Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1362results about How to "Efficient cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

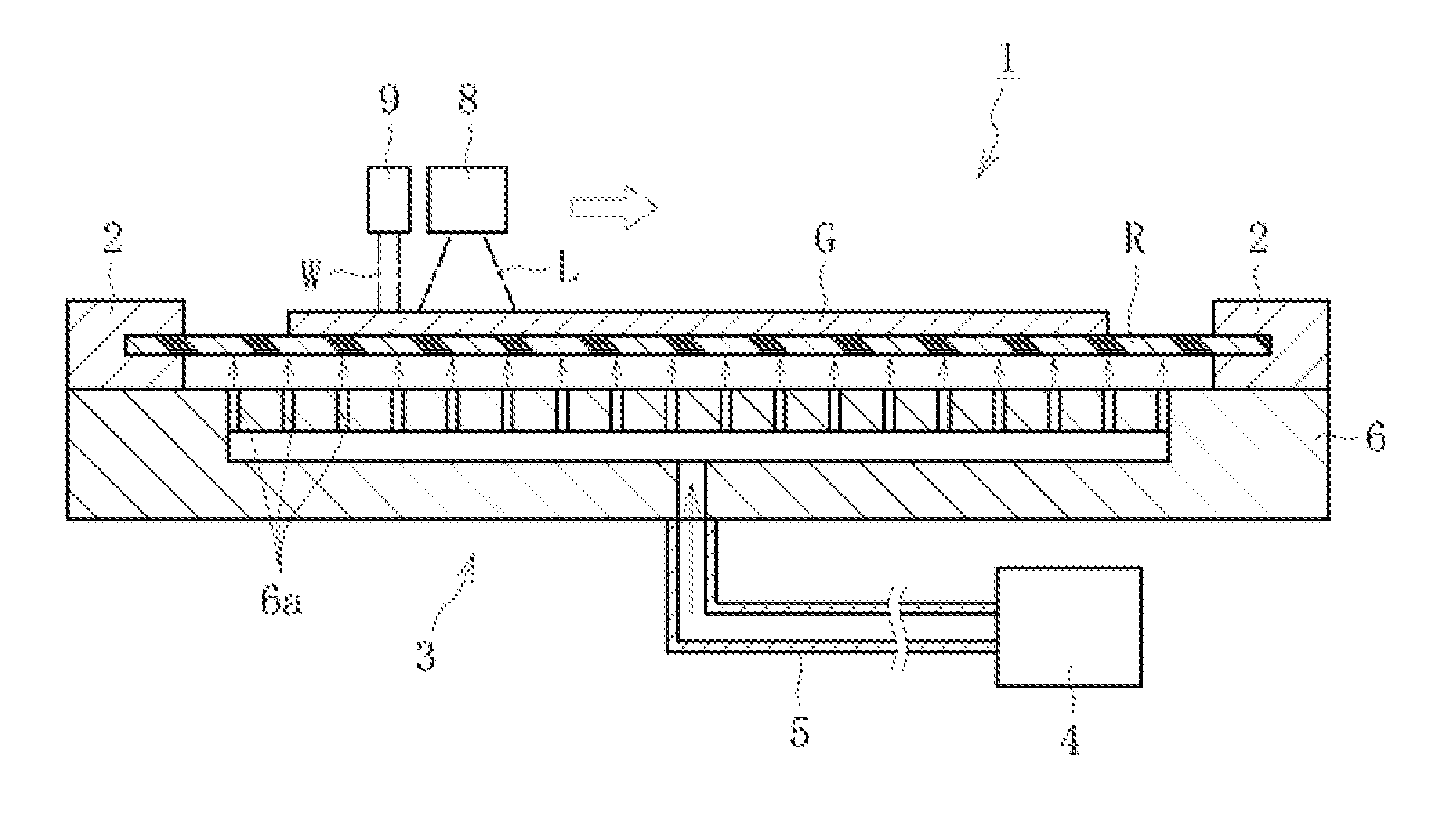

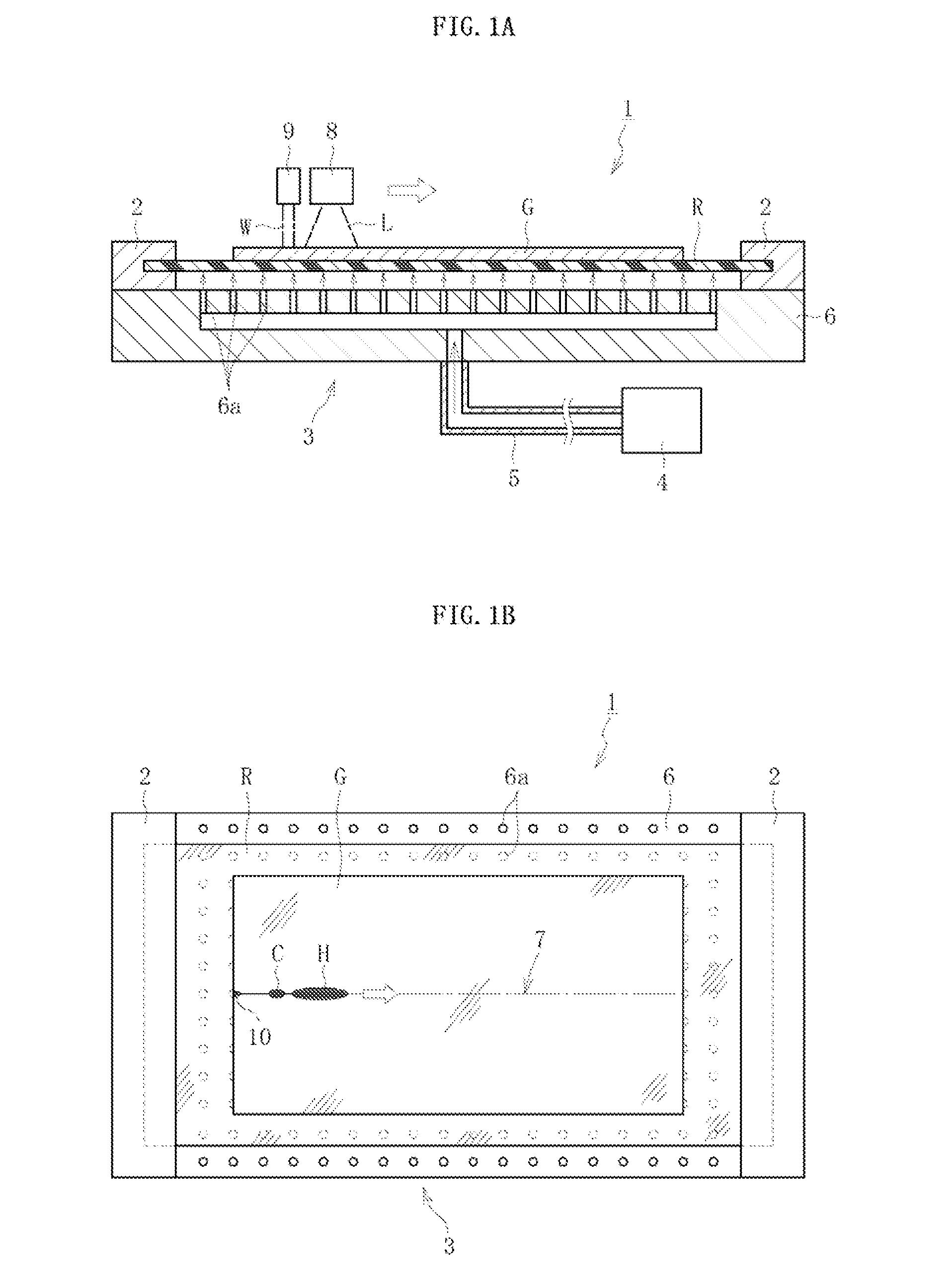

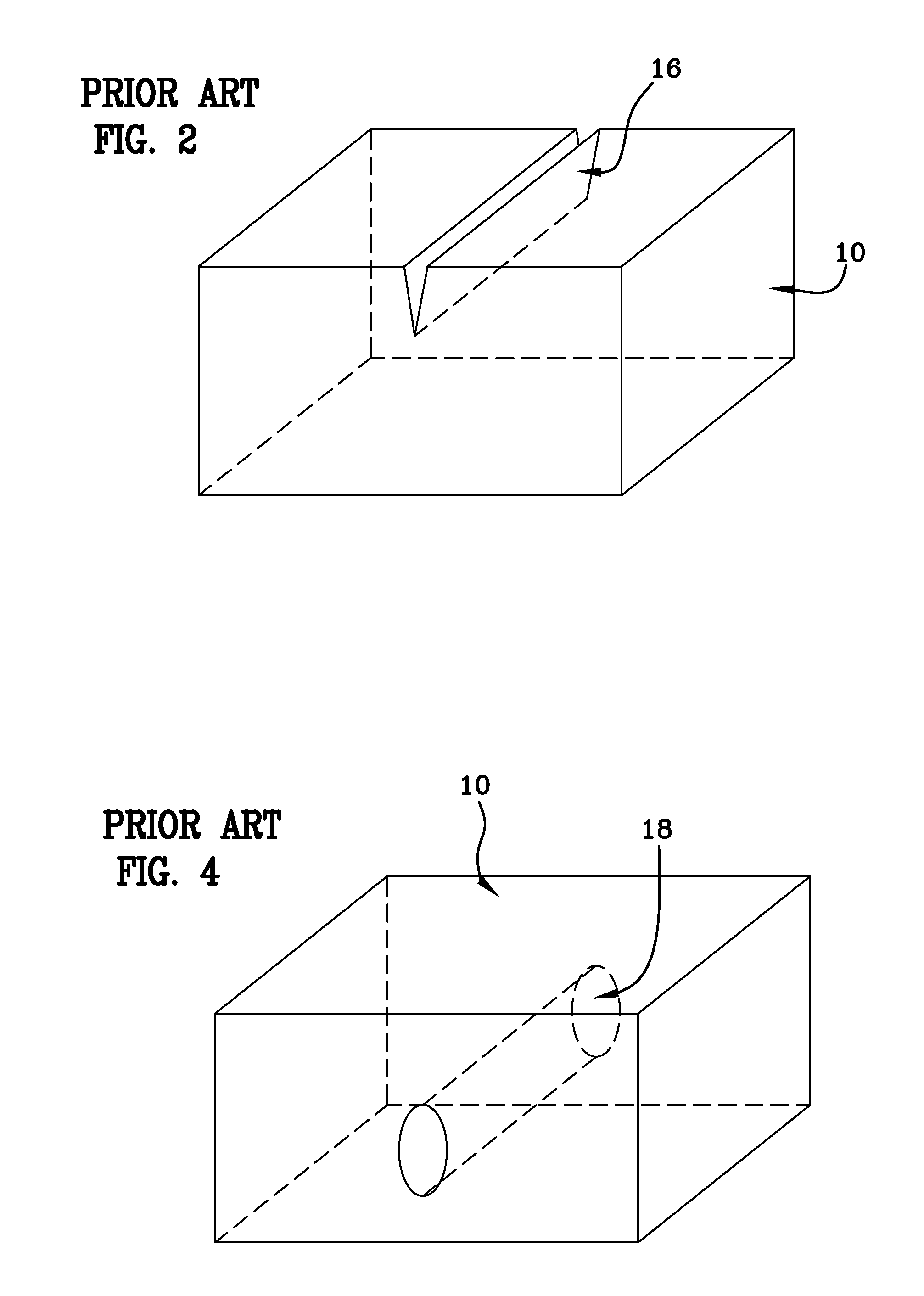

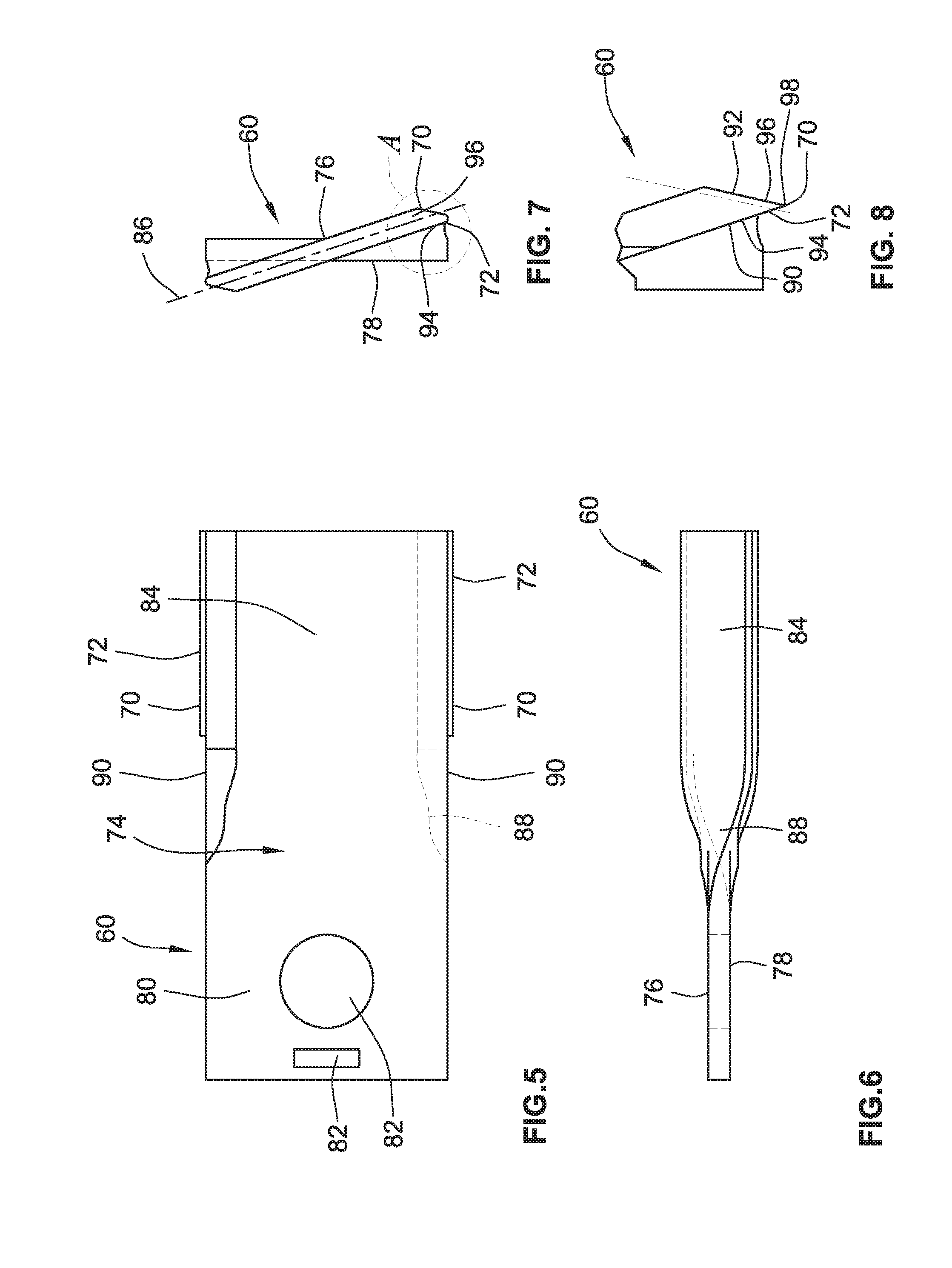

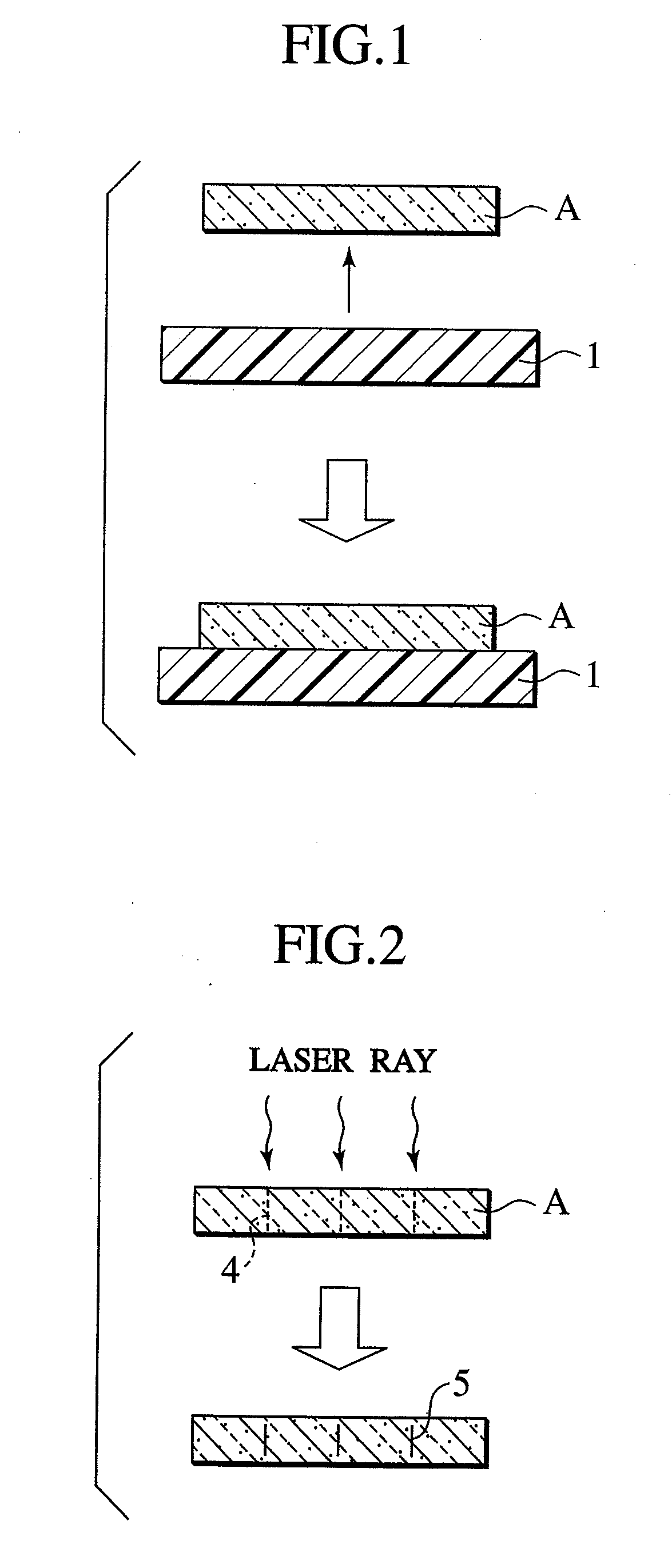

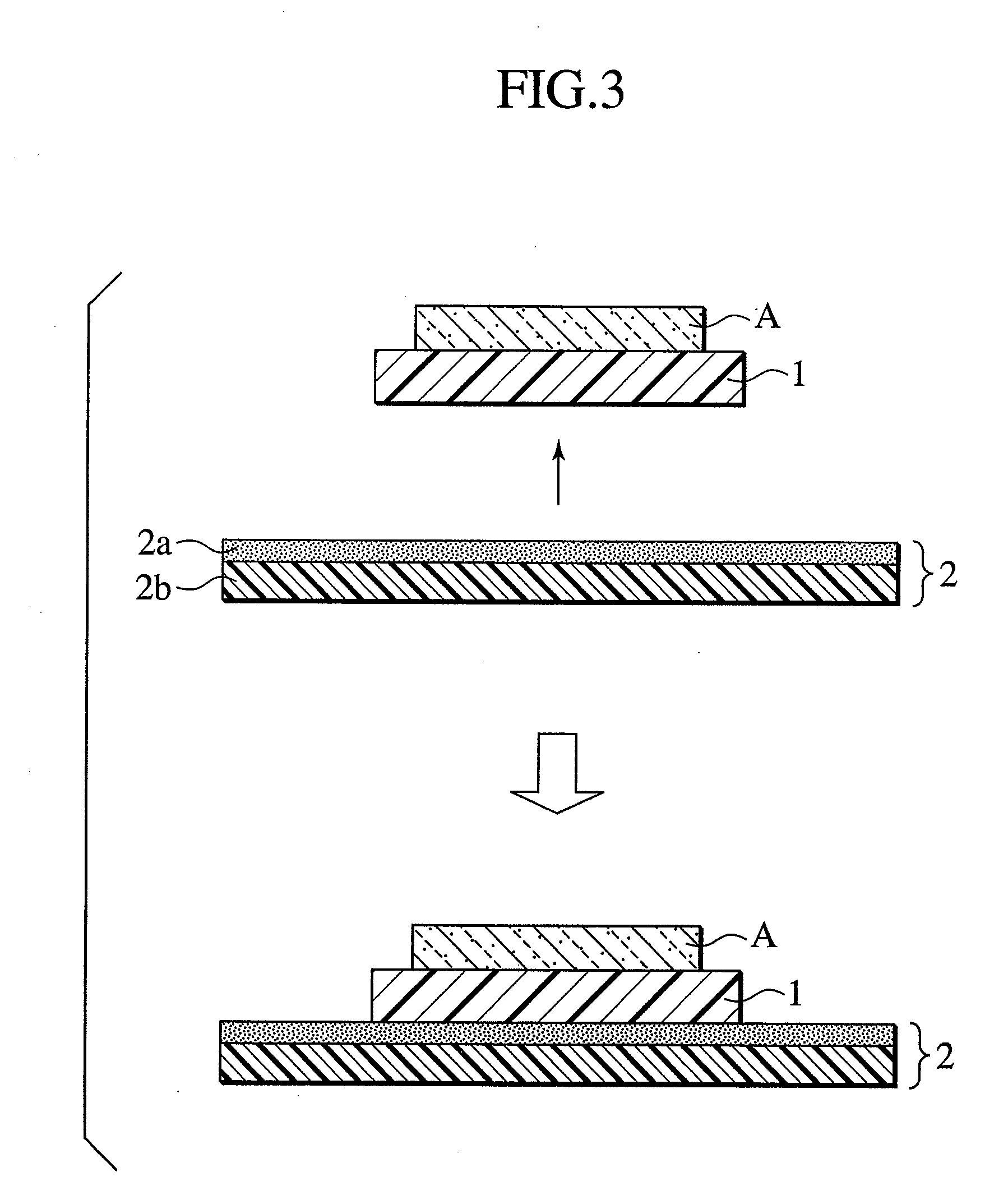

Cleaving method for a glass film, manufacturing method for a glass roll, and cleaving apparatus for a glass film

ActiveUS20120017642A1Efficient cuttingGlass drawing apparatusGlass transportation apparatusMaterials scienceGlass film

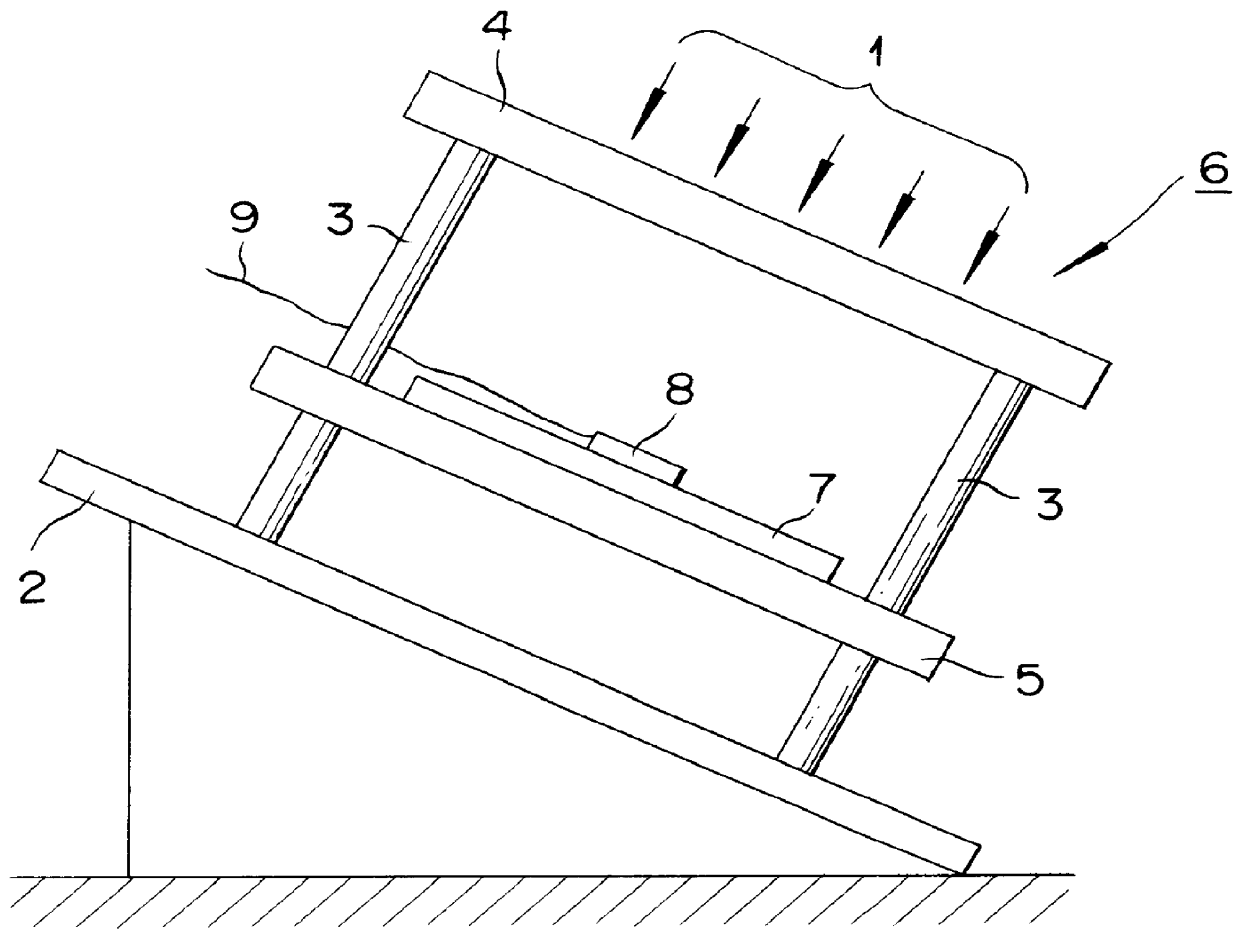

In a cleaving apparatus (1) for a glass film, an initial crack (10), which is formed at a leading end portion of a preset cleaving line (7) of a glass film (G), is propagated along the preset cleaving line (7) by a thermal stress generated in the glass film (G) through localized heating performed along the preset cleaving line (7) and cooling of a heated region resulting from the localized heating. At this time, a resin sheet (R) having higher flexibility than the glass film (G) is arranged in a cleaving region, and the resin sheet (R) is floated by blowing a gas on a lower surface of the resin sheet (R) by a floating unit (3). Then, a preset cleaving portion of the glass film (G) including the preset cleaving line (7) is lifted and supported while being covered with the floated resin sheet (R) from below, and in this state, the glass film (G) is cleaved.

