Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5469 results about "Process equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Removal of surface dopants from a substrate

InactiveUS20090162996A1Semiconductor/solid-state device detailsSolid-state devicesDopantHigh concentration

A method and apparatus for removing excess dopant from a doped substrate is provided. In one embodiment, a substrate is doped by surfaced deposition of dopant followed by formation of a capping layer and thermal diffusion drive-in. A reactive etchant mixture is provided to the process chamber, with optional plasma, to etch away the capping layer and form volatile compounds by reacting with excess dopant. In another embodiment, a substrate is doped by energetic implantation of dopant. A reactive gas mixture is provided to the process chamber, with optional plasma, to remove excess dopant adsorbed on the surface and high-concentration dopant near the surface by reacting with the dopant to form volatile compounds. The reactive gas mixture may be provided during thermal treatment, or it may be provided before or after at temperatures different from the thermal treatment temperature. The volatile compounds are removed. Substrates so treated do not form toxic compounds when stored or transported outside process equipment.

Owner:APPLIED MATERIALS INC

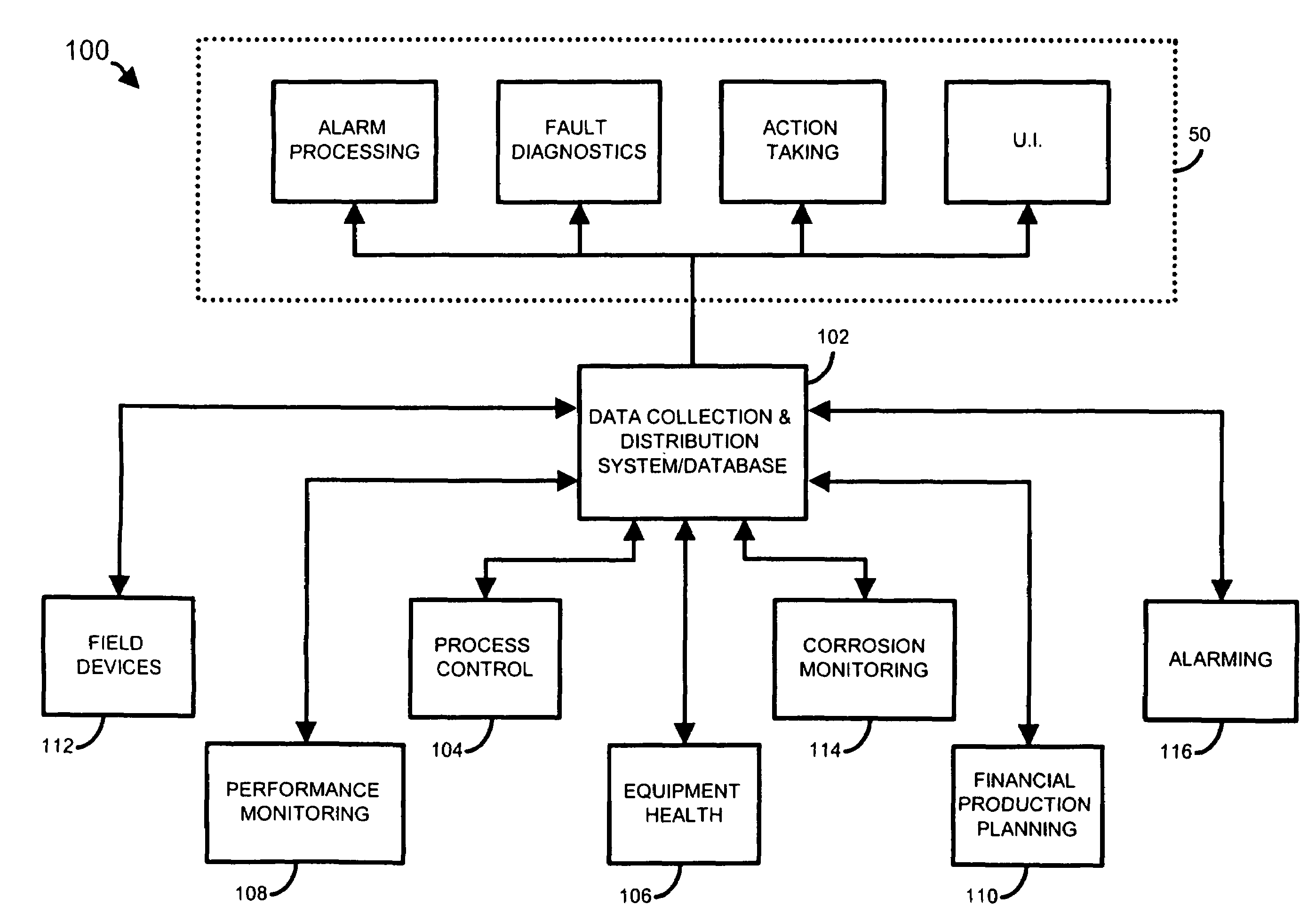

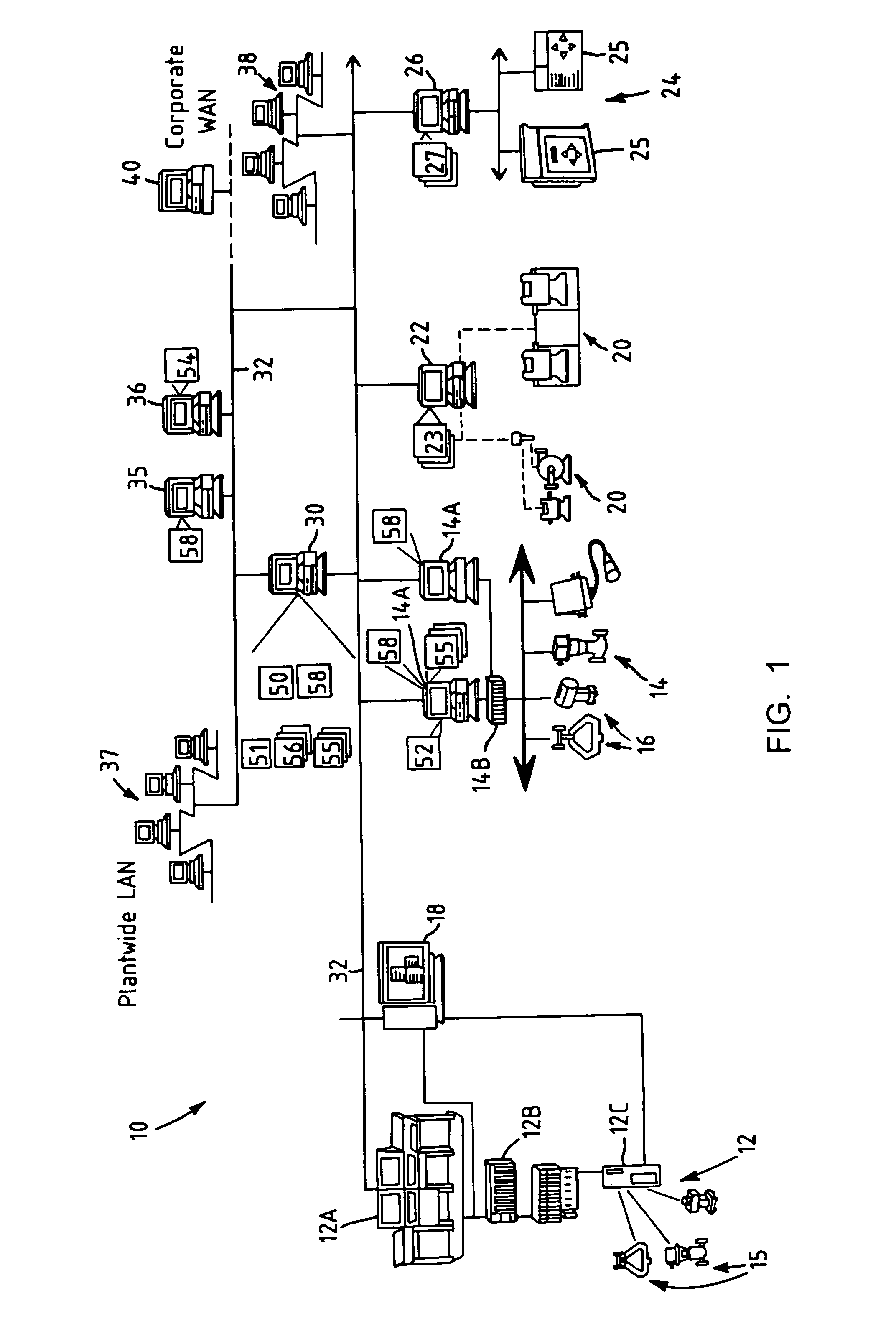

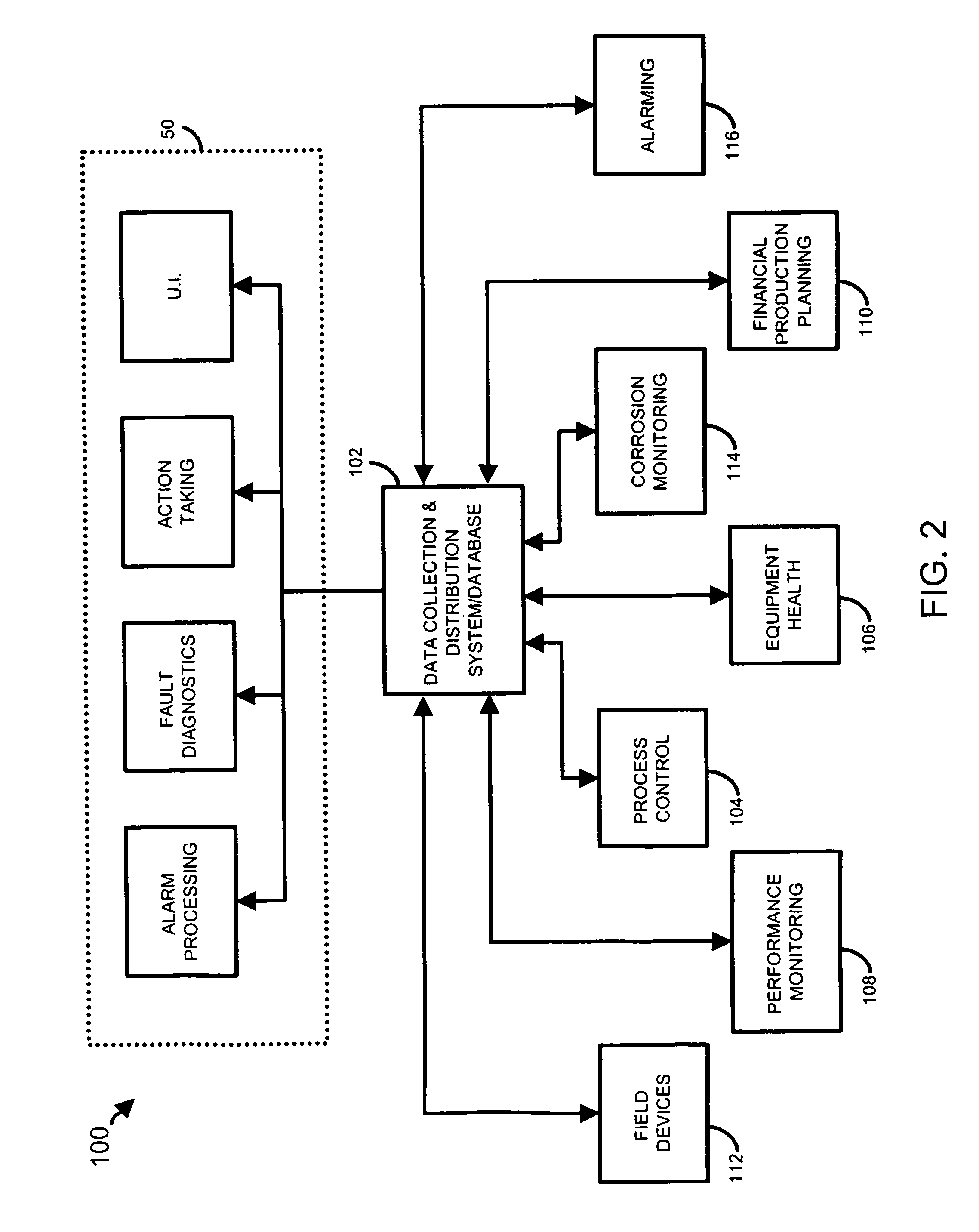

Method and apparatus for performing a function in a plant using process performance monitoring with process equipment monitoring and control

InactiveUS7206646B2Easy to operateBetter stateSafety arrangmentsCatalytic crackingProcess equipmentOptimal control

A process control system uses a data collection and distribution system and an asset utilization suite to collect data or information pertaining to the assets of a process plant from various sources or functional areas of the plant including, for example, the process control functional areas, the maintenance functional areas and the process performance monitoring functional areas. This data and information is manipulated in a coordinated manner by the data collection and distribution system and is redistributed to other applications where this it is used to perform overall better or more optimal control, maintenance and business activities. Information or data may be collected by maintenance functions pertaining to the health, variability, performance or utilization of a device, loop, unit, area, etc. and this information may then be sent to and displayed to a process operator or maintenance person to inform that person of a current or future problem. A user interface is provided that enables users to access and manipulate the expert engine to optimize plant operation or cause optimization of plant operation, to get information about the operation of the plant, etc. Furthermore, applications, such as work order generation applications may automatically generate work orders, parts or supplies orders, etc. based on events occurring within the plant.

Owner:FISHER-ROSEMOUNT SYST INC

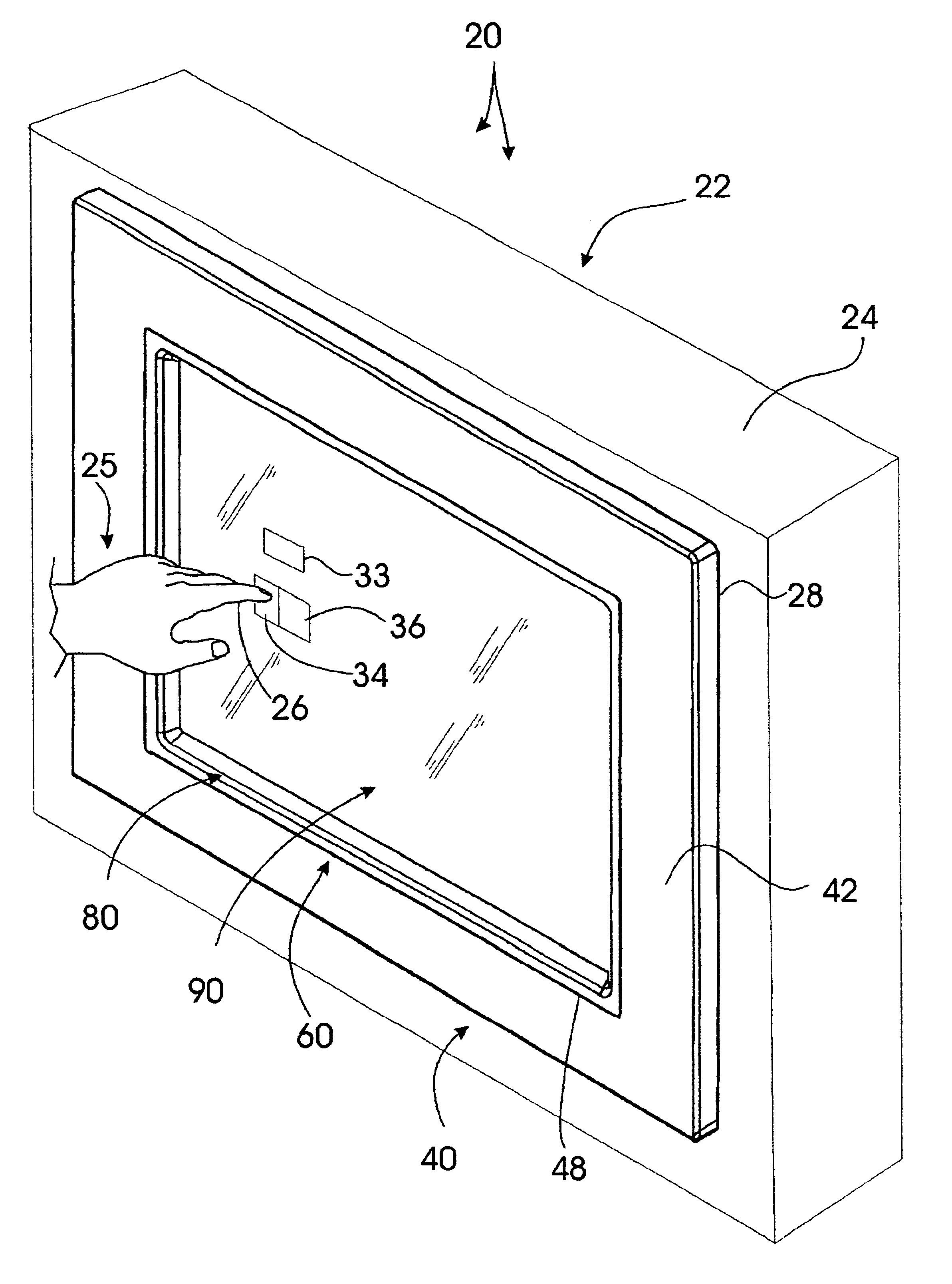

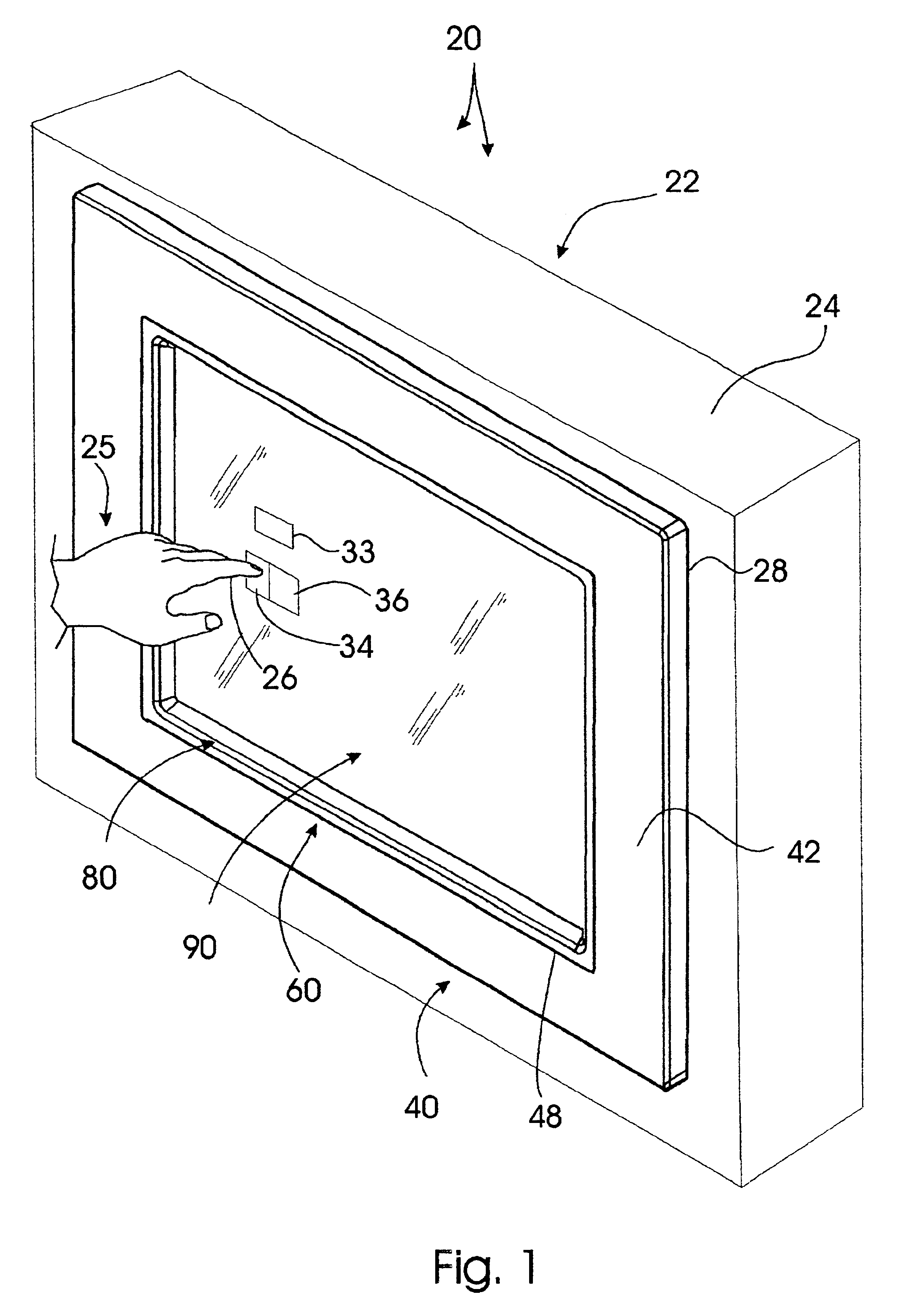

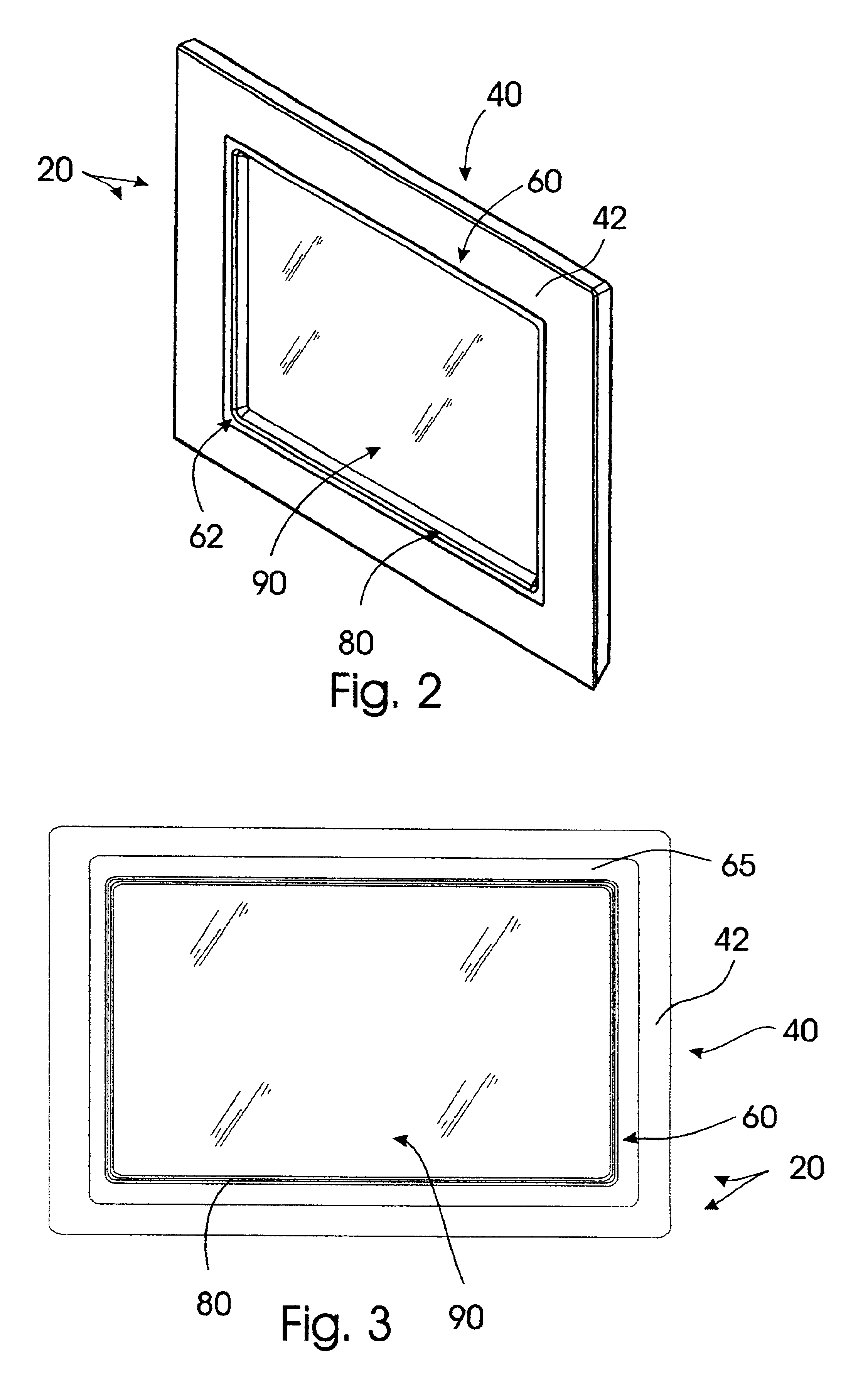

Unitary molded lens filter for touch screen interface

InactiveUS6900795B1Easy to cleanEasy to manufactureTelevision system detailsMaterial analysis by optical meansCamera lensGlass fiber

A durable unitary lens filter is provided for use with a touch sensitive display device for associated control process equipment. A front cover secures the unitary lens filter to the machine. The lens assembly includes a mounting bezel that supports an intermediate lens securing an integral rear lens filter through which a responsive display shows process information to an operator. The front cover captivates the integral bezel to secure the lens to the associated process device. The lens is molded from a semi-rigid material composition including glass fibers. An internal retainer compressibly captivates the bezel against the front cover. The bezel periphery extends substantially beyond the outermost peripheral edge of the rear lens so that forces thereto are transferred and dissipated to the machine housing.

Owner:WORD MACHINERY

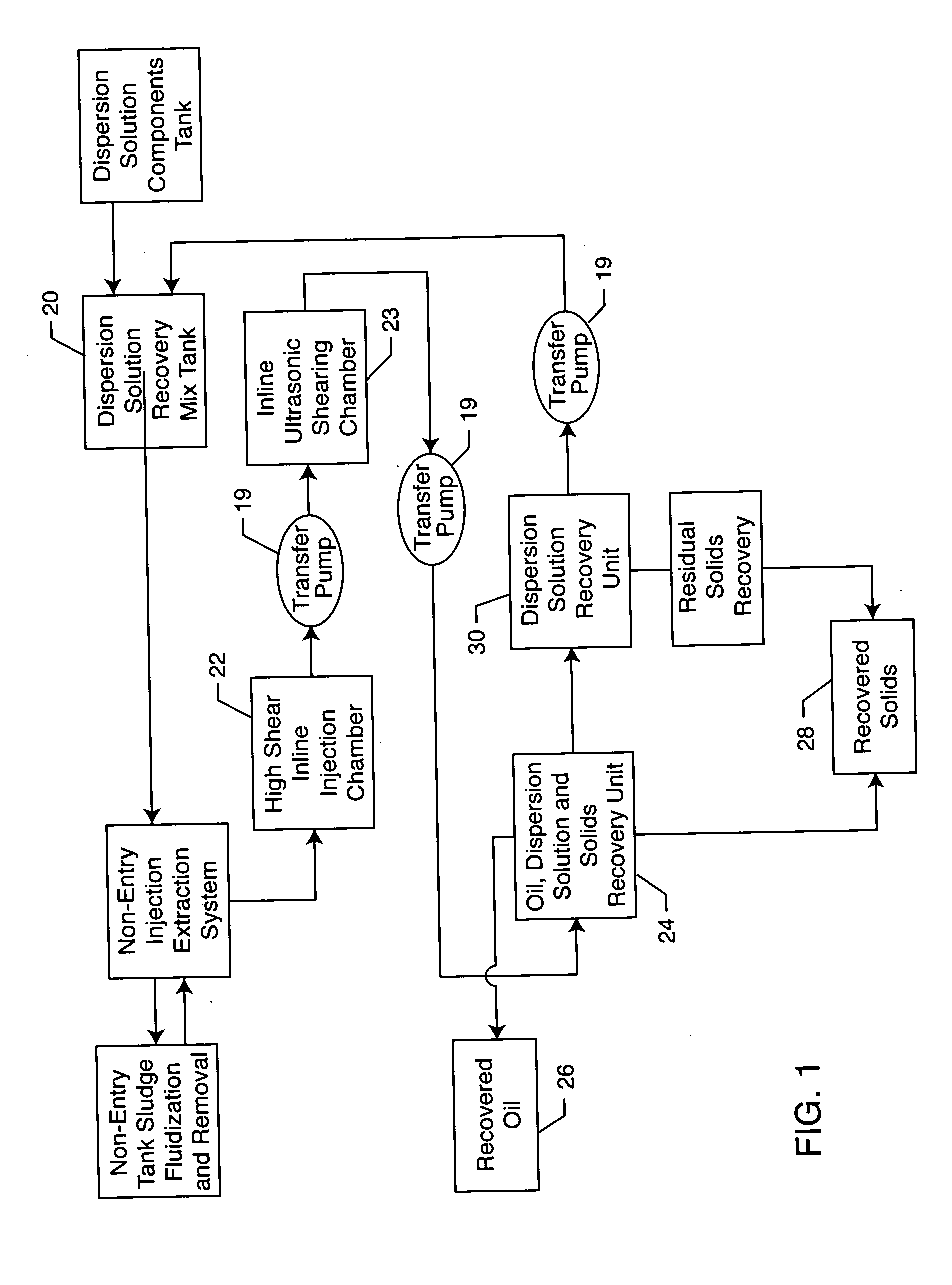

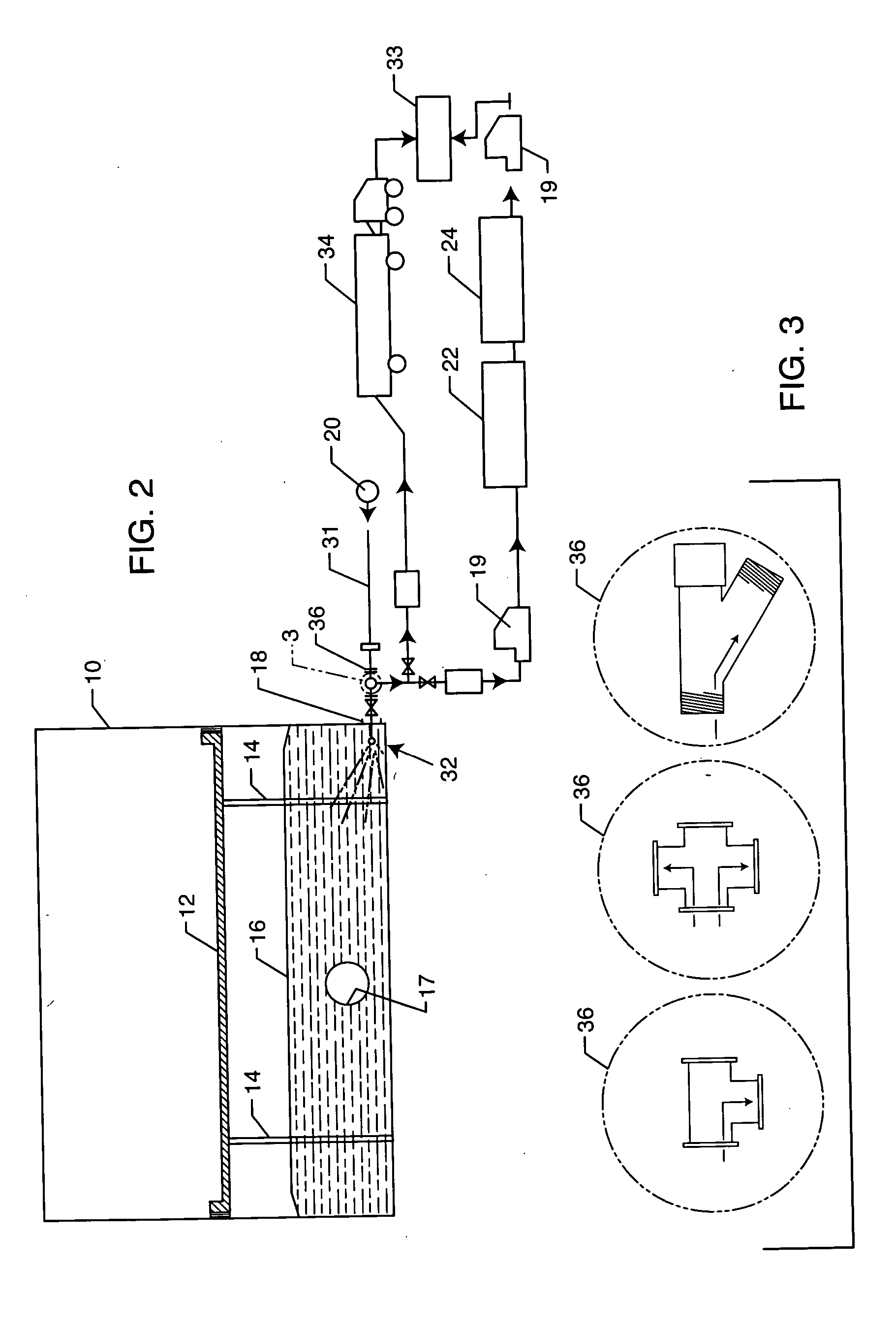

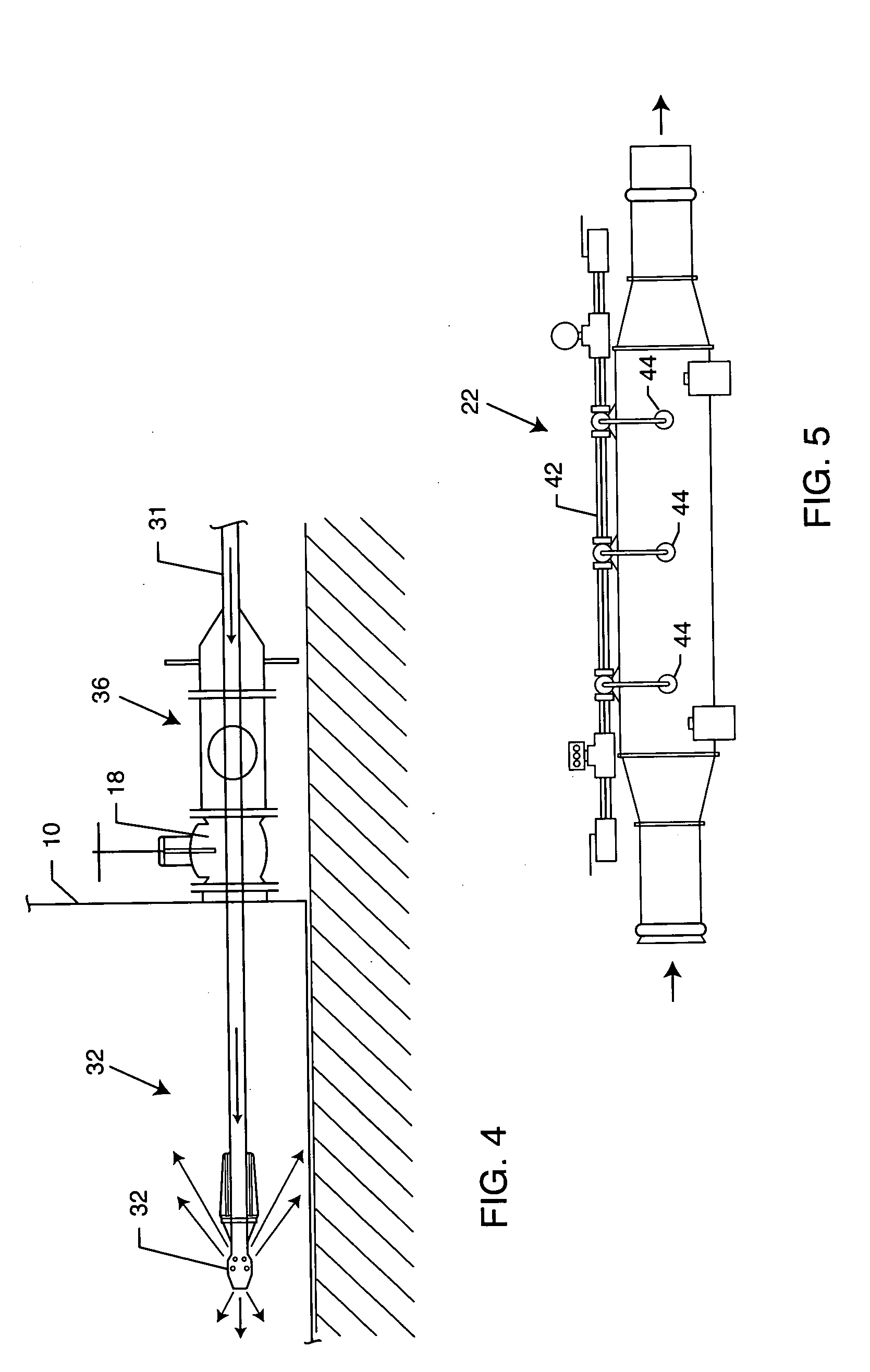

Petroleum recovery and cleaning system and process

InactiveUS20050161372A1Enhancing petroleum recoveryIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

