Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216 results about "Tufting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

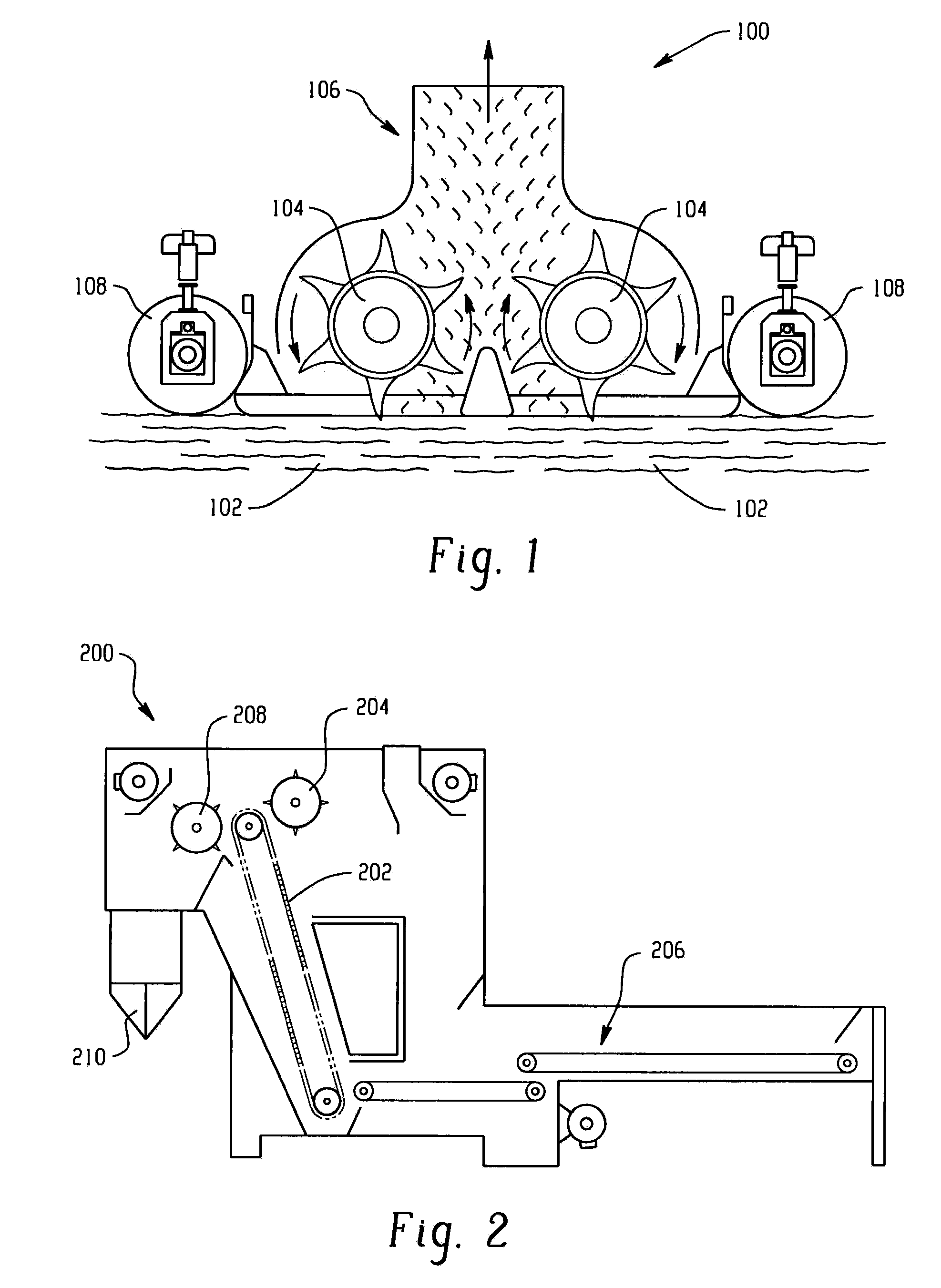

In the field of composite materials, tufting is an experimental technology to locally reinforce continuous fibre-reinforced plastics along the z-direction, with the objective of enhancing the shear and delamination resistance of the structure.

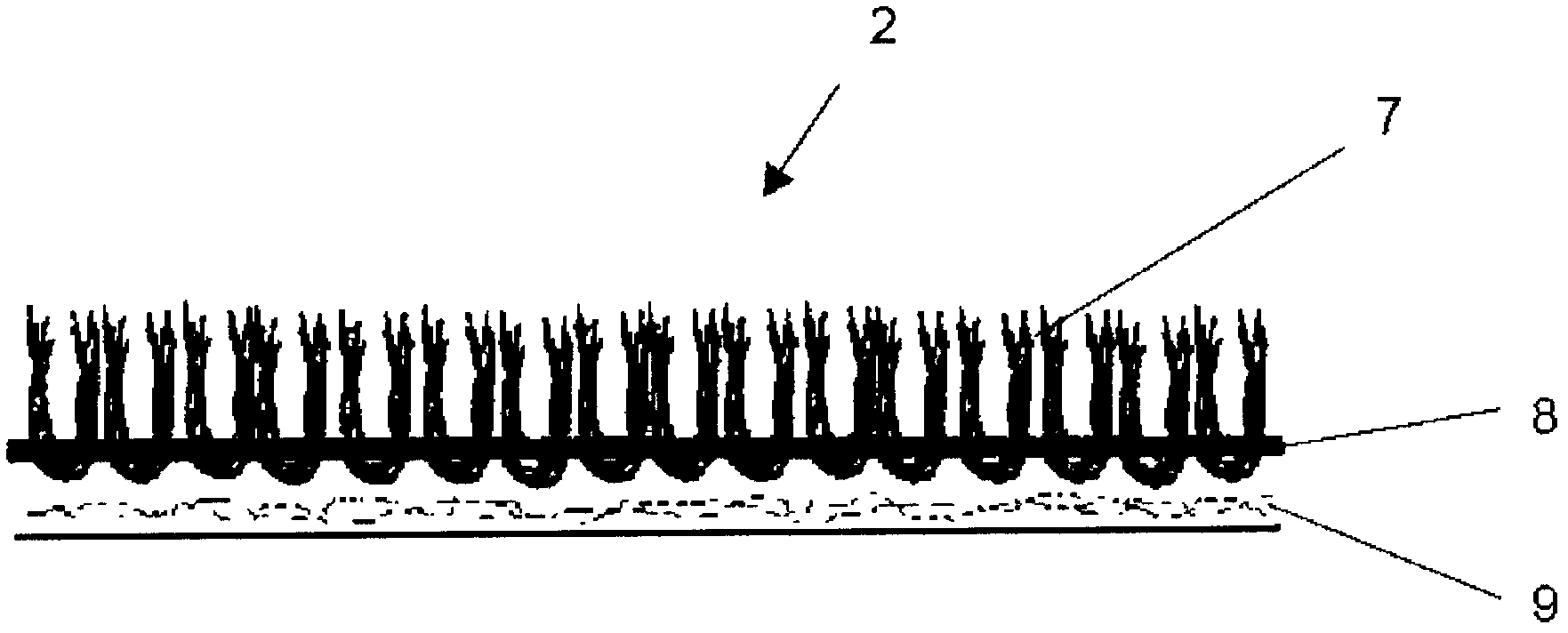

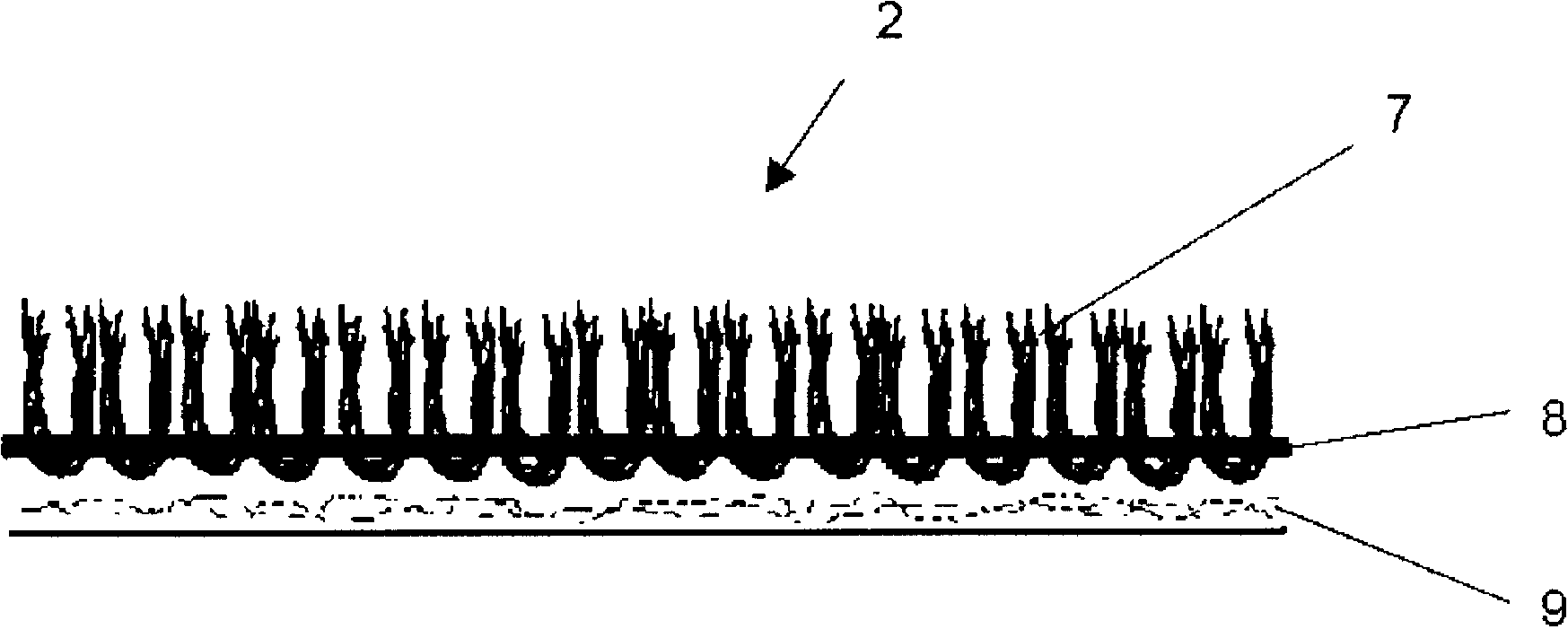

Carpet primary backing having enhanced tufting and tuft securing characteristics

InactiveUS20070270064A1Reduce in quantityFacilitates enhanced bondingLiquid surface applicatorsElectric shock equipmentsFiberYarn

A primary carpet backing is provided for use in the formation of a tufted carpet which eliminates or reduces the need for a latex adhesive layer or the use of a secondary backing. The external surfaces of a woven or non-woven fibrous mat are coated with thermoplastic polymer particles having a lower melting temperature than the fibers of the mat. The mat possesses sufficient openings between fibers to be capable of undergoing tufting. Following tufting the tufted mat is heat treated so as to melt the thermoplastic polymer particles and to create a bond between the tufted carpet yarn fibers and the primary backing mat.

