Patents

Literature

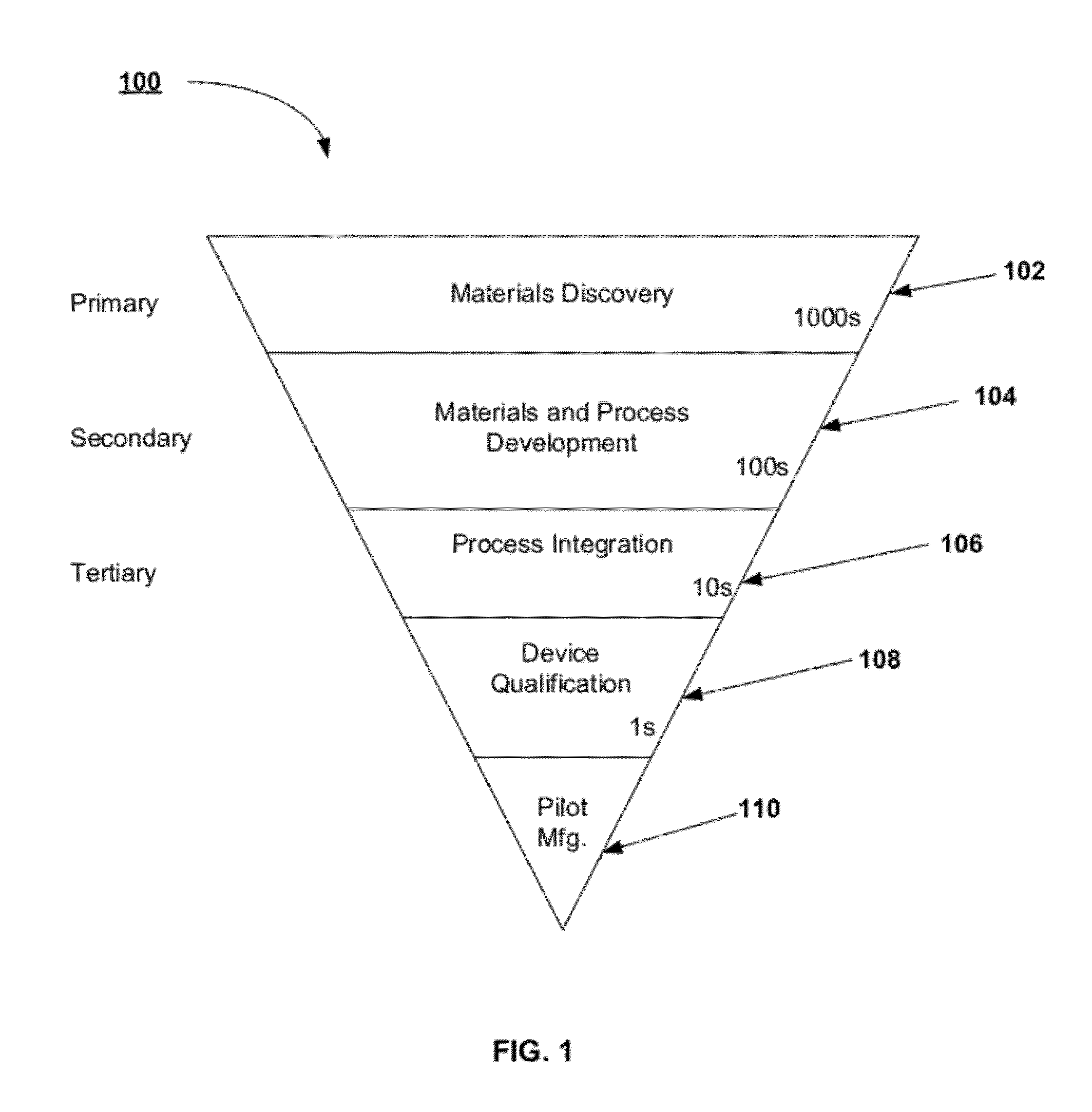

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1518 results about "Reactive gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most reactive gas is known as fluorine. Its oxidizing abilities make it highly reactive due to its ability to create strong bonds with fellow atoms.

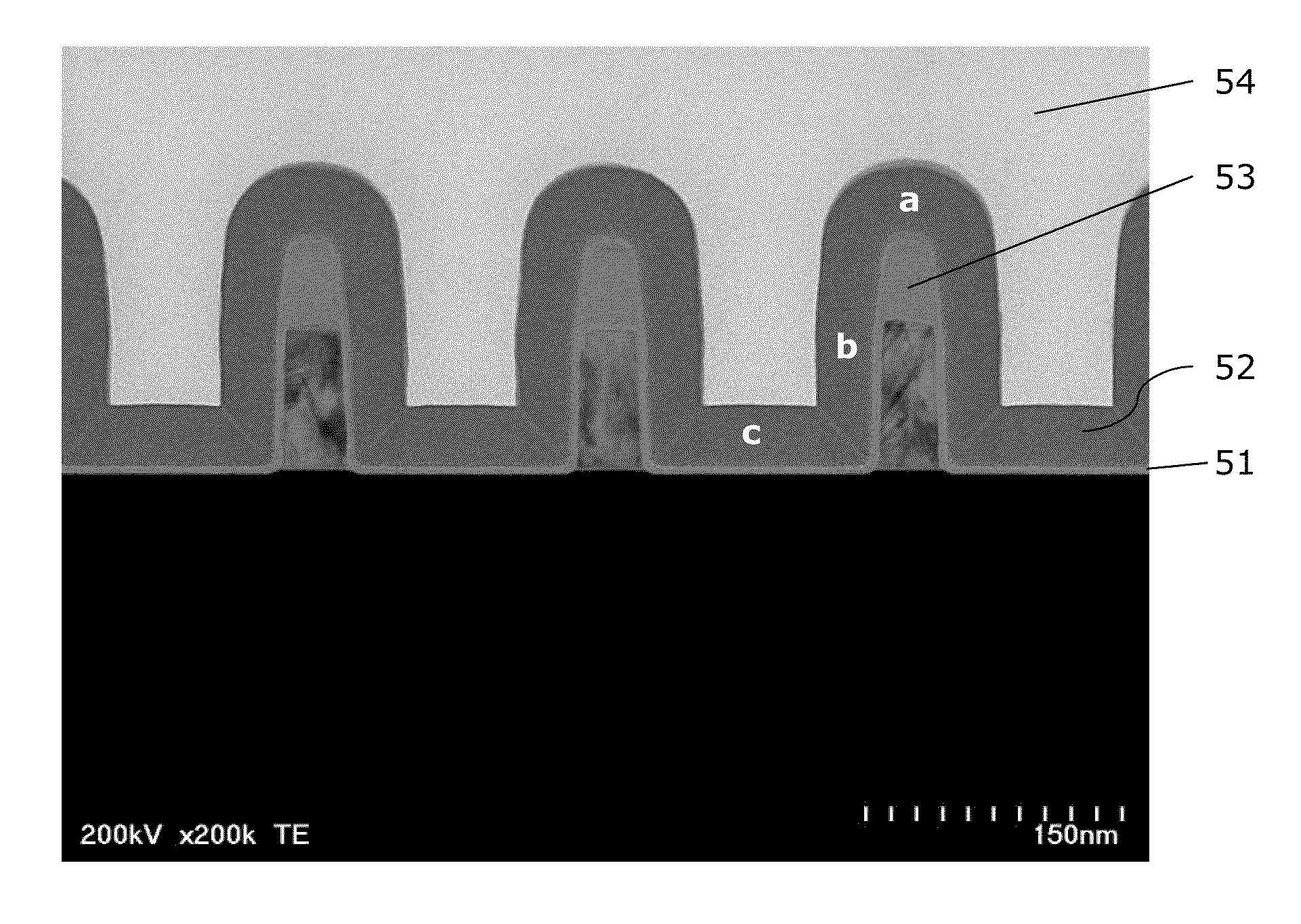

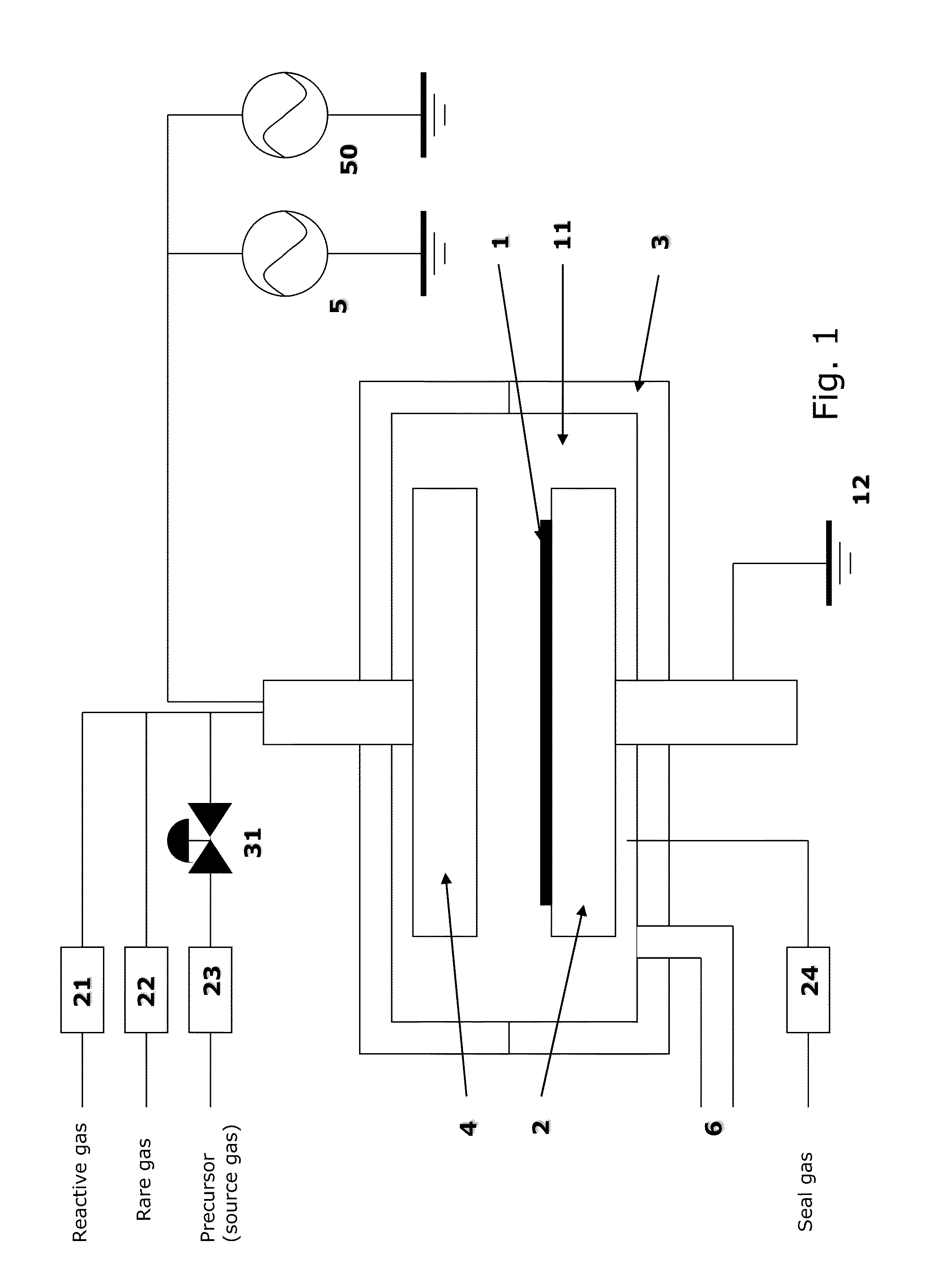

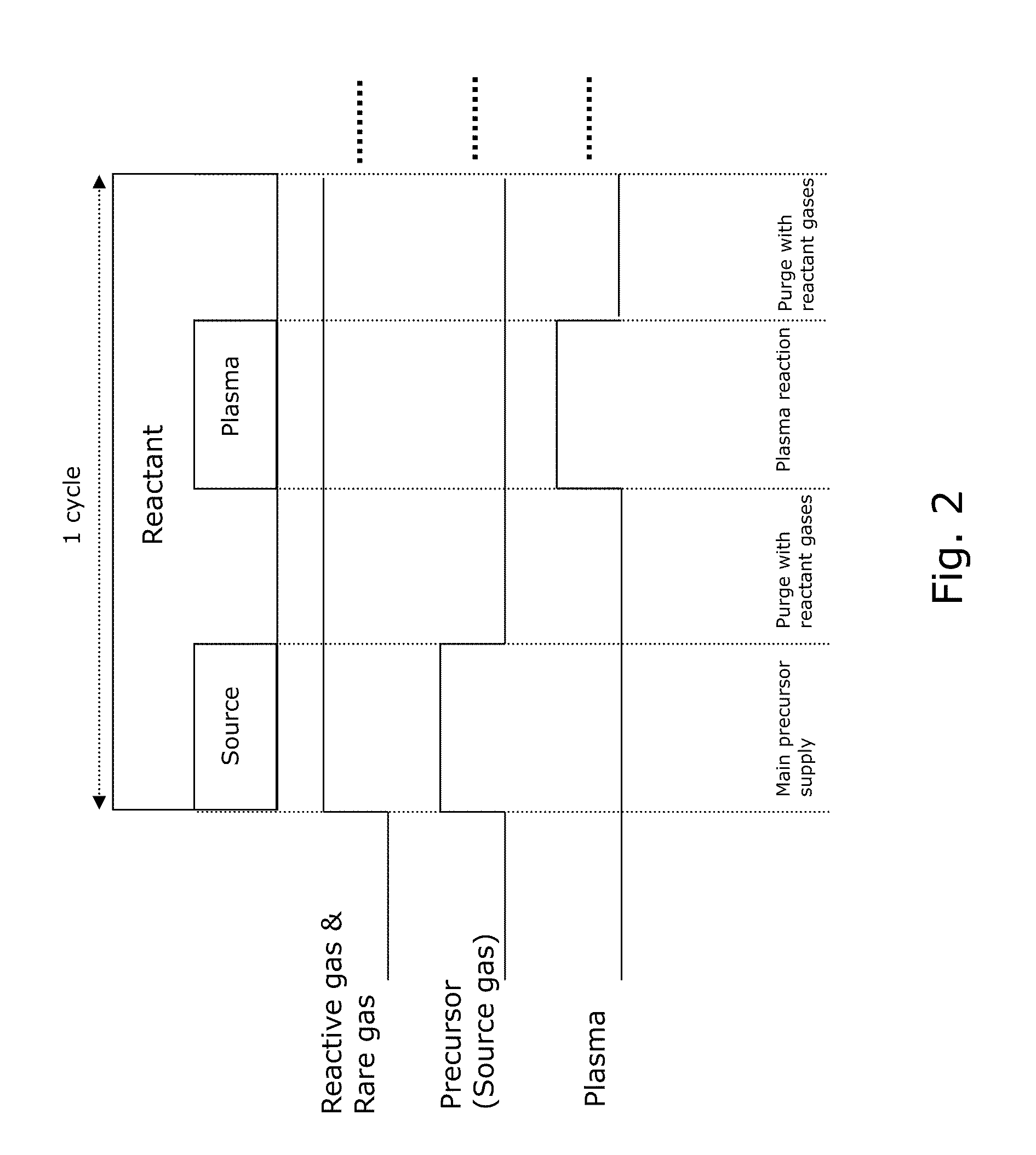

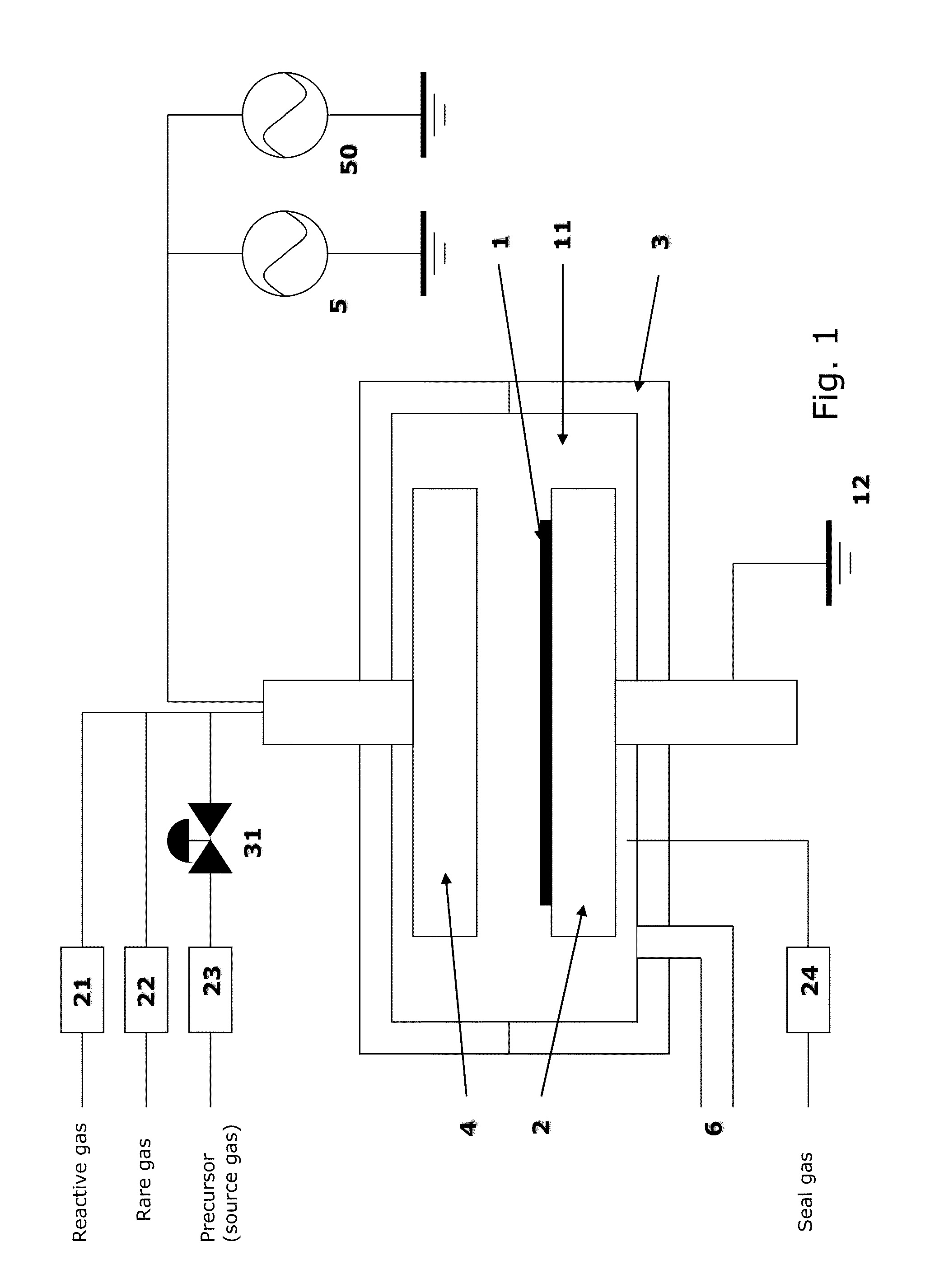

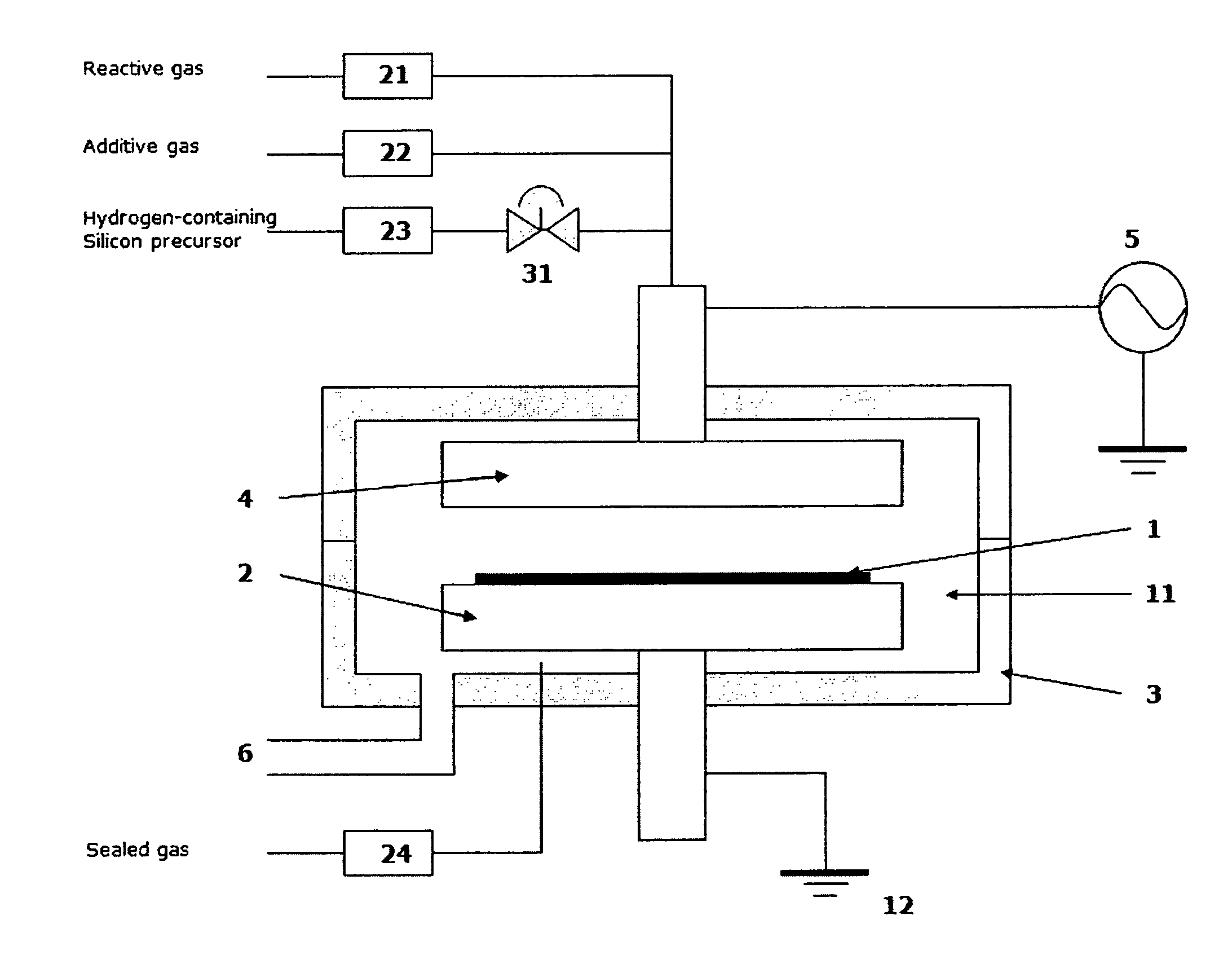

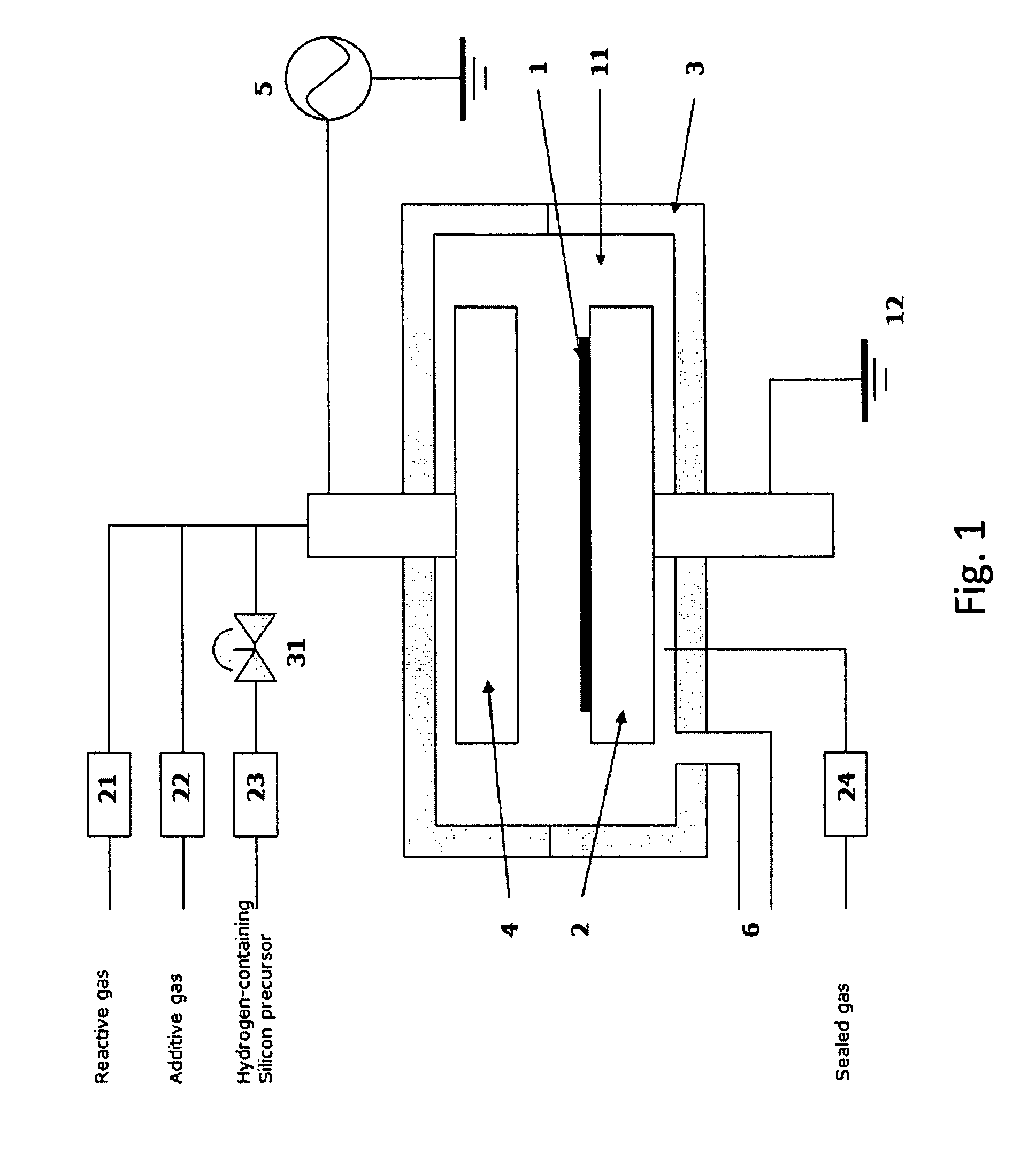

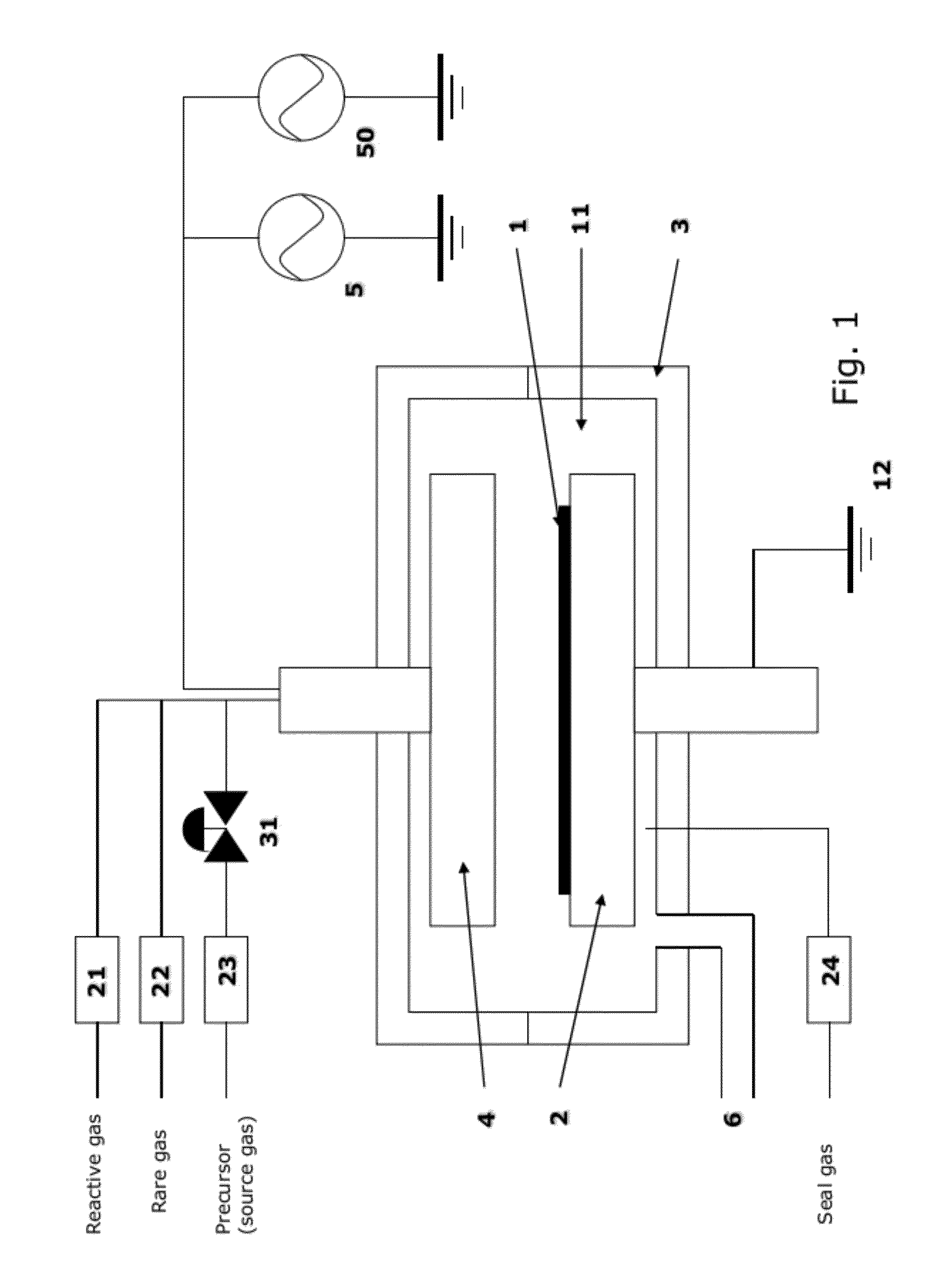

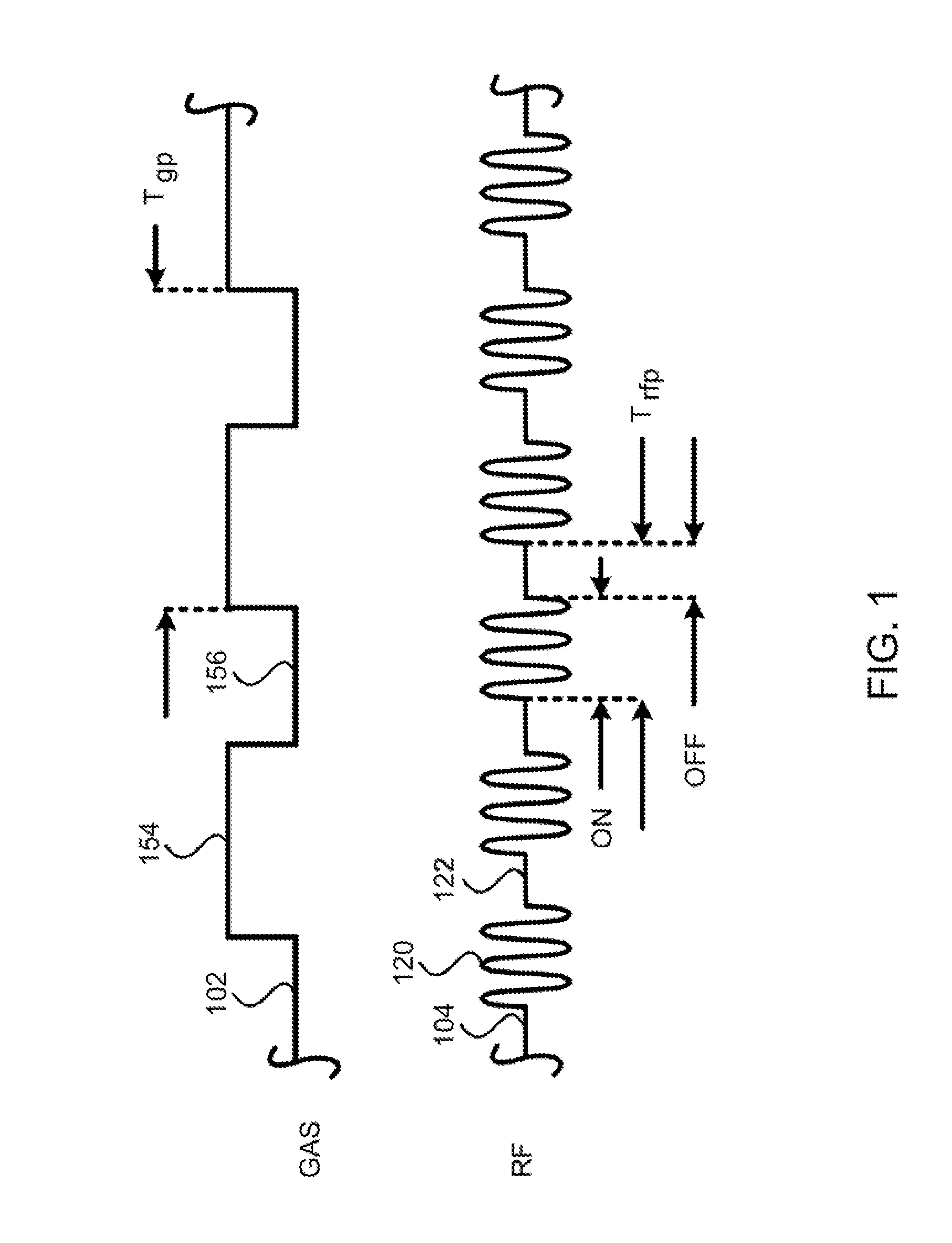

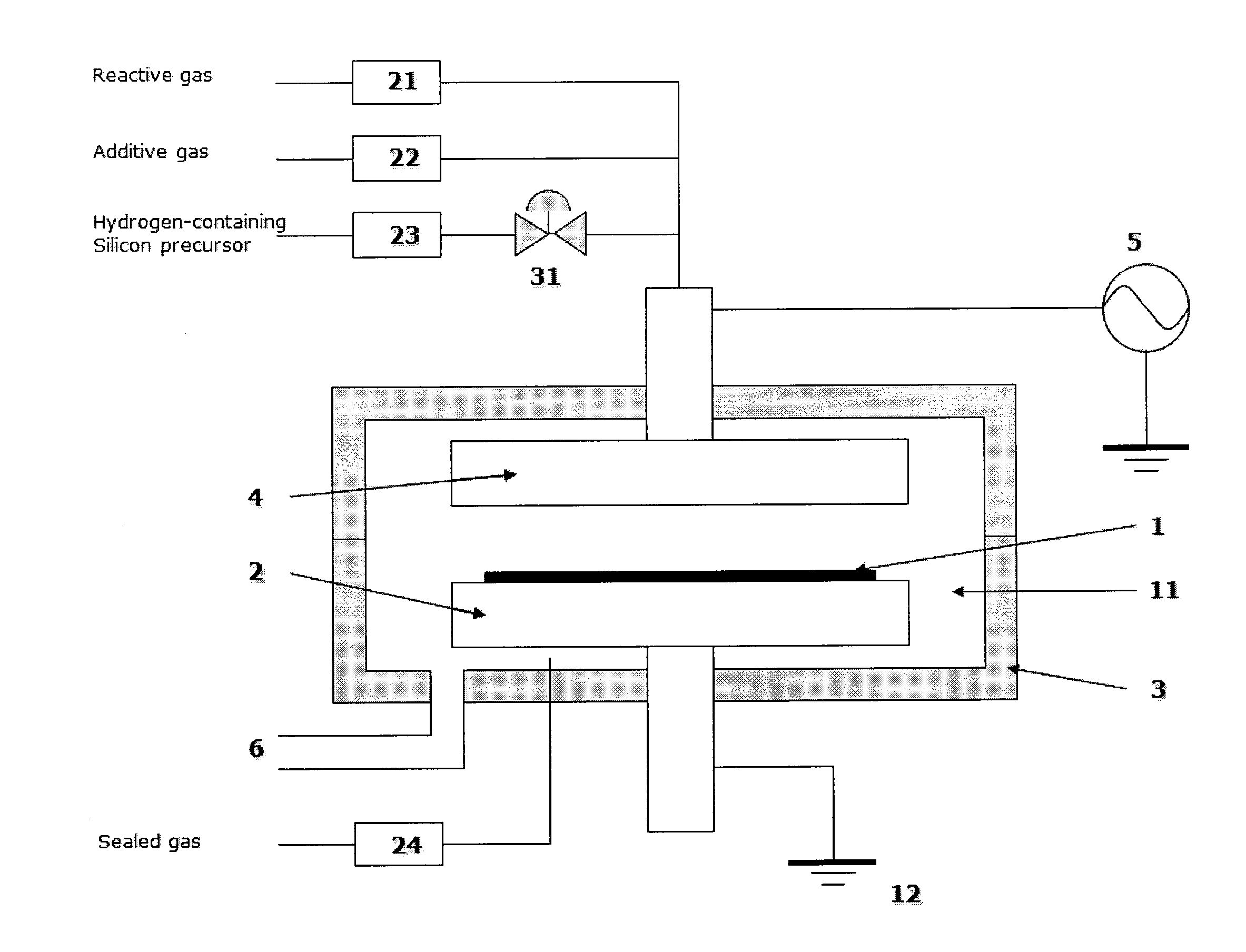

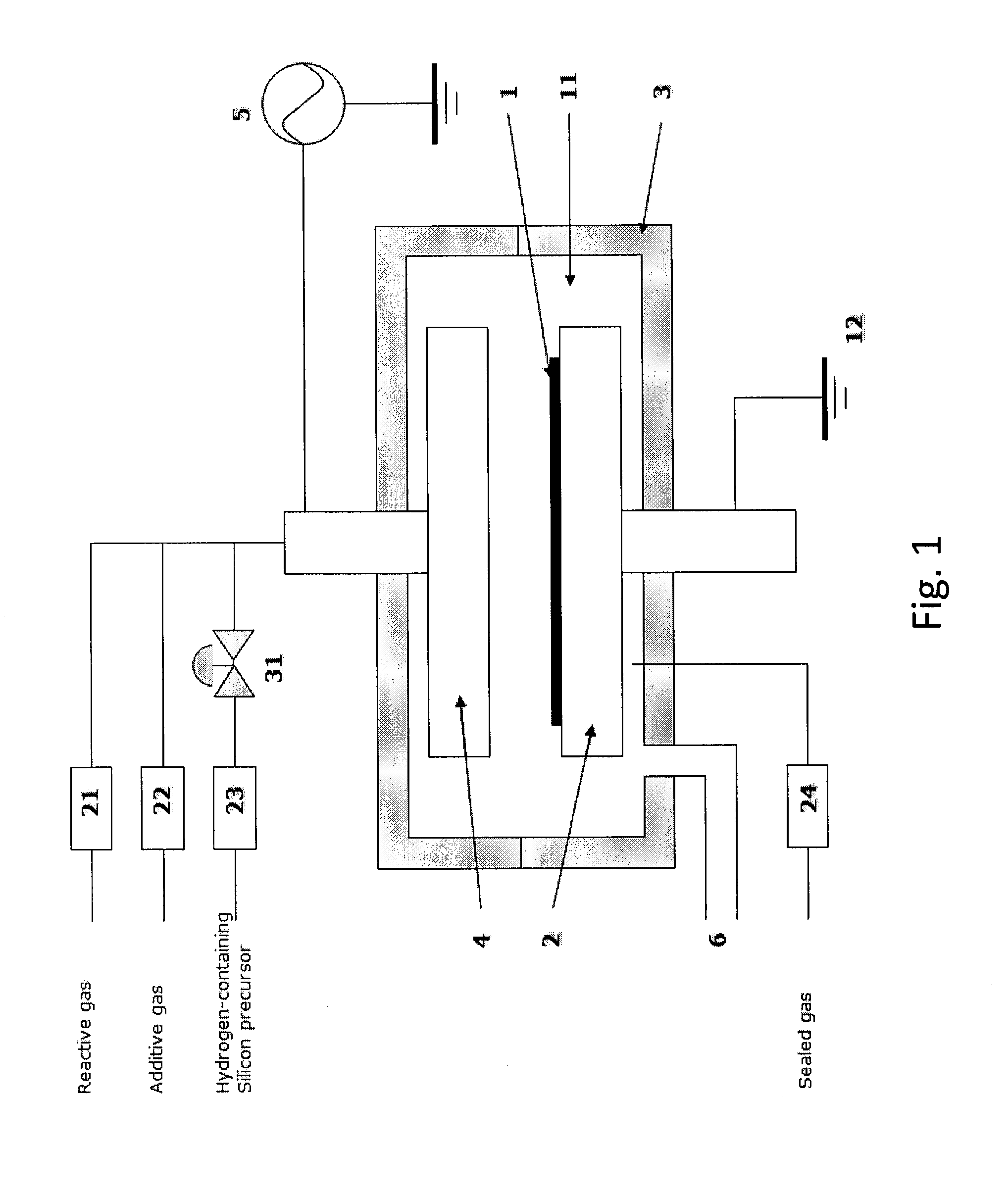

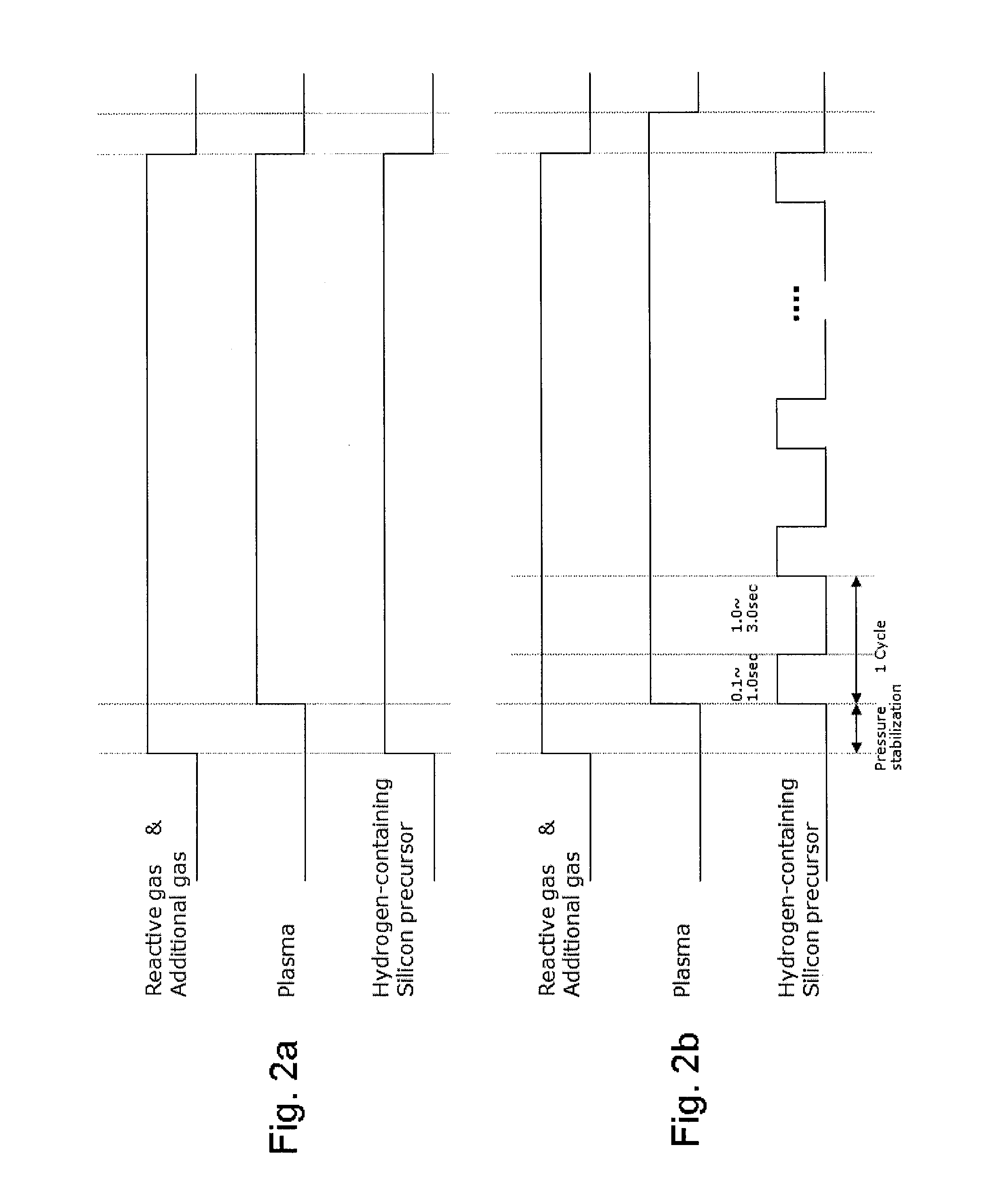

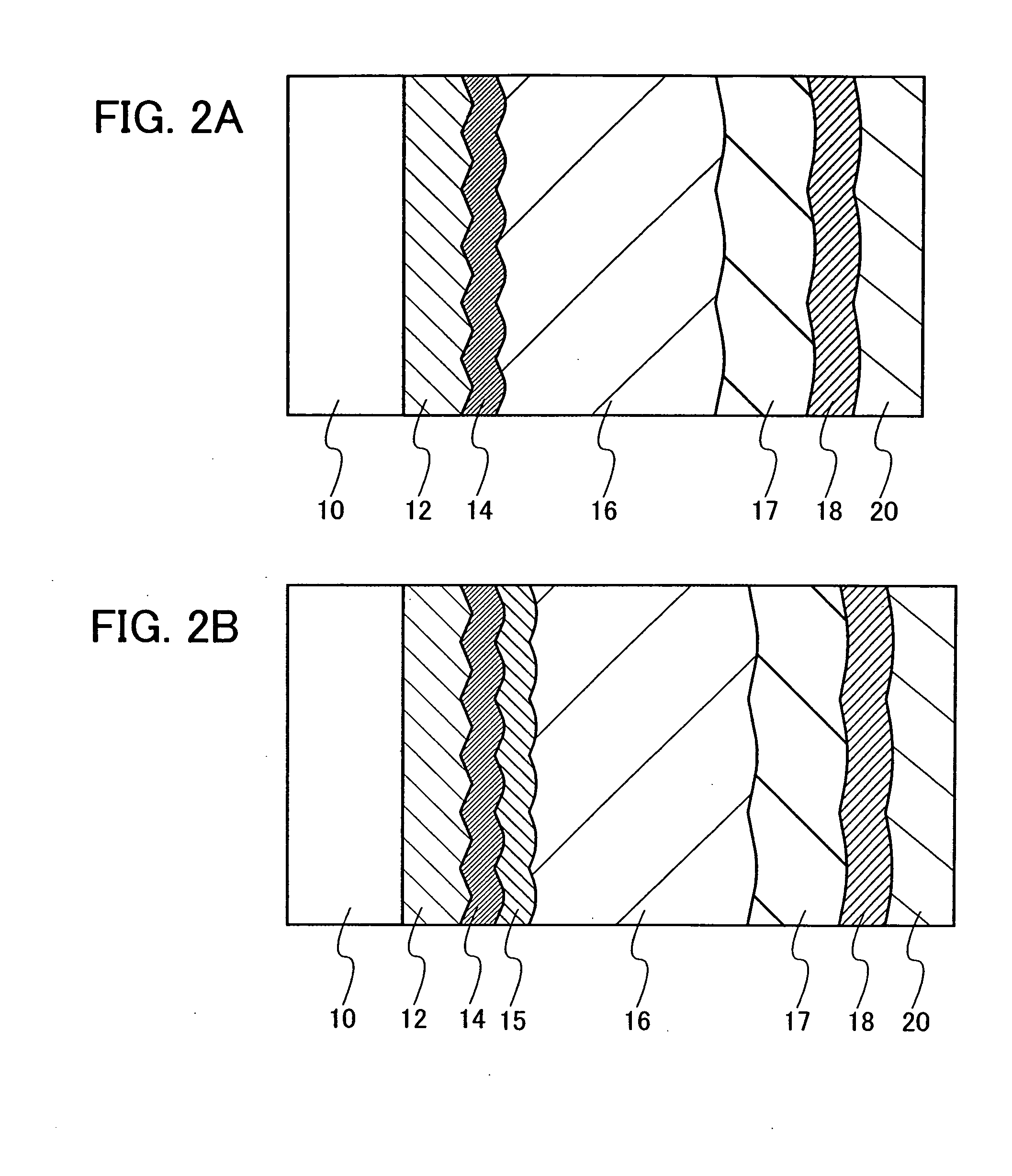

METHOD OF DEPOSITING DIELECTRIC FILM HAVING Si-N BONDS BY MODIFIED PEALD METHOD

ActiveUS20110086516A1High conformalityIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricNoble gas