Owner:AQUA TECH LLC

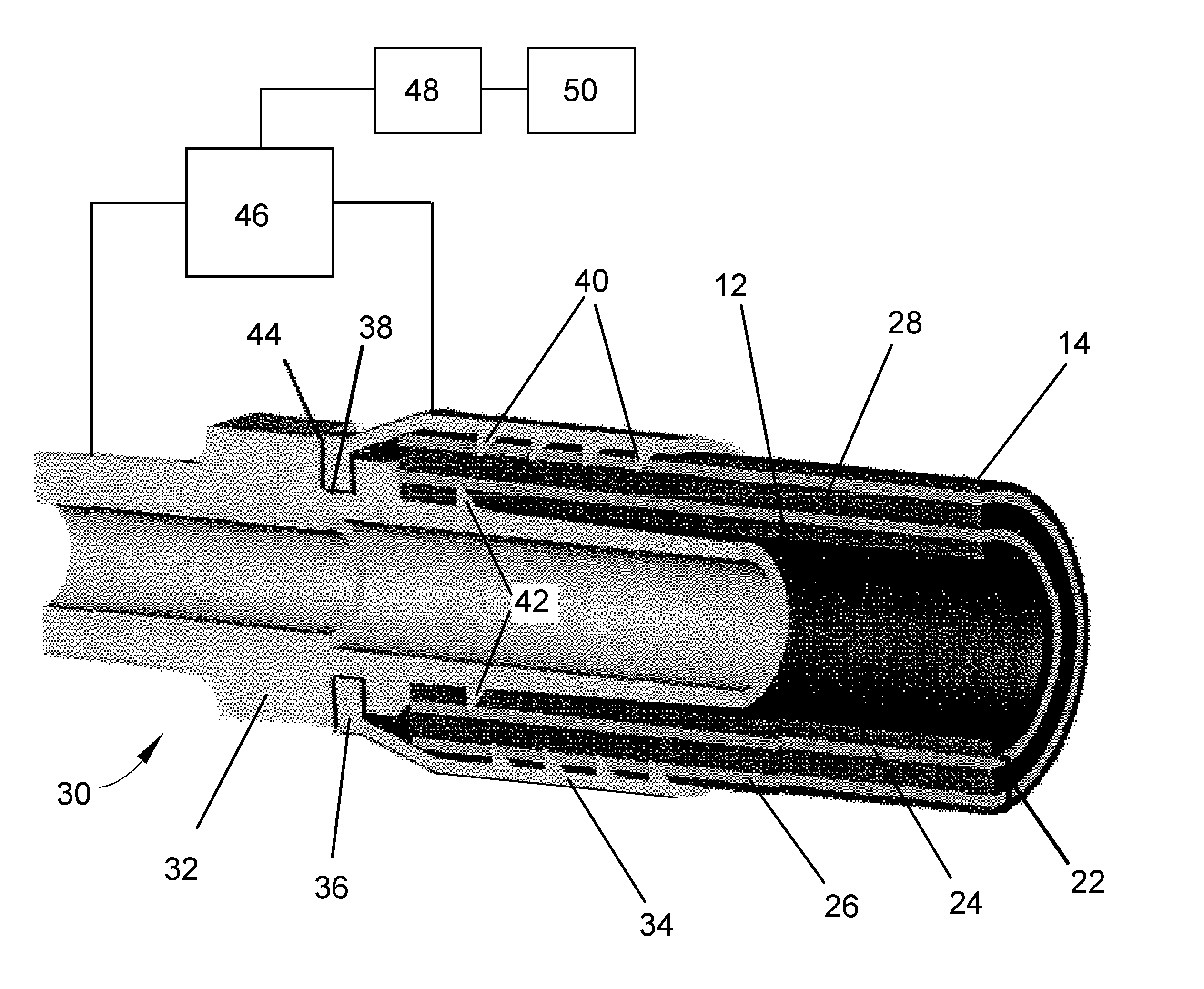

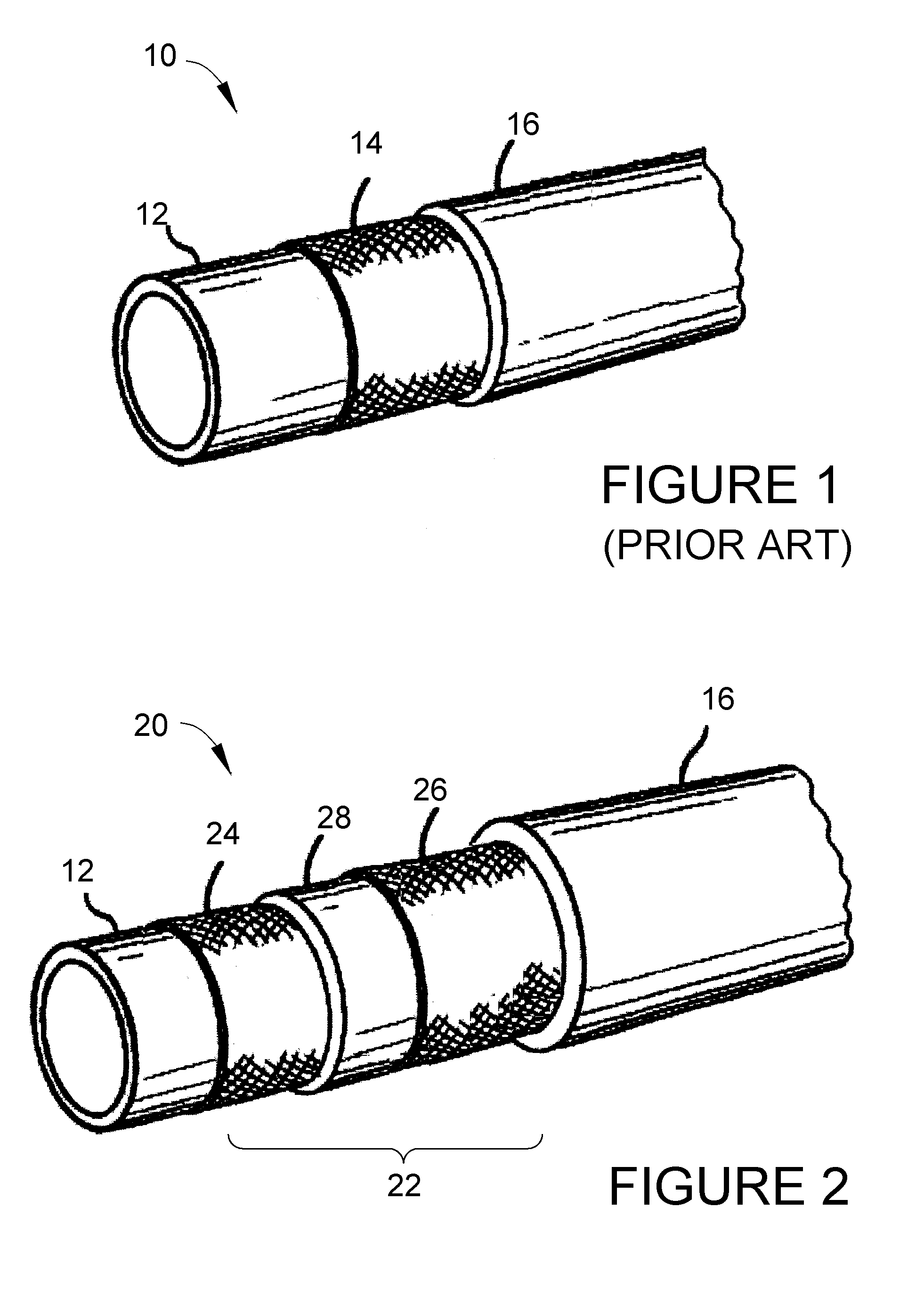

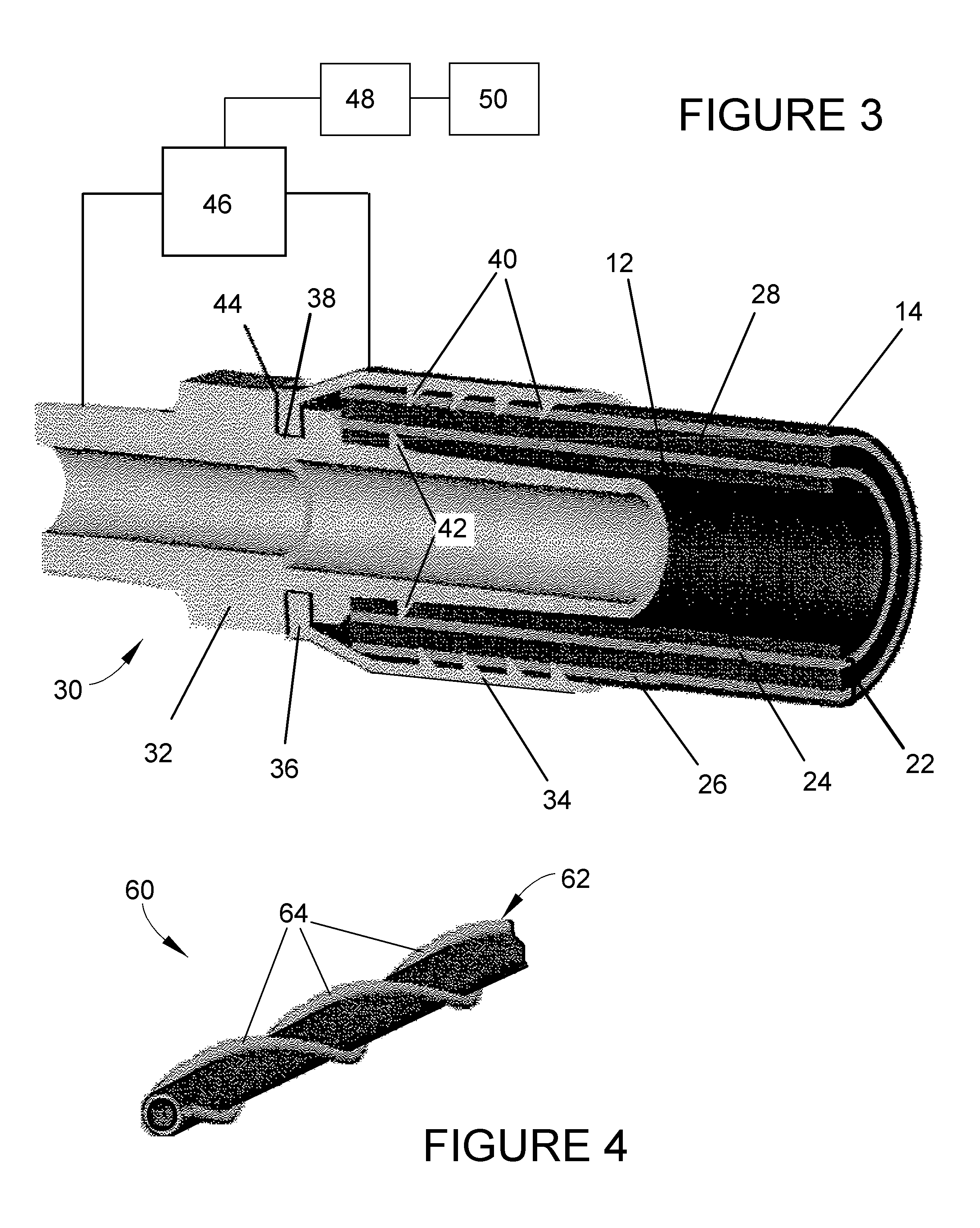

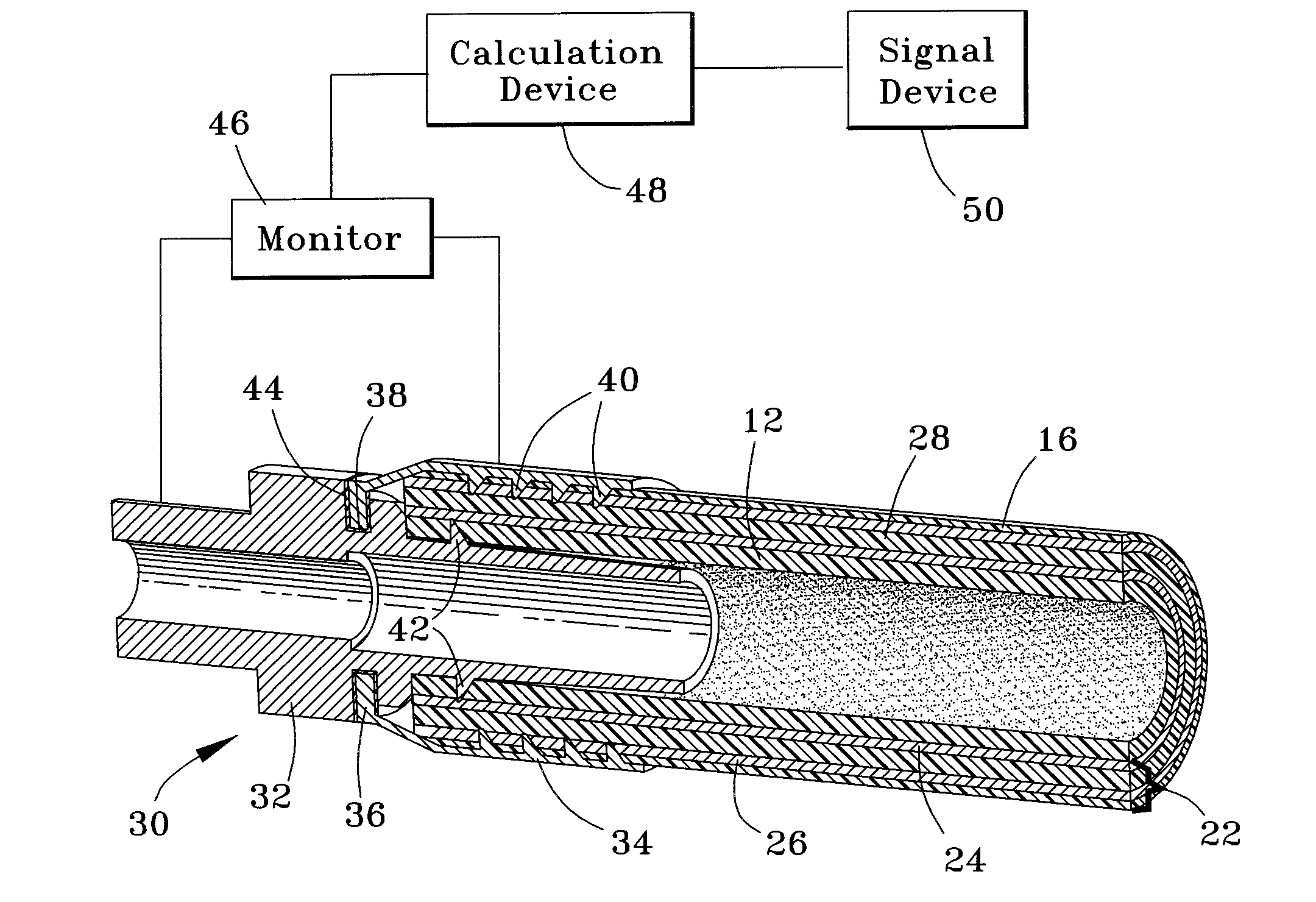

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS20060196252A1Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

A system and method for predicting structural failure of a wall of a fluid containment vessel, such as a hydraulic hose or other type of pressurized conduit of types used in mobile machinery, automotive, aerospace, manufacturing, and process equipment. The wall of the vessel has an innermost layer for contact with the fluid contained by the vessel, and an outermost layer parallel with the innermost layer. The system includes strain-sensing means between the innermost and outermost layers and comprising at least one conductor parallel to the innermost layer of the wall. The system and method entail sensing changes in an electrical property associated with the at least one conductor resulting from distortion of the wall of the vessel causing distortion of the at least one conductor.

