Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6451 results about "Bisphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

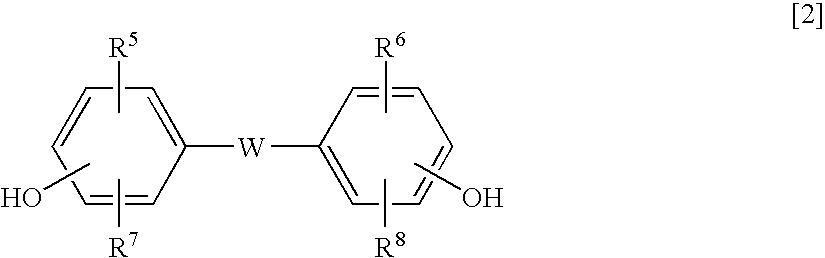

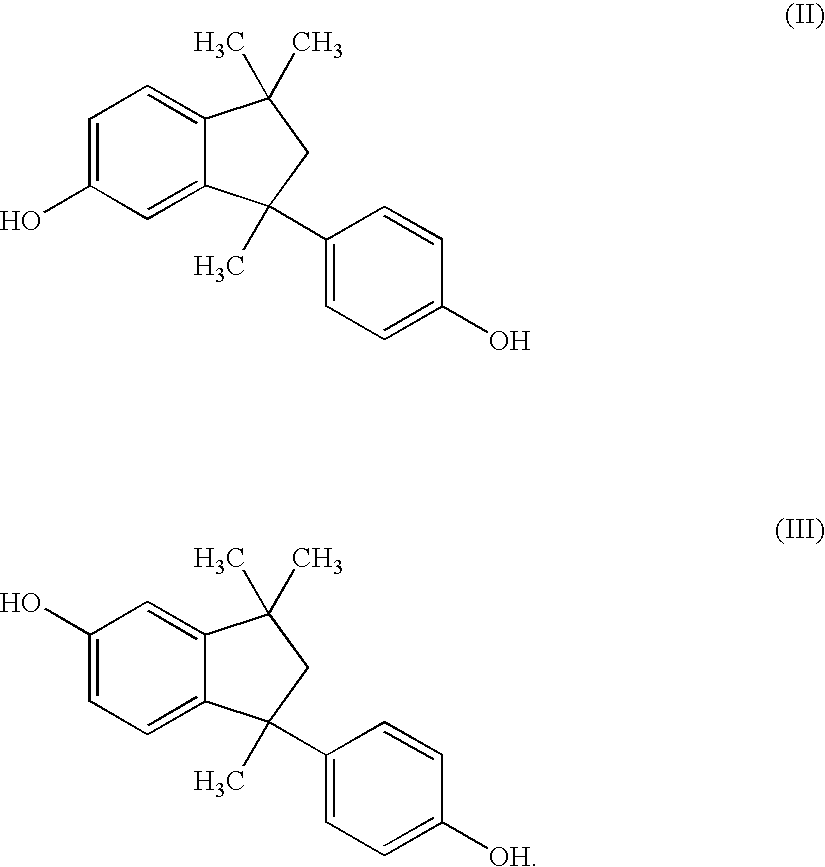

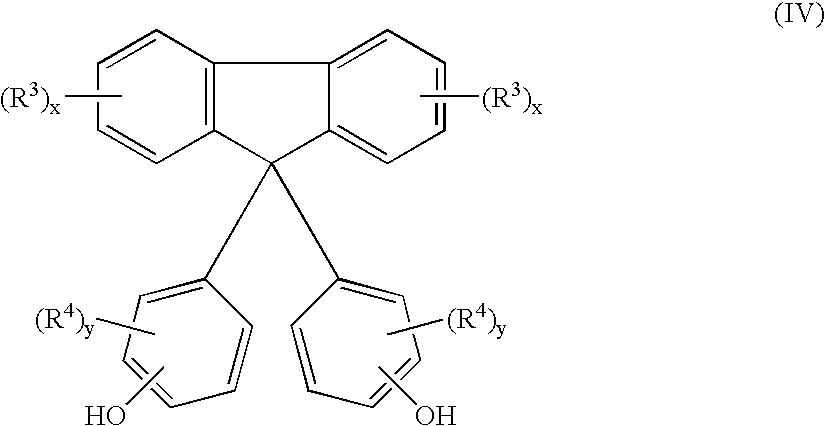

The bisphenols (/ˈbɪsfɪnɒl/) are a group of chemical compounds with two hydroxyphenyl functionalities. Most of them are based on diphenylmethane. The exceptions are bisphenol S, P, and M. "Bisphenol" is a common name; the letter following refers to one of the reactants. Bisphenol A is the most popular representative of this group, often simply called "bisphenol."

Phenolic antiseptic compositions and methods of use

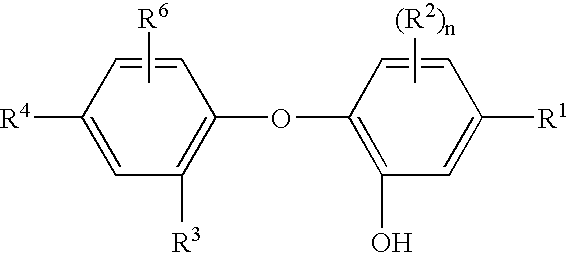

ActiveUS20060052452A1Reduce eliminateReduce and eliminate clinical signAntibacterial agentsBiocideDiphenyl etherSURFACTANT BLEND

Antimicrobial compositions, especially those useful when applied topically, particularly to mucosal tissues (i.e., mucous membranes), including an antiseptic selected from the group consisting of halogenated phenols, bisphenols, diphenyl ethers, anilides and derivatives thereof, and combinations thereof. The compositions can also include an enhancer component, a surfactant, a hydrophobic component, and / or a hydrophilic component. Such compositions provide effective topical antimicrobial activity and are accordingly useful in the treatment and / or prevention of conditions that are caused, or aggravated by, microorganisms (including viruses).

Owner:3M INNOVATIVE PROPERTIES CO

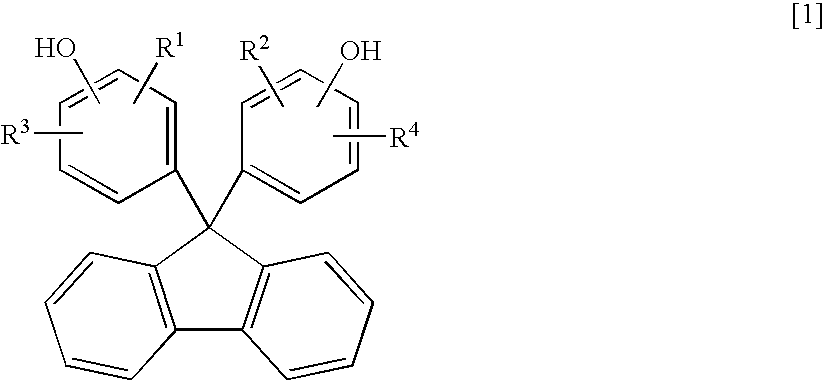

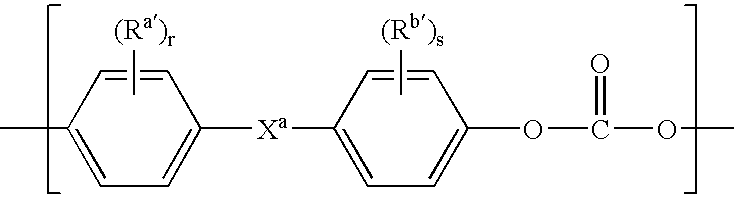

Polycarbonate copolymer, resin composition, and molded article

ActiveUS7244804B2Good colorIncrease resistanceSynthetic resin layered productsCeramic shaping apparatusPolymer scienceUv absorber

There are provided a polycarbonate copolymer (A) which has excellent light resistance and heat resistance and comprises an aromatic dihydroxy component comprising 5 to 95 mol % of fluorene-skeleton-containing dihydroxy compound (1) having a specific structure and 95 to 5 mol % of ordinary bisphenol type dihydroxy compound (2), the content of fluorene-9-one in the copolymer being not higher than 15 ppm; and a polycarbonate composition comprising 0.01 to 5 parts by weight of ultraviolet absorber (B) based on 100 parts by weight of the copolymer (A), and the composition comprising the copolymer.

Owner:TEIJIN KASEK KK

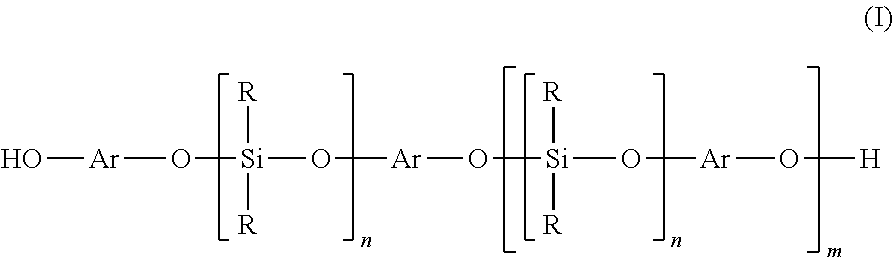

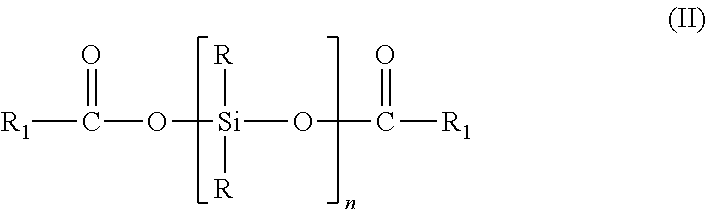

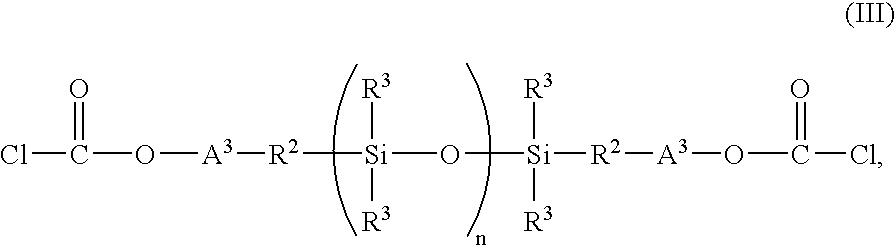

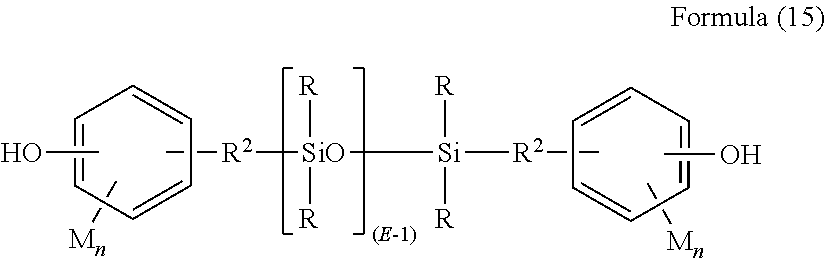

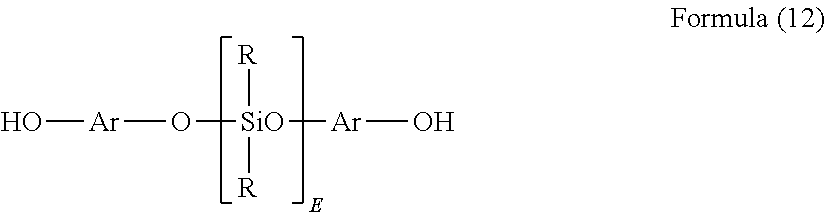

Process for producing functional siloxanes of controlled structure

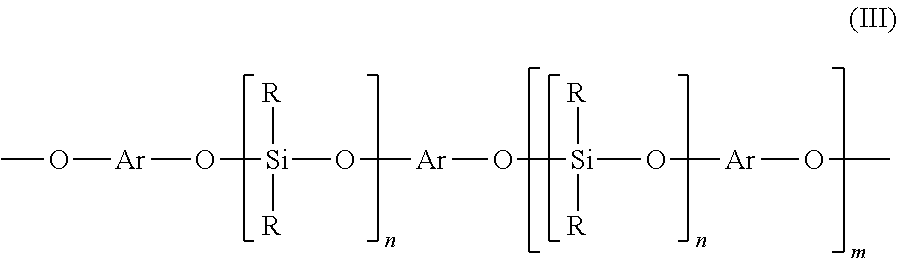

Disclosed herein is a process for preparing a linear hydroxyaryloxy-functional polydiorganosiloxanes having controlled structures. The process includes the step of reacting a linear α,ω-bisacyloxypolydiorganosiloxane with at least one bisphenolic compound, or hydroxy-functional oligomer thereof, in such a molar ratio that the phenolic groups in the bisphenolic compound or the hydroxy-functional oligomer thereof to the acyloxy groups in the α,ω-bisacyloxypolydiorganosiloxane is less than 2.0. Also disclosed are hydroxyaryloxy-functional polydiorganosiloxanes produced from the process and the polysiloxane / polyorgano block copolymers made using the hydroxyaryloxy-functional siloxanes.

Owner:MOMENTIVE-PERFORMANCE MATERIALS GMBH

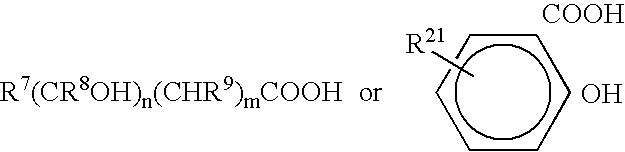

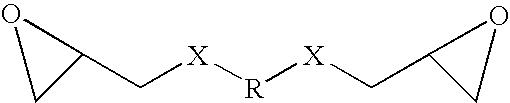

BIS epoxy polyesters and food cans coated with a composition comprising same

ActiveUS20070281179A1Loss in molecular weightEnvelopes/bags making machinerySynthetic resin layered productsPolyesterChemistry

Polyesters comprising the reaction product of a polyol and a bis-epoxy reacted with a mono- and / or di-phenolic carboxylic acid and / or ester are disclosed. Food cans coated at least in part on the interior with a composition comprising these polyesters are also disclosed. The composition used on the food cans is substantially free of BPA and BPF and substantially free of BADGE and BFDGE. Food cans coated at least in part on the interior with a composition comprising a polyester having a loss of molecular weight of less than 50% in an acidic medium are also disclosed.

Owner:PPG IND OHIO INC

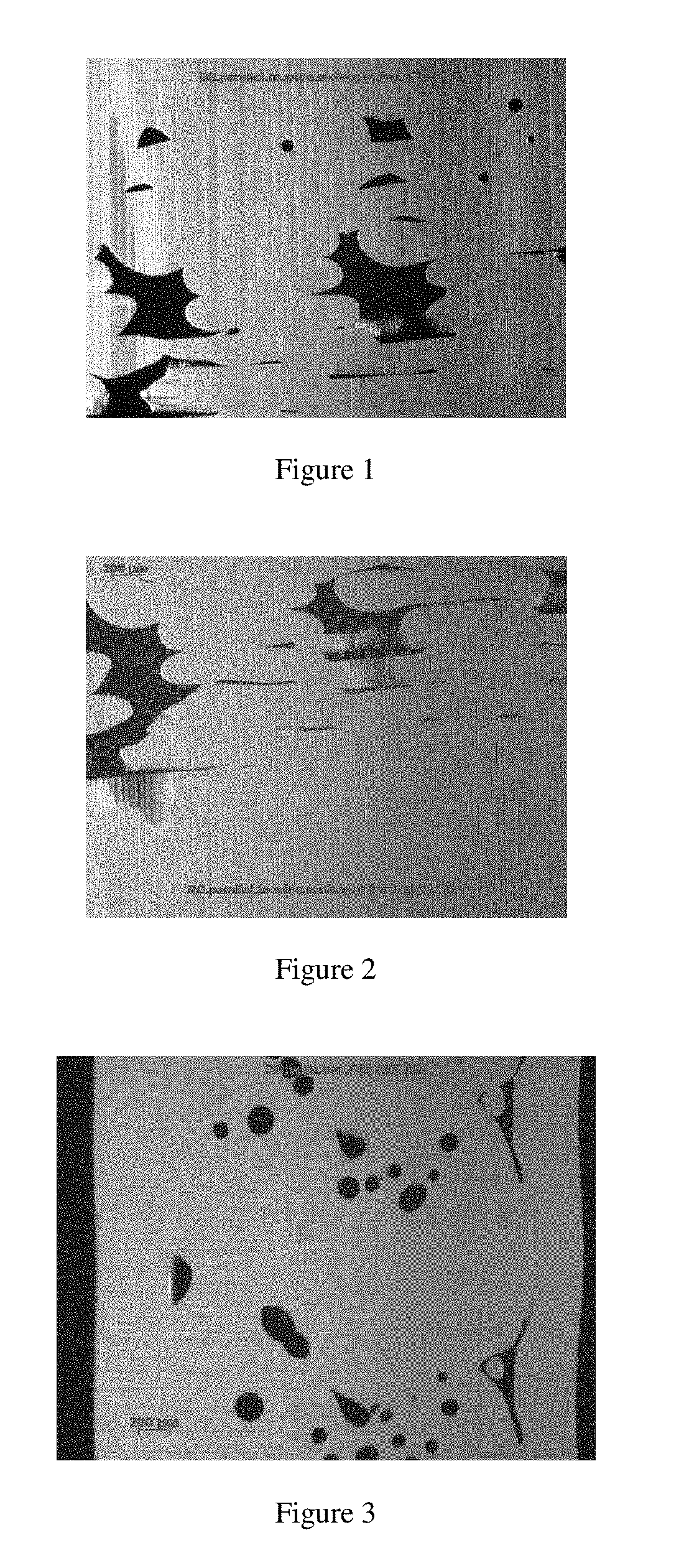

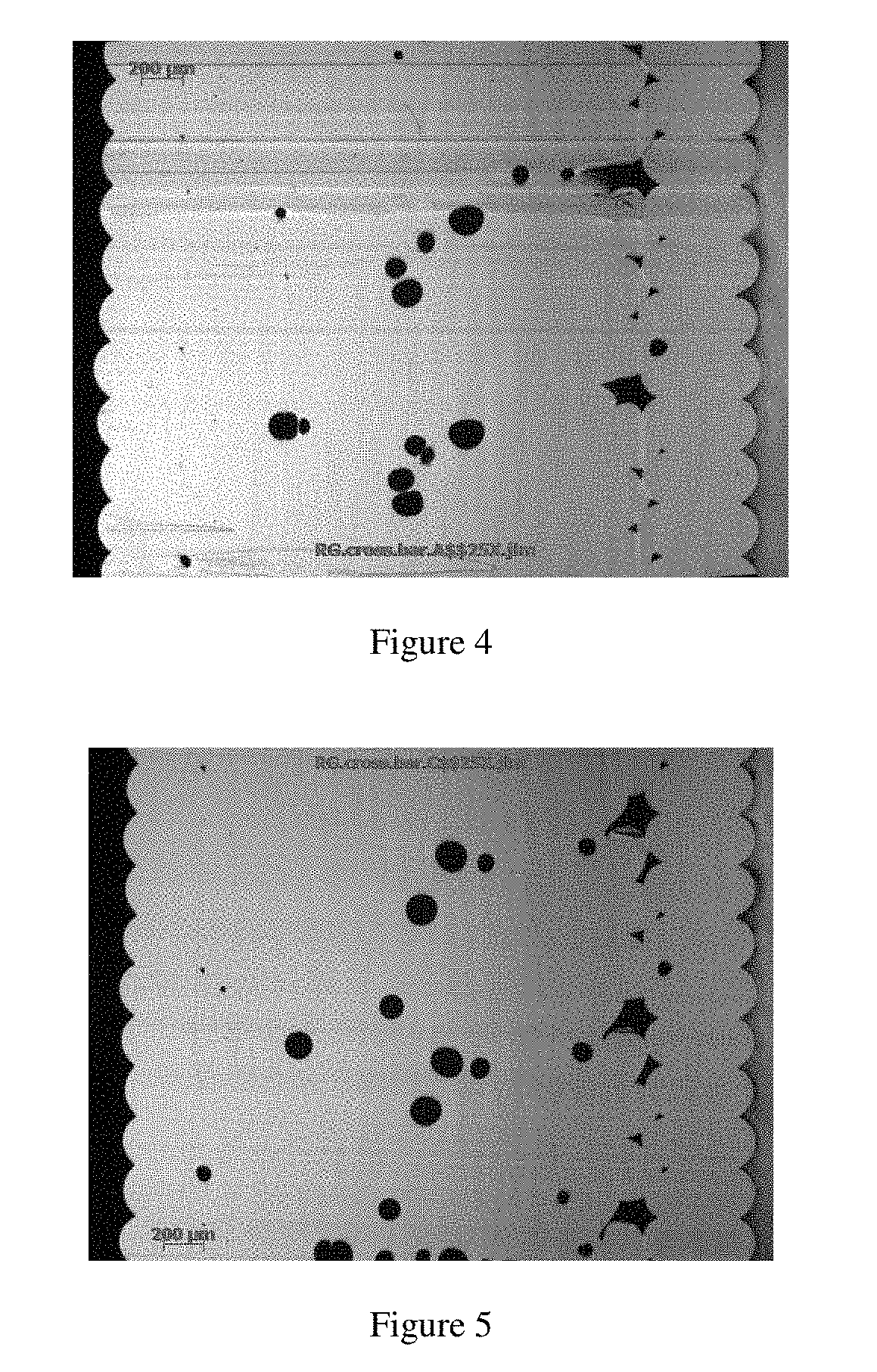

Reduced density article

InactiveUS10087556B2Additive manufacturing apparatusIncreasing energy efficiencyMicro structurePolymer science

