Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1146results about How to "Improve mining efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

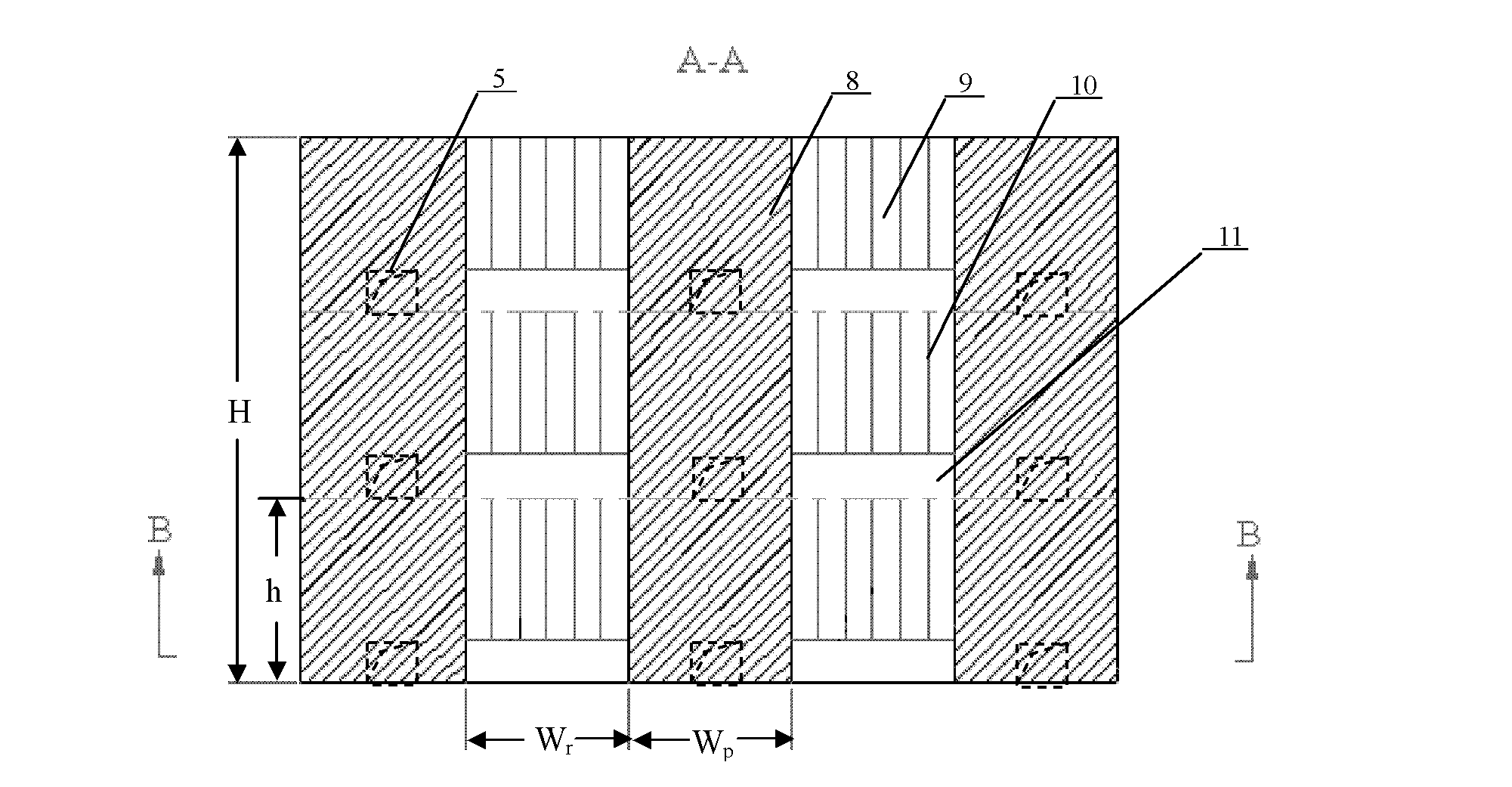

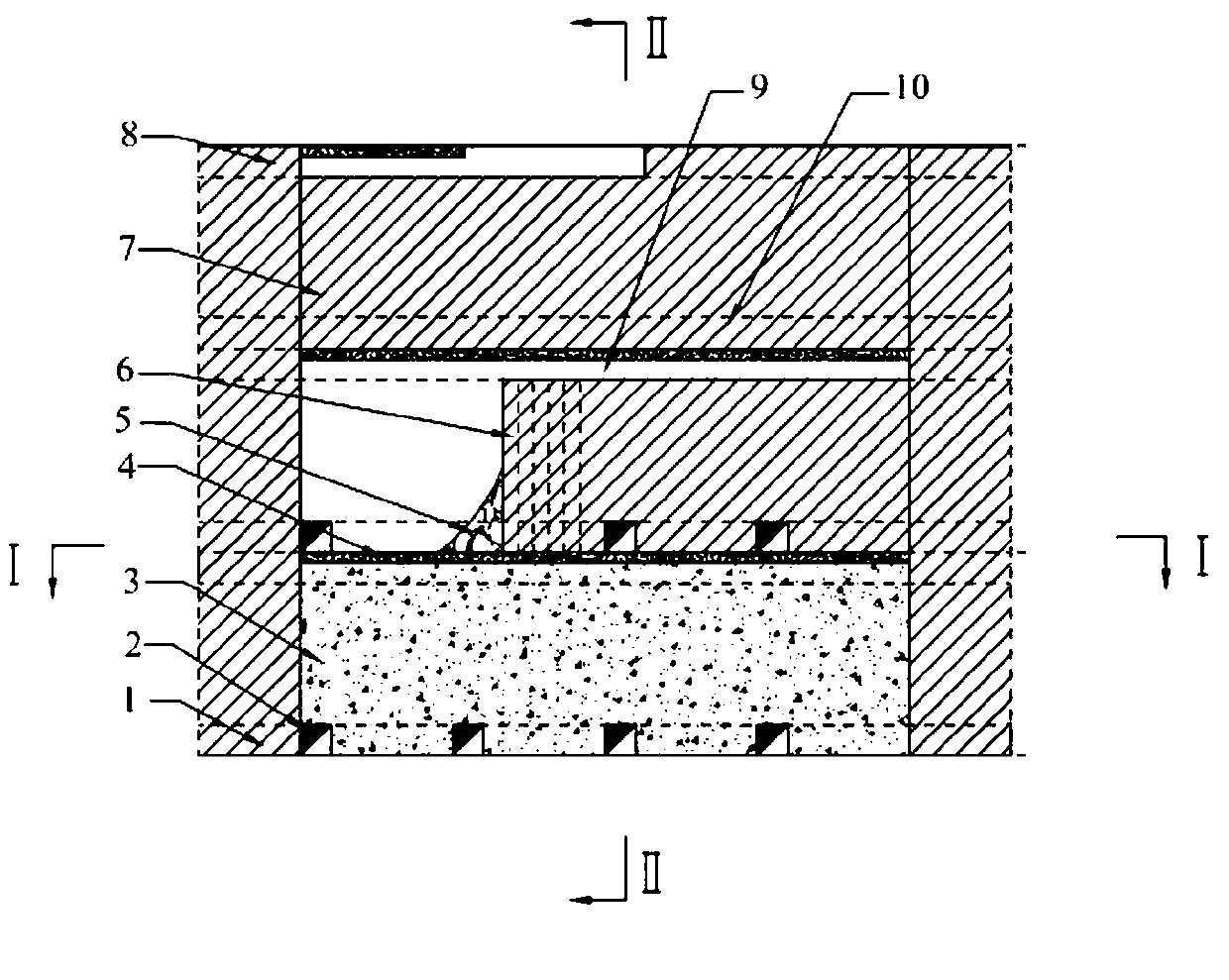

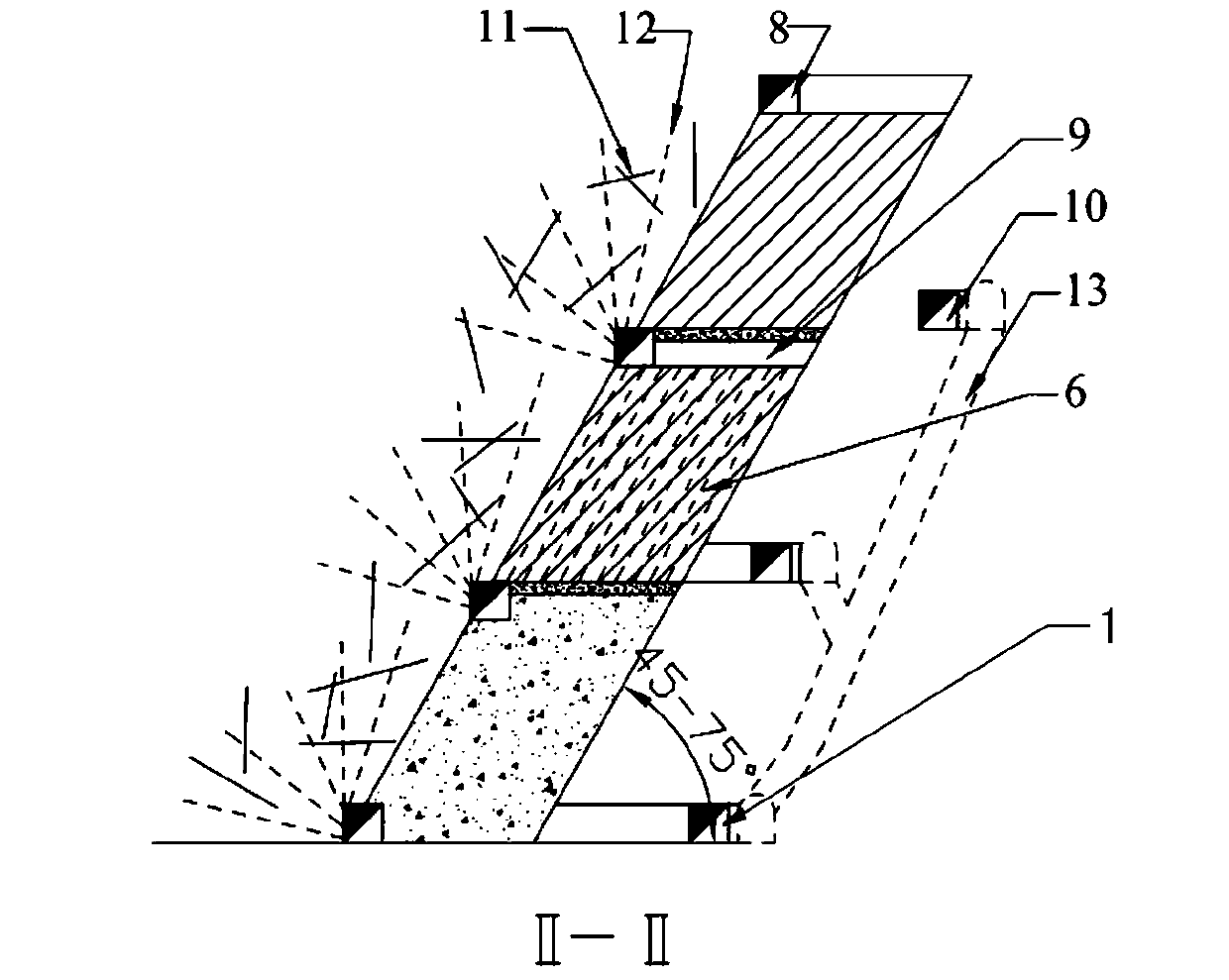

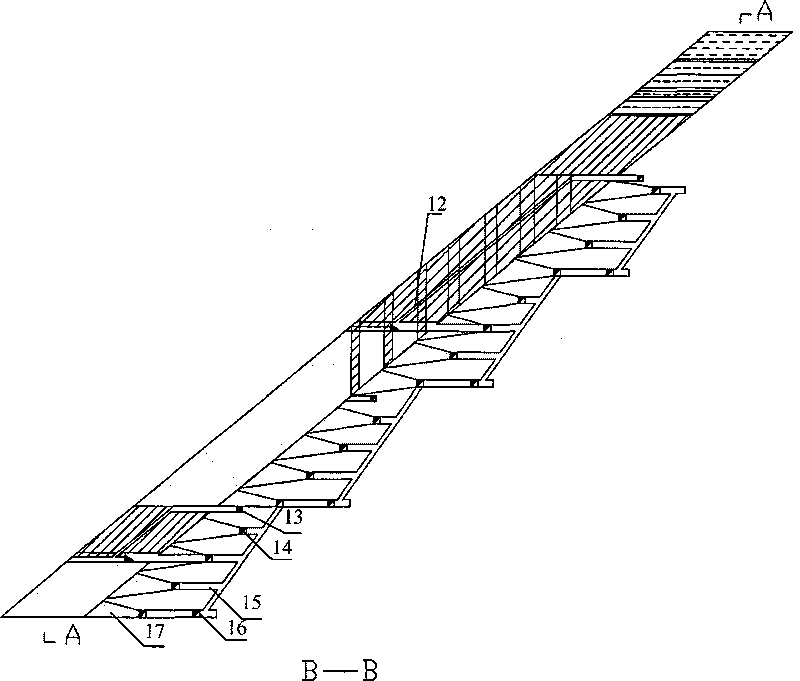

Sublevel open-stop and delayed filling mining method

InactiveCN102562065AImprove drilling positioning accuracyNo lossUnderground miningSurface miningTailings damFilling materials

The invention relates to a sublevel open-stop and delayed filling mining method. According to the method, cutting crosscuts are wholly undercut along the width of chambers and pillars so that the space of scope rock drilling is shared with ore drawing, drilling operations of vertical parallel blast holes are achieved in undercutting space, positioning accuracy of drilling the vertical parallel blast holes is high, the intervals among the blast holes are even, and the defect of high blasting boulder yield caused by drilling sector blast holes in traditional rock drilling cross cuts is avoided; during chamber (or pillar) scoping, driving of ore drawing gateways and ore drawing admission passages in fill materials of adjacent pillars (or chambers) isn't needed, and accordingly the safety is improved; simultaneously, ores are directly drawn from the undercutting space of the chambers and the pillars, the space of ore drawing is large, mutual interference is small, ore drawing efficiency is high, and ores are drawn completely without any dead space and secondary ore loss; artificial sill pillars are constructed, ore sill plates aren't needed to be reserved, the ores are free of primary loss, and the rate of resource recycling is high. Barren rocks and ore beneficiation tailings are used for filling gobs, the barren rocks are not taken out of pits, constructions of tailing dams and barren rock yards are reduced, and land occupation is small.

Owner:UNIV OF SCI & TECH BEIJING

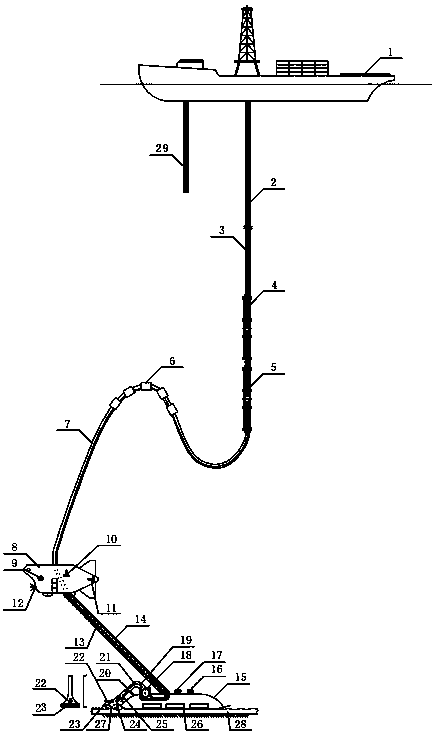

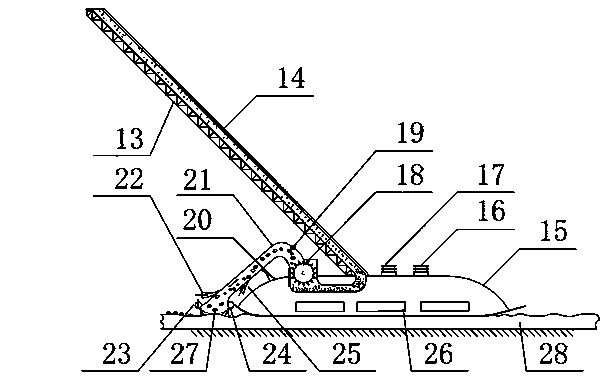

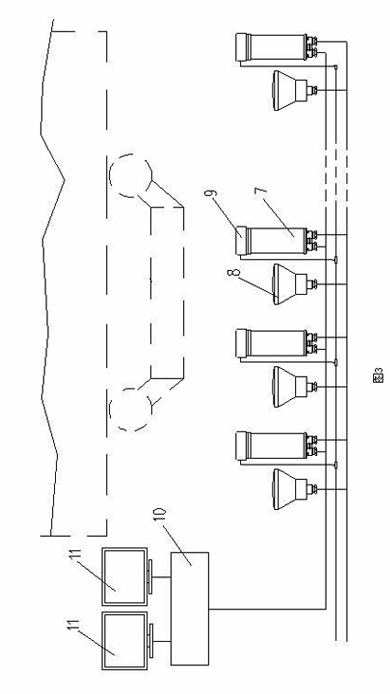

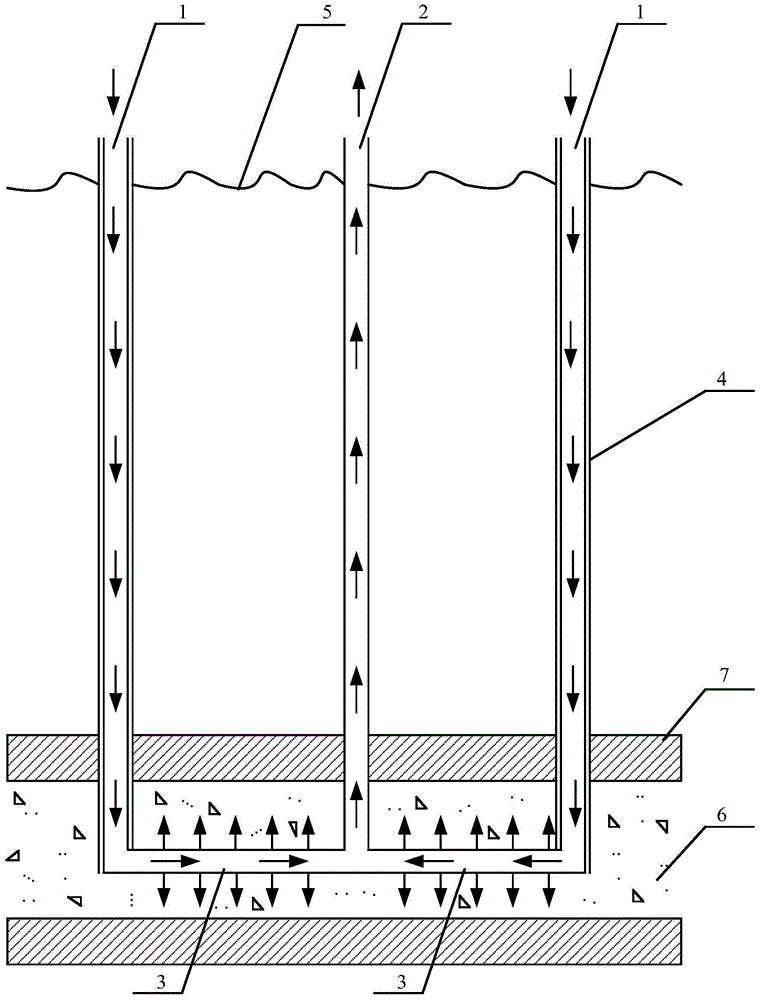

Oceanic mineral resource exploitation device and exploitation method

InactiveCN103628881AReduce disturbanceImprove reliabilityMineral miningFluid removalTerrainElectricity

The invention discloses an oceanic mineral resource exploitation device and exploitation method and aims to overcome the technological difficulty of the existing submarine mining vehicle and the pipeline waterpower lifting exploitation system. The exploitation device comprises a water surface mining vessel, a lifting pipe, a lifting electric pump station, a hose, a mineral crushing mechanism and a mining mechanism, wherein a plurality of perturbance jet flow nozzles, a plurality of ascending jet flow nozzles and a flow guide pipe are mounted on the mining mechanism; the flow guide pipe is communicated with the feeding hole of the mineral crushing mechanism; the lifting pipe, the lifting electric pump station, the hose and the mineral crushing mechanism are sequentially connected with the flow guide pipe in series to form an ore pulp lifting passage; the hose is fixed onto an ROV; the ROV is connected with the mining mechanism through a connecting device. The oceanic mineral resource exploitation device is not limited by the complicated terrain and gradient at the bottom of the sea, avoids the slipping and sinking of the underpan of the submarine mining vehicle on a settled layer, greatly reduces the disturbance of mineral mining to bottom sediments, and also solves the problem that the terrain clearance of the mining mechanism is difficult to control.