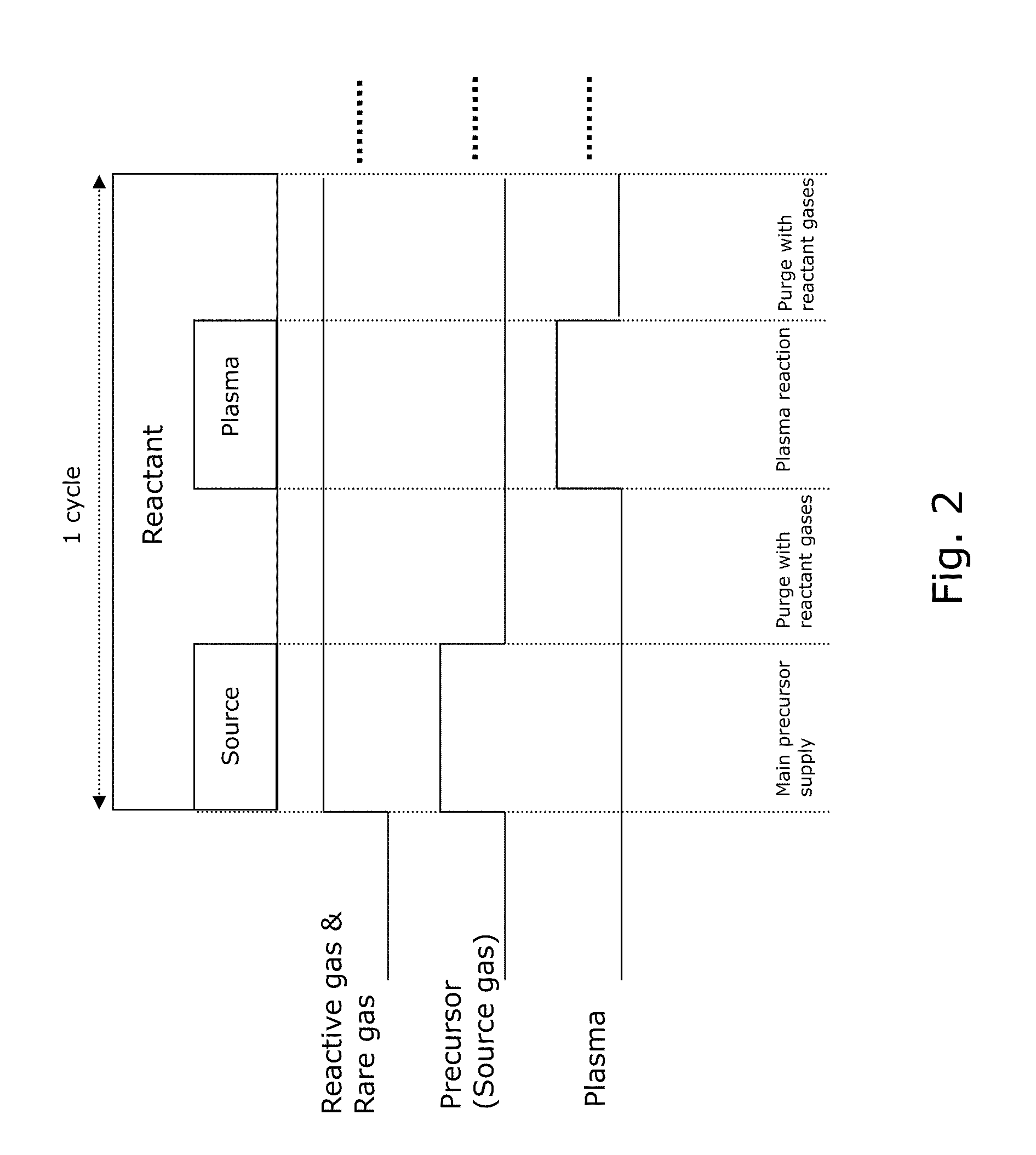

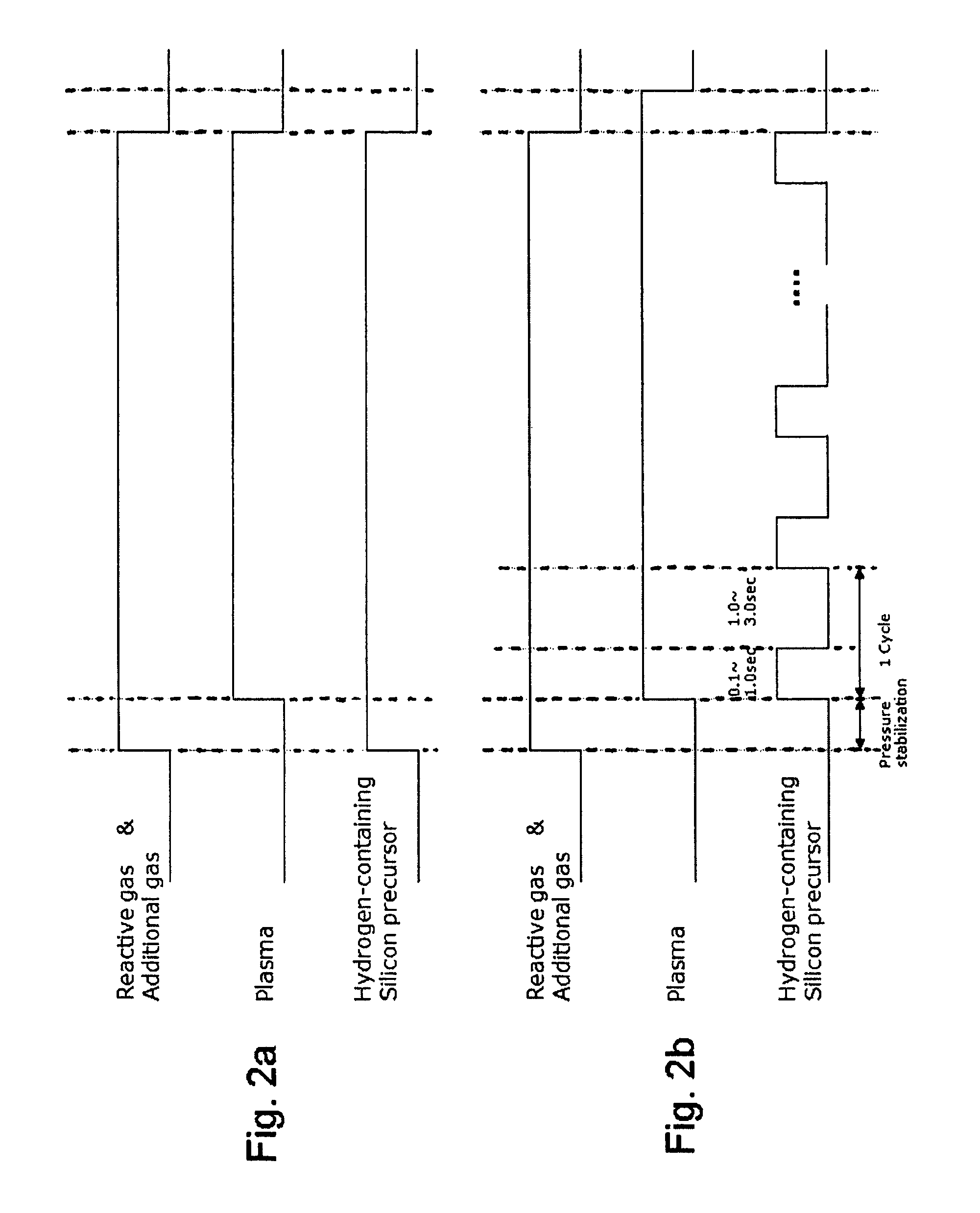

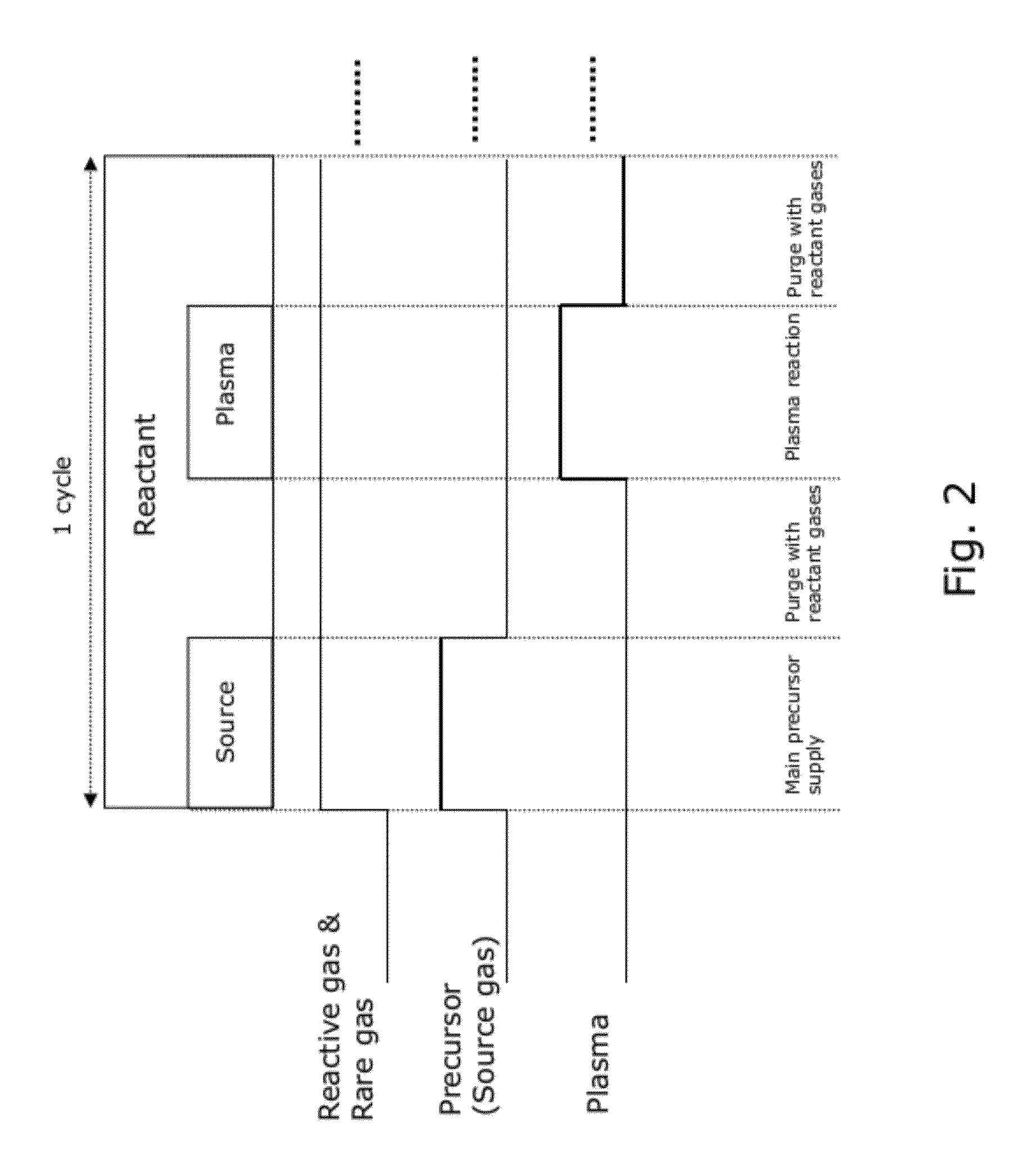

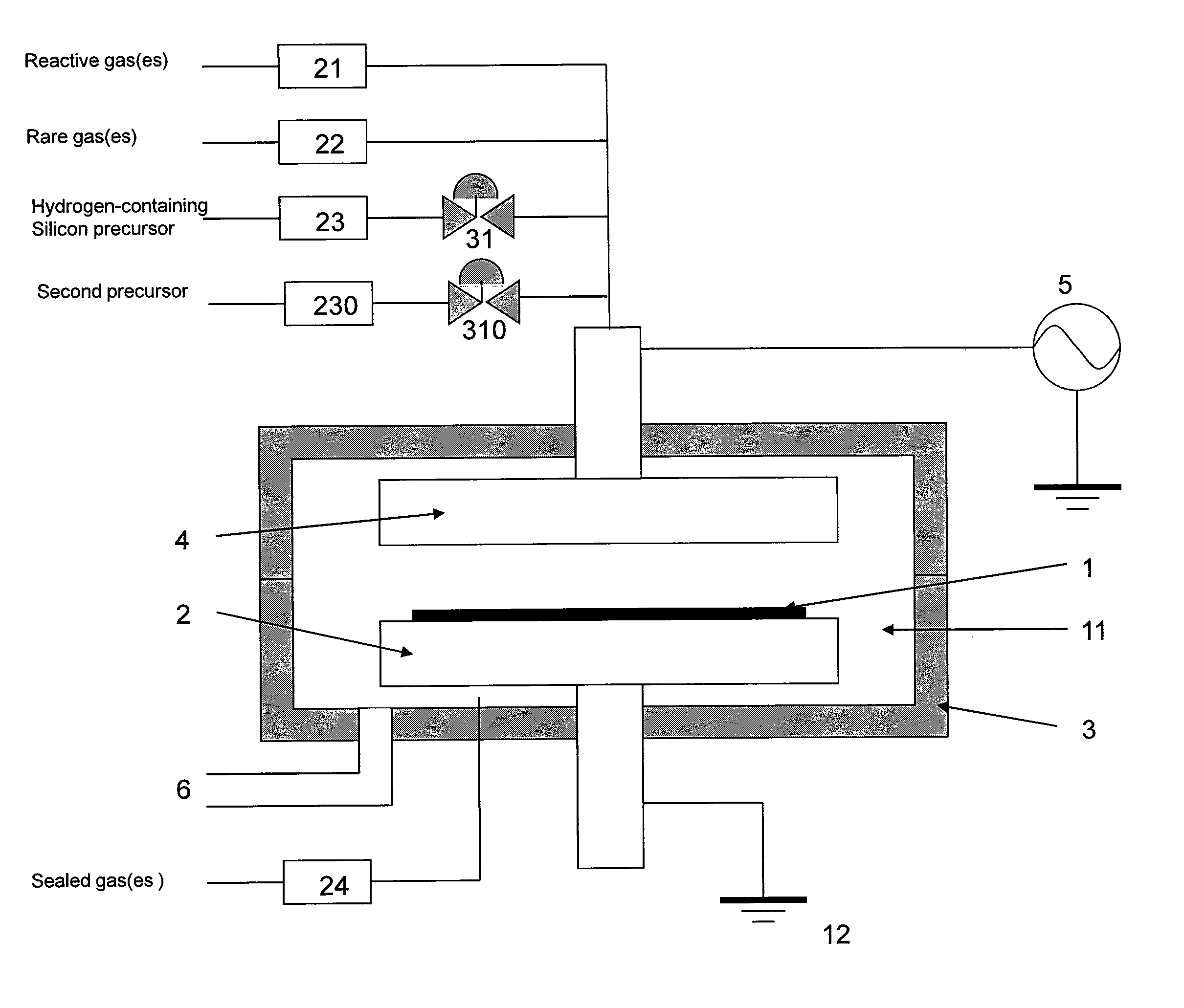

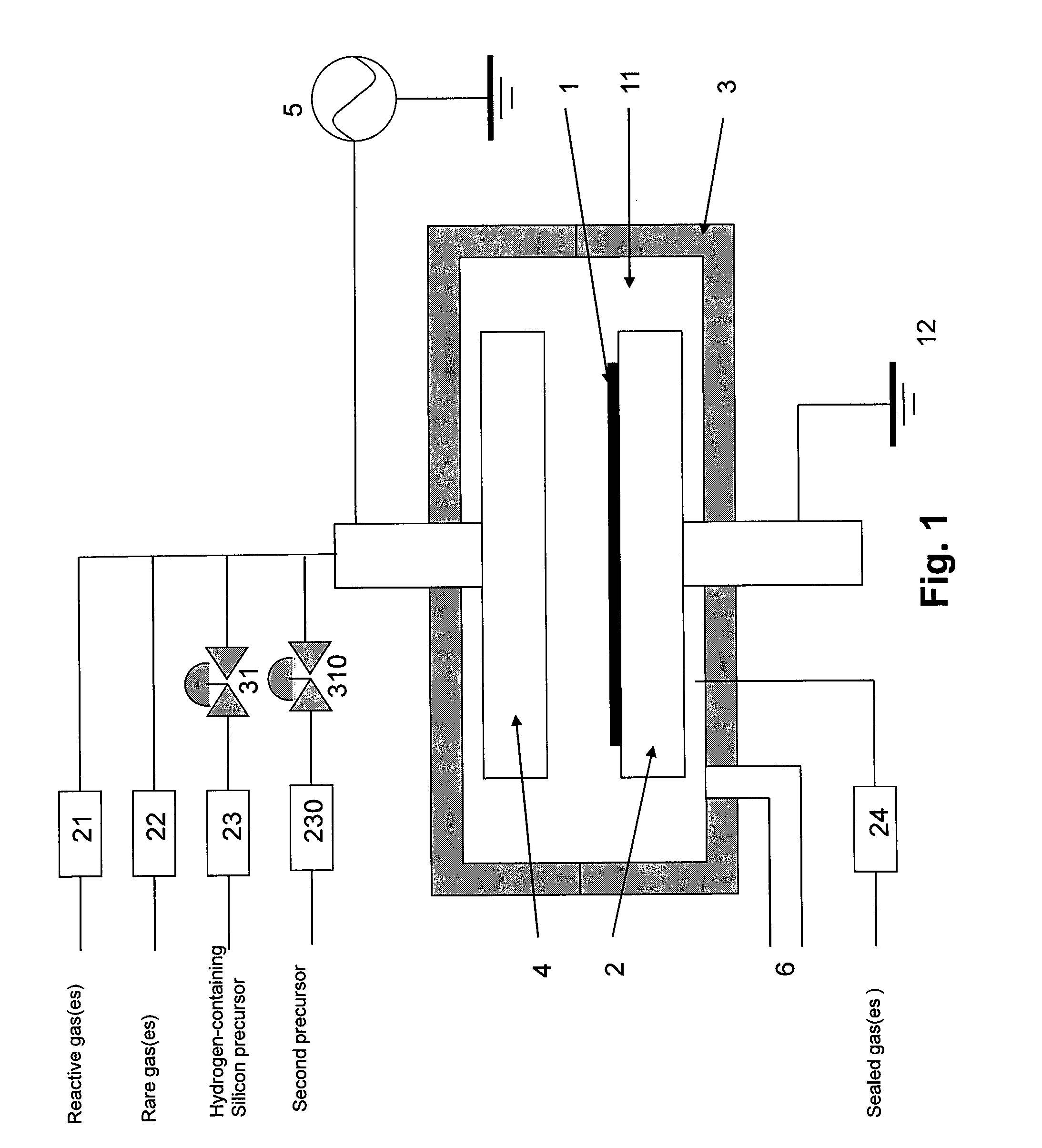

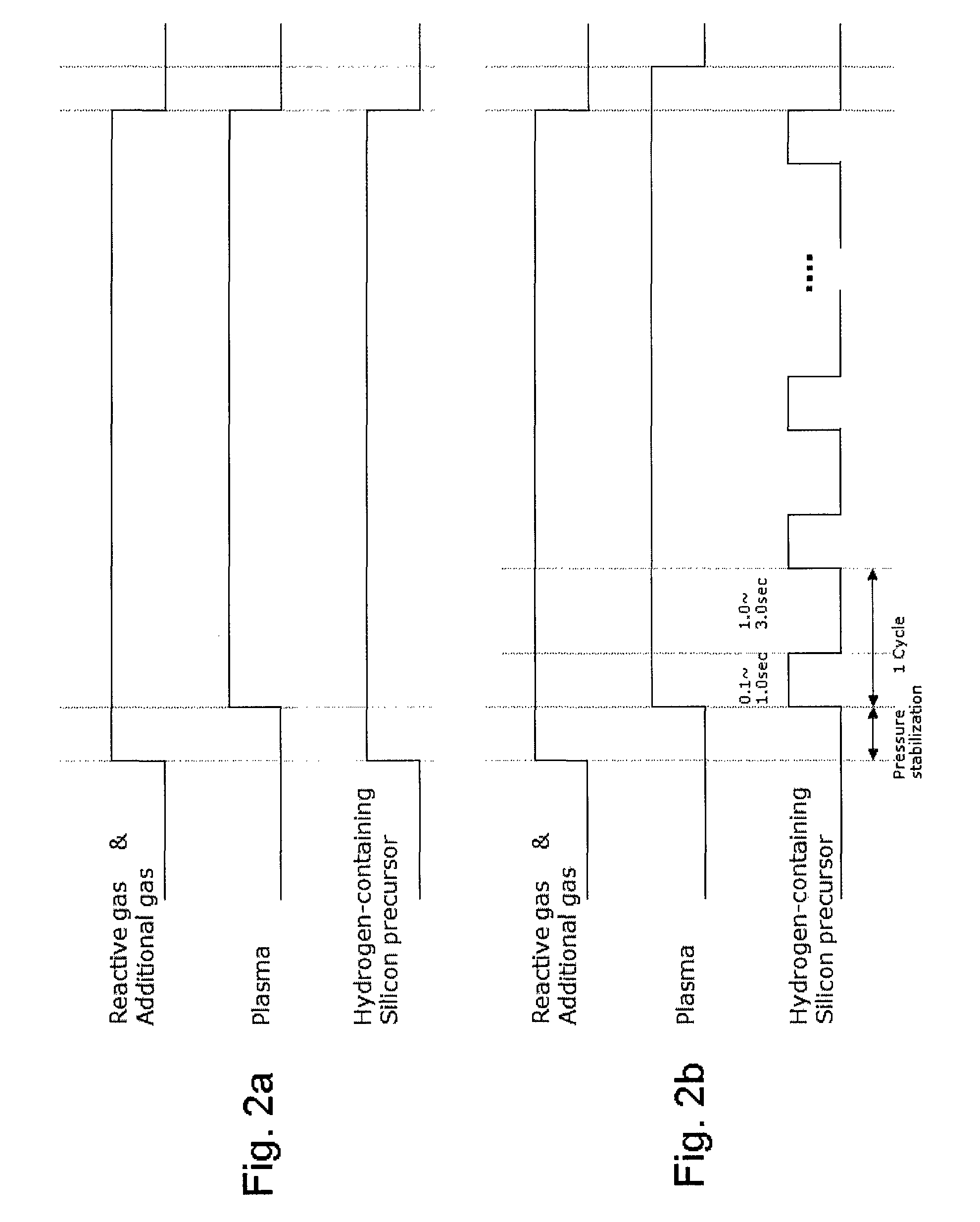

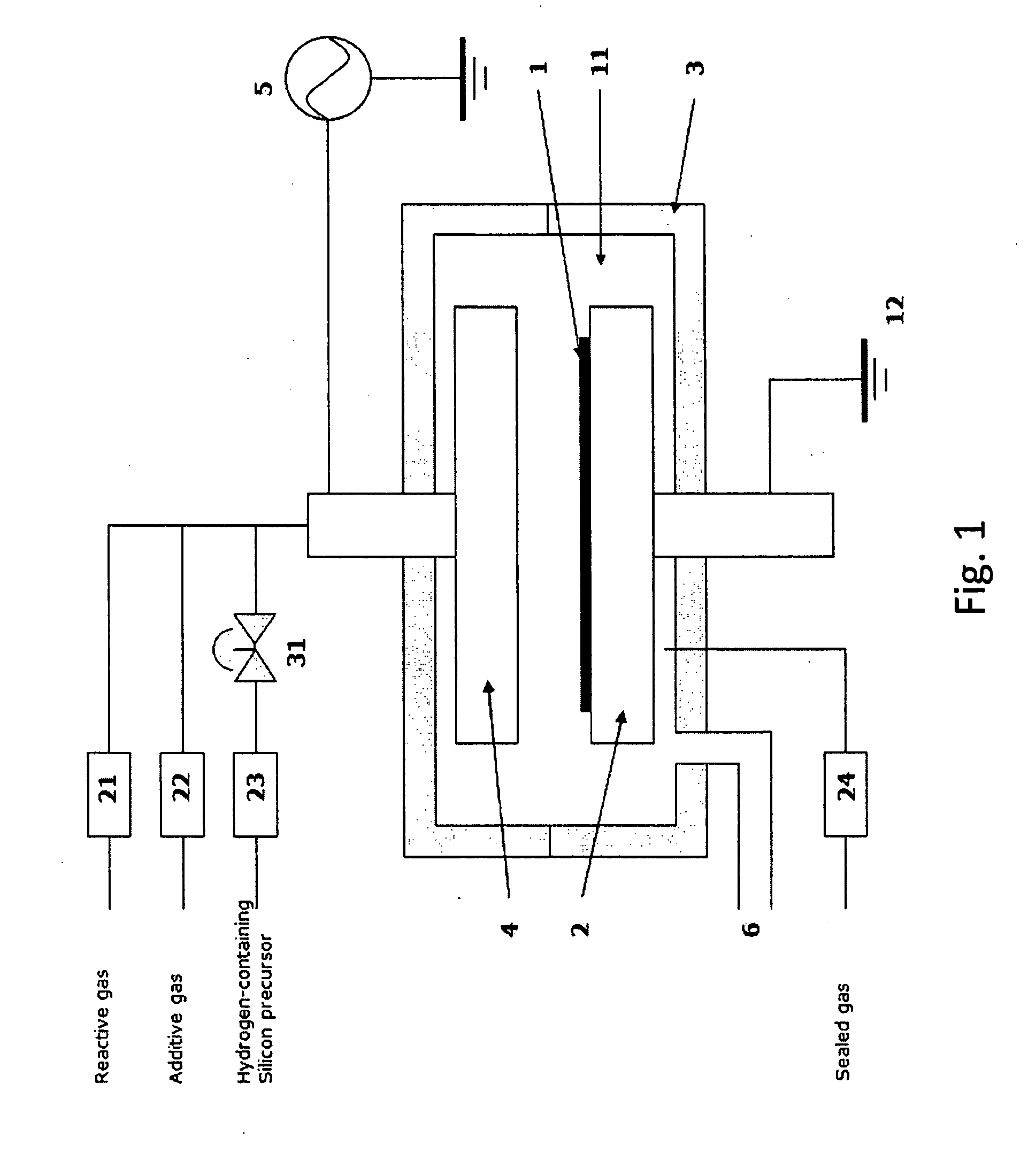

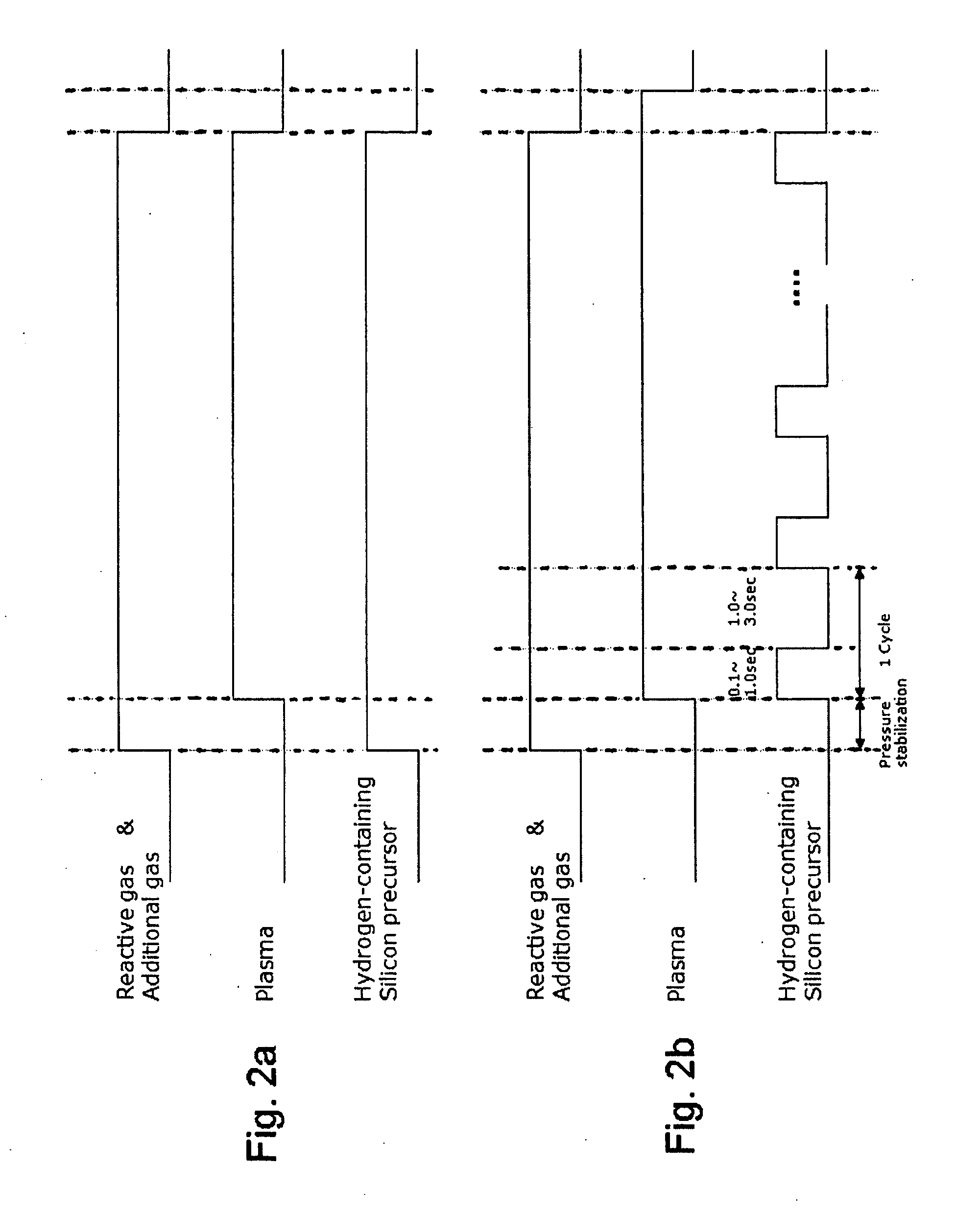

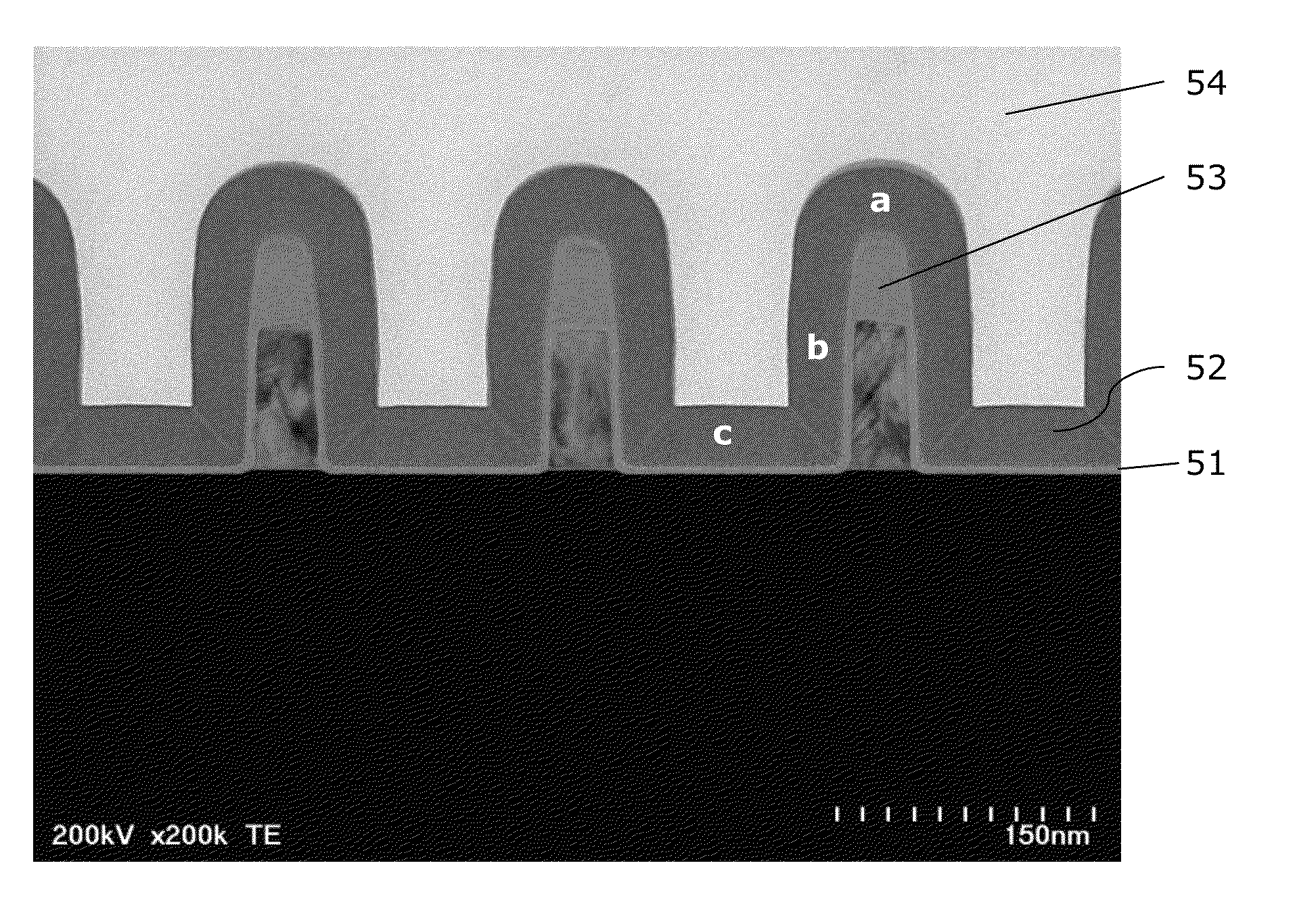

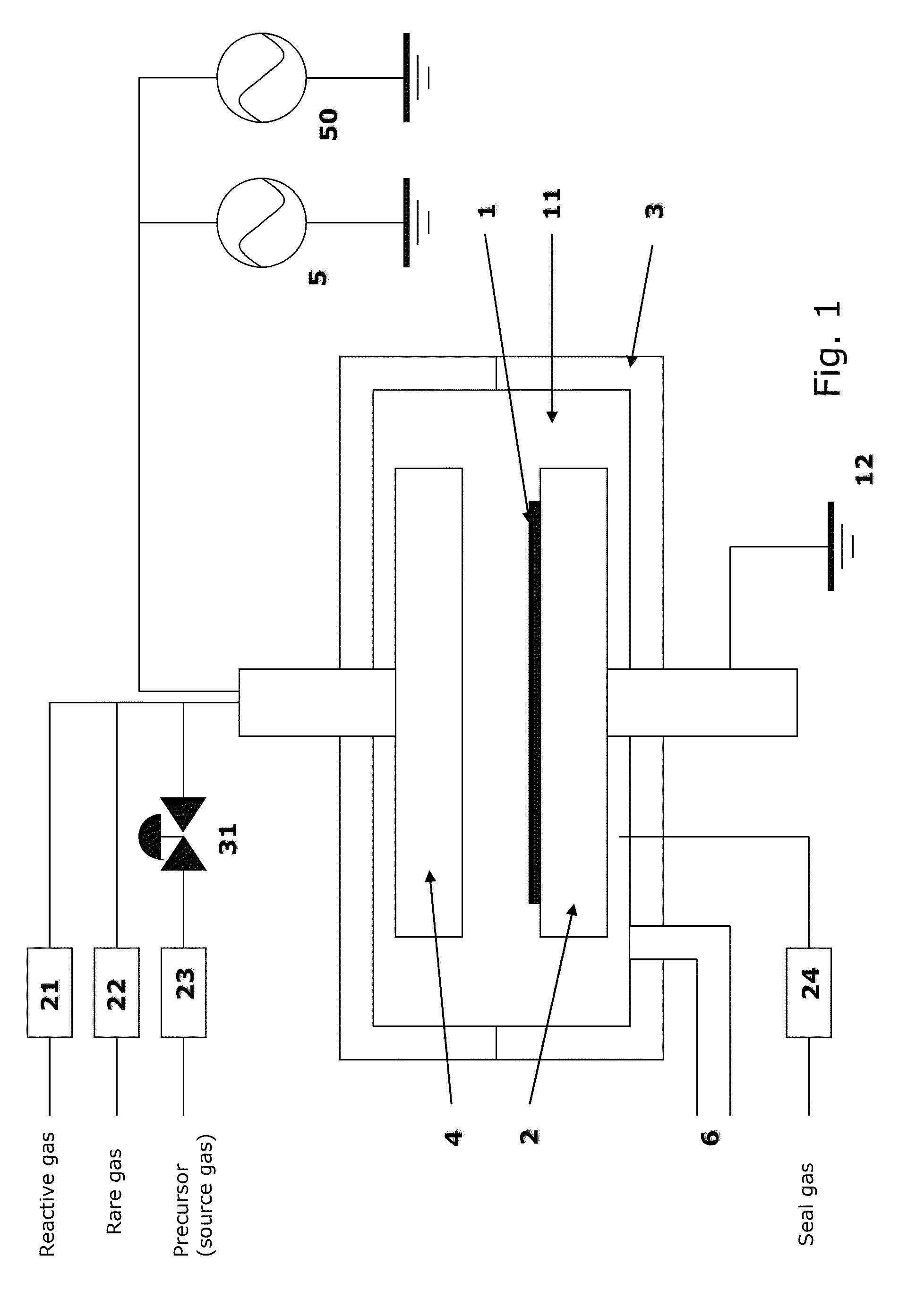

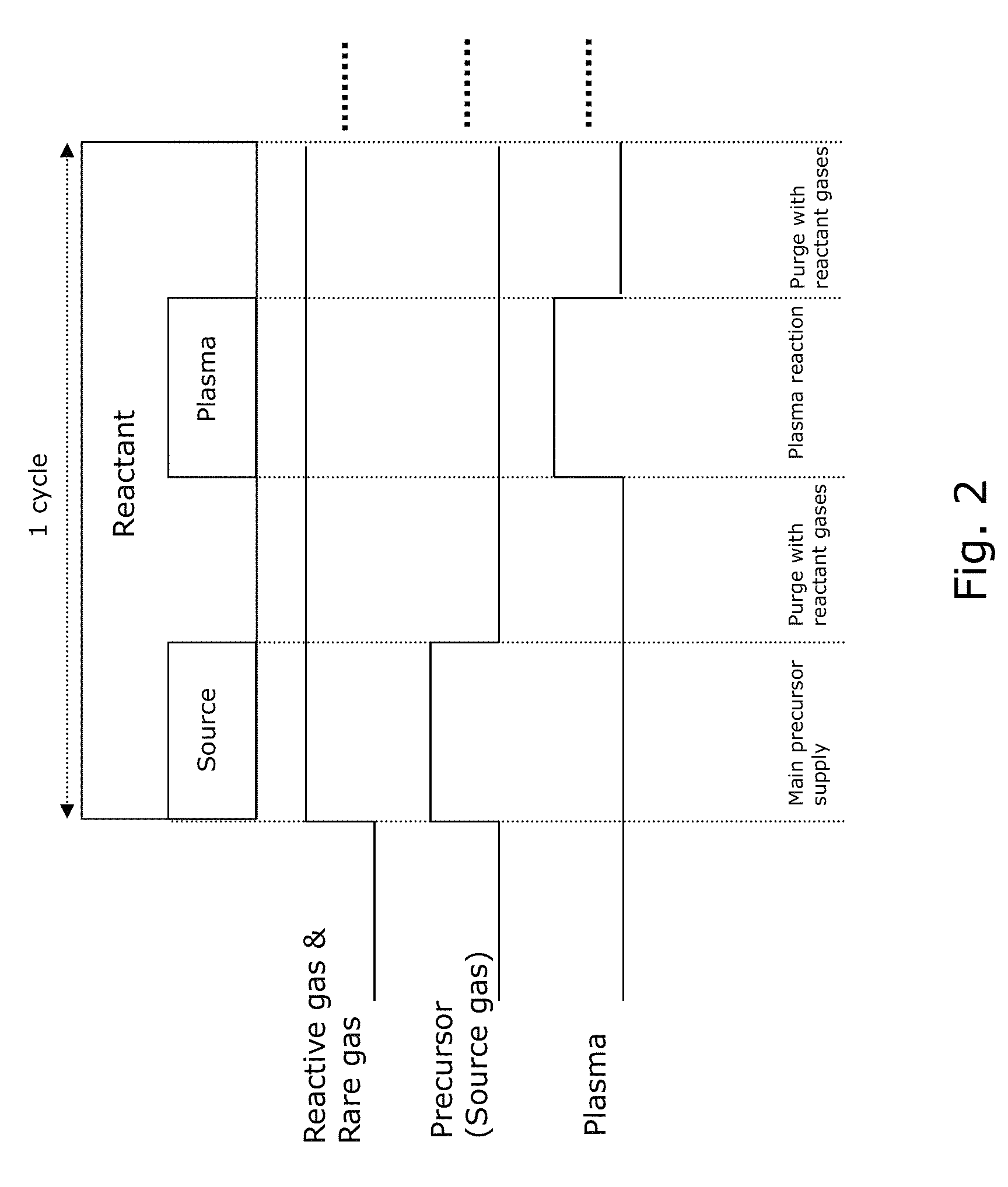

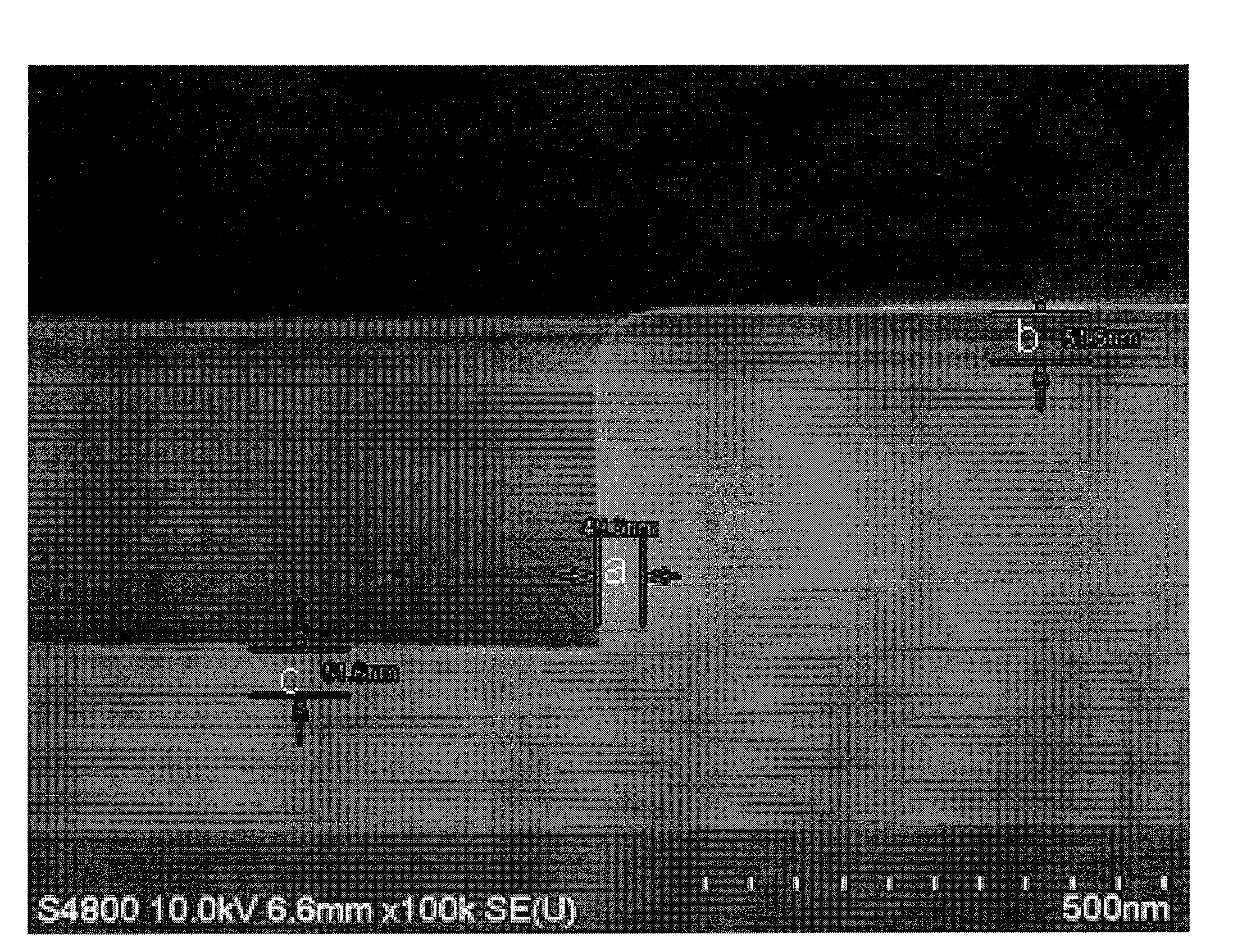

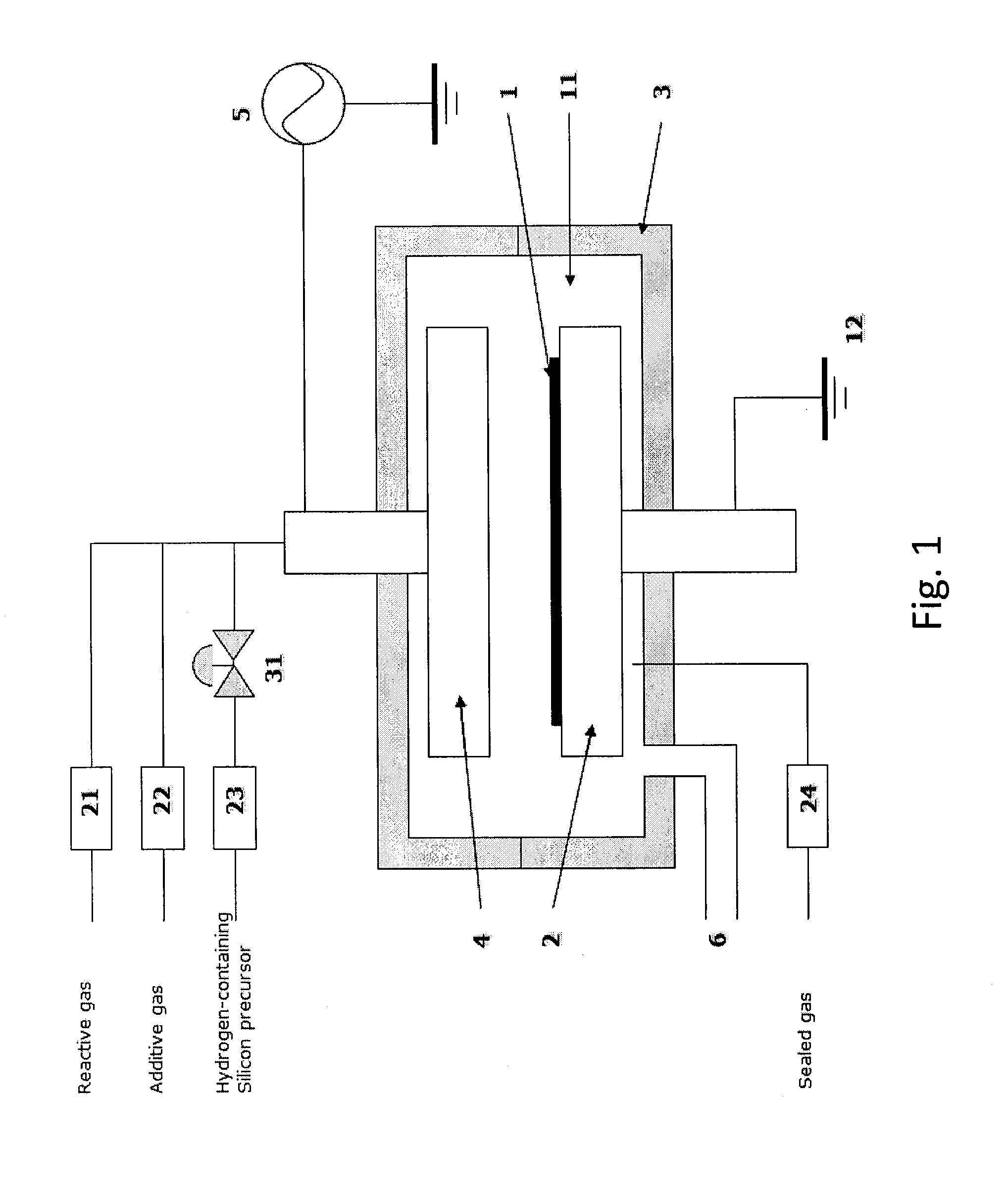

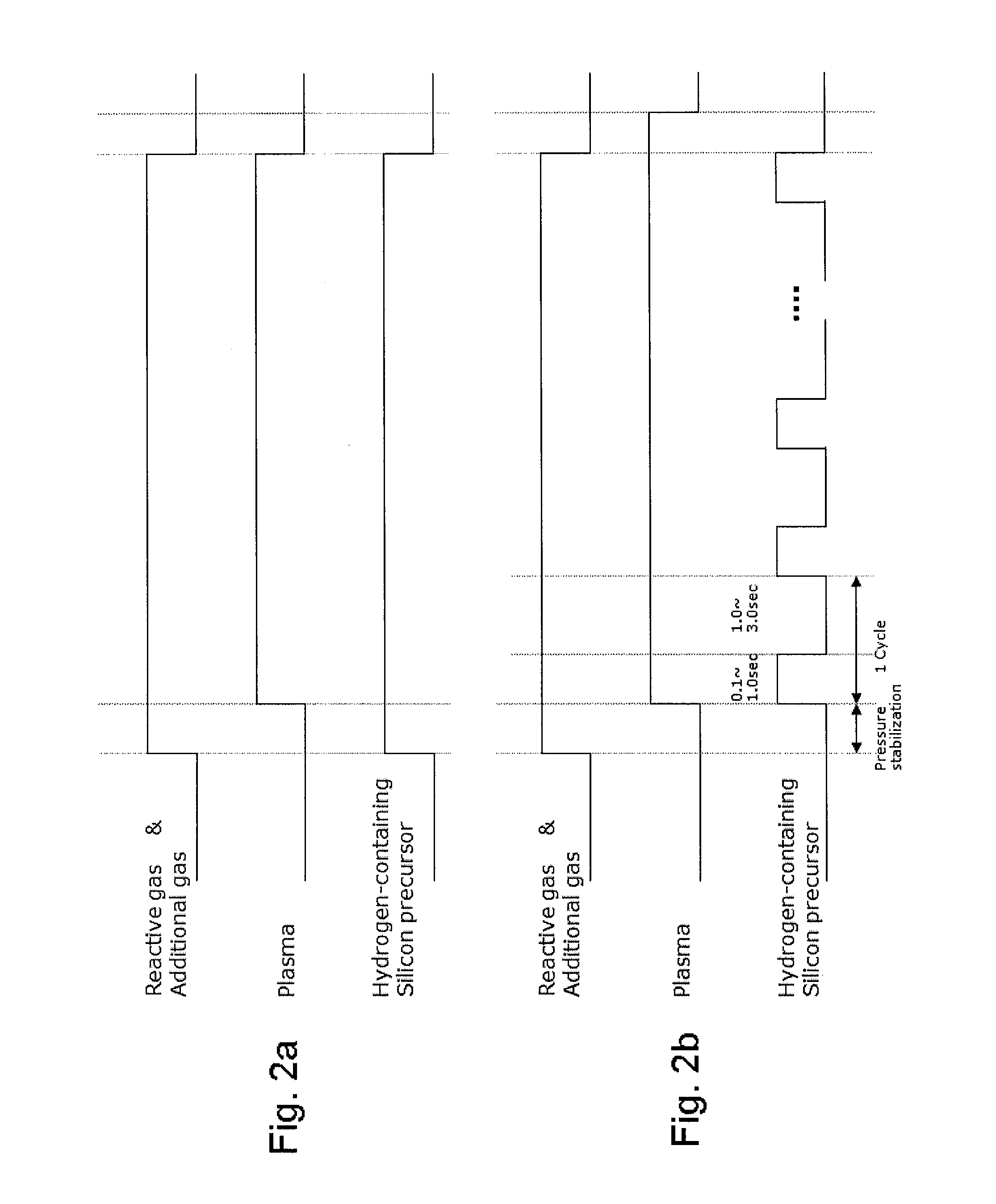

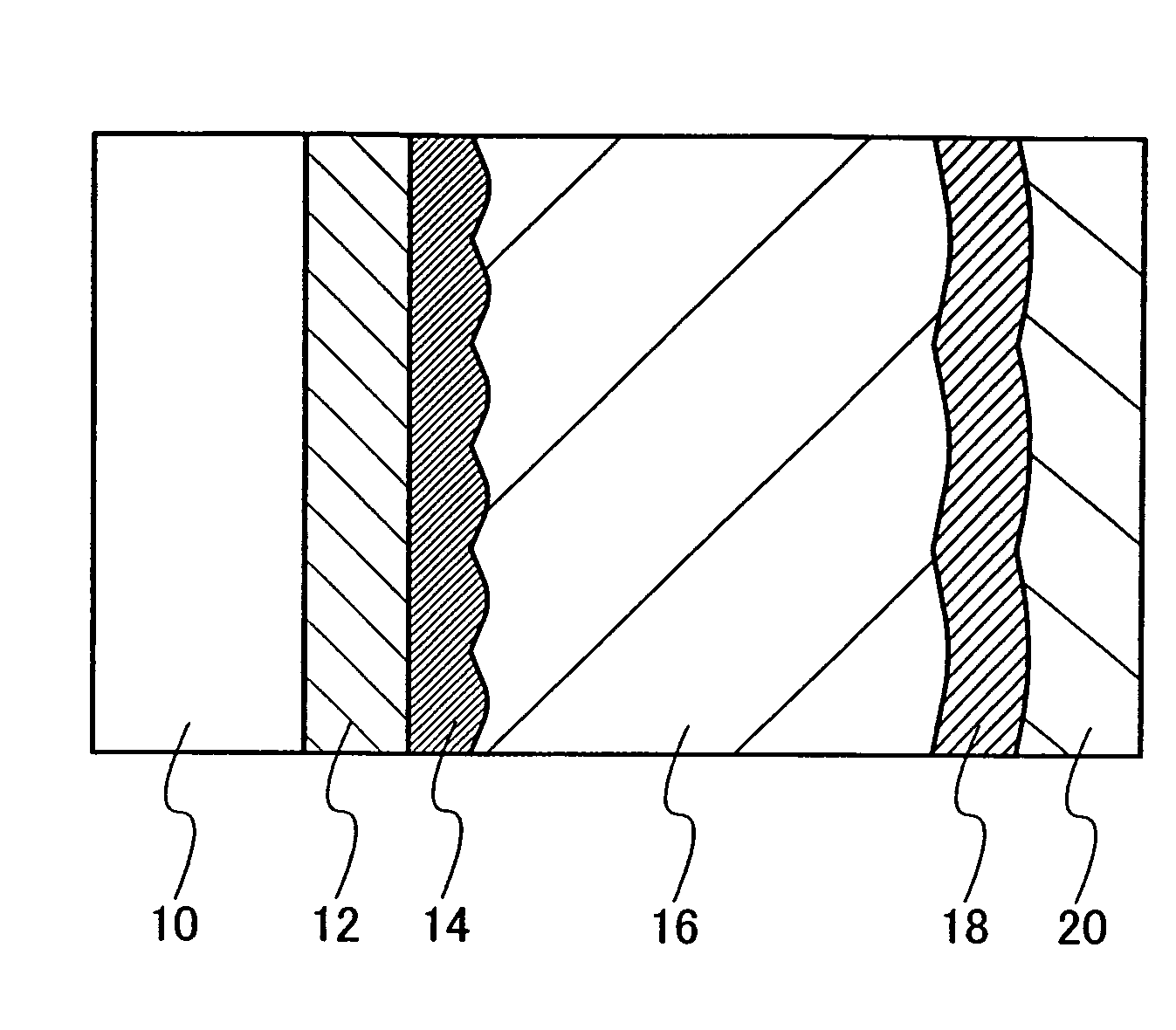

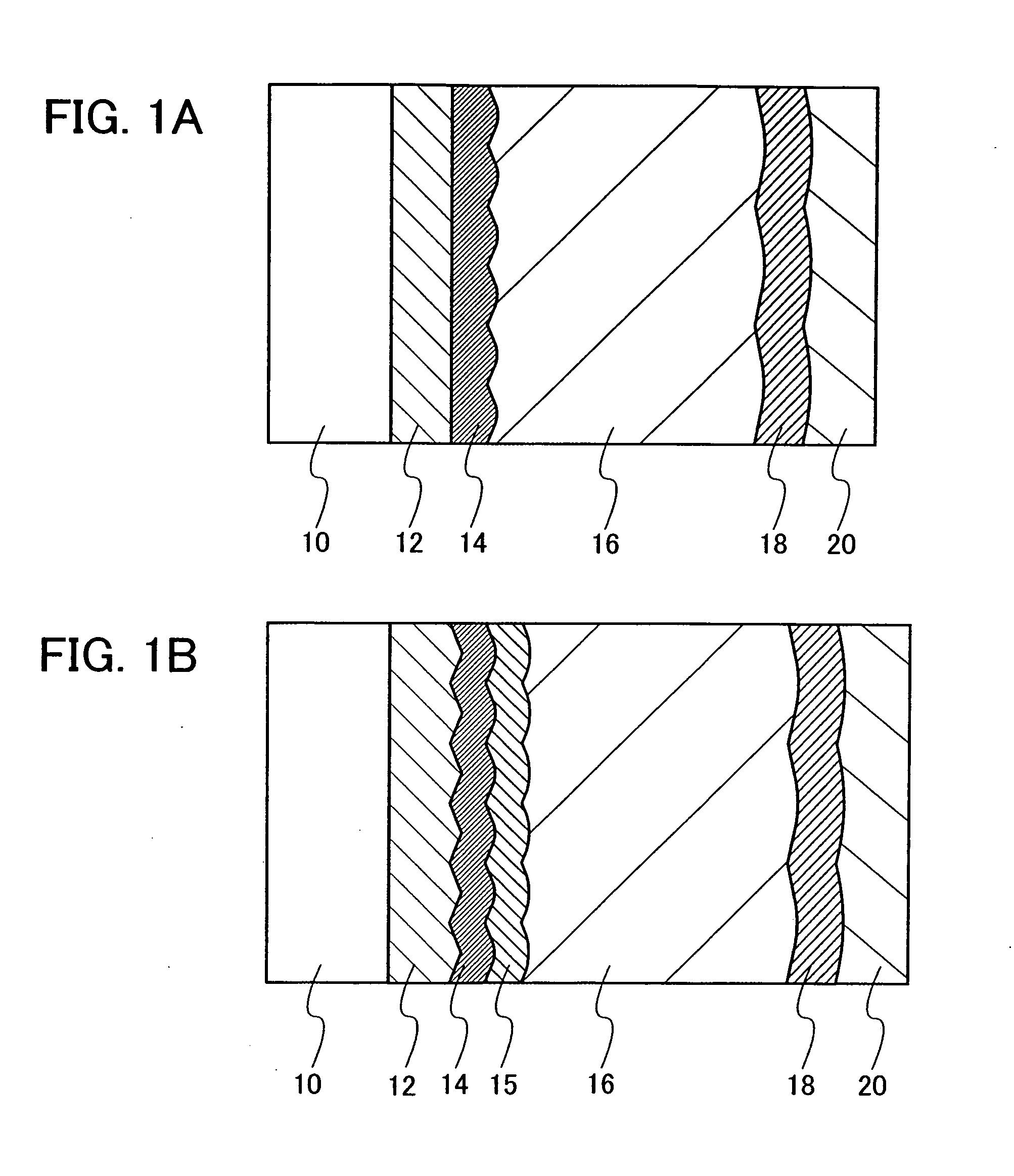

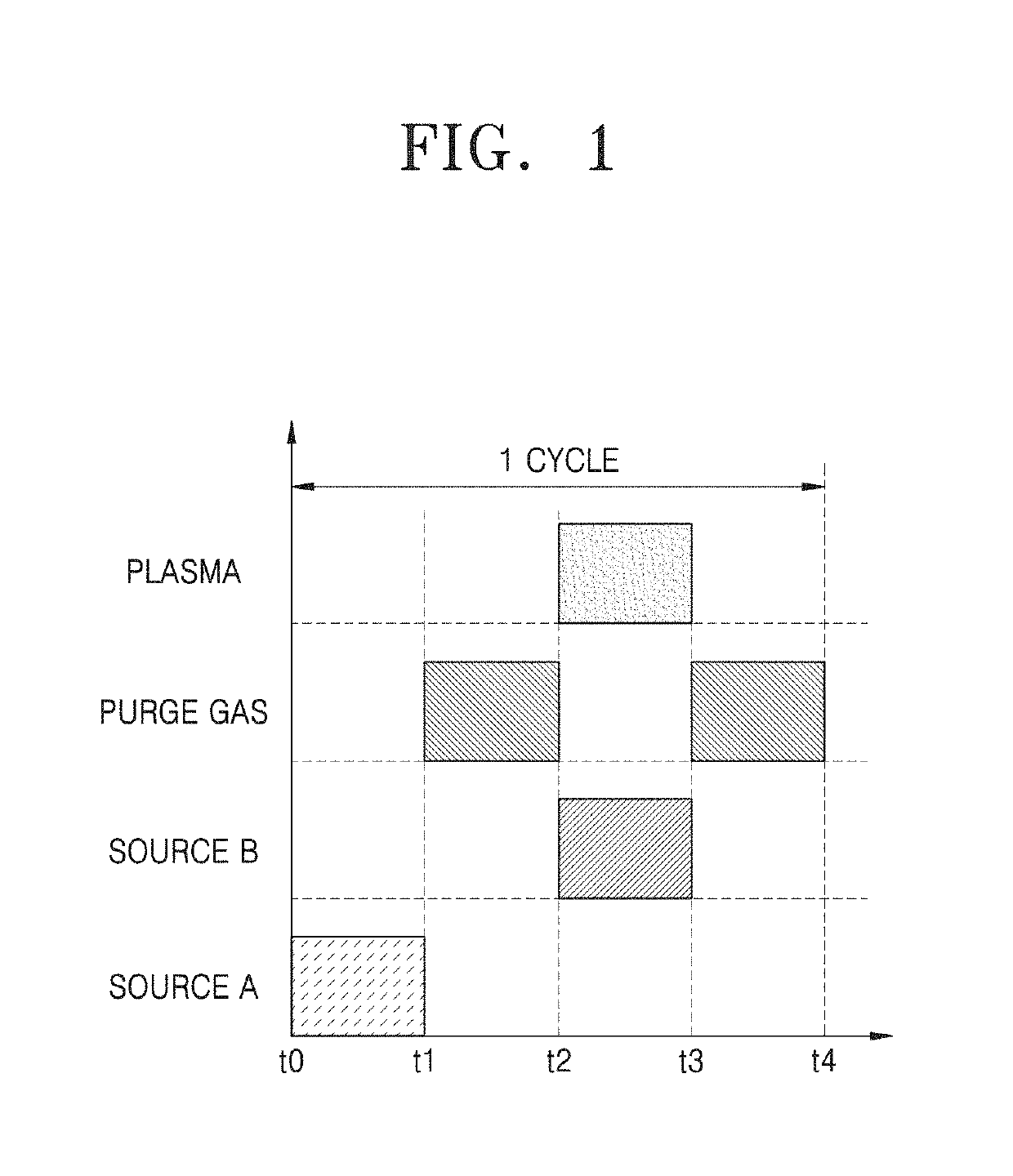

A method of forming dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a hydrogen-containing silicon precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the silicon precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

