Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3076 results about "Reactive diluent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

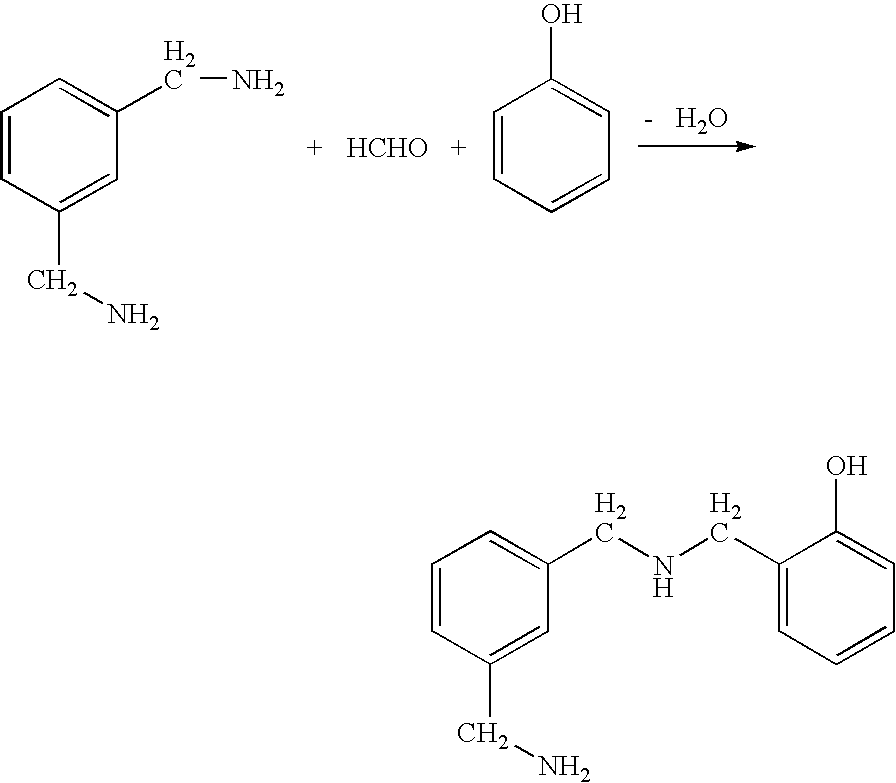

Reactive diluents are substances which reduce the viscosity of a lacquer for processing and become part of the lacquer during its subsequent curing via copolymerization. Diluents (or thinners) are usually added to lacquers to reduce their viscosity (they are used to adjust the rheology). In thermal cured lacquers, such diluents added are volatile substances which evaporate from the lacquer during drying. In the case of radiation-curing lacquers (for example UV lacquers), those diluents should be avoided. The addition of reactive diluents facilitates the processing of the lacquers, allows the addition of more fillers and improves the wetting behavior on the substrate. If volatile diluents are replaced by reactive diluents, flammability, smell, skin irritation and environmental compatibility (by lower or no VOC emissions) can be improved.

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

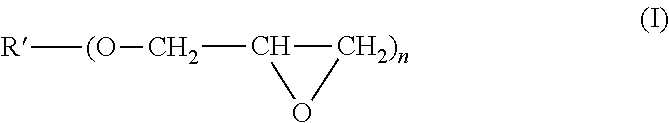

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

Reactive diluent and curable resin composition

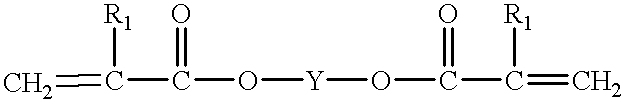

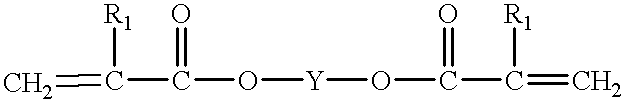

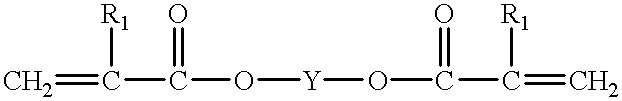

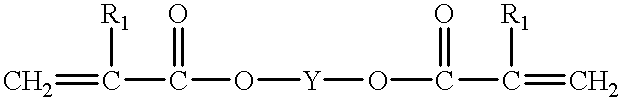

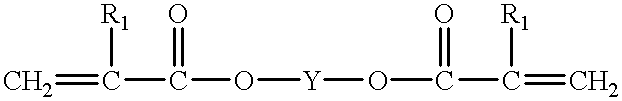

InactiveUS20030199655A1Effect is not sufficientLow water resistanceFatty acid chemical modificationFatty acids production/refiningVinyl etherHydrogen atom

The present invention provides a reactive diluent composition which overcomes drawbacks of both the radical-cure and the cationic-cure reactive diluents and can be applied in a broad variety of uses such as paints, inks, adhesives, pressure sensitive adhesives, surface-modifiers, and molding materials; a curable resin composition containing the same; an activated energy ray-curable resin composition; and an activated energy ray-curable ink composition for ink-jet printing. A reactive diluent composition comprising a vinyl ether group-containing (meth)acrylic ester represented by the following general formula (1): CH2=CR<1>-COO-R<2>-O-CH=CH-R<3> (1) wherein R<1 >represents a hydrogen atom or a methyl group; R<2 >represents an organic residue of 2 to 20 carbon atoms; R<3 >represents a hydrogen atom or an organic residue of 1 to 11 carbon atoms and a hydroxyl group-containing polymerizable compound and / or divinyl ether.

Owner:NIPPON SHOKUBAI CO LTD

Aqueous dispersion of epoxy resin and blend of epoxy resin-polyoxyalkylene amines

PCT No. PCT / EP97 / 06364 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Nov. 14, 1997 PCT Pub. No. WO98 / 25988 PCT Pub. Date Jun. 18, 1998A blend of epoxy-amine adducts are useful as emulsifiers of aqueous epoxy resin dispersions comprises (A-1) one or more epoxy-amine adduct(s) obtained by the reaction of (i) one or more aromatic, cycloaliphatic or novolac epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (A-2) one or more epoxy-amine adduct(s) derived from the reaction of (i) one or more aliphatic epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (B-1) aromatic, cycloaliphatic or novolac polyglycidyl ethers; (B-2) optionally, polyglycidyl esters of aromatic or cycloaliphatic polycarboxylic acids; and (C) optionally, at least one of reactive thinners, pigments, filler or other addtitives.

Owner:SIKA CHEM

Reactive diluent and curable resin composition

InactiveUS6767980B2Effect is not sufficientLow water resistanceFatty acid chemical modificationFatty acids production/refiningVinyl etherHydrogen atom

The present invention provides a reactive diluent composition which overcomes drawbacks of both the radical-cure and the cationic-cure reactive diluents and can be applied in a broad variety of uses such as paints, inks, adhesives, pressure sensitive adhesives, surface-modifiers, and molding materials; a curable resin composition containing the same; an activated energy ray-curable resin composition; and an activated energy ray-curable ink composition for ink-jet printing.A reactive diluent composition comprisinga vinyl ether group-containing (meth)acrylic ester represented by the following general formula (1):wherein R<1 >represents a hydrogen atom or a methyl group; R<2 >represents an organic residue of 2 to 20 carbon atoms; R<3 >represents a hydrogen atom or an organic residue of 1 to 11 carbon atoms anda hydroxyl group-containing polymerizable compound and / or divinyl ether.

Owner:NIPPON SHOKUBAI CO LTD

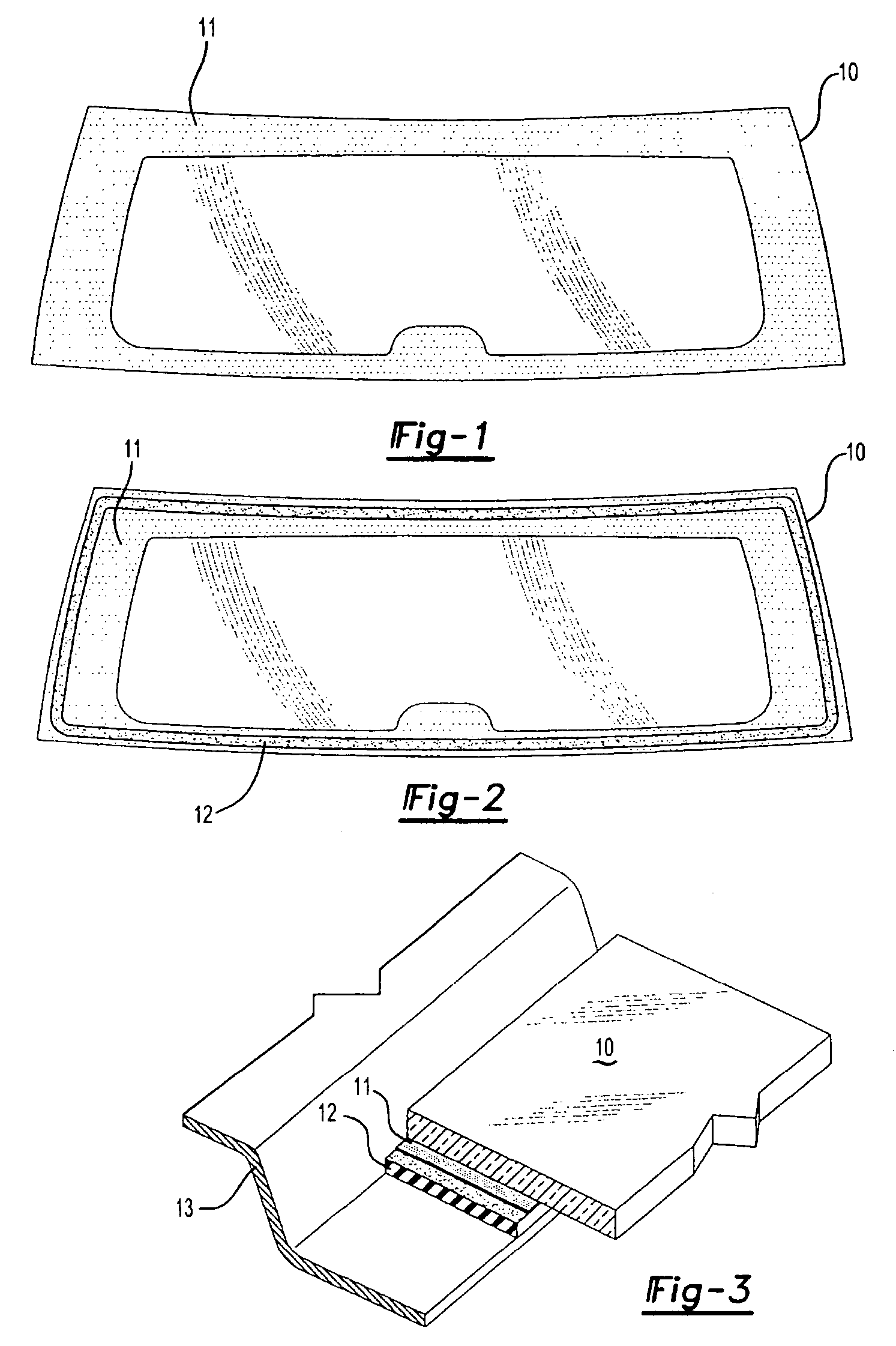

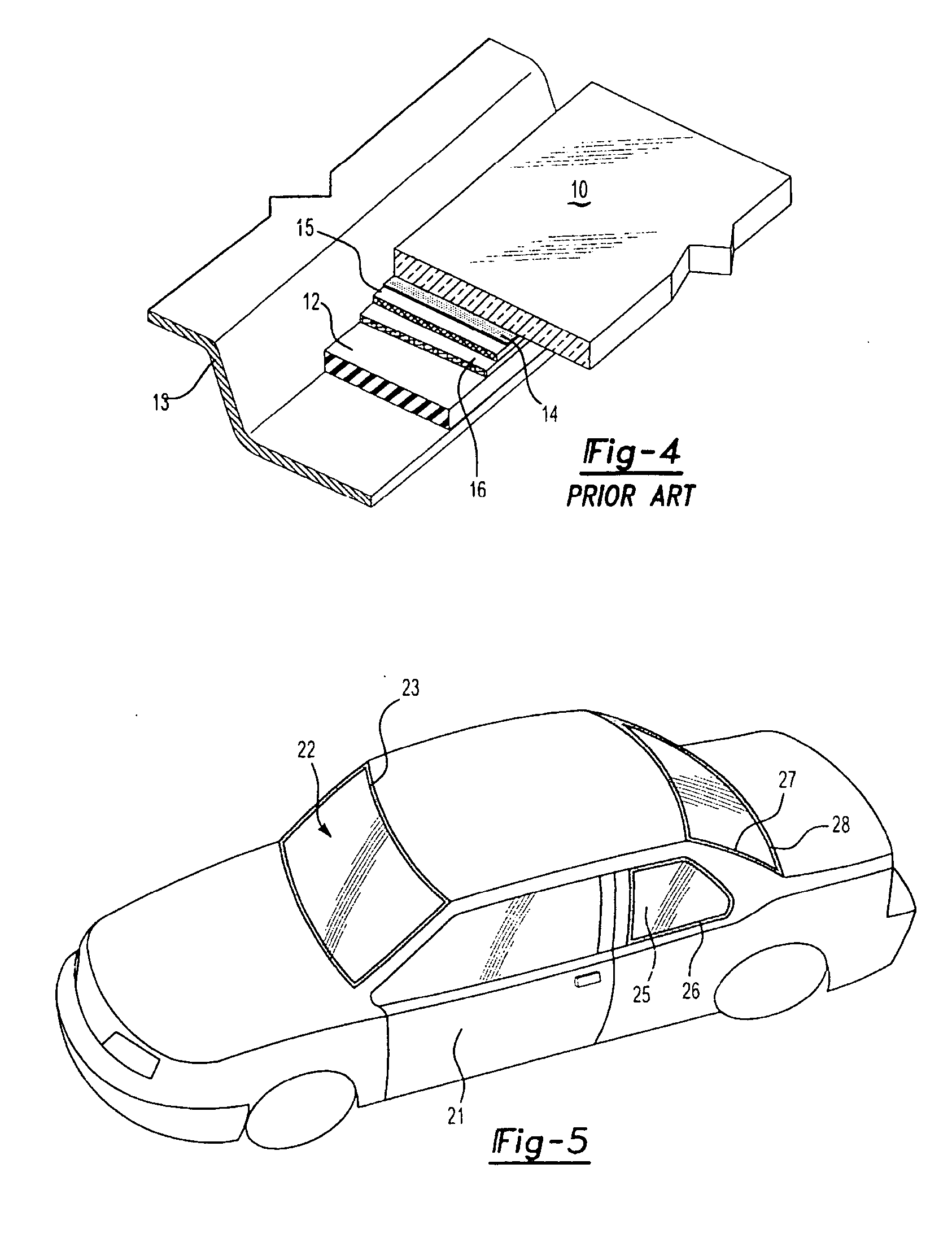

Protective coating for window glass

The invention is a composition comprising: a) one or more film forming resins having at least one functional group capable of polymerization; b) one or more reactive diluents capable of reacting with the film forming resin; c) one or more silicon, titanium, zirconium, aluminum or metal containing compounds capable of promoting adhesion of the composition to glass; d) one or more fillers capable of imparting abrasion resistance to the composition when cured; and e) one or more compounds which is reactive with the film forming resin which also contains at least one acidic moiety. The composition of the invention is useful as a frit on the window of a vehicle.