Owner:NIPPON ELECTRIC GLASS CO LTD

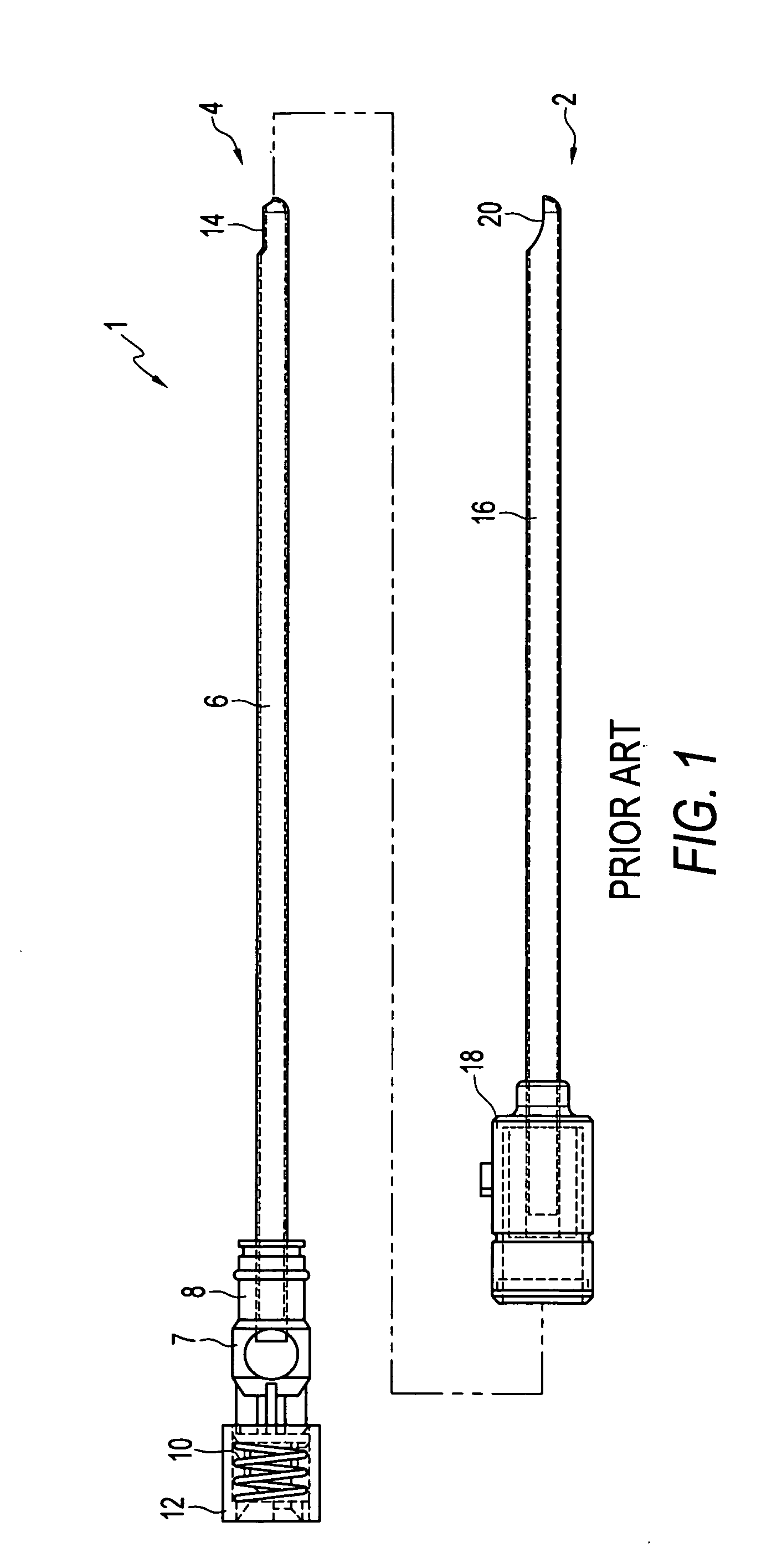

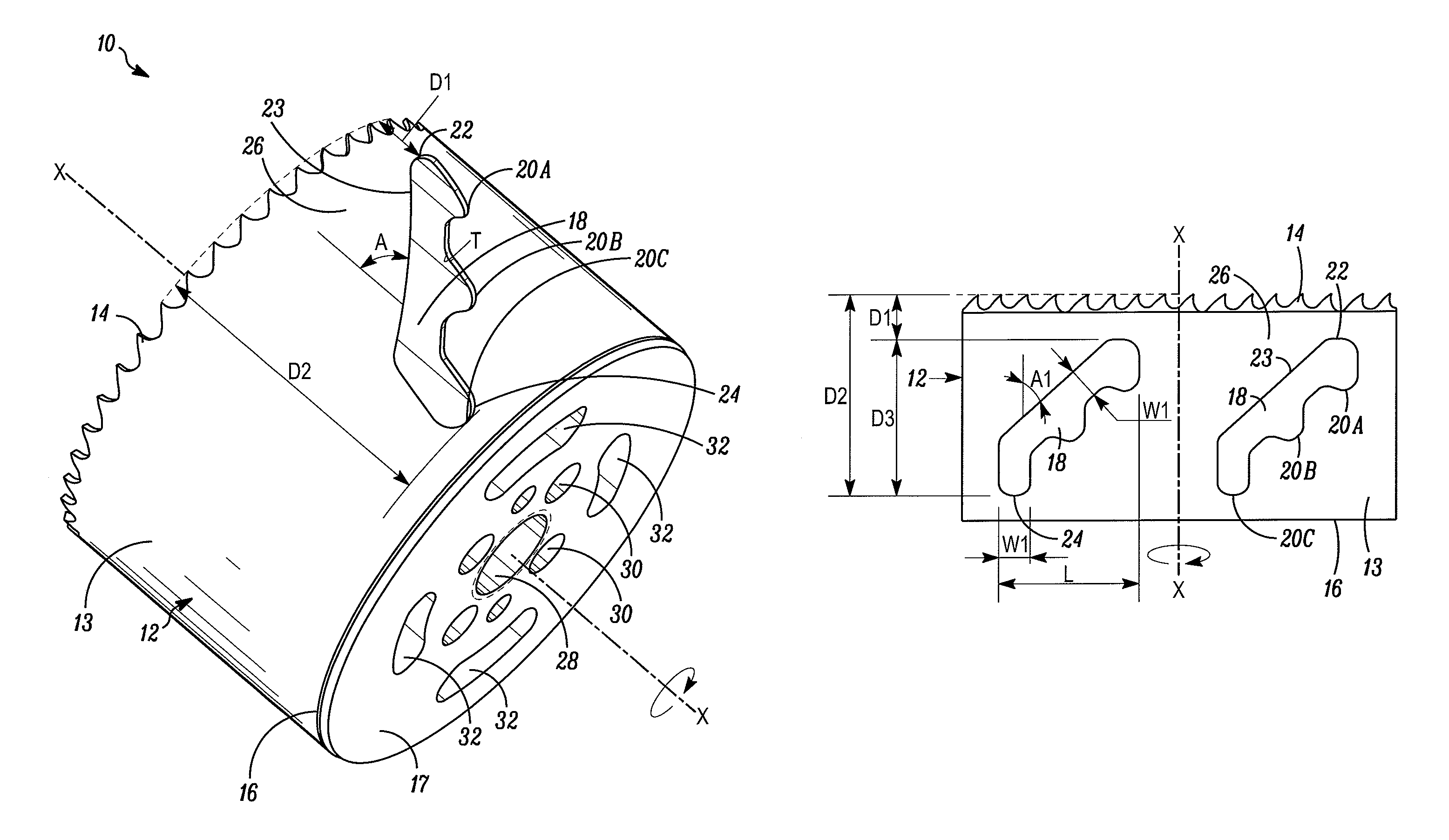

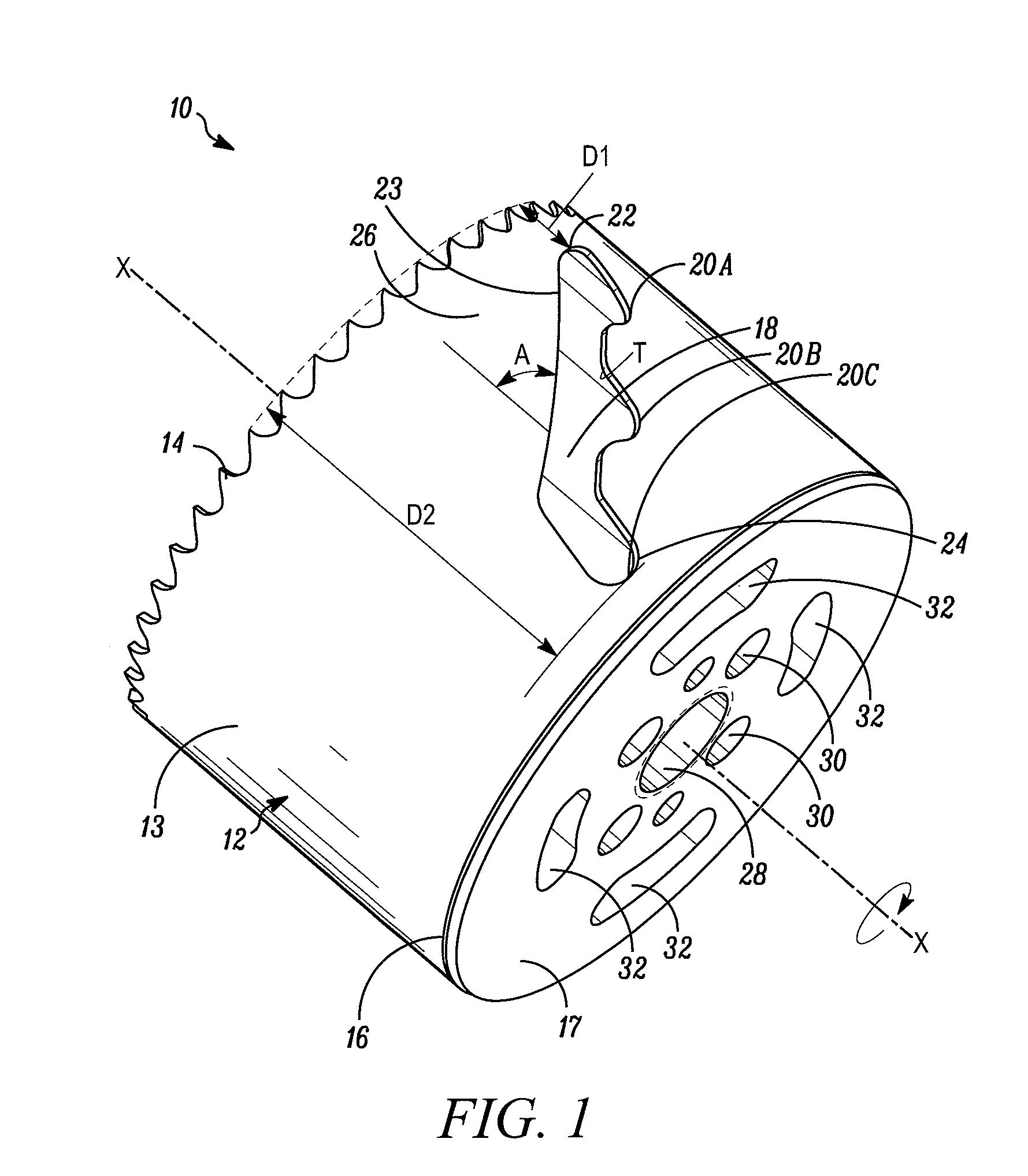

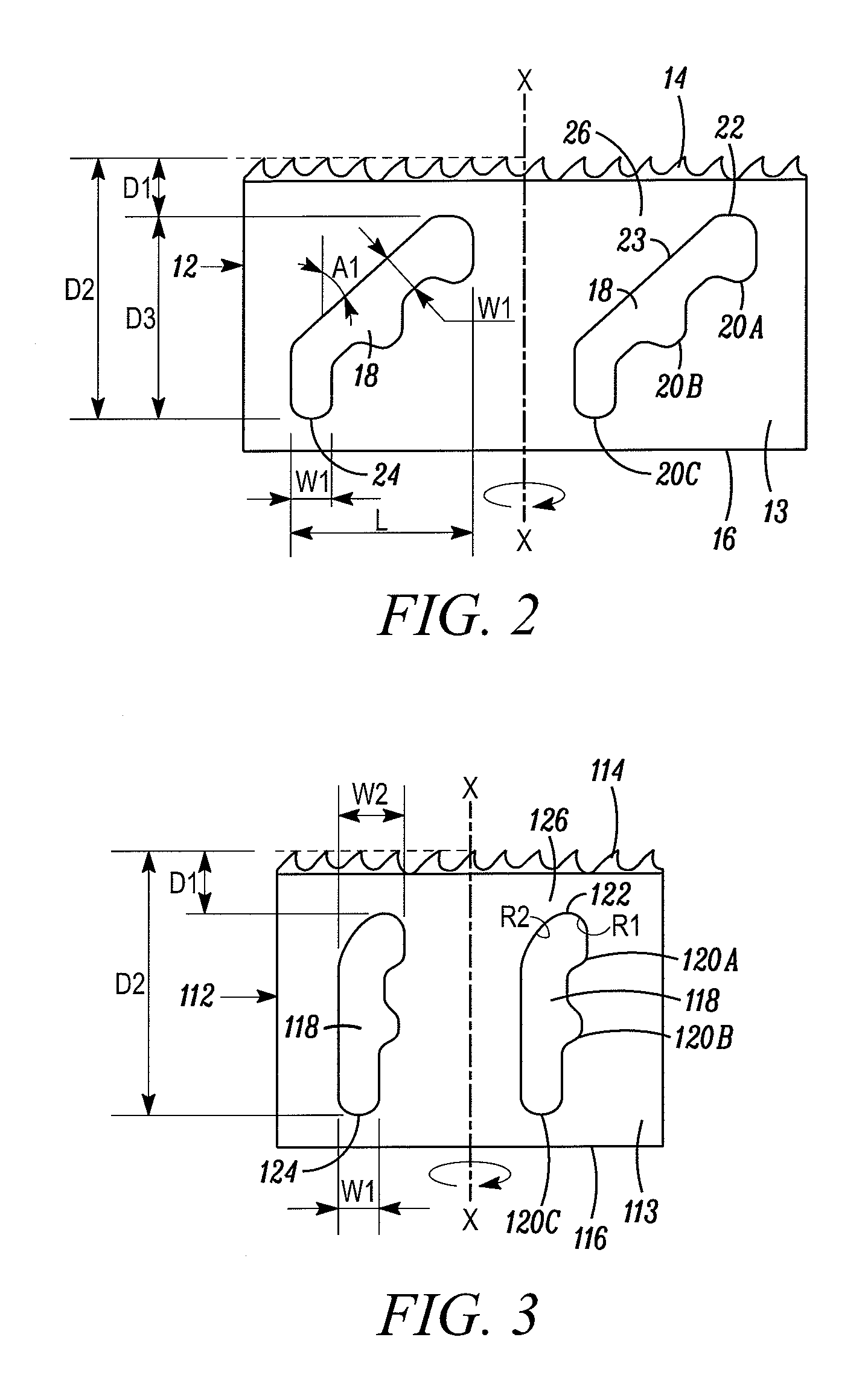

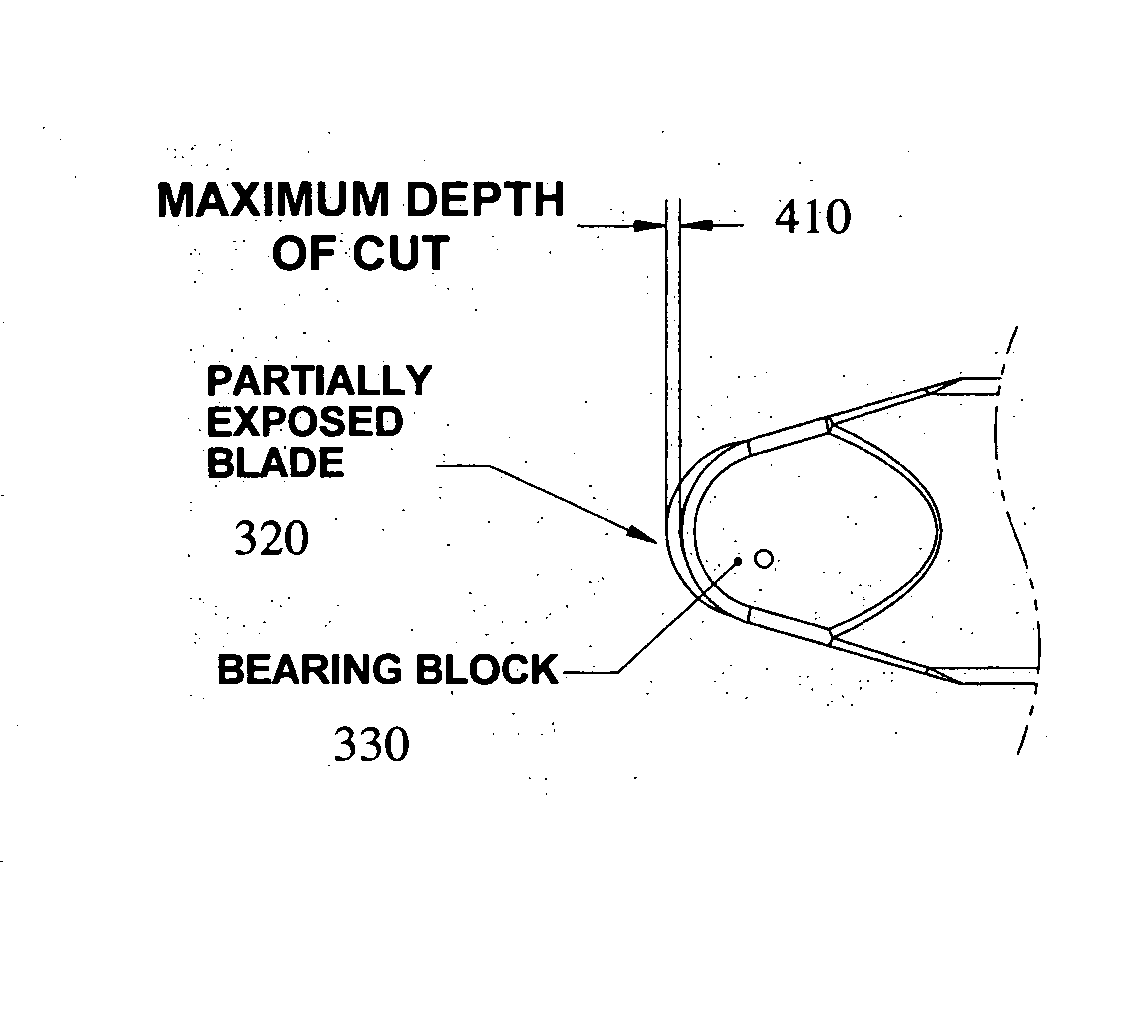

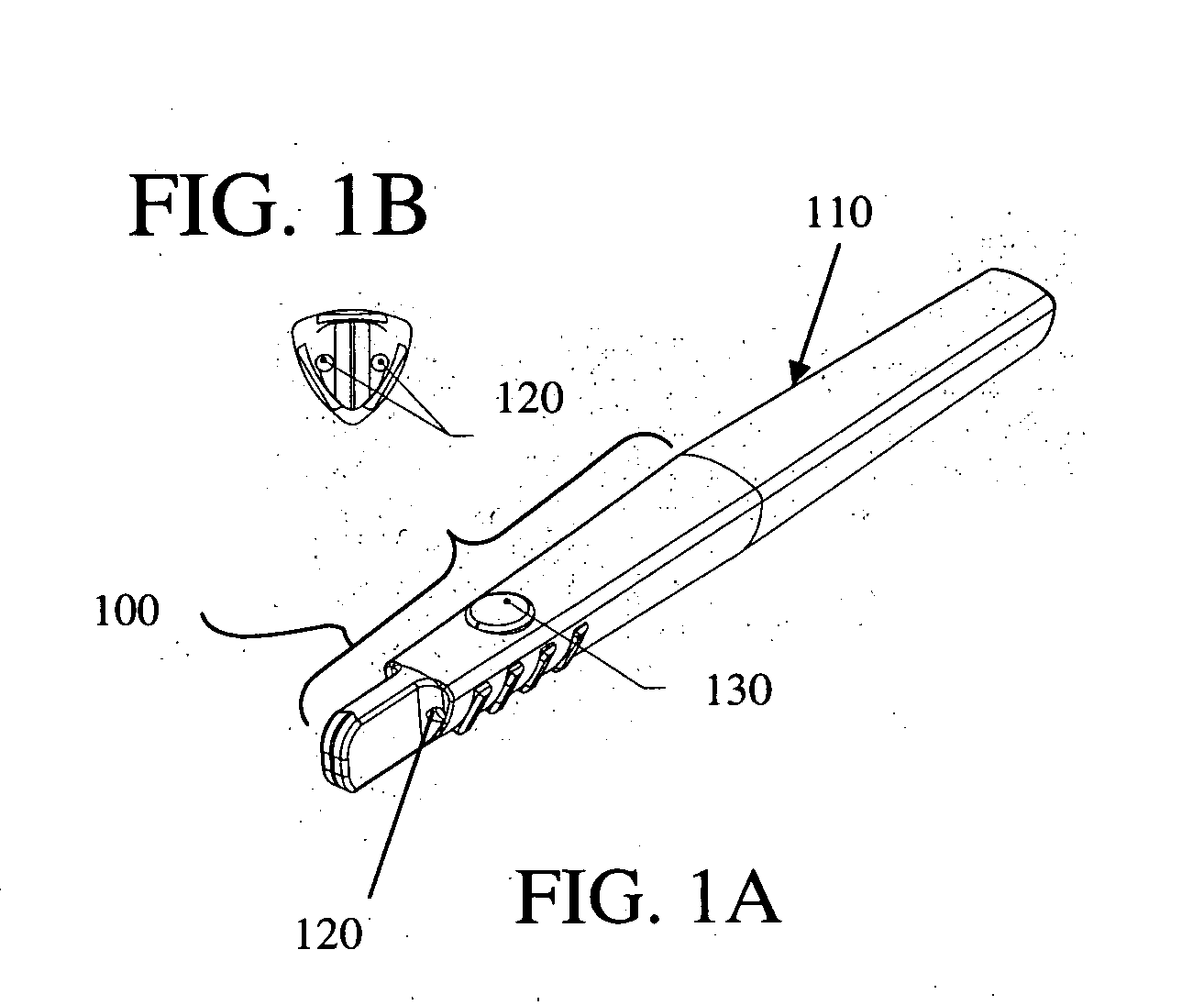

Arthroscopic shaver and method of manufacturing same

InactiveUS20060212060A1Improve efficiencyCuts bone efficientlyOther manufacturing equipments/toolsEndoscopic cutting instrumentsMilling cutterArthroscopy

An arthroscopic shaver with an inner cutting window having a plurality of teeth positioned along the lateral cutting edges, the teeth being configured for easy penetration into tissue to prevent ejection of tissue from the cutting window during closure. The inner cutting edges are formed in a milling operation using a milling cutter having an end radius equal to that of the surfaces forming the inner surfaces of the cutting edges. The teeth may be symmetrically or asymmetrically placed about the tube axis when viewed in a plan view.

Owner:ARTHREX

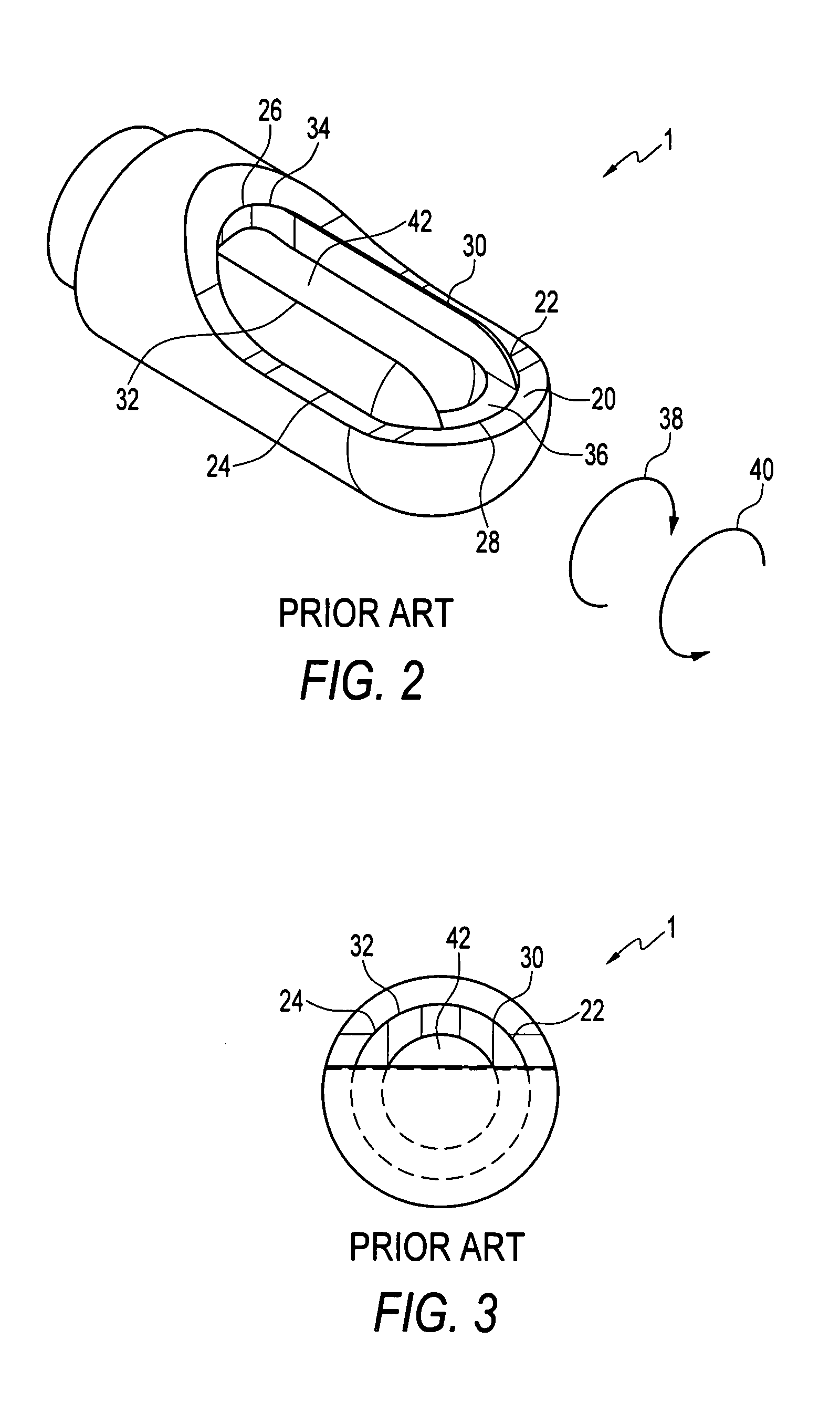

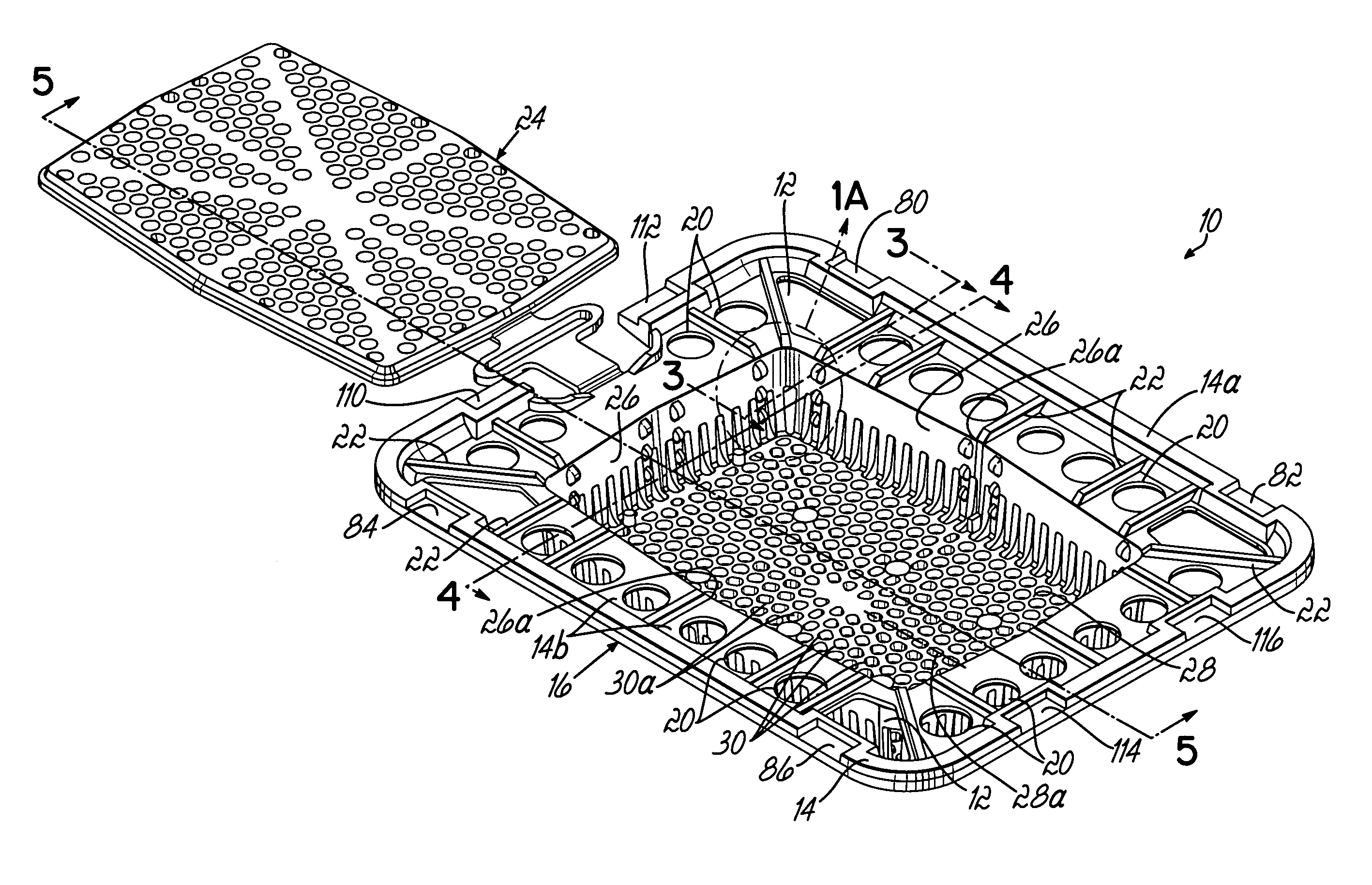

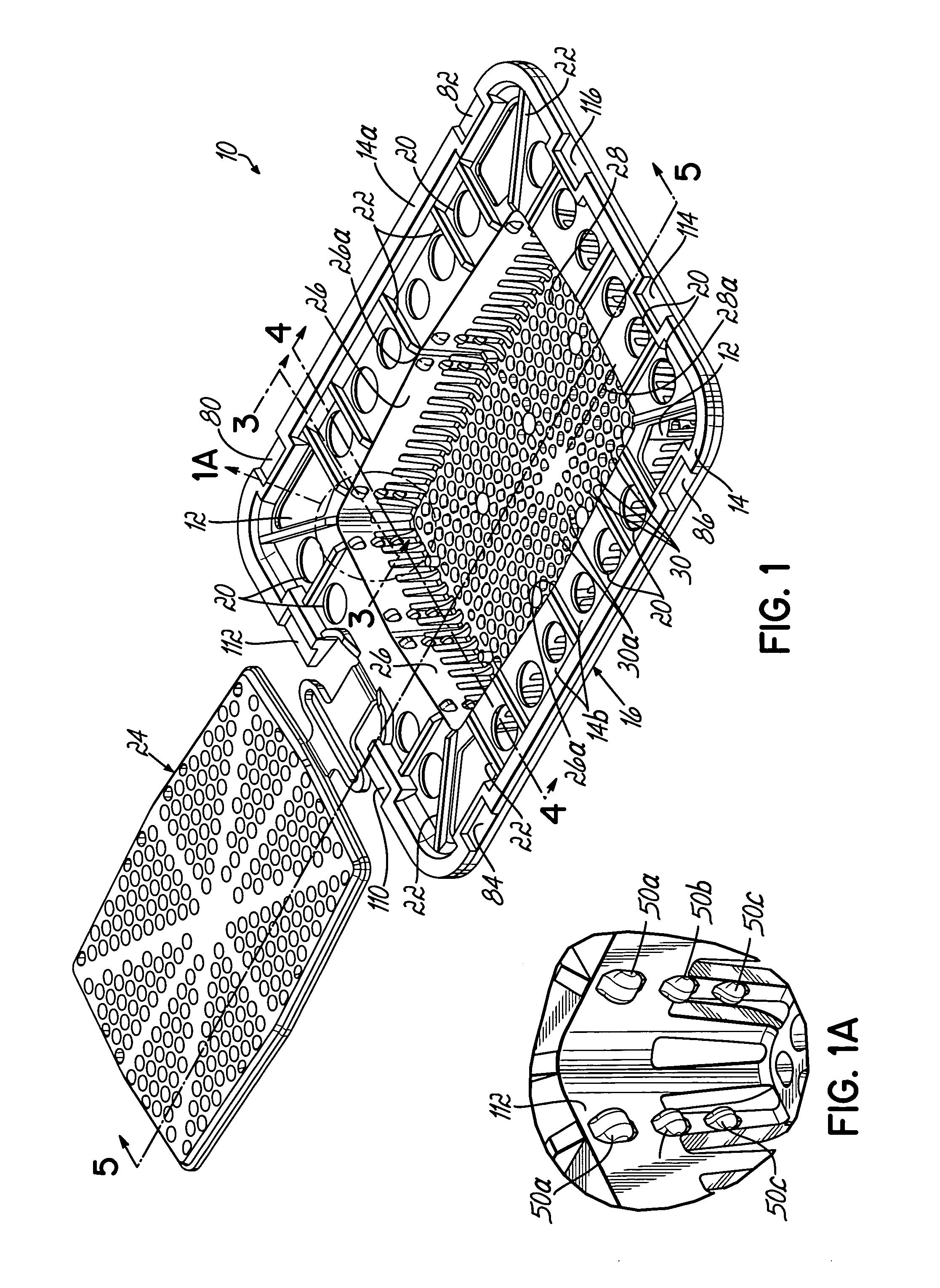

Cassette for handling and holding tissue samples during processing, embedding and microtome procedures, and methods therefor

ActiveUS7179424B2Simple processEfficient cuttingPreparing sample for investigationSurgeryInterior spaceTissue sample

A cassette for holding a tissue sample includes a body having a bottom wall and a plurality of side walls extending upwardly with respect to the bottom wall to define an interior space for receiving the tissue sample. A lid is configured to be received in the interior space, and the cassette is sectionable in a microtome. Sensing elements are associated with the body or lid and configured to allow an automated sensing system to determine at least one characteristic of the cassette. A flange extends along upper portions of at least two of the side walls and includes a plurality of holes. Other features are included to more effectively and efficiently manufacture and use the cassette.

