Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

570results about How to "Easy to anchor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

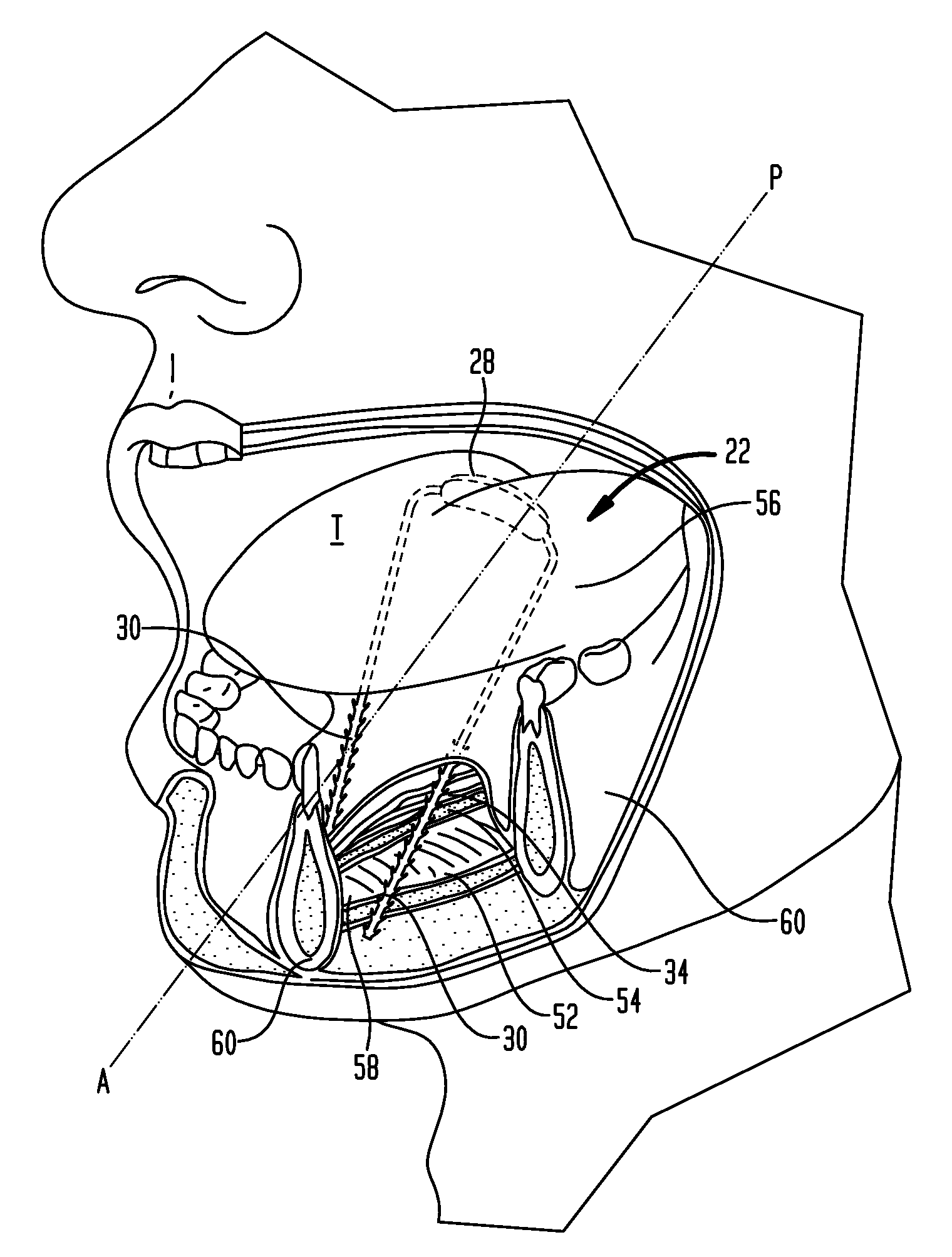

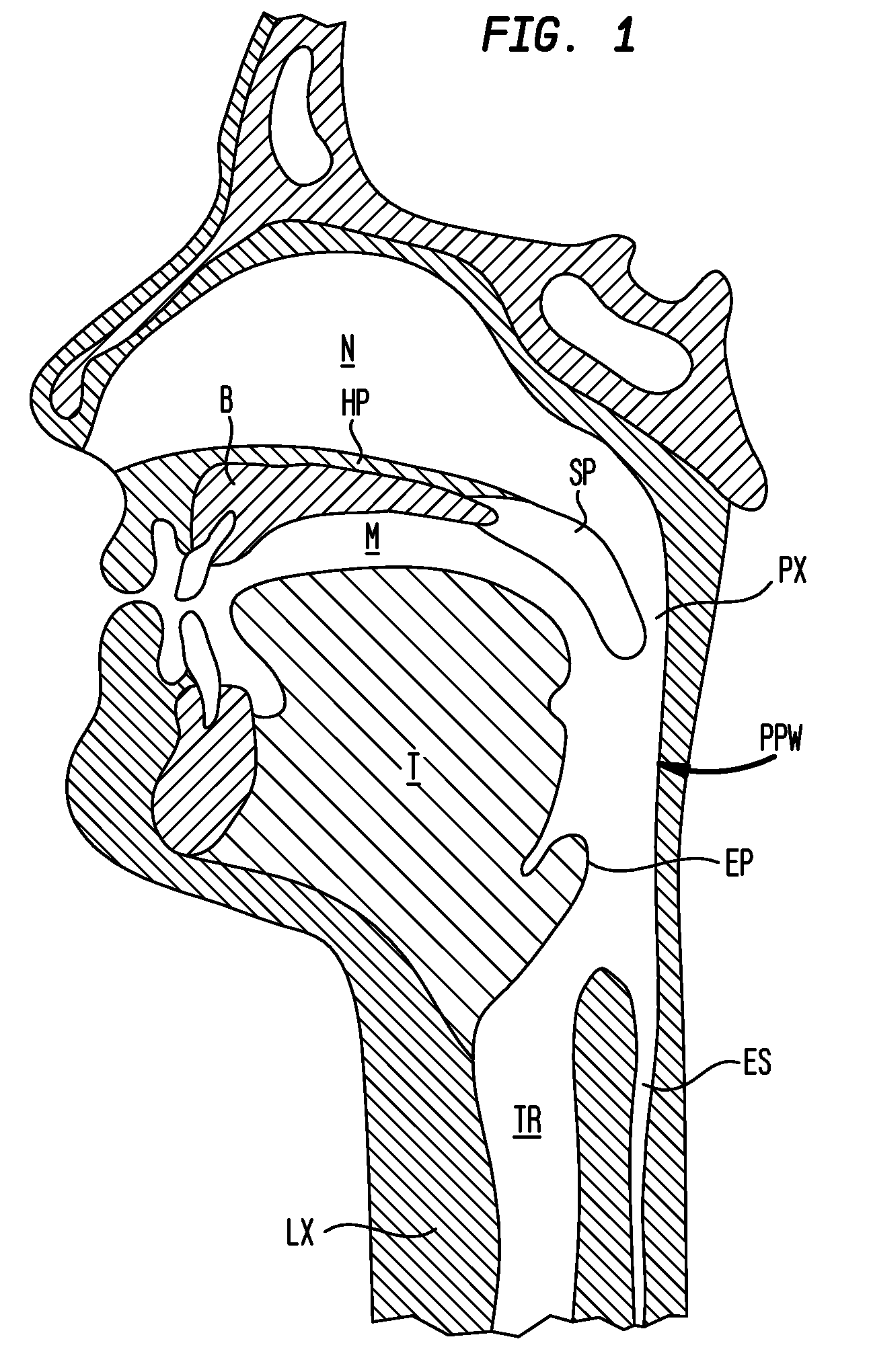

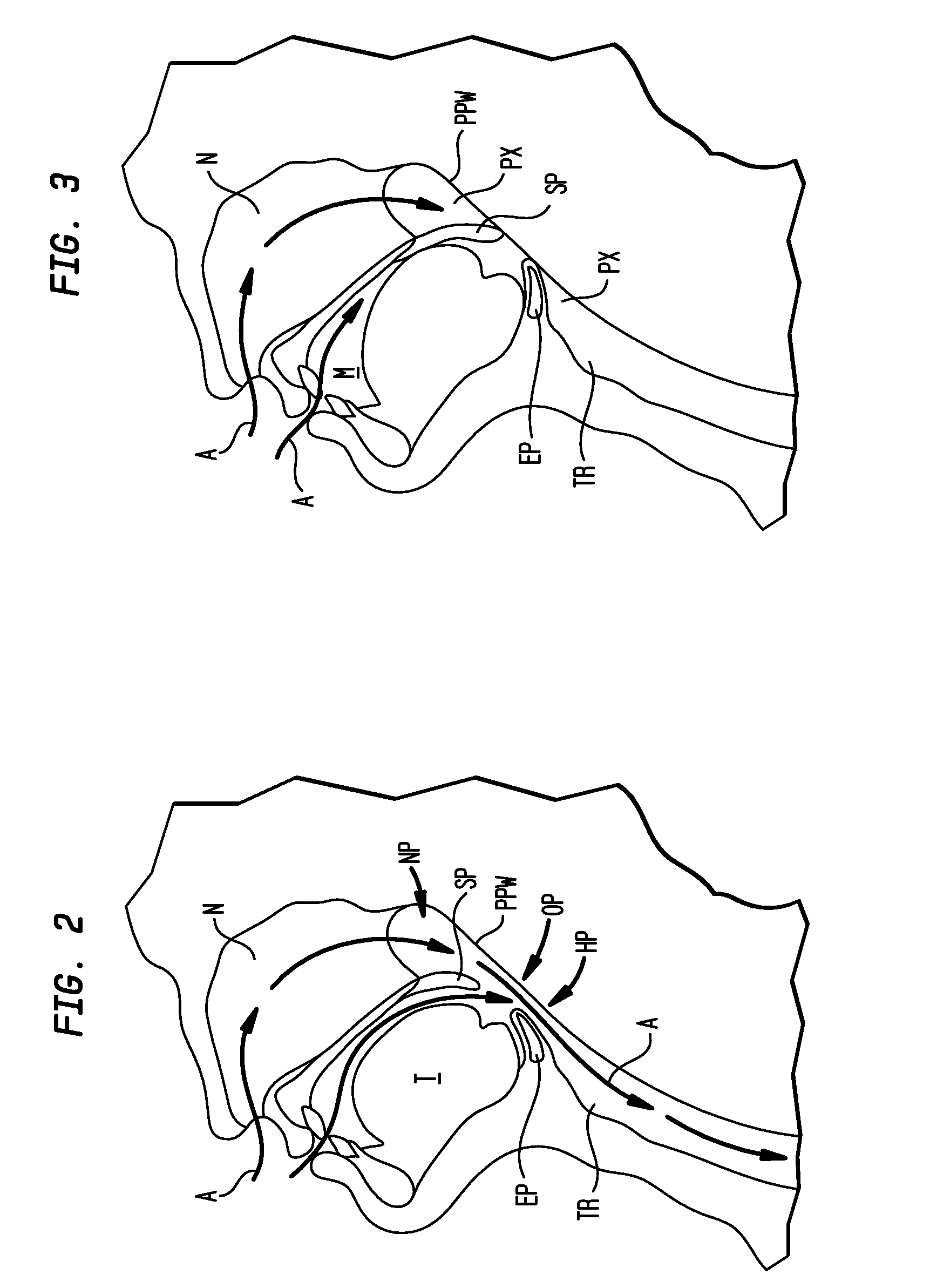

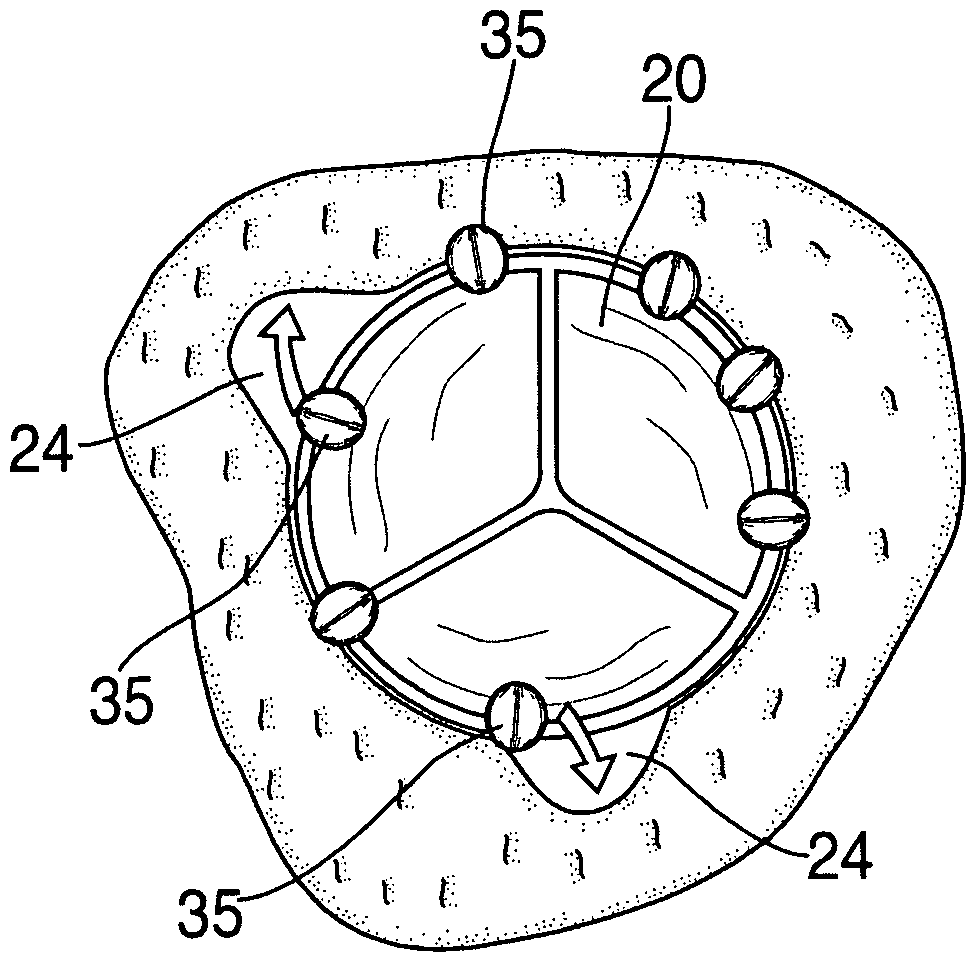

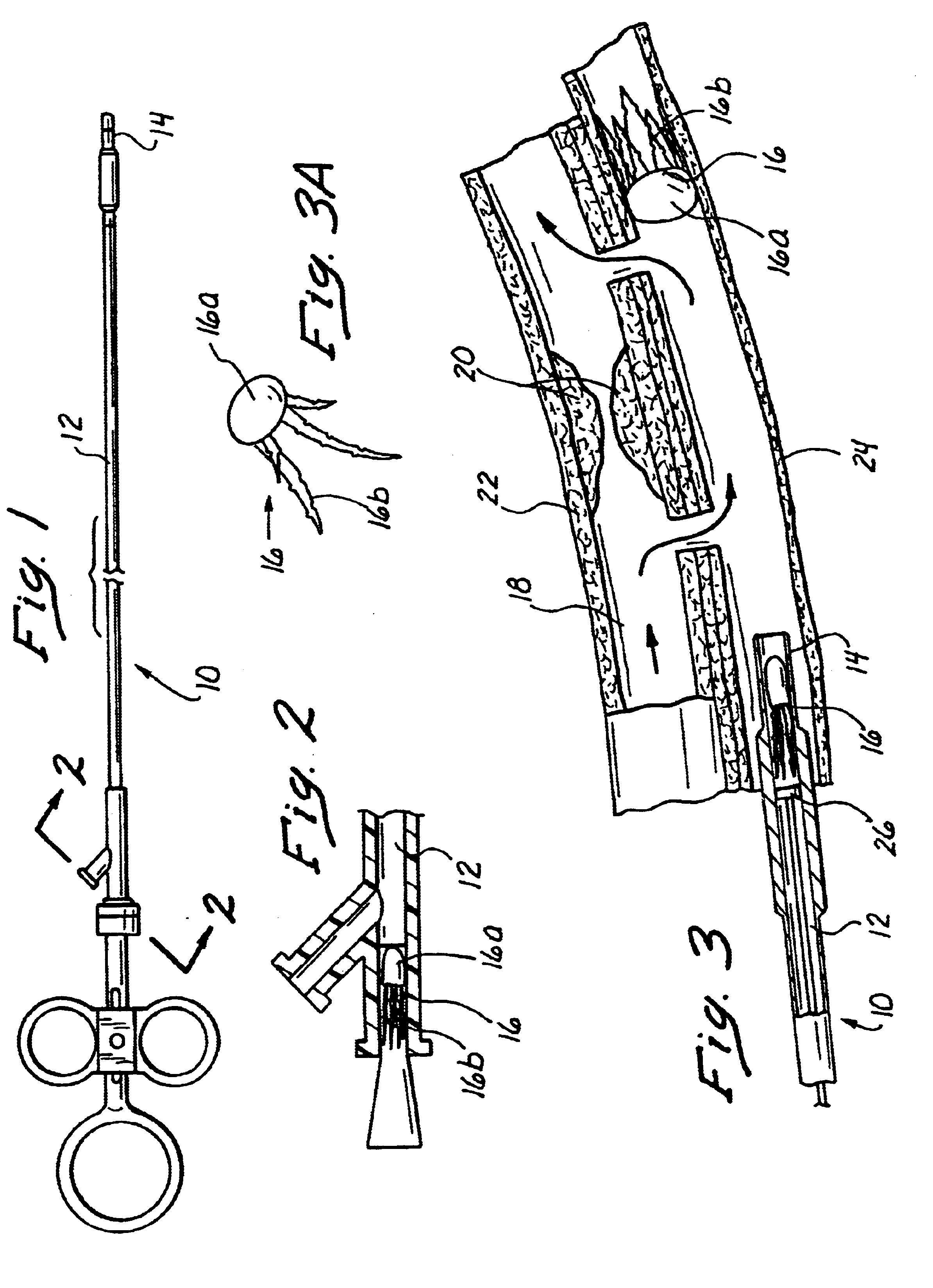

Implant systems and methods for treating obstructive sleep apnea

ActiveUS8561617B2Easy to anchorLarge cross-sectional widthDiagnosticsTracheaeButtressBiomedical engineering

A method of treating obstructive sleep apnea includes providing an elongated element having a central buttress area and first and second arms extending from opposite ends of the central buttress area. The method includes implanting the central buttress area in a tongue so that a longitudinal axis of the central buttress area intersects an anterior-posterior axis of the tongue. The first and second arms are advanced through the tongue until the first and second arms engage inframandibular musculature. Tension is applied to the first and second arms for pulling the central buttress area toward the inframandibular musculature for moving a posterior surface of the tongue away from an opposing surface of a pharyngeal wall. The first and second arms are anchored to the inframandibular musculature for maintaining a space between the posterior surface of the tongue and the opposing surface of the pharyngeal wall.

