Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

211results about How to "Improve bond reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One component resin composition curable with combination of light and heat and use of the same

InactiveUS20070096056A1Improve curing effectAvoid pollutionLiquid crystal compositionsPhotomechanical apparatusEpoxyMethacrylate

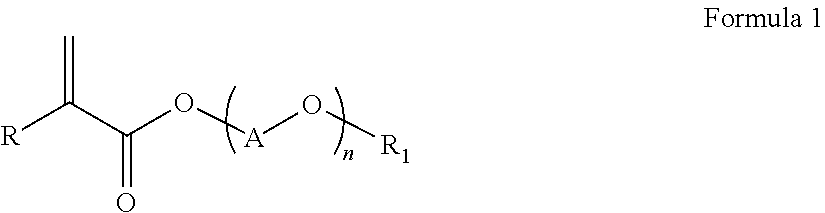

A one component resin composition curable with a combination of light and heat, which comprises (1) an epoxy resin, (2) an acrylic ester monomer and / or methacrylic ester monomer, or an oligomer thereof, (3) a latent epoxy curing agent, (4) a photo radical initiator, and (5) a compound having two or more thiol groups per molecule, wherein the ingredient (5) is contained in an amount of 0.001 to 5.0 parts by weight per 100 parts by weight of this resin composition. According to the present invention, a one component resin composition curable with a combination of light and heat, which has excellent curability especially in a light-shielded area can be provided. Also, a liquid crystal sealant composition curable with a combination of light and heat, which is applicable to the one-drop-fill method and has excellent curability in light-shielded areas and adhesion reliability, especially high-temperature and high-humidity adhesion reliability, can be provided.

Owner:MITSUI CHEM INC +1

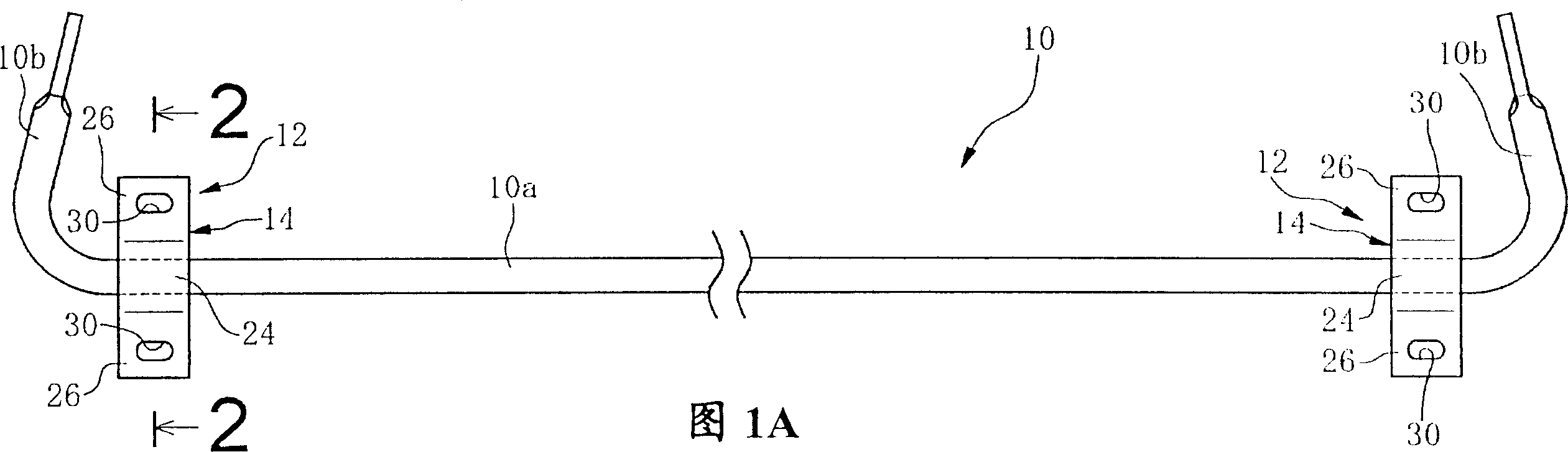

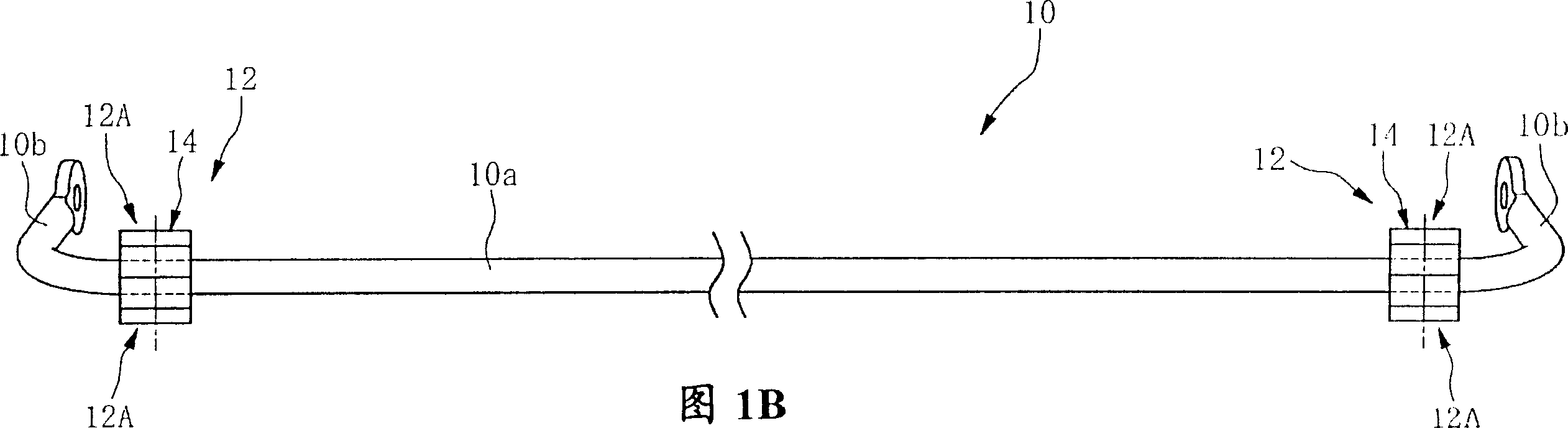

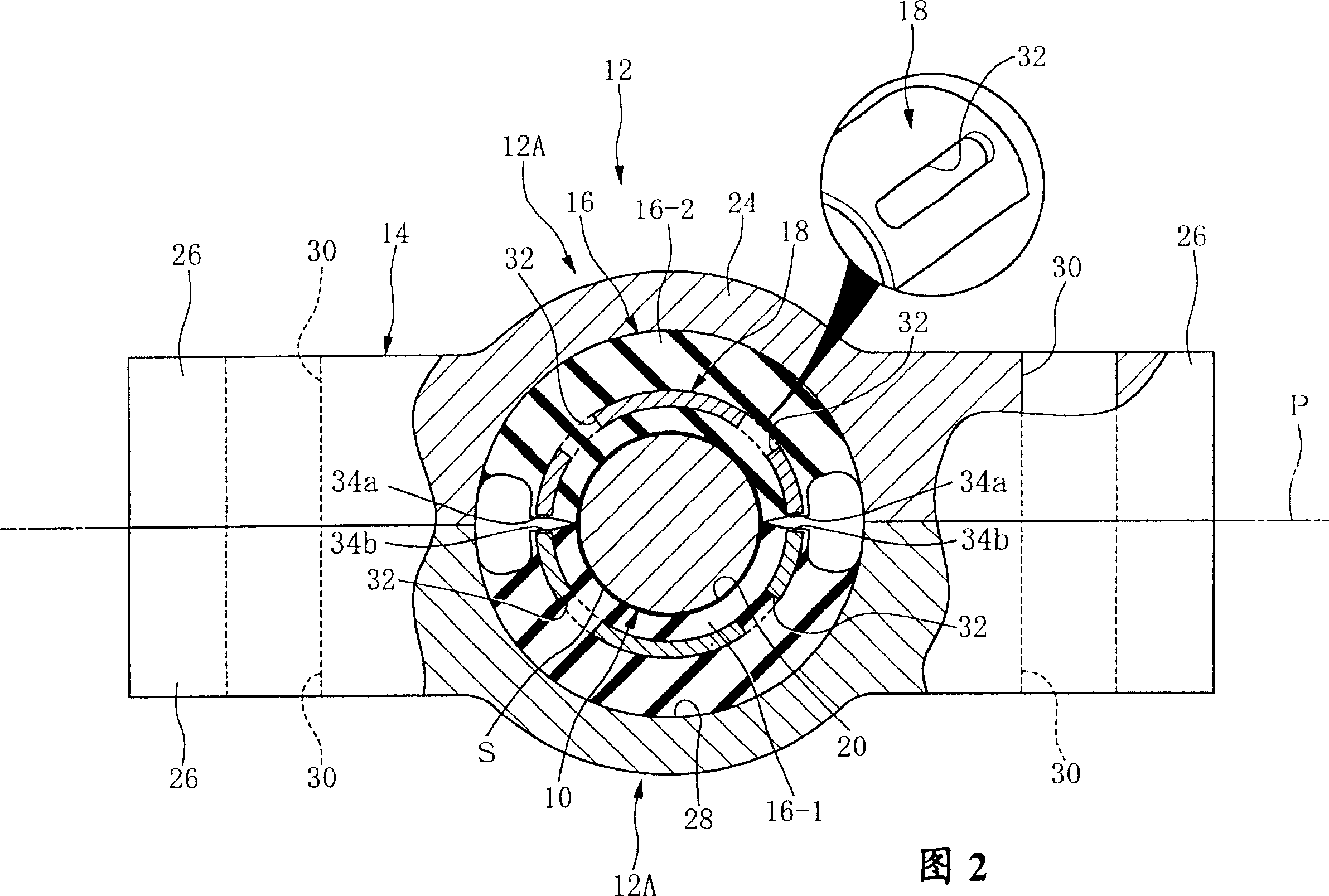

Stabilizer bushing

InactiveCN1766362AReduce axial flowReduce stress concentrationInterconnection systemsRubber-like material springsElastomerAdhesive

The invention relates to a stabilizer bar bushing (12), comprising a rubber elastic body (16); a bracket (14) and a middle part embedded in the rubber elastic body along the axis vertical direction so as to extend substantially the entire axial direction of the rubber elastic body An intermediate plate (18) extending in length, whereby the rubber elastic body is divided by the intermediate plate into an inner rubber layer (16-1) and an outer rubber layer (16-2) with a spring constant smaller than the inner rubber layer. The stabilizer bar bushing is composed of two circumferential divisions (12A, 12A), wherein the bracket and the middle plate are integrally vulcanized with the divisions, and the divisions are assembled together to clamp the stabilizer bar along the vertical direction of the axis ( 10) and withstand the compression along the vertical direction of the axis, so that the inner surface of the through hole (20) is bonded to the outer peripheral surface of the stabilizer bar through the adhesive (S).

Owner:TOYOTA JIDOSHA KK +1

Sealing composition for liquid crystal displays and process for production of liquid crystal display panels

InactiveCN1682149APollution suppressionImprove featuresOther chemical processesNon-linear opticsEpoxyMethacrylate

The sealing composition for liquid crystal displays according to the invention is characterized by consisting of a one-pack type photo- and thermo-setting resin composition comprising (1) a solid epoxy resin having a softening point of 40 DEG C or above as determined by ring and ball method, (2) an acrylate ester monomer and / or a methacrylate ester monomer or an oligomer thereof, (3) a thermoplastic polymer obtained by copolymerizing an acrylate ester monomer and / or a methacrylate ester monomer with a monomer copolymerizable therewith and having a softening point of 50 to 120 DEG C as determined by ring and ball method, (4) a photoradical polymerization initiator, and (5) a latent epoxy curing agent. The photo- and thermo-setting sealing composition for liquid crystal displays is applicable to the dispenser method, can give a cured product having excellent characteristics through photosetting in the first step, and permits the formation of stable cell gaps. Further, the sealing composition is inhibited from polluting liquid crystal in thermosetting in the second step and attains excellent setting properties in the shaded areas and high adhesion reliability.

Owner:MITSUI CHEM INC

Automotive fuel hose and method for producing the same

InactiveUS20050208248A1Low layerSimple molding processSynthetic resin layered productsLaminationEngineeringAutomotive fuel

An automotive fuel hose excellent in interlaminar adhesion between a low permeability resin layer and a rubber layer, wherein the low permeability resin layer and the rubber layer are directly adhered to each other without forming an adhesive layer at the interface between both layers. The automotive fuel hose has a laminated structure of a low permeability resin layer and a rubber layer, the low permeability resin layer is formed by the following (A) and the rubber layer is formed by the following (B). (A) a polyphenylene sulfide resin containing a softening component, or a modified fluororesin. (B) a rubber composition composed of at least one of an amine additive and an amine vulcanizing agent as an essential component.