Method of depositing dielectric film having Si-N bonds by modified peald method

ActiveUS8173554B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHydrogen

A method of forming dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a hydrogen-containing silicon precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the silicon precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

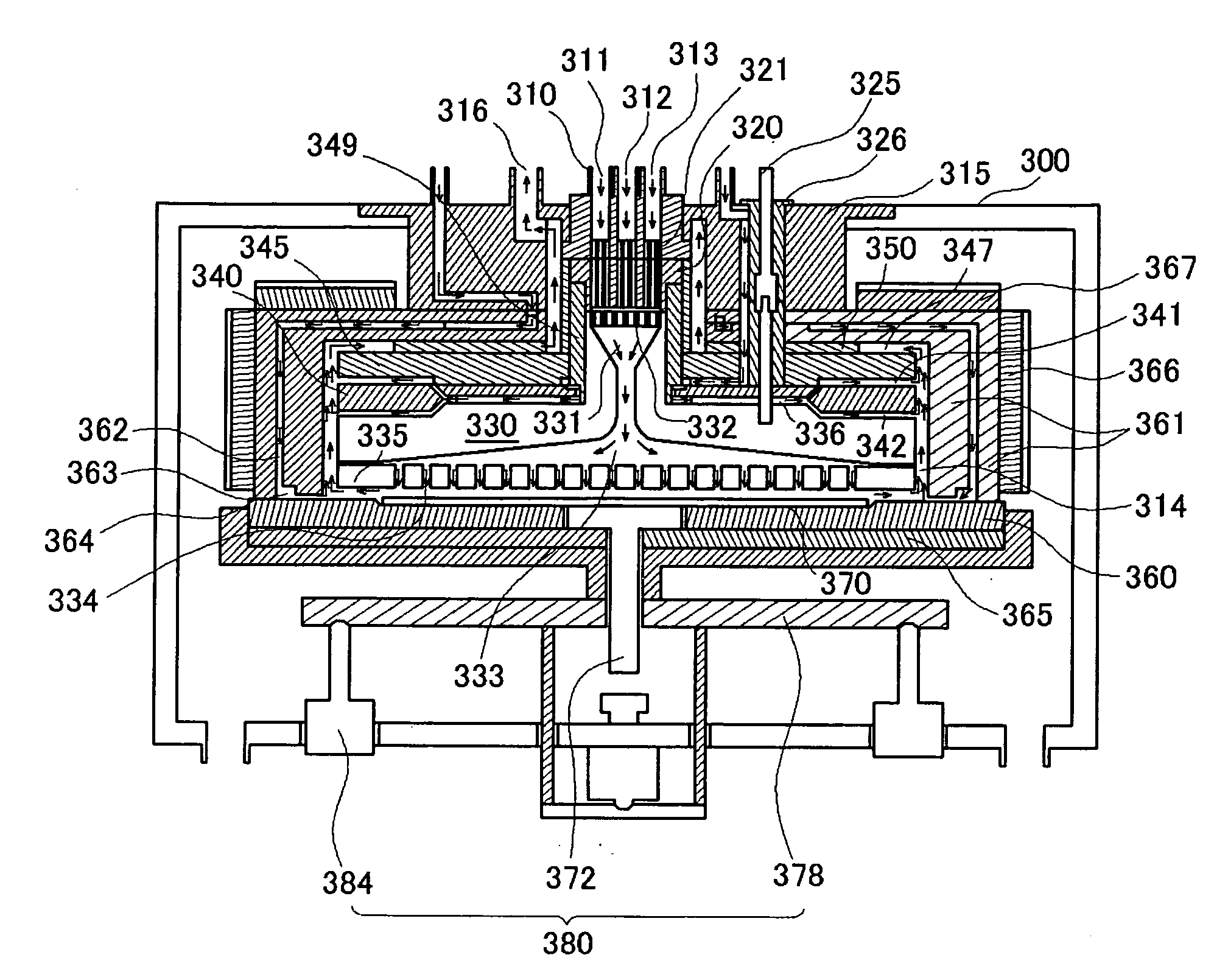

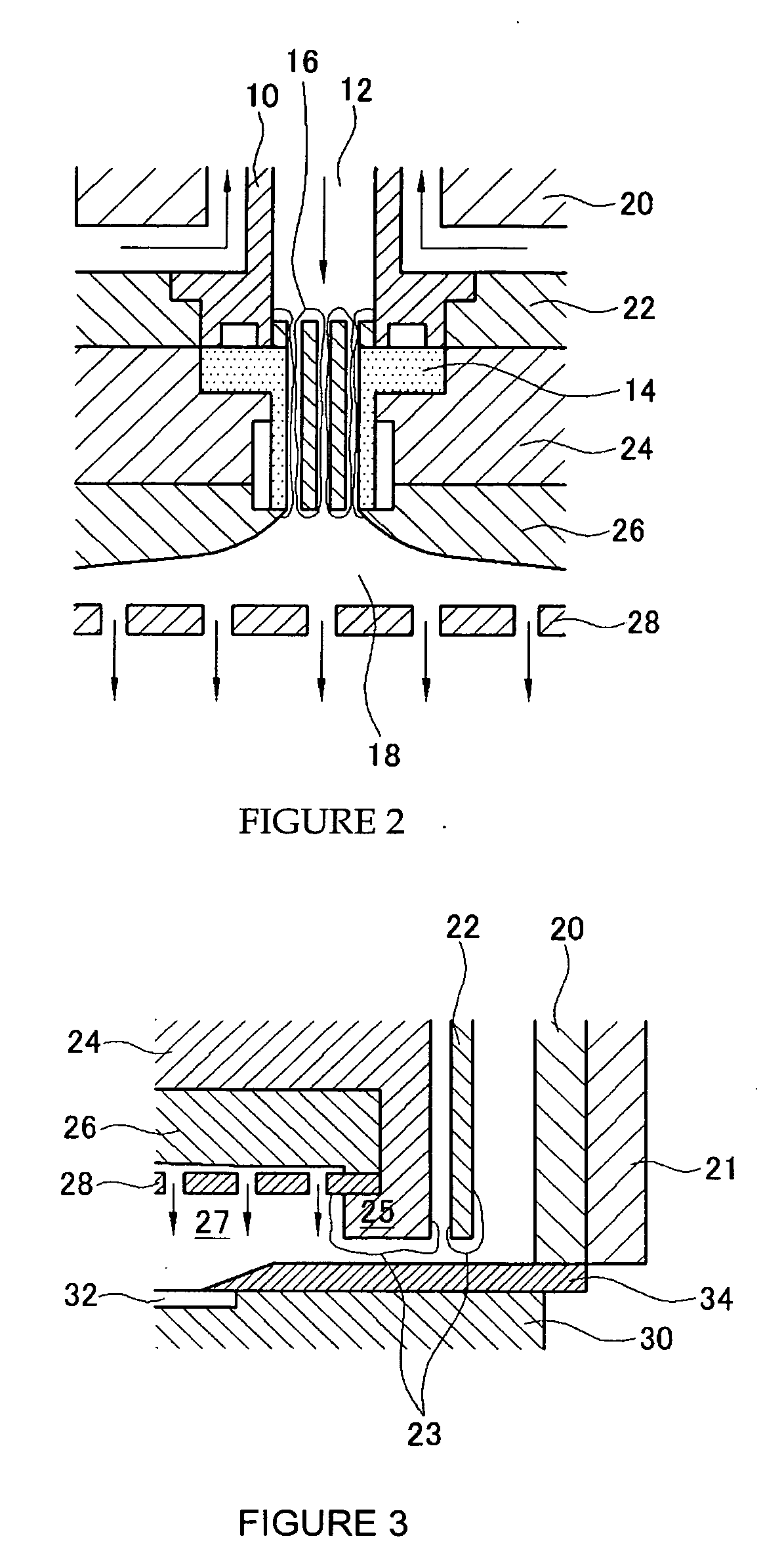

Apparatus for chemical vapor deposition (CVD) with showerhead and method thereof

ActiveUS20060263522A1Unwanted chemical reactionFrom chemically reactive gasesChemical vapor deposition coatingSource materialGas phase

Owner:KOREA INST OF IND TECH +1

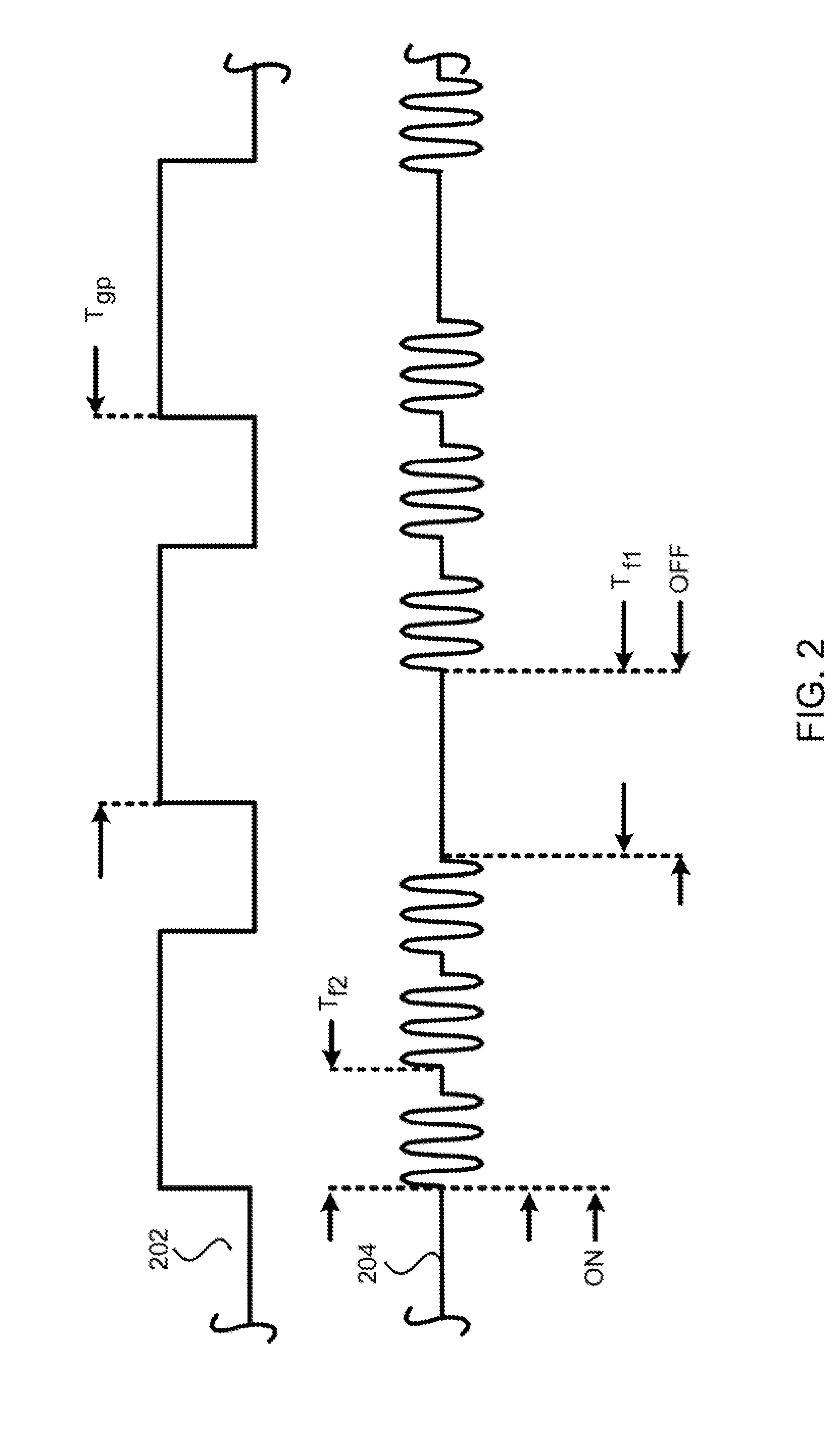

Method of forming conformal dielectric film having Si-N bonds by PECVD

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and an additive gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film having Si—N bonds on the substrate.