Owner:ETHICON INC

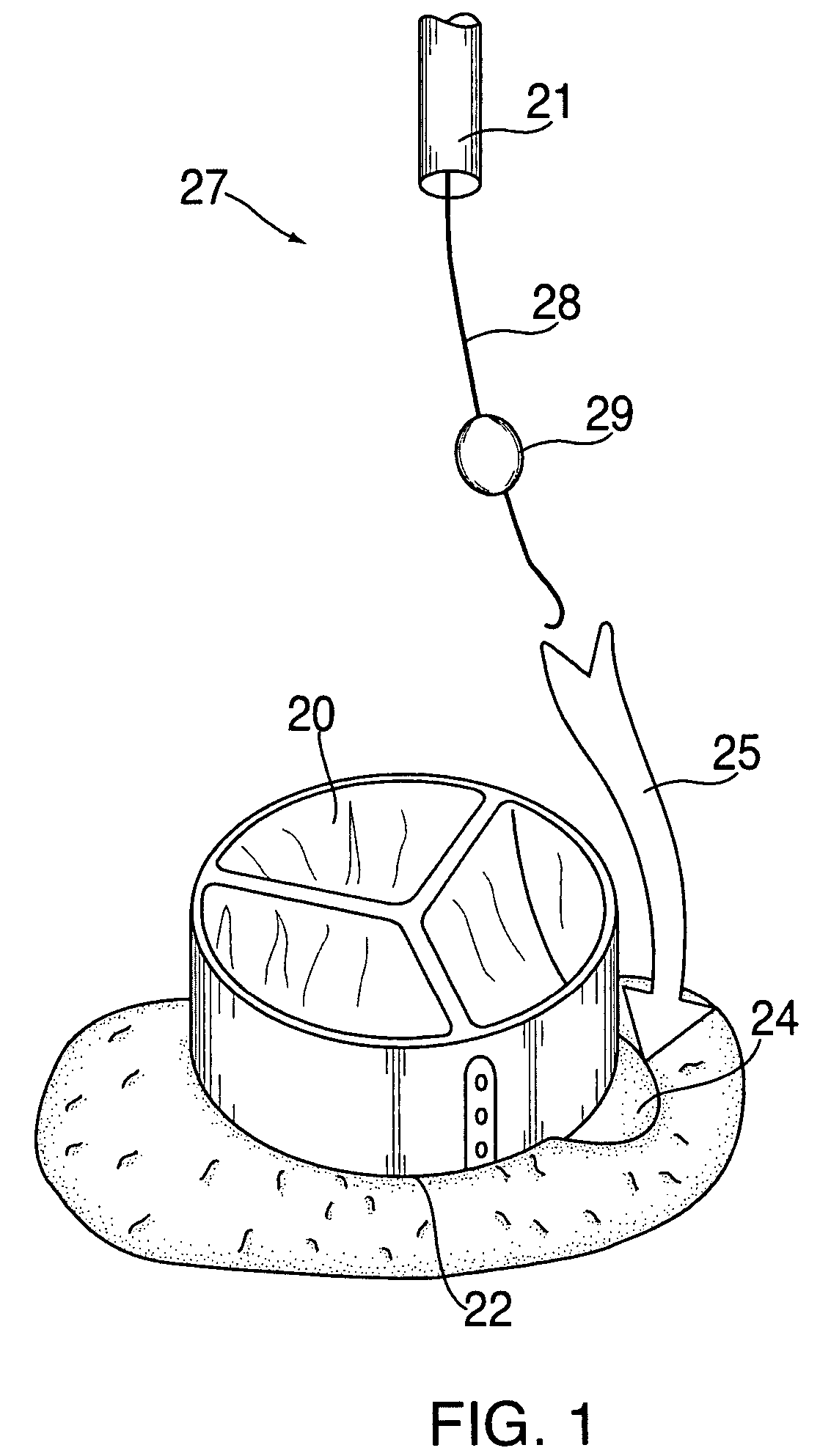

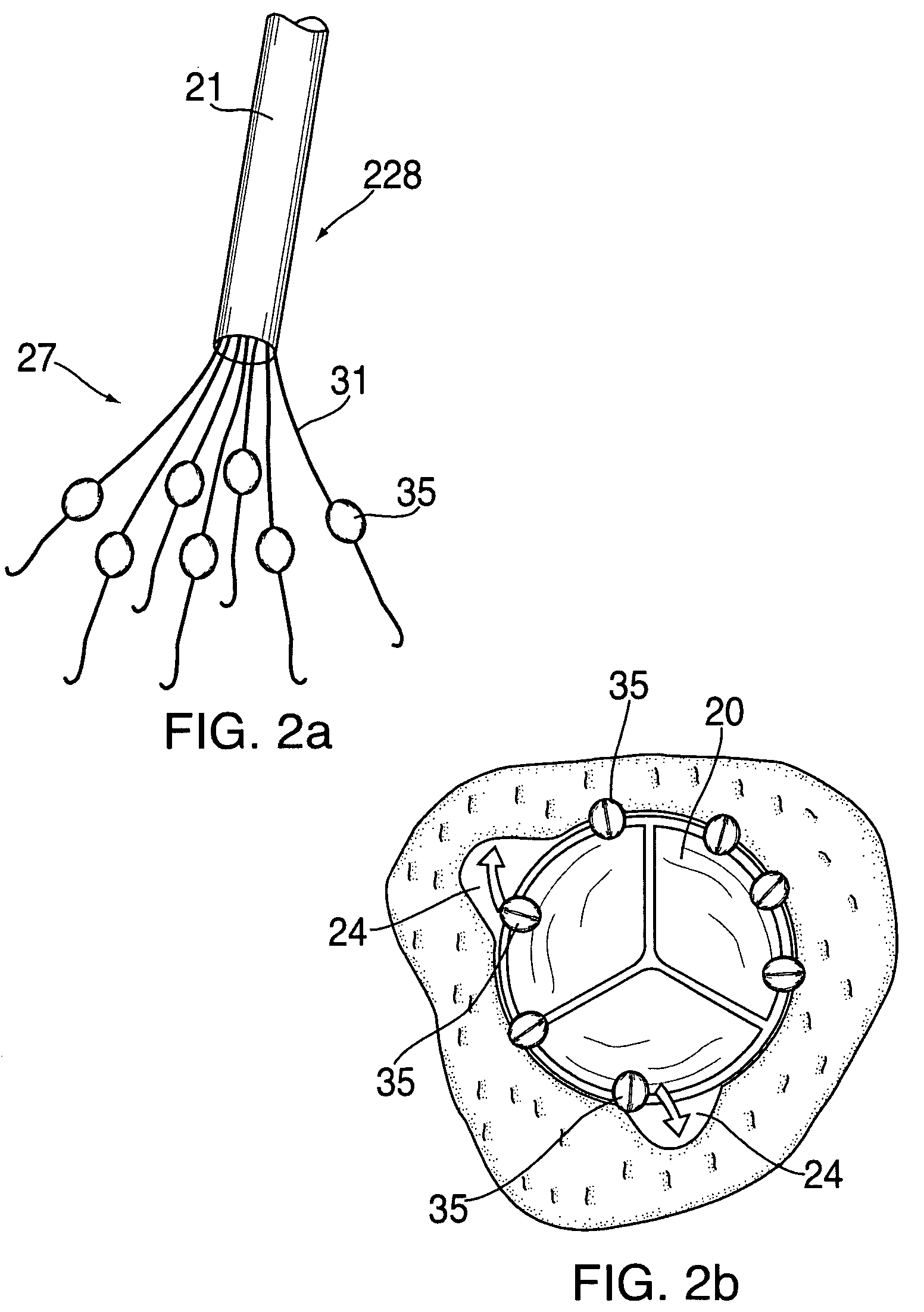

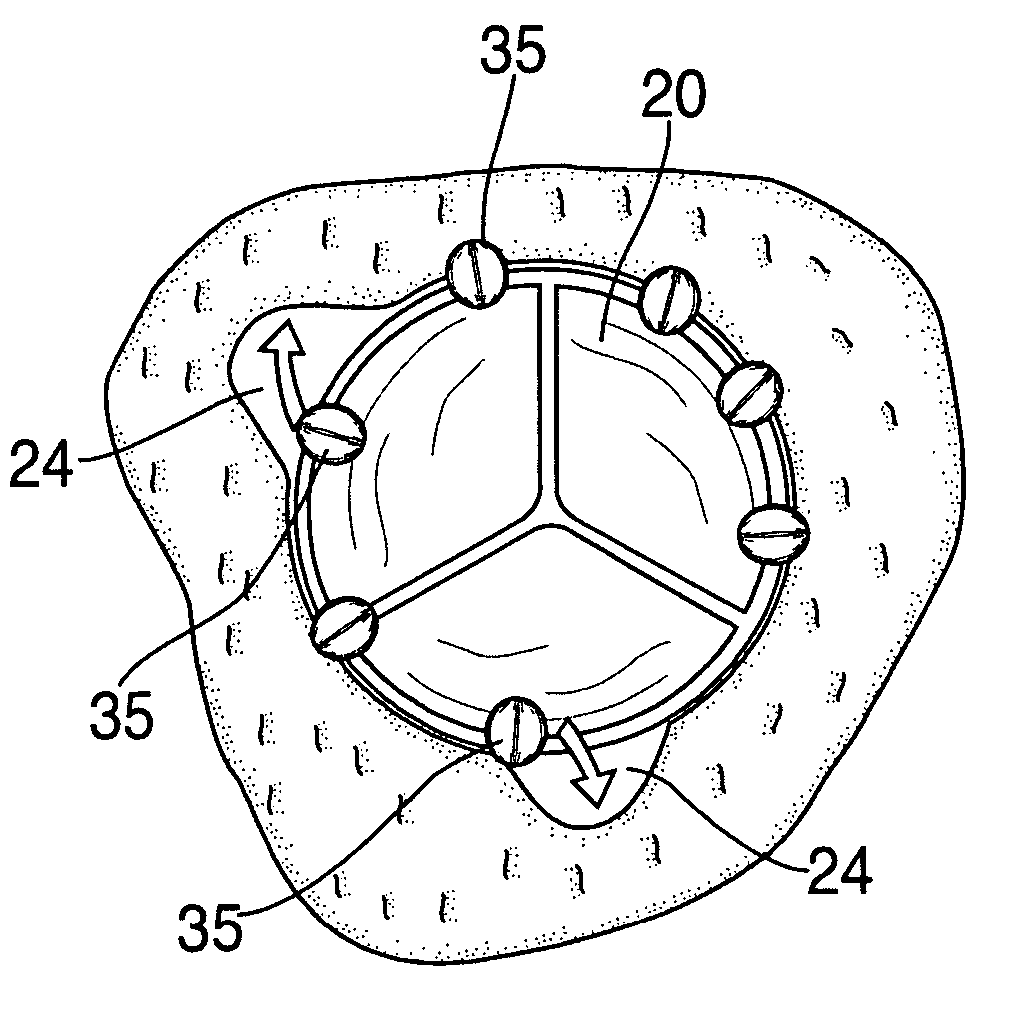

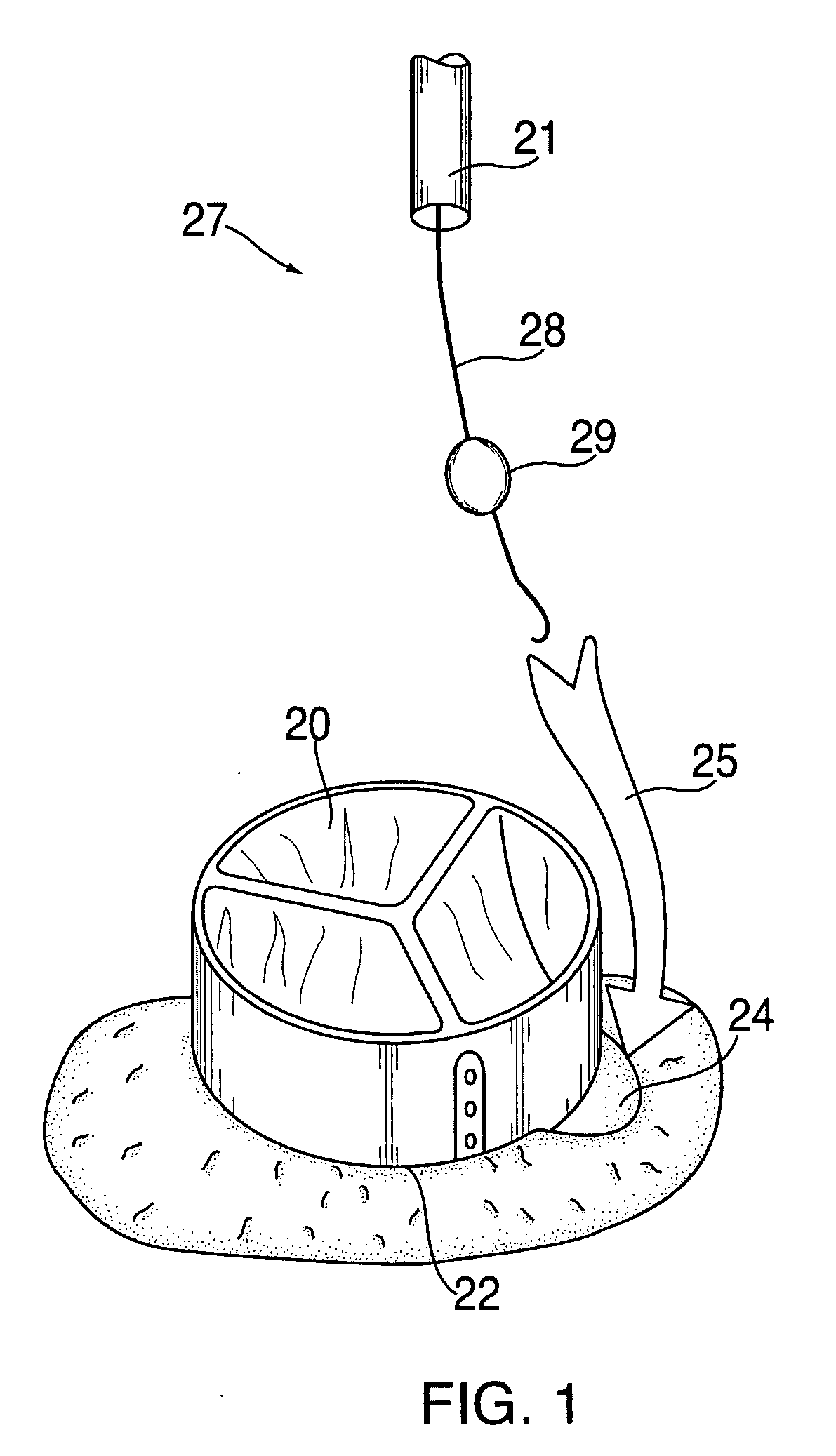

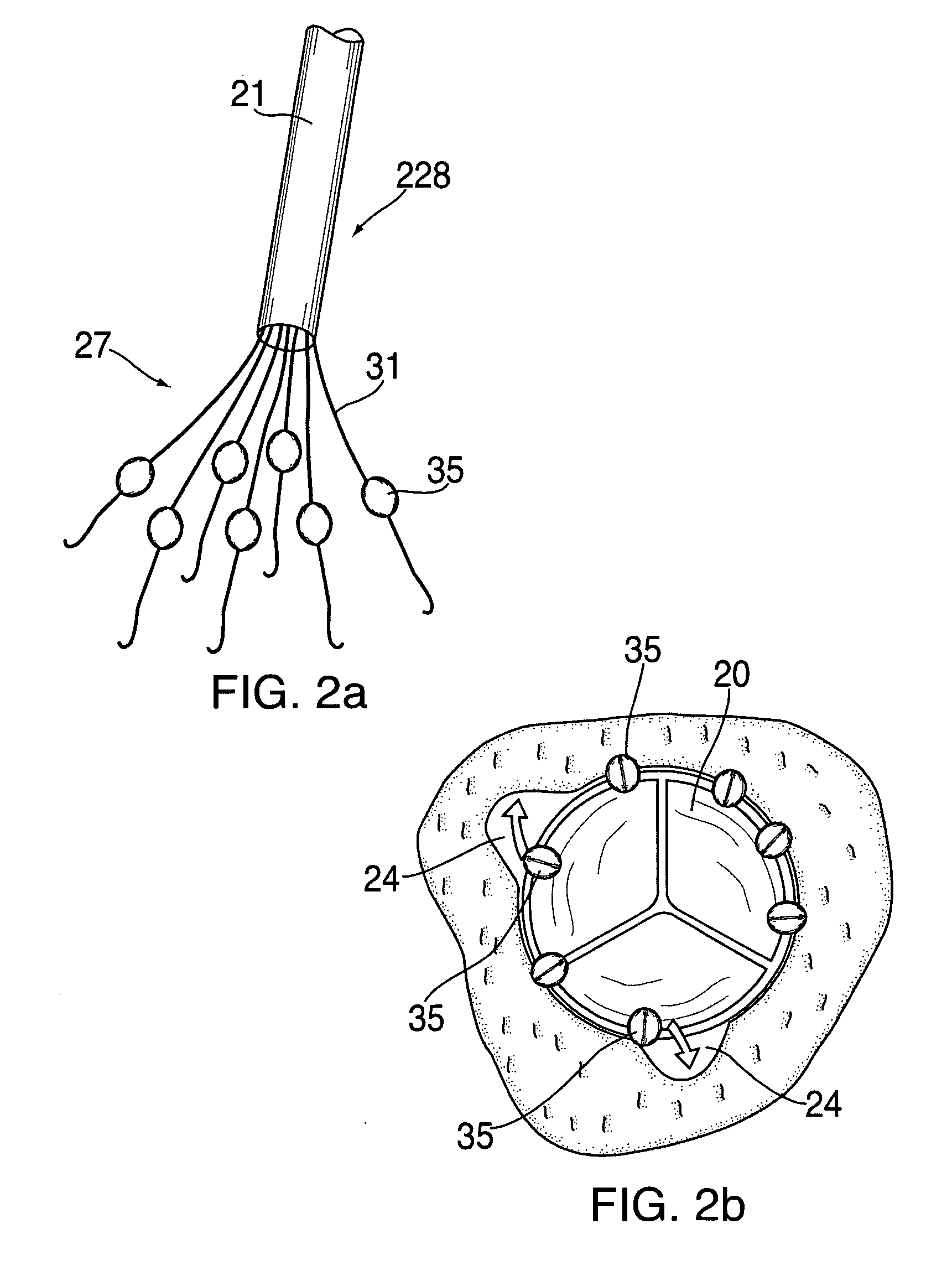

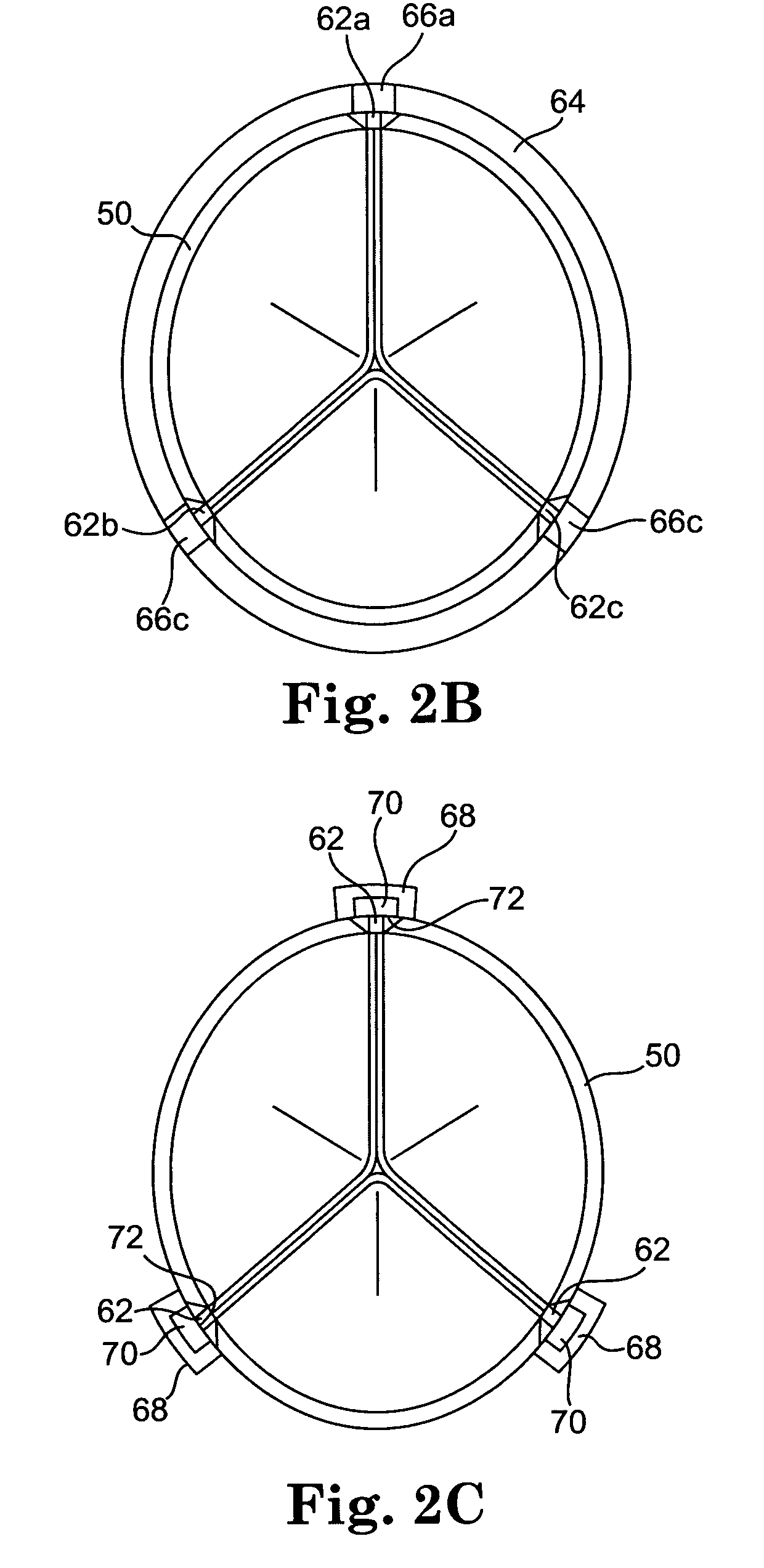

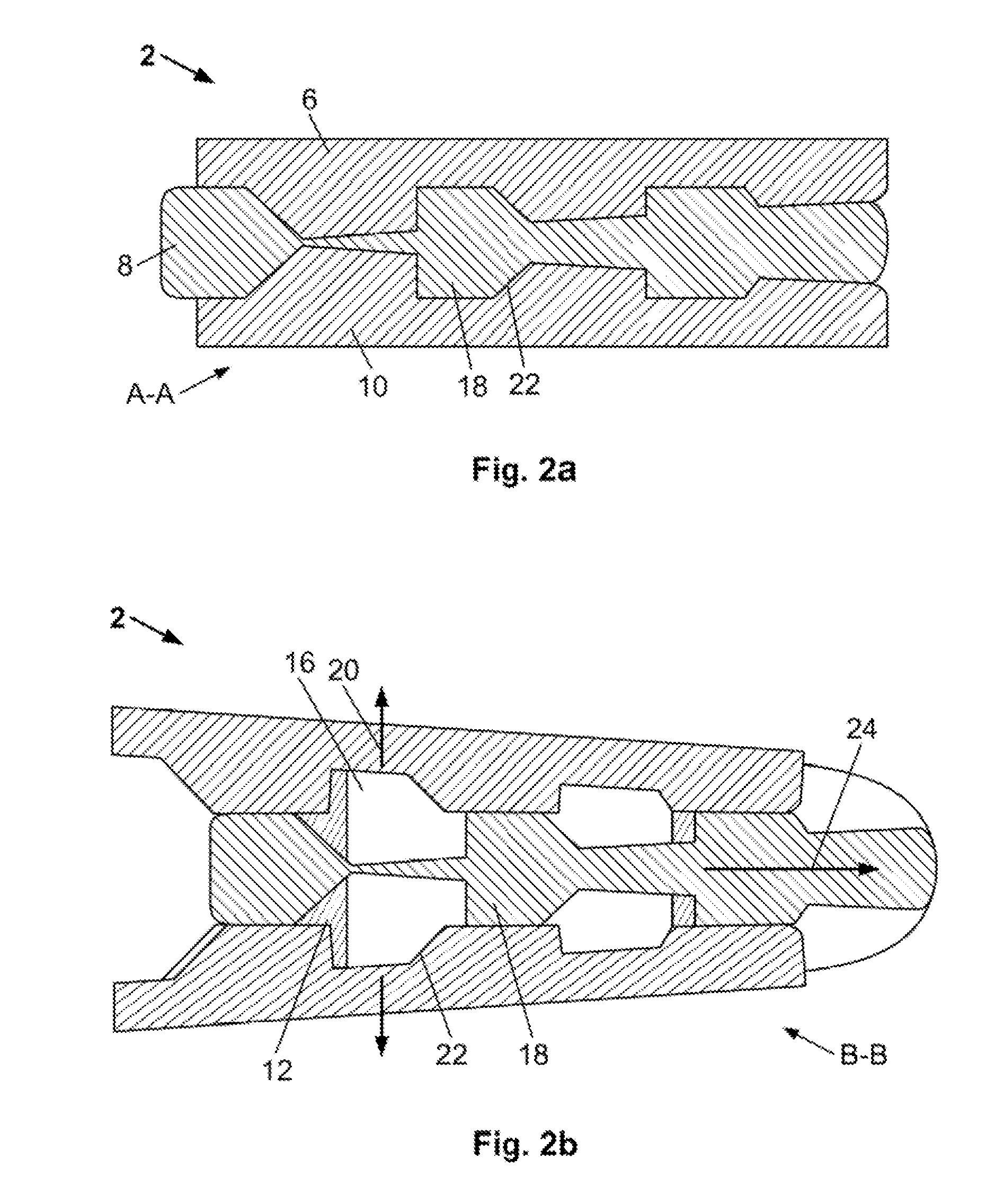

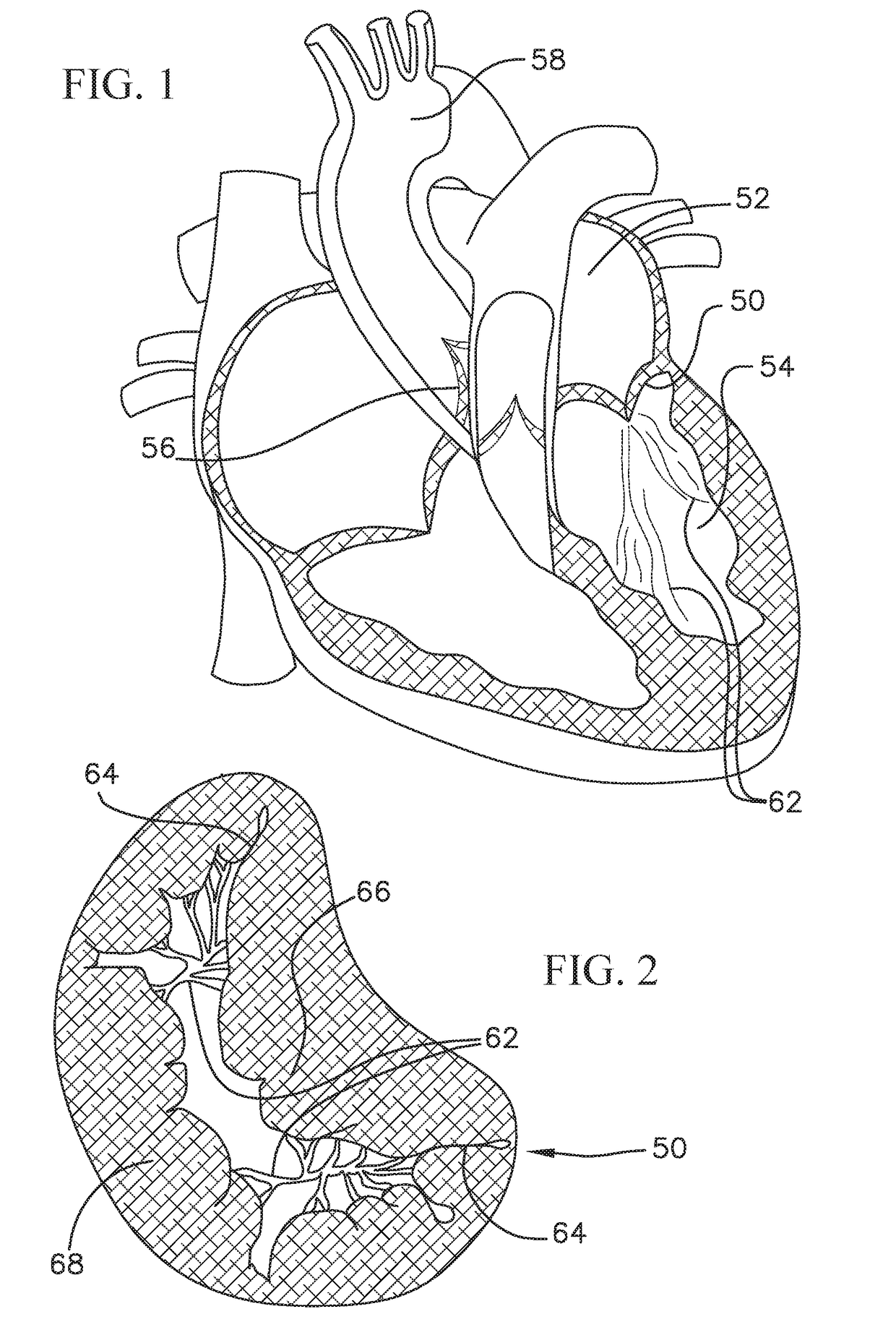

Paravalvular leak detection, sealing, and prevention

The present invention provides a series of new percutaneous concepts of paravalvular repairs including identifying the leak location, several repair techniques and finally built-in means for leak prevention, built on percutaneous valves. A catheter-delivered device locates cavities occurring between a prosthetic valve and the wall of the body vessel where the valve is implanted, the cavities producing paravalvular leaks during diastole, the device comprising at least one of a plurality of flexible wires, the wire having attached to it a balloon, wherein the balloon is pulled by the leak through the cavity and wherein the wire then serves to mark the cavity location.

Owner:EDWARDS LIFESCI PVT

Paravalvular leak detection, sealing, and prevention

The present invention provides a series of new percutaneous concepts of paravalvular repairs including identifying the leak location, several repair techniques and finally built-in means for leak prevention, built on percutaneous valves. A catheter-delivered device locates cavities occurring between a prosthetic valve and the wall of the body vessel where the valve is implanted, the cavities producing paravalvular leaks during diastole, the device comprising at least one of a plurality of flexible wires, the wire having attached to it a balloon, wherein the balloon is pulled by the leak through the cavity and wherein the wire then serves to mark the cavity location.