Owner:SUMITOMO RIKO CO LTD

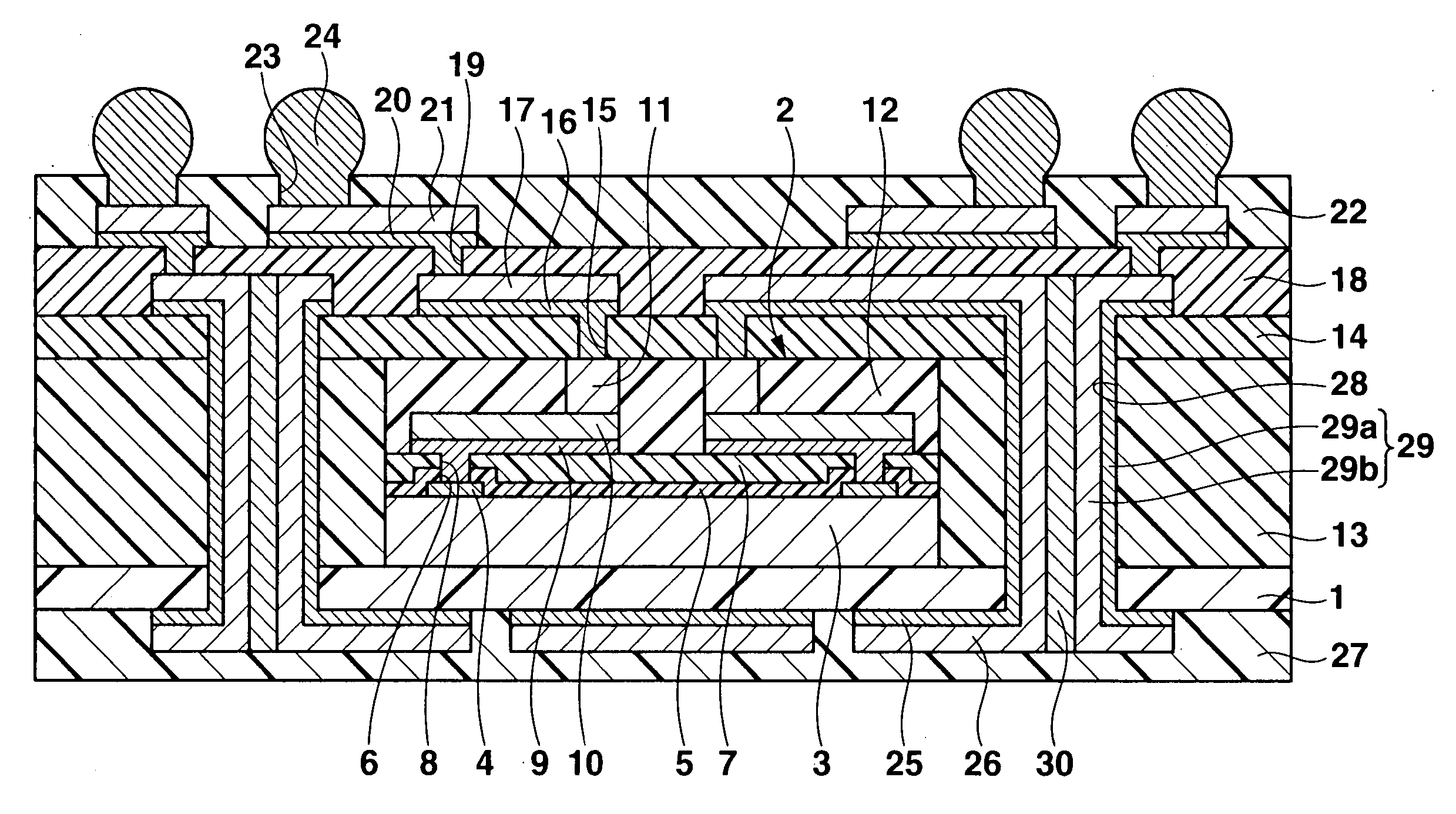

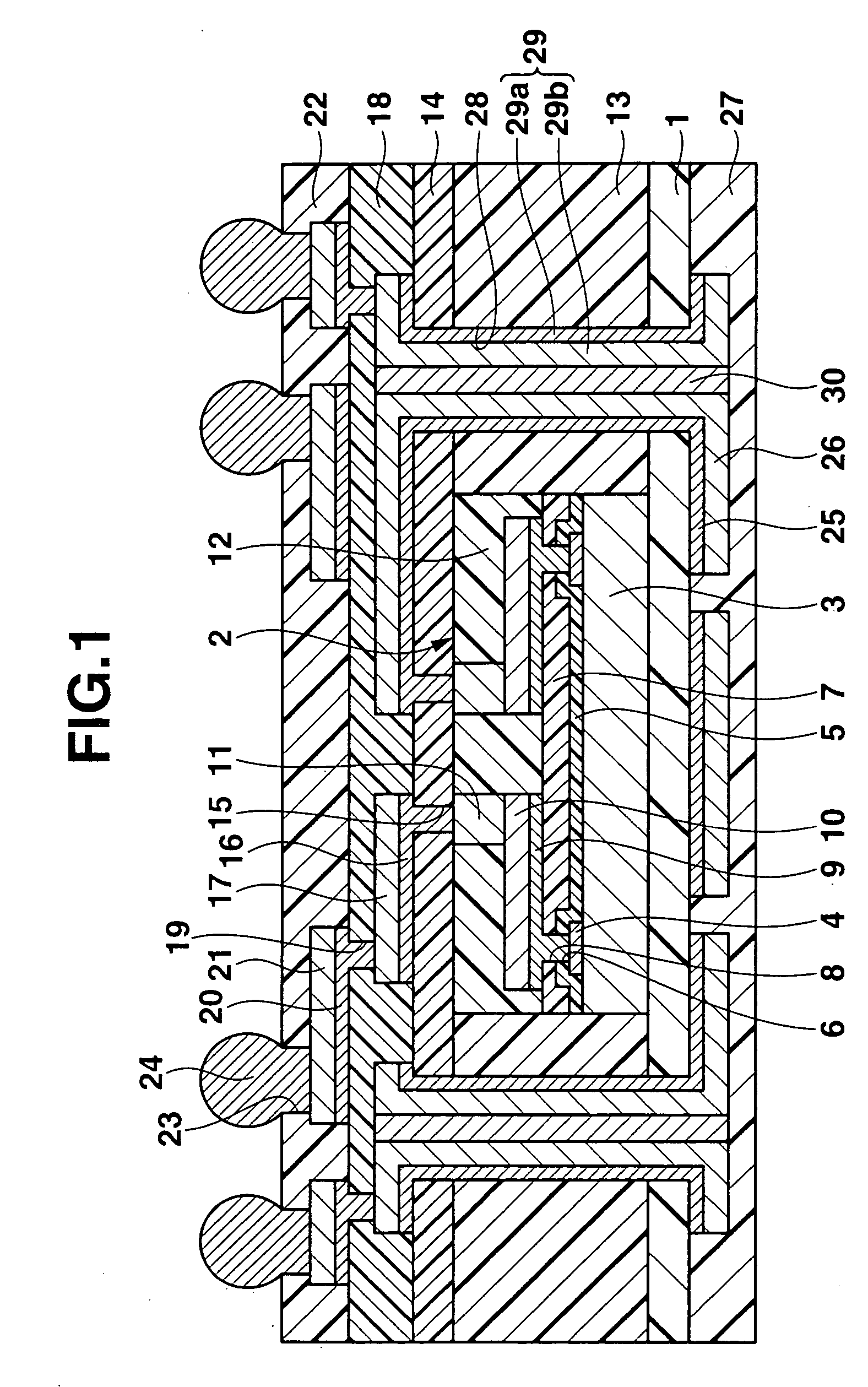

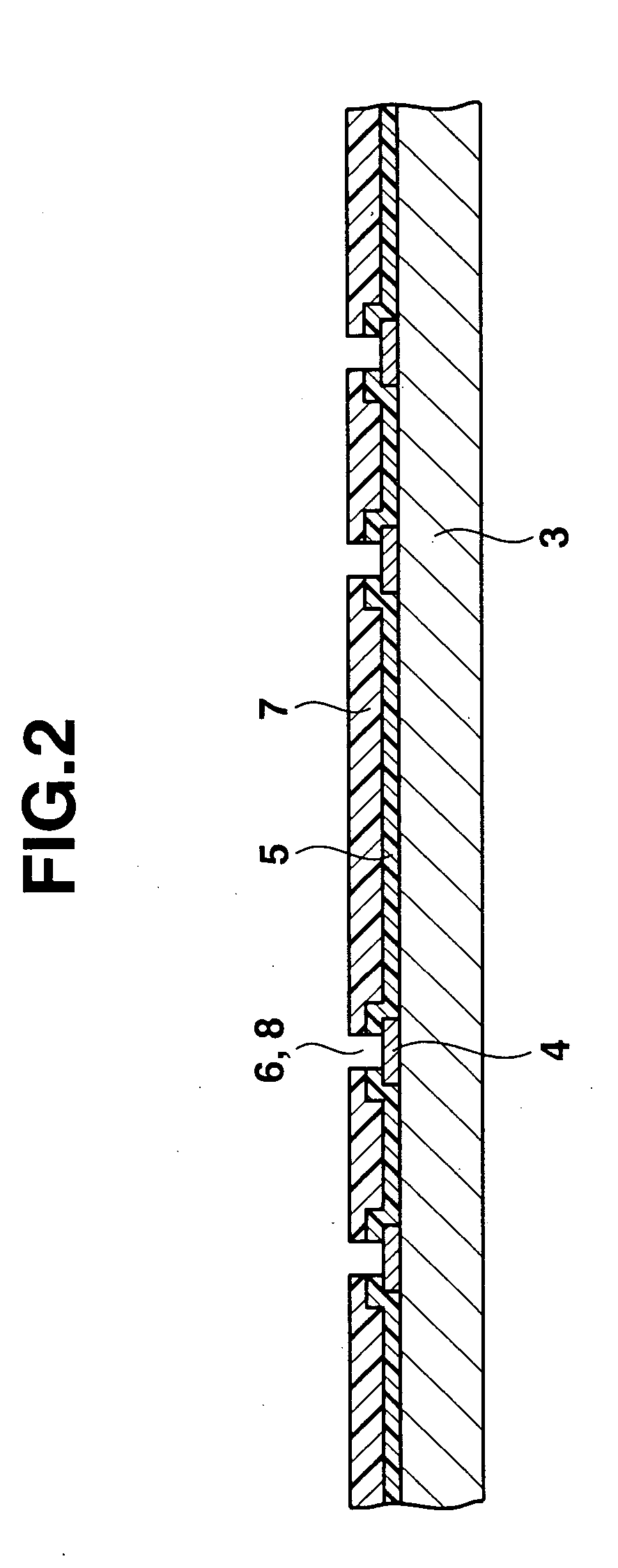

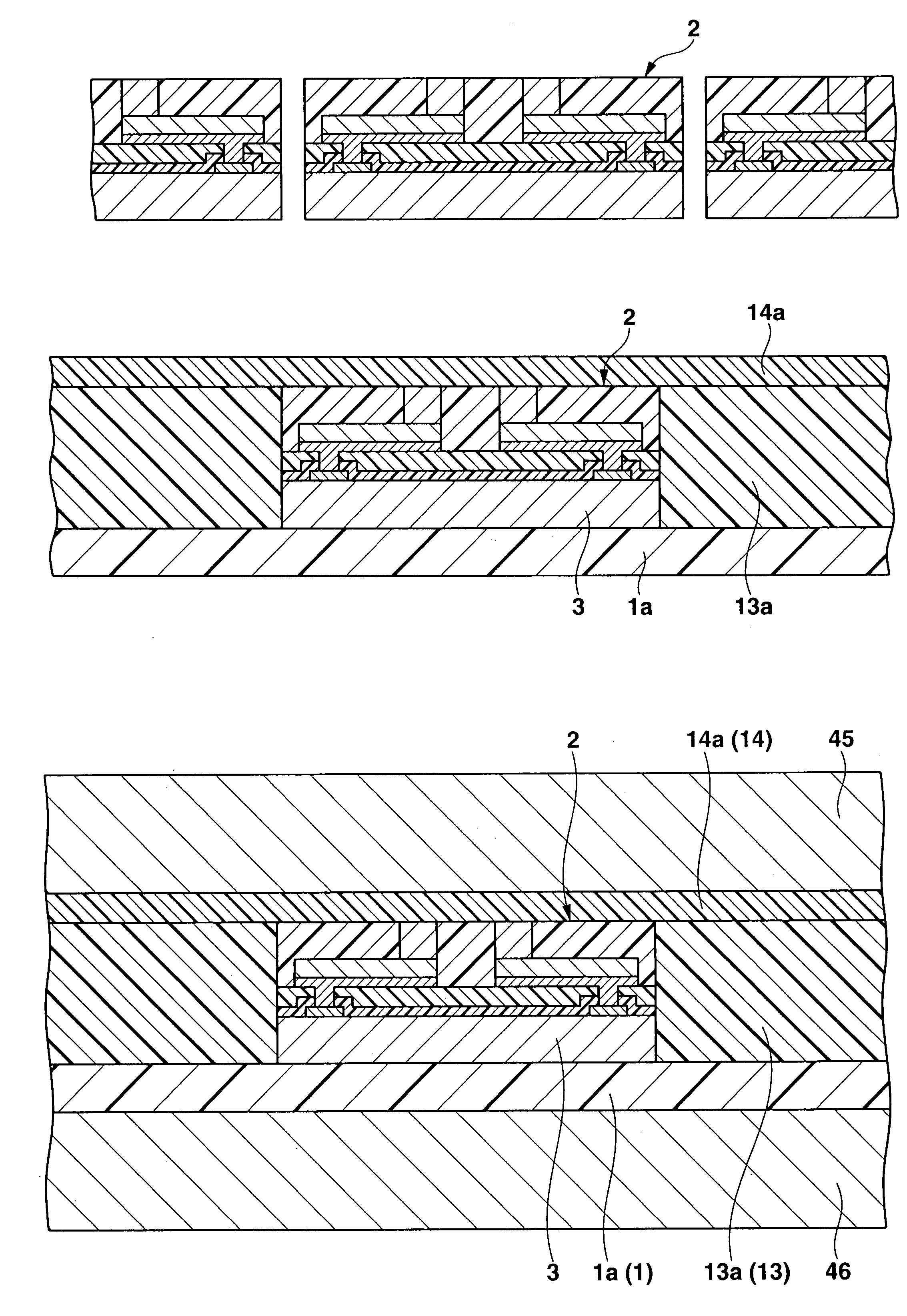

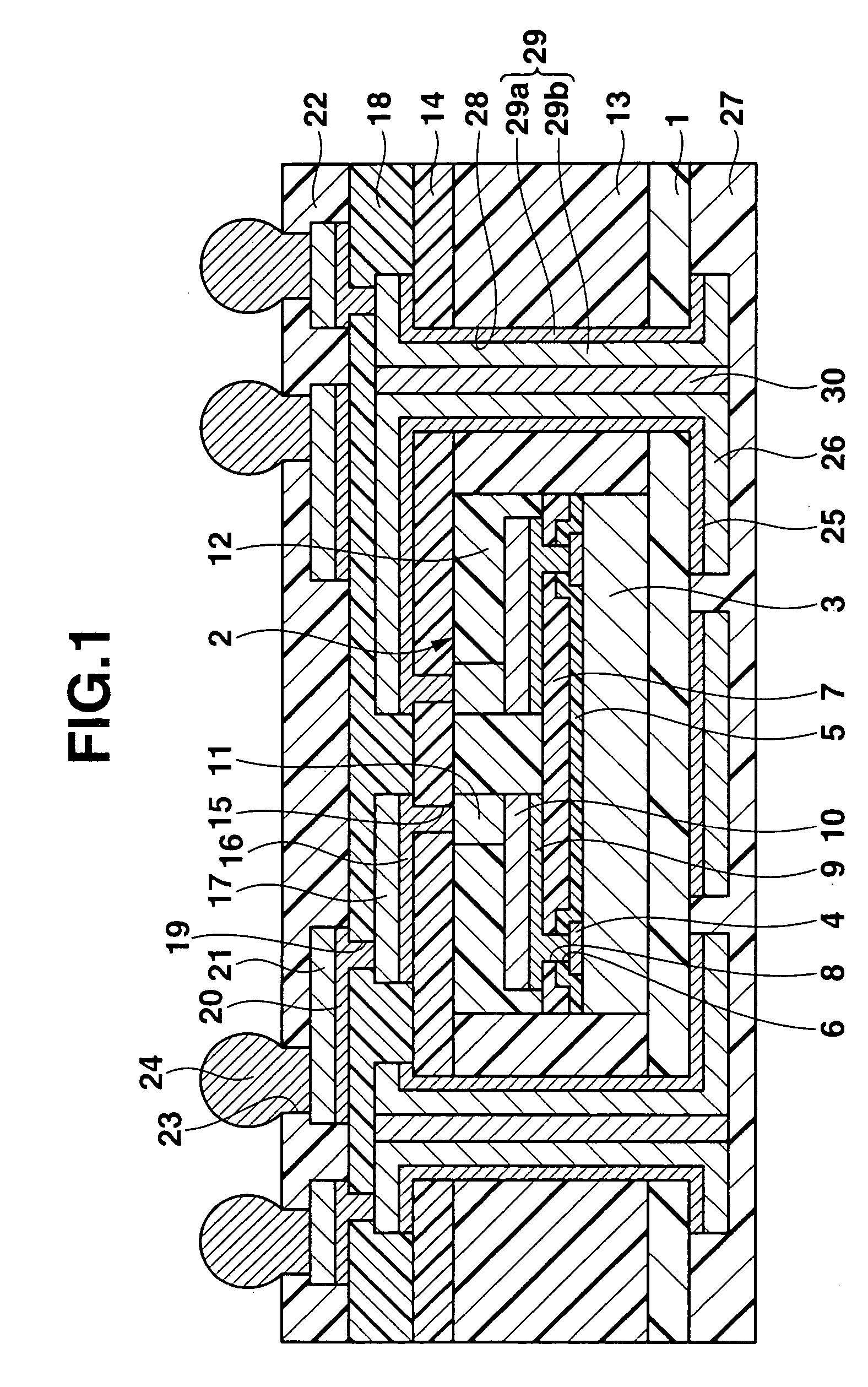

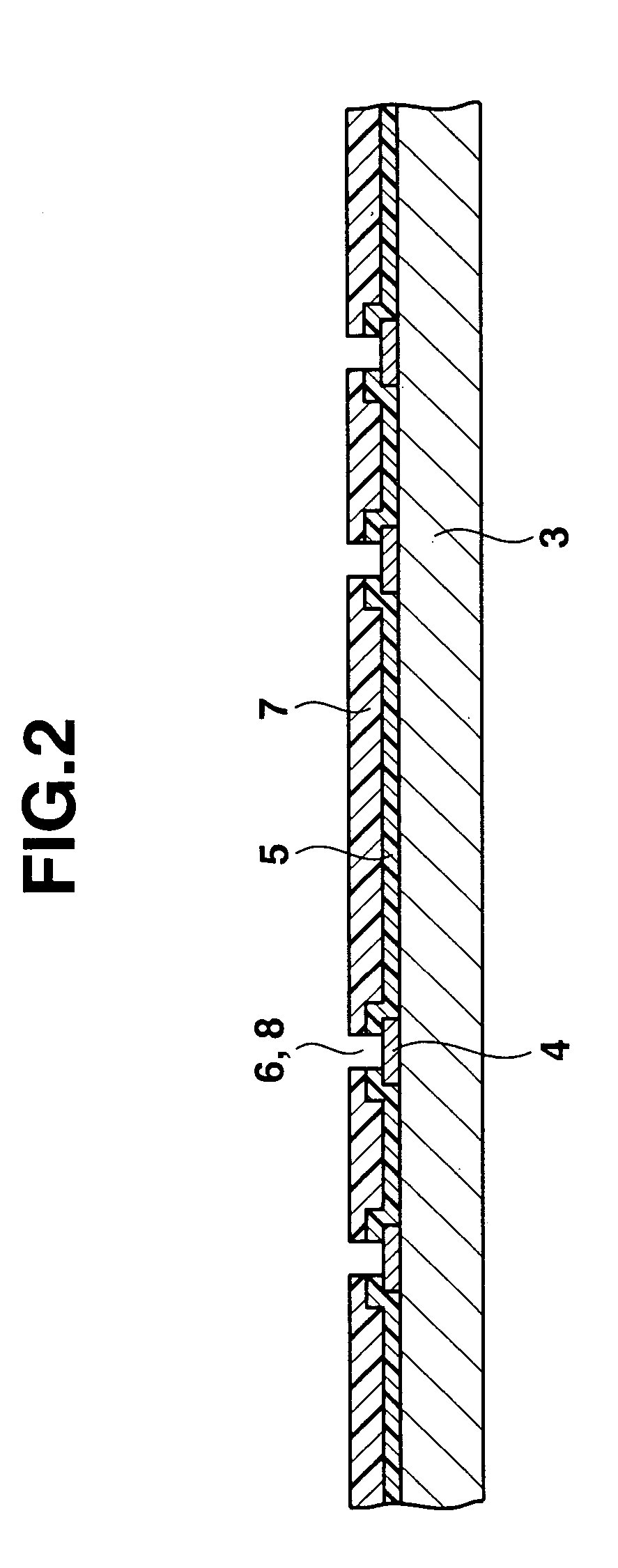

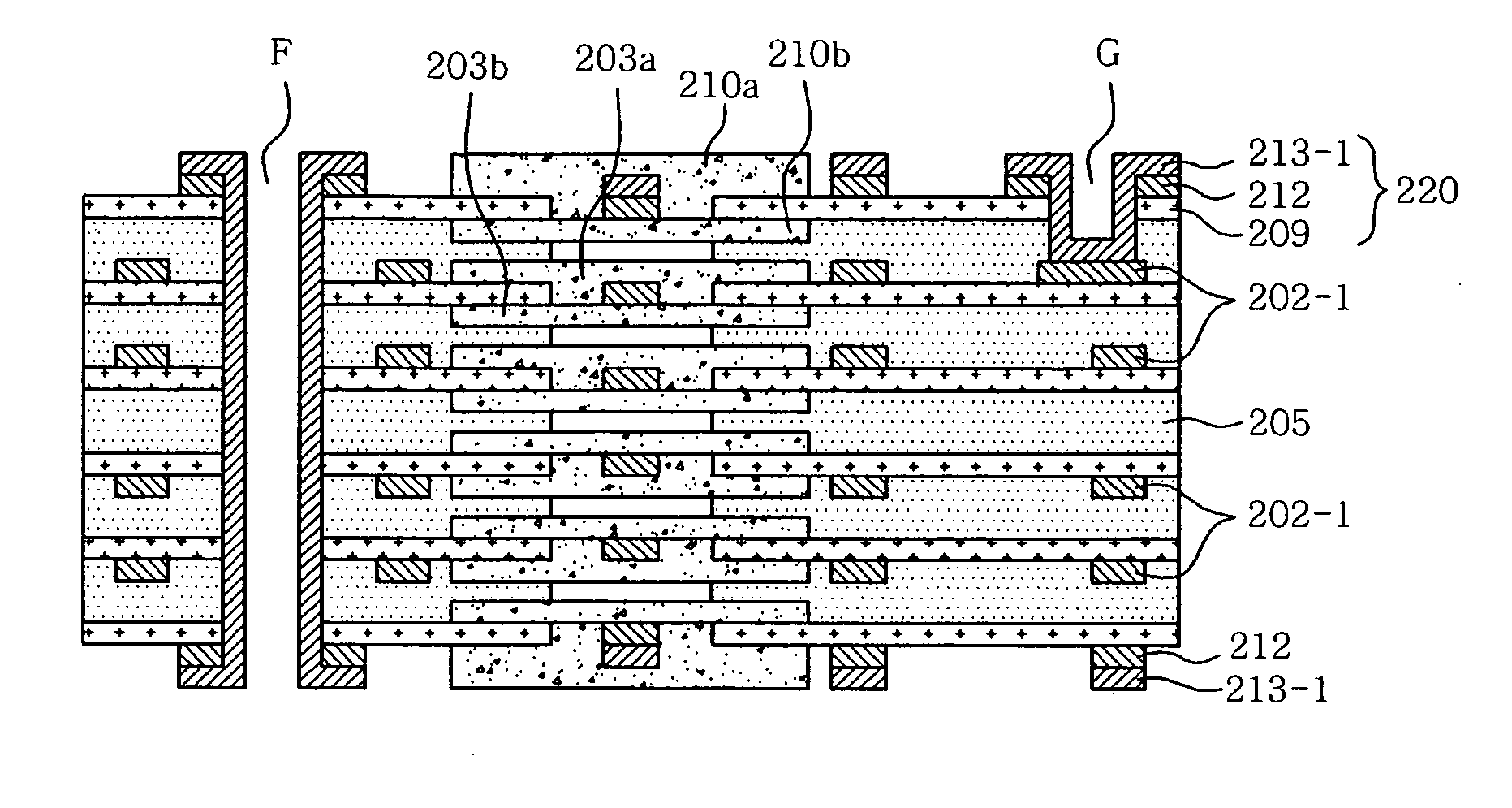

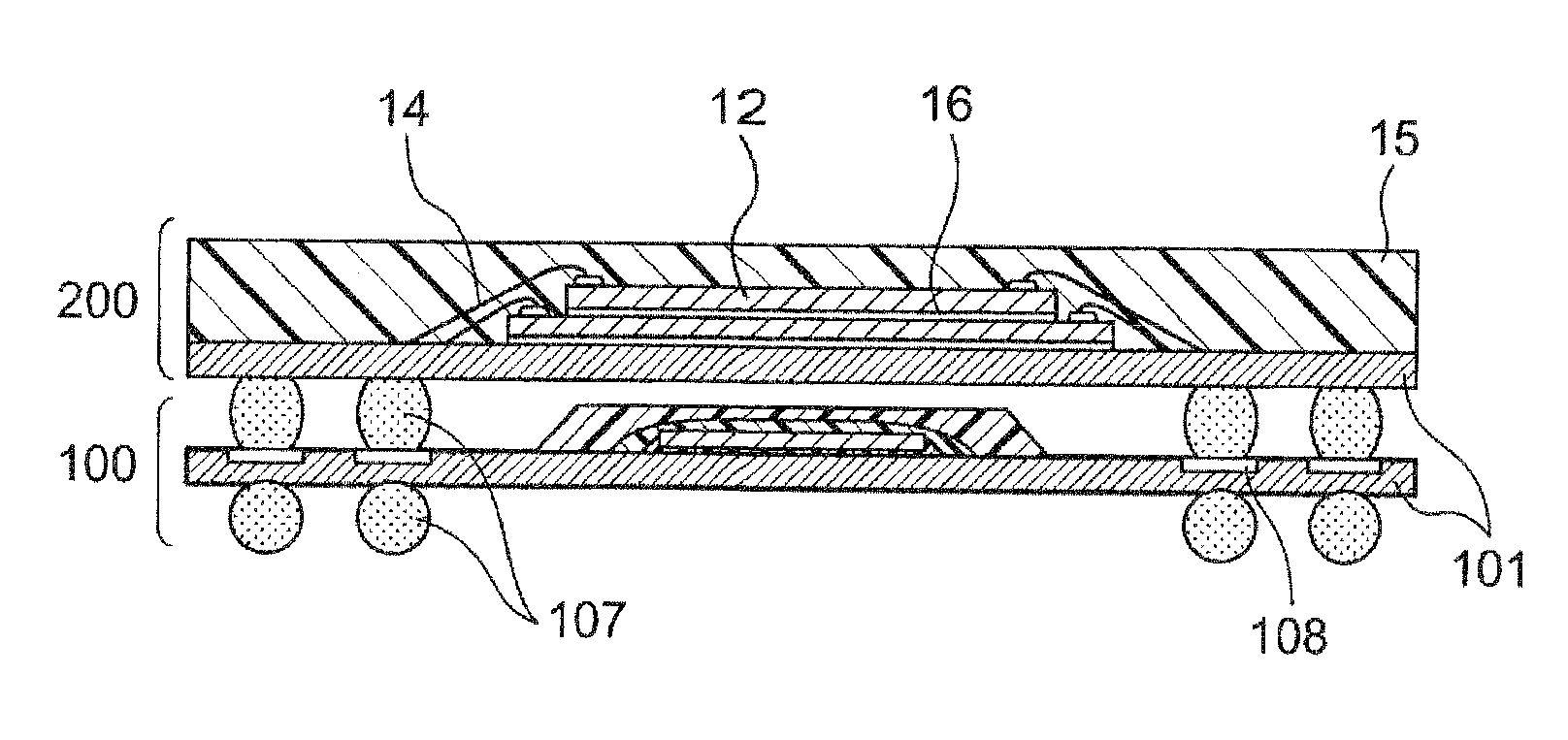

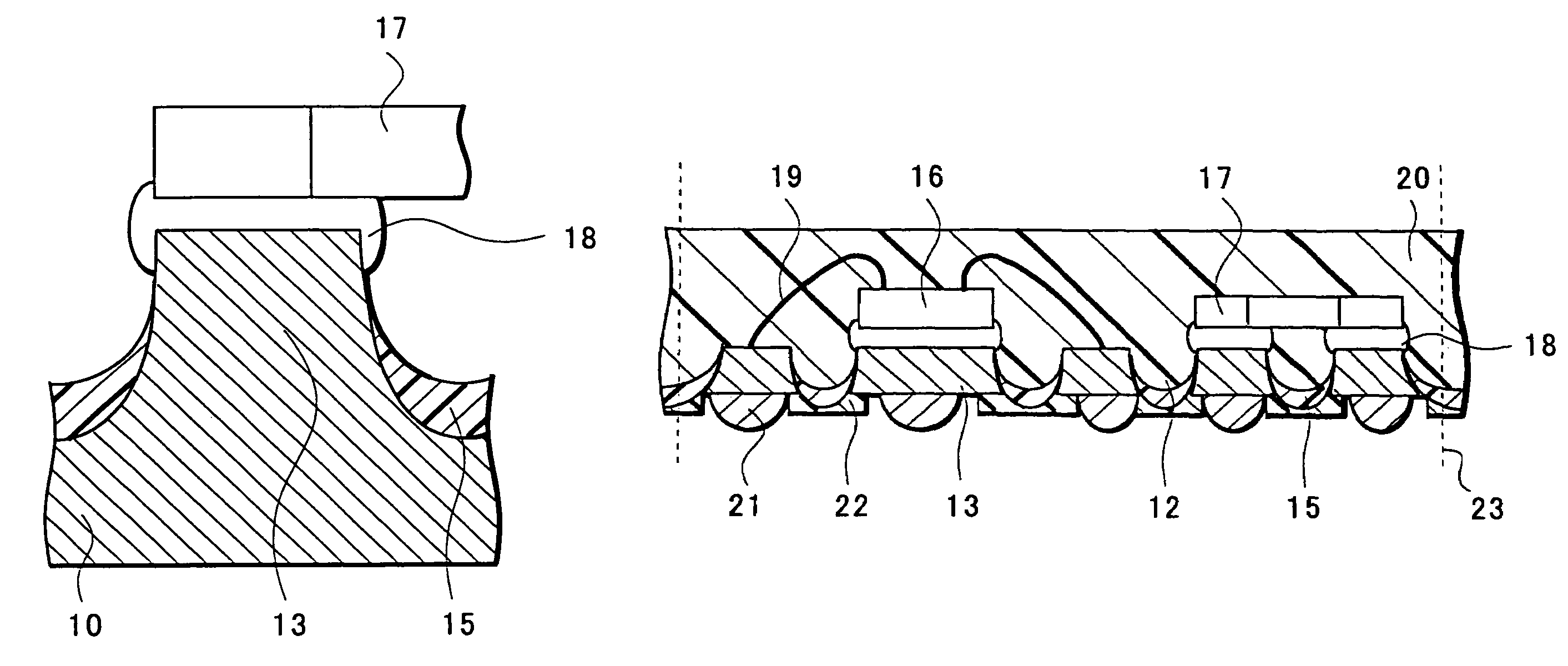

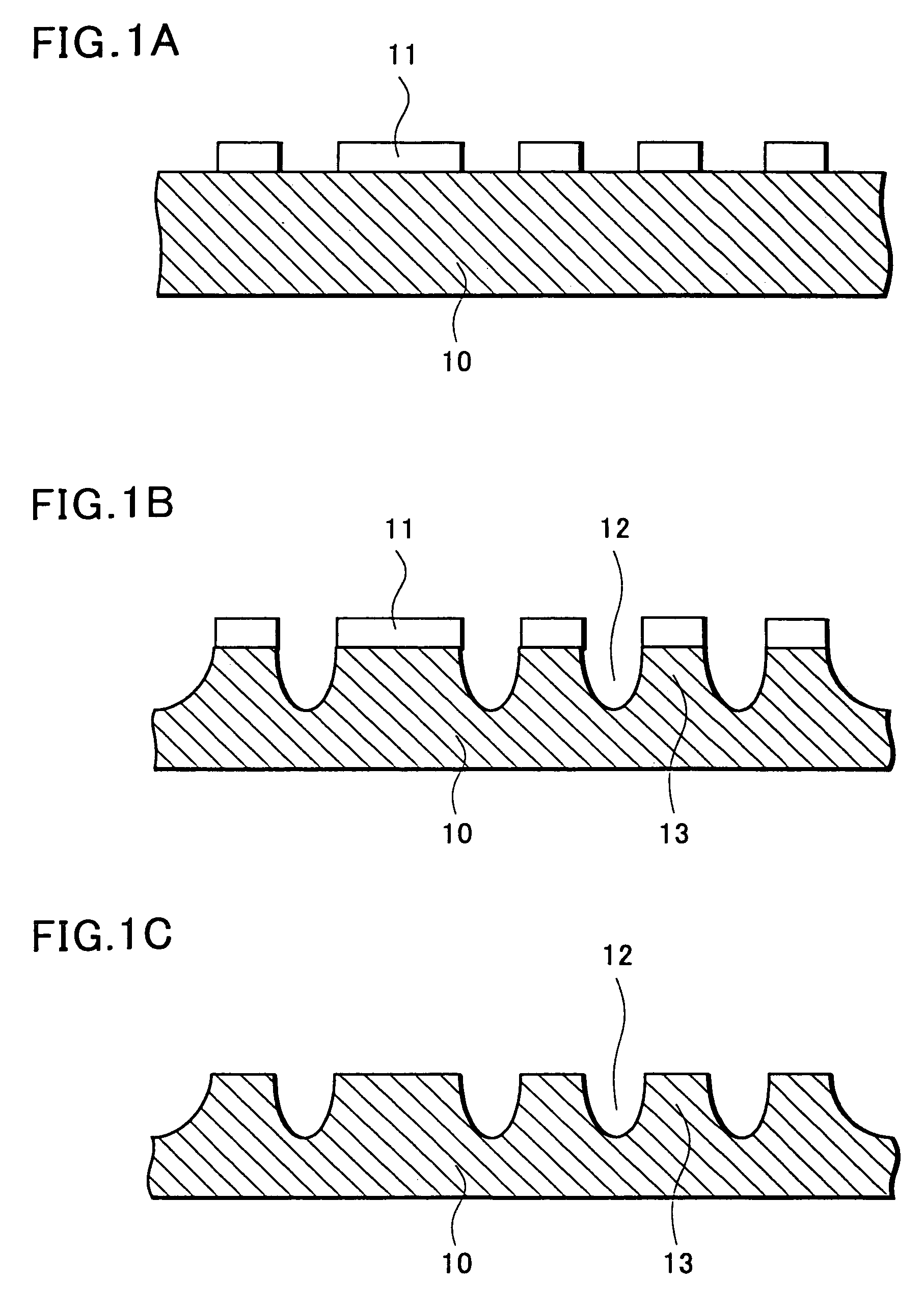

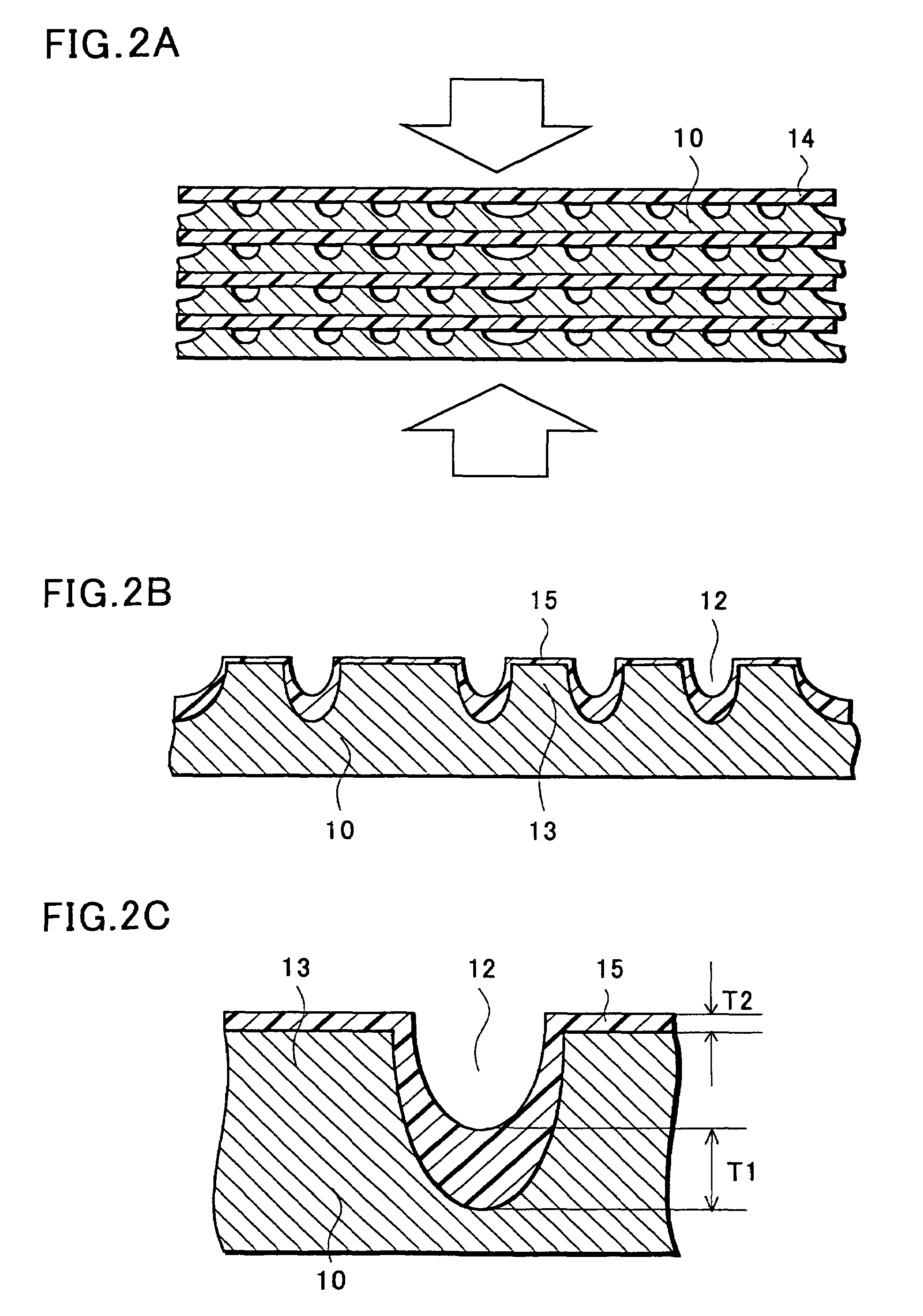

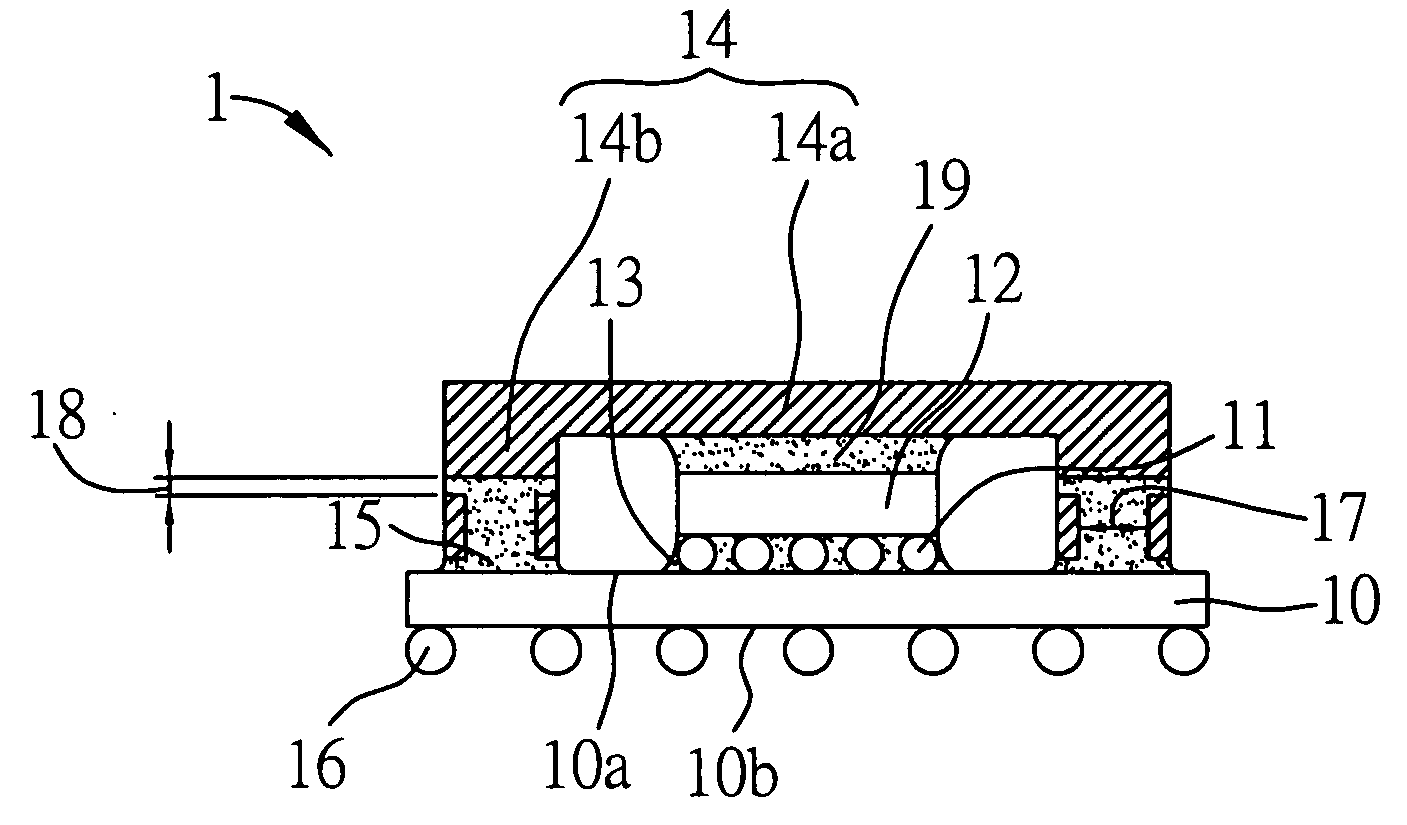

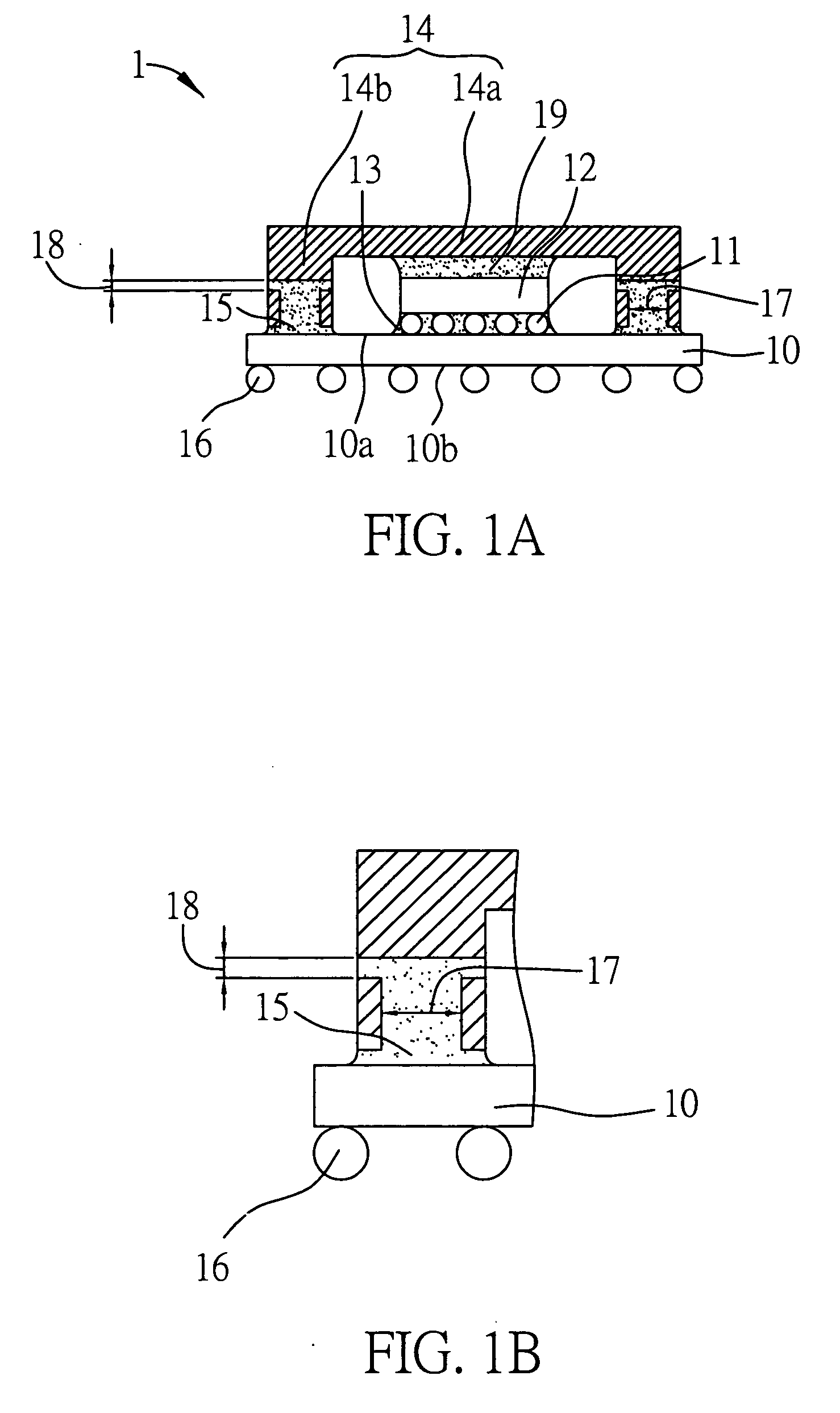

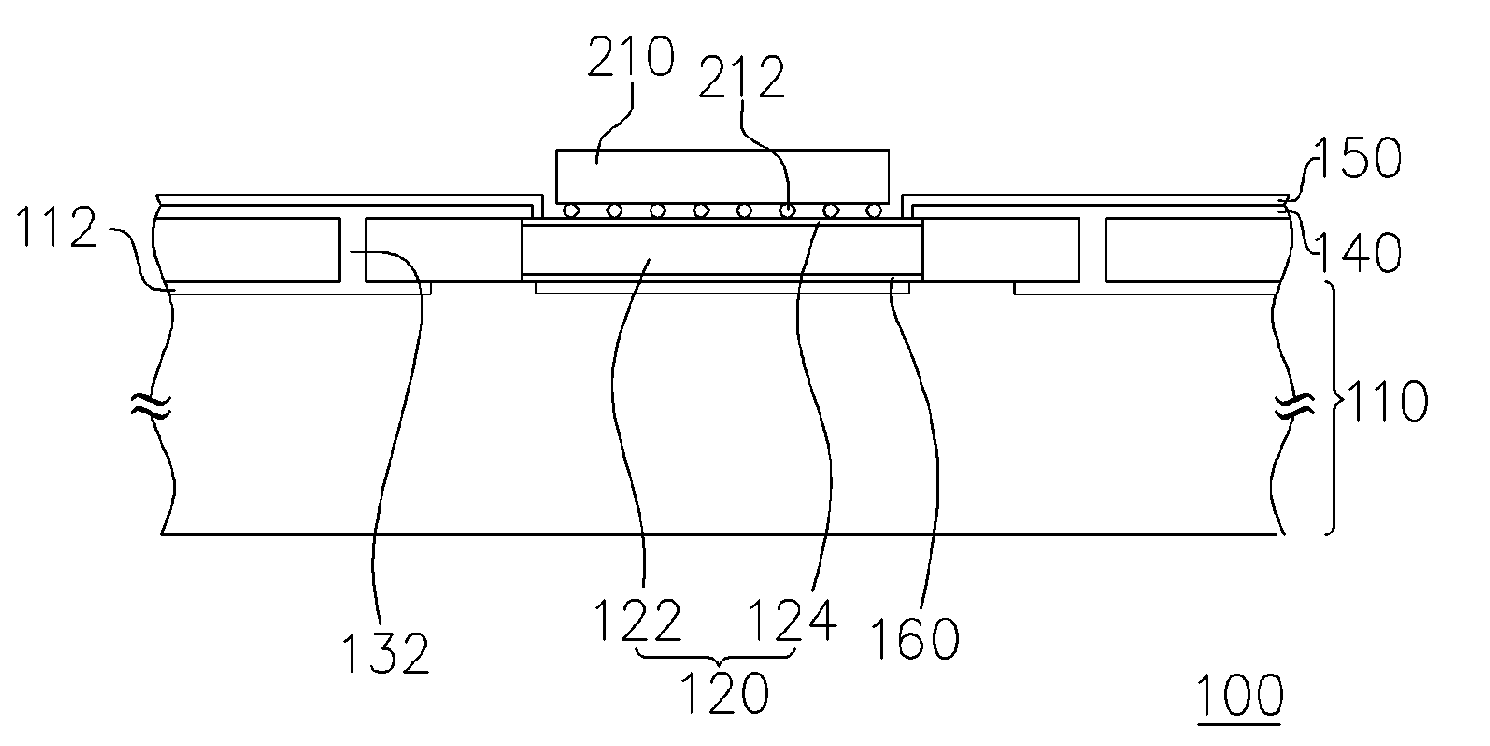

Semiconductor device and method of fabricating the same

InactiveUS20050161803A1Improve bond reliabilityImprove reliabilitySpecific water treatment objectivesSemiconductor/solid-state device detailsInterconnectionEngineering

A semiconductor device includes a base member made of a material containing at least a thermosetting resin, and at least one semiconductor constructing body mounted on the base member, and having a semiconductor substrate and a plurality of external connecting electrodes formed on the semiconductor substrate. An insulating layer is formed on the base member around the semiconductor constructing body. An interconnection of at least one layer is formed on one sides of the semiconductor constructing body and insulating layer, electrically connected to the external connecting electrode of the semiconductor constructing body, and having a connecting pad portion, the semiconductor substrate is fixed to the base member by fixing force of the base member.

Owner:AOI ELECTRONICS CO LTD

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets and surface protecting films

ActiveCN1749344AReduce pollutionPrevent static electricityFilm/foil adhesivesEster polymer adhesivesMonomer compositionAcid value

An adhesive combination comprises (methyl) acrylic acid series polymer and alkali metal salt, wherein the (methyl) acrylic acid series polymer takes the following compositions as monomer composition: 5 to 100 weight percent (methyl) acrylic acid alkylene oxide addition compound, 0 to 95 weight percent (methyl) acrylic acid series monomer of alkyl with one to fourteen carbon atoms except the addition compound and 0 to 95 weight percent other polymerizing monomer; moreover, the acid value of the (methyl) acrylic acid series polymer is less than ten. Therefore, the invention can provide an anti-static adhesive combination which can prevent an adherend receiving no destaticization from carrying static electricity during stripping, thereby reducing the pollution on the adherend and having high adhesion reliability; moreover, the invention also provides an anti-static adhesion slice class and surface protective film formed by the combination.