Owner:BIOPATH AUTOMATION

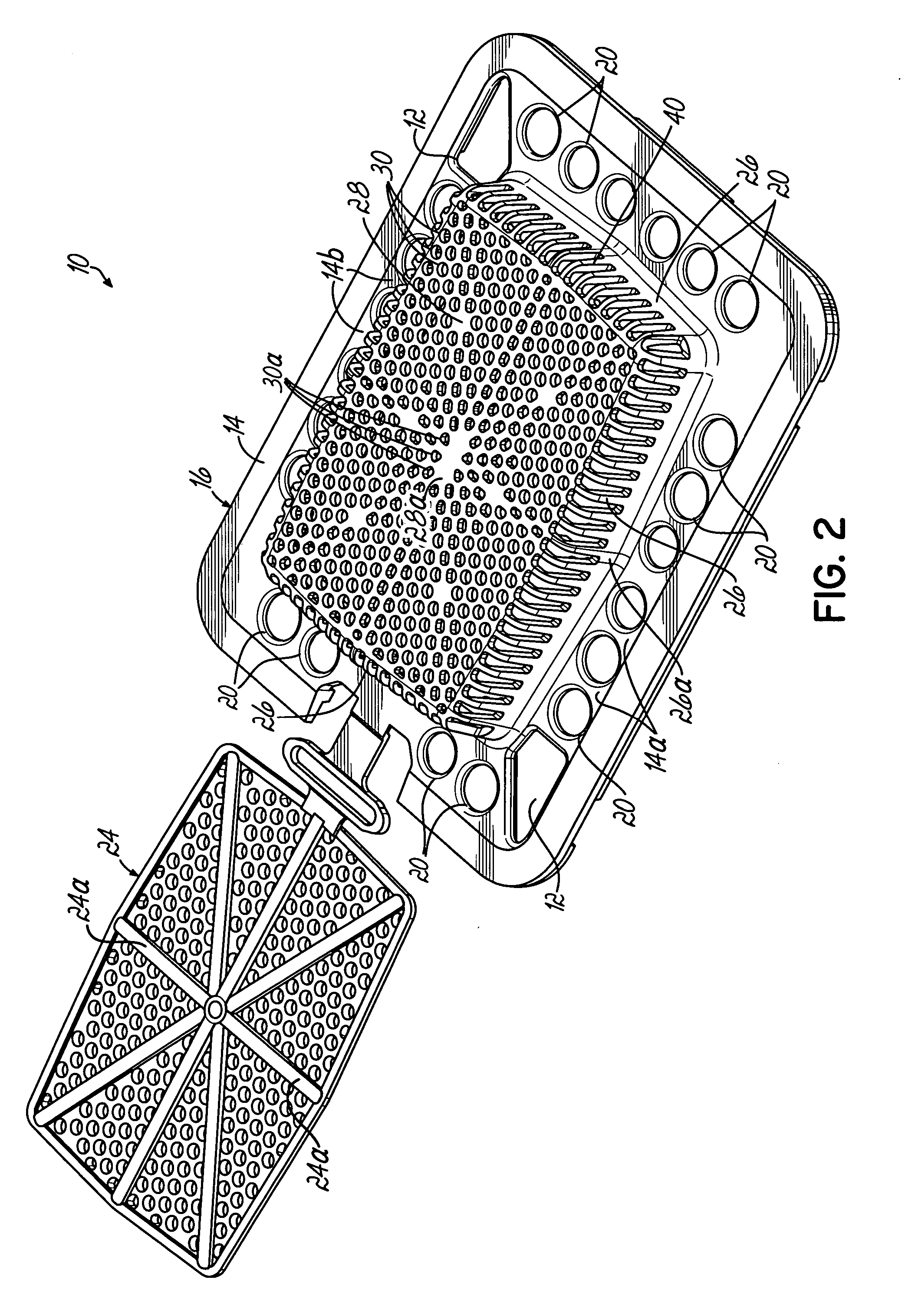

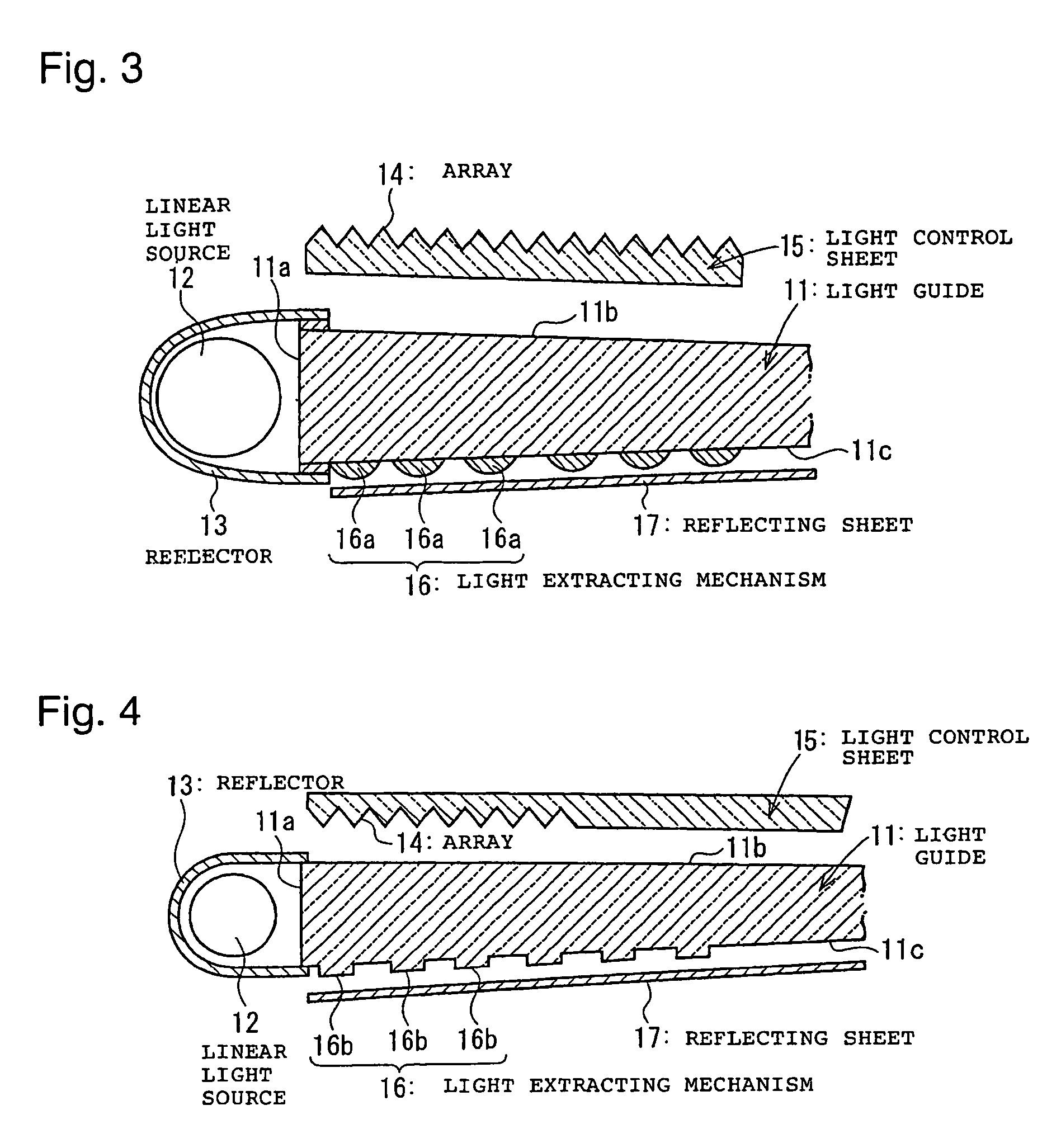

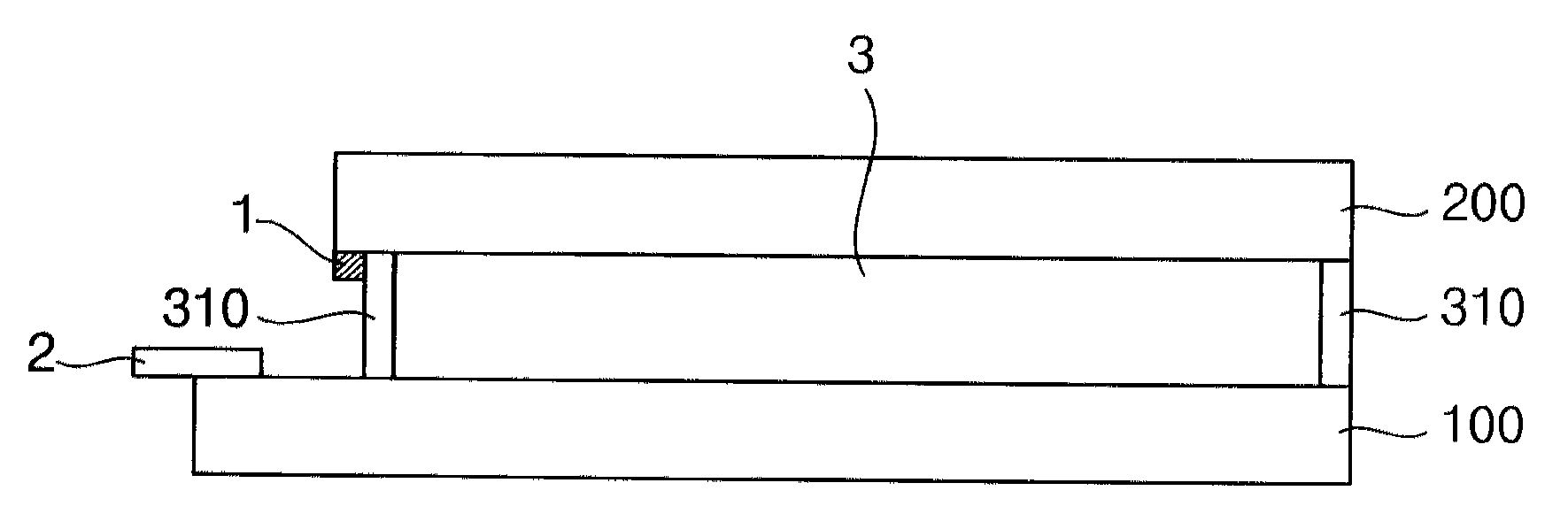

Color liquid crystal display devices

InactiveUS7006172B2High emission intensityIncrease brightnessOptical filtersPlanar/plate-like light guidesLiquid-crystal displayTransmission illumination

The invention relates to a color liquid crystal display device with a combination of light shutters that utilize a liquid crystal, a color filter having color elements of at least three colors of red, green and blue corresponding to the light shutters, and a backlight for transmission illumination.

Owner:MITSUBISHI CHEM CORP

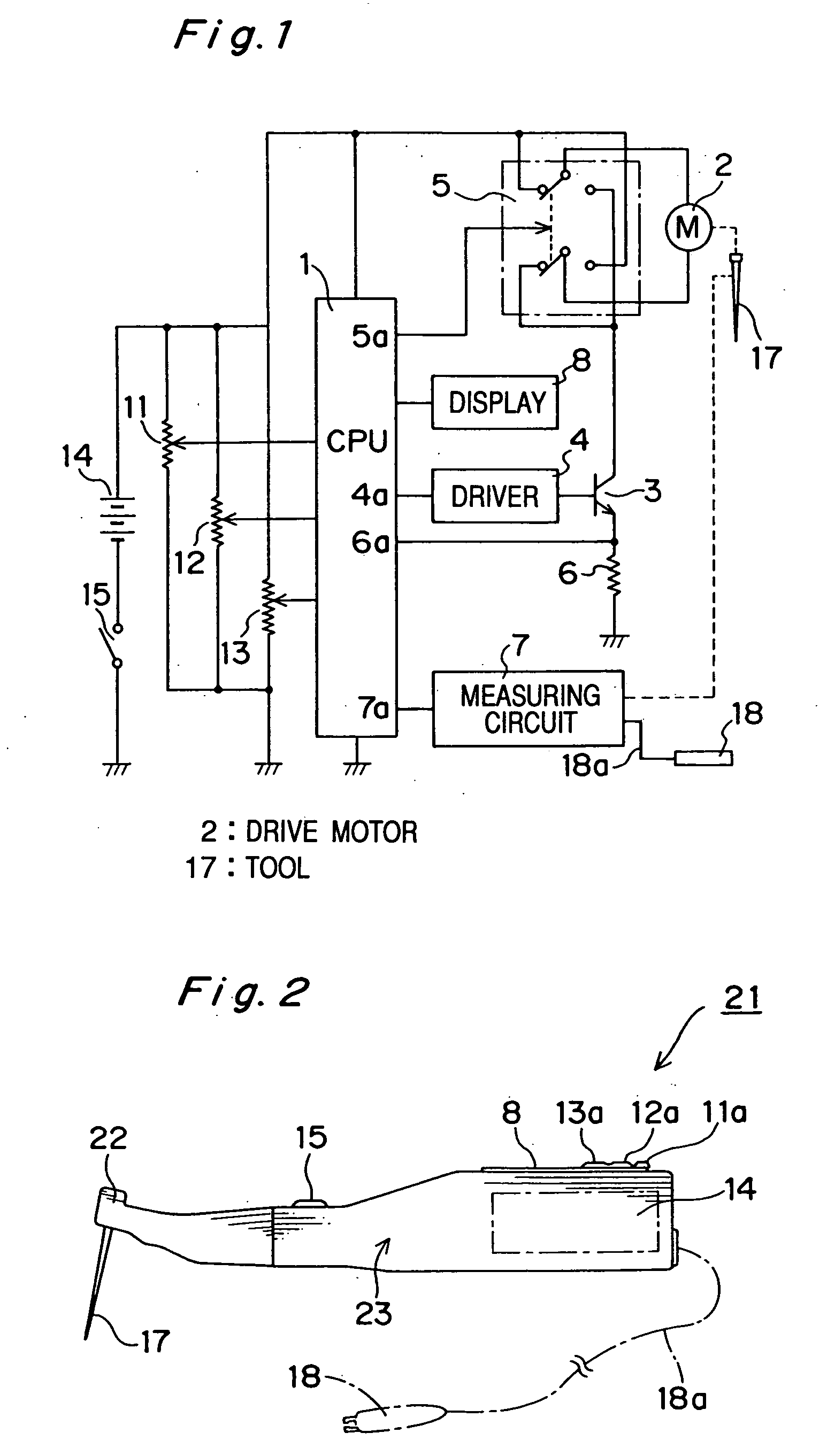

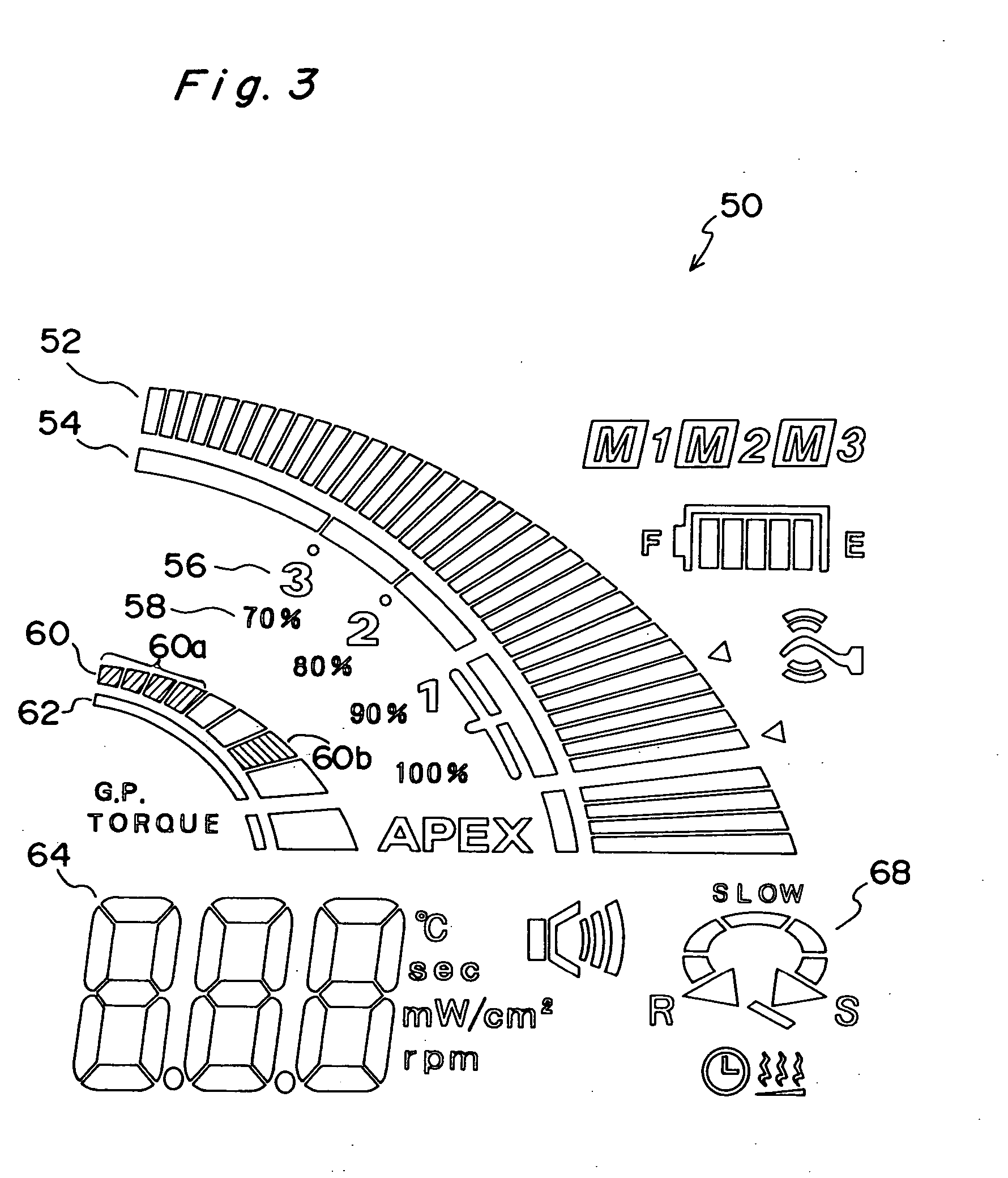

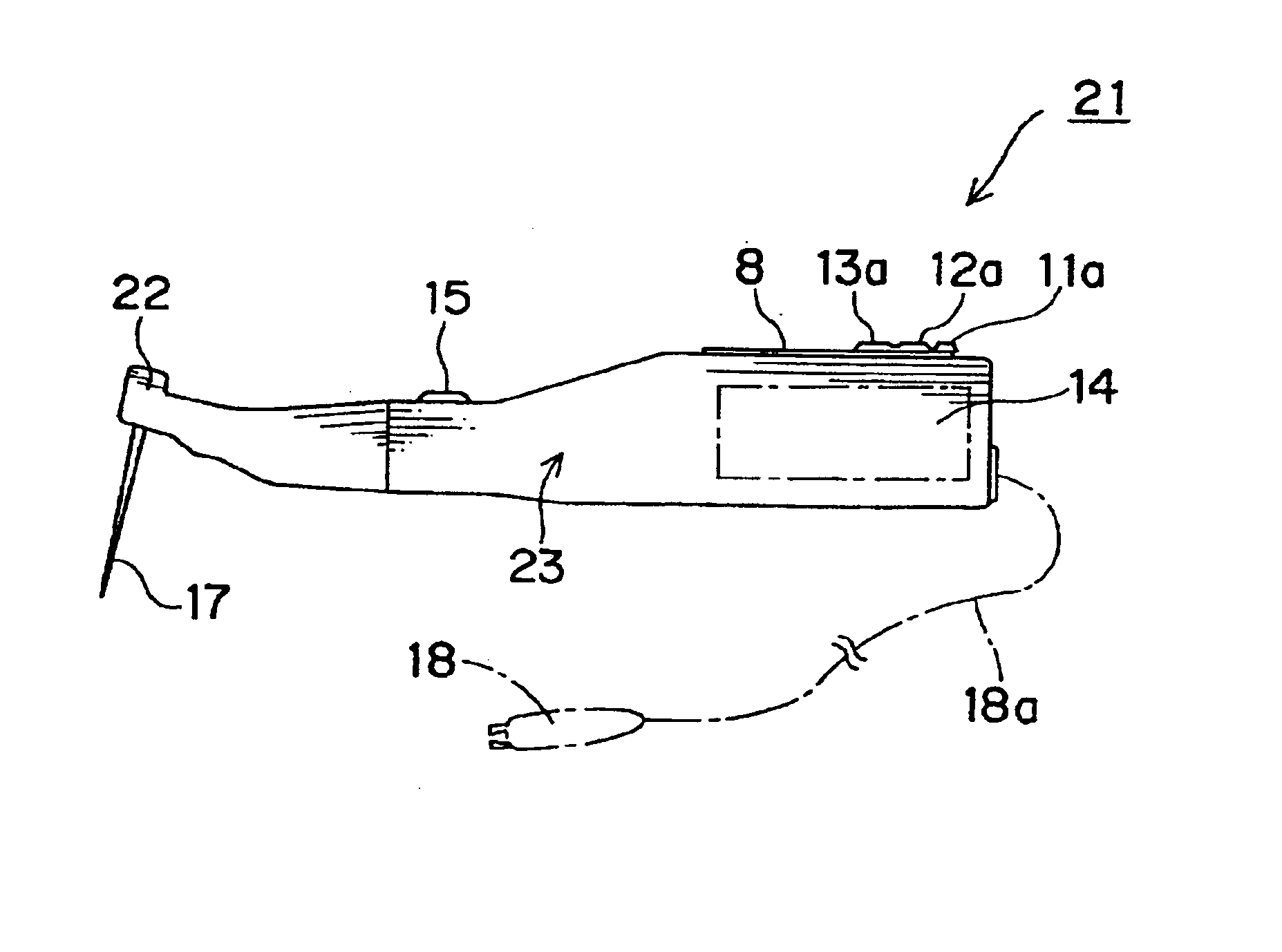

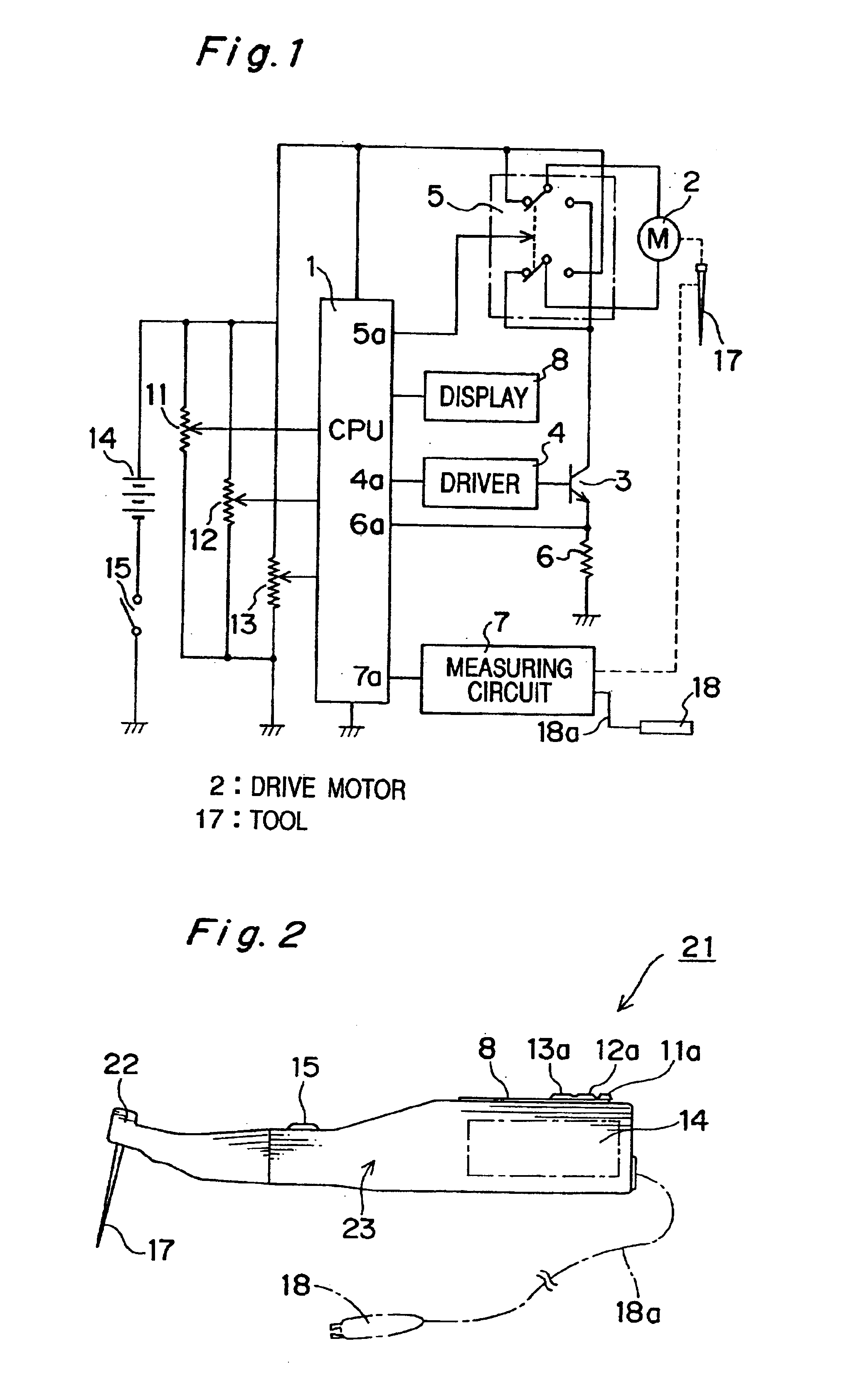

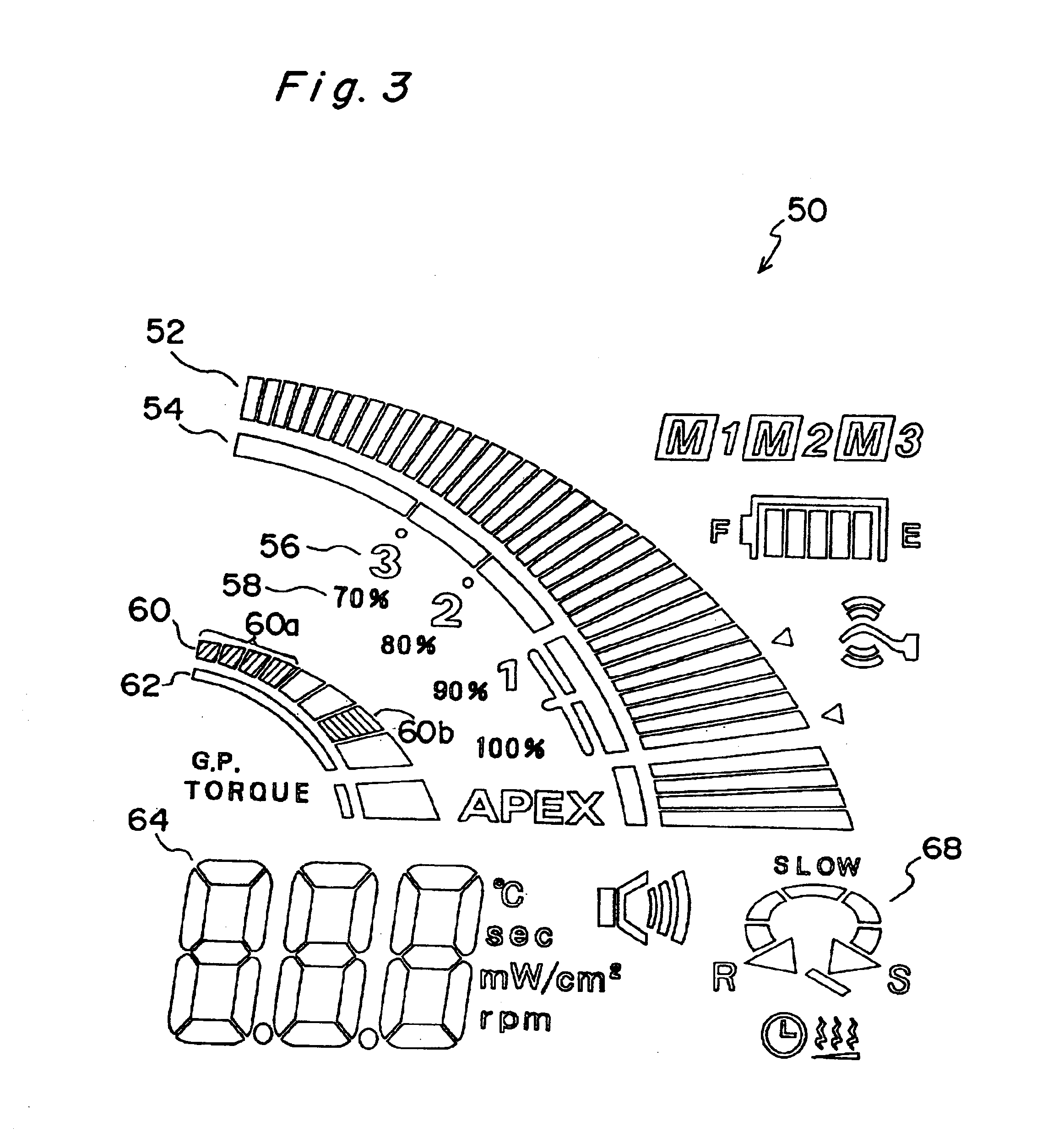

Dental apparatus

InactiveUS20050042572A1Guaranteed to workCarrying out cutting efficientlyTeeth fillingDental toolsDental instrumentsDental Equipment

A dental equipment for cutting teeth, forming root canals and so on. The dental apparatus includes: an actuator for actuating a cutting tool; a load sensor for sensing a load worked in the cutting tool; and a load indicator for making an operator know the load sensed by the load sensor visually, aurally and / or tactily.