Owner:DOW GLOBAL TECH LLC

Abrasion resistant urethane coatings

InactiveUS6228433B1Improve wear resistanceResistant to stainsPolyurea/polyurethane coatingsThin material handlingOligomerReactive diluent

A radiation curable and abrasion resistant coating composition is provided comprising: (a) 70% to 98% by weight of an urethane-acrylate oligomer; (b) 2% to 30% of fine particles of a filler capable of imparting abrasion resistance having an average particle size in the range of 1-20 microns; (c) optionally a reactive diluent; and (d) optionally an synthetic resin. The coatings when applied to wood floorings impart superior abrasion resistance.

Owner:PRISM ENTERPRISES

UV-light solidifying paint having decorative effect and preparation method thereof

The invention relates to a UV-light solidifying paint having decorative effect and preparation method thereof, in particular to a light solidifying paint containing mica coated with metallic oxides as a paint. The paint is composed of the followings in proportions: the content of low polymer is 30-70wt%; the content of reactive diluent is 25-65wt%; the content of light trigger is 0.5-10wt%; the content of pearlescent pigment is 3-30wt%; the content of accessory ingredient is 0.2-8wt%; the content of solvent is 0-50wt%. As added pearlescent pigment has strong metallic performance, the prepared light solidifying paint has the character of strong pearl effect and also has very good water resisting property, higher rigidity and abrasive resistance. The paint can be applied to decoration on the surfaces of motor vehicles, electric appliance, furniture, articles for daily use, toys, walls, leather products, etc.

Owner:SICHUAN UNIV

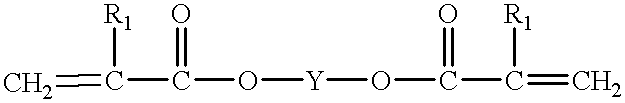

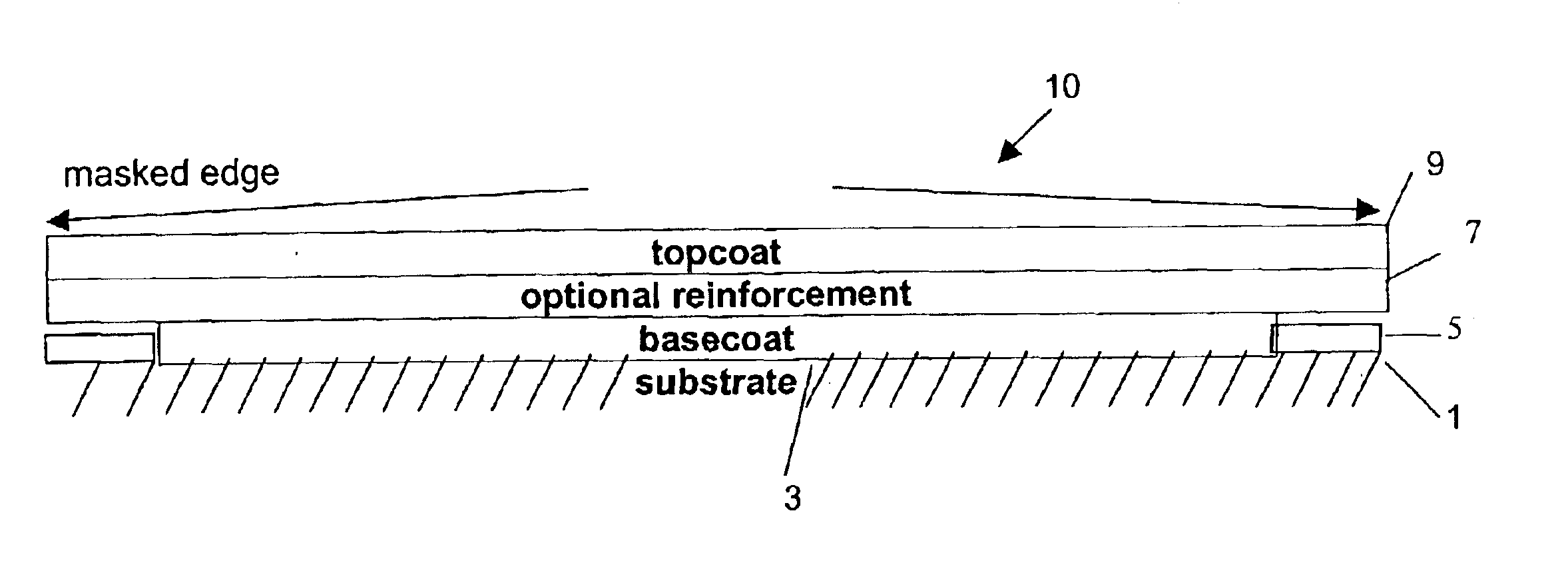

Coating system for a porous substrate using an asphalt-containing thermosetting basecoat composition and a thermoplastic top coat composition

InactiveUS6849338B2Reduce viscosity of compositionIncreasing imperfectionSynthetic resin layered productsPretreated surfacesPorous substrateCross-link

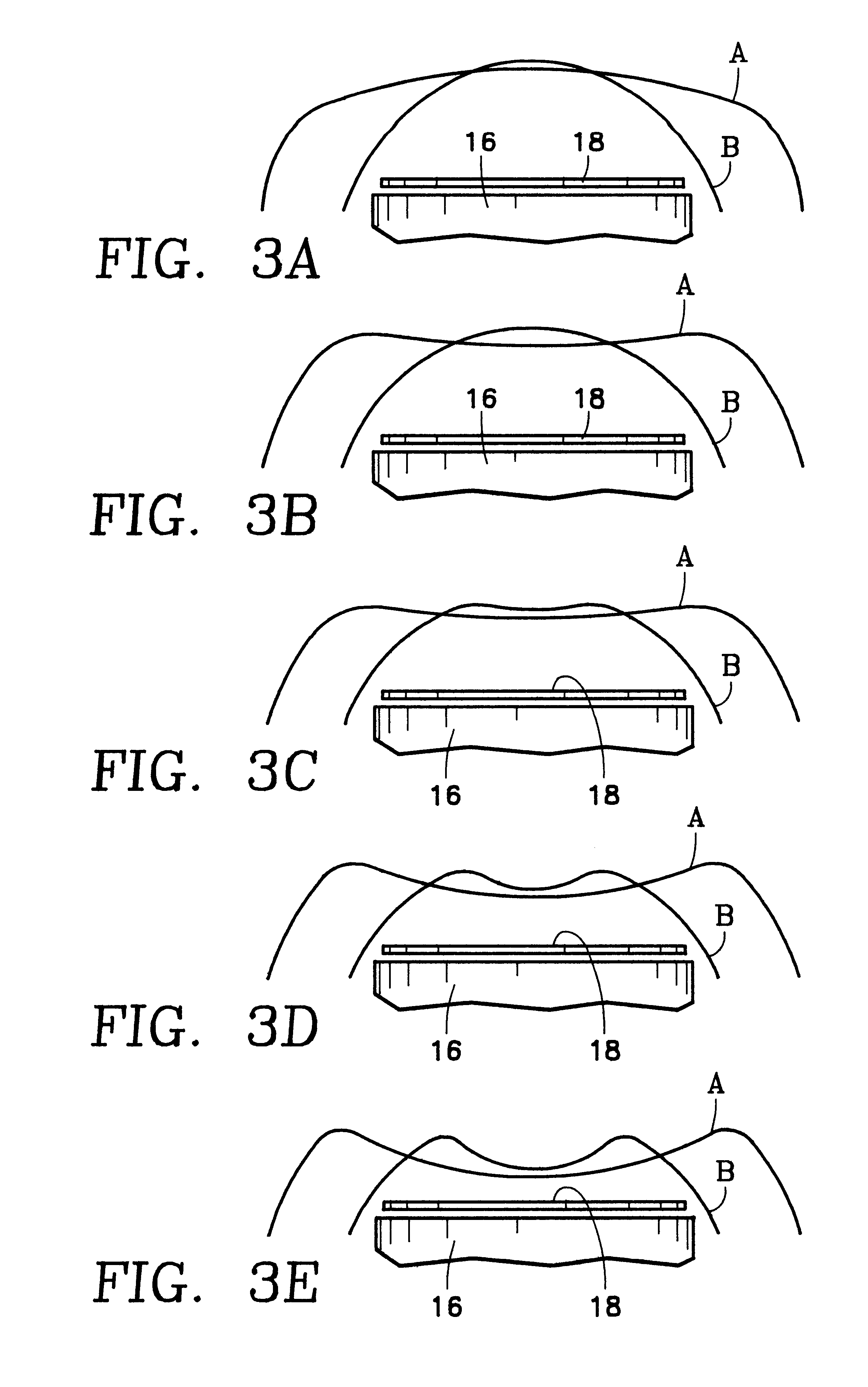

A coating system comprises a basecoat of an thermosetting asphalt extended, chemically cross linked-urethane / epoxy hybrid basecoat resting on a substrate, preferably a porous substrate such as concrete or wood that off-gas when coated with a thermoplastic material; and a thermoplastic powder coating topcoat overlying at least the base coat. The thermosetting basecoat composition consisting essentially of, in weight percent based on final formulation, and between 10 and 90% of a petroleum asphalt; between 10 and 90%, of a hydroxy-terminated homopolymer; and between 0.1 and 30% of a functional epoxy reactive diluent for reducing the viscosity of the composition; and further up to 5% of a surfactant for improving surface imperfections, up to 5% of an anti-oxidant; and up to 25% of a thickening agent.

Owner:PACIFIC NORTHWEST COATINGS

High pressure high non-reactive diluent gas content high plasma ion density plasma oxide etch process

InactiveUS6238588B1Increase pressureHigh strengthElectric discharge tubesDecorative surface effectsHigh plasmaOxygen

