Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

976results about "Open-pit mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

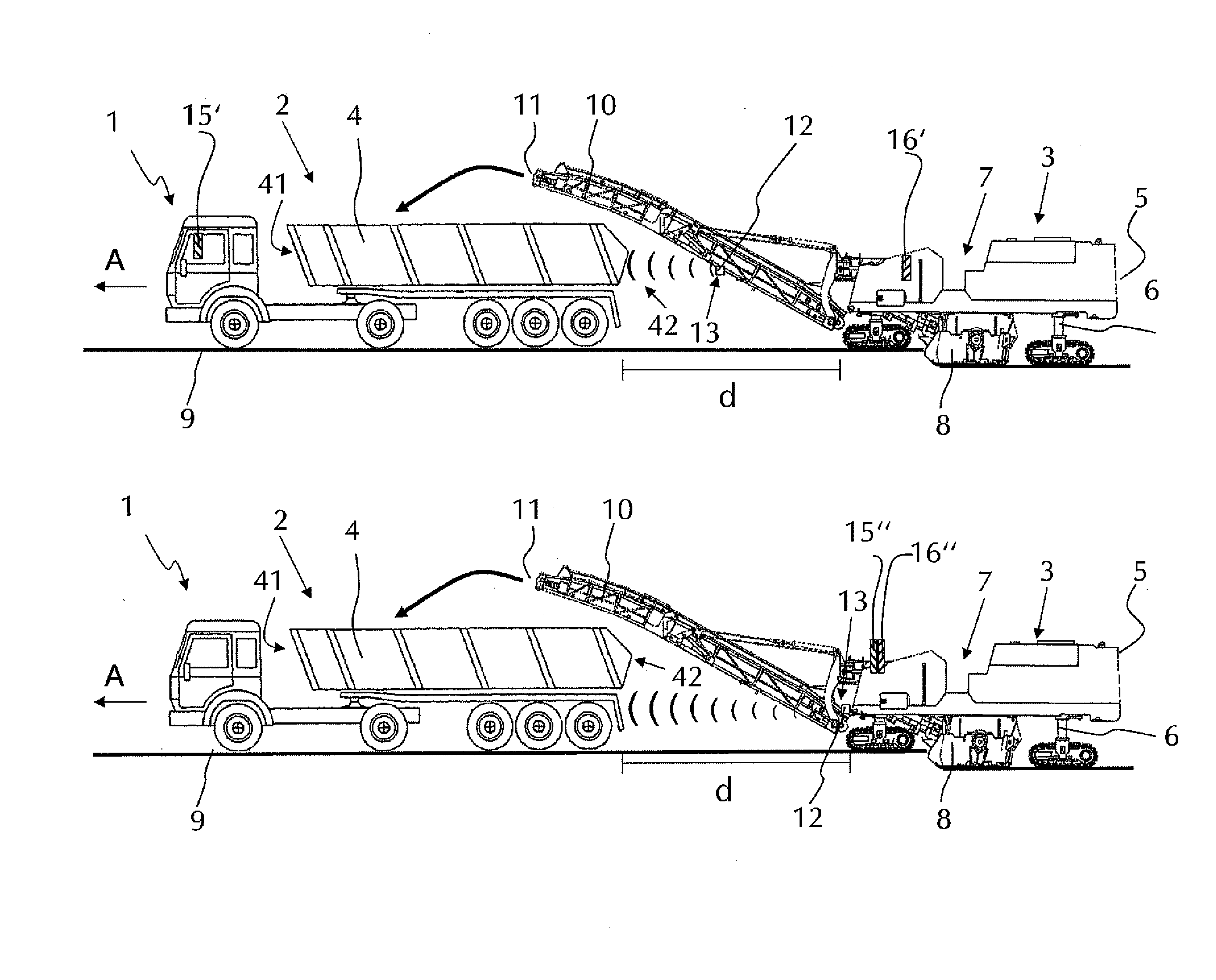

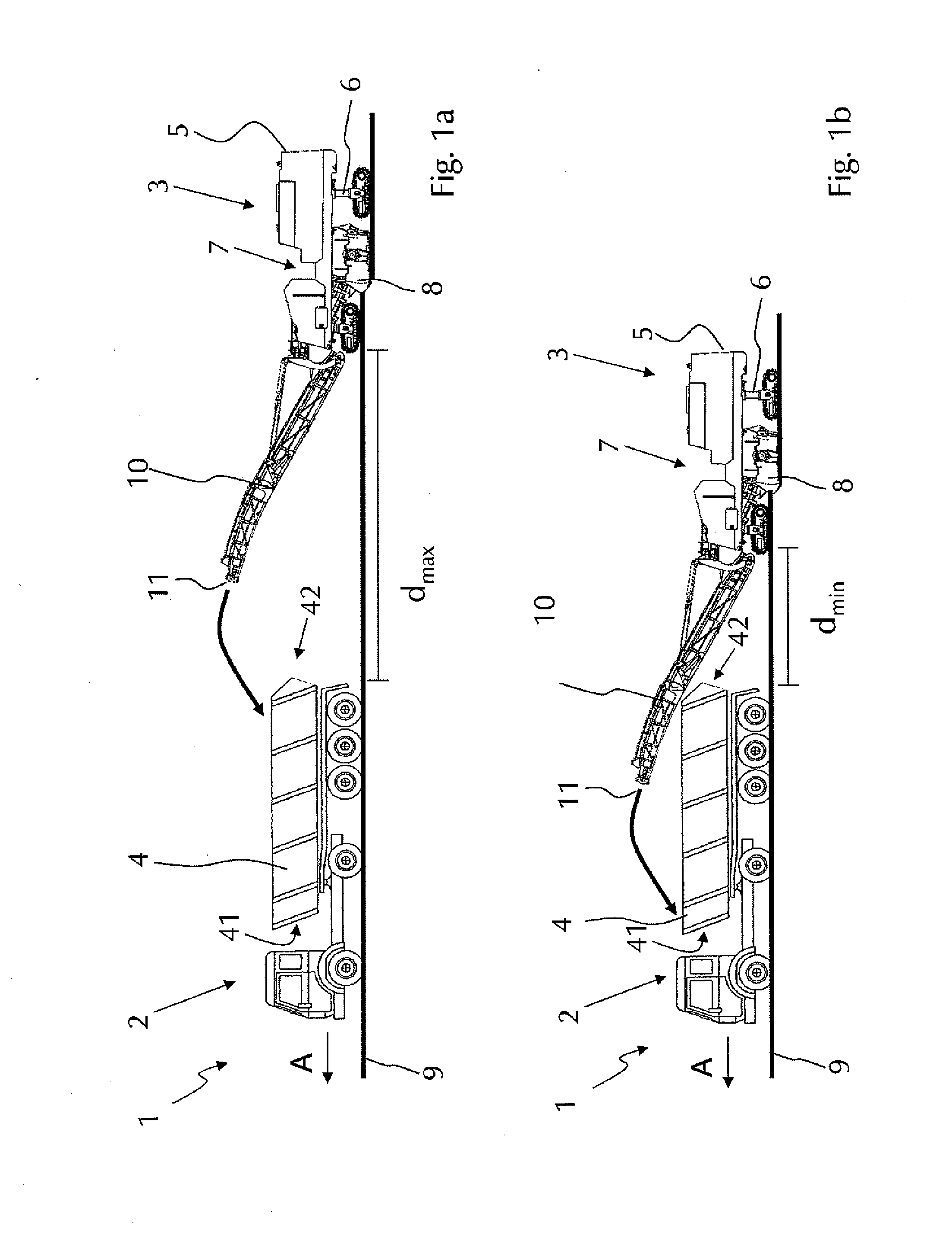

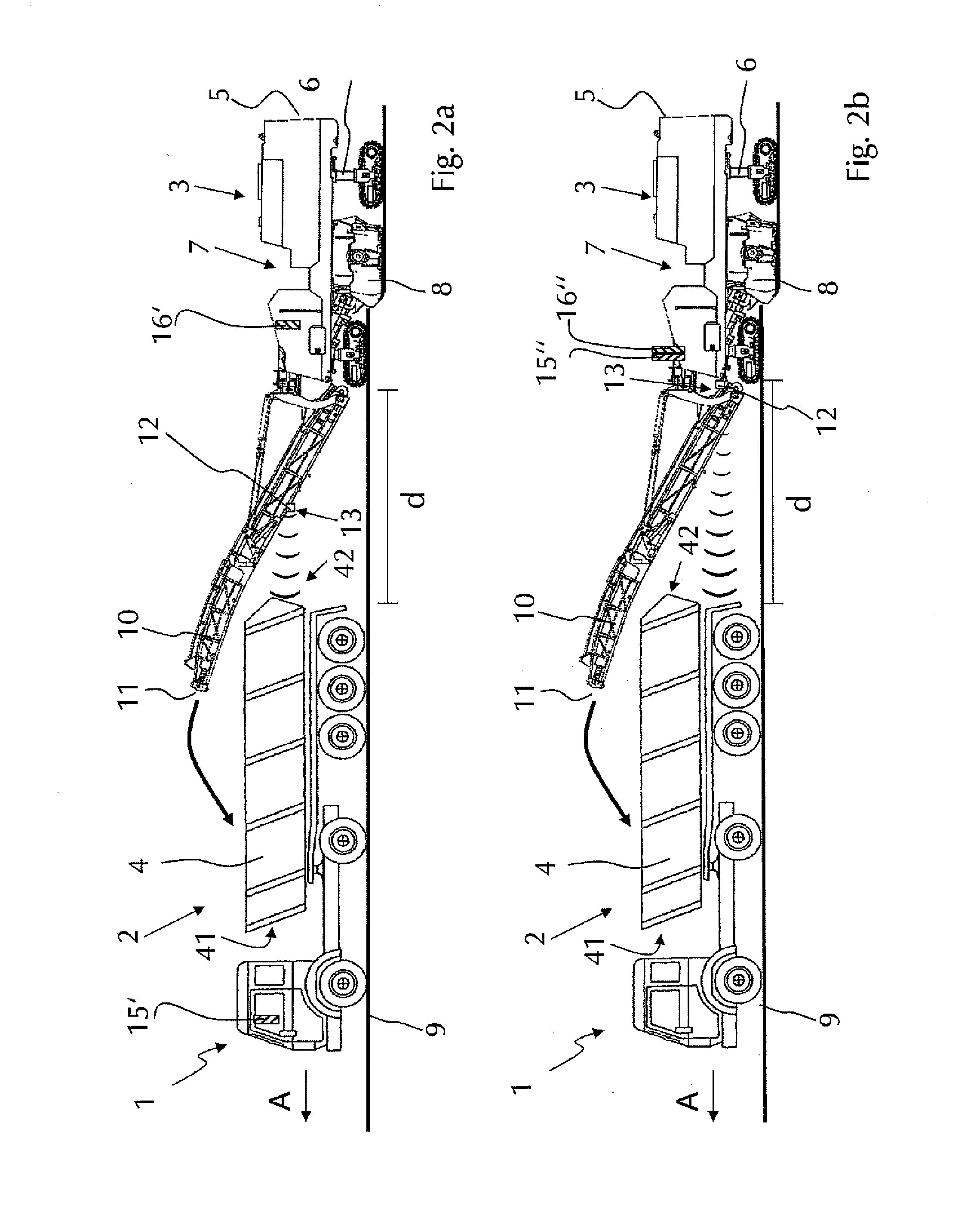

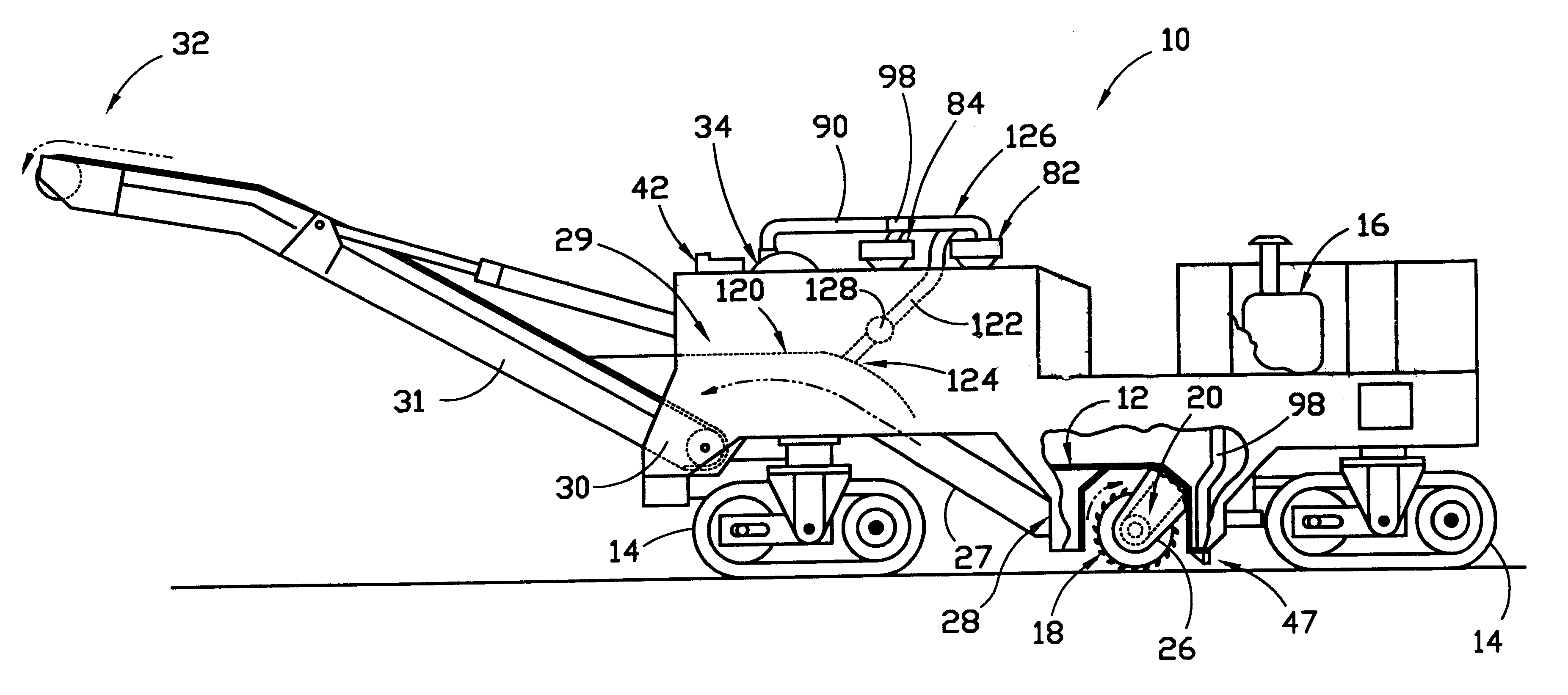

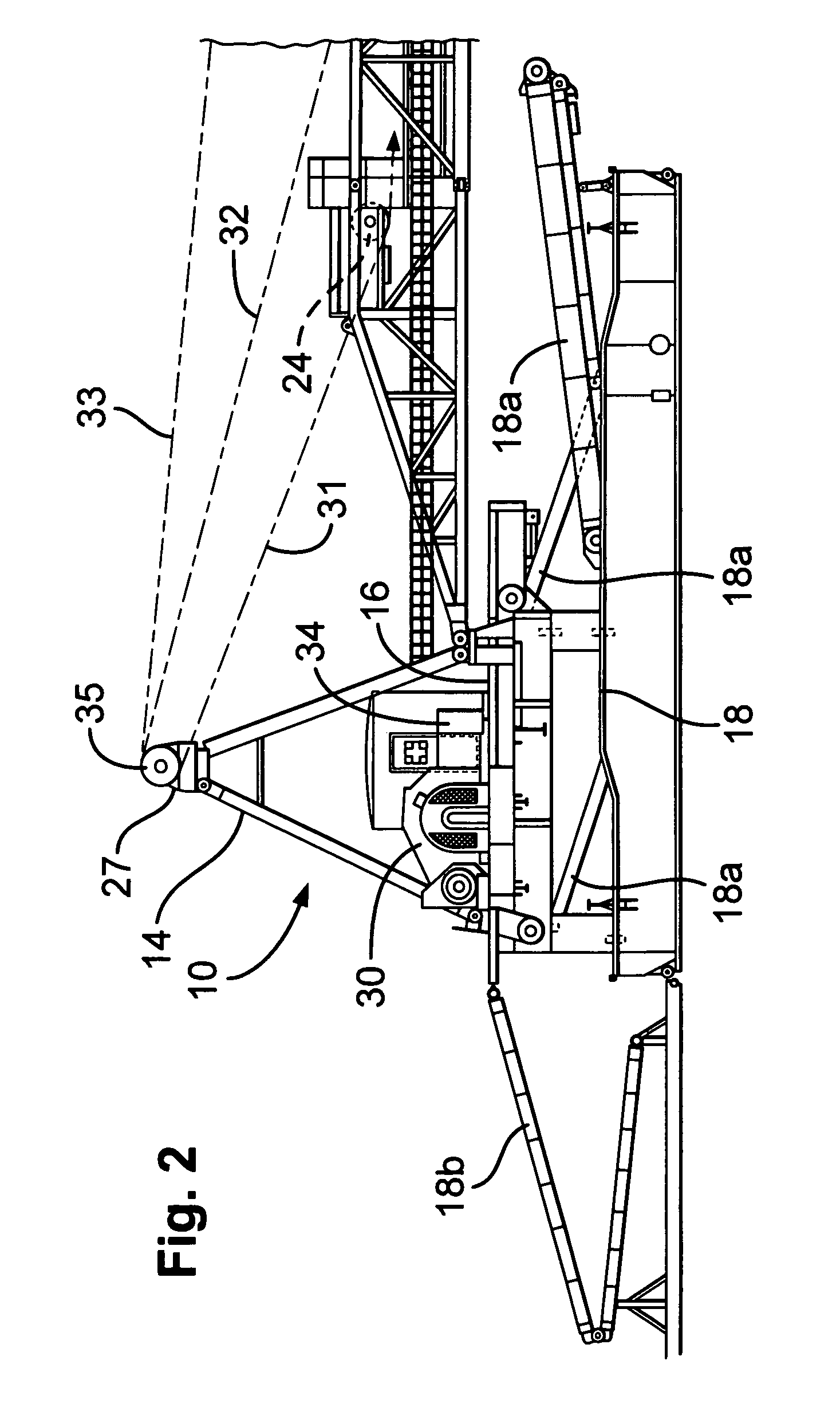

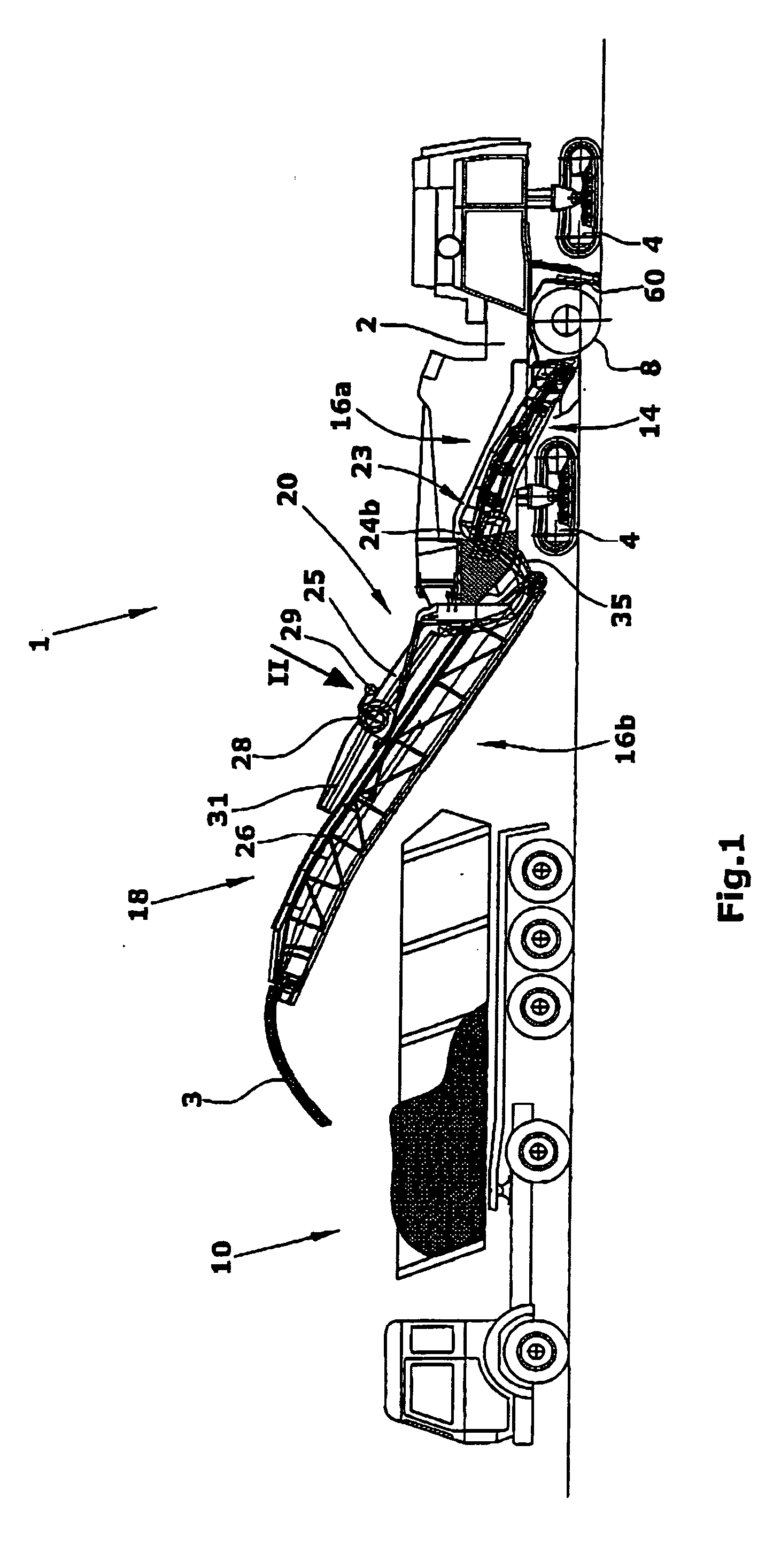

Work Train With A Milling Device And A Transport Device With A Sensor Device For Distance Monitoring, Milling Device With A Sensor Device And Method For Distance Monitoring With A Work Train

ActiveUS20130076101A1Relieve pressureMinimize disruptionVehicle testingRegistering/indicating working of vehiclesDisplay deviceEngineering

The present invention relates to a work train, a device and a method for distance measurement between a transport device and a milling device. During the loading of a transport device with milled material from the milling device, the operator of the milling device normally transmits control commands to the transport device driver for coordination of the loading process. Through the automated distance measuring between the transport device and the milling device and control of a display device according to the present invention, this task is taken over from the operator of the milling device, who can concentrate on the actual milling process.