Owner:HUNAN UNIV

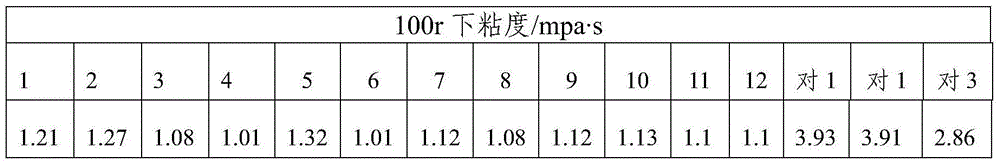

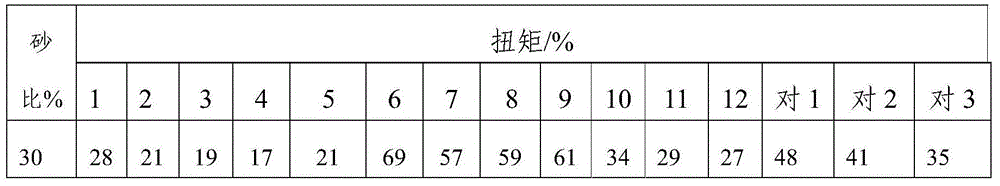

Self-suspension supporting agent for natural water fracturing

ActiveCN104946233AGood physical properties and chemical stabilityImprove efficiencyFluid removalDrilling compositionShale gasWater soluble

The invention belongs to the field of exploitation of fluid ores such as petroleum, natural gases and shale gases and provides a self-suspension supporting agent for natural water fracturing construction. The self-suspension supporting agent is formed by coating or partially coating water-soluble high polymer materials on aggregate, wherein the aggregate refers to solid particles with enough mechanical strength capable of bearing fracture closure stress and is selected from one or more of quartz sand, ceramsite, metal particles, spherical glass particles, sintered bauxite, sintered alumina, sintered zirconia, synthetic resins, precoated sand and crushed shell particles; and the amount of water-soluble high polymers is 0.1-5wt% of the amount of the aggregate. According to the self-suspension supporting agent provided by the invention, proper high polymer materials and adhesive materials are selected, the supporting agent has good physical properties and chemical stability, the high polymer materials do not enter the reservoir cracks along with a fracturing fluid and can smoothly flow back, and the mining efficiency is obviously improved.

Owner:BEIJING RECHSAND SCI & TECH GRP

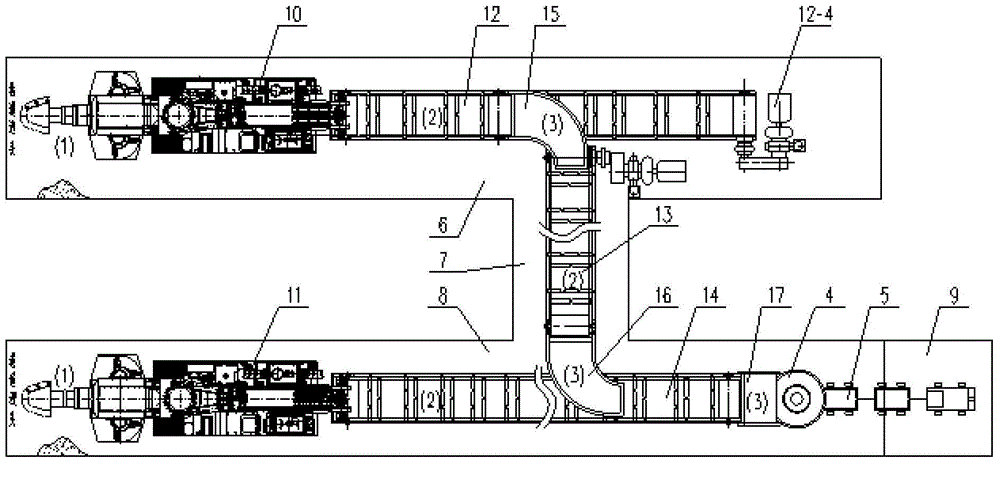

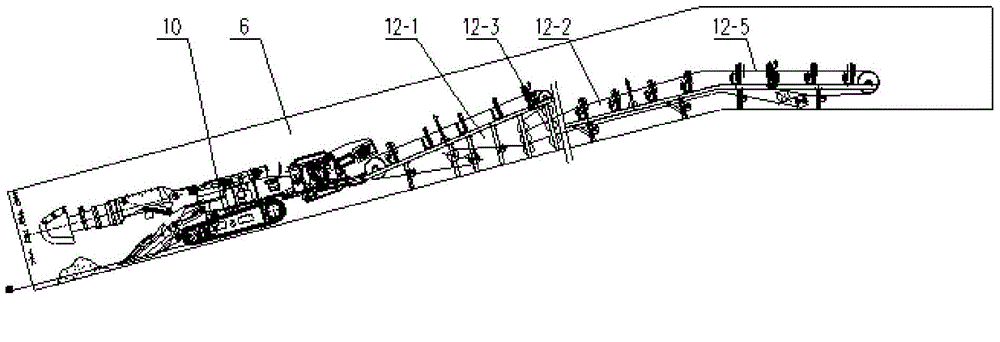

Continuous coal mining process method of open-pit coal mine

The invention relates to a continuous coal mining process method of an open-pit coal mine, the used main devices comprises a continuous coal mining machine, a walking type crushing machine of a continuous conveying machine unit, a bridge type transloading machine, a walking type transloading machine, an unloading car, a working face belt type conveyor, an outward transport heading belt type conveying machine and an outward transport machine lane belt type conveying machine, and the continuous coal mining process method adopts the continuous mining-continuous conveying way, and adopts the automatic mining, crushing, transloading, unloading and transportation. The coal mining method has advanced process, reasonable design, compact and continuous arrangement of the devices, safety, stability and reliability, high excavating efficiency, multi-stage transportation, smooth conveying and small occupied area, and can effectively improve the recovery rate of resources, reduce the consumption of fuel oil, reduce the carbon emission, be applicable to needs on low carbon, energy conservation and environmental protection and be a very ideal continuous coal mining process method of the open-pit coal mine.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