Owner:EDWARDS LIFESCI PVT

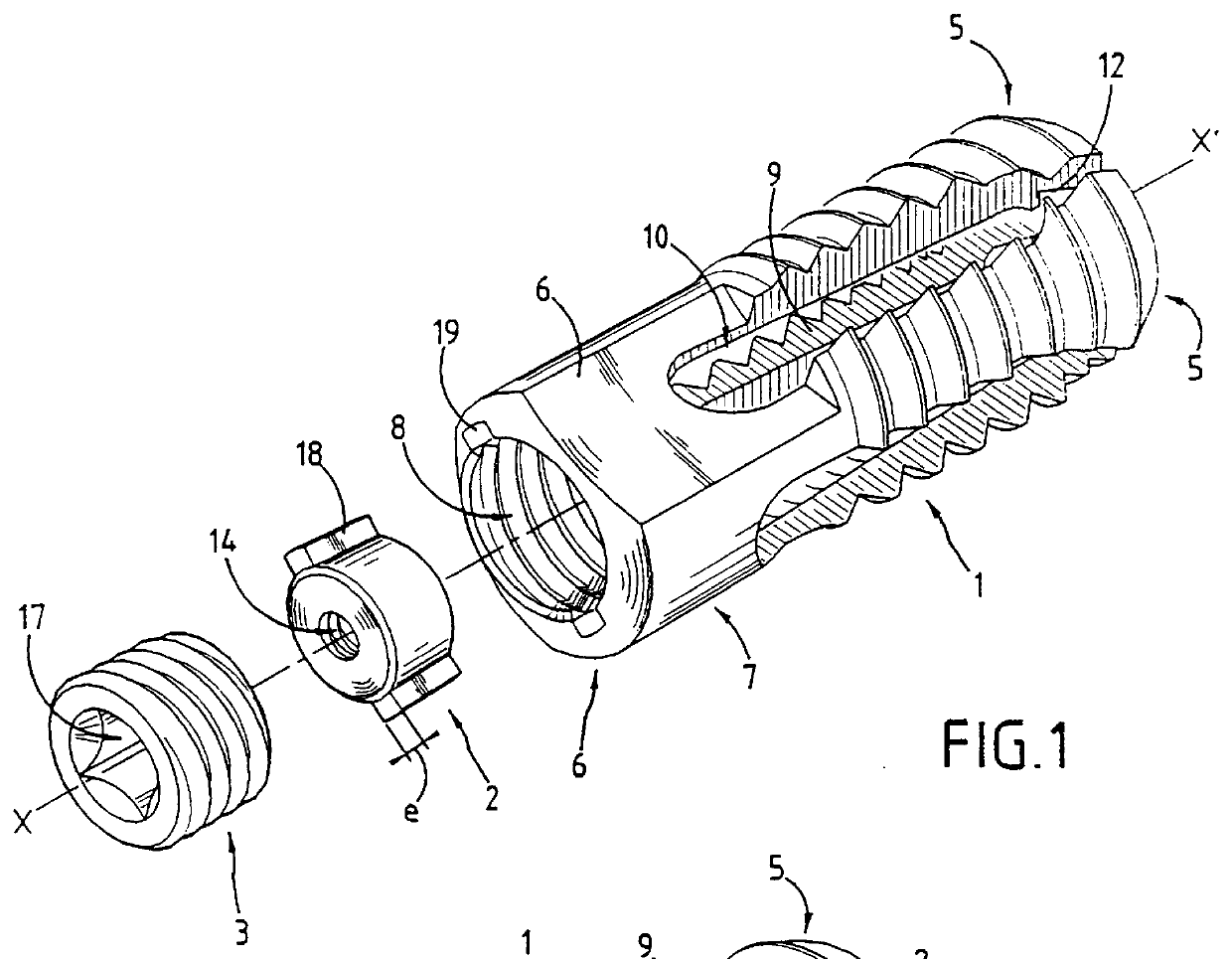

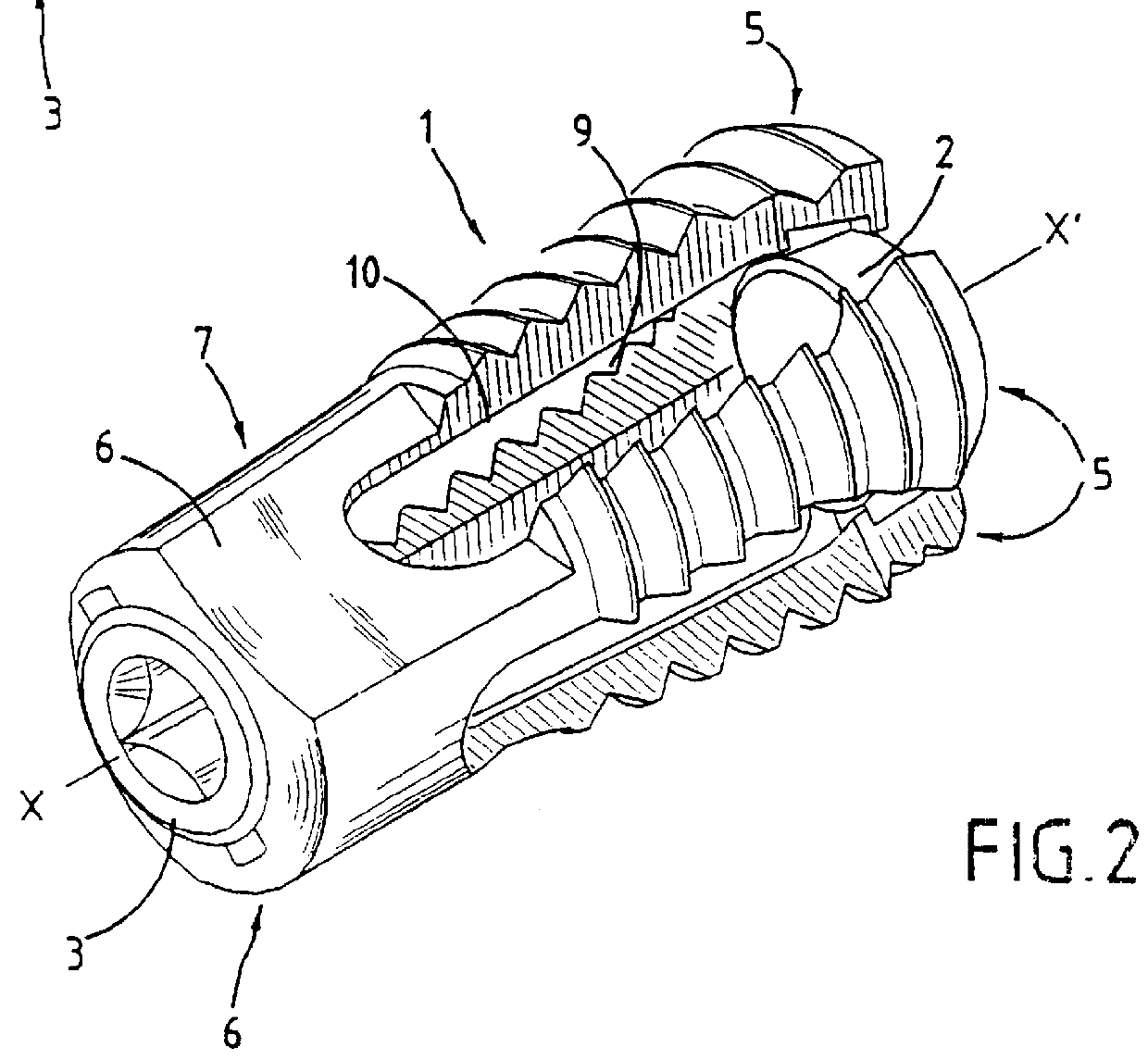

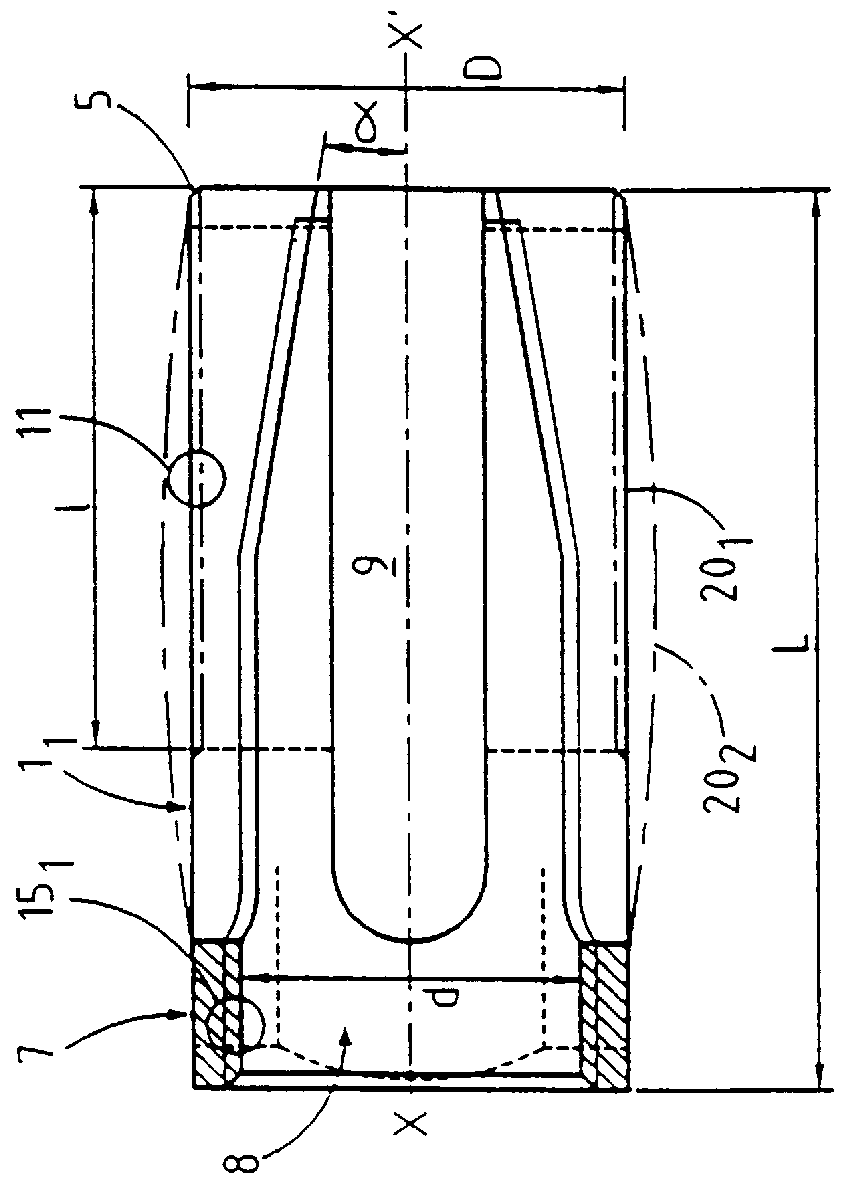

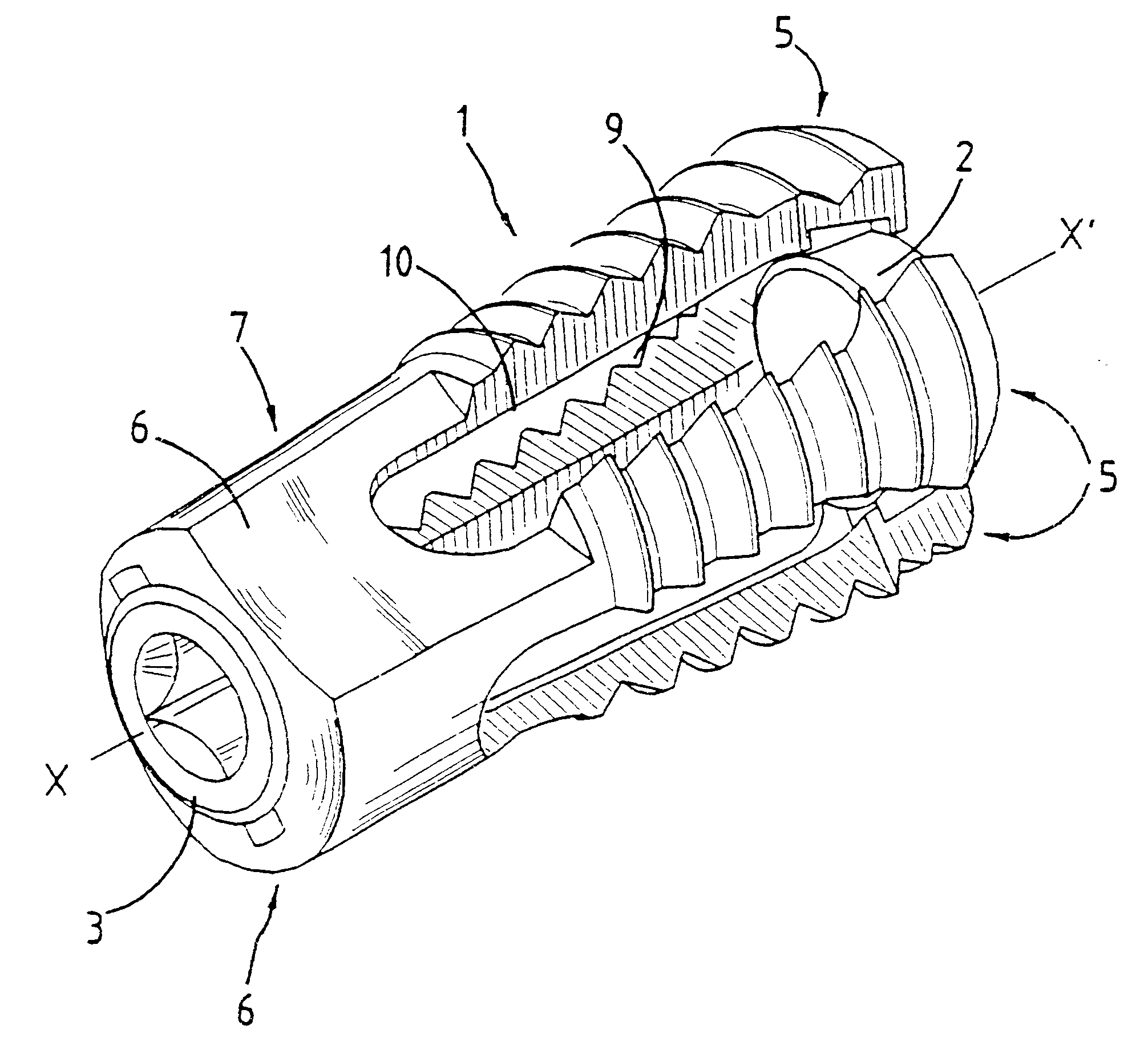

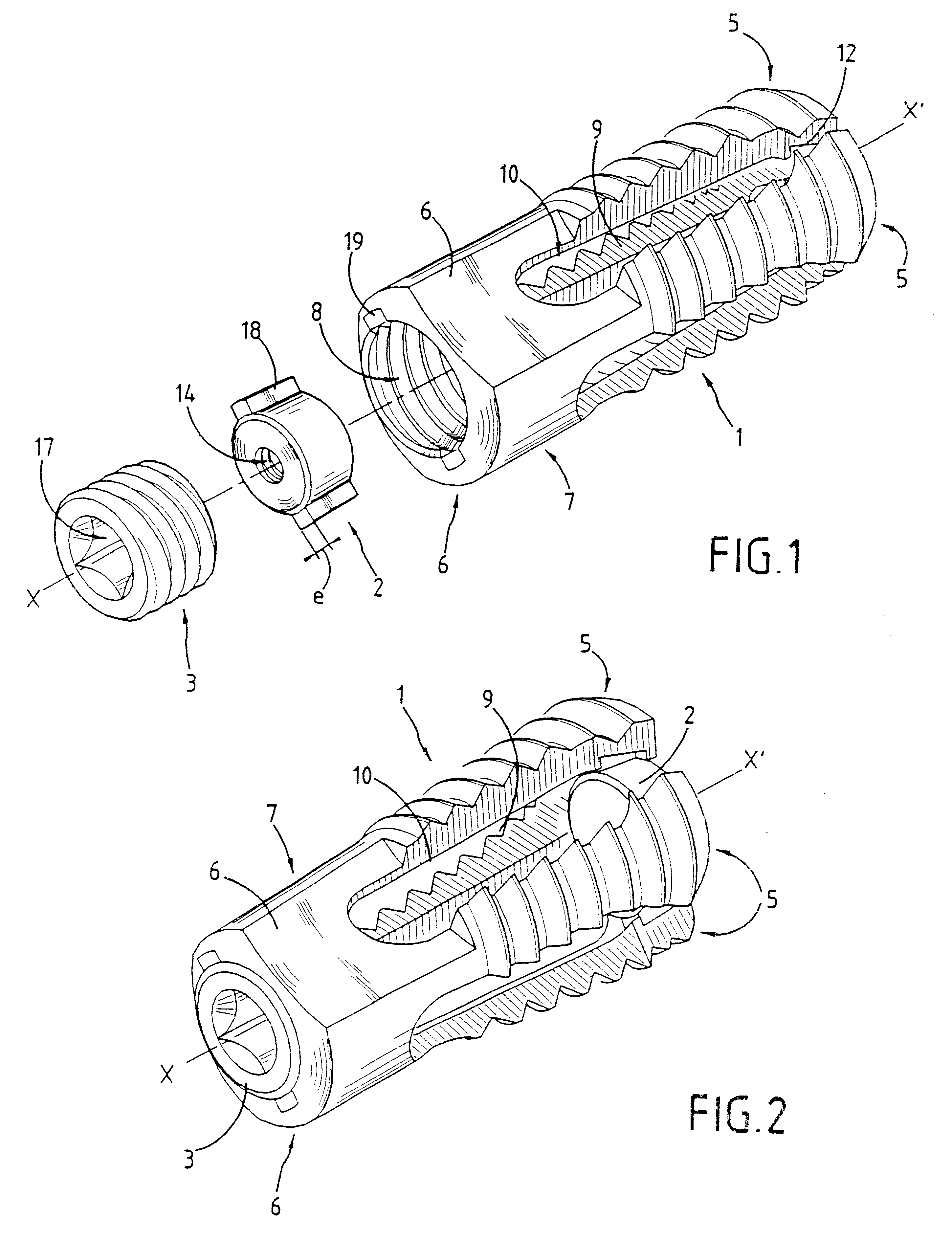

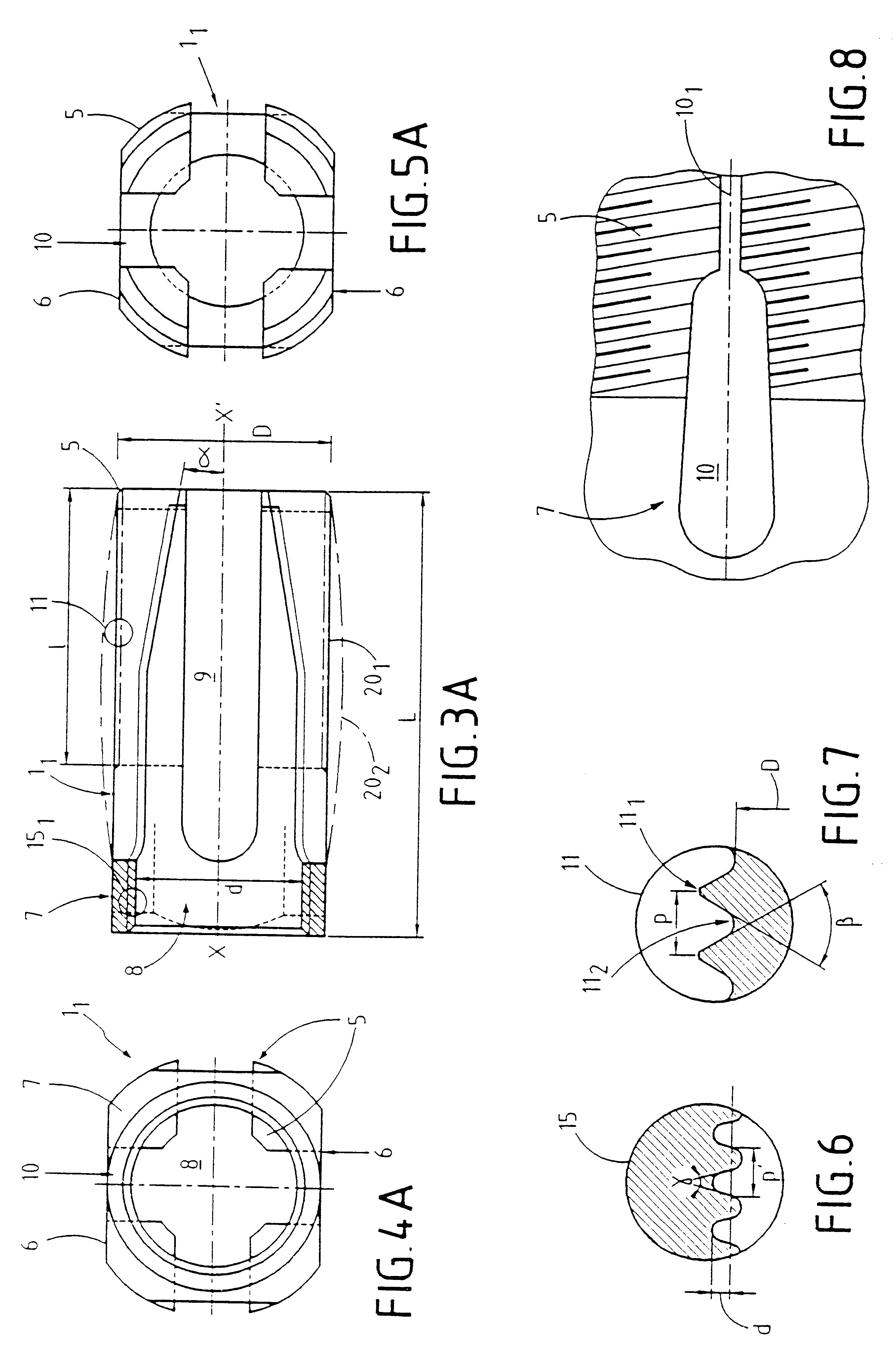

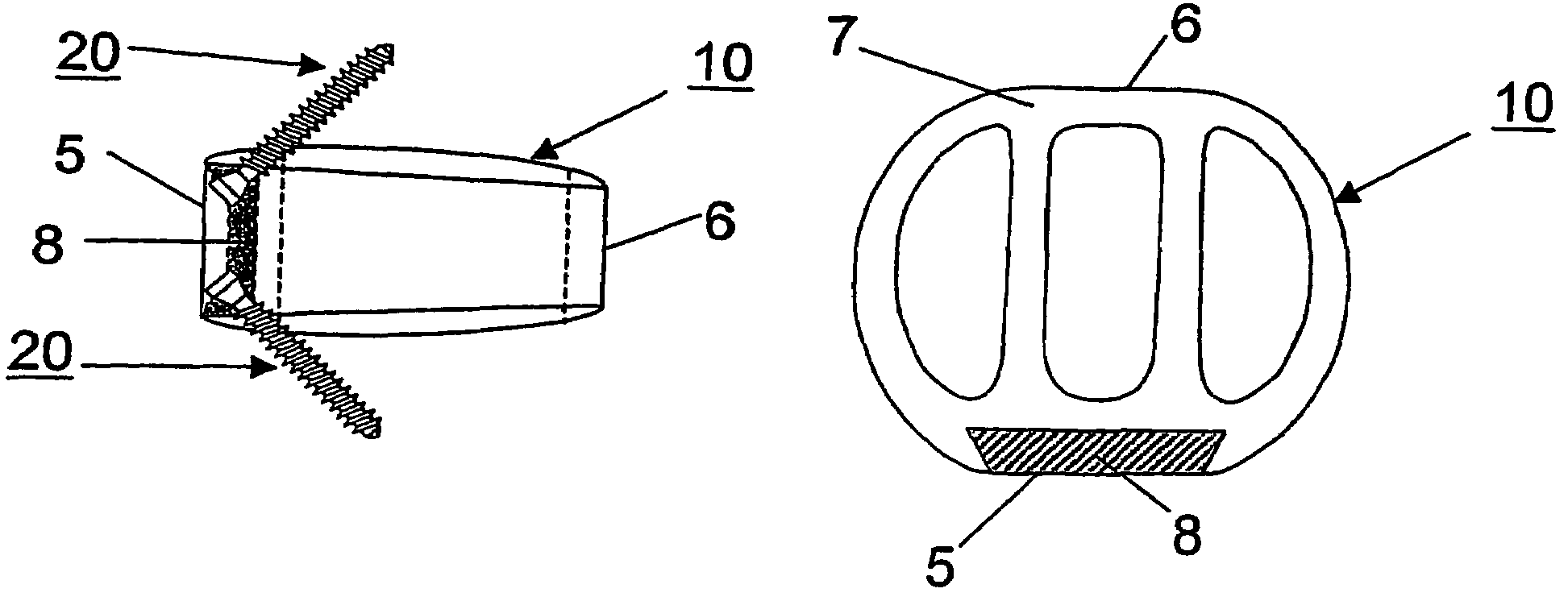

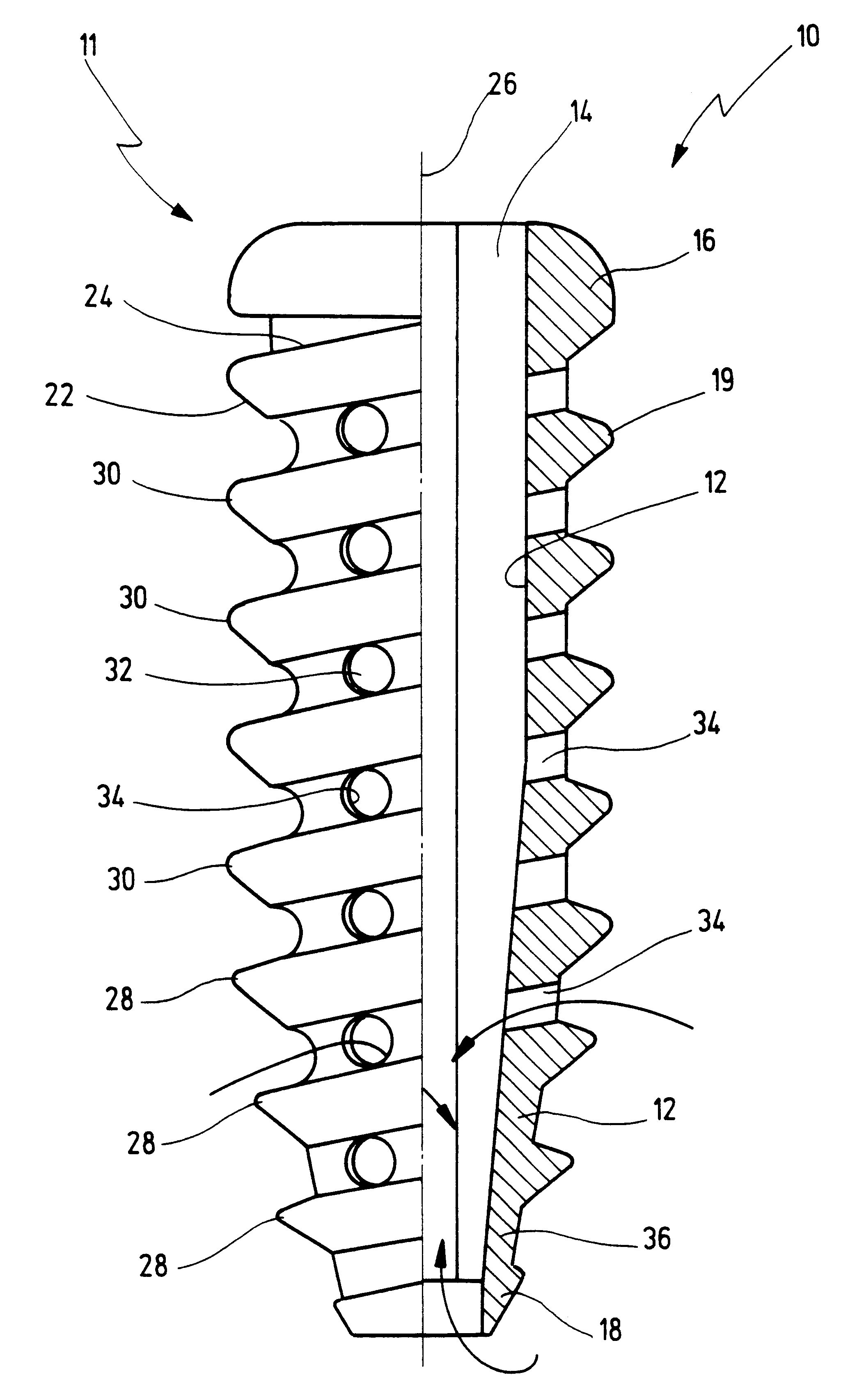

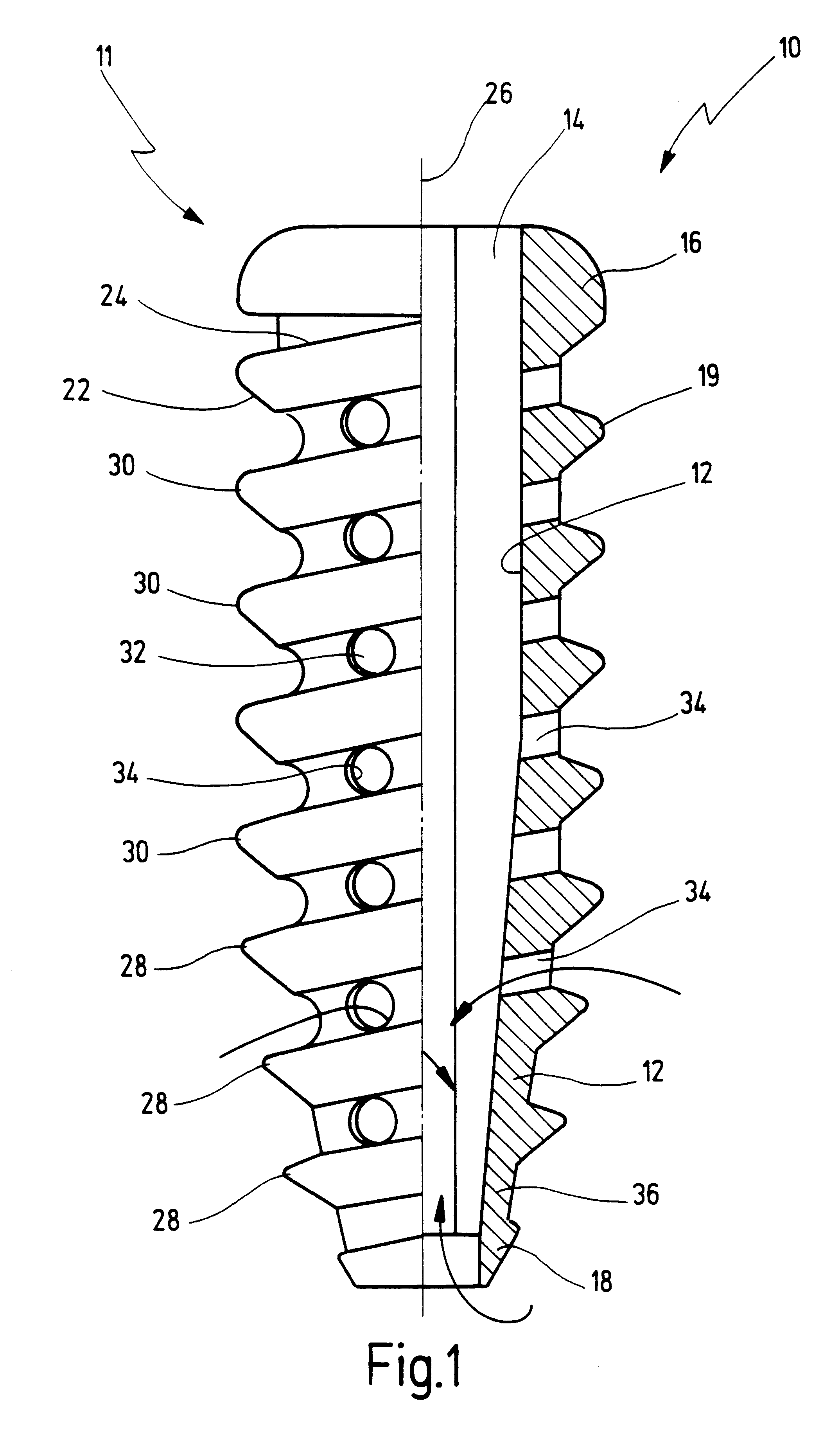

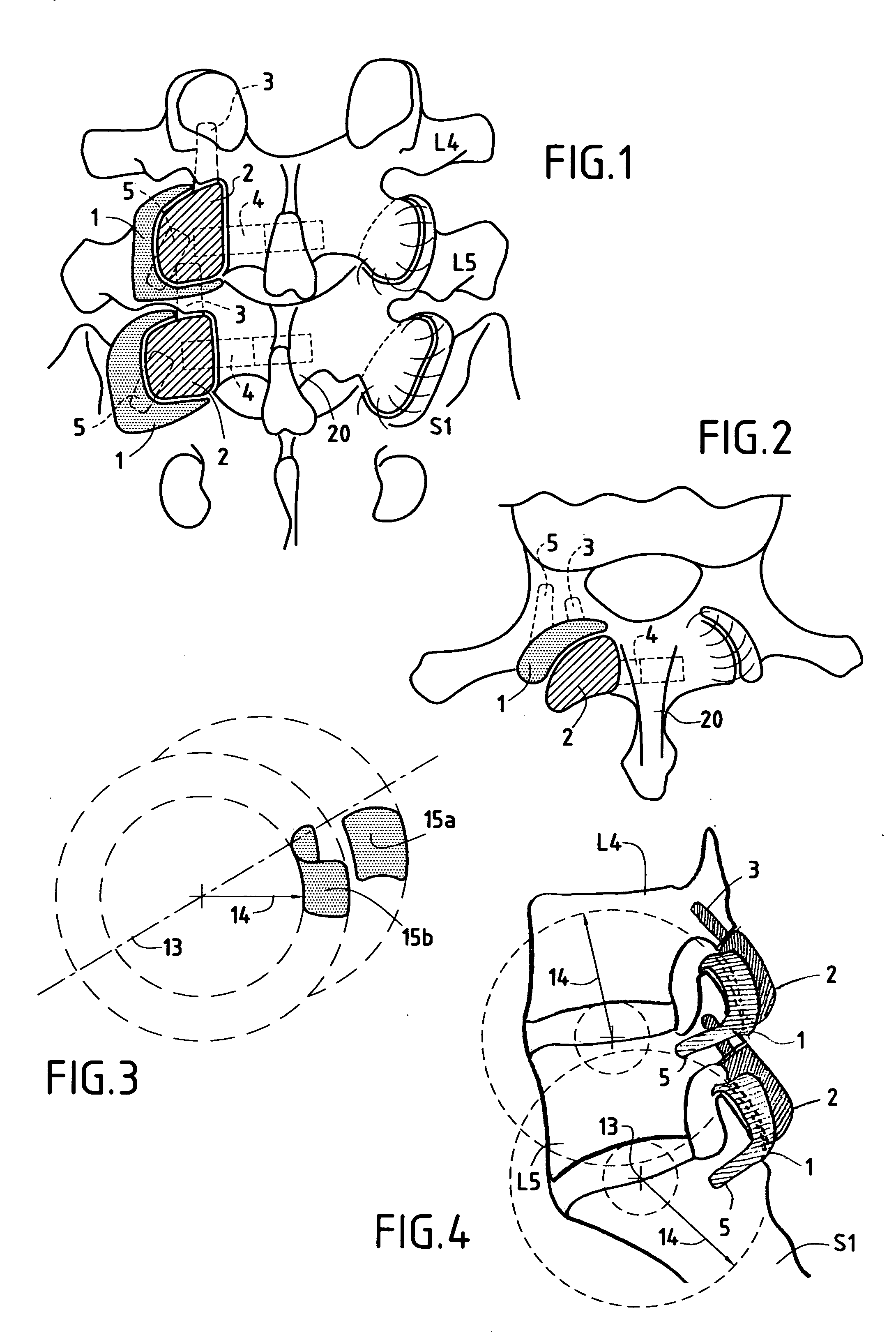

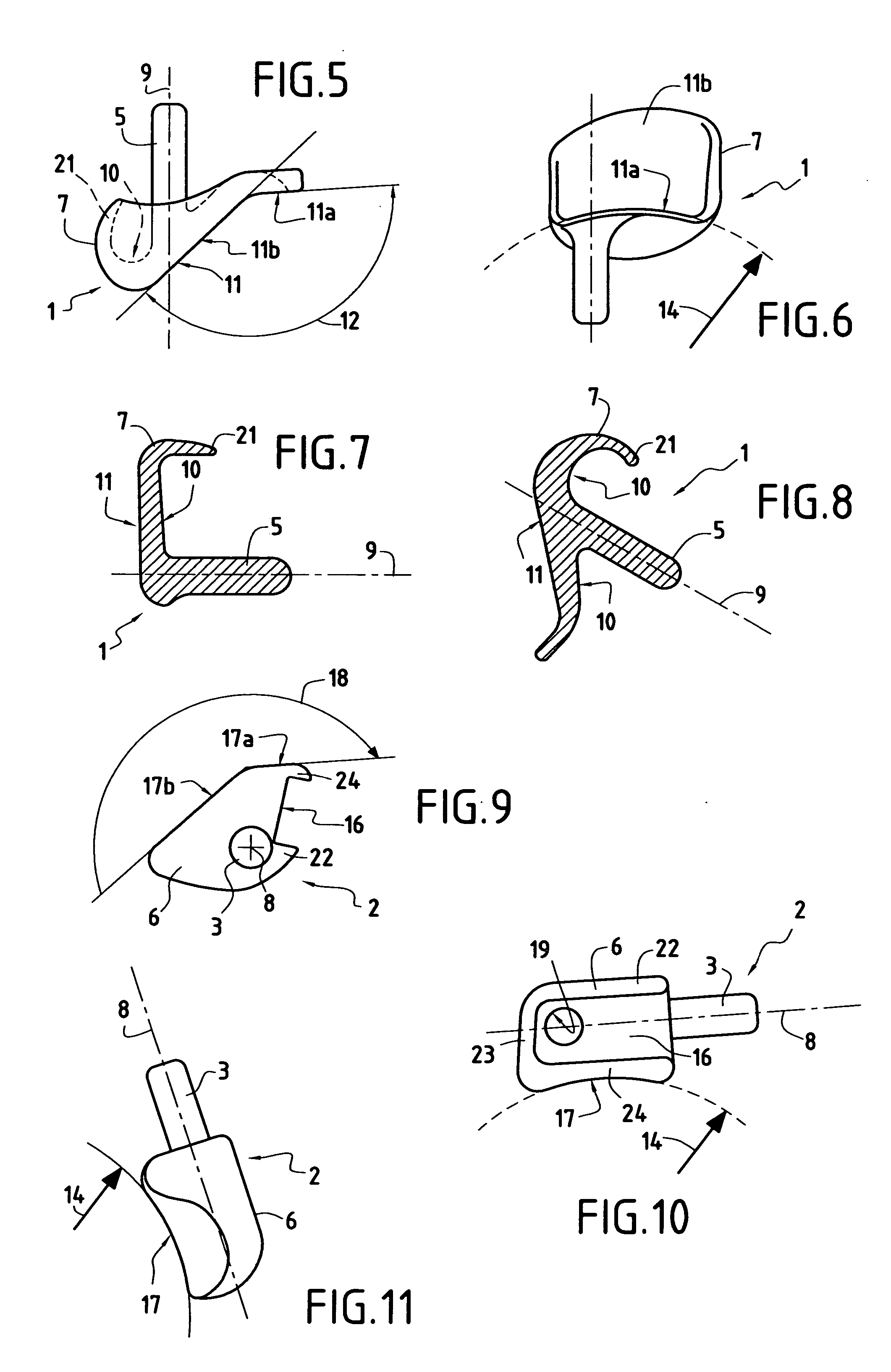

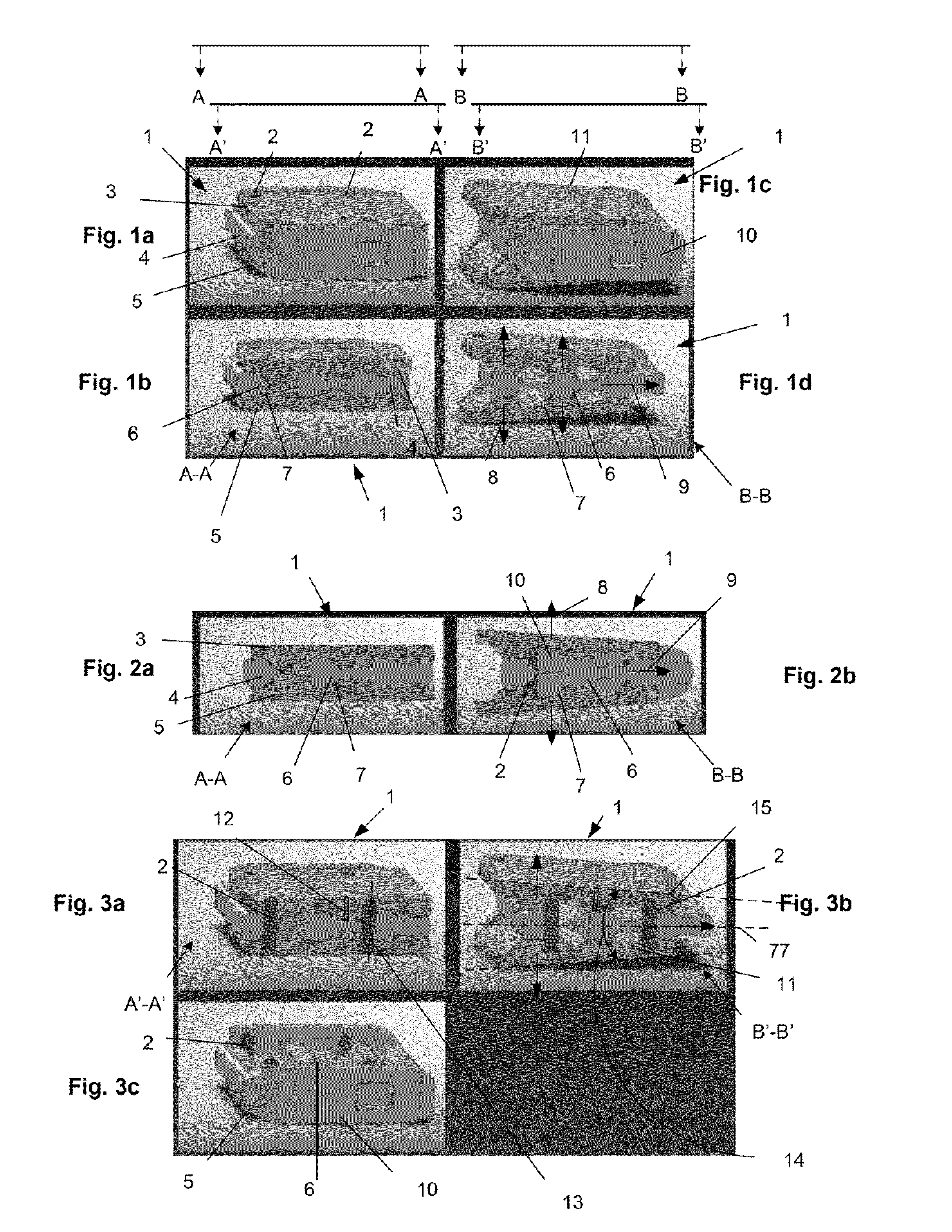

Expandable osteosynthesis cage

InactiveUS6129763AGood jamLarge inside volumeBone implantJoint implantsSpinal columnBiomedical engineering

PCT No. PCT / FR97 / 01617 Sec. 371 Date Jul. 28, 1998 Sec. 102(e) Date Jul. 28, 1998 PCT Filed Sep. 12, 1997 PCT Pub. No. WO98 / 10722 PCT Pub. Date Mar. 19, 1998An expandable osteosynthesis implant has branches (5) each connected at one end to a seat (7) which is pierced by an orifice (8), suitable for being slid from a posterior direction between the facing faces of two consecutive vertebrae in order to hold them a given distance apart and restore stability of the spinal column. According to the invention, the branches (5) and the seat (7) define a hollow cage (1) which, in a "rest" position, has an outside general shape that is a cylinder of circular section, and a portion at least of the inside volume (9) of the cage (1) towards the distal ends of the branches (5) is in the form of a circular truncated cone whose large base is towards the seat (7), which implant has at least three branches (5) and, inside the inside volume (9) at least one spacer (2) suitable for passing through the orifice (8) and the large base of the truncated cone.

Owner:OSTEOIMPLANT TECH

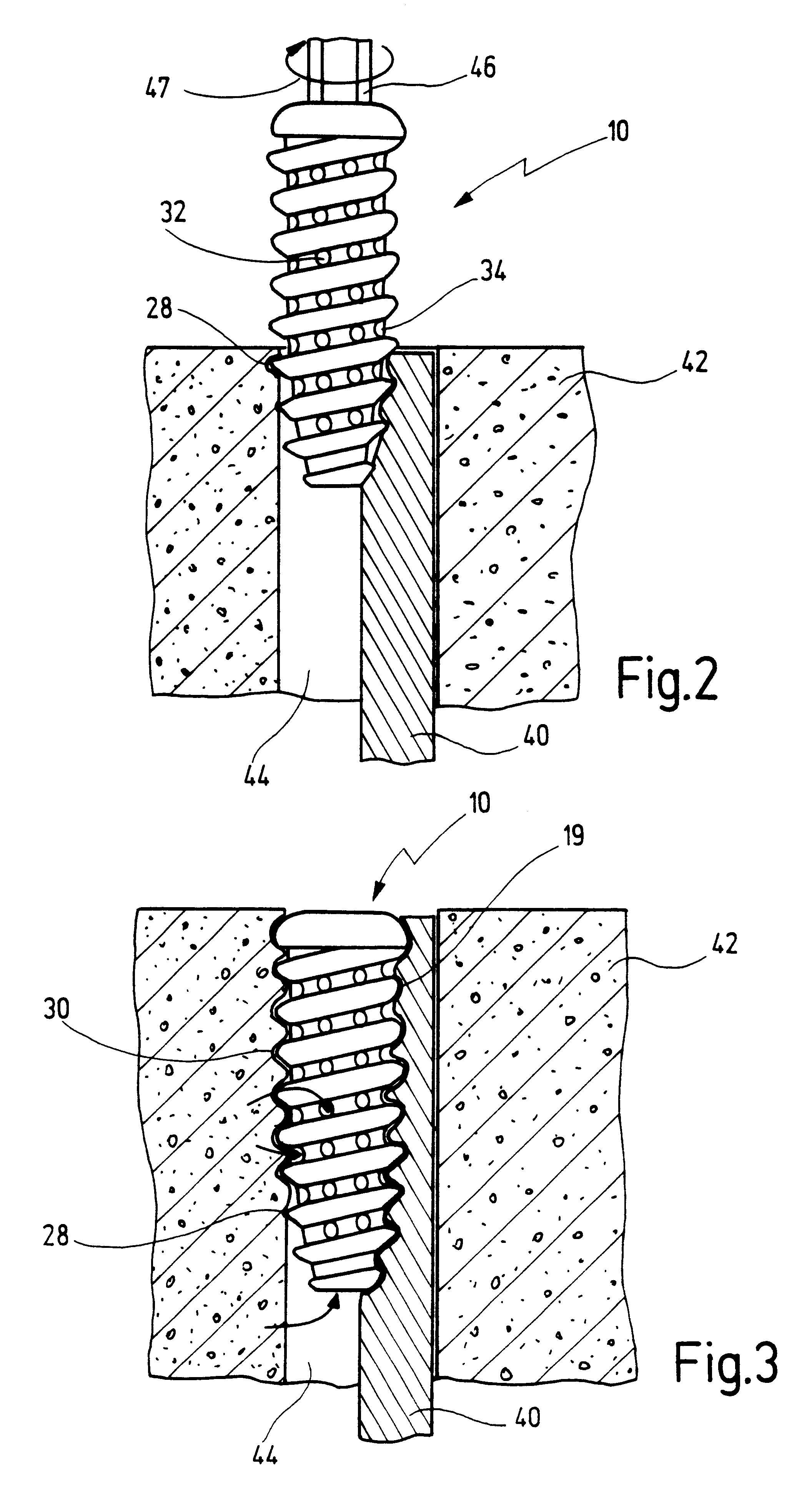

Method of providing proper vertebral spacing

InactiveUS6371989B1Easy to anchorInhibit migrationBone implantJoint implantsSpinal columnBiomedical engineering

An expandable osteosynthesis implant has branches (5) each connected at one end to a seat (7) which is pierced by an orifice (8), suitable for being slid from a posterior direction between the facing faces of two consecutive vertebrae in order to hold them a given distance apart and restore stability of the spinal column. According to the invention, the branches (5) and the seat (7) define a hollow cage (1) which, in a "rest" position, has an outside general shape that is a cylinder of circular section, and a portion at least of the inside volume (9) of the cage (1) towards the distal ends of the branches (5) is in the form of a circular truncated cone whose large base is towards the seat (7), which implant has at least three branches (5) and, inside the inside volume (9) at least one spacer (2) suitable for passing through the orifice (8) and the large base of the truncated cone.

Owner:OSTEOIMPLANT TECH

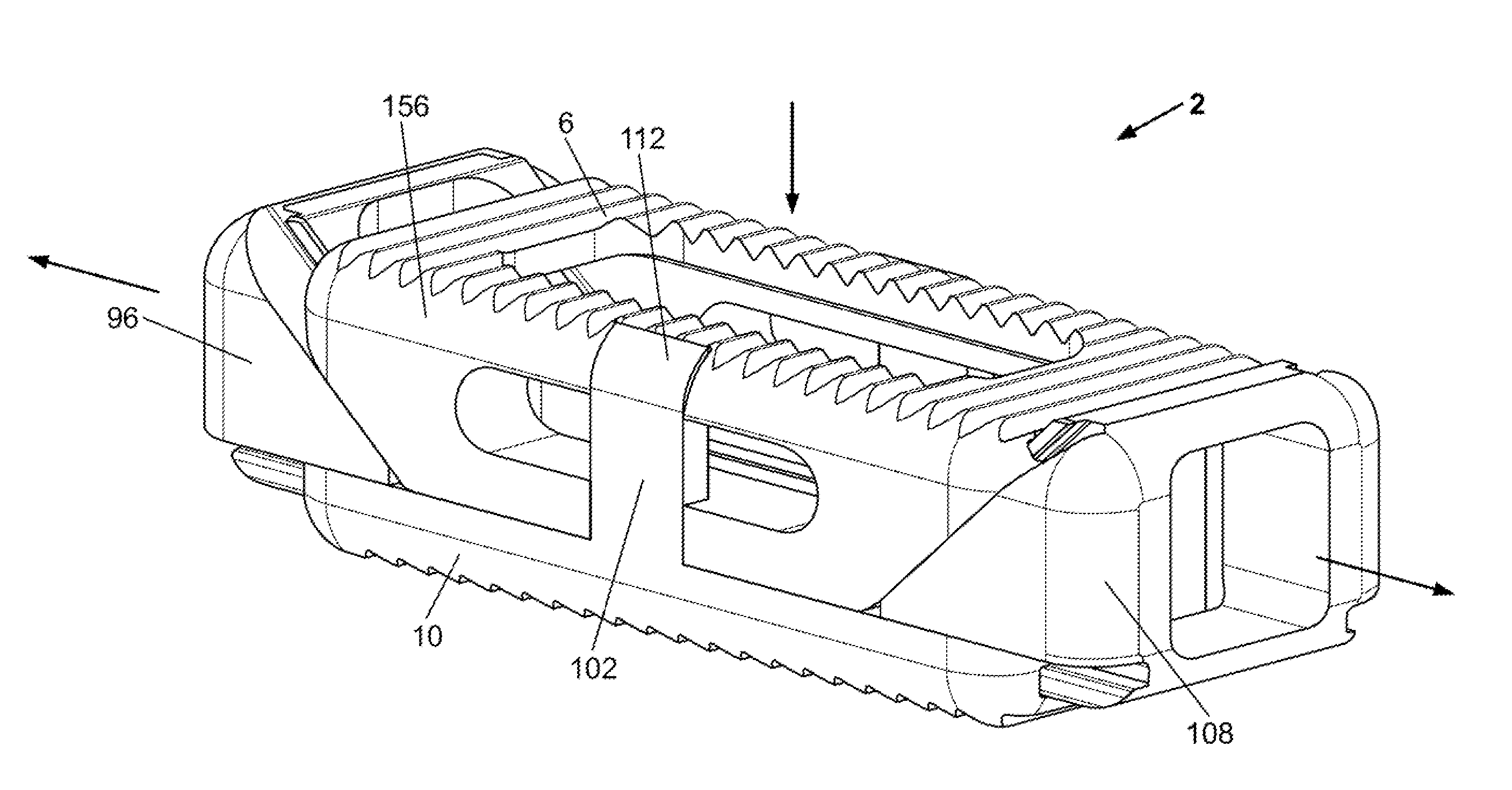

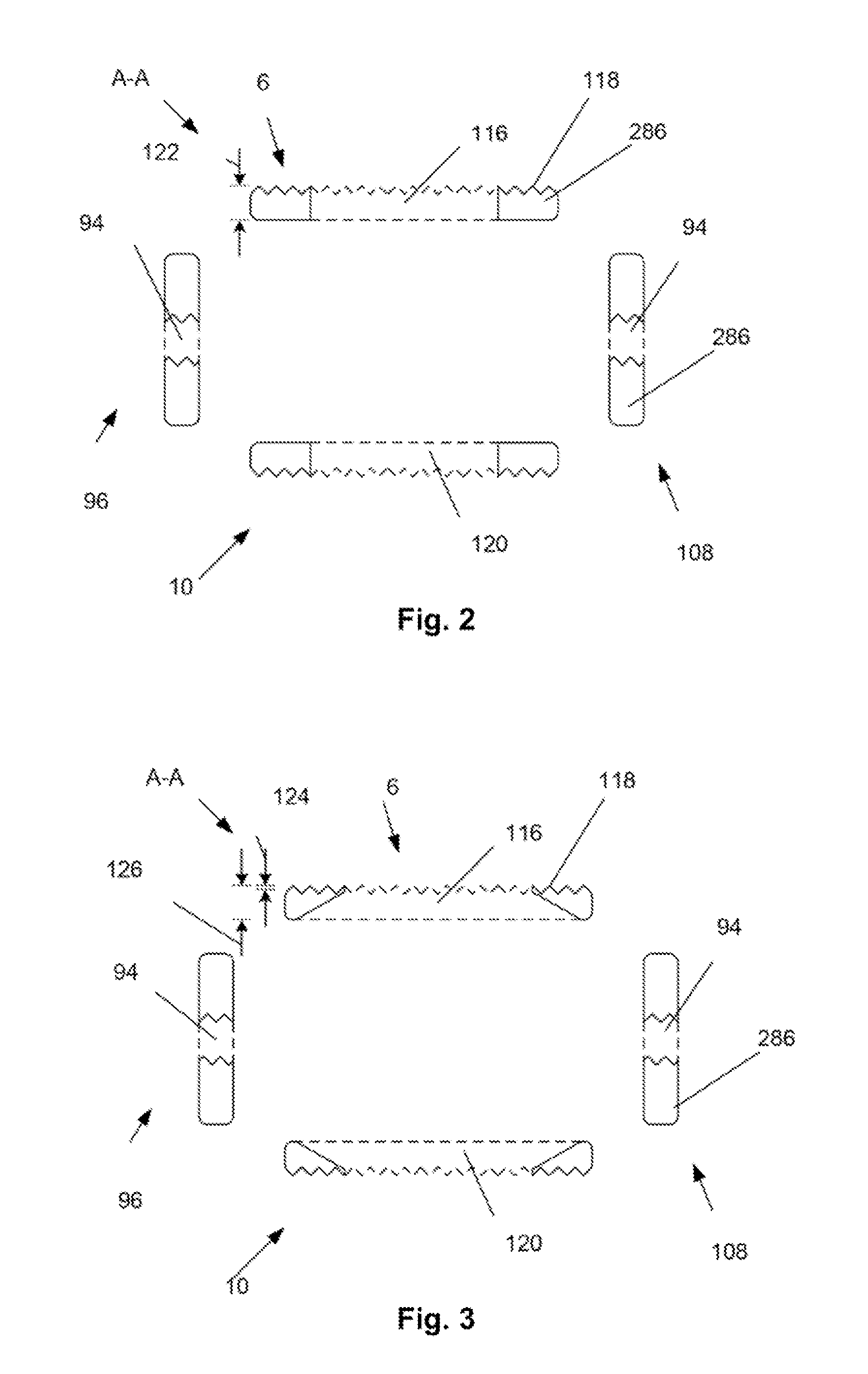

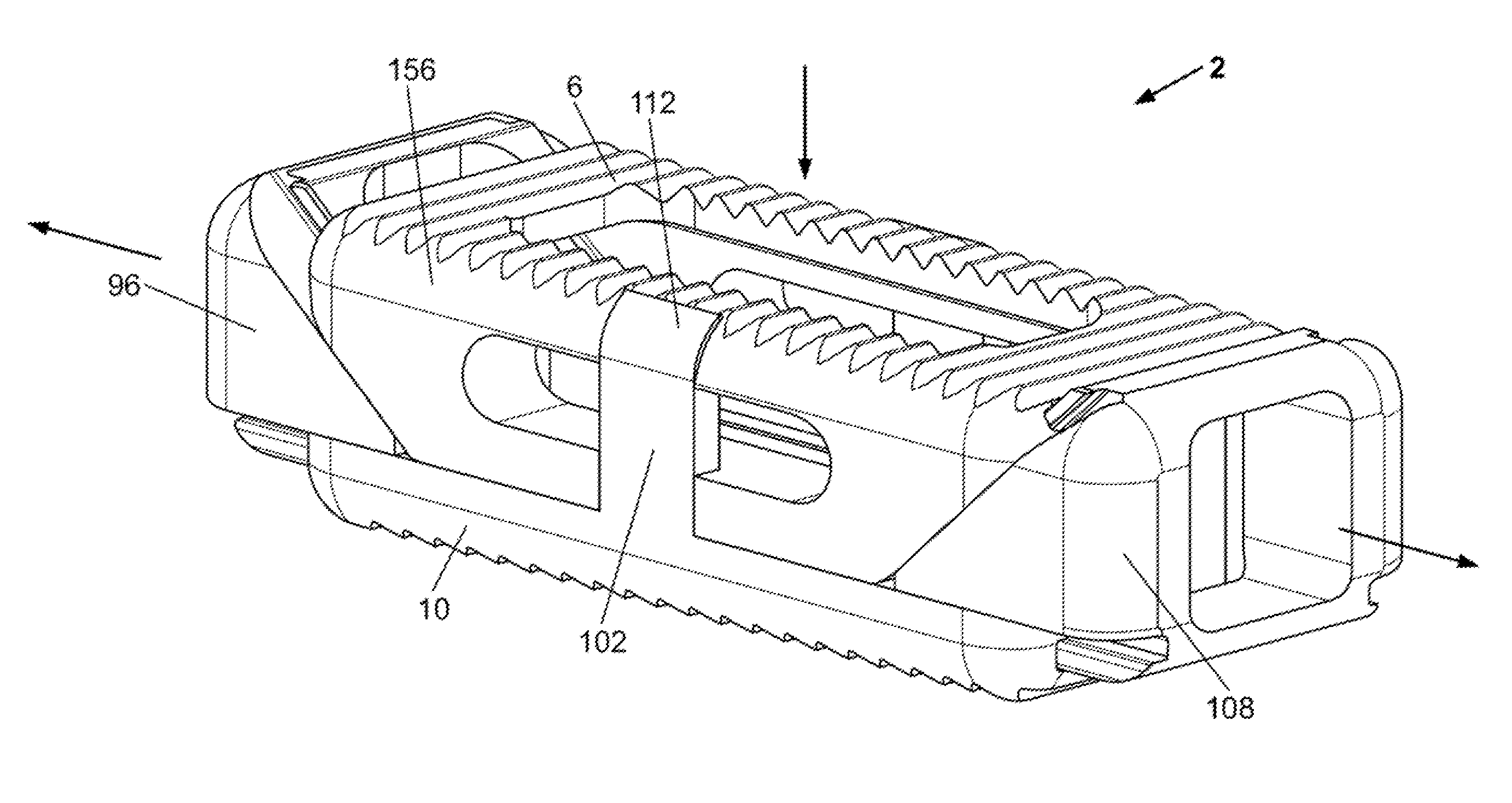

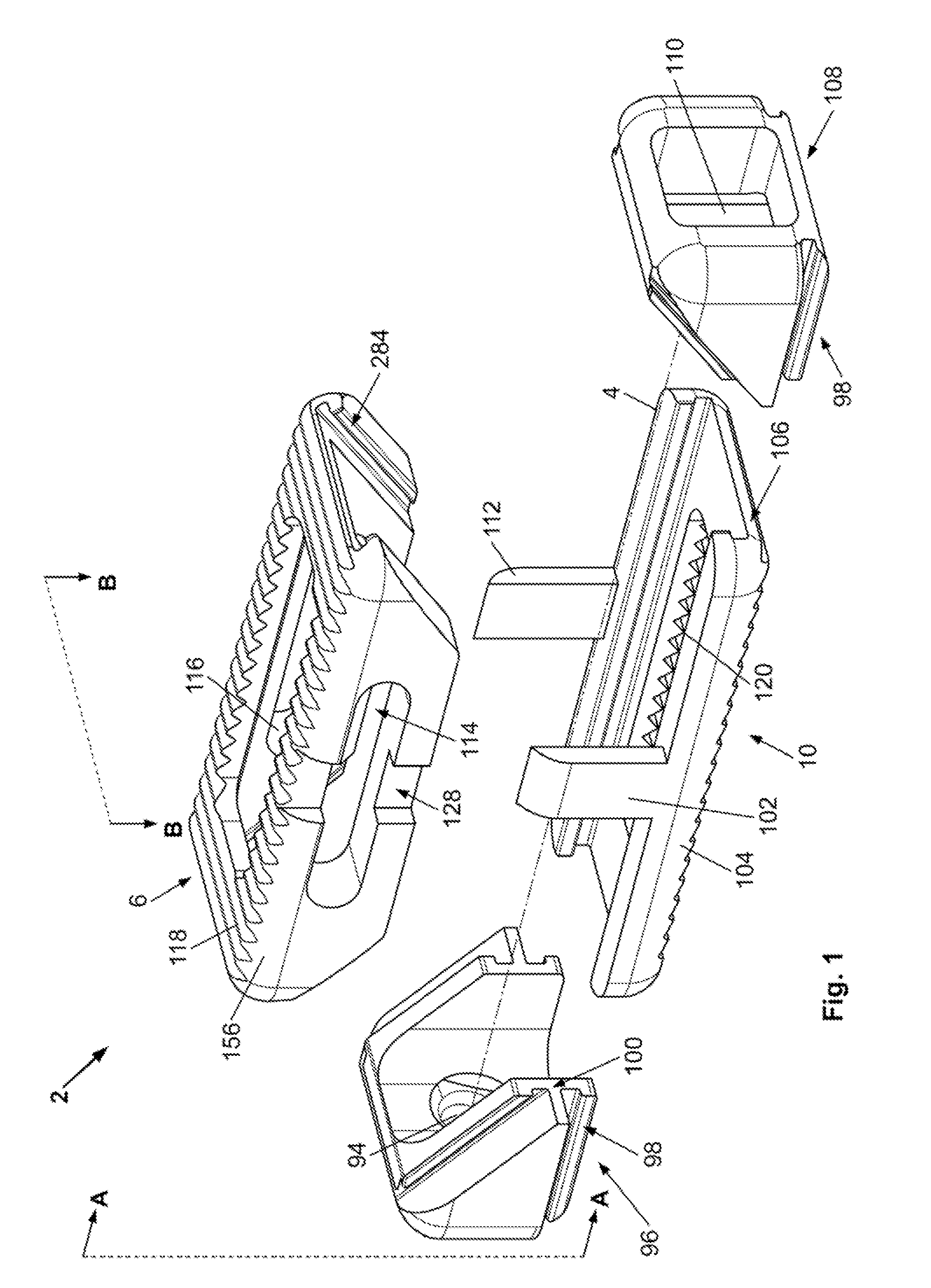

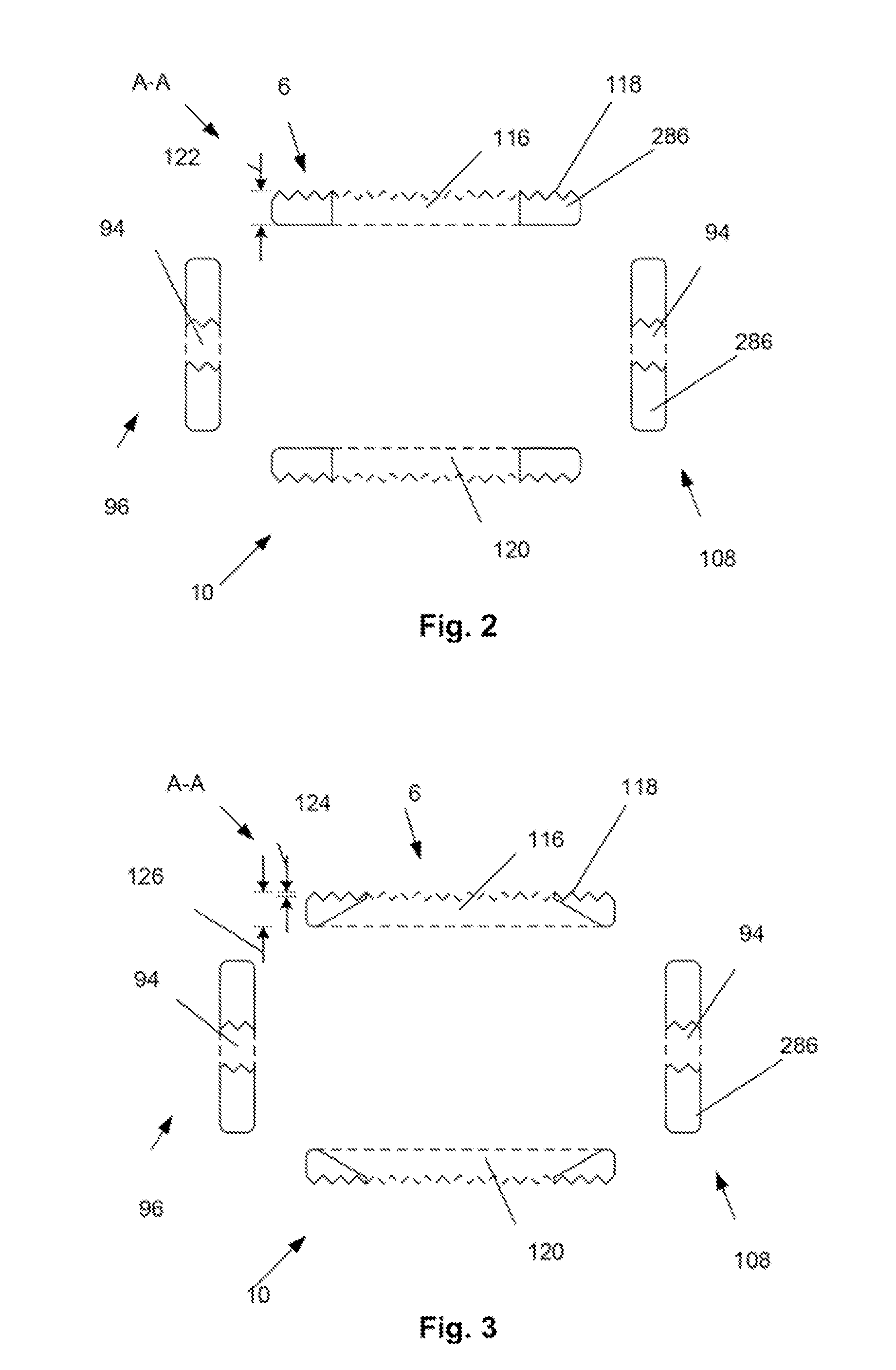

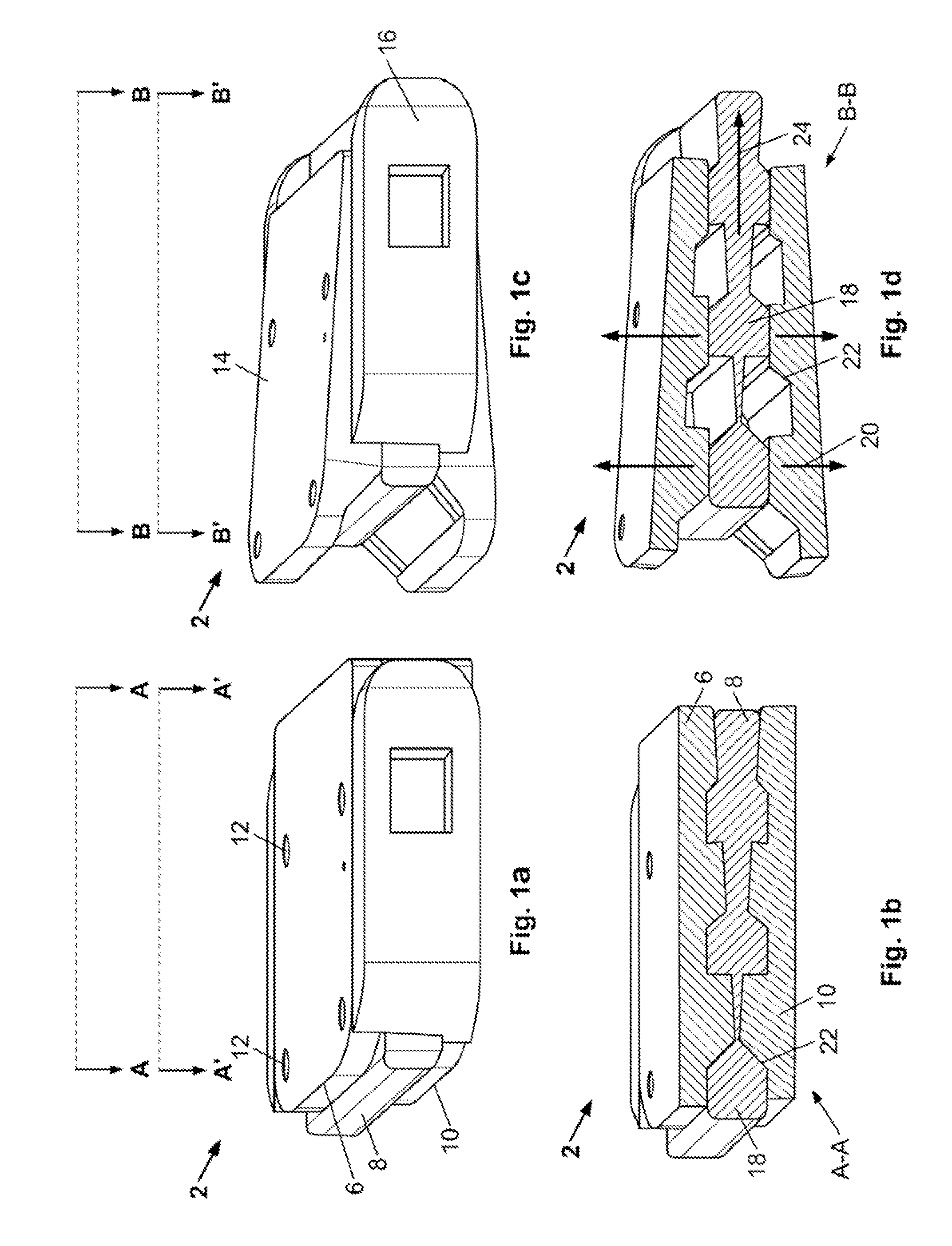

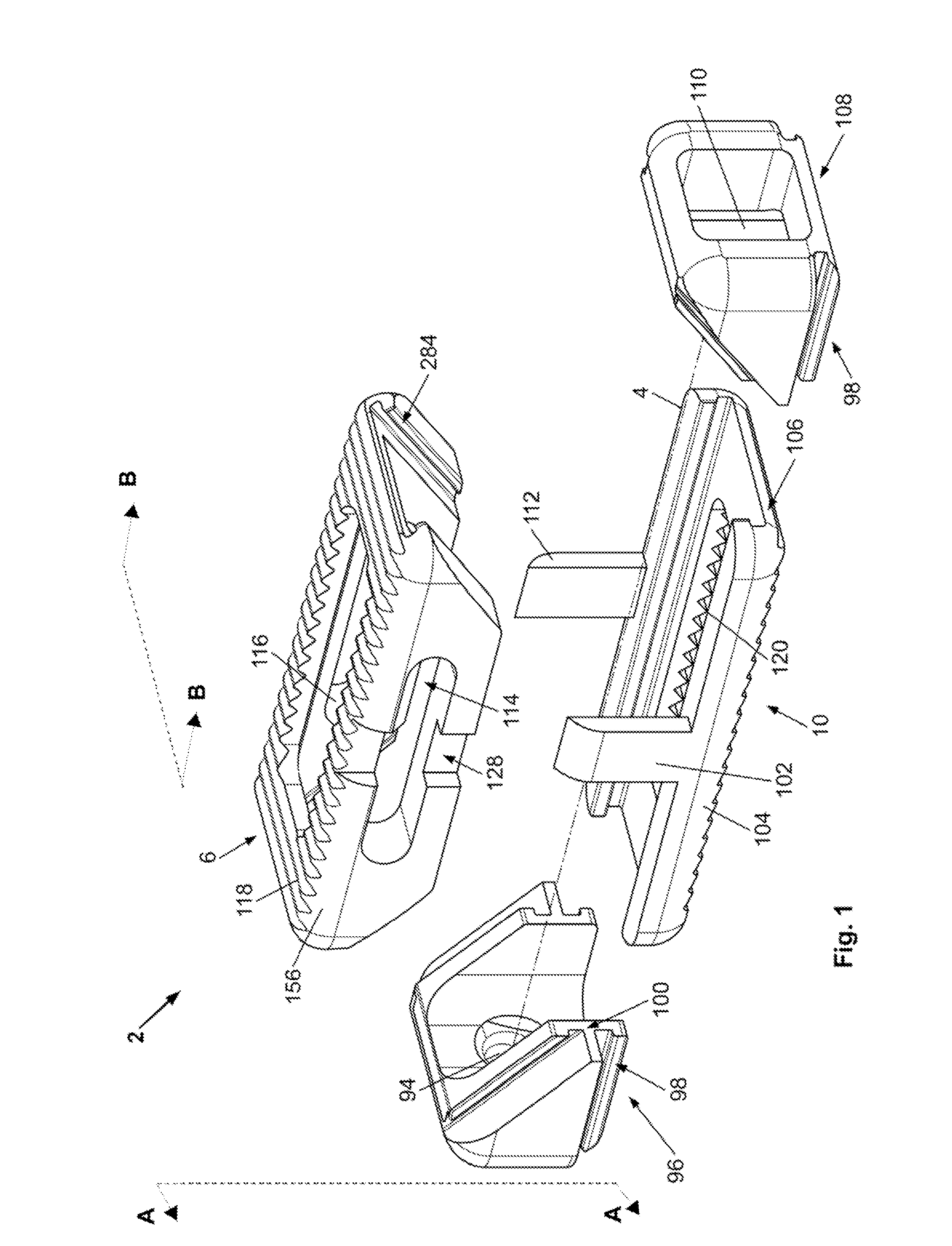

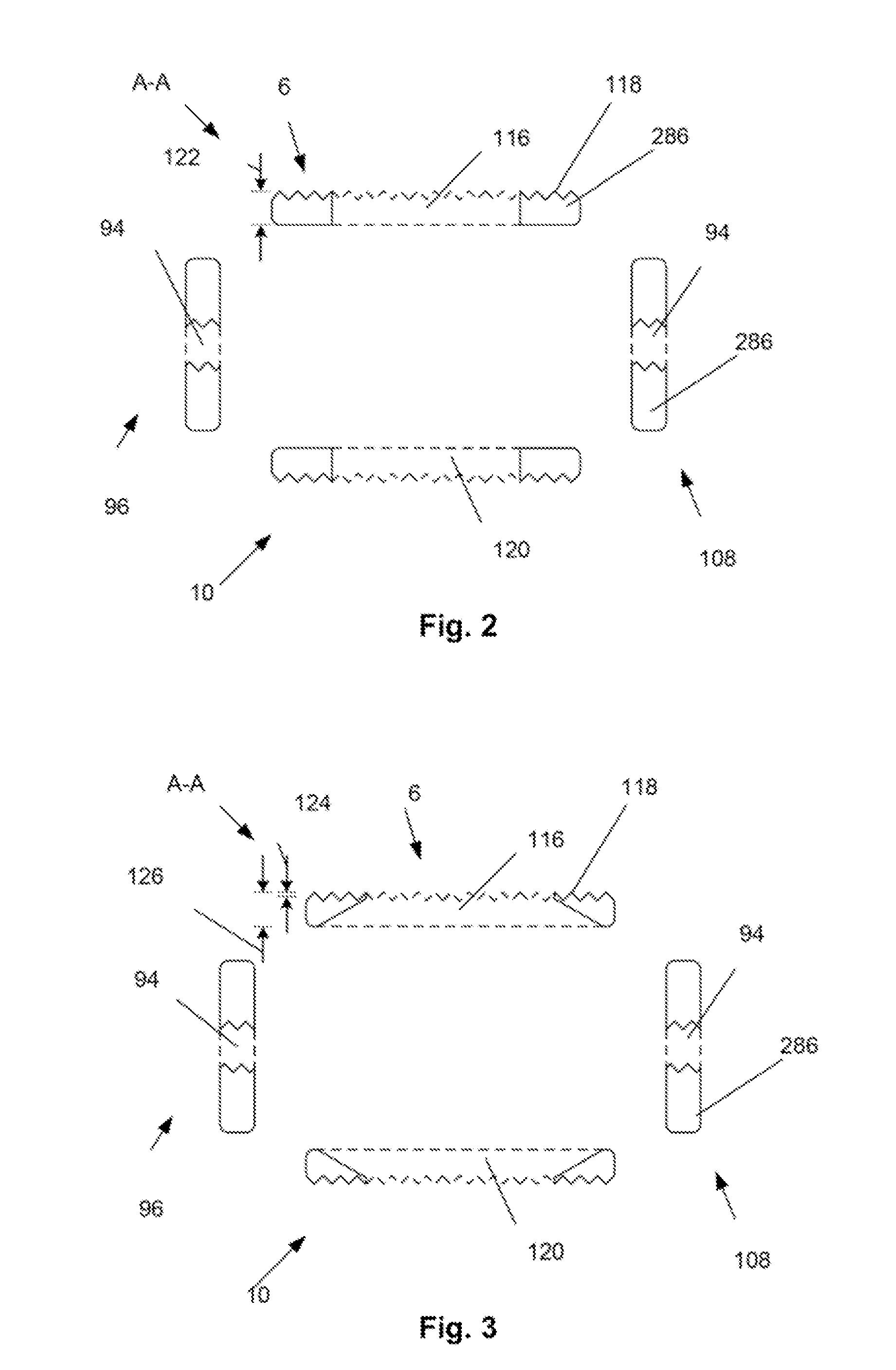

Fixation device and method

InactiveUS20100211176A1Less invasiveEasy to anchorSpinal implantsCoatingsPlastic surgeryBiomedical engineering