Owner:NITTO DENKO CORP

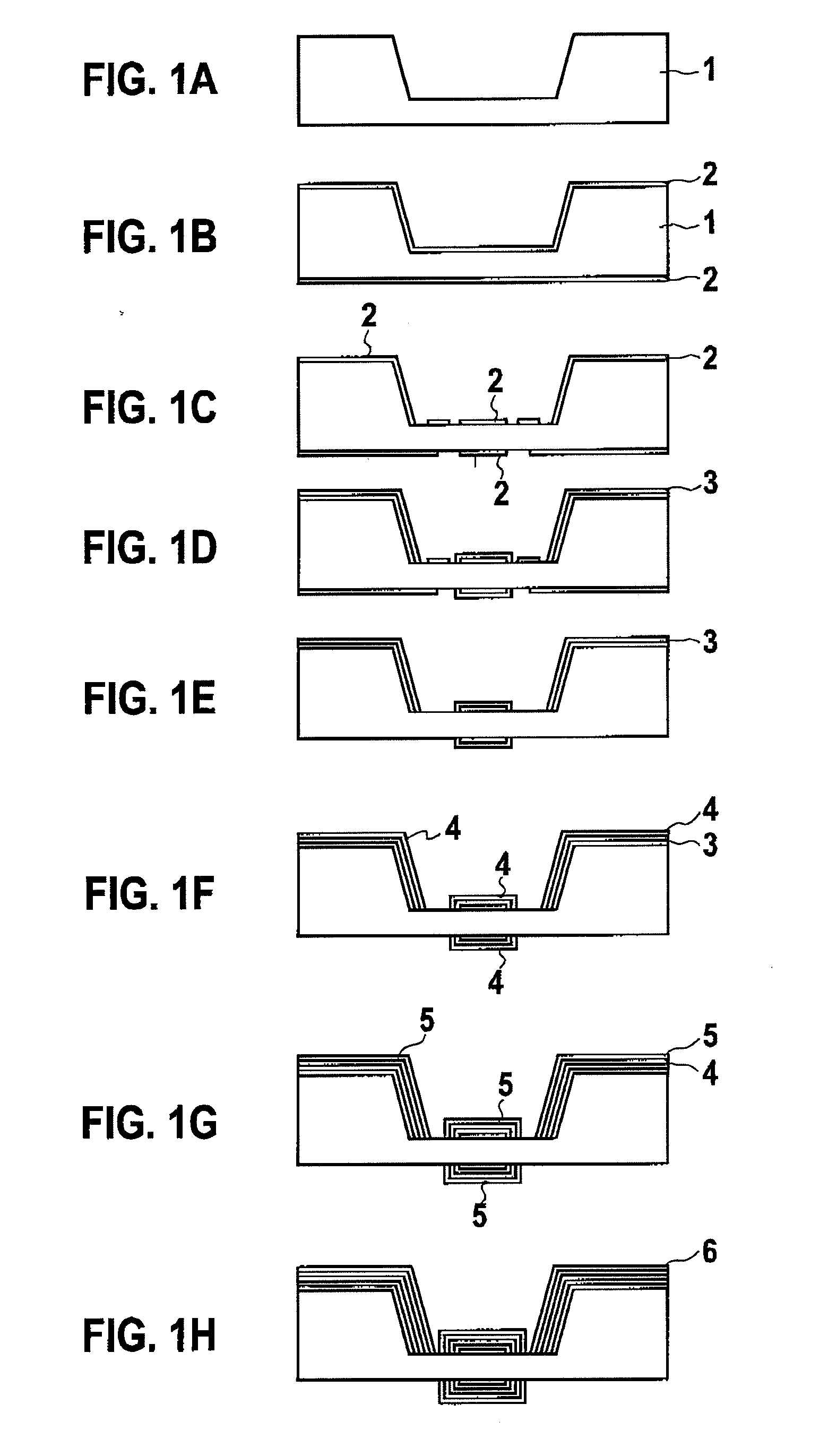

Method of fabricating a semiconductor package utilizing a thermosetting resin base member

InactiveUS7112469B2Improve bond reliabilityImprove reliabilitySpecific water treatment objectivesSemiconductor/solid-state device detailsSemiconductor packageEngineering

A semiconductor device includes a base member made of a material containing at least a thermosetting resin, and at least one semiconductor constructing body mounted on the base member, and having a semiconductor substrate and a plurality of external connecting electrodes formed on the semiconductor substrate. An insulating layer is formed on the base member around the semiconductor constructing body. An interconnection of at least one layer is formed on one sides of the semiconductor constructing body and insulating layer, electrically connected to the external connecting electrode of the semiconductor constructing body, and having a connecting pad portion, the semiconductor substrate is fixed to the base member by fixing force of the base member.

Owner:AOI ELECTRONICS CO LTD

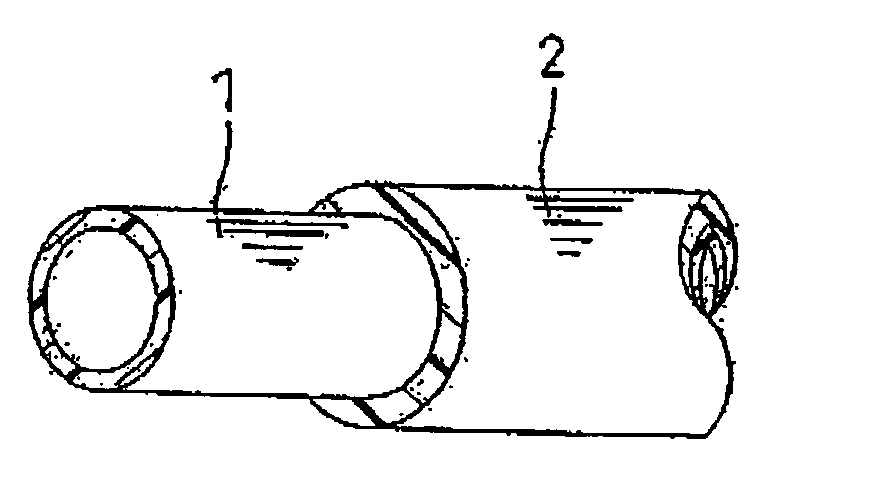

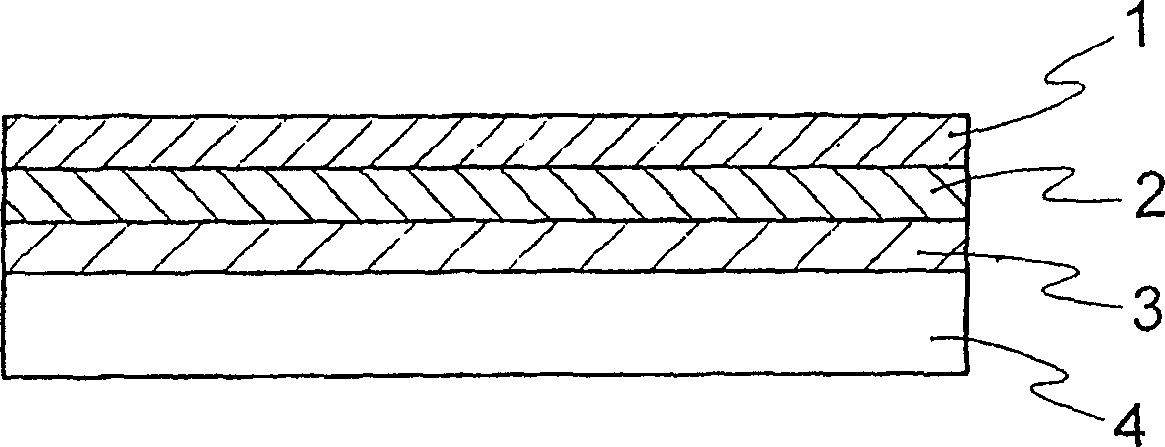

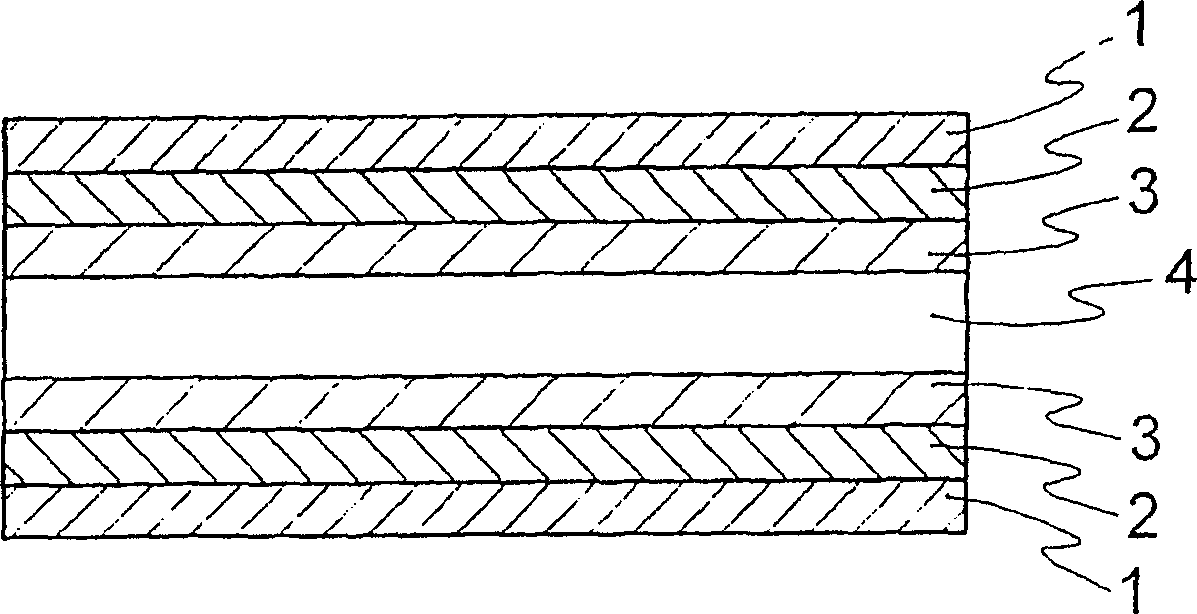

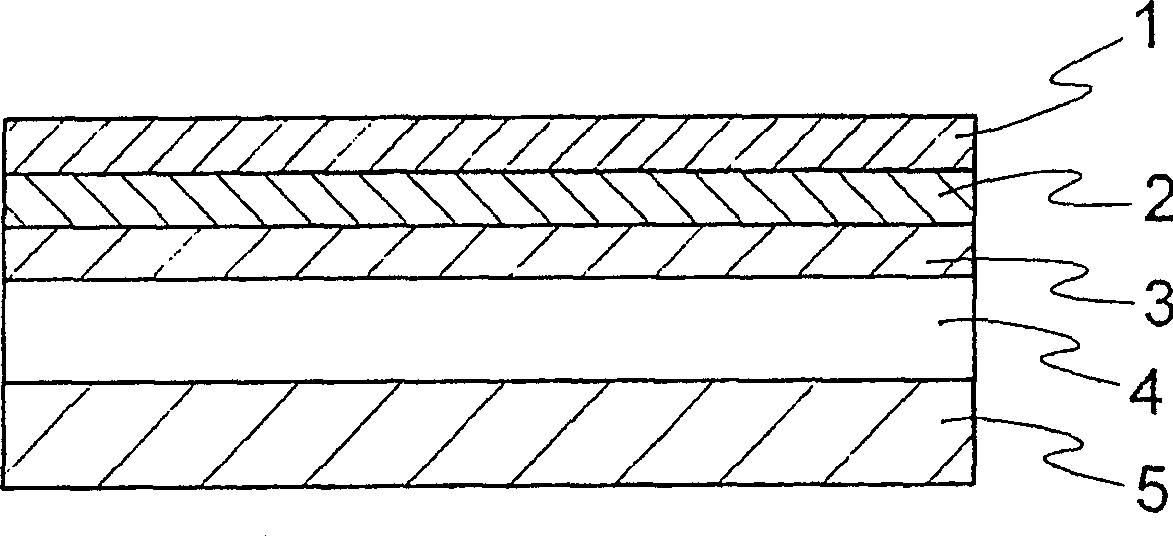

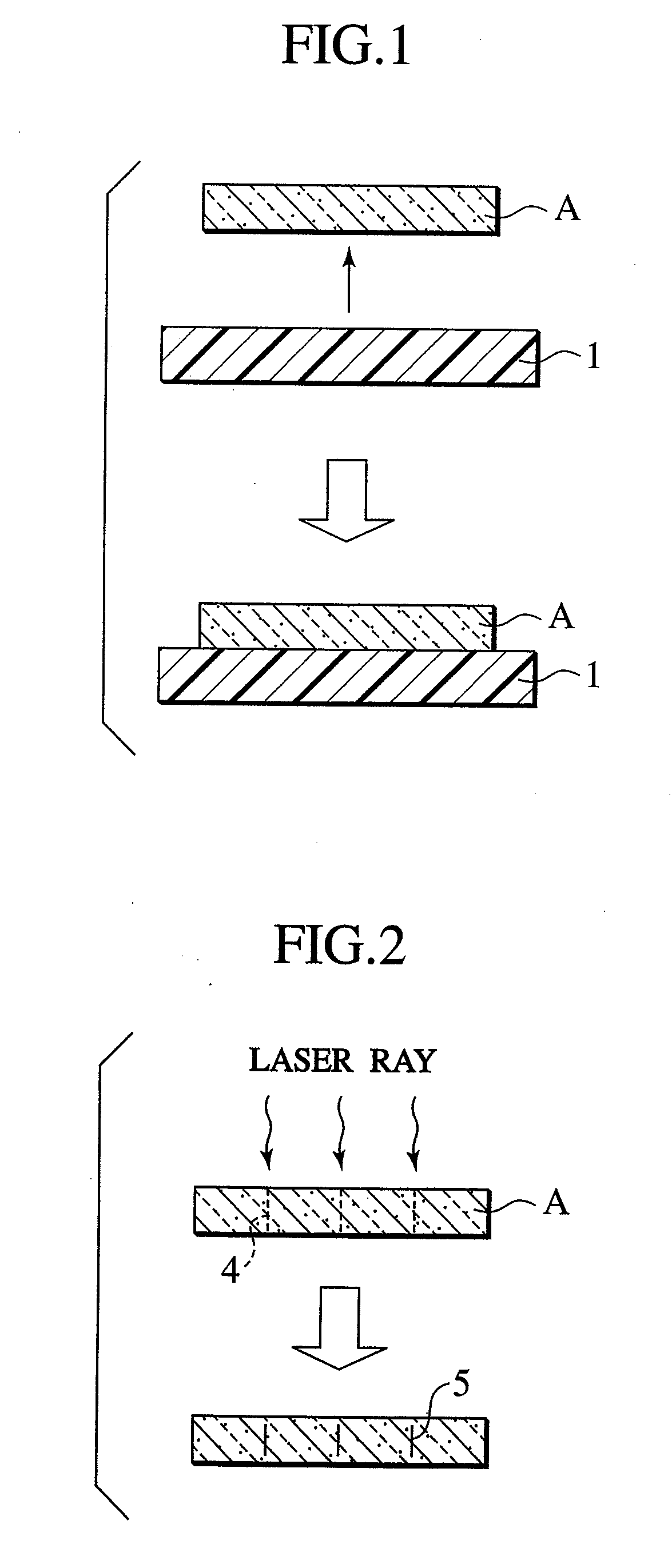

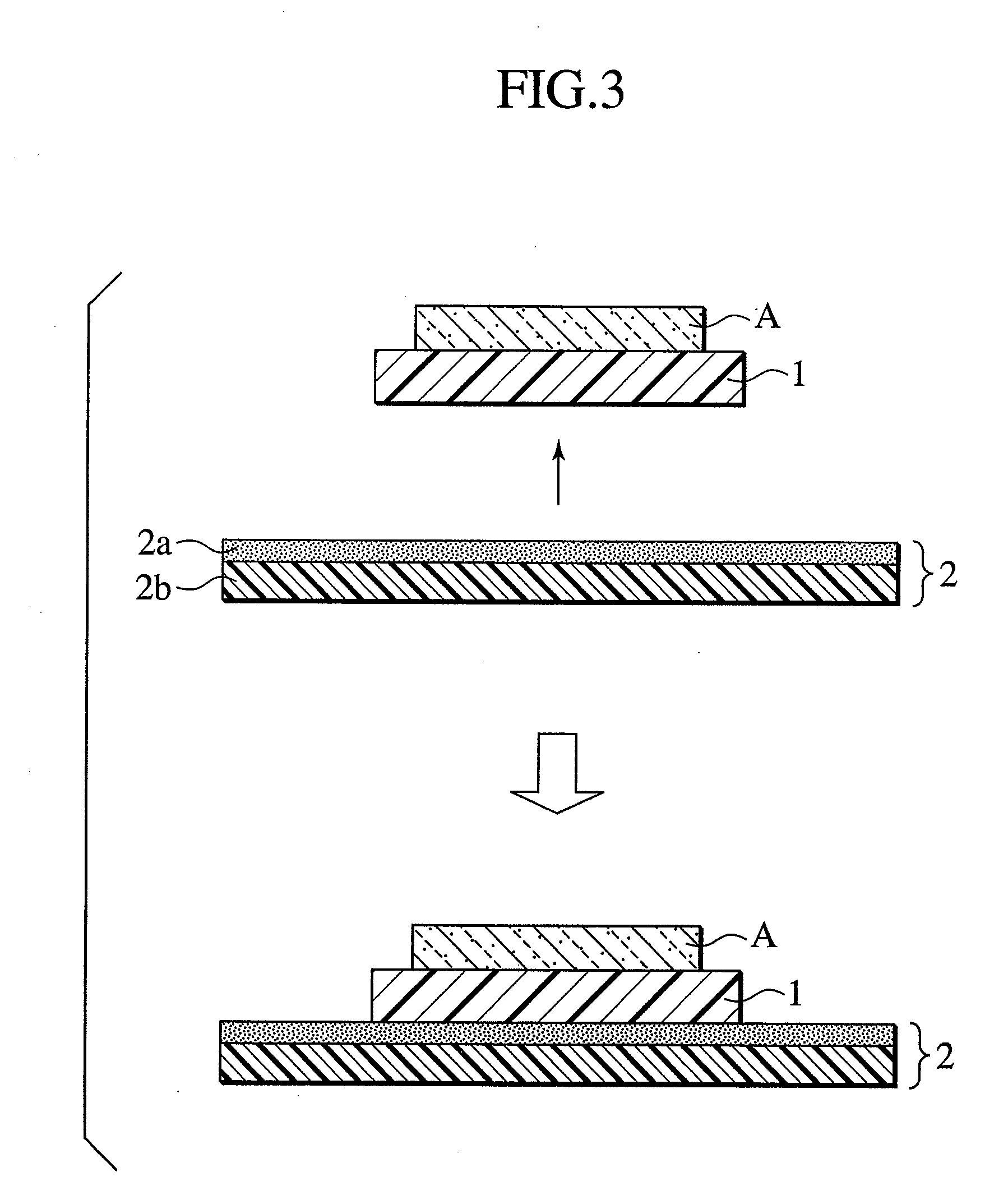

Method of producing fuel hose and fuel hose obtained thereby

InactiveUS6602565B1Improve bond reliabilityAdhesive strengthLayered product treatmentSynthetic resin layered productsEngineeringThermal aging

A method of producing a fuel hose having superior adhesive reliability with superior initial adhesive strength between a tubular fluororesin inner layer and a thermoplastic resin outer layer and with restrained deterioration in adhesive strength after heat aging and immersion into fuel under severe conditions such as an inside of an engine compartment. The method includes plasma treatment on a peripheral surface of the tubular fluororesin inner layer, at least one treatment of water treatment and silane coupling agent treatment on the plasma treated surface and formation of the thermoplastic resin outer layer on the treated peripheral surface.