Owner:PURDUE RES FOUND INC

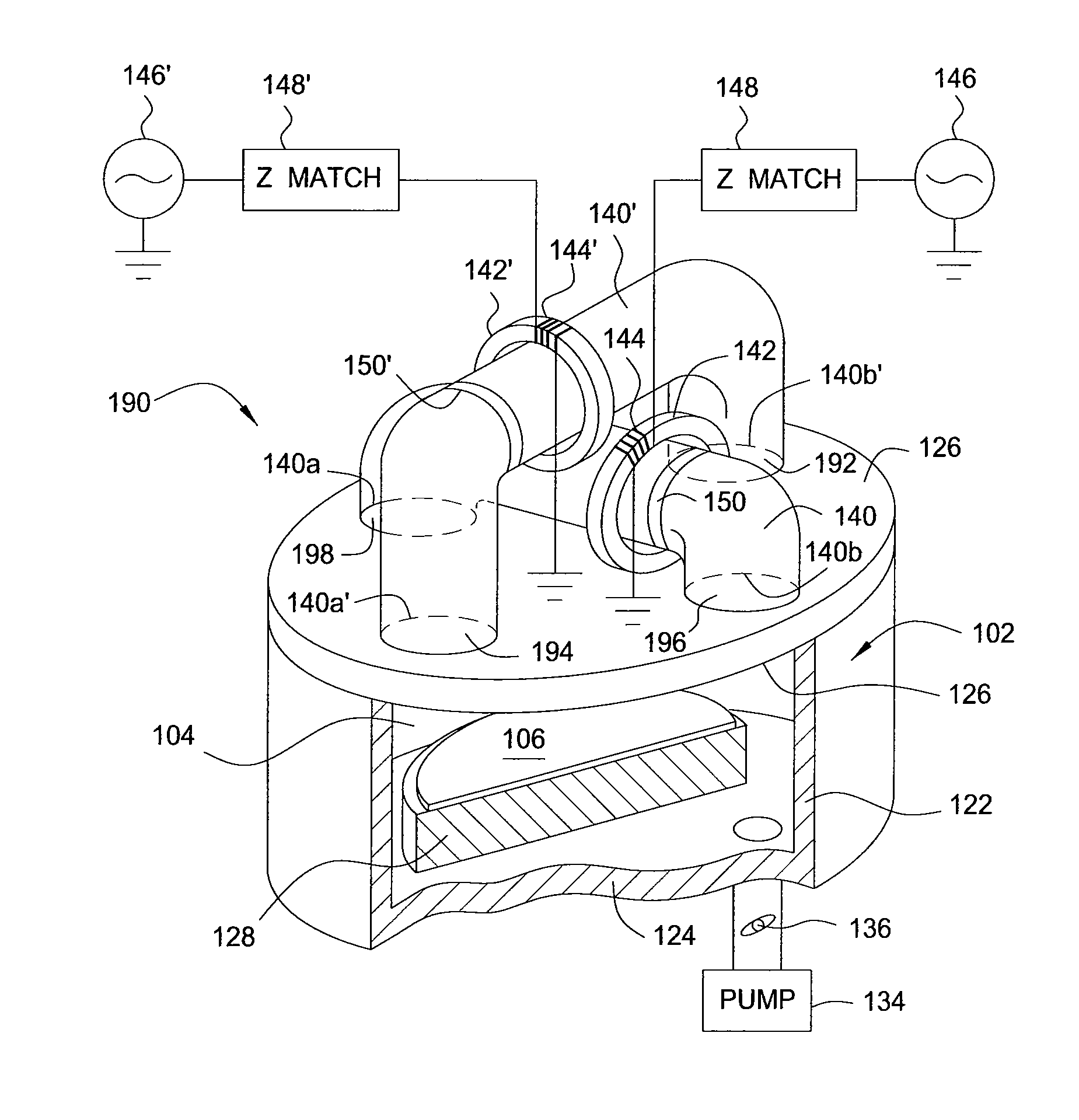

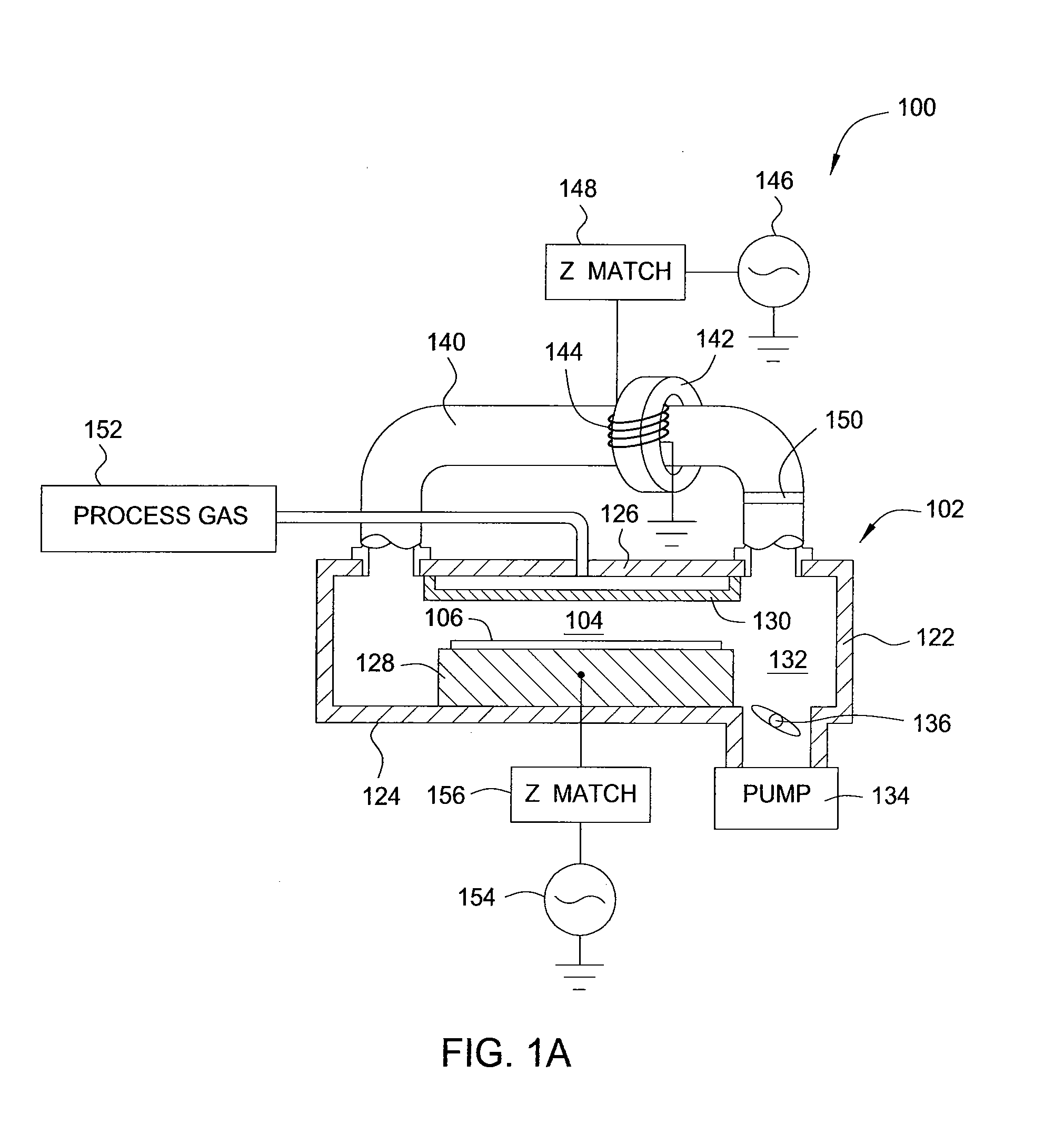

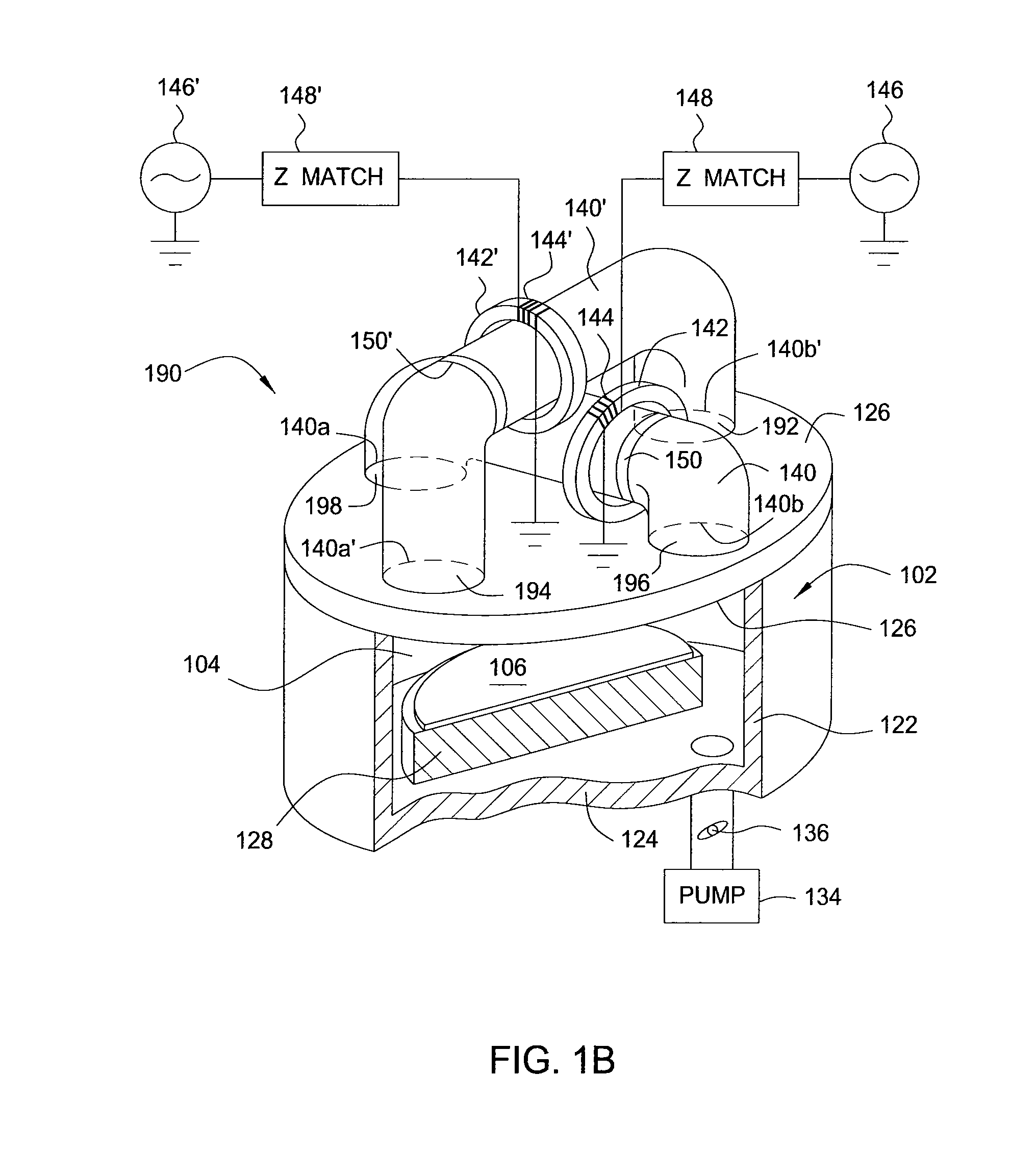

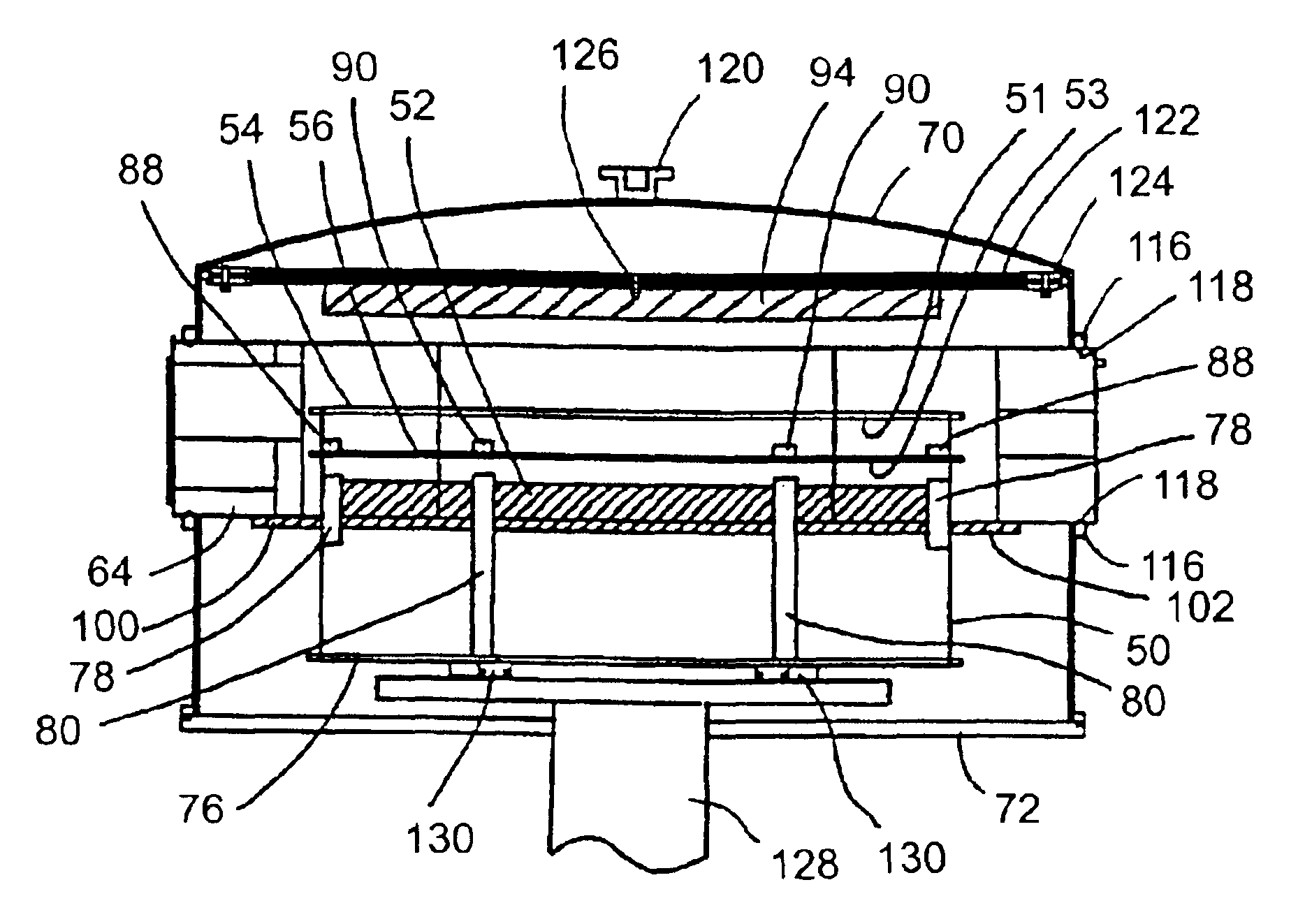

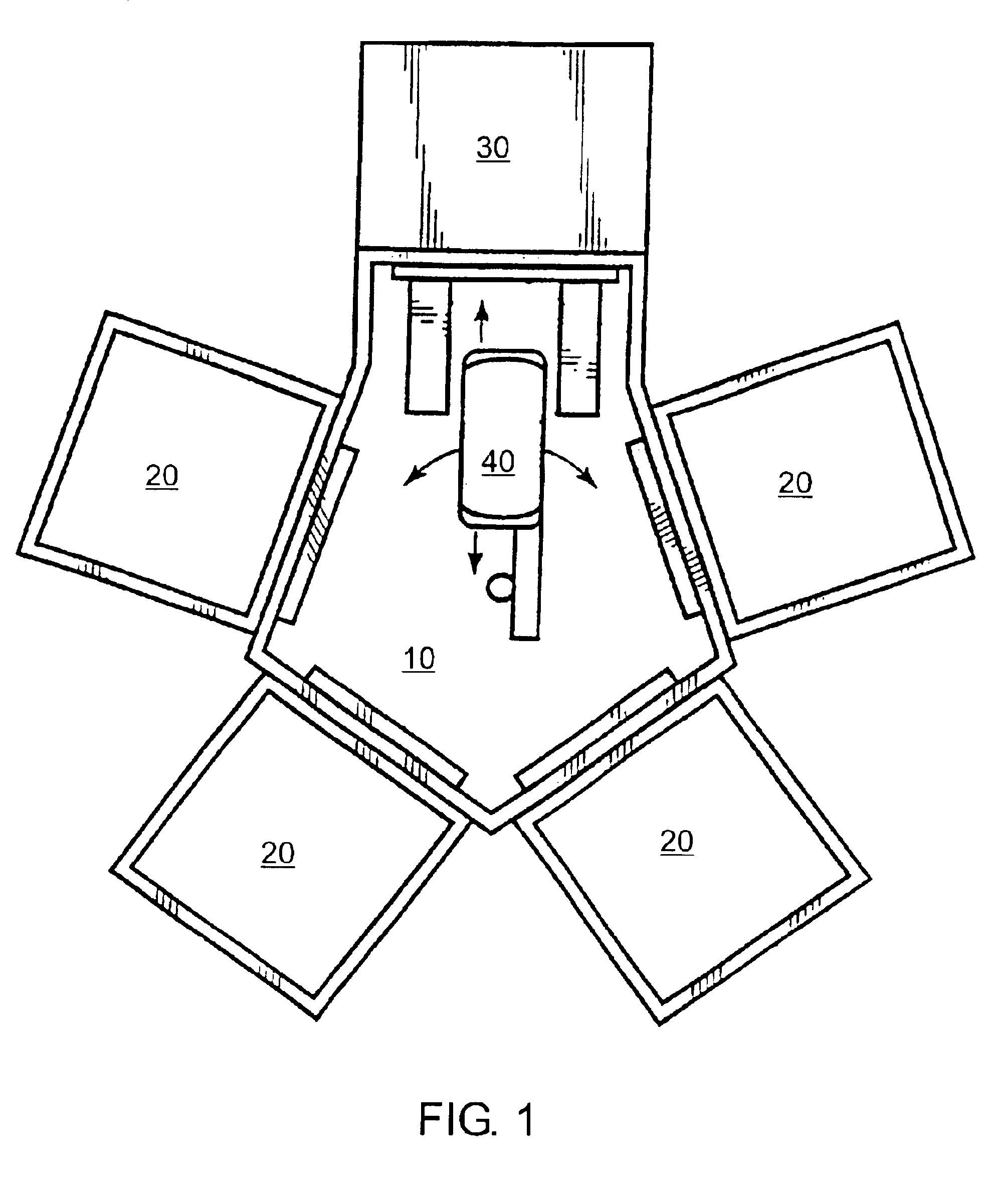

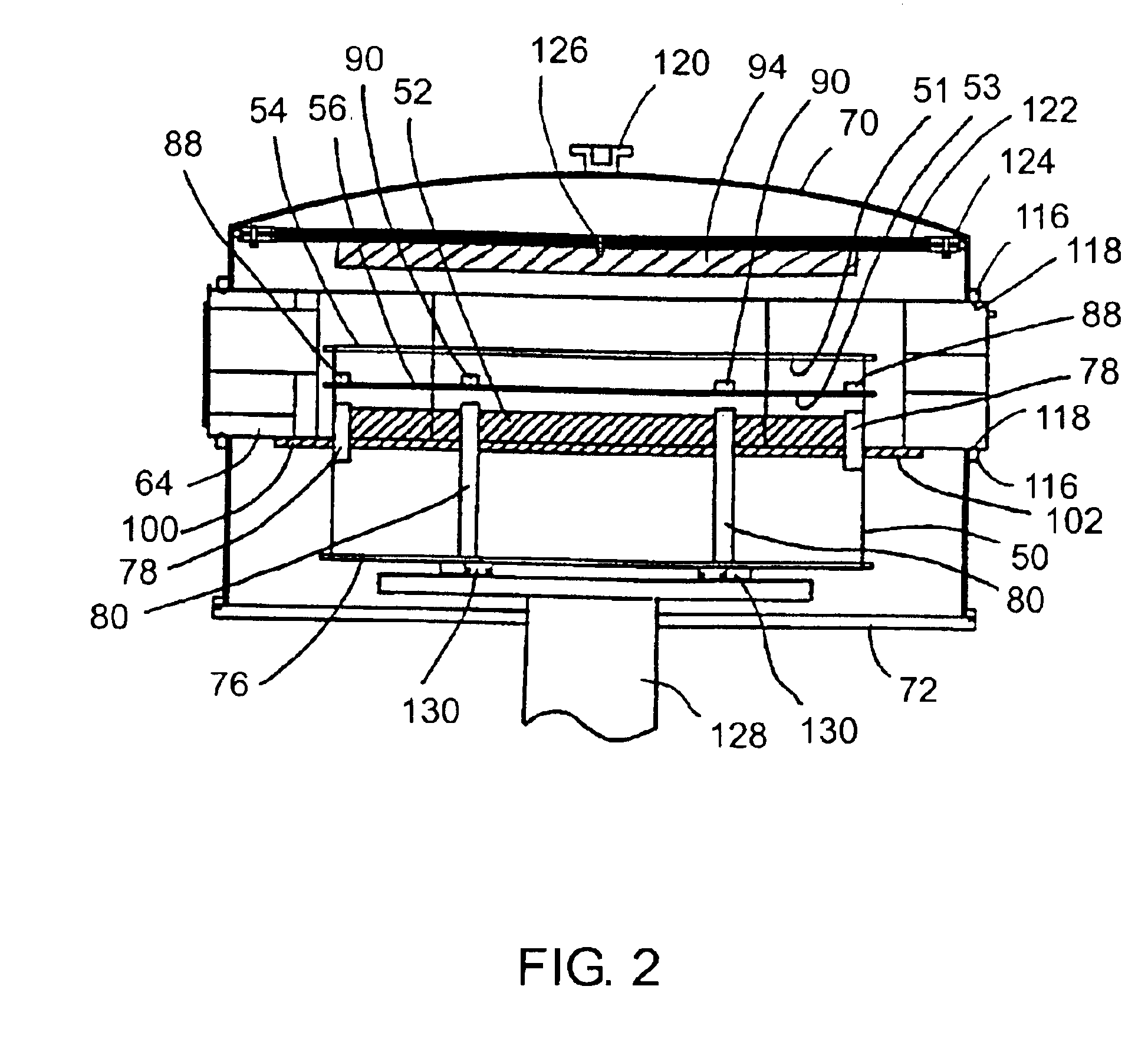

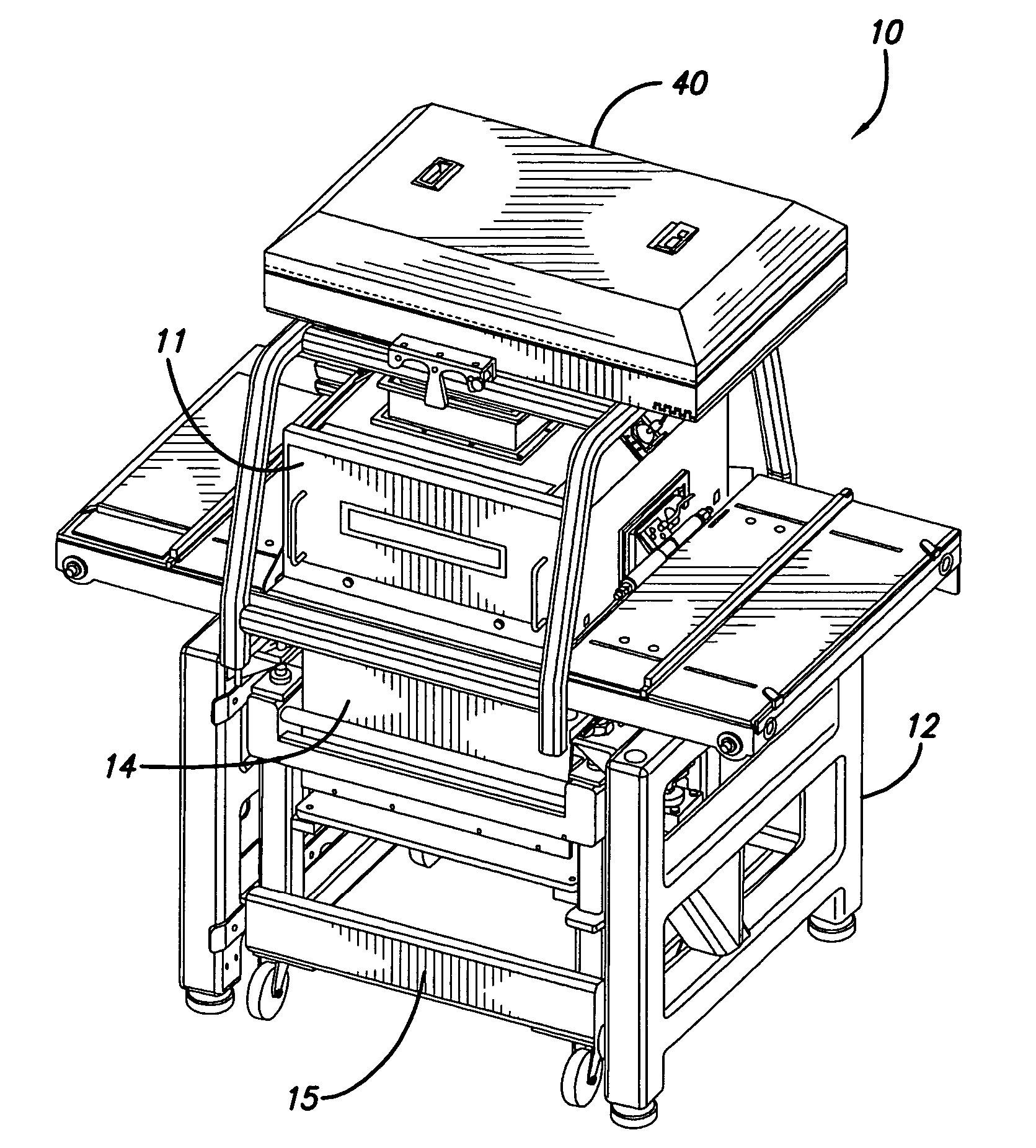

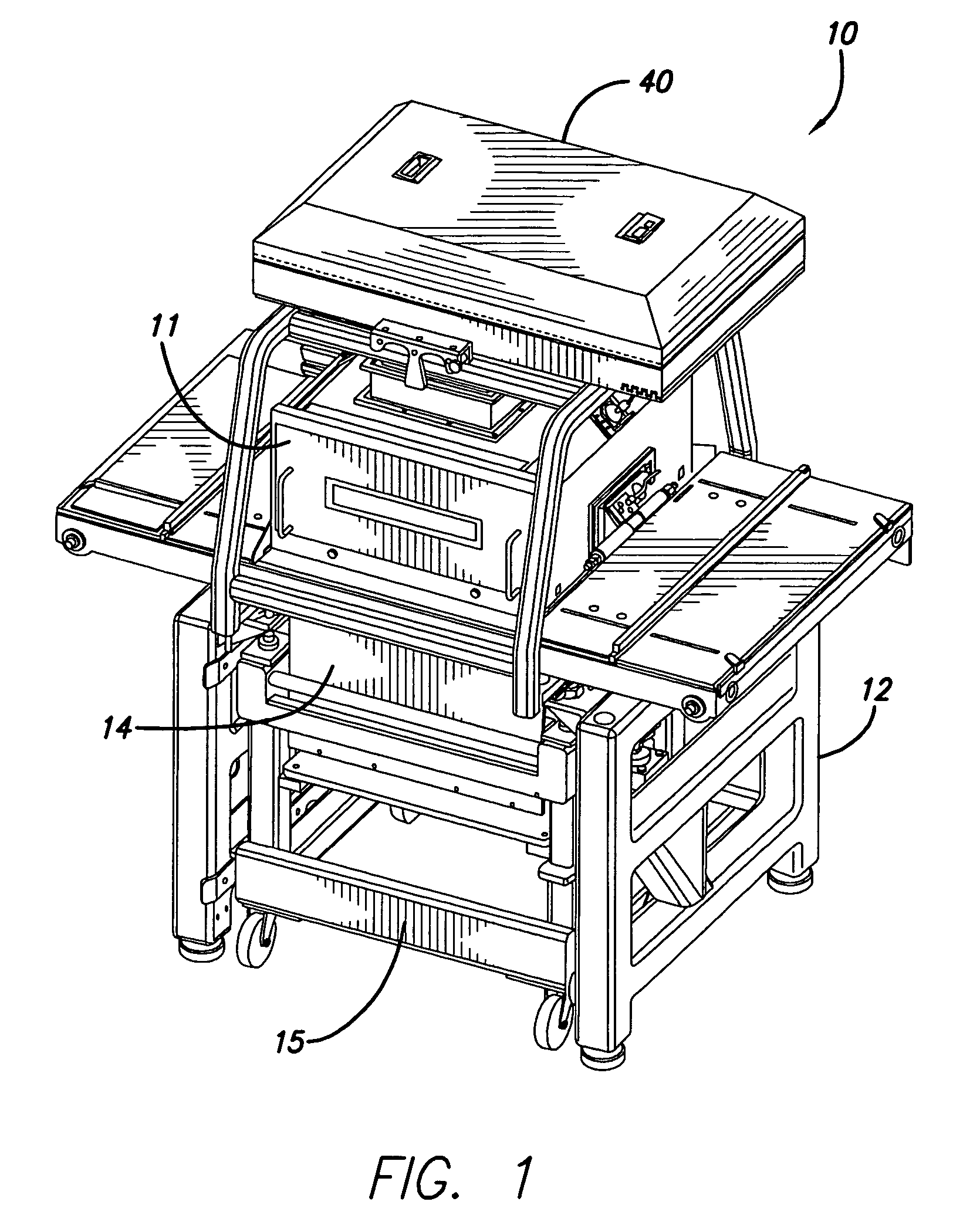

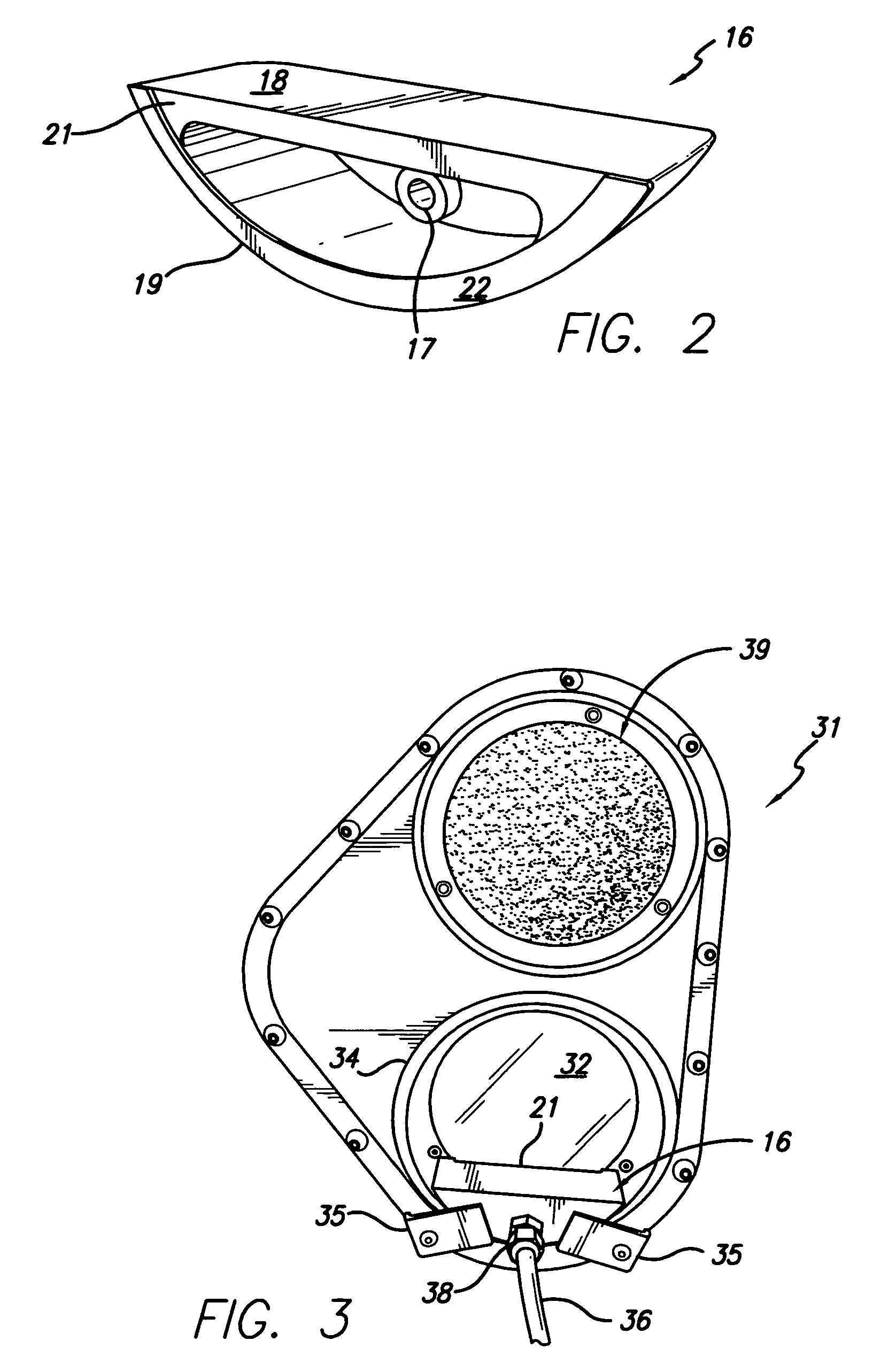

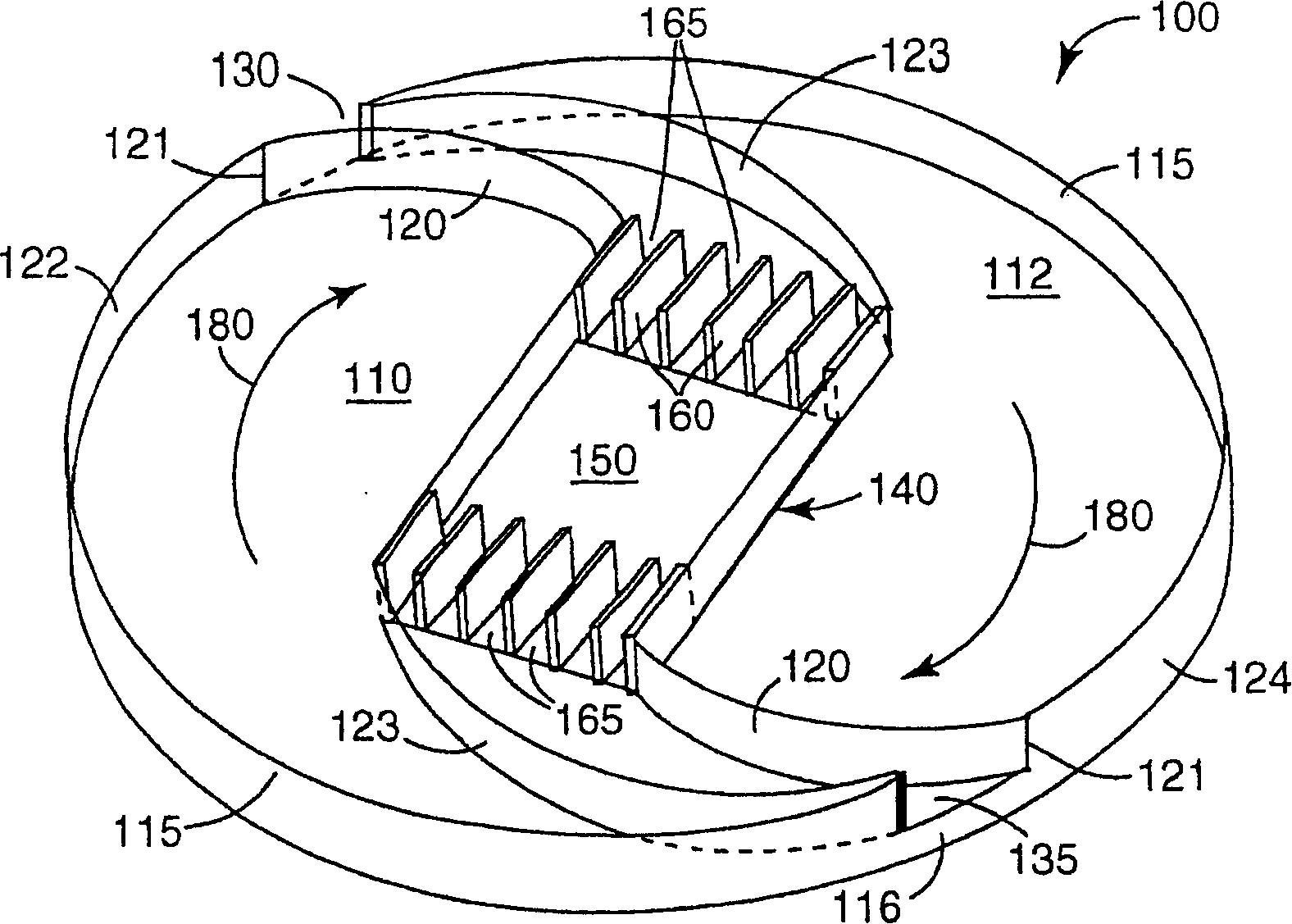

Dual substrate loadlock process equipment

One embodiment relates to a loadlock having a first support structure therein to support one unprocessed substrate and a second support structure therein to support one processed substrate. The first support structure is located above the second support structure. The loadlock includes an elevator to control the vertical position of the support structures. The loadlock also includes a first aperture to permit insertion of an unprocessed substrate into the loadlock and removal of a processed substrate from the loadlock, as wall as a second aperture to permit removal of an unprocessed substrate from the loadlock and insertion of a processed substrate into the loadlock. A cooling plate is also located in the loadlock. The cooling plate includes a surface adapted to support a processed substrate thereon. A heating device may be located in the loadlock above the first support structure.

Owner:APPLIED MATERIALS INC

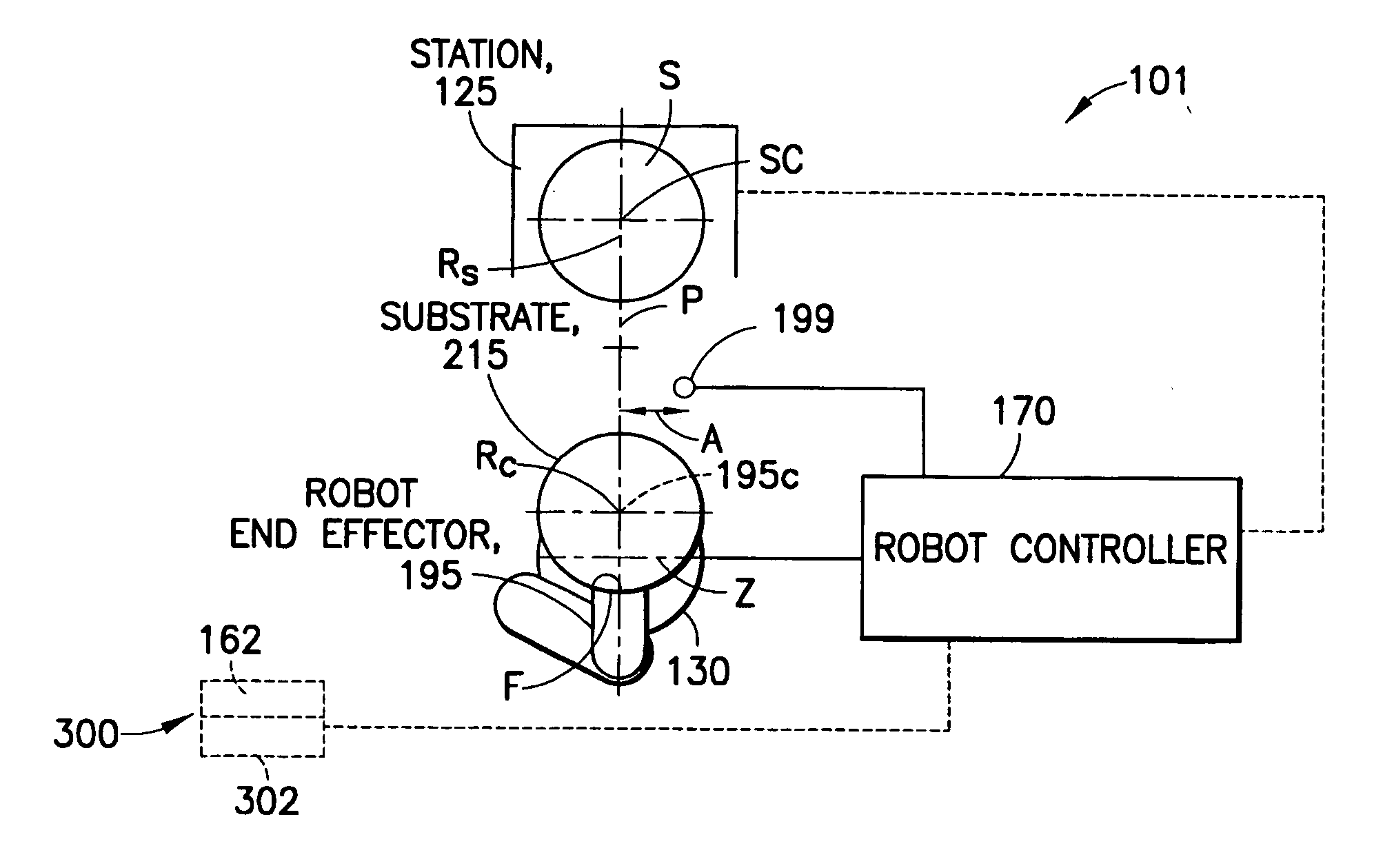

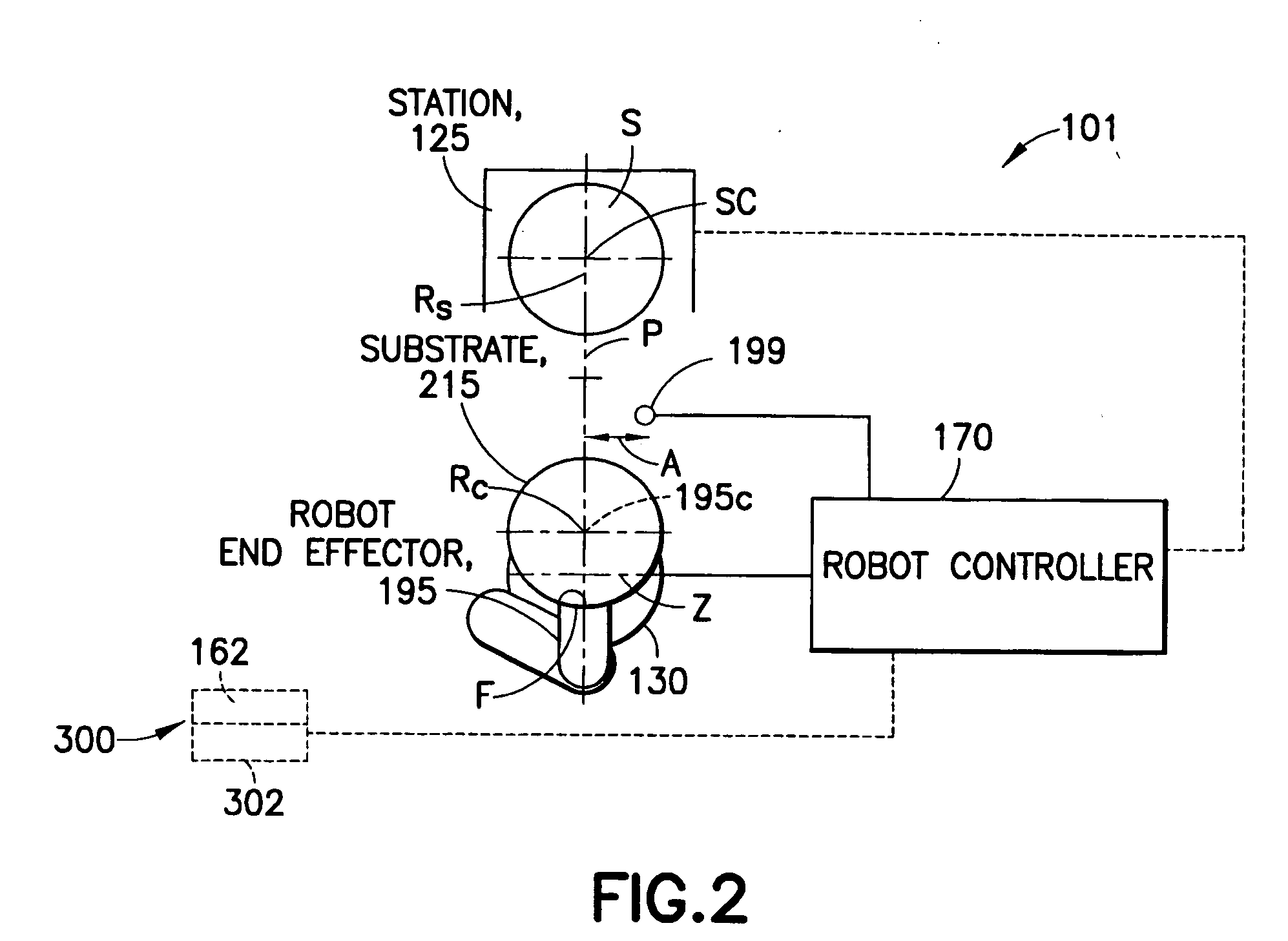

Process apparatus with on-the-fly workpiece centering

ActiveUS20070071581A1Digital data processing detailsSemiconductor/solid-state device manufacturingProcess equipmentElectrical and Electronics engineering

A substrate processing apparatus having a transport apparatus, at least one sensor connected to the transport apparatus and a controller. The transport apparatus is adapted for transporting the substrate between processing stations of the processing apparatus. The sensor is capable of sensing the substrate transported by the transporting apparatus. The sensor is arranged for sending at least one signal in response to sensing the substrate. The controller is communicably connected to the sensor and arranged to determine alignment of the substrate in at least two directions, angled relative to each other, relative to a predetermined location. The controller is capable of determining alignment from the at least one signal identifying no more than two points on the substrate and independent of radial variances between substrates.