Owner:JOHNS MANVILLE CORP

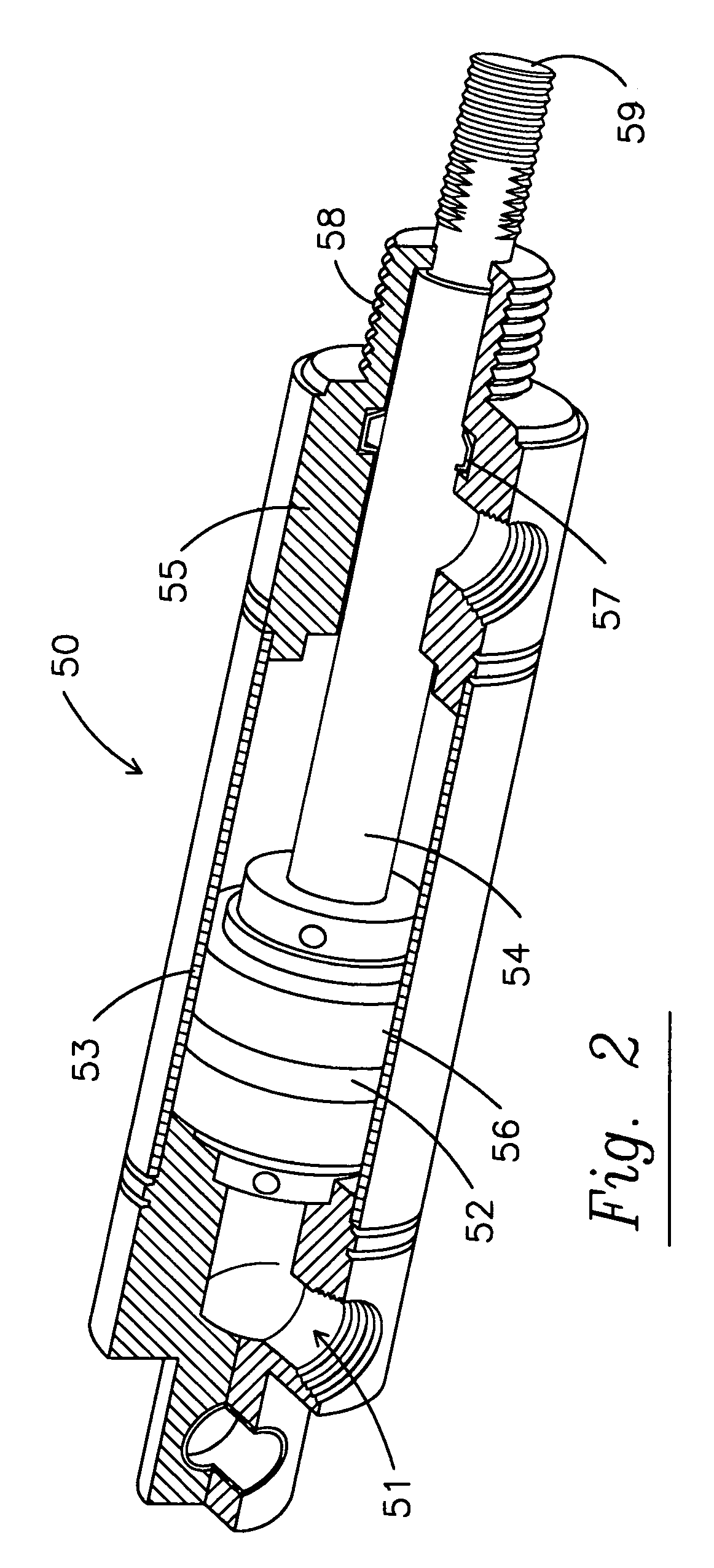

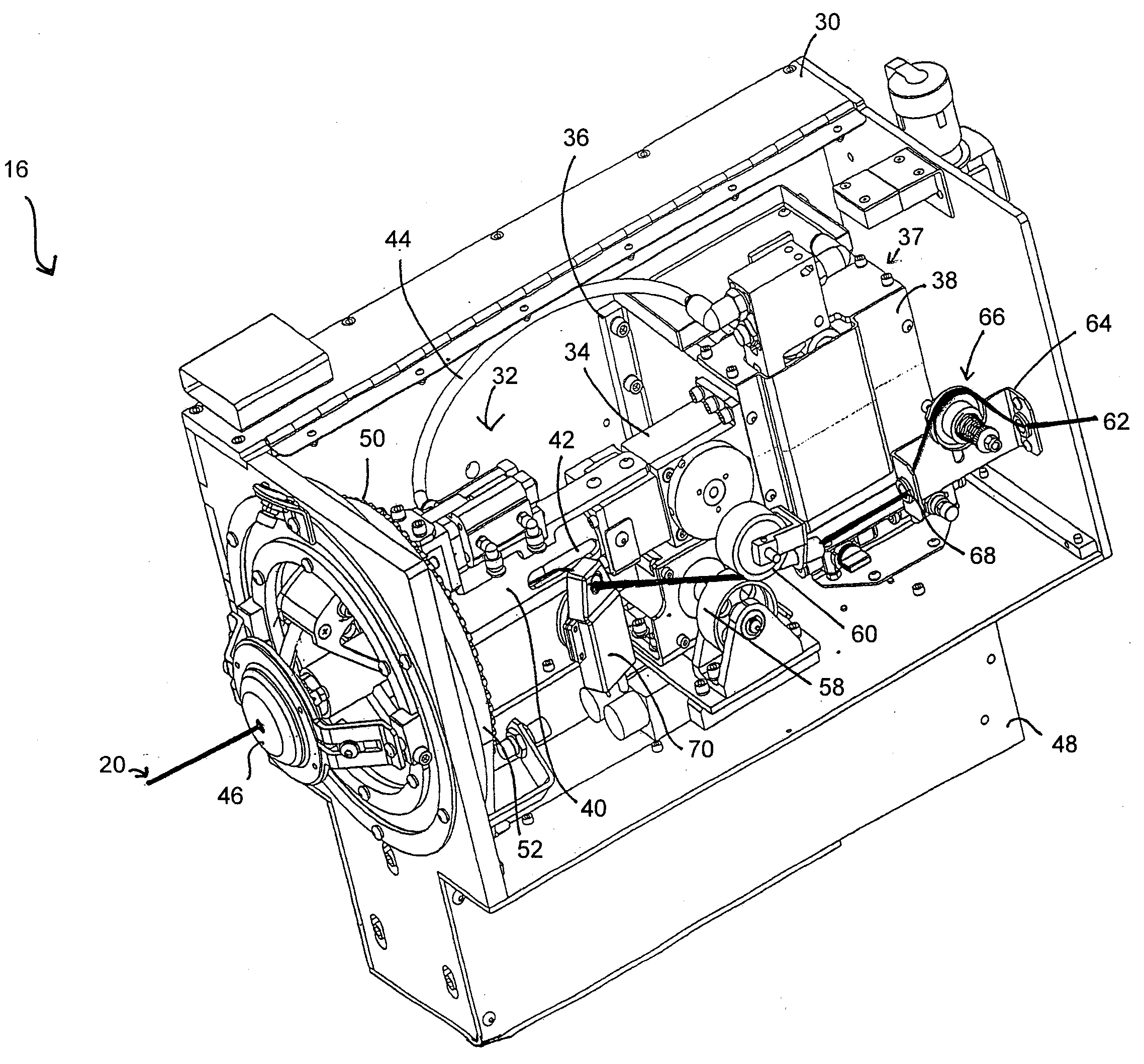

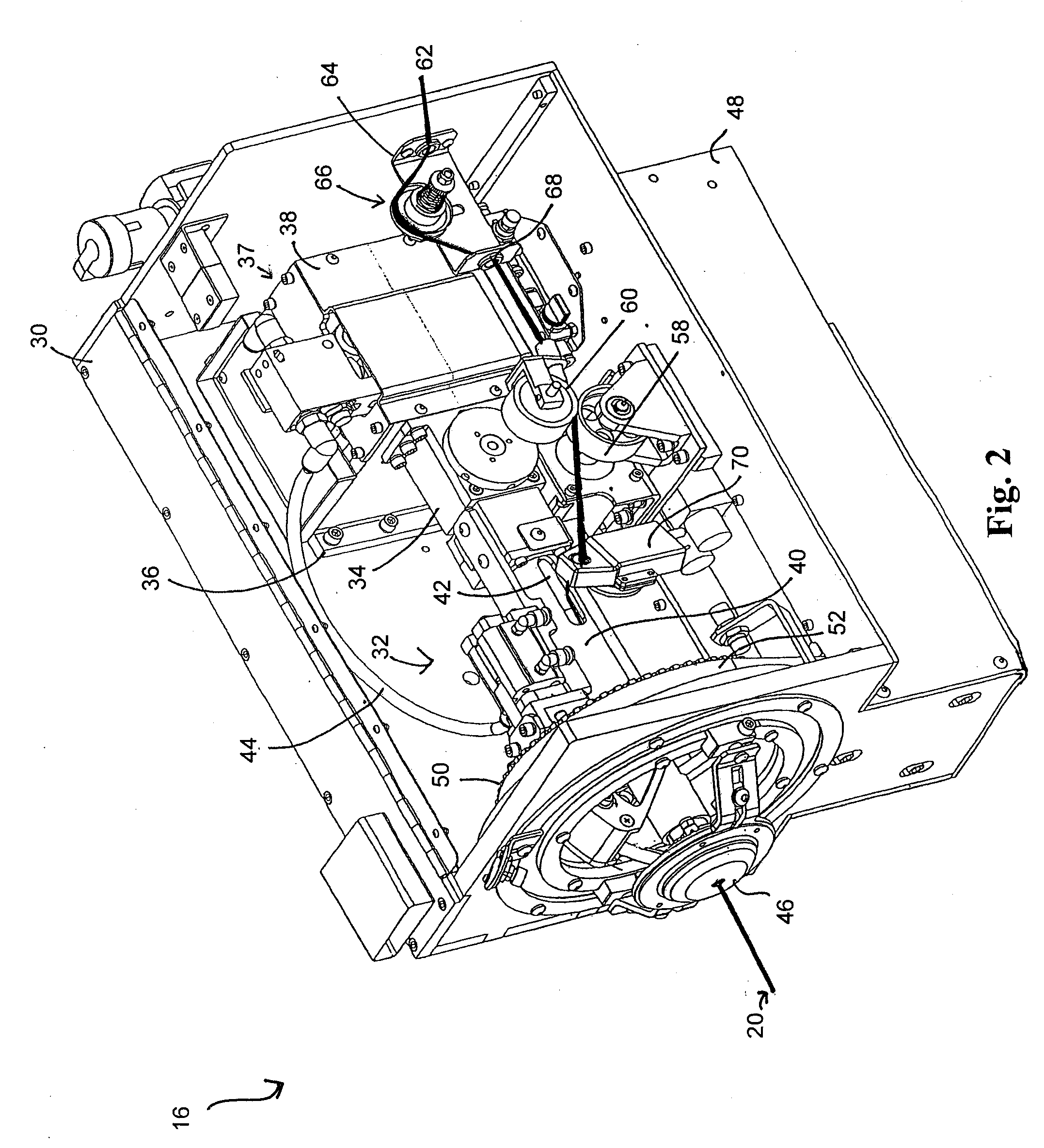

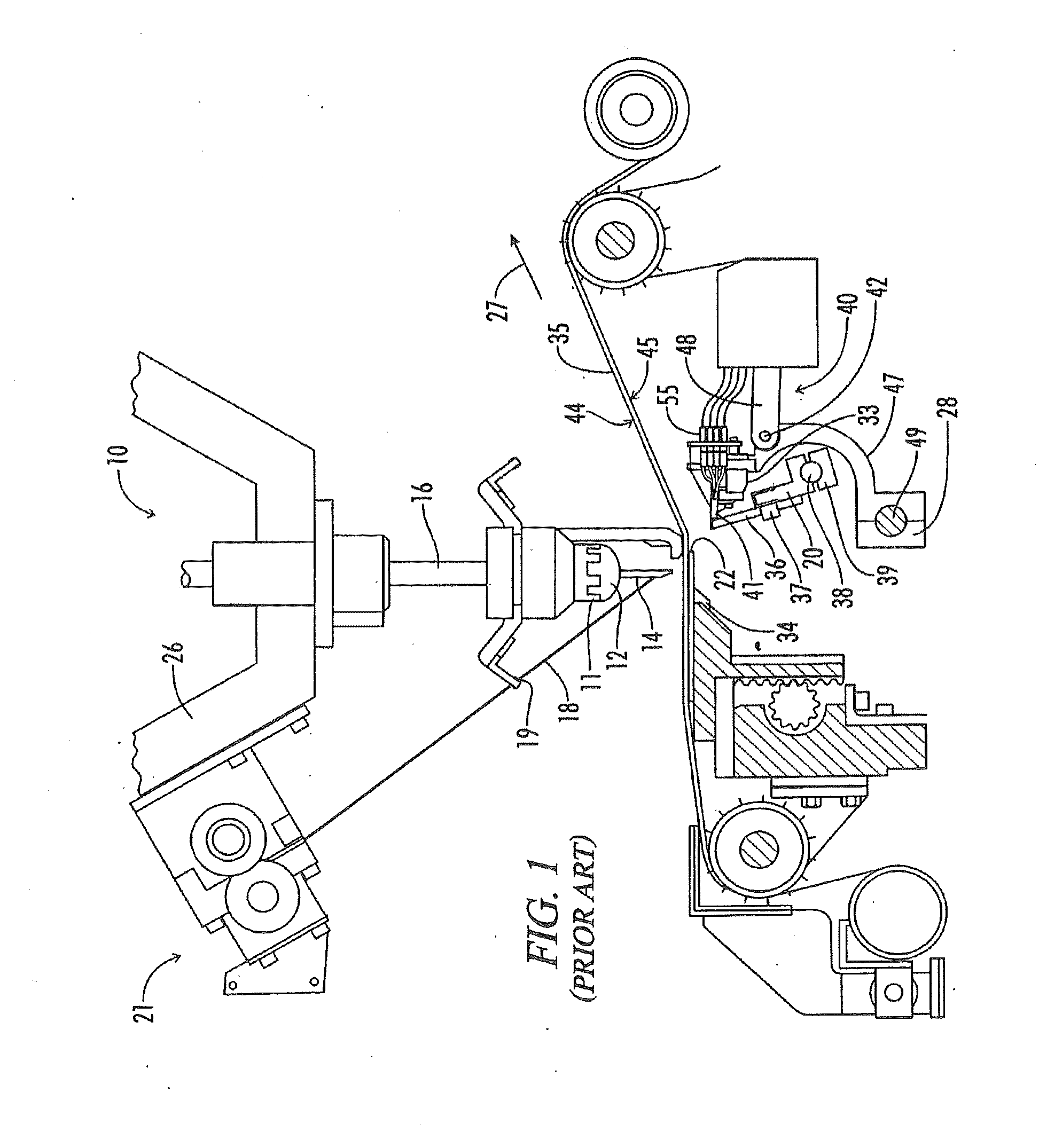

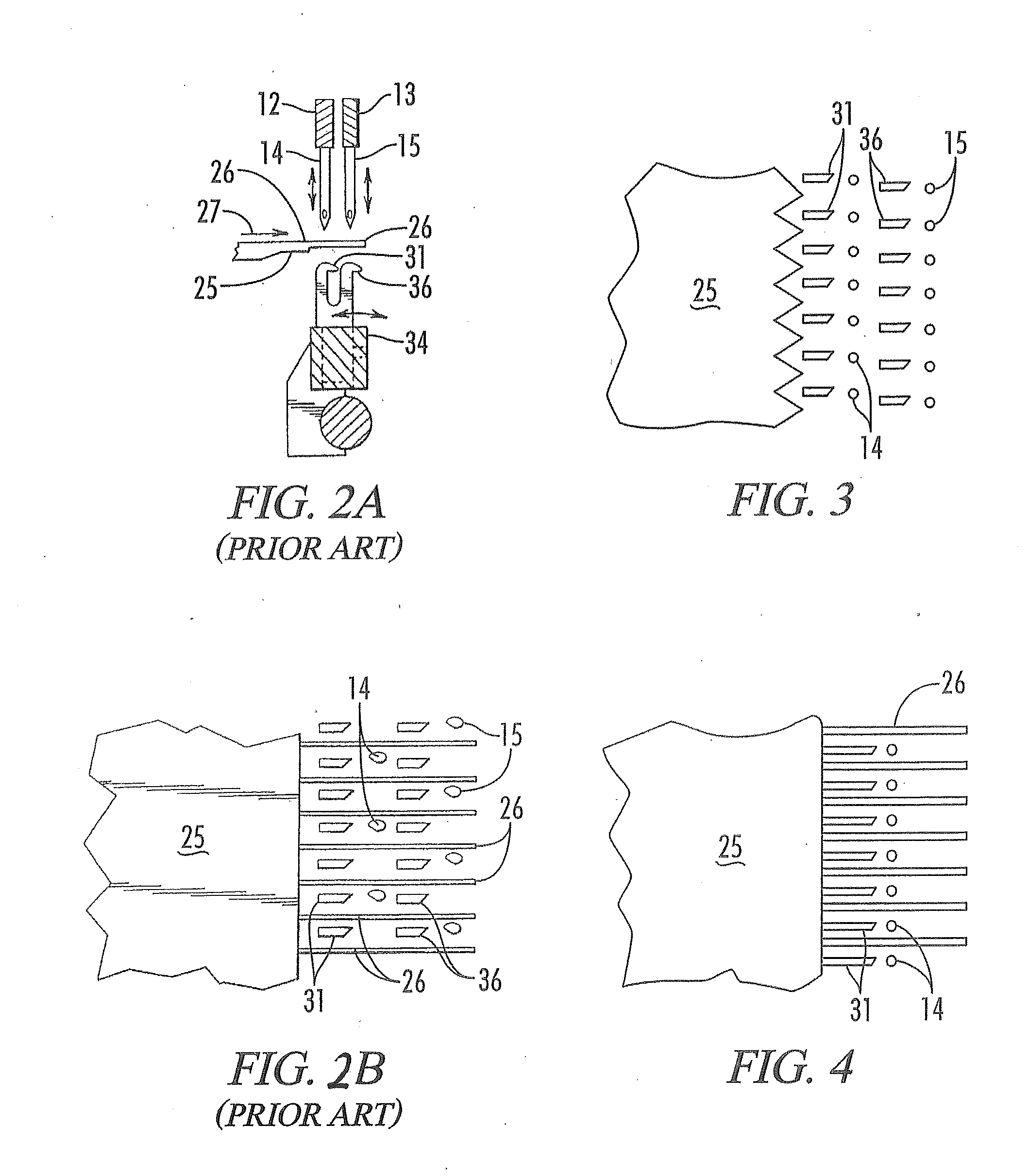

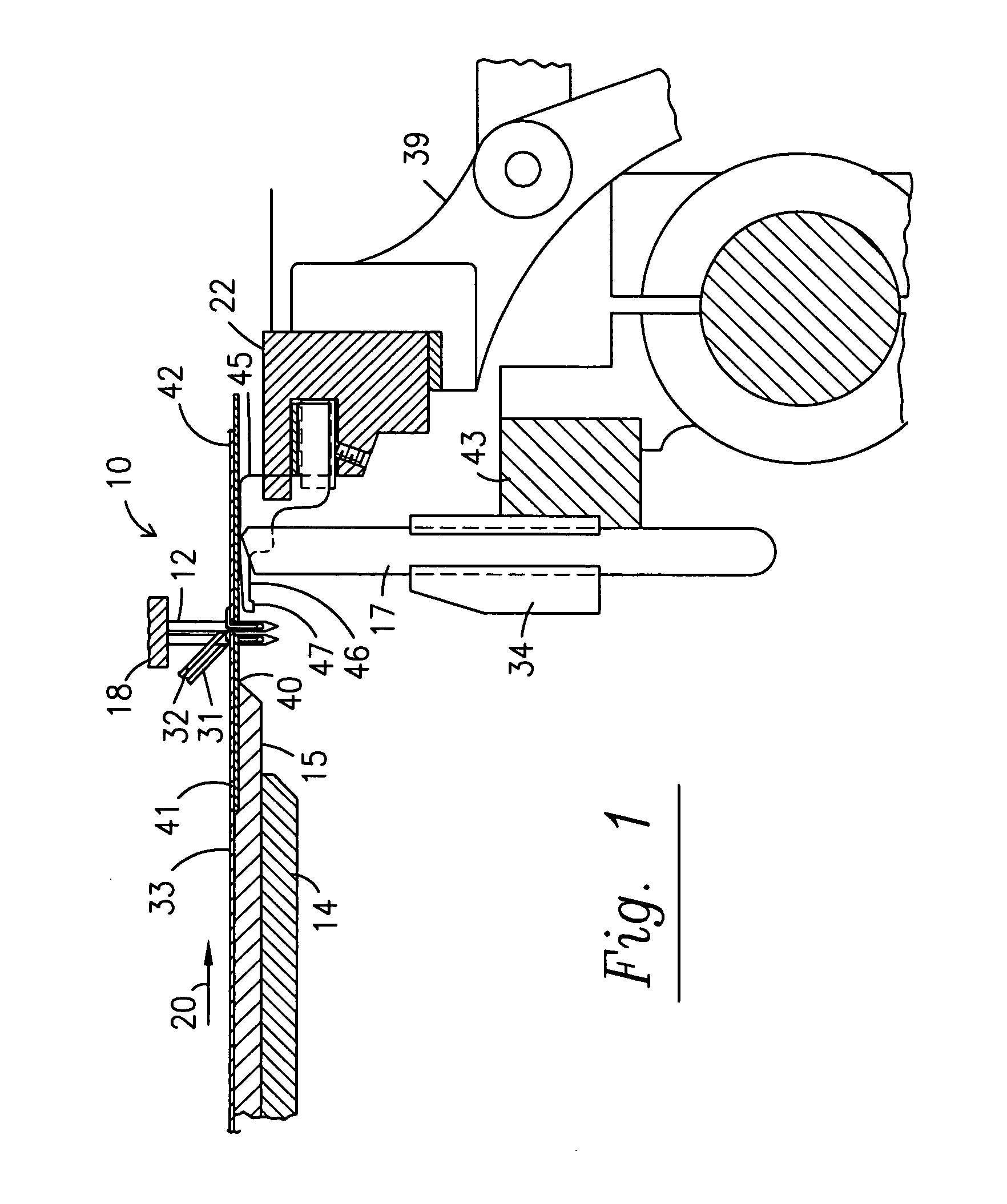

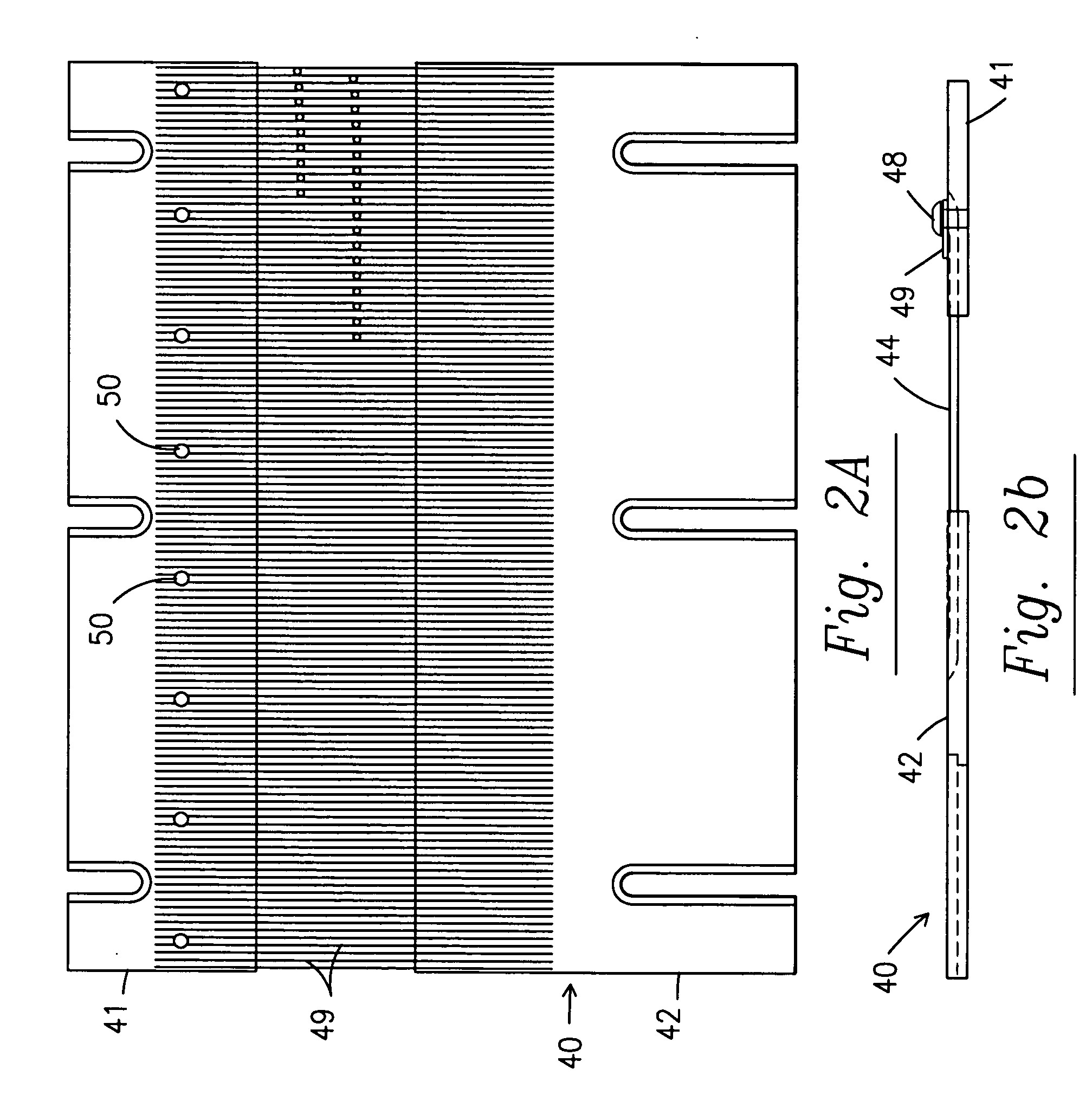

Gate apparatus for tufting loop and cut pile stitches

InactiveUS7222576B2Efficiently employedTufting apparatusLoop takersEngineeringMechanical engineering

A gated looper apparatus has an array of individually mounted pressurizable air cylinders with piston rods acting against biased slider bars in communication with looper gates. Baising elements are mounted external of pneumatic cylinders about slider bars with protective ferules to provide greater responsiveness and ease of maintenance.

Owner:TUFTCO

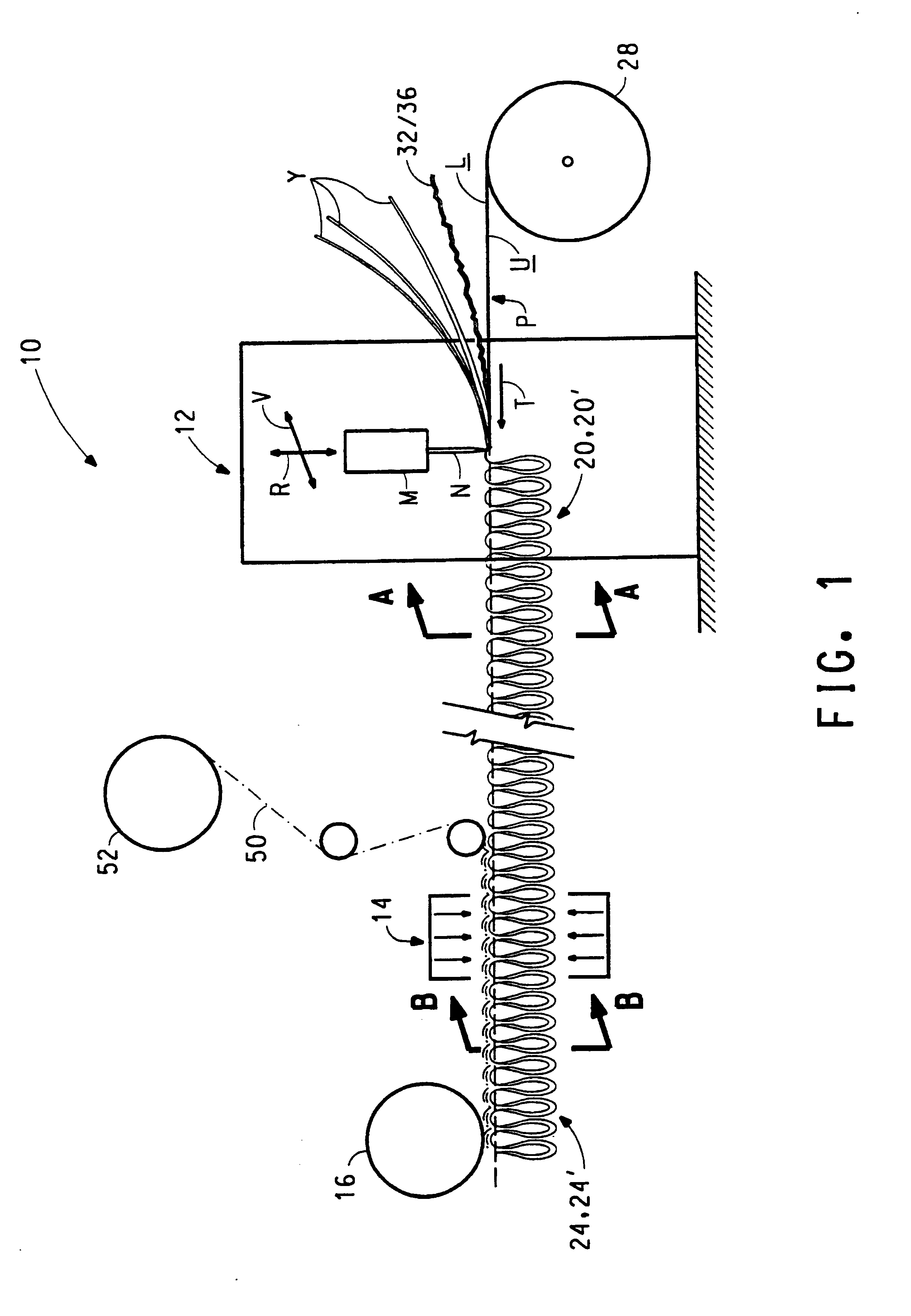

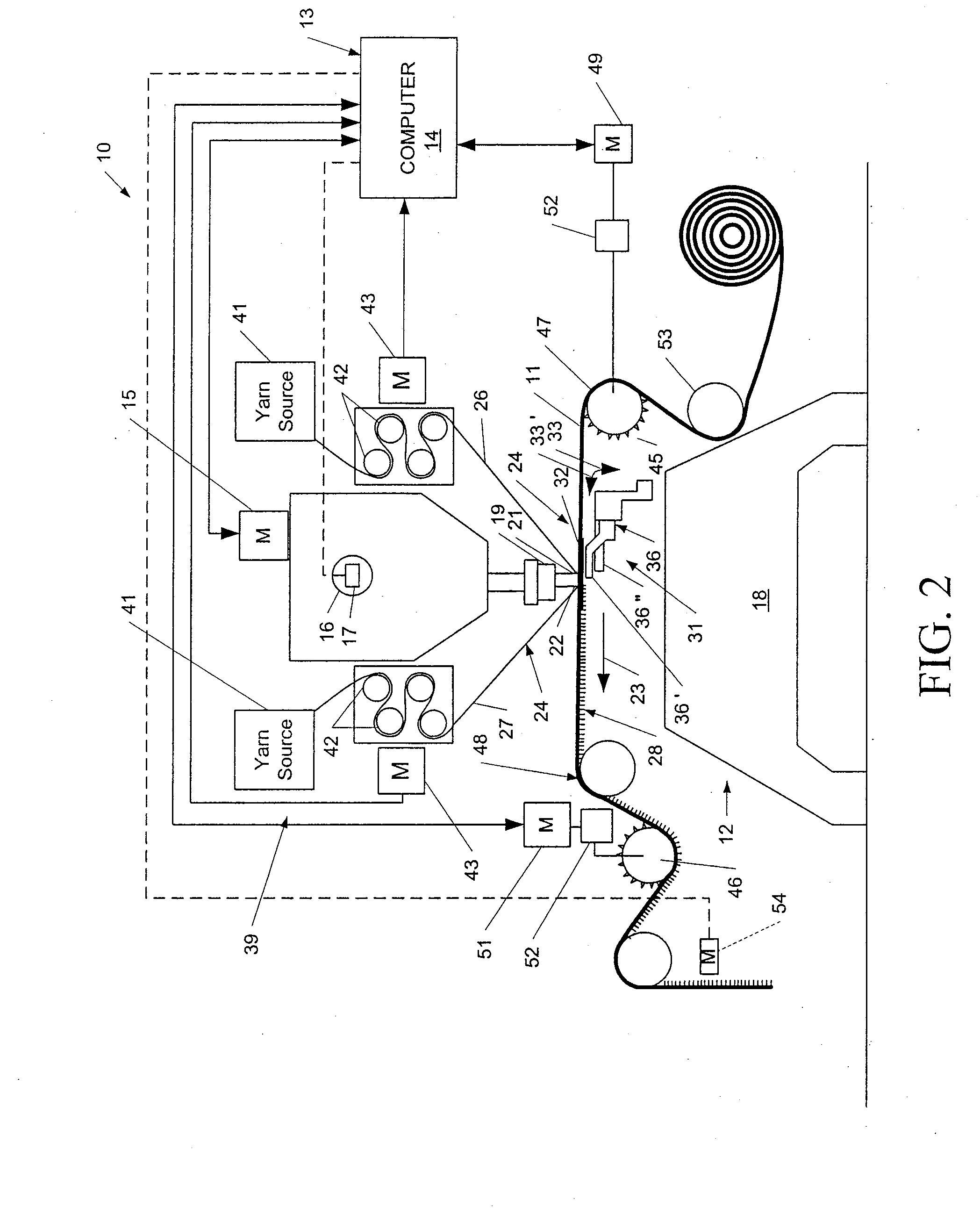

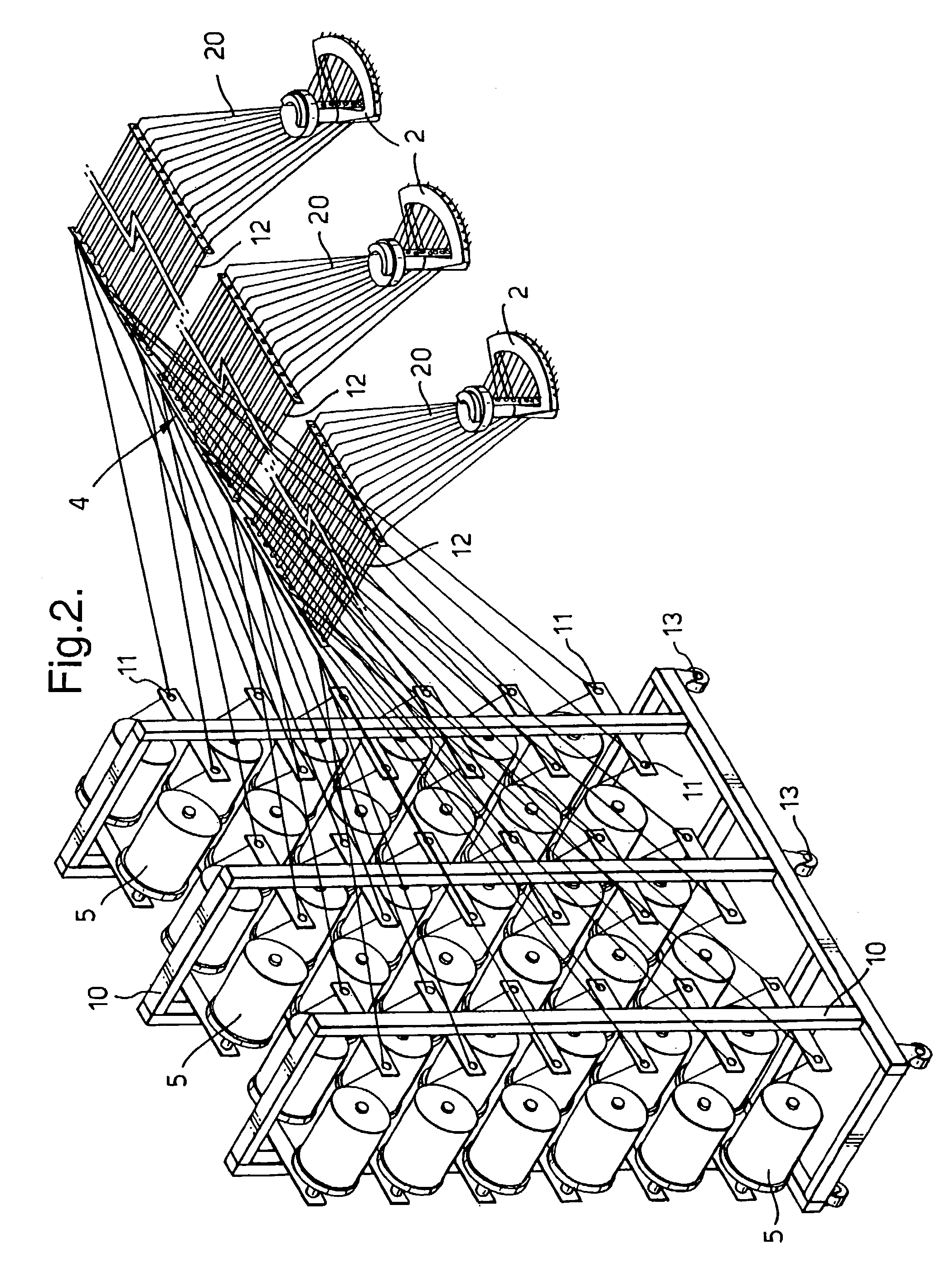

Tufting machine and process for variable stitch rate tufting

A tufting machine as disclosed with a variable yarn feed mechanism and a method for tufting patterns with yarns from two rows of needles offset longitudinally from one another in a fashion that the different stitch lengths are selected in a fashion that the yarns from each row of needles are complementary to the other and maintain a consistent stitch density.

Owner:TUFTCO

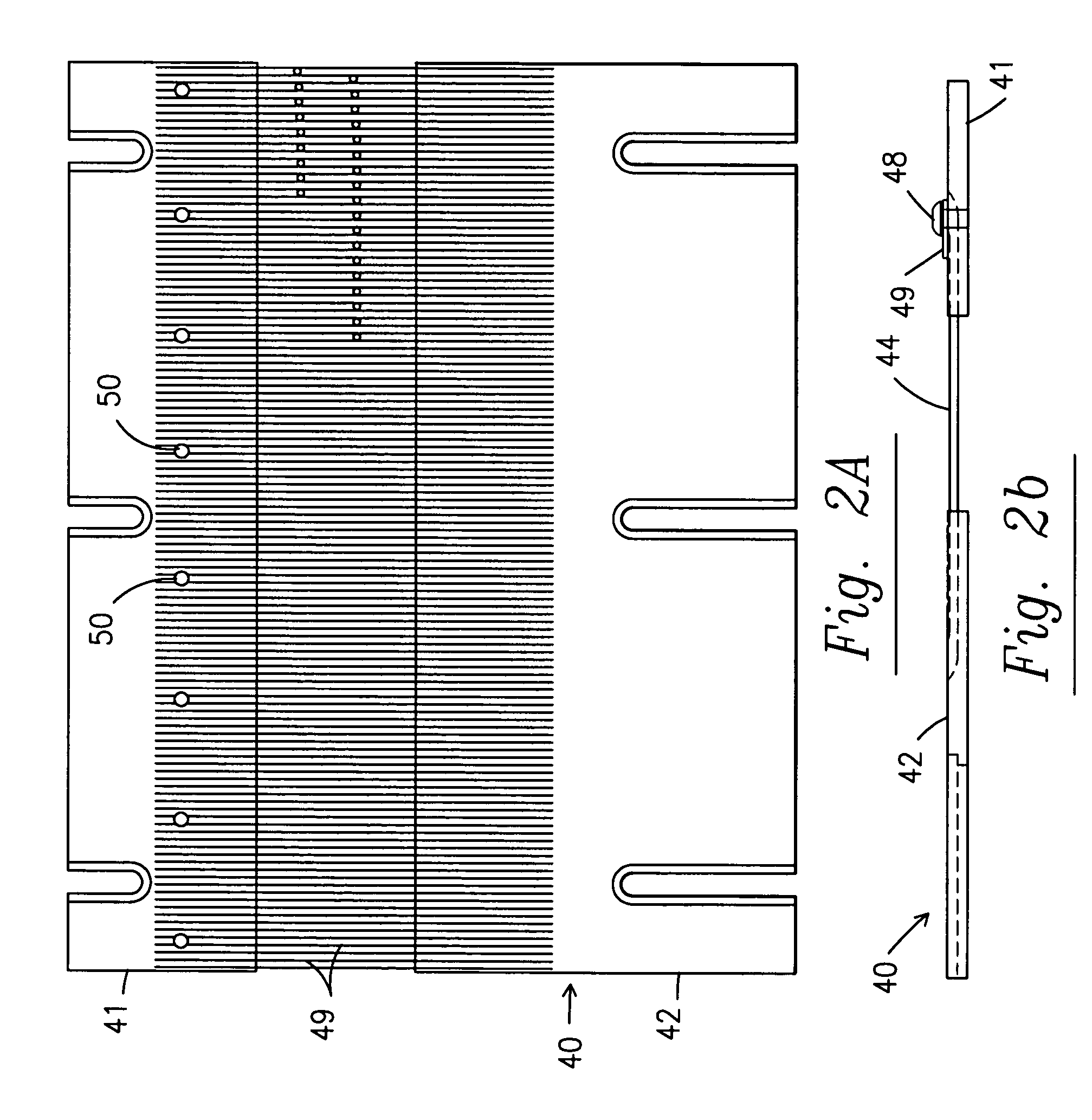

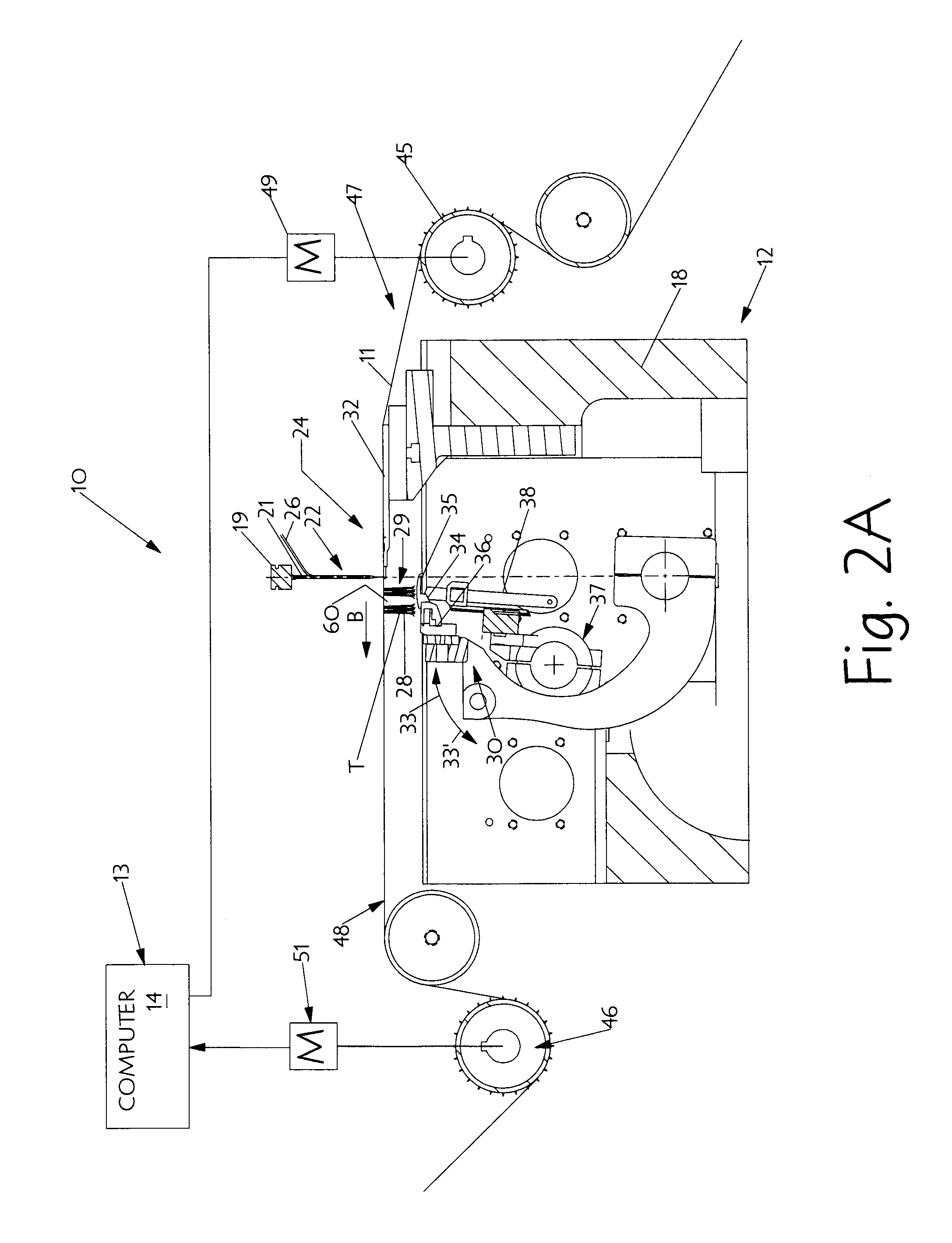

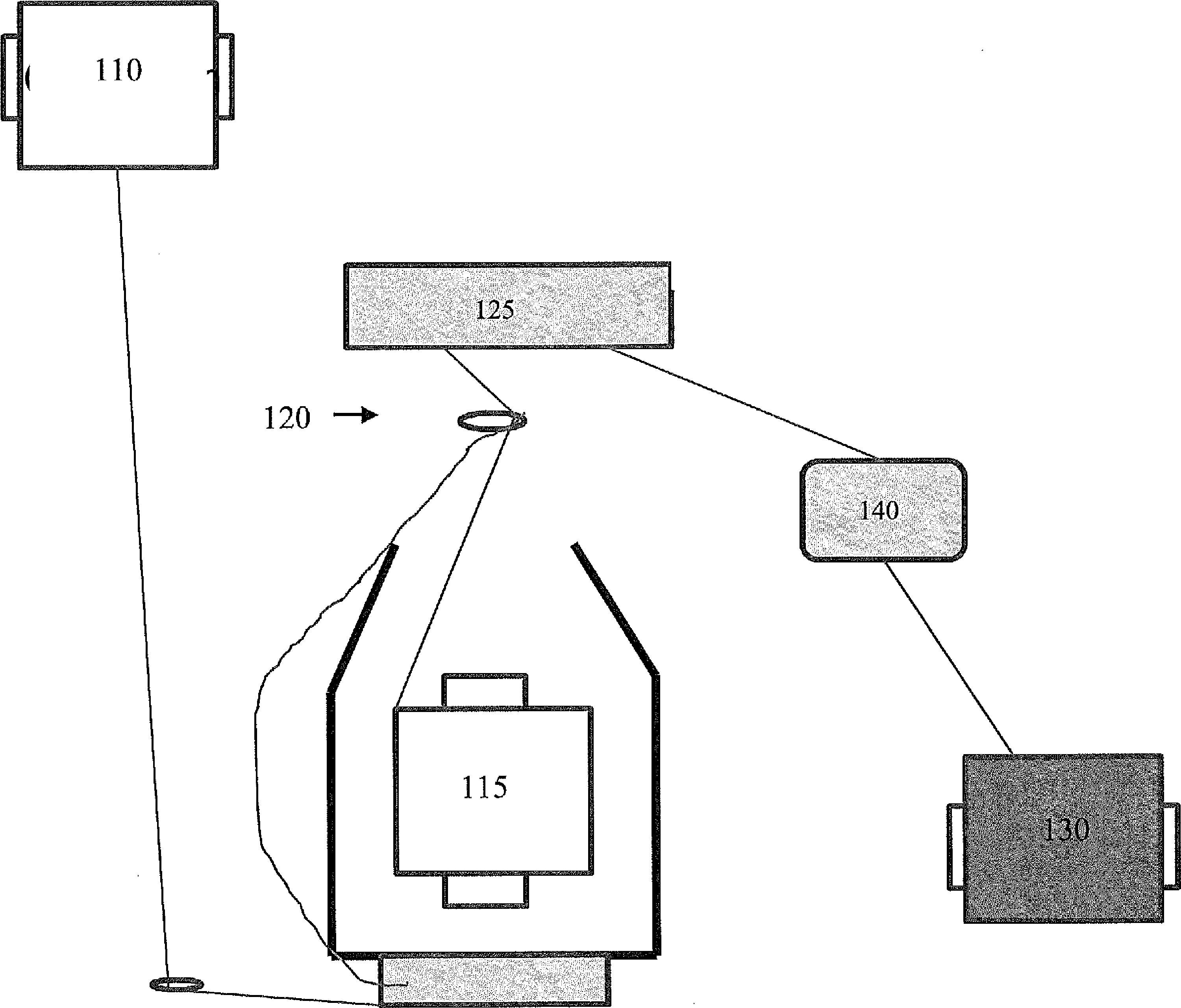

System and method for control of the backing feed for a tufting machine

ActiveUS7717051B1Further pattern effectsProgramme-controlled sewing machinesTufting apparatusMechanical engineeringTufting