Owner:ASM JAPAN

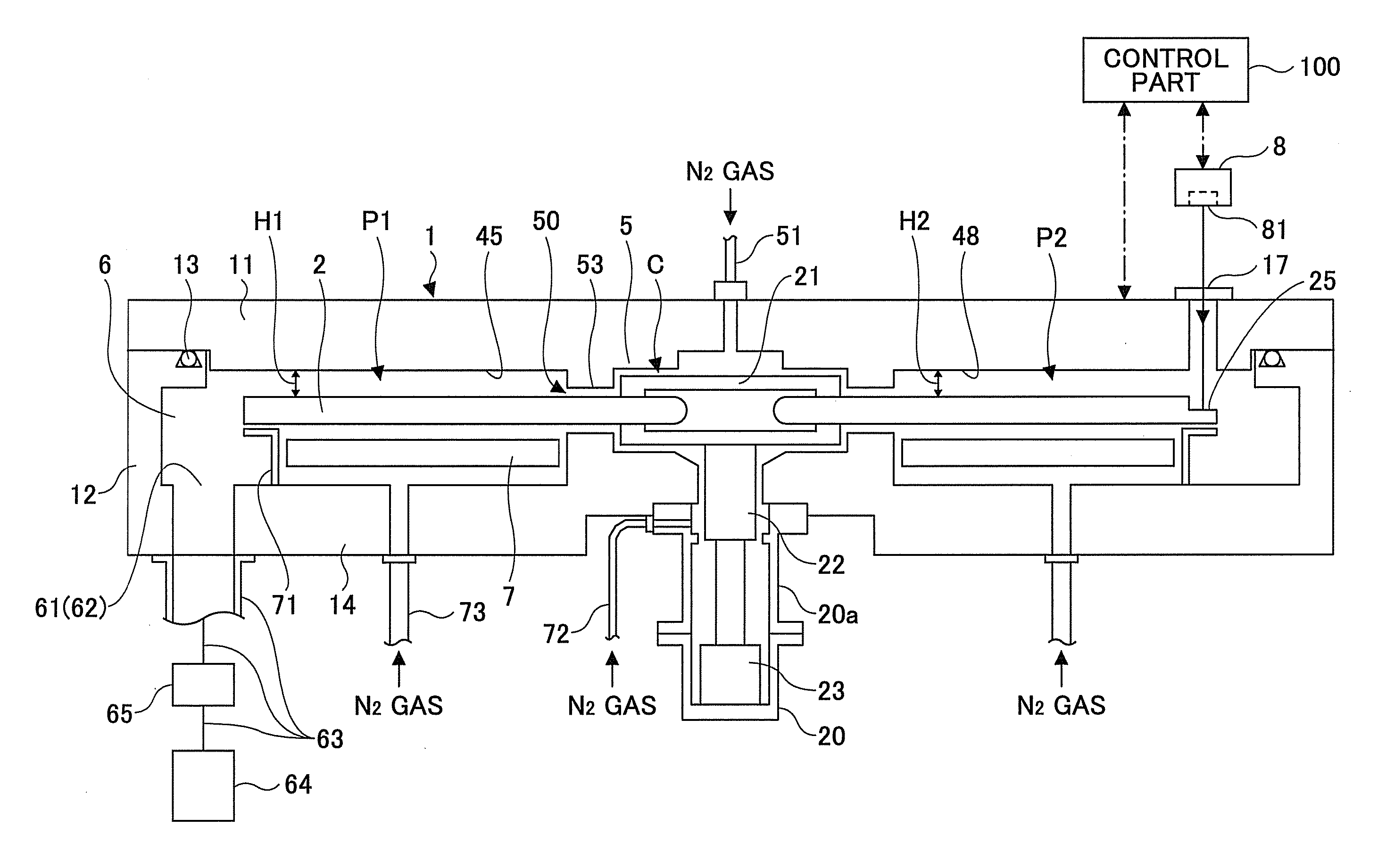

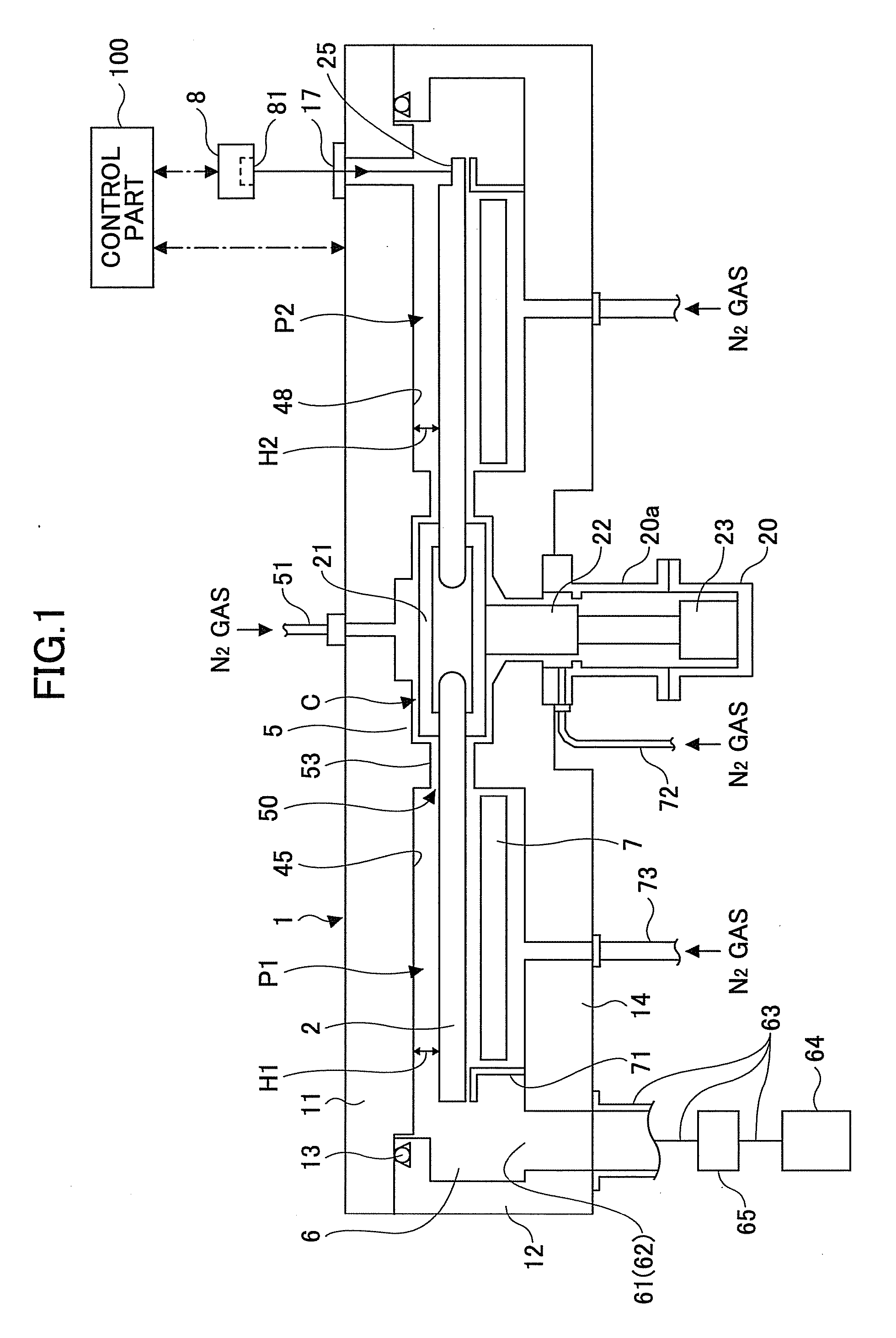

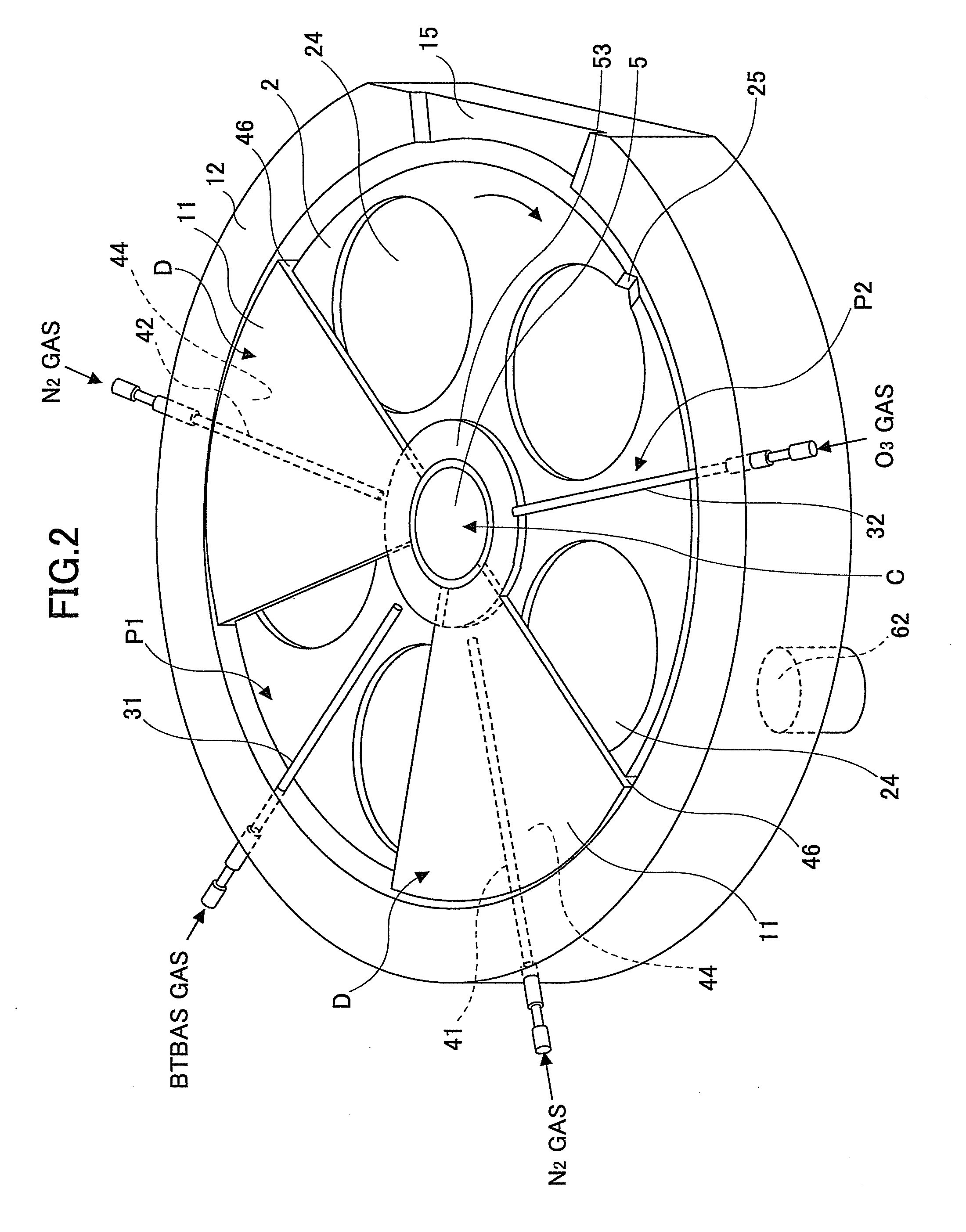

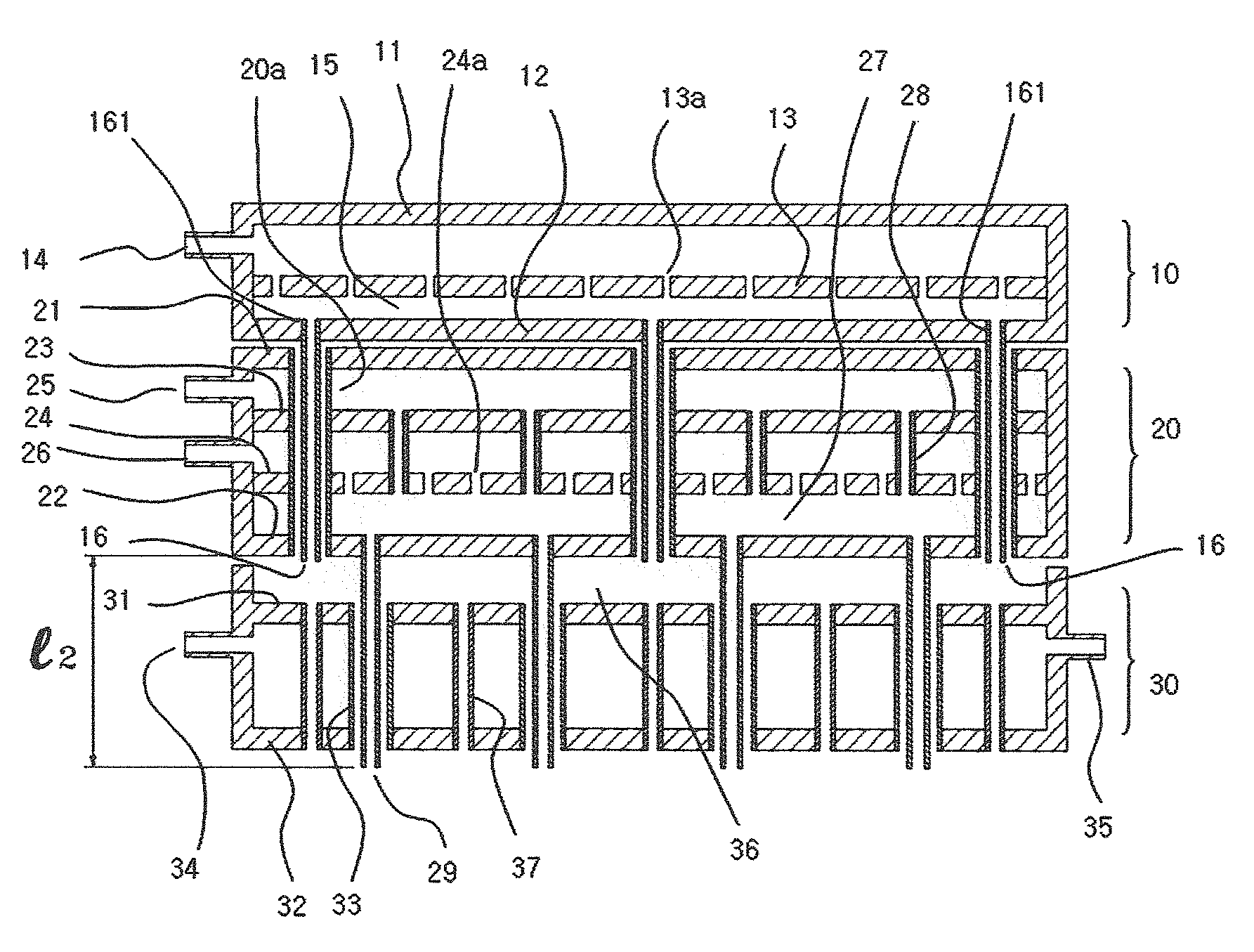

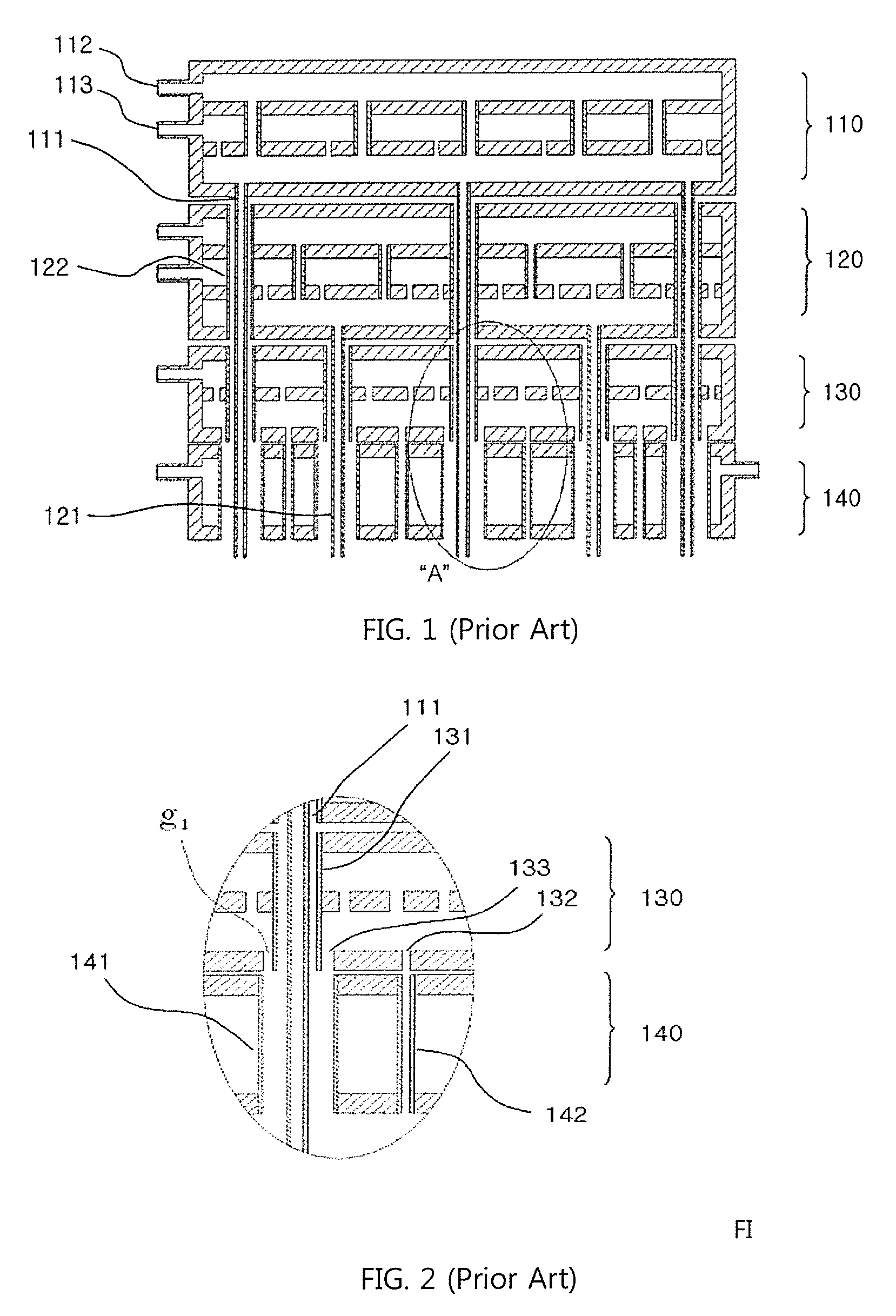

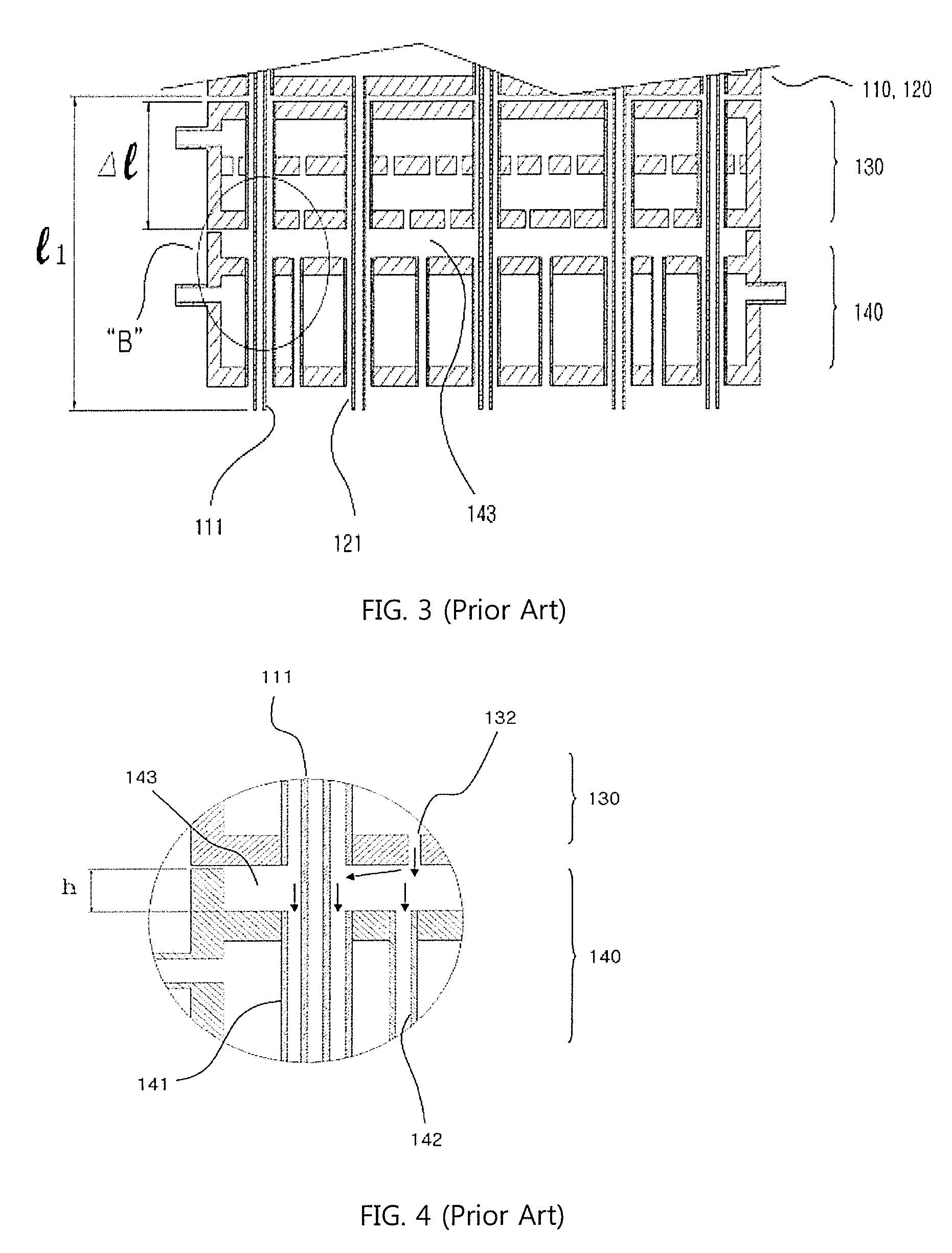

Film deposition apparatus, substrate processing apparatus, film deposition method, and computer-readable storage medium

InactiveUS20100055312A1Accurate detectionAccurate correctionLiquid surface applicatorsVacuum evaporation coatingReactive gasEngineering

In a film deposition apparatus which deposits a thin film on a substrate by supplying first and second reactive gases in a vacuum chamber, there are provided a turntable, a first reactive gas supplying portion and a second reactive gas supplying portion which are arranged to extend from circumferential positions of the turntable to a center of rotation of the turntable, a first separation gas supplying portion arranged between the first and second reactive gas supplying portions, a first space having a first height and including the first separation gas supplying portion, a second space having a second height and including the second reactive gas supplying portion, a third space having a height lower than the first height and the second height and including the first separation gas supplying portion, a position detecting unit detecting a rotation position of the turntable, and a detection part arranged at a circumferential portion of the turntable and detected by the position detecting unit.

Owner:TOKYO ELECTRON LTD

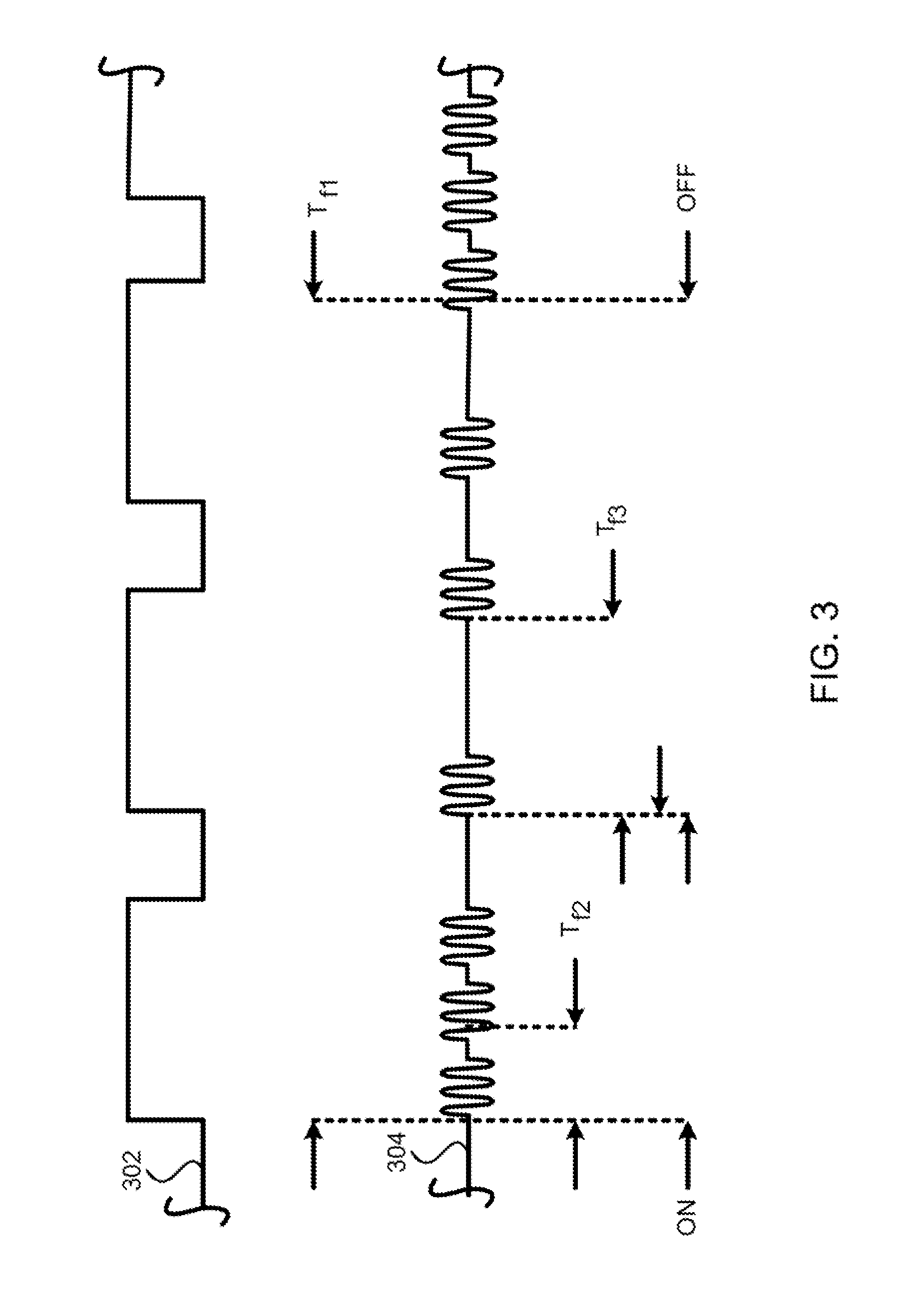

Method of depositing dielectric film by modified peald method

ActiveUS20120220139A1Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasHydrogen

A method of forming a film on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

Method of forming conformal dielectric film having Si-N bonds by PECVD

ActiveUS7972980B2Increase deposition rateHigh conformalitySemiconductor/solid-state device detailsSolid-state devicesDielectricNoble gas

Owner:ASM JAPAN

Mixed mode pulsing etching in plasma processing systems

A method for processing substrate in a chamber, which has at least one plasma generating source, a reactive gas source for providing reactive gas into the interior region of the chamber, and a non-reactive gas source for providing non-reactive gas into the interior region, is provided. The method includes performing a mixed-mode pulsing (MMP) preparation phase, including flowing reactive gas into the interior region and forming a first plasma to process the substrate that is disposed on a work piece holder. The method further includes performing a MMP reactive phase, including flowing at least non-reactive gas into the interior region, and forming a second plasma to process the substrate, the second plasma is formed with a reactive gas flow during the MMP reactive phase that is less than a reactive gas flow during the MMP preparation phase. Perform the method steps a plurality of times.

Owner:LAM RES CORP

Method of Forming Conformal Dielectric Film Having Si-N Bonds by PECVD

ActiveUS20100184302A1Reduce the temperatureSemiconductor/solid-state device detailsSolid-state devicesDielectricHydrogen

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and an additive gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film having Si—N bonds on the substrate.

Owner:ASM JAPAN

Method of depositing dielectric film by modified PEALD method

ActiveUS8415259B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectricityNoble gas

A method of forming a film on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

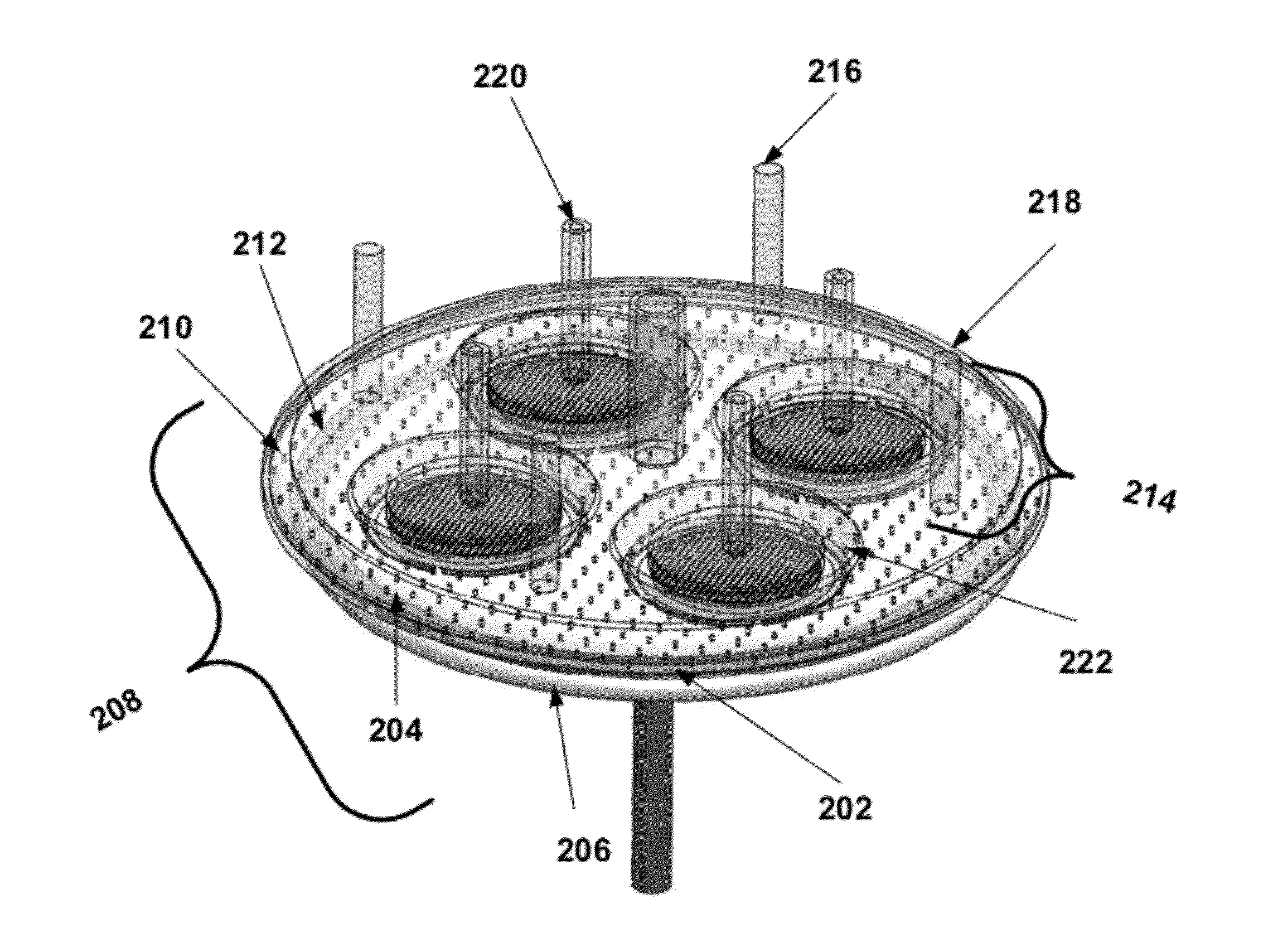

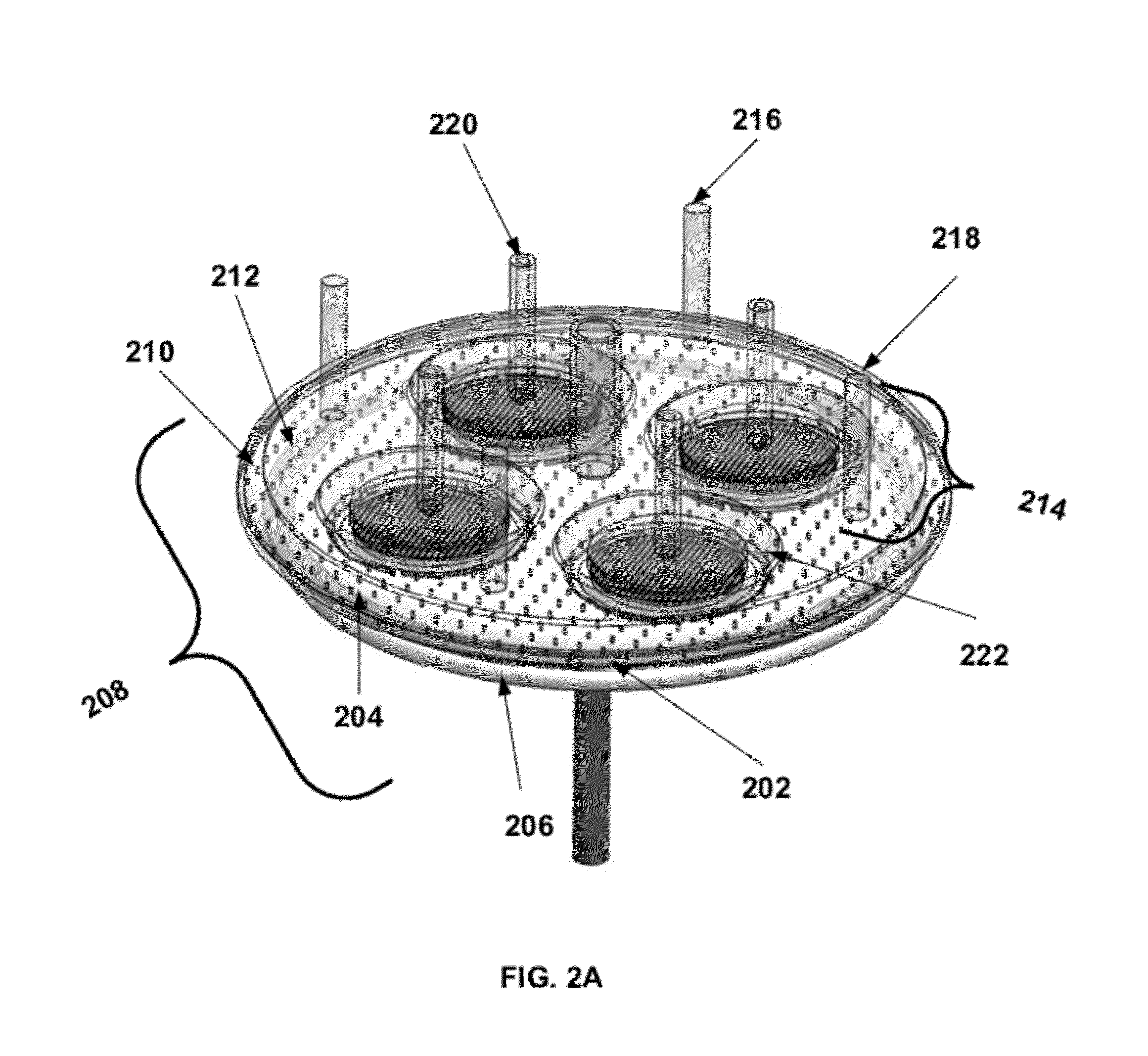

System for multi-region processing

ActiveUS20120321786A1Avoid cross contaminationChemical vapor deposition coatingReactive gasEngineering

A gas distribution structure for supplying reactant gases and purge gases to independent process cells to deposit thin films on separate regions of a substrate is described. Each process cell has an associated ring purge and exhaust manifold to prevent reactive gases from forming deposits on the surface of the wafer between the isolated regions. Each process cell has an associated showerhead for conveying the reactive gases to the substrate. The showerheads can be independently rotated to simulate the rotation parameter for the deposition process.