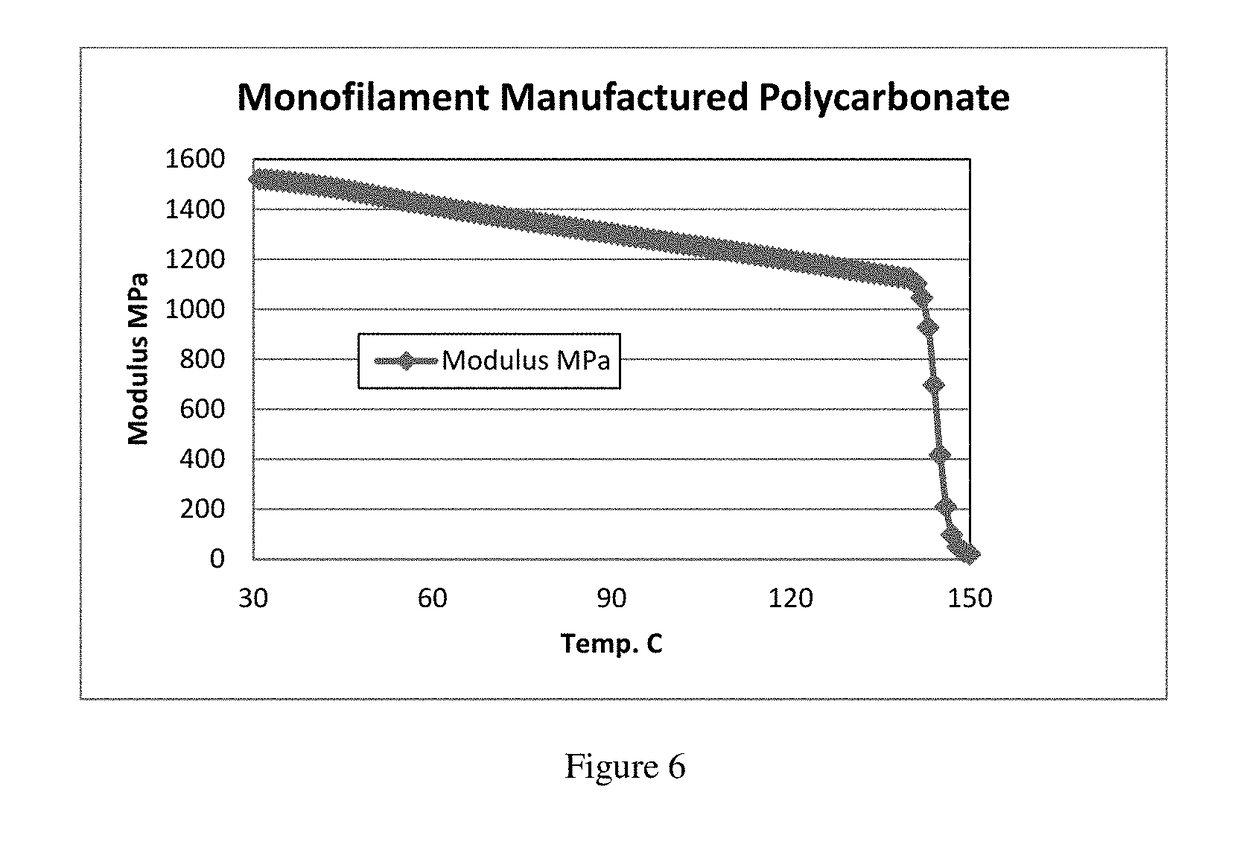

A reduced density article of manufacture, and process for making same, made from a thermoplastic polycarbonate composition. The reduced density article of manufacture has (1) a certain density and (2) a certain micro structure containing from 1% to 20% by volume of voids wherein at least 80% of the voids are high aspect voids and less than 20% of the voids are spherical voids with a diameter of 10 to 100 microns. The polycarbonate thermoplastic composition comprises at least 50 mole % of a certain bisphenol A. The reduced density article of manufacture is made by a monofilament additive manufacturing technique.

Owner:SHPP GLOBAL TECH BV

Radiation-curable flame retardant optical fiber coatings

A buffer coating for optical fibers is disclosed which includes a halogenated epoxy resin for flame-retardancy, and elastomer modified epoxy resin for tensile strength and flexibility, a low viscosity bisphenol resin for structural integrity, a viscosity modifier for improved process or extrusion properties, a polyol to increase the cure rate and cross-linking during curing, a slip agent or surfactant to reduce the adhesion of the buffer layer to the cladding and to further improve the flow characteristics during extrusion, and a photo-initiator. The buffer layer is flame-retardant and has a fast UV cure rate.

Owner:ADDISON CLEAR WAVE

Poly(arylene ether) compositions and methods of manufacture thereof

Dielectric compositions encompassing one or more poly(arylene ether) polymers are provided. The dielectric compositions have the repetitive structural unit: where n=0 to 1; m=0 to 1-n; and Y1, Y2, Ar1 and Ar2 are each a divalent arylene radical, Y1 and Y2 derived from biphenol compounds, Ar1 derived from difluoroarylethynes and Ar2 derived from difluoroaryl compounds. Where both Y1 and Y2 are derived from fluorene bisphenol, n=0.1 to 1. Such poly(arylene ether) polymers are employed with a variety of microelectronic devices, for example, integrated circuits and multichip modules.

