Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6448 results about "Coal mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content and since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production. In the United Kingdom and South Africa, a coal mine and its structures are a colliery, a coal mine - a pit, and the above-ground structures - a pit head. In Australia, "colliery" generally refers to an underground coal mine. In the United States, "colliery" has been used to describe a coal mine operation but nowadays the word is not commonly used.

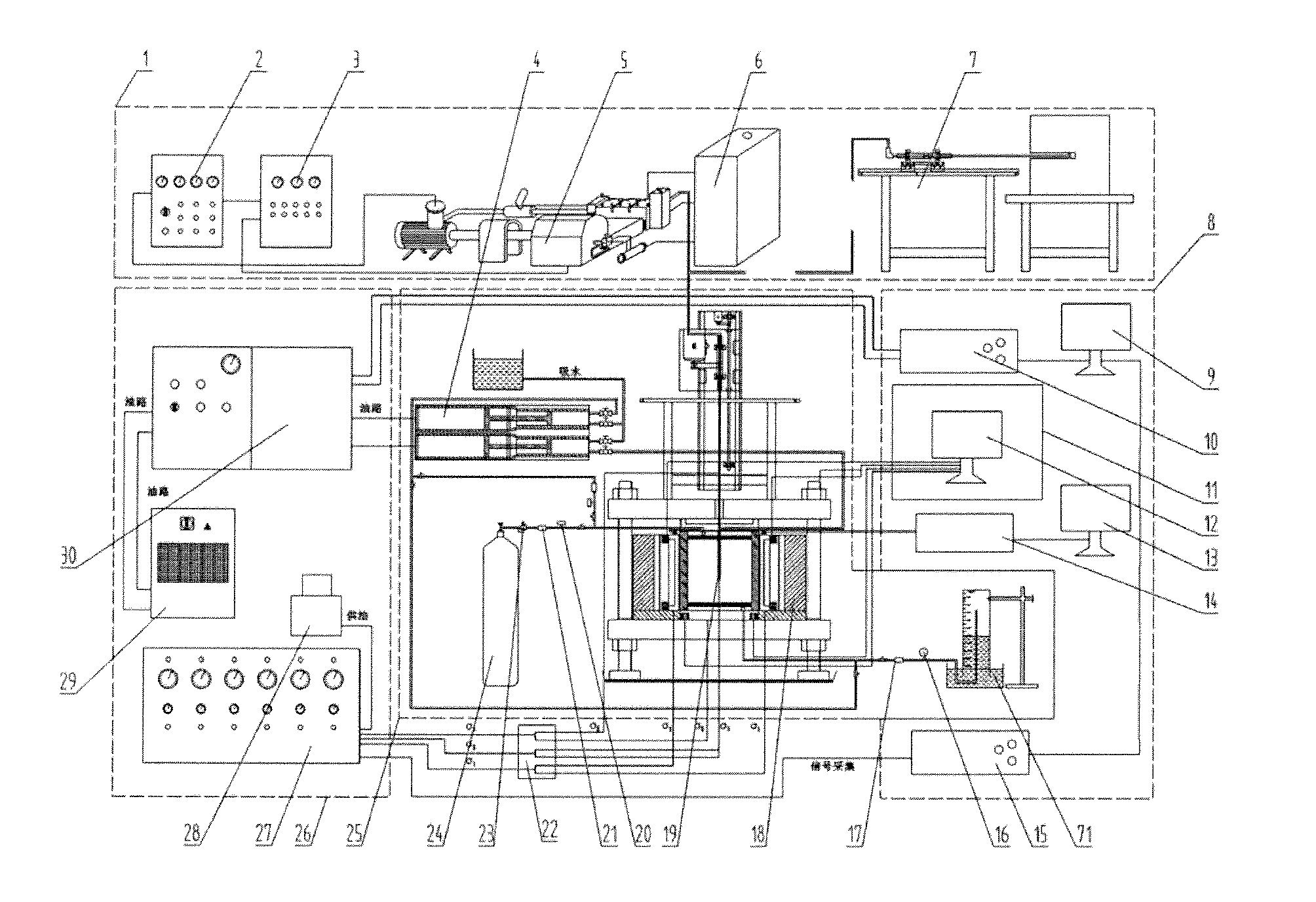

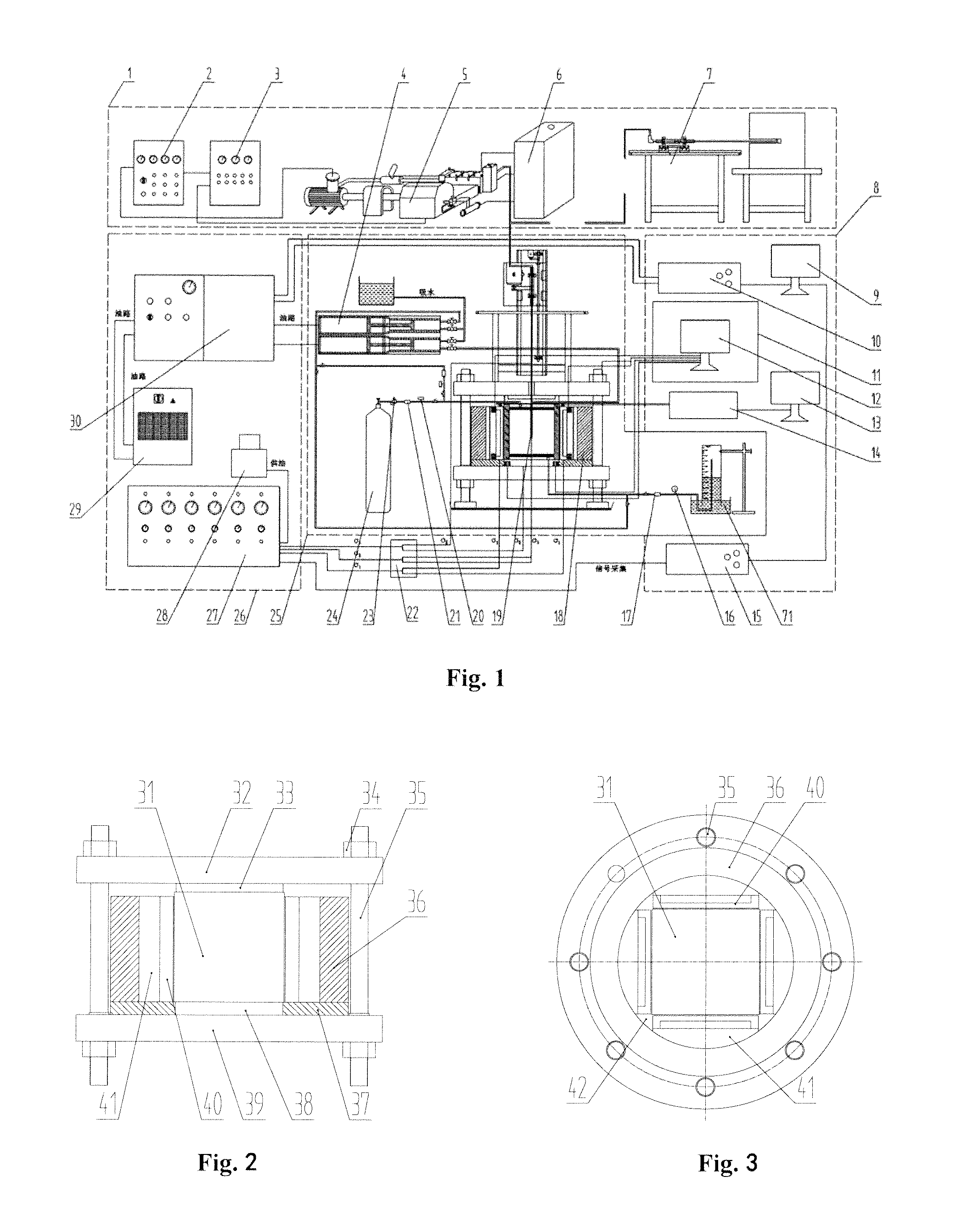

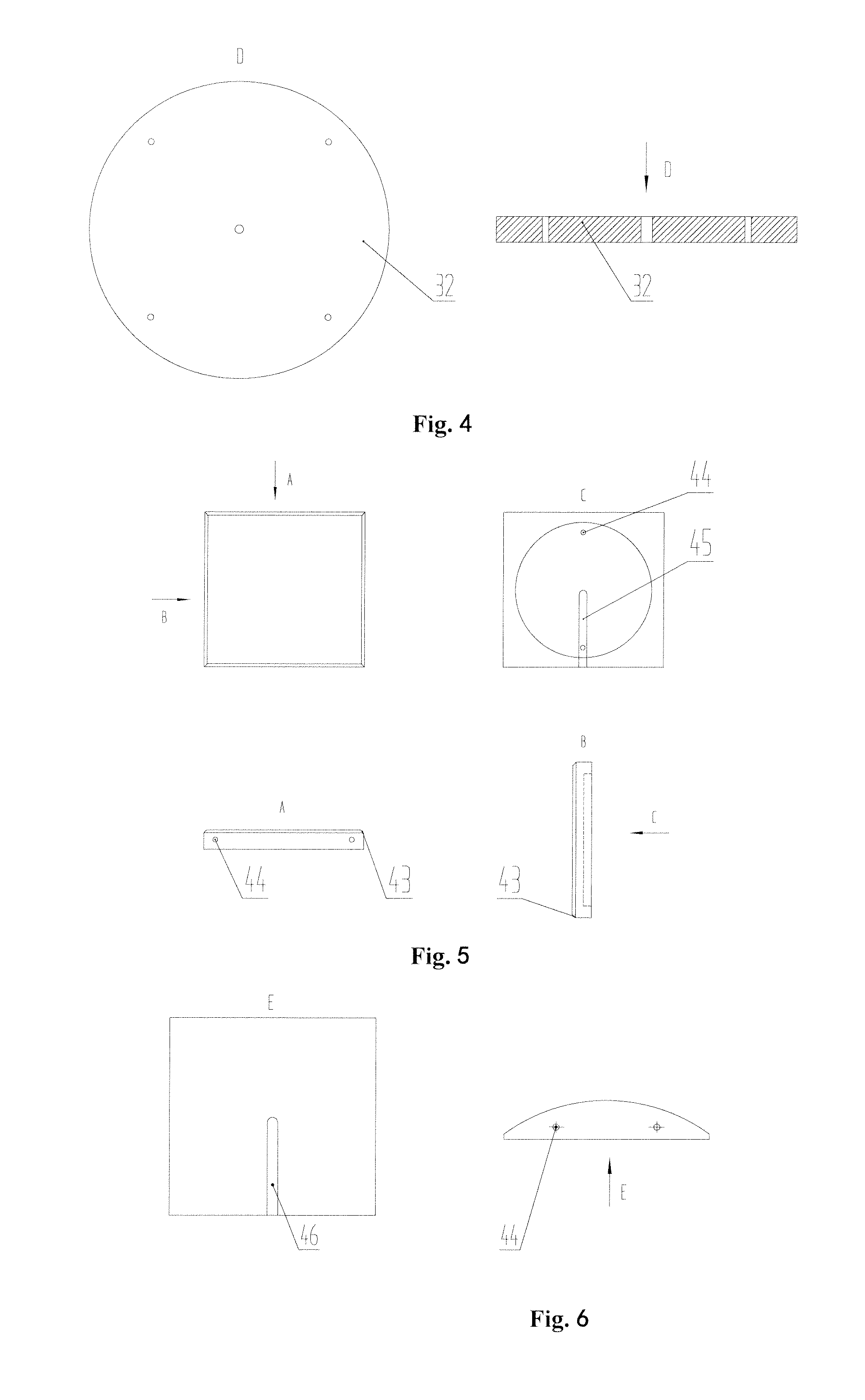

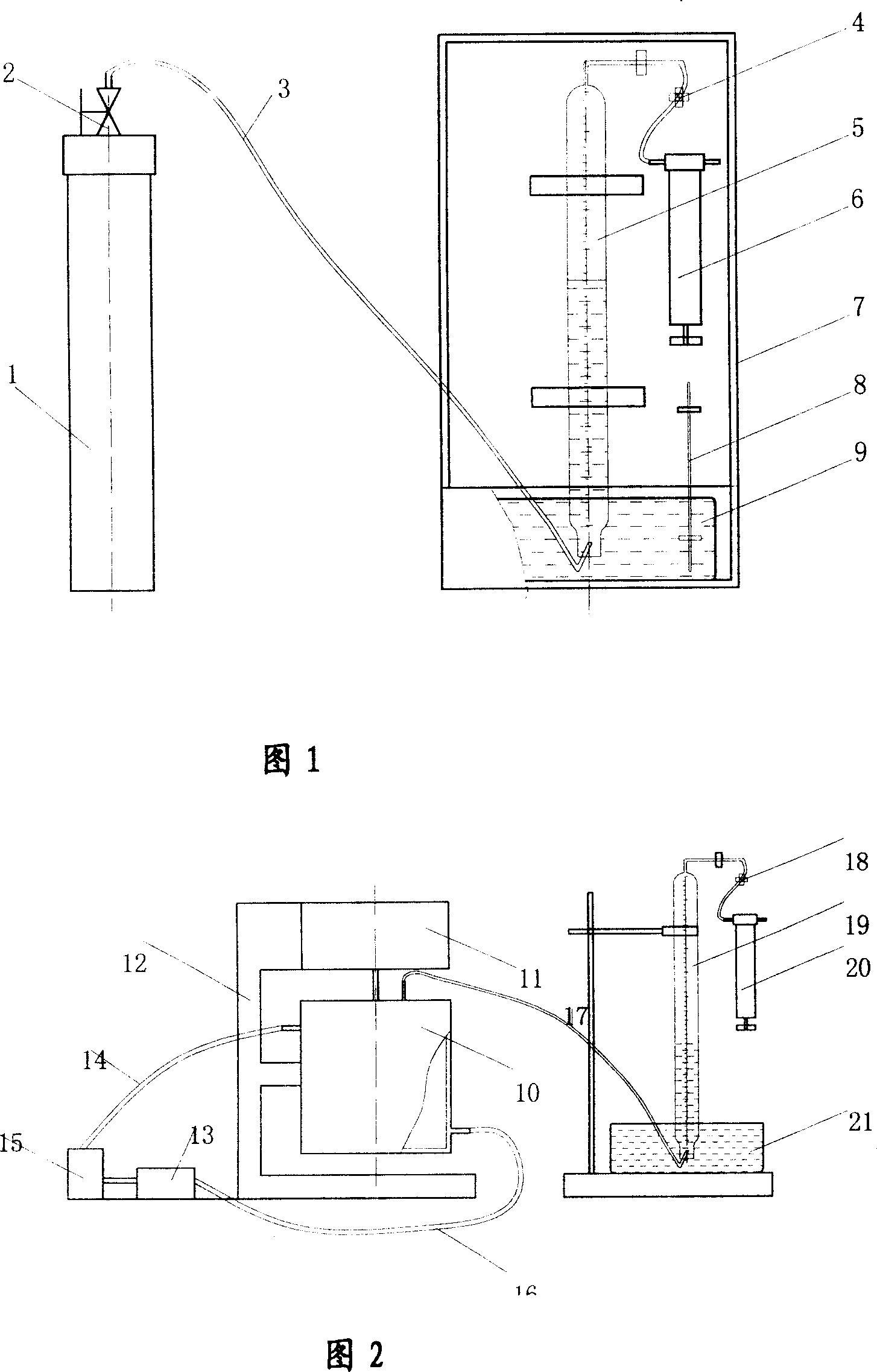

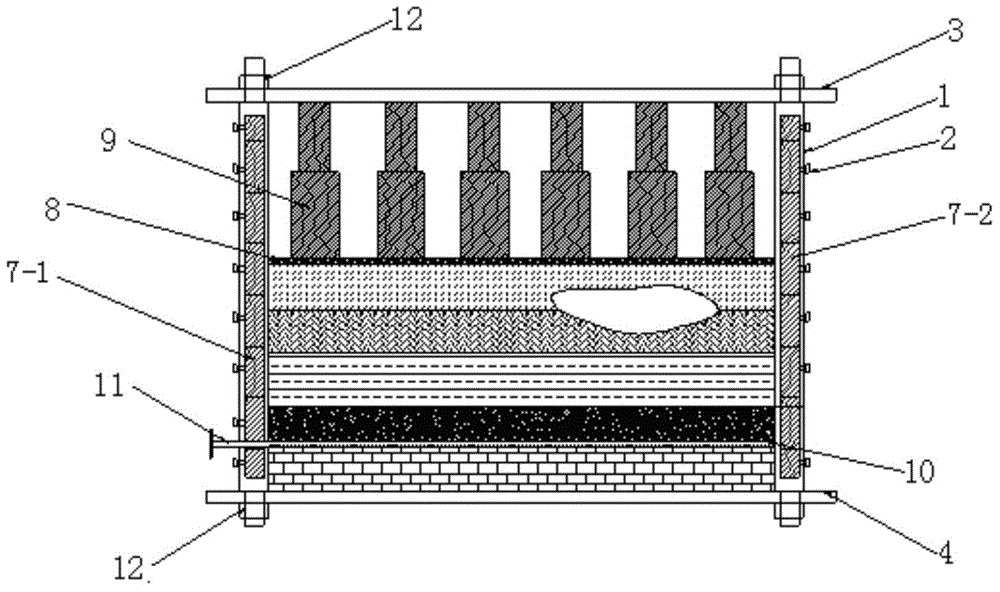

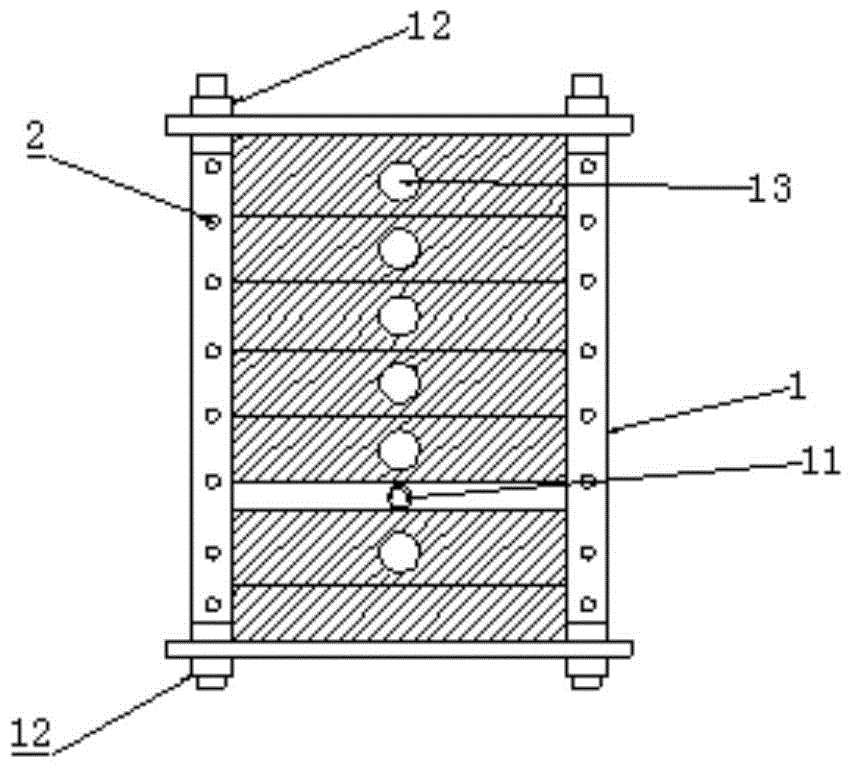

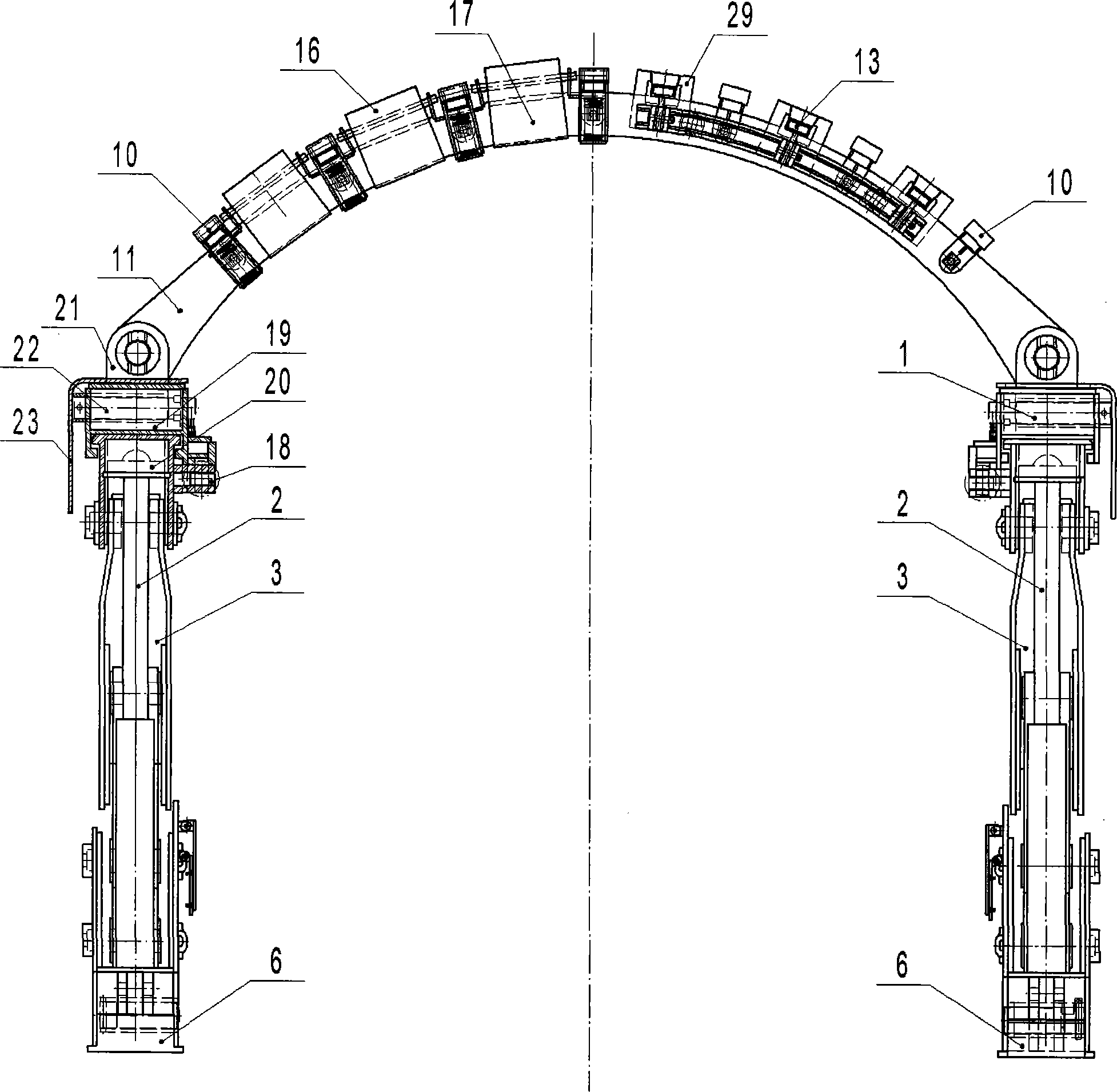

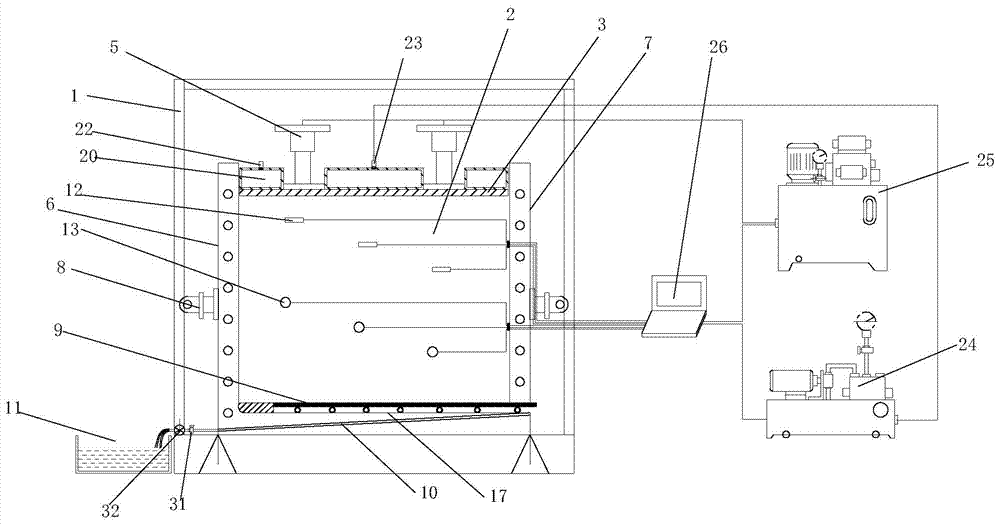

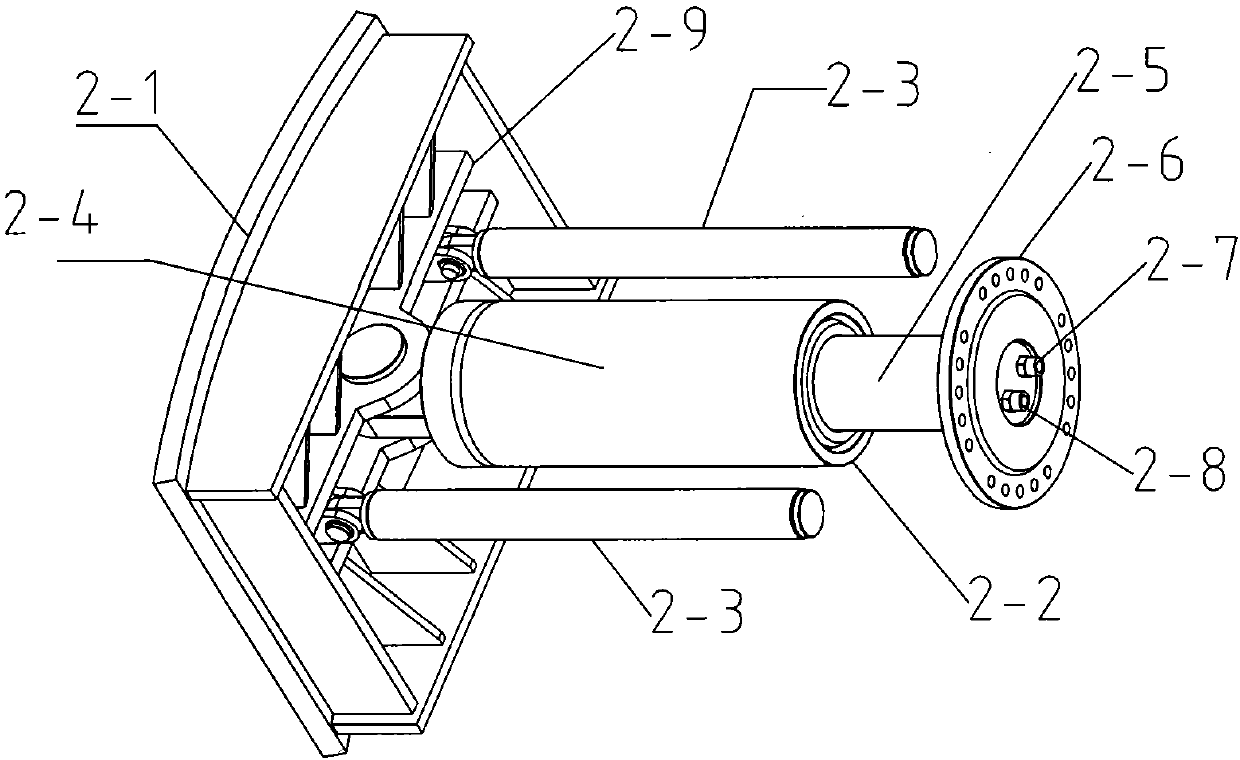

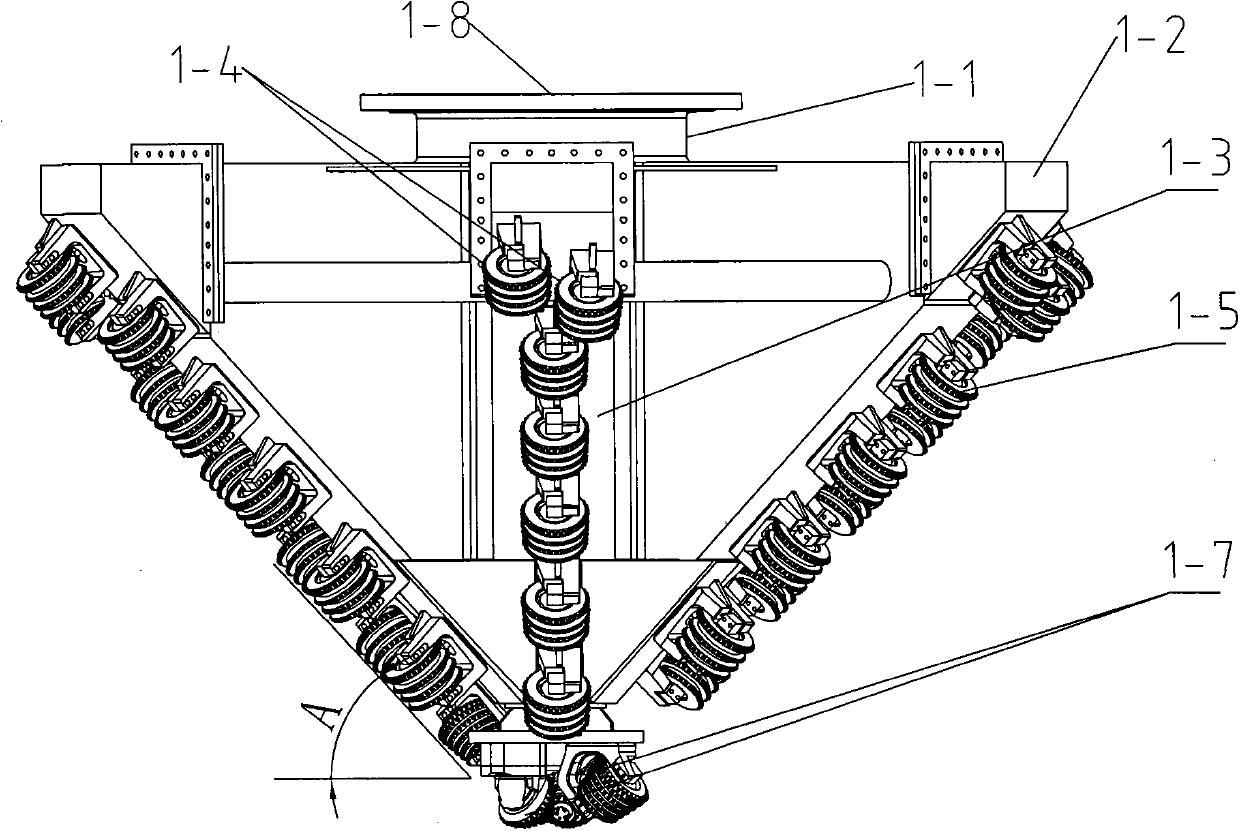

Integrated experimental system of hydrofracturing, water jet slotting, seepage and gas displacement under true triaxial stress