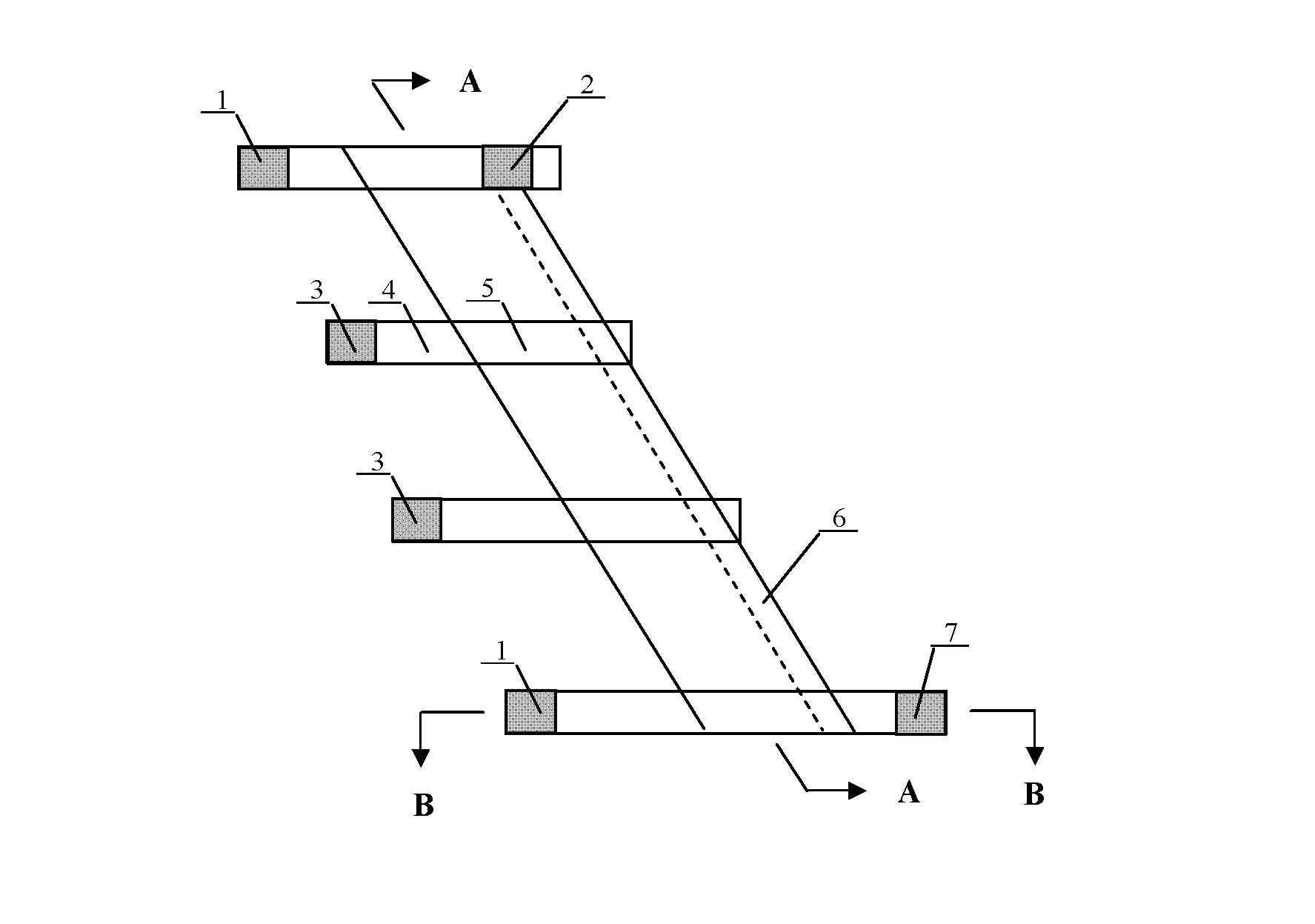

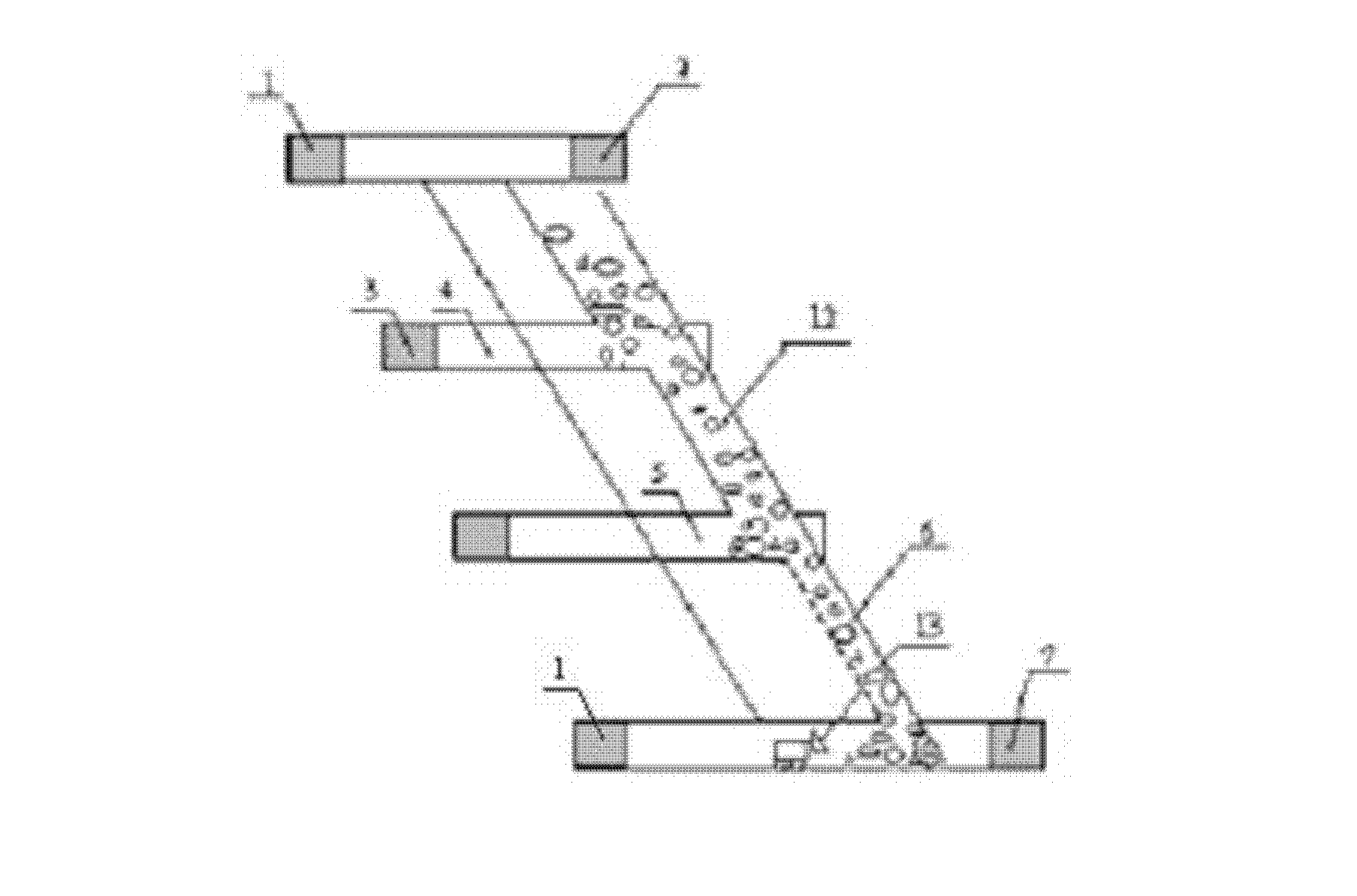

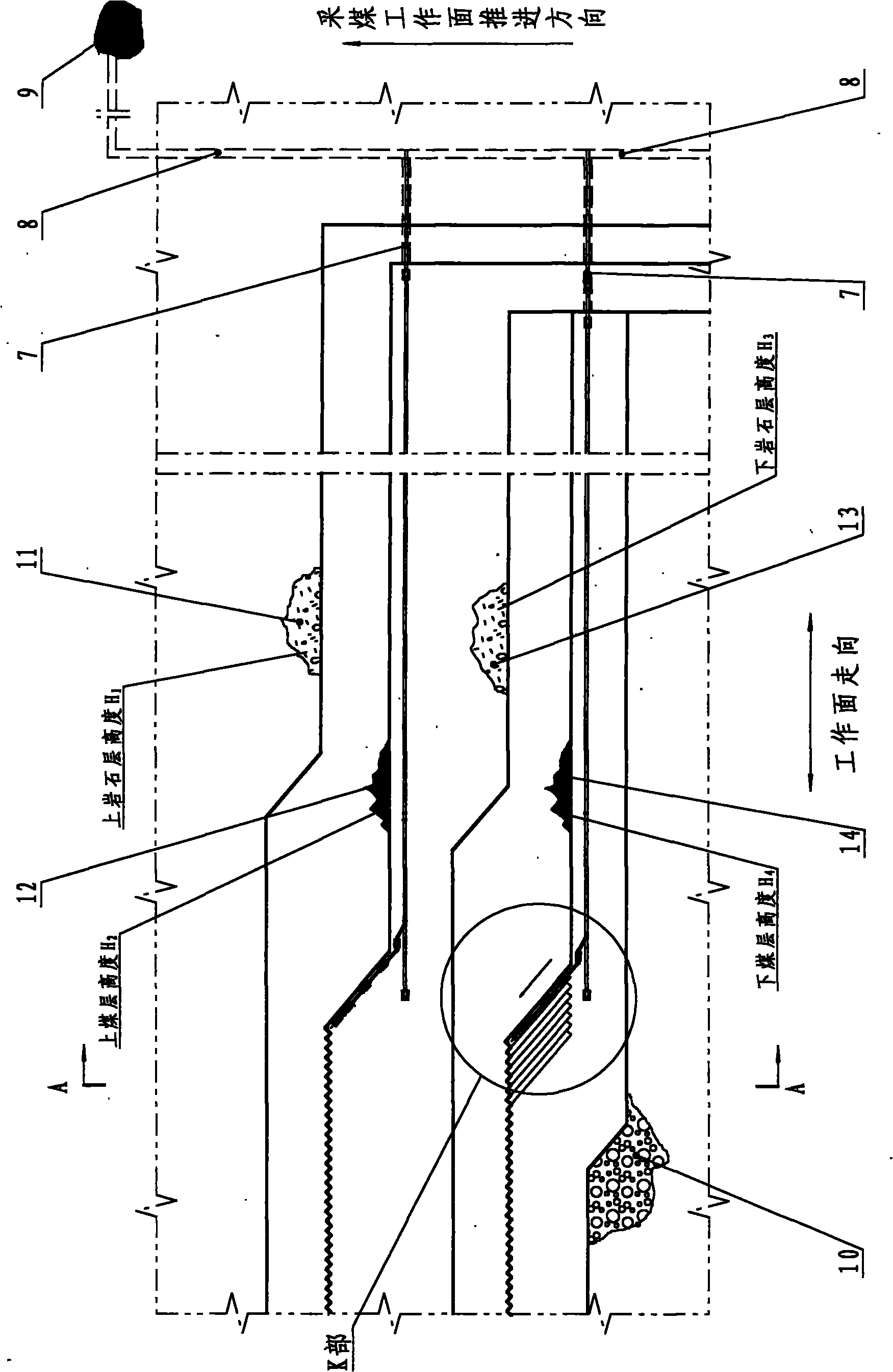

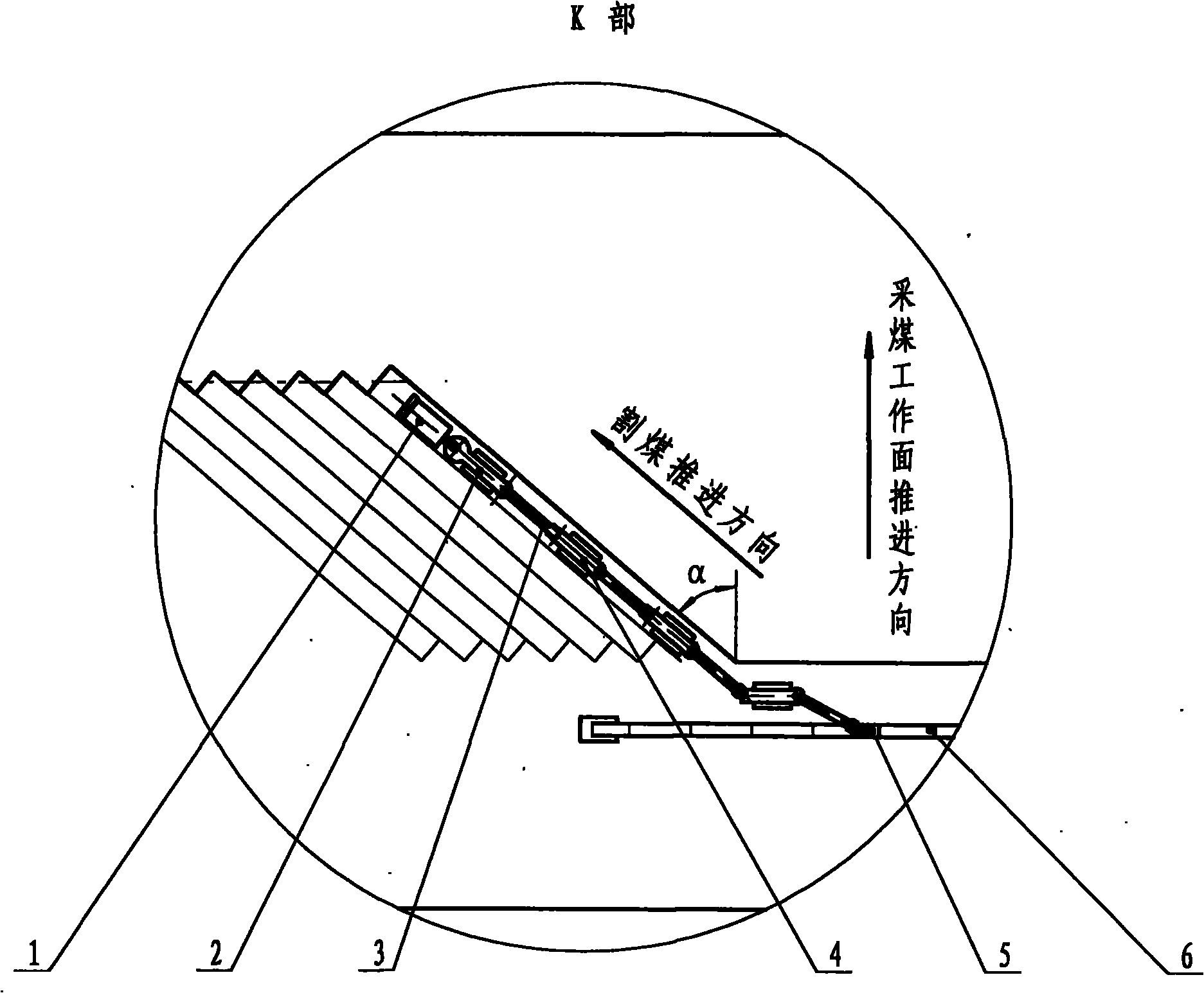

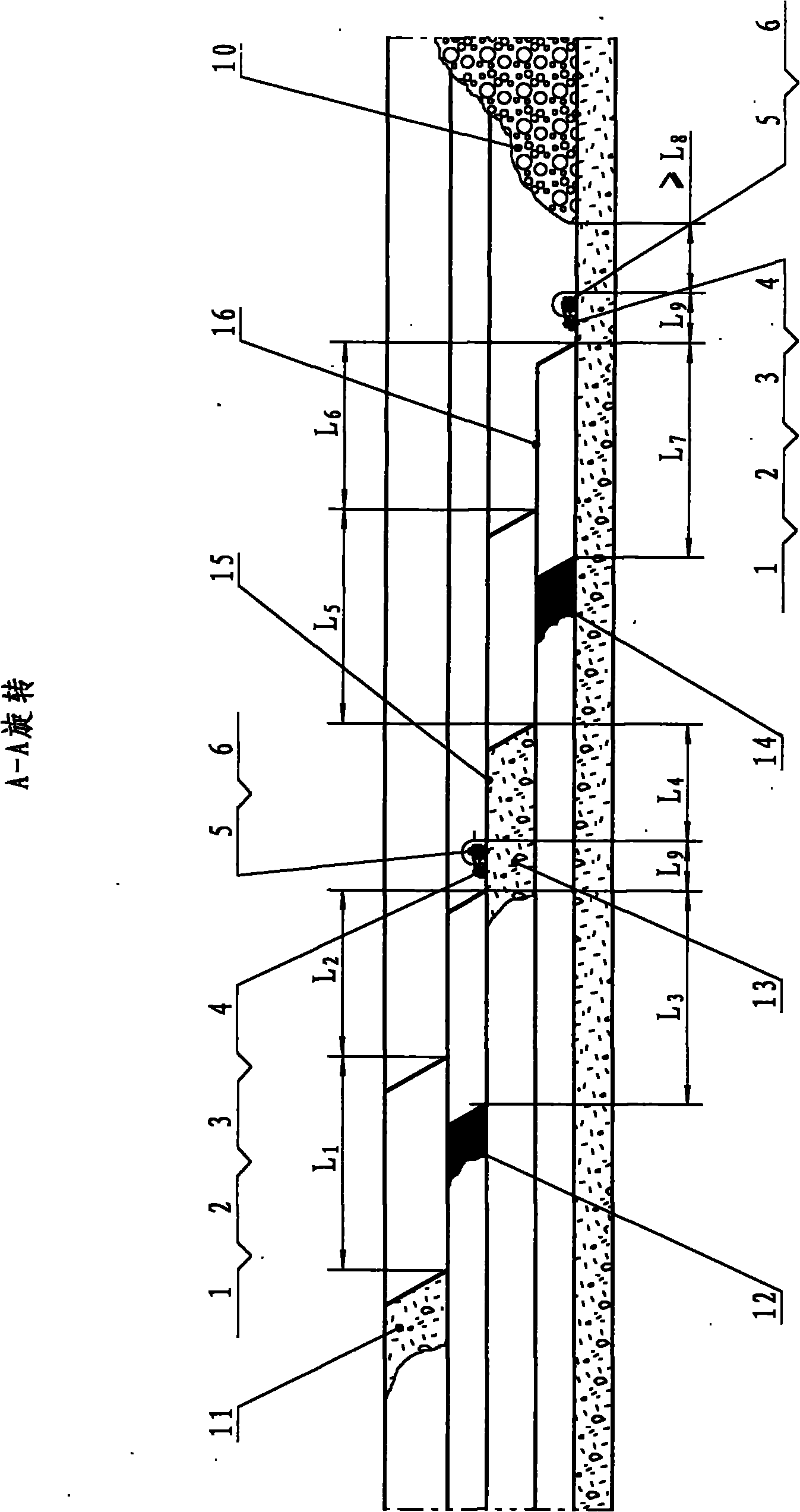

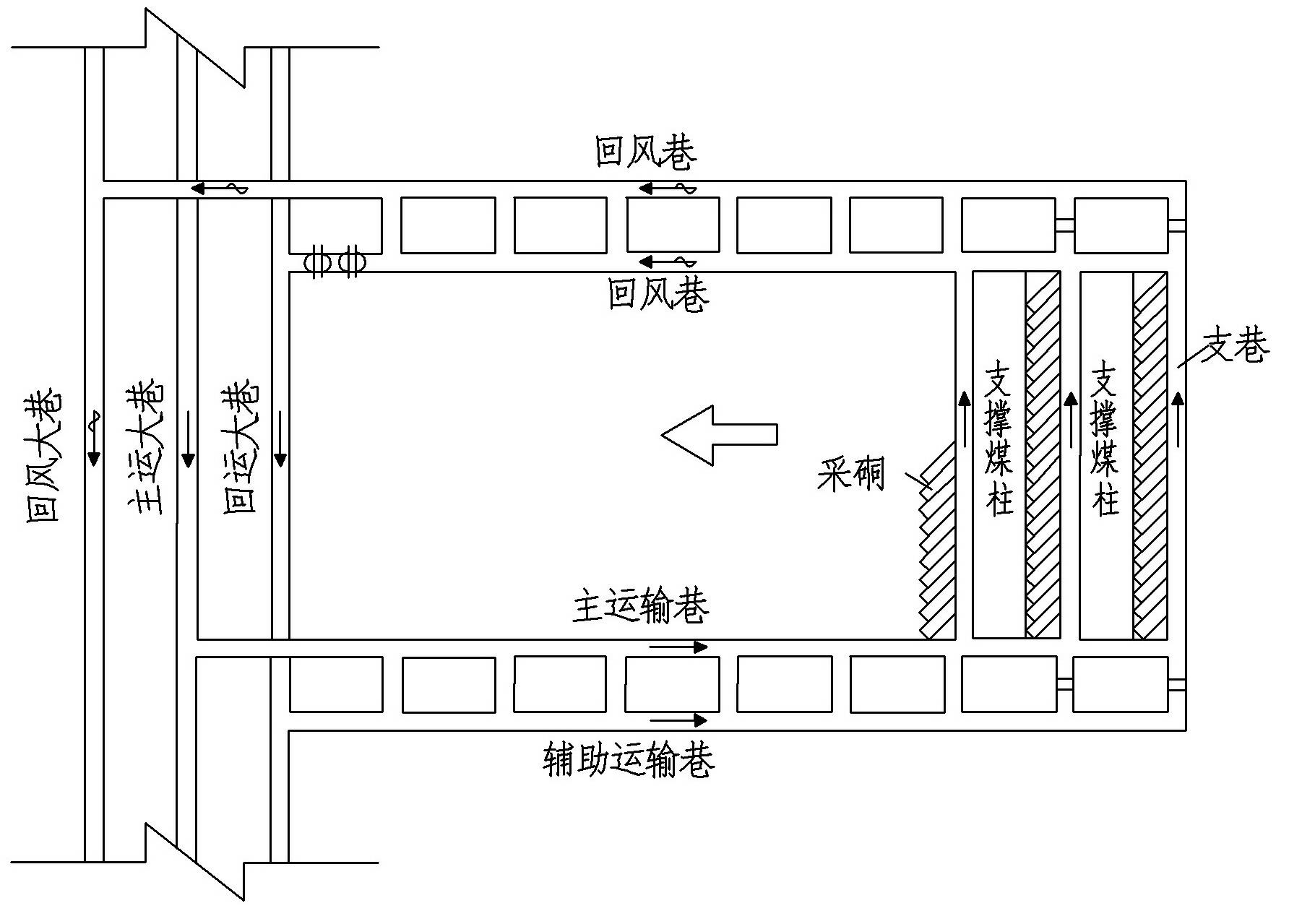

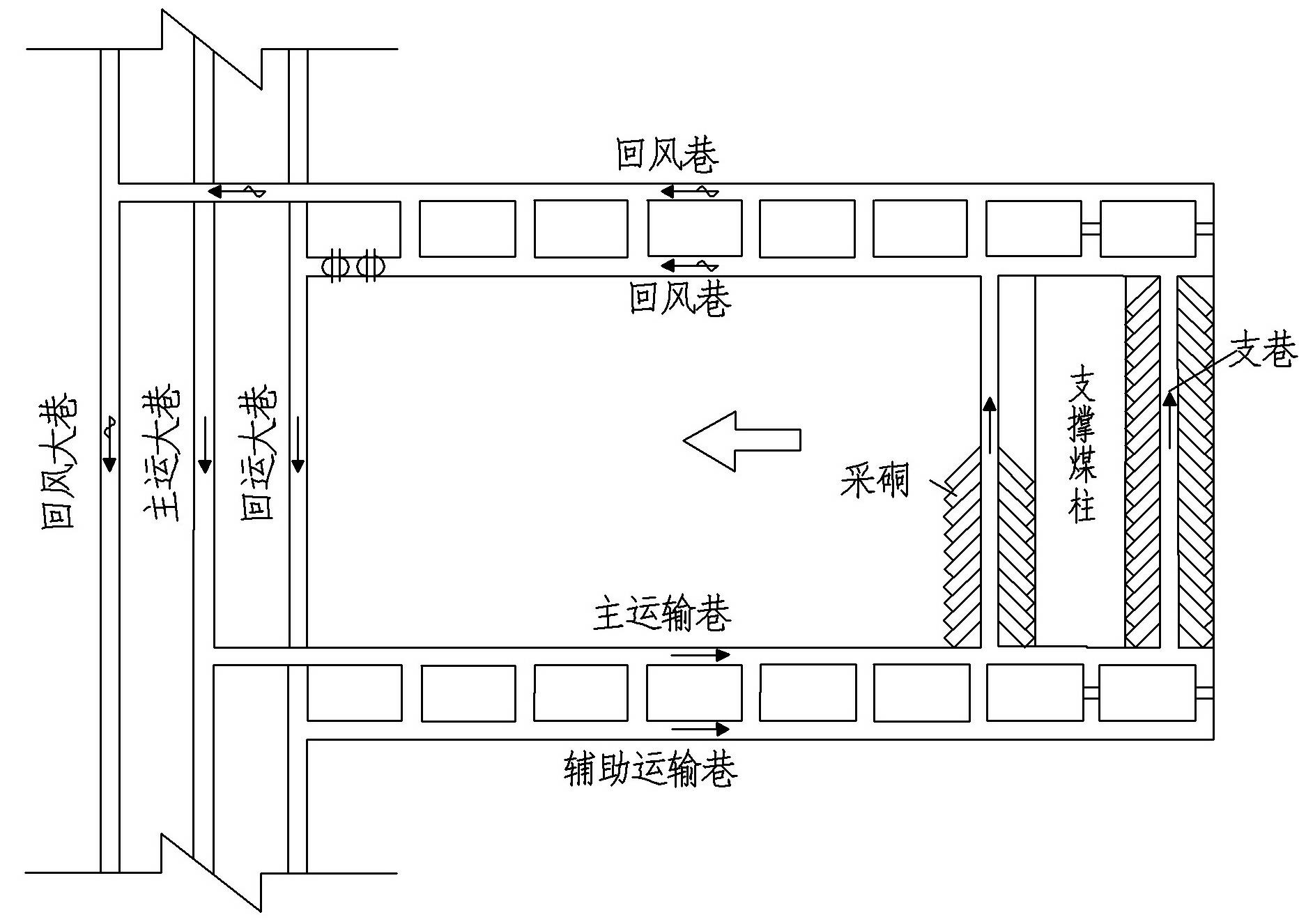

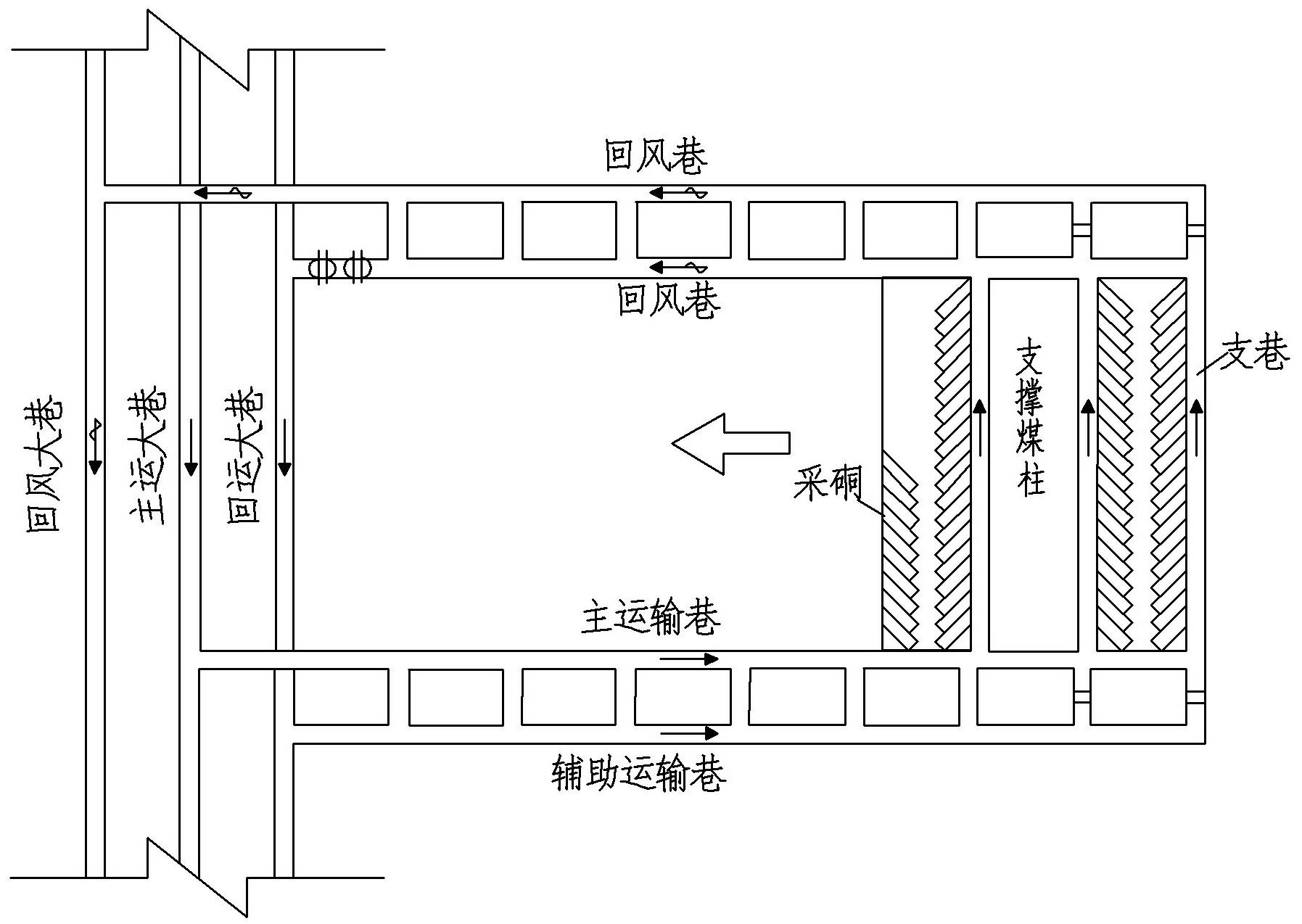

Strip-type Wongawilli mining method of coal buried under building

InactiveCN102587914AFlexible arrangementImprove the recovery rate of coal resourcesUnderground miningSurface miningCoal pillarEngineering

The invention discloses a strip-type Wongawilli mining method of coal buried under a building, which includes the steps that the coal mining area under the building adopts a strip type overall arrangement manner to plan the working face, and then a Wongawilli continuous mining method is adopted to conduct short wall backstopping at the mining fields which are located at one side or two sides of a strip type hole drift and angle at 40-60 degrees with the hole drift. The technique provided by the invention can give full play to the respective advantages of strip mining and Wongawilli mining and overcomes the disadvantages of frequent shifting of the working face, low mining efficiency of the strip mining method and the disadvantages of poor aeration condition and poor longtime stability of the coal pillars of the Wongawilli mining method. The method disclosed by the invention realizes efficient recovery of the coal buried under buildings, railways, and water bodies.