Owner:MORITA MFG CO LTD

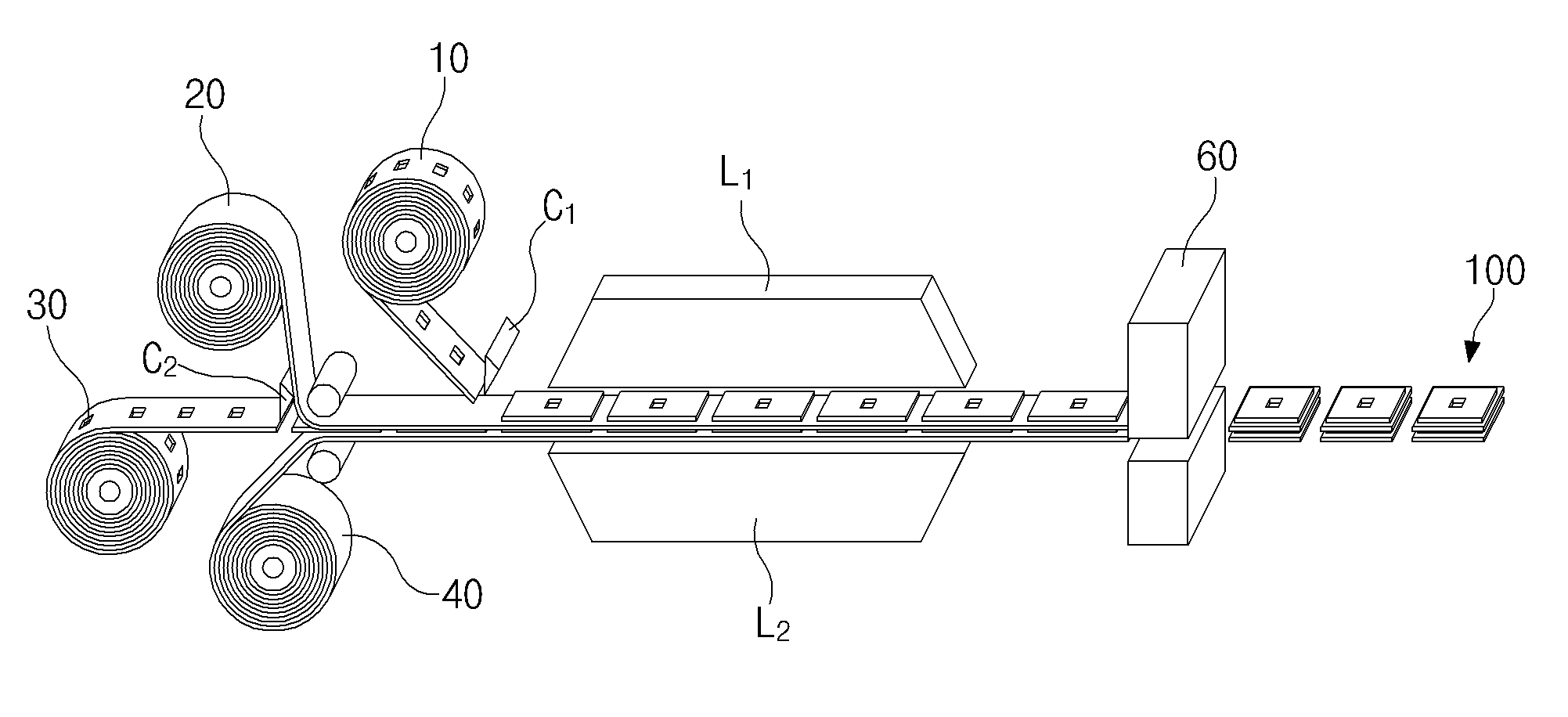

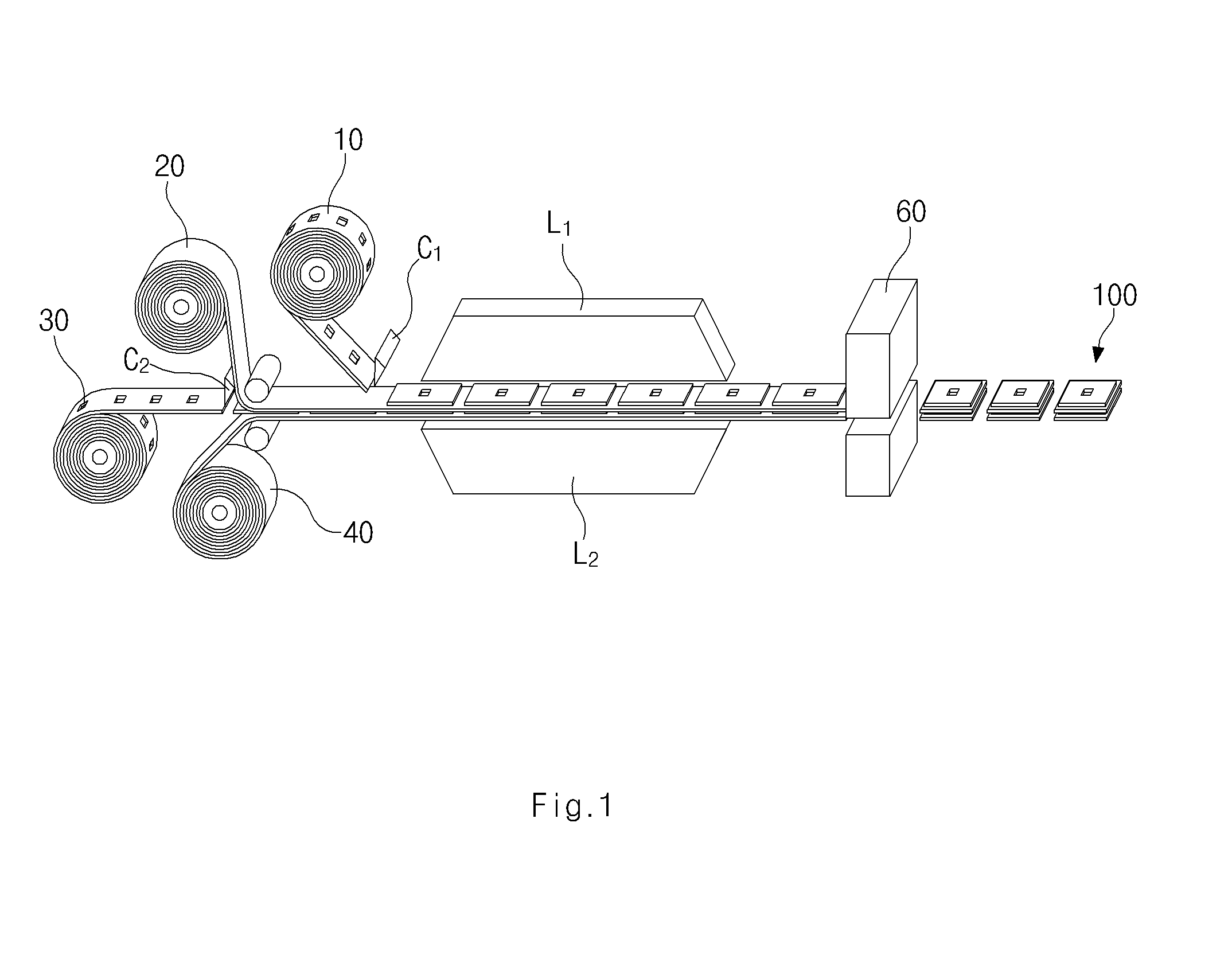

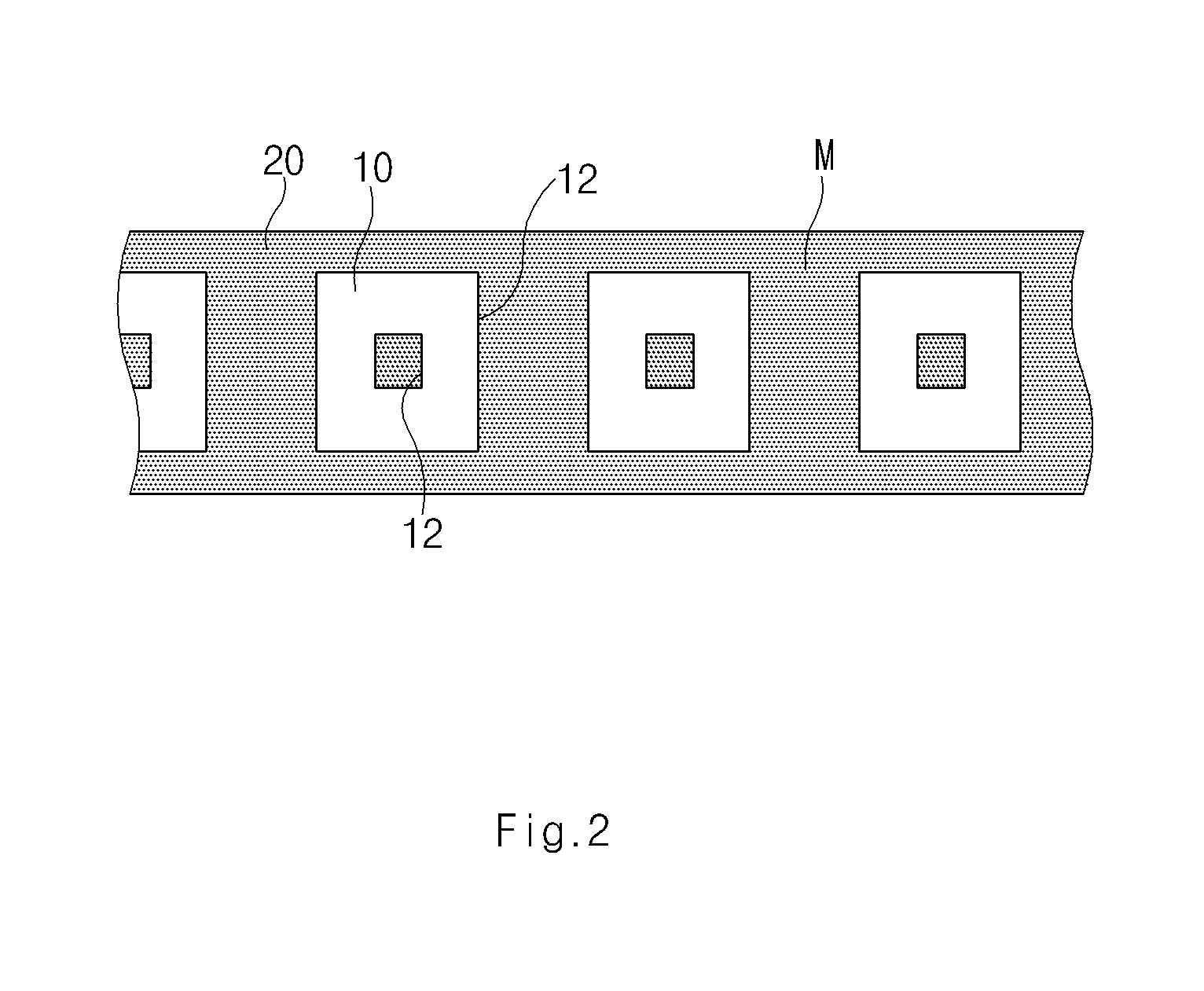

Electrode assembly manufacturing method including separator cutting process

ActiveUS20150033547A1Efficient cuttingAvoid damageElectrode manufacturing processesAssembling battery machinesEngineeringElectrode material

Provided is an electrode assembly manufacturing method including a process of cutting a separator included in an electrode assembly to have a margin protruding from an electrode plate. The method includes a first process of manufacturing one type of basic unit sheets having a structure in which electrode materials and separator materials, which are the same in number, are alternately stacked, or two or more types of basic unit sheets having a structure in which electrode materials and separator materials, which are the same in number, are alternately stacked, and a second-A process of cutting a portion of a margin area of the separator materials, which are not covered with the electrode materials, such that the separator materials of the basic unit sheets protrude over a specific distance from edges of the electrode materials.

Owner:LG ENERGY SOLUTION LTD

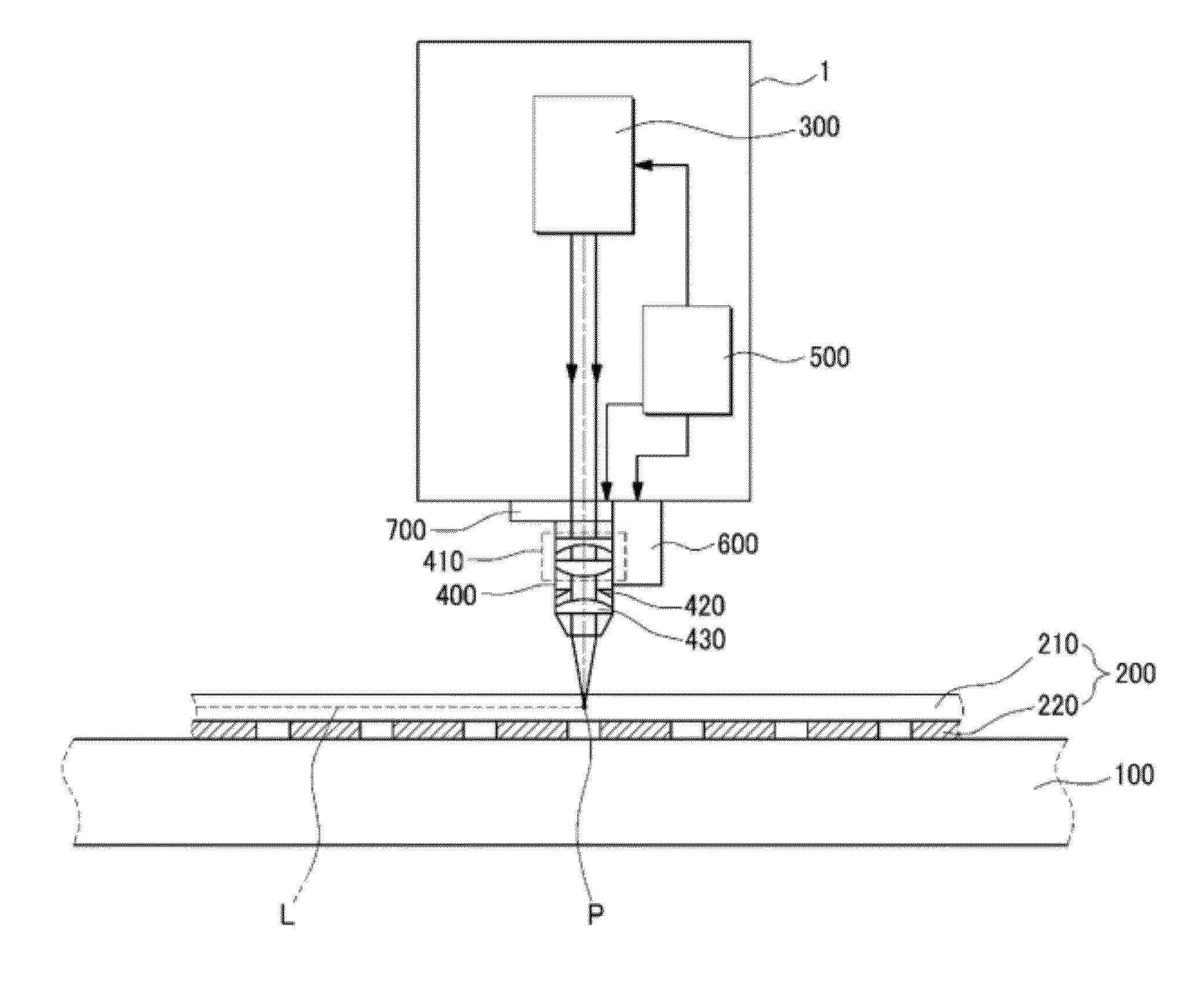

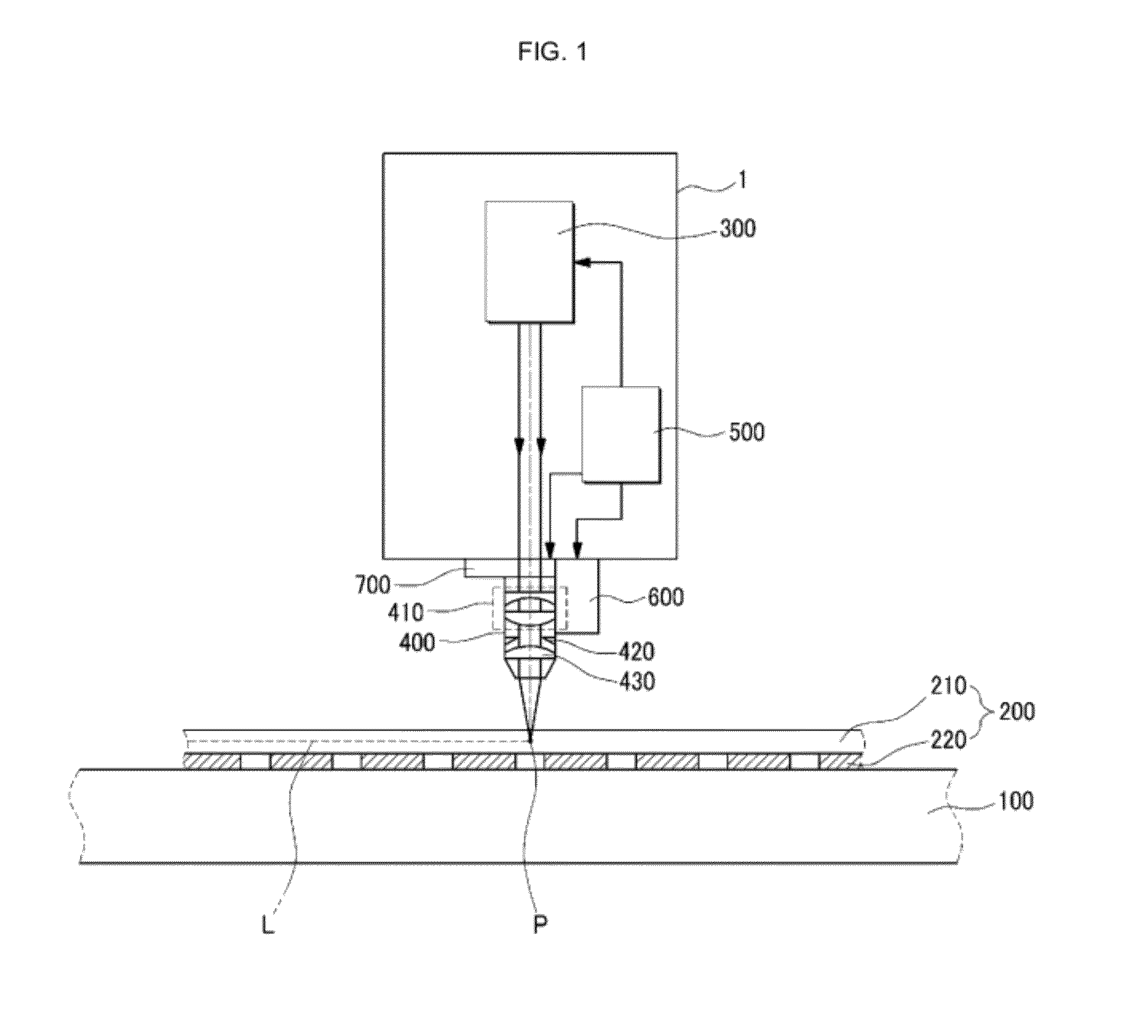

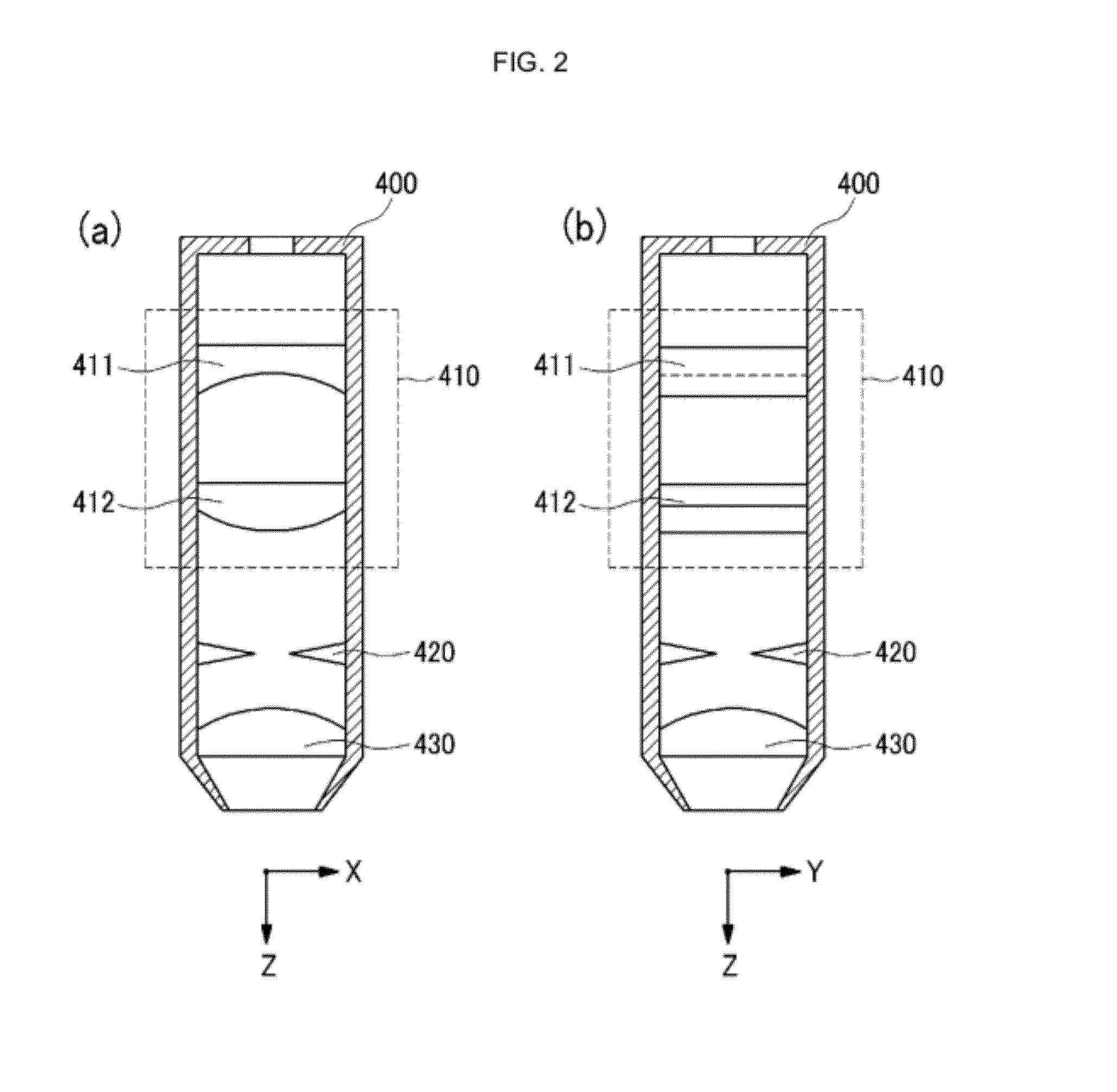

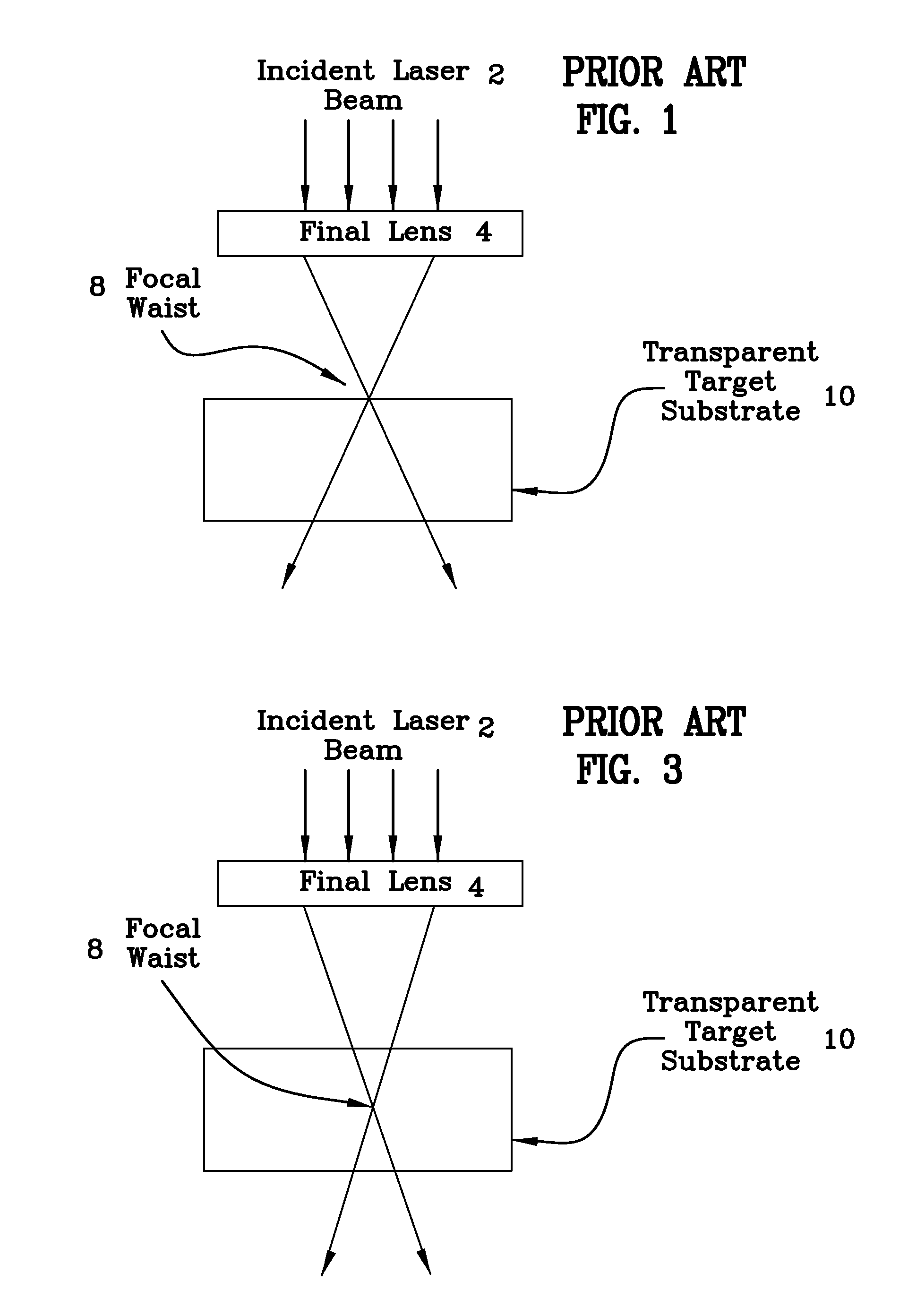

Target object processing method and target object processing apparatus

ActiveUS20120111310A1Suppress generationPreventing of sectionFine working devicesGlass severing apparatusDivergence angleLight beam

There is provided a target object processing method capable of self-breaking a target object with a laser beam. The target object processing method includes: generating a laser beam from a laser beam source; correcting a divergence angle of the generated laser beam; and forming a spot by condensing the corrected laser beam to the inside of the target object. A shape or a size of the spot is adjusted by correcting the divergence angle of the laser beam, a phase transformation area is formed within the target object by the spot, and the target object is subject to self-breaking with the phase transformation area as the starting point.

