Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7047results about "Abrasion apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

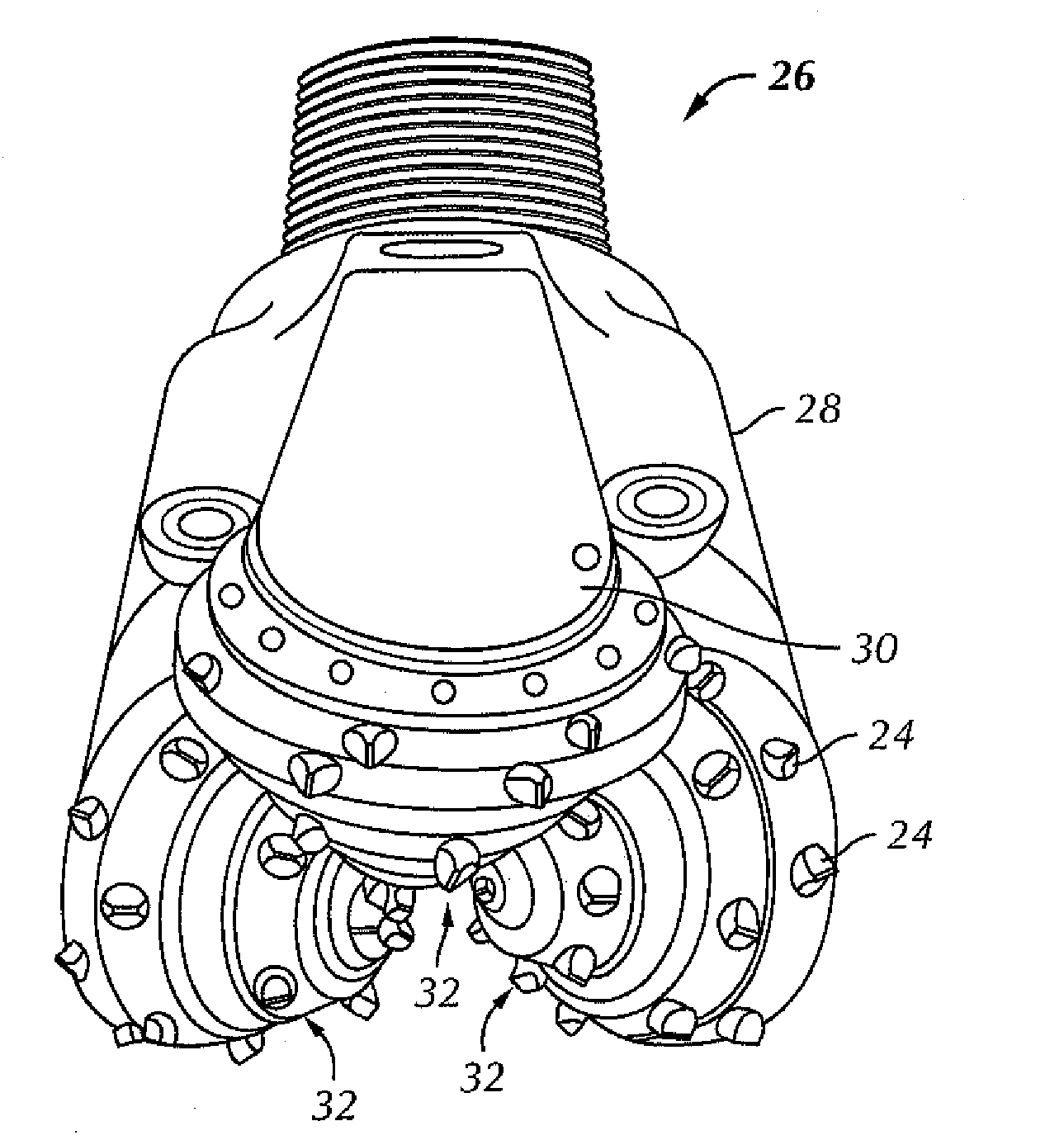

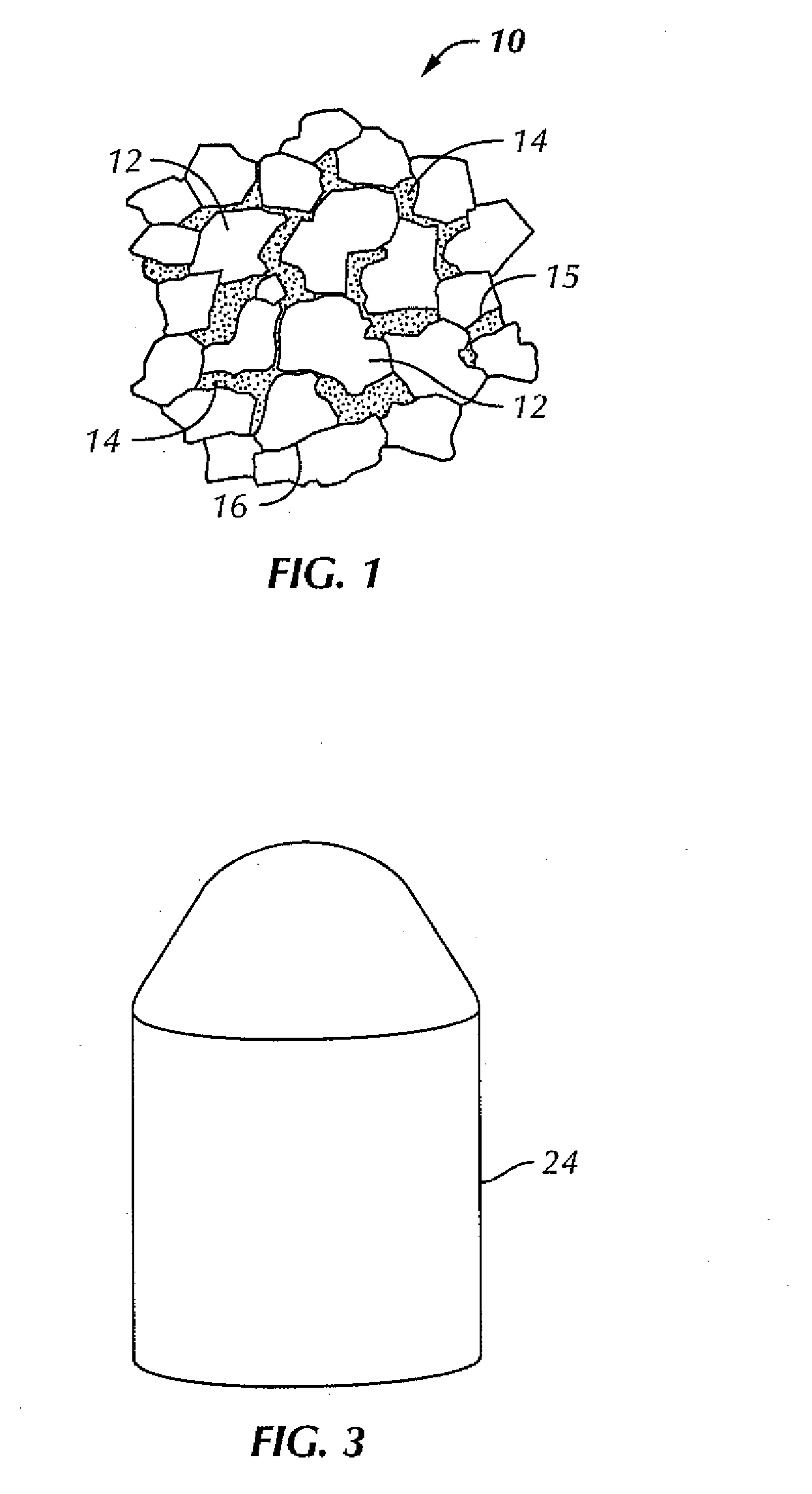

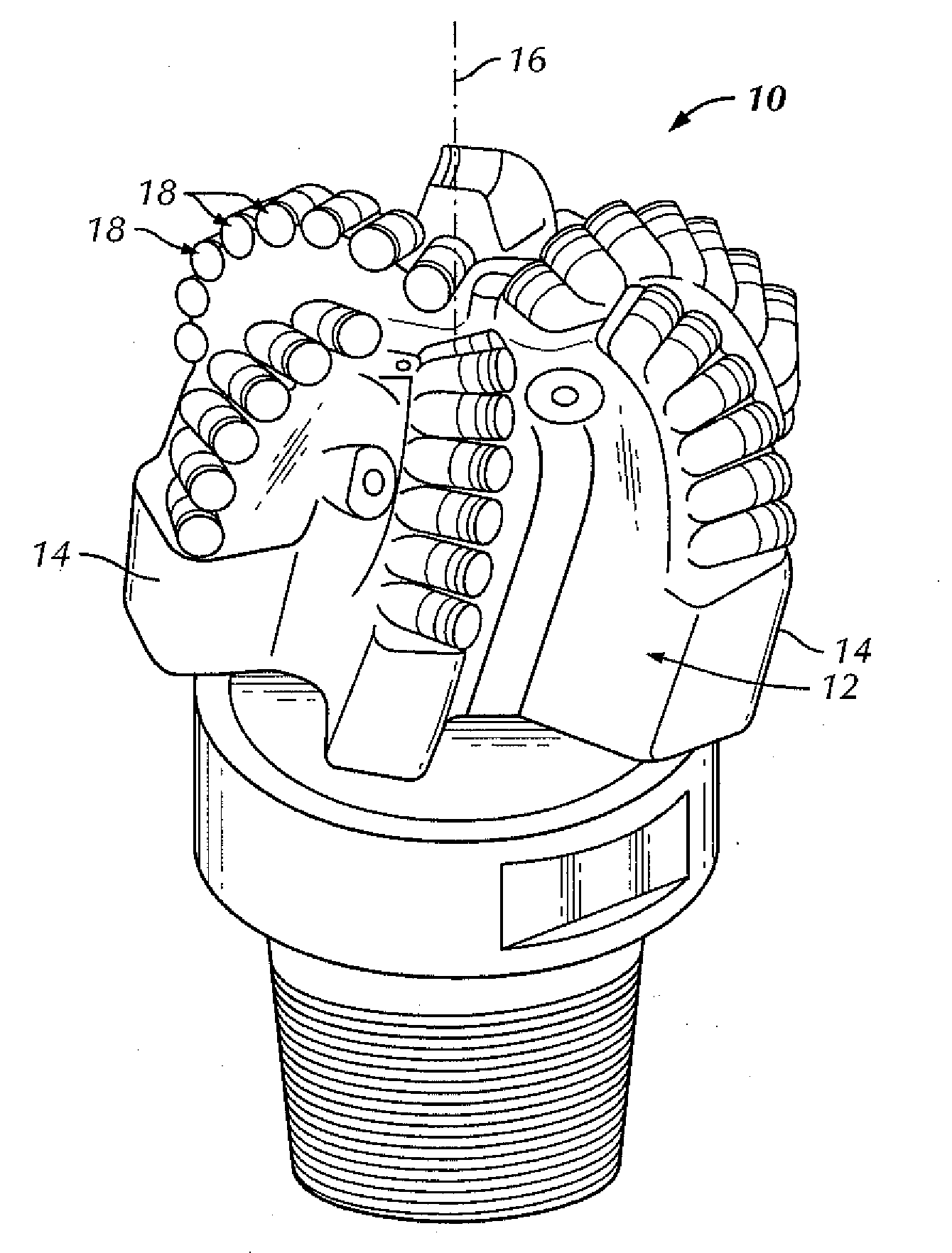

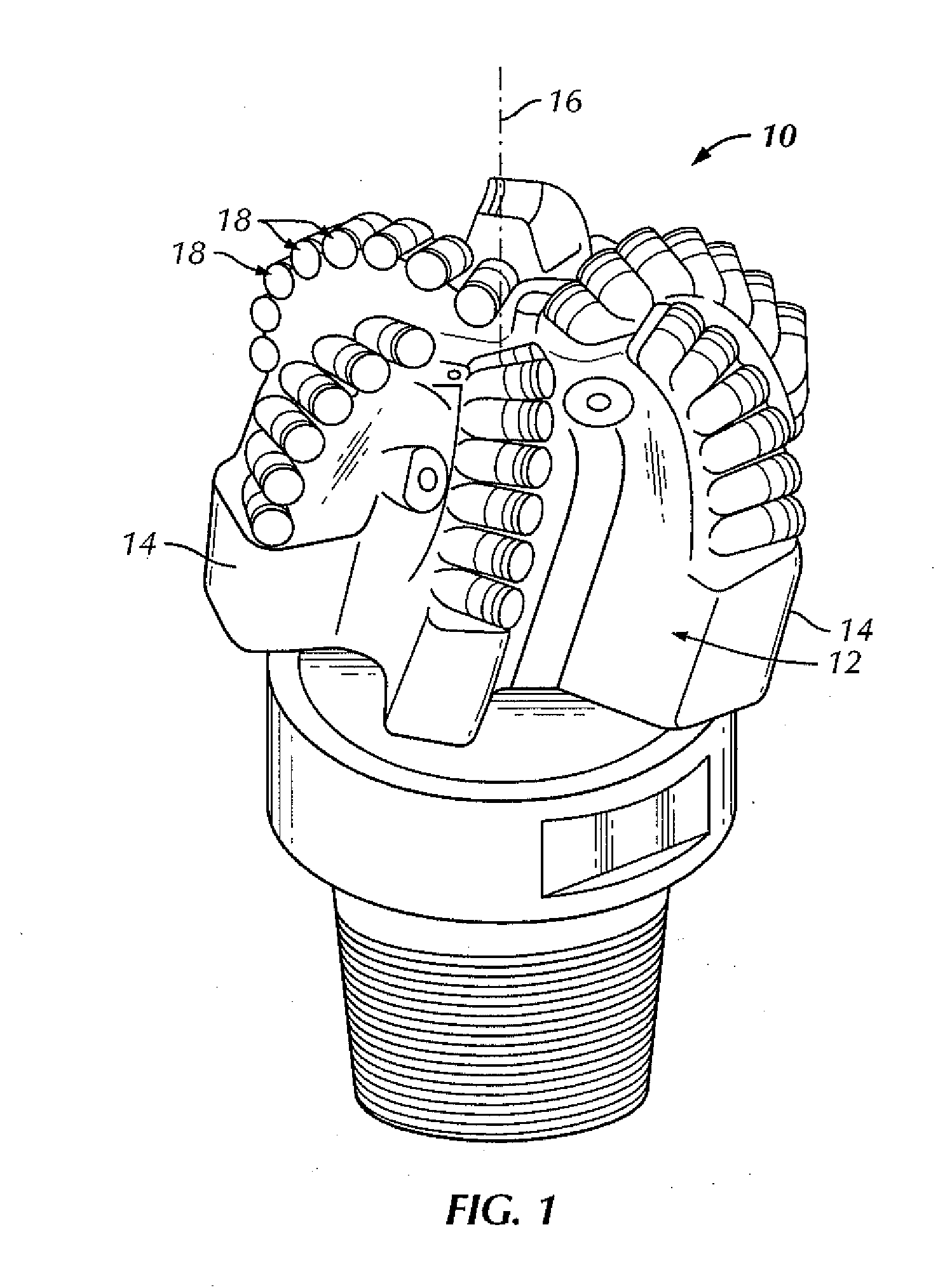

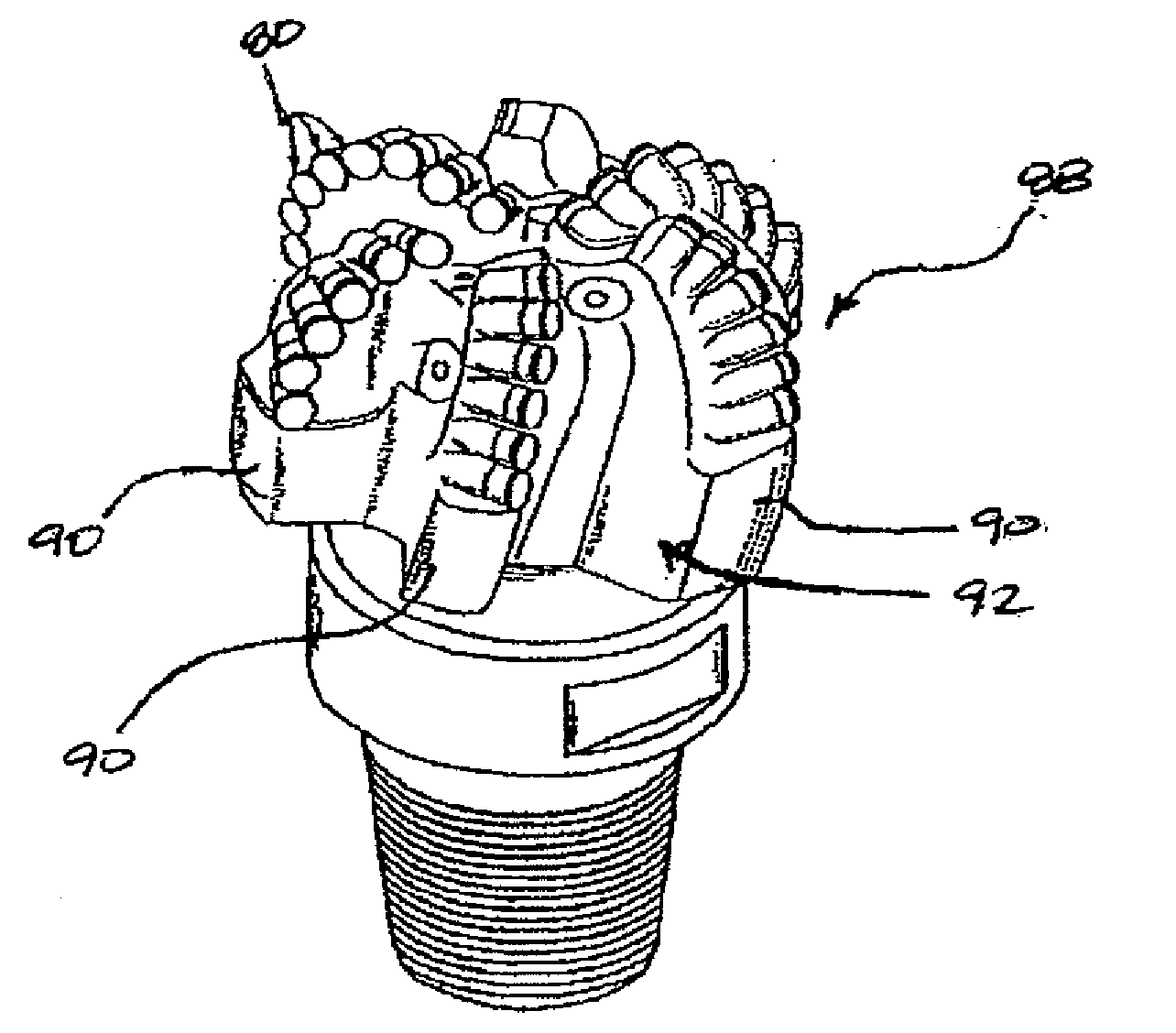

Nano-reinforced wc-co for improved properties

InactiveUS20080179104A1Increase resistanceImprove toughnessMaterial nanotechnologyDrill bitsCarbideNanometre

A drill bit that includes a bit body; and at least one cutting element for engaging the formation disposed on the bit body, the at least one cutting element comprising: a ductile phase; a plurality of carbide particles dispersed in the ductile phase; and a plurality of nanotubes integrated into the cutting element is disclosed.

Owner:SMITH INT INC

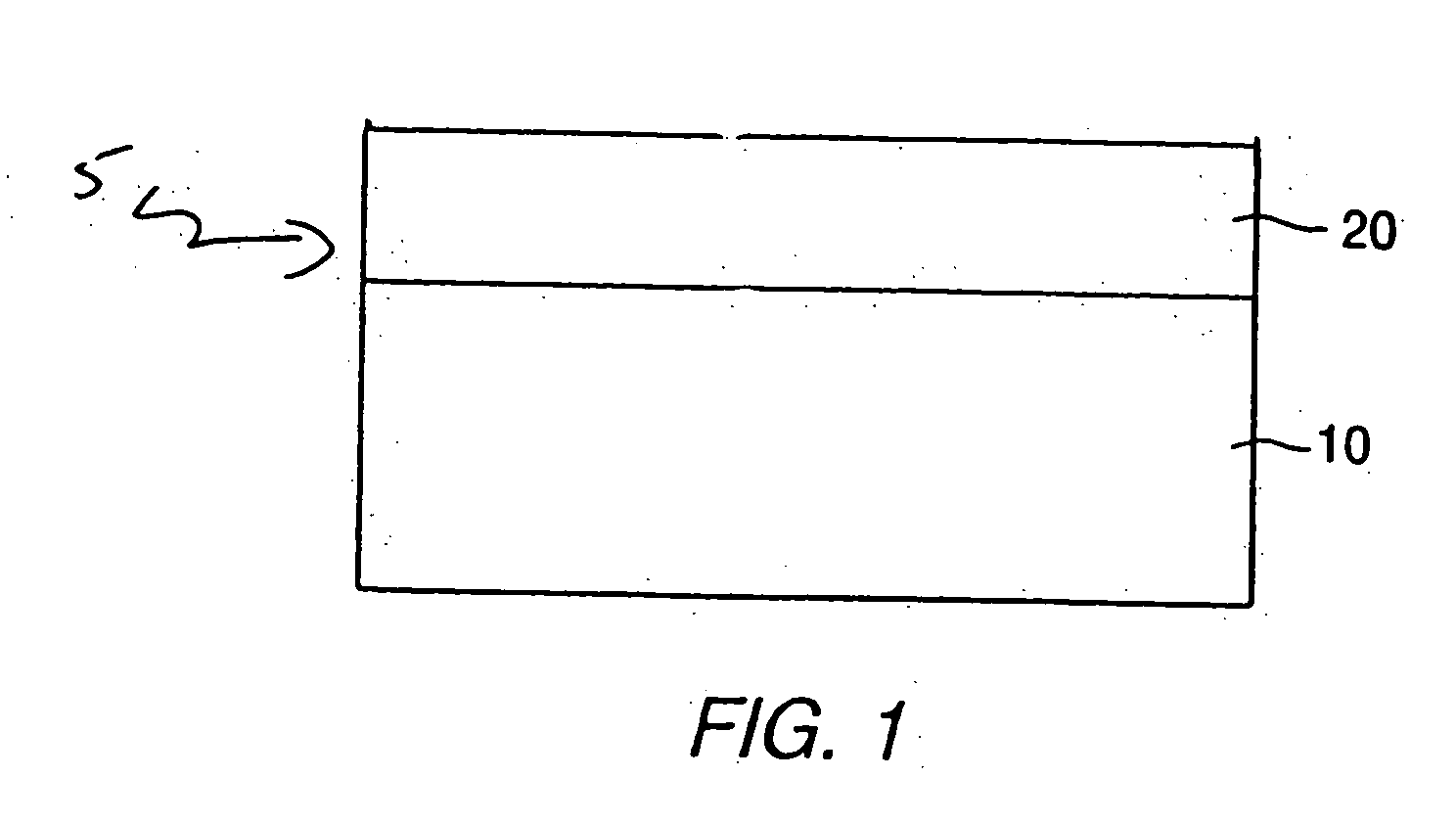

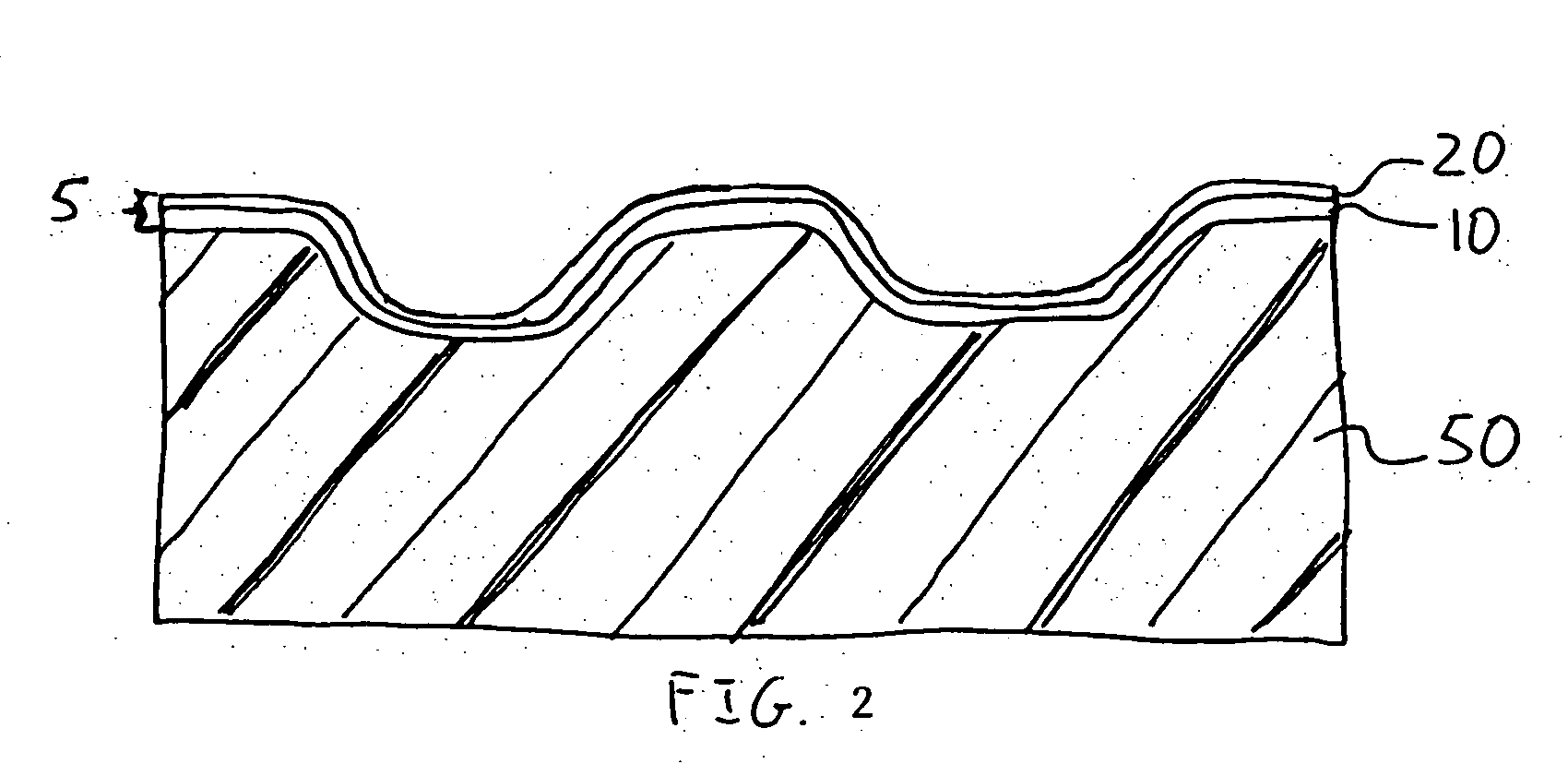

Nanoparticle coatings for flexible and/or drawable substrates

ActiveUS20050287348A1Better able to withstandHigh glossPretreated surfacesRecord information storageNanometreMaterials science

