Continuous coal mining process method of open-pit coal mine

A technology of open-pit coal mines and process methods, which is applied in open-pit mine mining, earthwork drilling, special mining, etc., and can solve problems such as high mining costs, reduced economic benefits, and small scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

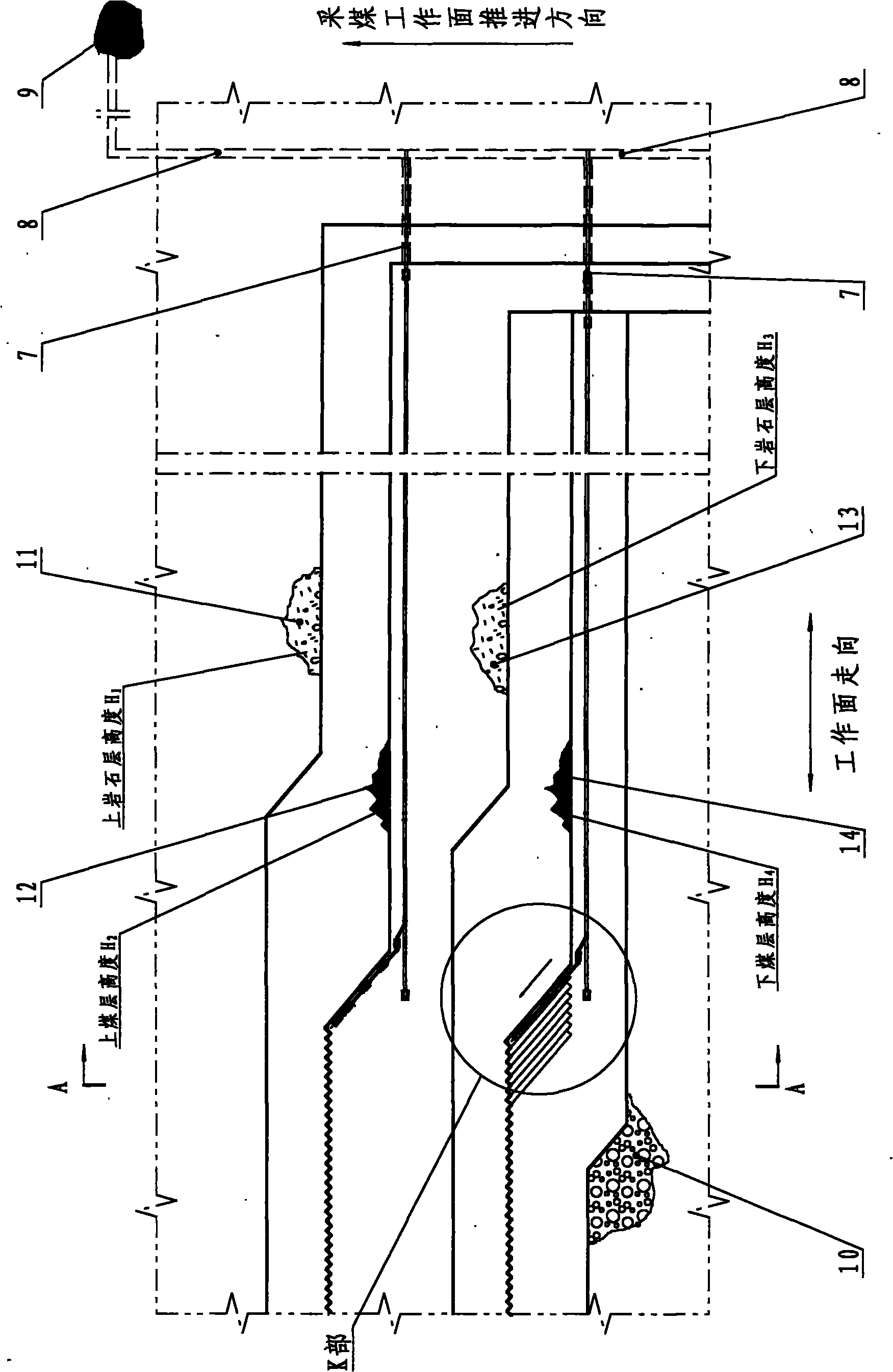

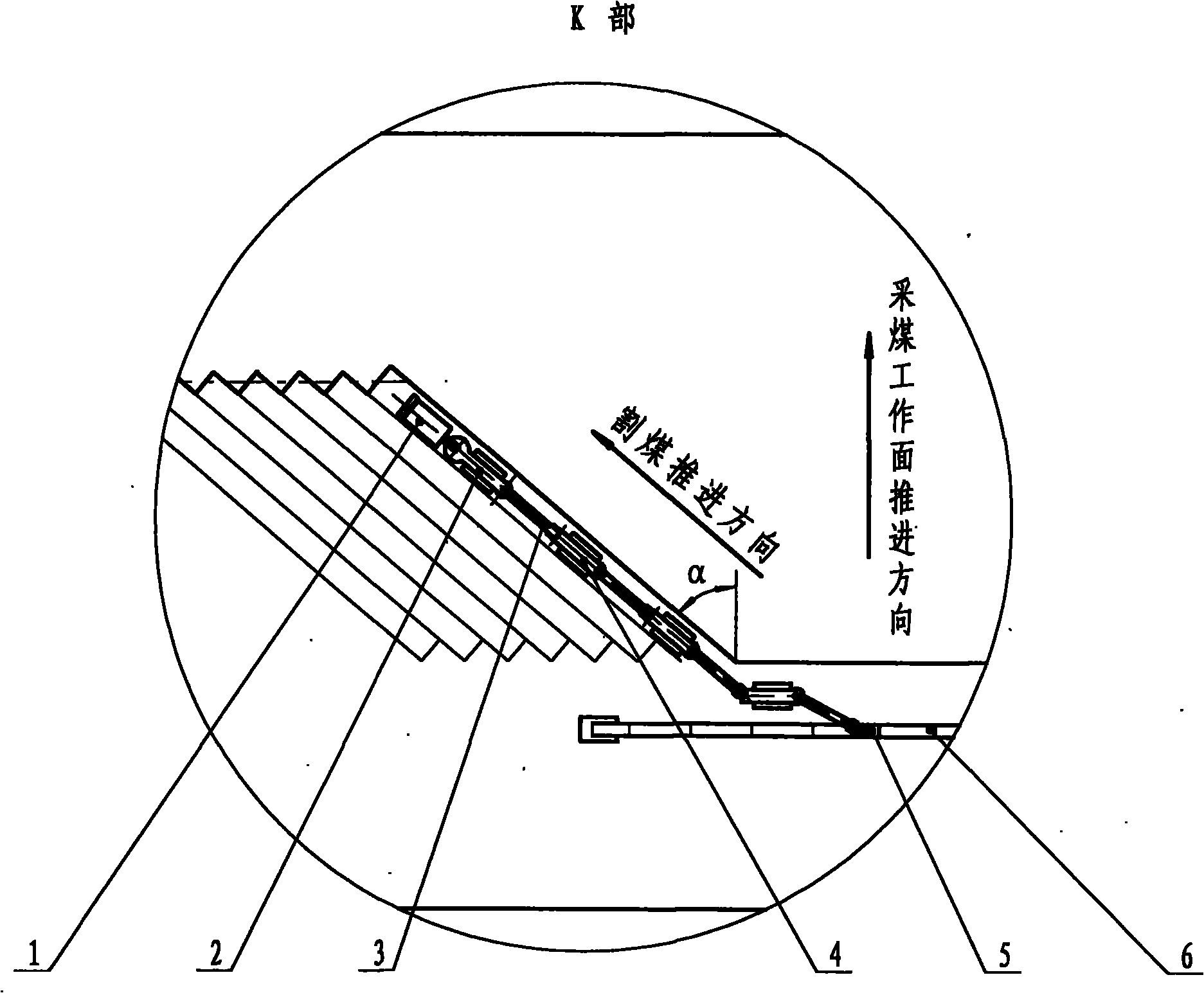

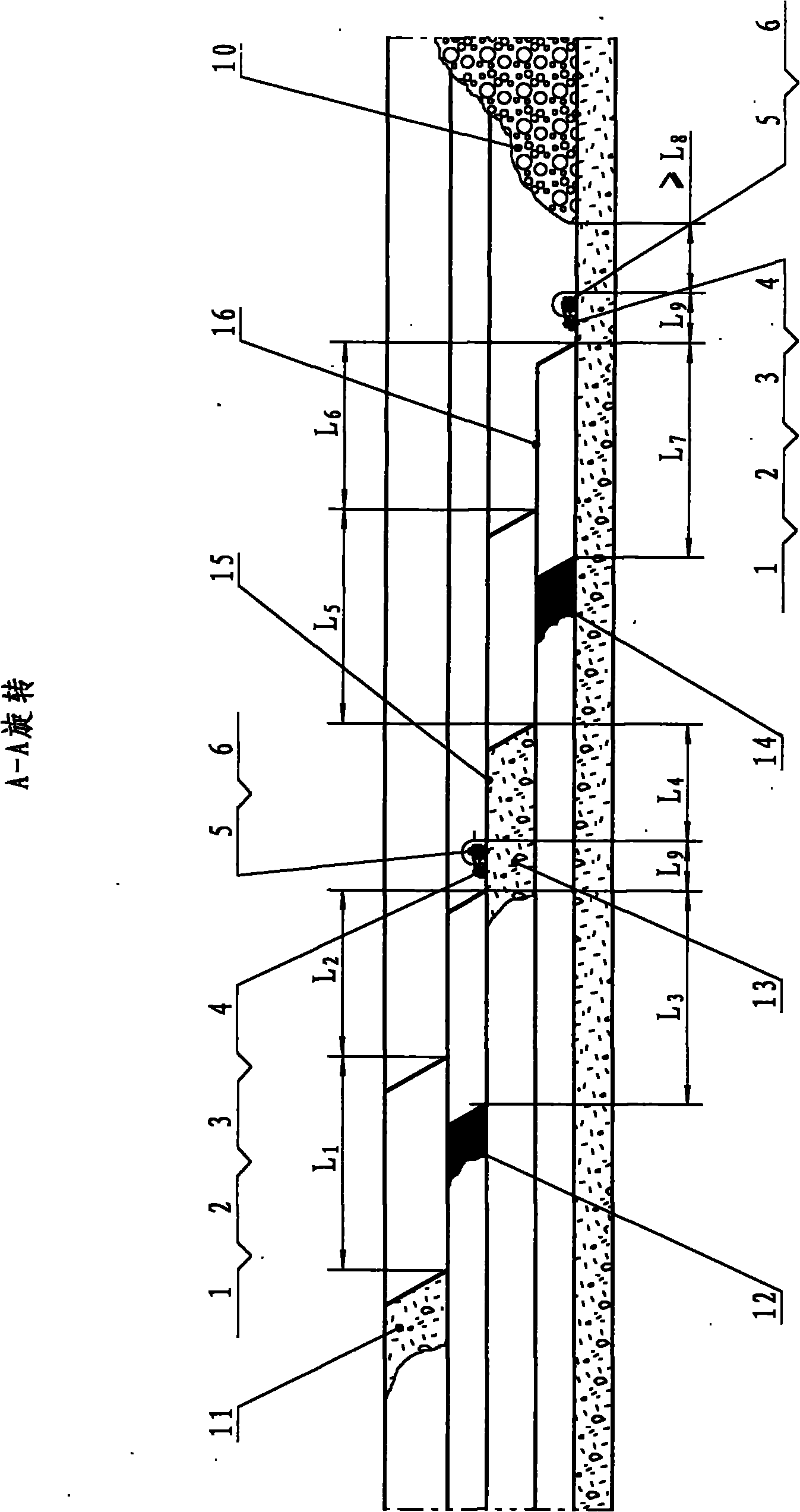

Method used

Image

Examples

Embodiment 1

[0061] All coal mining equipment, supporting equipment, tools and auxiliary materials are in ready working condition;

[0062] Prepare for coal mining according to the coal mining process;

[0063] Coal is mined by a continuous coal miner, and transferred to the unloading trolley by the walking crushing, bridge-type loader, and walk-type loader of the continuous conveying unit;

[0064] Use the unloading trolley to unload coal to the working face belt conveyor for coal transportation;

[0065] The belt conveyor in the working face transports coal to the belt conveyor in the Sinotrans level roadway;

[0066] The Sinotrans flat roadway belt conveyor transports coal to the Sinotrans machine roadway belt conveyor;

[0067] Coal is transported to the storage yard by the belt conveyor of the foreign transport machine for storage;

[0068] Coal conveying speed 2500-3200t / h;

[0069] Through the above process procedures, the whole process of coal mining-crushing-reloading-transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com