Owner:QMC +1

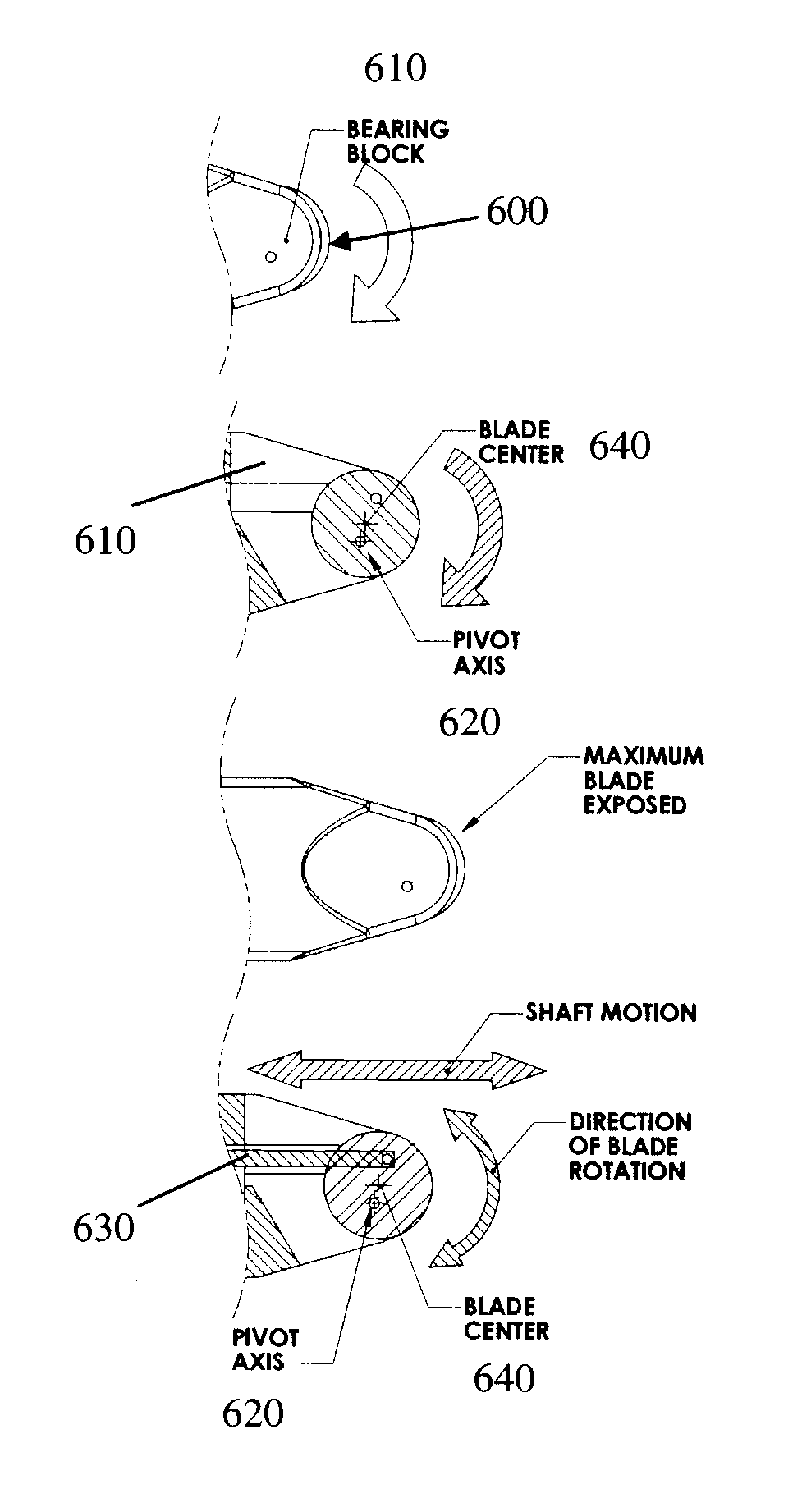

Method and apparatus for machining diamonds and gemstones using filamentation by burst ultrafast laser pulses

InactiveUS20150121960A1Efficient cuttingLess-waste is producedBlowing machine gearingsFine working devicesNon ablativeFilamentation

A non-ablative laser machining method and apparatus for cutting facets of a diamond, using a material machining technique involving filamentation by burst ultrafast laser pulses well suited to mass production. Coupled with 3D modeling and the computerized laser machining system, complex geometric surfaces can be created on the diamond. The facets of the diamond need not be planar in configuration, and may incorporate acute as well as oblique angles. This method minimizes the need for diamond polishing, speeds up production, and realizes great reductions in the quantity of lost material from the cutting process.

Owner:ROFIN SINAR TECH

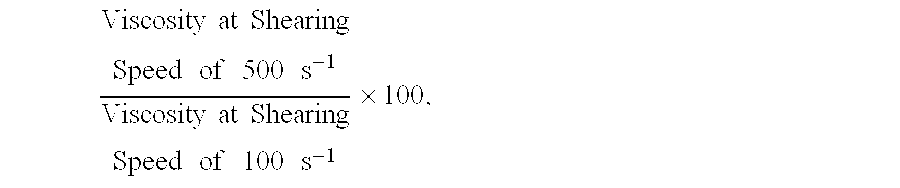

Cutting oil composition

InactiveUS6383991B1Good dispersionEasy to cleanWork treatment devicesAdditivesHydrogen atomChemical composition

The present invention relates to a cutting oil comprising (a) a polyether compound represented by the formula (I):wherein each of R1 and R2, which may be identical or different, is hydrogen atom or a hydrocarbon group having 1 to 24 carbon atoms, at least one of which is a hydrocarbon group; EO is oxyethylene group; AO is an oxyalkylene group having 3 or 4 carbon atoms; and each of m and n is 1 to 50, wherein a sum of m and n is from 4 to 100; a cutting oil composition comprising the above cutting oil and an abrasive; a cutting method using the above cutting oil composition; and a process of cleaning a wafer, comprising the steps of cleaning a wafer obtainable by cutting an ingot with a wire saw using the above cutting oil composition; heating the resulting waste water to a temperature equal to or higher than a cloud point of a polyether compound represented by the formula (I) contained in the waste water, to allow separation into an oil phase and an aqueous phase; and removing the oil phase comprising the polyether compound from the waste water. According to the present invention, there can be obtained excellent dispersibility of the abrasive, and excellent re-dispersibility, cutting performance and workability when sedimented, and the object to be cut obtained after cutting can be easily cleaned.

Owner:KAO CORP

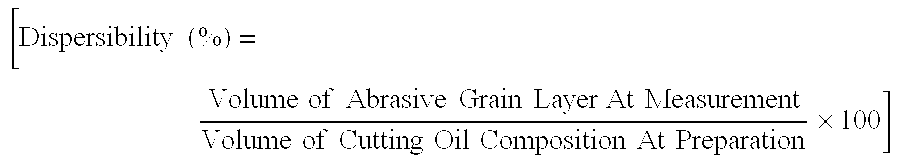

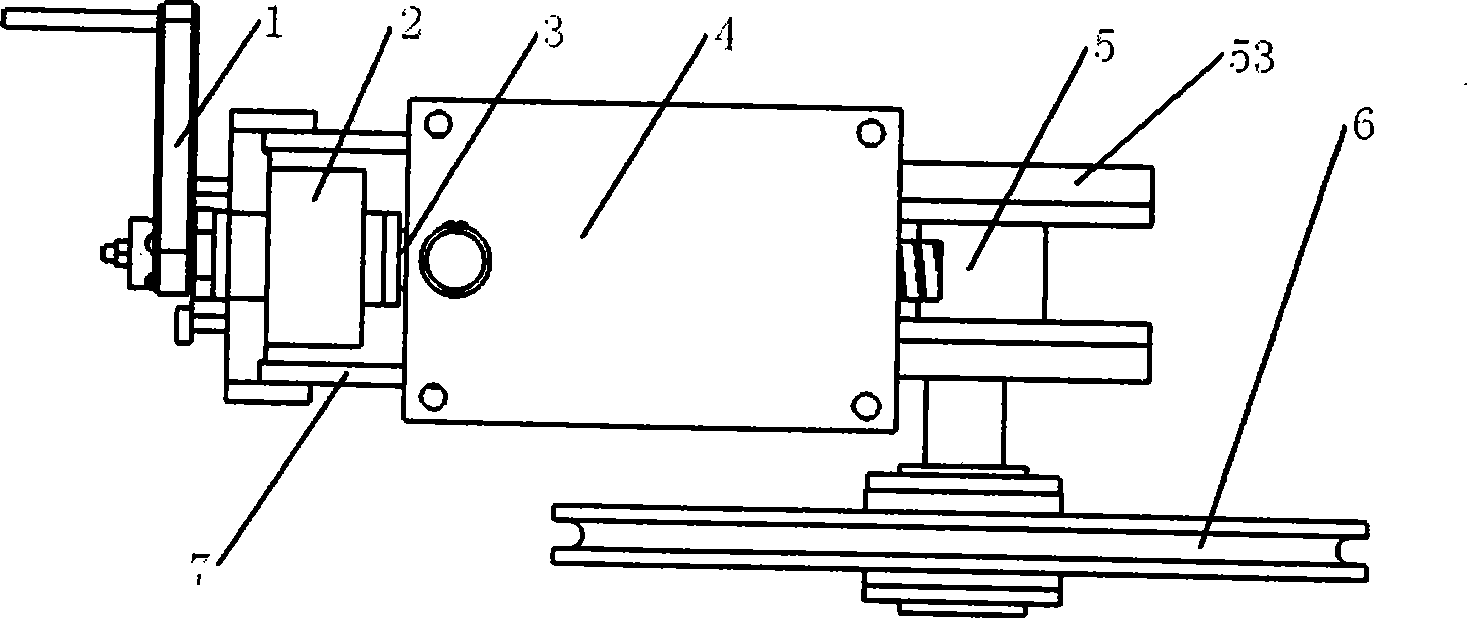

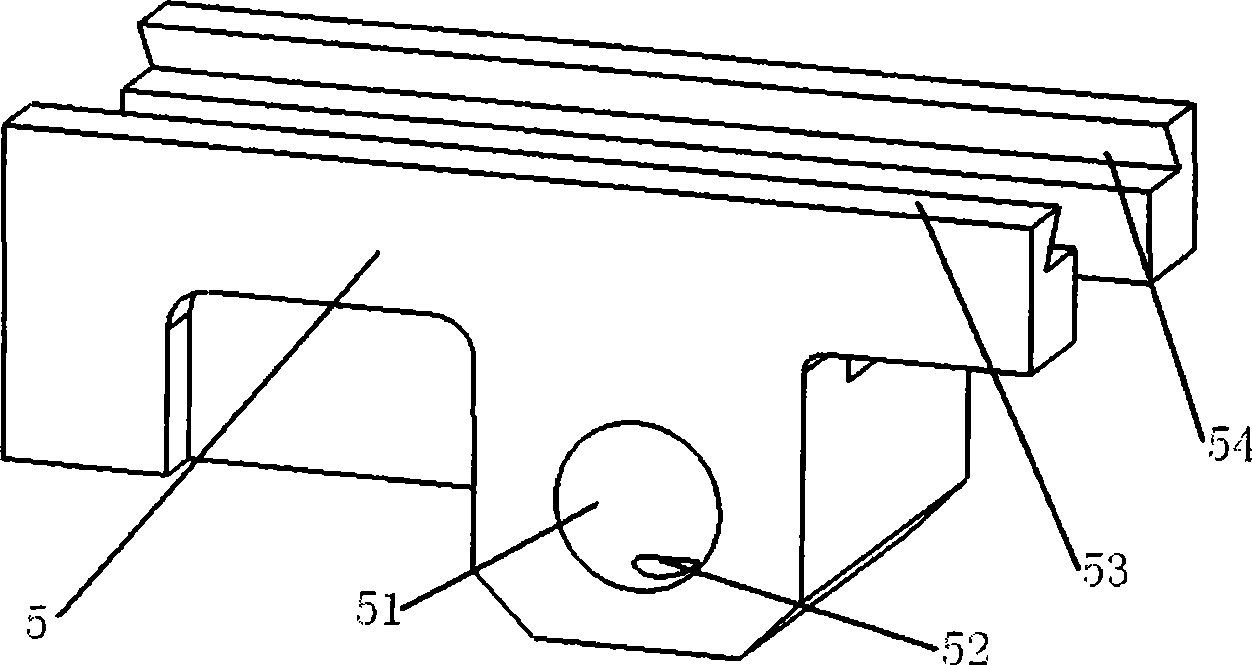

Fixed-length cutting device for tubes

ActiveCN105689788AEasy to cut to lengthImprove securityTube shearing machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a fixed-length cutting device for tubes. The fixed-length cutting device comprises a cutting table, a cutting device, support elements, a location table, a support shaft, a location disc and baffles, wherein the cutting device is arranged at the front end of the cutting table; the plurality of support elements are arranged on the cutting table along the same straight line, wherein the support element at the forefront is located in front of the cutting device; the location table is arranged in front of the cutting table; the support shaft is erected on the location table in a manner of being capable of sliding forwards and backwards; the location disc is rotatably arranged at the rear end of the support shaft in a sleeving manner, a plurality of U-shaped grooves are arranged in the rear end surface of the location disc in a sinking manner along a peripheral direction, and the opening of each U-shaped groove penetrates through the sidewall of the location disc; one baffle is arranged at the opening of each U-shaped groove in a covering manner; and one end of each baffle is hinged at one side of the opening of the corresponding U-shaped groove through a pin shaft, and a torsional spring is arranged on each pin shaft in a sleeving manner. The fixed-length cutting device disclosed by the invention is capable of conveniently carrying out fixed-length cutting on the tubes, safe and efficient in cutting process, and low in cost.

Owner:海宁经开产业园区开发建设有限公司

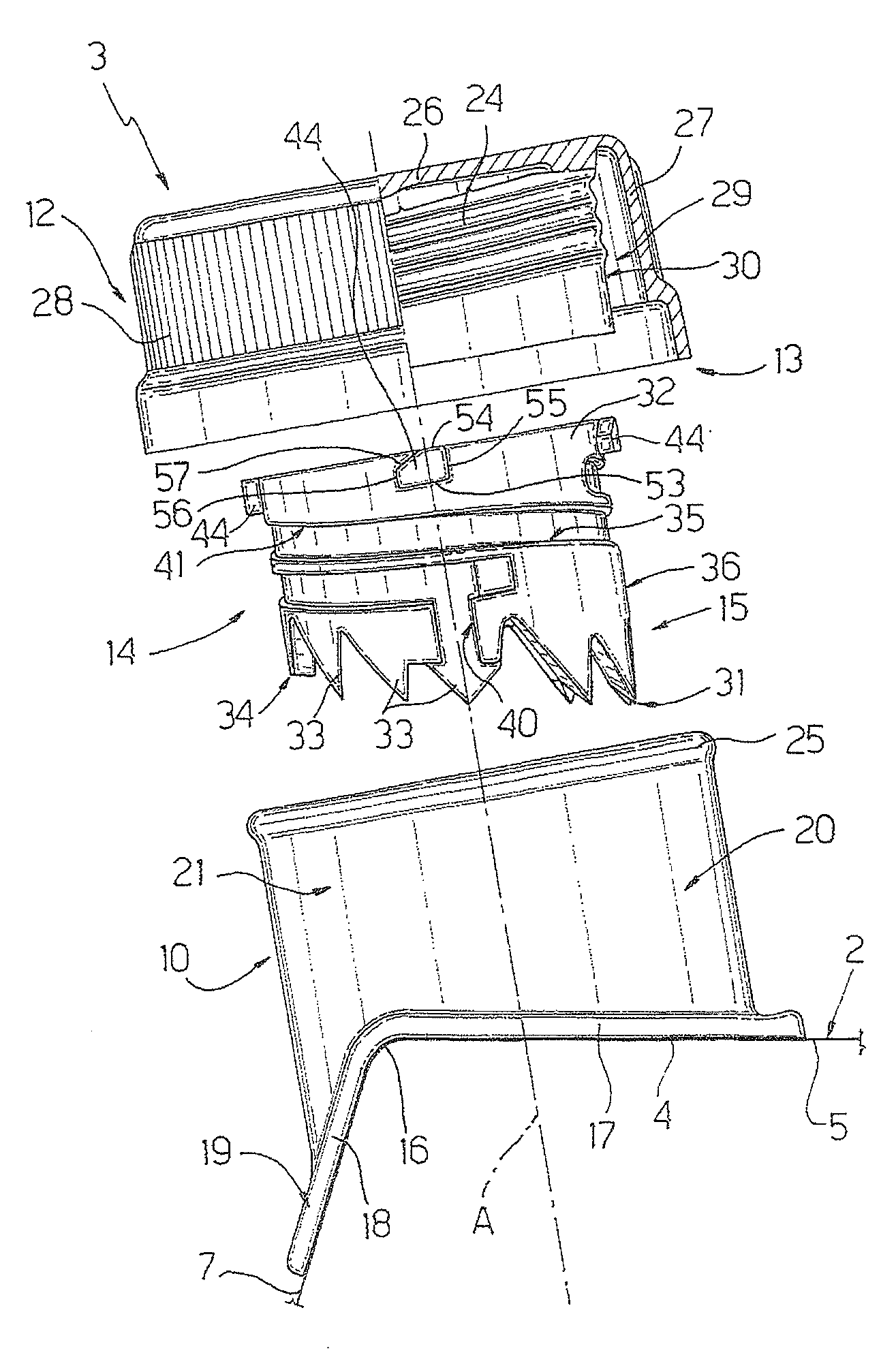

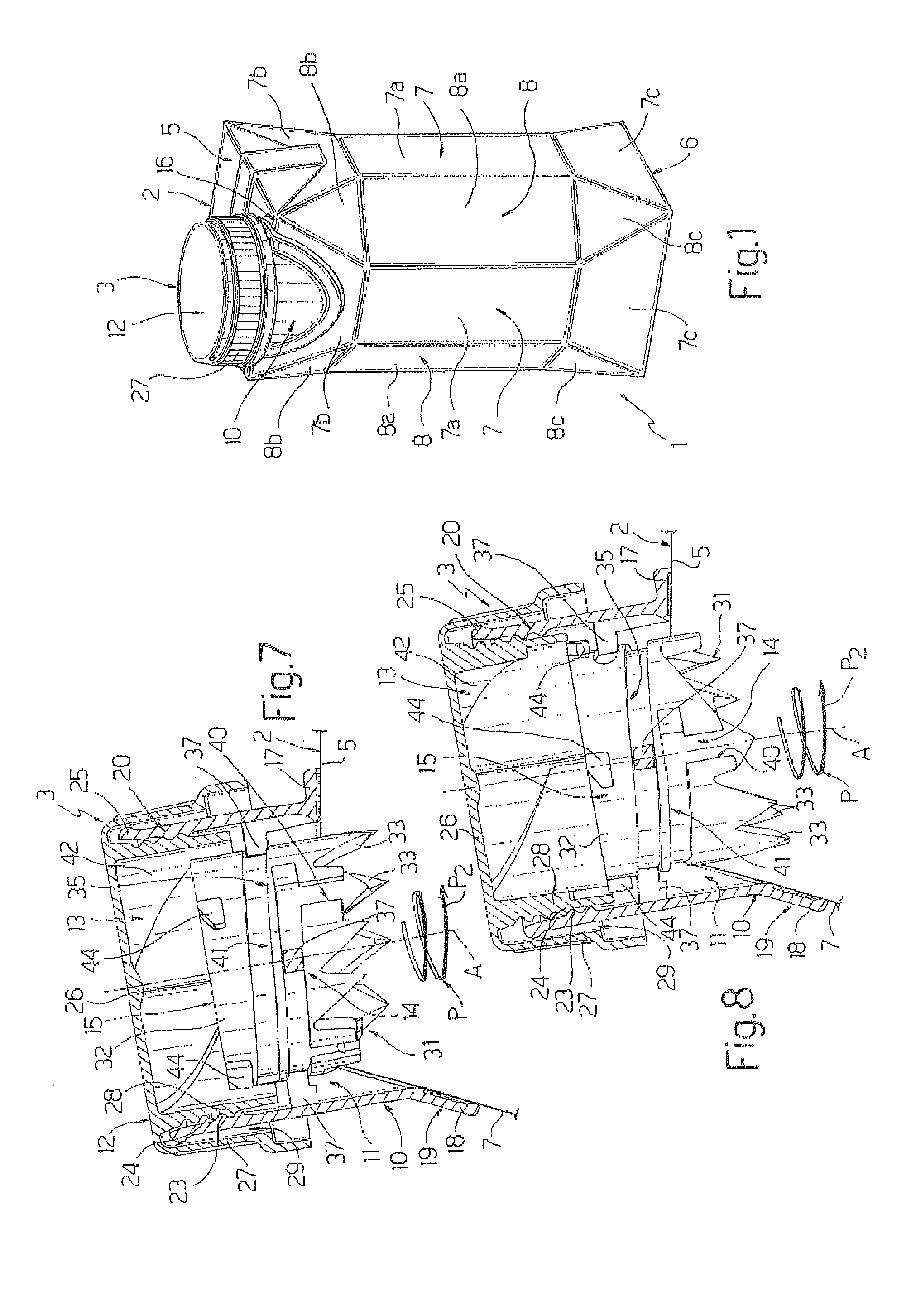

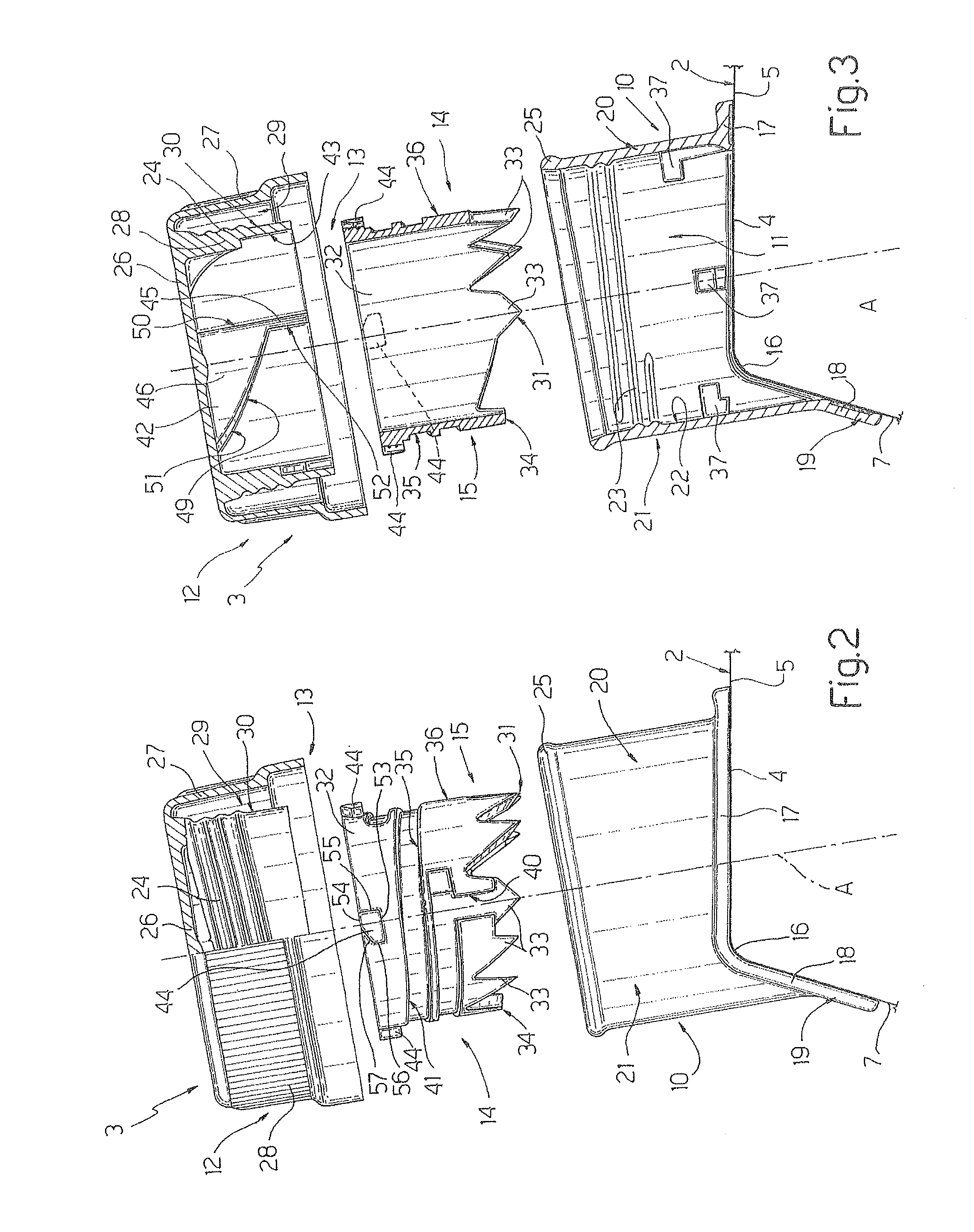

Reclosable opening device for packages of pourable food products

A reclosable opening device for a sealed package of a pourable food product includes a frame fitted about a pierceable portion of the package and defining a through pour opening; a removable threaded cap that screws onto the frame to close the pour opening; a tubular cutter engaging the pour opening and having a cutting device which cooperates with the pierceable portion to unseal the package; a first connector connecting the cap to the cutter, and which, as the cap is unscrewed, pushes the cutter towards the pierceable portion and a second connector connecting the frame to the cutter, and which, in use, feed the cutter along a predetermined piercing path through the pierceable portion in response to unscrewing of the cap; and the piercing path, as the cap is unscrewed, has a first portion of pure axial translation, followed by a second portion of both axial and rotary motion.

Owner:TETRA LAVAL HLDG & FINANCE SA

Hole cutter with minimum tooth pitch to blade body thickness ratio

ActiveUS8573907B2Avoid collectingSmall volumeTransportation and packagingCircular sawsEngineeringMetal working

A hole cutter for cutting a work piece, such as a wood and / or metal work piece, has a substantially cylindrical blade body defining a wall thickness within the range of about 0.032 inch to about 0.038 inch, and a cutting edge formed on one end of the blade body including a plurality of teeth defining an average tooth pitch within the range of about 3.5 TPI to about 5.5 TPI for cutting the work piece and forming chips therefrom. The substantially cylindrical blade body and cutting edge define an average tooth pitch to blade body thickness ratio of at least about 110.