Owner:PPG IND OHIO INC

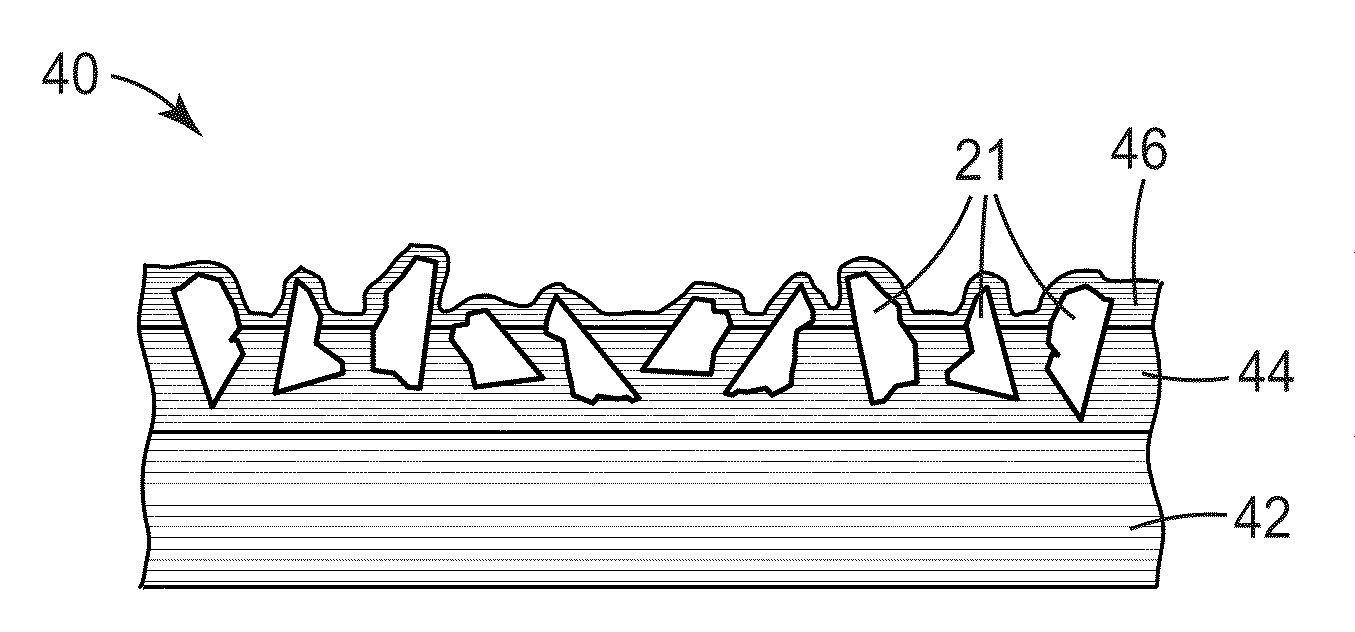

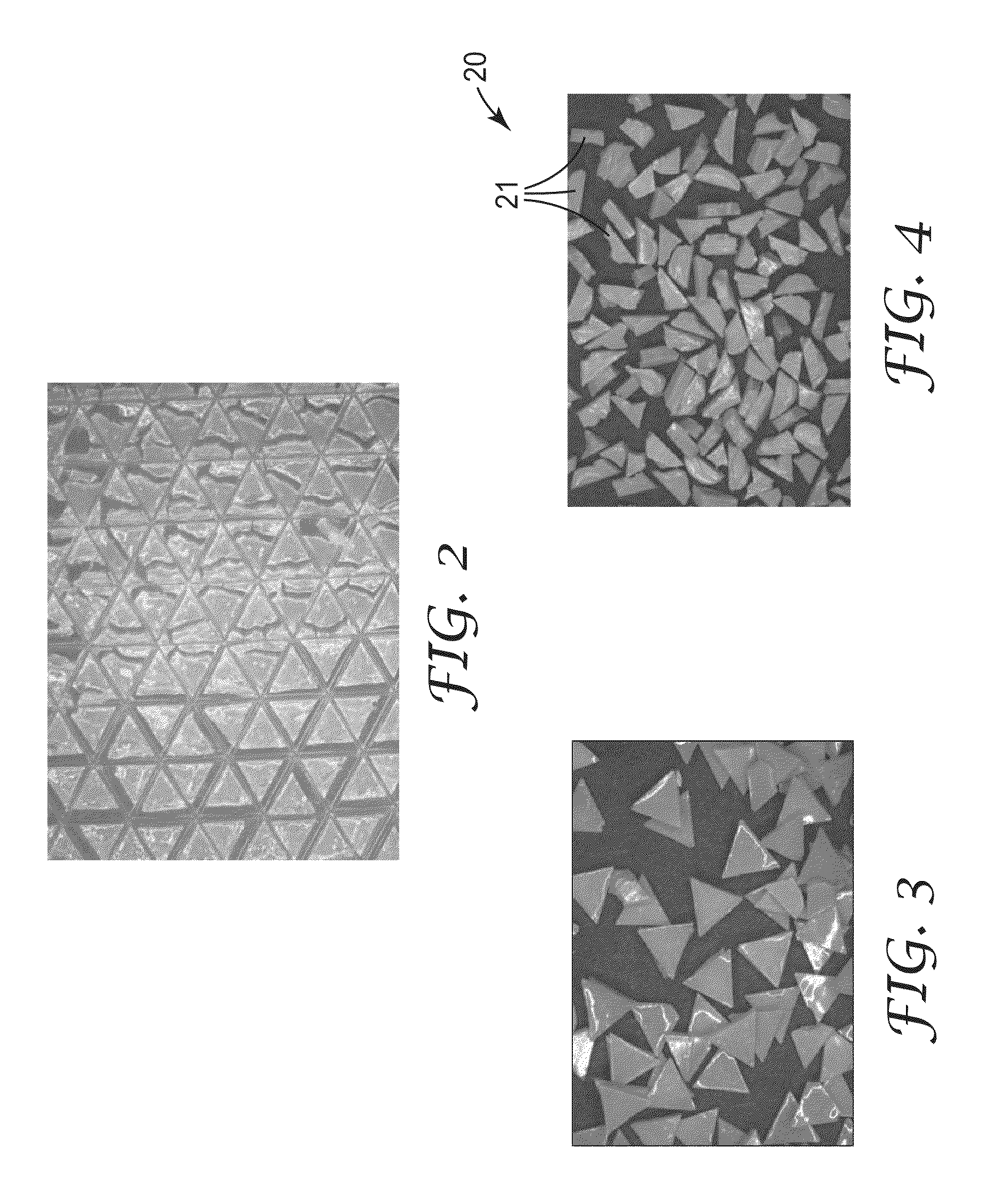

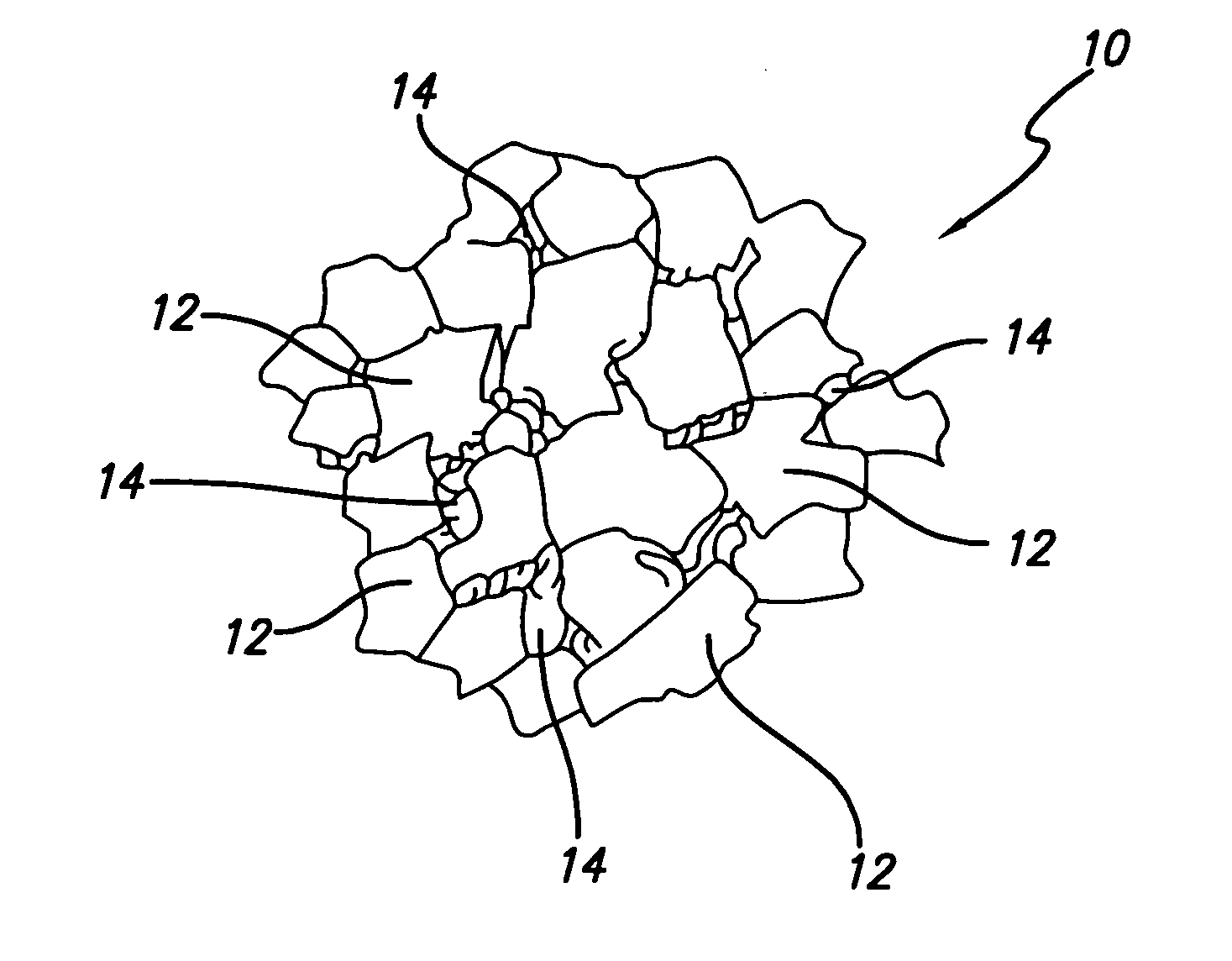

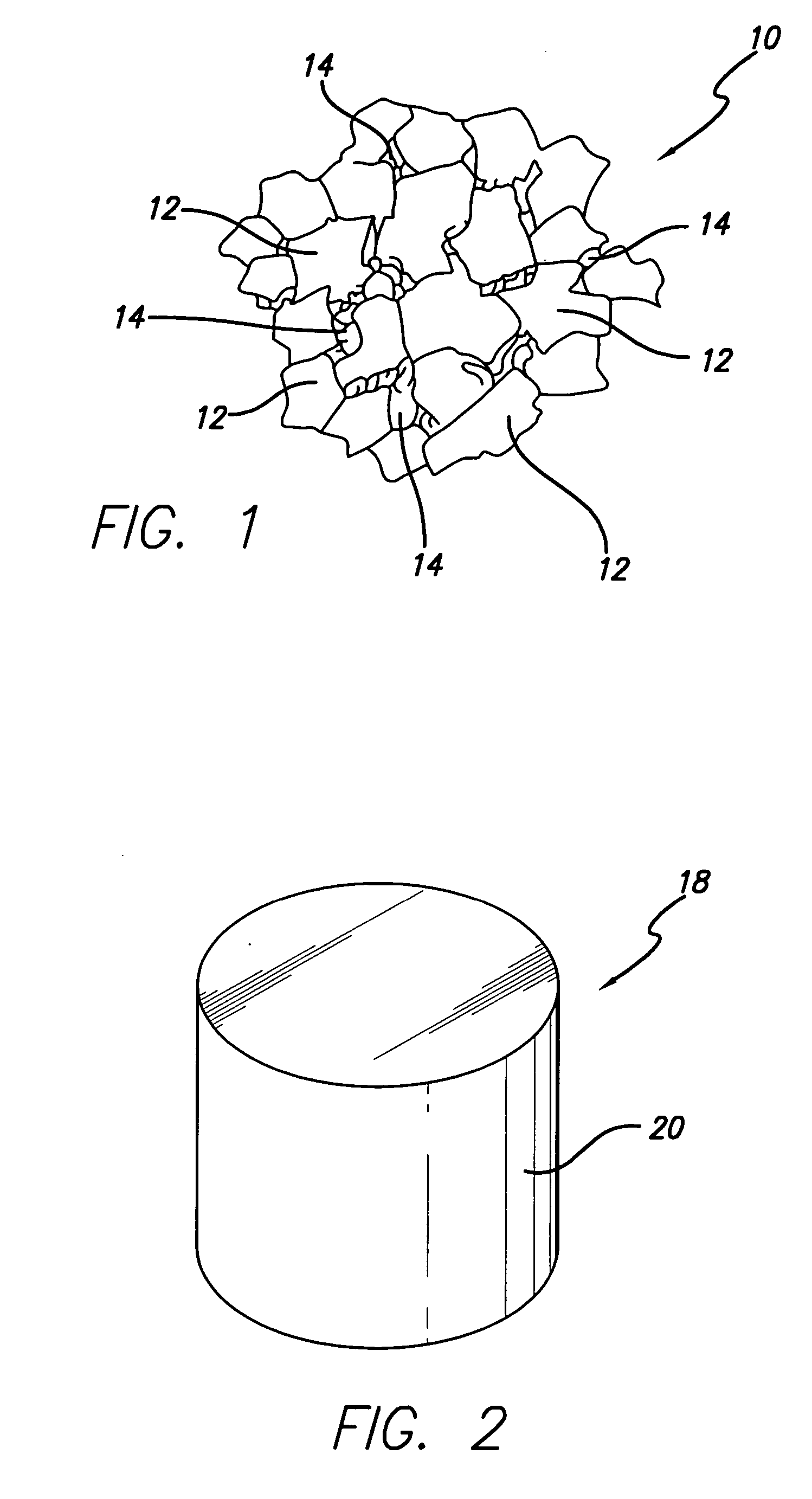

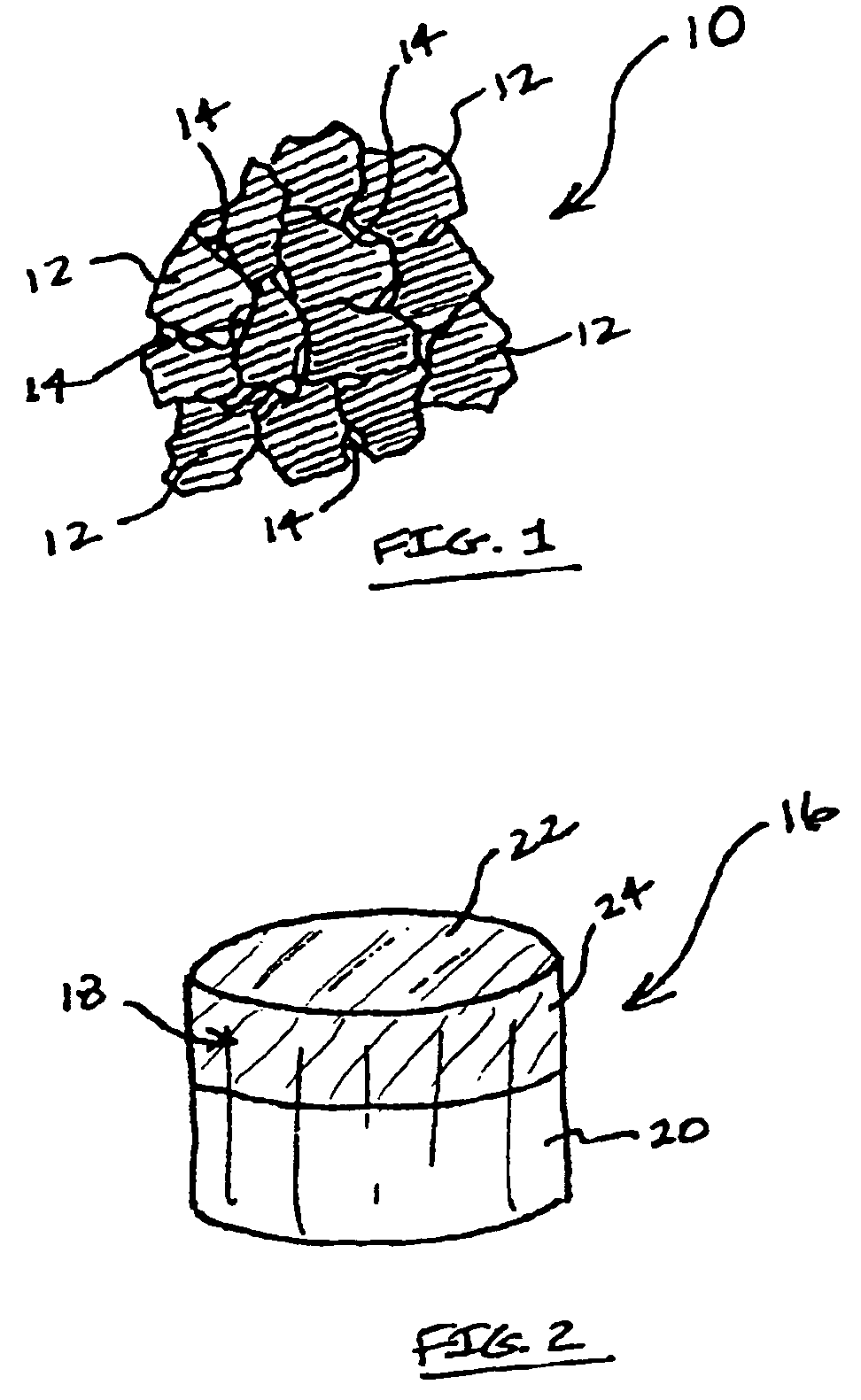

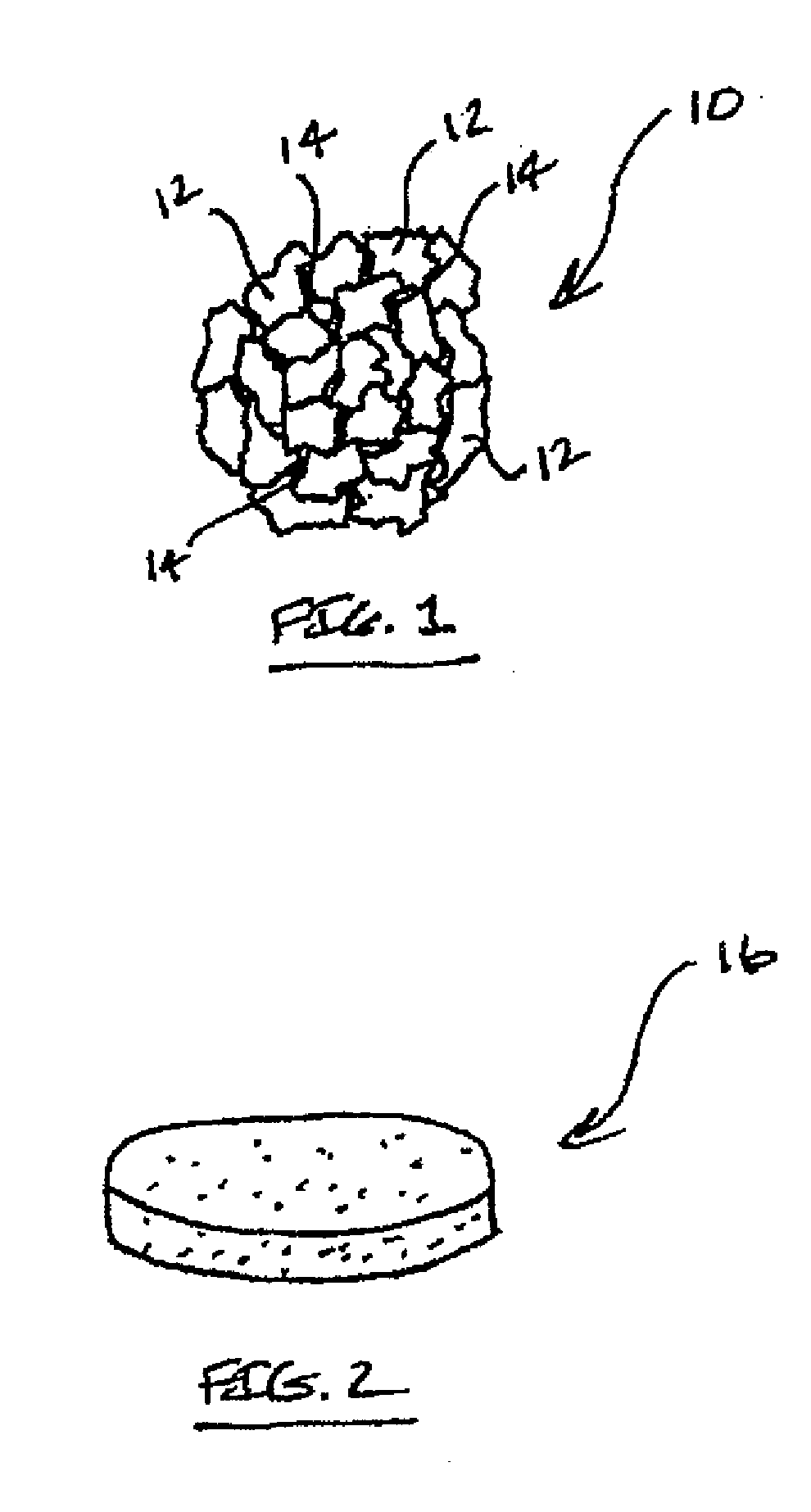

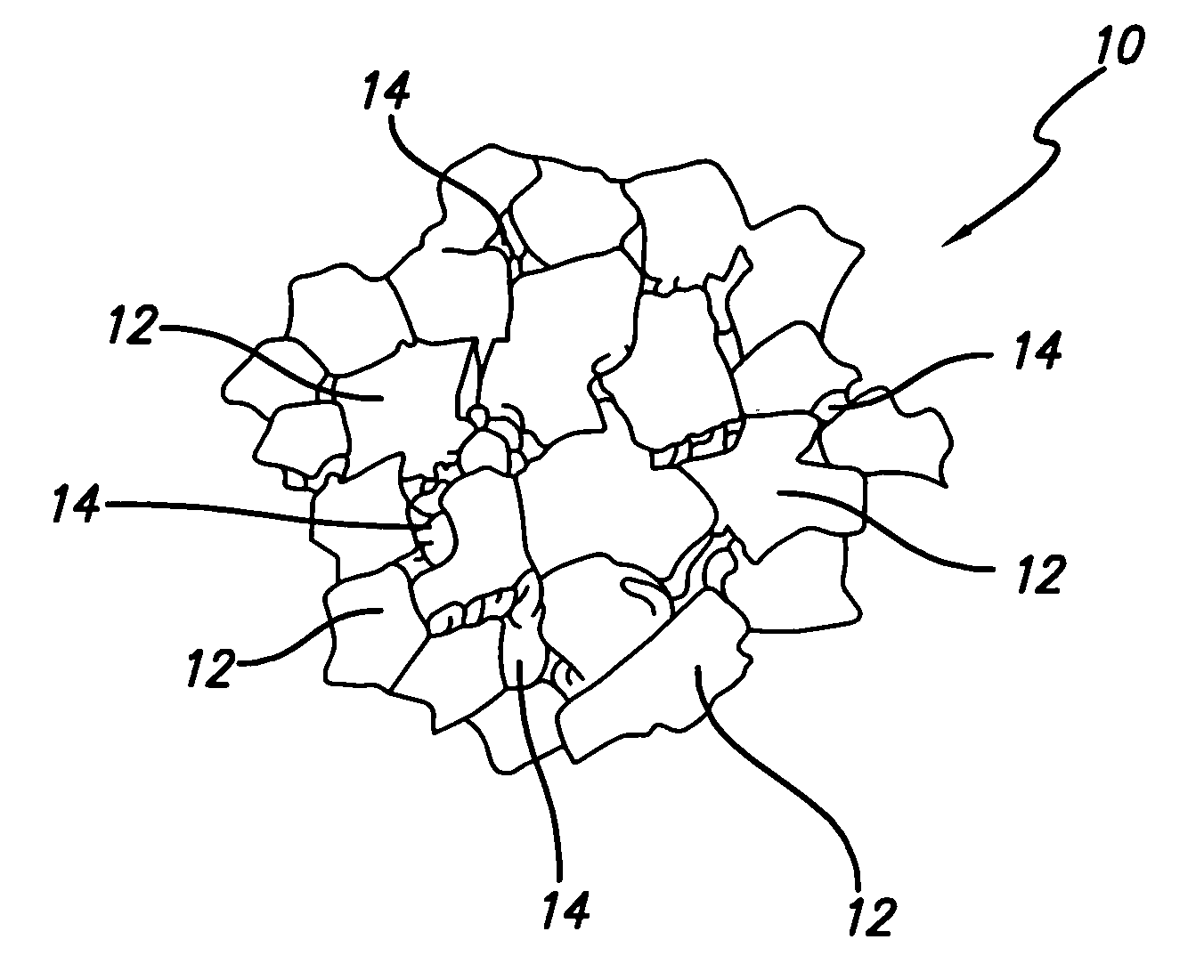

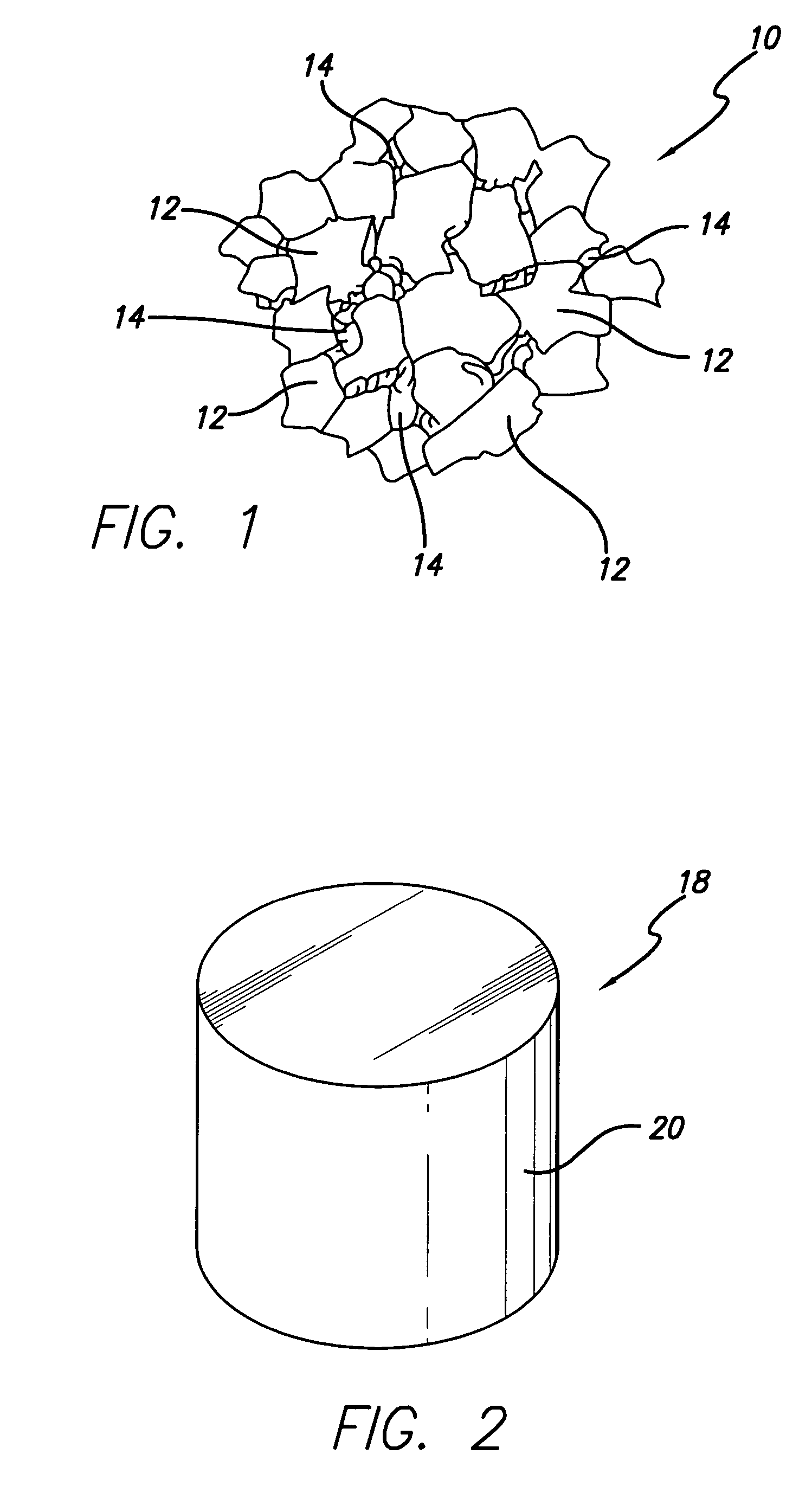

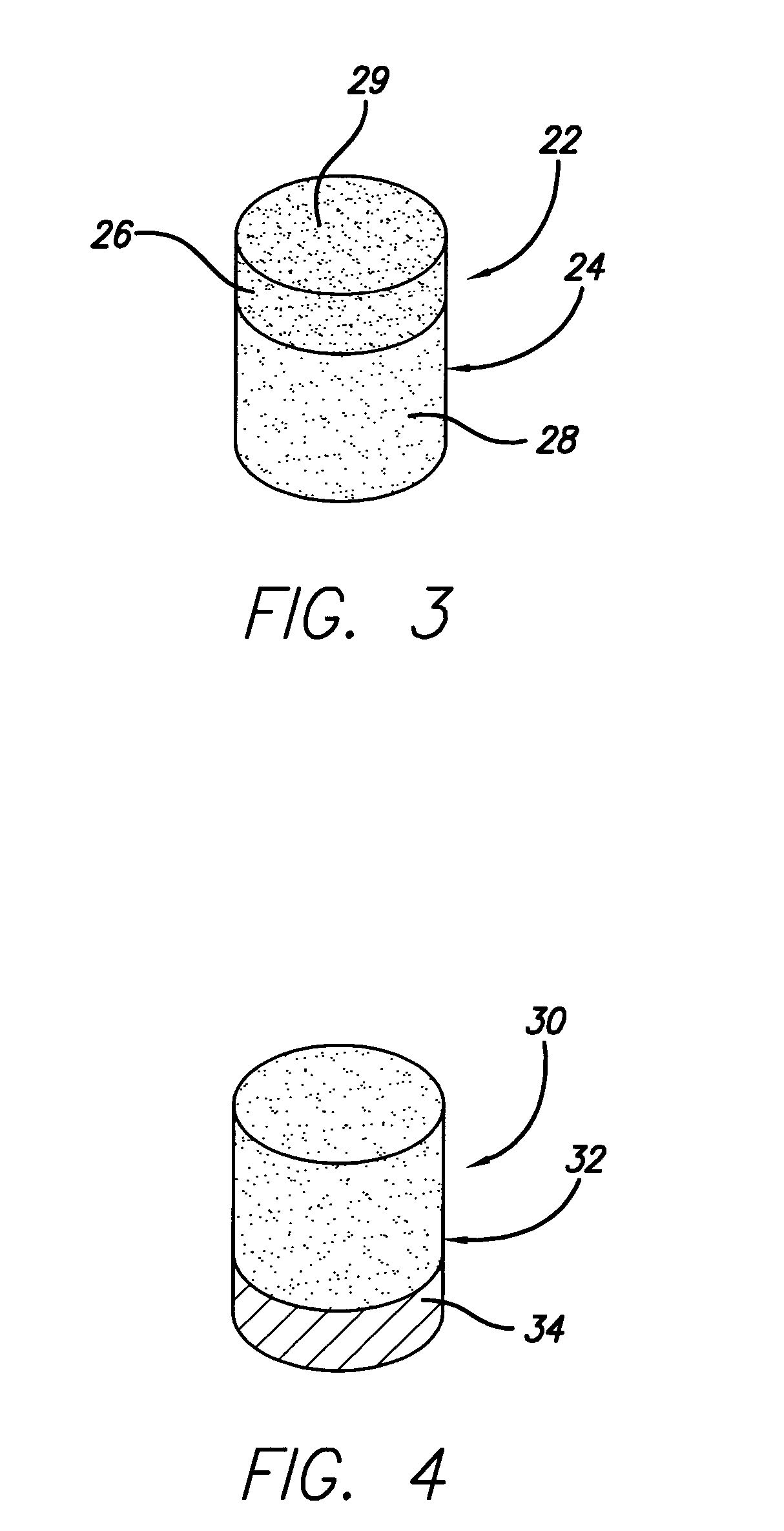

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

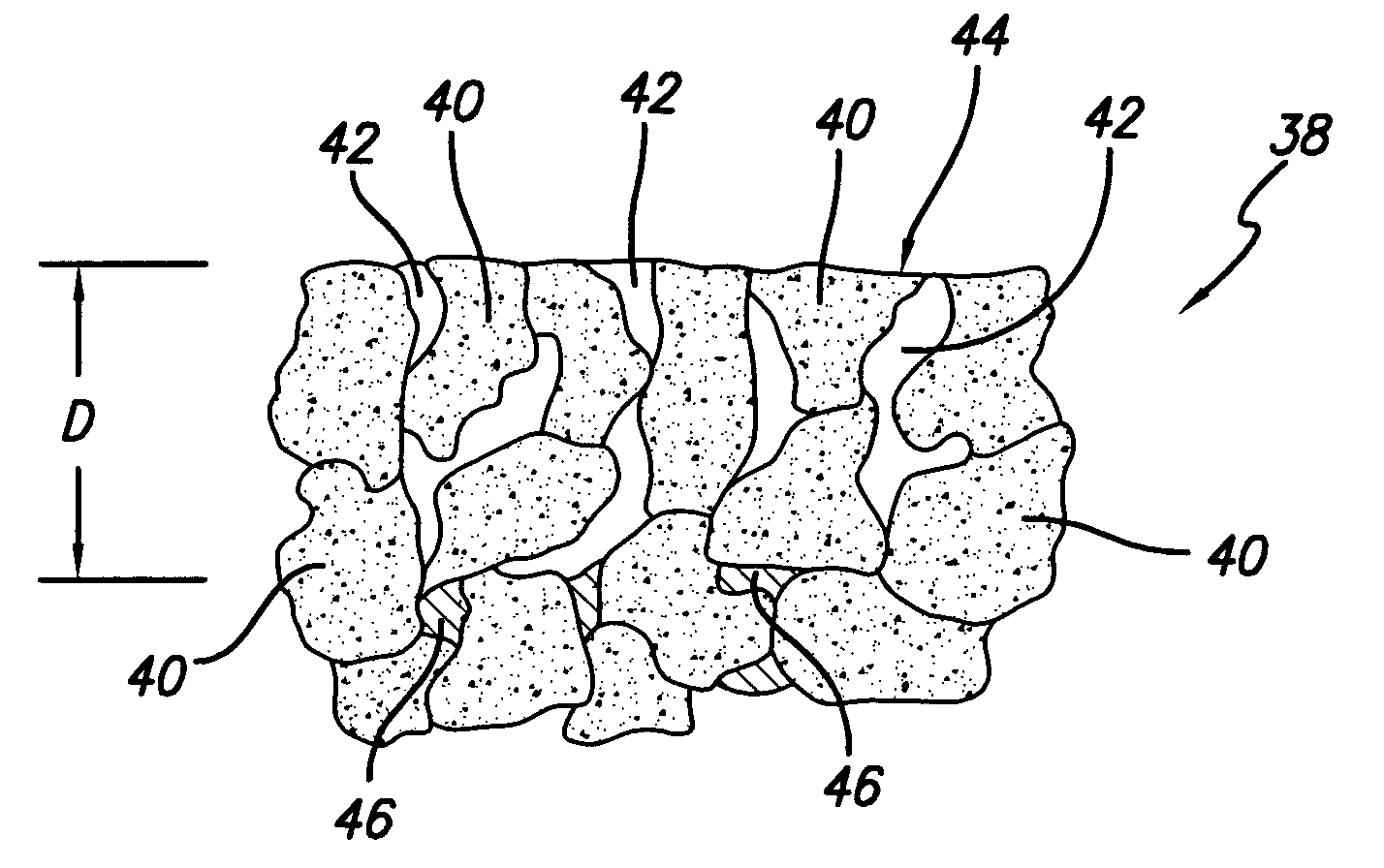

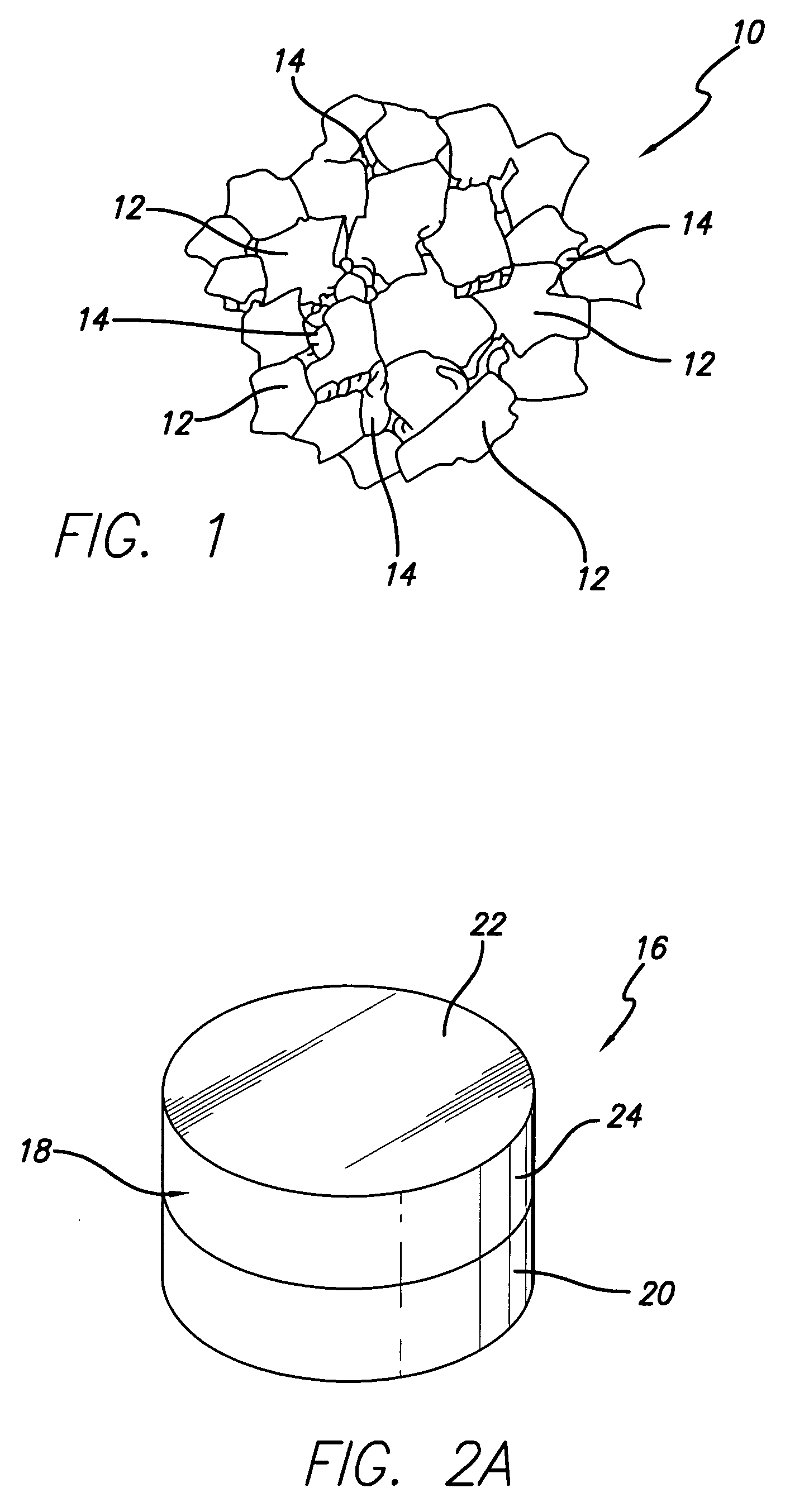

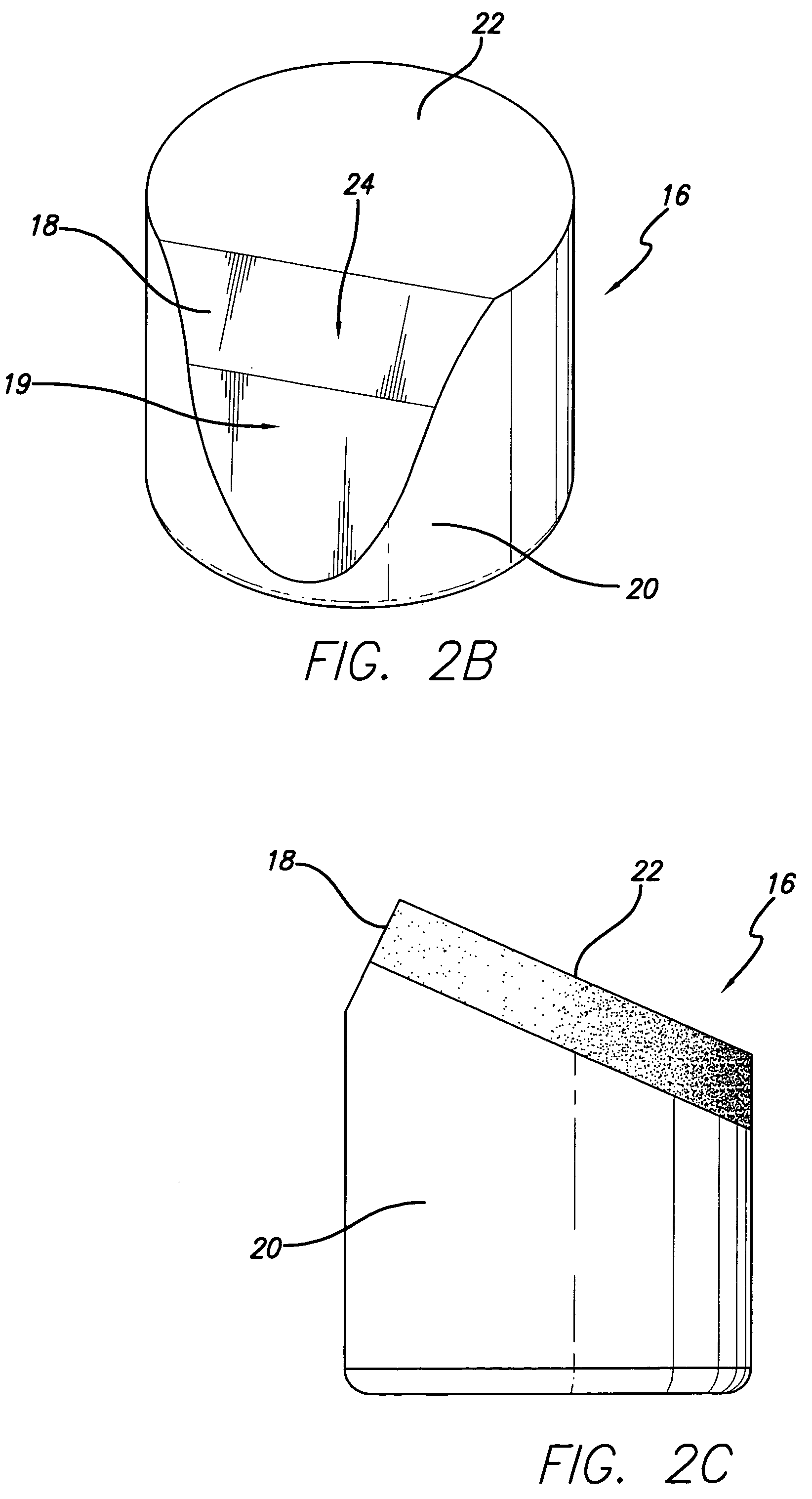

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

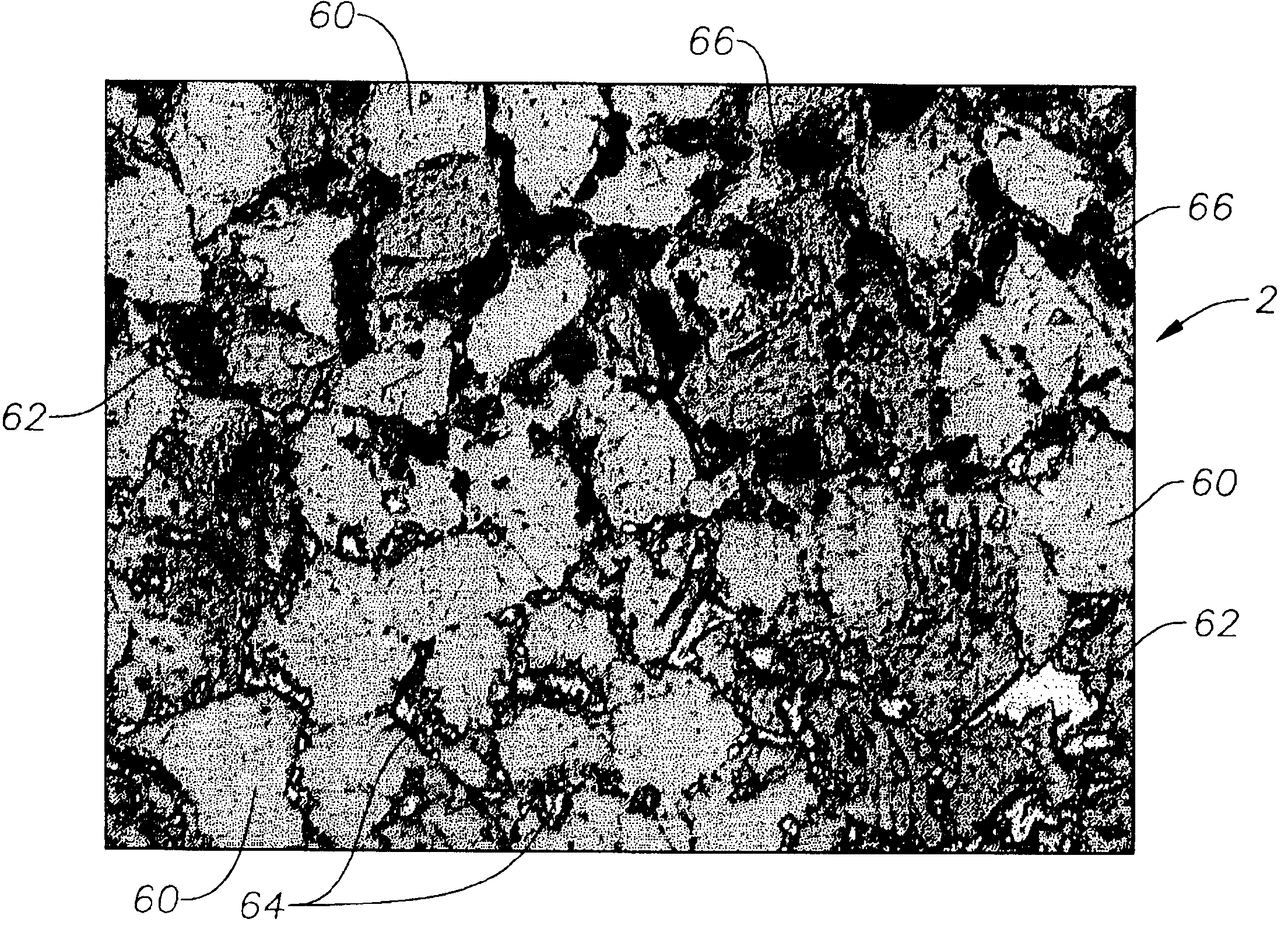

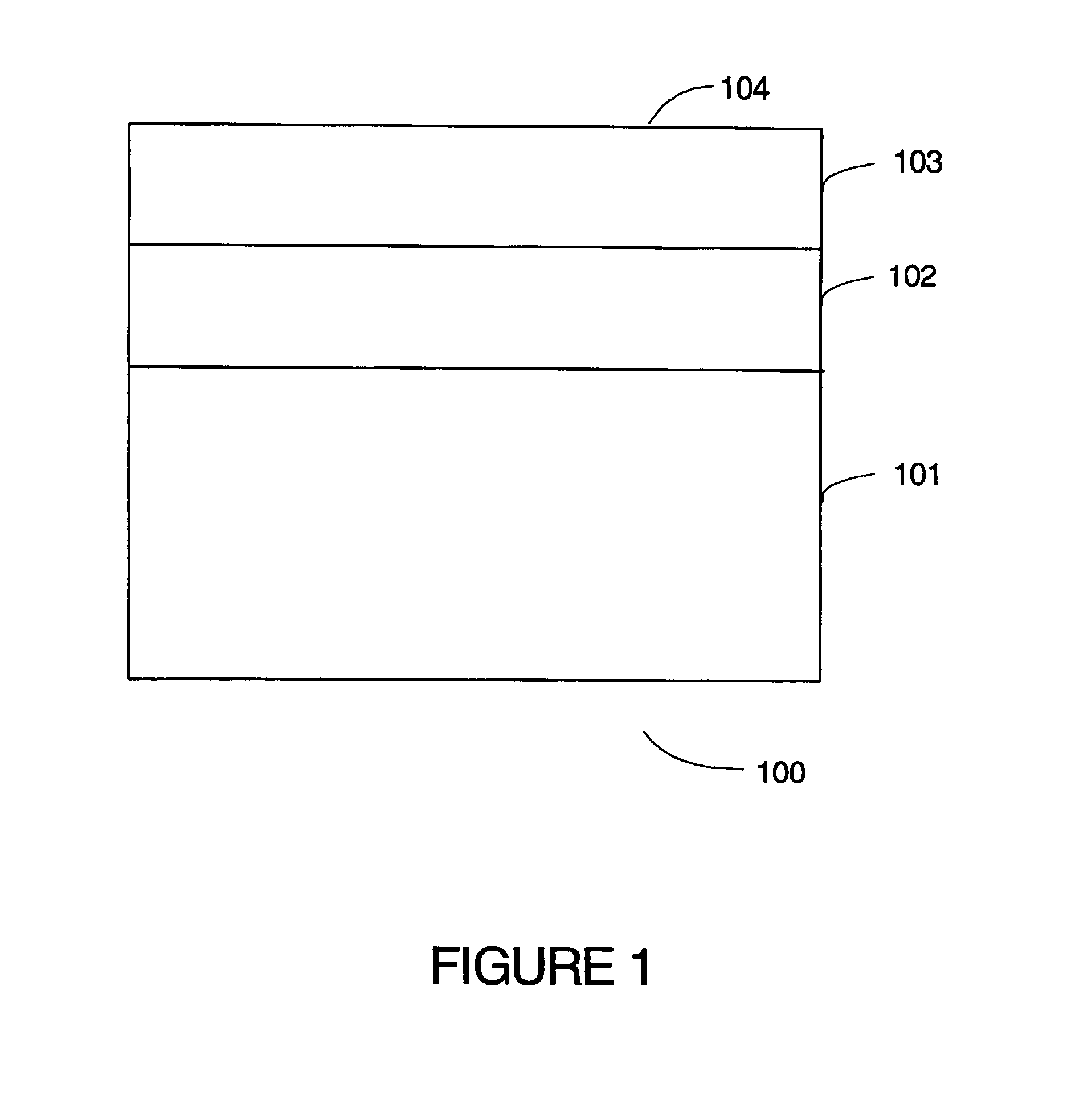