ActiveUS20170003263A1Good effectImprove securityEarth material testingMultiple fluid pressure valves simultaneous measurementMonitoring systemHydraulic fracturing

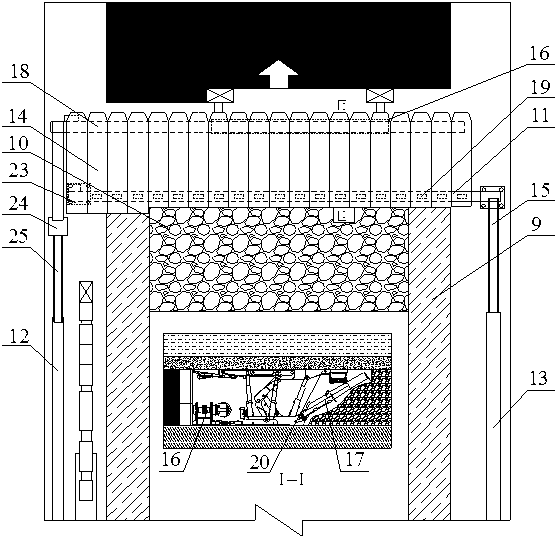

This invention relates to the coal mining field, specifically, to an integrated experimental system of hydrofracturing, water jet slotting, seepage and gas displacement under true triaxial stress. This invention consists of true triaxial stress loading experimental framework, a loading system and a monitoring system. Under true triaxial stress, experiments can be conducted with sample size as large as of 500 mm×500 mm×500 mm. The hydrofracturing experiment can be controlled by as many as 5 independent boreholes at the same time. The borehole water pressure in hydraulic fracturing can reach 63 MPa. Experiments of seepage and fluid-structure interaction with high seepage pressure can be achieved with sample dimension as large as 400 mm×400 mm×400 mm. Mine-used experimental bench of high pressure pump with rated flow of 70 L / min and maximum water pressure of 70 MPa can be used to drill borehole and the like.

Owner:CHINA UNIV OF MINING & TECH

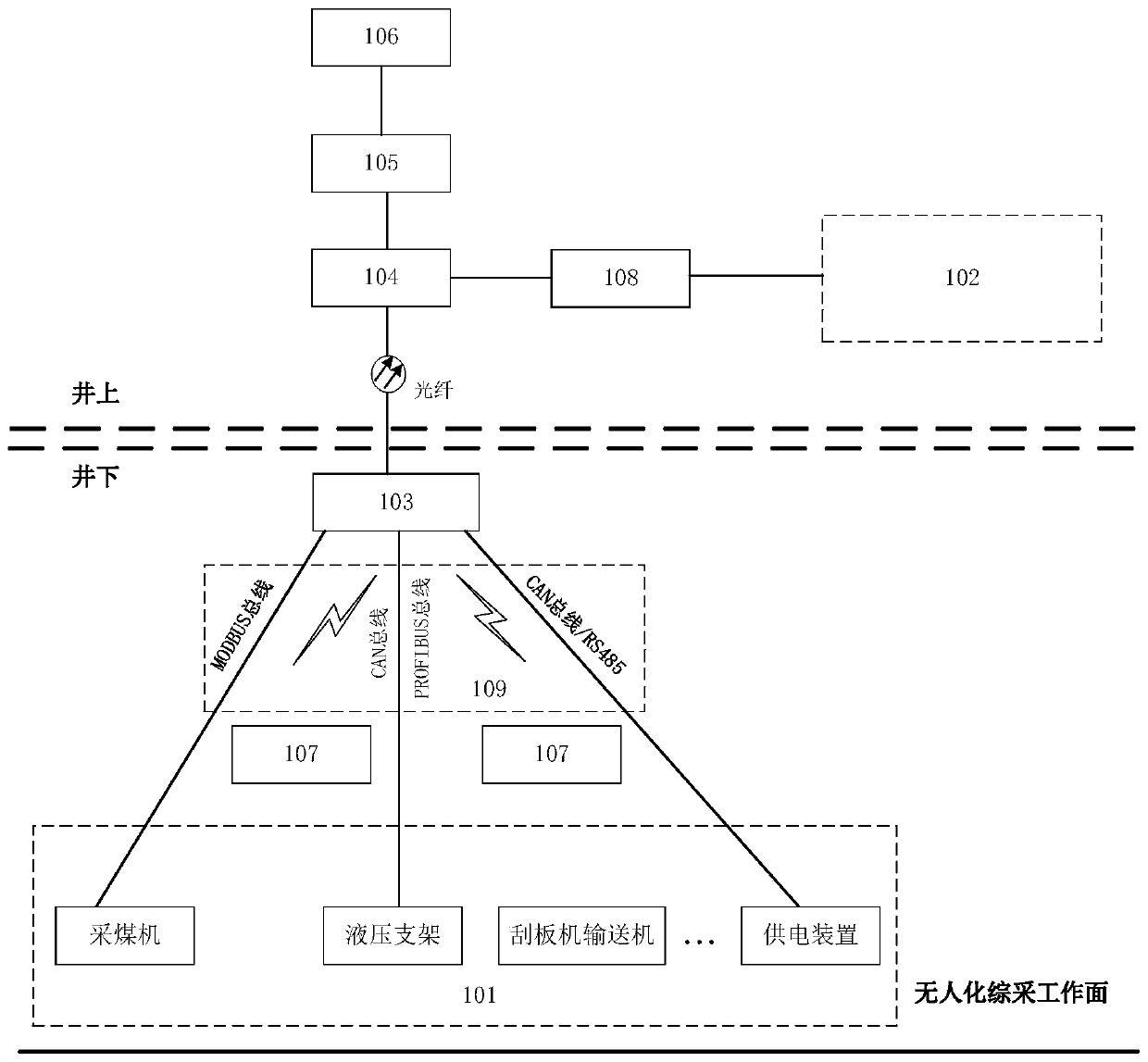

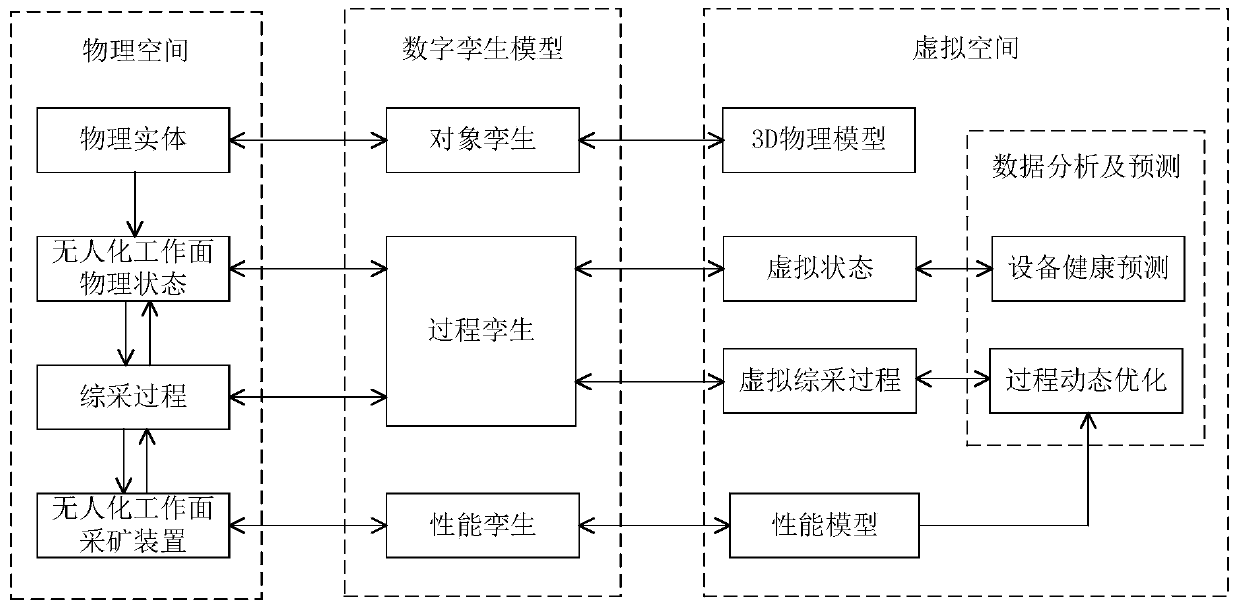

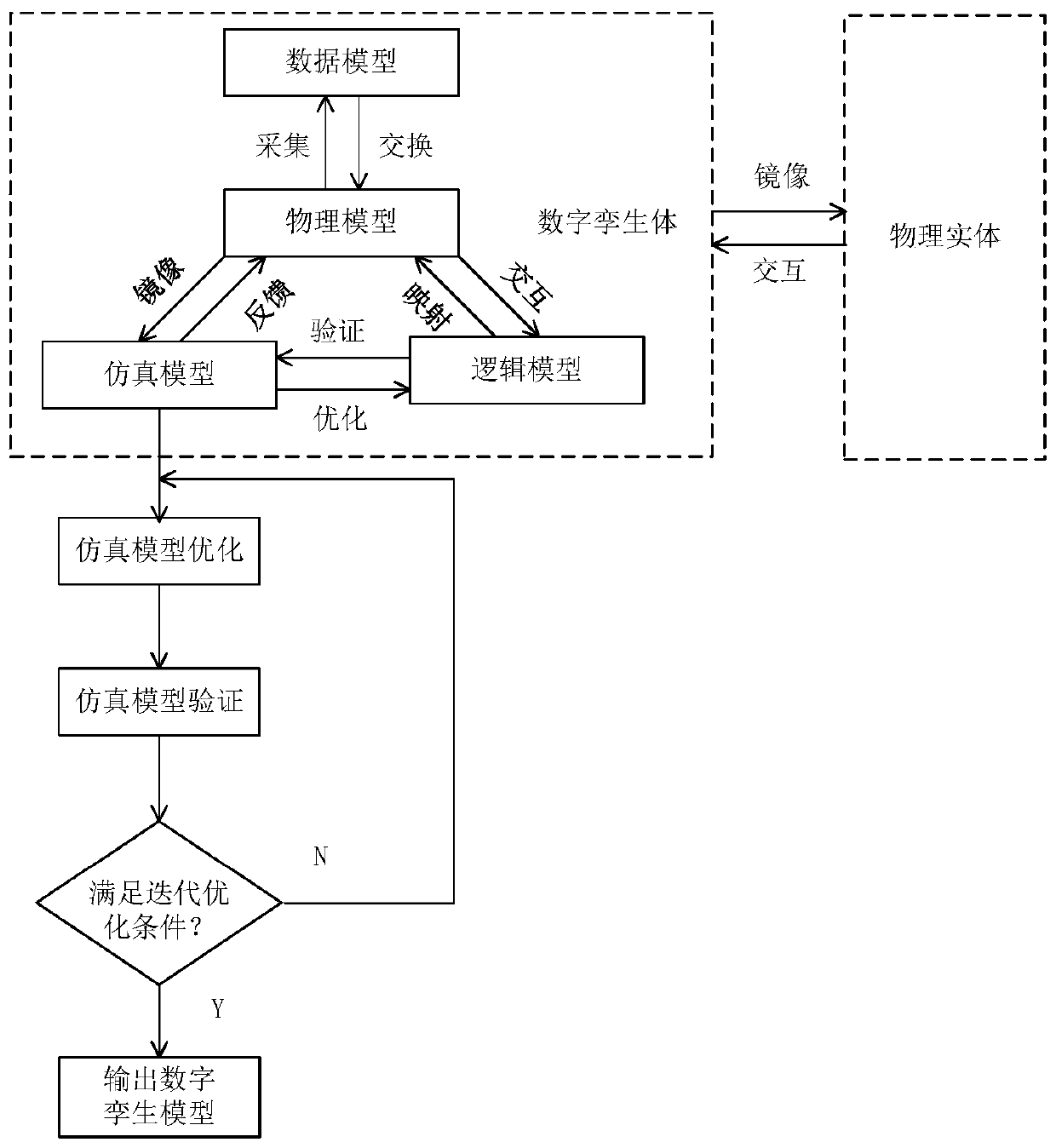

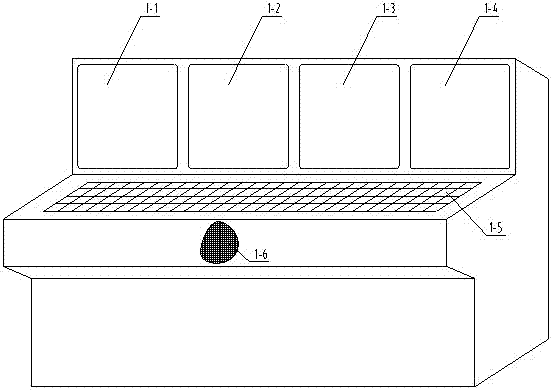

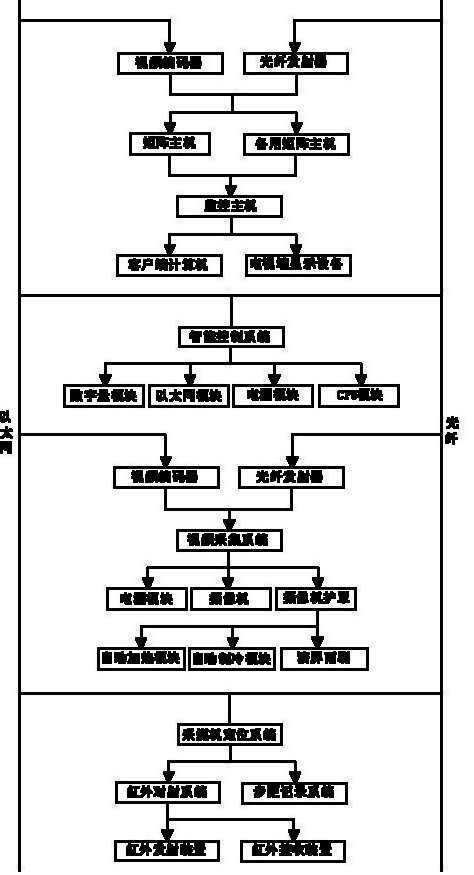

Digital twin intelligent monitoring system for unmanned fully mechanized coal mining face of mine

ActiveCN111208759AImprove real-time performanceImprove accuracyProgramme controlComputer controlVideo monitoringDecision control

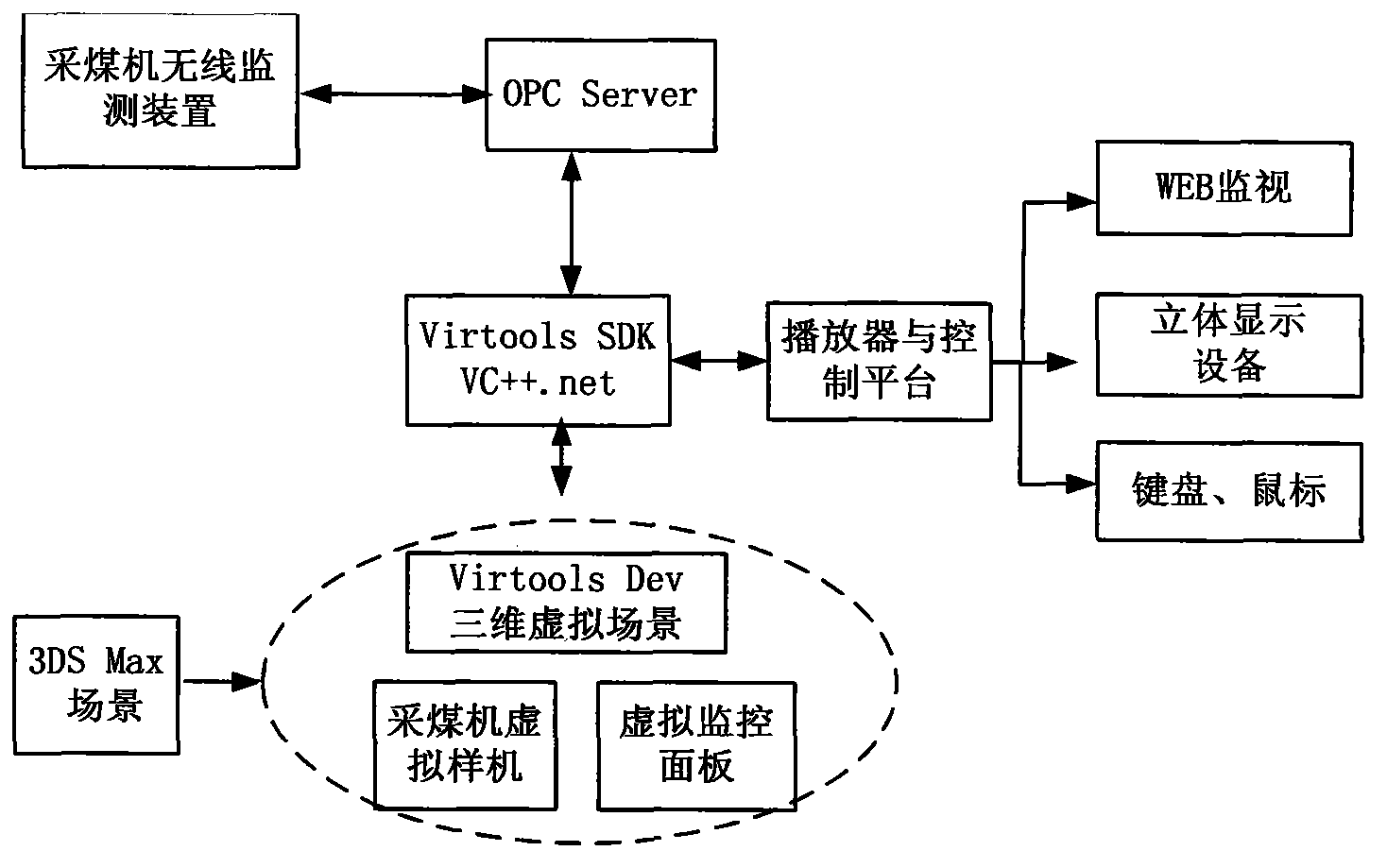

The invention discloses a digital twin intelligent monitoring system and method for an unmanned fully mechanized coal mining face of a mine. The system for realizing the method is composed of a physical entity, a digital twin body, an intelligent gateway, a cloud server, a cloud database, a 5G base station, a machine vision device, a communication interface, a network switch and a video terminal.According to the method, a digital twin model is constructed, and perception analysis, analogue simulation, iterative optimization and decision control are carried out by using a convolutional networkdeep learning algorithm based on a three-dimensional visual virtual scene; real-time monitoring, intelligent sensing, accurate positioning and health prediction of the remote physical space mine unmanned fully mechanized coal mining face are achieved through the virtual space digital twin unmanned fully mechanized coal mining face based on data twinning and data driving. The problems of non-uniform communication interfaces, weak equipment integration capability, poor video monitoring image processing real-time performance and the like of the existing monitoring system are solved, and the real-time performance, the accuracy and the robustness of the intelligent monitoring system for the unmanned fully mechanized coal mining face of the mine are improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

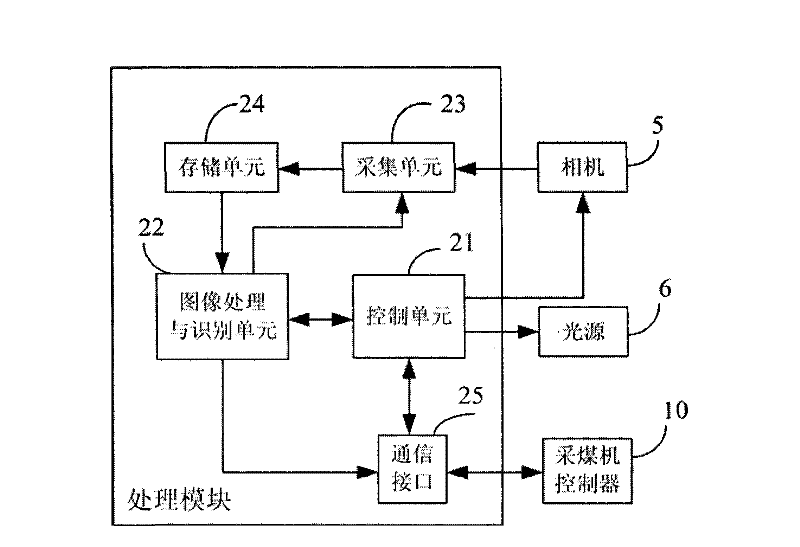

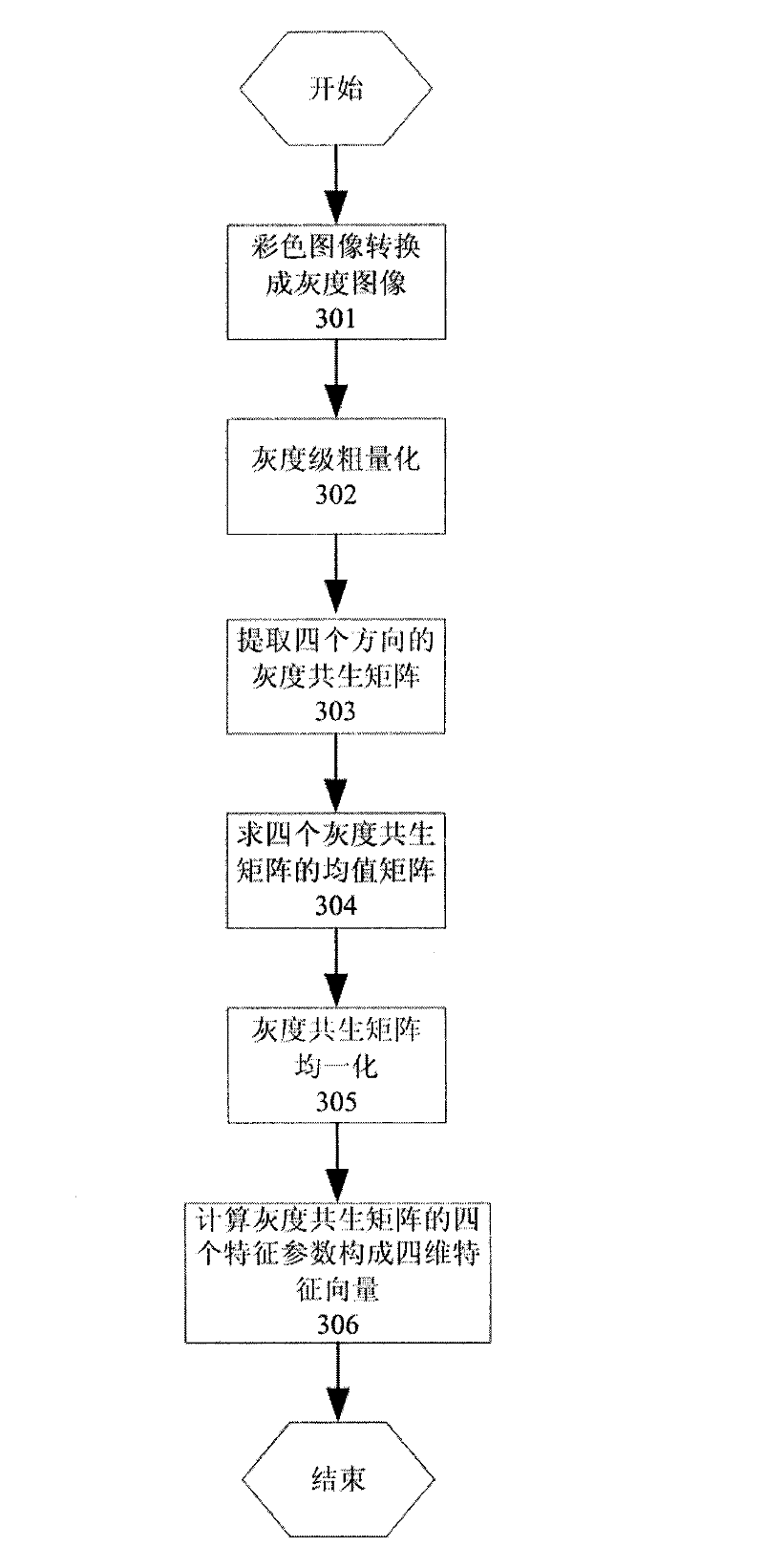

Coal-rock interface identifying method and system based on image

ActiveCN102496004AReal-time identificationAutomatic IdentificationTelevision system detailsCharacter and pattern recognitionFeature vectorColor image

