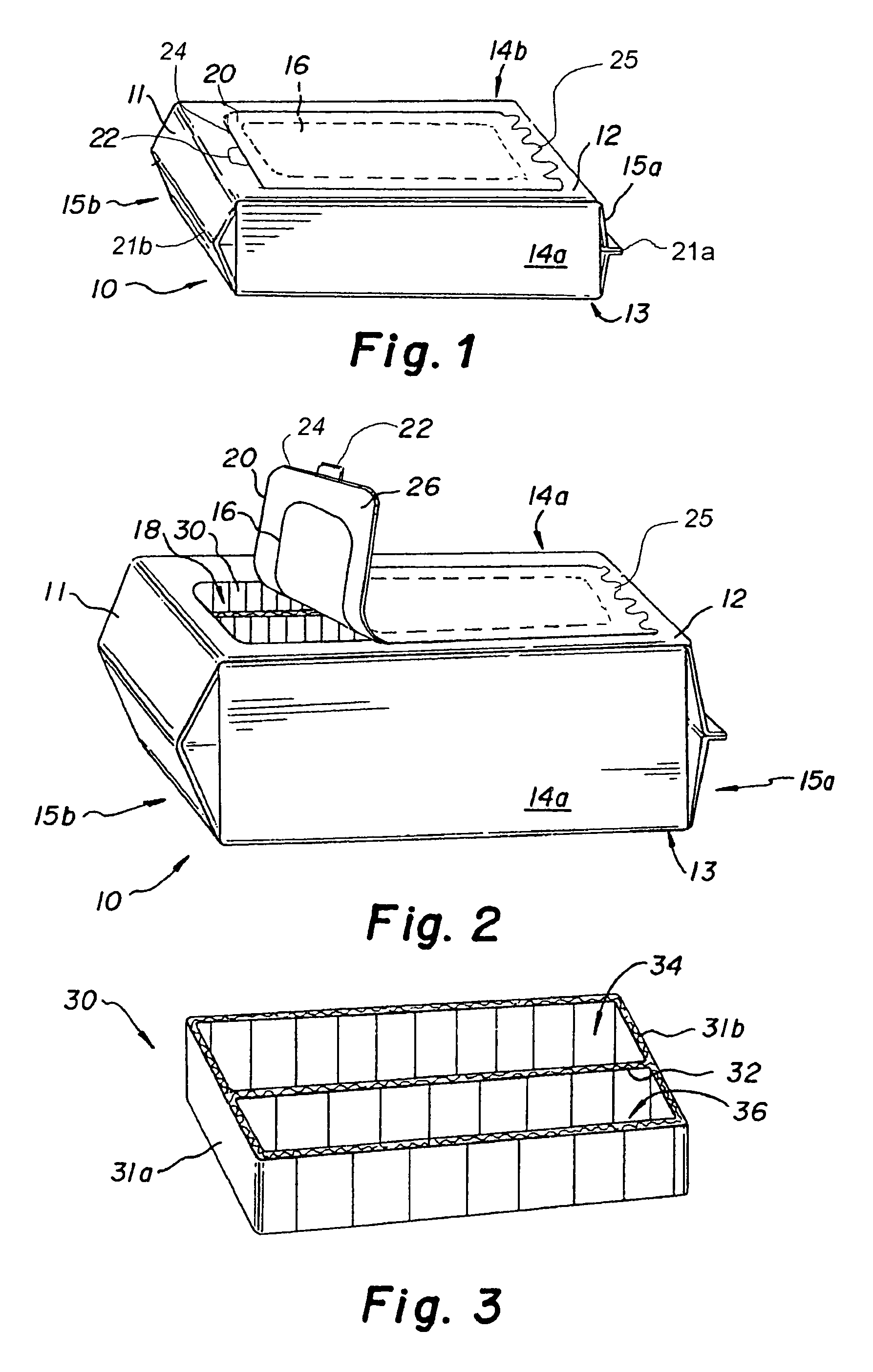

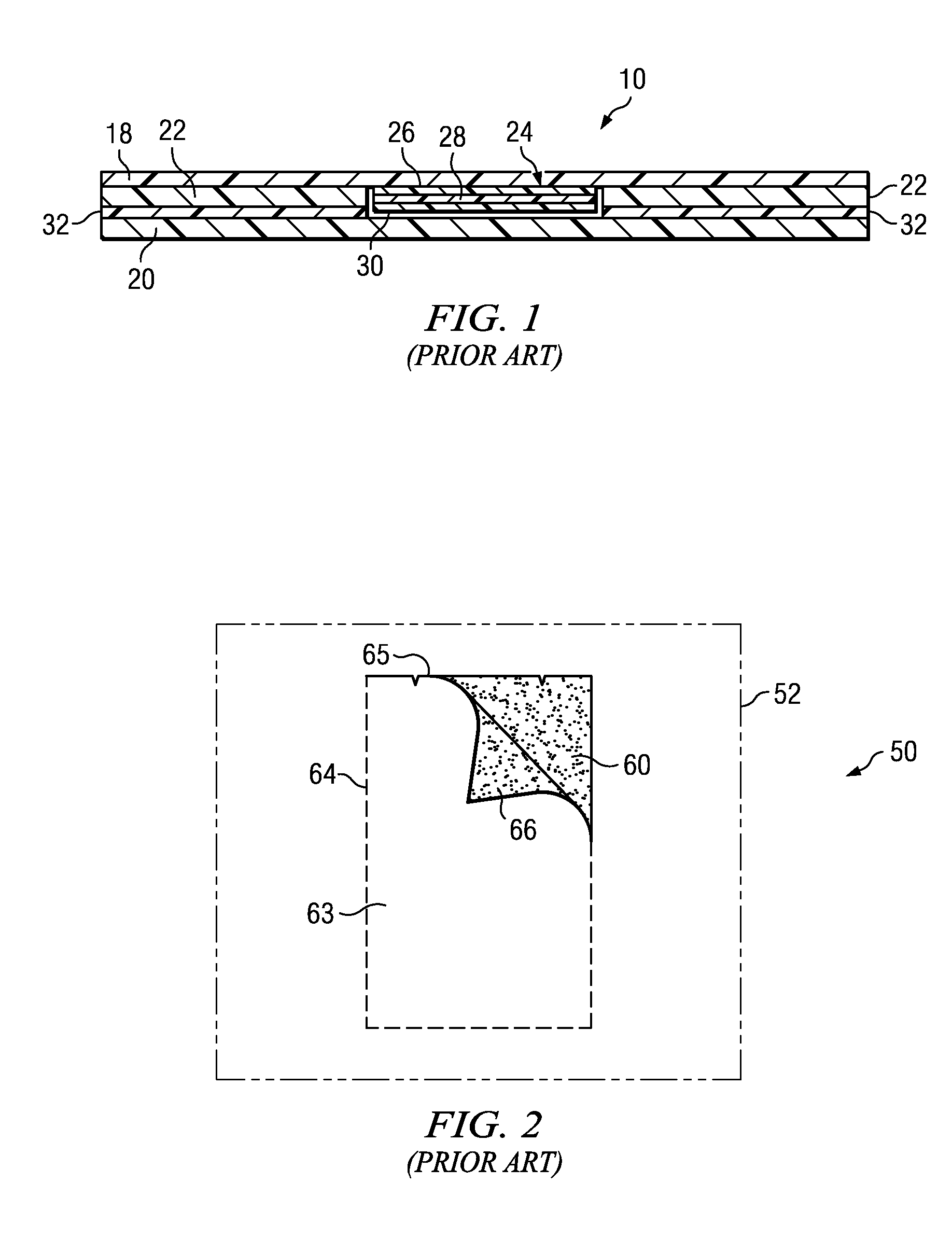

Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

ActiveCN101542777AAvoid separationPrevent electrical short circuitSolid electrolytesLi-accumulatorsPorous substratePolyolefin

Owner:LG ENERGY SOLUTION LTD +1

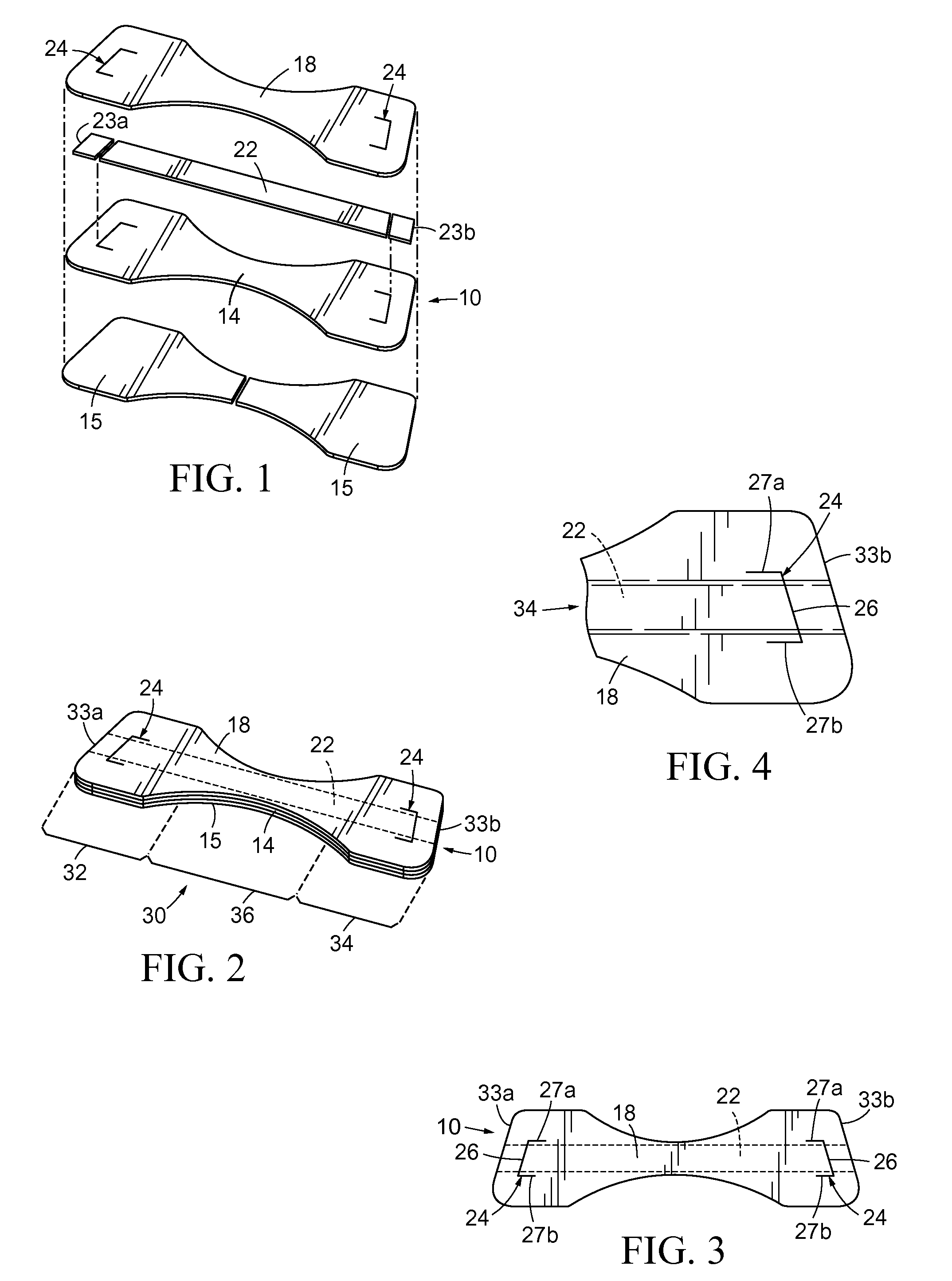

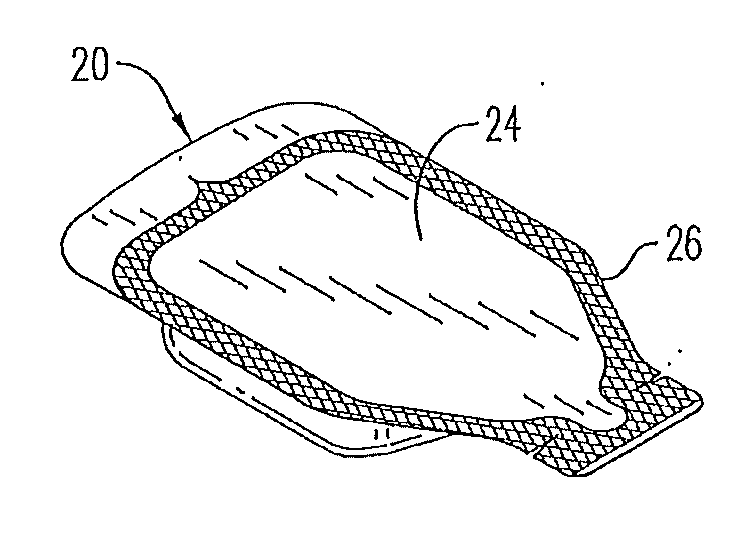

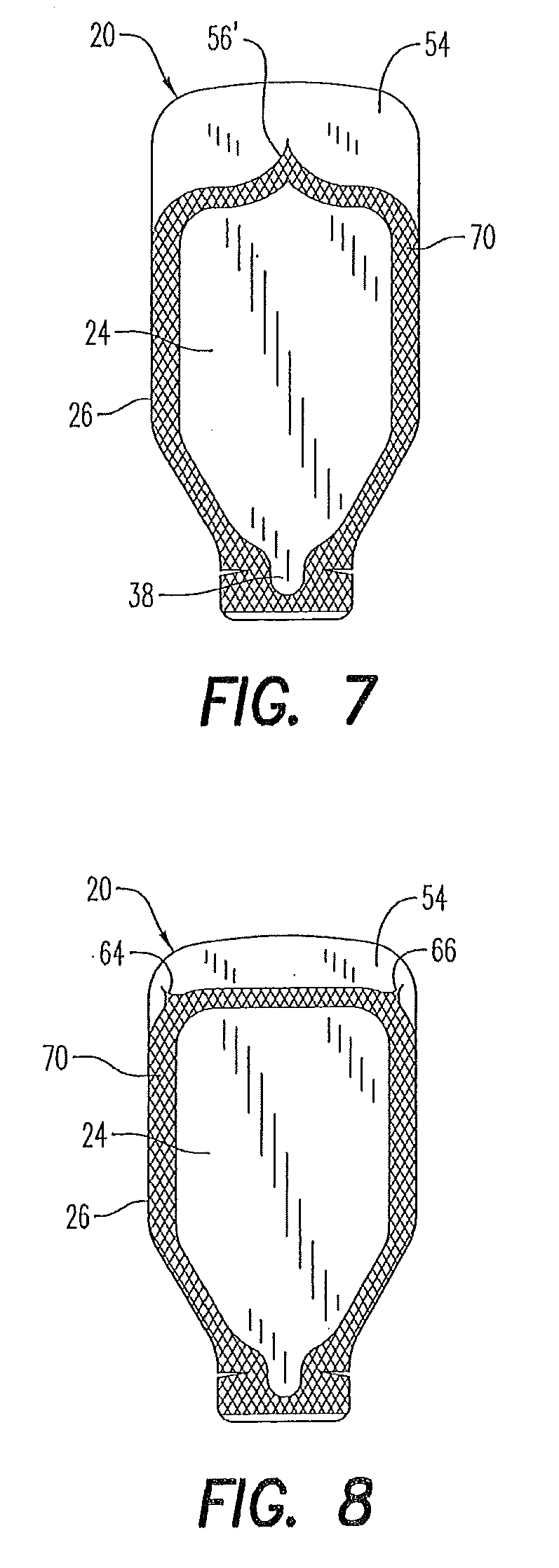

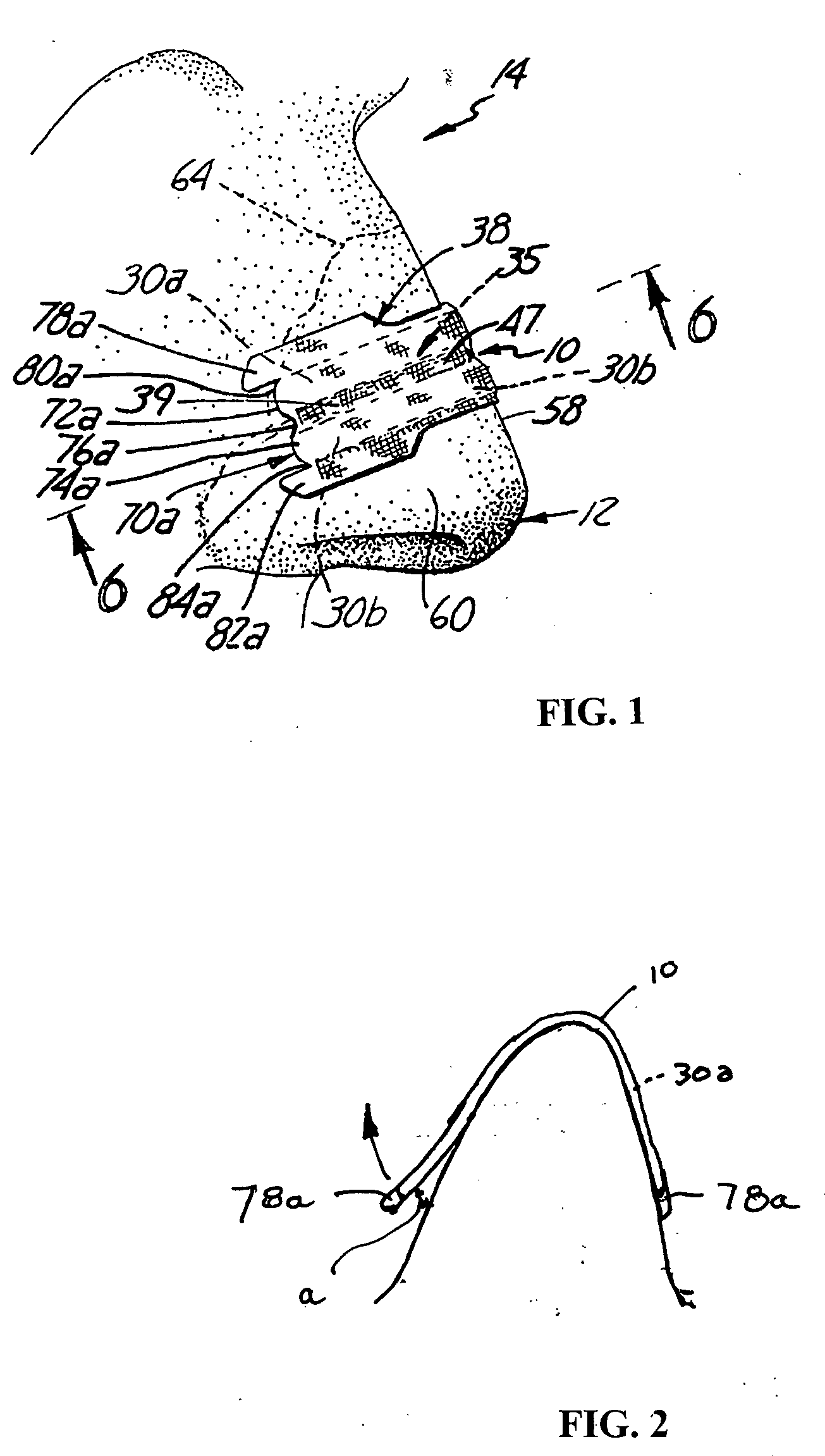

Nasal dilator with means to direct resilient properties

ActiveUS8062329B2Great delaminating tendencyReduce forceRespiratorsBreathing masksNasal passageNasal passages

A nasal dilator comprises a laminate of vertical layers each consisting of one or more members or components. The laminated layers form a unitary, or single body, truss featuring horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. When in use the dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. The dilator includes means to direct its resilient properties comprising one or more interior or exterior material separations, or discontinuity of shape of material, formed in at least one region of the truss and extending through at least one layer of the dilator. Said material separation or discontinuity of shape may comprise an opening, relief cut, slit or notch, and which may be configured to separate or vertically protrude, in part, from the truss when the dilator is in use on the nose of a wearer. Said separation or vertical protrusion changes the angle of focused delaminating spring biasing forces generated by the resilient layer, transforming said forces, at least in part, from primarily peel forces into primarily shear forces, and further redistributing or imparting said transformed forces to tissue engaging surface areas extending outward and beyond said material separation.