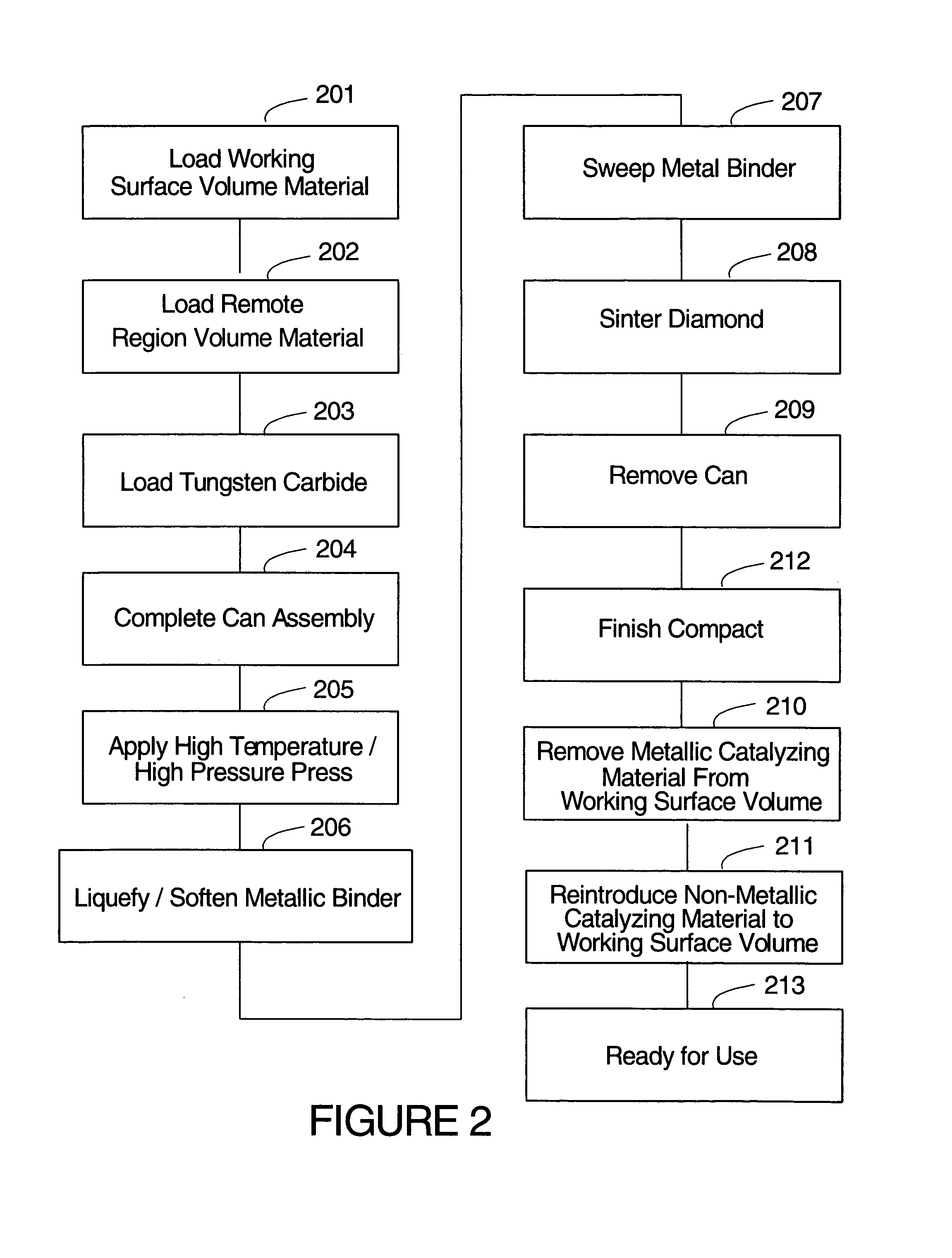

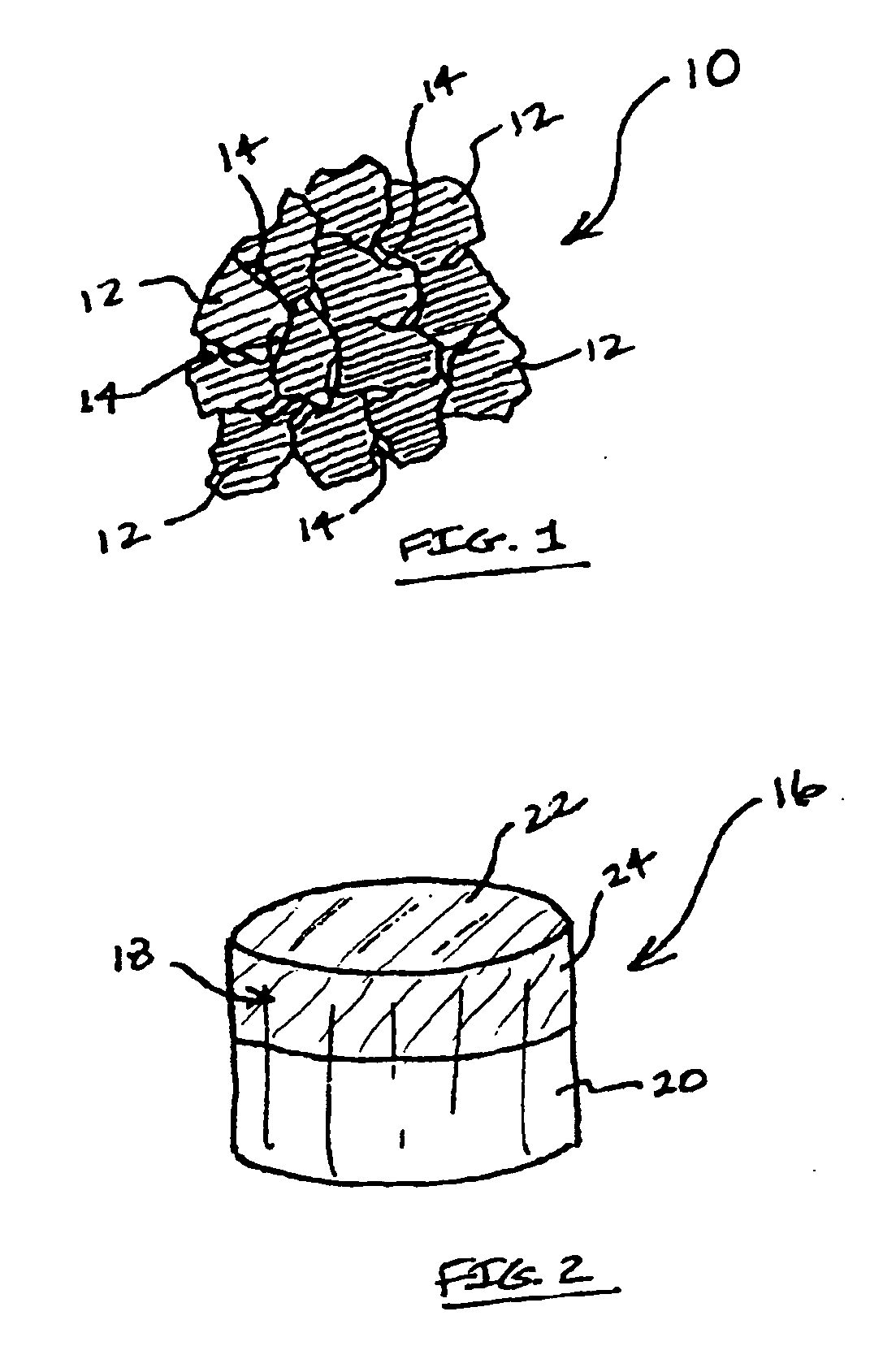

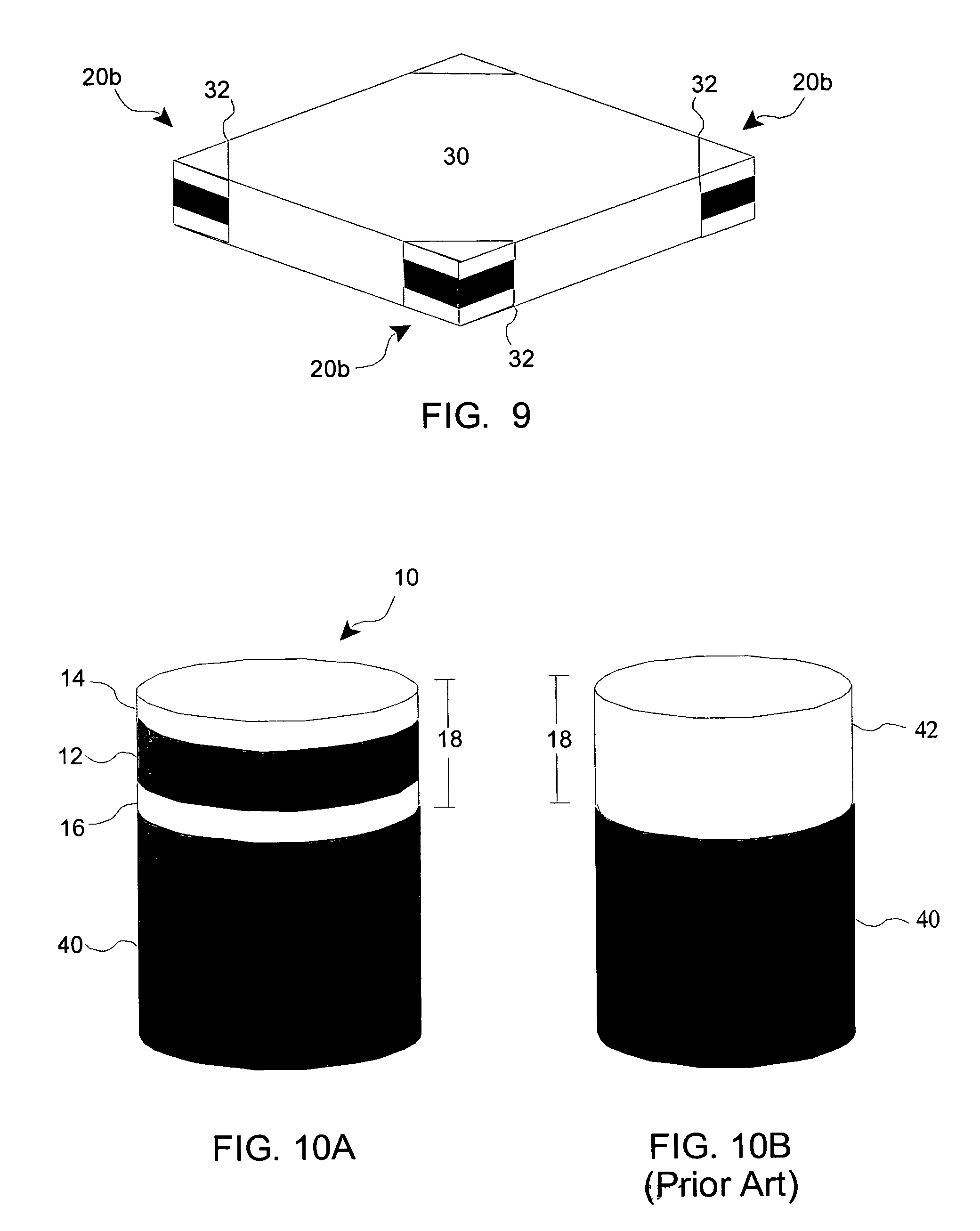

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

Abrasive grain, abrasive articles, and methods of making and using the same

Owner:3M INNOVATIVE PROPERTIES CO

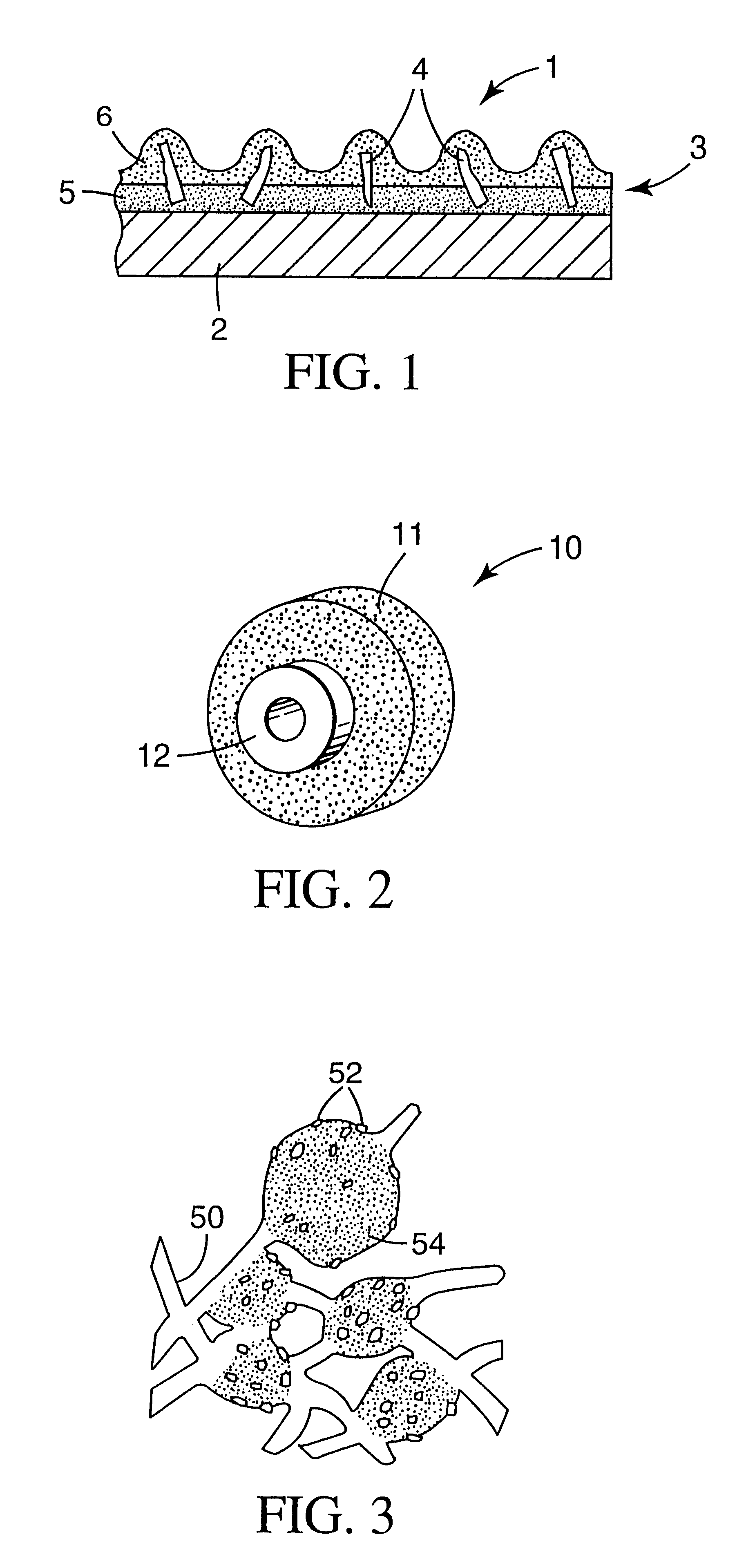

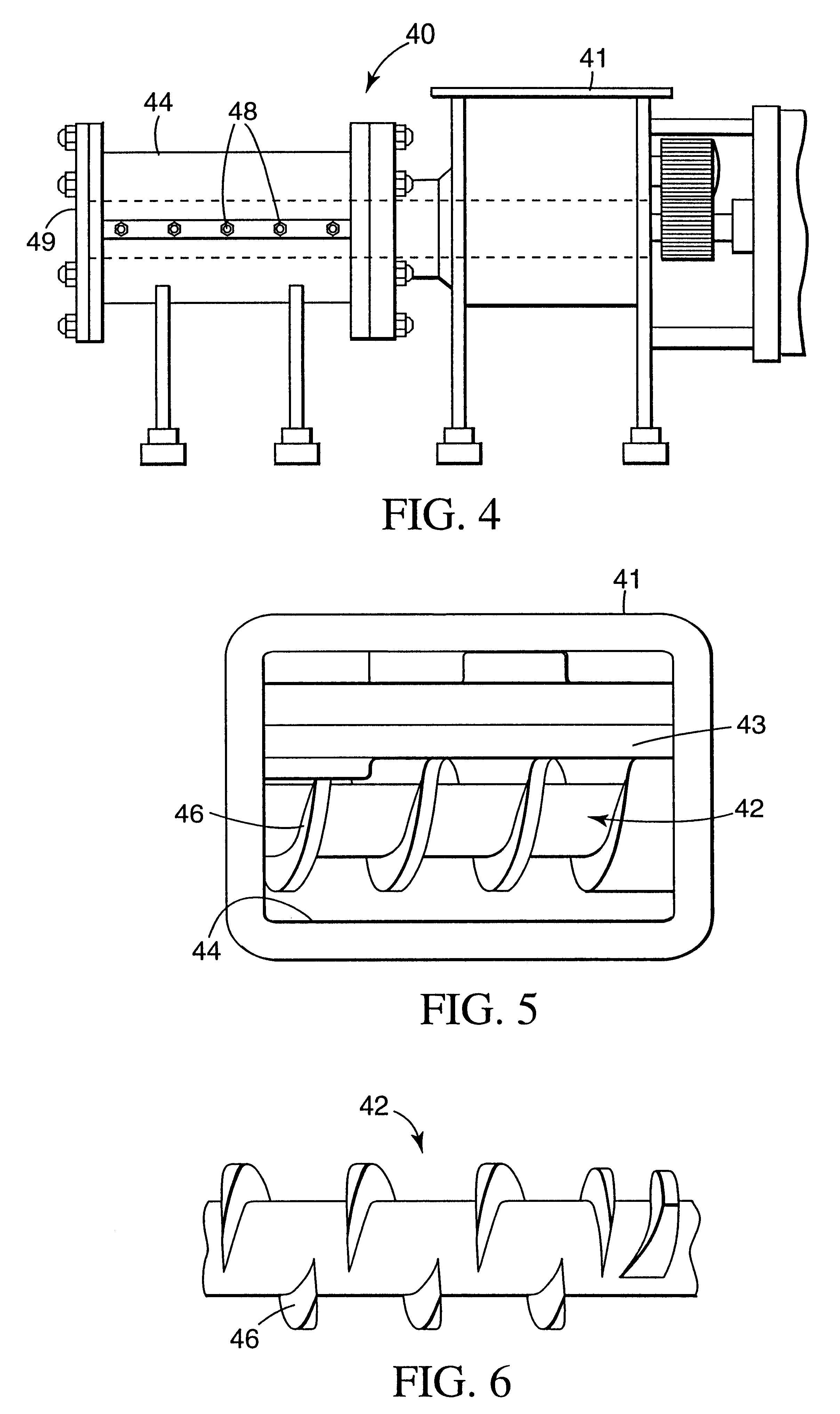

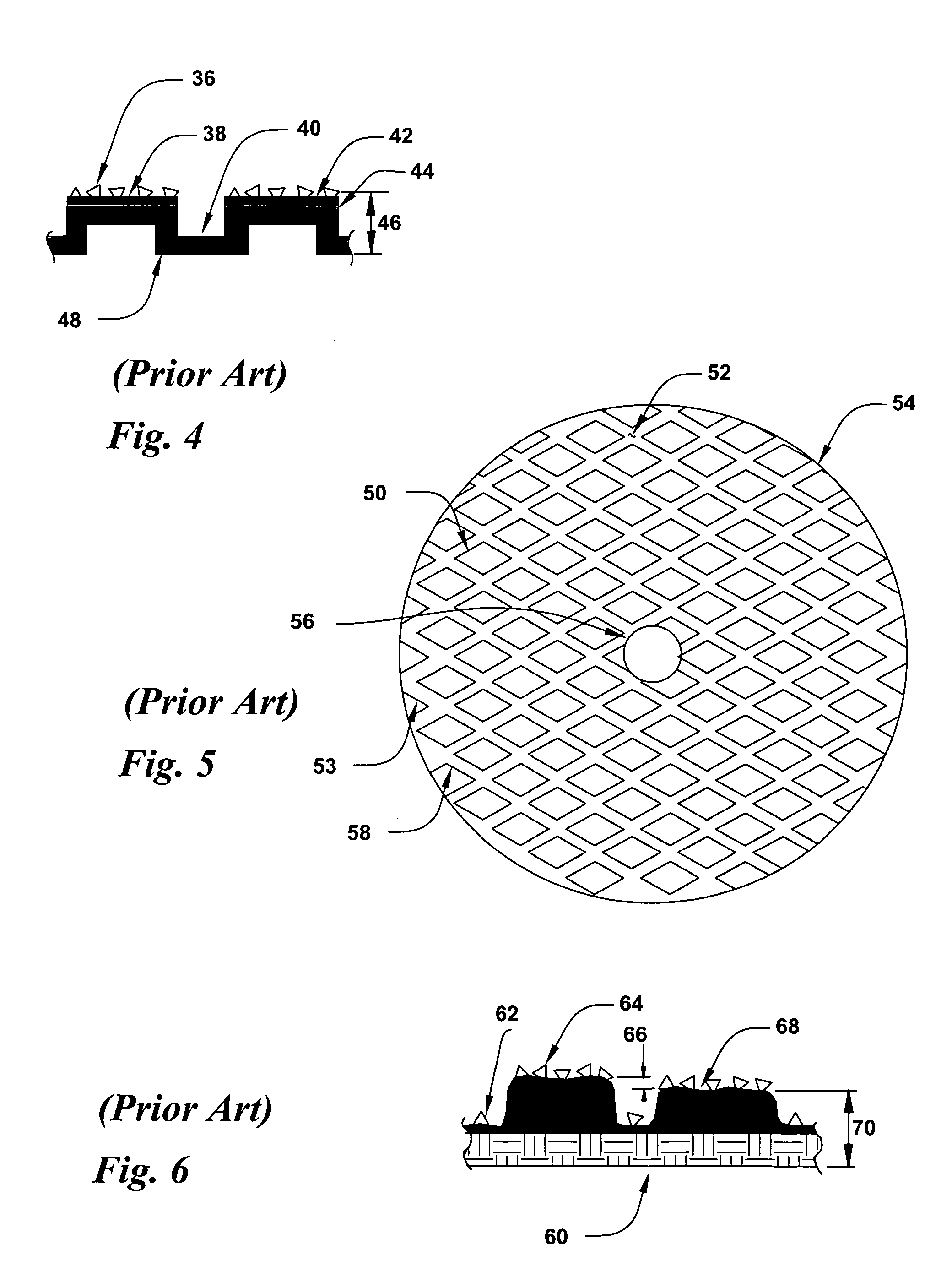

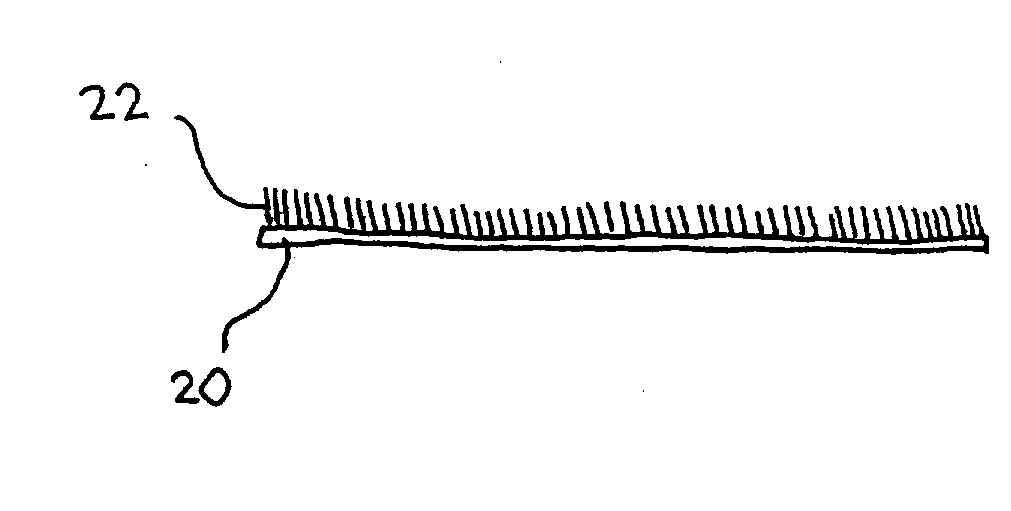

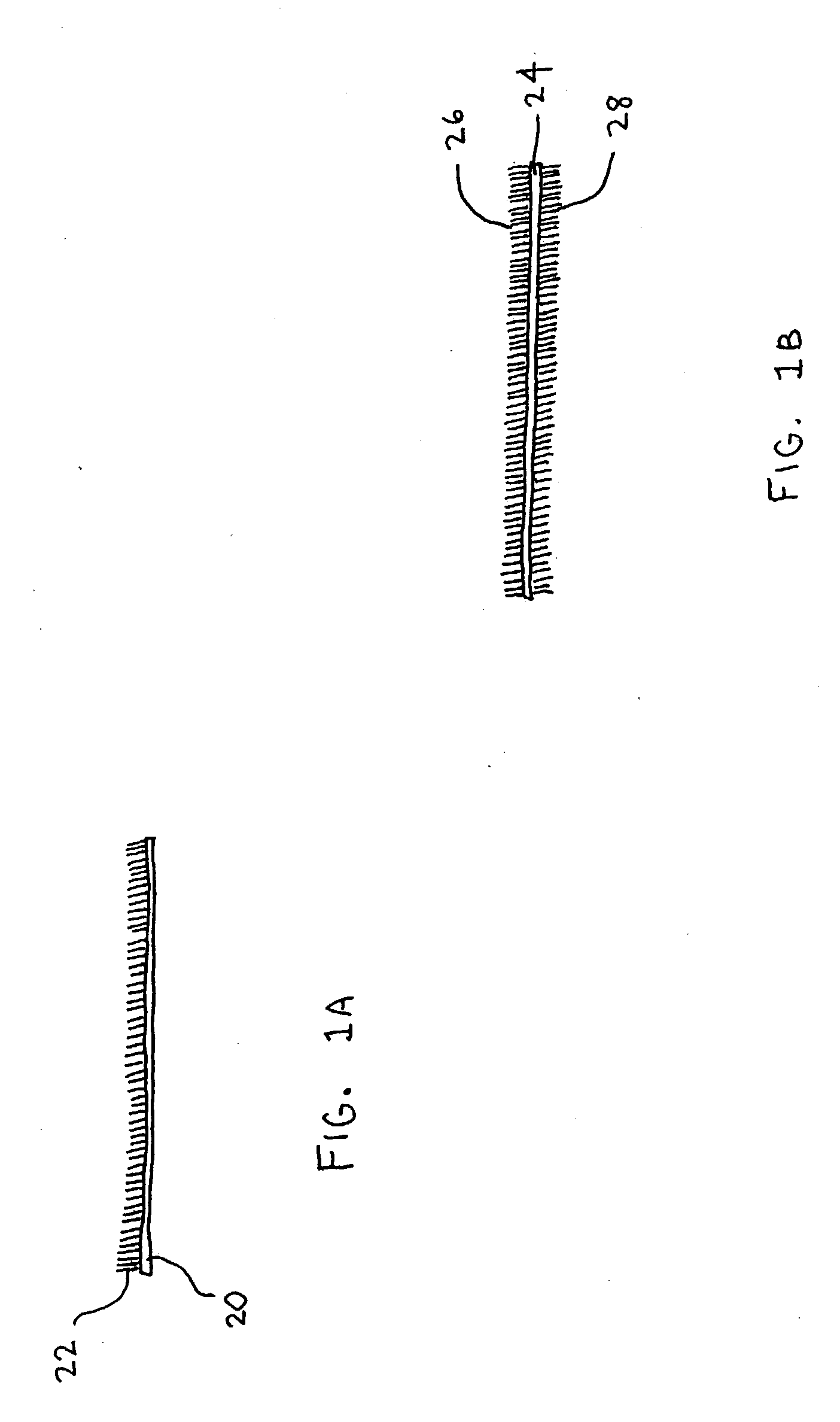

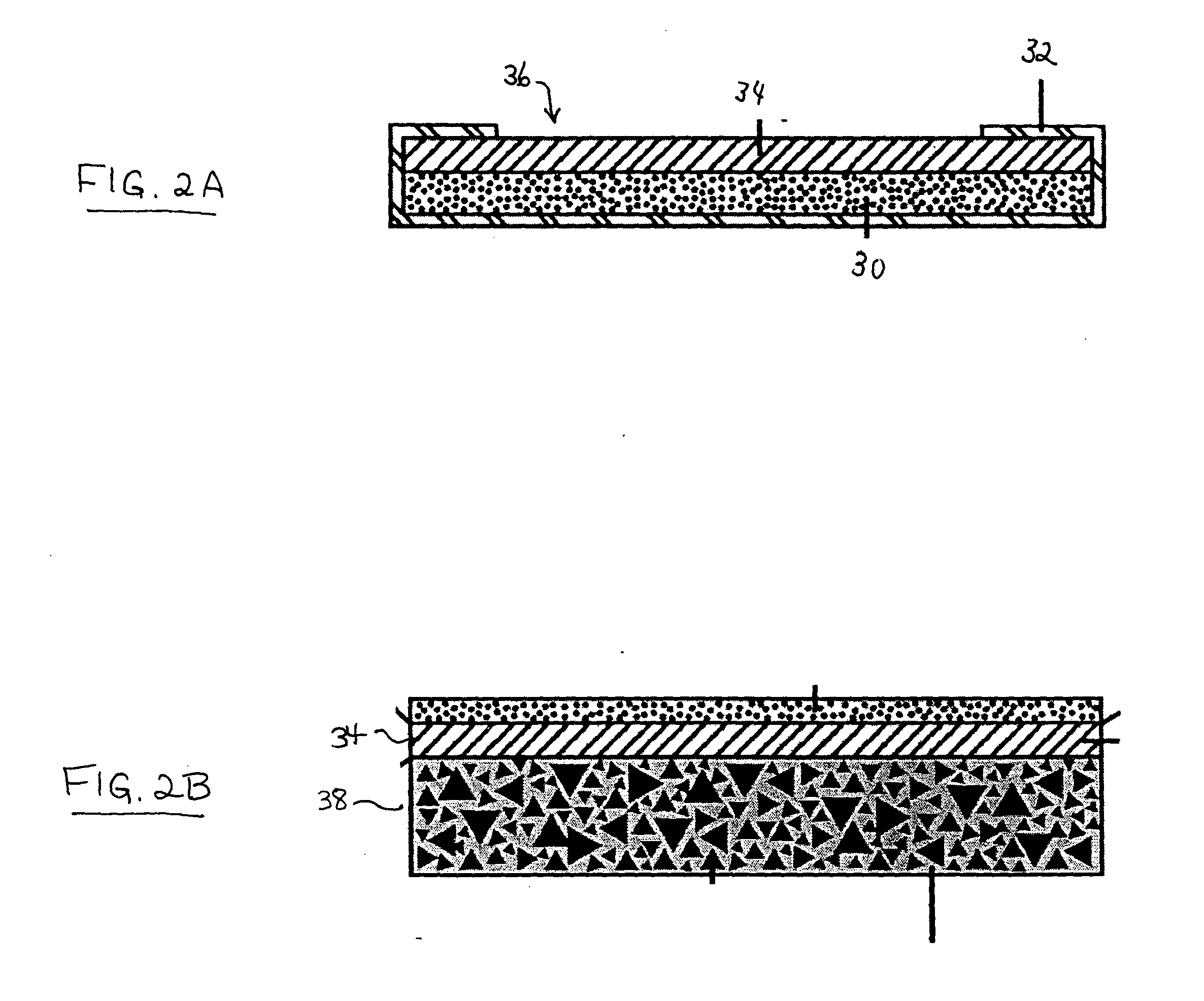

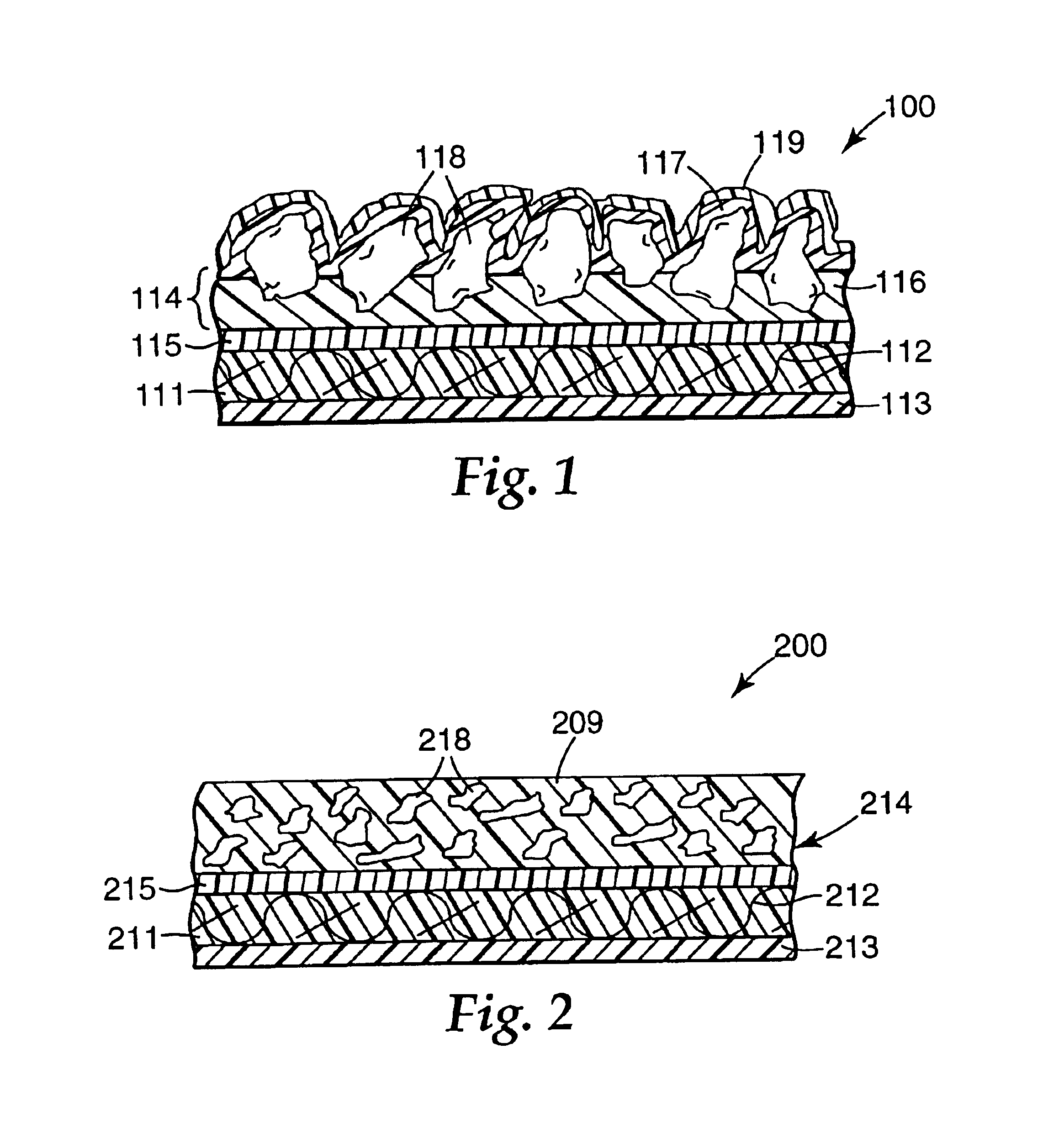

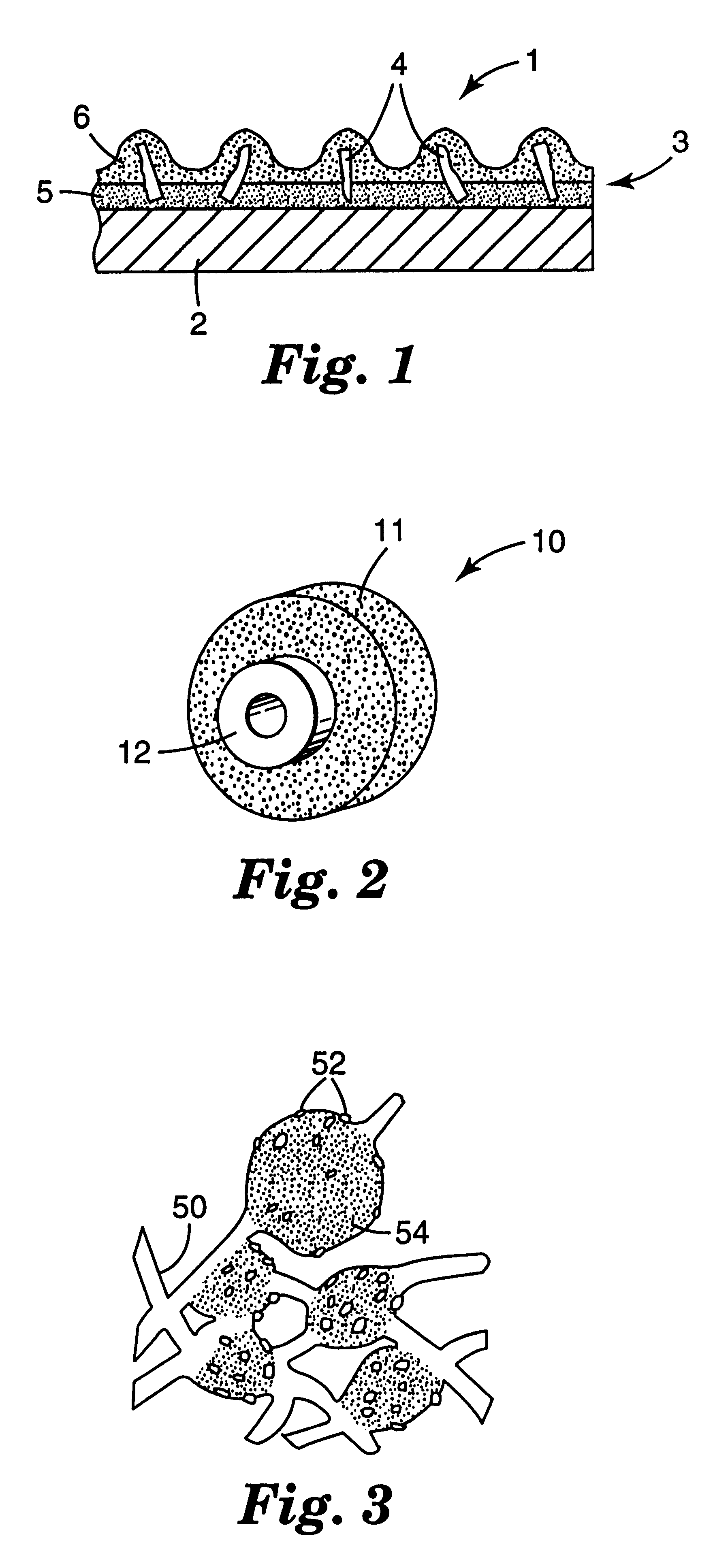

Abrasive bead coated sheet and island articles

InactiveUS20050118939A1Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedSlurry