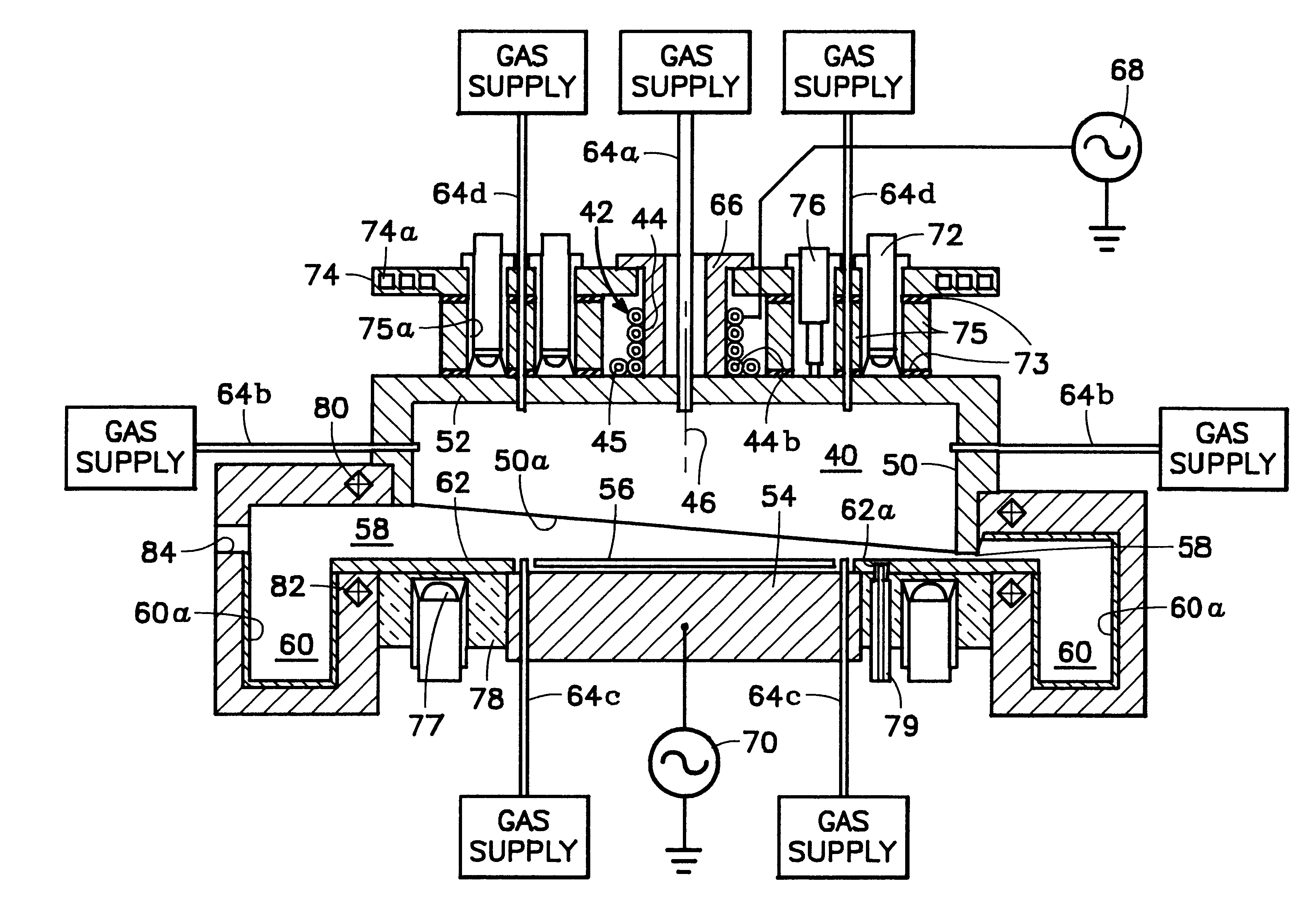

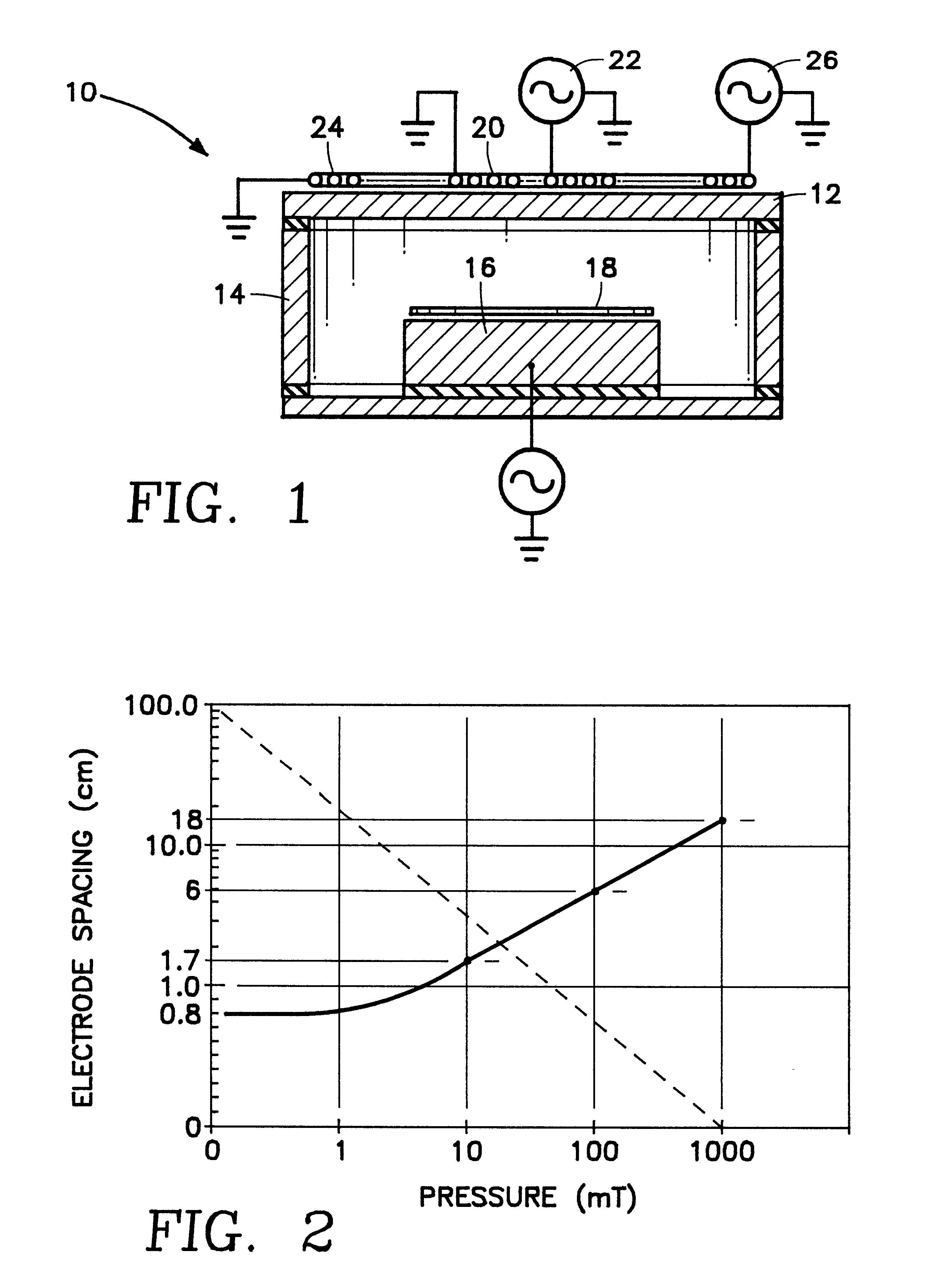

The invention is embodied in a method of processing a semiconductor workpiece in a plasma reactor chamber, including supplying a polymer and etchant precursor gas containing at least carbon and fluorine into the chamber at a first flow rate sufficient of itself to maintain a gas pressure in the chamber in a low pressure range below about 20 mT, supplying a relatively non-reactive gas into the chamber at second flow rate sufficient about one half or more of the total gas flow rate into the chamber, in combination with the first flow rate of the precursor gas, to maintain the gas pressure in the chamber in a high pressure range above 20 mT, and applying plasma source power into the chamber to form a high ion density plasma having an ion density in excess of 1010 ions per cubic centimeter. In one application of the invention, the workpiece includes an oxygen-containing overlayer to be etched by the process and a non-oxygen-containing underlayer to be protected from etching, the precursor gas dissociating in the plasma into fluorine-containing etchant species which etch the oxygen-containing layer and carbon-containing polymer species which accumulate on the non-oxygen-containing underlayer. Alternatively, the high pressure range may be defined as a pressure at which the skin depth of the inductive field exceeds {fraction (1 / 10)} of the gap between the inductive antenna and the workpiece.

Owner:APPLIED MATERIALS INC

Heat-curable eproxy resin composition

InactiveUS20050159511A1Other chemical processesPolyureas/polyurethane adhesivesAdhesiveReactive diluent

The invention relates to compositions containing at least one epoxy resin A with on average more than one epoxy group per molecule; at least one epoxy adduct B with on average one epoxy group per molecule; at least one thixotropic agent C, based on a urea derivative in a non-diffusing support material; and at least one curing agent D for epoxy resins, which is activated by an increased temperature. According to preferred embodiments, the invention also relates to compositions containing at least one core-shell polymer E and / or filler F and / or reactive diluent G. The invention also relates to the use of said compositions as a single-component adhesive and to a method for producing the compositions. The invention further relates to the use of the thixotropic agent C, based on a urea derivative in a non-diffusing support material as an agent for increasing the impact resistance.

Owner:SIKA SCHWEIZ AG

Radiation-curable coating composition

The present invention relates to a radiation-curable solvent-free coating composition for optical fiber having a radiation-curable urethane (meth)acrylate oligomer comprising an alkyd backbone,a reactive diluent, and a photoinitiator, and optionally an additive.

Owner:DSM IP ASSETS BV

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

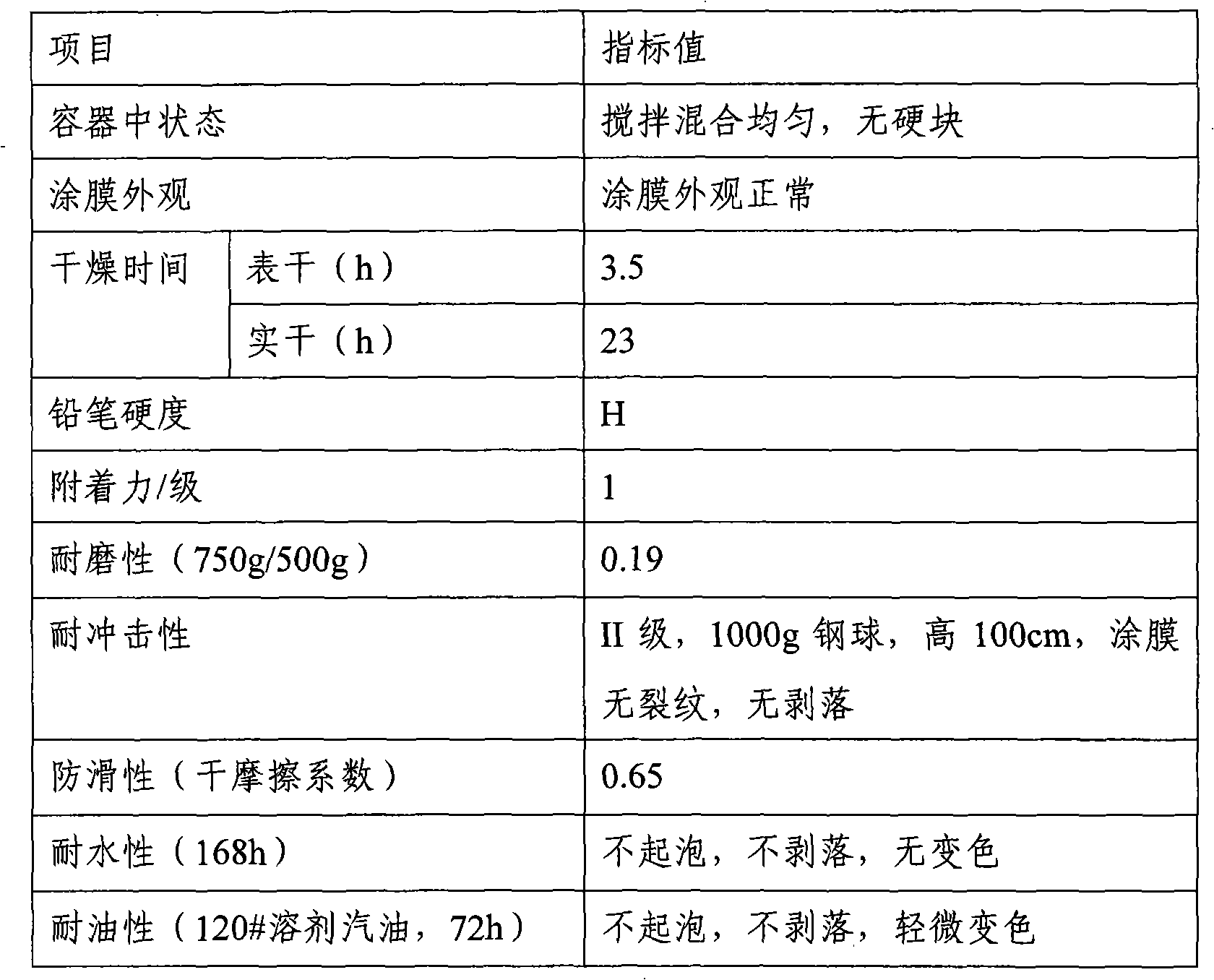

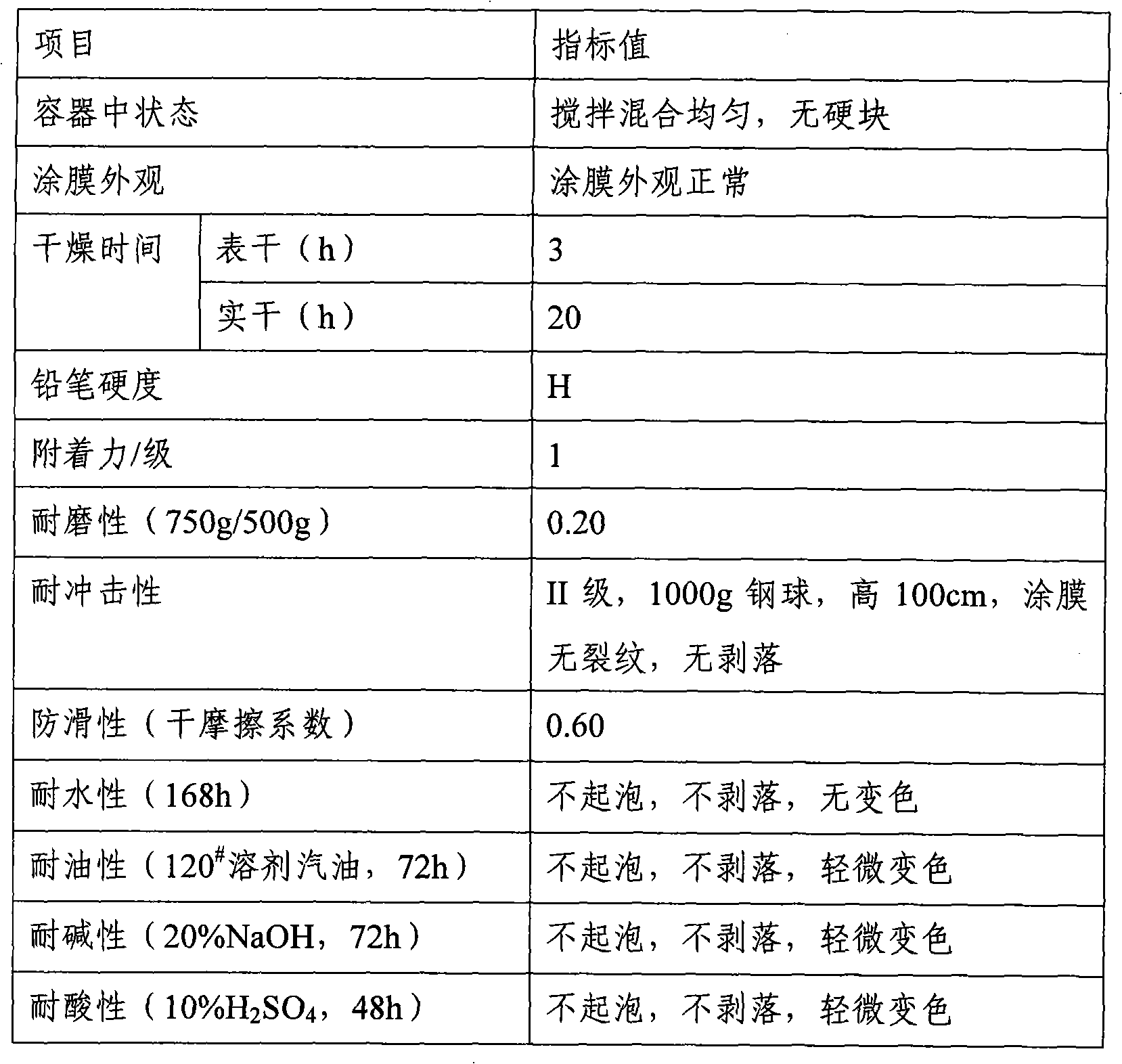

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

High-solid anticorrosive coating composition, high-solid rapidly-curable anticorrosive coating composition, method of coating ship or the like, high-solid anticorrosive film and rapidly cured high- anticorrosive film obtained, and coated ship and underwater structure coated with these coating films

InactiveUS20090226729A1Improve anti-corrosion performanceIncrease contentLiquid surface applicatorsAntifouling/underwater paintsOrganic solventBoiling point

A high-solids anticorrosive coating composition which comprises a main ingredient (A) comprising an epoxy resin (a1) and a hardener ingredient (B) comprising an alicyclic amine hardener (b1) and / or a Mannich type hardener (b2), the ingredient (A) and / or the ingredient (B) containing at least either of an additive (a2) selected among epoxidized reactive diluents and modified epoxy resins and a coating film modifier (ab) selected among petroleum resins, xylene resins, coumarone resins, terpene phenol resins and vinyl chloride copolymers. The high-solids anticorrosive coating composition especially of the rapidly curable type is characterized by containing a high-boiling organic solvent having a boiling point exceeding 150° C. and containing substantially no organic solvent having a boiling point of 150° C. or lower.