Owner:HENAN POLYTECHNIC UNIV

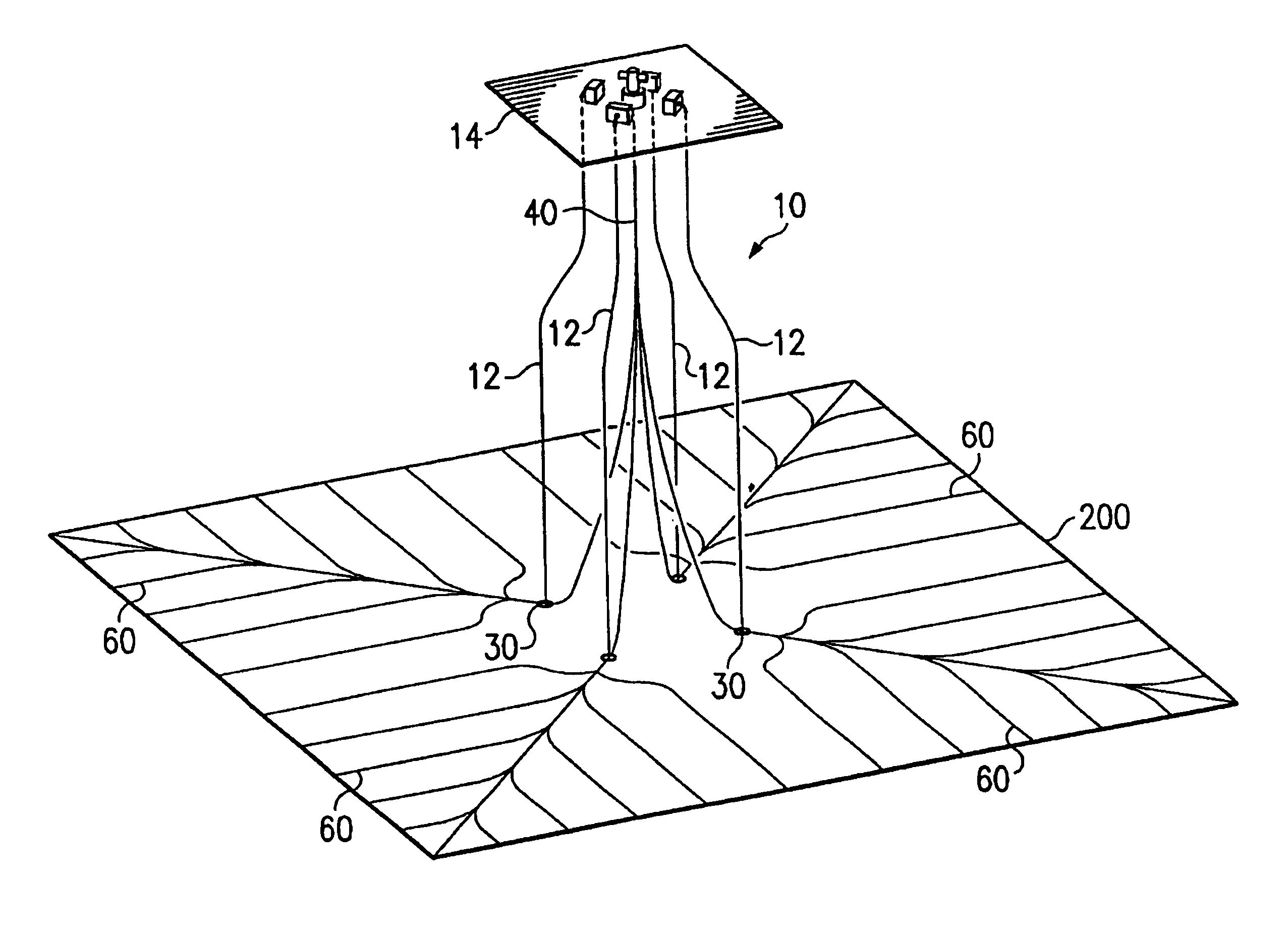

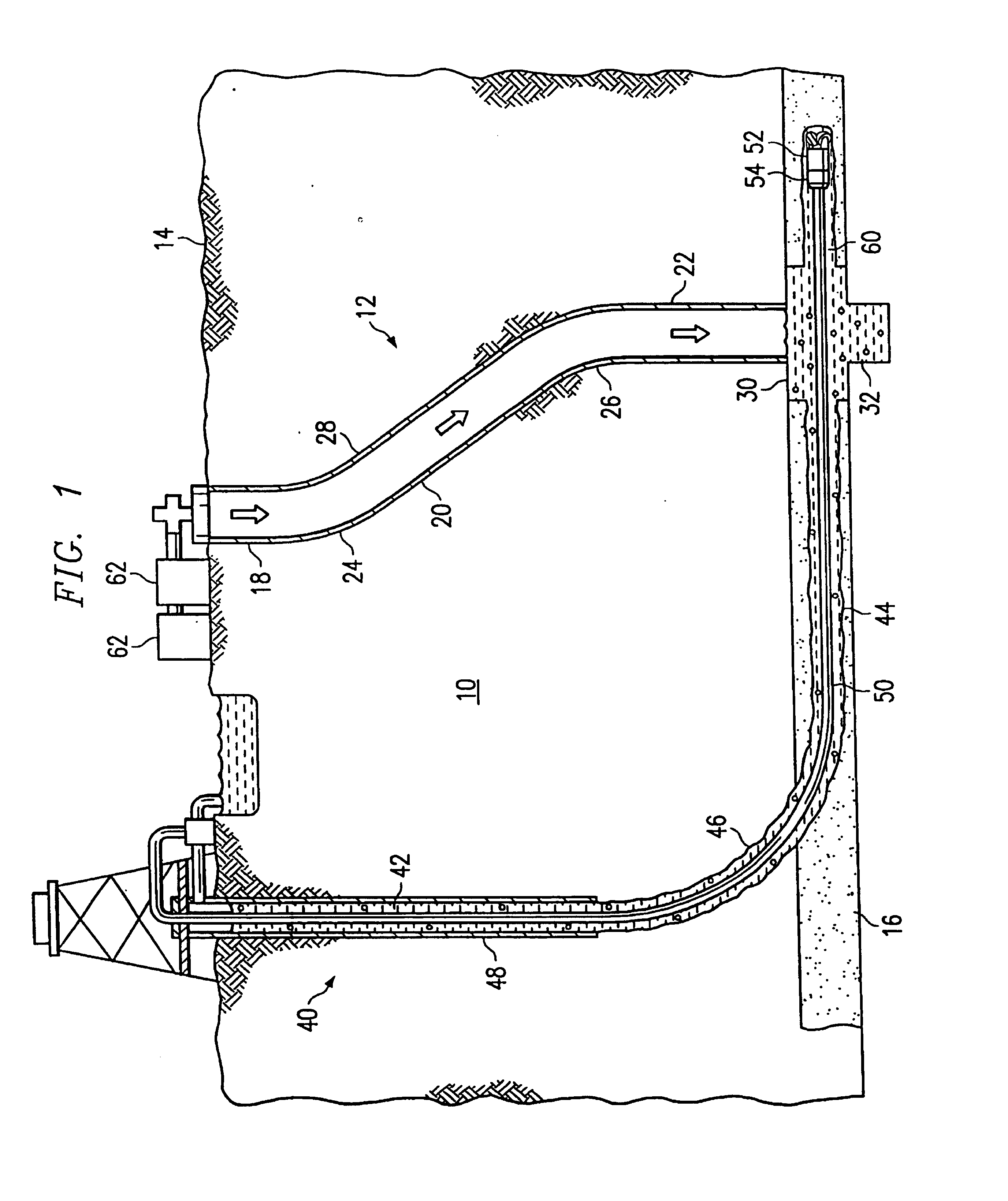

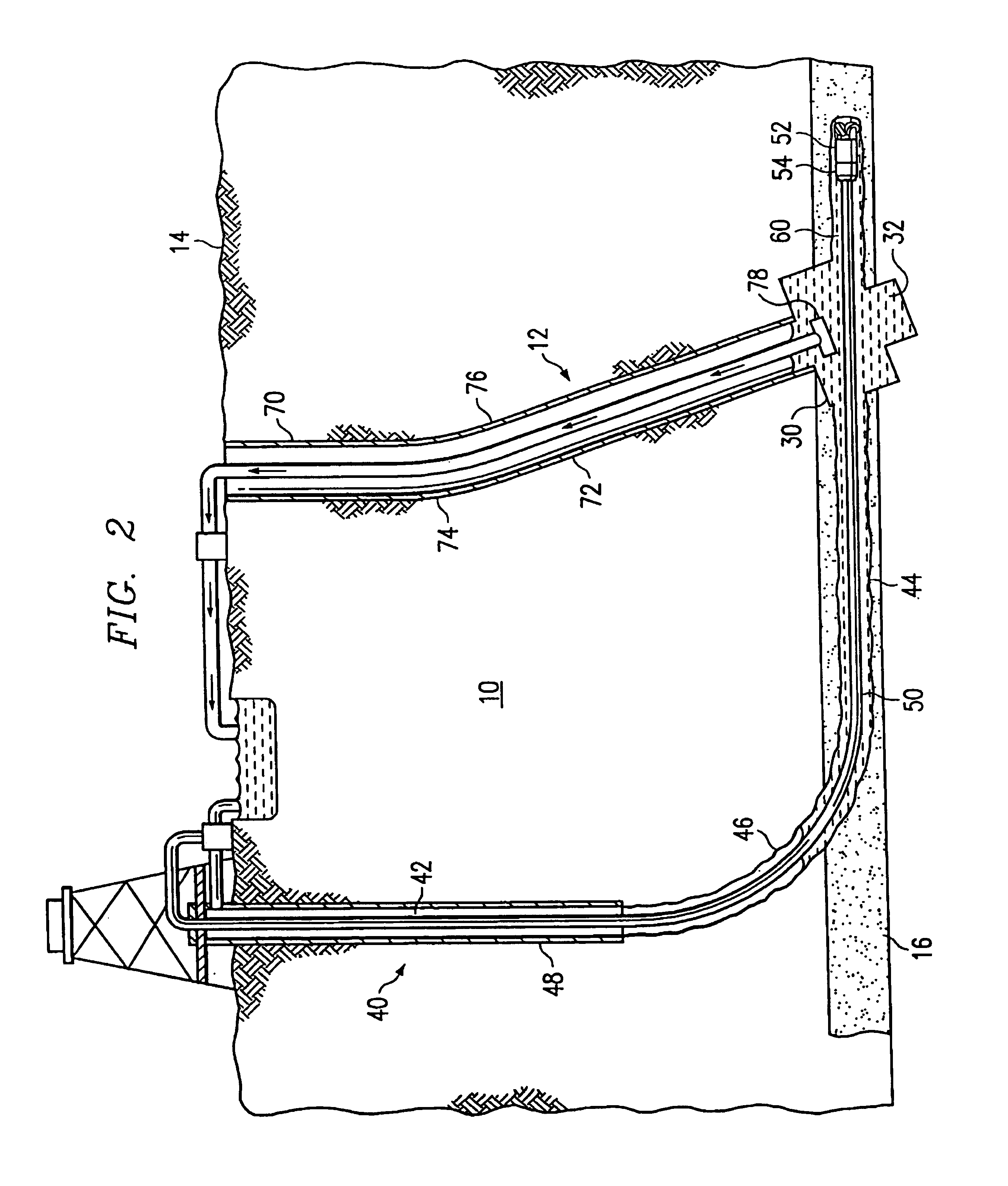

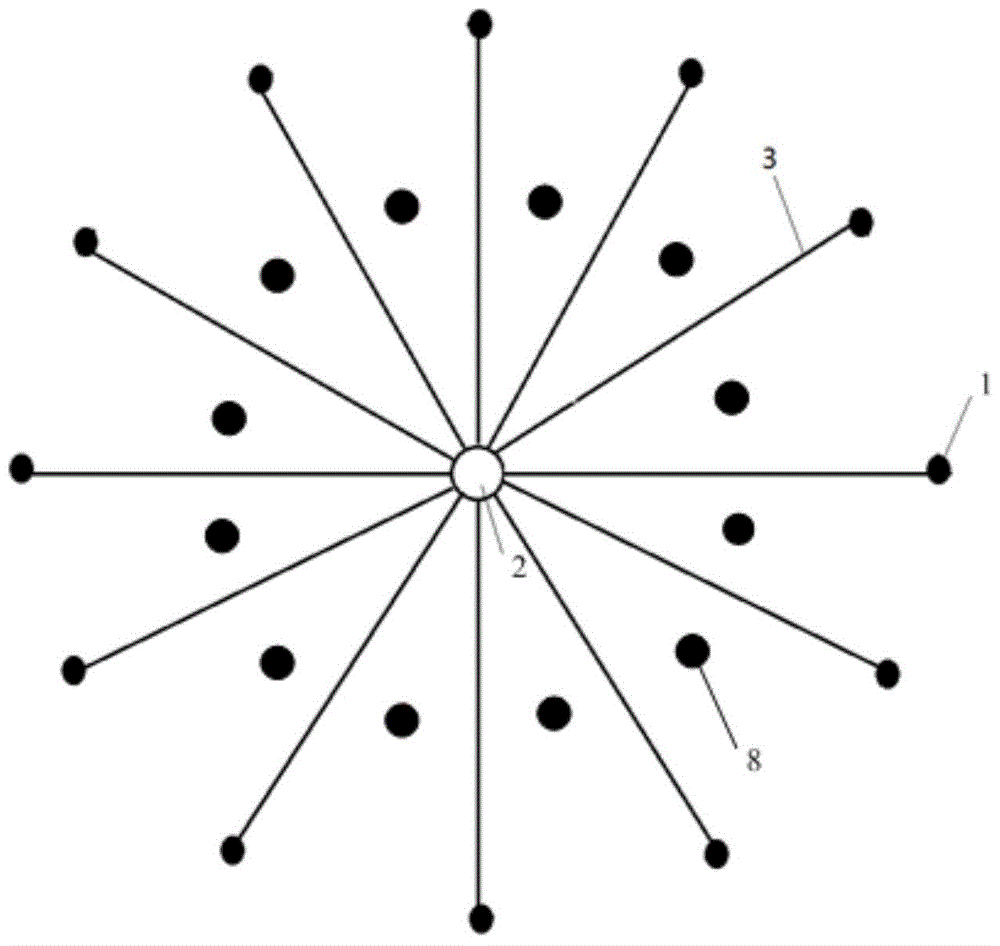

Method and system for accessing a subterranean zone from a limited surface area

InactiveUS7036584B2Shorten the timeImprove mining efficiencyFluid removalDirectional drillingWellboreEnvironmental geology

A method and system for accessing subterranean resources from a limited surface area includes a first well bore extending from the surface to the target zone. The first well bore includes an angled portion disposed between the target zone and the surface to provide an offset between a surface location of the first well bore and an intersection of the first well bore with the subterranean resource. The system also includes an articulated well bore extending from the surface to the target zone. The articulated well bore is offset from the first well bore at the surface and intersects the first well bore proximate the target zone. The system further includes a well bore pattern extending from the intersection of the first well bore and the articulated well bore in the target zone to provide access to the target zone.

Owner:EFFECTIVE EXPLORATION

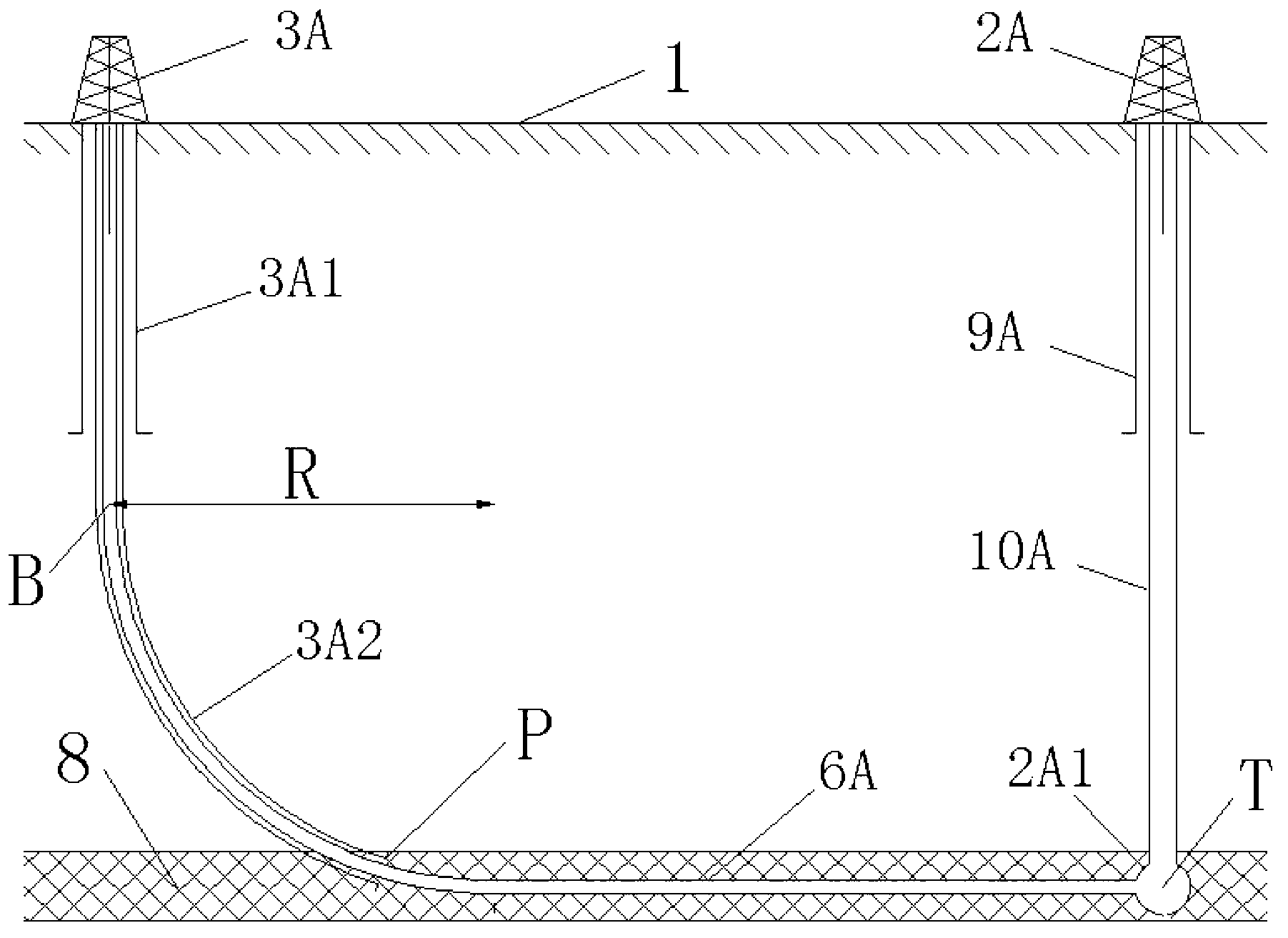

Horizontal branch multi-well-group butted well and construction method thereof

ActiveCN103216234AGuarantee normal implementationAvoid cloggingUnderground miningFluid removalWell drillingHorizontal branch

The invention discloses a horizontal branch multi-well-group butted well and a construction method thereof. The butted well adopts a distribution structure that a horizontal well corresponds to at least two vertical well groups; each vertical well group comprises at least two vertical wells; the vertical wells of each vertical well group are respectively communicated with the horizontal well at the target points respectively arranged at the bottoms of the vertical wells, so that horizontal mining channels which correspond to the vertical well groups one to one can be formed; and the target points arranged at the bottoms of the vertical wells are arranged in a target ore bed. By adopting a novel well drilling distribution form, the horizontal branch multi-well-group butted well enlarges the bare area of the ore bed, improves the mining efficiency, lowers the well drilling cost, reduces the construction period and reduces the mining risk.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI +1

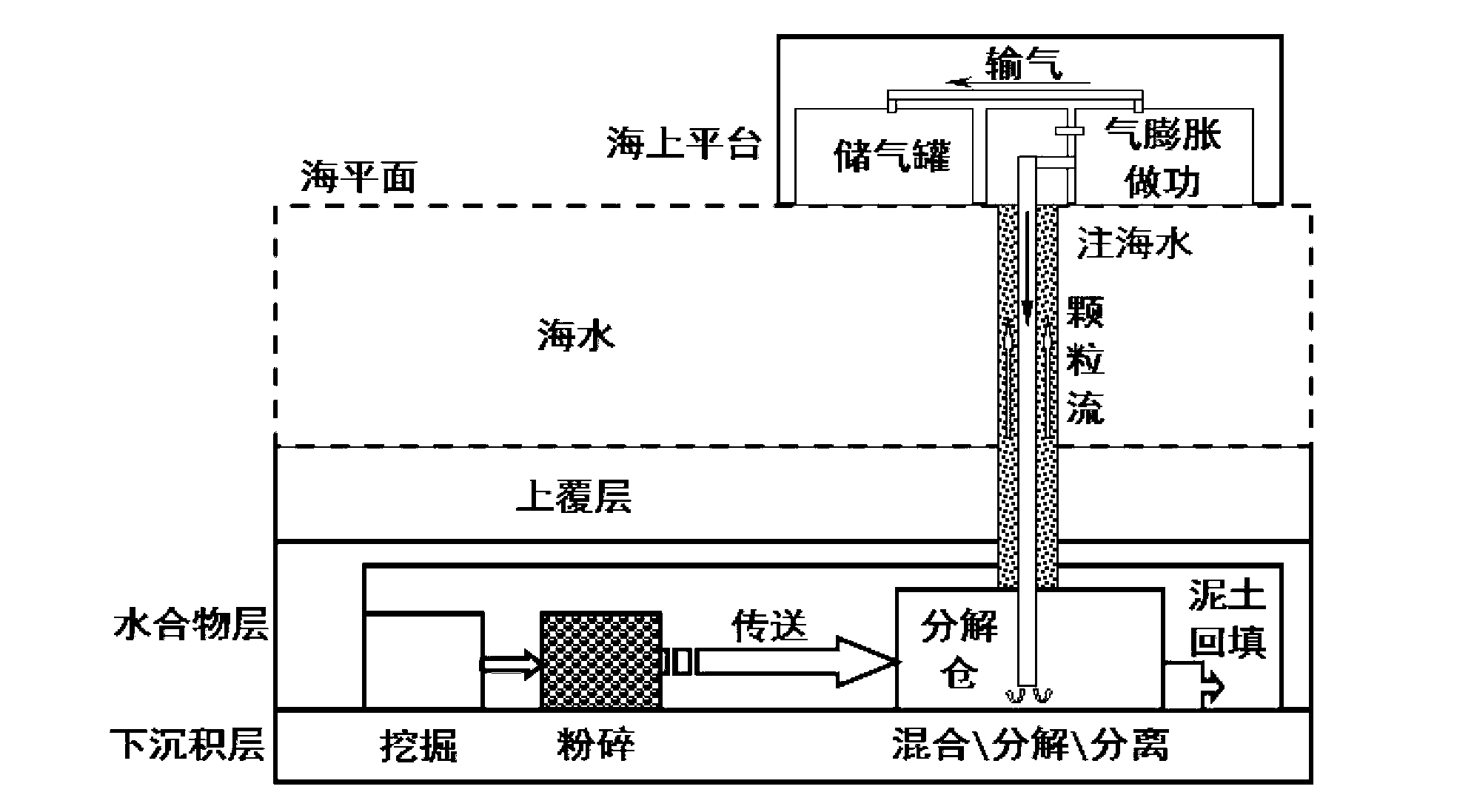

Mechanical-thermal hydrate exploiting method

The invention discloses a mechanical-thermal hydrate exploiting method. The mechanical-thermal hydrate exploiting method comprises the following steps: excavating a hydrate stratum, crushing hydrate sediment into hydrate sediment granules, and conveying the hydrate sediment granules into a decomposing chamber; stirring and mixing relatively hot seawater and the hydrate sediment granules in the decomposing chamber, partially decomposing the hydrate sediment granules, separating the obtained mixture, and removing the separated sediment; upwardly conveying the remaining mixture along an exploiting shaft, further decomposing the hydrate in the mixture in the conveying process, and separating the remaining mixture and generated gas from the sediment in the mixture; and collecting the obtained gas on an exploiting platform. By the method, hydrate decomposing heat can be supplied by a huge heat source from seawater and convective heat transfer; expansion energy of gas which is generated in a centralized way can be made full use; backfill of the sediment can restore certain stratum strength; and leakage of the hydrate decomposing gas from a covering layer can be avoided.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