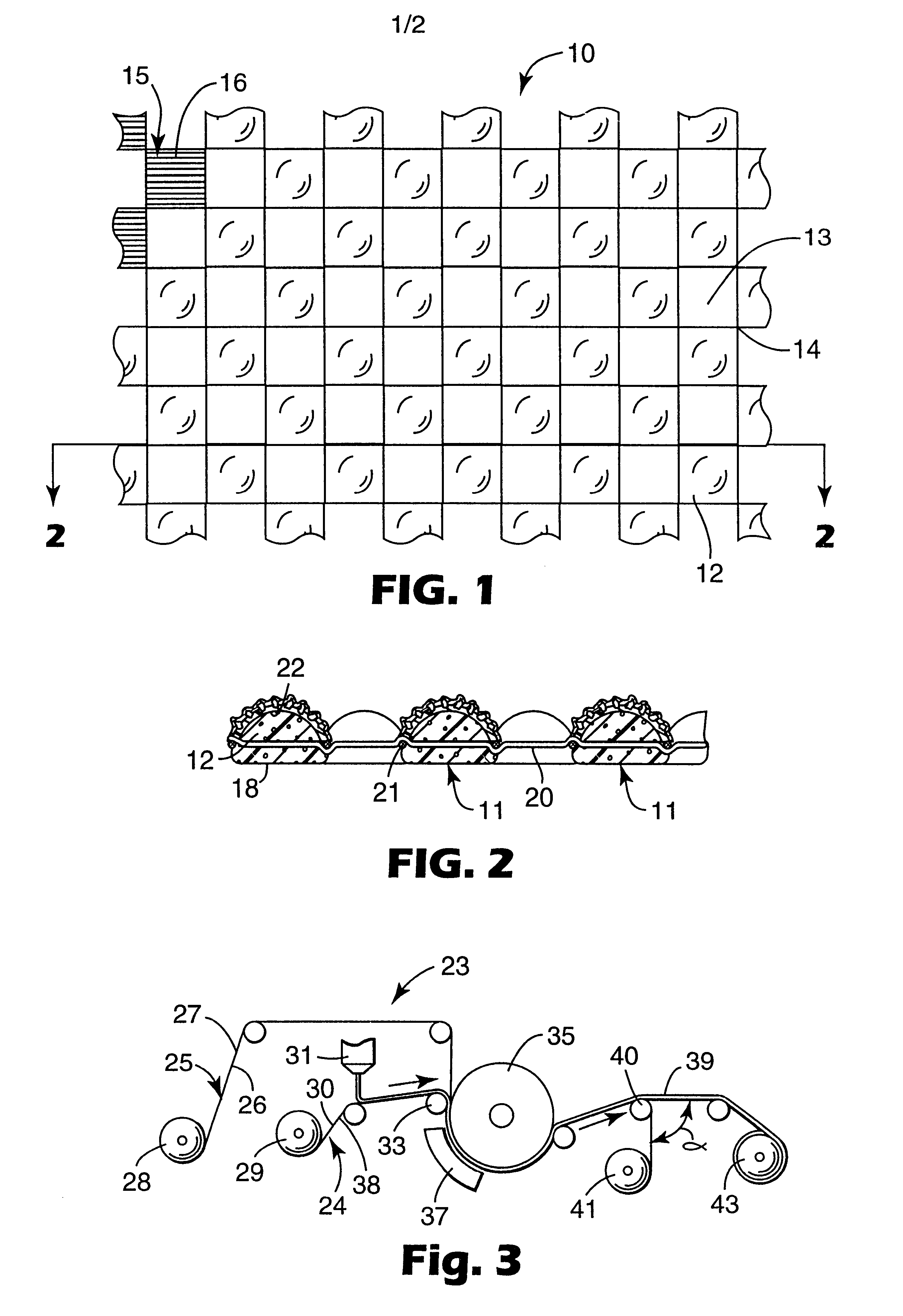

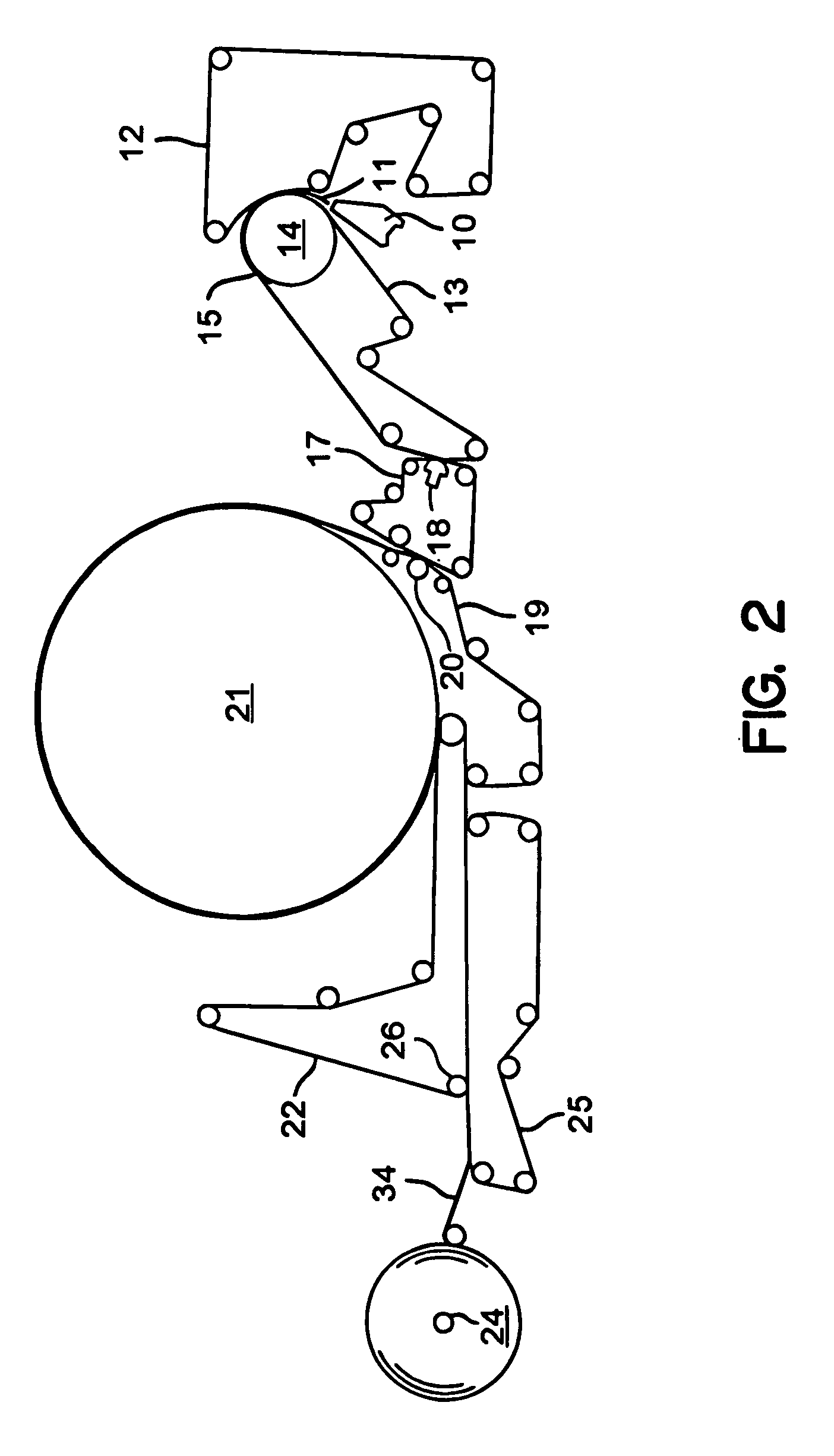

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

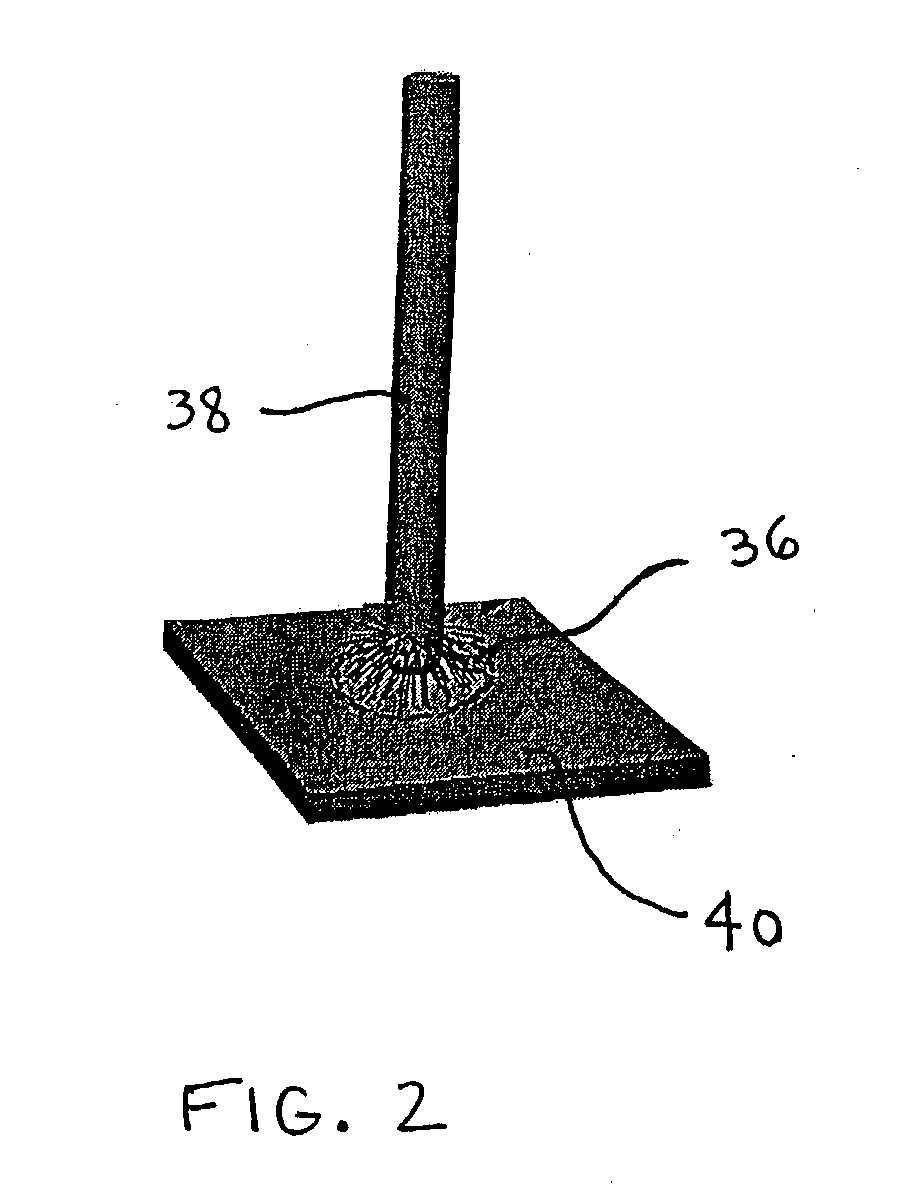

Fiber adhesive material

InactiveUS20040071870A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsDielectricFiber

