Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

795 results about "Auger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An auger is a drilling device, or drill bit, used for making holes in wood or in the ground. It usually includes a rotating helical screw blade called a "flighting" to act as a screw conveyor to remove the drilled out material. The rotation of the blade causes the material to move out of the hole being drilled.

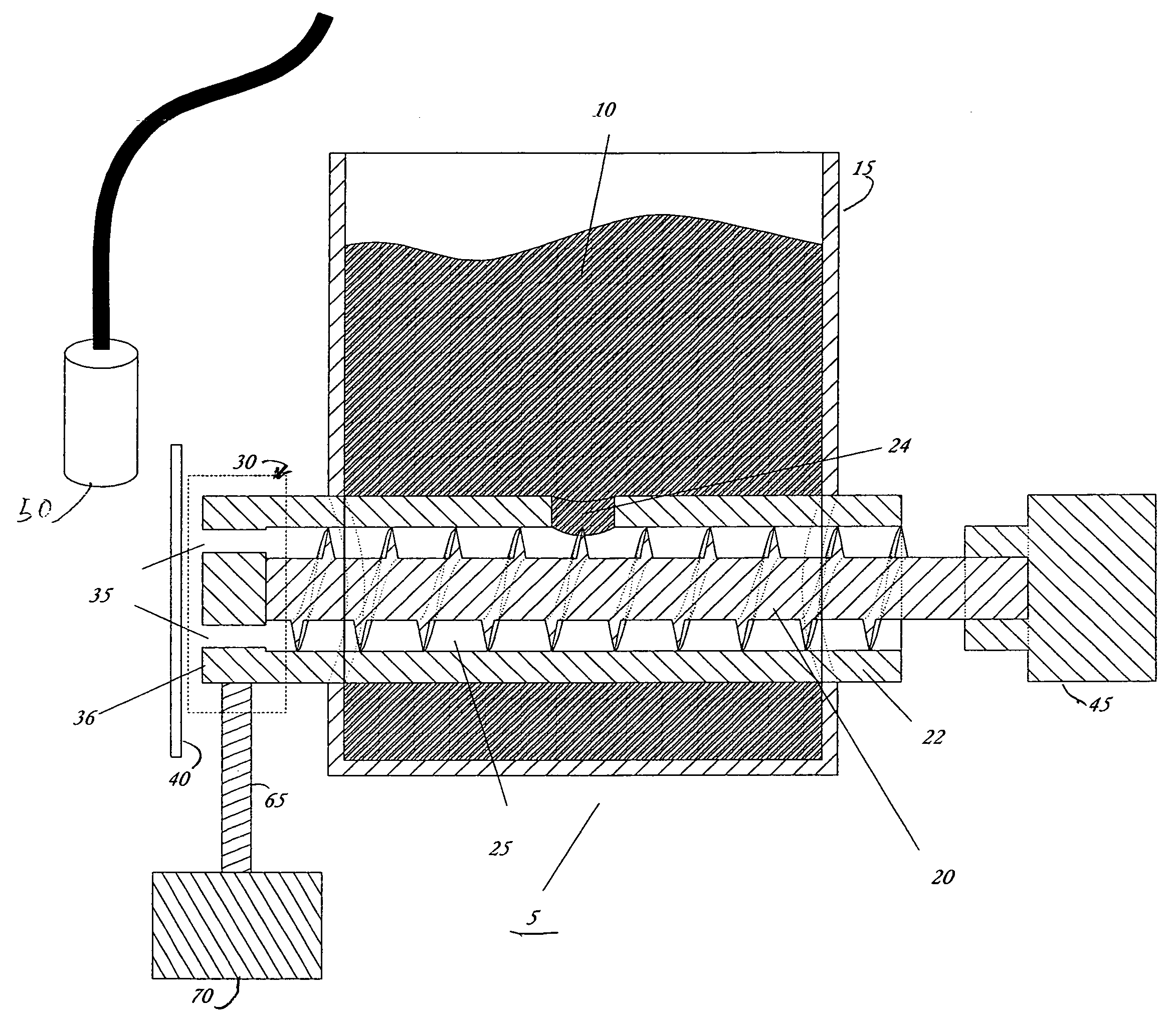

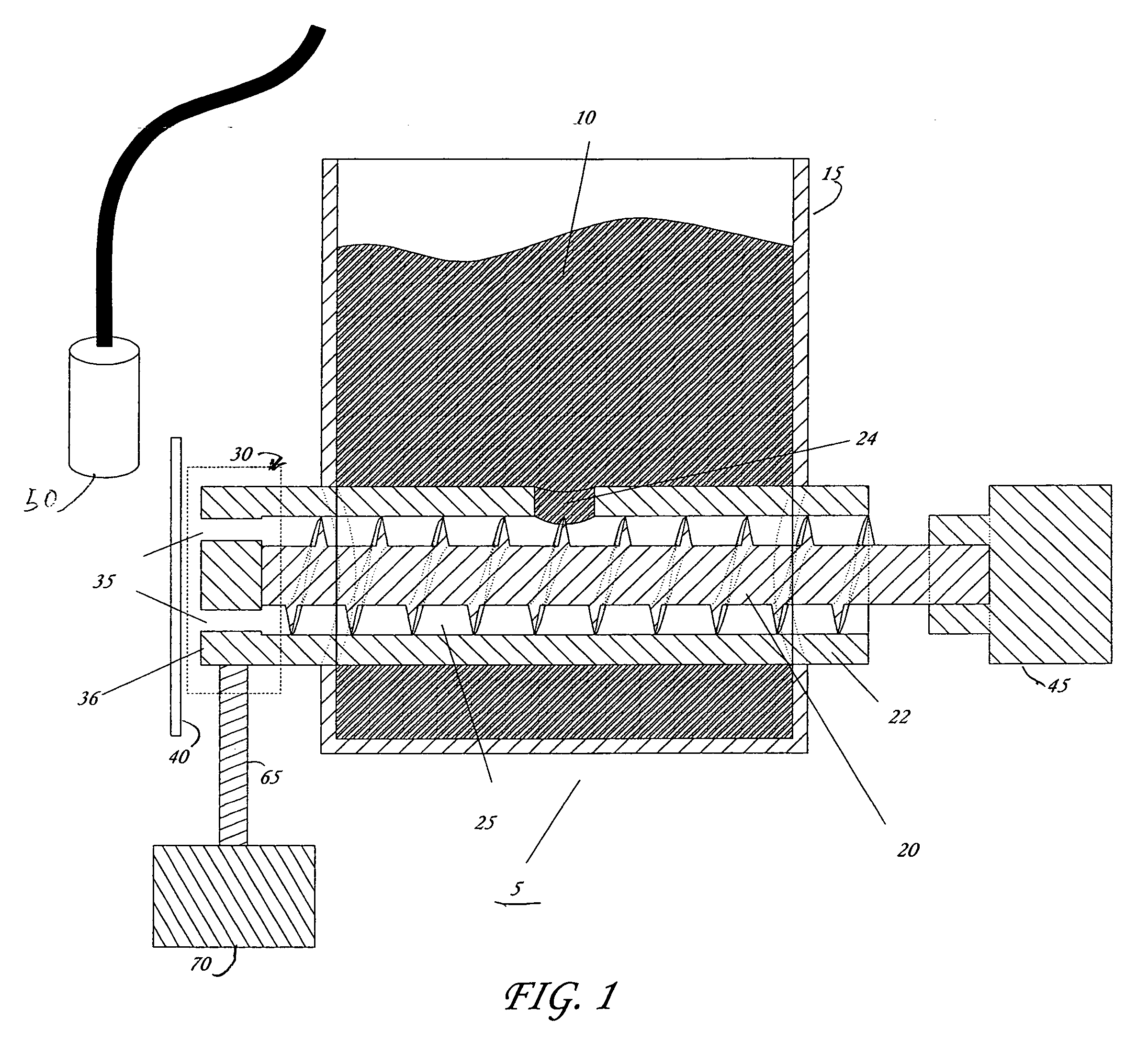

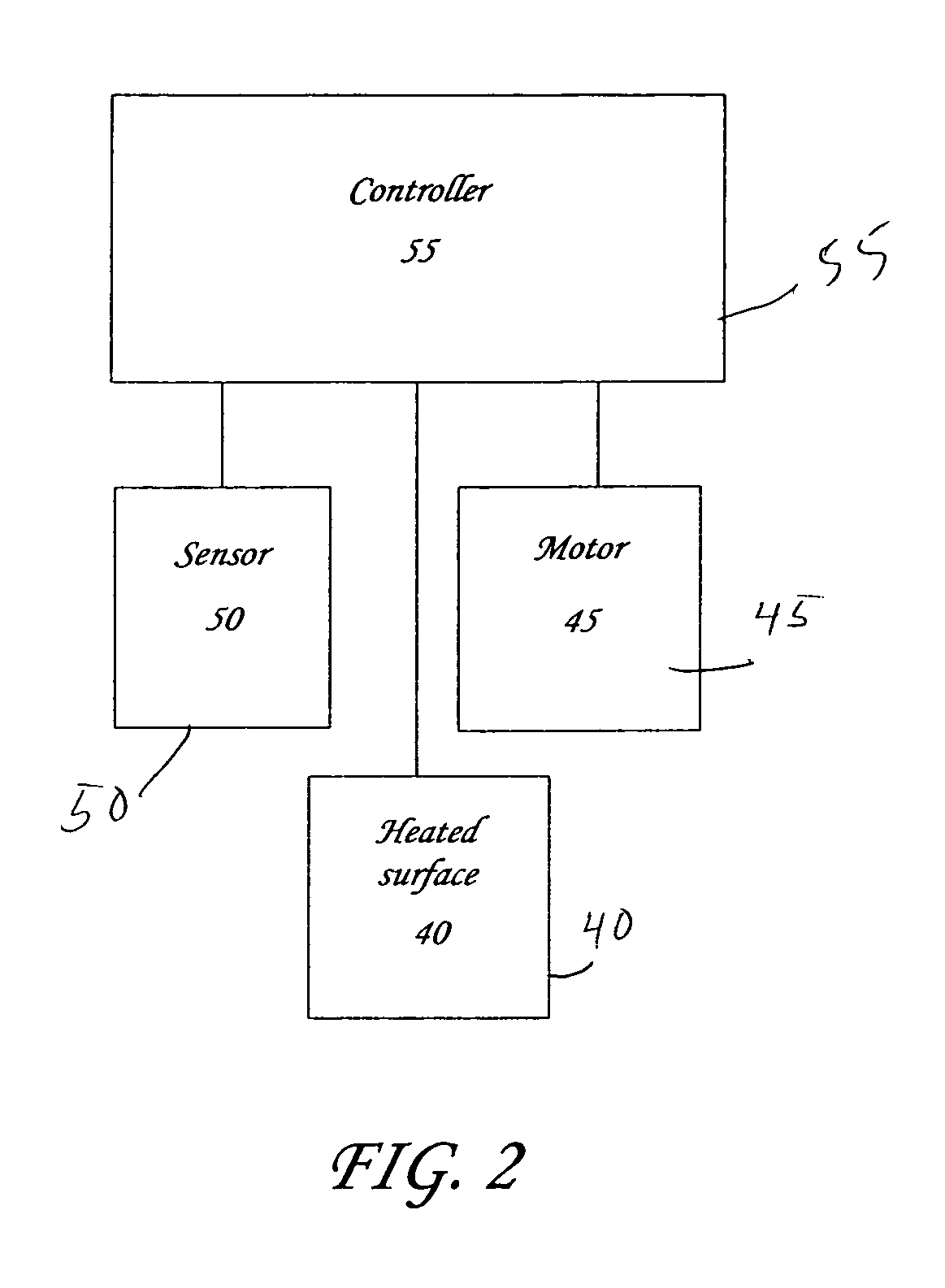

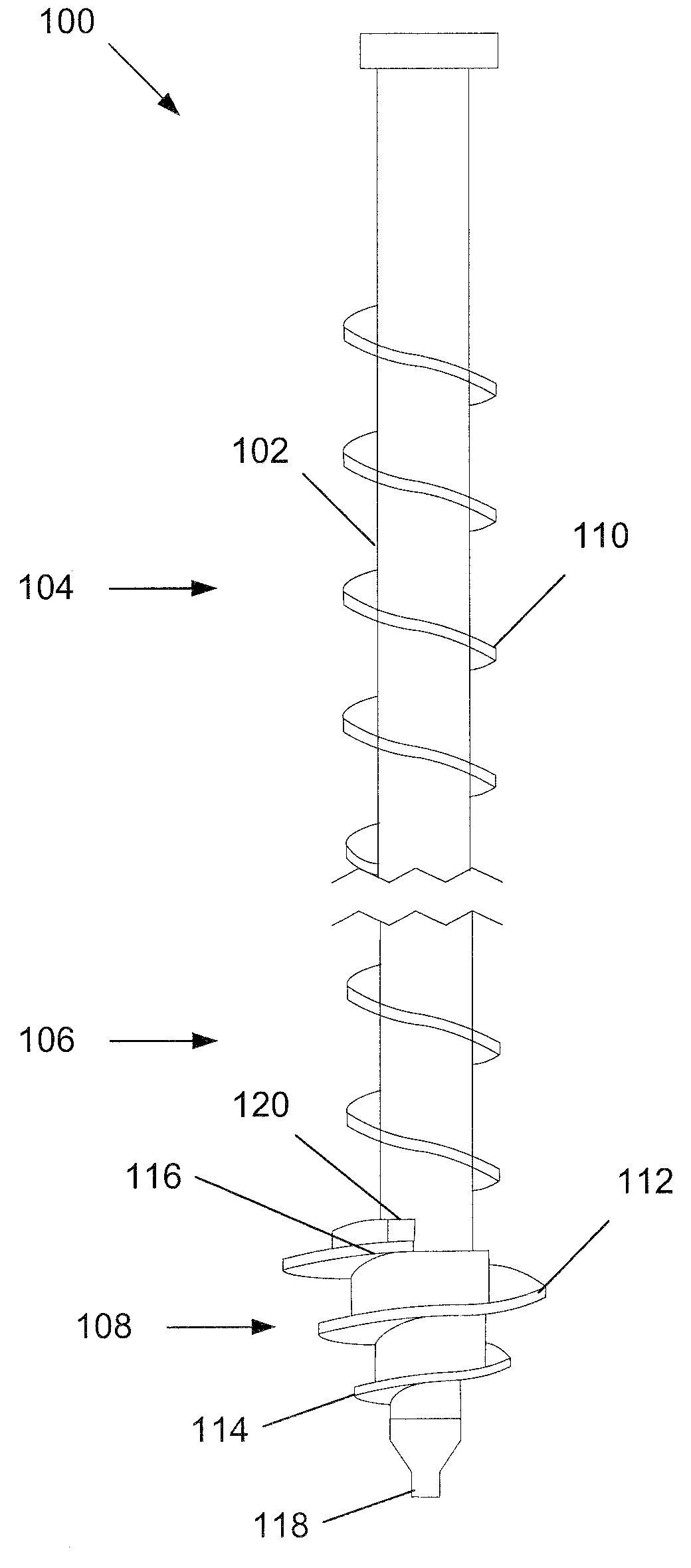

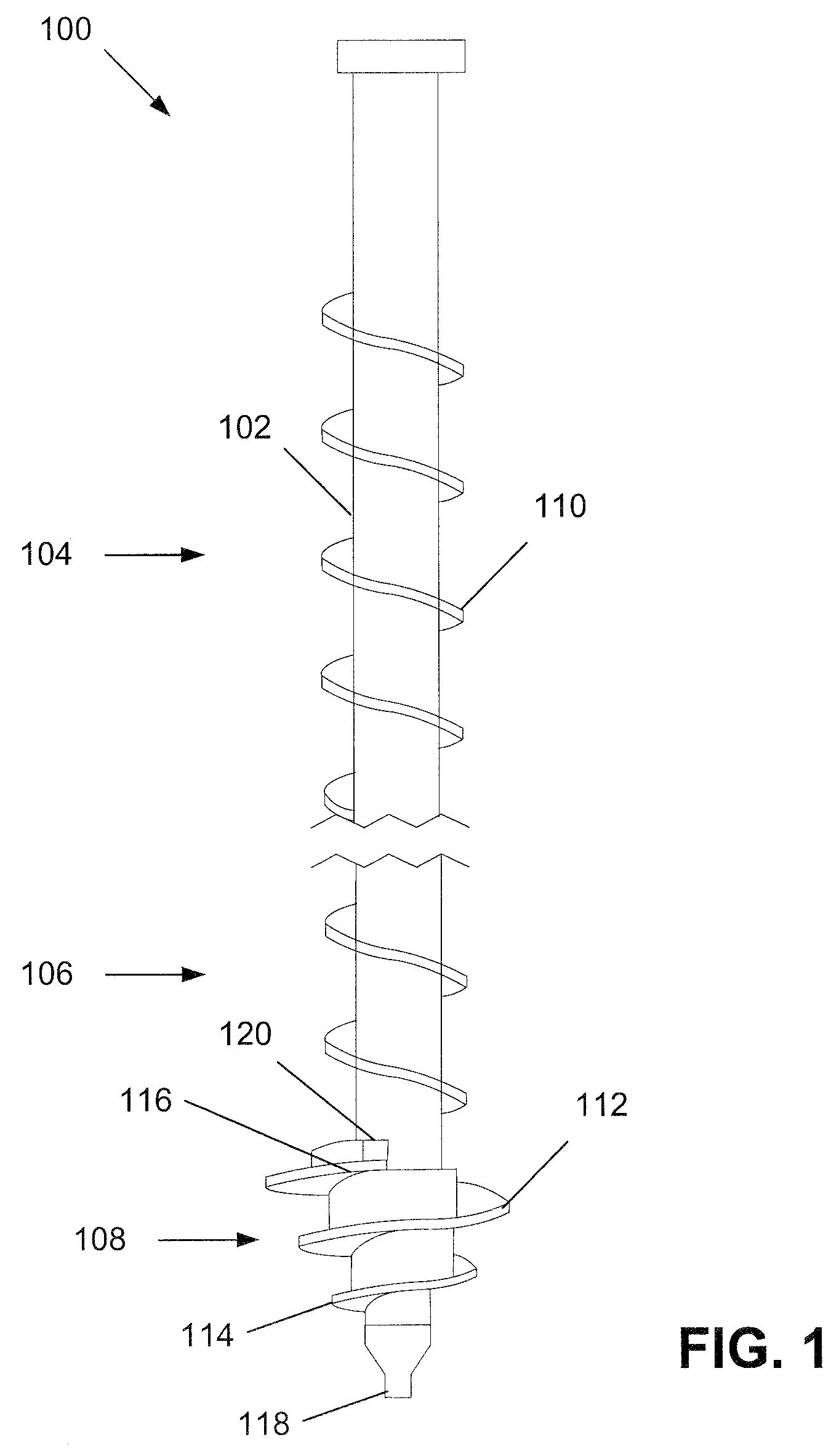

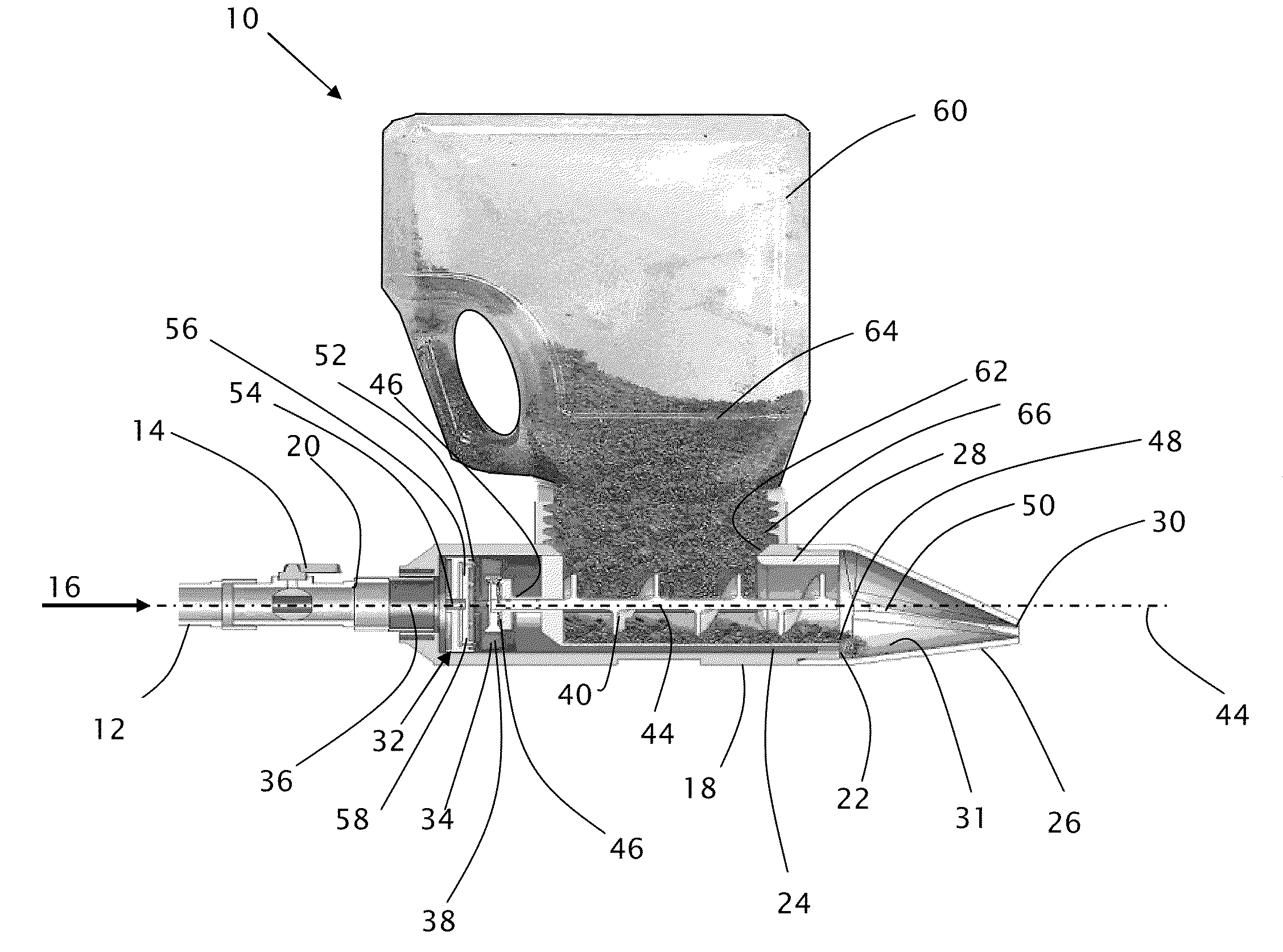

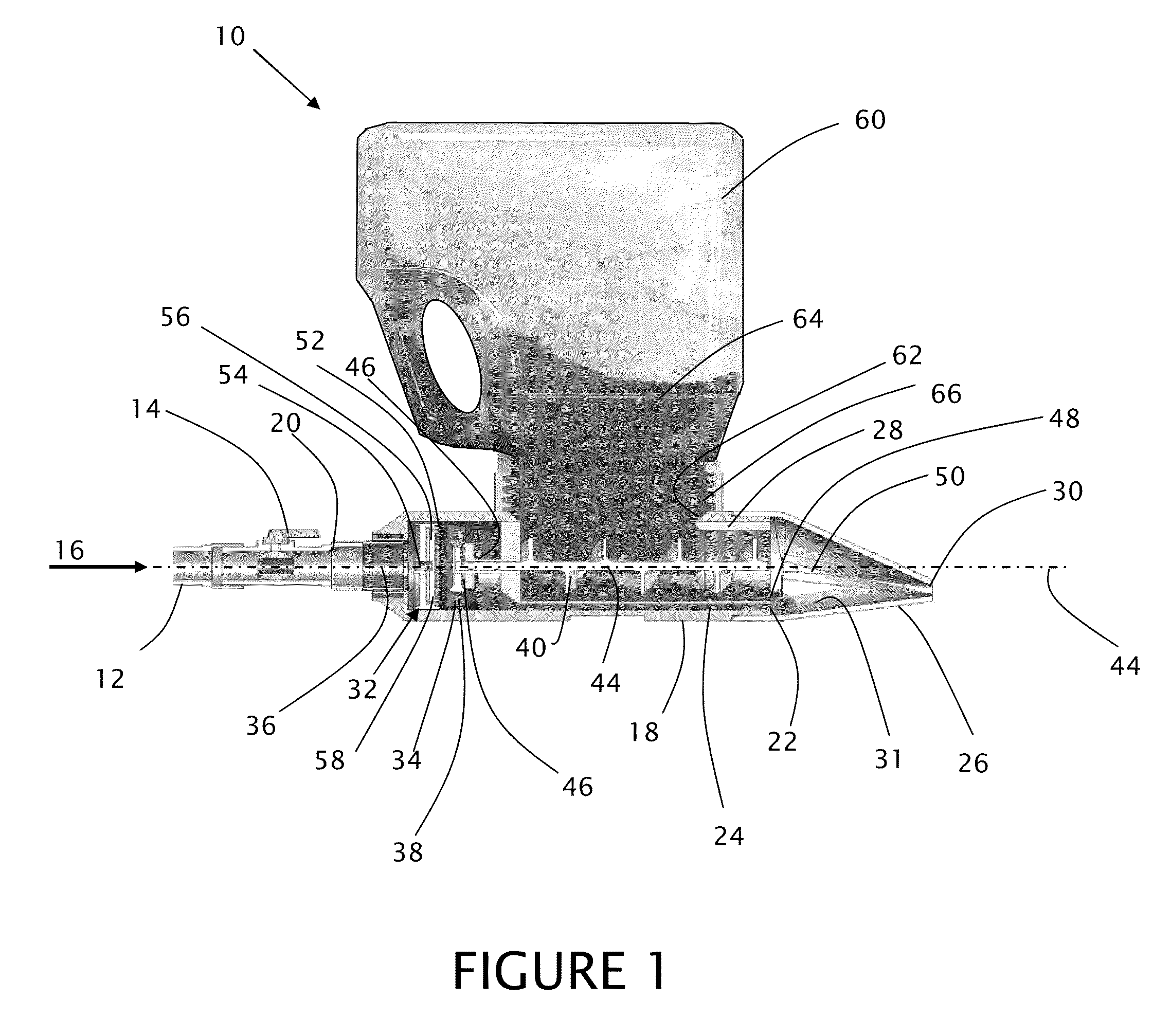

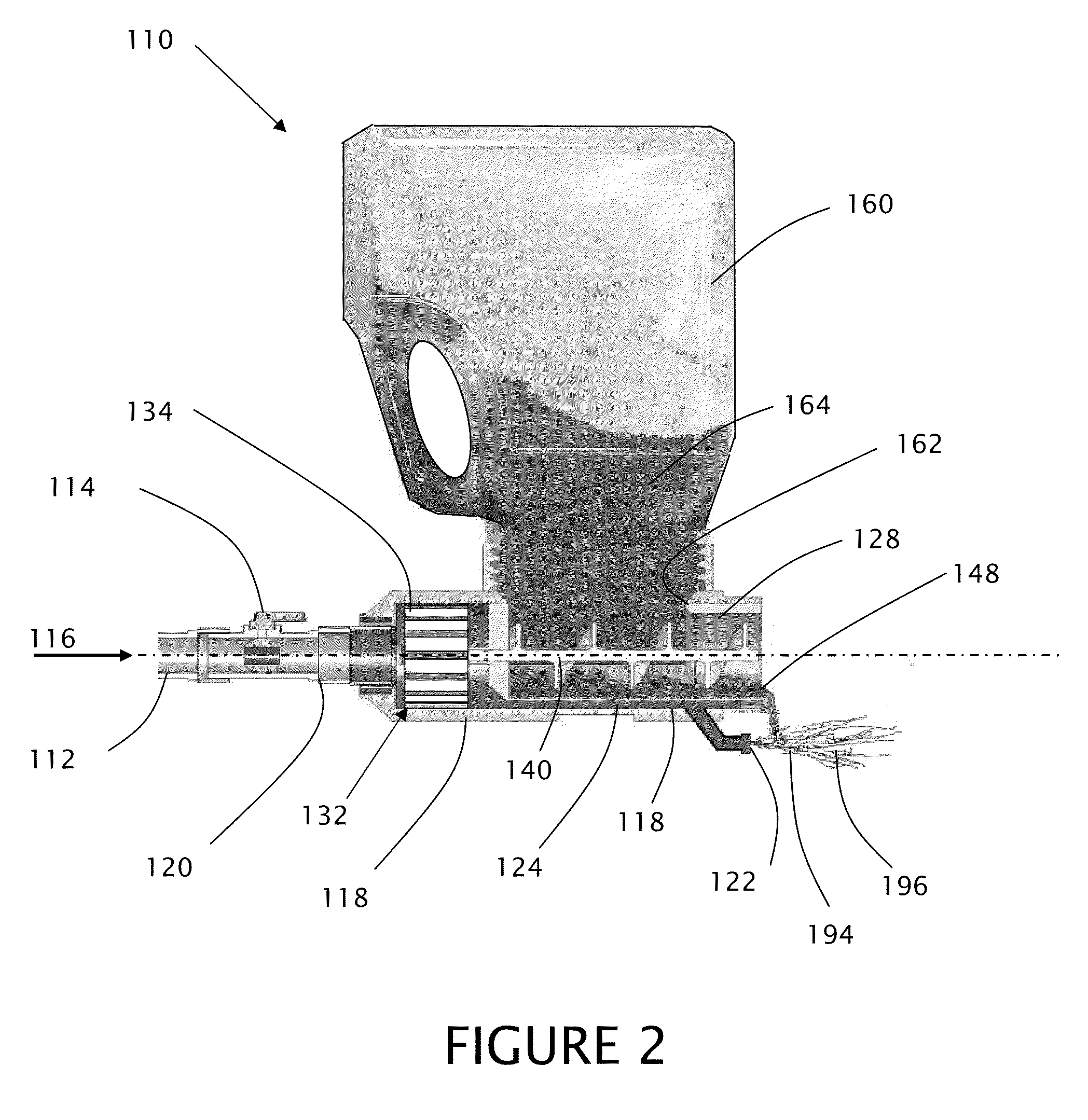

Controllably feeding organic material in making OLEDs

ActiveUS20060177576A1Effective waySolid-state devicesVacuum evaporation coatingOLEDMaterials science

A method for metering powdered or granular material onto a heated surface to vaporize such material, includes providing a container with powdered or granular material having at least one component; providing a rotatable auger disposed in material receiving relationship with the container for receiving powdered or granular material from the container and as the auger rotates, such rotating auger translates such powdered or granular material along a feed path to a feeding location; and providing at least one opening at the feeding location such that the pressure produced by the rotating auger at the feeding location causes the powdered or granular material to be forced through the opening onto the heated surface in a controllable manner.