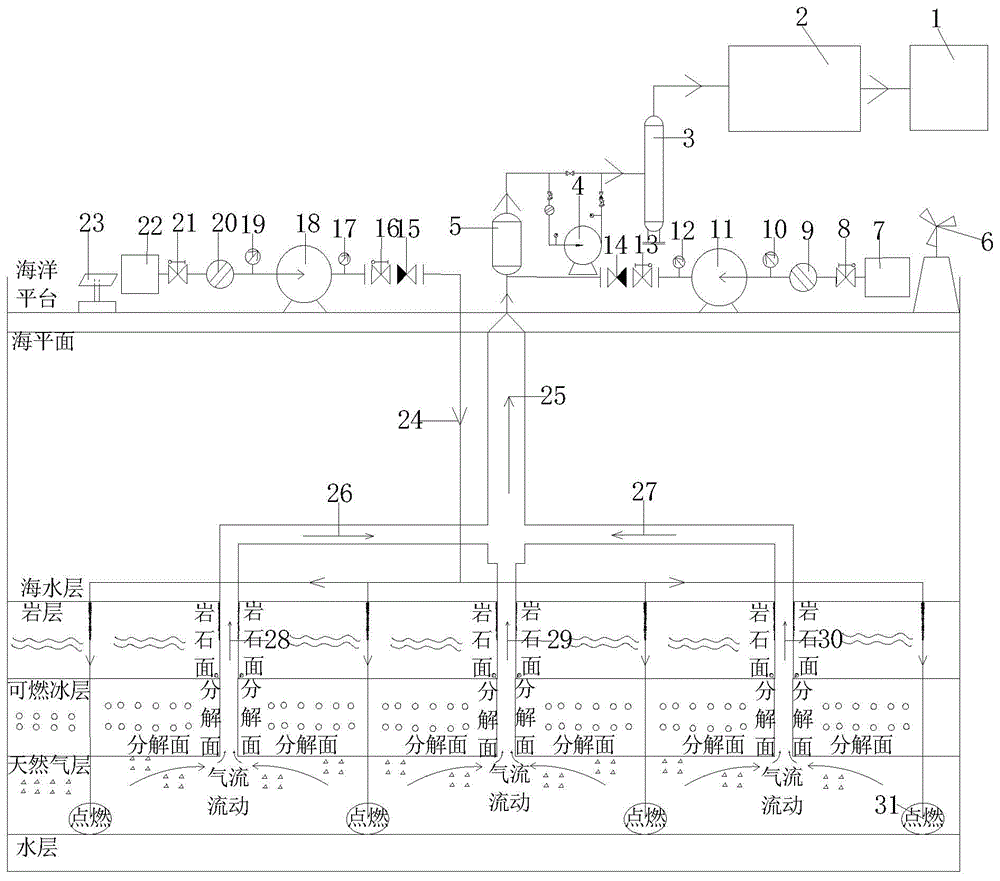

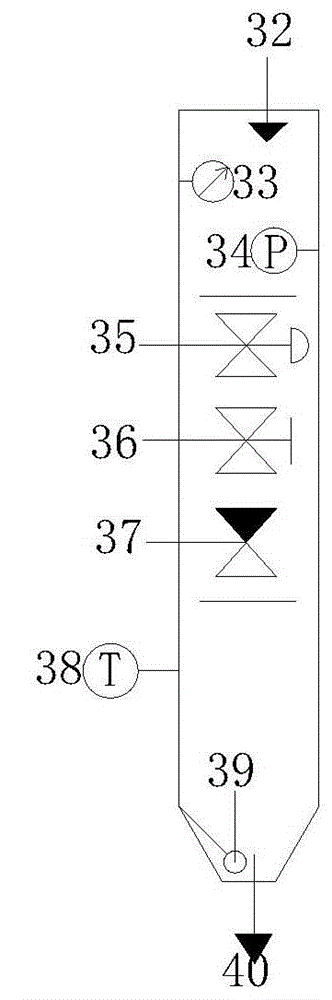

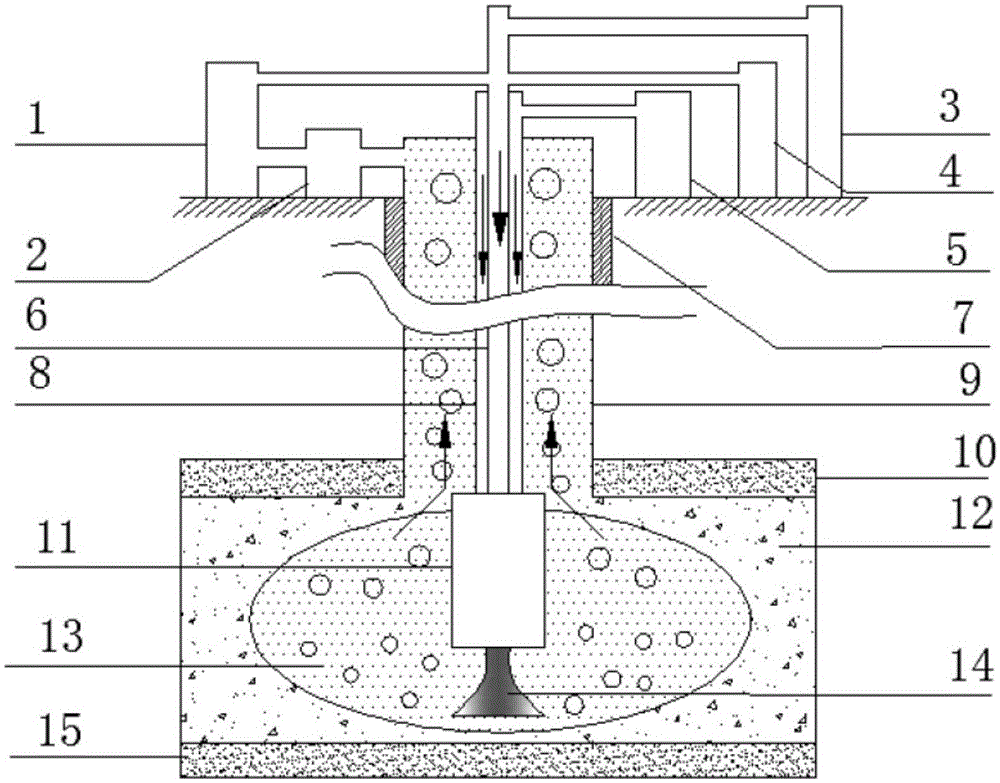

Method and device for exploiting combustible ice in seabed

InactiveCN104481467AHigh purityReduce the impact of airflowConstructionsFluid removalCombustionDecomposition

Combustible ice, also called as Natural Gas Hydrate (NGH), is formed at the high pressure and low temperature, and much of the combustible ice is reserved in the seabed and tundra layer and is the third energy source human found. The invention provides a method and a device for exploiting combustible ice in the seabed by seabed firing. The method includes injecting combustion-supporting gas into a natural gas layer of the seabed combustible ice, strictly controlling flow velocity and flow of the combustion-supporting gas, firing through an electromagnetic ignitor, providing head for decomposition of NGH by burning a small part of natural gas, and accelerating decomposition of the combustible ice so as to improve gas production efficiency. Due to burning, the temperature of the natural gas is slightly higher than the balance temperature of the combustible ice, high pressure of gas reservoir of the combustible ice can be kept, and no hydrate of the integral seabed gas collection area is generated.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method and system for extracting natural gas hydrate through thermal jet flow

ActiveCN105134152APromote decompositionInhibition of reformationConstructionsFluid removalProcess engineeringSystem structure

The invention provides a method and system for extracting natural gas hydrate through thermal jet flow. The method includes the steps that a combustion reaction device is lowered to a downhole target position of a natural gas hydrate reservoir, oxygen and fuel are injected into the downhole target position, the combustion reaction device is powered on, ignition is performed, combustion products are jet out of the combustion reaction device to form high-speed jet flow, the jet flow and heat generated during combustion act on the natural gas hydrate reservoir so that natural gas hydrate can be decomposed, and decomposed natural gas returns upwards to the ground; the amount of injected fuel is gradually reduced till injection stops, meanwhile part of the natural gas returning upwards to the ground and water are injected and mixed with oxygen for continuous combustion, and natural gas hydrate can be furthermore decomposed. The system at least comprises the combustion reaction device, a continuous oil tube inner tube, a continuous oil tube outer tube, a cable, a production sleeve, a water supply device, a fuel supplying device, an oxygen supplying device, a natural gas storing, collecting and supplying device and a pump set. The method and system for extracting natural gas hydrate through thermal jet flow have the advantages that extracting cost is low, extracting efficiency is high and the system structure is simple.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

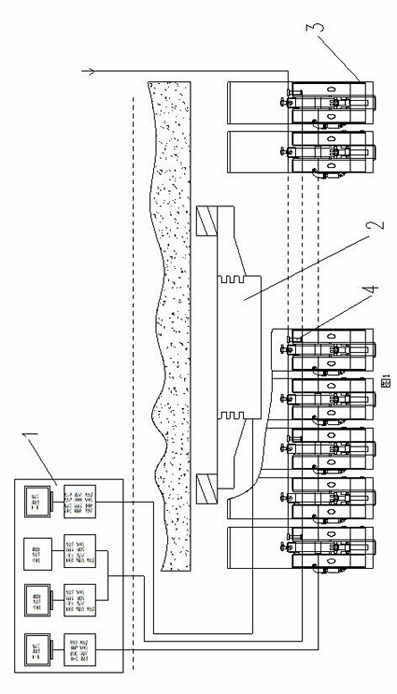

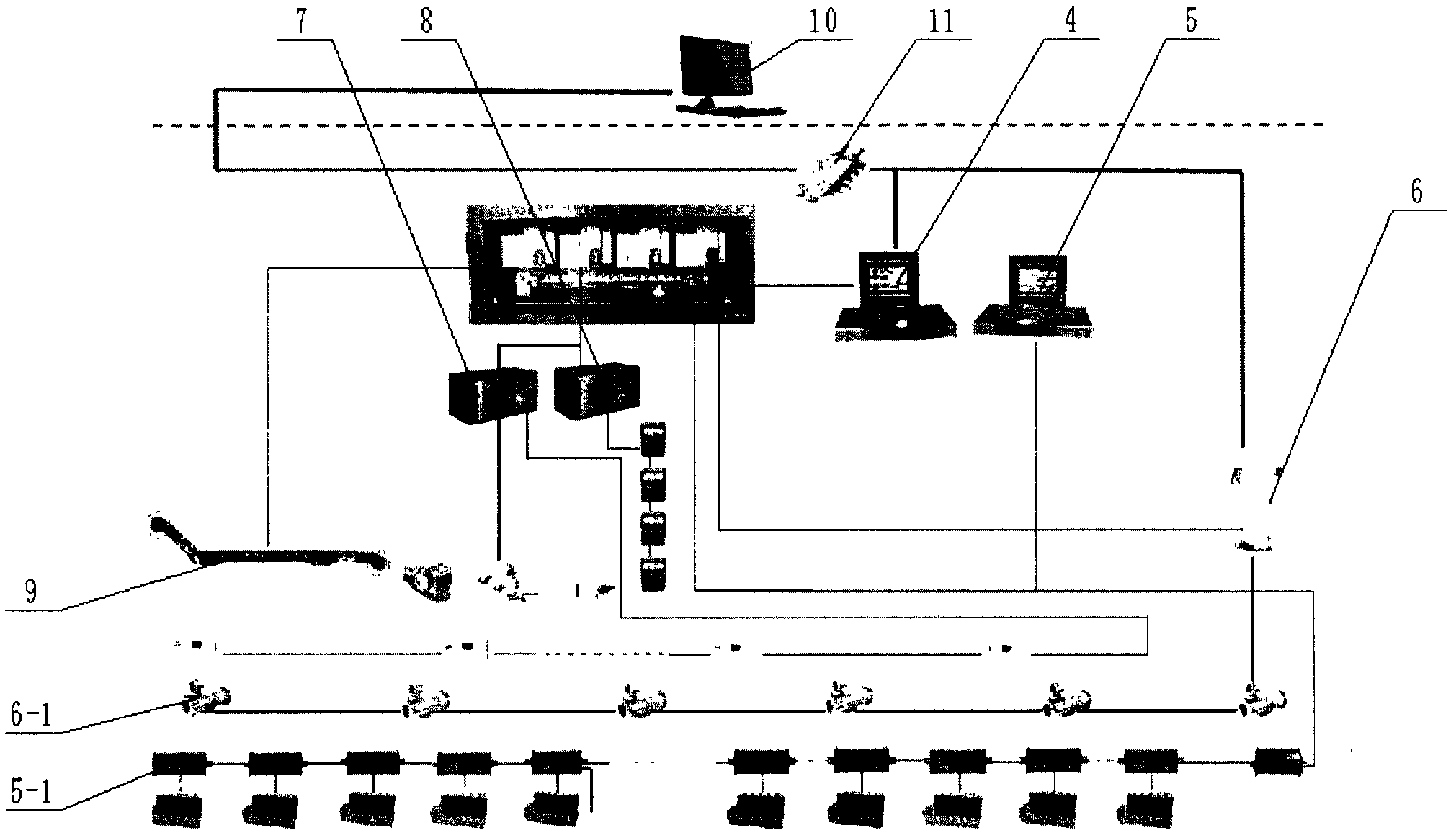

Fully-mechanized mining digital manless working face control system

InactiveCN102004483ARealize on-site operatorsReduce on-site operatorsSlitting machinesMine roof supportsVideo monitoringControl system

The invention discloses a fully-mechanized mining digital manless working face control system which mainly comprises a centralized control console, a coal mining combine control system, a hydraulic rack control system and a video monitoring system, wherein the centralized control console is respectively connected with the coal mining combine control system, the hydraulic rack control system and the video monitoring system through mine communication cables. The fully-mechanized mining digital manless working face control system has a plurality of flexible and reliable control modes, and can be used for remotely centrally controlling equipment of a coal mining combine, a hydraulic rack and the like, thereby reducing the quantity of site operators of the coal mining combine and the hydraulic rack, realizing automatic, manless or few man mining of a fully-mechanized working face, improving the mining efficiency of coal resources, and avoiding or reducing serious loss of life and personal injury in a mine.

Owner:HEBEI SHENFENG HEAVY MACHINERY

Seabed natural gas hydrate slurry decomposition separation and mud sand removal modular mining system

InactiveCN105822266AKeep the original appearanceSave energyConstructionsFluid removalOcean bottomDecomposition

The invention relates to a seabed natural gas hydrate slurry decomposition separation and silt removal modular mining system, which comprises a seabed excavating robot, a seabed decomposition separation and siltremoval gathering and transportation treatment station, an offshore mining operation platform and a seabed silt backfilling robot, wherein the seabed decomposition separation and silt removal gathering and transportation treatment station realizes fast connection with the seabed excavating robot, the offshore mining operation platform and the seabed silt backfilling robot through an integrated passage and fast plugs; devices in the gathering and transportation station are connected with fast sockets arranged on the inner wall of a sealed cabin through the fast plugs; the hydrate slurry is stored, decomposed and separated; the separated hydrate slurry is conveyed to an offshore platform; the separated silt is backfilled in situ by the seabed silt backfilling robot. The system has the beneficial effects that the problems of great energy consumption in the conveying process of directly lifting silt-containing slurry, easy occurrence of sand blockage in the pipeline conveying process, pipe explosion due to pressure jump in the pipeline and the like are solved; fast connection, operation and maintenance can be conveniently realized among the modules.