Owner:ALLIEDSIGNAL INC

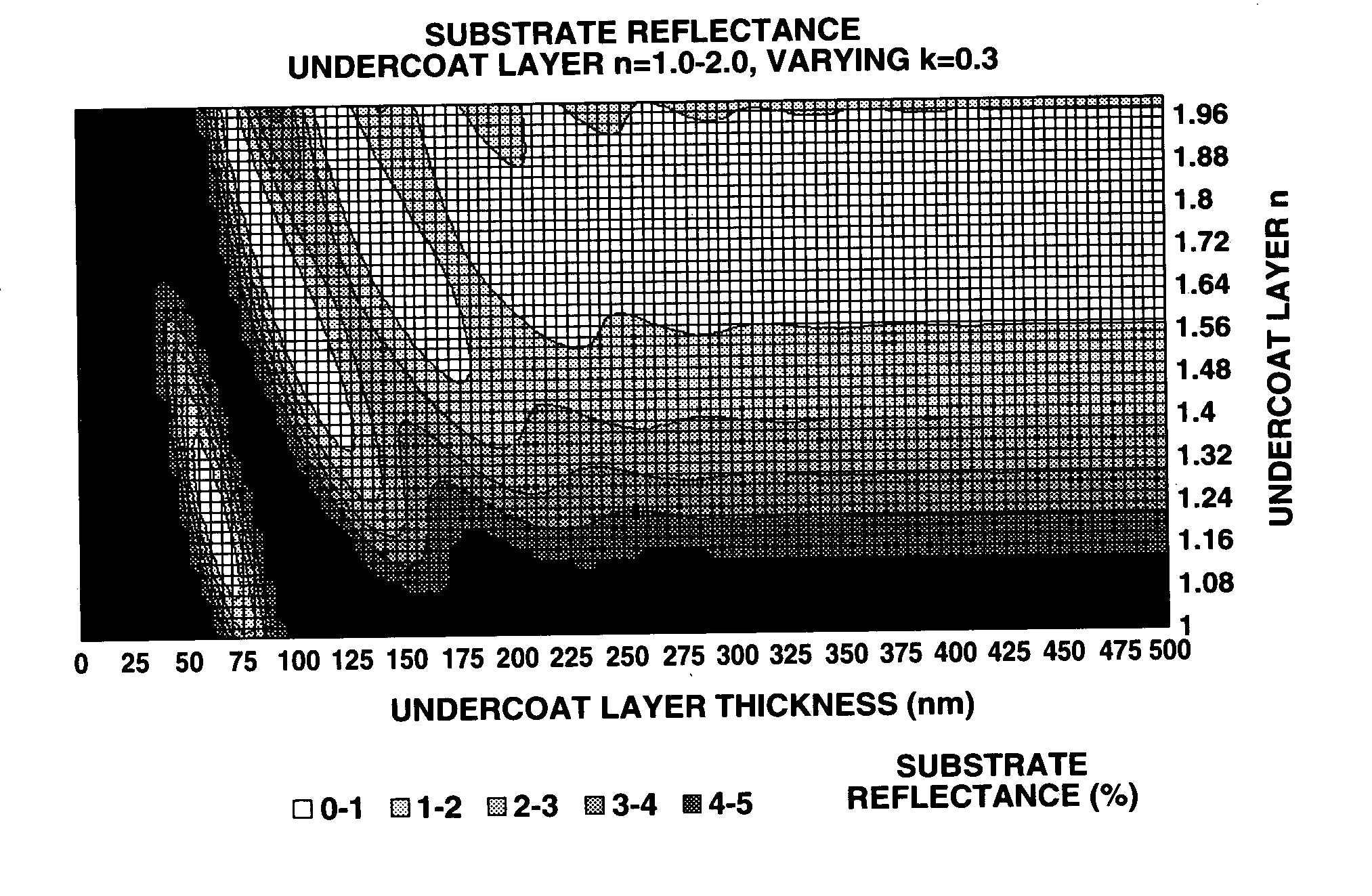

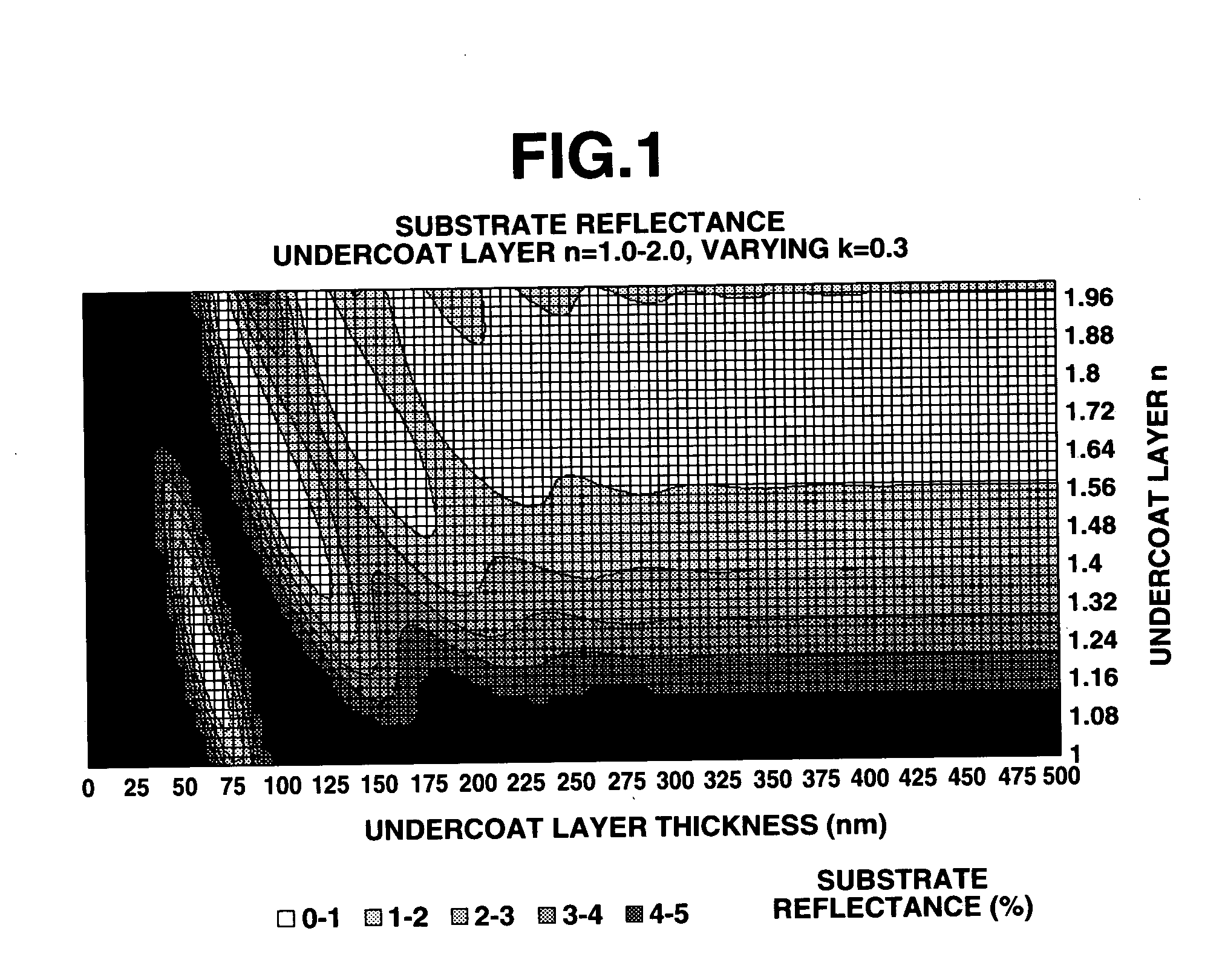

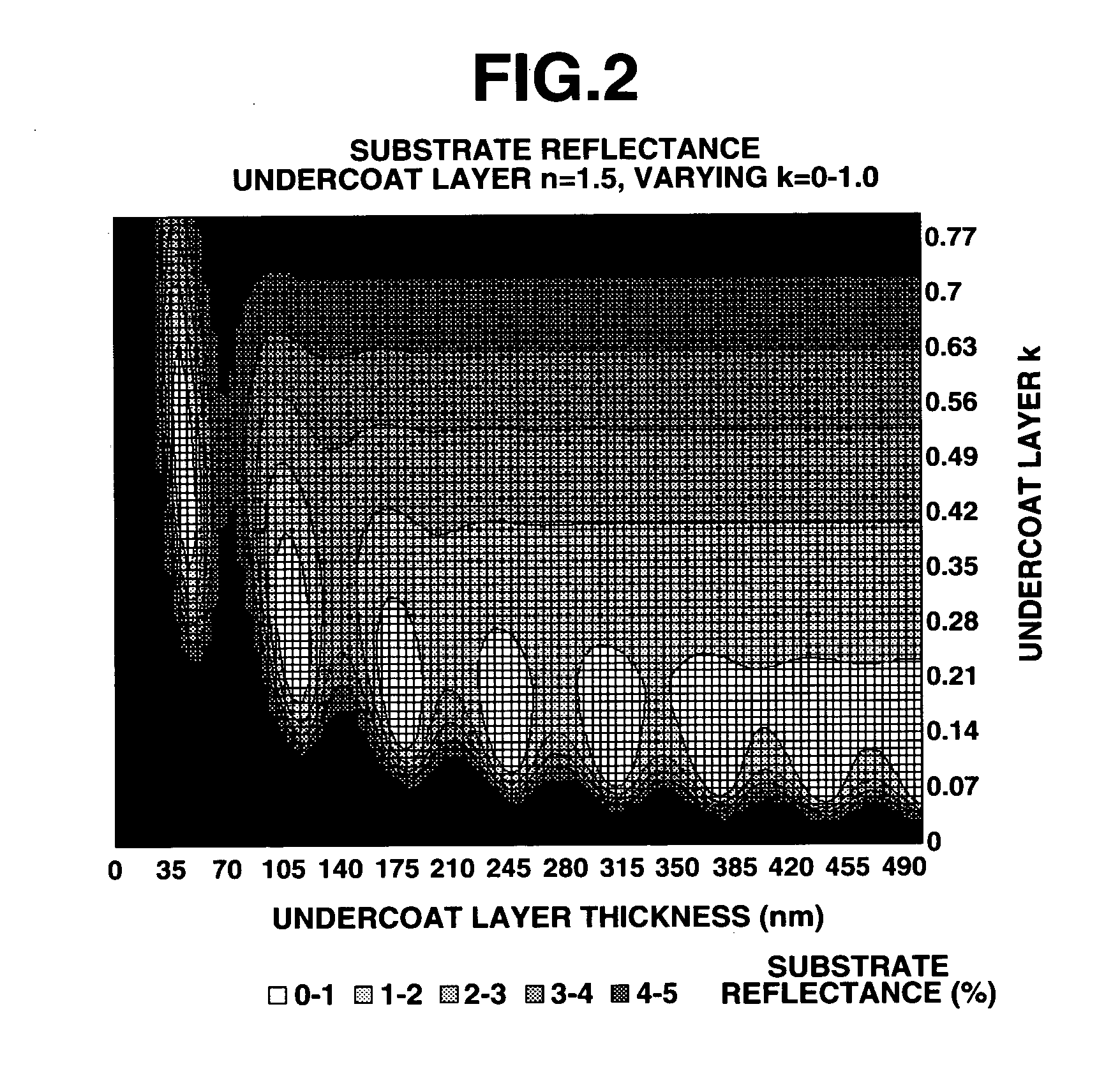

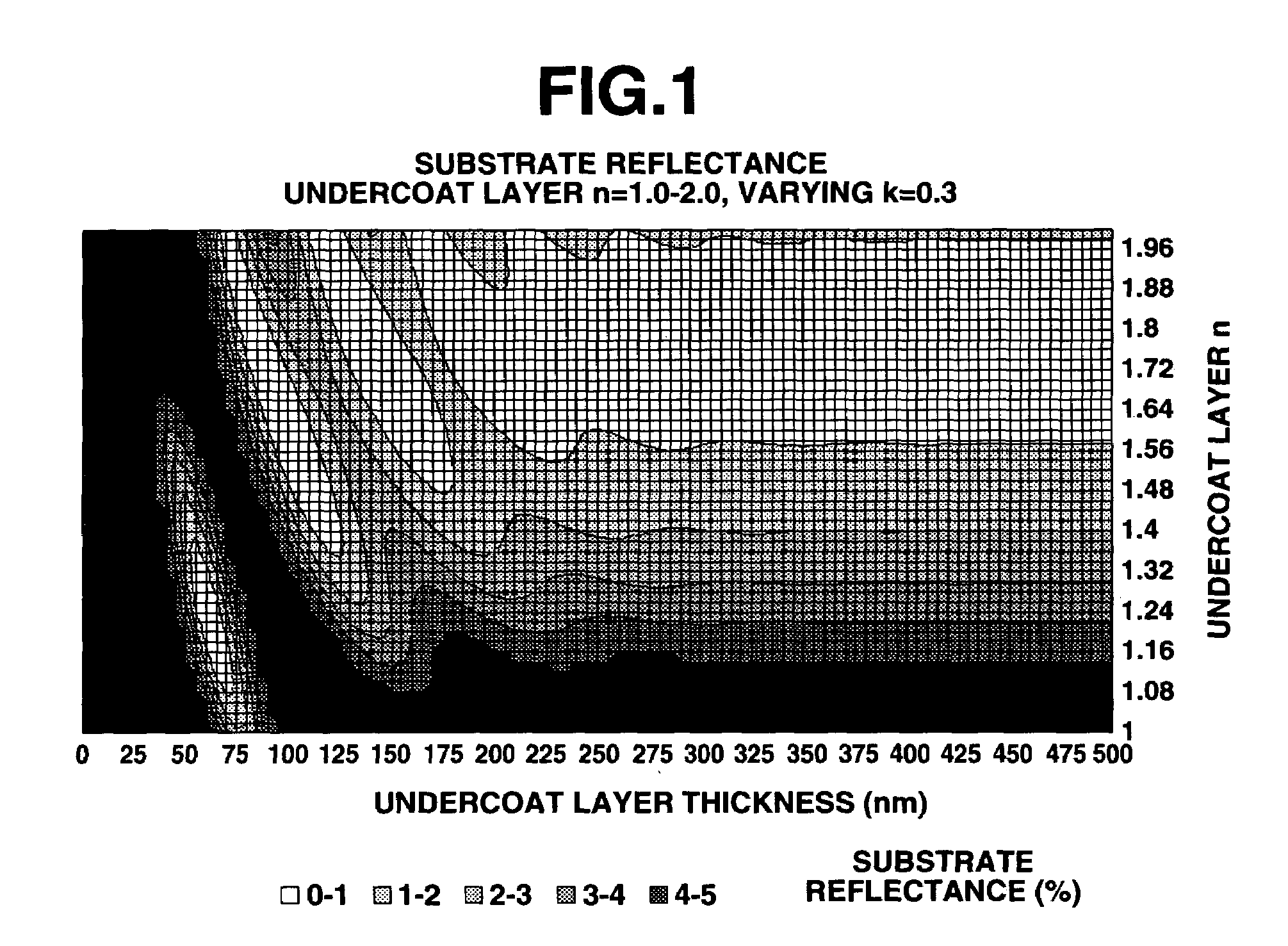

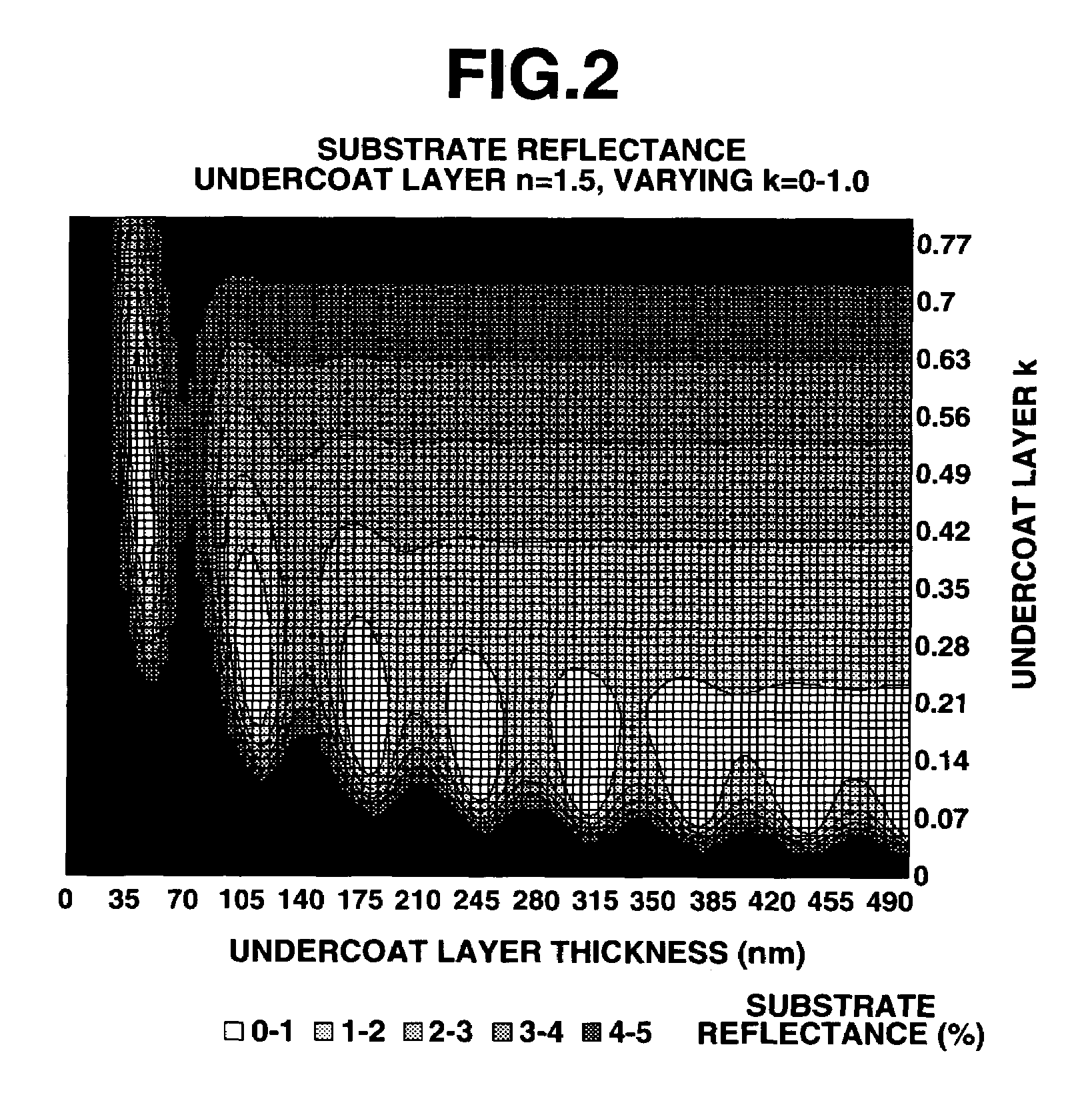

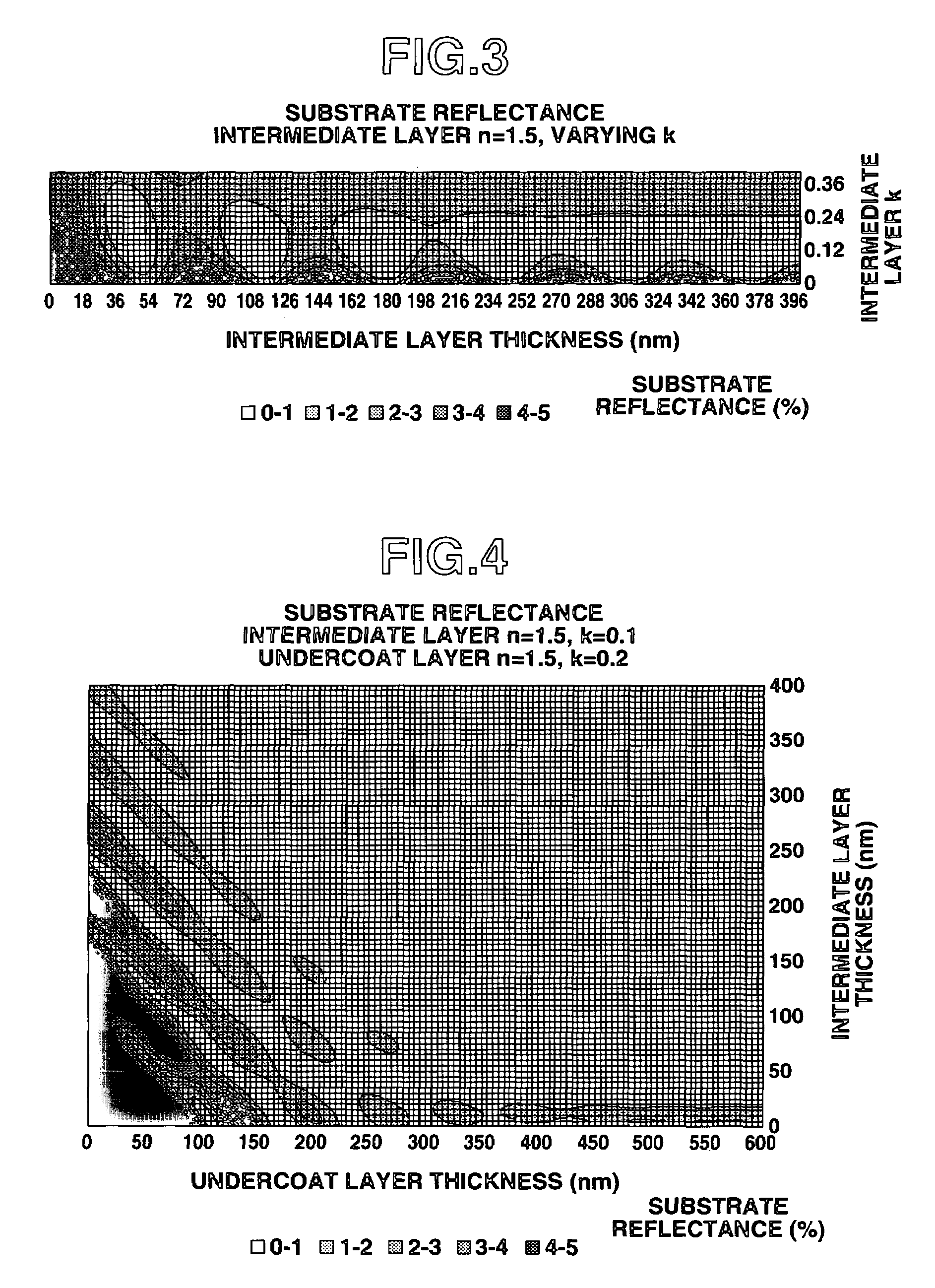

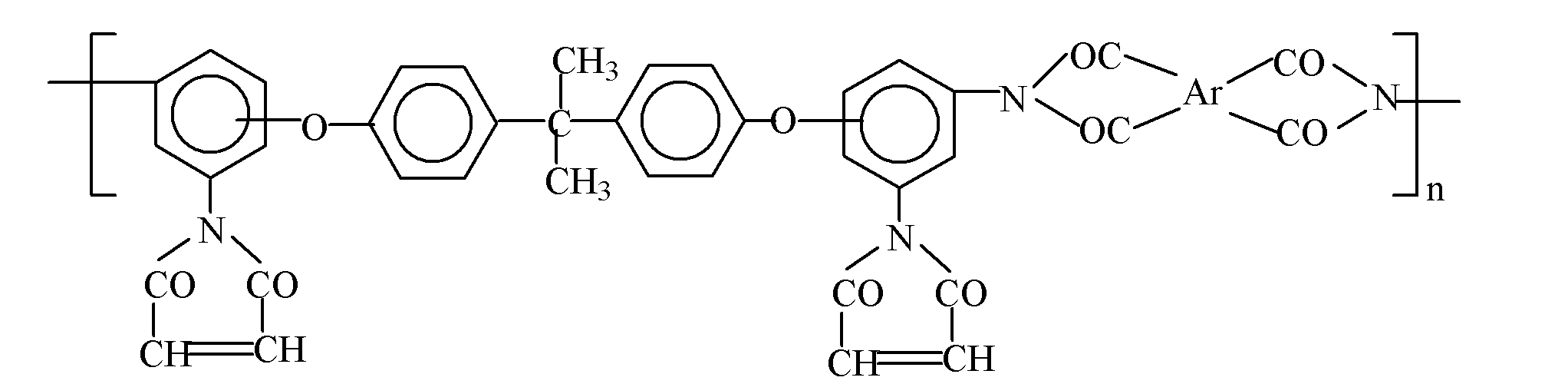

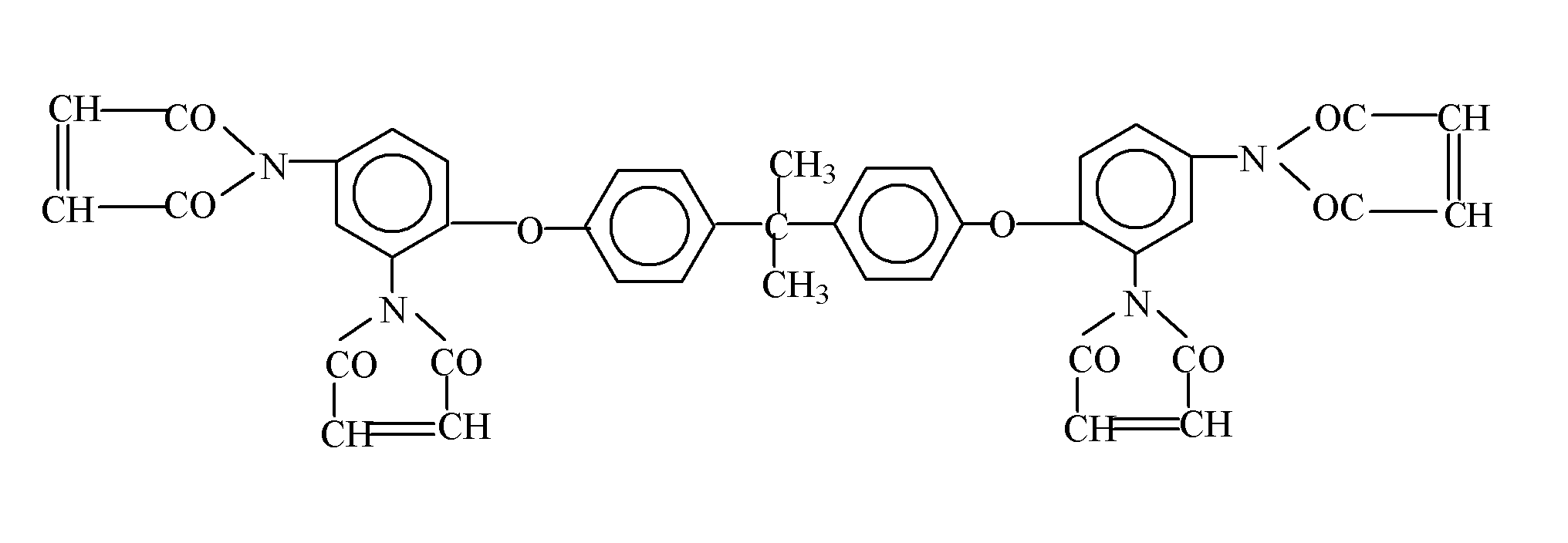

Photoresist undercoat-forming material and patterning process

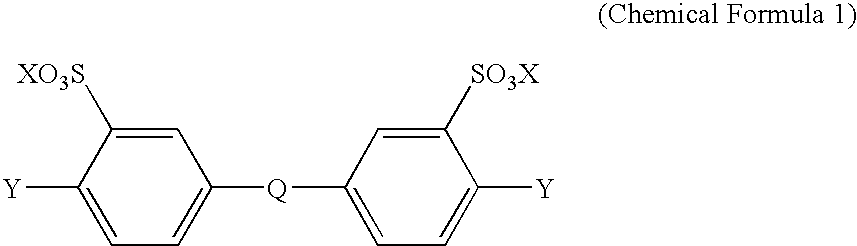

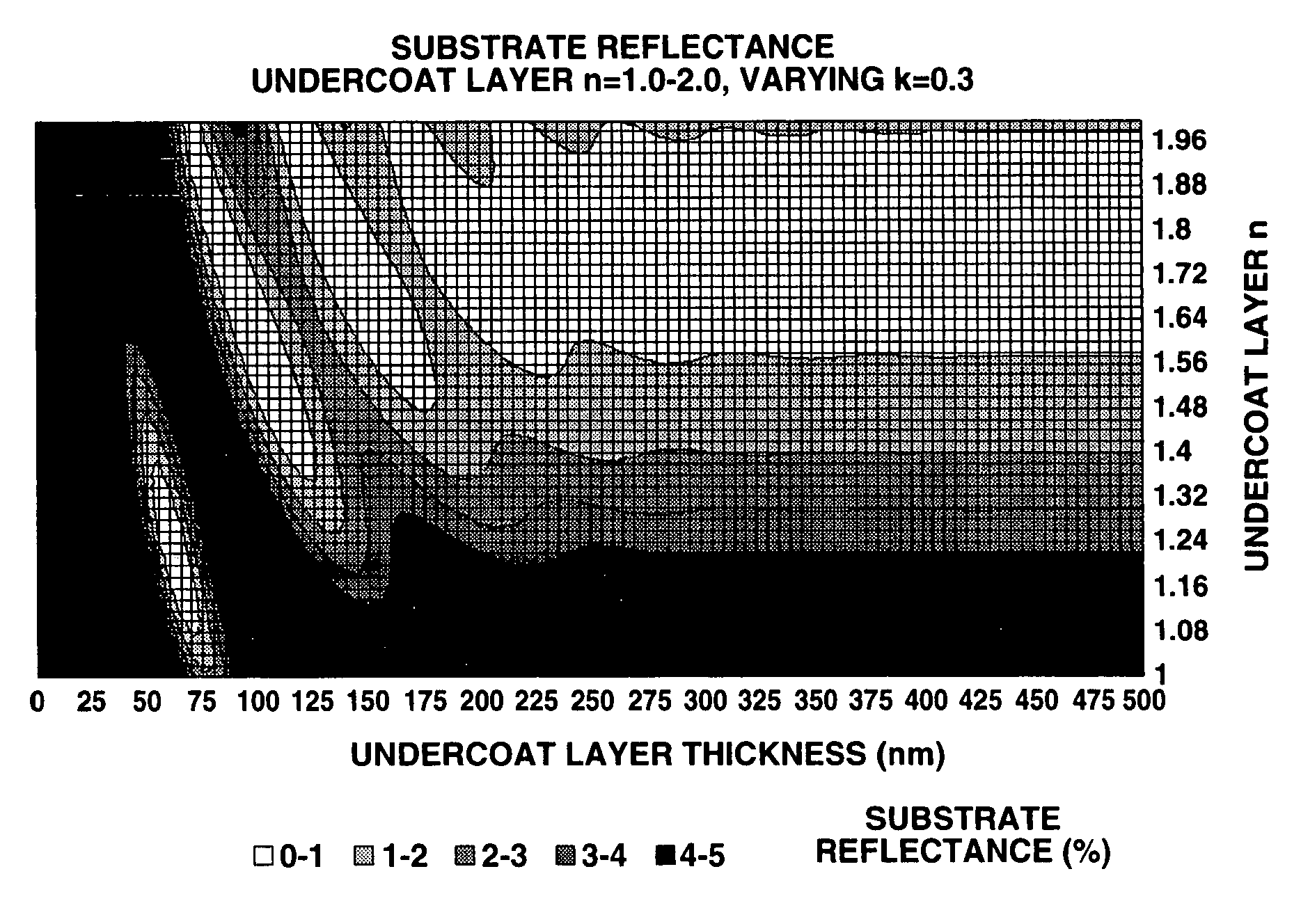

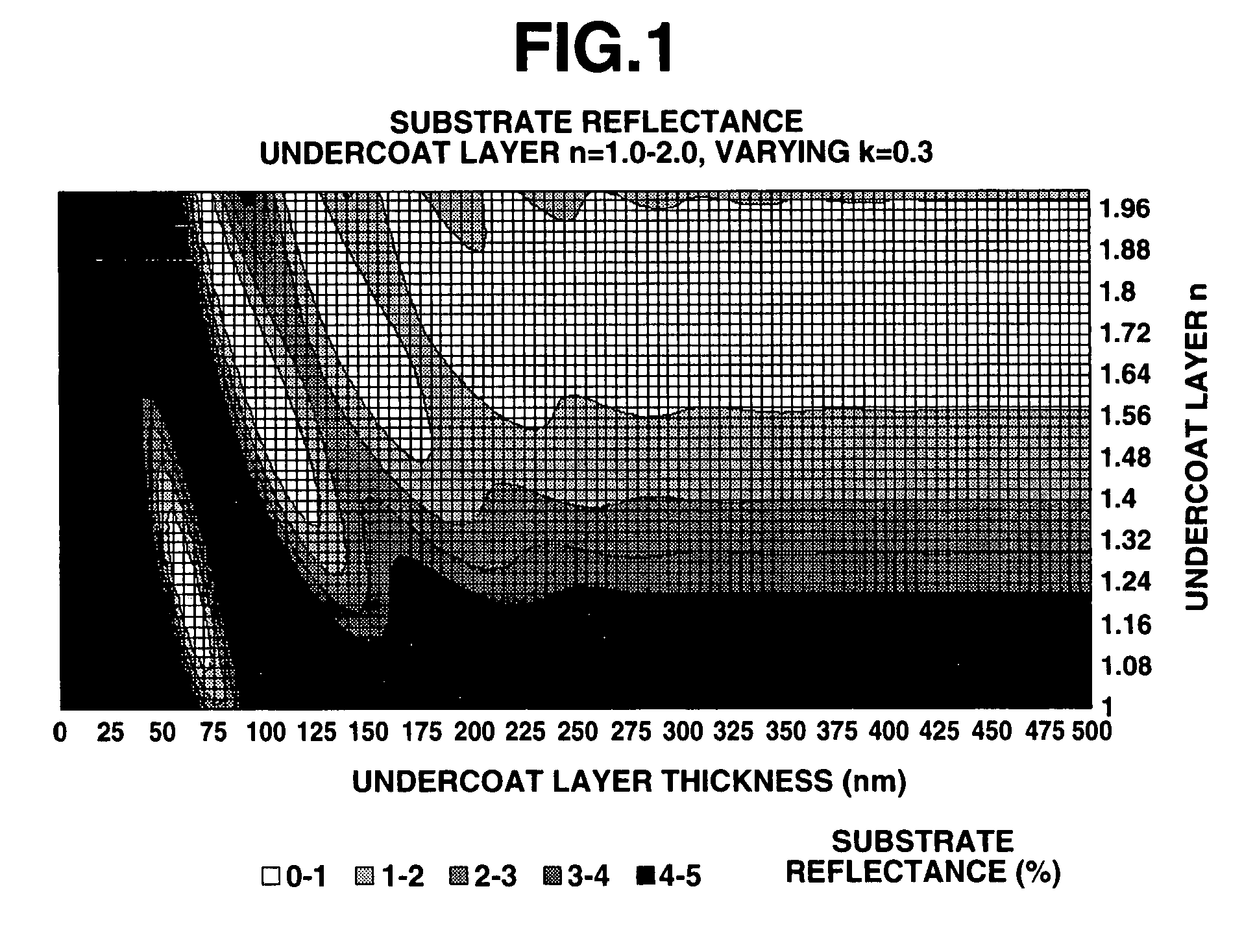

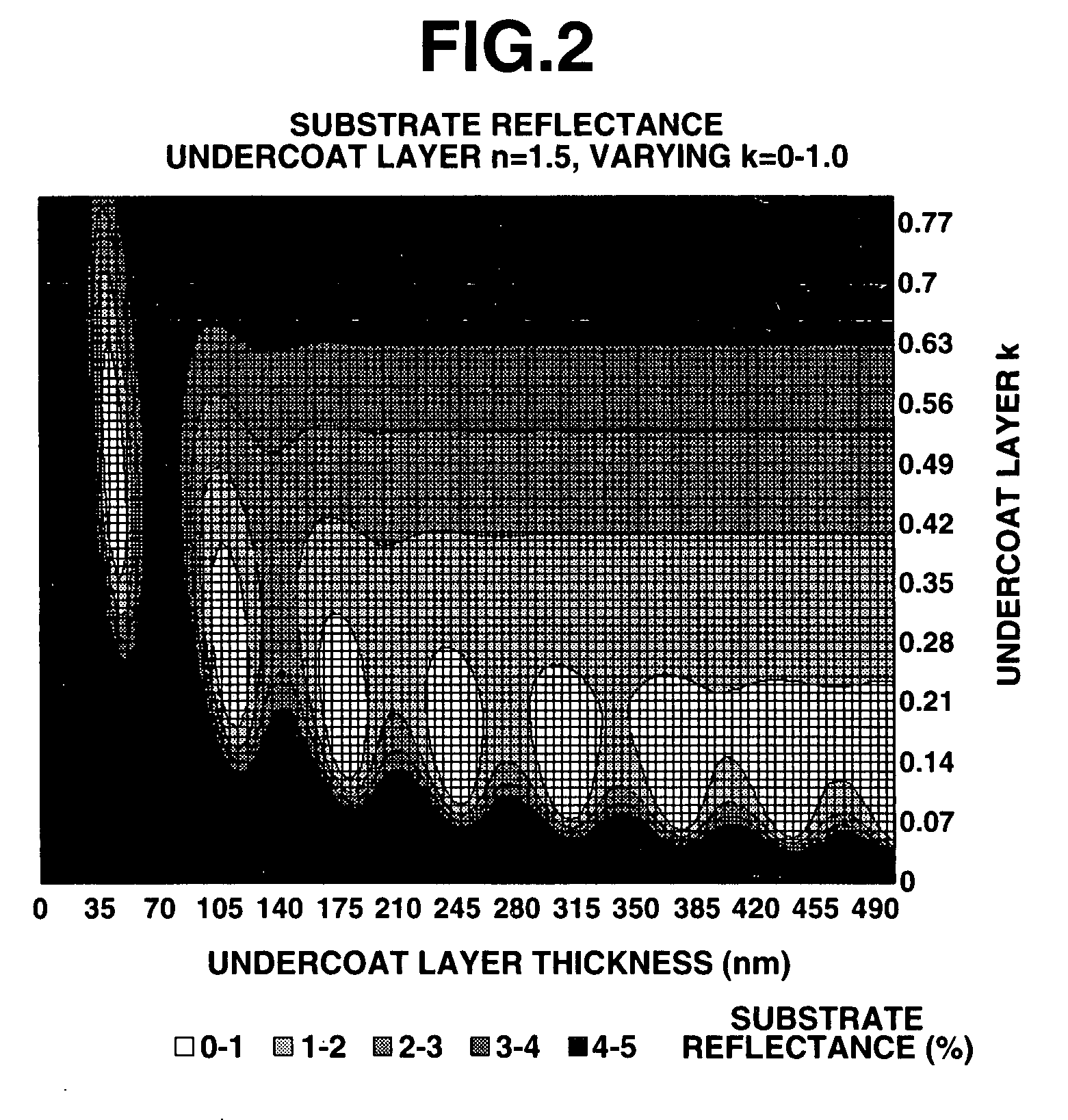

ActiveUS20060204891A1Improve the immunityIncrease resistanceDiazo compound compositionsPhotosensitive material auxillary/base layersInter layerBisphenol