Owner:SUMITOMO RIKO CO LTD

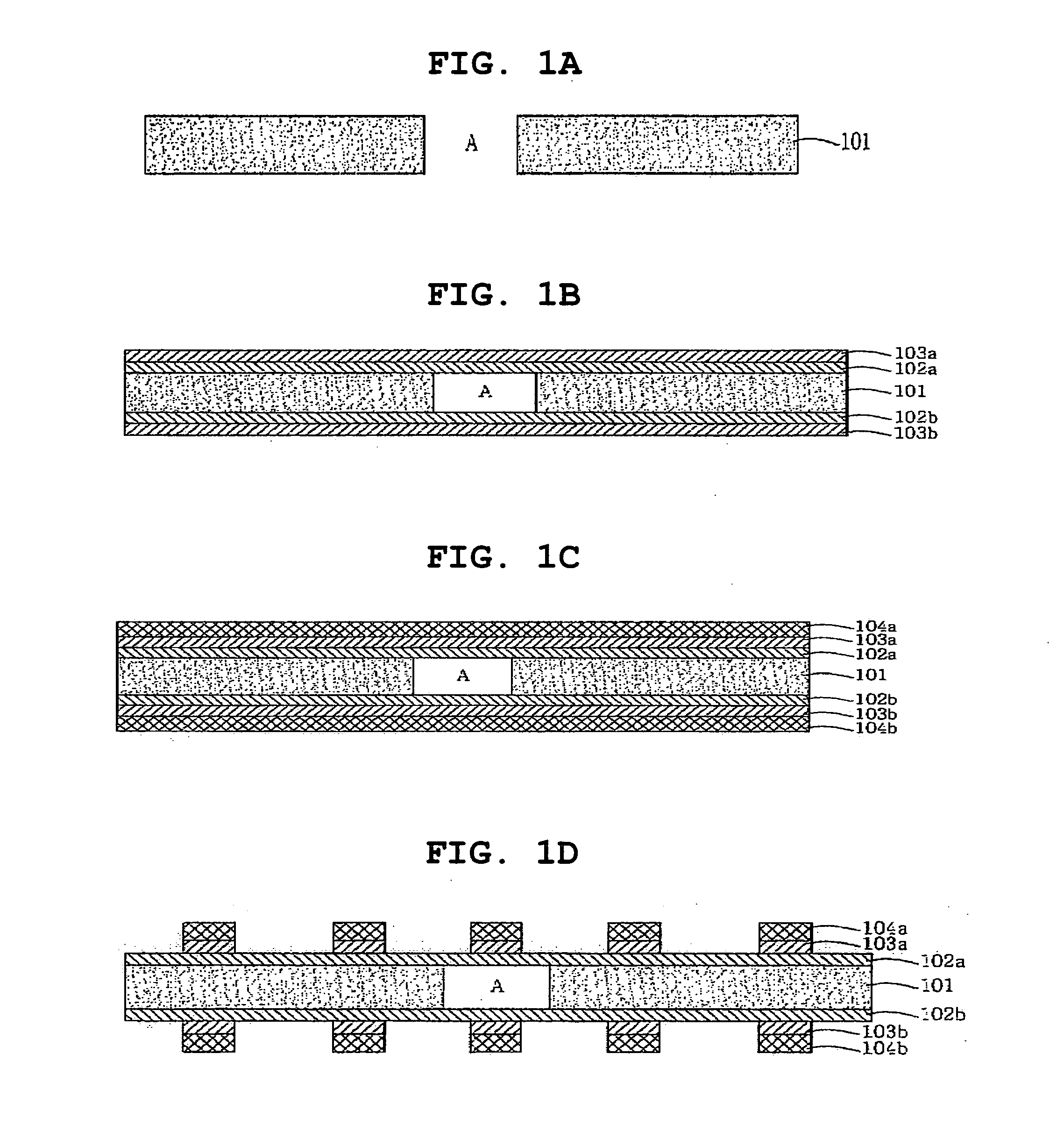

Laminate, printed wiring board and method for manufacturing them

InactiveCN1720136AImproves bond stabilityImprove bond reliabilityPrinted circuit manufactureMetal layered productsHigh densityEngineering

The invention provides a laminate which can be used for forming a high density circuit thereon, with good resistance to further processing such as decontamination and excellent adhesion, and excellent adhesion reliability in a high temperature atmosphere, as well as a print circuit wiring board, that is, the invention relates to a laminate and a print circuit wiring board, comprising a thermoplastic polyimide film layer and a metal layer which are formed on one side or two sides thereof or a non-thermoplastic polyimide film layer.

Owner:KANEKA CORP

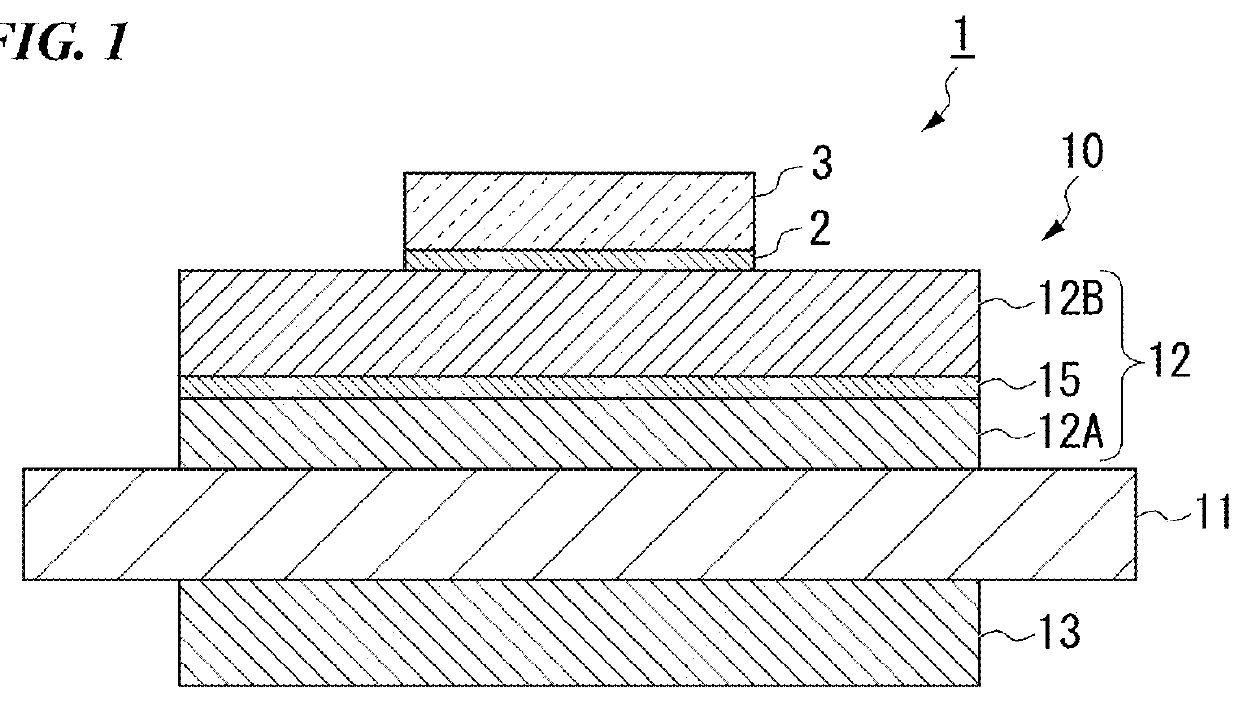

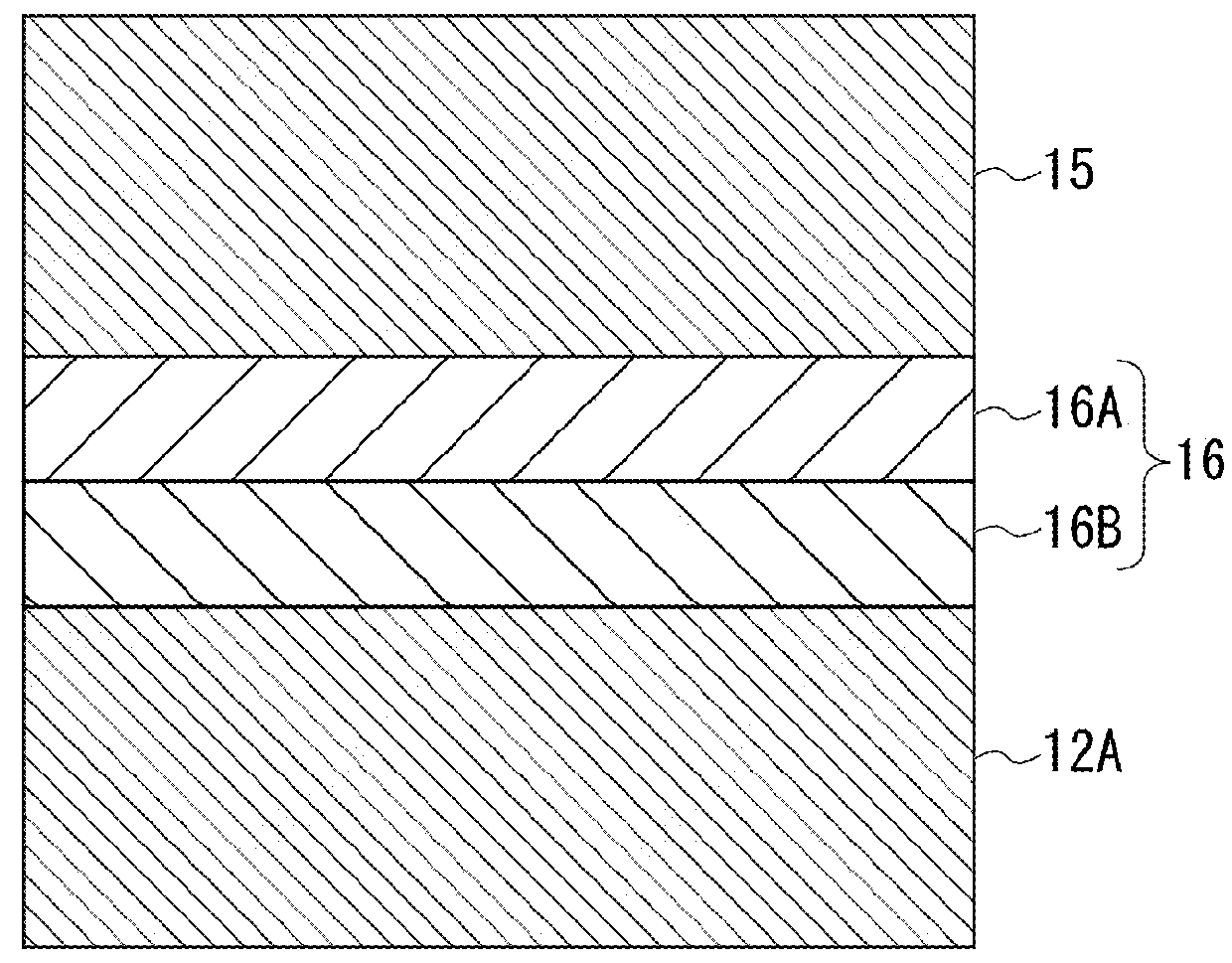

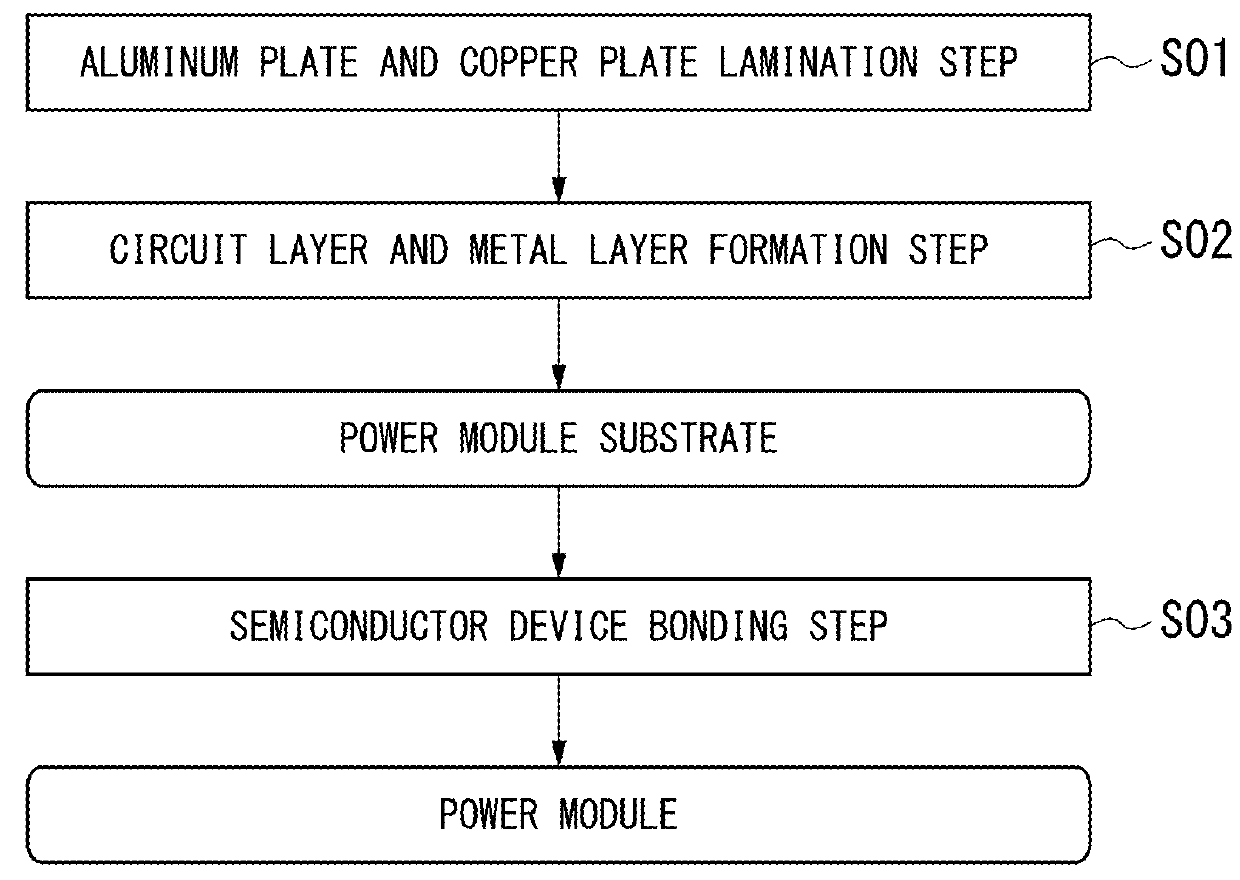

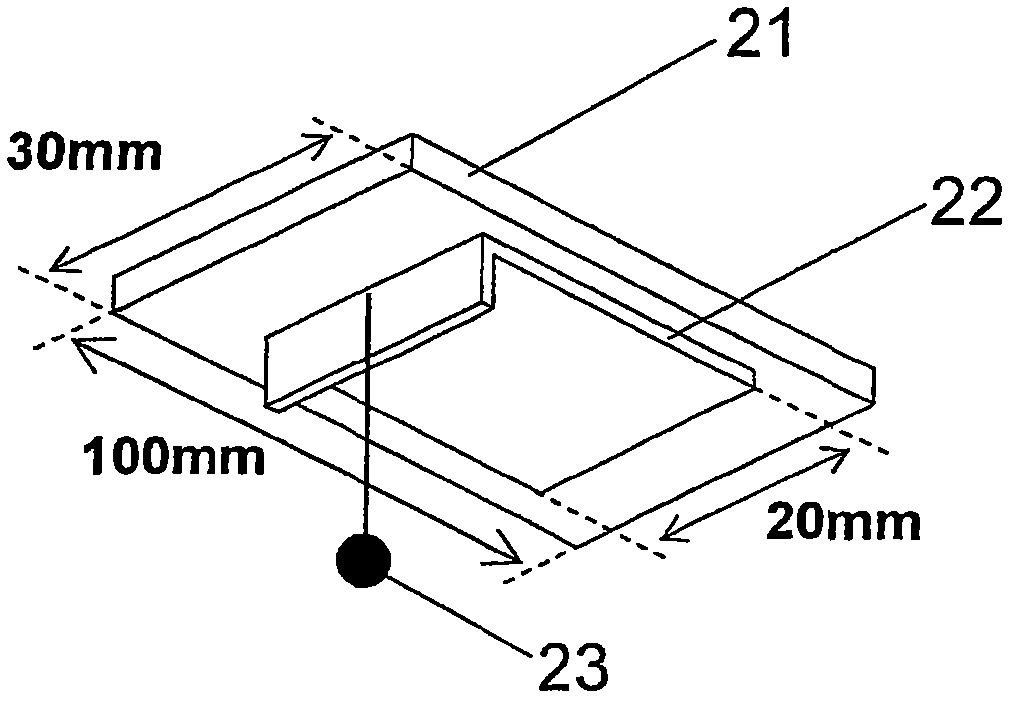

Bonding body, power module substrate, and heat-sink-attached power module substrate

ActiveUS20160035660A1Improve bond reliabilityAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesBond interfaceCopper

A bonding body includes: an aluminum member composed of aluminum; and a metal member composed of any one of copper, nickel, and silver, wherein the aluminum member and the metal member are bonded together. In a bonding interface between the aluminum member and the metal member, a Ti layer and an Al—Ti—Si layer are formed, the Ti layer being disposed at the metal member side in the bonding interface, and the Al—Ti—Si layer being disposed between the Ti layer the aluminum member and containing Si which is solid-solubilized into Al3Ti. The Al—Ti—Si layer includes: a first Al—Ti—Si layer formed at the Ti layer side; and a second Al—Ti—Si layer formed at the aluminum member side and a Si concentration of which is lower than a Si concentration of the first Al—Ti—Si layer.

Owner:MITSUBISHI MATERIALS CORP

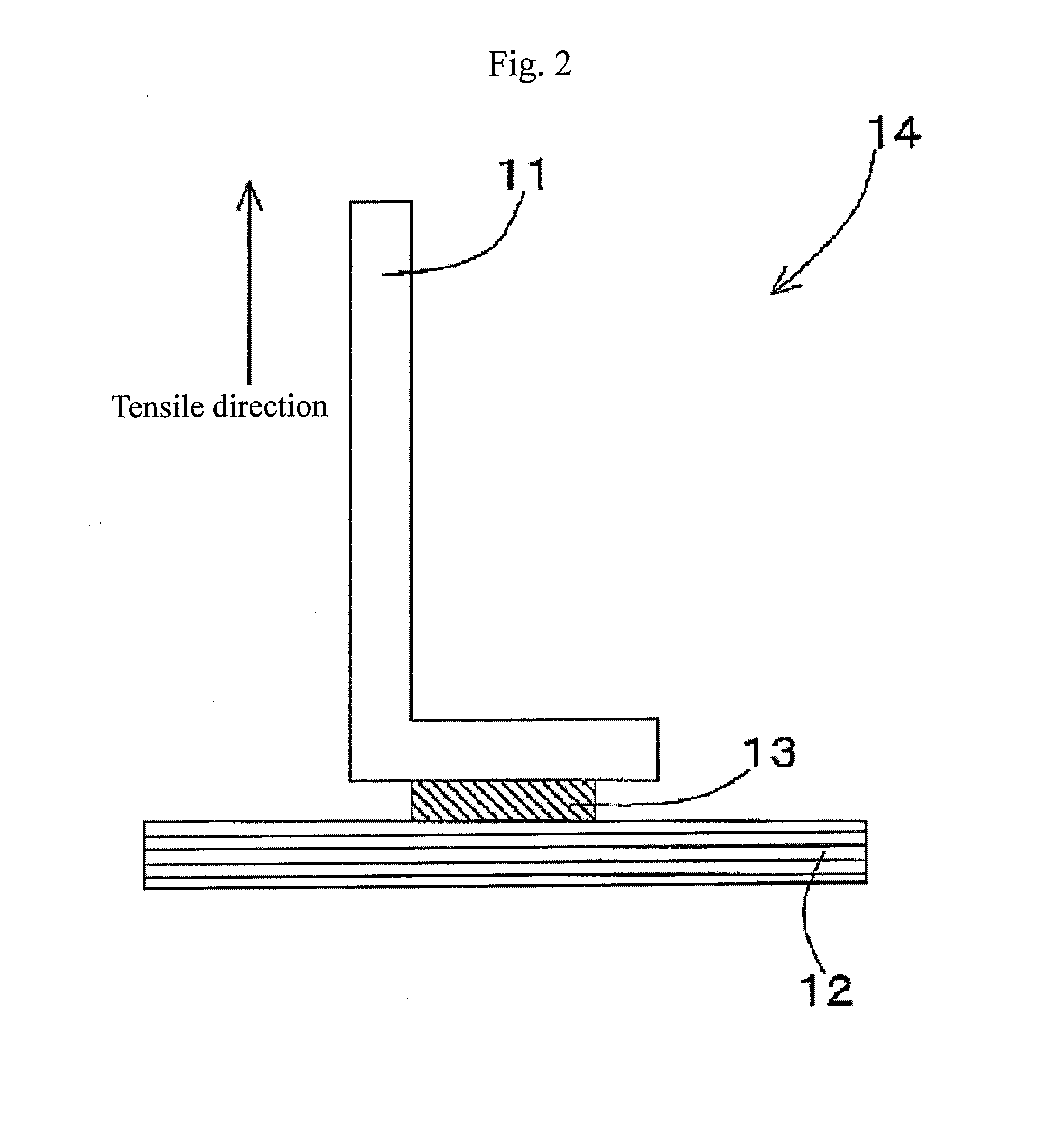

Optical-use pressure-sensitive adhesive sheet

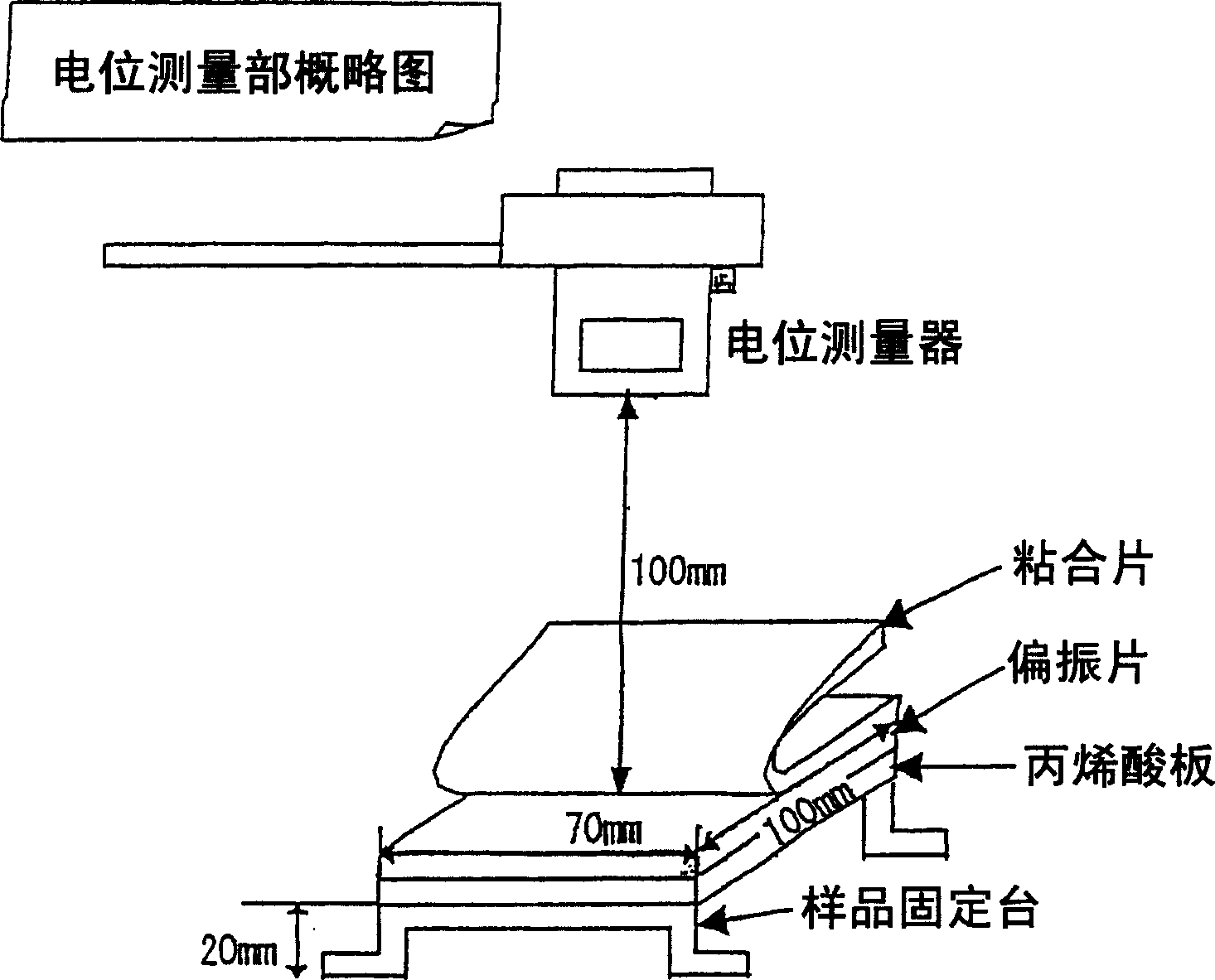

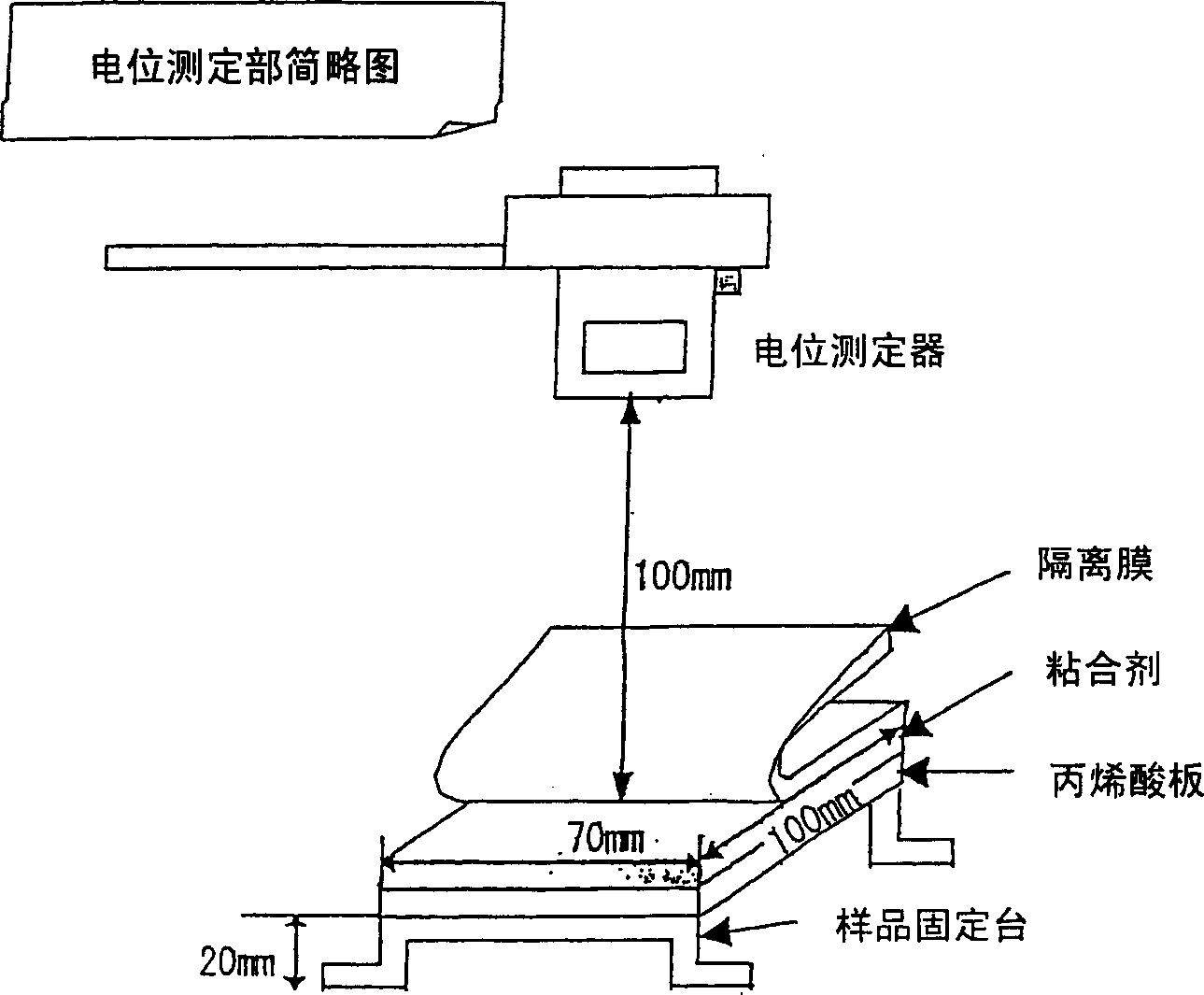

ActiveCN102051133AStripping does not produceImprove bond reliabilityMonocarboxylic acid ester polymer adhesivesOpticsConstant loadPeel force

The invention provides an optical-use adhesive sheet excellent in adhesiveness under bending, twisting or distorting stress. The optical-use adhesive sheet has an adhesive layer having a storage elastic modulus at 80 DEG C of at least 2.0X10 4 Pa and a loss elastic modulus at 80 DEG C of at least 1.0X10 4 Pa, the optical-use adhesive sheet is characterized in that the adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test, of at most 50 mm. In the L-shape peel test, an L-shaped stainless steel clamp is adhered with an acrylicresin plate through the adhesive sheet, the acrylicresin plate and the stainless steel clamp are processed for 15 minutes at 50 DEG C under 5 atm, and then, the stainless steel clamp is drawn along a direction vertical to a surface of the acrylicresin plate so as to test the peel force. In the constant-load peel test, a double-faced adhesive sheet is adhered on the acrylicresin plate, then, the acrylicresin plate and the double-faced adhesive sheet are processed for 10 minutes at 50 DEG C under 5 atm, and then, a load of 100gf is applied along the direction vertical to the surface of the acrylicresin plate on a tail end in a length direction of the adhesive sheet so as to test the peel distance of the adhesive sheet after 3 hours.

