Air-contained coal gas gasification and separation process and equipment

A technology for liquefaction separation and coalbed methane, applied in liquefaction, cold treatment separation, refrigeration and liquefaction, etc., can solve the problems of easy explosion of air-containing coalbed methane, high input cost, low recovery rate, etc., which is beneficial to large-scale promotion and input cost Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

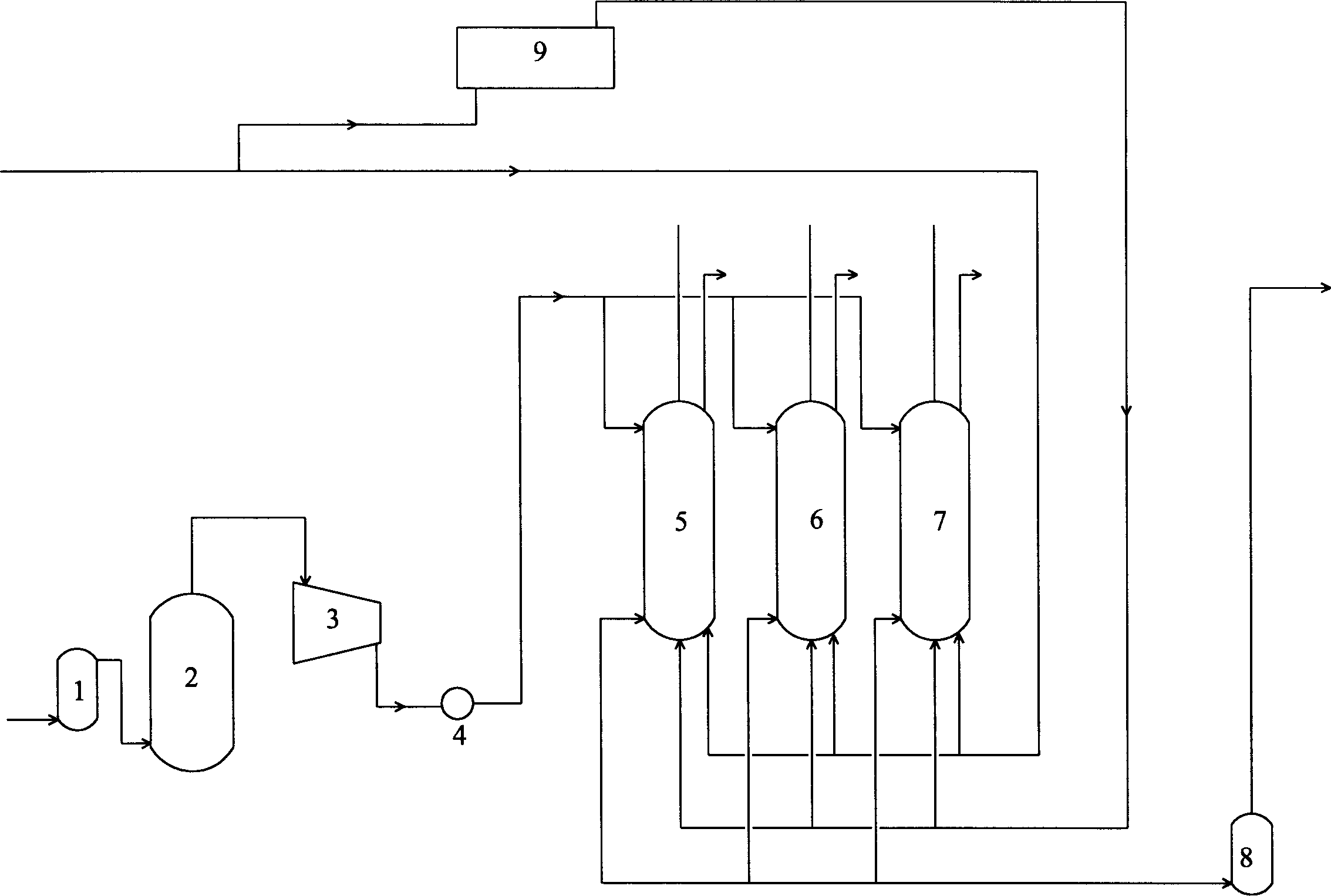

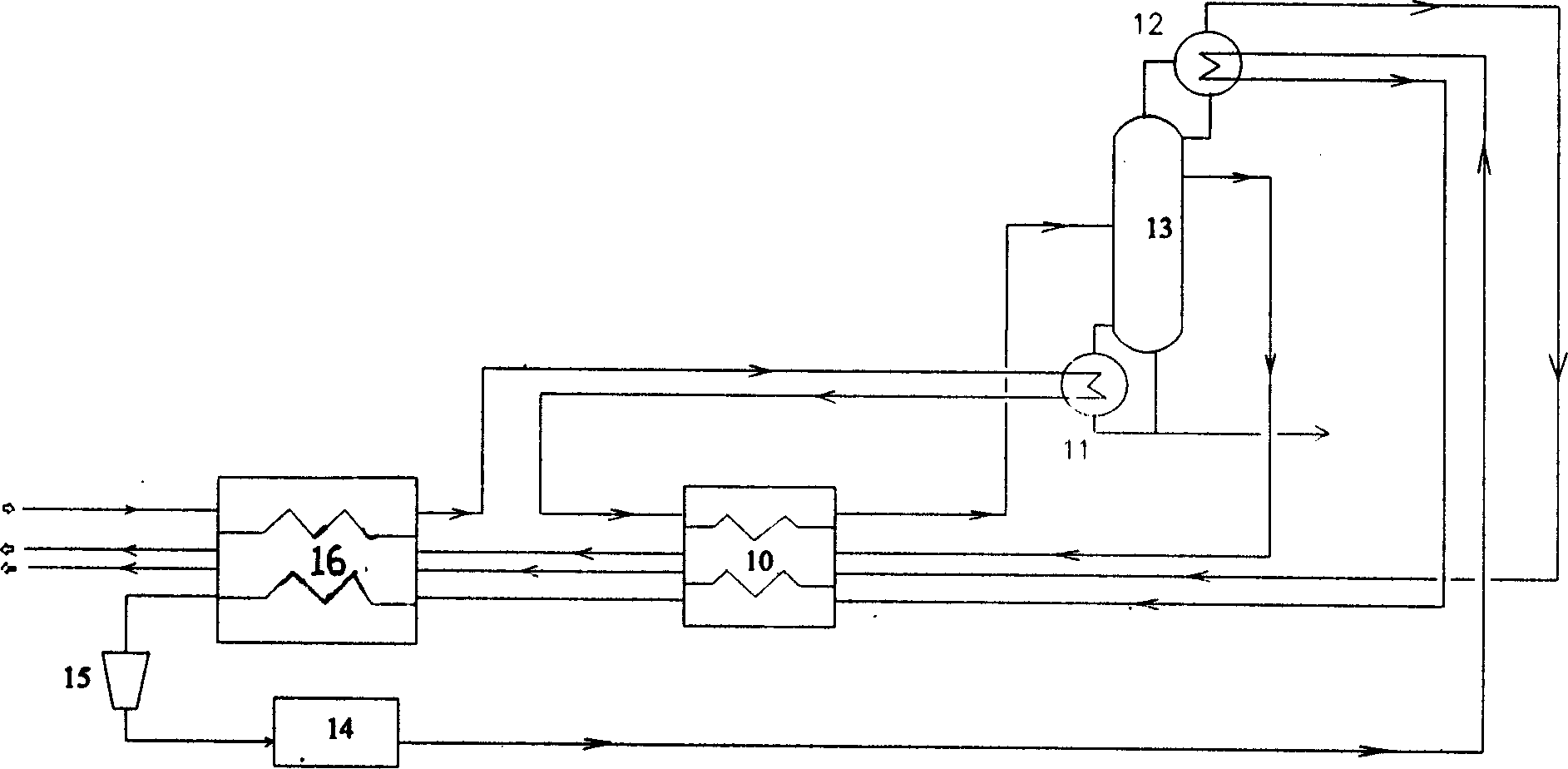

[0021] refer to figure 1 , figure 2 , is a schematic diagram of the air-containing coalbed methane liquefaction separation equipment in Example 1 of the present invention, including two parts. First, the air-containing coalbed methane raw material gas is firstly compressed and purified, and then liquefied and separated to obtain liquefied natural gas, wherein the liquefied separation process requires The cooling capacity is provided by the refrigeration system, and the specific equipment and process are described as follows:

[0022] refer to figure 1 , is a schematic diagram of the compression purification equipment of the present invention. Including filter 1, gas-liquid separator 2, compressor 3, cooler 4, molecular sieve equipment group, the molecular sieve drying equipment group includes three molecular sieve dryers 5, 6, 7, when the first molecular sieve dryer 5 works , the second molecular sieve dryer 6 is heated and regenerated, and the third molecular sieve dryer ...

Embodiment 2

[0039]Embodiment 2 The compression purification process and equipment are the same as in Embodiment 1.