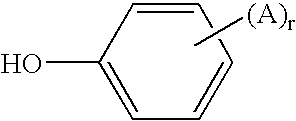

A material comprising a specific bisphenol compound with a group of many carbon atoms is useful in forming a photoresist undercoat. The undercoat-forming material, optionally combined with an intermediate layer having an antireflective effect, has an absorptivity coefficient sufficient to provide an antireflective effect at a thickness of at least 200 nm and a high etching resistance as demonstrated by slow etching rates with CF4 / CHF3 and Cl2 / BCl3 gases for substrate processing.

Owner:SHIN ETSU CHEM IND CO LTD

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

Storage stable autodepositable dispersions of epoxy resins and processes therefor and therewith

InactiveUS6096806AIncreased particle refinementSolvent extractionIon-exchanger regenerationStandard hydrogen electrodePolymer chemistry

PCT No. PCT / US96 / 12540 Sec. 371 Date Feb. 17, 1998 Sec. 102(e) Date Feb. 17, 1998 PCT Filed Aug. 7, 1996 PCT Pub. No. WO97 / 07163 PCT Pub. Date Feb. 27, 1997Epoxy resins, particularly those based on bisphenol A, can constitute the principal film forming polymer component of a storage stable autodepositable composition wherein the particle size distribution of all the film forming polymers in the composition satisfies certain criteria of size distribution, and an accelerator component which is an acid, oxidizing agent or complexing agent is present in amount sufficient to provide an oxidation-reduction potential at least 100 mV more oxidizing than a standard hydrogen electrode. Such dispersions can conveniently be prepared using a two stage process in which a solution of the film forming polymers is emulsified into water to form a preliminary dispersion and this preliminary dispersion is subjected to at least one particle size refinement stage in which the preliminary dispersion is forced through a narrow aperture.

Owner:HENKEL KGAA

Method for preparation of copolyorganosiloxanecarbonates of high clarity

Owner:SHPP GLOBAL TECH BV

Permanent resist composition, cured product thereof, and use thereof

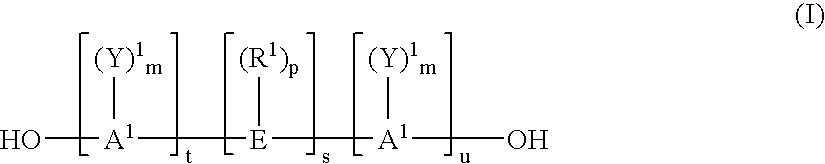

InactiveUS20050260522A1High densityImprove film adhesionNanoinformaticsPhotomechanical apparatusPolymer sciencePhotoacid generator

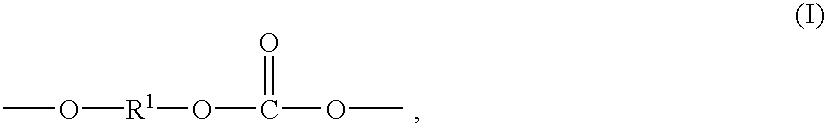

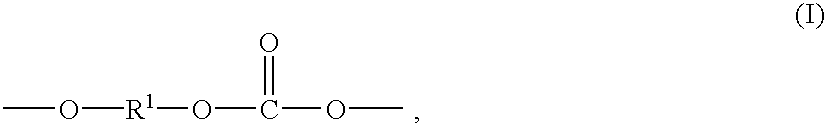

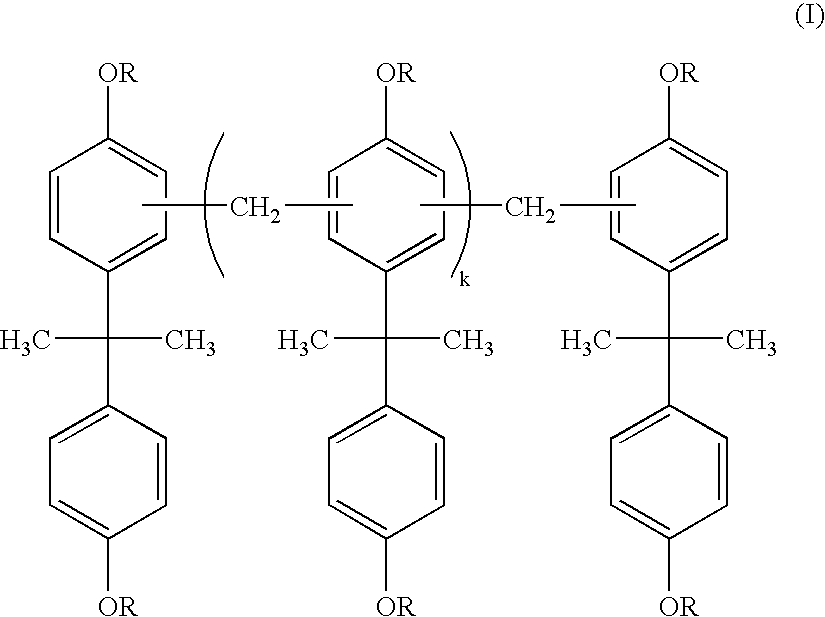

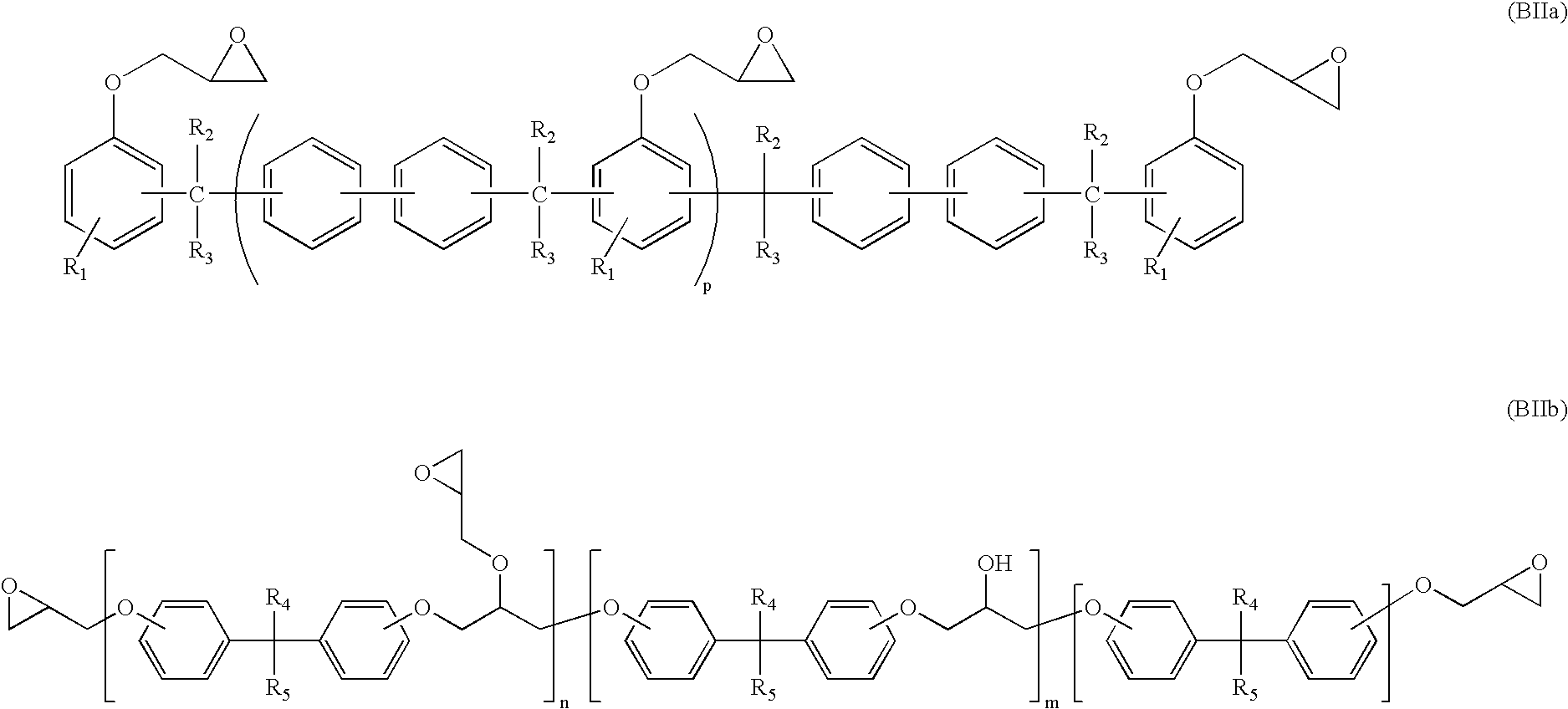

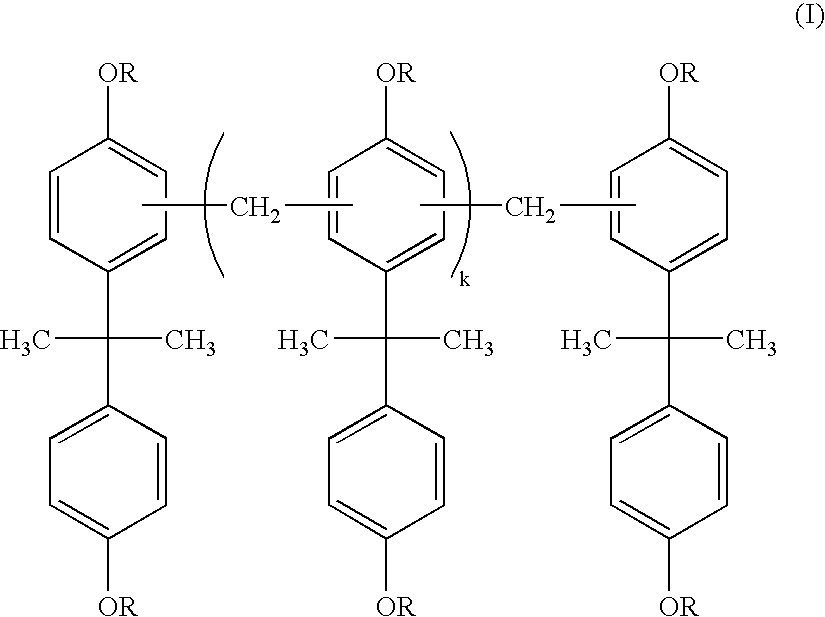

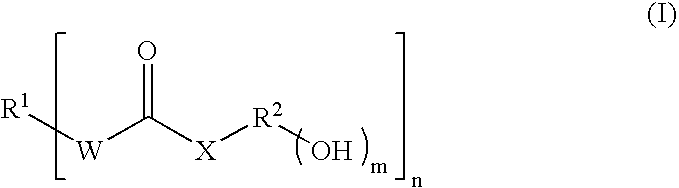

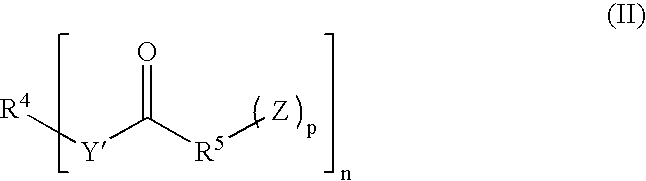

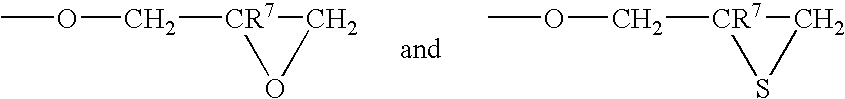

A permanent photoresist composition comprising: (A) one or more bisphenol A-novolac epoxy resins according to Formula I; wherein each group R in Formula I is individually selected from glycidyl or hydrogen and k in Formula I is a real number ranging from 0 to about 30; (B) one or more epoxy resins selected from the group represented by Formulas BIIa and BIIb; wherein each R1, R2 and R3 in Formula BIIa are independently selected from the group consisting of hydrogen or alkyl groups having 1 to 4 carbon atoms and the value of p in Formula BIIa is a real number ranging from 1 to 30; the values of n and m in Formula BIIb are independently real numbers ranging from 1 to 30 and each R4 and R5 in Formula BIIb are independently selected from hydrogen, alkyl groups having 1 to 4 carbon atoms, or trifluoromethyl; (C) one or more cationic photoinitiators (also known as photoacid generators or PAGs); and (D) one or more solvents.

Owner:MICROCHEM CORP +1

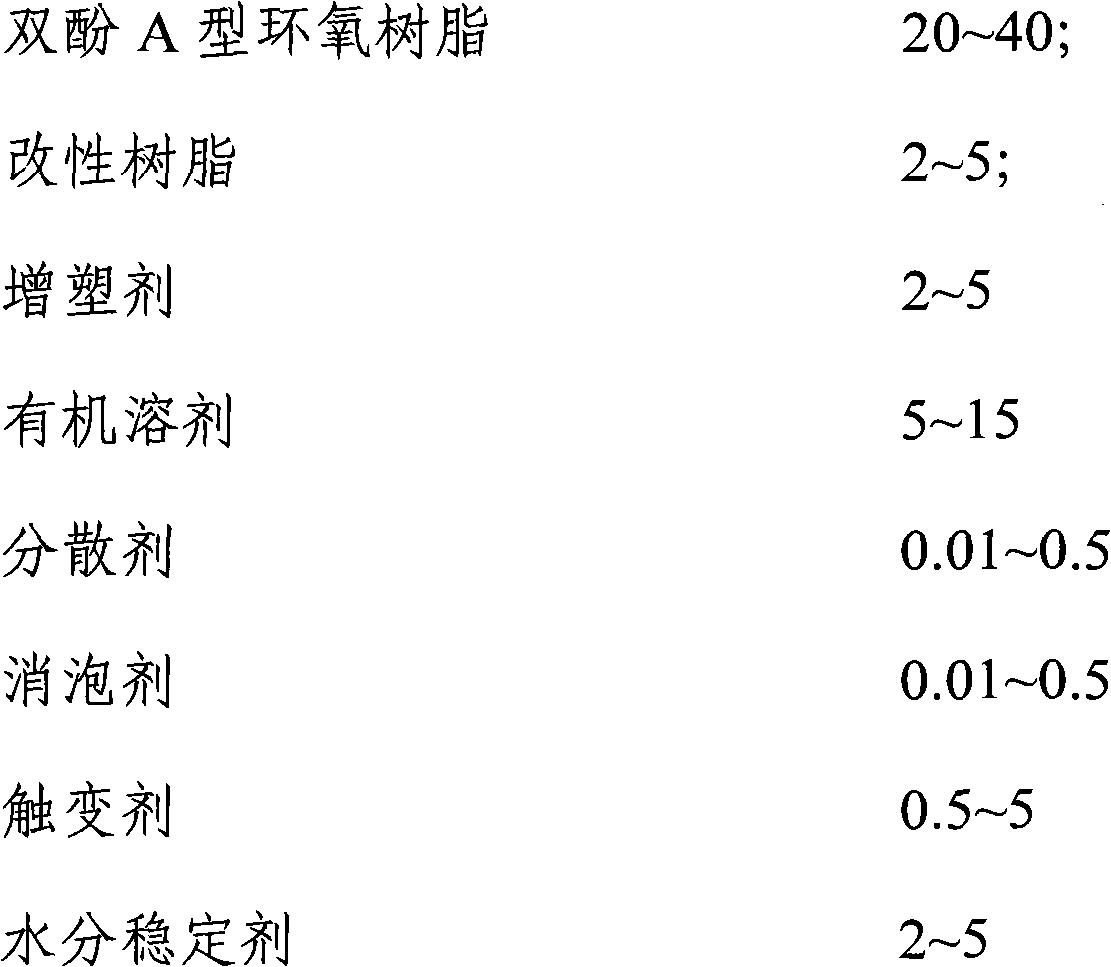

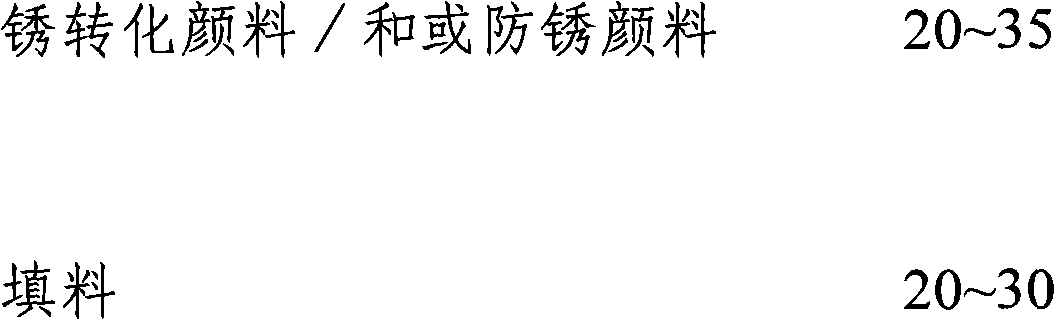

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

Heat-resistant structural epoxy resins

ActiveUS20080251202A1Improve suppression propertiesAvoid excessive adhesionLaminationLamination apparatusMicrosphereEpoxy adhesive

Epoxy adhesive compositions containing a rubber-modified epoxy resin contain a bisphenol. The bisphenol can be pre-reacted with the rubber-modified epoxy resin to advance the resin. The adhesives are resistant to thermal degradation as can occur in so-called “overbake” conditions, in which the adhesive is heated to high temperatures for prolonged periods of time. In addition, expanded microballoons are included in epoxy structural adhesives to promote a desired fracture mode.