Owner:CARD MONROE

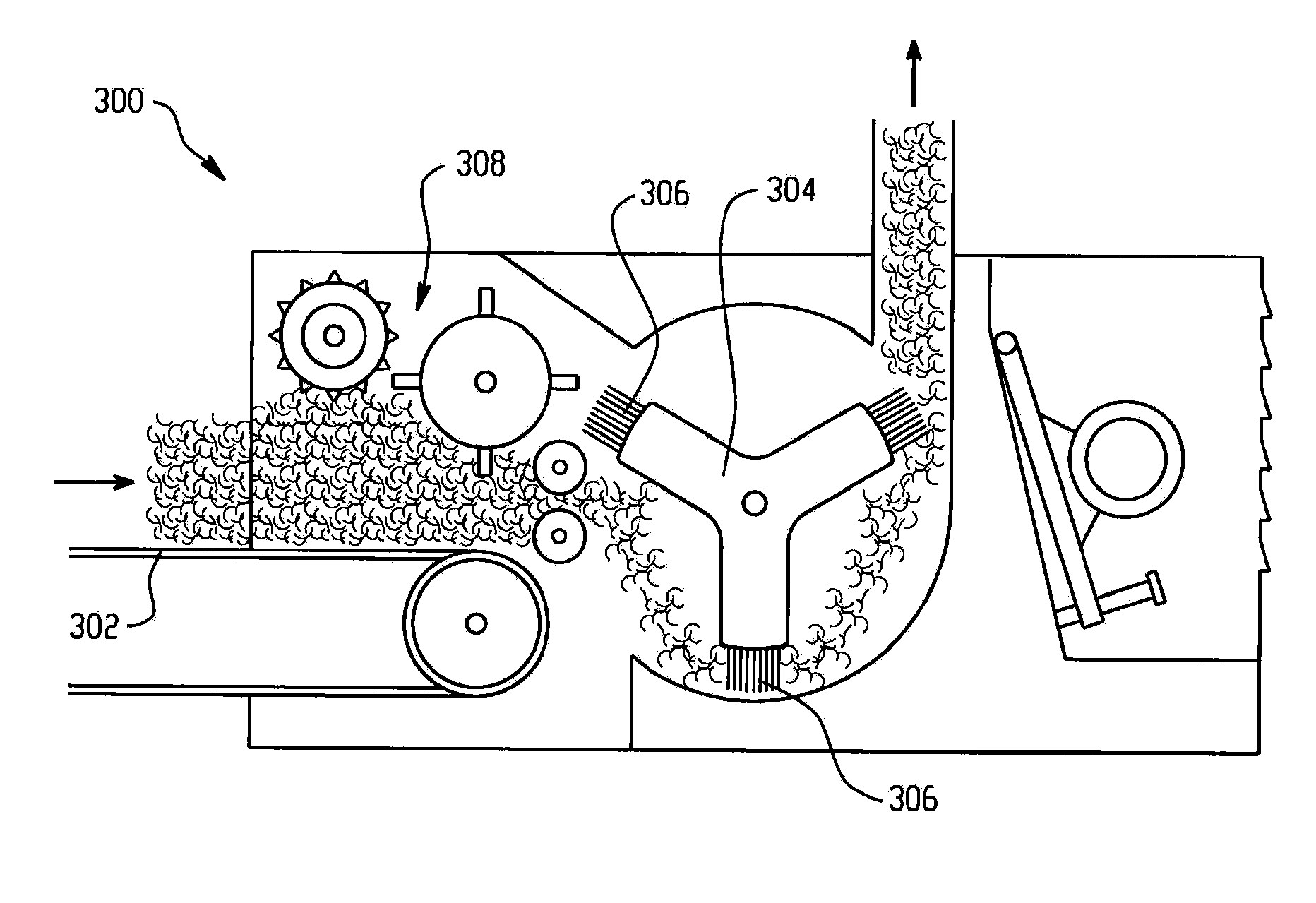

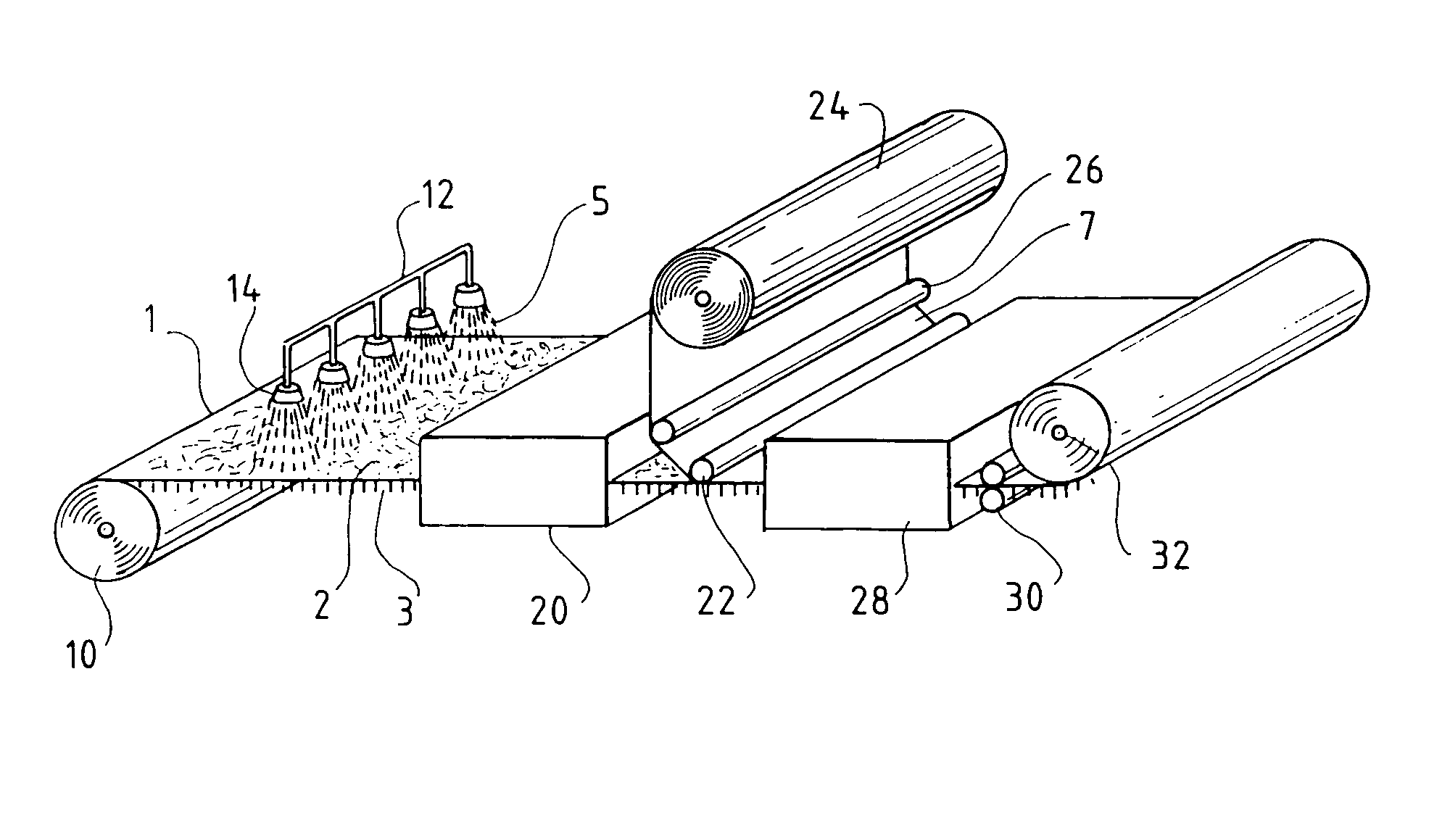

Process for making bamboo fiberfill and articles thereof

InactiveUS20090101294A1Small sizeNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

A process for producing bamboo fiberfill from raw bamboo fiber includes, obtaining a bale of the raw bamboo fiber, picking up and separating the raw bamboo bale fiber into tufts of bamboo fiber with a bale opener, feeding the bamboo fiber tufts into a blending hopper configured to blend the bamboo fiber tufts, feeding the blended bamboo fiber tufts into a beater configured to open the bamboo fiber tufts, and feeding the opened bamboo fiber tufts into a fine opener configured to reduce the size of the opened bamboo fiber tufts and refine the opened bamboo fiber tufts into the bamboo fiberfill, wherein the bamboo fiberfill has a fiber length of about 30 millimeters to about 60 millimeters and a linear density of about 0.5 denier to about 5.0 denier.

Owner:FAIRFIELD PROCESSING CORP

Method for Selective Display of Yarn in a Tufted Fabric With Double End Yarn Drives

A novel method of tufting carpets is provided to allow the use of four or more colors of yarn at sufficient stitch density to provide for a solid appearance of any of the selected colors at any location on the carpet, and utilizing natural tacking of rear yarns to minimize loose yarn on the backing.

Owner:TUFTCO

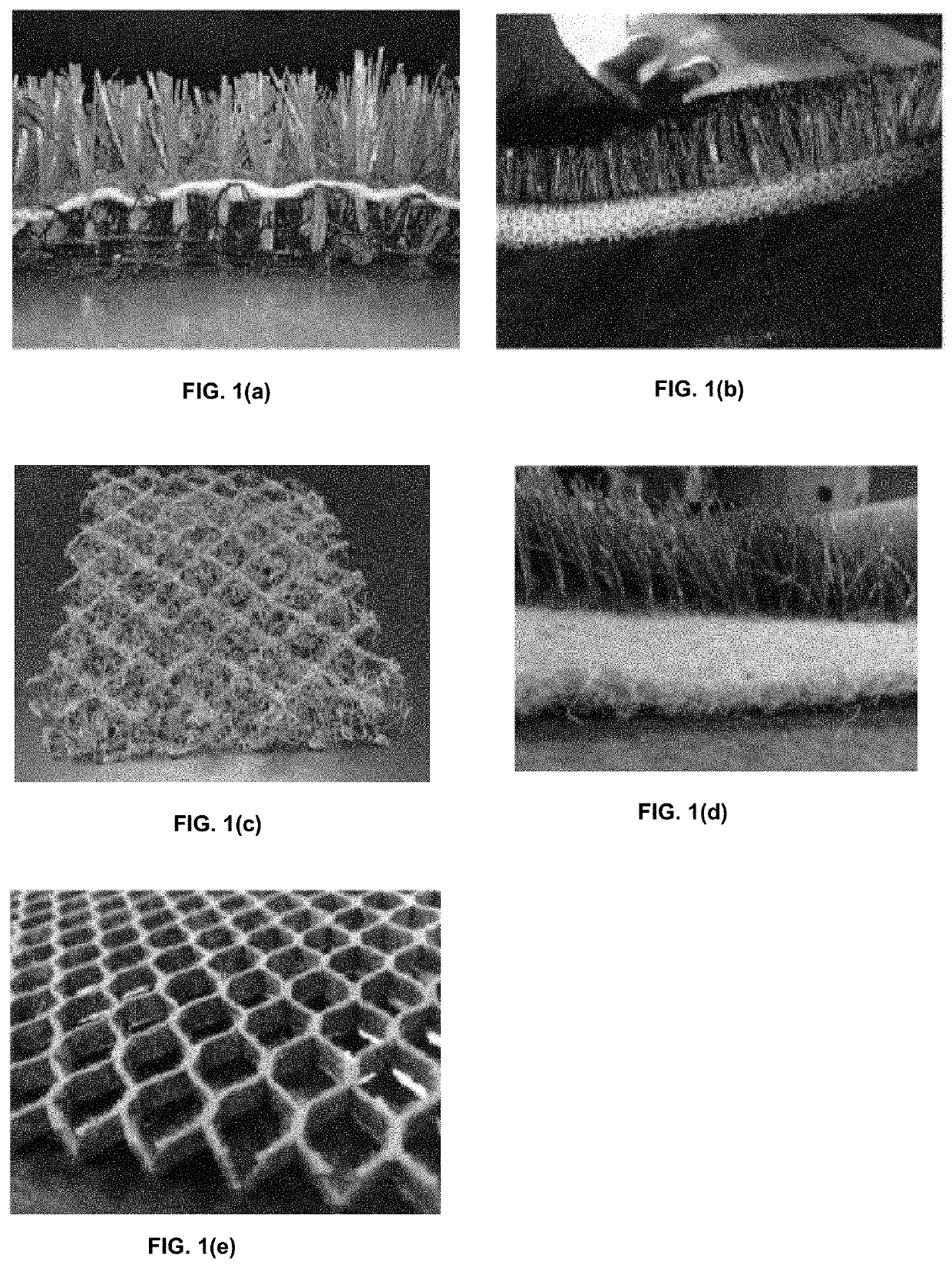

Carpets with improved fuzz-resistance

Tufted carpets bonded with thermoplastic binders and having improved resistance to fuzz formation due to removal of pile yarn filaments from tuft bundles comprise one or more backings, face yarn that forms a pile on one side and stitches on an opposite side, a thermoplastic binder that binds stitches and the backing or backings, and an organic polymer that bonds filaments of the stitches. Processes for making carpets comprise applying to a stitched side of a tufted backing a liquid stitch bind composition comprising an organic polymer component, removing a liquid component of the composition to bond filaments of the stitches and bonding stitches and one or more backings with a thermoplastic binder that is melted or applied as a melt in contact with the stitched side and the backing or backings and solidified.

Owner:PROPEX OPERATING

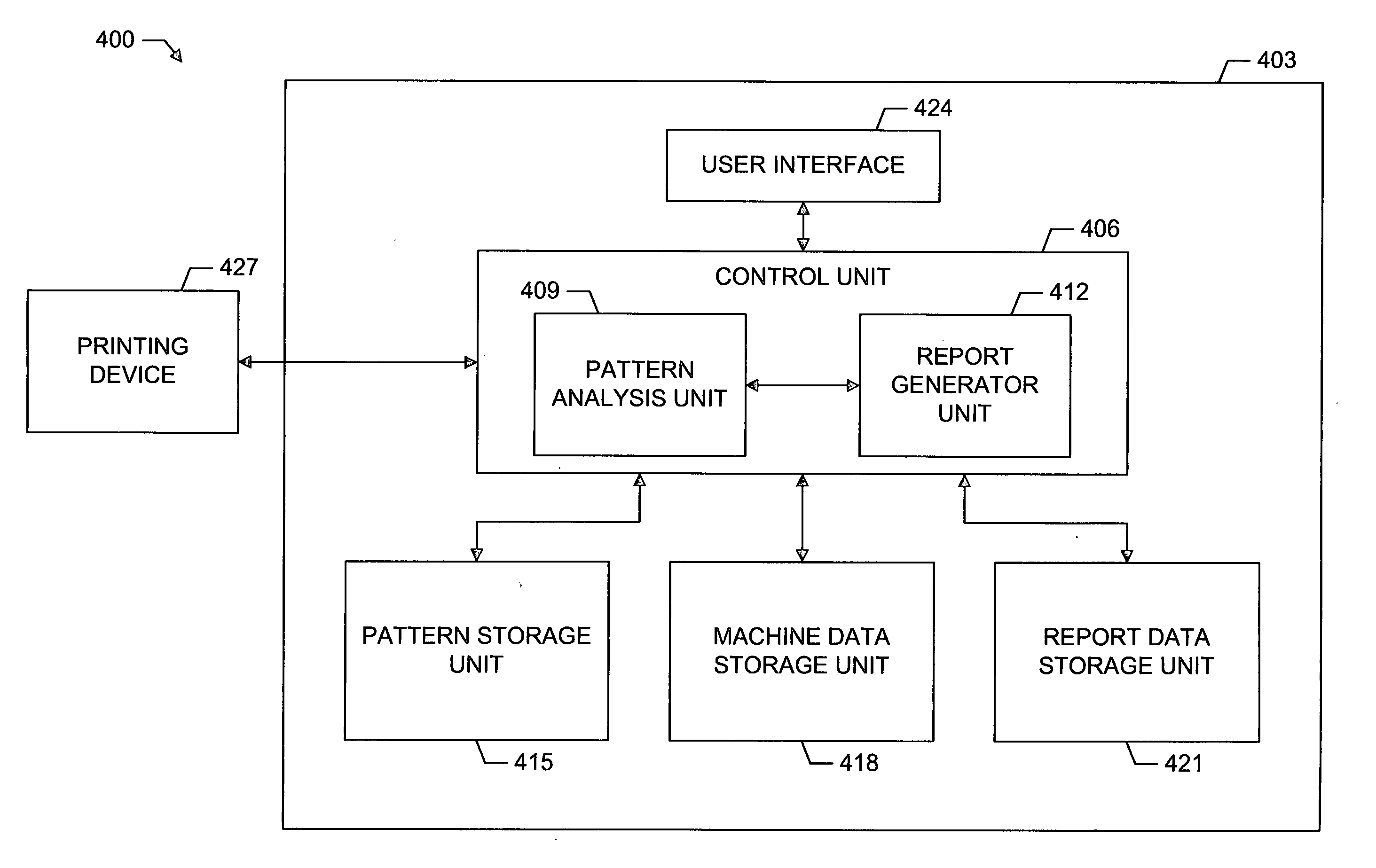

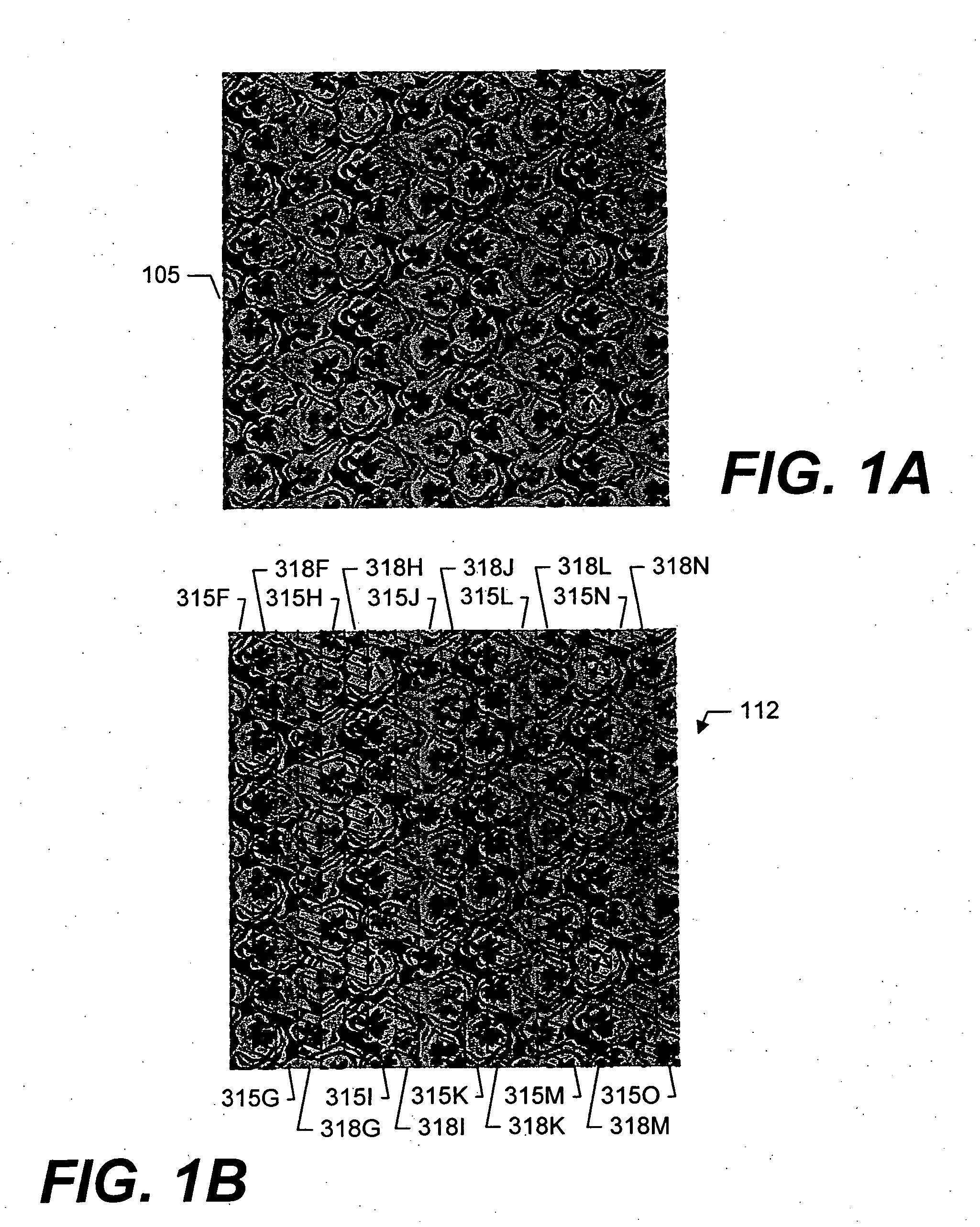

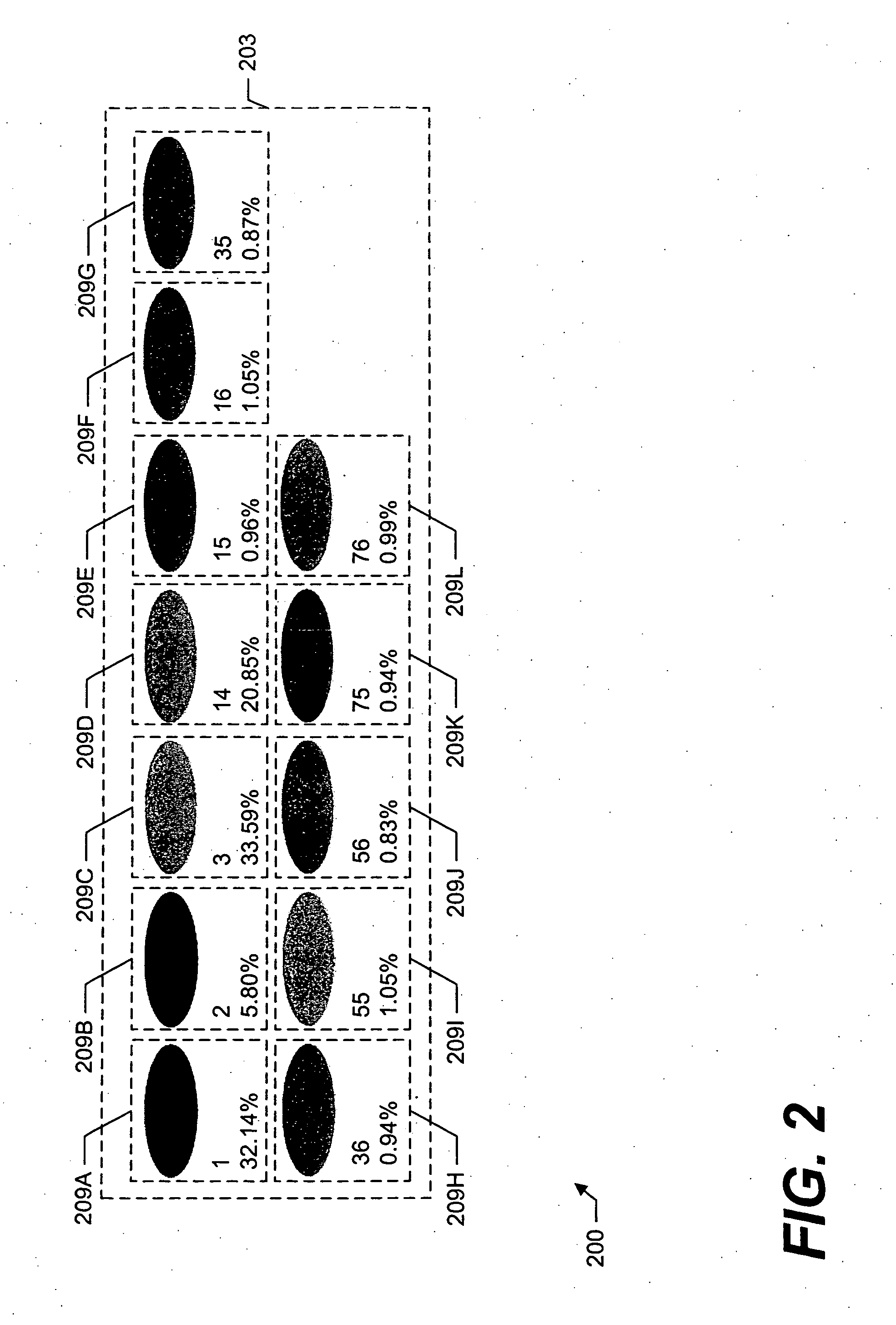

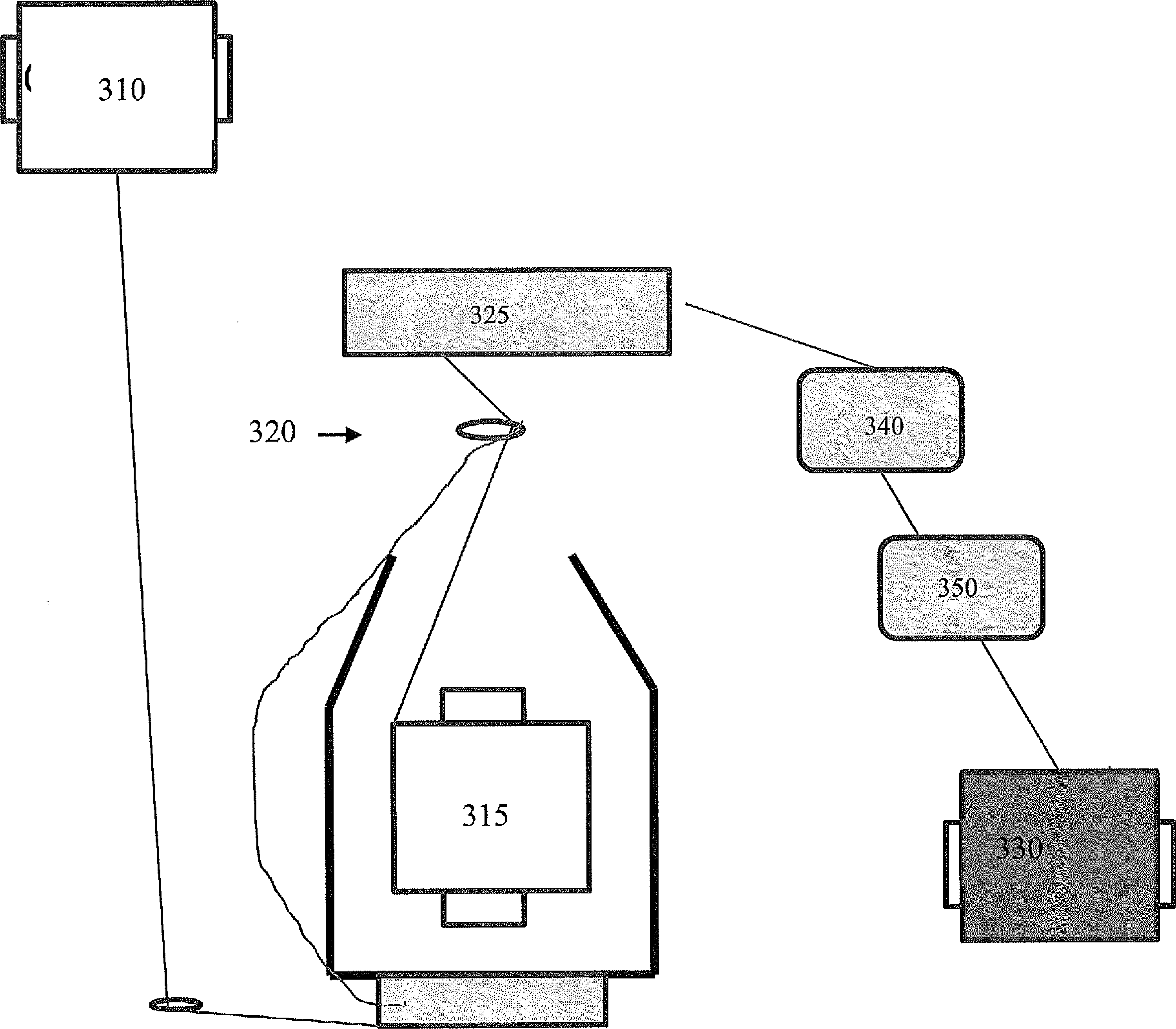

System and method of producing multi-colored carpets

A system and method for producing multi-colored carpets using a tufting machine. The present invention features a system and method for: providing a multi-colored pattern which is analyzed for validity with reference to a particular tufting machine; collecting parameters concerning a particular tufting machine; determining the colors of yarn to load with each needle of the particular tufting machine; and generating a report including a palette of colors used within the pattern, a chart indicating which color of yarns are used within each needle position, and a summary of the number of yarn cones needed to create a carpet of a predetermined size with the particular tufting machine.