Owner:GLOBAL OLED TECH

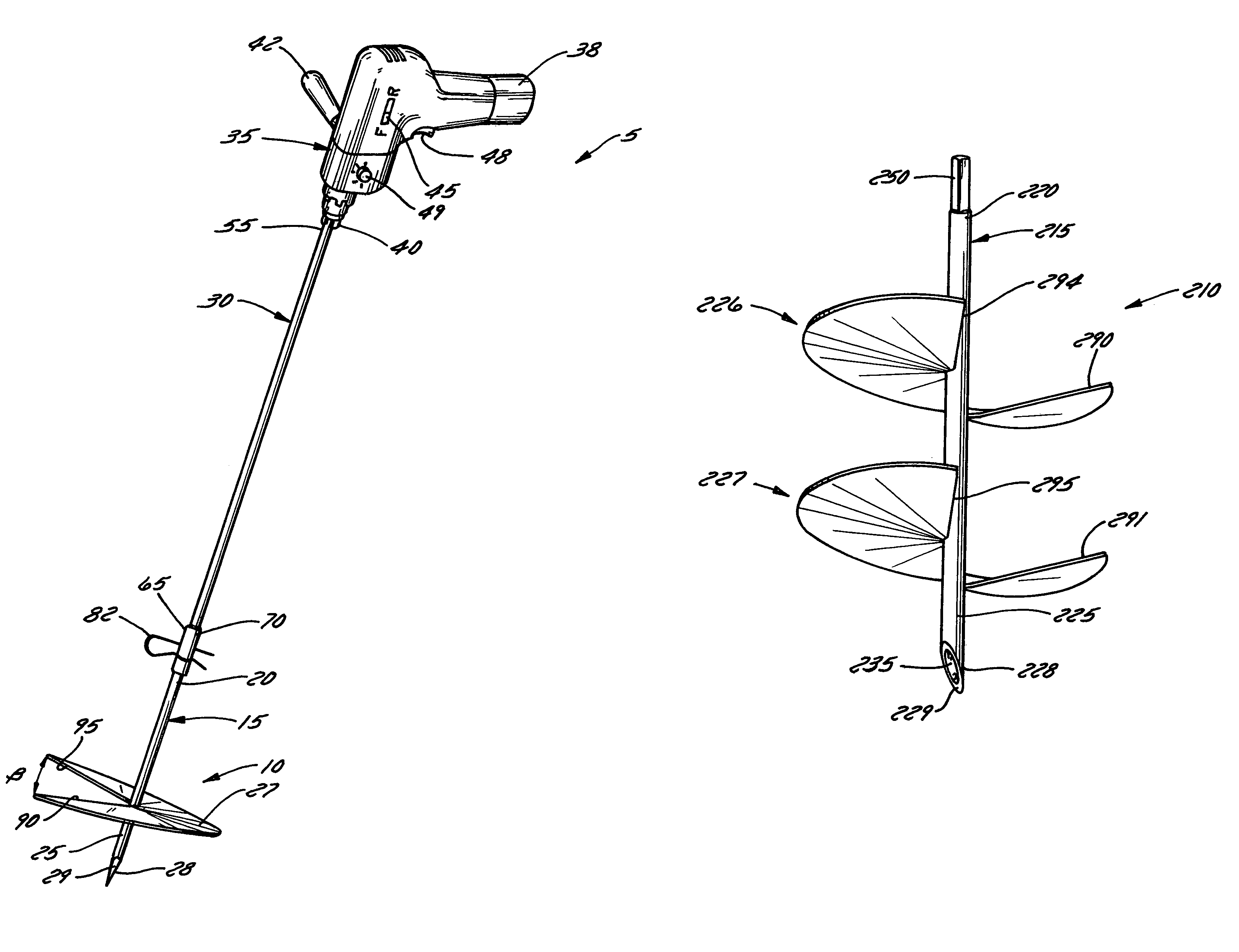

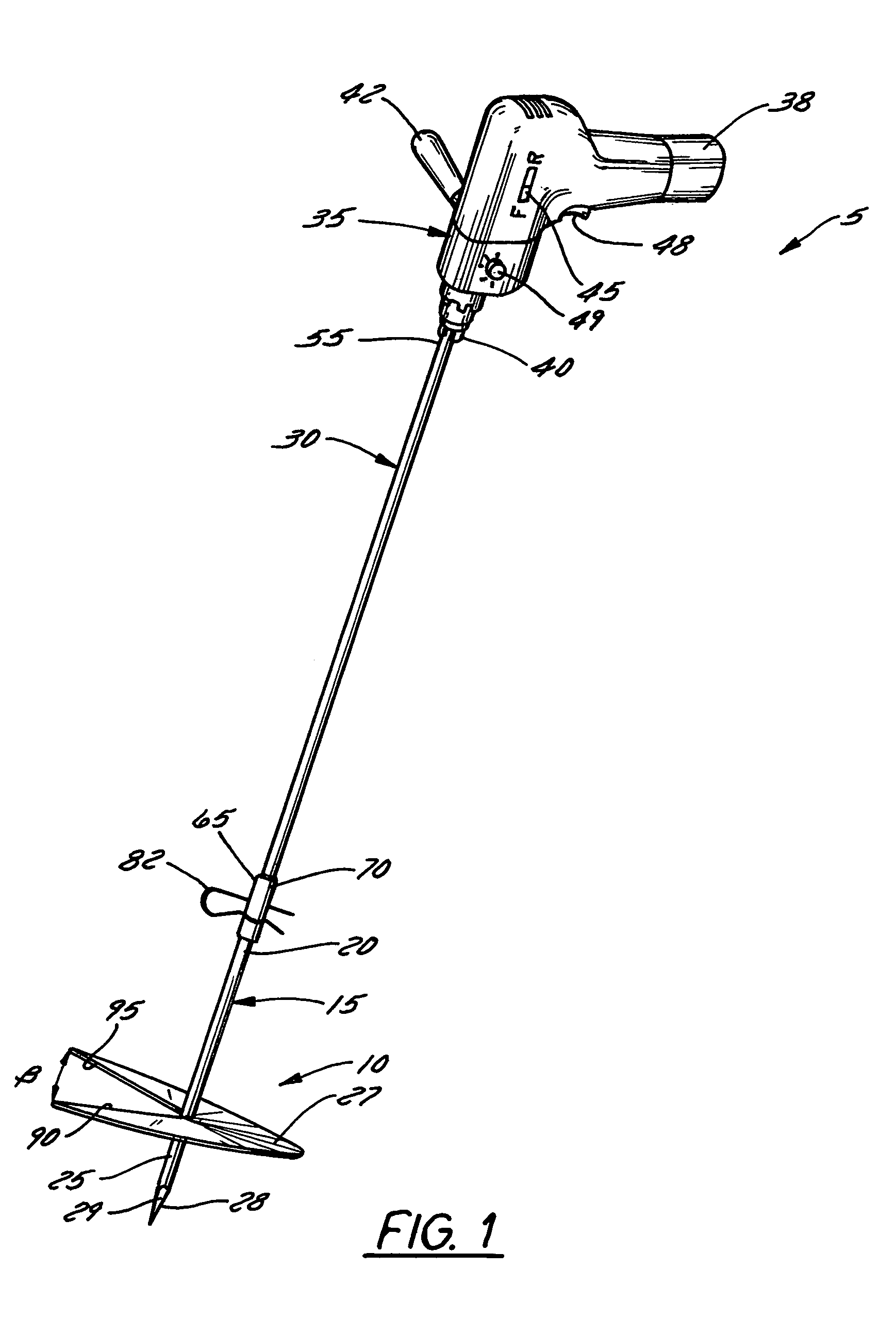

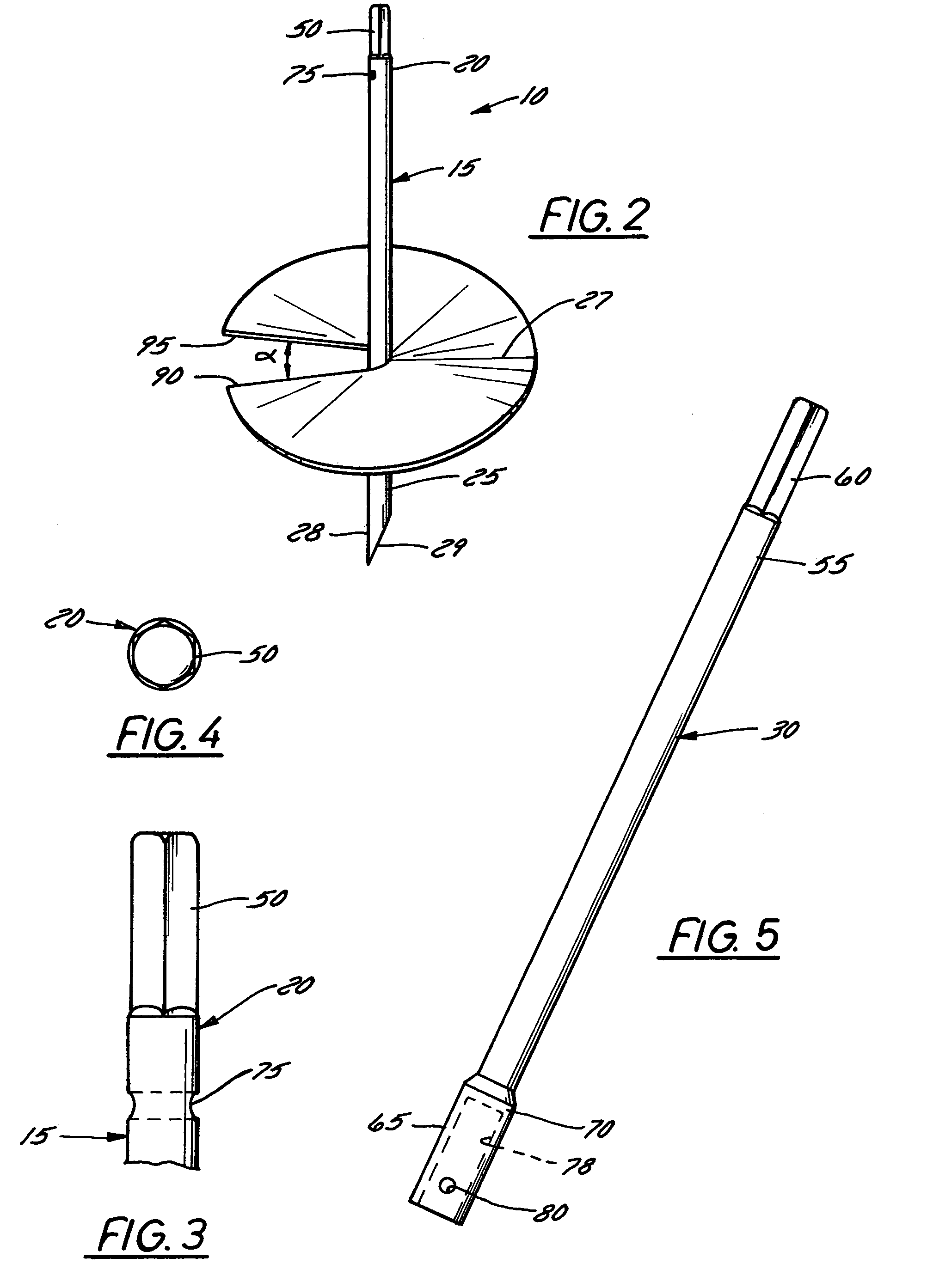

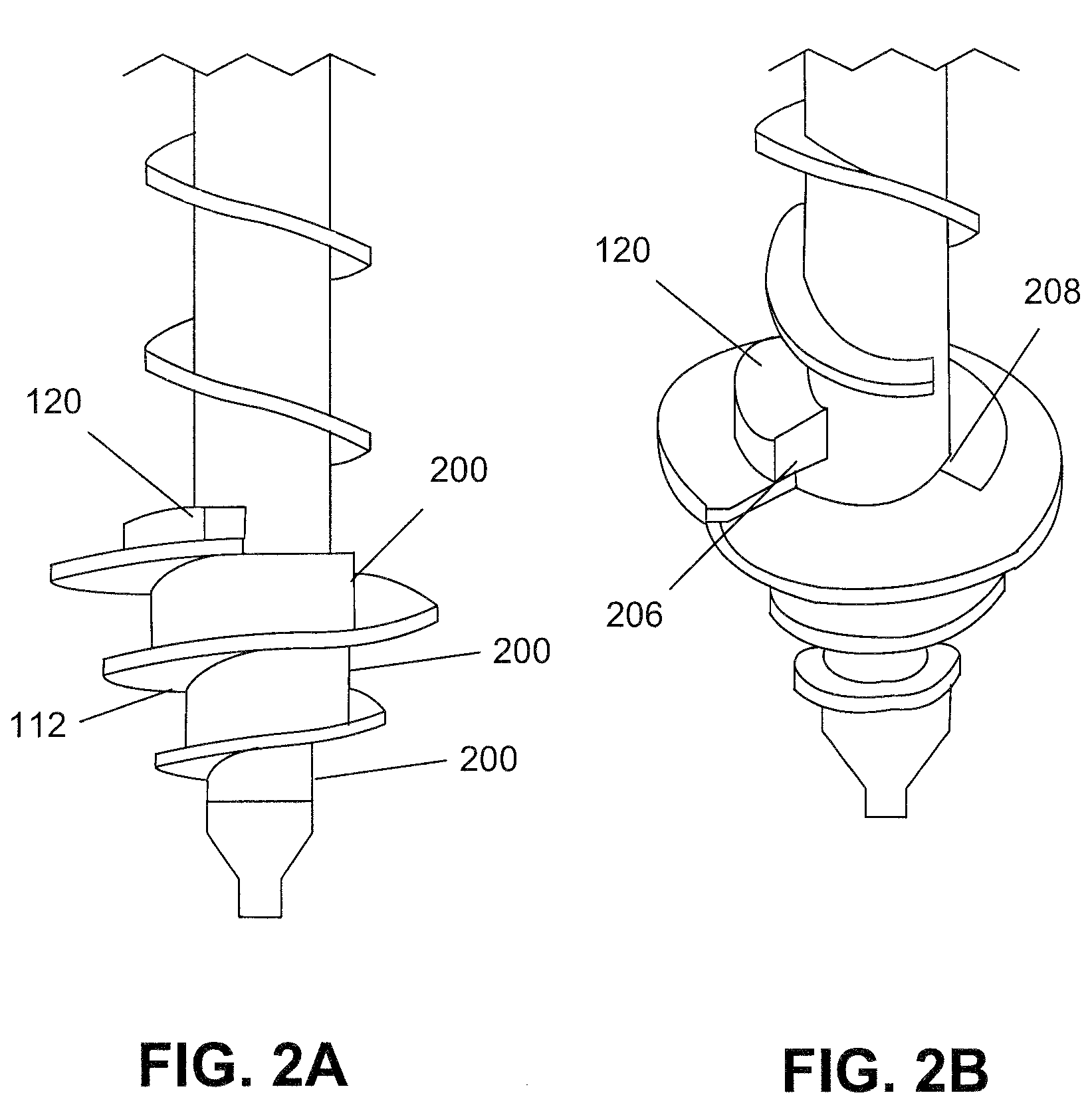

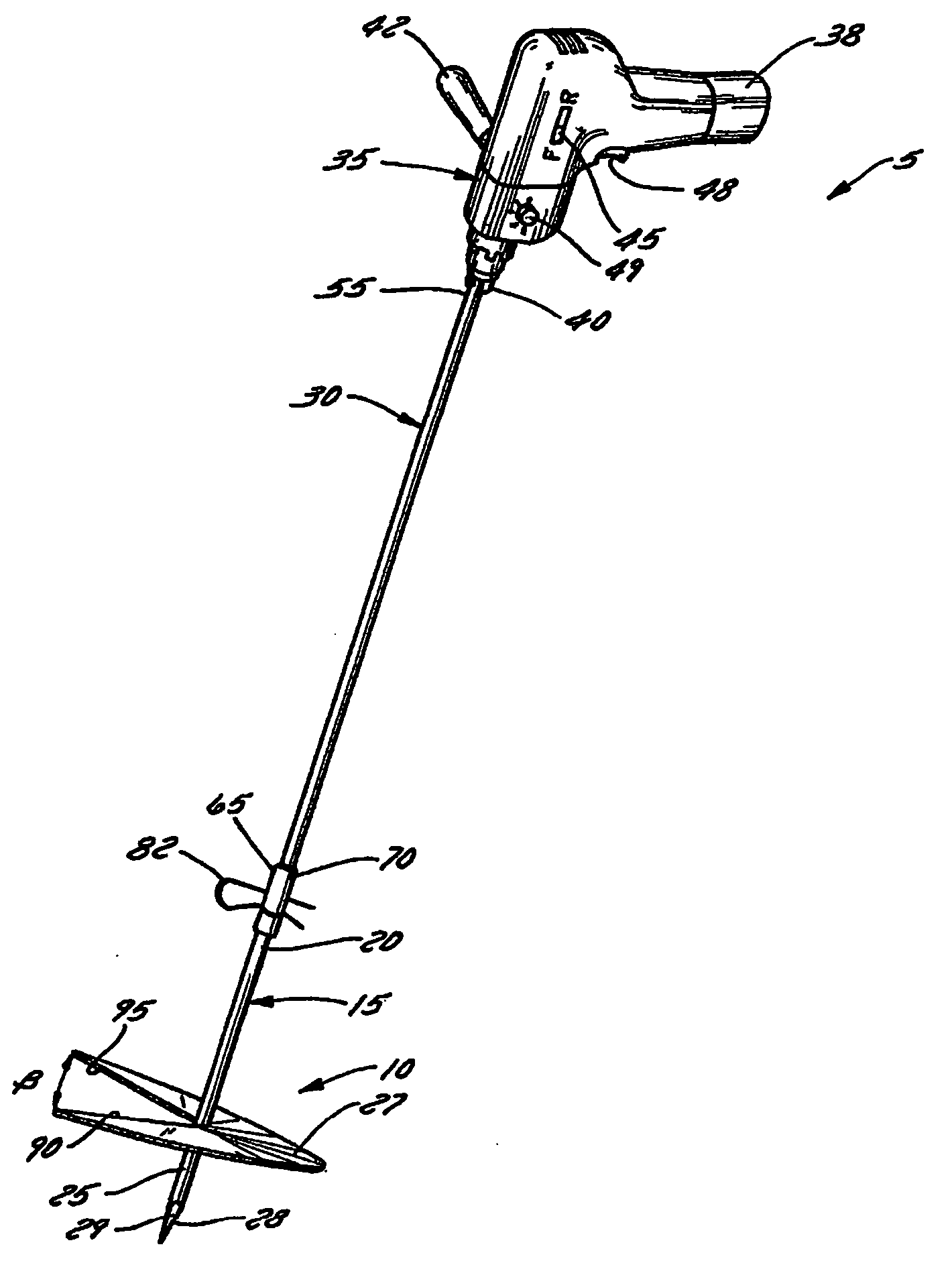

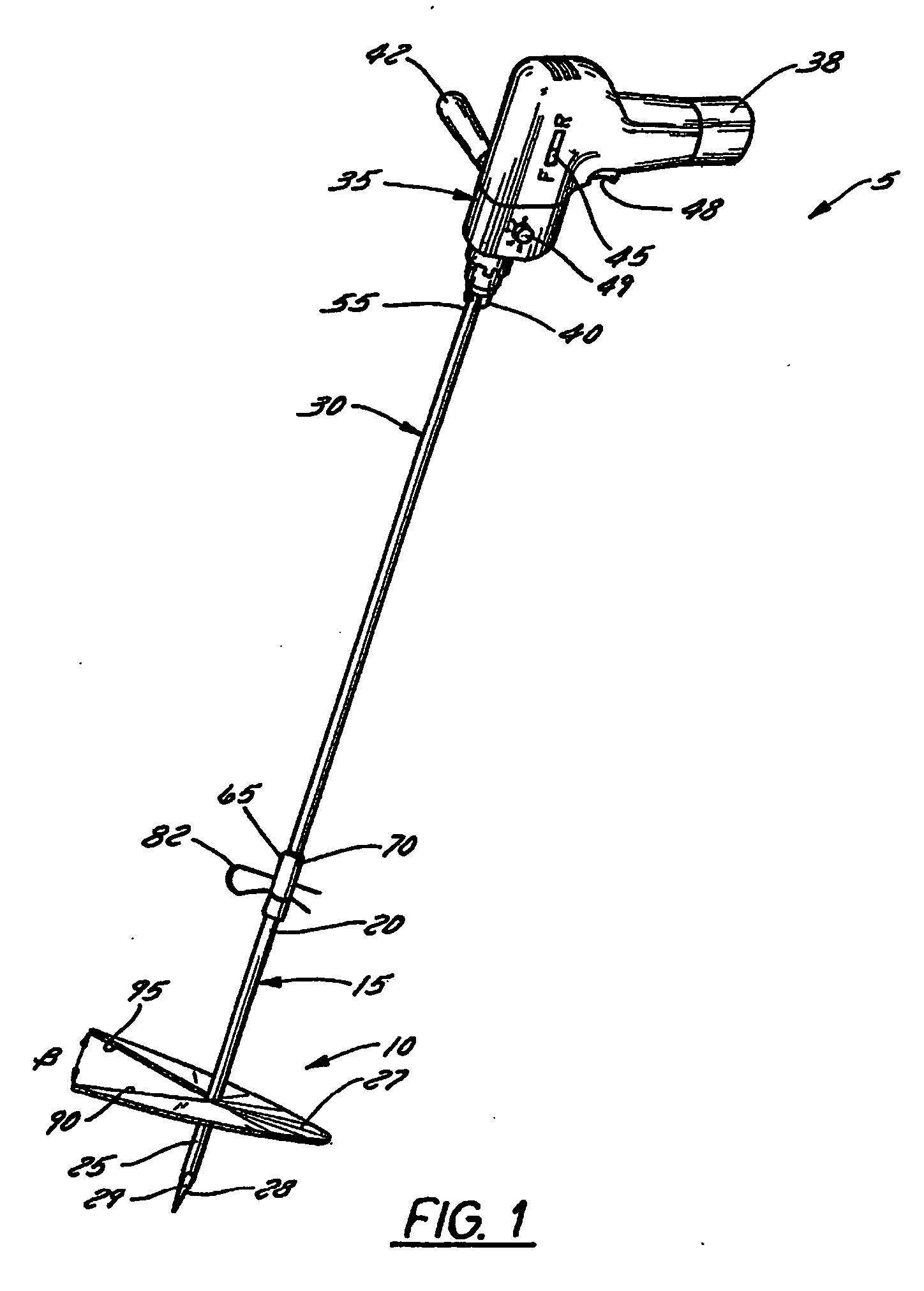

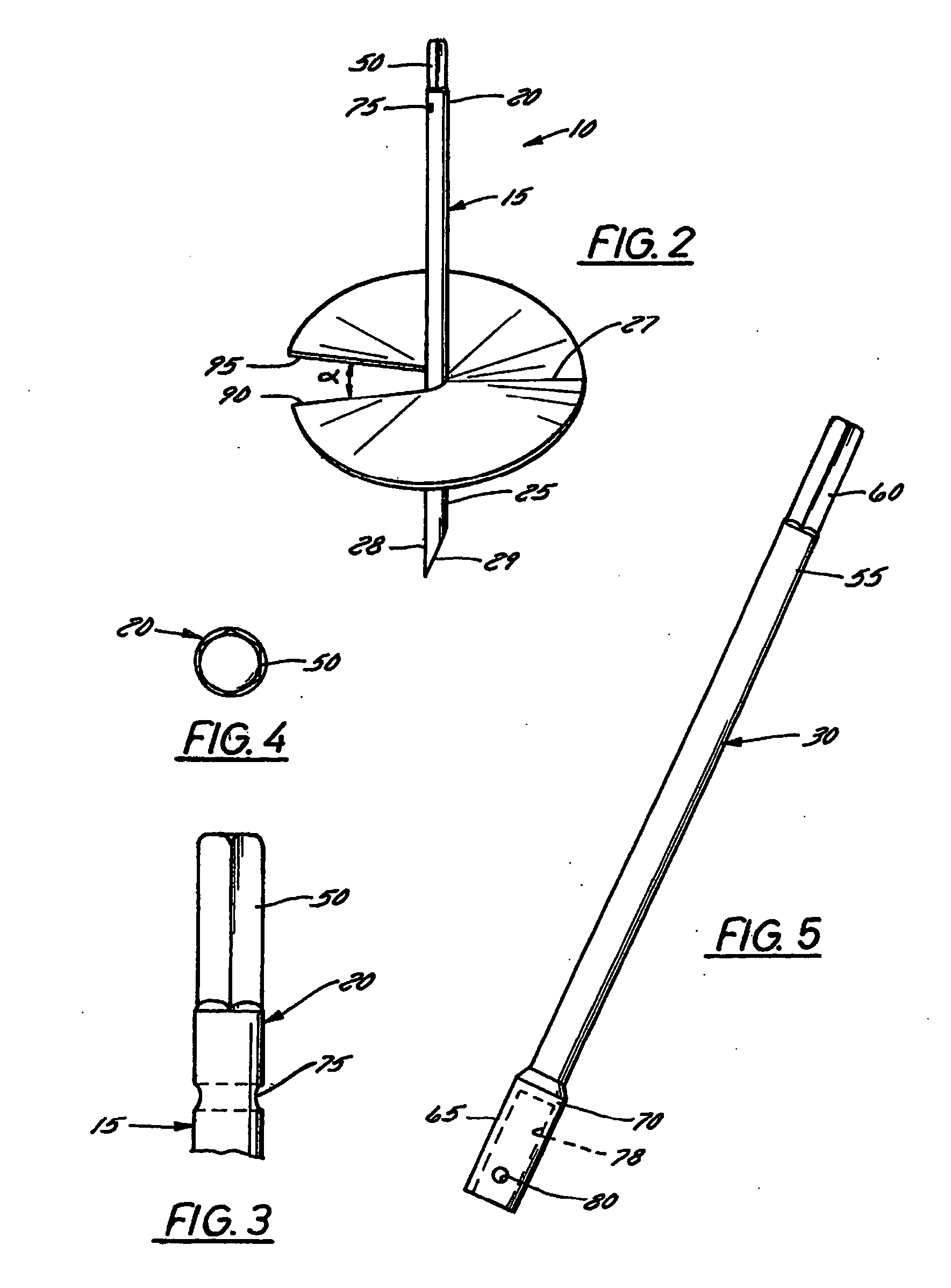

Auger for mixing and burrowing

An auger to assist in ground-burrowing or mixing paint or concrete, is used by attaching it to an electric or cordless power source. The major advantages over previous augers are: a hex head design prevents slipping in the drill chuck, an offset boring tip provides better digging, and a removable extension allows for the digging holes from a sitting or standing position possible without straining. The cutting edge of the auger's discs is sharpened for easier digging in hard soil. A single spring pin lock connects a first shaft to the extension shaft.

Owner:SAS GRP

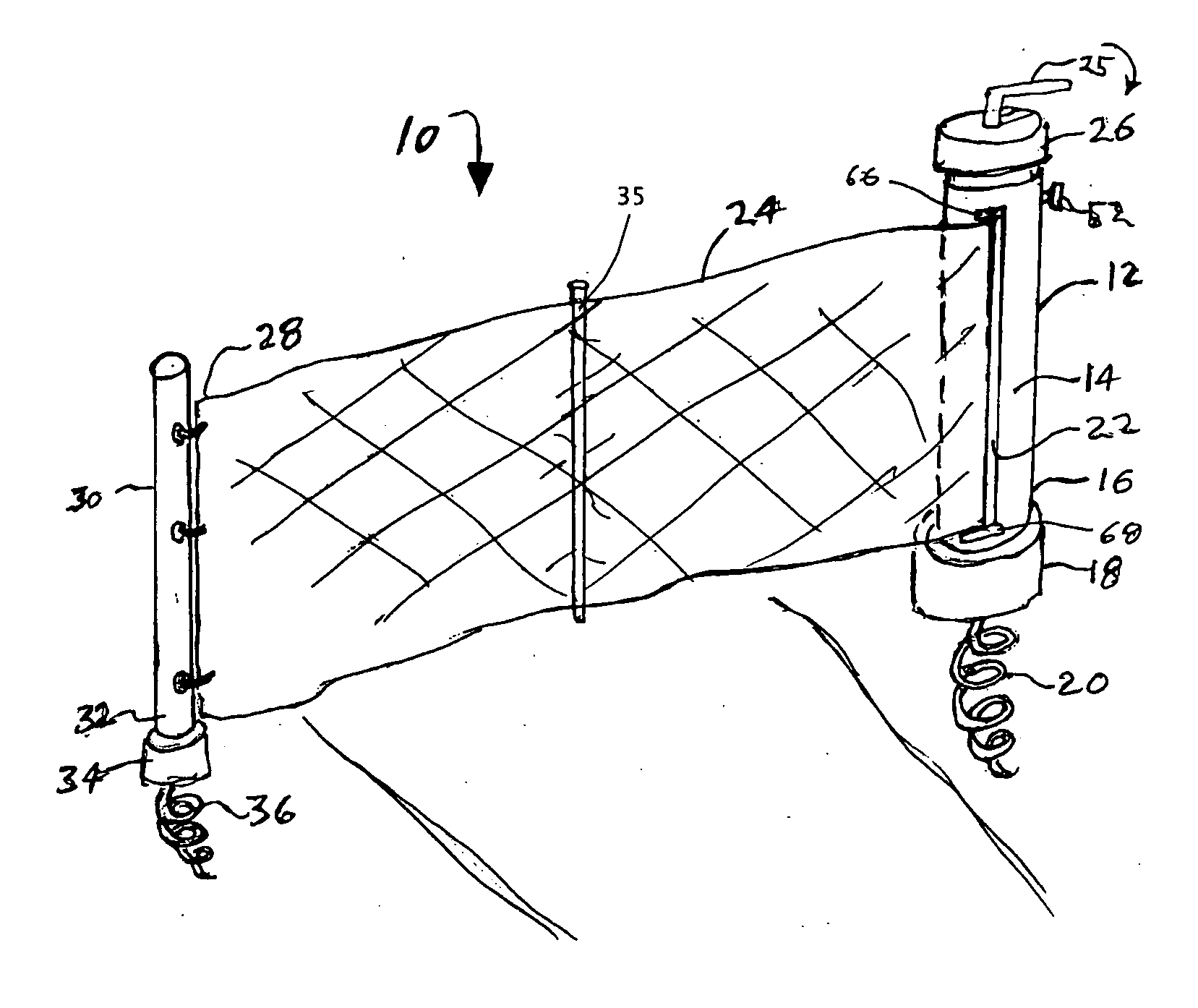

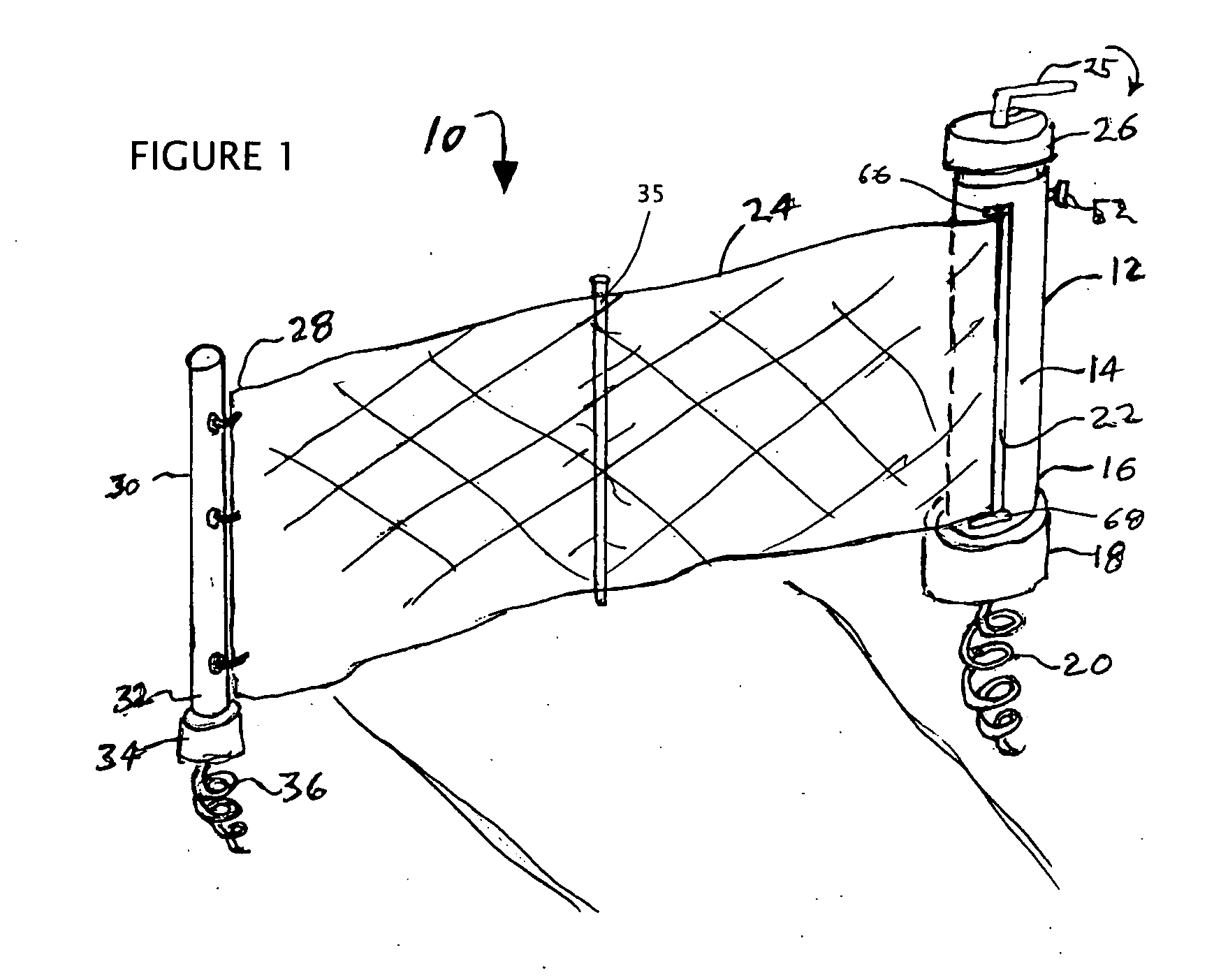

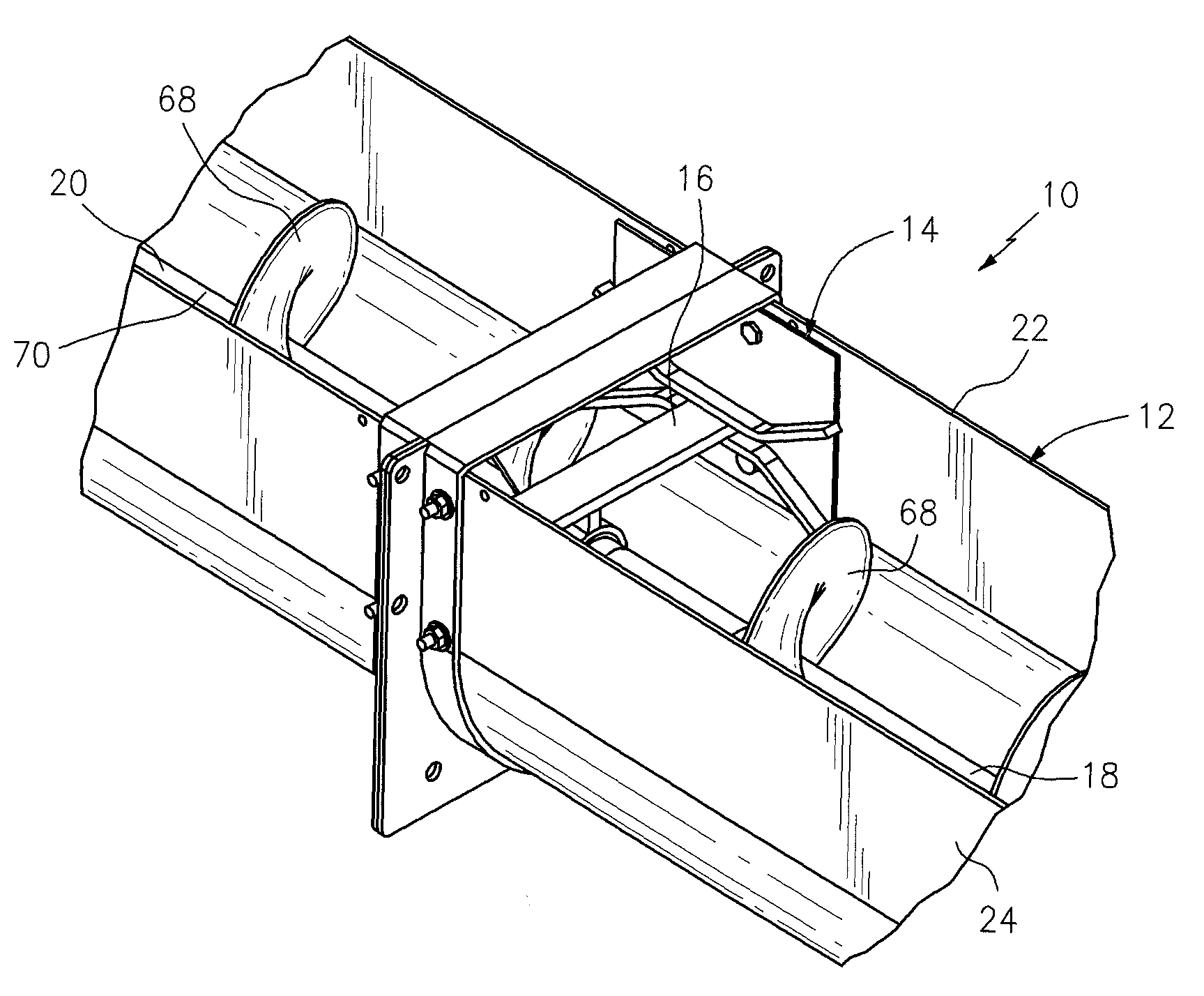

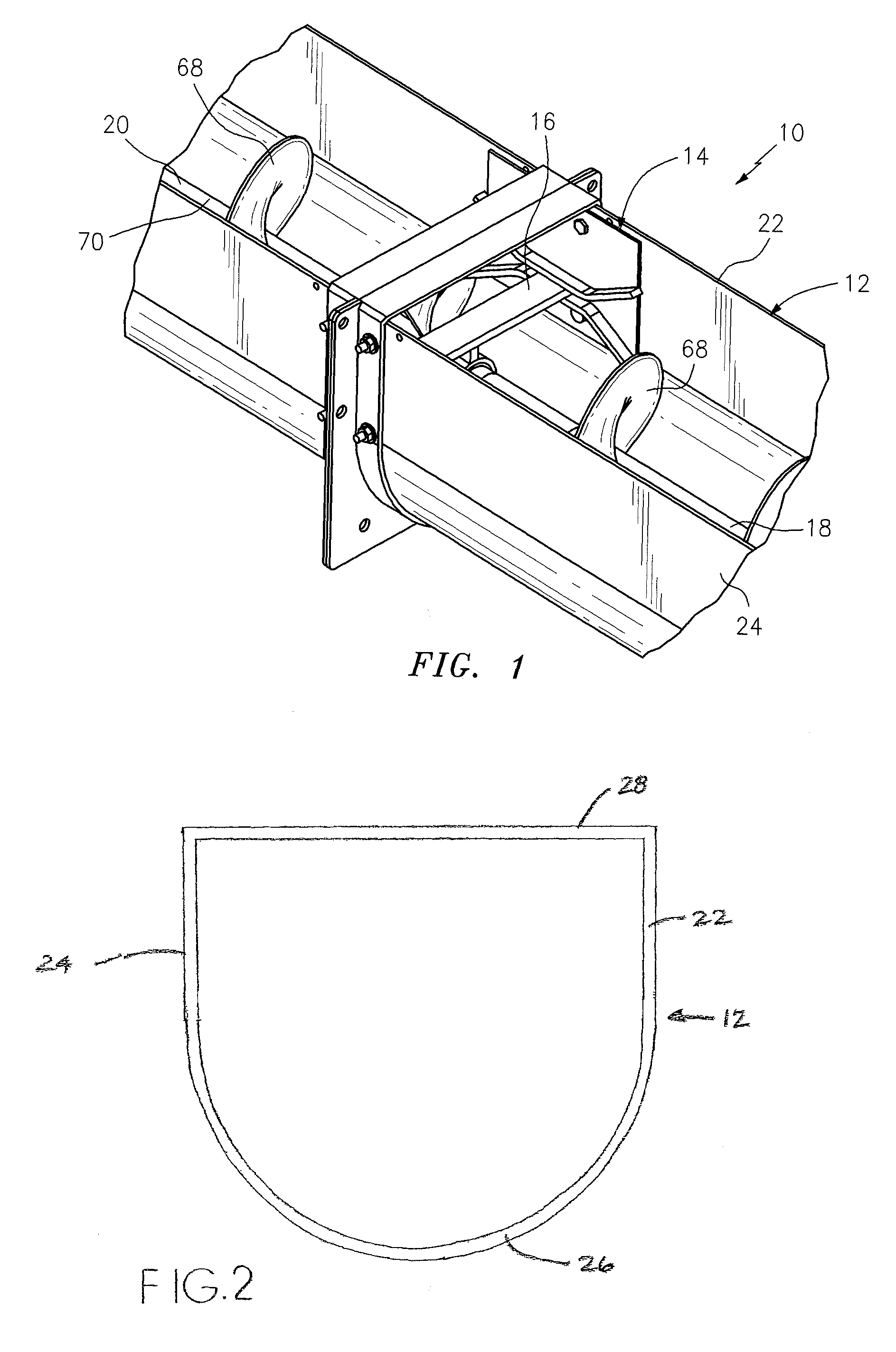

Portable safety barrier

InactiveUS20070176158A1Facilitate manual rewindingEasy to rewindProtective constructionTraffic restrictionsEngineeringGear train

A portable safety barrier that can be set up across a drive way or other path to provide a visible and physical indication of a safe zone boundary particularly for children. Netting attached to a core or reel disposed in a housing forms the barrier. The netting is free to deploy from the housing for attachment to a remote post; both the housing and post including an auger for anchoring the housing and post to ground. The housing has a rewind system to reel in the netting which includes a gear train for mechanical advantage. The rewind system operates manually and with out a bias assist. A selectively operated stop cooperates with the rewind system to tighten the netting after deployment and keeps the netting taut.

