Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about "Hand lacing/braiding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

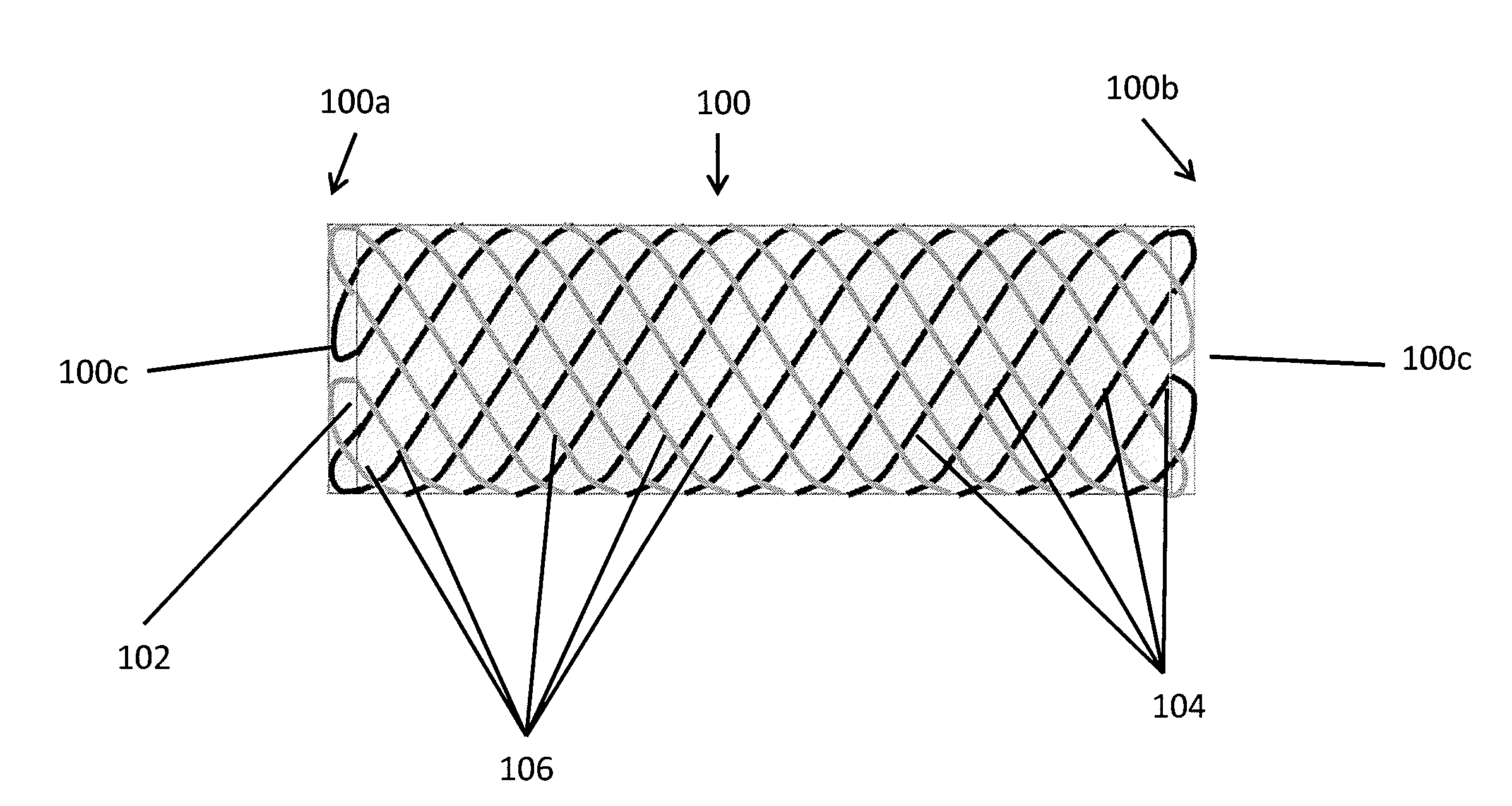

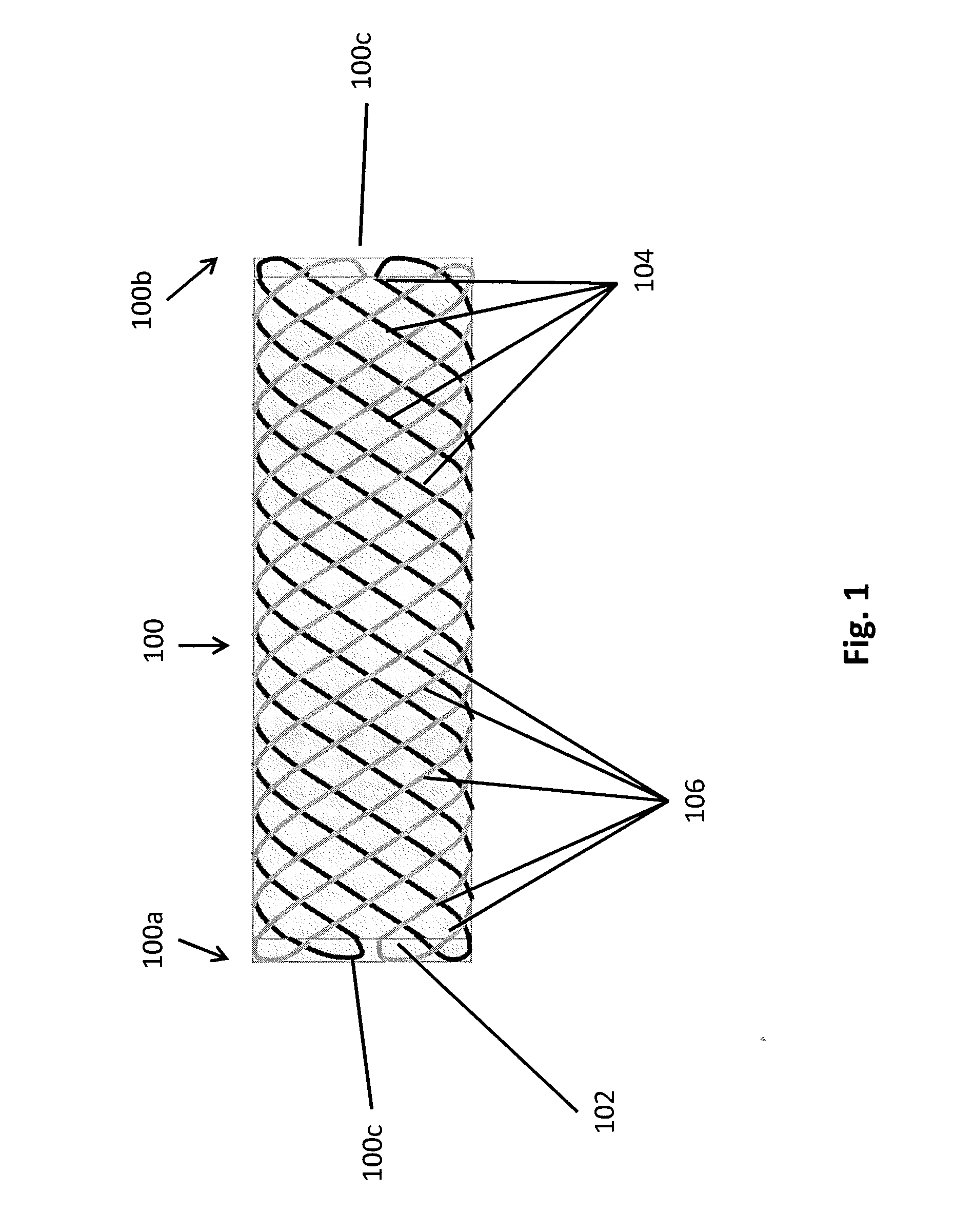

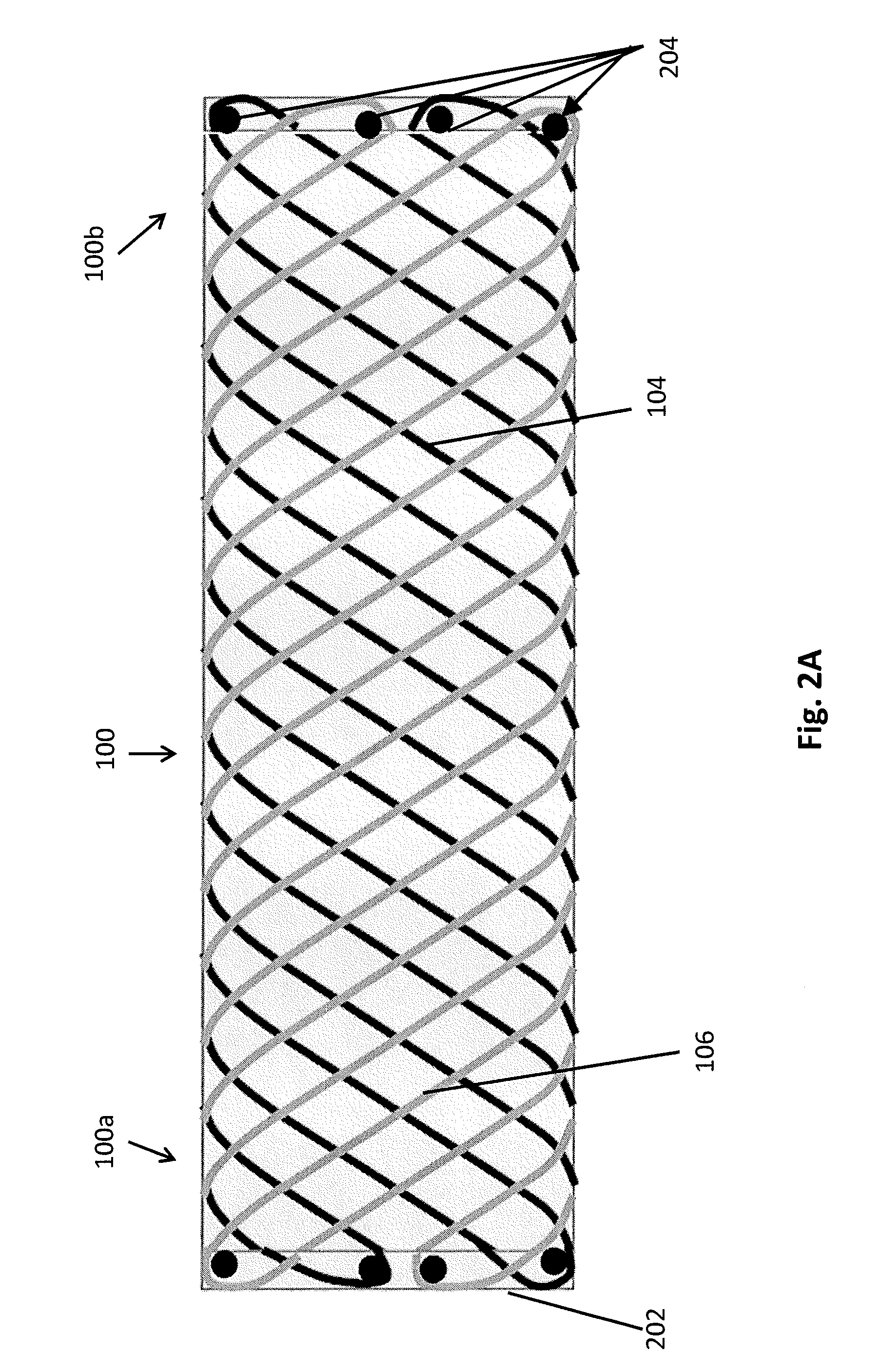

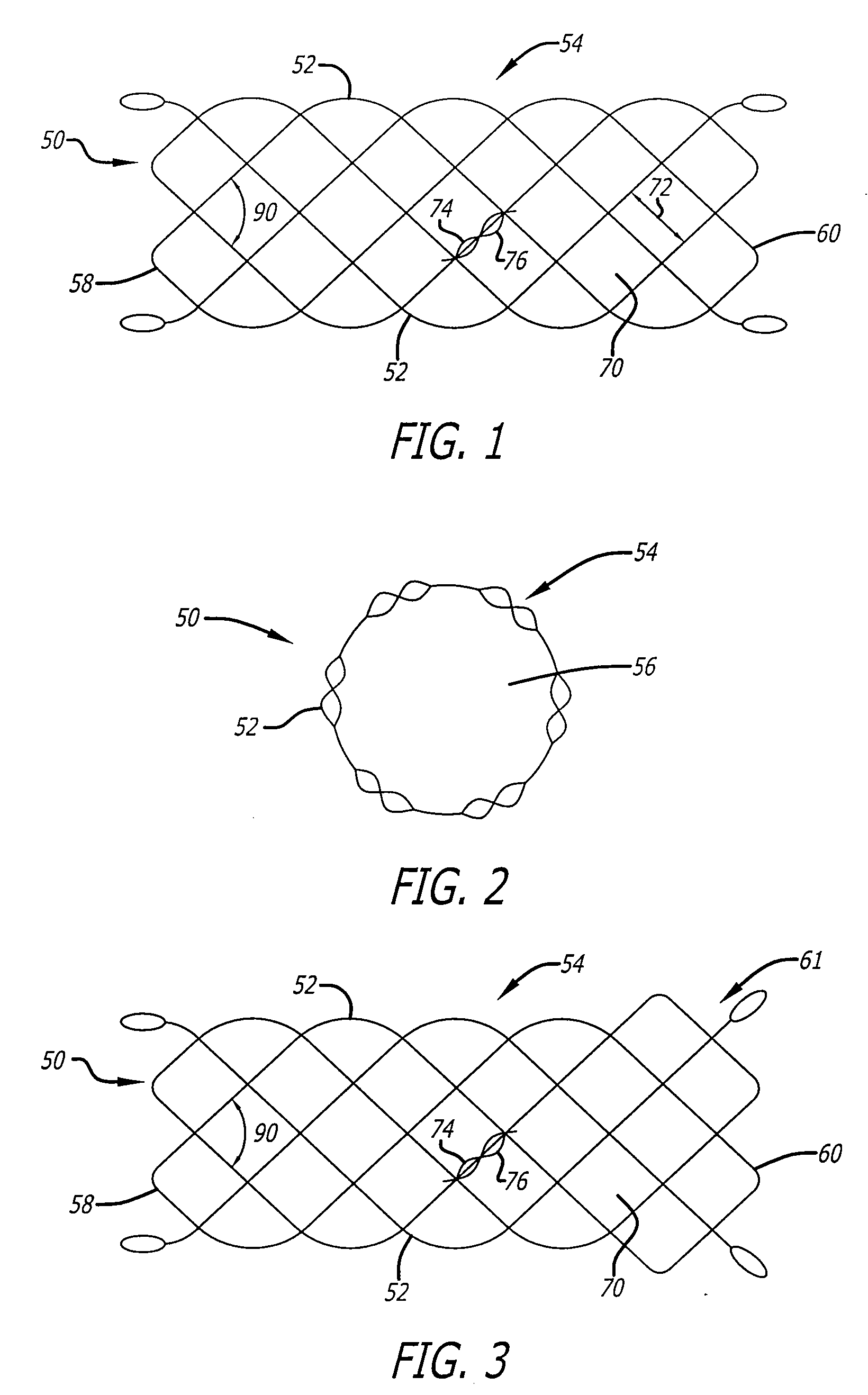

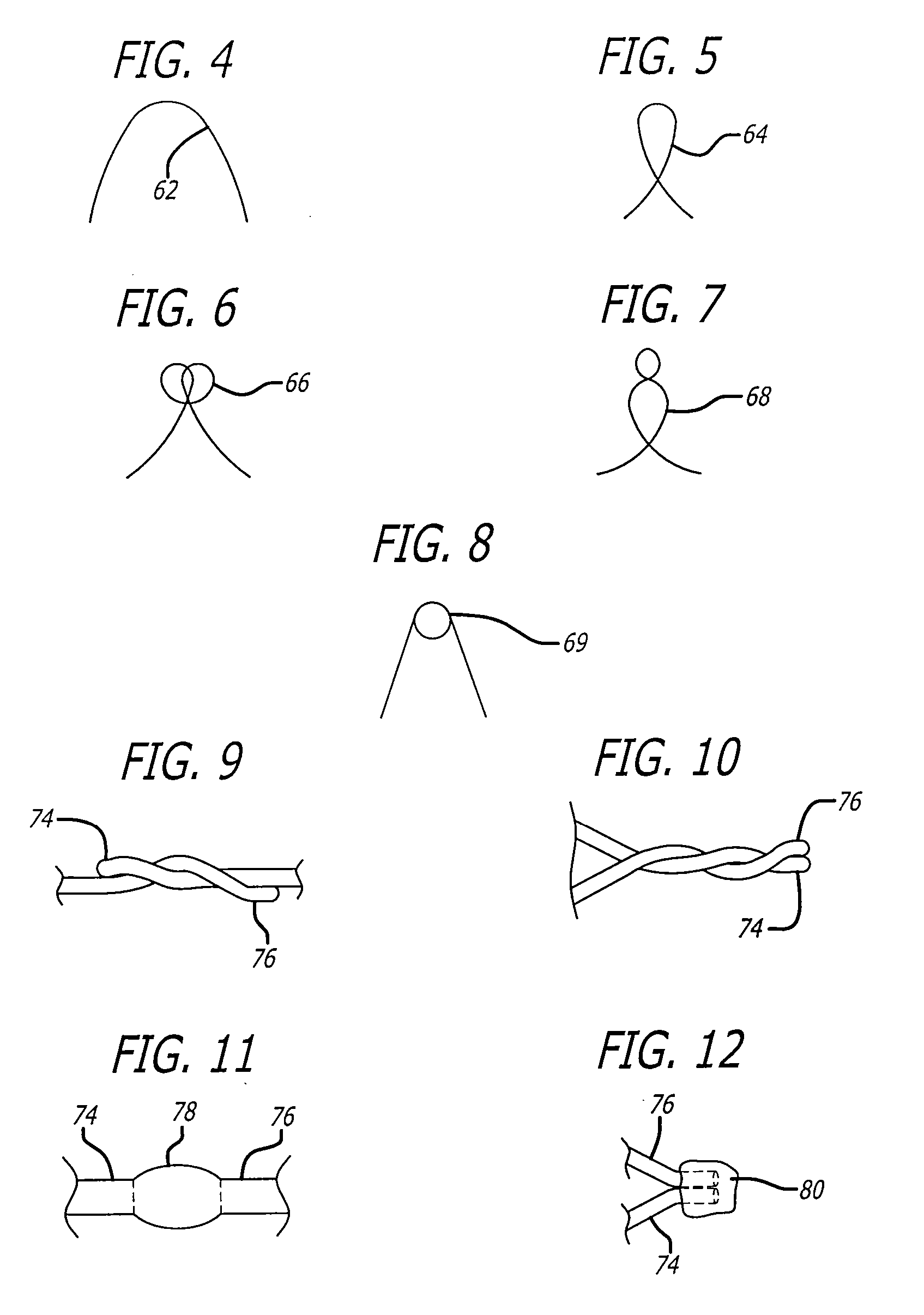

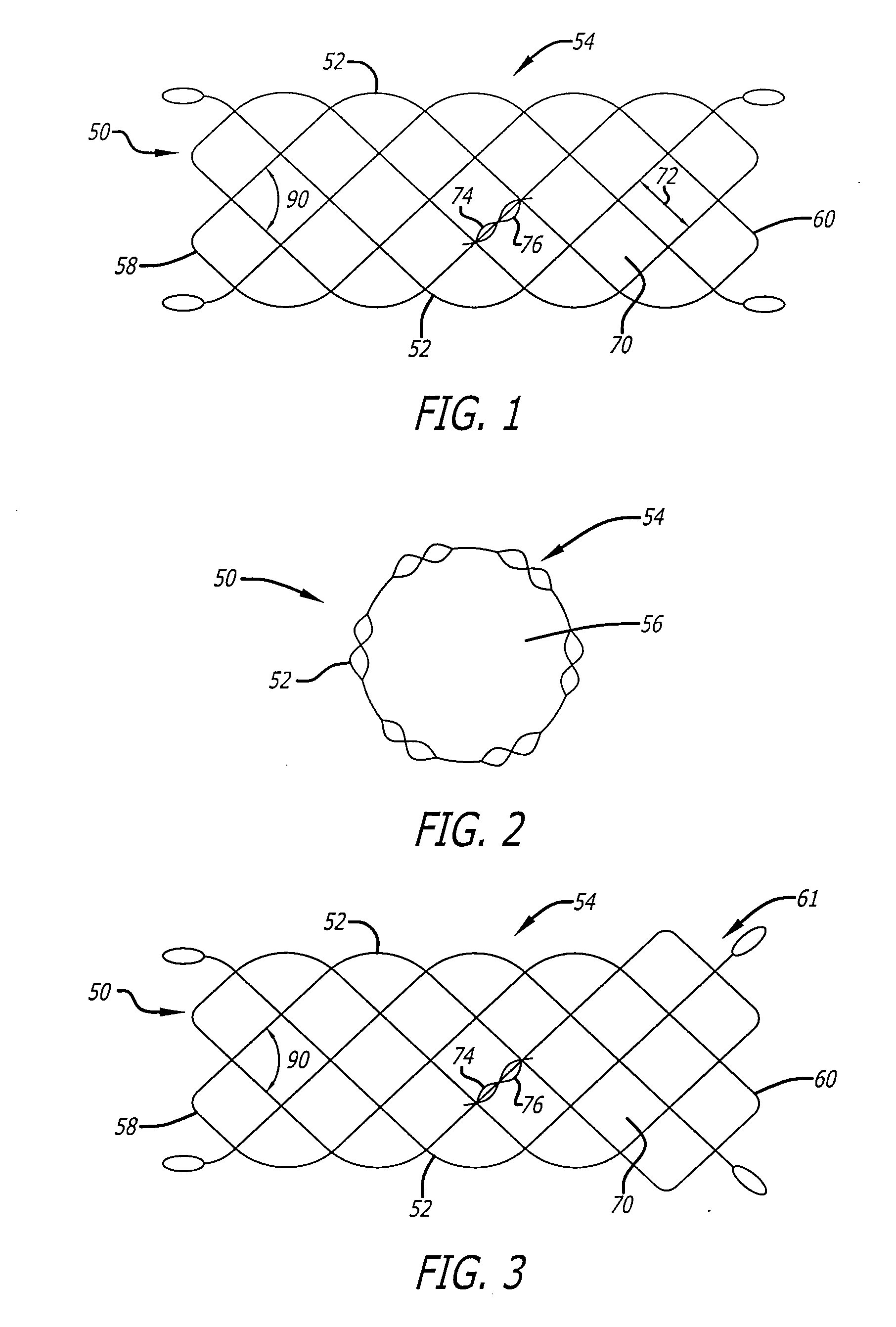

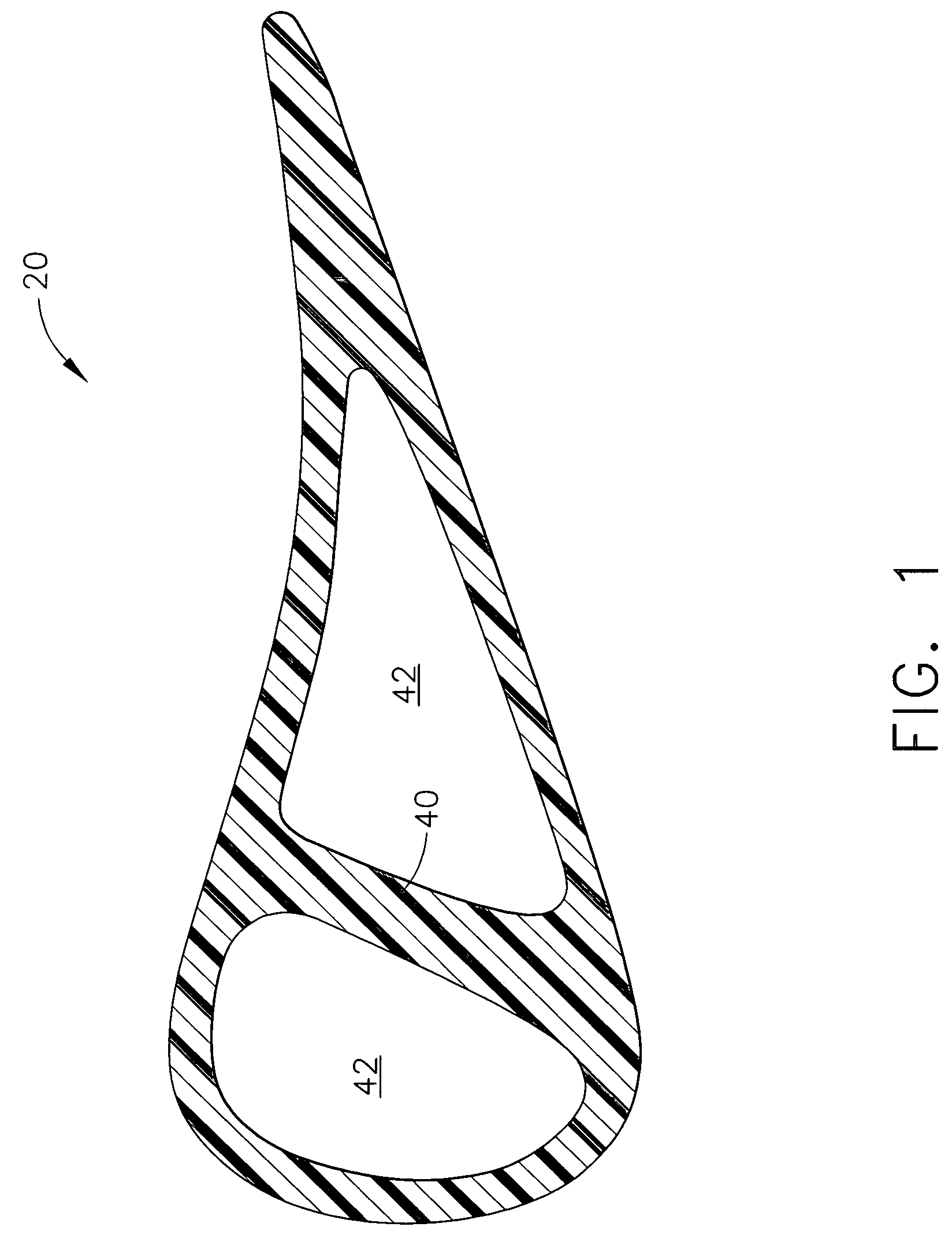

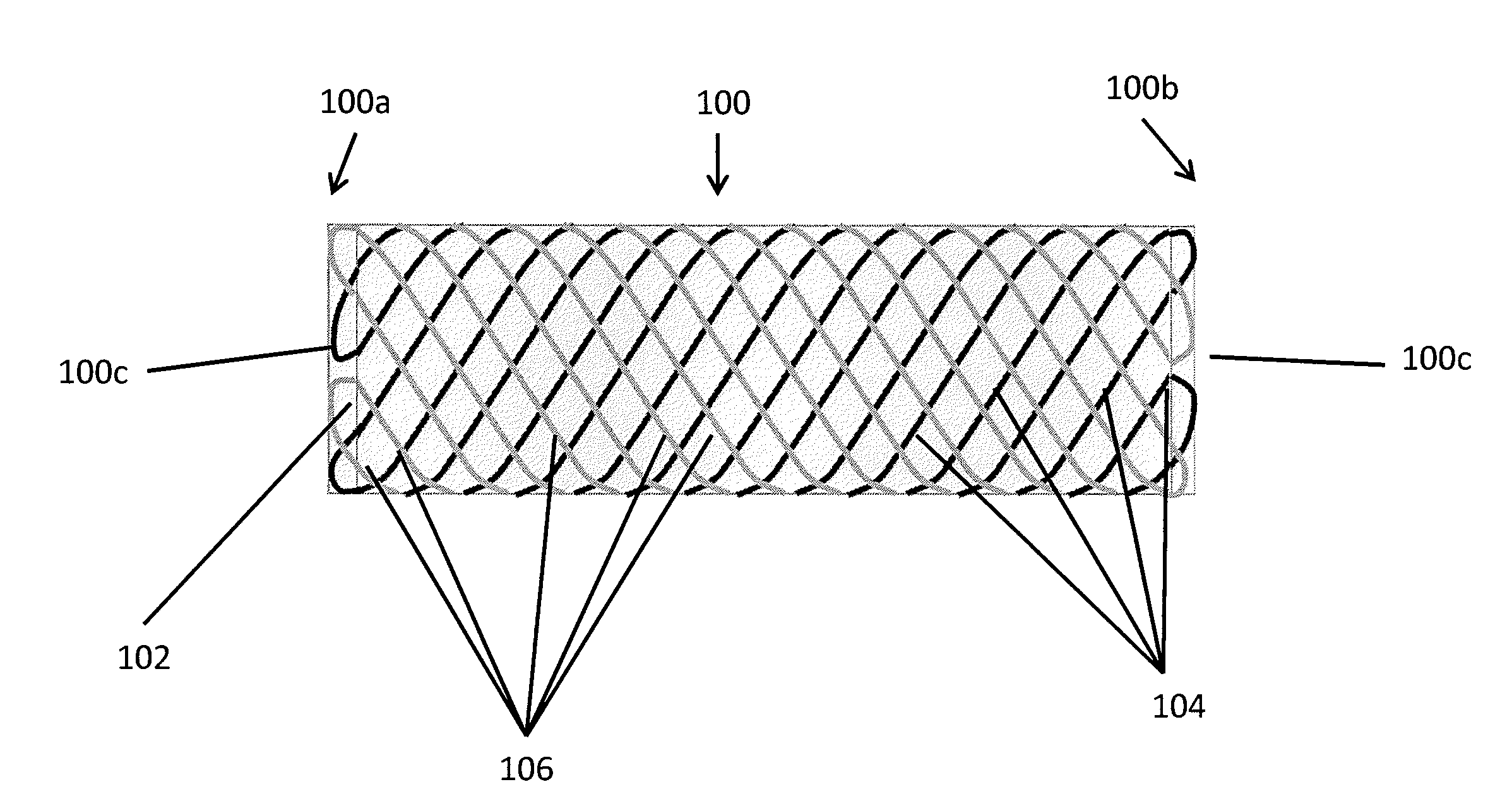

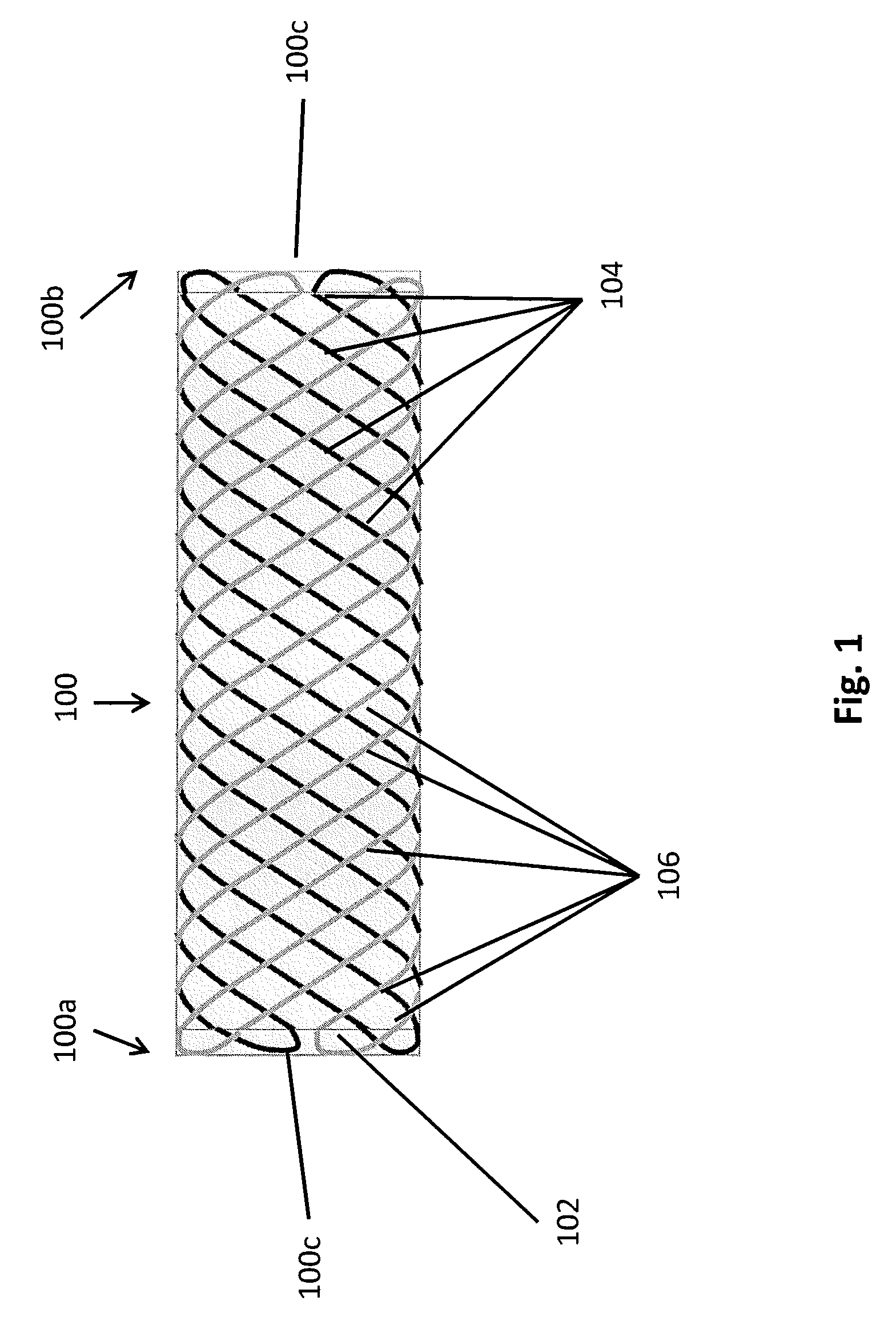

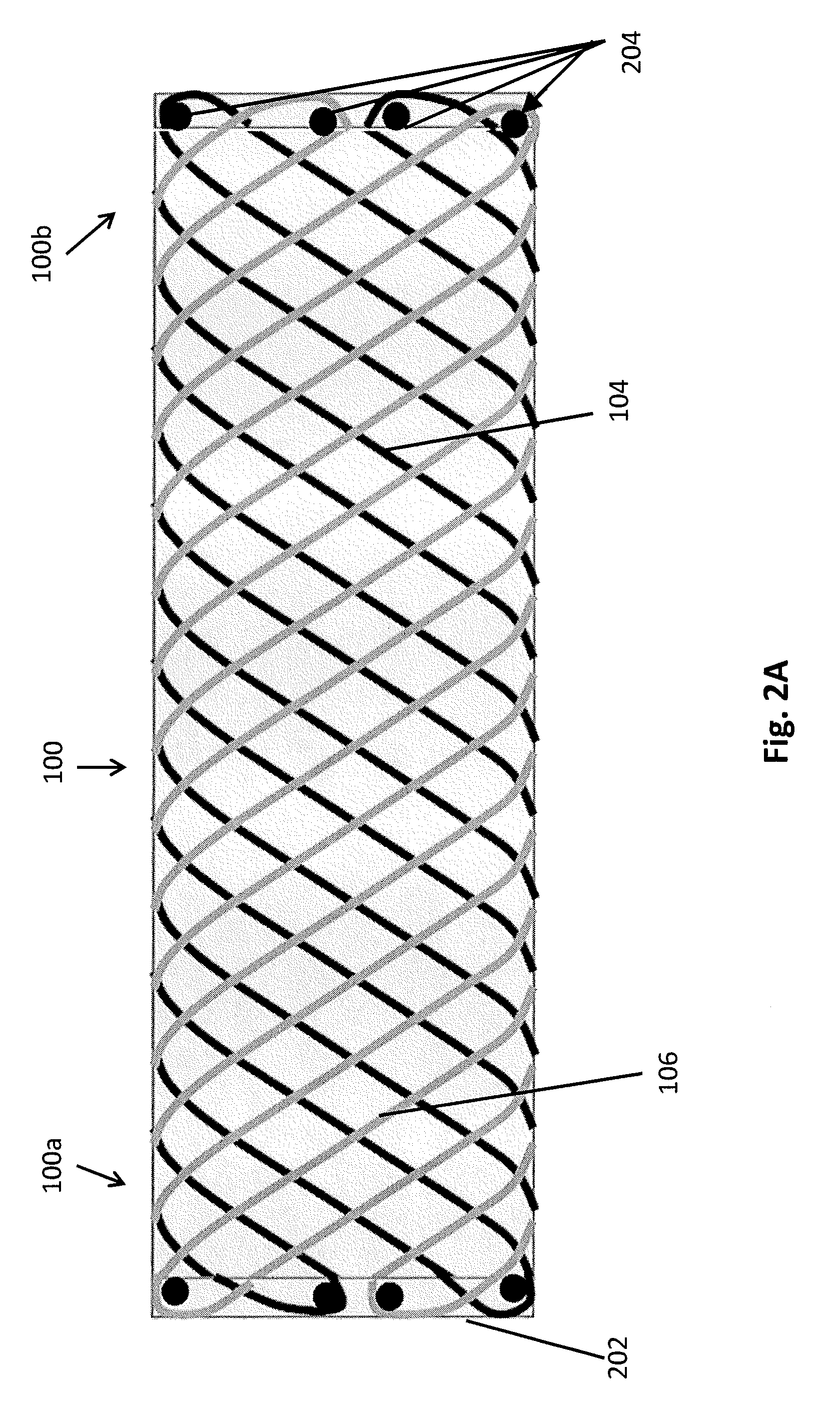

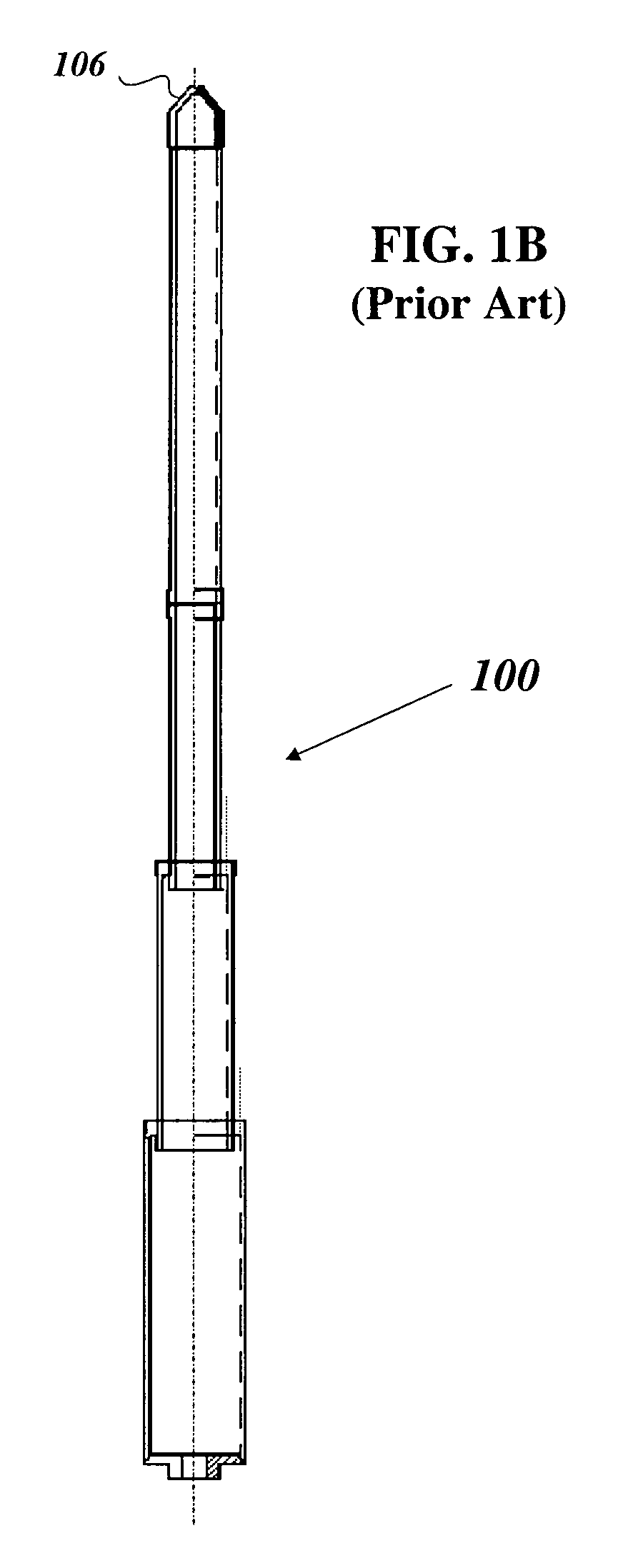

Braided helical wire stent

ActiveUS20130060323A1Reduce human costReduce the cost of the whole machineStentsHand lacing/braidingMechanical stabilityEngineering

Exemplary non-woven helical stents are described that are efficient to fabricate in terms of labor and resources by being able to be manufactured by hand or machine while providing mechanical stability equivalent or close thereto of known braided or woven stents.

Owner:COOK MEDICAL TECH LLC

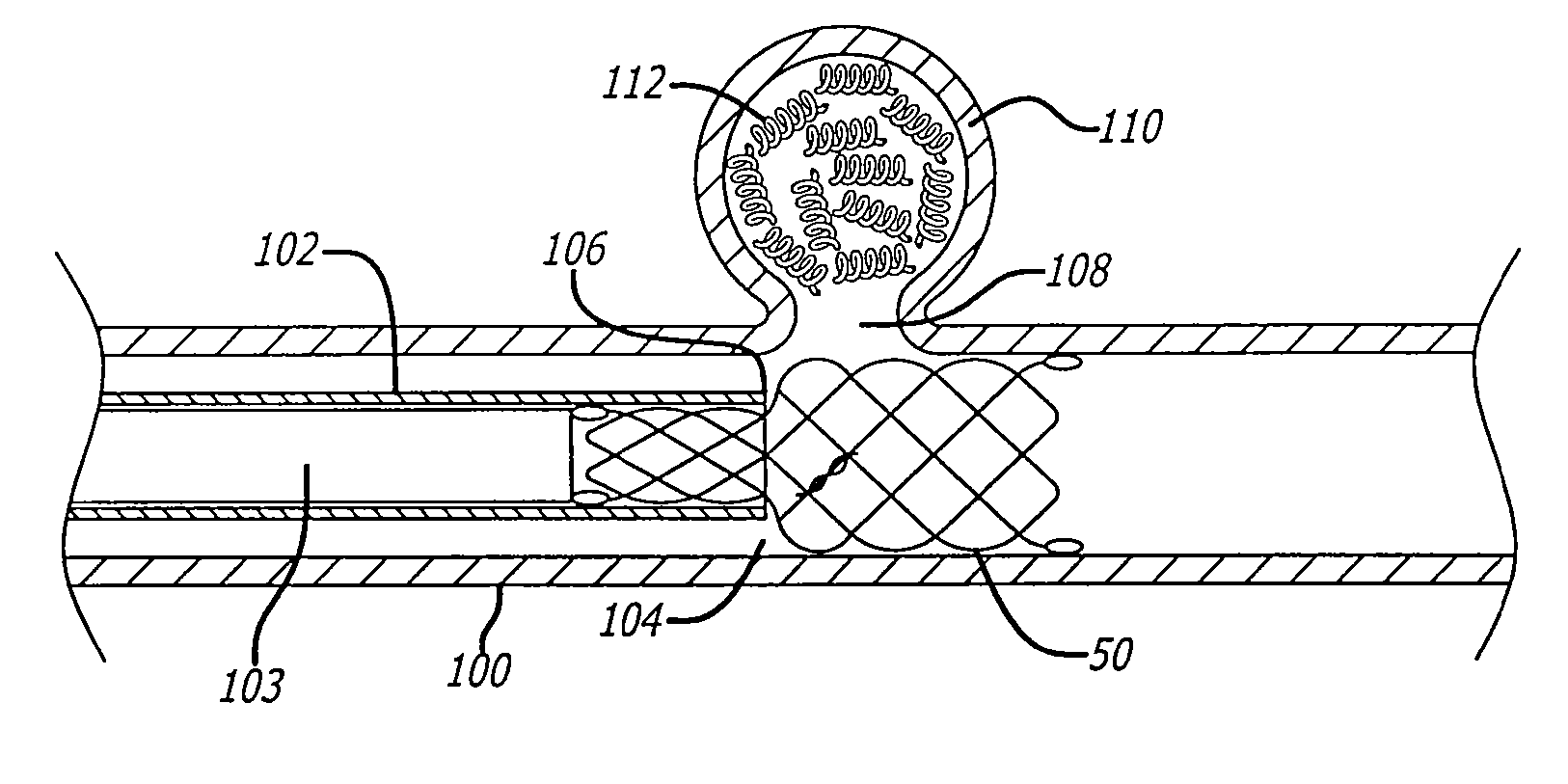

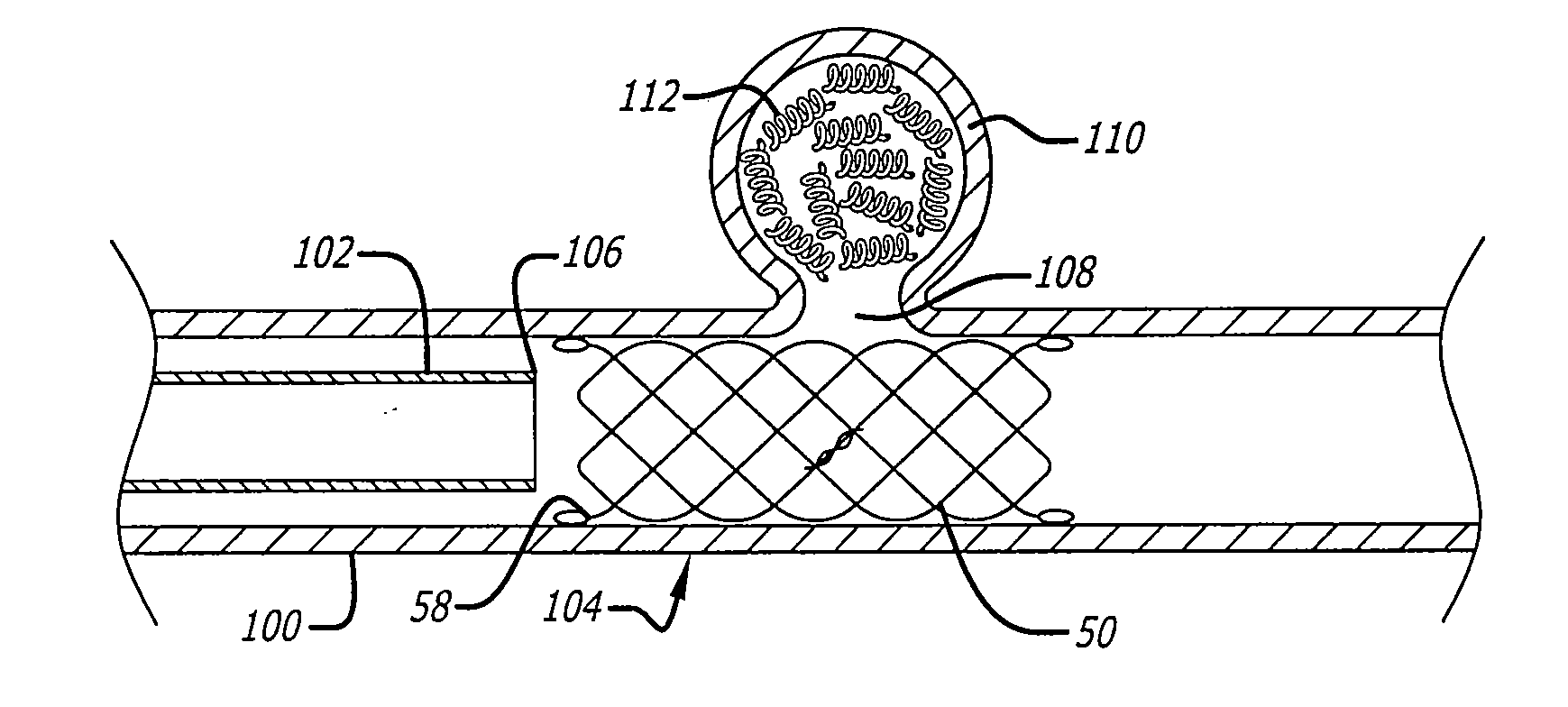

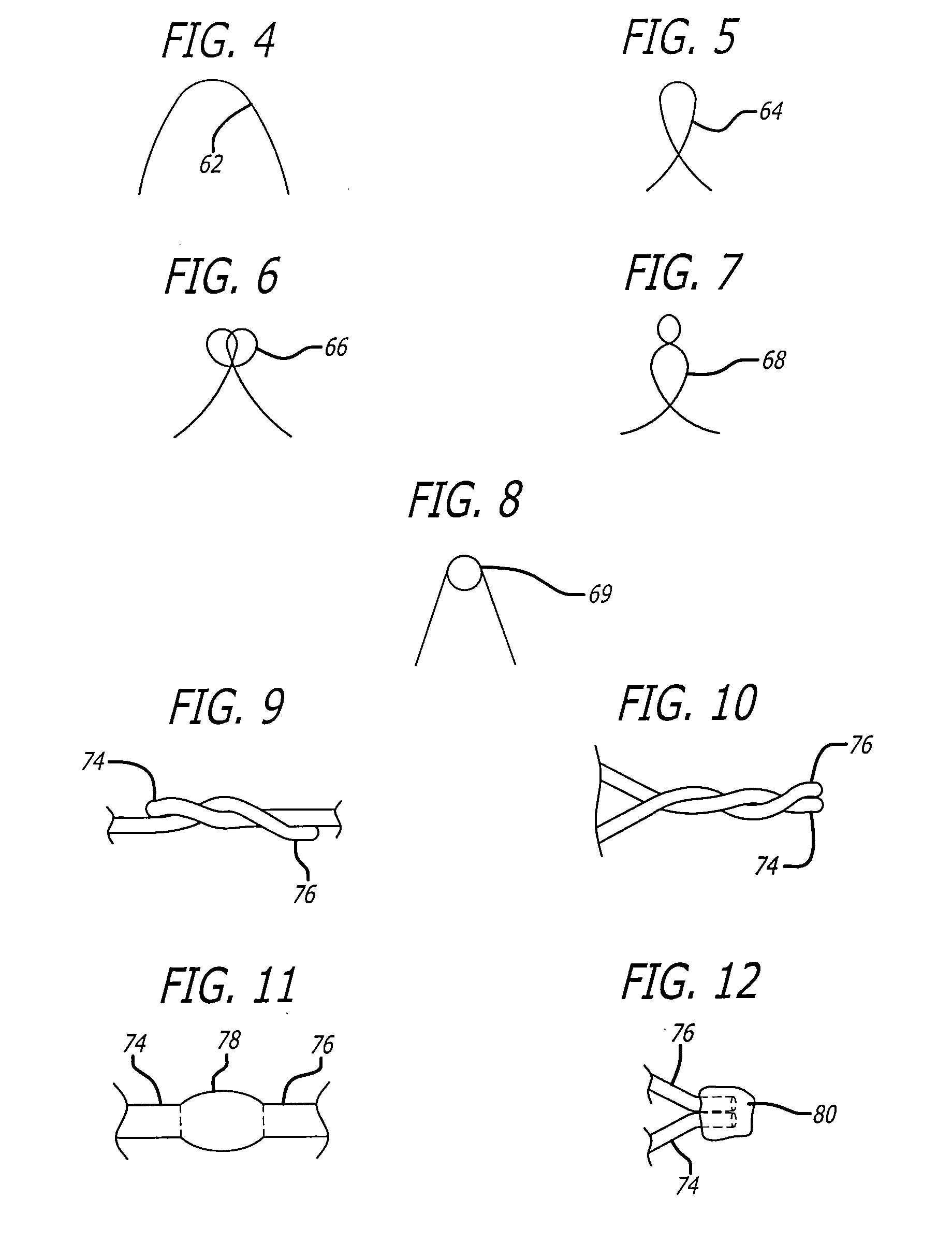

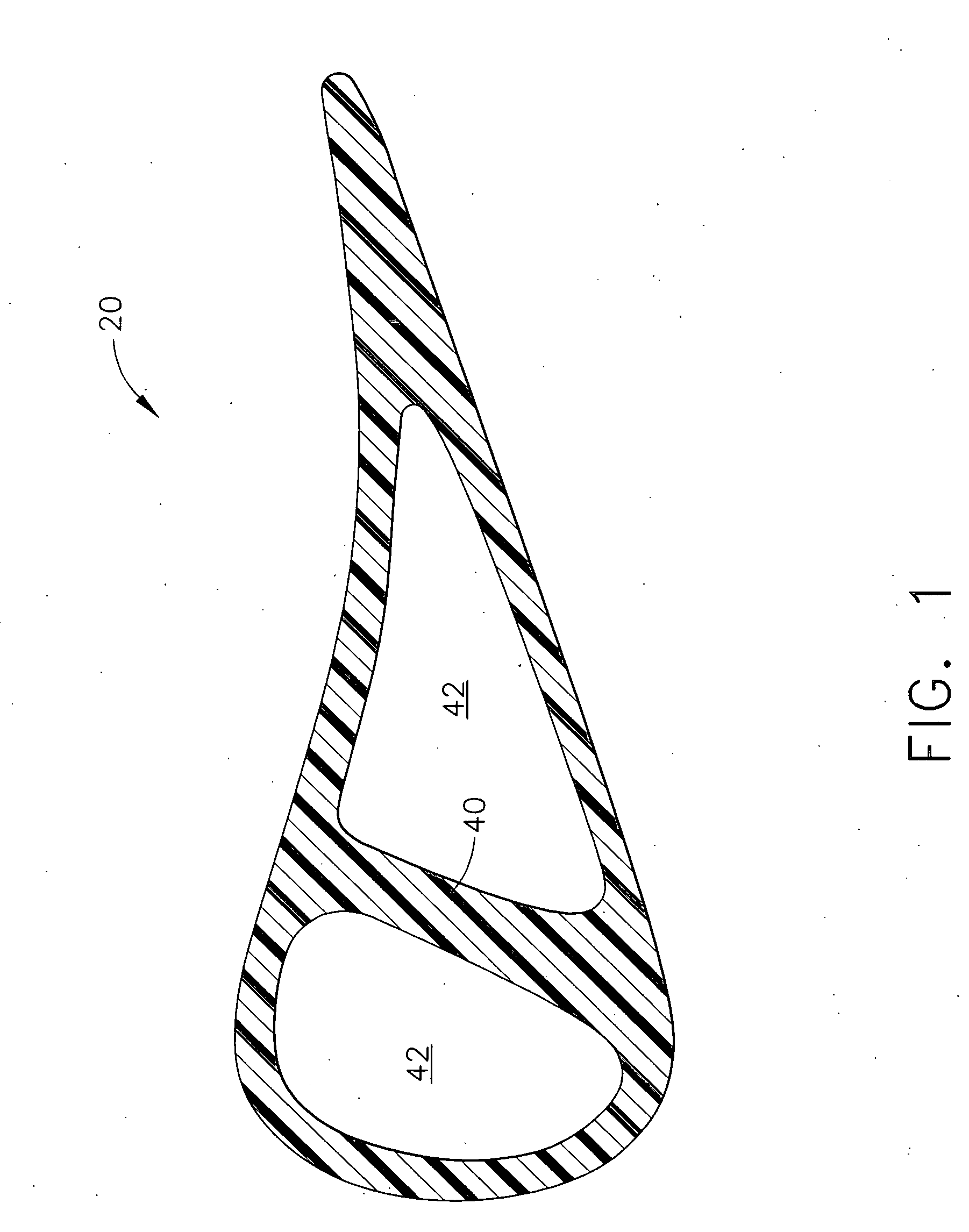

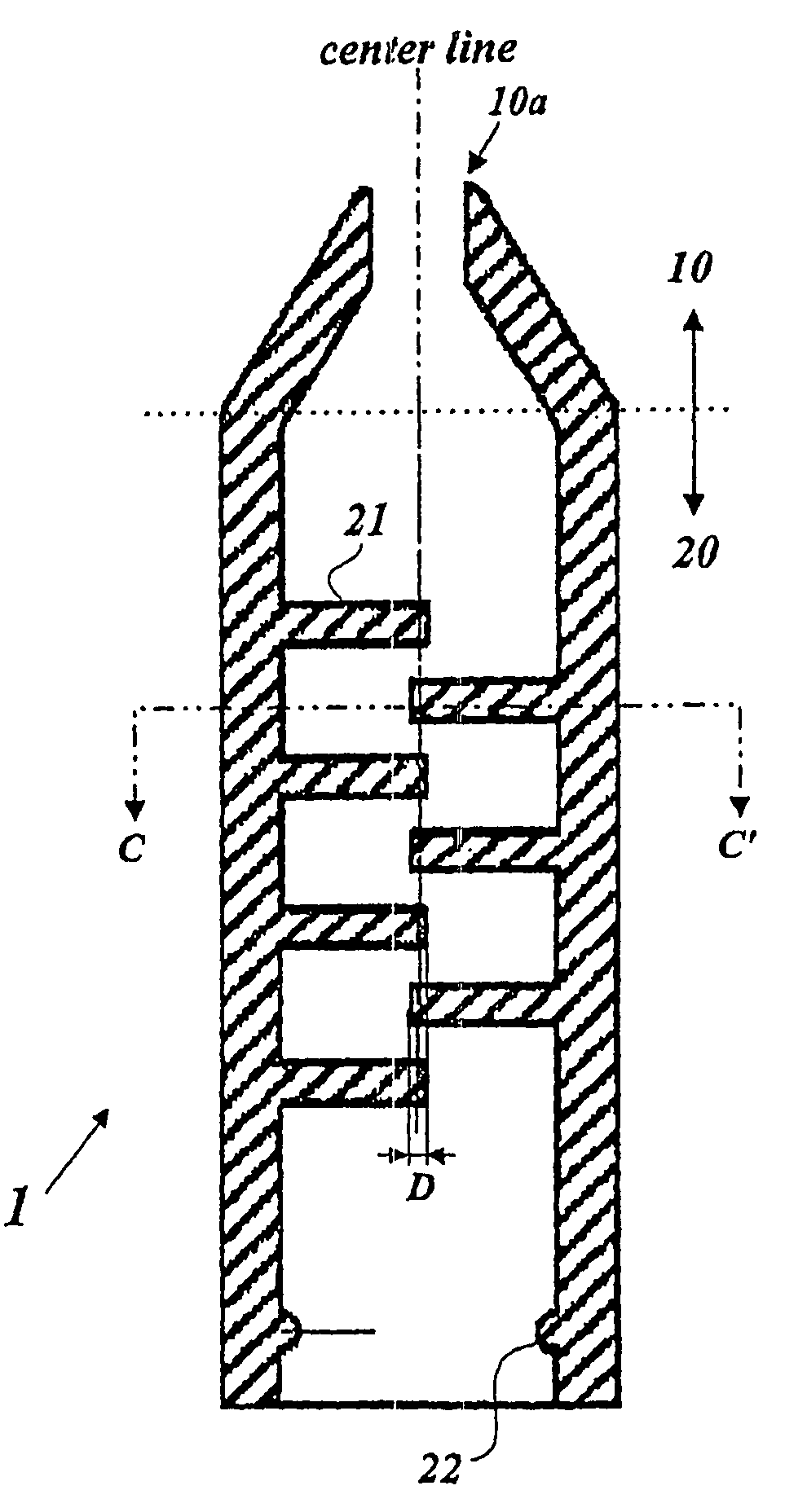

Self-expanding, pseudo-braided intravascular device

InactiveUS20080109063A1Large expansion ratioIncrease flexibilityStentsHand lacing/braidingThrombusTubular stenosis

A self-expanding, pseudo-braided device embodying a high expansion ratio and flexibility as well as comformability and improved radial force. The pseudo-braided device is particularly suited for advancement through and deployment within highly tortuous and very distal vasculature. Various forms of the pseudo-braided device are adapted for the repair of aneurysms and stenoses as well as for use in thrombectomies and embolic protection therapy.

Owner:ENDOVASCULAR TECH

Self-expanding pseudo-braided intravascular device

InactiveUS20100004726A1Large expansion ratioIncrease flexibilityStentsHand lacing/braidingThrombusRepair aneurysm

A self-expanding, pseudo-braided device embodying a high expansion ratio and flexibility as well as comformability and improved radial force. The pseudo-braided device is particularly suited for advancement through and deployment within highly tortuous and very distal vasculature. Various forms of the pseudo-braided device are adapted for the repair of aneurysms and stenoses as well as for use in thrombectomies and embolic protection therapy.