Owner:BOOKS AUTOMATION US LLC

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS7555936B2Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

Owner:PURDUE RES FOUND INC

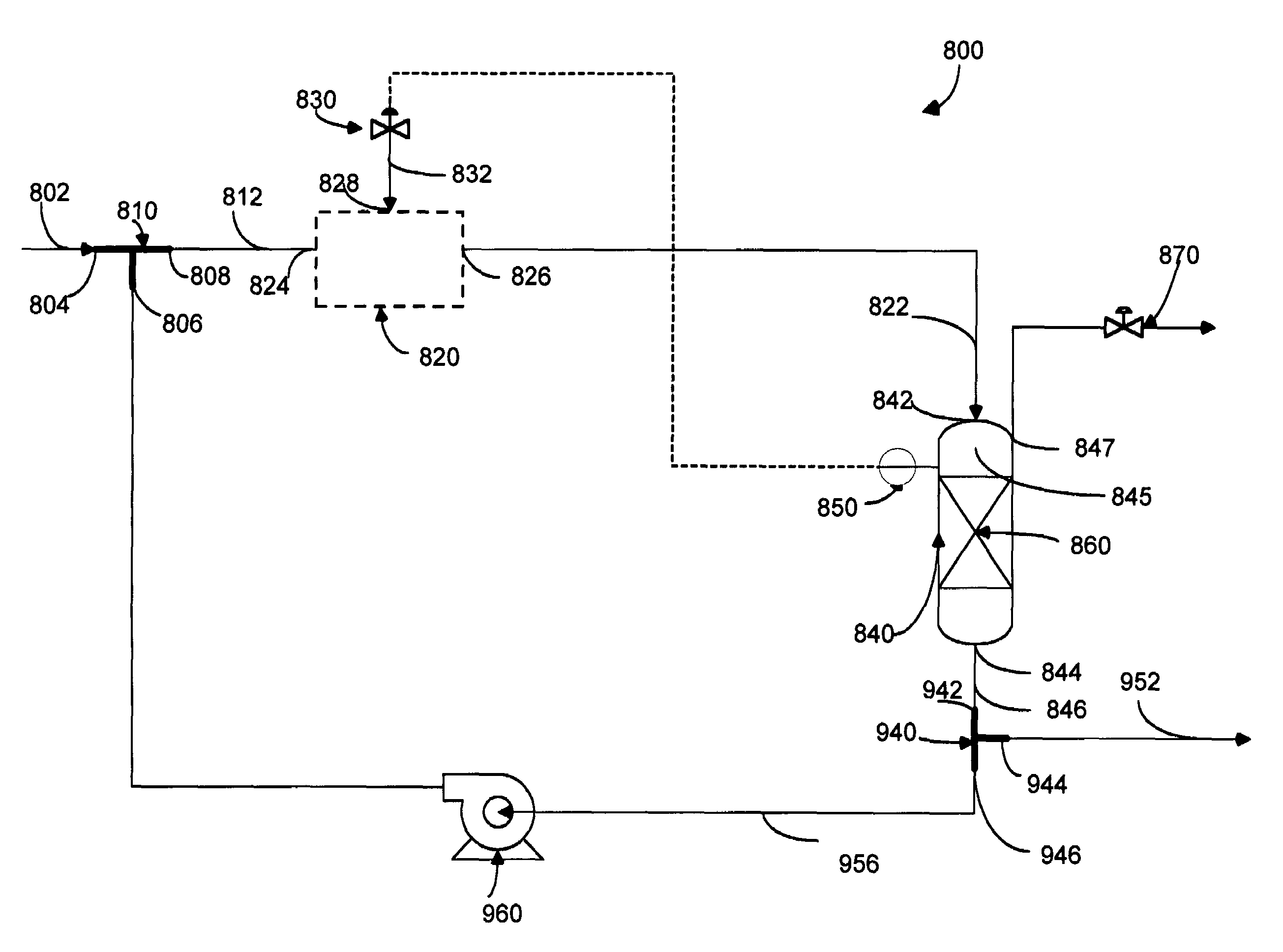

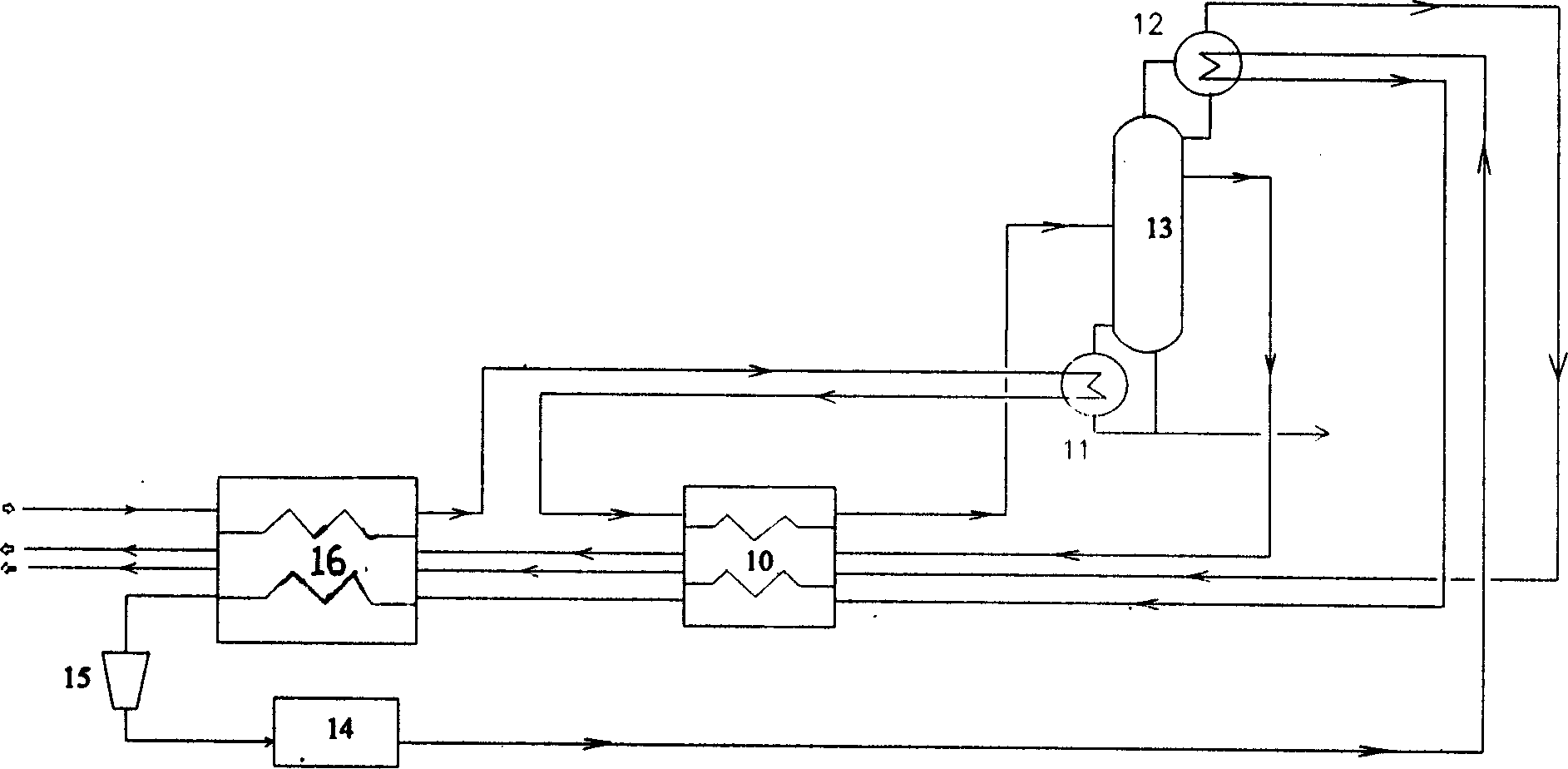

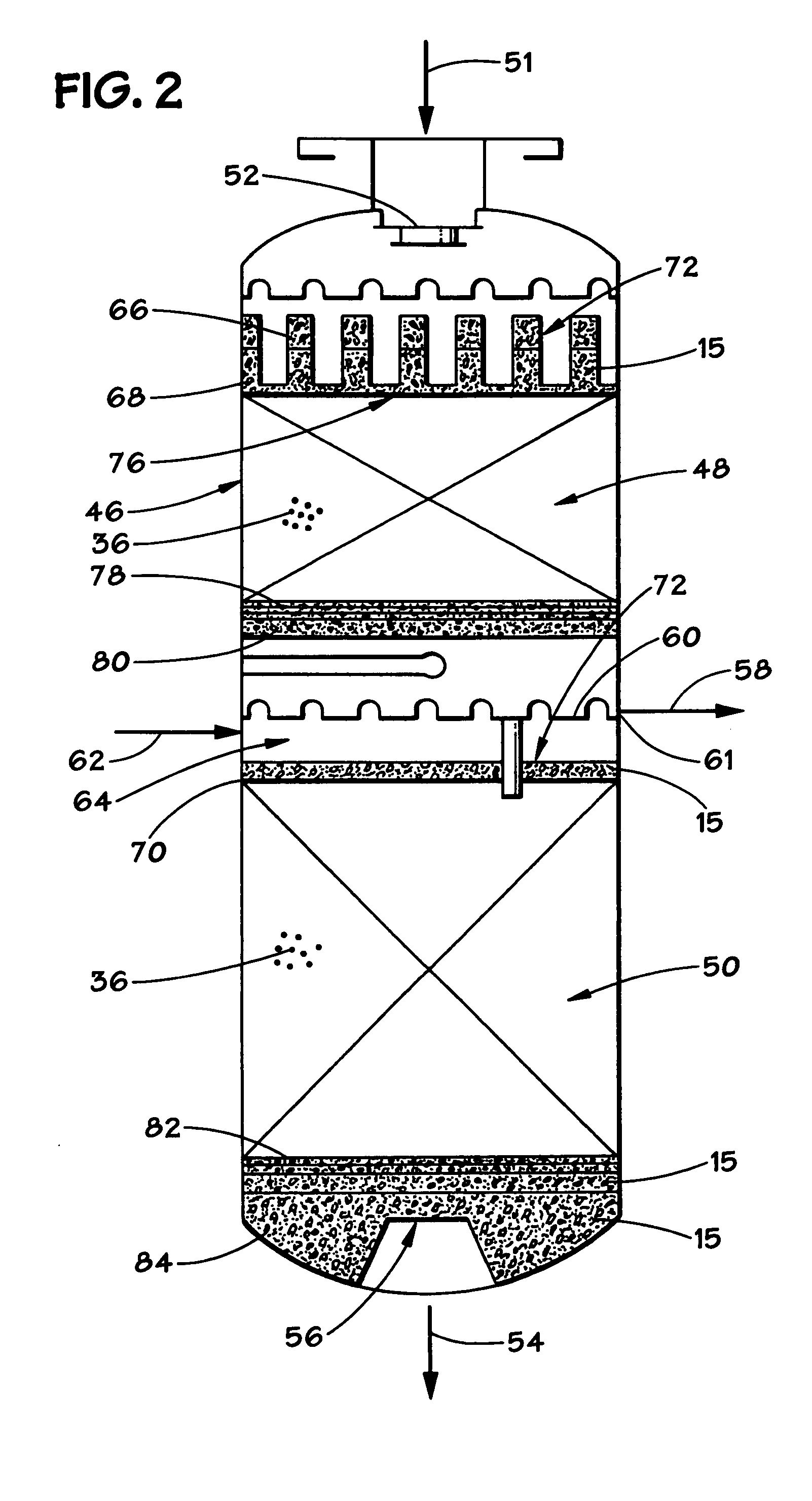

Control system method and apparatus for two phase hydroprocessing

InactiveUS7569136B2Hydrogen solubility is “Eliminate needPhysical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

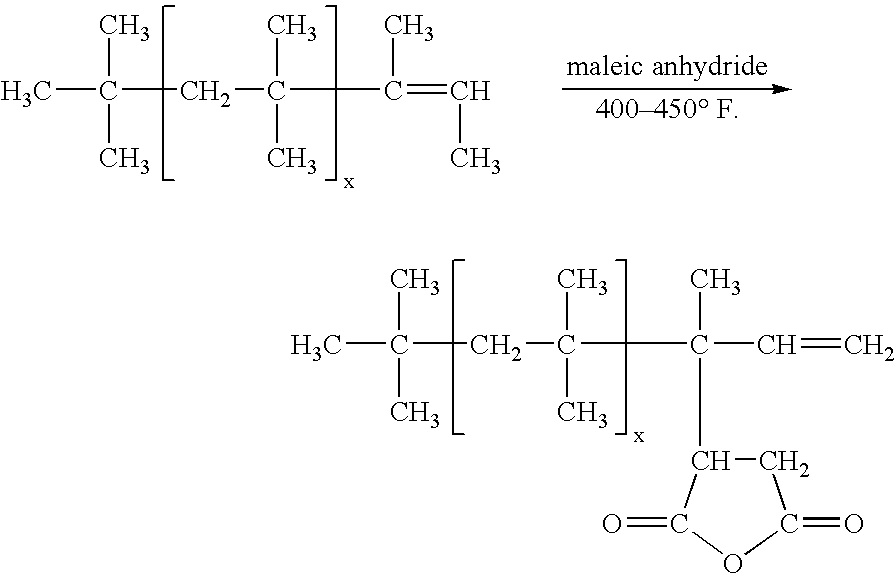

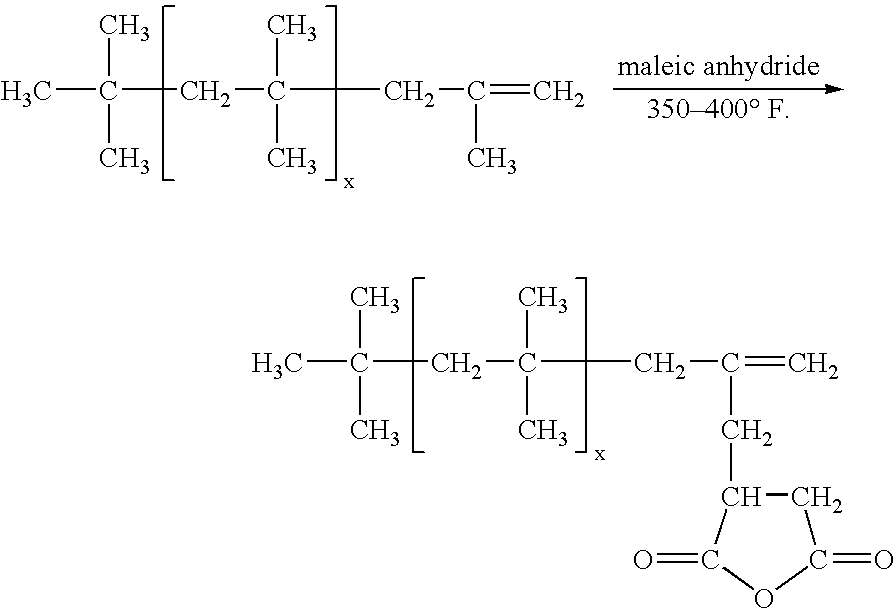

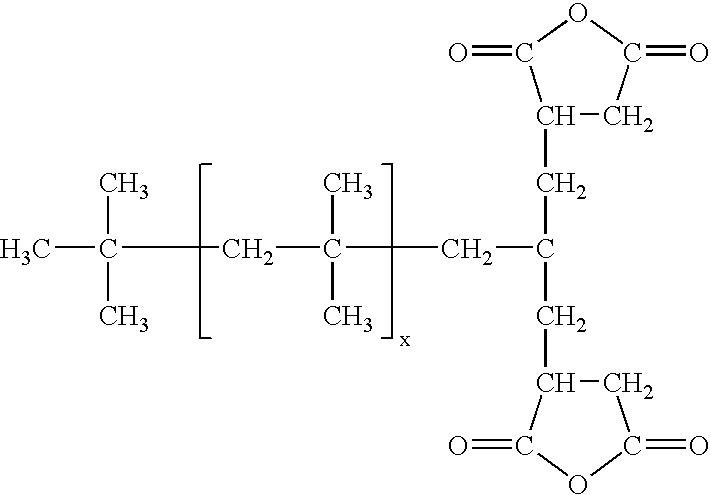

Dispersant material for mitigating crude oil fouling of process equipment and method for using same

InactiveUS20050261440A1Improved high quality PIBSA-PAMConvenience to mergeLiquid carbonaceous fuelsFuel additivesProcess equipmentNitrogen

An improved dispersant material for mitigating crude oil fouling comprises a reaction product of a polyamine and a polyisobutylene succinyl anhydride made with a polyisobutylene having a vinylidene double bond content of at least 50%. The reaction product has an active nitrogen atom content of at least about 2% by weight. The reaction product is prepared by thermally reacting the polyisobutylene with maleic anhydride to produce said polyisobutylene succinyl anhydride and thereafter reacting the polyisobutylene succinyl anhydride with a polyamine having 5 to 7 active nitrogen atoms.

Owner:TPC GROUP

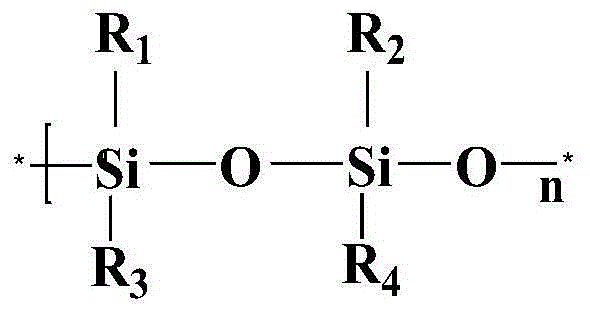

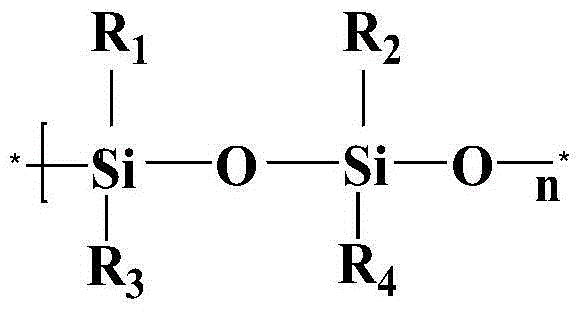

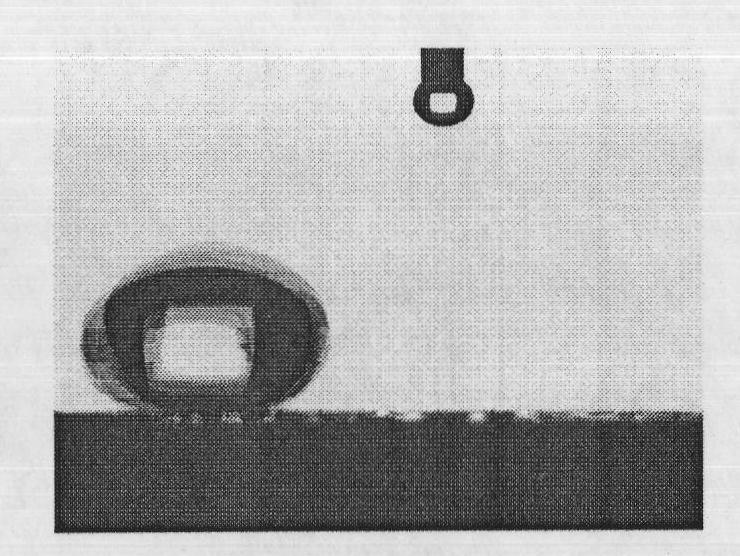

Preparation method of functional fabric

InactiveCN104805680AOvercome strong adsorptionDestruction of the entangled bonded statePhysical treatmentEcological environmentProcess equipment

The invention relates to a preparation method of a functional fabric, and belongs to the technical field of textile materials. Functional nanoparticles are compounded on the surface of the fabric through the preparation of the functional nanoparticles and the preparation of the functional fabric. The existence of vinyl polysiloxane overcomes high adsorption capacity of functional nanoparticle aggregate, so that the uniformly dispersed functional nanoparticles are firmly adhered to the surface of the fabric, and the fabric has multiple functions of ultraviolet resistance, super-hydrophobicity, pollution resistance, antibacterial property, health and the like through the synergistic effect of the vinyl polysiloxane and the functional nanoparticles. According to the preparation method of the functional fabric disclosed by the invention, the vinyl polysiloxane is efficiently utilized, the productive value of the vinyl polysiloxane is improved, and the application of the vinyl polysiloxane to other fields is developed; moreover, the whole process is simple in equipment, relatively low in cost and free of pollution to ecological environment, and has a great application prospect.

Owner:WUHAN TEXTILE UNIV

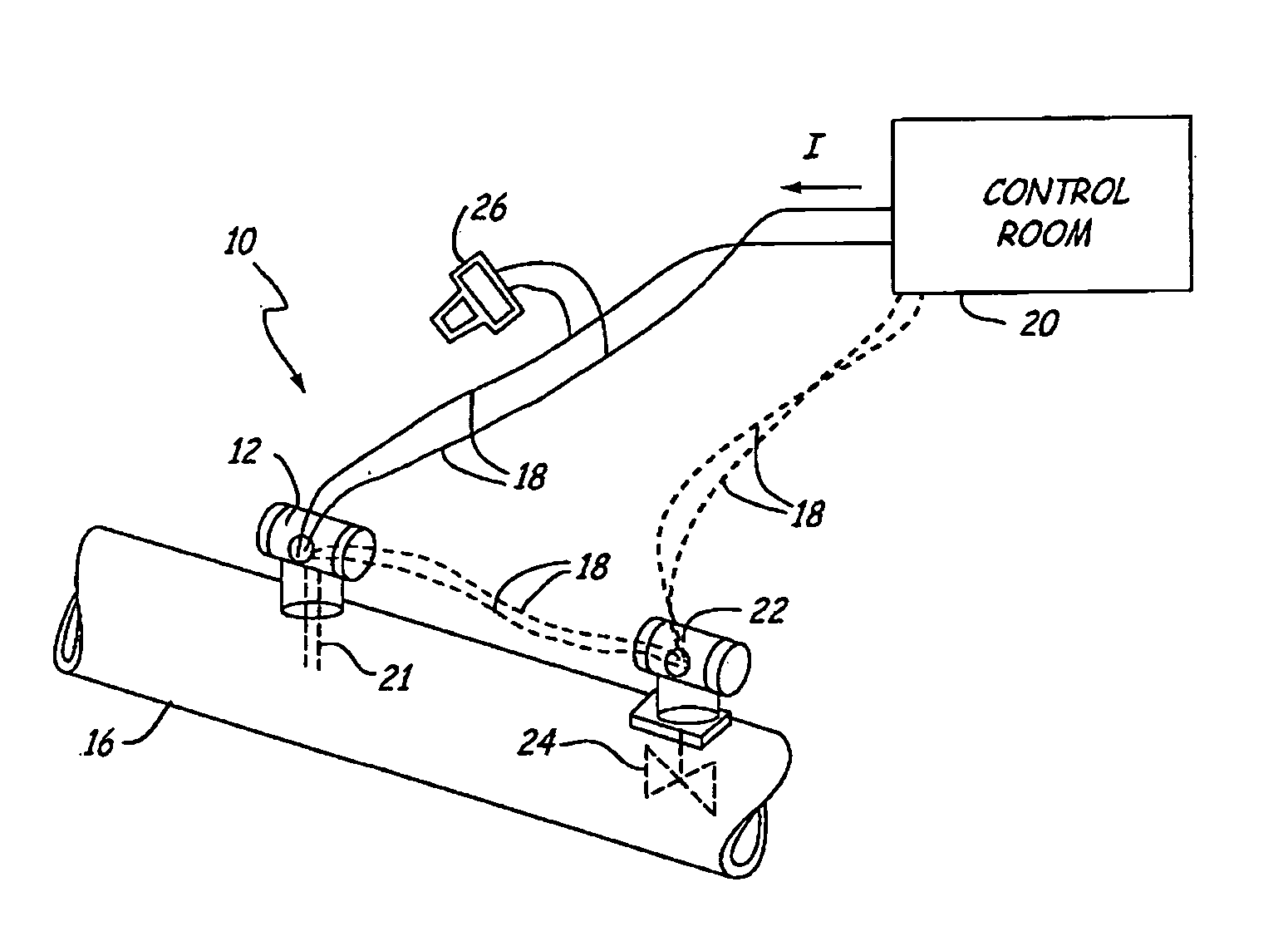

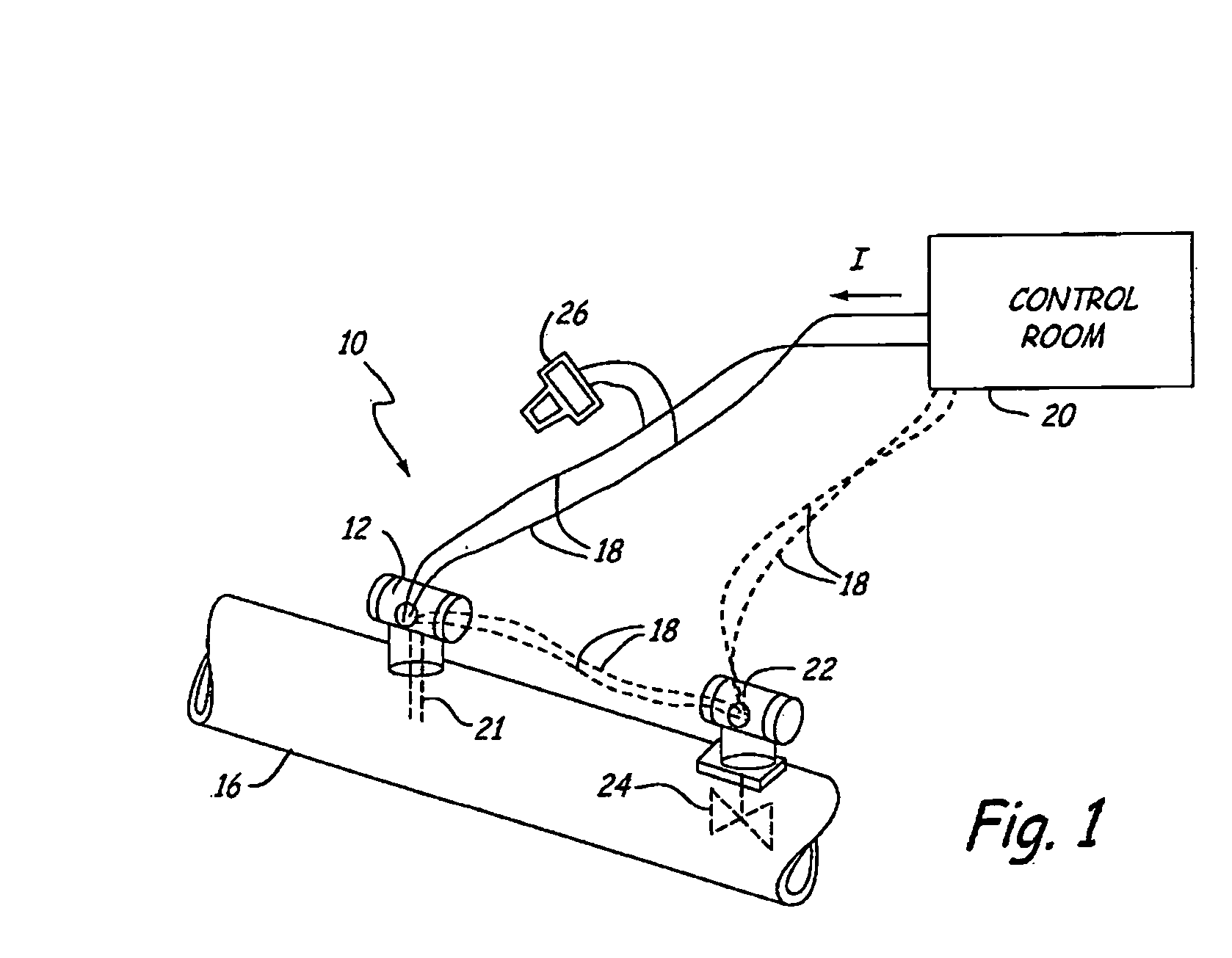

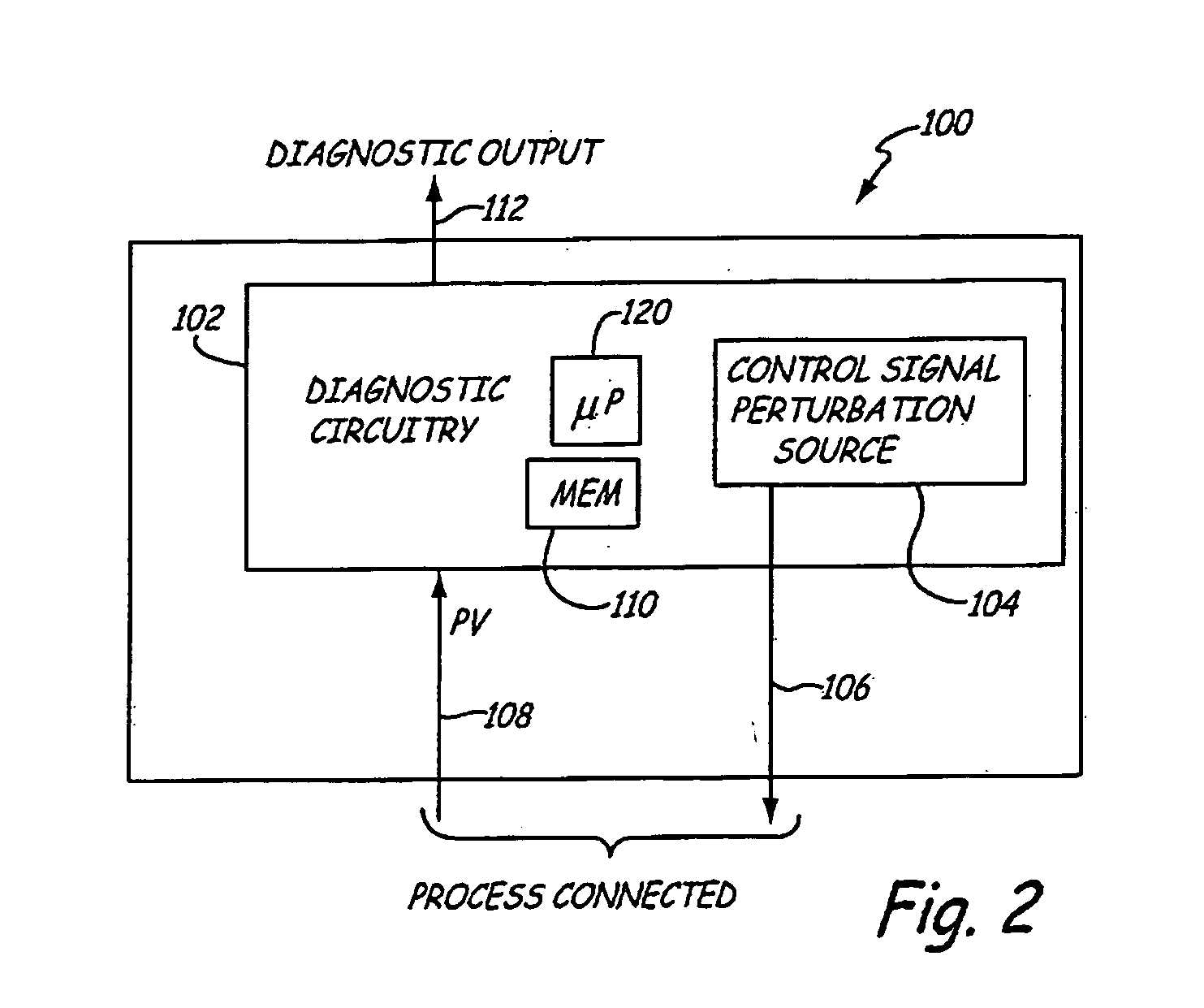

Process equipment validation

ActiveUS20050274417A1Vehicle testingElectric testing/monitoringControl flowSafety instrumented system

A Safety Instrumented System for use with a process control system receives pressure of process fluid in the process piping. A valve positioner positions a valve which controls flow of process fluid through the process piping. The valve positioner is caused to perform a partial stroke of the valve or otherwise introduce a perturbation into the process. A resulting change in sensed pressure due to the perturbation is used to diagnose operation of the process.

Owner:ROSEMOUNT INC

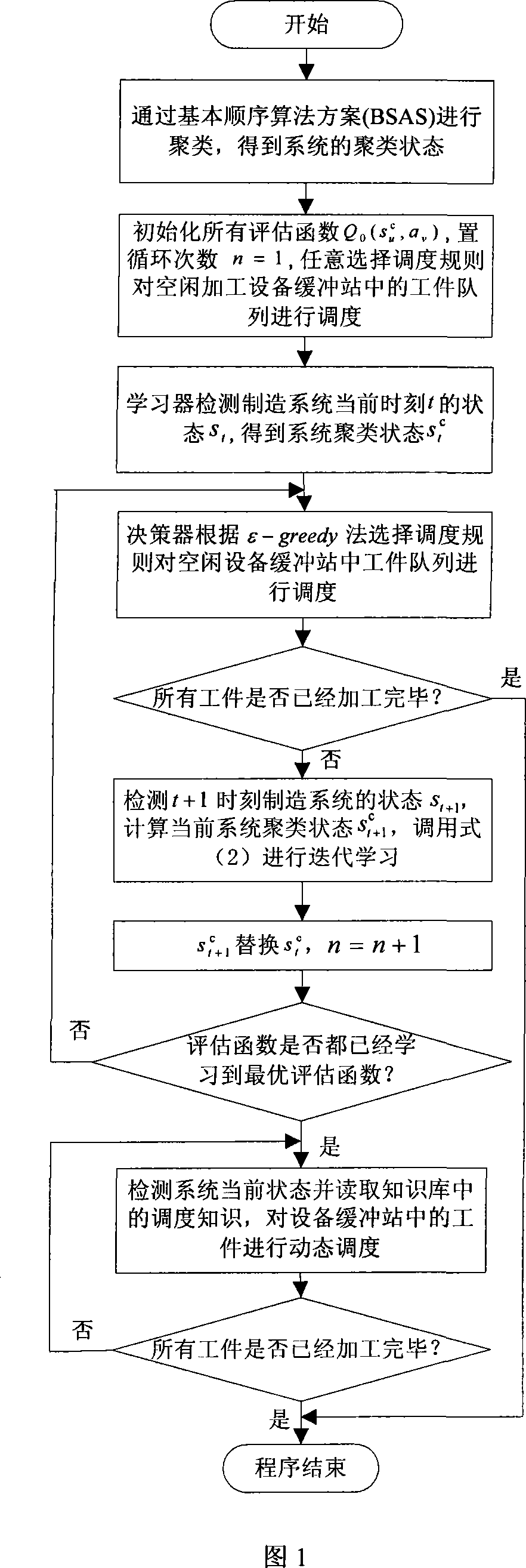

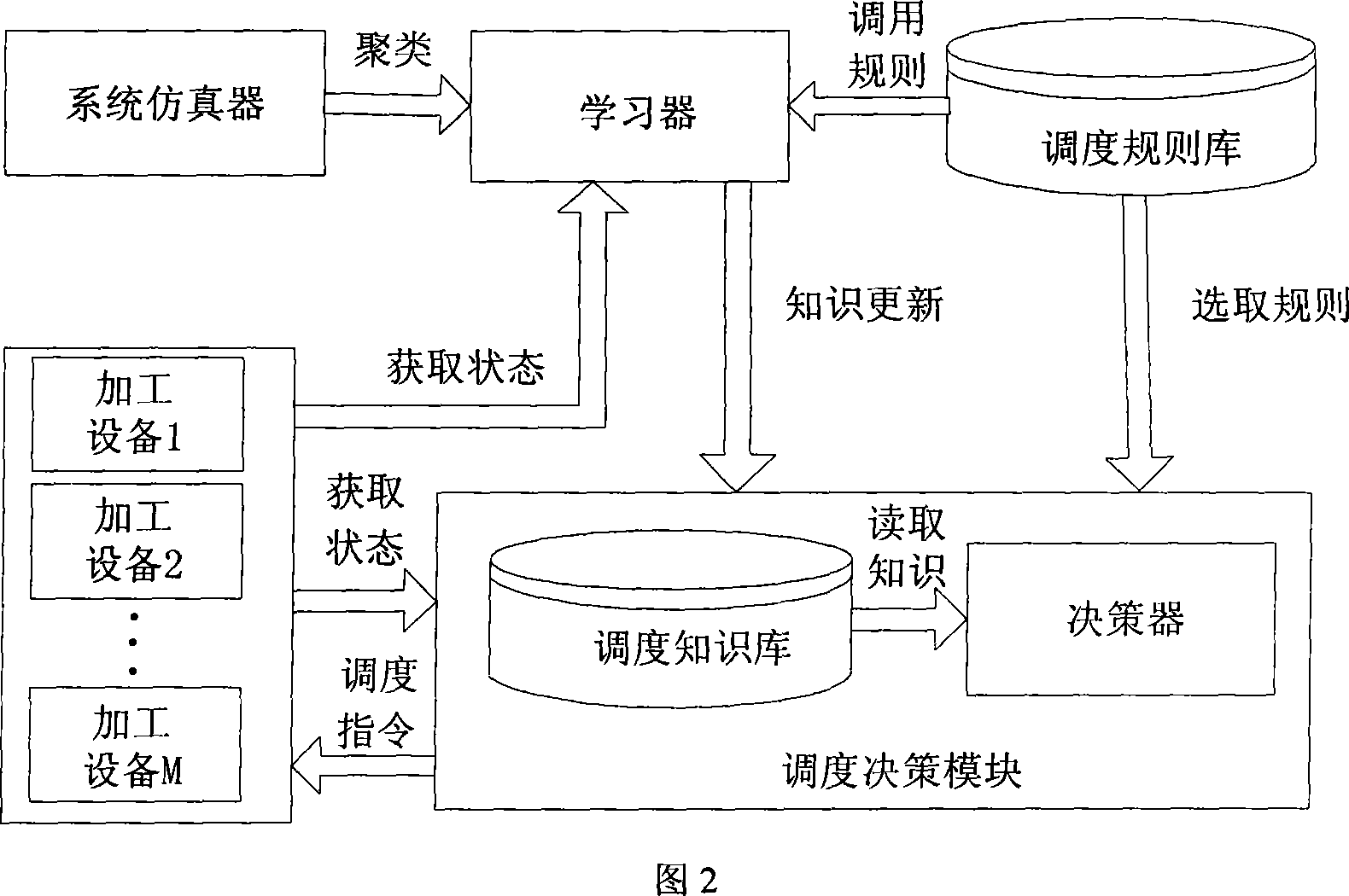

Self-adapting selection dynamic production scheduling control system accomplished through computer

InactiveCN101216710AReduce delaysReduce average time overdueTotal factory controlProgramme total factory controlLearning machineProduction schedule

A self-adaptive selection dynamic production scheduling control system, which is realized via a computer, is characterized in that: the system comprises a system emulator, a learning machine, a decision-making machine, a scheduling rules base, a scheduling knowledge base, a carrier, processing equipments and a buffer station thereof; the buffer station is provided with an optical grating, a sensor and a detection equipment; when a working piece reaches the buffer station and is processed, the learning machine detects the current system status for learning, so as to acquire dynamic scheduling knowledge about the system and update the knowledge in the scheduling knowledge base; when one processing equipment needs to be scheduled, the decision-making machine reads corresponding scheduling knowledge in the scheduling knowledge base according to the detected system status, acquires new scheduling knowledge through continuous interactive learning with the processing system, dynamically selects the scheduling rules based on the status of the processing equipments and the working piece in the system, and chooses the optimized scheduling rules to schedule the processing equipments. The invention can adapt to instable time-varying workshop dynamic production environments, obtain a better working-piece arrangement than prior rule-based scheduling technology, effectively reduce the process waiting time, and improve the fill rate of product delivery time.