Owner:NITTO DENKO CORP

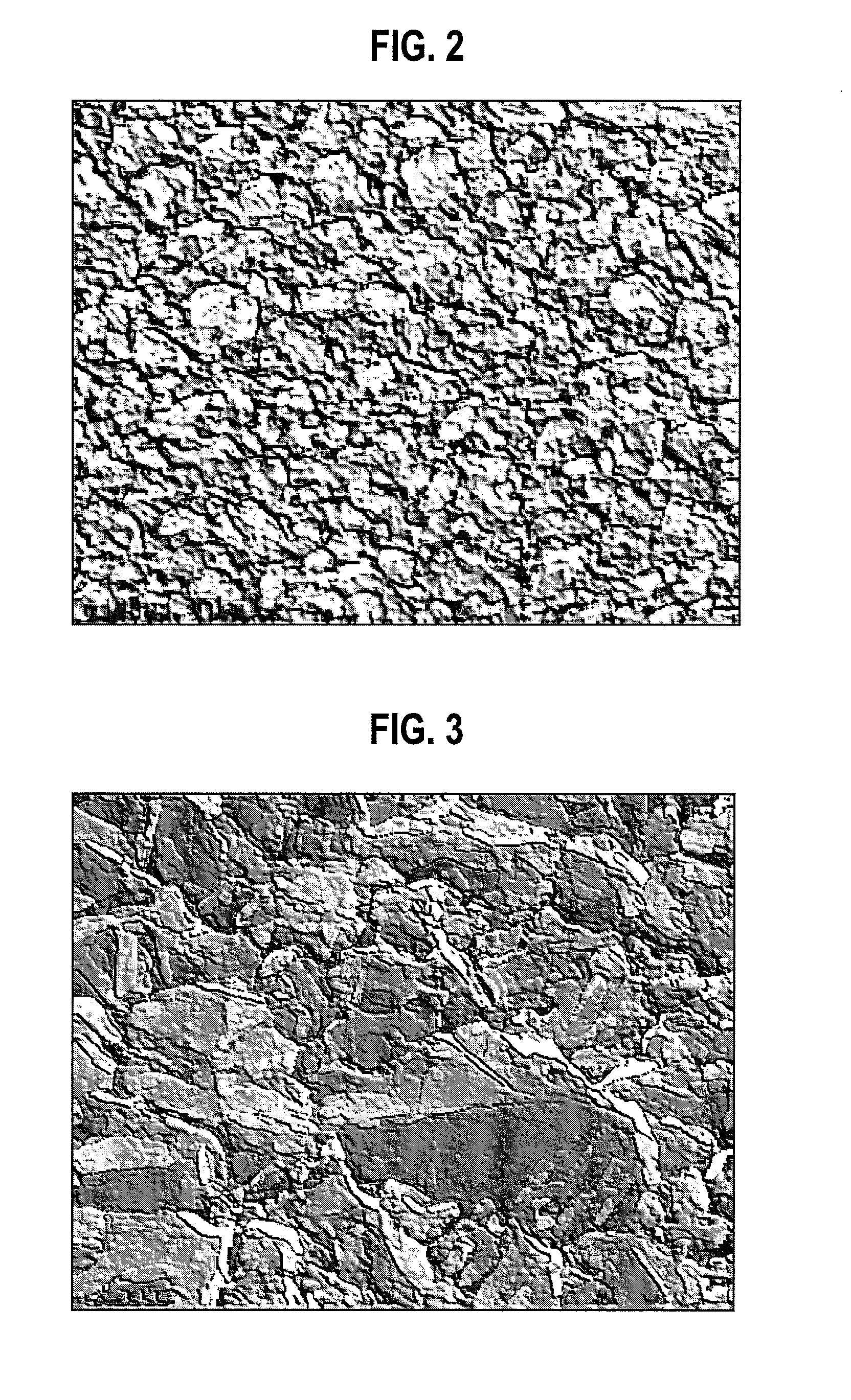

Silver layer formed by electrosilvering substrate material

InactiveUS20080006911A1Effective reflectionInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesSilver plateSilver coating

Owner:MATSUSHITA ELECTRIC WORKS LTD

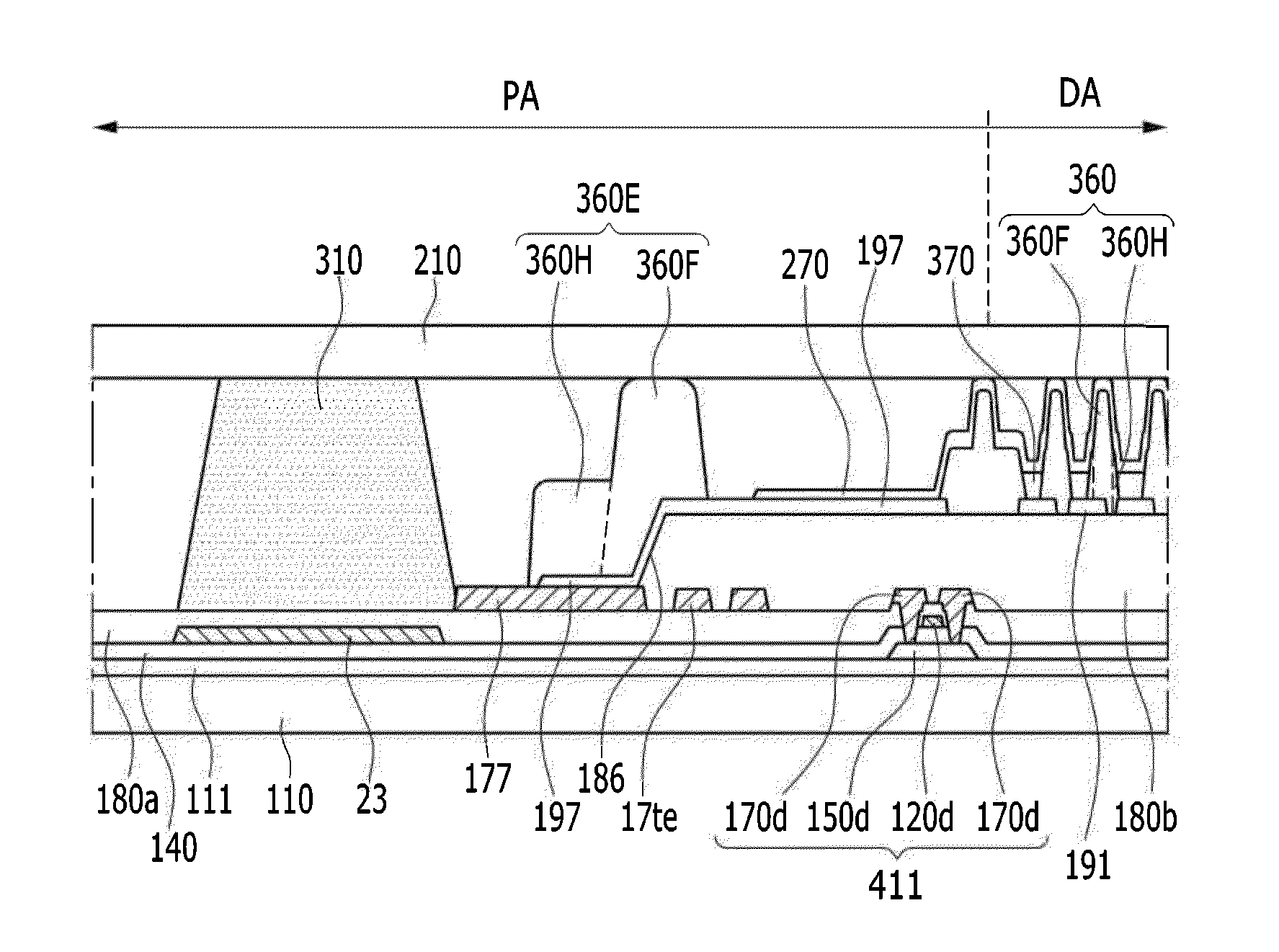

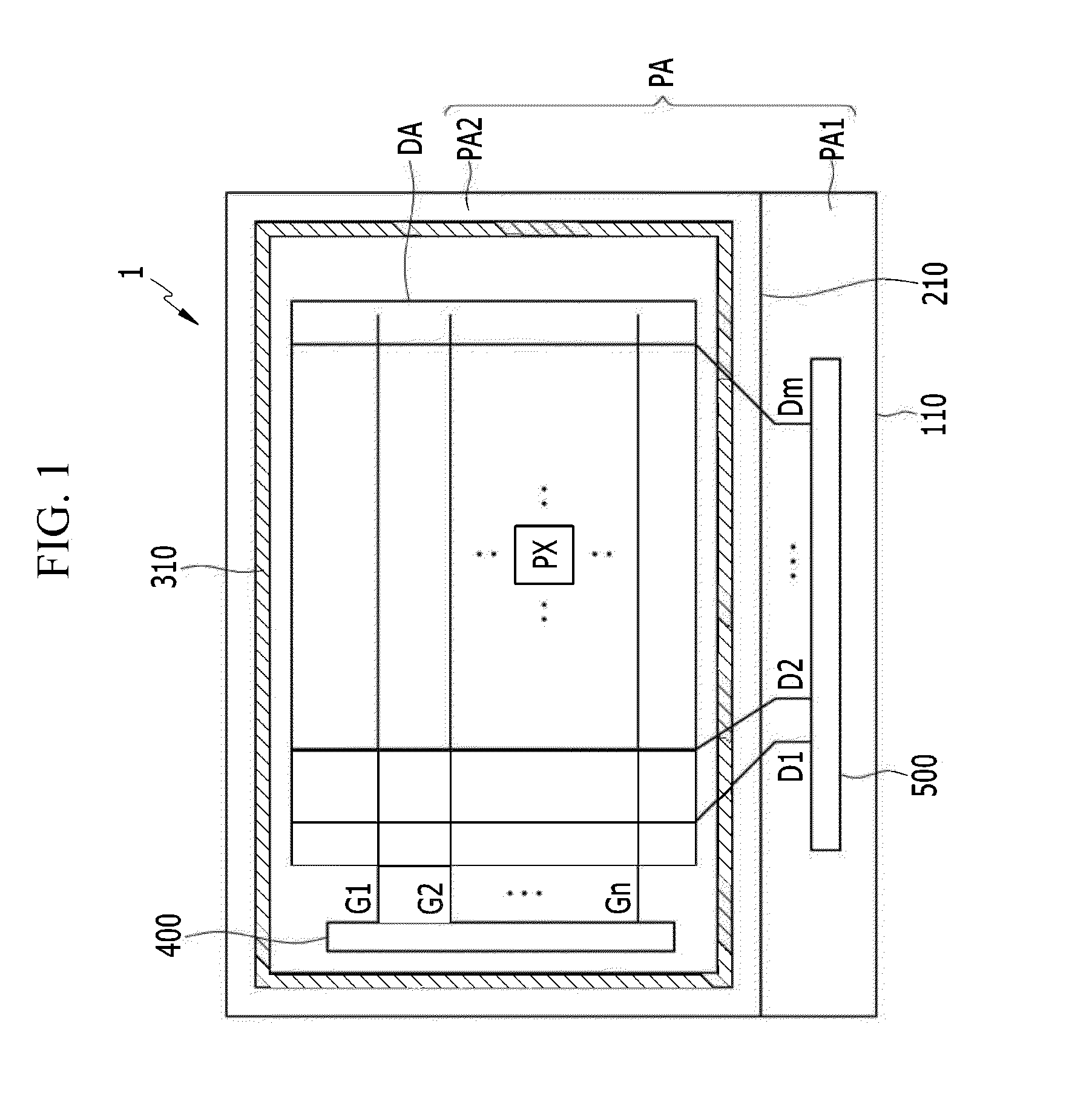

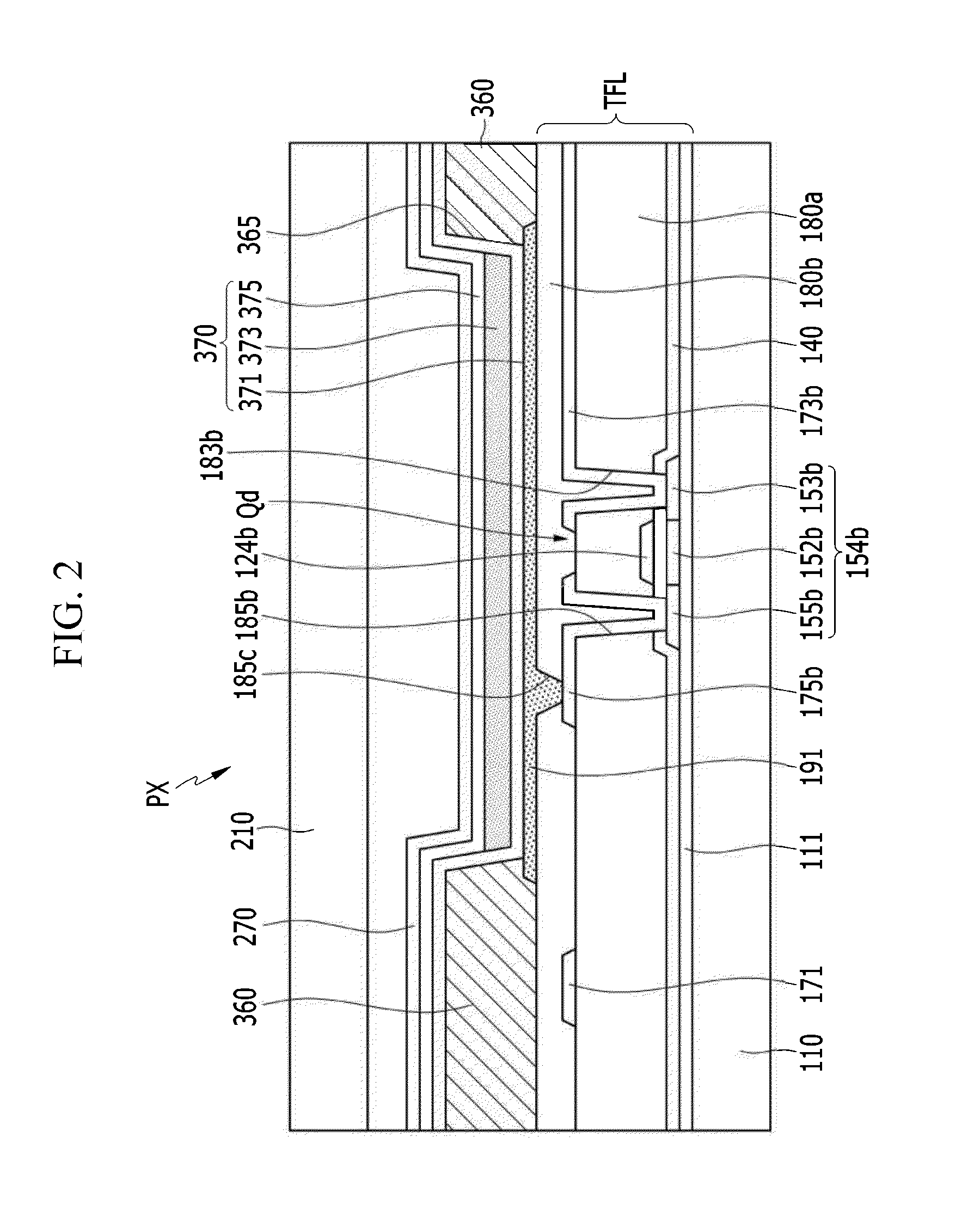

Display device and manufacturing method thereof

ActiveUS20160268356A1Increased strengthIncrease reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

A display device includes: a first substrate including: a display area including a plurality of pixels, and a peripheral area positioned around the display area; a thin film transistor positioned on the first substrate; a pixel electrode layer positioned on the thin film transistor and including more than one pixel electrodes positioned in the display area; and a pixel definition layer positioned on the pixel electrode layer and including a peripheral portion overlapping a voltage transmission electrode. The peripheral portion includes a spacer and an inclination portion connected to the spacer and positioned at a first side of the spacer, and the inclination portion has a concave inclination surface.

Owner:SAMSUNG DISPLAY CO LTD

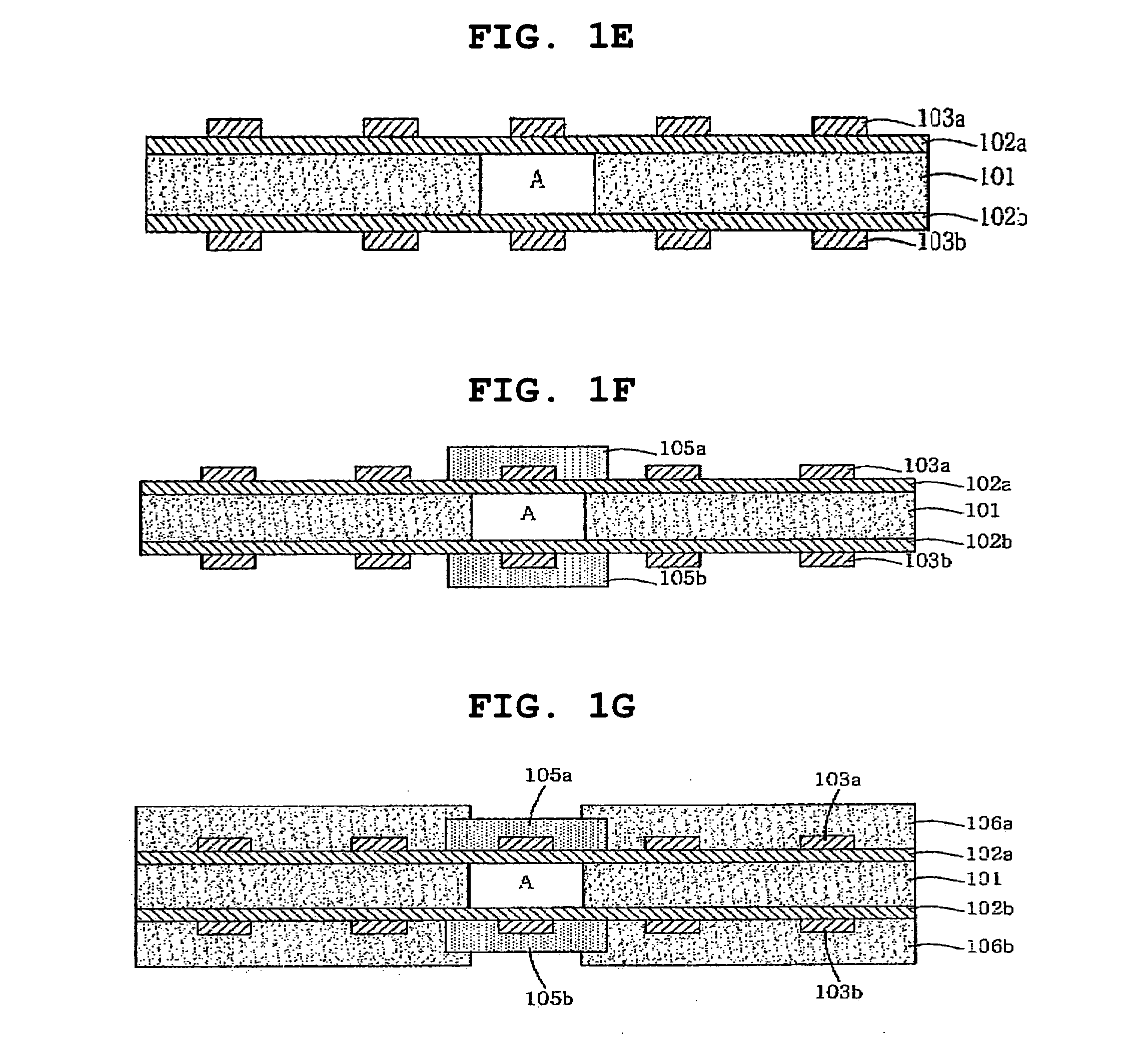

Adhesive sheet, dicing tape integrated type adhesive sheet, and method of producing semiconductor device

InactiveUS20080171187A1Efficient cuttingImprove bond reliabilityGroup 4/14 element organic compoundsSynthetic resin layered productsBreaking strengthDicing tape

The invention provides an adhesive sheet which can be stuck to a wafer at low temperatures of 100° C. or below, which is soft to the extent that it can be handled at room temperature, and which can be cut simultaneously with a wafer under usual cutting conditions; a dicing tape integrated type adhesive sheet formed by lamination of the adhesive sheet and a dicing tape; and a method of producing a semiconductor device using them. In order to achieve this object, the invention is characterized by specifying the breaking strength, breaking elongation, and elastic modulus of the adhesive sheet in particular numerical ranges.