Owner:ABBOTT CARDIOVASCULAR

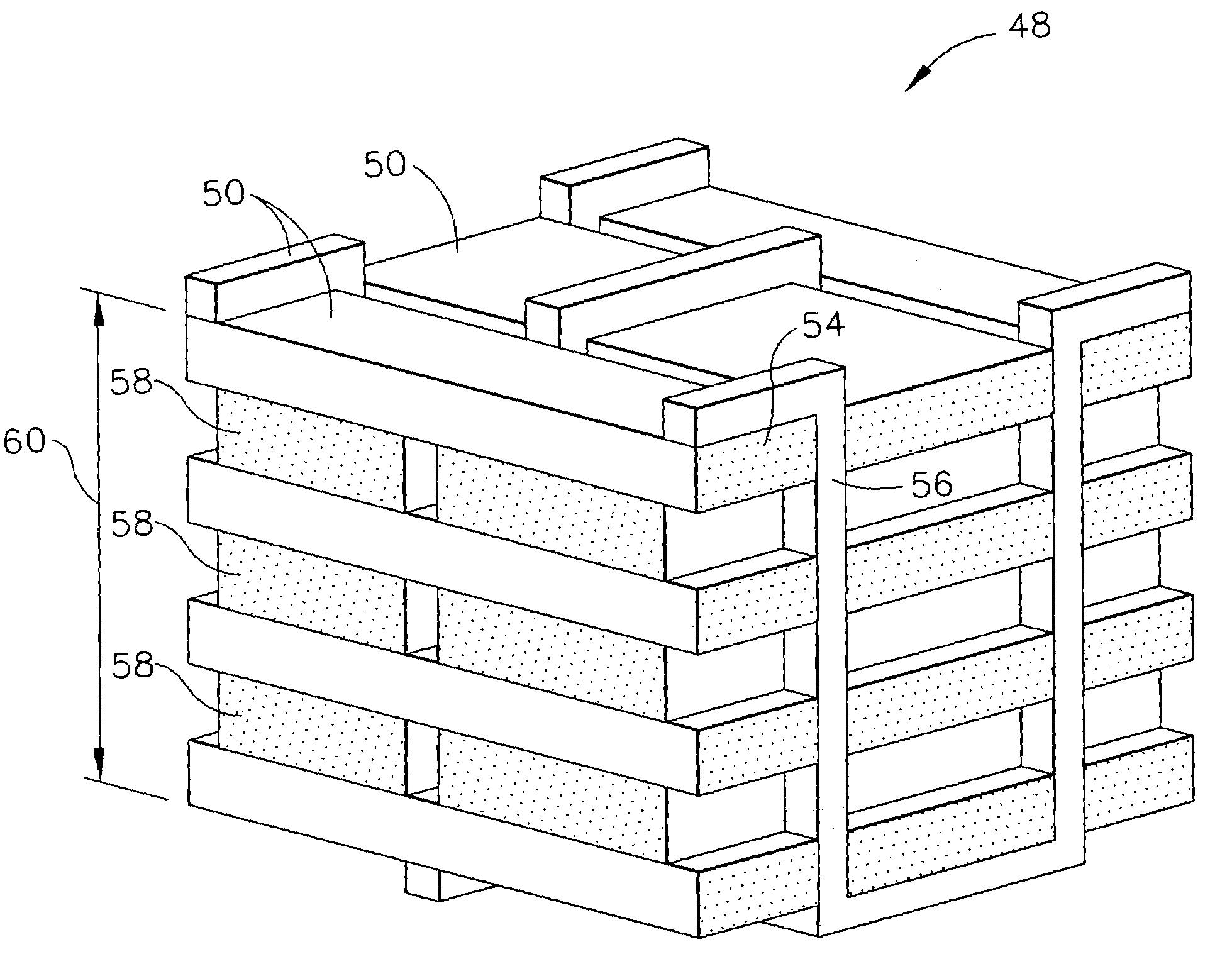

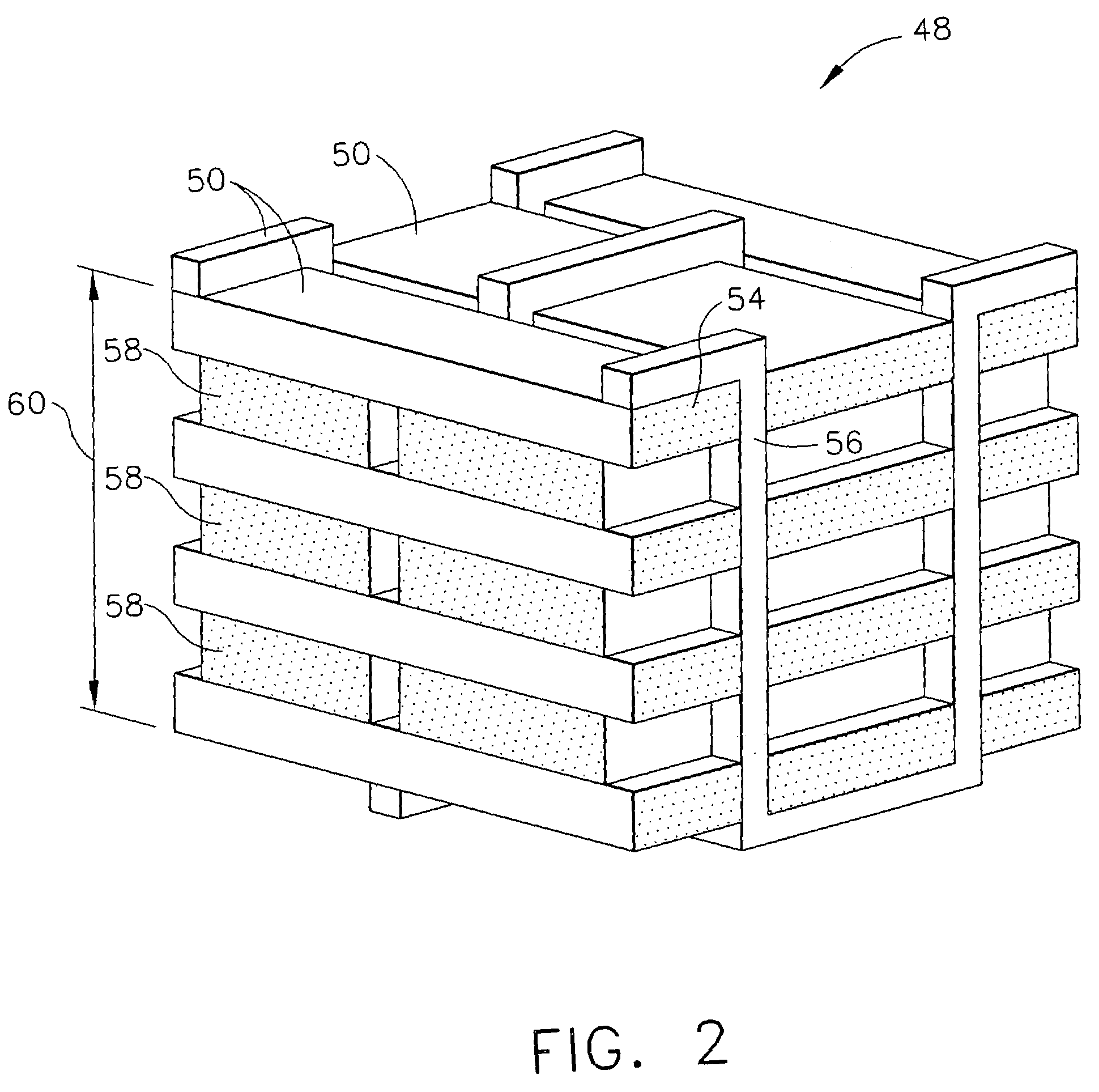

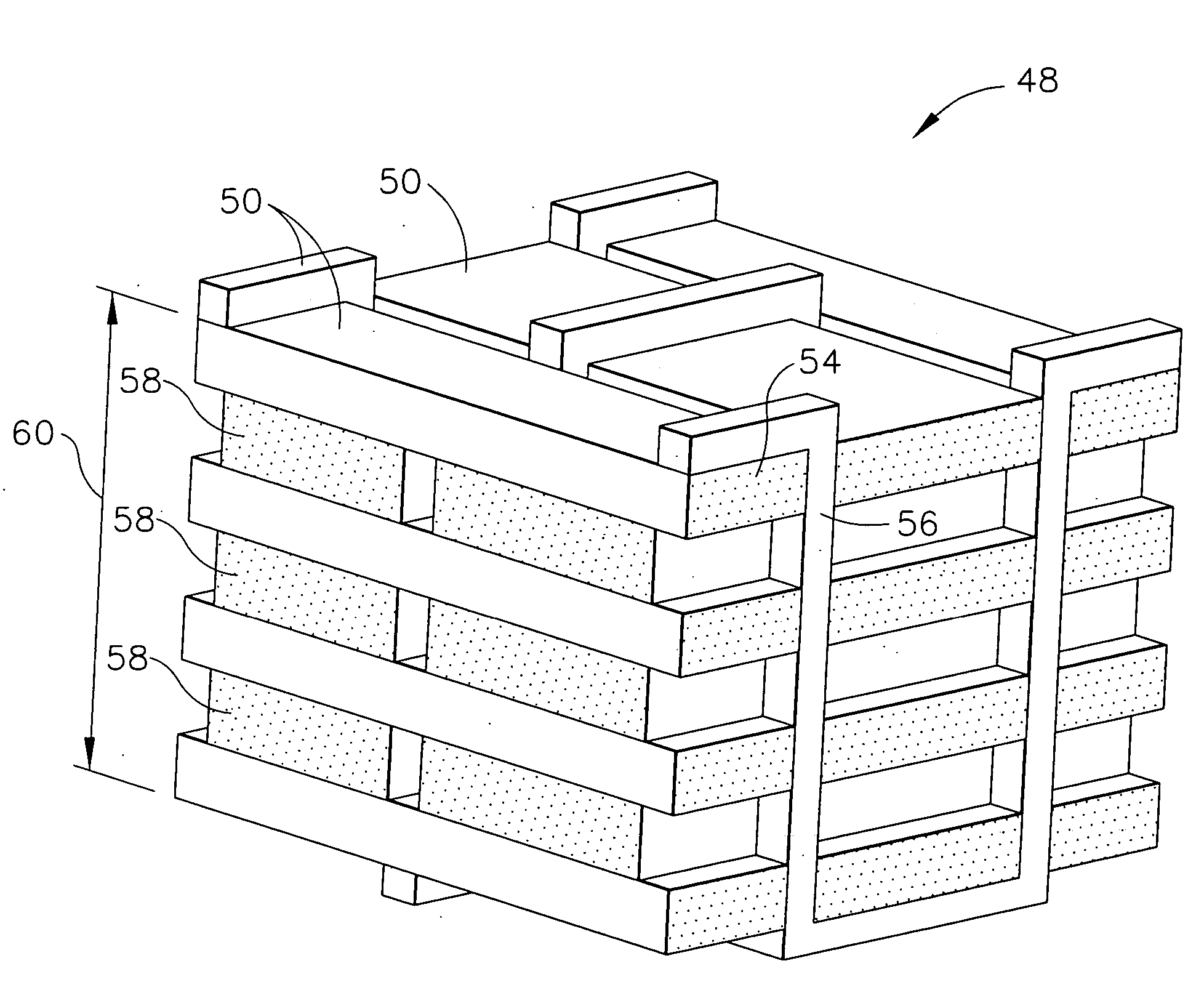

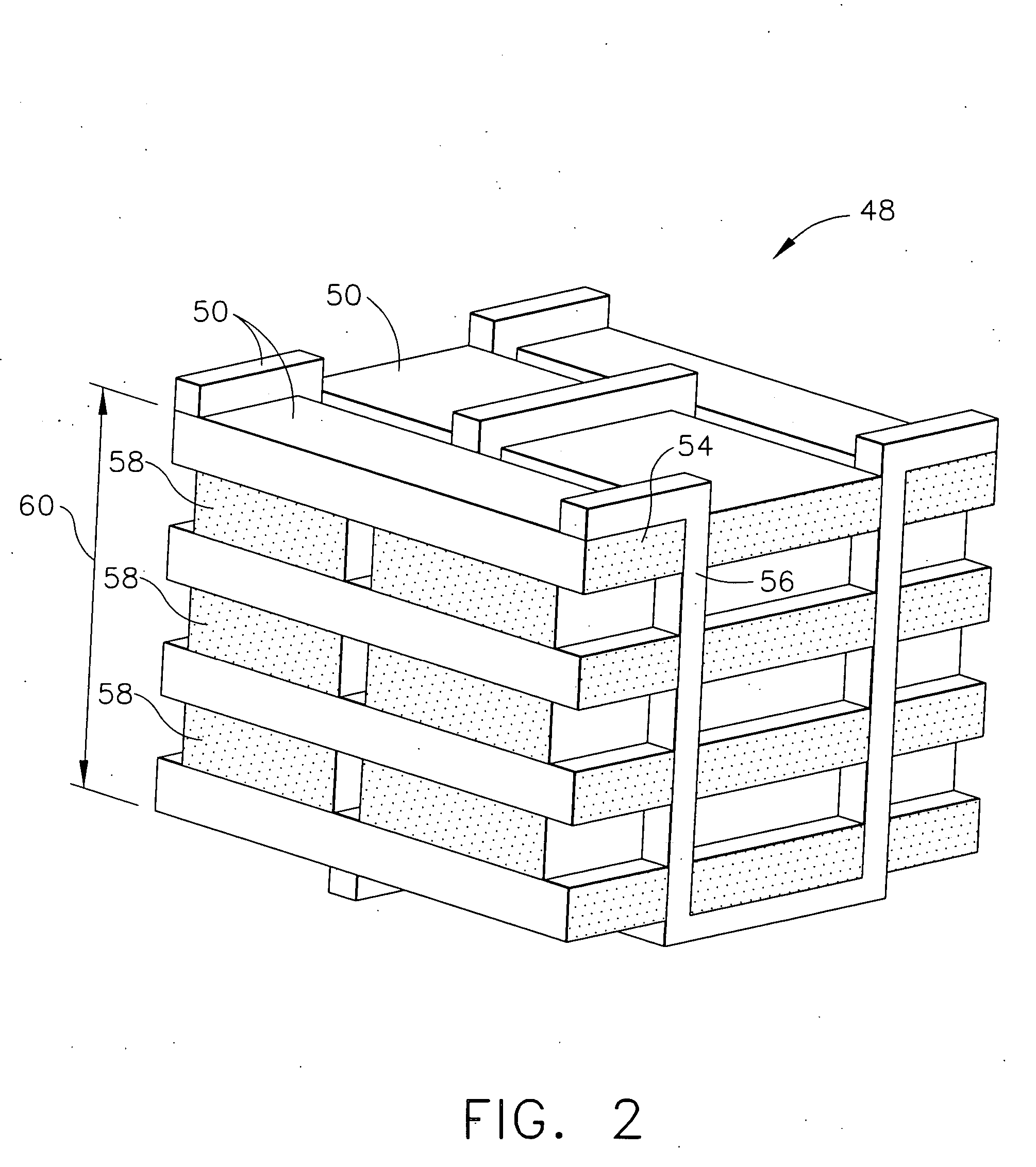

Orthogonal weaving for complex shape preforms

ActiveUS7247212B2Low costImprove performanceWeft knittingOrnamental textile articlesEngineeringNear net shape

An orthogonal stitch-weave method and fiber architecture. The architecture allows near-net-shape composite preforms to be fabricated, thereby reducing costs associated with complex preform shapes and increasing desired strengths of the composite.

Owner:GENERAL ELECTRIC CO

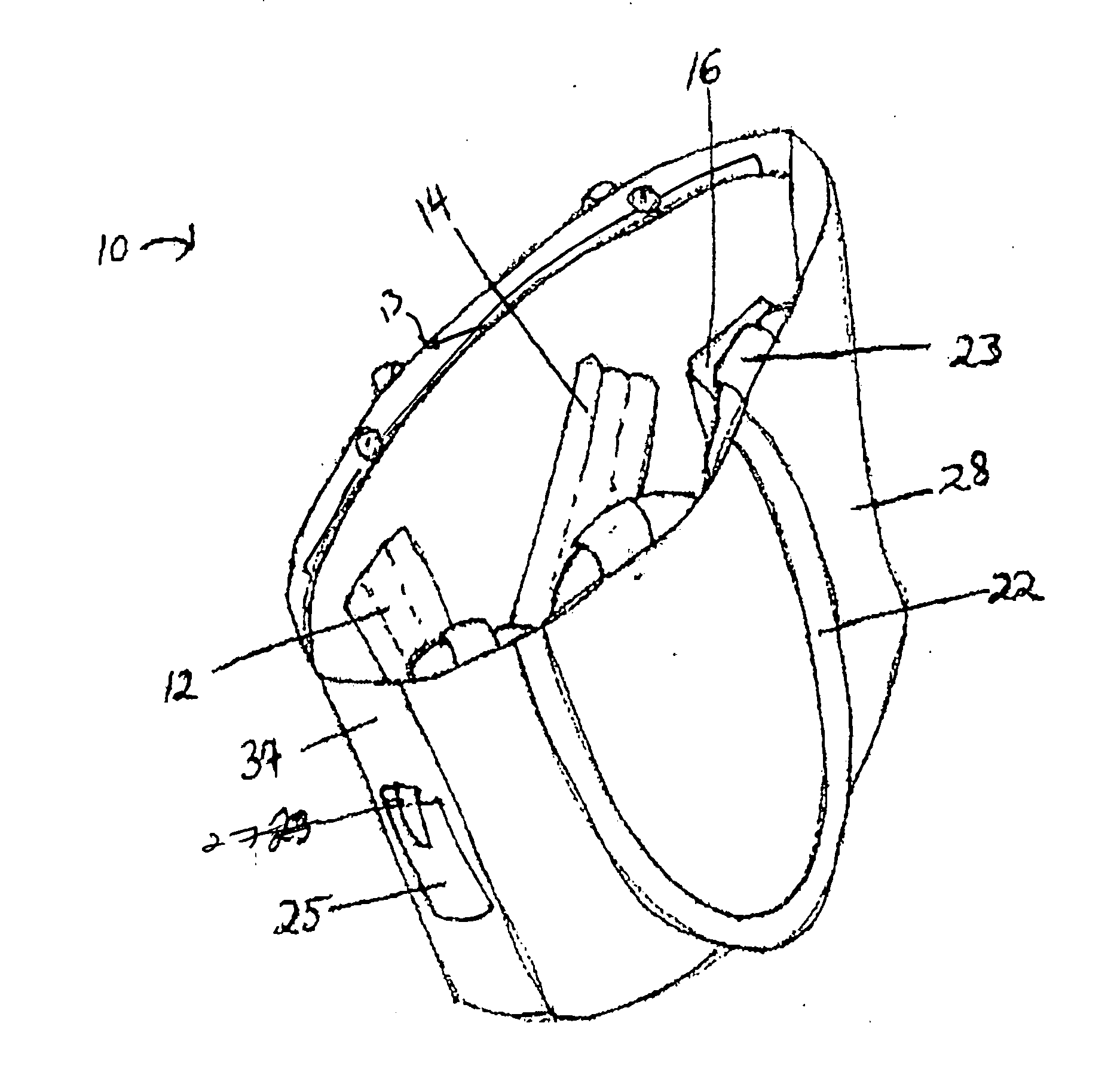

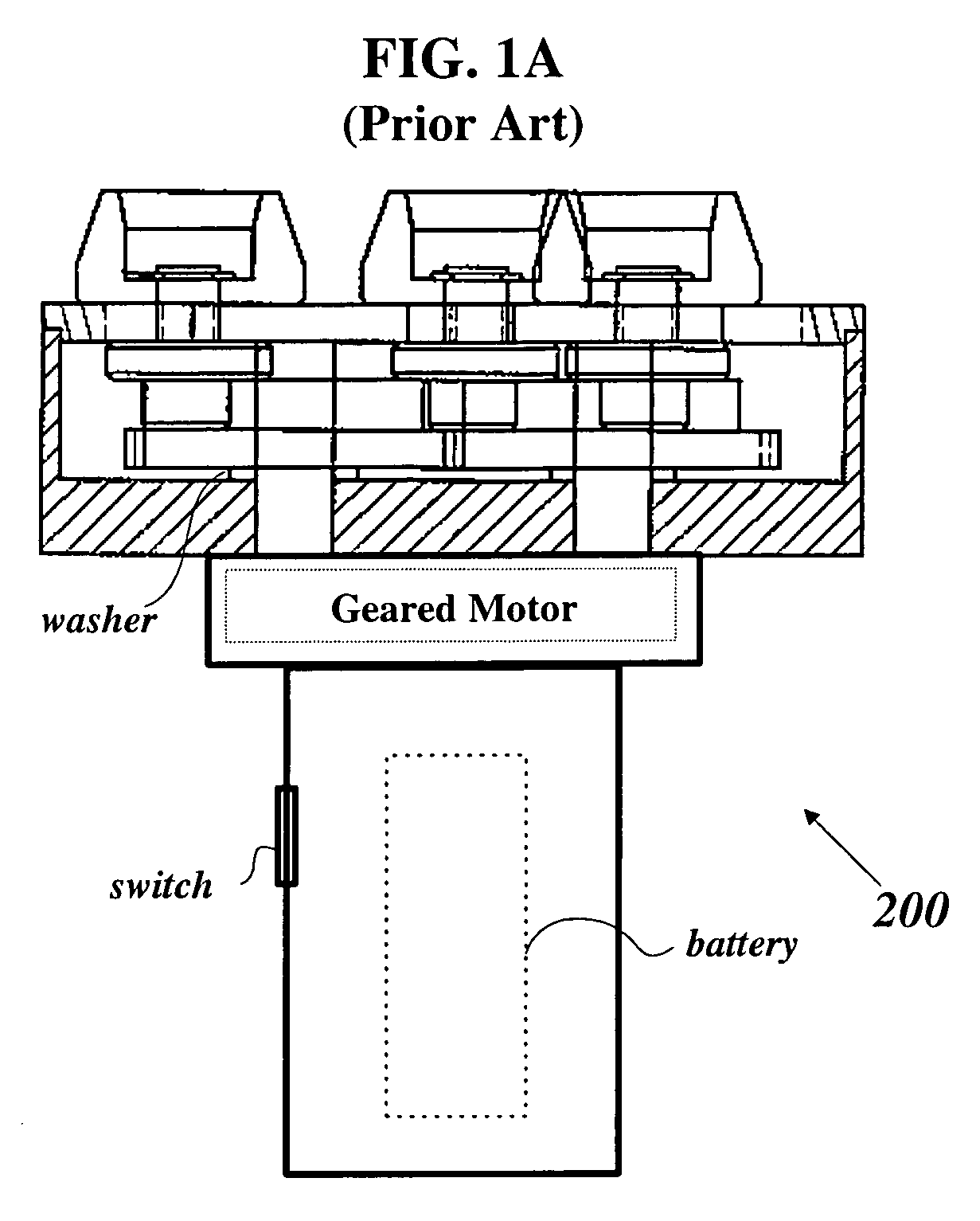

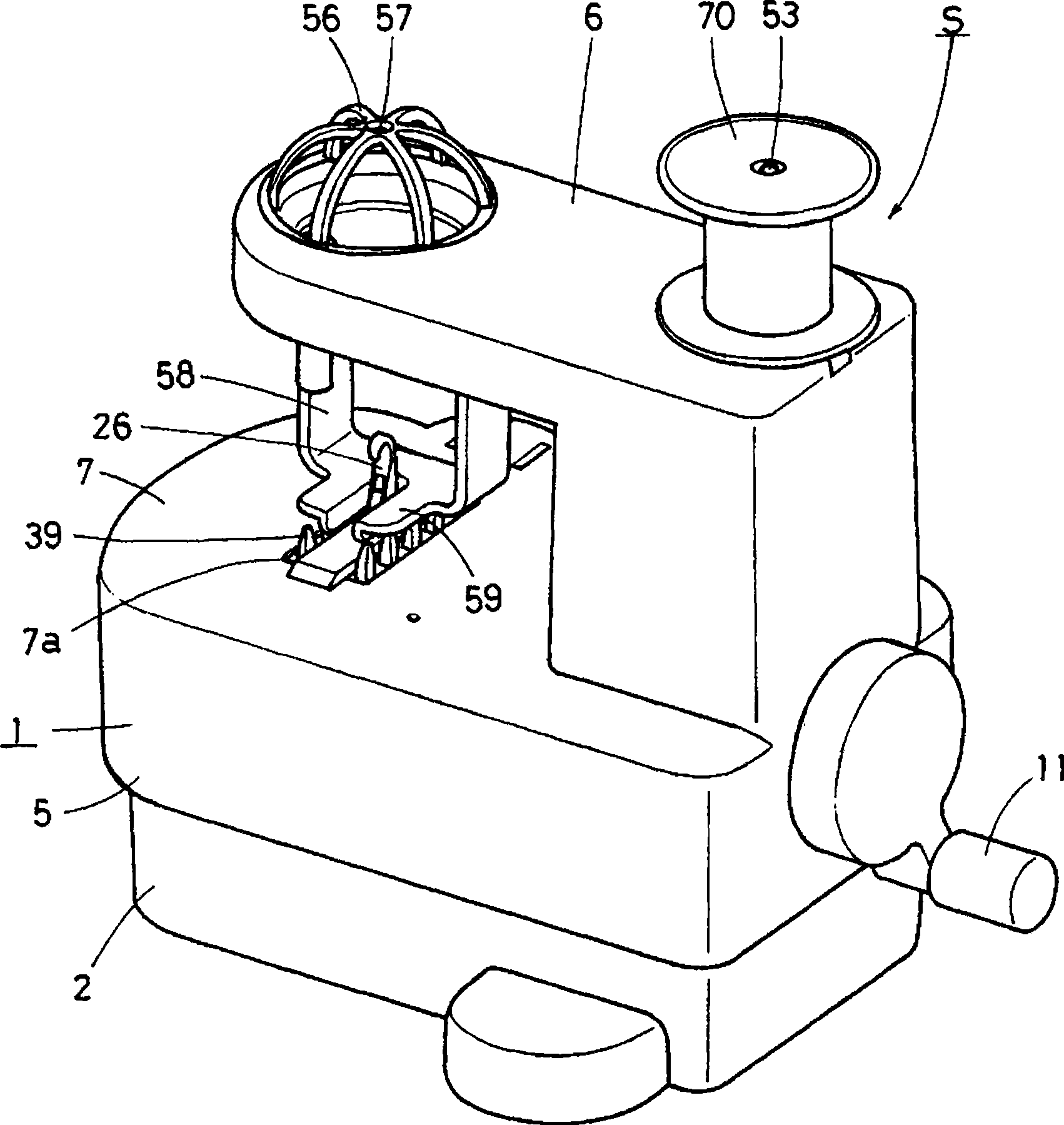

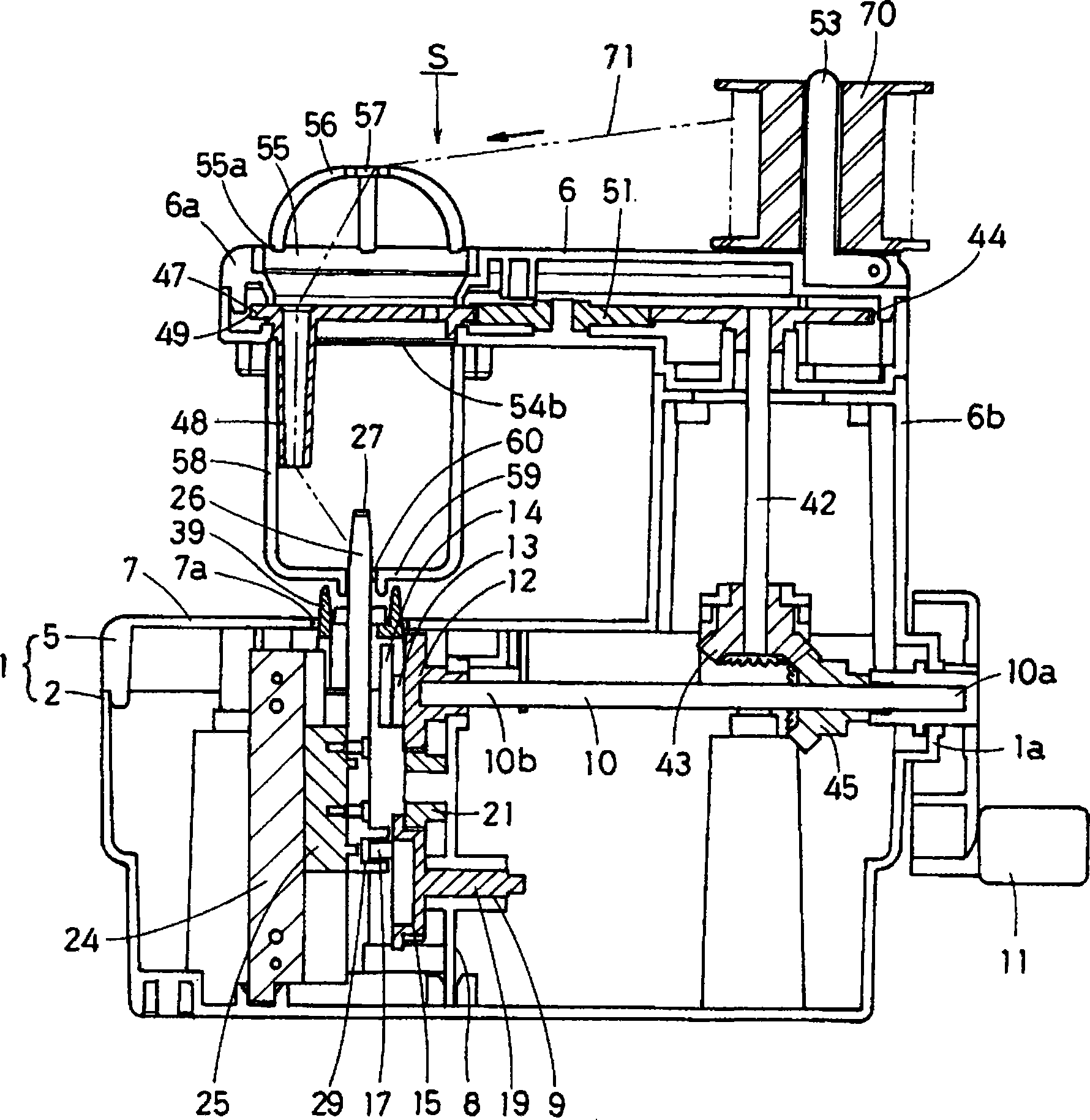

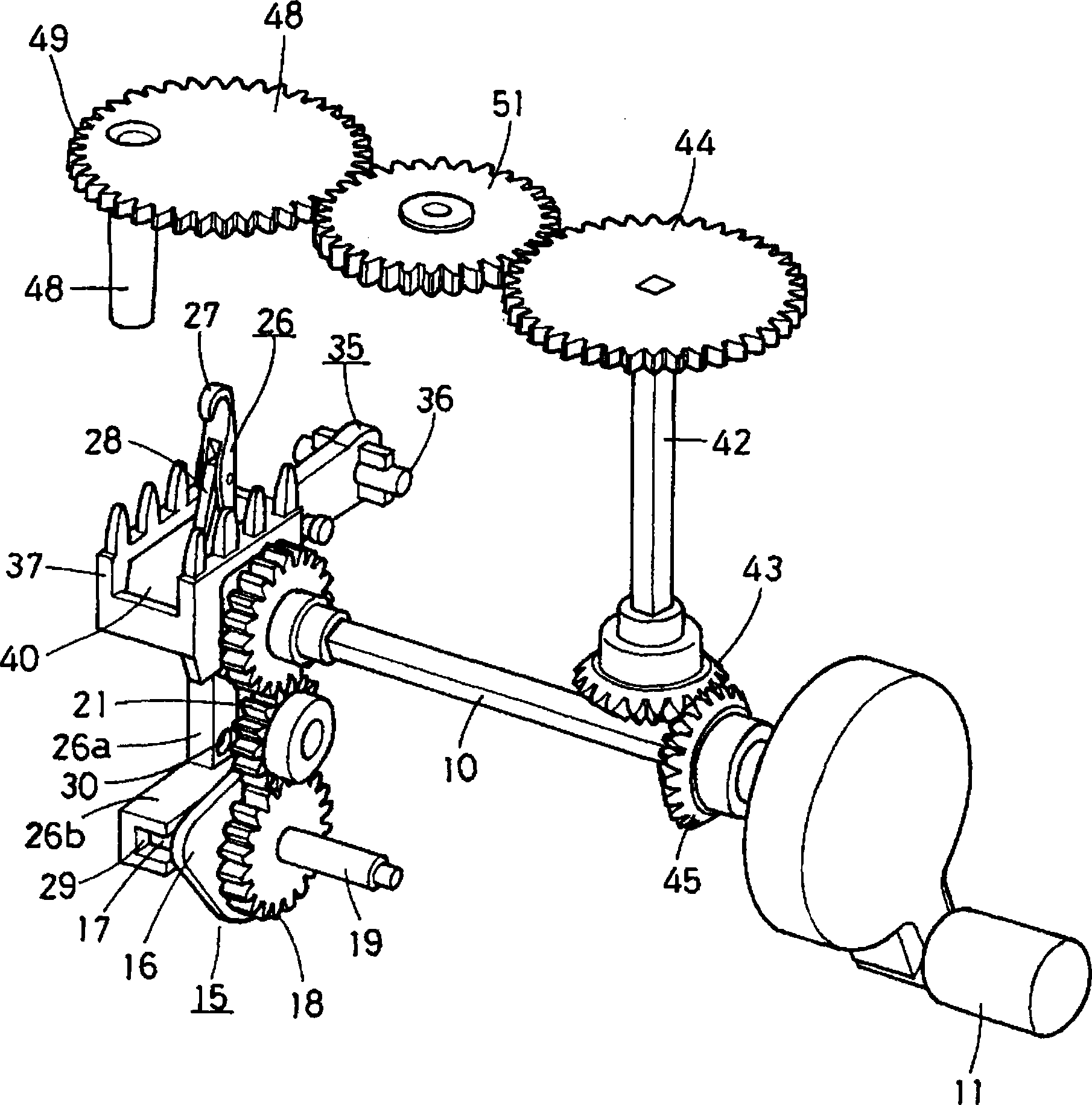

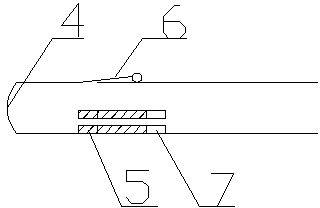

Hair braider and auxiliary devices

InactiveUS6520187B1Stable trackingShorten the timeHand lacing/braidingCurling devicesMechanical engineering

Owner:LEE MYUN WOO

Hair knitting machine

A hair braider for a three-bundle plait or braid includes a body having a handle (120) and a head portion (110) at one end of the handle; a selectively actuatable drive source (130) disposed within the body; and first and second rotatable rotors (300, 330) disposed within and accessible through openings formed in the head portion. They are operatively coupled to the drive source through a plurality of gears such that they rotate in opposite directions. The hair braider further includes a plurality of hair retaining members (200) that are received within openings formed through the first and second rotatable rotors, wherein each hair retaining member has a bore (216) formed therethrough for receiving one bundle of hair. A mechanism (400) transfers at a transfer location one hair retaining member from one rotor to the other rotor as the rotors rotate.; The rotation of the rotors in opposie directions and he successive transfer of one hair retaining member from one rotor to the other rotor results in a true, three-bundle braid being formed.