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KULR TECH

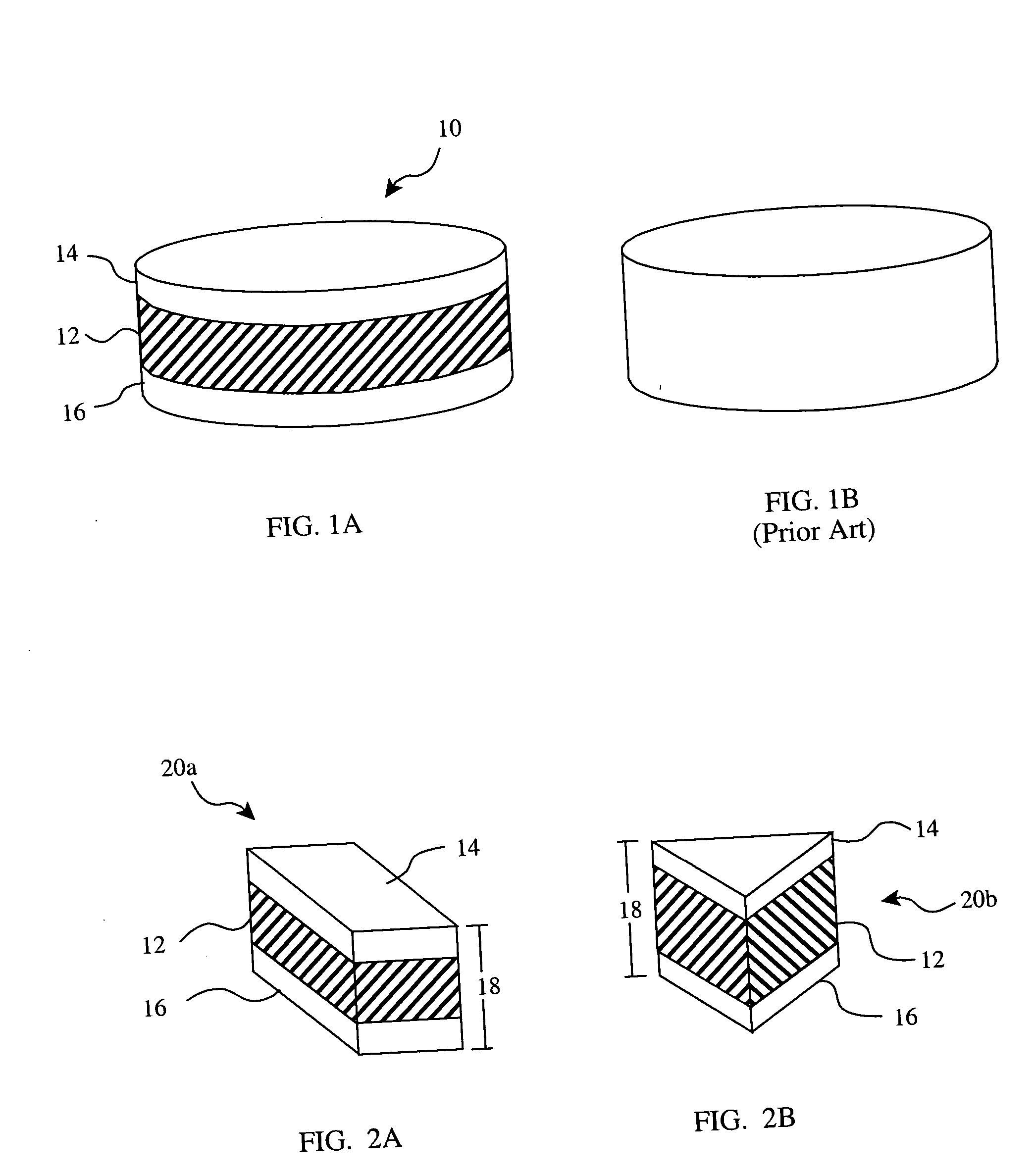

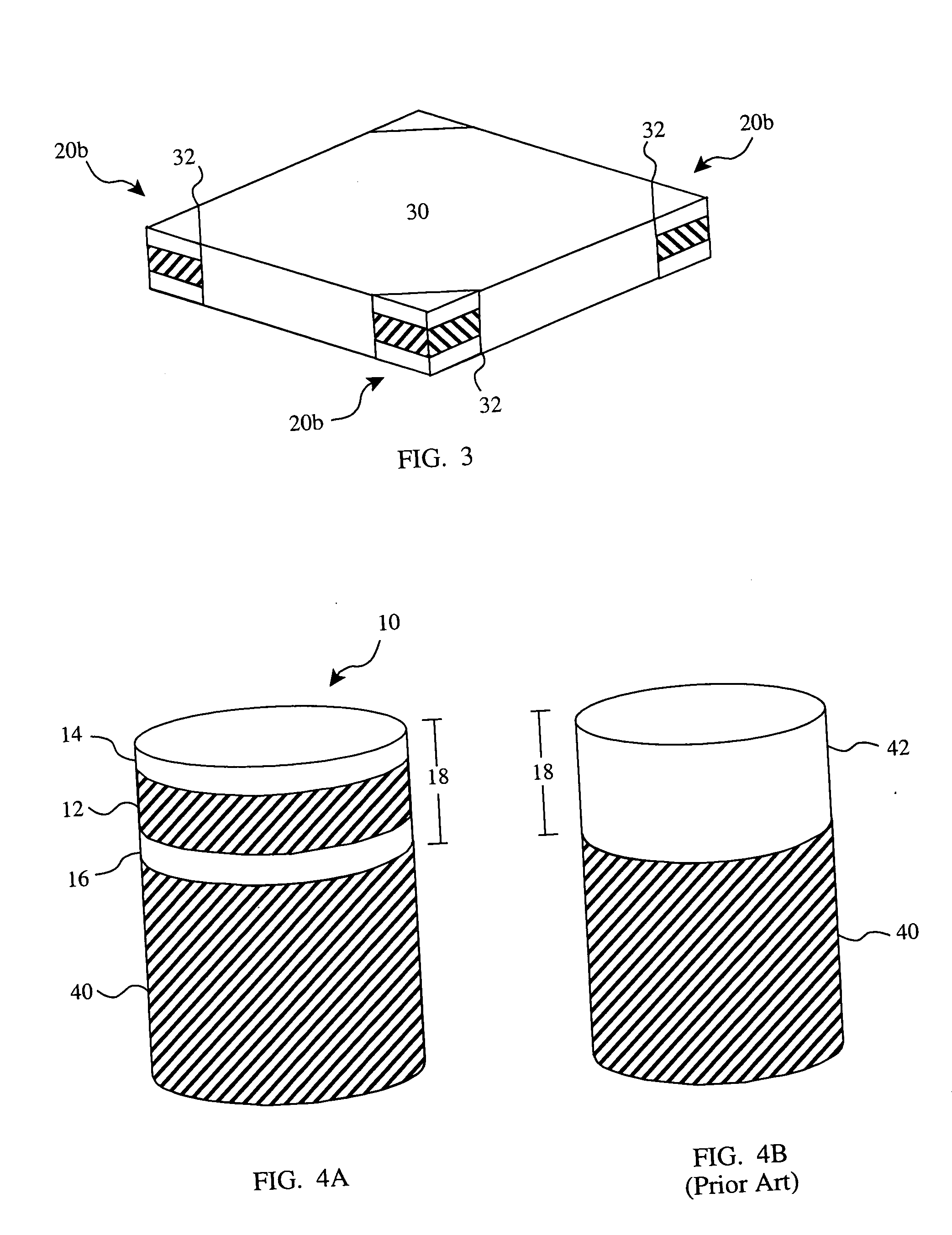

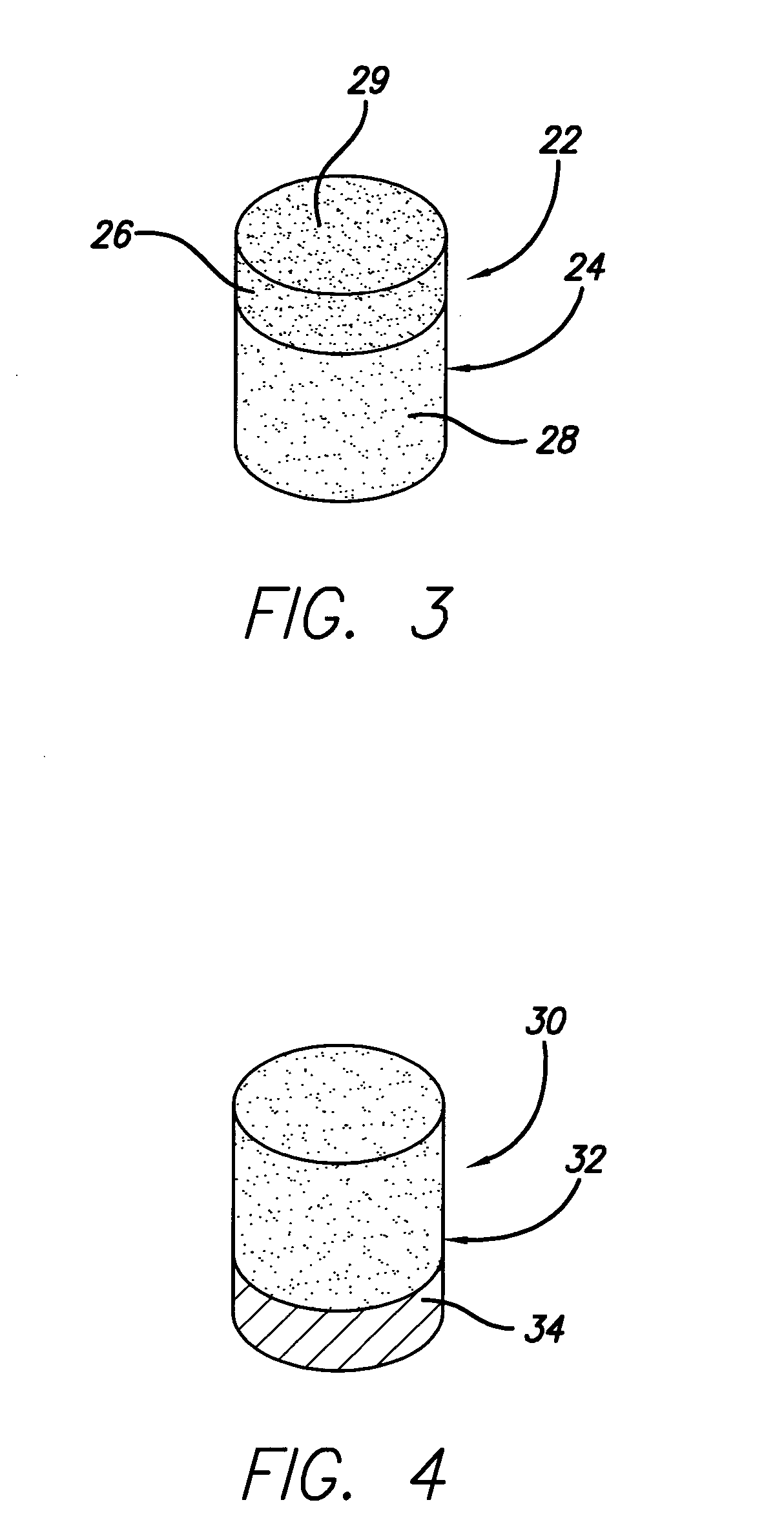

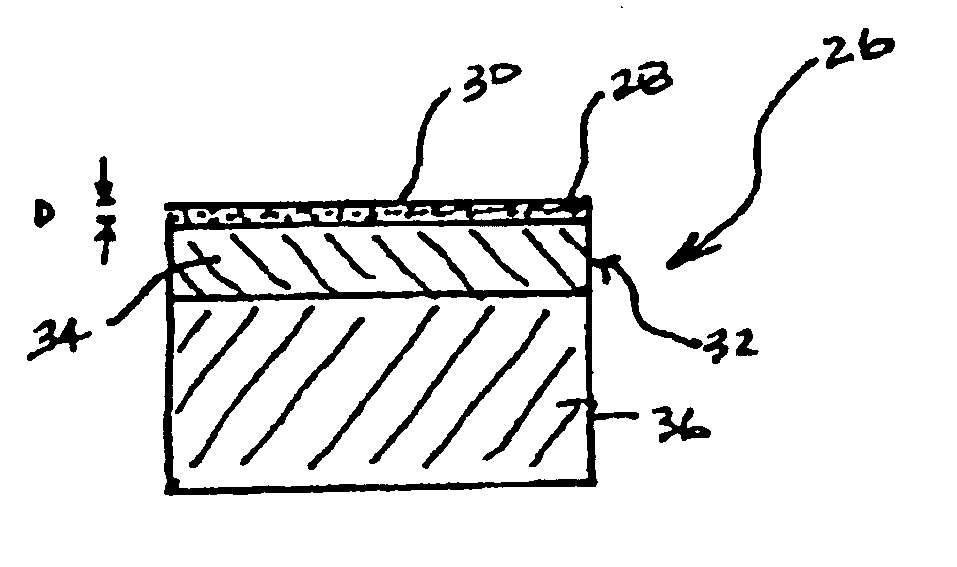

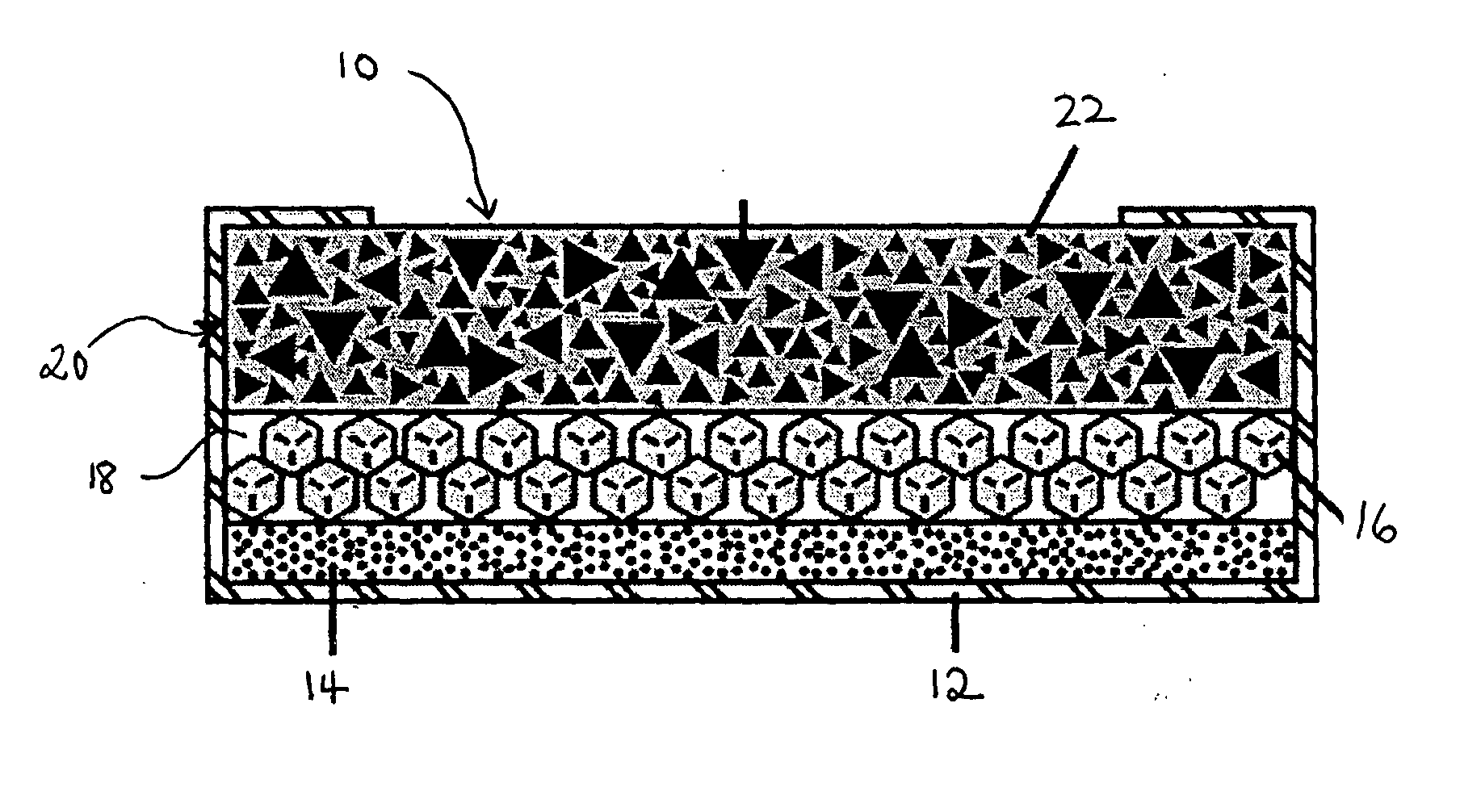

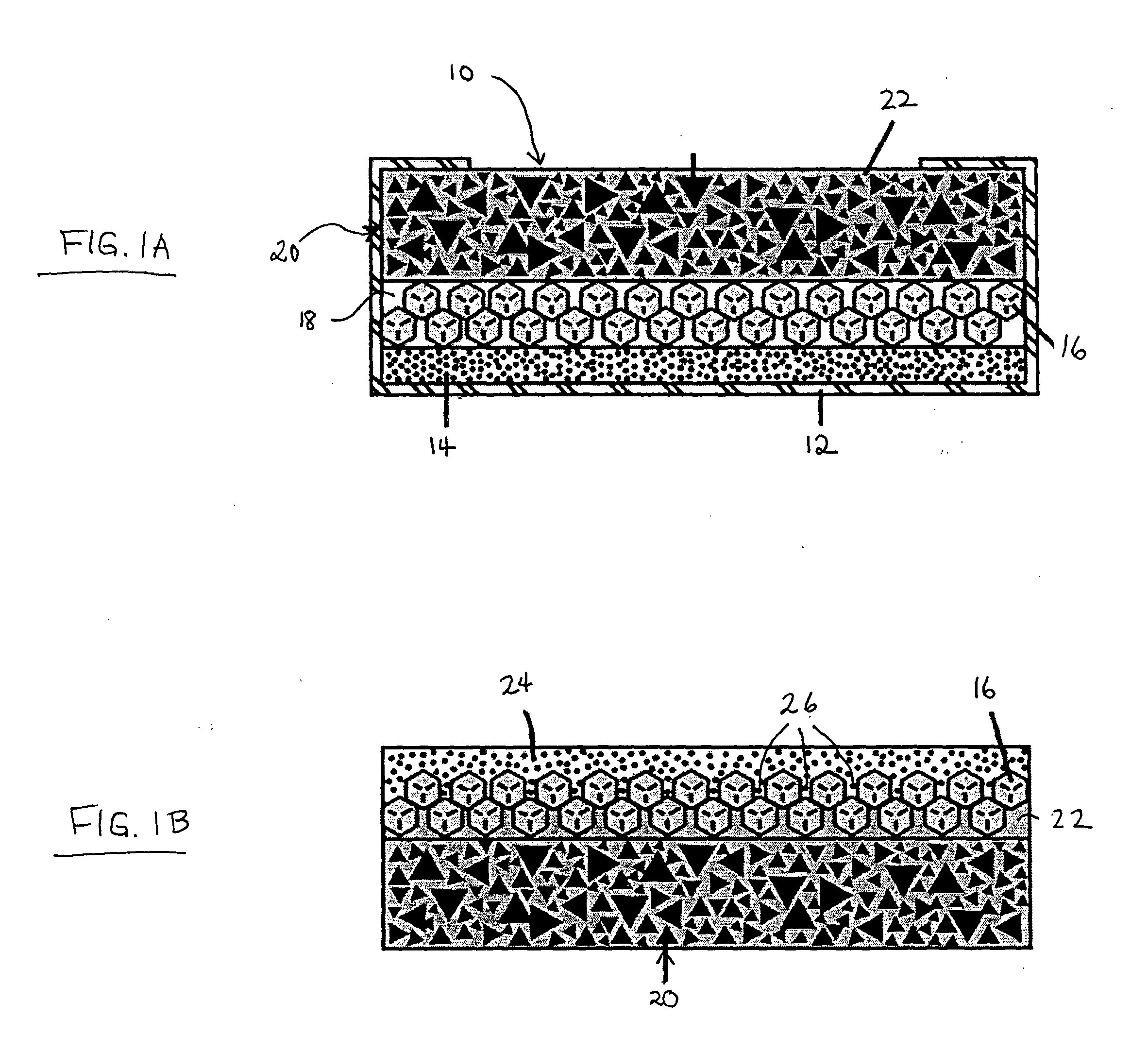

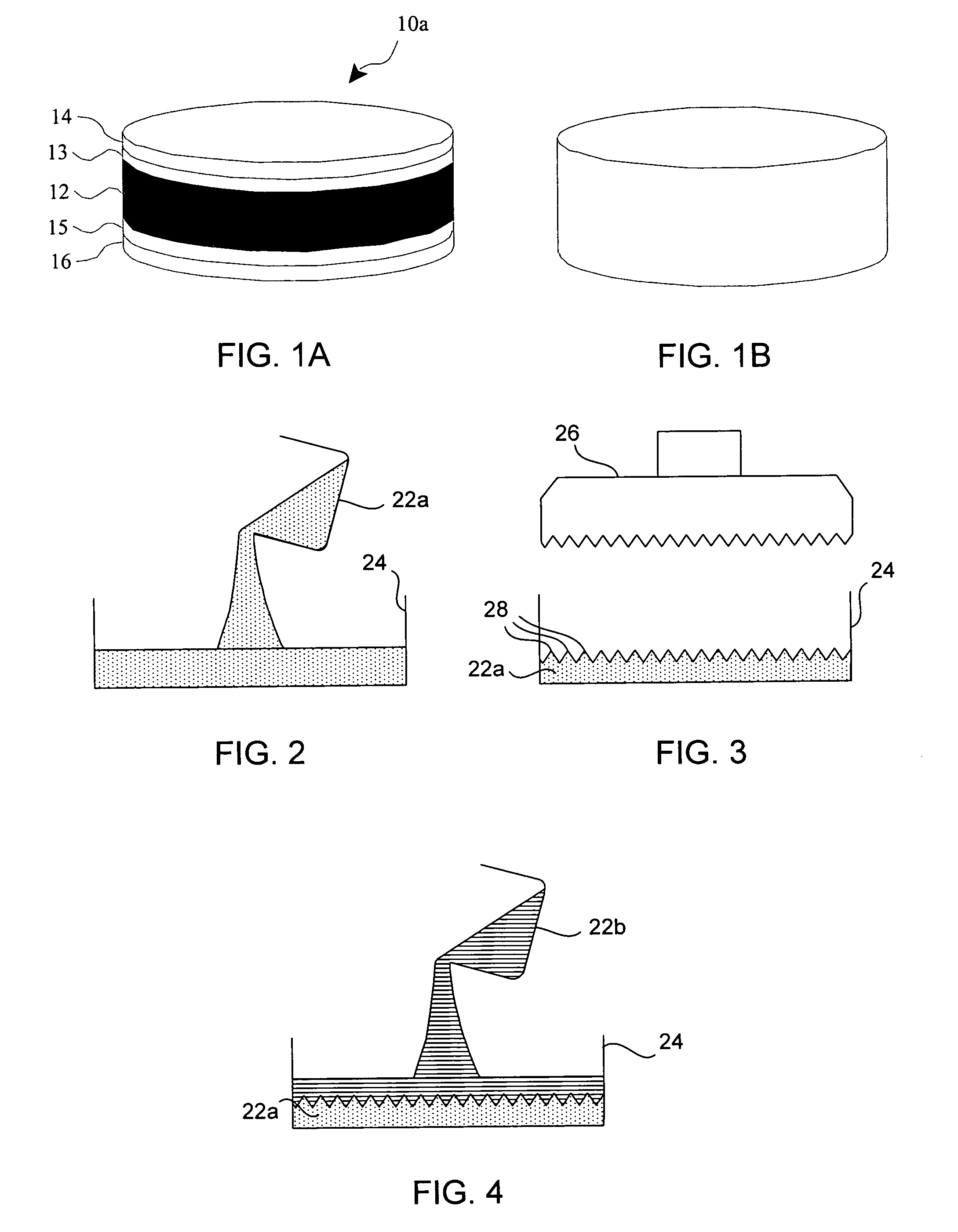

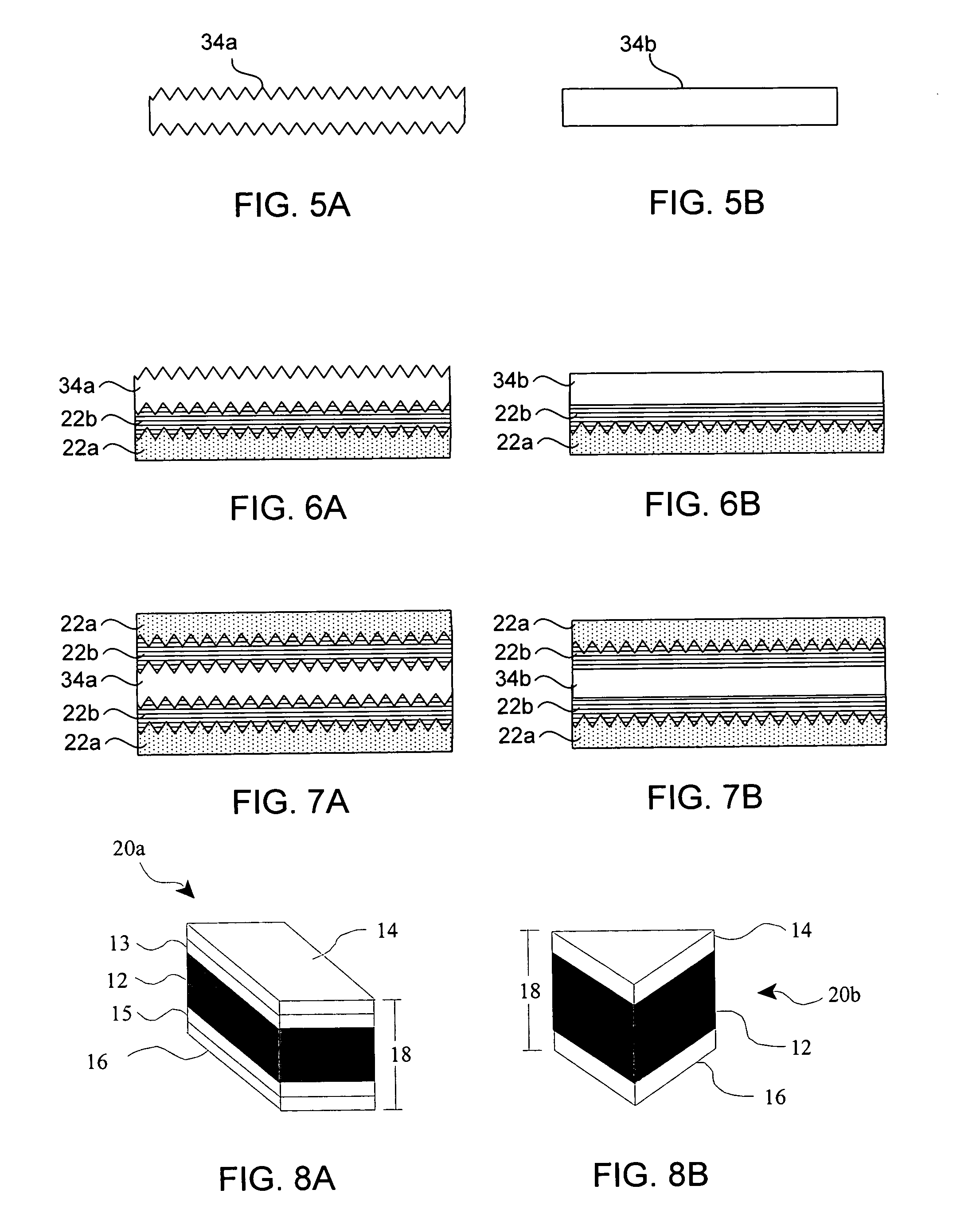

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

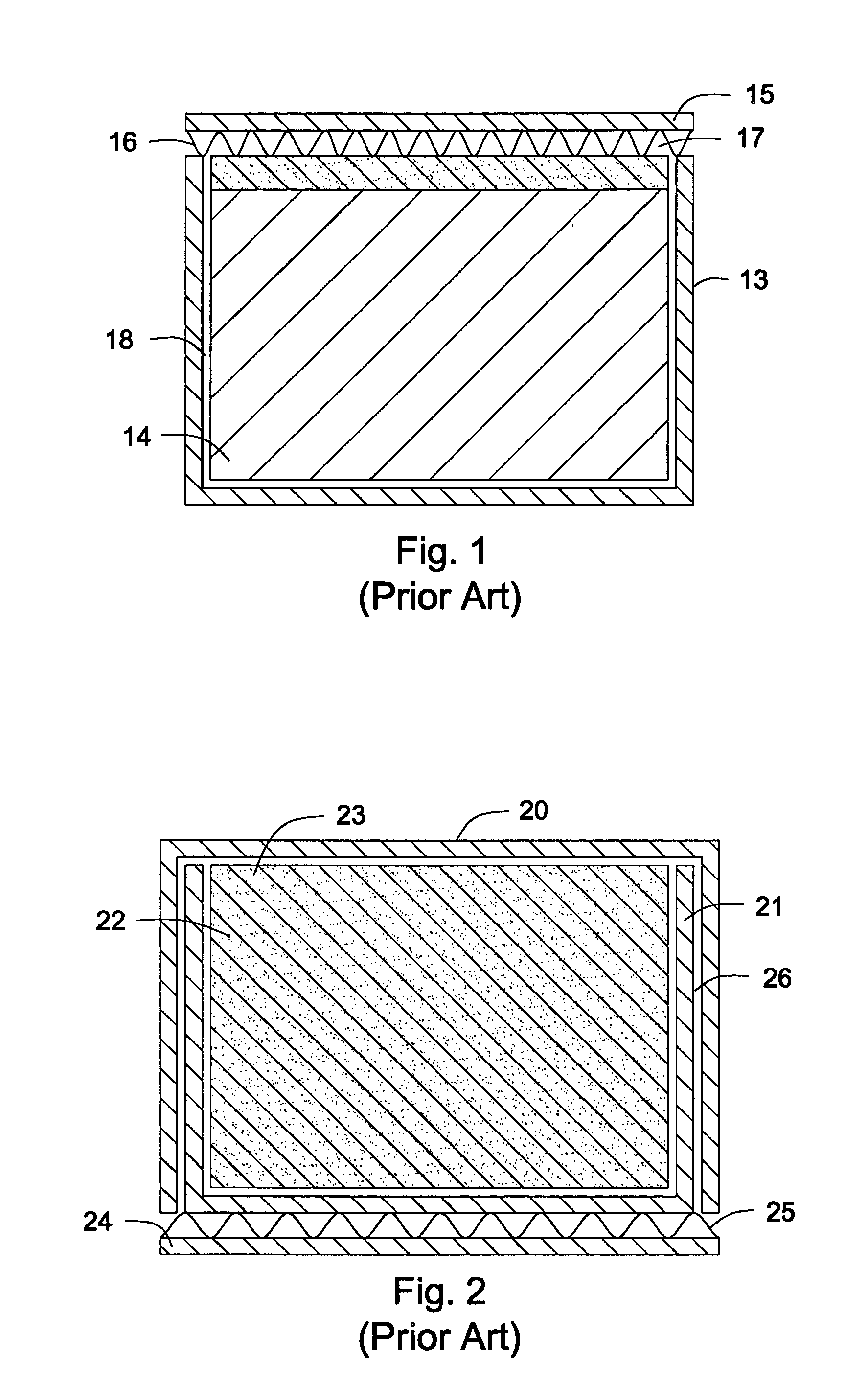

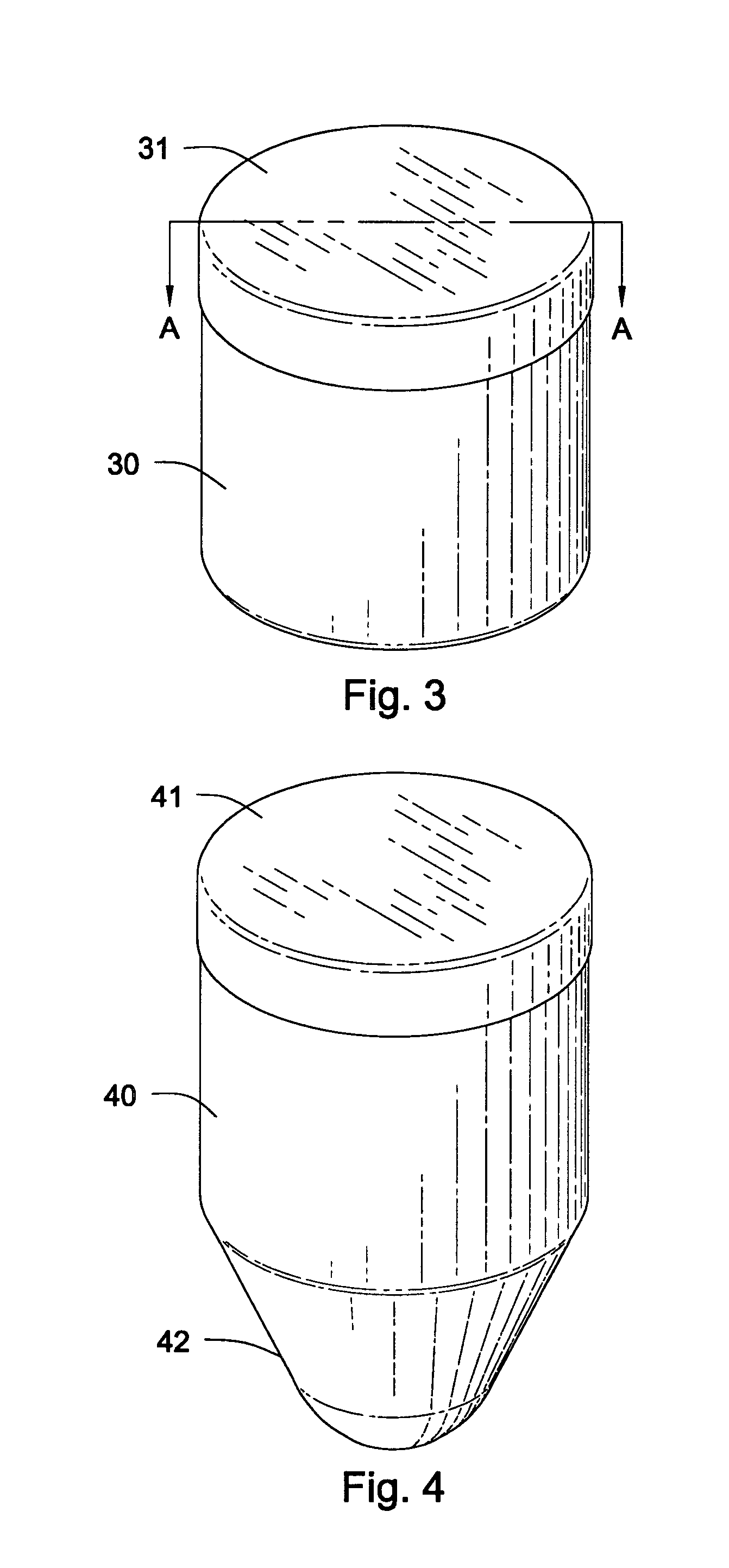

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

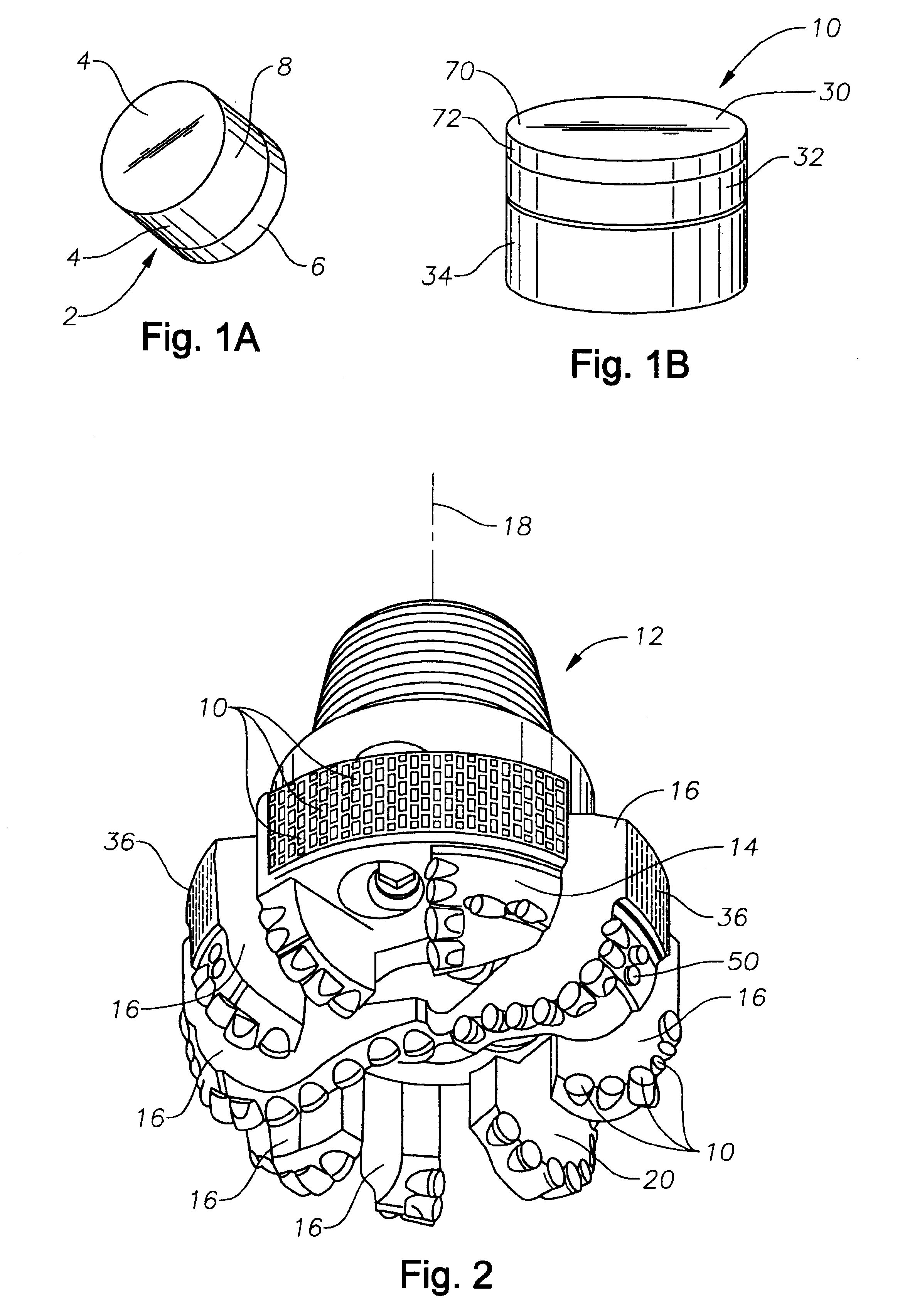

Polycrystalline diamond compact (PDC) cutting element having multiple catalytic elements

InactiveUS7635035B1Improve thermal stabilityPigmenting treatmentDrill bitsPolycrystalline diamondThermal stability

A polycrystalline diamond compact useful for wear, cutting, drilling, drawing and like applications is provided with a first diamond region remote from the working surface which has a metallic catalyzing material and a second diamond region adjacent to or including the working surface containing a non-metallic catalyst and the method of making such a compact is provided. This compact is particularly useful in high temperature operations, such as hard rock drilling because of the improved thermal stability at the working surface.