Owner:INTERMOLECULAR

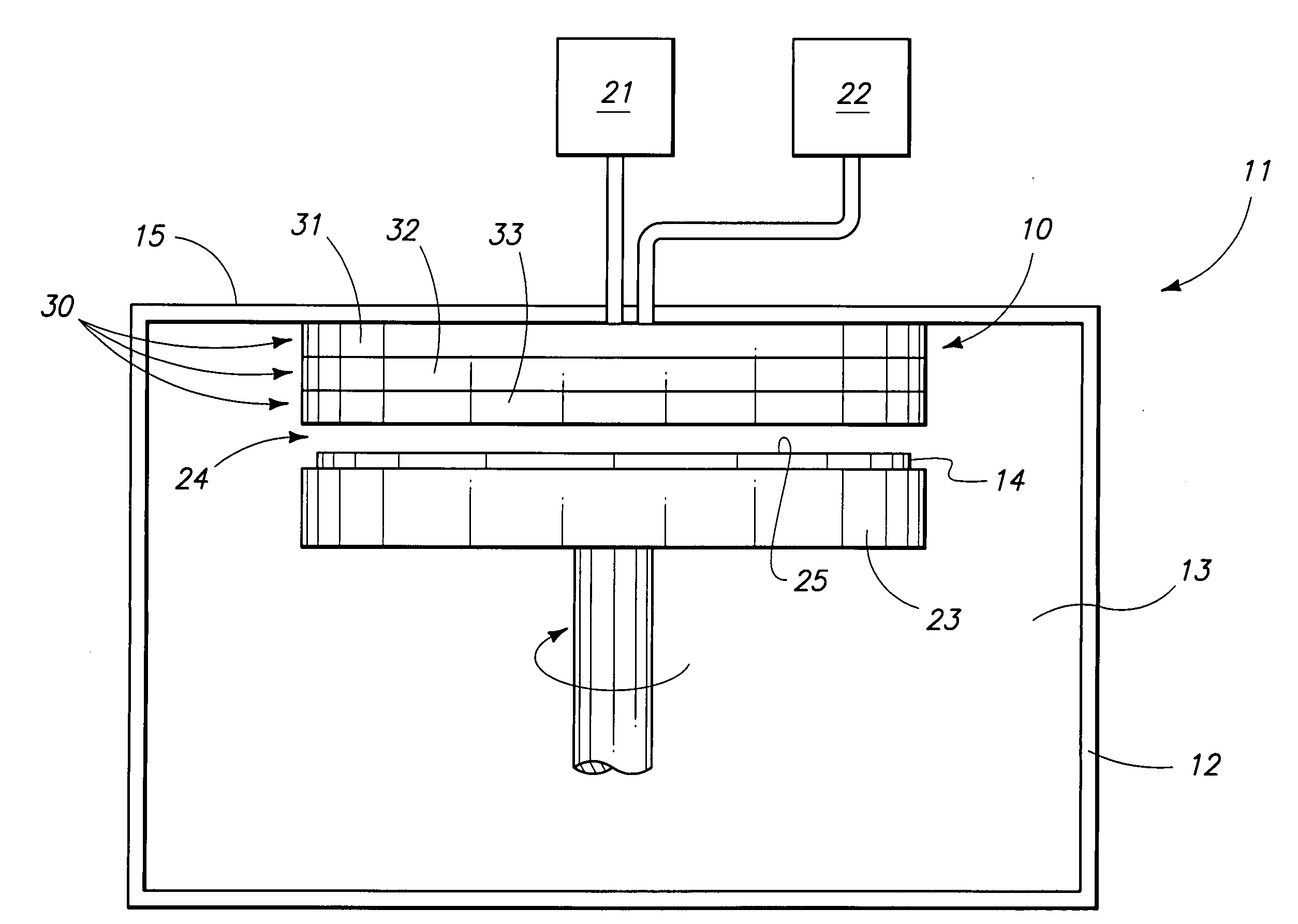

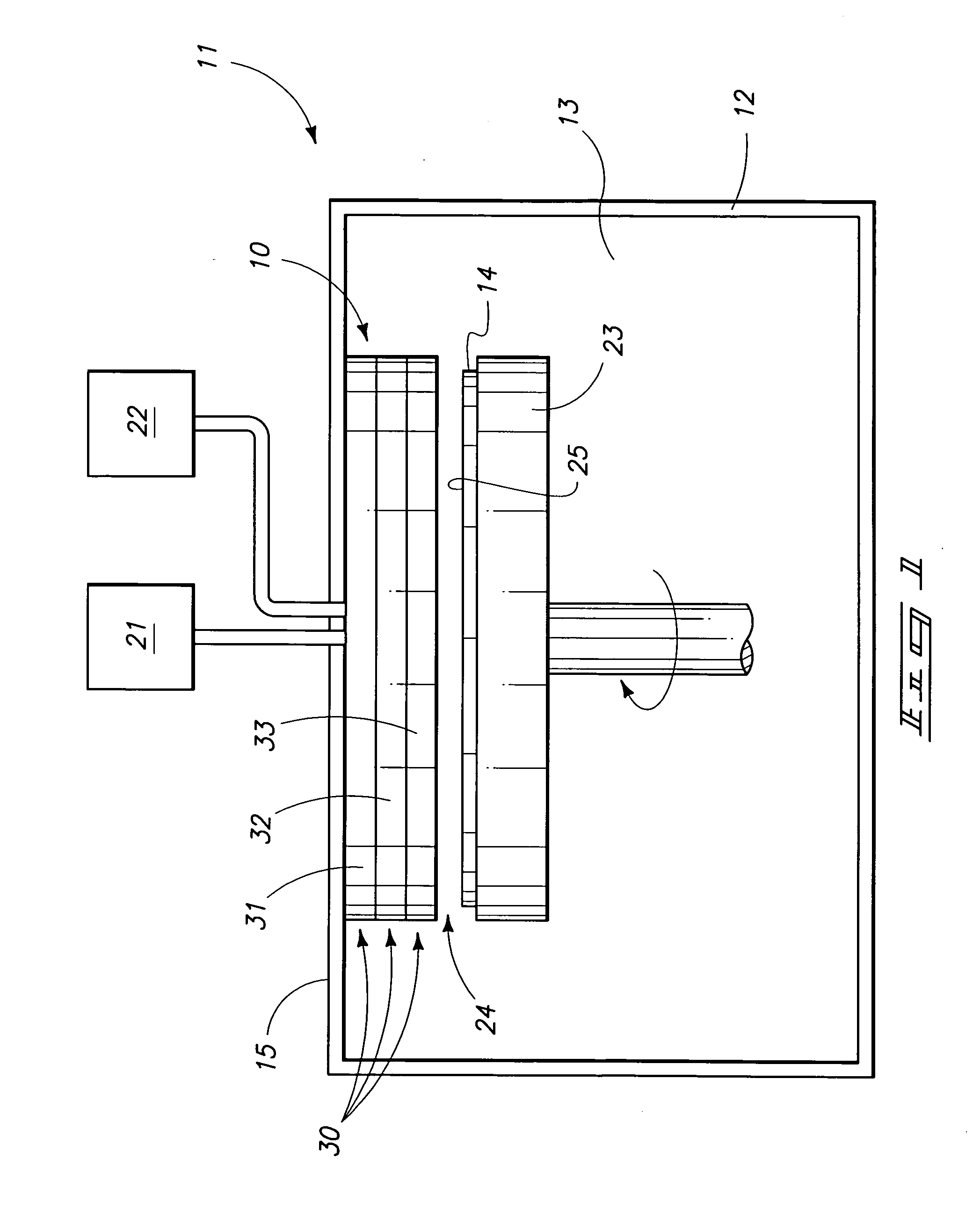

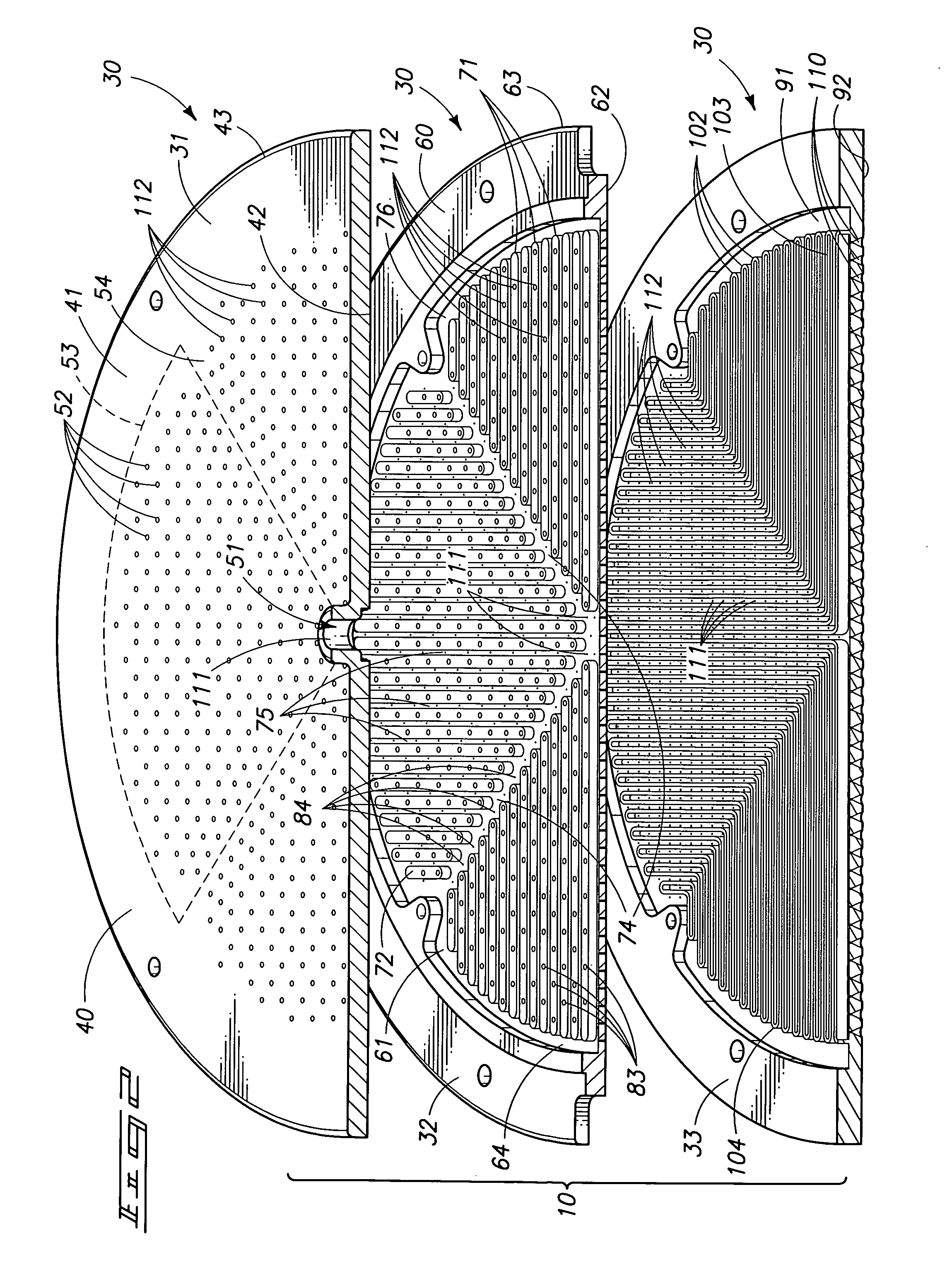

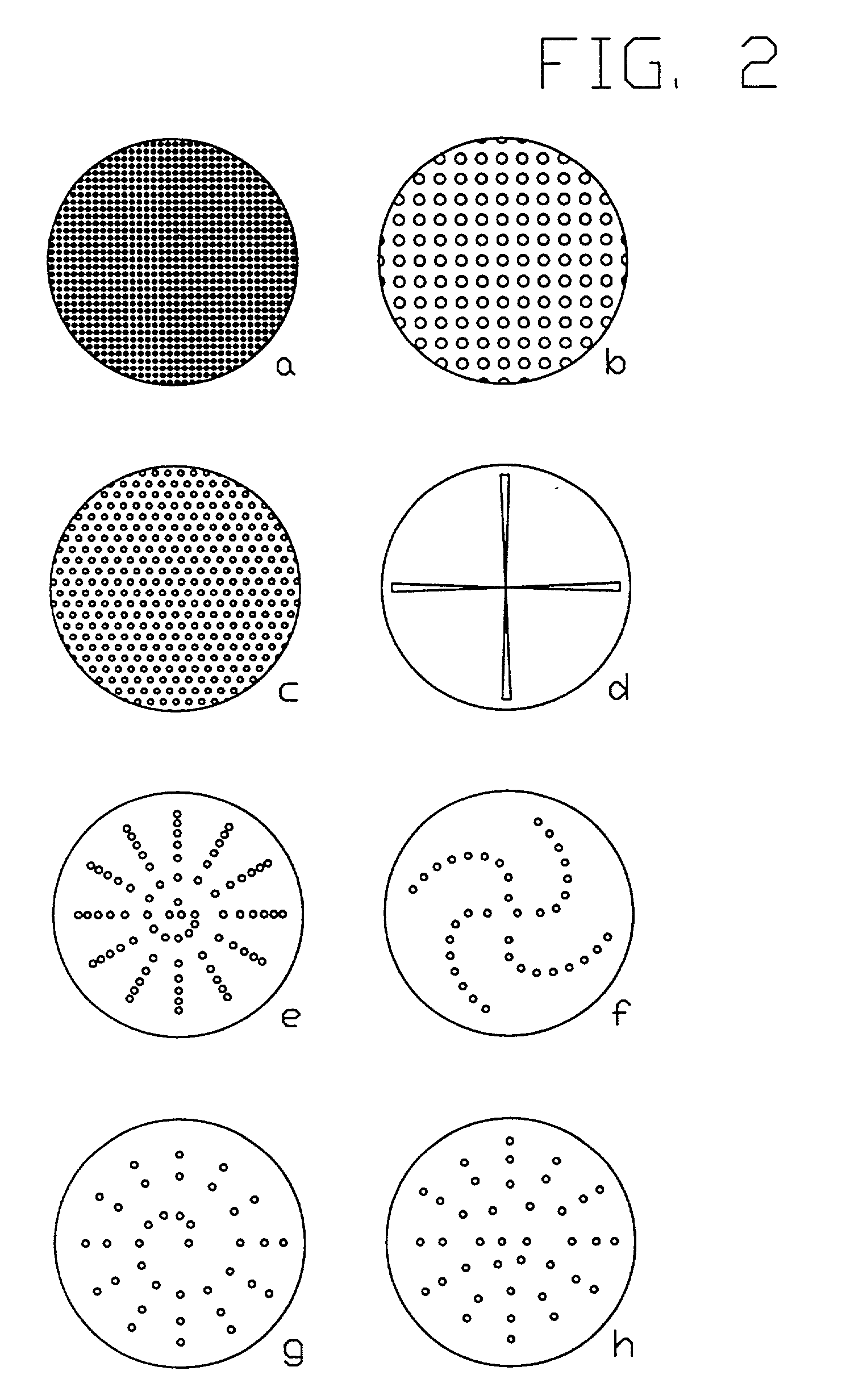

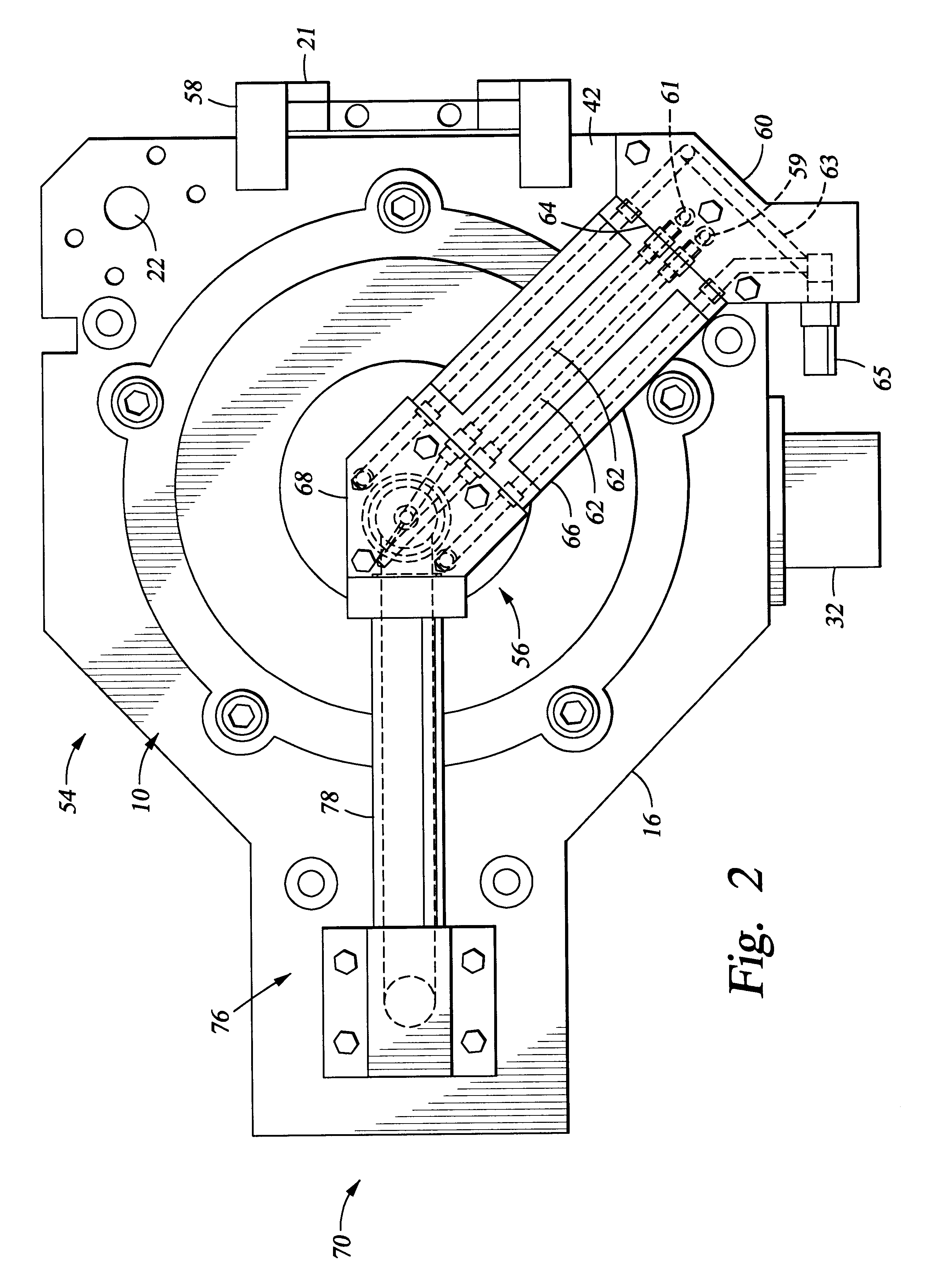

Gas distribution assembly for use in a semiconductor work piece processing reactor

ActiveUS20080092815A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasEngineering

A semiconductor work piece processing reactor is described and which includes a processing chamber defining a deposition region; a pedestal which supports and moves a semiconductor work piece to be processed within the deposition region of the processing chamber; and a gas distribution assembly mounted within the processing chamber and which defines first and second reactive gas passageways which are separated from each other, and which deliver two reactant gases to a semiconductor work piece which is positioned near the gas distribution assembly.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Method of forming conformal dielectric film having Si-N bonds by PECVD

ActiveUS8142862B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingSolid state diffusion coatingDielectricElectricity

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and an additive gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film having Si—N bonds on the substrate.

Owner:ASM JAPAN

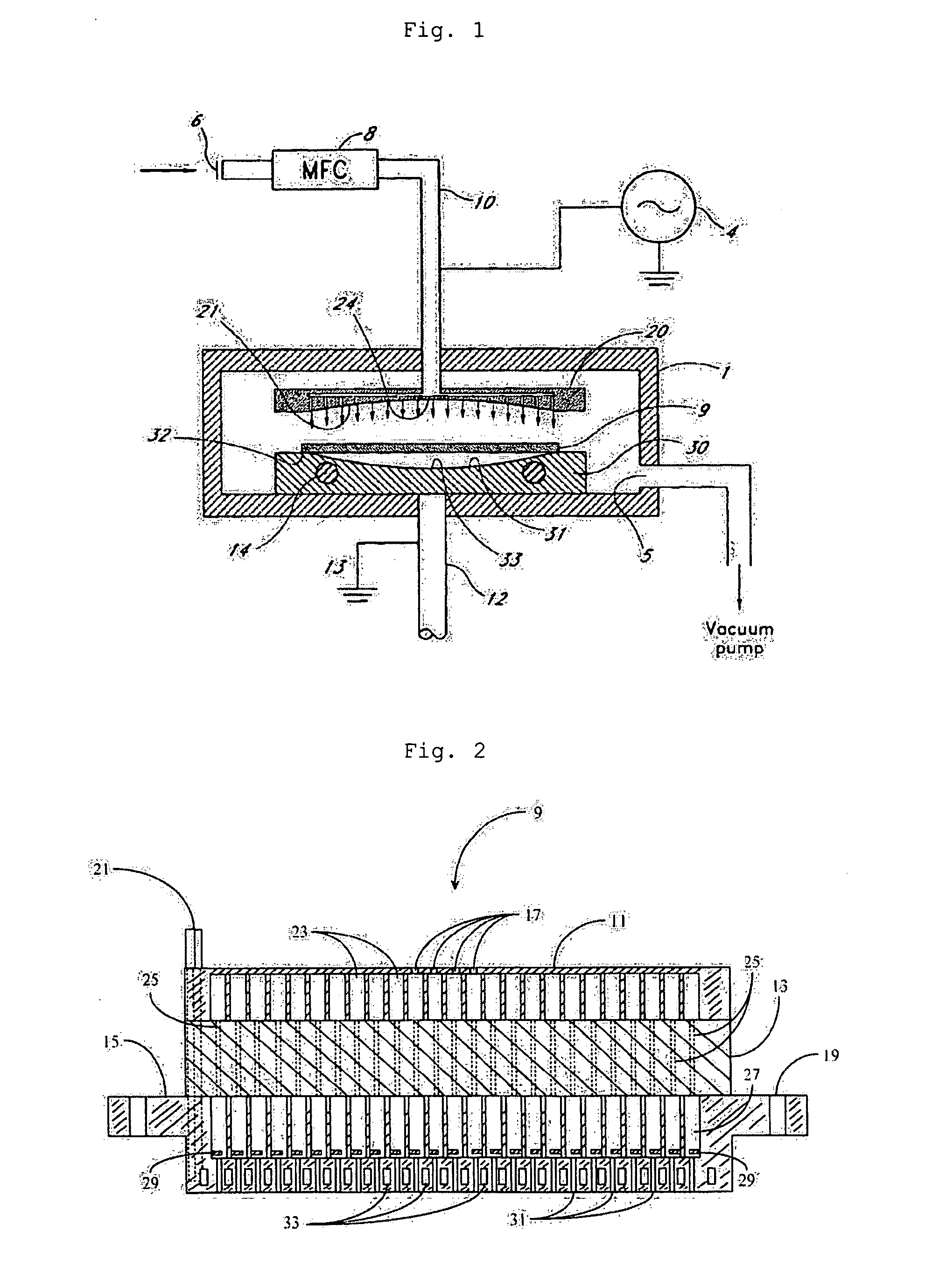

Atomic layer deposition apparatus

InactiveUS20060137608A1Uniform thicknessEasy to controlChemical vapor deposition coatingEngineeringAtomic layer deposition

An atomic layer deposition (ALD) apparatus is, suitable for thermal ALD and plasma-enhanced ALD of conductive and non-conductive films. The ALD apparatus can maintain electrical insulation of a gas dispersion structure, such as a showerhead assembly, which acts as an RF electrode to generate plasma inside a reaction chamber while depositing electrically conductive films in the reaction chamber. Fine tubules of micro-feeding tube assembly prevents plasma generation in them and reactive gases each have separate flow paths through the micro-feeding tube assembly. Process gases out of the micro-feeding tube assembly enter narrow grooves of a helical flow inducing plate and form helical flows which mix well each other. Symmetrically mounted pads on showerhead assembly and flow guiding plate maintain a symmetrical gap through which an inert gas flows continuously to keep reactive gases outside the gap and unwanted film deposition in the gap. Longer operating time before maintenance (cleaning) and thus higher productivity can be achieved.

Owner:ASM GENITECH KOREA

METHOD OF FORMING CONFORMAL DIELECTRIC FILM HAVING Si-N BONDS BY PECVD

ActiveUS20100144162A1Reduce the temperatureIncrease deposition rateSemiconductor/solid-state device manufacturingSolid state diffusion coatingDielectricHydrogen

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and an additive gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film having Si—N bonds on the substrate.

Owner:ASM JAPAN

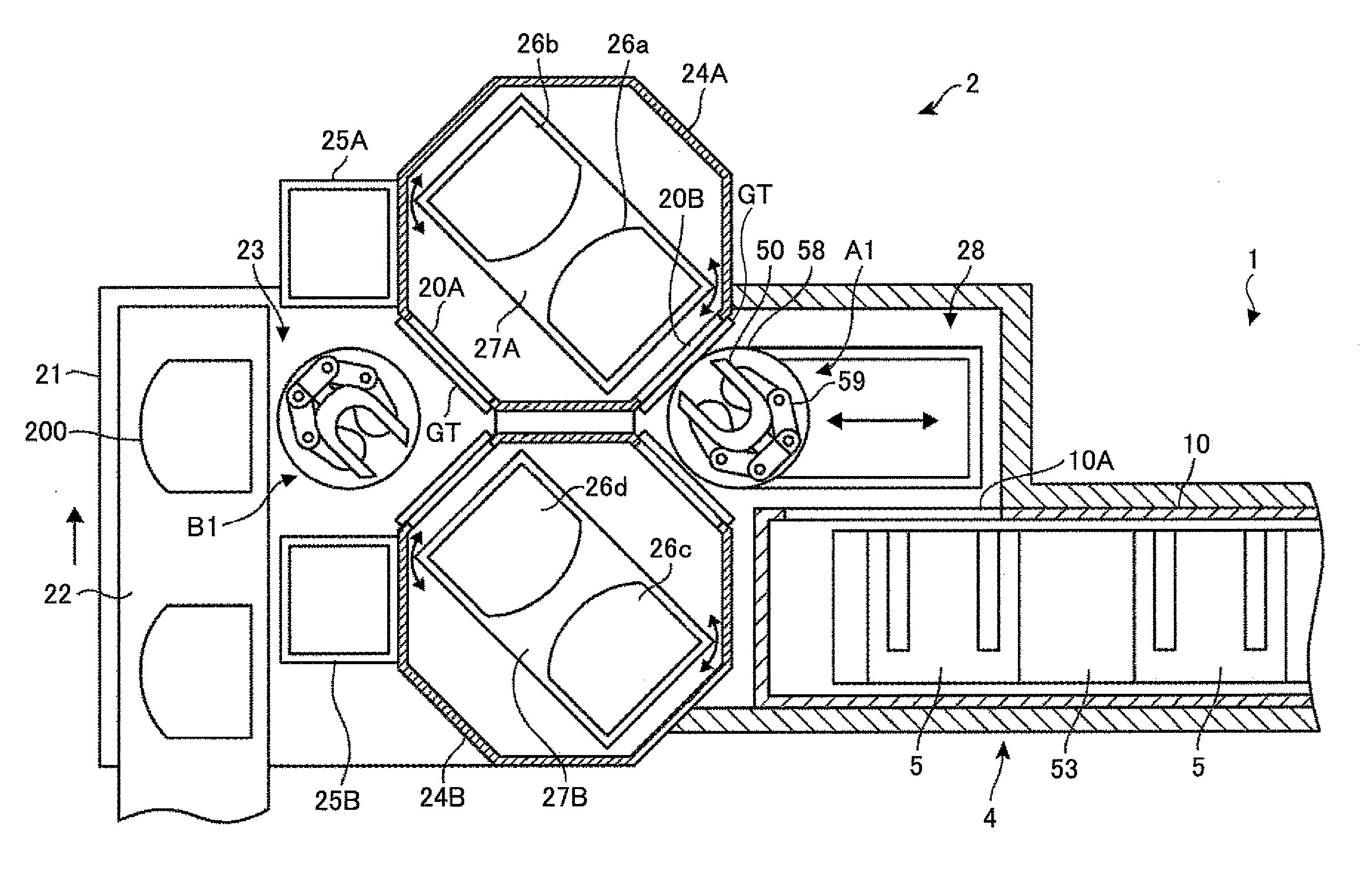

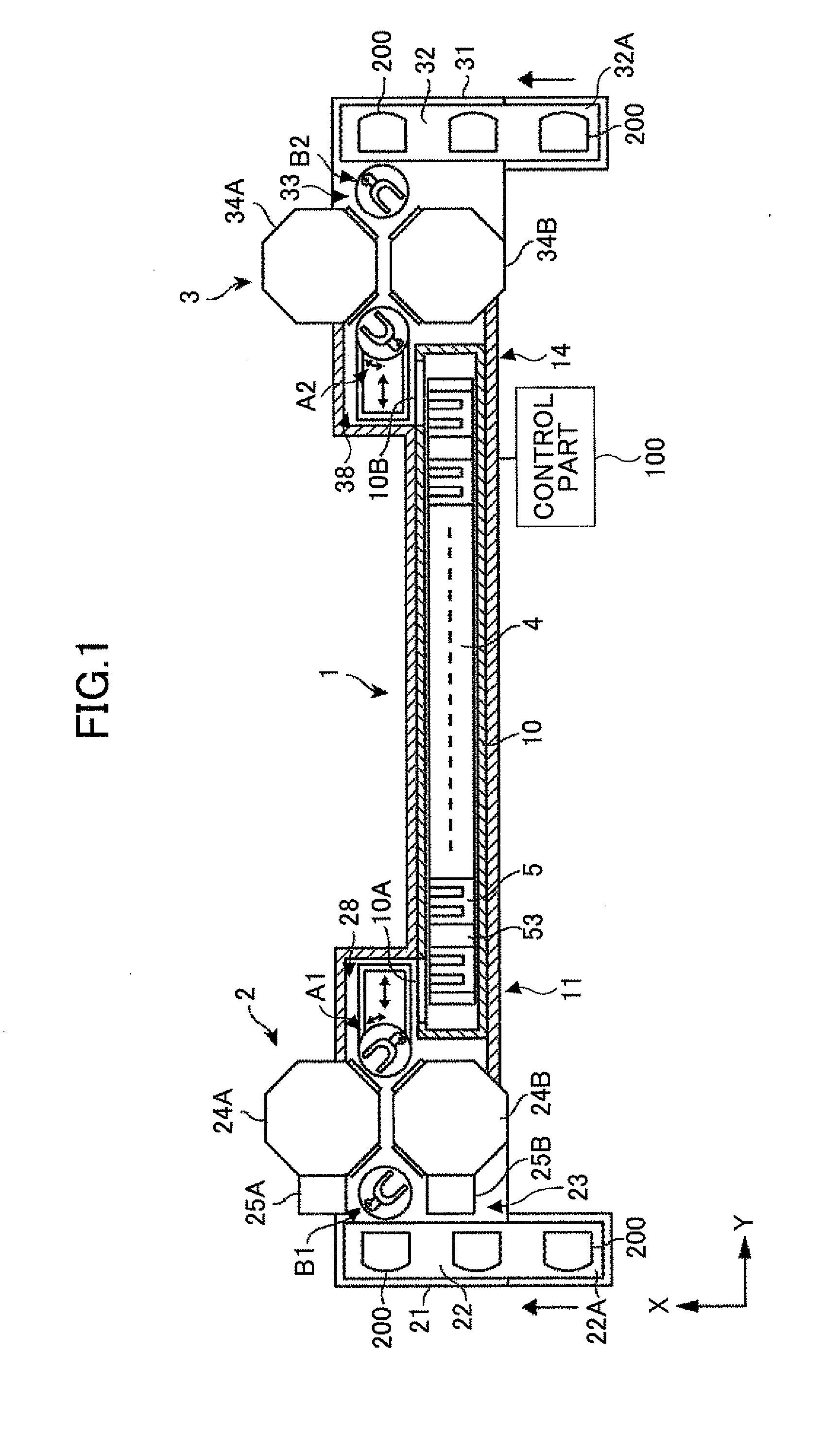

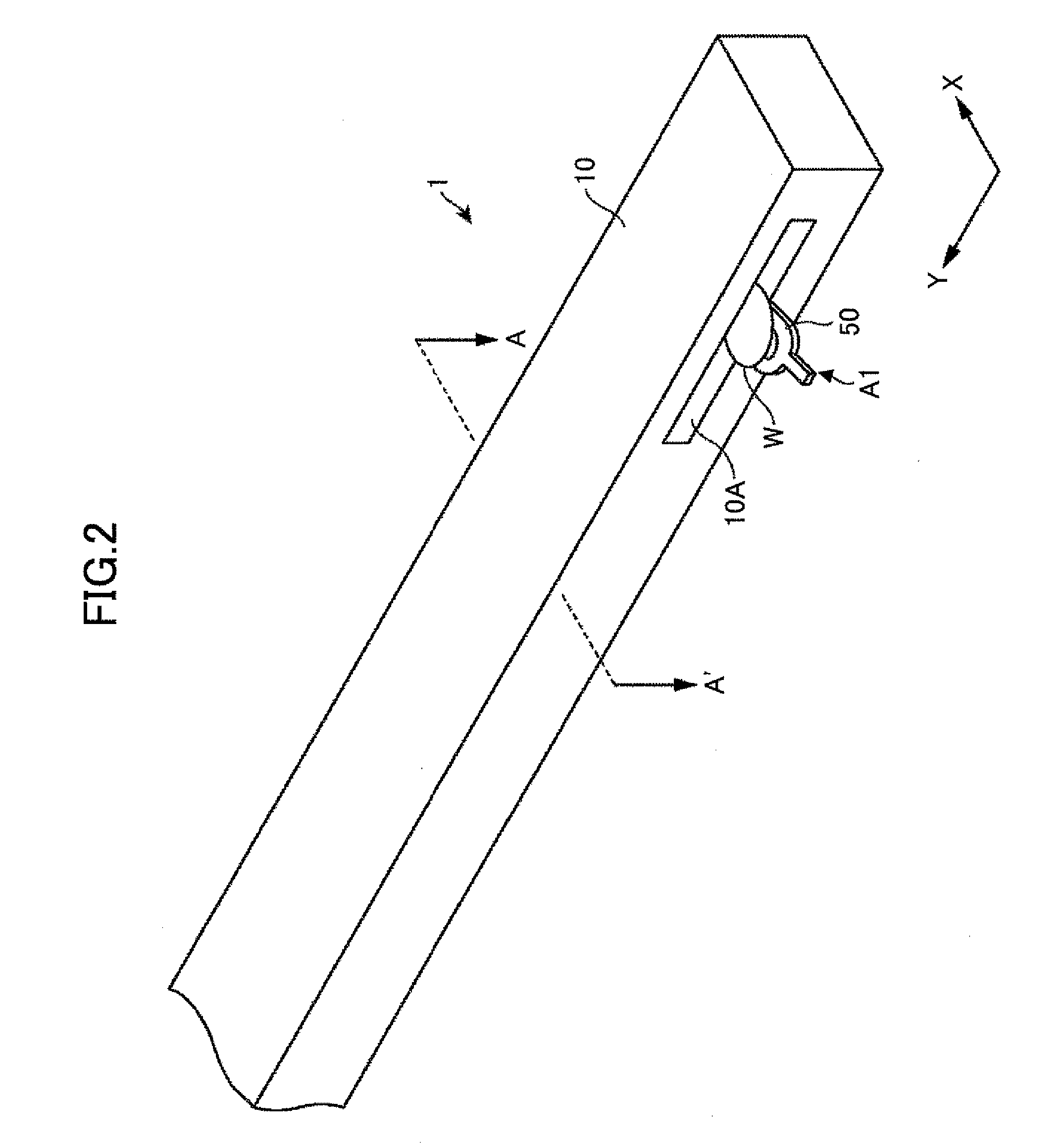

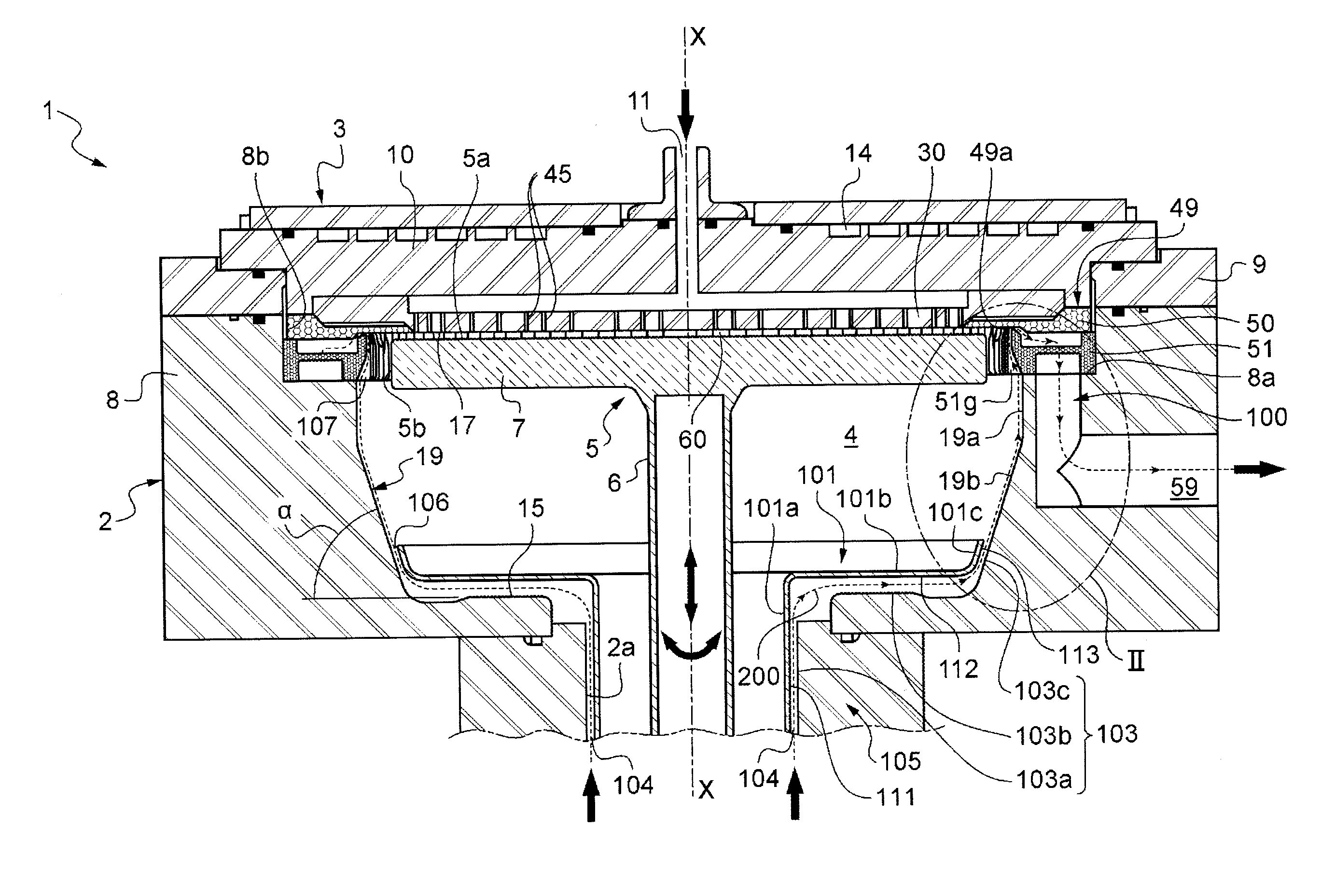

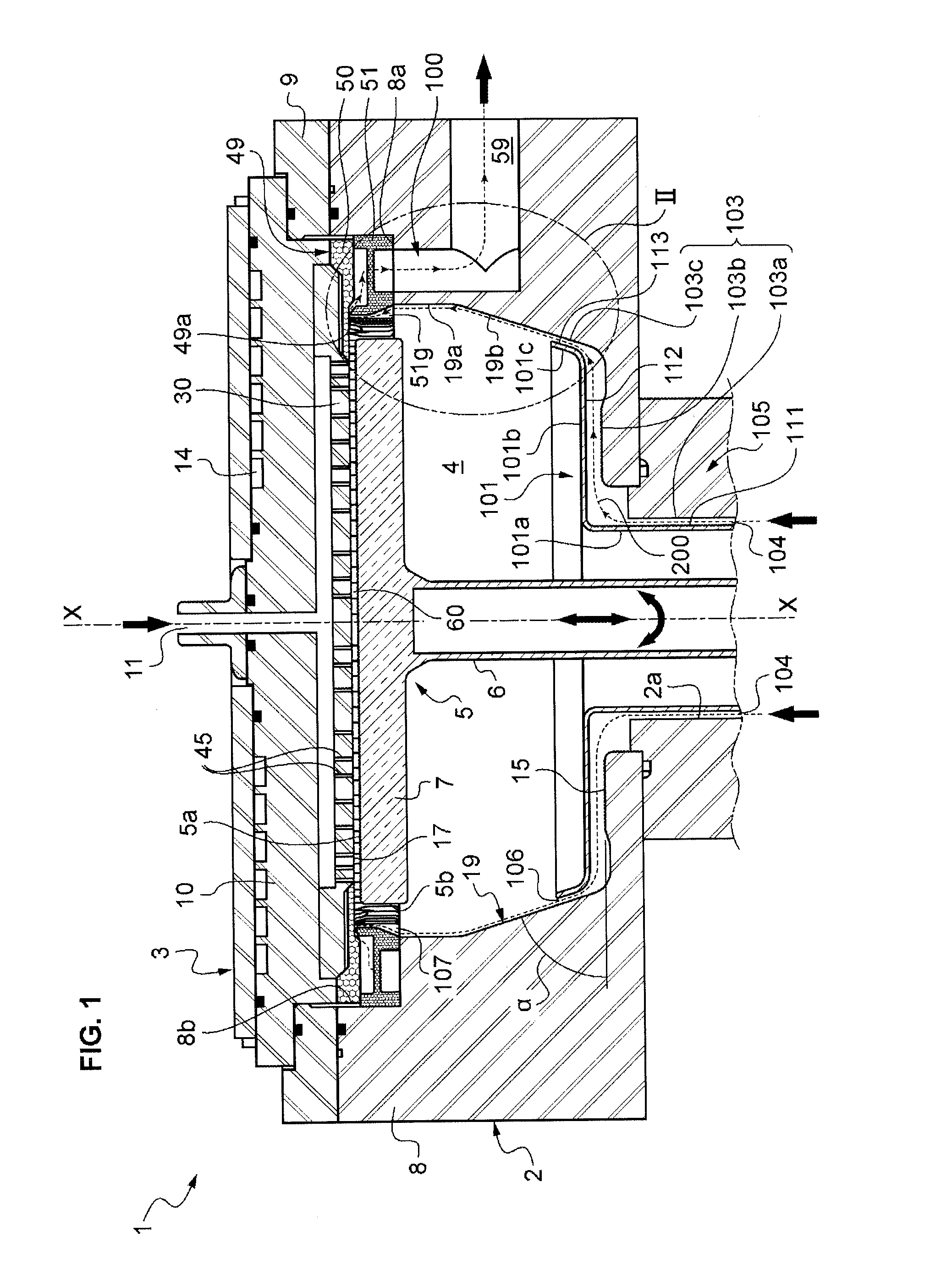

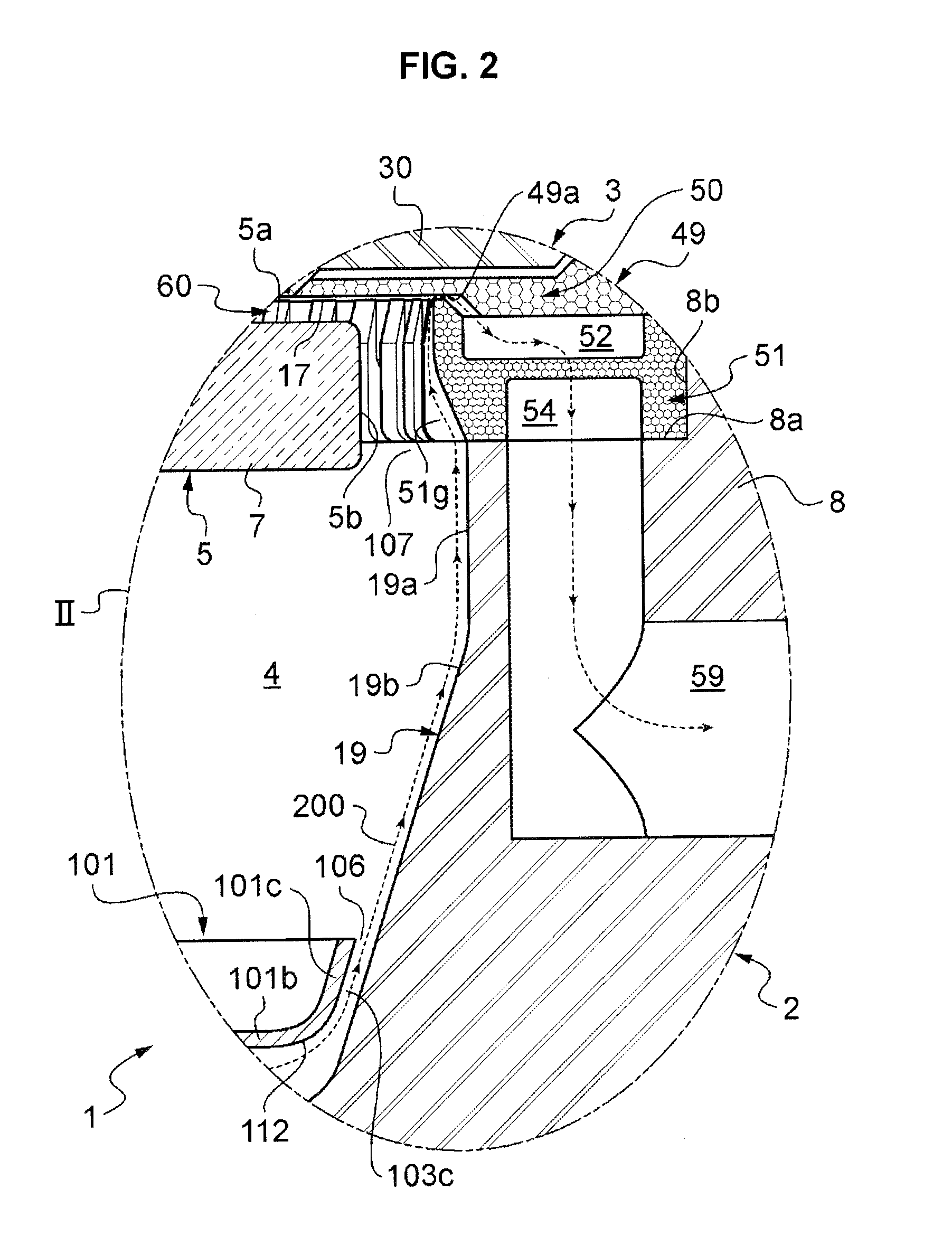

Film deposition device and substrate processing device

InactiveUS20110265725A1Improve throughputLow gas consumptionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasGas supply

A film deposition device includes a substrate transporting device arranged in a vacuum chamber to include a circulatory transport path in which substrate mounting parts arranged in a row are transported in a circulatory manner, the circulatory transport path including a linear transport path in which the substrate mounting parts are transported linearly. A first reactive gas supplying part is arranged along a transporting direction in which the substrate mounting parts are transported in the linear transport path, to supply a first reactive gas to the substrate mounting parts. A second reactive gas supplying part is arranged alternately with the first reactive gas supplying part along the transporting direction, to supply a second reactive gas to the substrate mounting parts. A separation gas supplying part is arranged to supply a separation gas to a space between the first reactive gas supplying part and the second reactive gas supplying part.