Owner:ELYSEE BEAUTY PROD

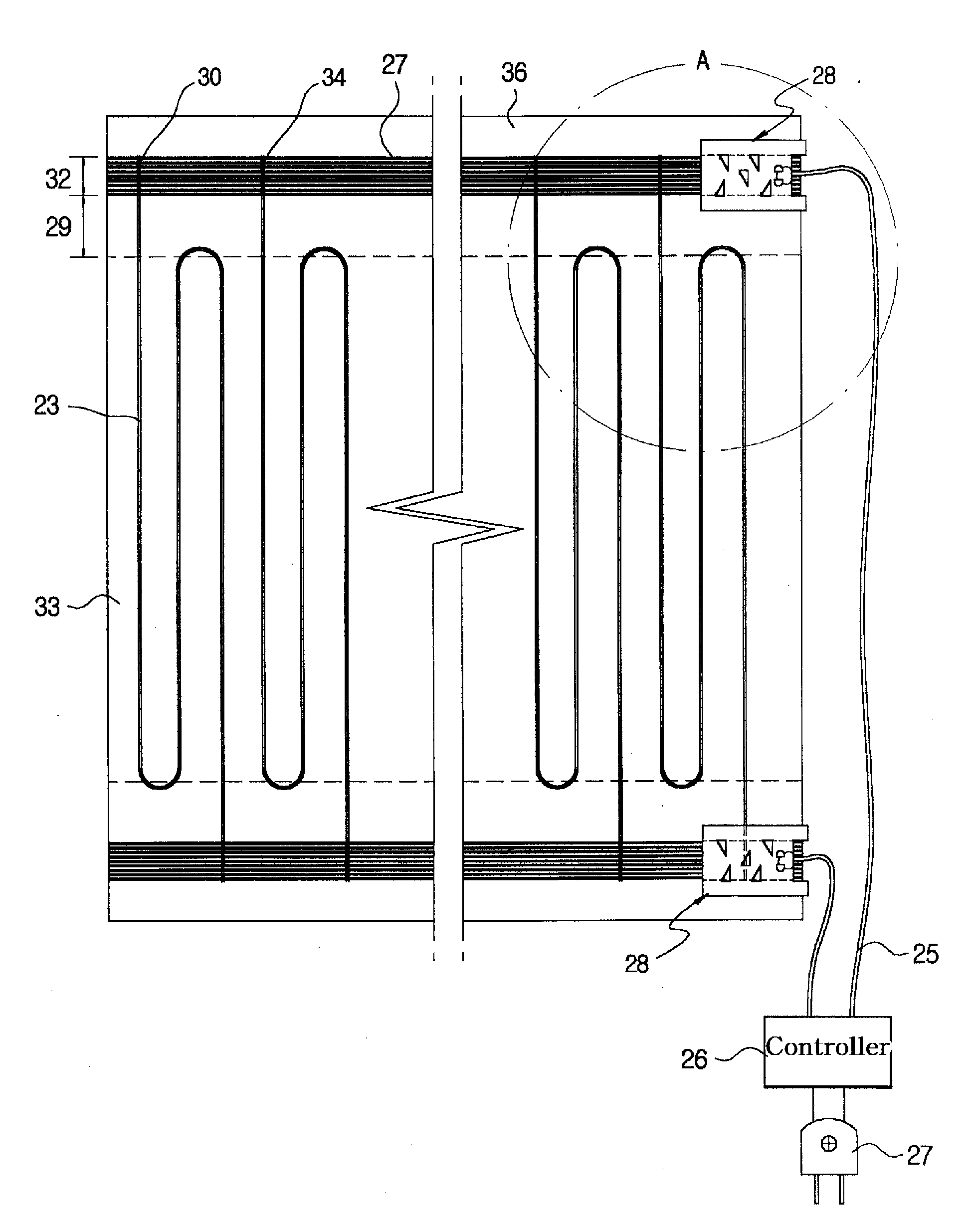

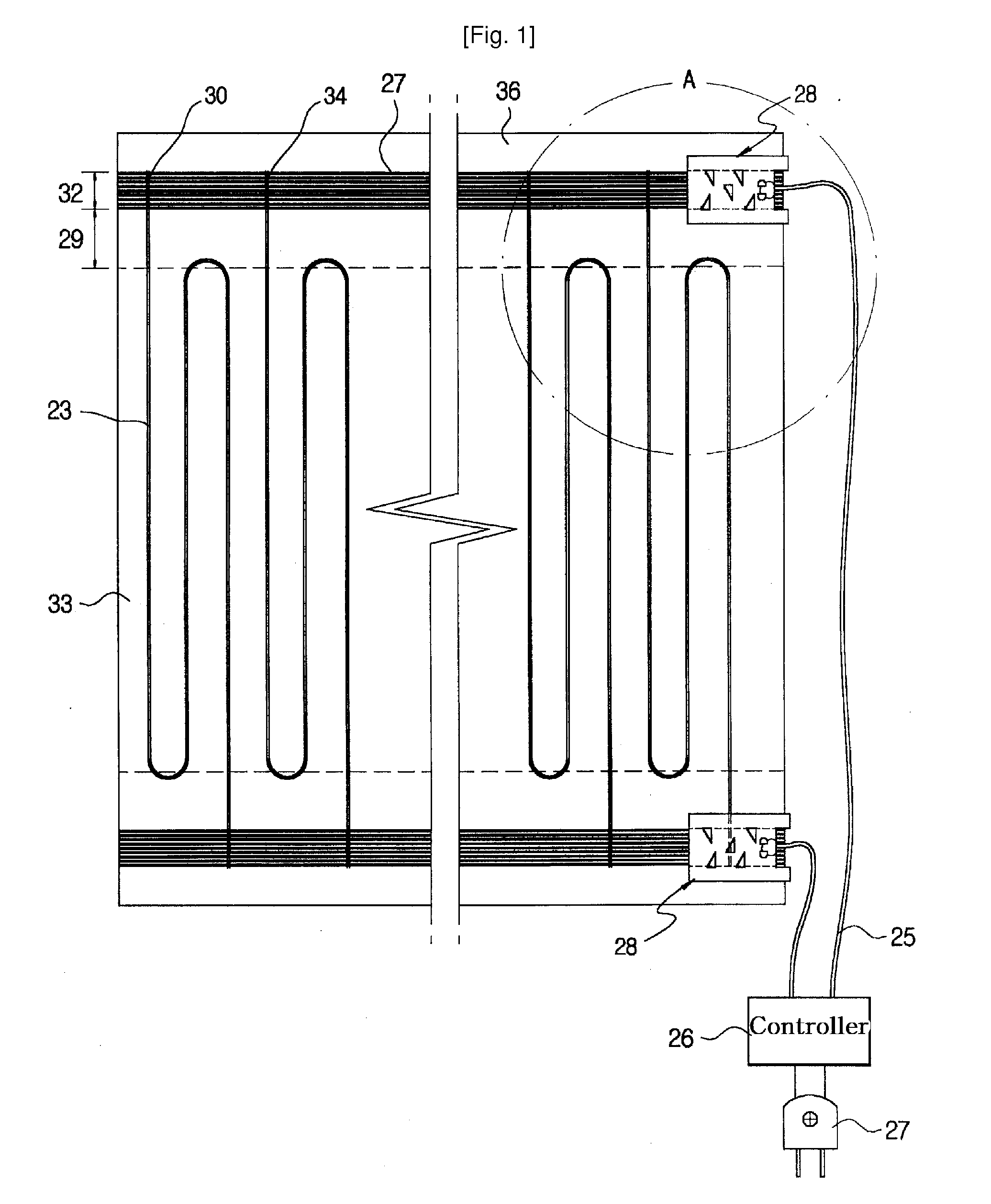

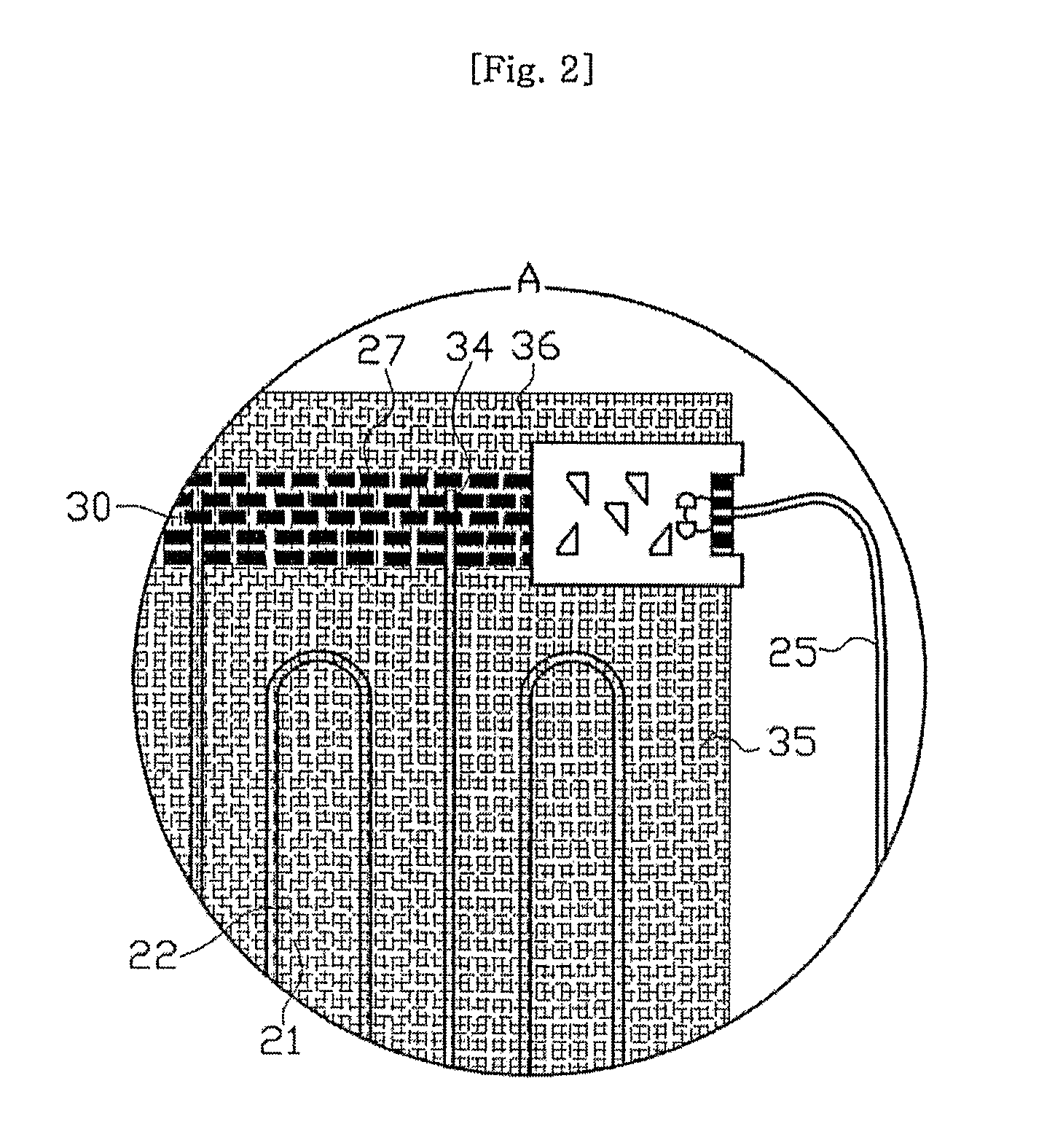

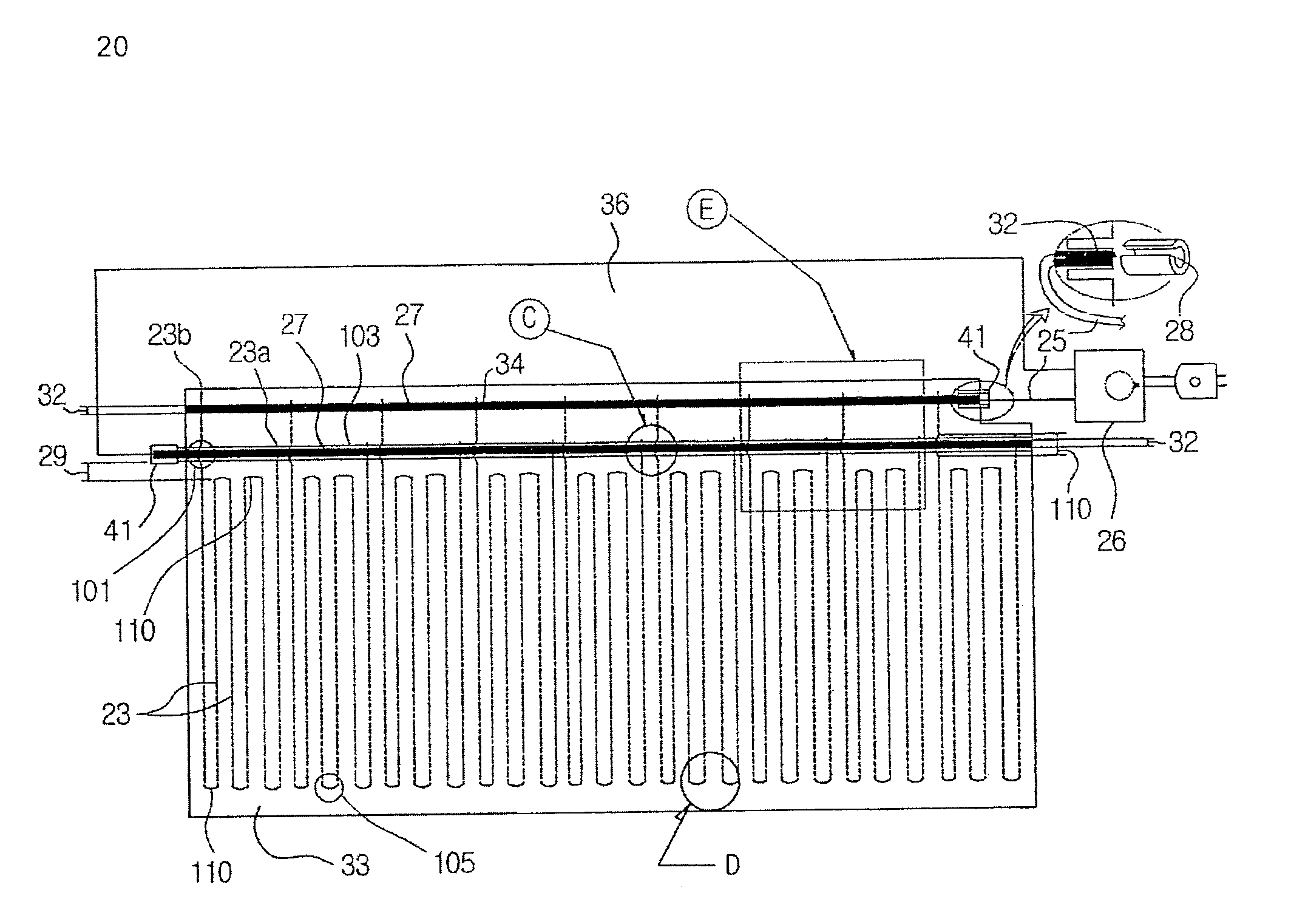

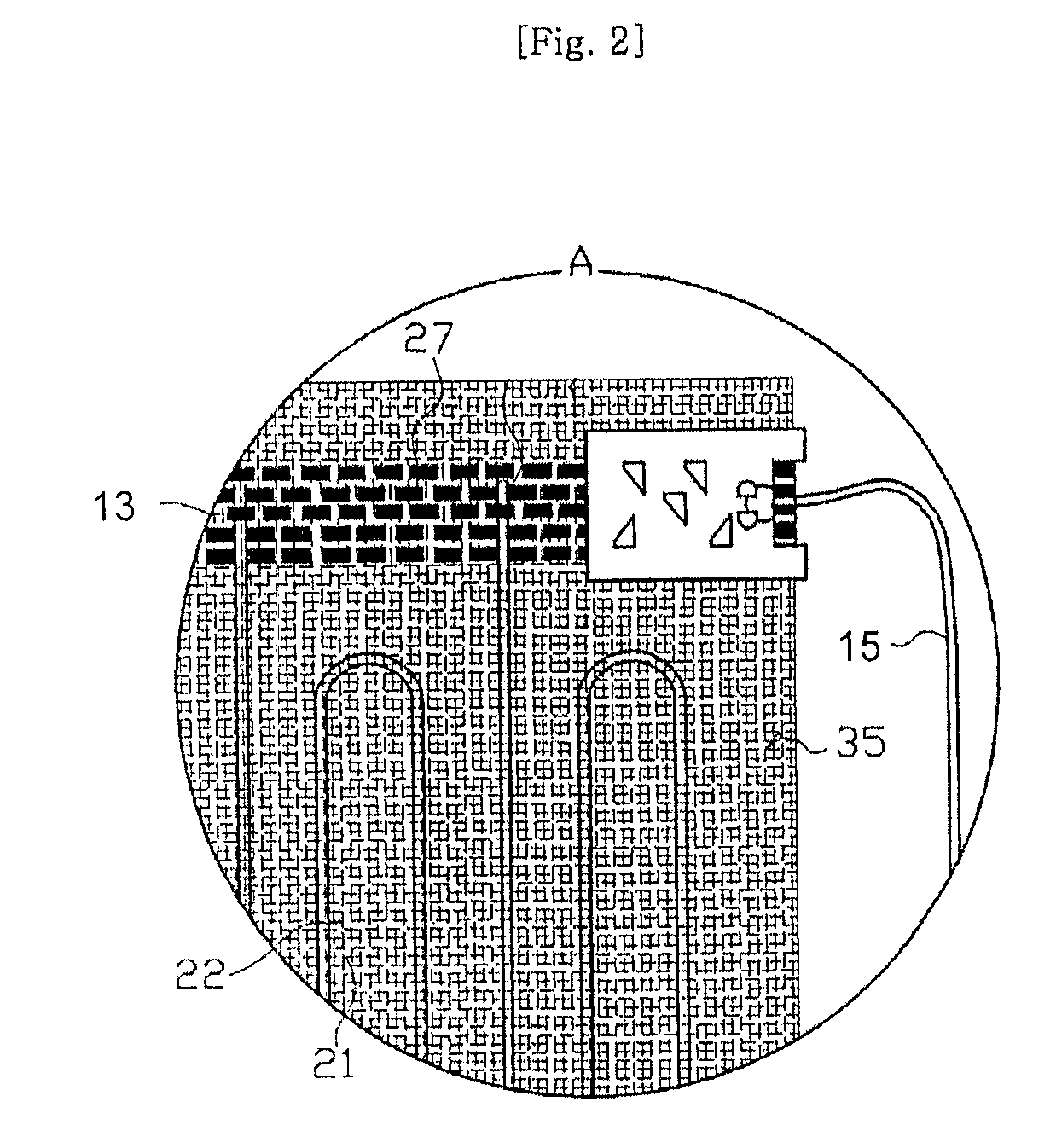

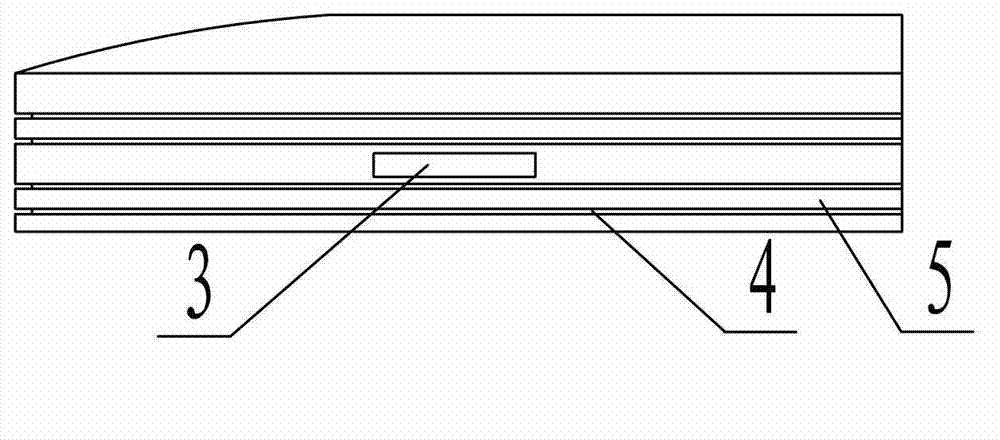

Heating Fabric and Manufacturing Method Thereof

InactiveUS20080135120A1Firmly connectedReduce product failureCrochetingOrnamental textile articlesFiberCarbon fibers

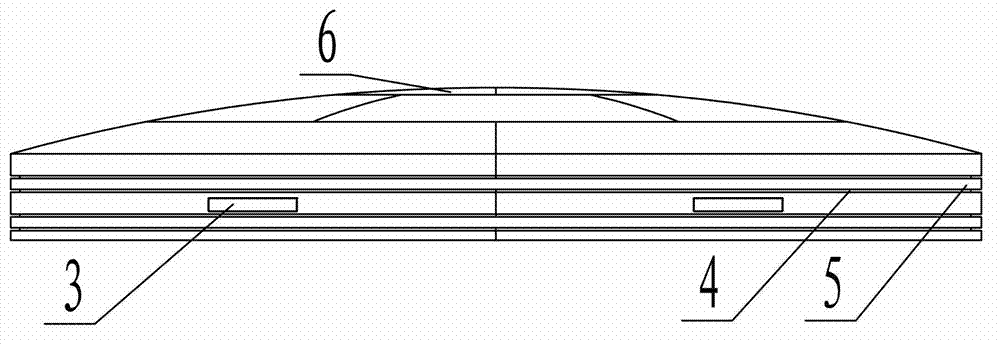

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

Orthogonal weaving for complex shape preforms

ActiveUS20060130957A1Improve performanceLow costWeft knittingOrnamental textile articlesEngineeringNear net shape

An orthogonal stitch-weave method and fiber architecture. The architecture allows near-net-shape composite preforms to be fabricated, thereby reducing costs associated with complex preform shapes and increasing desired strengths of the composite.

Owner:GENERAL ELECTRIC CO

Heating fabric and manufacturing method thereof

InactiveUS7820945B2Firmly connectedImprove product reliabilityCrochetingOrnamental textile articlesFiberCarbon fibers

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

Needlecraft tote carrier

The present invention relates to a needlecraft tote carrier appropriate for storage. More specifically, the carrier provides specialized compartments for receiving yarn, instructions or instruction manuals, needles, crochet hooks and a main compartment for receiving the project. The yarn pockets can include a closure member for securing the yarn pocket. The closure member is selected to expeditiously release yarn from the pocket without tangling. The closure member can retain a ball or skein of yarn or thread in the yarn pocket while allowing a strand from the ball or skein to extend from the yarn pocket and be unraveled from the ball or skein. The carrier can also comprise at least one pocket, or a plurality of pockets for receiving writing utensils, crochet hooks, scissors, tape measures, cable hooks, stitch markers, stitch holders, needle caps, cellular phones or other notions.

Owner:SCHRINER PAULA H

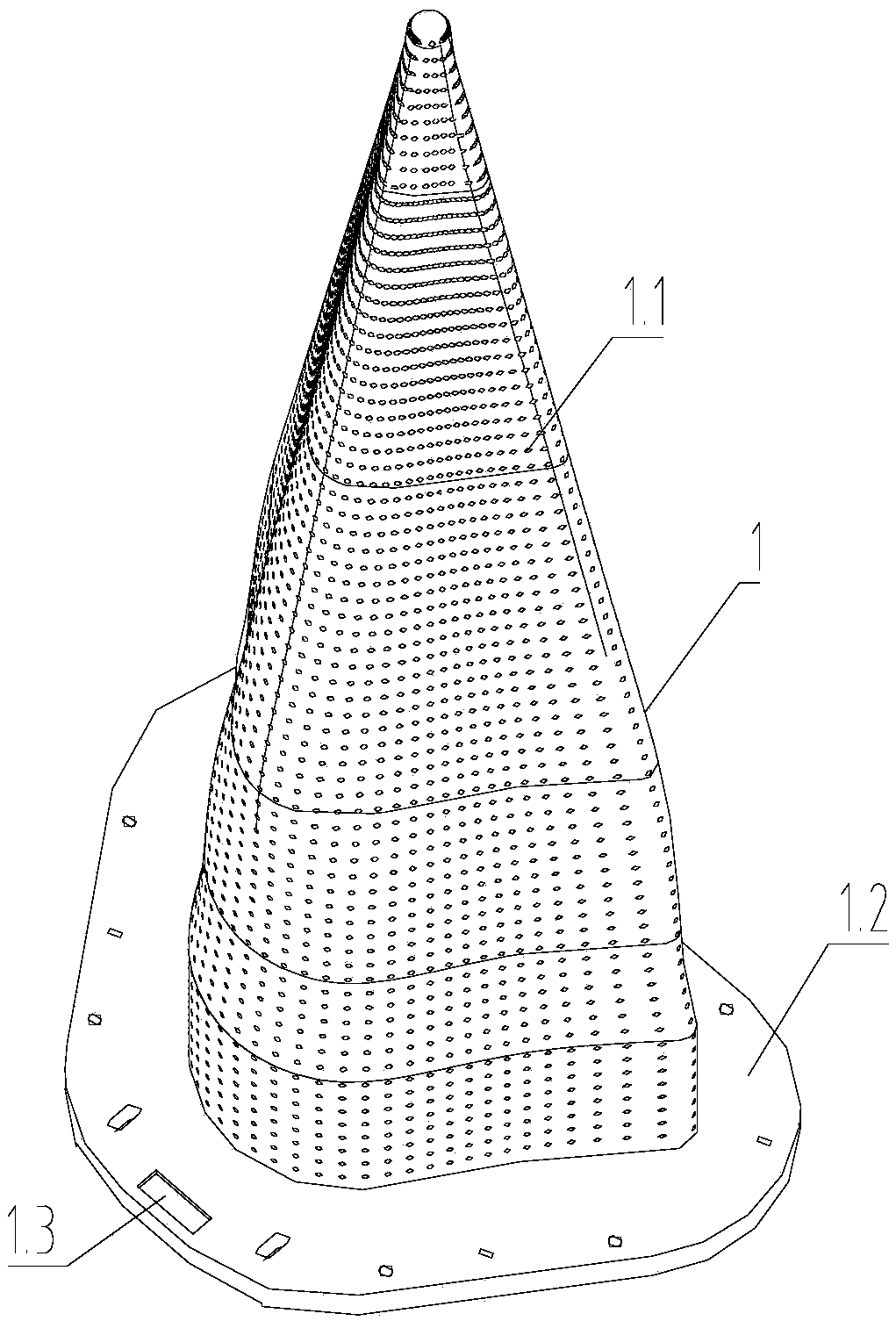

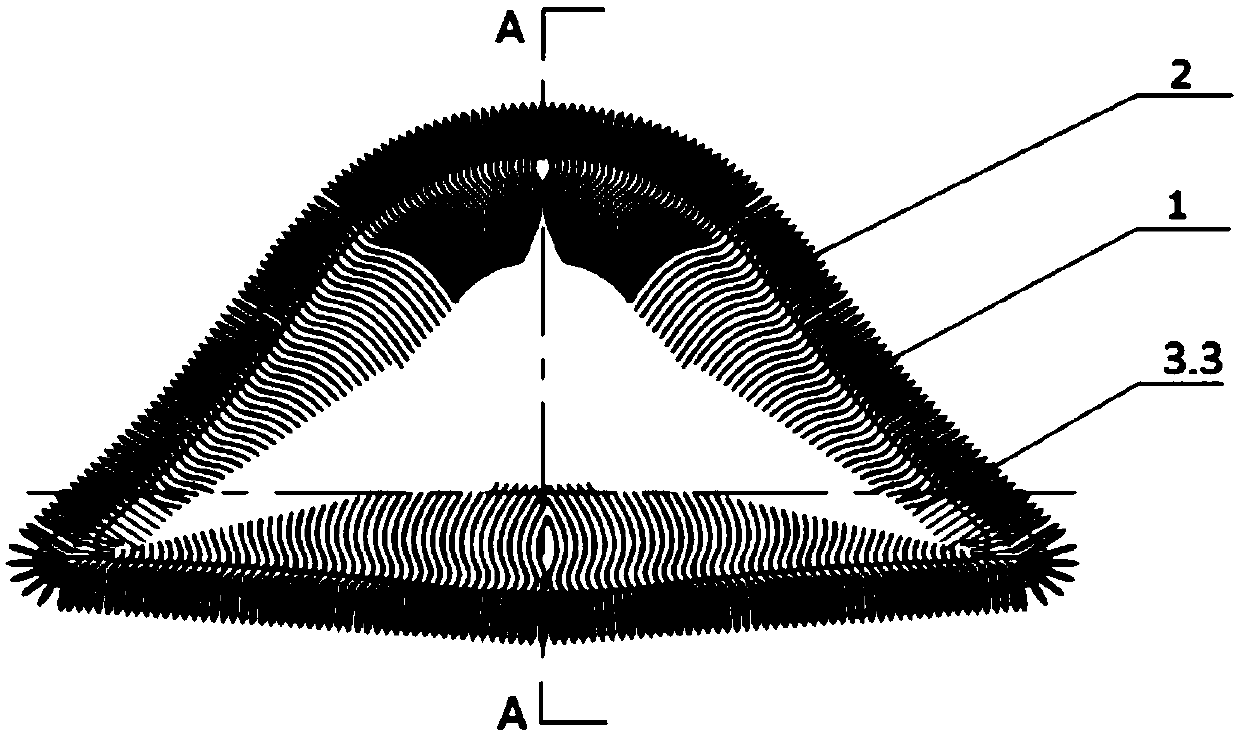

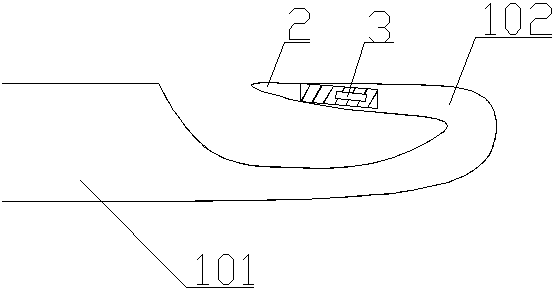

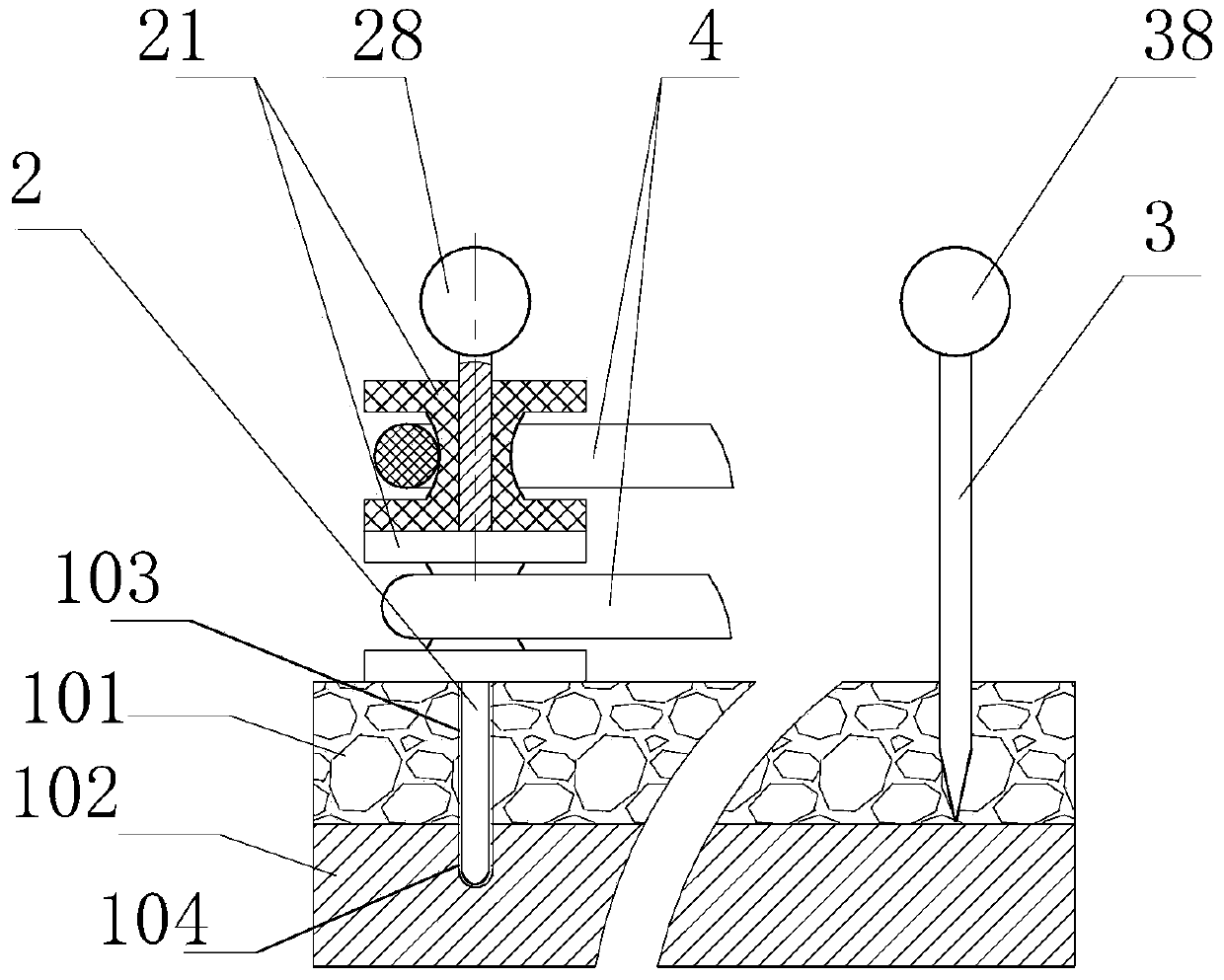

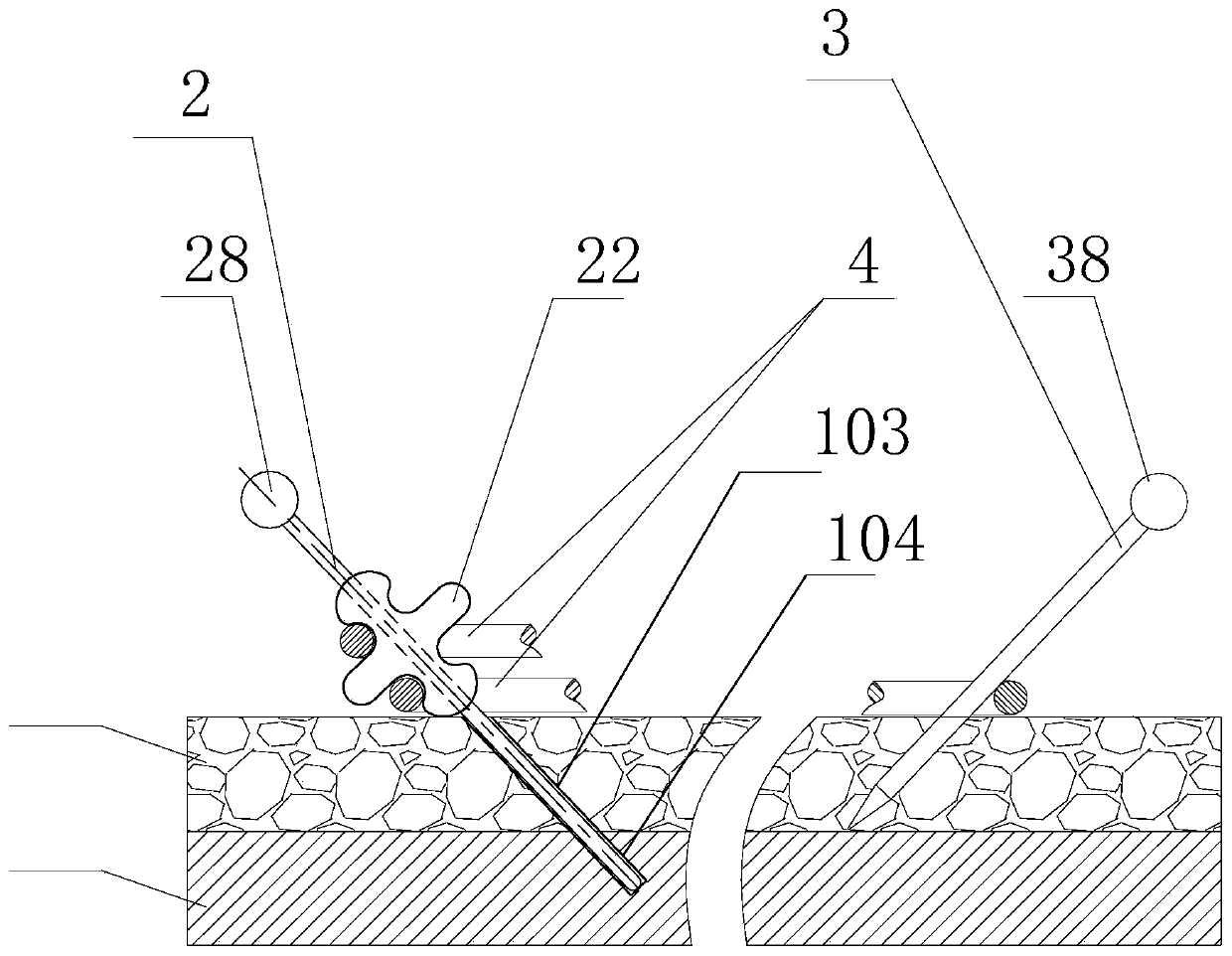

Special-shaped curved surface quasi-triaxial fabric, knitting process method thereof and application of fabric

ActiveCN109652918AChange volume contentAchieve relative continuityHand lacing/braidingFiberEngineering

The invention discloses a special-shaped curved surface quasi-triaxial fabric, a knitting process method thereof and an application of the fabric. The method includes the steps: 1) designing and manufacturing a core mold with a hollow structure according to the appearance of the fabric and forming a plurality of needle holes in the core mold; 2) threading normal fibers at the tails of steel needles, enabling the tip of each steel needle to penetrate one needle hole outwards from the inside of the core mold and retaining the tails in the needle holes; 3) winding warp-wise fibers and weft-wise fibers in gaps of the steel needles on the outer surface of the core mold, and knitting warp-wise and weft-wise fiber layers; 4) pulling out the steel needles one by one, reserving the normal fibers inthe fiber layers, pressing the fiber layers by a prepressing tool and releasing the mold to obtain the special-shaped curved surface quasi-triaxial fabric when the warp-wise fibers and the weft-wisefibers reach specified thickness distribution. The thickness of each needle hole is equivalent to that of each normal fiber. Damage to the fibers caused by needling and integrated piercing is overcome, and a special-shaped fabric structure achieves good mechanical properties and high reliability.