Owner:HORIZON IP TECH LLC

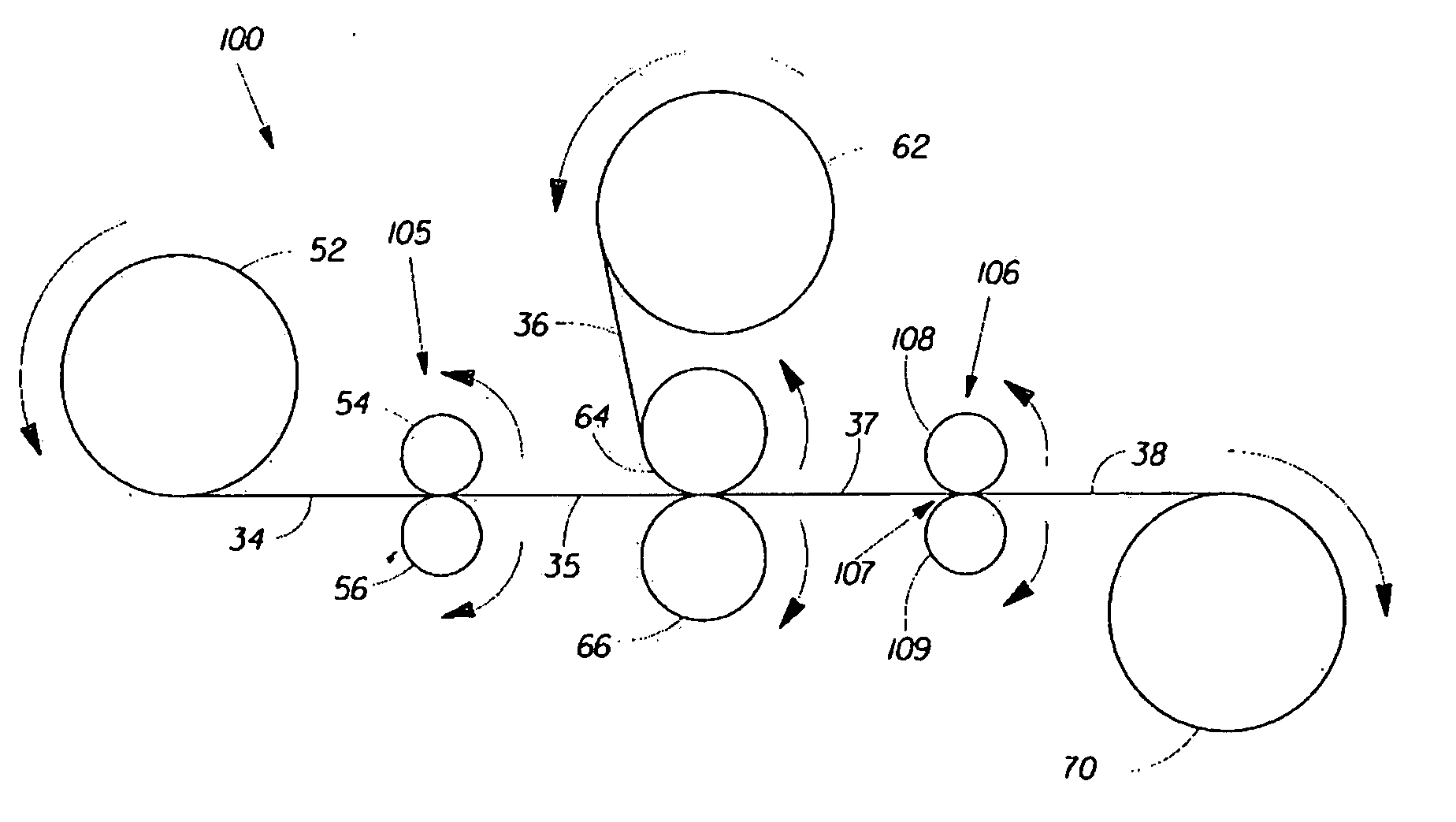

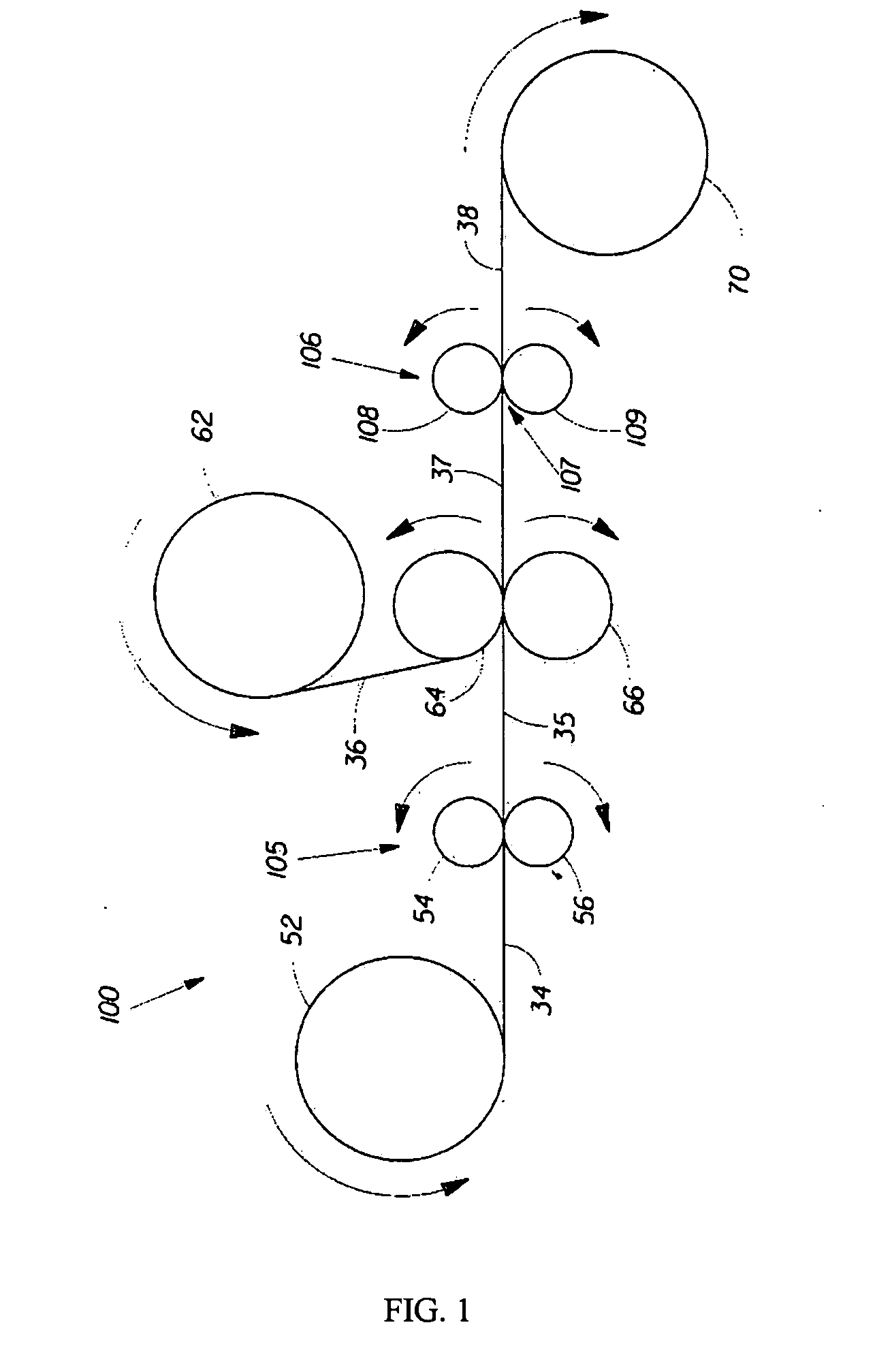

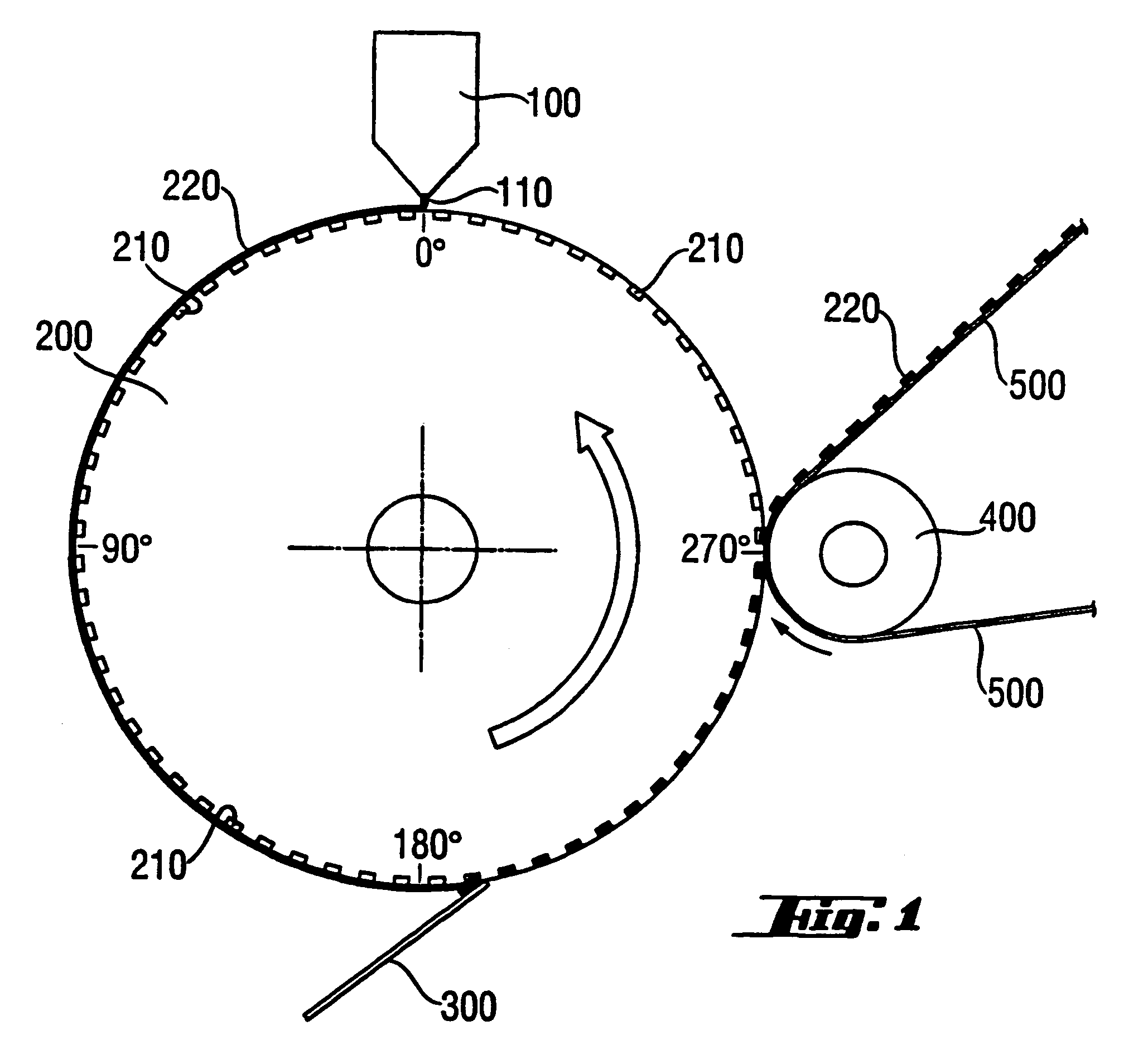

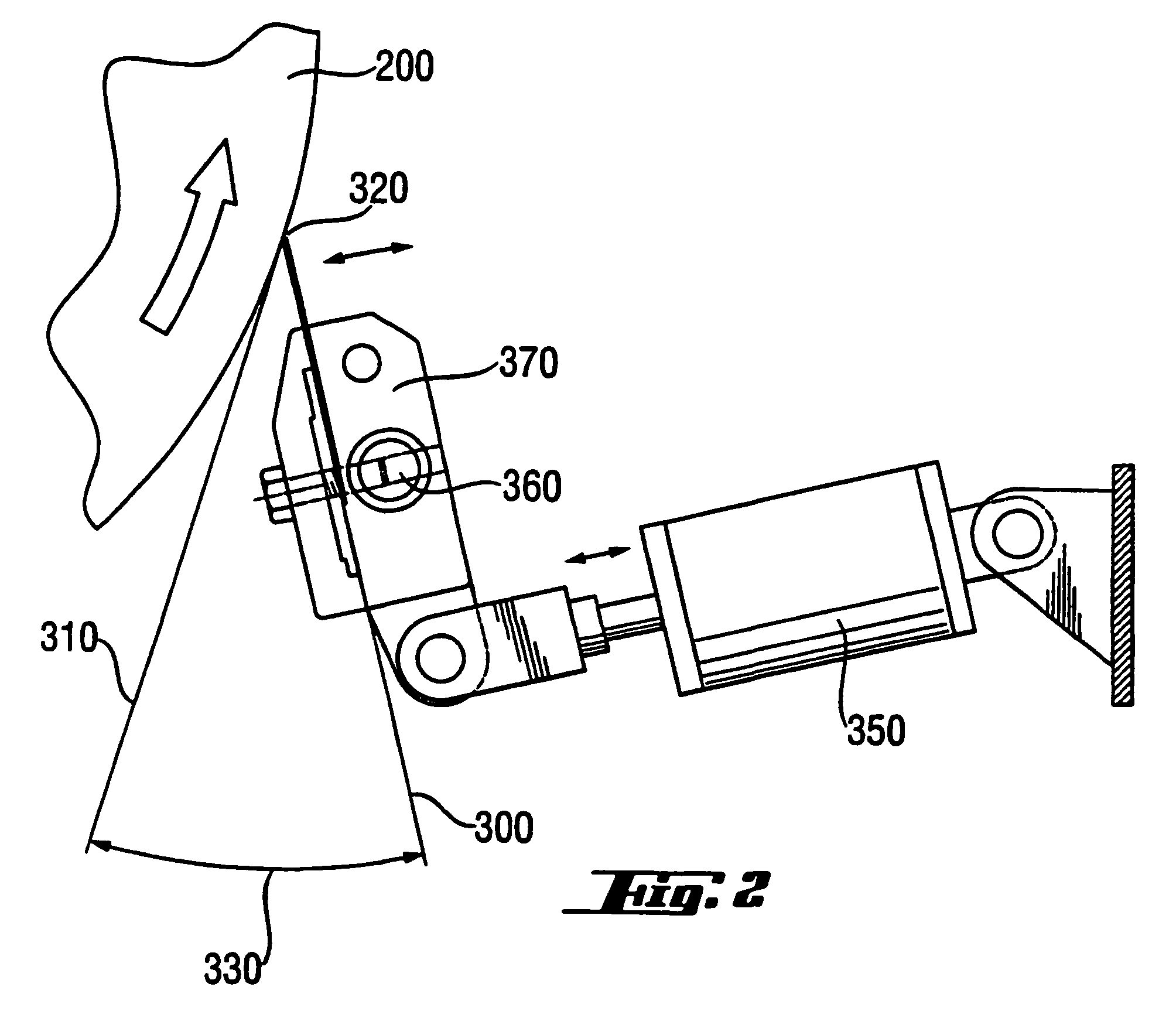

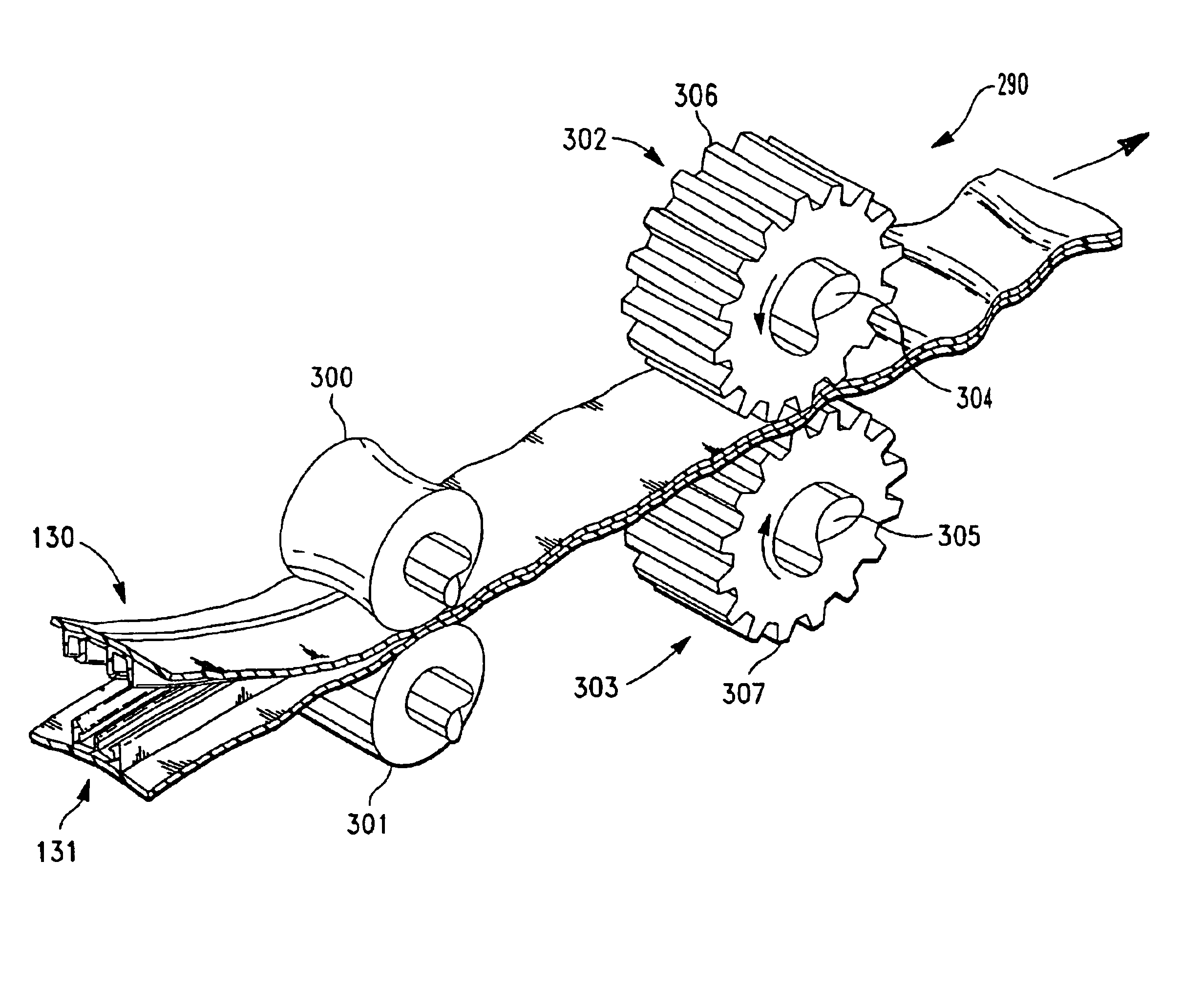

Method of gravure printing elastomeric compositions

The present invention relates to a process of manufacturing a stretch composite, said method comprising: a) providing a first substrate in a machine direction, wherein said substrate has opposing first and second surfaces; b) providing a gravure printing roll having an exterior surface that comprises one or more cells wherein at least a portion of the surface is relatively cool; c) depositing a molten, non-adhesive, elastomeric composition onto the exterior surface of the gravure printing device which comprises a gravure printing roll, wherein said composition is characterized as having a peel force of less than about 3 N / cm; d) causing said composition to be pushed into said cells; and e) contacting said first surface of said substrate with said gravure printing roll and substantially completely transferring said elastomeric composition from said cells of said exterior surface on said gravure printing roll to said first surface; wherein said process is substantially free of tackifier.

Owner:THE PROCTER & GAMBLE COMPANY

Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

ActiveUS20090111026A1Prevent extractionImprove electrochemical stabilitySolid electrolytesLi-accumulatorsPorous substratePolyolefin

An organic / inorganic composite separator includes (a) a polyolefin porous substrate having pores; and (b) a porous active layer containing a mixture of inorganic particles and a binder polymer, with which at least one surface of the polyolefin porous substrate is coated, wherein the porous active layer has a peeling force of 5 gf / cm or above, and a thermal shrinkage of the separator after being left alone at 150° C. for 1 hour is 50% or below in a machine direction (MD) or in a transverse direction (TD). This organic / inorganic composite separator solves the problem that inorganic particles in the porous active layer formed on the porous substrate are extracted during an assembly process of an electrochemical device, and also it may prevent an electric short circuit between cathode and anode even when the electrochemical device is overheated.

Owner:TORAY BATTERY SEPARATOR FILM +1

Resealable food container

InactiveUS20060144911A1Reduce noiseIncrease surface areaReady-for-oven doughsFlexible coversLow noiseEngineering

A container for a food product includes a wrapper which surrounds a frame. The container can be any polygonal shape which is defined by the shape of the frame. The wrapper forms a top of the container which has an access opening. A sealing cover is adhesively sealed to the top around the opening. The sealing cover is operable to expose the access opening and reclosable against the top to seal the access opening. The sealing cover, adhesive and top surface are optimized to provide sealing characteristics of sufficiently resealing frequency, relatively low noise level during unsealing and desirable peel forces to separate the seal between the sealing cover and the top.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Process for printing adhesives, adhesive articles and printing equipment

The present invention relates to a process for printing specific adhesives onto articles, such as absorbent articles or release paper, using a specific transfer tool and / or a specific adhesive, having a specific peel force, viscosity, elastic loss modulus, elastic modulus, surface energy and loss tangent modulus; the invention also relates to articles comprising the specific adhesives and to specific printing rolls.

Owner:THE PROCTER & GAMBLE COMPANY

Multi-layer flexible package with removable section

InactiveUS7686513B2Easy to disassembleContainer decorationsLevel indicationsThin membraneEngineering

A flexible container with a wall structure comprised of multi-layer, flexible thin films, including a first film layer that is affixed to the wall structure by a releasable adherence and that incorporates a removable piece. The removable piece is incorporated into the first film layer such that, other than at least one continuous cut facilitating removal and any conspicuous printing on the removable portion, it is indistinguishable from the rest of the exterior of the package. The continuous cut allows for full or partial detachment of the removable portion from the first film layer so that only the releasable adherence prevents it from separating from the container. The removable piece is removed by peeling it away from the container, where the initiation of the peeling is facilitated by a smaller peel force adjacent the continuous cut. The removable piece may function as a promotional or collectible piece such as a gaming piece or redeemable coupon, or may be designed to retain a tacky surface and function as a sticker or as a piece of tape to close an opened bag. The removable piece can also expose a tacky surface on the container to permit closure of the opened bag.