Owner:TOKYO ELECTRON LTD

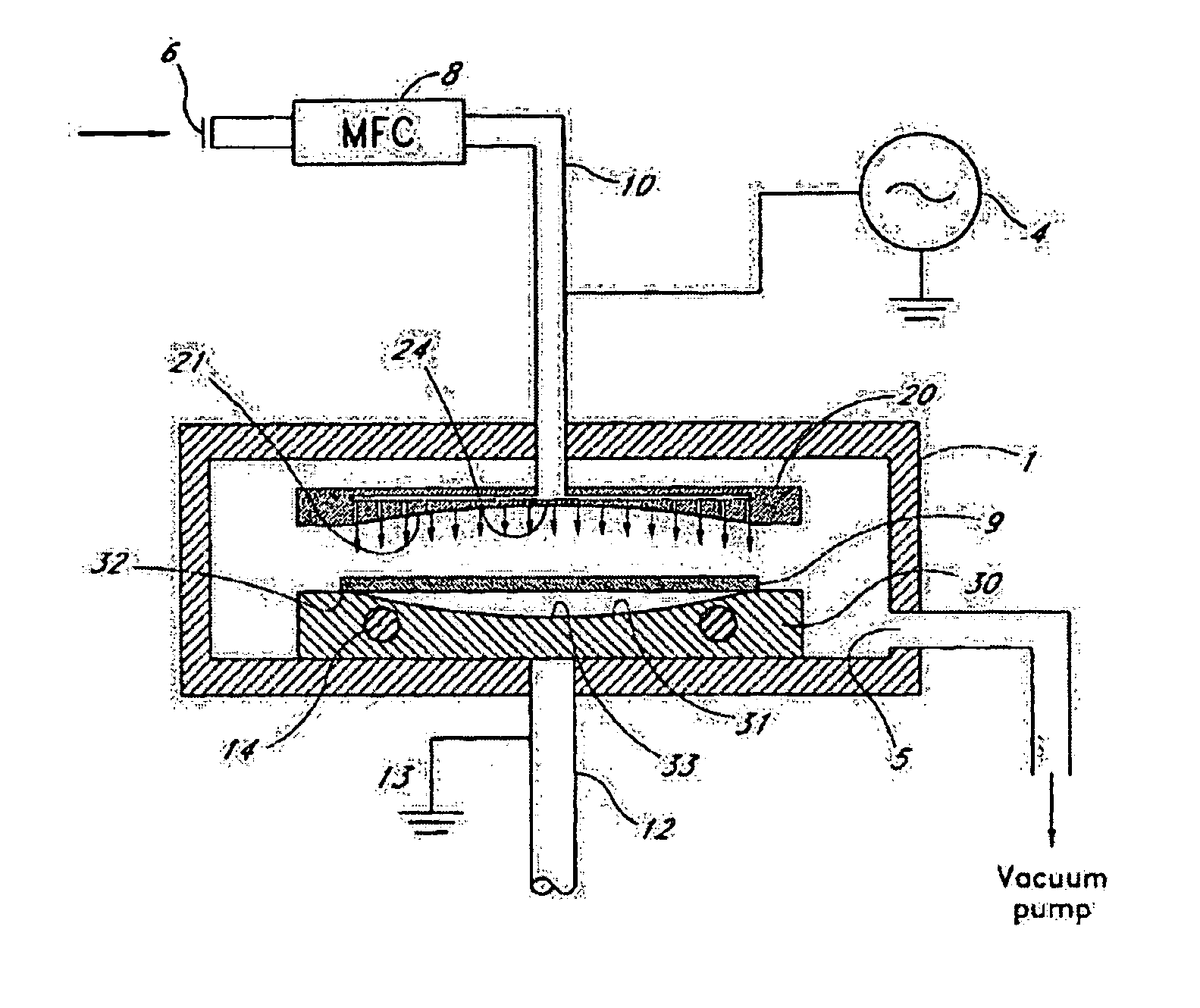

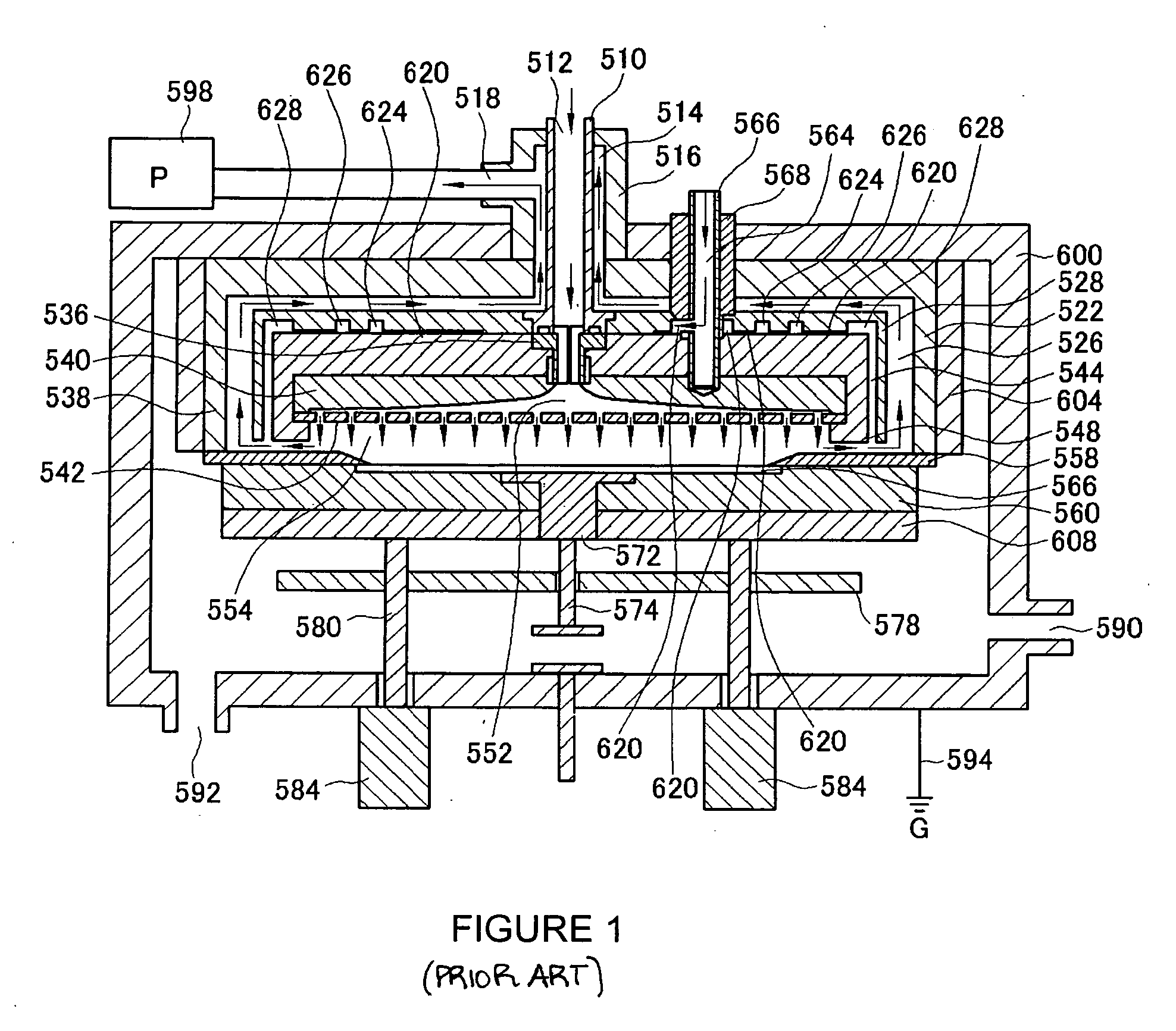

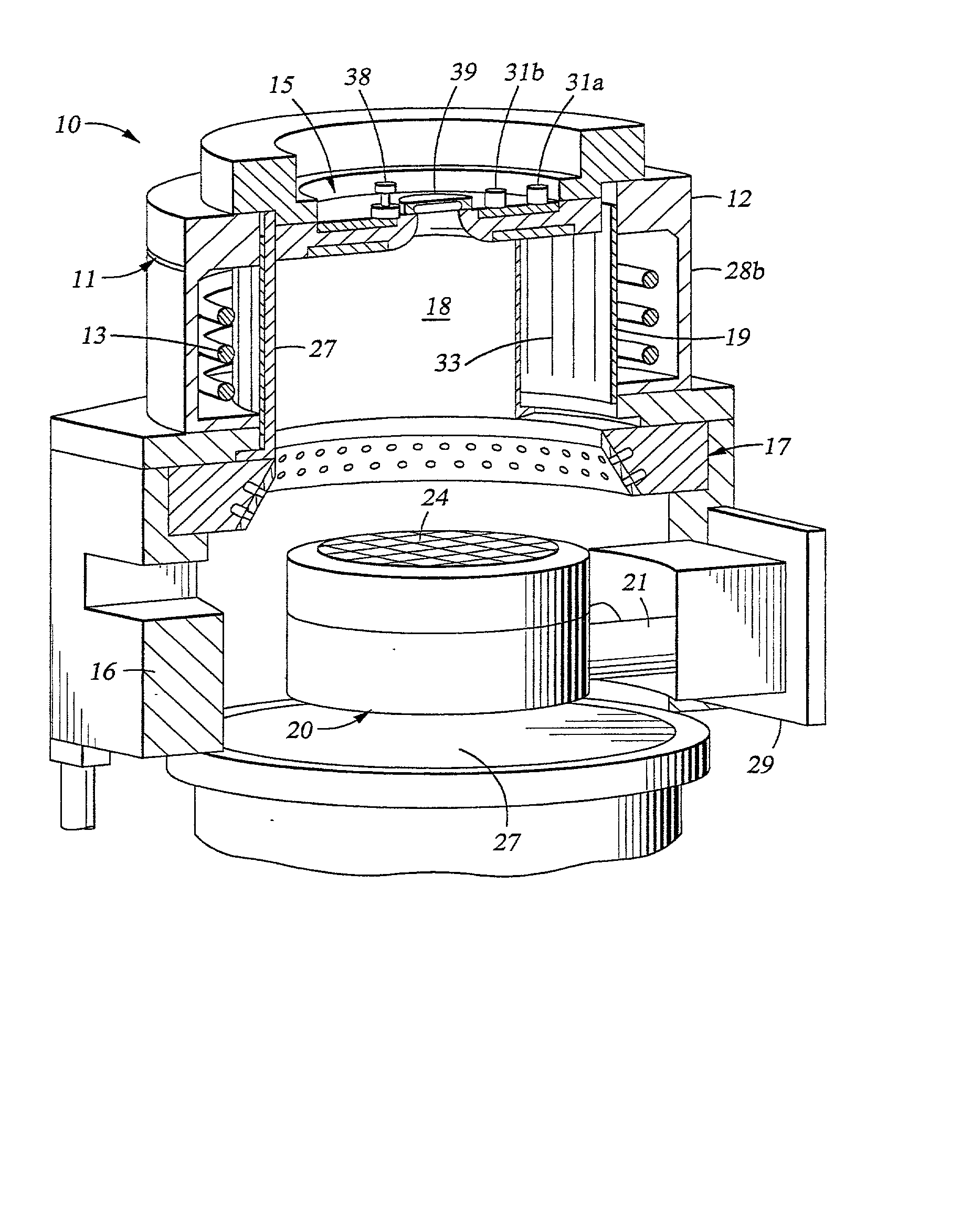

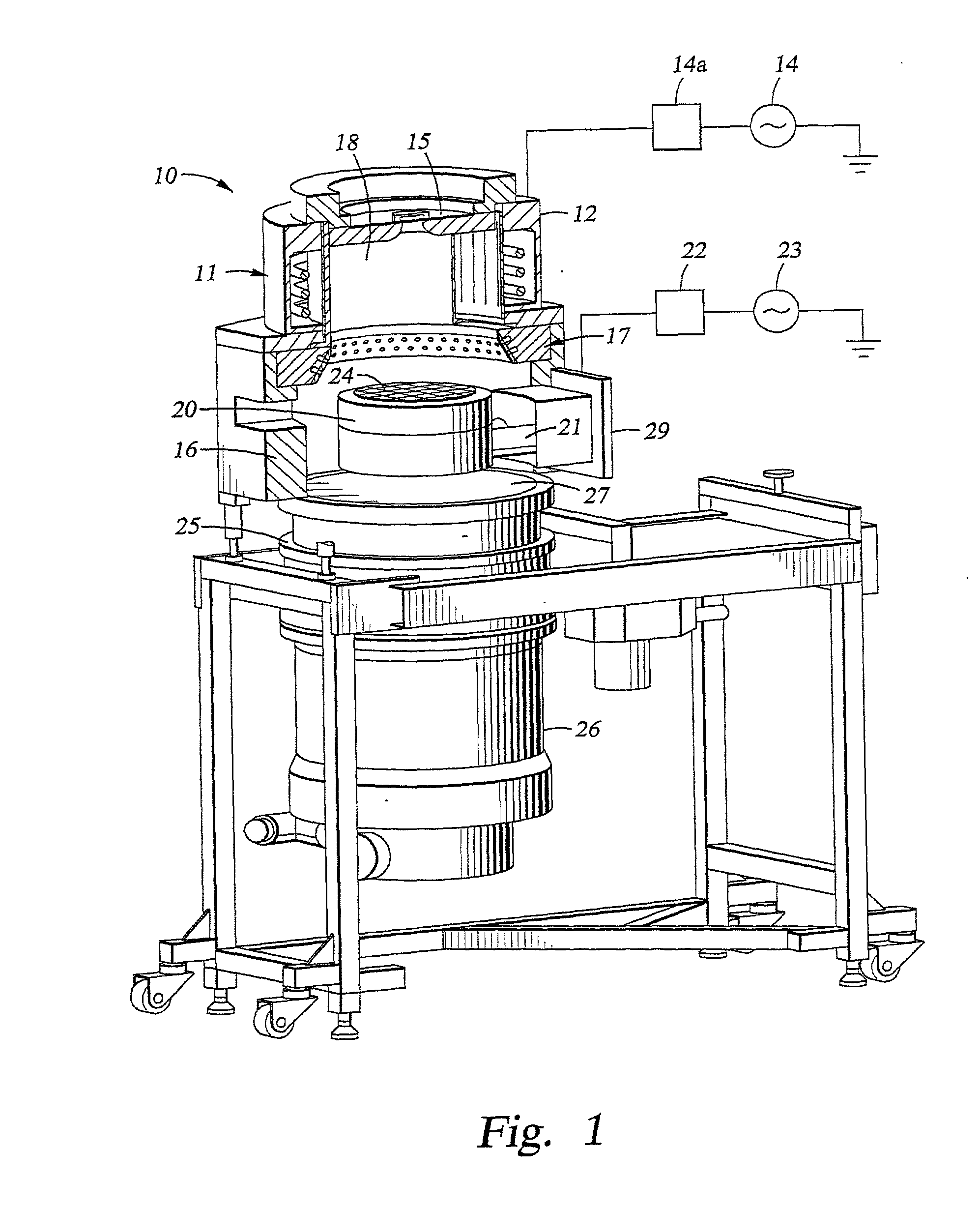

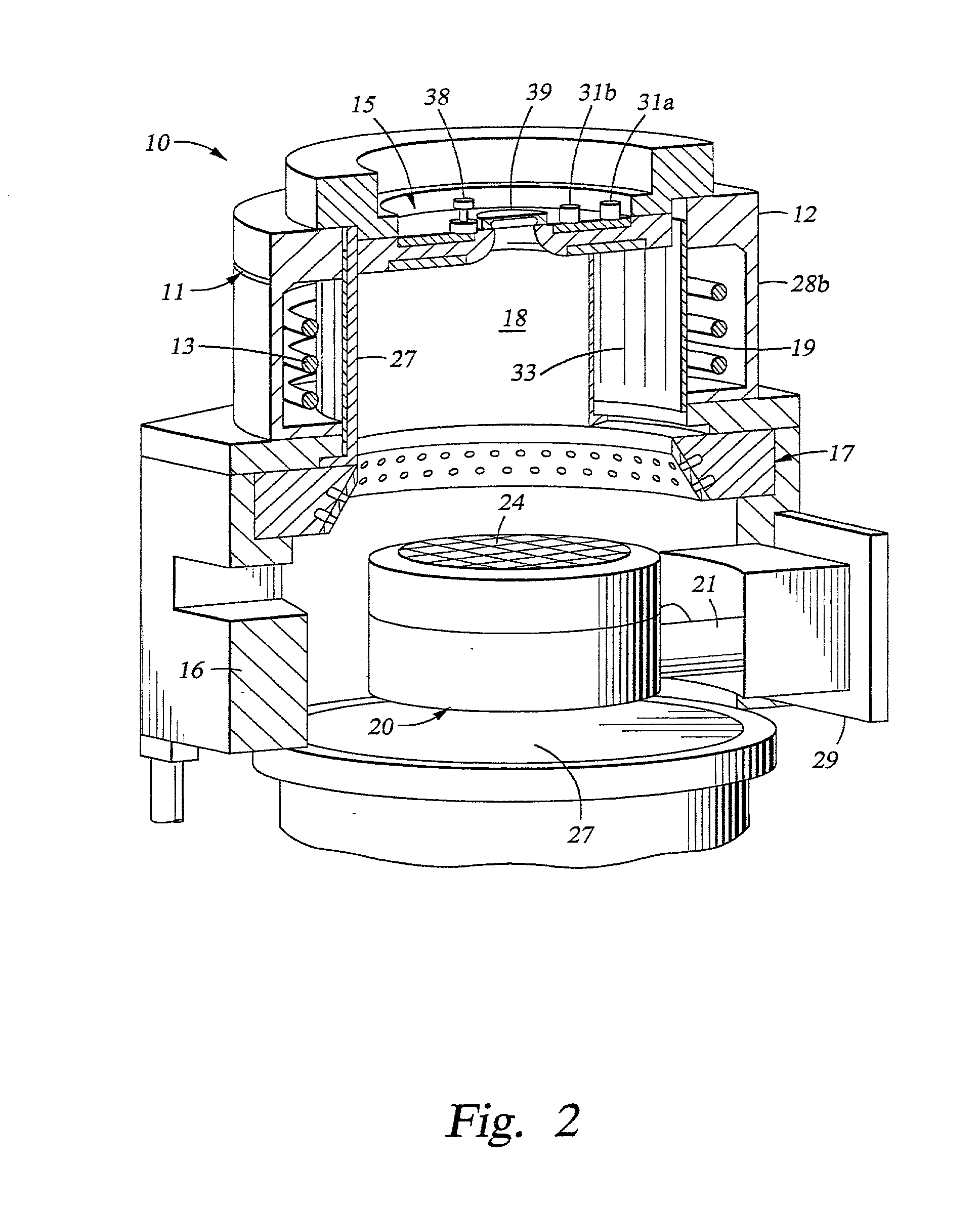

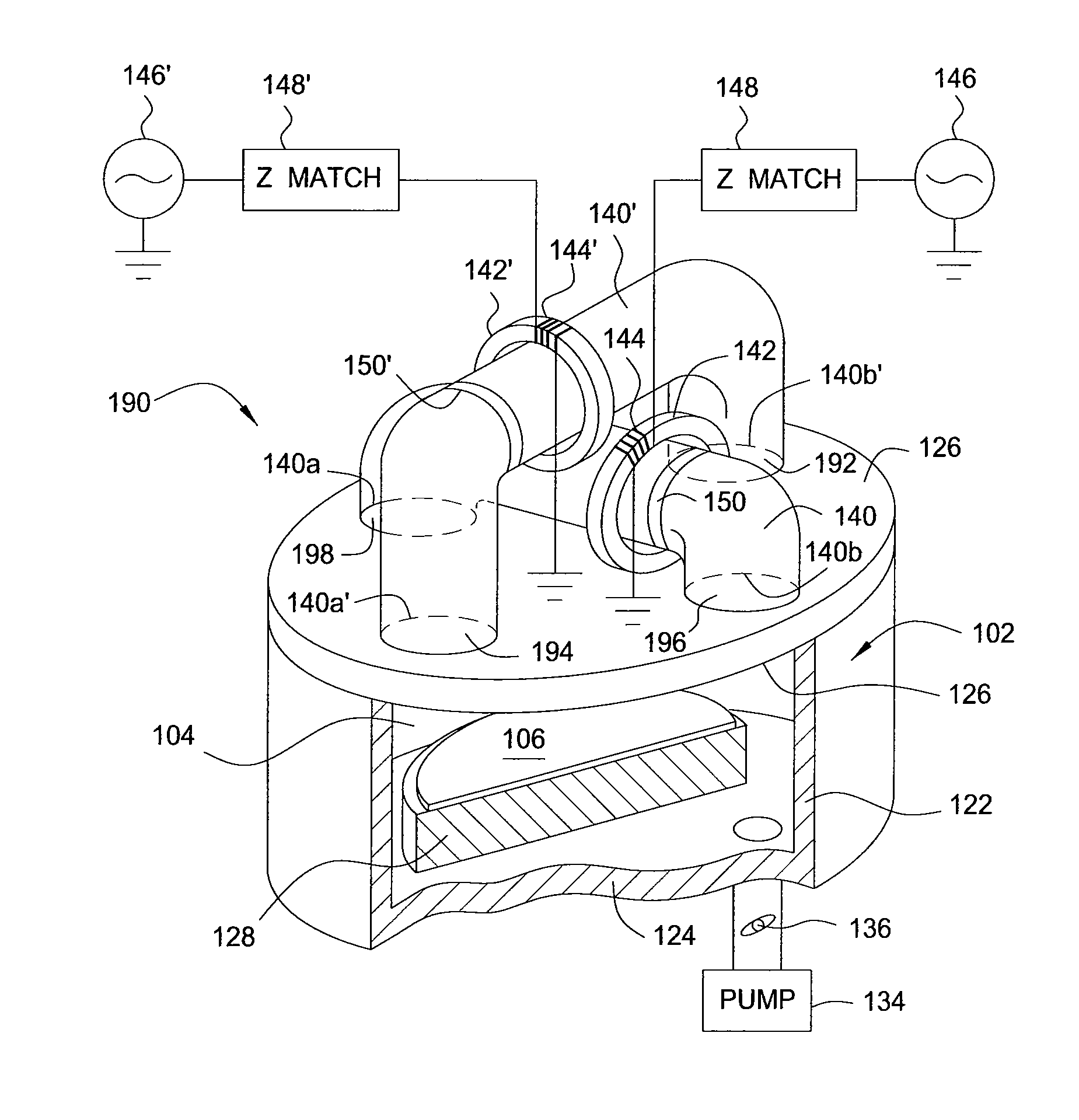

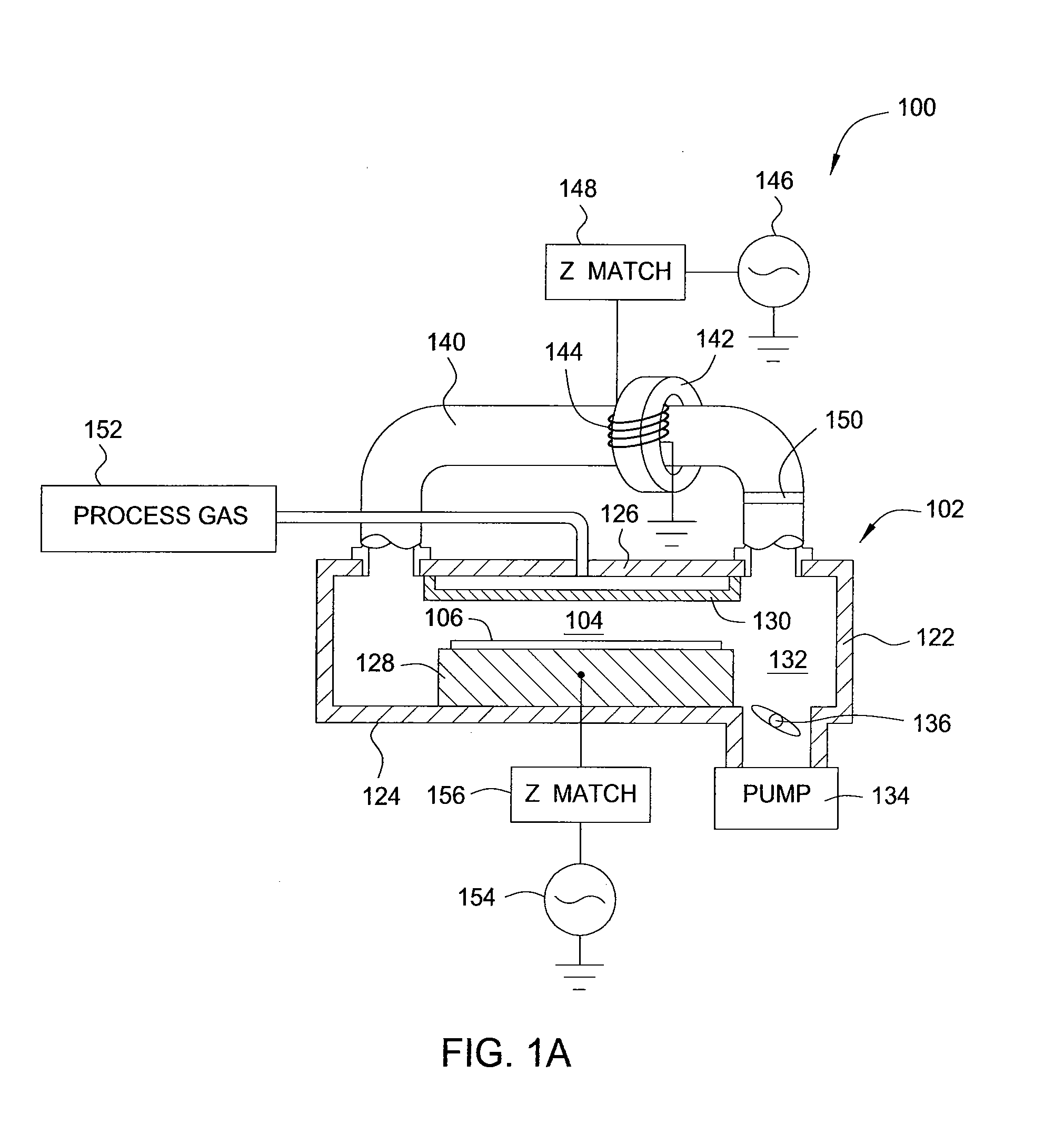

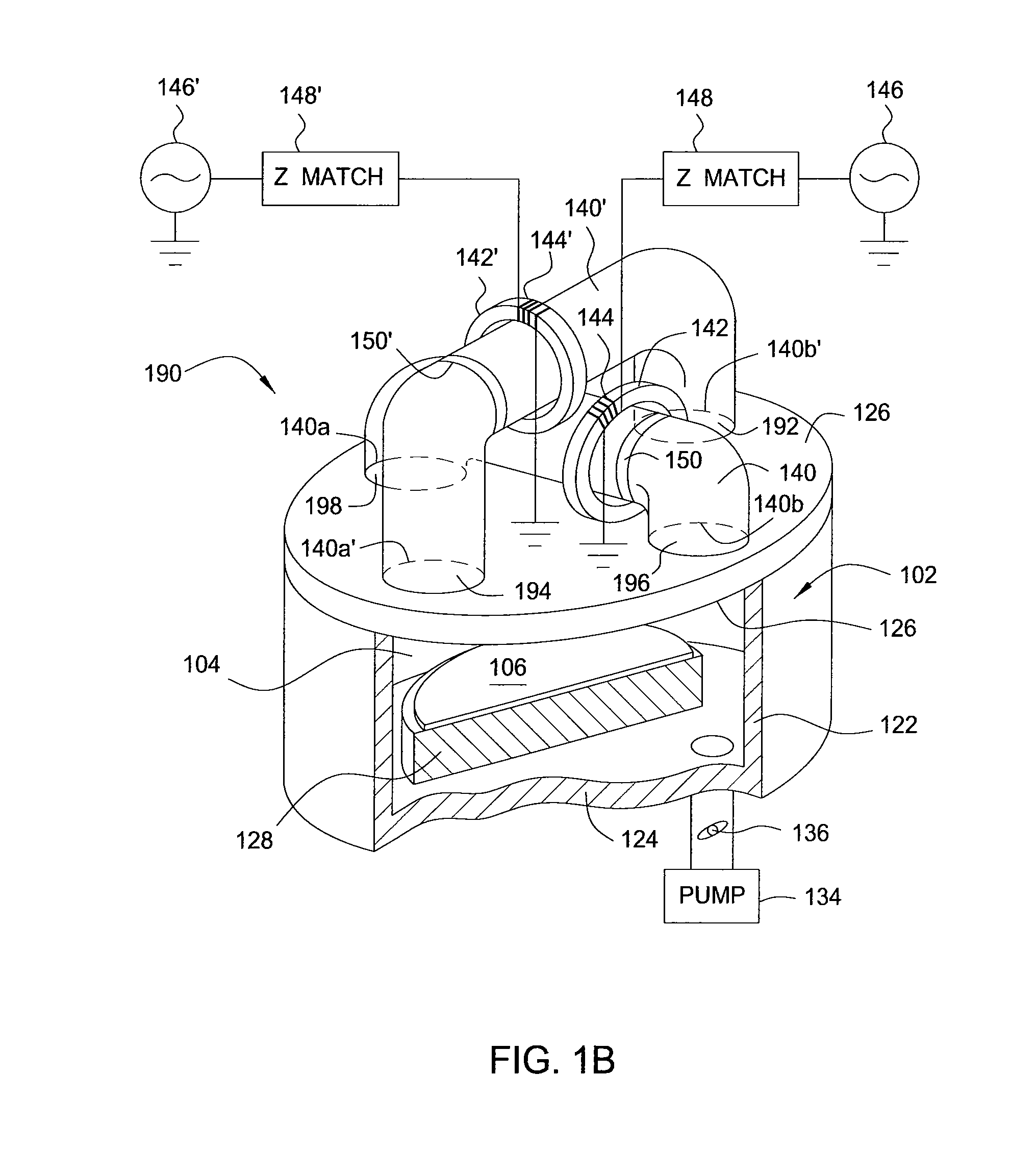

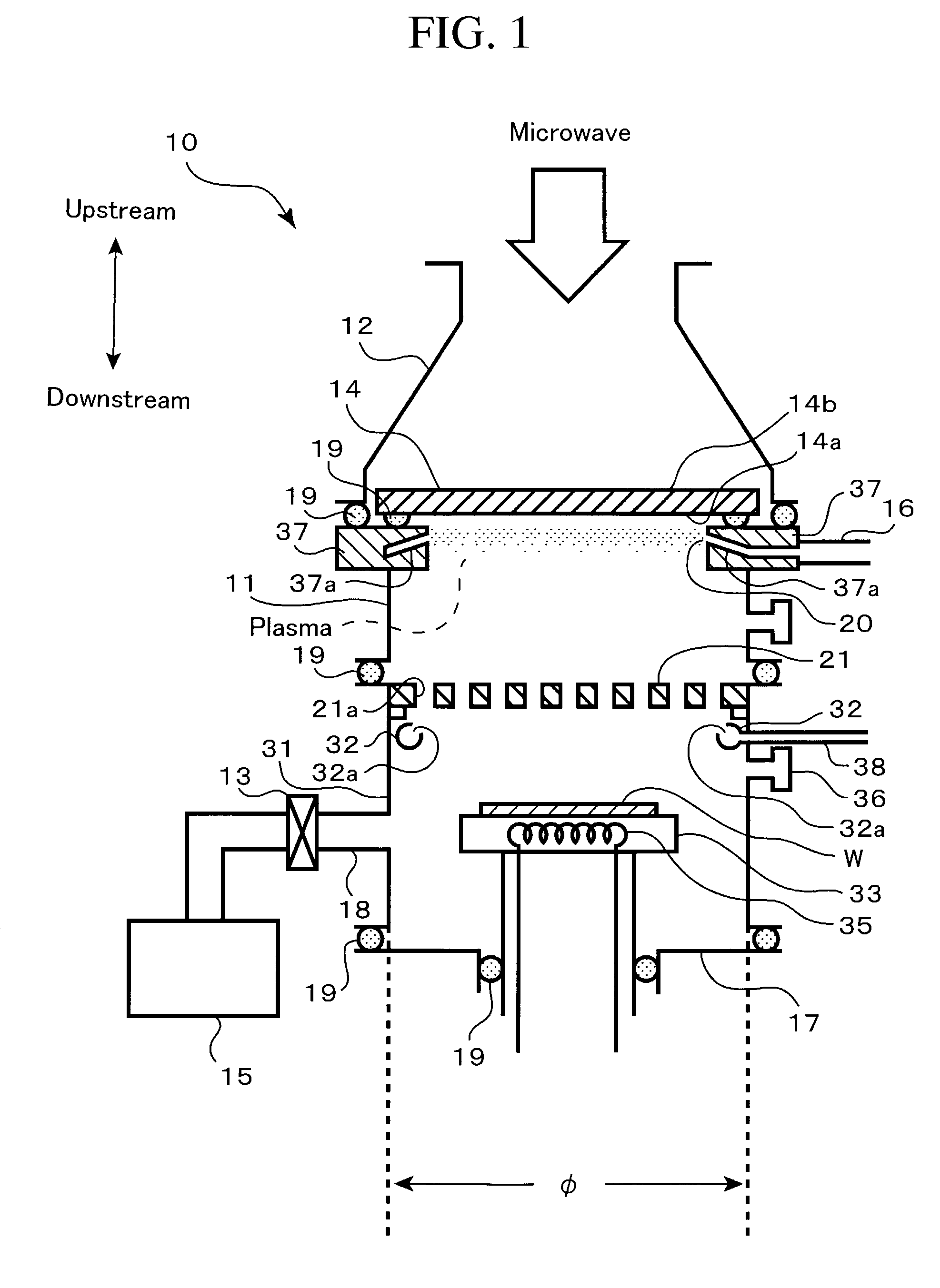

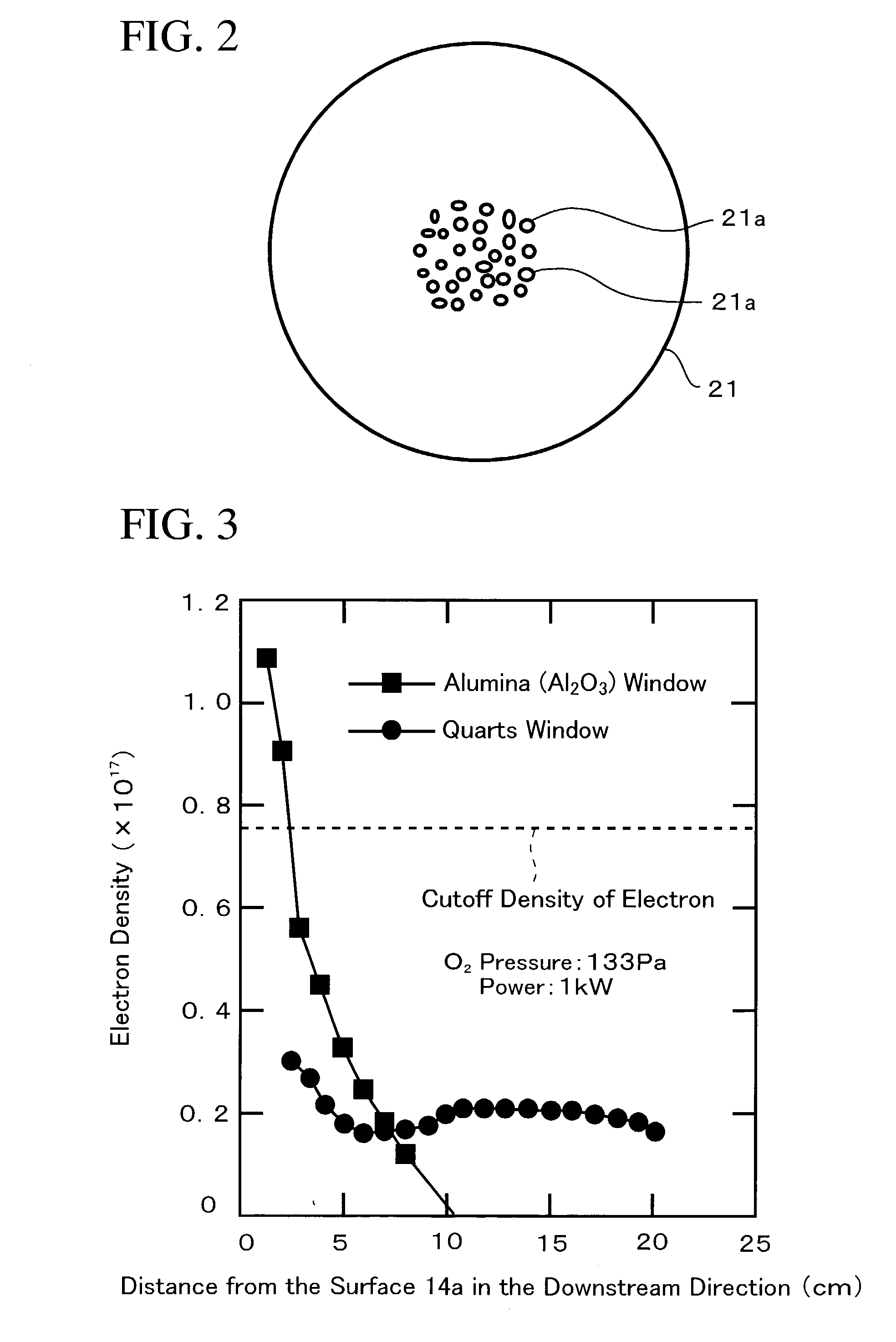

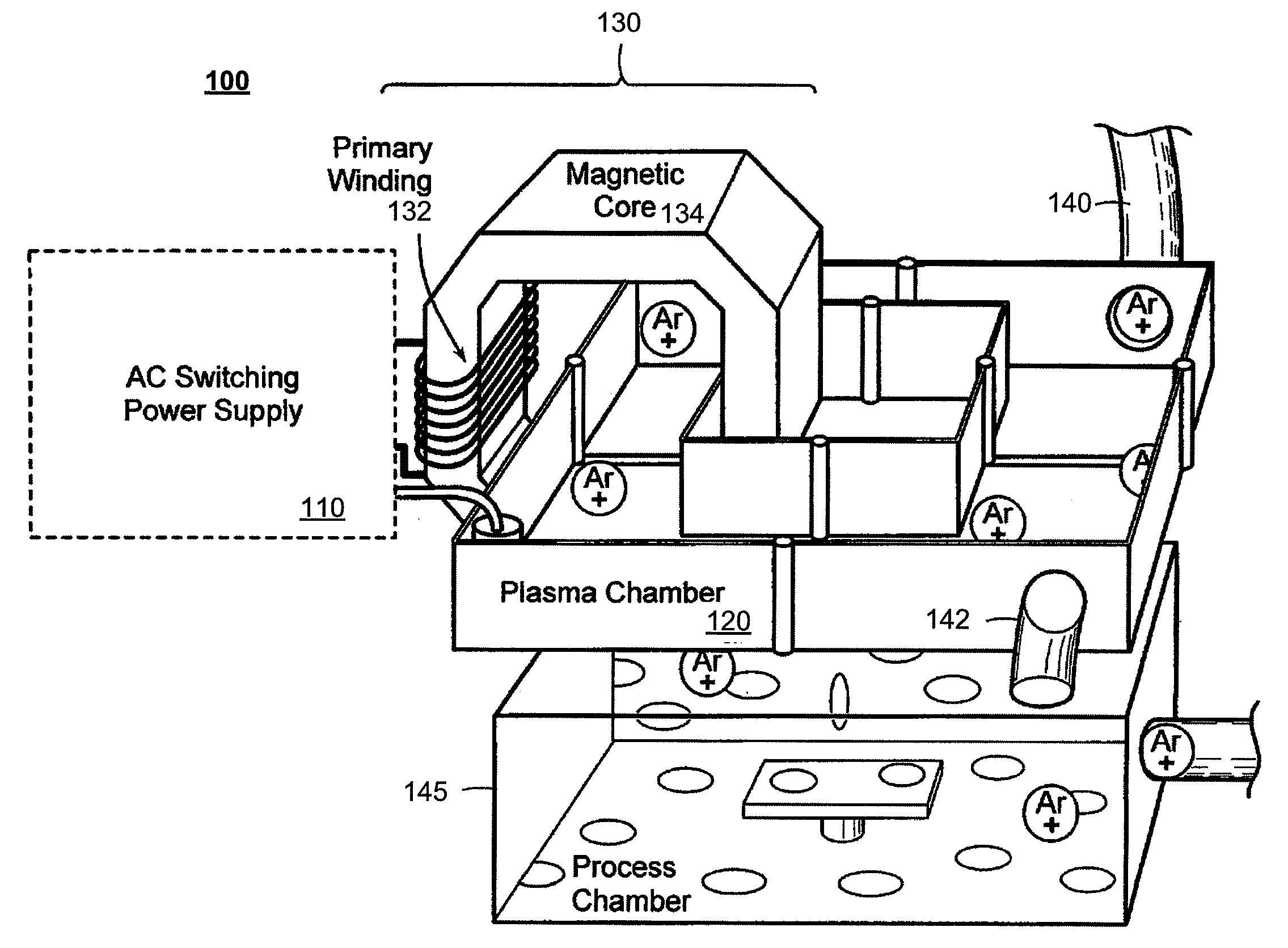

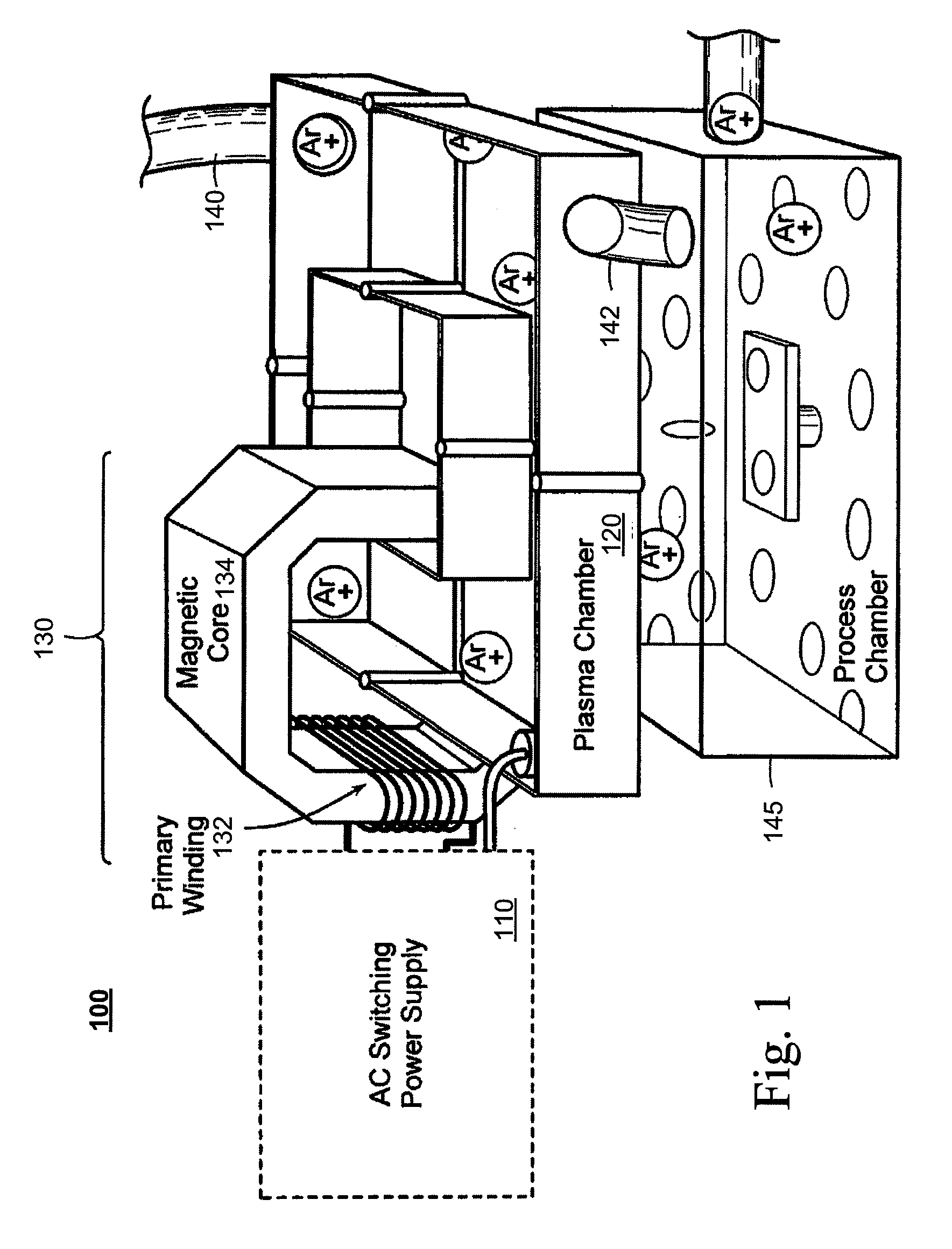

Plasma enhanced chemical processing reactor and method

InactiveUS20020078893A1Improve film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingChemical treatmentReactive gas

A plasma enhanced chemical processing reactor and method. The reactor includes a plasma chamber including a first gas injection manifold and a source of electromagnetic energy. The plasma chamber is in communication with a process chamber which includes a wafer support and a second gas manifold. The plasma generated in the plasma chamber extends into the process chamber and interacts with the reactive gases to deposit a layer of material on the wafer. The reactor also includes a vacuum system for exhausting the reactor. The method includes the steps of generating a plasma within the plasma chamber, introducing at least one gaseous chemical into the process chamber proximate to the wafer support and applying r.f. gradient to induce diffusion of the plasma to the area proximate the wafer support.

Owner:APPLIED MATERIALS INC

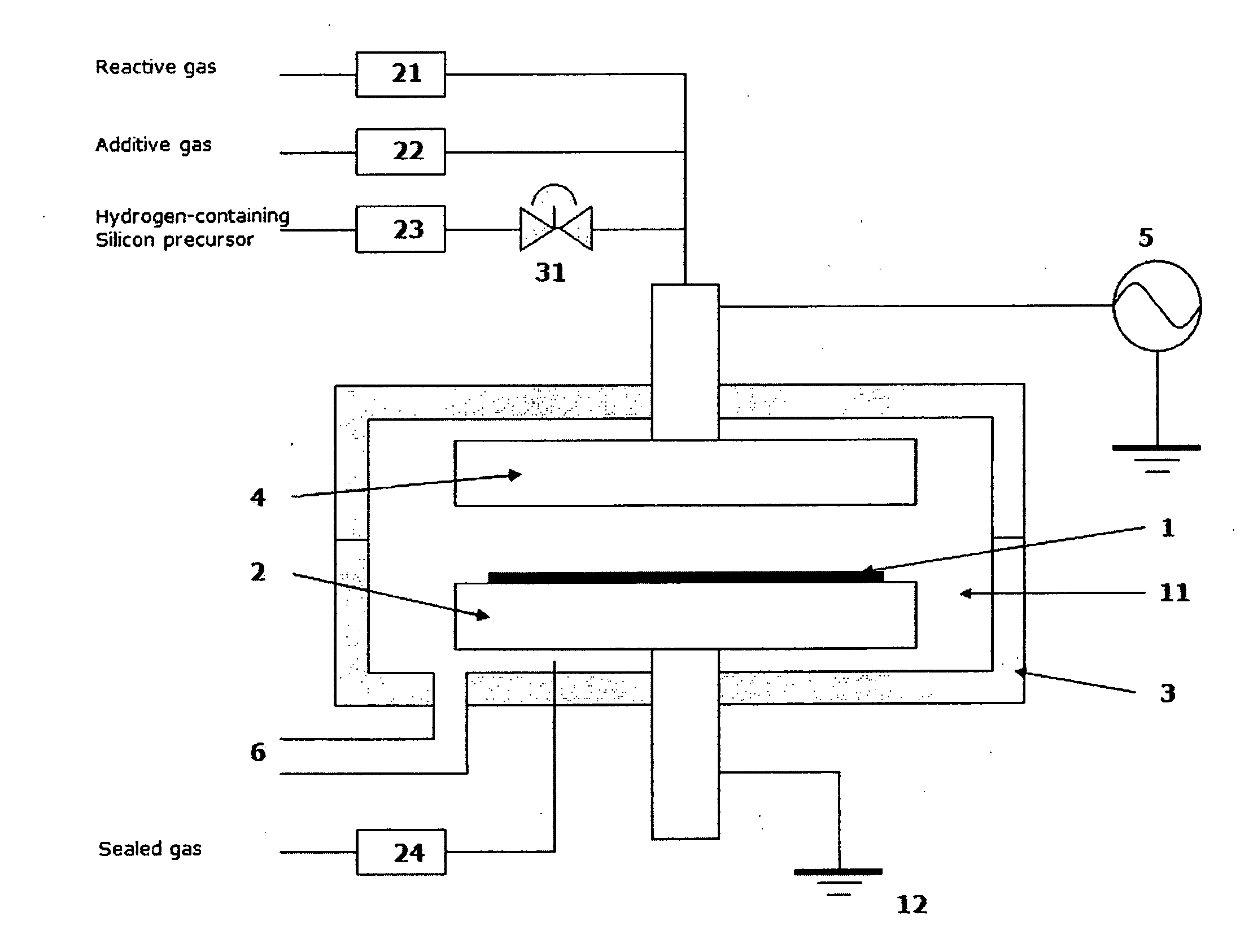

Method for manufacturing photoelectric conversion device

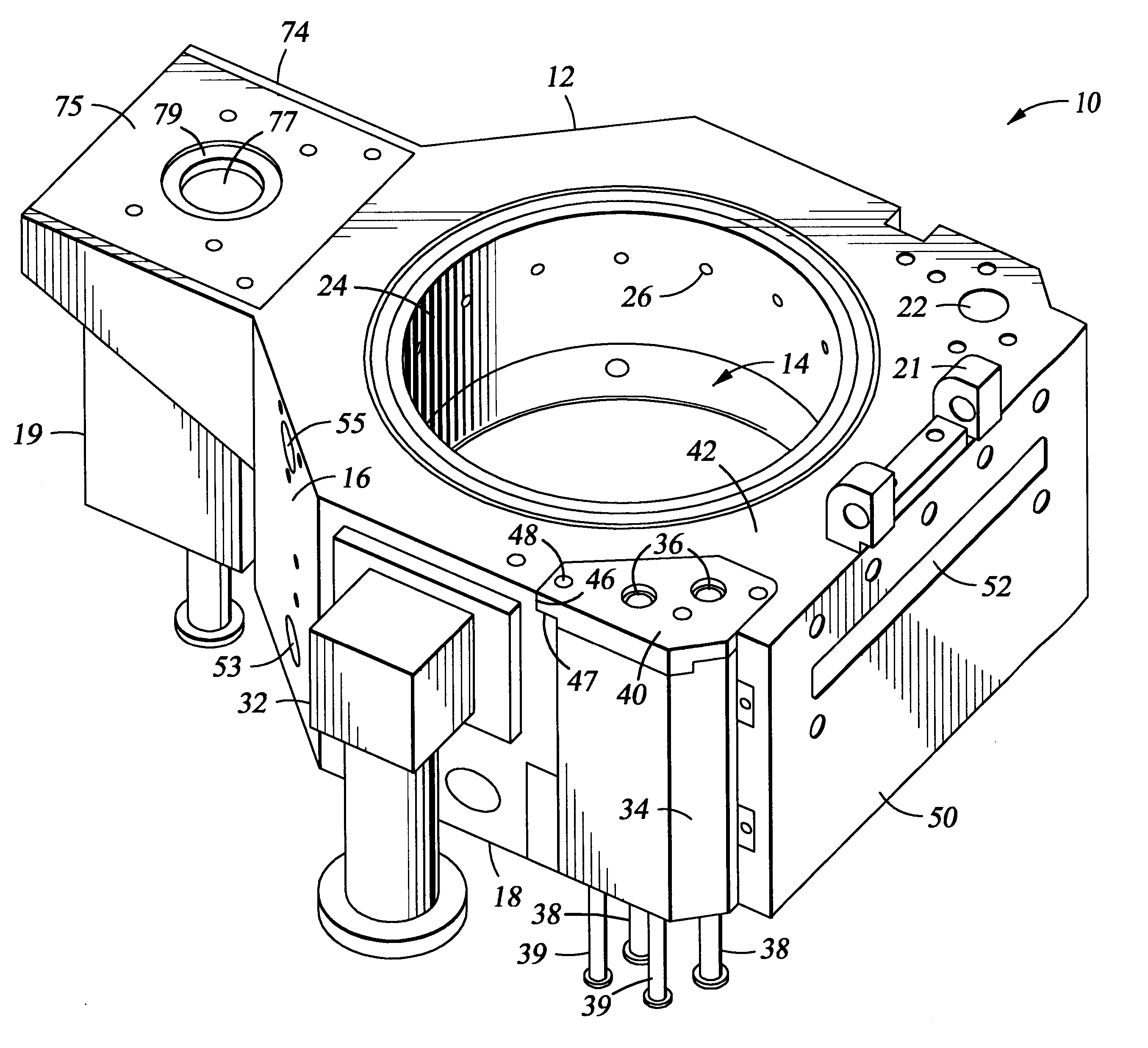

InactiveUS20090029503A1Quality improvementReduce deterioration rateFinal product manufactureSemiconductor/solid-state device manufacturingProduction rateMicrowave

To form a microcrystalline semiconductor with high quality which can be directly formed at equal to or less than 500° C. over a large substrate with high productivity without decreasing a deposition rate. In addition, to provide a photoelectric conversion device which employs the microcrystalline semiconductor as a photoelectric conversion layer. A reactive gas containing helium is supplied to a treatment chamber which is surrounded by a plurality of juxtaposed waveguides and a wall, the pressure in the treatment chamber is maintained at an atmospheric pressure or a subatmospheric pressure, microwave is supplied to a space sandwiched between the juxtaposed waveguides to generate plasma, and a photoelectric conversion layer of a microcrystalline semiconductor is deposited over a substrate which is placed in the treatment chamber.