Owner:湖北三江航天江北机械工程有限公司

Finger knitting auxiliary method using computer drawing

InactiveCN1737809ARealize drawingHand lacing/braidingSpecial data processing applicationsTight frameAuxiliary memory

This invention discloses one computer assistant hand knitting method, which comprises the following steps: opening Word graph process on Windows platform and inputting fonts and graph formed pattern; pre-processing step by the amplifying, color filling and extending in tool box. The steps comprise form process, frame unit copy process and the finally graph printing step.

Owner:刘立宏

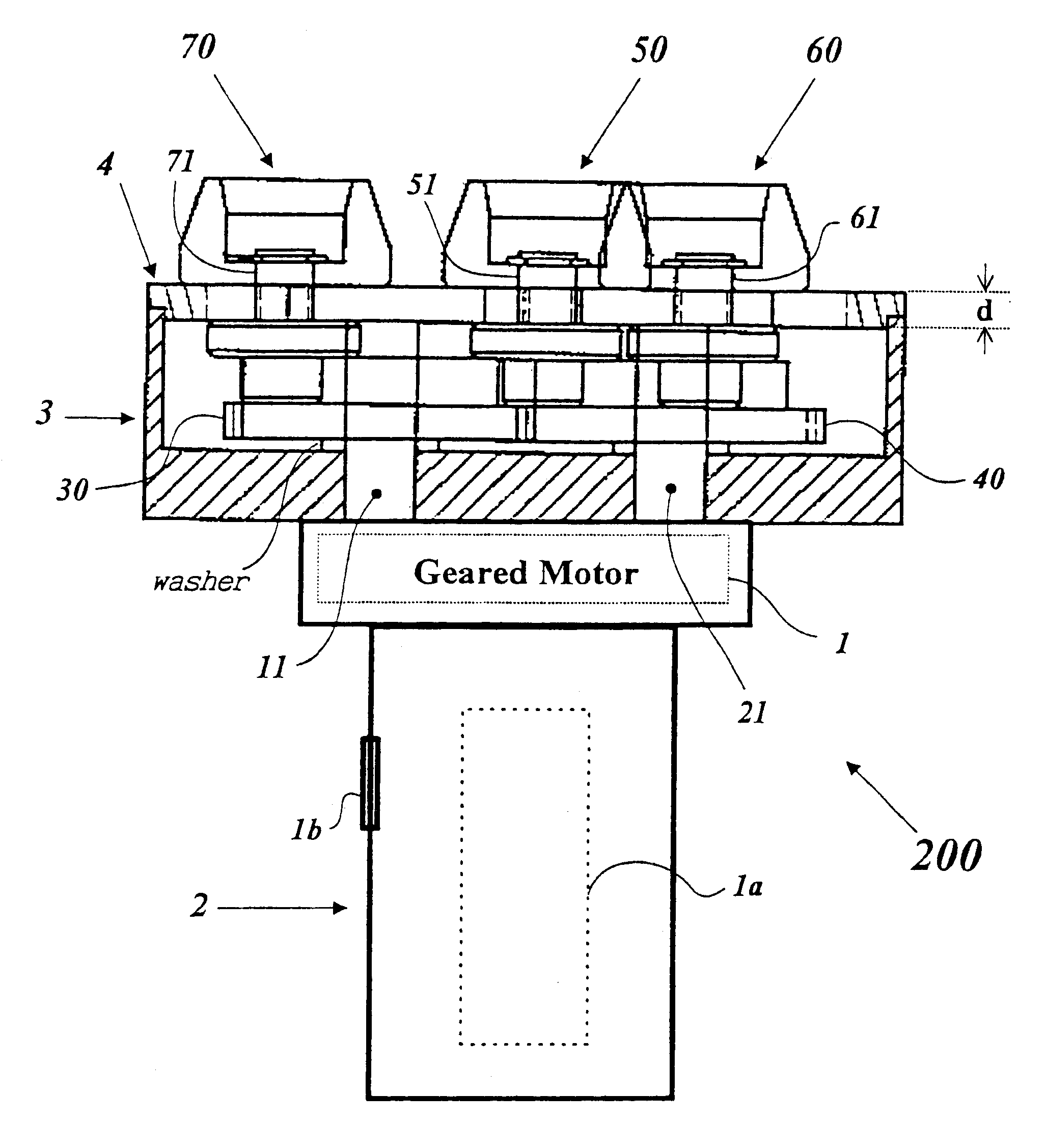

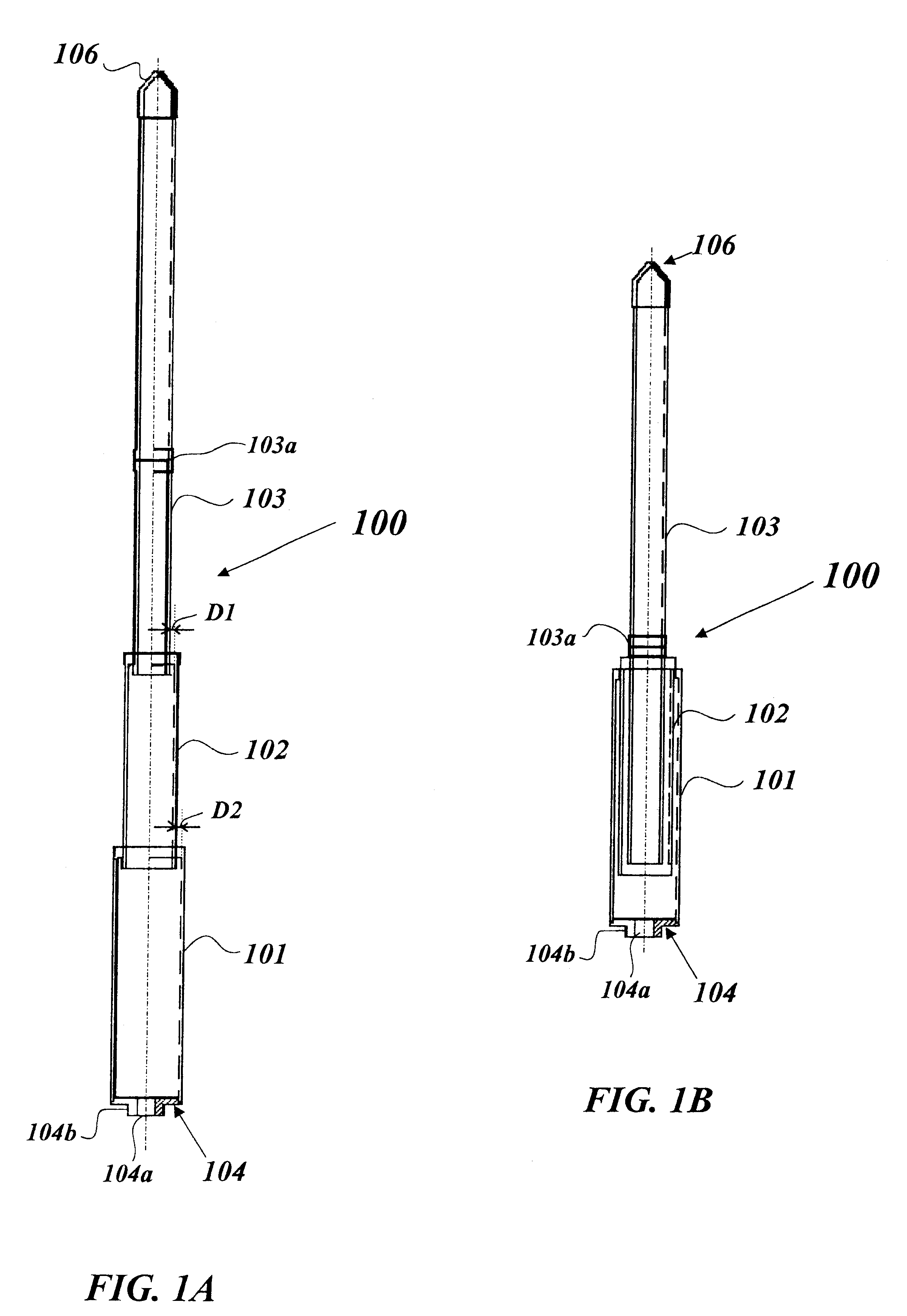

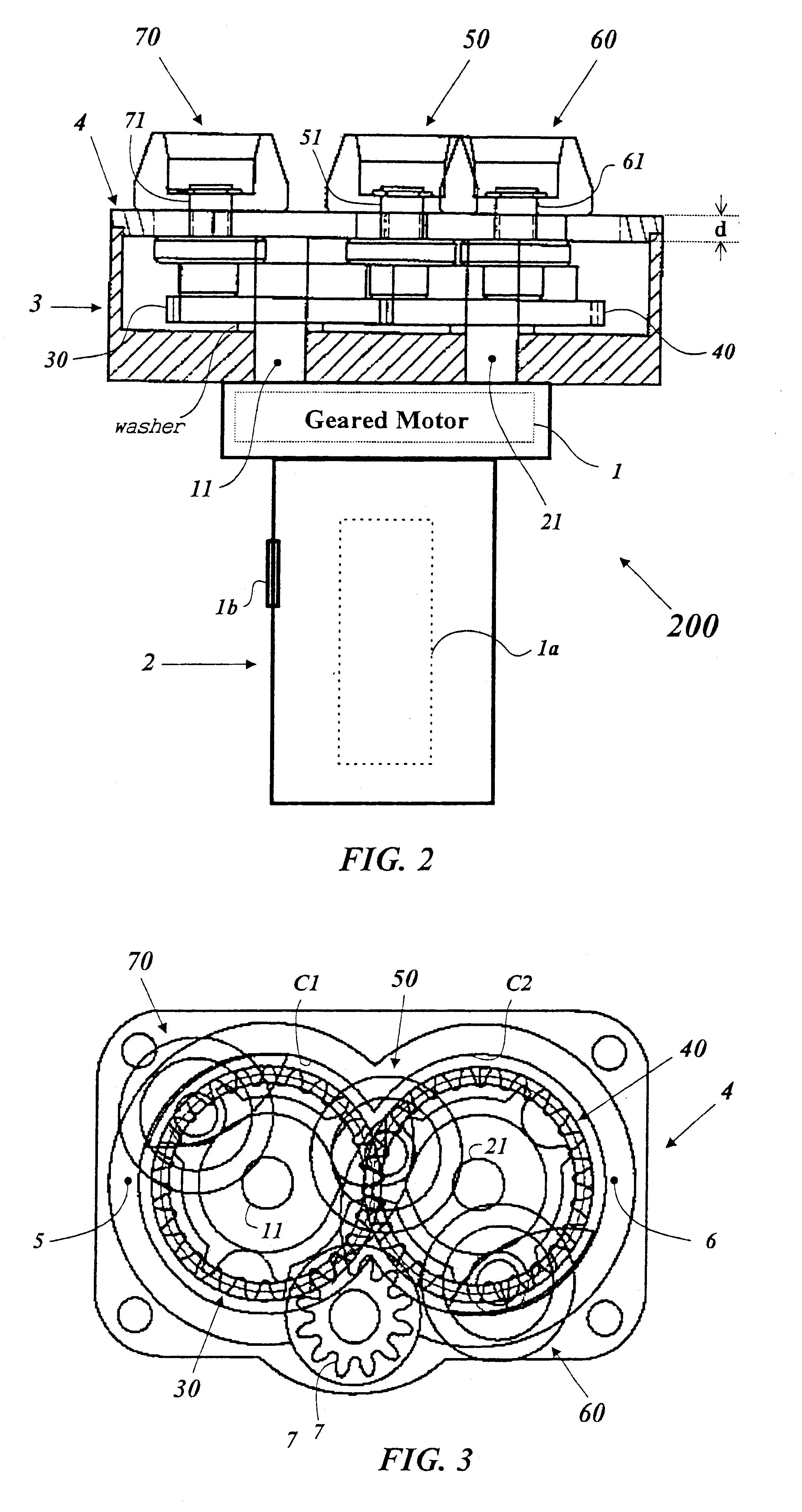

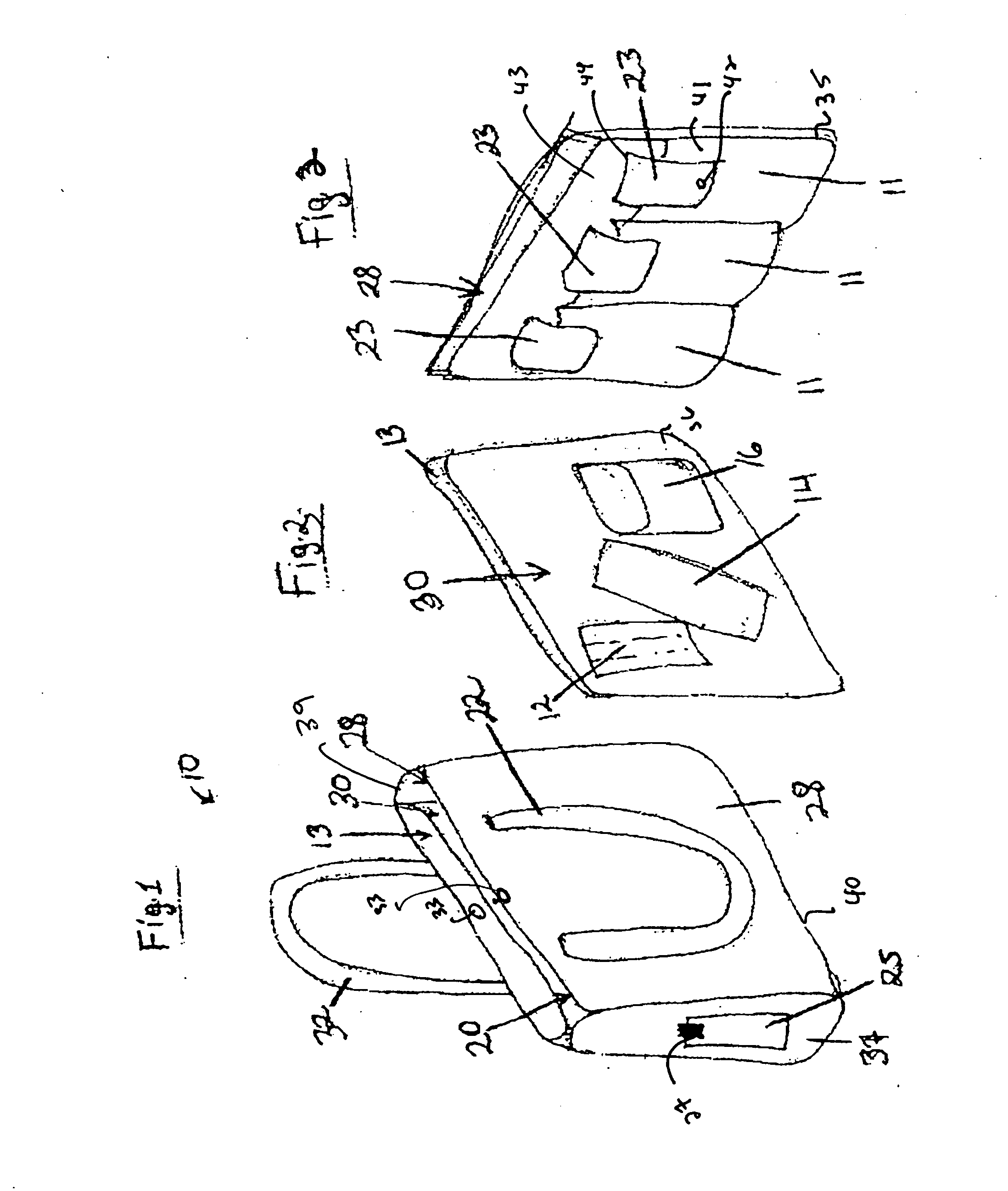

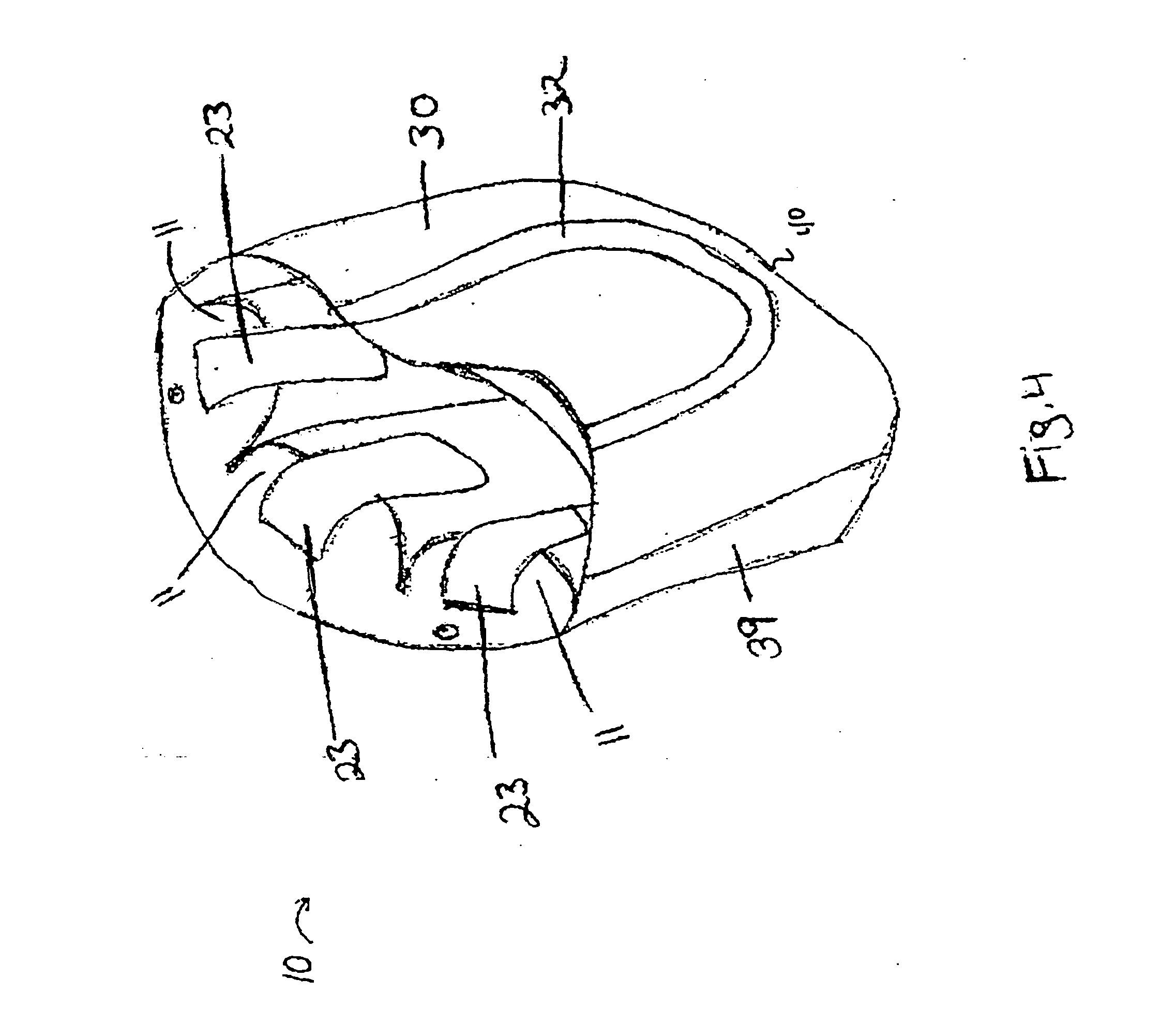

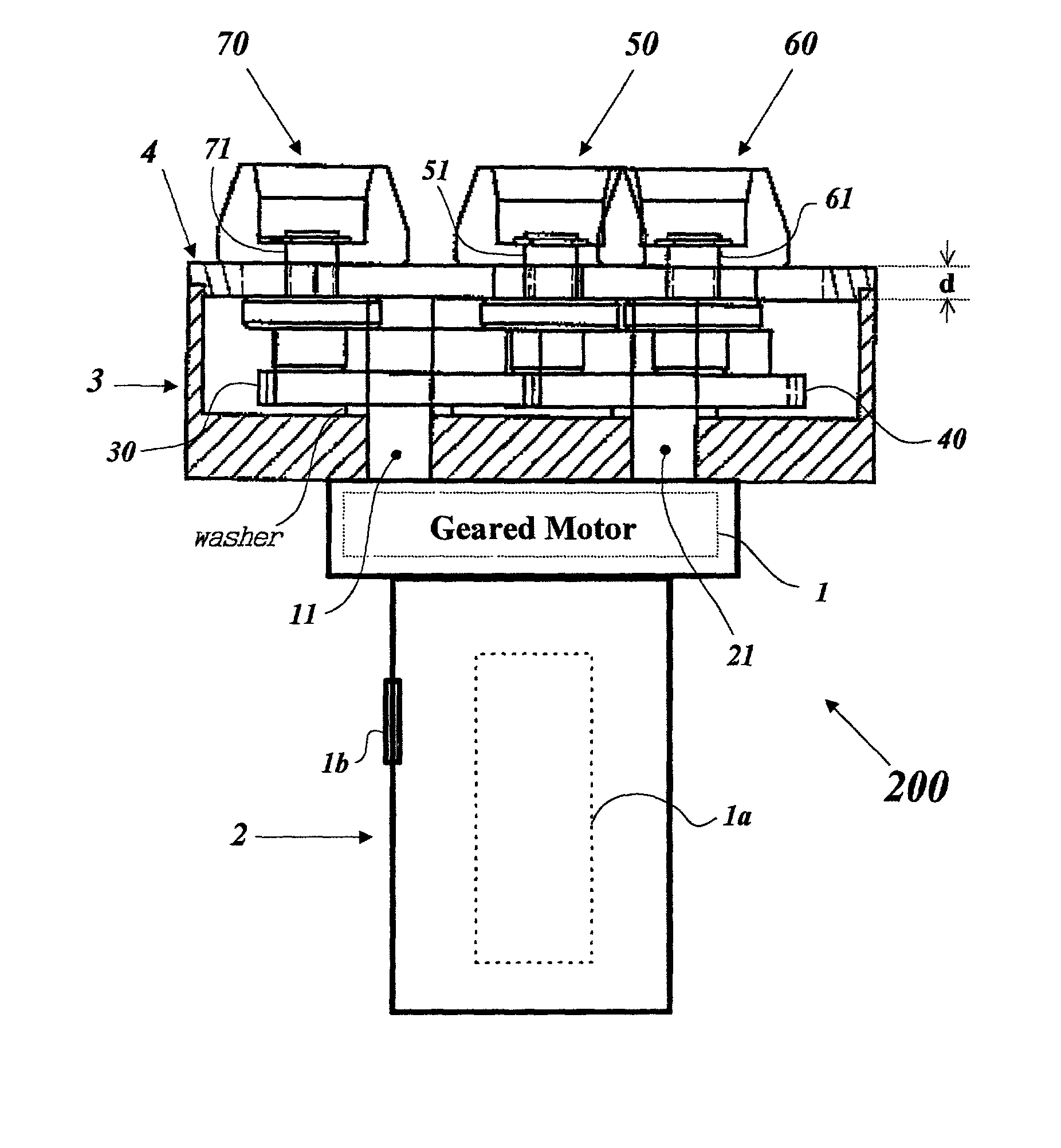

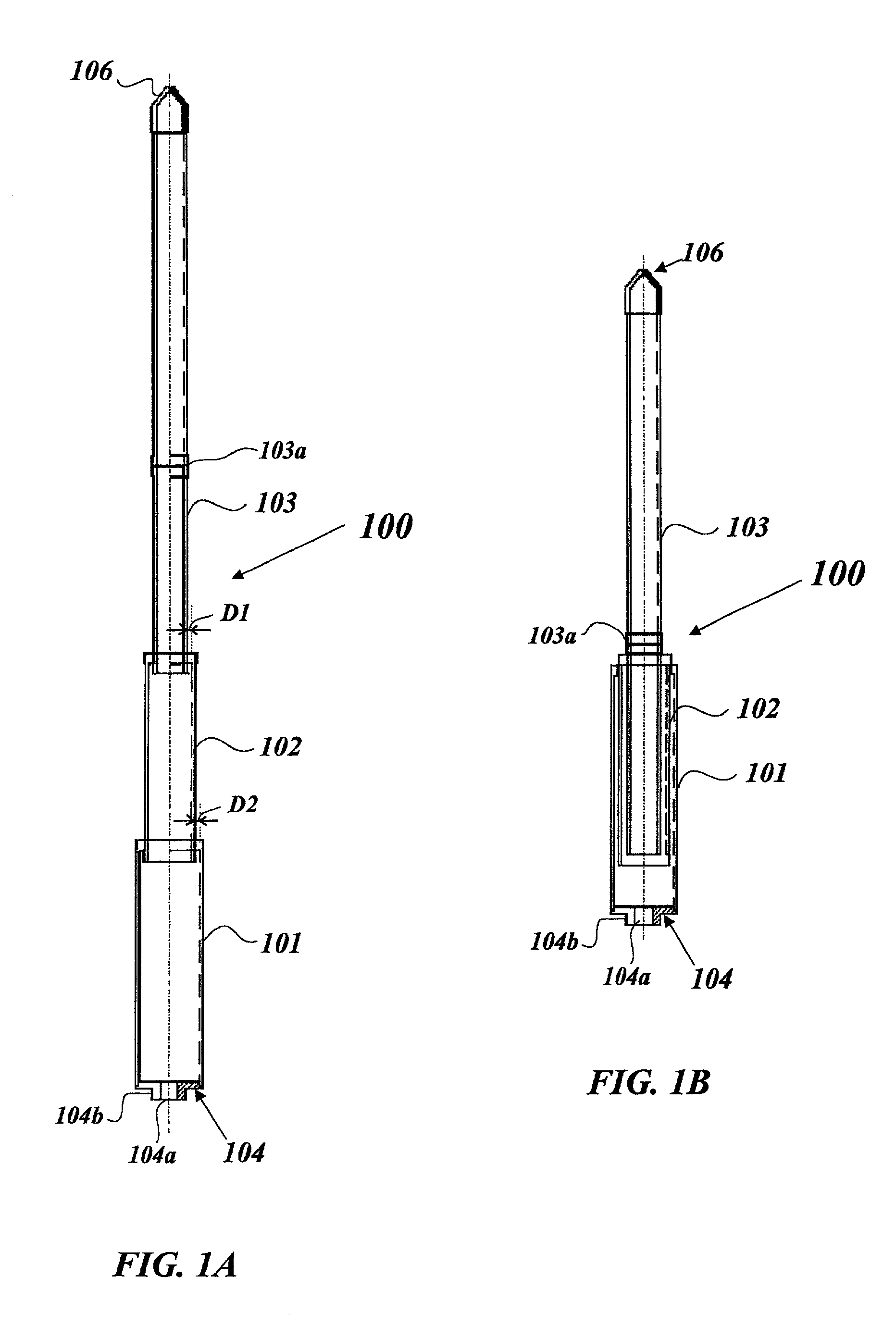

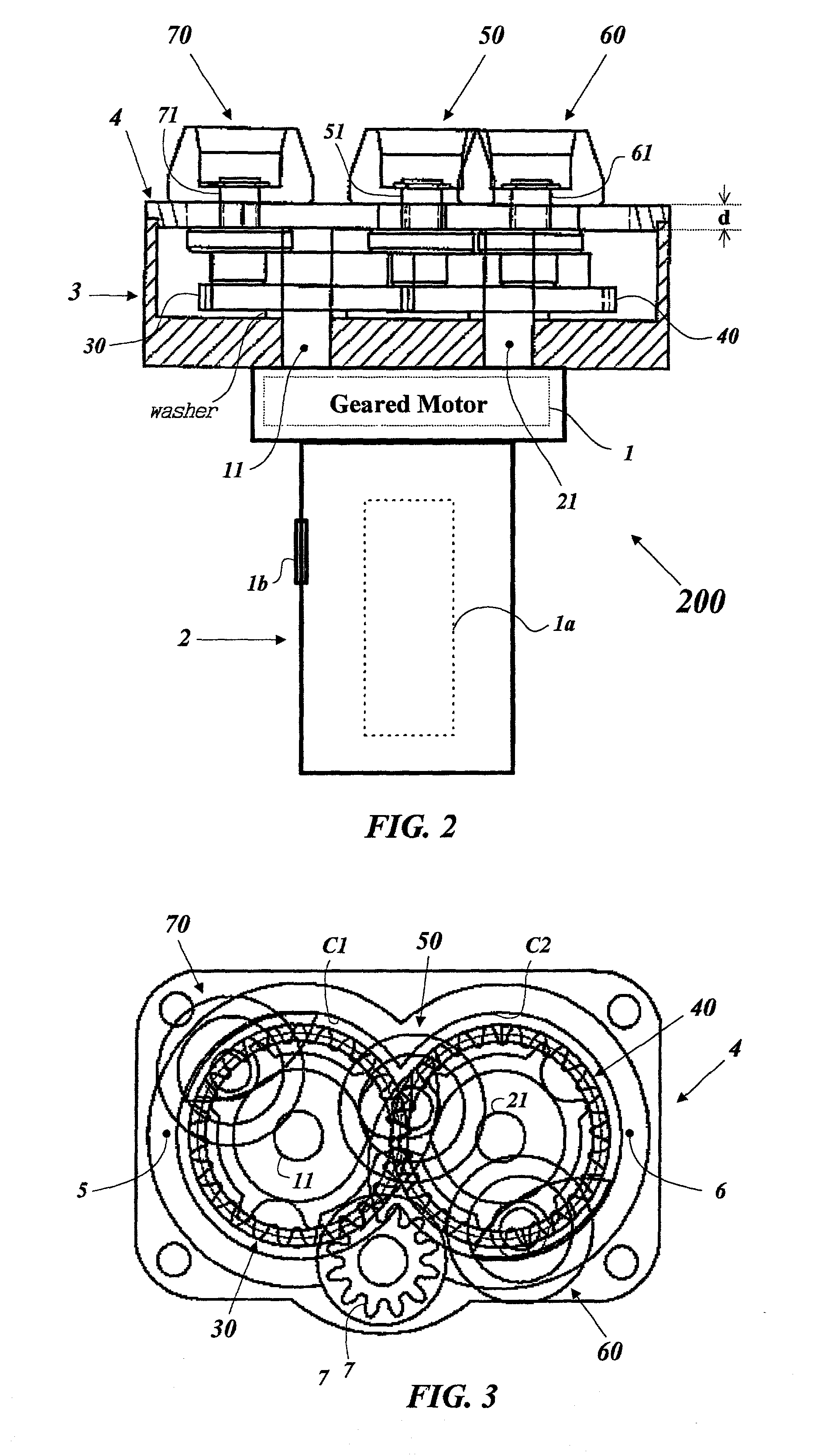

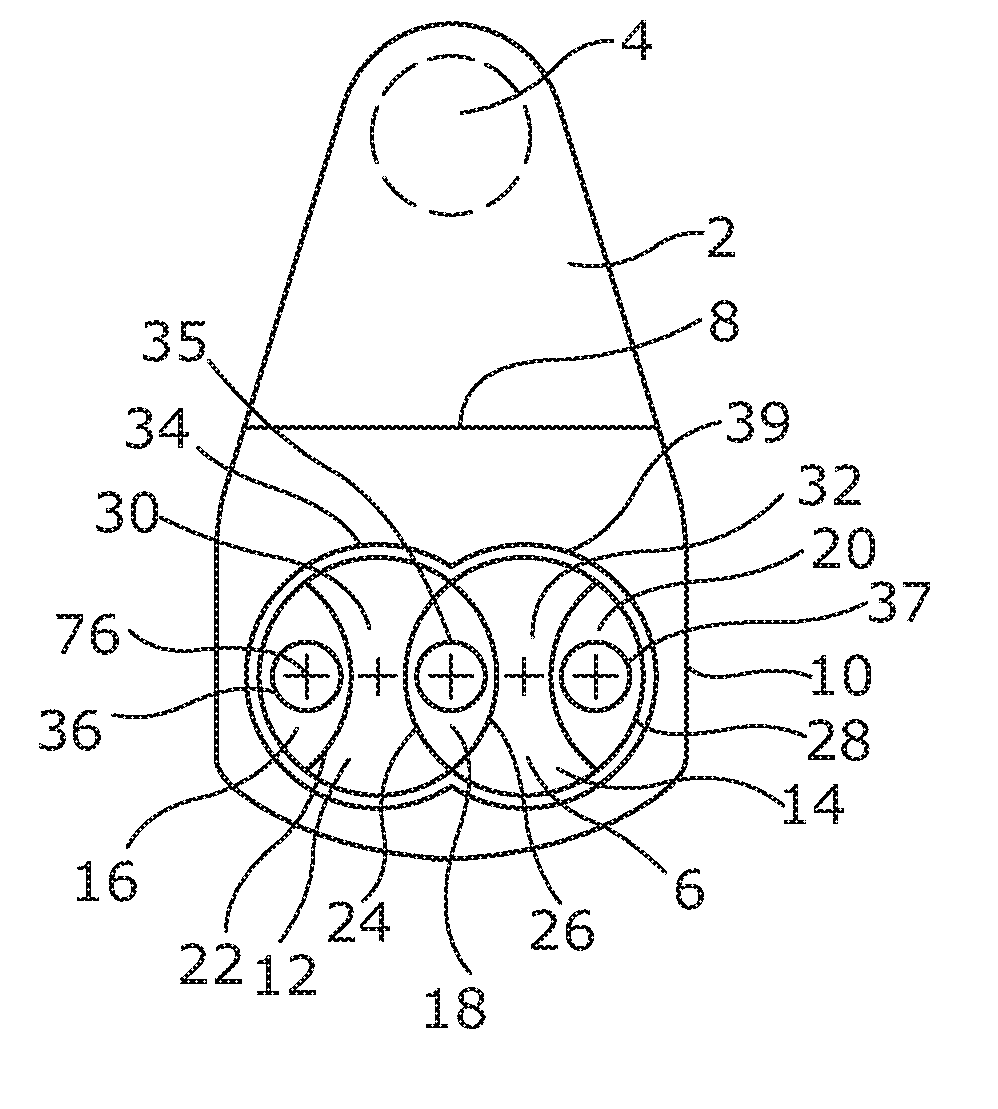

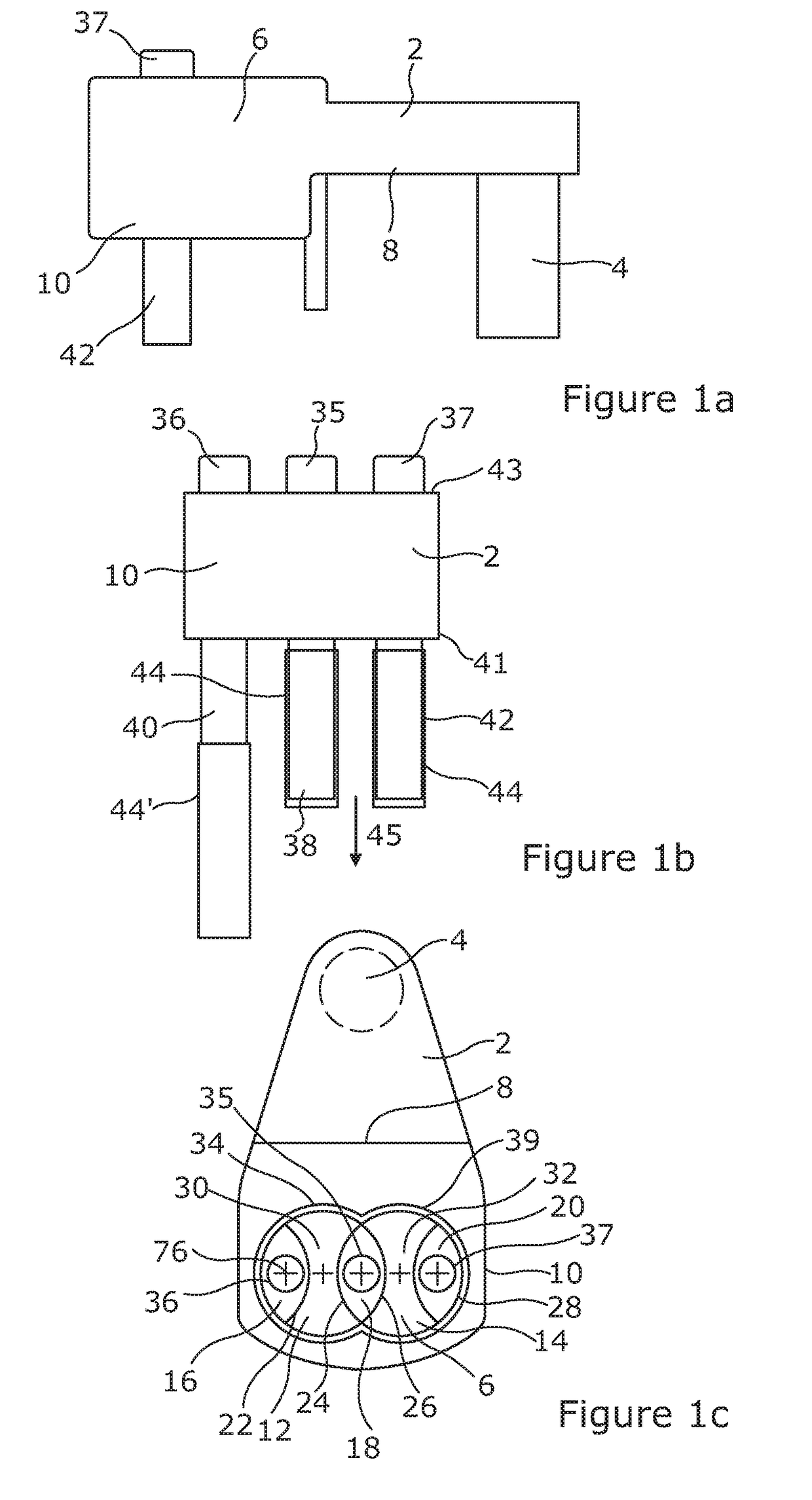

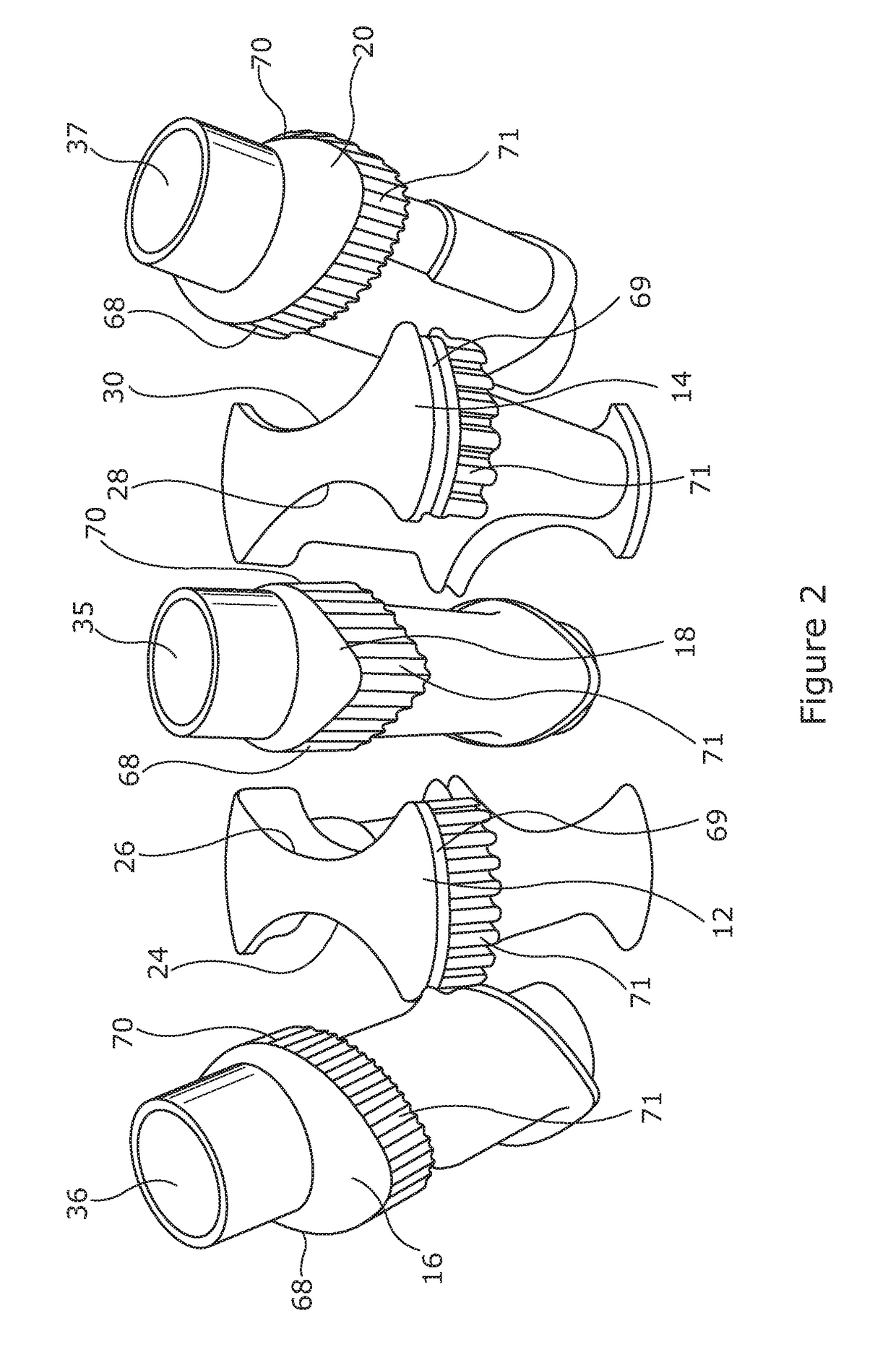

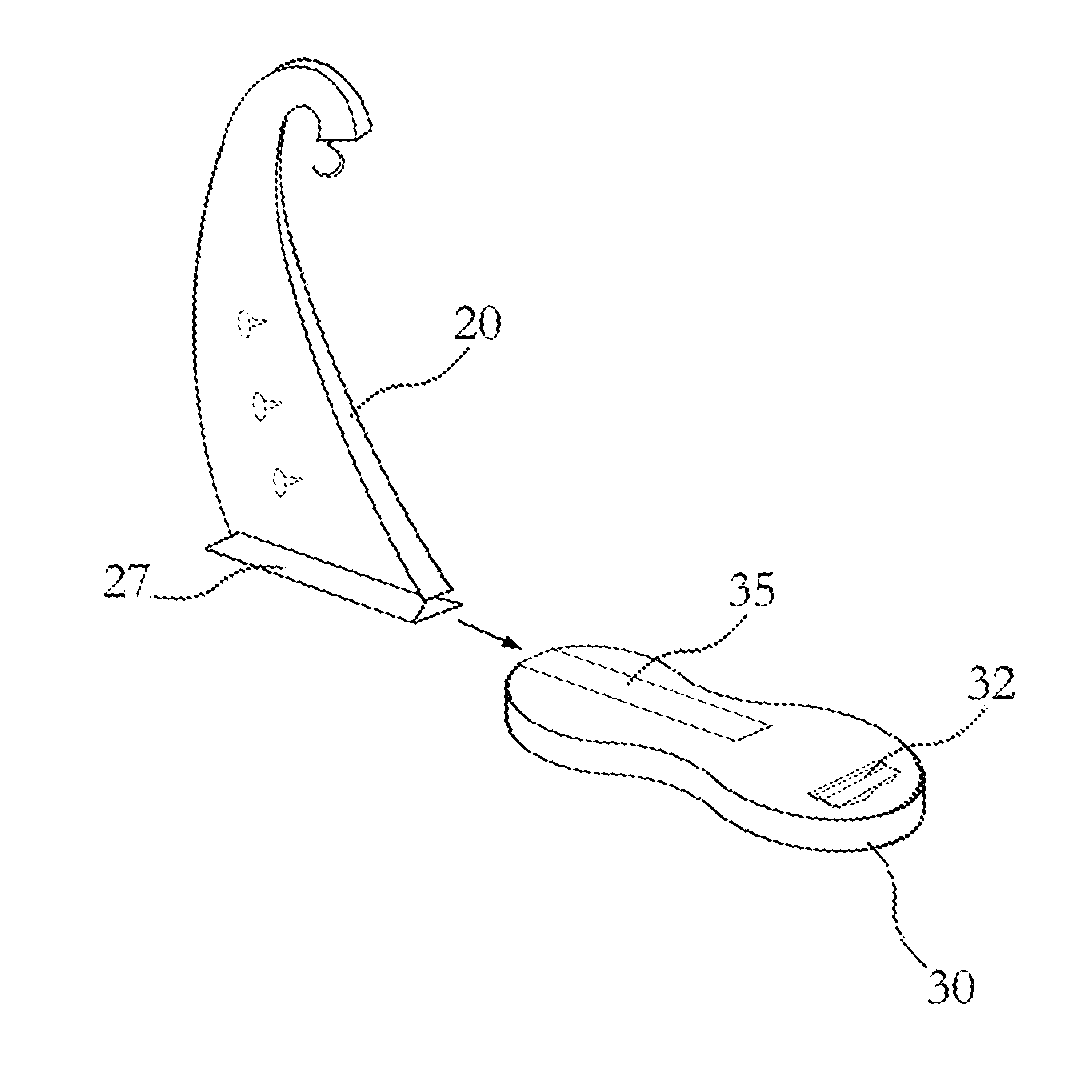

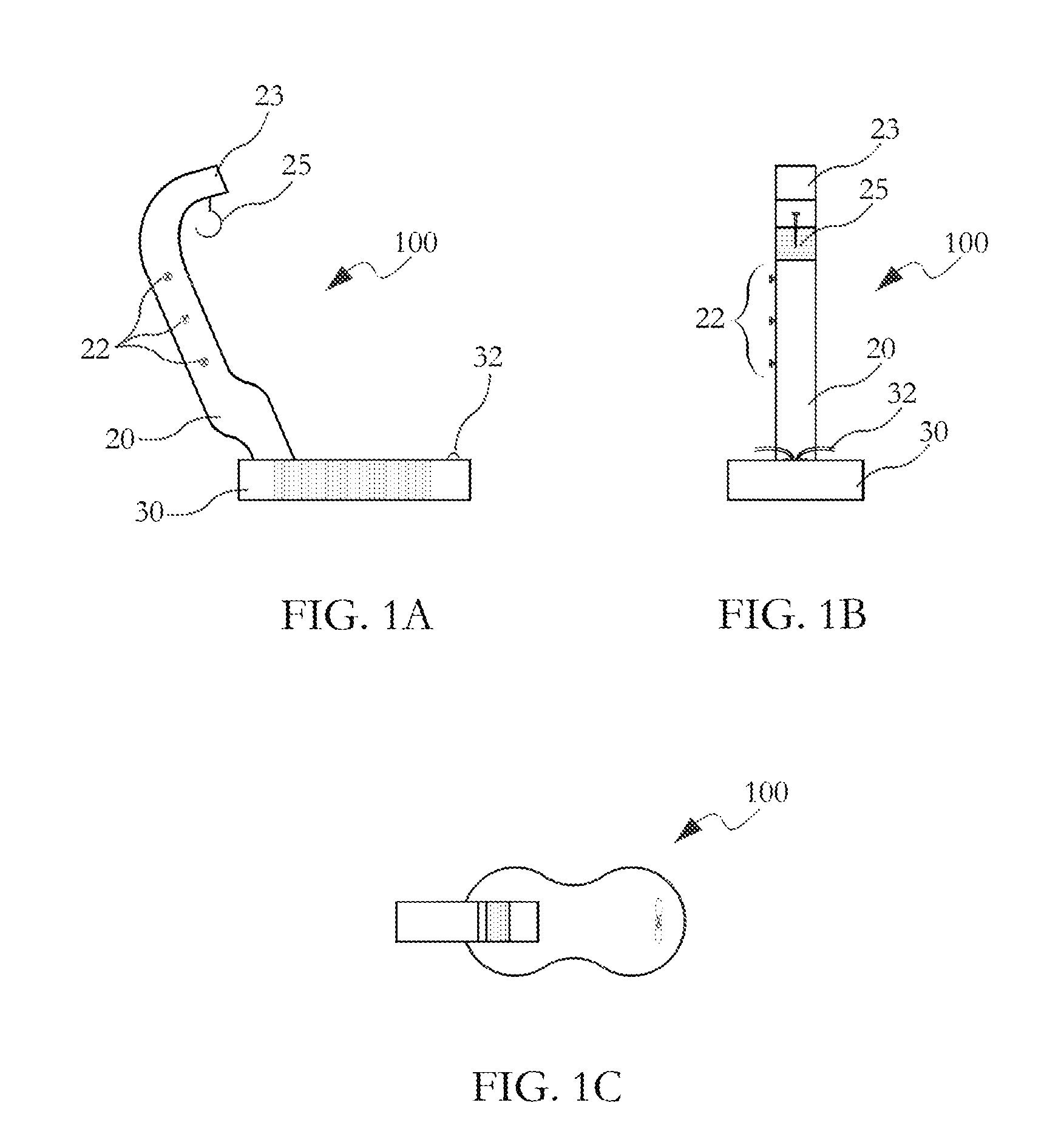

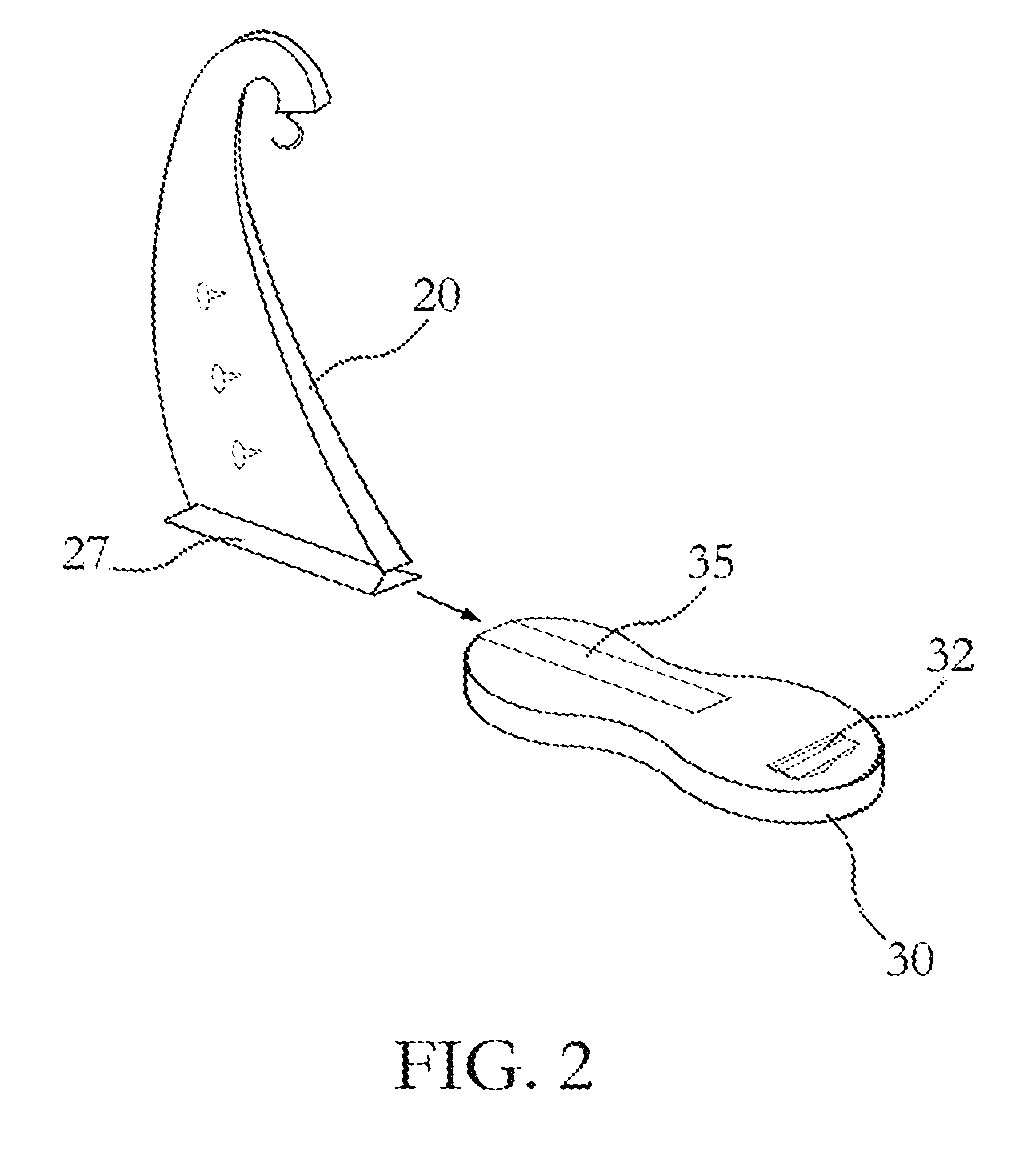

Hair braider and an auxiliary device thereof

InactiveUS20020092540A1Shorten the timeLow costHand lacing/braidingCurling devicesEngineeringMechanical engineering