Owner:CHUGOKU MARINE PAINTS

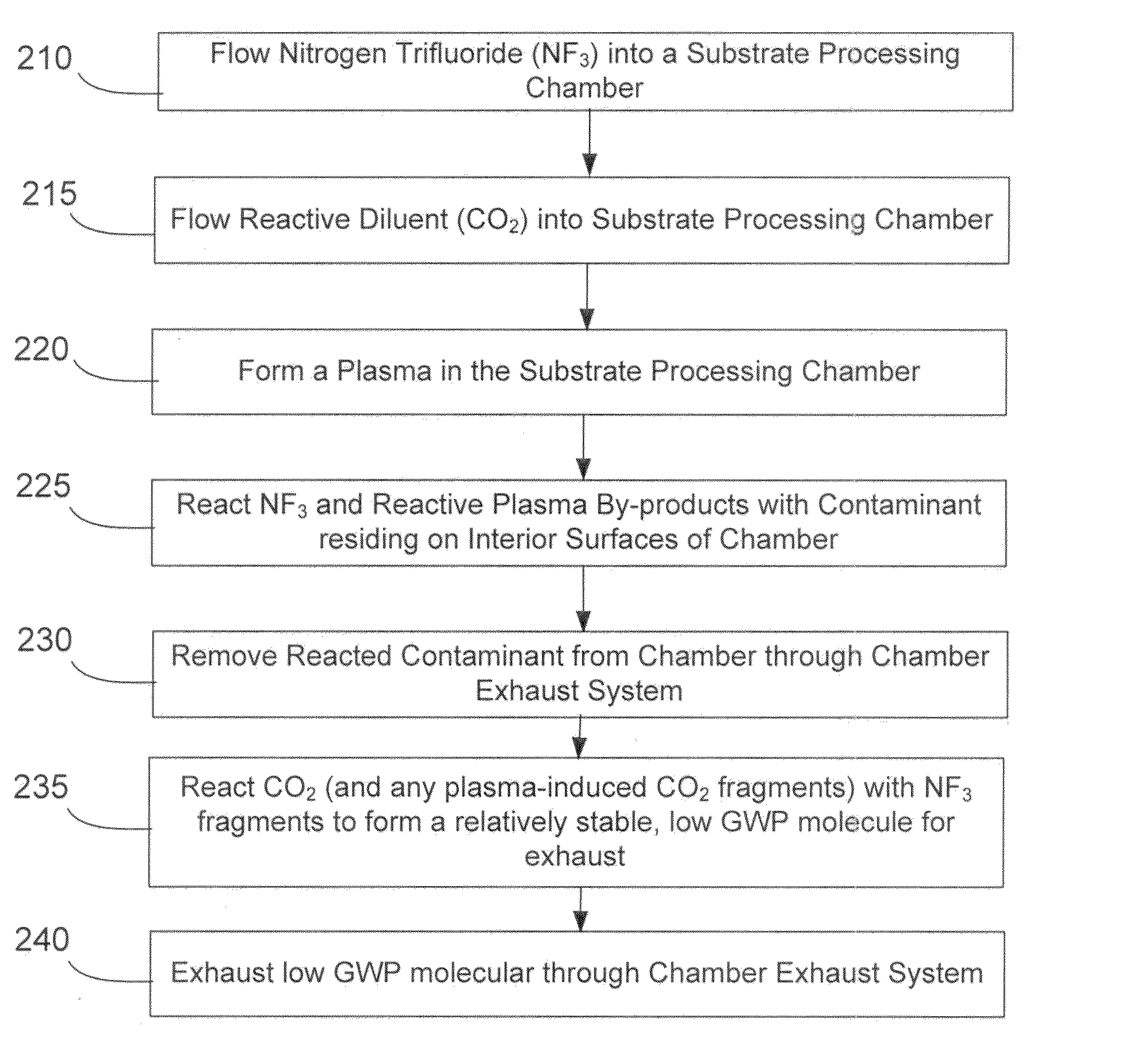

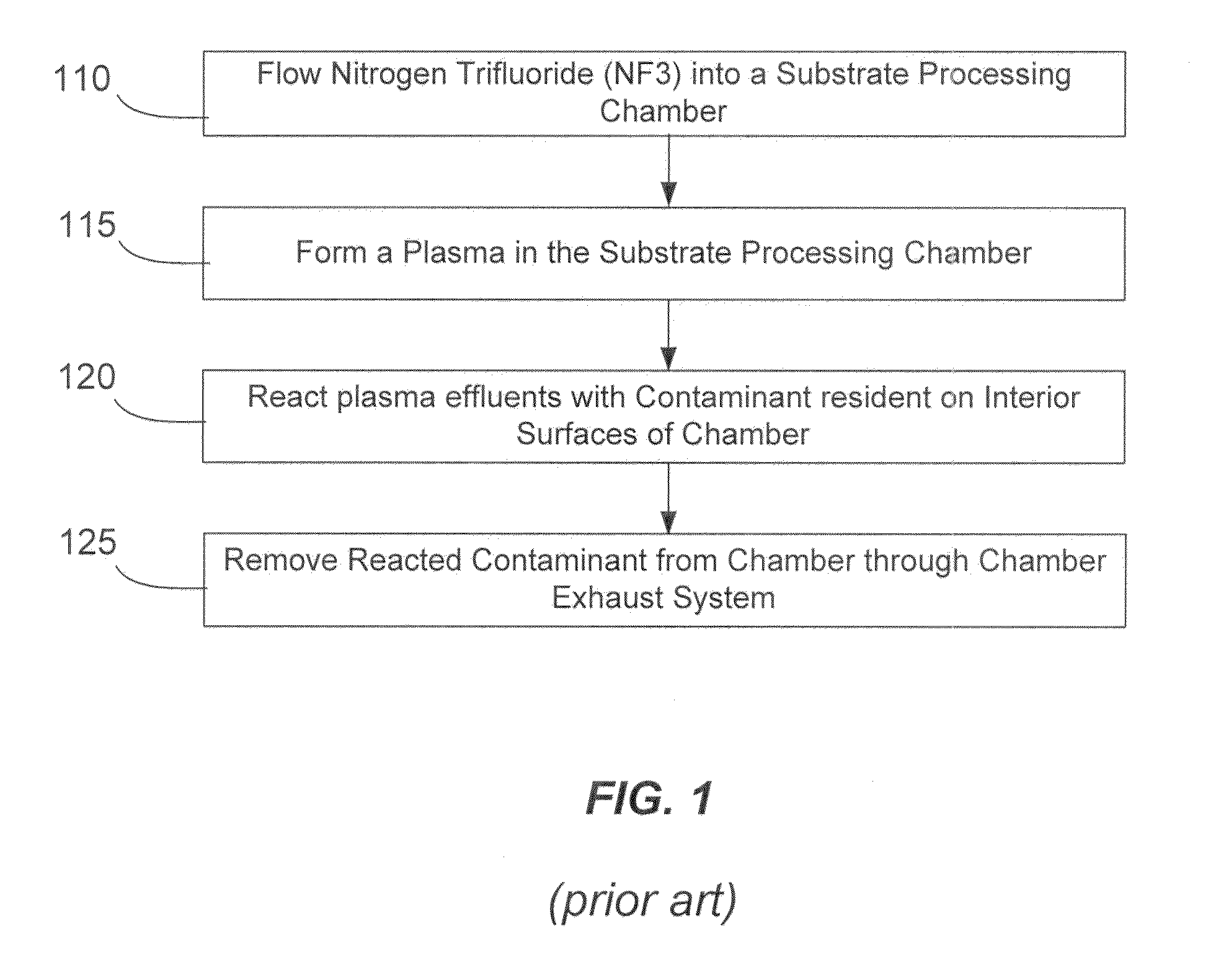

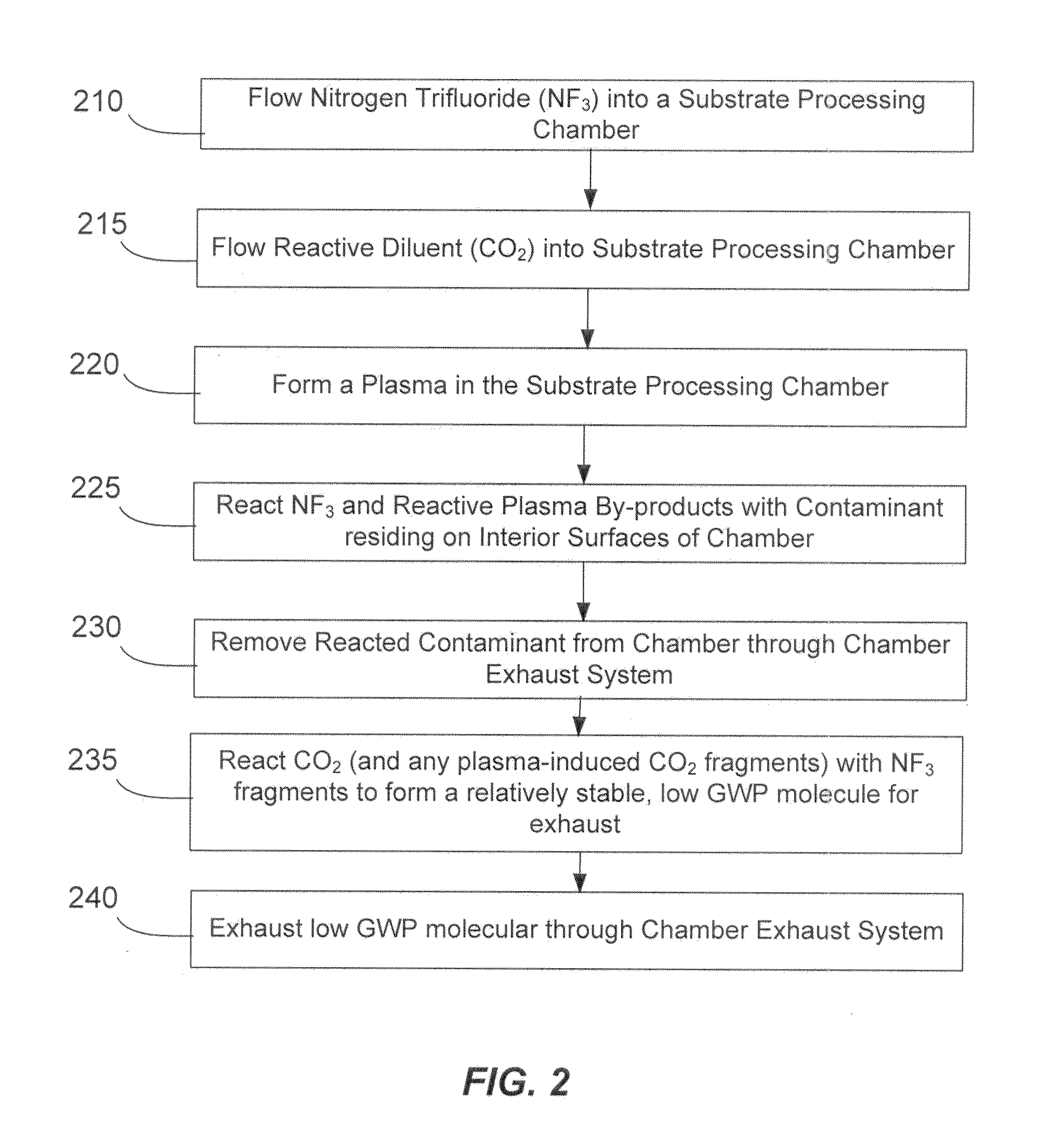

NF3 chamber clean additive

InactiveUS8623148B2Improve efficiencyReduce capacityElectric discharge tubesHollow article cleaningRemote plasmaReactive diluent

Methods of cleaning a processing chamber with nitrogen trifluoride (NF3) are described. The methods involve a concurrent introduction of nitrogen trifluoride and a reactive diluent into the chamber. The NF3 may be excited in a plasma inside the chamber or in a remote plasma region upstream from the chamber. The reactive diluent may be introduced upstream or downstream of the remote plasma such that both NF3 and the reactive diluent (and any plasma-generated effluents) are present in the chamber during cleaning. The presence of the reactive diluent enhances the chamber-cleaning effectiveness of the NF3.

Owner:MATHESON TRI GAS INC

Photoimageable coating composition and composite article thereof

InactiveUS20050266335A1Photosensitive materialsPhotomechanical coating apparatusResistPhotoacid generator

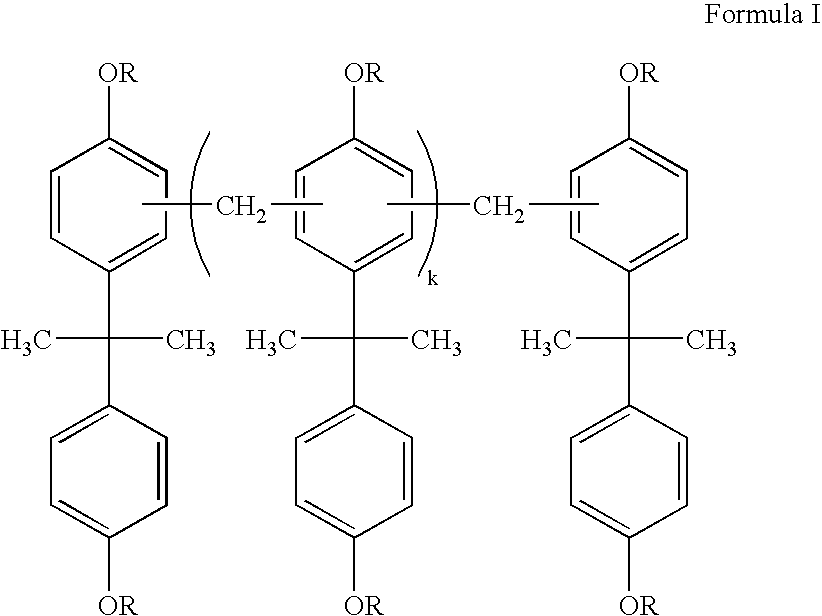

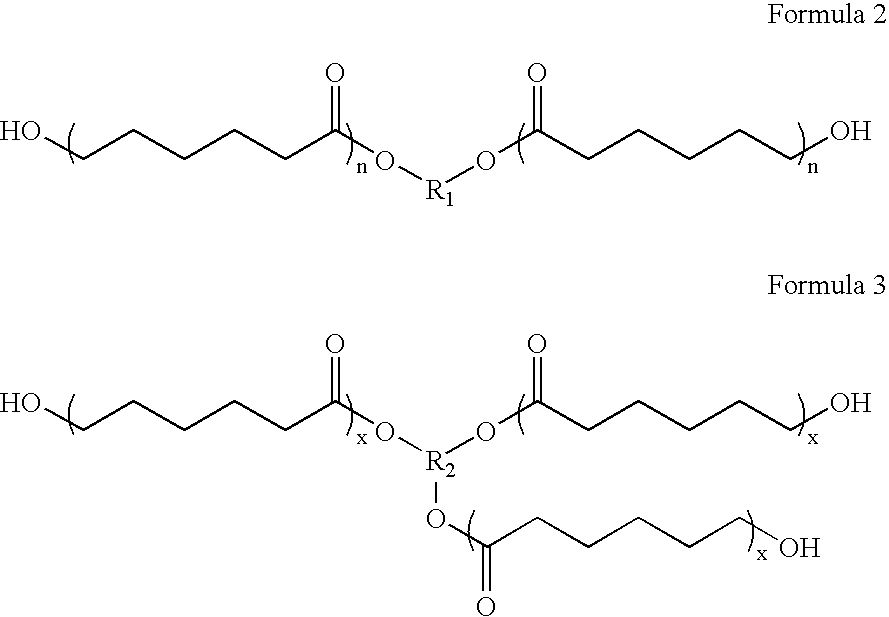

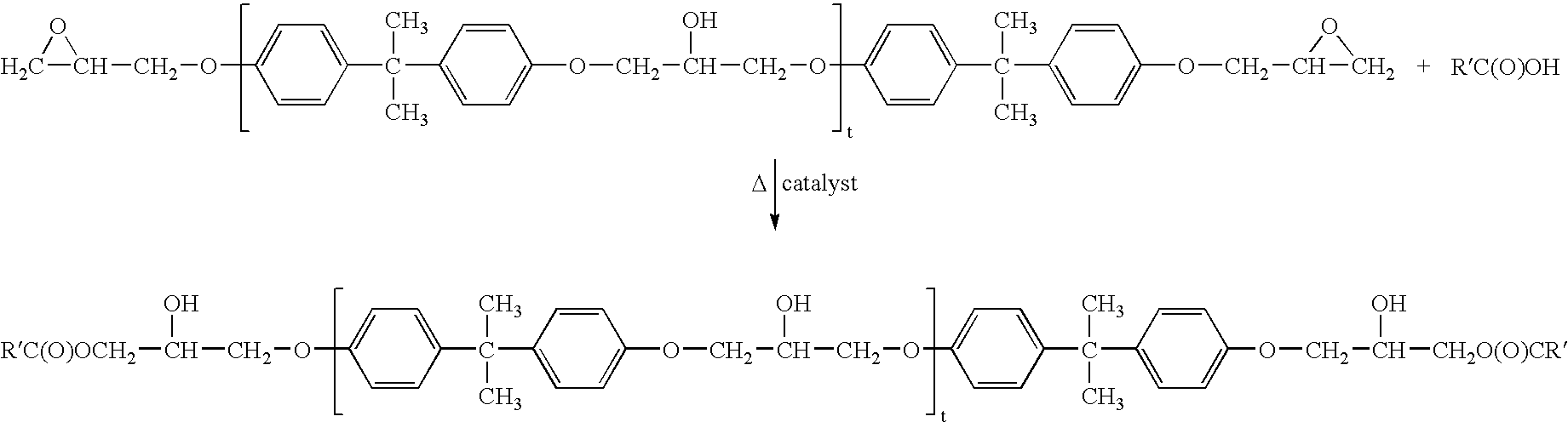

A photoimagable composition suitable for use as a negative photoresist comprising: (A) at least one epoxidized polyfunctional bisphenol A formaldehyde novolak resin; (B) at least one polycaprolactone polyol reactive diluent, wherein the amount of component (A) is from about 95% to about 75% by weight of the sum of (A) and (B) and the amount of component (B) is from about 5% to about 25% by weight of the sum of (A) and (B); (C) at least one photoacid generator in an amount from about 2.5 to about 12.5 parts per hundred parts of resin and reactive diluent, which initiates polymerization upon exposure to actinic radiation; and (D) a sufficient amount of solvent to dissolve (A), (B) and (C); wherein the solvent comprises 2-pentanone, 3-pentanone, and 1,3-dioxolane and mixtures thereof.