Owner:SEMICON ENERGY LAB CO LTD

Showerhead for film depositing vacuum equipment

ActiveUS9315897B2Shorten the lengthAccurate supplySpraying apparatusSemiconductor/solid-state device manufacturingReactive gasMixed gas

A showerhead for film-depositing vacuum equipment having an effect shortening the length of injection tubes for a reactive gas is presented. The injection tubes extend from the bottom of a reactive gas showerhead module, and two different kinds of reactive gases are mixed with an injection support gas within a reactive showerhead module so as to inject the mixed gas. The showerhead for film-depositing vacuum equipment includes the reactive gas showerhead module above a cooling jacket and a purge gas showerhead module above the reactive gas showerhead module. The injection tubes of the reactive gas showerhead module pass through the cooling jacket disposed below the reactive gas showerhead module, and the injection tubes of the purge gas showerhead module pass through the reactive gas showerhead module disposed below the purge gas showerhead module, thereby enabling the purge gas to flow into a purge gas redistribution space defined above the cooling jacket.

Owner:KOREA INST OF IND TECH

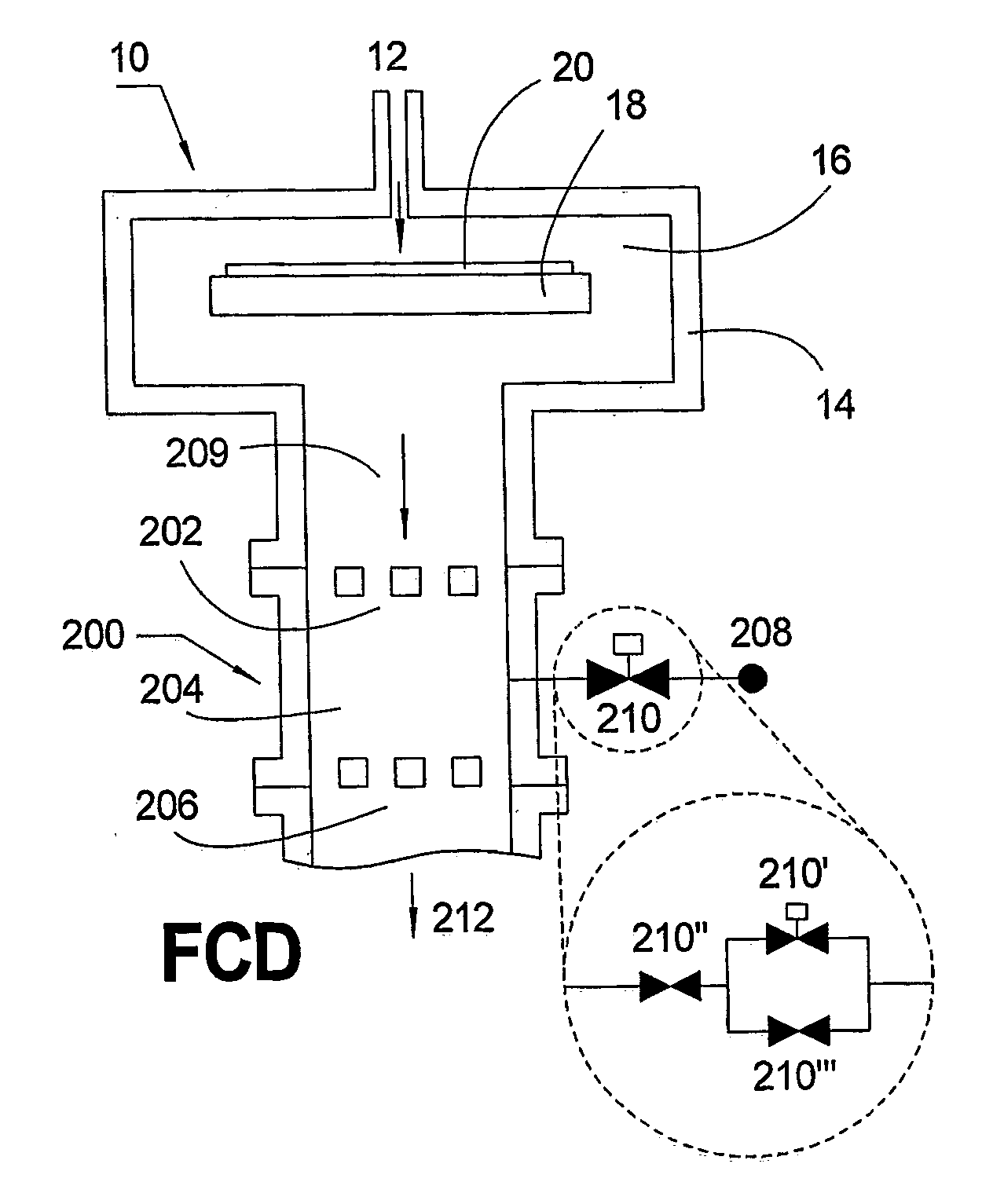

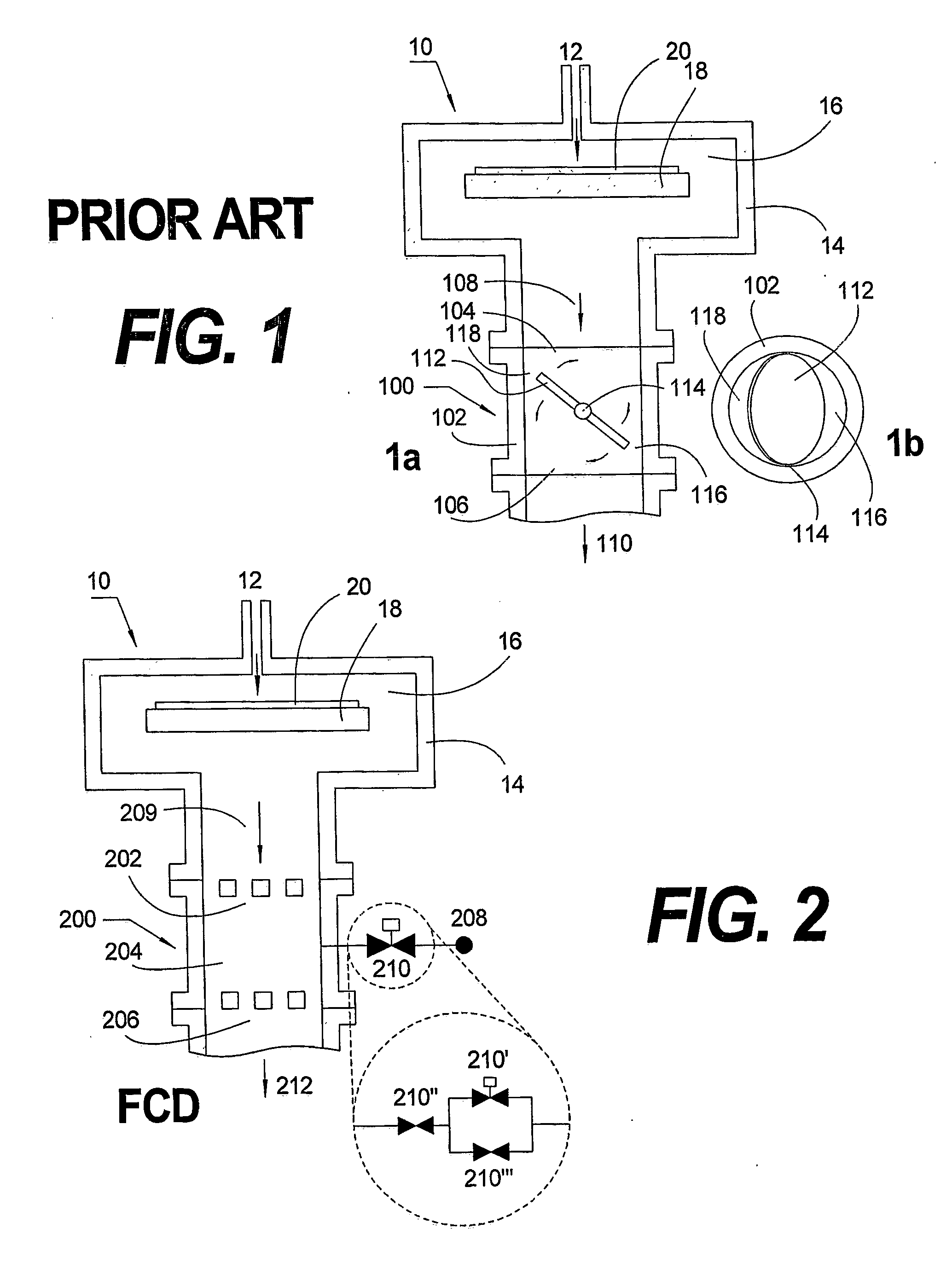

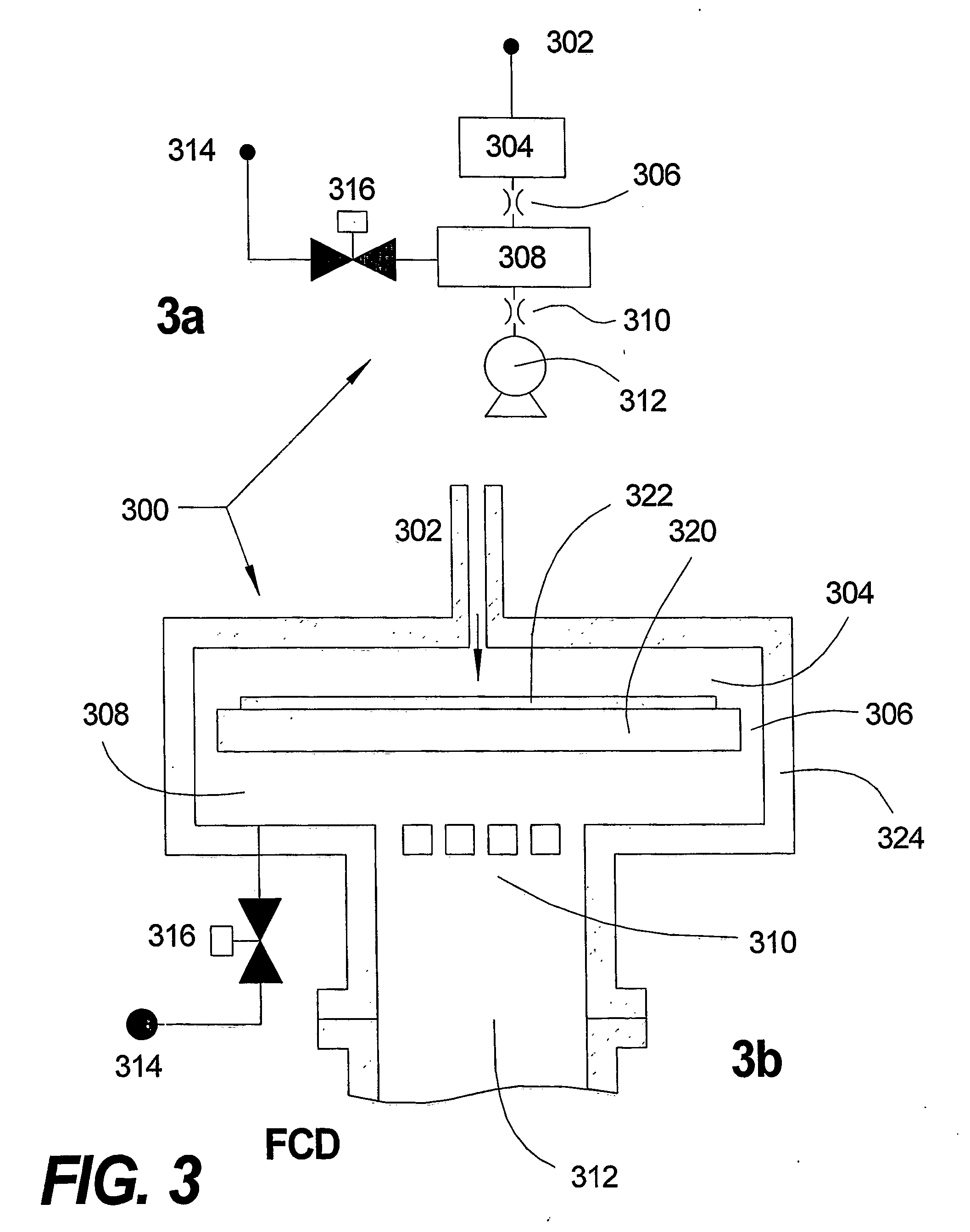

Apparatus and method for downstream pressure control and sub-atmospheric reactive gas abatement

InactiveUS20070012402A1Rapid responseOptimized and smooth flow passageSemiconductor/solid-state device manufacturingPipeline systemsReactive gasStream flow

A sub-atmospheric downstream pressure control apparatus (200) includes a first flow restricting element (FRE) (202); a pressure control chamber (PCC) (204) located in serial fluidic communication downstream from the first FRE; a second FRE (206) located in serial fluidic communication downstream from the PCC; a gas source (208); and a flow controlling device (210) in serial fluidic communication downstream from the gas source and upstream from the PCC.

Owner:SUNDEW TECH

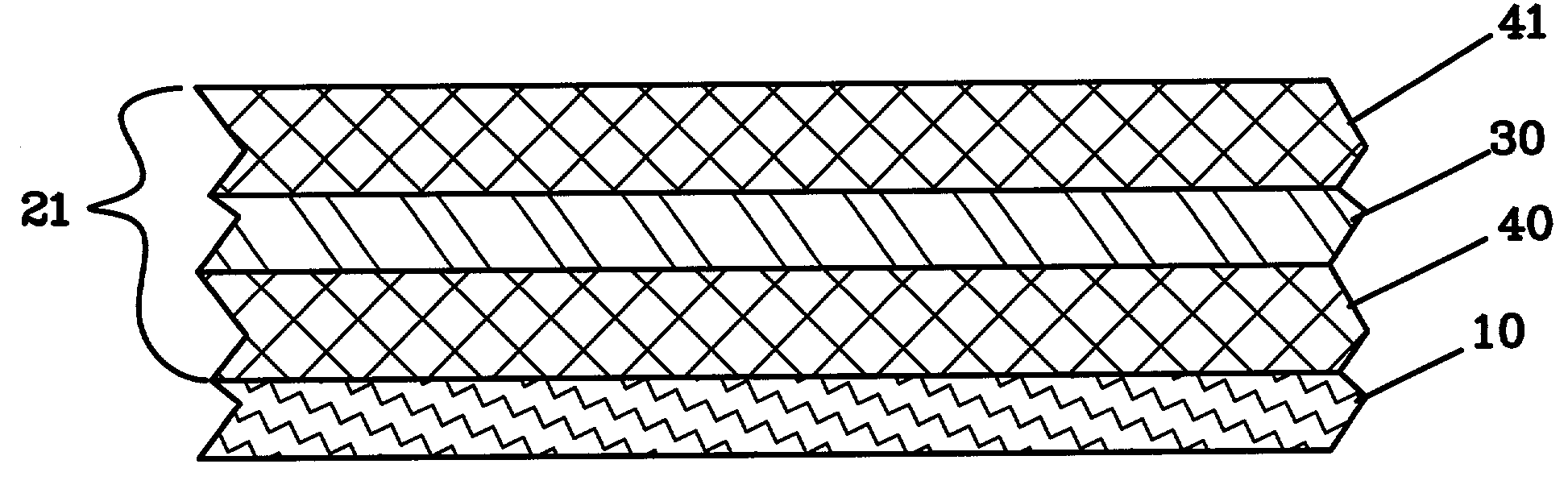

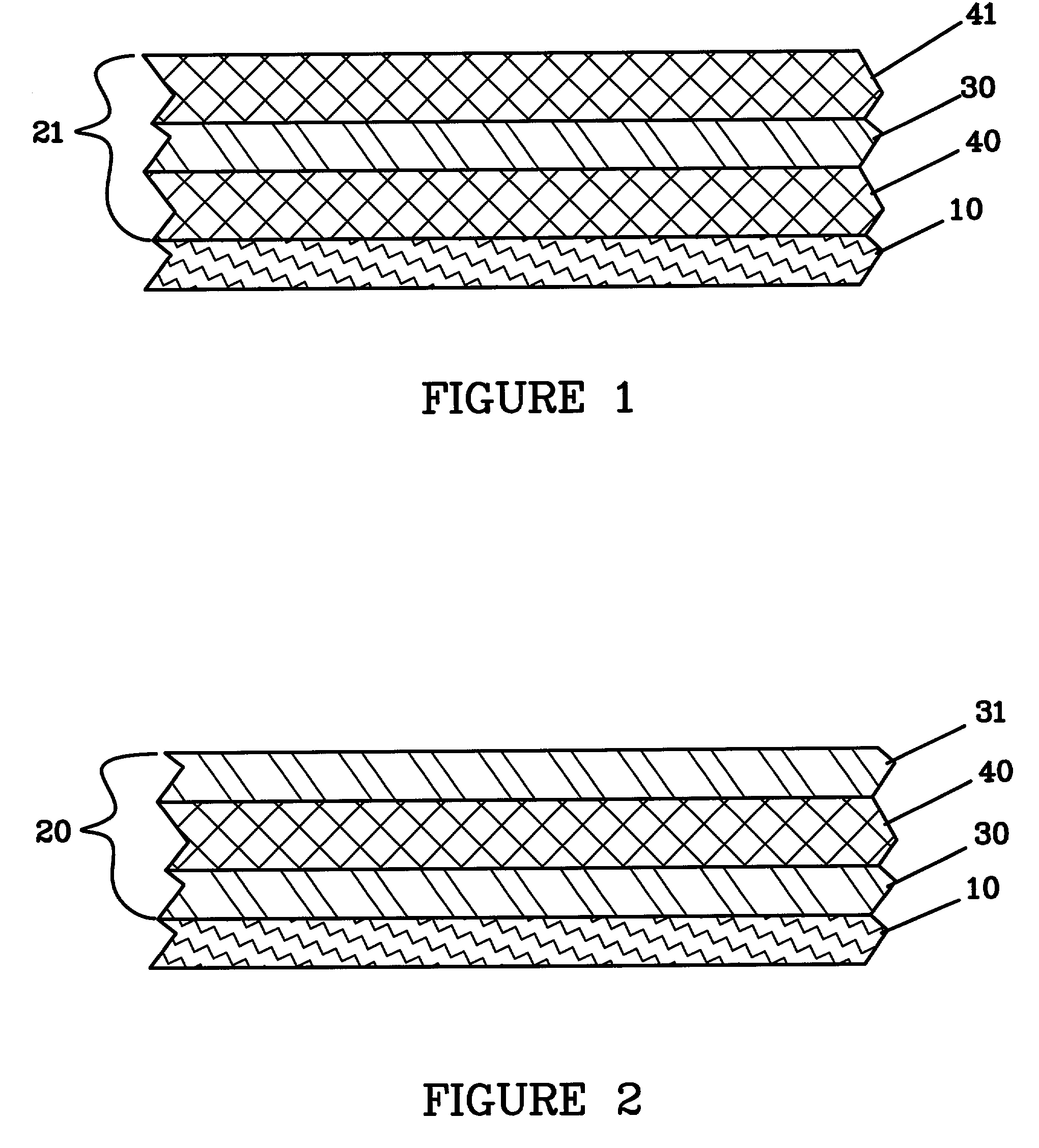

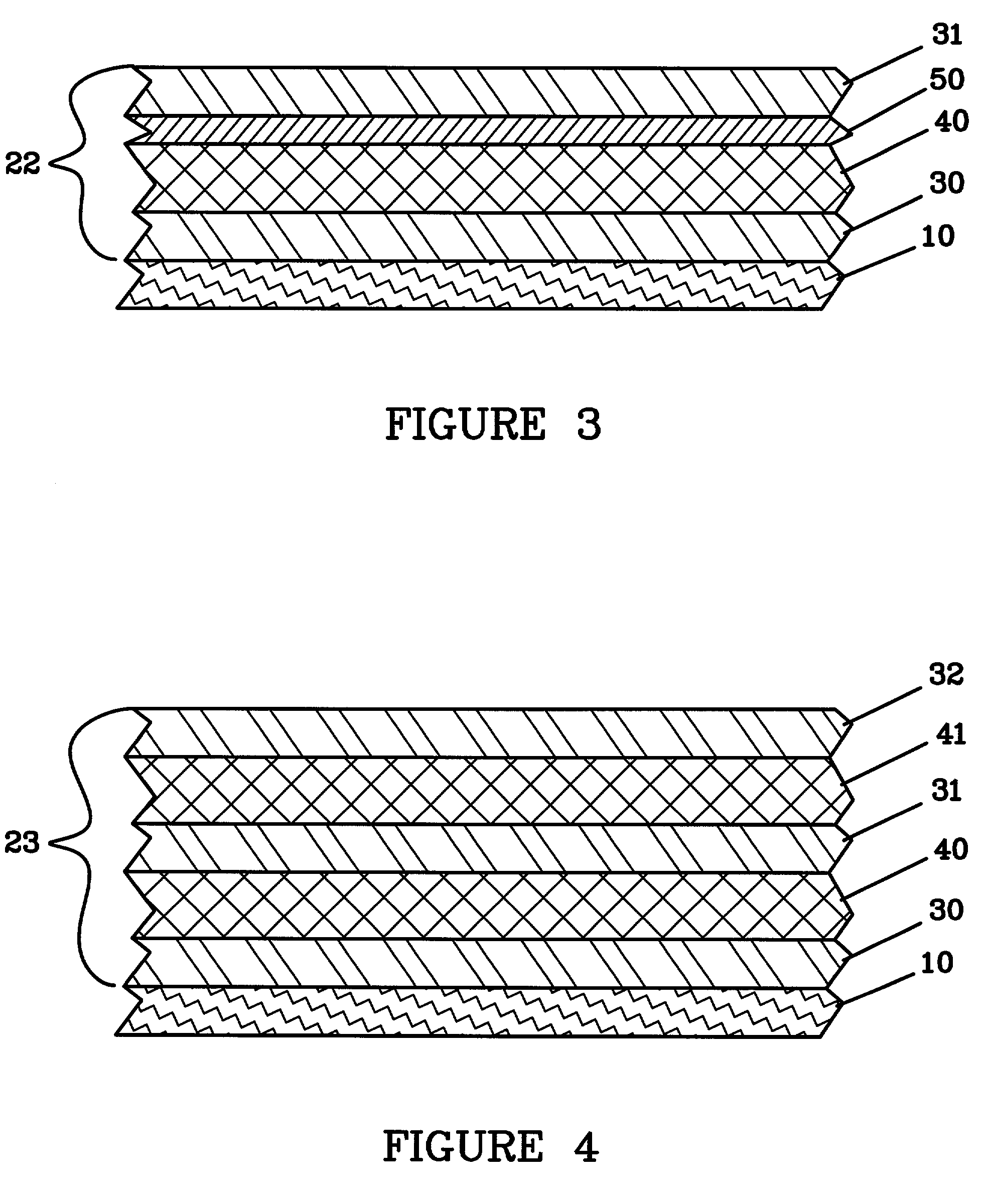

Lithium anodes for electrochemical cells

InactiveUS7247408B2Light weightFinal product manufactureElectrode carriers/collectorsLithium metalReactive gas

Provided is an anode for use in electrochemical cells, wherein the anode active layer has a first layer comprising lithium metal and a multi-layer structure comprising single ion conducting layers and polymer layers in contact with the first layer comprising lithium metal or in contact with an intermediate protective layer, such as a temporary protective metal layer, on the surface of the lithium-containing first layer. Another aspect of the invention provides an anode active layer formed by the in-situ deposition of lithium vapor and a reactive gas. The anodes of the current invention are particularly useful in electrochemical cells comprising sulfur-containing cathode active materials, such as elemental sulfur.

Owner:SION POWER CORP

Removal of surface dopants from a substrate

InactiveUS20090162996A1Semiconductor/solid-state device detailsSolid-state devicesDopantHigh concentration

A method and apparatus for removing excess dopant from a doped substrate is provided. In one embodiment, a substrate is doped by surfaced deposition of dopant followed by formation of a capping layer and thermal diffusion drive-in. A reactive etchant mixture is provided to the process chamber, with optional plasma, to etch away the capping layer and form volatile compounds by reacting with excess dopant. In another embodiment, a substrate is doped by energetic implantation of dopant. A reactive gas mixture is provided to the process chamber, with optional plasma, to remove excess dopant adsorbed on the surface and high-concentration dopant near the surface by reacting with the dopant to form volatile compounds. The reactive gas mixture may be provided during thermal treatment, or it may be provided before or after at temperatures different from the thermal treatment temperature. The volatile compounds are removed. Substrates so treated do not form toxic compounds when stored or transported outside process equipment.

Owner:APPLIED MATERIALS INC

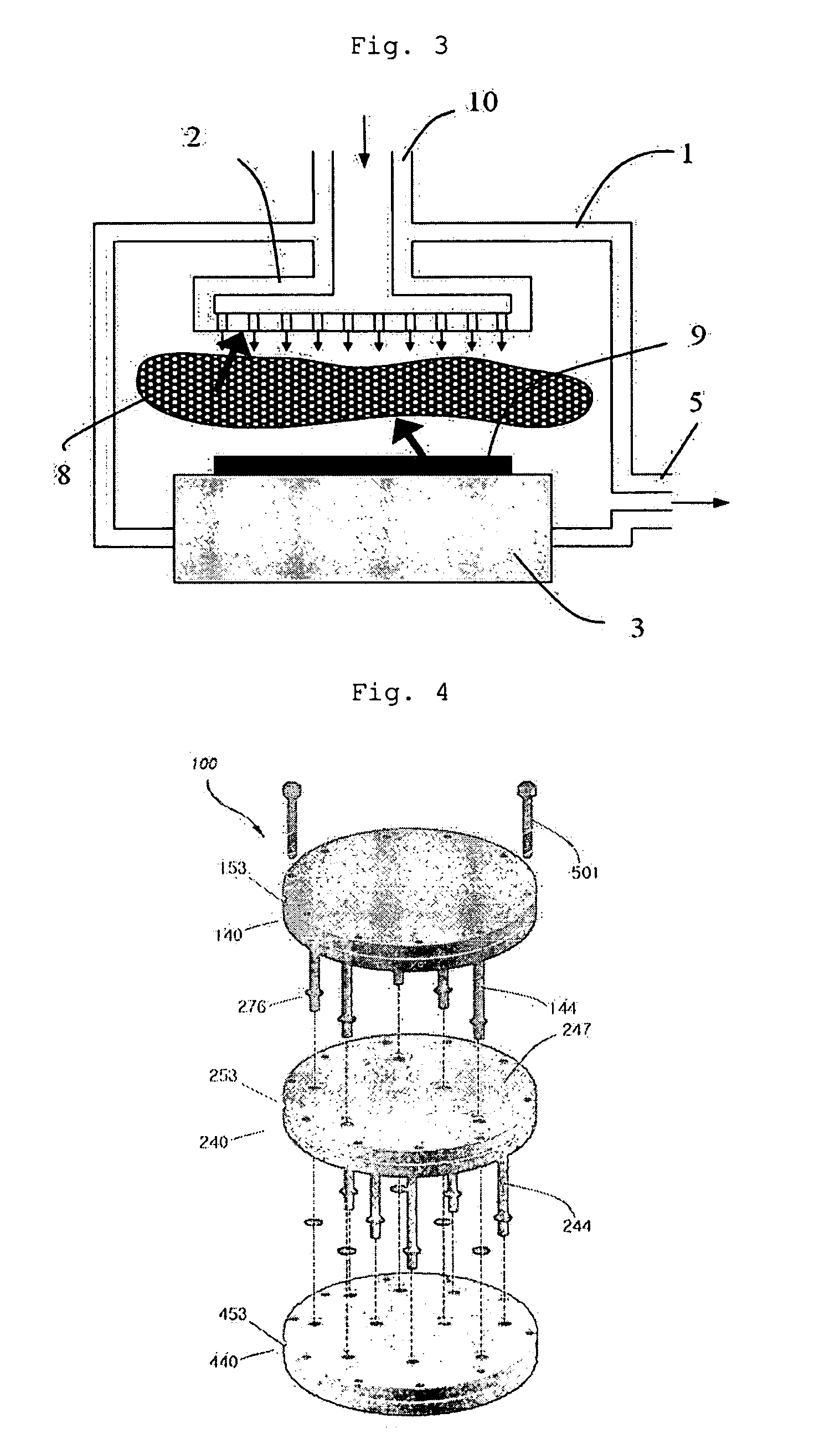

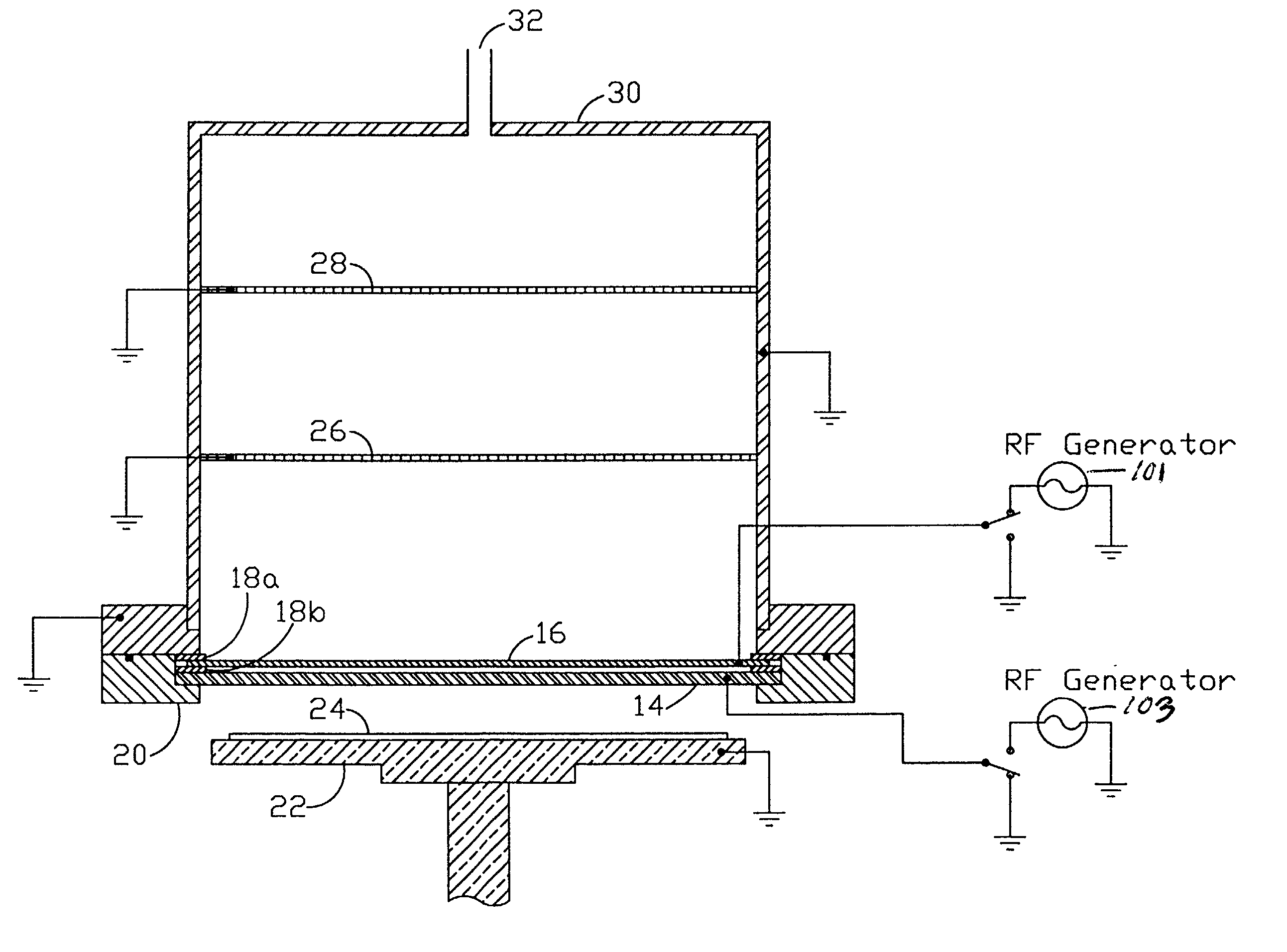

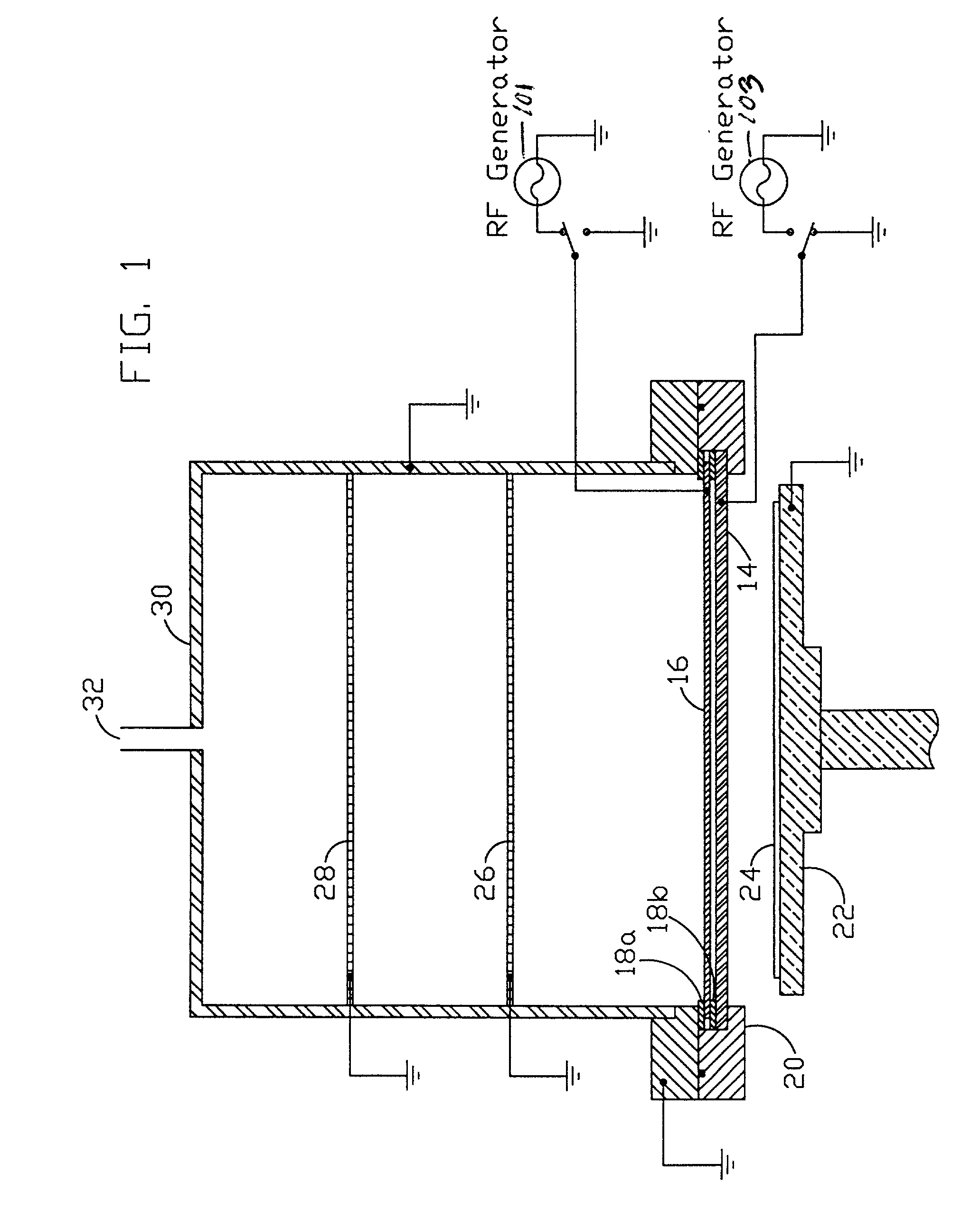

Low-temperature compatible wide-pressure-range plasma flow device

InactiveUS20020129902A1Electric discharge tubesSemiconductor/solid-state device manufacturingGas phaseReactive gas

The invention is embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and a substrate or work piece is placed in the gas flow downstream of the electrodes, such that said substrate or work piece is substantially uniformly contacted across a large surface area with the reactive gases emanating therefrom. The invention is also embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and one of the grounded electrodes contains a means of mixing in other chemical precursors to combine with the plasma stream, and a substrate or work piece placed in the gas flow downstream of the electrodes, such that said substrate or work piece is contacted by the reactive gases emanating therefrom. In one embodiment, the plasma flow device removes organic materials from a substrate or work piece, and is a stripping or cleaning device. In another embodiment, the plasma flow device kills biological microorganisms on a substrate or work piece, and is a sterilization device. In another embodiment, the plasma flow device activates the surface of a substrate or work piece, and is a surface activation device. In another embodiment, the plasma flow device etches materials from a substrate or work piece, and is a plasma etcher. In another embodiment, the plasma flow device deposits thin films onto a substrate or work piece, and is a plasma-enhanced chemical vapor deposition device or reactor.