The invention discloses a coal-rock interface identifying method and system based on an image. The method comprises the following steps of: acquiring multiple color images of coal and rock on a coal mining working face; extracting a vector based on an image characteristic serving as a sample characteristic vector specific to each color image to obtain a known sample set of coal and rock; and establishing a coal-rock classifier model by adopting a Fisher linear judging method and taking the known sample set of the coal and rock as a training sample set. In the working process of a coal mining machine, a color image of the coal and rock which is cut by using a drum is acquired in real time, and the extracted characteristic vector is input into the coal-rock classifier model to identify a coal-rock type. The system consists of a light source module, an imaging module, a processing module and an anti-explosion shell. The coal-rock interface identifying method and the system provided by the invention have the characteristics of simple structure, easiness for distributing, high suitability and the like, the coal-rock type cut by using the drum can be automatically identified in real time, and reliable coal-rock interface information is provided for automatic heightening of the drum of the coal mining machine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

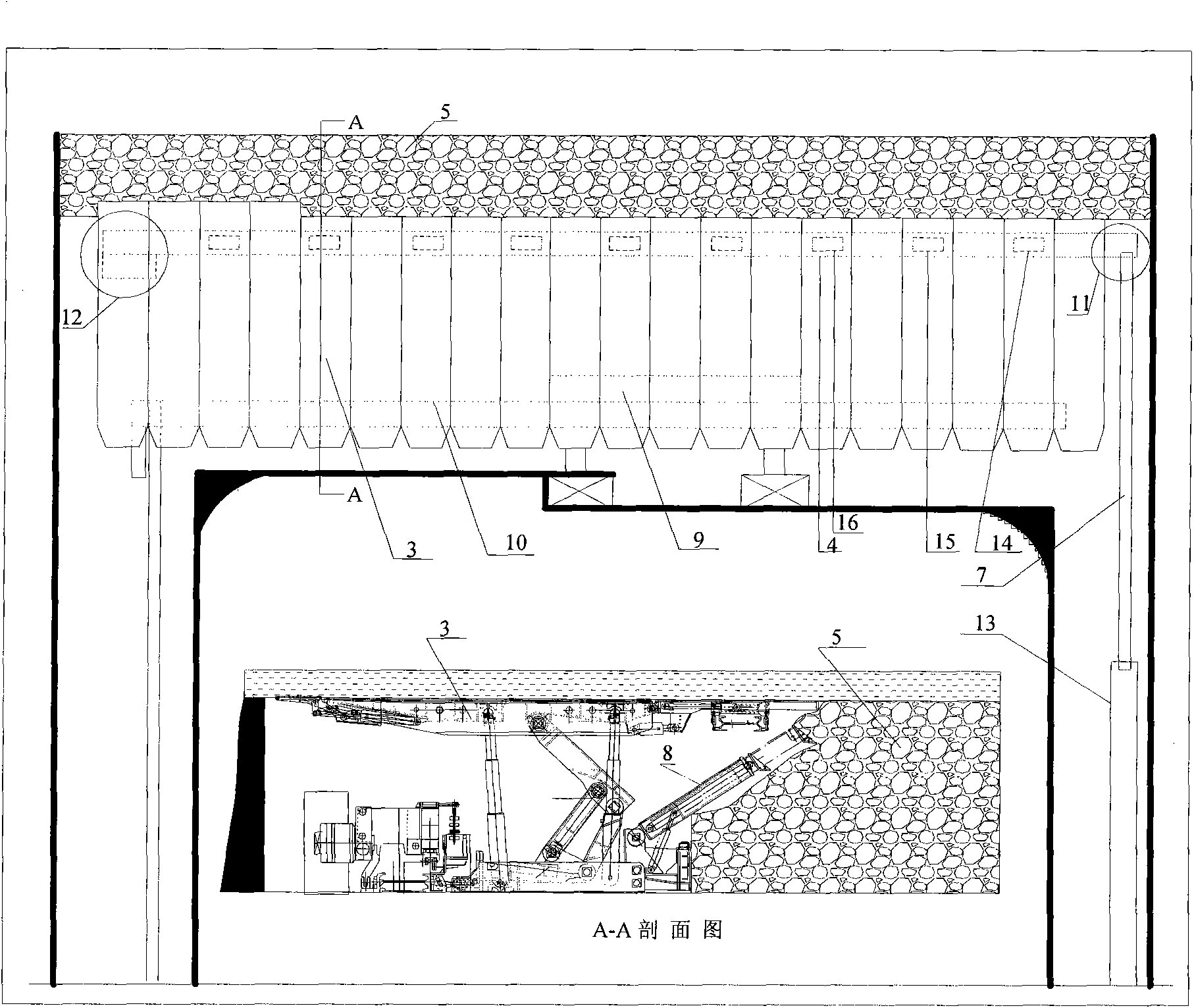

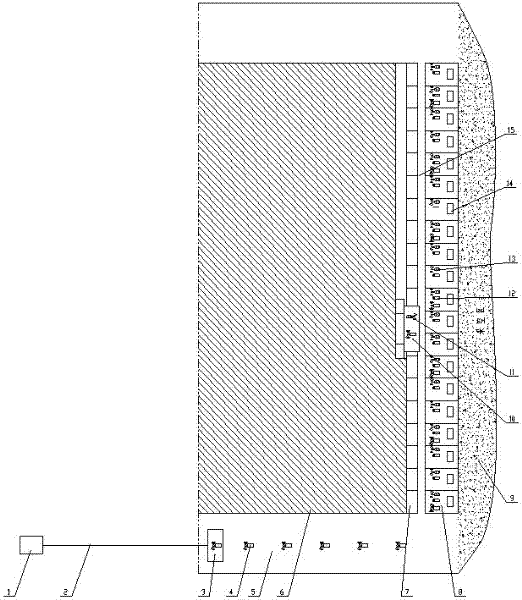

Coal mining solid filling method

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

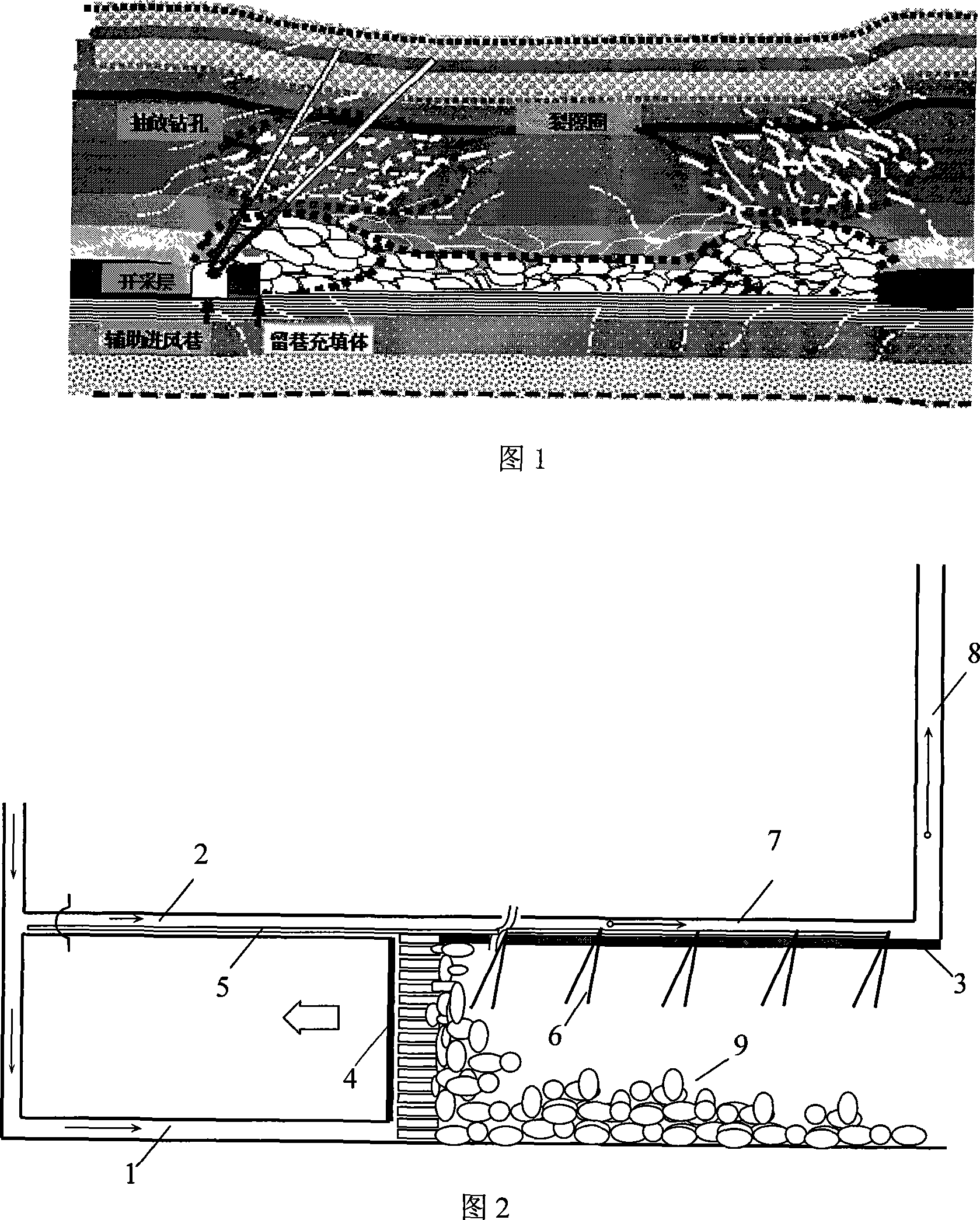

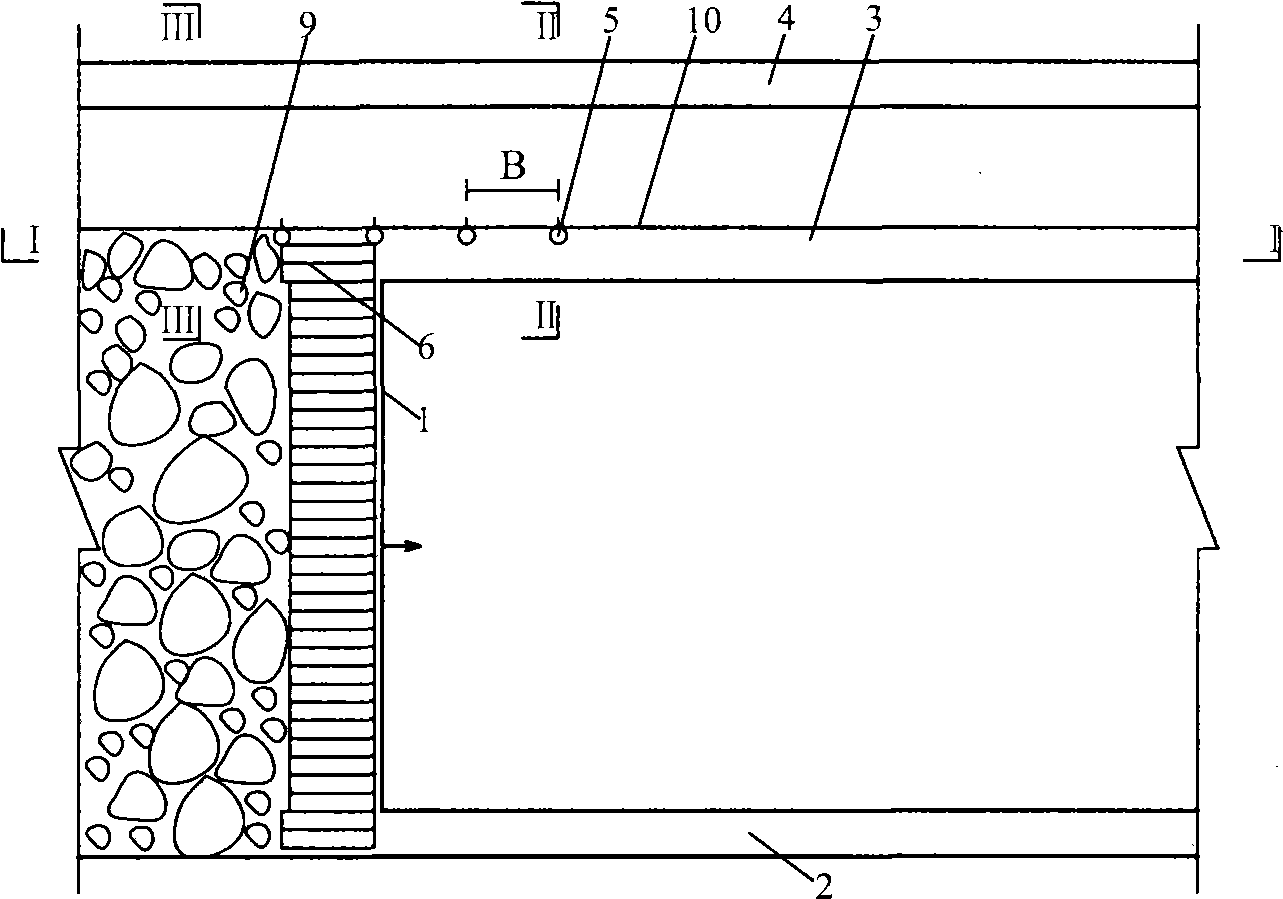

Gob-side entry retaining Y-type ventilation goaf top plate pressure relief gas pumping mining method

ActiveCN101082283ASolve the overrun problemReduce differential pressureTunnel/mines ventillationGas removalPlate pressureHigh density

A method to suck pressure relief firedamp along Y-shape ventilating gob roof of the empty tunnel is characterized in that: in the high-firedamp coal mining working-face pressure relief zone along the empty tunnel gob roof, it sucks the stripping and free firedamp from the exploiting and pressure relief layer which gathers in the gob upper part and the ring slit loop through the slit channel formed by the mining influence on the gob upper rock stratum through the dip sucking firedamp bore-hole which are distributed in the pressure relief ring slit loop. The pressure relief ring slit loop locates in the separation layer slit zone above the caving zone on the Y-shape ventilating working-face along the empty tunnel gob roof. The invention resolves the air firedamp overrun in the corner and the return airway on the coal mining working-face basically, realizes the sucking and application of the high density firedamp, improves the resource utilization ratio, exploits the high firedamp coal seam without coal wedges, improves the mine resource recovery and assures the high-efficiency and safe exploitation of the coal mining working-face.

Owner:HUAINAN MINING IND GRP +2

The roof caving and tunnel protecting method

InactiveCN101509395AHighlight substantiveReduce widthUnderground chambersMaterial fill-upMining engineeringFissure

The invention relates to a method for controlling caving and lane-guarding. The method is characterized in that in a working surface roadway, drilling, blasting or cracking are carried out on a roof of a coal seam of complete hard strata with large thickness of a hanging arch in a goaf; bursting or cutting off are carried out on a complete hard roof strata with large thickness to facilitate the hanging arch in the goaf to collapse at the back of a force piece; collapsed waste rock fills the goaf, supports superincumbent stratum in a fissure zone and releases high bearing stress passed into the coal body adjacent to the goaf from weight of the large-thickness complete hard strata of the hanging arch in the goaf and the superincumbent stratum in the fissure zone thereof, so that the bearing stress in the coal body adjacent to the goaf is reduced and laneways in the space are protected. The method of the invention fundamentally improves stability of surrounding rock of laneways adjacent to the goaf and increases coal mining rate of ends of thick coal seam caving coal working surface.