Owner:BOMAG

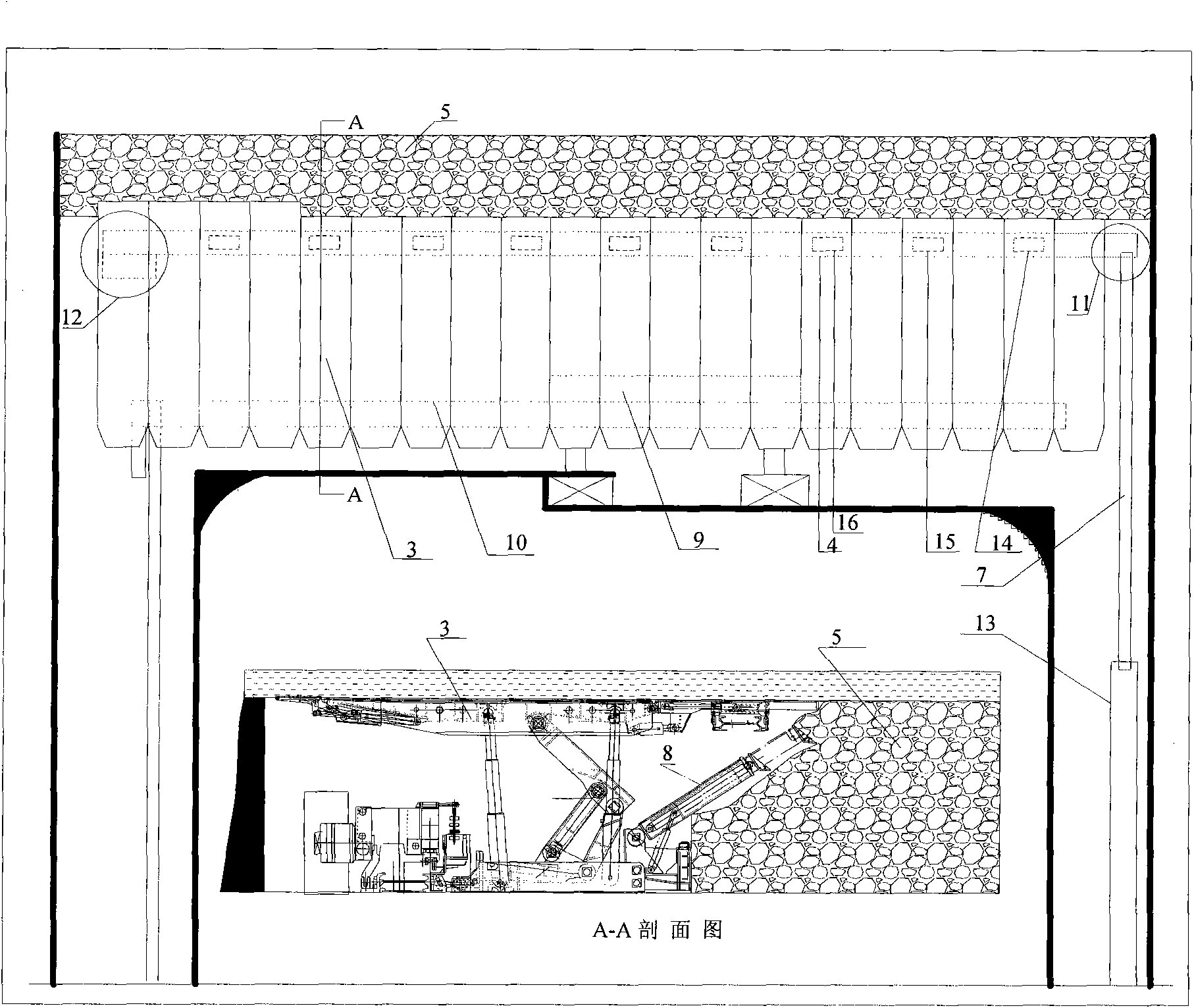

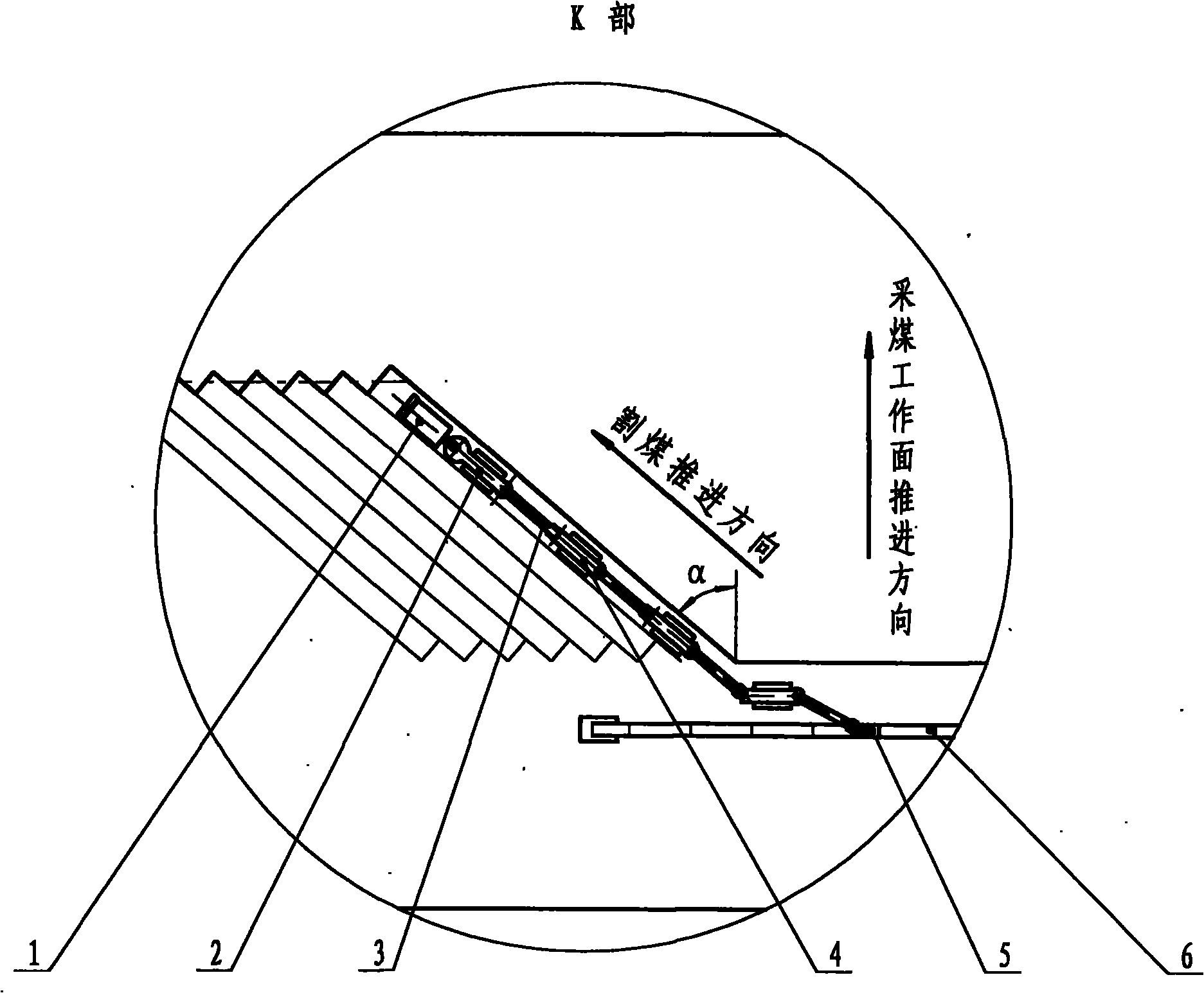

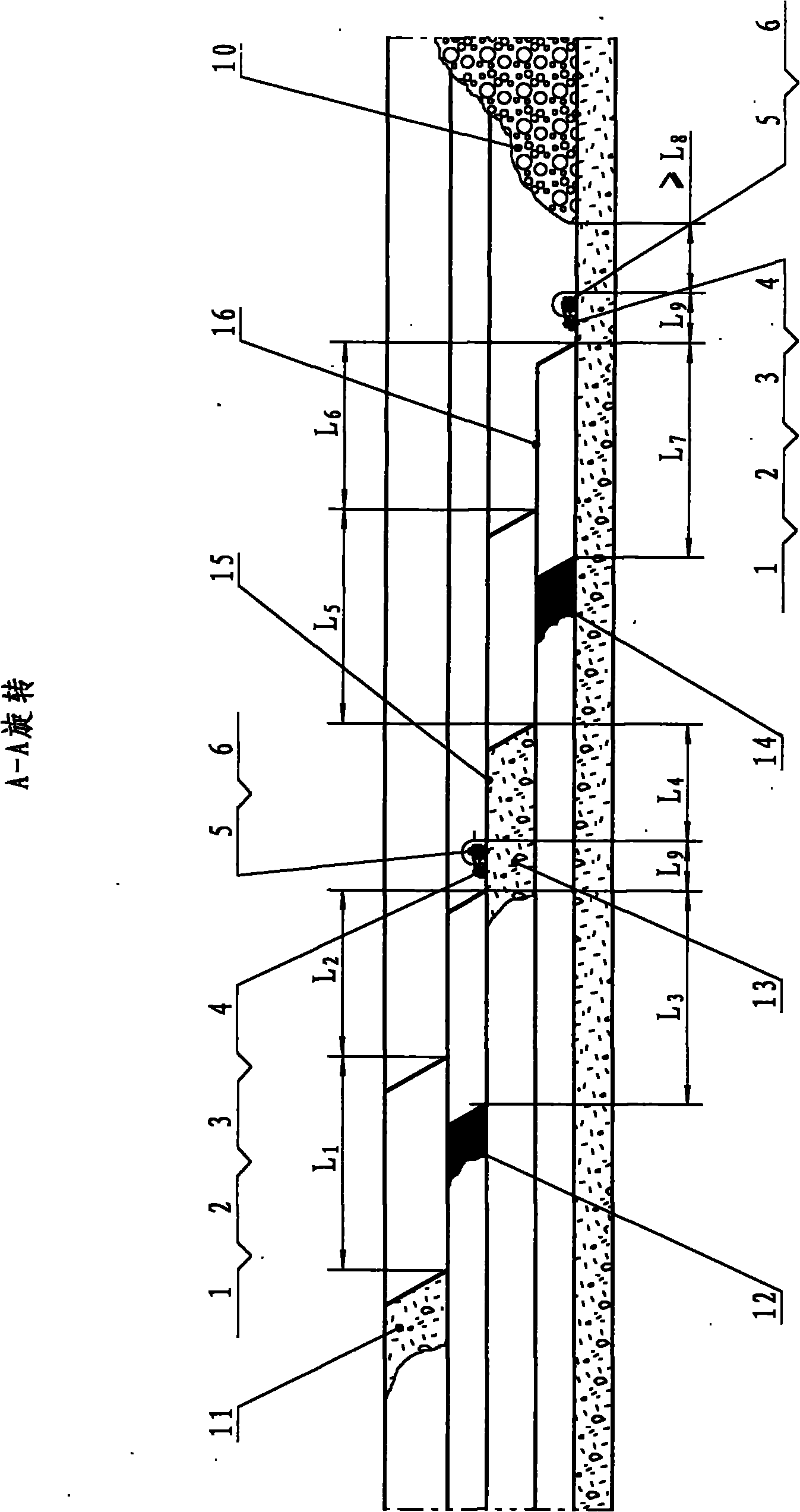

Coal mining solid filling method

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

Vacuum system for milling machine

A vacuum system is mounted on a portable milling machine for extracting material cut by the milling drum of the machine from the surface of a roadway. The milling machine includes a frame, a propulsion system for advancing the machine across a surface to be milled, a milling drum mounted on the frame for rotation about its axis, and a conveyor for conveying material cut by the milling drum away from the drum. The vacuum system includes a vacuum pump having an air inlet and an air outlet and a nozzle mounted behind the milling drum having an opening for receiving material cut from the surface by the drum. The vacuum system also includes a material collector having an inlet, an air outlet and a material outlet. The collector is adapted for collecting material entrained in air by the pump through the collector inlet and for discharging such material through the material outlet onto the conveyor. The vacuum system also includes a first conduit and a second conduit. The first conduit connects the nozzle and the inlet of the material collector, and the second conduit connects the air, outlet of the material collector and the air inlet of the pump.

Owner:ROADTEC

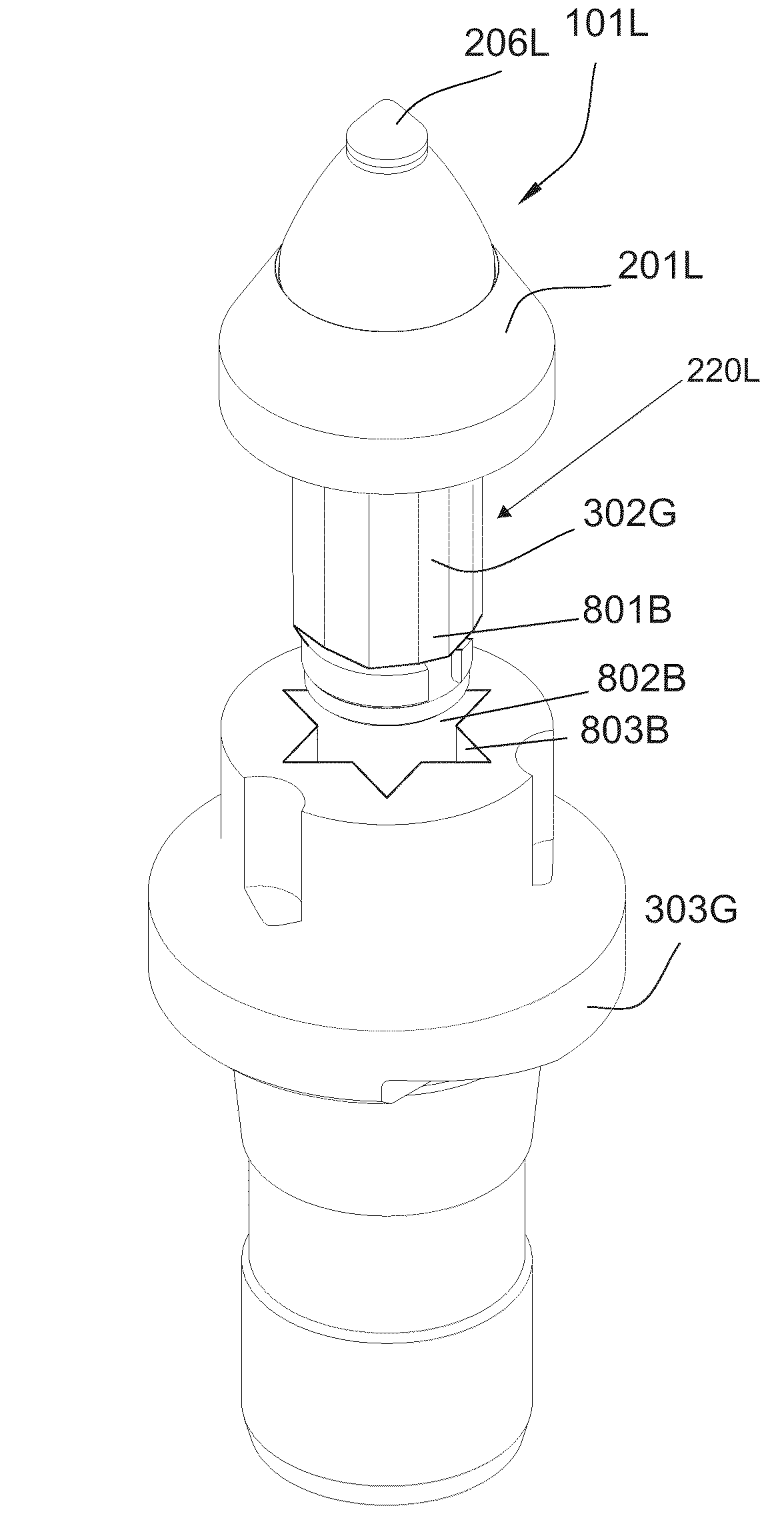

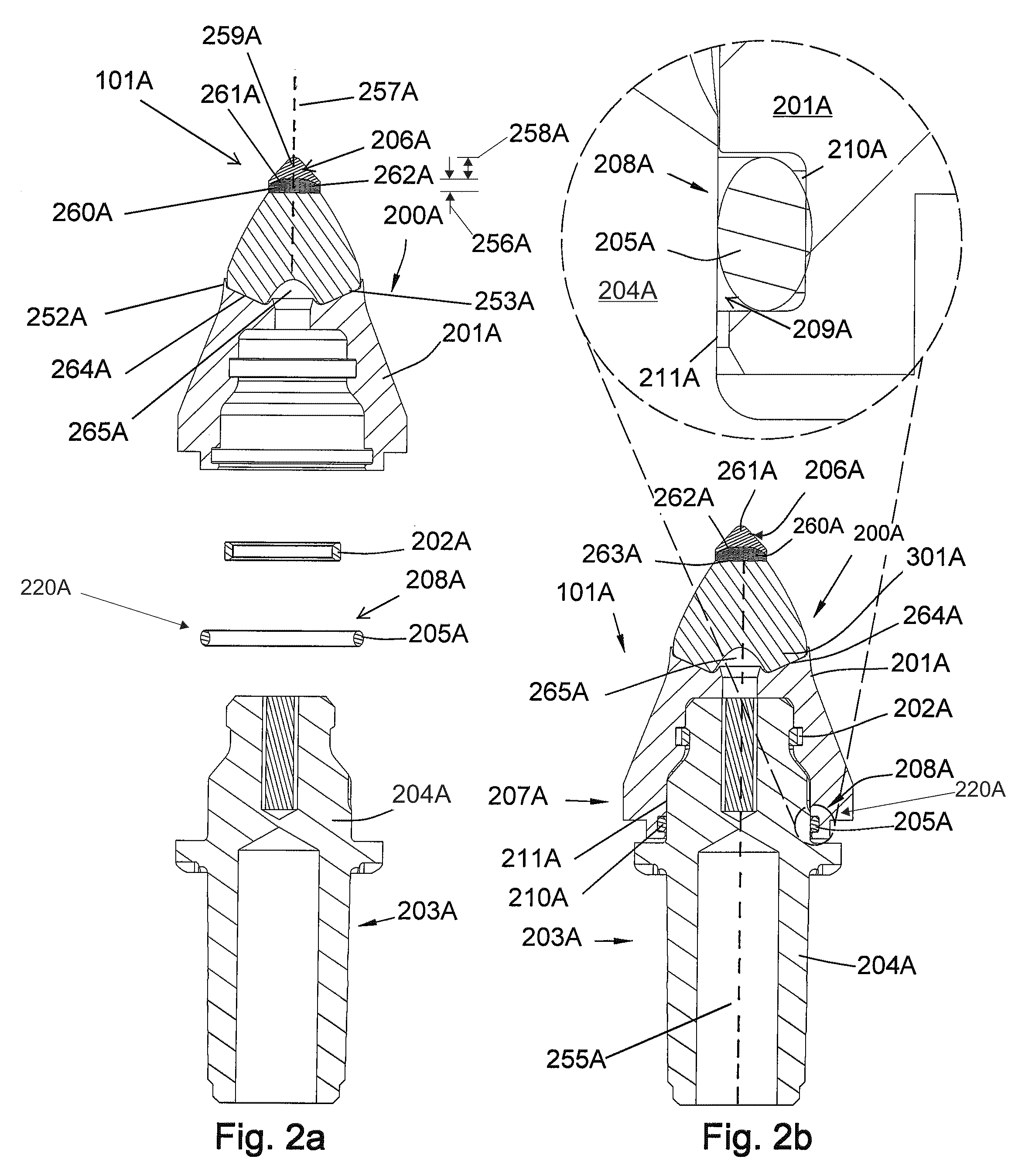

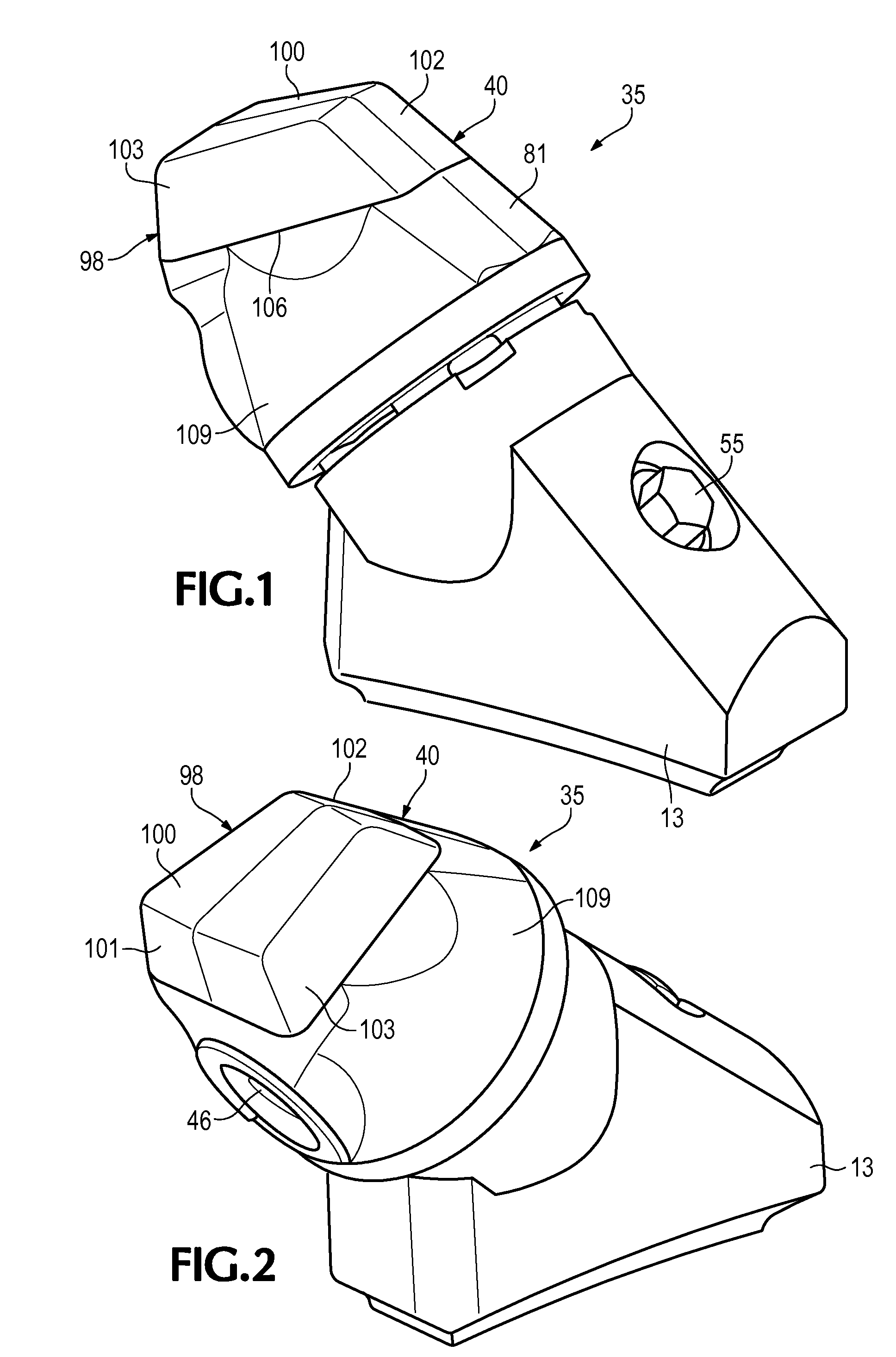

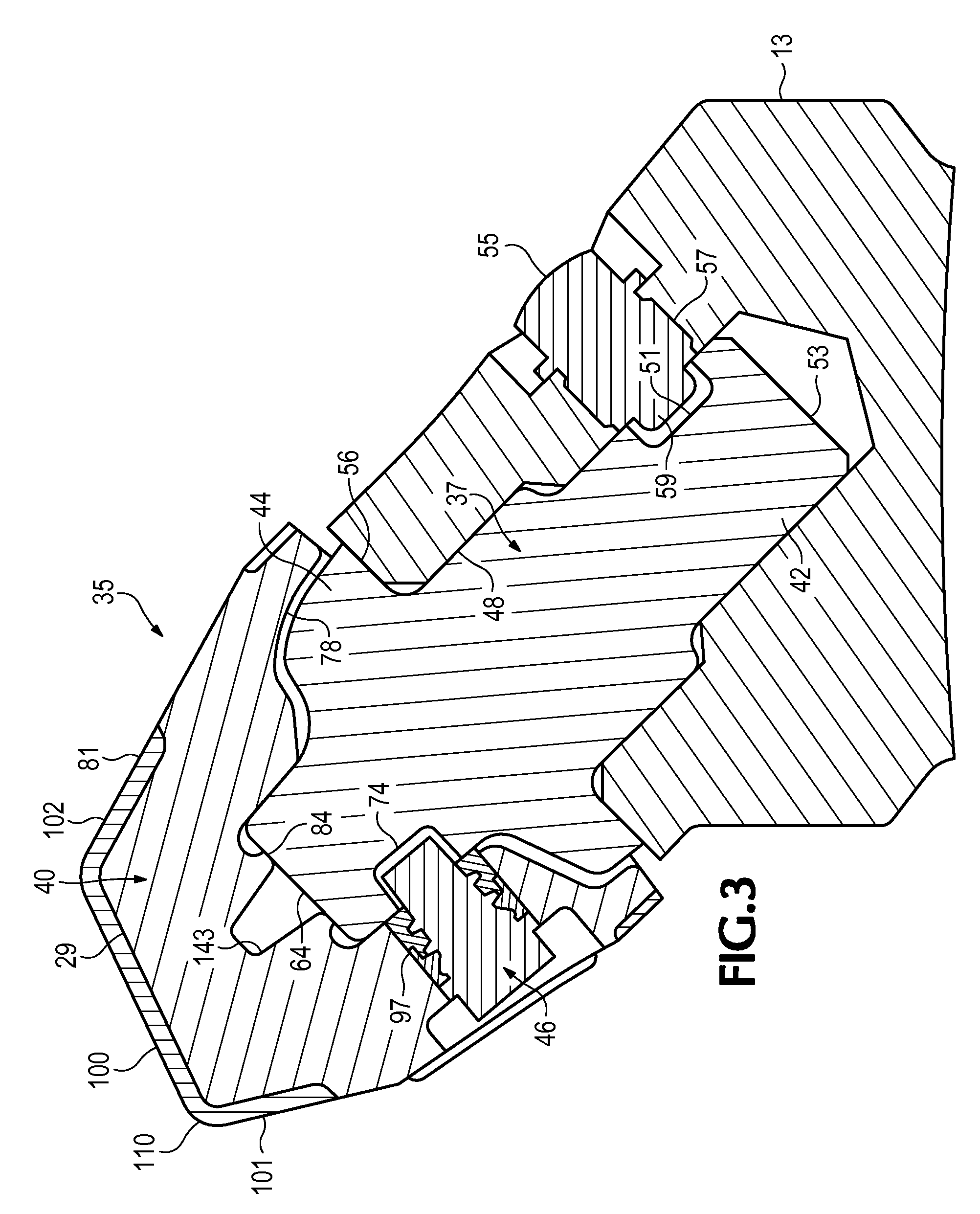

Manually rotatable tool

A degradation assembly comprises a rotary portion and a stationary portion. The rotary portion includes a cemented metal bolster bonded to a tip. The tip comprises a asymmetric, substantially conically shaped tip formed of diamond and a cemented metal carbide substrate. The stationary portion comprises a holder configured to be coupled to a block mounted to a driving mechanism. A compressible element is disposed between and in mechanical contact with both the rotary portion and the stationary portion.