An implantable orthopedic stability device is disclosed. The device can have a contracted and an expanded configuration. A method of using the device between adjacent vertebral body surfaces surfaces for support and / or fixation of either or both of the adjacent vertebrae is also disclosed.

Owner:STOUT MEDICAL GROUP

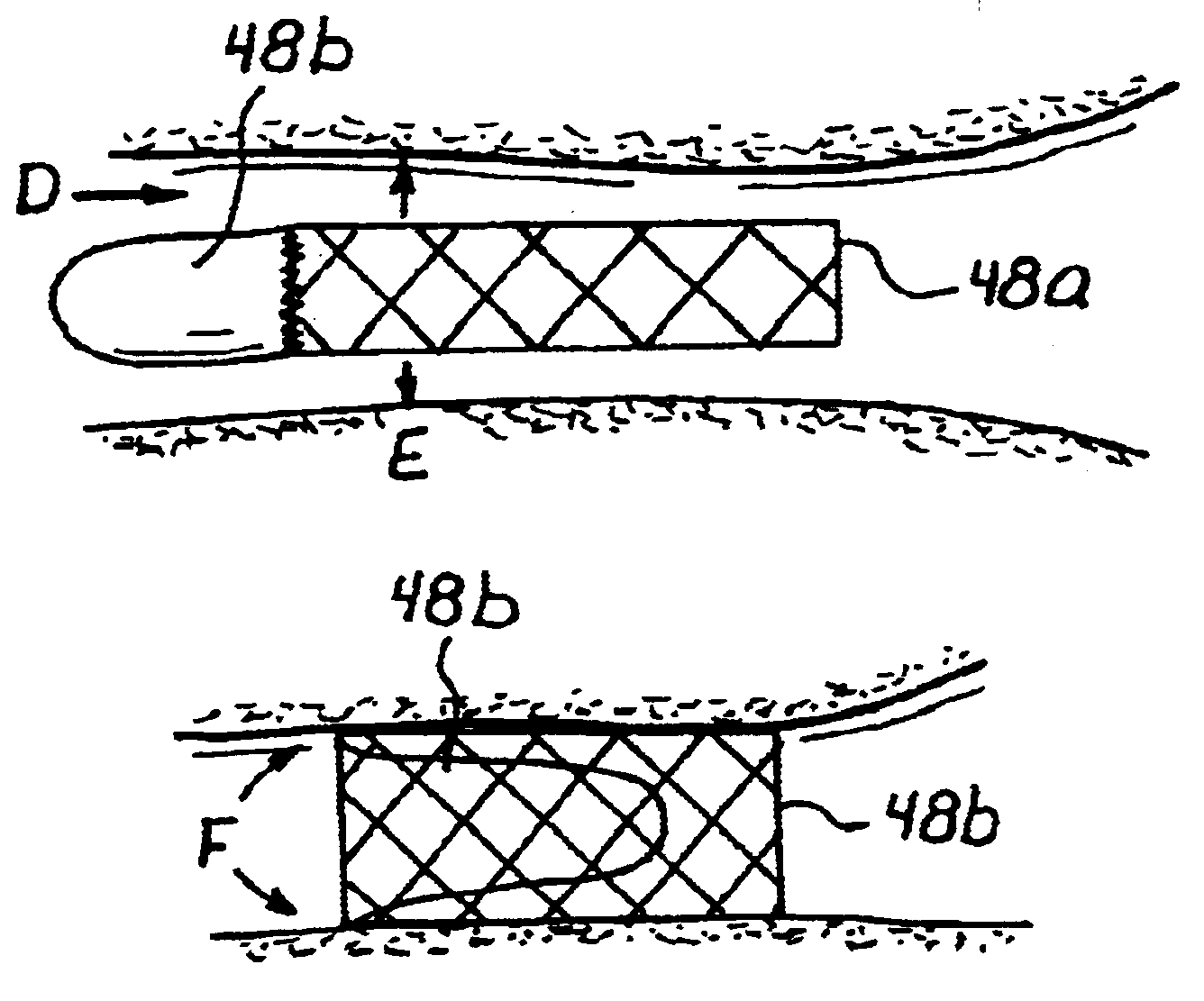

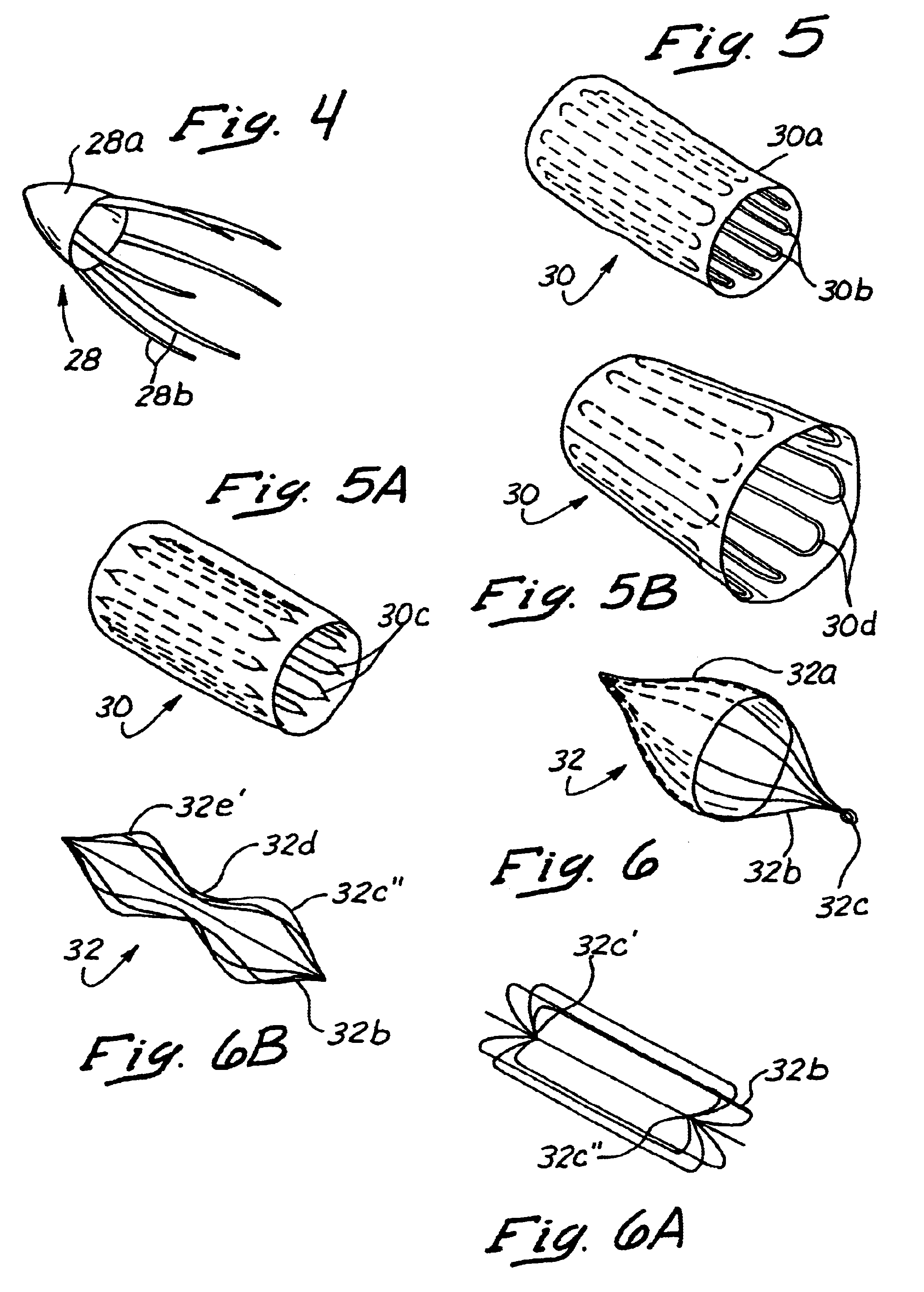

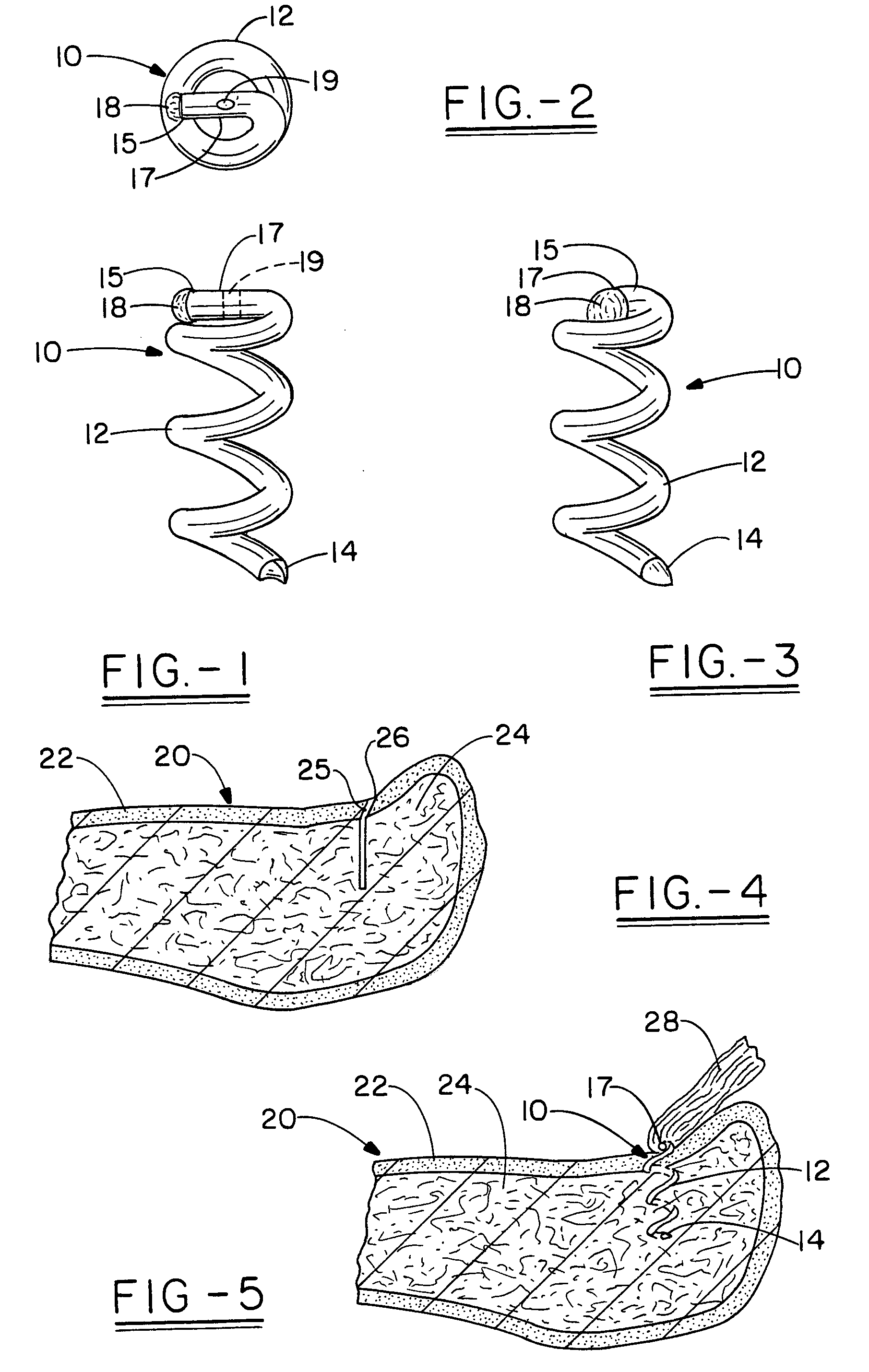

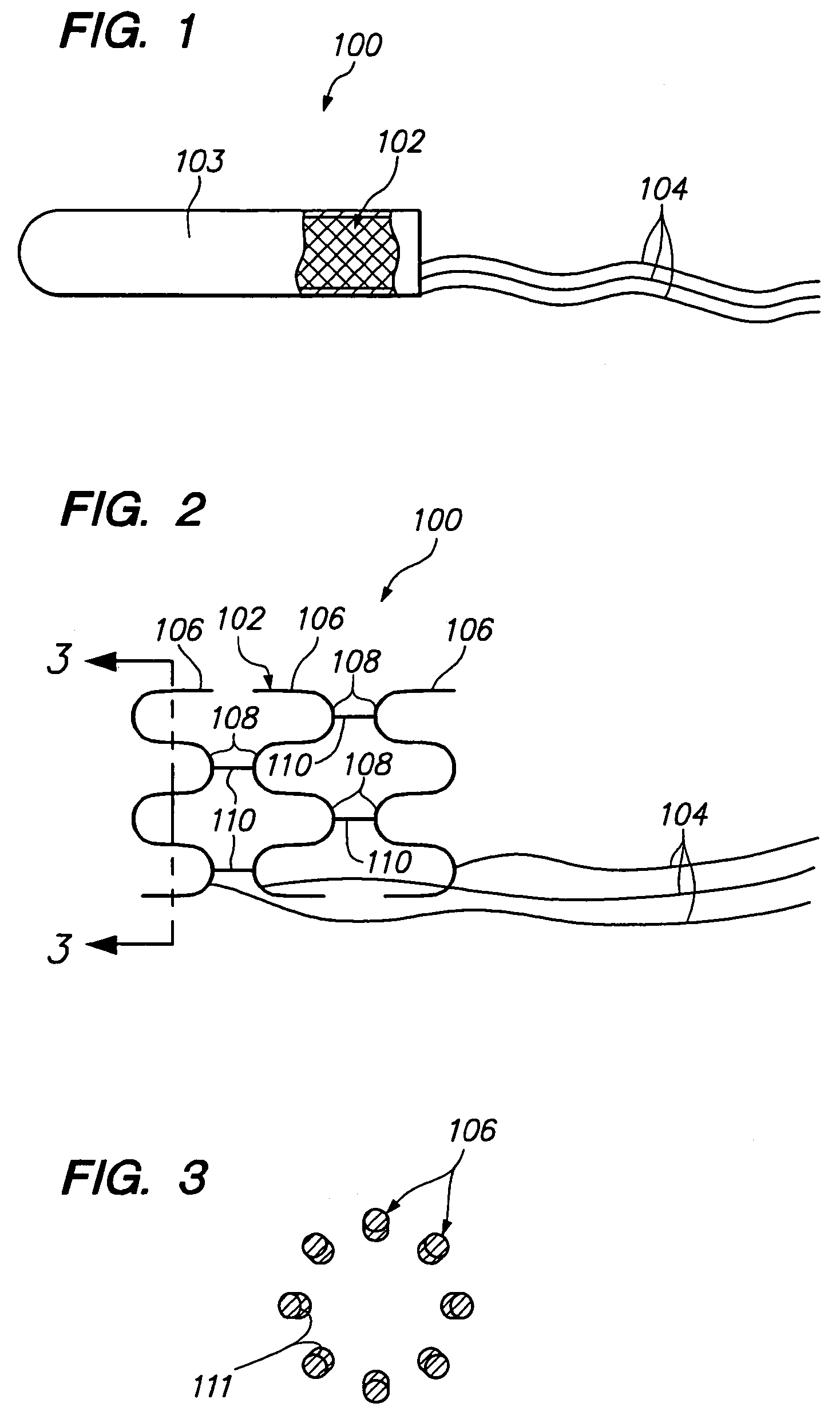

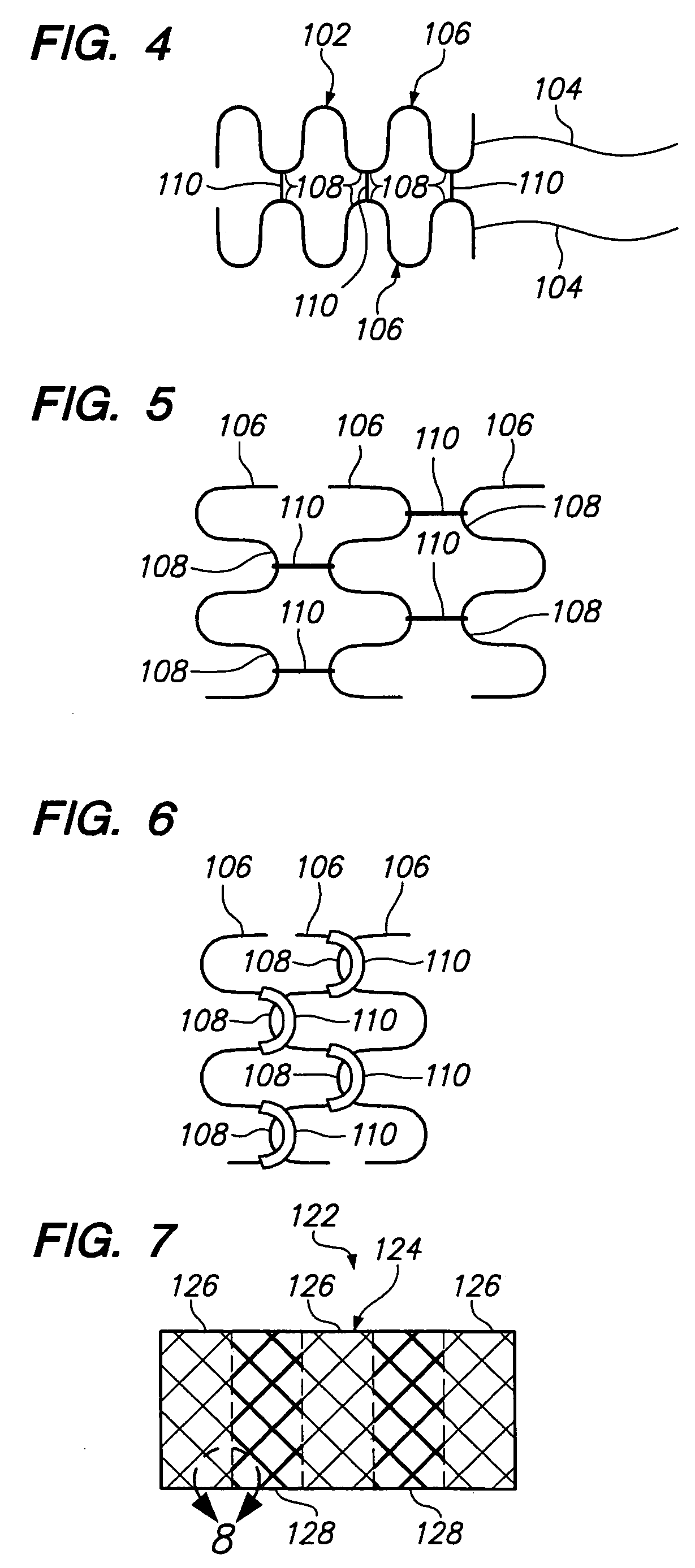

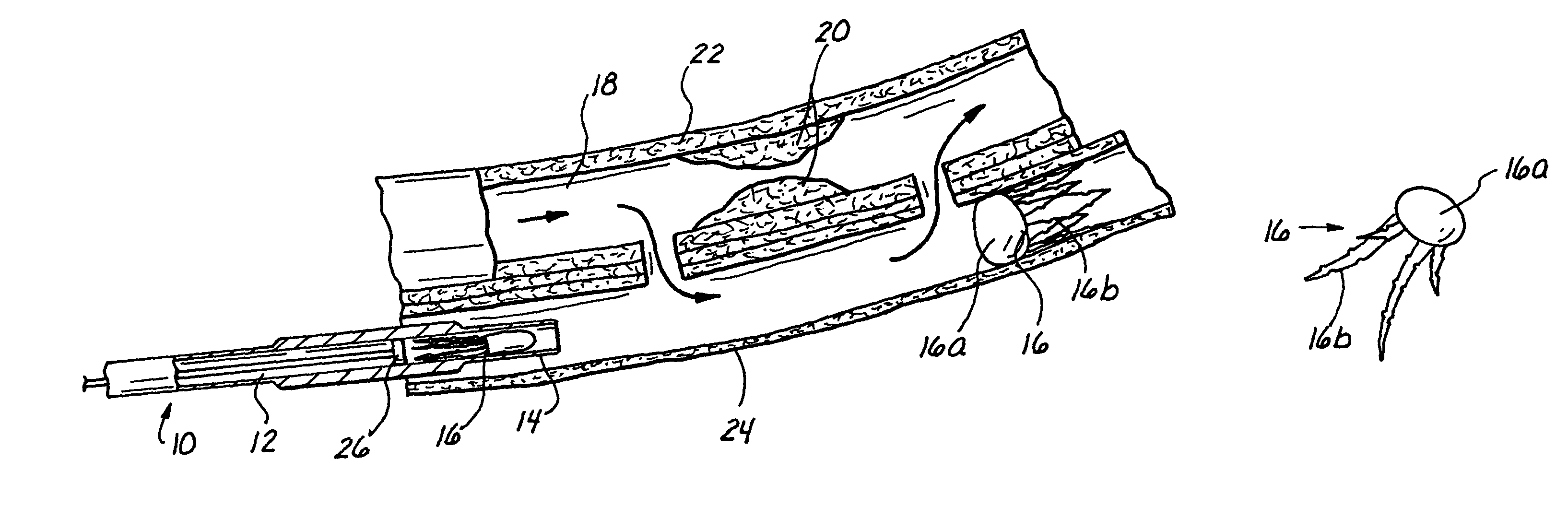

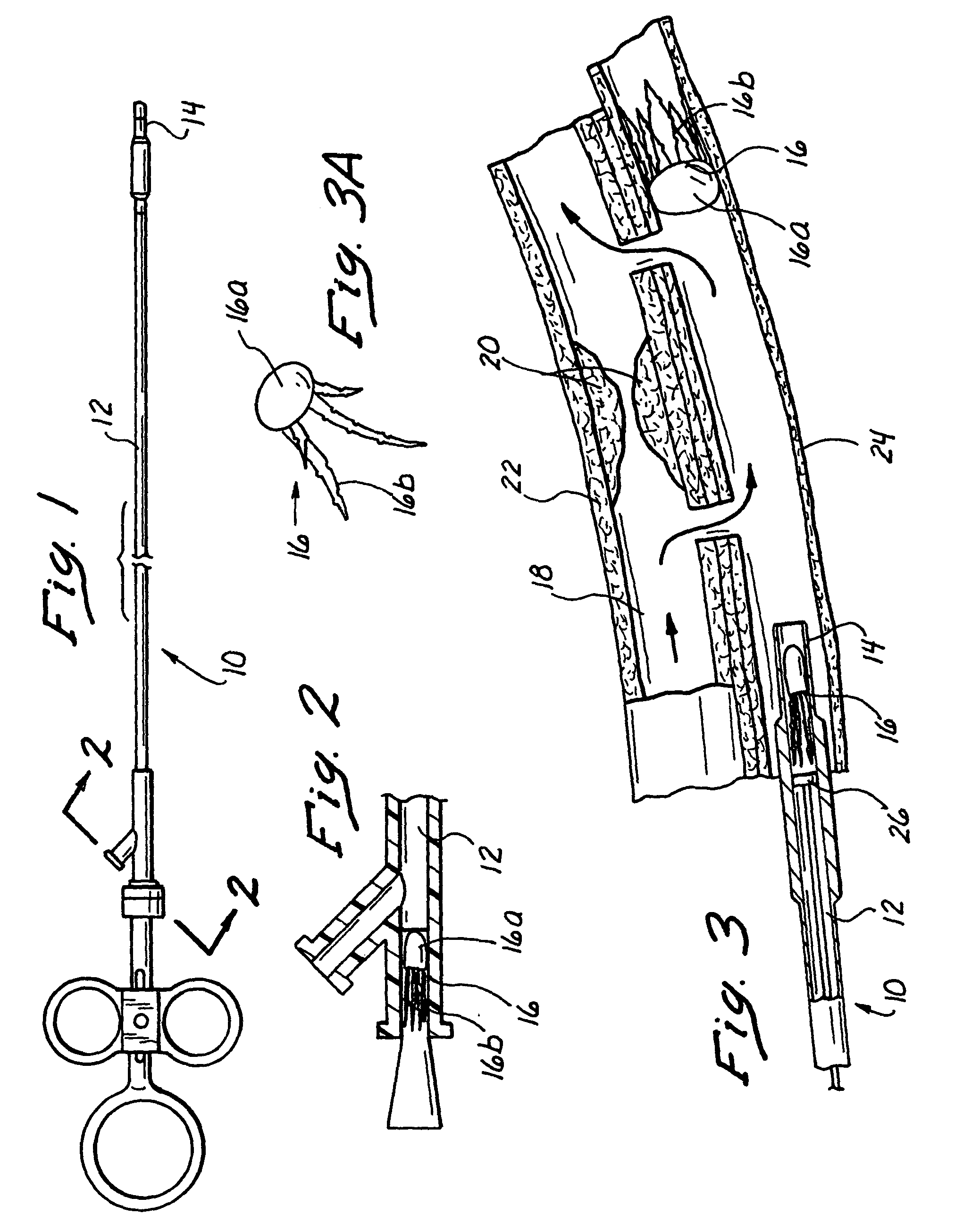

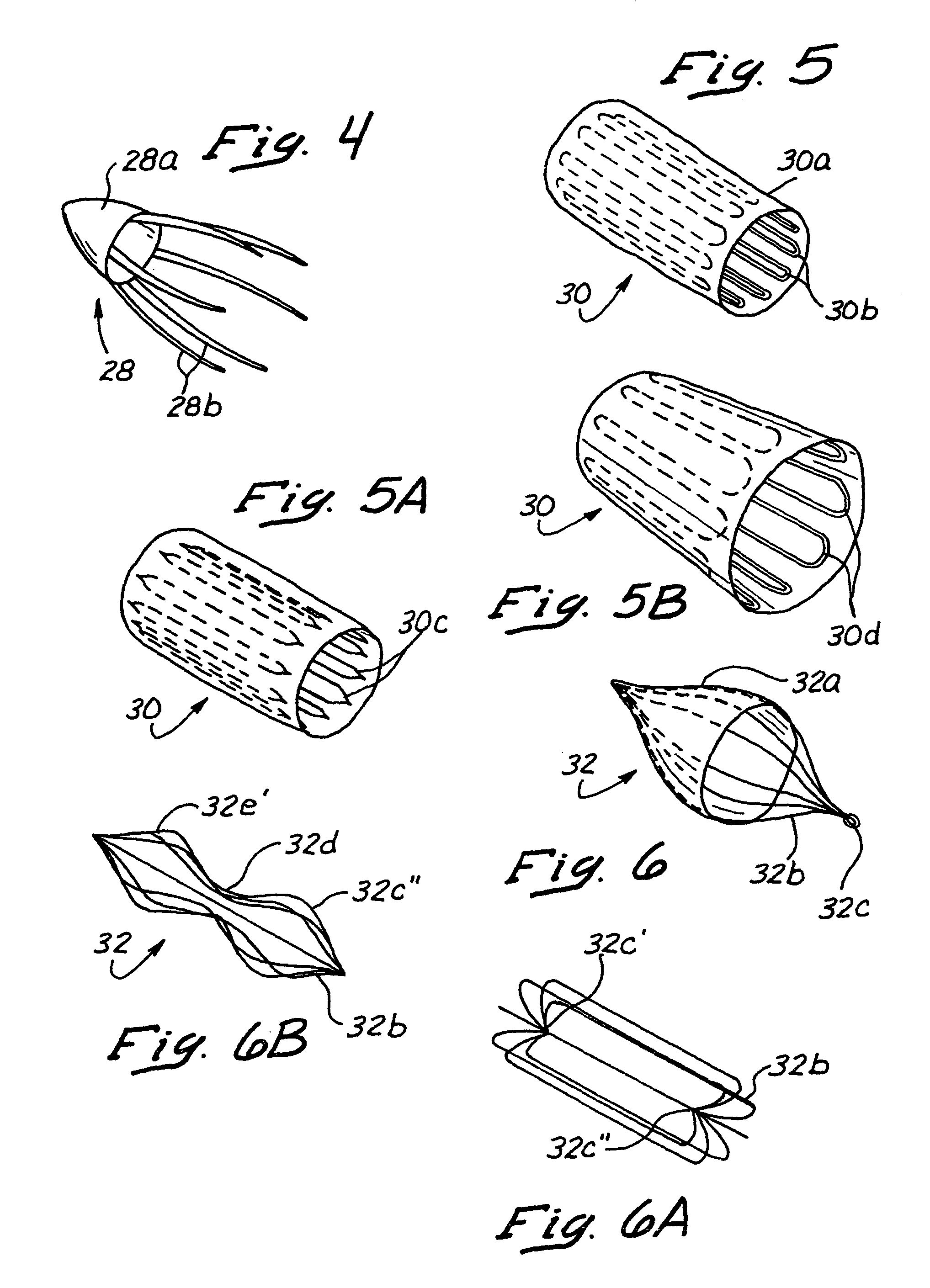

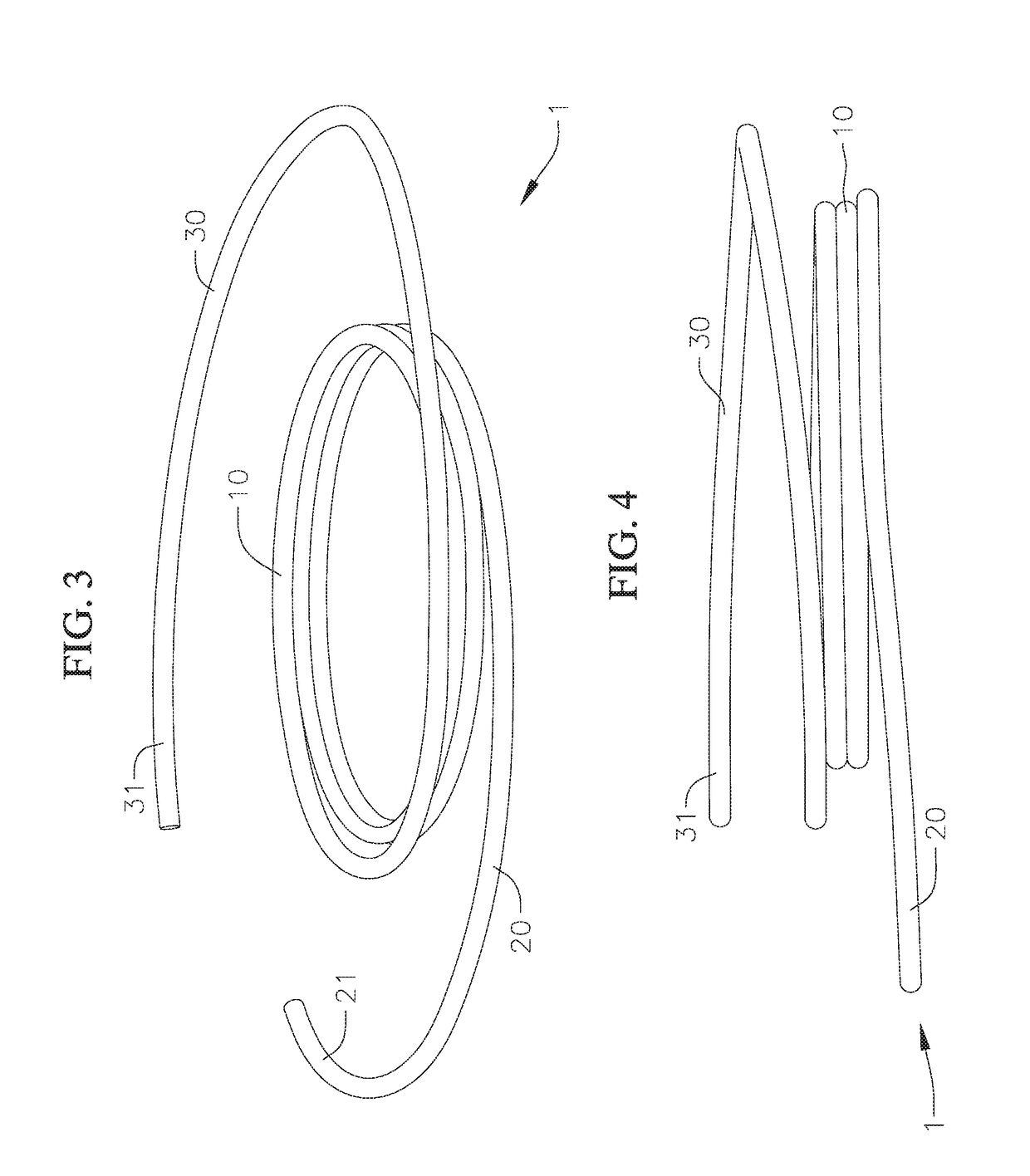

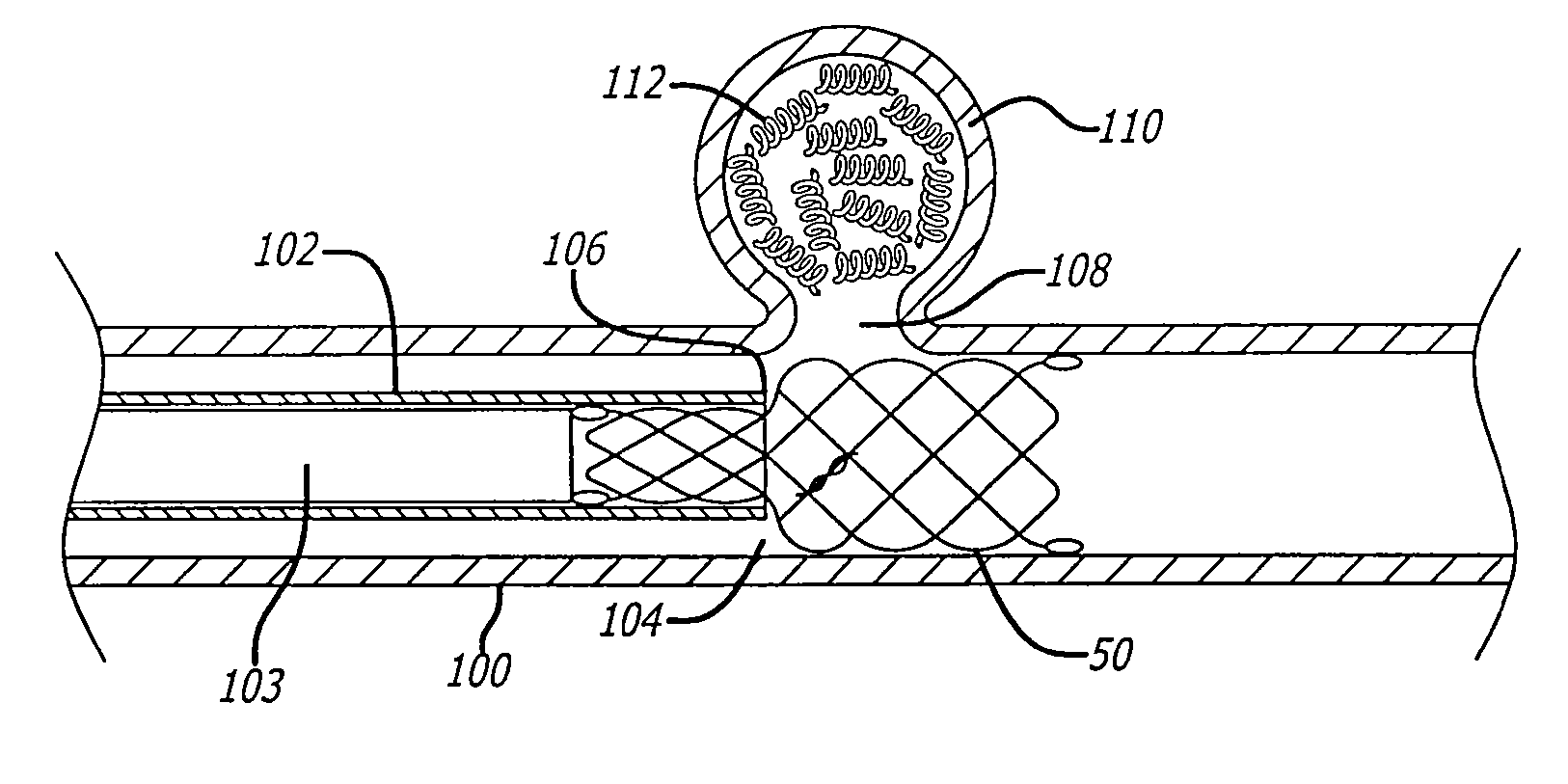

Methods and apparatus for blocking flow through blood vessels

This invention is methods and apparatus for occluding blood flow within a blood vessel (22). In a first series of embodiments, the present invention comprises a plurality of embolic devices (16) deployable through the lumen (12) of a conventional catheter (10) such that when deployed, said embolic devices (16) remain resident and occlude blood flow at a specific site within the lumen of the blood vessel (22). Such embolic devices (16) comprise either mechanical embolic devices that become embedded within or compress against the lumen of the vessel or chemical vaso occlusive agents that seal off blood flow at a given site. A second embodiment of the present invention comprises utilization of a vacuum / cauterizing device capable of sucking in the lumen of the vessel about the device to maintain the vessel in a closed condition where there is then applied a sufficient amount of energy to cause the tissue collapsed about the device to denature into a closure. In a third series of embodiments, the present invention comprises the combination of an embolization facilitator coupled with the application of an energy force to form an intraluminal closure at a specified site within a vessel.

