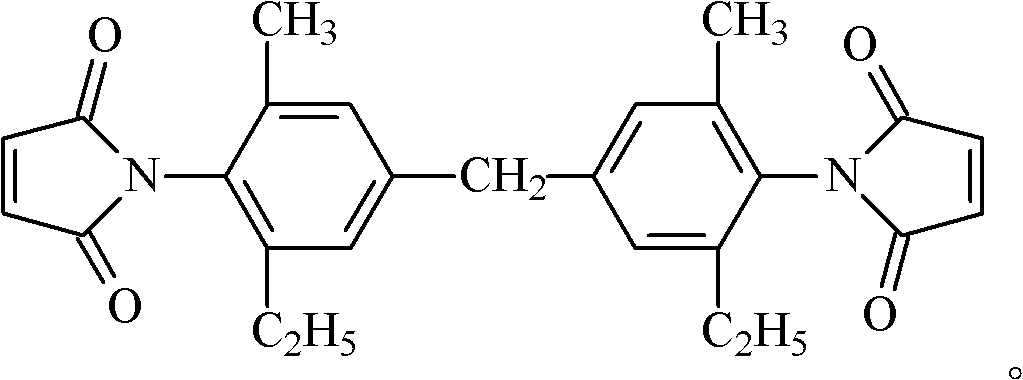

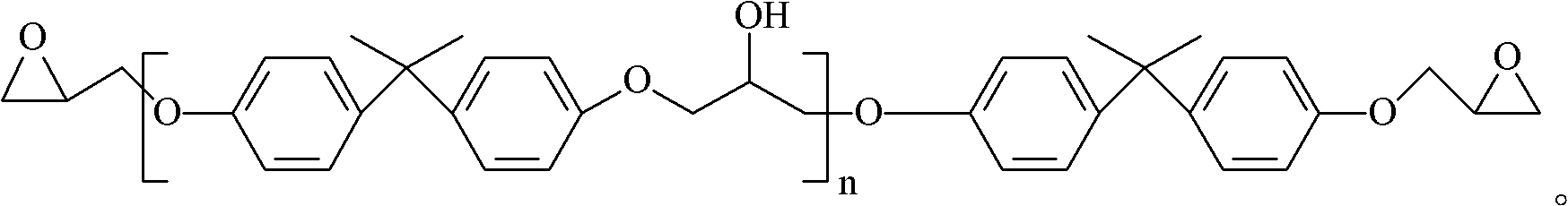

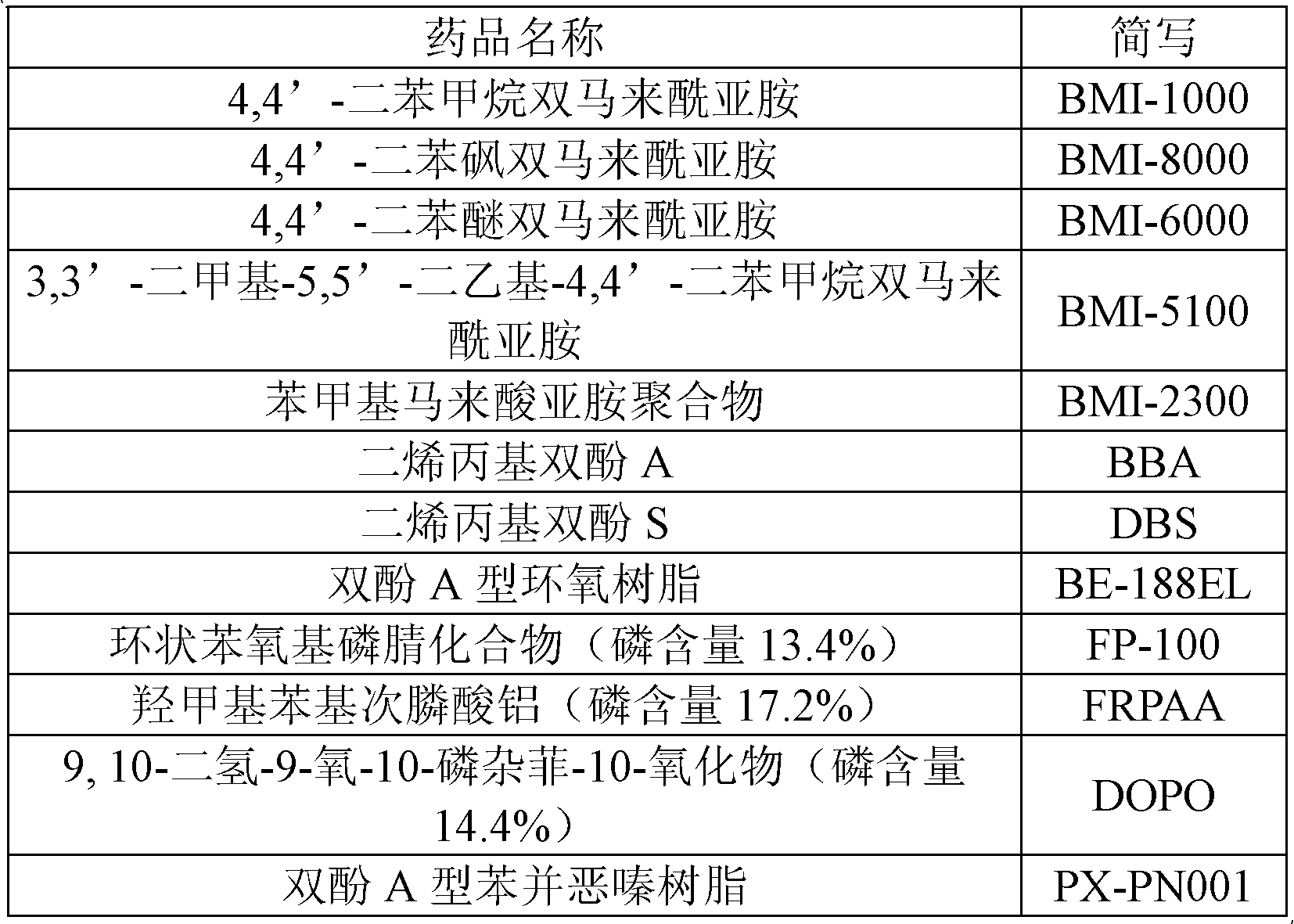

Halogen-free phosphorus-containing flame-retardant polyimide resin composition and preparation method thereof

A technology of polyimide resin and composition, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of reducing the brittleness of cured products, achieve improved toughness, excellent heat and humidity resistance, and storage Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Add 180g of BMI-1000, 90g of BBA, 10g of BE-188EL, and 49.1g of FP-100 into the reaction kettle, and react at 120°C for 5 hours to obtain a polyimide resin composition. The obtained polyimide resin The phosphorus content in the composition is 2.00%.

[0049] Production of copper foil substrate:

[0050] Dilute the resin composition prepared in the above example 1 with methyl ethyl ketone to a solid content of 55%, stir for 3 hours at a stirring speed of 120 rpm, and impregnate 7628 glass fiber cloth on an impregnation machine to make 7628 The glass fiber cloth is impregnated with a resin composition of 43% relative to the weight of the glass fiber cloth, and baked at 210°C for 4 minutes to make a film; stack 6 films, put copper foil on both sides and then press them together , the pressing temperature is 240° C., the pressing time is 3 hours, and the pressing pressure is 400 psi to make a copper foil substrate.

Embodiment 2

[0052] Add 160g of BMI-8000, 100g of DBS, 20g of BE-188EL, and 28.7g of FRPAA into the reaction kettle, and react at 125°C for 4 hours to obtain a polyimide resin composition. The obtained polyimide resin composition The phosphorus content in is 1.60%.