Owner:RGT UNIV OF CALIFORNIA

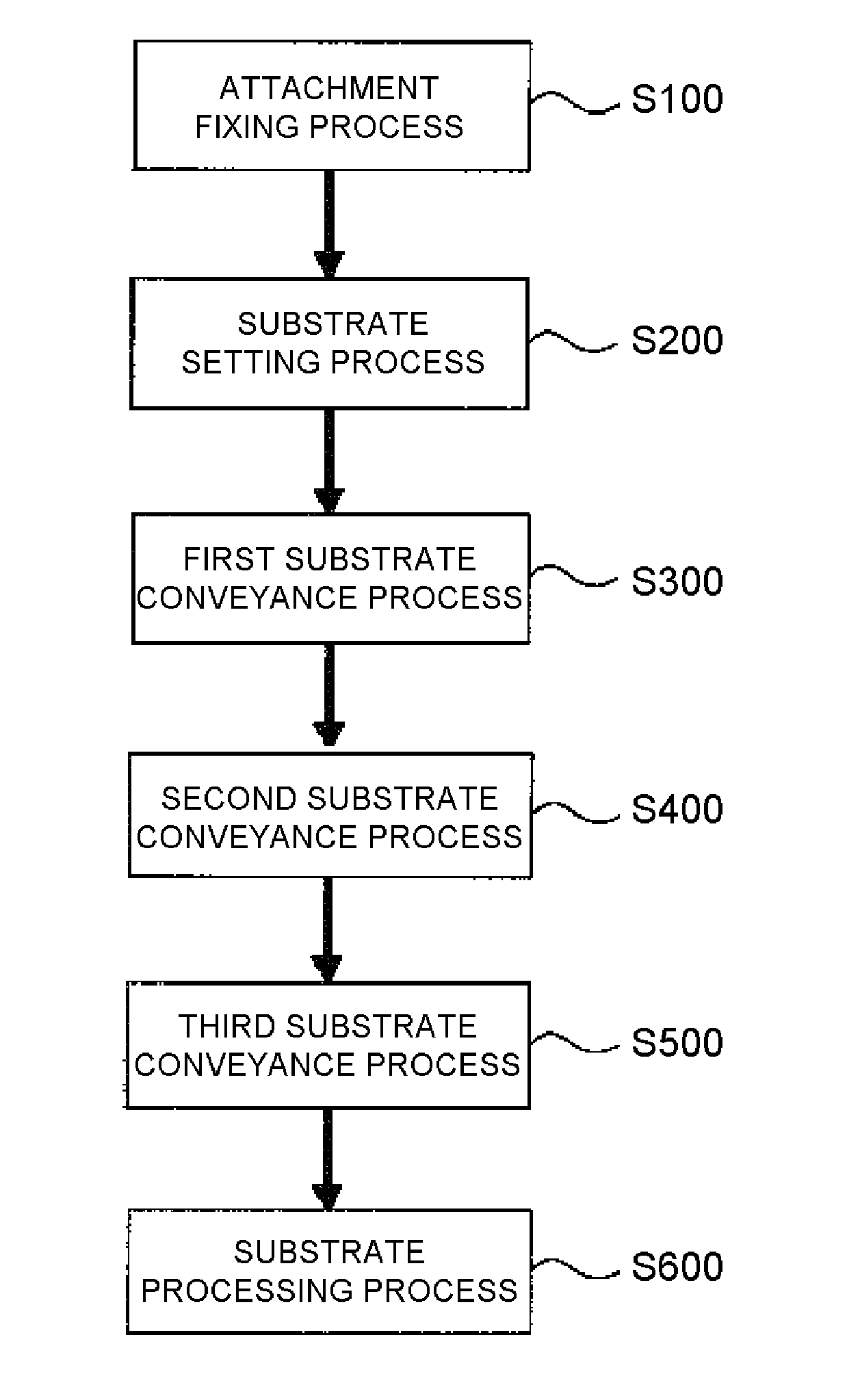

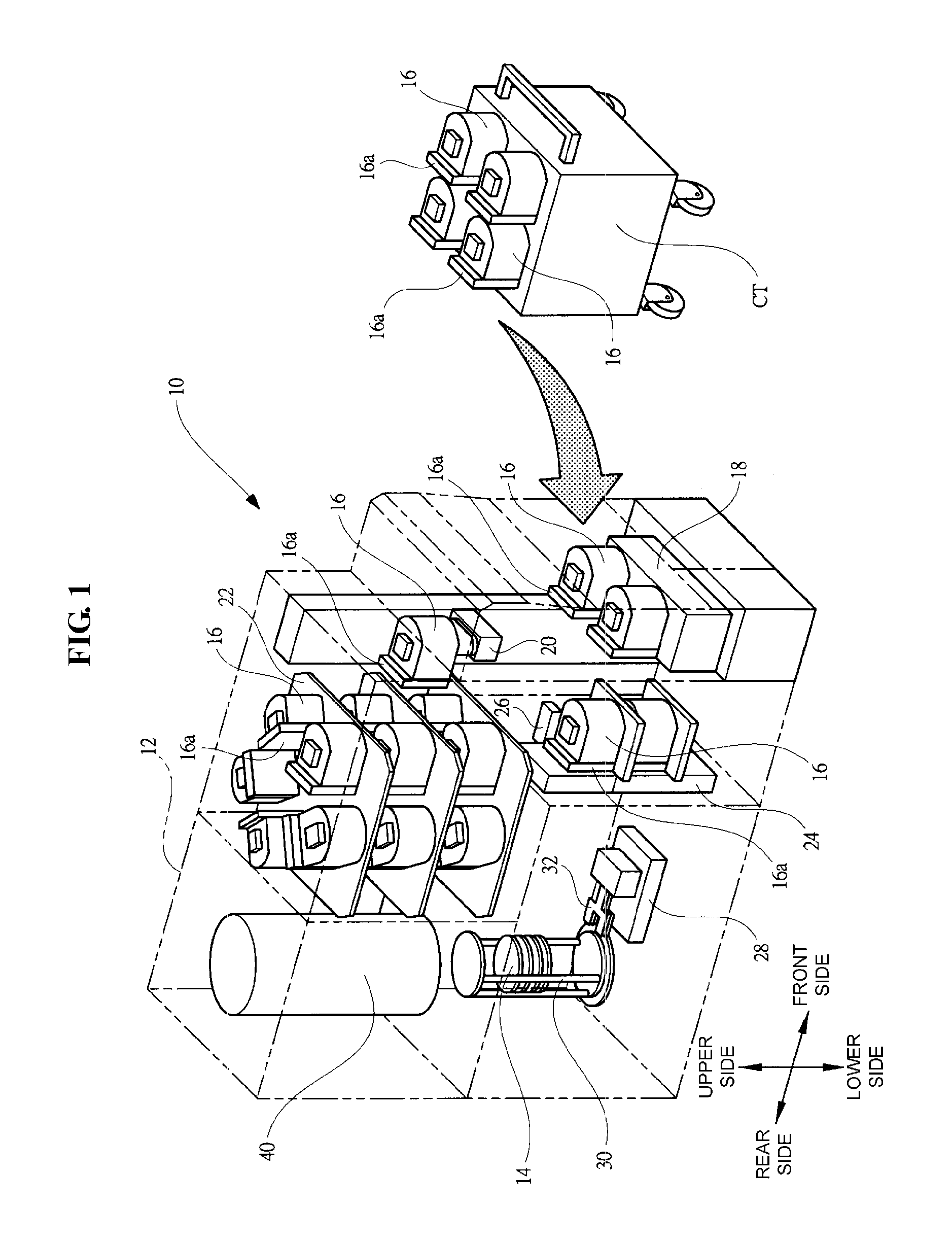

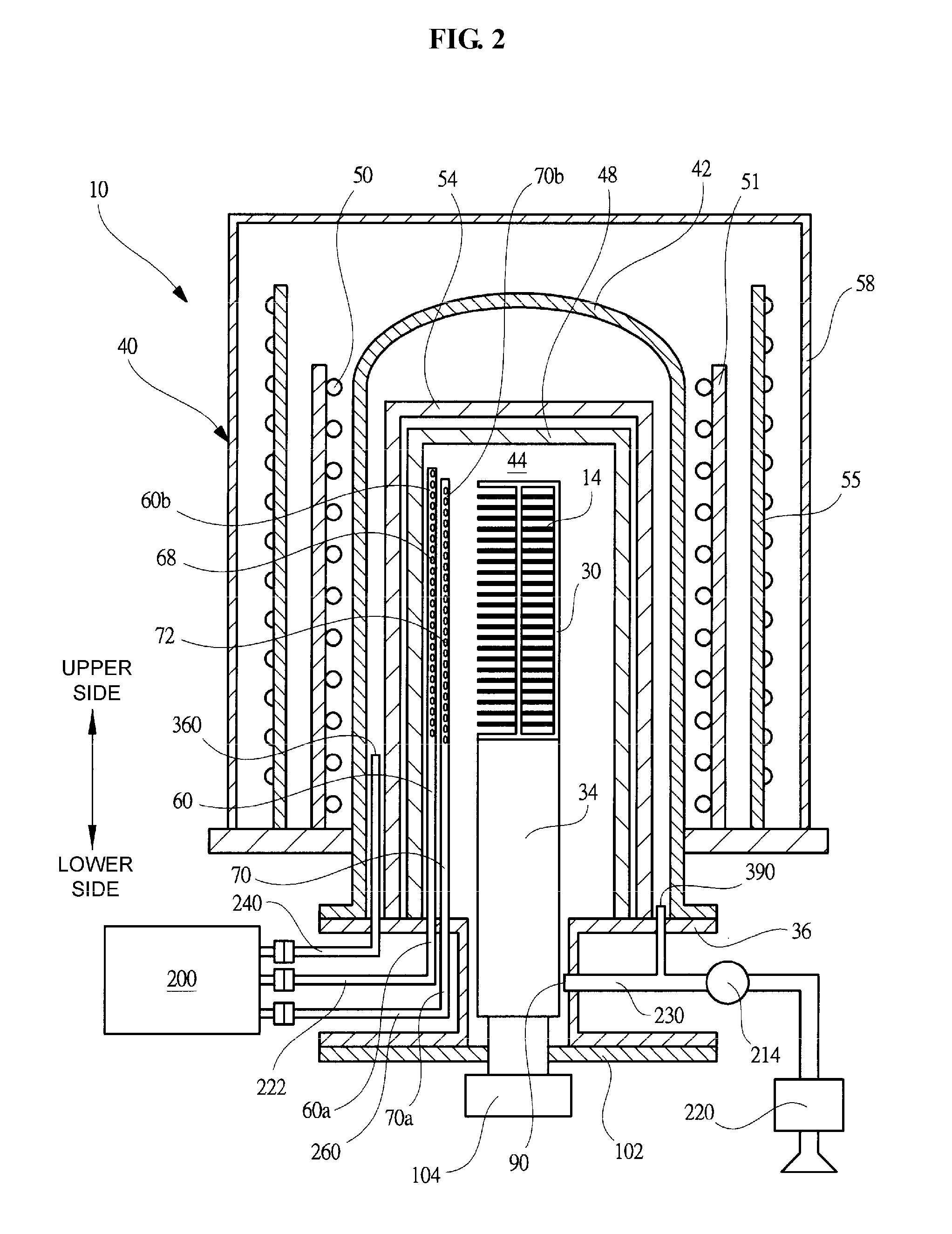

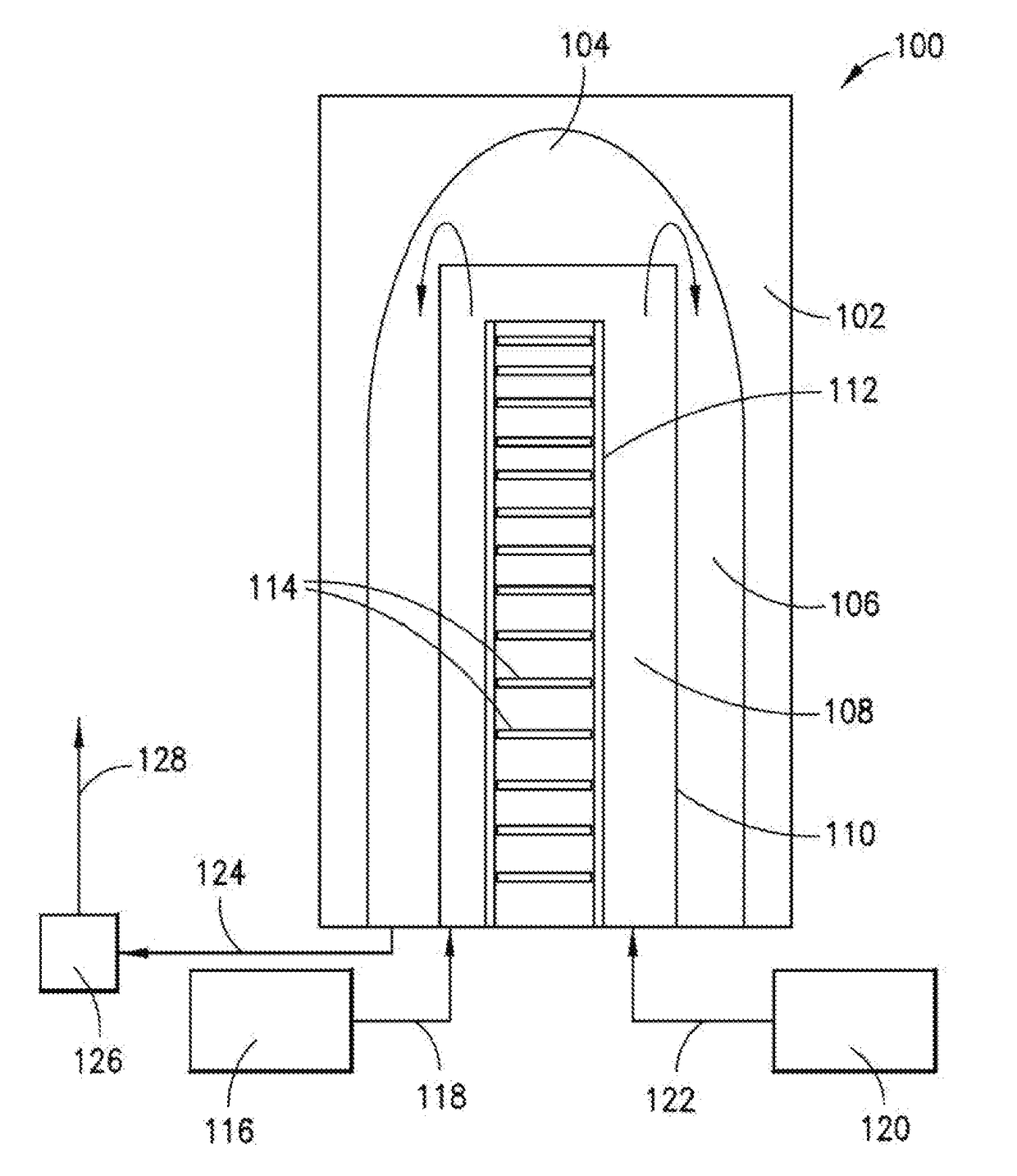

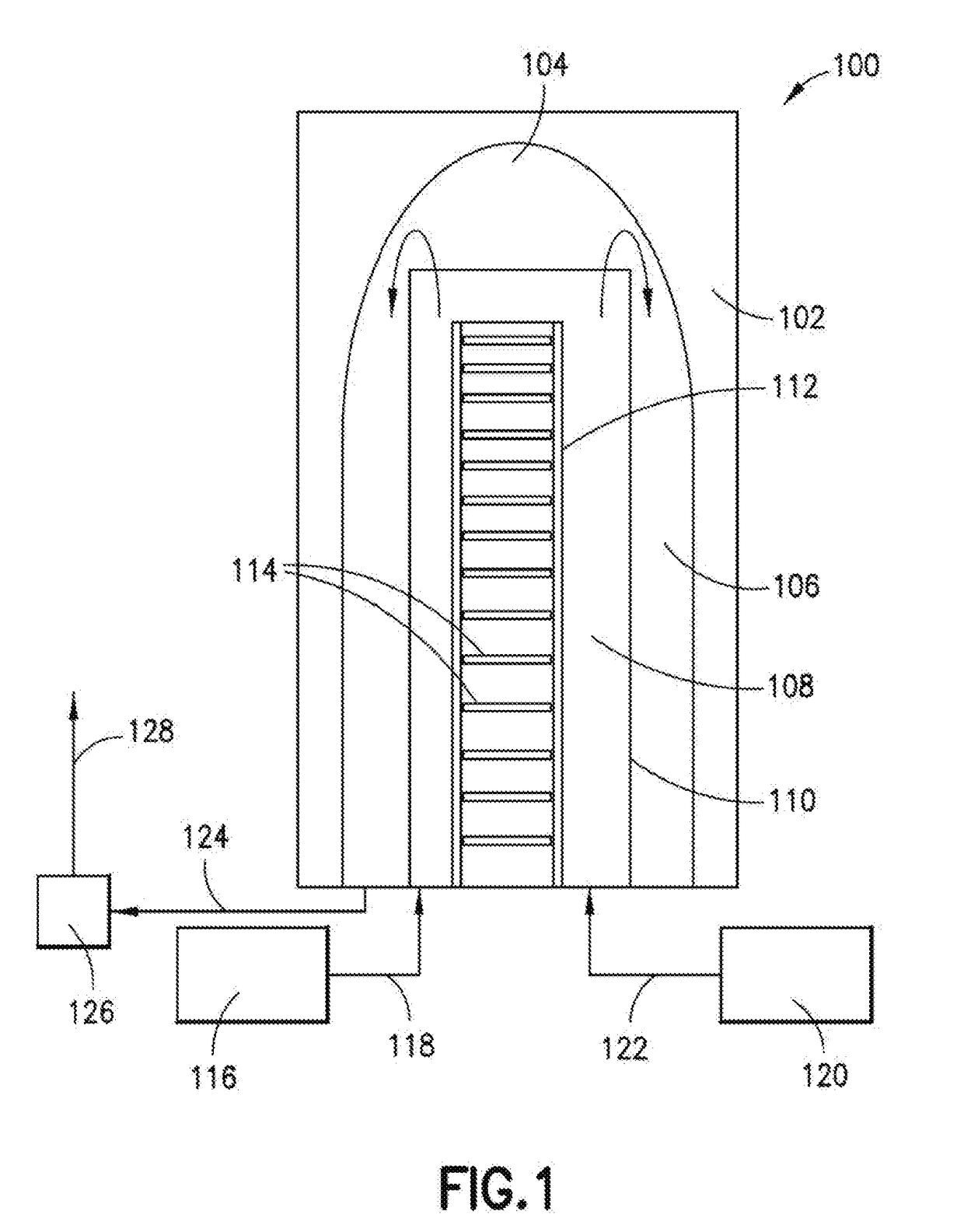

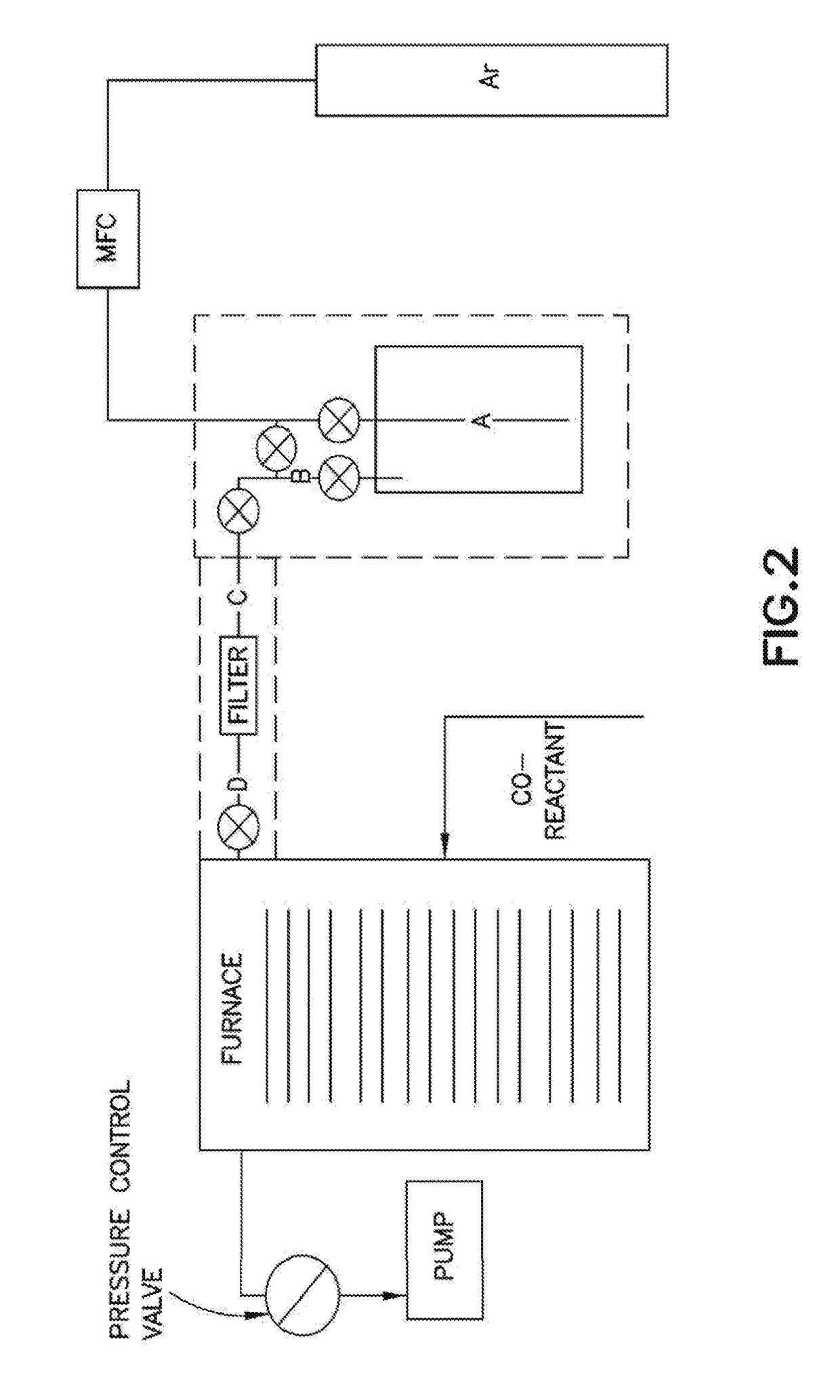

Attachment for substrates having different diameters, substrate processing apparatus, and method of manufacturing substrate or semiconductor device

InactiveUS20120216743A1Low costImprove film-forming precisionPolycrystalline material growthSemiconductor/solid-state device manufacturingReactive gasDevice material

A downsized substrate may be housed in a substrate accommodation vessel (FOUP) constituting a transfer system corresponding to a large diameter substrate. An attachment includes an upper plate and a lower plate supported by a first support groove that can support an 8-inch wafer, and holding columns installed at the upper plate and the lower plate and including a second support groove that can support a 2-inch wafer (if necessary, via a wafer holder and a holder member). Accordingly, the 2-inch wafer can be housed in a pod corresponding to the 8-inch wafer, and the pod, which is a transfer system, can be standardized to reduce cost of a semiconductor manufacturing apparatus. In addition, a distance from each gas supply nozzle to the wafer can be increased to sufficiently mix reactive gases before arrival at the wafer and improve film-forming precision to the wafer.

Owner:KOKUSA ELECTRIC CO LTD

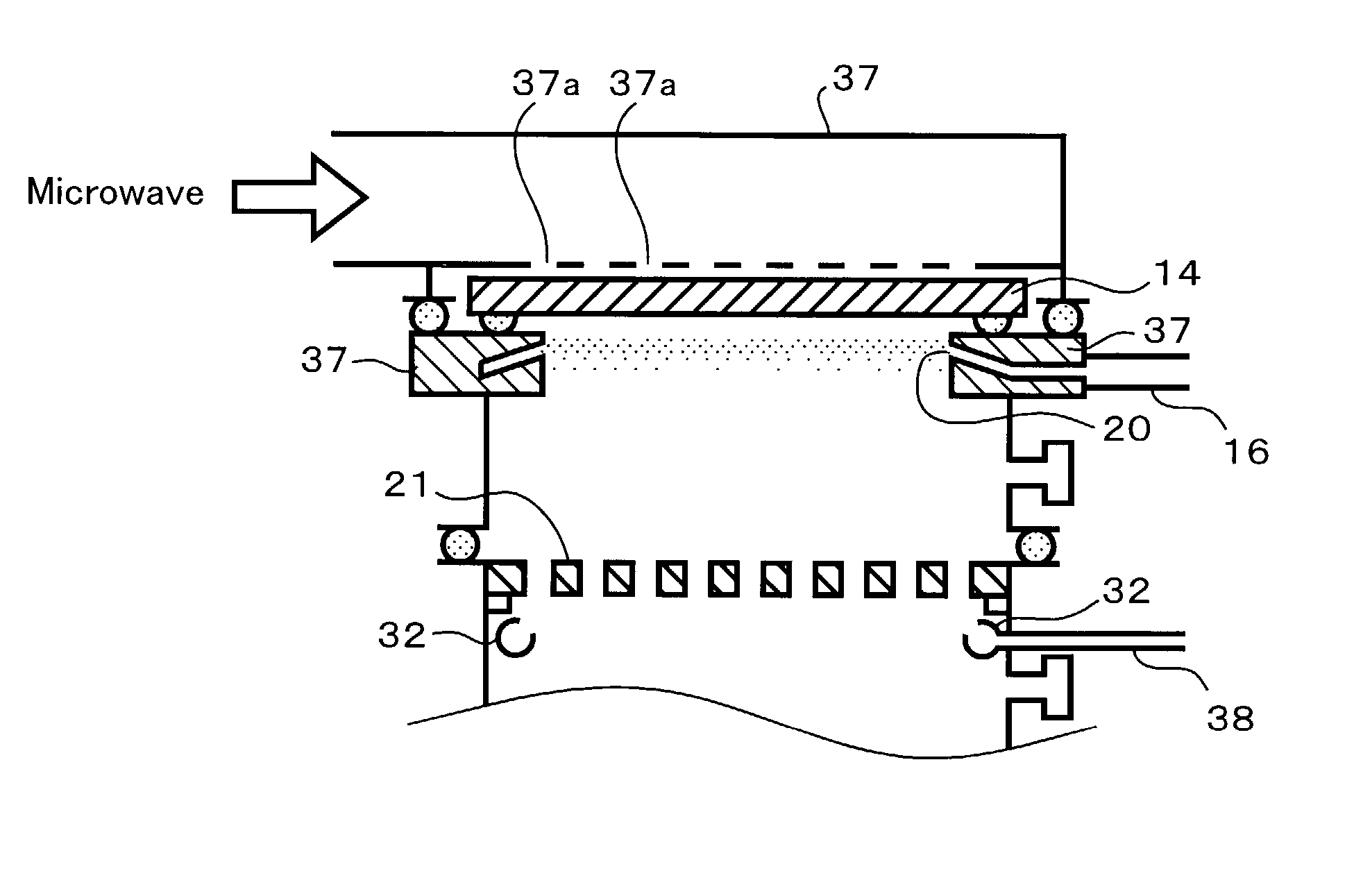

Deposition method, deposition apparatus, and semiconductor device

InactiveUS20030077883A1Avoid it happening againAvoid breakingFrom solid stateSemiconductor/solid-state device detailsMicrowaveReactive gas

To provide a deposition method and a deposition apparatus, in which deposition can be performed under a low temperature and a substrate does not suffer from charge-up damage, and a semiconductor device produced thereby. The deposition method is that reactive gas is made to pass through communication holes and guided toward downstream of the communication holes after the gas is exposed to surface wave of microwave, and it is reacted with silicon compound gas to deposit a silicon-containing film on a substrate arranged in the downstream.

Owner:ARIES RES

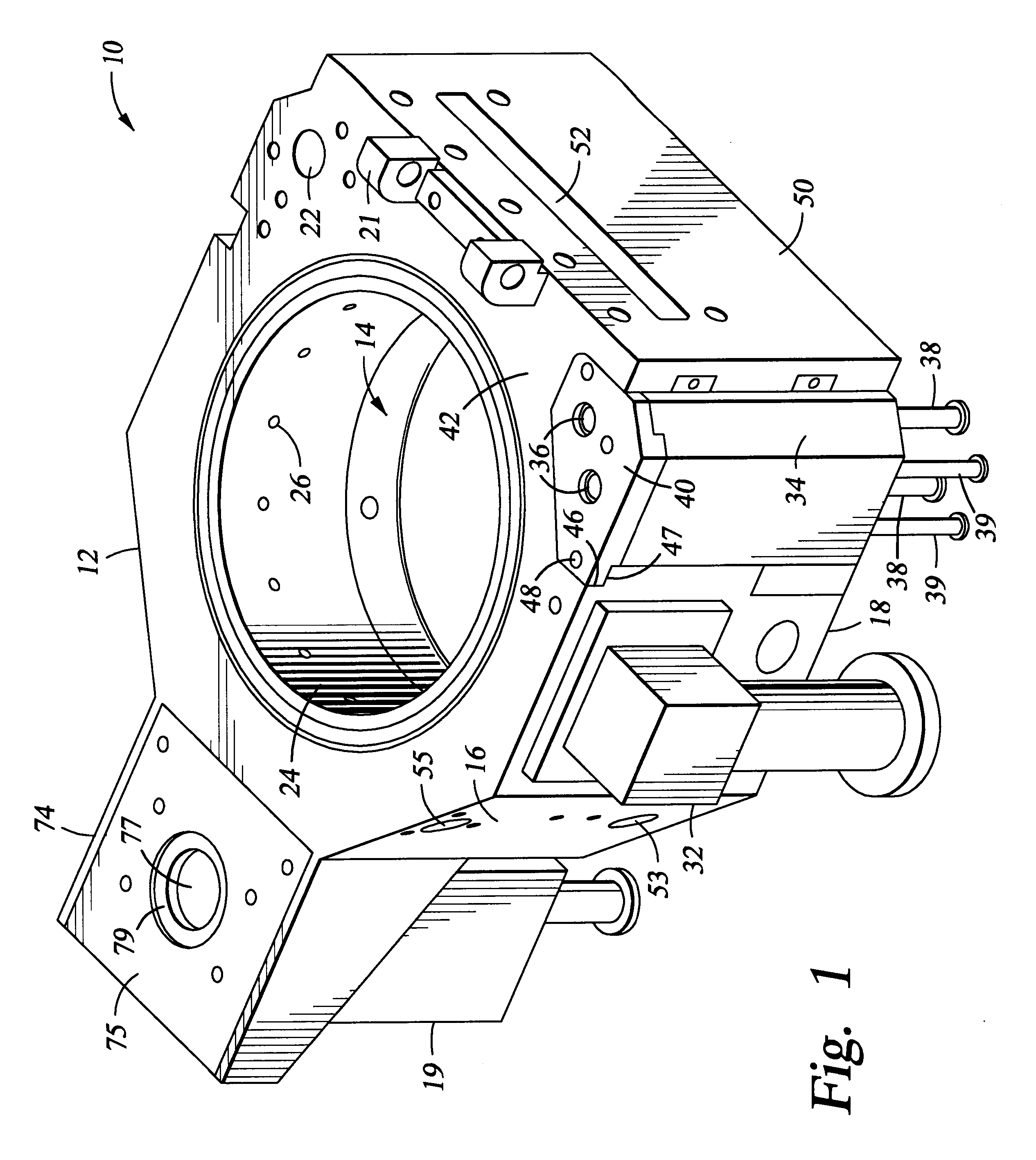

Apparatus and method for depositing low K dielectric materials

The invention provides a deposition system and methods of depositing materials onto substrates. In one aspect, a modular processing chamber is provided which includes a chamber body defining a processing region. The chamber body includes a removable gas feedthrough, an electrical feedthrough, a gas distribution assembly mounted on a chamber lid and a microwave applicator for generating reactive gases remote from the processing region.

Owner:APPLIED MATERIALS INC

Chemical vapor deposition device

A reactor device for chemical vapor deposition includes a reaction chamber having a side wall and a substrate stand having a peripheral surface and a main surface facing a reactive gas injector, the injector and said surface defining a work space therebetween. The substrate stand is arranged in the reaction chamber such as to form an annular passage between the peripheral surface of the substrate stand and the side wall of the reaction chamber. A system for discharging gases is in fluid connection with the reaction chamber. A purge gas injector includes an injection channel leading into the reaction chamber through an annular opening. A laminar flow of purge gas is injected through the annular opening and flows in said annular passage to an opening.

Owner:KOBUS SAS

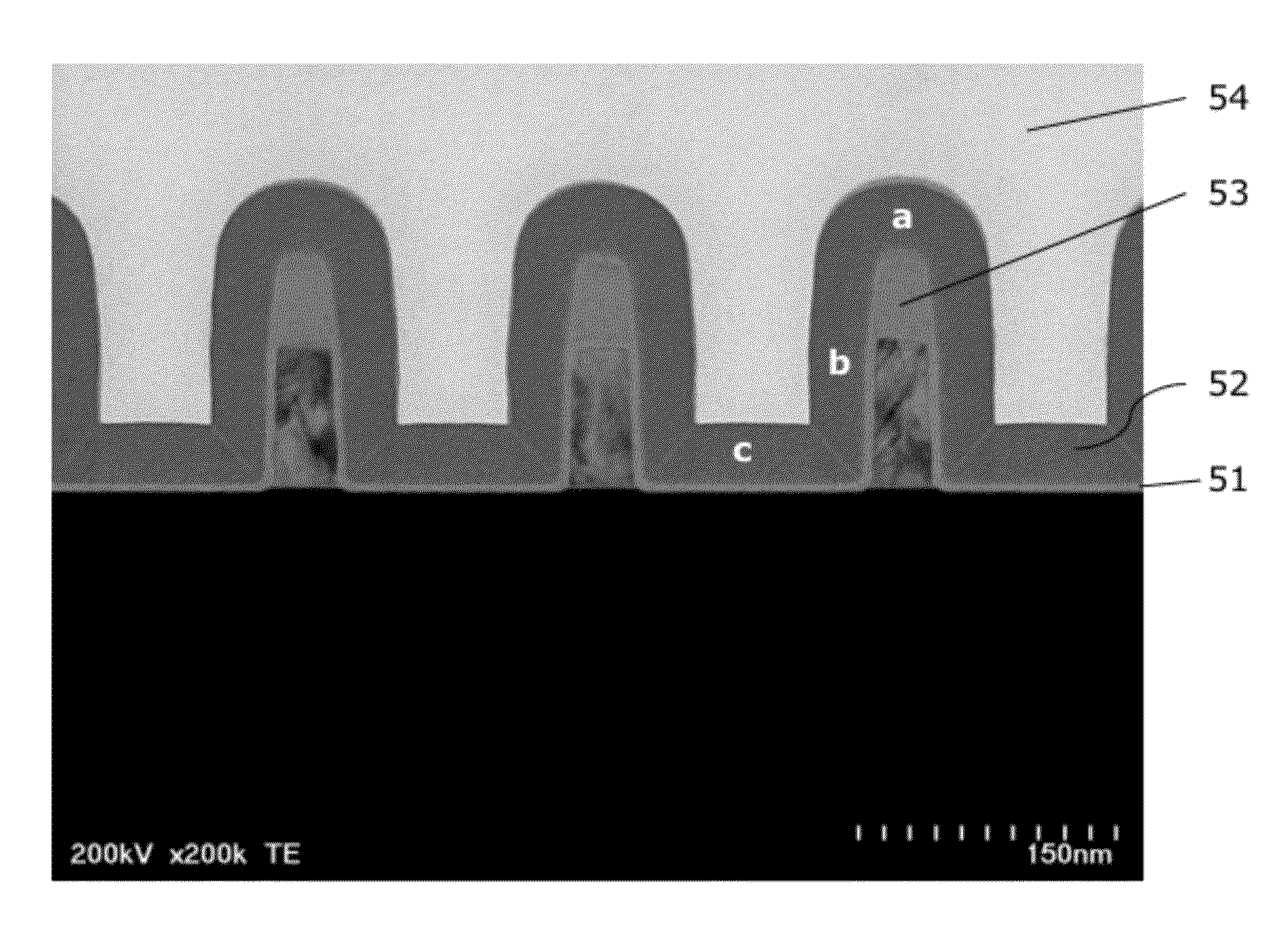

Method of depositing thin film and method of manufacturing semiconductor device

ActiveUS20190115206A1Good shape retentionAvoid damageElectric discharge tubesSemiconductor/solid-state device manufacturingReactive gasEngineering

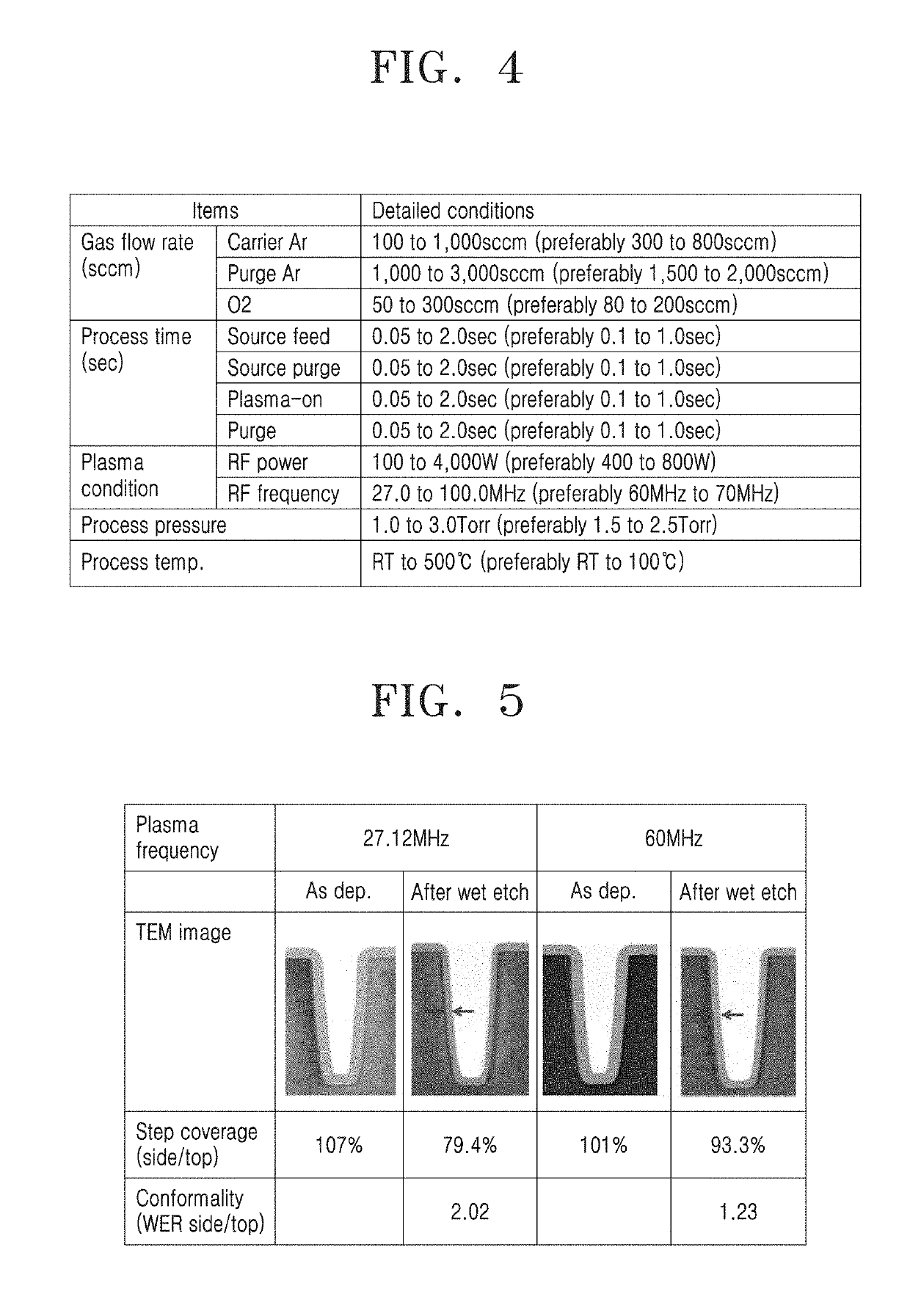

Provided is a method of depositing a thin film on a pattern structure of a semiconductor substrate, the method including (a) supplying a source gas; (b) supplying a reactive gas; and (c) supplying plasma, wherein the steps (a), (b), and (c) are sequentially repeated on the semiconductor substrate within a reaction space until a desired thickness is obtained, and a frequency of the plasma is a high frequency of 60 MHz or greater.

Owner:ASM IP HLDG BV

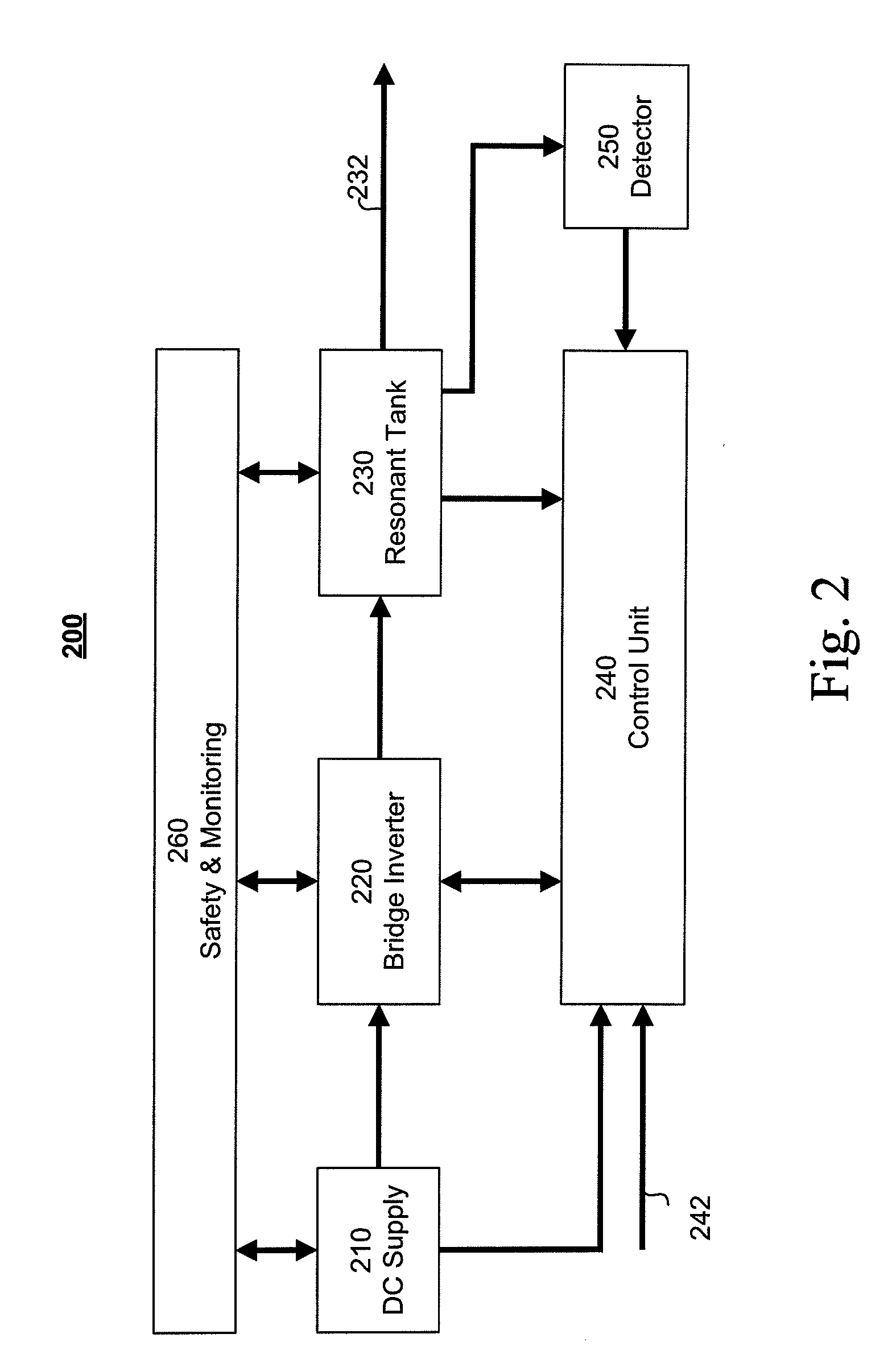

Method and Apparatus of Providing Power to Ignite and Sustain a Plasma in a Reactive Gas Generator

ActiveUS20100219757A1Eliminating and minimizing riskBig spaceElectric discharge tubesElectric arc lampsReactive gasPlasma ignition

Described are methods and apparatuses, including computer program products, for igniting and / or sustaining a plasma in a reactive gas generator. Power is provided from an ignition power supply to a plasma ignition circuit. A pre-ignition signal of the plasma ignition circuit is measured. The power provided to the plasma ignition circuit is adjusted based on the measured pre-ignition signal and an adjustable pre-ignition control signal. The adjustable pre-ignition control signal is adjusted after a period of time has elapsed.

Owner:MKS INSTR INC

Coatings for enhancement of properties and performance of substrate articles and apparatus

PendingUS20180044800A1Avoid reactionGood semiconductor performanceSemi-permeable membranesVacuum evaporation coatingCoated surfaceReactive gas

Coatings applicable to a variety of substrate articles, structures, materials, and equipment are described. In various applications, the substrate includes metal surface susceptible to formation of oxide, nitride, fluoride, or chloride of such metal thereon, wherein the metal surface is configured to be contacted in use with gas, solid, or liquid that is reactive therewith to form a reaction product that is deleterious to the substrate article, structure, material, or equipment. The metal surface is coated with a protective coating preventing reaction of the coated surface with the reactive gas, and / or otherwise improving the electrical, chemical, thermal, or structural properties of the substrate article or equipment. Various methods of coating the metal surface are described, and for selecting the coating material that is utilized.

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com