Owner:ALADDIN MFG CORP +1

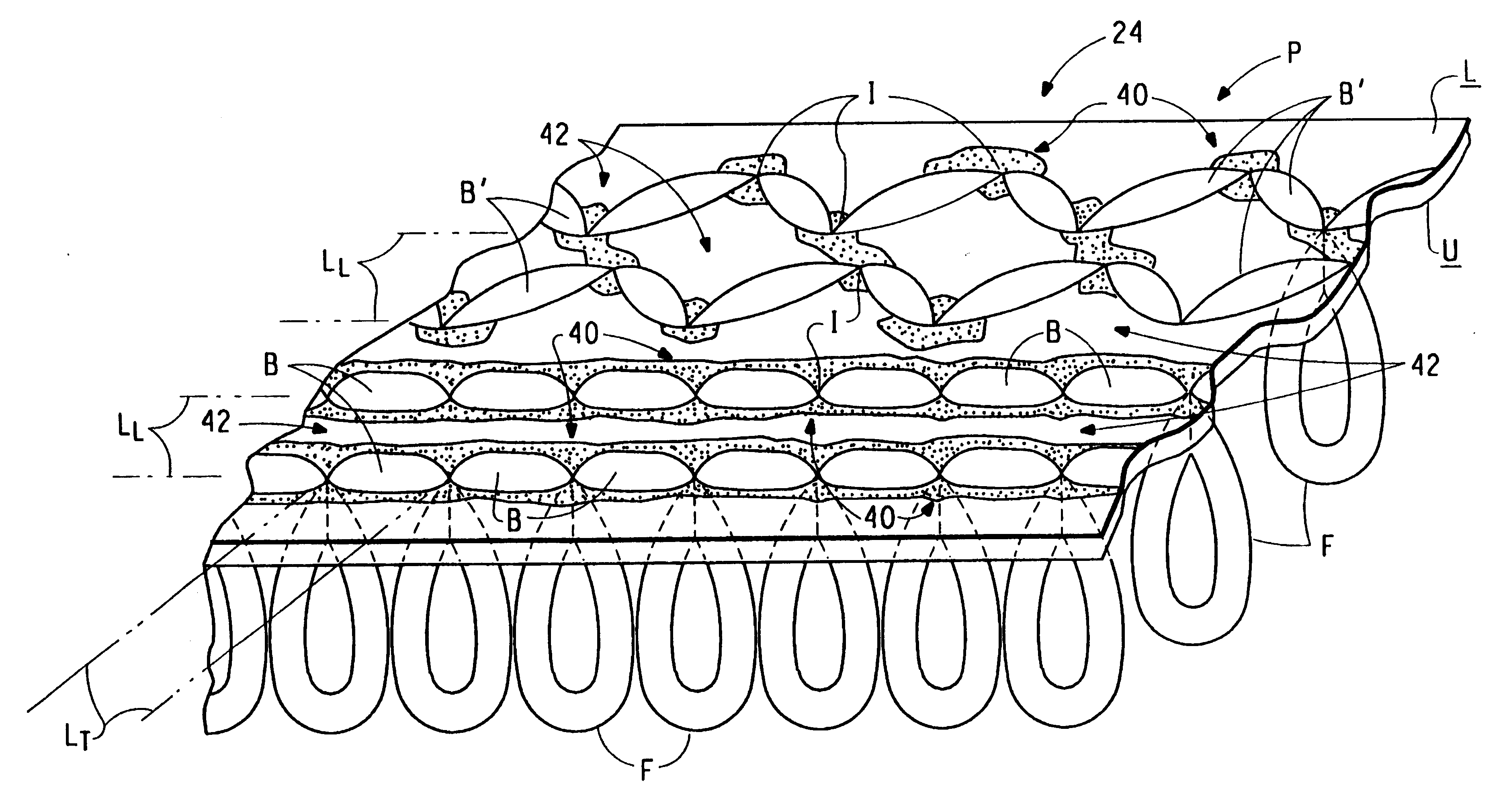

Tufted pile structure having binder concentrated beneath the backstitches

A concentrate of binder at the tufts produces a lighter and more flexible carpet, which allows for direct attachment of hook-and-loop means on the carpet backing. Thermoplastic binder yarns are pinned by the pile yarns against the primary backing. Subsequent application of heat melts the binder yarns and fuses the tufts and primary backing together. An alternate embodiment uses highly shrinkable binder sheet placed over the backing before tufting, instead of the binder yarns.

Owner:INVISTA NORTH AMERICA R L

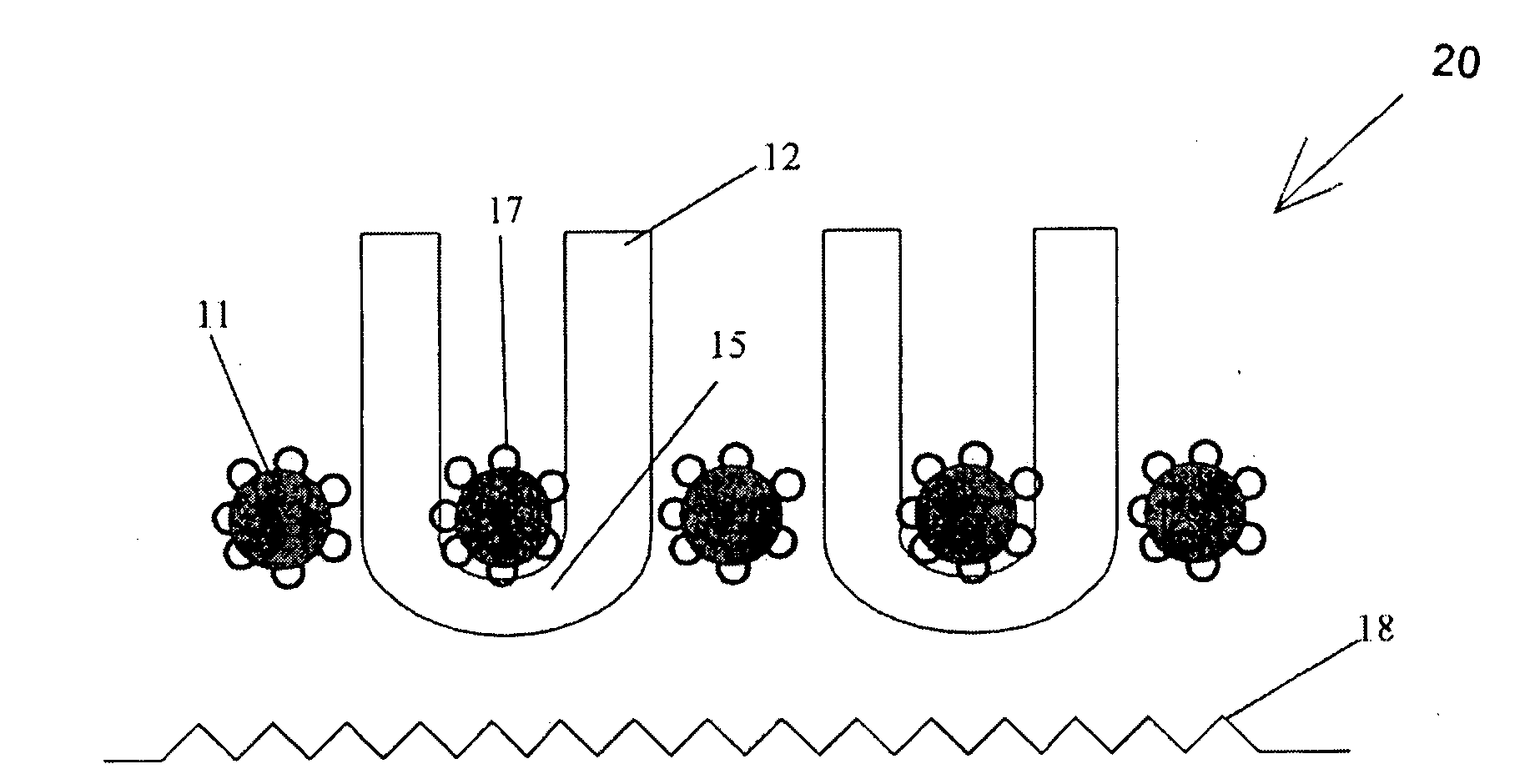

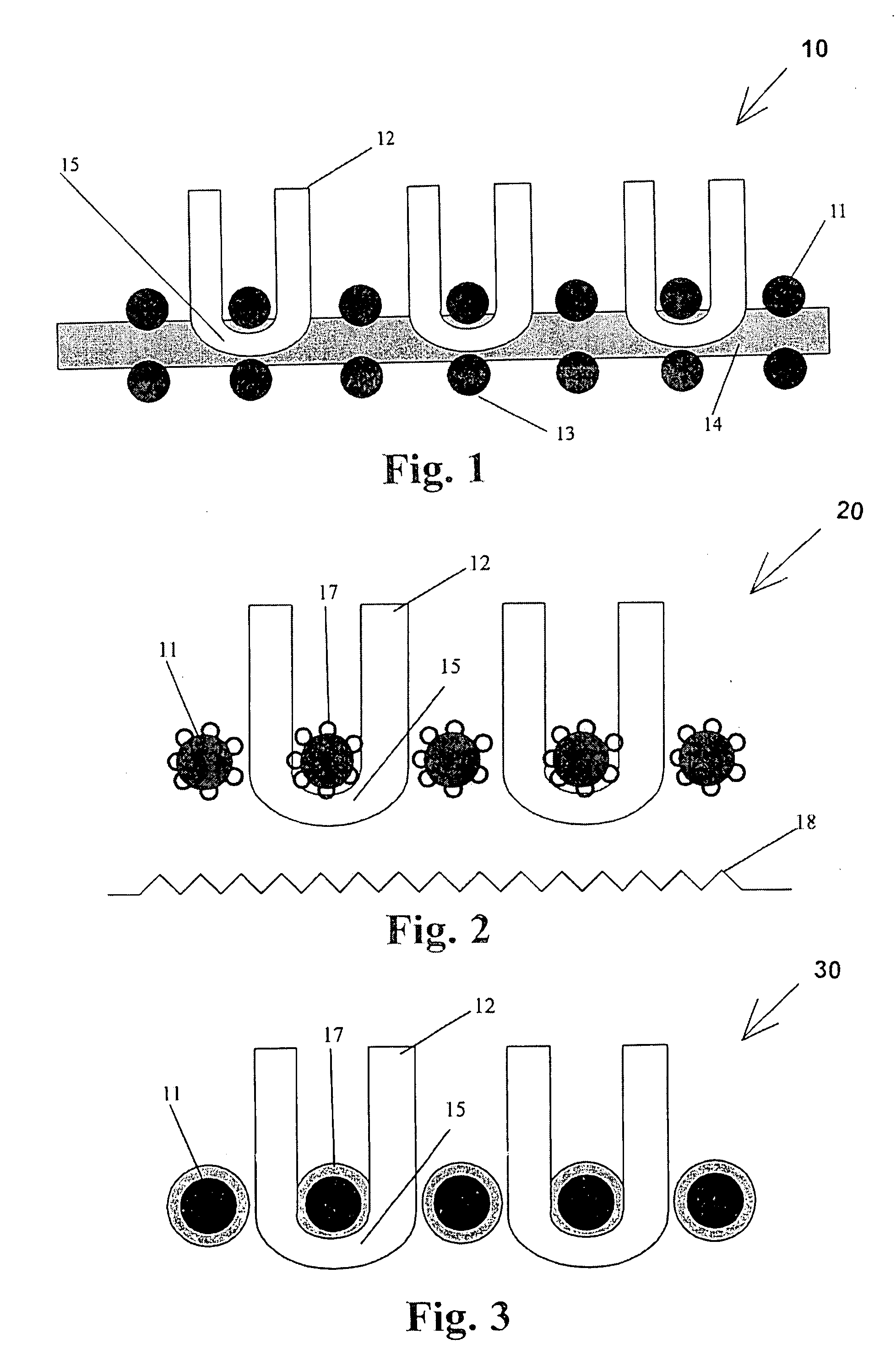

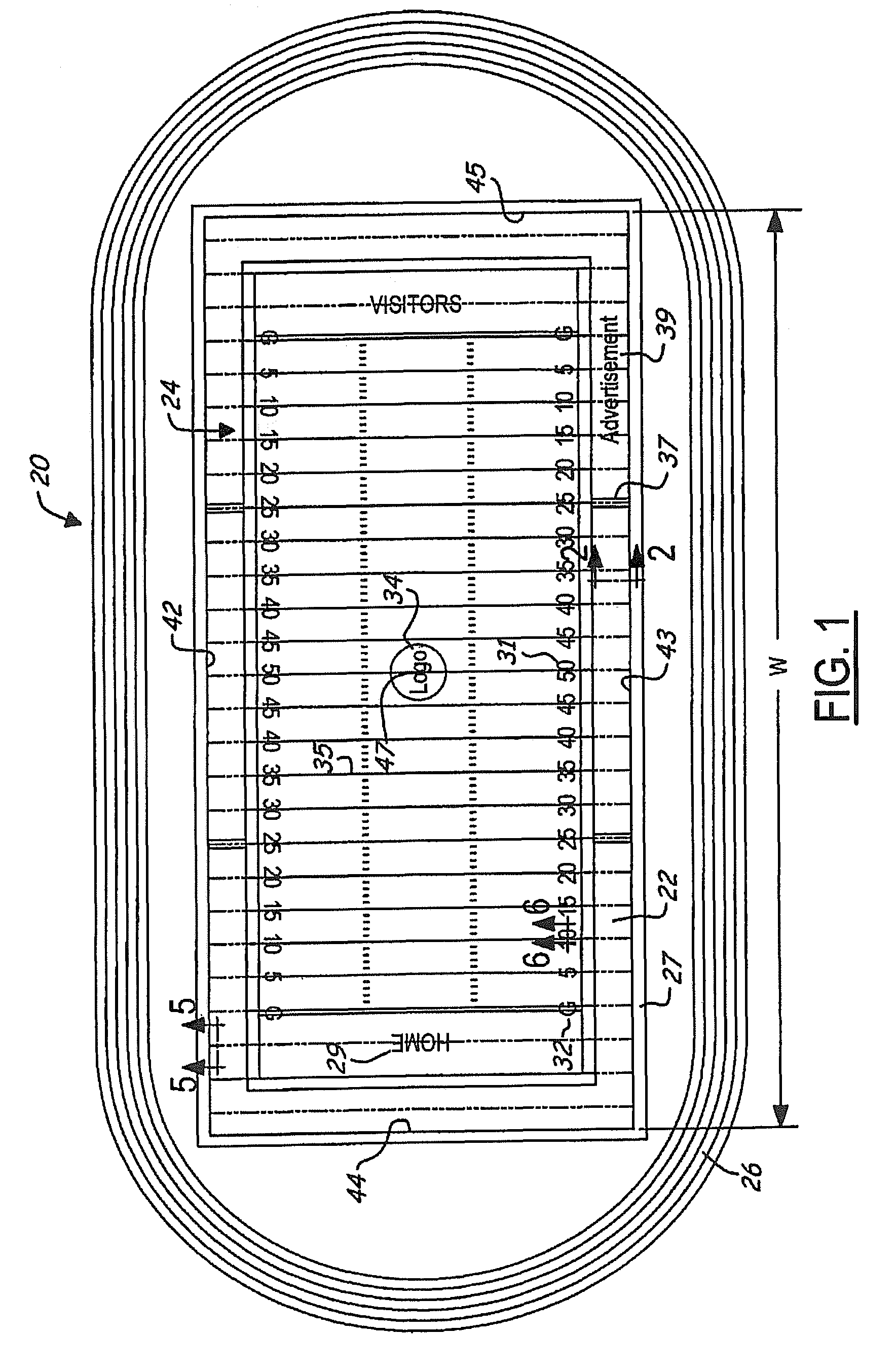

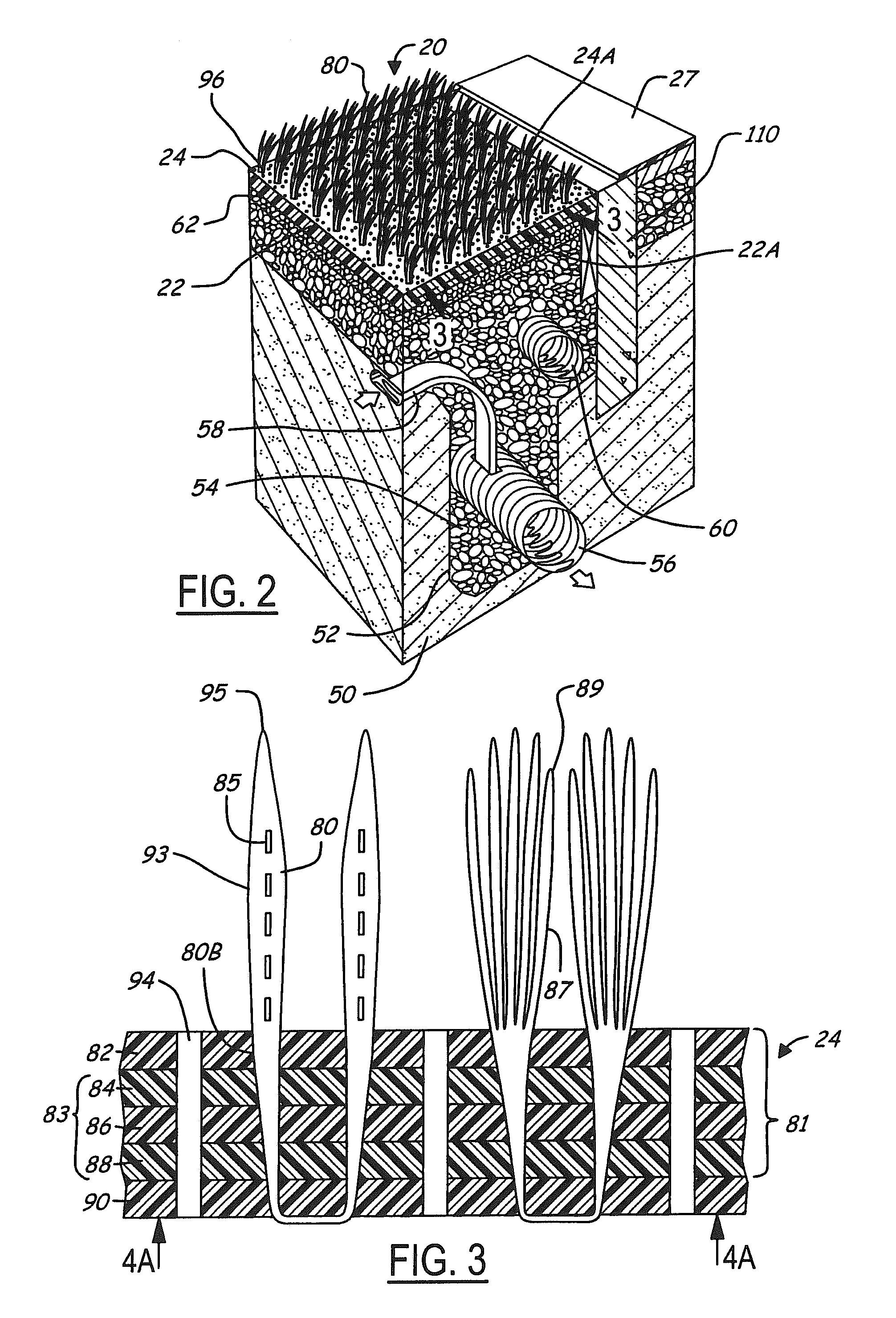

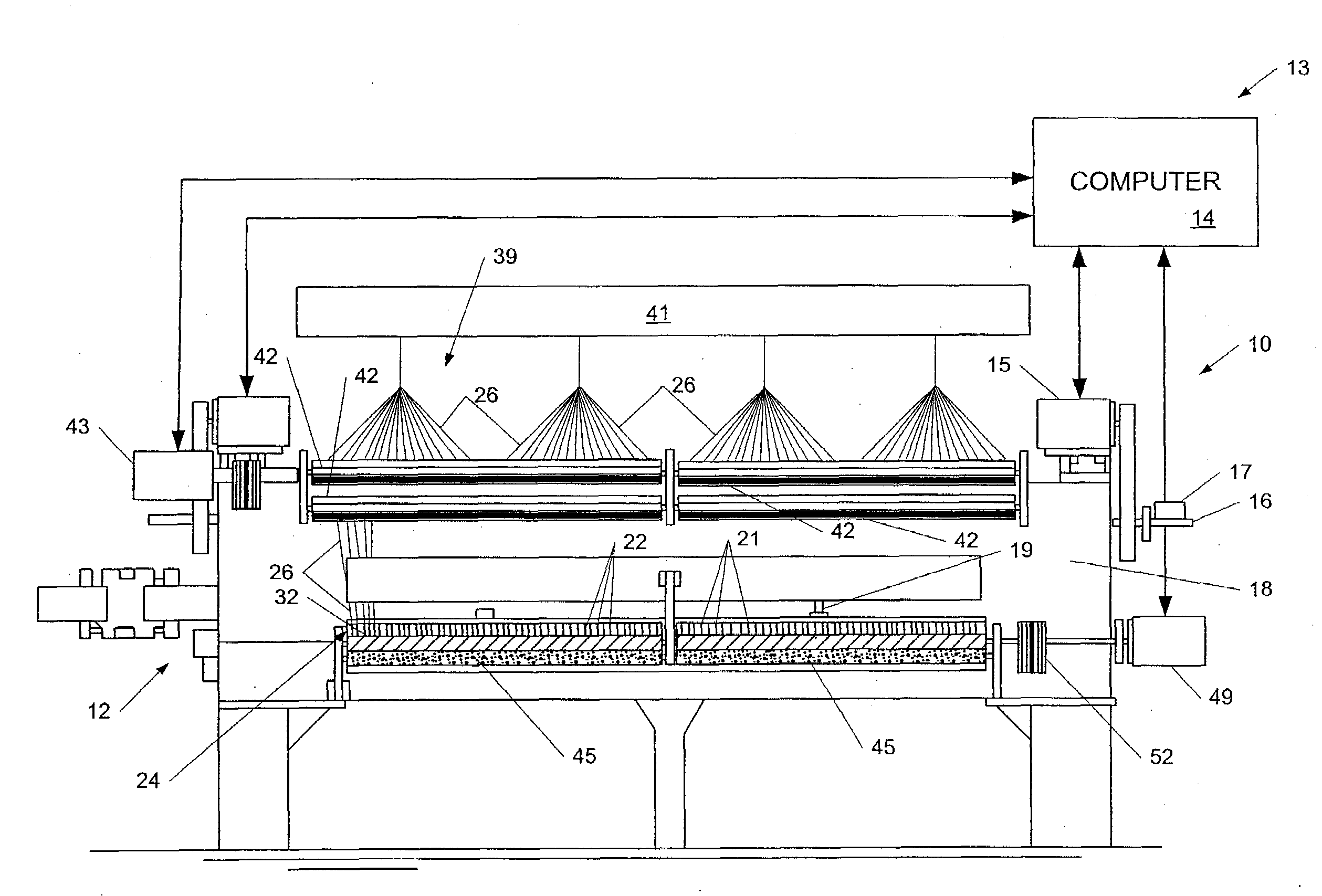

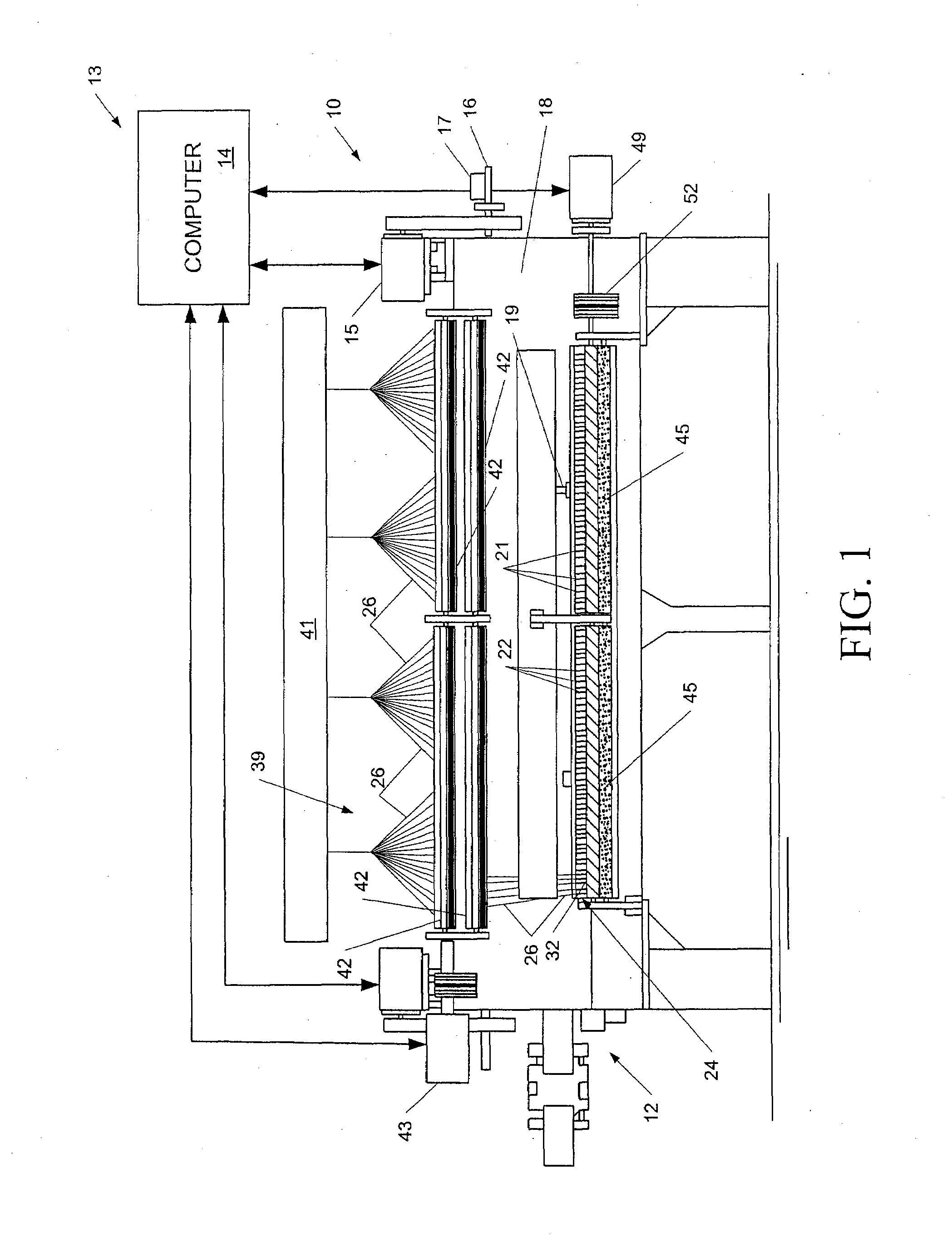

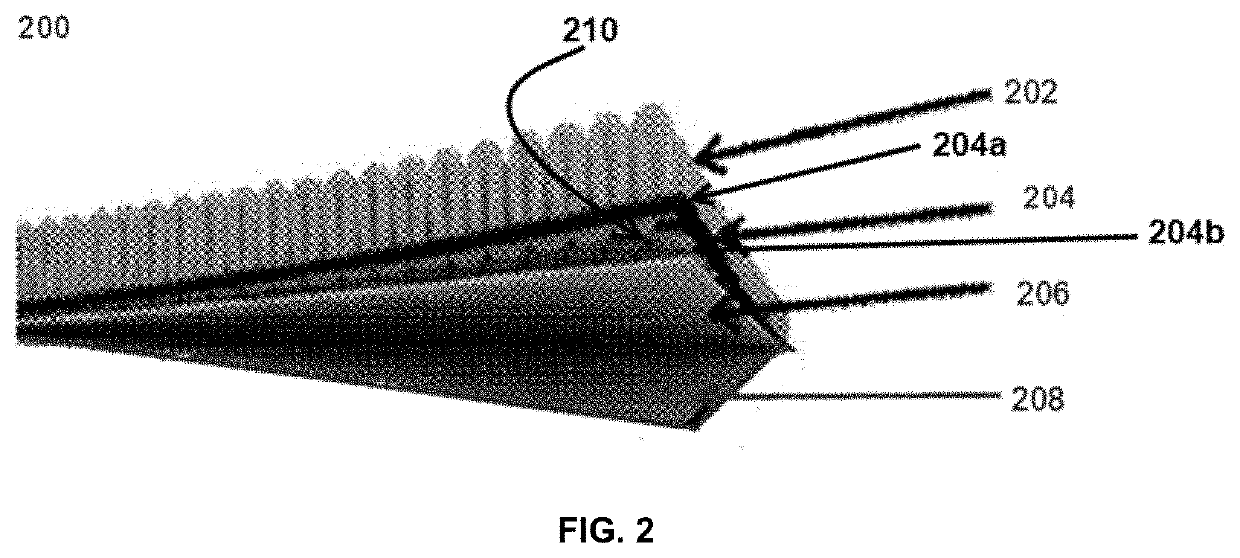

System and Method for Forming Artificial Turf Products with a Woven Appearance

InactiveUS20130180440A1Improved and precise distributionStable supportTufting apparatusYarnArtificial turf

A system and method for forming synthetic / artificial grass or turf tufted fabric materials in which a series of tufts or artificial / synthetic grass or turf yarns is formed in a backing material. The system generally will include a row of needles mounted along a tufting zone and which are reciprocated through the backing material to deliver a series of yarns into the backing materials. The needles are arranged in needle groups with the needle groups spaced apart along the length of the needle bar. A series of gauge parts, typically including cut-pile hooks, will be aligned with and will engage the needles in order to form cut and pile tufts defining spaced grass / turf tuft formations in the backing material.