Owner:TAIYUAN UNIV OF TECH

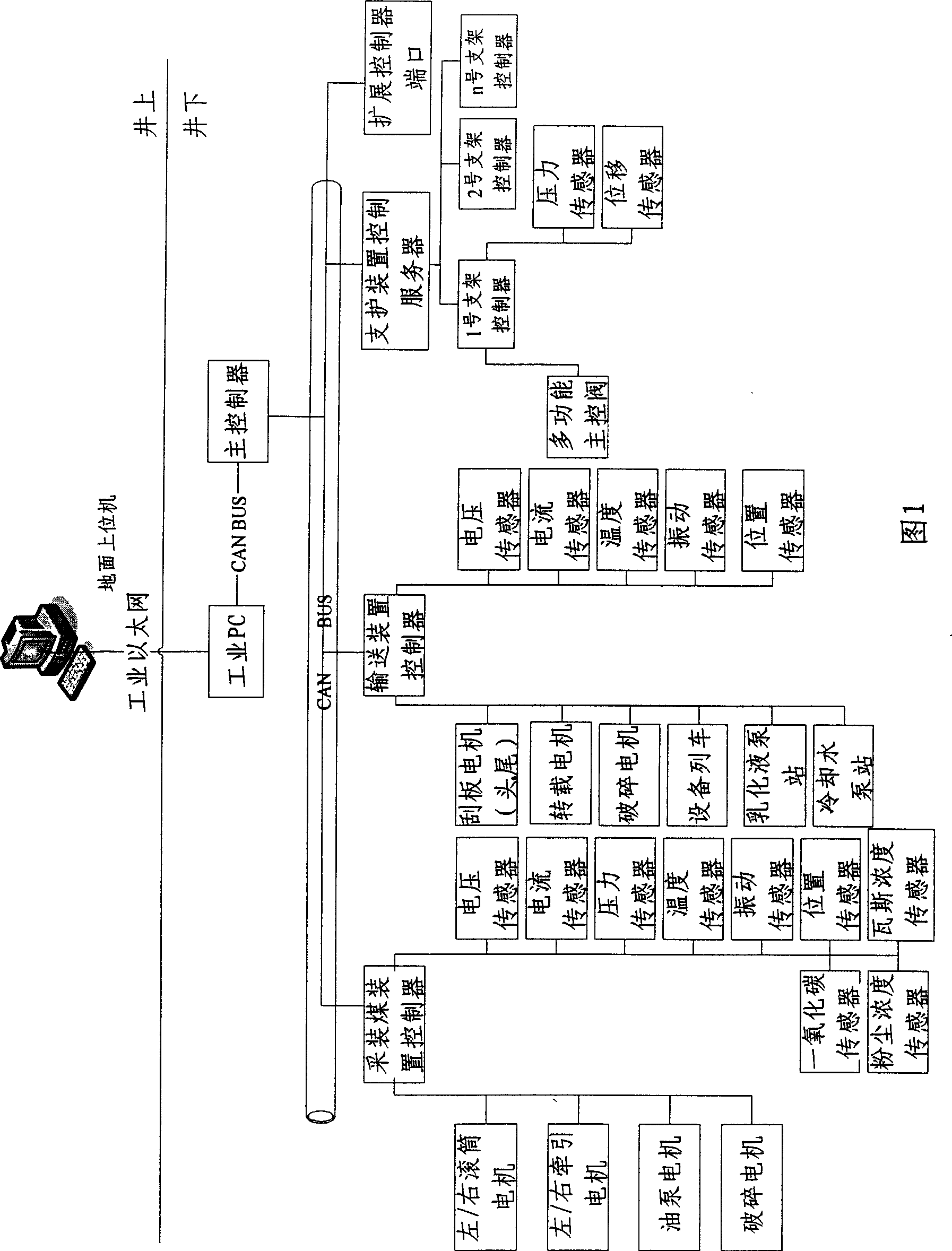

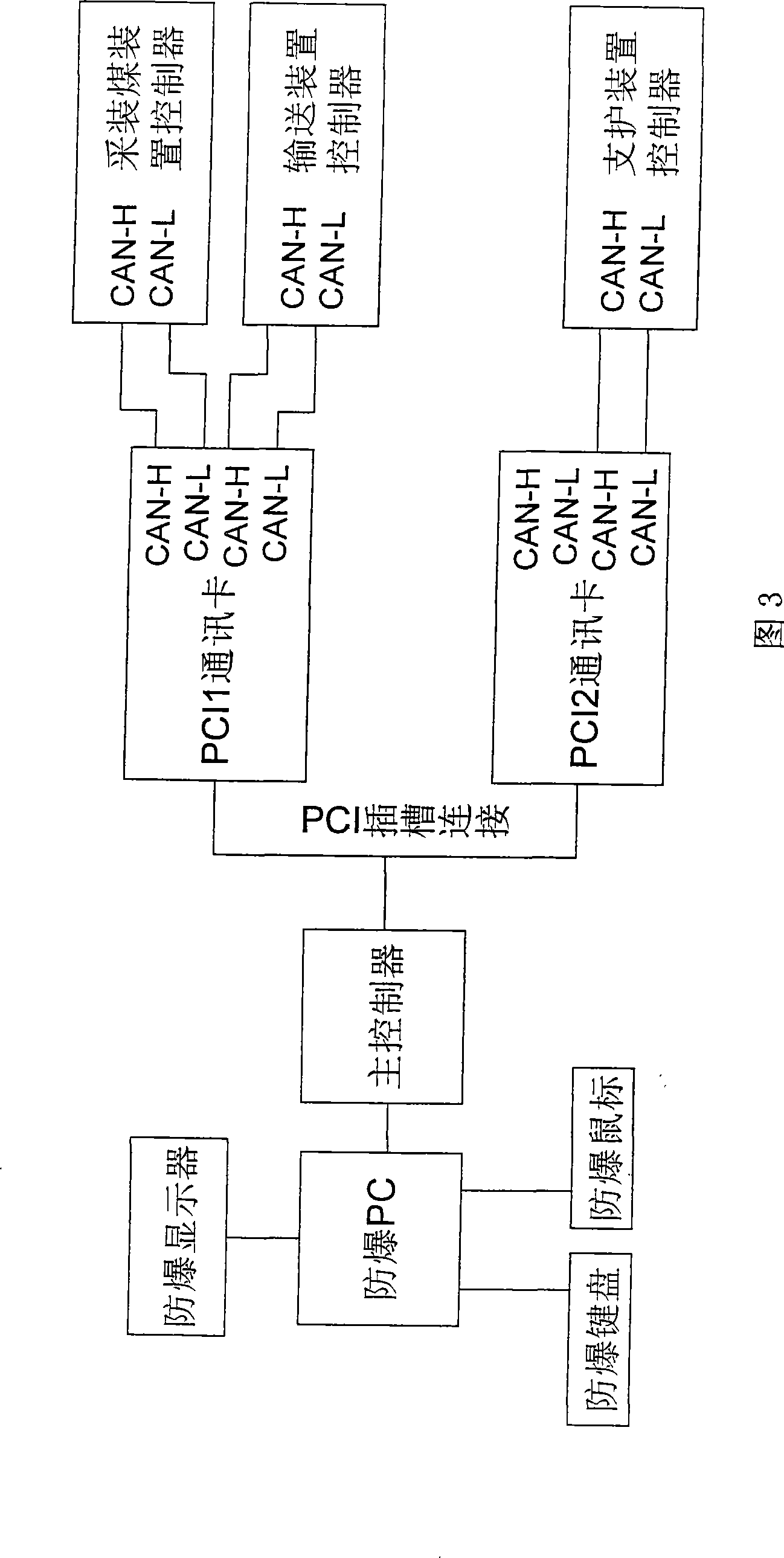

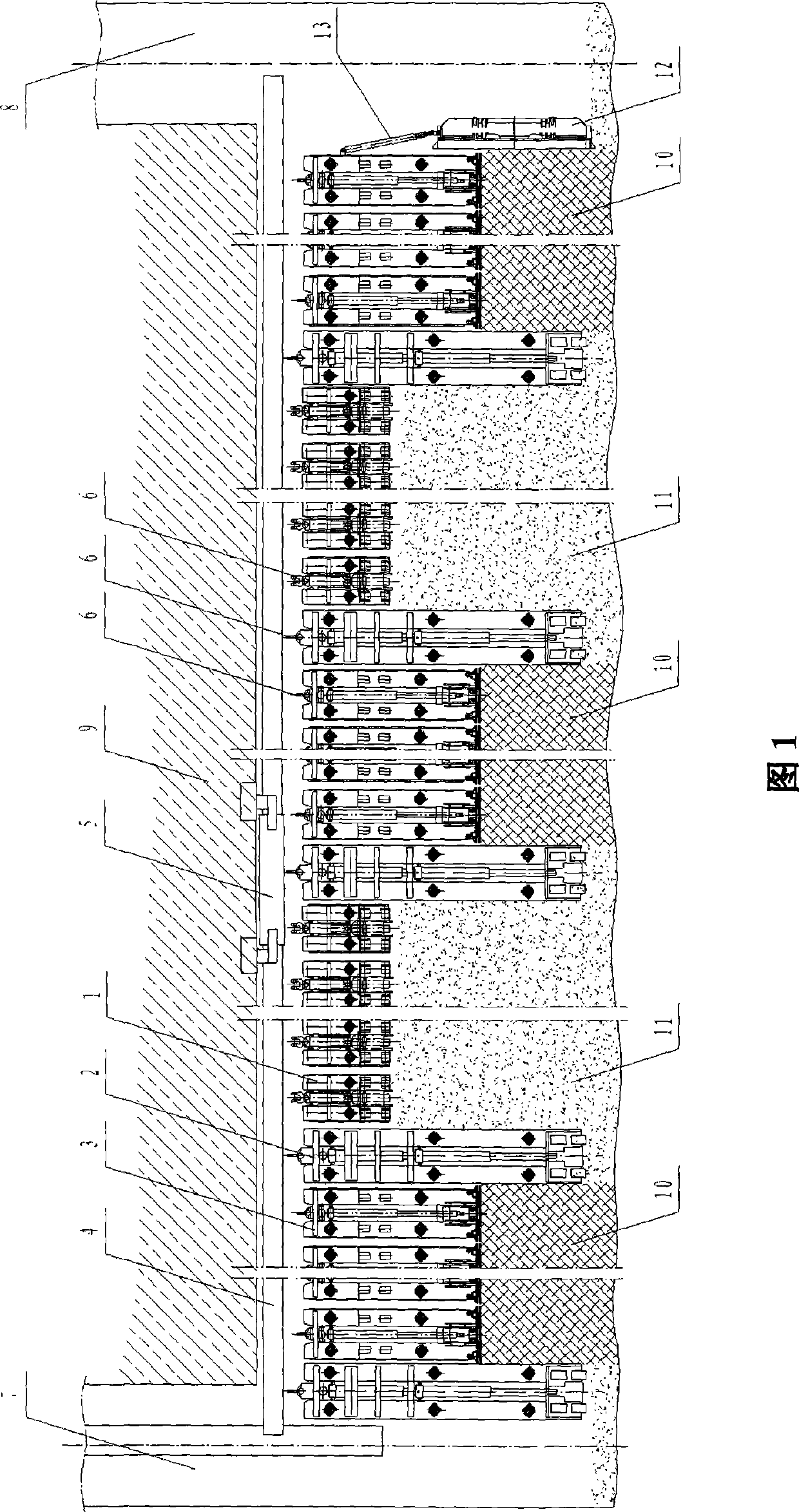

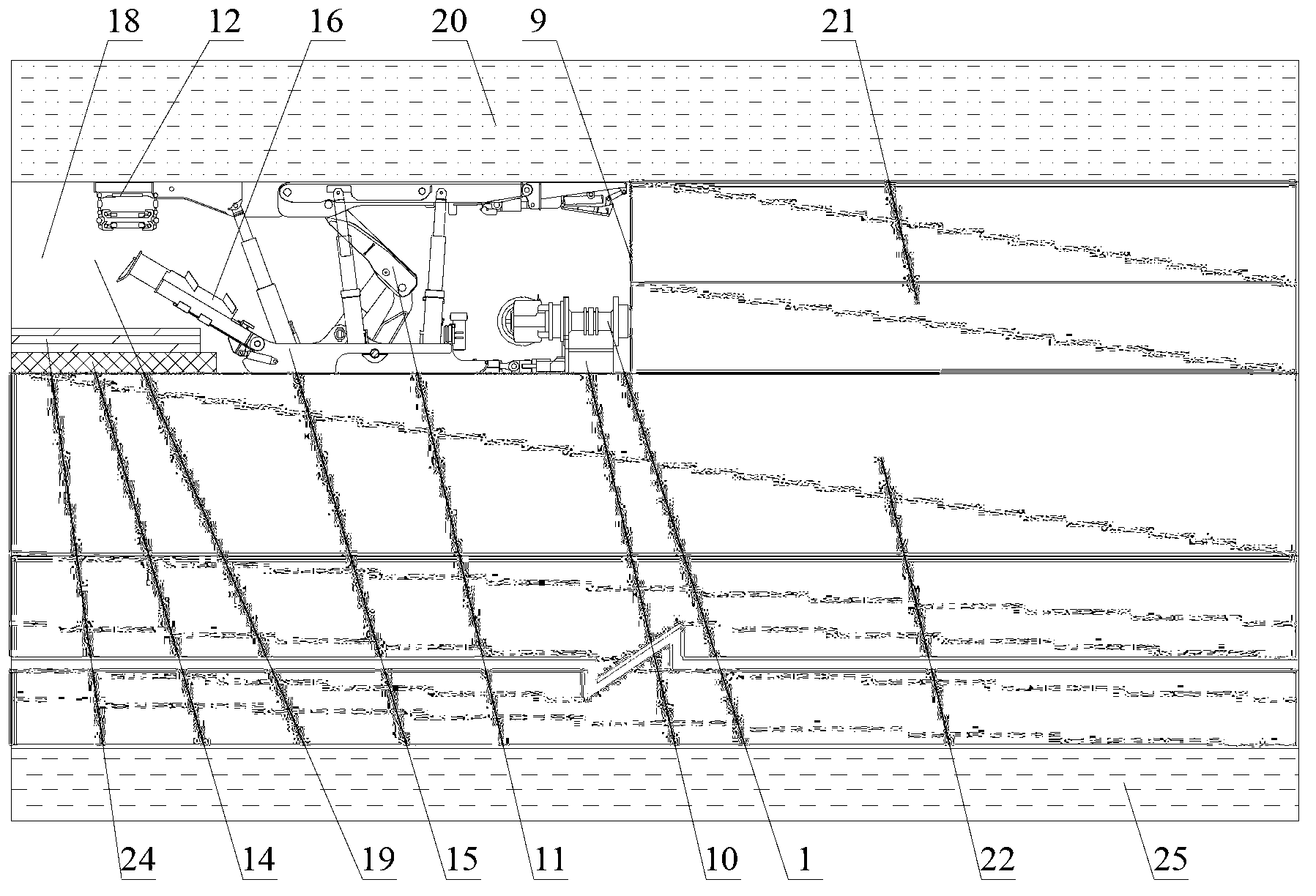

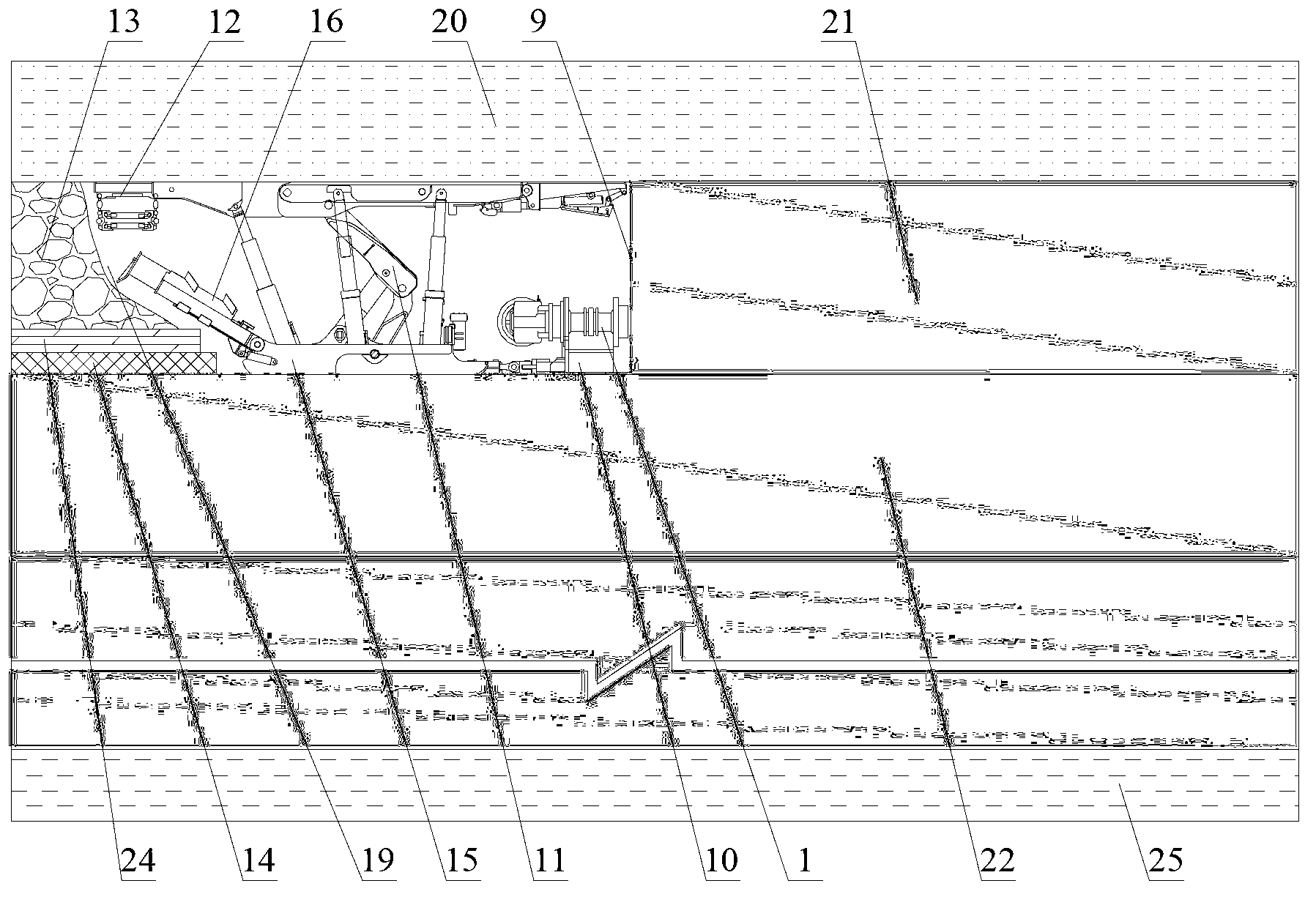

Intelligent full automatic combine coal mining system

ActiveCN101418688ARealize comprehensive applicationImprove completenessMining devicesUnderground miningProcess engineeringControl equipment

The invention relates to an intelligent type full-automatic combined coal mining system, which comprises a coal mining and loading device, a conveying device, a supporting device, and an equipment train, and is mounted in the working face and crossheading in the coal mine well. The coal mining and loading device is mounted on the conveying device, the coal conveying port of the conveying device is conveyed to the outside of the well or the coal bunker through a belt type conveyor in the crossheading, the supporting device is arranged behind the conveying device for supporting the top plate of the coal seam and linking with the conveying device, the equipment train comprises a central control chamber of a central control equipment, a starter, a power device, and a lifesaving cabin, the central control equipment monitors and controls the coordination operation of the devices, the equipment train, and the power device of the equipment train, the power device provide power source for the devices and the equipment train, and the equipment train moves freely in the crossheading with the feeding of the working faces. The invention improves system complete ability and execution efficiency, and has strong function, high intelligent degree, high safety, high production efficiency, and the like.

Owner:SANY HEAVY EQUIP

Direct rapid measuring method capable of desorbing mash gas content with coal seam

ActiveCN101135621AThe amount of measurement work is smallLow assay costWithdrawing sample devicesPreparing sample for investigationDesorptionGrind

The method comprises: sampling coal core from underground mining; at underground mining, measuring and calculating the gas loss quantity of coal core; at the ground, measuring and calculating the desorption of the coal mining gas; measuring and calculation the grind gas desorption of partial coal core; calculating the content of gas capable of being desorbed.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

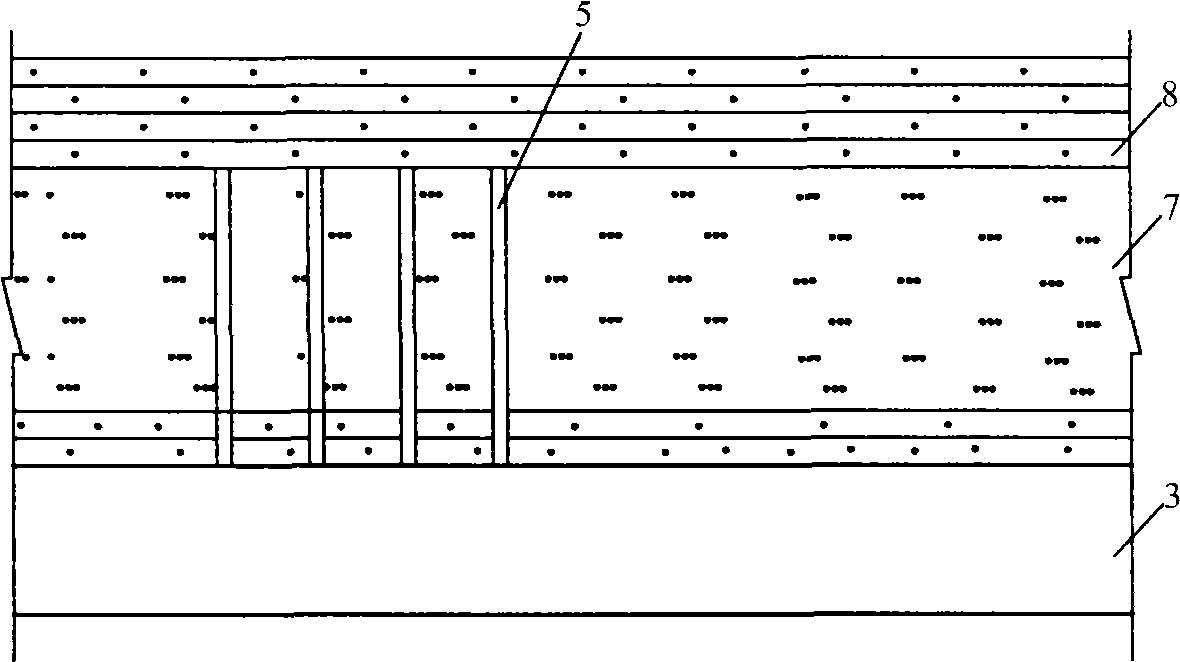

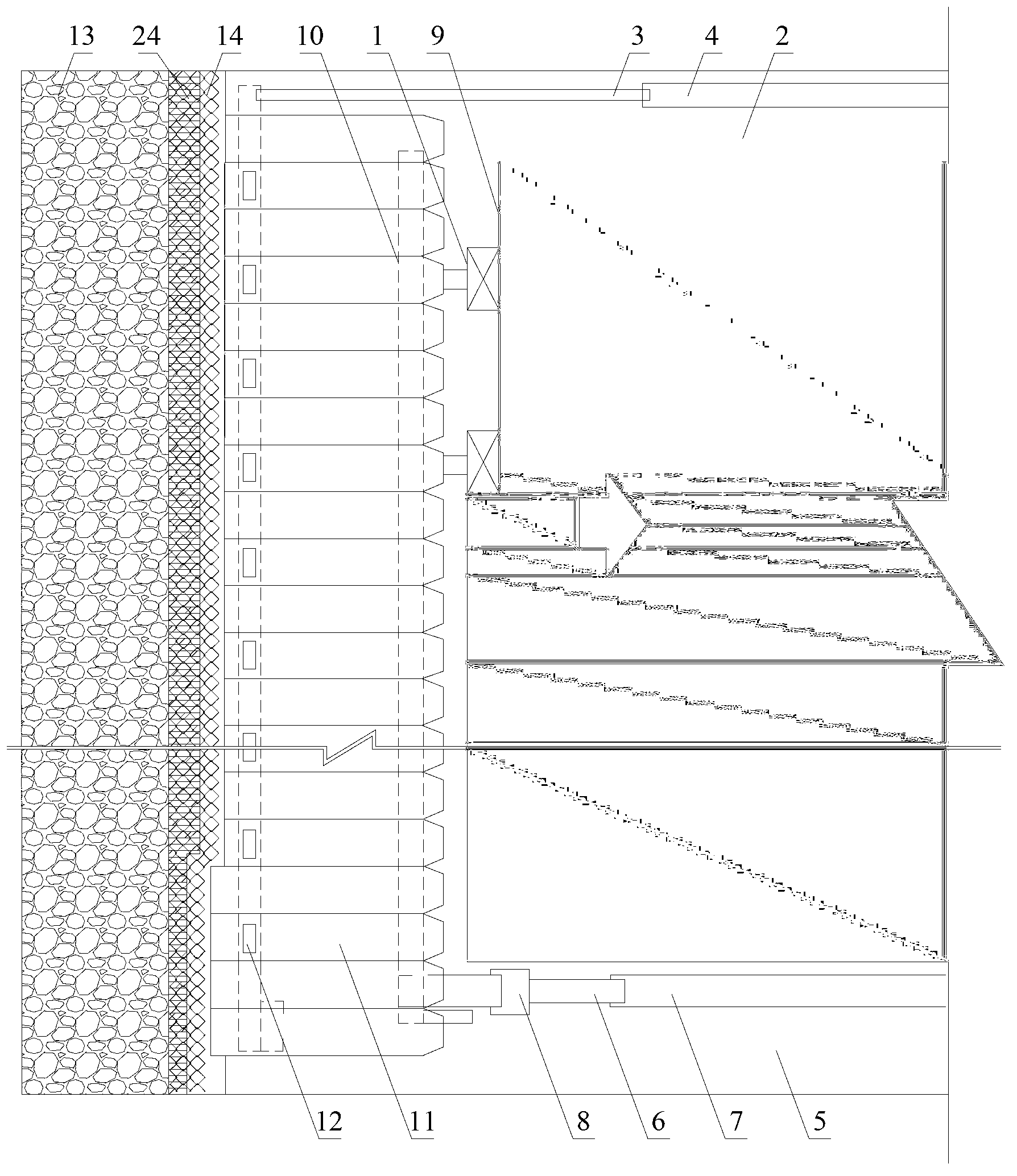

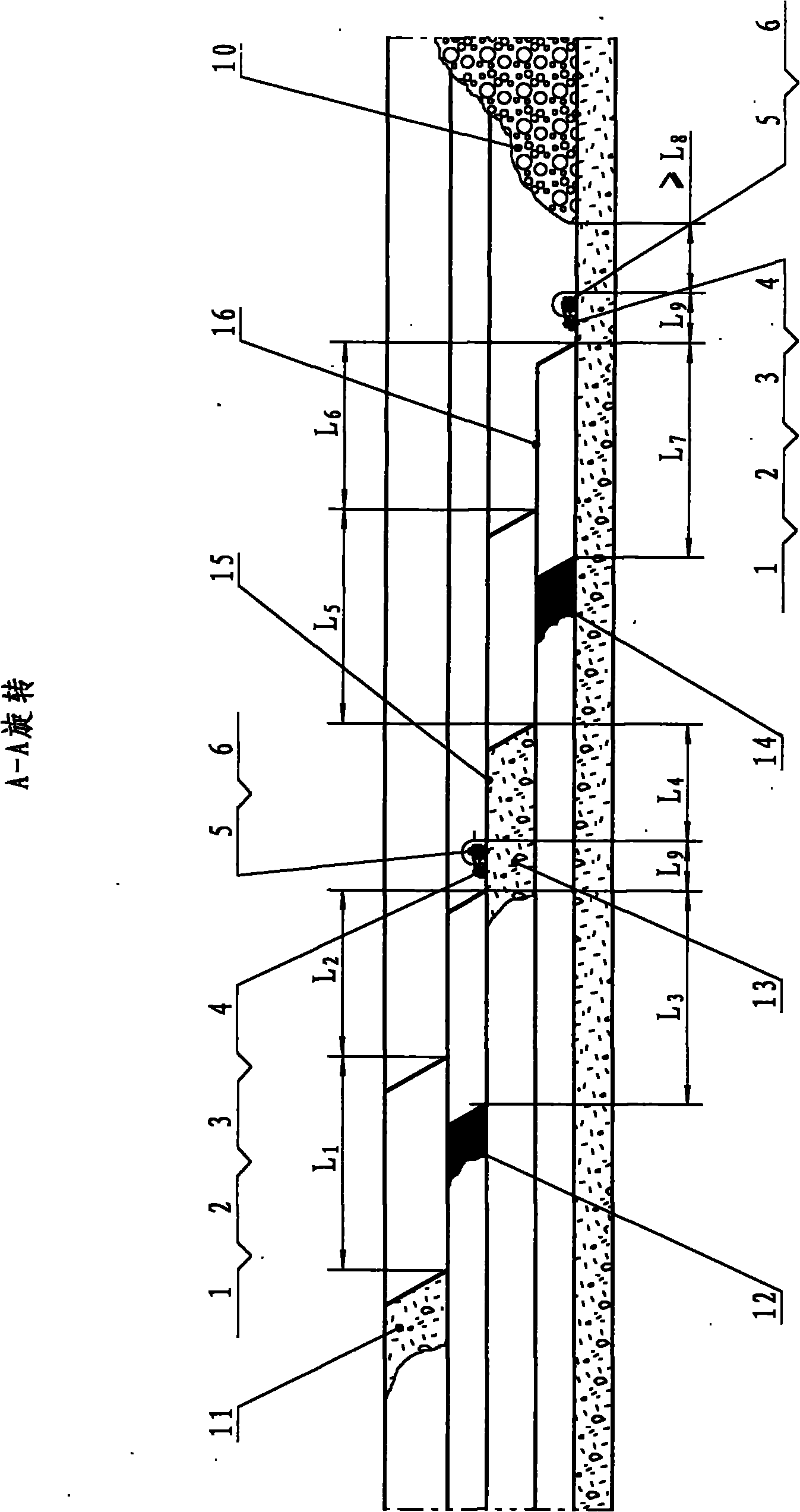

Solid-filling coal mining method with two pre-excavating tunnels for advancing

ActiveCN102996131ASolve the technical problems that cannot guarantee the filling effectEasy to useUnderground miningSurface miningFilling materialsMining engineering

The invention discloses a solid-filling coal mining method with two pre-excavating tunnels for advancing. A mining roadway adopts an arrangement mode that the pre-excavating tunnels are taken as air return and inlet roadways and a gob-side entry retaining roadway is taken as a roadway for transporting filling materials and coal; coal extraction and gob backfilling are carried out by a comprehensive mechanical solid-filling coal mining process; and according to the coal mining method, a mining sequence is propelled by making a filling coal mining work surface be back to the direction for transporting the coal to a mountain in a mining area. The pre-excavating tunnels are formed before the extraction of the work surface by tunneling, and the gob-side entry retaining roadway is formed by optimally designed filling bodies beside the roadway along with the implementation of advancing filling coal mining operation along the work surface. The coal mining method is simple in process and technically and completely realizes coal milling without pillars, and the resource extraction rate of the coal is high. The coal mining method can not only solve the technical problems that a draw-back-type down-mining and up-filling work surface cannot ensure a filling effect during a filling milling process of a mine with shortage of resources, but also materialize the comprehensive mechanical solid-filling coal mining of mines with limited geological conditions by virtue of an advancing up-milling and down-filling work surface.

Owner:CHINA UNIV OF MINING & TECH

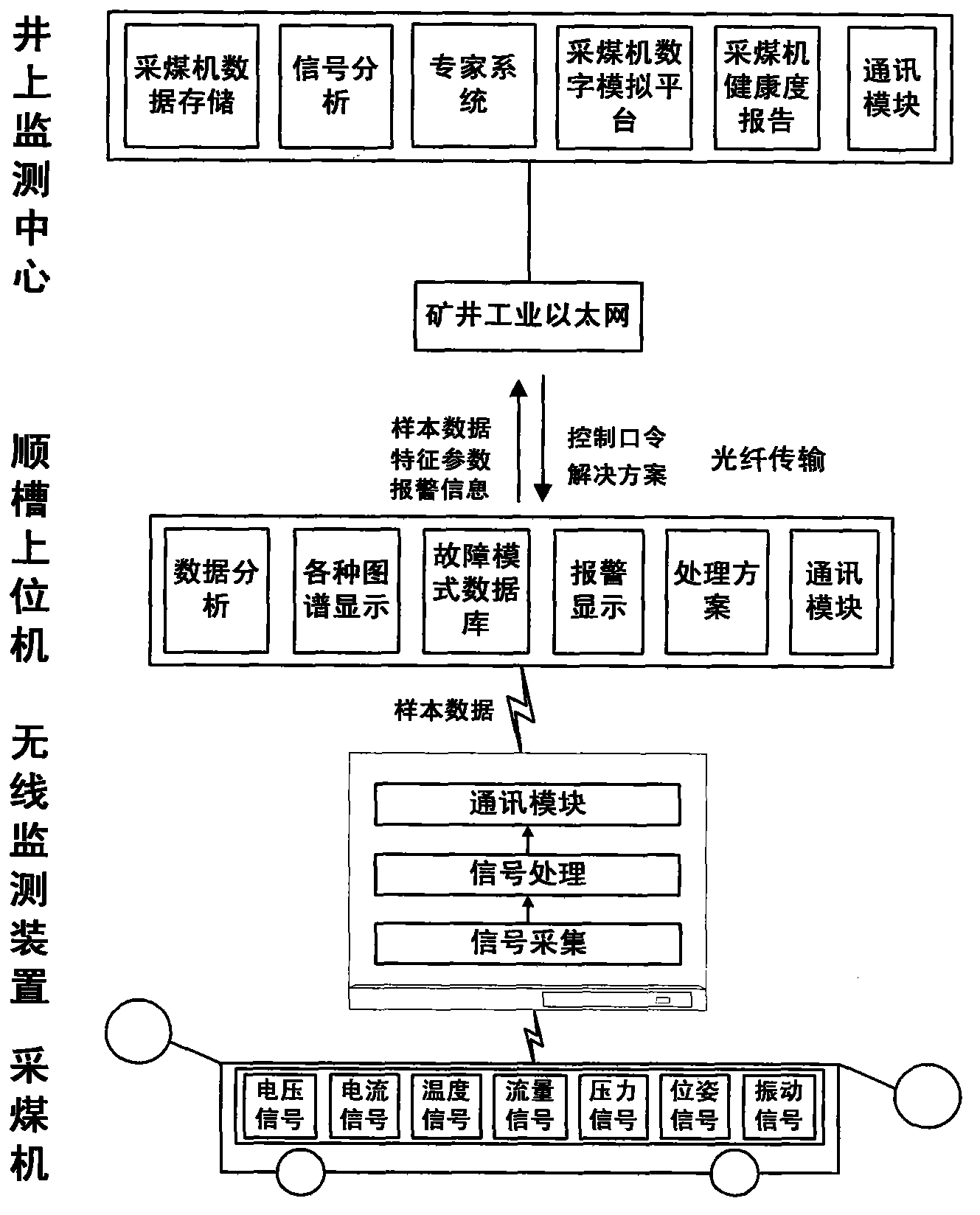

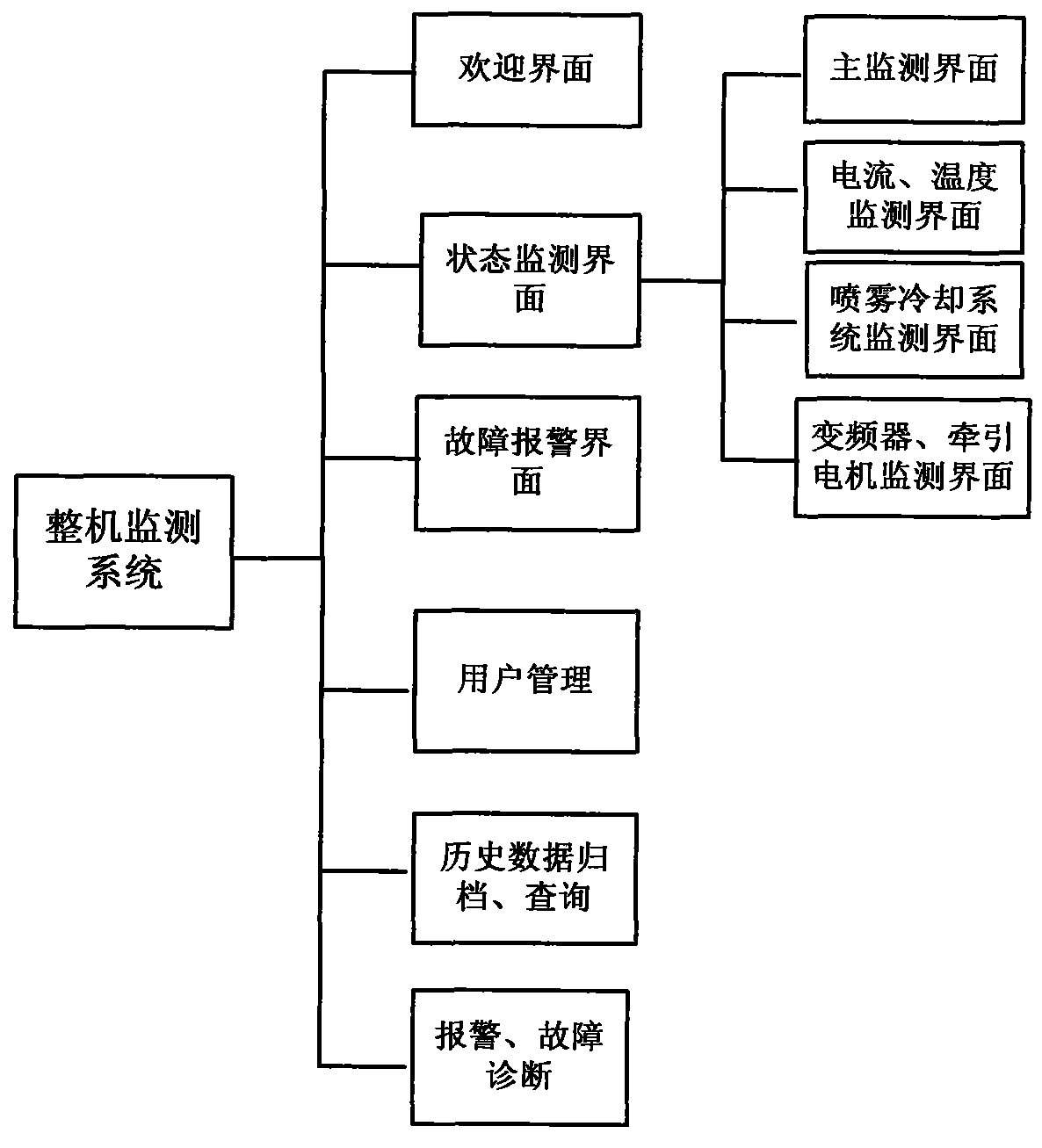

Real-time monitoring and intelligent evaluation system for health degree of electric traction coal mining machine and method thereof

Owner:HUABEI MINING GRP

Thin coal seam unmanned automated mining mode

The invention discloses a drum-coal-mining-machine-based thin coal seam unmanned automated mining technology. The technology has the characteristics that: persons do not exist on an operating surface; operators know about conditions of the operating surface through video in a control center far from the operating surface and simultaneously complete various kinds of operation; video signals and control instructions are transmitted through a wireless switch; a coal mining machine has a function of memory cutting and is provided with a position monitoring device and an infrared transmitter at the same time, coal is automatically cut according to a preprogram, and operation parameters such as positions, directions and the like are sent out at any time; a bracket controller receives the parameters, automatically drives an electric hydraulic control valve to do actions of column lowering, frame moving, pushing, column erecting and the like according to the preprogram, and a hydraulic bracket is pushed to move forward along with the coal mining machine, so that the unmanned automated mining on the operating surface is realized; and when the thickness of coal seams, and top and bottom boards are changed, the operators regulate operation programs and the parameters in the control center and perform manual intervention on the coal mining machine and the hydraulic bracket, so that the remote-control unmanned automated mining on the operating surface is realized.