Owner:FRITO LAY NORTH AMERICA INC

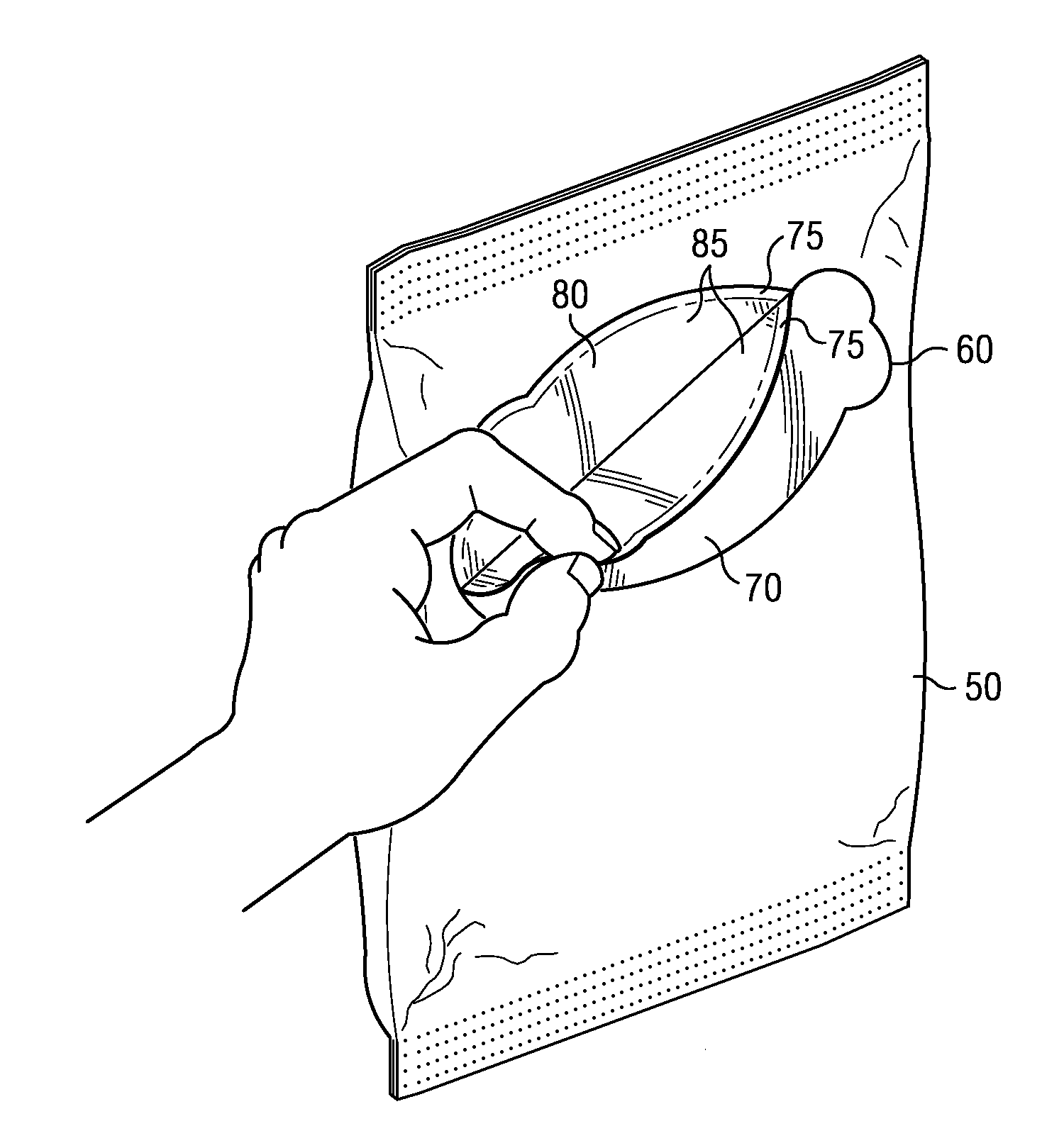

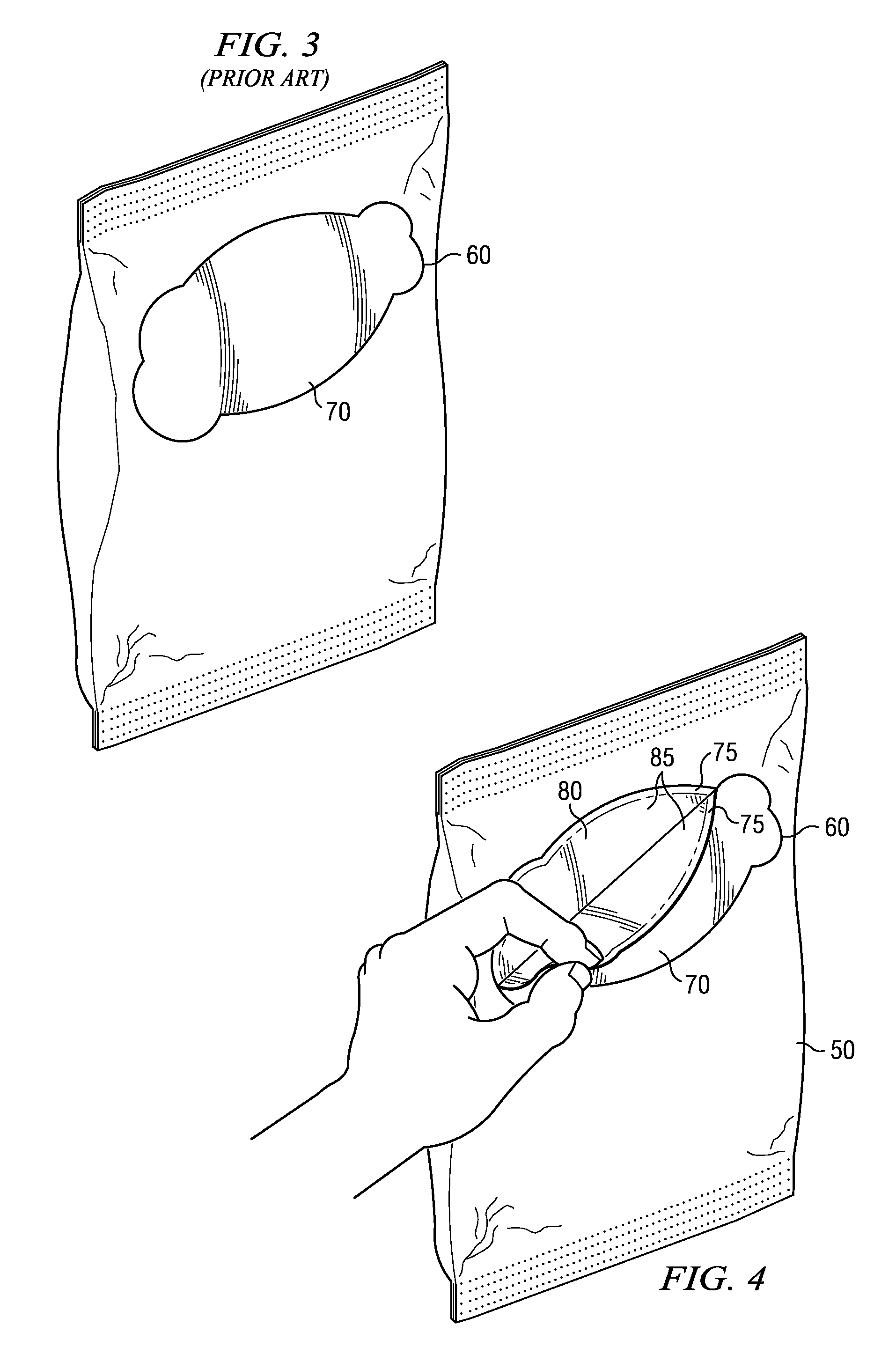

Peel-to-open packages

Improved peel-to-open packages including sachets, pouches, and the like are disclosed. The packages are made of substrate layers removably adhered together using an adhesive pattern of seal(s) that are characterized by peel forces. The adhesive pattern is designed to provide for controlled opening of the packages, in some embodiments to a predetermined stopping point, such that any product(s) contained therein are presented to the consumer for removal. Further design features include, but are not limited to, offset tabs, textures, color variations and text, which may further provide for easy, intuitive opening.