Owner:SCHLUMBERGER TECH CORP

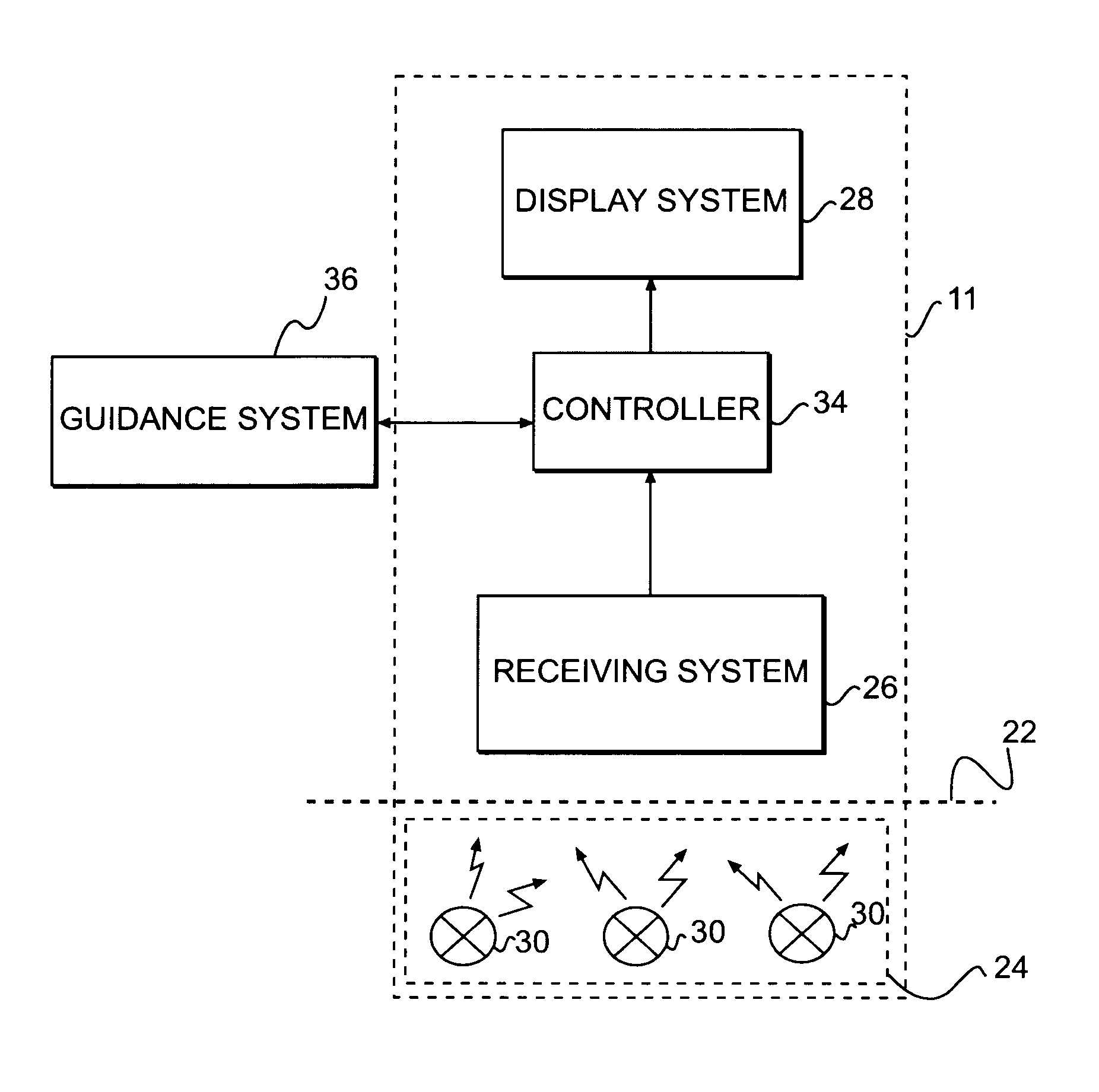

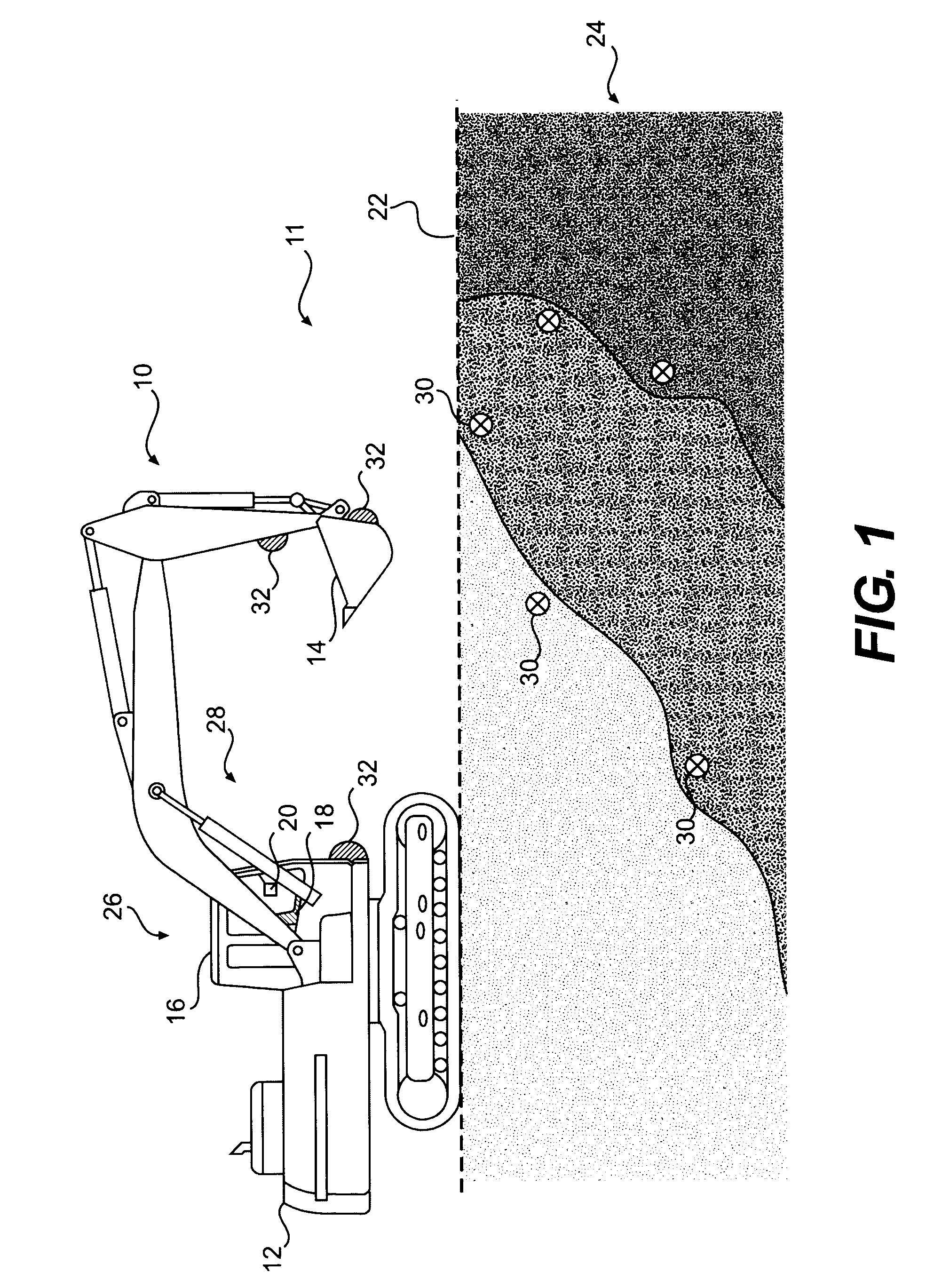

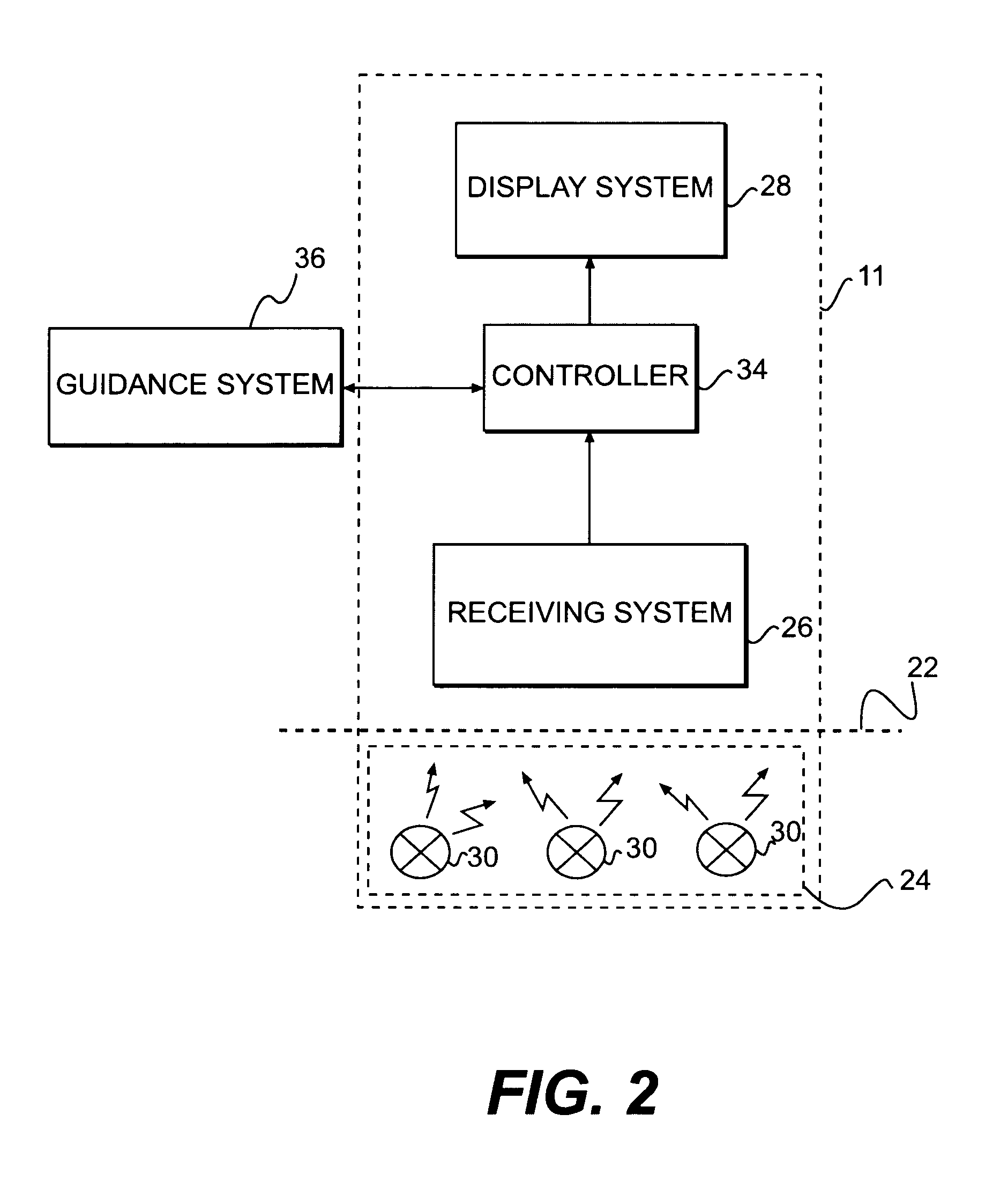

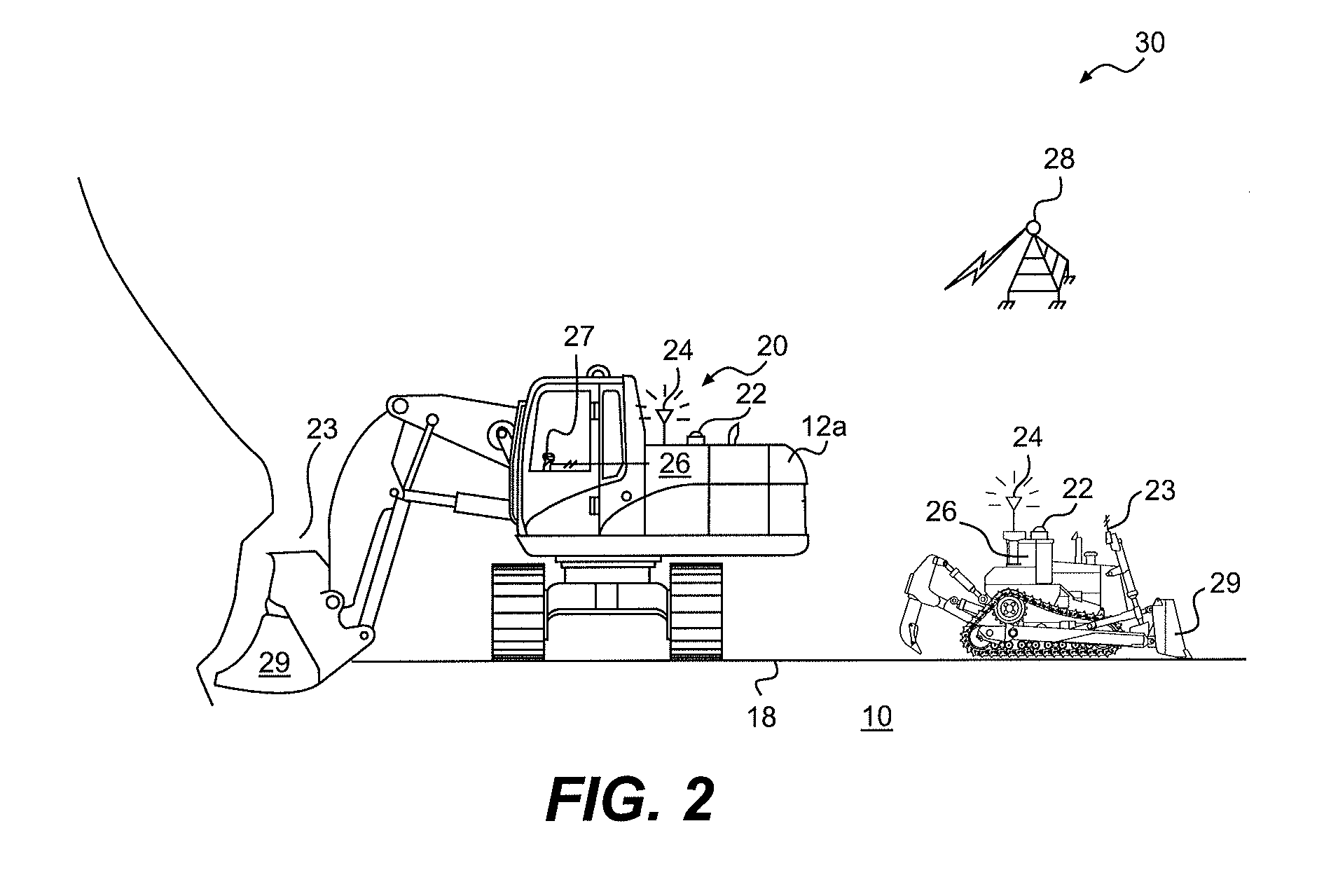

Work machine having boundary tracking system

The boundary tracking system has a plurality of signal transmitting devices located to represent at least one boundary of a work site. The boundary tracking system also has a receiving device configured to receive signals transmitted from one or more of the plurality of transmitting devices and to generate an output based on the received signals. The boundary tracking system also has a controller configured to determine a location of at least one of the plurality of transmitting devices based on the output from the receiving device.

Owner:CATERPILLAR INC

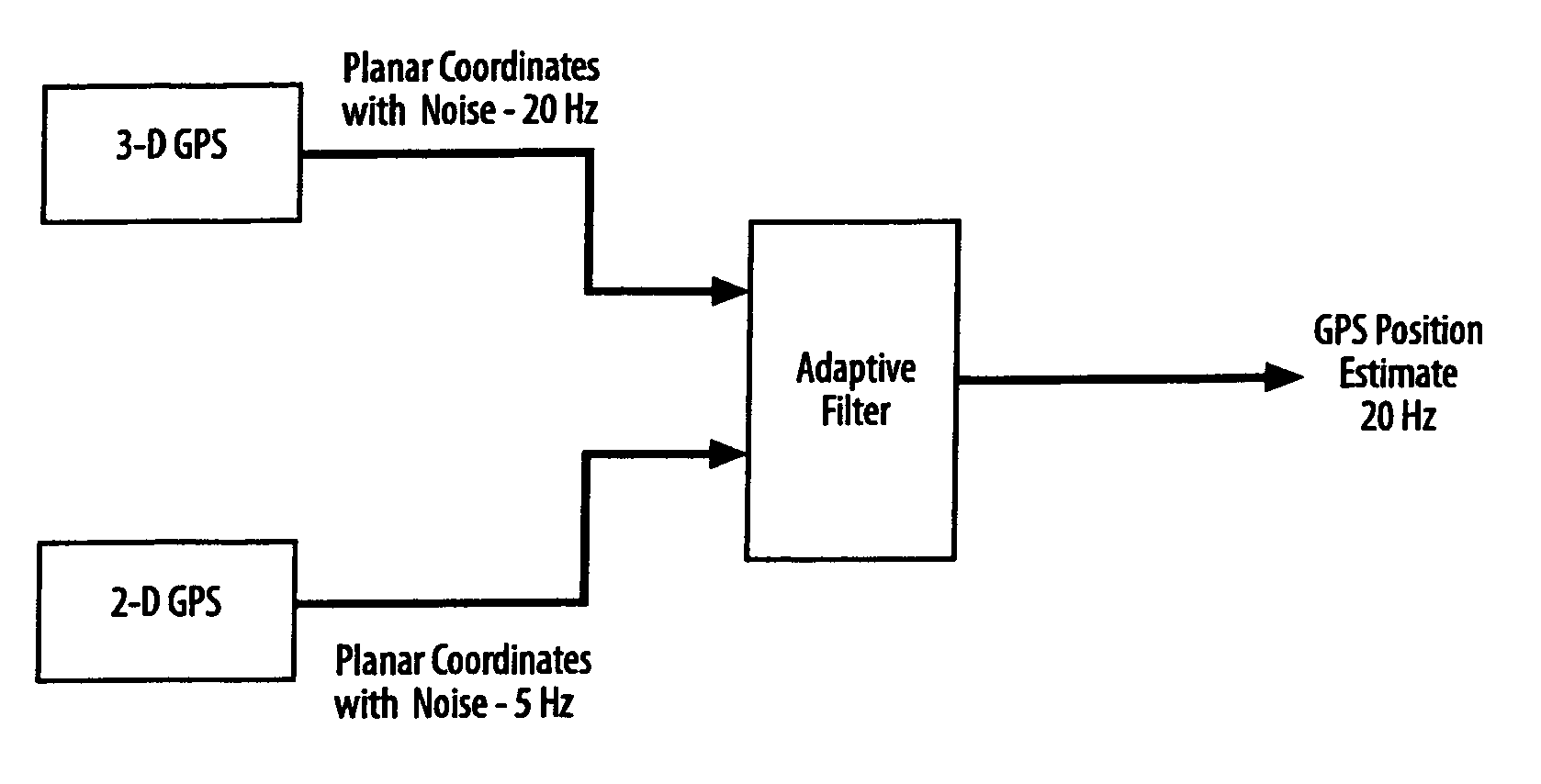

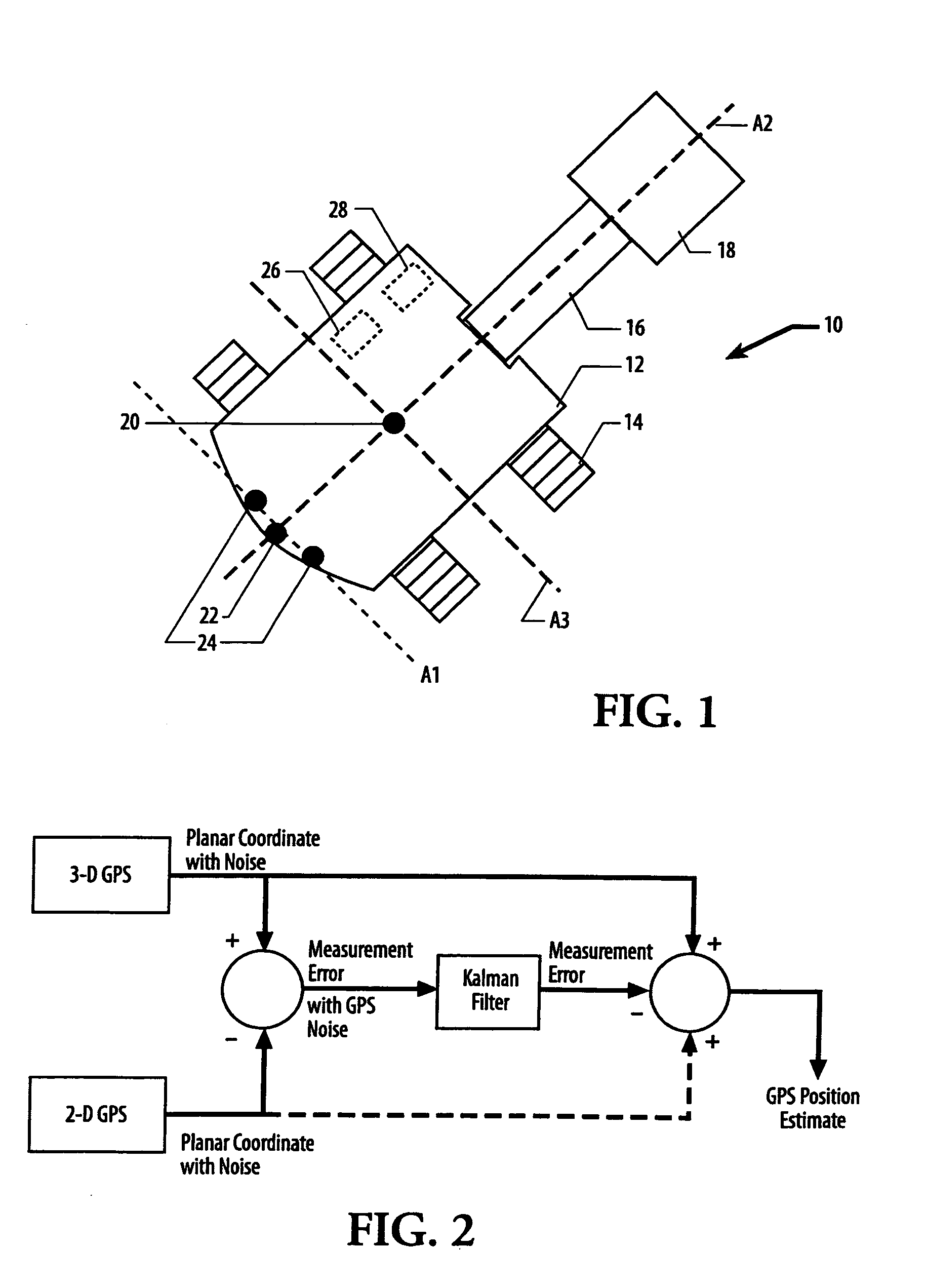

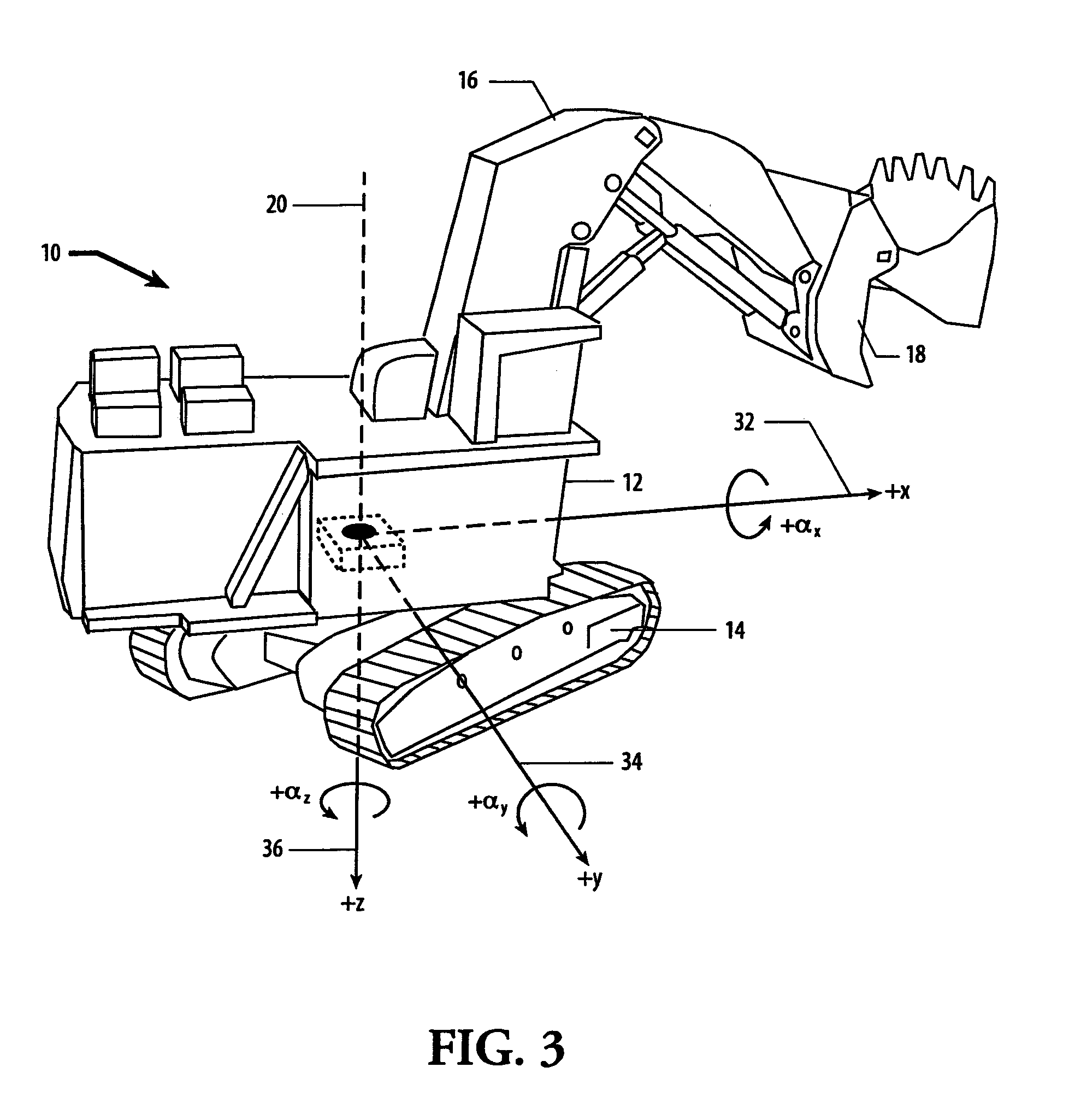

Multi-source positioning system for work machines

ActiveUS7139651B2Improve positionIncrease valueAnalogue computers for trafficPosition fixationAccelerometer dataKaiman filter

A three-dimensional and a two-dimensional GPS unit periodically provide coordinate positions of points on the work machine and are combined with a Kalman filter to produce a point of reference on a work machine. The point of reference is improved by combining the position with an inertial position derived from accelerometer data in another Kalman filter. Additionally, the two-dimensional GPS unit provides a heading that is combined with an inertial orientation derived by the angular rate from a gyroscope in another Kalman filter to produce a precise orientation estimate. Inclinometers provide pitch and roll of the work machine. With the point of reference, orientation estimate, pitch, roll and known geometry of the work machine, the GPS unit calculates the location and orientation of machine components and continuously tracks its movement throughout the mine. Additionally, the accelerometers and gyroscope provide position and orientation when the GPS units are inoperable.