Owner:BLACK & DECKER INC

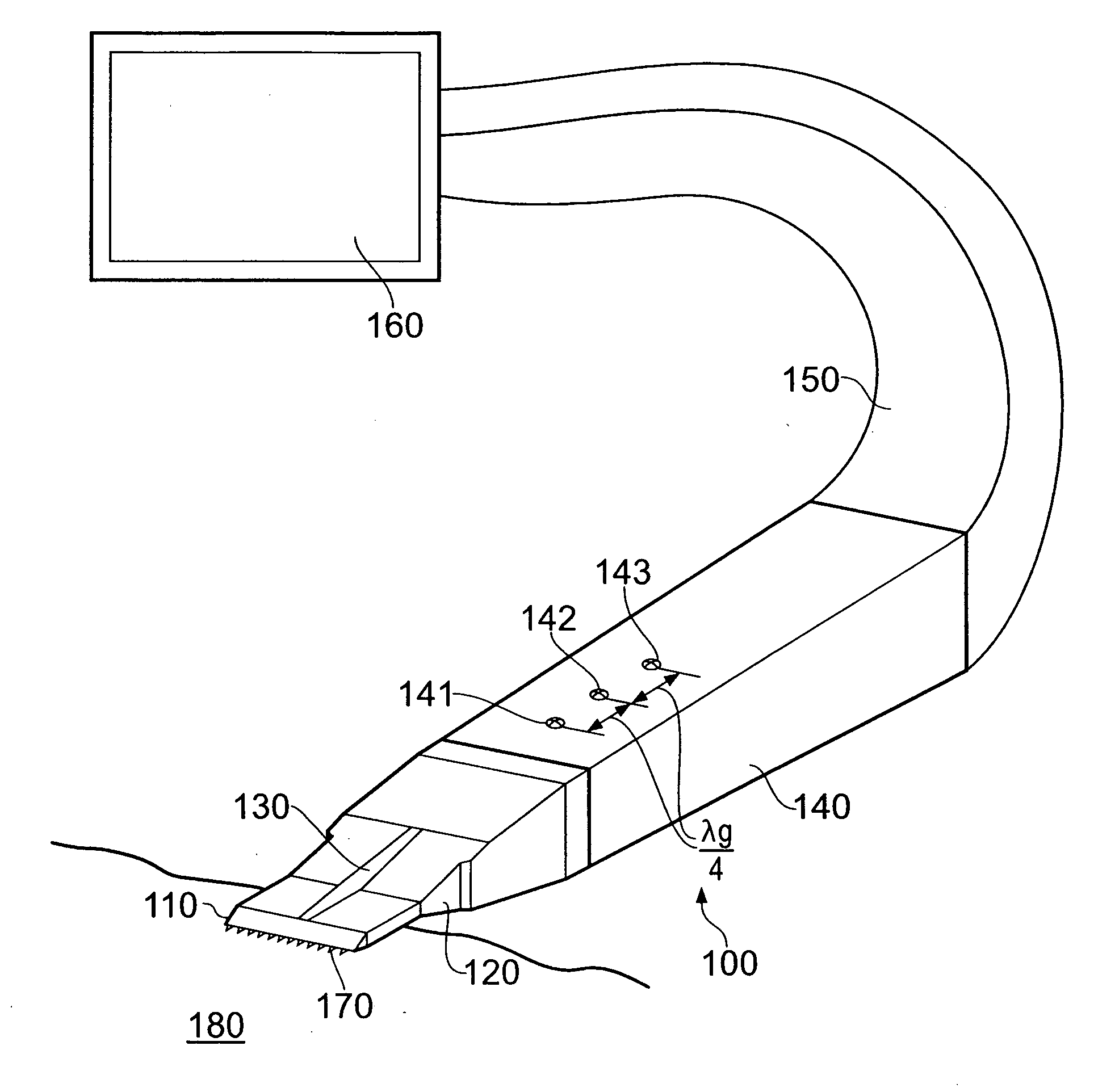

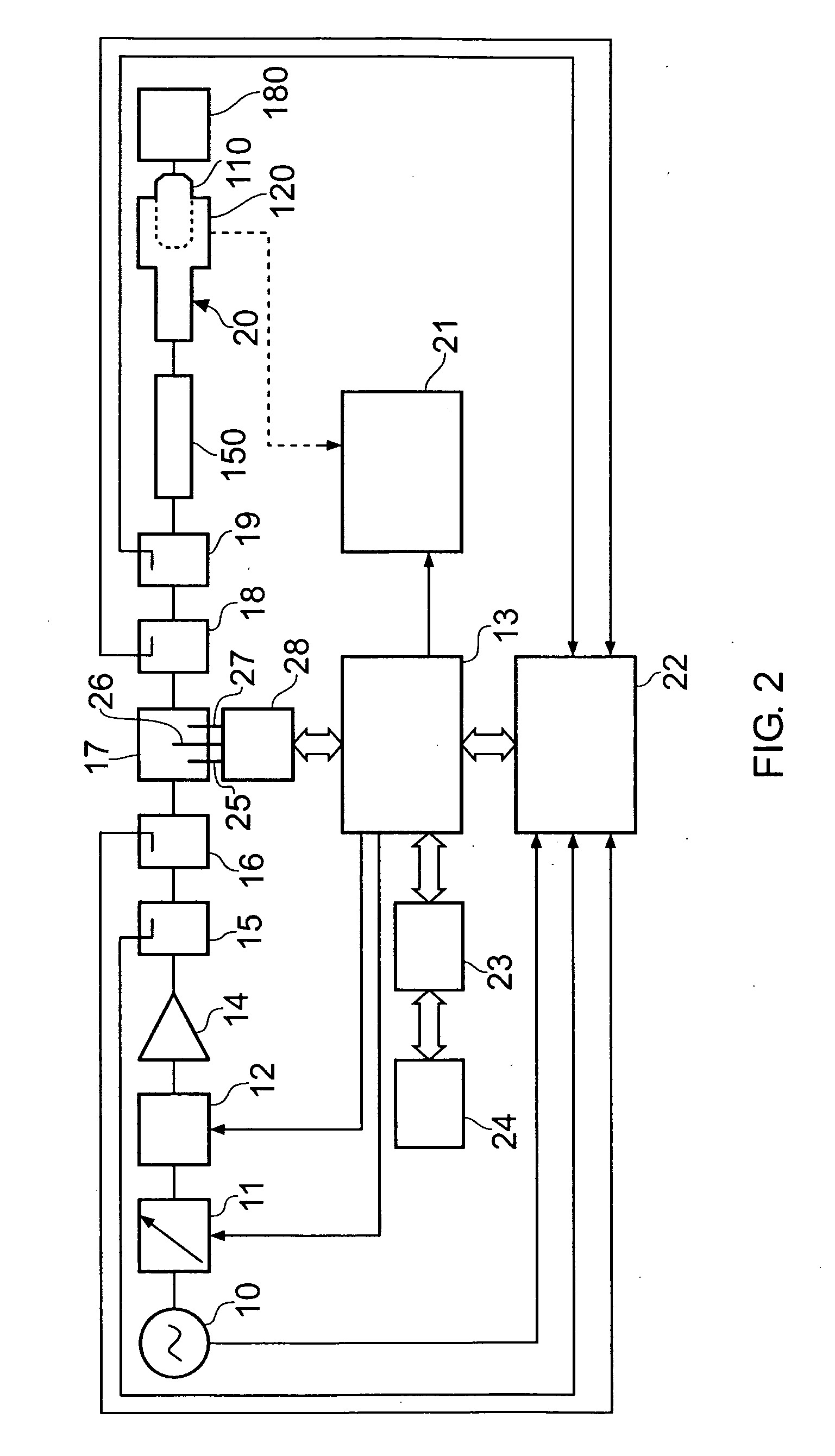

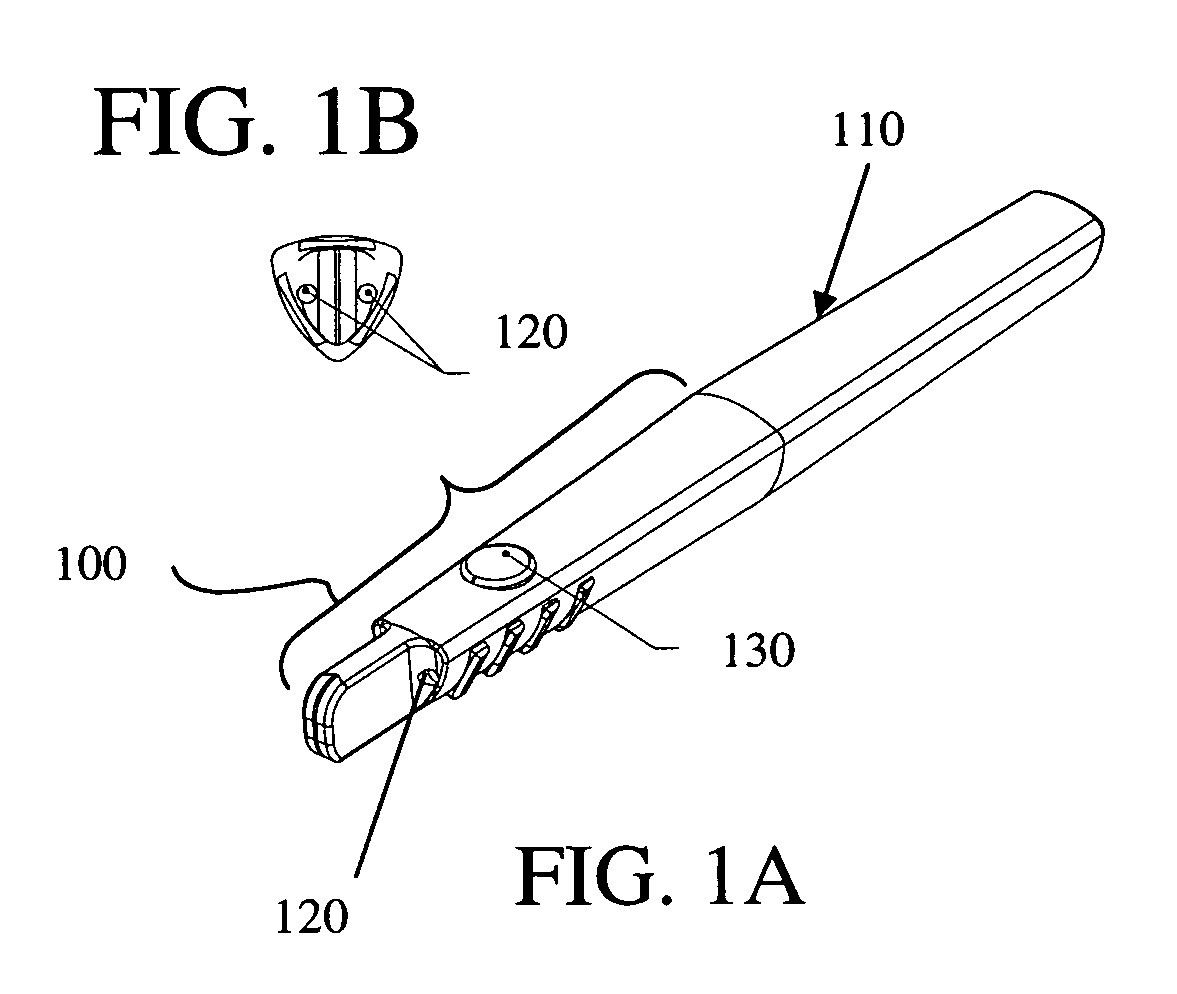

Surgical antenna

ActiveUS20100030207A1Ensure efficient flowPrevents tissue charringIncision instrumentsSurgical instruments for heatingTransformerImpedance matching

A surgical instrument (100) (e.g. scalpel) is disclosed which has an antenna arranged to emit a substantially uniform microwave radiation field (e.g. having a frequency of 5-100 GHz) at an edge of a cutting element (110) (e.g. blade). The emitted radiation can cauterise tissue e.g. broken blood vessels simultaneously with cutting. The antenna may be integral with the cutting element, e.g. a metallised piece of ceramic attachable at an end of a waveguide (120, 150) to receive radiation therefrom. The cutting element (110) can include a quarter wave transformer to couple power efficiently from the waveguide (120). The instrument can be used with impedance matching apparatus to control the energy delivered into the tissue. Also disclosed is an invasive ablation probe (e.g. insertable through a catheter) having a plurality of radiating elements whose emitted field combine to give a uniform effect at an insertion end of the probe.

Owner:CREO MEDICAL LTD

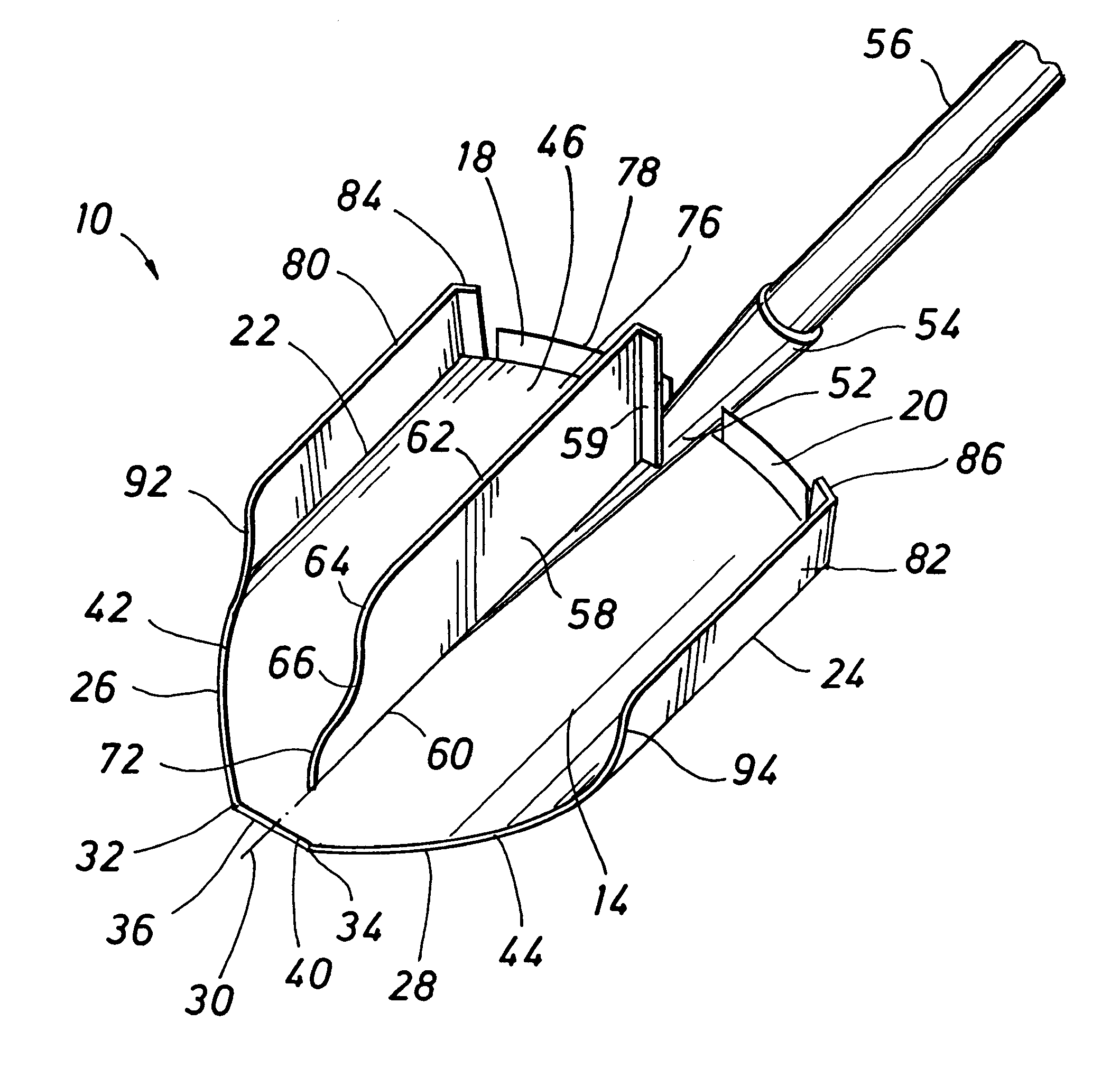

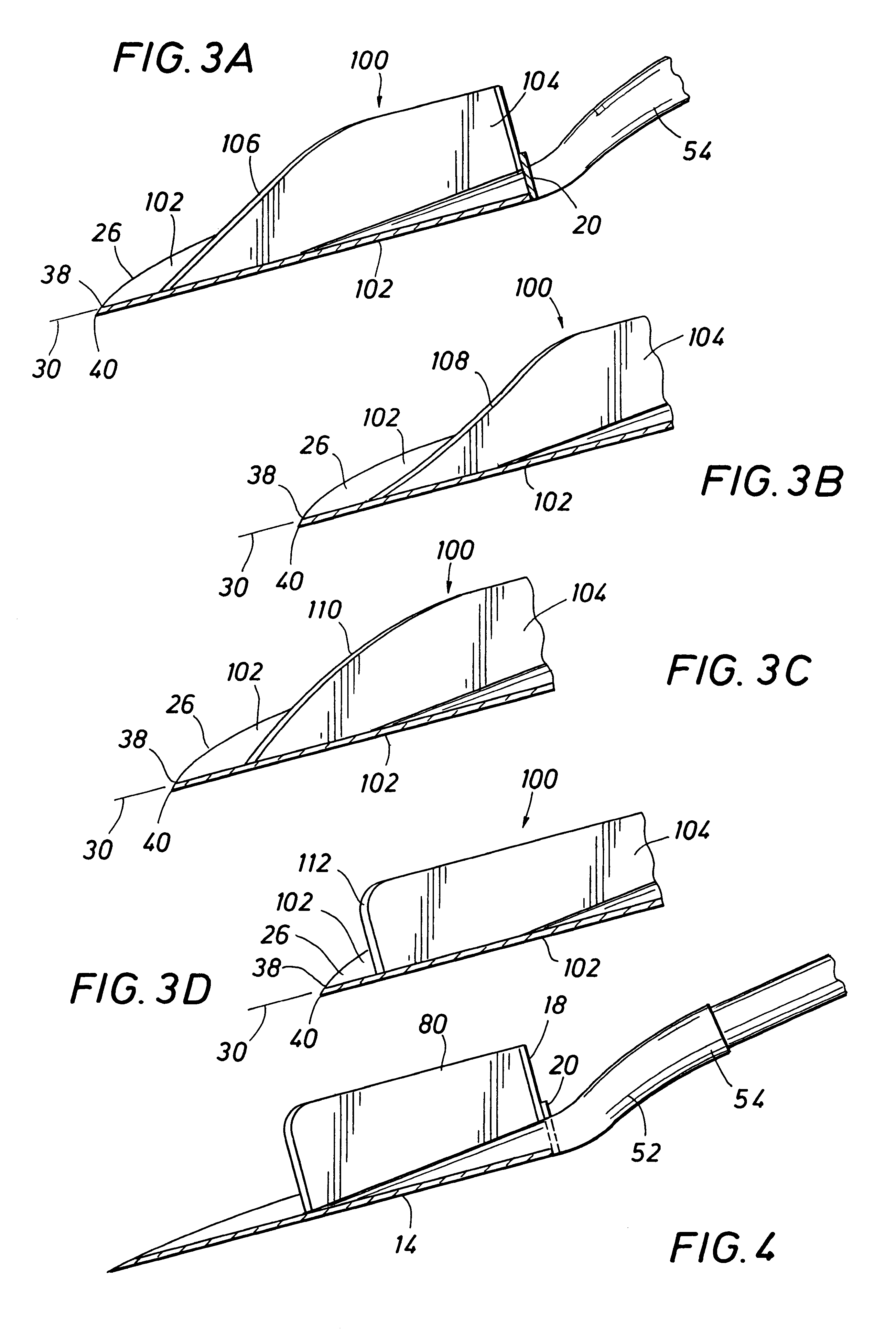

Root cutting shovel

A shovel for manual use, comprising a shovel blade having concave and convex faces and defining a longitudinal center-line and having side edges, an upper edge and a forward cutting edge. The shovel blade defines a handle connector receptable having a shovel handle fixed therein. A root cutting blade is fixed to the shovel blade substantially along the longitudinal center-line and projects from the concave face of the shovel blade. A sharpened root cutting edge is defined on the root cutting blade and is oriented toward the forward cutting edge of the shovel blade. The root cutting edge of the central blade preferably defines an intermediate edge recess and forms a slightly inclined sharp edge section for enhancing root cutting action. A pair of side blades are fixed to side edge portions of the shovel blade and are oriented in diverging relation projecting from the convex face of the shovel blade. The side blades also preferably define forwardly inclined sharpened cutting edges and are located for cutting surface roots at respective sides of the shovel blade to facilitate efficient fracturing of the soil when the shovel blade has penetrated into the soil and is pivoted to pry a soil load loose from the surrounding soil.

Owner:DOUGLAS ORMOND S +1

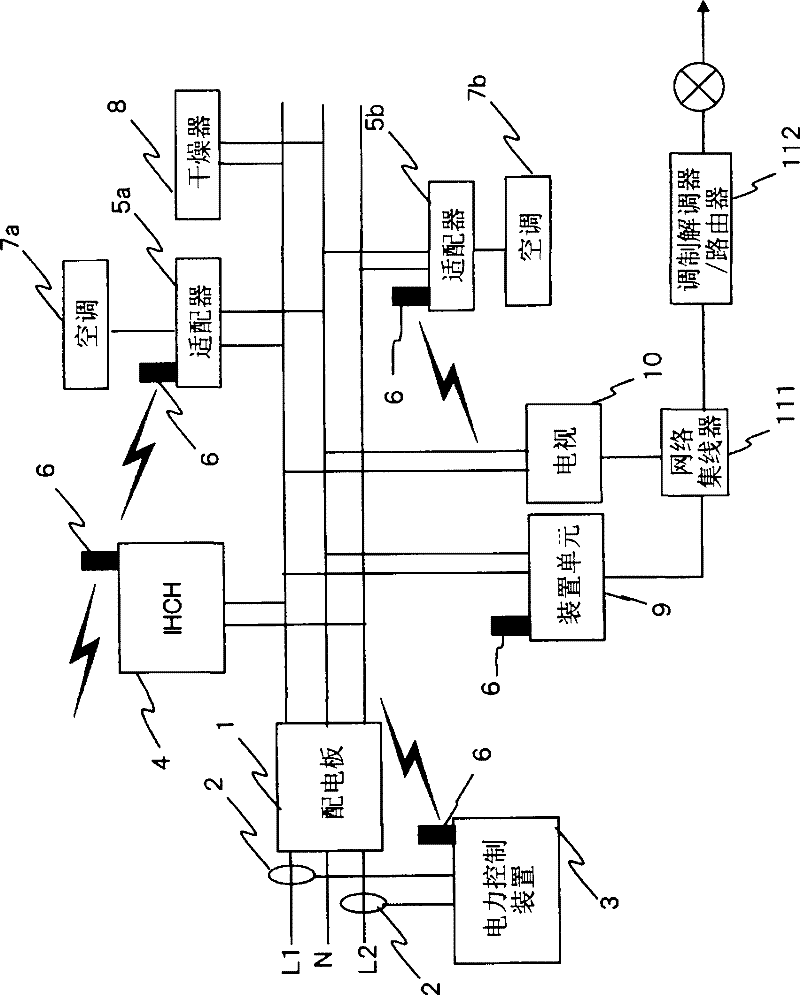

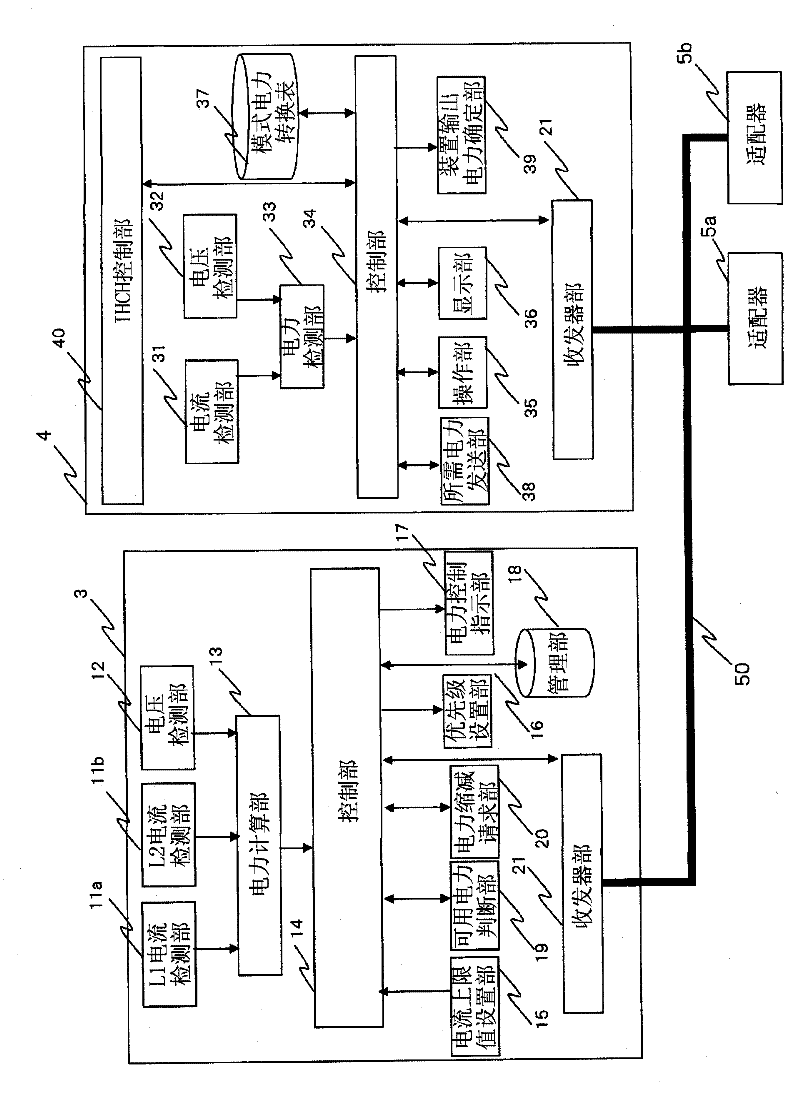

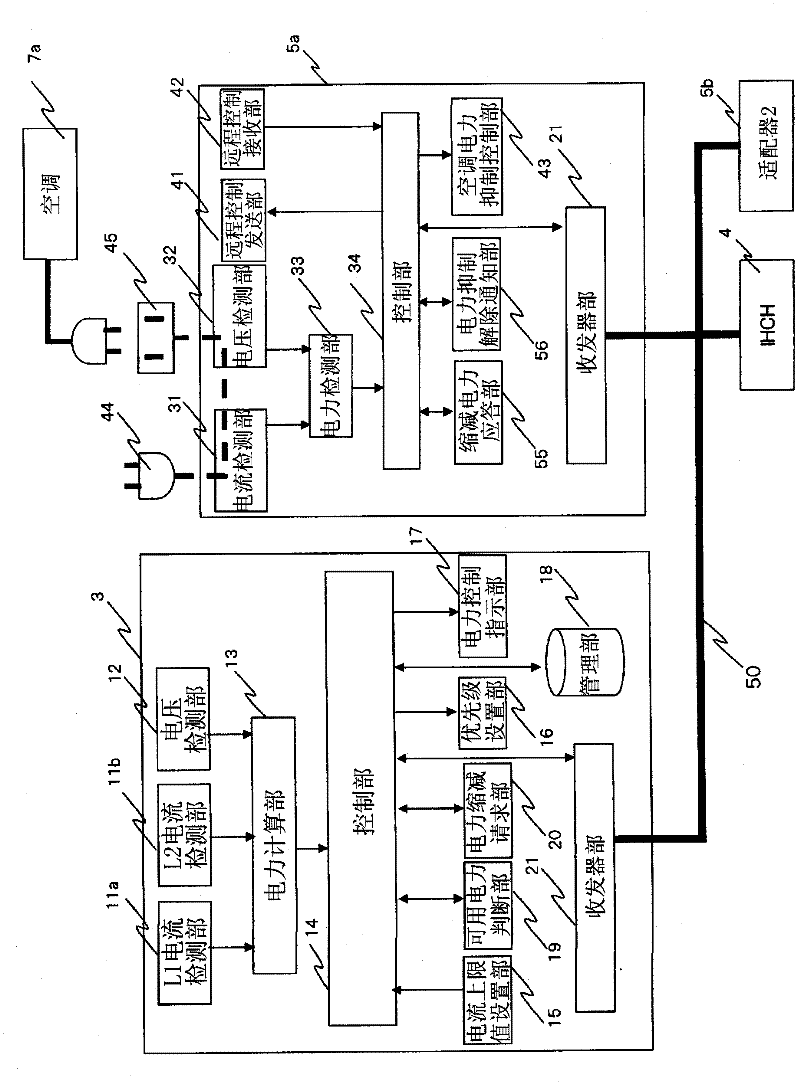

Power control system and method and program for controlling power control system

InactiveCN102341991AAvoid cutsEfficient cuttingTelemetry/telecontrol selection arrangementsPower network operation systems integrationControl systemPower control system

When a user wants to operate a device, if electric power is being used at a level such that a circuit breaker will shut off, he cannot use the device he wants to use unless he himself intentionally reduces the electric power being used for the other devices to increase the amount of usable power. A power control device (3) is provided with a priority setting unit (16) that is capable of setting usage priorities for household devices connected by wire or wirelessly or for adaptors connected to the household devices. A household device or an adaptor connected to the household device operates within the usable power resulting from an inquiry to the power control device (3). When there is no excess in usable power over the power required in the inquiry, the power control device (3) reduces the power used by a device which has a lower priority than the device which made the inquiry in order to allow the device with the higher priority to be used.