Owner:THE PROCTER & GAMBLE COMPANY

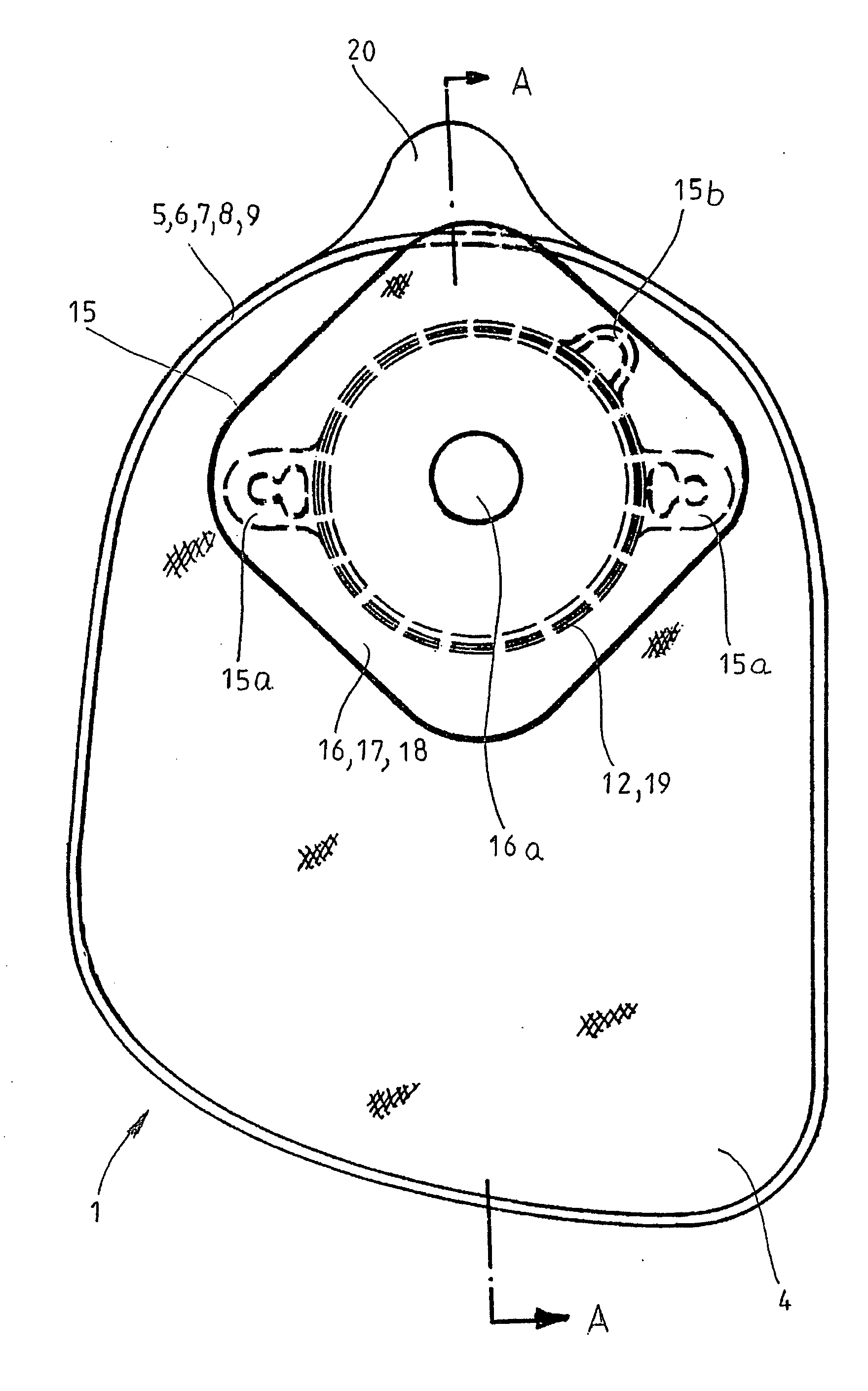

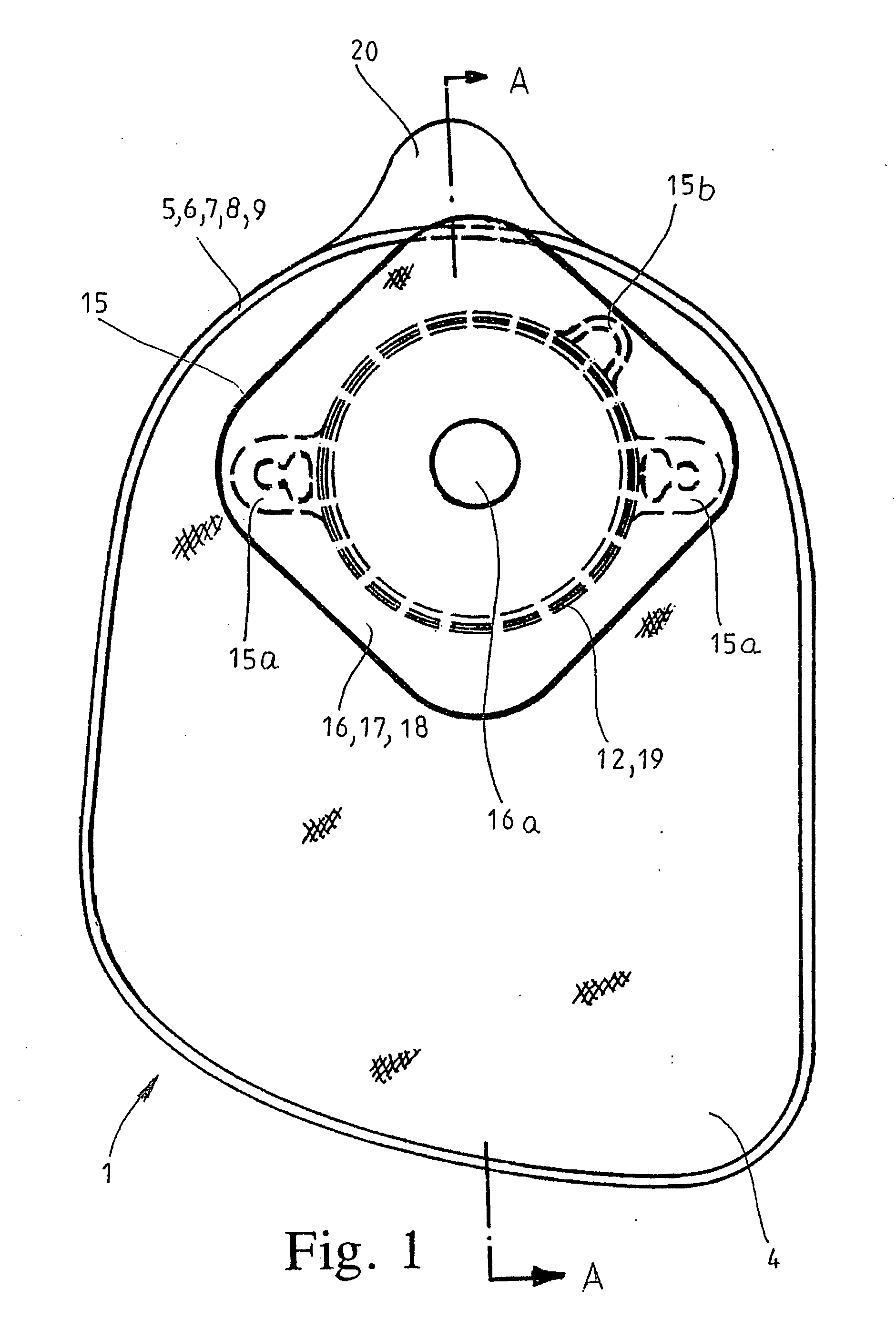

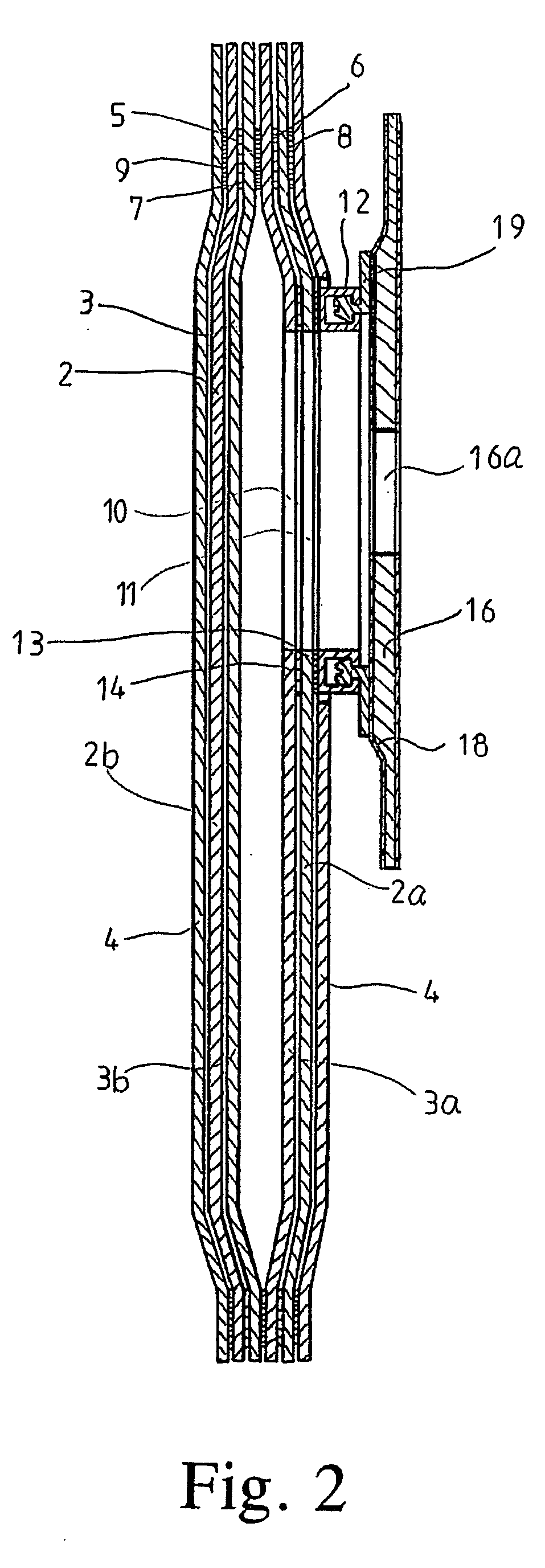

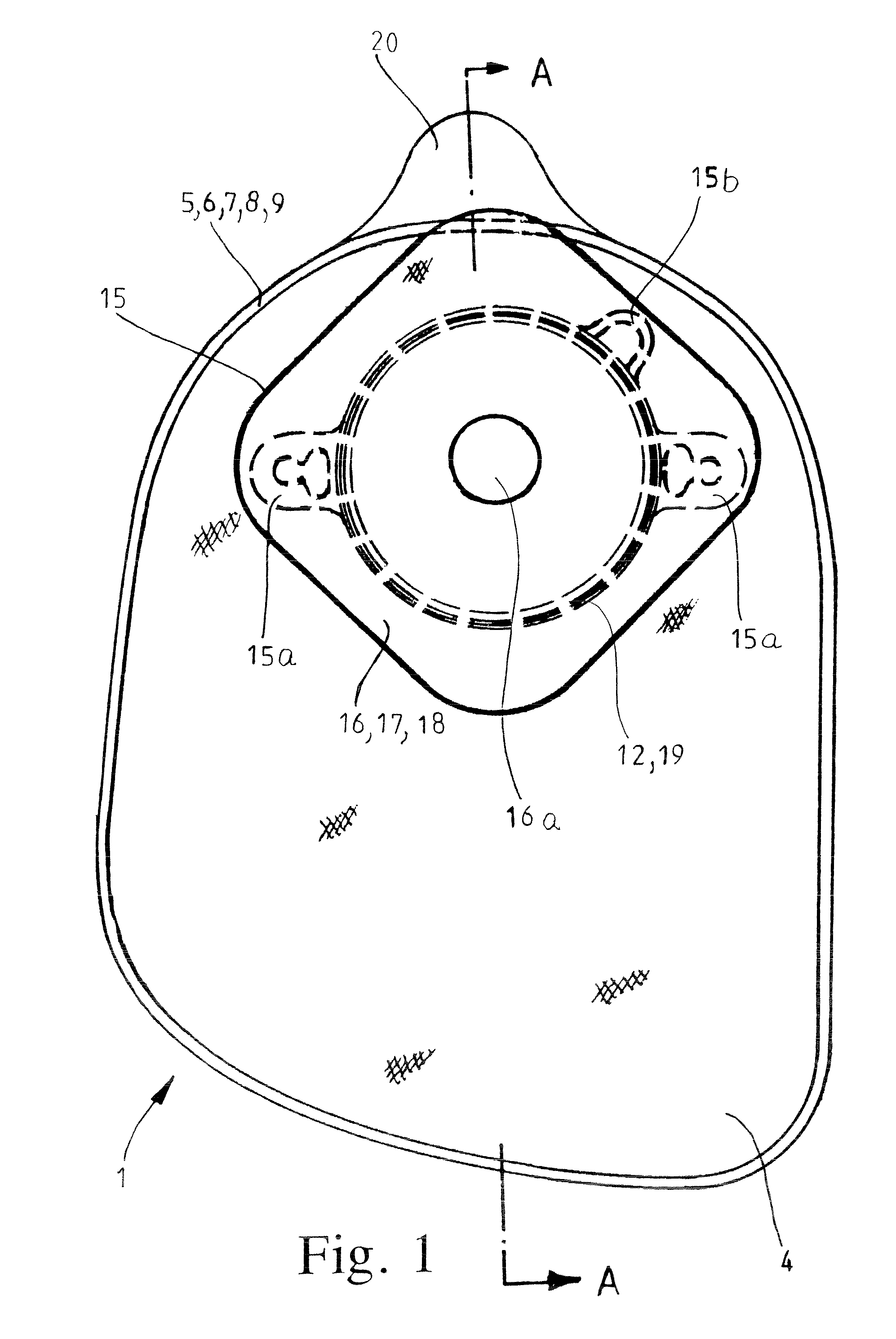

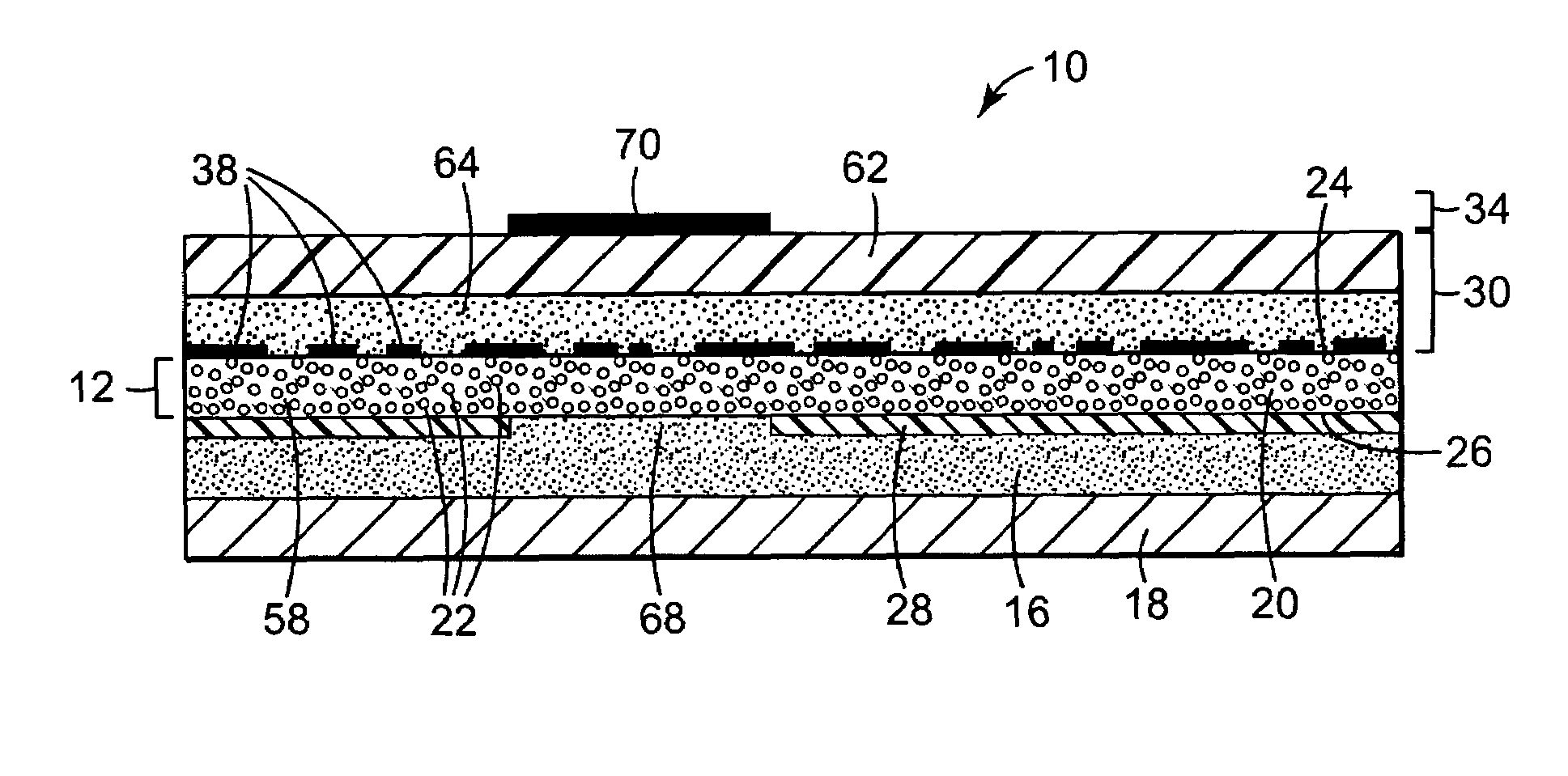

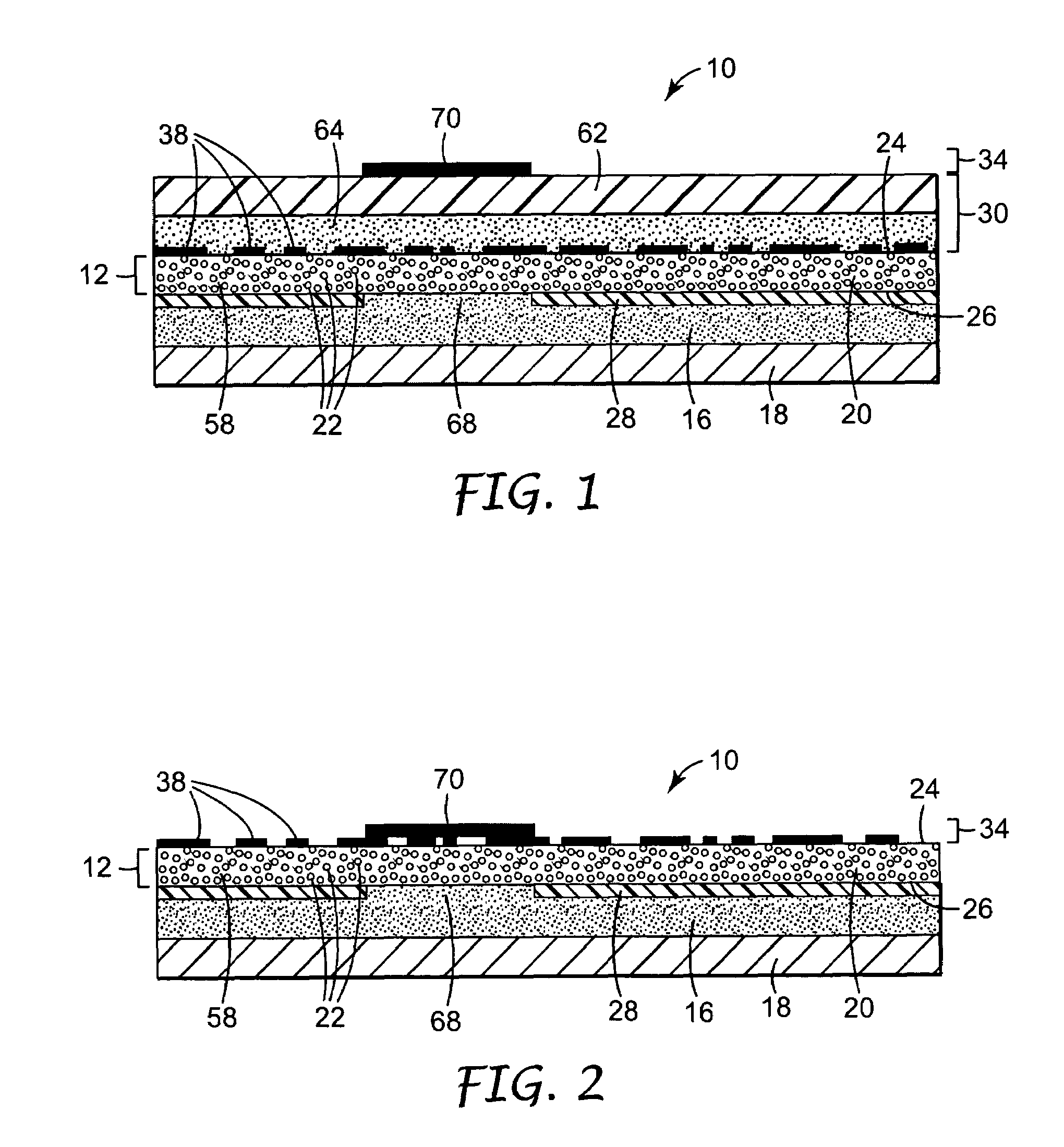

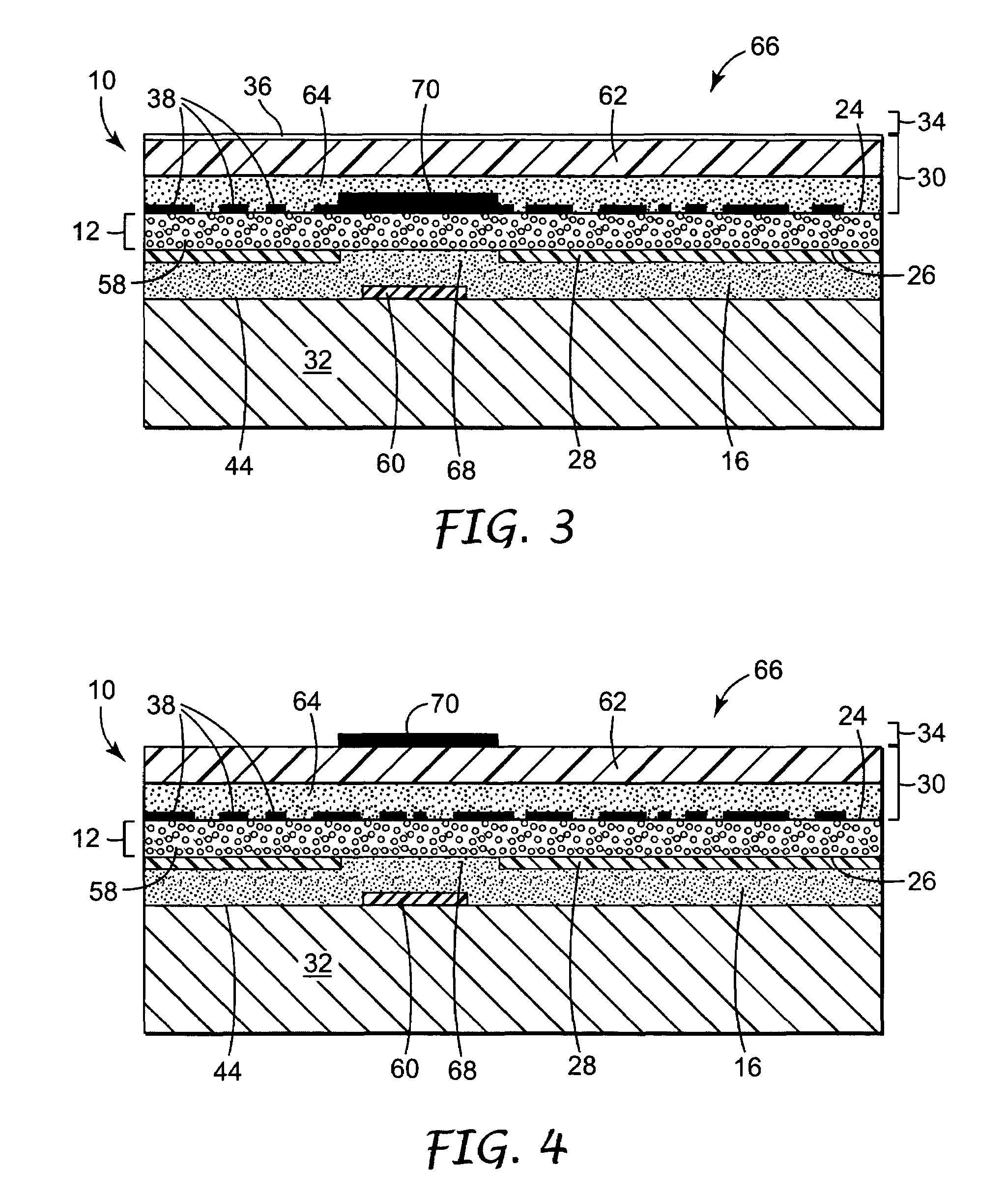

Peelable and flushable ostomy pouch and method of use

ActiveUS20050113770A1Prevents wickingNeat and uniform peelingSynthetic resin layered productsMedical devicesPeel forceSurgery

An ostomy appliance having a face plate assembly and inner and outer pouches joined thereto, has its outer pouch provided with one or more peripherally-extending sealing seams that allow the walls of the outer pouch to be separated by peeling forces applied in directions transverse to such seam or seams. In preferred embodiments, the sealing seam, also peelably join the peripheral edges of the outer pouch to those of the inner pouch. A method of disposing of the pouch assembly of such an ostomy appliance is also disclosed.

Owner:HOLLISTER INCORPORAED

Polymeric optical conductors

InactiveUS20040001682A1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingFiberZero shear viscosity

An optical cable, which is flame-retardant, and has excellent adhesion of the protective covering to the fiber cladding and uniform thickness of the fiber cladding, contains a polymer optical conductor containing a fiber core; a single-layer or multi-layer fiber cladding; an inner external layer which adheres to the fiber cladding with a peel force of at least 50 N; and an outer external layer which adheres to the inner external layer with a peel force of not more than 30 N. The inner external layer contains a molding composition having a first polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, and f) mixtures thereof. The first polyamide contains at least 50 mueq / g of amino end groups. The first molding composition has a zero-shear viscosity of from 400 to 6000 Pas. The outer external layer contains a second molding composition which has the following i)-iii): i) from 20 to 95% by weight of a second polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, f) a polyetheramide of at least one of a)-e), and g) mixtures thereof, ii) from 5 to 45% by weight of a flame retardant, and iii) from 0 to 60% by weight of an impact modifier.

Owner:EVONIK DEGUSSA GMBH

Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

ActiveUS7709152B2Prevent extractionImprove electrochemical stabilitySolid electrolytesNon-aqueous electrolyte accumulator electrodesPorous substratePolyolefin

An organic / inorganic composite separator includes (a) a polyolefin porous substrate having pores; and (b) a porous active layer containing a mixture of inorganic particles and a binder polymer, with which at least one surface of the polyolefin porous substrate is coated, wherein the porous active layer has a peeling force of 5 gf / cm or above, and a thermal shrinkage of the separator after being left alone at 150° C. for 1 hour is 50% or below in a machine direction (MD) or in a transverse direction (TD). This organic / inorganic composite separator solves the problem that inorganic particles in the porous active layer formed on the porous substrate are extracted during an assembly process of an electrochemical device, and also it may prevent an electric short circuit between cathode and anode even when the electrochemical device is overheated.

Owner:TORAY BATTERY SEPARATOR FILM +1

Replaceable cleaning pads for cleaning device

A pad for cleaning a hard target surface. The pad may be removably attached to a device for cleaning debris from a target surface. The pad has a predetermined 90 degree peel force to prevent undue removal force from the device and prevent the pad from coming loose during the cleaning task.

Owner:PROCTER & GAMBLE CO

PRESSURE SENSITIVE ADHESIVE COMPOSITION (As Amended)

ActiveUS20120328800A1Improve wettabilityReduction in peel forceLiquid crystal compositionsEster polymer adhesivesPeel forcePressure sensitive

The present invention relates to a pressure sensitive adhesive composition. The present invention may effectively provide a pressure sensitive adhesive where peel forces for both sides are different and an modulus differs along the thickness direction. By applying the pressure sensitive adhesive as above, the present invention may provide, for example, an optical element, such as a polarizing plate, which can effectively inhibit light leakage and shows excellent durability, while being formed to have a thin thickness as well.