Owner:INADA TEIICHI +2

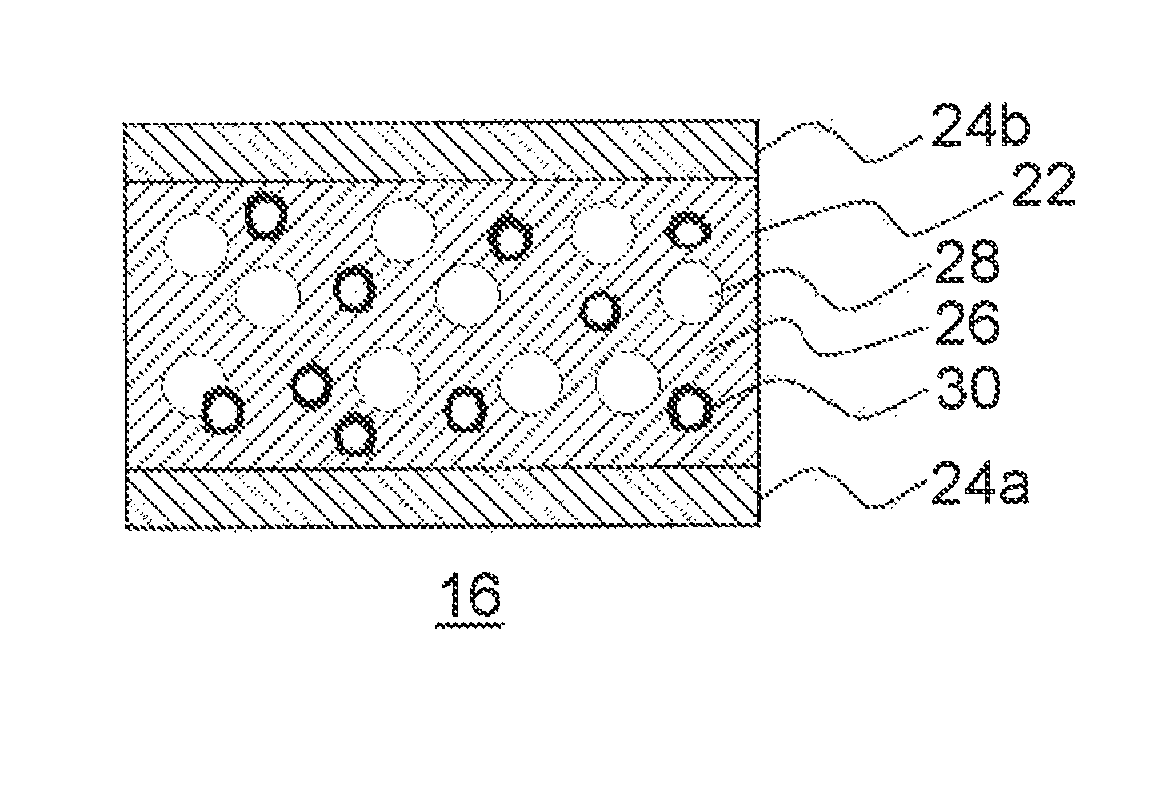

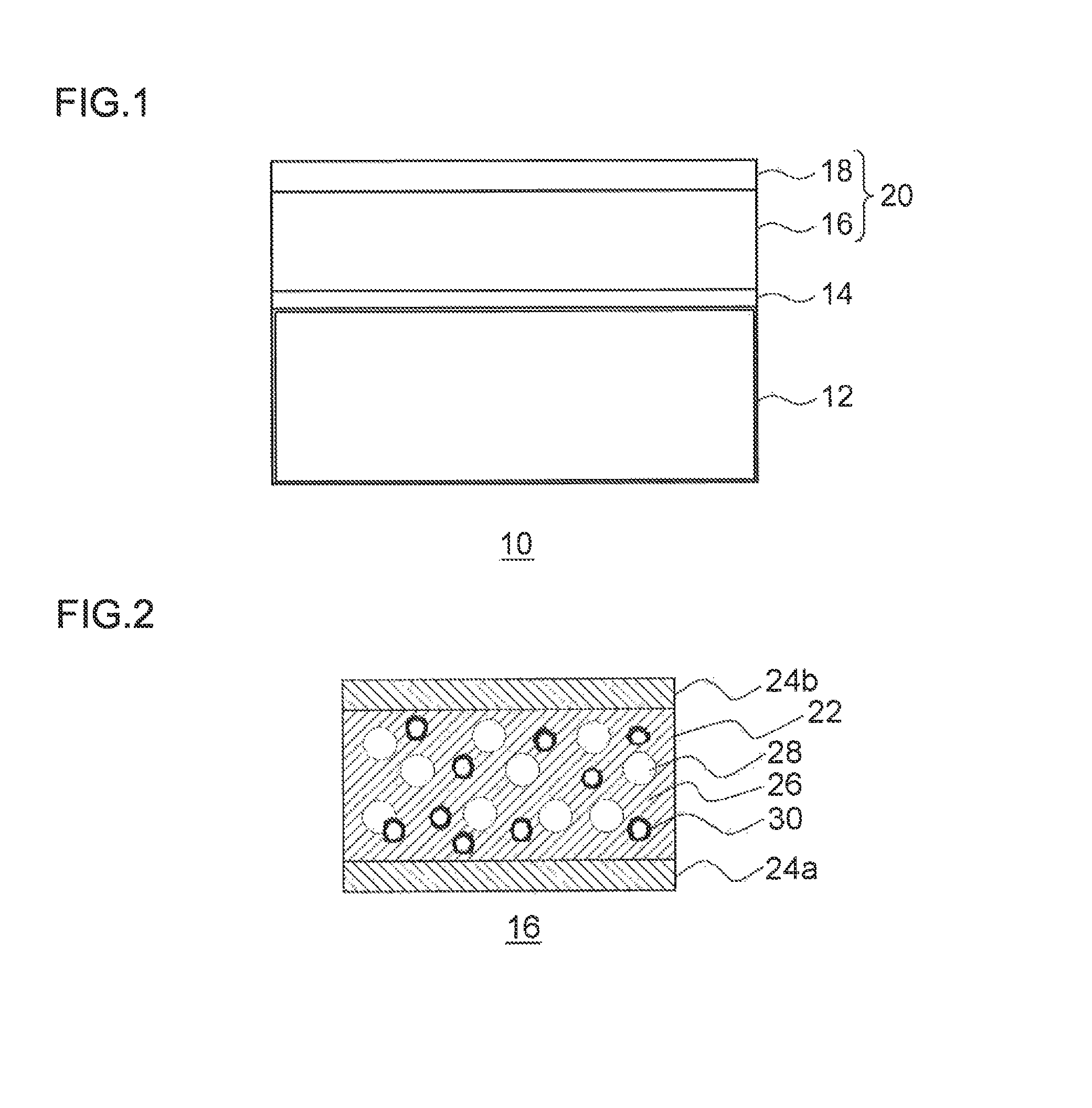

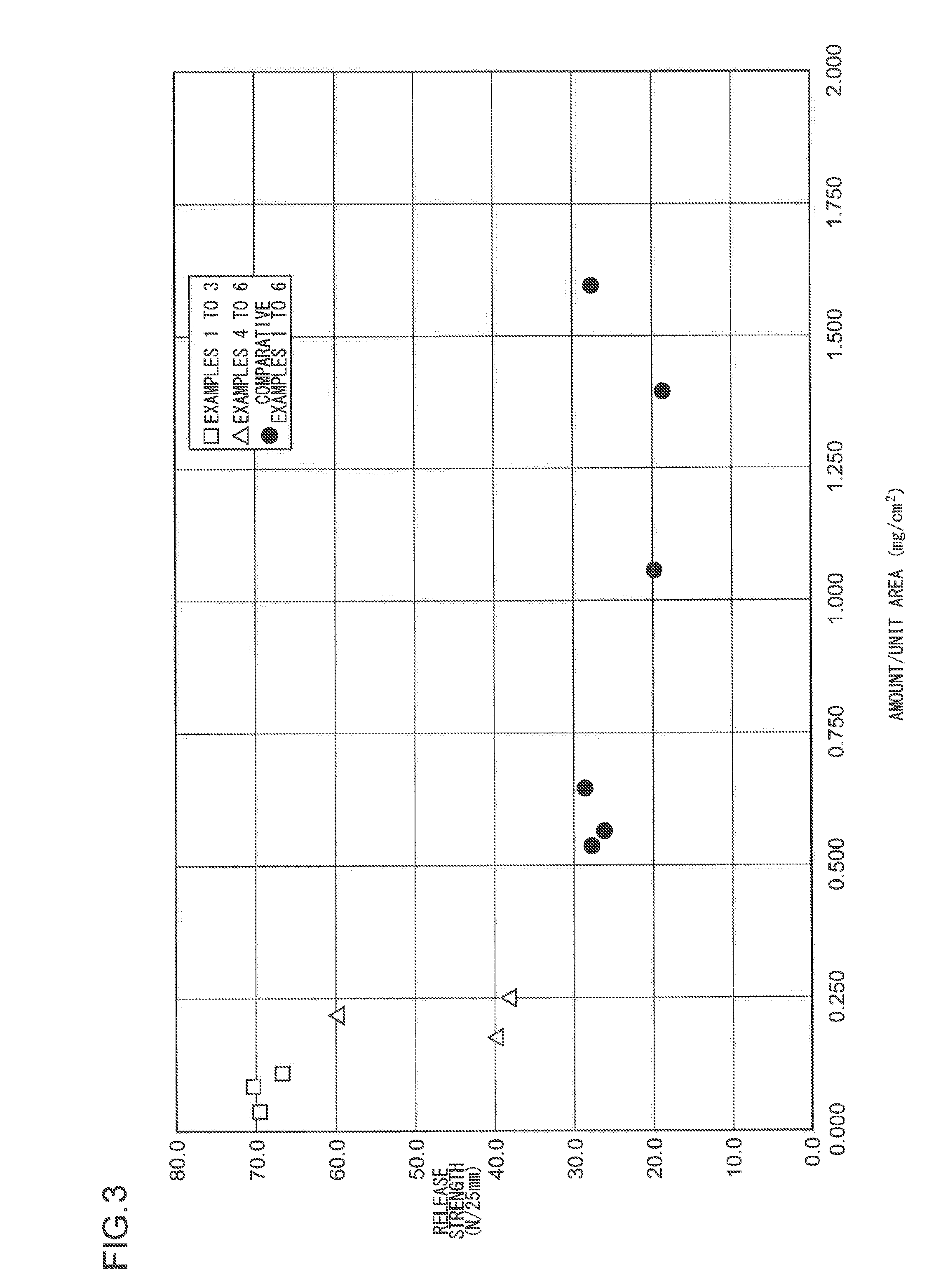

Joined body and method of producing joined body

InactiveUS20130011670A1Improve bond reliabilityFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyvinyl chloride

A joined body includes: an adherend; a primer layer provided on the adherend; and a pressure-sensitive adhesive layer provided on the primer layer. The primer layer contains, as an effective component, at least one of chlorinated polypropylene and chlorinated polyethylene and an amount of the effective component per unit area is 0.5 [mg / cm2] or less. The surface of the adherend may be formed of at least one of polypropylene (PP), polyvinyl chloride (PVC), and ethylene-propylene-diene rubber (EPDM).

Owner:NITTO DENKO CORP

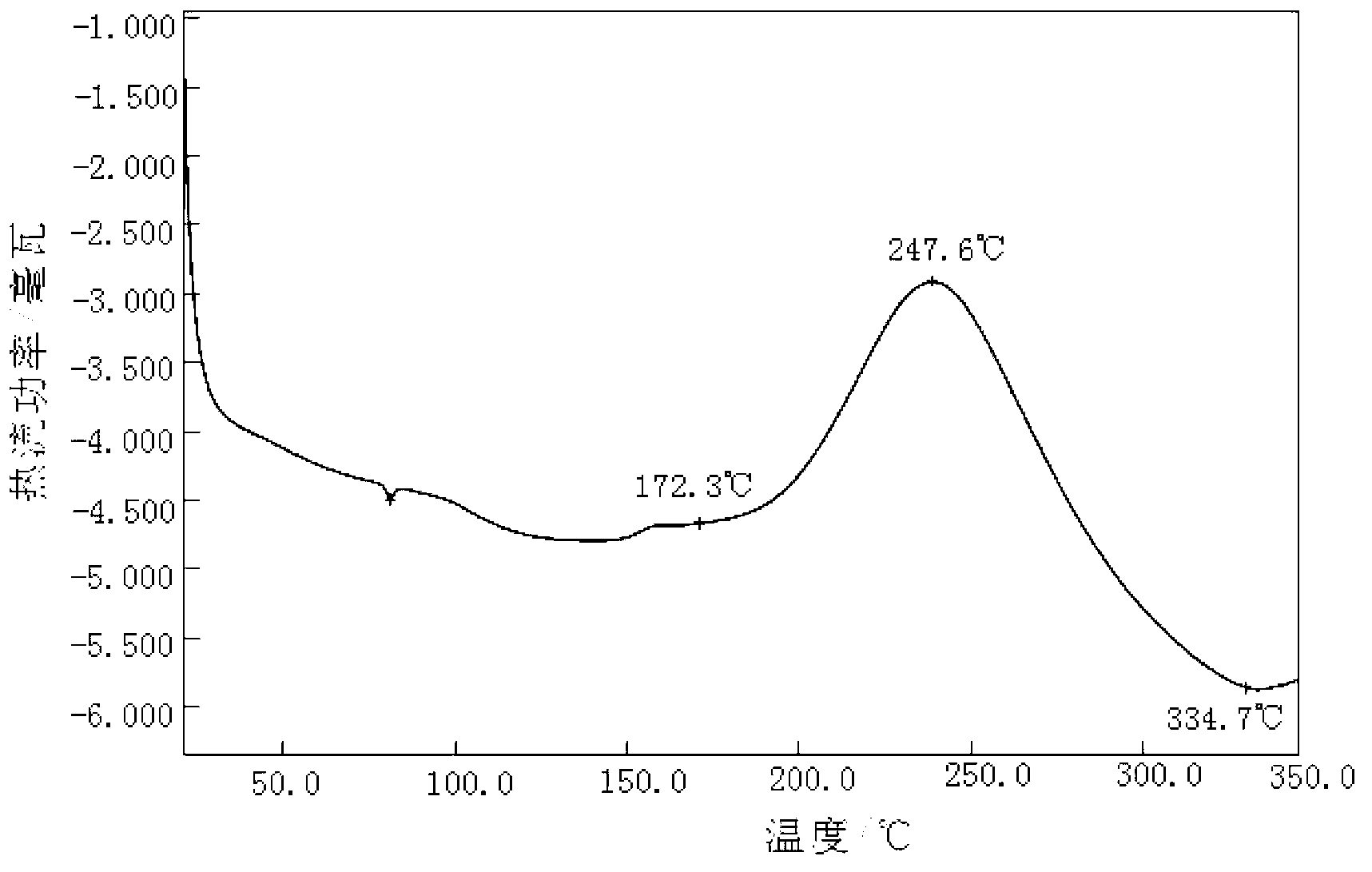

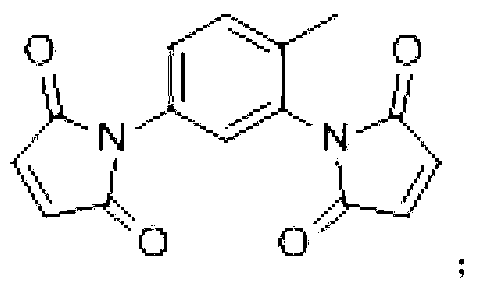

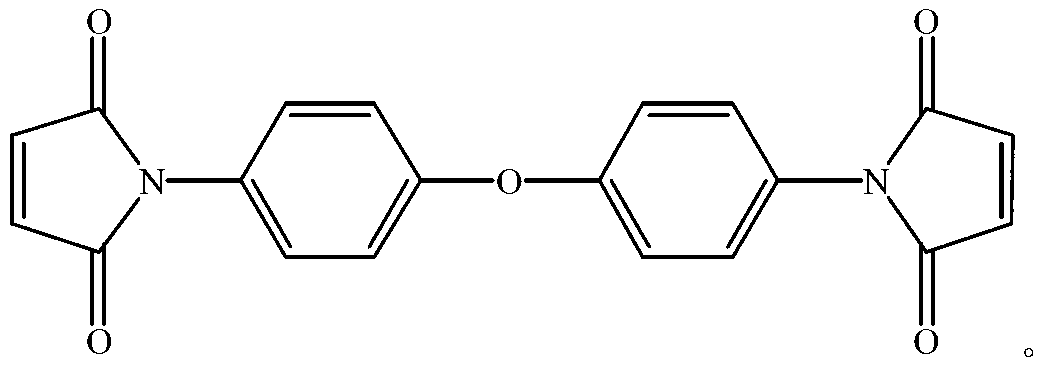

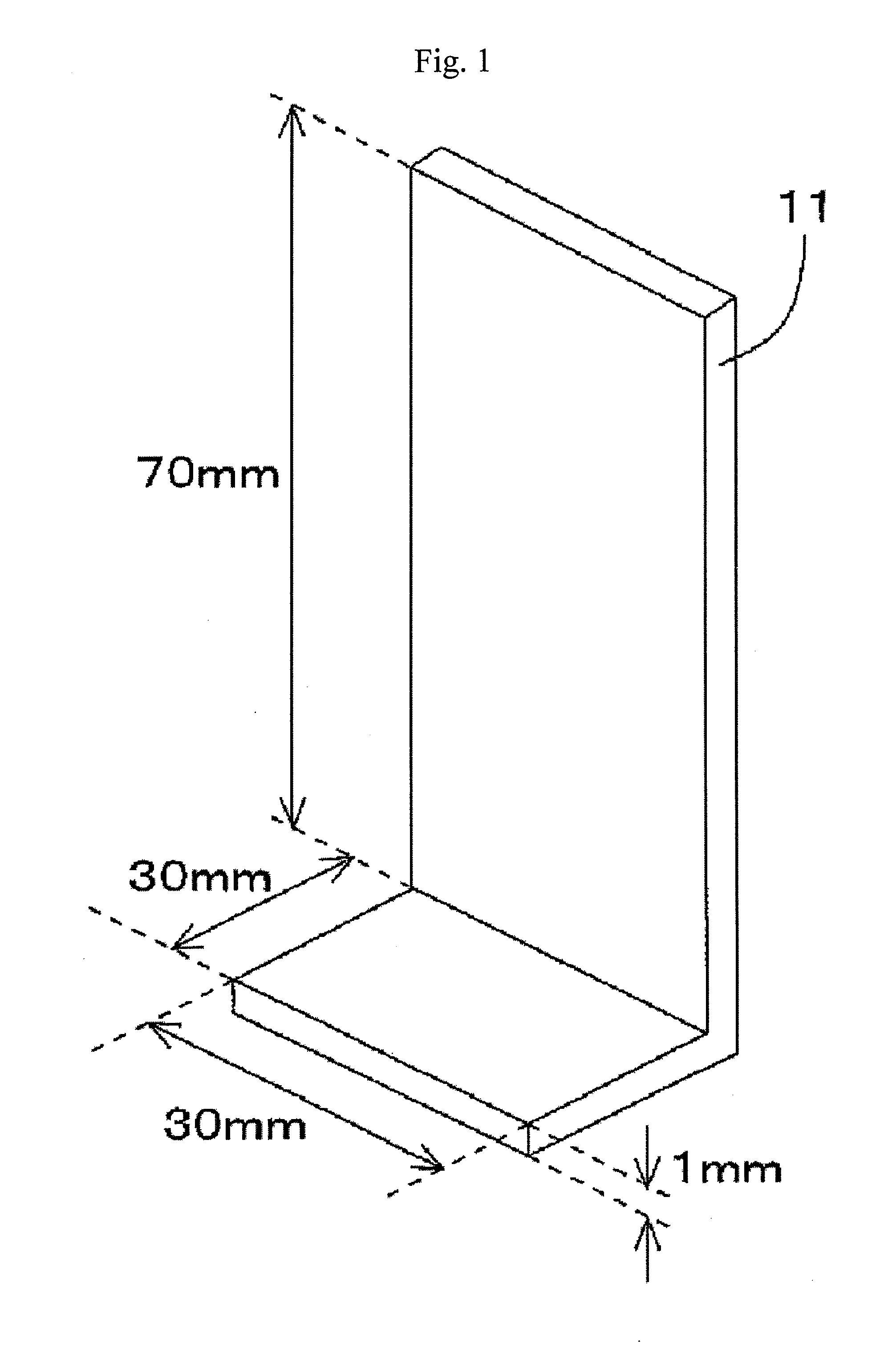

High-temperature-resistant bismaleimide resin carrier structure adhesive film and preparation method thereof

ActiveCN103242767AImprove bond reliabilityHigh temperature resistance hasNon-macromolecular adhesive additivesFilm/foil adhesivesTemperature resistanceGlass transition

The invention provides a high-temperature-resistant bismaleimide resin carrier structure adhesive film and a preparation method thereof, and relates to a high-temperature curing high-temperature-resistant structure adhesive. The invention aims to solve the problems that the conventional bismaleimide adhesive film does not have high temperature-resistant grade and high toughness. The adhesive film consists of bismaleimide resin, a technical modifier, a toughening modifier, a compatibilizer and a thixotropic agent. The preparation method comprises the following steps of: performing prepolymerization on the bismaleimide resin and the technical modifier to obtain a bismaleimide resin prepolymer; mixing the bismaleimide resin prepolymer, the toughening modifier, the compatibilizer and the thixotropic agent uniformly by a mechanical blending method to prepare an adhesive material; and preparing the adhesive by using a three-roller coating film-making machine under the film-forming assistance of the carrier. The adhesive has the characteristics of high-temperature resistance and high toughness, wherein the glass-transition temperature reaches above 280 DEG C and the honeycomb roller peeling strength reaches about 75.0 N.m / m. The adhesive is applied to adhesion of metal or composite material high-temperature-resistant structure members in the field of aerospace.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Heat-releasable pressure -sensitive adhesive tape or sheet

InactiveUS20120058334A1Improve adhesionEasy peelabilityLayered productsAdhesive processes with adhesive heatingCarbon numberPolymer science

The present invention provides a pressure-sensitive adhesive tape or sheet exhibiting good adhesiveness to a variety of adherends and further having both characteristics of repelling resistance and easy peelability. The heat-releasable pressure-sensitive adhesive tape or sheet according to the present invention has a heat-releasable pressure-sensitive adhesive layer containing: as an essential component, an acrylic copolymer formed of a monomer mixture comprising the following monomer (ml) and monomer (m2), with a content of the monomer (m1) being from 40 to 97.5% by weight and a content of the monomer (m2) being from 0.5 to 20% by weight, relative to the whole of monomer components; and a thermal foaming agent:(m1) an alkyl(meth)acrylate monomer having an alkyl group with a carbon number of from 1 to 12, represented by the following formula (1):[Chem. 1]CH2═C(R1)COOR2 (1)(in the formula (1), R1 represents a hydrogen atom or a methyl group, and R2 represents an alkyl group with a carbon number of from 1 to 12); and(m2) an N-hydroxyalkyl(meth)acrylamide monomer having a hydroxyalkyl group with a carbon number of from 1 to 4, represented by the following formula (2):[Chem. 2]CH2═C(R3)CONHR4 (2)(in the formula (2), R3 represents a hydrogen atom or a methyl group, and R4 represents a hydroxyalkyl group with a carbon number of from 1 to 4).

Owner:NITTO DENKO CORP

Rigid flexible printed circuit board and method of fabricating same

InactiveUS20060193970A1Excellent reliabilityImprove bond reliabilityPrinted circuit aspectsLiquid/solution decomposition chemical coatingPolyimidePrinted circuit board

A rigid flexible printed circuit board (PCB) and a method of fabricating the same. Since a polyimide copper clad laminate is not used during the fabrication of the rigid flexible PCB, an increase in cost resulting from use of the polyimide copper clad laminate and poor reliability of adhesion at an interface between different materials are avoided.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