Owner:DOW GLOBAL TECH LLC

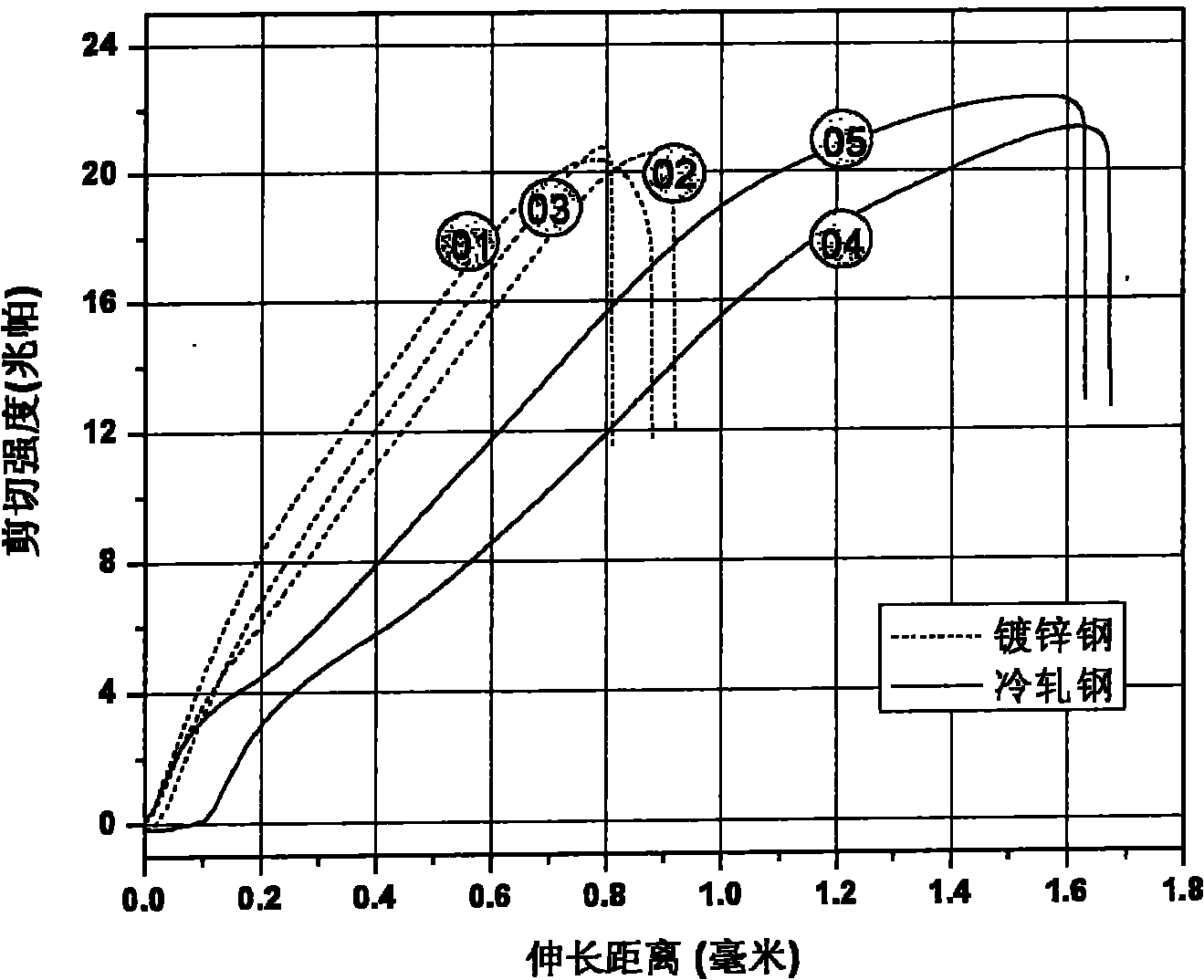

Room-temperature curing epoxy structural adhesive composition and preparation method thereof

InactiveCN101818037AIncreased shear strengthHigh T-peel strengthEpoxy resin adhesivesNitrile rubberAdhesive

The invention relates to a room-temperature curing epoxy structural adhesive composition, which comprises a component A and a component B, wherein the component A comprises bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, silane coupling agent, thixotropic agent and colorant; and the component B comprises polyamide, polyether amine, a filler and a curing accelerator; the toughness modified bisphenol A epoxy resin is liquid nitrile rubber-modified bisphenol A epoxy resin and / or polymer-toughened bisphenol A epoxy resin with a nuclear shell structure; meanwhile, the invention also provides a method for preparing the room-temperature curing epoxy structural adhesive compositiion. The structural adhesive of the invention has the advantages of good toughness, strong high-temperature strength, short curing time, simple preparation method, and the like.

Owner:HENKELCHINAINVESTMENT

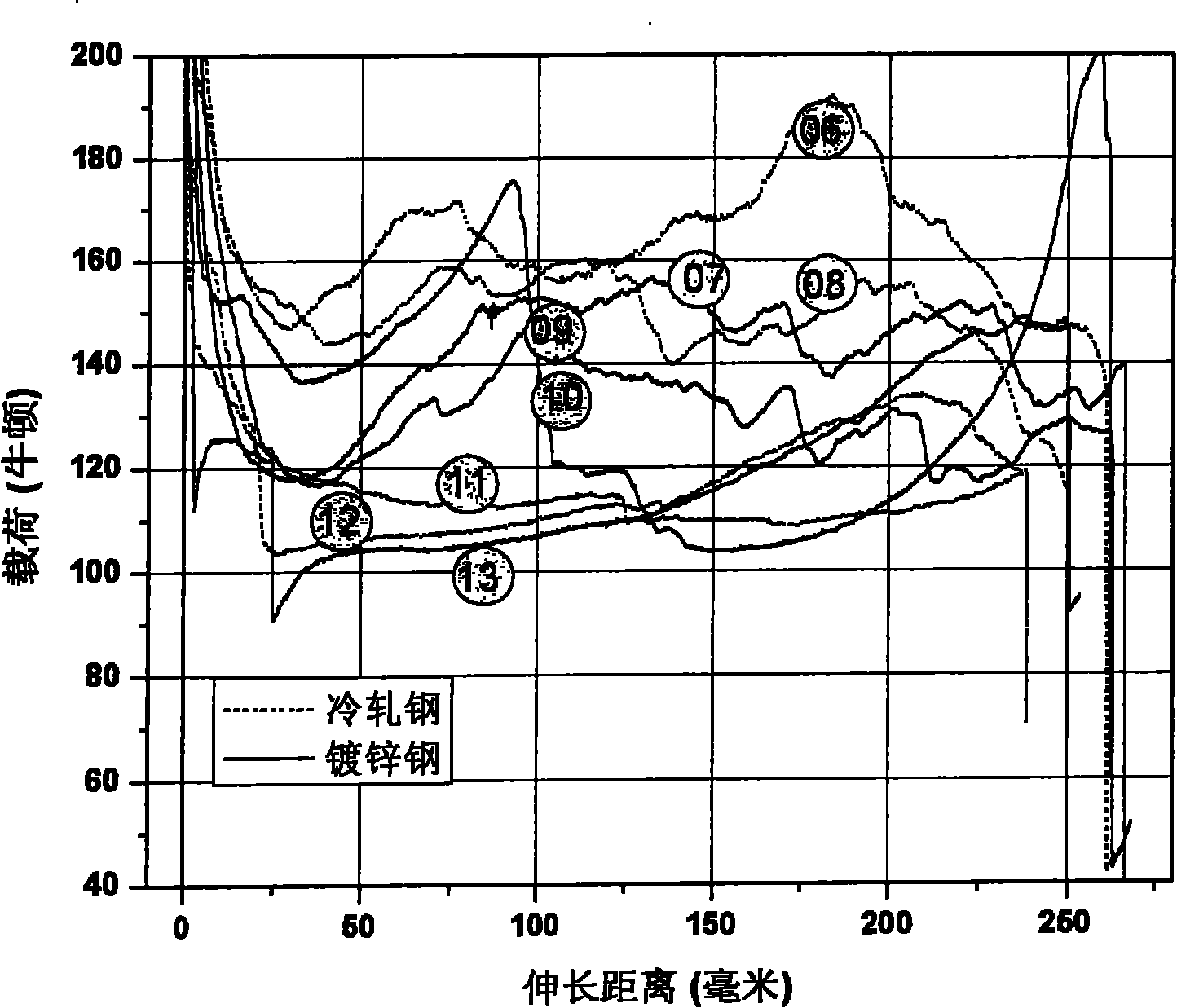

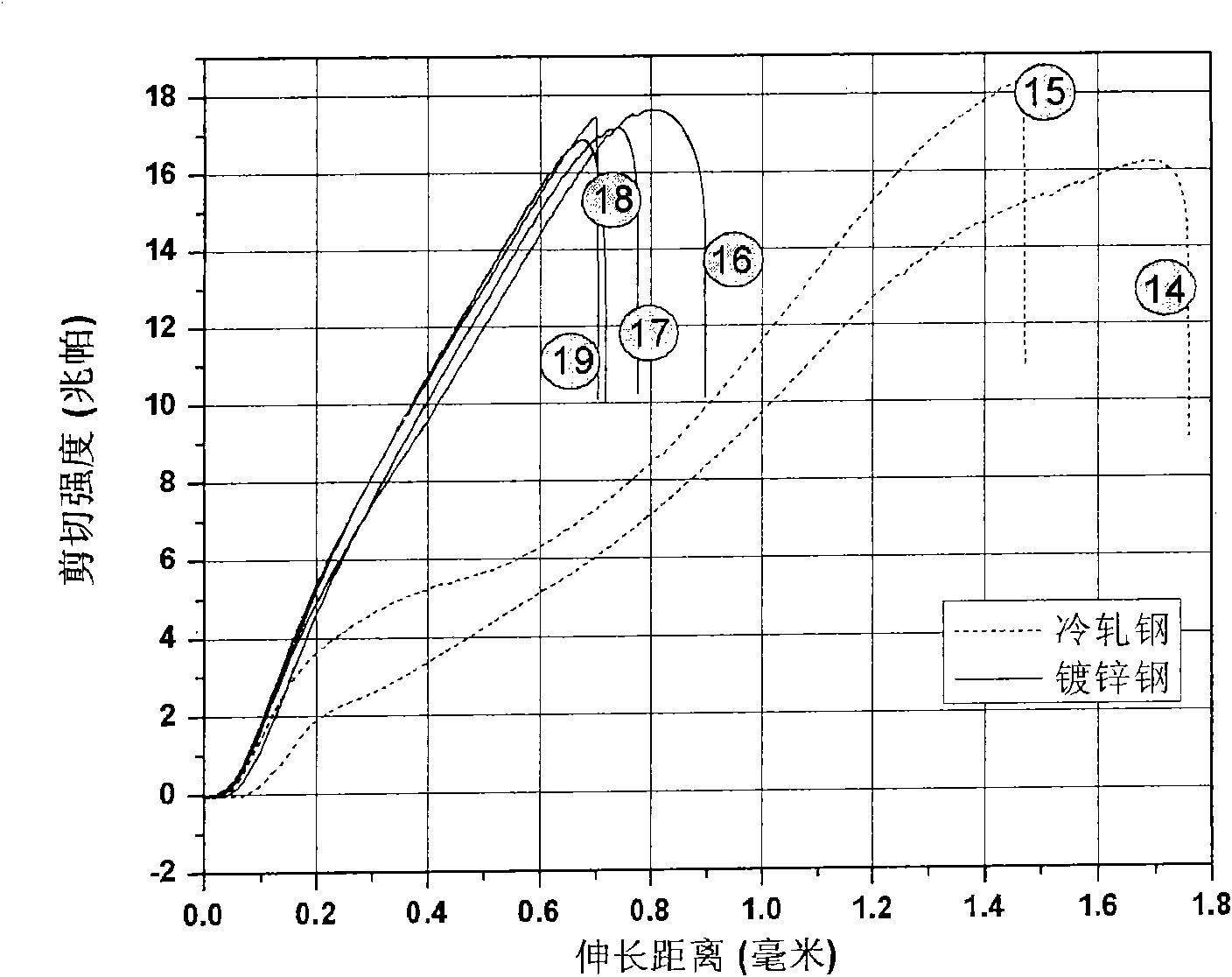

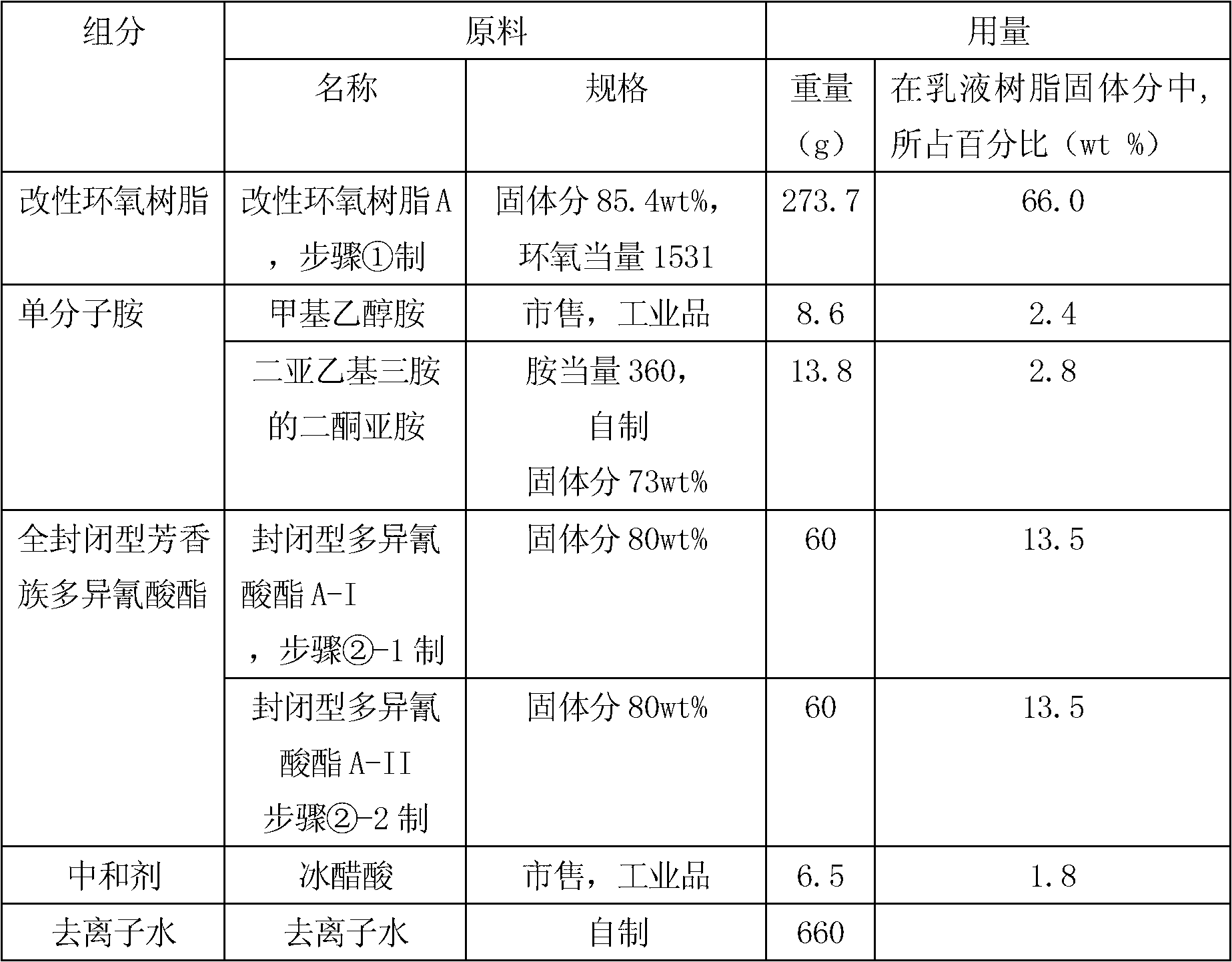

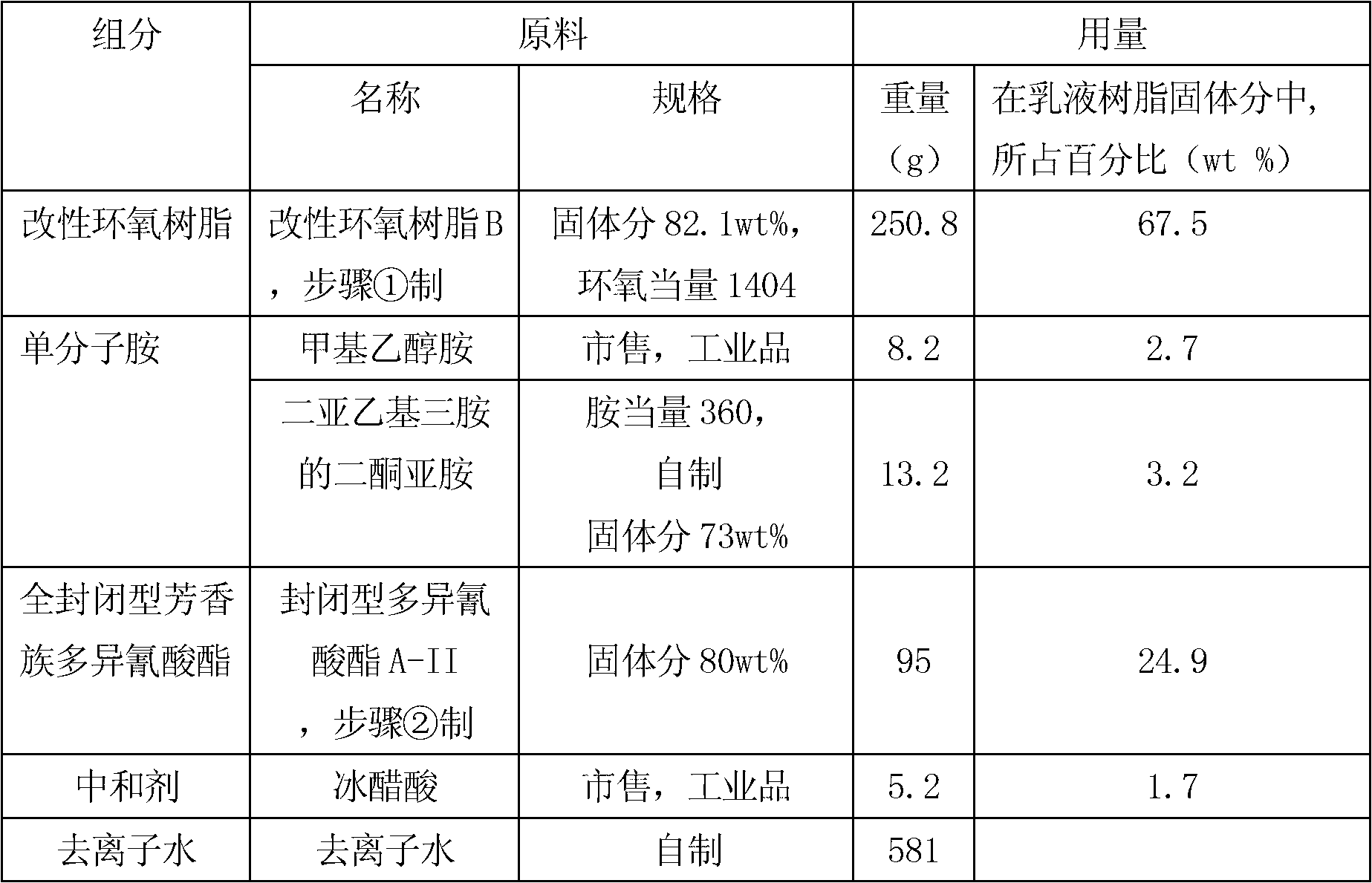

Resin emulsion for cathode electrophoretic coating with high throwing power and preparation method thereof

ActiveCN102838846ASuitable glass transition temperatureIncrease construction voltagePaints for electrolytic applicationsEpoxy resin coatingsOrganic acidEmulsion

The invention relates to resin emulsion for cathode electrophoretic coating with high throwing power and a preparation method of the resin emulsion, wherein the emulsion is obtained by the following steps: heating and mixing modified epoxy resin aminated by various single molecular amines and one or two of fully-closed aromatic polyisocyanates; using organic acid to neutralize the mixture; and using de-ionized water to disperse the mixture, wherein the weight ratio of raw materials in the resin emulsion solid is as follows: 45-70wt% of modified epoxy resin, 4-10wt% of total single molecular amines, 20-40wt% of fully-closed aromatic polyisocyanates and 1.6-3.5wt% of organic acid; the modified epoxy resin is obtained by replacing part of solvent with plasticizer, and using flexible polymer to extend chain of bisphenol A epoxy resin to be of molecular weight of 1500-3000; in the modified epoxy resin solid, the content of flexible polymer is 10-35% and the content of the plasticizer is 4-14%. The resin emulsion is stable and low in solvent content; the film has smooth appearance and throwing power of more than 22cm.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Clear silicone polycarbonate elastomeric copolymers

Silicone polycarbonate block copolymers are disclosed that have a high elongation before yield, are clear, and have elastomeric properties. Generally, the silicone blocks are very short (less than about 50 organosiloxane repeat units) and the silicone blocks are substantially isolated from each other by bisphenol carbonate spacers.

Owner:SHPP GLOBAL TECH BV

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

Photoresist undercoat-forming material and patterning process

ActiveUS7358025B2Improve the immunityDiazo compound compositionsPhotosensitive material processingInter layerBisphenol

A material comprising a specific bisphenol compound with a group of many carbon atoms is useful in forming a photoresist undercoat. The undercoat-forming material, optionally combined with an intermediate layer having an antireflective effect, has an absorptivity coefficient sufficient to provide an antireflective effect at a thickness of at least 200 nm and a high etching resistance as demonstrated by slow etching rates with CF4 / CHF3 and Cl2 / BCl3 gases for substrate processing.