Owner:CARD MONROE

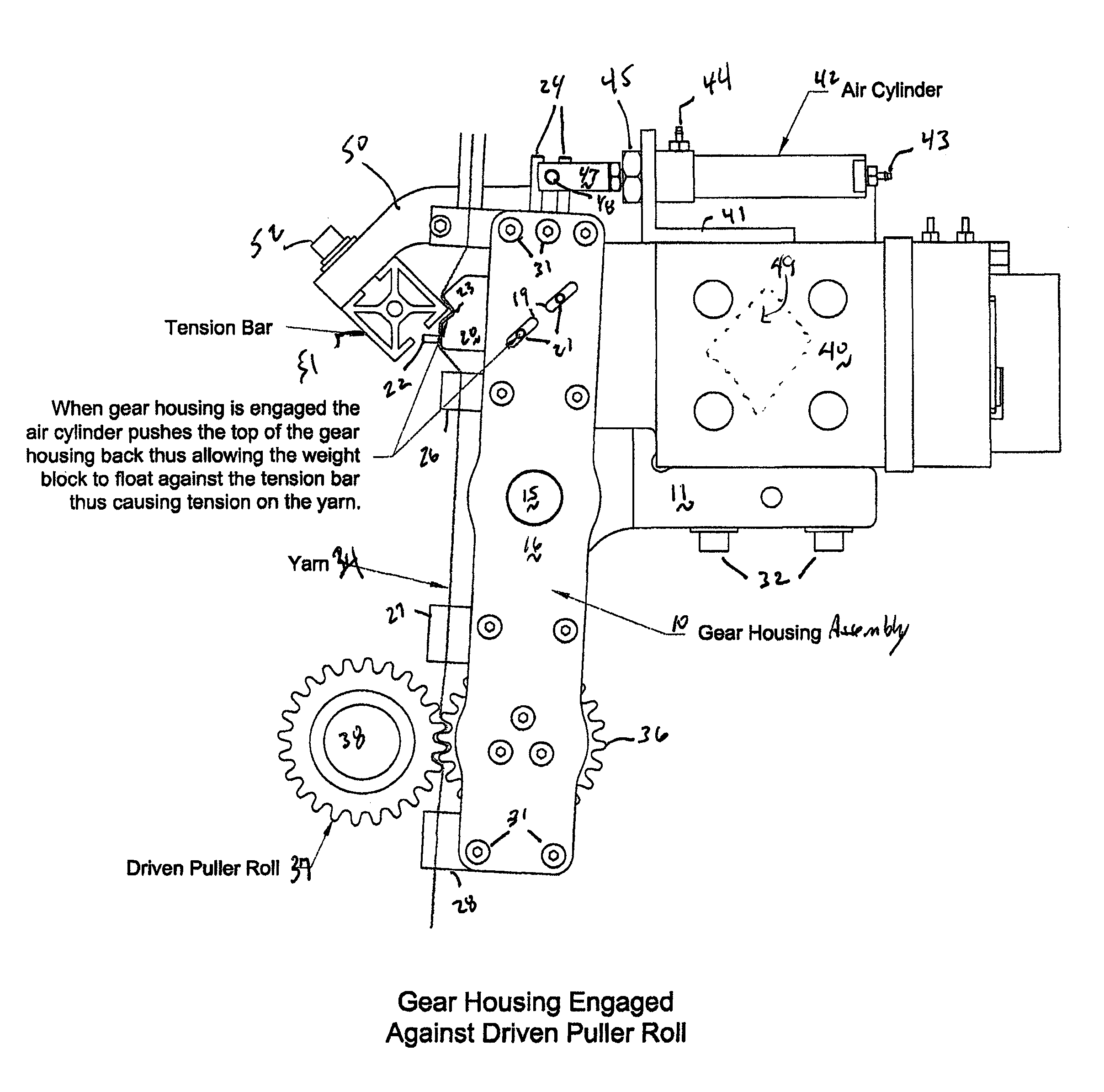

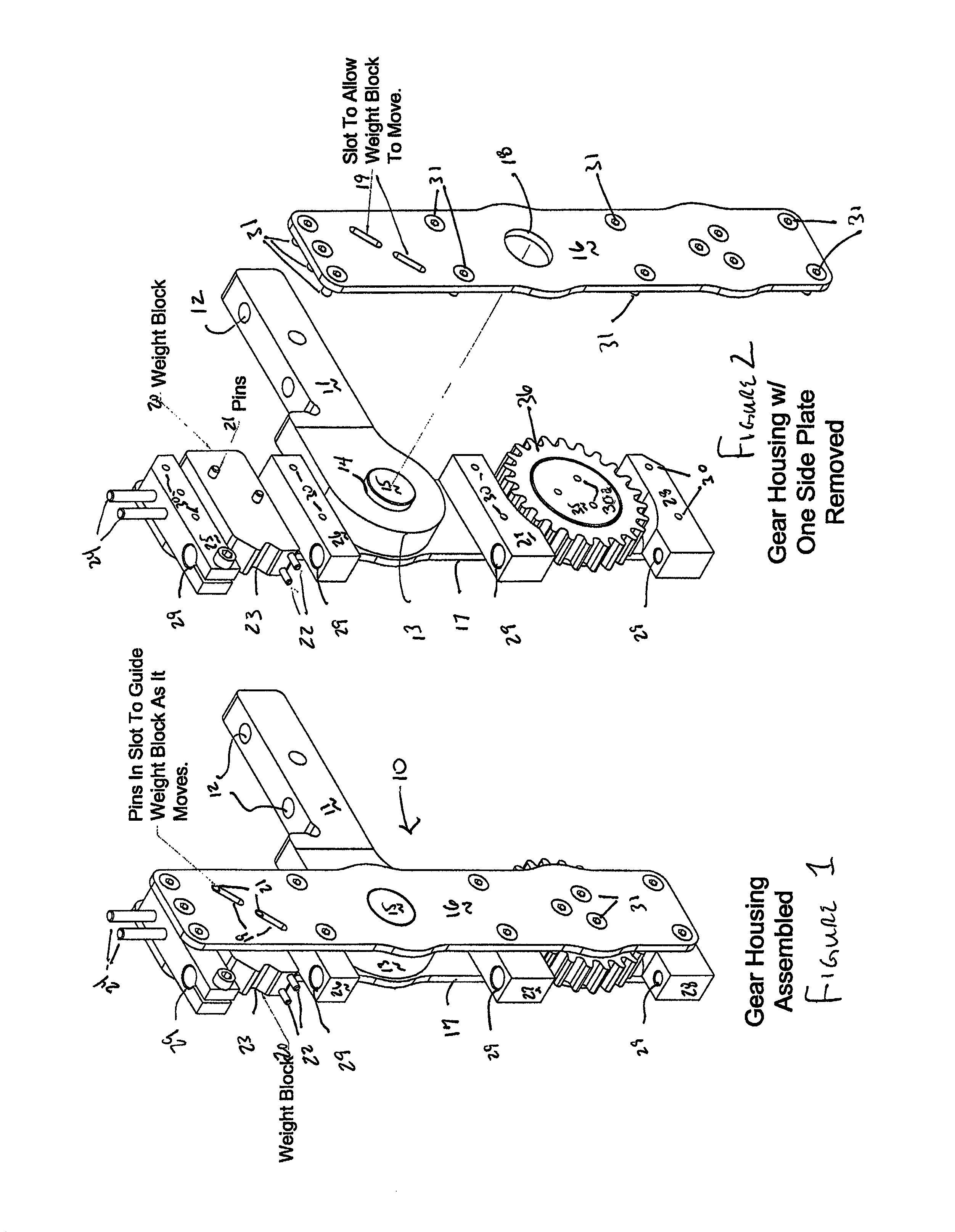

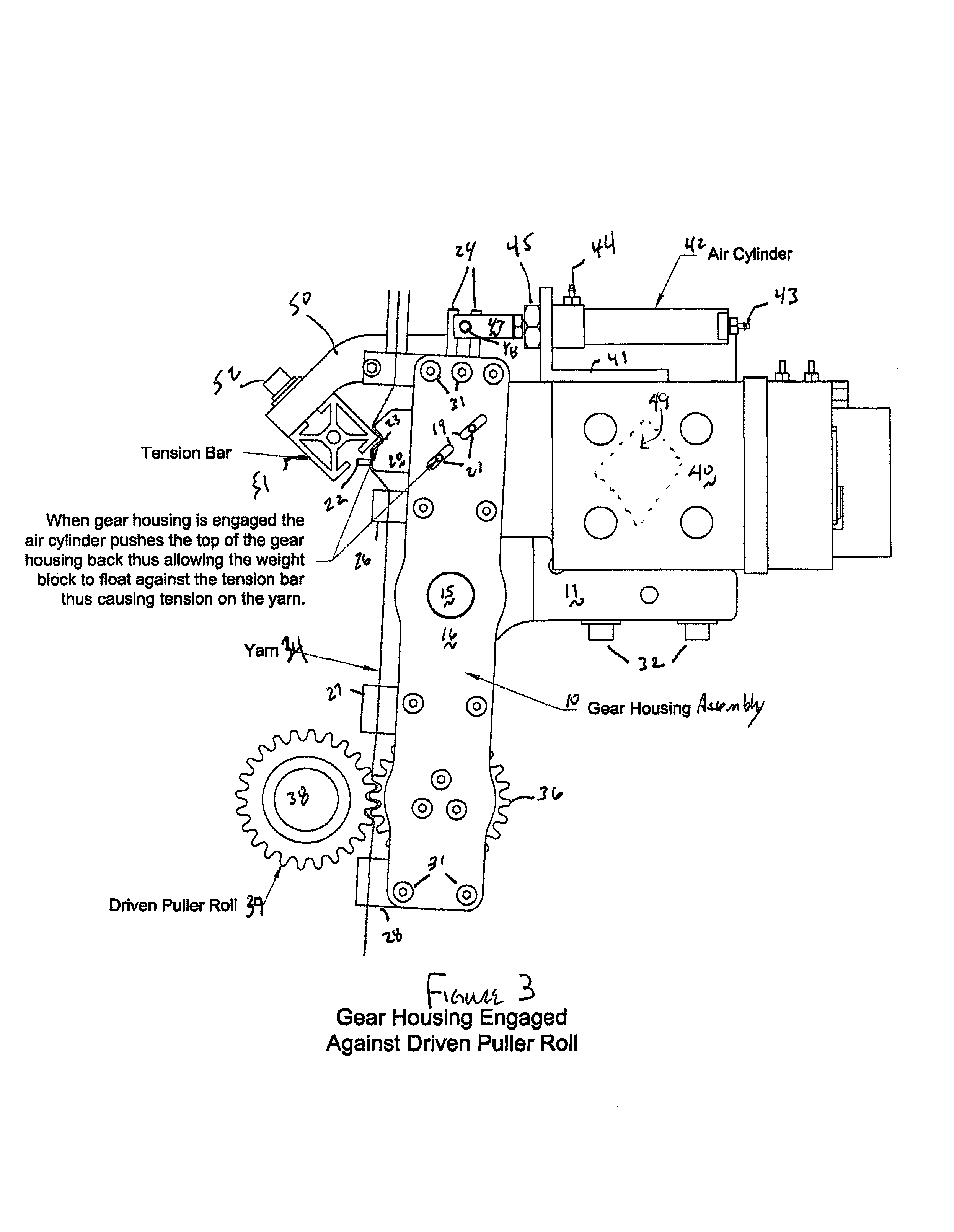

Yarn tensioning mechanism

InactiveUS8127698B1Positively grip and feed yarnsNo slippage of yarnsTufting apparatusYarnEngineering

Owner:TUFTCO

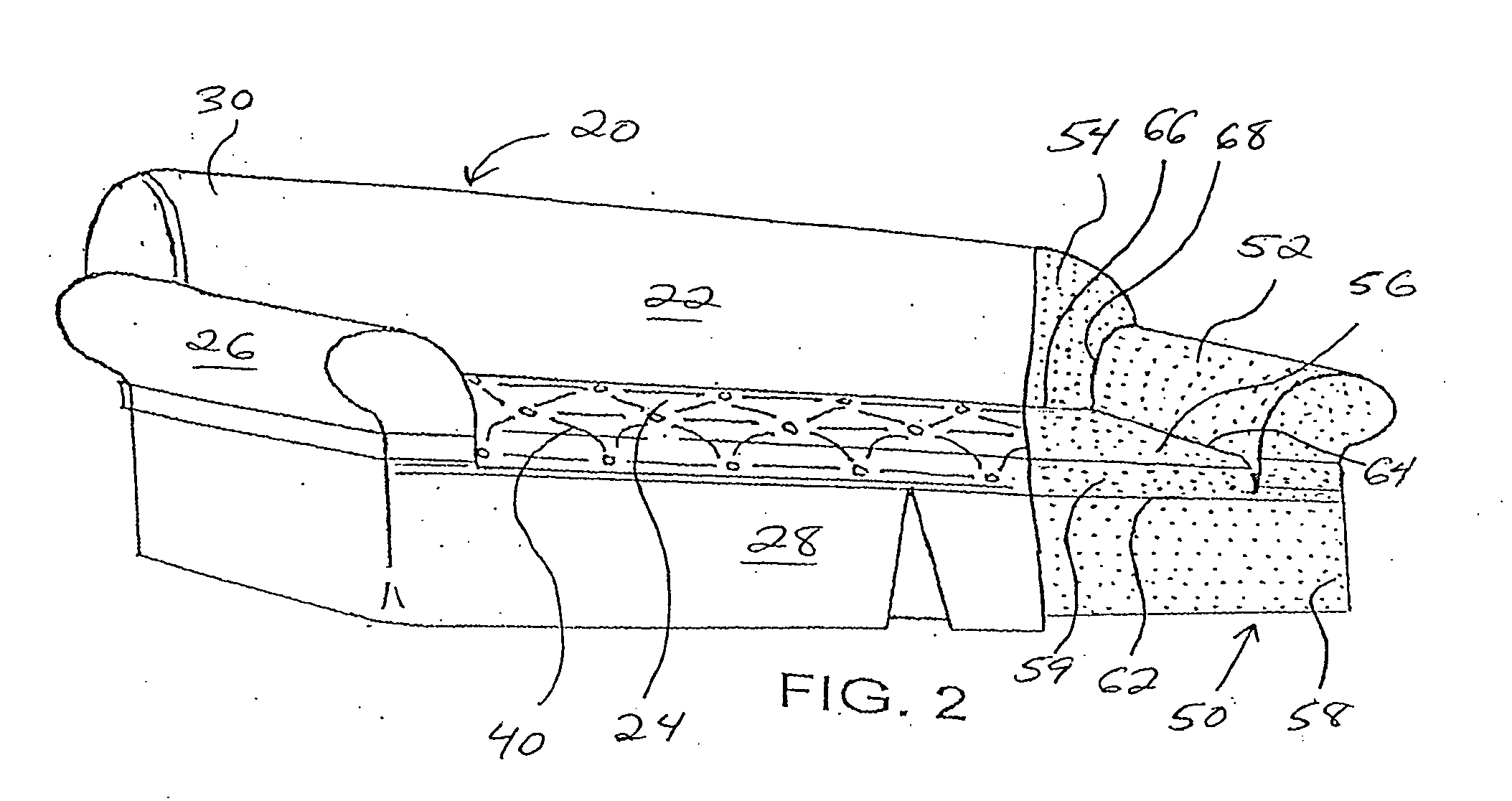

Slipcover with integrated padded and decorative component

A slipcover includes a fitted, semi-fitted or unfitted sheet of fabric and a decorative and padded multi-layered component integrated with the sheet of fabric in selected locations. The multi-layered component includes a cushion material and at least a top layer of material. The multi-layered component of fabric and cushion material is tufted, quilted, or assembled such that the layers are secured in position to provide an aesthetic quality to the slipcover. The multi-layered component and the sheet of fabric are integrated either by attachment, or by replacement or substitution of portions of the sheet of fabric with the multi-layered component. The multi-layered component can also be removable.

Owner:NEUSTAT PAULA S

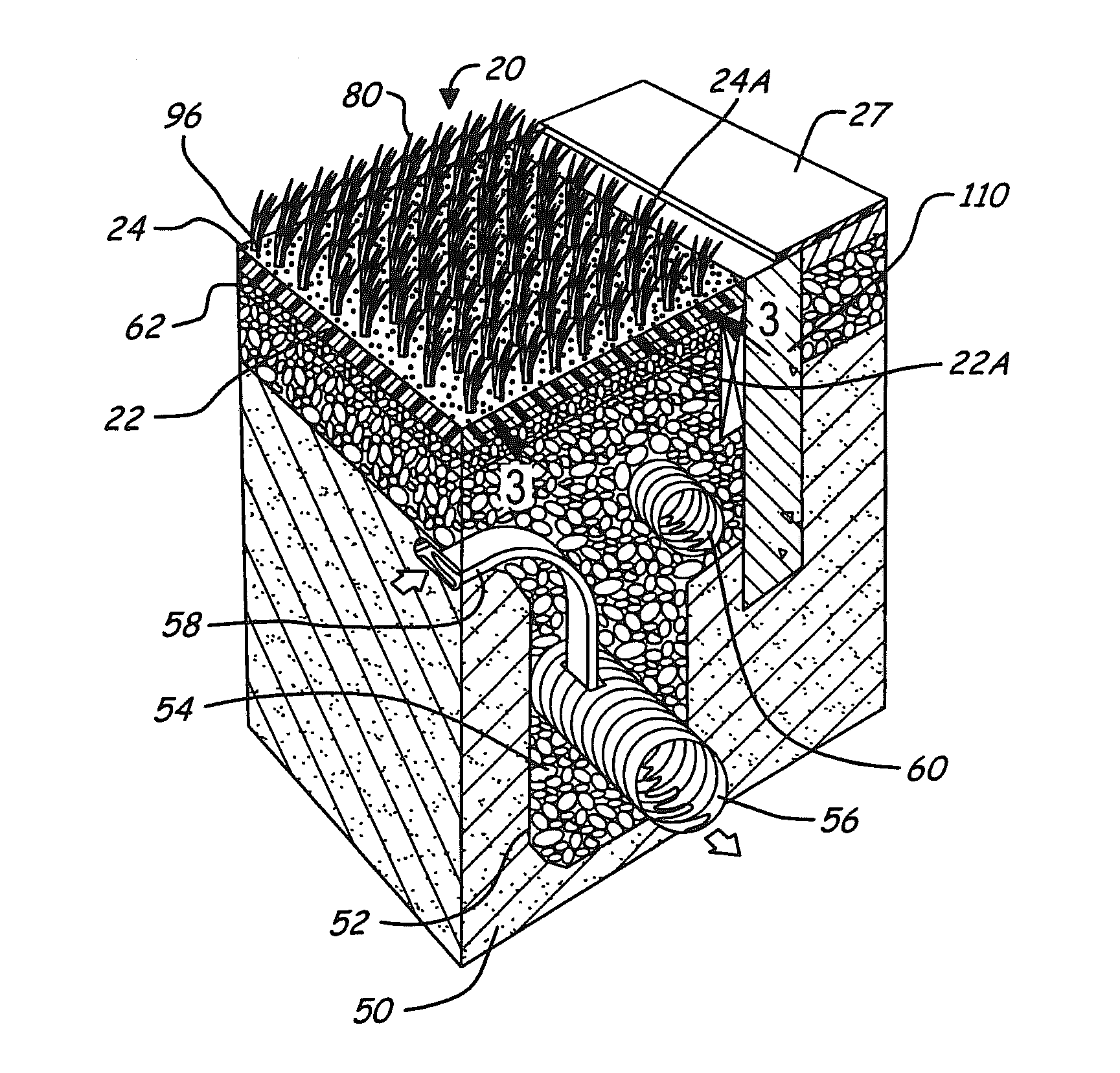

Synthetic sports turf having improved playability and wearability

A durable and wear resistant synthetic sports field having at least one strip having a plurality of fibrillated polypropylene strands tufted within a multilayer backing material. The strands are tufted in a wide variety of pile heights, patterns, gauges, and stitch patterns depending upon end use. The multiplayer backing material has a top mesh polypropylene layer at least three layers of a backing material coated with a secondary coating used to contain the ends of the plurality of strands. The strips are placed onto a fine aggregate layer placed over a coarse aggregate layer and a geotextile fabric. The geotextile fabric is placed onto a compacted and leveled subgrade. A ground rubber infill, with or without sand particles and diatomaceous earth, is introduced onto the strips. In alternative arrangements, a series of perforated drains and drain tiles may be introduced to the coarse aggregate layer to promote drainage.

Owner:GENERAL SPORTS VENUE

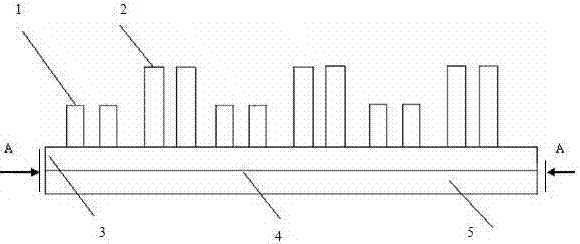

Method and device for manufacturing color tufting product

InactiveCN102535059AAccurate displacementImprove surface jacquard effectTufting apparatusScan lineLinear distribution

The invention relates to a method and a device for manufacturing a color tufting product, belonging to the technical field for manufacturing the color tufting product. The solved technical problem in the invention is to provide the method and the device for manufacturing the tufting product with colorful jacquards, wherein high piles of the tufting product completely cover low piles; the technical scheme for solving the technical problem is as follows: a non-vector pattern is adopted and a tufting faller or a tufting base cloth is scanned line by line according to pattern pixel points rearranged in rows when at different positions, each tufting faller corresponds to effective pixel points and invalid pixel points at different positions in each tufting process, so that high-feed piles and low-feed piles are in non-linear distribution on the surface of the tufting product; and the method and the device are mainly used for manufacturing the color tufting product.