Owner:US SYNTHETIC CORP

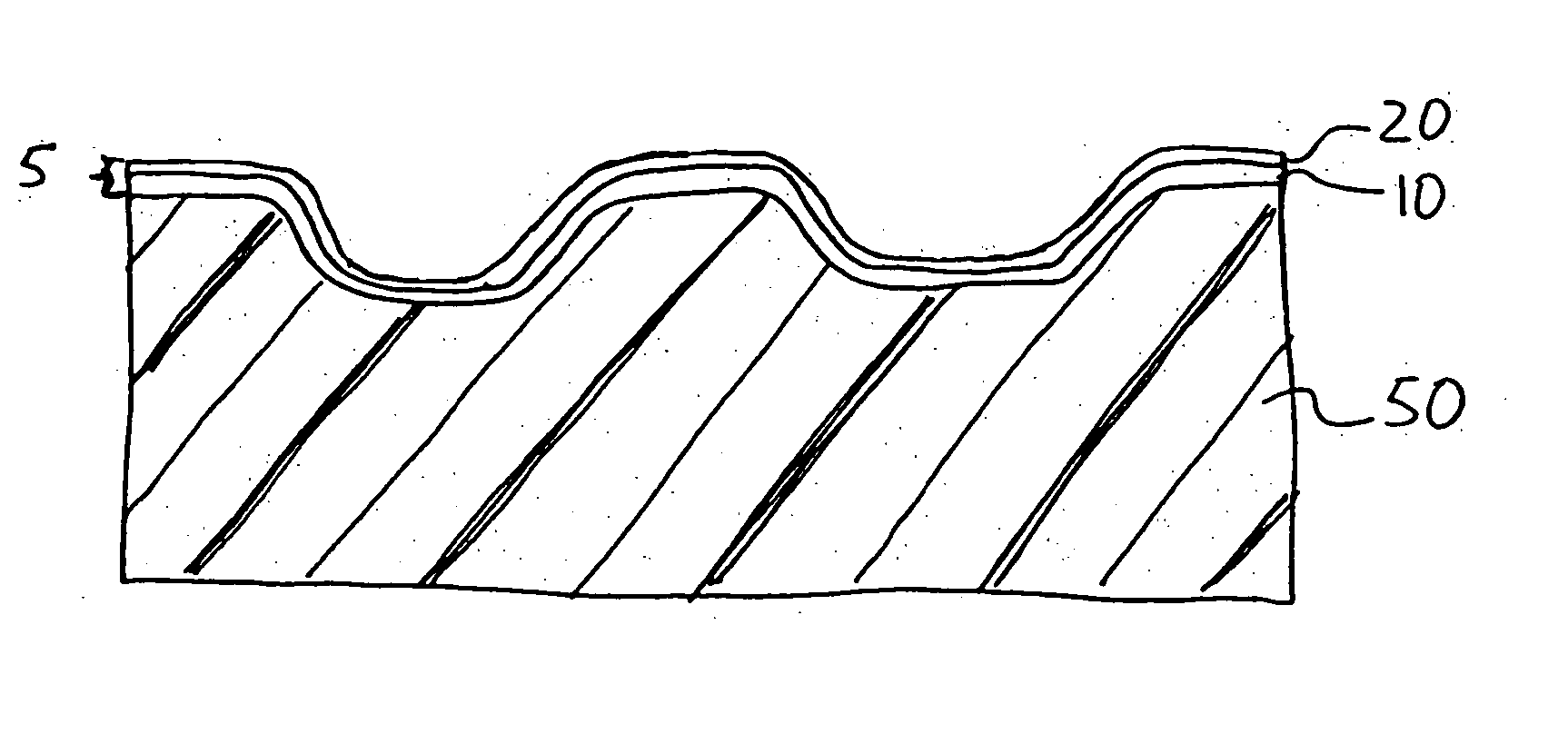

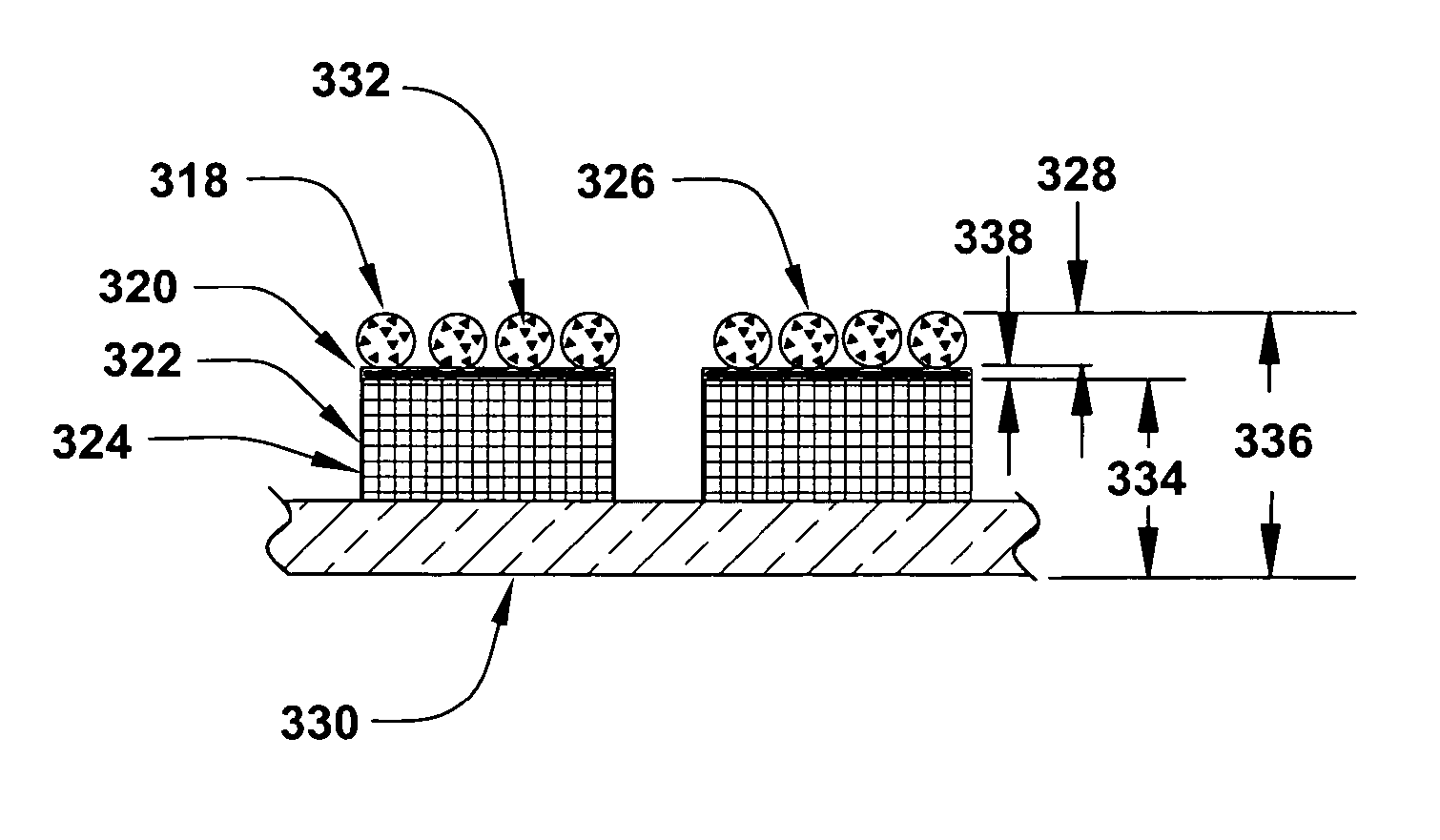

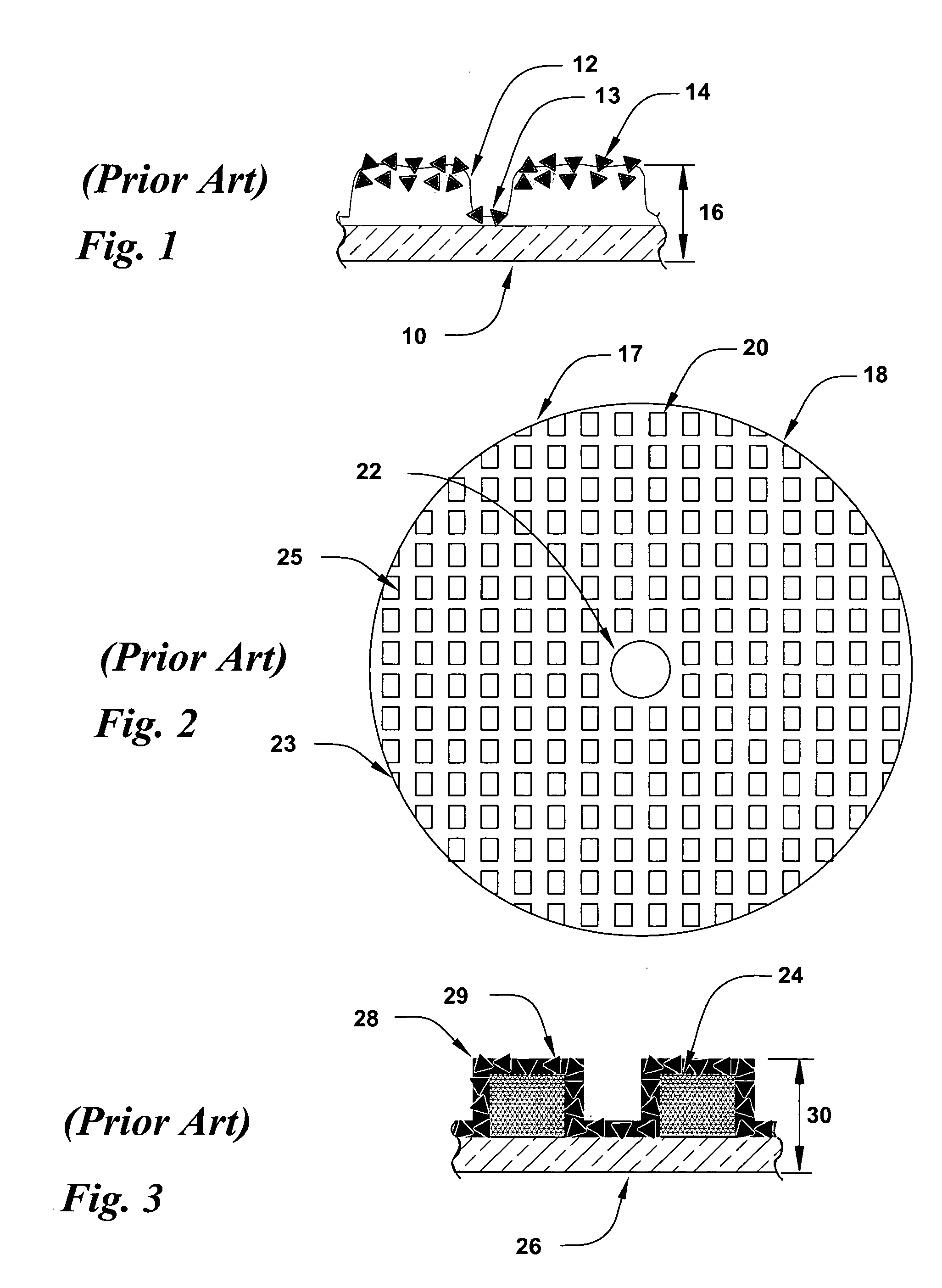

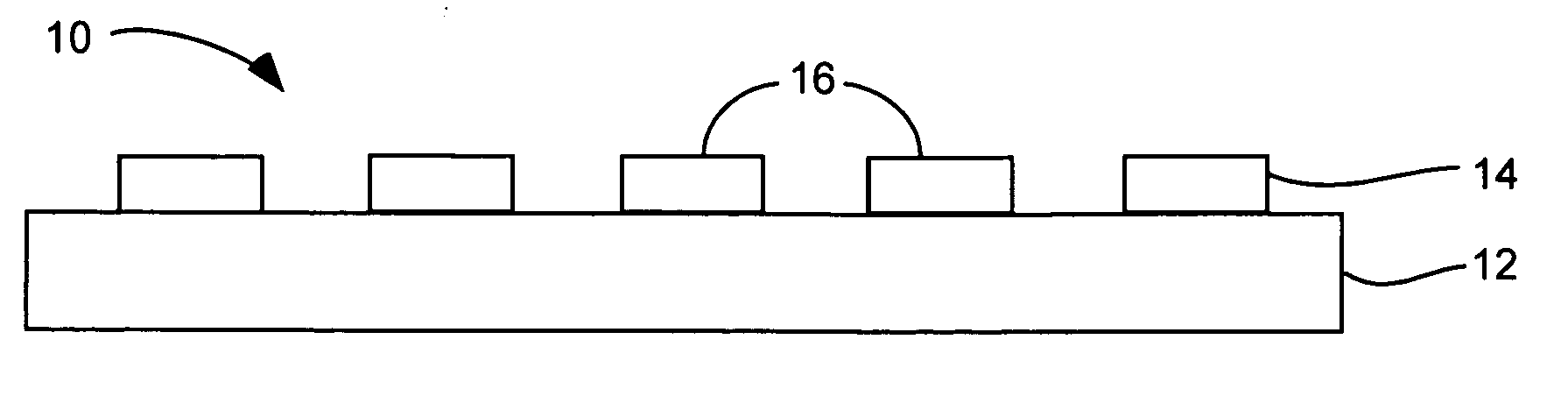

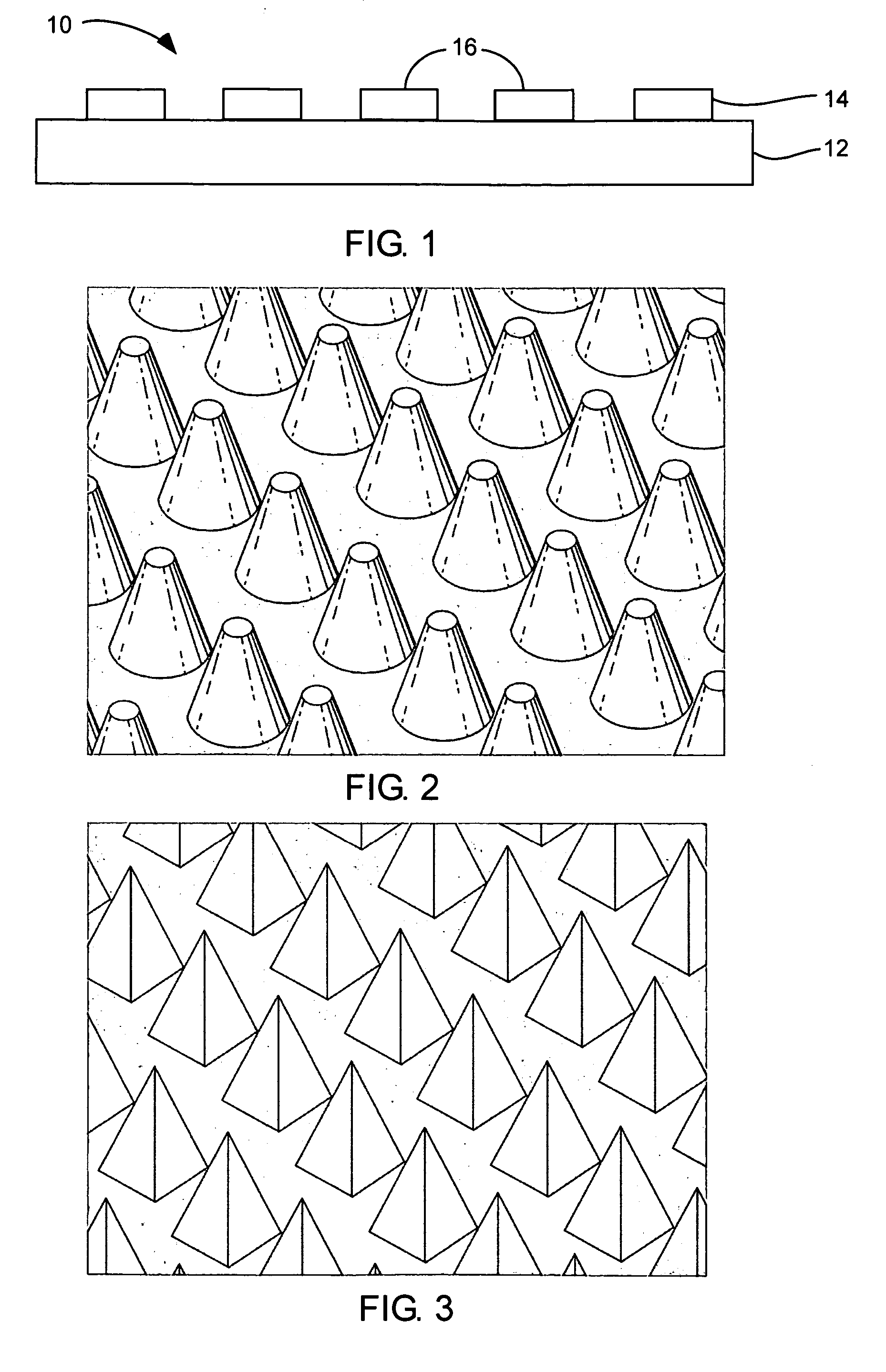

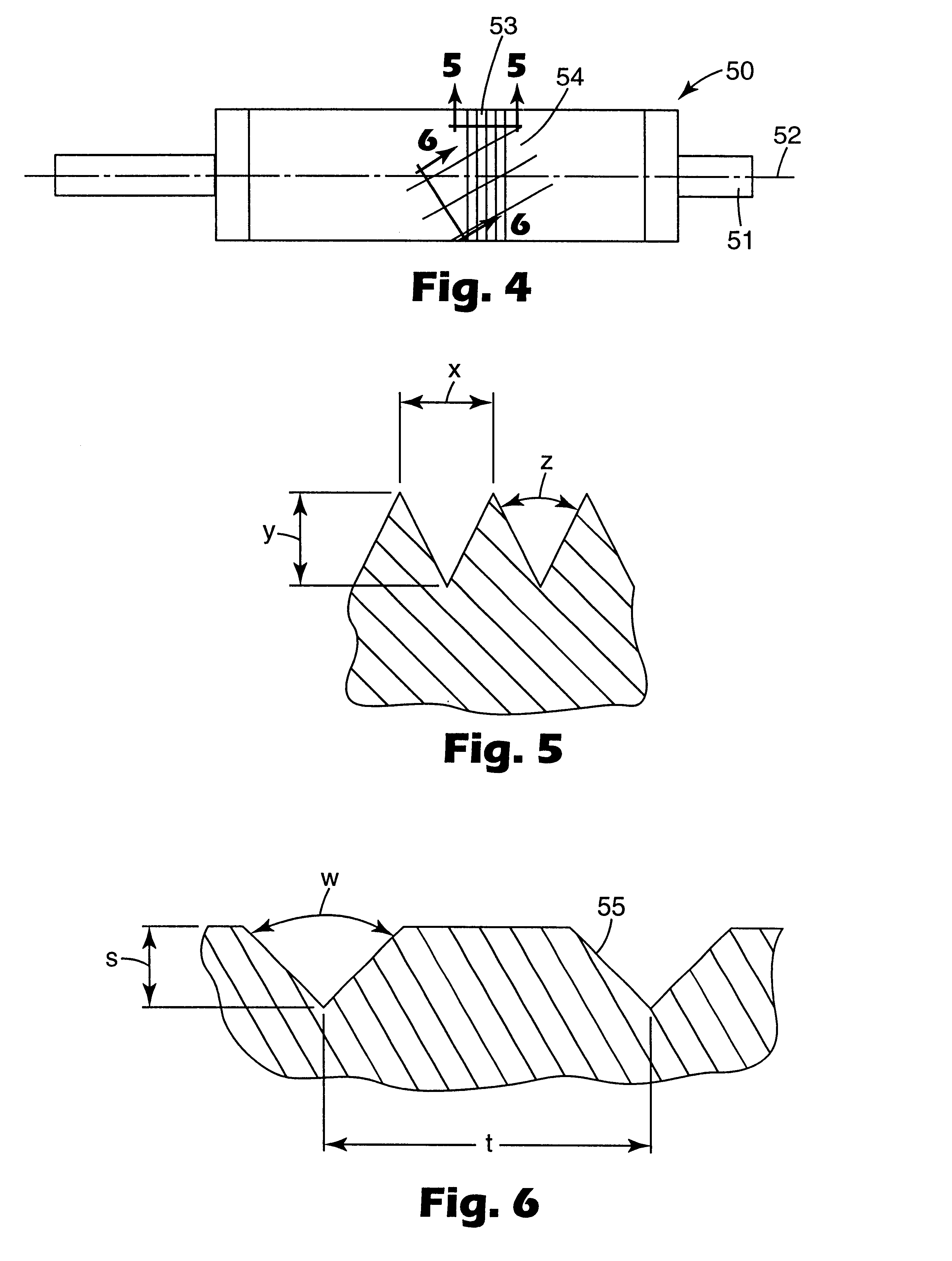

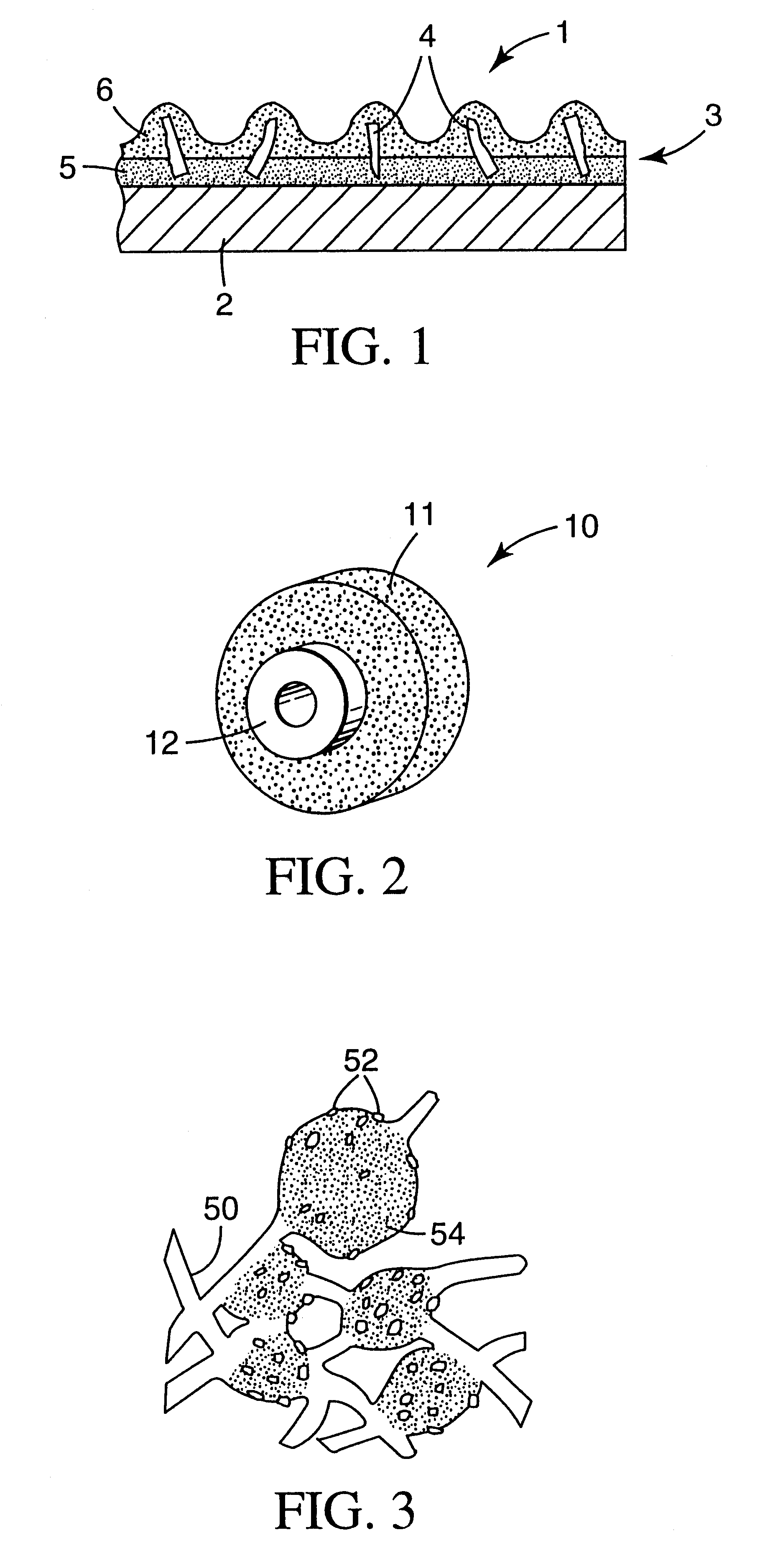

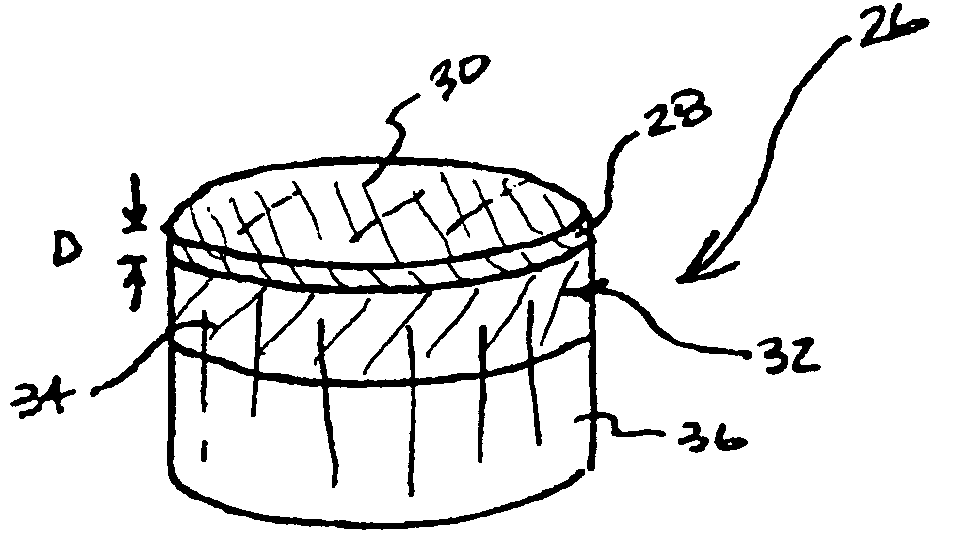

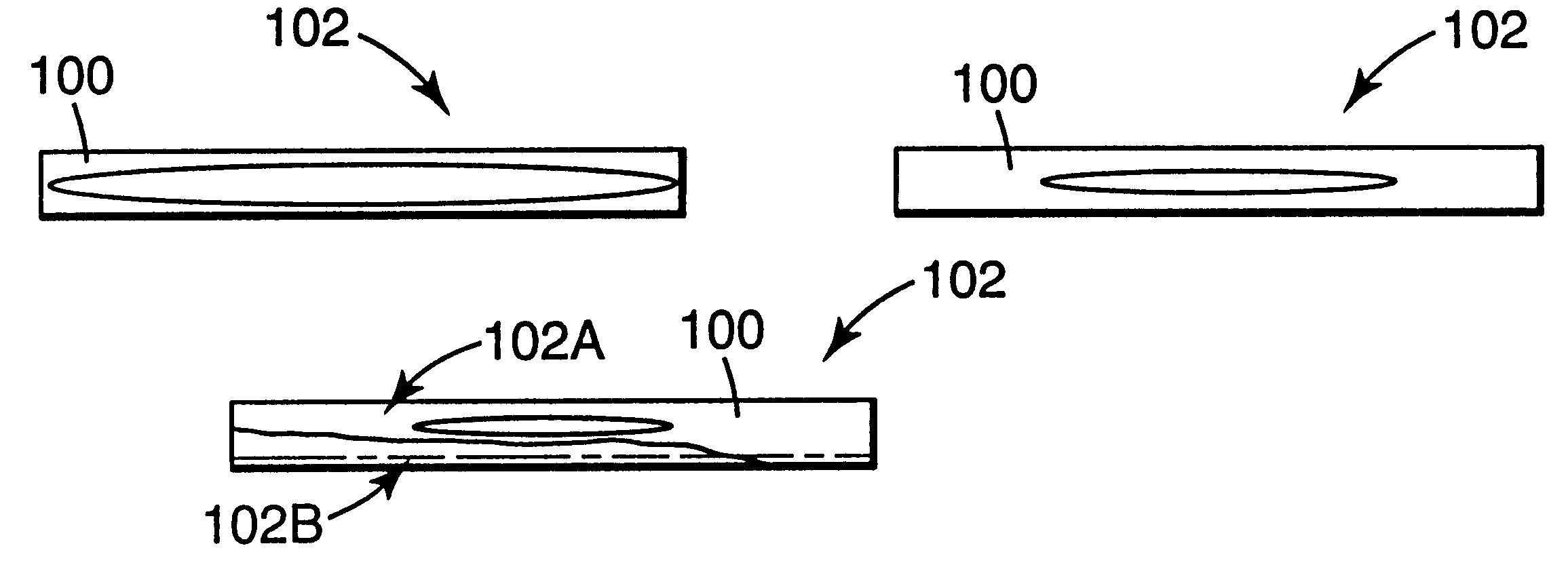

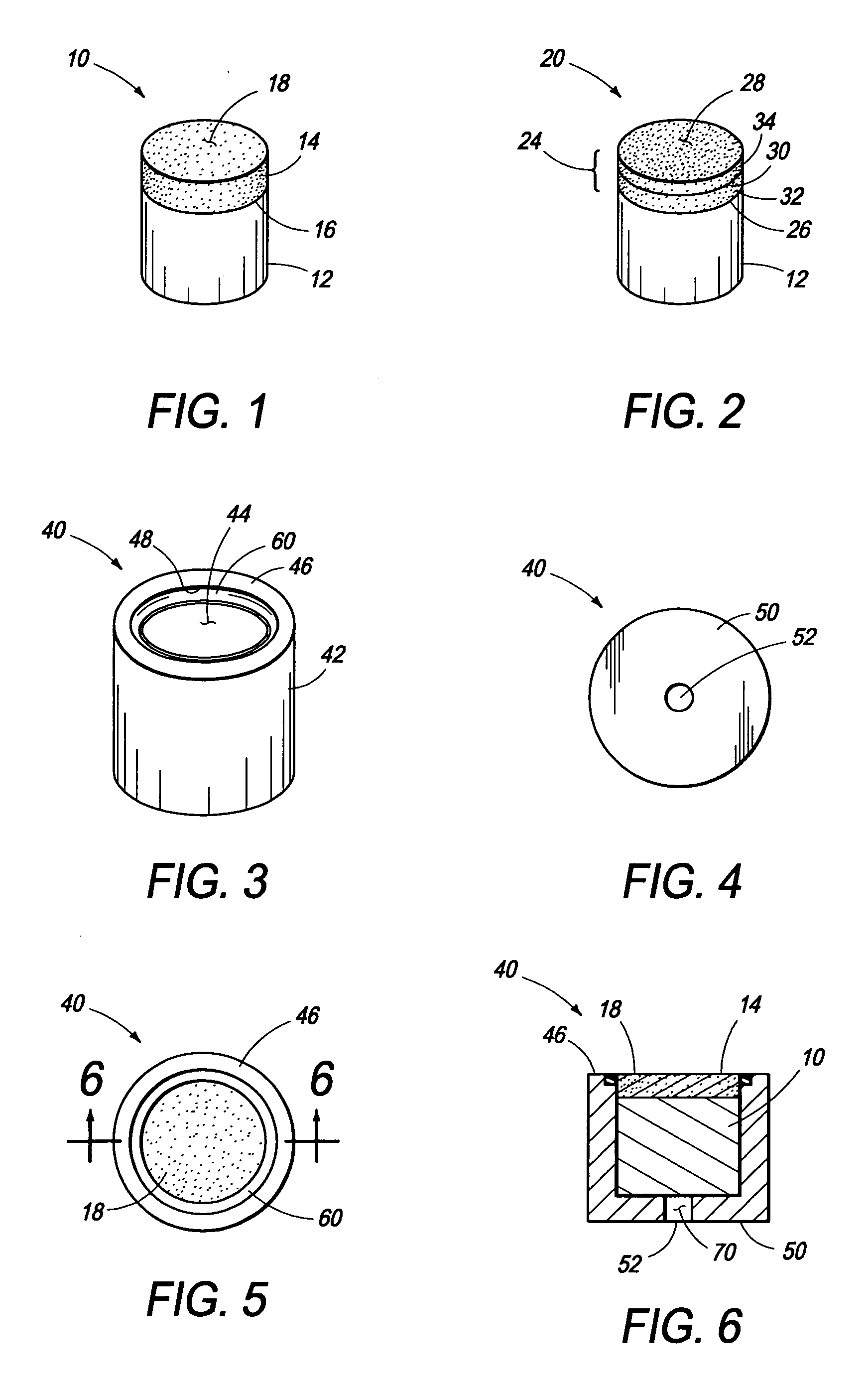

Fixed abrasive tools and associated methods

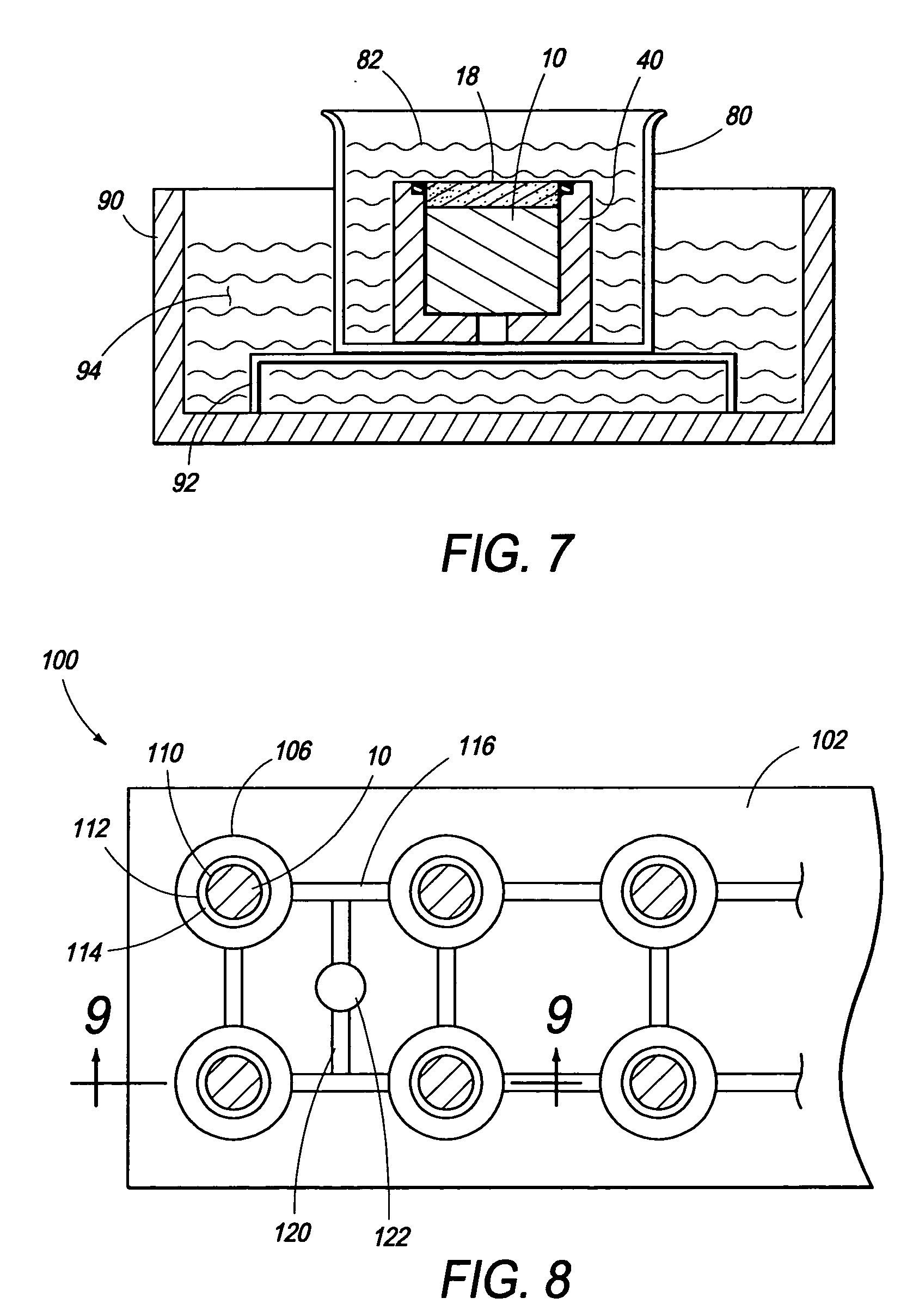

InactiveUS20050227590A1Easy to remove debrisAdequate material removal rateAbrasion apparatusPlane surface grinding machinesScreen printingMostly True

A fixed abrasive tool incorporating nanodiamond particles is described and disclosed. A fixed abrasive tool can include a polishing layer on a substrate. The polishing layer can include an organic matrix with nanodiamond particles therein. The polishing layer can be formed in a wide variety of configurations, depending on the specific polishing application. Most often, the polishing layer can include a plurality of projections which can have a wide variety of configurations in order to achieve a particular polishing performance. Nanodiamond particles used in the present invention can have a particle size from about 1 nm to about 50 nm, and preferably about 2 nm to about 10 nm. Optionally, the nanodiamond particles can include a carbonaceous coating. Such fixed abrasive tools can be formed by screen printing of a slurry of nanodiamond particles and an organic binder to form a predetermined three-dimensional pattern. Other methods can also be used to form the disclosed nanodiamond fixed abrasive tools. These fixed abrasive tools are particularly suitable for polishing expensive workpieces such as silicon wafers, integrated circuitry, gemstones, and hard drive platters.

Owner:SUNG CHIEN MIN

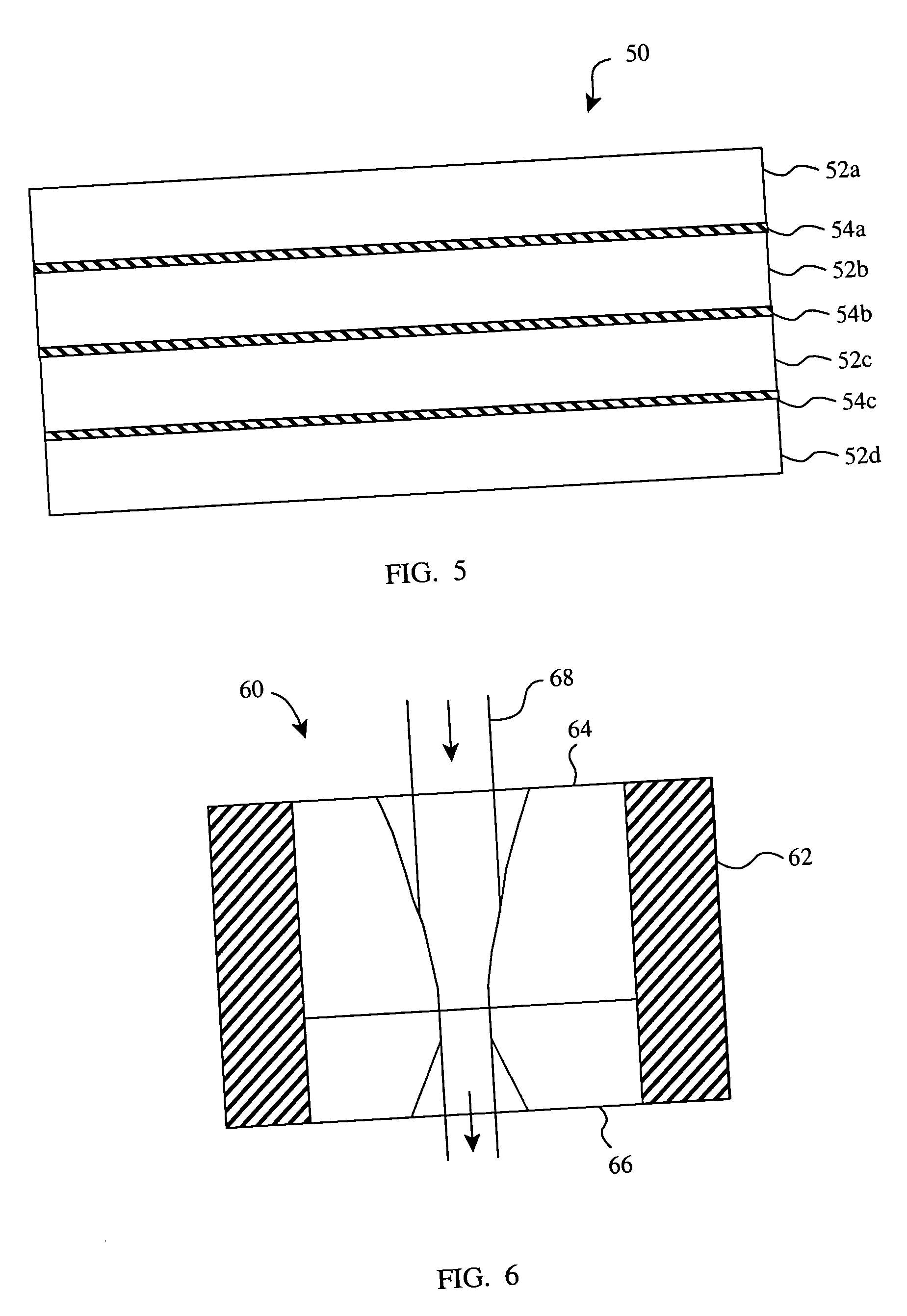

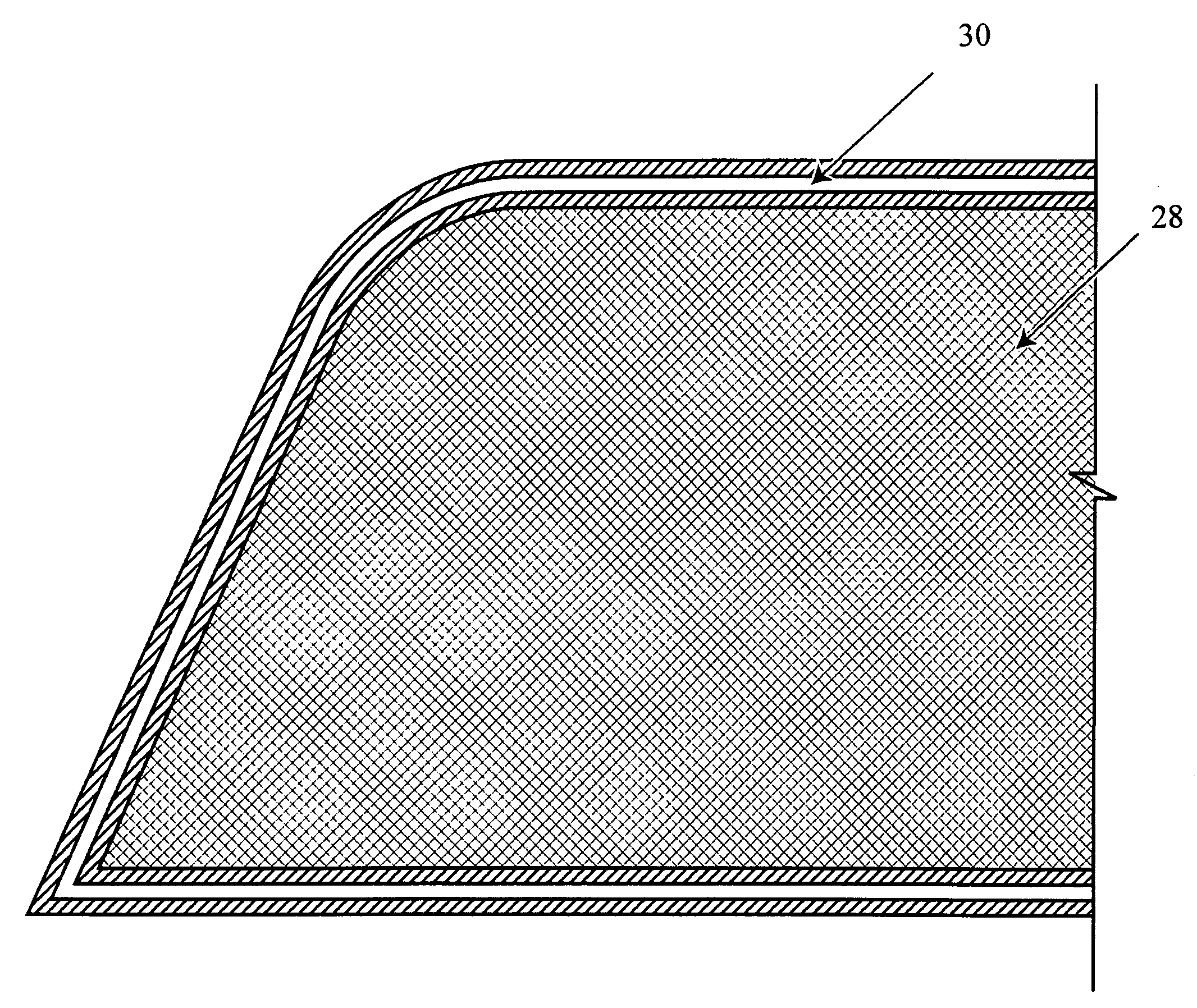

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060390A1Improve thermal stabilityGood adhesionPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

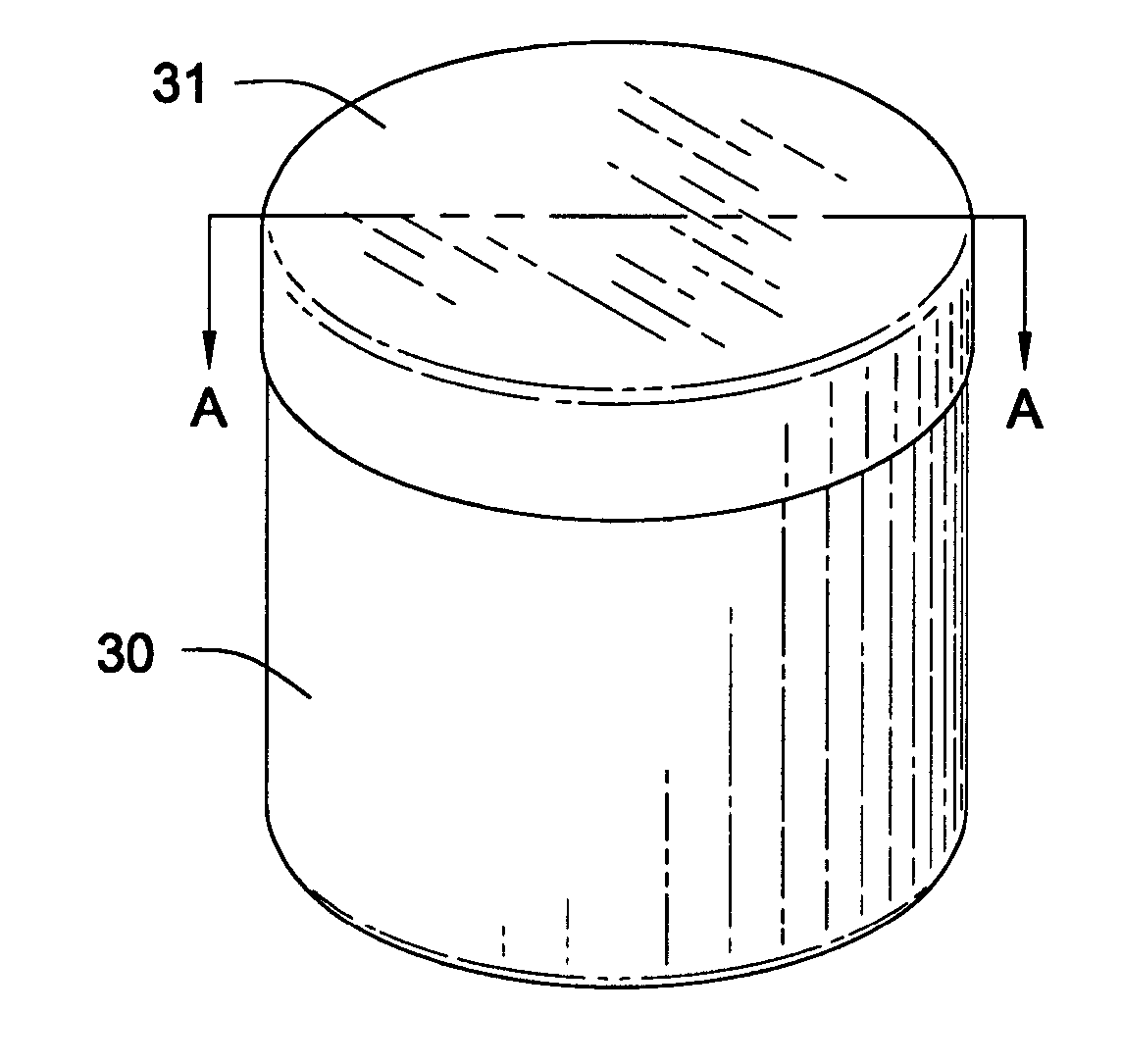

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body. The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

Abrasive product and method of making the same

InactiveUS6613113B2Effectively removing the sanding dust from the abrasive surfaceLess abrasive surfacePigmenting treatmentOther chemical processesElastomerMaterials science

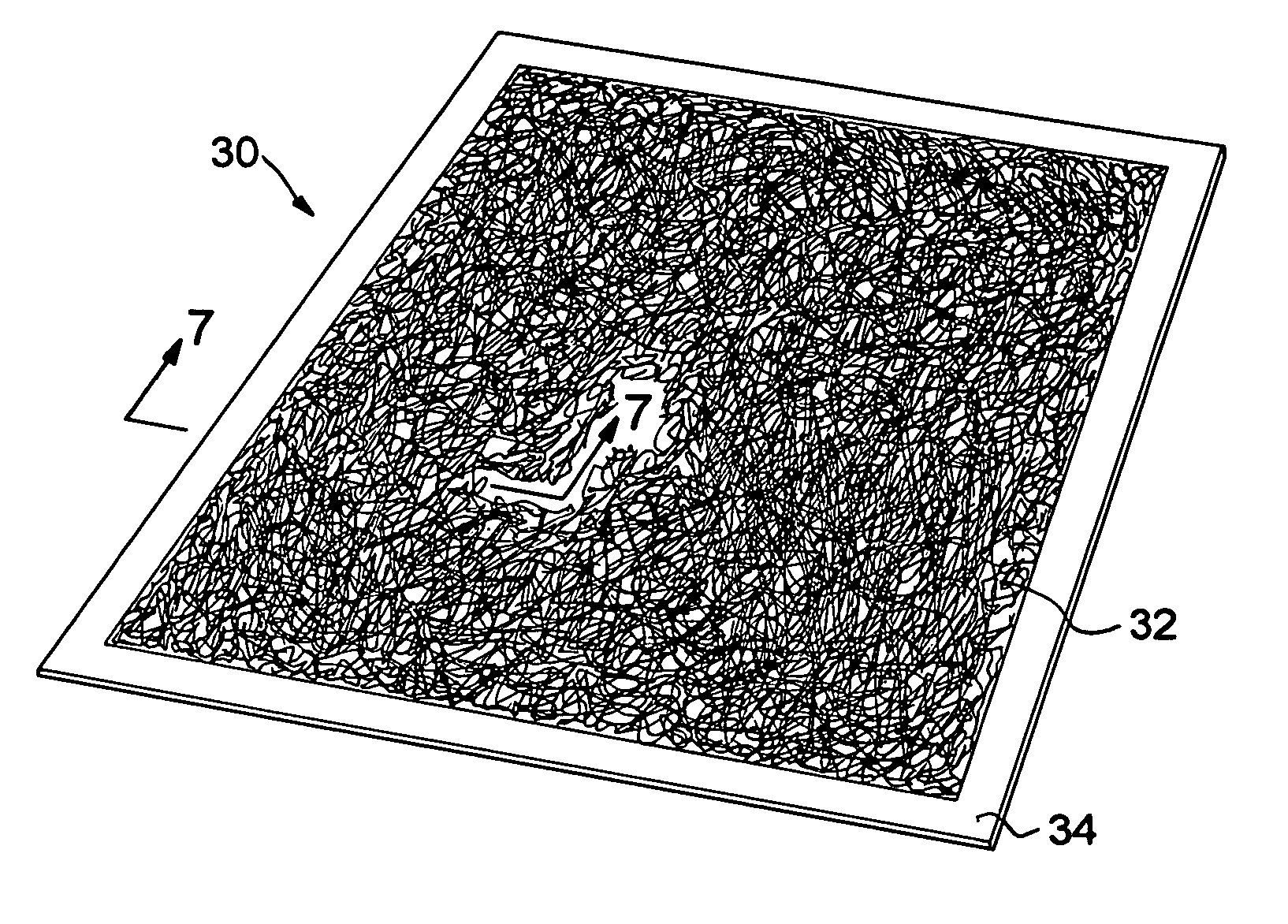

The invention provides a flexible abrasive product comprising a flexible sheet-like substrate comprising a multiplicity of separated resilient bodies connected to each other in a generally planar array in a pattern which provides open spaces between adjacent connected bodies, each body having a first surface and an opposite second surface; and abrasive particles to cause at least the first surface to be an abrasive surface. A method of making the abrasive is provided by providing the substrate and providing abrasive particles to at least the first surface to provide an abrasive surface.

Owner:3M INNOVATIVE PROPERTIES CO

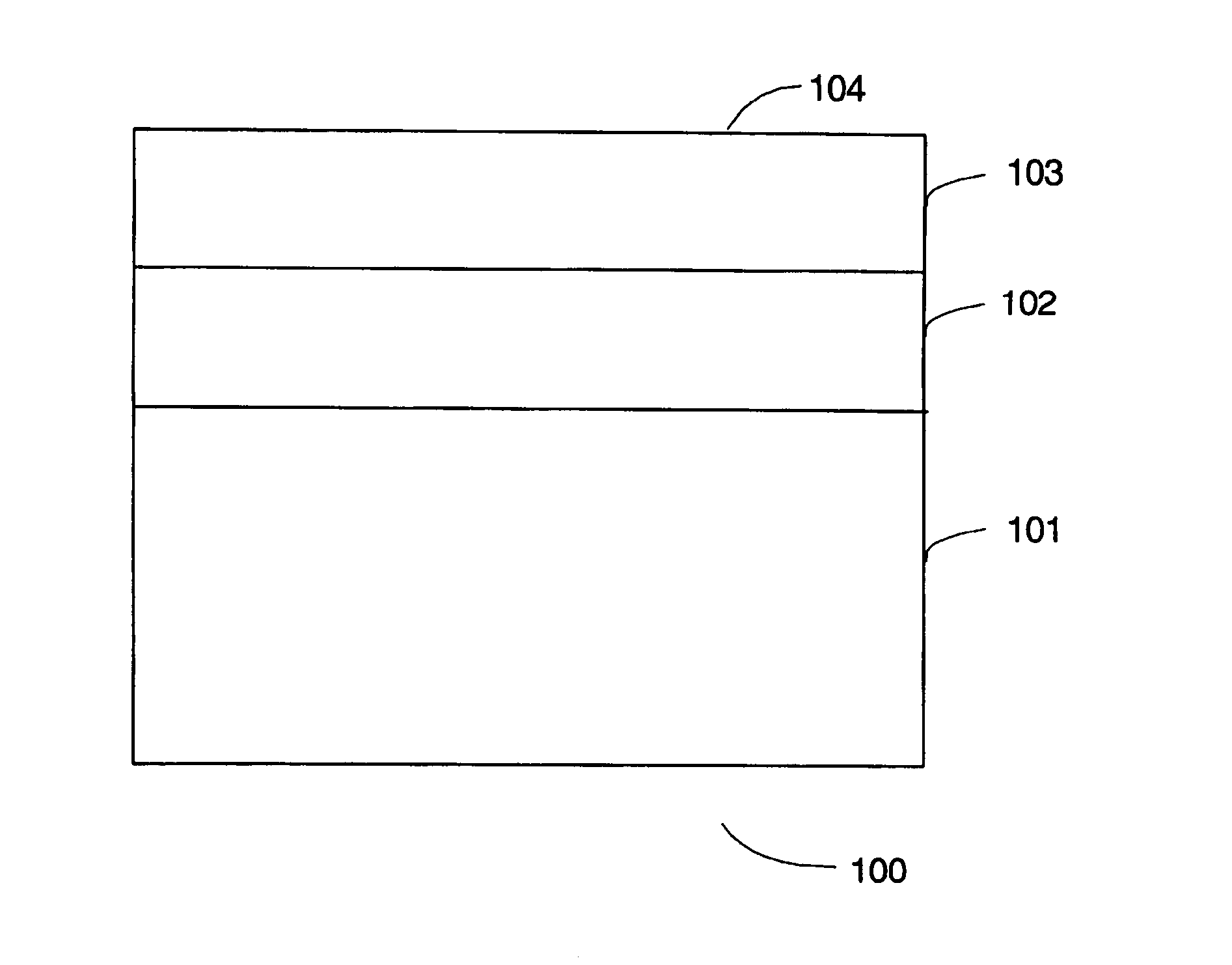

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS20050230156A1Improve thermal stabilityImprove bindingDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