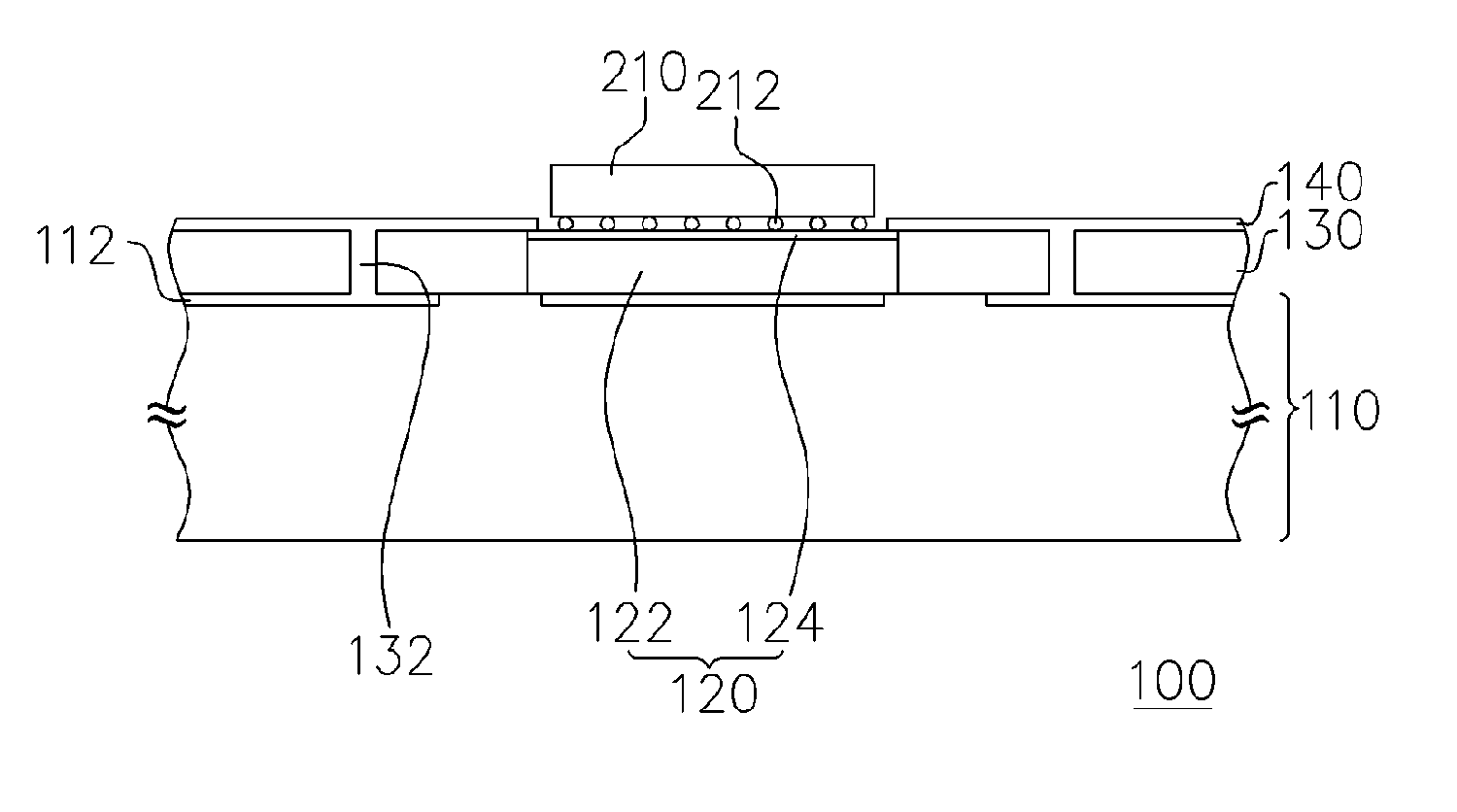

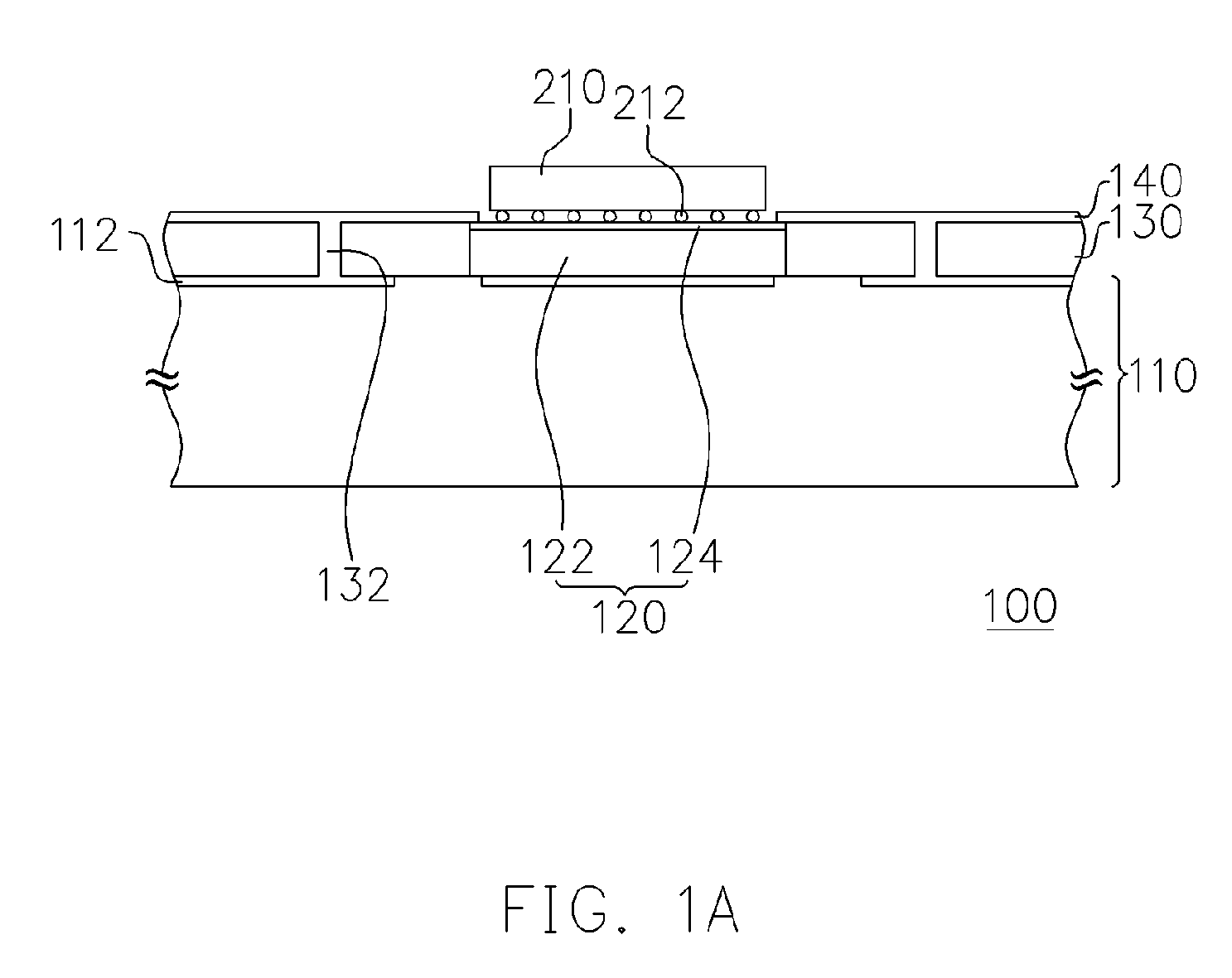

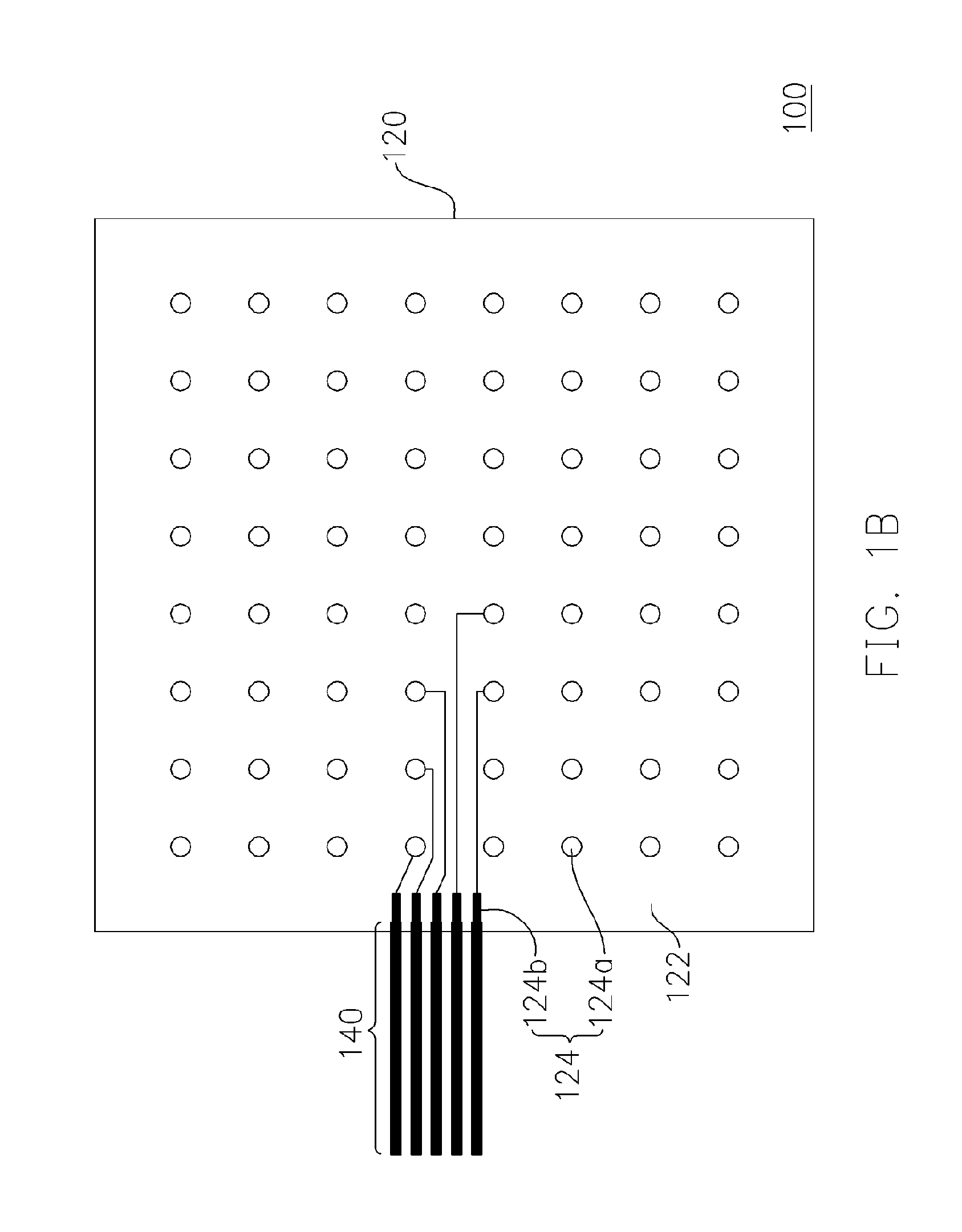

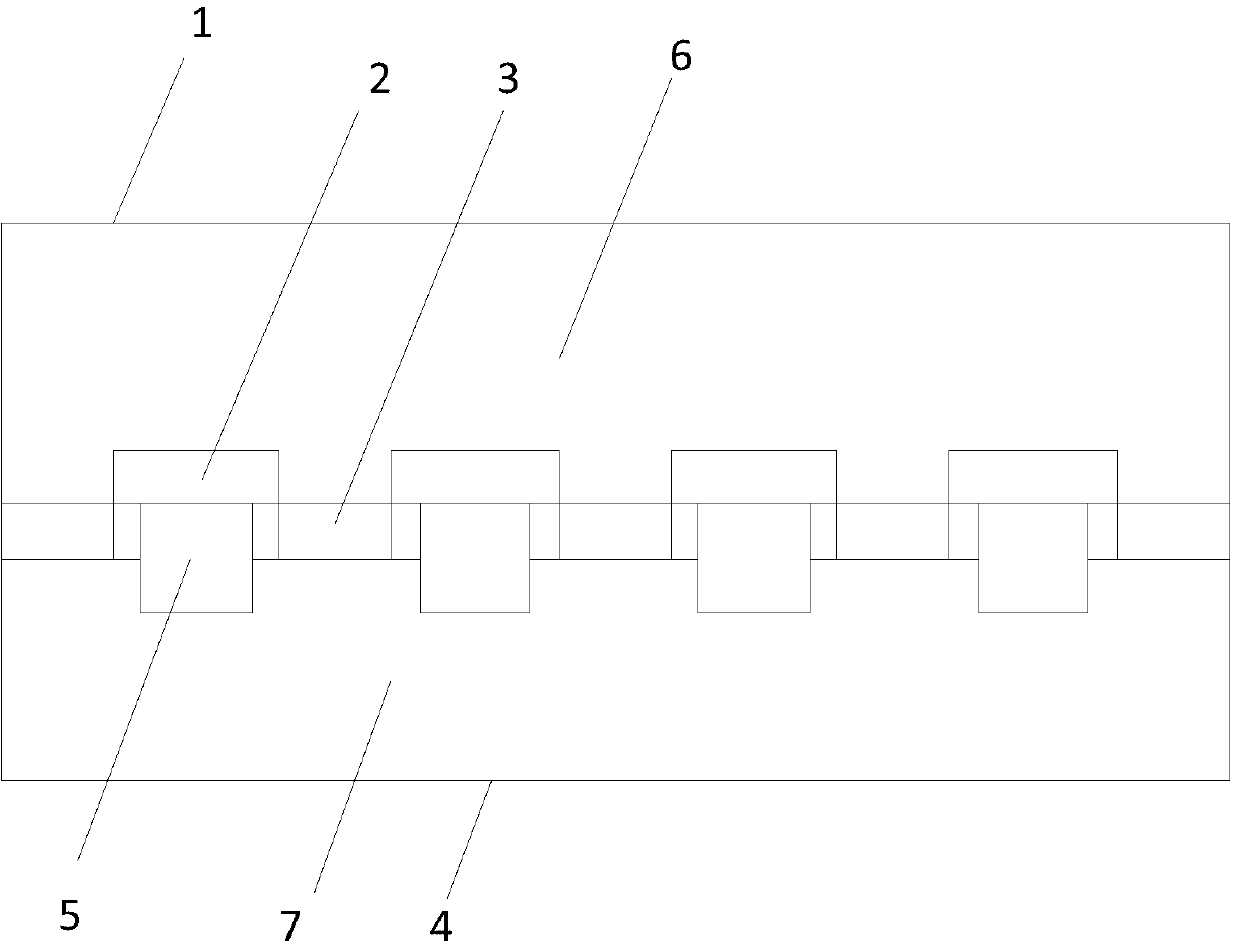

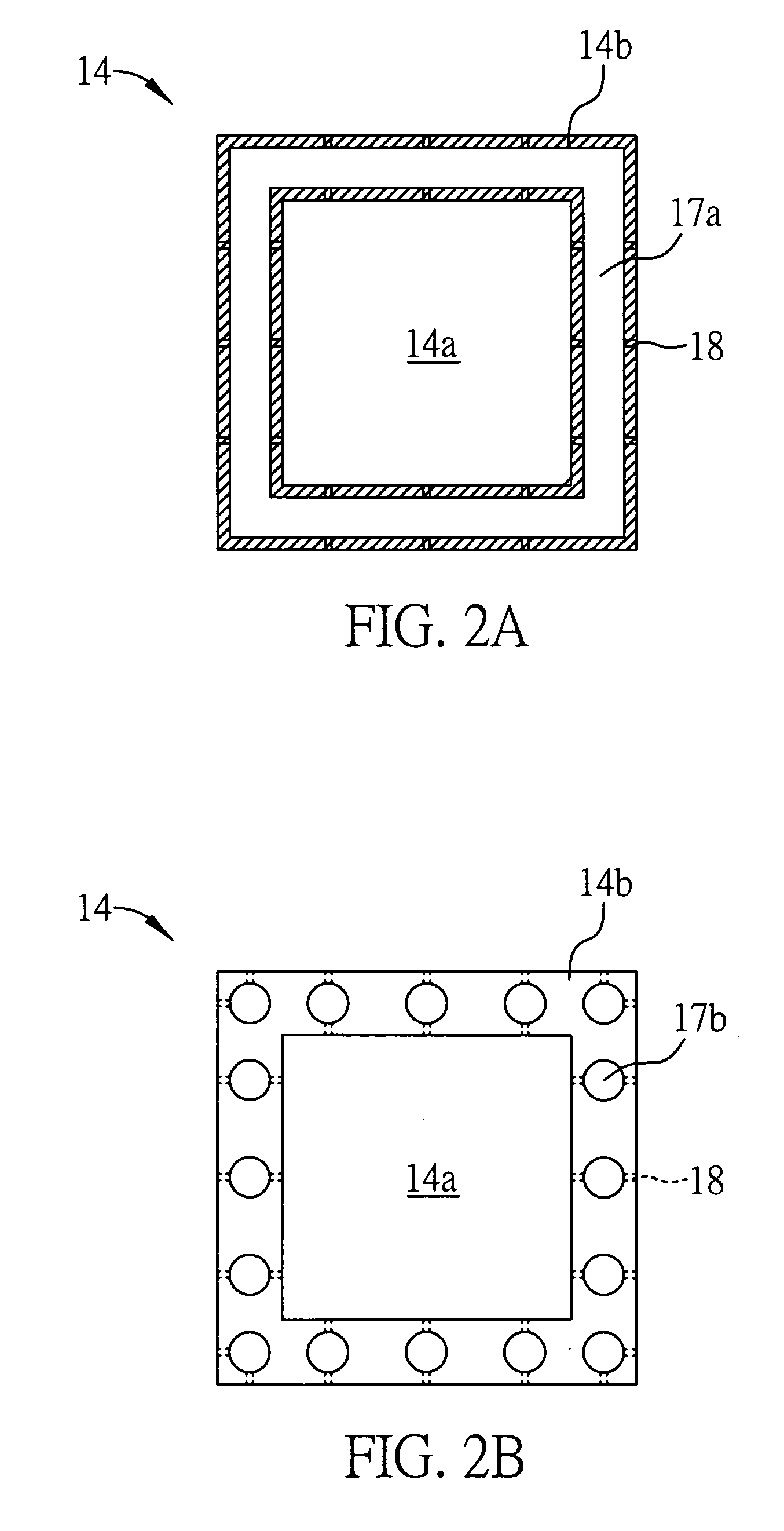

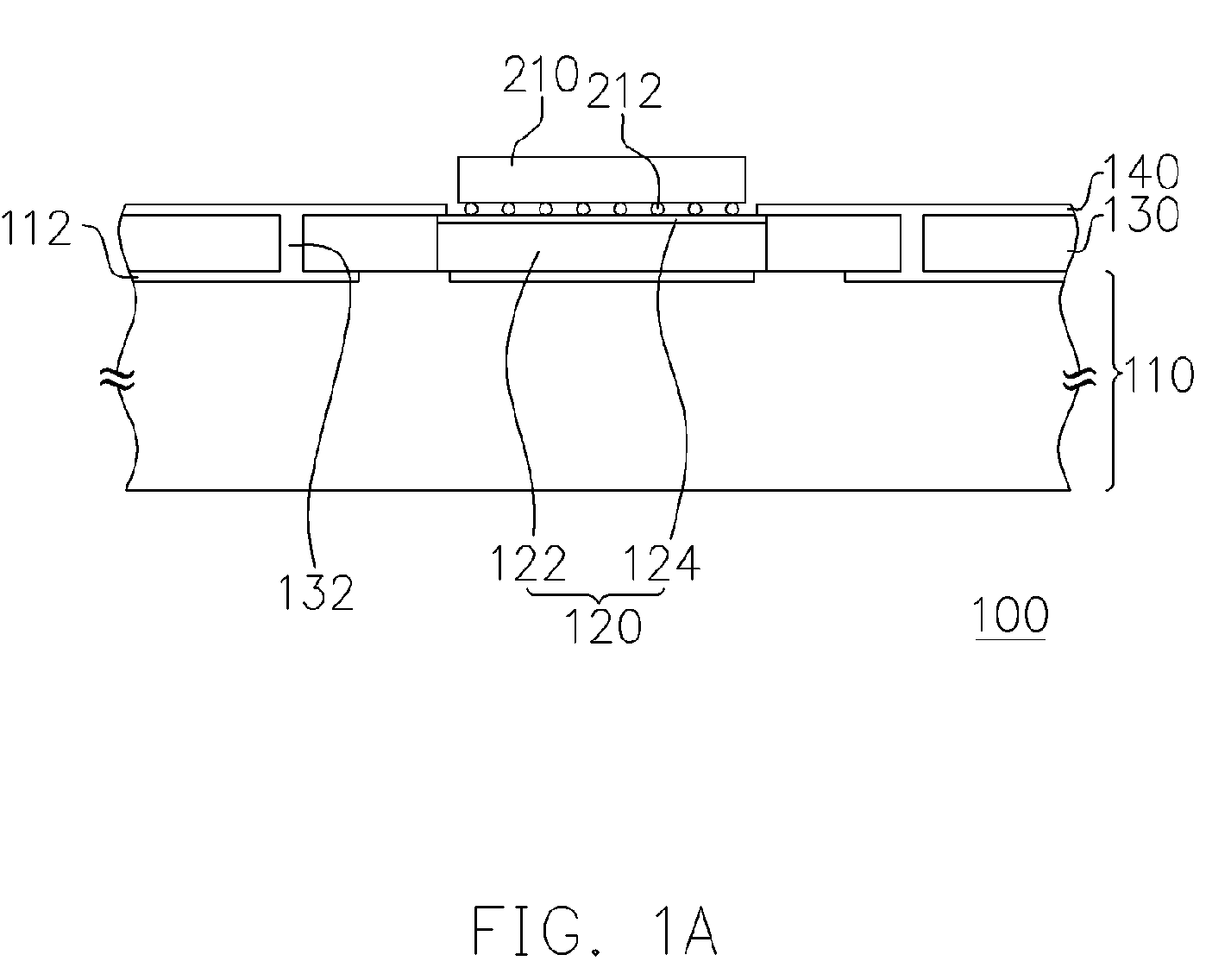

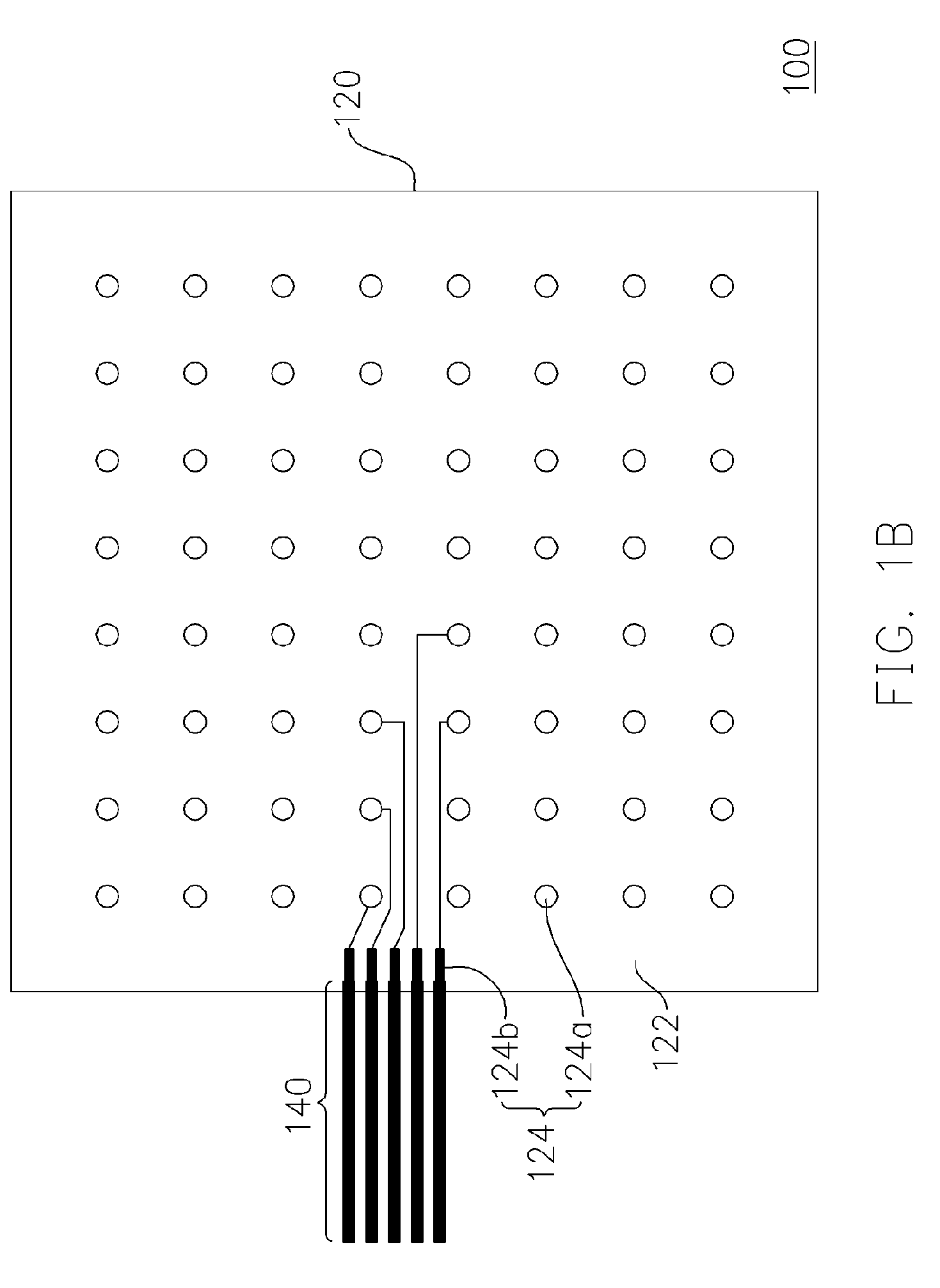

Chip package structure, package substrate and manufacturing method thereof

ActiveUS20060076659A1Similar thermal expansion coefficientImprove bond reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsInterposerEngineering

A package substrate for carrying a chip with a plurality of bumps thereon is provided. The package substrate includes a first substrate, and an interposer. The first substrate has a first circuit layer disposed on a surface thereof. The interposer includes a second substrate and a second circuit layer formed thereon. The second circuit layer comprises a plurality of bonding pads and traces. The traces are electrically connected to the corresponding bonding pads. Furthermore, the bonding pads are used for being connected to the bumps. The second circuit layer of the interposer is physically and electrically connected to the first circuit layer of the first substrate, and the second substrate and the first substrate are made of different materials.

Owner:ADVANCED SEMICON ENG INC

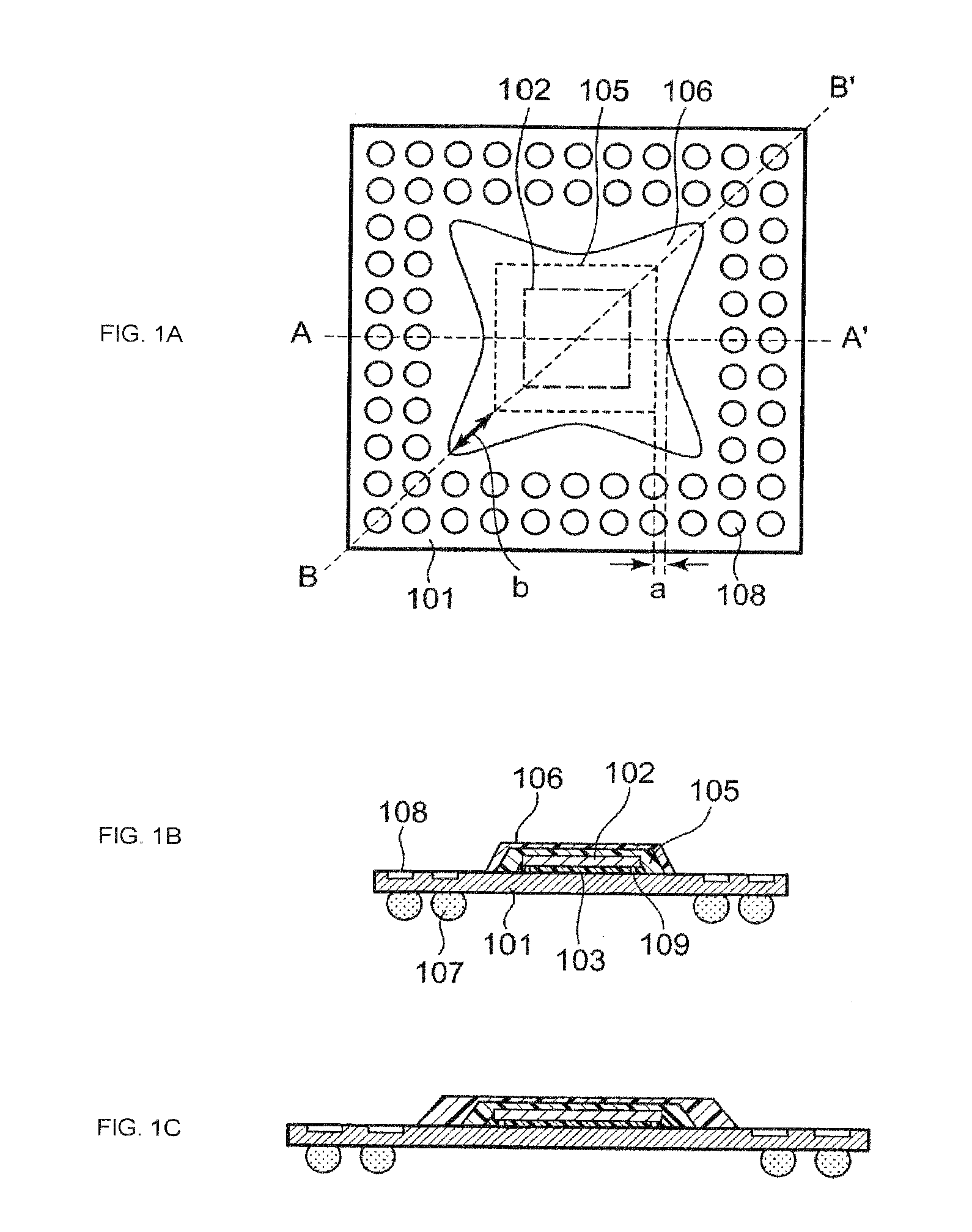

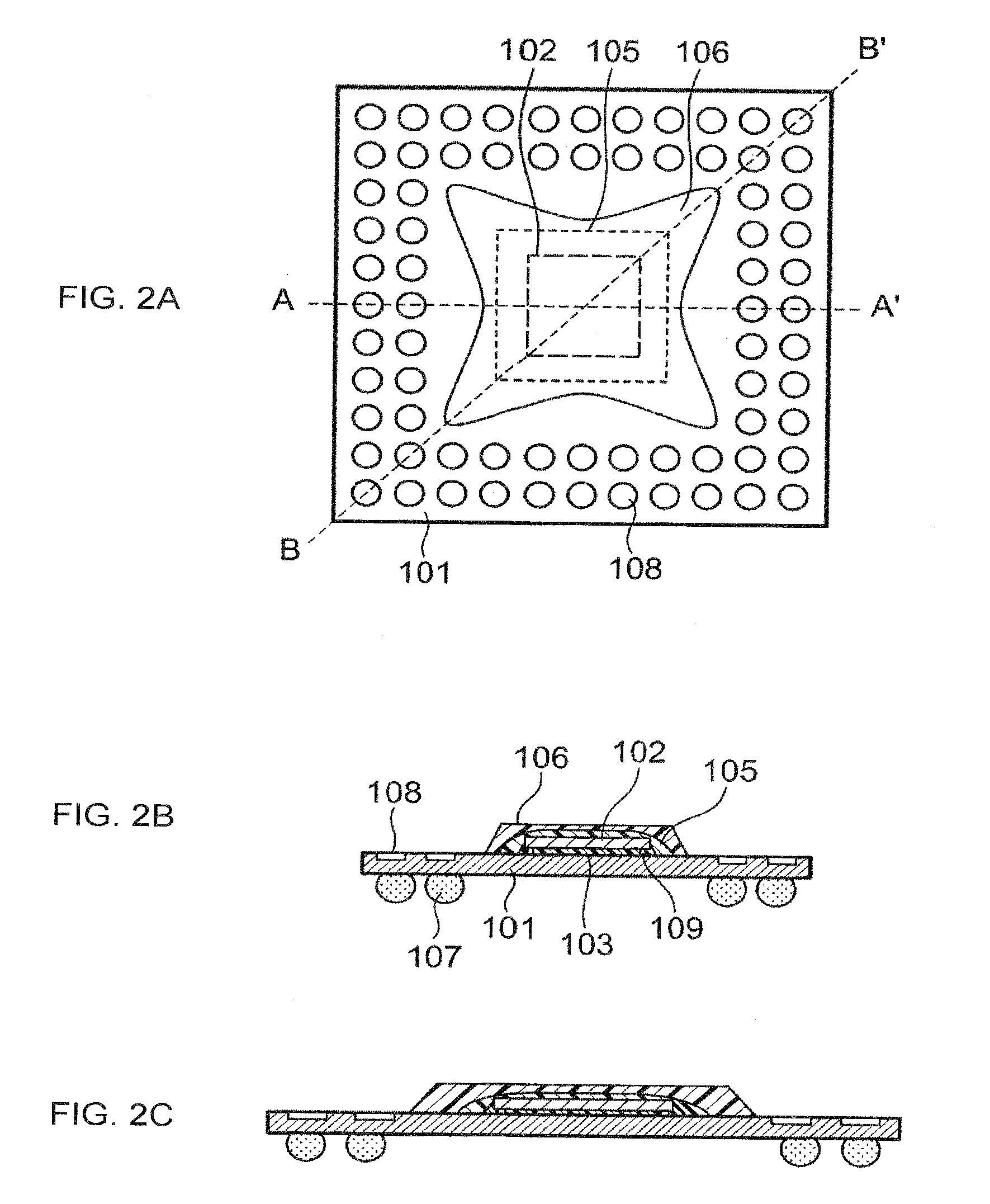

Semiconductor device

ActiveUS20080258317A1Suppress stressLong processSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A resin layer covering a semiconductor chip on a wiring board is composed of a first resin layer and a second resin layer, wherein the first resin layer and the second resin layer differ in their plan view pattern, satisfying a relation of a<b, where “a” is difference in length in the direction from the center of the board towards the edges between the first resin layer and the second resin layer, and “b” is difference in length in the direction from the center of the board towards the corners between the first resin layer and the second resin layer.