Owner:PANASONIC CORP

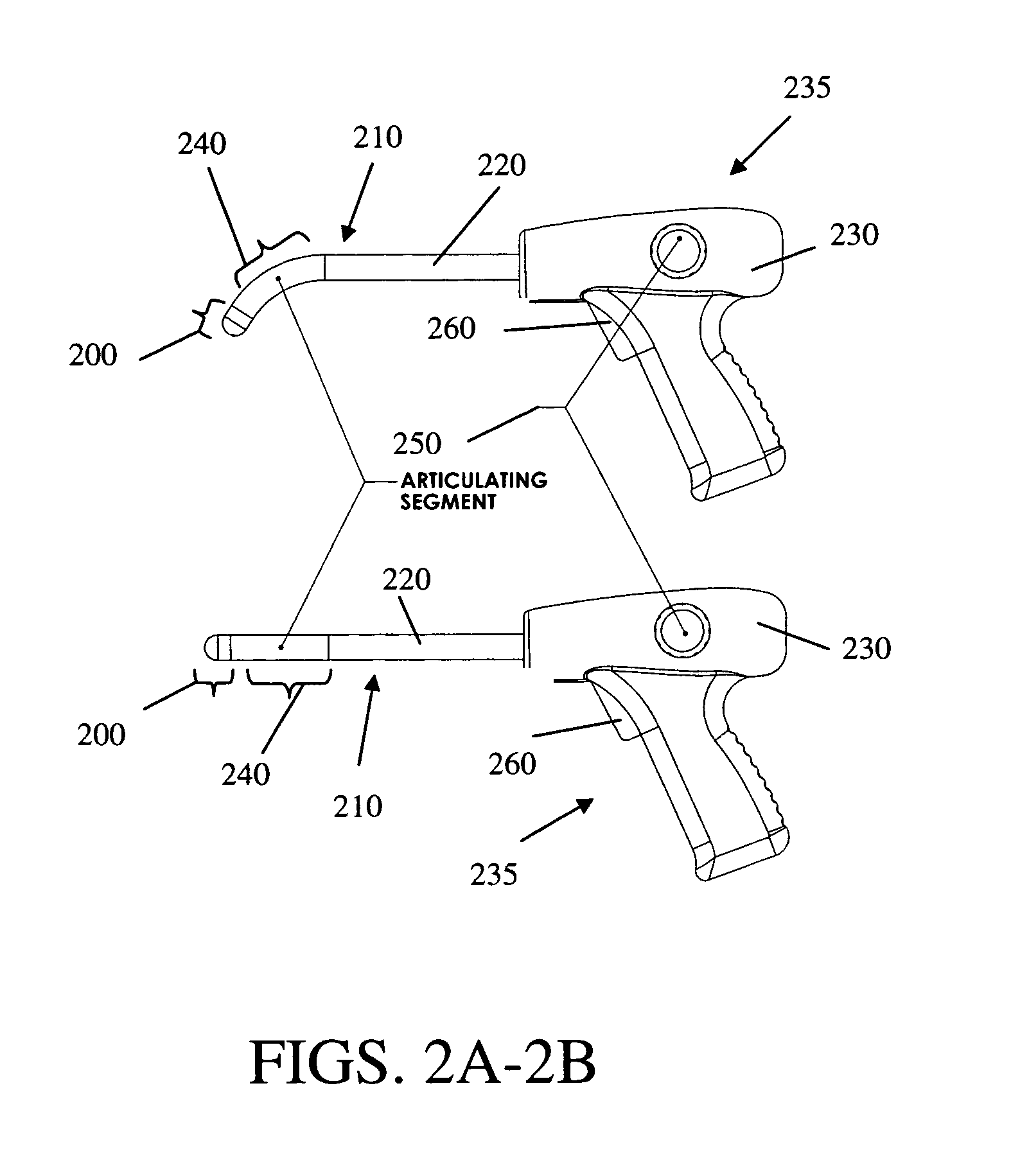

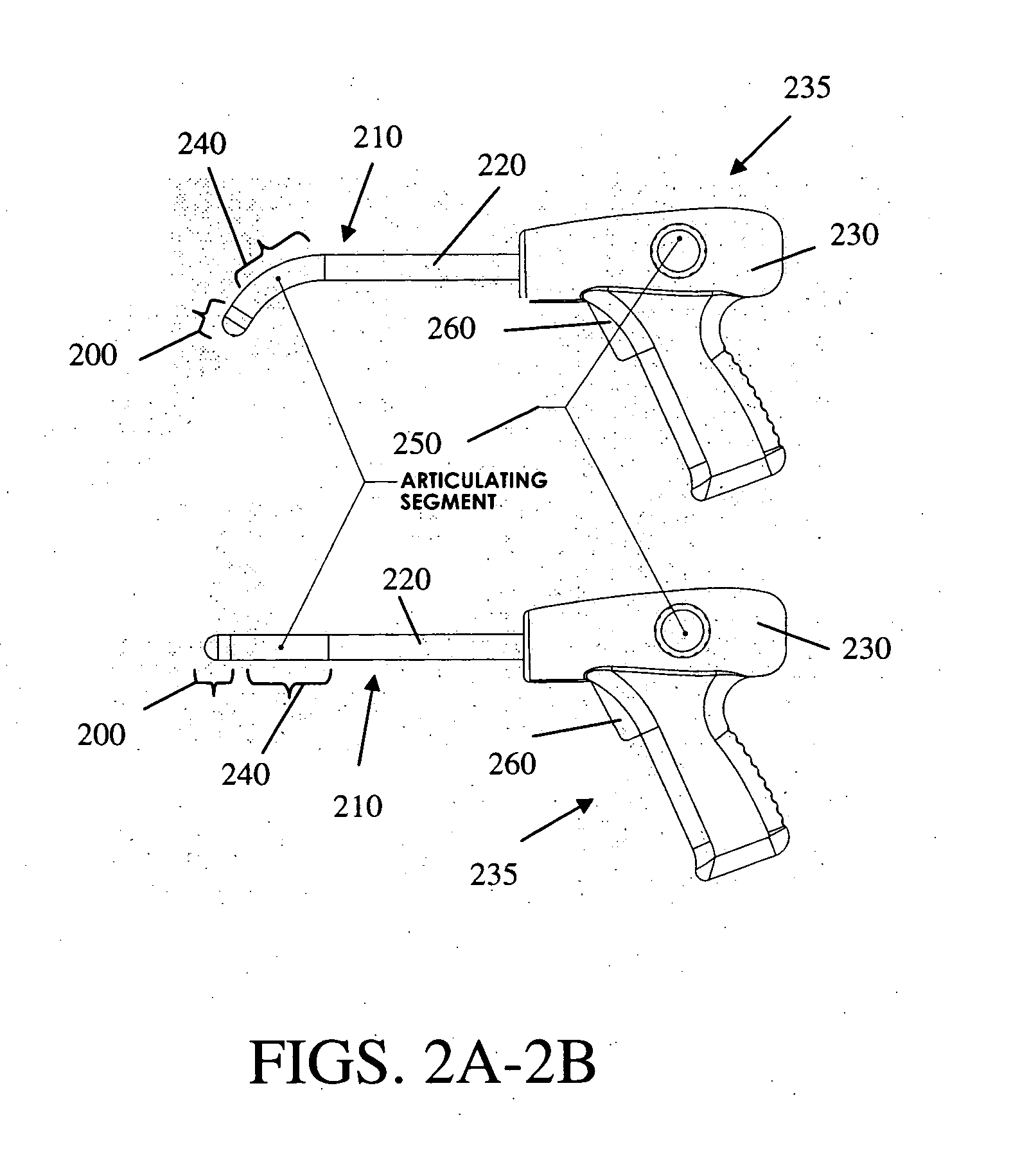

Manipulation and cutting system and method

InactiveUS7842058B2Improve efficiencyReduce materialIncision instrumentsDiagnosticsRelative motionBiomedical engineering

A system for rapid manipulation and cutting that includes a housing, a first cutting element, and a drive mechanism adapted to be mounted at least partly within the housing and connected to the first cutting element for imparting relative motion to the first cutting element as a combination of slicing and downward forces at the portion of the first cutting element which is adapted to contact the tissue.

Owner:FLEX PARTNERS

Dental apparatus

InactiveUS6929476B2Efficient cuttingTooth pluggers/hammersTeeth fillingDental instrumentsDental Equipment

A dental equipment for cutting teeth, forming root canals and so on. The dental apparatus includes: an actuator for actuating a cutting tool; a load sensor for sensing a load worked in the cutting tool; and a load indicator for making an operator know the load sensed by the load sensor visually, aurally and / or tactily.

Owner:MORITA MFG CO LTD

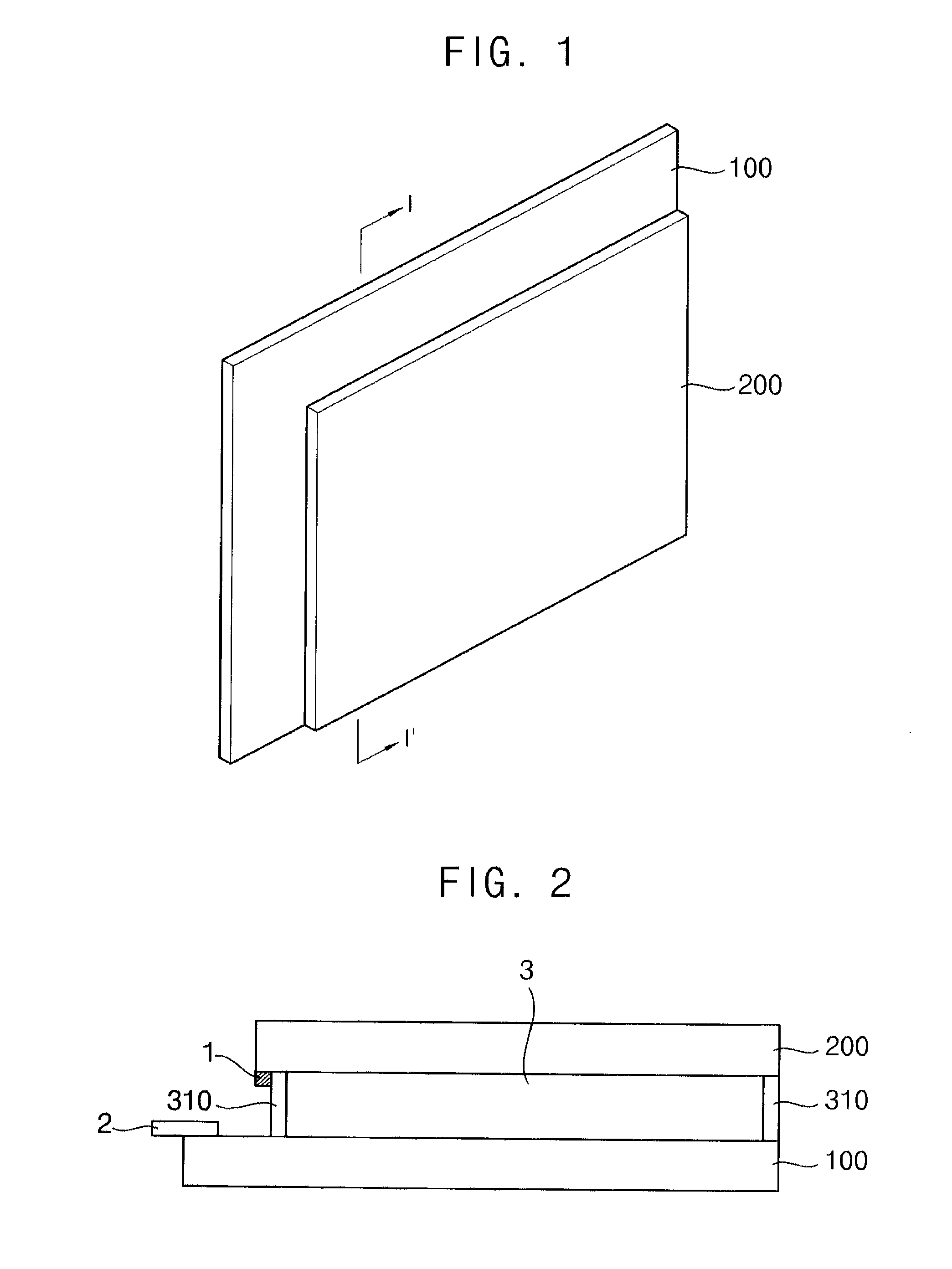

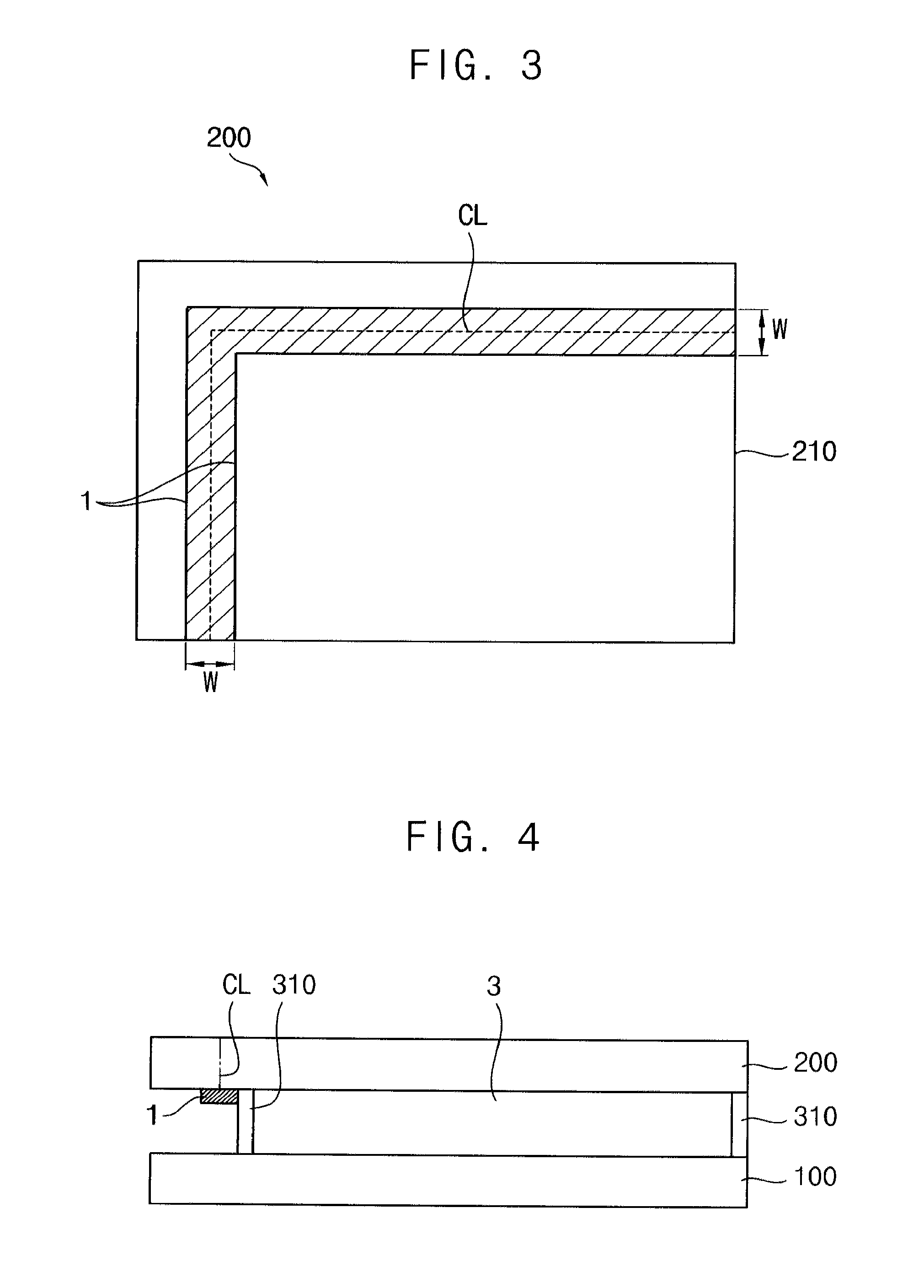

Display panel, display apparatus having the same, method of manufacturing the same and method of cutting the same

InactiveUS20120099056A1Not to damageEfficient cuttingVessels or leading-in conductors manufactureNon-linear opticsEngineeringBlocking layer

A display apparatus includes a first substrate, a second substrate, and a blocking layer disposed on the first substrate adjacent to an outer edge of the first substrate. The second substrate includes first and second areas. The first area faces the first substrate. The outer edge of the first substrate is aligned with a boundary between the first area and the second area of the second substrate.

Owner:SAMSUNG DISPLAY CO LTD

Manipulation and cutting system and method

InactiveUS20070167966A1Improve efficiencyReduce materialIncision instrumentsDiagnosticsRelative motionBiomedical engineering

A system for rapid manipulation and cutting that includes comprising a housing, a first cutting element, and a drive mechanism adapted to be mounted at least partly within the housing and connected to the first cutting element for imparting relative motion to the first cutting element as a combination of slicing and downward forces at the portion of the first cutting element which is adapted to contact the tissue.

Owner:FLEX PARTNERS

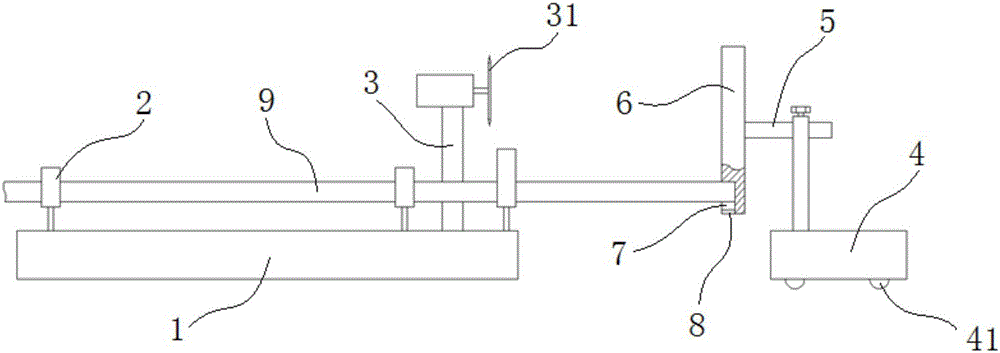

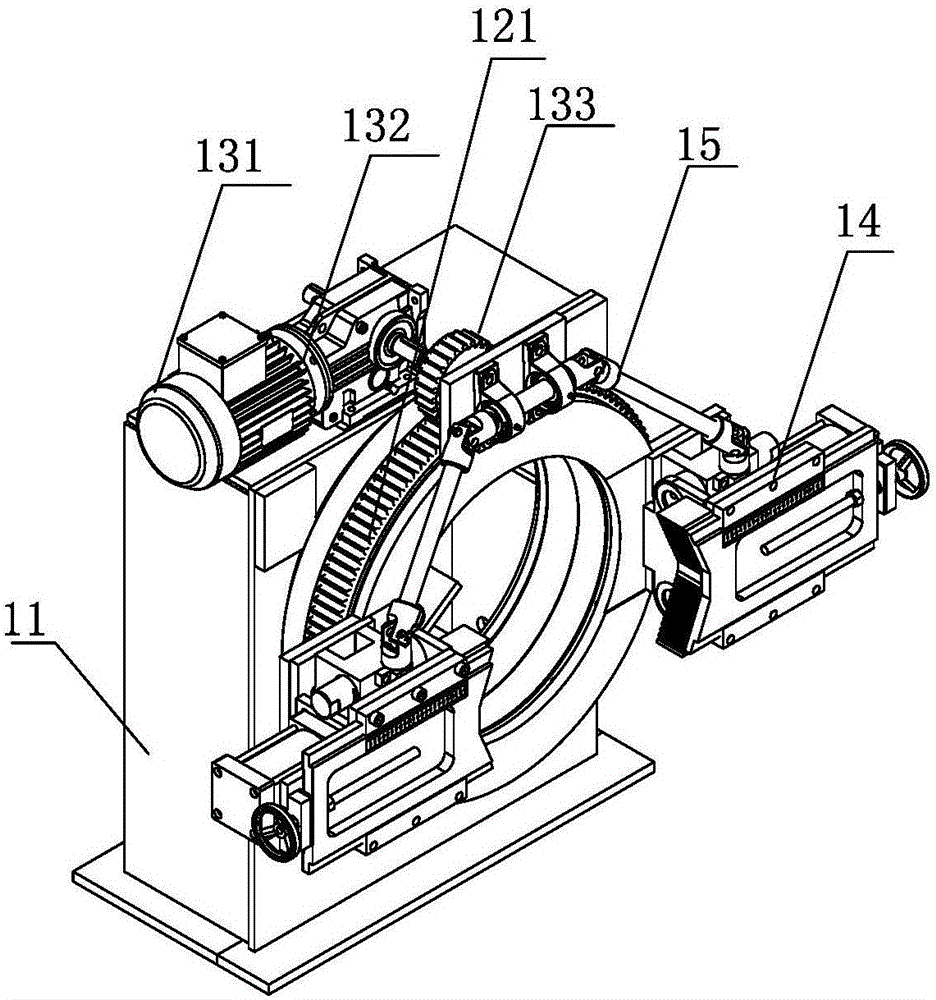

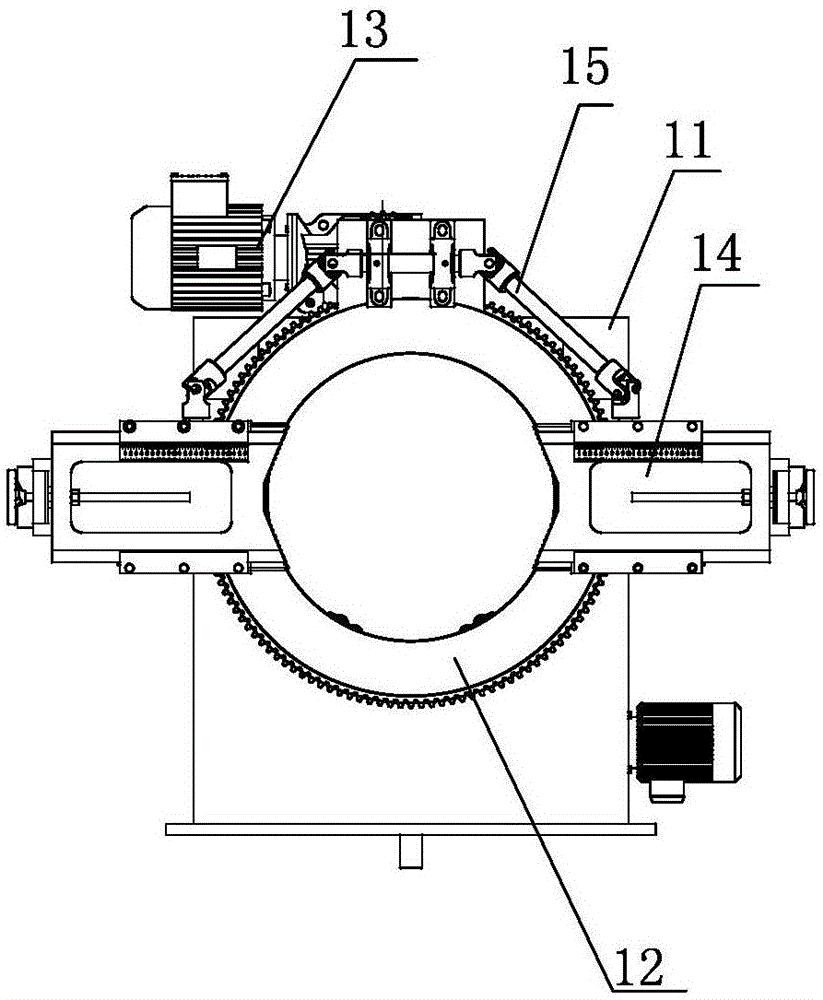

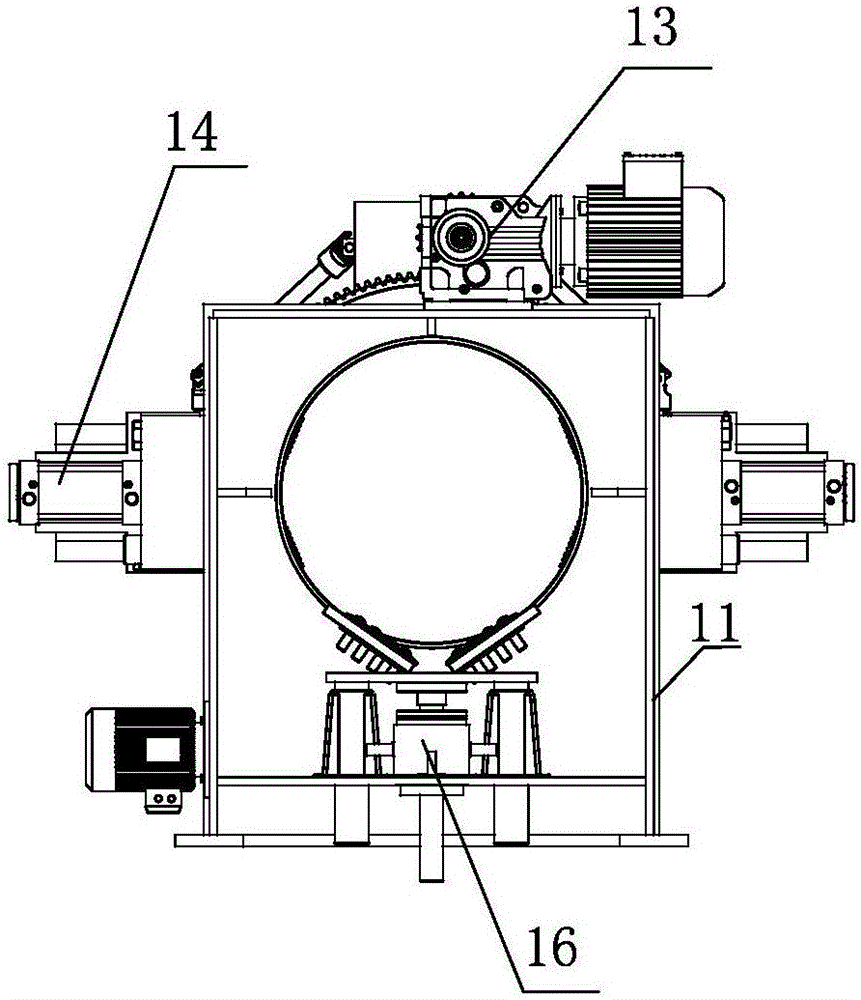

Double-direction synchronous rotating and clamping device for steel pipe cutting

ActiveCN106238887AEfficient cuttingRealize two-way synchronous clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel tube

The invention provides a double-direction synchronous rotating and clamping device for steel pipe cutting. The technical problem that in the cutting process of a steel pipe, clamping and rotating can not be achieved is solved. The device comprises a clamping mounting frame, a rotary disc mechanism, a clamping mechanism and a double-direction synchronous clamping drive connection mechanism; a lifting mechanism is arranged at the rear end of the clamping mounting frame, and the clamping mechanism comprises a fine adjustment mechanism; a turnover discharging device is arranged in front of the rotating and clamping mechanism; the device has the beneficial effects that in the process of using a plasma cutting machine for cutting the steel pipe, the steel pipe is synchronously clamped in a double-direction manner and driven to rotate, and the steel pipe cutting process is more efficient.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

Phthalocyanine compound, method for production thereof, and use thereof

InactiveUS6069244AImprove solubilityImprove efficiencyOrganic chemistryReactive dyesHeat resistancePhthalocyanine

A phthalocyanine compound possessing an excellent ability to absorb near infrared ray, exhibiting excellent compatibility with resin, and excelling in such special qualities as heat resistance, light resistance, and resistance to weather conditions is provided. This phthalocyanine compound is represented by the following general formula (1) wherein Z2, Z3, Z6, Z7, Z10, Z11, Z14, and Z15 are independently SR1, OR2, or a fluorine atom, and at least one of them is for SR1 or OR2, Z1, Z4, Z5, Z8, Z9, Z12, Z13, and Z16 independently stand for NHR3, SR1, OR2, or a fluorine atom and at least one of them is NHR3, at least one of Z1 to Z16 is a fluorine atom or OR2, R1, R2, and R3 are independently a substituted or non-substituted phenyl group, a substituted or non-substituted aralkyl group, or a substituted or non-substituted alkyl group of 1 to 20 carbon atoms, and M is for a nonmetal, a metal, a metal oxide, or a metal halide.