Owner:MODULAR MINING SYSTEMS

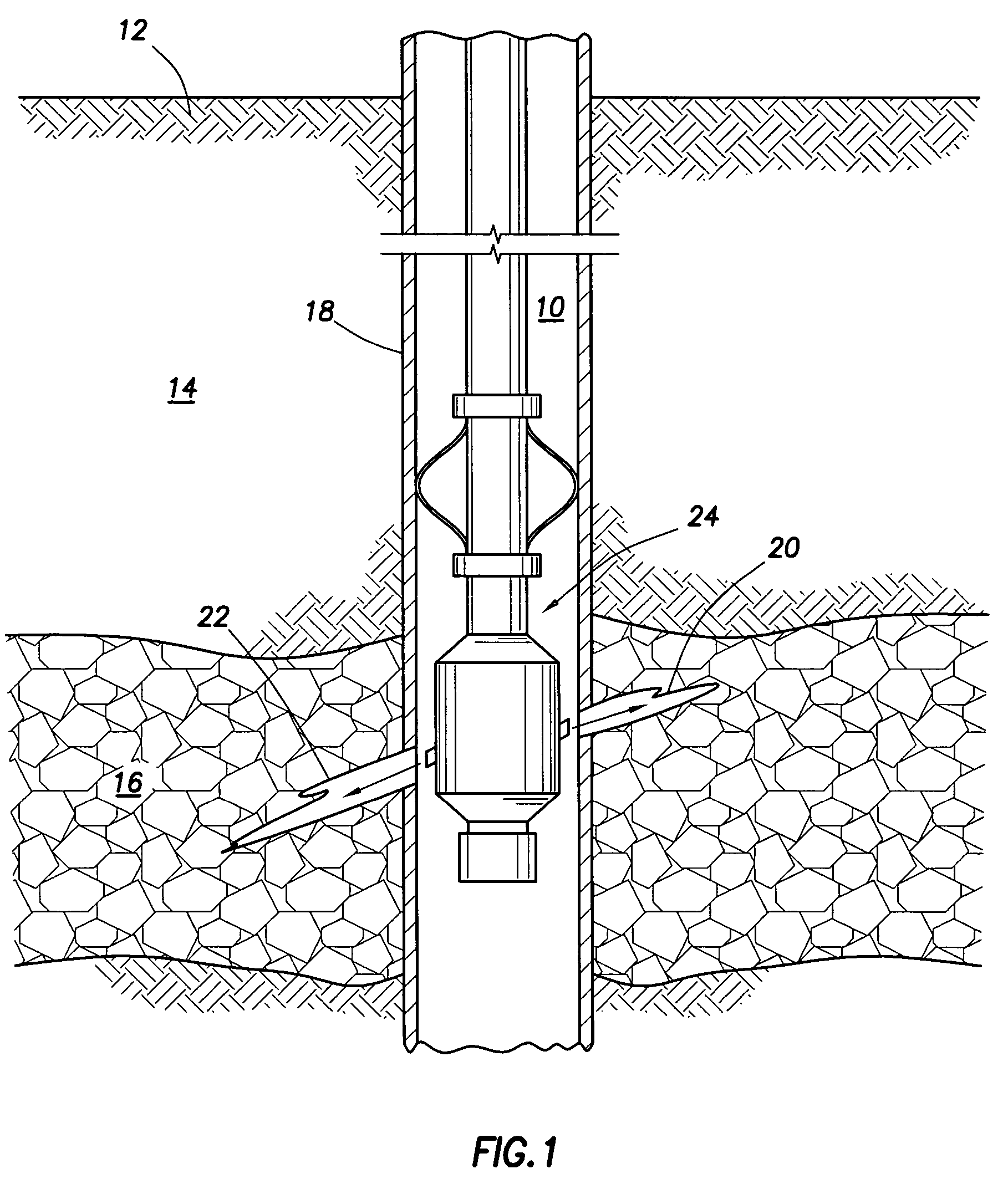

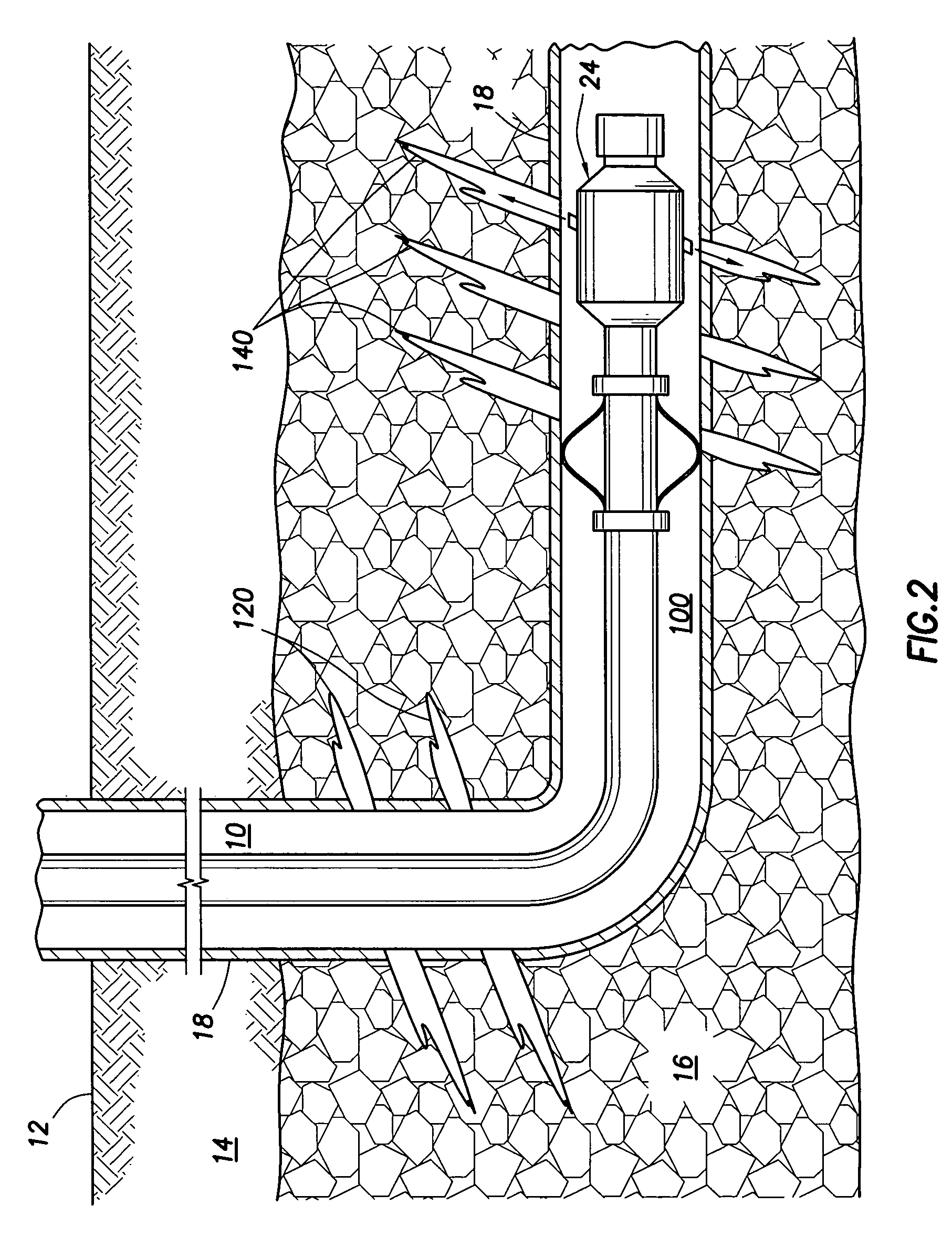

Method of optimizing production of gas from vertical wells in coal seams

ActiveUS7445045B2Maximize interferenceIncrease gas productionSurveyDisloding machinesProduct gasCoal

The present invention is directed to a method for producing gas from a subterranean formation containing a coal seam. The method includes the steps of drilling a substantially vertical well bore into the subterranean formation, which intersects the coal seam and fracturing the coal seam using a hydrajetting tool to produce at least one pair of opposed bi-wing fractures substantially along a plane of maximum stress. One or more horizontal well bores may also be drilled into the coal seam along which the coal seam can be further fractured.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods and systems for raising and lowering a rig mast and substructure by remote control

Systems for drilling operations, the systems including: a drilling rig with a base; a mast movably connected to the base of the drilling rig; a drawworks system for raising and lowering the mast; a drawworks control system for controlling the drawworks as it raises and lowers the mast; a remote control system for remotely controlling the drawworks control system so that the mast can be raised and lowered by personnel spaced apart from the drilling rig; and, in certain aspects, the rig including a substructure which can be raised, and lowered by remote control. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