Owner:斯马特(太原)技术发展有限公司

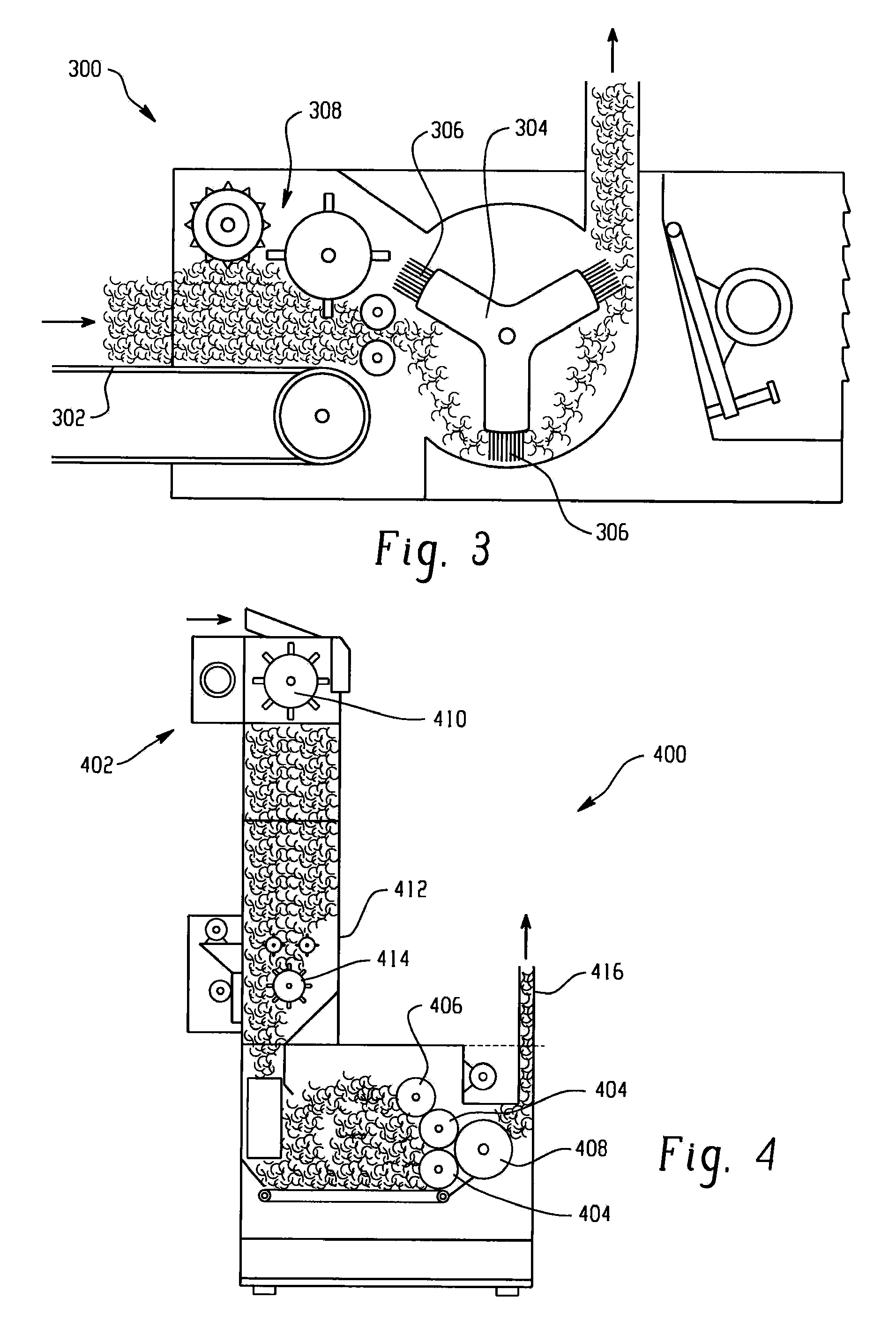

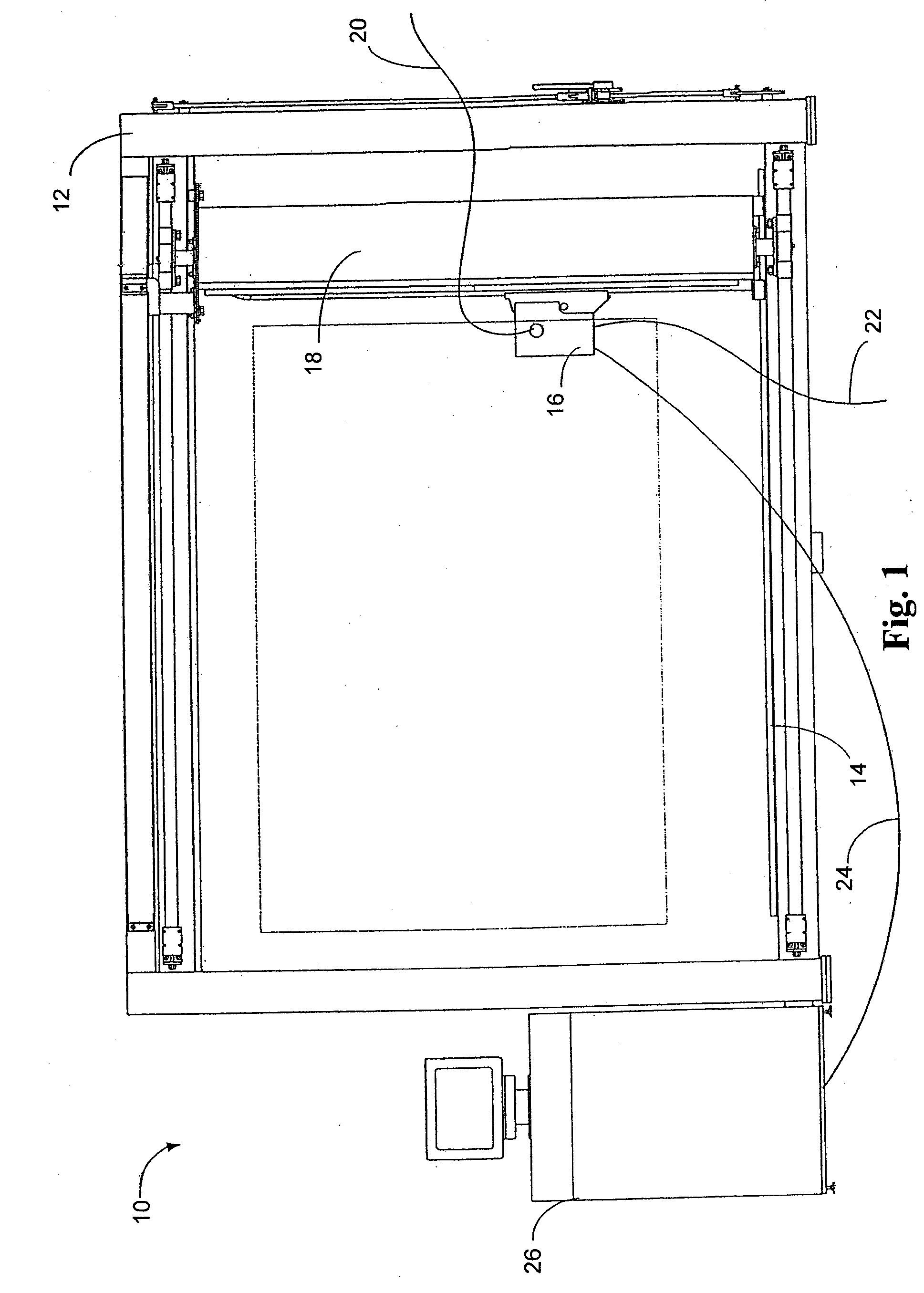

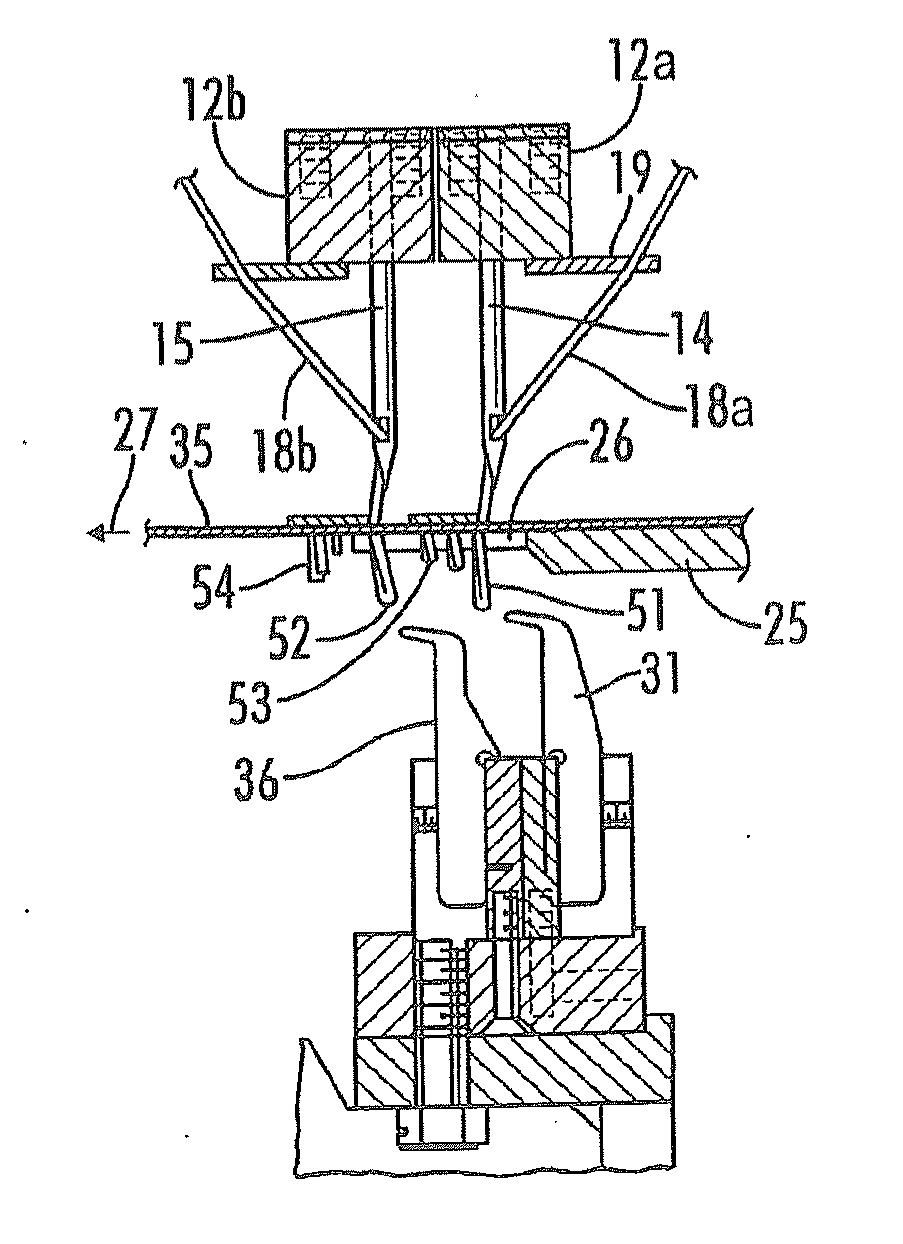

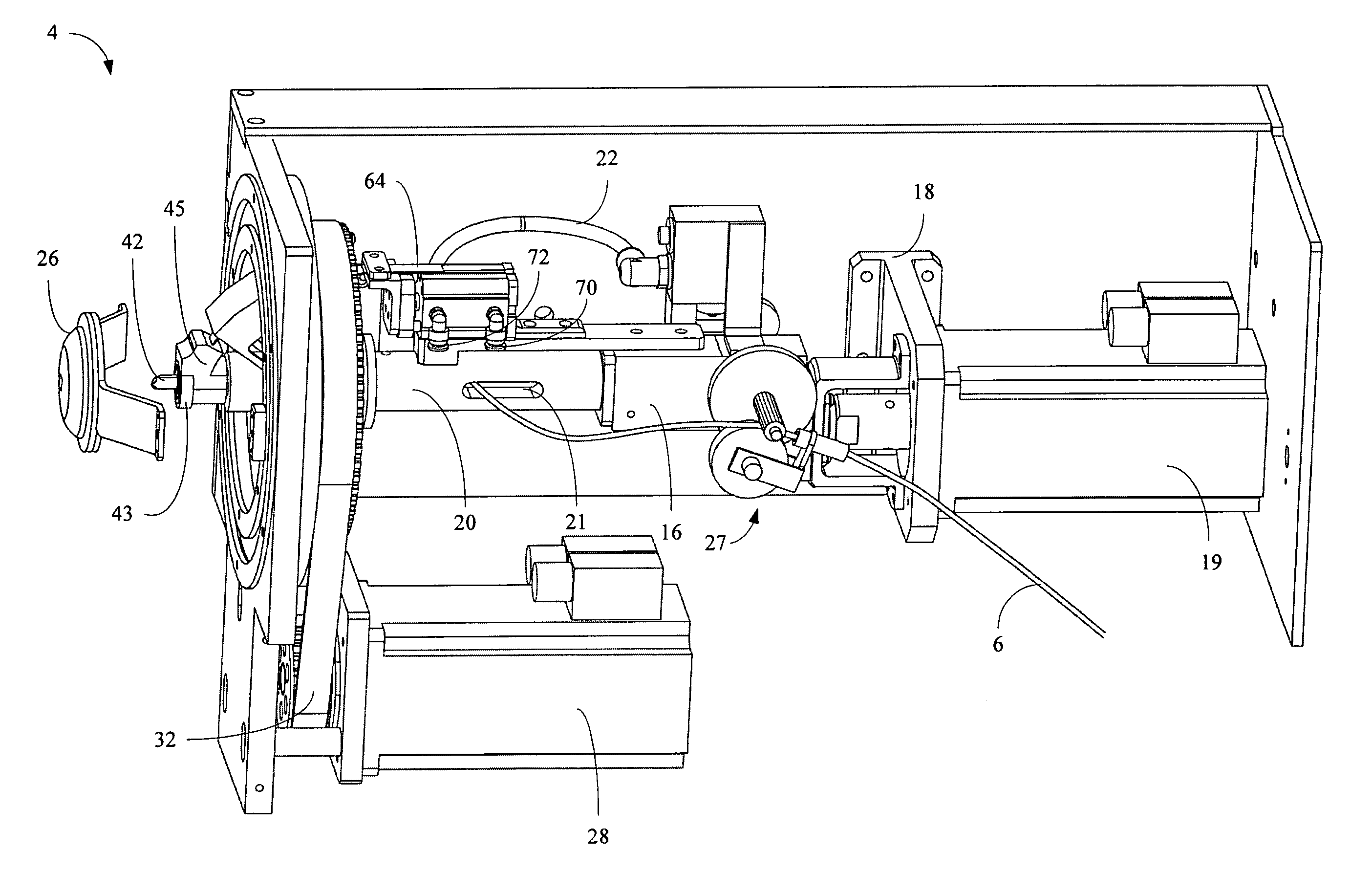

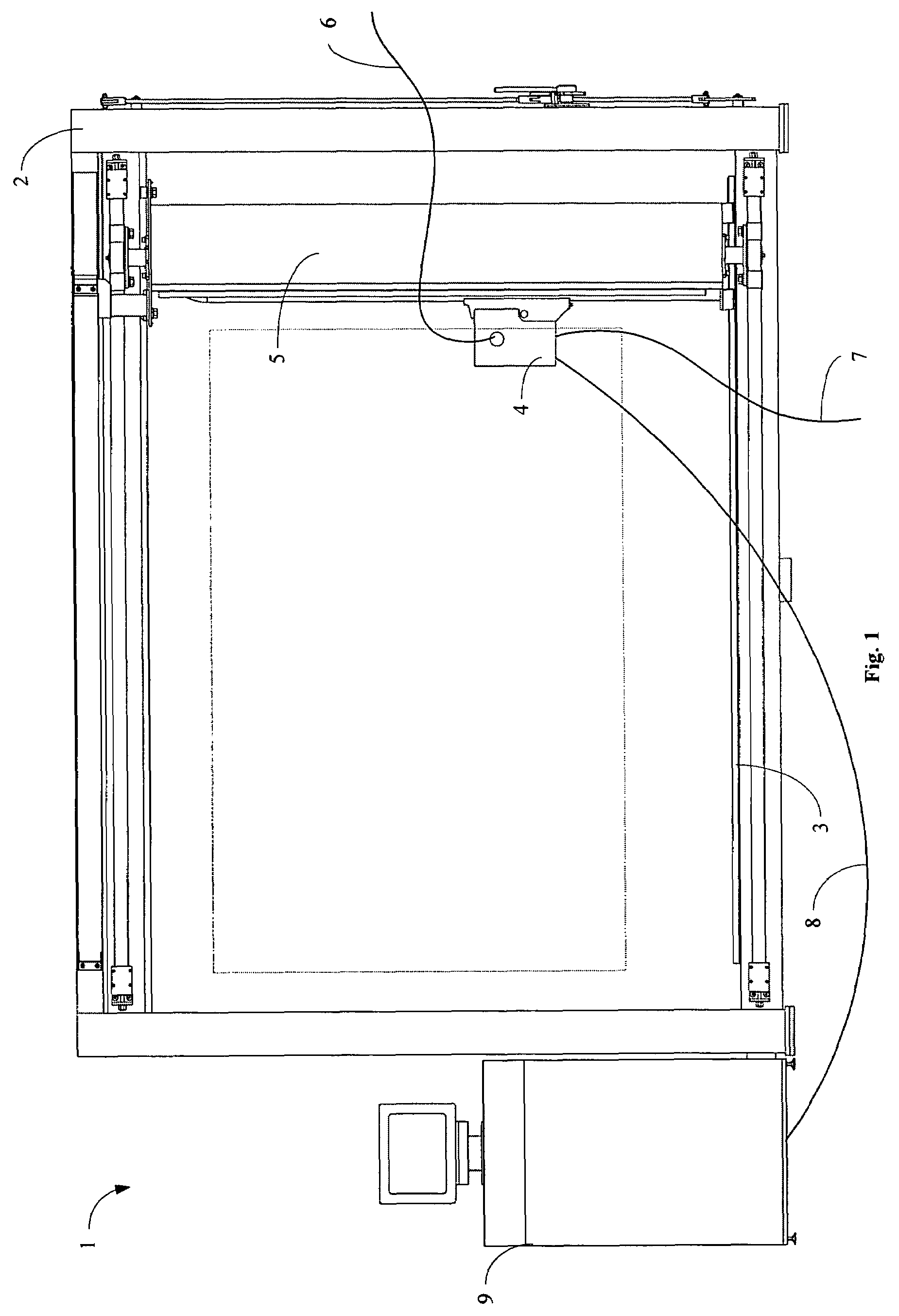

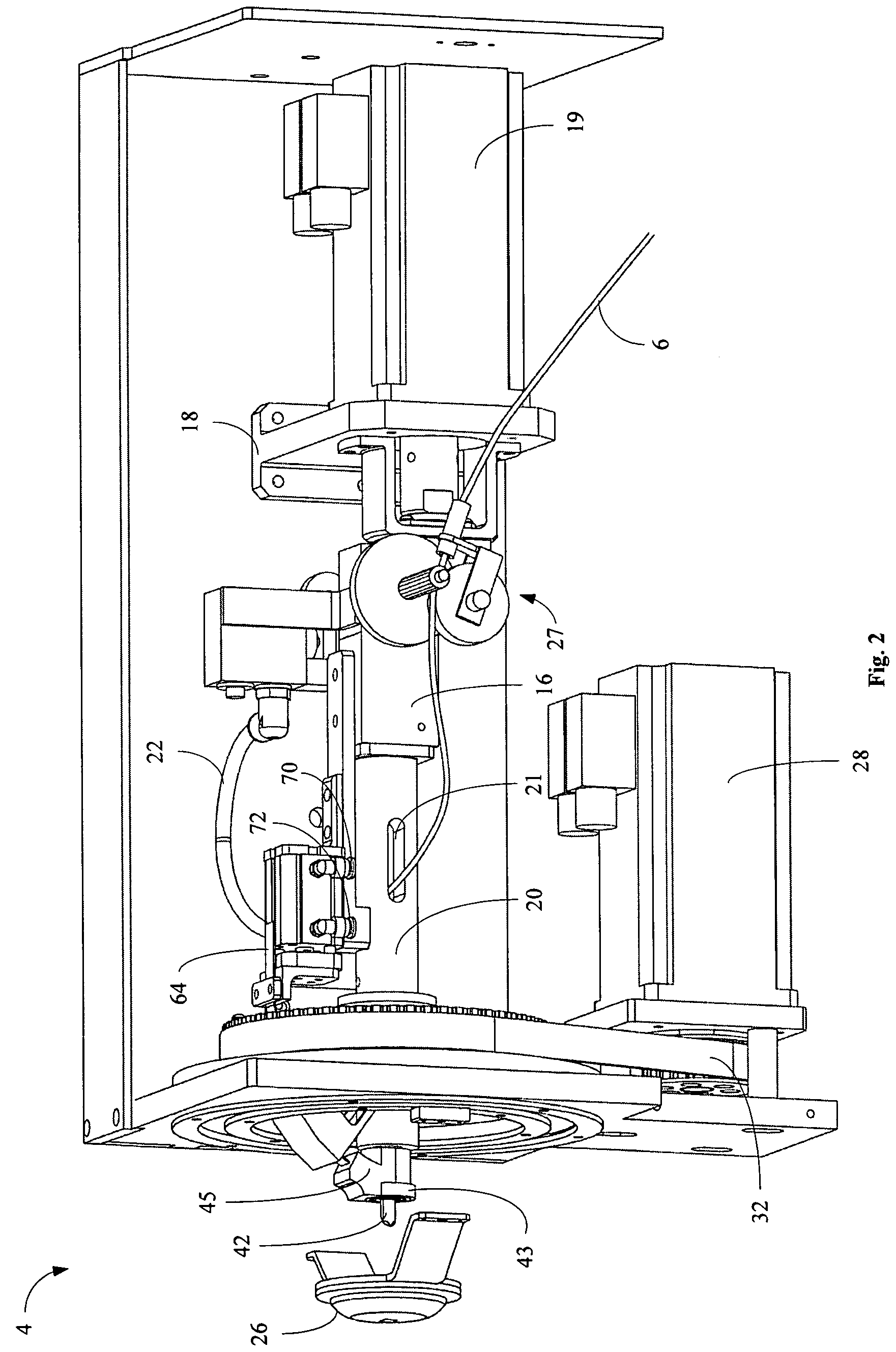

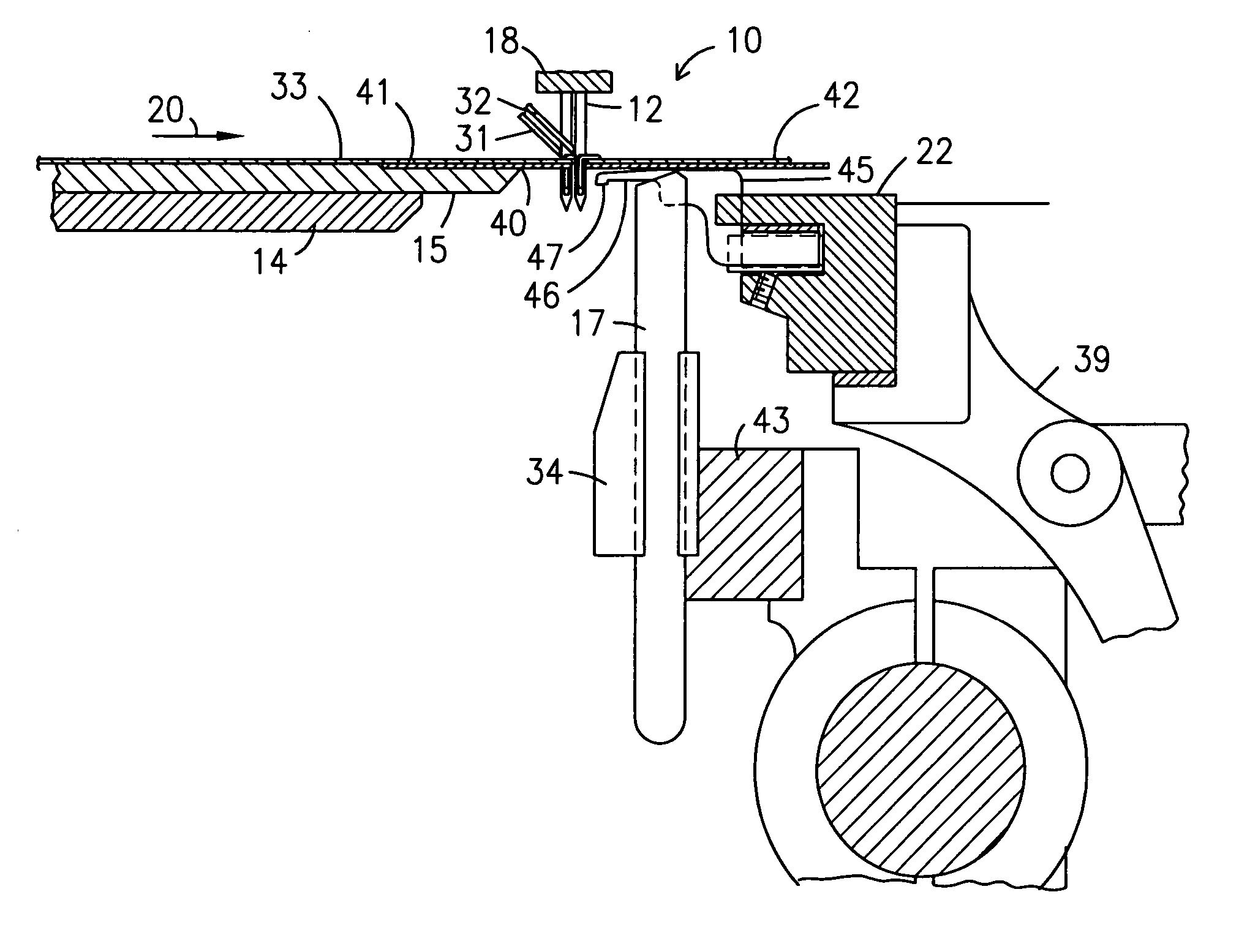

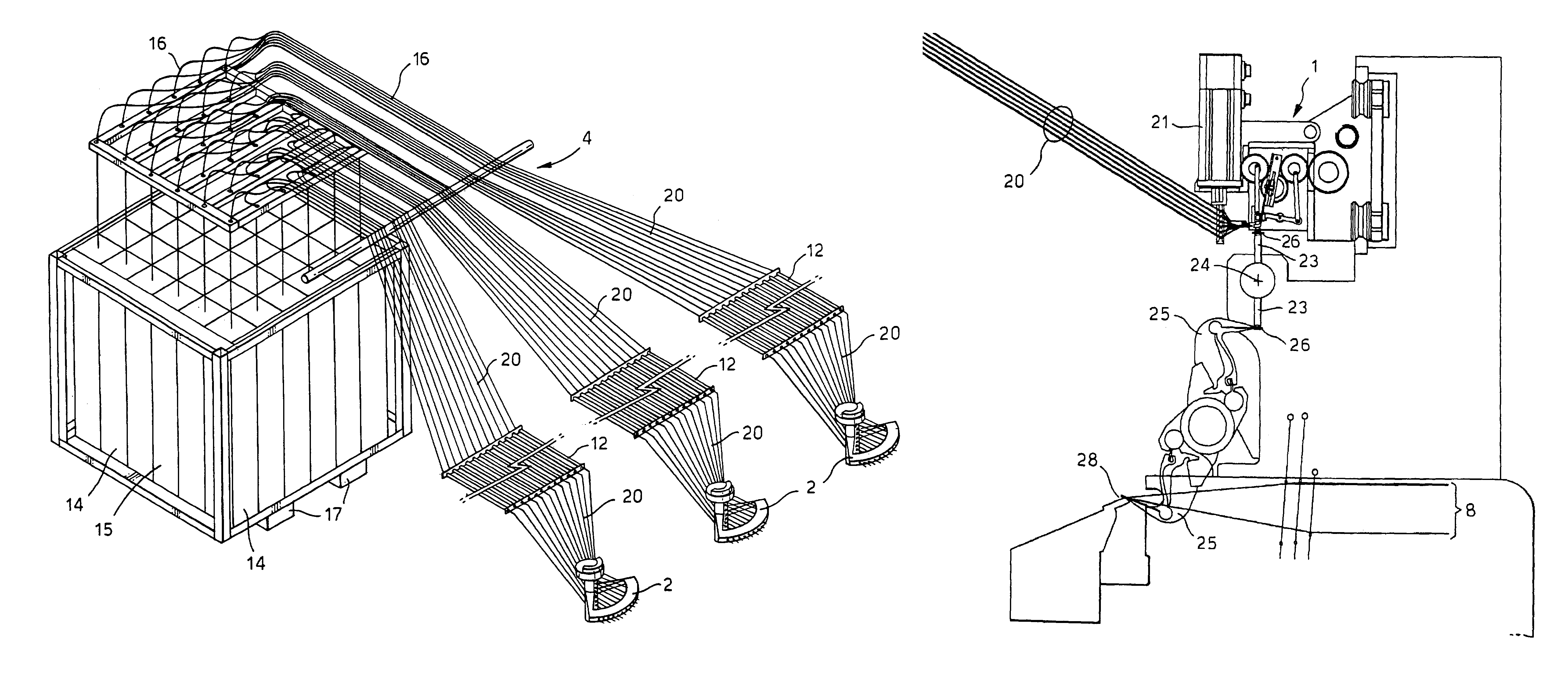

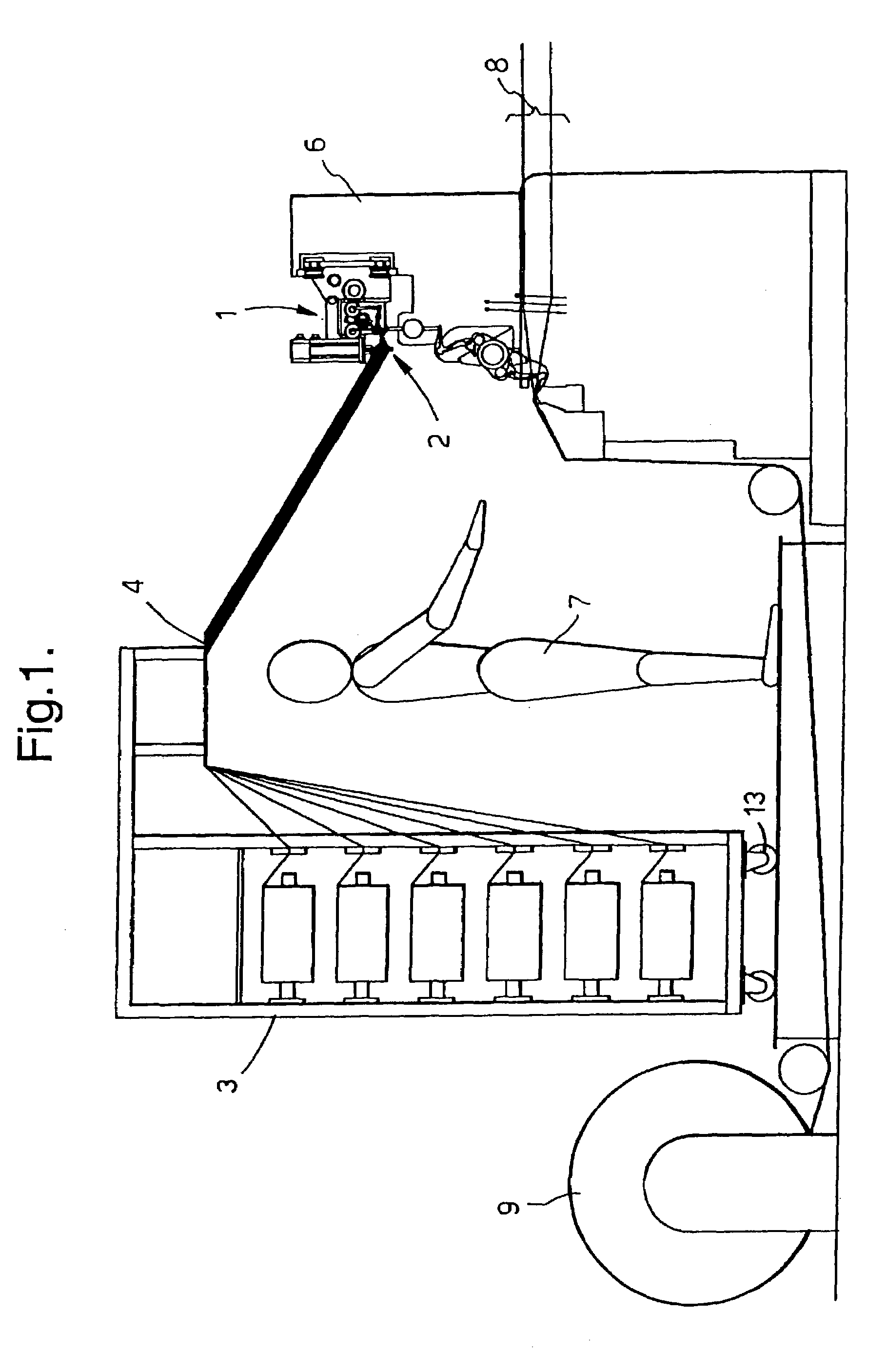

Tufting Machine

The invention concerns an improved tufting machine which comprises a tufting head translatable within said tufting machine in X- and Y-directions with respect to backing fabric by means of a movement system. The tufting head comprises a tufting mechanism having a cyclic mode of operation, a hollow needle mounted in the tufting mechanism that is moveable relative to a cooperating foot in a reciprocating manner to insert a tuft of yam into backing fabric in each cycle, a yarn supply mechanism mounted in the tufting mechanism and operable to supply a length of yam to the hollow needle in each cycle, a yarn cutter mounted in the tufting head that is selectively operable to cut the length of yam in selected cycles to produce loop or cut pile, and a computer-operated motion control system.