Owner:TIANDI SCI & TECH CO LTD

Strip filling integral backstopping coal mining method

ActiveCN101372891AHigh recovery rateMining operation safetyUnderground miningSurface miningResource recoveryBand shape

A band filling stoping mining method effectively solves the problems in the prior stoping mining of a 'three-low' coal bed, such as the sedimentation and distortion of the earth surface, the low recycling rate of coal and charcoal resources, the existence of safety hazards, etc. The method comprises the following steps: a transporter and a coal mining machine are laid on the working face of the mining area; in the direction perpendicular to the direction of the transporter movement, a timbering device which is composed of a hydraulic bracket of the working face, a side molding board bracket for filling beside the lane and a back molding board bracket for filling beside the lane, and connected with the connecting head of the transporter is arranged; after the brackets are pushed along the working face, paste concrete is injected through a pipeline into a filling mold cavity enclosed by the brackets, so as to form a band-shaped filling wall which is supported between the top plate above the goaf and the bottom plate of the coal bed. By the method, safe and convenient mining operation is ensured; the recycling rate for coal and charcoal is increased; meanwhile, the sedimentation and distortion of the overlying strata of the coal bed and the earth surface can be controlled in a very small range of deformation permitted by a building, thereby minimizing the amount of gentle sedimentation of the earth surface, and protecting buildings and attachments on the earth surface.

Owner:沈阳天安特种机器人有限公司

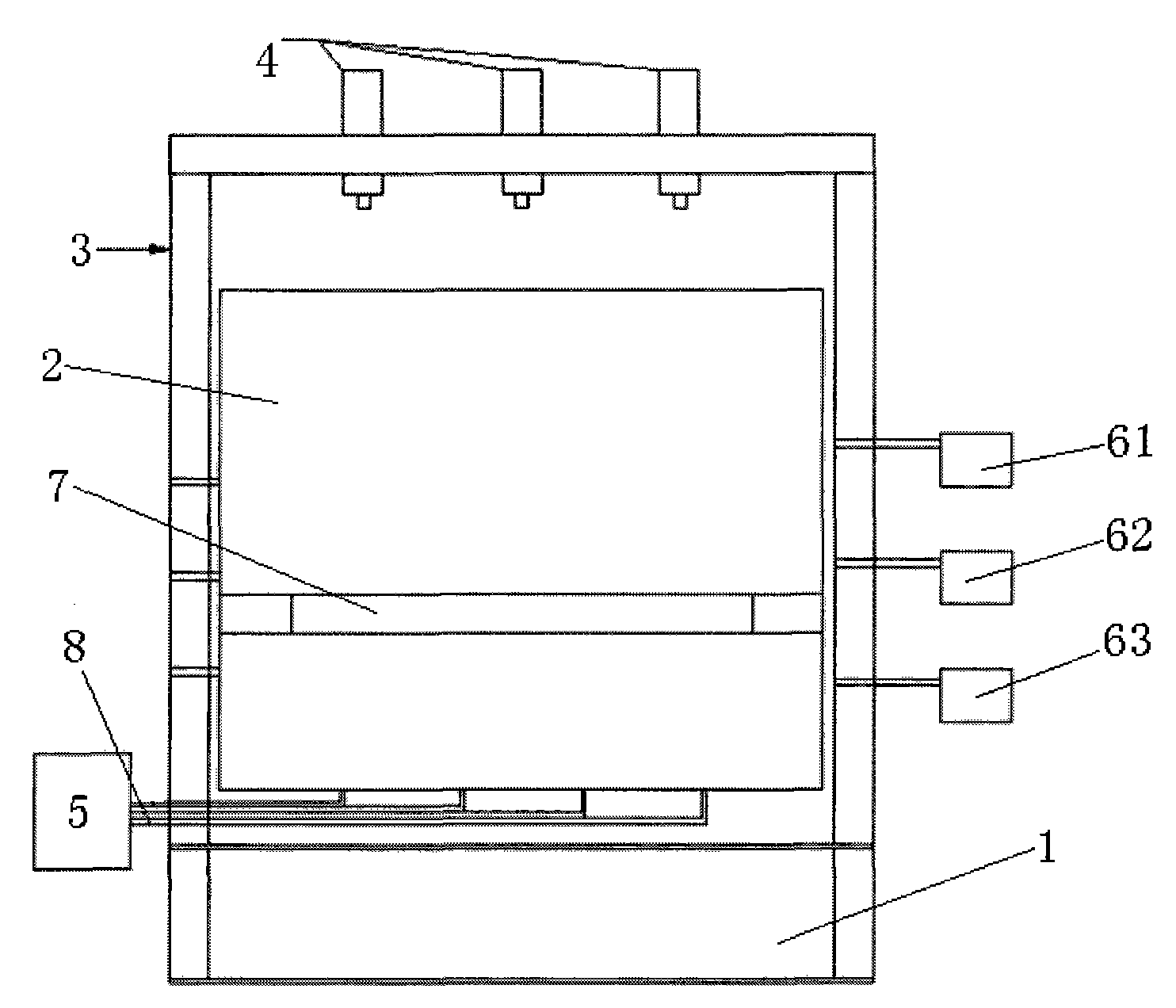

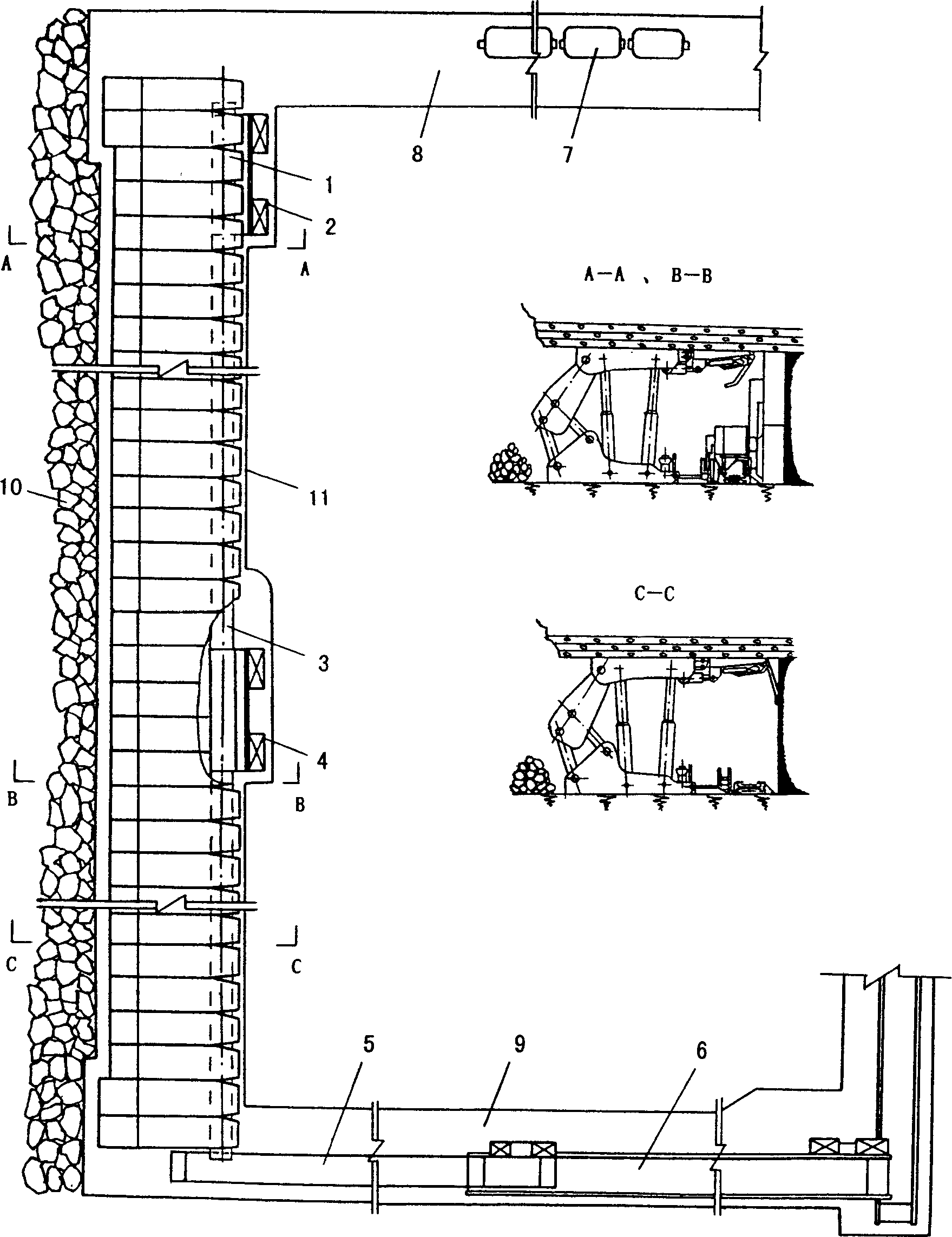

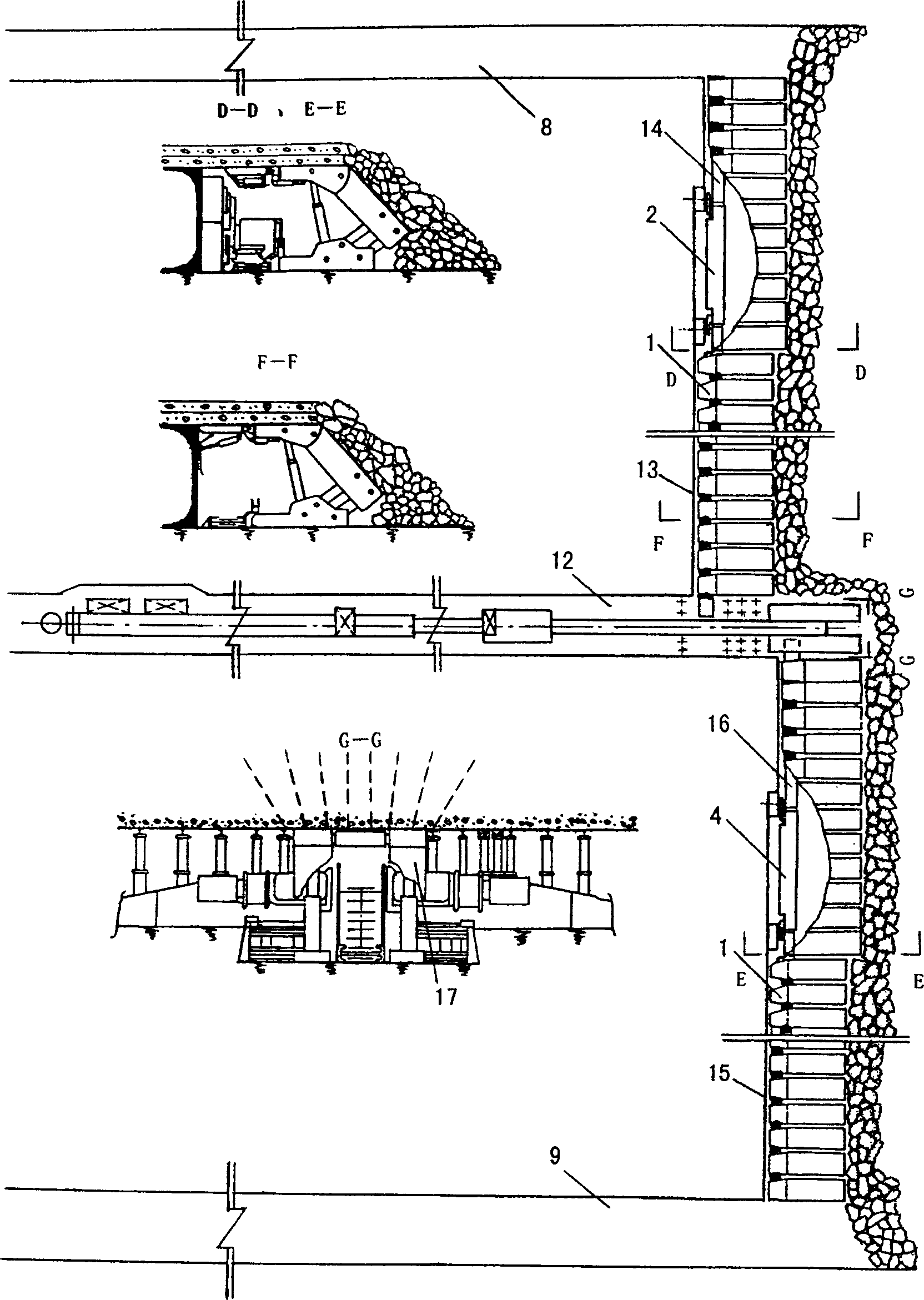

Geomechanics test platform for water invasion regularity of mine

InactiveCN101576458AMonitor changes in real timeMaterial strength using tensile/compressive forcesPore water pressureData acquisition

The invention discloses a geomechanics test platform for the water invasion regularity of a mine, which comprises a base, a box body, a reaction frame, a pressurized jack, a hydraulic control system and a data acquisition system and the like. When simulating the water invasion of the mine, test material is paved in the box body according to a calculated similarity ratio; an electrode, a stress sensor and a pore water pressure sensor are paved on a coal seam bottom plate by layers; and a data cable is led out from a pore preserved on a side surface. By filling water into the paved test material through the bottom plate of the box body, when the water in an aquifer is saturated, a pore preserved for coal mining in the front of the box body is opened for excavation, simultaneously, the hydraulic control system continue to fill water according to the pre-calculated water pressure, and the data acquisition system is started to record the test data until water invasion occurs at the bottom plate, and then excavation is stopped and the test is ended. The system structure is simple, can effectively simulate the water invasion regularity of the mine, and solves the problems that the indoor test can not simulate the role of seepage and erosion of confined water.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

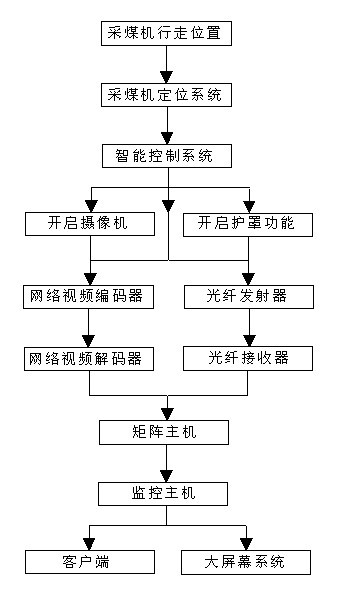

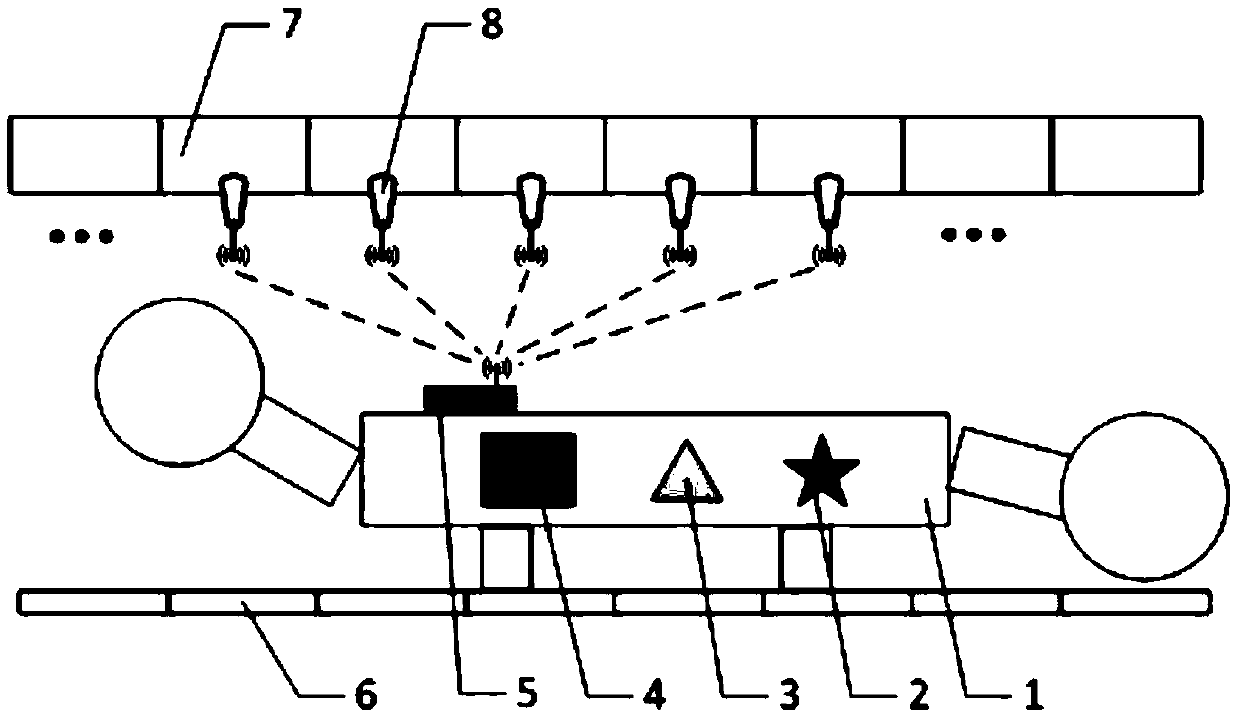

Intelligent fully mechanized mining face video surveillance system

ActiveCN102291575ATroubleshoot image capture issuesImprove the level of security detectionMining devicesClosed circuit television systemsVideo monitoringVideo transmission

The invention discloses a monitoring system and a method for an integrative mining working surface. The intelligent video monitoring system comprises a coal mining machine positioning system, a video collecting system, an intelligent control system, a video transmitting system and a ground display system. The coal mining machine positioning system judges a position where a coalmining machine is positioned; the video collecting system obtains a real-time video image of the integrative mining working surface; the intelligent control system can quickly judge the position where the coal mining machine is positioned, controls the opening of a shield function of an area where the coal mining machine is positioned, and enables the ground display system to be capable of being automatically switched to an image of a camera in the area where the coal mining machine is positioned; the video transmitting system can convey a video signal to a ground monitoring center through an Ethernet or an optical fiber; and the ground display system can automatically display the video image at the position where the coal mining machine is positioned and also can randomly retrieve the real-time image of any camera. The monitoring system and the method are advanced and scientific; the blank that the integrative mining working surface does not have video monitoring is filled; and the monitoring system and the method have the advantages of high degree of intelligence, safety, reliability and the like.

Owner:TIANDI SCI & TECH CO LTD

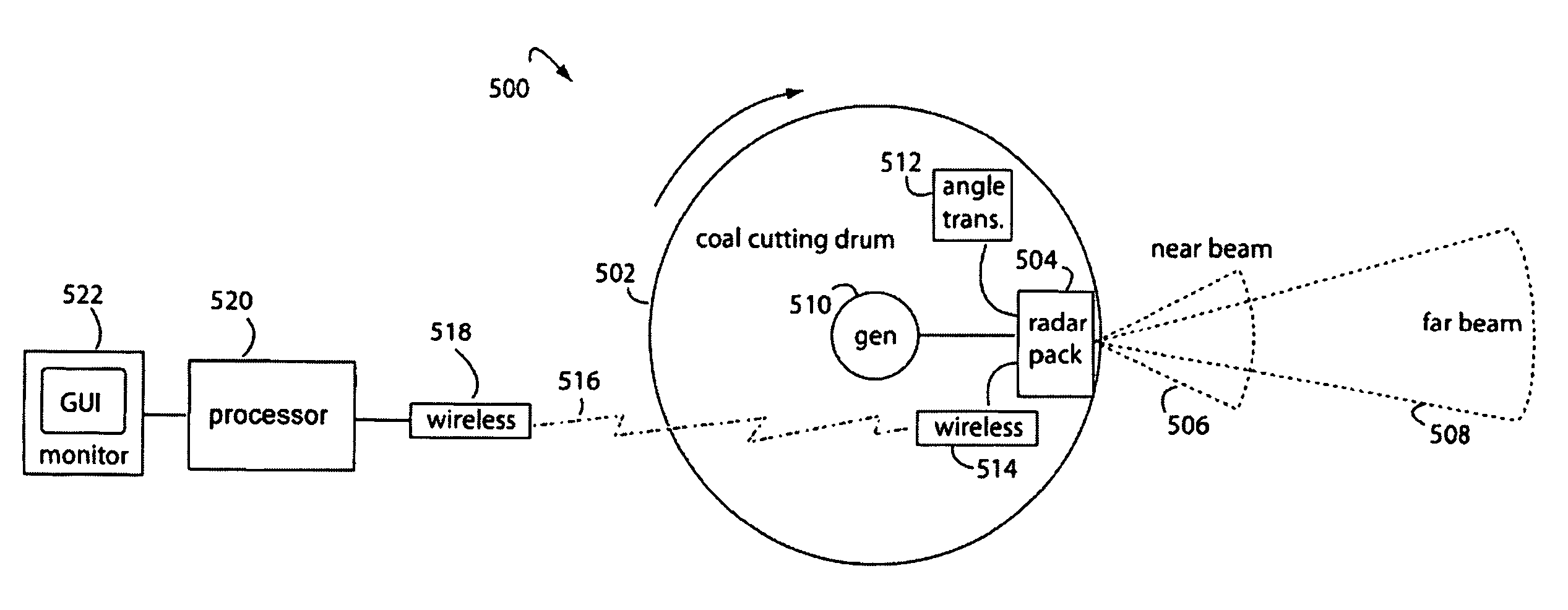

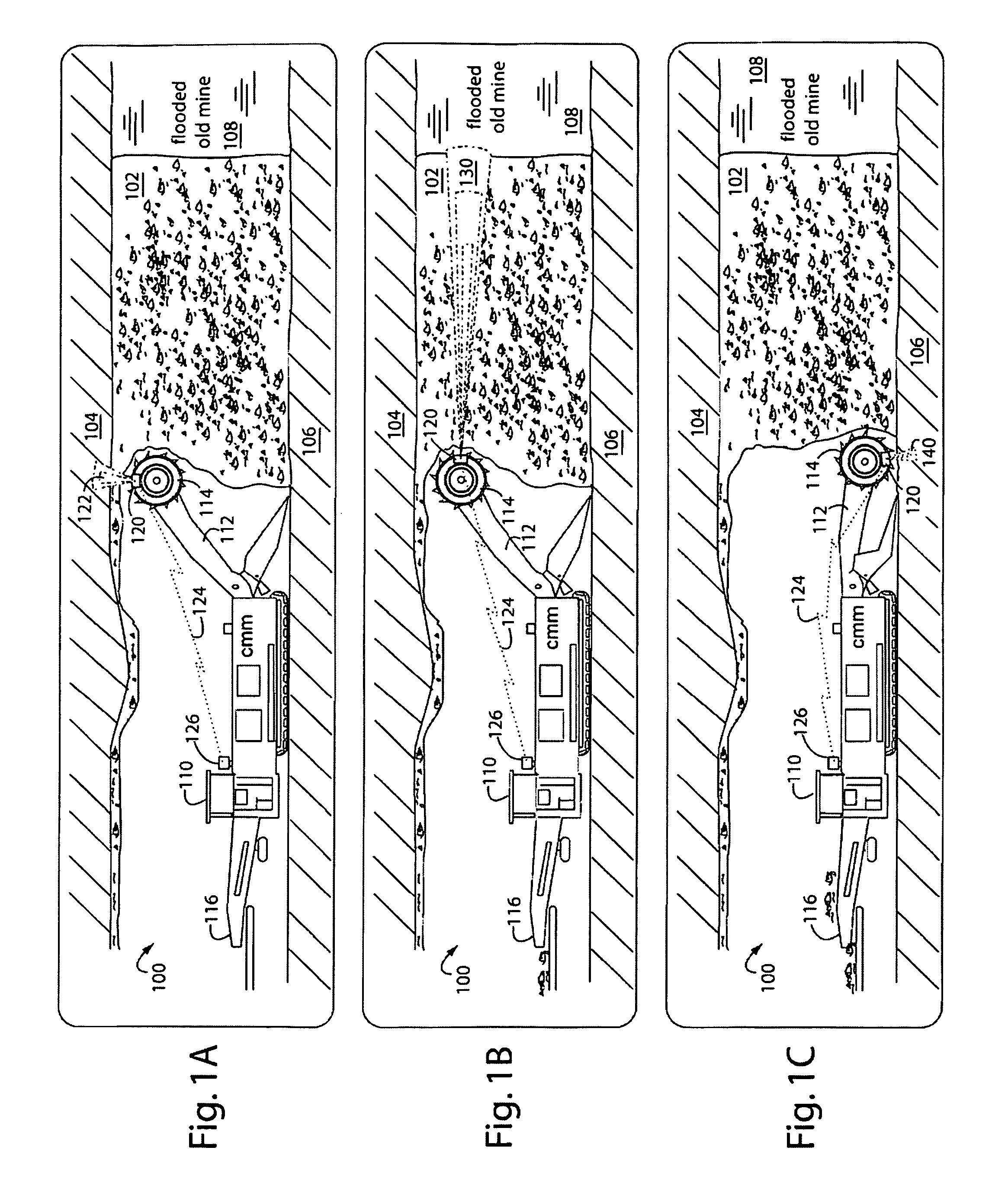

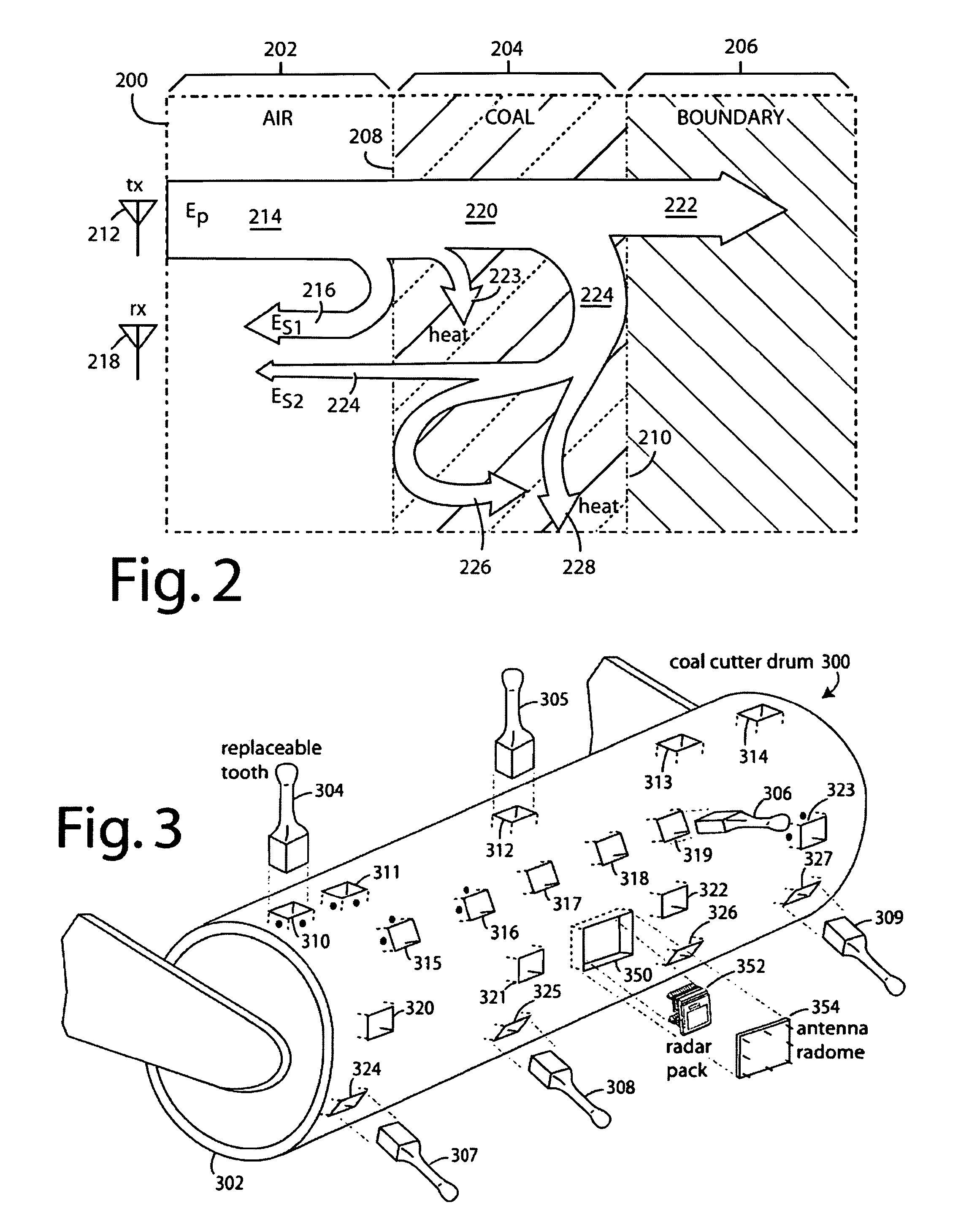

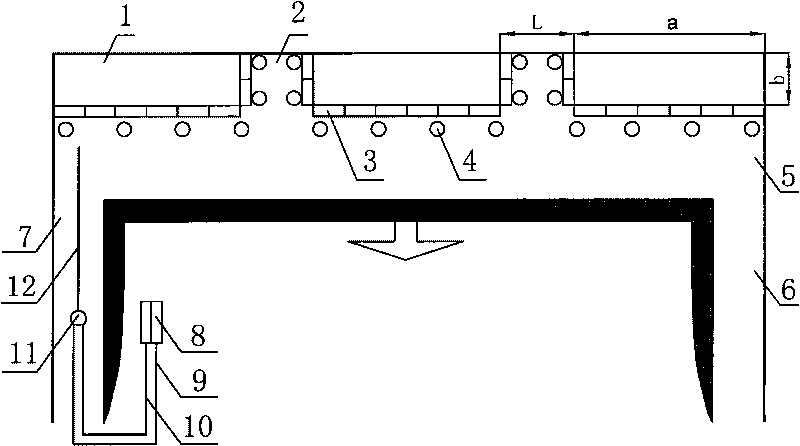

Radar mining guidance control system

InactiveUS7659847B2Increase reflectionSlitting machinesDetection using electromagnetic wavesGuidance controlCarrier signal

A coal-mining machine uses a ground-penetrating radar based on a software-definable transmitter for launching pairs of widely separated and coherent continuous waves. Each pair is separated by a constant or variable different amount double-sideband suppressed carrier modulation such as 10 MHz, 20 MHz, and 30 MHz. Processing suppresses the larger first interface reflection and emphasizes the smaller second, third, etc. reflections. Processing determines the electrical parameter of the natural medium adjacent to the antenna. Deep reflections at 90-degrees and 270-degrees create maximum reflection and will be illuminated with modulation signal peaks. Quadrature detection, mixing, and down-conversion result in 0-degree and 180-degree reflections effectively dropping out in demodulation.