Owner:SOUTHEAST UNIV

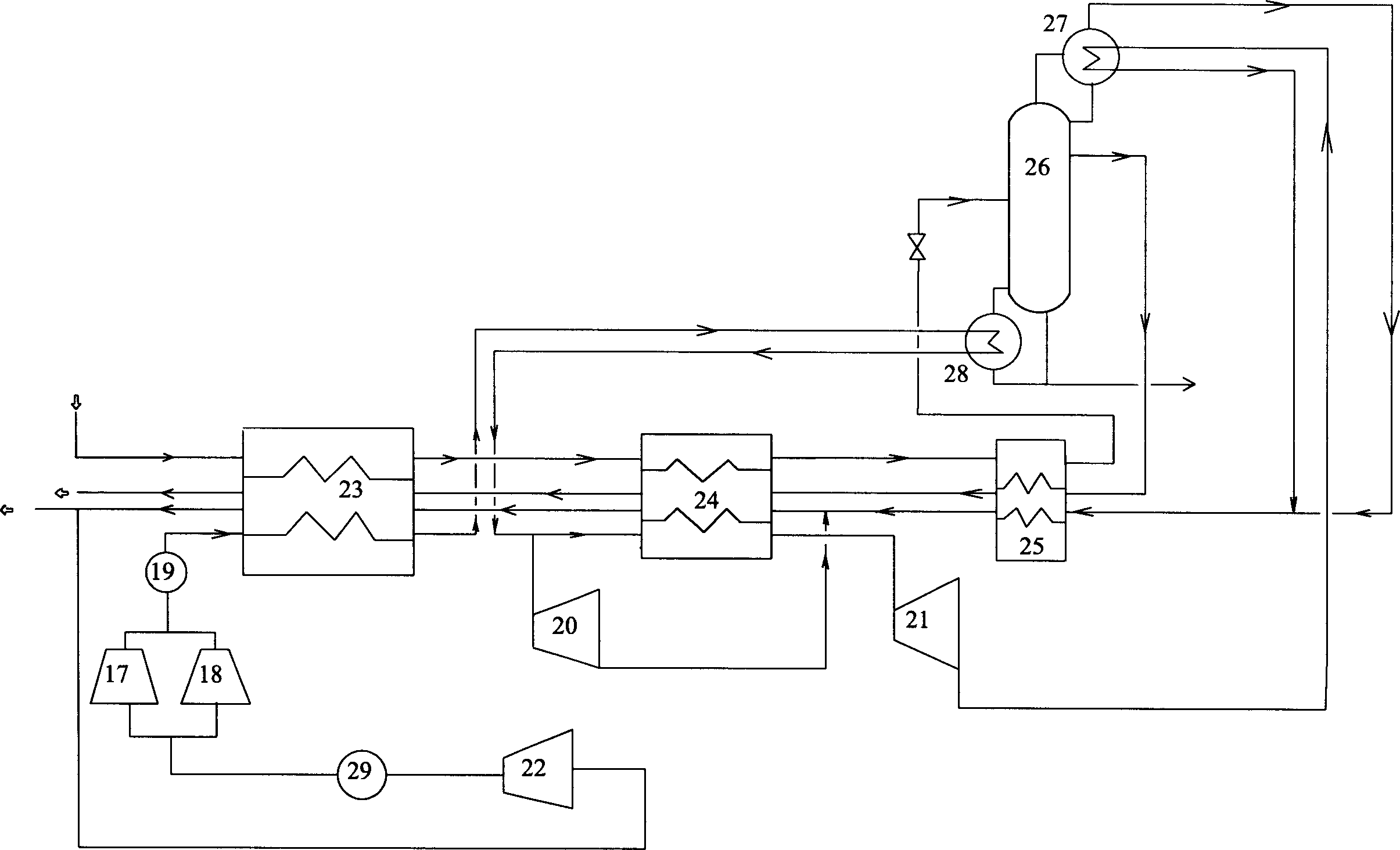

Air-contained coal gas gasification and separation process and equipment

The present invention relates to an air-contained coal gas gasification and separation process, which is chiefly to passing over the air-contained coalbed gas to the middle of the fractionating tower after cooling, through the evaporation of the evaporator in the bottom of the fractionating tower and the condensation of the top condenser, gas fraction inside the inner of the tower, the sufficient quality and heat exchange of the liquid fraction. The high purity nitrogen gas is obtained in the top of the fractionating tower and the high purity liquid natural gas is obtained in the bottom of the fractionating tower, wherein one part of pure air is induced to the heat exchanger at the entrance between the top of the fractionating tower and the air-contained coalbed gas. The invention also provides an equipment of the separation process. The air-contained coal gas gasification and separation process and equipment are separation liquefaction process specially designed for the air-contained coalbed gas, which adopts the single stage rectifying still simpler than the doublestage rectifying, and has convenient operation, low cost and easy to popularize in large scale.

Owner:BEIJING ZHONGKE RUIAO ENERGY TECH CO LTD

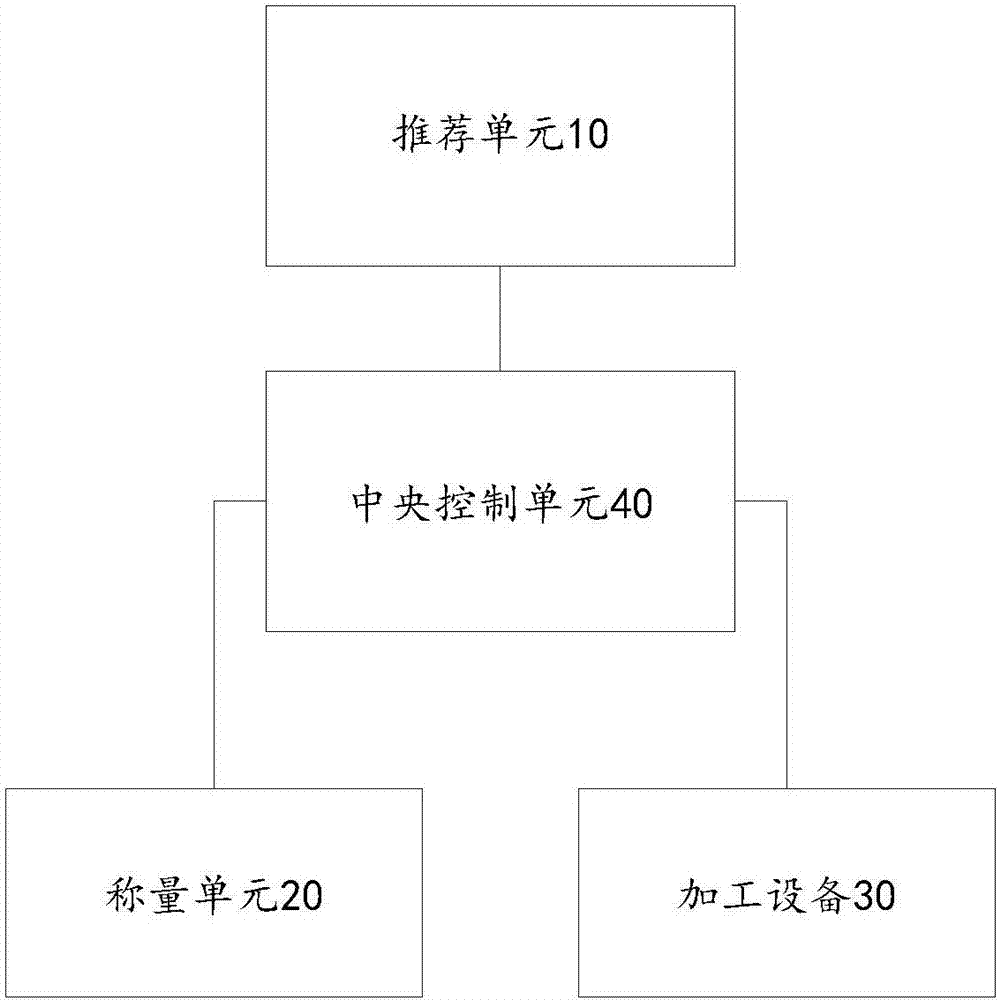

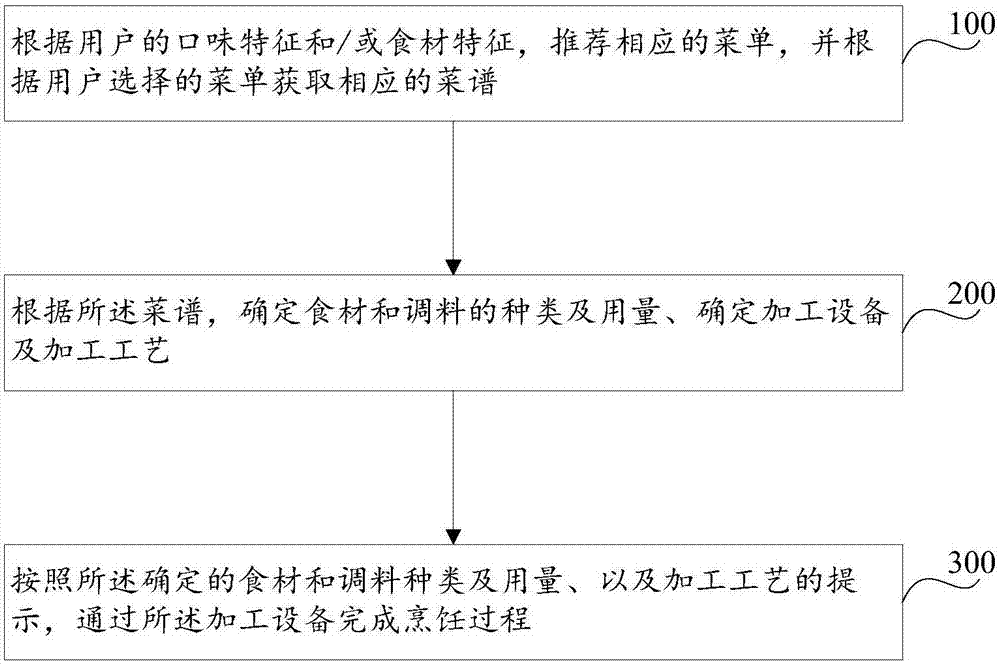

Smart kitchen cooking system and smart cooking aiding method

The invention discloses an intelligent kitchen cooking system, comprising: a recommending unit for recommending corresponding menus according to the user's taste characteristics and / or material characteristics, and searching for corresponding recipes according to the menu selected by the user; a weighing unit, It is used to weigh ingredients and seasonings; processing equipment is used to process and cook ingredients and seasonings; the central control unit is connected to the recommendation unit, weighing unit and processing equipment respectively, and is used to recommend menus and recipes based on the recommendation unit , control the weighing unit and processing equipment to work in coordination to complete the cooking process. In addition, the invention also discloses an intelligent auxiliary cooking method. The intelligent kitchen cooking system proposed by the present invention is an intelligent kitchen cooking system based on personalized recommendation, which can recommend corresponding menus and cooking plans according to the user's taste characteristics and / or ingredients characteristics, so as to better solve what the user eats and how to do it. question.

Owner:PHICOMM (SHANGHAI) CO LTD

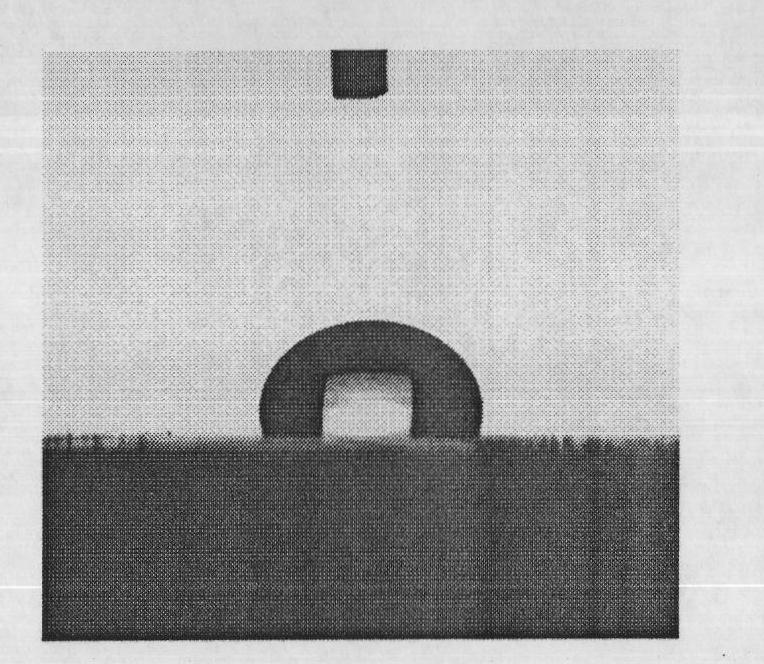

Super-hydrophobic nano-composite coating and preparation method thereof

InactiveCN101845242AExcellent superhydrophobic propertiesAchieve self-cleaning effectCoatingsProcess equipmentHydrophobic polymer

The invention discloses a super-hydrophobic nano-composite coating comprising the following components in percentage by weight: 0.5-10.5 percent of hydrophobic silicon dioxide, 0.2-5.4 percent of hydrophobic polymer material and 86.5-99.3 percent of solvent, wherein a contact angle of a water drop on a membrane surface prepared by the coating is 152-169 degrees, and a rolling angle is 1-9 degrees. When the coating is transparent, the visible light transmission of the membrane prepared from the coating is 80-94 percent. The invention also discloses a preparation method of the super-hydrophobic nano-composite coating. The nano-composite coating not only has excellent super-hydrophobicity and low cost of products, but also can obtain higher transparency by reducing the contents of the hydrophobic silicon dioxide and the hydrophobic polymer material and has simple preparation processing equipment and high production efficiency.

Owner:SICHUAN UNIV

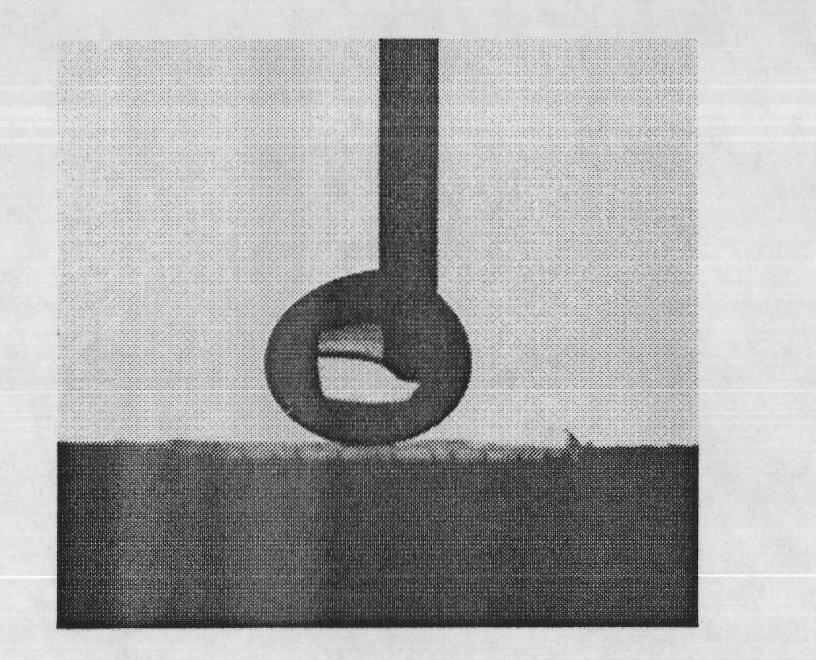

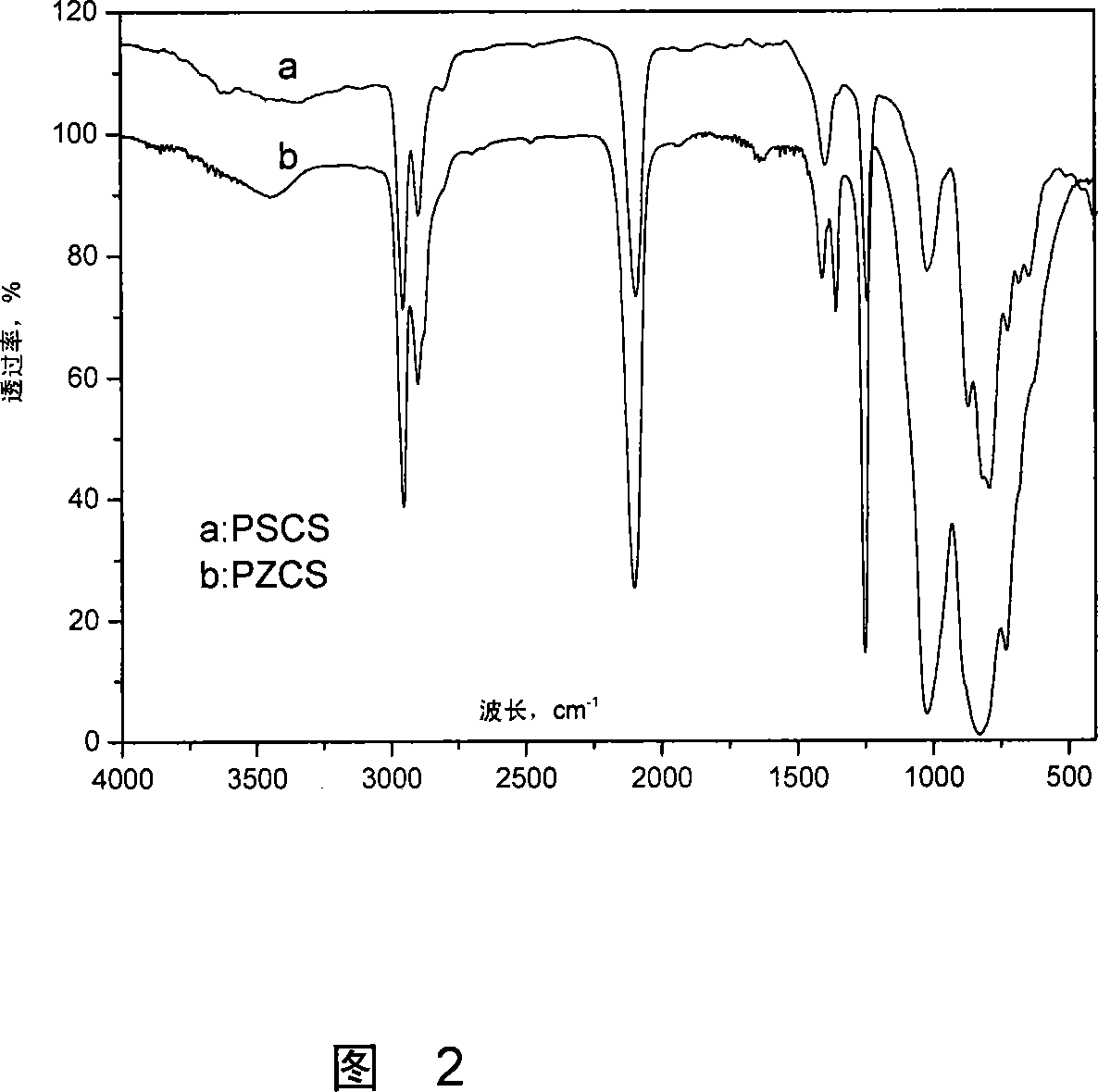

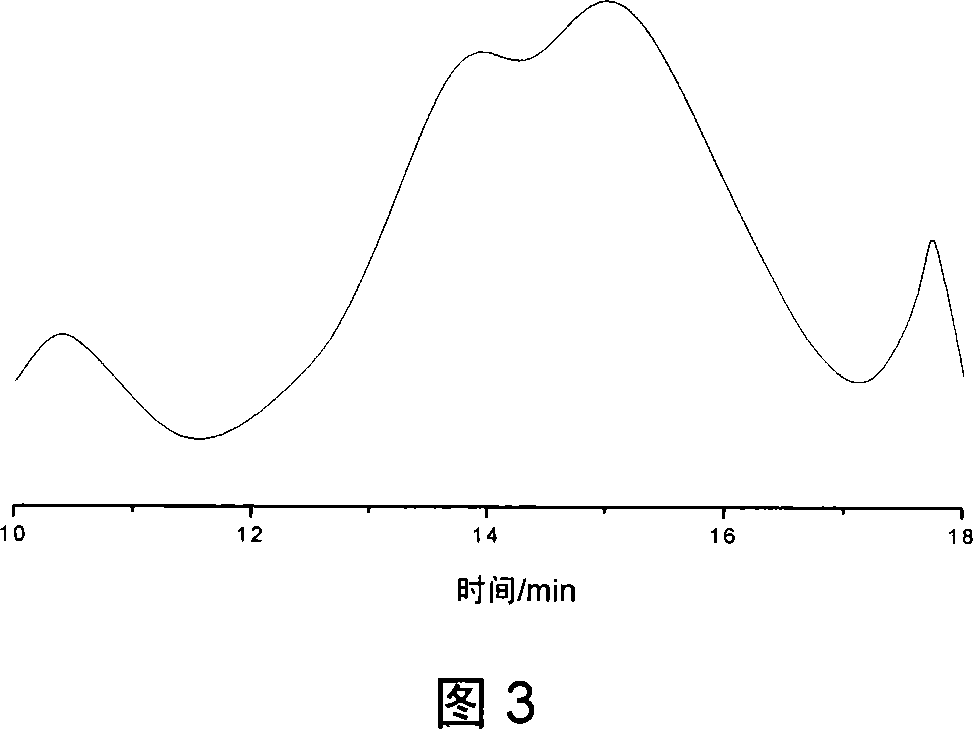

Method and equipment for preparing precursor body of poly carbon silane ceramics of containing zirconium

This invention discloses method and apparatus for preparing polycarbosilane ceramic precursor containing Zr. The method comprises: utilizing low molecular weight polymer with S-H bonds (polysilane, polycarbosilane or poly(dimethyl silane)) as the raw material, organic metallic compound containing Zr as the additive, and Ar, N2 or their mixture as the protective atmosphere, and pyrolyzing at high temperatures and normal pressure to obtain Zr-containing SiC ceramic precursor PZCS. The pyrolysis apparatus comprises a three-necked flask in the heater, a pyrolysis column in the electric heating jacket, a condensing tube, a separatory funnel, and a vacuum system seam. The method is simple, and can control the content and properties of Zr in the precursor and the ceramic. The product has such advantages as high purity, high remoldability, and high heat resistance.

Owner:NAT UNIV OF DEFENSE TECH

Laser sintering process chamber gas curtain window cleansing in a laser sintering system

ActiveUS20060249485A1Control lossAvoid lostAdditive manufacturing apparatusAdditive manufacturing with solidsProcess equipmentMetallurgy

An inert gas dispenser for mounting to a process equipment functional window is provided to dispense an inert gas in a laminar flow at an effective velocity across the exposed surface to form a curtain of inert gas across the exposed surface to prevent a build-up of chemical by-product from the powder material during laser sintering. The gas flow rate is characteristic of a flow geometry having a Reynolds number below the turbulent range. The diffuser is used in a laser sintering system.

Owner:3D SYST INC

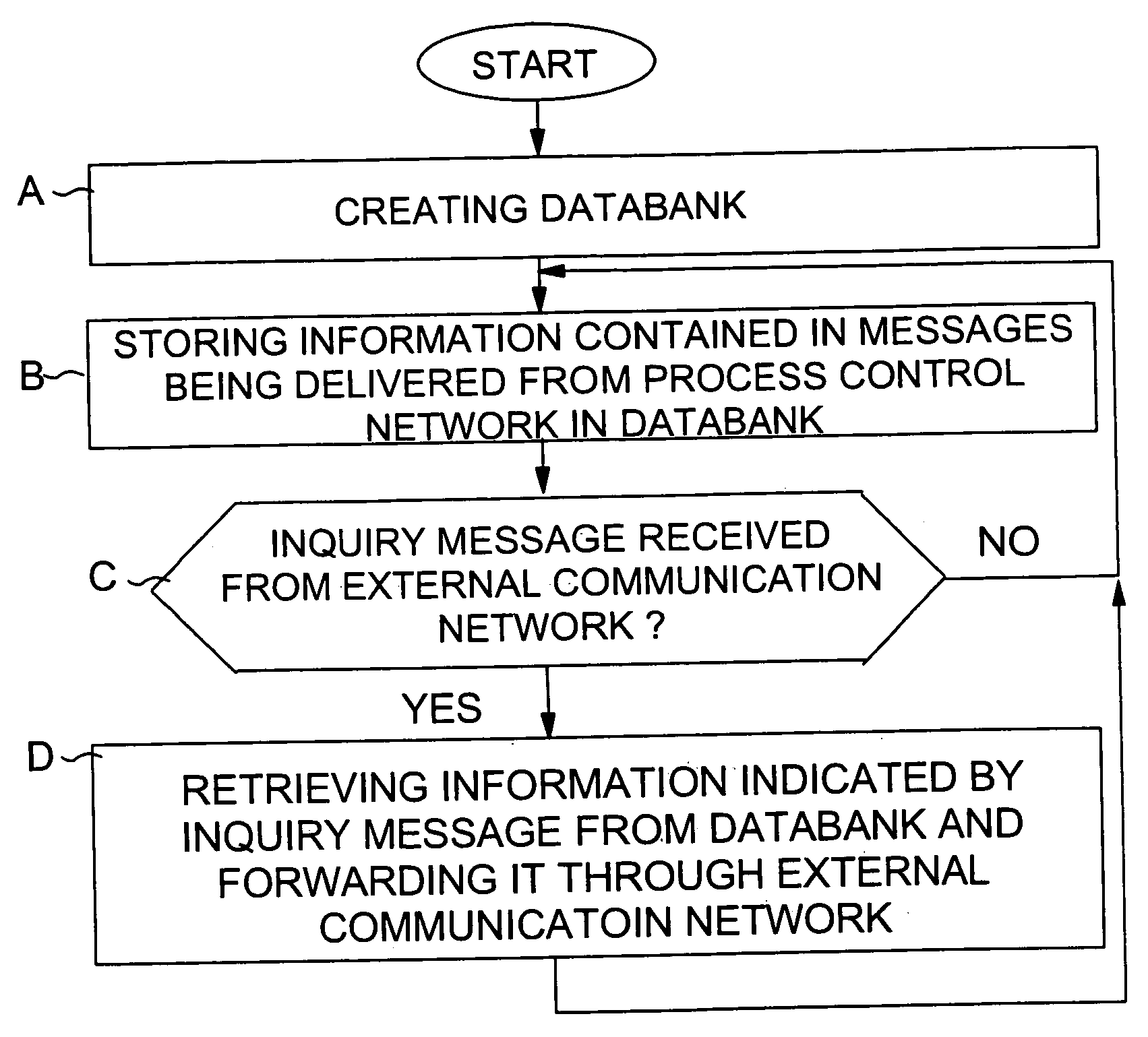

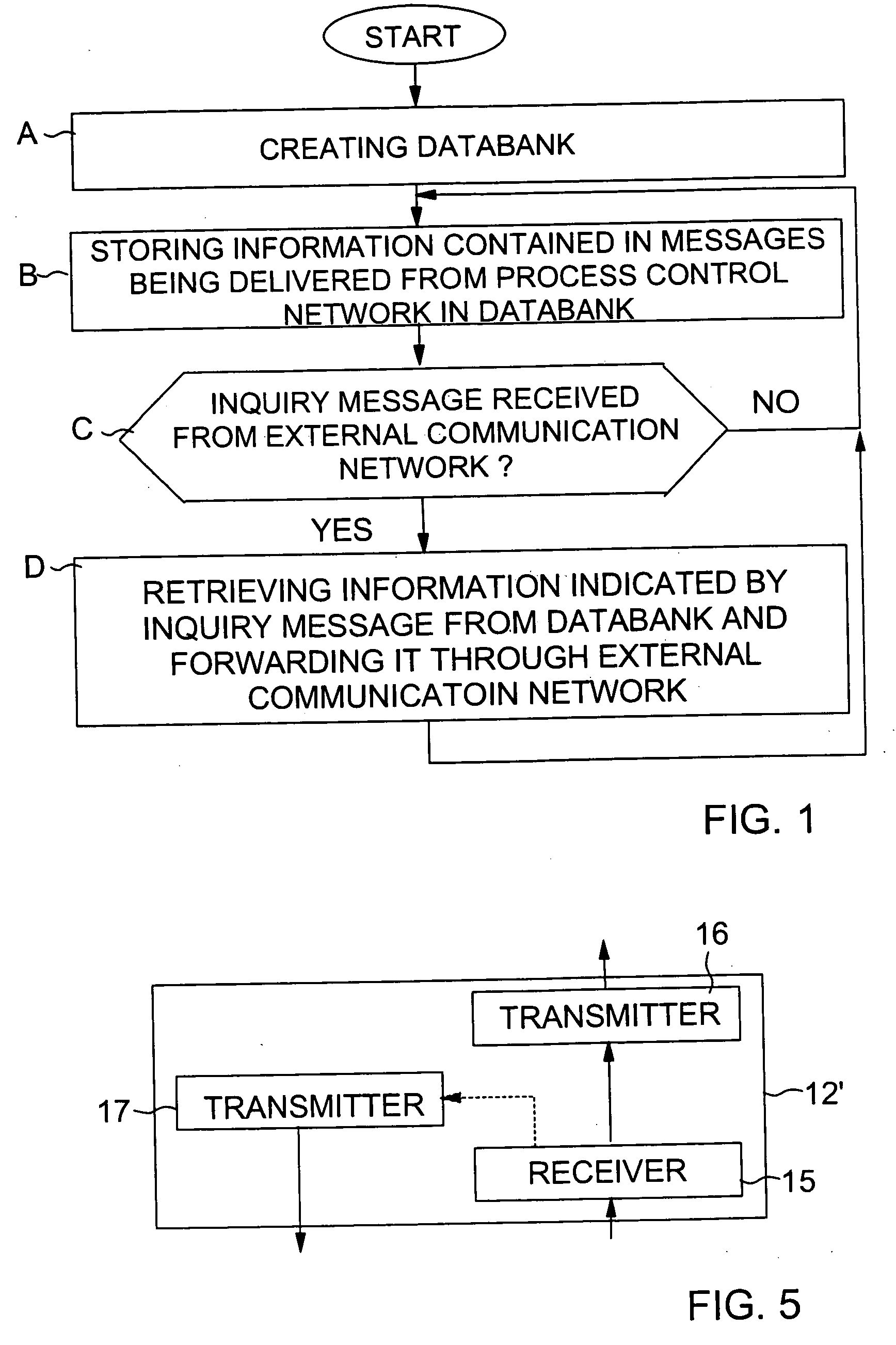

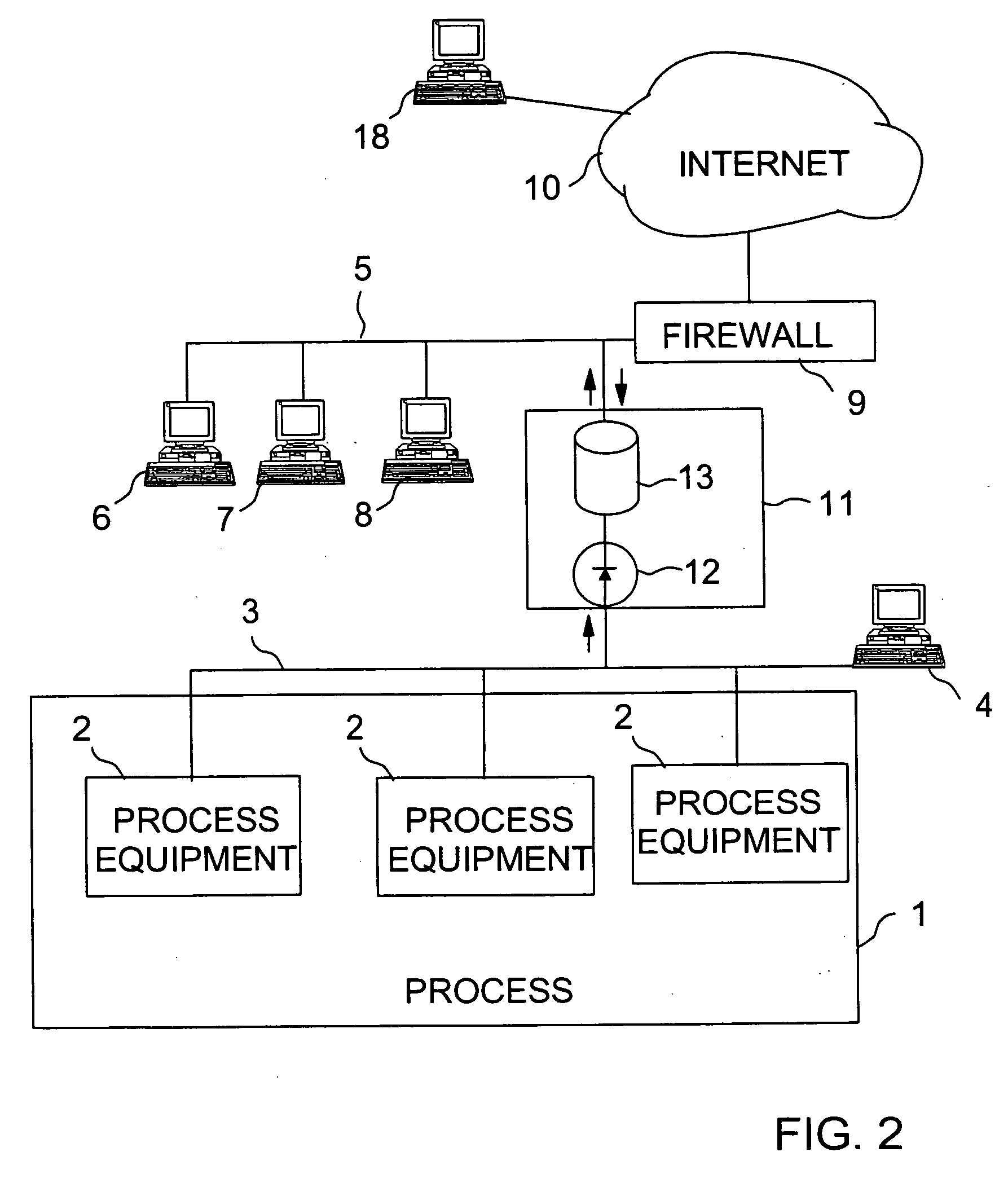

System, communication network and method for transmitting information

InactiveUS20050165939A1Control safetyProgramme controlComputer controlProcess control networkProcess equipment