This invention relates to a hair braider and its auxiliary device, which are portable and braids three bunches of hair into a strand. The hair braider has a substantially figure "8'-configured cam track allowing three carriers to move along the cam track for a "8' track motion. Three carriers combined detachably with three grabbing members accommodating three bunches of hair therein travels along the cam track as a couple of rotors rotate in opposite direction. While three hair grabbing member held on the holders of the carriers conduct the figure "8' motion, three bunches of hair in three hair grabbing members are braided into one strand.

Owner:LEE MYUN WOO

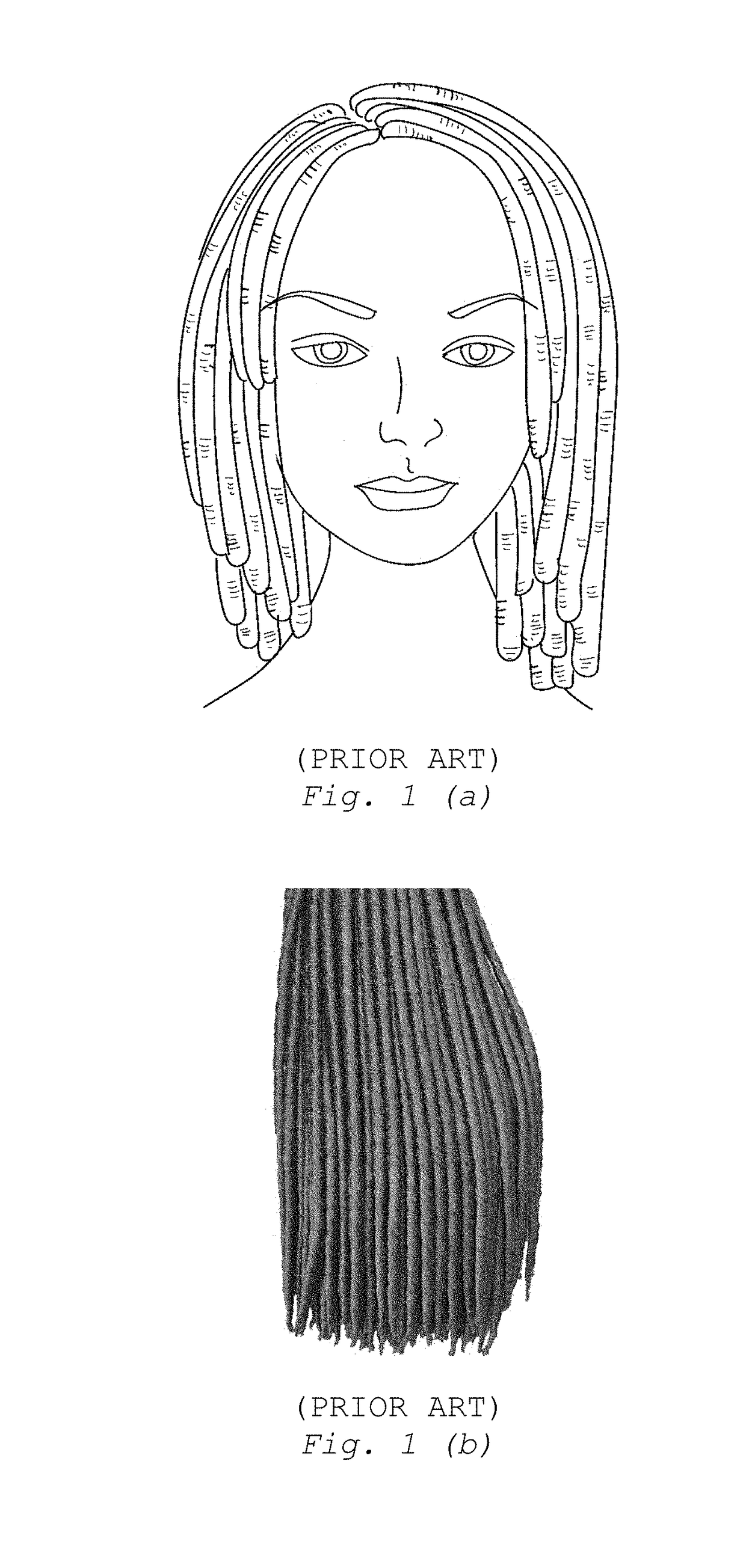

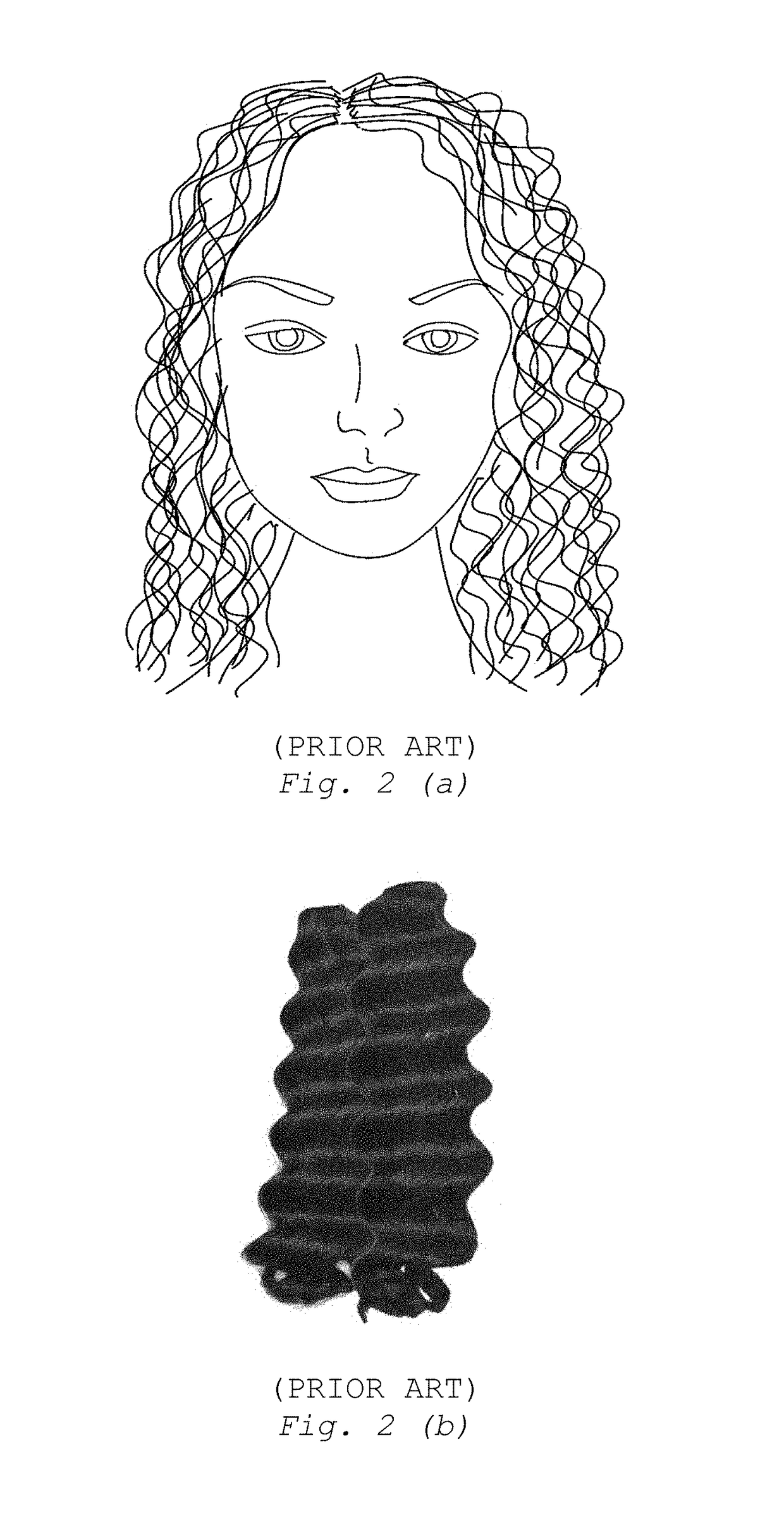

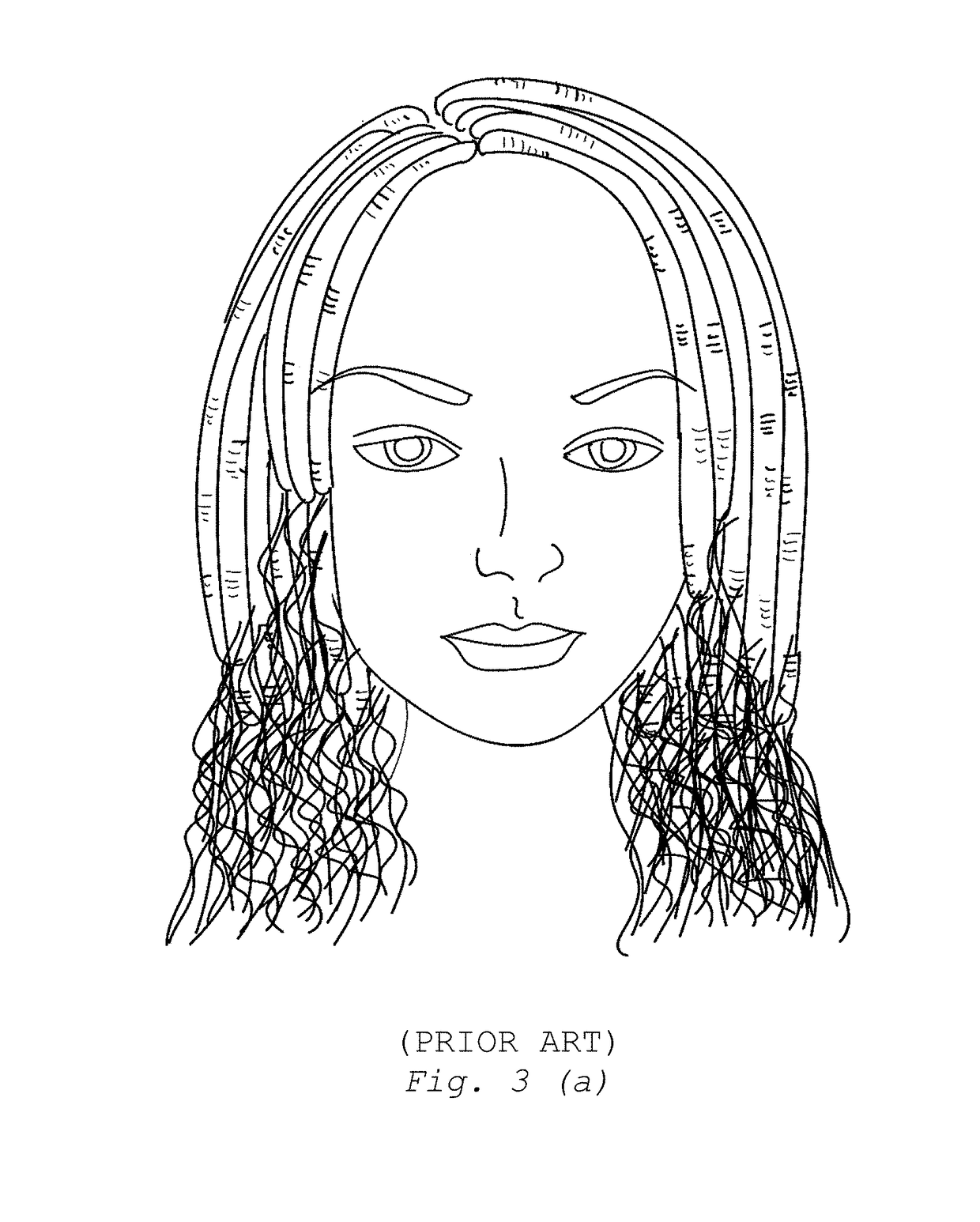

Synthetic braiding hair and its manufacturing method

InactiveUS20190075870A1Lose weightDamage to hairHair accessoriesHair cosmeticsBiomedical engineeringHelix

Owner:HAN HYUN

Braided helical wire stent

Exemplary non-woven helical stents are described that are efficient to fabricate in terms of labor and resources by being able to be manufactured by hand or machine while providing mechanical stability equivalent or close thereto of known braided or woven stents.