Owner:ROBINSON JEFFERY A

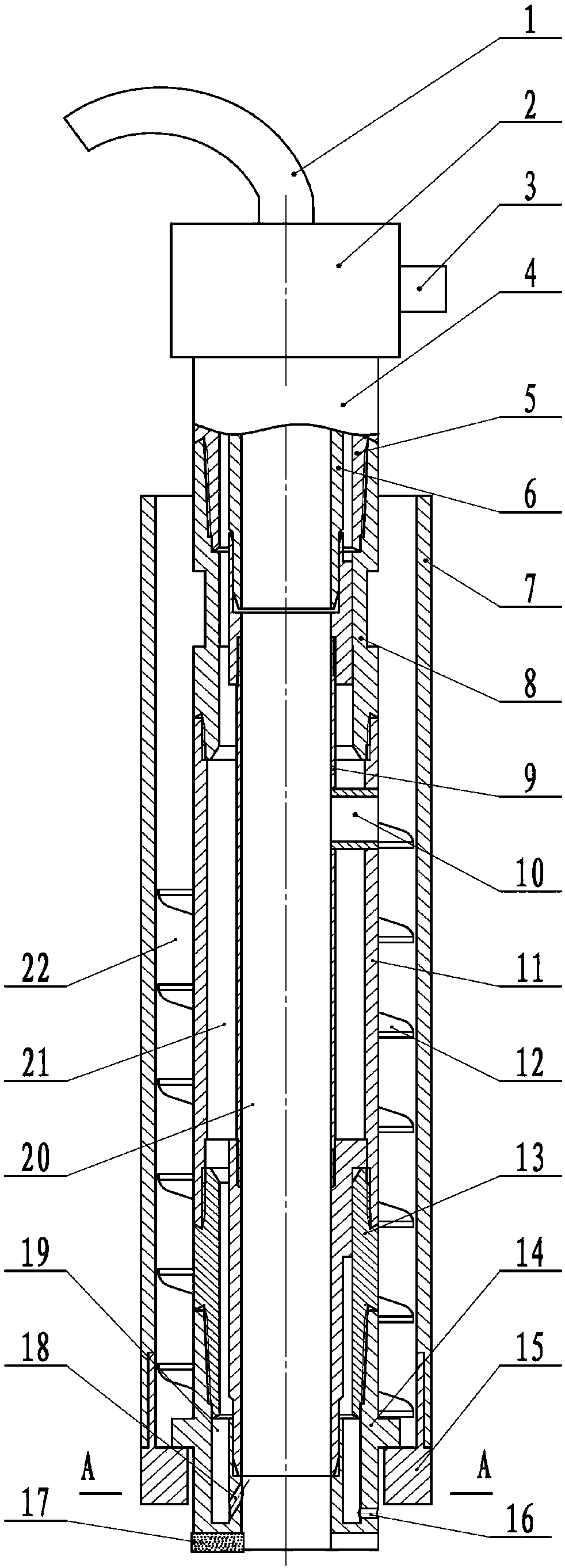

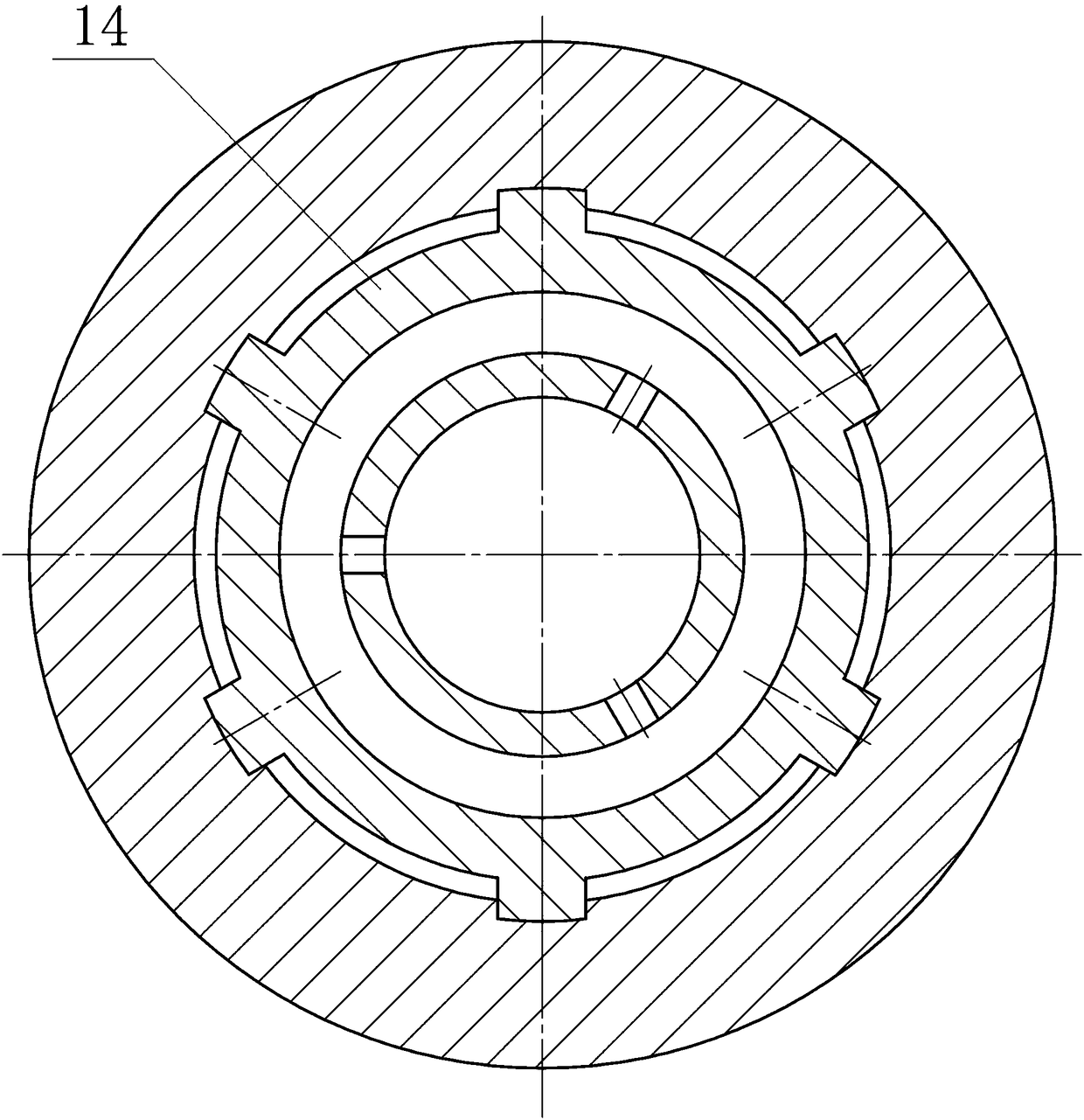

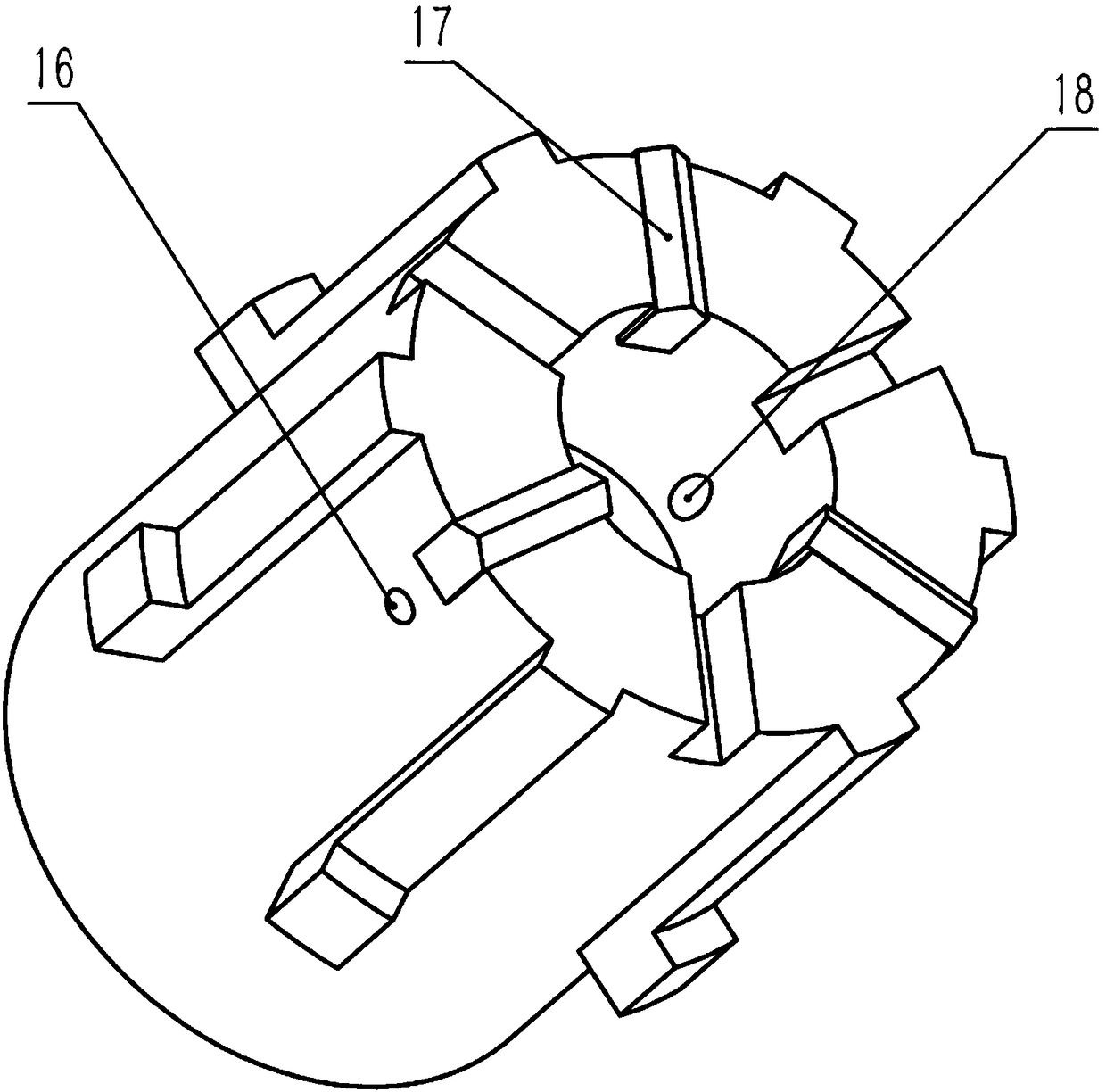

Loose-soft rock soil stratum reverse circulation casing-following drilling tool and drilling process

PendingCN108086930AImprove migration efficiencyImprove connection strengthDrilling rodsConstructionsAugerHelical blade

The invention discloses a loose-soft rock soil stratum reverse circulation casing-following drilling tool and a drilling process. The drilling tool is of a coaxial three-passage structure and comprises a double-wall drilling stem, an auger stem, a drilling bit, a casing and a casing shoe, a central hole of an inner tube of the double-wall drilling stem and a central hole of an inner tube of the auger stem form a slag discharging passage, an annular gap between the inner tube of the auger stem and an outer tube of the auger stem forms an air incoming passage, and an annular gap between the outer tube of the auger stem and the casing forms an outer ring passage; compressed air enters the drilling bit through the air incoming passage and then is diverted and used for assisting a cutting bladeto break a stratum and realize reverse circulation deslagging. Drillings suspended in the outer ring passage go up along spiral blades, enters a deslagging passage through a deslagging window and then returns to the ground surface. Reverse circulation deslagging through a fluid medium and deslagging assisted by the spiral blades are adopted in the process of drilling, so that casing-following drilling is realized to protect hole walls, the problems of bit burying and difficulty in deslagging and hole forming in the process of loose-soft rock soil drilling can be solved, and integration of drilling, collapse preventing, dedusting and wall protecting is realized.