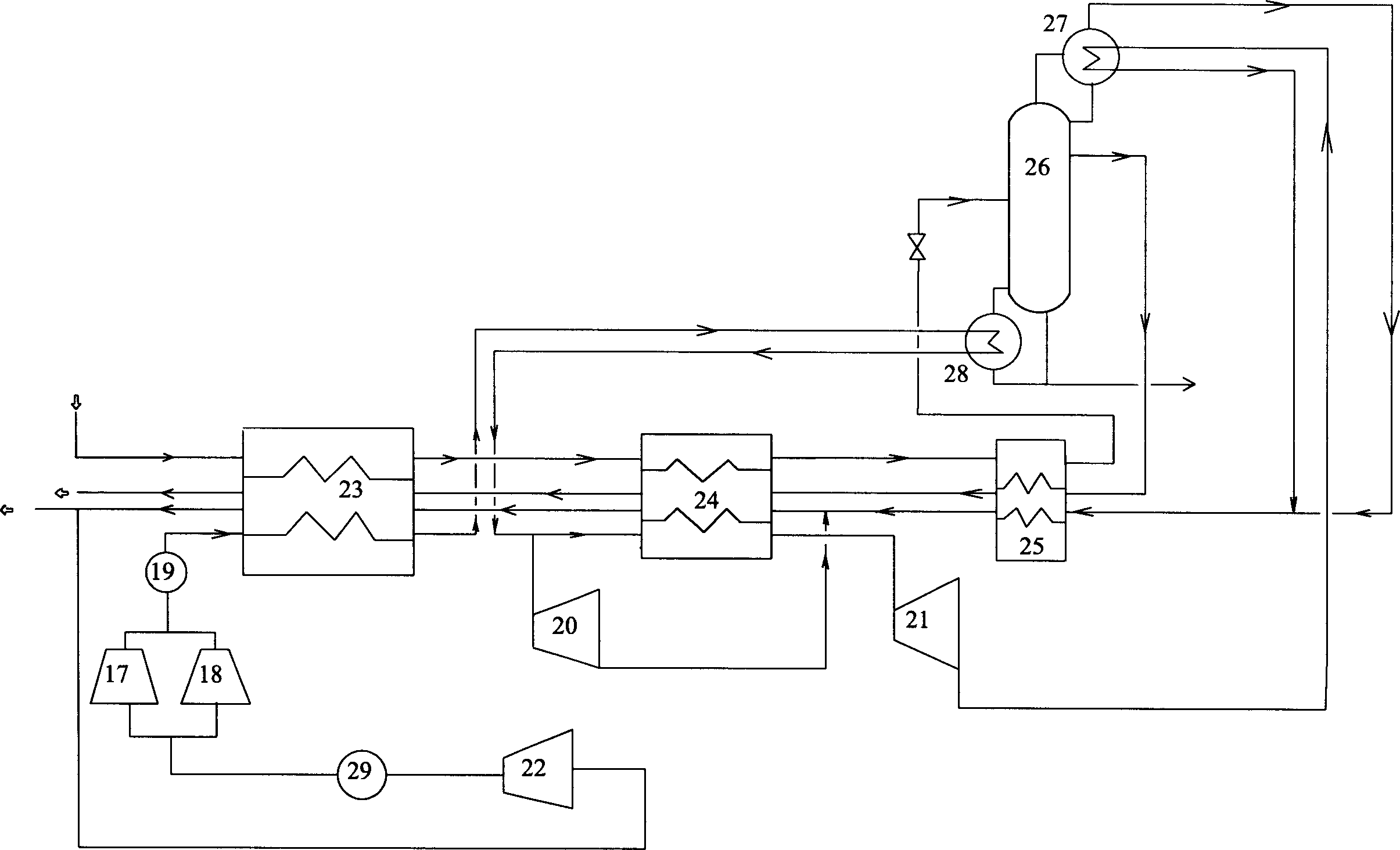

[0040] refer to image 3 , is a schematic diagram of air-containing coalbed methane refrigeration equipment and liquefaction separation equipment in Example 2 of the present invention. The liquefaction and separation equipment includes three-stage heat exchangers 23, 24, 25, a fractionation tower 26, a condenser 27 at the top of the fractionation tower, and an evaporator 28 at the bottom of the fractionation tower. The structure of the fractionation tower is the same as in Embodiment 1. The refrigerating equipment is a gas compression expansion refrigeration system, which employs a compressor 22, a cooler 29 and two turboexpanders 17,18. The fractionation column condenser 27 has a gas pipeline to introduce gas into the pipeline of the refrigeration equipment. The refrigerating pipeline of the condenser 27 is connected with the pipeline of the refrigerating equipment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com