Owner:METSO AUTOMATION OY

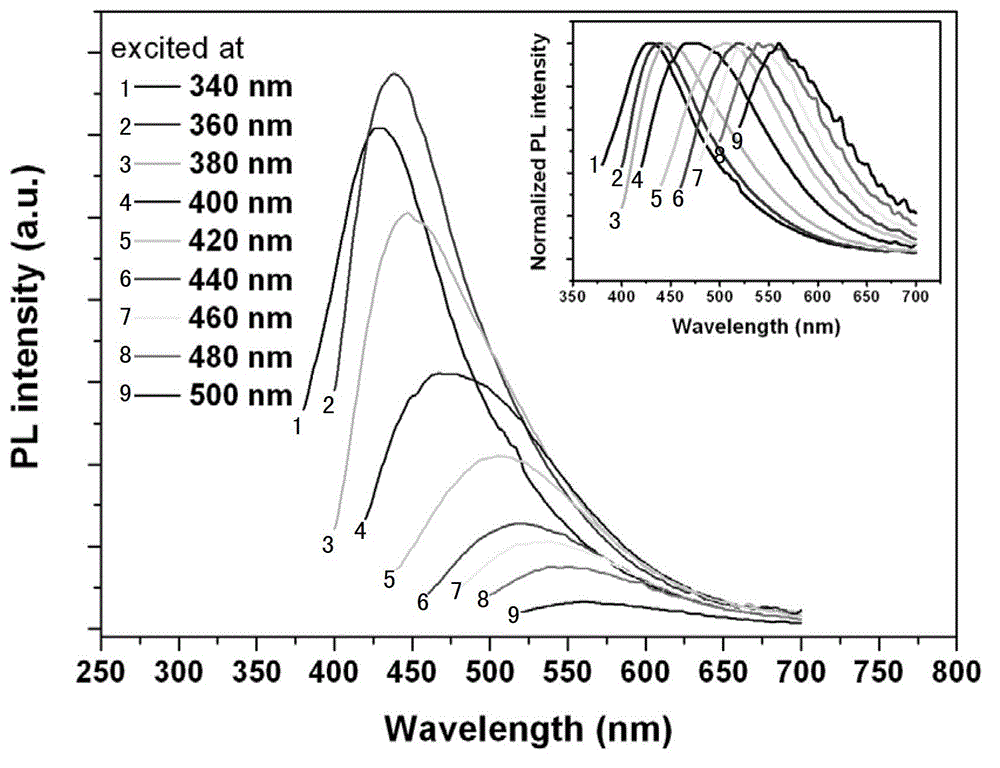

Method for preparing photoluminescence carbon quantum dot

ActiveCN102745669AWide variety of sourcesLow costMaterial nanotechnologyNano-carbonProcess equipmentPhotoluminescence

The invention discloses a method for preparing a photoluminescence carbon quantum dot. The method includes the following steps of drying and dehydrating a solid residue obtained after squeezing soybeans into soya-bean milk, placing the dried and dehydrated solid residue in an electrothermal blowing dry box to heat and carbonize to obtain a crude product of the carbon quantum dot, grinding the crude product of the carbon quantum dot, sieving, dispersing the sieved crude product of the carbon quantum dot in deionized water, uniformly stirring, still standing, centrifuging, evaporating an obtained aqueous solution containing the carbon quantum dot, and freeze drying to form a powdered shape to finally obtain the photoluminescence carbon quantum dot. According to the method for preparing the photoluminescence carbon quantum dot, a household bean juice maker is used for obtaining soybean dregs which serve as raw materials, the source of the raw materials is wide, the photoluminescence carbon quantum dot is prepared through low temperature heating and carbonization, the operation is simple, the cost is low, the yield is high, the preparation process equipment is simple and easy, the operation can be completed within an extremely short time, and the method is easy to popularize.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

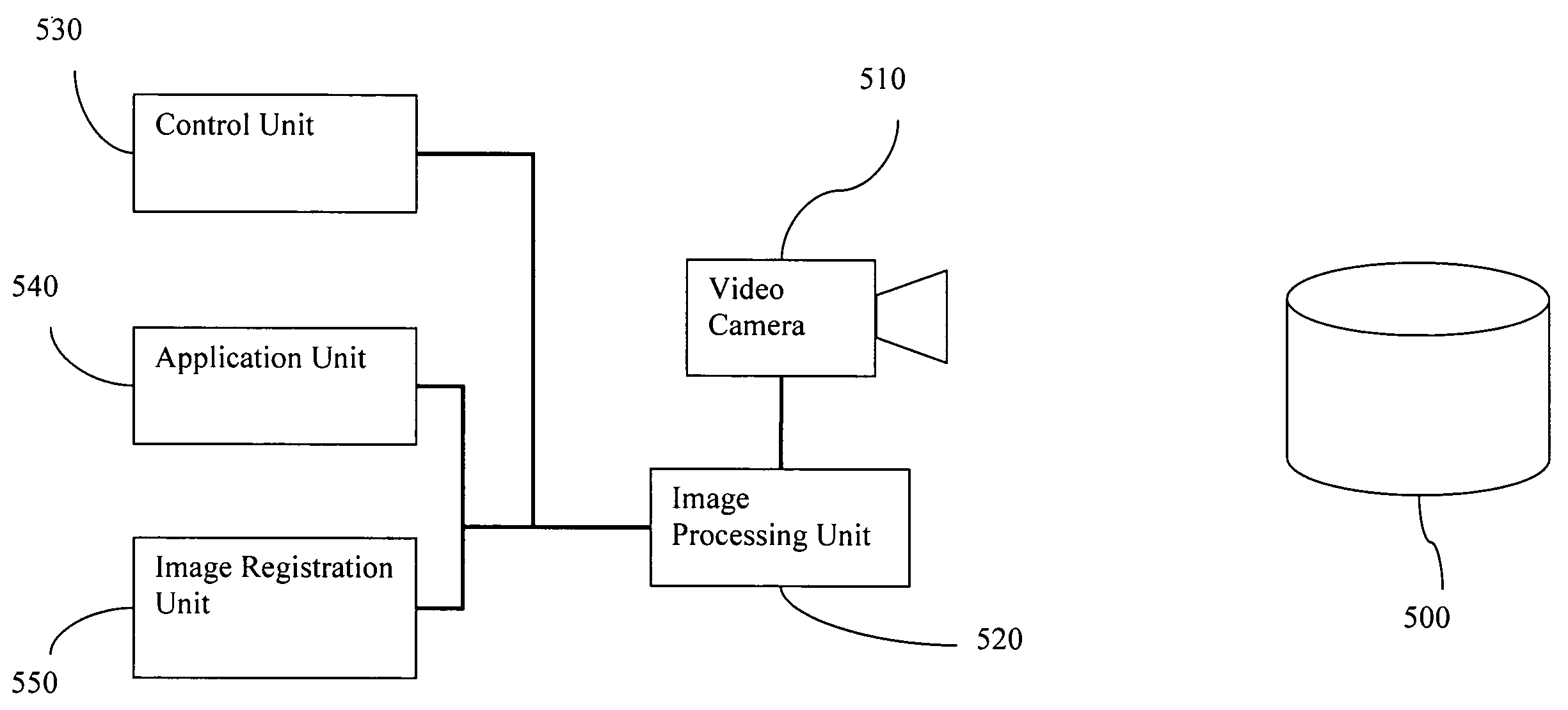

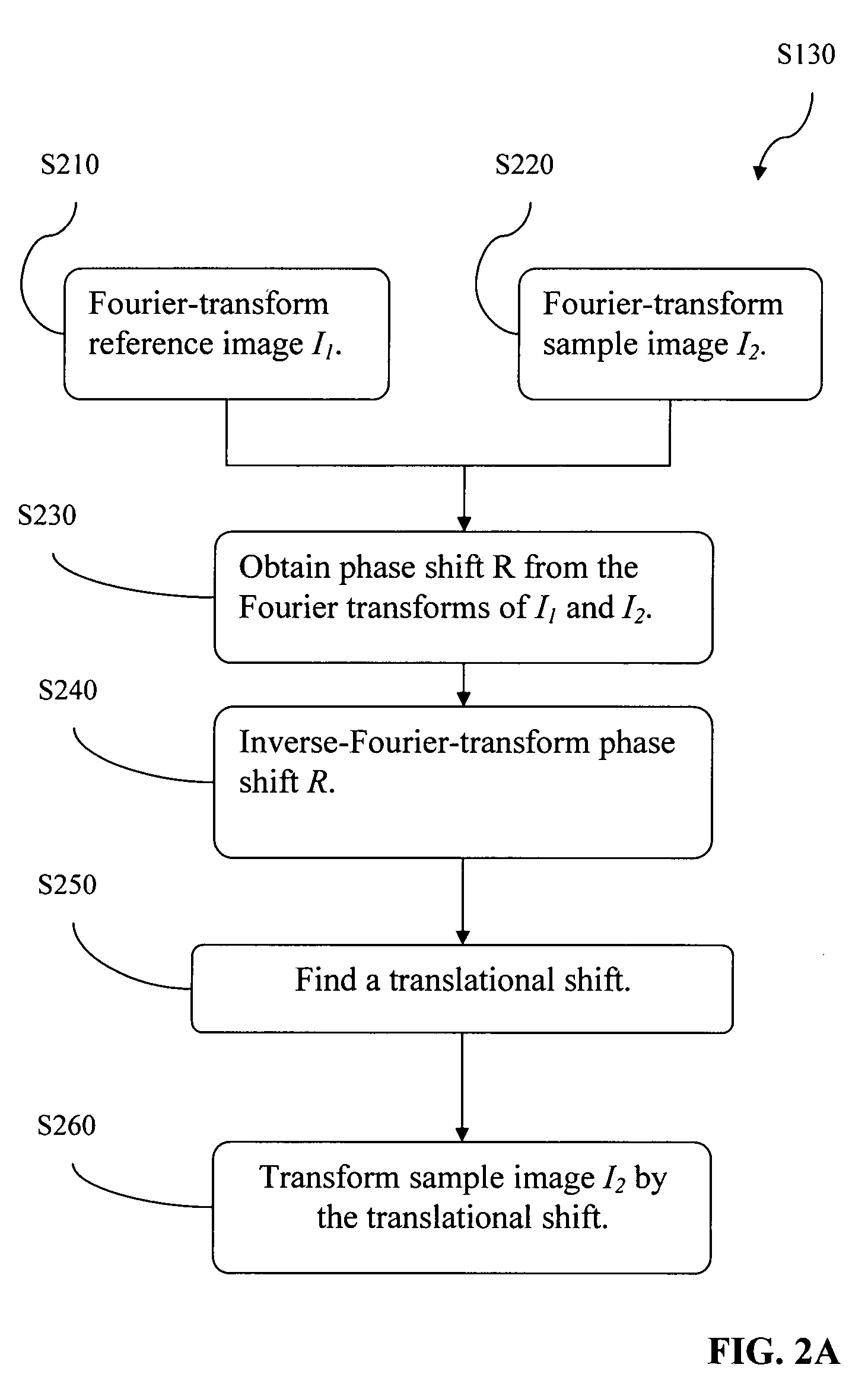

Automatic alignment of video frames for image processing

InactiveUS20080063298A1Reduce errorsImprove stabilityImage enhancementImage analysisProcess equipmentConfocal

The provided is a method that can automatically align image frames in recorded video clips. Individual frames in video may shift and rotate due to shaking or vibration of a video camera. Unaligned frames make some imaging processing techniques difficult or infeasible. One example of image processing techniques is to isolate, recognize, and / or quantitatively analyze vapor plume images captured by an Infrared (IR) camera. Such techniques have a great potential to be used to automatically detect volatile organic compounds (VOC) leaked from process equipment at refineries and chemical plants. This invention is a technique for various subsequent image processing techniques. The invention uses spatially based Fast Fourier Transforms (FFT) to determine amount of shift, rotation, and scaling to align image frames, and uses a digital filtering technique to improve the alignment.

Owner:PROVIDENCE PHOTONICS

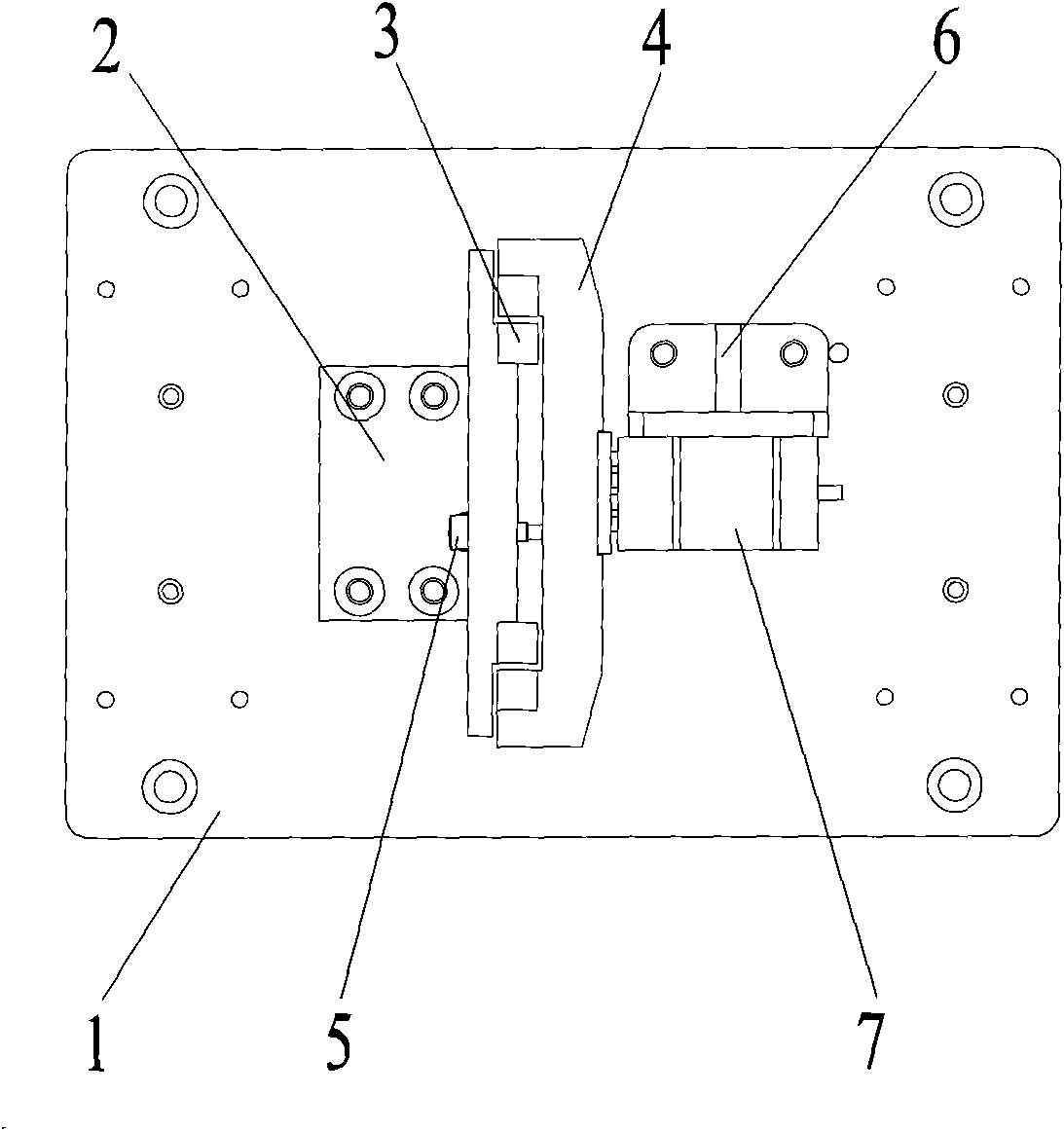

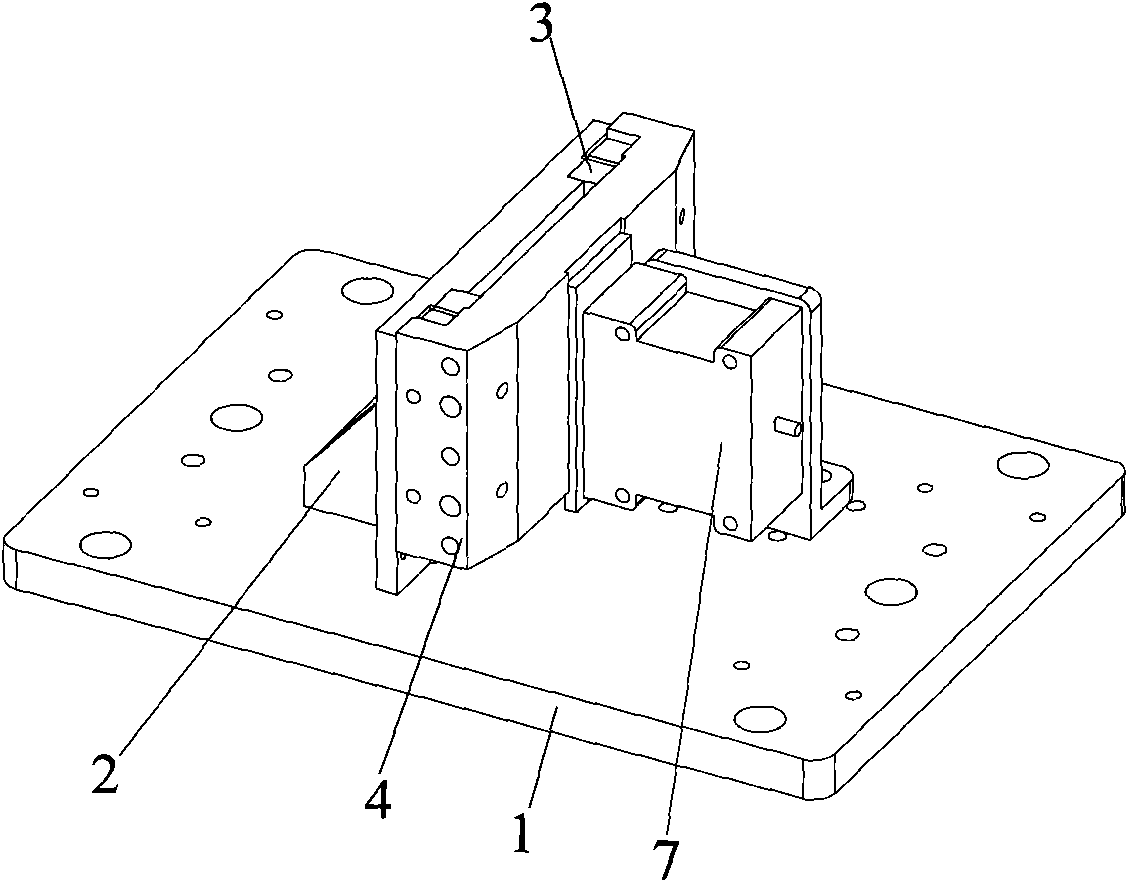

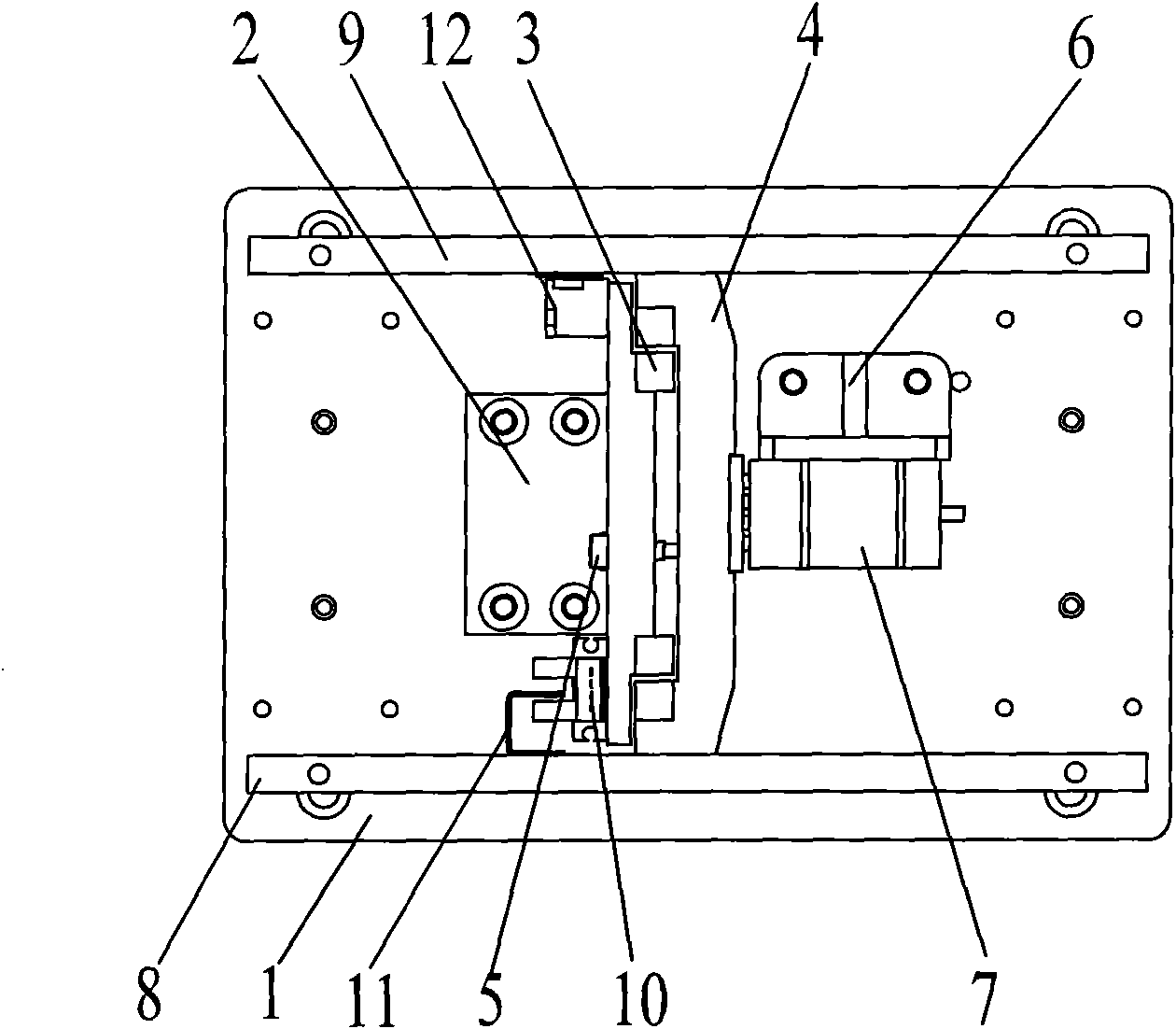

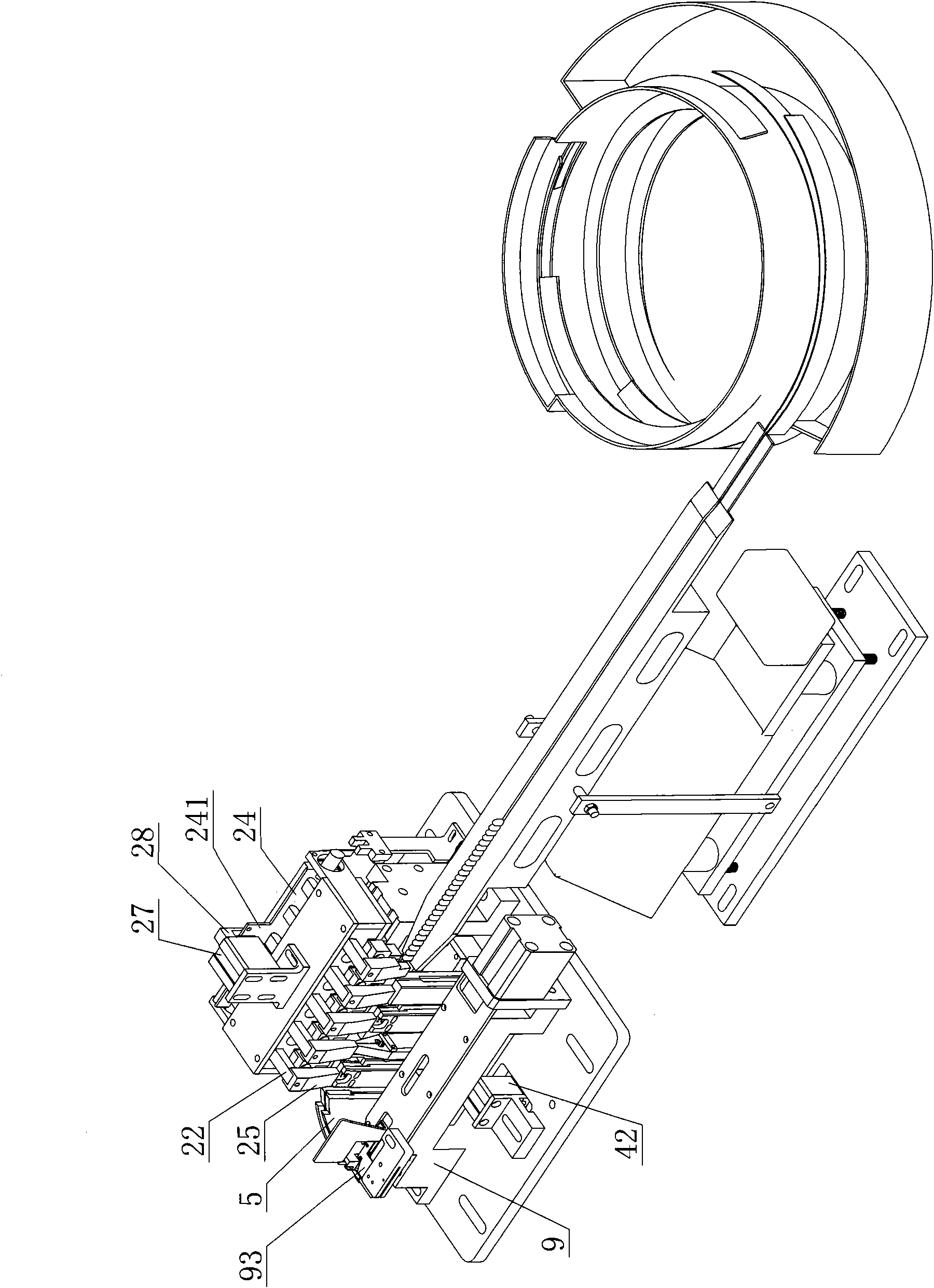

High-precision Z-axis carrier platform of picosecond laser process equipment

ActiveCN101637849AAddress dynamic thrustSolve the problem of insufficient static holding forceLaser beam welding apparatusPicosecond laserGrating

The invention relates to a high-precision Z-shaft carrier platform of picosecond laser process equipment. A Z fixed plate is fixed on the base plate of a Z platform, a vertical guide rail is installedon the Z fixed plate, an elevating plate capable of moving upwards and downwards along the guide rail is installed on the guide rail, a piezoelectric ceramic motor for controlling the elevating plateto move upwards and downwards is installed on the base plate of the Z platform, a vertical front side plate is fixed on the front side surface of the elevating plate, a vertical back side plate is fixed on the back side surface of the elevating plate, and the front side plate and the back side plate are arranged symmetrically in parallel; a sensor is arranged on the Z fixed plate, and the internal surface of the front side plate or the back side plate is provided with a sensing plate of the sensor; a reading head is arranged on the Z fixed plate, and a grating gage is stuck to the internal surface of the front side plate or the back side plate; and fixture plates are arranged on the front side plate and the back side plate. The high-precision Z-shaft carrier platform of the picosecond laser process equipment controls the Z-shaft to start, stop and elevate by using the high-resolution piezoelectric ceramic motor. The grating gage ensures the precision of elevation and positioning. Thebalancing mechanism solves the problems of insufficient thrust and static retaining force of the piezoelectric ceramic motor.

Owner:SUZHOU DELPHI LASER

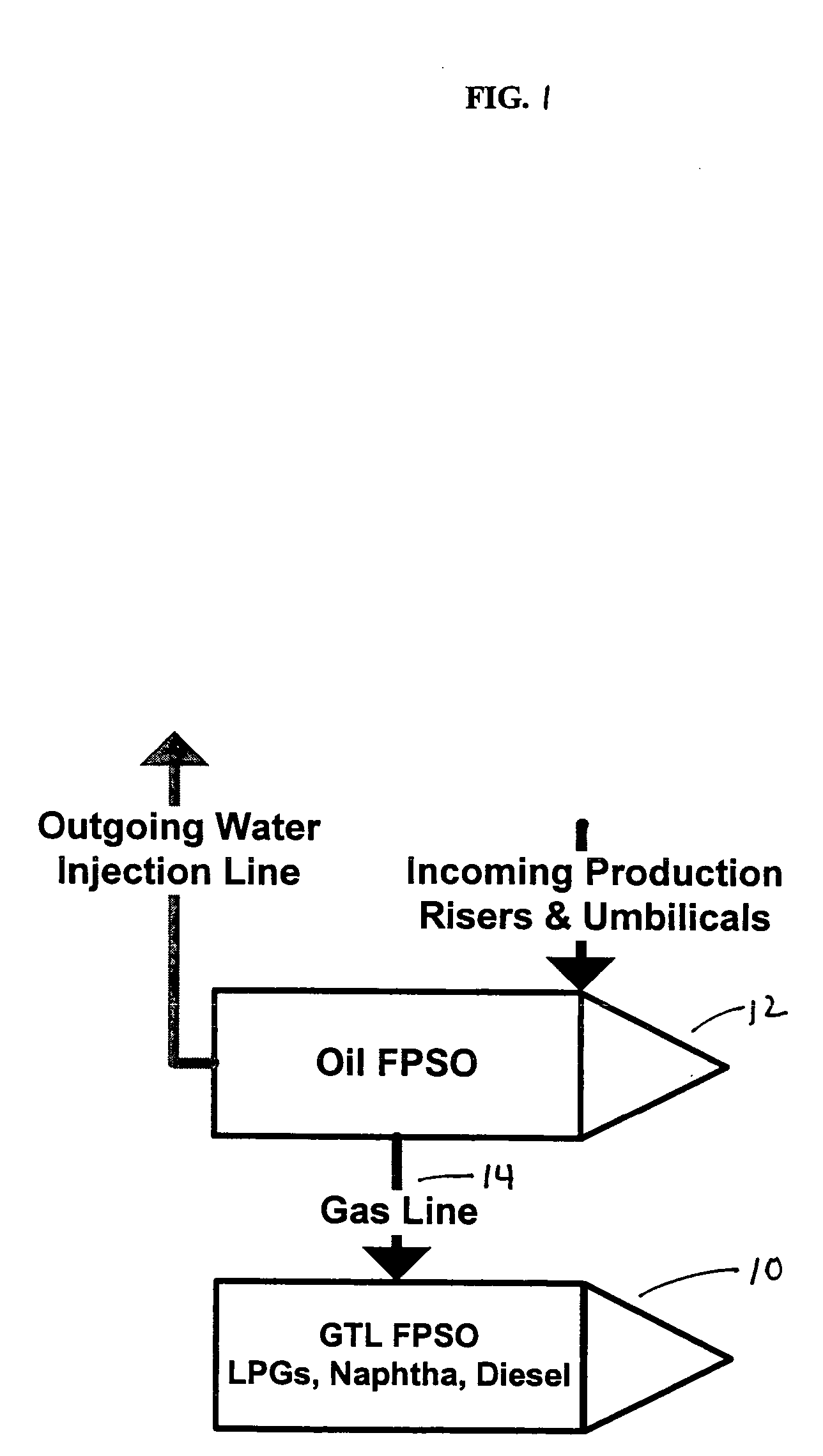

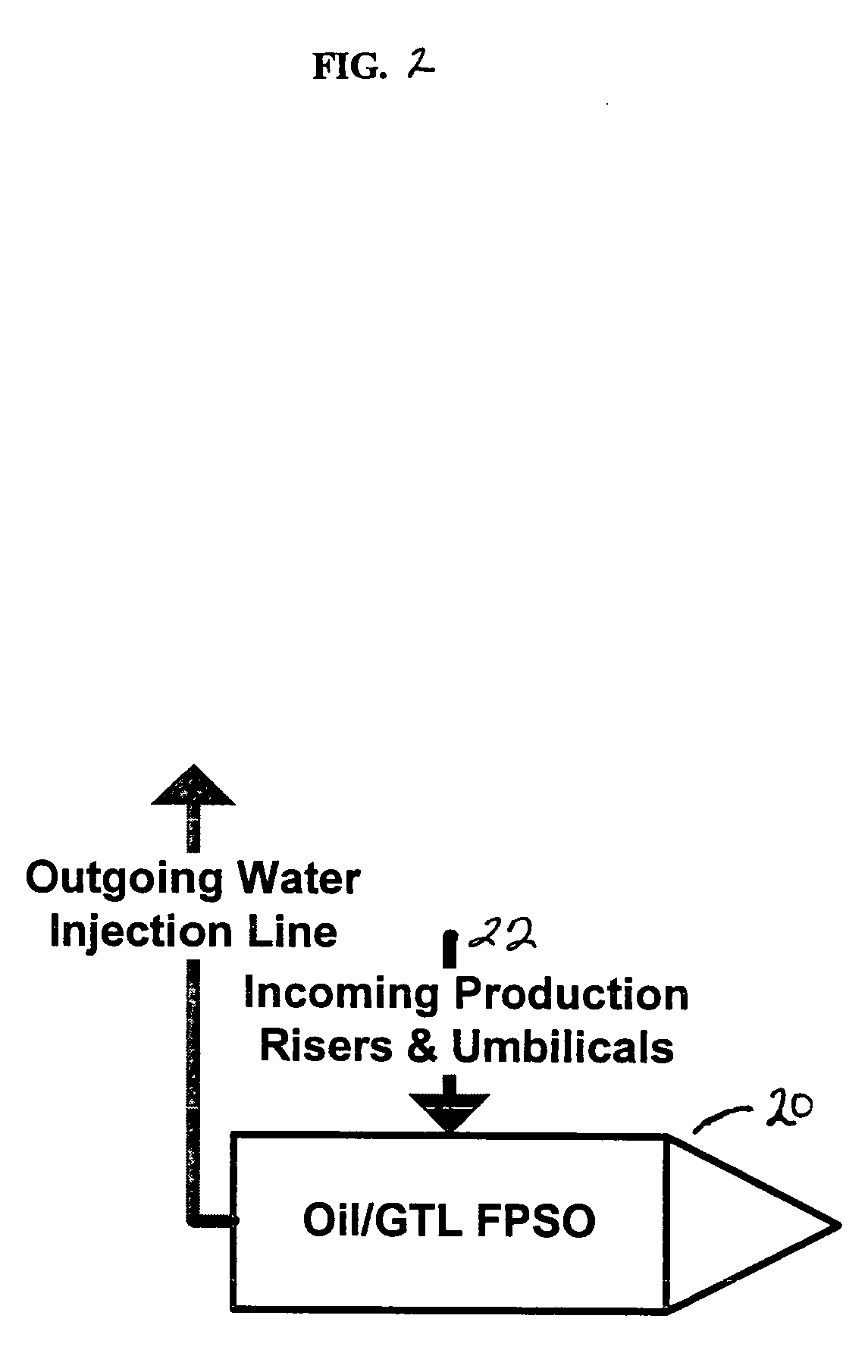

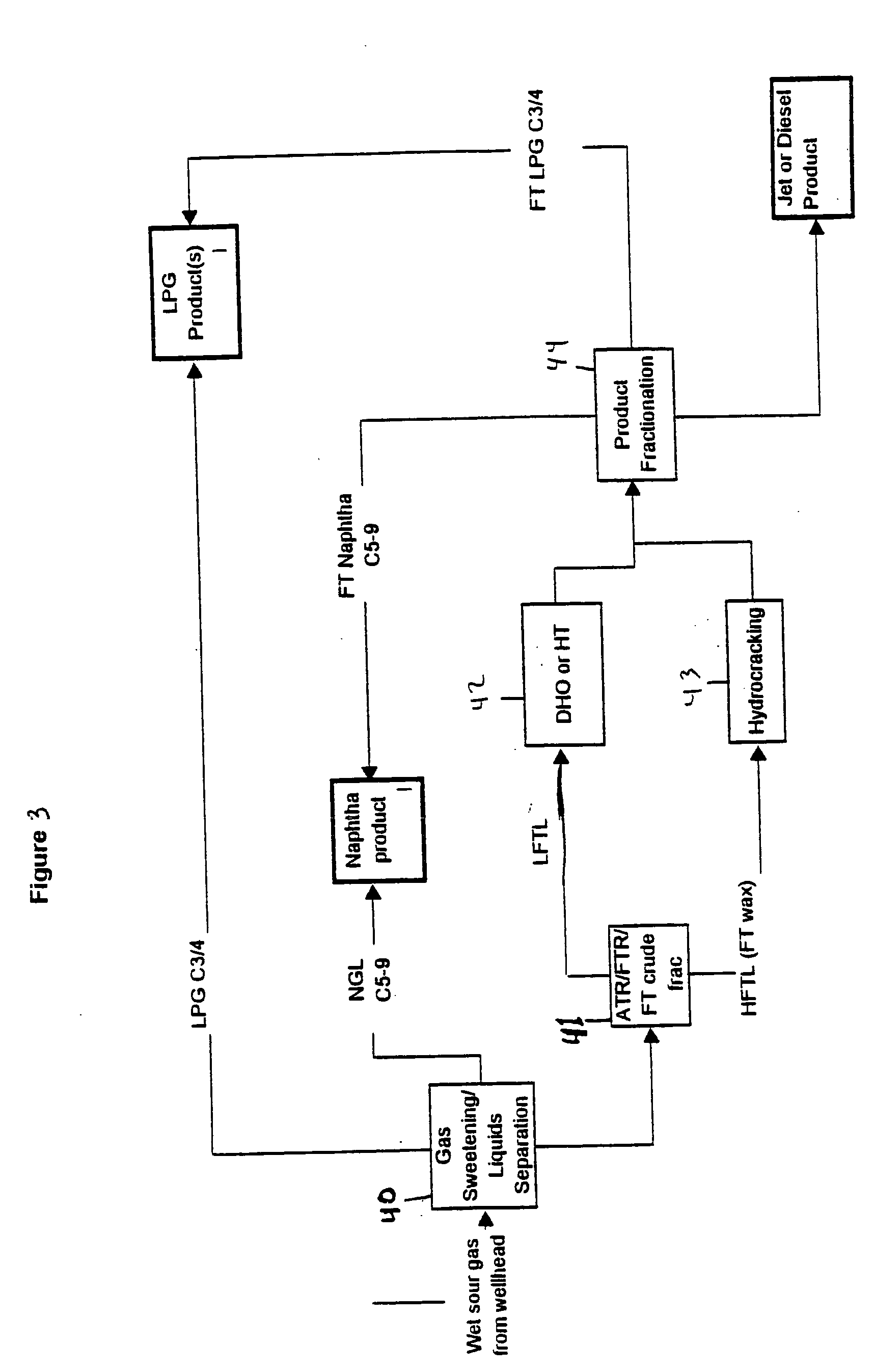

Movable gas-to-liquid system and process

InactiveUS20050106086A1Organic compounds purification/separation/stabilisationWaterborne vesselsProcess equipmentGas to liquids

A system having a movable platform including synthesis gas production, synthetic crude production and product upgrading is provided. The system may include one or more movable platforms on which the various production and / or upgrading facilities are located. A process for converting natural gas to hydrocarbon products is also provided where the process occurs on a movable platform. The process may occur on one or more operationally connected vessels. The movable platform may be any of a number of movable or transportable bases on which process equipment may be placed and / or in which hydrocarbon products may be stored.