Owner:SHIN ETSU CHEM IND CO LTD

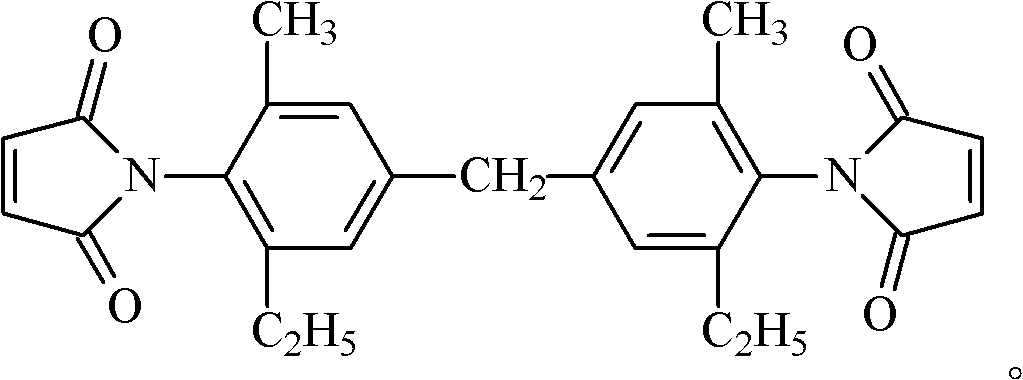

Thermosetting polyimide resin and preparation method thereof

The invention relates to a thermosetting polyimide resin and a preparation method thereof. A homogeneous transparent sticky maleimide-based polyimide resin solution is taken as a component A, and a 4-maleimide-based bisphenol solution A is taken as a component B. The preparation method of the thermosetting polyimide resin comprises the following steps: (1) preparing the maleimide-based polyimide resin solution as the component A; (2) preparing the 4-maleimide-based bisphenol solution A as the component B; and (3) uniformly mixing the component A and the component B at room temperature to obtain the thermosetting polyimide resin. The thermosetting polyimide resin of the invention not only can be applied to the matrix resin of high temperature resistant adhesives and glass fiber reinforced composite materials but also can be applied to the matrix resin of high-performance fiber (carbon fiber, aramid fiber and the like) reinforced advanced composite materials, thus the thermosetting polyimide resin has wide application prospects; and the invention has simple preparation technology, low cost and environmental protection, can finish preparation processes in the general equipment, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

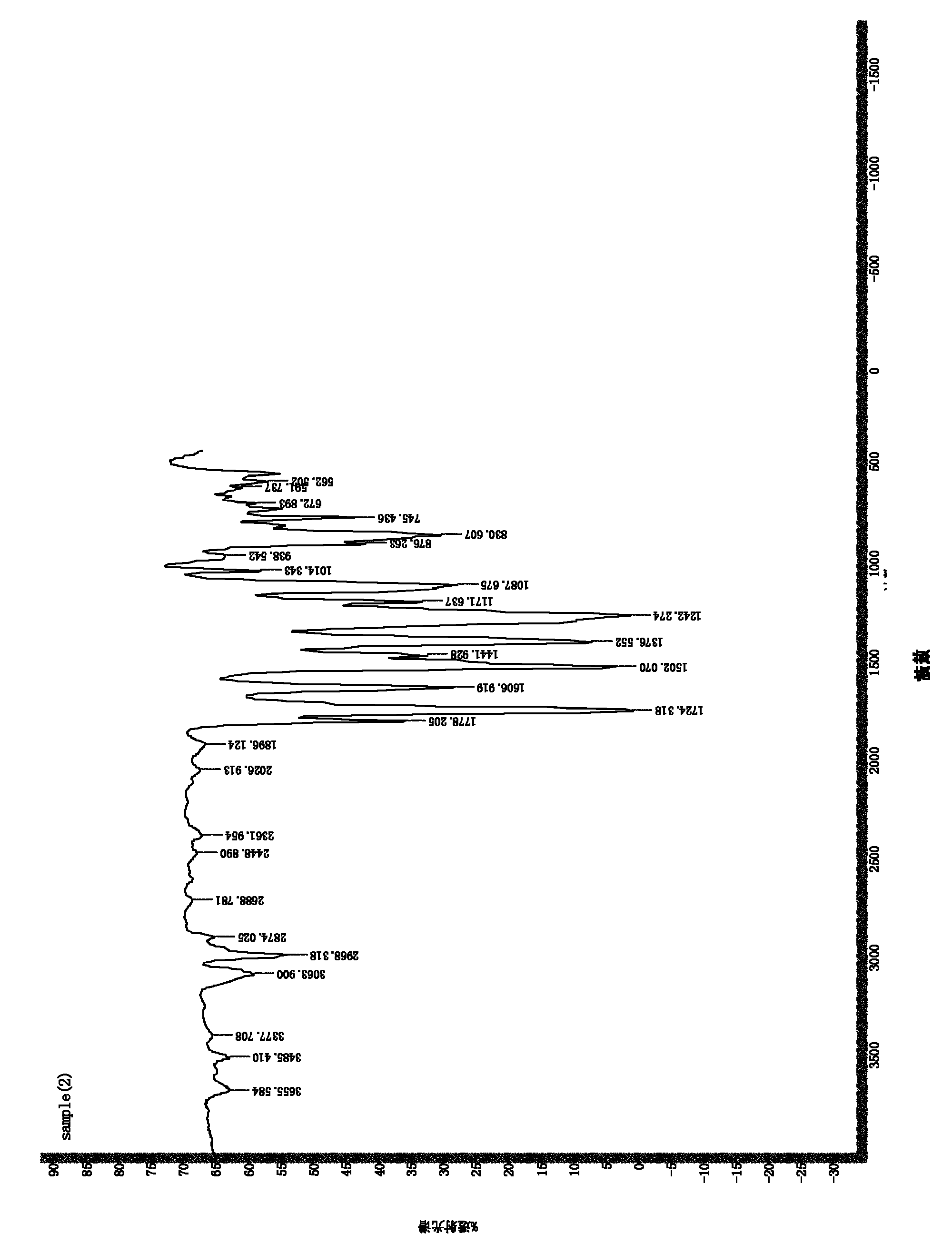

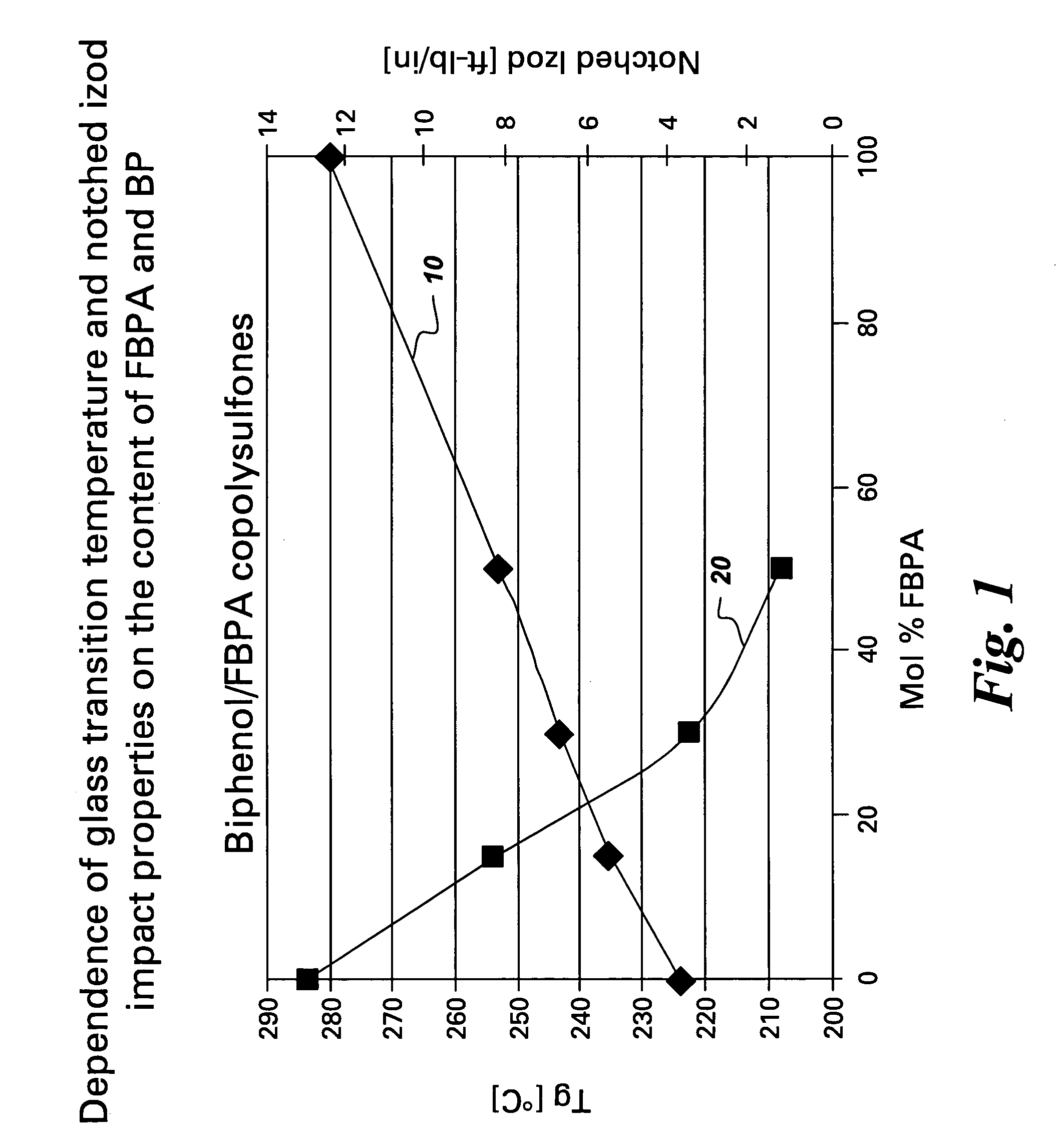

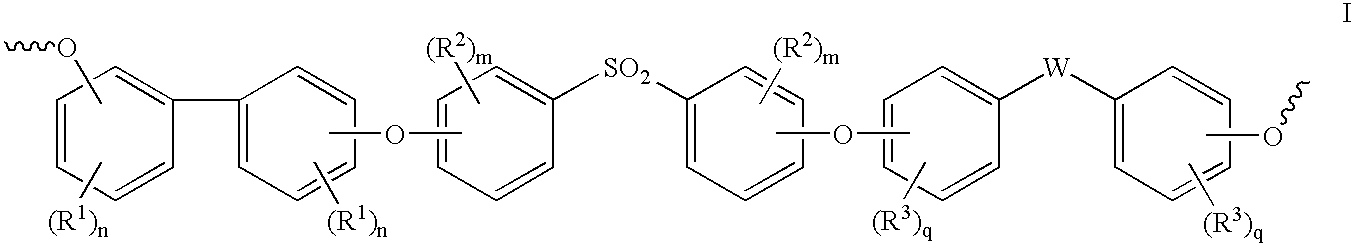

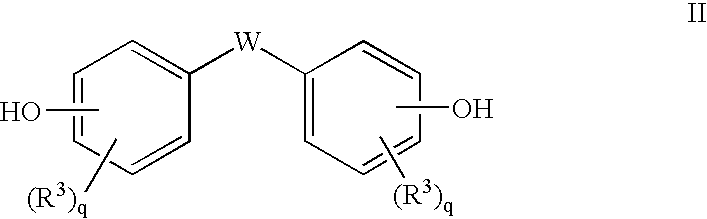

Polyethersulfone compositions with high heat and good impact resistance

A polyethersulfone composition is disclosed which comprises structural units derived from a monomer mixture comprising fluorenylidene bisphenol-A and at least 50 mole percent of 4,4′-biphenol based on total moles of diphenolic monomers, wherein the polyethersulfone has a minimum glass transition temperature of 235° C. and a notched Izod impact value of 1 ft-lb / in. as measured by ASTM D256.

Owner:GENERAL ELECTRIC CO

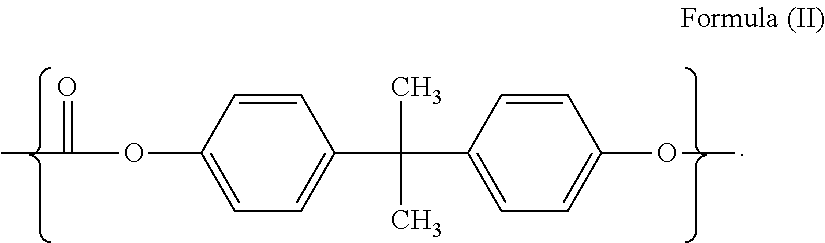

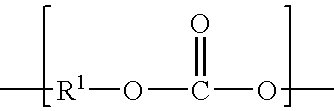

Method of polycarbonate preparation

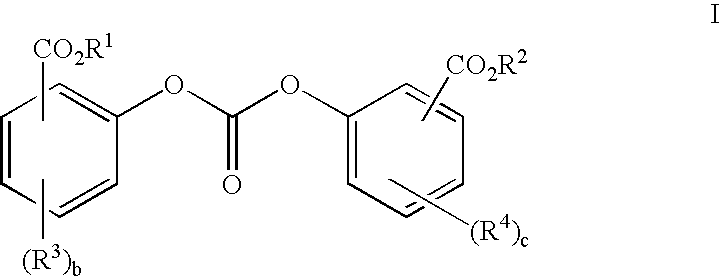

InactiveUS20050261460A1Low levelImprove the level ofCeramic shaping apparatusFries rearrangementHydroquinone Compound

Polycarbonates containing low or undetectable levels of Fries rearrangement products and comprising repeat units derived from one or more of resorcinol, hydroquinone, methylhydroquinone, bisphenol A, and 4,4′-biphenol have been prepared by the melt reaction of one or more of the aforementioned dihydroxy aromatic compounds with an ester-substituted diaryl carbonate such as bis-methyl salicyl carbonate. Low, or in many instances undetectable, levels of Fries rearrangement products are found in the product polycarbonates obtained as the combined result of a highly effective catalyst system which suppresses the Fries reaction and the use of lower melt polymerization temperatures relative to temperatures required for the analogous polymerization reactions using diphenyl carbonate.

Owner:SABIC INNOVATIVE PLASTICS IP BV

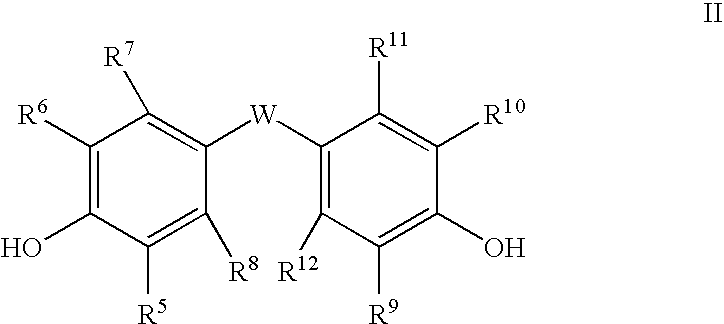

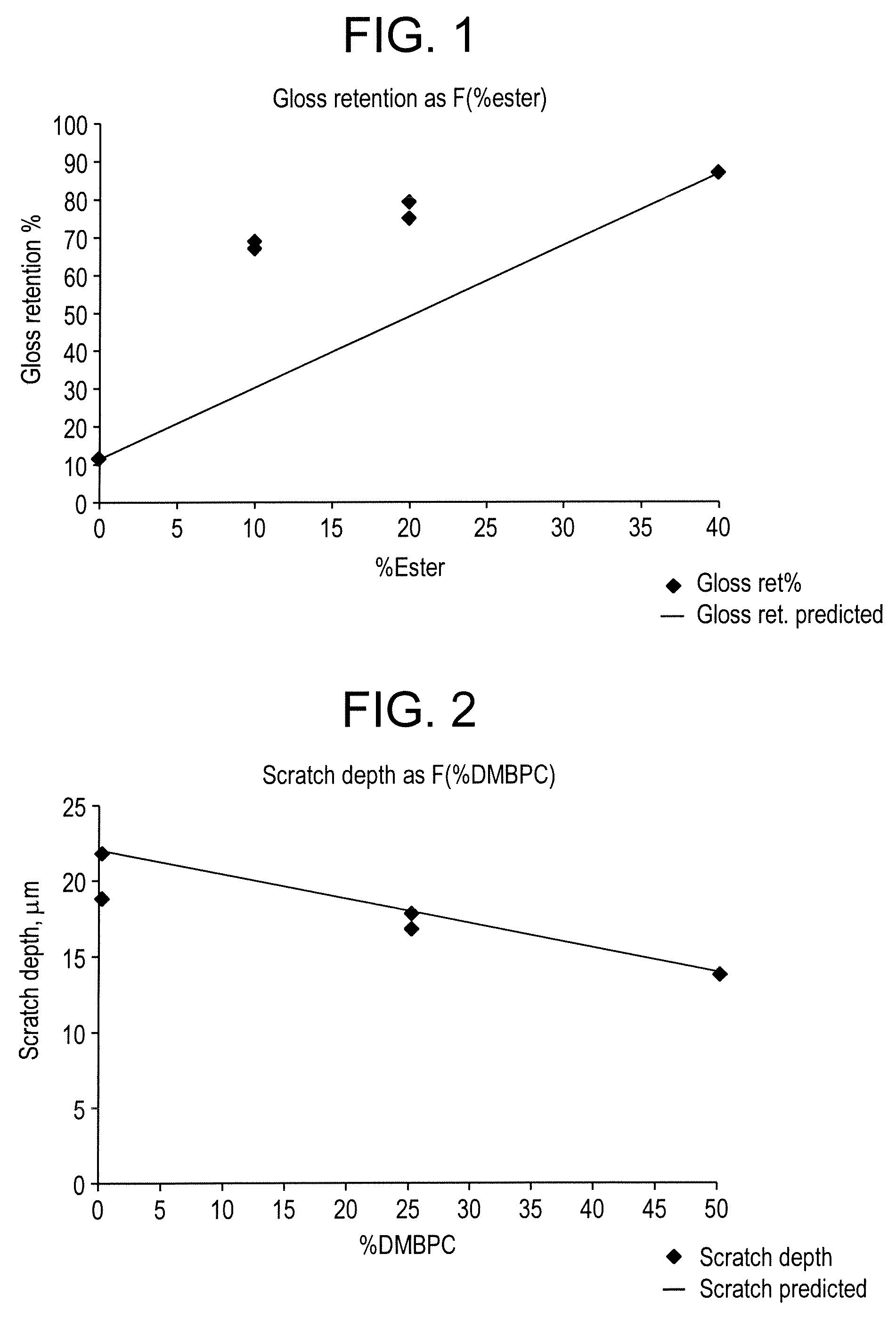

Thermoplastic composition having improved scratch resistance, and articles formed therefrom

A thermoplastic composition comprises A) 25 to 95 parts by weight of a first polycarbonate consisting essentially of i) 25 to 100 mole percent of a first carbonate unit comprising an alkyl-substituted bisphenol carbonate unit, ii) 0 to 75 mole percent of a second carbonate unit where the first and second carbonate units are not identical, and the sum of the mole percentages of the first and second carbonate units in the first polycarbonate is 100 mole percent; B) 5 to 75 parts by weight of a polyester-polycarbonate where the molar ratio of carbonate unit to arylate ester unit is 95:5 to 10:90; and C) 0 to 65 parts by weight of a second polycarbonate, where the first polycarbonate and second polycarbonate are not identical, and the sum of the parts by weight of the first polycarbonate, the polyester-polycarbonate, and the second polycarbonate is 100 parts by weight.