Owner:PERPETUAL MACHINE CO

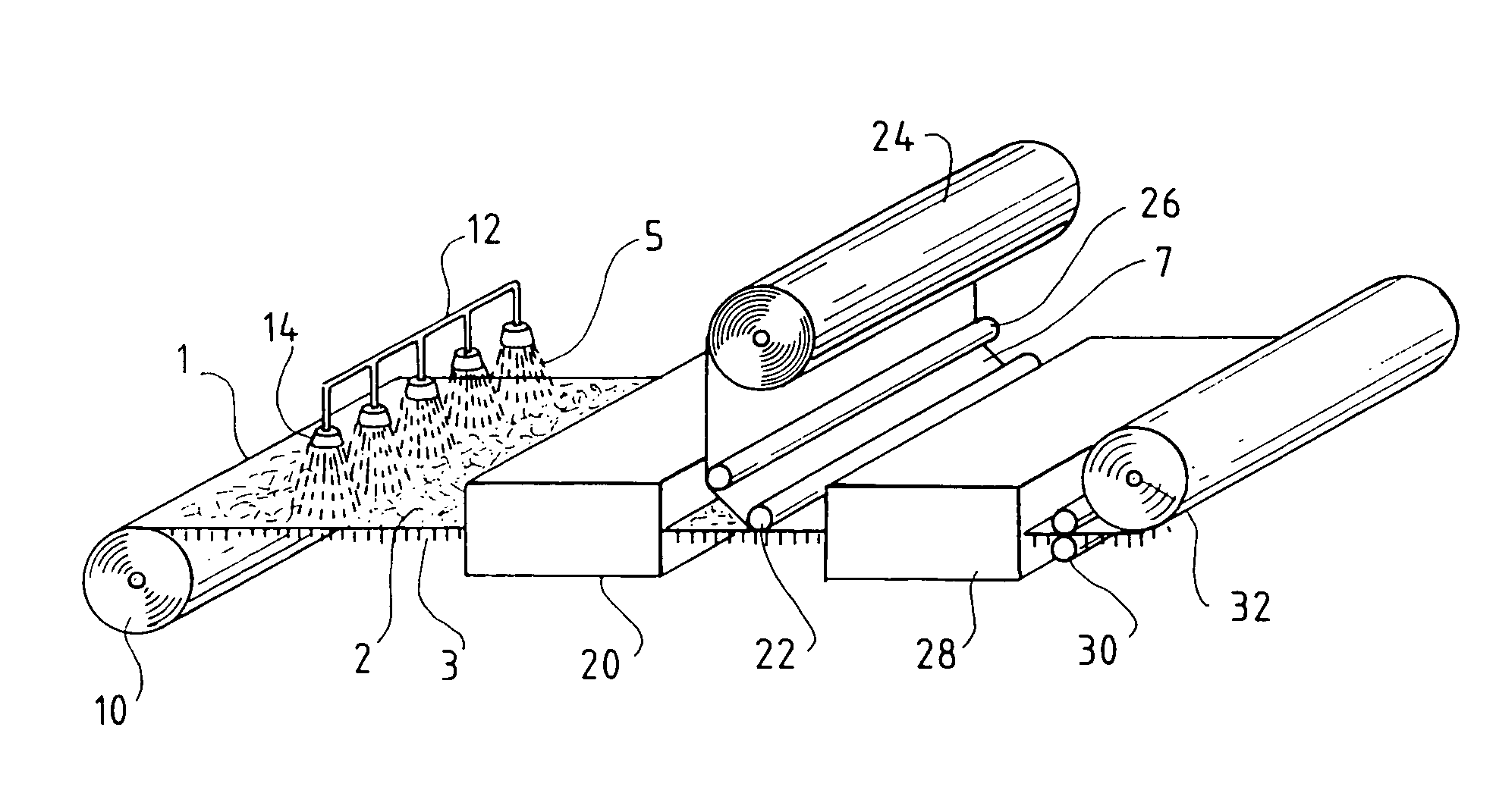

Processes to dye and treat BCF yarn

Disclosed are processes for applying dyes, stain blocker and anti-soil compositions on BCF yarns during cable or air twisting processes, or heat setting processes, prior to weaving, knitting or tufting. Further discloses are process for applying dyes, stain blocker and anti-soil compositions on BCF yarns prior to heat setting. The processes forego the need to dye and otherwise treat carpets and other textiles made from the BCF yarn using current methods. Also disclosed are systems, BCF yarns, and carpets made from the BCF yarn treated by the disclosed process.

Owner:INVISTA TECHNOLOG IES S A R L

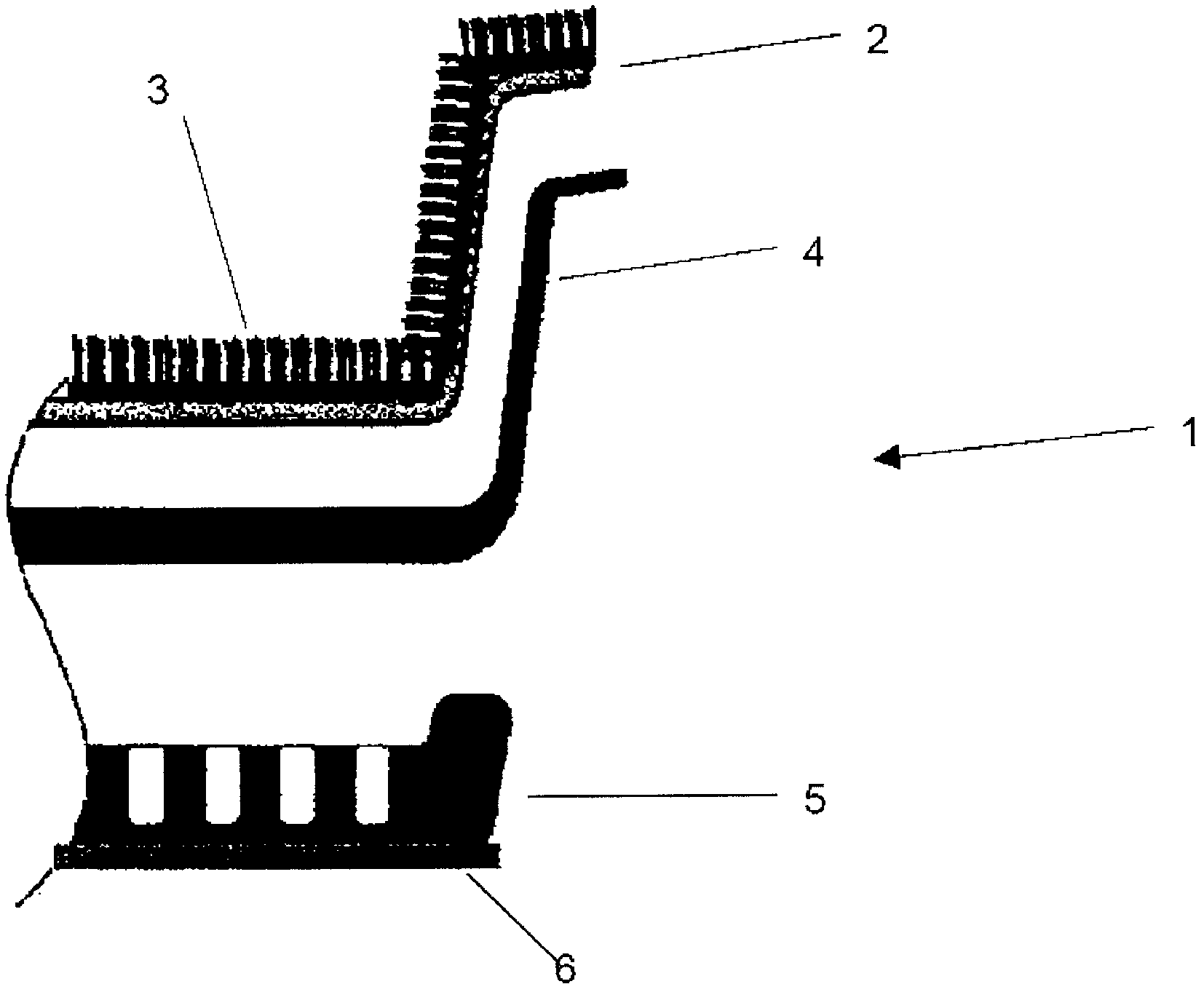

Tufted carpet for automotive applications

ActiveCN102459737AVehicle arrangementsTextile/flexible product manufactureYarnPolyethylene terephthalate

A tufted carpet for use in automotive applications is comprised of a pile layer and at least a primary backing layer. The pile layer has a pile weight and is comprised of a bulked continuous filament (BCF) yarn comprised of a predetermined number of filaments that are of a predetermined diameter. The carpet is tufted at a predetermined gauge. The BCF yarn is consisting of a polypropylene (PP) yarn with a tenacity between 2.6 cN / dtex (centinewton per decitex) and 3.2 cN / dtex at an elongation of 50 % to 70%, or polyethylene terephthalate (PET) with a tenacity between 2.6 cN / dtex to 3.4 cN / dtex at an elongation of 20 % to 40%.

Owner:AUTONEUM MANAGEMENT AG

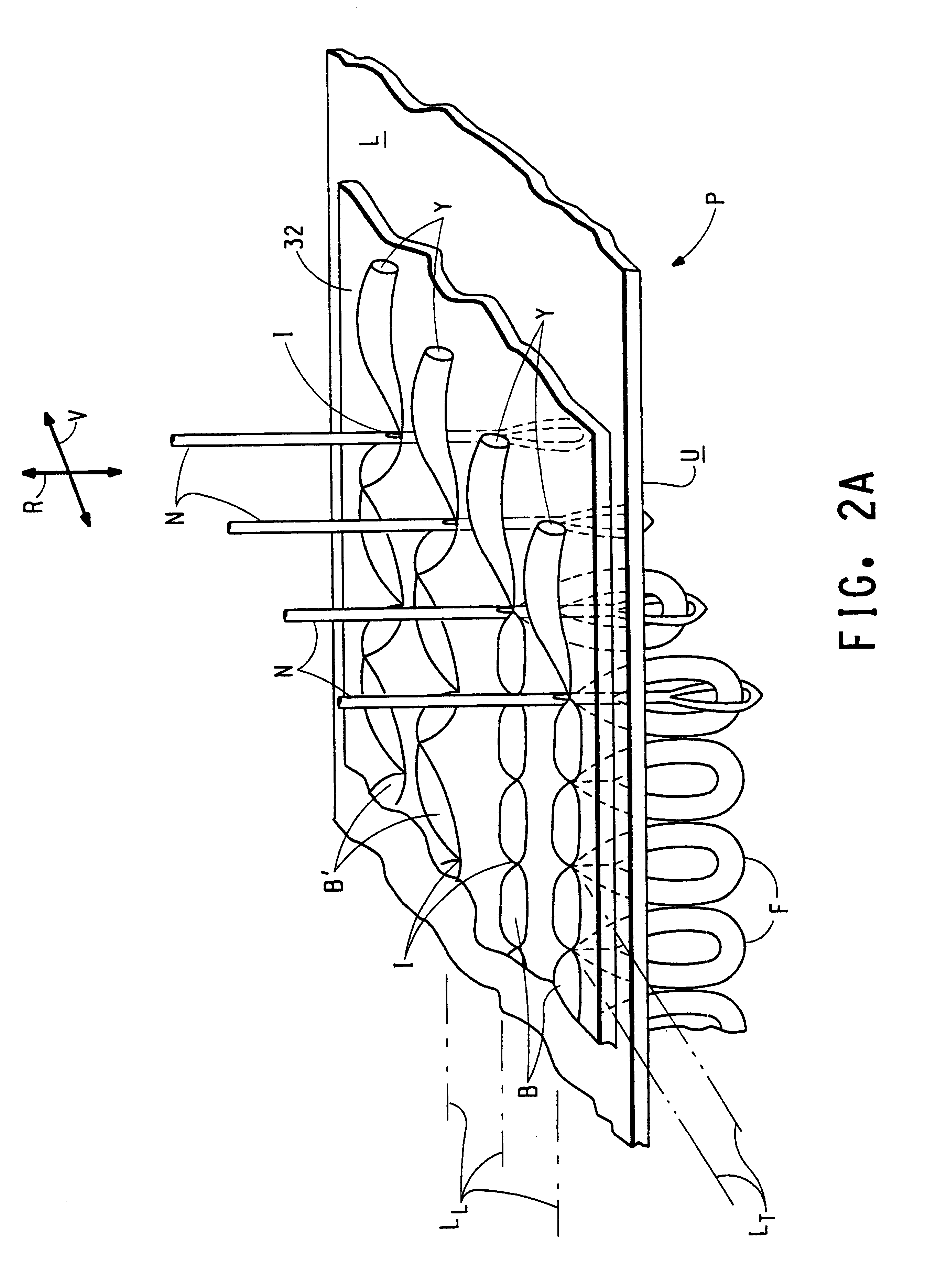

Method for Selective Display of Yarn in a Tufted Fabric with Offset Rows of Needles

ActiveUS20160069010A1Solve the lack of densityMinimizing the tacking stitches necessaryTufting apparatusAutomatic machinesYarnEngineering

A novel method of tufting carpets is provided to allow the use of the same sequence of colored yarns on front and rear staggered needle bars to yield sufficient gauge stitch density to provide for a solid appearance of any of the selected colors et, and utilizing optimized tacking of rear yarns to minimize loose yarn on the backing.