Owner:STOLAR

Goaf bag-type packing method

InactiveCN101701526AReduce bending and sinkingReduce the amount of delaminationMaterial fill-upEngineeringSlurry

The invention discloses a goaf bag-type packing method, comprising the following steps: suspending a plurality of flexible filling bags at intervals in a goaf from an open-off cut, arranging a plurality of individual props at the outer side of a plurality of flexible packing bags, then erecting a formwork supported by the individual props outside the flexible filling bags; filling high-water material seriflux containing more than 85% of moisture into the bags until the bags are full, and removing the framework and the individual props after the high-water material in the bags are consolidated to complete a row of filling cycle. With the propulsion of coal mining working face, the following row of filling work is carried out continuously, flexible filling bags are suspended next to the front row to perform bag suspension and filling circularly of the next cycle until the filling work of the whole goaf is finished. The invention can directly support the top plate of the goaf, thereby effectively reducing the submergence of the top plate and controlling ground surface movement. The bag-type packing method is particularly suitable for filling the goaf of an inclined mining working surface with smaller strike propulsion or coal seam pitch, and has the advantages of simple technology, easy construction, low cost, simple operation and high filling efficiency.

Owner:JIZHONG ENERGY HANDAN MINING GROUP +1

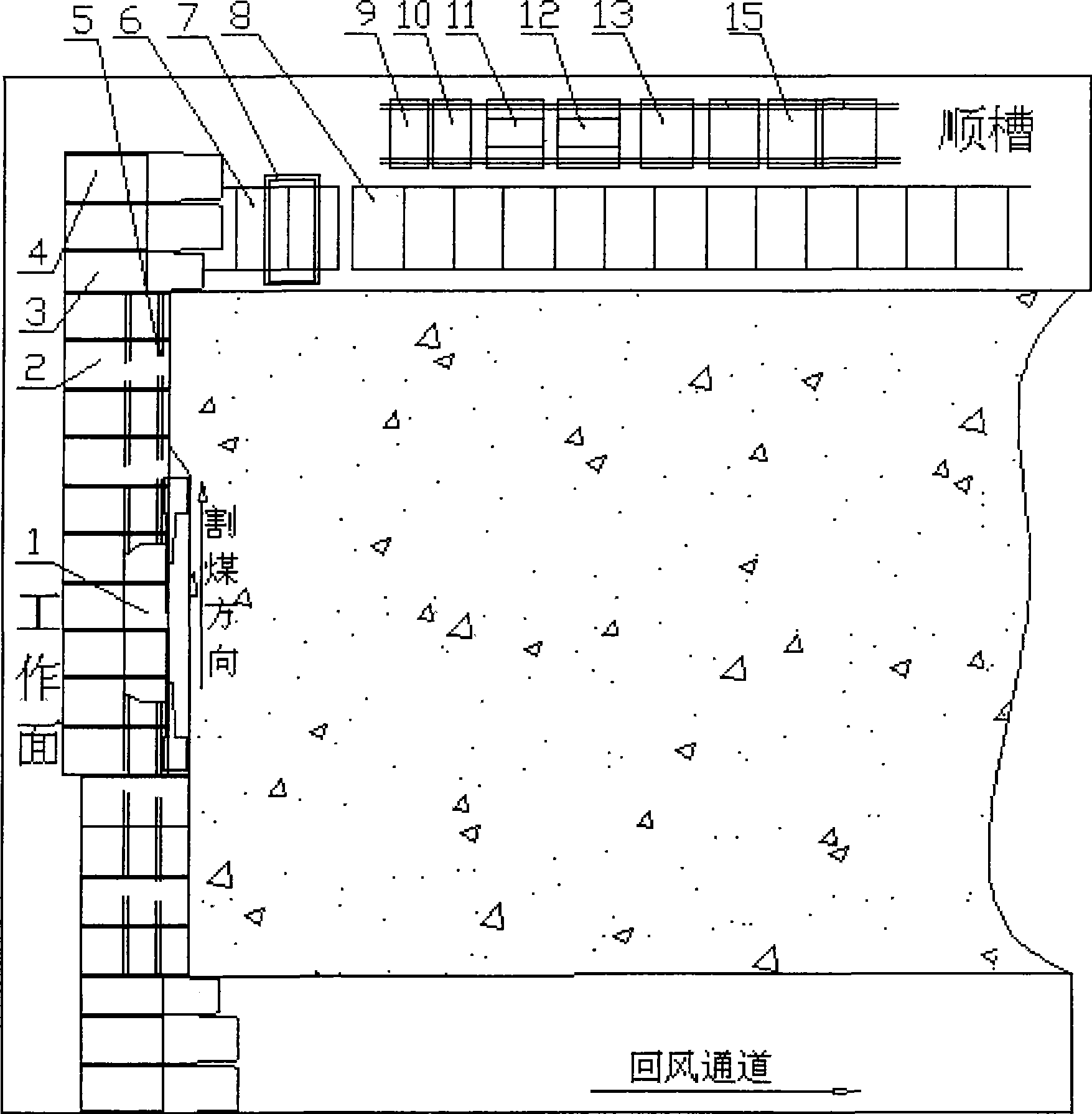

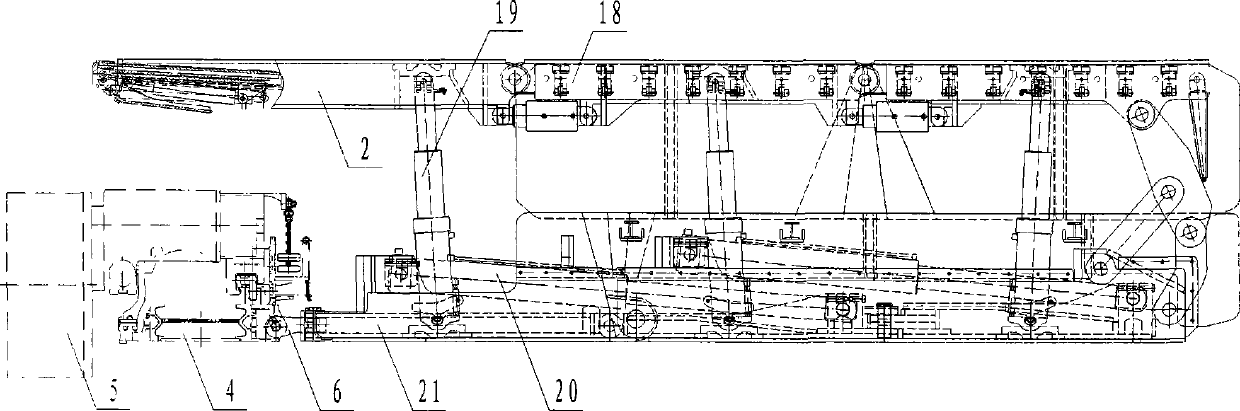

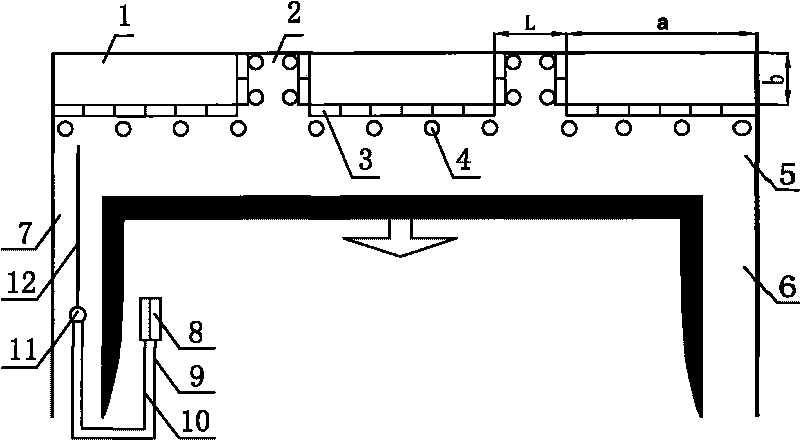

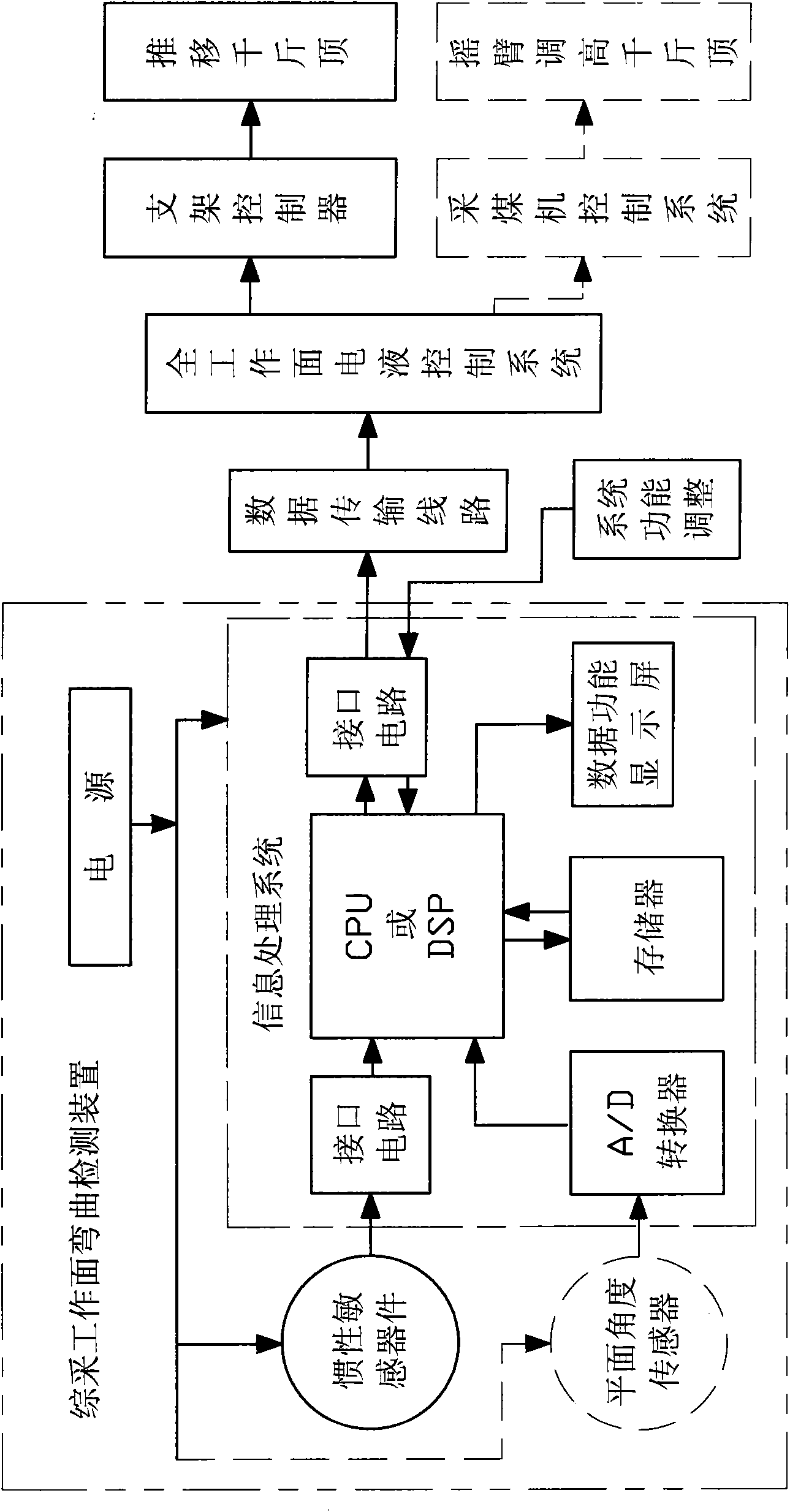

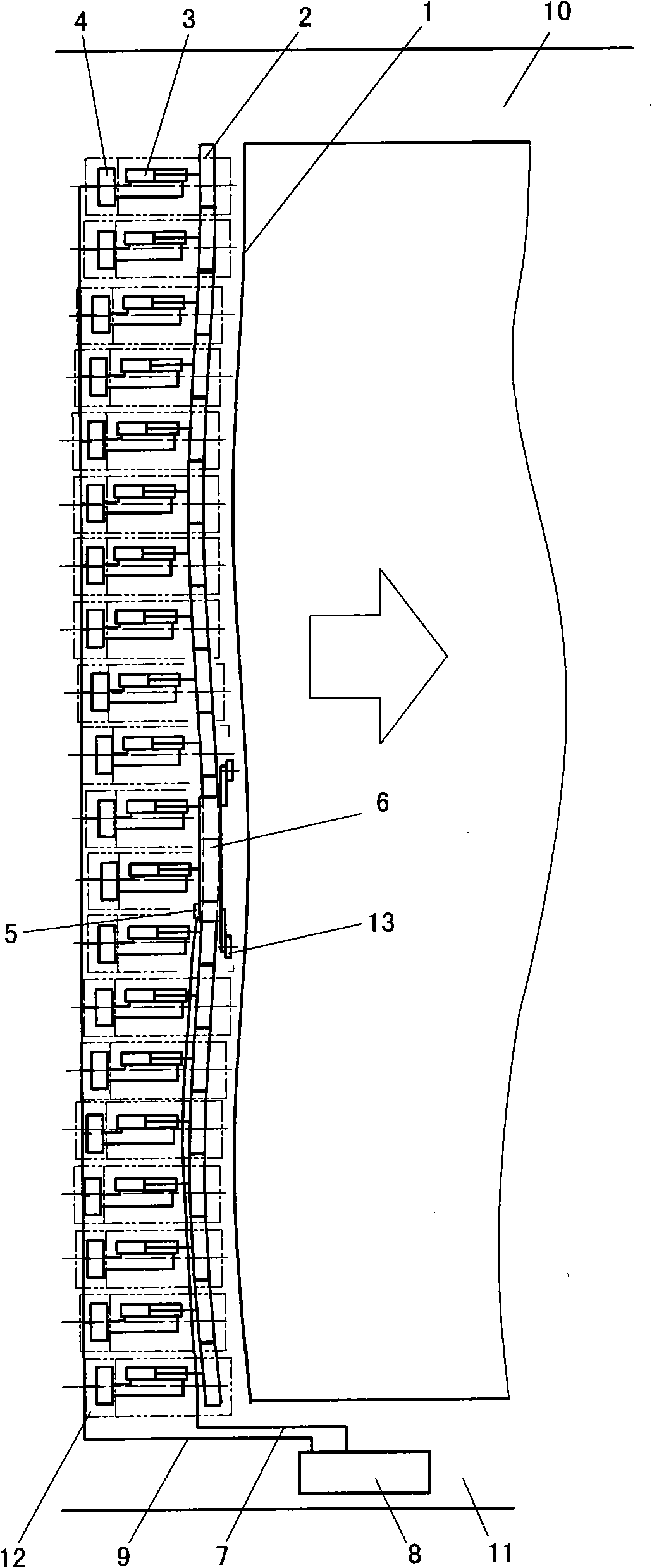

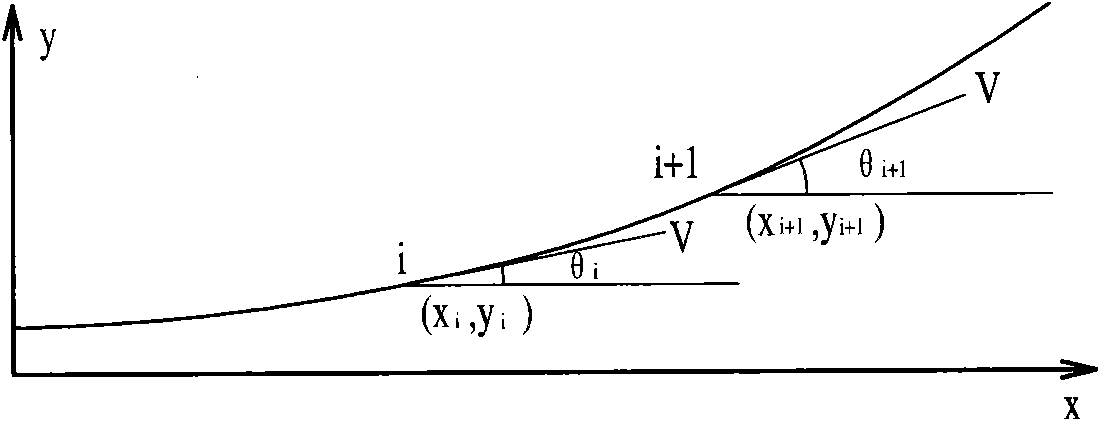

Fully mechanized mining working face bending detection and straightening method and system

InactiveCN102102512ASolve the problem of accurate bending measurementFully automatedProgramme controlSurveyFace detectionSignal processing circuits

The invention discloses a fully mechanized mining working face bending detection and straightening method. A track and a posture of a coal mining machine running along a scraper conveyer 2 are detected in real time by using an inertial sensitive element on a coal mining machine 6 or a combination of the inertia sensitive element and an angular sensor and a signal processing circuit; and working face detection data is analyzed, is output through the signal processing circuit and is transmitted to a support controller 4 of each hydraulic support 12 through a data transmission line and a full working face electro-hydraulic control system to control and push a push jack 3, so that the scraper conveyer meets a linear requirement. The detection data can also be transmitted to a coal mining machine control system to control a height adjusting jack to adjust the height of a drum cut bottom; and the coal mining machine cuts a coal wall again to straighten the bend. A fully mechanized mining working face bending detection and straightening system comprises the inertial sensitive element, the combination of the inertia sensitive element and the angular sensor, a signal processing system, thefull working face electro-hydraulic control system, the coal mining machine control system and the like. The method and the system are used for fully mechanized mining working face bending detection and straightening, so that the bend of the working face is automatically straightened.

Owner:张永亮

Comprehensive coal-mining process by using long wall mining method

InactiveCN1865657ALow costReduce in quantityUnderground miningSurface miningEngineeringEarth surface

The invention relates to a long-wall coal method, which can be used in stable coal bed, rigid top plate, non-broken incline middle-thickness coal bed, and thick coal bed layered long-wall method. Wherein, it arranges hydraulic support, scrape transporter, and roller coal machine at the long-wall working surface; arranges groove transporter and flexible band transporter at the transport channel; the working surface has ultra long length, which is two times of integrated coal surface; it uses two coal machines on one scrape transporter, to scrape the upper half surface and the lower half surface; and it can arrange middle channel at the middle of integrated surface as the transport channel; and arranges scrape transporters at the upper and lower half working surfaces. The invention has high efficiency, while it can reduce the digging rate and improve the resource recycle rate.