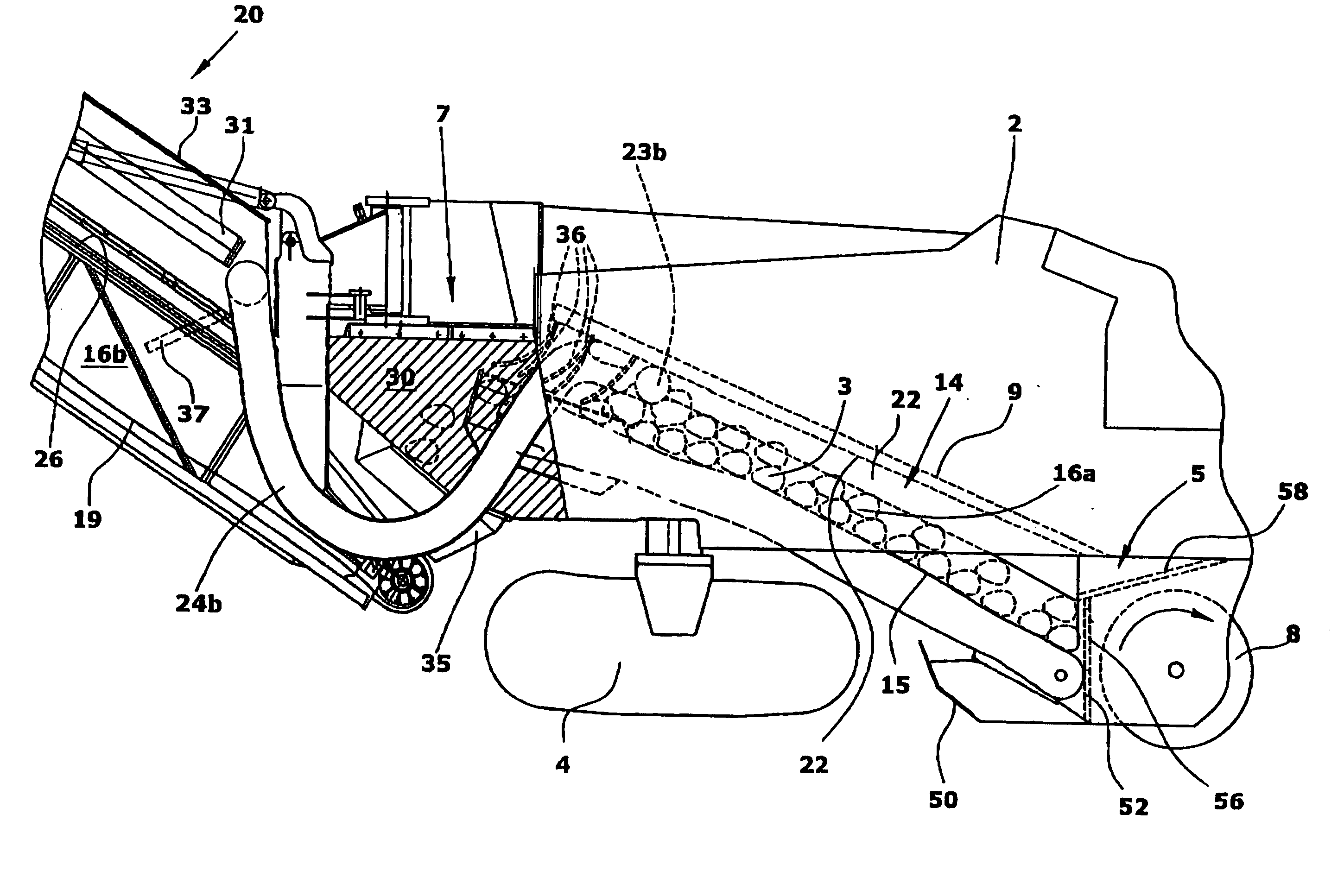

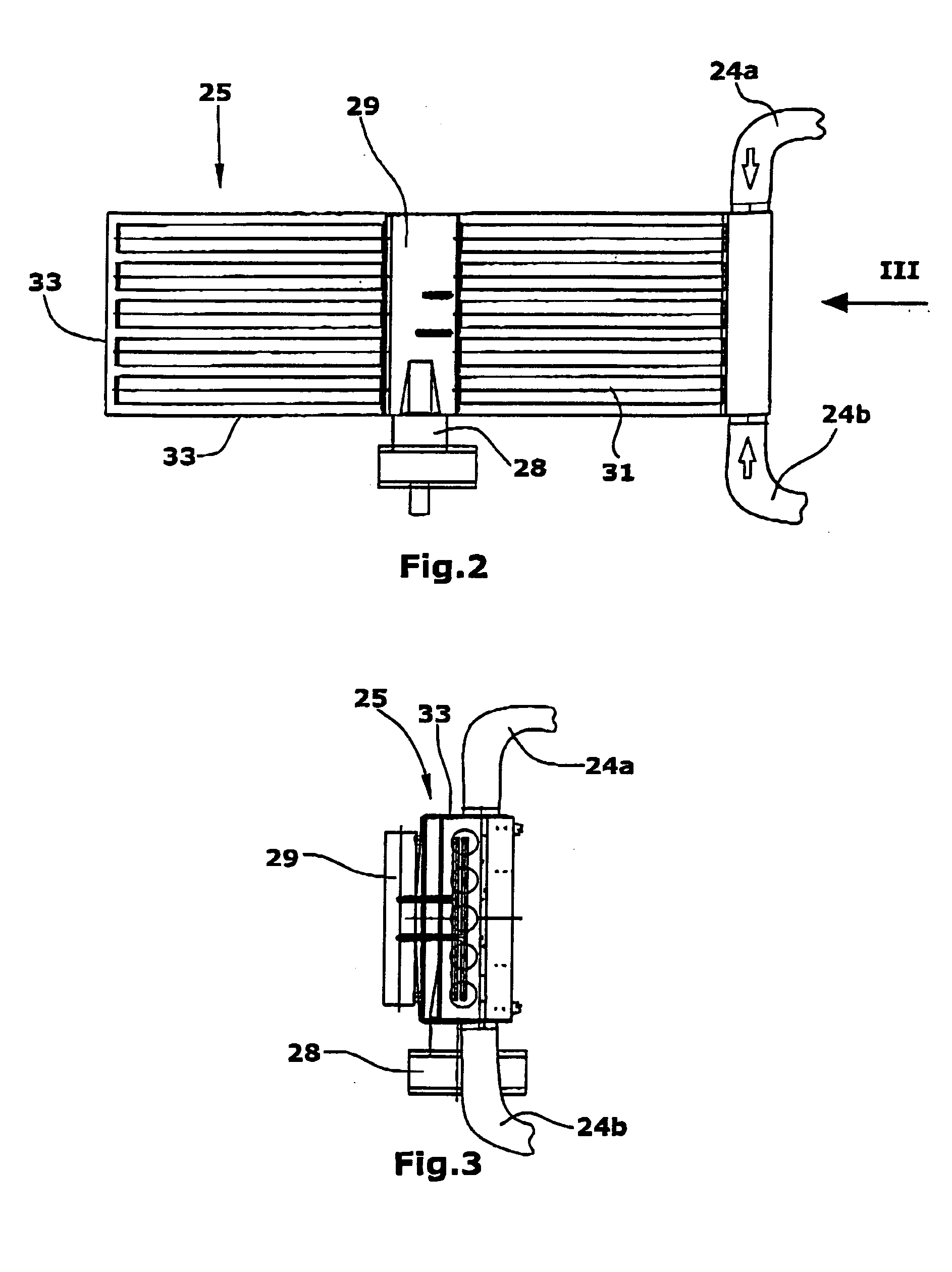

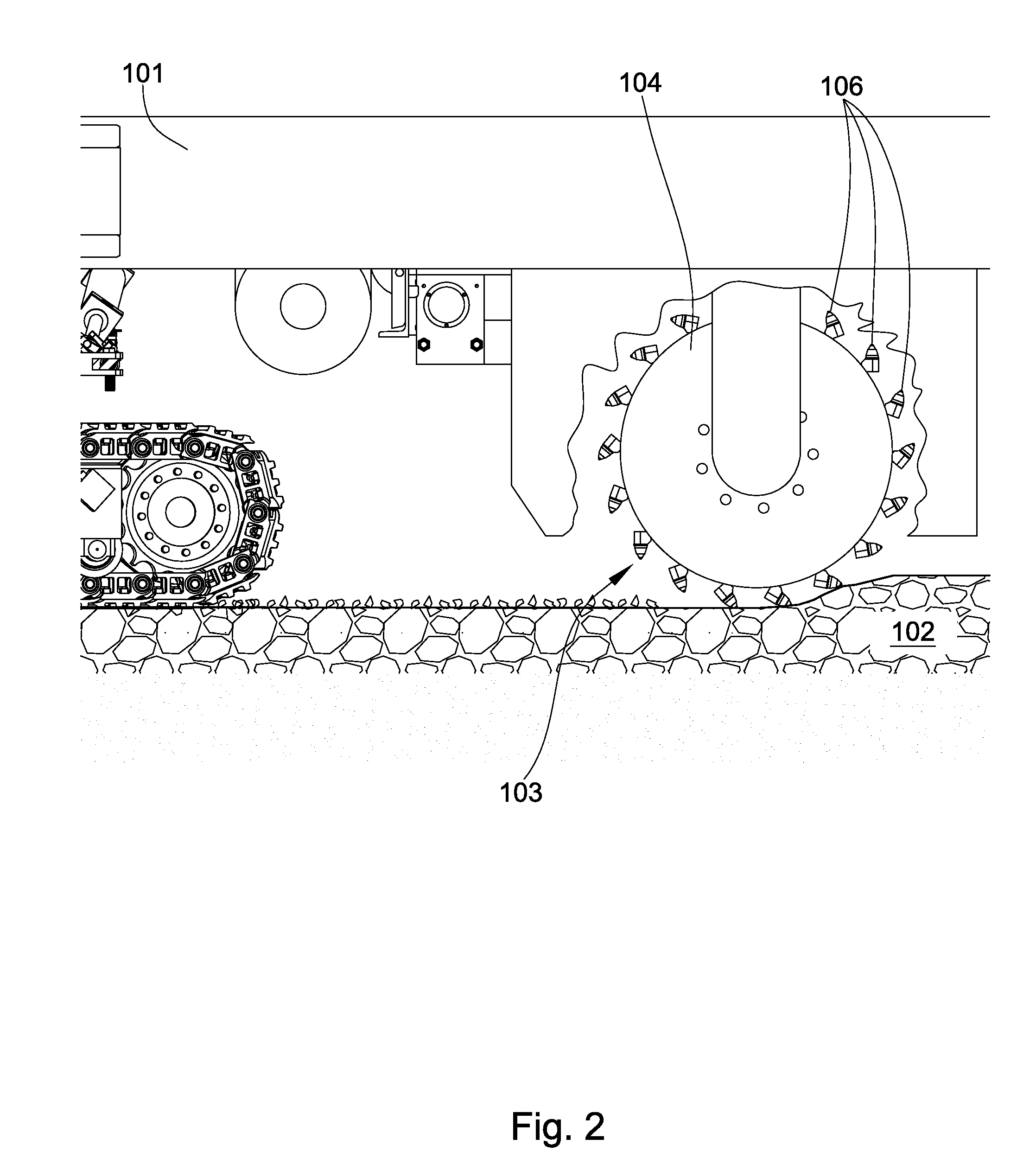

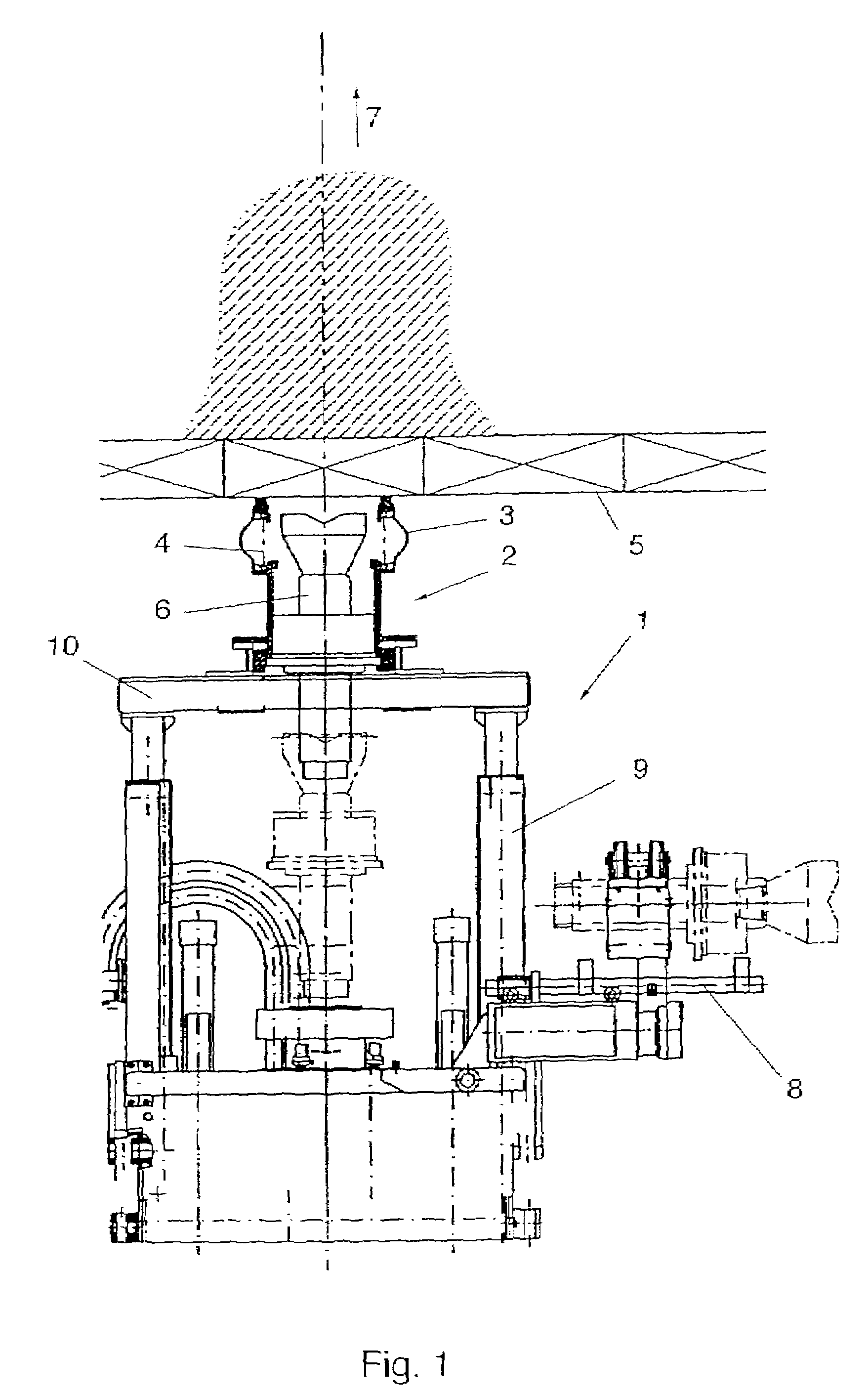

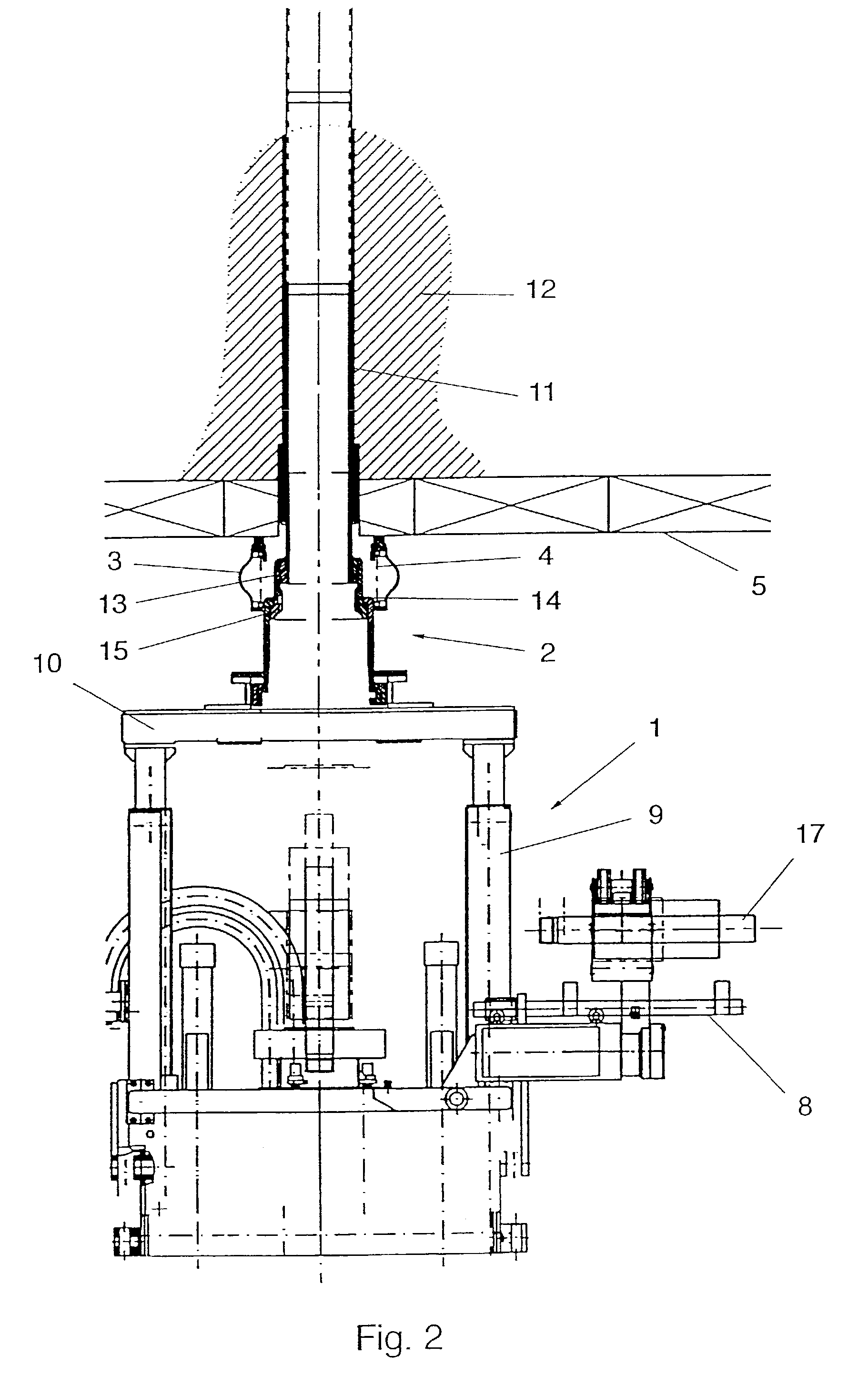

Milling machine as well as method for working ground surfaces

ActiveUS20050179309A1Inhibit currentEasy to useCombination devicesSlitting machinesEngineeringContaminated air

At a milling machine to work ground surfaces, with a machine frame, a milling drum supported at the machine frame, at least one transport device arranged at the machine frame which accepts the milled material from the milling drum, as well as with a suction device for the air polluted with dusts and vapors, whereby the milled material on the at least one transport device is enclosed by a channel, the suction device is connected to a rear channel section of the channel in the direction of the material transport and sucks off the air polluted during milling at the milling drum and in the rear channel section essentially in the direction of the material transport, it is provided that the suction device consists of a suction ventilator, a separator device for solids and a suction channel which is connected to the rear channel section, that the suction ventilator is arranged downstream of the separator device, and that the suction device disposes of the separated solids onto the transport device in a forward channel section in the direction of the material transport or into a collecting device, and the suction ventilator blows off the cleaned air into the environment.

Owner:WIRTGEN GMBH

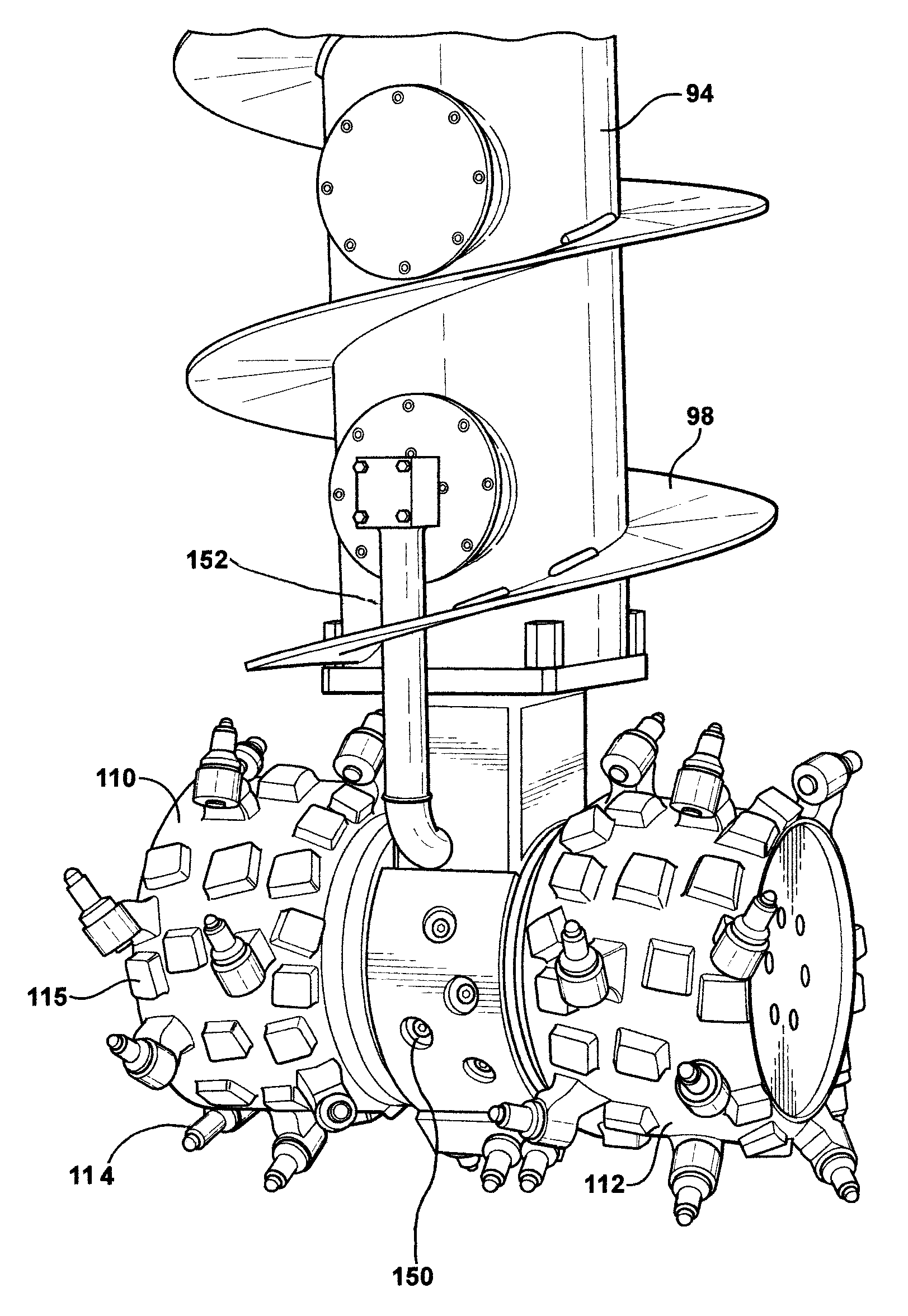

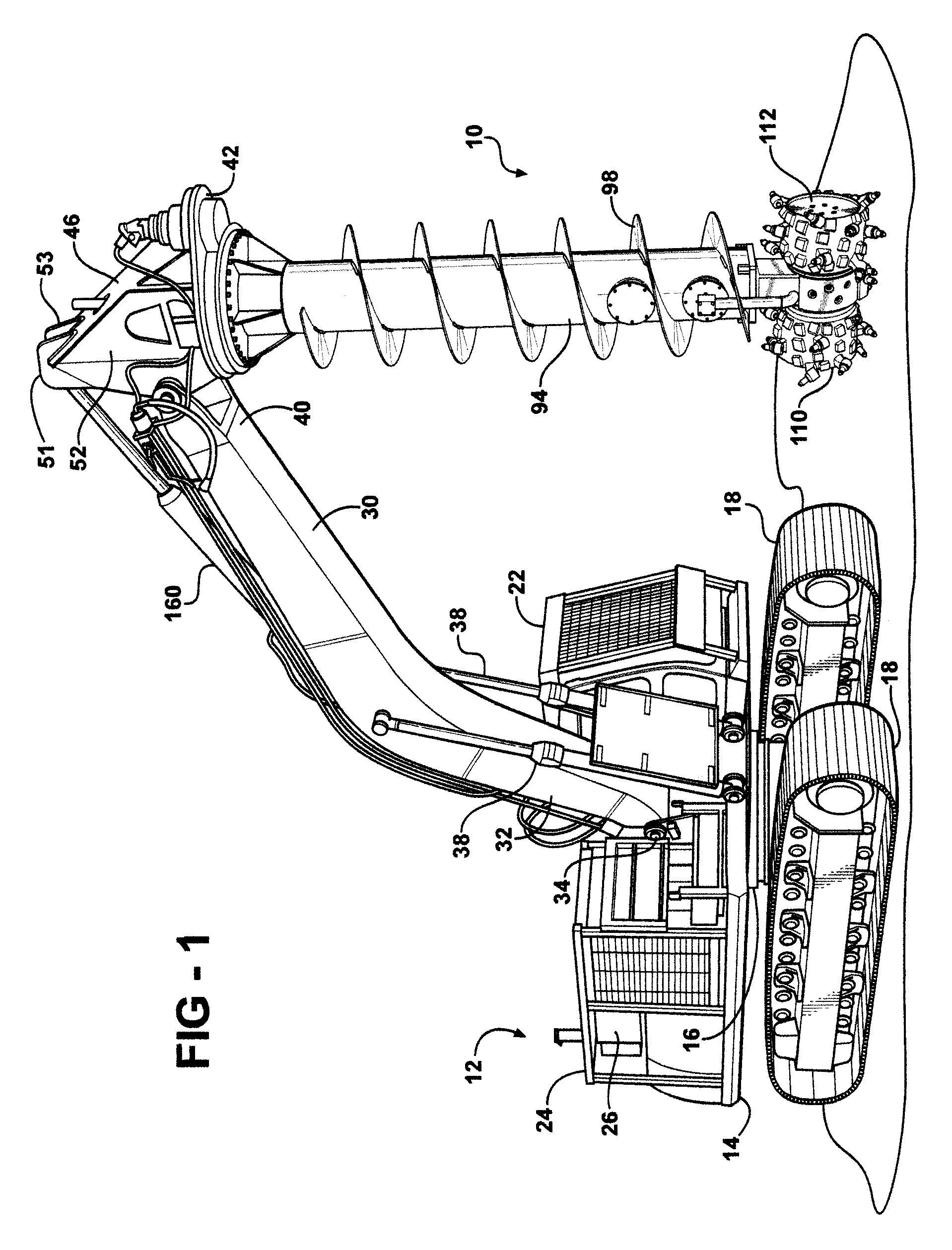

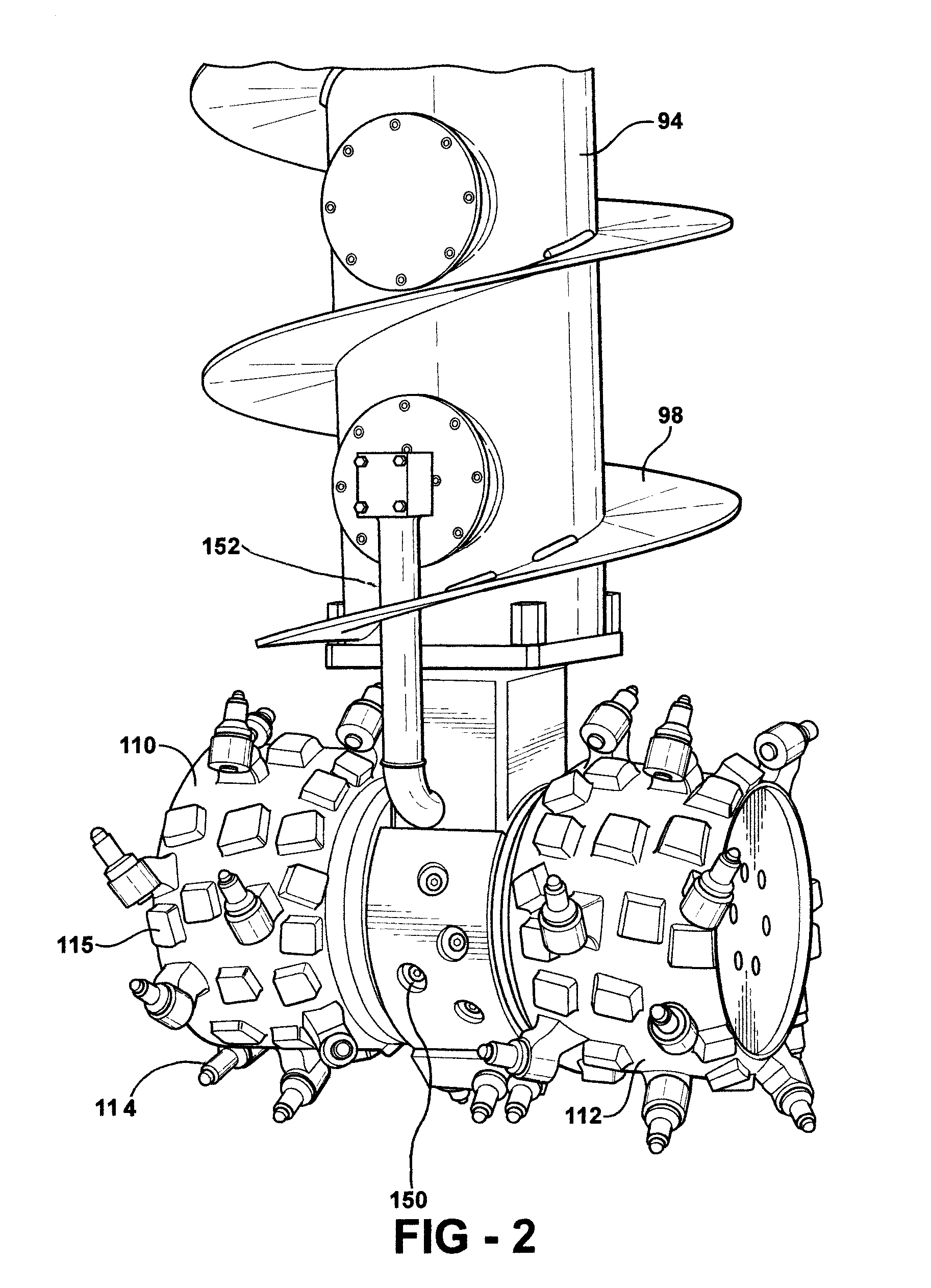

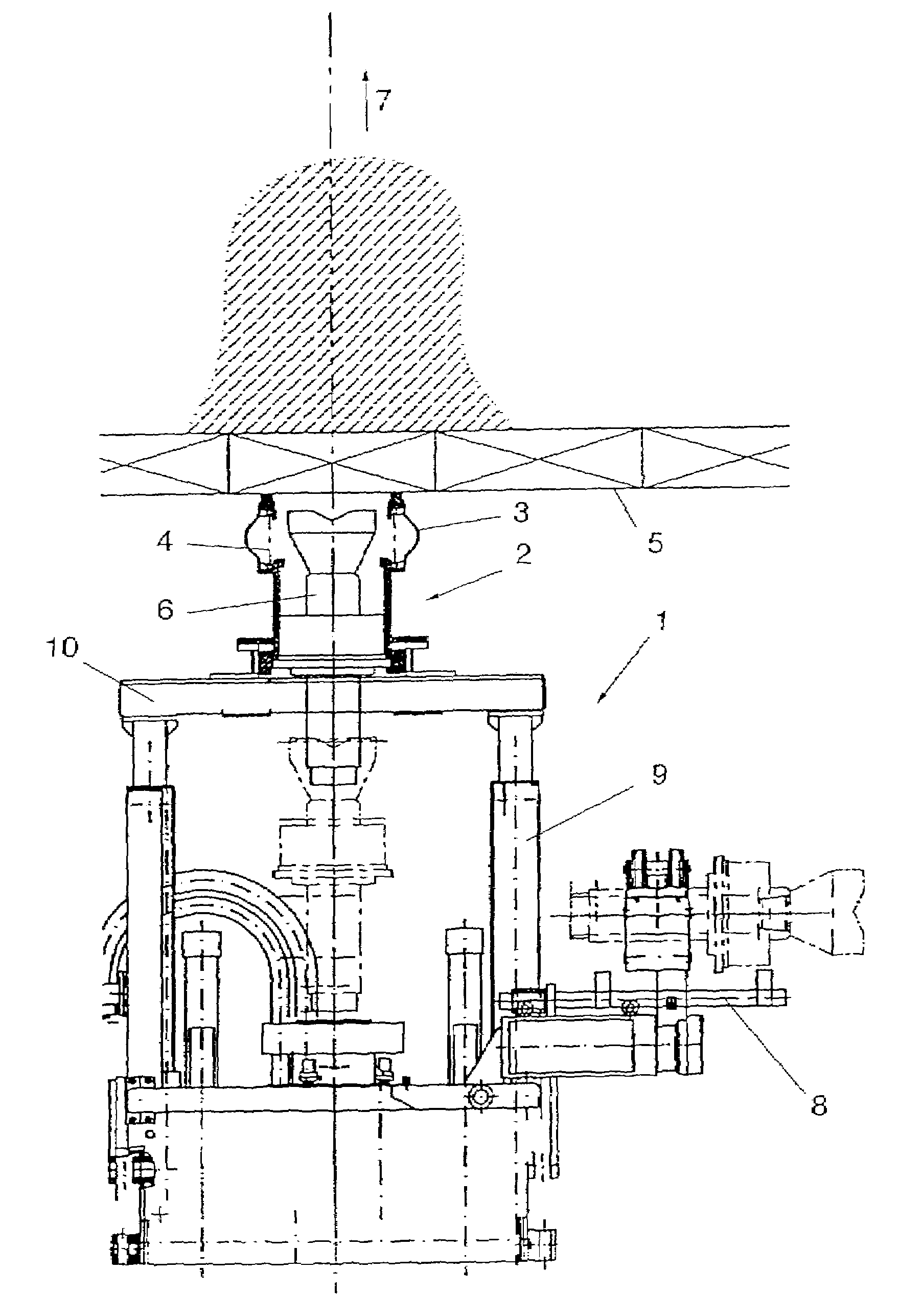

Dual axis grinder blender

InactiveUS7604301B1Enhanced mixing processMechanical machines/dredgersSlitting machinesHydraulic motorHorizontal axis

The dual axis grinder includes a support frame with a plate and a mast. The mast is connected to the boom of an excavator and to a hydraulic stick control cylinder. An auger tube is journaled in a bore through the support frame plate for rotation about a vertical axis. Auger flighting may be attached to the auger tube. A central support housing is attached to the bottom of the auger tube. Two cylindrical drums with grinder teeth are journaled on the central support housing for rotation about a horizontal axis that intersects the vertical axis. The auger tube is rotated by a reversible hydraulic motor. The cylindrical drums are driven by one or two reversible hydraulic motors. Hydraulic fluid is provided to drive the two drums cylindrical through a rotary hydraulic manifold. Chemicals to treat environmental contaminates are supplied through a nozzle adjacent to the cylindrical drums.

Owner:LANG WILLIAM J

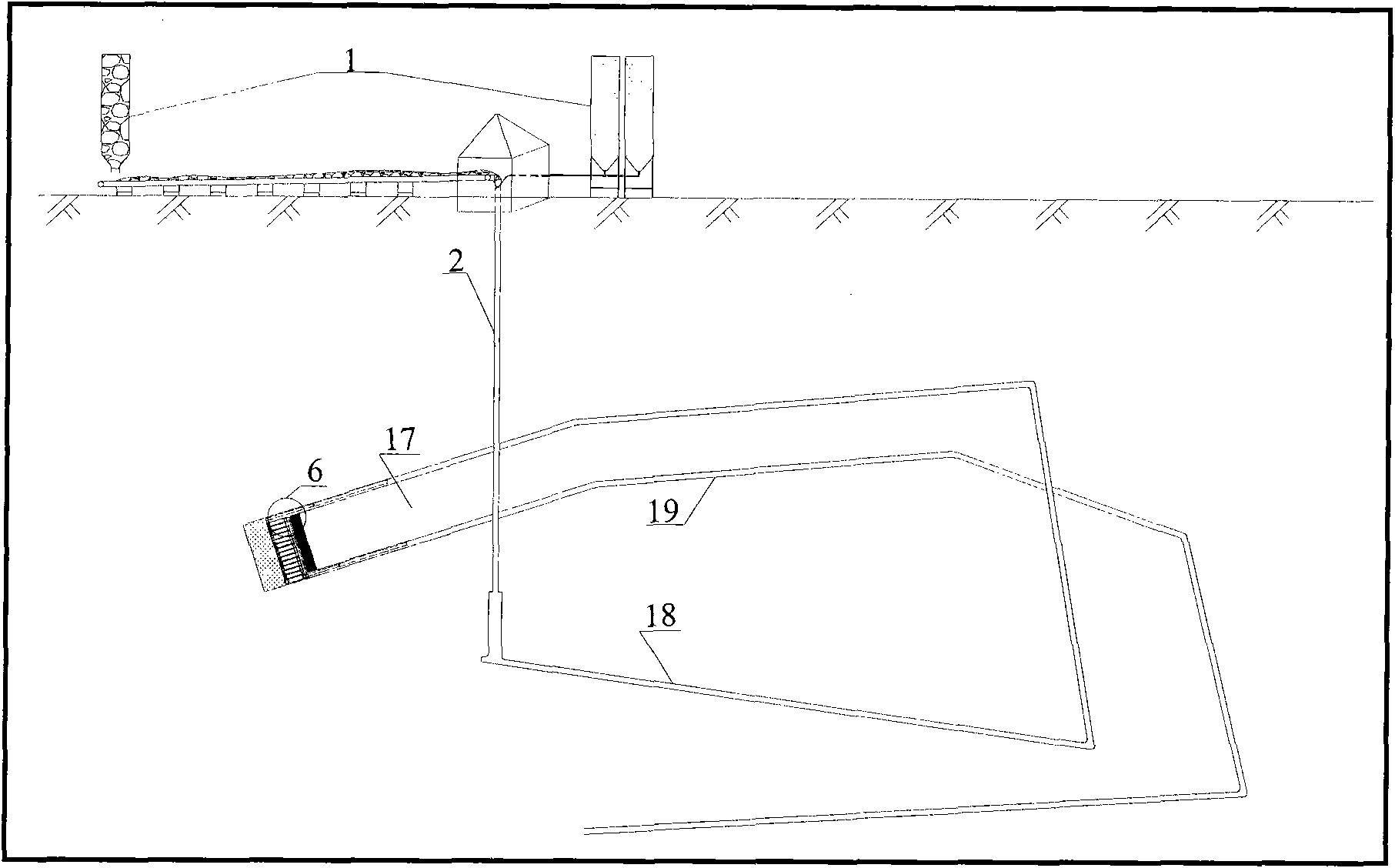

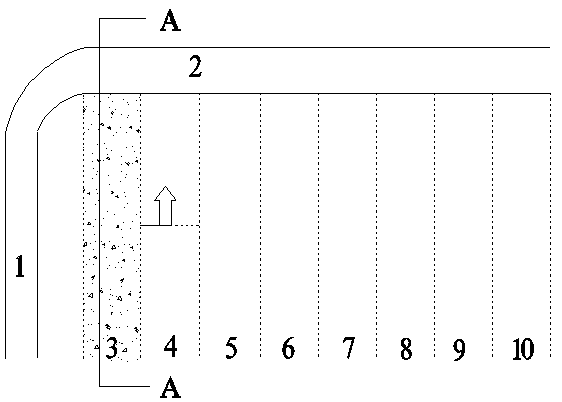

Opencast coal mine end slope filling mining method

InactiveCN103758568AReduce wasteSolve the problem of reduced recovery rateMaterial fill-upOpen-pit miningMining engineeringCoal pillar

Provided is an opencast coal mine end slope filling mining method. The opencast coal mine end slope filling mining method includes the steps that a coal pillar reserved at an opencast coal mine end slope is divided into a plurality of stalls which are equal to an end slope coal mining machine roller in width; a stowboard is tunnelled to the position of an earth surface safety boundary line in the coal seam trend direction, and a stowboard is tunnelled in the coal seam inclination direction; an end slope coal mining machine is used for mining the stalls on the side of the stowboard in the coal seam inclination direction at intervals, after mining of the stalls is completed, the end slope coal mining machine is removed, mining openings in the sides of stall side slopes are sealed, and filling is performed on the stalls which are mined at intervals; then, mining is performed on stalls at intervals, the stalls are not mined, filling is performed on the mined stalls, and the steps are repeated until mining of all the stalls which are not mined is completed. According to the opencast coal mine end slope filling mining method, rock and soil discharged by an opencast coal mine can be effectively used, the discharge amount of the rock and soil of the opencast coal mine is reduced, the stripping ratio is lowered, mines end slope coal resources are mined in a maximization mode, meanwhile the side slope safety is guaranteed, and the efficient environment-friendly production process of the opencast coal mine is achieved.