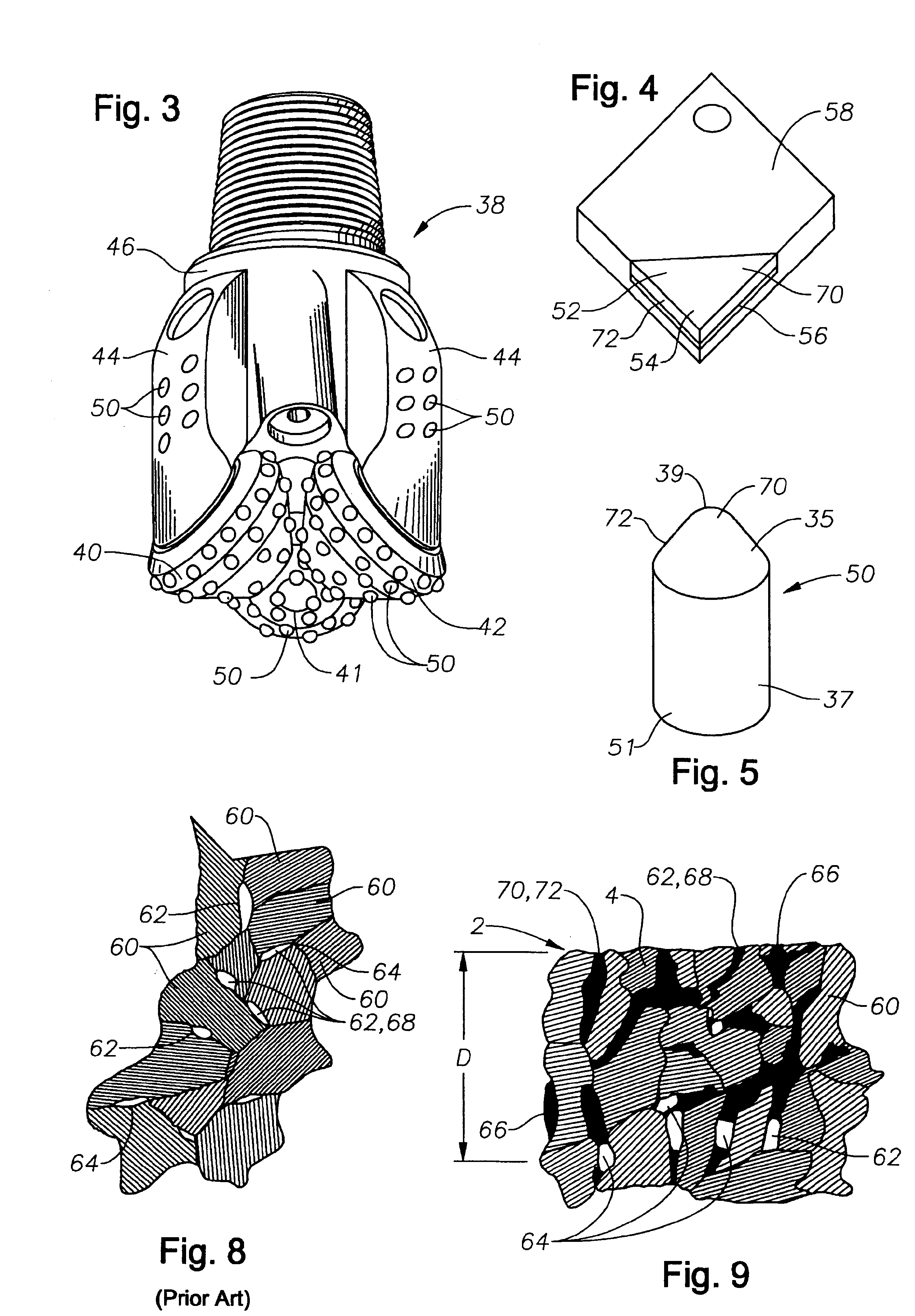

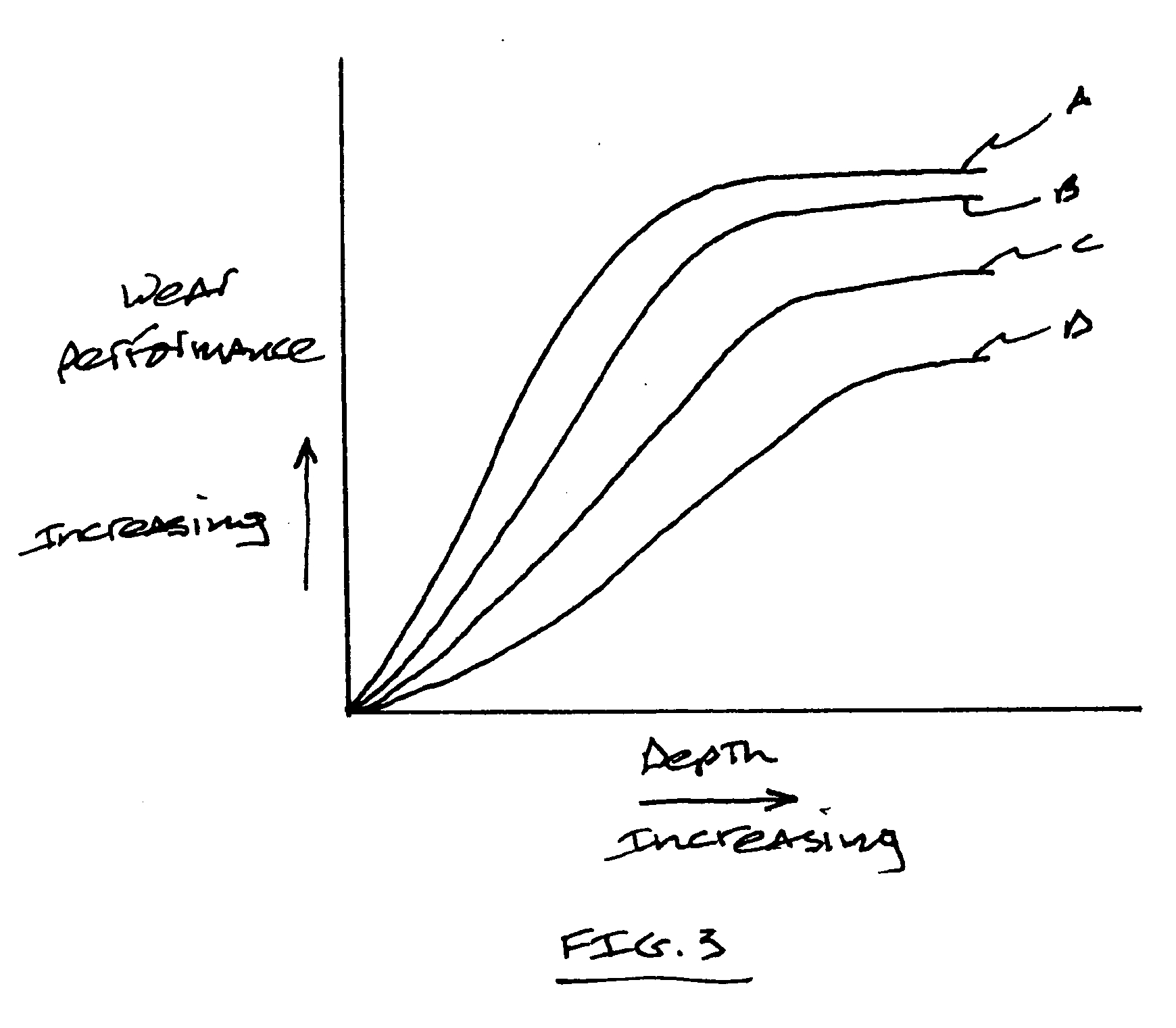

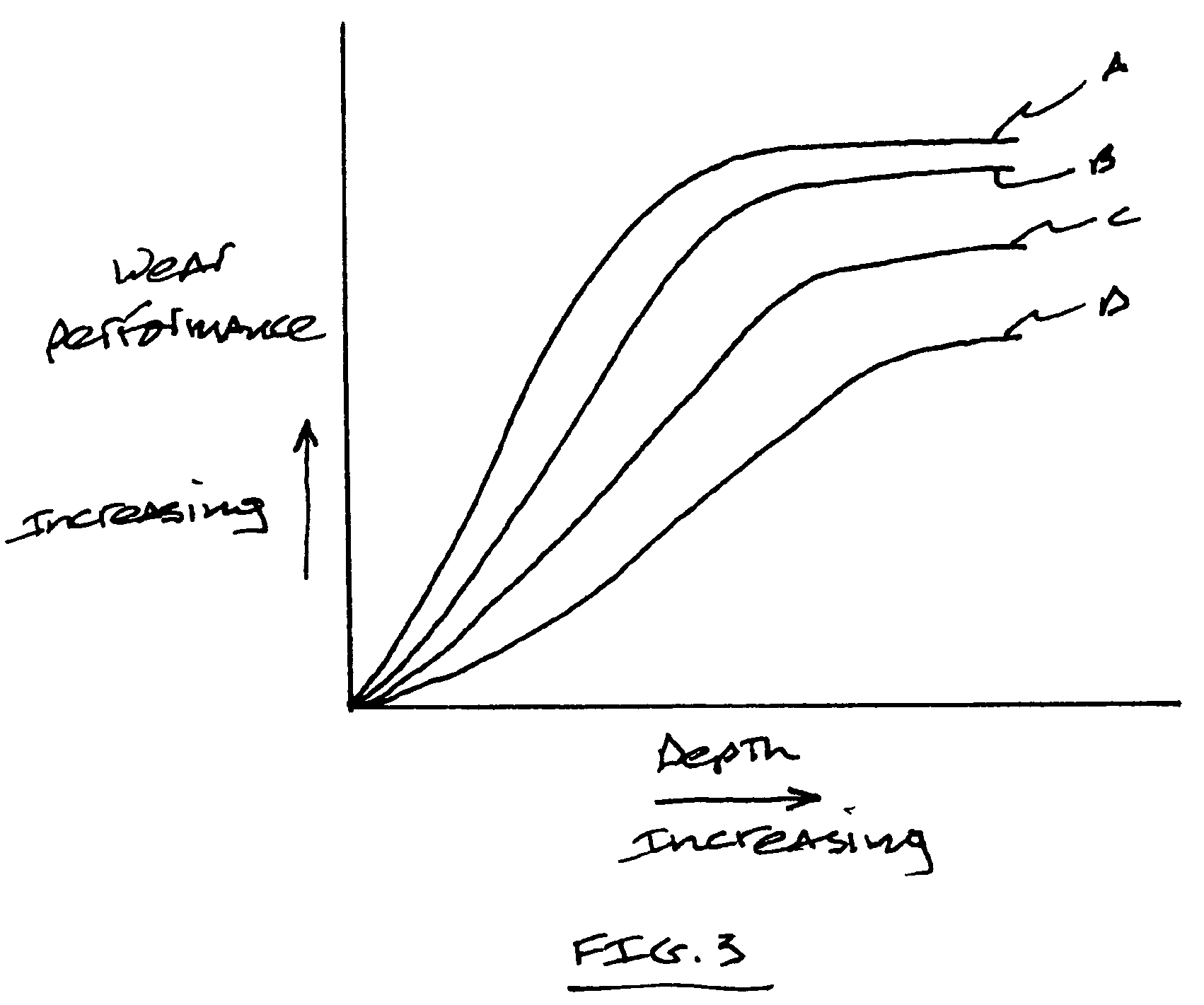

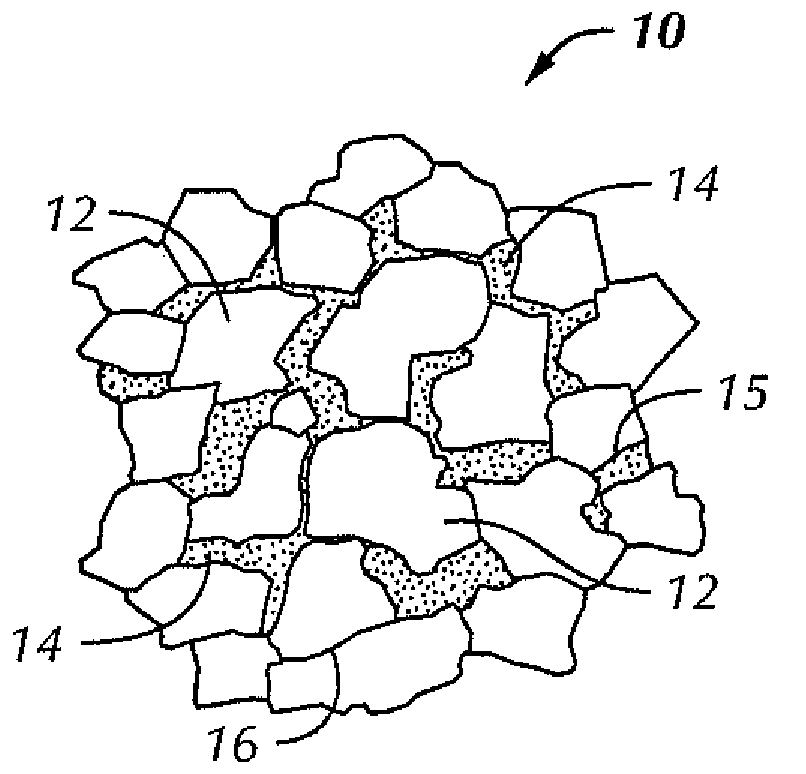

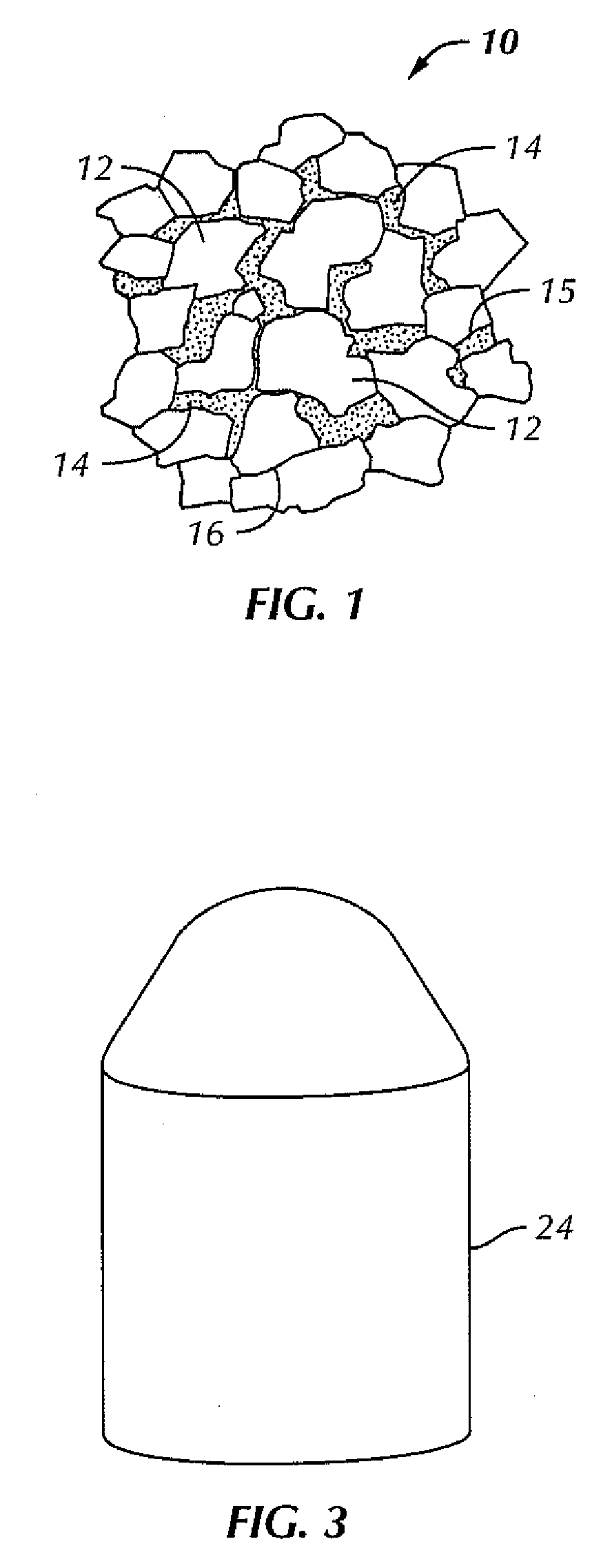

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

ActiveUS20060266559A1Improve propertiesDrill bitsConstructionsDiamond crystalPolycrystalline diamond

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

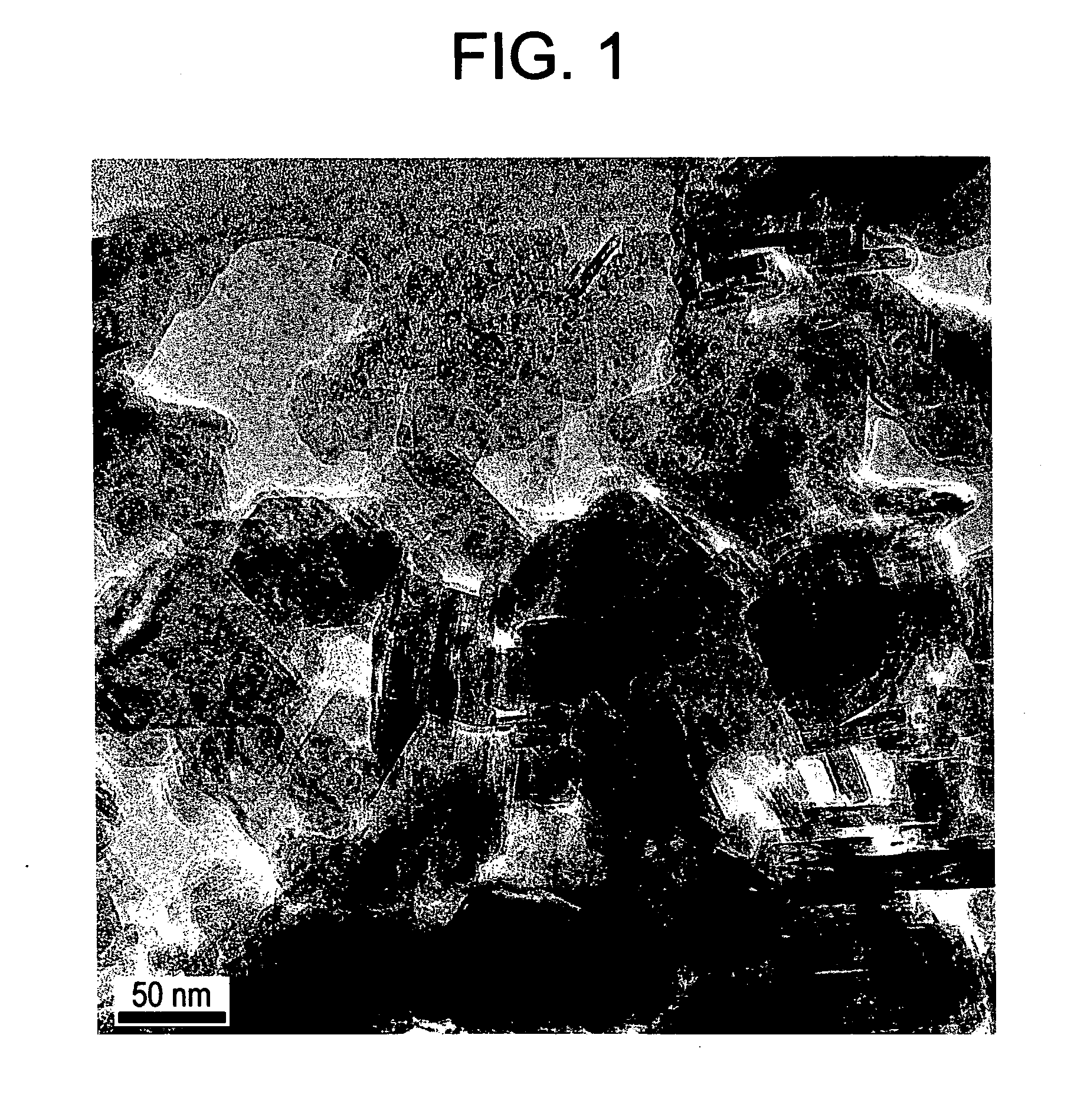

Nanodiamond PCD and methods of forming

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

Abrasive grain, abrasive articles, and methods of making and using the same

InactiveUS6287353B1Easy accessImprove grinding efficiencyPigmenting treatmentOther chemical processesComposite materialCeramic materials

Owner:3M INNOVATIVE PROPERTIES CO

Manufacture of thermally stable cutting elements

ActiveUS20080185189A1Pigmenting treatmentPressurized chemical processMaterials scienceTemperature and pressure

A method of forming a thermally stable cutting element that includes disposing at least a portion of a polycrystalline abrasive body containing a catalyzing material to be leached into a leaching agent; and subjecting the polycrystalline abrasive object to an elevated temperature and pressure is disclosed. Thermally stable cutting elements and systems and other methods for forming thermally stable cutting elements are also disclosed.

Owner:SMITH INT INC

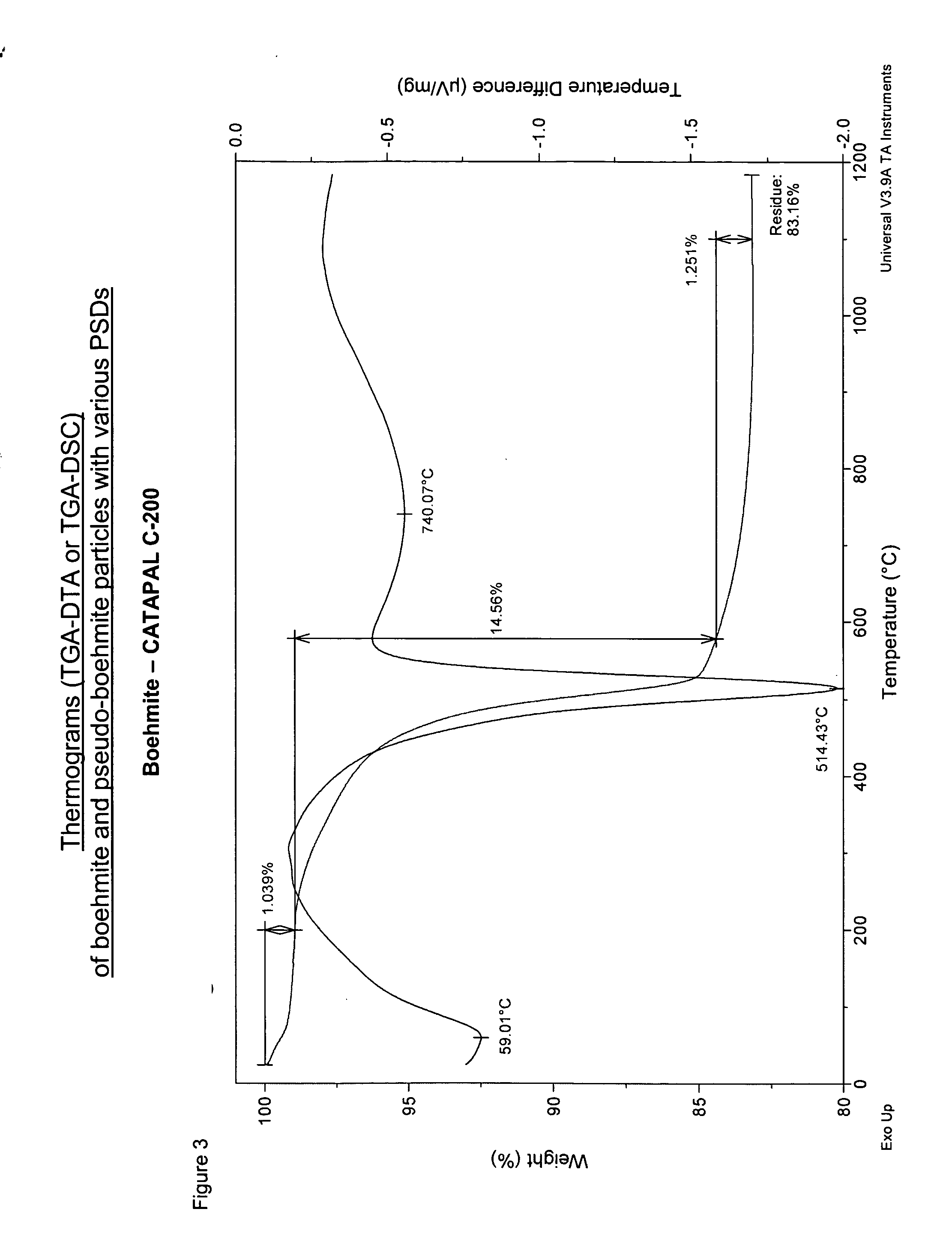

Planarization composition

The present invention provides CMP abrasive slurry that is substantially free of aluminum oxide and comprises liquid and solids wherein the solids comprises: (a) in an amount of at least about 90 weight percent based on the solids, at least one non-spherical component having formula Al2O3.xH2O where x ranges from 1 to 3; and (b) up to about one weight percent based on the solids portion of submicron alpha-alumina. The CMP abrasive slurry may be used to polish metallic or dielectric surfaces in computer wafers.

Owner:BASF AG +1

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

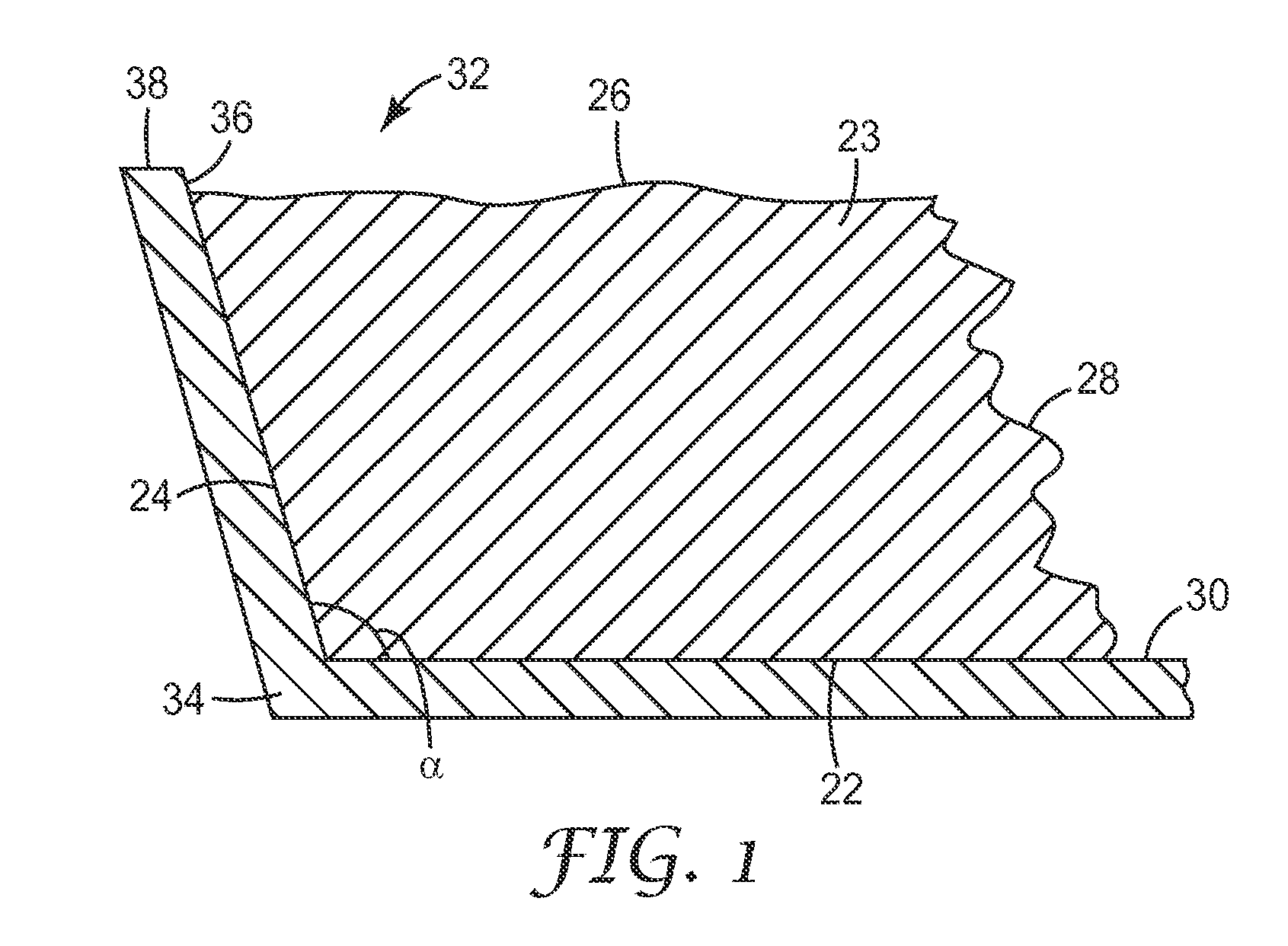

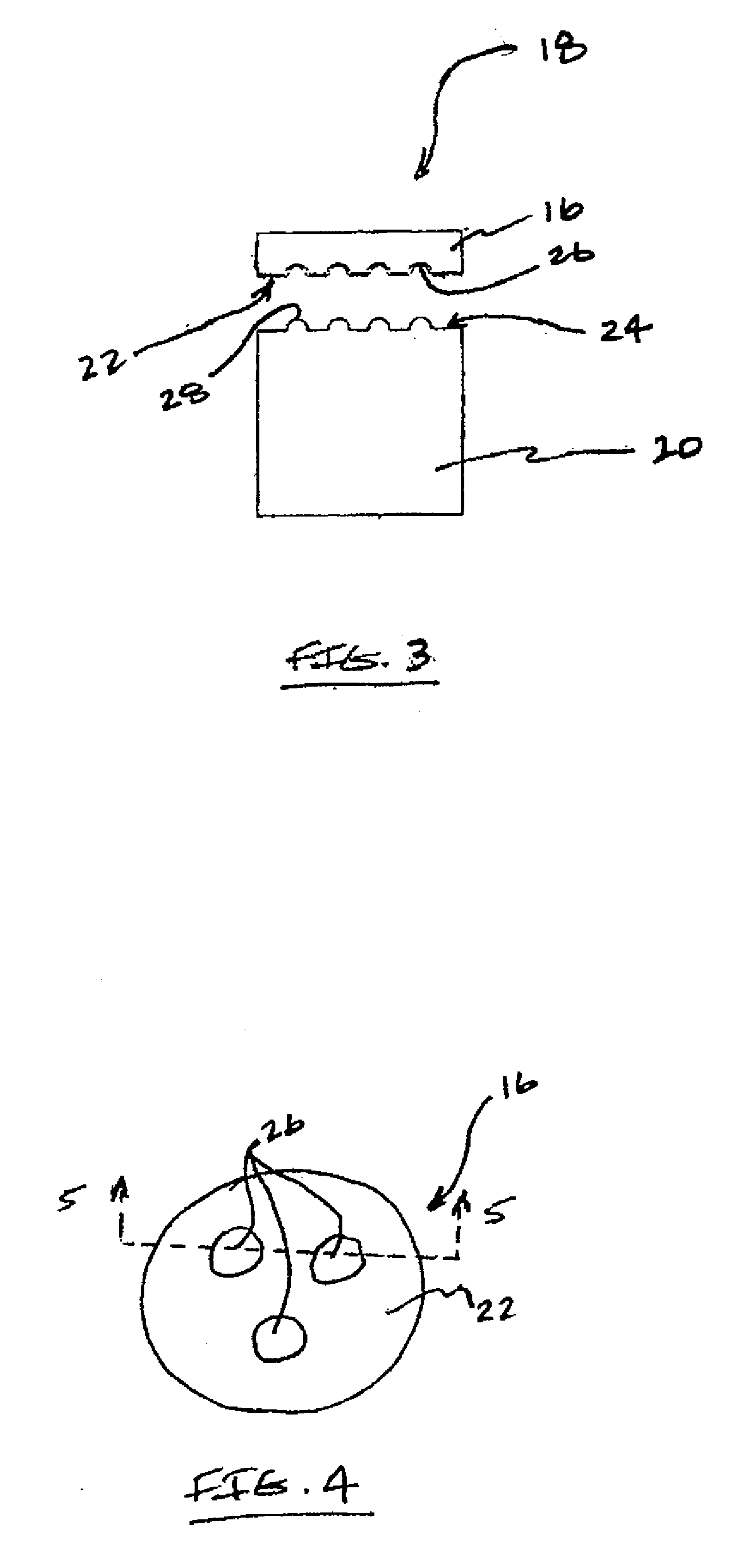

Thermally stable ultra-hard material compact constructions

InactiveUS20080142276A1Extend effective lifePigmenting treatmentDrill bitsSuperhard materialPolycrystalline diamond

Thermally stable ultra-hard compact constructions comprise a polycrystalline diamond body substantially free of a catalyst material, and a substrate that is joined thereto. The substrate can be ceramic, metallic, cermet and combinations thereof, and can be joined to the body by a braze material or other material that forms an attachment bond at high pressure / high temperature conditions. The body and substrate are specially formed having complementary interfacing surface features to facilitate providing an improved degree of attachment therebetween. The complementary surface features can in the form of openings and projections, e.g., one of the body or substrate can comprise one or more openings, and the other of the body or substrate can comprise one or more projections, disposed within or extending from respective interfacing surfaces. The complementary surface features operate to resist unwanted delamination between the body and substrate, thereby extending effective service life of the construction.

Owner:SMITH INT INC

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

Coated abrasive articles and method of abrading

A curable composition comprises epoxy resin preparable by reaction of epichlorohydrin with at least one of bisphenol A or bisphenol F, polyfunctional (meth)acrylate, dicyandiamide and photoinitiator. The curable composition is useful for preparing treated backings and coated abrasive articles.

Owner:3M INNOVATIVE PROPERTIES CO

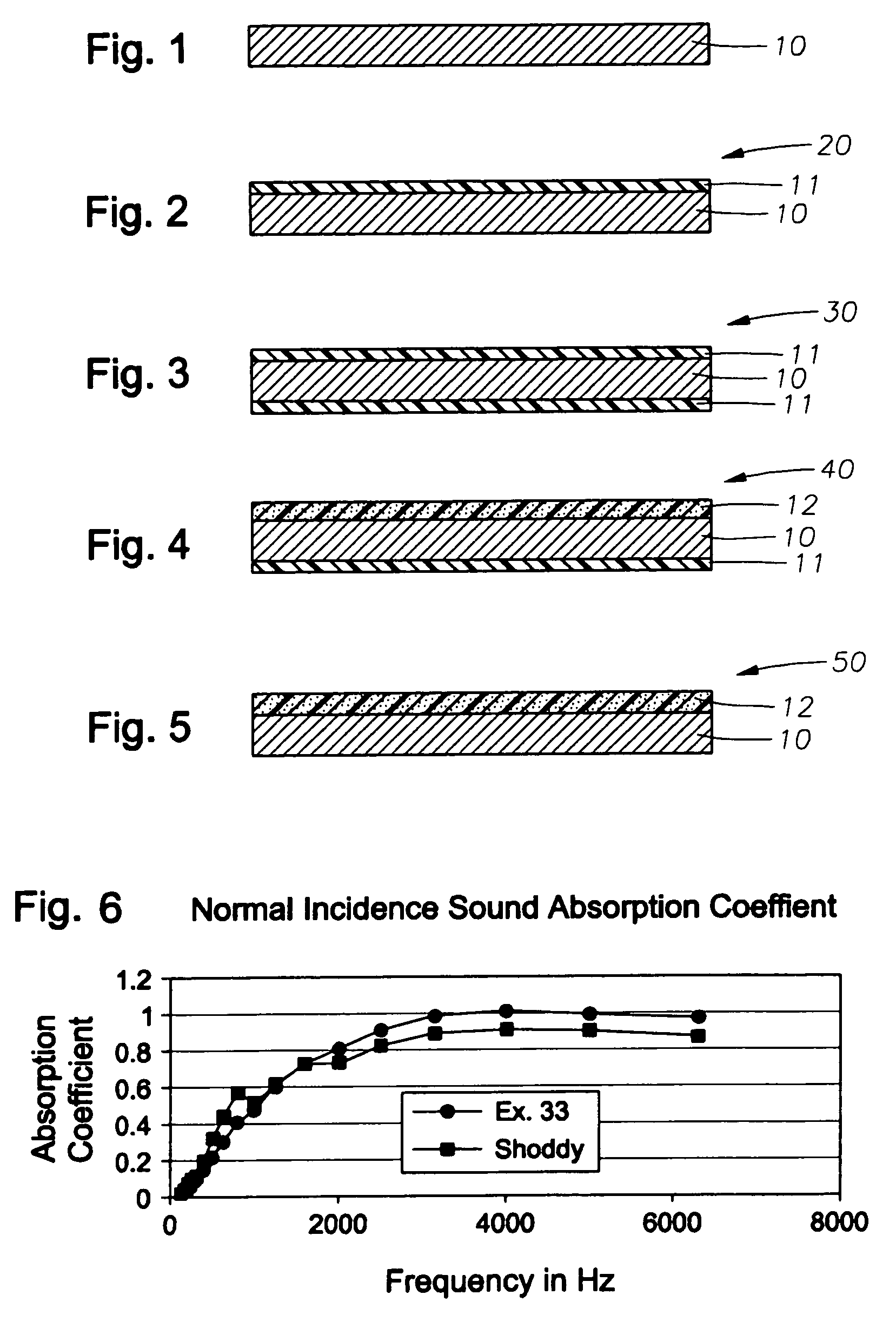

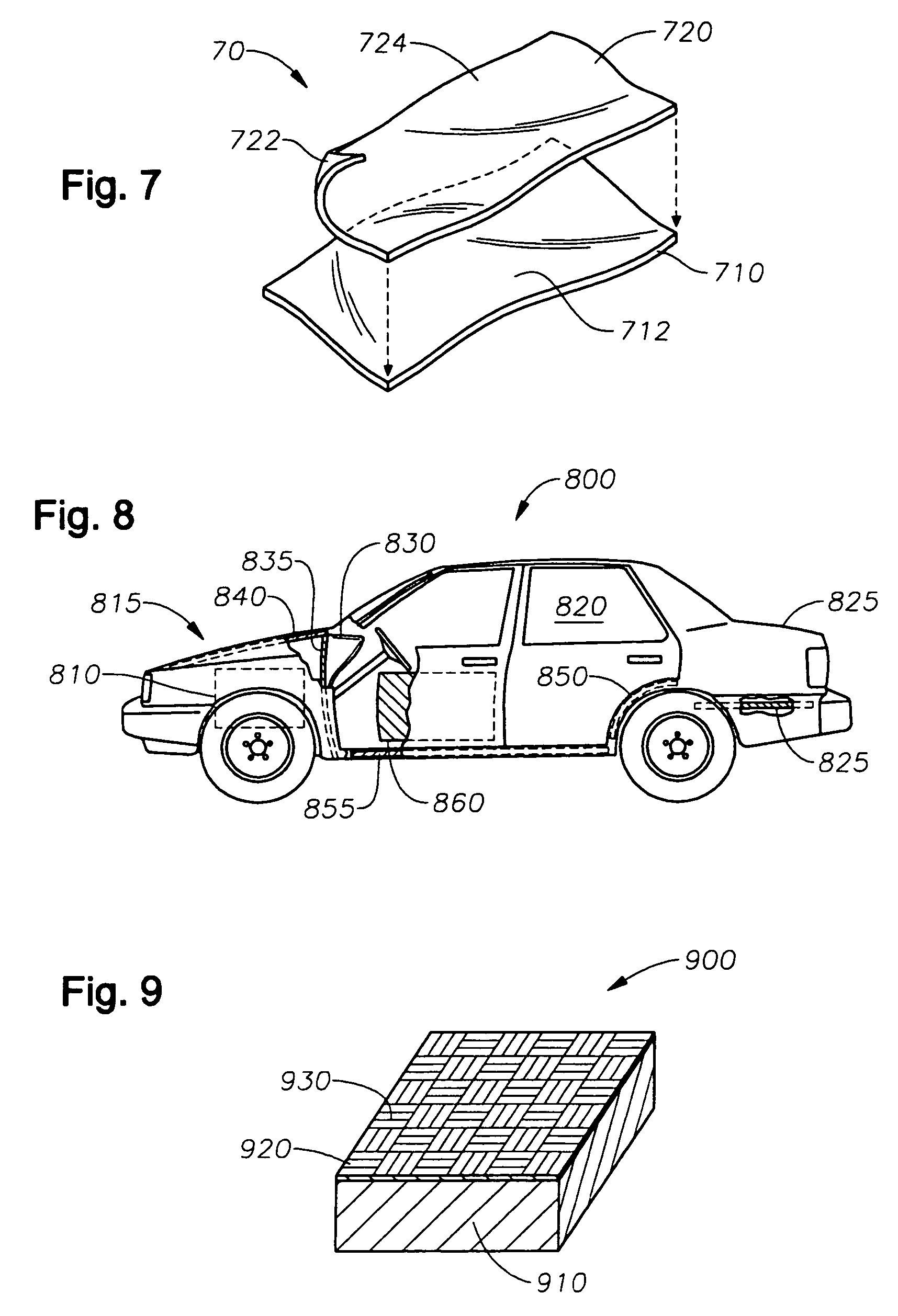

Nonwoven material for acoustic insulation, and process for manufacture

An improved acoustically and thermally insulating composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles, comprising at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim.