Owner:LG CHEM LTD

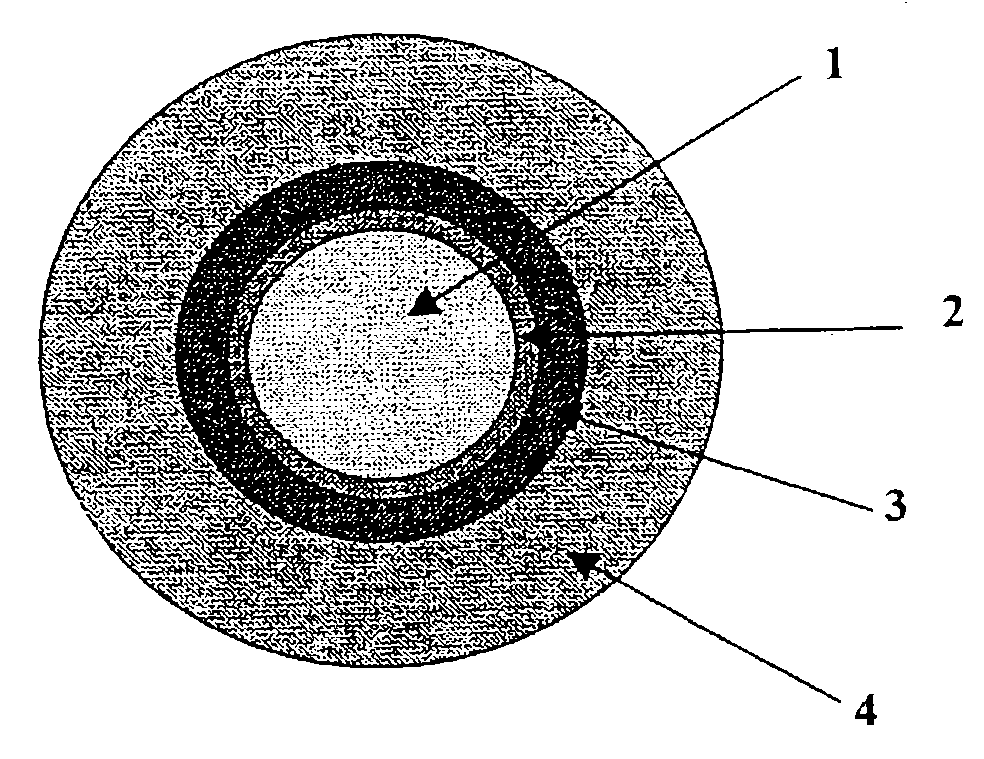

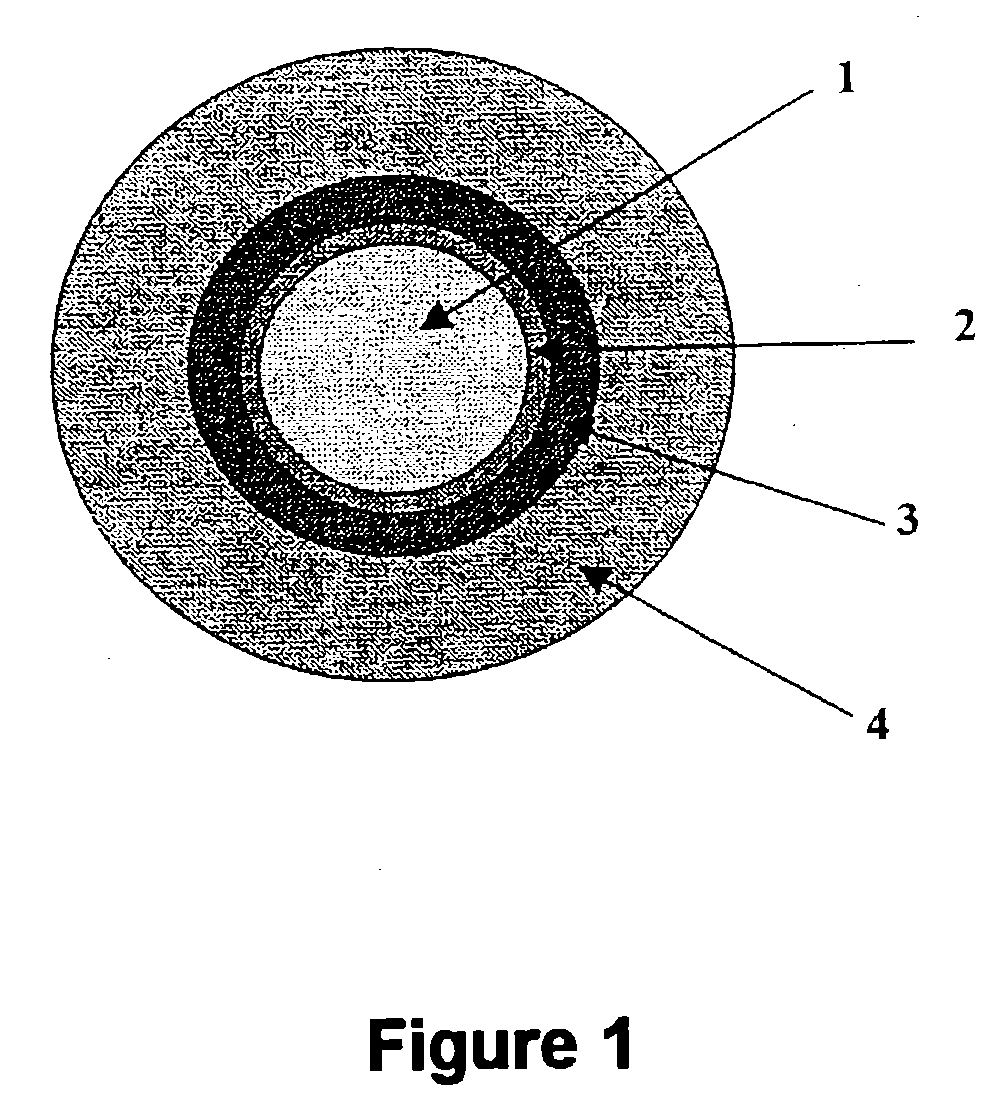

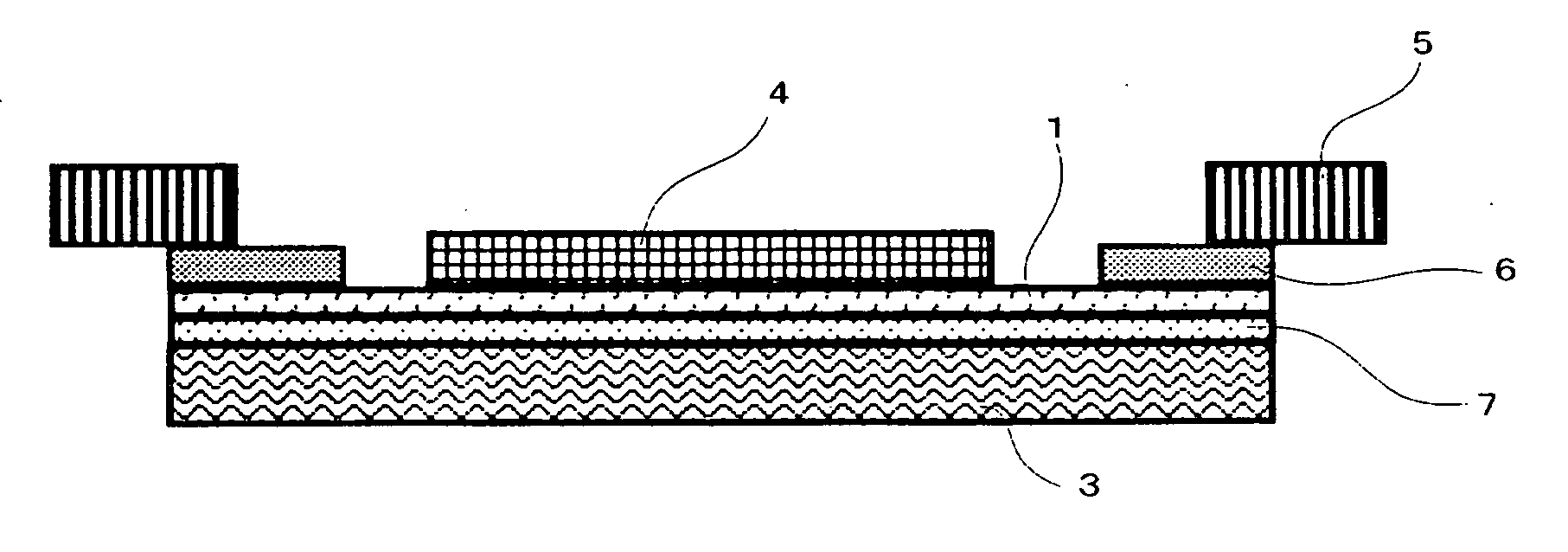

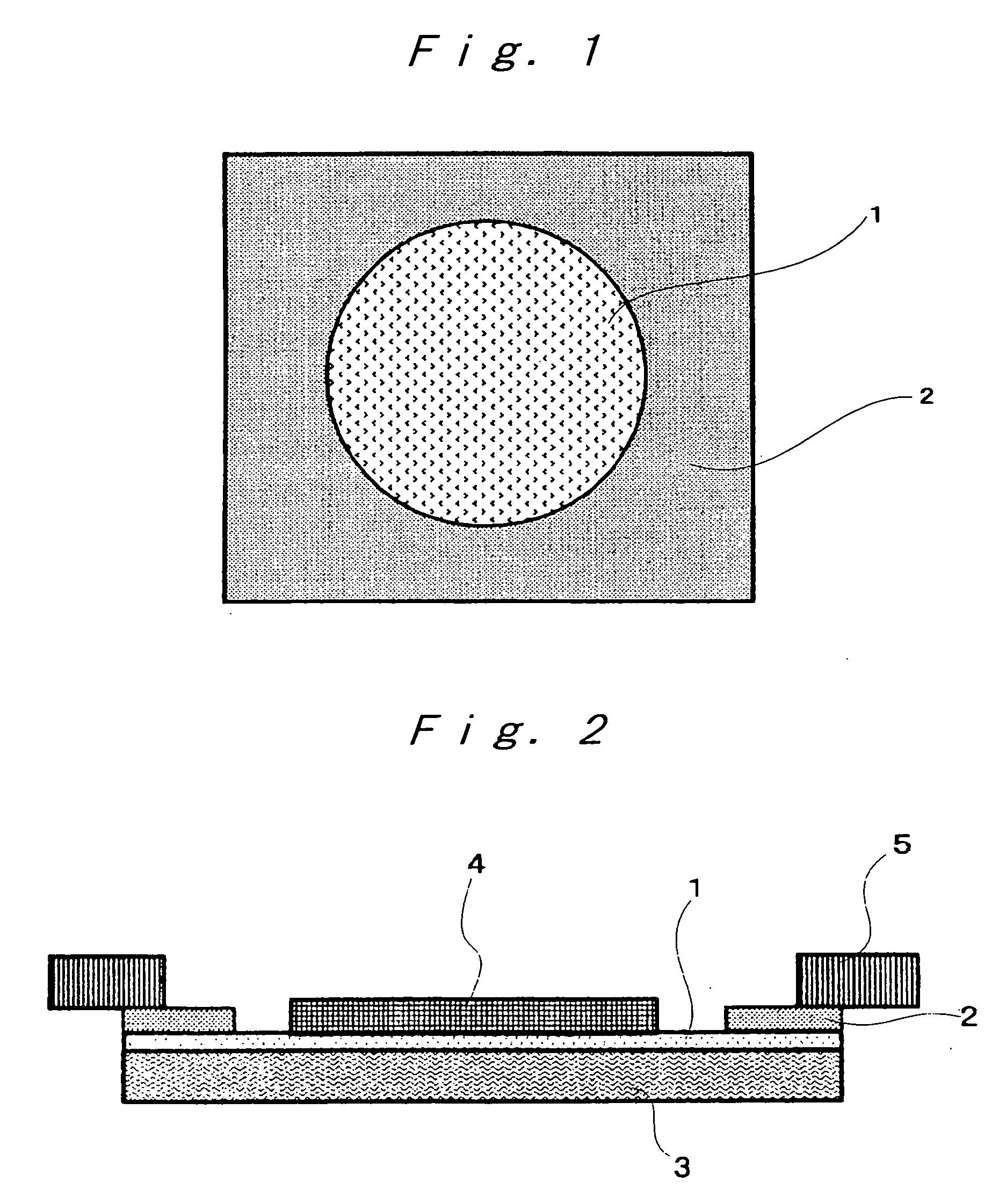

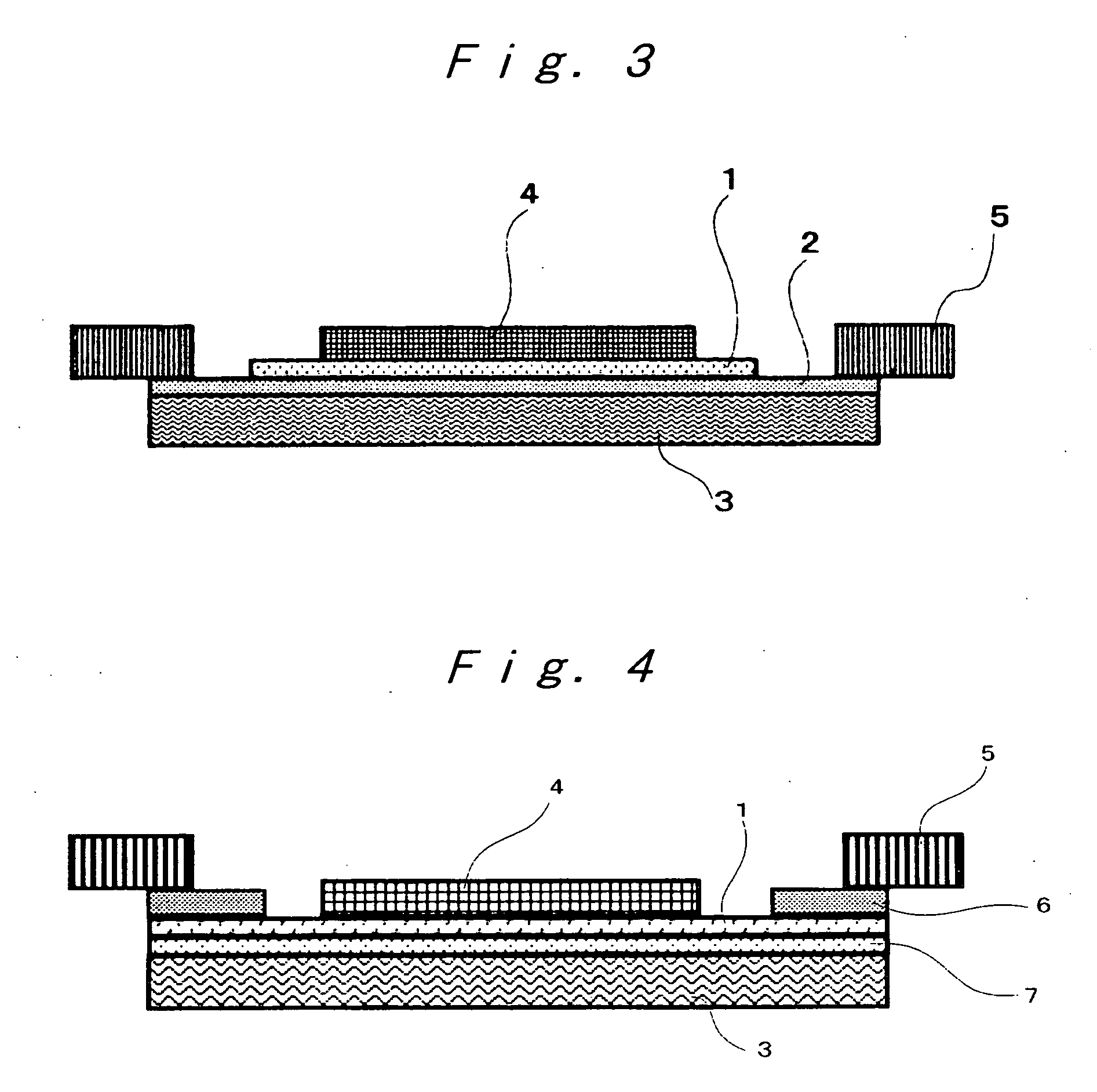

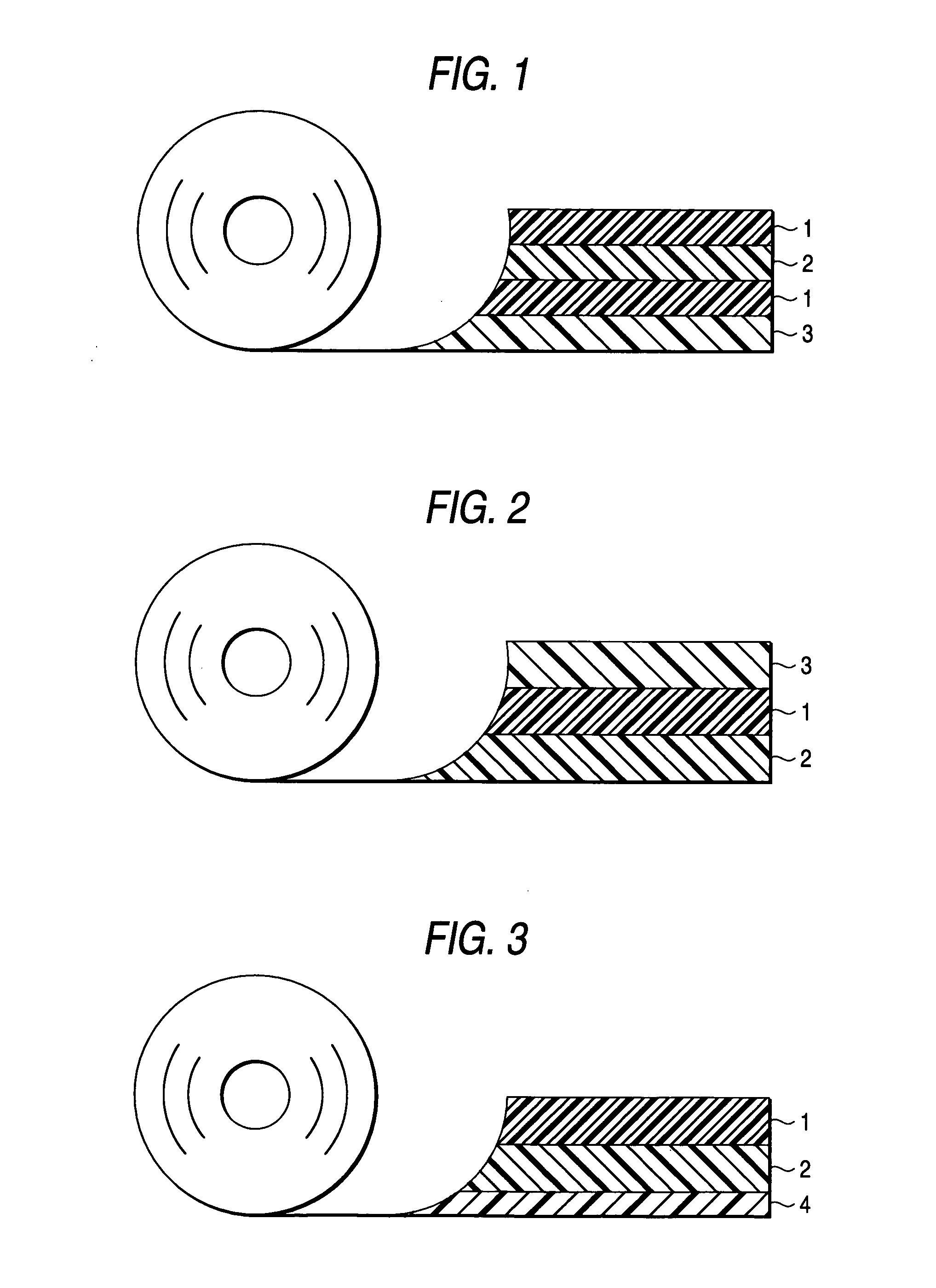

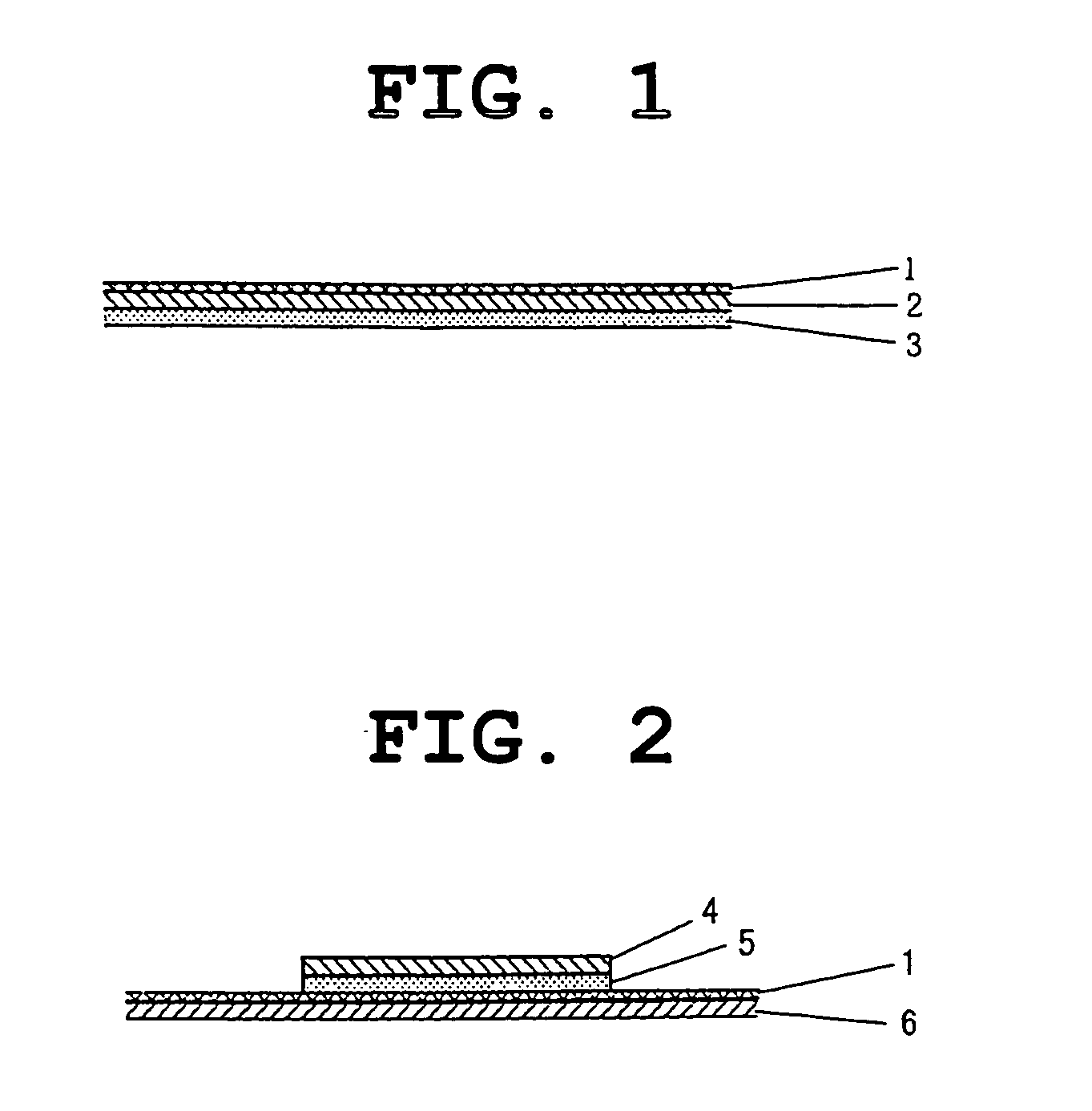

Wafer-processing tape and method of producing the same

ActiveUS20060154066A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringPeel force

A wafer-processing tape, which has an adhesive layer (1) and a removable adhesive layer (2) formed on a surface of a base film (3), and which has an area where B>A, and an area where A>B, in which a peeling force between the base film (3) and the adhesive layer (1) is designated as A, and peeling forces between a target to be bonded (4) and the adhesive layer (1) and between a target to be bonded (5) and the removable adhesive layer (2) are designated as B, wherein the adhesive layer (1) is transferred onto the chip side during pickup in the area where B>A, and the removable adhesive layer (2) is not transferred onto the target to be bonded (5) in the area where A>B during peeling off the tape.

Owner:FURUKAWA ELECTRIC CO LTD

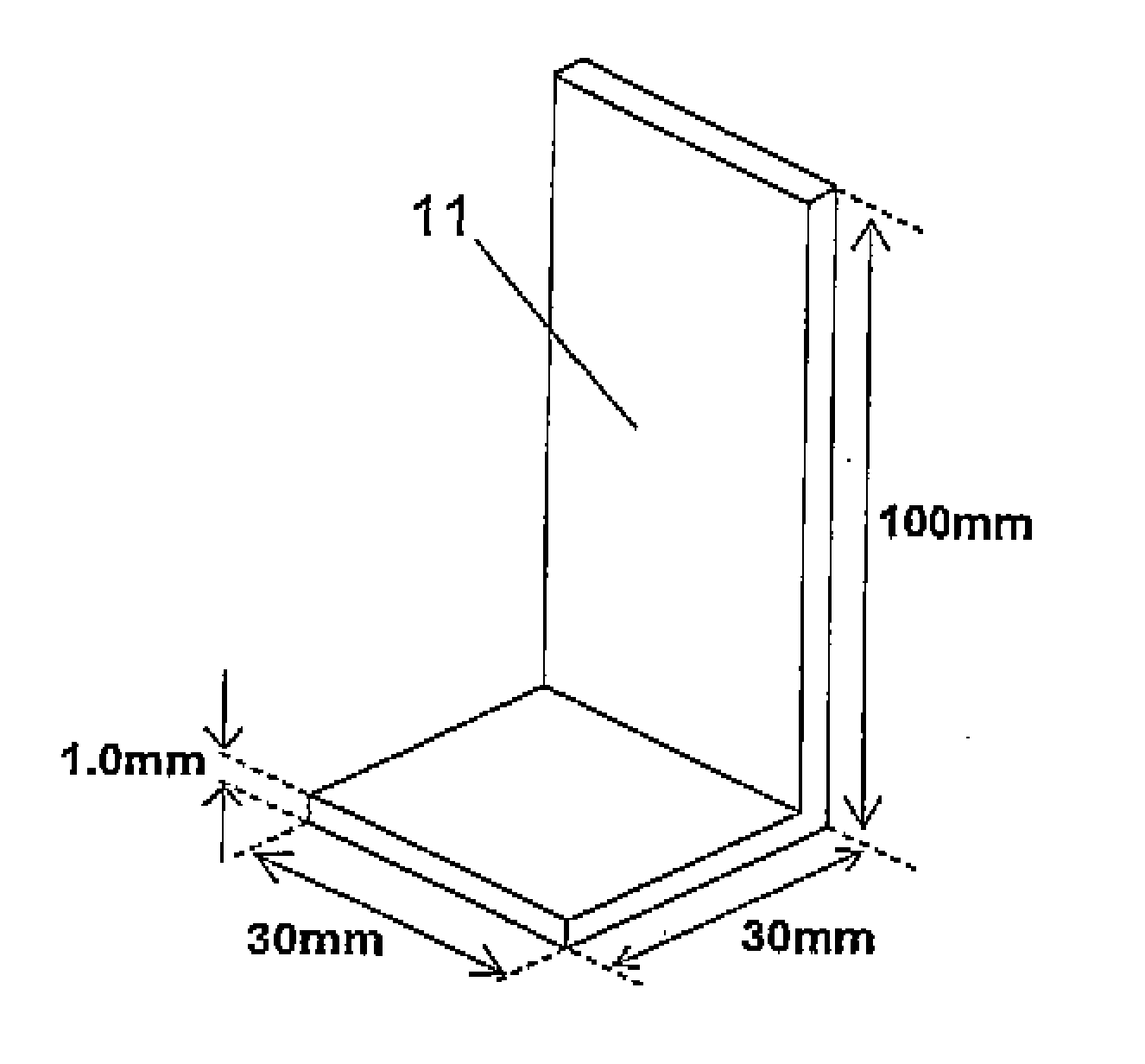

Optical-use pressure-sensitive adhesive sheet

InactiveUS20110111220A1Improve adhesionExcellent in twist-proof adhesivenessMonocarboxylic acid ester polymer adhesivesOpticsConstant loadDynamic viscoelasticity

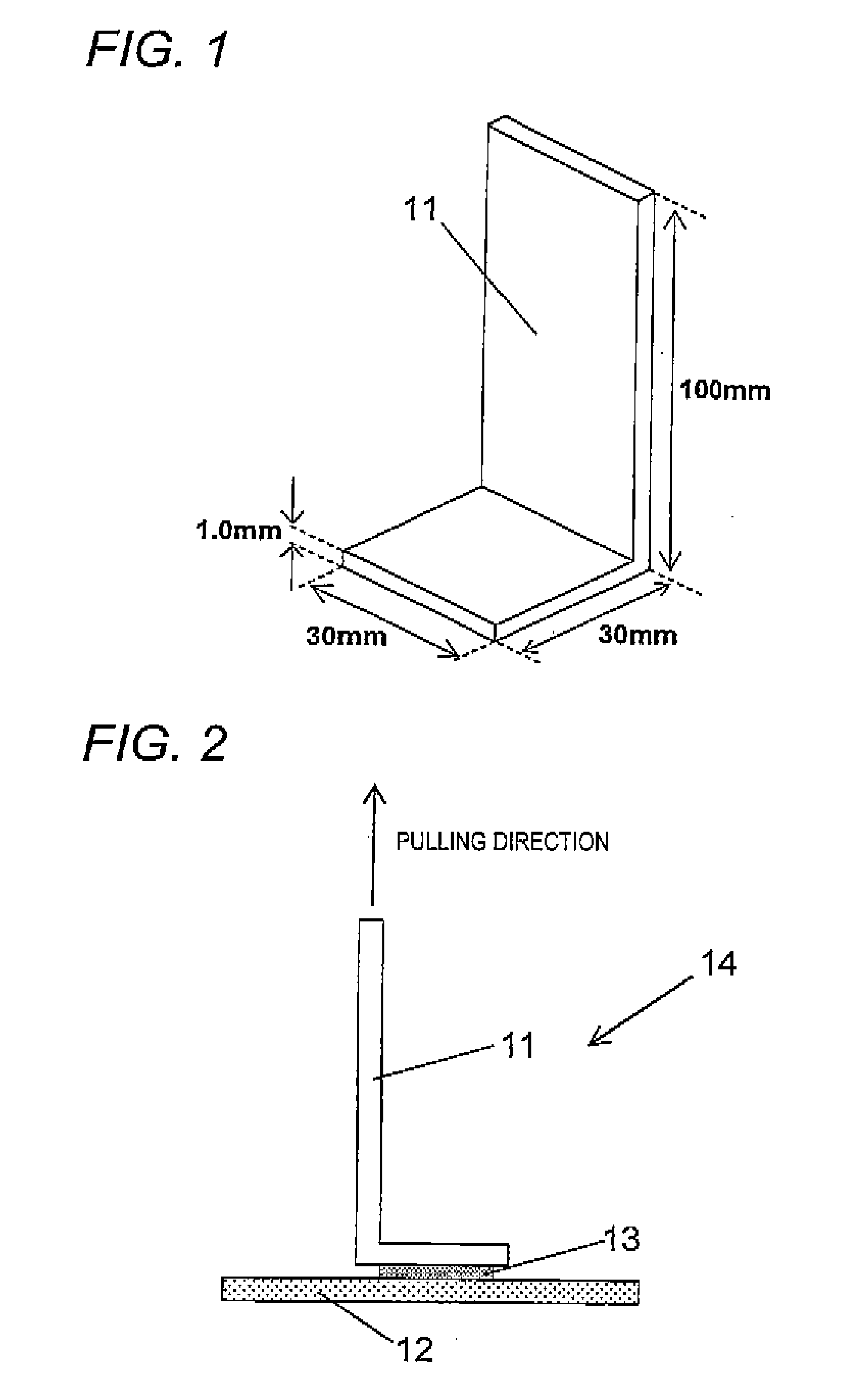

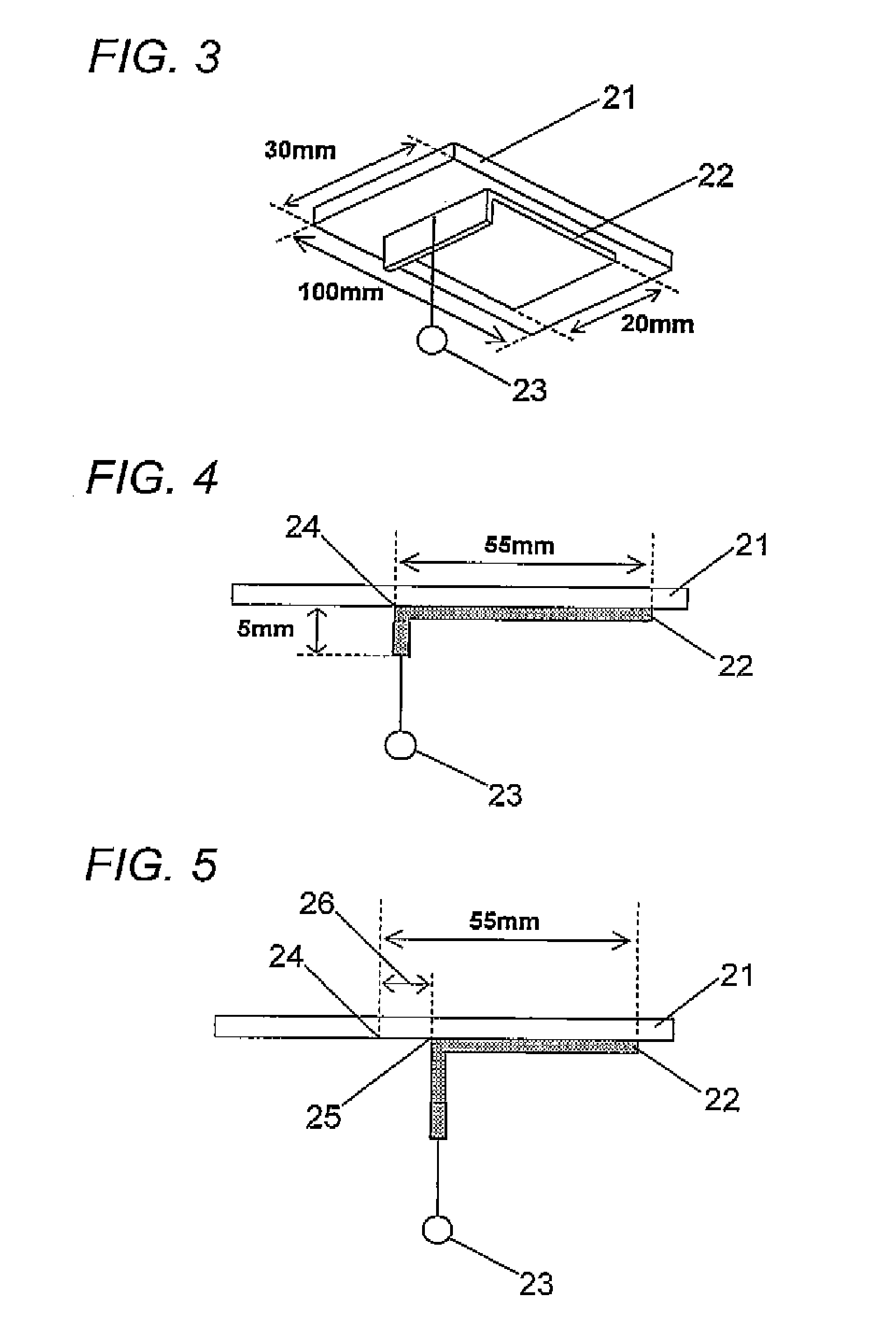

The present invention provides an optical-use pressure-sensitive adhesive sheet including a pressure-sensitive adhesive layer having, as measured through dynamic viscoelastometry, a storage elastic modulus at 80° C. of at least 2.0×104 Pa and a loss elastic modulus at 80° C. of at least 1.0×104 Pa, in which the pressure-sensitive adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test (under a load of 100 gf for 3 hours), of at most 50 mm.