Owner:MEDTRONIC VASCULAR INC

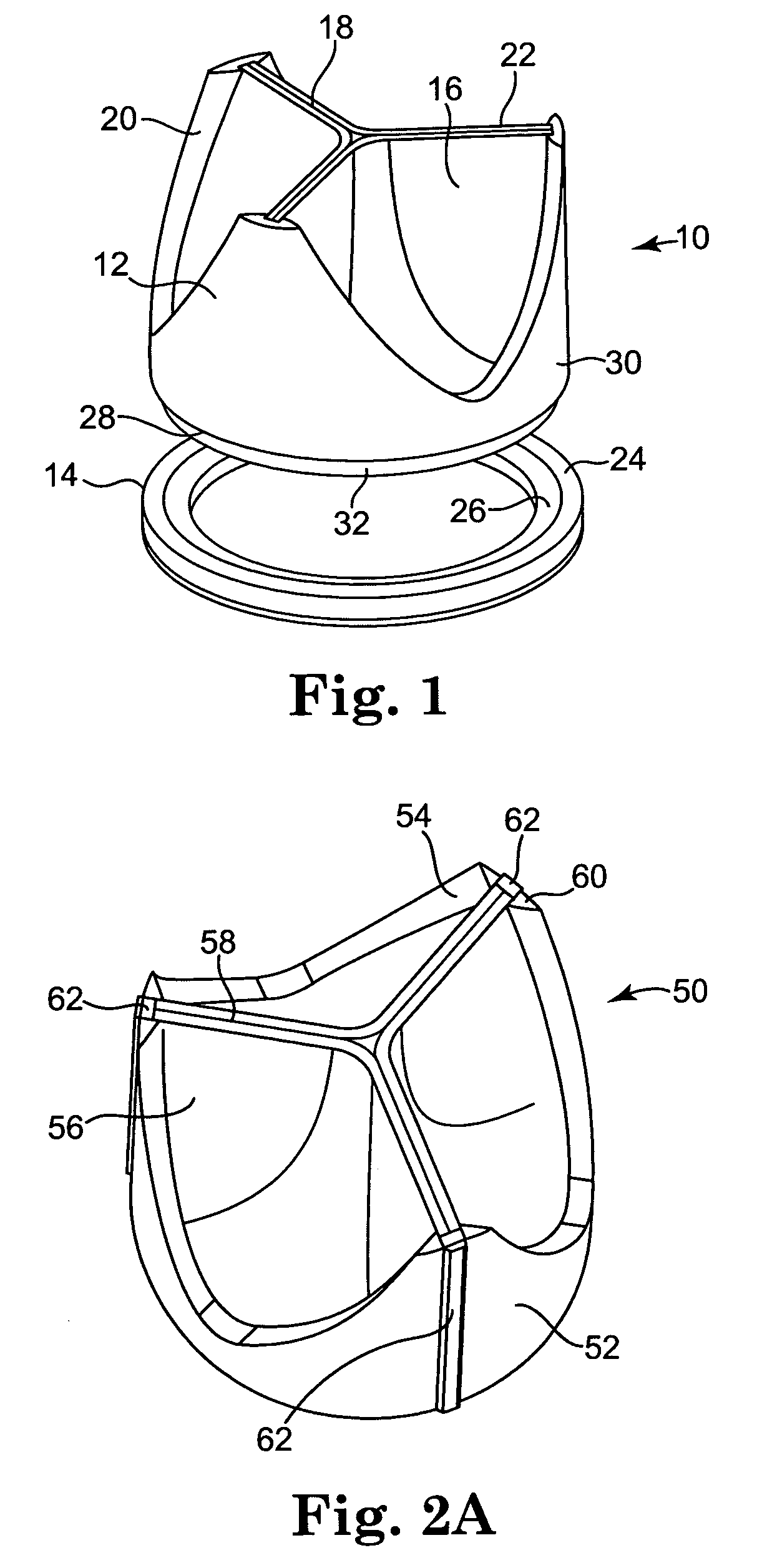

Prosthetic cardiac valves and systems and methods for implanting thereof

ActiveUS7186265B2Easy to anchorFacilitate delivery and deploymentHeart valvesProsthetic valveProsthesis

Owner:MEDTRONIC INC

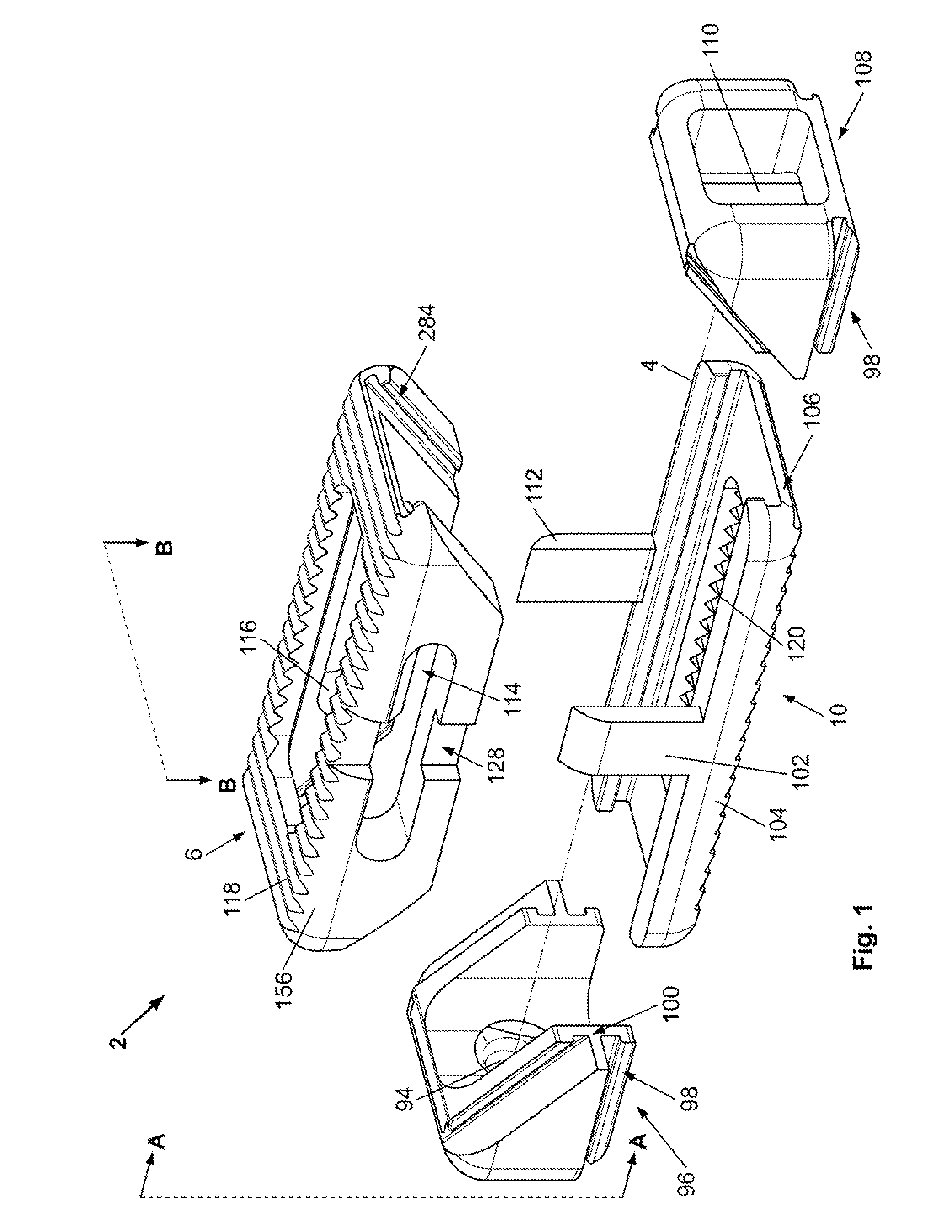

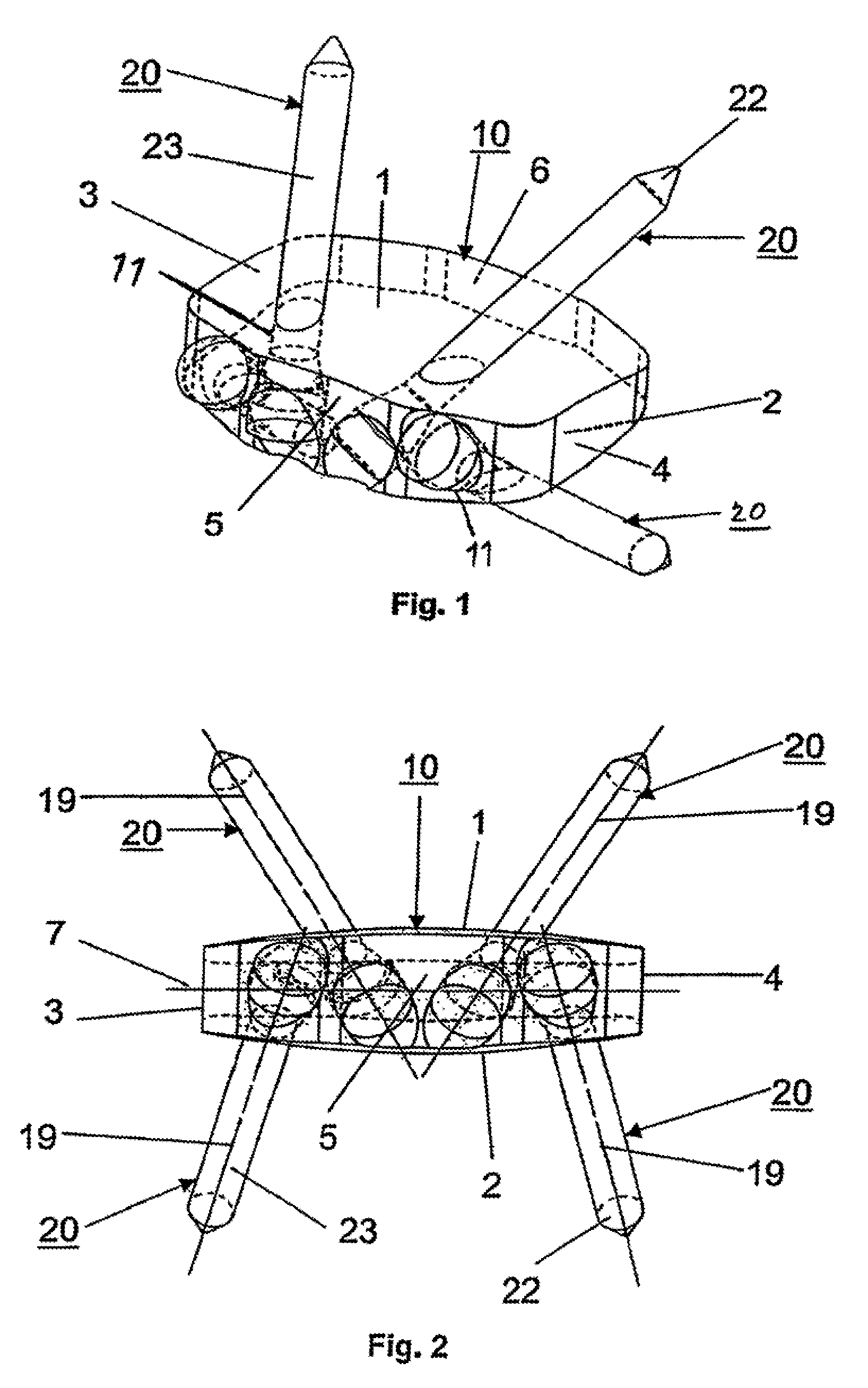

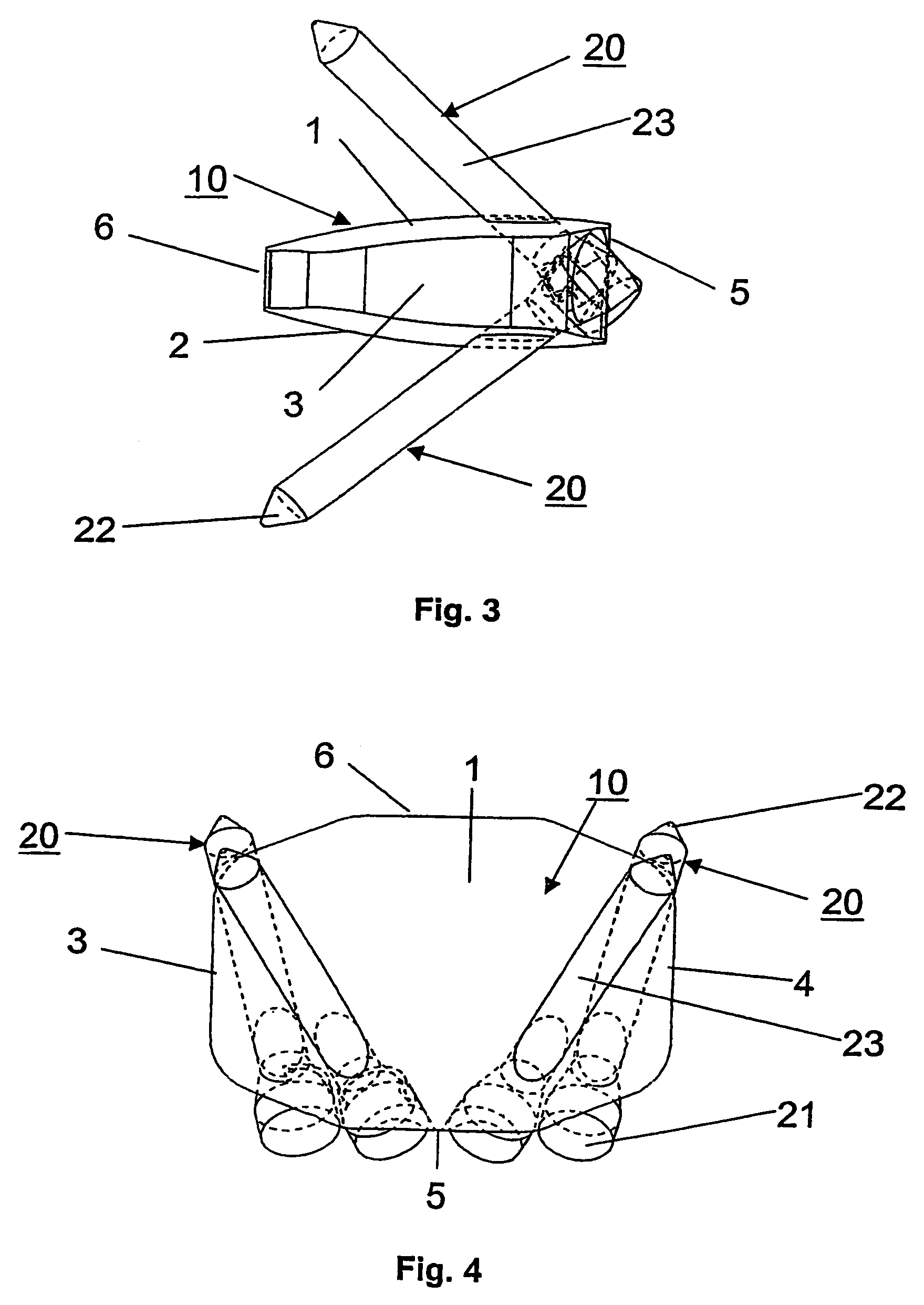

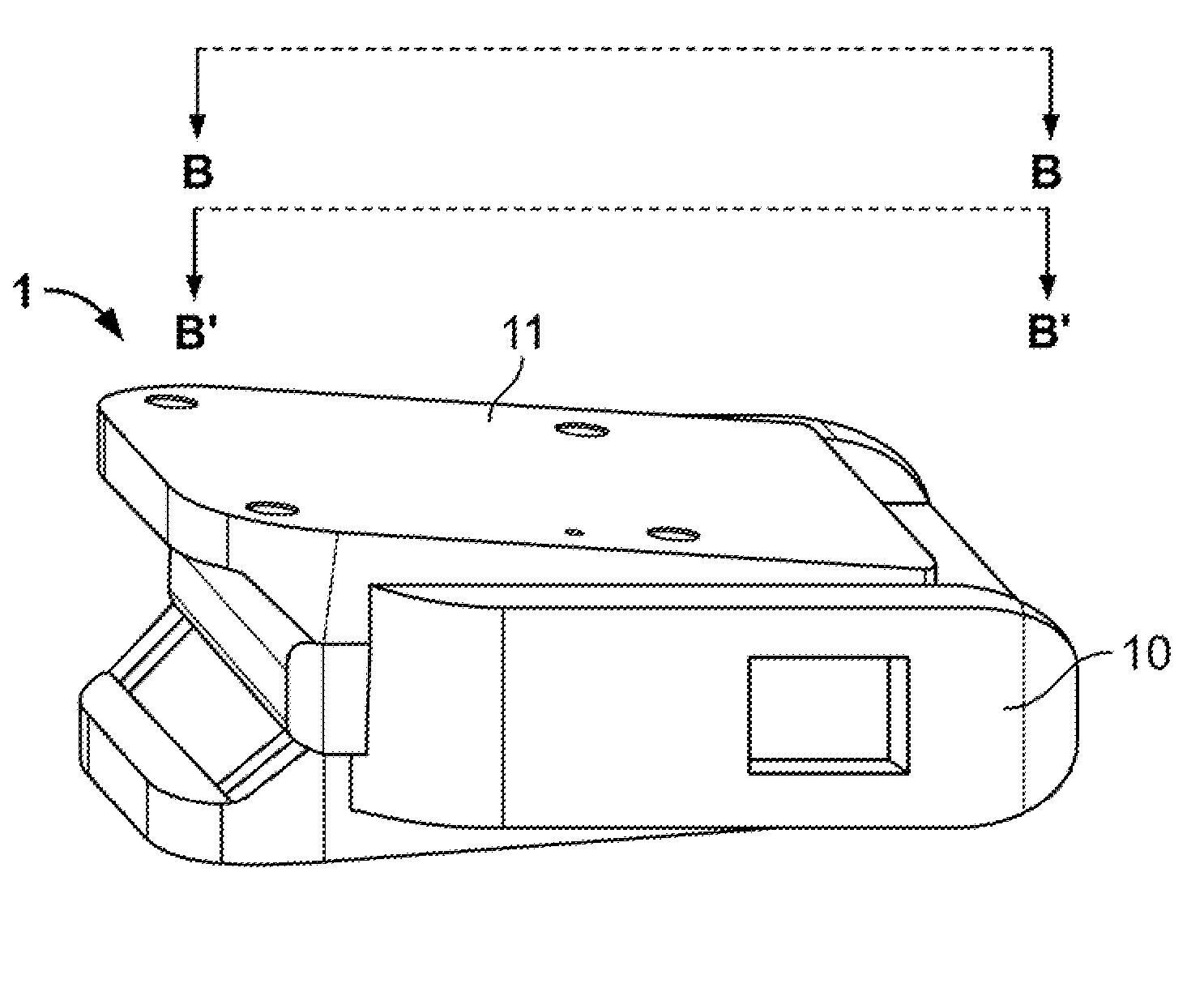

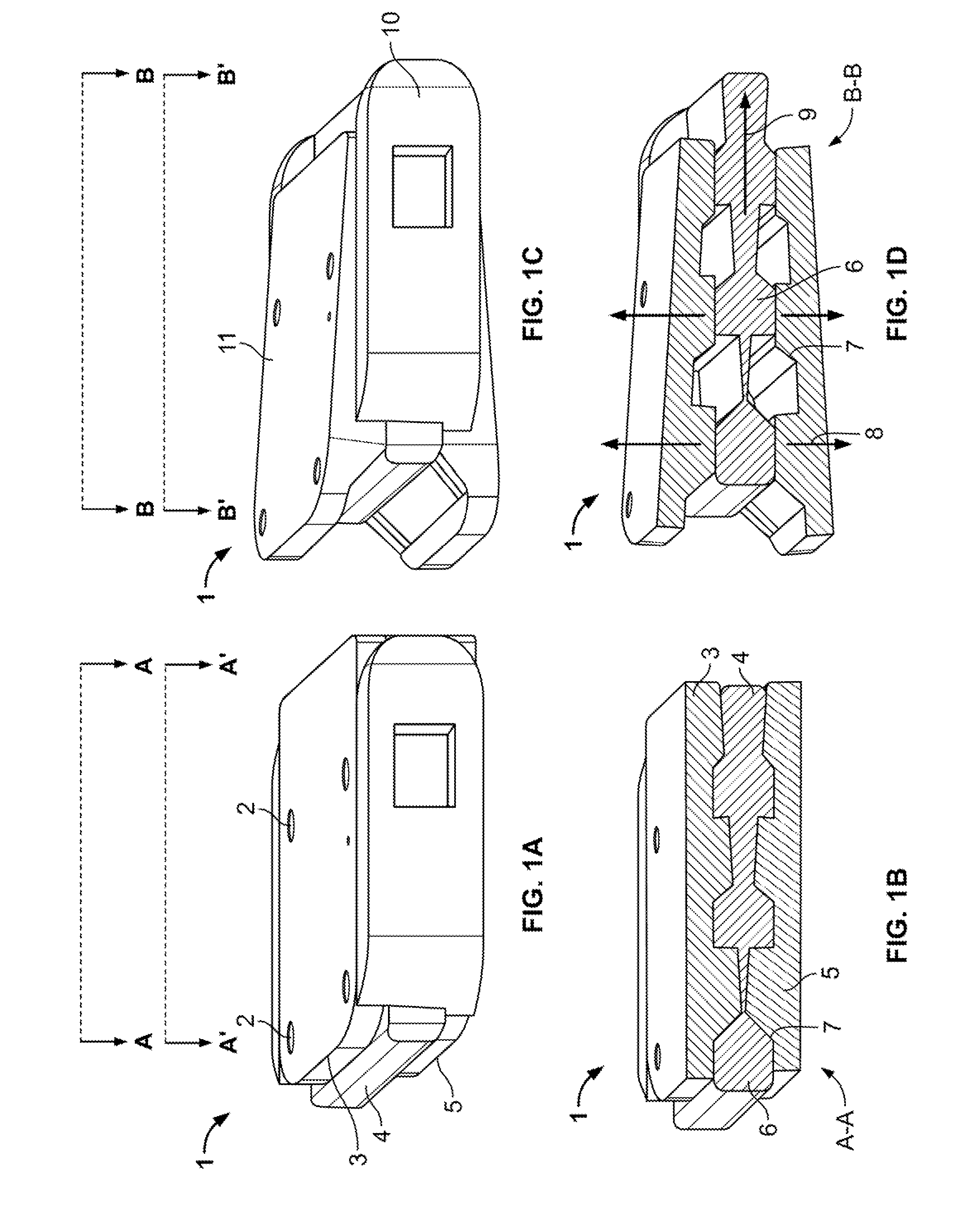

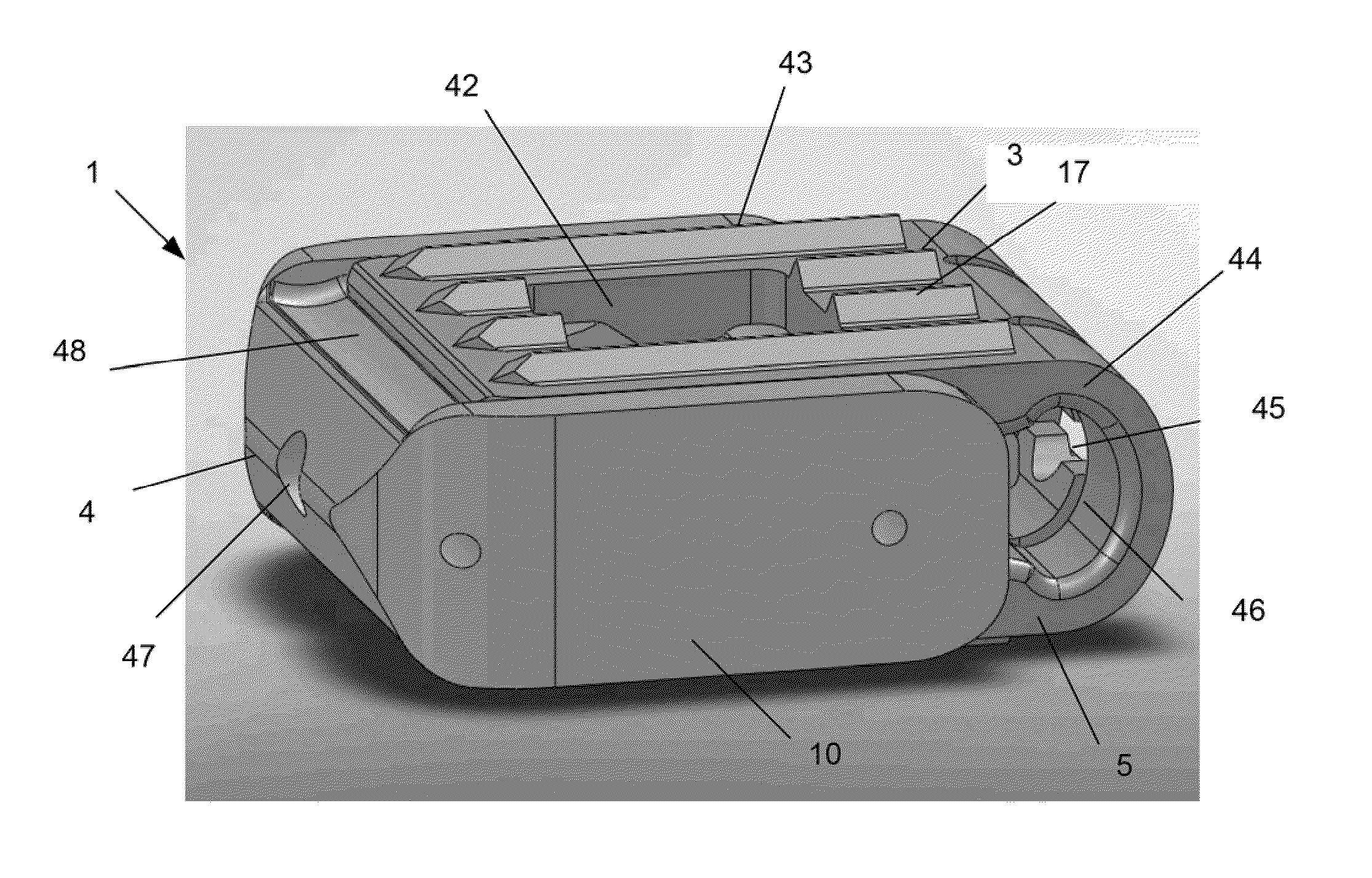

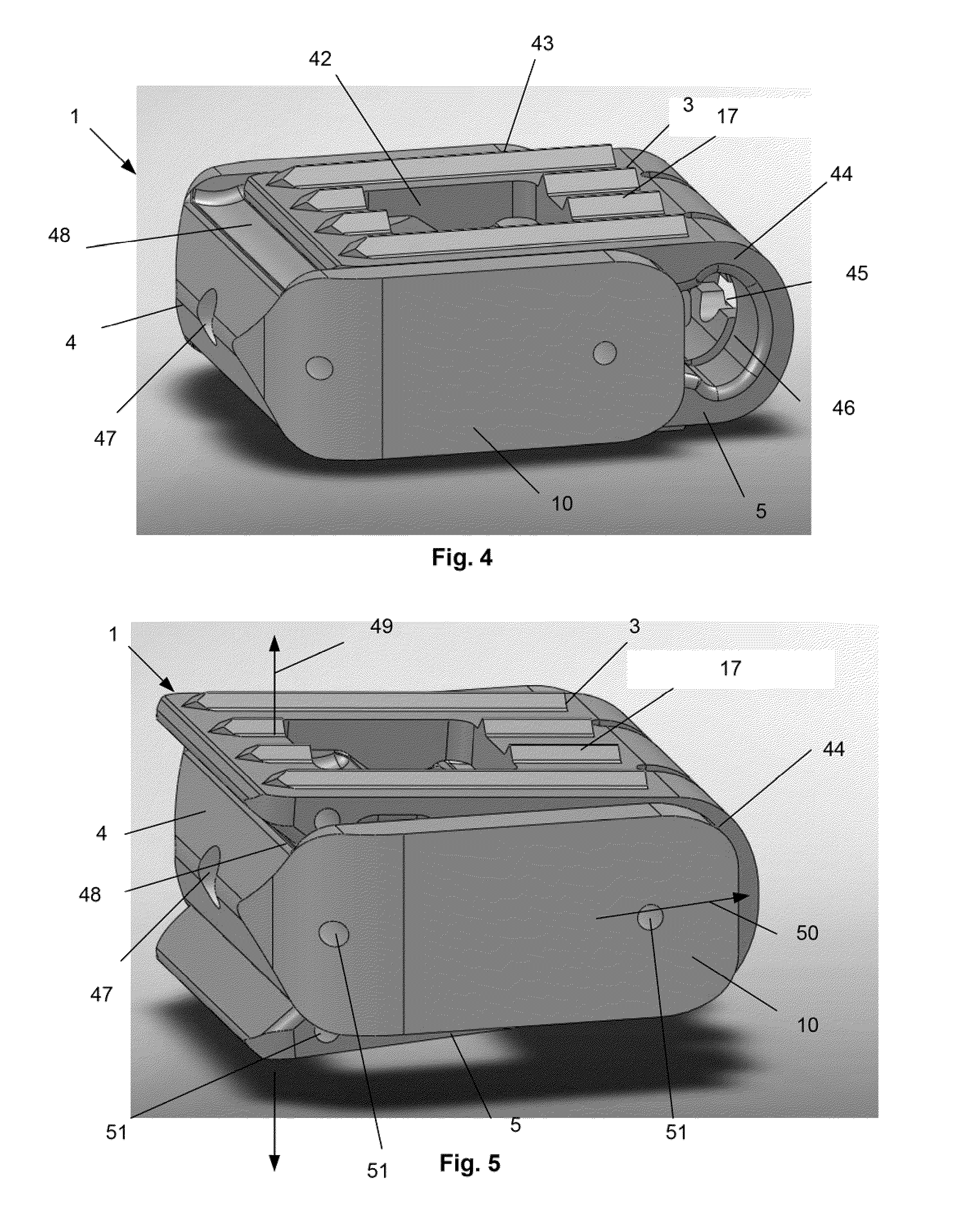

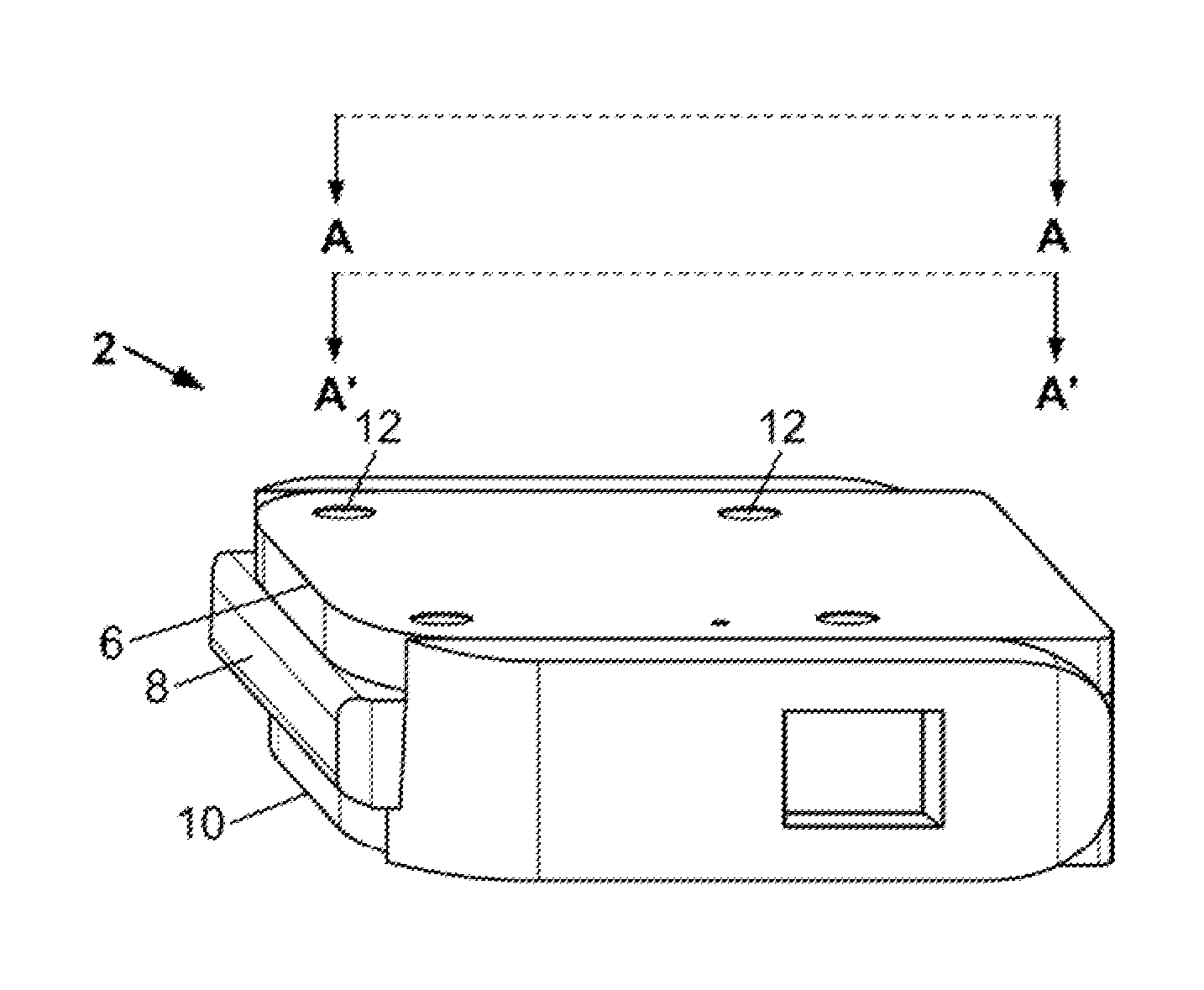

Intervertebral implant

InactiveUS7232464B2The way is simple and fastGreater danger to the surrounding structuresJoint implantsSpinal implantsBiomedical engineeringVertebra

The intervertebral implant is in the form of a three-dimensional structure (10) comprising (a) a top side (1) and an underside (2) which are designed to rest against the end plates of two adjacent vertebras, (b) a left side face (3) and a right side face (4), (c) a front face (5) and a rear face (6), (d) a horizontal center plane situated between the top side (1) and the underside (2), (e) a vertical center plane (8) situated between the left side face (3) and the right side face (8) and (f) a plurality of boreholes (9) passing through the implant structure (10) that are designed to receive longitudinal affixation elements (20), the axes (19) of said elements intersecting the horizontal center plane (7). At least one of the boreholes (9) is designed in a manner that the affixation element (10) received in it can be rigidly connected to the intervertebral implant. Said connection is implemented using a thread or by matching conical surfaces.

Owner:DEPUY SYNTHES PROD INC

Fixation device and method

InactiveUS20110282453A1Less invasiveEasy to anchorSpinal implantsOsteosynthesis devicesPlastic surgeryBiomedical engineering

An implantable orthopedic stability device is disclosed. The device can have a contracted and an expanded configuration. A method of using the device between adjacent vertebral body surfaces surfaces for support and / or fixation of either or both of the adjacent vertebrae is also disclosed.

Owner:STOUT MEDICAL GROUP

Biodegradable fixation element

InactiveUS6863671B1Stable and durable anchoringFast bone growthSuture equipmentsJoint implantsMedicineMaterial Perforation

A biodegradable fixation element is provided for anchoring a transplant on bone. A rigid body is made of a biodegradable material, said body having an outer side and a hollow interior surrounded by a wall of said body. Numerous perforations are provided in said wall of said body for allowing growth of bone material into said interior of said body via said numerous perforations. It is proposed that the perforations are formed between said anchoring members and said perforations are formed as holes passing through said wall of said body (FIG. 1).

Owner:KARL STORZ GMBH & CO KG

Fixation device and method

InactiveUS20100204795A1Less invasiveEasy to anchorInternal osteosythesisSpinal implantsPlastic surgeryBiomedical engineering

An implantable orthopedic stability device is disclosed. The device can have a contracted and an expanded configuration. A method of using the device between adjacent facet surfaces for support and / or fixation of either or both of the adjacent vertebrae is also disclosed.

Owner:STOUT MEDICAL GROUP

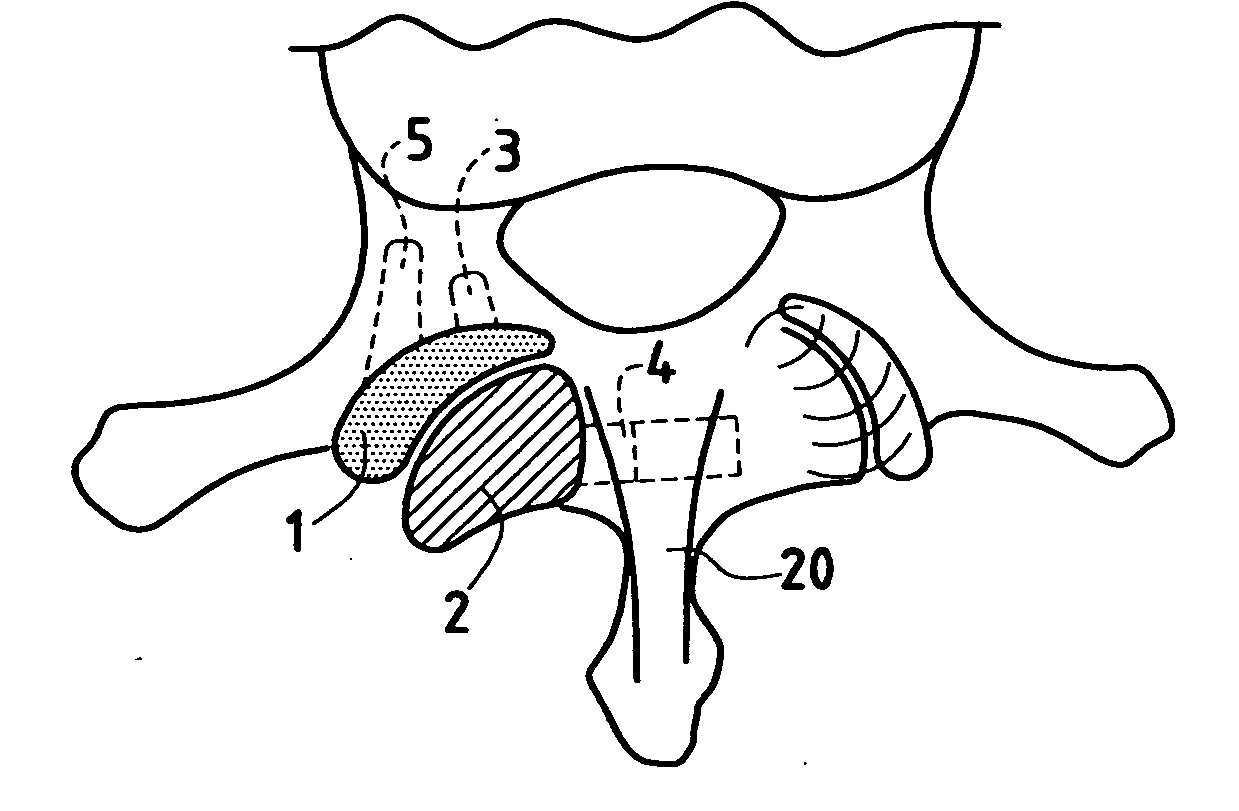

Posterior vertebral joint prosthesis

InactiveUS20050015146A1Easy to slideConserve high degree of mobilityJoint implantsSpinal implantsProsthesisVertebral Joint

The present invention relates to a posterior vertebral joint prosthesis. The left or right posterior vertebral joint prosthesis of the invention presents a smooth bearing surface and said surface presents antero-posterior curvature.