Owner:YANKUANG GRP CO LTD

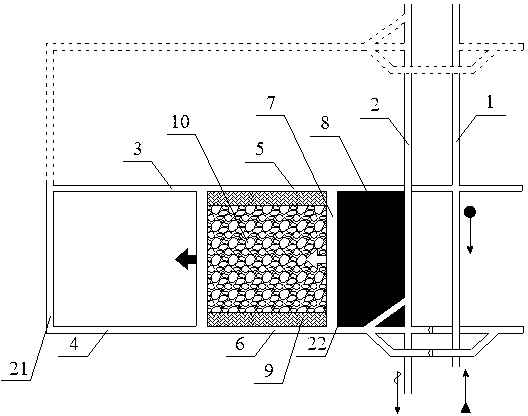

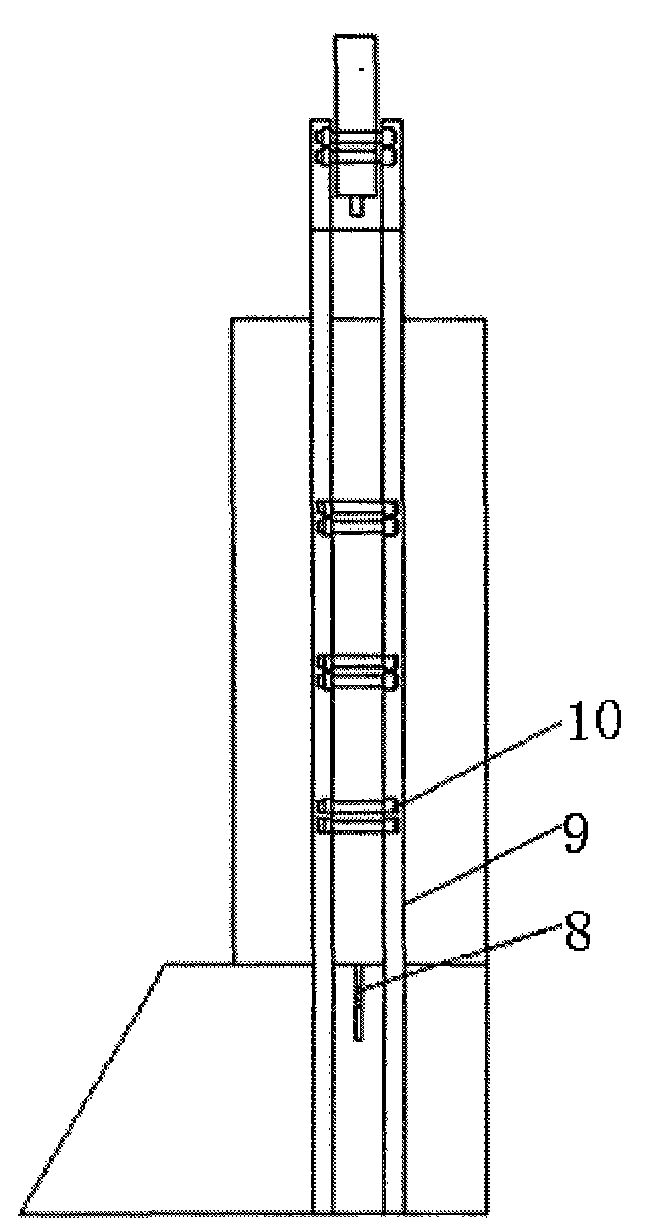

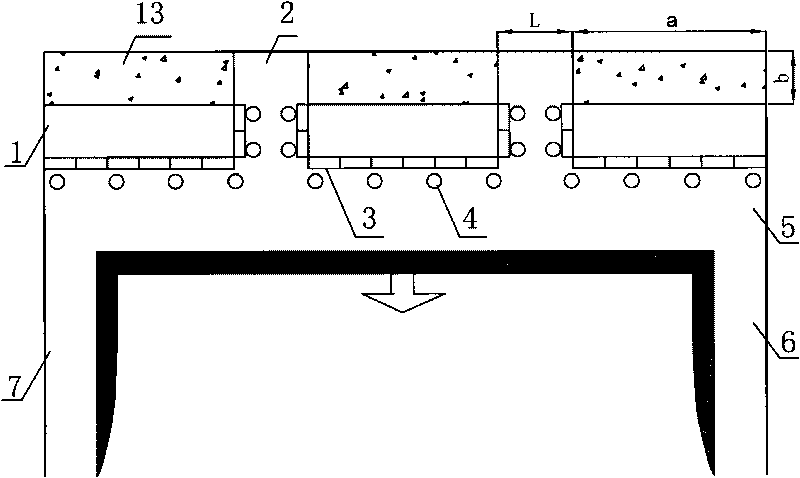

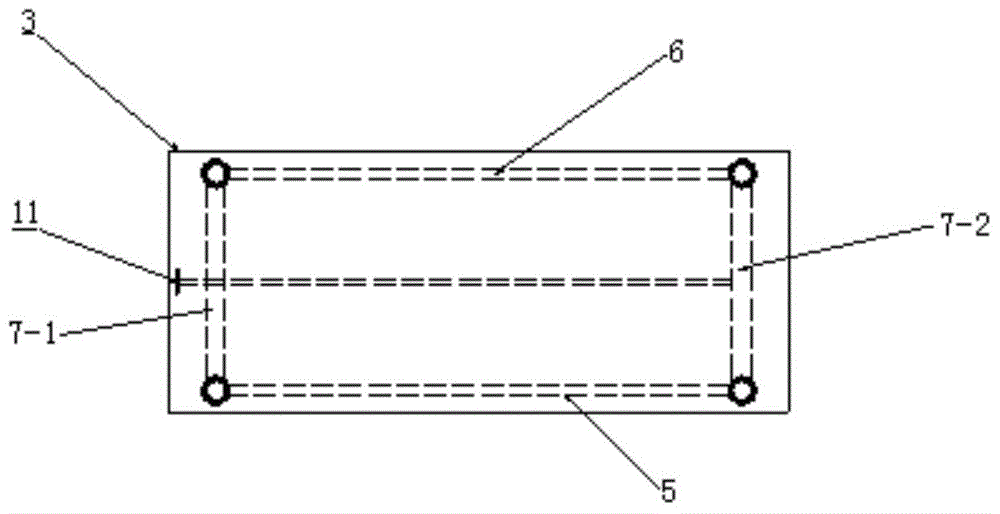

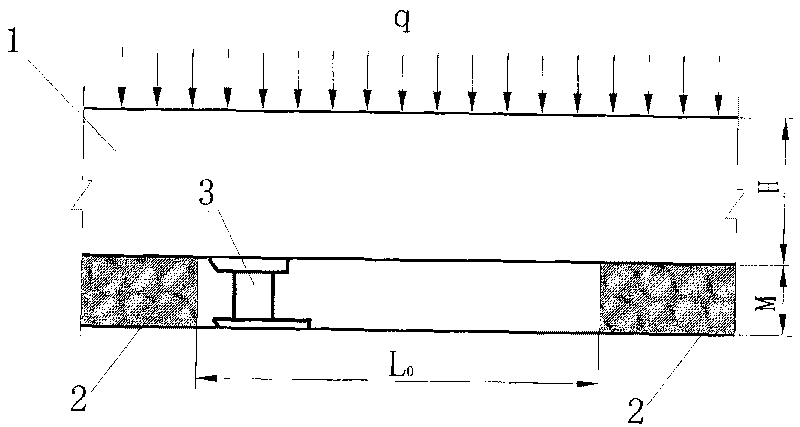

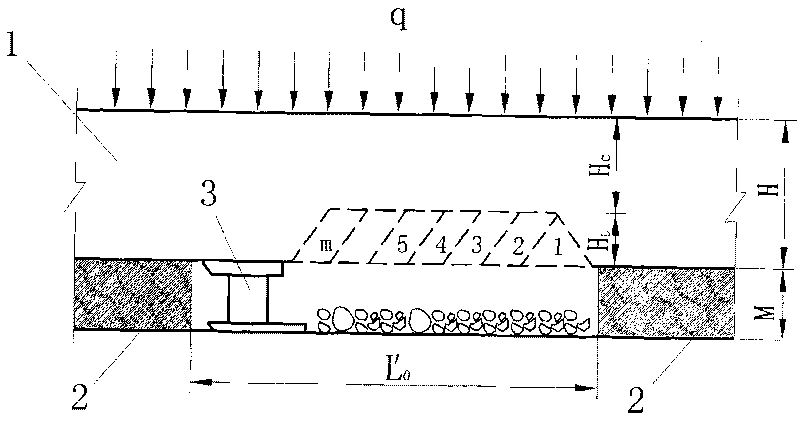

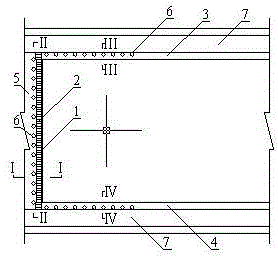

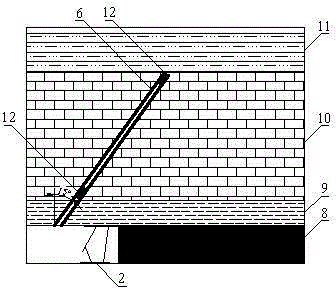

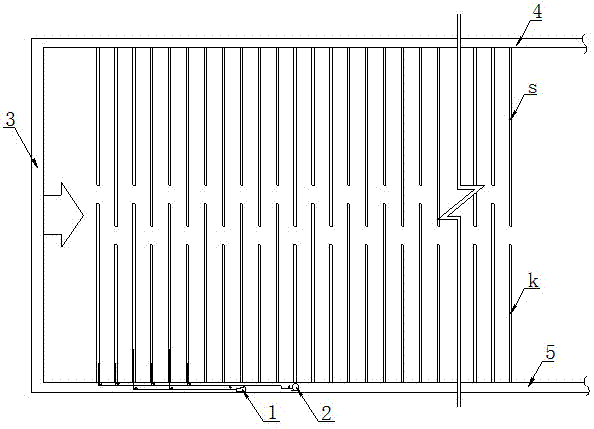

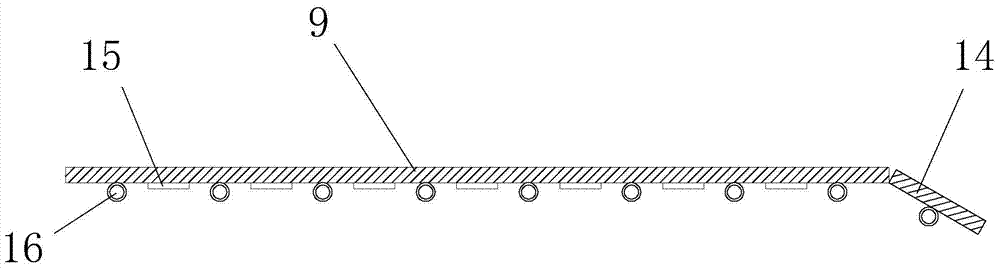

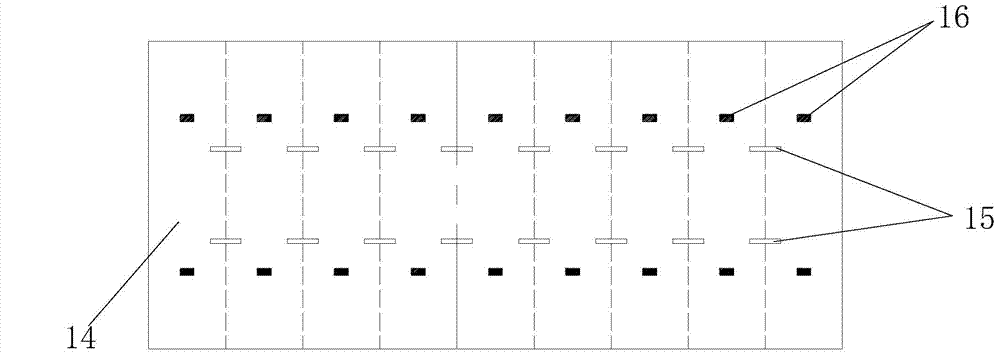

Fluid-solid coupled similar simulation experimental platform

InactiveCN104568706ASimple structureReduce manufacturing costEarth material testingPermeability/surface area analysisDirect observationEngineering

The invention discloses a fluid-solid coupled similar simulation experimental platform which comprises a box body top plate, a box body bottom plate, a front baffle, a rear baffle, a left lateral insertion plate and a right lateral insertion plate, wherein the box body bottom plate, the front baffle, the rear baffle, the left lateral insertion plate, the right lateral insertion plate and the box body top plate form a closed box body structure of the experimental platform; a transmission bar is arranged in the box body structure and is positioned above the box body bottom plate; a mining steel plate is arranged above the transmission bar and is movably connected with the transmission bar; a coal layer is laid on the mining steel plate; a simulated rock stratum is arranged above the coal layer; a data monitoring system is arranged in the simulated rock stratum; a pressure-bearing steel plate covers the top of the simulated rock stratum; and a hydraulic jack is arranged between the pressure-bearing steel plate and the box body top plate. The experimental platform disclosed by the invention is simple in structure and low in manufacturing cost, a research worker can directly observe and record the movement and deformation conditions of overlying rock and the water permeability condition in the rock stratum cracks under the mining action, and the influence of coal mining on permeability rules of surface water and karstic water is analyzed.

Owner:HUNAN UNIV OF SCI & TECH

Method for controlling roof caving under condition of hardroof in coal mining

InactiveCN101705821AControl scienceControl Accuracy and SimplificationUnderground miningSurface miningControl mannerProcess engineering

The invention discloses a method for controlling roof caving under a condition of hardroof in coal mining, belongs to the technical field of coal mining and particularly relates to a quantitative method for controlling roof caving under the condition of hardroof in coal mining. The invention adopts a technical scheme that the method mainly comprises a method for determining a trough pull position, trough pull depth and explosion work amount for initial roof caving under the condition of hardroof and a method for determining the reasonable length of a hanging arch for periodical roof caving under the condition of hardroof. In the invention, the roof caving mode is controlled to reduce the pace of initial top coal collapsing of a working face, the through pull depth and the explosion work amount are the smallest in all hardroof control modes and the operation is easy; the relationship between the pace of initial top coal collapsing and the trough pull depth is specified quantitatively; based on the design working resistance of a bracket of the working face, the method for determining the reasonable length of the hanging arch of a hardroof rock beam is obtained, so the hardroof control is more scientific, quantitative, accurate and simple; and the method can be widely used in control of roof caving under the condition of hardroof in various kinds of coal mining.

Owner:TAIYUAN UNIV OF TECH

Environment-friendly flame-retardant high-molecular gel inhibitor for preventing coal from spontaneously combusting of coal mine

InactiveCN101793160AReduced propensity to spontaneous combustionPrevent spontaneous combustionOther chemical processesDust removalSpontaneous combustionSurface-active agents

The invention discloses an environment-friendly flame-retardant high-molecular gel inhibitor for preventing coal from spontaneously combusting of coal mine, which takes water as a solvent and comprises the following components with percentage concentration by weight: 7-10 percent of high-molecular base material, 0.1-0.5 percent of inorganic inhibitor, 0.1-0.5 percent of flame retardant agent, 0.01-0.5 percent of surface active agent and 0.1-3 percent of reinforcing agent. The environment-friendly flame-retardant high-molecular gel inhibitor has the advantages of simple operation, good wall-absorbing property and inhibiting effect, flame retardant property and environment protection; a coating layer can bear the action of flame for a plurality of times and has large mechanical strength, and a coating film is stable and does not fall off in the humid environment. In the process of coal mining, the inhibitor solution is sprayed to superficial coal and combustible areas behind a coal-mining working surface and the spontaneous combustion tendency of coal can be reduced, therefore, the environment-friendly flame-retardant high-molecular gel inhibitor prevents the spontaneous combustion of coal thoroughly and is applicable to the operation under a mine and coal storage.

Owner:BEIJING UNIV OF TECH +2

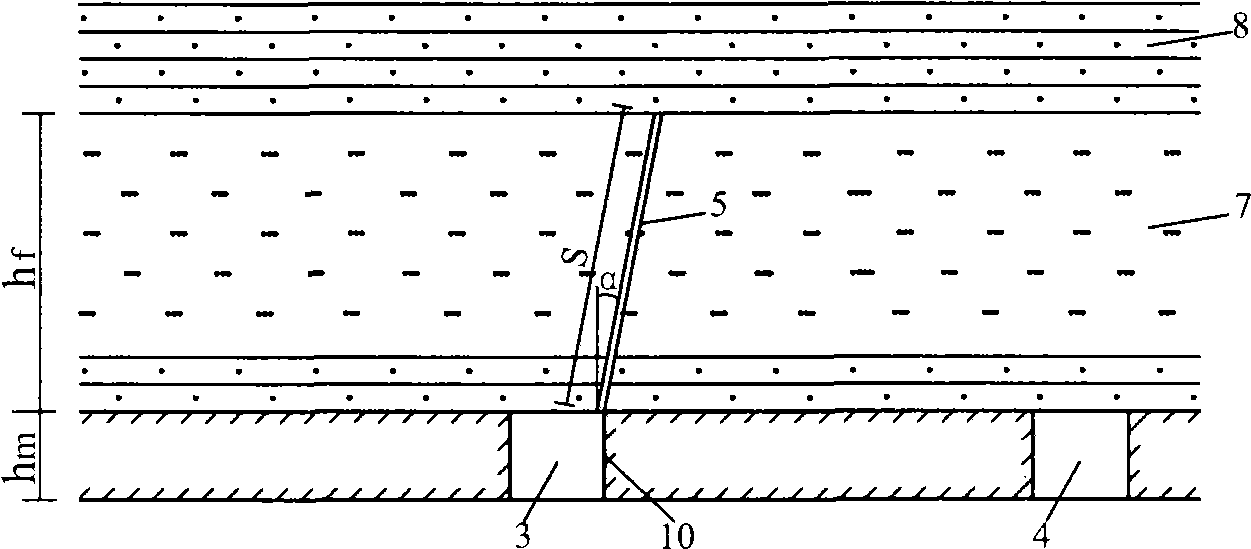

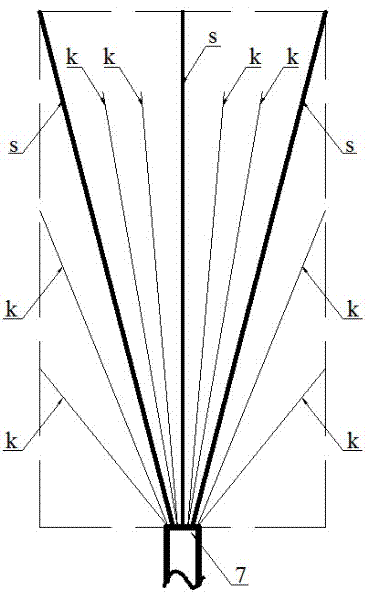

Method for controlling roof caving under condition of hardroof in coal seam

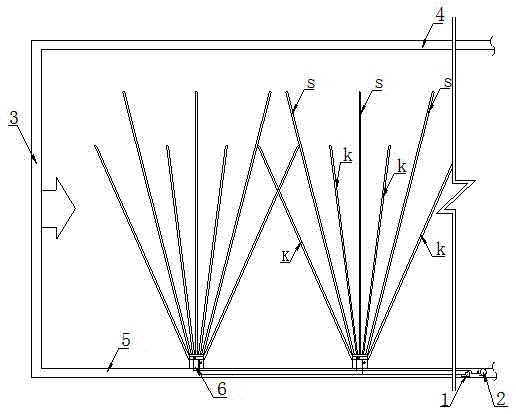

ActiveCN103953343AEliminate hidden dangers that are difficult to controlImprove controllabilityUnderground miningSurface miningHydraulic fracturingControllability

The invention relates to a method for controlling roof caving under condition of hardroof in coal seam, which belongs to the technical field of coal mining and tunnel surrounding rocks controlling, and solves the problems of influence by crustal stress, poor controllability, pollution and inapplicability for high gas seam in the prior art. The method comprises the following steps: 1) constructing and boring rock stratum at the top of the coal seam along an open-off cut of a fully mechanized working face at the beginning of mining process and along one side of a return air laneway and a transporting mining roadway of the working face close to a coal column at a primarily mining phase and at a normal robbing phase; 2)implementing the operation of hydraulic slotting along a borehole, wherein the slotting direction is respectively consistent with the direction of the open-off cut, the return air laneway and the transporting mining roadway; and 3) sealing holes at two ends of the borehole, implementing hydraulic fracturing in the boring, and communicating the pressing cracks generated in the adjacent boreholes. The method for controlling roof caving under condition of hardroof in coal seam is used for controlling roof caving of high gas seam and hardroof, and has the advantages of good controllability, no influence by crustal stress, no pollution and easy operation.