Owner:SHPP GLOBAL TECH BV

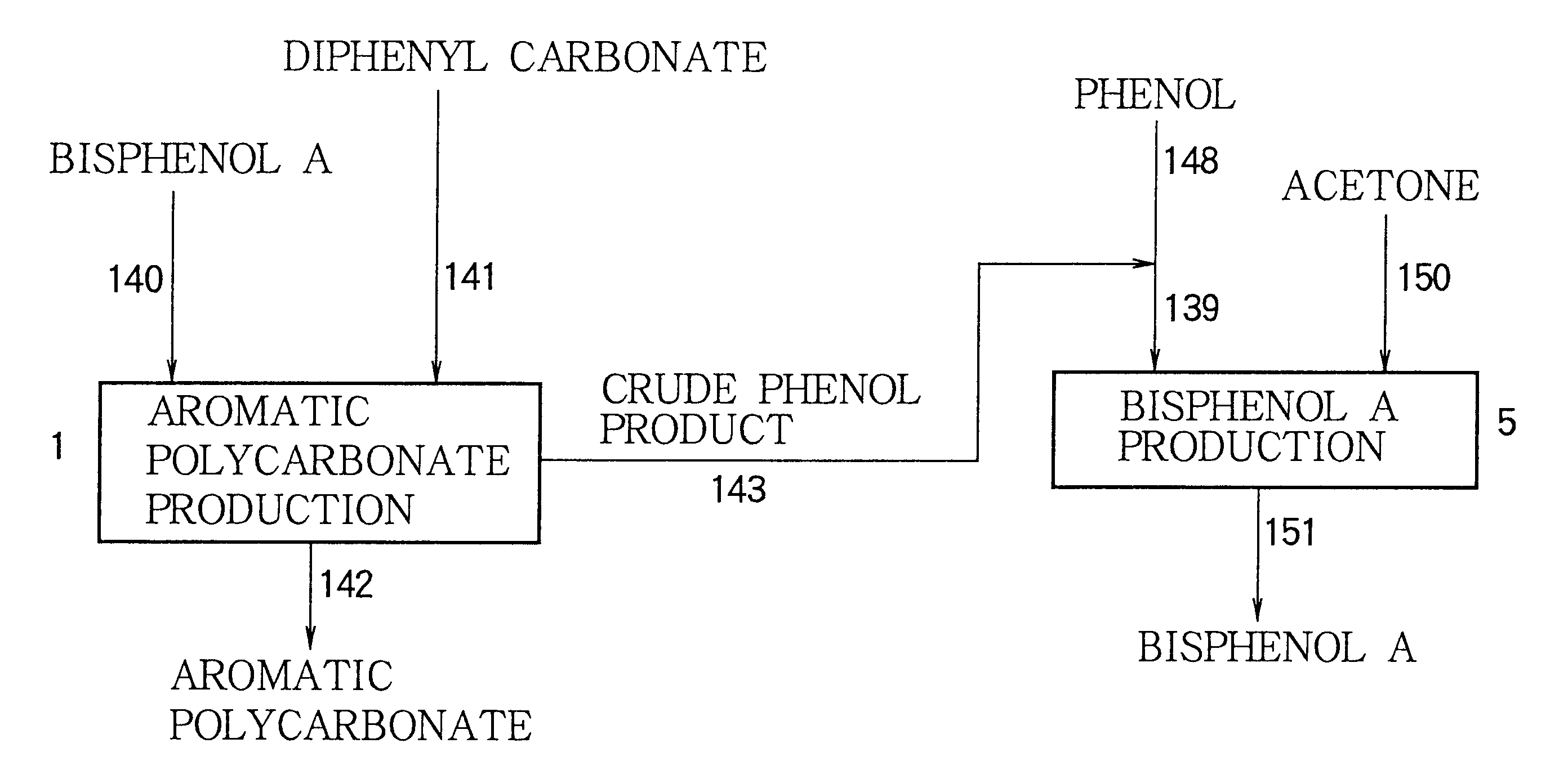

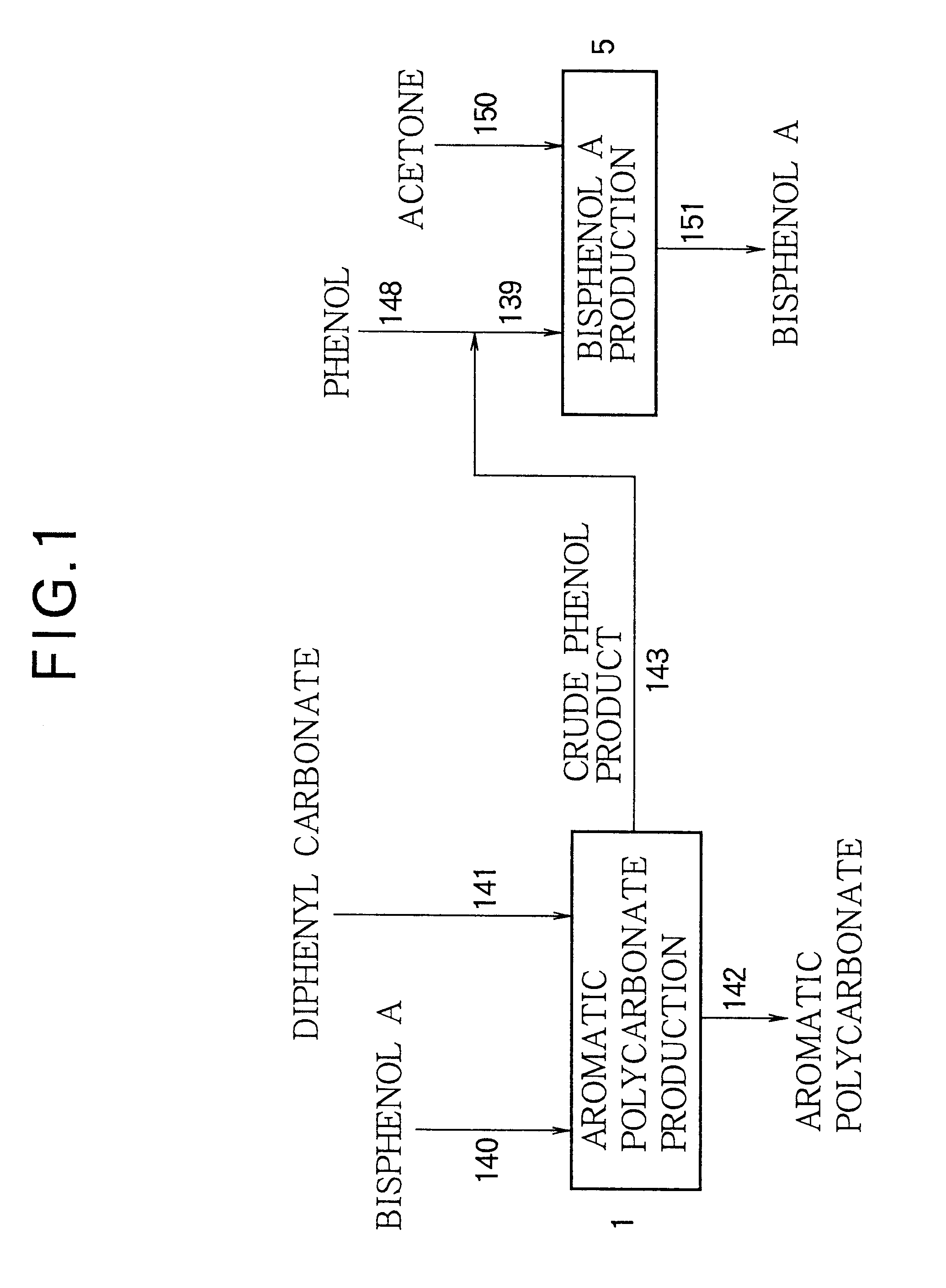

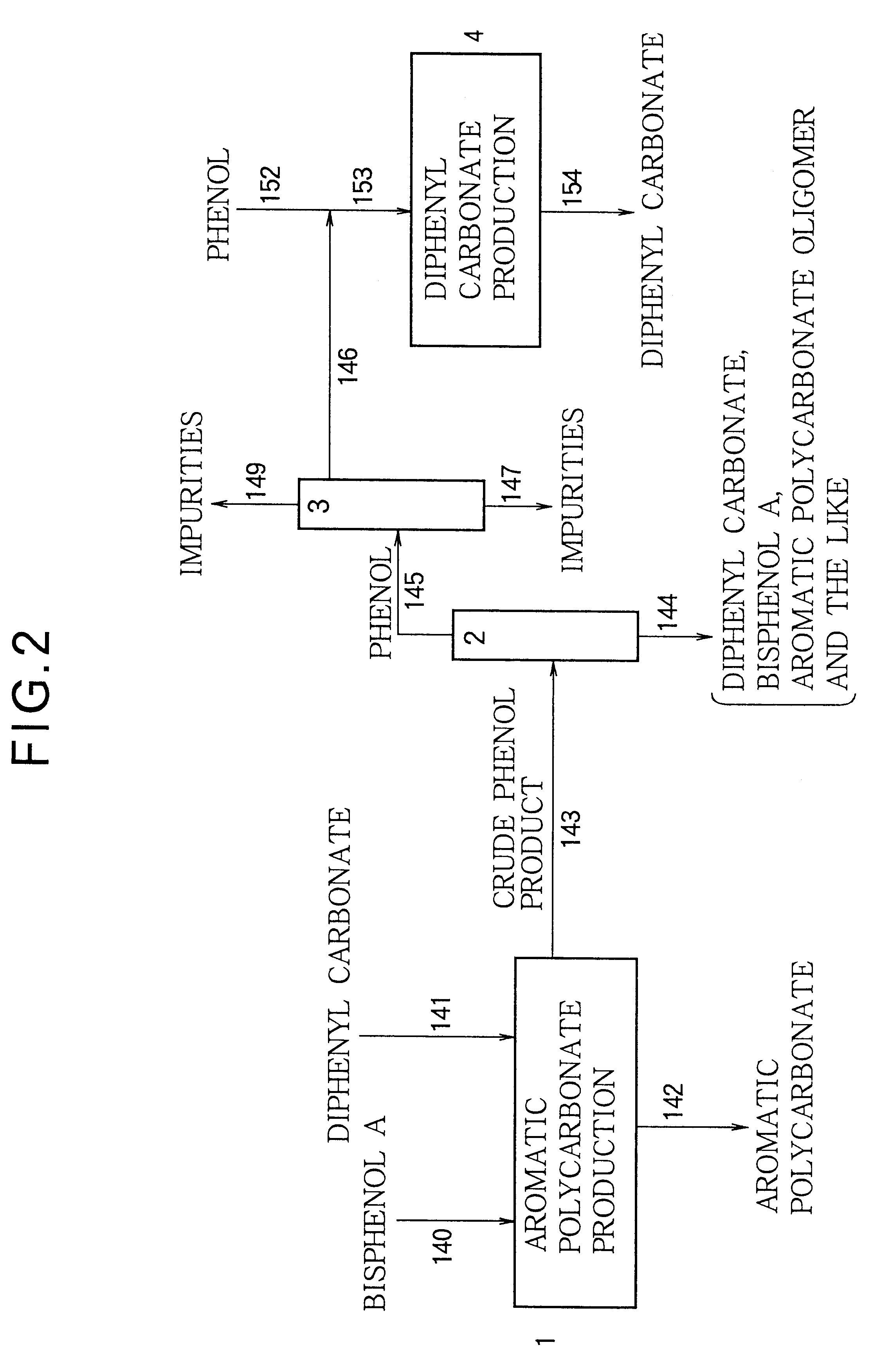

Method for producing an aromatic polycarbonate

Disclosed is a method for producing an aromatic polycarbonate, which comprises reacting acetone with a phenol material, thereby producing bisphenol A, and polymerizing the resultant bisphenol A with diphenyl carbonate to produce an aromatic polycarbonate while producing phenol as a by-product, wherein the by-product phenol is recovered as a crude phenol product containing the by-product phenol as a main component and containing impurities, and the crude phenol product is used as at least a part of the phenol material for producing bisphenol A. According to the method of the present invention, a crude phenol product as such, containing, as a main component, a by-product phenol which is by-produced during the polymerization reaction for producing an aromatic polycarbonate, and containing impurities, can be utilized for producing an aromatic polycarbonate, without any purification or the like. In the method of the present invention, not only can a necessity for complicated operations, such as a purification treatment, be reduced, but also the amount of wastes can be reduced and the yield of the aromatic polycarbonate, based on any of phenol and bisphenol A, can be improved.