Owner:LOUIS CHRISTIAN +1

Fixation device and method

InactiveUS20100191336A1Less invasiveEasy to anchorSpinal implantsCoatingsPlastic surgeryBiomedical engineering

Owner:STOUT MEDICAL GROUP

Fixation device and method

ActiveUS20100222884A1Less invasiveEasy to anchorInternal osteosythesisSpinal implantsPlastic surgeryBiomedical engineering

An implantable orthopedic stability device is disclosed. The device can have a contracted and an expanded configuration. A method of using the device between adjacent facet surfaces for support and / or fixation of either or both of the adjacent vertebrae is also disclosed.

Owner:STOUT MEDICAL GROUP

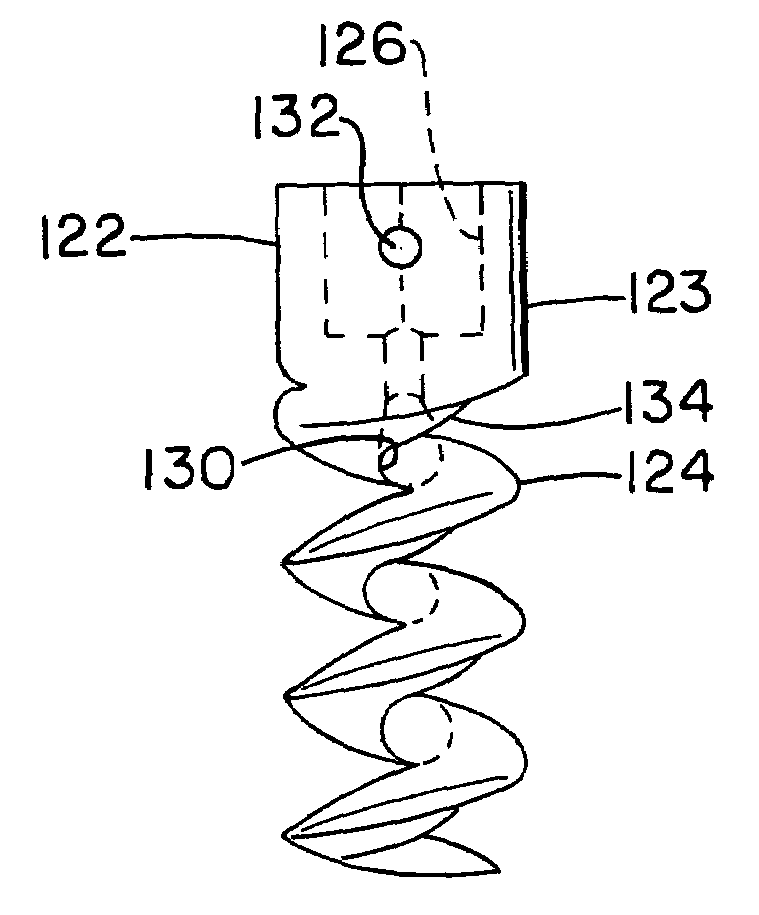

Open helical organic tissue anchor having recessible head and method of making the organic tissue anchor

InactiveUS7189251B2Easy to anchorStrengthens helixSuture equipmentsPinsSelf reinforcedLigament structure

The invention relates to a tissue anchor which is an open helix of biocompatible material having a slope of from 0.5 to 10 turns per centimeter, a length from 3 to 75 millimeters, a diameter of from 1.5 to 11 millimeters, and an aspect ratio of from about 3 to about 5 to 1. The anchor can have a head which is capable of securing or clamping tissue together, such as holding a suture to secure a ligament or tendon to bone. The anchor can also have a head which causes an inward, compressive loading for use in fastening bone to bone, orthopedic plates to bone, or cartilage to bone. The head may be an integral member and may include a self-reinforcing wedge which joins the helix to the head. Further, the elongate member, or filament that forms the helix may have a tapering diameter along its length.

Owner:ORTHOHELIX SURGICAL DESIGNS

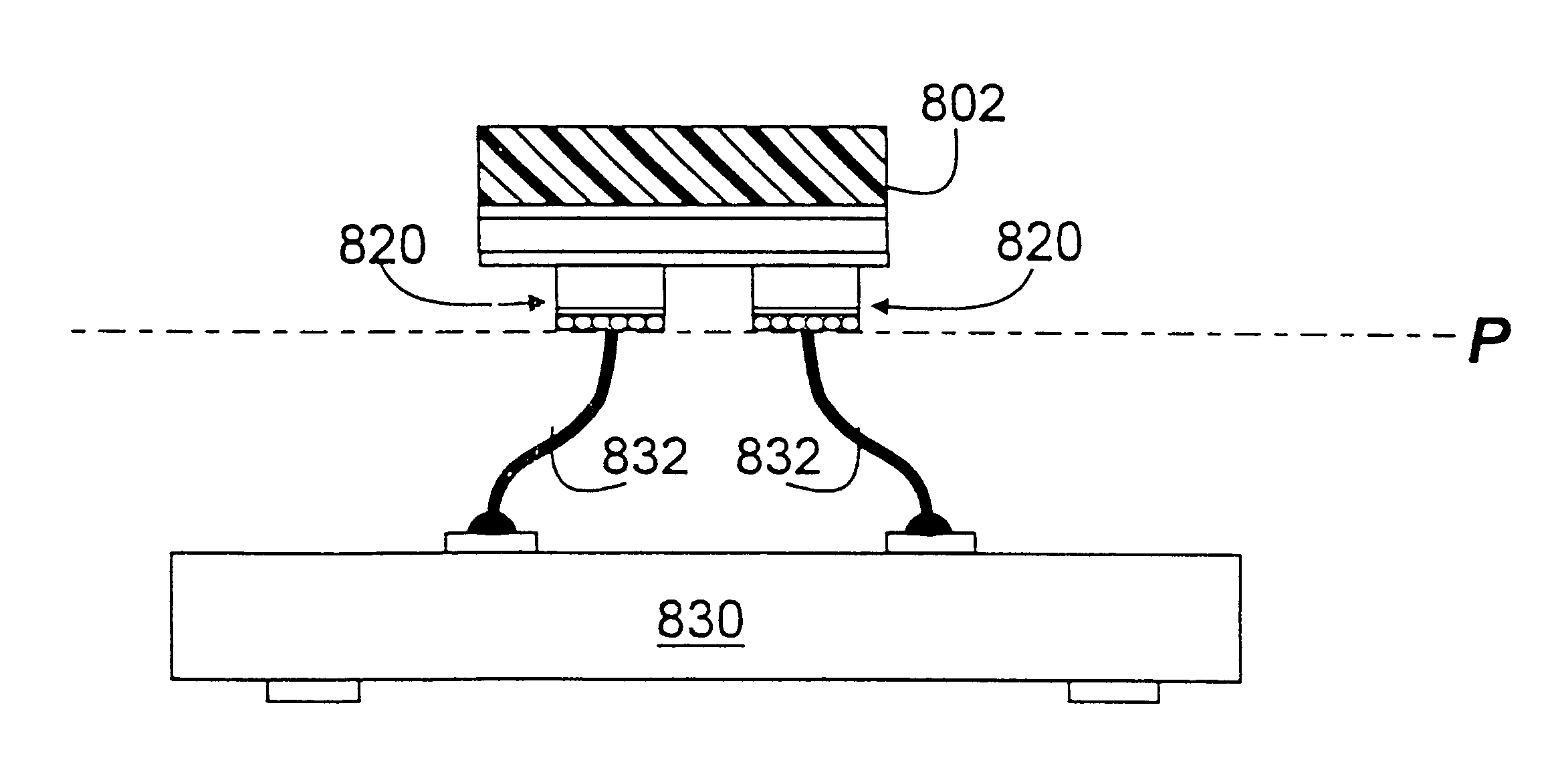

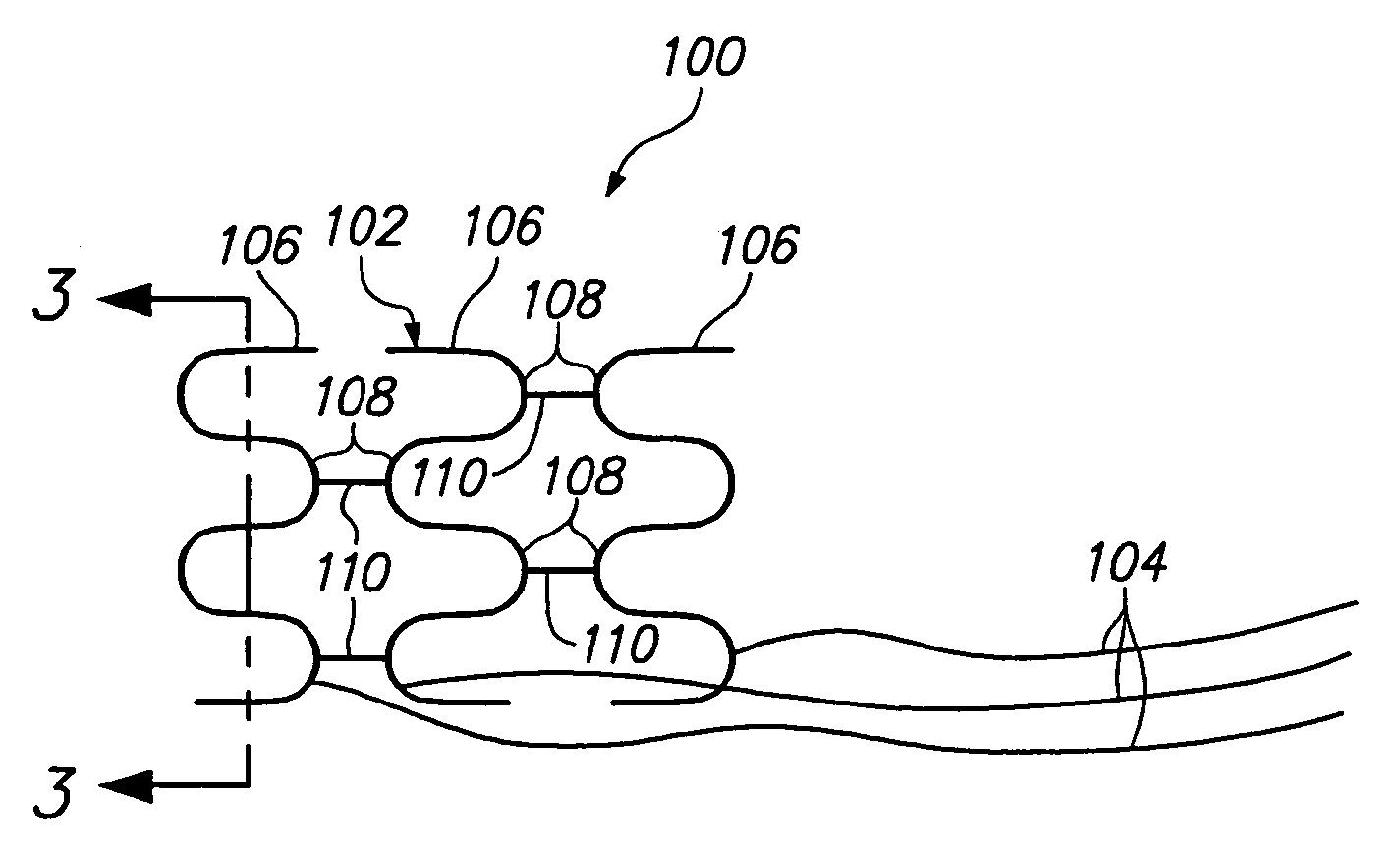

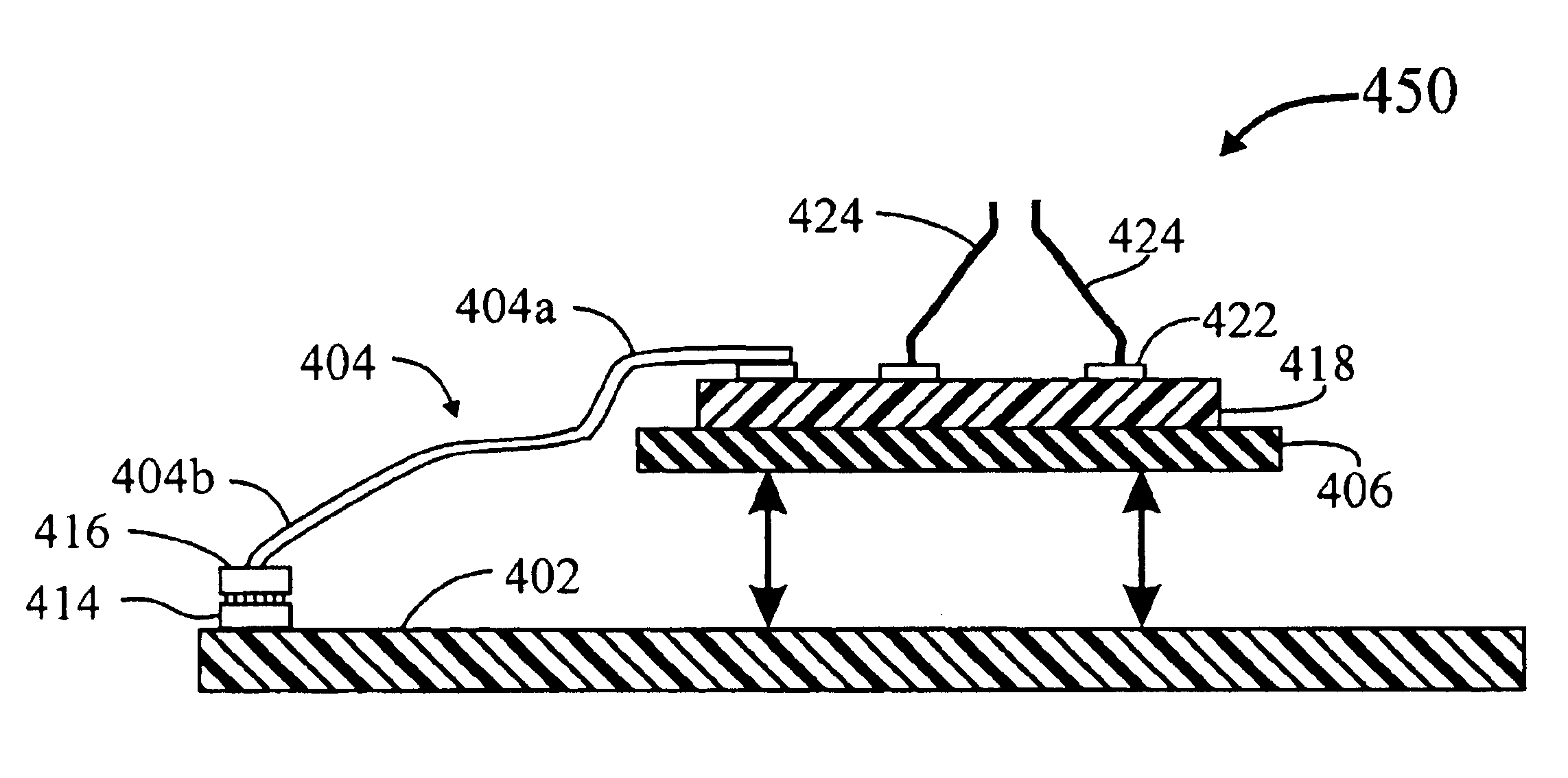

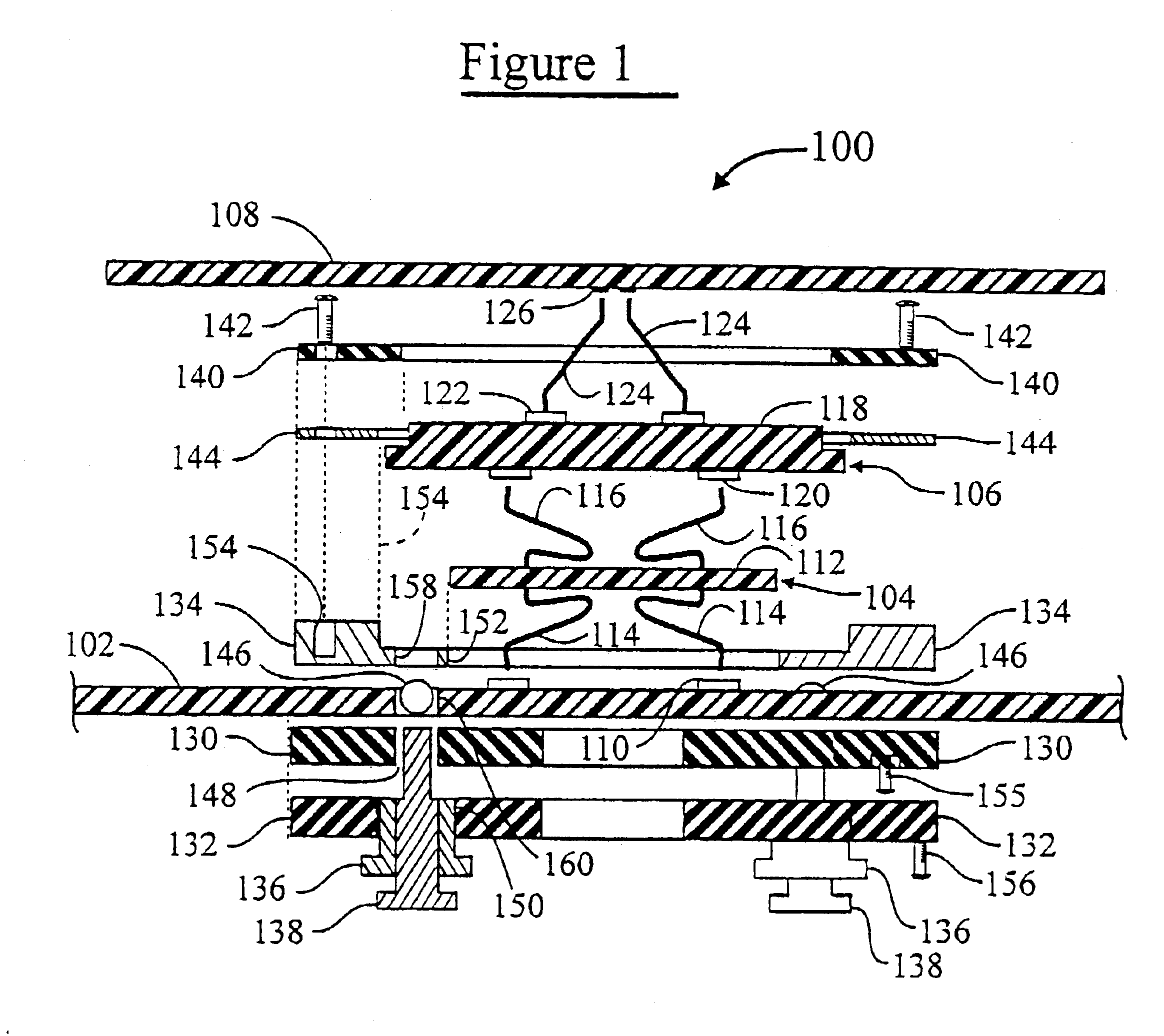

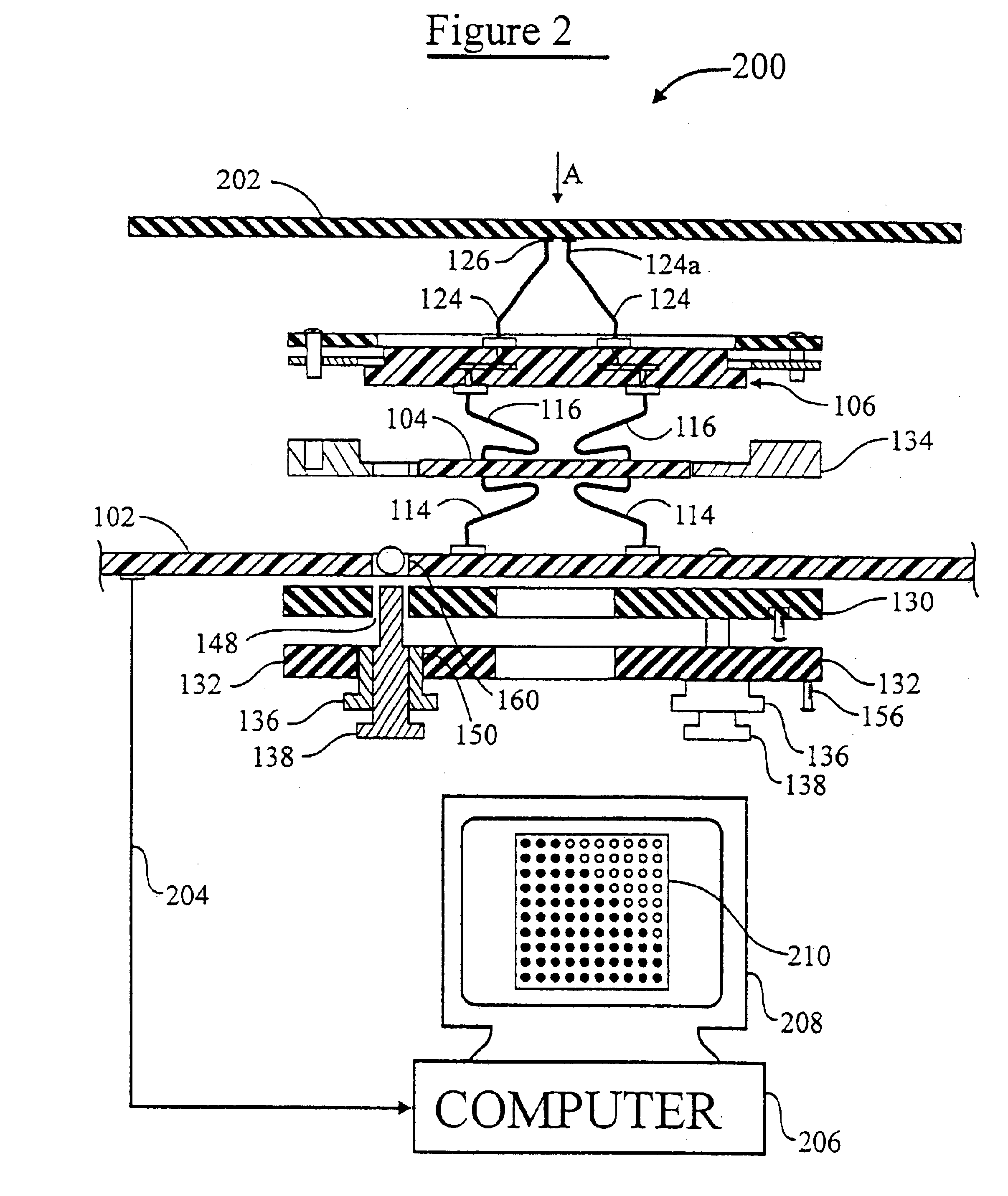

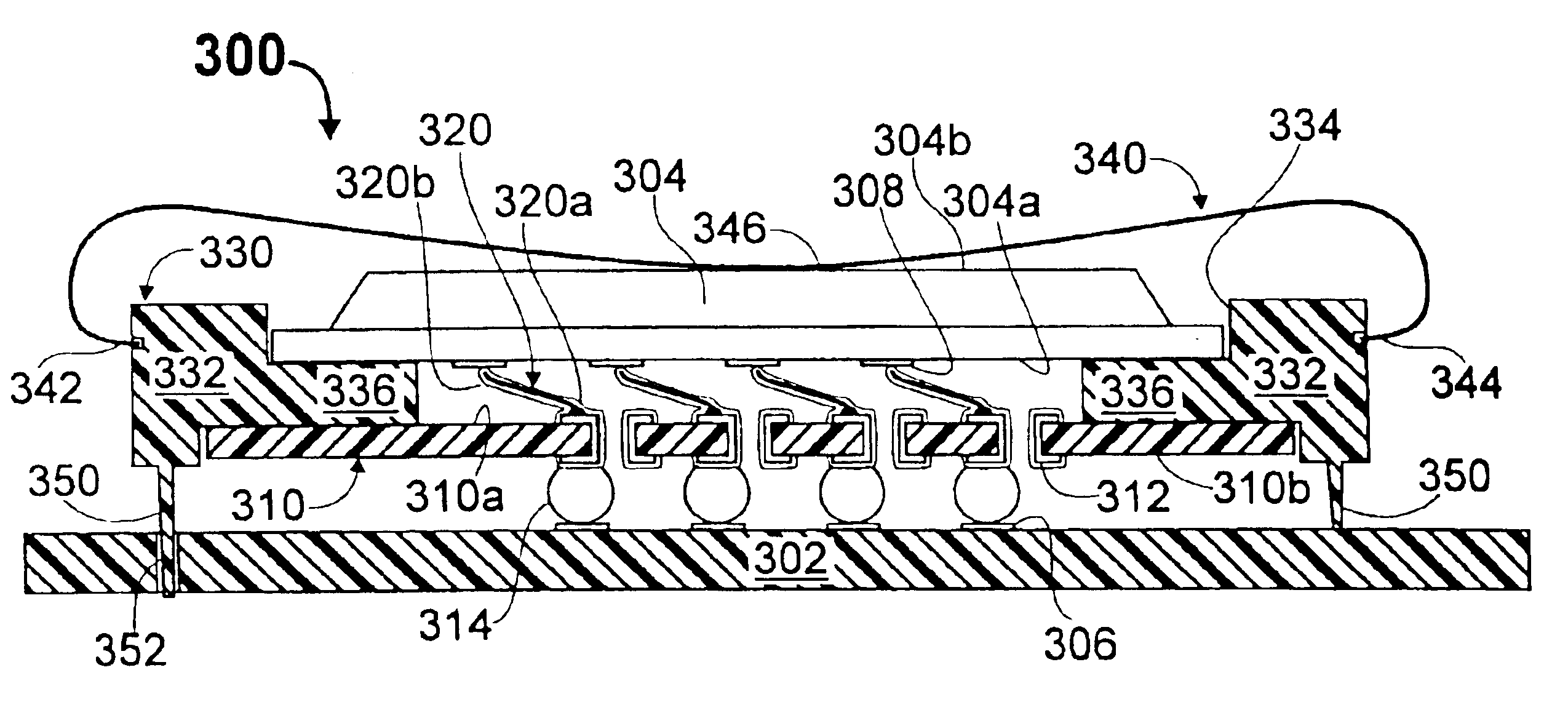

Probe card assembly and kit, and methods of using same

InactiveUS6246247B1Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureElectricityProbe card

A probe card assembly includes a probe card, a space transformer having resilient contact structures (probe elements) mounted directly thereto (i.e., without the need for additional connecting wires or the like) and extending from terminals on a surface thereof, and an interposer disposed between the space transformer and the probe card. The space transformer and interposer are "stacked up" so that the orientation of the space transformer, hence the orientation of the tips of the probe elements, can be adjusted without changing the orientation of the probe card. Suitable mechanisms for adjusting the orientation of the space transformer, and for determining what adjustments to make, are disclosed. The interposer has resilient contact structures extending from both the top and bottom surfaces thereof, and ensures that electrical connections are maintained between the space transformer and the probe card throughout the space transformer's range of adjustment, by virtue of the interposer's inherent compliance. Multiple die sites on a semiconductor wafer are readily probed using the disclosed techniques, and the probe elements can be arranged to optimize probing of an entire wafer. Composite interconnection elements having a relatively soft core overcoated by a relatively hard shell, as the resilient contact structures are described.

Owner:FORMFACTOR INC

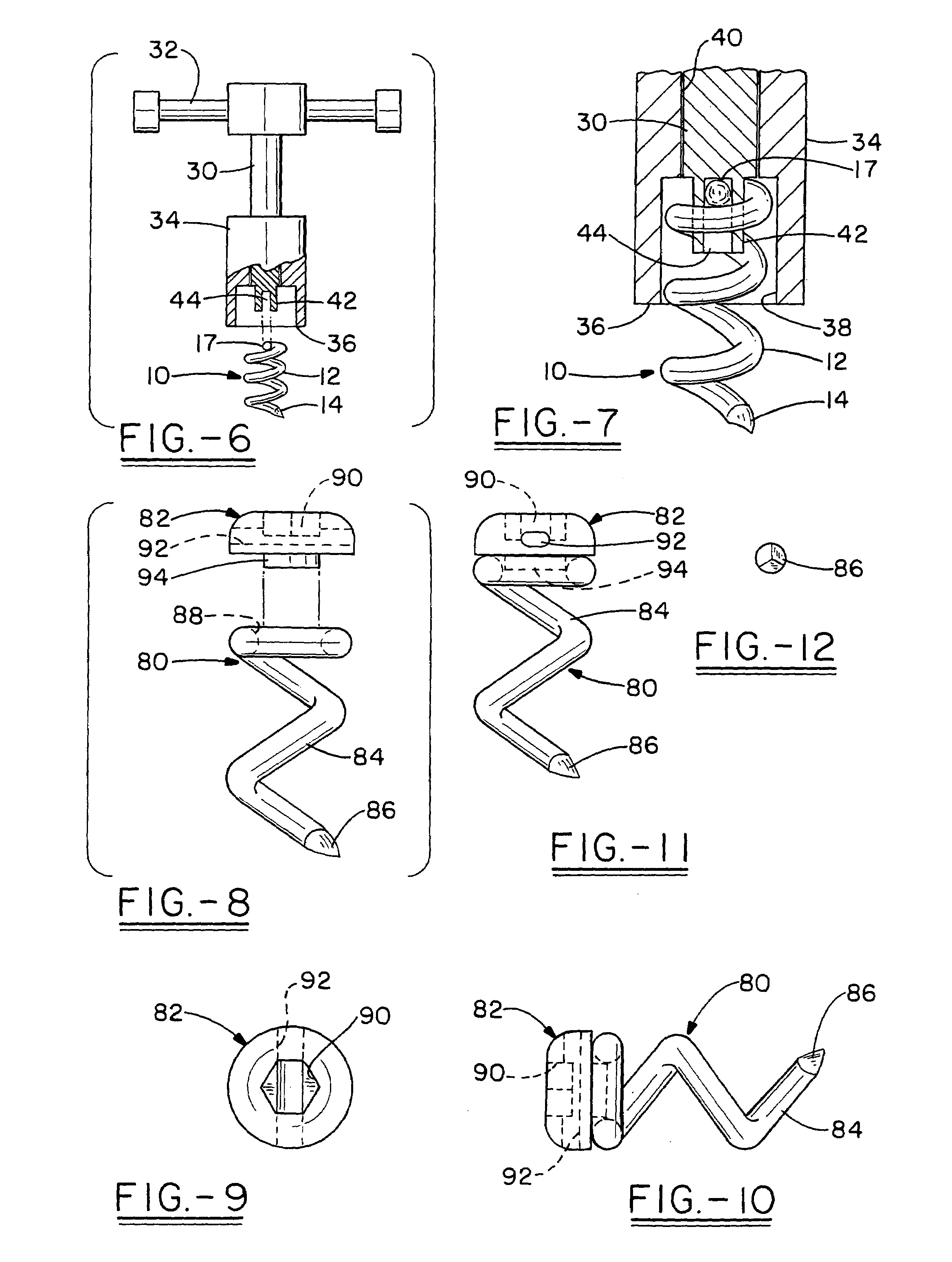

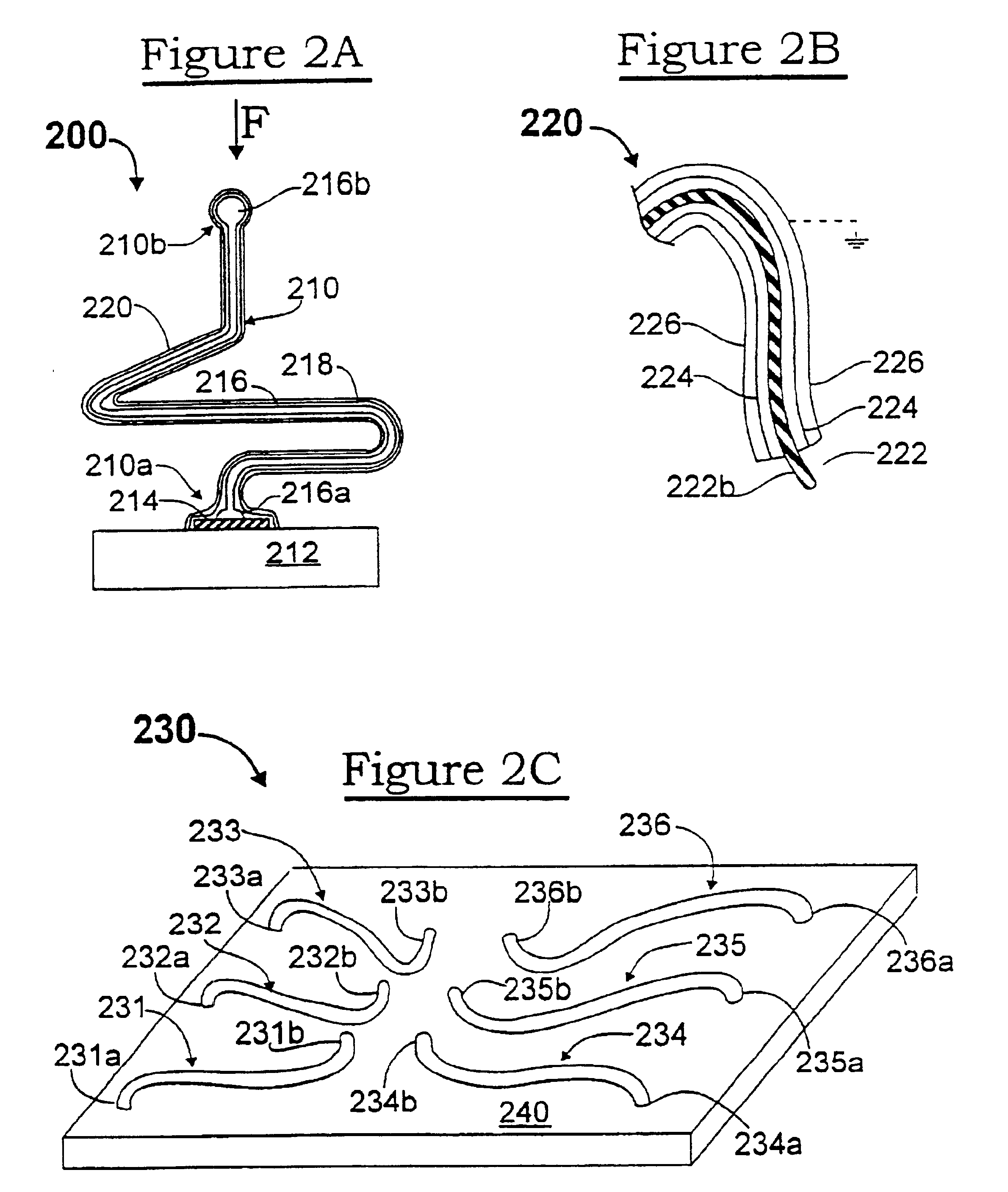

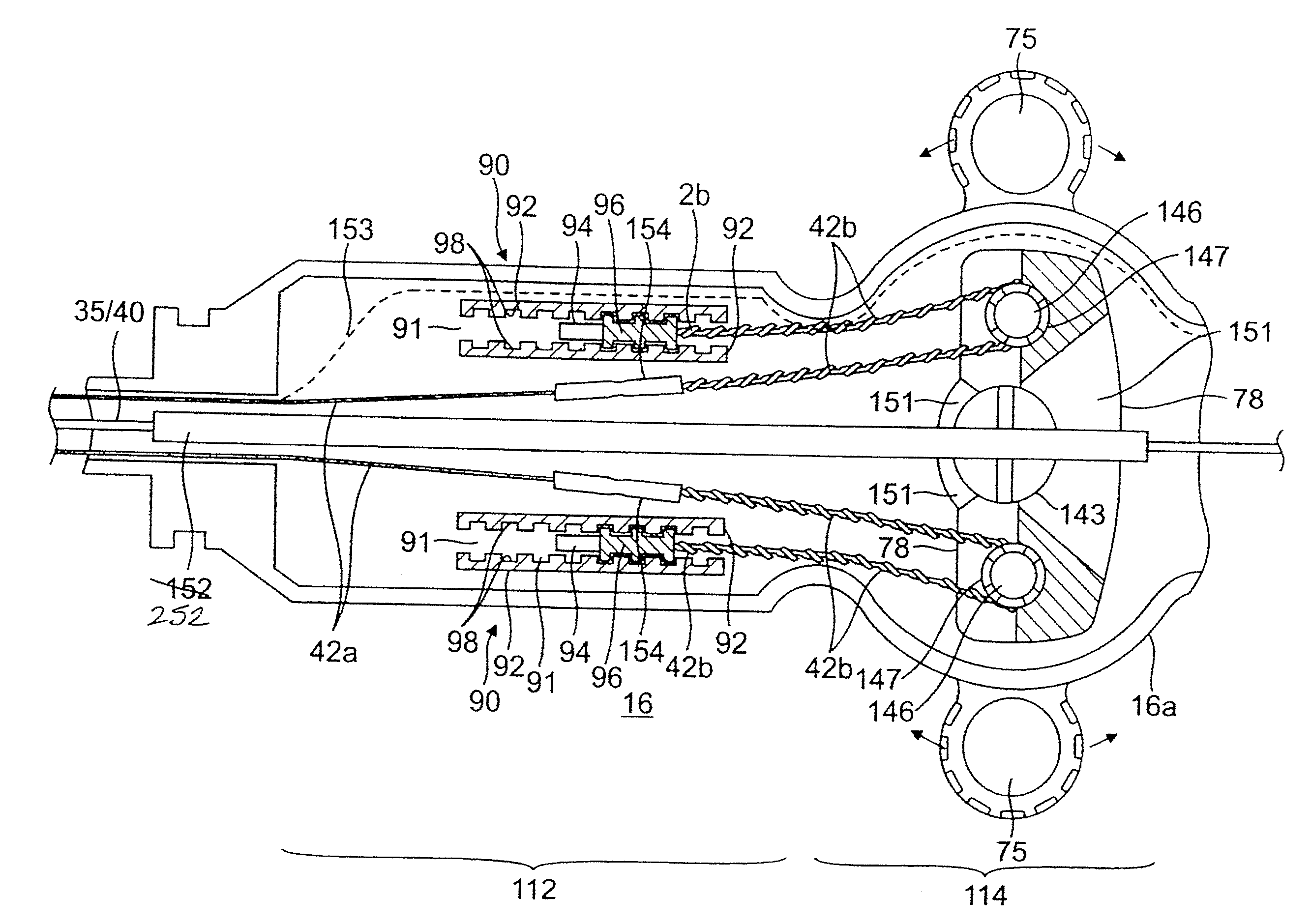

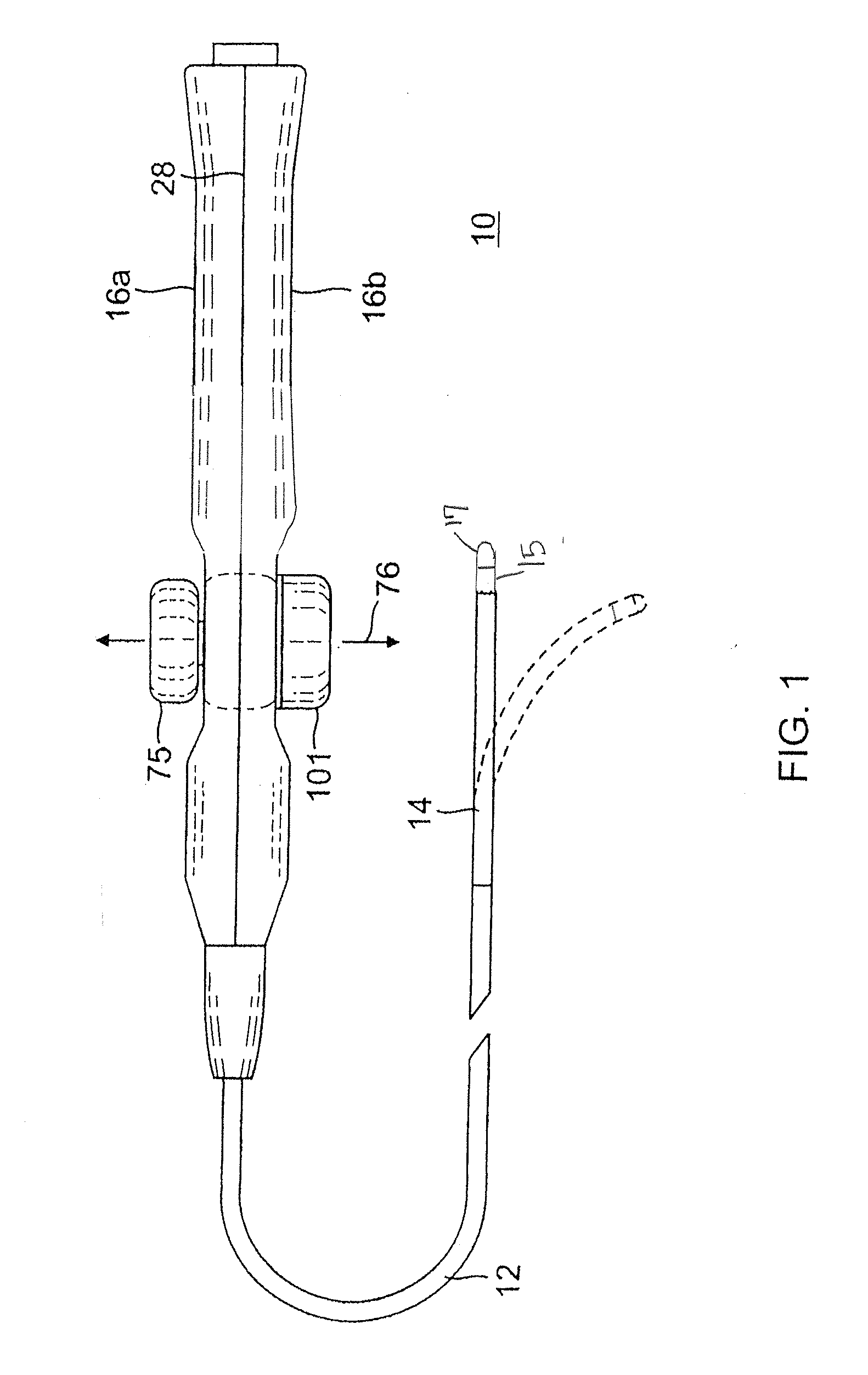

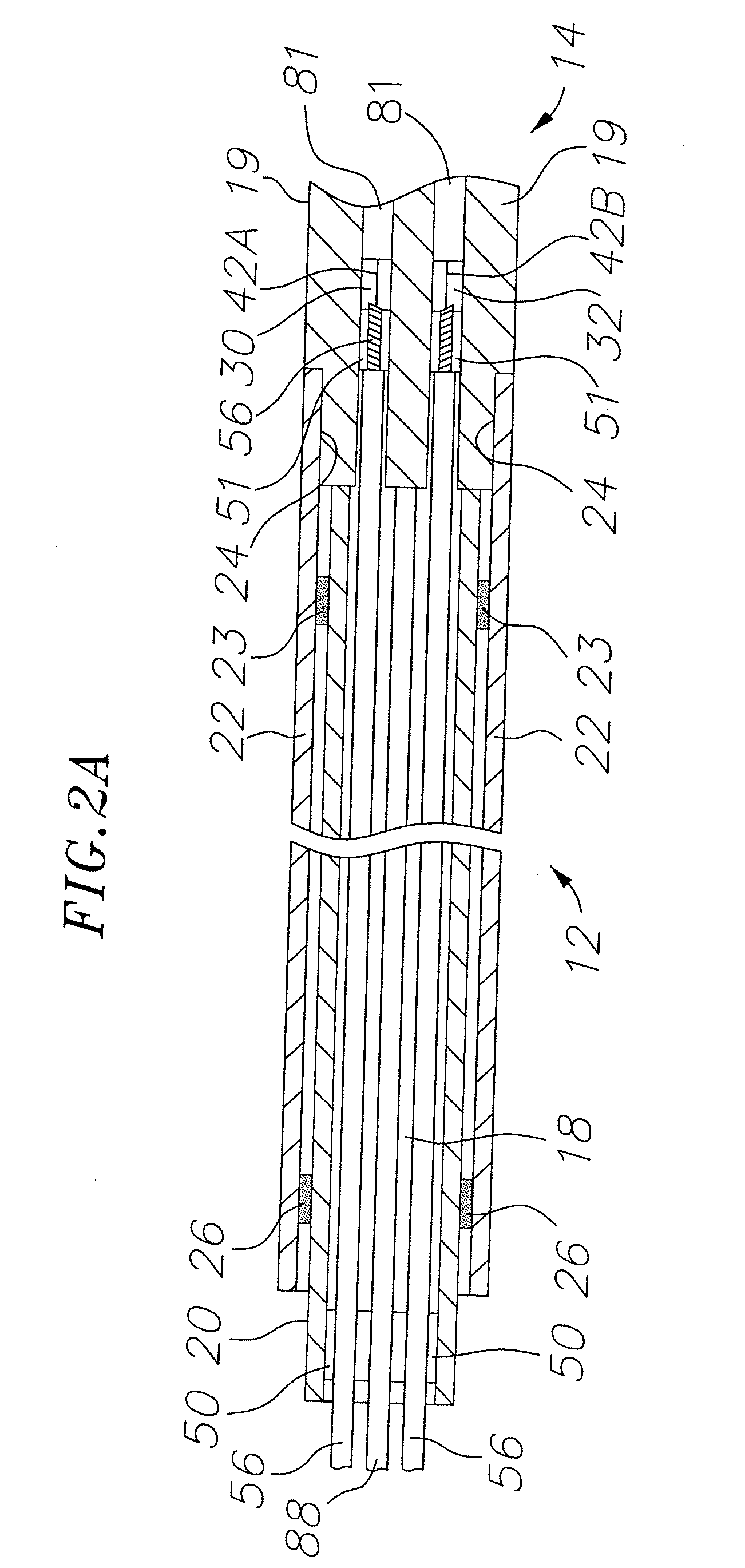

Intravascular self-anchoring electrode body with arcuate springs, spring loops, or arms