Owner:RENESAS ELECTRONICS CORP

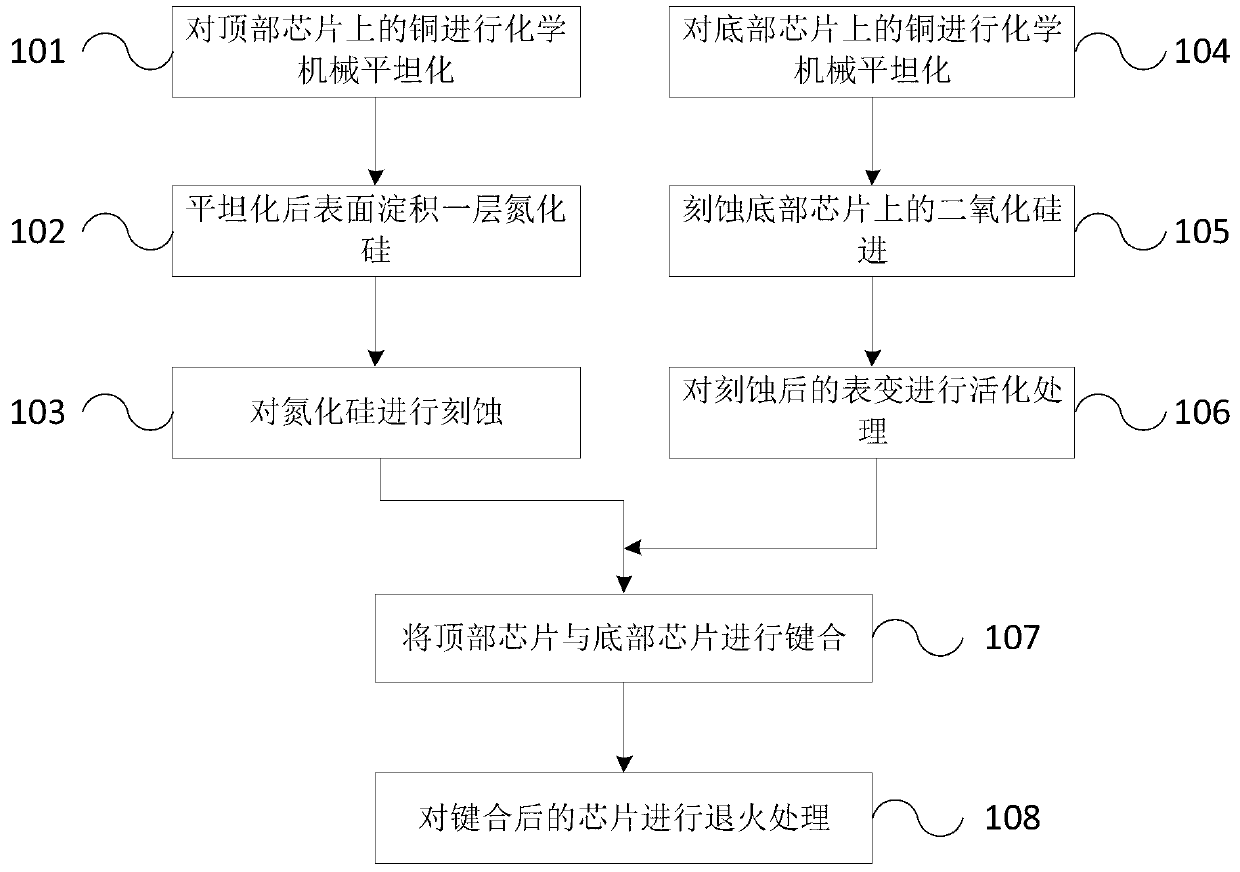

Metal bonding method of three-dimensional chip structure and bonding structure

ActiveCN103107128AStop the spreadImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesBond qualityThin layer

The invention relates to the field of semiconductor fabrication, in particular to a metal bonding method of a three-dimensional chip structure and a bonding structure. The method comprises that copper of a top chip is processed in a chemical machinery planarization mode, a silicon nitride layer is deposited on the surface after being processed in a chemical machinery planarization mode, the silicon nitride layer attached to the copper of the top chip is etched, a groove is formed, the bottom of the groove is the copper of the top chip, copper of a bottom chip is processed in a chemical machinery planarization mode, a bottom silica layer is etched, the copper is enabled to be protruded, activating treatment is carried out to the surface after etch of the copper of the bottom chip is achieved, the copper of the top chip and the copper of the bottom chip are aligned and bonded, and annealing treatment is carried out to the chips after being bonded. According to the metal bonding method of the three-dimensional chip structure and the bonding structure, silicon oxide and silicon nitride are used for being matched with metal and metal bonding, bonding quality is enabled to be better, a silicon nitride layer thin layer can prevent the metal from diffusing into around materials, and goals that a technology process is simplified, temperature needed by bonding is reduced, bonding reliability is improved, bonding efficiency is improved, and bonding cost is reduced can be achieved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Pressure-sensitive adhesive composition

ActiveUS20140016067A1Improve cohesionIncreased durabilityFilm/foil adhesivesLayered productsExtended timePhysical property

A pressure-sensitive adhesive composition is provided. The pressure-sensitive adhesive composition shows stable antistatic performance, and in particular, stably maintains its antistatic performance even when the pressure-sensitive adhesive composition is kept for an extended time under extreme conditions or conditions in which environmental changes are severe, and also has excellent general physical properties such as pressure-sensitive adhesive properties, durability and workability.

Owner:LG CHEM LTD

Thermoplastic resin composition, adhesive film and wiring film using the same

InactiveCN102382382AImprove adhesionImprove bond reliabilityFilm/foil adhesivesAdhesive articlesLow dissipationElastomer

The present invention relates to a thermoplastic resin composition having a low dielectric constant, a low dissipation factor and excellent adhesiveness to a substrate film or a conductor wiring, an adhesive film and a wiring film using the same. The thermoplastic resin composition includes a polyphenylene ether-based polymer having hydroxyl groups in its chemical structure and having 2,6-dimethylphenylene ether as a repeating unit, an isocyanate compound having a plurality of isocyanate groups in its structure; or a reaction product of the polyphenylene ether-based polymer having 2,6-dimethylphenylene ether as a repeating unit and the isocyanate compound having a plurality of isocyanate groups in its structure; and a hydrogenated styrene-based elastomer. .

Owner:HITACHI CABLE

Circuit device and manufacturing method thereof

InactiveUS7329957B2Improve bond reliabilityReduce formationPrinted circuit assemblingSemiconductor/solid-state device detailsEngineering

Owner:SANYO ELECTRIC CO LTD

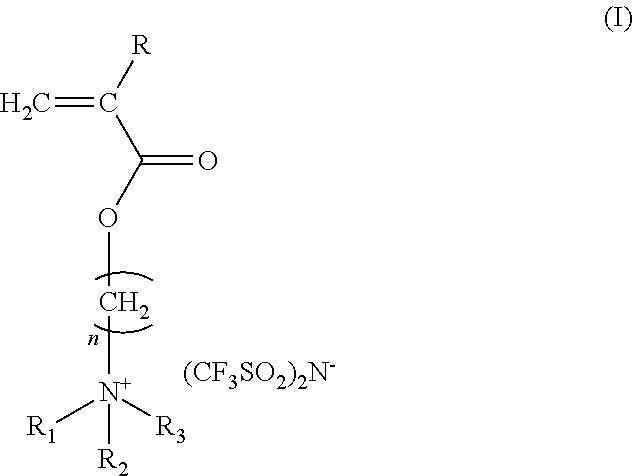

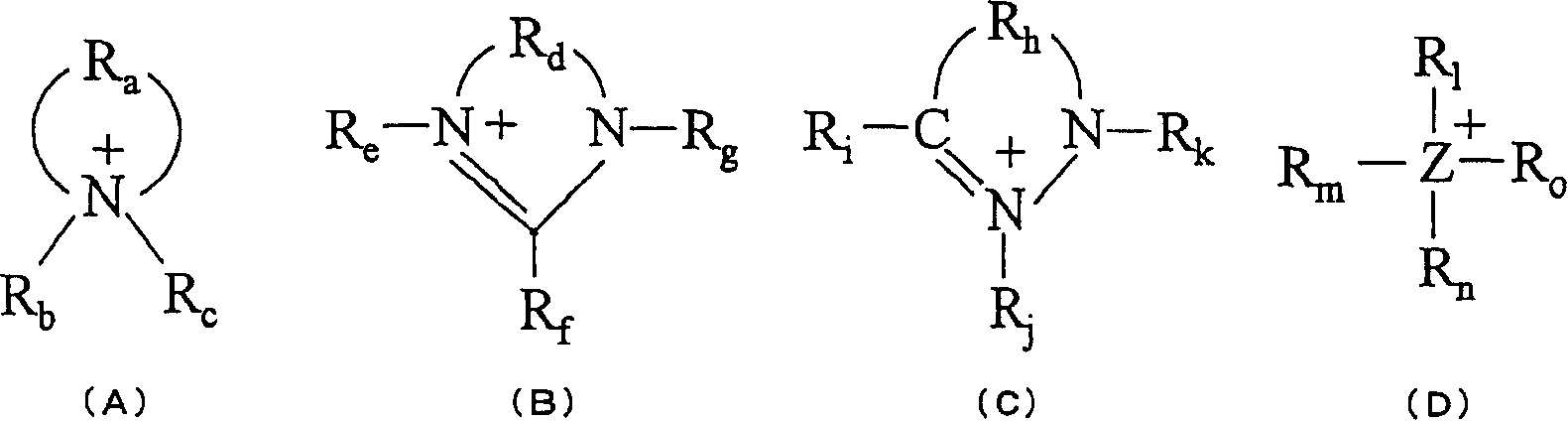

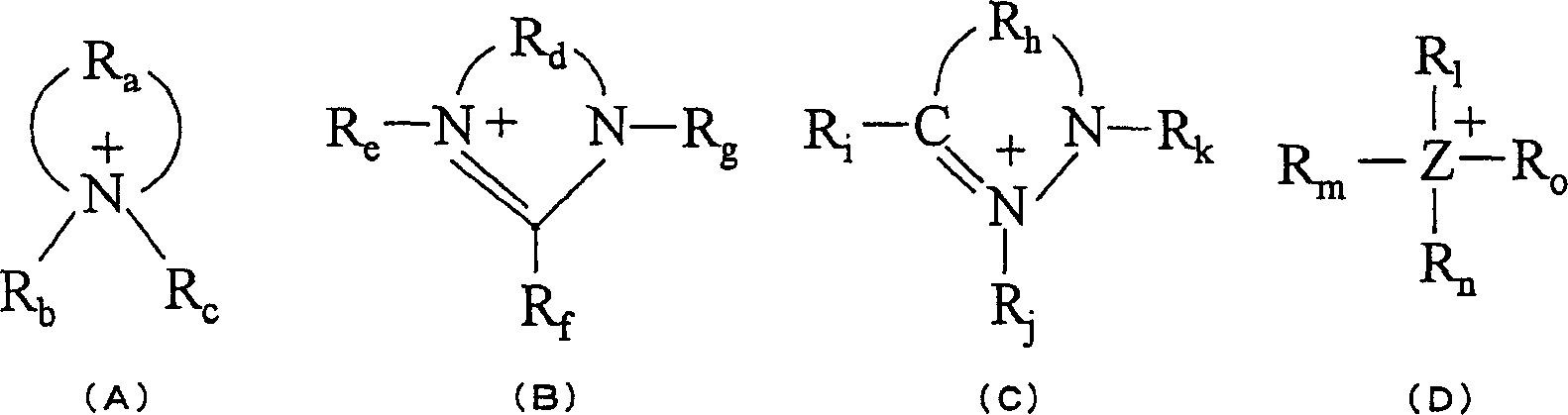

Antistatic ionic compound, oligomer thereof, copolymer thereof, and pressure-sensitive adhesive composition

InactiveUS20110021691A1Excellent reliabilityExcellent anti-static propertyOrganic chemistryAcid polymer adhesivesPressure sensitiveOligomer

A pressure-sensitive composition contains an ionic compound, or an oligomer or co-polymer of the ionic compound which is composed of a ((meth) acryloyloxy) alkyl ammonium cation and (CF3SO2)2N− anion, or a combination thereof, to obtain a pressure-sensitive adhesive sheet having excellent antistatic properties without adhesion deterioration.

Owner:DAXON TECH INC

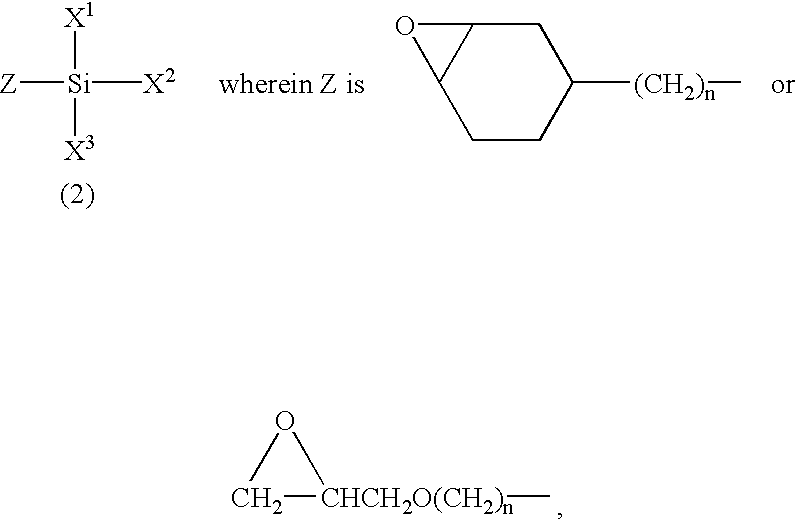

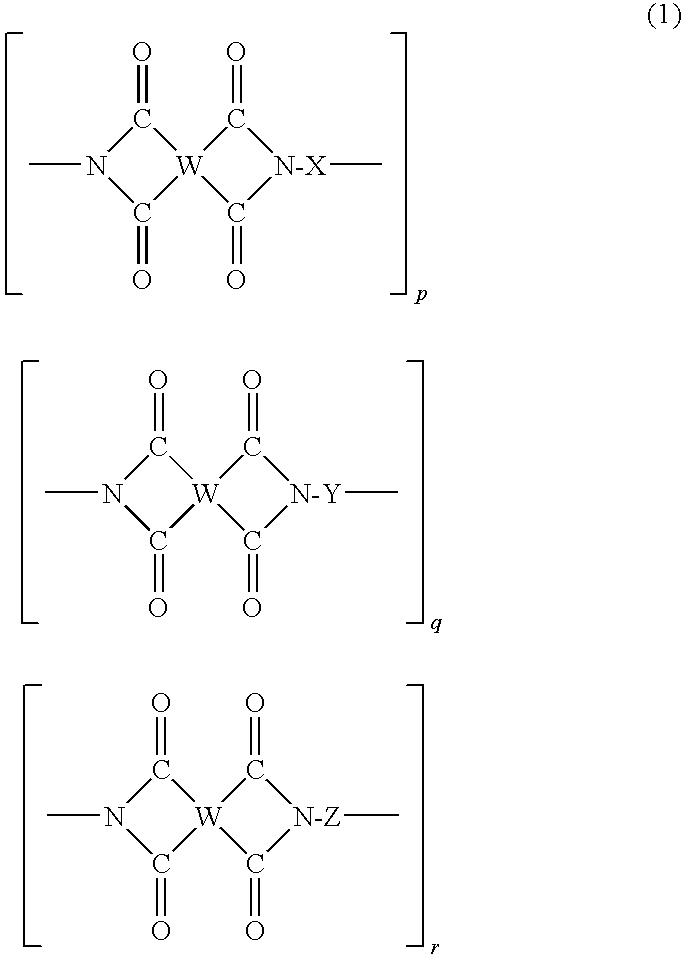

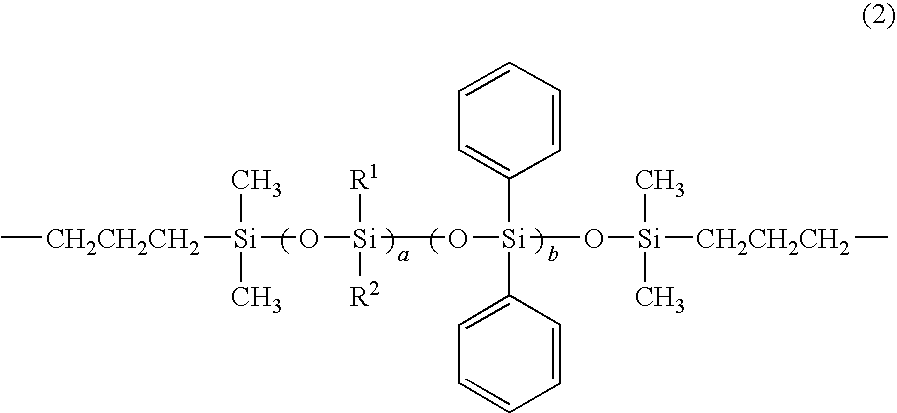

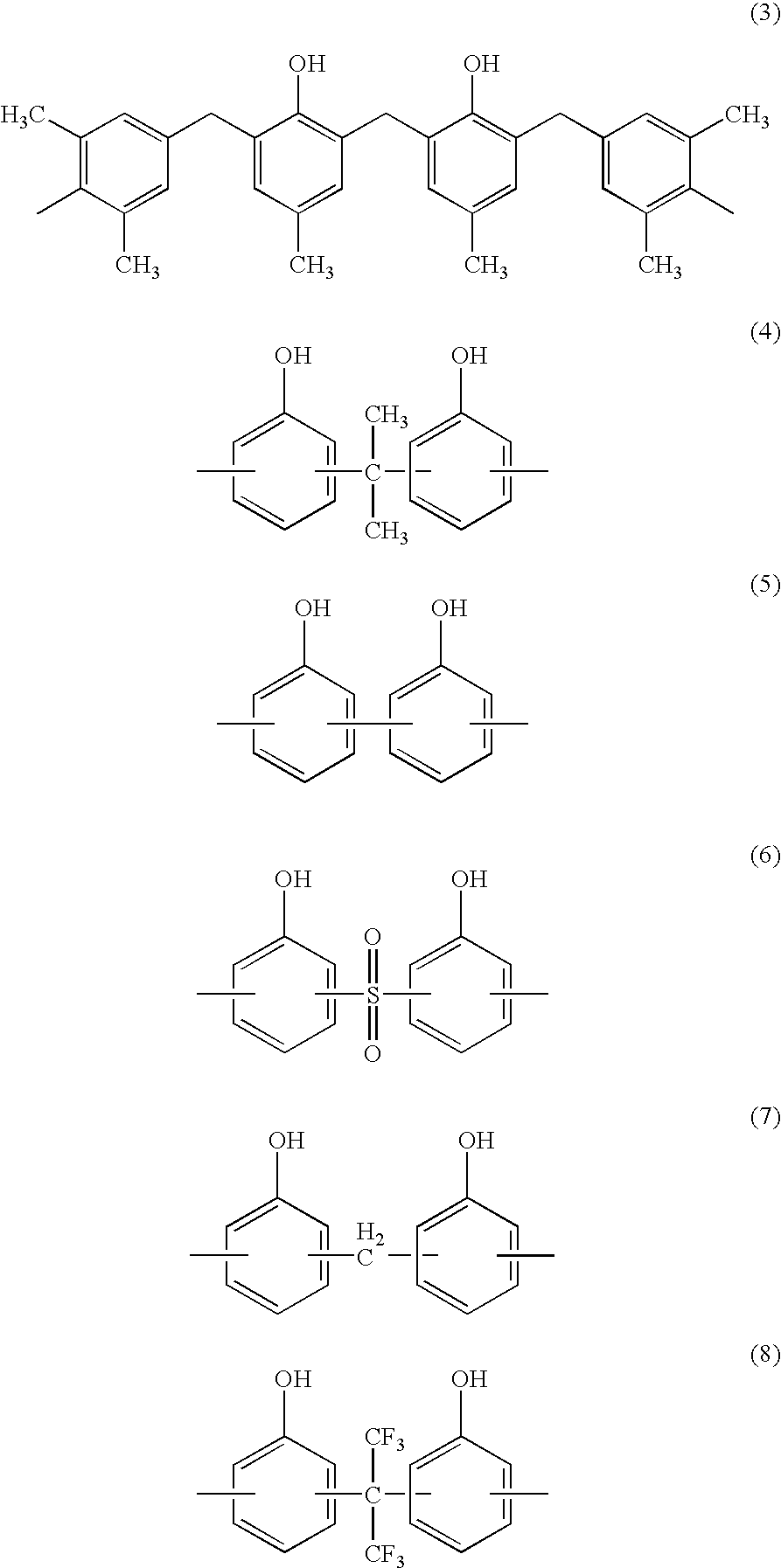

Solvent-free polyimide silicone resin composition and cured product thereof

A solvent-free polyimide silicone resin composition, and a cured product thereof, includes (A) a polyimide silicone resin having recurring units having a specific type of structure and having a weight average molecular weight of 5,000 to 150,000, (B) an epoxy resin, and (C) an epoxy resin curing agent wherein the resin composition having a fluidity at 25° C. and is free of a solvent.

Owner:SHIN ETSU CHEM IND CO LTD

Heat dissipating structure and semiconductor package with the same

InactiveUS20050056926A1Easy to checkImprove bond reliabilitySemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor package

A heat dissipating structure and a semiconductor package with the same are proposed. A substrate is used to accommodate at least one chip thereon, and the chip is electrically connected to the substrate. A heat dissipating structure having a flat portion and a support portion is mount on the substrate via the support portion by means of an adhesive. At least one groove is formed on the support portion and at least one air vent is formed around the groove to allow the groove to communicate with the outside via the air vent, such that the adhesive is allowed to fill the groove to expel air from the groove to the atmosphere through the air vent, thereby preventing the air from trapped in the groove.

Owner:SILICONWARE PRECISION IND CO LTD

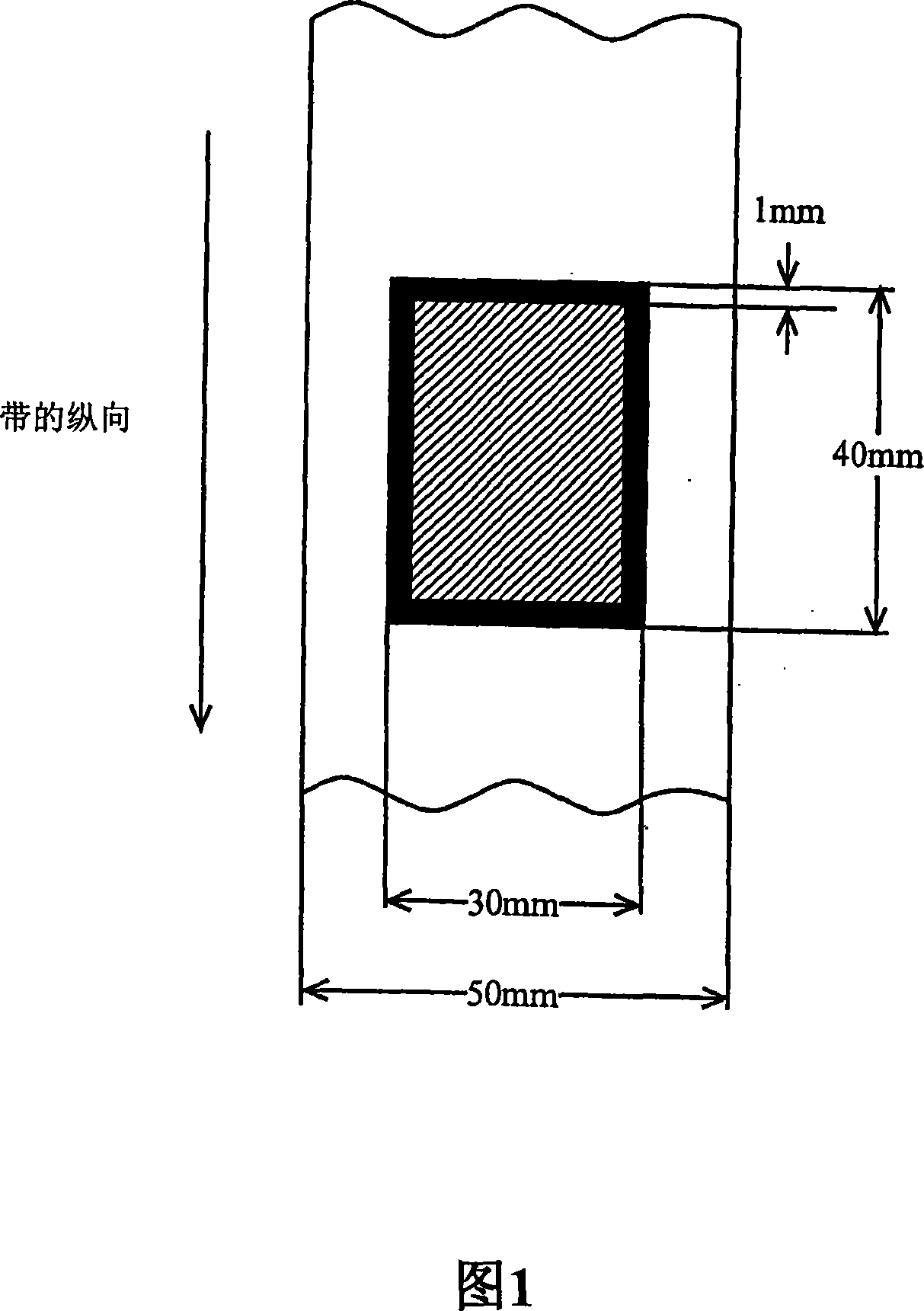

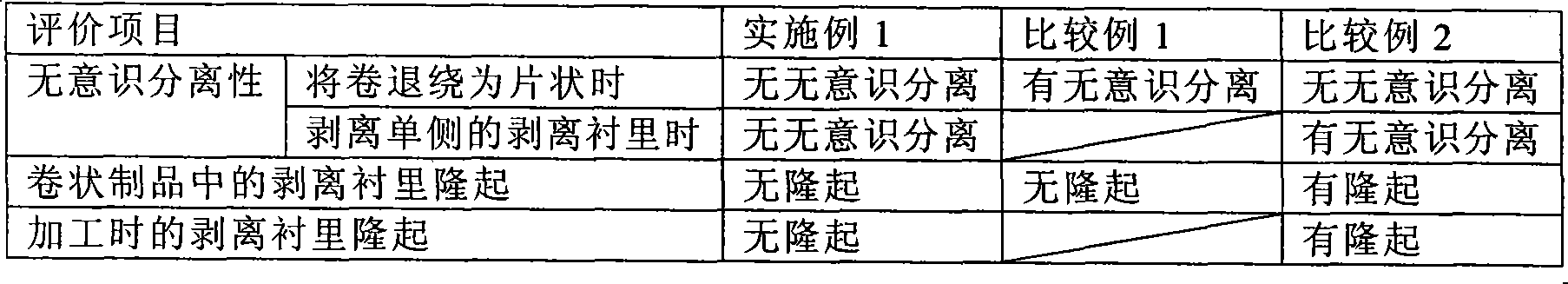

Heat-activated adhesive sheet

InactiveCN101220246ARapid positioningAdhesive force is smallSolid-state devicesFilm/foil adhesives without carriersPolyesterRelease liner

Disclosed is a heat-activated adhesive sheet which includes a heat-activated adhesive layer, and two release liners arranged so as to sandwich and protect the heat-activated adhesive layer. One of the two release liners is a release liner containing a polyolefinic film as a base material, and the other is a release liner containing a polyester film as a base material. This heat-activated adhesive sheet has a transfer heat-activated adhesive layer, can thereby have a small thickness, is unlikely to suffer from "unintended separation", and is unlikely to cause lifting and delamination of release liners when the sheet is stored as a roll.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets, and double-sided pressure-sensitive adhesive tapes

InactiveCN1824722AImprove bond reliabilityPrevent static electricityFilm/foil adhesivesEster polymer adhesivesOligomerGlass transition

An object of the present invention is to provide a pressure-sensitive adhesive composition which is excellent in antistatic property of a pressure-sensitive adhesive tapes when separators are peeled off, and has reduced stainability in an adherend, and excellent in transparency, and prevention of occurrence of peeling off and separation, and an antistatic pressure-sensitive adhesive sheet and a double-sided pressure-sensitive adhesive tape using the same. There is provided a pressure-sensitive composition comprising an ionic liquid, a (meth)acryl-based oligomer of weight-average molecular weight of 1,000 to 50,000, and a (meth)acryl-based polymer of glass transition temperature (Tg) of 0°C or less as base polymer.

Owner:NITTO DENKO CORP

Chip package structure, package substrate and manufacturing method thereof

ActiveUS7327018B2Similar thermal expansion coefficientImprove bond reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsInterposerEngineering

A package substrate for carrying a chip with a plurality of bumps thereon is provided. The package substrate includes a first substrate, and an interposer. The first substrate has a first circuit layer disposed on a surface thereof. The interposer includes a second substrate and a second circuit layer formed thereon. The second circuit layer comprises a plurality of bonding pads and traces. The traces are electrically connected to the corresponding bonding pads. Furthermore, the bonding pads are used for being connected to the bumps. The second circuit layer of the interposer is physically and electrically connected to the first circuit layer of the first substrate, and the second substrate and the first substrate are made of different materials.

Owner:ADVANCED SEMICON ENG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com