Owner:CHINA UNIV OF MINING & TECH

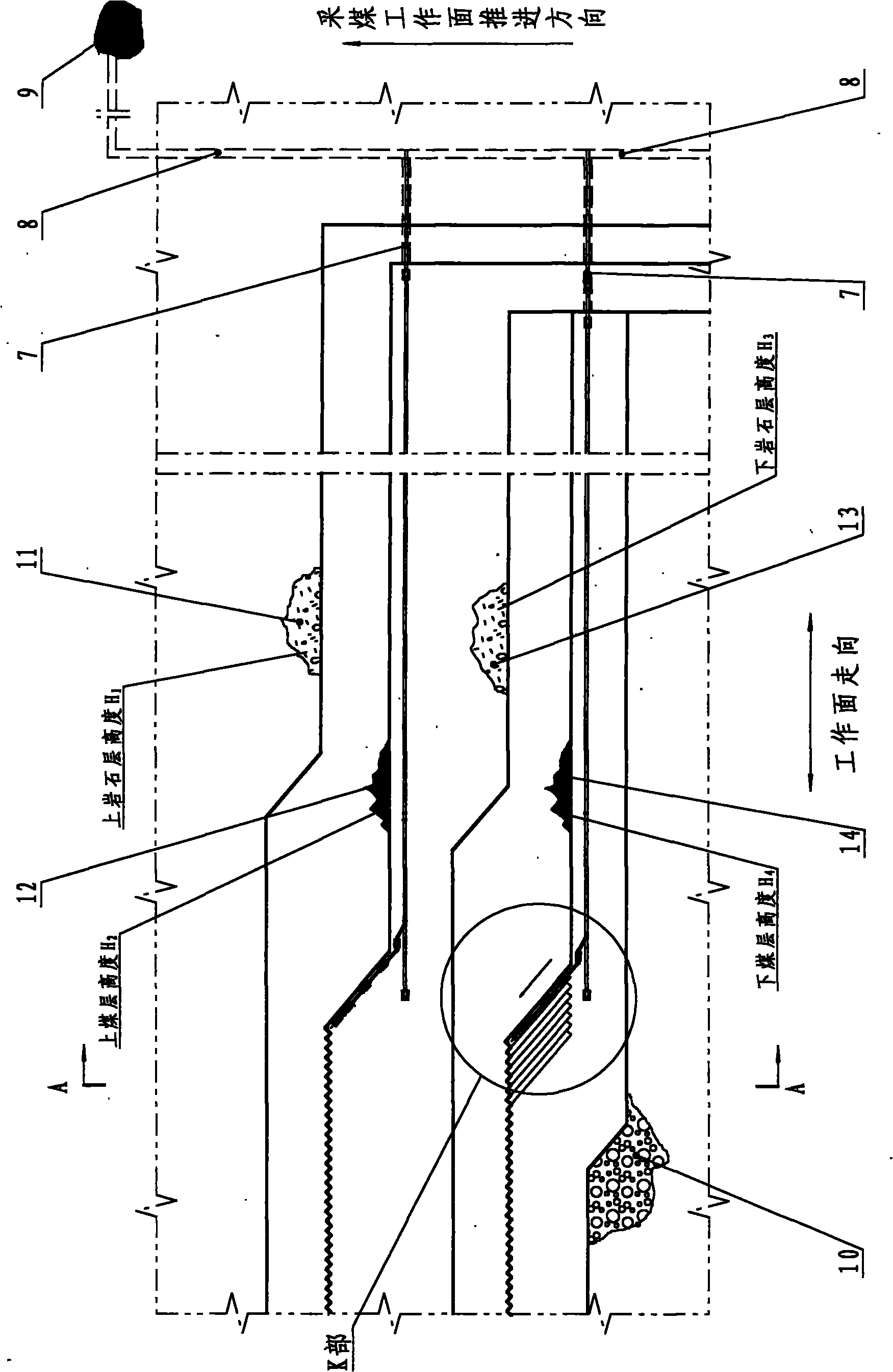

Continuous coal mining process method of open-pit coal mine

The invention relates to a continuous coal mining process method of an open-pit coal mine, the used main devices comprises a continuous coal mining machine, a walking type crushing machine of a continuous conveying machine unit, a bridge type transloading machine, a walking type transloading machine, an unloading car, a working face belt type conveyor, an outward transport heading belt type conveying machine and an outward transport machine lane belt type conveying machine, and the continuous coal mining process method adopts the continuous mining-continuous conveying way, and adopts the automatic mining, crushing, transloading, unloading and transportation. The coal mining method has advanced process, reasonable design, compact and continuous arrangement of the devices, safety, stability and reliability, high excavating efficiency, multi-stage transportation, smooth conveying and small occupied area, and can effectively improve the recovery rate of resources, reduce the consumption of fuel oil, reduce the carbon emission, be applicable to needs on low carbon, energy conservation and environmental protection and be a very ideal continuous coal mining process method of the open-pit coal mine.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

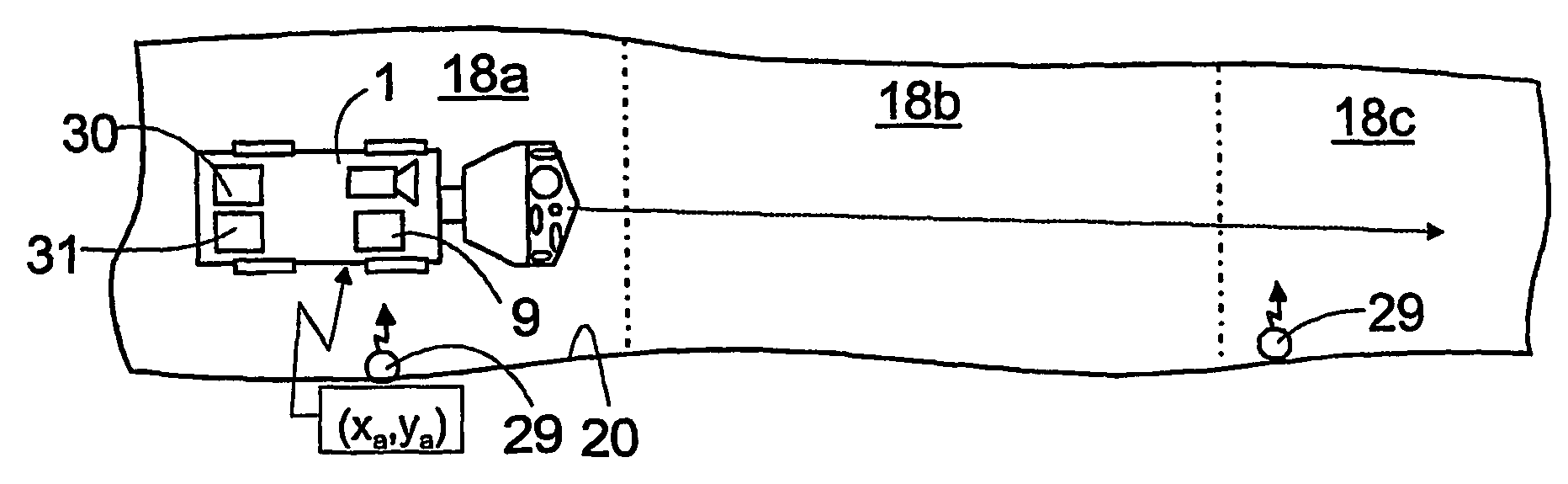

Arrangement for monitoring the location of a mining vehicle in a mine

ActiveUS7725232B2Accurate monitoringTasks performed in the mine to be controlled more efficientlyUnderground miningRoad vehicles traffic controlControl systemExact location

A method and a system for monitoring the location of a mining vehicle in a mine. The mine comprises a first and a second work area. At least one identifier (29) whose exact location is known is arranged in the first work area (18a). The location of the mining vehicle (1) is determined continuously by means of a dead reckoning. The location data, based on the dead reckoning, can be updated by means of the identifier. The location data are transmitted to a mine control system for monitoring the mining vehicle.