InactiveUS7231260B2Efficient receptionGuaranteed normal transmissionStentsTransvascular endocardial electrodesMedicineMedical device

An expandable intravascular medical device comprises an arcuate spring configured to be expanded into contact with the inner surface of a blood vessel. Another medical device comprises an electrode support structure, e.g., a non-tubular arcuate structure or a cylindrical member, and a plurality of resilient spring loops laterally extending from the support structure. The contact created between the loops and a blood vessel is sufficient to anchor the medical device within the blood vessel. In another embodiment, the medical device comprises an elongated member and two resilient spring arms extending distally from the elongated member. The arms are configured to be laterally moved towards each other to place the medical device in a collapsed geometry, and configured to be laterally moved away from each into contact with an inner surface of a blood vessel to place the medical device an expanded geometry.

Owner:BOSTON SCI SCIMED INC

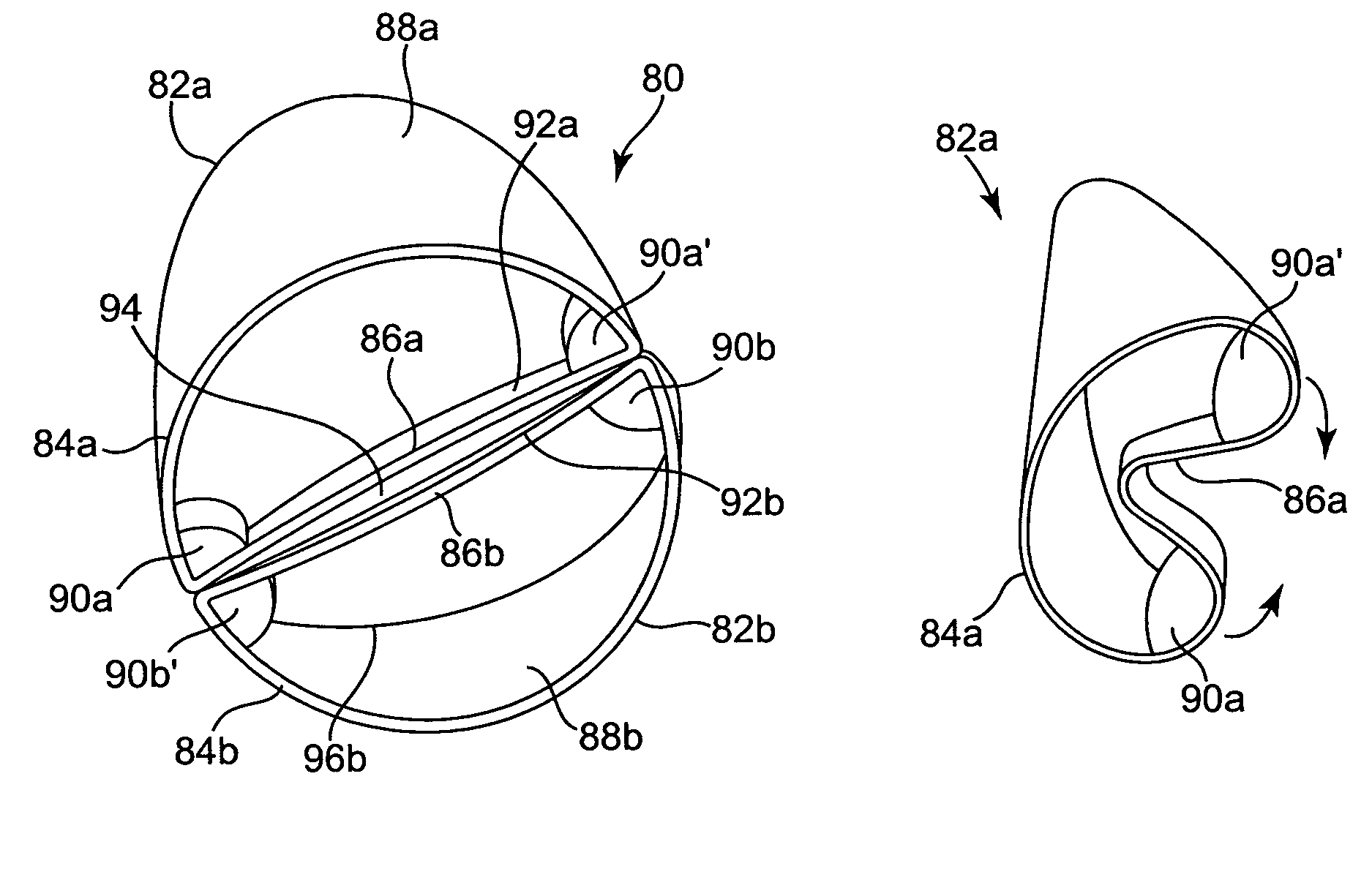

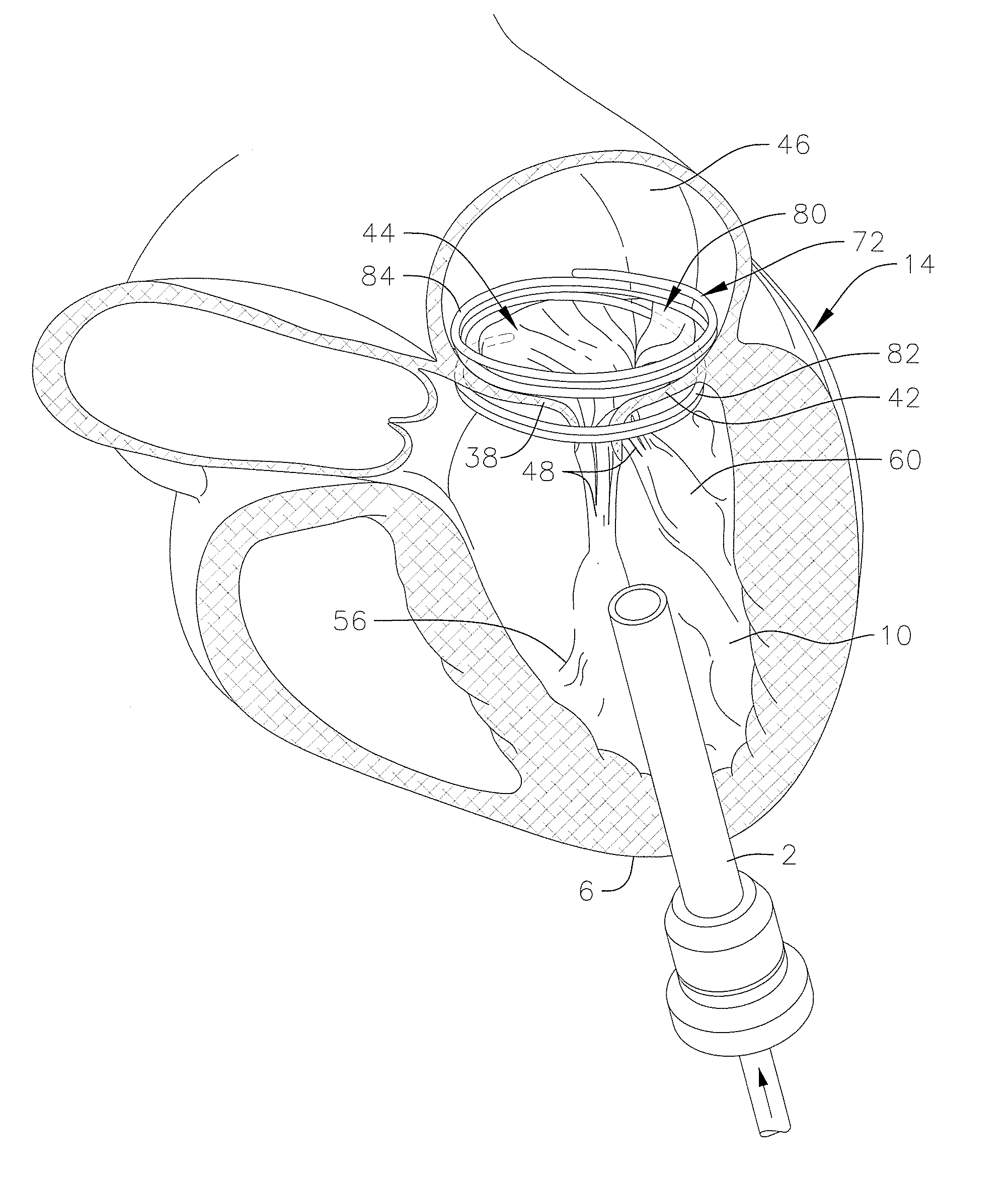

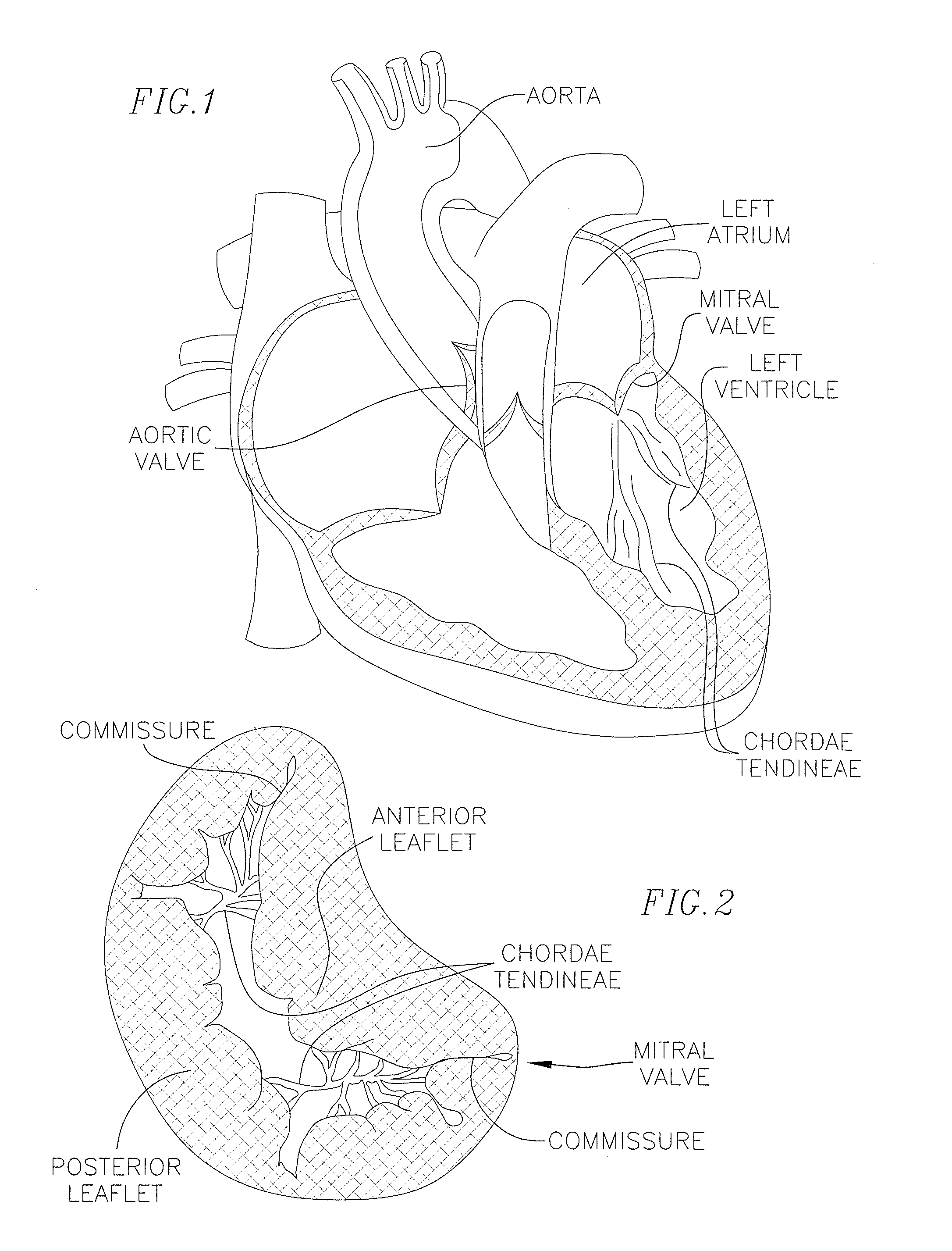

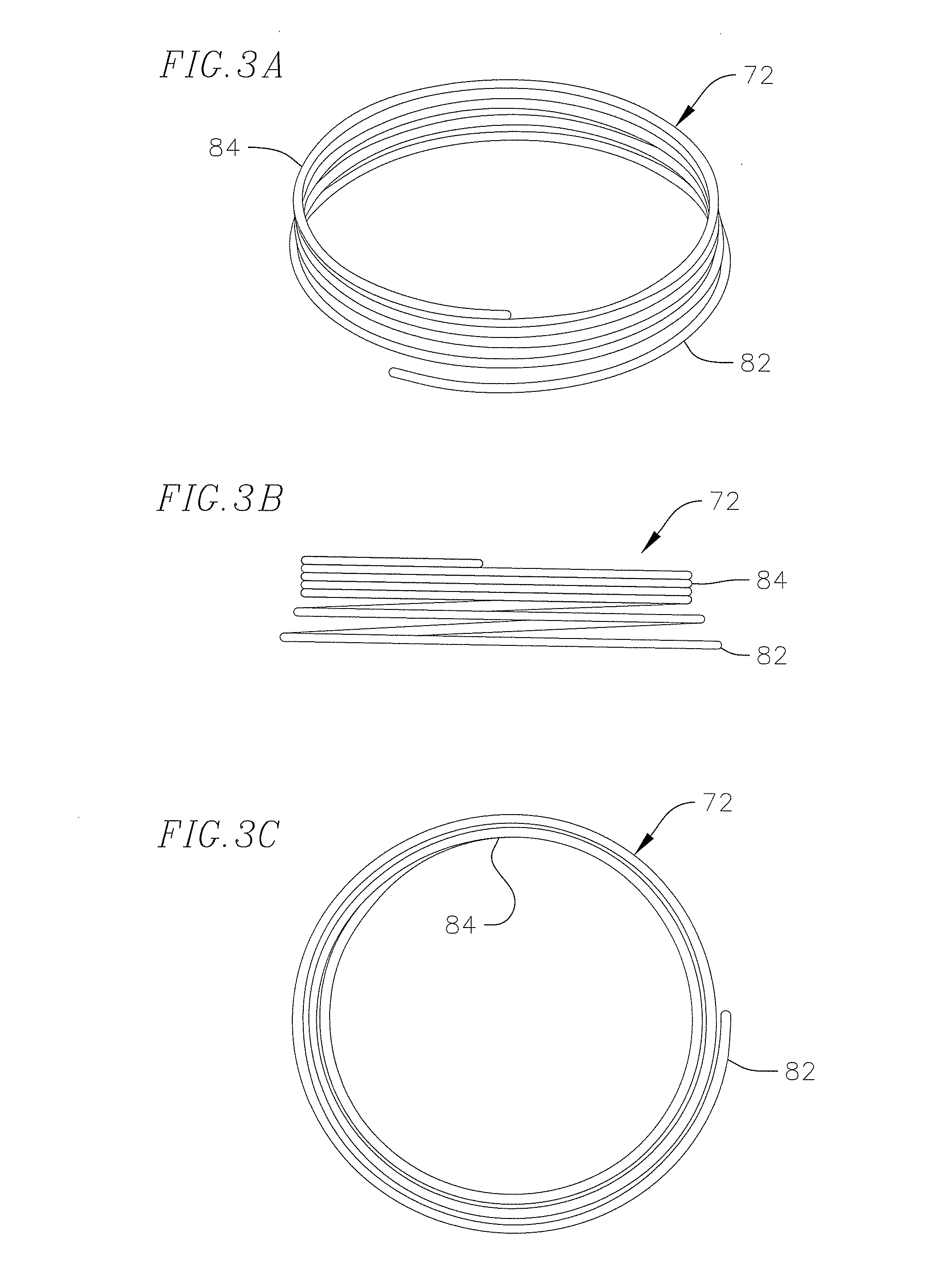

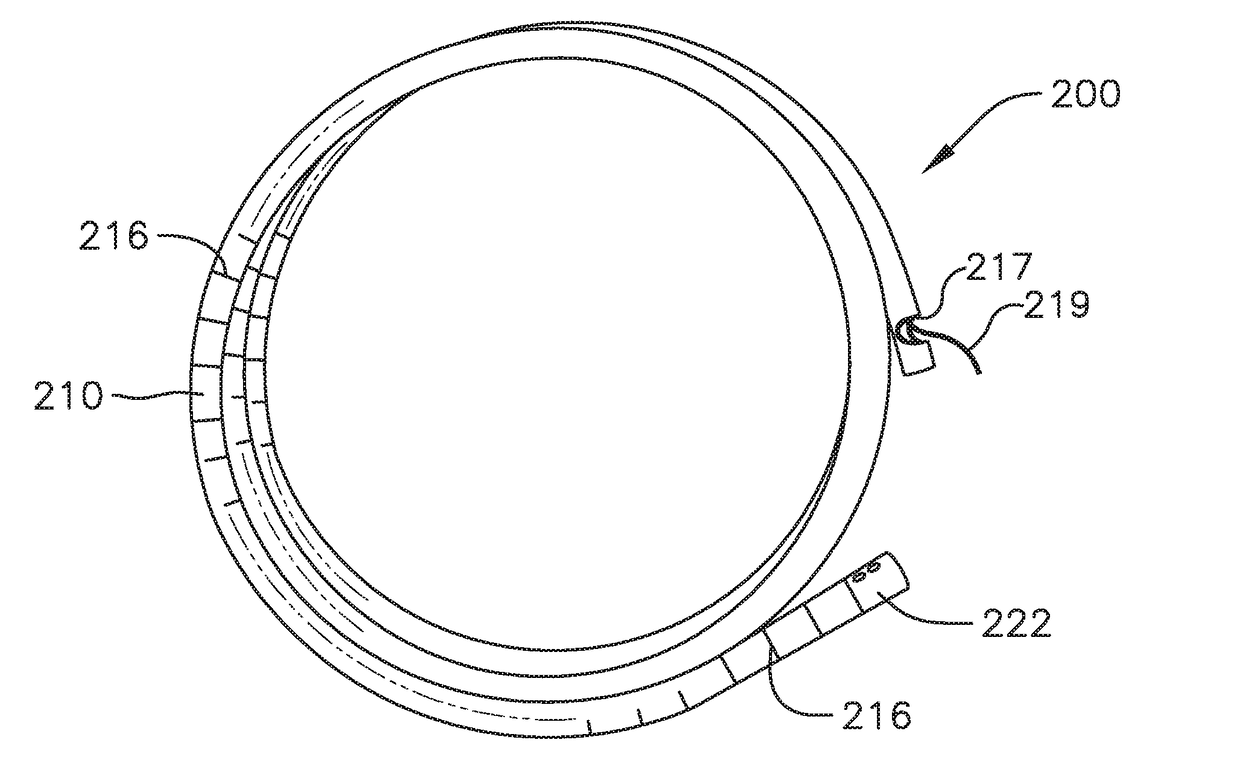

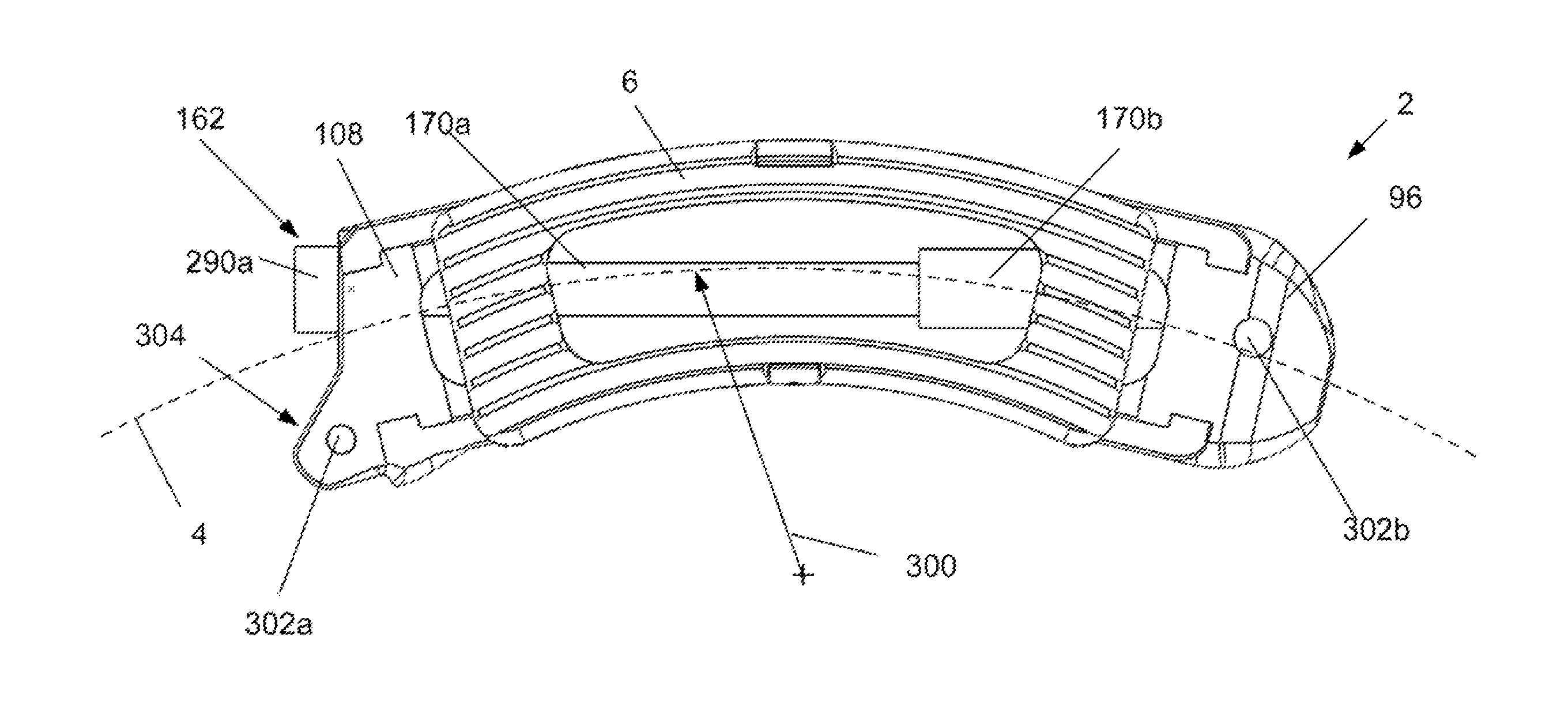

Coiled anchor for supporting prosthetic heart valve, prosthetic heart valve, and deployment device

A coiled anchor for docking a mitral valve prosthesis at a native mitral valve of a heart has a first end, a second end, and a central axis extending between the first and second ends, and defines an inner space coaxial with the central axis. The coiled anchor includes a coiled core including a bio-compatible metal or metal alloy and having a plurality of turns extending around the central axis in a first position, and a cover layer around the core, the cover layer including a bio-compatible material that is less rigid than the metal or metal alloy of the coiled core.

Owner:MITRAL VALVE TECHNOLOGIES SARL

Probe card assembly

InactiveUS6838893B2Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureProbe cardTransformer

In a probe card assembly, a series of probe elements can be arrayed on a silicon space transformer. The silicon space transformer can be fabricated with an array of primary contacts in a very tight pitch, comparable to the pitch of a semiconductor device. One preferred primary contact is a resilient spring contact. Conductive elements in the space transformer are routed to second contacts at a more relaxed pitch. In one preferred embodiment, the second contacts are suitable for directly attaching a ribbon cable, which in turn can be connected to provide selective connection to each primary contact. The silicon space transformer is mounted in a fixture that provides for resilient connection to a wafer or device to be tested. This fixture can be adjusted to planarize the primary contacts with the plane of a support probe card board.

Owner:FORMFACTOR INC

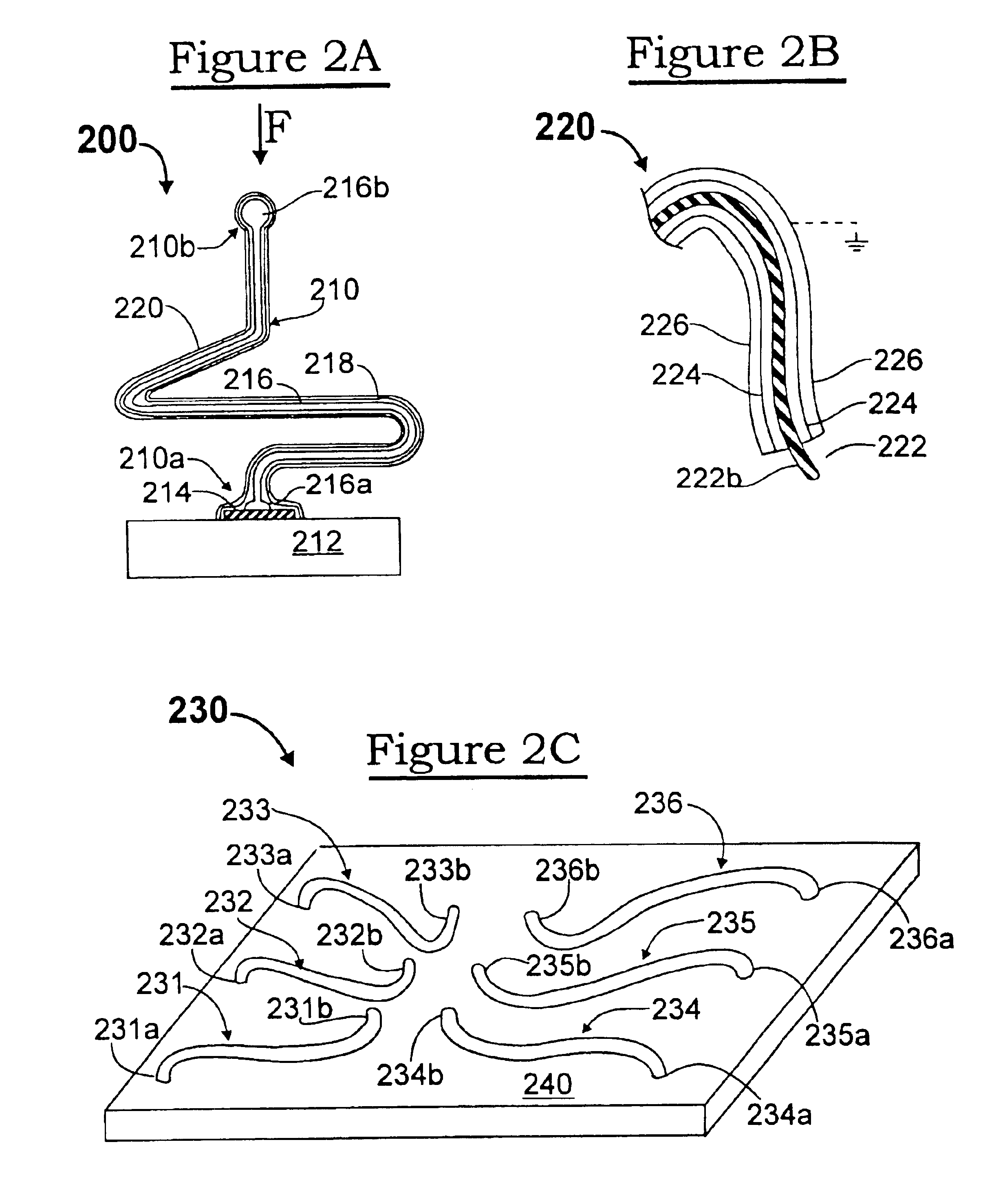

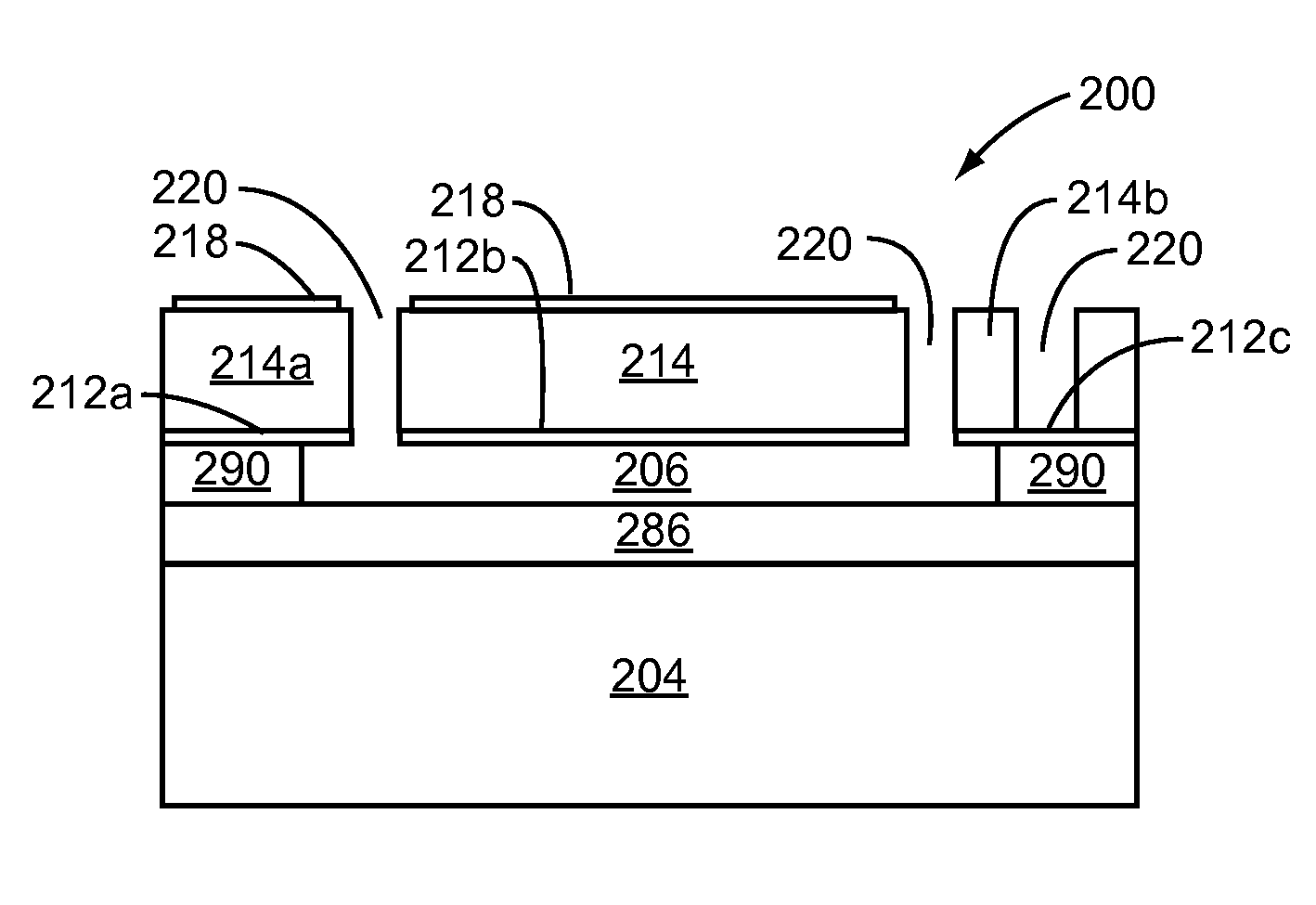

Methods of removably mounting electronic components to a circuit board, and sockets formed by the methods

InactiveUS6913468B2Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureSurface mountingSolder ball

Surface-mount, solder-down sockets are described which permit electronic components such as semiconductor packages to be releasably mounted to a circuit board. Generally, the socket includes resilient contact structures extending from a top surface of a support substrate, and solder-ball (or other suitable) contact structures disposed on a bottom surface of the support substrate. Composite interconnection elements are described for use as the resilient contact structures disposed atop the support substrate. In use, the support substrate is soldered down onto the circuit board, the contact structures on the bottom surface of the support substrate contacting corresponding contact areas on the circuit board. In any suitable manner, selected ones of the resilient contact structures atop the support substrate are connected, via the support substrate, to corresponding ones of the contact structures on the bottom surface of the support substrate.

Owner:FORMFACTOR INC

Methods and apparatus for blocking flow through blood vessels

Methods and apparatus for occluding blood flow within a blood vessel. In a first series of embodiments, the present invention comprises a plurality of embolic devices deployable through the lumen of a conventional catheter such that when deployed, said embolic devices remain resident and occlude blood flow at a specific site within the lumen of the blood vessel. Such embolic devices comprise either mechanical embolic devices that become embedded within or compress against the lumen of the vessel or chemical vaso-occlusive agents that seal off blood flow at a given site. A second embodiment of the present invention comprises utilization of a vacuum / cauterizing device capable of sucking in the lumen of the vessel about the device to maintain the vessel in a closed condition where there is then applied a sufficient amount of energy to cause the tissue collapsed about the device to denature into a closure. In a third series of embodiments, the present invention comprises the combination of an embolization facilitator coupled with the application of an energy force to form an intraluminal closure at a specified site within a vessel.