Owner:GLATFELTER CORP

Method for making abrasive grain using impregnation, and abrasive articles

InactiveUS6206942B1High densityImprove performancePigmenting treatmentOther chemical processesAbrasive

Method for making alpha alumina-based abrasive grain, wherein during an impregnation step of the method, alpha alumina-based ceramic precursor particles conchoidally fracture. The abrasive grain can be incorporated into abrasive products such as coated abrasives, bonded abrasives, and non-woven abrasives.

Owner:3M CO

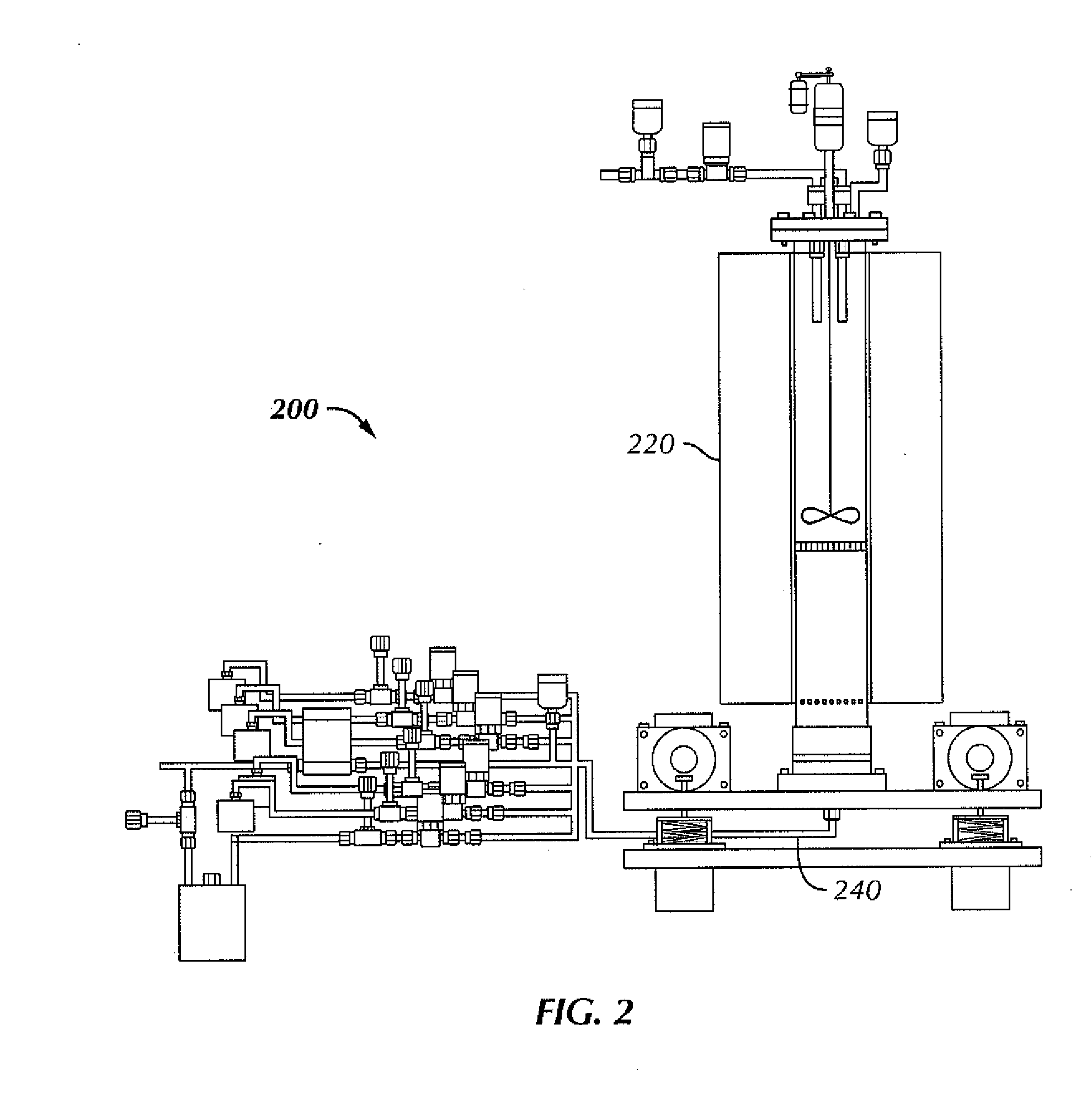

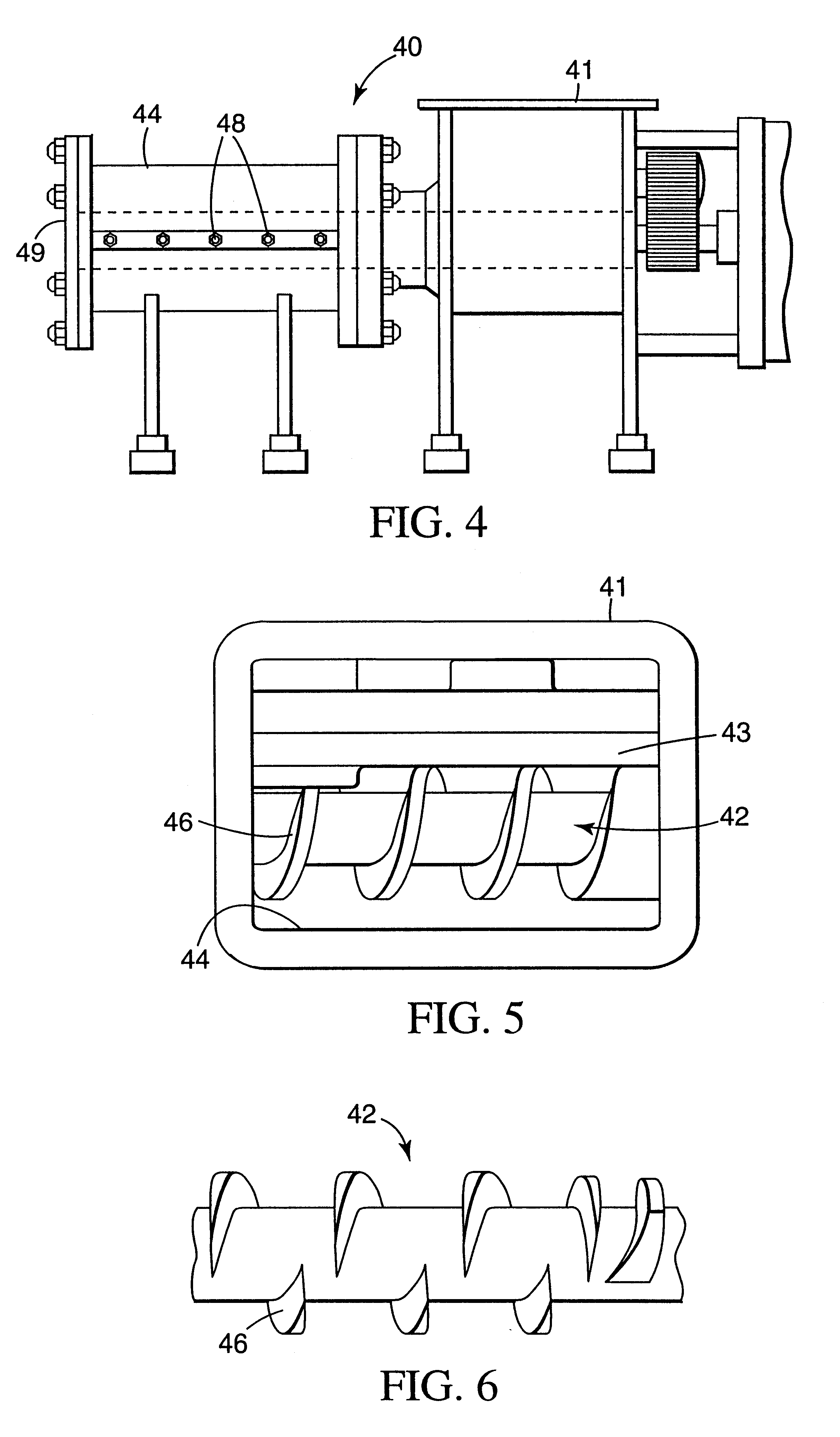

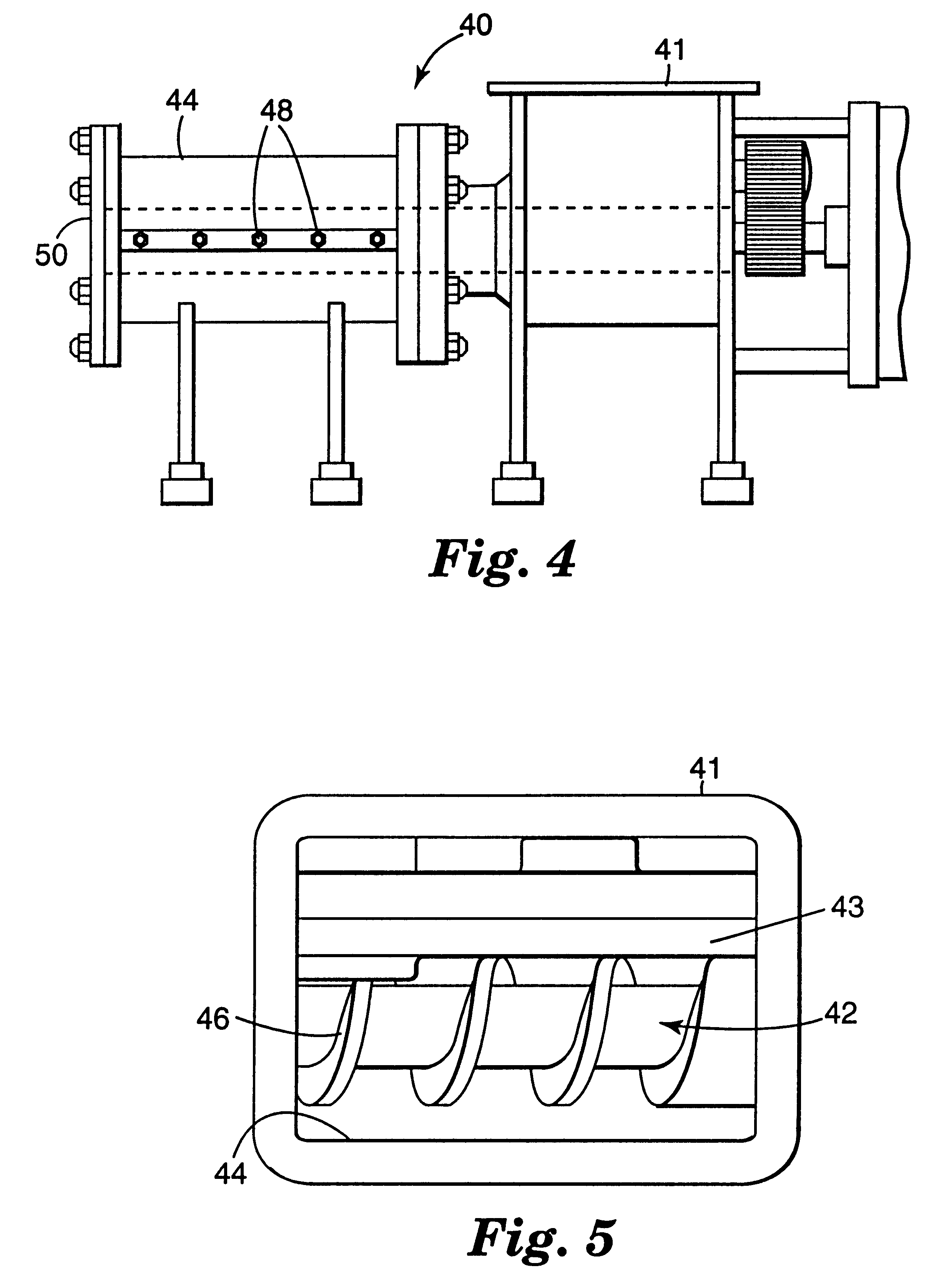

Sonochemical leaching of polycrystalline diamond

InactiveUS20070169419A1Reduce generationKnown methodOther chemical processesAbrasion apparatusMetallurgyPolycrystalline diamond

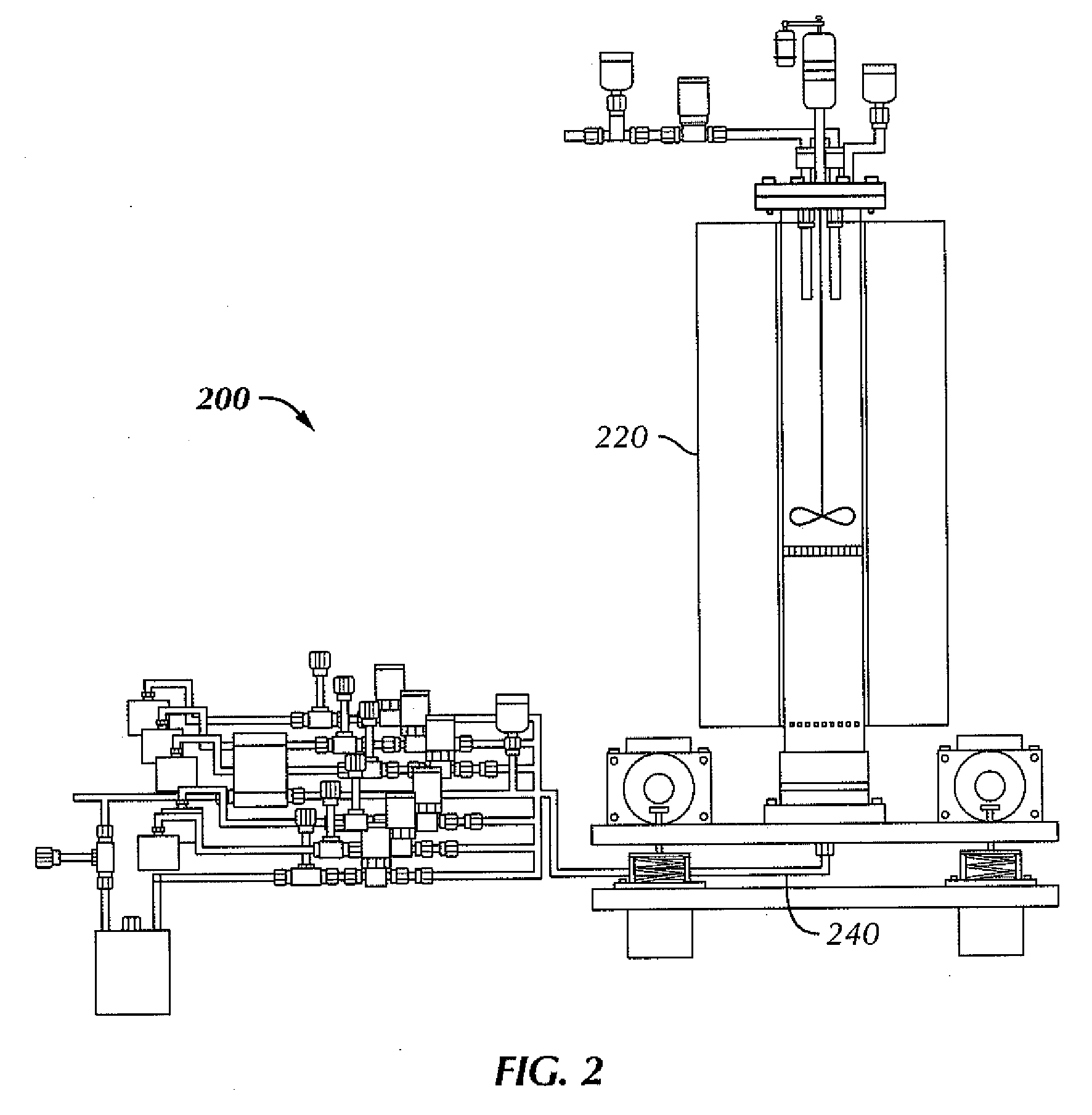

A method for accelerated leaching of binder-catalyst material from the polycrystalline diamond structure of a PDC is disclosed. The PDC is sonochemically leached. Also disclosed are fixture, equipment and a system for sonochemically leaching the polycrystalline diamond structure of a PDC.

Owner:GEN ELECTRIC CAPITAL

Disposable scrubbing product

InactiveUS20050130536A1High yieldResists effect of waterPersonal careCarpet cleanersEngineeringFibrous layer

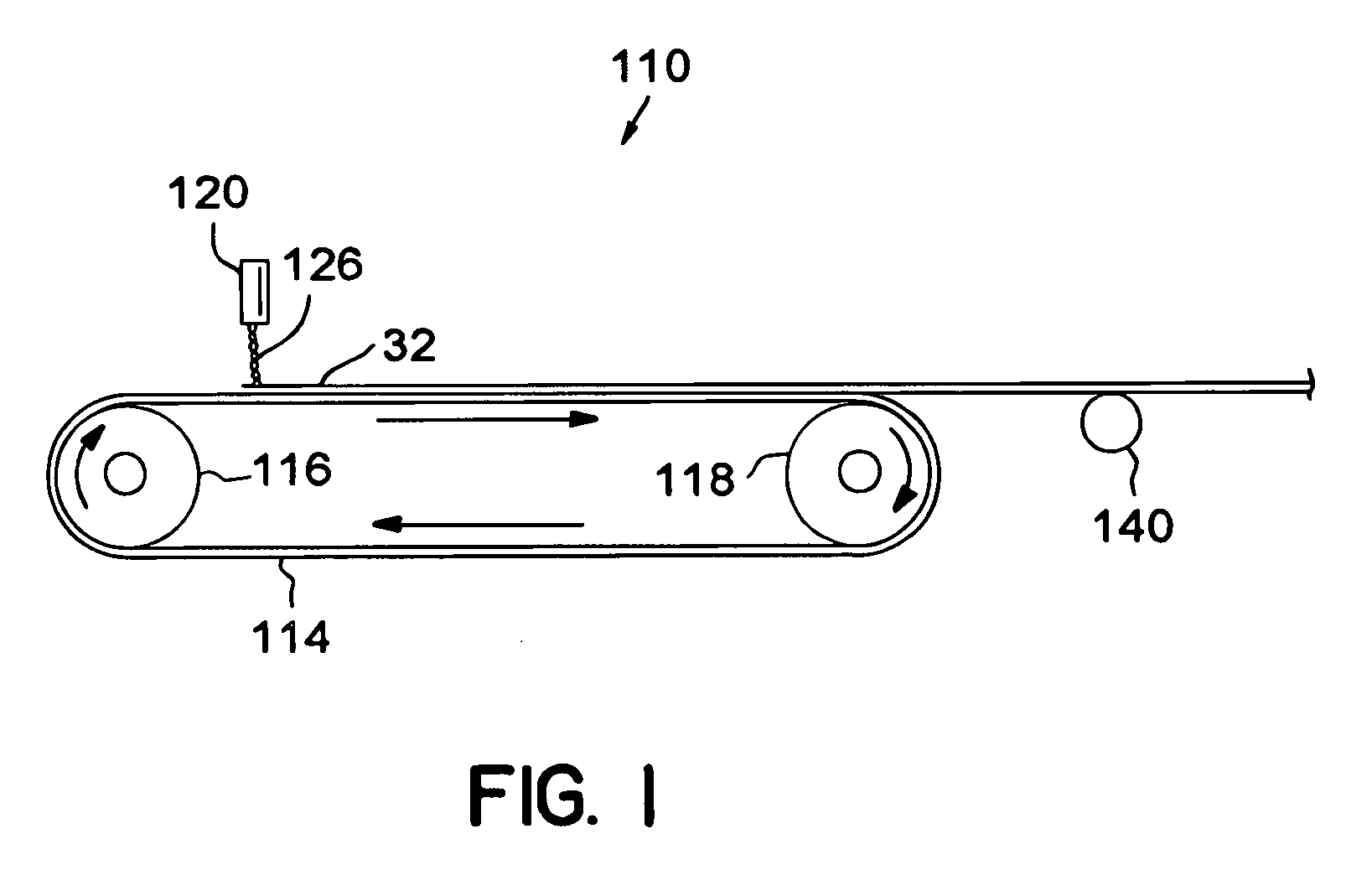

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, the abrasive layer comprises multifilamentary aggregate fibers. In one embodiment, the absorbent fibrous layer is an uncreped, through dried paper web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS7473287B2Improve thermal stabilityImprove bindingPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

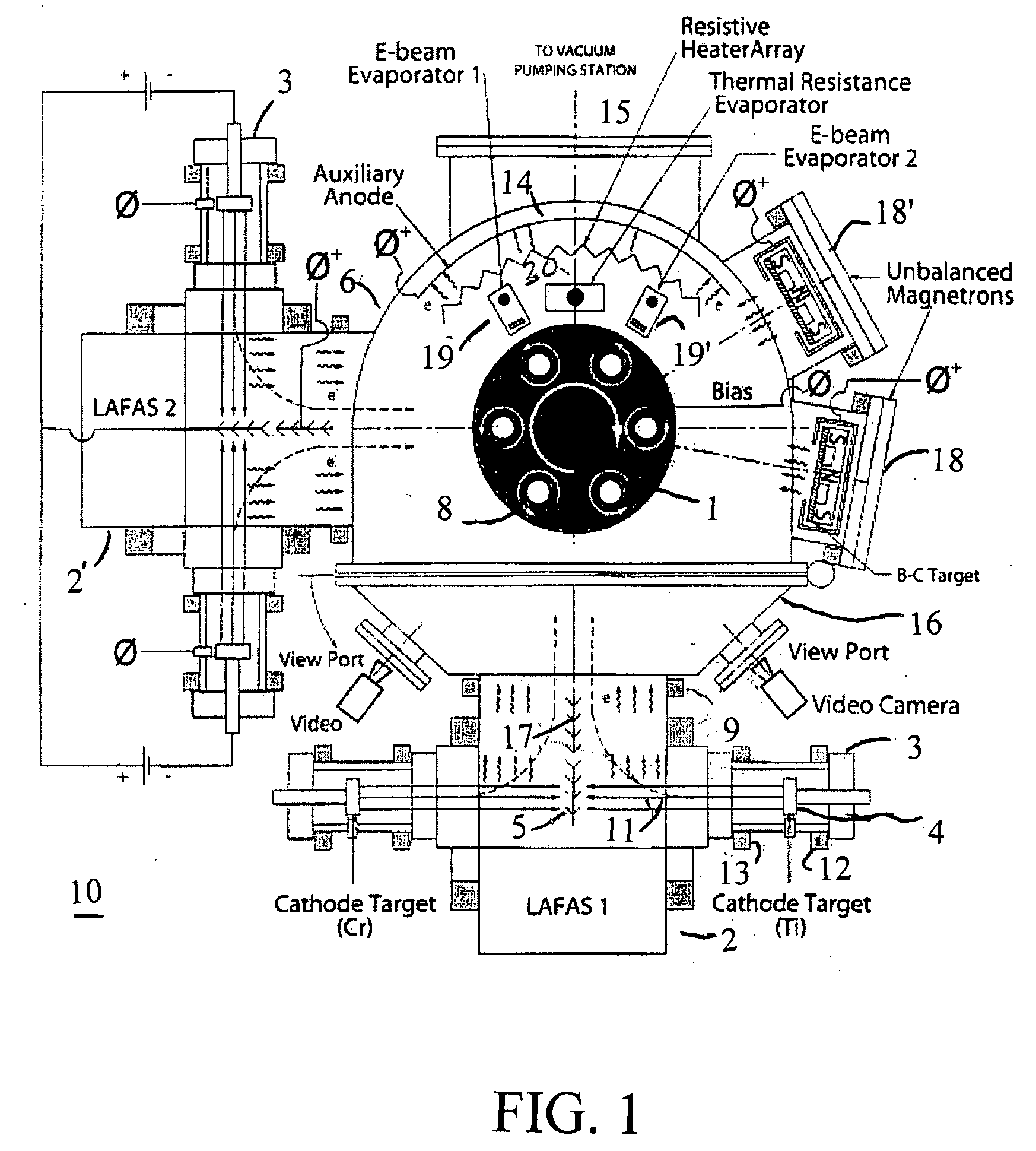

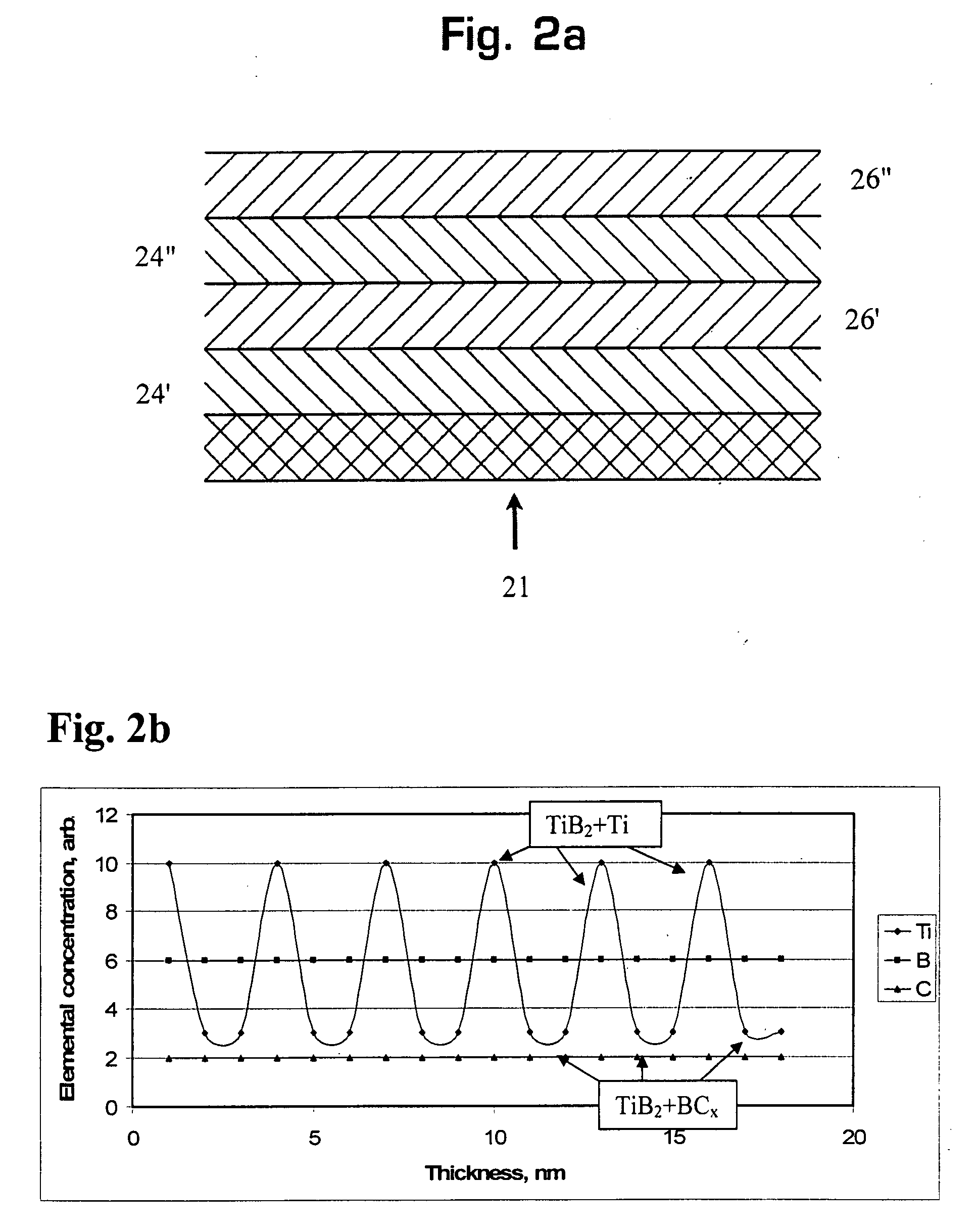

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

Polycrystalline composites reinforced with elongated nanostructures

A sintered polycrystalline composite for cutting tools that includes a plurality of diamond or cubic boron nitride particles; a plurality of nanotube materials; and a refractory or binder material is disclosed. Methods of forming such polycrystalline composites that include integrating or mixing a plurality of nanotube materials with diamond or cubic boron nitride particle and / or refractory or binder particles are also disclosed.

Owner:SMITH INT INC

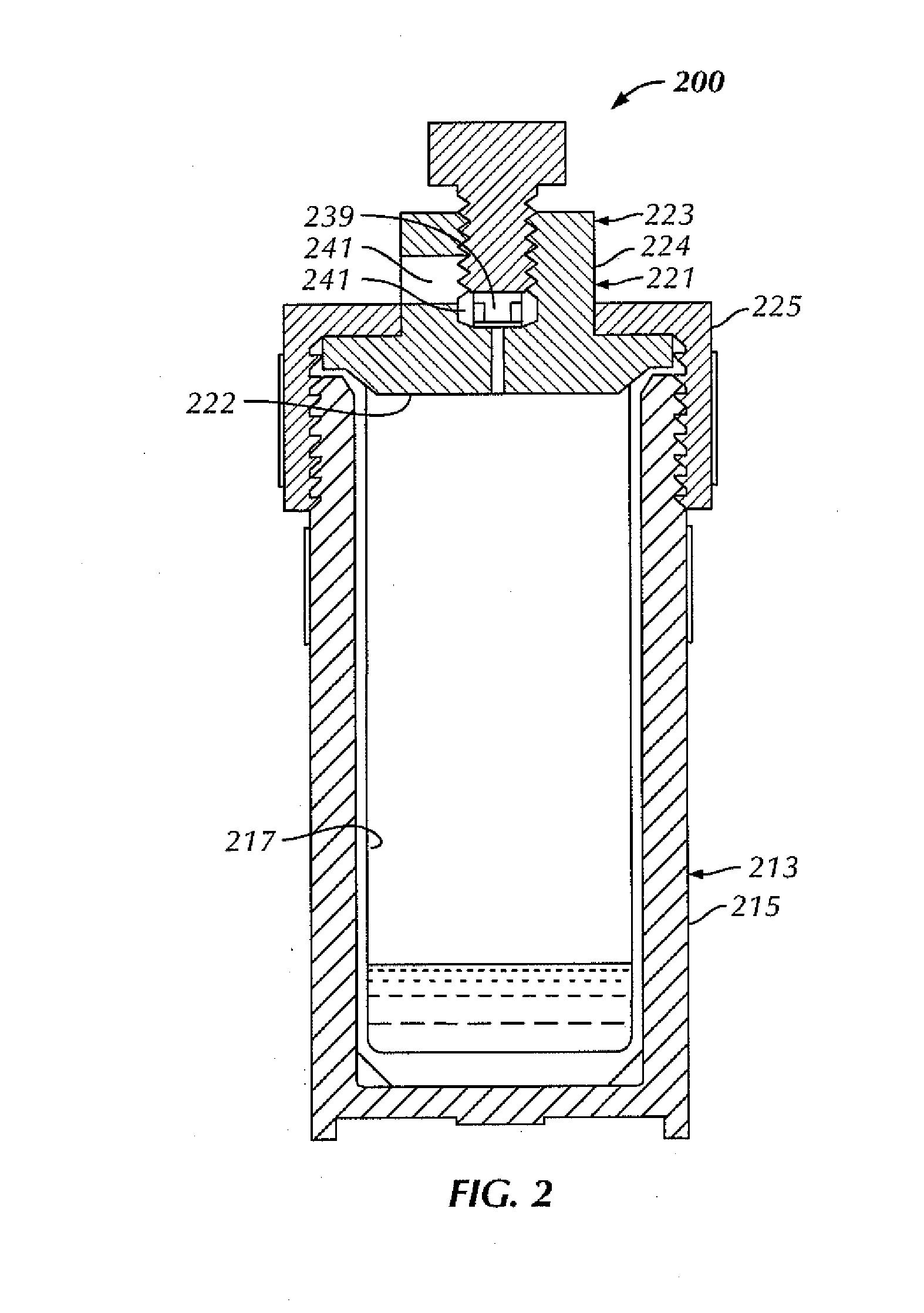

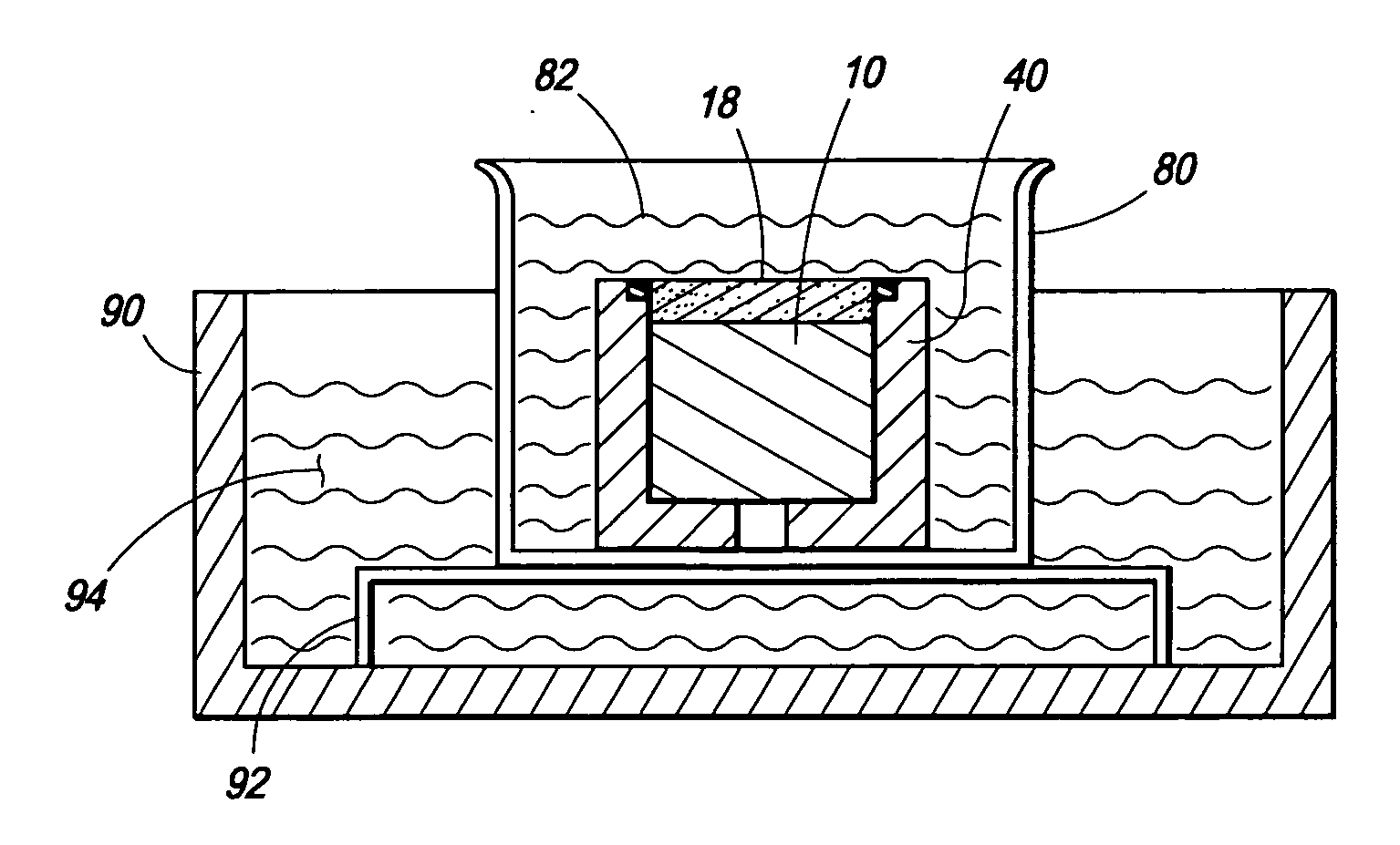

Container assembly for HPHT processing

InactiveUS20050044800A1Extended pathPigmenting treatmentPressurized chemical processHermetic sealCarbide

An assembly for High-Pressure High-Temperature (HPHT) processing comprising a can, a cap, a meltable sealant and sealant barrier, and a superhard mixture comprising superhard particles. The superhard particles may be positioned adjacent a substrate of cemented metal carbide. The can and cap contain the superhard mixture with the sealant barrier positioned within the assembly so as to be intermediate the sealant and at least a portion of the mixture, thereby preventing the sealant from coming in contact with the mixture during processing. The assembly is placed within a vacuum chamber and heated to a temperature sufficient to cleanse the assembly and then melt the sealant providing a hermetic seal for the assembly in preparation for further HPHT processing.

Owner:REEDHYCALOG UTAH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com