Owner:SANDVIK MINING & CONSTR OY

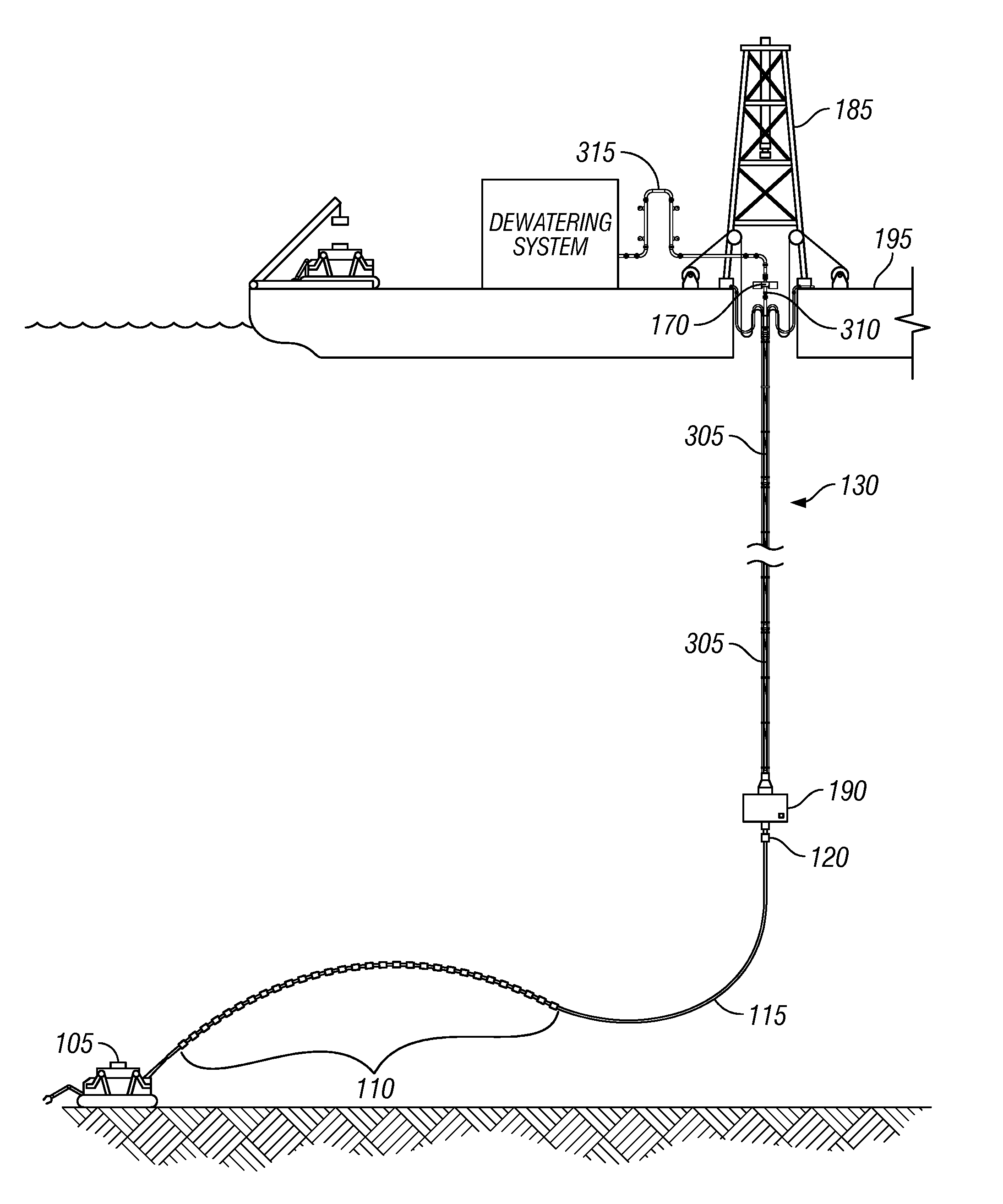

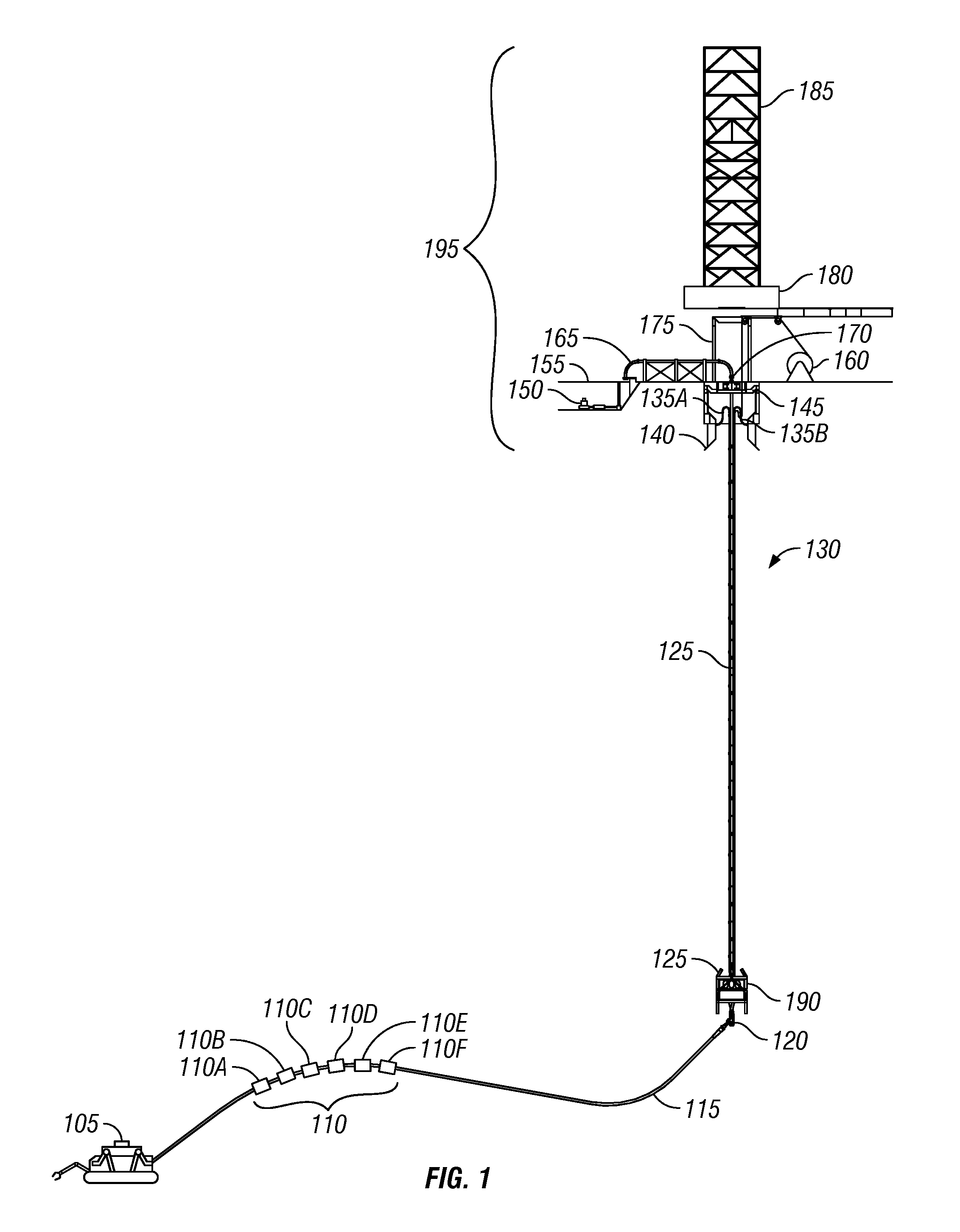

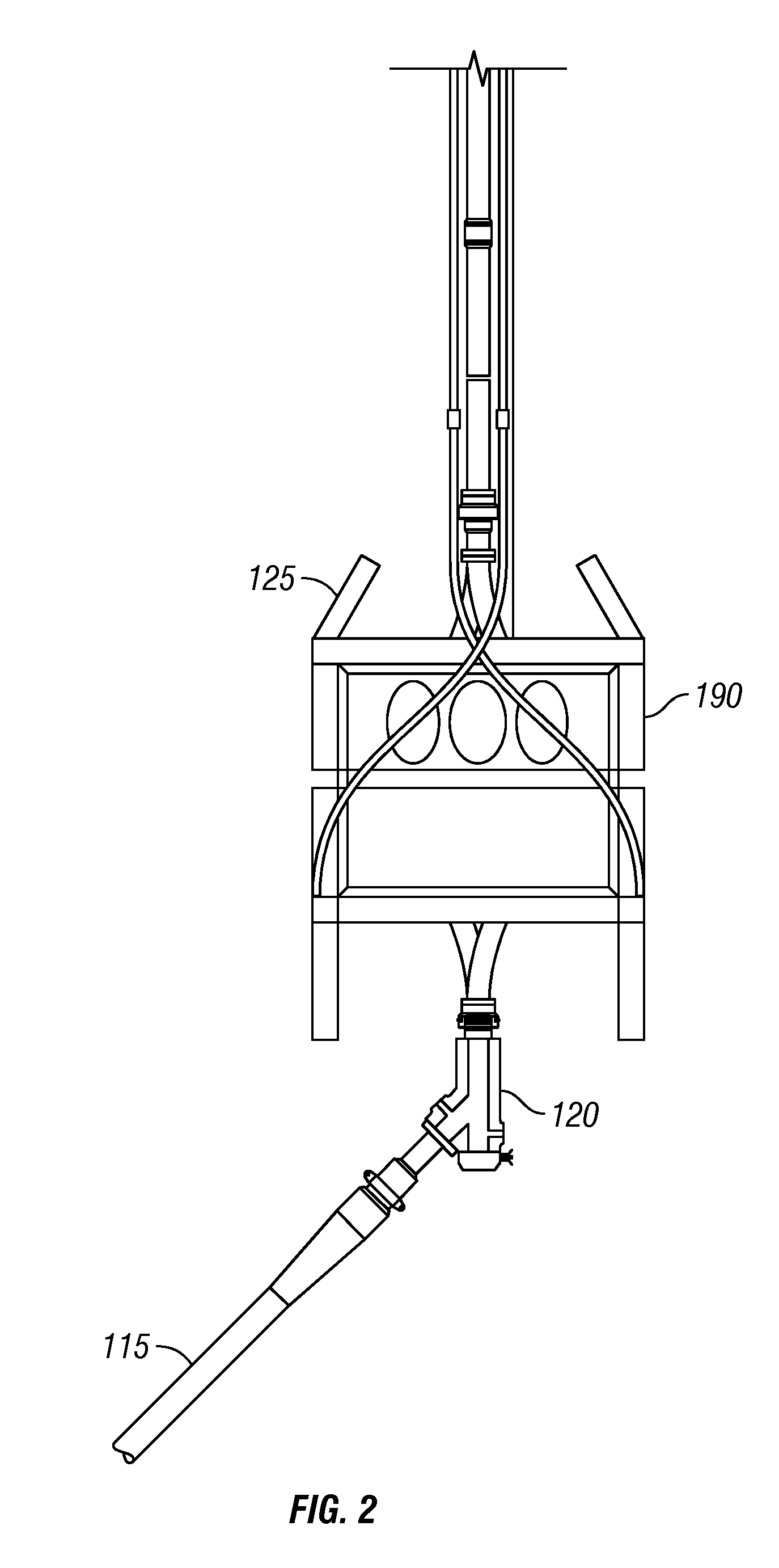

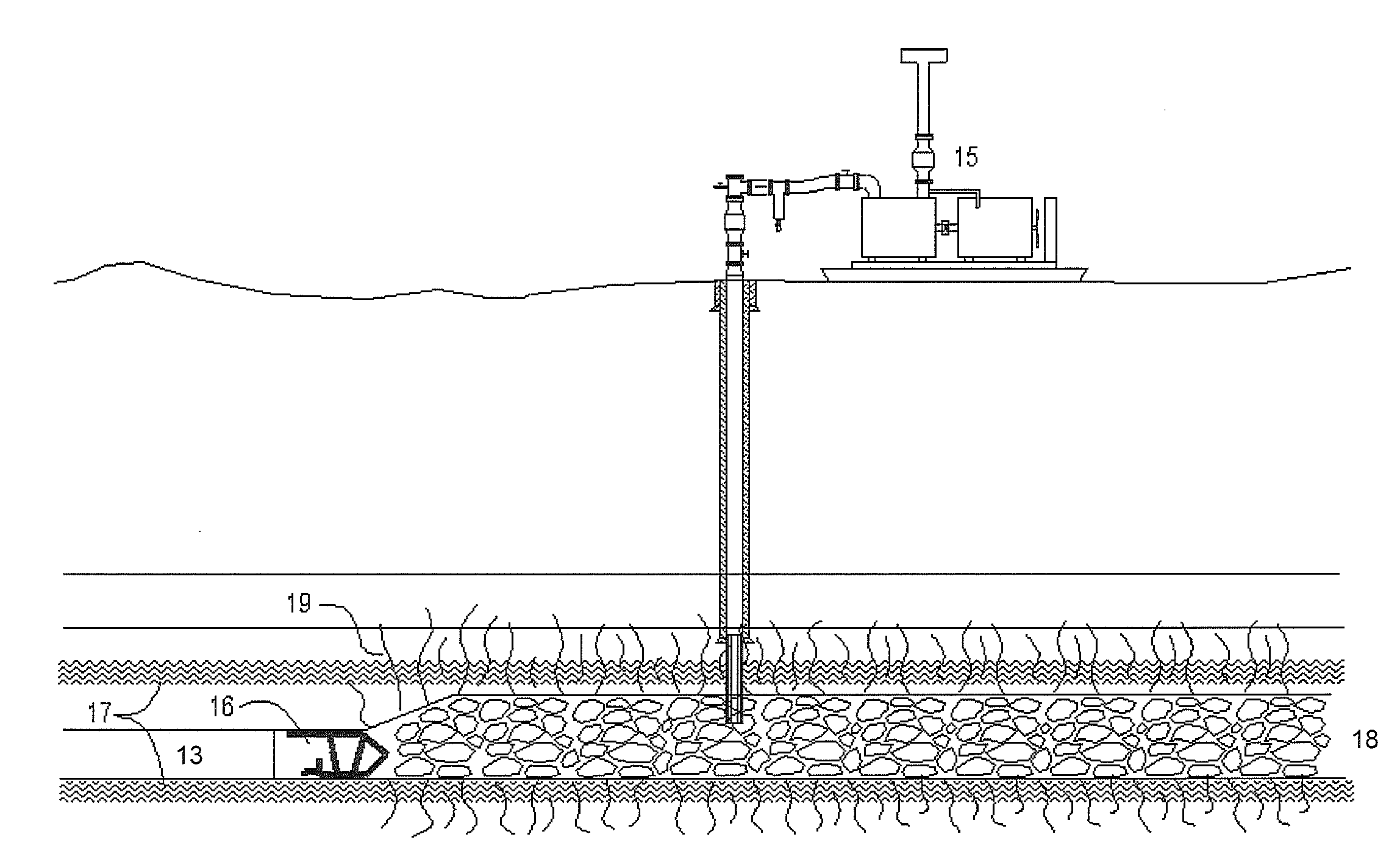

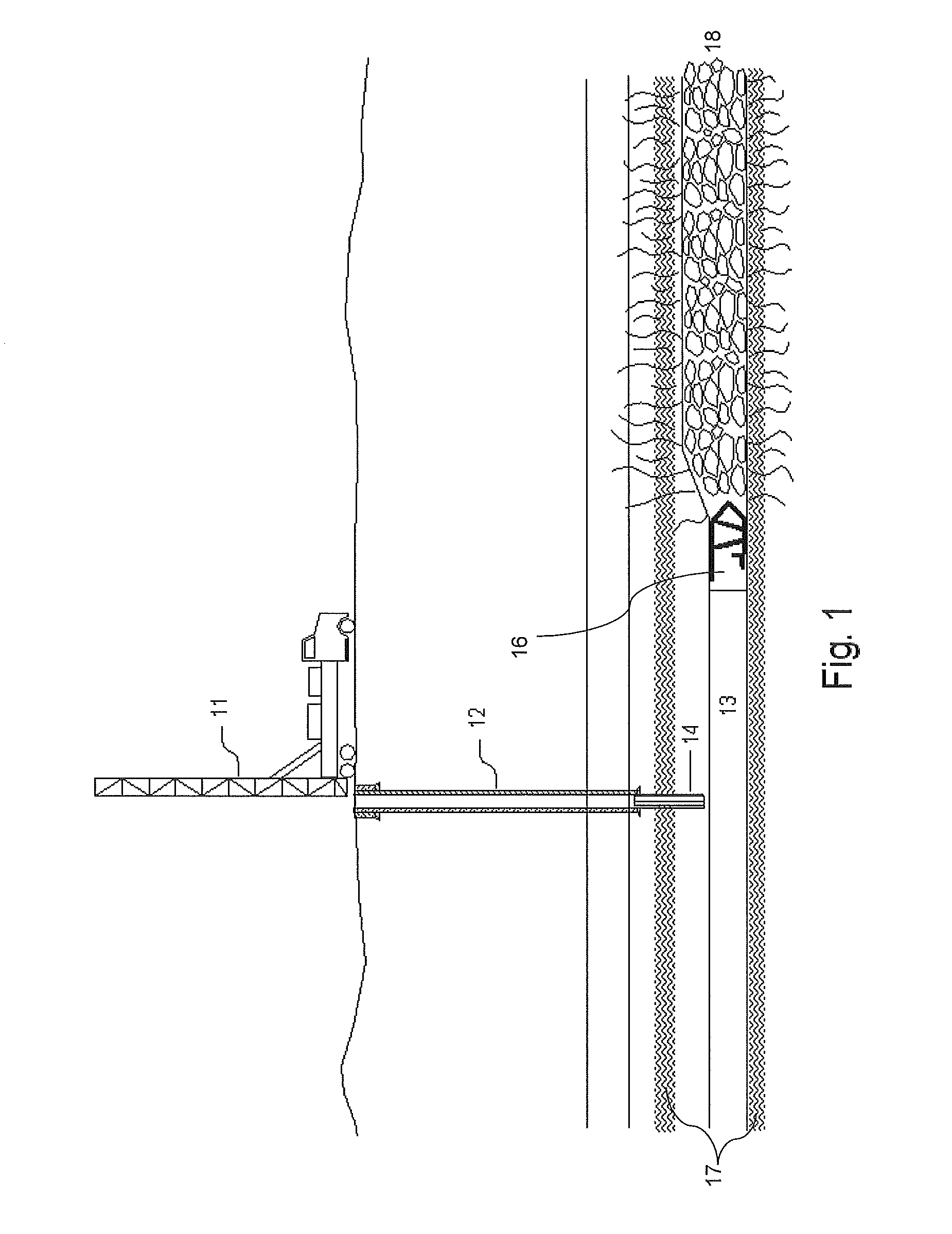

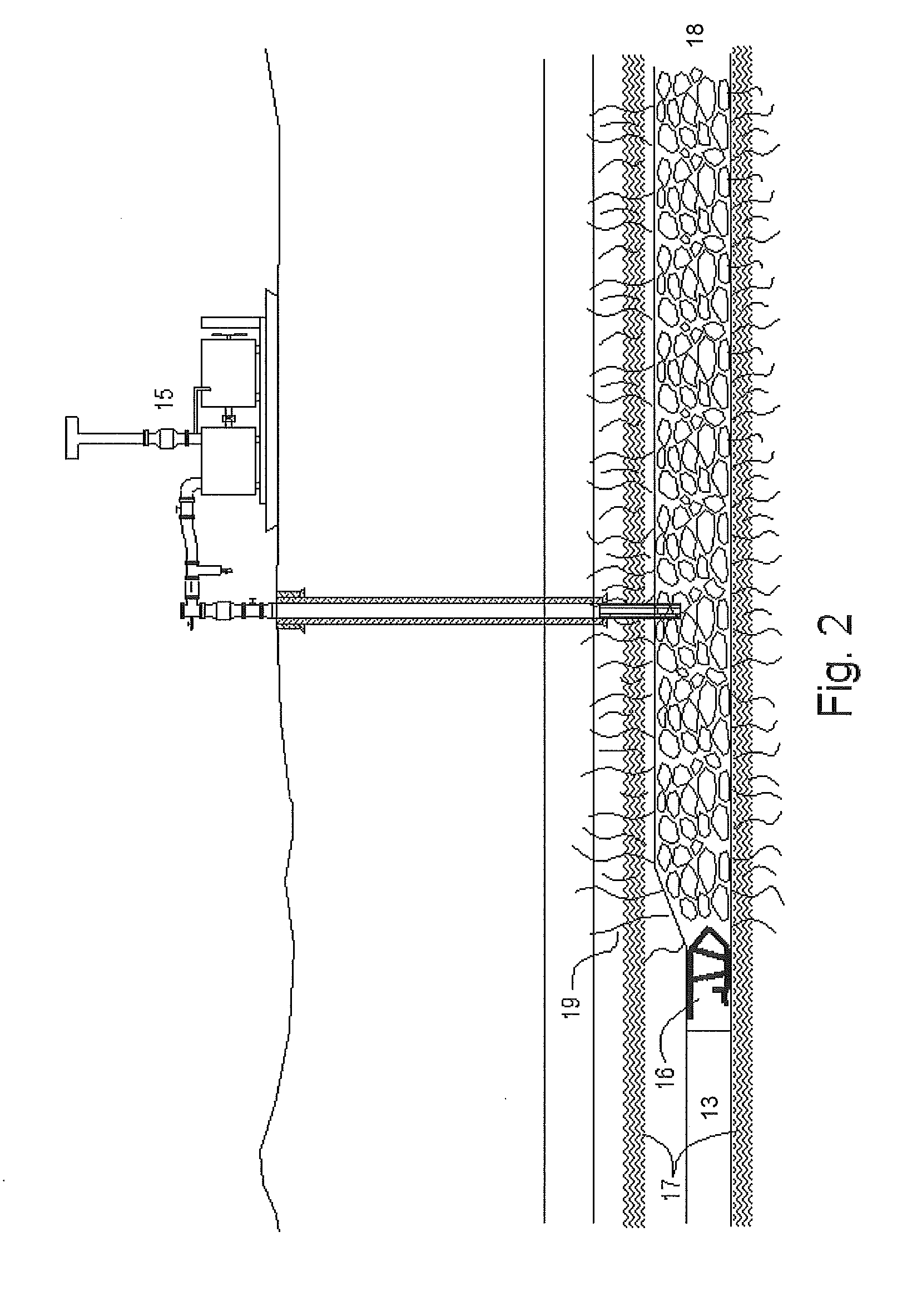

System and method of utilizing monitoring data to enhance seafloor sulfide production for deepwater mining system

Applicants have created a method and system of deep sea mining comprising mining SMS deposits from the sea floor with a subsea miner, pumping the solids from the subsea miner through a jumper and pumping the solids from the jumper up a riser to a surface vessel. Further, applicants have created a method of deploying a deep sea mining system, comprising stacking a riser hangoff structure on top of a subsea pump module forming an assembly; picking up the assembly by a hanging mechanism, hanging the assembly on a moon pool, attaching a first riser joint; disconnecting the riser hangoff structure from the assembly; and attaching at least one second riser joint to form the riser.

Owner:EDA KOPA SOLWARA

Pick assembly with integrated piston

Owner:NOVATEK IP

Mining Apparatus With Precision Navigation System

ActiveUS20070216216A1Clear operationRule out the possibilityDisloding machinesUnderground miningNavigation systemActuator

A mining apparatus includes a miner, a conveyor unit and a steering unit connecting the miner and conveyor unit. The apparatus also includes a heading sensor and a controller responsive to the heading sensor. A first actuator is carried on the miner, the control unit or the steering unit. The first actuator is positioned to a first side of a midline of the miner. Further a second actuator is carried on one of the miner, the conveyor unit and the steering unit. The second actuator is positioned to a second opposite side of the midline of the miner. The first and second actuators are utilized to adjust a connection angle between the miner and the conveyor unit either side of parallel in order to maintain the miner on the desired directional heading.

Owner:EAGLE HIGHWALL MINING SYST LLC

Tip for an earth working roll

ActiveUS20090174252A1Reduce wearReduced service lifeDisloding machinesUnderground miningWork rollCrusher

A tip for use on an earth working roll for mining, construction and public works machines such as crushers, surface miners, milling machines and the like includes a working end provided with side relief to reduce drag and wearing, require less power to drive the rolls, and lengthen the usable life of the tip. The working end can also have a generally flat front surface to improve the yield in a crushing or other similar operation. The tip includes a base and a wear cap releasably secured together by a retainer.

Owner:ESCO GRP LLC

Method of optimizing production of gas from vertical wells in coal seams

ActiveUS20050121196A1Maximize interferenceIncrease gas productionSurveyDisloding machinesCoalWellbore

The present invention is directed to a method for producing gas from a subterranean formation containing a coal seam. The method includes the steps of drilling a substantially vertical well bore into the subterranean formation, which intersects the coal seam and fracturing the coal seam using a hydrajetting tool to produce at least one pair of opposed bi-wing fractures substantially along a plane of maximum stress. One or more horizontal well bores may also be drilled into the coal seam along which the coal seam can be further fractured.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for forming a barrier

A method for forming a barrier to seal off a remote chamber includes the steps of: forming a borehole that communicates between a first location and the remote chamber; inserting a conduit through the borehole to extend into the remote chamber; introducing a flowable material through the conduit to the remote chamber and dispensing the flowable material from the conduit to the desired location for the barrier, the flowable material upon being dispensed producing a substantially solid, self-sustaining composition; maintaining dispensing the flowable material to produce a sufficient quantity of the self-sustaining composition to form the barrier to seal the remote chamber, while ensuring that the composition does not block the borehole from communicating between the first location and the remote chamber; and thereafter removing the conduit to allow access to the borehole.

Owner:OZMENT ALDEN

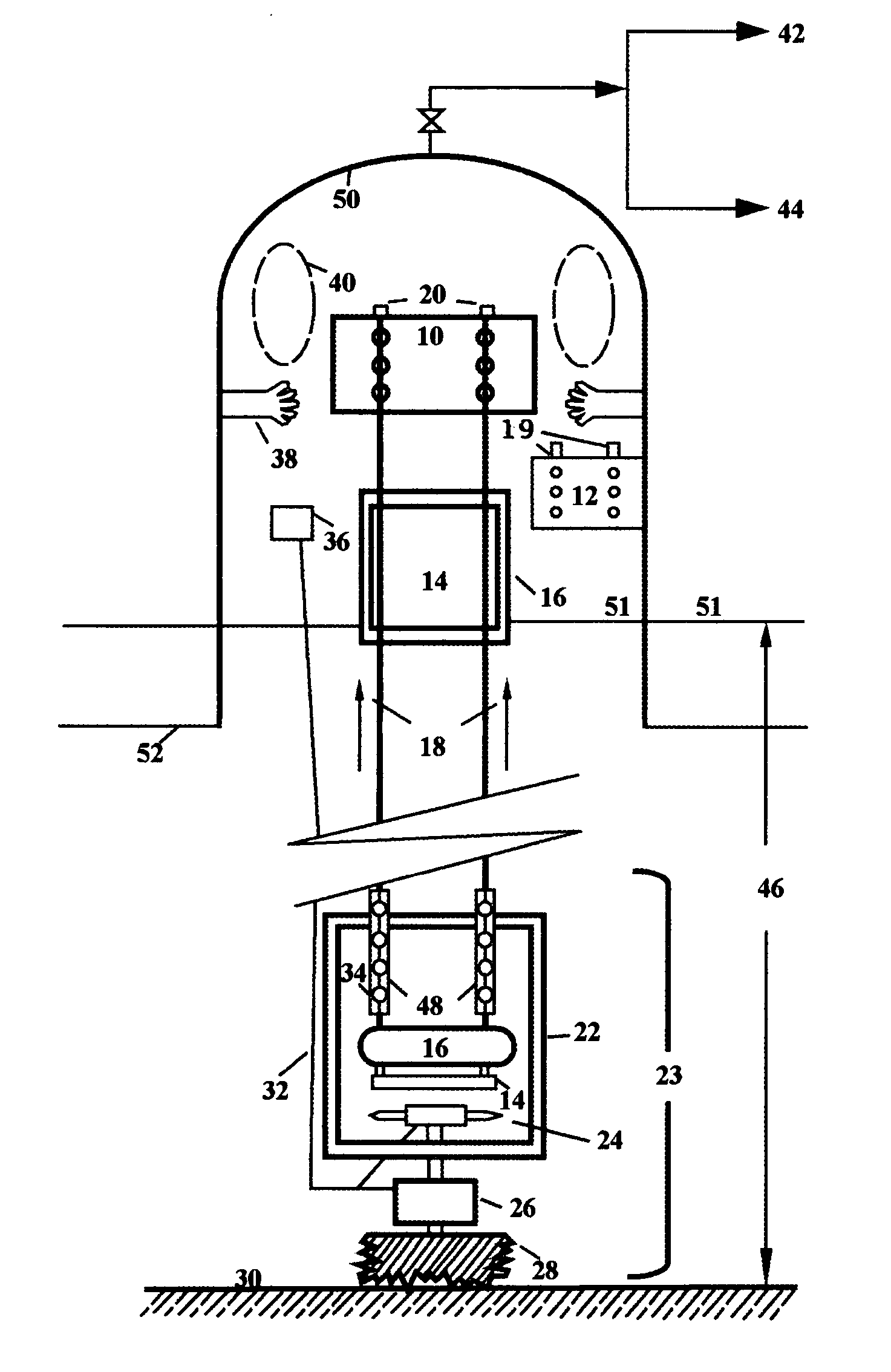

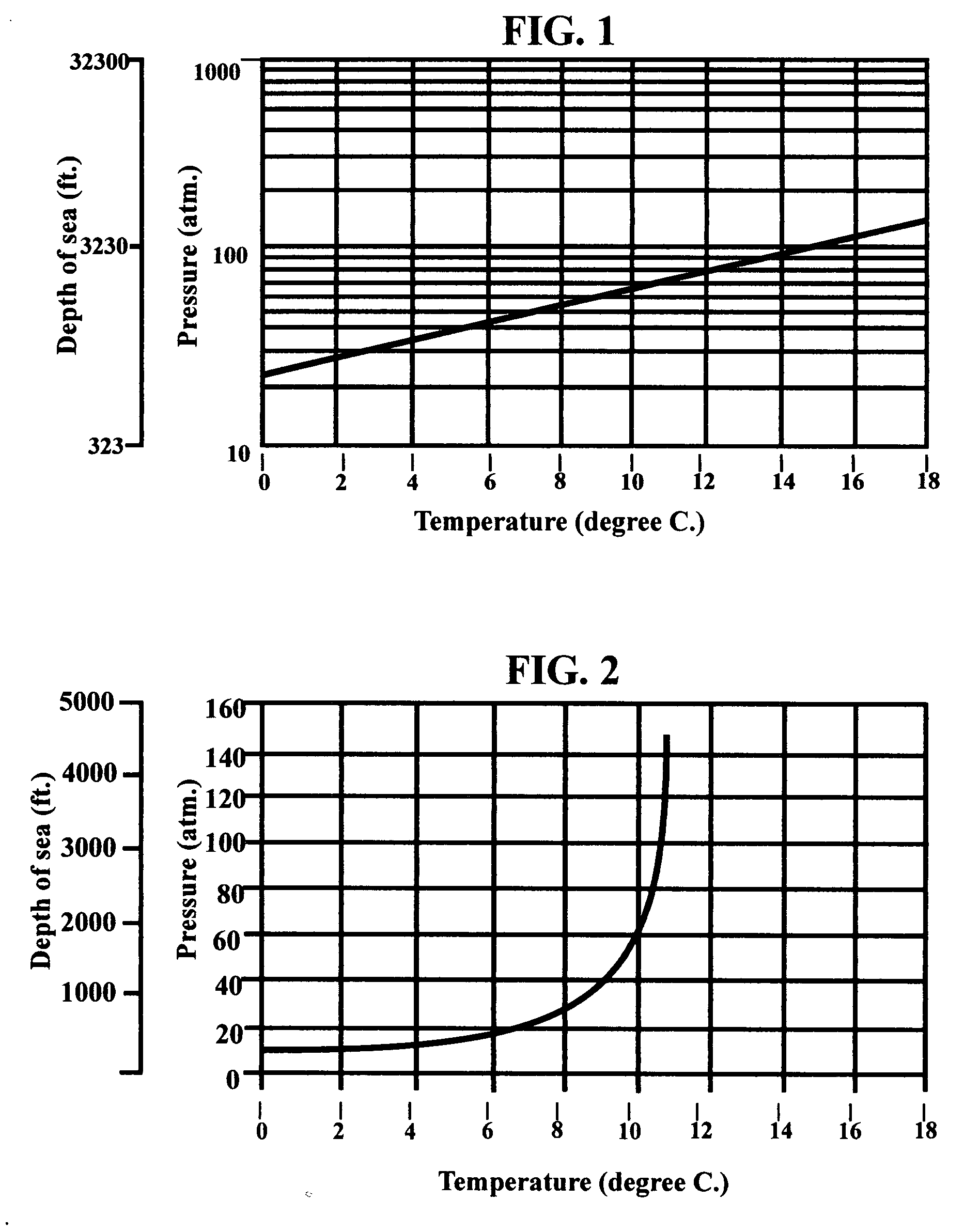

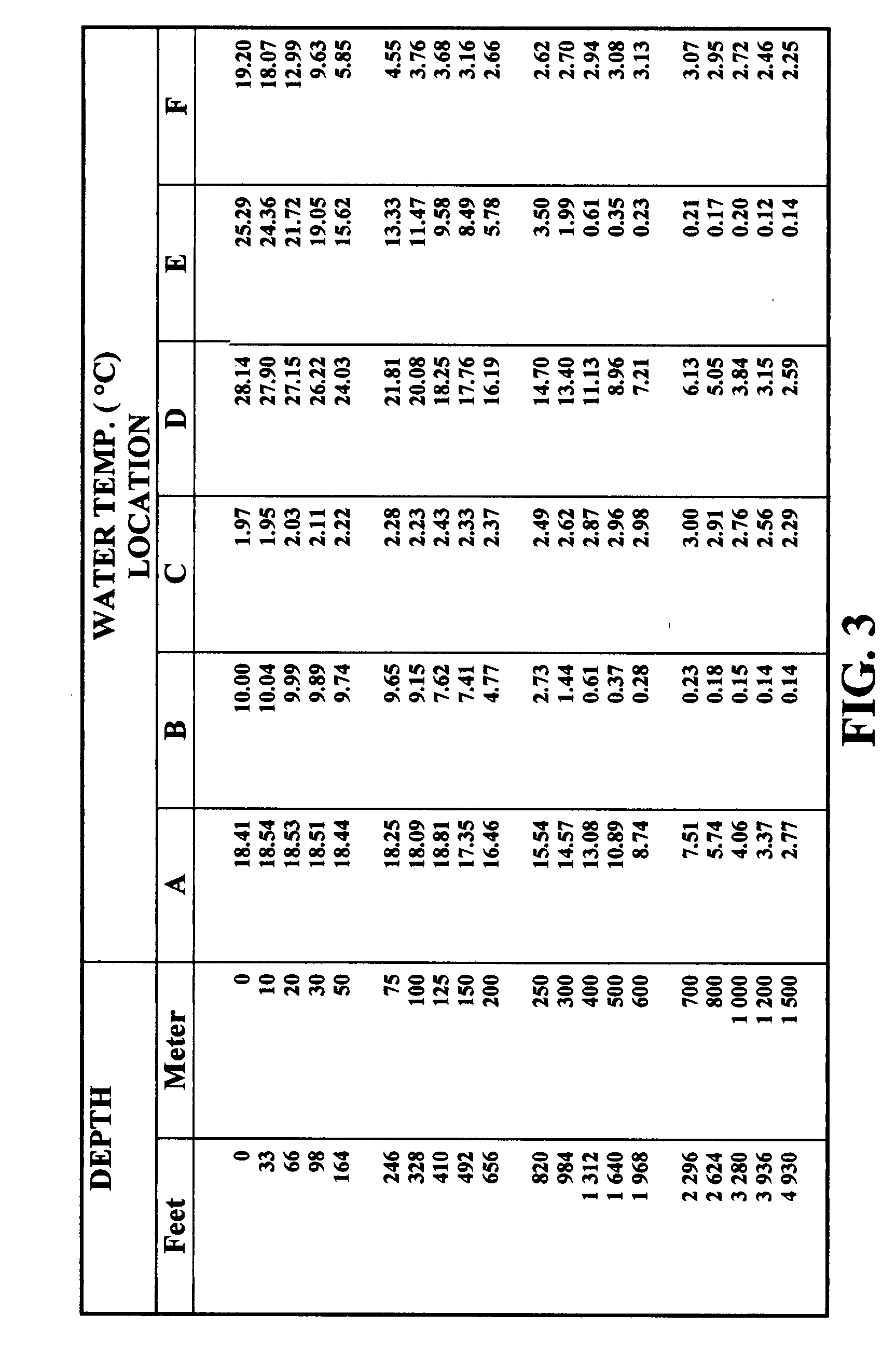

Mining methane, sequestering carbon dioxide and farming in oceans

The present invention is a multiple purposed system of producing methane from its hydrates and sequestering carbon dioxide into its hydrates. Methane hydrates mixed with mud, prepared with methane mining assembly 23 are brought to sea surface by a series of buckets 16 attaching to rotating chains 18. The decomposed methane is collected into the methane dome 50 and is processed into liquefied natural gas or synthetic liquid fuels. Liquid carbon dioxide is brought down through a tube 70 and a sequestering device 86 into the sea where the pressure and the temperature are adequate for carbon dioxide hydrates to form and settle down to the sea bottom. The unconverted gaseous carbon dioxide is collected into carbon dioxide dome 49 and is liquefied again for recycling. A specially designed marine plantation, comprising of plurality of planting units 352 and a fleet of seeding and harvesting boats, is employed to remove the residual carbon dioxide from the sequestering, to alleviate the global warming, to serves as an abundant source of renewable energy, and as a huge sink for carbon. In addition, it could provide a profusion of less-polluted seafood. The operations of mining methane, sequestering carbon dioxide and marine plantation are fully integrated and optimized

Owner:CHENG SHANG I

Method and apparatus for monitoring gateroad structural change

ActiveUS20090134692A1Overcome problemsElectric/magnetic detection for well-loggingMining devicesMultiple sensorEngineering

Owner:COMMONWEALTH SCI & IND RES ORG

Mobile oil sands mining system

Owner:SUNCOR ENERGY INC

Control system having tool tracking

A control system is disclosed for use with a machine having a work tool and operating at a work site. The control system may have a sensor associated with the work tool and configured to generate a signal indicative of a position of the work tool, an offboard worksite controller, and an onboard controller in communication with the sensor and the offboard worksite controller. The onboard controller may be configured to receive from an operator an input indicative of a current task being performed by the machine, and track movement of a portion of the work tool corresponding with the operator input. The onboard controller may also be configured to communicate the tracked movement to the offboard worksite controller.

Owner:CATERPILLAR INC

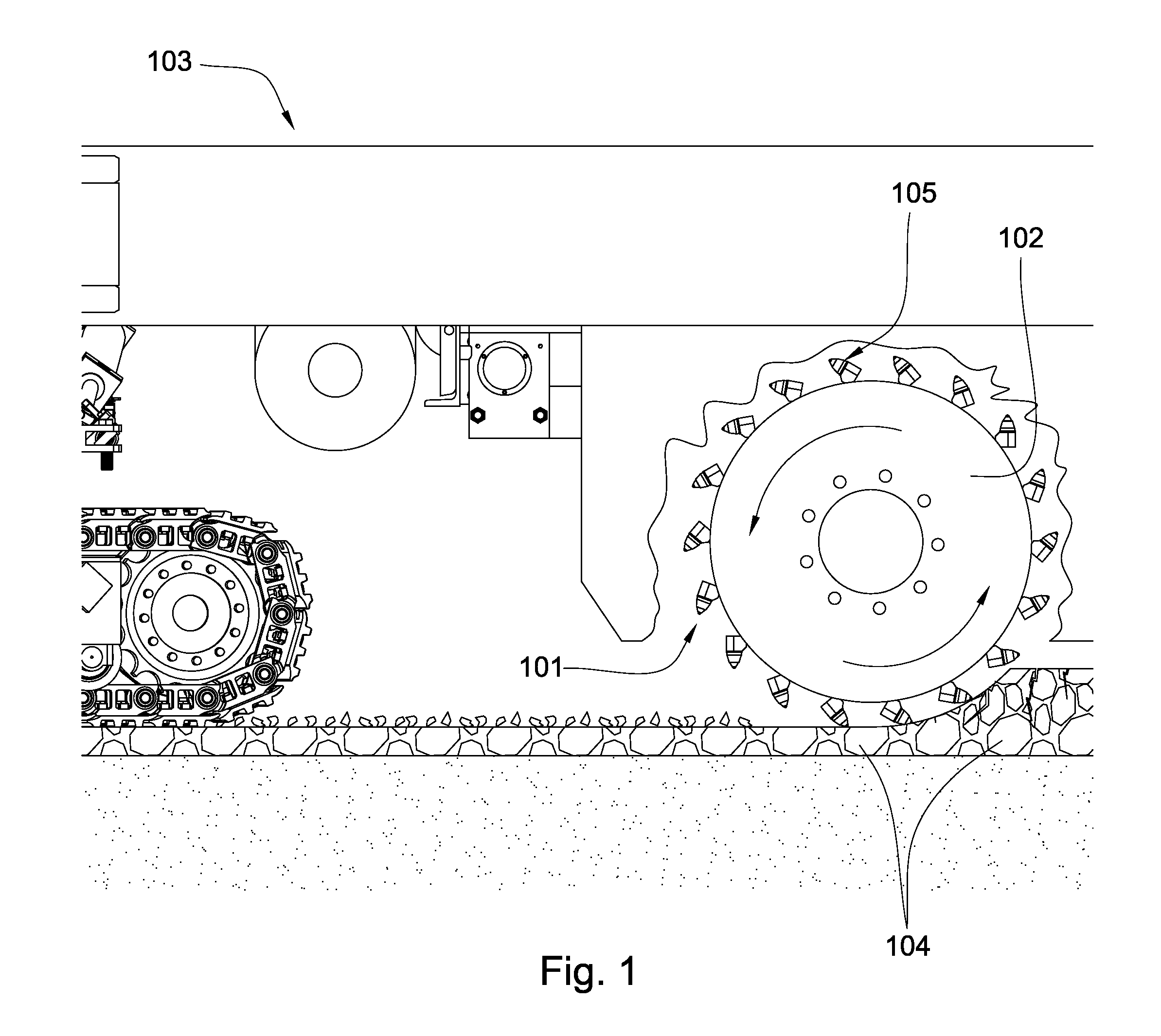

Milling Drum

In one aspect of the invention a system for removing a layer of a paved surface comprising a vehicle is adapted to traverse a paved surface in a selected direction. The vehicle has a milling drum with an axle substantially parallel and connected to the vehicle within a milling chamber. The drum is adapted to rotate around the axle between the paved surface and the vehicle. A conveyor belt is attached to a forward end of the vehicle and comprises a portion proximate an opening of the milling chamber. The belt is adapted to carry loose aggregate from the milling drum away from the paved surface. At least one nozzle is disposed on an underside of the vehicle and is in communication with a reservoir through a pathway. The at least one nozzle is adapted to direct the loose aggregate towards the portion of the conveyor belt.