Owner:MICROCHEM CORP +1

Water-borne dispersions of oil modified urethane polymers

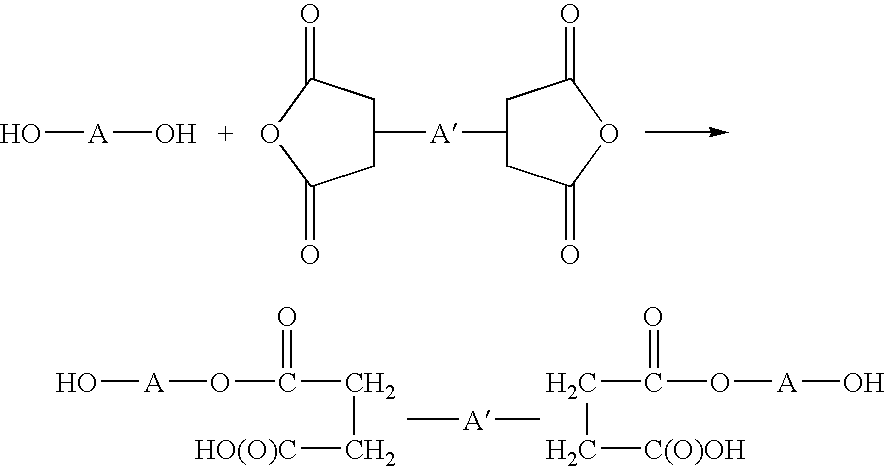

A composition comprising a self-crosslinkable aqueous dispersion of a polyurethane polymer having pendant auto-oxidizable functional groups is disclosed, said composition obtainable by reacting: (a) an organic polyisocyanate; (b) an isocyanate reactive compound containing pendant fatty acid unsaturation; (c) an isocyanate reactive polymeric polyol containing neutralizable pendant carboxylic acid groups; and (d) a reactive diluent containing at least two polymerizable, ethylenically unsaturated double bonds. The obtained polyurethane dispersion is suitable for application in self-curing coating compositions.

Owner:LUBRIZOL ADVANCED MATERIALS INC

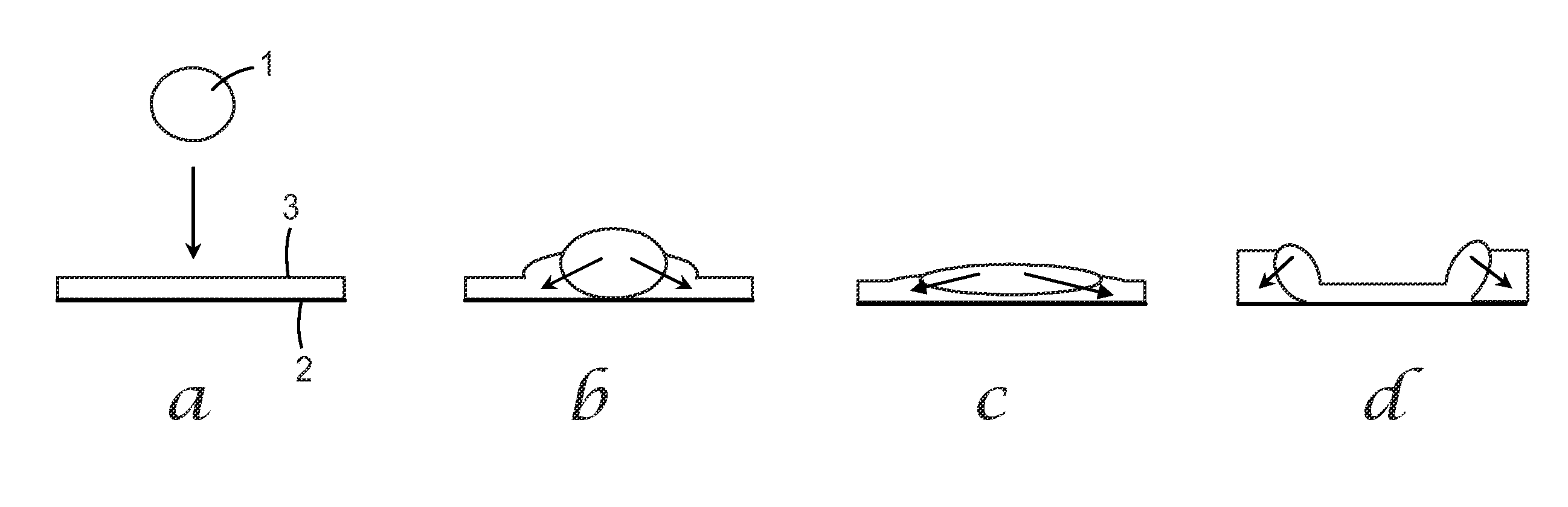

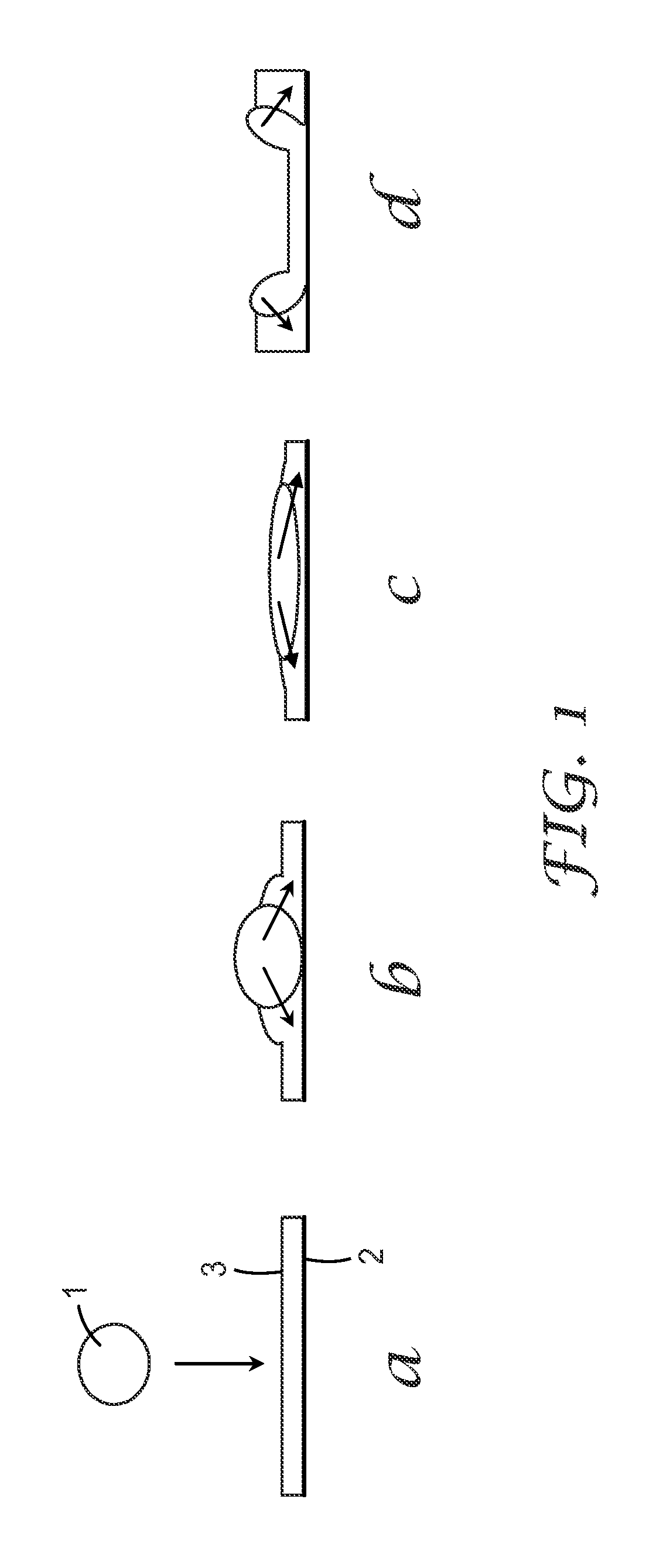

Fixed abrasive grinding polishing pad and method of manufacturing the same

InactiveCN101428404AImprove flatnessPlay a cutting roleAbrasion apparatusGrinding devicesReactive diluentEngineering

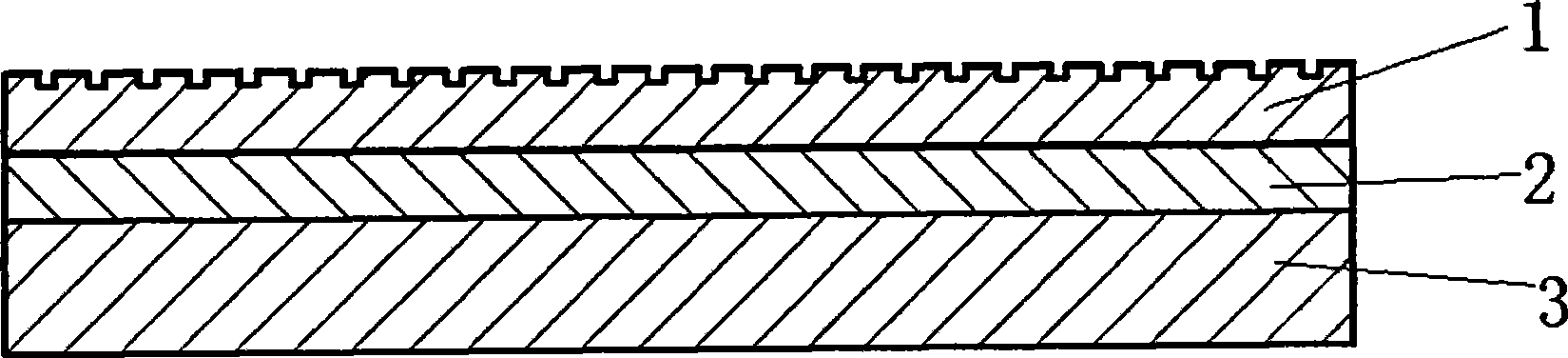

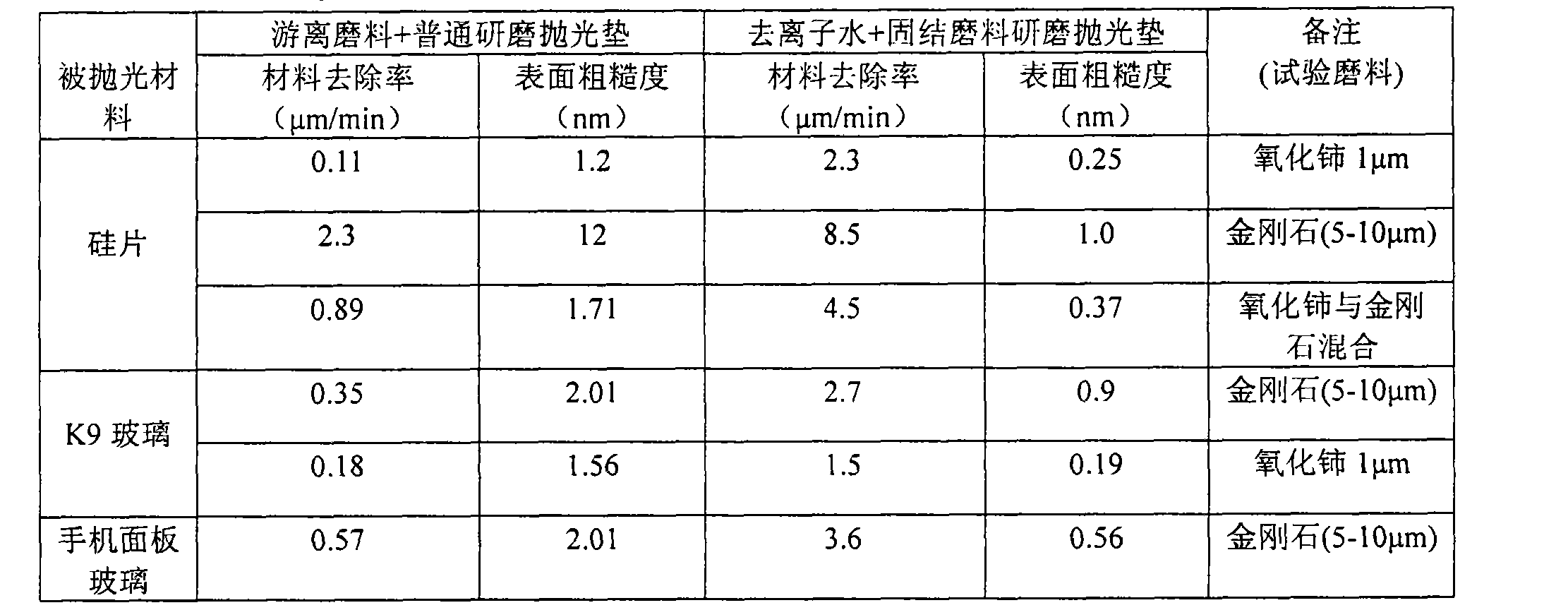

The invention provides a solidified abrading agent polishing pad and the preparation method thereof. The solidified abrading agent polishing pad comprises at least three layers, including an elastic layer (3), a rigid layer (2) and an abrading agent layer (1) sequentially arranged from the bottom layer to the top layer. The solidified abrading agent polishing pad is characterized in that the abrading agent layer (1) comprises the following components by the weight percentage: 1% to 40% of an abrading agent with the particle size being 1 nm to 40 Mum, 20% to 80% of polyacrylate prepolymer, 0.05% to 3% of free radical photoinitiator, 0% to 2% of poly-dimethylsiloxane / acrylic polymer, 0% to 20% of a performance adjusting addition agent, and 5% to 40% of esterified acrylic acid reactive diluent. The solidified abrading agent polishing pad which is prepared by the figure-transfer method has a series of advantages of stable grinding and polishing performance, high polishing efficiency, high surface texture of processed workpieces, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Abrasion resistant urethane coatings

InactiveUS20010051229A1Reduce contentRapidly cured and polymerizedSynthetic resin layered productsSpecial tyresOligomerReactive diluent

Owner:PERMAGRAIN PROD

Ultraviolet-cured hydrophilic coating composition and preparation method thereof

InactiveCN102585691AHigh content of hydrophilic substancesCreate pollutionPolyurea/polyurethane coatingsPolyether coatingsHydrophilic coatingPolymer science