[0053] Production of copper foil substrate:

[0054] Dilute the resin composition prepared in the above example 2 with methyl ethyl ketone to a solid content of 40%, stir for 5 hours at a stirring speed of 50 rpm, and impregnate 7628 glass fiber cloth on an impregnation machine to make 7628 The glass fiber cloth is impregnated with a resin composition of 40% relative to the weight of the glass fiber cloth, and baked at 170°C for 5 minutes to make a film; stack 6 films, put copper foil on both sides and then press them , the pressing temperature is 220° C., the pressing time is 4 hours, and the pressing pressure is 200 psi to make a copper foil substrate.

Embodiment 3

[0056] Add 150g of BMI-6000, 110g of BBA, 15g of BE-188EL, and 27g of FP-100 into the reaction kettle, and react at 130°C for 3 hours to obtain a polyimide resin composition. The obtained polyimide resin composition The phosphorus content in the product is 1.20%.

[0057] Production of copper foil substrate:

[0058] Dilute the resin composition prepared in the above example 3 with methyl ethyl ketone to a solid content of 50%, stir for 4 hours at a stirring speed of 100 rpm, and impregnate 7628 glass fiber cloth on an impregnation machine to make 7628 The glass fiber cloth is impregnated with a resin composition that is 50% of the weight of the glass fiber cloth, and baked at 200°C for 4 minutes to make a film; stack 8 films, put copper foil on both sides and then press them together , the pressing temperature is 230° C., the pressing time is 4 hours, and the pressing pressure is 300 psi to make a copper foil substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com