Owner:JILIN UNIV

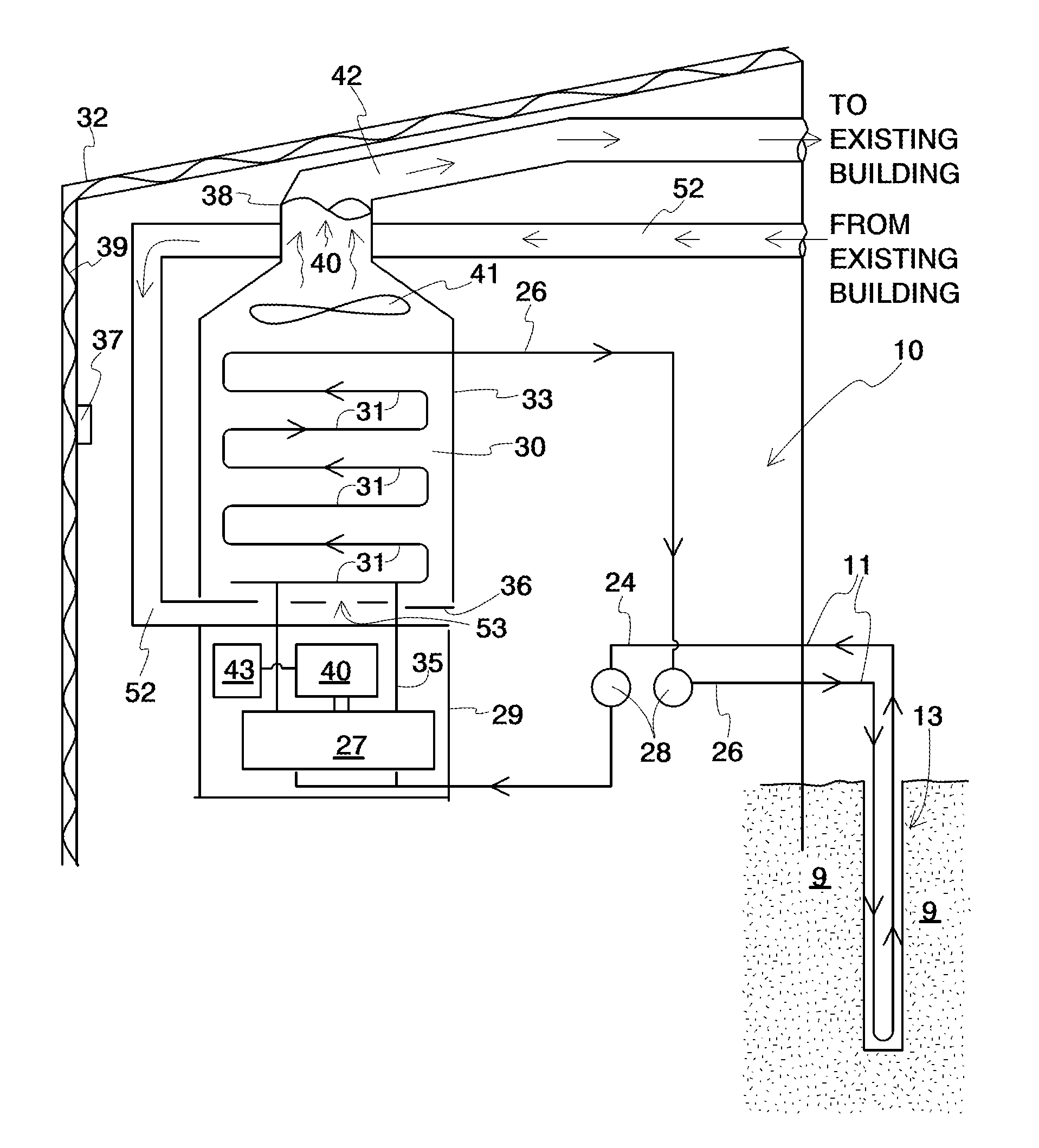

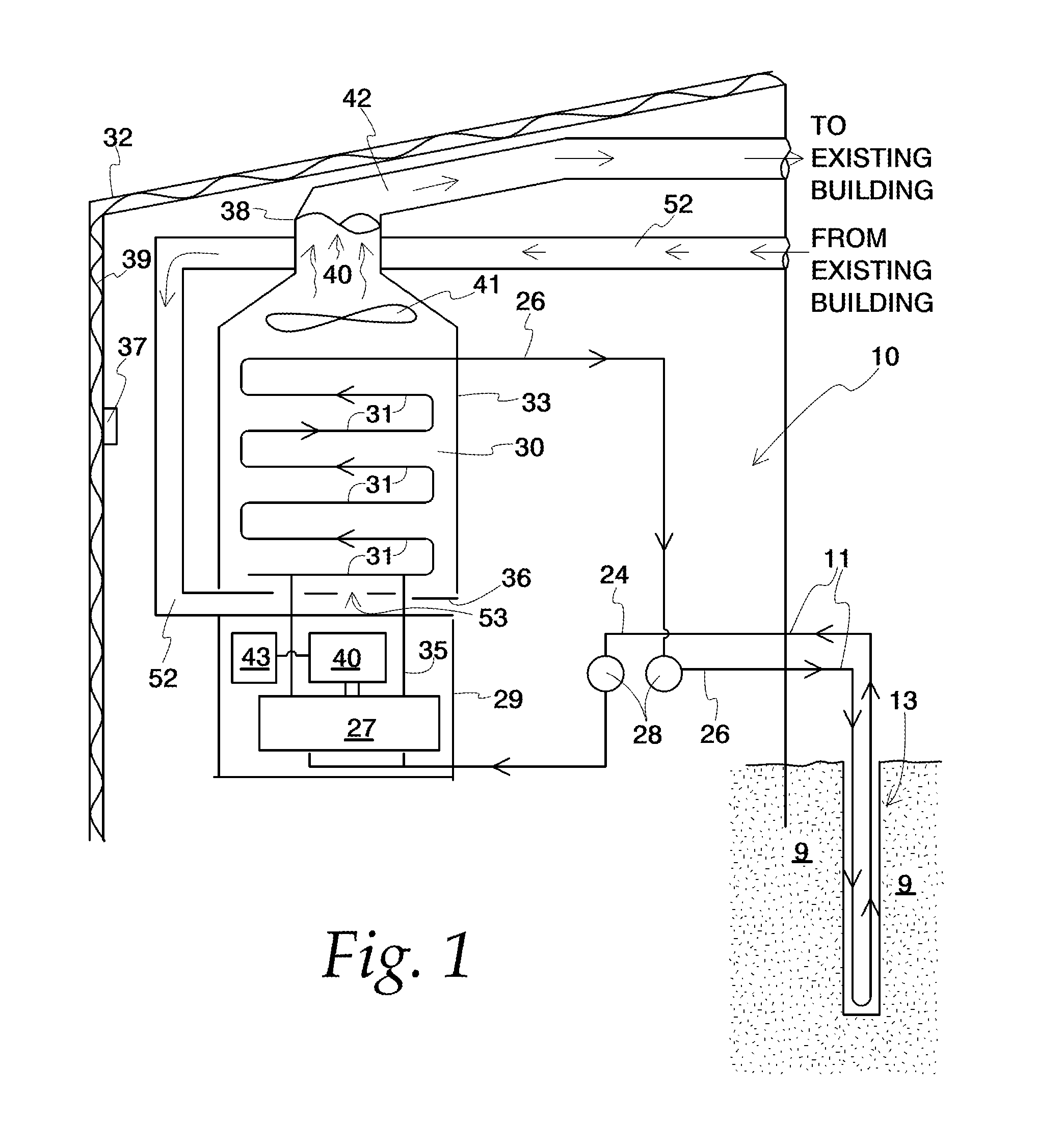

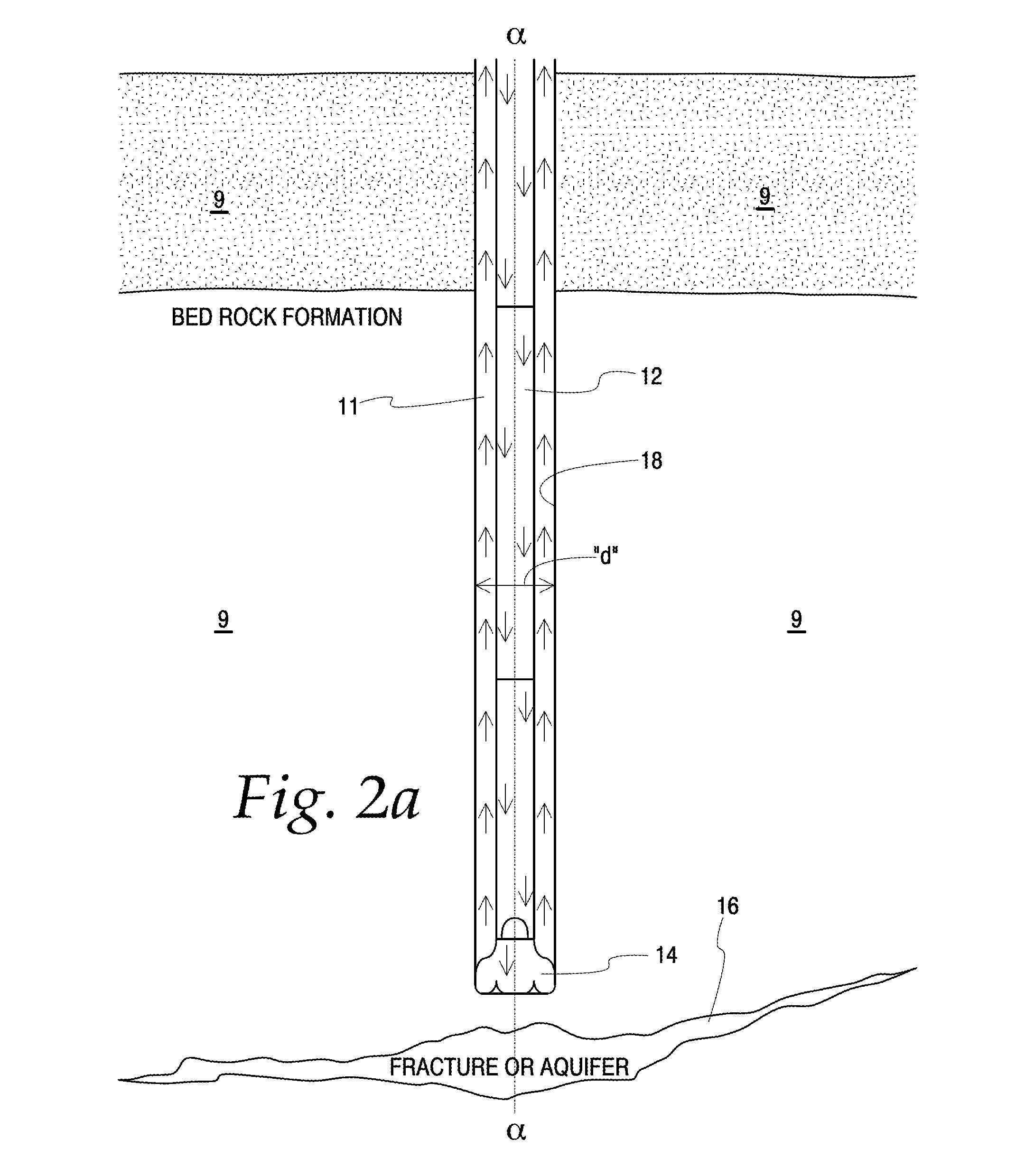

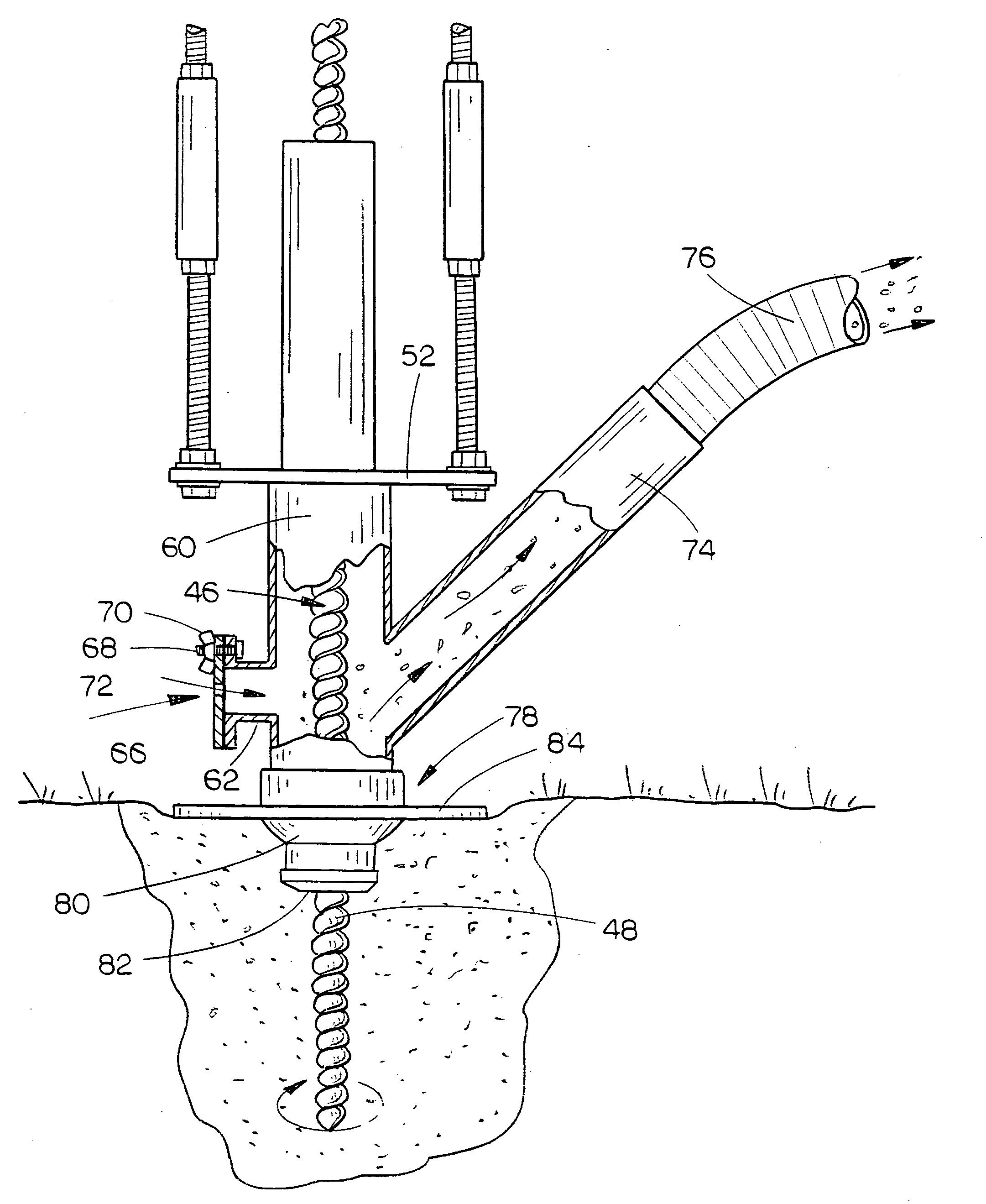

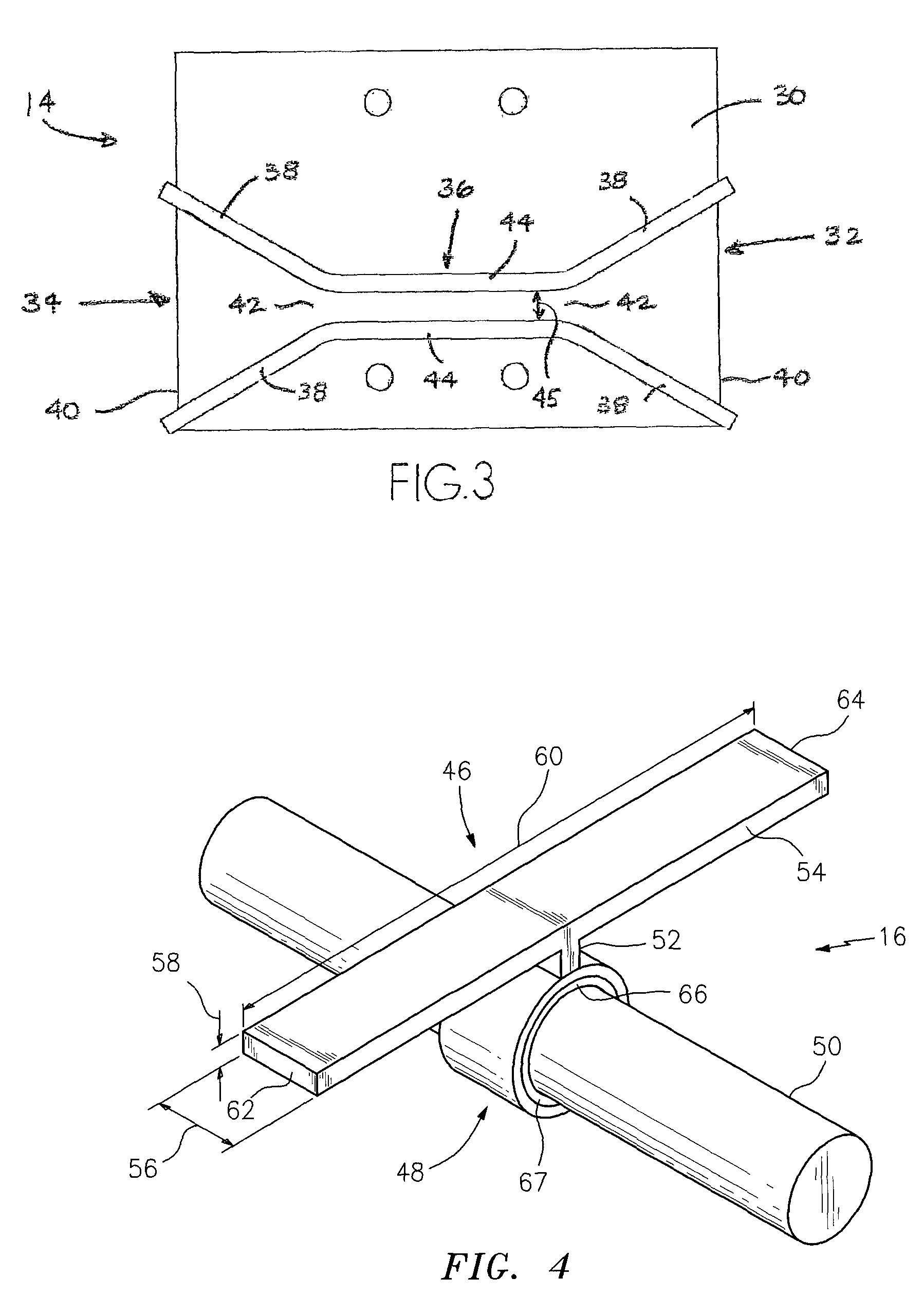

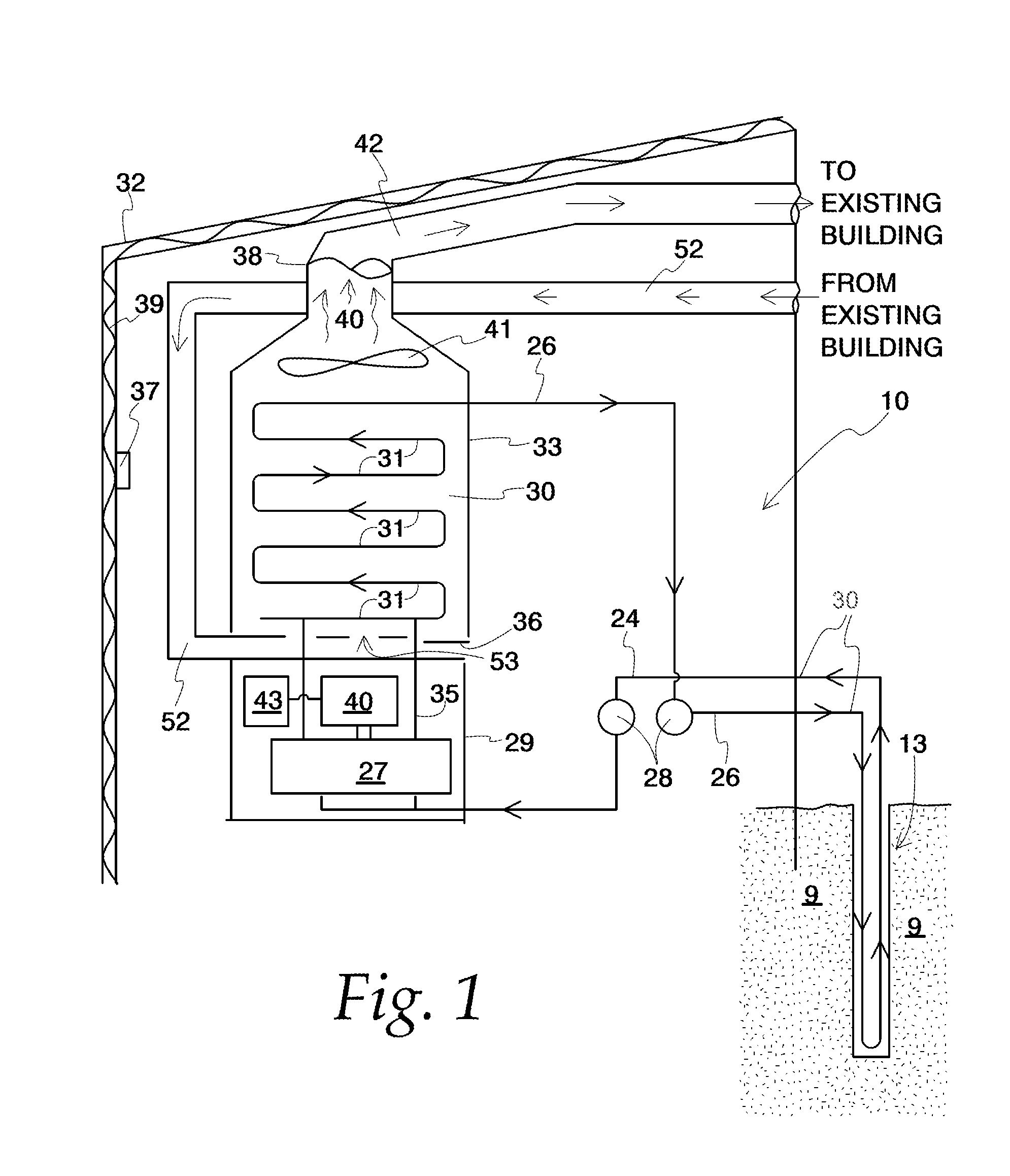

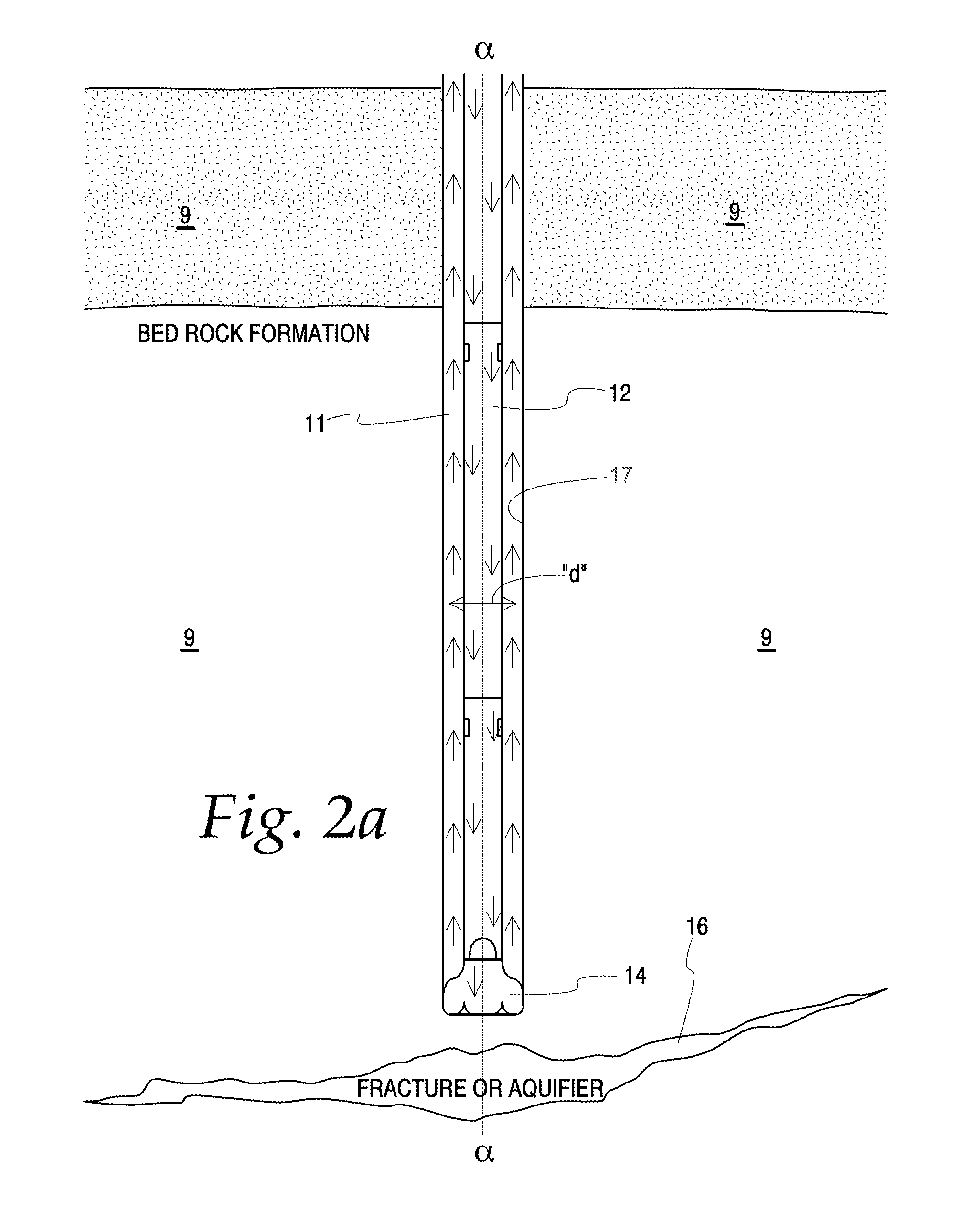

System to enable geothermal field interaction with existing HVAC systems, method to enable geothermal field interaction with existing HVAC system

InactiveUS20110011557A1Increase capacityAdd depthCollector components/accessoriesDrilling rodsThermodynamicsAuger

The invention provides a system for adapting an HVAC system in an existing building for utilizing geothermal energy, the system comprising an incoming flux of geothermal energy; a plurality of heat exchange surfaces adapted to receive the incoming flux of geothermal energy; and an interface between the HVAC system and the heat exchange surfaces, said interface adapted to transfer the geothermal energy to the system. Also provided is a method for repairing aberrations in drill borings, the method comprising using a rotary mud drill system to produce a drill hole up to the location of the aberrations; removing the rotary mud drill from the drill hole; inserting an auger into the drill hole to a point directly above the location of the aberrations; actuating the auger; introducing loose substrate into the drill hole; allowing the substrate to contact the auger; and lifting and lowering the auger along longitudinally extending regions of the drill hole defining the aberrations for a time and in substrate amounts sufficient to fill the aberrations. The invention also provides a system which facilitates rotating drill bits at an rpm which are multiples faster than their associated drill strings.

Owner:GEOTHERMAL TECH

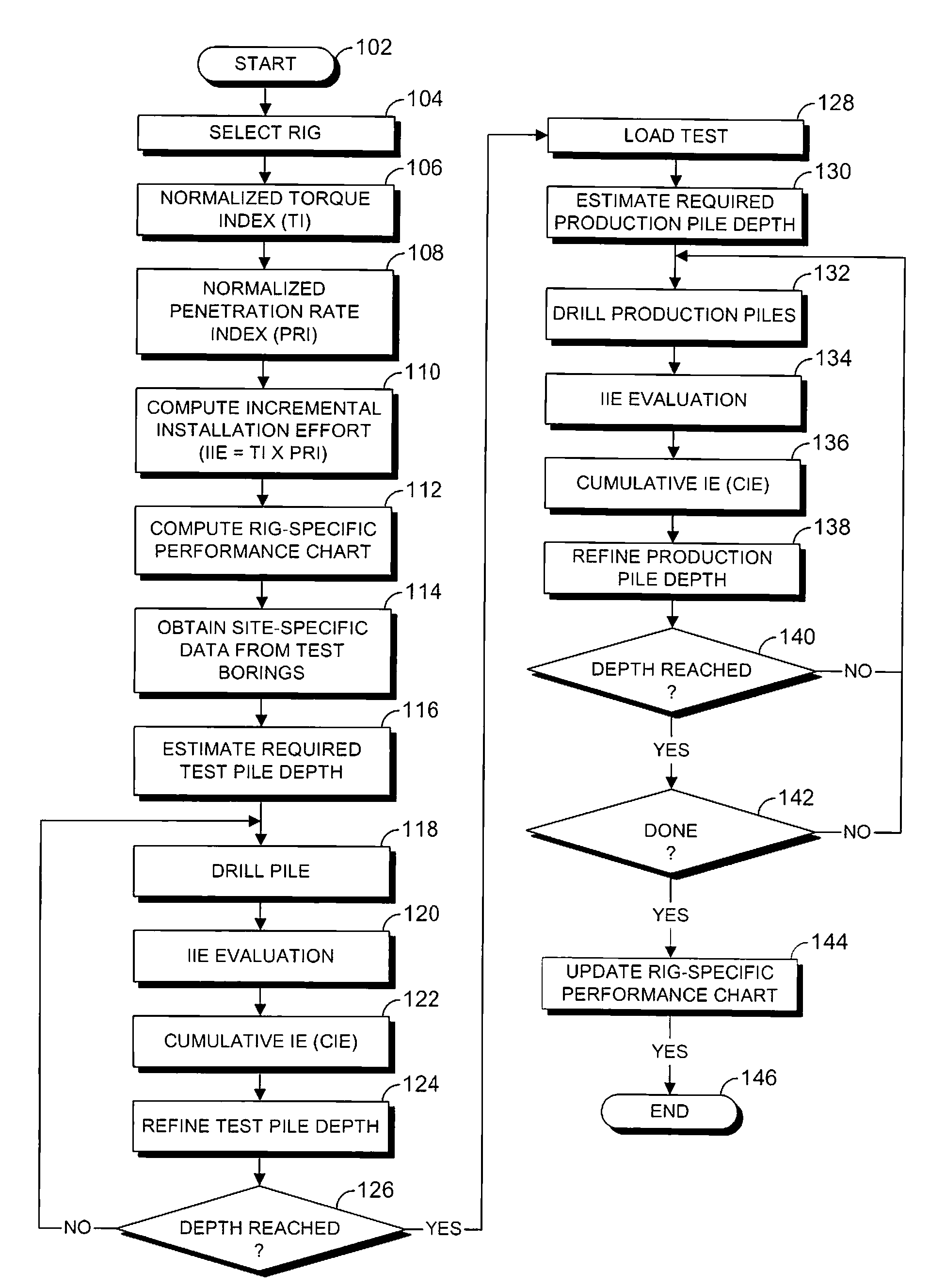

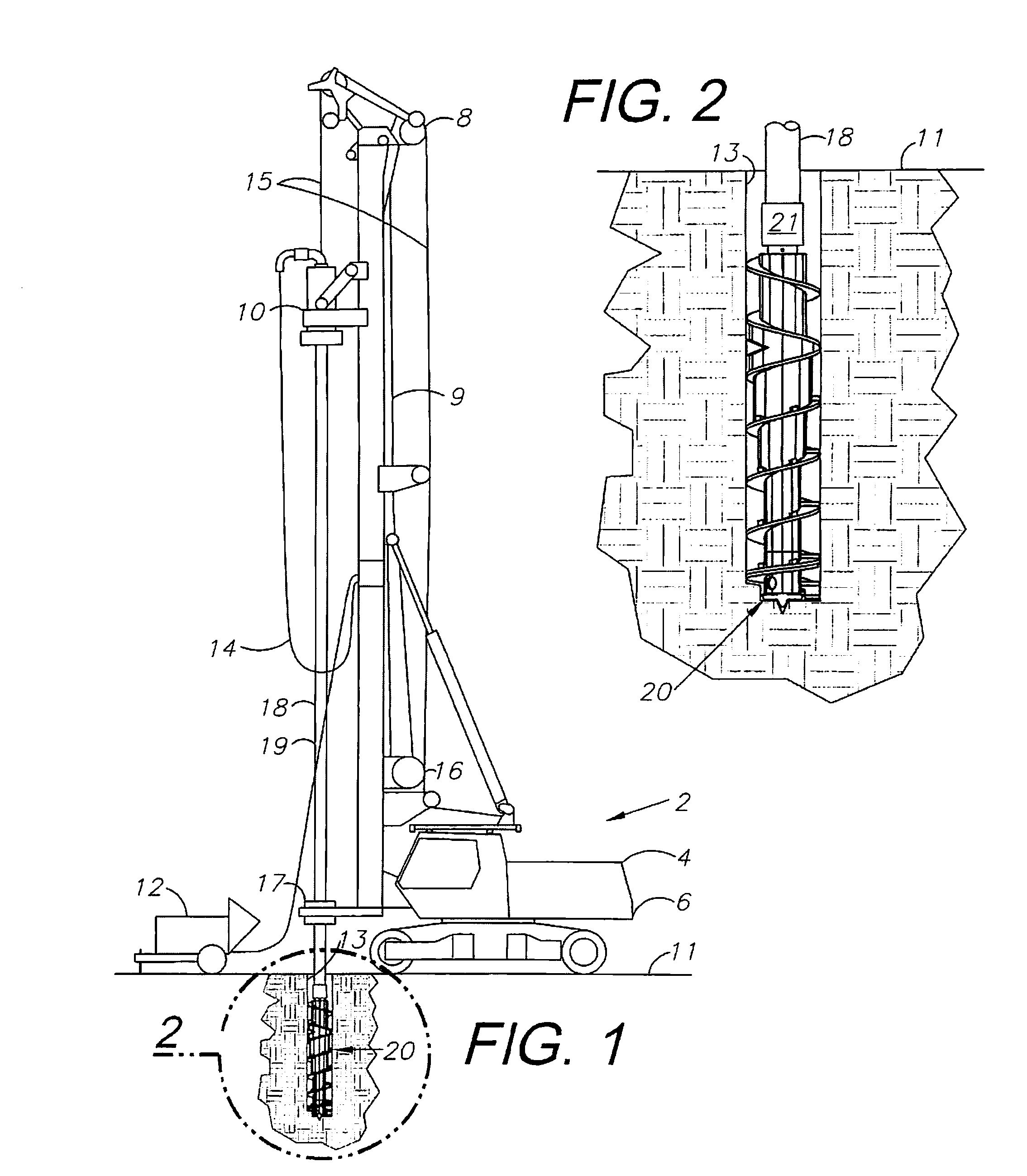

Installation effort deep foudnation method

An auger bit is provided for a foundation pile system including a drilling rig adapted for mounting and rotating a grout pipe connected to the auger bit to form an auger. The auger bit includes a stem with lower and upper sections, which taper towards a transition whereat the stem has a maximum diameter. A pile foundation forming method includes the steps of providing a drilling rig, forming an auger with a grout pipe coupled to an auger bit, rotating the auger with the rig, forming a borehole with laterally displaced soil, pumping pressurized grout through the auger and into the borehole, placing a reinforcing cage in the wet grout and curing same. Another aspect of the invention involves correlating installation effort (IE) based on rig-specific performance charts with ultimate pile capacity (Qult).

Owner:NESMITH WILLIE M +1

Auger grouted displacement pile

Disclosed in this specification is a method and apparatus for placing a helical pile in the soil with minimal disturbances to the soil. The helical pile has an elongated pipe with a central chamber. The pipe has a helical blade with an opening in the trailing edge of the blade where grout is extruded. The grout fills those portions of the soil which were disturbed by the blade. Advantageously, those portions of the soil which were not disturbed by the blade are not infused with grout.

Owner:STROYER BEN

Oscillatory auger hole and dredging device

InactiveCN1995688ASmall frictional resistanceReduce torqueDrill bitsMechanical machines/dredgersGuide tubeEnergy consumption

The invention relates to a vibration helical drilling hole and dredging device for drilling hole of stratum and dredging, comprising power head, helical drilling bar, central guide tube, drill bit, expanding drill bit, casing pipe and expanding casing pipe so on. In working, the drilling bar and drill bit generate high-frequency micro-breadth vibration and liquefaction is generated between soil and helical face so that friction resistance is decreased and plugging in often is avoided. The helical drilling bar with the same diameter can be used to drill holes with different diameters by expanding diameter. The central guide tube is used to jet concrete while drilling, it is more important to carry dredging operation by no cycling liquid method. The vibration spiral is used to transport bottom mud and the water is not used as the medium for transporting the bottom mud. So secondary pollution for water is decreased greatly, the efficiency is improved and the energy consumption is decreased. It is provided with easy production, low cost for equipment and construction.

Owner:孙孝庆

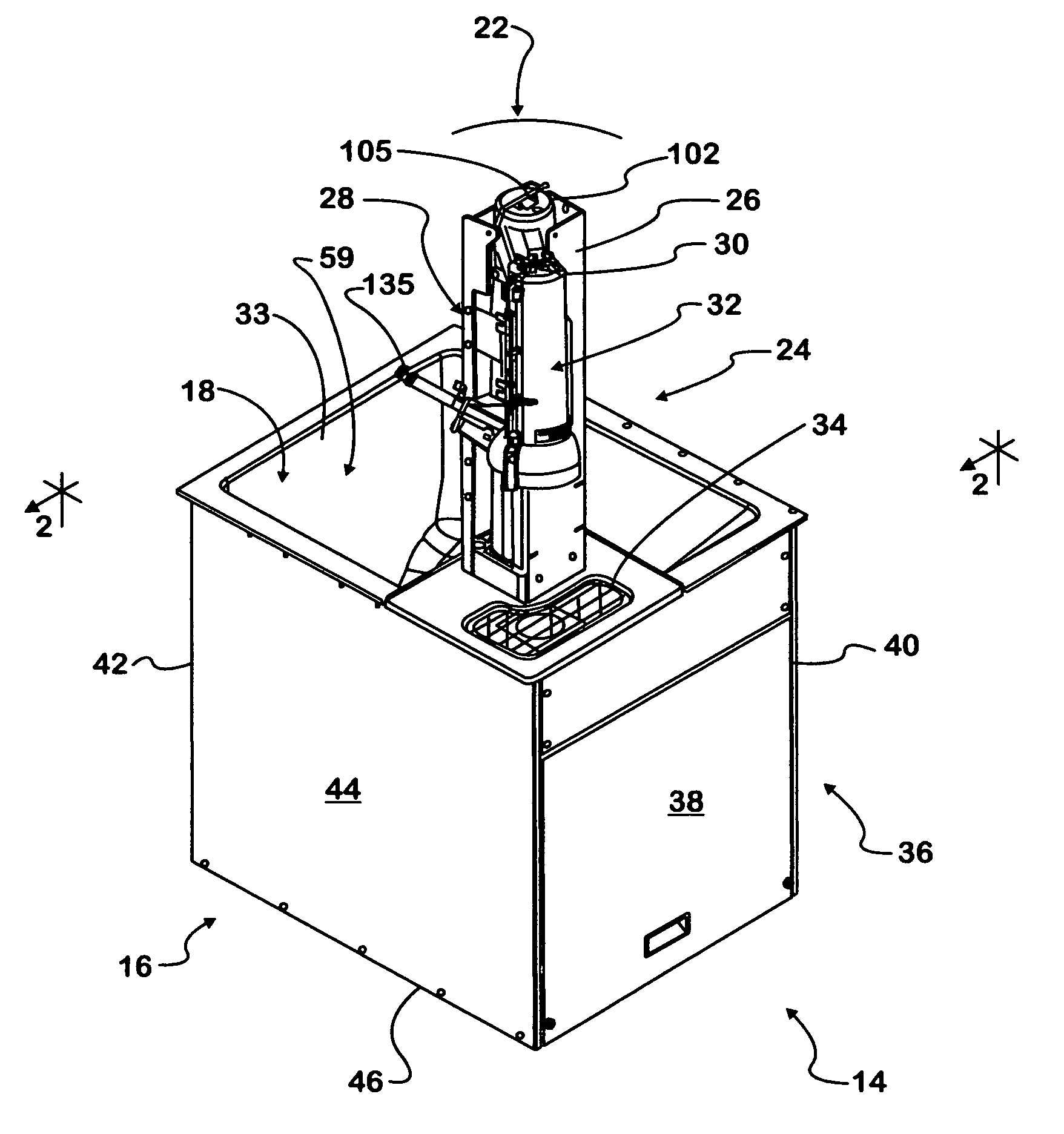

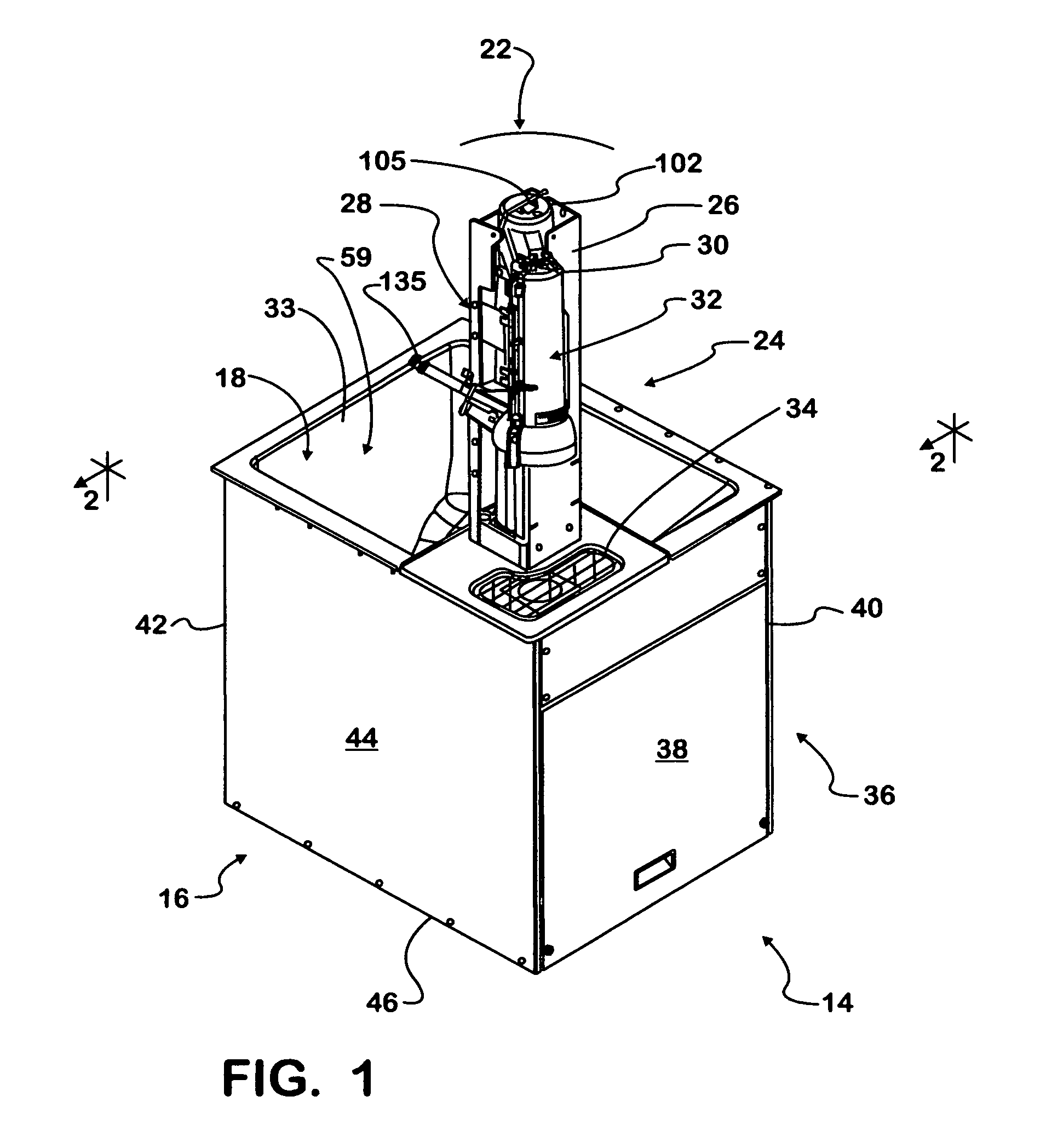

Undercounter ice dispenser

InactiveUS20110049190A1Easy to installEasy to makeLighting and heating apparatusMovable measuring chambersAugerEngineering

An improved undercounter ice dispenser is disclosed that has a multiple piece auger made in sections for moving ice from the dispenser bin to its ice chute. The auger ice chute invention includes a sensor to reduce ice jamming and to detect when the ice chute is filled or needs filling and works in conjunction with a paddle on the auger to help make the transition. Proportional size ice quantities may also be selected via an interface and auger control.