The invention relates to a highly-hydrophilic transparent ultraviolet-cured coating composition and a preparation method thereof. The ultraviolet-cured hydrophilic coating composition comprises light-cured resin, a polymerization monomer, a reactive diluent, a light initiator, an auxiliary and pigment. The preparation method comprises accurately weighing the light-cured resin according to a formula and pouring the light-cured resin into a mixing kettle, sequentially adding the polymerization monomer, the reactive diluent and the auxiliary into the mixing kettle, and stirring the mixture for 20-45 minutes; adding the light initiator into the mixing kettle, mixing for 15-35 minutes to obtain ultraviolet-cured hydrophilic coating, and storing the ultraviolet-cured hydrophilic coating away from the light; and when the ultraviolet-cured hydrophilic coating is used, adding the pigment and performing even mixing. The ultraviolet-cured hydrophilic coating composition can be coated on base materials of plastic, metal, glass and the like. An ultraviolet-cured coating has excellent hydrophilcity and good physical performance, adhesive force, hydrolytic resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

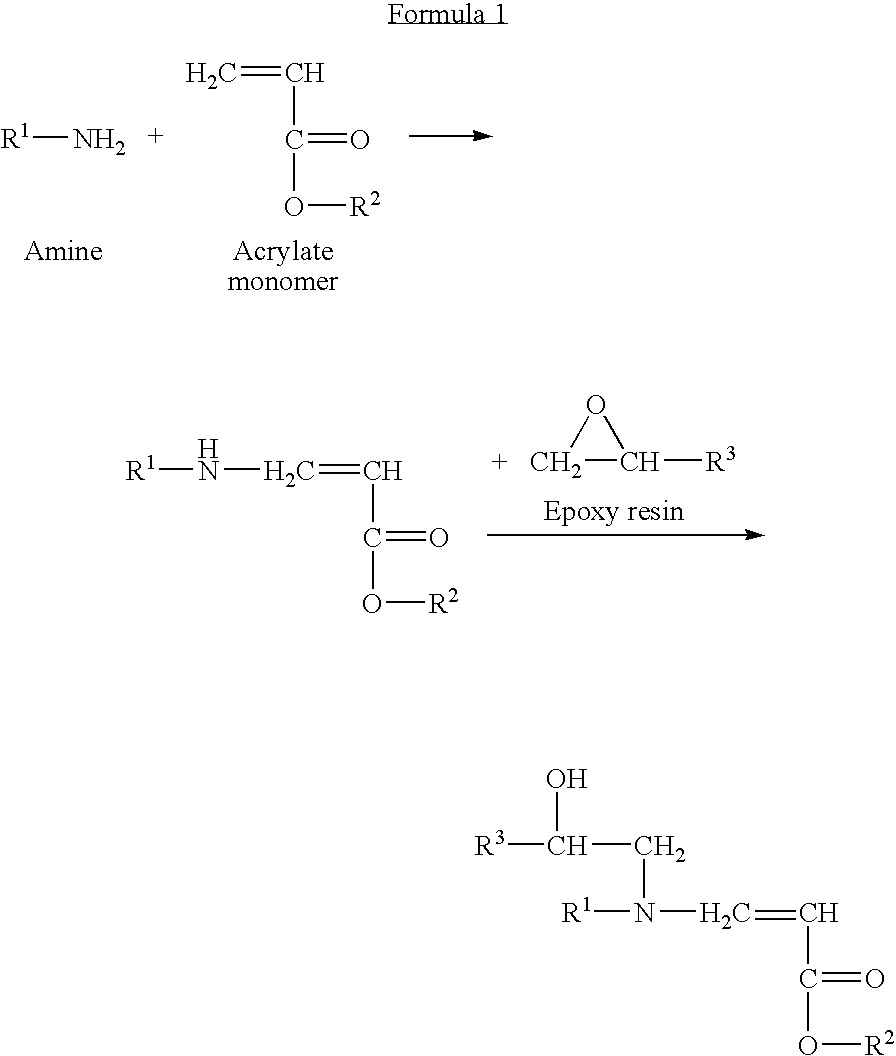

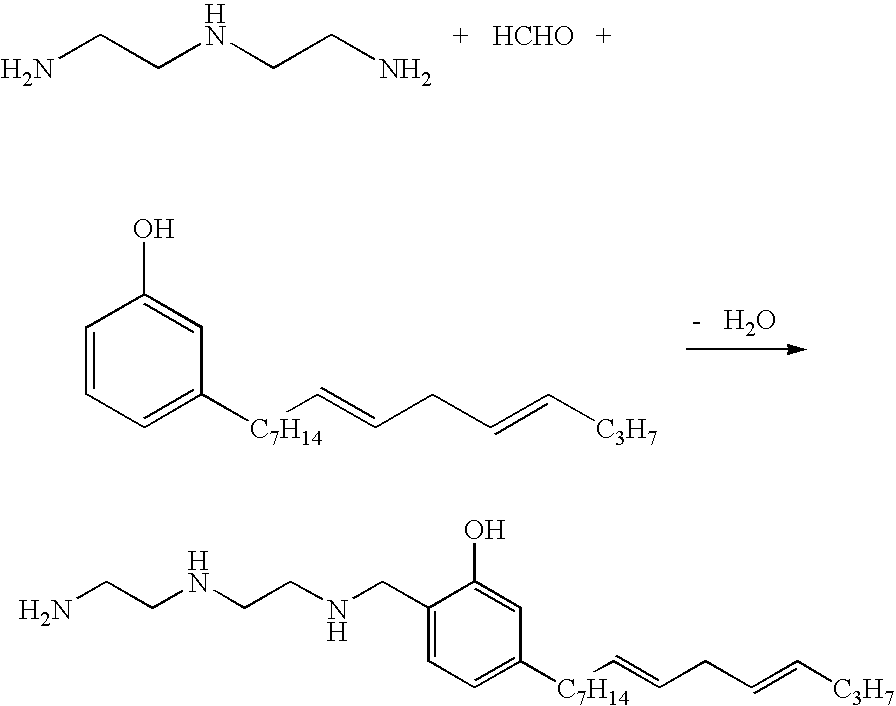

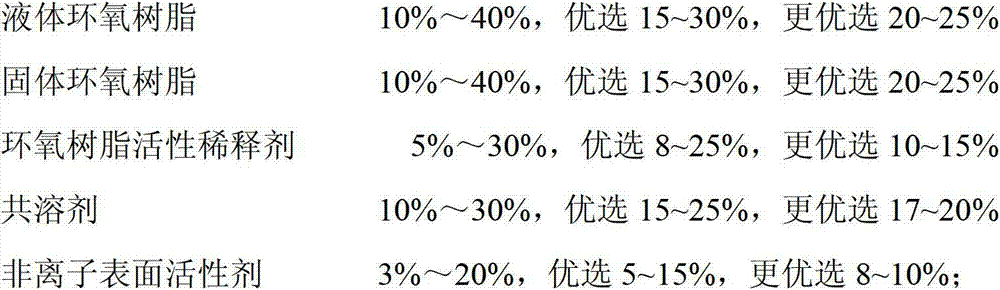

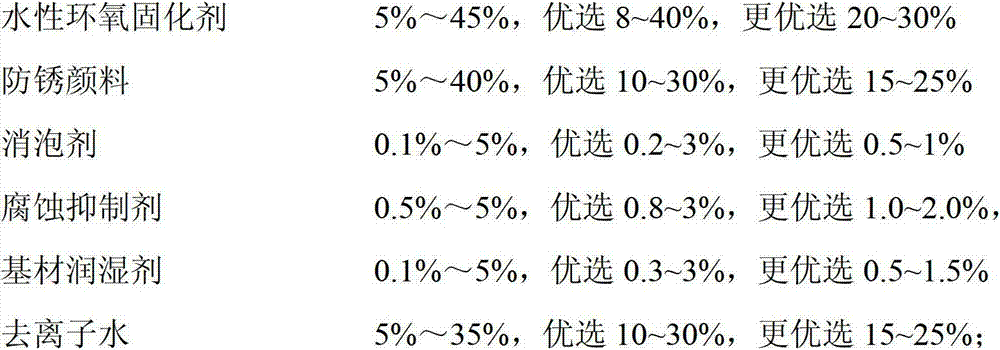

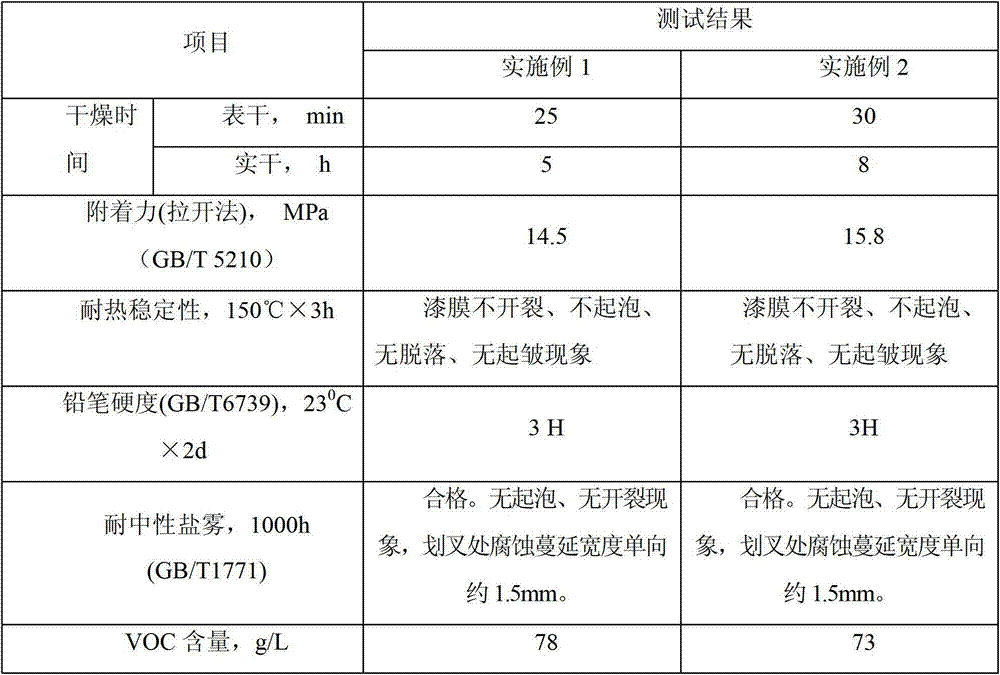

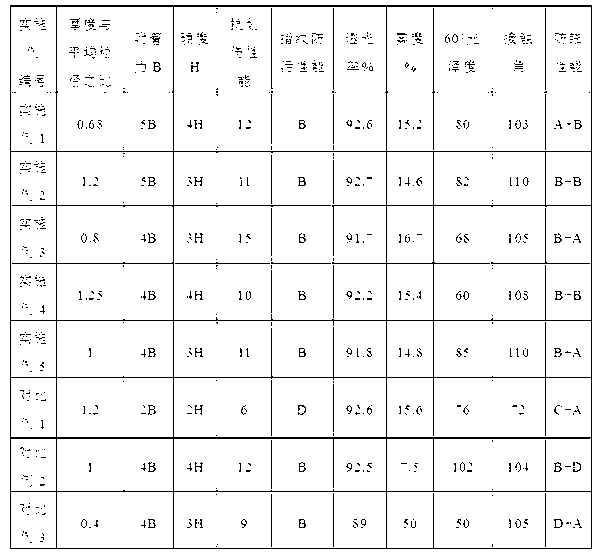

Room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and preparation method thereof

ActiveCN103087612AImprove anti-corrosion performanceFast curingAnti-corrosive paintsEpoxy resin coatingsSurface-active agentsChemistry

The invention provides a room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and a preparation method for the coating. The coating comprises A and B two components, wherein the A component consists of liquid epoxy resin, solid epoxy resin, an epoxy resin reactive diluent, a cosolvent, and a non-ionic surface active agent; the B component consists of a waterborne epoxy curing agent, an anticorrosive pigment, a foam killer, a corrosion inhibitor, a substrate wetting agent and de-ionized water, and during application, mass proportion of the A component to B component is 1:3-6. The coating is high in curing speed of coated film, the surface is dried in 30min at room temperature without being roasted; the coating has high early hardness, and the hardness can reach 3H in 48 hours; and in addition, the coating is good in thermal resistance stability, low in VOC (Volatile Organic Compound) content, excellent in anti-corrosion performance, and is capable of replacing a solvent type two-component epoxy coating to be applied to the anti-corrosion of a steel structure.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