Owner:COOK MEDICAL TECH LLC

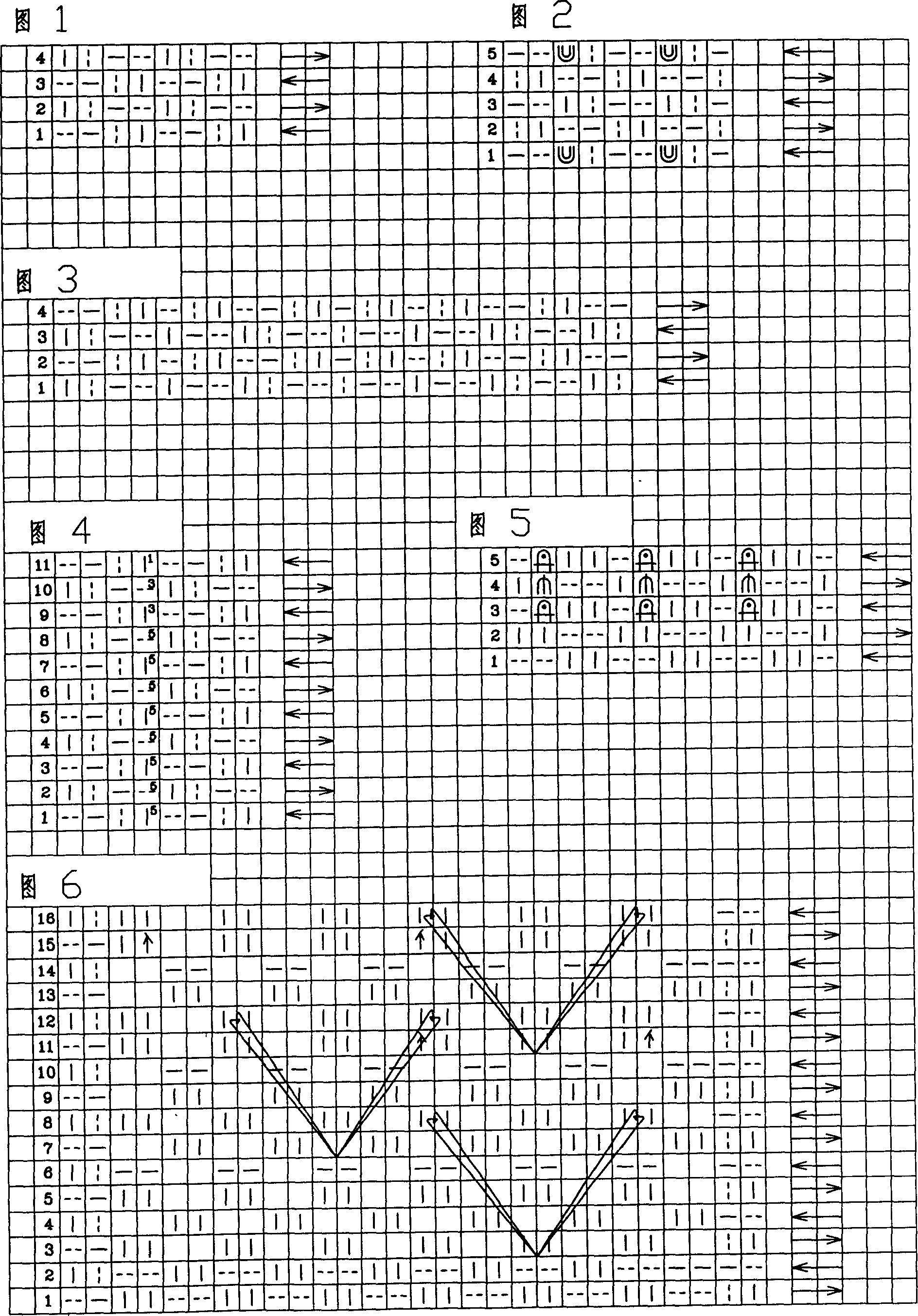

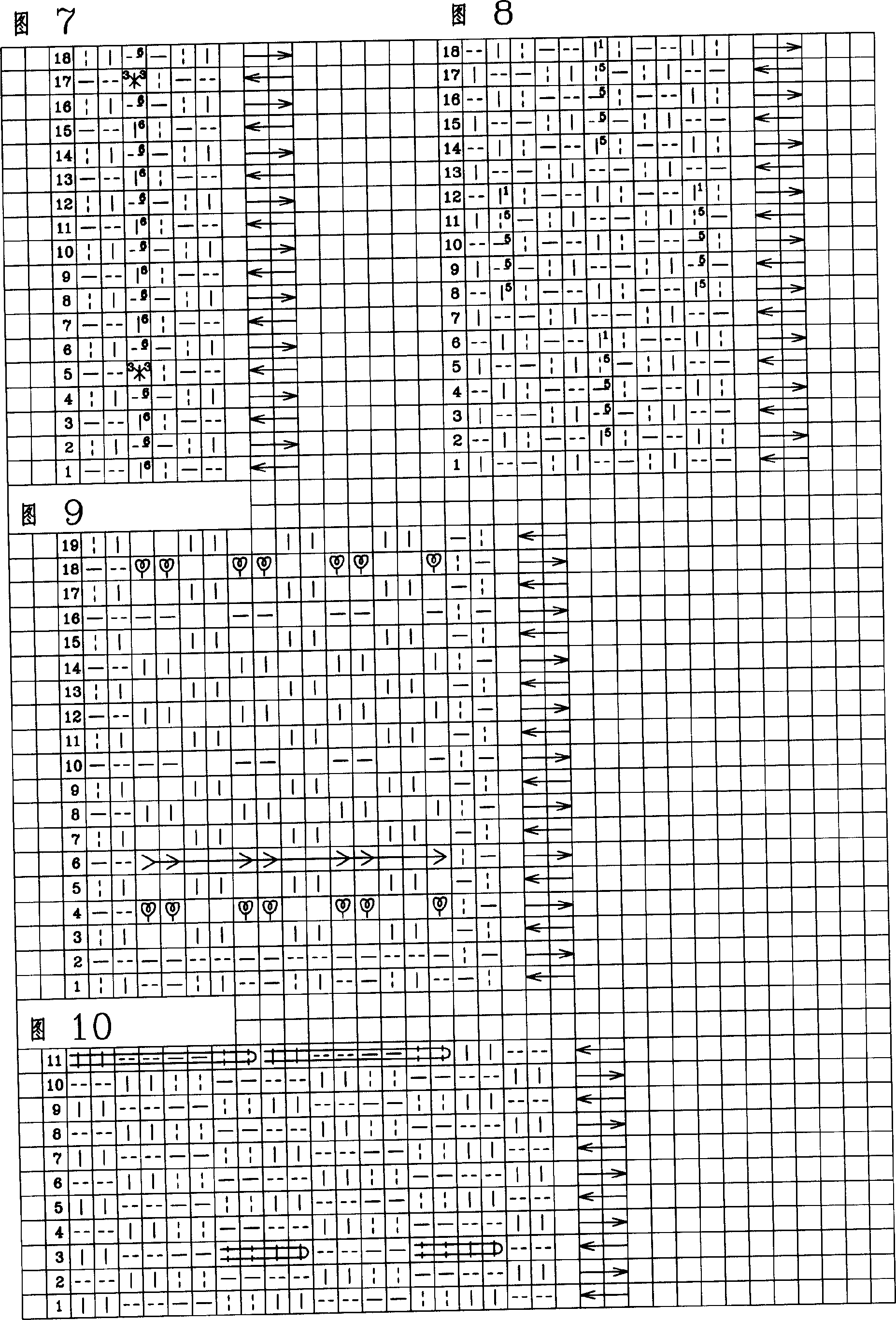

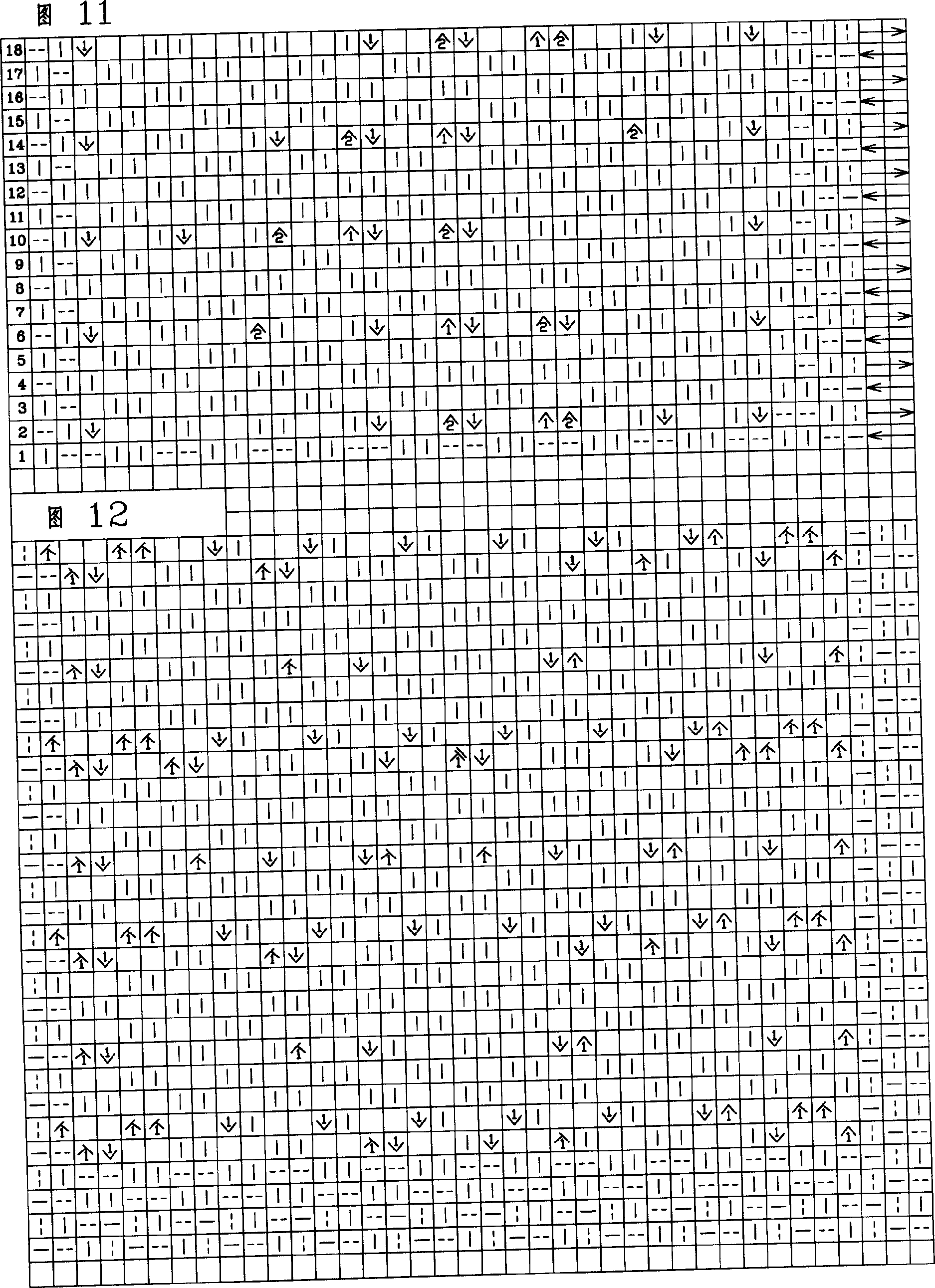

Method for braiding compound rib double-layer and double-side fabric by bar needles

The present invention is rod needle knitting process of complex rib double-layer double-sided knitted fabric. Two pieces of rod needles of diameter 1-20 mm or even large are used during the knitting. The complex rib double-layer double-sided knitted fabric has the same ribs on its two sides, may be knitted with unicolor or bicolor wools and may be plain or jacquard. There are 18 kinds one basic knitting process and various beautiful patterns may be knitted. The complex rib double-layer double-sided knitted fabric is flat, stiff and neat, thick and wash and wear.

Owner:戚建威

Apparatus and method for the weaving or interweaving of elongate members to form braids or plaits

ActiveUS20170099927A1Prevent excessive torqueAvoid damageHand lacing/braidingCurling devicesEngineeringRelative motion

Owner:FUSE LONDON

Multi-strand braiding device and method

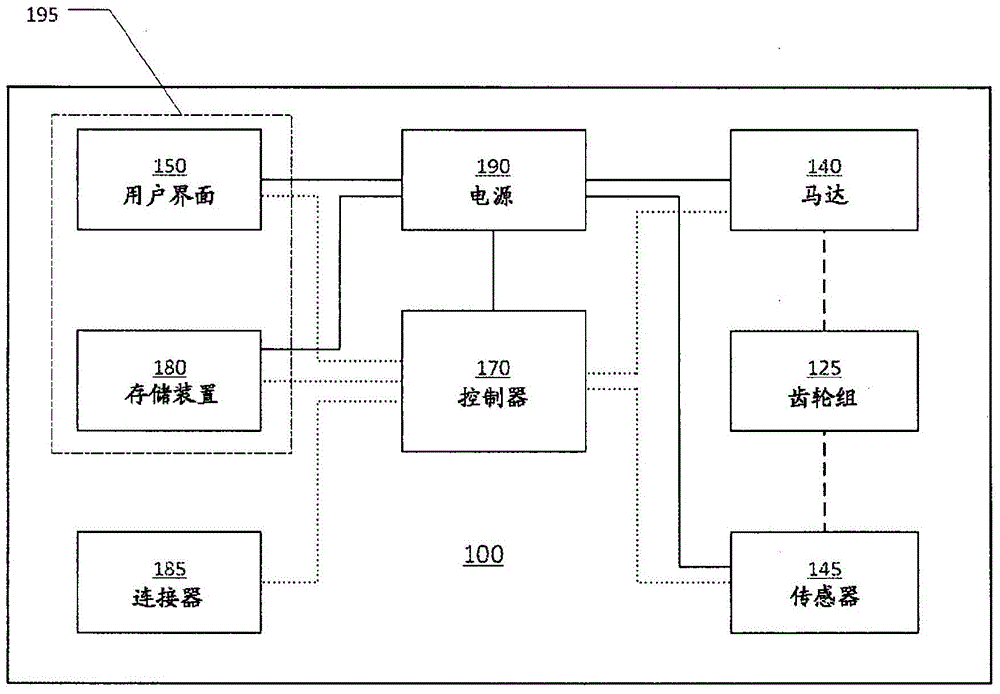

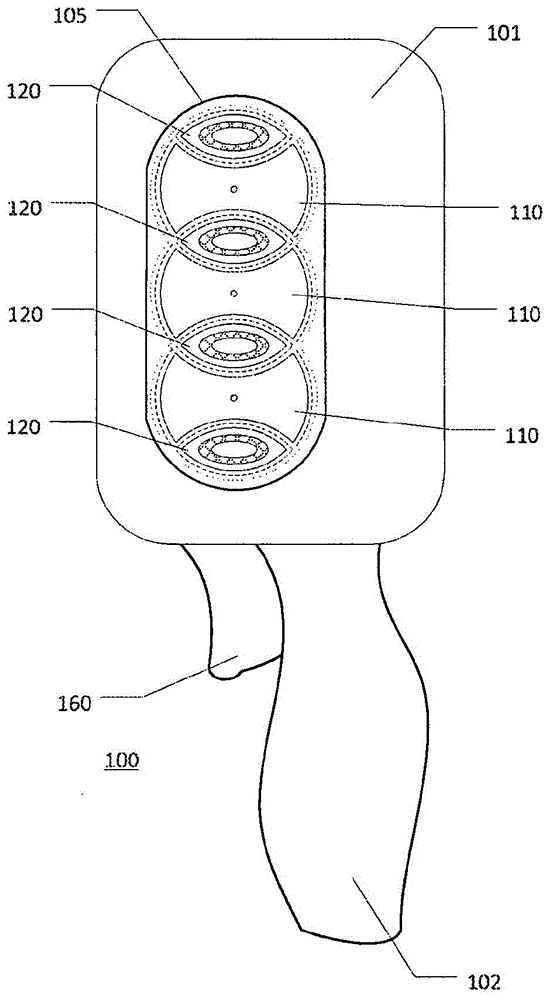

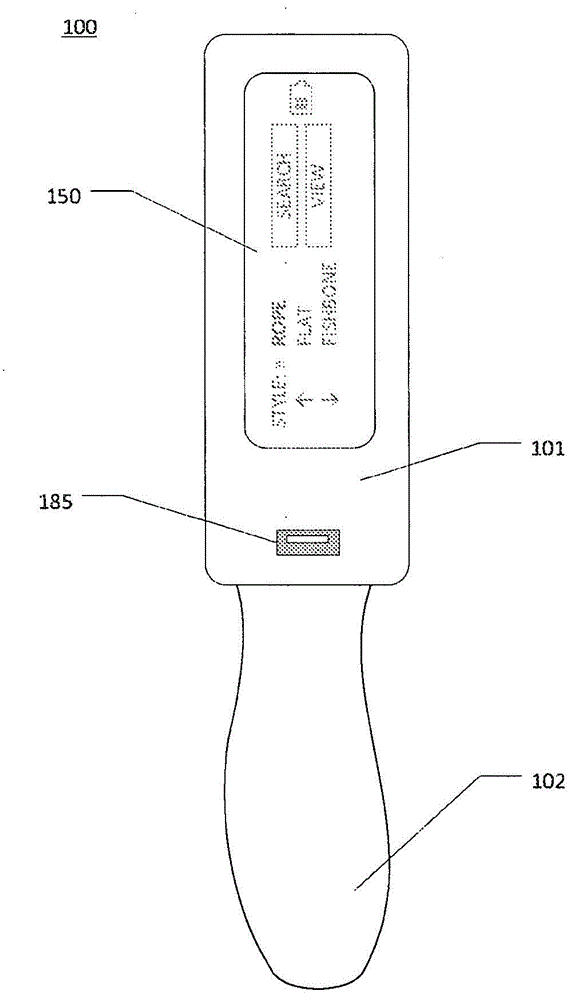

A device and method for braiding hair or other flexible filaments is disclosed herein. The device comprises a set of gears comprising sector gears and elliptical gears, the elliptical gears having a hollow center portion for receiving the hair or other flexible material. The device further comprises a controller, a motor, a power source, and a user interface. The user interface allows the user to select a variety of weaving patterns. The device and method of the present disclosure may be employed to weave four or more strands of material into a braid.

Owner:GIVING TOYS

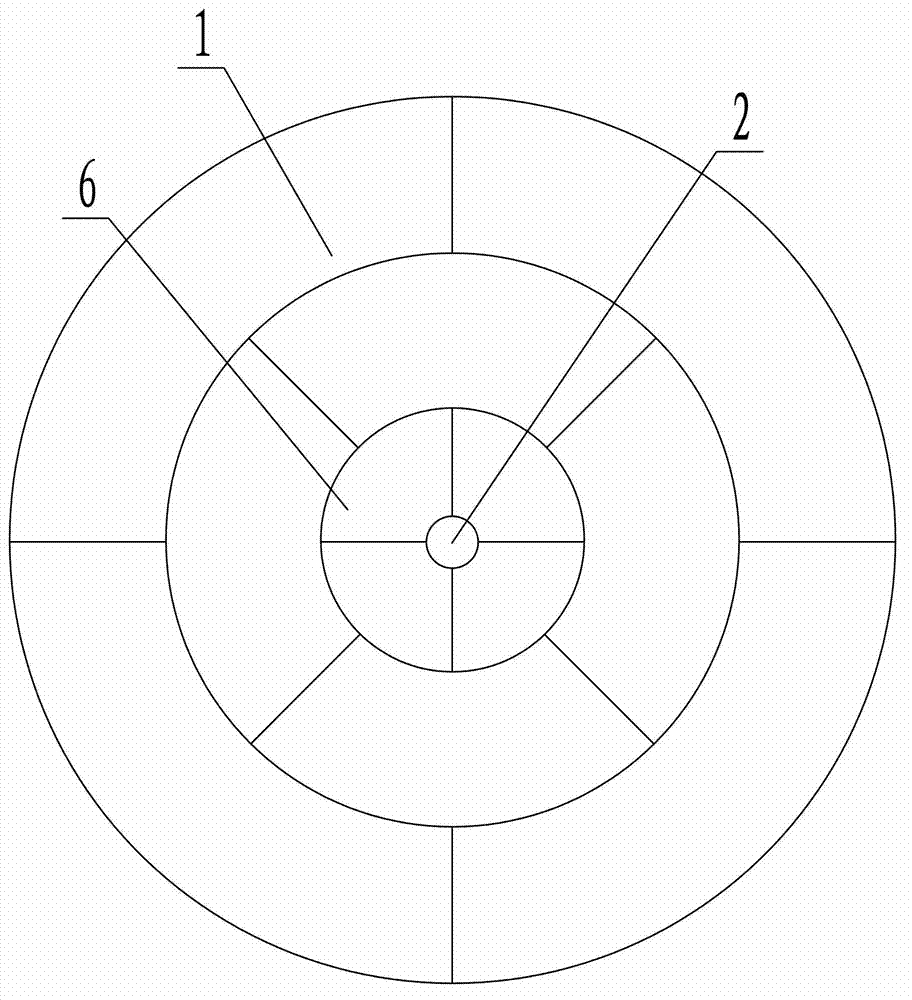

Die and method for braiding curve limiting mesh of inflatable membrane

The invention discloses a die and a method for braiding a curve limiting mesh of an inflatable membrane, belongs to the field of fabrication of the limiting net, and solves the problem that an arc curve limiting mesh cannot be fabricated by the prior art. In order to solve the problem, the die for braiding the curve limiting mesh of the inflatable membrane is provided. The die comprises a template; the template is of a cake shape; the upper end face of the template is an arc curve surface; the center position of the upper end face of the template is the highest point of the arc curve surface; the method for braiding the curve limiting mesh of the inflatable membrane by the die is achieved according to the following steps that: 1, a plurality of annular braided lines are arranged around the center of the upper end face of the template as a circle center at the upper end face of the template; and 2, the plurality of annular braided lines are connected together through a plurality of curve braided lines to form a braided mesh; and the length of each edge of each grid in the braided mesh is smaller than 3cm. The method disclosed by the invention is used for braiding the curve limiting mesh of the inflatable membrane.