Owner:TAIYUAN UNIV OF TECH

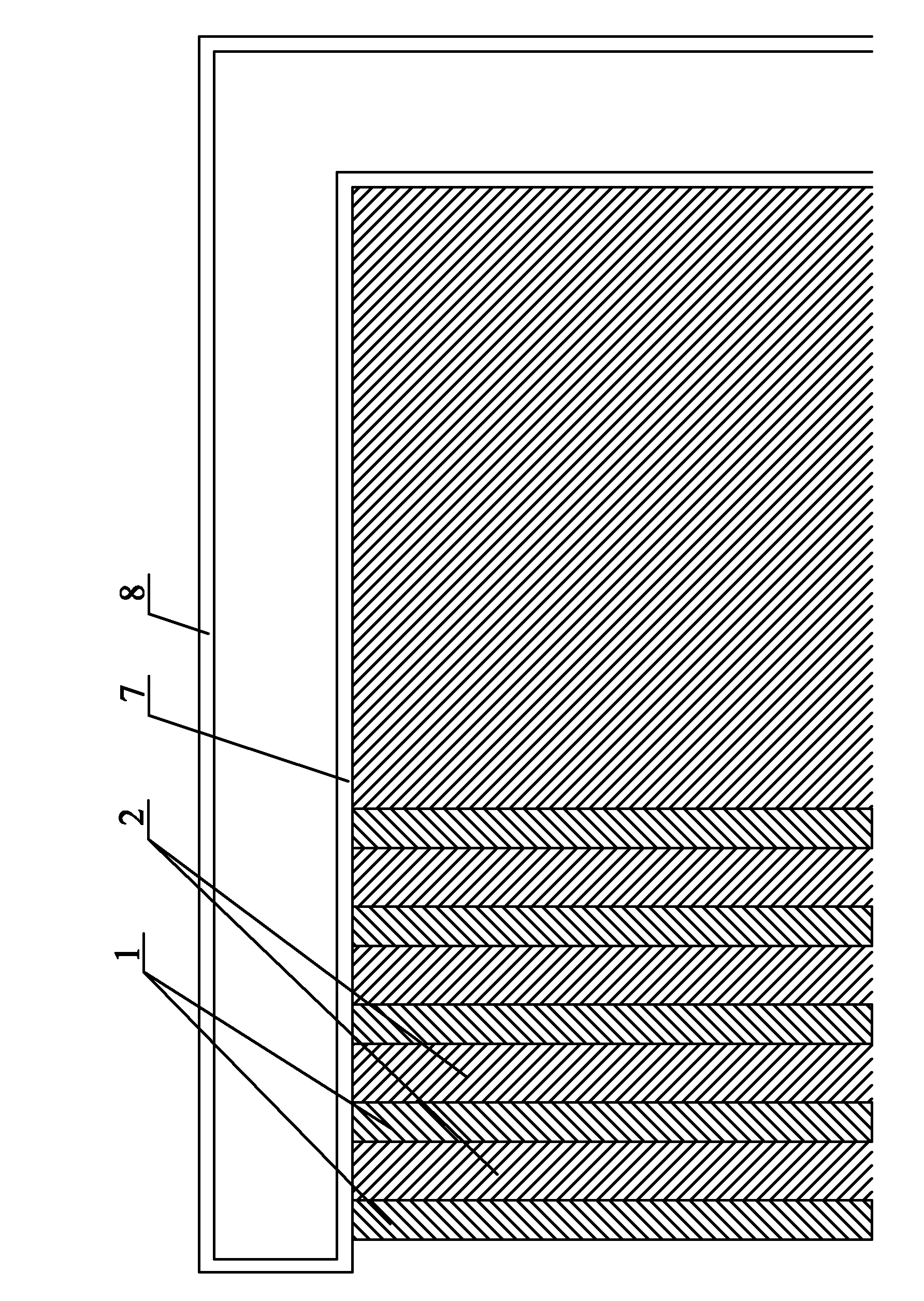

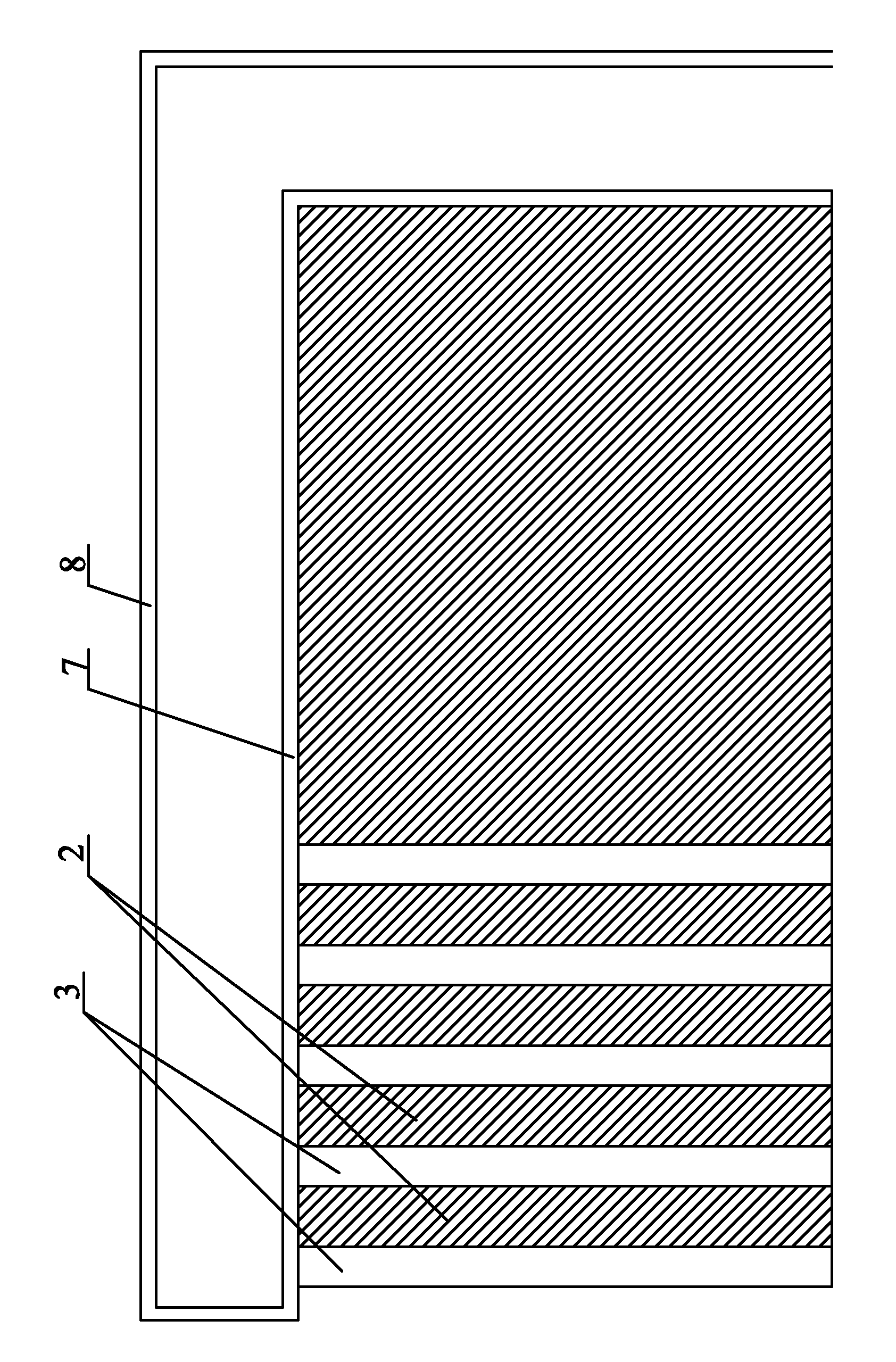

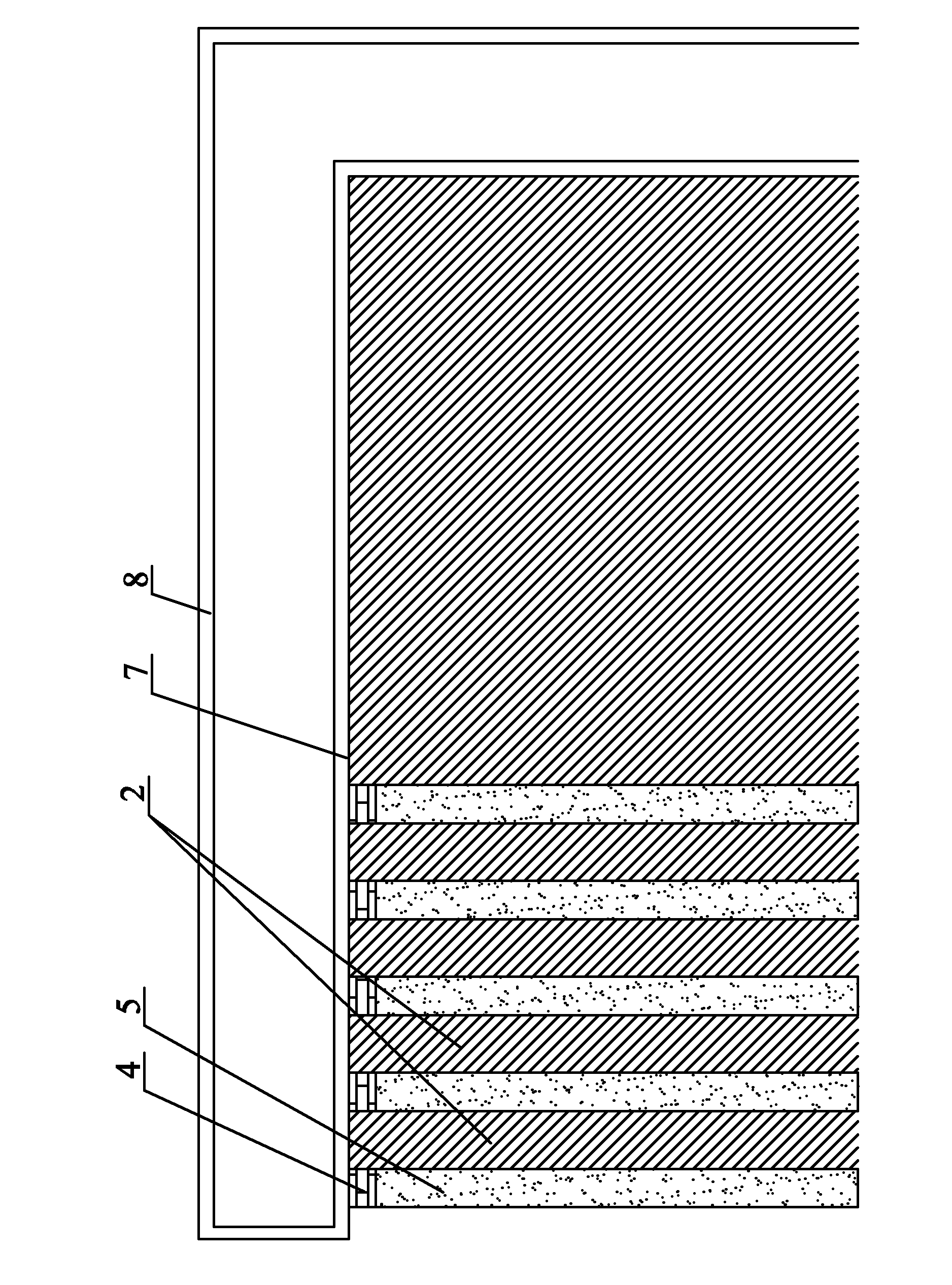

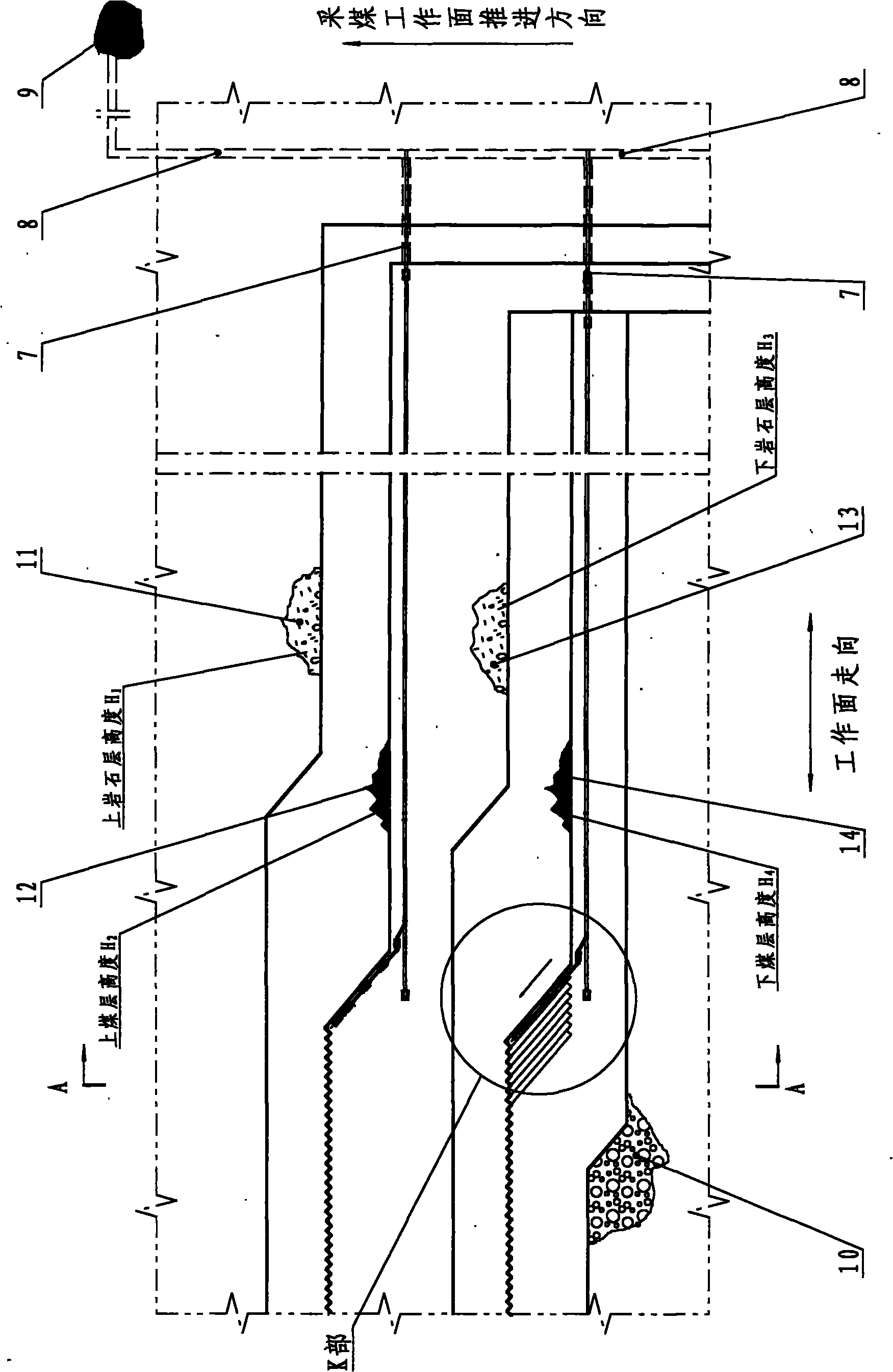

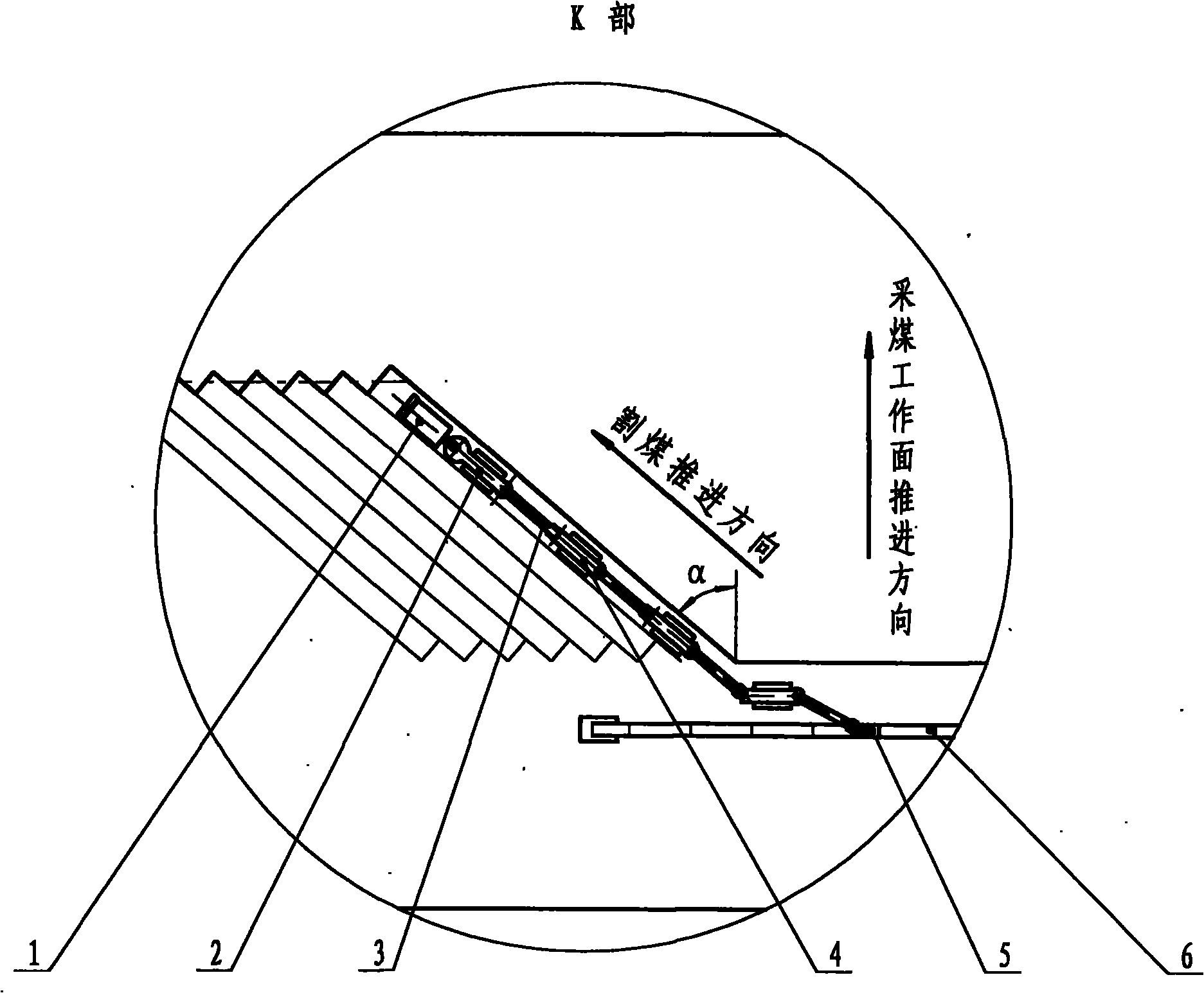

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

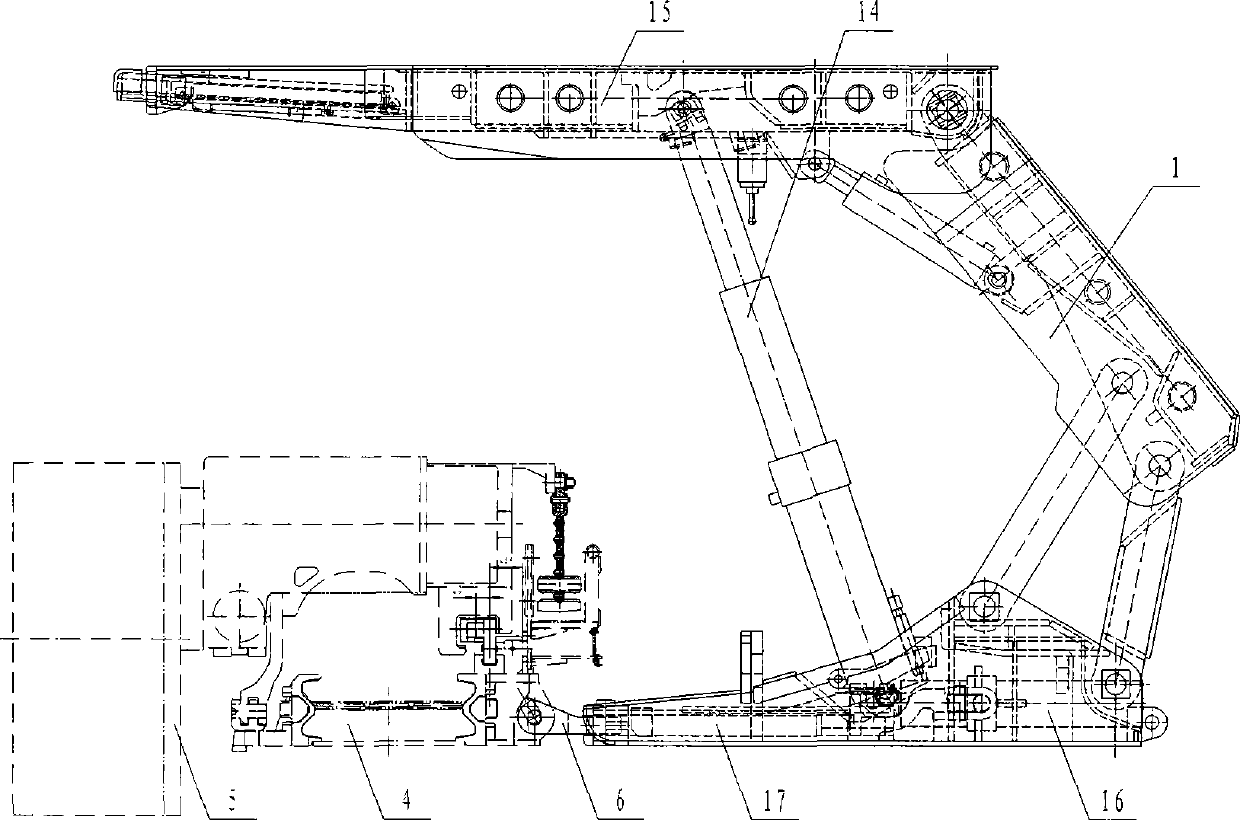

Immediate support device for digging machine

ActiveCN101251022AAvoid distortionAvoid out of syncMine roof supportsHydraulic cylinderContinuous operation

The invention relates to an in-time supporting device for a fully-mechanized coal mining machine, comprising a pedestal, a top beam, a hydraulic upright post which connects the pedestal and the top beam, side frames which consist of four link mechanisms, and a telescopic connecting beam and a hydraulic cylinder which are hinged between two side frames. The invention adopts the technical key points that: top beams of the side frames adopt front top beams or continuous top beams; the side frames which are arranged in parallel and provided with the front top beams or the continuous top beams are hinged into a front support or a continuous support through an arched beam or a horizontal beam; shun beams are arranged on the arched beam or the horizontal beam at intervals; belt guard beams or telescopic shun beams are arranged between adjacent shun beams. The in-time supporting device for the fully-mechanized coal mining machine effectively solves the problems in the prior art of lagged supporting means, difficult frame movement, requirement of stop operation, low efficiency and so on, is reasonable in structural design, stable in supporting operation, convenient in assembly and disassembly and maintenance, and safe and reliable in use, preferably meets the requirements of matched operation of underworkings and the fully-mechanized coal mining machine, realizes in-time mechanical support of a just exposed roof of a tunneling work surface of a laneway, and shields the fully-mechanized coal mining machine to realize continuous operation.

Owner:SHENYANG TIAN AN TECH CO LTD

Combined initial alignment system and alignment method for strapdown inertial navigation system of underground coal mining machine

ActiveCN105371871AHigh positioning accuracyAddresses difficulty relying on external positioning systems for initial alignment of SINSNavigation by terrestrial meansNetwork topologiesWireless sensor networkingEngineering

A combined initial alignment system and alignment method for a strapdown inertial navigation system of an underground coal mining machine belong to initial alignment system and alignment method for positioning navigation of underground coal mining machines. The system is composed of a strapdown inertial navigation system installed on the coal mining machine, a wireless sensor network mobile node, an inclination sensor, a geomagnetic field sensor and anchor nodes installed on a hydraulic support. After coarse alignment of the strapdown inertial navigation system, the wireless sensor network is used to detect the location information of the underground coal mining machine, the inclination sensor measures the roll and pitch angle, and the geomagnetic field sensor measures the yaw angle. A pose measurement equation of the coal mining machine is constructed, and the pose measurement equation is combined with an error model after the coarse alignment of the strapdown inertial navigation system to establish a state equation; fusion smoothing is carried out to obtain the accurate location information of the coal mining machine; and the precise alignment of the strapdown inertial navigation system is conducted to complete the initial alignment. The invention realizes precise initial alignment of strapdown inertial navigation combination under the severe closed condition in coal mine, and greatly improves the precision of the integrated positioning under large misalignment angle of the strapdown inertial navigation system of the coal mining machine.

Owner:CHINA UNIV OF MINING & TECH

Refection reducing and outburst eliminating method for deep-hole hydraulic fracture driving gas shallow hole extraction

InactiveCN102383828AHigh extraction rateRelieve pressureFluid removalGas removalEngineeringHigh pressure water

The invention discloses a refection reducing and outburst eliminating method for deep-hole hydraulic fracture driving gas shallow hole extraction. The method comprises the following steps of: gradually and alternately constructing hydraulic fracture holes and gas extraction holes in the coal bed direction in a coal mining working face tunnel, an airway or a tunneling working face, and performing high-pressure water injection and gas extraction; stopping injecting water after the water is injected into the hydraulic fracture holes for 0.5 to 5 hours, and changing gas extraction pipe joints to extract gas; after the hydraulic fracture hole or gas extraction concentration is lower than 5%, changing water injection pipes to perform static pressure water injection; and when the coal mining working face is recovered to the position 5 meters away from the static pressure water injection holes or the tunneled working face is tunneled again, stopping a pump or closing a static pressure water valve to stop water injection. According to the method, refection reduction of the gas-containing coal bed is realized, the gas extraction rate is improved, the gas in the mining space is effectively prevented from exceeding the limit, outburst risks of coal and gas are reduced, and safe and efficient recovery of coal is ensured. The method is simple and good in effect.

Owner:CHINA UNIV OF MINING & TECH +1

Roadway backfill mining method for coal seams with medium-high thickness

InactiveCN102155226AIncrease profitExtended service lifeUnderground miningSurface miningMining engineeringUltimate tensile strength

Owner:ZIBO WANGZHUANG COAL MINE

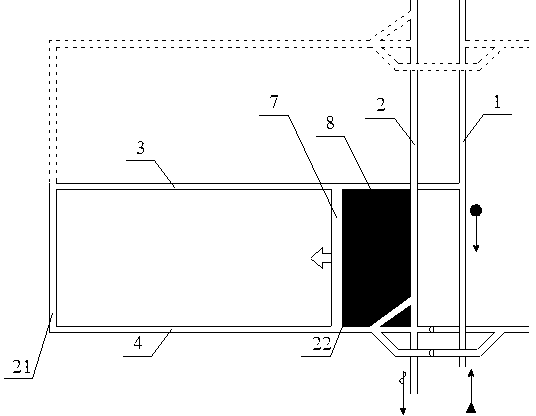

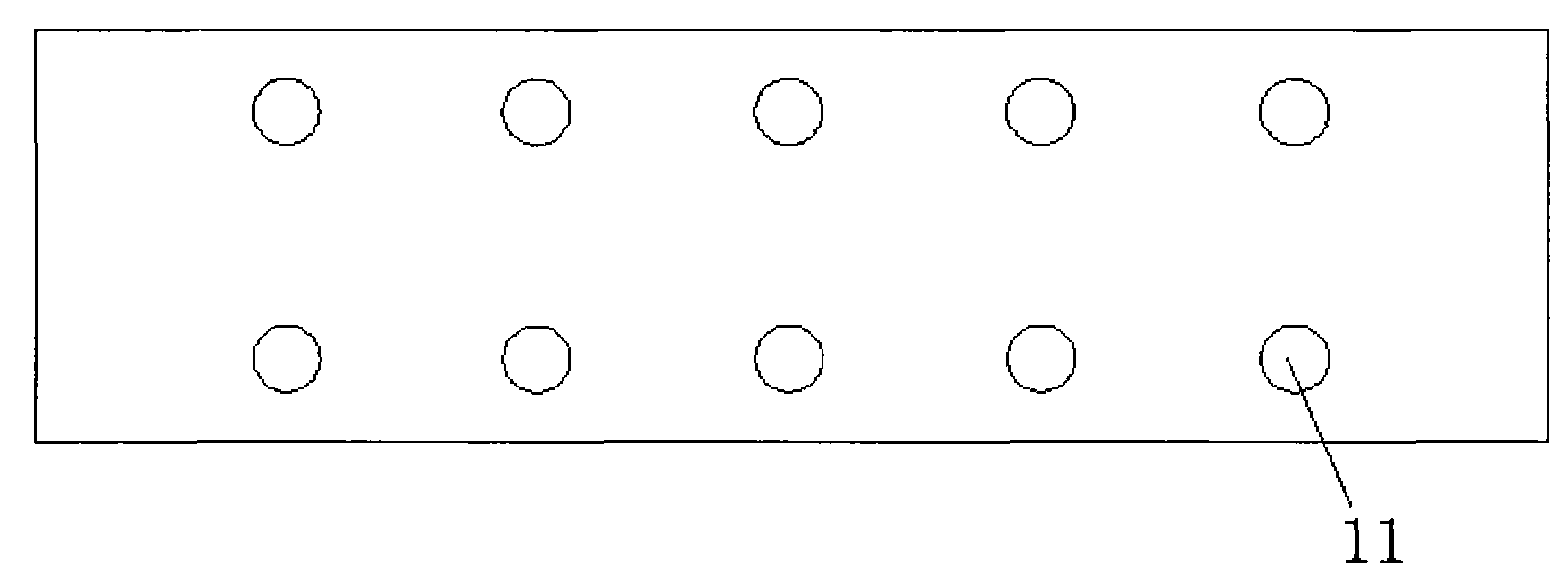

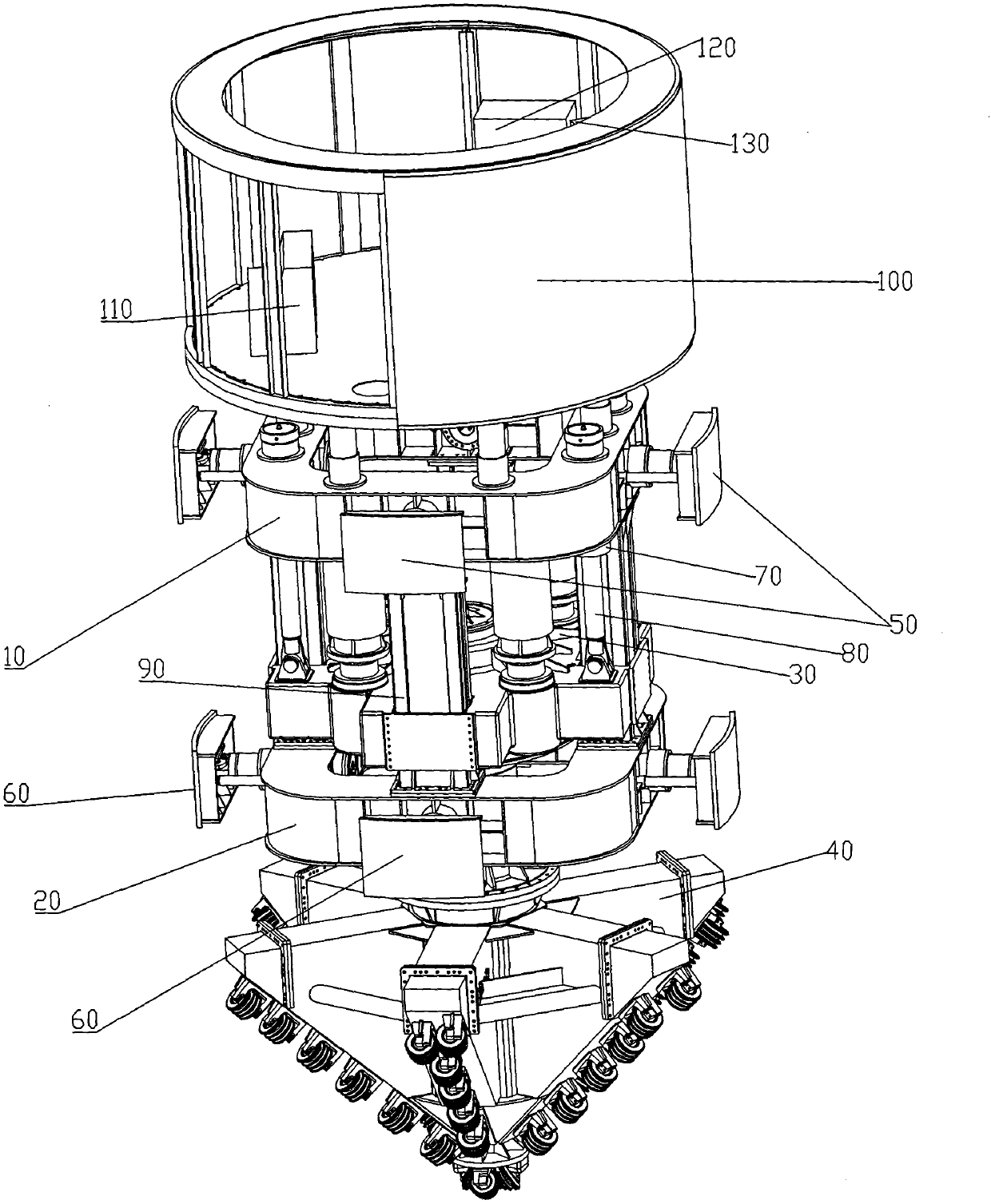

Simulation test system and monitoring method for disaster of roof water burst and sand inrush induced by coal seam mining

InactiveCN103675237AImprove stabilityImprove sealingEarth material testingCoal measuresPore water pressure

The invention discloses a simulation test system and monitoring method for a disaster of roof water burst and sand inrush induced by coal seam mining. The simulation test system comprises a bracket, wherein a test bin is arranged inside the bracket; a movable coal-mining simulating dragging plate is arranged at the bottom of the test bin; a water-sand gathering channel obliquely arranged is arranged below the coal-mining simulating dragging plate; a water-sand collecting device is arranged at the outlet of the water-sand gathering channel; the test bin is formed by a bottom plate, a right side wall, a front transparent plate body, a back transparent plate body and the coal-mining simulating dragging plate; a plurality of pore water pressure sensors and a plurality of pressure sensors are arranged inside the test bin. According to the invention, the simulation test for the disaster of the roof water burst and sand inrush induced by coal seam mining is carried out by adopting the technical scheme that the test bin is filled with coal measure strata simulating materials, so as to obtain water-sand inrush parameters of different stratum combinations, therefore, the identification degree of the characteristics of the disaster of operating face water burst and sand inrush induced by coal seam mining is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Sinking technology for expanding pilot well drilled by raise-boring machine, by using vertical well heading machine

The invention discloses a sinking technology for expanding a pilot well drilled by a raise-boring machine, by using a vertical well heading machine, which comprises the following steps of (a) drilling the pilot well by using the raise-boring machine; (b) drilling by using the vertical well heading machine to enable the pilot well to be enlarged into a vertical well at a desirable diameter in a brushing way; (c) hanging a net on and jetting concrete onto the wall of the vertical well to form a temporary supporting well wall; (d) after enlarging in the brushing way and heading to a lower tunnel by using the vertical well heading machine, gradually removing components of the vertical well heading machine from top to bottom. By the adoption of the technology provided by the invention, in the presence of the pilot well, a vertical well hole at a design diameter is formed through the one-time drilling of the vertical well heading machine; therefore the technology is applicable for the construction of underground mine vertical well holes for coal mining, metal, nonmetal and the like.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

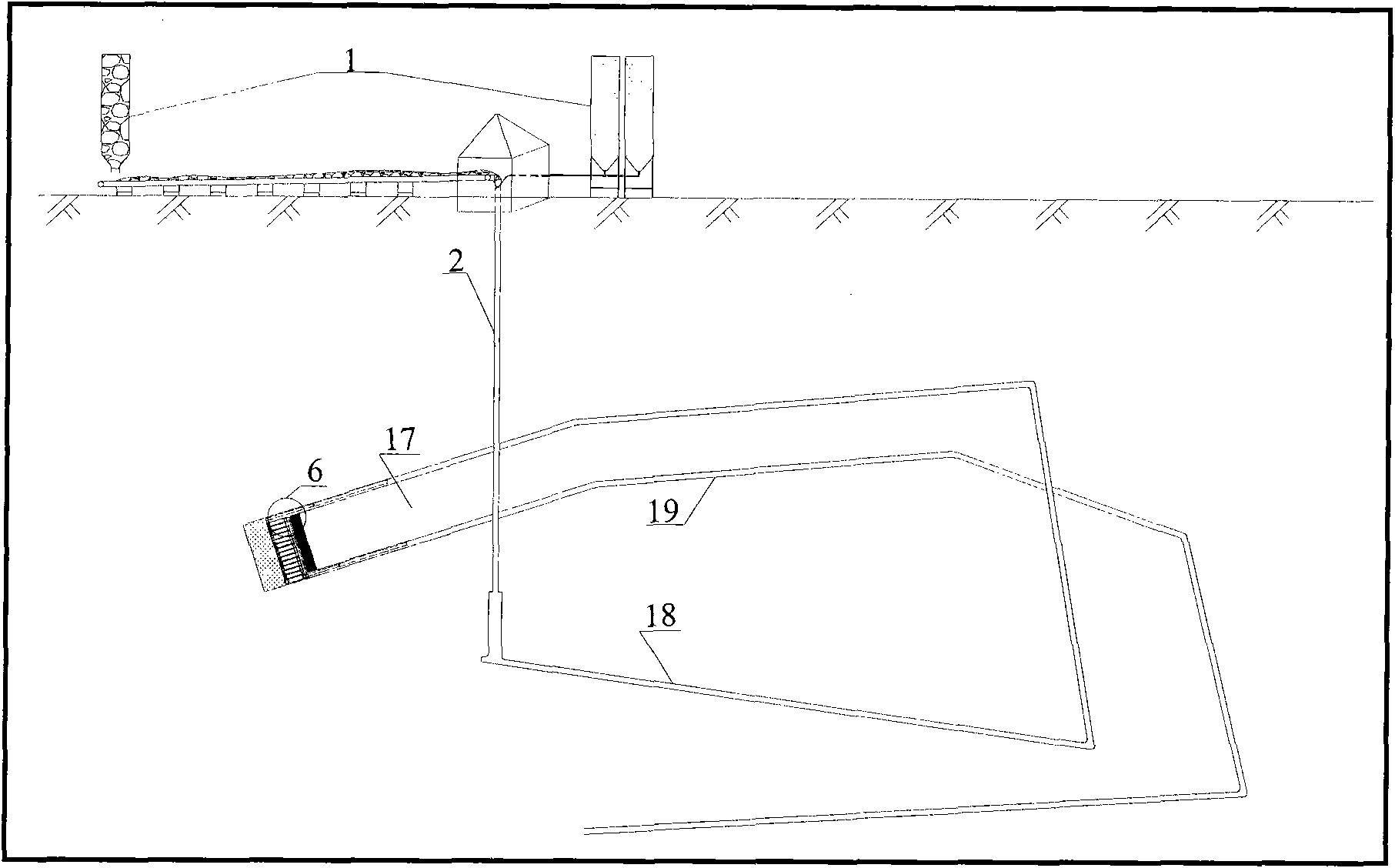

Continuous coal mining process method of open-pit coal mine

The invention relates to a continuous coal mining process method of an open-pit coal mine, the used main devices comprises a continuous coal mining machine, a walking type crushing machine of a continuous conveying machine unit, a bridge type transloading machine, a walking type transloading machine, an unloading car, a working face belt type conveyor, an outward transport heading belt type conveying machine and an outward transport machine lane belt type conveying machine, and the continuous coal mining process method adopts the continuous mining-continuous conveying way, and adopts the automatic mining, crushing, transloading, unloading and transportation. The coal mining method has advanced process, reasonable design, compact and continuous arrangement of the devices, safety, stability and reliability, high excavating efficiency, multi-stage transportation, smooth conveying and small occupied area, and can effectively improve the recovery rate of resources, reduce the consumption of fuel oil, reduce the carbon emission, be applicable to needs on low carbon, energy conservation and environmental protection and be a very ideal continuous coal mining process method of the open-pit coal mine.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com