Owner:NITTO DENKO CORP

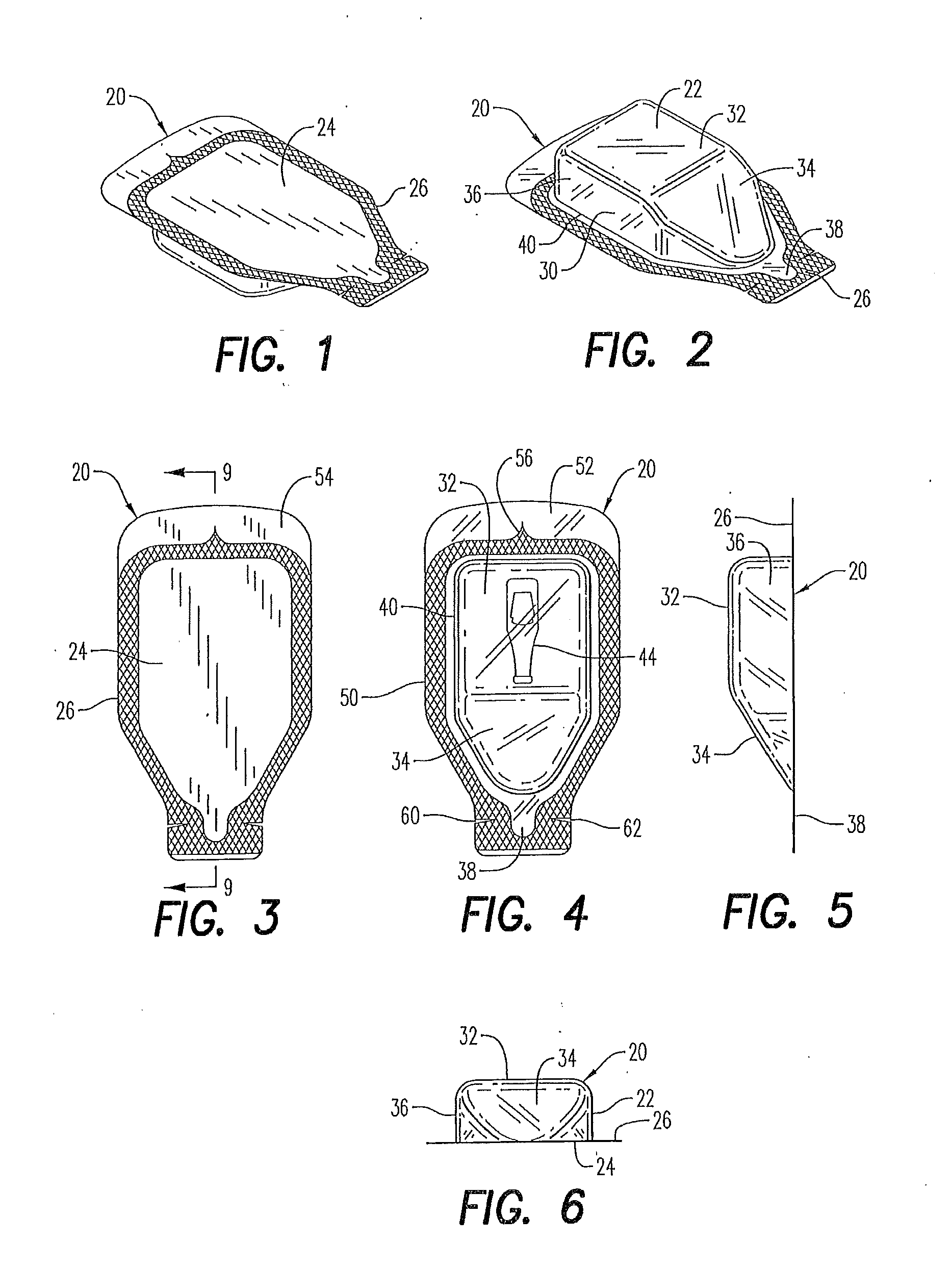

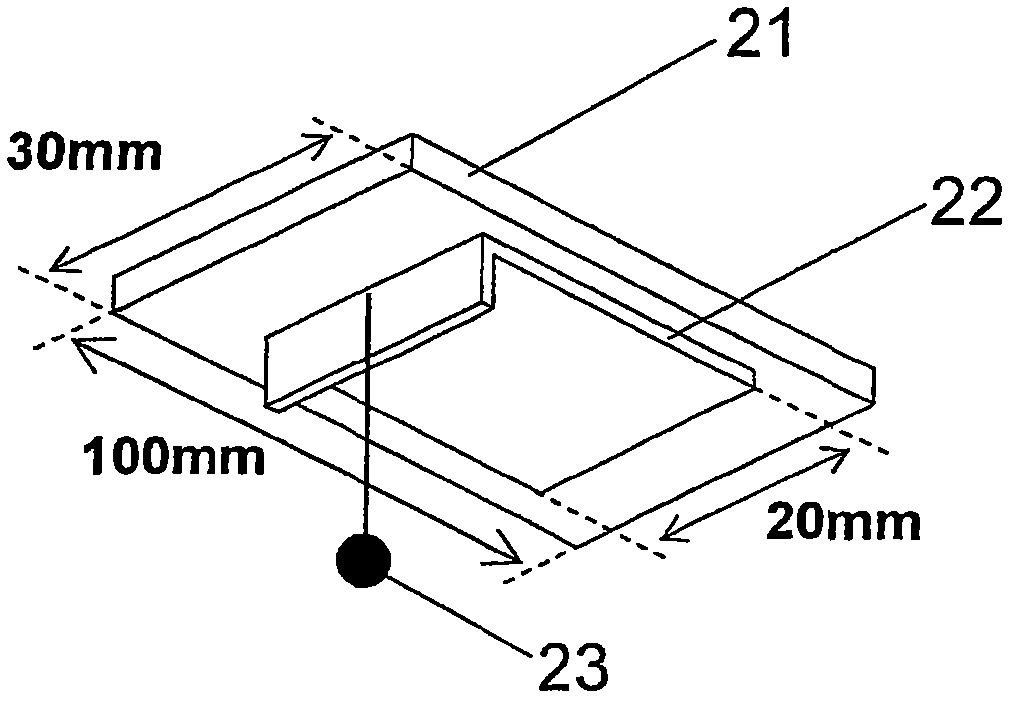

Carrier-bonding methods and articles for semiconductor and interposer processing

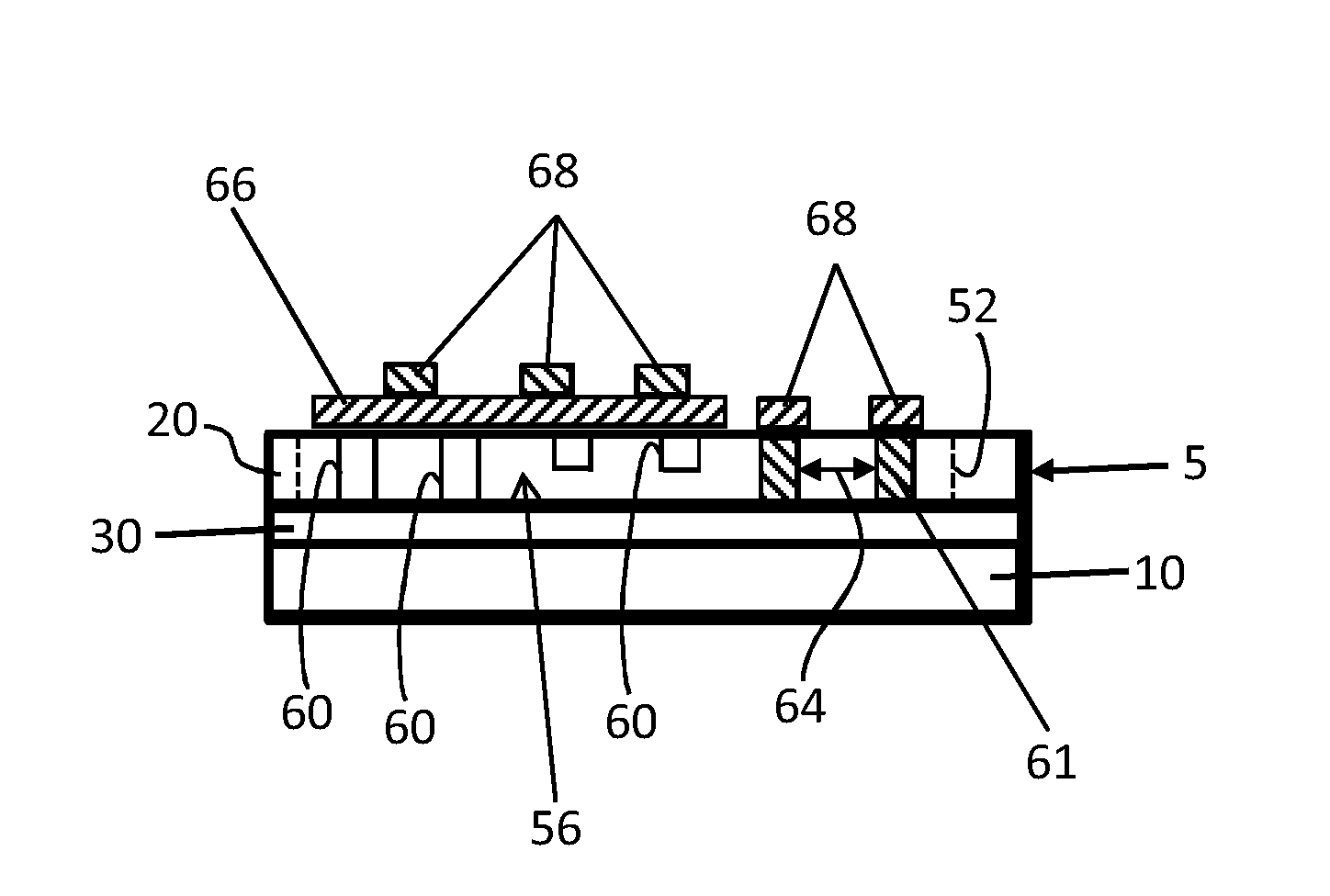

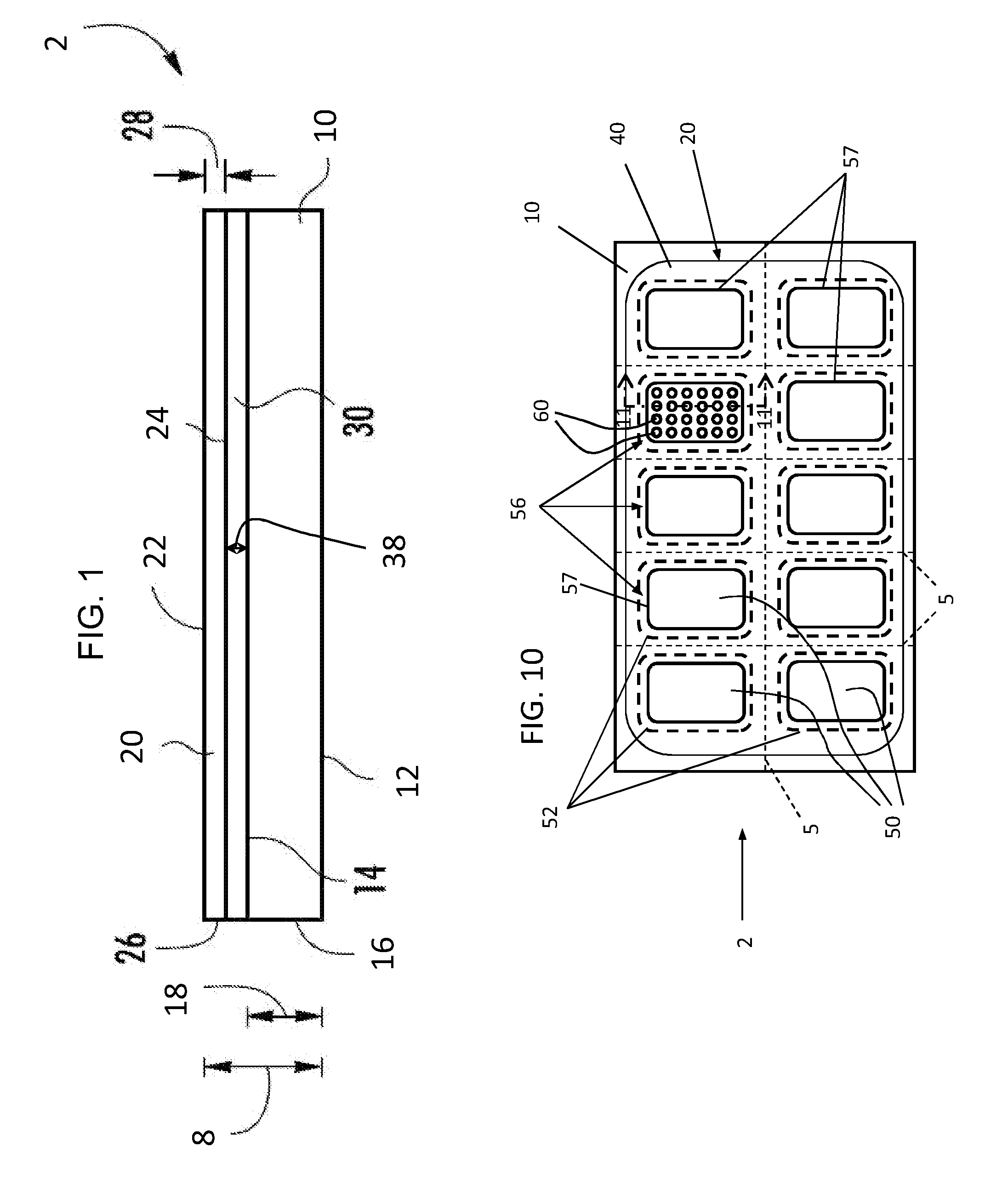

ActiveUS20150102498A1Avoiding waste and potential yield reductionPrevent removalSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureInterposer

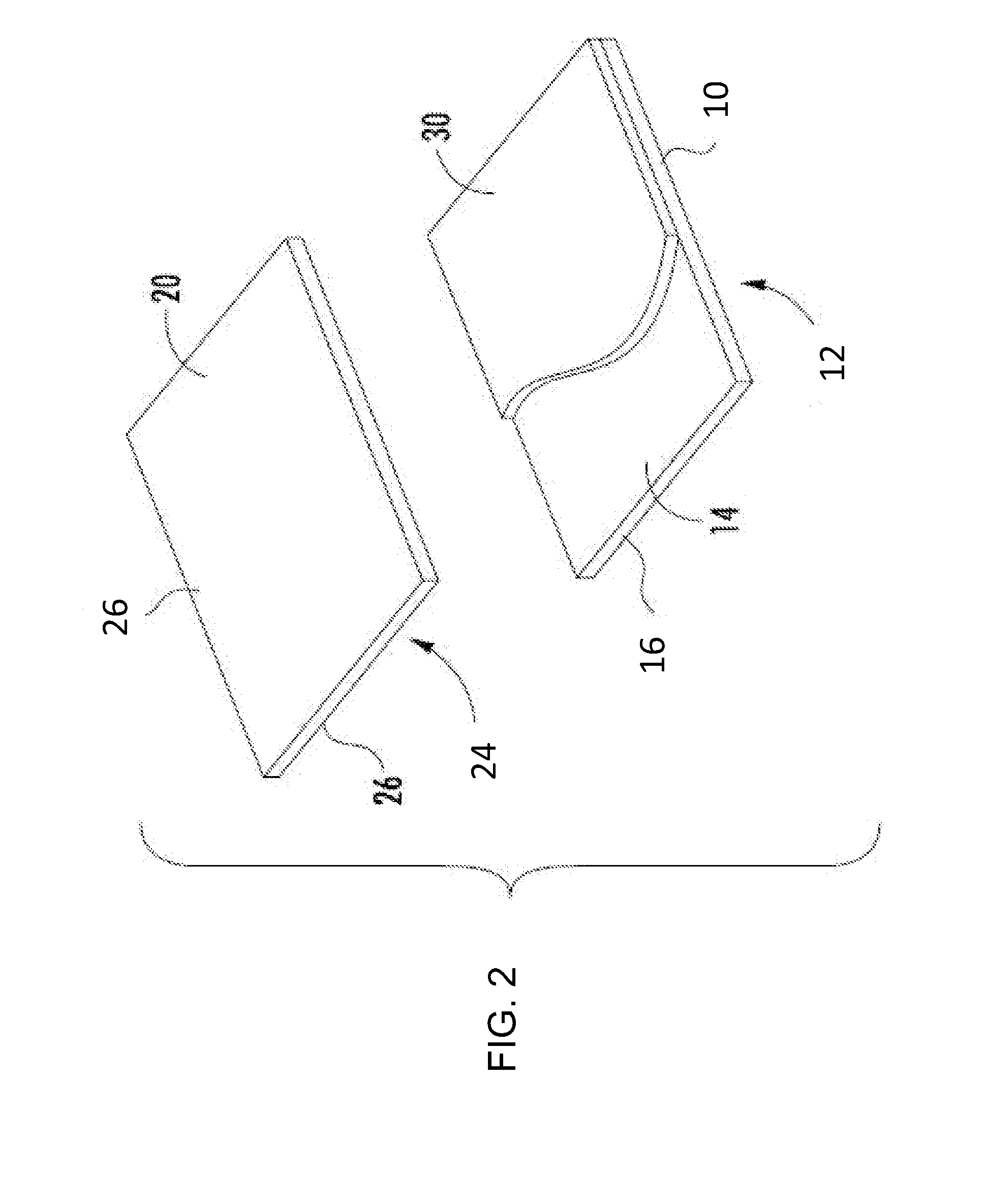

A thin sheet (20) disposed on a carrier (10) via a surface modification layer (30) to form an article (2), wherein the article may be subjected to high temperature processing, as in FEOL semiconductor processing, not outgas and have the thin sheet maintained on the carrier without separation therefrom during the processing, yet be separated therefrom upon room temperature peeling force that leaves the thinner one of the thin sheet and carrier intact. Interposers (56) having arrays (50) of vias (60) may be formed on the thin sheet, and devices (66) formed on the interposers. Alternatively, the thin sheet may be a substrate on which semiconductor circuits are formed during FEOL processing.