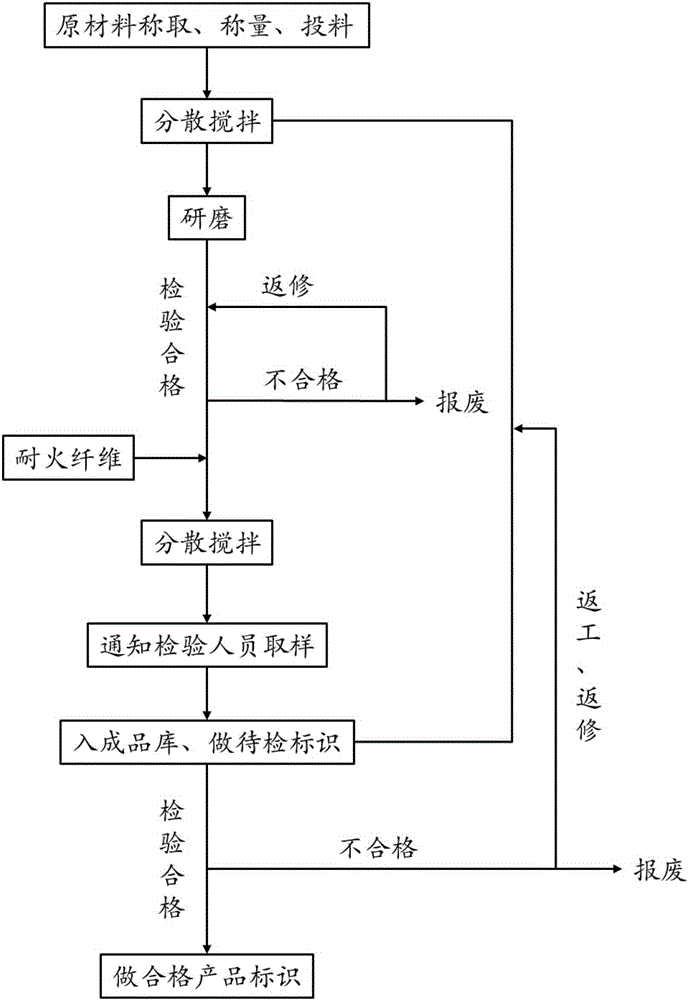

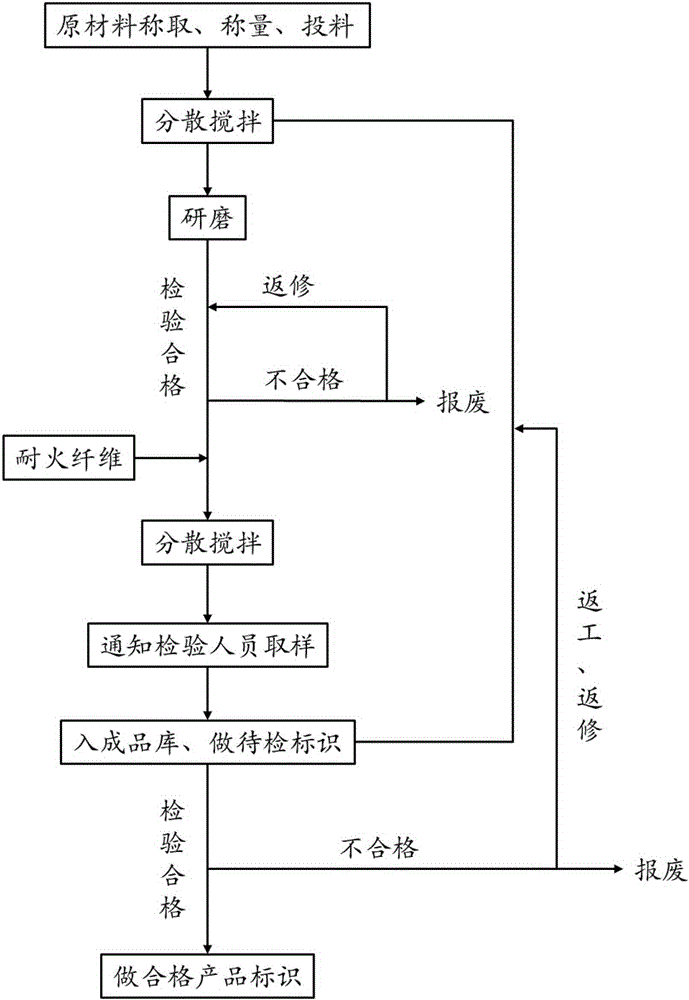

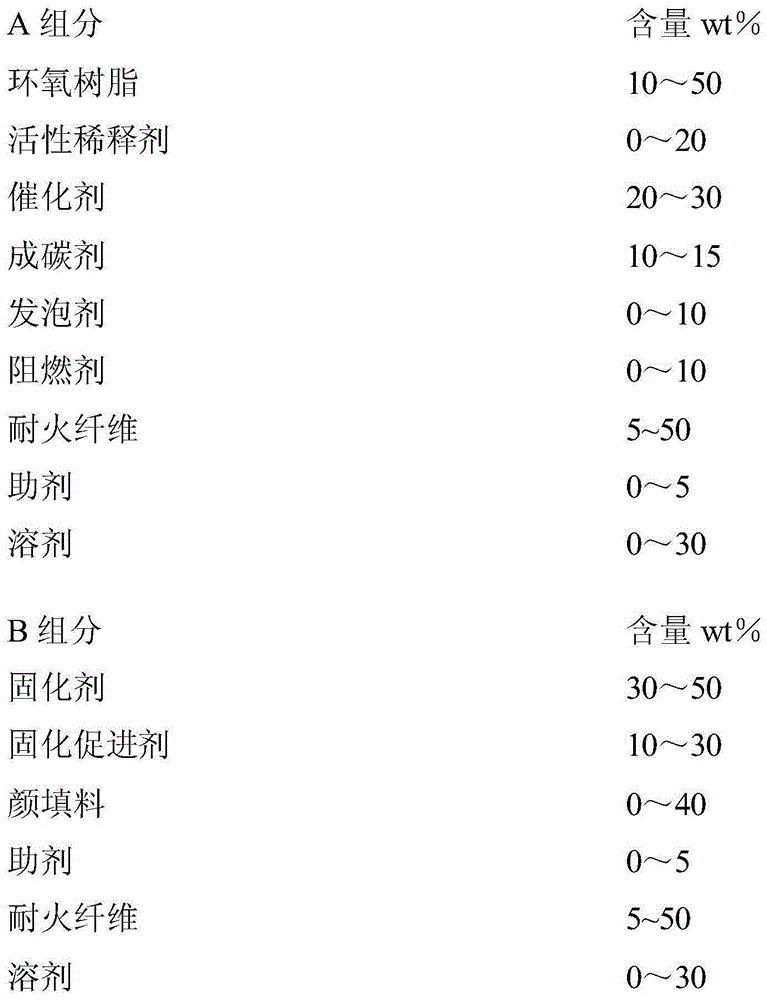

Environment-friendly epoxy intumescent fire-retardant coating and preparing method thereof

ActiveCN105238222AImprove acid resistanceGood alkali resistanceFireproof paintsEpoxy resin coatingsFiberAlkylphenol

The invention relates to an environment-friendly epoxy intumescent fire-retardant coating and a preparing method thereof, and belongs to the field of functional coatings. The environment-friendly epoxy intumescent fire-retardant coating is prepared from a component A and a component B, wherein the component A uses epoxy resin as a main film forming matter and is added with a reactive diluent, a catalyst, a carbon-forming agent, a foaming agent, fire retardant, auxiliaries and solvent, and the component B is composed of a curing agent, a curing accelerator, pigment filler, auxiliaries, refractory fibers and solvent. In the component A, the ratio of the epoxy resin to the reactive diluent is 1:1-5:1. In the component B, the ratio of the curing agent to the curing accelerator is 1:1-5:1, and the usage quantity of the refractory fibers accounts for 5-50% of the total mass. The environment-friendly epoxy intumescent fire-retardant coating is free of alkylphenol, or halogen compounds, or boron compounds or sulfocompounds. The prepared environment-friendly epoxy intumescent fire-retardant coating is good in acid resistance, alkali resistance, water resistance, ageing resistance and salt mist resistance and is particularly suitable for fire-retardant protection for maritime and severe outdoor environments, the petrochemical industry and places with hydrocarbon fire potential hazards.

Owner:MARINE CHEM RES INST

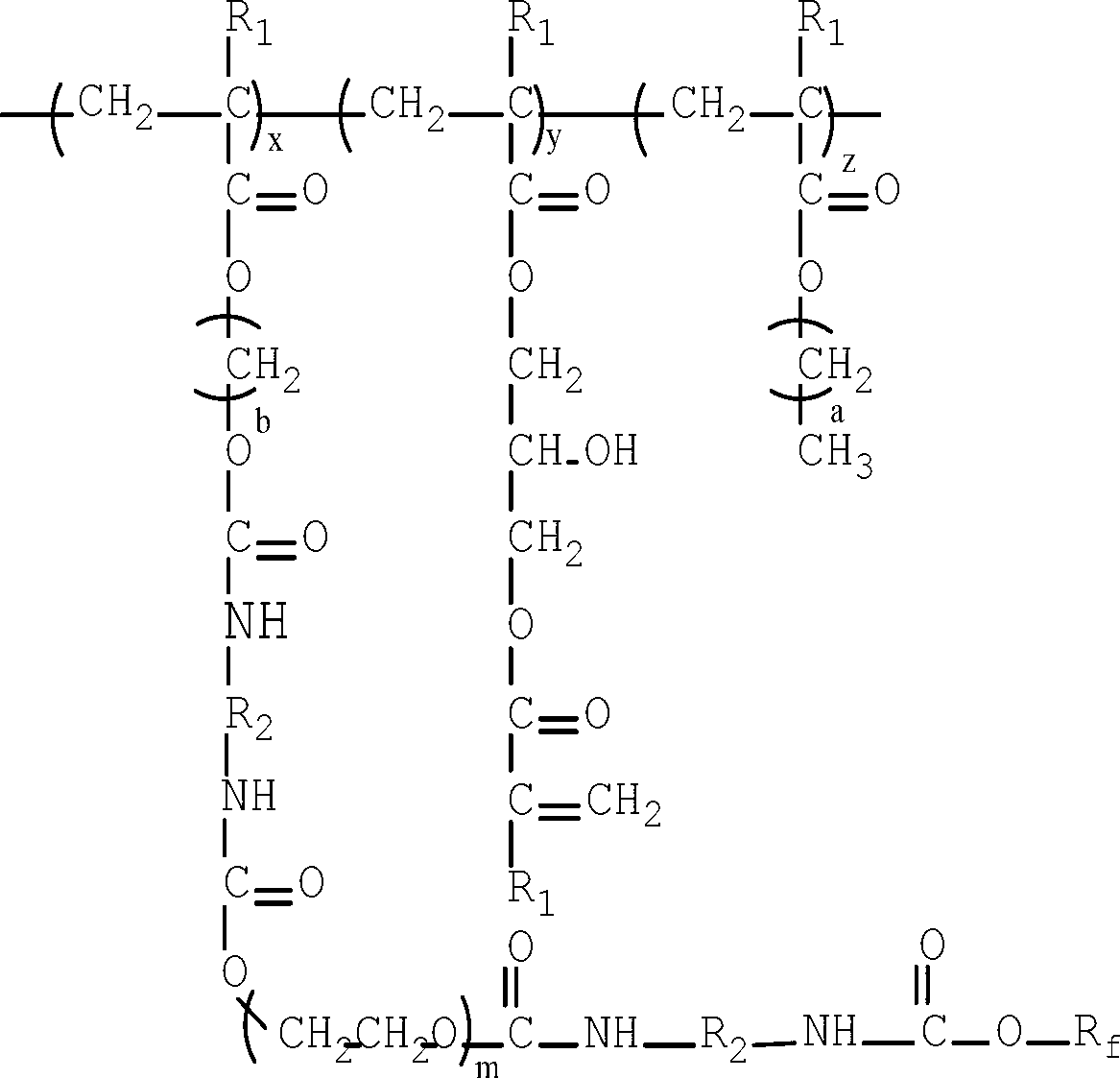

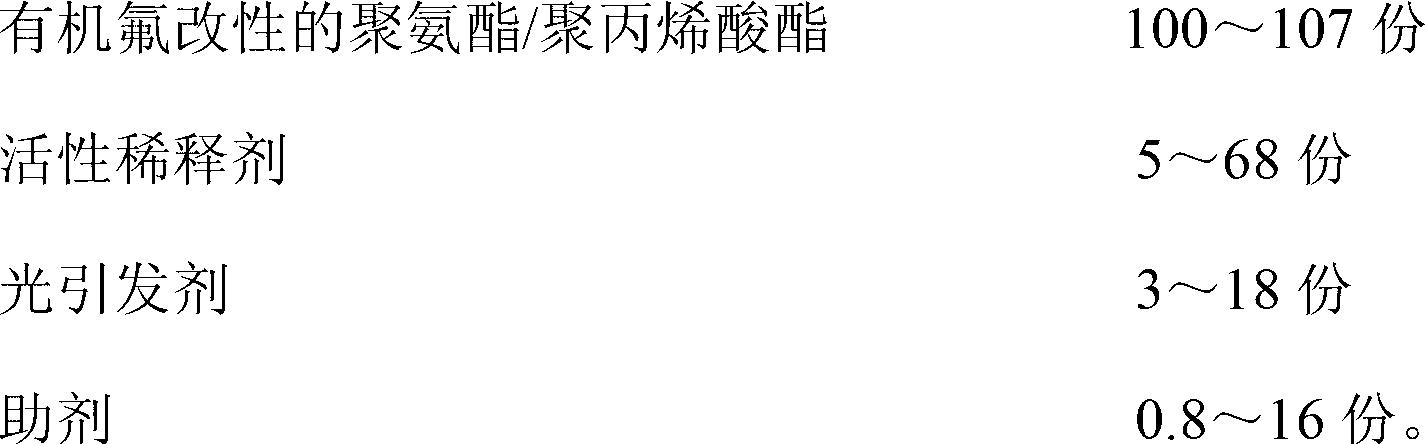

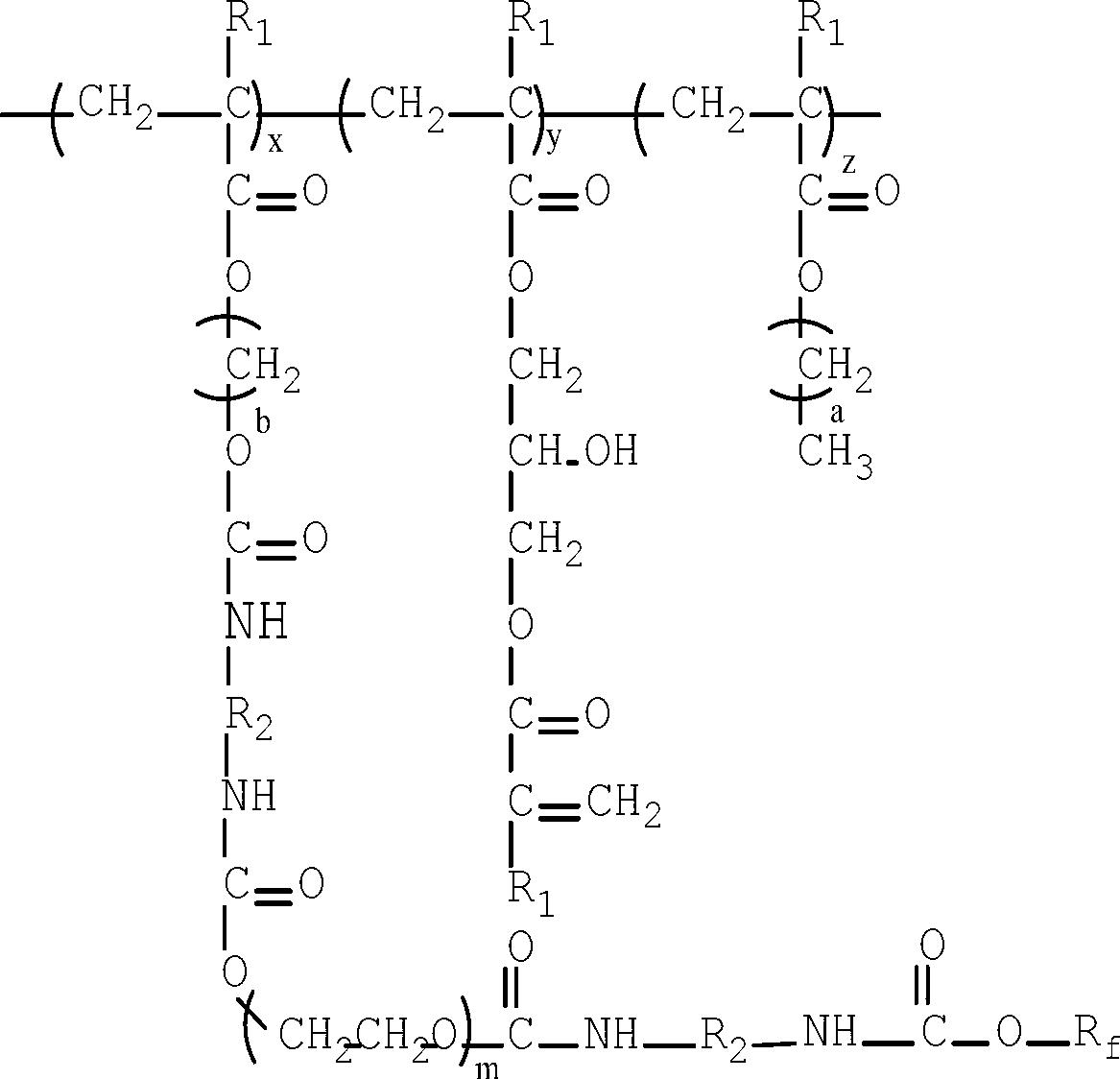

Polyurethane/polyacrylate copolymer modified by organic fluoride and ultraviolet curing coating prepared by polyurethane/polyacrylate copolymer