Owner:NOVATEK IP

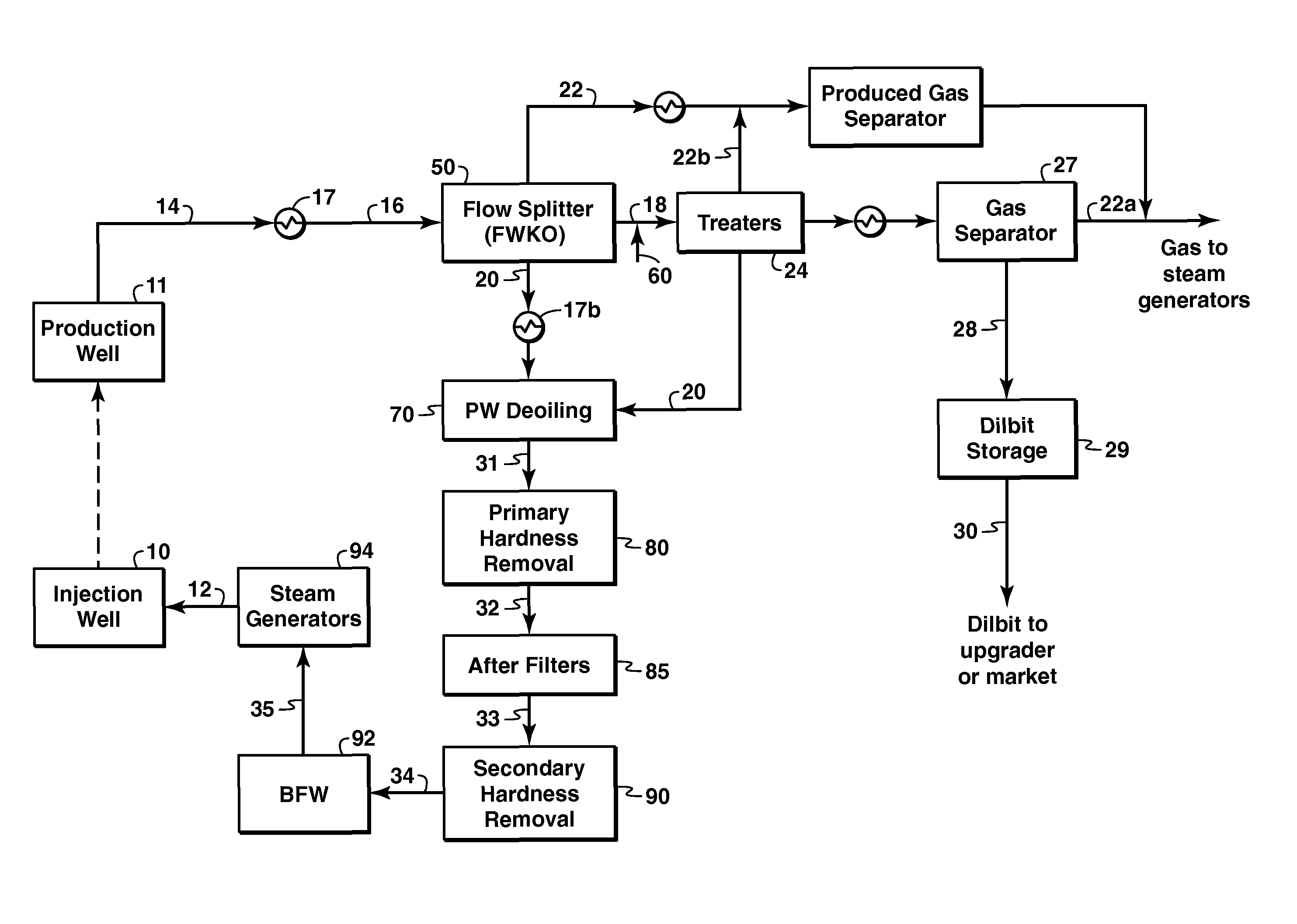

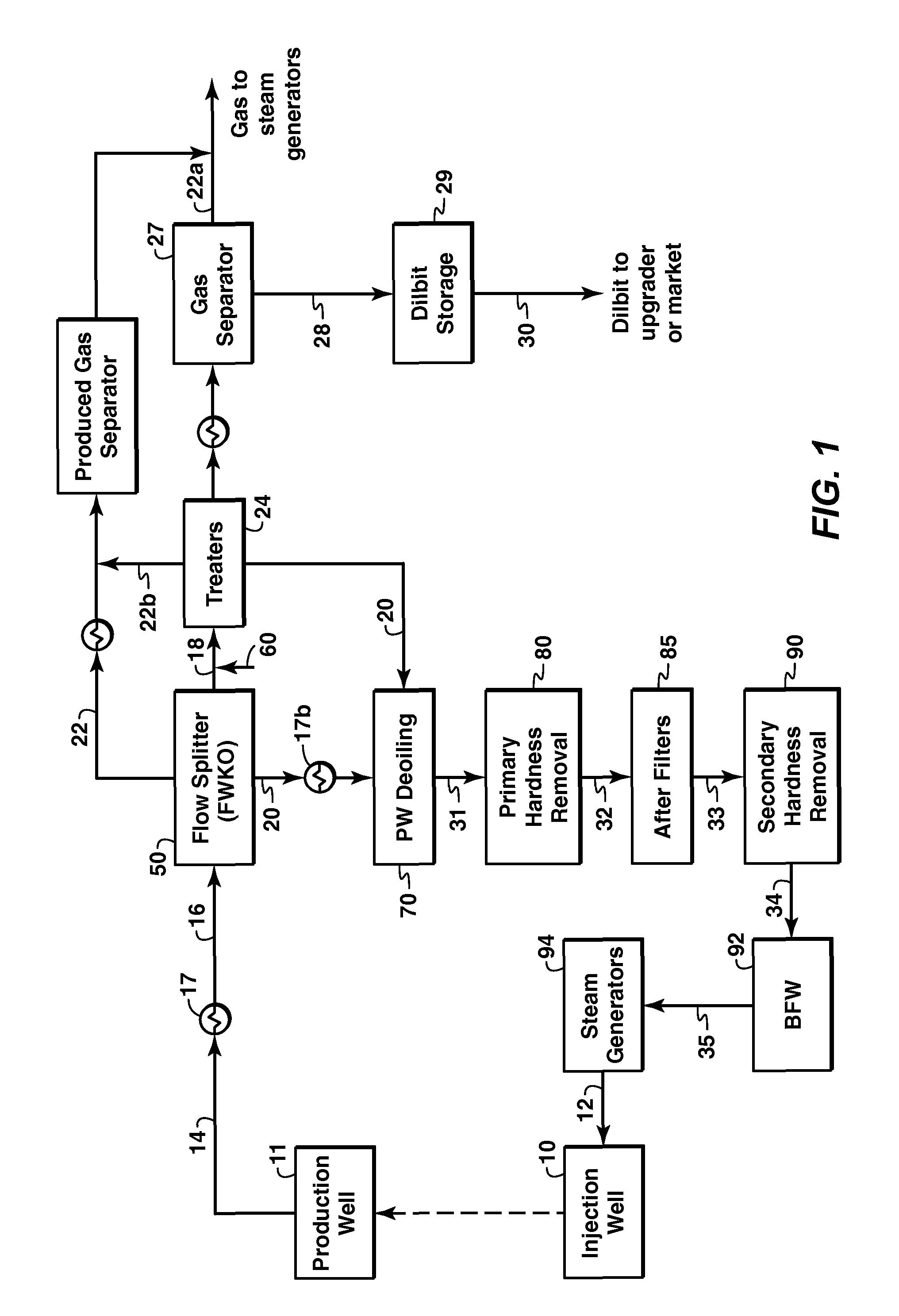

Integration of an in-situ recovery operation with a mining operation

InactiveUS20100276983A1Disloding machinesUnderground chambersSteam-assisted gravity drainageIntegrated systems

This description is directed to a method and system for integrating an in-situ bitumen recovery operation with a bitumen mining operation for improved efficiencies and synergies therebetween. The method comprises obtaining a production fluid from the in-situ bitumen recovery operation, directing the production fluid to the bitumen mining operation, and incorporating the production fluid into the bitumen mining operation. The basic integrated system comprises a production well for recovering production fluid from the in-situ bitumen recovery operation, a bitumen mining and extraction facility, and a transporter for directing the production fluid from the production well to the bitumen mining and extraction facility for incorporation into the mining and extraction operation. The in-situ recovery operation may be a thermal operation, such as steam-assisted gravity drainage (SAGD), cyclic steam stimulation (CSS), or a derivative thereof.

Owner:EXXONMOBIL UPSTREAM RES CO

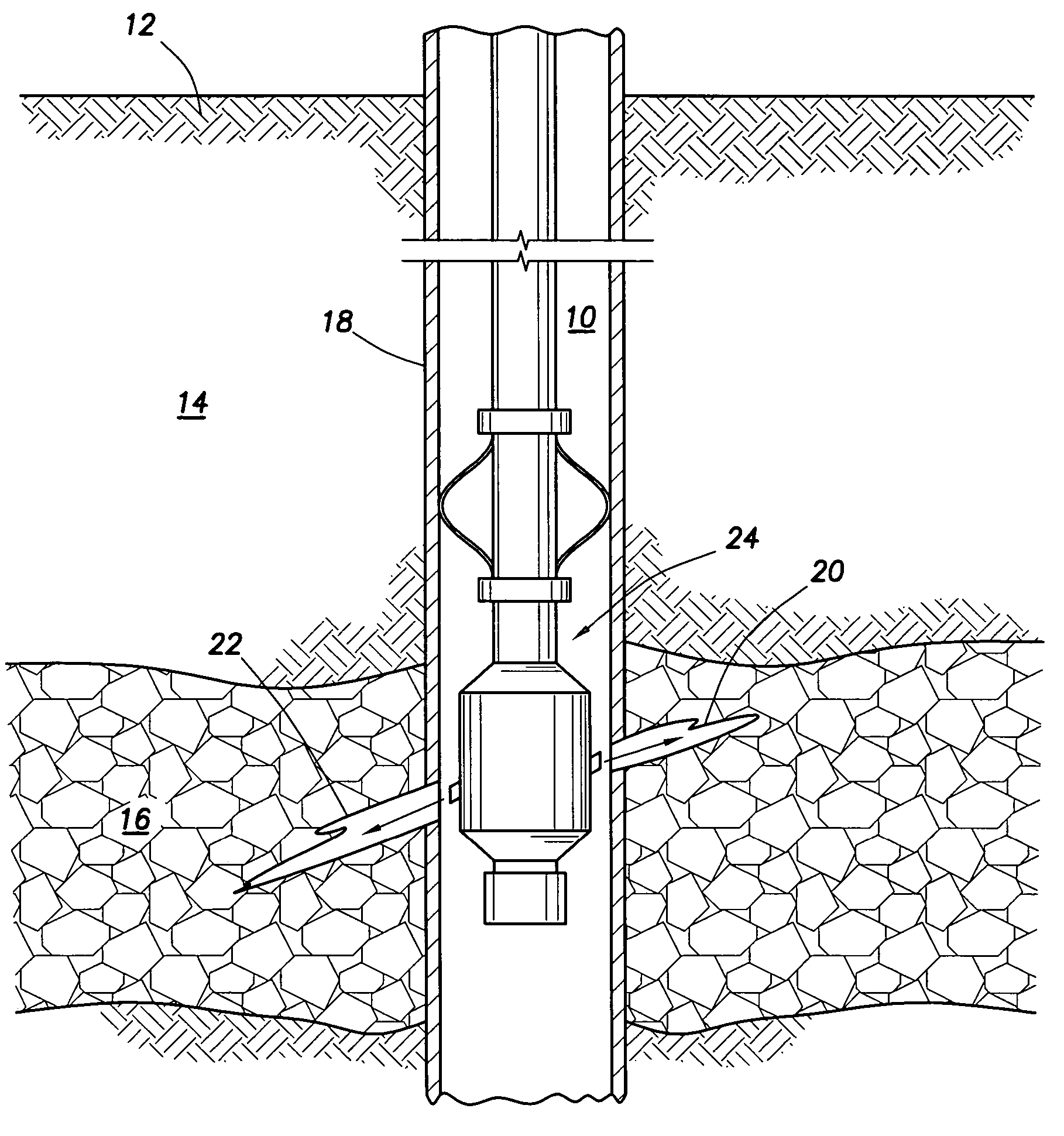

Device for sealing a drill hole and for discharging drillings or stripped extraction material

InactiveUS7011167B2Improve securityImprove sealingDrilling rodsConstructionsEngineeringDrill cuttings

In a device for sealing a bore hole and discharging drill cuttings and stripped excavation material, including a housing adapted to receive sealing elements and an opening capable of being connected to the bore hole, one side wall of the housing is provided with at least one opening for the connection of a haulage duct, wherein the housing end side facing the bore hole is equipped with a lockable, particularly screwable, sealing flange (13) for the detachable connection with a bore hole lining (11). The sealing flange (13) is rotationally and sealingly mounted within the housing and carries projections, in particular an annular brim (15) which is overlapped by a stop (14) of the housing.

Owner:VOEST ALPINE BERGTECHNIK GMBH +1

Electronic blasting capsule

An electronic blasting capsule which includes a housing which contains a propellant, a fuse, a sensor for detecting the position of the housing in a capsule delivery path, an energy arrangement for obtaining energy from an external energy source, and a controller, responsive to the sensor and the energy arrangement, for firing the fuse to initiate the propellant.

Owner:SANDVIK MINING & CONSTR RSA (PTY) LTD

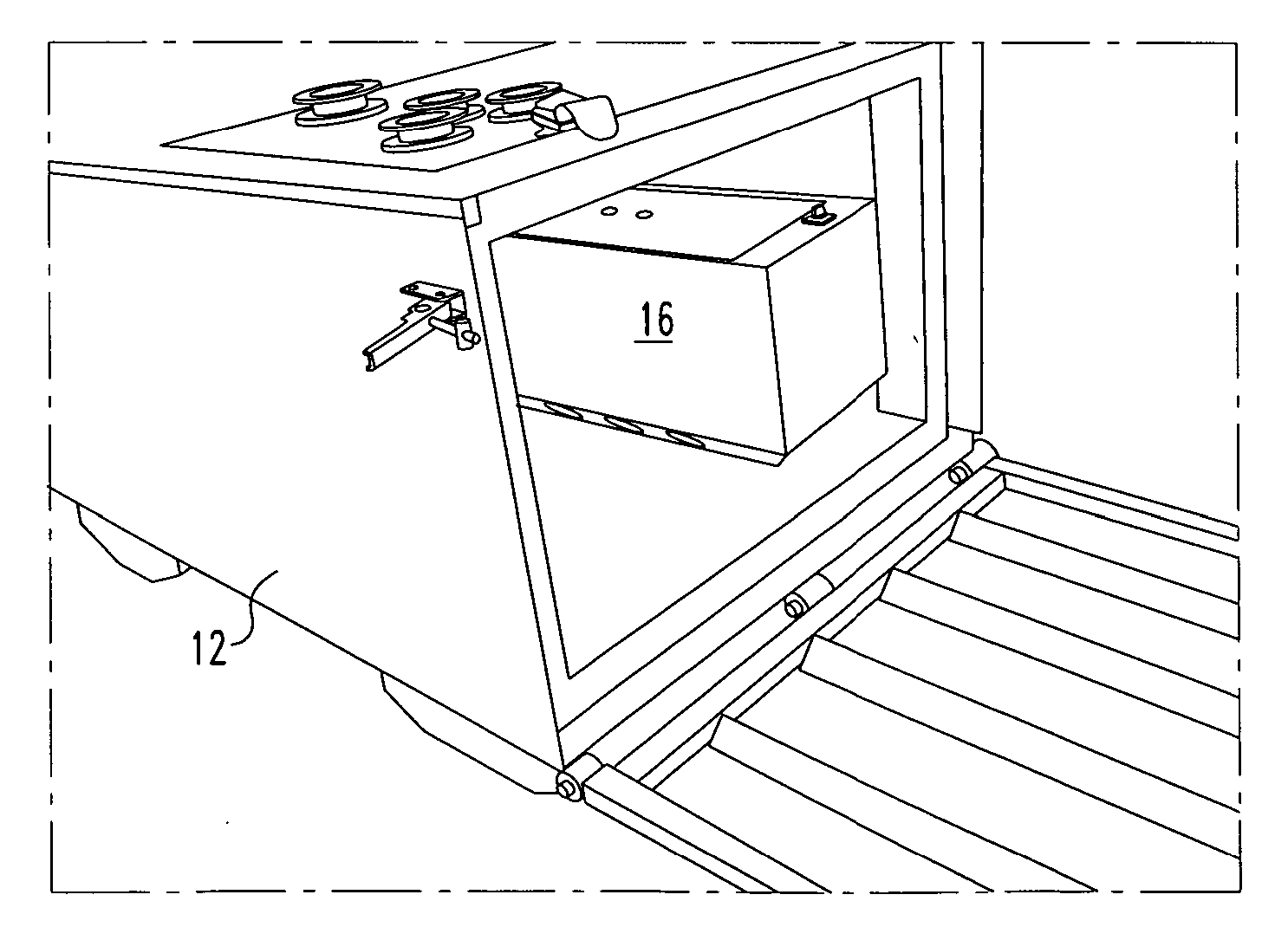

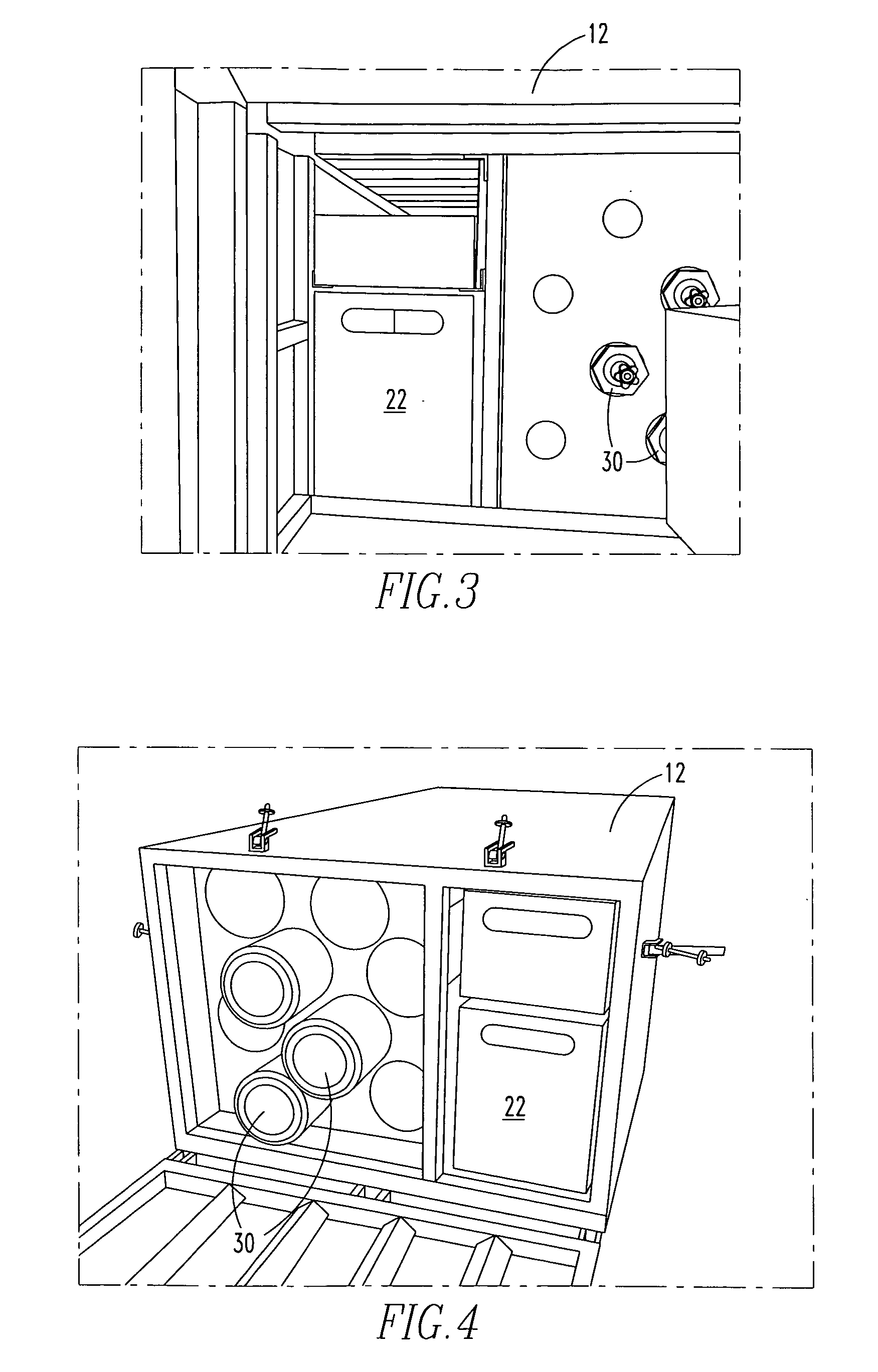

Refuge chamber and method

A refuge chamber for miners in a mine includes a skid. The chamber includes a tent that is disposed in the skid in an undeployed state which is expandable to a deployed state and extends from the skid to provide a protected atmosphere for the miners. A method for providing a refuge chamber for miners in a mine including the steps of opening a skid made of metal. There is the step of expanding a tent that is disposed in the skid in an undeployed state to a deployed state that extends from the skid to provide a protected atmosphere for the miners.

Owner:STRATA PRODS WORLDWIDE

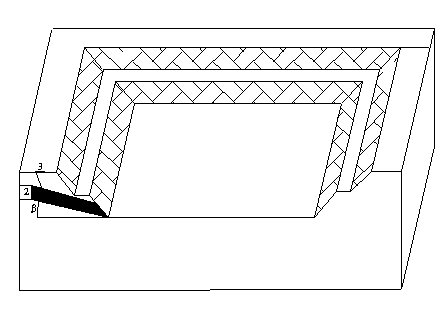

Opencast mine end slope near-slope mining method

ActiveCN103133003AReduce stripping ratioLow application costOpen-pit miningSlope stabilityOpen-pit mining

The invention discloses an opencast mine end slope near-slope mining method. During an opencast mining process, for integral side slopes of end slopes on two horizontal sides of a mining field, near-border mining is carried out according to a stable angle alpha as in an initial design; according to a timeliness slope principle, inner dump is followed up in time; a pit bottom distance is shortened to a minimal safety distance Dmin required by mining, and integral height H of the side slope of the end slope is reduced; according to a side slope stable condition, the side slope angle is increased to beta; and near-slope mining is realized. The height of inner dump bottom layer slope-pressing step is 2-3 times that of mining working slope step. Stripped soil and rock are transported to the inner dump bottom layer slope-pressing step through a built soil-discharge bridge. With the method provided by the invention, side slope angle can be increased on a basis that slope end stability is ensured. Therefore, end slope residual coal can be recovered; stripping ratio can be reduced; and transportation cost can be reduced.

Owner:CHINA UNIV OF MINING & TECH

Mining method for co-extraction of non-combustible ore and mine methane

ActiveUS20090315388A1Safer working environment undergroundAvoid excessive dilutionDisloding machinesUnderground miningMineralogyMethane

Mining method for co-extraction of non-combustible ore and mine methane A method for co-extracting non-combustible ore (e.g., trona) and methane from an underground formation comprising at least one methane-bearing layer and a non-combustible ore bed having a rock roof, comprising:providing a well having a downhole end positioned above the ore bed roof;mining an ore region from an initial cavity and removing the mined ore, thereby creating a subsequent cavity;advancing the mining step to another ore region from the subsequent cavity;allowing the roof of the initial cavity to cave so as to create a gob;repeating the mining, advancing and caving steps, the caving being effective in generating fluid communication between the gob and the well downhole end and in fracturing the methane-bearing layer so as to release methane into the gob; andrecovering a gob gas comprising released methane through the well to the surface.

Owner:SOLVAY CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com