Owner:MARMON FOODSERVICE TECH INC

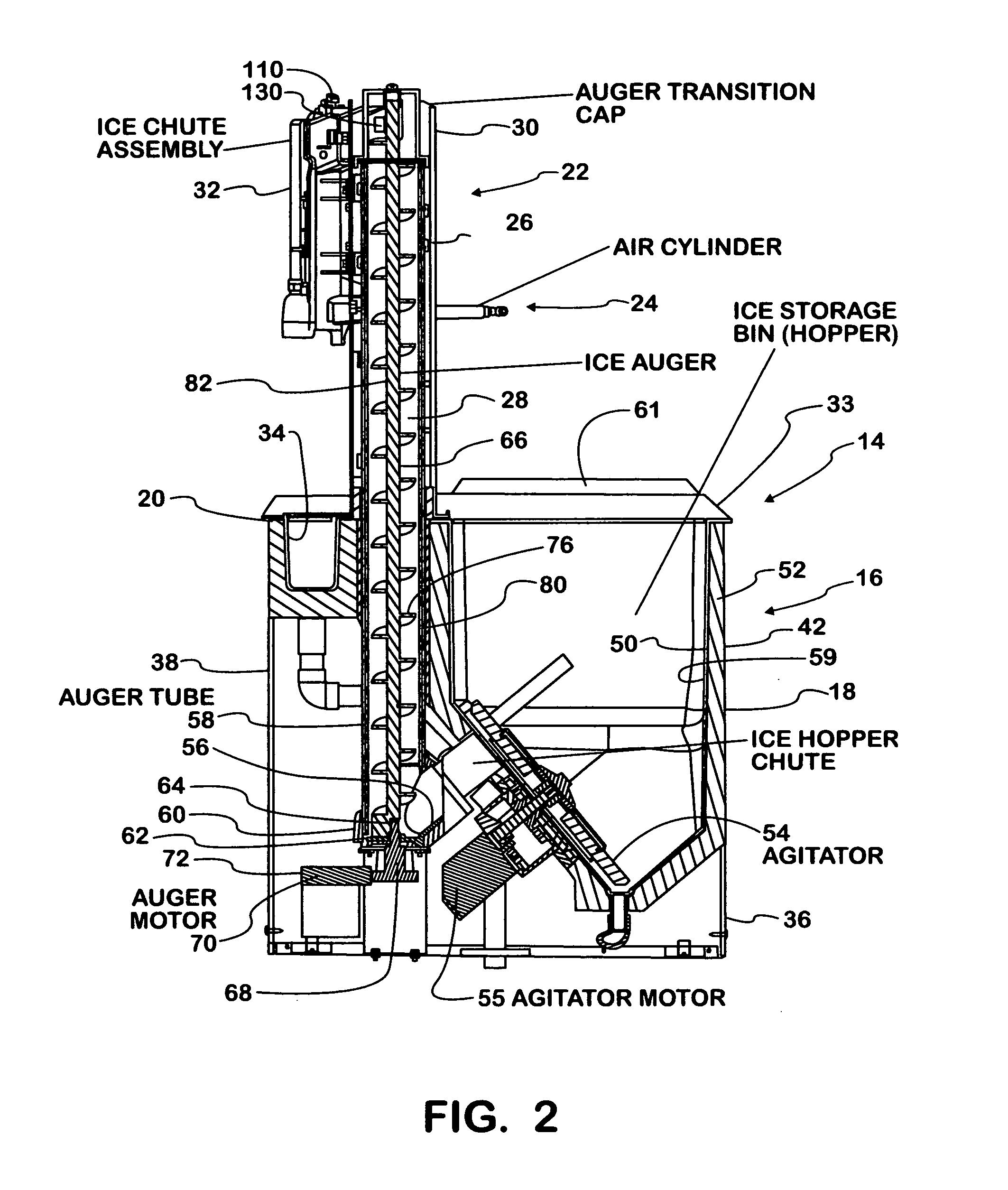

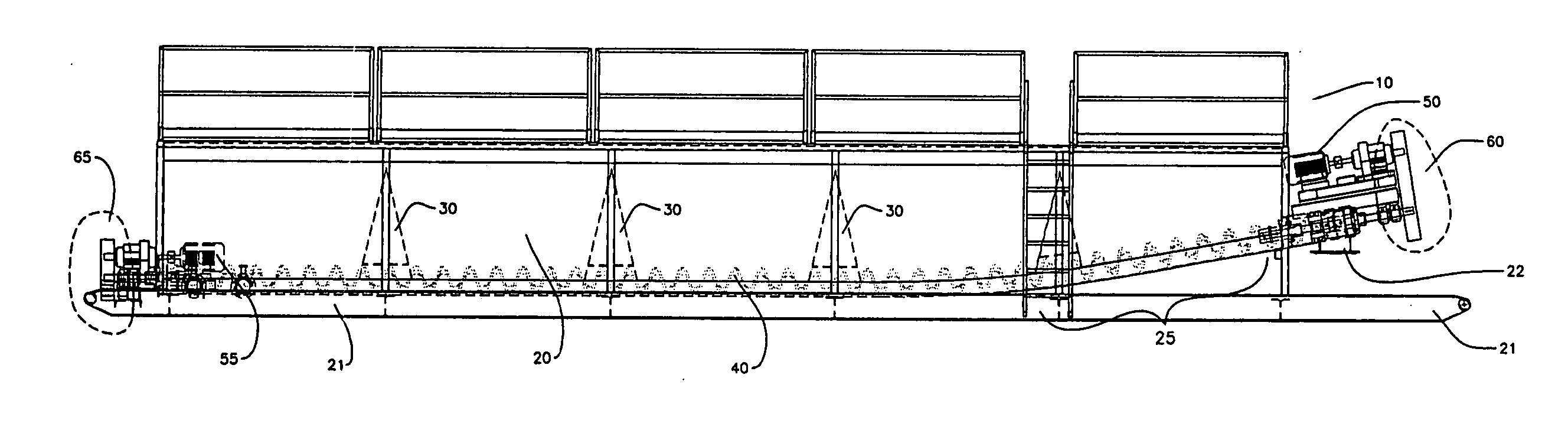

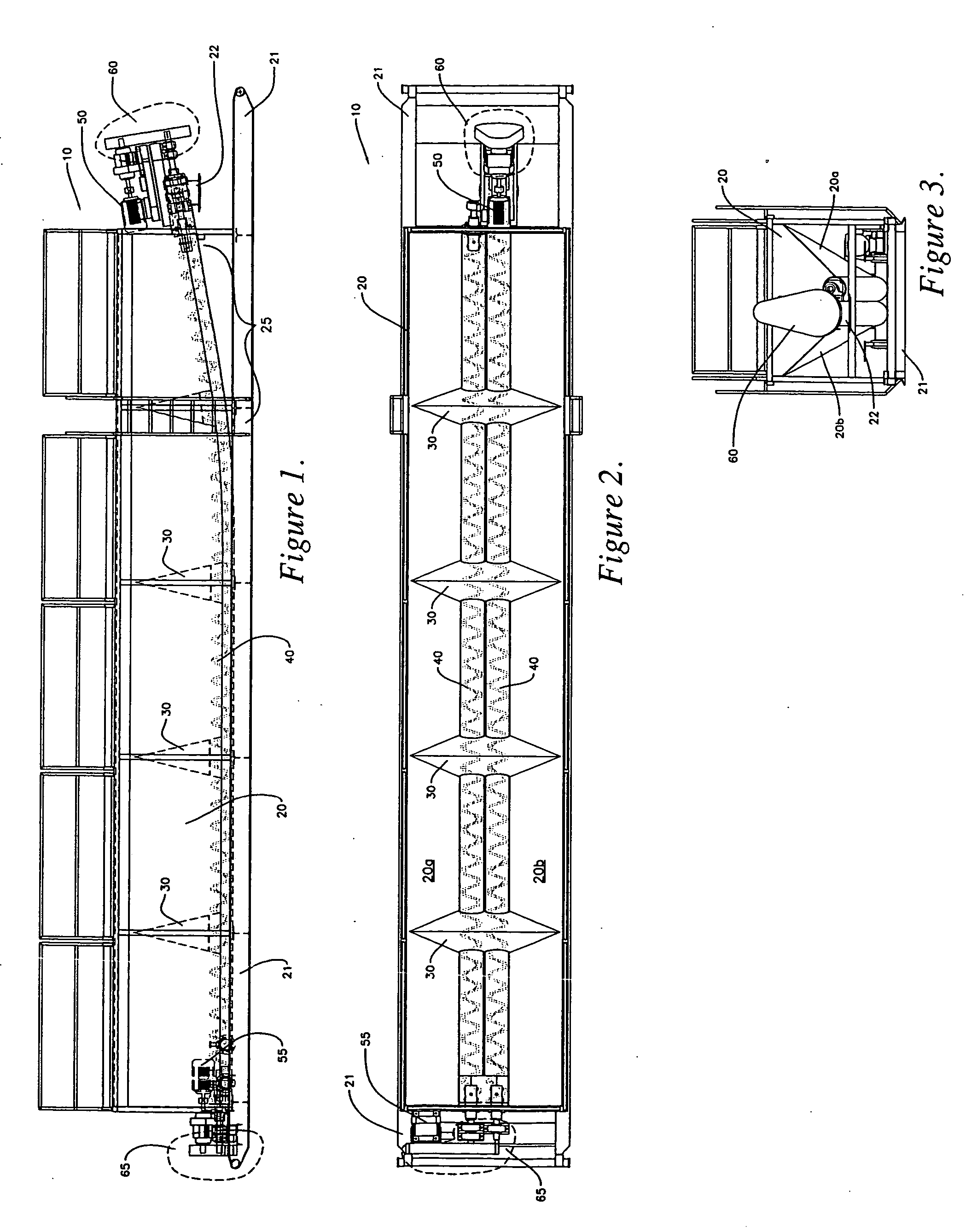

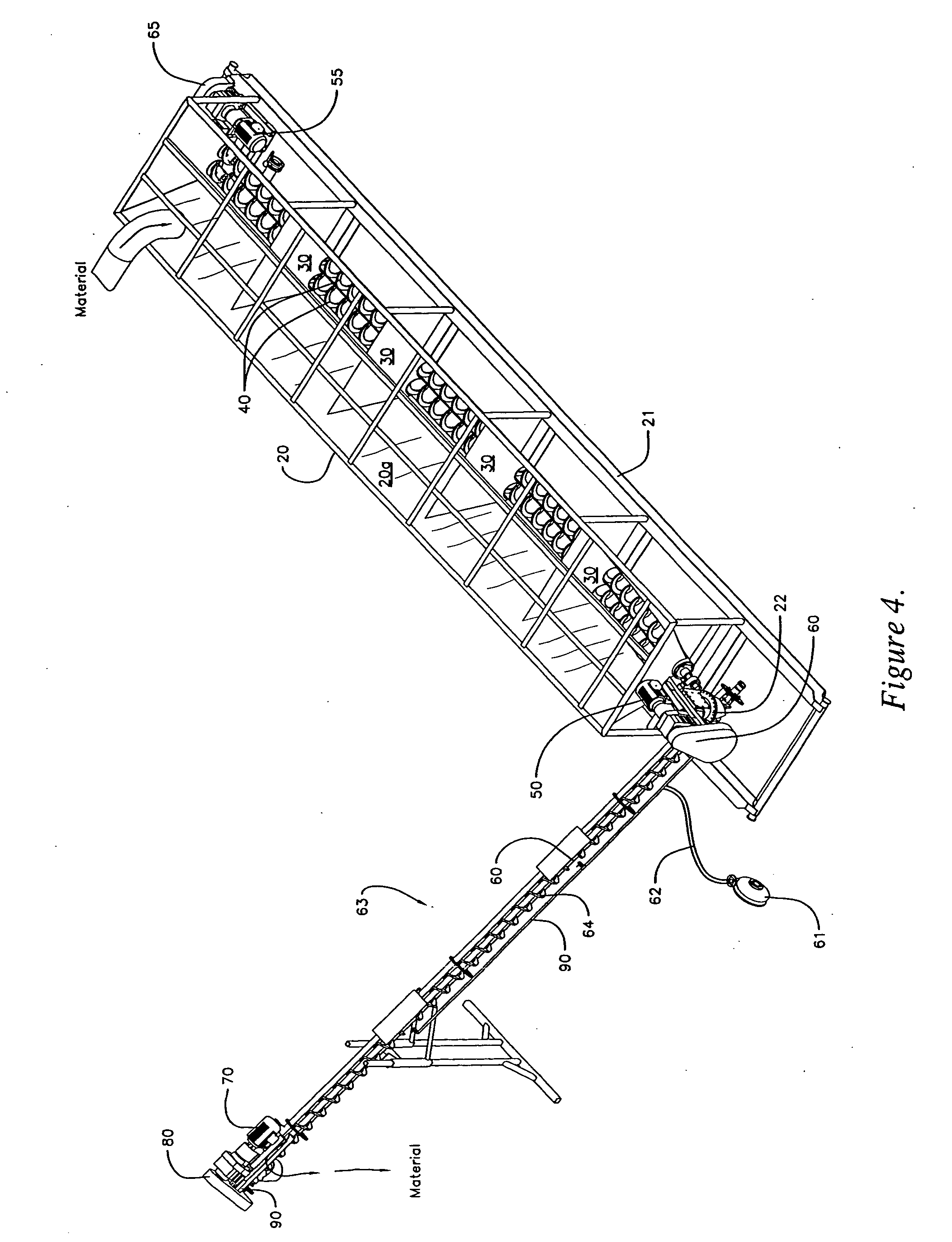

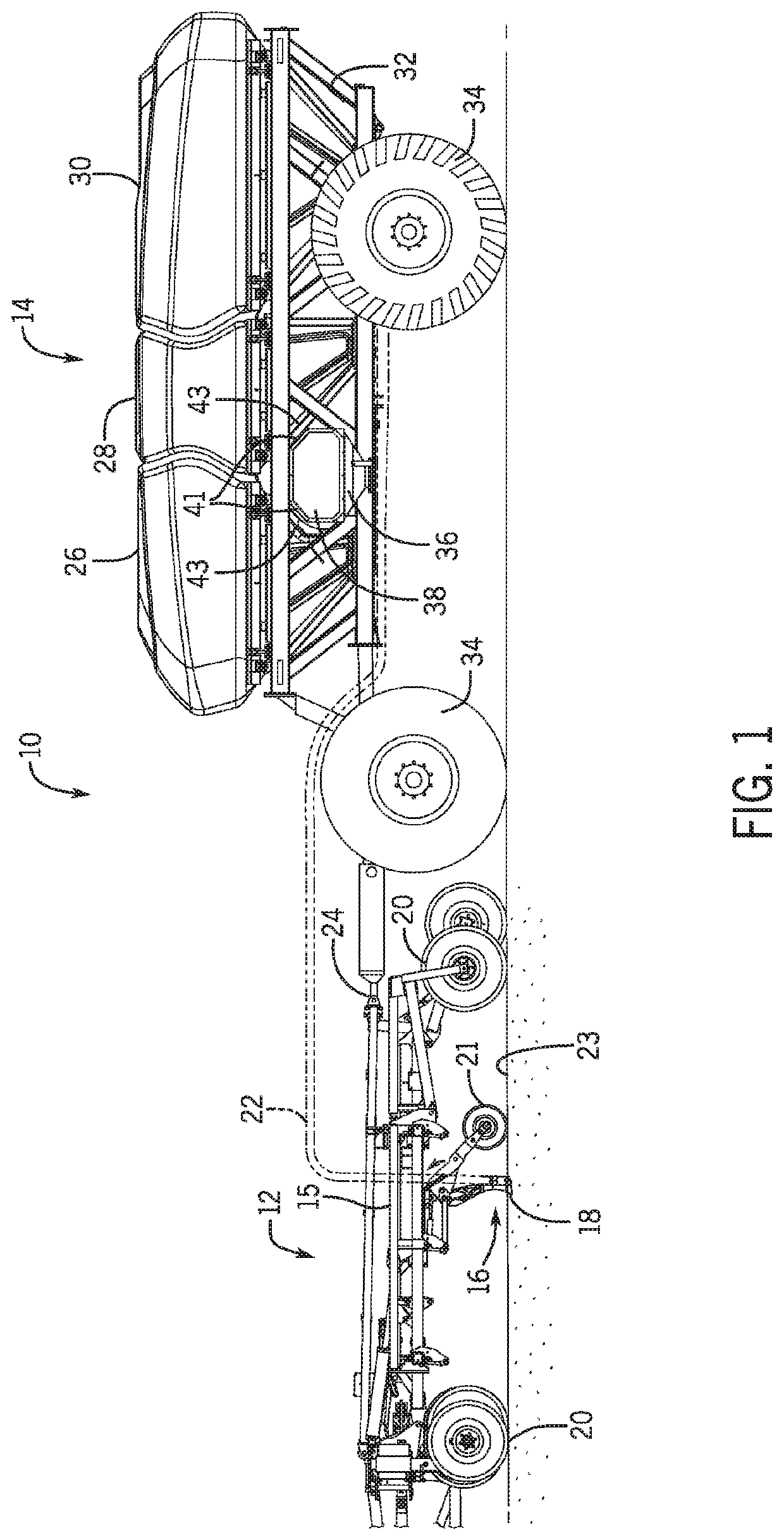

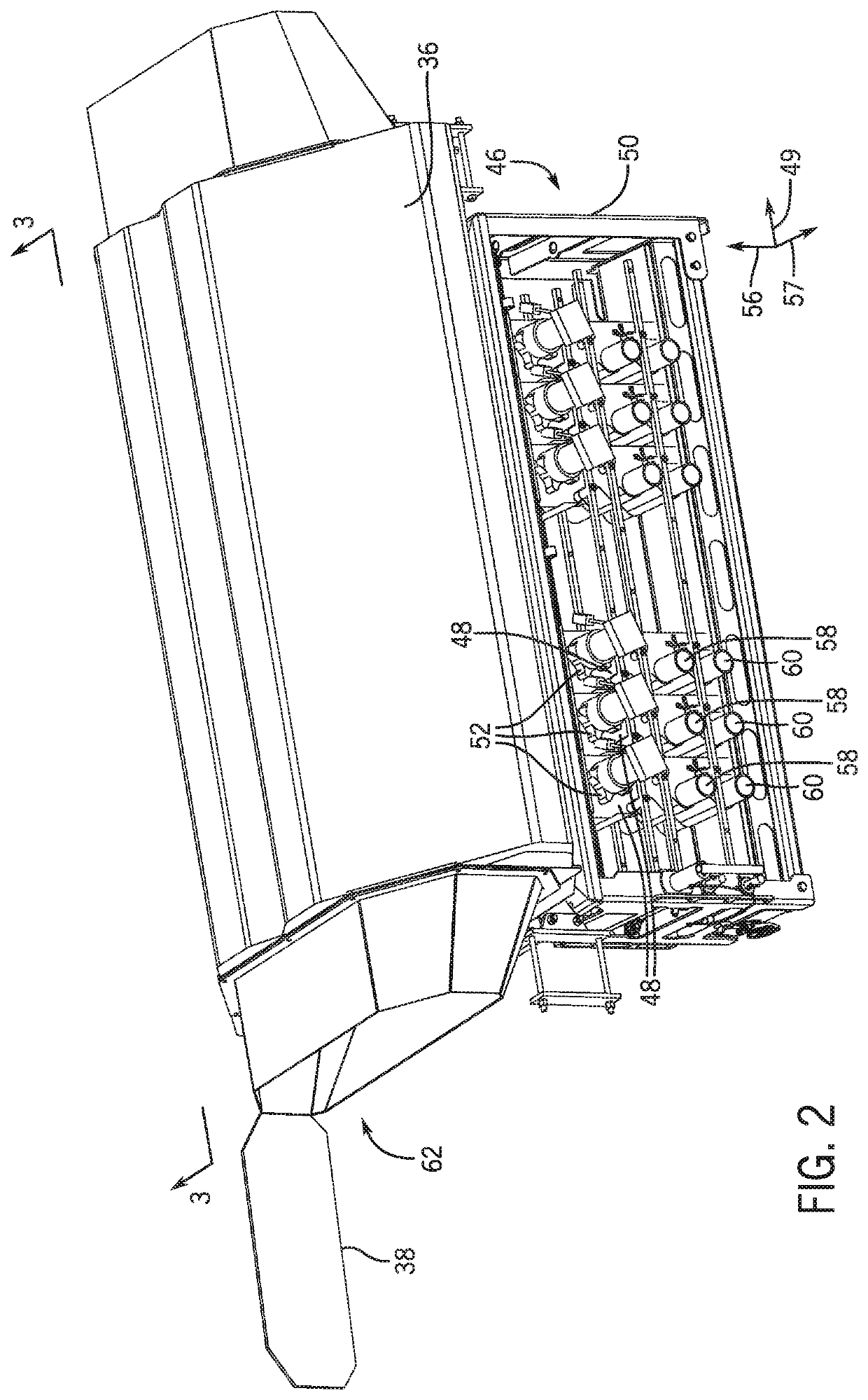

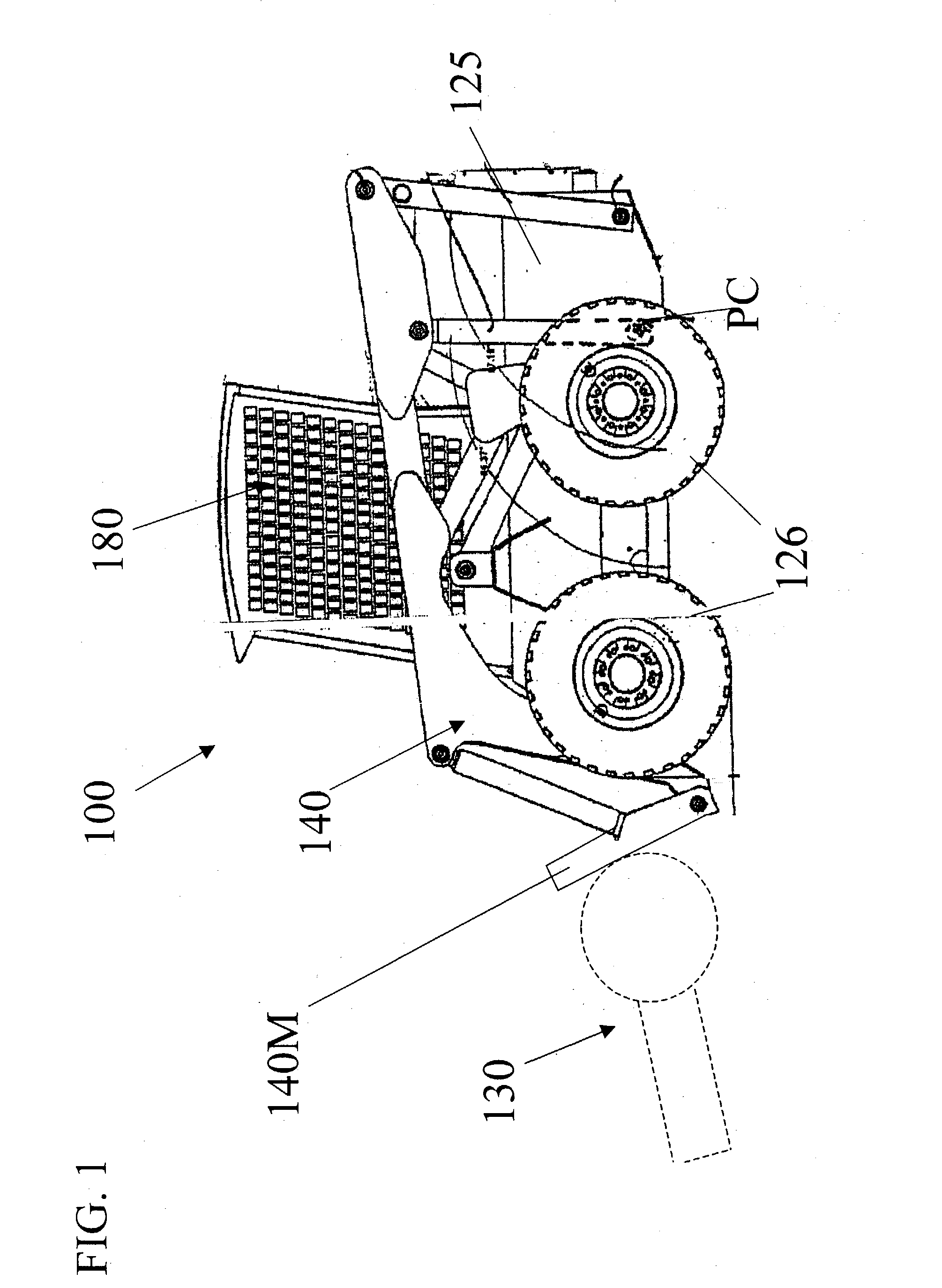

Combined Auger and Screening Apparatus for Screening and Conveyance of Granular Fertilizer or the Like

A combined auger conveyor and screening apparatus features an inlet hopper mounted to an auger housing adjacent an inlet end thereof, and a screen support frame disposed atop the inlet hopper and supporting a screen over an area of the inlet hopper. A screen drive mechanism is removably mounted to the auger housing, coupled to the screen support frame and operable to drive oscillatory motion of the screen. An angle adjustment mechanism is operable to vary a position of ground wheels relative to the auger housing in order to change an inclination angle of the auger housing and screen relative to the ground. A hydraulic circuit supplying hydraulic motors for both the auger and the screen drive mechanism comprises a control valve operable to adjust an oscillatory speed of the screen support frame.

Owner:ANDERSON NEIL

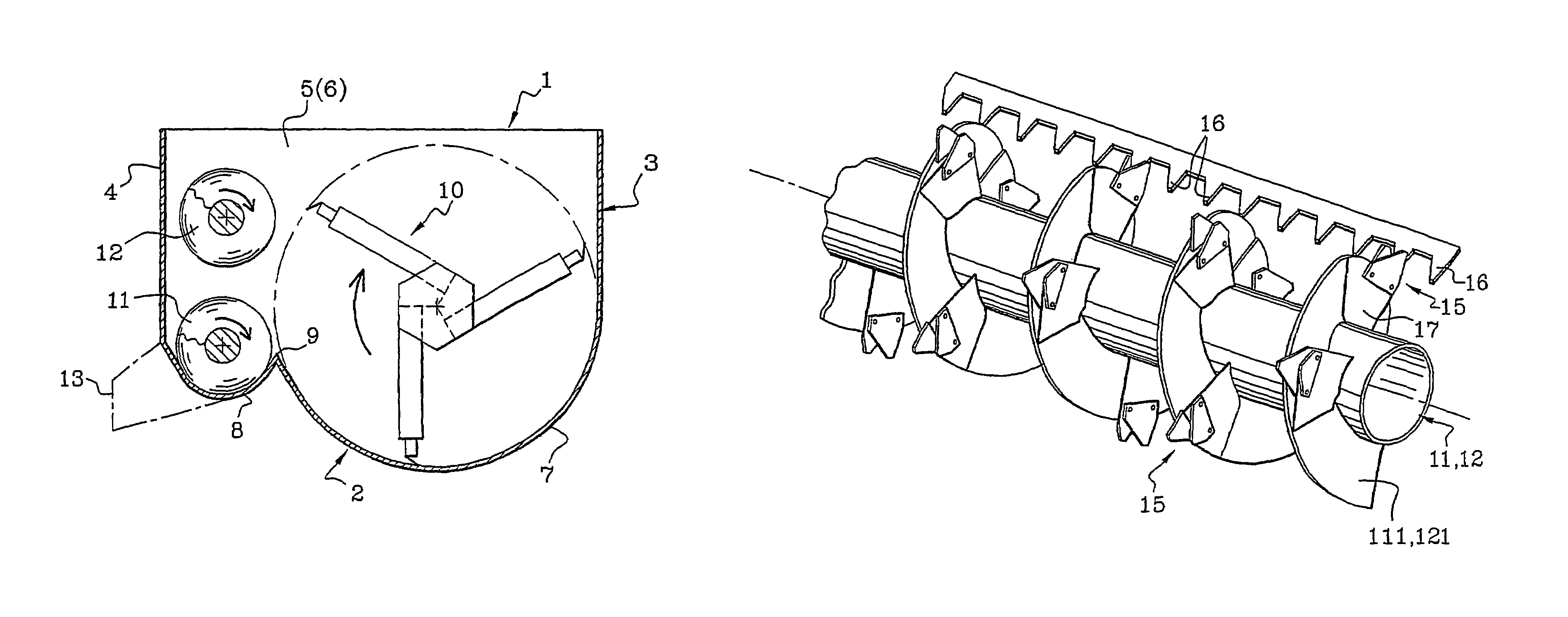

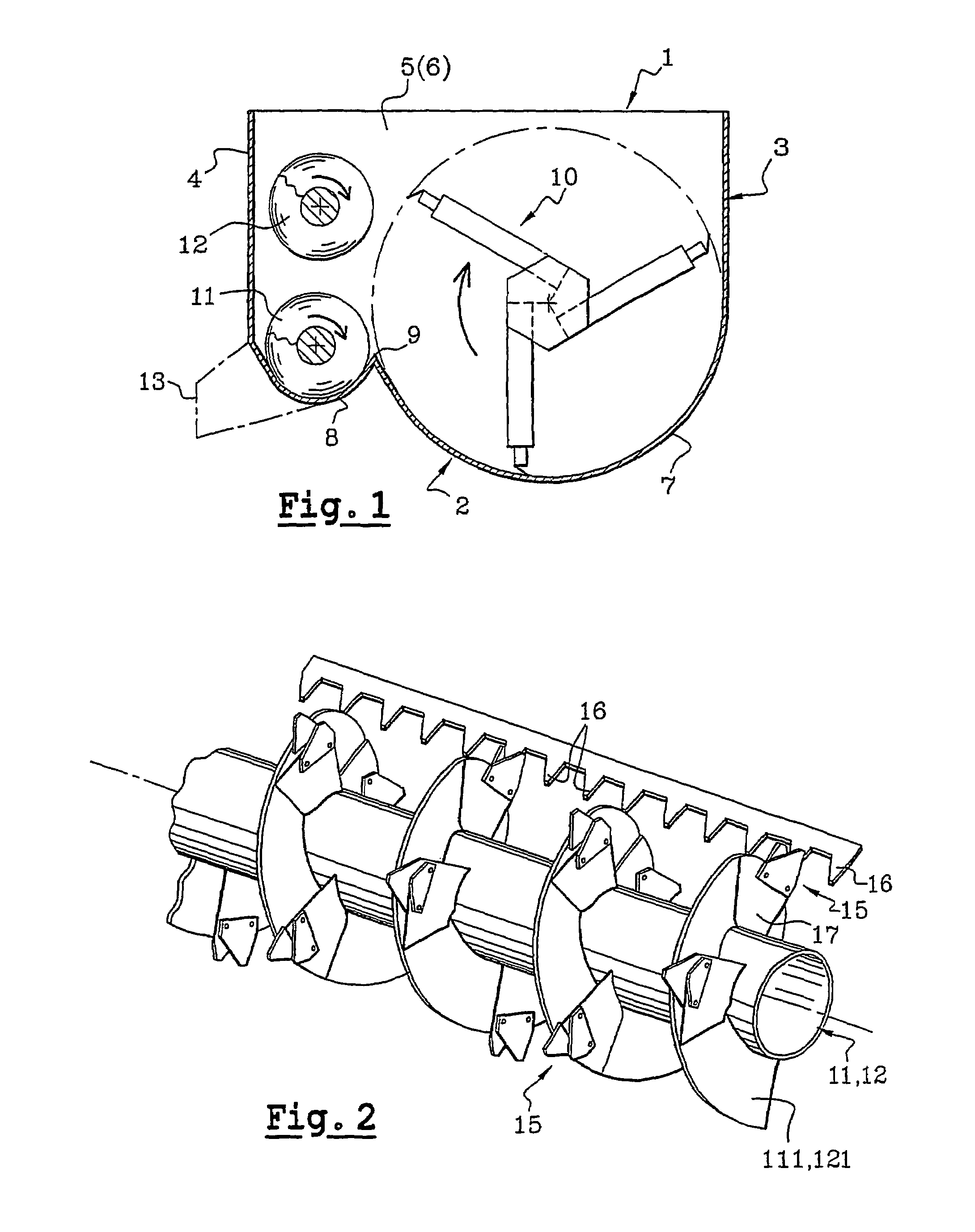

Machine for mixing and distributing products used to feed livestock

A machine including a container fitted with a base that extends between lateral walls and end walls. The base partially covers (i) a mixing rotor and (ii) a feed auger which moves products in the skip either in a closed circuit or in a circuit towards a distributing chute. A transfer screw is mounted on top of the feed auger. The transfer screw can include cutting members in the form of sectioning parts. The sectioning parts co-operate with teeth which are disposed on a beam. The teeth can be positioned as necessary either on a beam located in the container or on one or more beams located on the lateral wall. Similarly, the feed auger can also include sectioning parts that co-operate with teeth if required.

Owner:LUCAS G

Silo unloader

The silo unloader having one or more augers journaled for rotation therein is arranged to travel in a circular manner within a tower silo to auger silage to a collection point at the center thereof. Located proximate the central collection point is a transfer conveyor comprising two vertically oriented snowmobile track assemblies arranged to have corresponding flights of the track belt engaged with one another. As the tracks are driven by an electric motor, silage becomes entrained between the two adjacent tracks and is propelled therealong onto a discharge conveyor that leads to a drop chute opening in the wall of the silo.

Owner:HANSON SILO

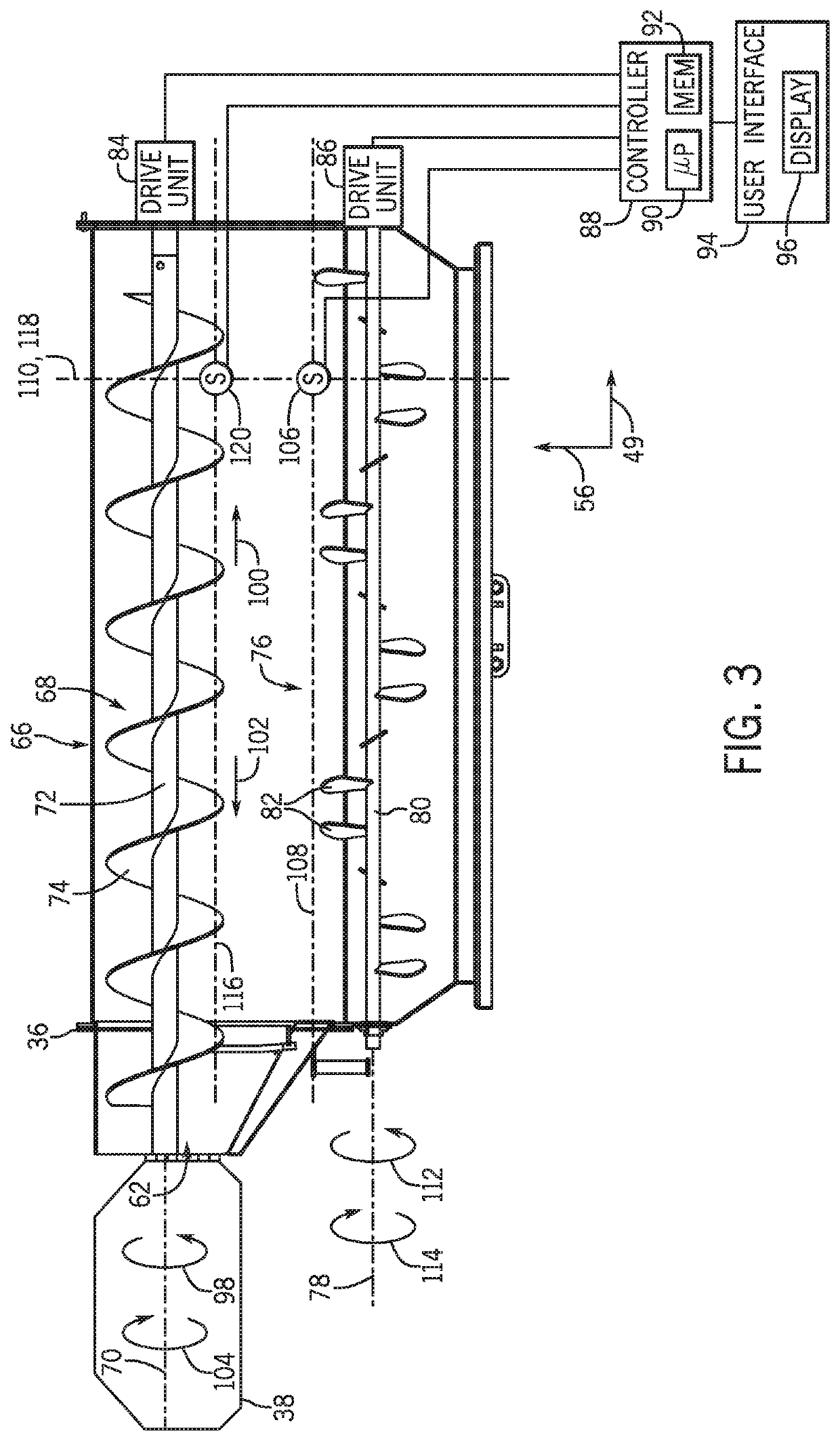

Tank having multipe screw-type transfer augers

A multi-screw auger equipped tank comprises opposing sides sloping downward and inwardly toward one another. A plurality of shaftless screw transfer augers run along the tank bottom. Drivers and transmissions coupled to the transfer augers permit simultaneous rotation of the augers in the same or opposite directions of rotation, at the same or different rotational speeds. Materials within the tank, typically slurries or sludges, can be moved to one end of the tank by the transfer augers. An inclined screw auger is disposed near the end of the tank distal from the location at which materials are deposited in the tank. The inclined screw auger picks up the materials and moves them out of the tank. Baffles in the tank aid in dewatering slurries and sludges. Circulation of materials within the tank may be done by rotating the transfer augers in different directions and / or rotational speeds.

Owner:DEL

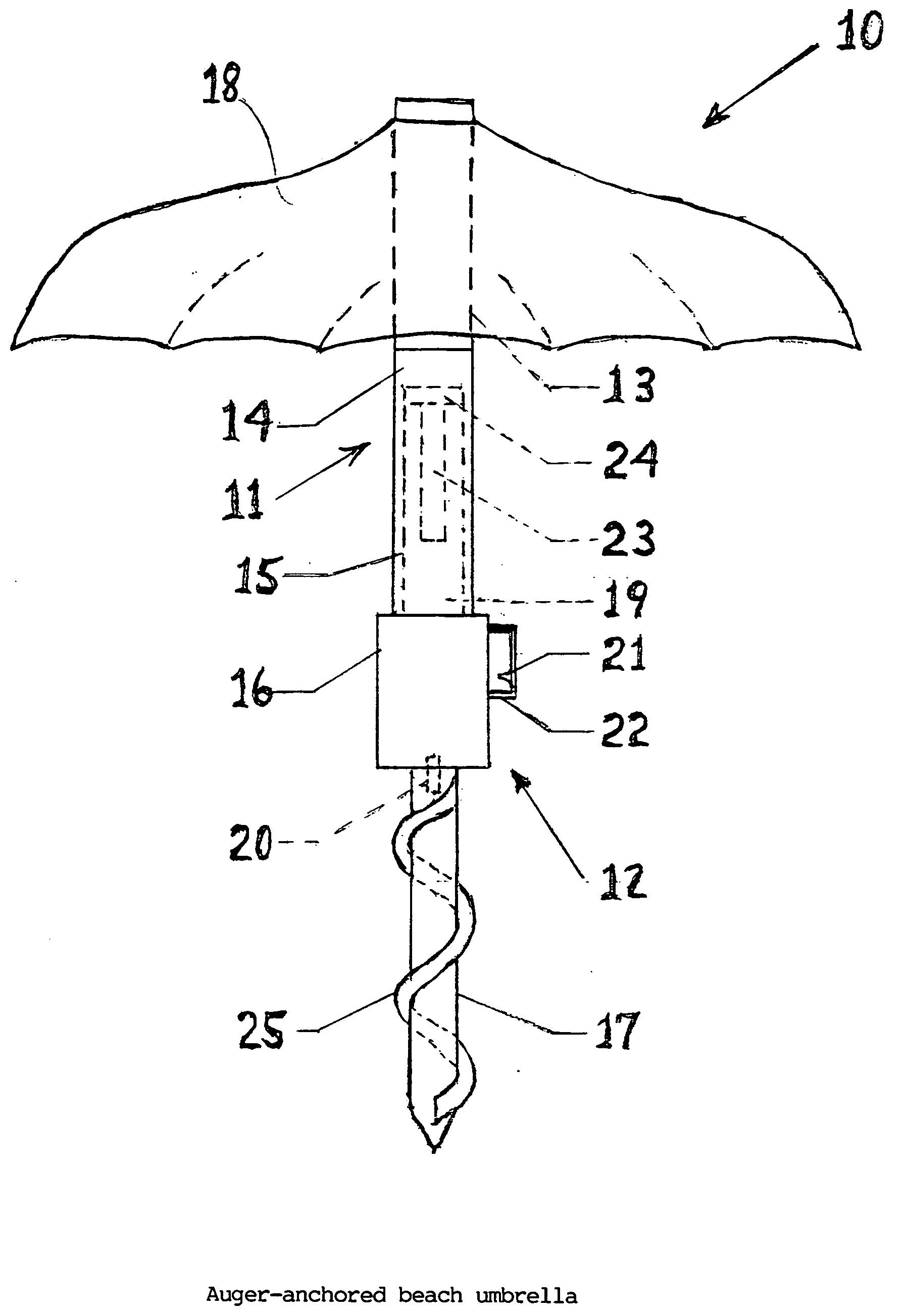

Auger-anchored beach umbrella

InactiveUS20050211282A1Easy to anchorArea maximizationWalking sticksUmbrellasEngineeringElectric motor

An auger-anchored beach umbrella has a canopy member for supporting the canopy and a pole member for anchoring the umbrella in the ground. The canopy member has a lower tubular element within which is formed an axial lumen. The pole member has an upper element which slides snugly into the axial lumen of the canopy member. The pole member has a motor element, within which is enclosed a reversible electric motor. Coupled to the motor's shaft is an auger. The motor is electrically connected to one or more batteries and to a switch. The user inserts the pole member into the ground by activating the switch in the forward direction, thereby causing the auger to bore into the ground. In the preferred embodiment, the user grasps a handle attached to the upper element to guide the pole member into the ground and to exert a supplemental downward force on it. After the auger is firmly anchored in the ground, the canopy member is mounted on the pole member by sliding the axial lumen over the upper element of the pole member. When the beach umbrella is removed from the ground, the canopy member is removed from the pole member. The user activates the switch in the reverse direction, thereby causing the auger to disengage from the ground. In the preferred embodiment, the user grasps the handle to guide the pole member out of the ground and to exert a supplemental upward force on it.