Owner:CORE FITNESS SYST

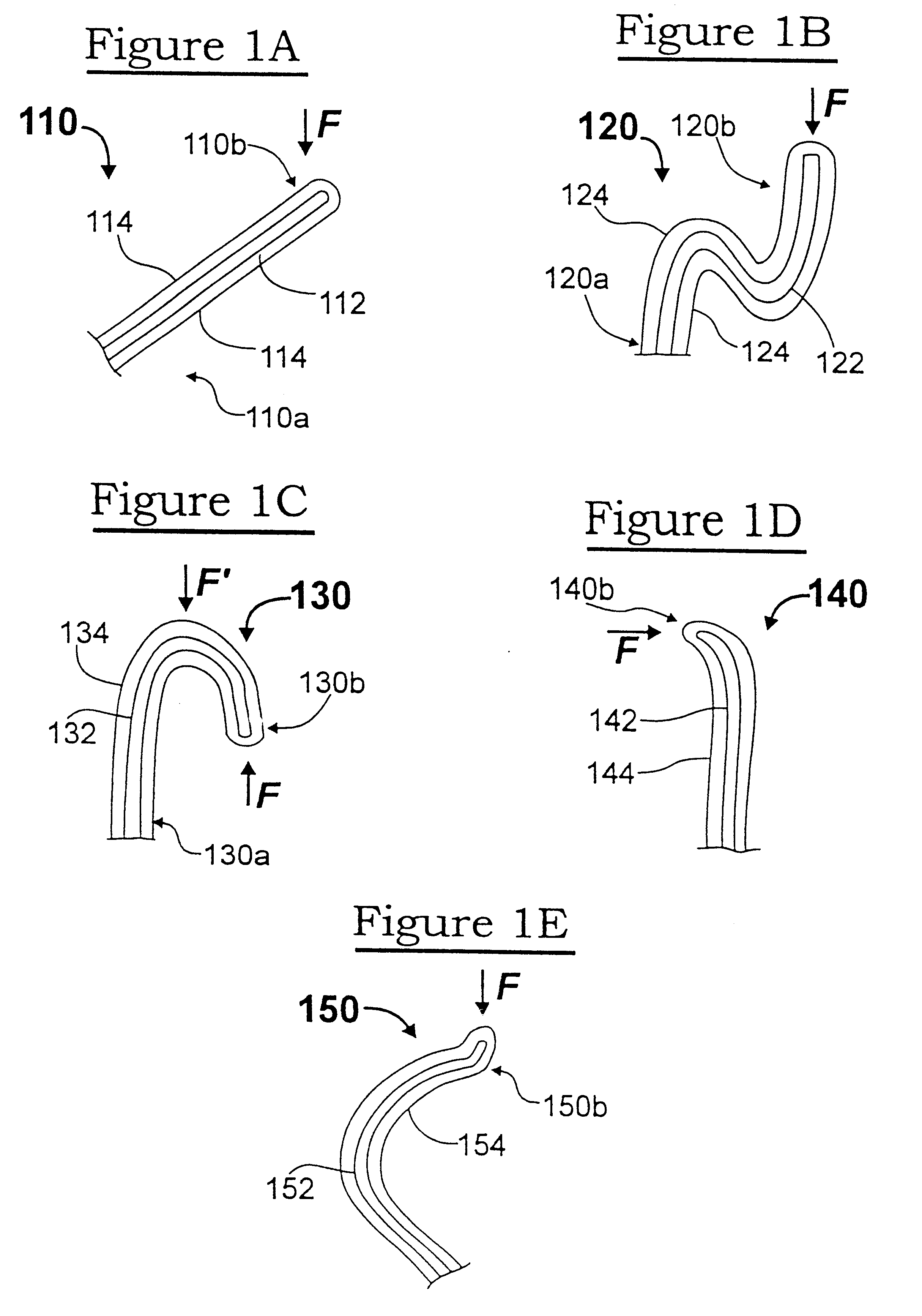

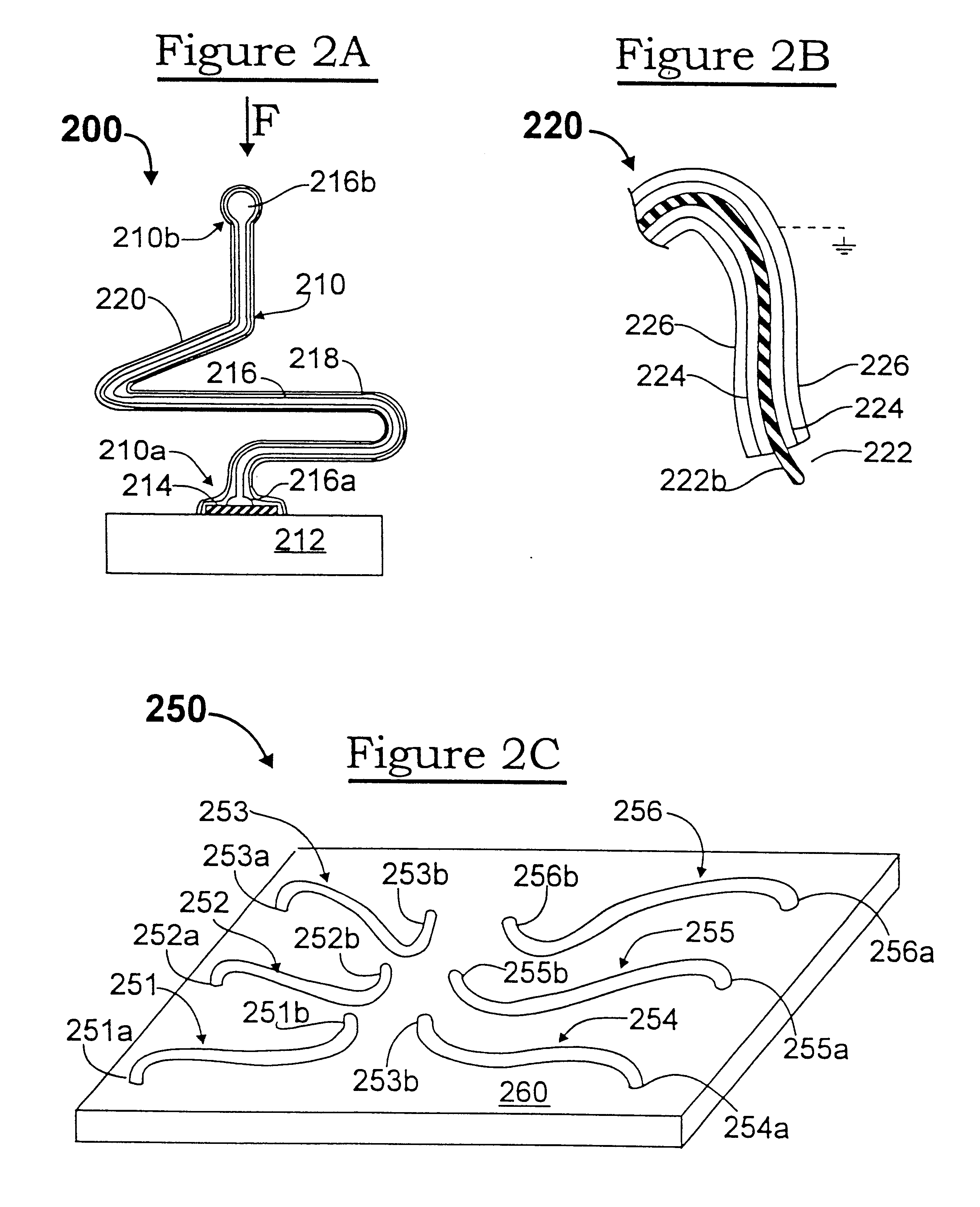

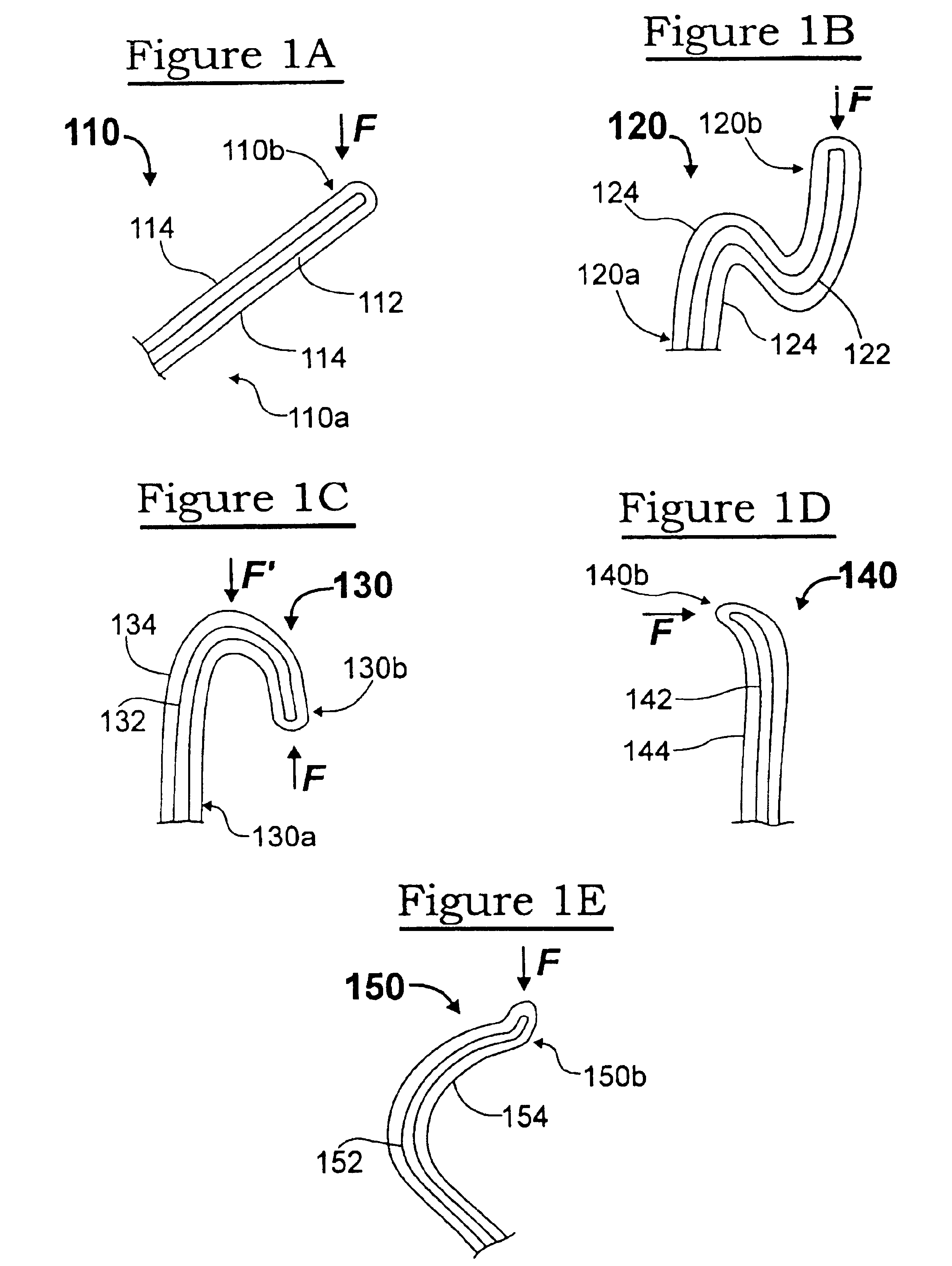

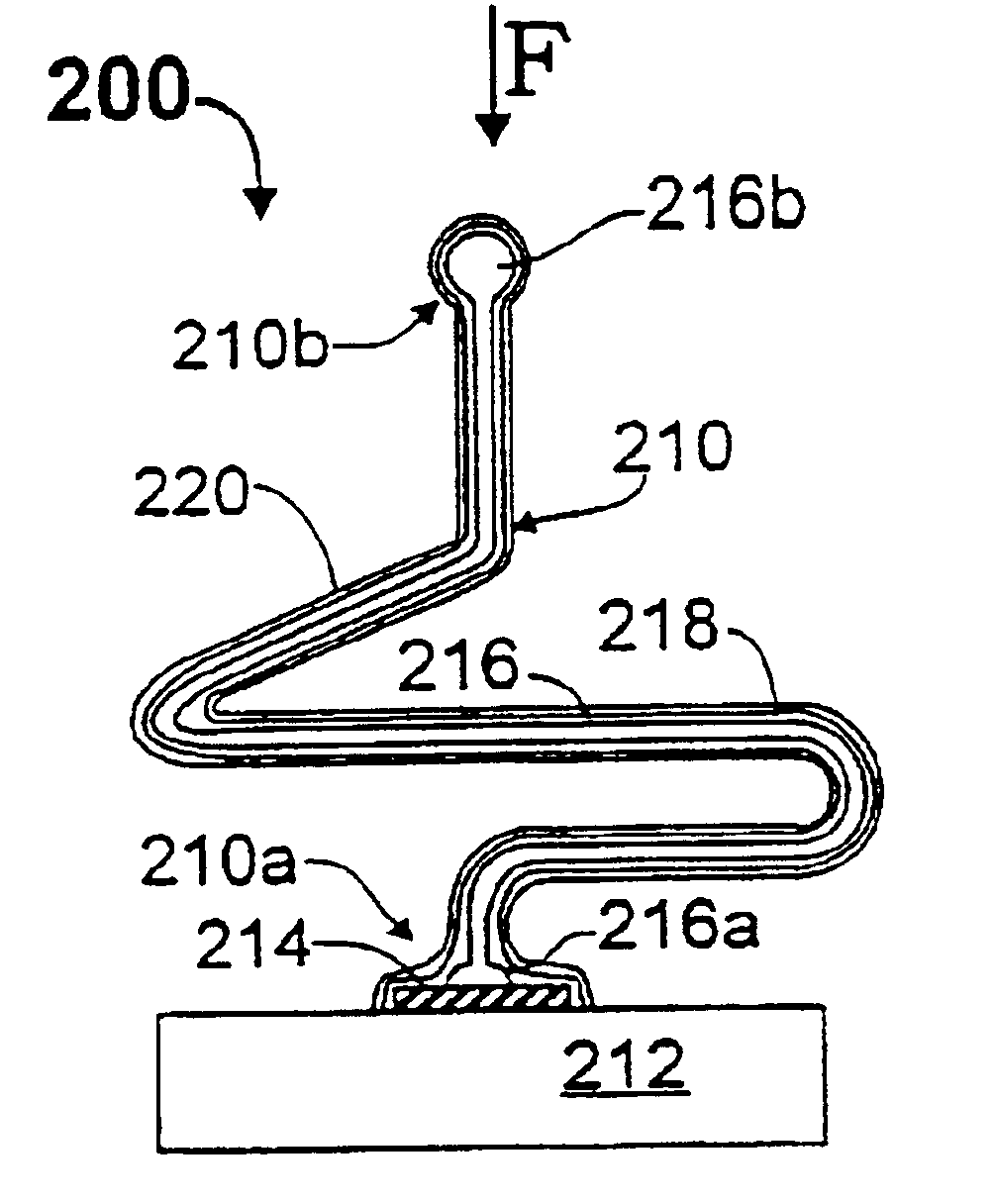

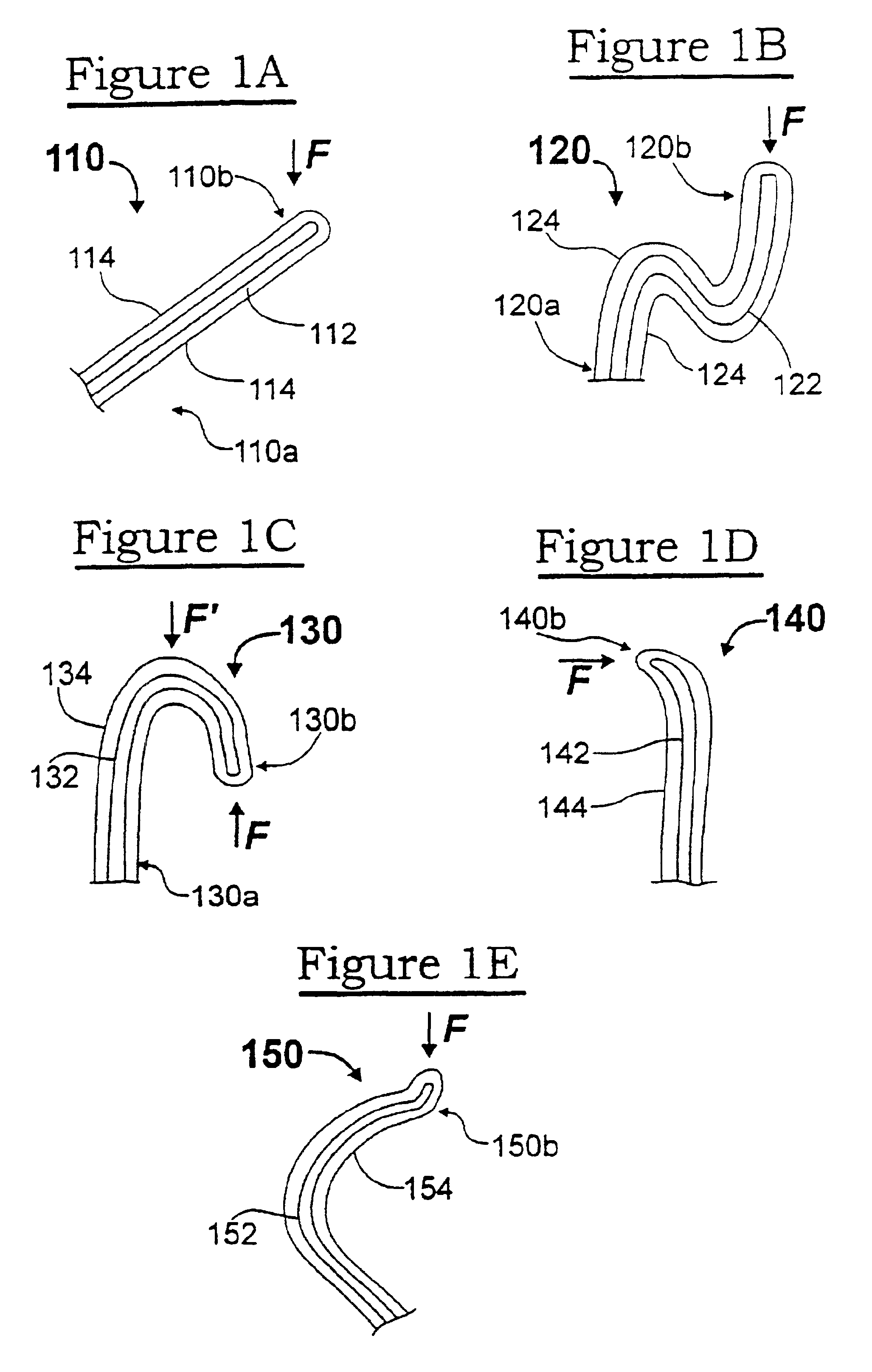

Method and apparatus for shaping spring elements

InactiveUS6836962B2Easy to disassembleEasy to manufactureElectrically conductive connectionsContact member assembly/disassemblyProbe cardCopper wire

Interconnection elements for electronic components, exhibiting desirable mechanical characteristic (such as resiliency, for making pressure contacts) are formed by using a shaping tool (512) to shape an elongate core element (502) of a soft material (such as gold or soft copper wire) to have a springable shape (including cantilever beam, S-shape, U-shape), and overcoating the shaped core element with a hard material (such as nickel and its alloys), to impart to desired spring (resilient) characteristic to the resulting composite interconnection element. A final overcoat of a material having superior electrical qualities (e.g., electrical conductivity and / or solderability) may be applied to the composite interconnection element. The resulting interconnection elements may be mounted to a variety of electronic components, including directly to semiconductor dies and wafers (in which case the overcoat material anchors the composite interconnection element to a terminal (or the like) on the electronic component), may be mounted to support substrates for use as interposers and may be mounted to substrates for use as probe cards or probe card inserts. The shaping tool may be an anvil (622) and a die (624), and may nick or sever successive shaped portions of the elongate elements, and the elongate element may be of an inherently hard (springy) material. Methods of fabricating interconnection elements on sacrificial substrates are described. Methods of fabricating tip structures (258) and contact tips at the end of interconnection elements are also described.

Owner:FORMFACTOR INC

Heart valve docking coils and systems

Anchoring or docking devices configured to be positioned at a native valve of a human heart and to provide structural support for docking a prosthetic valve therein. The docking devices can have coiled structures that define an inner space in which the prosthetic valve can be held. The docking devices can have enlarged end regions with circular or non-circular shapes, for example, to facilitate implantation of the docking device or to better hold the docking device in position once deployed. The docking devices can be laser-cut tubes with locking wires to assist in better maintaining a shape of the docking device. The docking devices can include various features to promote friction, such as frictional cover layers. Such docking devices can have ends configured to more securely attach the cover layers to cores of the docking devices.

Owner:EDWARDS LIFESCIENCES CORP

Fixation device and method

InactiveUS8535380B2Less invasiveEasy to anchorSpinal implantsOsteosynthesis devicesPlastic surgeryBiomedical engineering

An implantable orthopedic stability device is disclosed. The device can have a contracted and an expanded configuration. A method of using the device between adjacent vertebral body surfaces surfaces for support and / or fixation of either or both of the adjacent vertebrae is also disclosed.

Owner:STOUT MEDICAL GROUP

Paravalvular leak detection, sealing and prevention

The present invention provides a series of new percutaneous concepts of paravalvular repairs including identifying the leak location, several repair techniques and finally built-in means for leak prevention, built on percutaneous valves. A catheter-delivered device locates cavities occurring between a prosthetic valve and the wall of the body vessel where the valve is implanted, the cavities producing paravalvular leaks during diastole, the device comprising at least one of a plurality of flexible wires, the wire having attached to it a balloon, wherein the balloon is pulled by the leak through the cavity and wherein the wire then serves to mark the cavity location.

Owner:EDWARDS LIFESCI PVT

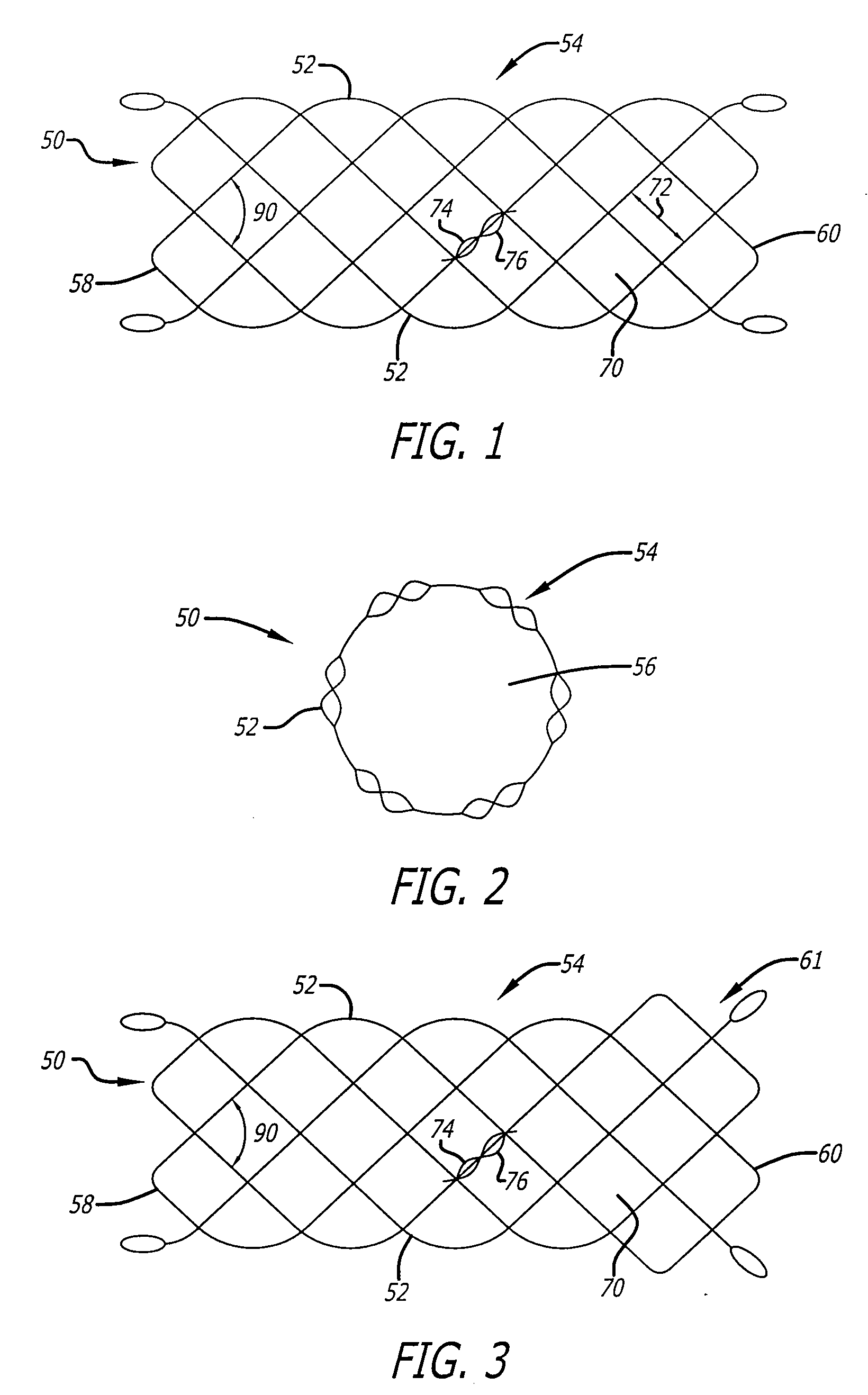

Self-expanding, pseudo-braided intravascular device

InactiveUS20080109063A1Large expansion ratioIncrease flexibilityStentsHand lacing/braidingThrombusTubular stenosis

A self-expanding, pseudo-braided device embodying a high expansion ratio and flexibility as well as comformability and improved radial force. The pseudo-braided device is particularly suited for advancement through and deployment within highly tortuous and very distal vasculature. Various forms of the pseudo-braided device are adapted for the repair of aneurysms and stenoses as well as for use in thrombectomies and embolic protection therapy.

Owner:ENDOVASCULAR TECH

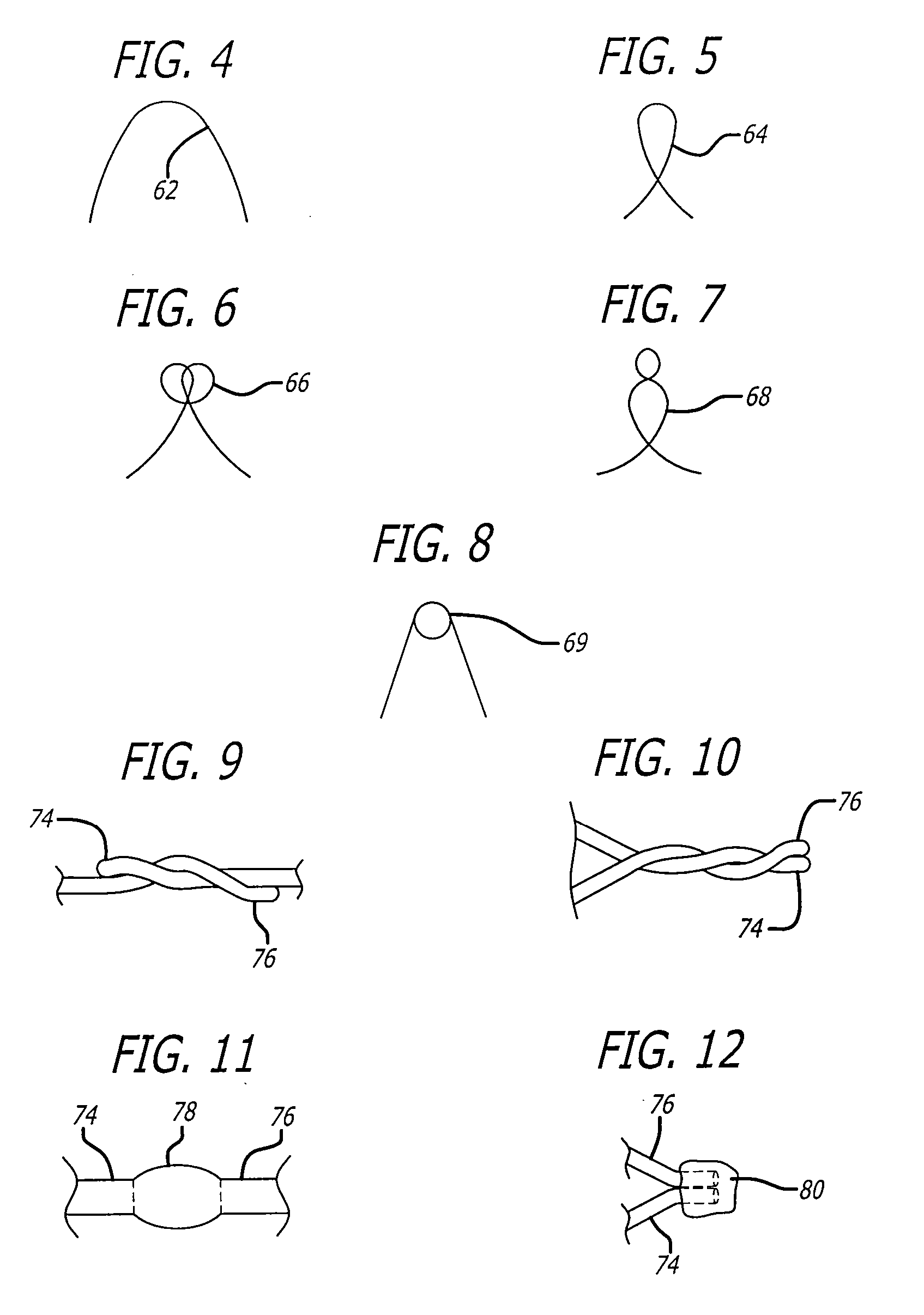

Planarized sacrificial layer for MEMS fabrication

ActiveUS8278802B1Easy to anchorEasy to controlPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesSingle crystalComputational physics

A method of forming a device is provided. The method includes providing a substrate, forming a sacrificial layer over the substrate, and forming an field layer around the sacrificial layer. After formation, both the sacrificial layer and the field layer are planarized. A component is then formed over the planarized sacrificial layer and the planarized field layer. The component has a first electrode and a second electrode and a single crystal wafer disposed between the first electrode and the second electrode. The component also includes anchors disposed substantially over the field layer. Once the component is formed, the sacrificial layer is released with an etchant having a selectivity for the sacrificial layer such that a cavity is formed beneath the component. The cavity allows free movement component within the cavity during operation of the device. In addition, the etchant does not release the field layer and the component such that the field layer remains below the anchors.

Owner:QORVO US INC

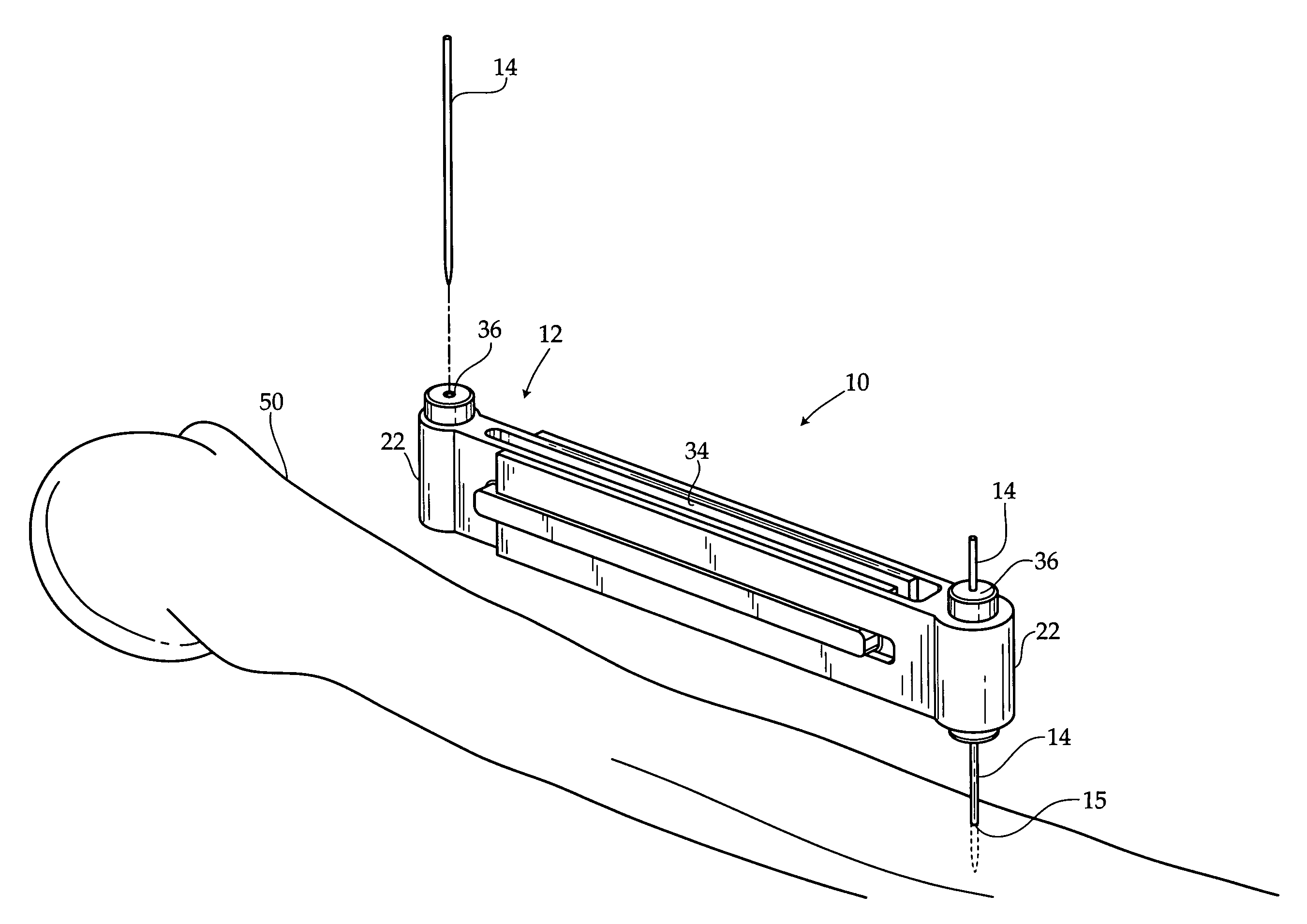

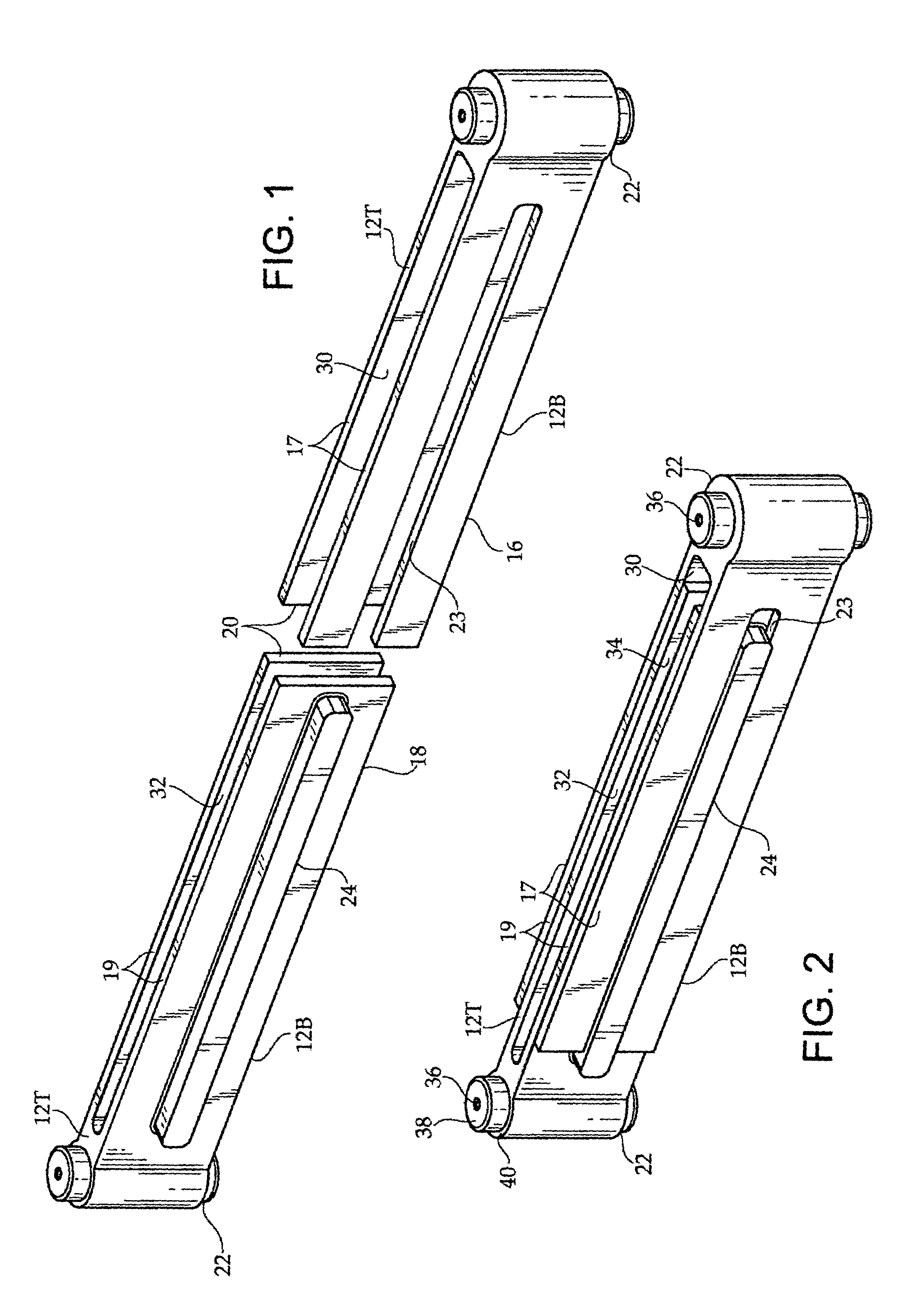

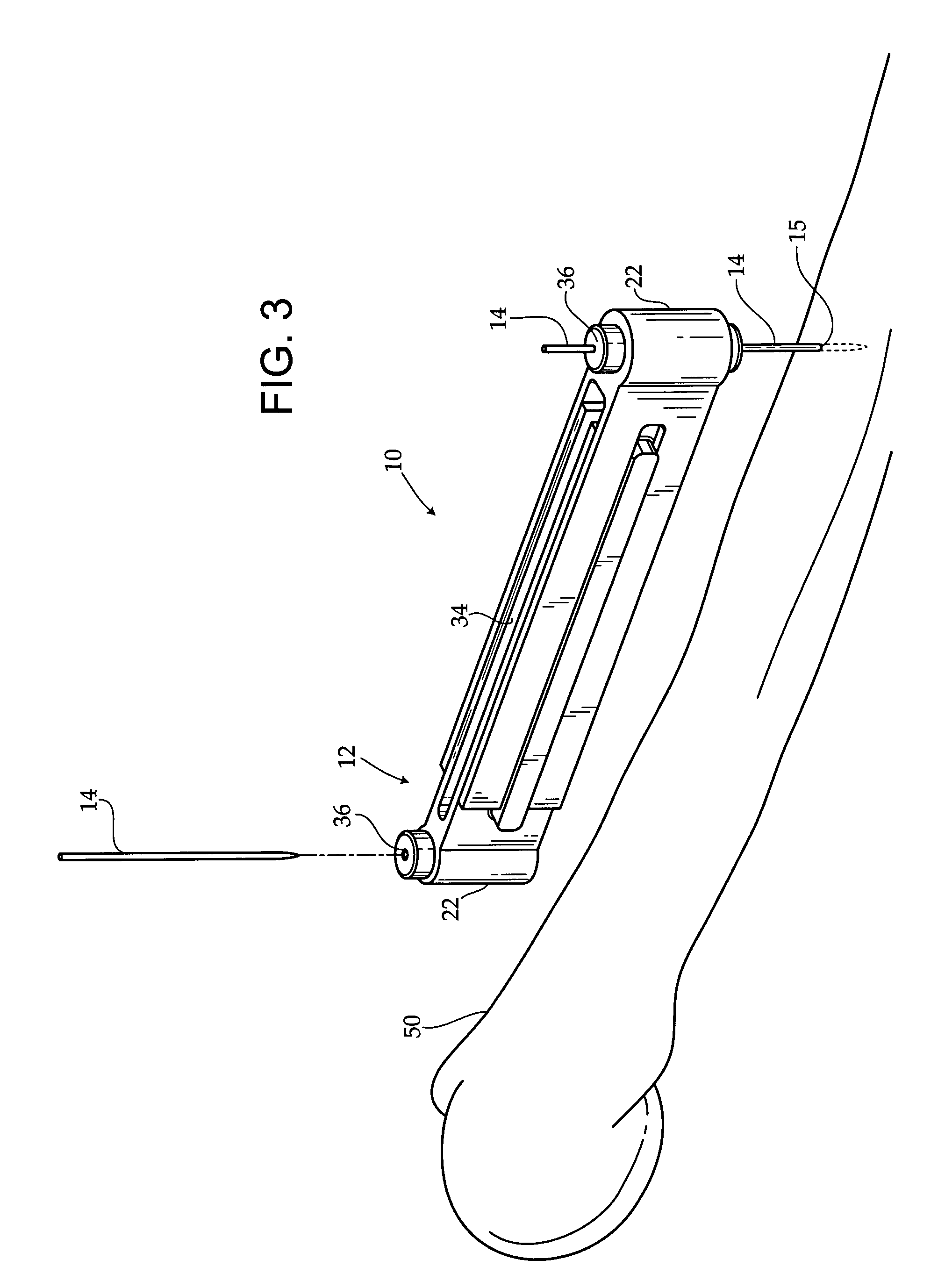

Adjustable osteotomy guide

InactiveUS7182766B1Precise positioningEasy to manufactureNon-surgical orthopedic devicesSurgical sawsEngineeringOsteotomy guide

An osteotomy guide having a frame and a pair of guide pins, for creating a desired cut in a bone. The frame has an outer frame, and an inner frame which is telescopically mounted within the outer frame. Both the inner frame and outer frame having open ends and a guide pin sleeve. The inner frame and outer frame together define a main slot which is adjustable in length by moving the inner frame with respect to the outer frame. The frame is mounted to the bone by creating anchoring holes in the bone and extending the guide pins through the guide pin sleeves and into the anchoring holes, such that the guide pins are parallel in all planes. A controlled cut is created by using the guide pins as a visual guide or inserting a saw blade through the main slot.

Owner:MOGUL STUART

Catheter with single axial sensors

ActiveUS20120172703A1Easy to anchorElectrocardiographySurgical navigation systemsLocalization systemMedicine

A catheter is provided with improved position and / or location sensing with the use of single axis sensors that are mounted directly along a length or portion of the catheter whose position / location is of interest. The magnetic based, single axis sensors are provided on a single axis sensor (SAS) assembly, which can be linear or nonlinear as needed. A catheter of the present invention thus includes a catheter body and a distal member of a particular 2D or 3D configuration that is provided by a support member on which at least one, if not at least three single axis sensors, are mounted serially along a length of the support member. In one embodiment, the magnetic-based sensor assembly including at least one coil member that is wrapped on the support member, wherein the coil member is connected via a joint region to a respective cable member adapted to transmit a signal providing location information from the coil member to a mapping and localization system. The joint region advantageously provides strain relief adaptations to the at least one coil member and the respective cable member from detaching.

Owner:BIOSENSE WEBSTER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com