Owner:REG SYNTHETIC FUELS LLC

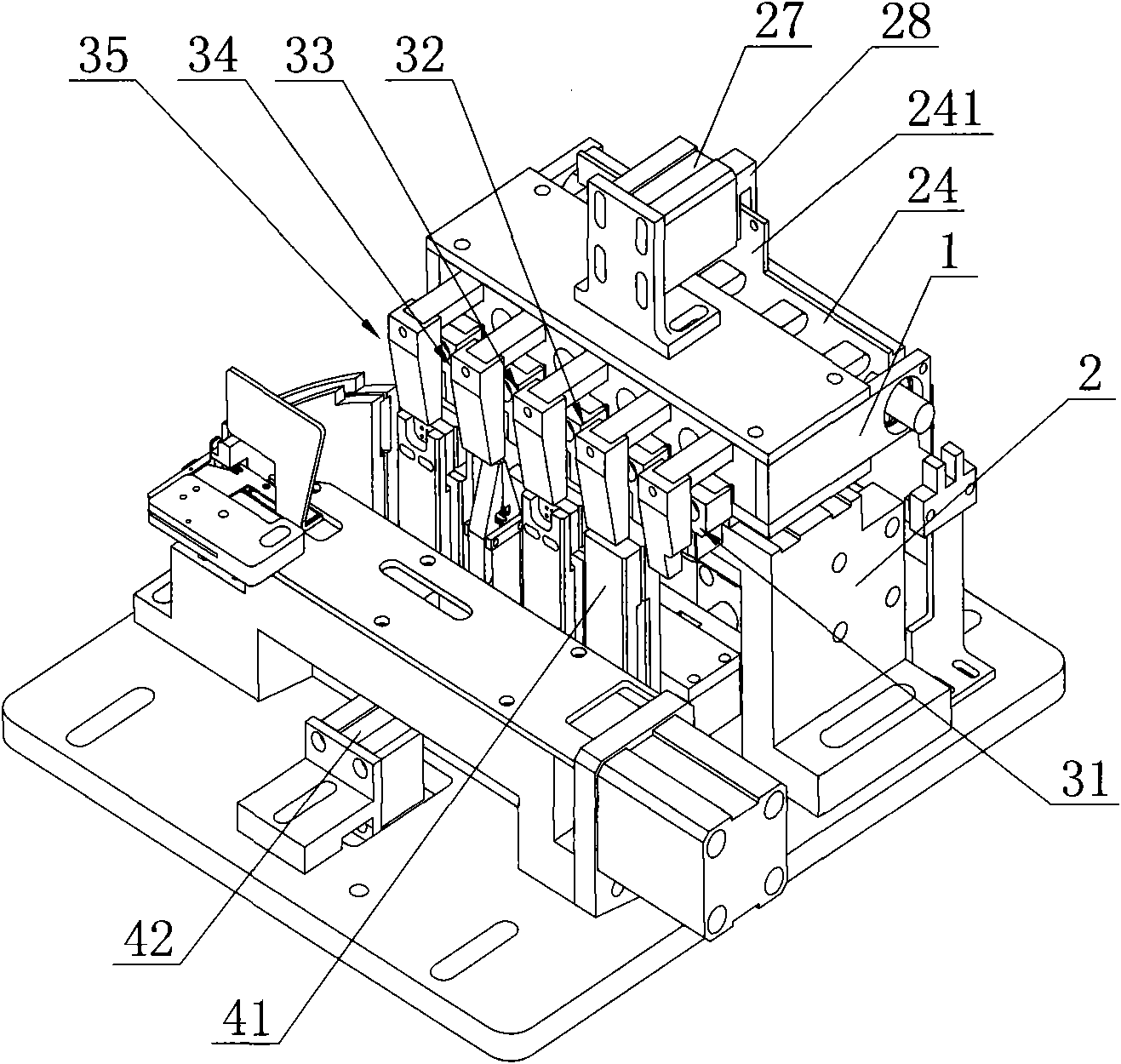

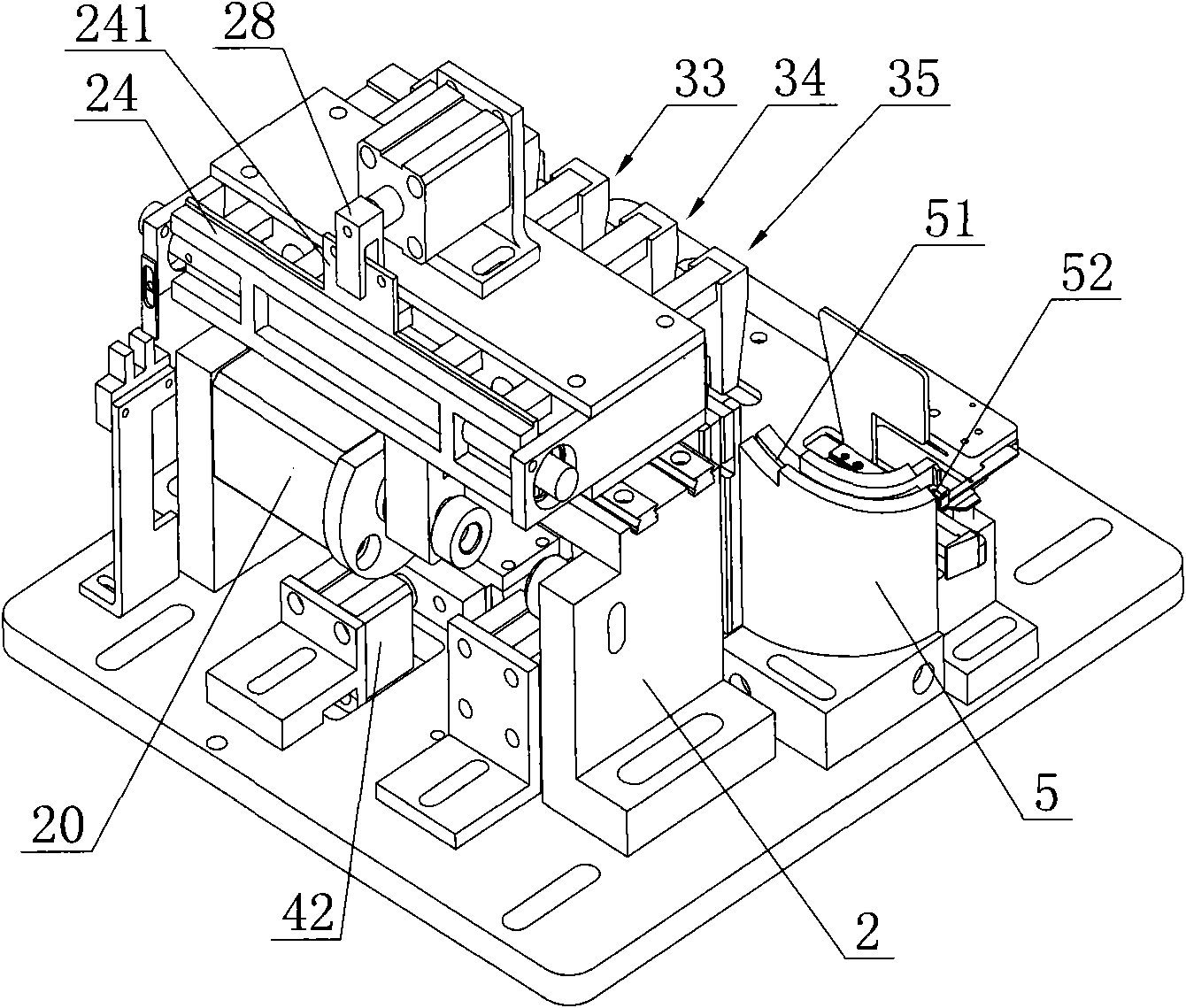

Bulk light-emitting diode (LED) feeder

ActiveCN101834243ALower acquisition costsLow production costConveyor partsSemiconductor devicesProcess equipmentEngineering

The invention relates to the technical field of electronic processing equipment and in particular relates to a bulk light-emitting diode (LED) feeder. The bulk LED feeder comprises a working table, a vibrating plate, a straight-line vibrator and an LED feeding body, wherein the vibrating plate, the straight-line vibrator and the LED feeding body are arranged on the working table in a working order. The bulk LED feeder is characterized in that: the LED feeding body comprises a material-clamping and material-pushing mechanism, a shaping mechanism, a polarity detecting and adjusting mechanism, a down-sliding guide rail mechanism and a feeding station mechanism. In the bulk LED feeder, the vibrating plate conveys the bulk LED elements to the straight-line vibrator; the straight-line vibrator conveys the LED elements to the LED feeding body sequentially; and after the LED elements are shaped and the polarity is detected and adjusted by the LED feeding body, other process equipment such as a vertical plug-in machine and the like is directly supplied to perform the next assembling step or plug-in procedure.

Owner:海宁经开产业园区开发建设有限公司

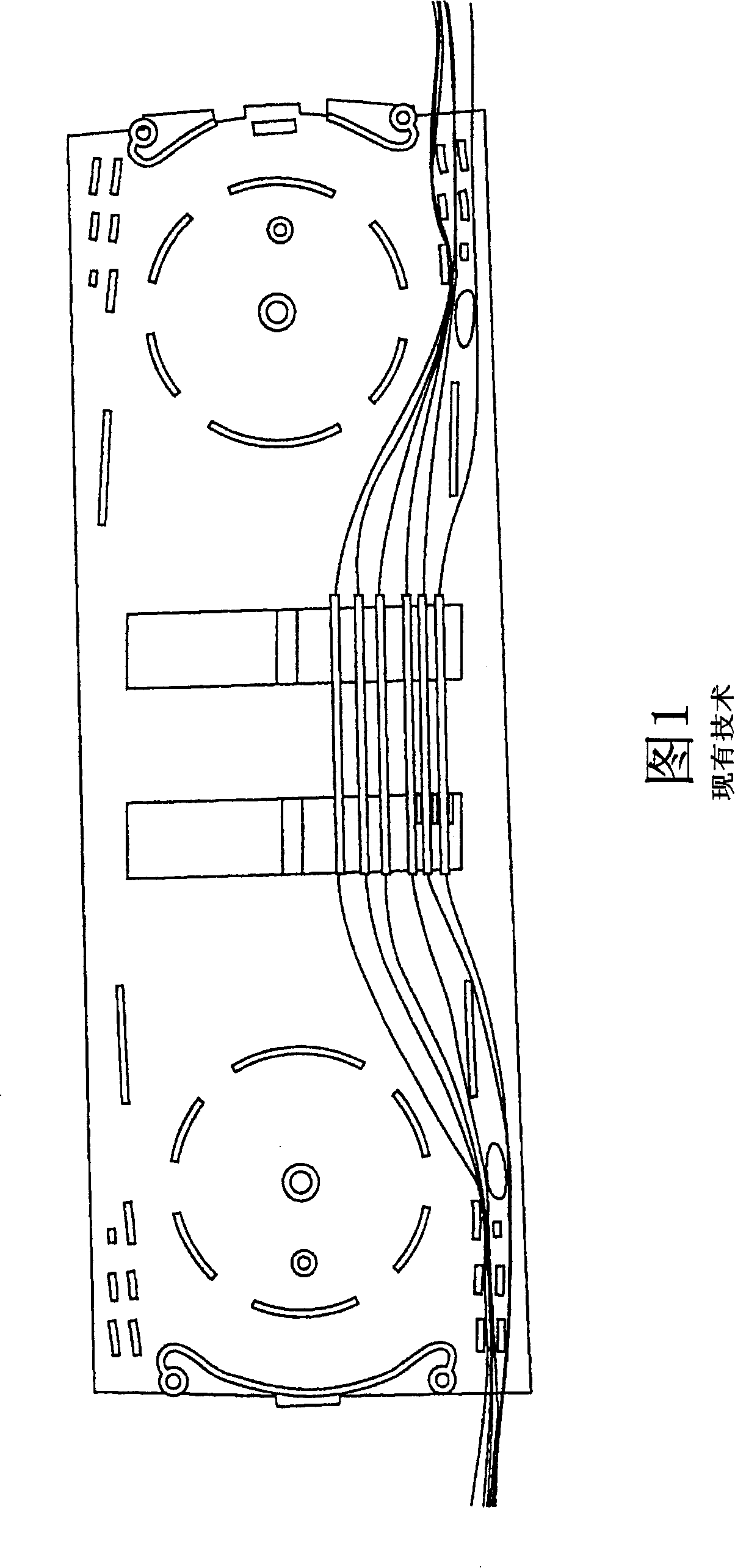

Cable slack process equipment

InactiveCN101195453AArrangements using take-up reel/drumOptical light guidesProcess equipmentEngineering

The invention discloses a cable treatment device, which comprises a base portion provided with a first valve leaflet and a second valve leaflet. Both of the valve leaflets are partially combined with the base. For containing relaxed cables on the periphery of the cable relaxation treatment device, both of the first and the second valve leaflets are provided with arch outer wall portions. A connection equipment holder is located between portions of the first valve leaflet and the second valve leaflet. The connection equipment holder is applicable to include a cable connection device. The connection equipment holder is provided with two relative ends, both of which are applicable to receive cables.

Owner:3M INNOVATIVE PROPERTIES CO

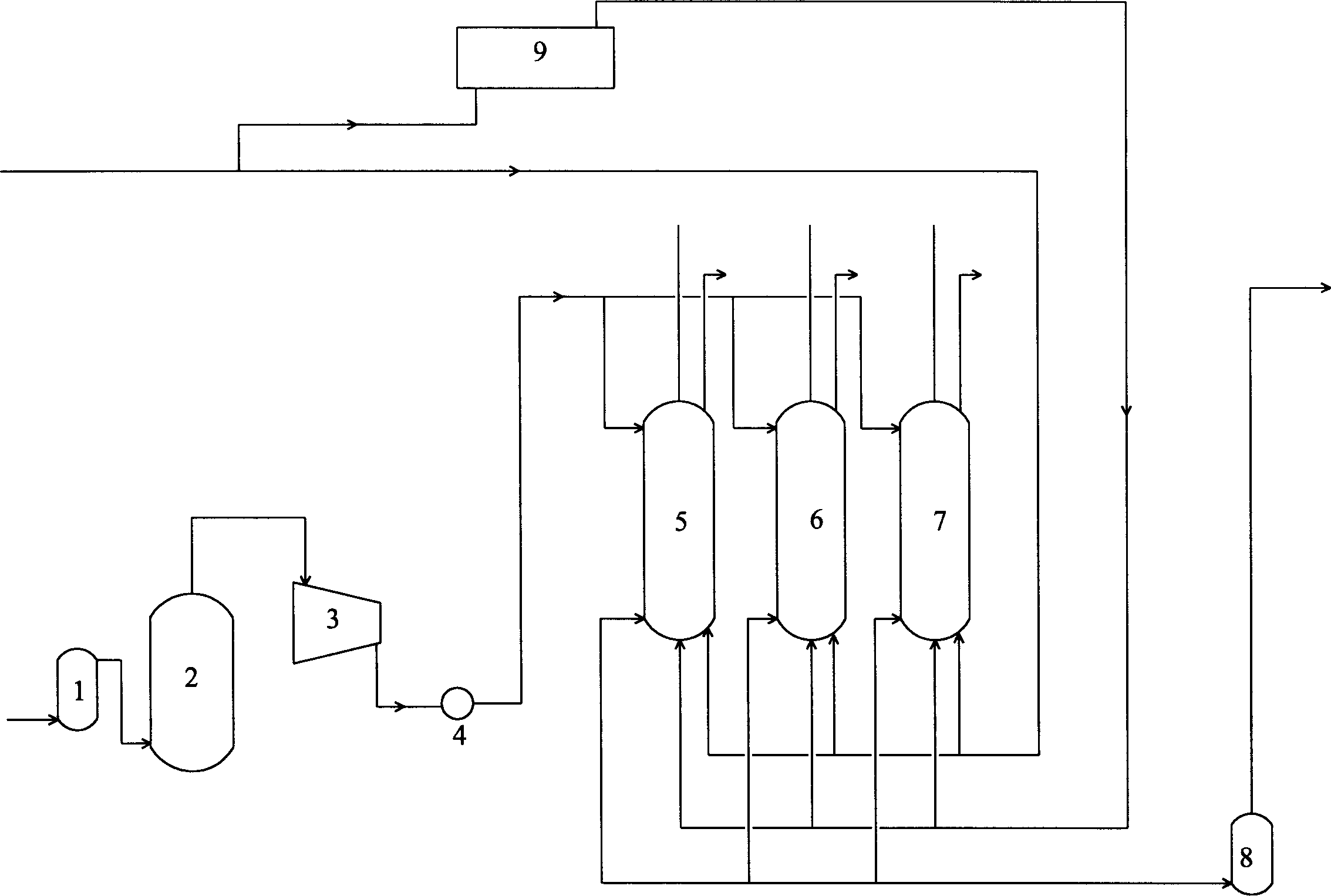

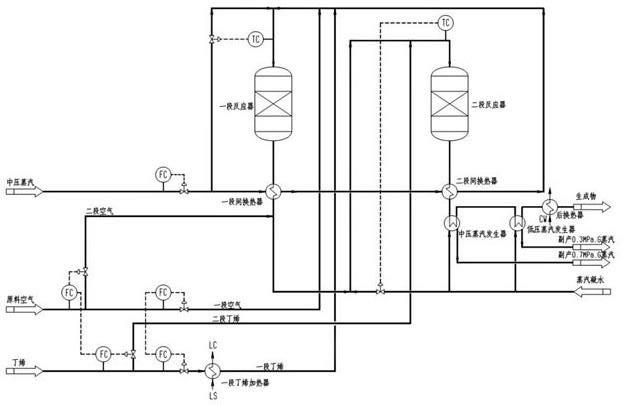

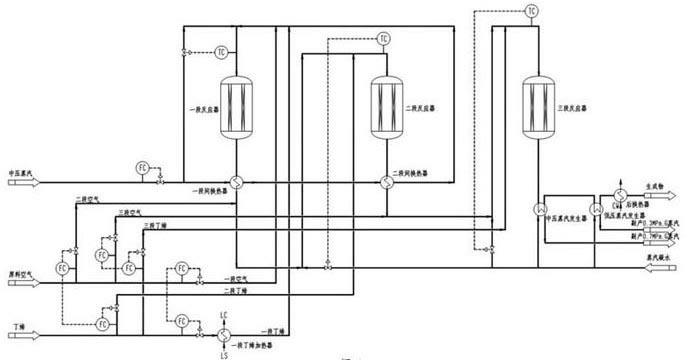

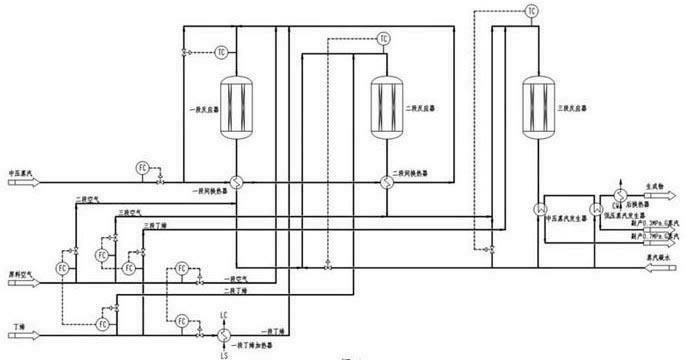

Process for preparing butadiene through oxidative dehydrogenation of butene

InactiveCN102675027ARunner shortReduce resistanceChemical industryHydrocarbonsProcess equipmentWater vapor

The invention relates to a process for preparing butadiene through the oxidative dehydrogenation of butene on an adiabatic radial fixed bed. The process comprises the step of performing oxidative dehydrogenation reaction of butene, air and water vapor in an adiabatic radial fixed bed reactor to obtain the butadiene. The radial fixed bed reactor is divided into three sections (or three stages); and process equipment sequentially comprises a first-section reactor, a first-section recuperative heat exchanger, a second-section reactor, a second-section recuperative heat exchanger, a third-section reactor, a medium-pressure steam generator, a low-pressure steam generator, a rear heat exchanger and the like. The preparation process is technically characterized in that the yield of the butadiene is high, the selectivity is high, the production device has high production capacity, the unit consumption of steam is low, and the heat energy is reasonably utilized; and the yield of wastewater, the pretreatment capacity of internal wastewater and the discharge amount of sewage can also be effectively reduced.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