Owner:DEVENEZIA CECILIA +1

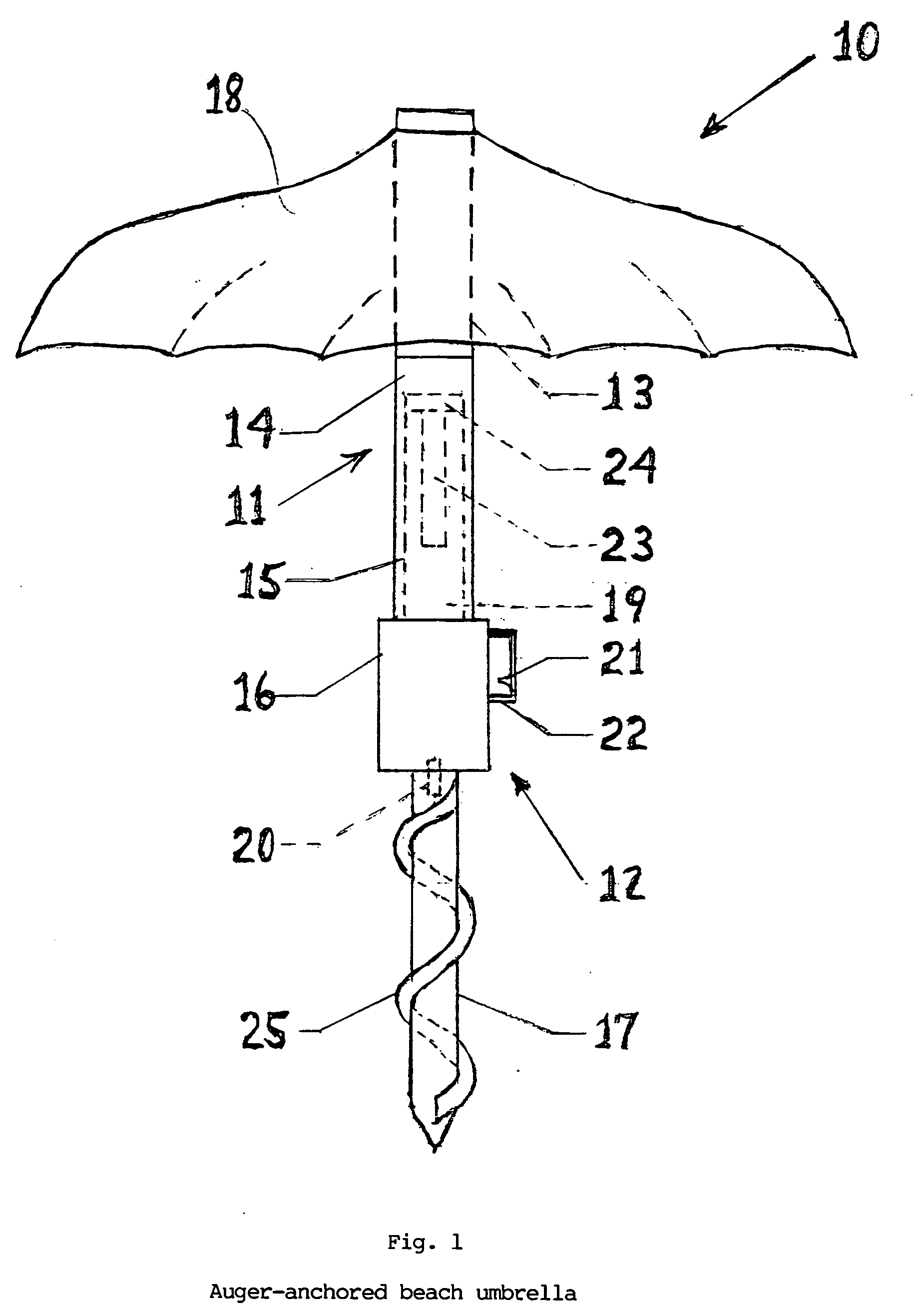

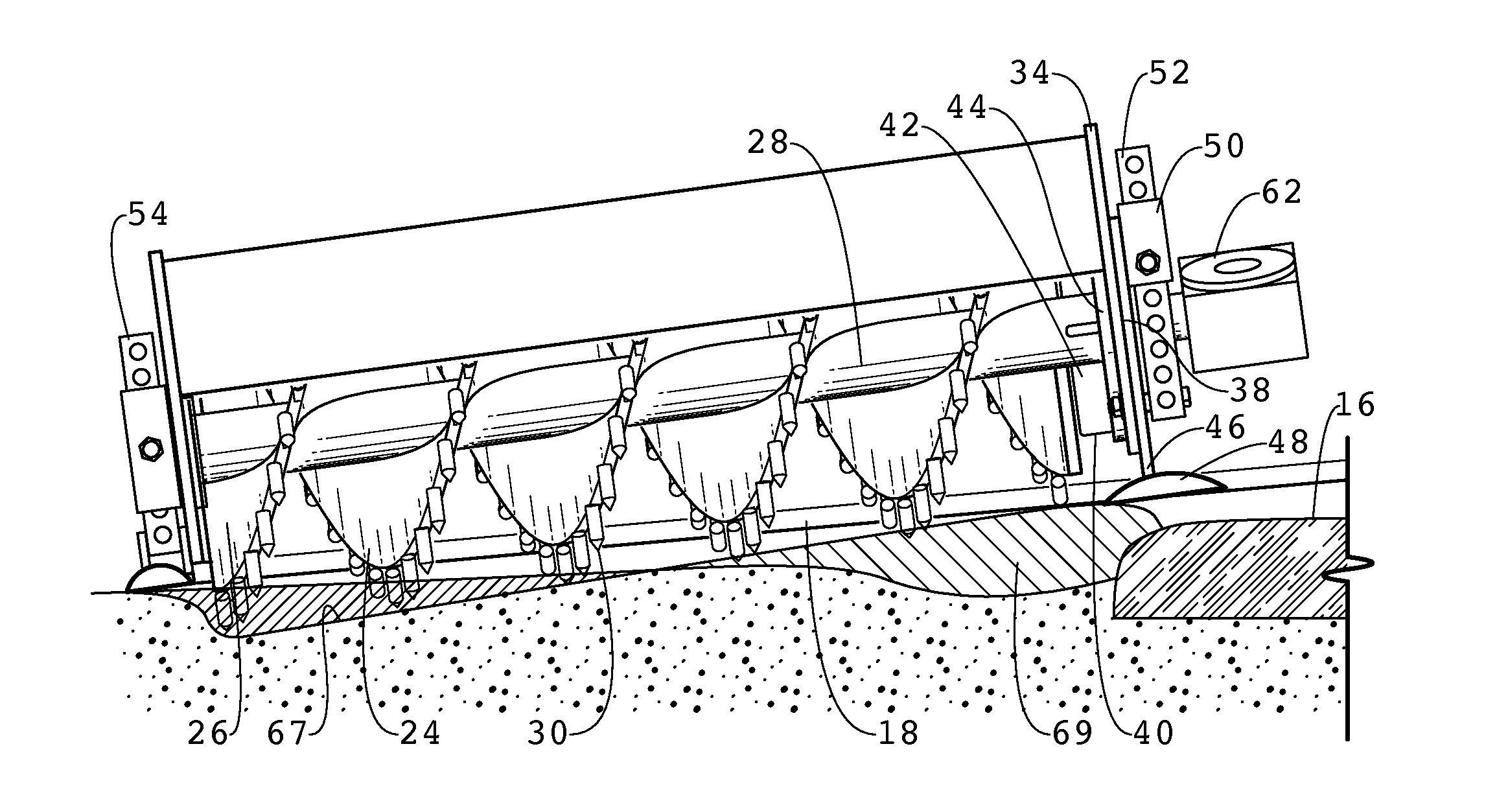

Padding machine and method of use

InactiveUS7186059B2Easy to operateIncrease consumptionPipe supportsPipe laying and repairDust controlMonitoring system

An integrated padding machine that incorporates a front digging auger that is preferably mechanically as opposed to hydraulically powered, which in conjunction with a breaker bar assembly provides for digging and crushing capabilities, and that incorporates several other improvements and advances, including screen and cross-pass conveyor level control, a real-time padding level monitoring system, and an assistant's control module, improved controls, dust control, and cold weather padding, and methods of using the machine.

Owner:BARNES TOMMY

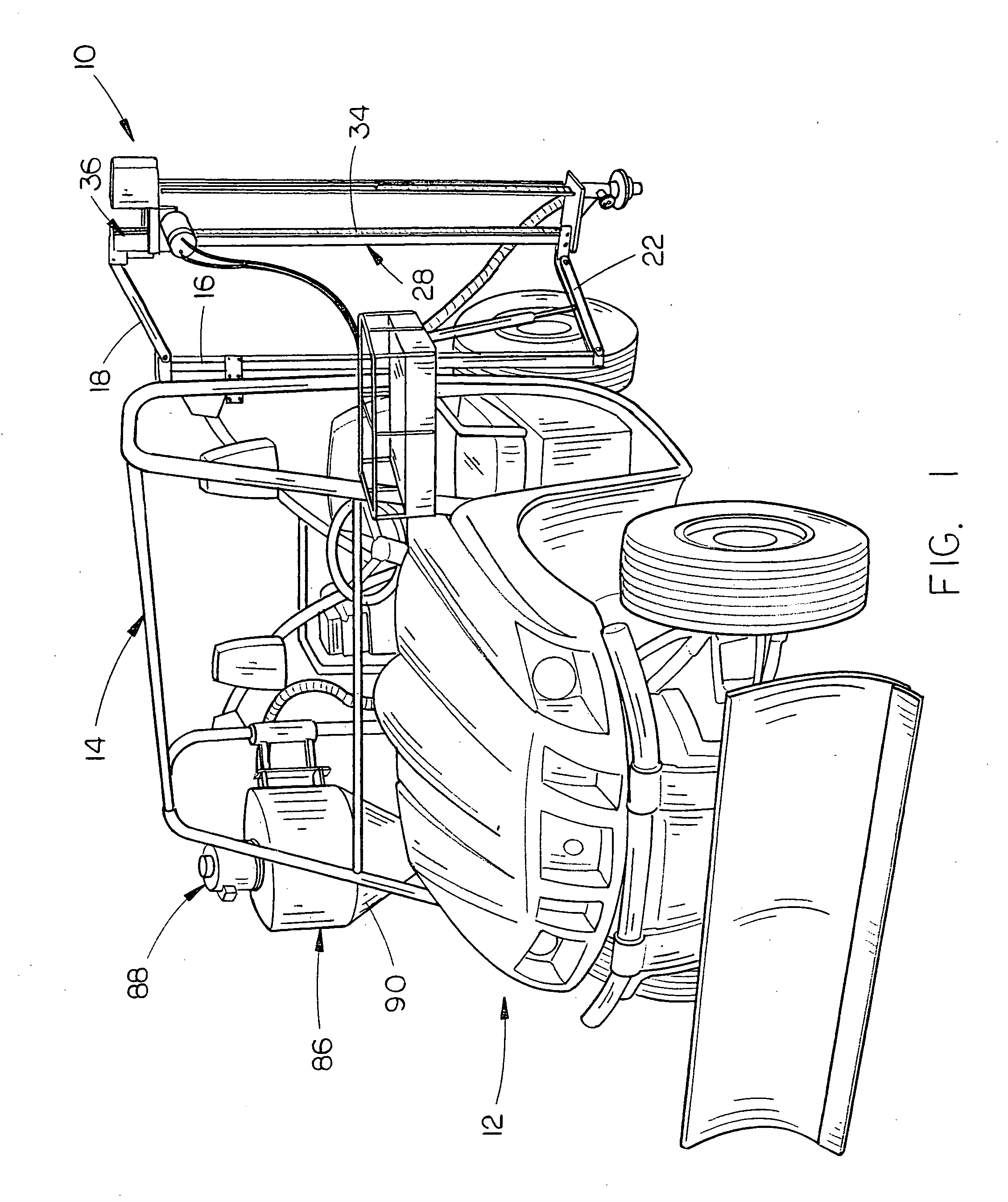

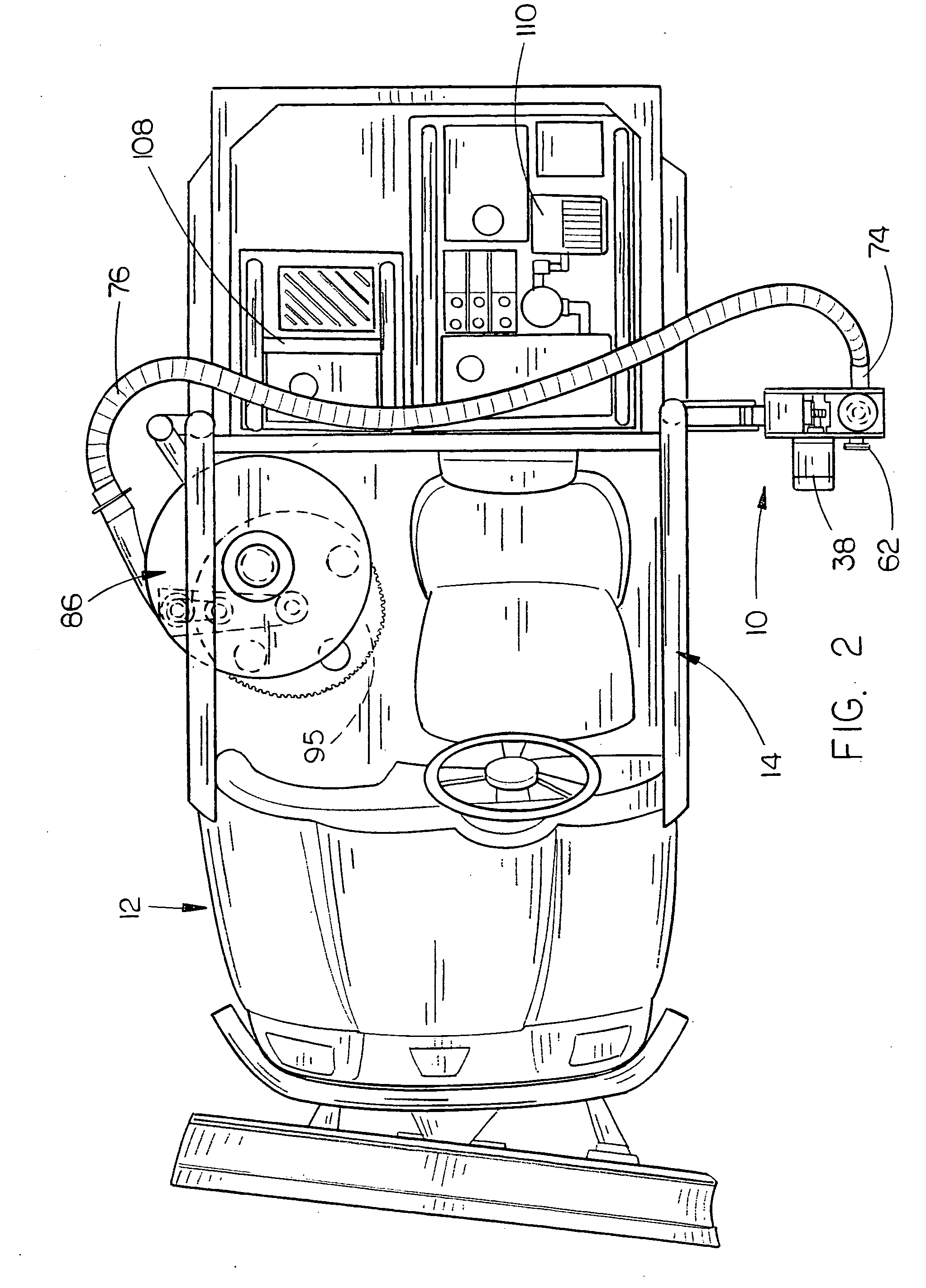

Mobile soil sampling device with vacuum collector

InactiveUS20090178853A1Easy to disassembleAvoid pollutionEarth drilling toolsDrill bitsActuatorPinion

A mobile soil sampling device is mounted on the side of a vehicle such as an ATV or UTV and includes an upstanding frame member which is vertically movable with respect to the vehicle by means of a parallel arm linkage and actuator. A vertically disposed and rotatable auger is mounted on the frame member and is moved upwardly and downwardly with respect thereto through the use of a motor and pinion gear with the pinion gear engaging a gear rack on the frame member. The auger is rotated so as to dig into the ground to the desired depth with the soil sample being conveyed upwardly into a vacuum collection chamber with the soil sample being conveyed to a vacuum chamber mounted on the vehicle. A sample collection device is mounted beneath the vacuum chamber for receiving the desired soil samples. An auger flute cleaning apparatus is mounted on the device to remove soil from the flutes of the auger as the auger is raised from a soil penetration position. The soil removed from the auger by the flute cleaning apparatus drops downwardly into the collection chamber.

Owner:PAVLIK JOHN L

Distribution and leveling system for an agricultural product storage compartment

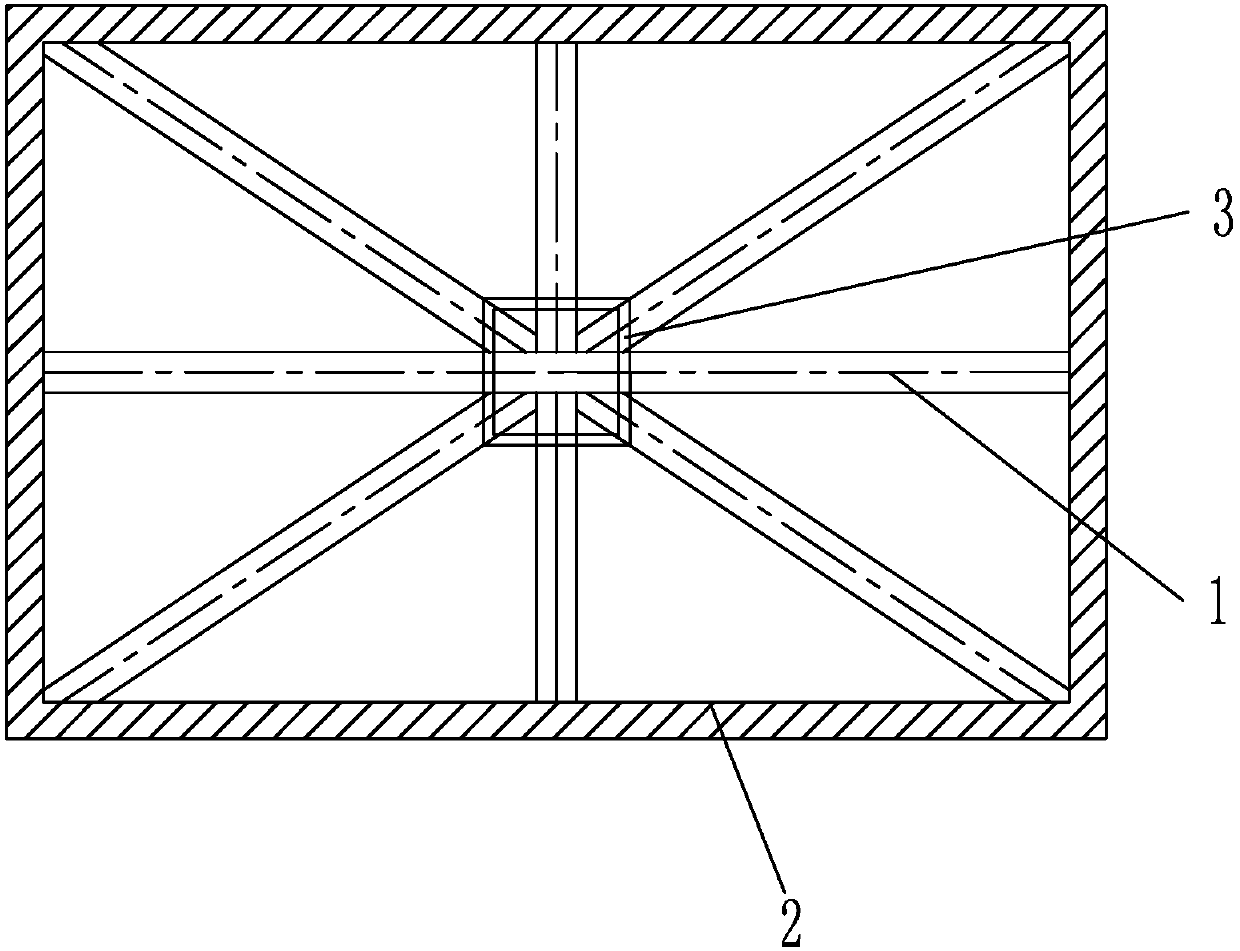

ActiveUS20200245535A1Rotary stirring mixersTransportation and packagingRotational axisAgricultural science

A distribution and leveling system for a particulate material storage compartment includes an auger configured to be disposed within the particulate material storage compartment. The auger is configured to move particulate material across the particulate material storage compartment via rotation of the auger about a first rotational axis. The distribution and leveling system also includes an agitator positioned below the auger. The agitator is configured to agitate the particulate material via rotation of the agitator about a second rotational axis. In addition, the first rotational axis is substantially parallel to the second rotational axis, rotation of the auger and rotation of the agitator are independently controllable, and the first rotational axis and the second rotational axis are substantially aligned with one another along a longitudinal axis of the particulate material storage compartment.

Owner:CNH IND CANADA

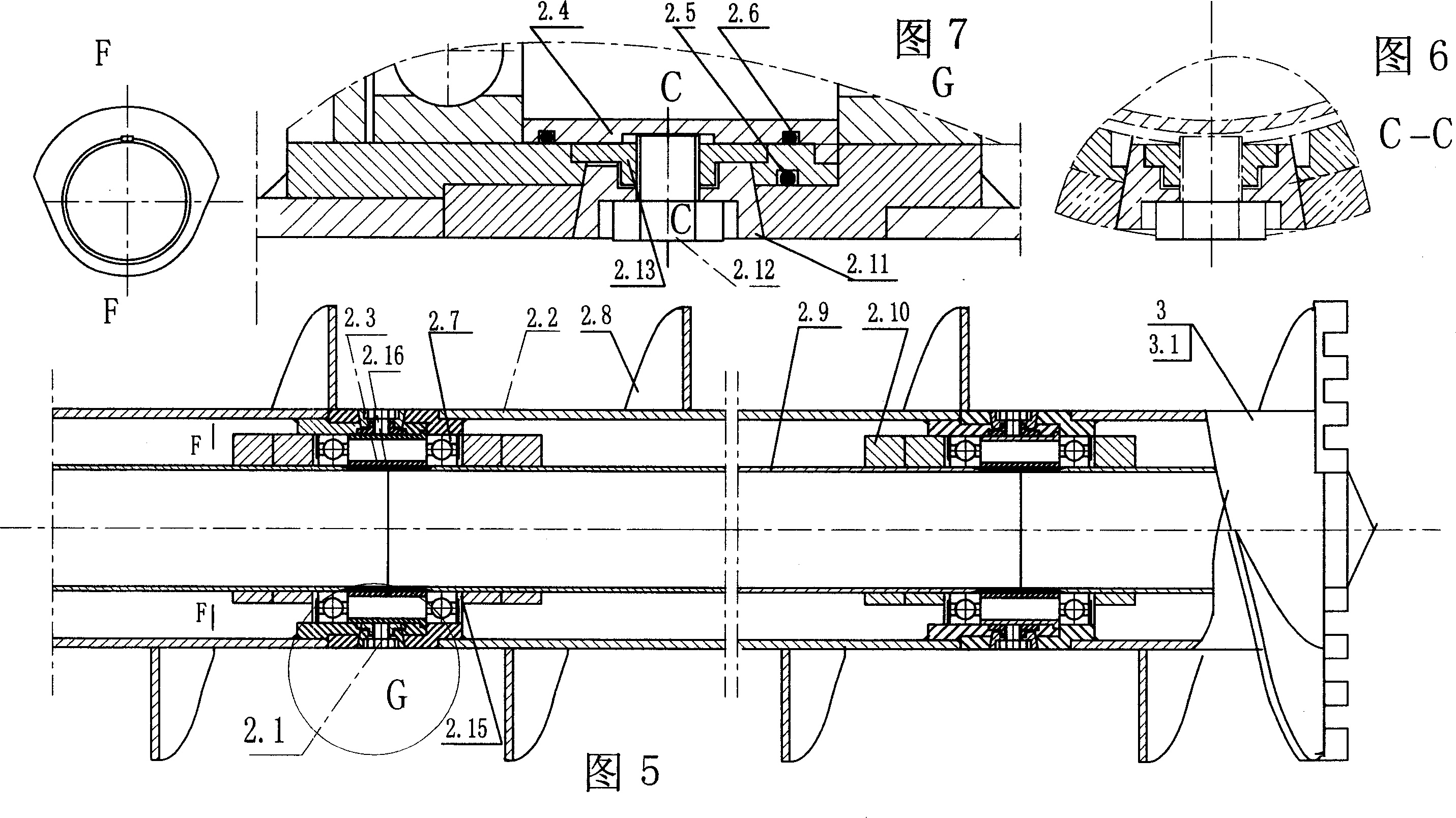

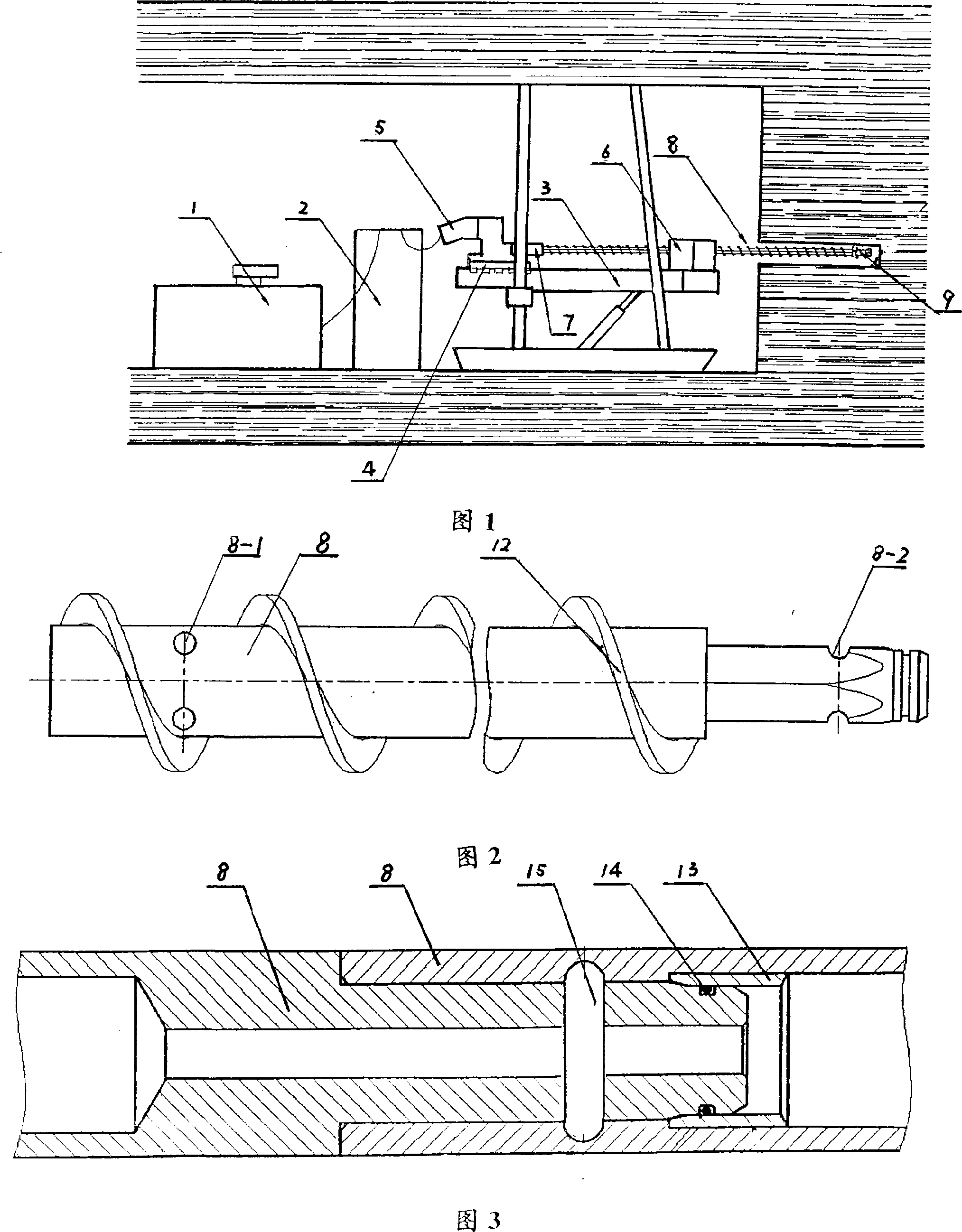

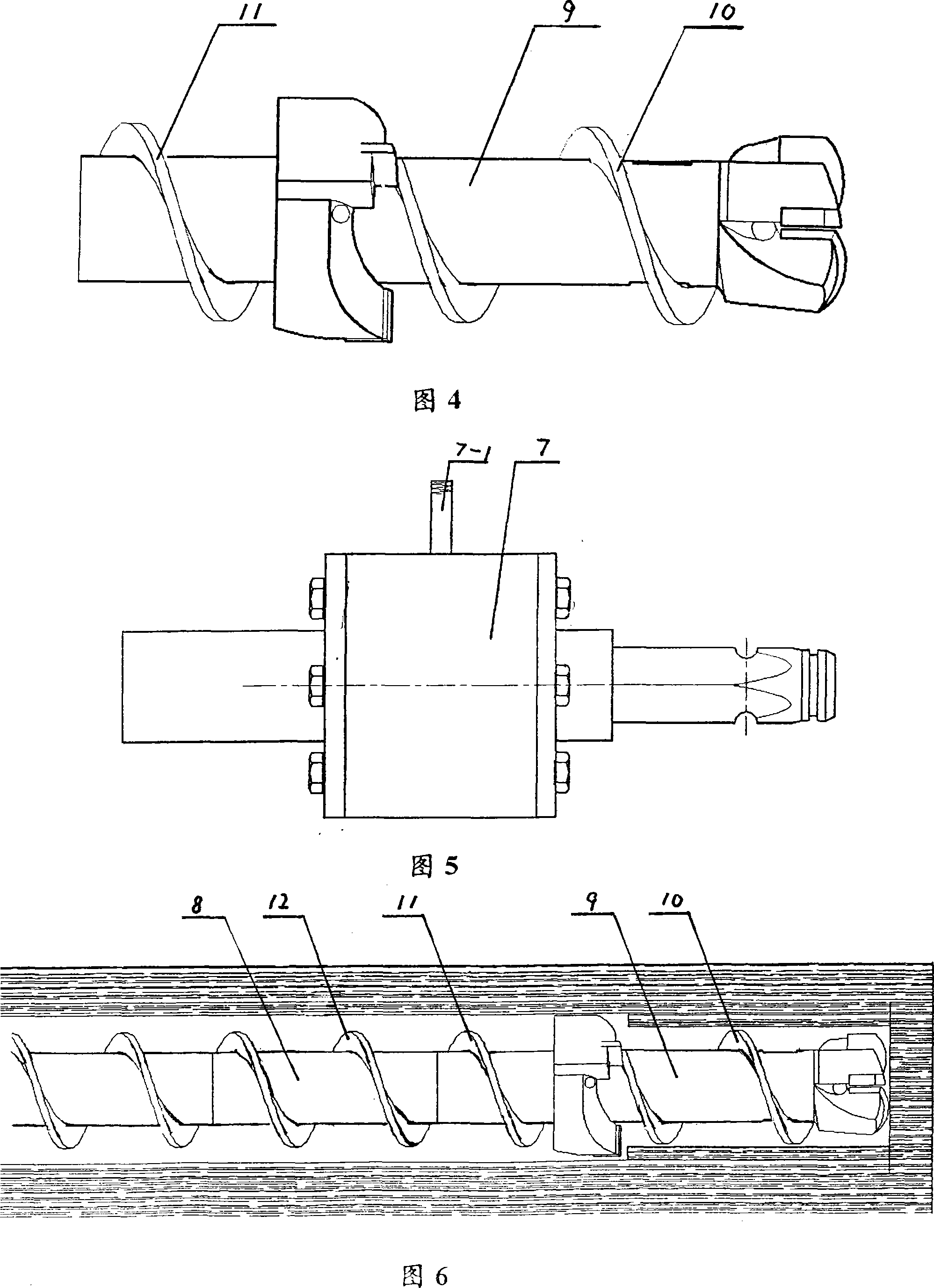

Down-hole coal bed air-pressing helix drilling tools and drilling method using the same

InactiveCN101131091AImprove the pumping effectEnsure safe productionDrill bitsDrilling rodsCoalDrill bit

The present invention relates to compressed air underground coal bed drilling auger, which includes one pump station, one operating console, one machine frame, one traveling unit, and one power head set on the traveling unit. The underground coal bed drilling auger features the air feeding change-over unit with one end fitting to the power head and one compressed air inlet connected the mine air compressing system, the hollow auger stem with one end connected to the air feeding change-over unit and the other end stretched through one gripper, and the two-stage combined drill fitting to the hollow auger stem. The underground coal bed drilling auger has rotation speed of the power head controlled in 180-650 rpm, homogeneous drilling rate controlled in 0.5-1 m / min, and air feeding pressure maintained in 0.2-0.75 MPa. The present invention has great hole forming depth, high hole forming rate, high hole forming rate and high gas exhausting effect.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