Owner:HARBIN INST OF TECH

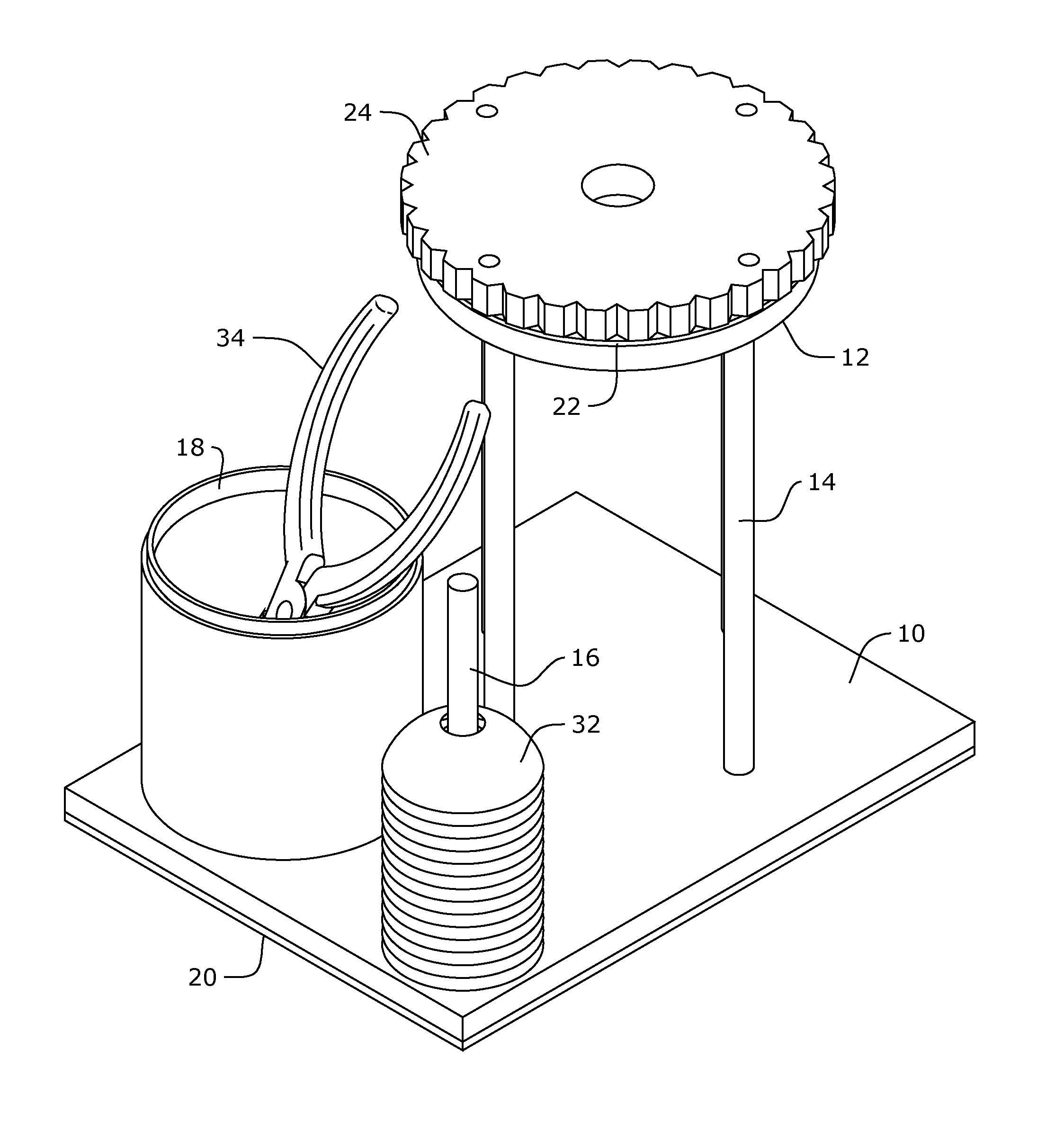

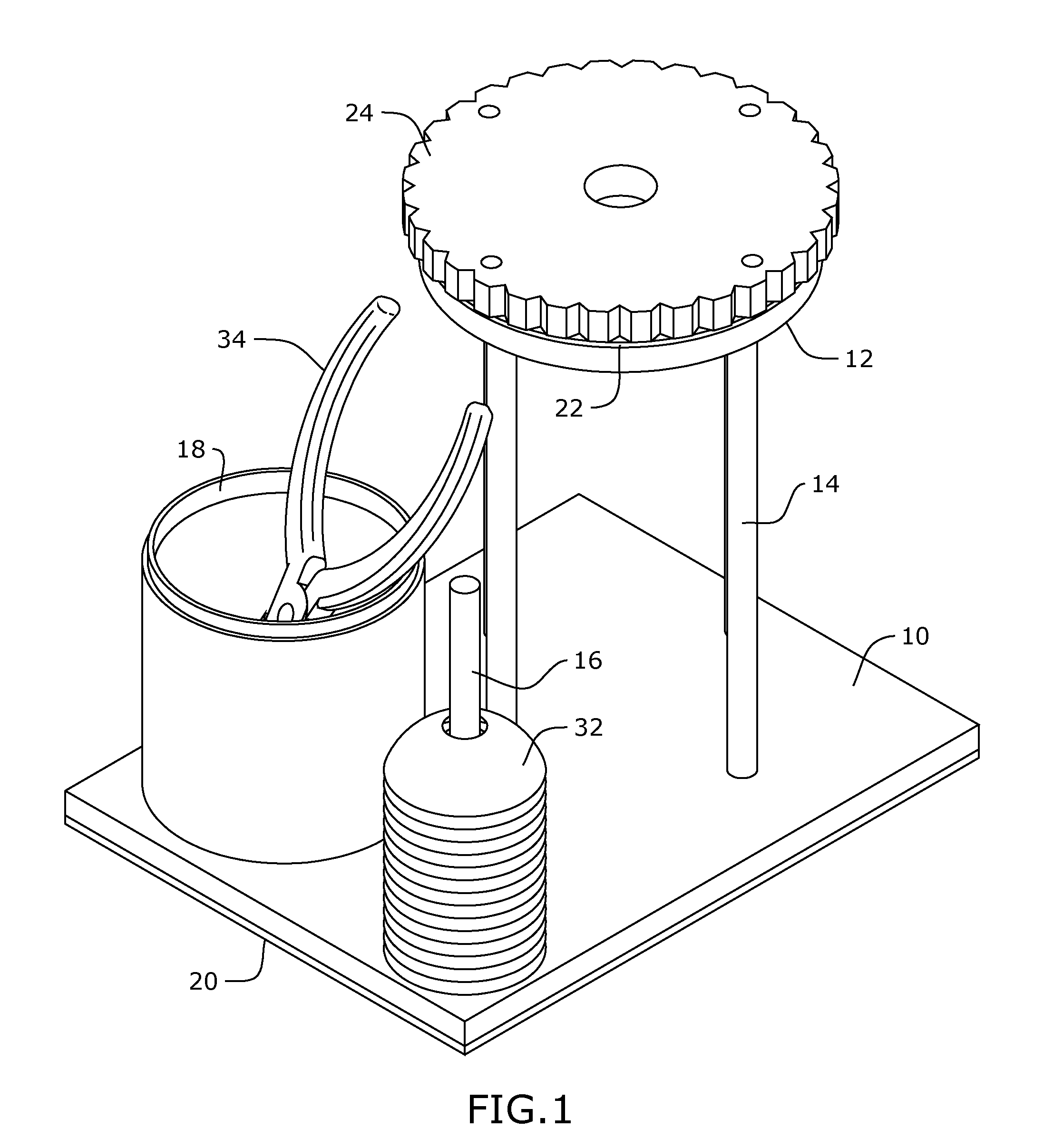

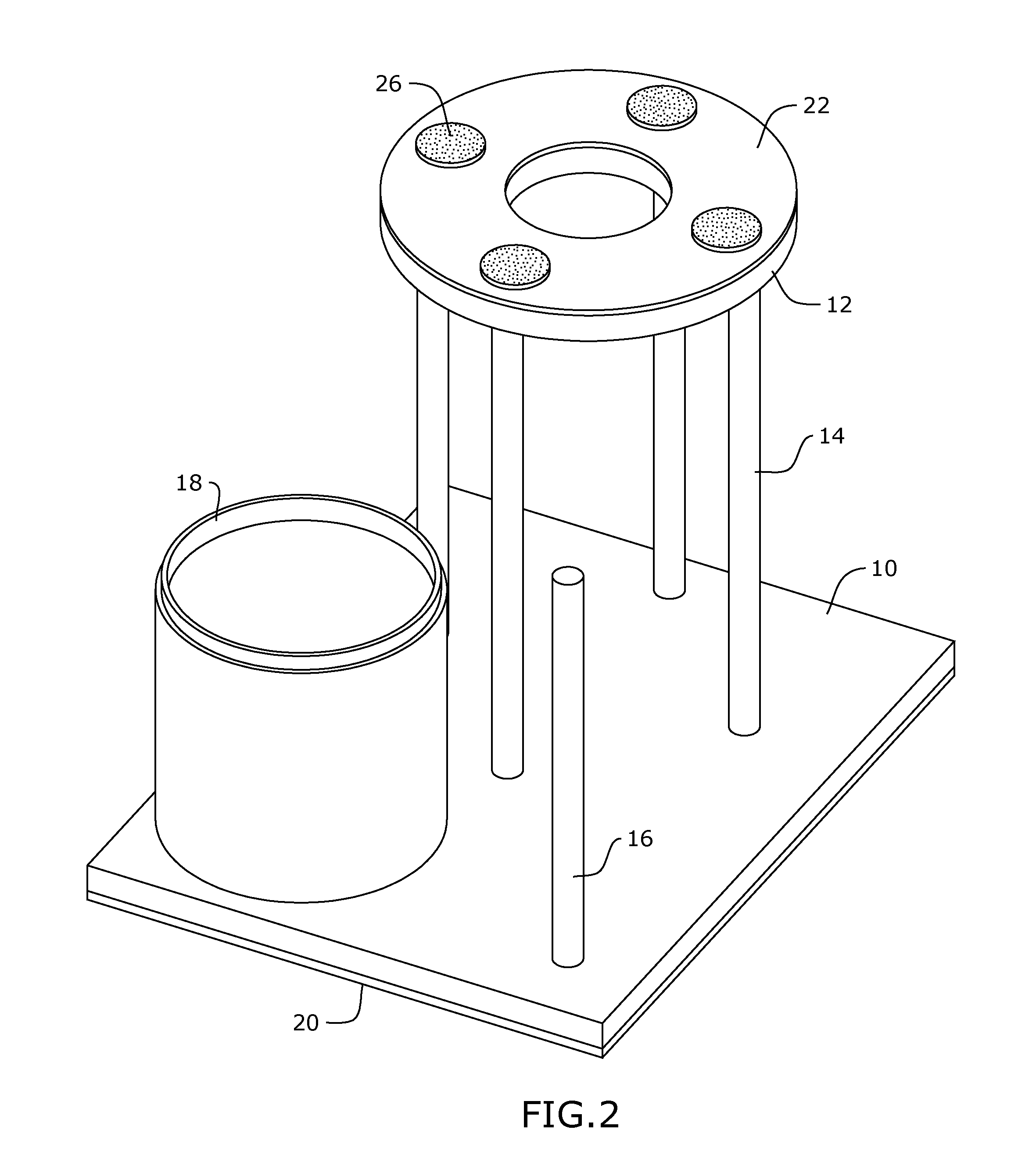

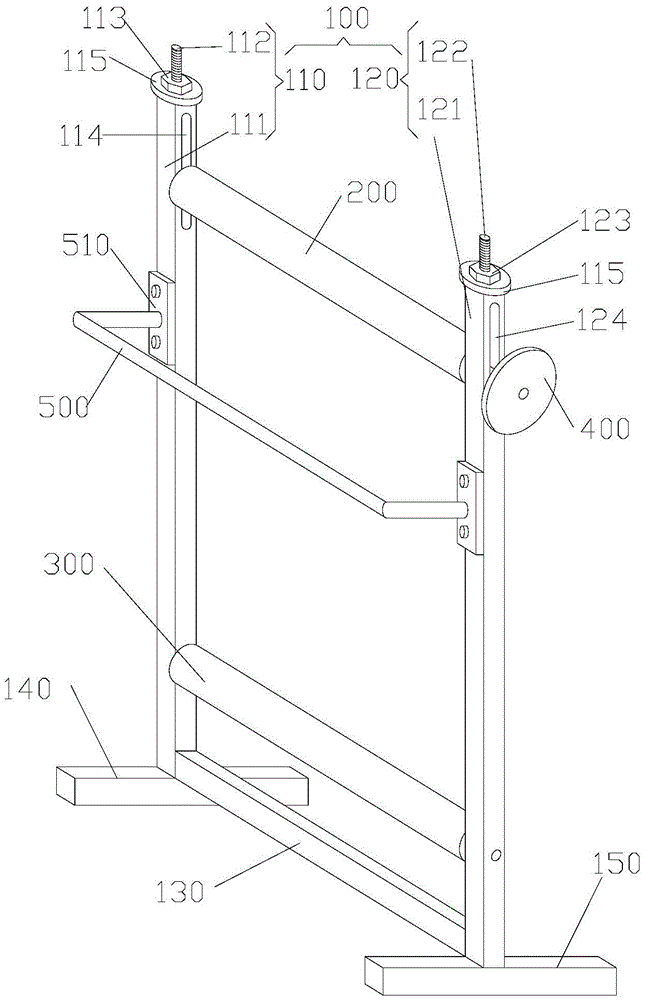

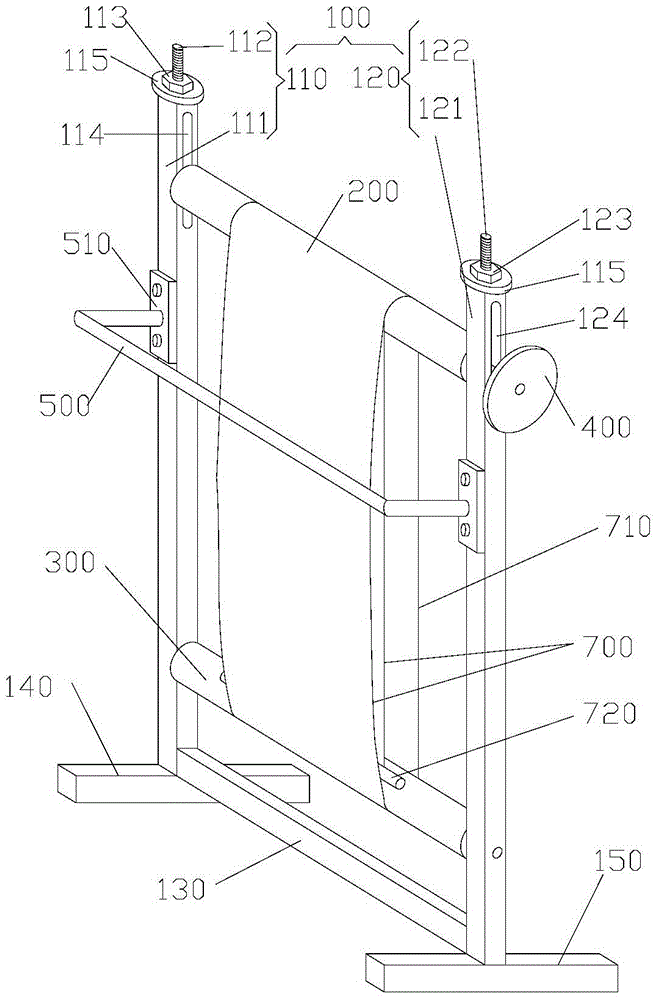

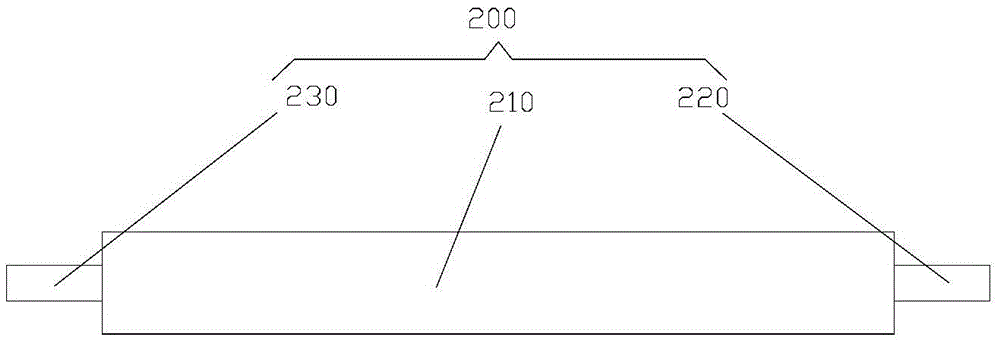

Kumihimo braiding stand

A kumihimo braiding stand is provided. The stand includes a base formed to support the stand in an upright position. The present invention includes at least one dowel having a top end and a bottom end. The bottom end is secured to the base. A support ring includes a substantially flat upper surface. The lower surface of the support ring secures to the top end of the dowel. The support ring includes a circular outer edge and a circular inner edge forming an opening within. The opening is positioned to align with an opening of a kumihimo braiding disc. The present invention further includes a connector operable to releasably connect the kumihimo braiding disc to the upper surface of the support ring.

Owner:THOMPSON MARGARET L

Method of weaving simulated tufted carpet manually

The invention relates to the field of carpets, and provides a method for hand-knitting imitation tufted carpets. The raw material of the hand-knitted imitation tufted carpets is 100-400 tons of pure cotton or pure wool or blended yarns. The new hand-knitted carpets The knitting tool is a stick needle adapted to the yarn, and the method for hand-knitting the imitation tufted carpet includes the steps of weaving the basic unit from the bottom and connecting into a carpet. The invention has the advantage of overturning the traditional hand-woven carpet method of tufting on the warp thread by dots, and completing the hand-made carpet weaving by the knitting method, and the color change makes the whole carpet body have a good visual effect.

Owner:TIANJIN SHILANG CARPET

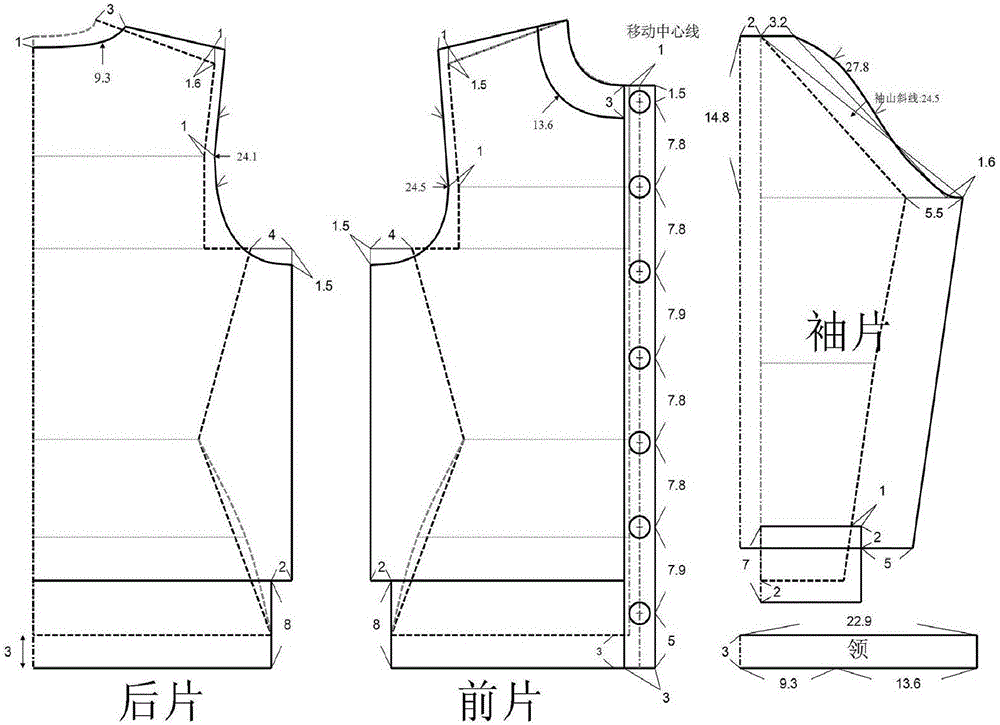

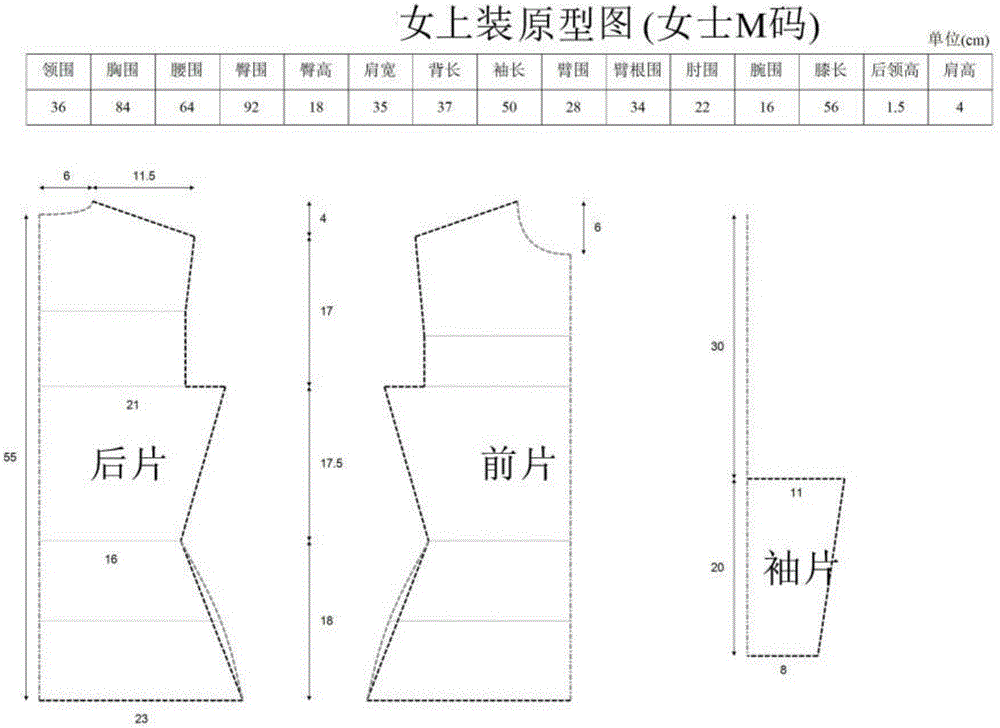

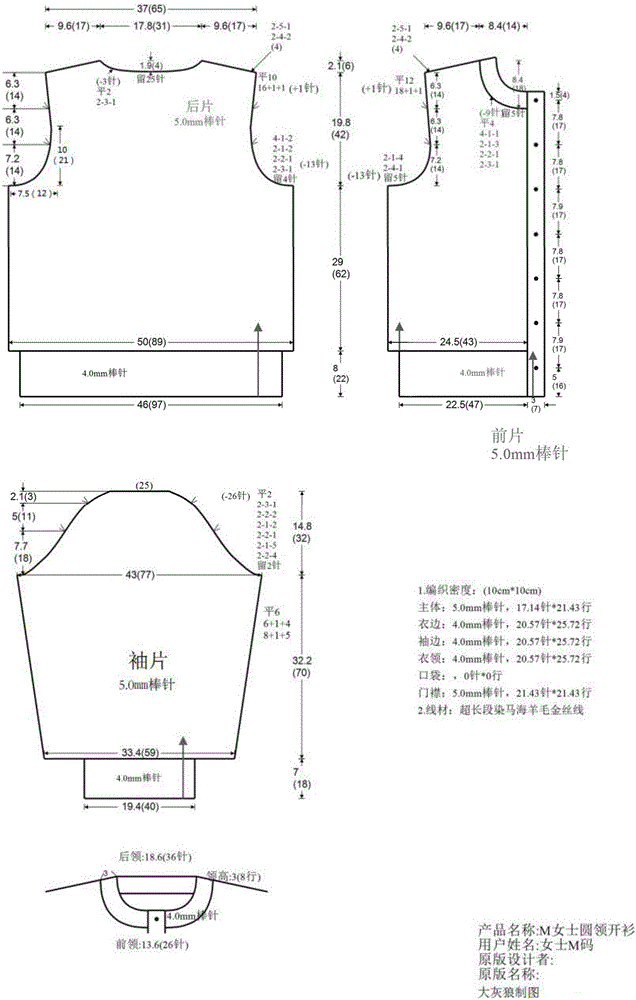

Braiding method and braiding device

InactiveCN106436009AImprove the efficiency of making braidsWeft knittingHand lacing/braidingComputer scienceSoftware

The invention discloses a braiding method and a braiding device. The method comprises the following steps: acquiring parameters of a braided fabric, wherein the parameters comprise a prototype parameter, a prototype extended parameter, a weave structure, a braiding density and a pattern; making the braiding diagram of the braided fabric according to all the parameters, wherein the braiding diagram comprises the prototype extended graph, a braiding scheme and a technologic list; and braiding the braided fabric according to the braiding diagram. The parameters of the braided fabric acquired, the braiding diagram of the braided fabric is made by the terminal according to all the parameters, and the braided fabric is braided by using the braiding diagram, so making of the braided fabric is completed without learning a complex cloth design, a pattern making technology, knitting software and pattern making software by an operator, thereby the making efficiency of the braided fabric is improved.

Owner:济南爱编织信息科技有限公司

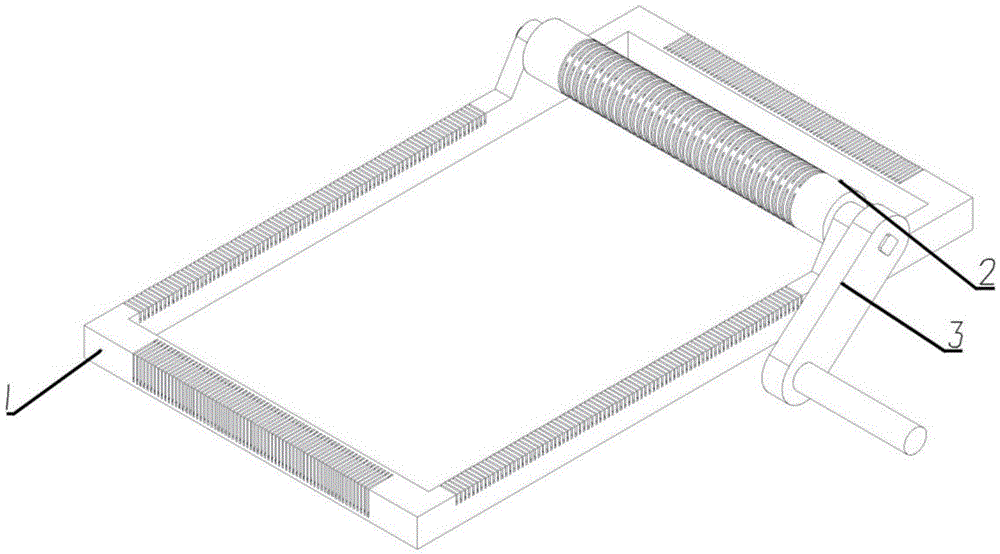

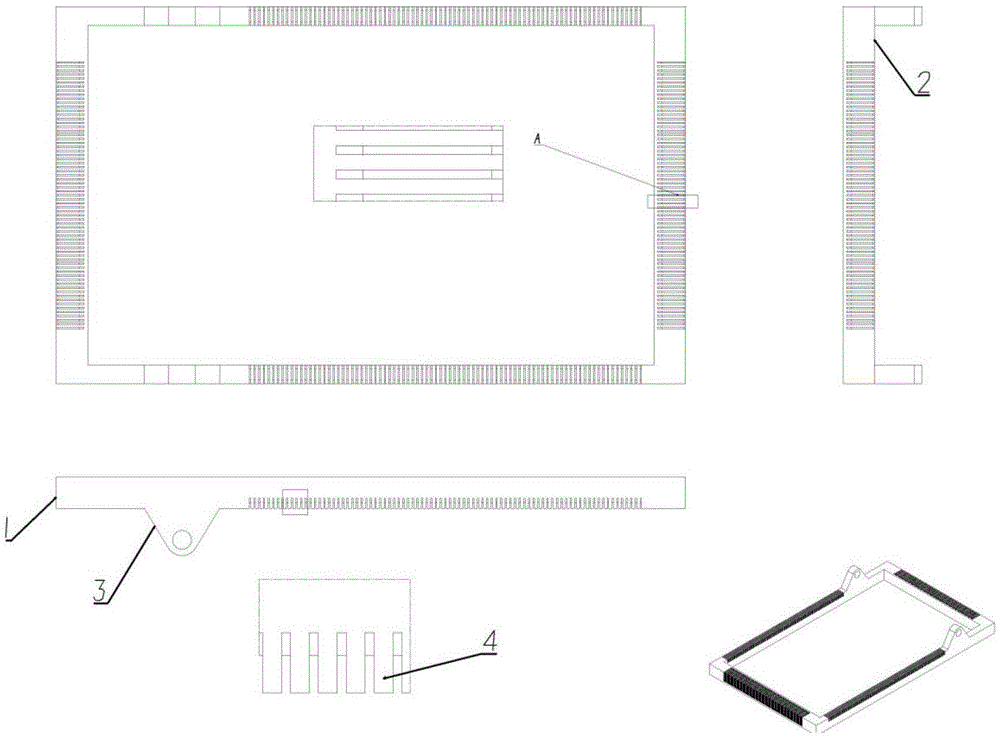

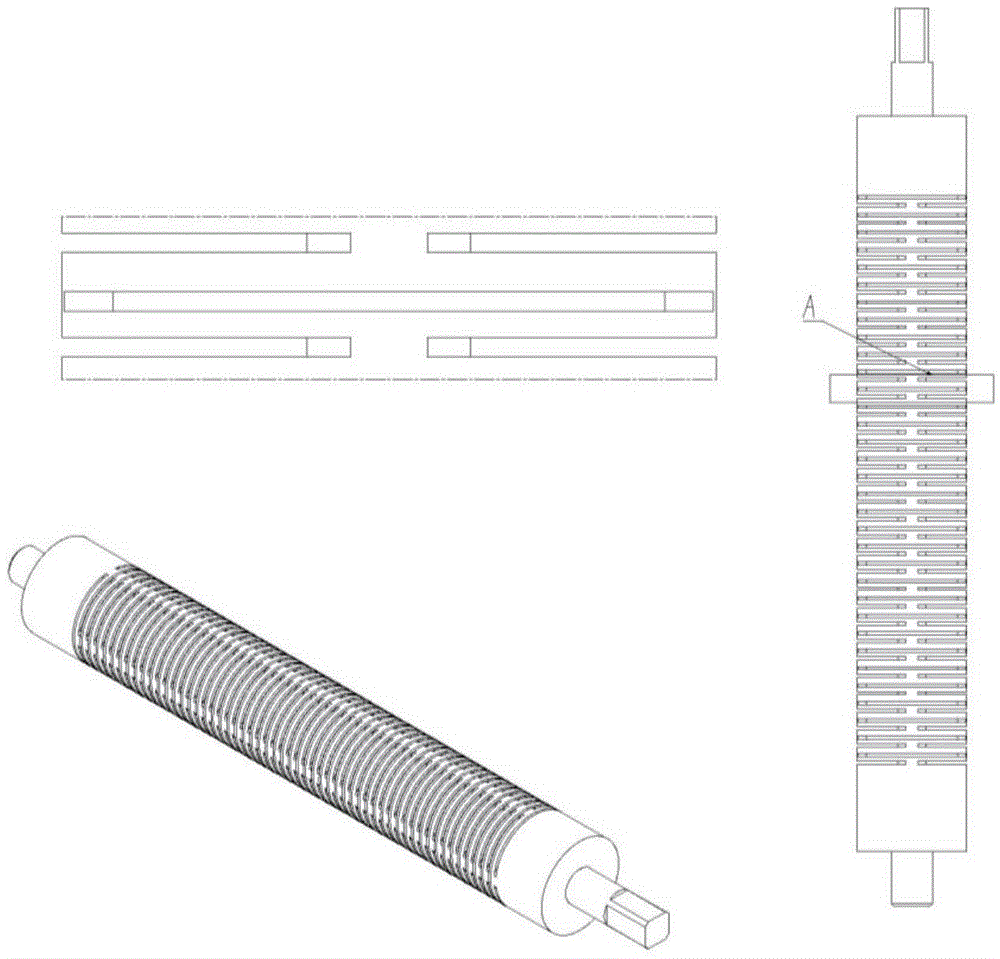

Mold capable of weaving plane oblique-crossing woven fabric of any angle and gap

A weaving machine capable of weaving a plane oblique-crossing woven fabric of any angle and gap can be specially used for weaving the plane oblique-crossing composite woven fabric of any angle and gap, and is characterized by being composed of a metal frame with a warp and weft fiber beam fixing groove, a warp fiber beam splitting shaft, a splitting shaft crank and the like; according to the position and connection relations, the fiber beam splitting shaft is flat put on the frame and connected with the frame through reinforcing ribs, and the splitting shaft crank is connected with a boss of the warp fiber beam splitting shaft. By means of the weaving machine, the plane oblique-crossing composite fiber cloth of any angle and gap can be easily, conveniently and rapidly woven, use cost is low, and the technical support is provided for development of flexible composite smooth bind.

Owner:BEIHANG UNIV

Knitting frame

ActiveCN105463695ASimple structureEasy to adjustHand lacing/braidingEngineeringMechanical engineering

Owner:青海索琳手工艺术品有限公司

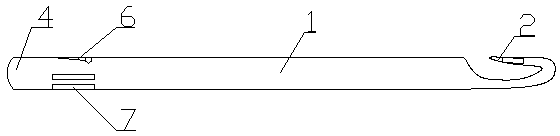

Hair holding cap for a hair braider

InactiveUS7201093B2Constant precisionExact tensionHand lacing/braidingCurling devicesEngineeringFriction force

Owner:LEE MYUN WOO

Manual knitting machine

The invention claims a small-scaled and simple manual knitting machine that can knit yarn into a flat net where a plurality of holes is formed into grid in a knitting way, wherein a slider including a knitting needle is arranged to up and down move by a drive shaft that is driven by a handle. A feed rod where a feed pawl is formed is arranged to move up and down by a cam for moving forward and backward and a cam for moving downward and upward which are fixed to a drive shaft; a disc body forming a feeding nozzle is arranged to rotate interlocking with the drive shaft. The feed nozzle is used for supplying the yarn discharged from the yearn roll supported by an arm part over a workbench to the knitting needle around the axis; the handle is rotated under the condition that the feed pawl of the feed rod is buckled to the hole of the net, thus, the feed nozzle rotates around the knitting needle; when the yarn is wound on the upper part of the knitting needle and is hooked by a hook, the yarn is knitted to the grid of the net in a knitting way by the associative action of the up-and-down movement of the knitting needle and the quadrangular track movement of the feed cam.

Owner:BANDAI CO LTD

Waving method of novel hand-woven carpet

InactiveCN107523933ASpecial concave-convex three-dimensional effectSimple weaving methodCrochetingHand lacing/braidingWoolYarn

The invention relates to the field of carpets, and provides a method for weaving a novel hand-knitted carpet. The raw material of the new hand-knitted carpet is 100-400 tons of pure cotton or pure wool or blended yarn. The weaving tool for the new hand-knitted carpet is The crochet needles are adapted to the thickness of the yarn, and the weaving method of the novel hand-woven carpet includes starting weaving, basic unit weaving, and connecting into a blanket. The invention has the advantages that the weaving method is simple and easy to learn, and the produced blanket body has a special concave-convex three-dimensional effect.

Owner:TIANJIN SHILANG CARPET

Jewelry loom

Owner:STEVENSON LESLEY

Bearded needle for knitting

ActiveCN103774338APrevent slipping and losingImprove weaving efficiencyHand lacing/braidingHand toolsElastic rodsBiomedical engineering

The invention belongs to the field of manufacturing of articles for daily use and particularly relates to a bearded needle for knitting. The bearded needle for knitting comprises a needle body and a plurality of hook heads which are detachably connected with the needle body and are of different models, the needle body is formed by a needle rod part and a hollow hook part which is fixedly connected with the needle rod part, the hook heads are connected with the hollow hook part through a connecting part, a compression spring is arranged in the connecting part, and the compression spring pushes a stop plug at the end part of the compression spring into a fixing groove on the outer wall of the hollow hook part to realize clamping between the hook heads and the hollow hook part; a needle cap is arranged at the other end of the needle body, a connecting part which is contained in the needle body is arranged at the port of the needle cap, a sliding block and an elastic rod which is outwards warped is arranged on the connecting part, the sliding block is matched with a sliding groove arranged in the needle body to enable the tail part of the needle cap to be contained in the needle body, and when the needle cap is pulled out, the elastic rod is ejected out of the needle body and a clamp structure used for fixing the needle body is formed. The bearded needle for knitting has the advantage that the knitting efficiency is greatly improved since the needle body can be detachably connected with the hook heads of different models.

Owner:HENAN UNIV OF SCI & TECH

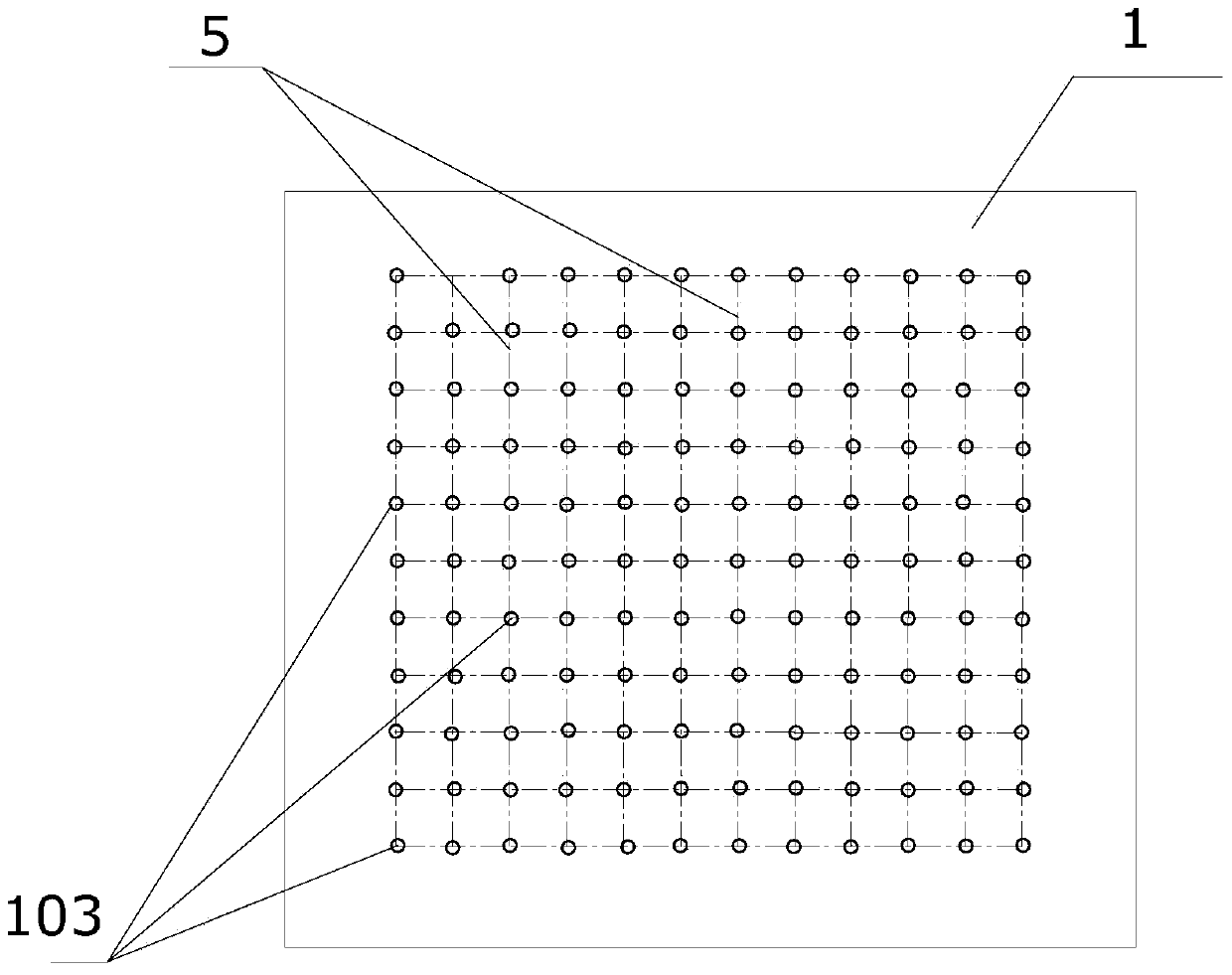

Auxiliary device for braiding disc long knot and method for braiding disc long knot

The present invention relates to the field of handicrafts, and provides an auxiliary apparatus for knitting a coil knot. The structure of the auxiliary apparatus comprises a base, main positioning pins and auxiliary positioning pins, wherein the base comprises a polymer foaming material surface plate on the upper layer and a hard bottom plate on the lower layer, and insertion holes are horizontally and vertically distributed on the polymer foaming material surface plate in a mesh manner. The method for knitting a coil knot by using the auxiliary apparatus comprises: respectively inserting the main positioning pins in a rectangular area on the base; and sequentially winding a rope on each main positioning pin, circling, and knitting. With the auxiliary apparatus of the present invention, the coil knots having different types and different sizes can be knitted according to the requirement, such that the versatility is strong; and the auxiliary apparatus is conveniently used by the beginner, and has characteristics of knitting accelerating, labor intensity reducing, and efficiency improving.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com