Owner:SOUTHWEST PETROLEUM UNIV

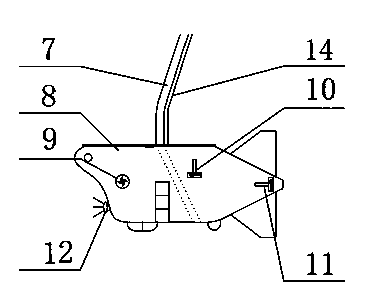

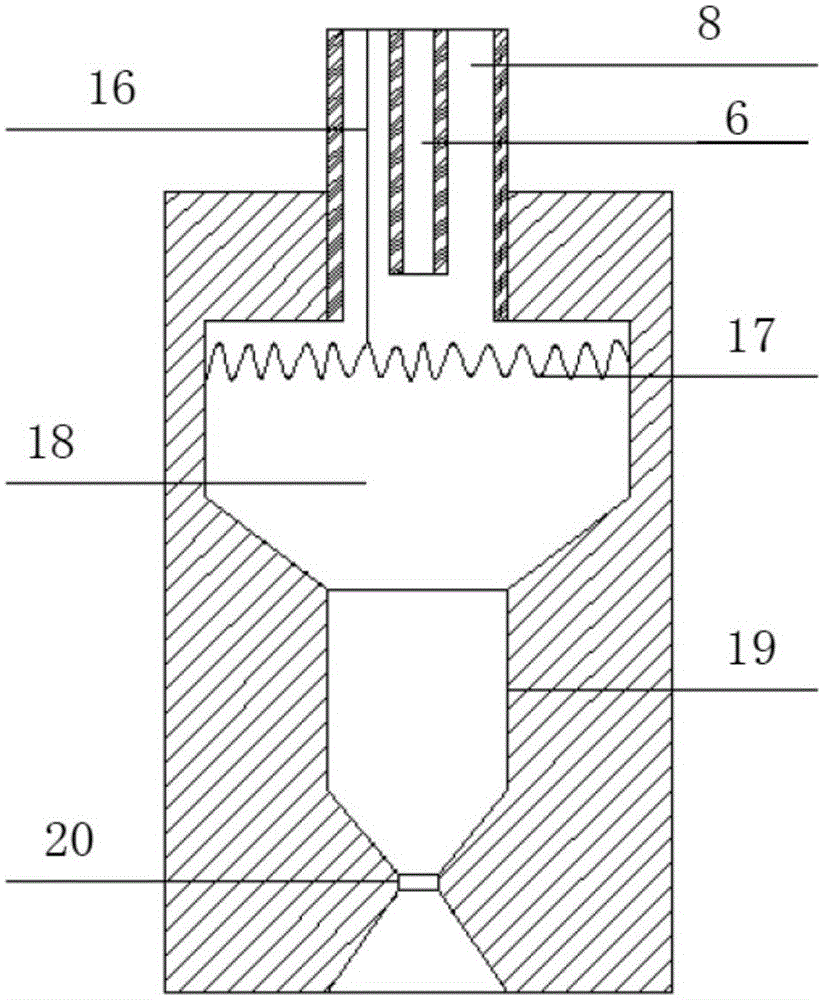

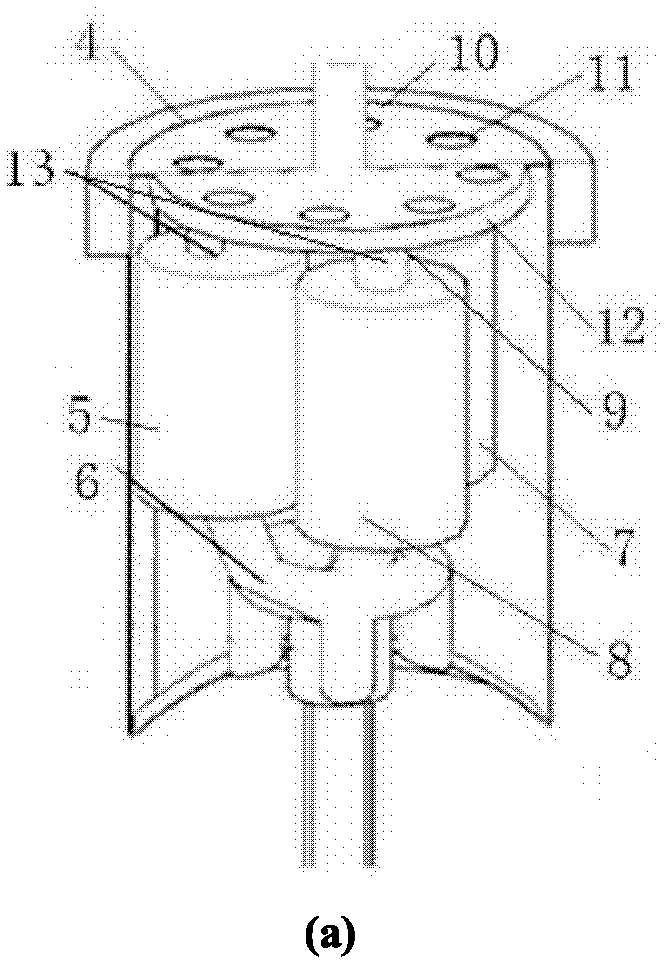

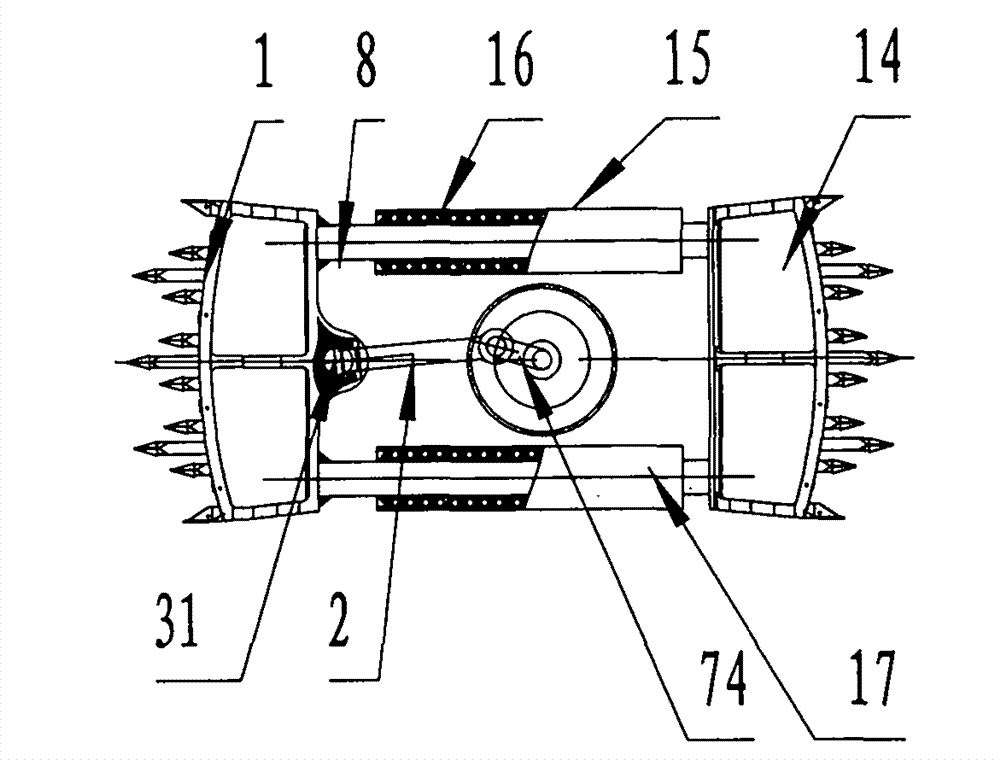

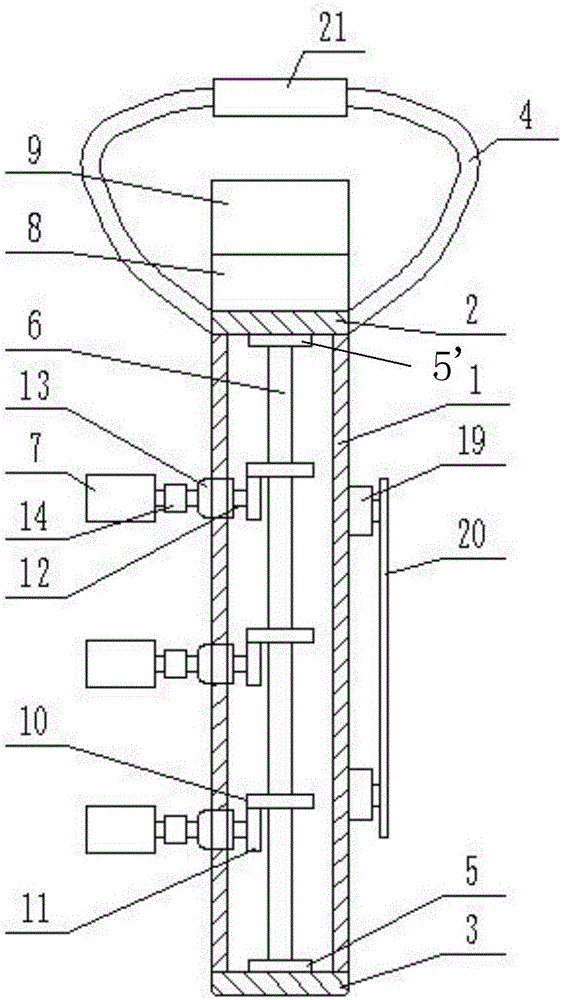

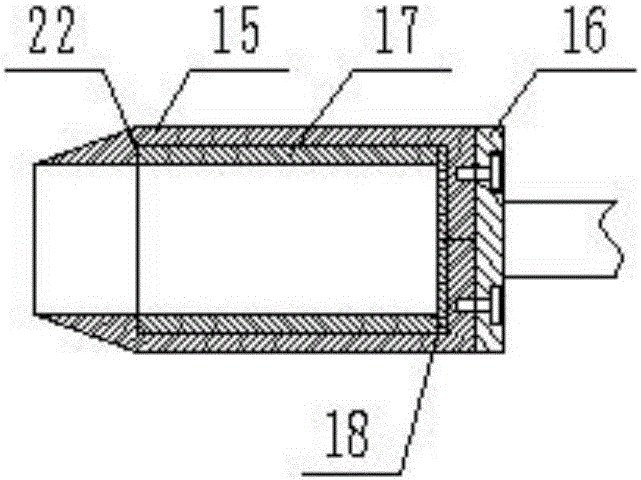

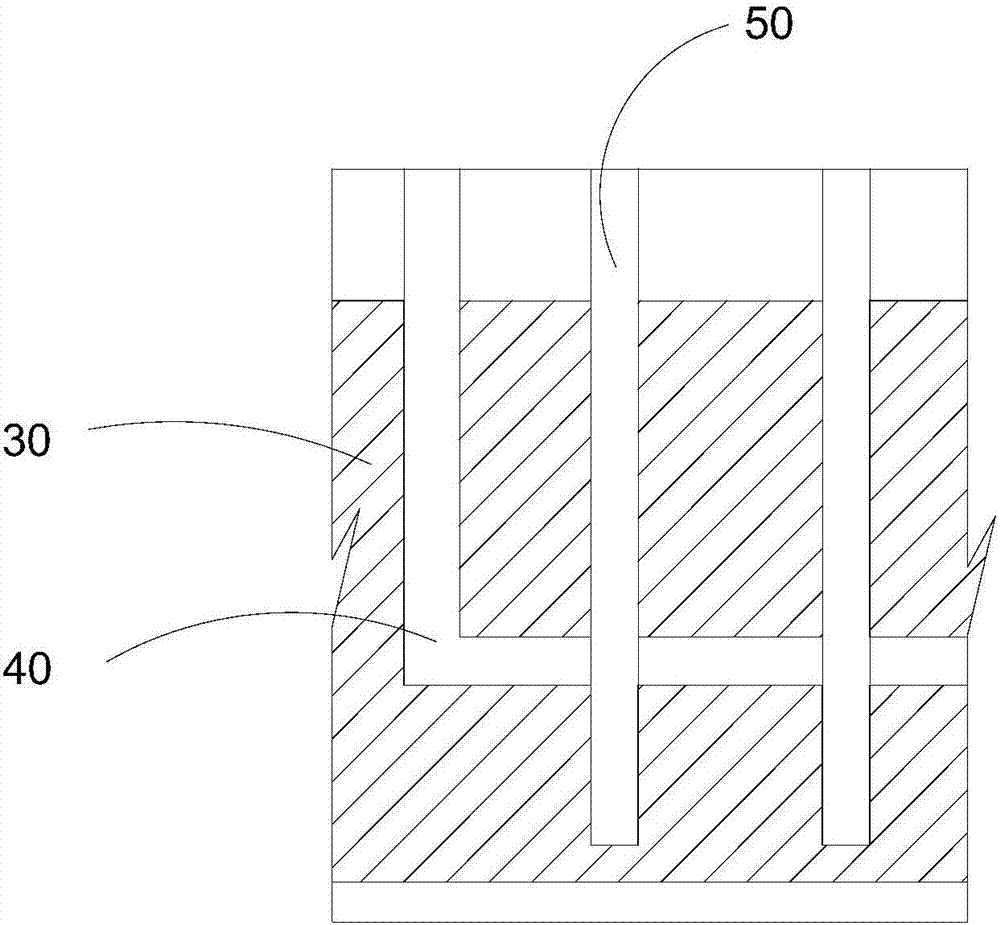

Gas hydrate exploitation device

A gas hydrate exploitation device, which belongs to the technical field of energy exploitation, comprises an upper exploitation drill part, a conveying lift pipe and a lower exploitation drill part. The device is easy to move, and can increase the efficiency and safety of exploitation, the device adopting a bottom-up exploitation method can preliminarily separate and backfill silt into a production well, is more convenient and faster, and can reduce energy consumption, moreover, the facilities of the device are simple, the cost is low, and the device is easy to control, and is highly reliable.

Owner:SHANGHAI JIAO TONG UNIV

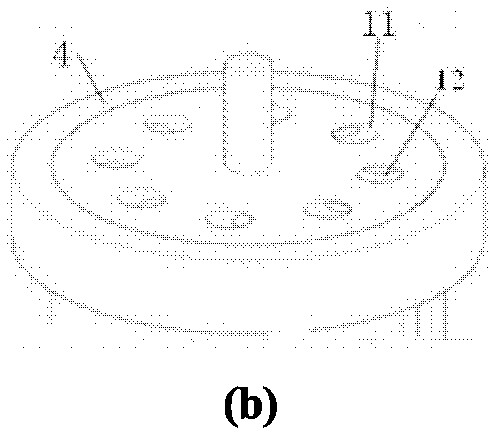

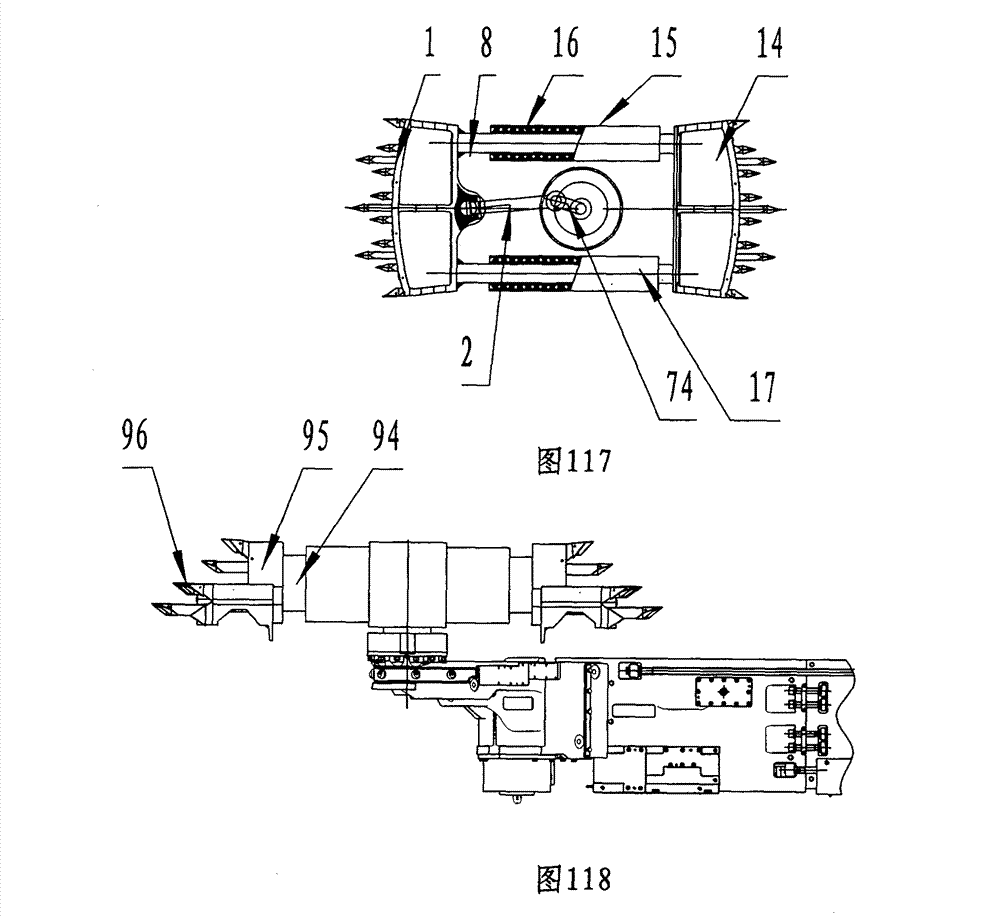

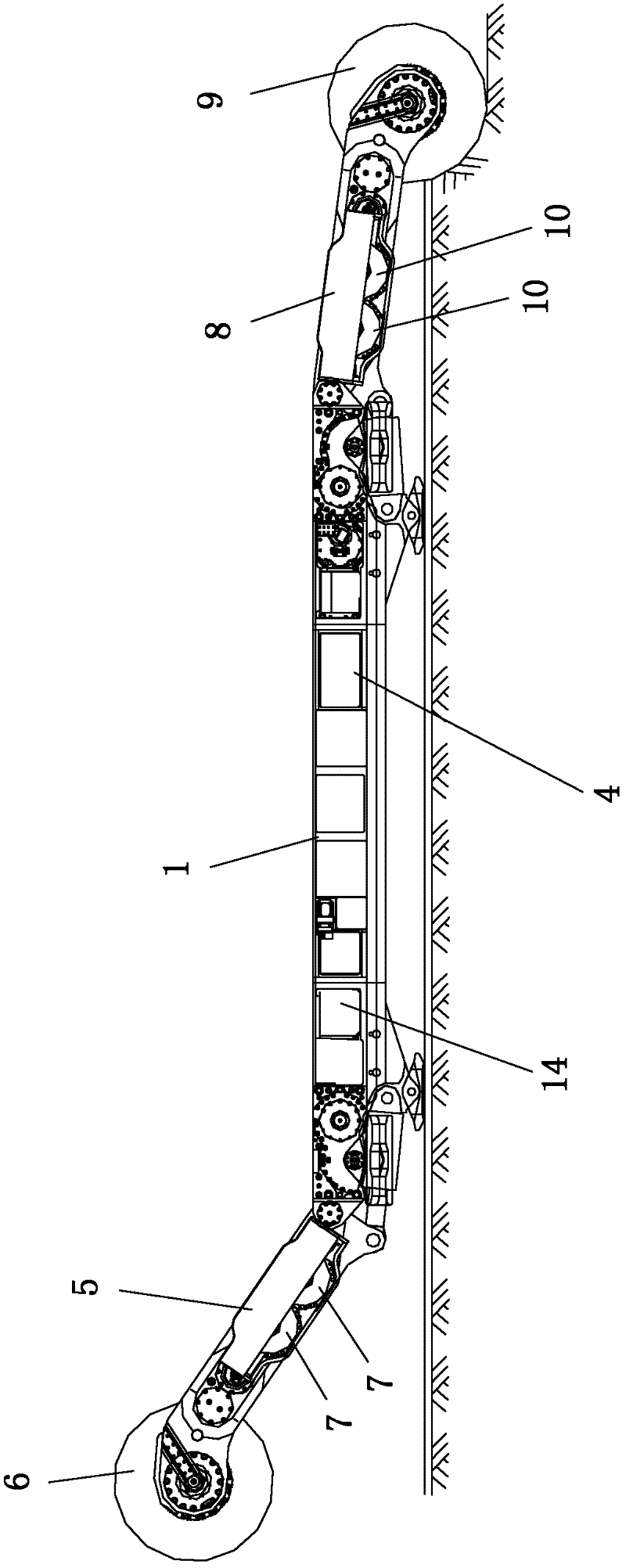

Bidirectional pounding and cutting excavating method and bidirectional pounding and cutting excavator for implementing same

ActiveCN103089259AReduce the number of adjustmentsExtend your lifeDriving meansReciprocating motionEngineering

The method provided by the invention comprises the following steps: a machine body, a walking part, a lifting part, a reciprocating pounding part and the like are arranged; a pounding guide element and the like are arranged on a pounding guide device; pounding heads are arranged at two ends of the pounding guide element, so that a power pounding element drives the pounding guide element; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; and the walking part drives the machine body to move ahead and retreats so as not to turn the machine body to excavate and drop materials forward and backward. Equipment provided by the invention comprises the machine body, the walking part, the lifting part, the reciprocating pounding part and the like; the reciprocating pounding part comprises the pounding guide device, the pounding driving device and the like; the pounding heads are both arranged at two ends of the pounding guide element; the pounding driving device comprises the power pounding element and the like; the power pounding element drives the pounding guide element to move in a reciprocating mode; the pounding guide element drives the pounding heads to pound; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; the walking part drives the machine body to move ahead and retreat so as not to turn the machine body to excavate and drop materials forward and backward.

Owner:刘素华

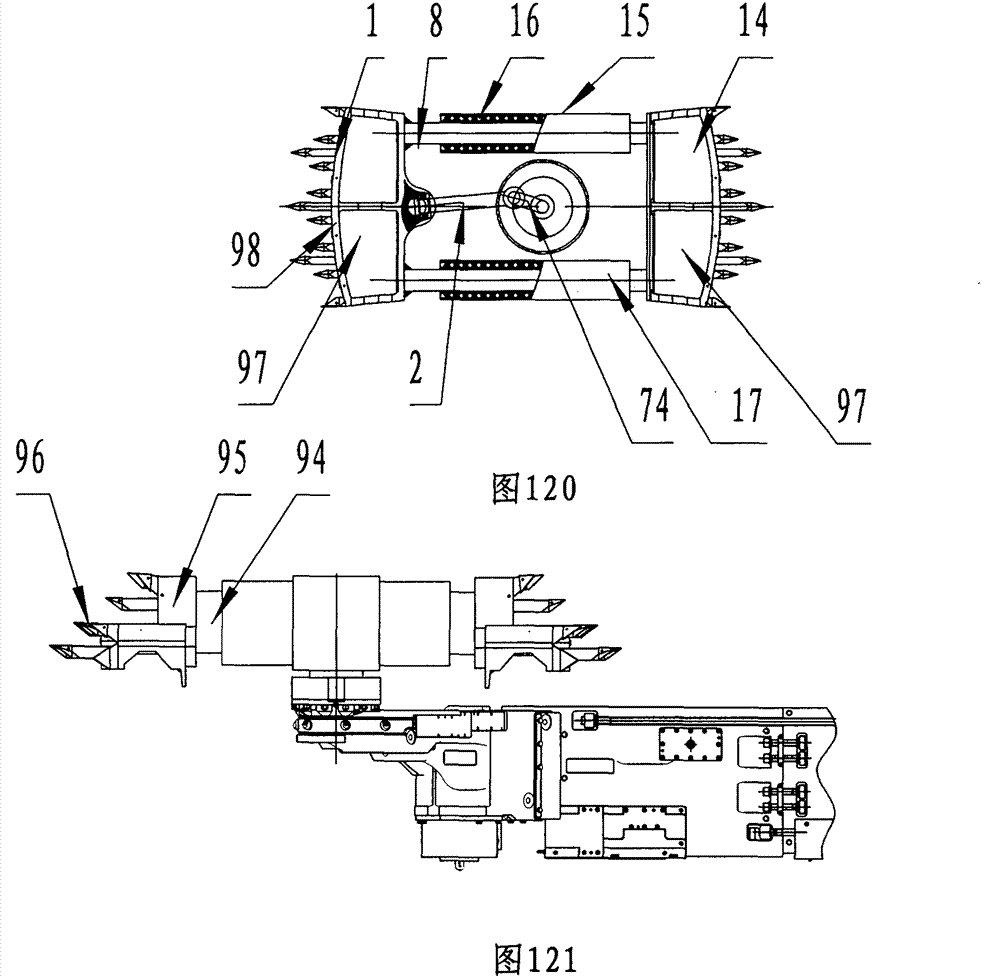

A high-power heavy-duty thin coal seam shearer

ActiveCN102287185AReasonable structural designEasy to operateMechanical energy handlingDriving meansEngineeringElectric control

The invention discloses a high-power heavy low seam mining machine, which comprises a machine body, a left traction part, a right traction part, a left cutting part, a right cutting part, a swinging arm elevating hydraulic system and an electric control system, wherein the electric control system comprises an electric control box and a controller; the left cutting part comprises a left swinging arm, a left roller and left cutting motors; the right cutting part comprises a right swinging arm, a right roller and right cutting motors; the left traction part comprises a left traction motor and a left traction transmission mechanism; the right traction part comprises a right traction motor and a right traction transmission mechanism; the left cutting motors, the right cutting motors, the left traction motor, the right traction motor and swinging arm elevating hydraulic system are controlled by the controller; and two left cutting motors and two right cutting motors are provided. The high-power heavy low seam mining machine has the advantages of reasonable design, high overall power, high mining efficiency, stable and reliable working performance and good using effect, and can be used for solving the problems of low power, low mining efficiency, poor using effect and the like existed in the conventional coal mining machine in the mining process of a low coal seam.