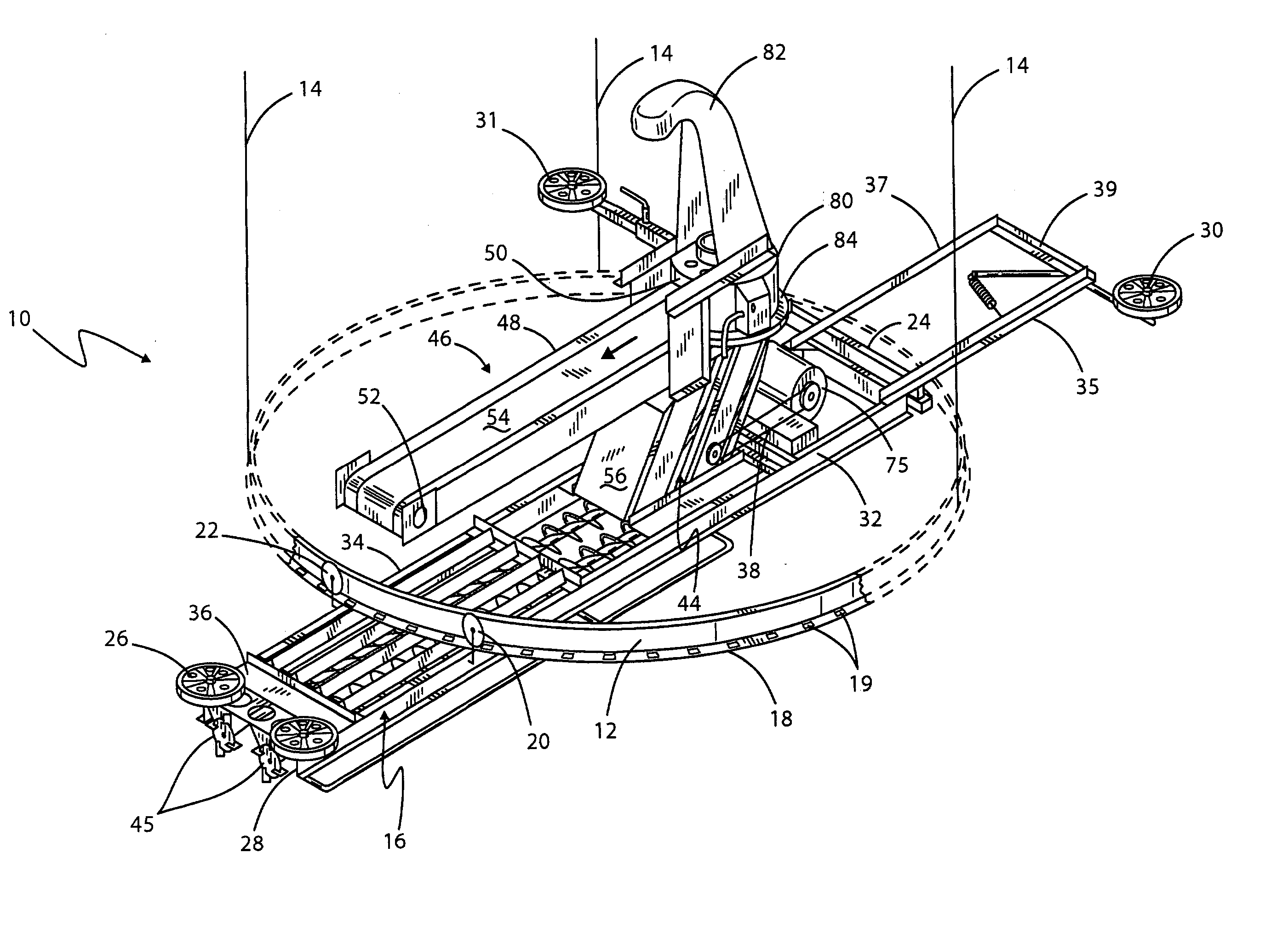

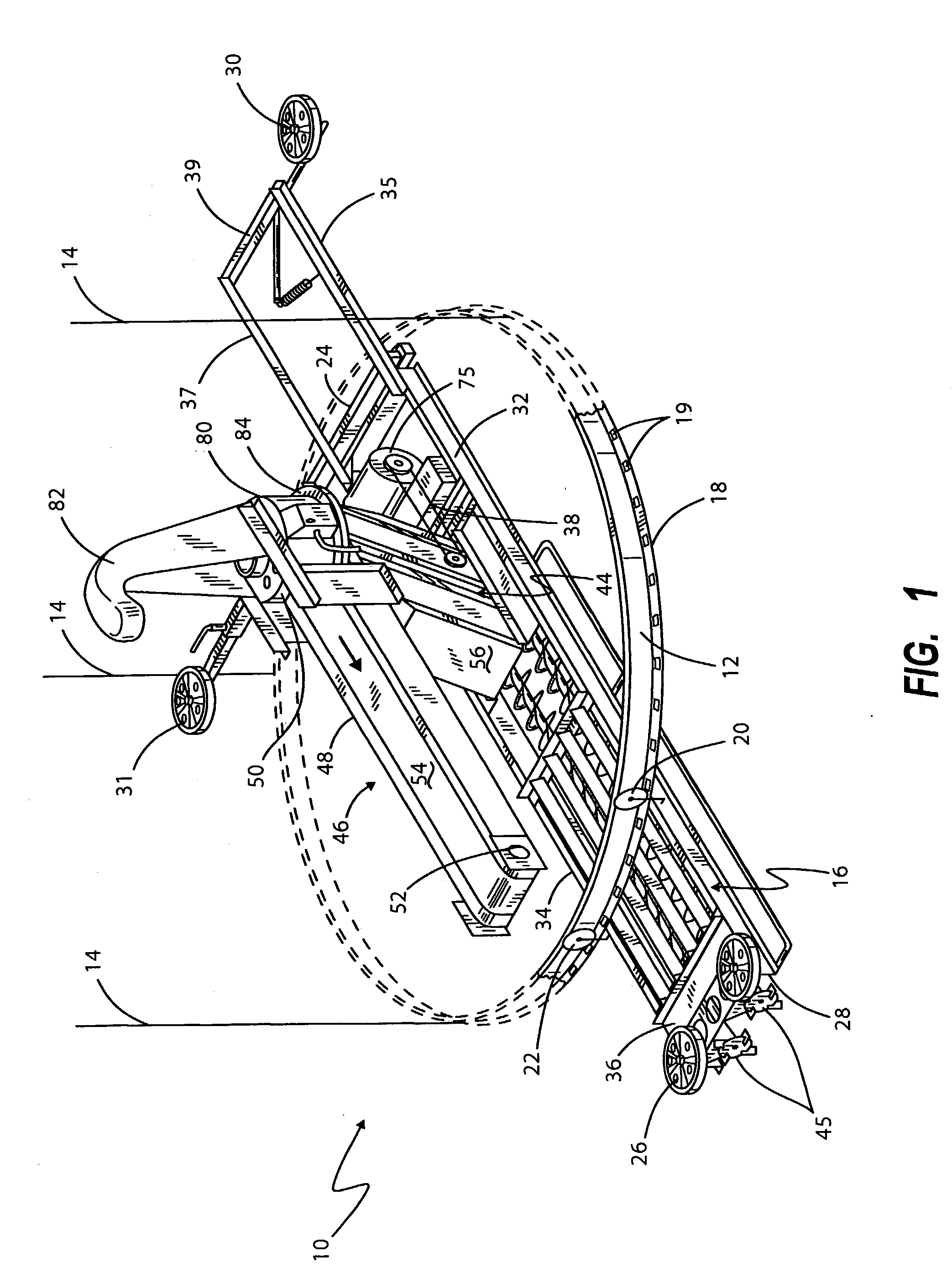

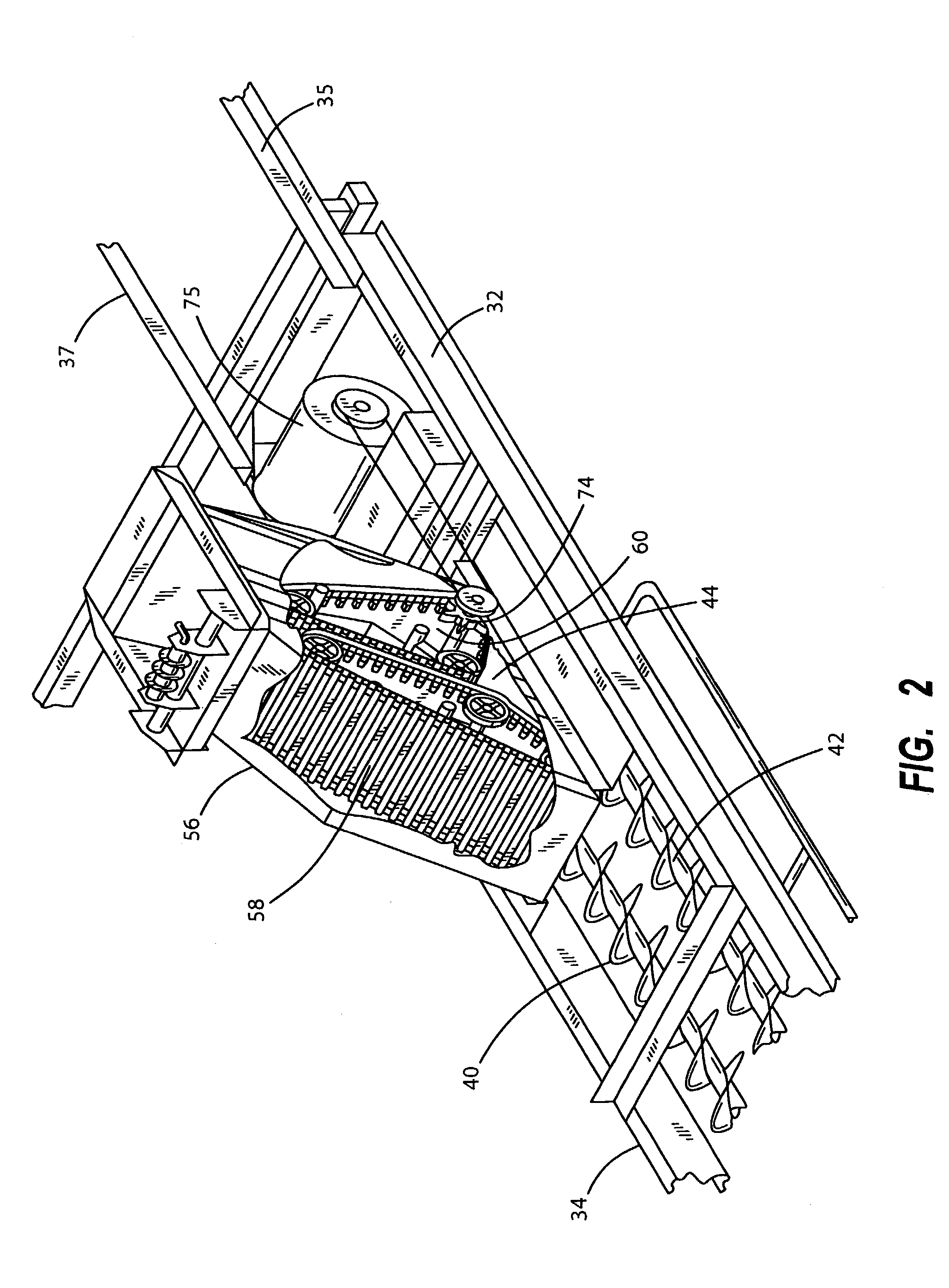

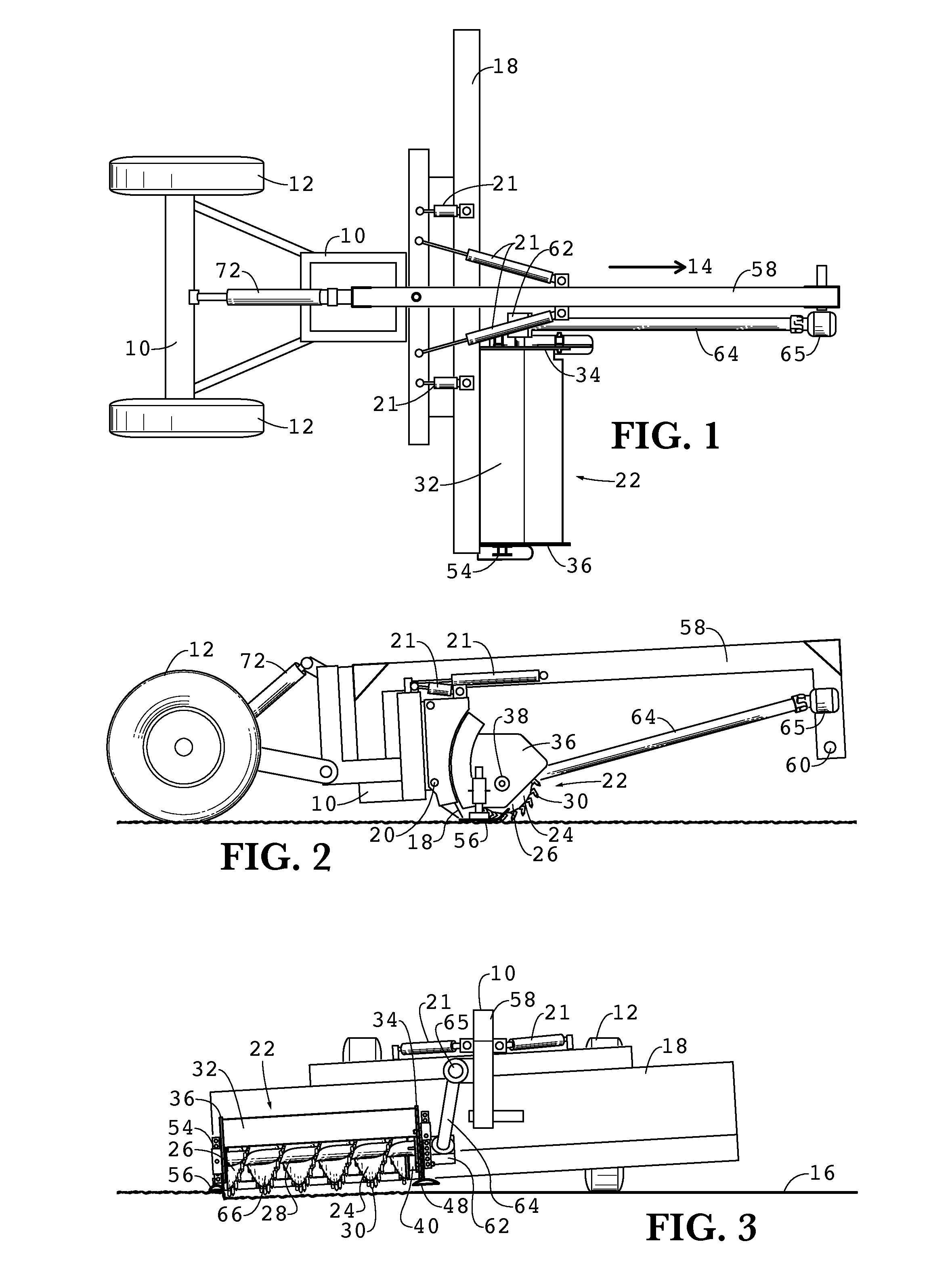

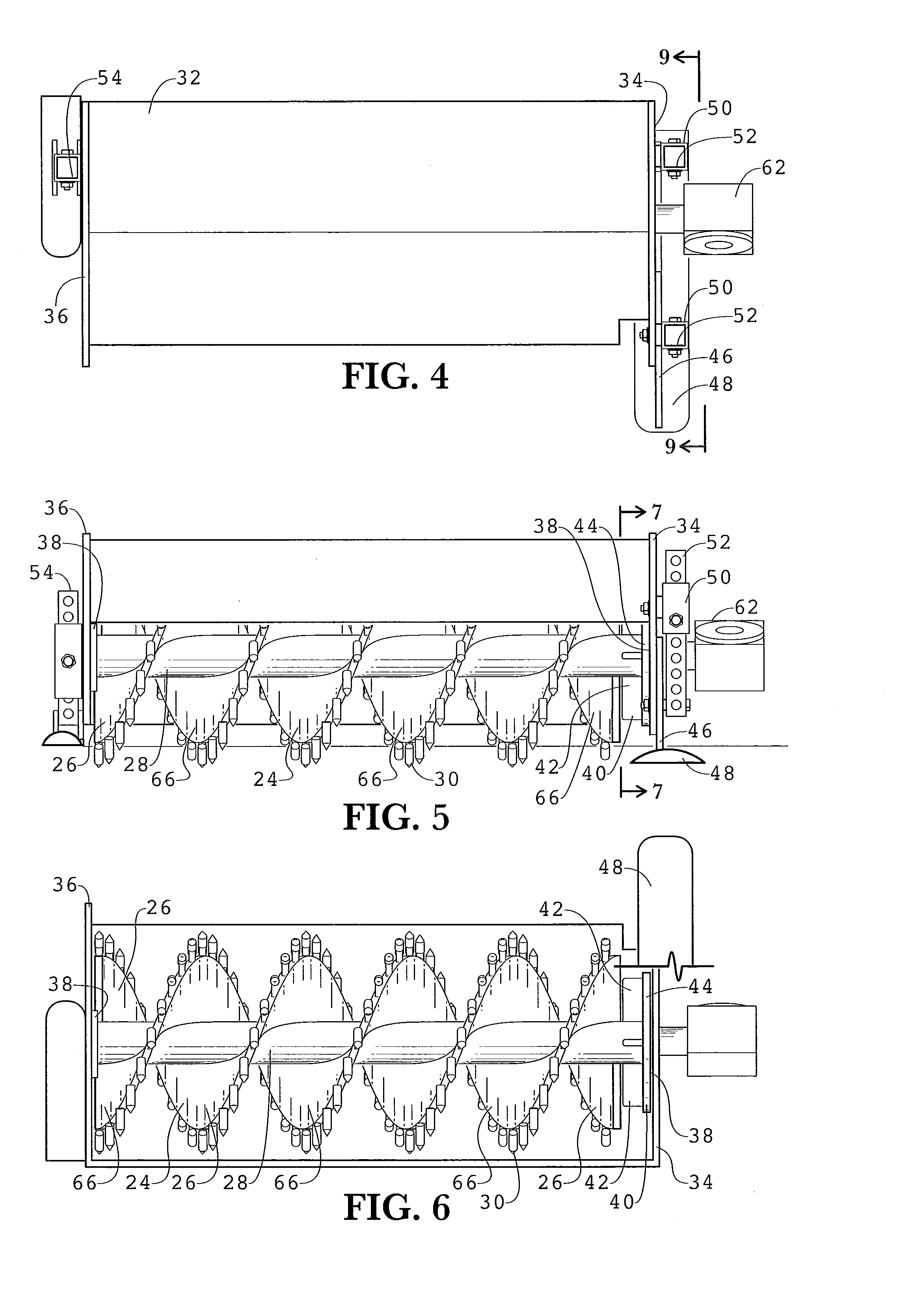

Machine for reclaiming and recycling roadway shoulder material while restoring shoulder grade and level

A grader blade mounted to a support frame has an auger-grinder mounted ahead of the grader blade. The auger-grinder has a first helical vane fixed to a rotatable axle with a plurality of teeth attached to and protruding outwardly from the auger. A shroud above and partially surrounding the auger-grinder has an inner shroud end wall, an outer shroud end wall and bearings in which the axle is journaled transverse to the direction of travel. A beater is fixed to the axle between an inner end of the helical vane and the inner wall. The beater has a plurality of paddles extending outwardly from the axle. An inner barrier wall is attached to the inner shroud wall and extends forward of the auger-grinder. A drive link is connected to the axle for connection to a prime mover for driving the axle in rotation.

Owner:R L PARSONS & SON EQUIP COMPANY

Auger conveyer

An auger conveyor is provided that includes a housing, at least one first mounting bracket, at least one second mounting bracket, an auger screw and one or more auger support assemblies. The first mounting bracket has a first landing and the second mounting bracket has a second landing. The first and second mounting brackets are attached to the housing at positions diametrically opposite one another. The auger screw has a rotational axis. The one or more auger support assemblies each have a lateral member connected to a bushing assembly. The auger screw is rotatably mounted relative to the bushing assembly. First and second ends of the lateral member each have a geometry adapted to slidably engage with the first landing and the second landing, respectively. The auger screw and the one or more auger support assemblies are adapted to be received within and removed from the housing as an assembled unit, by insertion / removal through the first end of the housing.

Owner:AG GROWTH IND INC

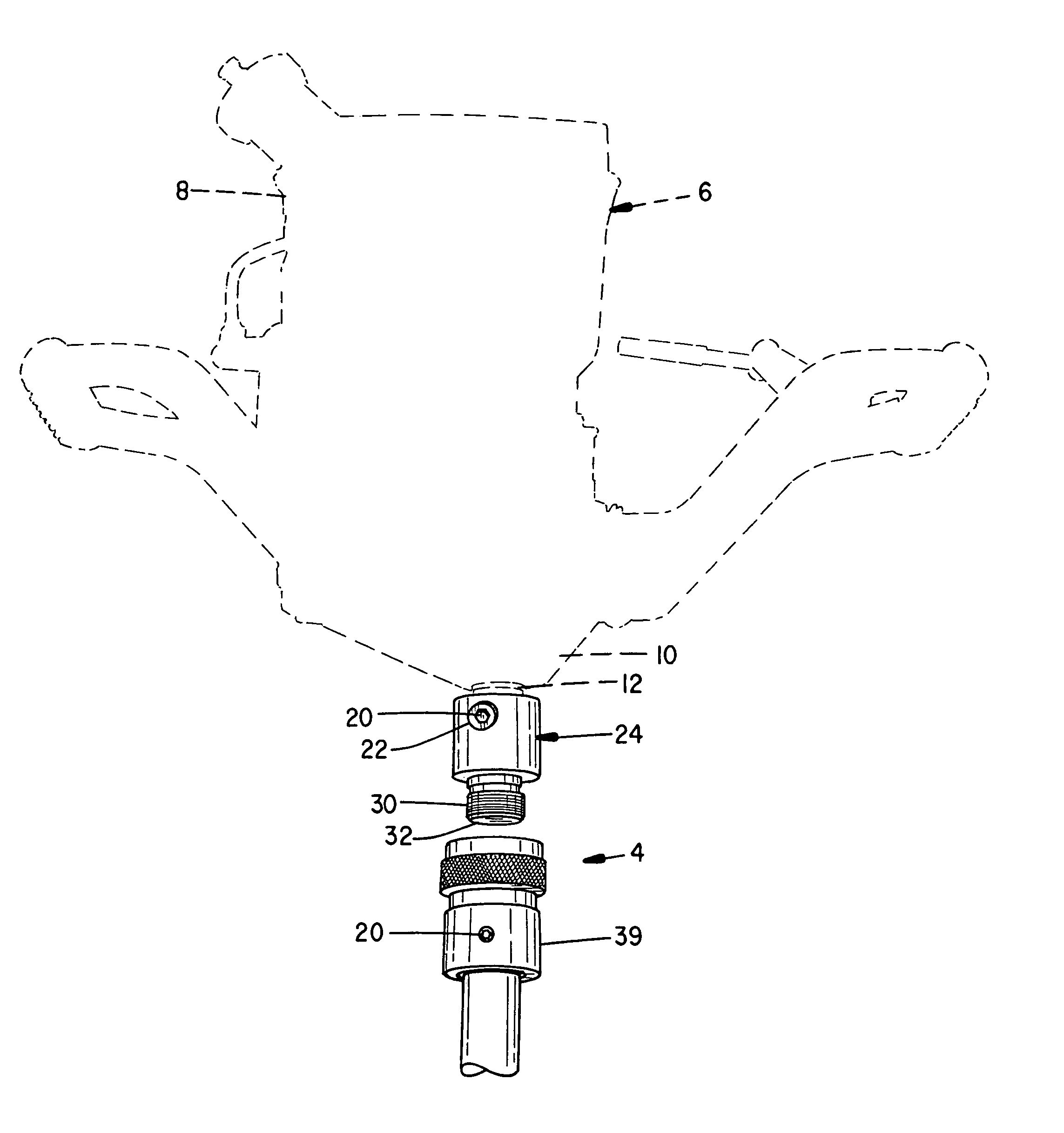

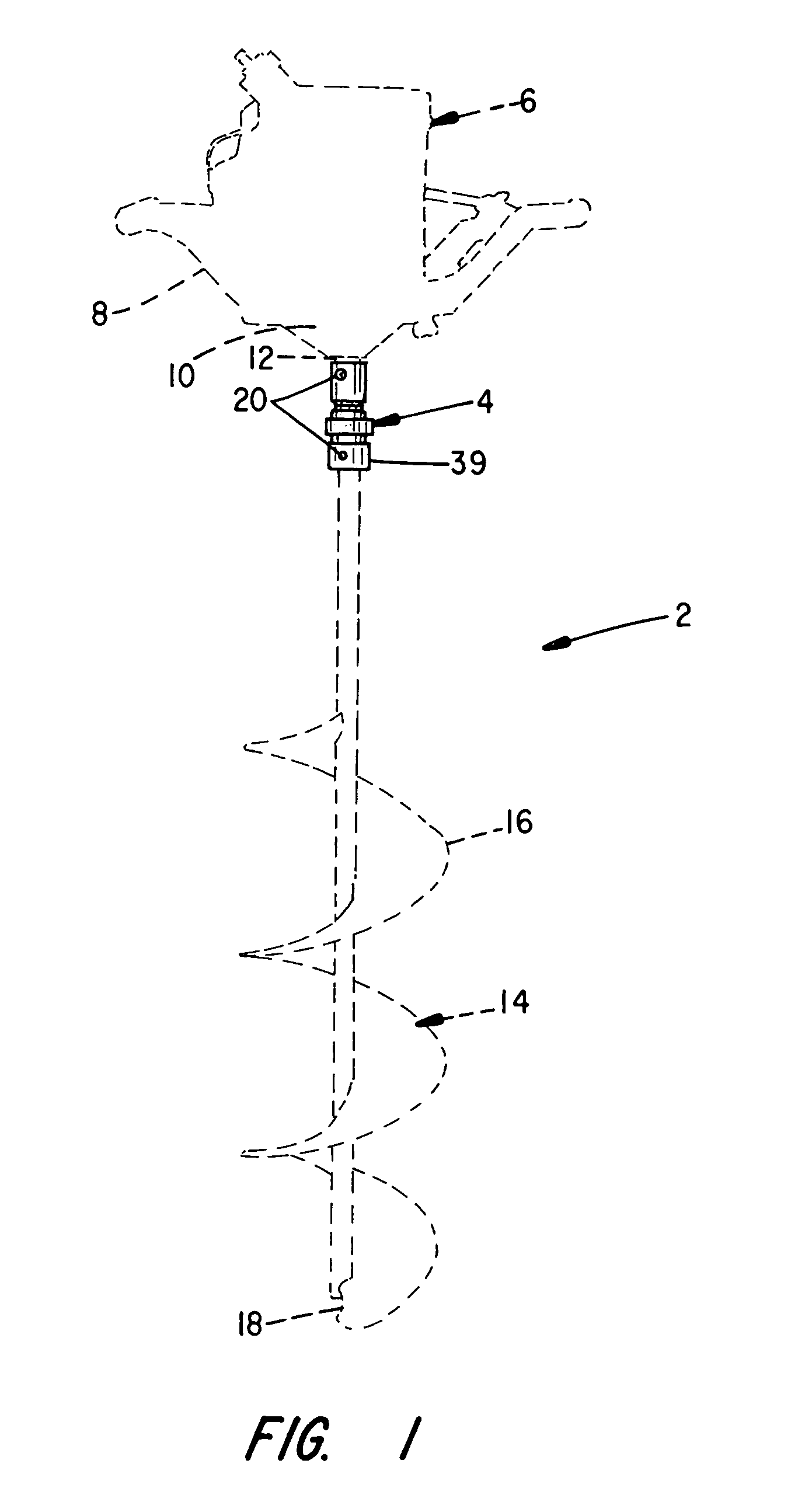

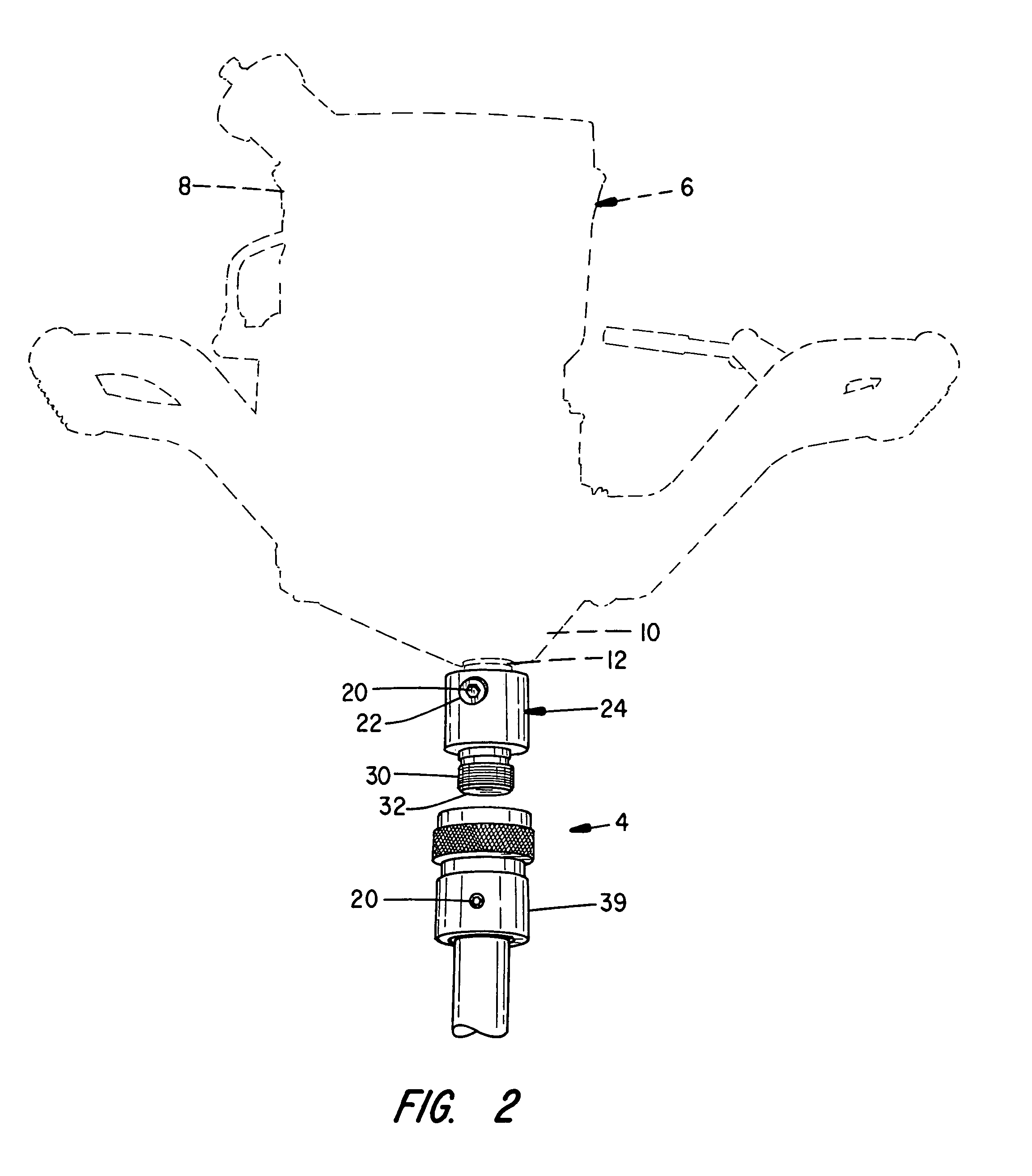

Auger quick coupler

InactiveUS7699119B1Facilitate auger detachmentMaintenance conditionDrill bitsDrilling rodsDetentEngineering

A coupler for securing an auger and / or extension piece(s) to a PTO shaft. In one construction, a threaded PTO collar mounts to a PTO shaft and mates with a suitable length stub shaft and captured, knurled hand nut mounted to an auger. The stub shaft indexes in non-rotational engagement to the PTO collar. In another construction, a PTO collar provides several detents that interconnect with resiliently biased projections at an auger collar. A hand piece maintains the connection. In other embodiments, key(s) at the PTO shaft mate in non-rotational engagement with keyway(s) at an auger and a resilient member latches the non-rotational connection. Shaped PTO shaft surfaces and complementary auger coupler surfaces can be included with the later couplers to enhance the connection.

Owner:LUNDE JAMES +1

Construction method for quick hole forming and concrete pouring of anti-slide pile auger drill

PendingCN107905236AImprove work efficiencyReduce construction costsFoundation engineeringDrilling machines and methodsStructural engineeringEngineering

The invention relates to a construction method for quick hole forming and concrete pouring of an anti-slide pile auger drill. The construction method comprises the following steps of measuring and staking out, site leveling and compaction treatment of the orifice position, orifice steel bushing mounting, peripheral soil cutting and taking through a small drill bit, middle soil taking through a large drill bit, trimming through a rectangular trimming device, orifice bottom trimmed soil taking through the large drill bit, mounting and fixing of a reinforcing cage through a crane and concrete pouring through a guide pipe method. According to the quick construction method, anti-sliding pile hole forming is performed through the auger drill, and the anti-sliding pile hole forming process is simple, quick, safe and systematic.