Owner:CORNING INC

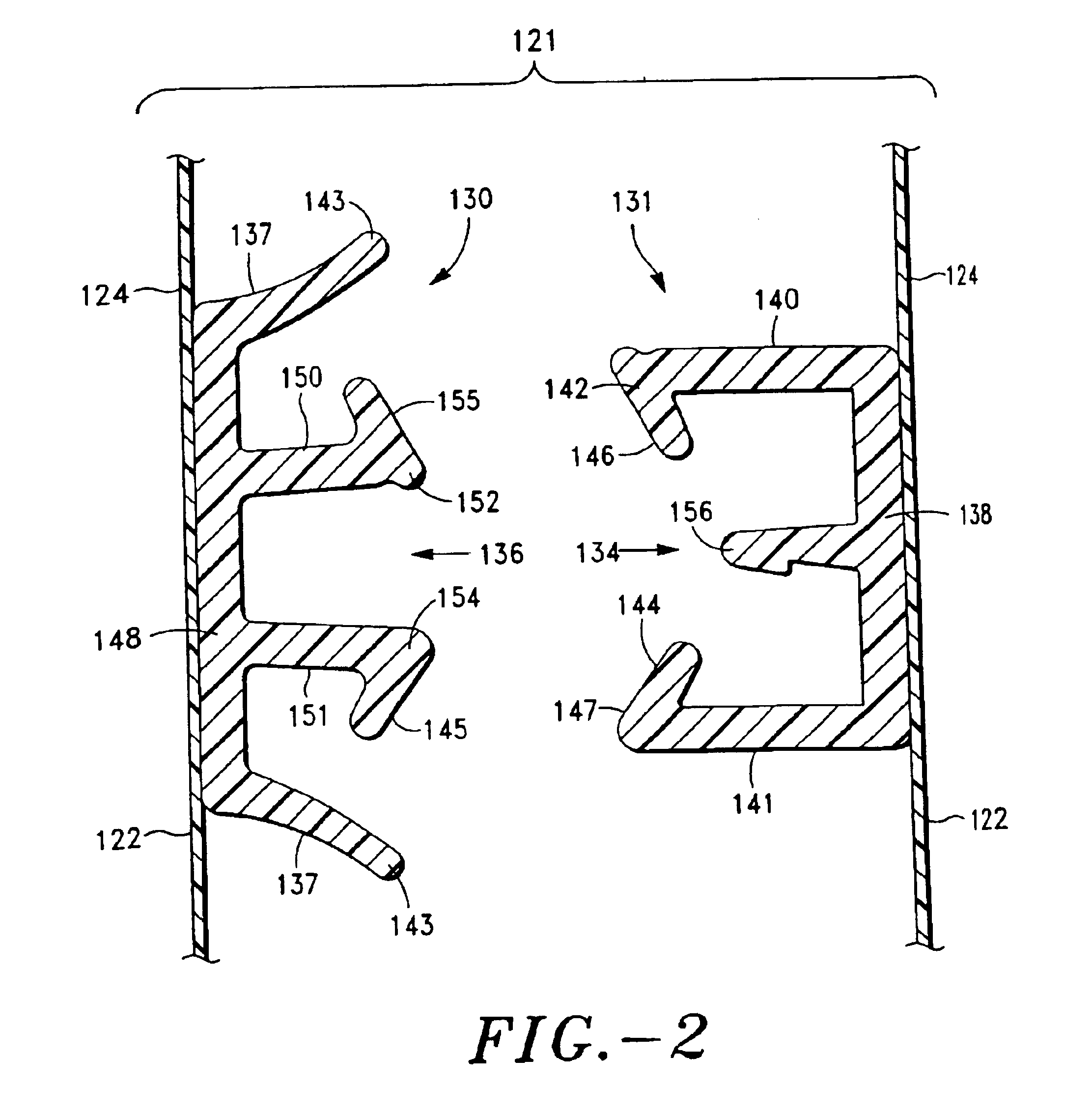

Interlocking closure device

InactiveUS6953542B2Improve leak-proof effectDesired audible and/or tactile effectsSnap fastenersMechanical working/deformationThermoplasticCold formed

A closure device for a thermoplastic bag which includes two opposing, longitudinally extending interlockable male and female fastening strips having respective male and female closure elements or profiles that are deformed to interdigitate and produce an audible clicking sound and or tactile effect that is perceptible to the touch as the closure device is opened and closed. Interdigitation of the two profiles is achieved by cold forming the profiles while interlocked. The shape of the cold form is a stepped deflection of both profiles so that their shapes are generally congruent. The stepped deflections provide a change in the occlusion and peel force of the interlocking closure device thereby resulting in an audible clicking or popping sound as the closure device is opened and closed and a tactile effect that is perceptible to the touch as the closure device is closed.

Owner:WATER KINETICS LTD

Peelable and flushable ostomy pouch and method of use

ActiveUS7517339B2Speed up the flowConveniently disposedSynthetic resin layered productsMedical devicesSurgeryPeel force

An ostomy appliance having a face plate assembly and inner and outer pouches joined thereto, has its outer pouch provided with one or more peripherally-extending sealing seams that allow the walls of the outer pouch to be separated by peeling forces applied in directions transverse to such seam or seams. In preferred embodiments, the sealing seam, also peelably join the peripheral edges of the outer pouch to those of the inner pouch. A method of disposing of the pouch assembly of such an ostomy appliance is also disclosed.

Owner:HOLLISTER INCORPORAED

Multi-function condiment container

InactiveUS20100320206A1Improve gripReduce and eliminate degradationCapsClosure capsEngineeringPeel force

A container for condiments includes a container portion having generally planar bottom, a generally parallel flange, and defining a cavity having a discharge spout adjacent the parallel flange. The container further includes a generally planar cover portion fashioned from a material more flexible that the material of the container portion and secured to the flange by an adhesive. The container preferably includes a weakened region transversely aligned with the spout but not having fluid communication therewith. Moreover, the container preferably includes a peel initiating structure aligned with the spout but spaced therefrom effective to reduce the peeling force required to separate the cover portion from the container portion.

Owner:HEINZ

Tamper indicating devices and methods for securing information

A tamper indicating device. A preferred embodiment of the invention provides a backing having a first side and a second side, wherein the backing comprises a first phase and a second phase, wherein the backing has a first level of light diffusion, and when a peeling force is applied to the backing, the backing fractures or internally delaminates and has a second level of light diffusion that is a higher level of light diffusion than the first level of light diffusion; a flood coat applied to the second side of the backing, the flood coat defining a window therein; and a mask applied to the tamper indicating device, the mask being in partial or whole registration with the window in the flood coat.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous dispersion type pressure-sensitive adhesive composition, and pressure-sensitive adhesive sheet

InactiveUS20050038152A1Small increase in peeling forceFilm/foil adhesivesLayered productsMeth-Organic compound

An aqueous dispersion type pressure-sensitive adhesive composition which has a small increase of a peel force to a release liner having a silicone release agent applied thereto or back coating layer, and pressure-sensitive adhesive sheets comprising the composition. The aqueous dispersion type pressure-sensitive adhesive composition comprises an aqueous dispersion of a polymer obtained by copolymerizing a monomer mixture comprising one or more alkyl (meth)acrylates as the main component and at least one silane monomer, and an organic compound capable of bonding to the silane monomer.

Owner:NITTO DENKO CORP

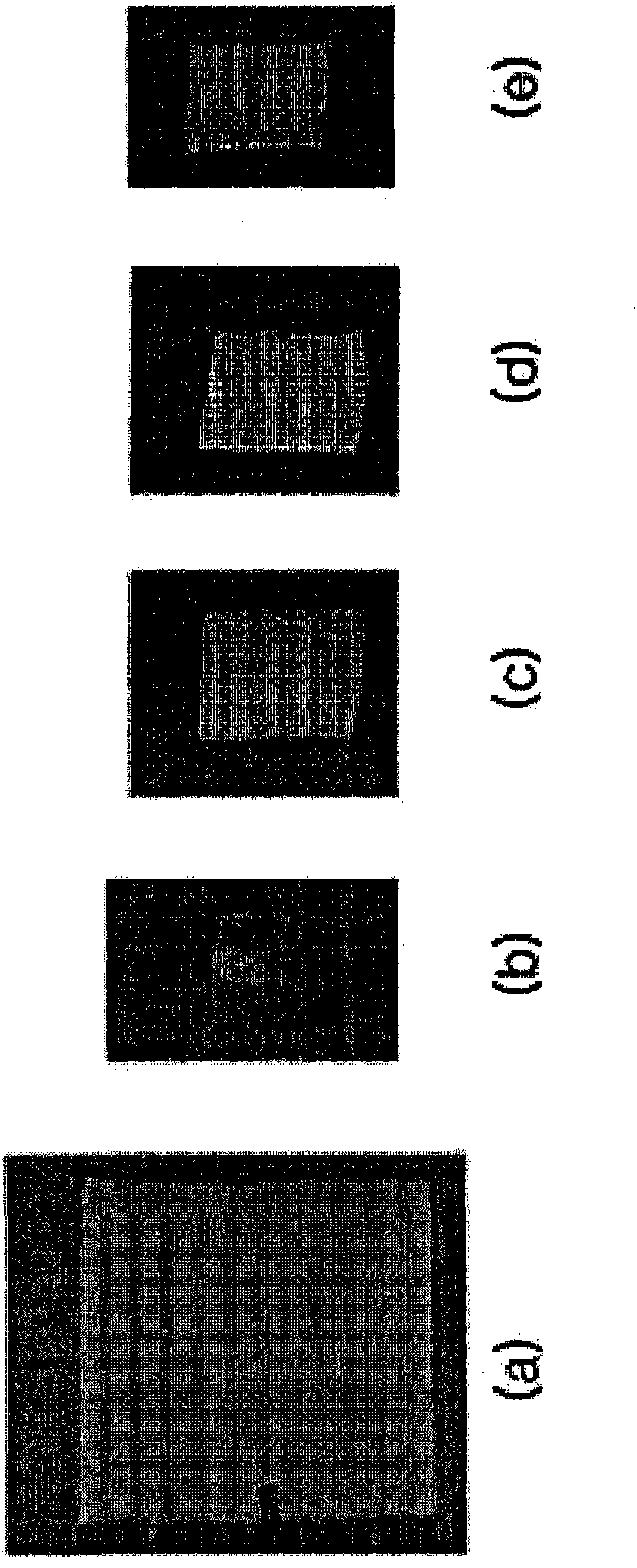

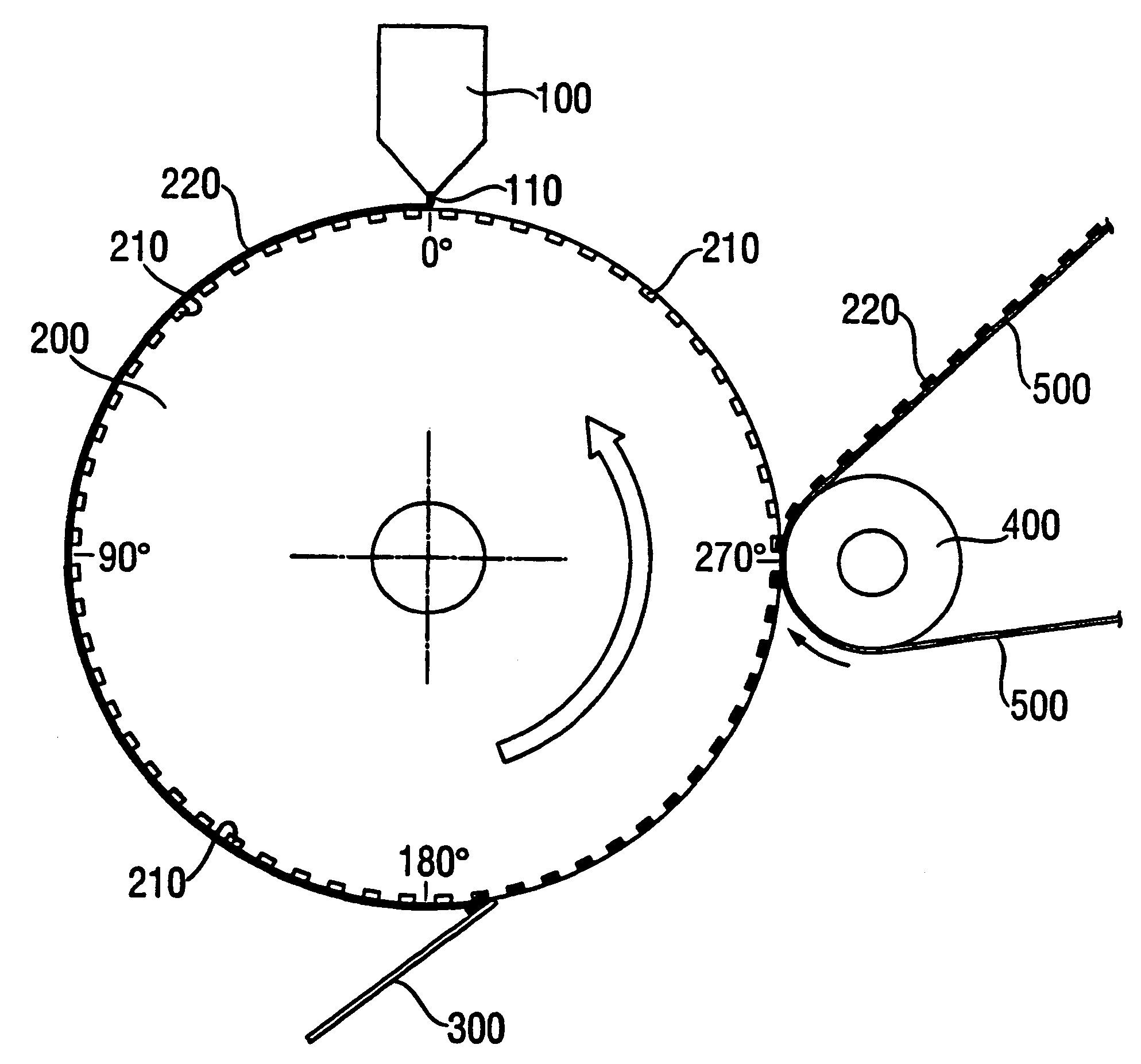

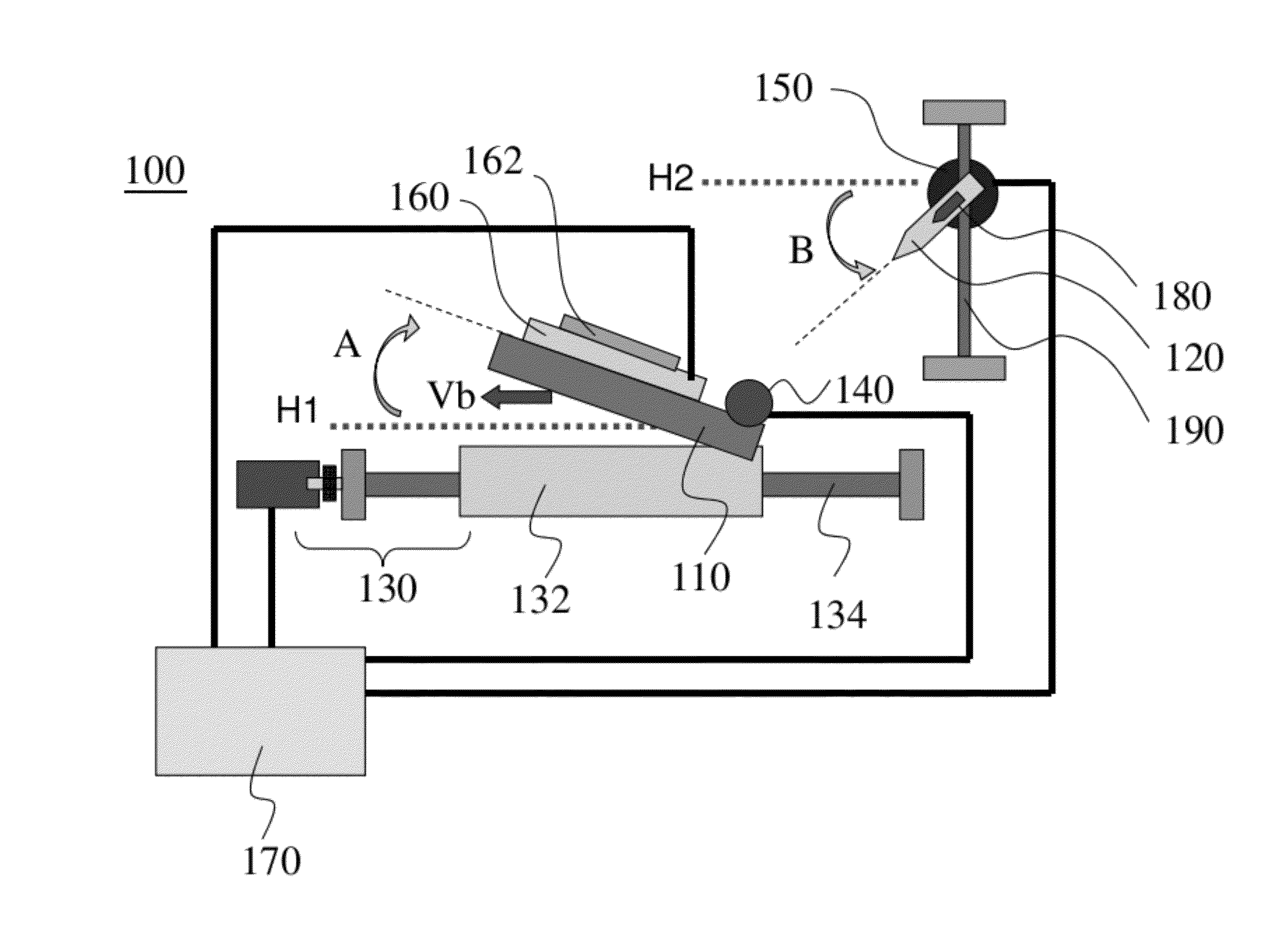

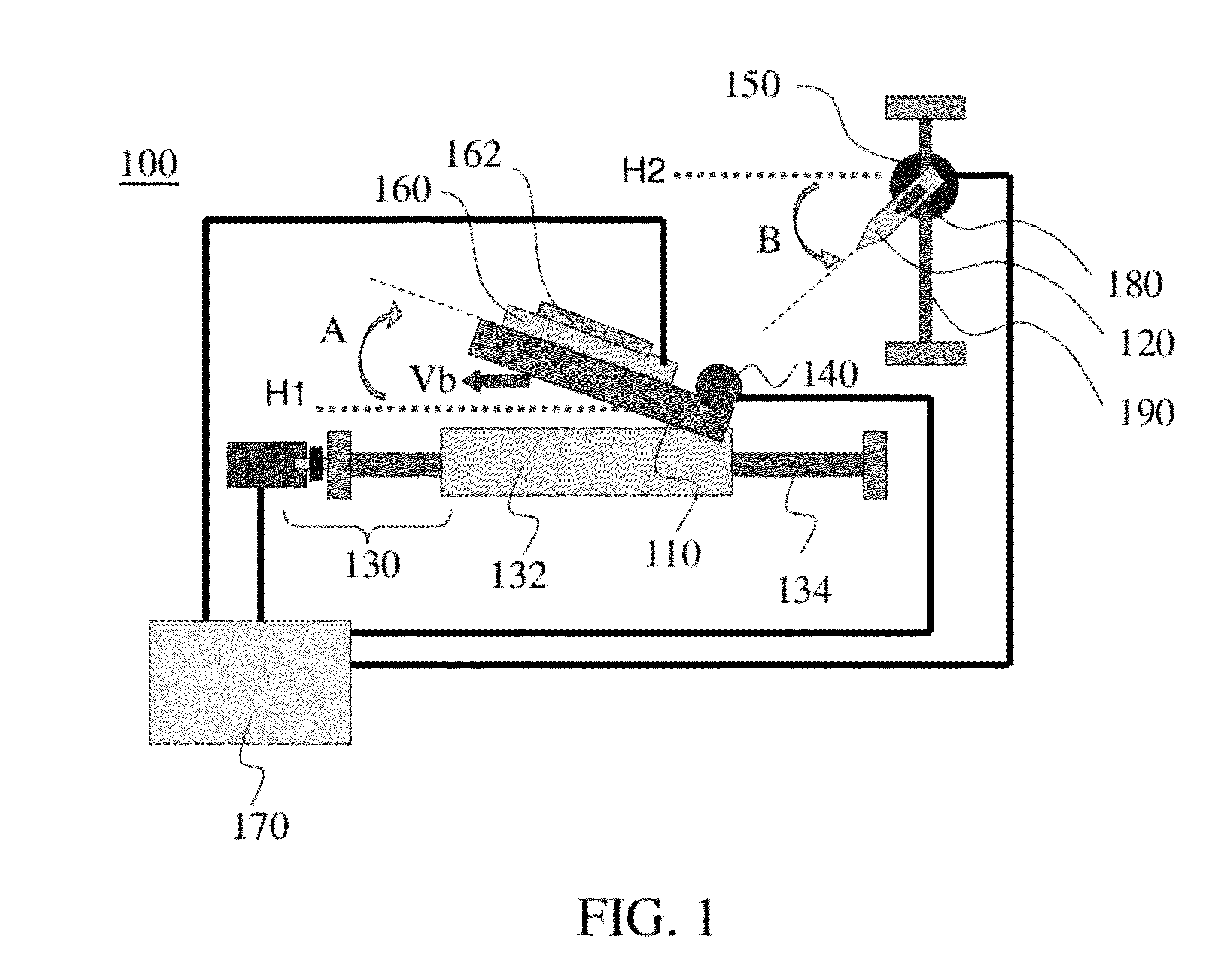

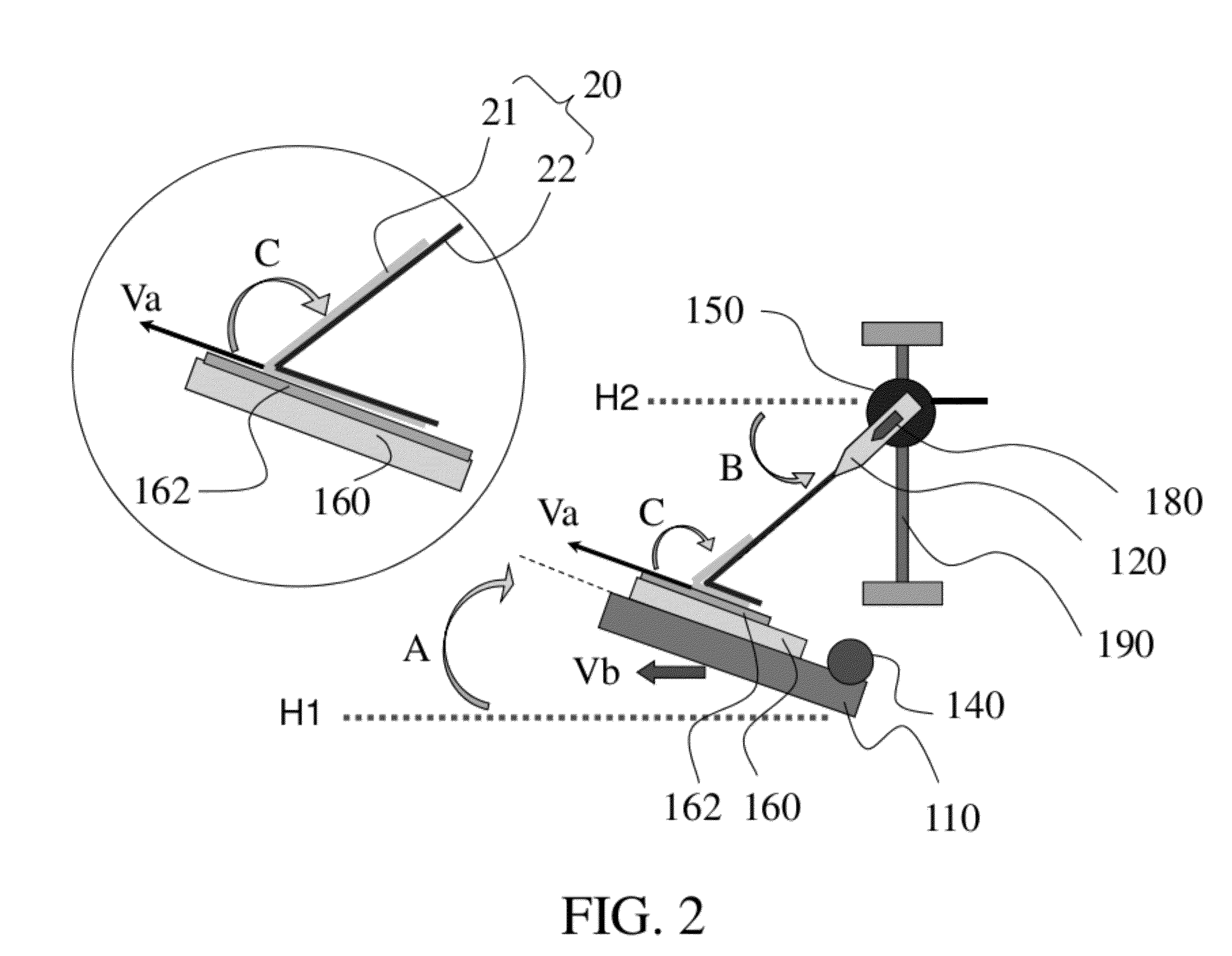

Apparatus for measuring peeling force of adhesive

Apparatus for measuring peeling force of an adhesive capable of varying different peeling angles and peeling rates, the apparatus comprising a force transducer for measuring a peeling force of a tape sample; and a peeling angle (angle C) defined by the adjustment a first angle (angle A) and a second angle (angle B); wherein said first angle (angle A) is defined by an angle between a test sled and a slide with a movement device, and said second angle (angle B) is defined by an angle between a force-bearing direction of said force transducer and a horizontal parallel plane of said slide.