The invention belongs to the field of coatings, and particularly relates to a polyurethane / polyacrylate copolymer modified by organic fluoride and an ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer. A method for preparing the polyurethane / polyacrylate copolymer modified by organic fluoride comprises the following steps: 1), preparing a polyurethane prepolymer modified by organic fluoride; 2), preparing a (methyl) acrylate prepolymer; and 3), preparing the polyurethane / polyacrylate copolymer modified by organic fluoride. A method for preparing an ultraviolet curing agent by taking the polyurethane / polyacrylate copolymer modified by organic fluoride as a raw material comprises the steps that taking 100-107 parts of polyurethane / polyacrylate, 50-68 parts of an reactive diluent, 13-18 parts of a photoinitiator and 8-16 parts of an auxiliary; stirring fully for 5-15 minutes until all the materials are mixed uniformly; and obtaining the polyurethane / polyacrylate copolymer modified by organic fluoride and the ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

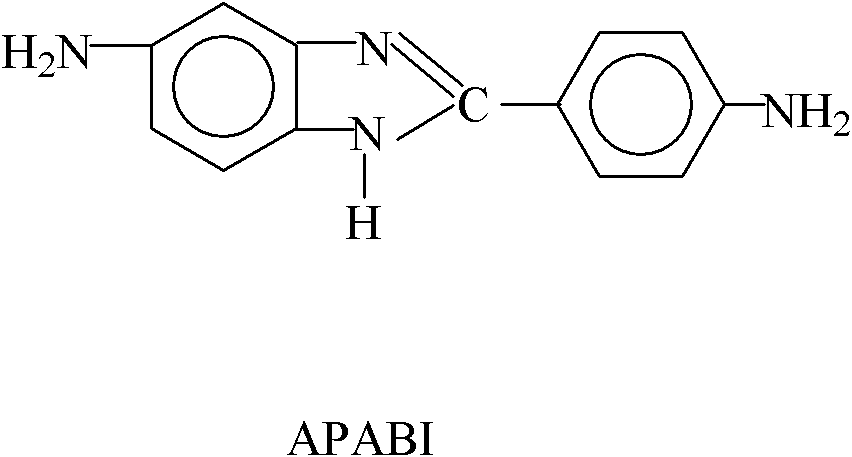

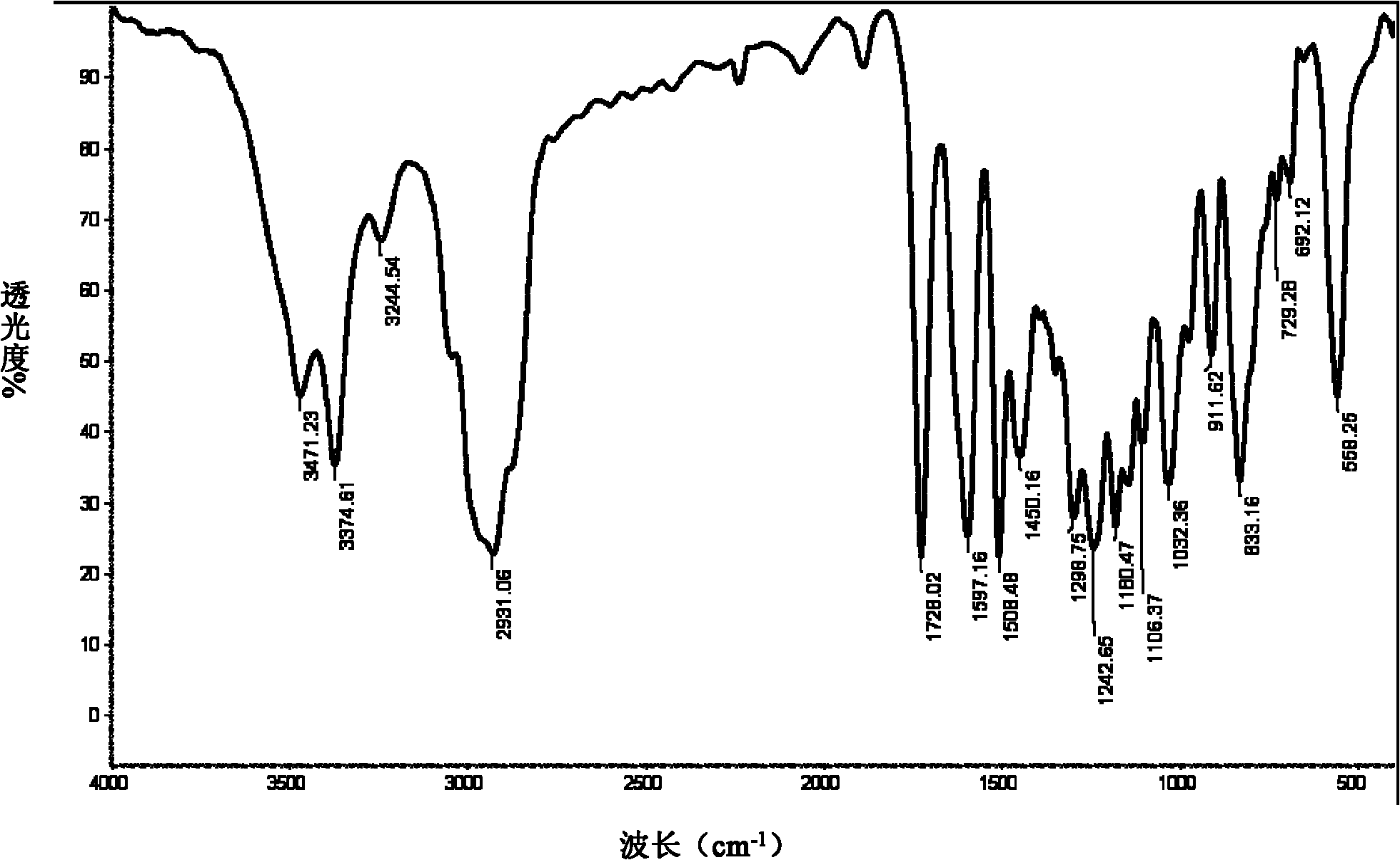

Benzimidazole diamine curing type epoxy adhesive and preparation method thereof

InactiveCN102031082AHigh tensile and shear strength at room temperatureConvenient sourceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesViscous liquidElectronics

The invention relates to a benzimidazole diamine curing type epoxy adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials: a component A, namely a benzimidazole diamine curing agent and a component B, wherein the component B is prepared from terminal carboxyl group butadiene-nitrile rubber, epoxy resin and a reactive diluent. The preparation method comprises the following steps of: (1) adding the terminal carboxyl group butadiene-nitrile rubber and the epoxy resin into a reaction kettle, reacting at the temperature of 90 DEG C with stirring, cooling to the temperature of 50 DEG C, adding the reactive diluent, and stirring at the temperature of 80 DEG C to obtain homogeneous and transparent viscous liquid, namely the component B; and (2) mixingthe components A and B, and stirring uniformly to obtain the adhesive. The tensile shear strength of the adhesive is 33.5MPa at the room temperature, and the adhesive has wide application prospect infields of electronics and microelectronics, rigid copper-clad laminates, motors, aerospace and the like; and the preparation process is simple, is low in cost and is convenient to operate, the resources of reaction raw materials are wide, and the adhesive can be conveniently industrially produced.

Owner:DONGHUA UNIV +1

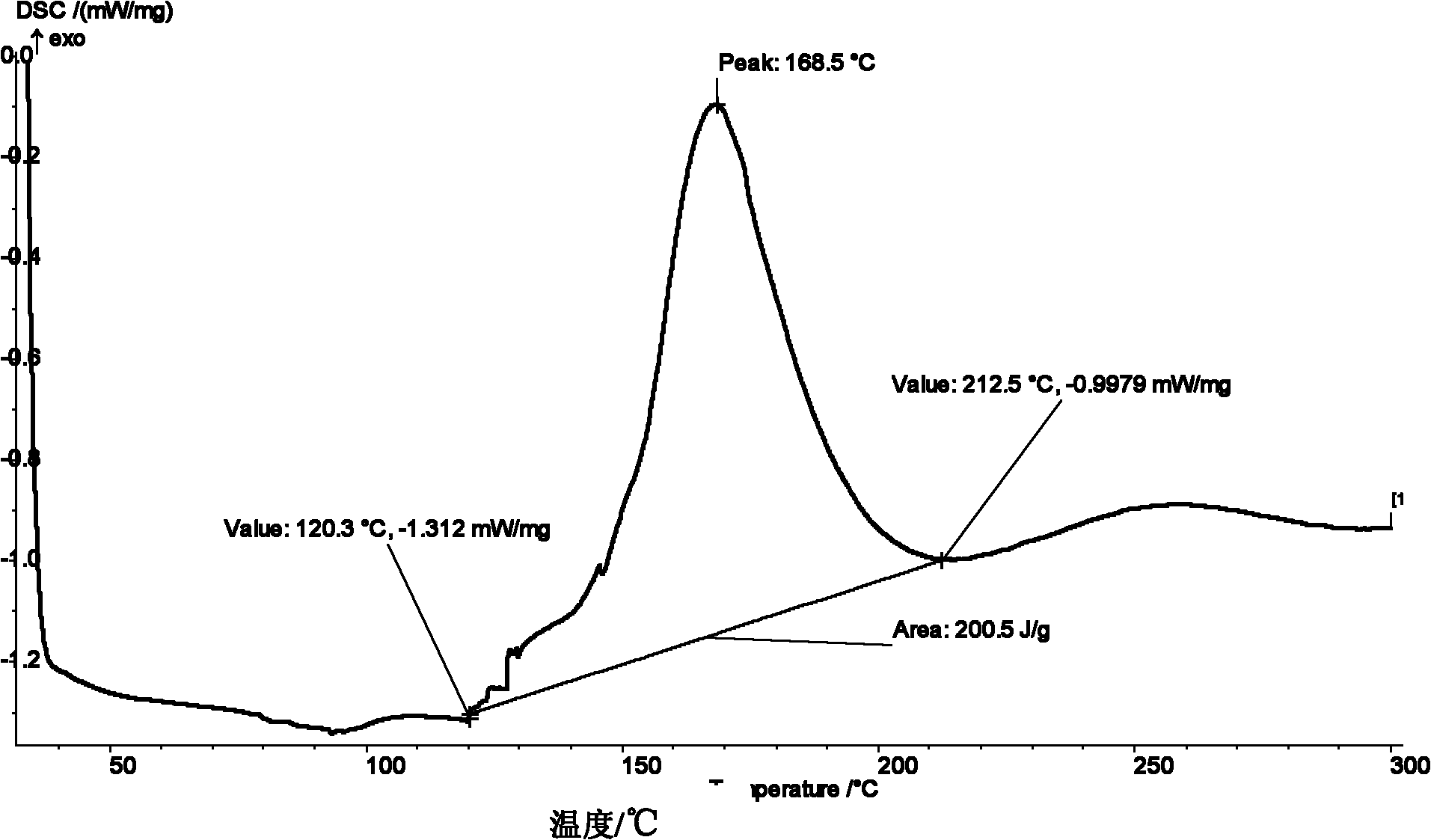

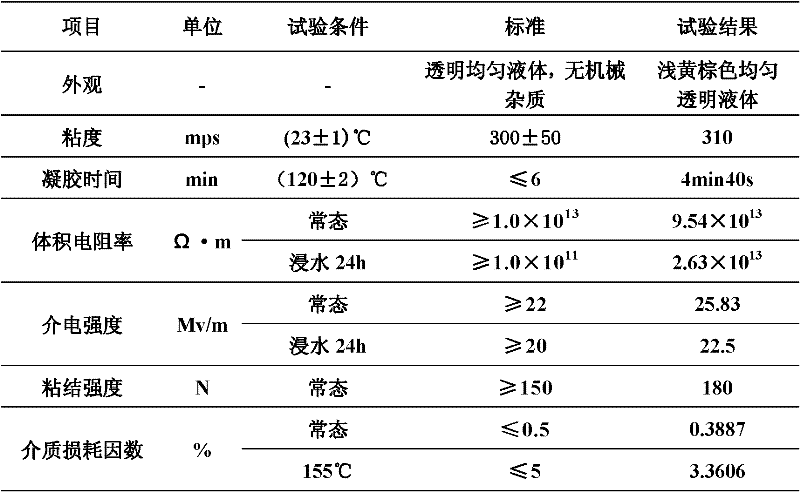

Environmentally-friendly type solvent-free impregnating resin and preparation method thereof

InactiveCN102225986AConservation TrendsPromote safe productionApplying solid insulationCoils manufactureLow voltageTransformer

The invention discloses an environmentally-friendly type solvent-free impregnating resin and a preparation method thereof. The impregnating resin comprises: 100 parts by weight of one or more high heat-resistant unsaturated polyester resins, 0 to 100 parts by weight of one or more modified epoxy resins, 50 to 200 parts by weight of one or more novel reactive diluents, 0.1 to 1 parts by weight of one or more polymerization inhibitors, 1.5 to 3.8 parts by weight of one or more initiators and 0 to 2 parts by weight of one or more auxiliary agents. Under the same work conditions, a baking time of the solvent-free impregnating resin is less than about one third of a baking time of the existing conventional solvent-free type impregnating resin utilized for middle and low voltage motors and transformers, and an energy consumption of the solvent-free impregnating resin is lower than about 25% of an energy consumption of the existing conventional solvent-free type impregnating resin middle and low voltage motors and transformers.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Form-in-place gasket for electronic applications

A non-silicone, form-in-place gasket produced using automated placement followed by curing of a pattern of an extrudable thixotropic material comprising a liquid polyolefin oligomer a reactive diluent a thixotropic filler and a curative. The form-in-place gasket, after curing, has a compression set of about 7% to about 20%, a level of outgassing components of about 10 mug / g to about 45 mug / g and a Shore A hardness from about 45 to about 65.

Owner:3M INNOVATIVE PROPERTIES CO

Two-part epoxy-based structural adhesives

A two-part epoxy-based structural adhesive composition comprising a curable epoxy resin, an amine curing agent, a toughening agent, and an oil-displacing agent. The structural adhesive may optionally include reactive liquid modifiers, fillers, secondary curatives, reactive diluents, surfactants, metal salts, pigments and combinations thereof. The structural adhesive may be used to form bonded joints between adherends having clean surfaces, as well as those having surfaces contaminated with hydrocarbon-containing materials, such as oils, processing aids and lubricating agents.

Owner:3M INNOVATIVE PROPERTIES CO

Ultraviolet-cured anti-dazzle hard film and application thereof

InactiveCN103205190AGood anti-glare effectGood compatibilityPolyurea/polyurethane coatingsPolyester coatingsUltravioletReactive diluent

The invention provides an ultraviolet-cured anti-dazzle hard film and application thereof. The ultraviolet-cured anti-dazzle hard film comprises a transparent supporter and an anti-dazzle hard film coating coated on at least one surface of the transparent supporter. A formula for the coating comprises, by weight, 5 to 90 parts of an ultraviolet-cured resin, 5 to 90 parts of a solvent, 1 to 10 parts of a photoinitiator, 0 to 80 parts of a reactive diluents, 1 to 40 parts of an anti-dazzle particle and 0 to 6 parts of an auxiliary agent. Compared with the prior art, the invention has the following advantages: the ultraviolet-cured resin contains a certain amount of an organic silicon resin, which enables the antifouling property of the surface of the anti-dazzle hard film to be improved; and the selected organic particle has good compatibility with the ultraviolet-cured resin, so transmission loss of light is reduced, which enables clarity of displaying by the anti-dazzle hard film to be improved. The ultraviolet-cured anti-dazzle hard film has good anti-dazzling performance, a good antifouling effect, high hardness, good scratch resistance, excellent flexibility and high resolution.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Radiation curable adhesive for digital versatile disc

Owner:DSM IP ASSETS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com