Owner:NIPPON SHOKUBAI CO LTD

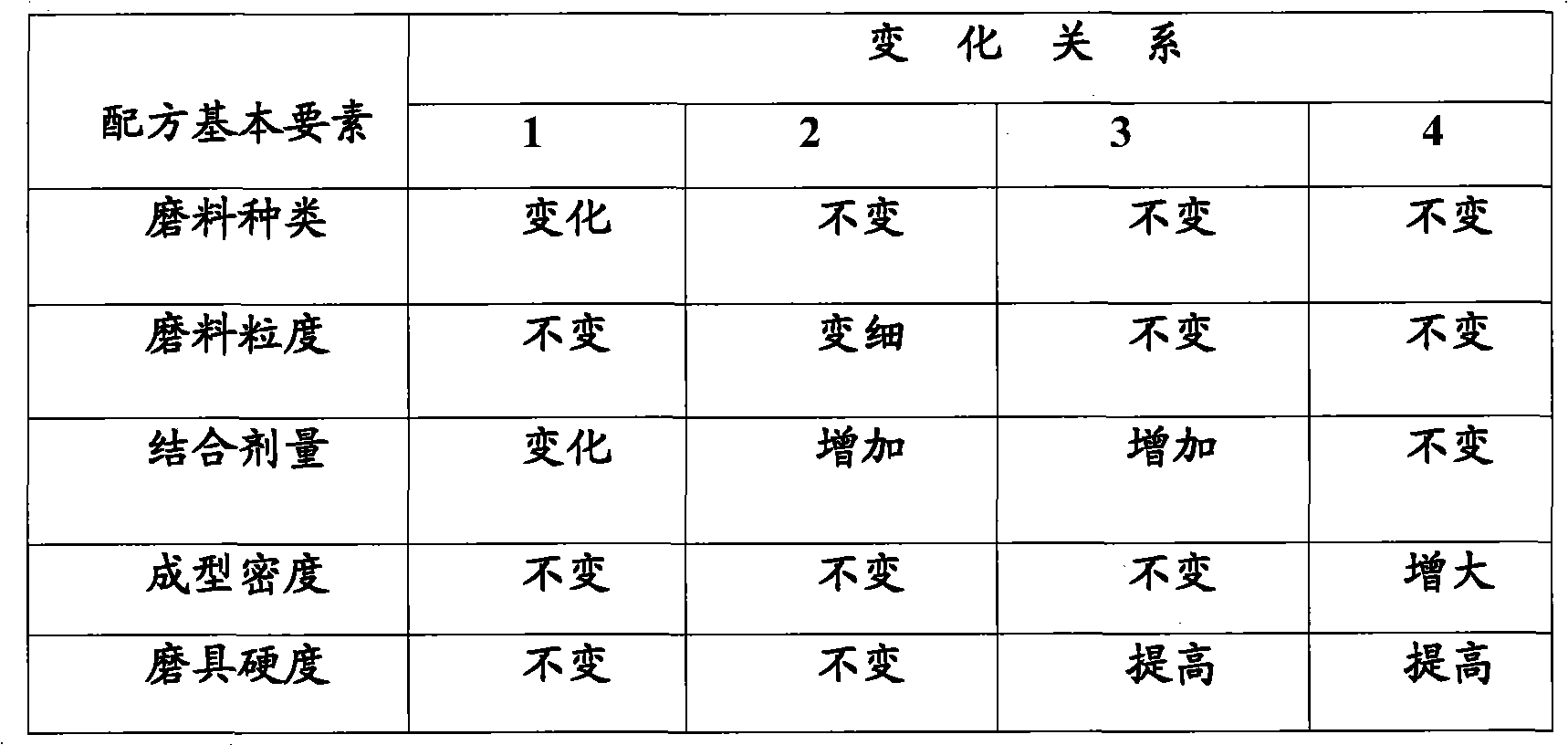

Precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials

InactiveCN101797724AGood toughnessSmall grinding deformationAbrasion apparatusAlumina ceramicAluminium oxide

The invention relates to a precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials, comprising a grinding wheel basal body, grinding material particles distributed on the grinding wheel basal body and a bonding agent bonded and fixed on the grinding material particles, wherein the bonding agent comprises the following components in percentage by weight: 10-15 clay powder, 30-50 feldspar powder, 20-40 talcum powder and 10-20 high-boron glass powder. The grinding wheel has the functions of large cutting depth, high feeding strength, large load and high-efficiency grinding. According to tests, over 0.3 mm can be reached for one-way feeding and the metal removing rate is over 2 times higher than that of a common corundum grinding wheel. The grinding wheel ahs the advantages of high durability, long service life which is 5-10 times that of the common corundum grinding wheel, favorable self sharpening, no blockage and high capability of maintaining stable grinding performance.

Owner:SUZHOU FAR EAST ABRASIVES

Laser clad cutting edge for agricultural cutting components

ActiveUS20160157423A1Reduce wearAvoid premature wearTransportation and packagingRotary stirring mixersSupport surfaceLaser

An agricultural cutting blade has top and bottom surfaces and mounting apertures extending through top and bottom surfaces. A cutting edge support surface (e.g. that may be a flat, pointed or rounded) is formed on the cutting blade body with the cutting edge support extending along a side of the cutting blade body transversely between the top and bottom surfaces. A clad material deposited upon the cutting edge support such as by laser cladding process. The clad material can be built up, that is layered in partial or full overlapping relation to provide at least 2 and often more than 4 layers of clad material at one or more locations. A cutting edge provided by the clad material that may be a ground surface into a laser clad bead.

Owner:KONDEX CORP

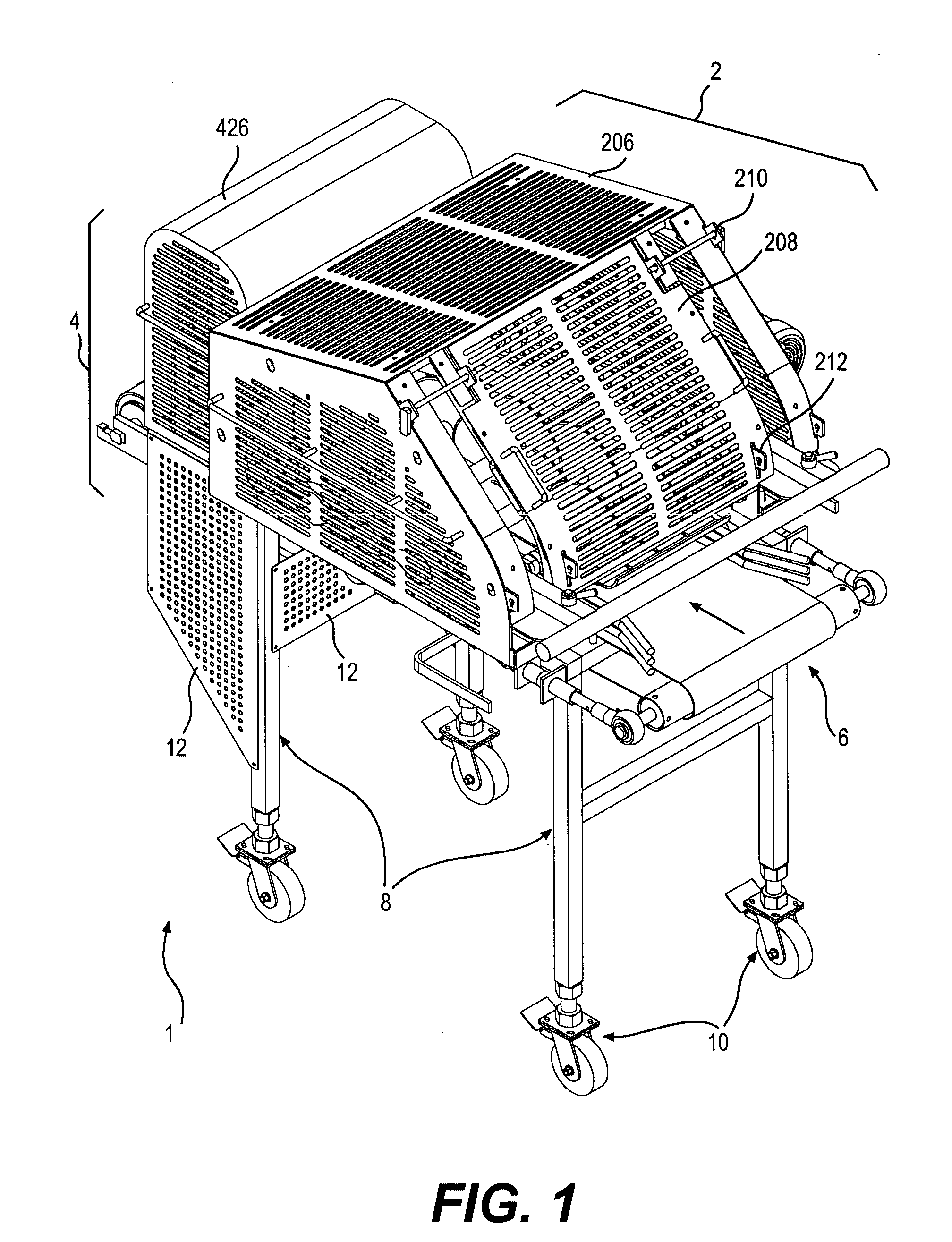

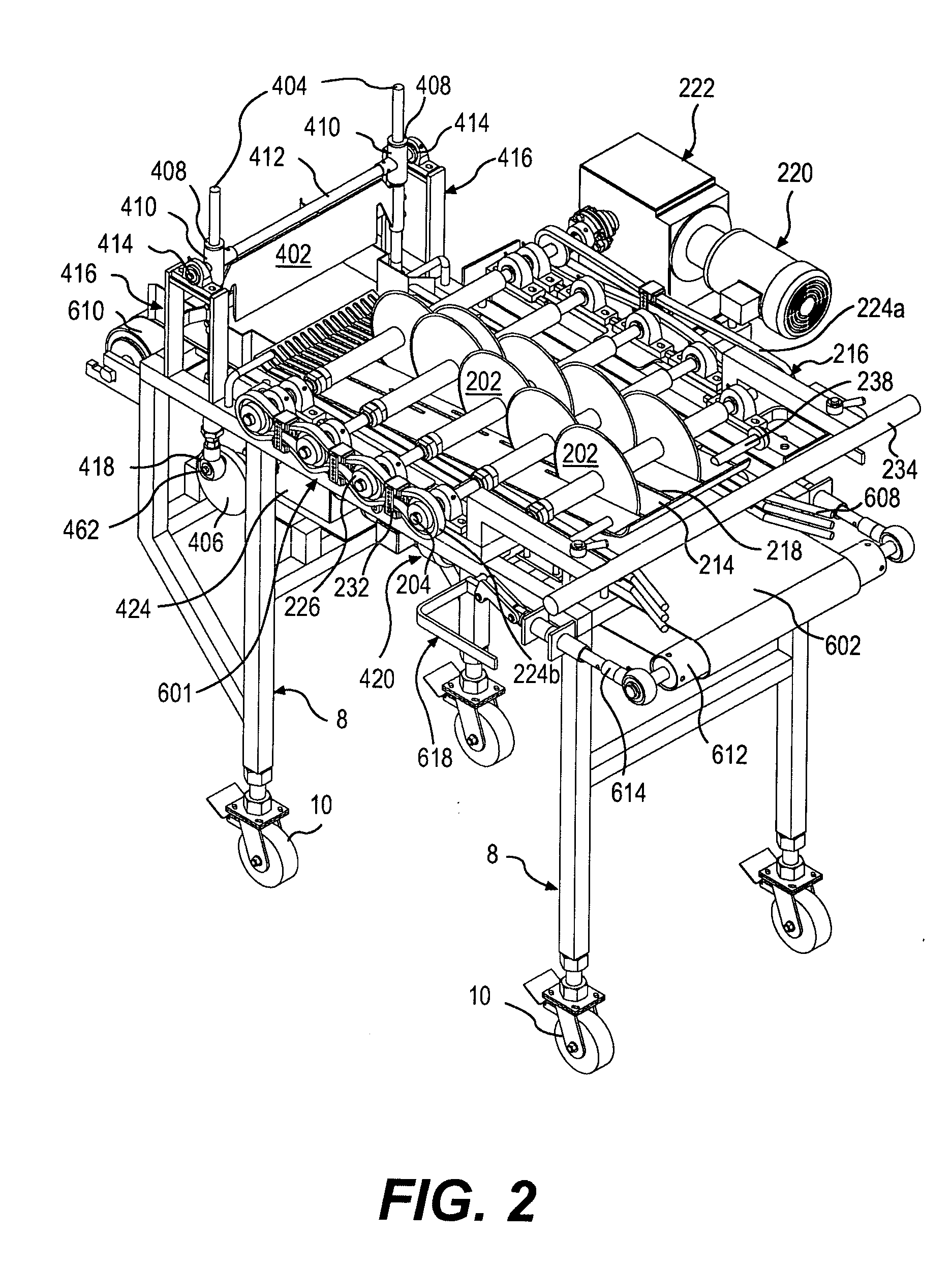

Apparatus and process for dicing a deformable product

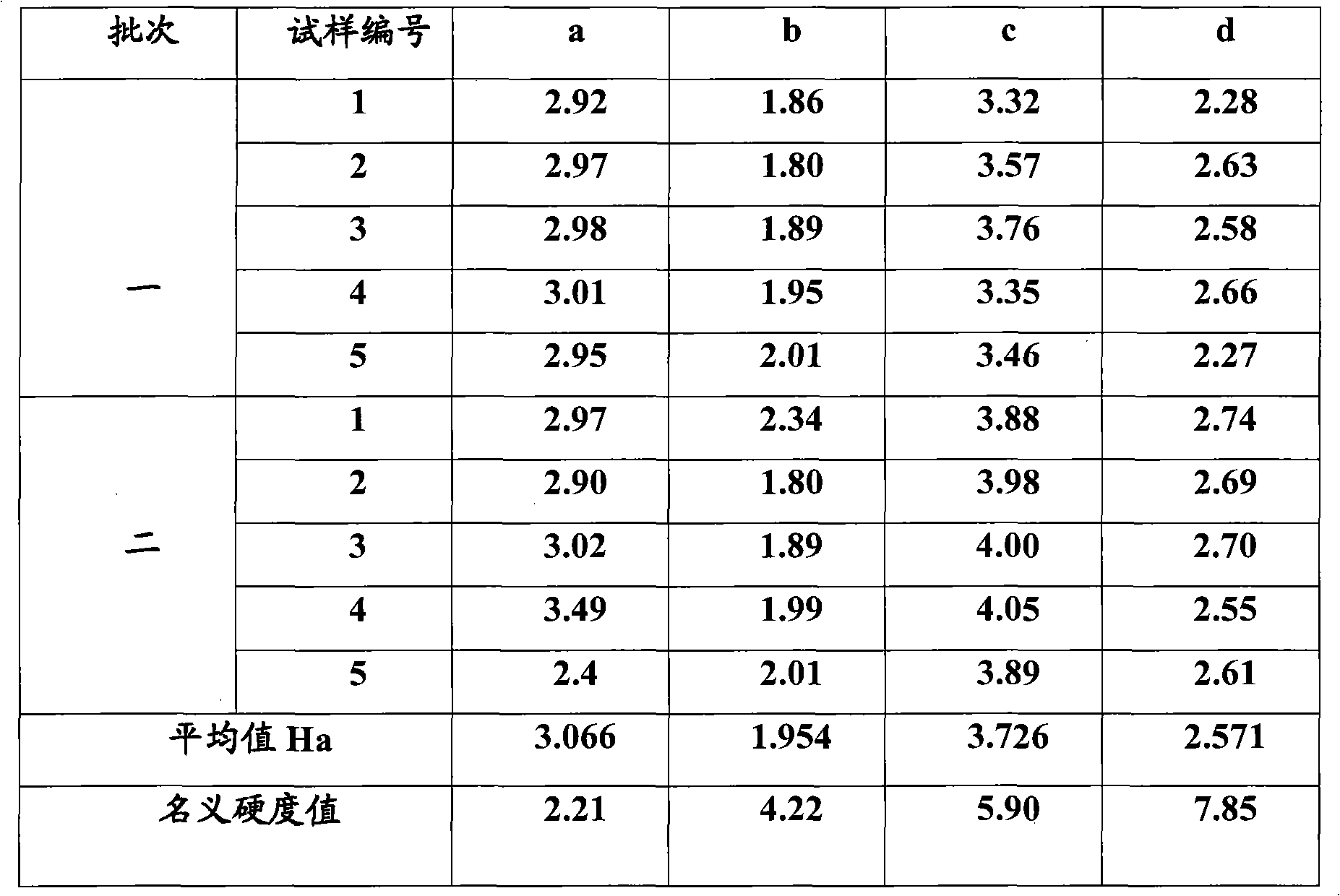

ActiveUS20050005745A1Reduce in quantityMore productiveGuide fencesFeeding devicesEngineeringMovement pattern

An apparatus for cutting a product includes a conveyor assembly and a slitter assembly. The conveyor assembly conveys the product in a feed direction and defines a conveyance surface, on which the product is conveyed. The slitter assembly slits the product into strips as the product is conveyed in the feed direction. The slitter assembly comprises a plurality of cutting elements arranged in a V shape and overlapping one another in the feed direction, as viewed in a direction substantially normal to the conveyance surface. A chopping assembly is positioned downstream of the slitter assembly. The chopping assembly comprises an elongated blade, which moves in an elliptical cutting motion, such that it has a component in the downward direction to sever the strips of product, and a component in the feed direction to toss the severed pieces of product in the feed direction.

Owner:LEPRINO FOODS

Methods and compositions relating to 5'-chimeric ribonucleic acids

InactiveUS20040220127A1Prevent cryptic aberrant trans-splicing reactionLittle effectMicrobiological testing/measurementGenetic material ingredientsChimeric RNAHigh throughput analysis

The disclosure provides, among other things, methods for producing and using 5'-chimeric RNAs and cDNAs. 5'-chimeric RNAs and cDNAs may be used, for example, for high-throughput analysis of the 5'-end sequences for RNA transcripts.

Owner:CALIFORNIA INST OF TECH

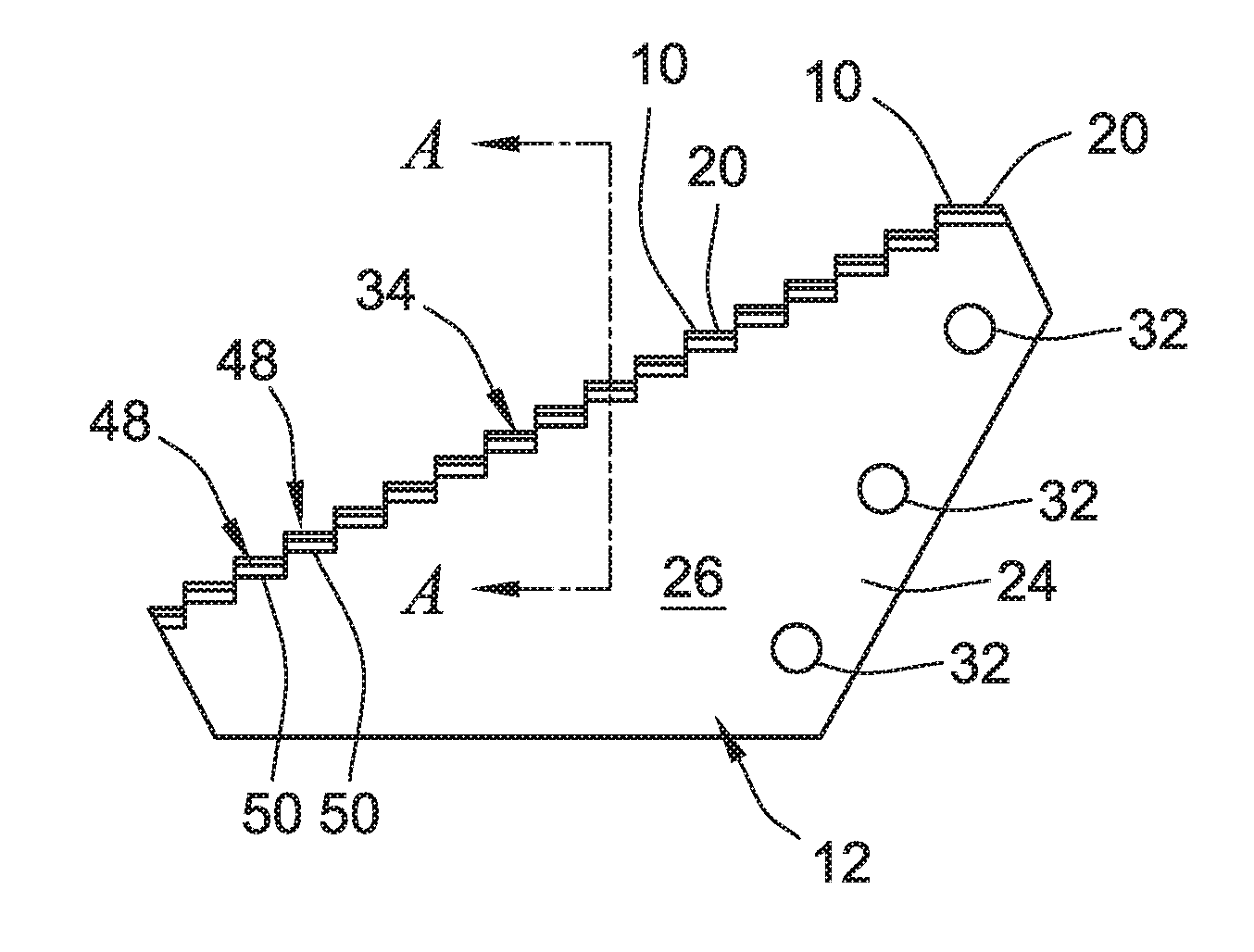

Self-counterboring, screw-threaded headed fastener with enlarged flanged portion or wings having cutting teeth thereon, and cutting wrench/screw gun sockets

InactiveUS20120266560A1Effectively boringEfficient cuttingRoof covering using slabs/sheetsCovering/liningsScrew threadBiomedical engineering

A self-counterboring screw-threaded headed fastener, for the threaded insertion into an underlying fixed support or substrate in order to fixedly secure a structural component, such as, for example, an insulated metal panel (IMP), to the underlying fixed support or substrate without the need for pre-drilling a bore within the insulated metal panel (IMP), in order to accommodate the screw-threaded head of the fastener, prior to the insertion of the screw-threaded fastener into and through the insulated metal panel (IMP) for fixation within and to the underlying fixed support or substrate, is disclosed. Cutting wrench or screw-gun sockets are also disclosed for similar purposes.

Owner:ILLINOIS TOOL WORKS INC

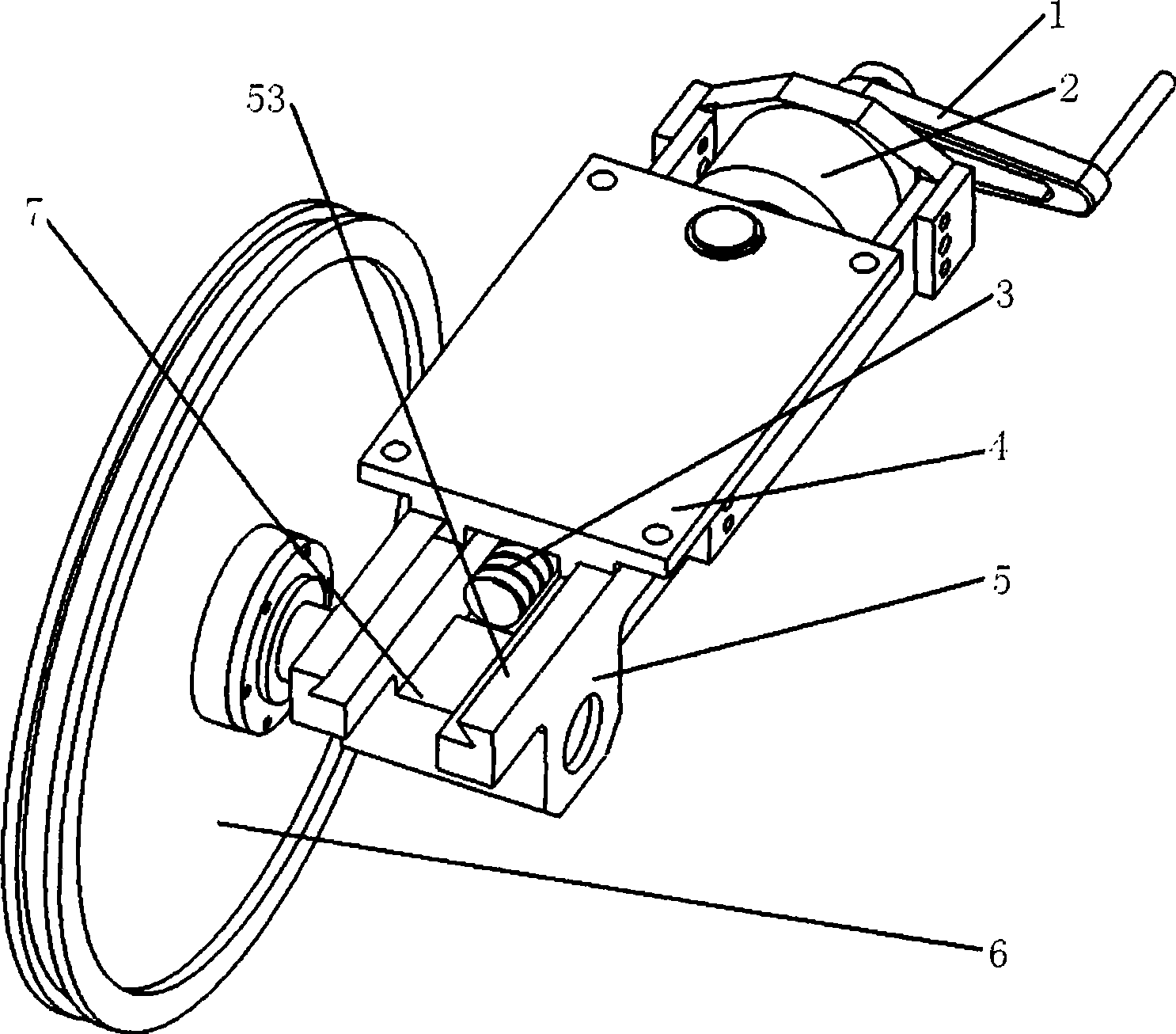

Tension device of underwater diamond rope saw

InactiveCN101468409AStable tensionEasy to assemble and disassembleMetal sawing devicesStone-like material working toolsMulti materialDiamond wire saw

The invention relates to a tensioning device of an underwater diamond wire saw, which comprises a tensioning wheel, a tensioning wheel axle seat, a tensioning force detection mechanism, an adjustment handle, a screw rod and a base, wherein the inner side surface of the base is in slide fit with the tensioning wheel axle seat, while the outer side surface is connected together with a frame of the diamond wire saw; the screw rod is positioned inside the tensioning wheel axle seat, and one end of the screw rod passes through the tensioning wheel axle seat to be connected and fixed with the adjustment handle; one end of the tensioning wheel axle seat is provided with an axle seat hole for the tensioning wheel axle seat to pass through so as to be positioned; and the tensioning force detection mechanism is sleeved on the screw rod and is positioned at one end of the tensioning wheel axle seat away from the axle seat hole. The tensioning device can ensure the initial tensioning force of a wire saw string bead wire, stable tensioning force during machining and convenient assembly and disassembly of the string bead wire; moreover, the tensioning device carries out realtime monitoring and controls the radial feeding speed of the string bead wire through a tension sensor, thereby ensuring safe, smooth, efficient and accurate cutting operation; therefore, the tensioning device can meet the requirements of large-diameter or multi-material filled pipes for carrying out cutting operation.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Dilation catheter assembly with bipolar cutting element

InactiveUS20070265617A1Easy to cutReducing and eliminating stray currentBalloon catheterDilatorsBipolar electrosurgeryCombined use

A method and apparatus for the dilatation of obstructed body vessels, orifices and conduits, combined with a controlled and regulated incision of the dilated body vessels using a bipolar or quasi-bipolar electrosurgical cutting wire arrangement is presented.

Owner:APPL MEDICAL RESOURCES CORP

Method of and apparatus for working structure

ActiveUS20080121078A1Improve productivityEfficient cuttingLathesAutomatic/semiautomatic turning machinesProduction rateFresnel lens

In a method of working a structure, a mold material is mounted on a mold material mount portion of a cutting / working apparatus and rotated about the C-axis serving as the rotation center while a cutting tool is driven and moved in directions X and Y. Then, a desired position of the mold material is cut with the cutting tool at a relatively formed desired cutting speed and elliptically vibrated / cut with the cutting tool, for forming a Fresnel lens molding cavity having an opening of a desired shape and a working surface (concave surface, for example) of a desired shape. According to this method, the productivity of an optical component mold employed as the structure can be efficiently improved when the mold for molding an optical component such as a Fresnel lens is worked by cutting the mold material employed as a workpiece with the cutting tool in a four-spindle lathe-type cutting / working apparatus including X-, Y-, Z- and C-axes of rotation.

Owner:TOWA

Adhesive sheet, dicing tape integrated type adhesive sheet, and method of producing semiconductor device

InactiveUS20080171187A1Efficient cuttingImprove bond reliabilityGroup 4/14 element organic compoundsSynthetic resin layered productsBreaking strengthDicing tape

The invention provides an adhesive sheet which can be stuck to a wafer at low temperatures of 100° C. or below, which is soft to the extent that it can be handled at room temperature, and which can be cut simultaneously with a wafer under usual cutting conditions; a dicing tape integrated type adhesive sheet formed by lamination of the adhesive sheet and a dicing tape; and a method of producing a semiconductor device using them. In order to achieve this object, the invention is characterized by specifying the breaking strength, breaking elongation, and elastic modulus of the adhesive sheet in particular numerical ranges.

Owner:INADA TEIICHI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com