Owner:XIAN COAL MINING MACHINERY

Mining method of thin minor ore body

ActiveCN104847356AAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringCircular economy

The invention discloses a mining method of a thin minor ore body, which comprises the steps of ore recovery and goaf filling, which are alternatively circularly performed from bottom to top in a horizontal layering manner, propelling is performed along with a work surface, lime, loess, dead rock and the like are adopted and mixed layer by layer to fill a goaf, a filling body supports hanging wall and heading wall surrounding rocks, and serves as a work platform of upper layering recovery and ore removal, the ore is conveyed to an ore chute with a mechanical method, spallation ore removal of each recovery spallation step length and the filling procedure of the goaf are performed alternatively, when the uppermost horizontal layer of a chamber is recovered, mechanical and manual fill tightening are performed. The method solves the problem of discharge of tunneled dead rocks, effectively processes the goaf, prevents surface subsidence, accords with requirements of circular economic development and green ore construction. Compared with a shallow hole shrinkage method, the mining method has the advantages of improving ore recovery rate, reducing ore dilution rate and improving ore removal grade and ore removal efficiency through production practice.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

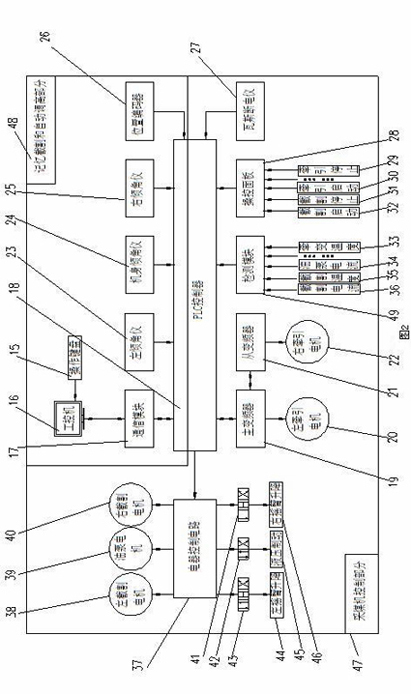

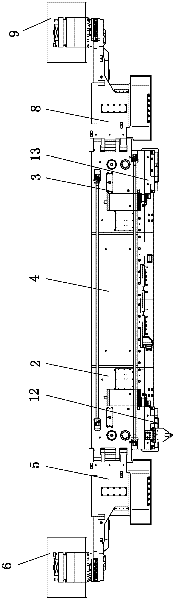

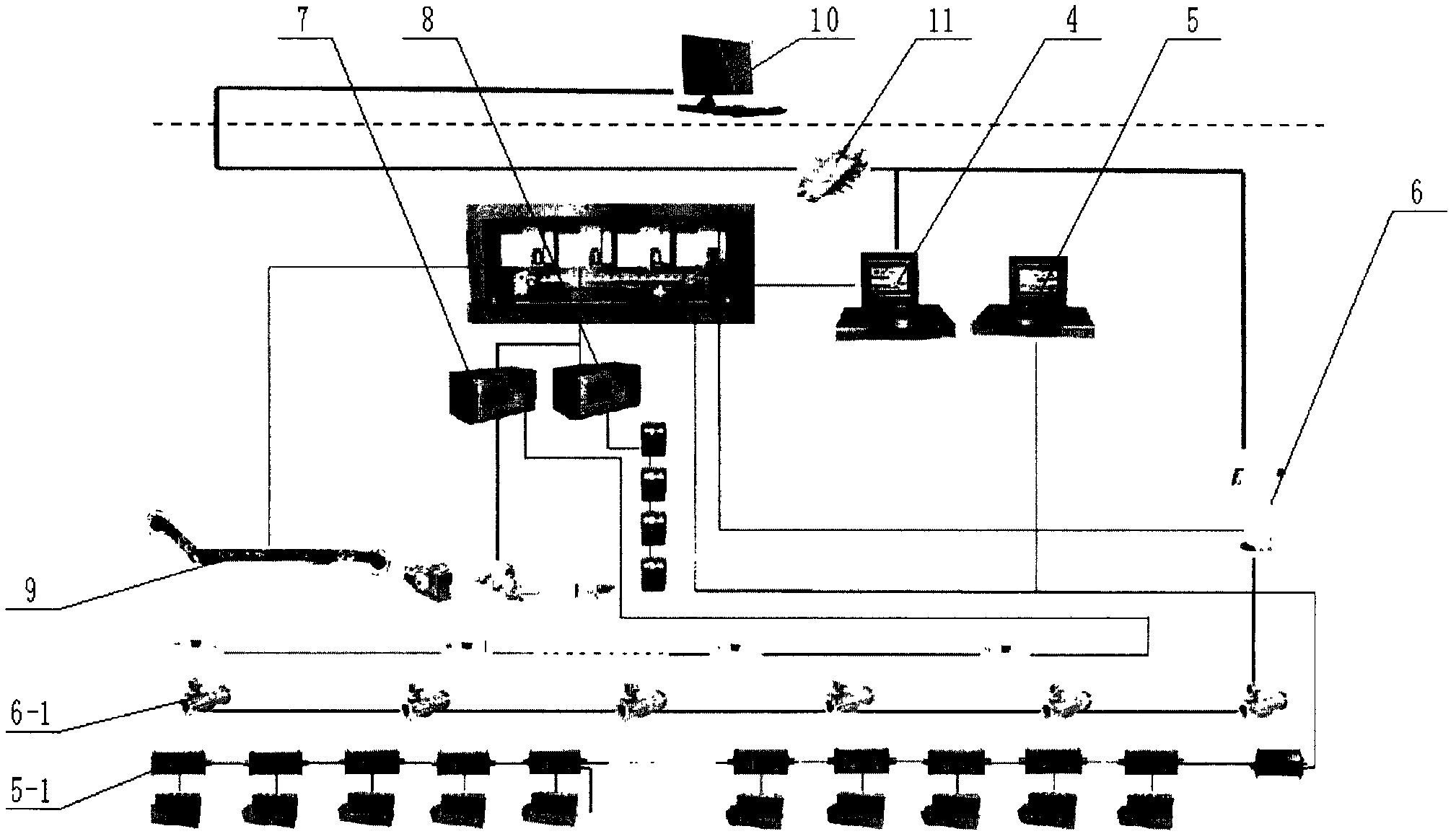

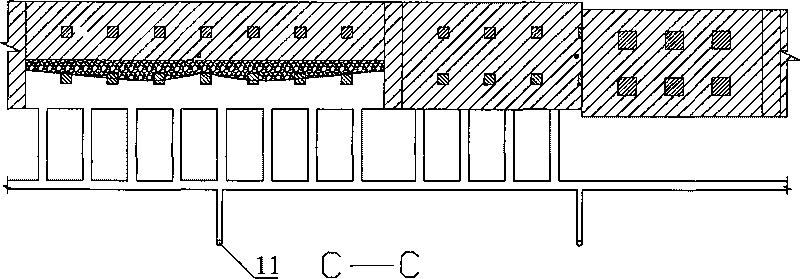

Working-face automated integrated control system for thin seam drum shearers

ActiveCN102619511AEasy to controlRealize monitoringSlitting machinesCutting machinesVideo monitoringReal-time data

A working-face automated integrated control system for thin seam drum shearers comprises a working-face central control system (4), an electrohydraulic support control system (5), a working-face video monitoring system (6), a working-face voice communication and scram control system (7), a whole-set conveyer equipment monitoring system (8), a shearer memory cutting and remote control system (9) and a ground control center (10), and electrohydraulic control system controllers (5-1) and cameras (6-1) are mounted on hydraulic supports. The working-face central control system (4) utilizes a data coupler to convert the data formats of the different control systems into a format in order to carry out unified control, and carries out two-way real-time data communication between a working face shearer, the hydraulic supports and a scraper conveyer, the cameras (6-1) carry out tracking rotation and automatic switching according to the working parameters sent by the shearer memory cutting and remote control system (9), meanwhile, the working-face video monitoring system (6) is utilized to adjust the foci and vertical and horizontal rotation of the cameras (6-1), and thereby the dead corner-less monitoring of the working face is realized.

Owner:CHINA NAT COAL MINING EQUIP

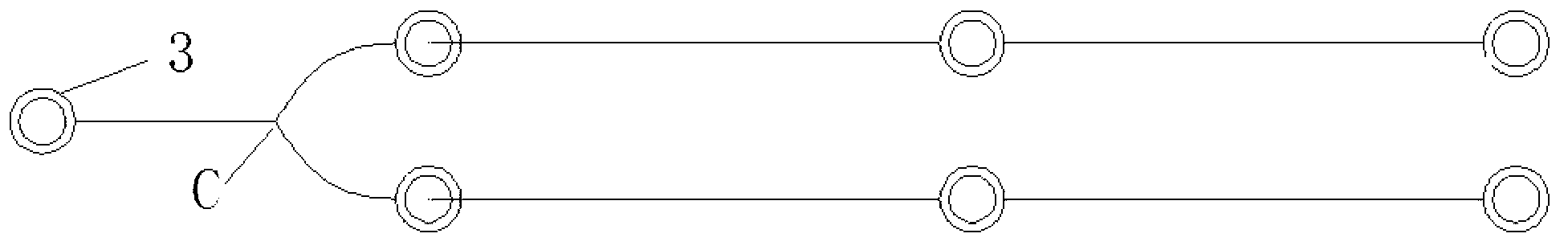

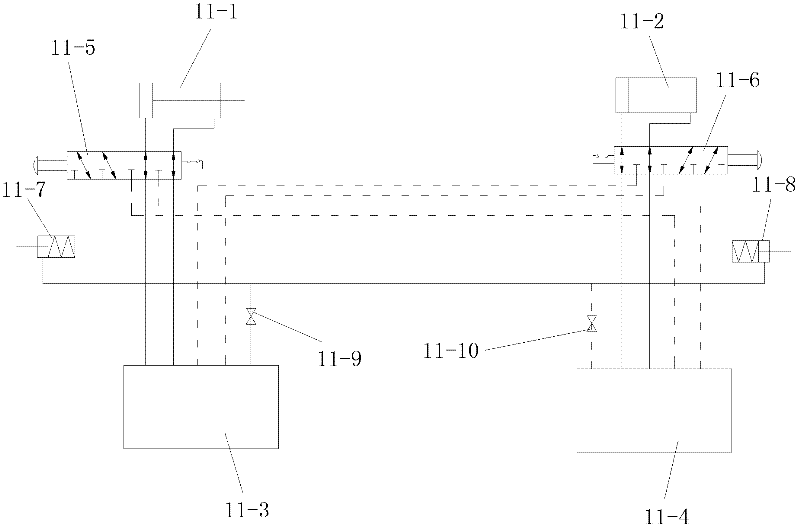

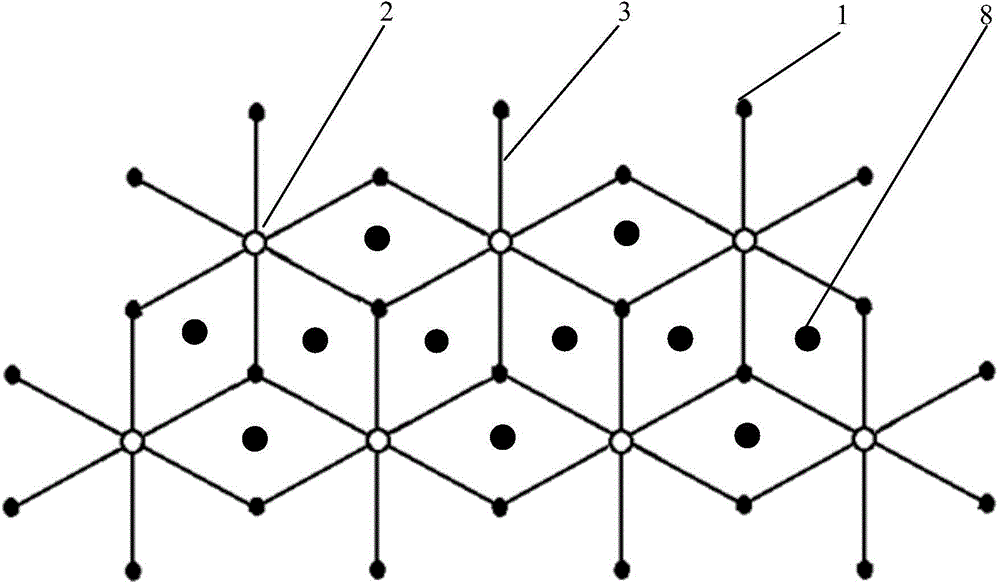

Device and method for exploiting seafloor natural gas hydrates through continuously injecting hot seawater

The invention provides a device for exploiting seafloor natural gas hydrates through continuously injecting hot seawater. The device comprises a plurality of water supply pipes (1), a plurality of heat radiation pipes (3) and at least one water outlet pipe (2), wherein the inlet end of each water supply pipe (1) is arranged at the offshore plane; the position of the inlet end of each water supply pipe (1) is higher than the sea level; the heat radiation pipes (3) are of cobweb type or hexagonal reticular or branch type or annular structures and are distributed at a seafloor hydrate layer (6); the outlet end of the water outlet pipe (2) is arranged at the offshore plane; the outlet end of the water outlet pipe (2) is flush with or below the water inlet ends of the water supply pipes (1); and the plurality of water supply pipes (1), the plurality of heat radiation pipes (3) and the at least one water outlet pipe (2) are sequentially connected to form a communicator. The hydrostatic transformation principle of the communicator is sufficiently utilized; high-temperature seawater at the sea surface layer is continuously pumped through the heat radiation pipes laid in the seafloor hydrate layer only by a low-power centrifugal pump in an ordinary model. Heat radiation pipelines are of reticular structures, so that the heat radiation efficiency can be improved; the heat radiation area is expanded; and the exploitation efficiency is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Nitrogen foam gel profile control agent and preparation method and application thereof

ActiveCN108203579AHigh film strengthImprove the blocking effectFluid removalDrilling compositionCross-linkCarboxymethyl cellulose

The invention discloses a nitrogen foam gel profile control agent and a preparation method and application thereof and belongs to the field of oilfield chemistry. The profile control agent comprises afoam gel skeleton and nitrogen gas distributed in the foam gel skeleton. The foam gel skeleton is obtained through feeding nitrogen gas into the gel. The gel is prepared from 1.5%-2.5% by mass of polyacrylamide, 0.3%-1% by mass of a foaming agent, 1%-3% by mass of a foam stabilizer, 1.5%-2.5% by mass of an organic chromium cross-linking agent and the balance of water through a cross-linking reaction. The foam stabilizer comprises sodium carboxymethyl cellulose or soluble starch. A volume ratio of the nitrogen gas to the foam gel skeleton is 70-95: 1. The profile control agent can seal and profile the medium and low temperature oil layers at 30 to 70 DEG C. The nitrogen foam gel skeleton has good membrane strength and good sealing effects and can greatly improve the mining efficiency of the crude oil.

Owner:PETROCHINA CO LTD

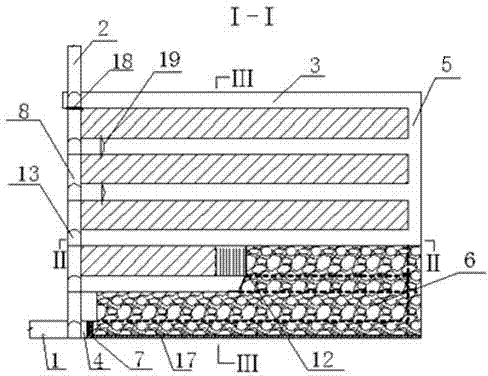

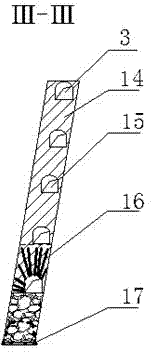

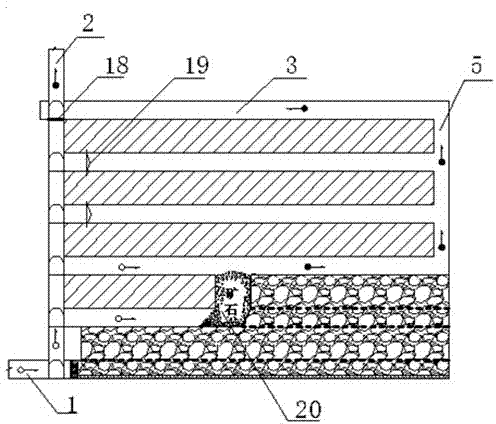

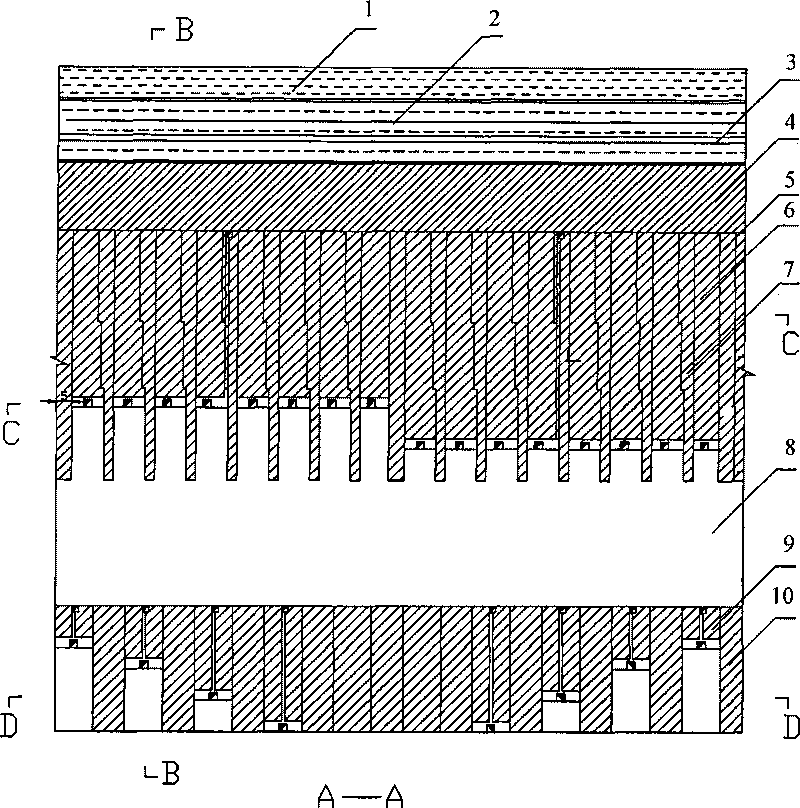

Inclination fragmentation ore body segment top board reconstruction middle-deep hole ore break down filling mining method

InactiveCN103104259AImprove mining efficiencyGuarantee stabilityUnderground miningSurface miningMineralogyMining engineering

The invention discloses an inclination fragmentation ore body segment top board reconstruction middle-deep hole ore break down filling mining method. According to the method, an intermediate section on an ore body direction is divided into several backstopping units; an intermediate section transport tunnel is arranged at the bottom of the intermediate section, a segment transport gallery is arranged in the segment; the segment transport gallery is connected to the intermediate section transport tunnel through a winze, the segment transport gallery is communicated to a stope; a slip-casting cavern chamber along the ore body direction is excavated at the contact position of each segment top ore body and the surrounding rocks; the fragmented surrounding rocks can be performed with slip-casting and reinforcing in the slip-casting cavern chamber to construct an artificial top board; the ore break down by blasting is carried out on a rock drilling platform under the artificial top board, the blasted ore is sent to a well, and is transported through the intermediate section transport gallery; lower layer segment backstopping is finished and then filling is carried out, and the artificial top board of the layer is taken as a base plate of an upper layer segment for backstopping work of the upper layer segment. The mining method is adapted to exploitation of fragmented inclination ore body, and has the characteristics of high production efficiency, strong security of the backstopping work, excellent index of ore dilution and good economic benefit.