Owner:ASAHI KASEI KK

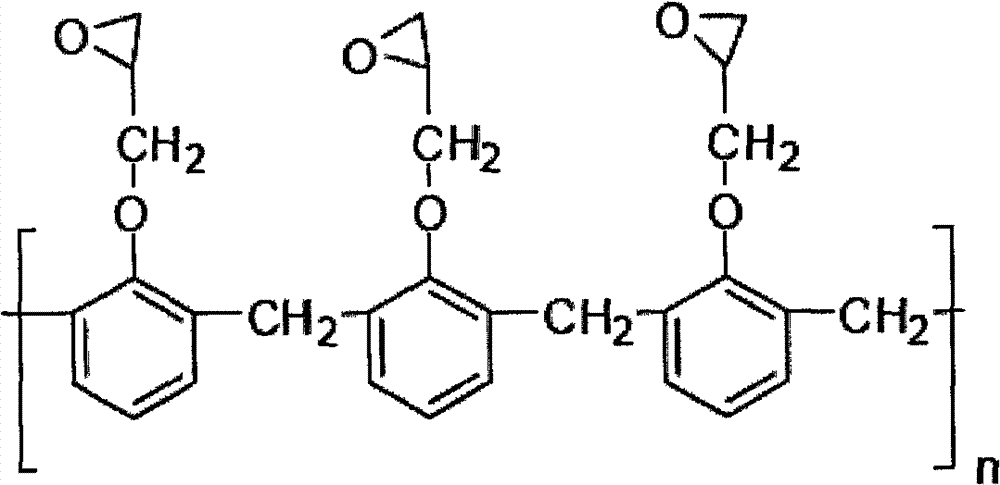

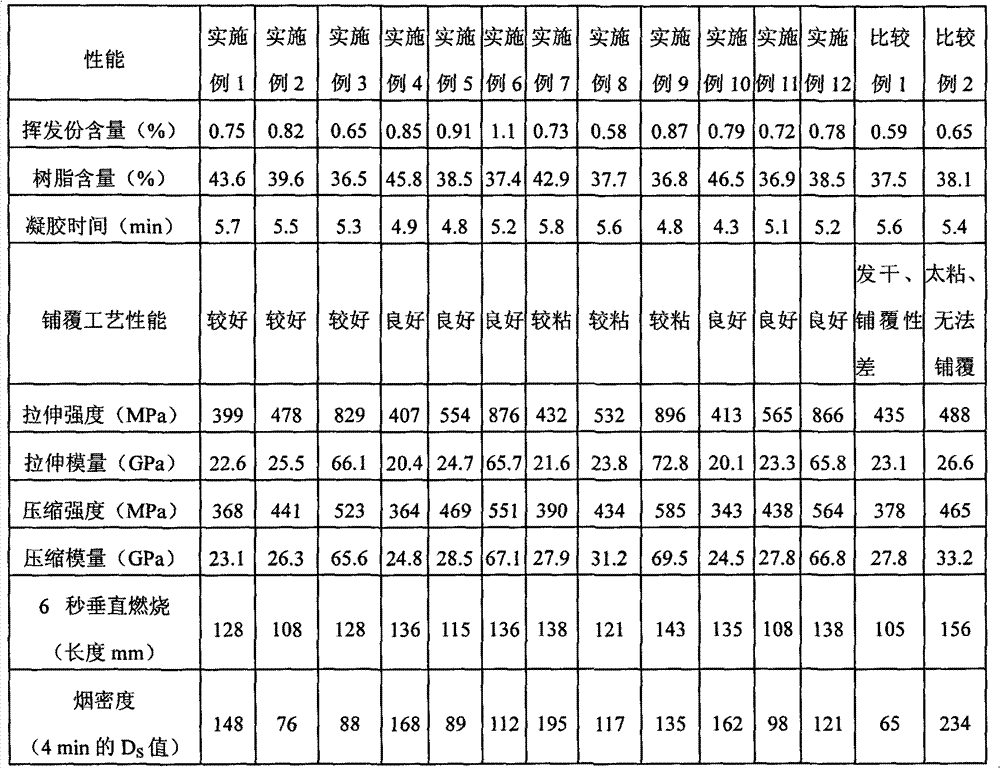

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

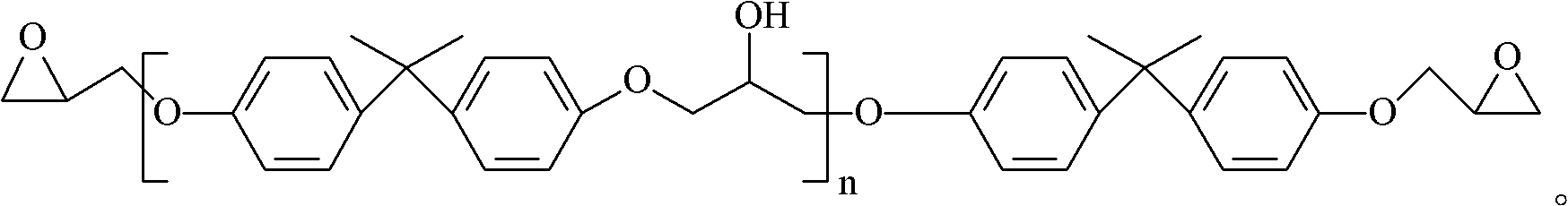

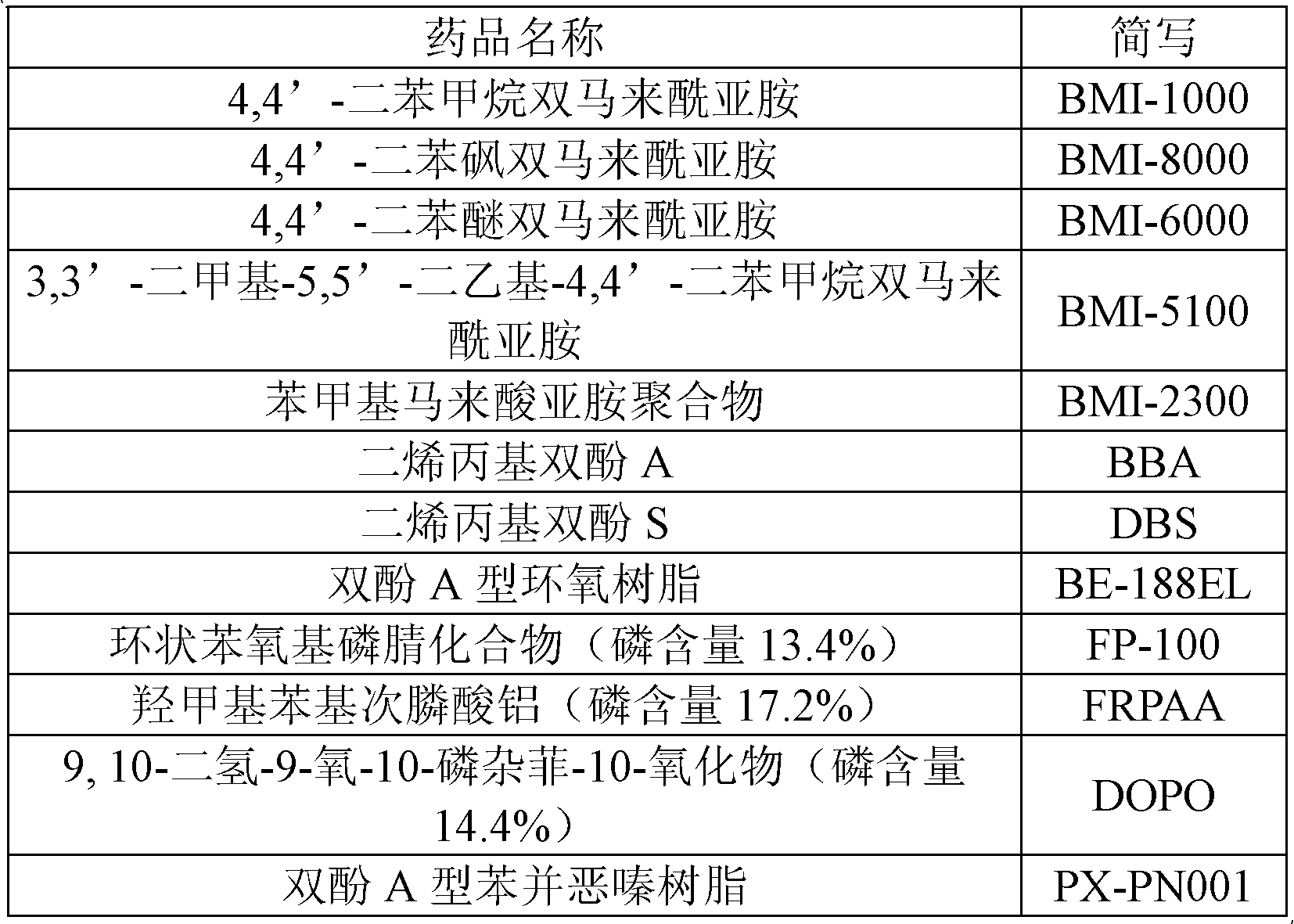

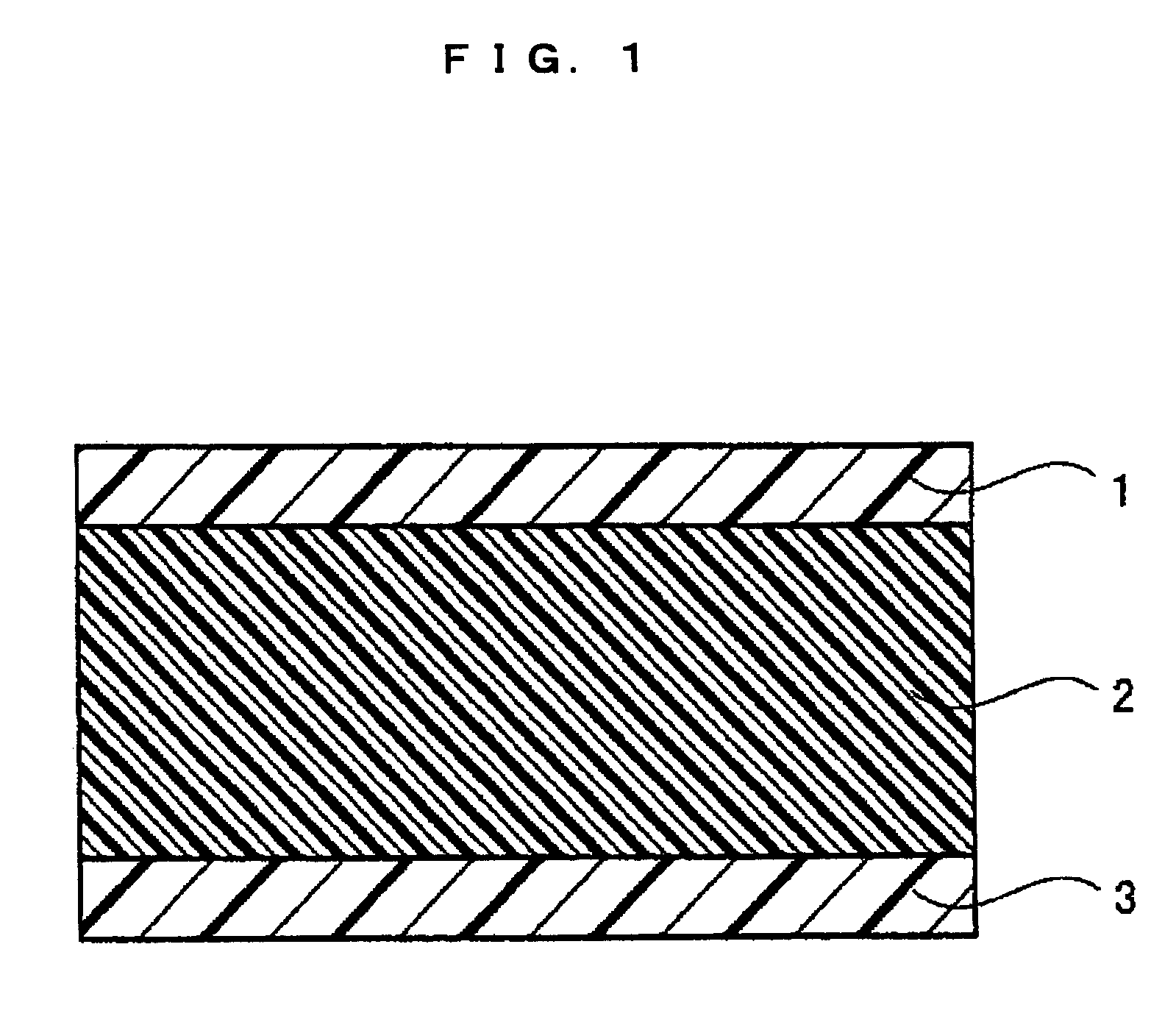

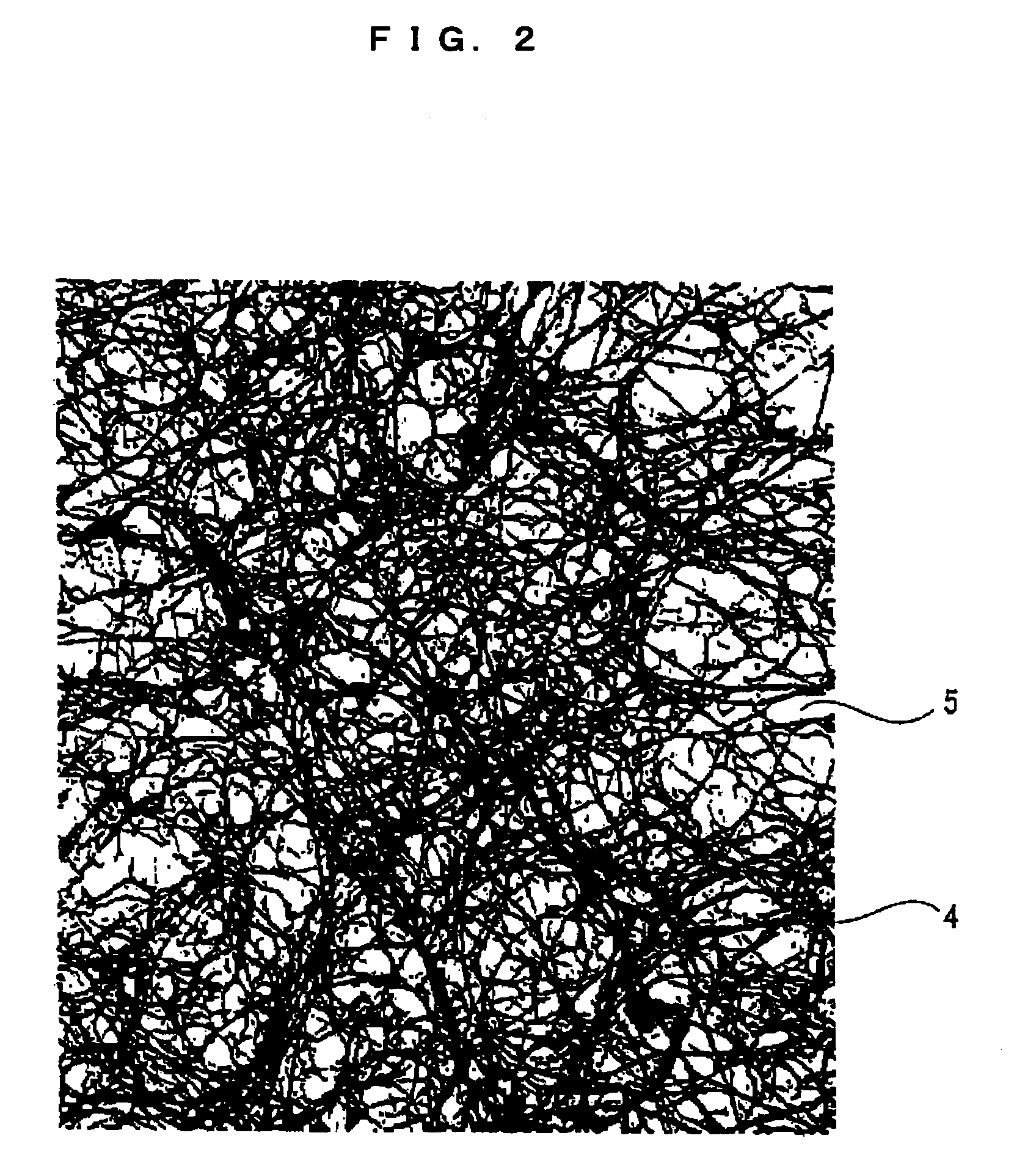

Halogen-free phosphorus-containing flame-retardant polyimide resin composition and preparation method thereof

ActiveCN102276837AImprove flame retardant performanceImprove toughnessGlass/slag layered productsMetal layered productsHalogenCopper

The invention relates to a halogen-free phosphorus-containing flame retardant polyimide resin composite, which is characterized by comprising the following components in part by weight: 150 to 180 parts of bismaleimide, 90 to 110 parts of allyl compound, 10 to 20 parts of bisphenol A epoxy resin and 10 to 50 parts of phosphorus-containing compound. The invention also relates to a preparation method for the halogen-free phosphorus-containing flame retardant polyimide resin composite. The method comprises the following steps of: adding the bismaleimide, the allyl compound, the bisphenol A epoxyresin and the phosphorus-containing compound into a reaction kettle, and reacting at the temperature of between 120 and 140 DEG C for 3 to 5 hours to obtain the halogen-free phosphorus-containing flame retardant polyimide resin composite. The halogen-free phosphorus-containing flame retardant polyimide resin composite is synthesized in one step and does not contain halogens and has high flame retardant performance; according to UL94 V0 flame retardant grade tests, the toughness of the cured composite is improved; and the moist heat resistant performance of the composite is high, and the composite meets the requirements of flame retardance and processing in the process of processing copper-clad plates and has high the storage stability.

Owner:INNOTEK TECH CHINA

Composite ion-exchange membrane

InactiveUS7649025B2Increased swelling resistanceImprove conductivityElectrolyte holding meansSolid electrolytesOrganic solventIon-exchange membranes

A composite ion exchange membrane having a high swelling resistance and being superior in mechanical strength and ion conductivity can be provided by means of an composite ion exchange membrane including an ion exchange resin composition and a support membrane having a continuous pore penetrating the support membrane, wherein the support membrane is one which accepts the ion exchange resin composition within the pore, and wherein the ion exchange resin composition is one which contains an ion exchange resin containing, as a main component, an aromatic polyether and / or its derivative, the aromatic polyether being obtained by mixing a compound having a specific structure, an aromatic dihalogenated compound and a bisphenol compound with a carbonate and / or a bicarbonate of an alkali metal and polymerizing the mixture in an organic solvent.

Owner:TOYOBO CO LTD

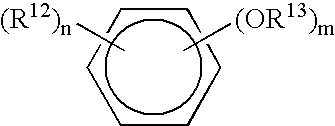

Photoresist undercoat-forming material and patterning process

ActiveUS20070275325A1Satisfactory antireflective effectImprove corrosion resistancePhotosensitive materialsPhotosensitive material processingResistGlycylxylidide

A material comprising a specific bisphenol compound of formula (1) is useful in forming a photoresist undercoat wherein R1 and R2 are H, alkyl, aryl or alkenyl, R3 and R4 are H, alkyl, alkenyl, aryl, acetal, acyl or glycidyl, R5 and R6 are alkyl having a ring structure, or R5 and R6 bond together to form a ring. The undercoat-forming material has an extinction coefficient sufficient to provide an antireflective effect at a thickness of at least 200 nm, and a high etching resistance as demonstrated by slow etching rates with CF4 / CHF3 and Cl2 / BCl3 gases for substrate processing.

Owner:SHIN ETSU CHEM IND CO LTD

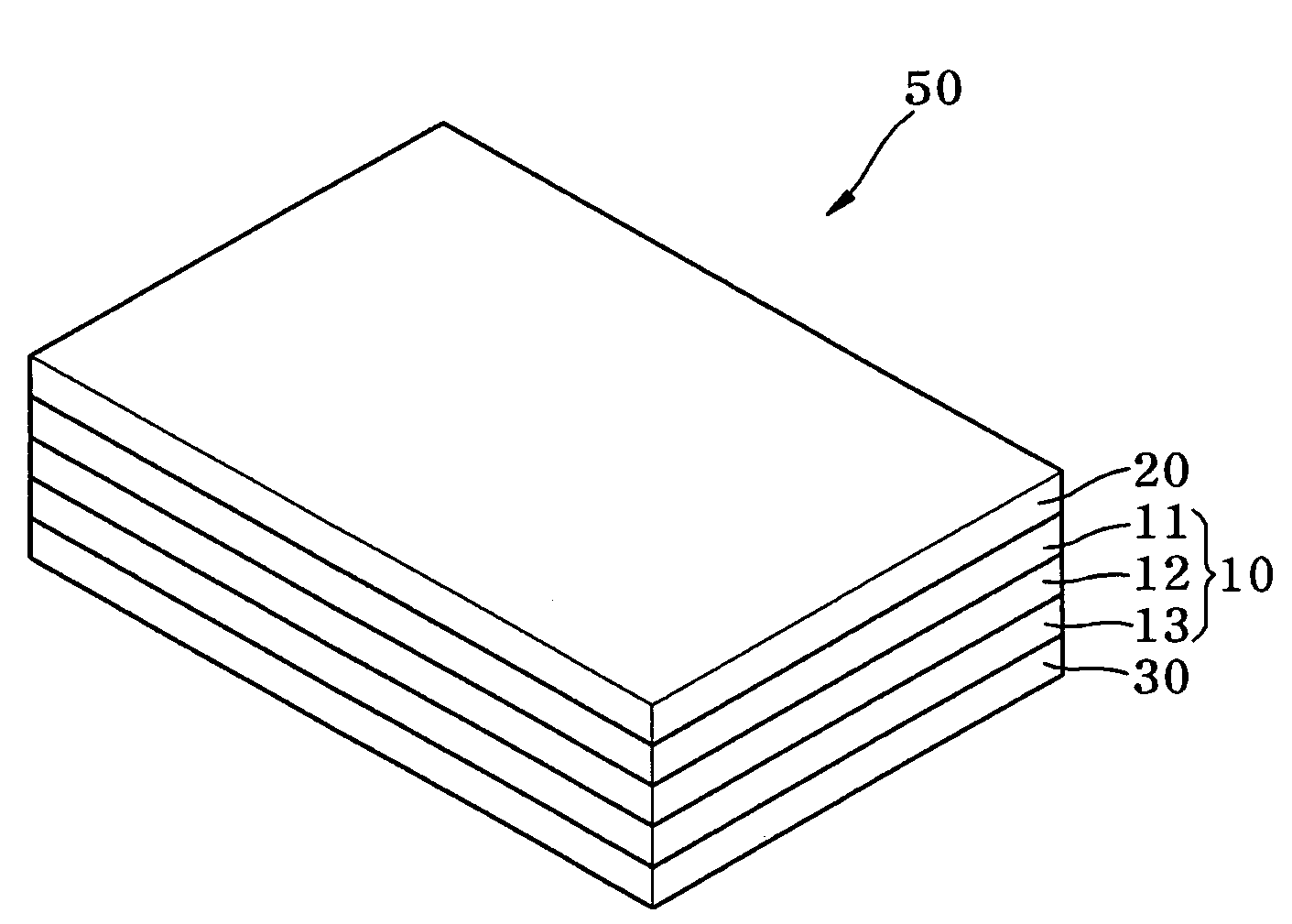

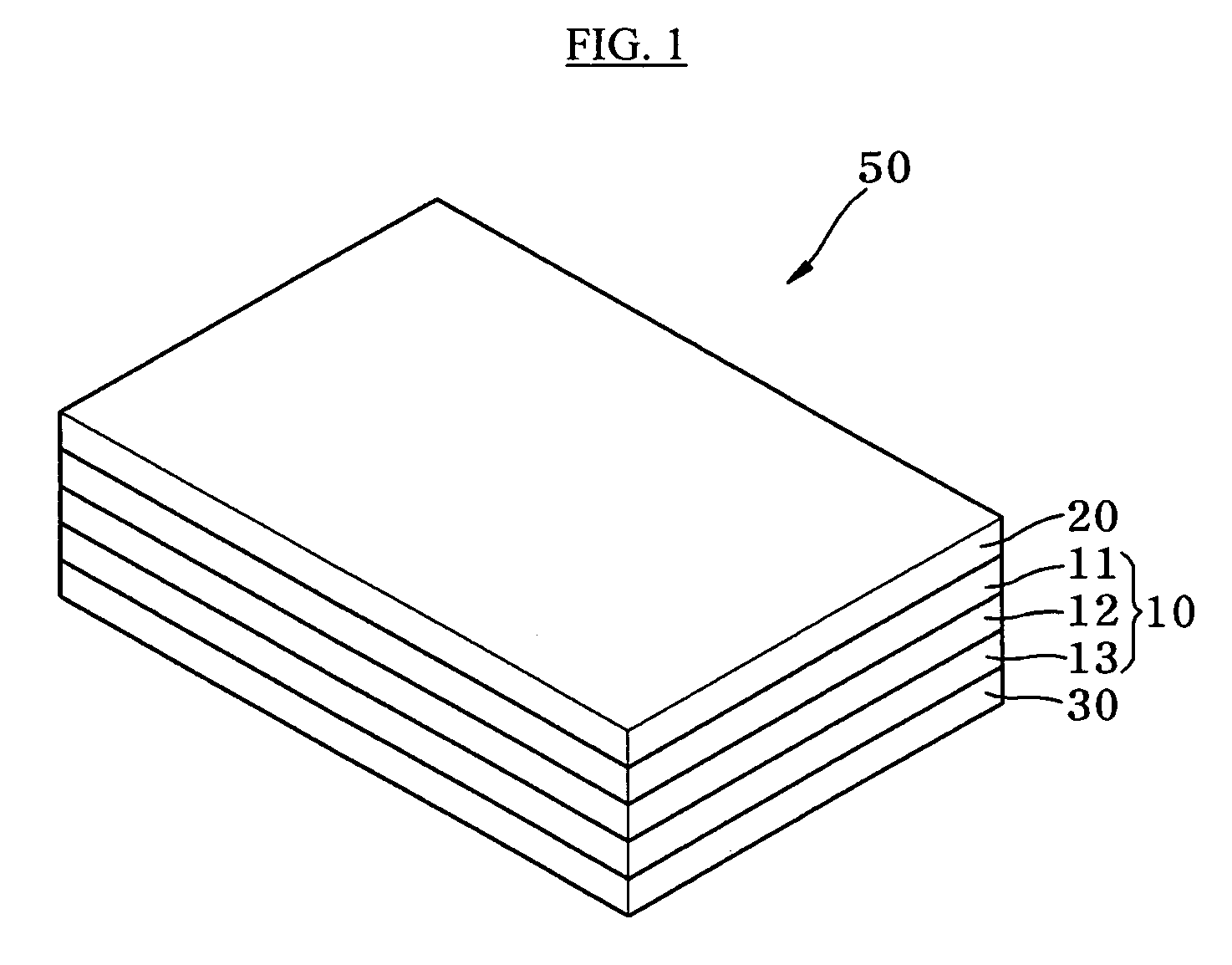

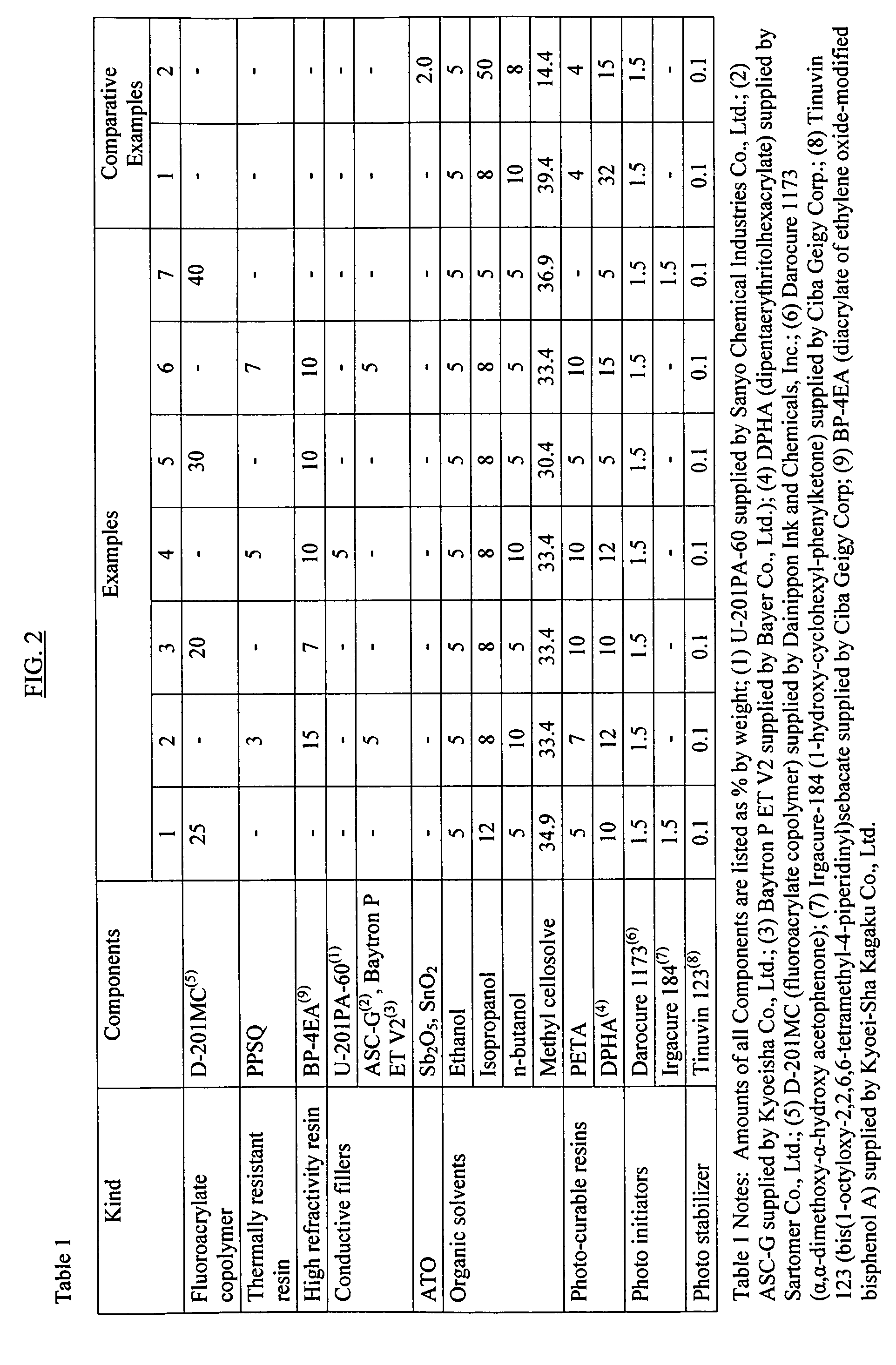

Sheet with hard coating and associated methods

InactiveUS20090169896A1Maintain good propertiesIncrease resistanceLiquid surface applicatorsSynthetic resin layered productsPlastic filmBisphenol

Disclosed herein is a plastic sheet with good anti-fouling properties, impact resistance, anti-static properties, and scratch resistance. The plastic sheet includes a transparent substrate, a first hard coat layer comprising a fluoroacrylate copolymer on one surface of the transparent substrate, and a second hard coat layer comprising a bisphenol-based resin and a conductive filler on the other surface of the transparent substrate.

Owner:CHEIL IND INC

Polyethersulfone composition, method of making and articles therefrom

A polyethersulfone composition is disclosed which comprises structural units derived from a monomer mixture comprising bisphenol-A and at least 55 mole percent of 4,4′-biphenol based on total moles of diphenolic monomers, wherein the polyethersulfone has a minimum weight average molecular weight which is a function of the mole percent of structural units derived from biphenol monomer. In addition the polyethersulfones possess a notched Izod impact strength value of greater than 470 Joules per meter as measured by ASTM D256.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com