Owner:中铁隧道集团一处有限公司

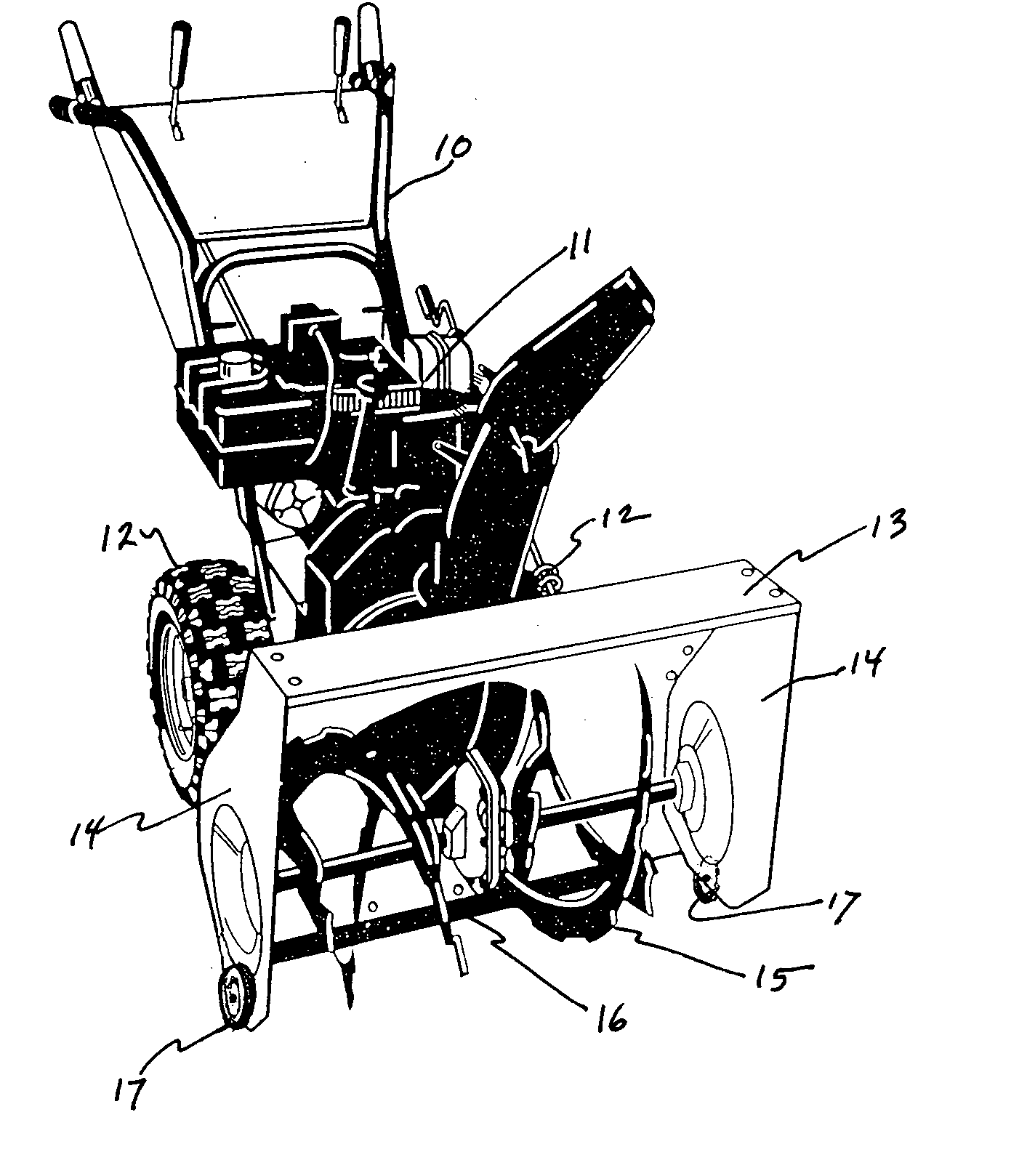

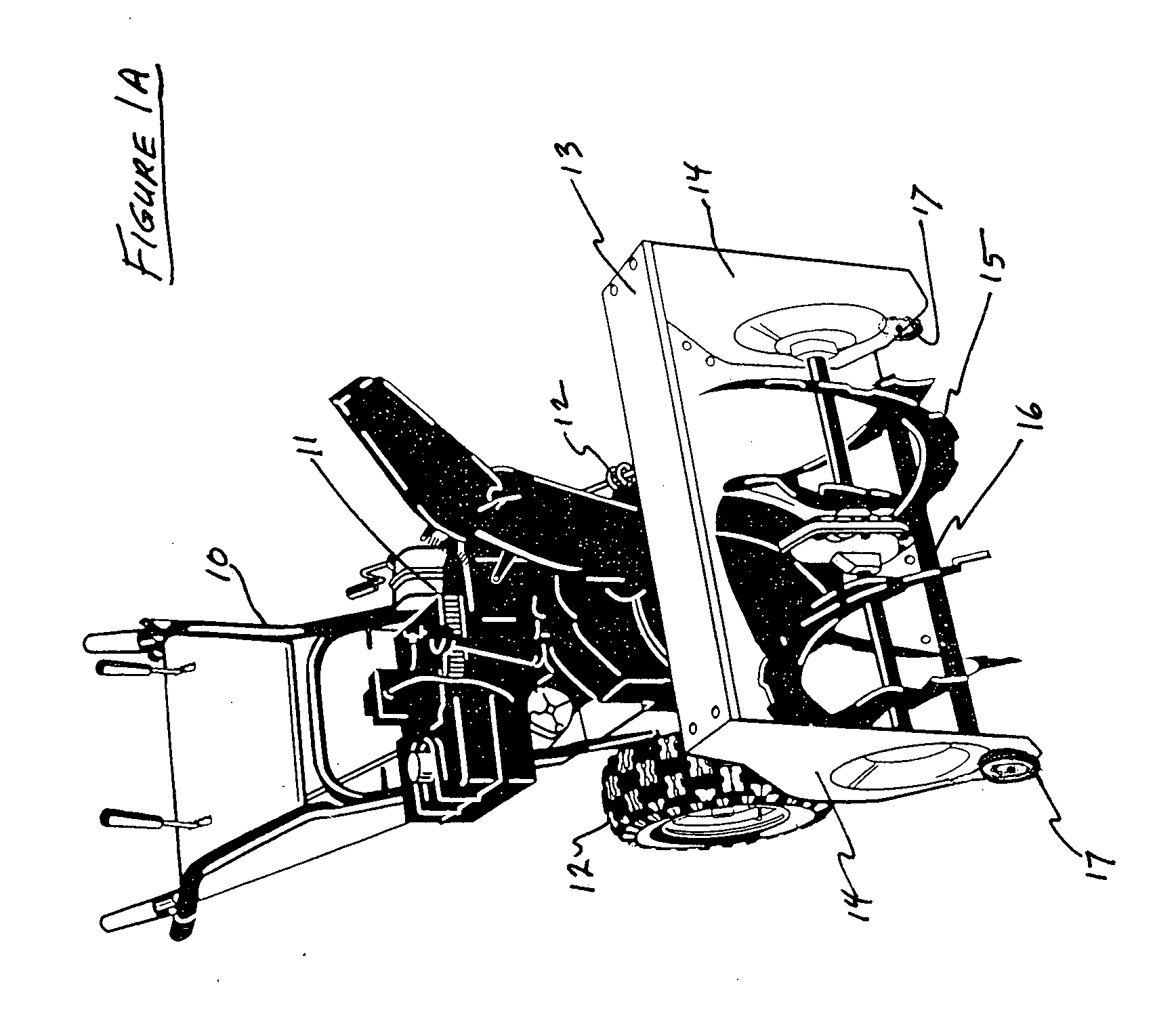

Snow blower with glide wheels

A device for selectively controlling the height of a snow blower auger housing relative to the surface from which snow is being removed. Glide wheels are attached to the sidewalls of the auger housing of a snow blower to support the snow blower auger housing and to provide for clearance between the scraper blade and the surface to be cleared of snow. A glide wheel assembly may be fixably appended to the side walls of the auger housing and provides for easily adjustable height to set and maintain the height of the scraper blade in the auger housing at a desirable distance above the surface.

Owner:LIGHT J

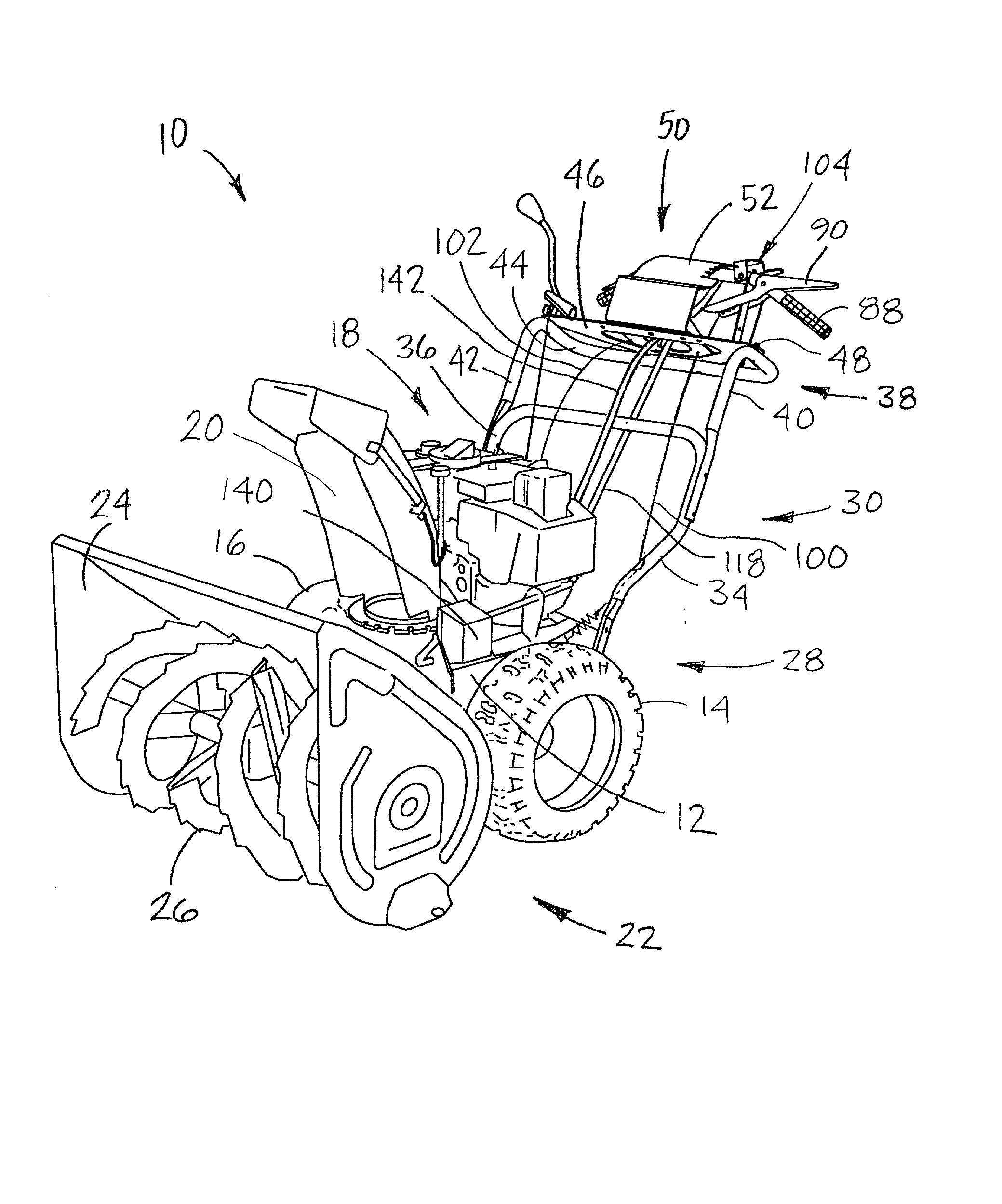

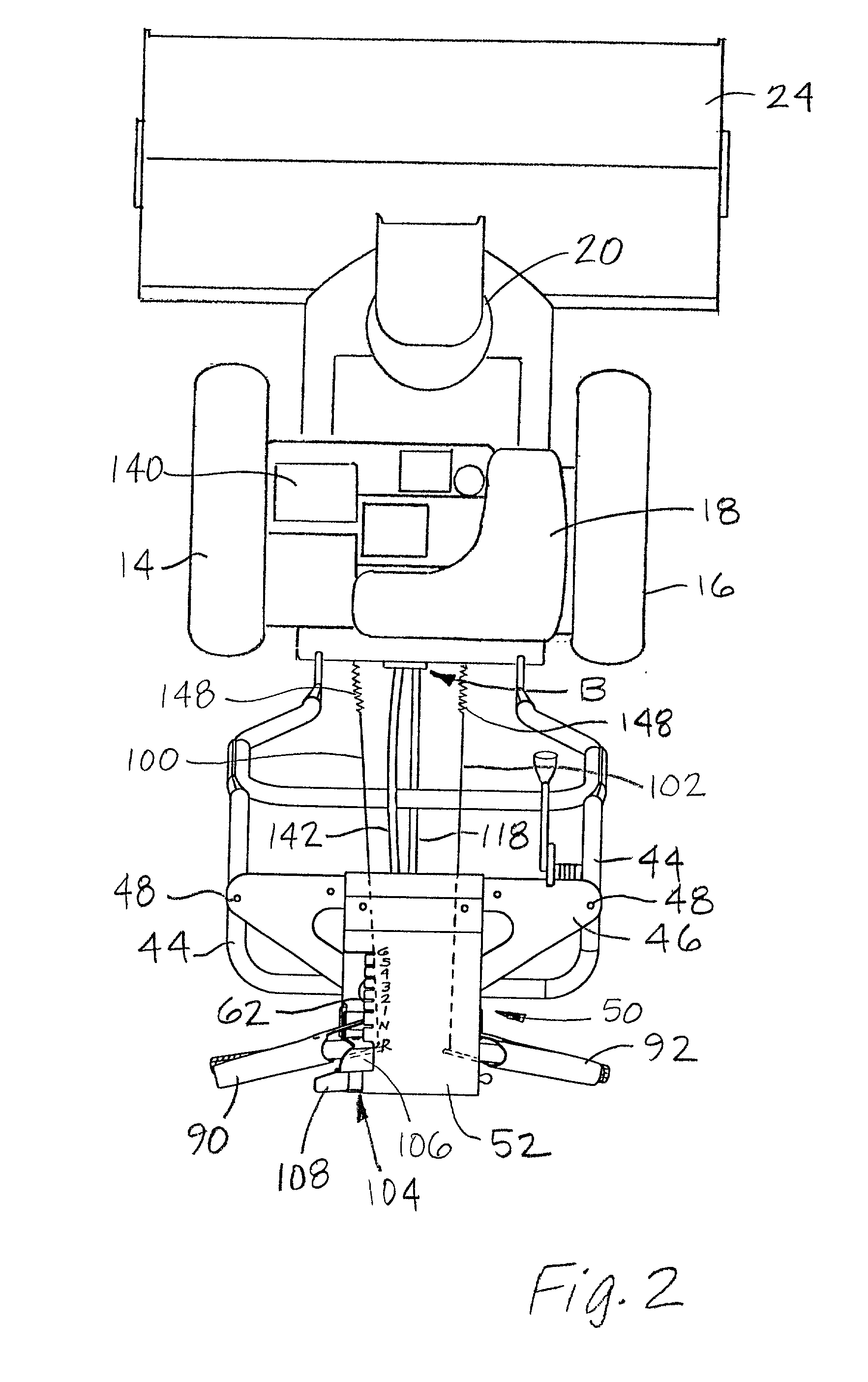

Snowblower controls

A control platform for directing the operation of a snowblower is provided. The platform includes a bail which is pivotably moveable within the platform. Attached to and moveable with the bail are levers for controlling the engagement or disengagement of the drives that power the snowblower's wheels and auger. Also attached with the bail are controls which permit the operator to change the speed and / or direction of the snowblower as well as the orientation of the discharge chute. Through their attachment to the bail and proximity relative to one another, an operator can use each of the levers and controls simultaneously. Accordingly, the platform permits an operator to engage or disengage the drives which power the snowblower's wheels and auger while, simultaneously, enabling a change in speed or direction as well as the direction towards which snow is directed during the removal process.

Owner:DEERE & CO

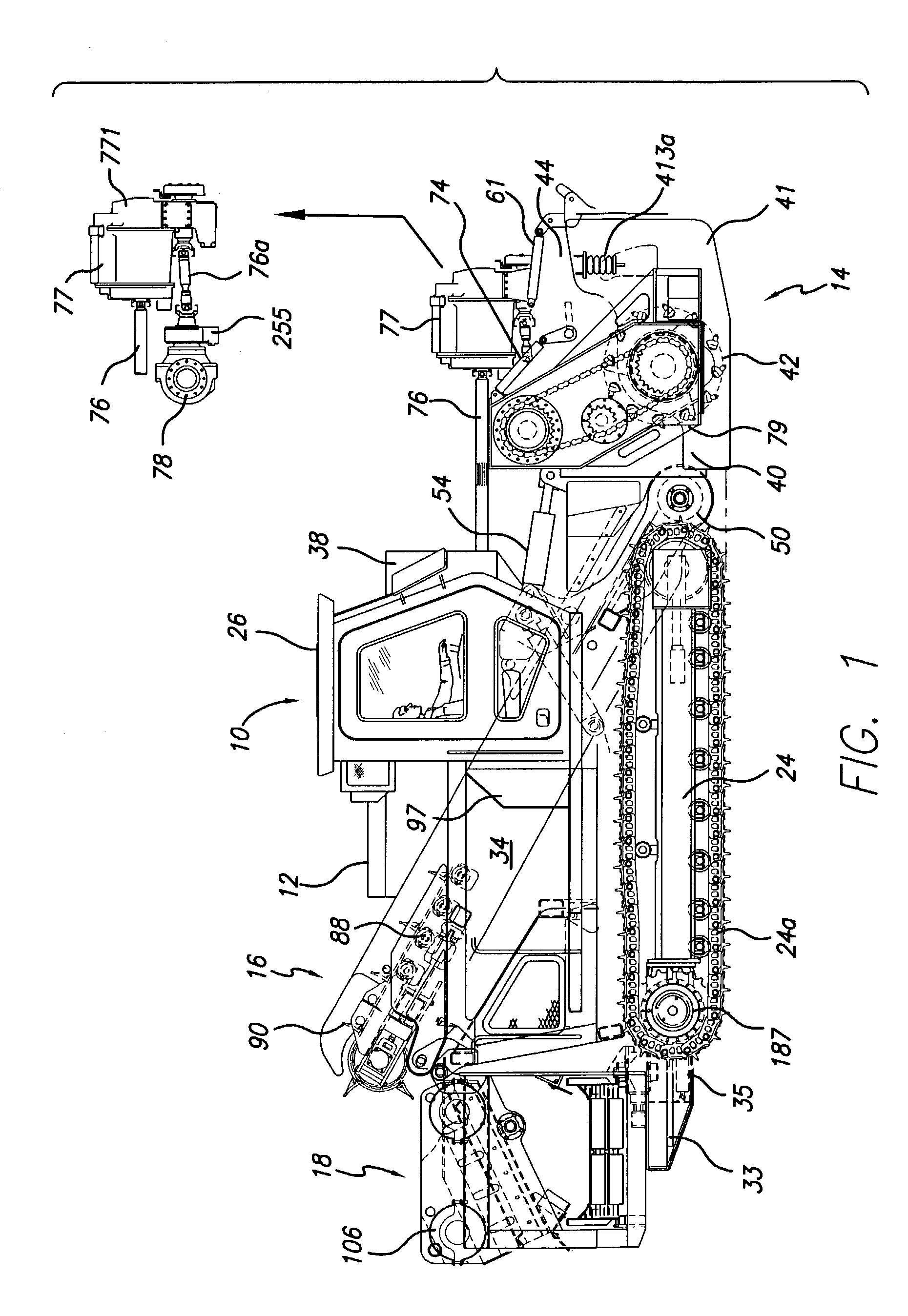

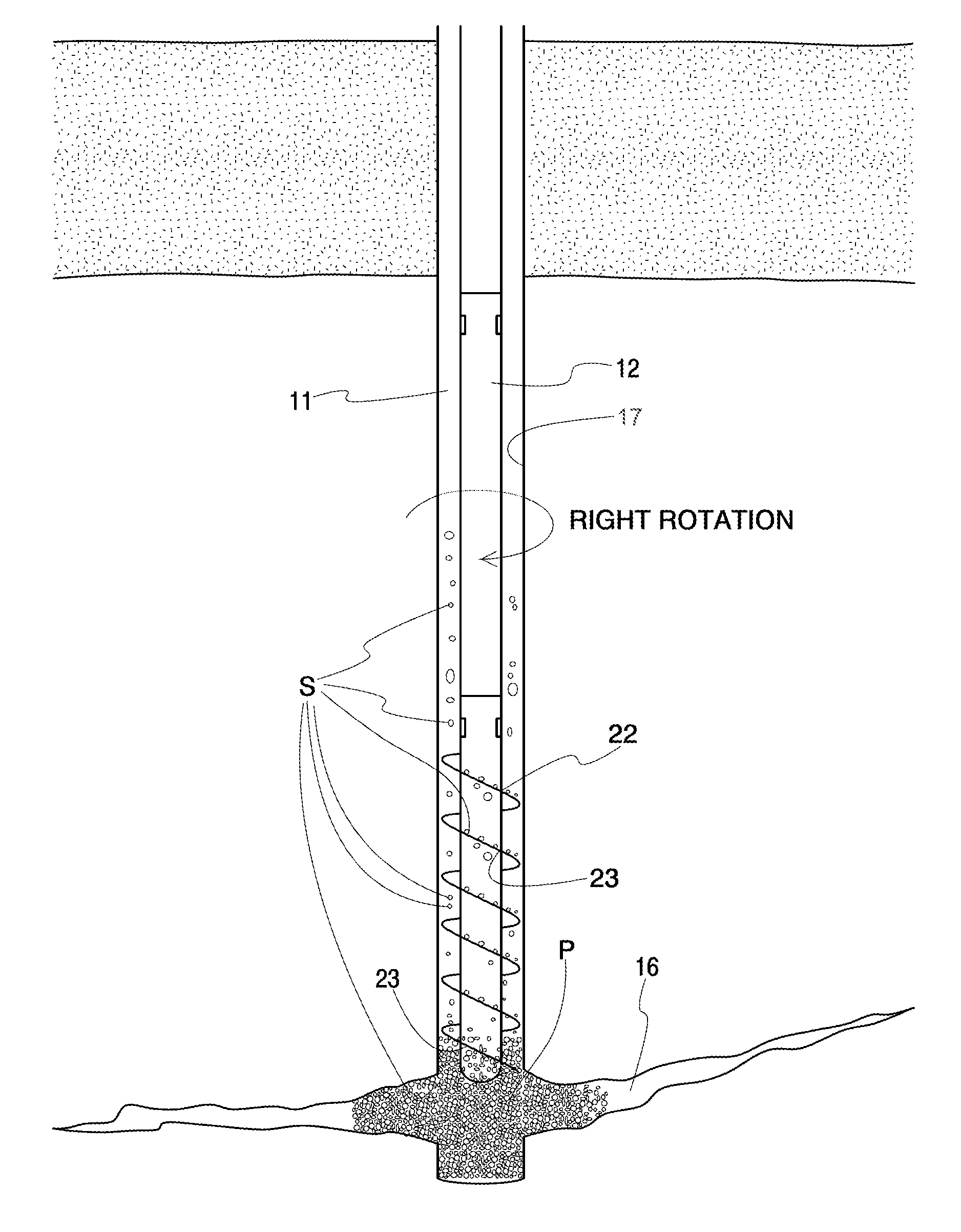

Method for repairing aberrations along a drill bore wall

InactiveUS8672058B2Increase capacityAdd depthEarth drilling toolsCollector components/accessoriesEngineeringDrill bit

The invention provides a system for adapting an HVAC system in an existing building for utilizing geothermal energy, the system comprising an incoming flux of geothermal energy; a plurality of heat exchange surfaces adapted to receive the incoming flux of geothermal energy; and an interface between the HVAC system and the heat exchange surfaces, said interface adapted to transfer the geothermal energy to the system. Also provided is a method for repairing aberrations in drill borings, the method comprising using a rotary mud drill system to produce a drill hole up to the location of the aberrations; removing the rotary mud drill from the drill hole; inserting an auger into the drill hole to a point directly above the location of the aberrations; actuating the auger; introducing loose substrate into the drill hole; allowing the substrate to contact the auger; and lifting and lowering the auger along longitudinally extending regions of the drill hole defining the aberrations for a time and in substrate amounts sufficient to fill the aberrations. The invention also provides a system which facilitates rotating drill bits at an rpm which are multiples faster than their associated drill strings.

Owner:GEOTHERMAL TECH

Utility device having an improved rotatable drive mechanism

A utility vehicle or other device for excavating soil or the like includes a utility mechanism, such as, e.g., a trencher, an auger or the like, with a motor-driven utility drum. In preferred embodiments, the motor is contained substantially entirely inside the drum. Preferably, the drive shaft is operatively connected to said drum to rotate the drum at a connection location that is displaced inward from ends of said drum. In some embodiments, the drive shaft is also preferably operatively connected to a second utility mechanism, such as, e.g., a trencher chain. In some embodiments, a planetary transmission is also located inside said drum.

Owner:UNVERFERTH MFG

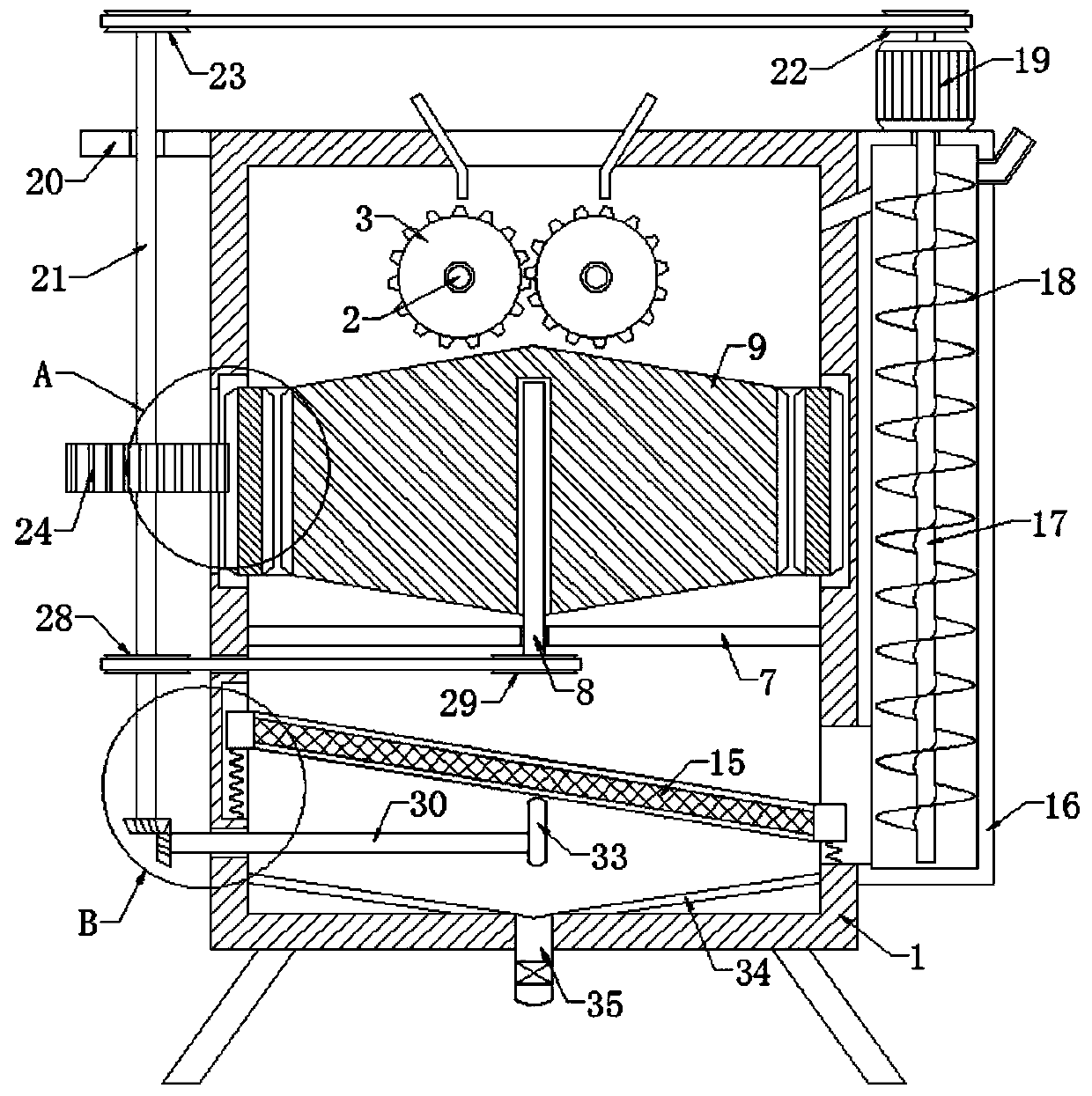

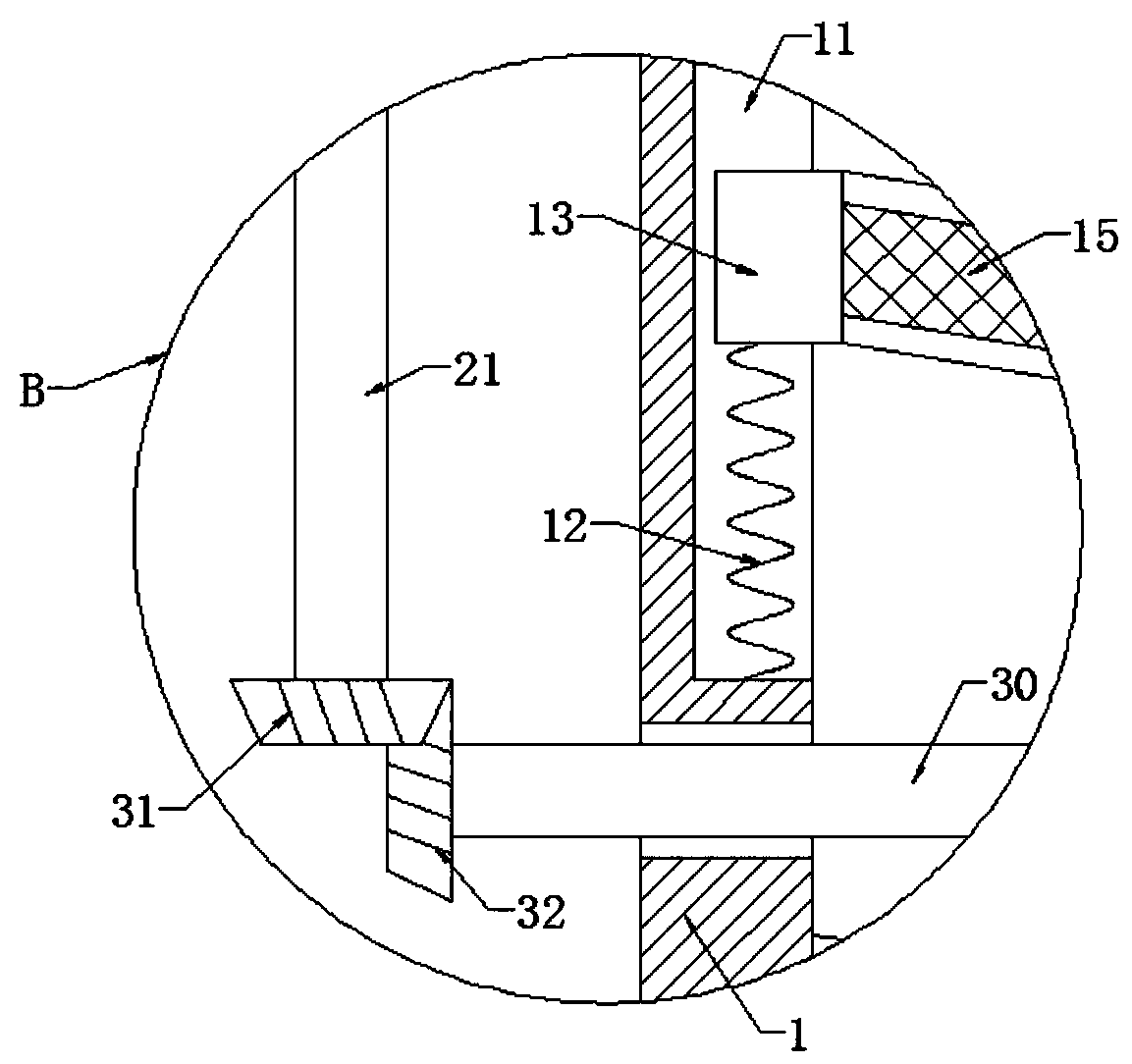

Ball-milling mixer for producing drilling-milling-integration hard alloy

The invention discloses a ball-milling mixer for producing a drilling-milling-integration hard alloy. The ball-milling mixer comprises a barrel, wherein two grinding rollers are rotationally connectedto the upper portion of the inner wall of the barrel through two rotating shafts correspondingly, a first annular groove is formed in the inner wall of the barrel, a first circular ring is slidably connected to the inner wall of the first annular groove, a transverse plate is fixedly connected to the inner wall of the barrel, the upper end of the transverse plate is rotationally connected with acylinder through a connecting rod, and the upper end and the lower end of the cylinder are conical. According to the mixer, by arranging the grinding rollers, first grinding teeth and second grindingteeth, materials can be fully and finely ground, a cam collides with a transverse rod in a clearance mode through rotation of a transverse column, the materials ground again can be filtered, large particles in the ground materials are removed, through rotation of a spiral blade of an auger, the large particles filtered by a filter screen can be conveyed, manual conveying of the large particles isnot needed, and the working intensity is reduced.

Owner:北京享云智汇科技有限公司

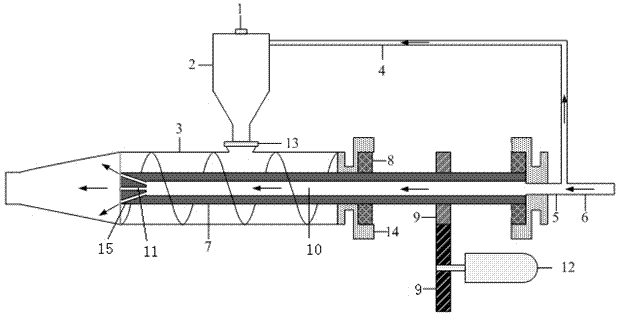

Rotary blowing type powder feeder

The invention discloses a rotary blowing type powder feeder which comprises a stock bin and a spiral conveyer shell. An outlet in the lower end of the stock bin is communicated with an inner cavity of the spiral conveyer shell, and a spiral auger is arranged in the spiral conveyer shell. The tail of the spiral auger penetrates out of the spiral conveyer shell, and the penetrating-out end of the tail of the spiral auger is connected with a power mechanism through a transmission mechanism. The spiral auger is provided with a central gas channel in the axial direction, the tail of the gas channel is connected with a fan through an air duct, the front end of the spiral auger is provided with a small hole communicated with the gas channel, and the small hole communicates the gas channel with a conical spraying area. The small hole in the front end of the spiral auger rotates along with rotation of a spiral auger shaft, gas sprayed out of the small hole has the automatic rotating blowing effect on the conical spraying area at the front end of the spiral conveyer shell, mineral powder particles, especially viscous fine mineral powder particles are prevented from being aggregated or stuck to the wall, and the powder is continuously conveyed and sprayed in a fluidization mode.

Owner:CHONGQING UNIV

Auger for boring and weeding

InactiveUS20060011358A1Easy to processEasy to assembleHoesRotary stirring mixersStanding PositionsEngineering

An auger to assist in ground burrowing or mixing paint or concrete, is used by attaching it to an electric or cordless power source. The major advantages over previous augers are: a hex head design prevents slipping in the drill chuck, an offset boring tip provides better digging, and a removable extension allows for the digging holes from a sitting or standing position possible without straining. The cutting edge of the auger's discs is sharpened and provided with a serrated edge for easier digging in hard soil. A single spring pin lock connects a first shaft to the extension shaft and multiple holes in the extension shaft allow for a multitude of auger heights.

Owner:MOTOSKO THOMAS P

Mixing applicator

An applicator mixes an additive with a fluid stream and dispenses the resultant mixture. The applicator includes a housing having a fluid inlet, a downstream auger chamber, a downstream mixing chamber, and a flow path fluidly connecting the fluid inlet to the mixing chamber. A turbine auger assembly including an auger and a rotor is rotatably connected to the housing to move the additive towards the mixing chamber, help mix the additive with the fluid stream, and then disperse the mixture to the auger chamber, which includes a hopper port and a downstream auger chamber exit exposed to the mixing chamber. The turbine auger assembly is rotatably connected to the housing.

Owner:THE FOUNTAIN HEAD GROUP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com