Owner:CENT SOUTH UNIV +1

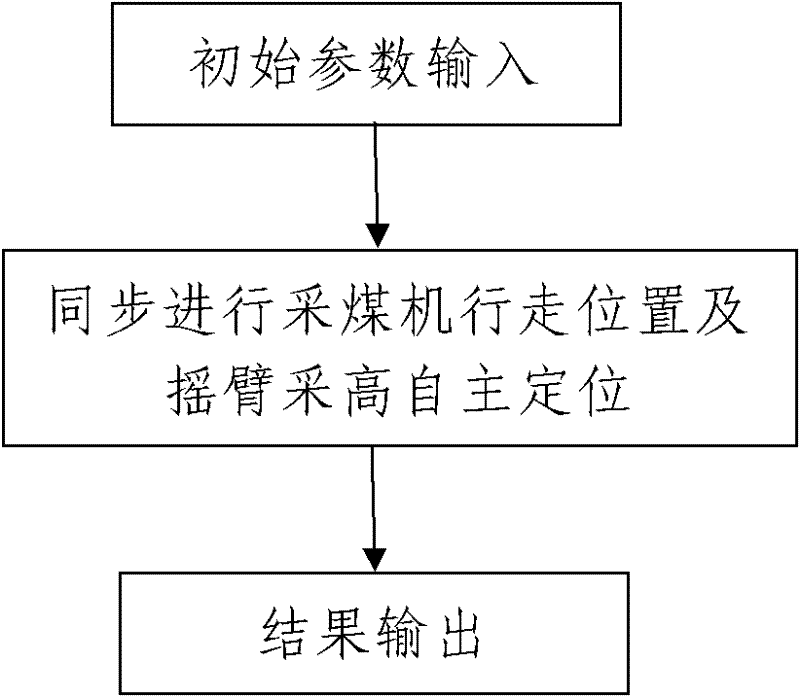

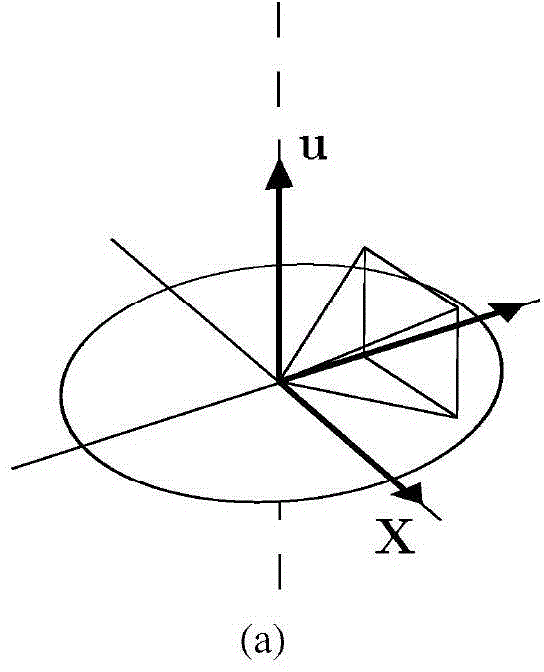

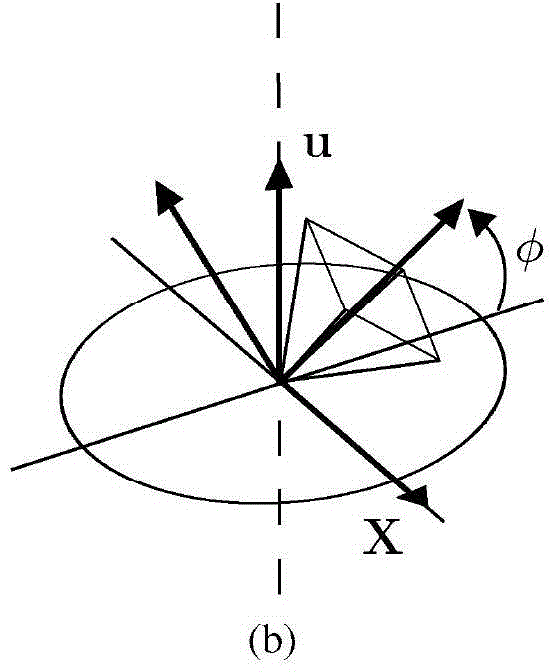

A coal mining machine autonomous positioning system and its autonomous positioning method

ActiveCN102287186AEasy to operateHigh degree of intelligenceMeasurement devicesDriving meansLocation detectionEngineering

The invention discloses a self-positioning system and a self-positioning method for a coal mining machine. The self-positioning system comprises a controller, a walking position detection unit for detecting a walking position of the coal mining machine in real time, a left mining height detection unit for detecting the mining height of a left rocker arm of the coal mining machine in real time, a right mining height detection unit for detecting the mining height of a right rocker arm of the coal mining machine in real time, and a display unit and a parameter input unit which are connected withthe controller. The self-positioning method comprises the following steps of: 1, inputting initial parameters; 2, synchronously performing self-positioning of the walking position of the coal mining machine and the mining heights of the rocker arms; and 3, outputting results. The invention has the advantages that: the self-positioning system is reasonable in design, easy and convenient to use andoperate, convenient to implement, good in using effect and high in positioning accuracy, can automatically accurately position the walking position of the coal mining machine and the mining heights of the rocker arms, and various practical problems that the conventional coal mining machine has low automation and intelligent degrees, does not have self-positioning function, has high labor intensity and poor using effect and the like are effectively solved.

Owner:XIAN COAL MINING MACHINERY

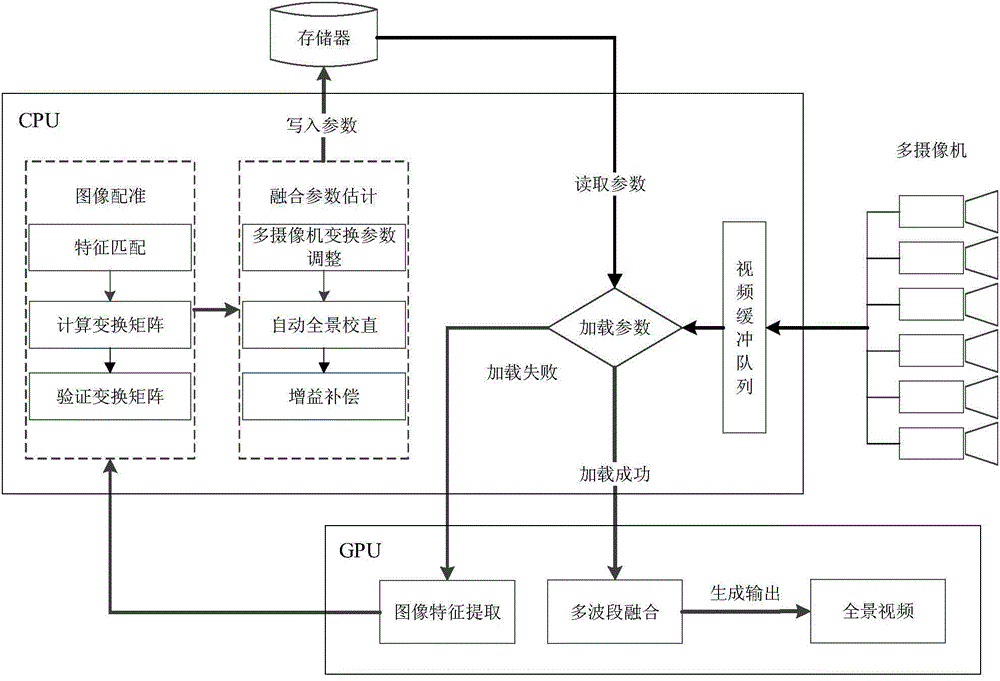

Mine multi-camera video fusion method based on GPU and CPU cooperative computing

InactiveCN104966063AAlleviate the status quo of poor real-time performanceSolve the deformationImage enhancementImage analysisMulti cameraUltrahigh resolution

The invention discloses a mine multi-camera video fusion method based on GPU and CPU cooperative computing and belongs to the mine multi-camera video fusion method. The method is characterized in that a GPU and CPU cooperative computing model is established, and thus current situation of poor real-time performance of an existing video fusion method is relieved; automatic matching is carried out by utilizing features of overlapped regions between adjacent video sources to determine relative position relation of the video sources, so that positions of cameras do not need to be assigned in advance, and automatic integration is realized; camera parameter bundle adjustment estimation and automatic alignment are carried out, so that the problem of deformation of panorama images after fusion is solved; and an exposure compensation and multiband fusion method is adopted, and finally, an ultrahigh-resolution large-visual angle mine mining (extraction) working face large-scale scene real-time integral video is generated, so that the method plays an important role for improving coal mining work efficiency and guaranteeing coal mine safety production. The advantages are that the multi-camera video fusion method utilizes the existing cameras of a coal mine fully to generate the mine mining (extraction) working face panorama video, thereby reducing equipment investment and improving safety of coal mine production.

Owner:CHINA UNIV OF MINING & TECH

Method for using phosphogypsum in mine goaf consolidated filling

The invention discloses a method for cemented filling of phosphogypsum in a mine goaf. The method mainly comprises the following steps: mixing the following materials in weight ratio: 0.8 to 1.2 percent of cement, 1.2 to 0.8 percent of water quenched iron (steel) slag, 10 to 14 percent of the phosphogypsum, and 0.4 to 0.8 percent of lime; adding water to the mixture and stirring the mixture to form filling slurry with the weight concentration of between 55 and 65 percent; conveying the filling slurry to the mine goaf; and curing the filling slurry to form a high-strength filling material. The method can significantly reduce the curing time of the filling slurry taking the phosphogypsum as the main raw material, is suitable for various mining techniques and the cement filling for various types of mine goafs, and has strong economic and social benefits.

Owner:TONGLING CHEM IND GRP

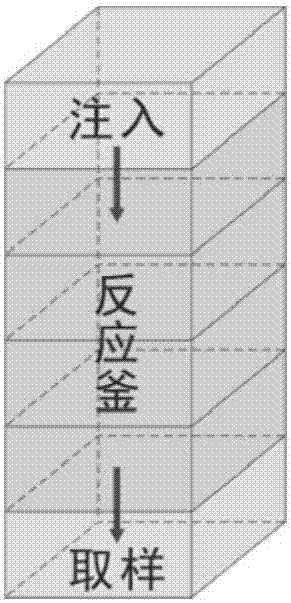

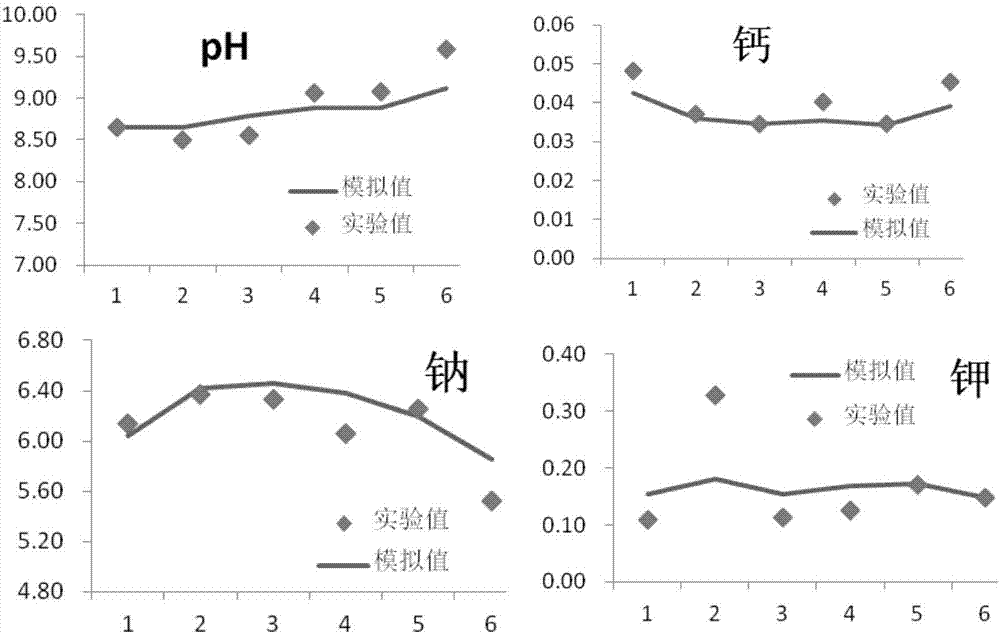

Method of quantitatively evaluating space-time evolution of porosity during reservoir diagenesis evolutionary process

ActiveCN107290506AImprove mining efficiencyRecovery evolution curveEarth material testingSoil scienceModel parameters

The invention provides a method of quantitatively evaluating space-time evolution of porosity during a reservoir diagenesis evolutionary process. The method includes the following steps: (1) determining a diagenesis sequence and porosity change tendency of a reservoir, recognizing main diagenesis events that the reservoir experiences, and establishing a diagenesis evolutionary process; (2) simulating the diagenesis evolutionary process in several stages, and determining the diagenesis evolutionary process, diagenesis periods and diagenesis conditions; (3) performing diagenesis effect indoor tests in different diagenesis periods, and detecting fluid components, rock sample components and pore structures before and after the tests in the different diagenesis periods; (4) in complete correspondence with the tests, performing diagenesis effect numerical simulation in different diagenesis periods, and calibrating mineral dynamics computation parameters and specific surface area in the simulation; (5) extending the time of numerical simulation to actual diagenesis time of the reservoir and calibrating the model parameters again to establish a quantitative simulation system in which the porosity is evolved with time; and (6) simulating the evolutionary process of the reservoir in an area range, and establishing a quantitative simulation system that the porosity is evolved with space and time, thereby achieving quantitatively evaluating and prediction of the porosity with time in space.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Solid phase-free drilling-in liquid

The invention relates to solid phase-free drilling-in liquid, belonging to the technical field of petroleum drilling engineering chemical agents. The solid phase-free drilling-in liquid is characterized in that: the solid phase-free drilling-in liquid is formed by the following ingredients in percentage by weight: 0.5-1 percent of tackifier, 0.1-0.6 percent of pH regulator, 1-4 percent of fluid loss additive, 3-30 percent of inhibitor, 1-5 percent of lubricant and the balance of sea water. The drilling-in liquid has dual biological and chemical degradation functions, has high viscosity and can meet the requirements of a horizontal well, and particularly a large-displacement horizontal well on the viscosity of low shearing rate; the drilling-in liquid is the solid phase-free drilling-in liquid and does not contain solid phase, the metal ion invading resisting capacity is strong, the shale inhibition is strong, the lubrication is high, the system performance is stable, the maintenance and usage are convenient, thereby having better oil-gas layer protecting effect; the oil field exploitation efficiency can be improved and the normal exploitation life of the oil field can be prolonged.

Owner:YANGTZE UNIVERSITY

Soil cutting-ring layering synchronous sampling device

ActiveCN106092642AAccurate analysisSimple structureWithdrawing sample devicesEngineeringSoil horizon

The invention relates to a soil cutting-ring layering synchronous sampling device, and belongs to the technical field of soil detection devices. The soil cutting-ring layering synchronous sampling device comprises a cylinder which is provided with a top plate at the top and provided with a bottom plate at the bottom, a secure hand is disposed on the top plate, and the top plate and the bottom plate are respectively provided with a first rolling bearing and a second rolling bearing; and the cylinder is inside provided with a rotation shaft which is installed on the first and the second rolling bearing, the top end of the rotation shaft is connected with a driving mechanism, the rotation shaft is provided with a plurality of transmission mechanisms from top to bottom, the cylinder is provided with a plurality of beating blades from top to bottom, and the transmission mechanisms are connected with the beating blades. The provided soil cutting-ring layering synchronous sampling device is applicable to layering synchronous sampling of reclamation soil at mine lots, is simple in structure, convenient to operate, capable of rapidly sampling from soil, and is time-saving, labor-saving, efficient and small in disturbance to soil layer structure.

Owner:SHANXI UNIV

High-sublevel multi-layer mining method of ultrathin copper ore body

InactiveCN102086765ALow cost of industrializationThe pit rate is reducedUnderground miningTunnel/mines ventillationResource protectionCopper mine

The invention discloses a high-sublevel multi-layer mining method of an ultrathin copper mine body. Mining channels are reclaimed to be connected with an upper middle section and a lower middle section based on the high-sublevel that the altitude difference of the middle section of the ore body is 50 meters, wherein, the thickness of the ore body bed is 0.4-1m, and the inclined angle of the ore body is above 25 degrees; the ore blocks between the middle sections are divided into extraction ore blocks with 50 meters square; a layered communication channel with small specification the altitude difference of which is 13-17m is reclaimed between the mining channels; the extraction ore blocks between the mining channel are divided into three extraction units; the ores mined by each extraction unit is centralized to the mining channel uniformly; and the ores are sent out from a trench after being transported to a transportation road. The method disclosed by the invention has the advantages that the copper ore resource mining recovery rate is effectively improved, cost is low, land is saved, unification of the resource protection and the environment protection is realized, and use is safe.

Owner:DAYAO GUIHUA COPPER SMELTING YONGREN ZHIJU BRANCH

Double-roadway combining speedy drivage waste rock exhaust system and method

InactiveCN104533429AReduce excavation costsAvoid unsafe factors in operationTunnelsUnderground transportAssembly lineLeather belt

The invention discloses a double-roadway combining speedy drivage waste rock exhaust system and method, the system comprises a speedy drivage waste rock exhaust assembly line consisting of a boom-type roadheader, a belt conveyer, a waste rock transfer device, a waste rock bin and a mine car. The roadheader is arranged in a roadway I and a roadway II respectively, the roadway I is communicated with the roadway II via a middle drivage connection roadway, the roadheader is connected with the belt conveyer via a tail bracket, the waste rock that is cut down is conveyed onto the belt conveyer via a roahheader scraper chain, the waste rock transfer device is connected at a position where the belt conveyer is close to the tail in the roadway I, so as to convey the waste rock into the roadway II, the waste rock on the roadway II directly enters into the waste rock bin at the upper part of the roadway II via belt conveying, the waste rock falls into the mine car in a traveling roadway via pipeline conveying, and by means of continuous waste lock loading by the mine car, the waste rock is conveyed to the ground for unloading. The system and method adopts double-roadway simultaneous drivage, exhaust the waste rock automatically in a combined manner, have a fast waste rock exhaust speed, reduce the auxiliary operation personnel, and can effectively improve the roadway mechanization level and efficiency.

Owner:CHINA UNIV OF MINING & TECH +1

Horizontal well seam forming method and method for extracting oil gas from underground oil shale

The invention relates to a horizontal well seam forming method and a method for extracting oil gas from an underground oil shale, and relates to technical field of petroleum extraction. The horizontal well seam forming method adopts fracturing fluid containing a microwave strong absorber to conduct fracturing seam forming, so that the microwave strong absorber can be uniformly distributed in the seam formed through fracturing by the method, and the utilization rate of microwave heating is increased. The method for extracting the oil gas from the underground oil shale comprises the steps that a horizontal well and a vertical production well are drilled in the oil shale layer; the horizontal well is subjected to fracturing seam forming through the fracturing fluid, and the fracturing fluid contains the microwave strong absorber; and microwave radiation is used for heating, so that the oil gas produced by kerogen pyrolysis is led out through the production well, and the heated efficiency of the oil shale and the extraction rate of shale oil are effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV

Middle-waisted bidirectional filling and mining method under canopy guard in thick and great metal mine in sea bed

InactiveCN101761340ASmall amount of deformationImprove mining safetyMineral miningMaterial fill-upOcean bottomFilling materials

The invention discloses a middle-waisted bidirectional filling and mining method under canopy guard in a thick and great metal mine in sea bed, which is characterized in that a safety isolating layer is preserved between an ore body and the sea bed; the ore body is divided into an upper part and a lower part at the middle waist in the altitude direction; the altitude from the middle waist position to the sea bed sea mud is 100-150m; stoping is carried out from the middle waist position of the ore body, wherein the upper part adopts upstroke mining and the lower part adopts downstroke mining; a rock trackless quasi-upward slicing cemented method with a regular post pillar is adopted in the upstroke mining method; a rock trackless quasi-ordinary slicing cemented method is adopted in the downstroke mining; the gob in the stope is filled with filling materials. The invention is characterized by having high safety of mining, little loss of resources, high degree of mechanism, low labor intensity, great production capacity, short stoping time, low mining settlement and the like.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com