Owner:TSAUR TUNG YUAN

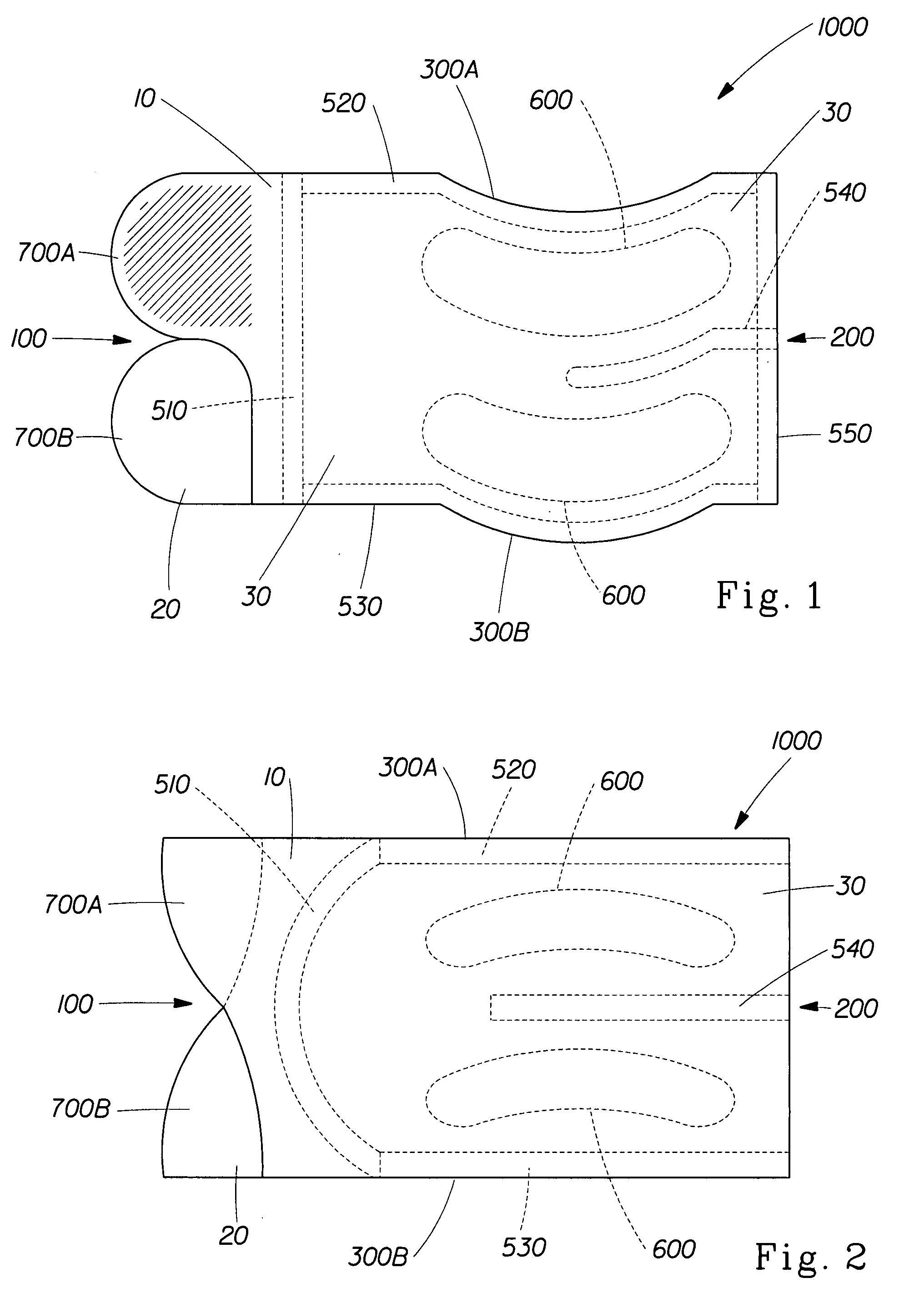

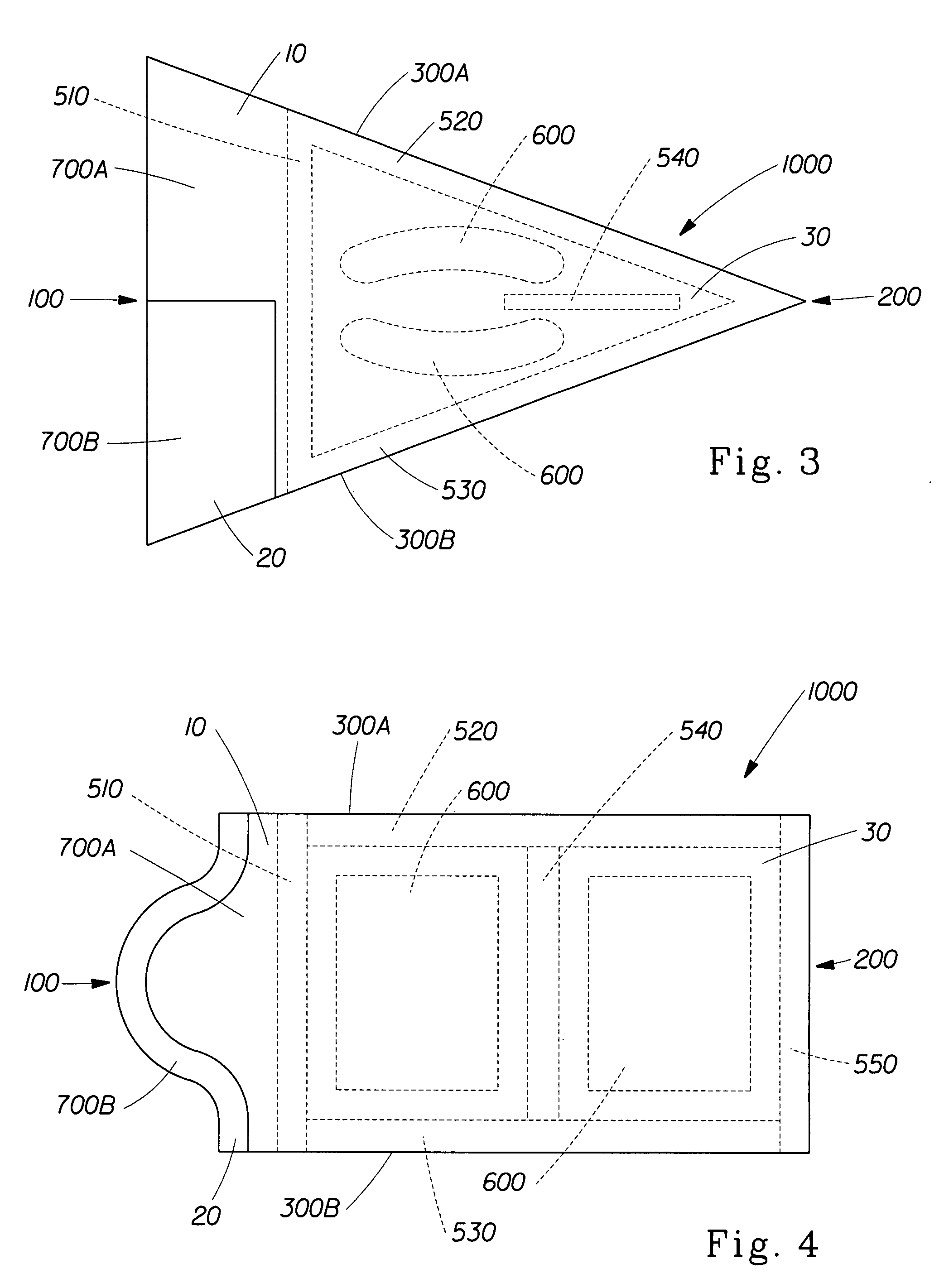

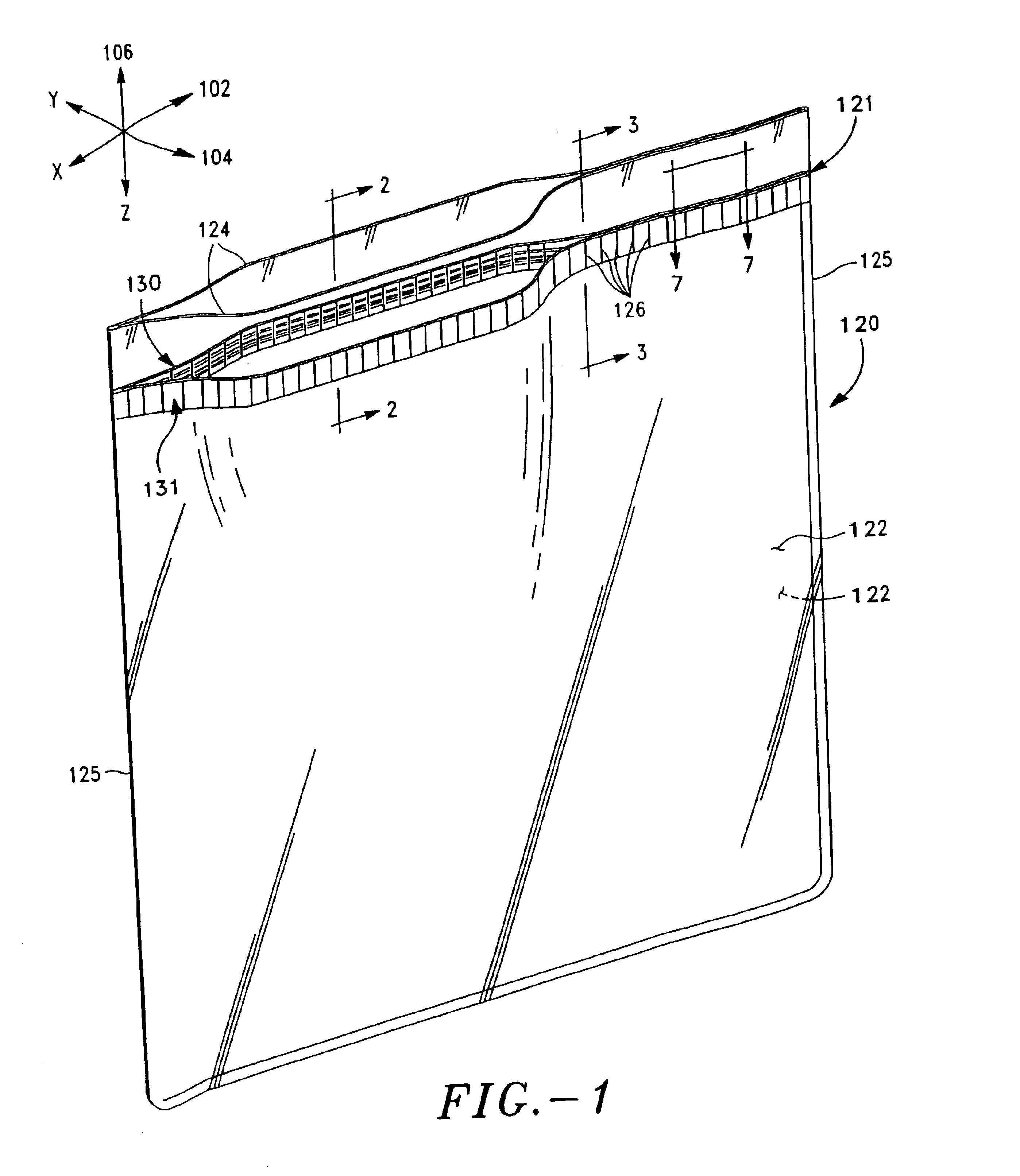

Multiple filament nasal strip with high peel angle release

InactiveUS20050081857A1Less peeling forceEasy to peelStentsBreathing filtersNasal passageNasal passages

The present invention relates to improved nasal dilators that prevent the outer wall of tissue of nasal passages of a nose from drawing in during breathing. The improved nasal dilator has a resilient element, or “spring,” made up of a plurality of small filaments for keeping the nasal passages from drawing in while breathing. The filaments may be a variety of shapes and sizes and may run both along the length of the nasal dilator and at a variety of different angles relative to the length of the nasal dilator. The filaments further allow the nasal dilator of the present invention to be removed from the nose in a “top-to-bottom” fashion. The top-to-bottom peel method allows a greater peel angle and so results in less peel force being transferred to the skin of the use.

Owner:CNS INC

Optical-use pressure-sensitive adhesive sheet

ActiveCN102051133AStripping does not produceImprove bond reliabilityMonocarboxylic acid ester polymer adhesivesOpticsConstant loadPeel force

The invention provides an optical-use adhesive sheet excellent in adhesiveness under bending, twisting or distorting stress. The optical-use adhesive sheet has an adhesive layer having a storage elastic modulus at 80 DEG C of at least 2.0X10 4 Pa and a loss elastic modulus at 80 DEG C of at least 1.0X10 4 Pa, the optical-use adhesive sheet is characterized in that the adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test, of at most 50 mm. In the L-shape peel test, an L-shaped stainless steel clamp is adhered with an acrylicresin plate through the adhesive sheet, the acrylicresin plate and the stainless steel clamp are processed for 15 minutes at 50 DEG C under 5 atm, and then, the stainless steel clamp is drawn along a direction vertical to a surface of the acrylicresin plate so as to test the peel force. In the constant-load peel test, a double-faced adhesive sheet is adhered on the acrylicresin plate, then, the acrylicresin plate and the double-faced adhesive sheet are processed for 10 minutes at 50 DEG C under 5 atm, and then, a load of 100gf is applied along the direction vertical to the surface of the acrylicresin plate on a tail end in a length direction of the adhesive sheet so as to test the peel distance of the adhesive sheet after 3 hours.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive members and processes for producing the same

InactiveUS20040224117A1Lightly peelableRetention stabilityLamination ancillary operationsAdhesive articlesFractionationElution

Owner:NITTO DENKO CORP

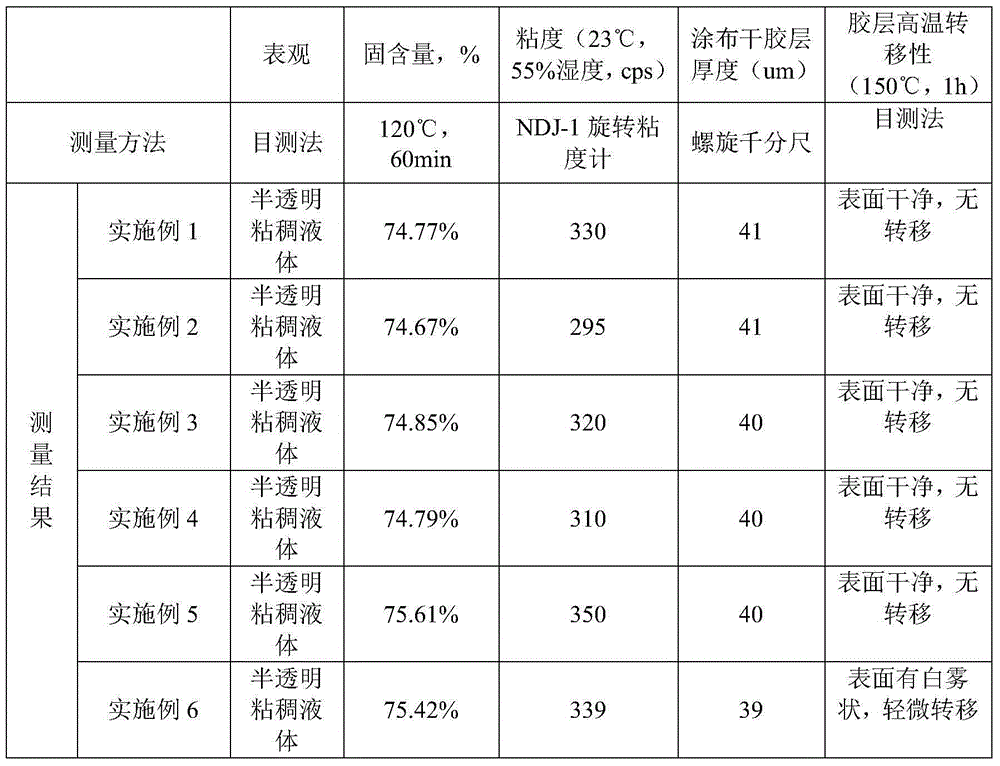

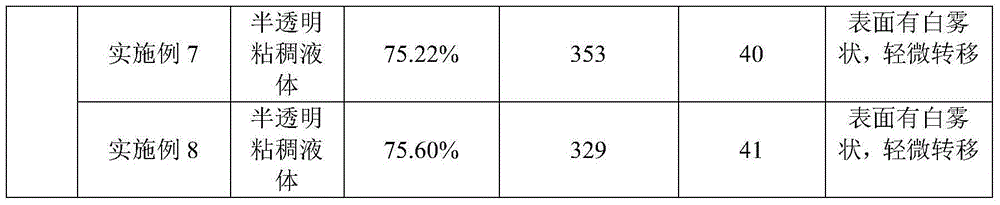

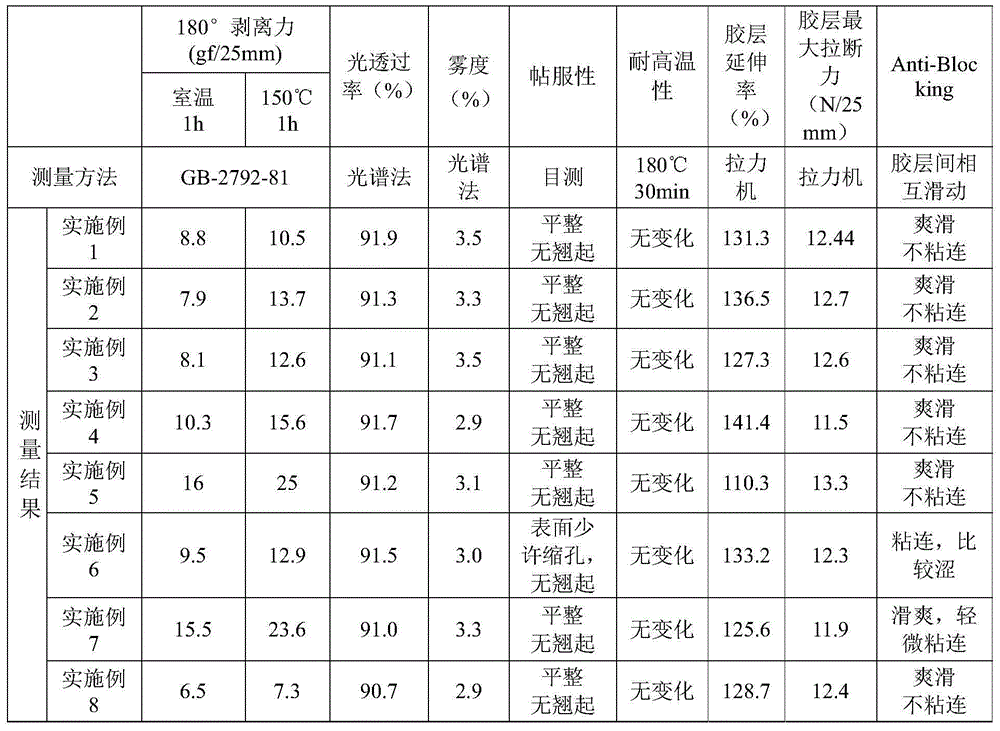

Peelable glue coating composition and peelable glue coating as well as preparation method and application of peelable glue coating

The invention provides a peelable glue coating composition and a peelable glue coating as well as a preparation method and an application of the peelable glue coating. The peelable glue coating composition comprises the following components in parts by weight: 80-120 parts of an acrylate type oligomer, 8-20 parts of a dilutive monomer, 0.1-1.5 parts of a peeling force modifying agent, 2-12 parts of a triggering agent and 30-50 parts of an organic solvent. The peelable glue coating composition is relatively high in transparency and relatively high in light transmittance and relatively low in haze after film formation. Meanwhile, a coating formed by curing the peelable glue coating composition is relatively high in high temperature resistance and relatively high in peelability. By the high temperature resistance, the coating is good in adhesion property on the surface of a functional hardened layer, and the problems of air bubbles and warping can be effectively improved. By the peelability, the problem of glue layer residues caused during peeling of the coating can be reduced.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Pressure-sensitive adhesive for surface-protective film and surface-protective film

InactiveUS20060177651A1Non-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylateMeth-

It is a pressure-sensitive adhesive for a surface-protective film which comprises the following components (A) and (B): (A) a (meth)acrylic ester copolymer obtained by copolymerizing at least the following components (a1) and (a2) (a1) 80 to 99% by mass of an alkyl (meth)acrylate in which the alkyl group has up to 12 carbon atoms; and (a2) 1 to 10% by mass of 4-hydroxybutyl acrylate or 4-hydroxybutyl methacrylate; and (B) an isocyanate crosslinking agent having a functionality of 3 or higher, the amount of the component (B) being 1 to 5 parts by weight per 100 parts by weight of the component (A). The pressure-sensitive adhesive has a gel fraction of 90% by mass or higher, a peel force as measured at a peel rate of 300 mm / min of 20 gf / inch or lower, and a peel force as measured at a peel rate of 2,000 mm / min of 50 gf / inch or lower. The pressure-sensitive adhesive for a surface-protective film of the invention has a satisfactory high-rate release property, changes little in peel force with peel rate, does not stain an adherend, and is satisfactory in properties including pot life.

Owner:SOKEN CHEM & ENG CO LTD

Double-sided adhesive tape and its use

Owner:TESA SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com