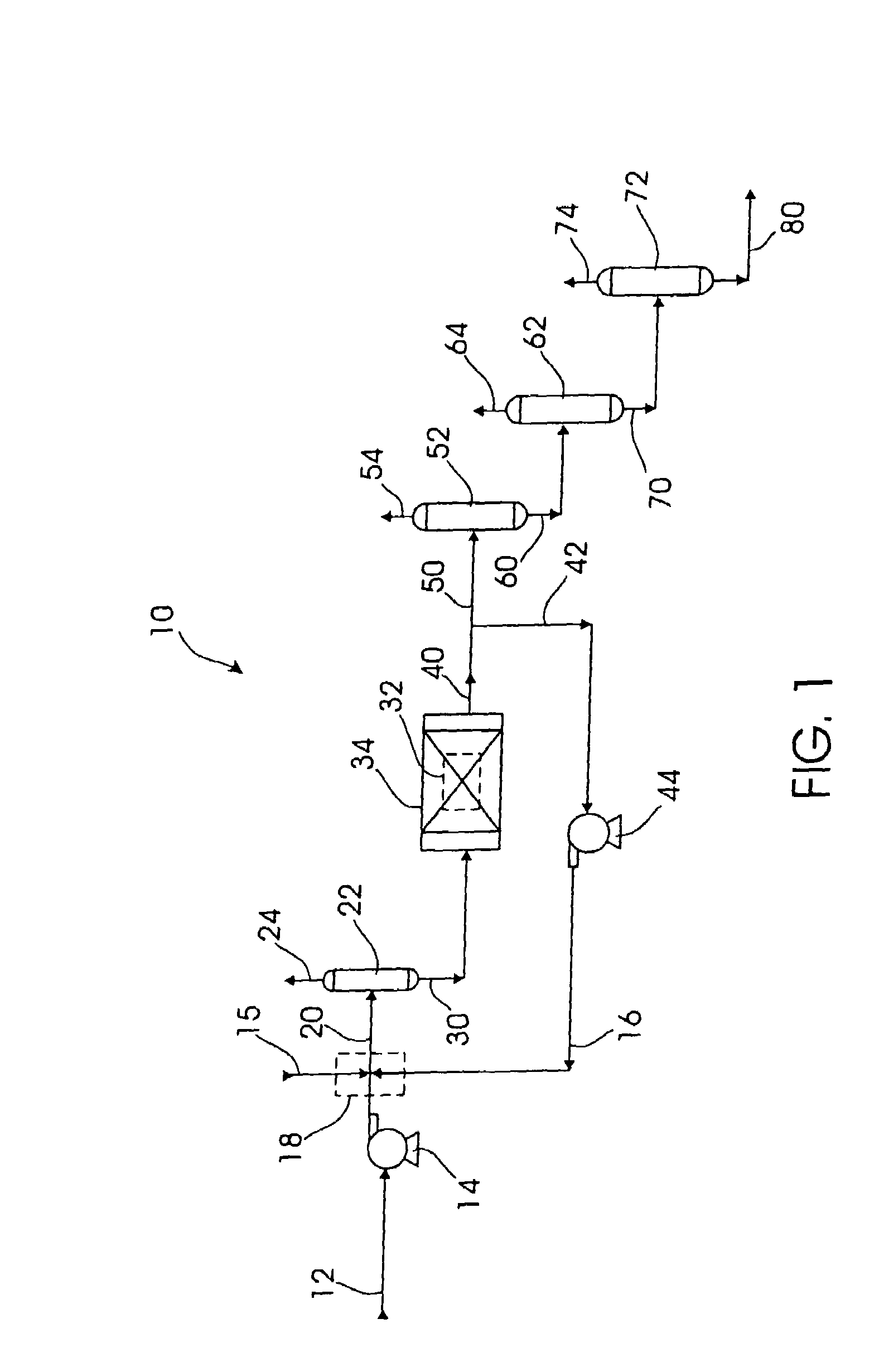

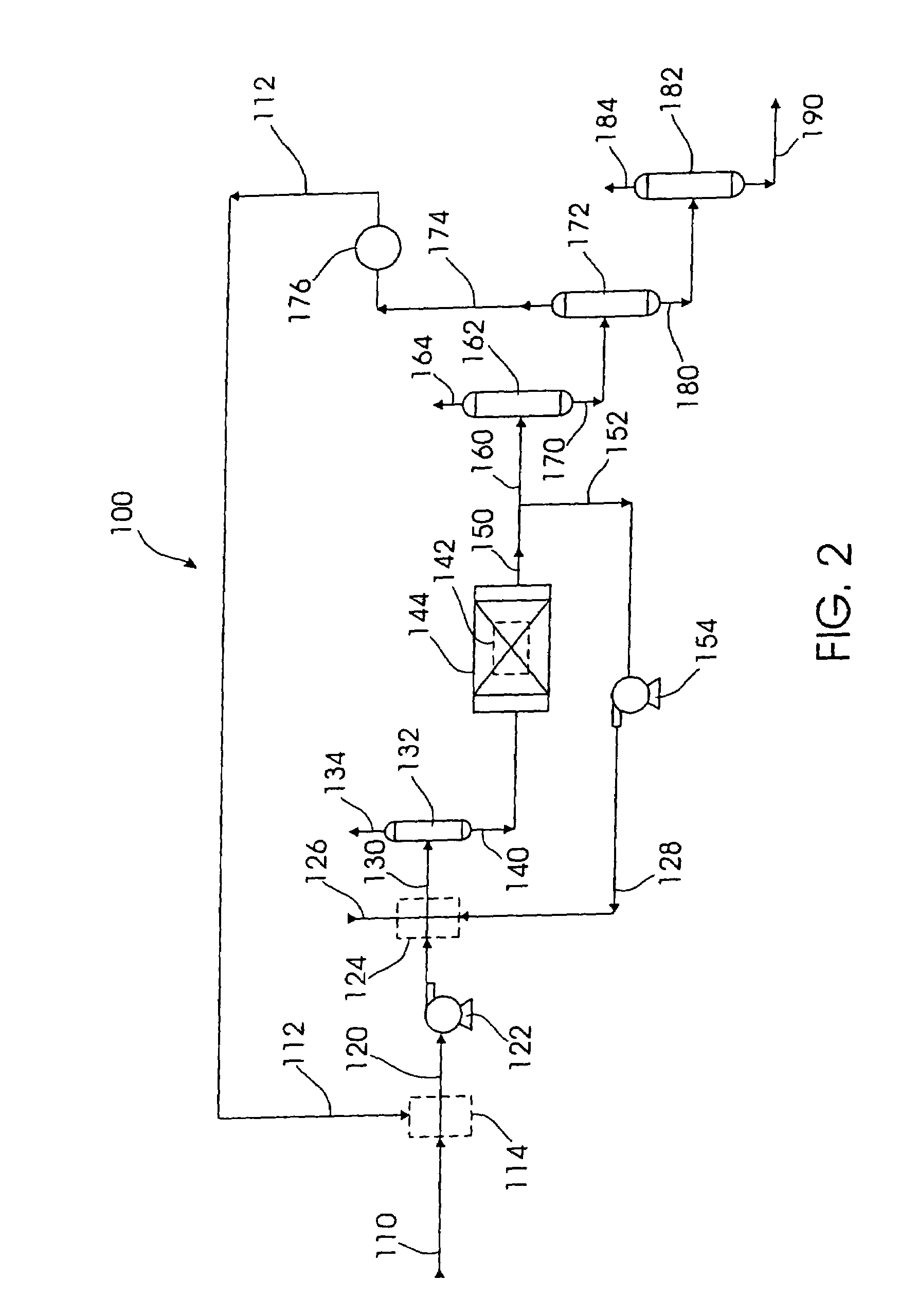

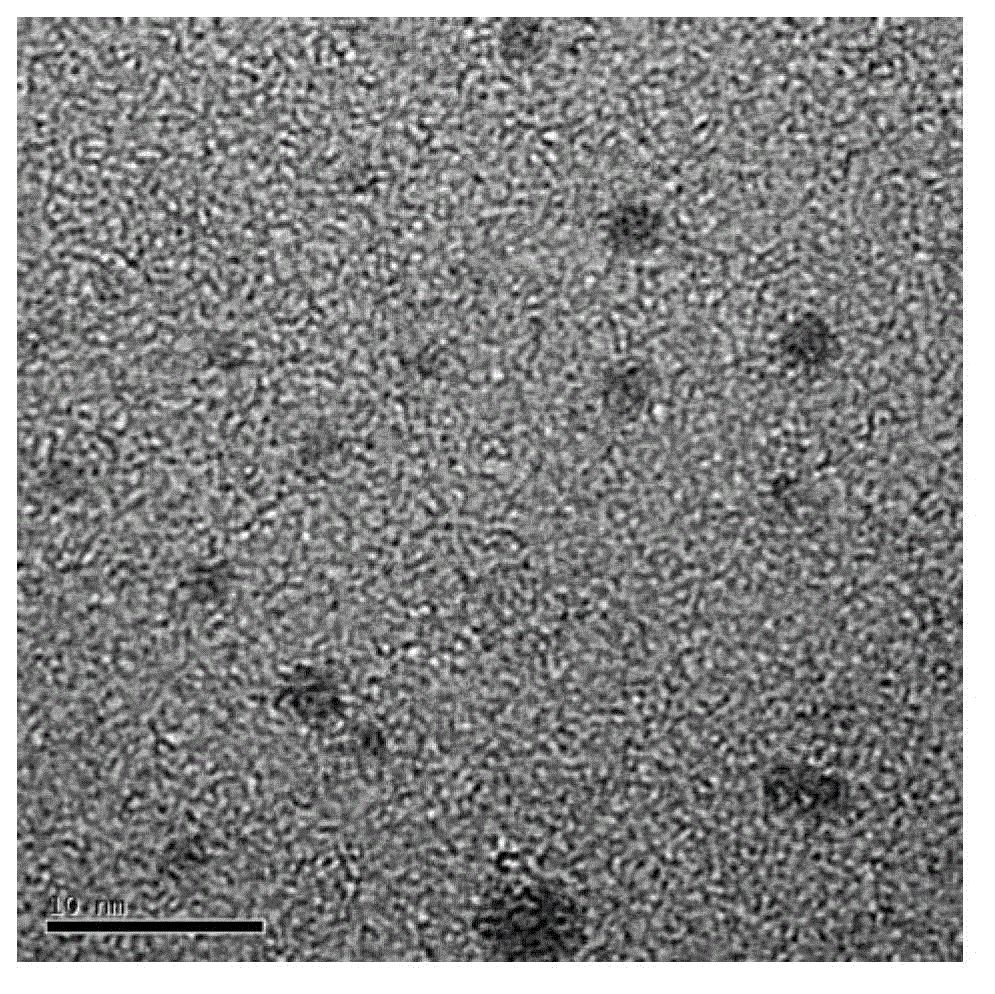

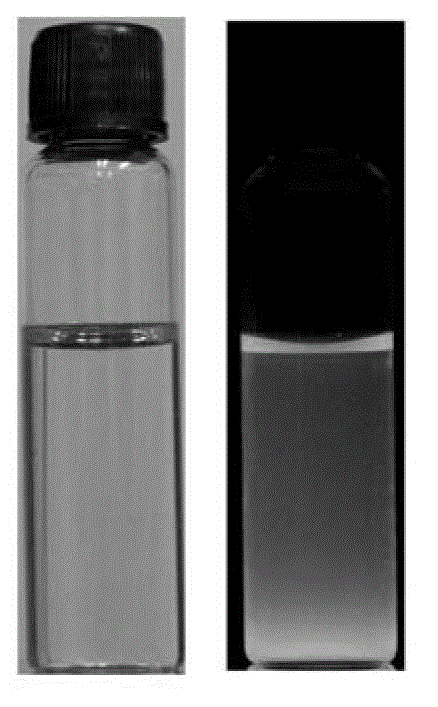

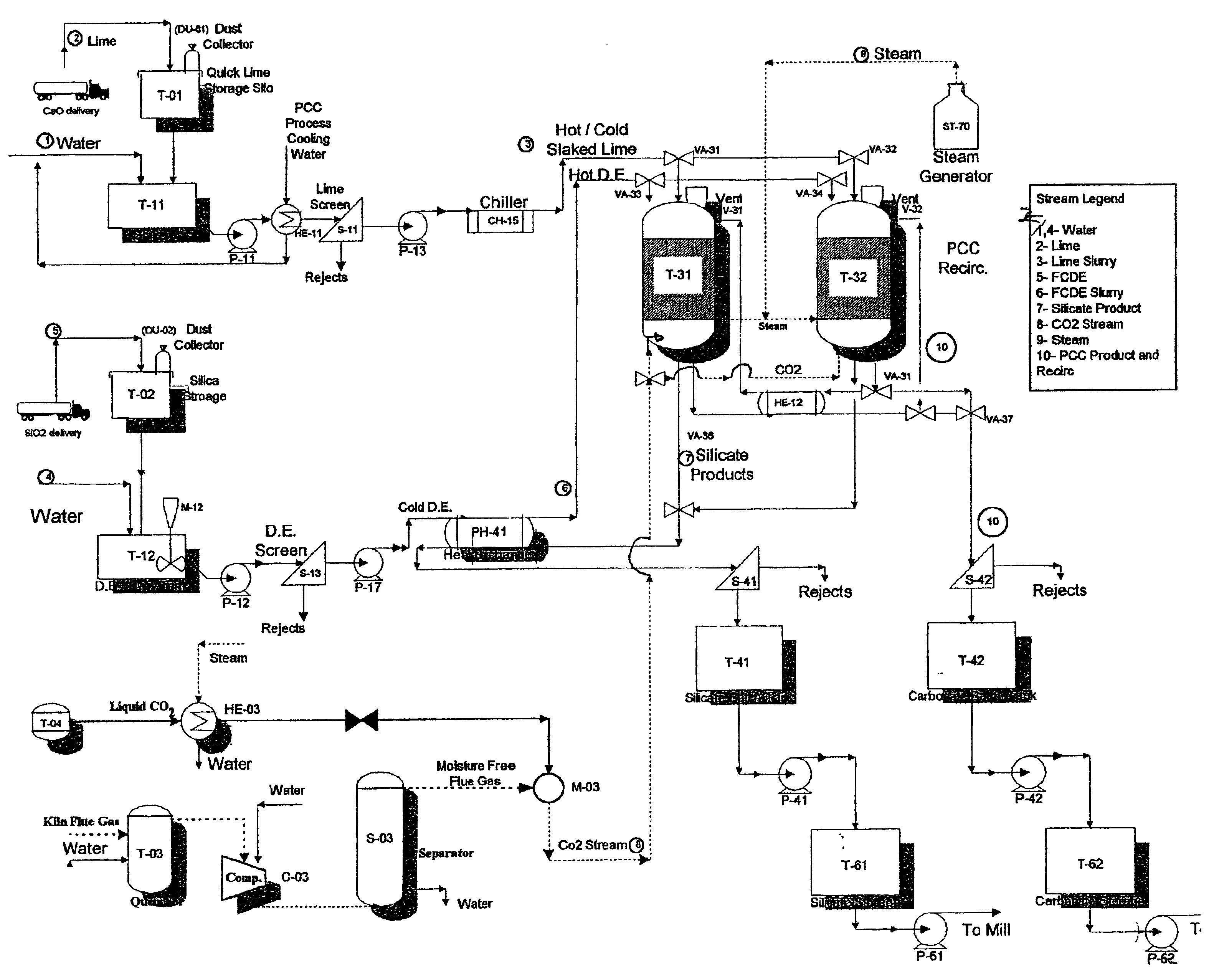

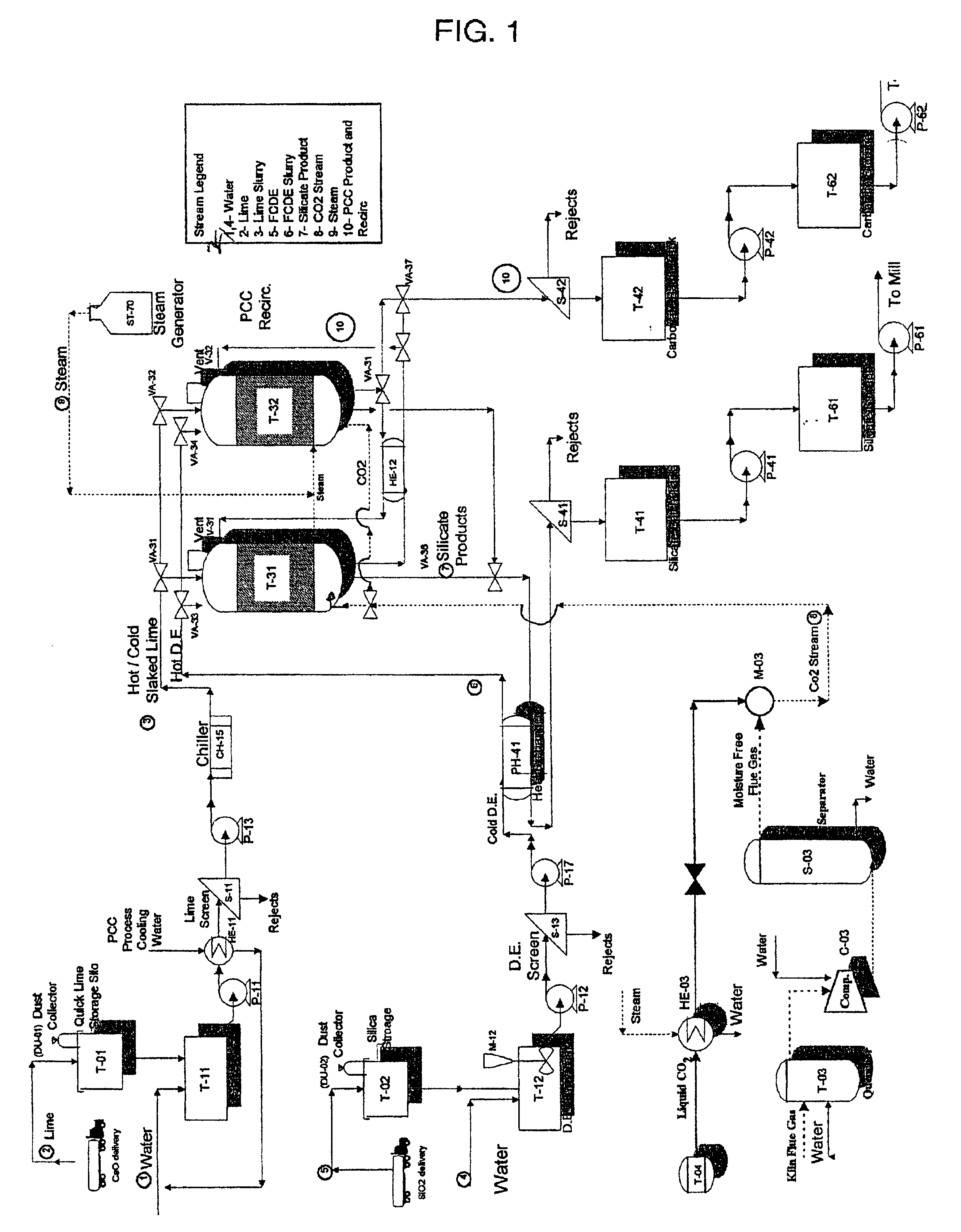

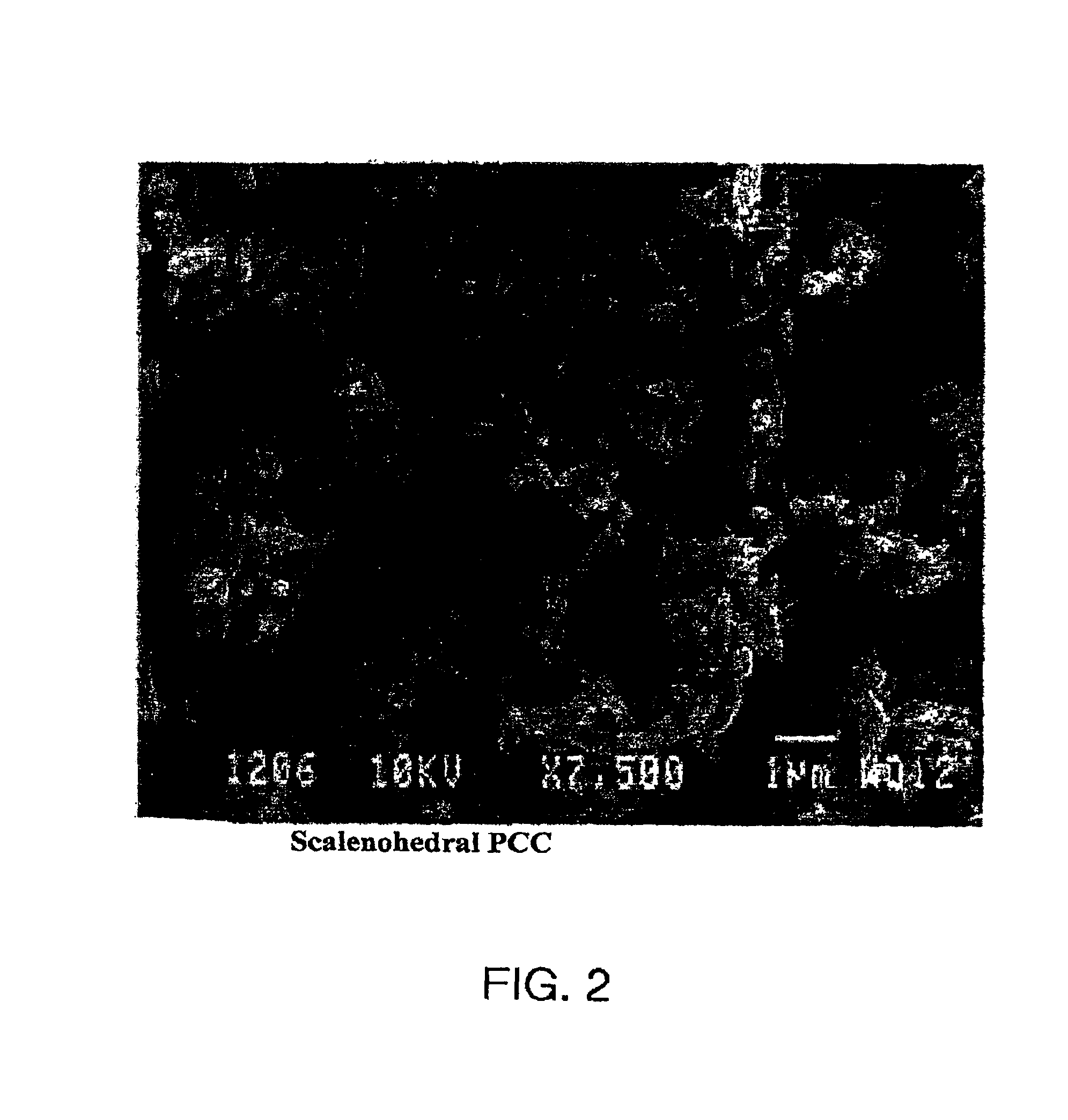

Method and apparatus for production of precipitated calcium carbonate and silicate compounds in common process equipment

InactiveUS7048900B2Increase brightnessHigh opacityCalcium/strontium/barium carbonatesPulp liquors combustionCalcium silicateProcess equipment

A method and apparatus for the production of calcium carbonate and calcium silicate in common superatmospheric reactors. Multiple reactors can be provided for switching production between reactors, and advantageously utilizing process waste heat. On site production of both PCC and Calcium Silicate Hydrates is thus achieved in a paper mill.

Owner:PACIFIC NANO PROD

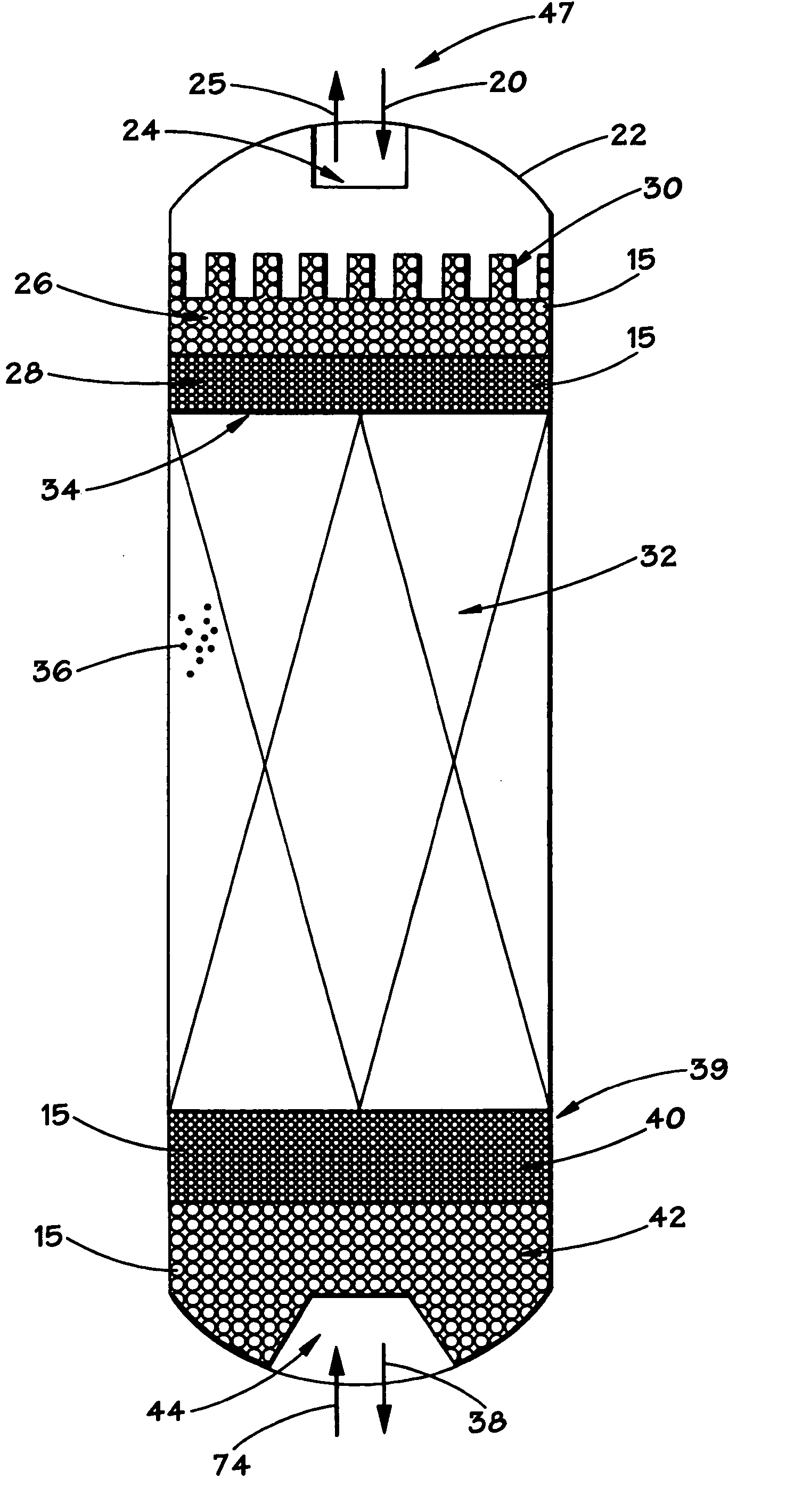

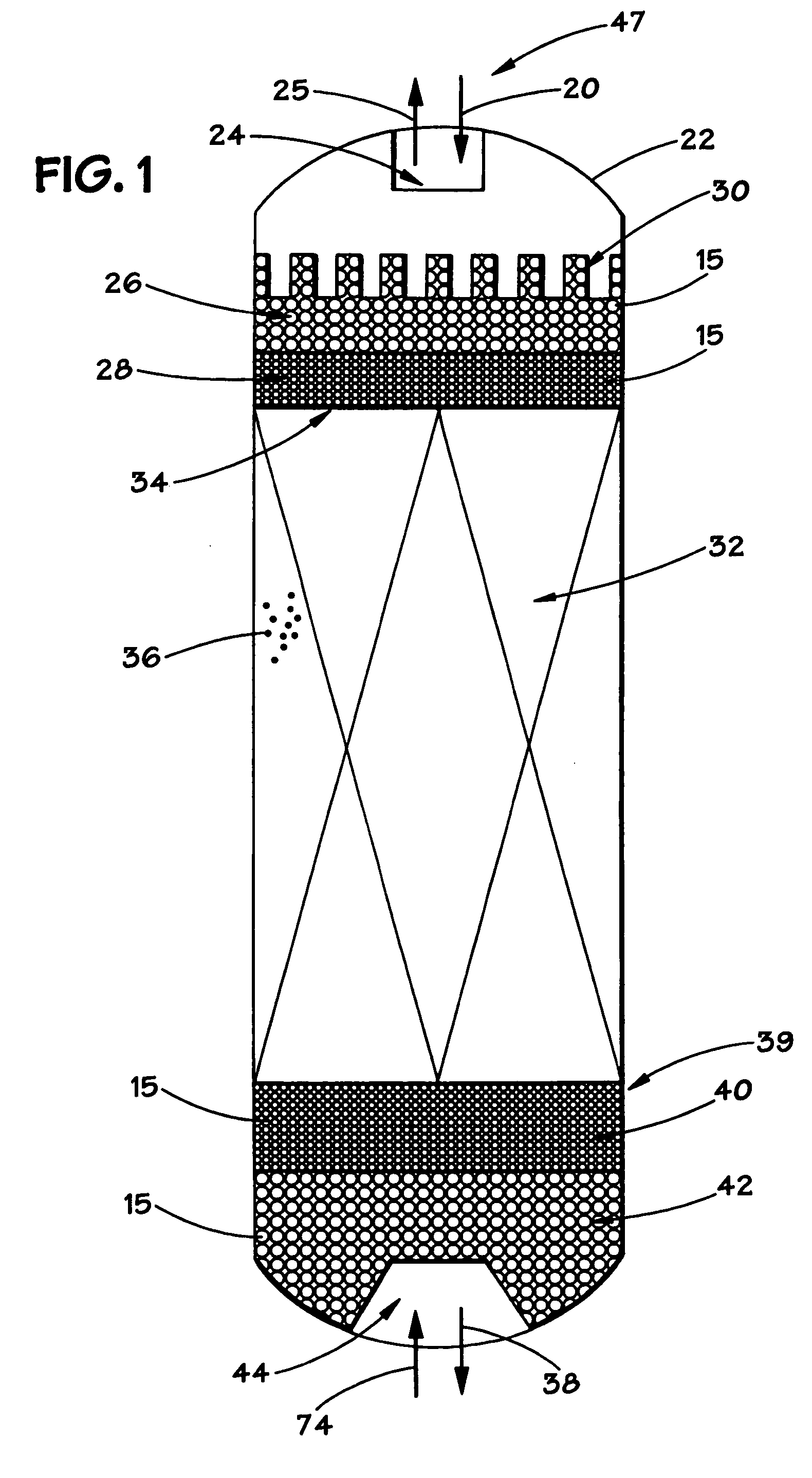

Filtration, flow distribution and catalytic method for process streams

ActiveUS20040192862A1Increased operating lifeExtended run timeDispersed particle filtrationMembrane filtersProcess equipmentCatalytic method

A method for removing contaminants from an process stream that includes the use of reticulated material to filter the process stream. The reticulated material also facilitate process stream flow distribution in process units. The reticulated material can be packed with a void space between a substantial number of the reticulated material that can be varied to enhance filtration and flow distribution. The method of filtering also provides a method of removing contaminants leaving process equipment. The methods can be used on a variety of process streams and process equipment. The reticulated material can include ceramics, metallic materials, and chemical vapor deposition elements. The reticulated material can be of various shapes and sizes, and can also be catalytically active.

Owner:CRYSTAPHASE PRODS

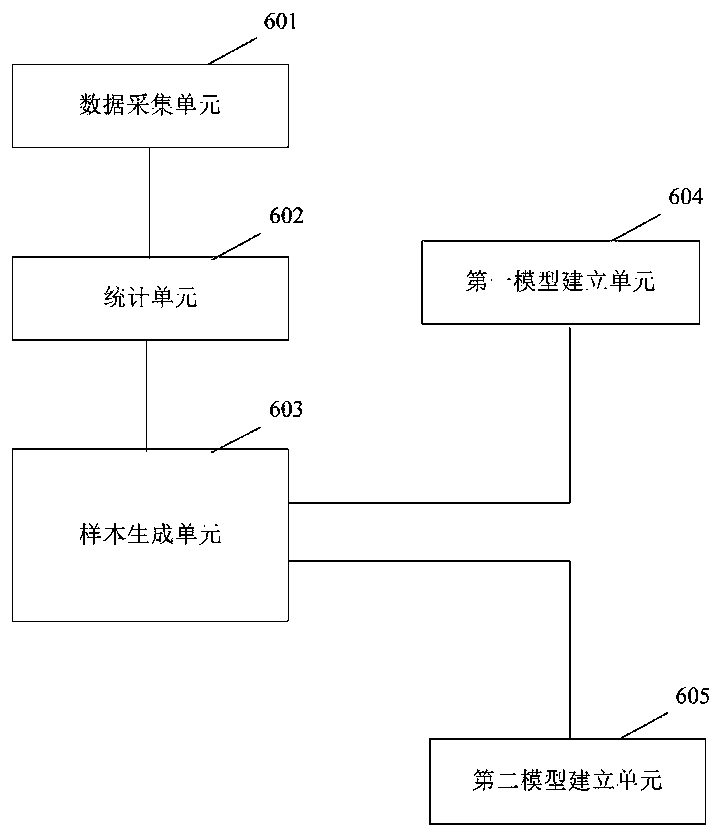

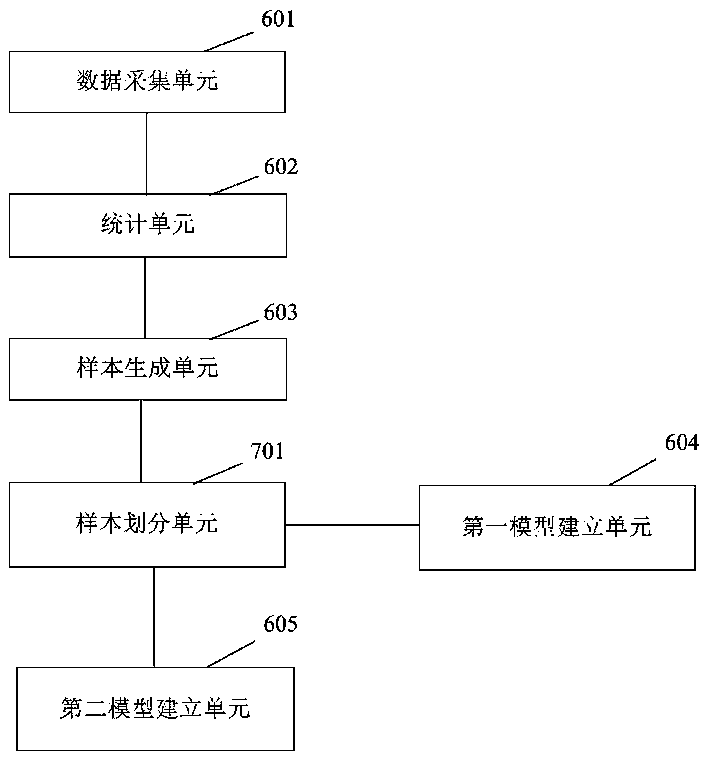

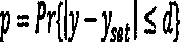

Processing equipment process parameter optimization method and system

ActiveCN111597729AImprove accuracyImprove stabilityForecastingDesign optimisation/simulationProcess equipmentData mining

The invention discloses a processing equipment technological parameter optimization method and system. The method comprises the following steps: collecting production line data in real time and obtaining a target value of a quality index; setting an initial value of a process parameter and a preset deviation value of the quality index; utilizing a section of historical production line data which comprises a current moment and the process parameters to respectively predict and obtain a predicted value of the quality index and an uncertainty range of the quality index; determining an optimization target according to the preset deviation value and the prediction value of the quality index and the uncertainty range of the quality index, and optimizing and updating the process parameters and the preset deviation value; performing an iterative optimization process by utilizing the updated process parameters and the preset deviation value until a termination condition is met; and after iterative optimization is completed, outputting the value of the current process parameter as the optimal process parameter under the current incoming material information and the environmental parameter. According to the invention, the accuracy and stability of the process parameter optimization result can be improved.

Owner:CYBERINSIGHT TECH CO LTD

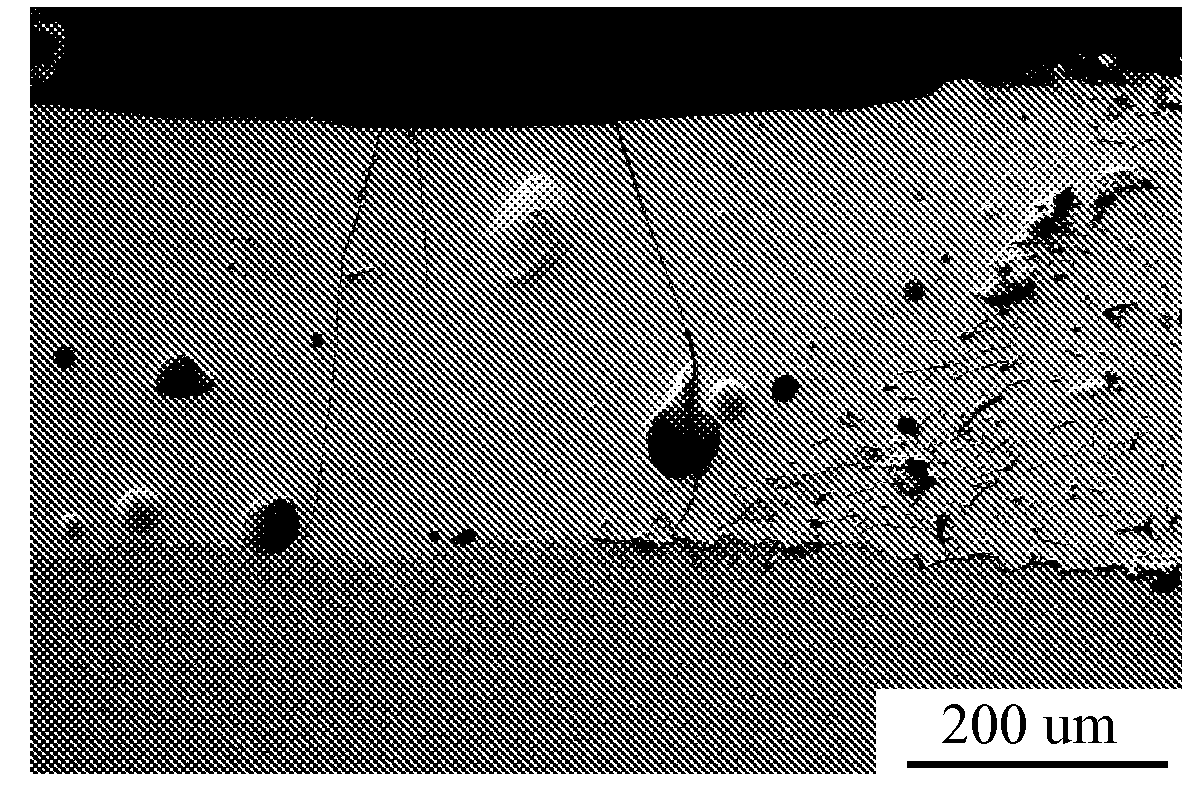

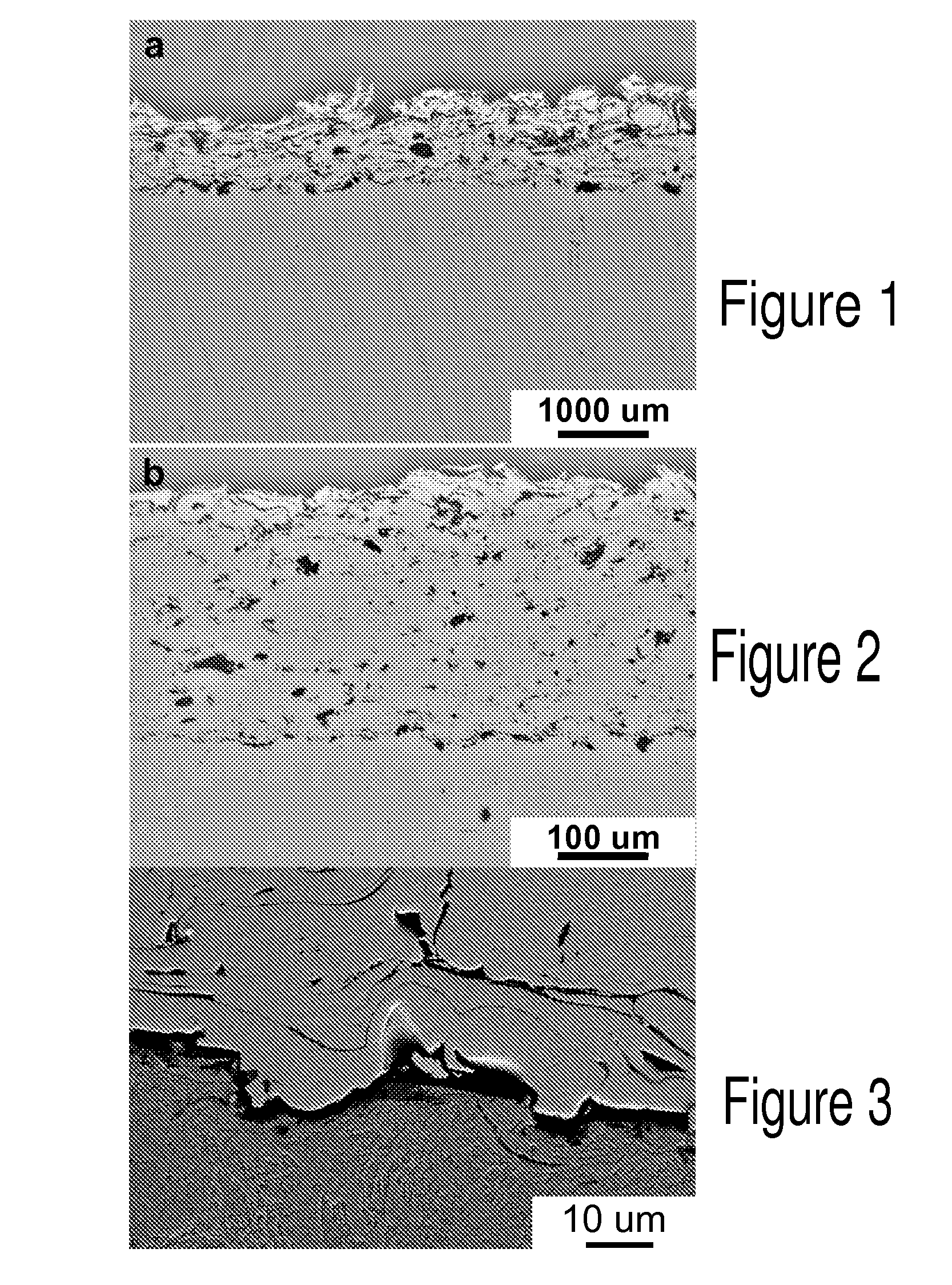

Surface Treatment of Amorphous Coatings

InactiveUS20100279023A1High hardnessMolten spray coatingPretreated surfacesProcess equipmentPetrochemical

A method to improve corrosion, abrasion, resistance to environmental degradationand fire resistant properties of structural components for use in oil, gas, exploration, refining and petrochemical applications is provided. The structural component is suitable for use as refinery and / or petrochemical process equipment and piping, having a substrate coated with a surface-treated amorphous metal layer. The surface of the structural component is surface treated with an energy source to cause a diffusion of at least a portion of the amorphous metal layer and at least a portion of the substrate, forming a diffusion layer disposed on a substrate. The diffusion layer has a negative hardness profile with the hardness increasing from the diffusion surface in contact with the substrate to the surface away from the substrate.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com