Owner:TUFTCO

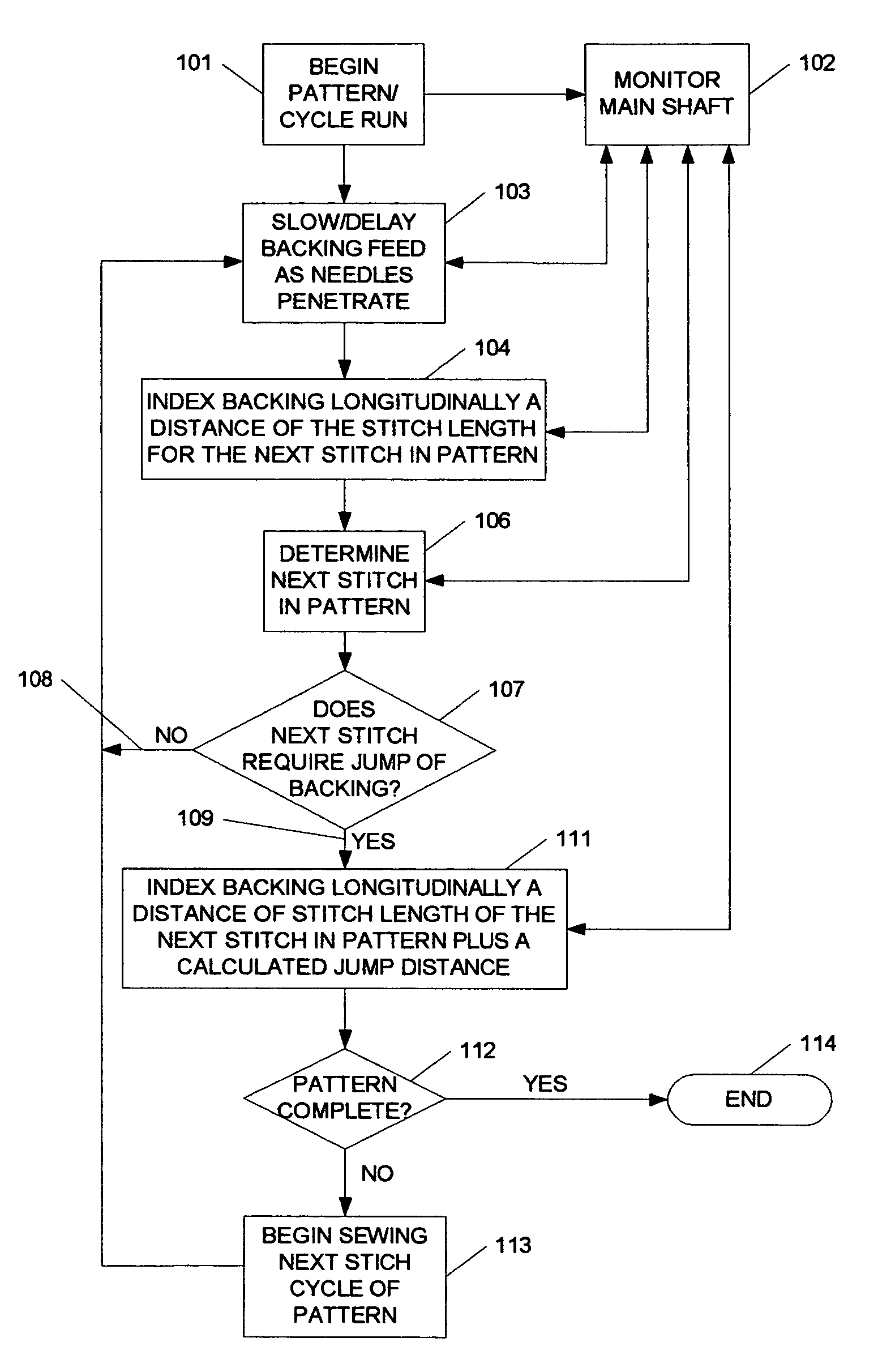

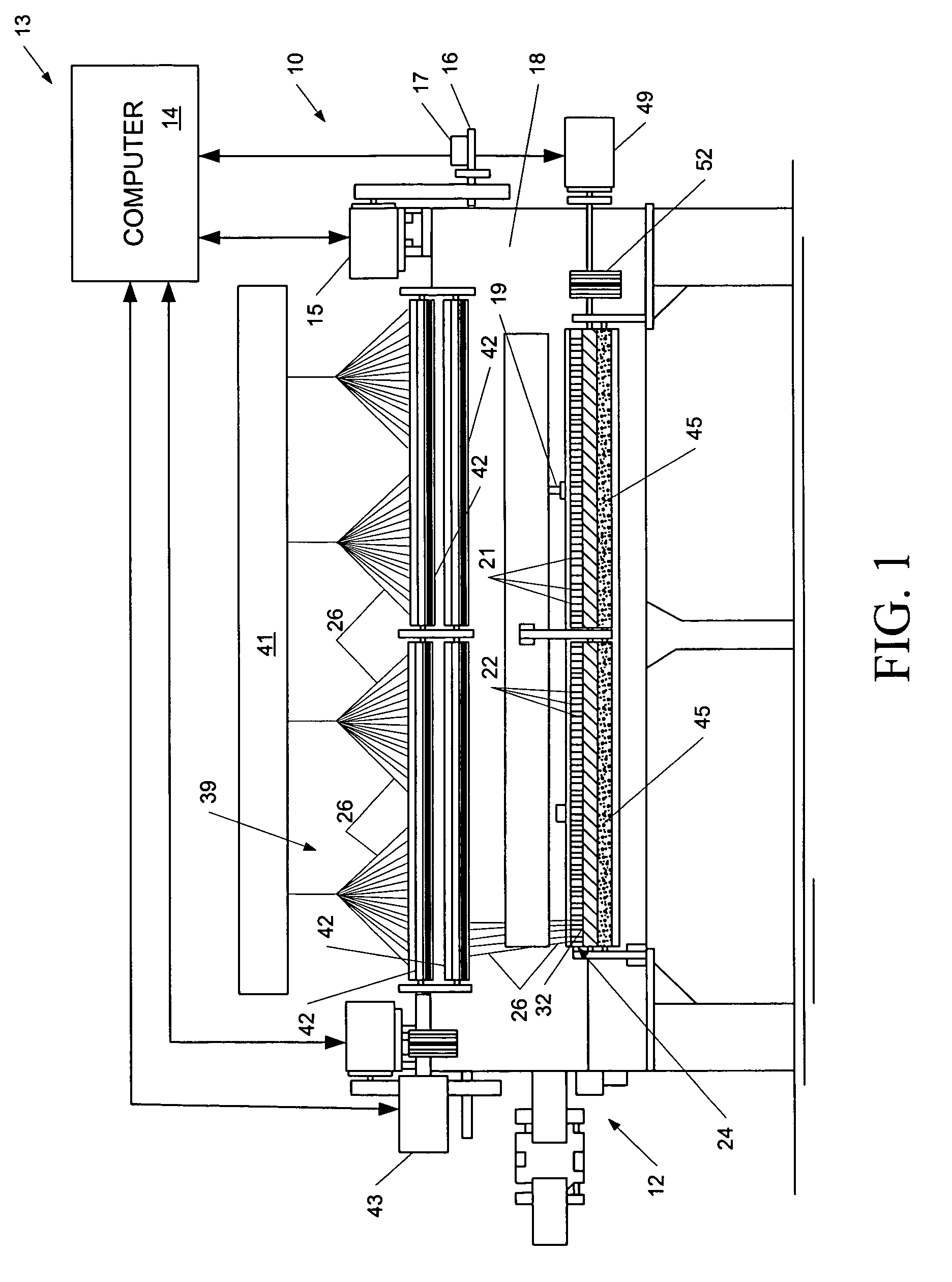

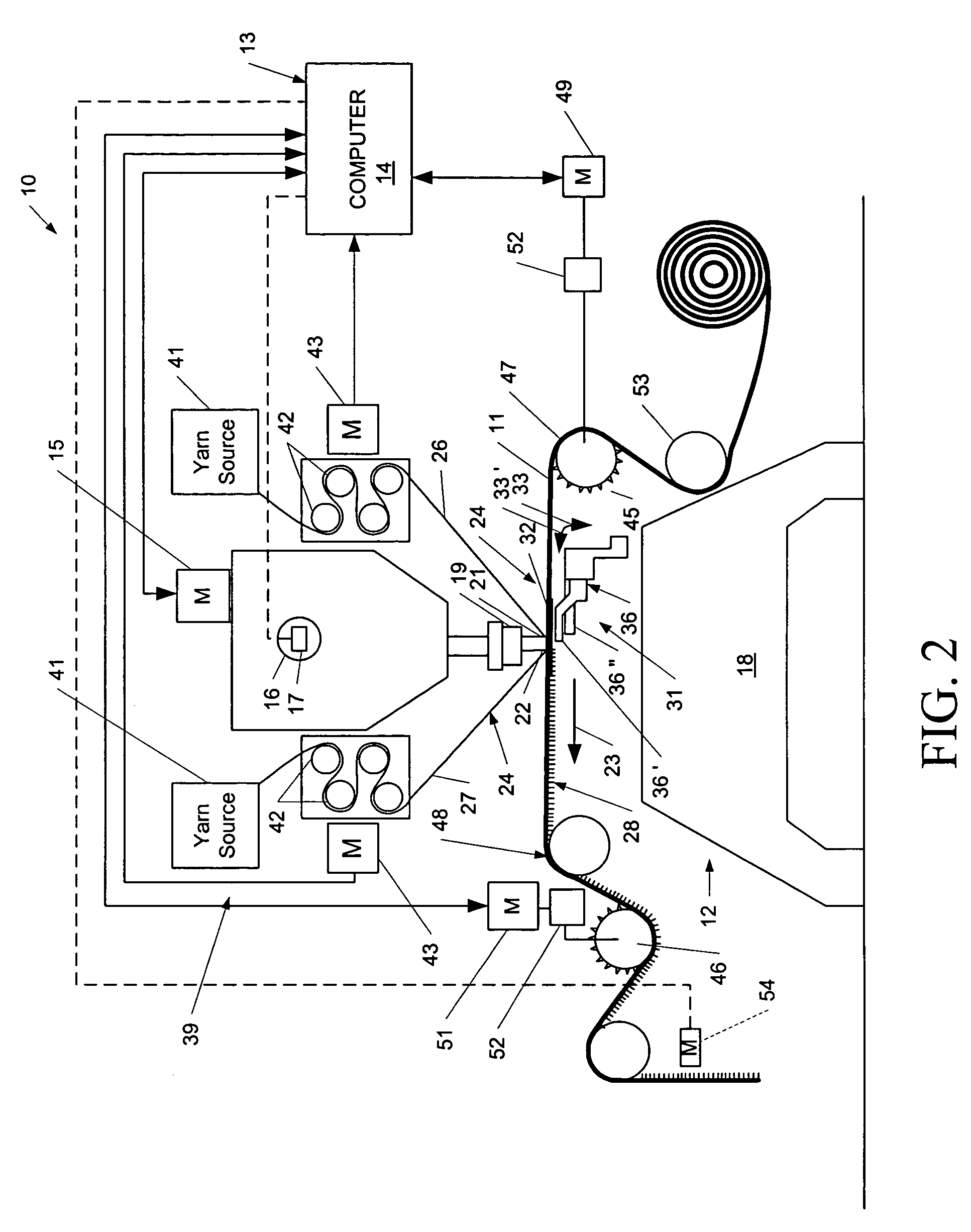

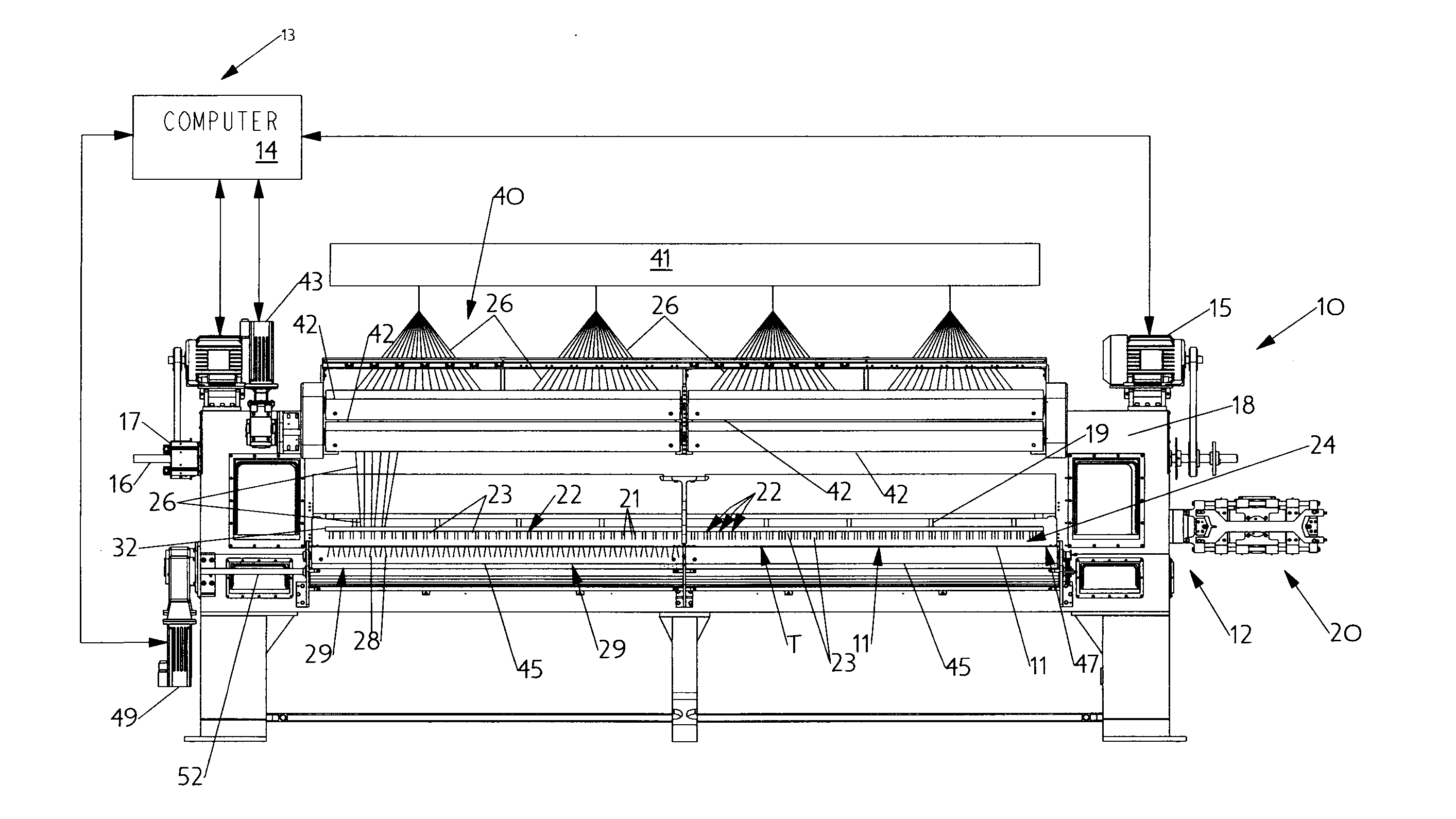

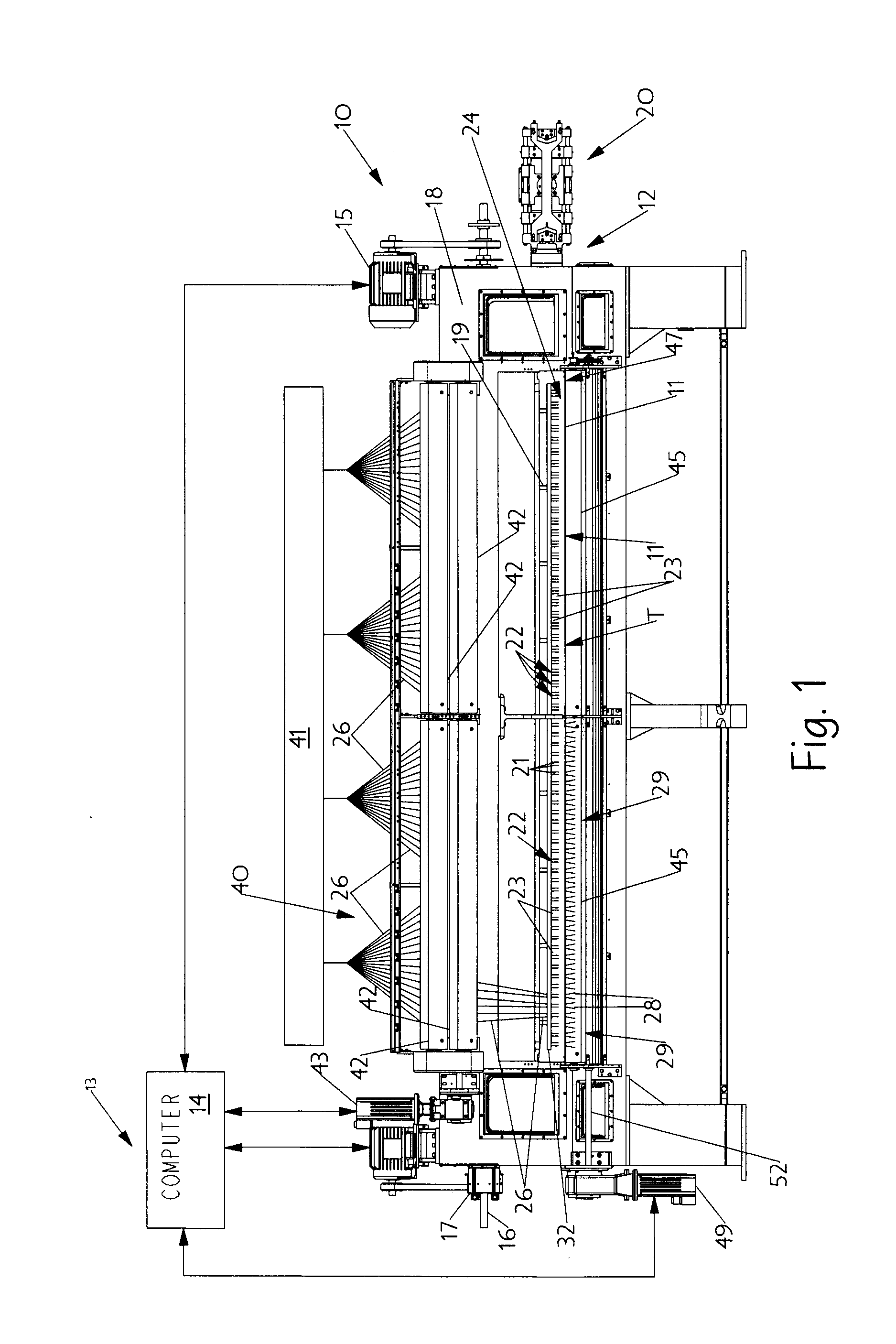

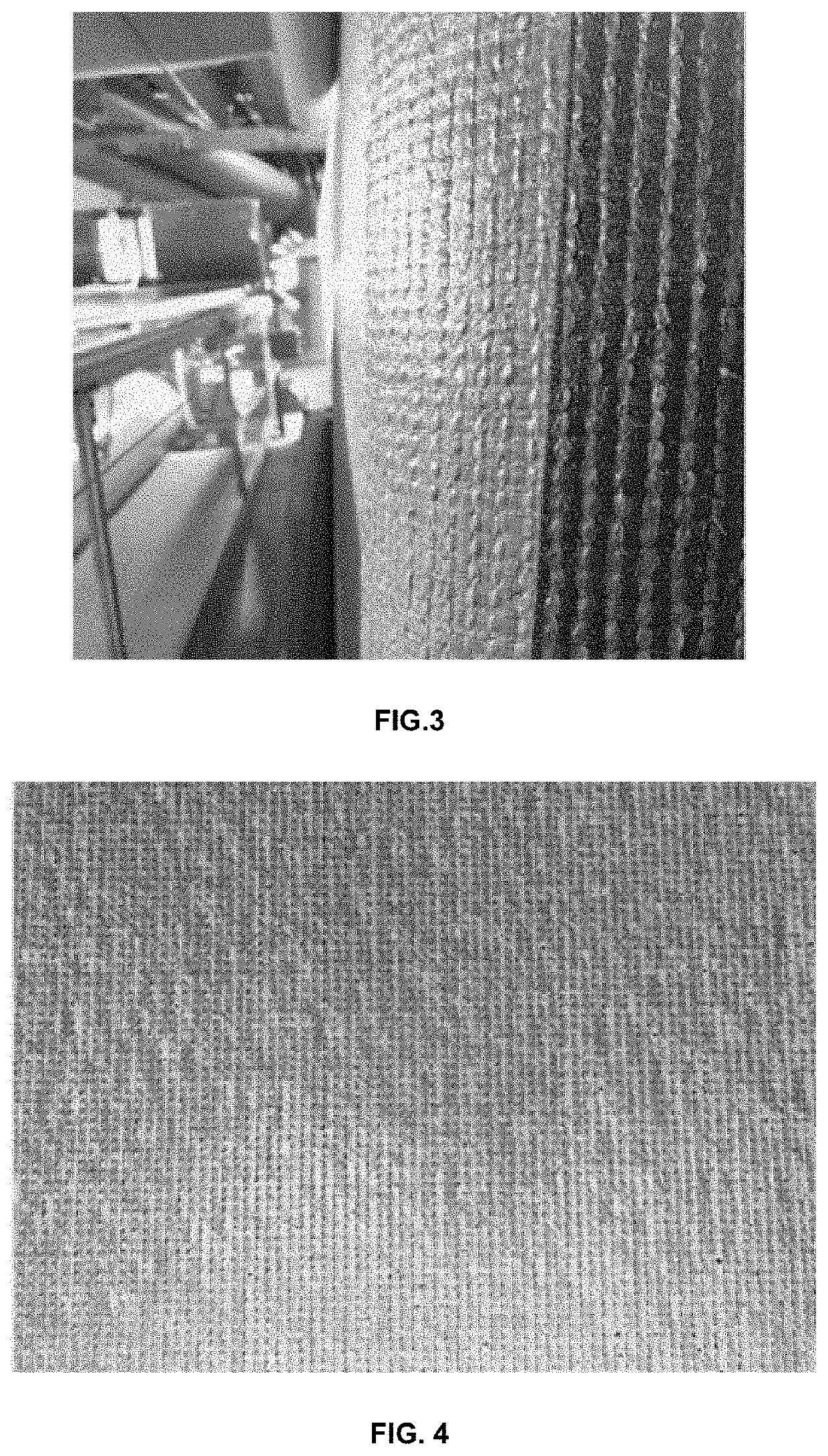

System and method for control of the backing feed for a tufting machine

ActiveUS20100064954A1Further pattern effectsProgramme-controlled sewing machinesTufting apparatusEngineeringMechanical engineering

A method of controlling the feeding of the backing material moving through a tufting machine in order to produce tufted articles such as carpets having a woven look or appearance. The backing material is indexed forwardly along its path of travel through the tufting machine by at least the stitch length for each stitch in a stitch cycle of the programmed pattern. At a desired point in the stitch cycle, the backing material can be indexed forwardly by a greater distance approximately equal to the program stitch length and a calculated jump distance to achieve a desired pattern effect.

Owner:CARD MONROE

Carpet compositions having laminated film backings and methods for making same

InactiveUS20190352845A1Lamination ancillary operationsSynthetic resin layered productsYarnEngineering

A carpet composition comprising a tufted yarn locked in place by a laminated film and methods of making same are disclosed.

Owner:COLUMBIA INSURANCE CO

Tufting machine

This invention concerns the production of so called “hand tufted rugs”, carpets and wall hangings by use a “tufting machine” which employs a single hollow needle through which yarn is fed into a backing fabric, to form tufts of yarn. The machine comprises a yarn cutter, in the tufting head, which is selectively operable to cause the tufts to be cut or loop pile. A computer operated motion control system is operable under the control of a machine readable tufting design pattern comprising a series of vectors and associated control codes, to drive the tufting gun as follows: (a) to operate the mechanism and reciprocate the needle to insert tufts into backing fabric. (b) to operate the movement system and move the needle across a two-dimensional plane while inserting tufts, in accordance with the vectors. (c) to lift and lower the foot, in accordance with respective control codes. And, (d) to selectively operate the yarn cutter, in accordance with respective control codes.

Owner:PERPETUAL MACHINE CO

Tufting machine and process for variable stitch rate tufting

A tufting machine as disclosed with a variable yarn feed mechanism and a method for tufting patterns with yarns from two rows of needles offset longitudinally from one another in a fashion that the different stitch lengths are selected in a fashion that the yarns from each row of needles are complementary to the other and maintain a consistent stitch density.

Owner:TUFTCO

Carpet weaving loom

Owner:CARLYLE STRATEGIC PARTNERS II LUXEMBOURG S A R L

Polyolefin based hot melt adhesive composition

InactiveUS20170029670A1Improve adhesionImprove balanceRosin adhesivesCarpet fastenersPolymer sciencePolyolefin

The present disclosure generally relates to a hot melt adhesive polyolefin composition comprising a high melt flow, butene-1 copolymer suitable to be used as a glue in the paper and packaging industry, in furniture manufacturing, e.g. for edgebands, square edges and softforming, for paneling in high moisture environments, and as a glue in tufted or needle punched carpets.

Owner:BASSELL POLIOLEFINE ITAL SRL

Process to laminate polyolefin sheets to urethane

The present invention relates to tufted goods comprising a greige good having fibers tufted into a primary backing, a precoat which is adhered to the back surface of the greige good, and a flexible film which is laminated to the back surface of the precoat. The flexible film is treated via corona-discharge prior to being laminated to the precoat. This invention also relates to a process for producing tufted goods. This process comprises treating a flexible film via corona-discharge, contacting the treated flexible film with the uncured or partially cured back surface of a precoated greige good, and curing the article. Optional embodiments of this invention include having a foam layer between the precoat and the flexible film, or having a foam layer on the back surface of the flexible film. An alternate embodiment of this invention comprises substituting a foam layer for the precoat.

Owner:BAYER ANTWERPEN NV

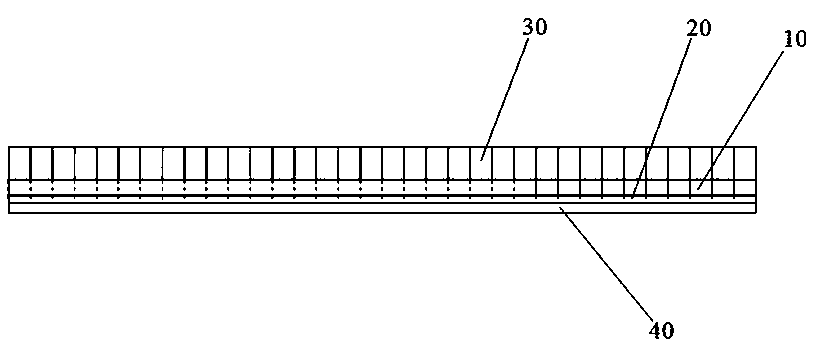

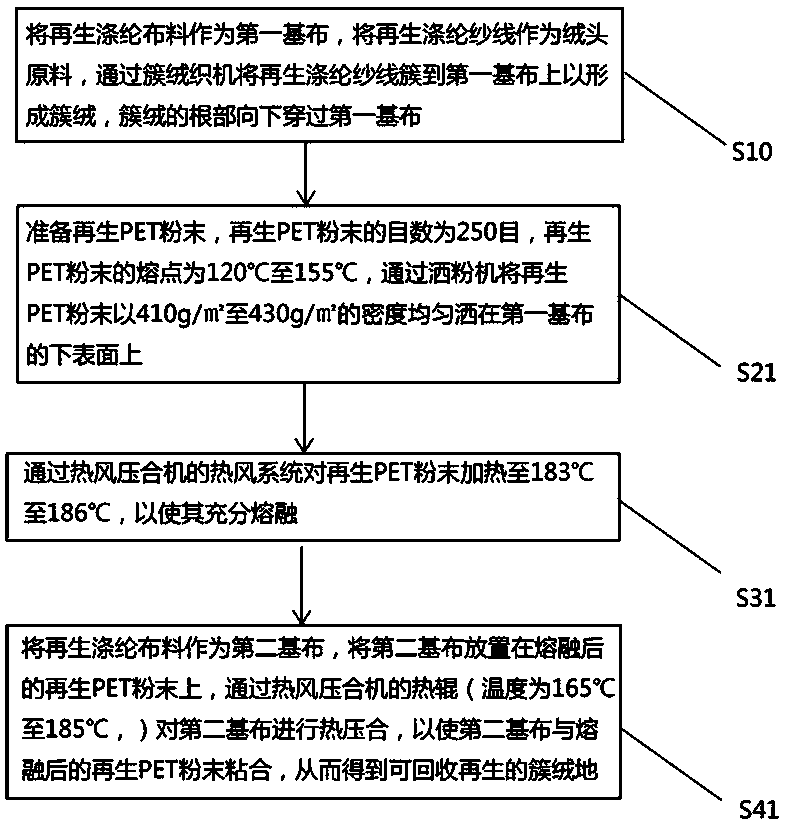

Tufted carpet and manufacturing method thereof

InactiveCN109199048AQuality improvementEnable recyclingSynthetic resin layered productsLaminationFiberYarn

The invention provides a tufted carpet and a manufacturing method thereof, wherein, the tufted carpet comprises a first base cloth made of regenerated polyester fiber; an adhesive layer provided on the lower surface of the first substrate, the adhesive layer being formed by melting of regenerated PET powder; tufted pile, arranged on the upper surface of the first base cloth, the root of tufted pile passing through the first base cloth downward and fixed with the first base cloth through an adhesive layer, the tufted pile being formed of regenerated polyester yarn; a second base cloth fixed onthe lower surface of the first base cloth by an adhesive layer, and the second base cloth is made of regenerated polyester. The scheme of the invention can effectively solve the problem that the tufted carpet in the prior art cannot be recycled and reused.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

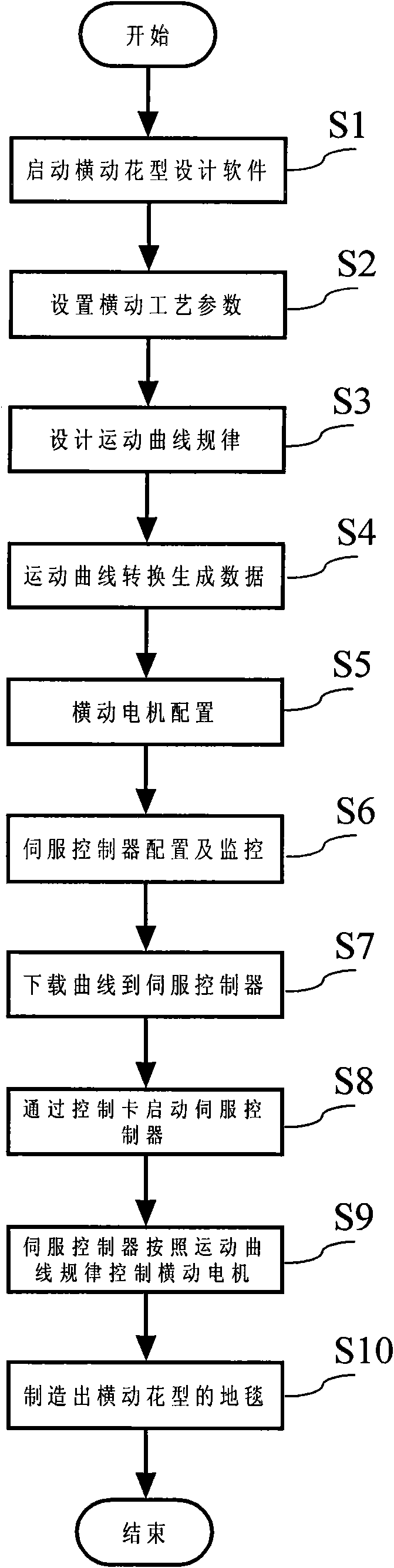

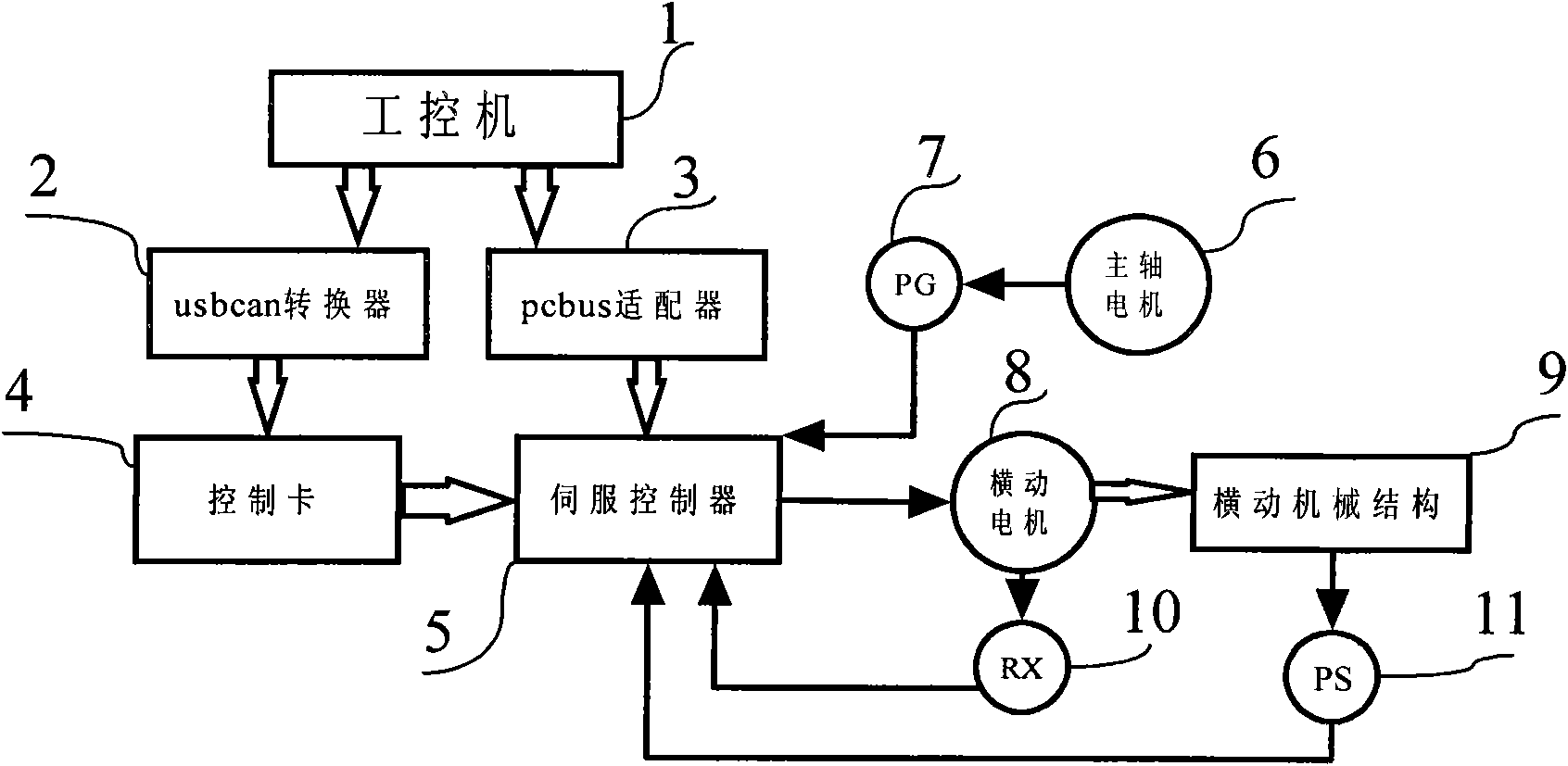

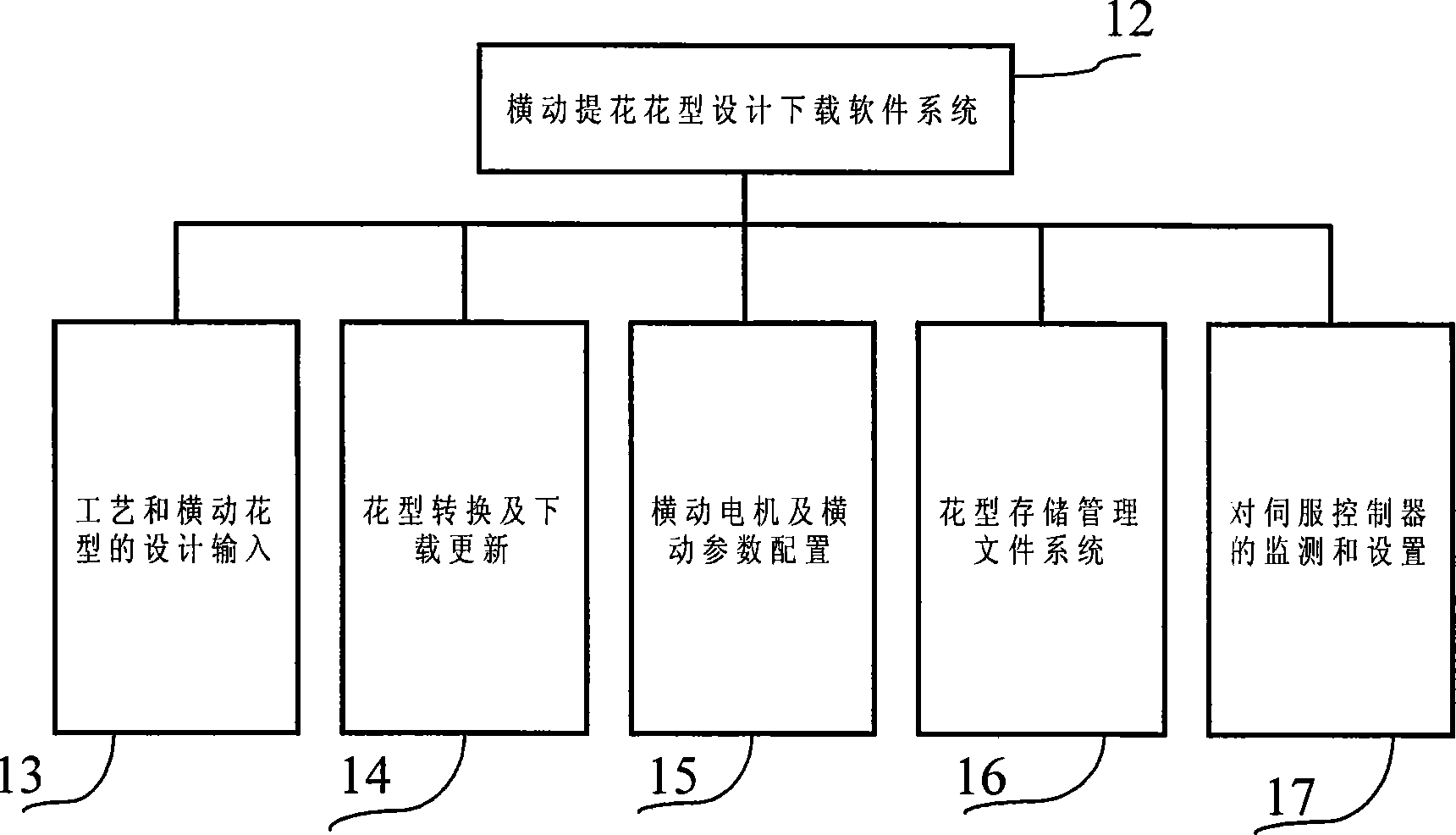

System and method for processing electric cam horizontal type tufted carpet with on-line flower shape updating

InactiveCN101619525AChange easy to wearChange difficultyTufting apparatusTotal factory controlCamControl curve

The invention relates to a system and a method for processing an electric cam transverse type tufted carpet with on-line flower shape updating. A hardware platform which comprises an industrial computer, a servo controller, a servo motor, a photoelectric encoder, an external control card and a bus communication converter is utilized to design a transverse flower shape, transverse cam control curves can be automatically converted, the control curves can be finally downloaded in an on-line way, and at most 8 transverse flower shape curves can be stored in the servo controller; and after the industrial computer downloads a plurality of curves at one time, the industrial computer only needs to fast switch different transverse flower shape curves in an on-line way through the control card according to a production technology requirement so as to be suitable for the processing requirements of different transverse type tufted carpets. The invention solves the problems of the long cam replacing time, the easy cam abrasion and the great processing difficulty of the transverse jacquard of the traditional mechanical type cam, and technologists can directly design transverse flower shape laws so as to automatically generate transverse control information needed by the servo controller.

Owner:DONGHUA UNIV

Manual tufting carpet with moisture absorption and moisture guide functions and weaving method of manual tufting carpet

ActiveCN102783892AImprove moisture absorption and moisture conduction functionIncrease contact areaEmbroidering machines apparatusFloor carpetsFiberHigh humidity

The invention discloses a piece of manual tufting carpet with moisture absorption and moisture guide functions and a weaving method of the manual tufting carpet. The carpet is woven by Coolmax fiber subjected to alkali weight reducing processing, after the Coolmax fiber is subjected to the alkali weight reducing processing, the cross section of the Coolmax fiber has special groove structures, the surface area is increased, the moisture absorption and moisture guide functions are further improved, fiber broken end and loop end alternate arrangement at intervals is adopted in the weaving method, the loop end and broken end height difference is regulated, the three-dimensional effect of veins is enhanced, the contact area between the Coolmax fiber and the air is increased, the moisture absorption and moisture guide speed is accelerated, and the function is enhanced. Bottom cloth with nonuniform warp and weft yarns, thick warp yarns, thin weft yarns and low density is used at the bottom of the carpet, so gap passages are formed on contact surfaces between the bottom and the ground, air with high humidity can be fast guided out from the bottom of the carpet, the moisture absorption and moisture guide effects of the carpet are promoted, the use comfort of the carpet is improved, the Coolmax cheese weight reducing time is controlled in the weaving process, and the twist degree of the weight reducing fiber is properly increased, so the softness of the carpet is enhanced, and the falling cannot easily occur.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Method for producing multicolored carpet

InactiveUS20080016625A1Increased durabilityEasy to manufactureOnium based azo dyesDetergent compounding agentsYarnPolyamide

A method of producing a multicolored textured carpet comprises blending a polyamide polymer and a color pigment to form a melt blend, extrusion spinning the melt blend to form pigmented polyamide yarns, tufting (1) the pigmented polyamide yarns and (2) white dyeable polyamide yarns into a carpet, and overdyeing the carpet with an amount of acid dye sufficient to produce the multicolored textured carpet. The color pigment and the acid dye are selected to provide desired multicolored effect in the carpet. The multicolored textured carpet having deeper color and dye light fastness is also disclosed.

Owner:INV PERFORMANCE SURFACES LLC

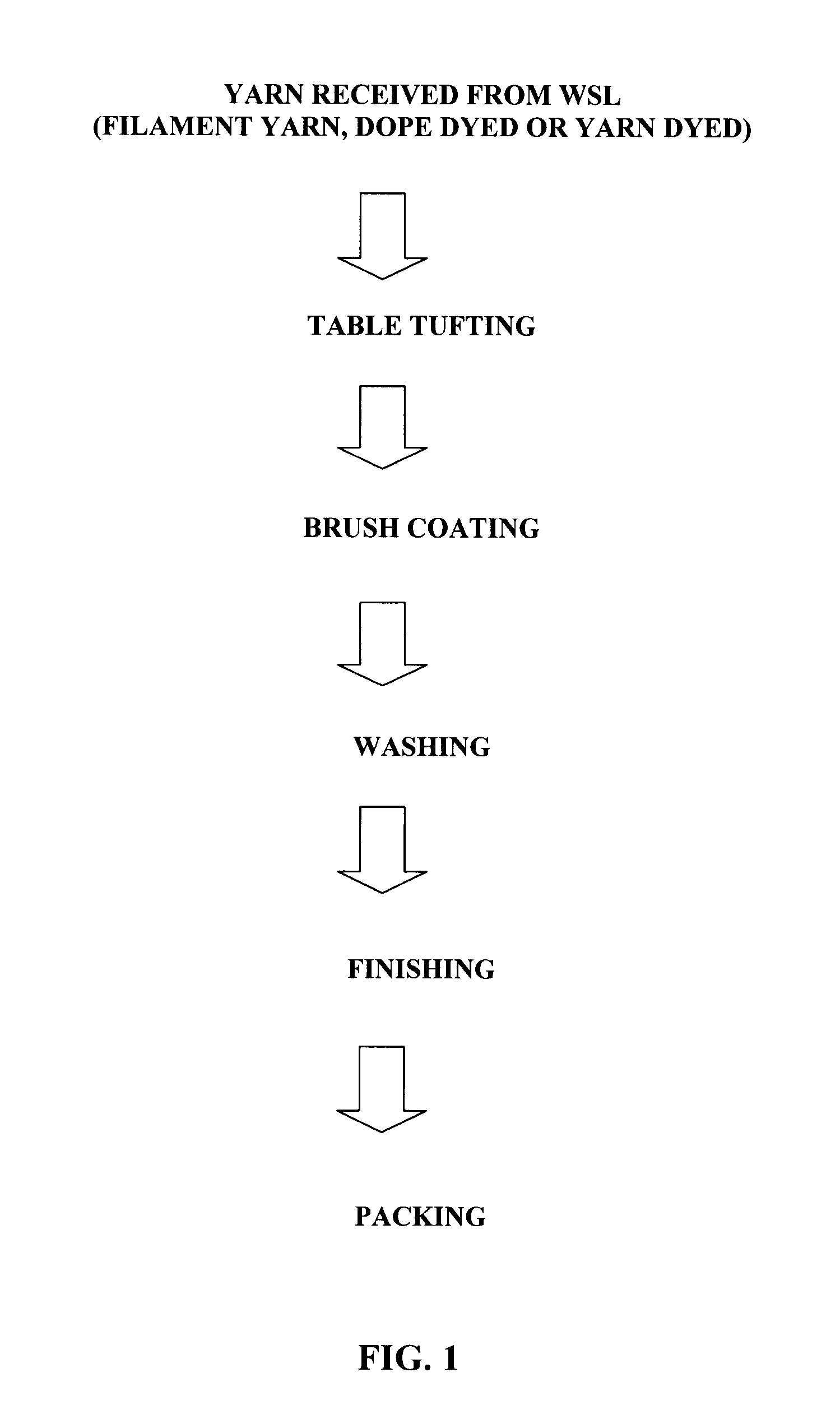

Bleach Safe, Stain Free, Quick Drying Drylon Rugs

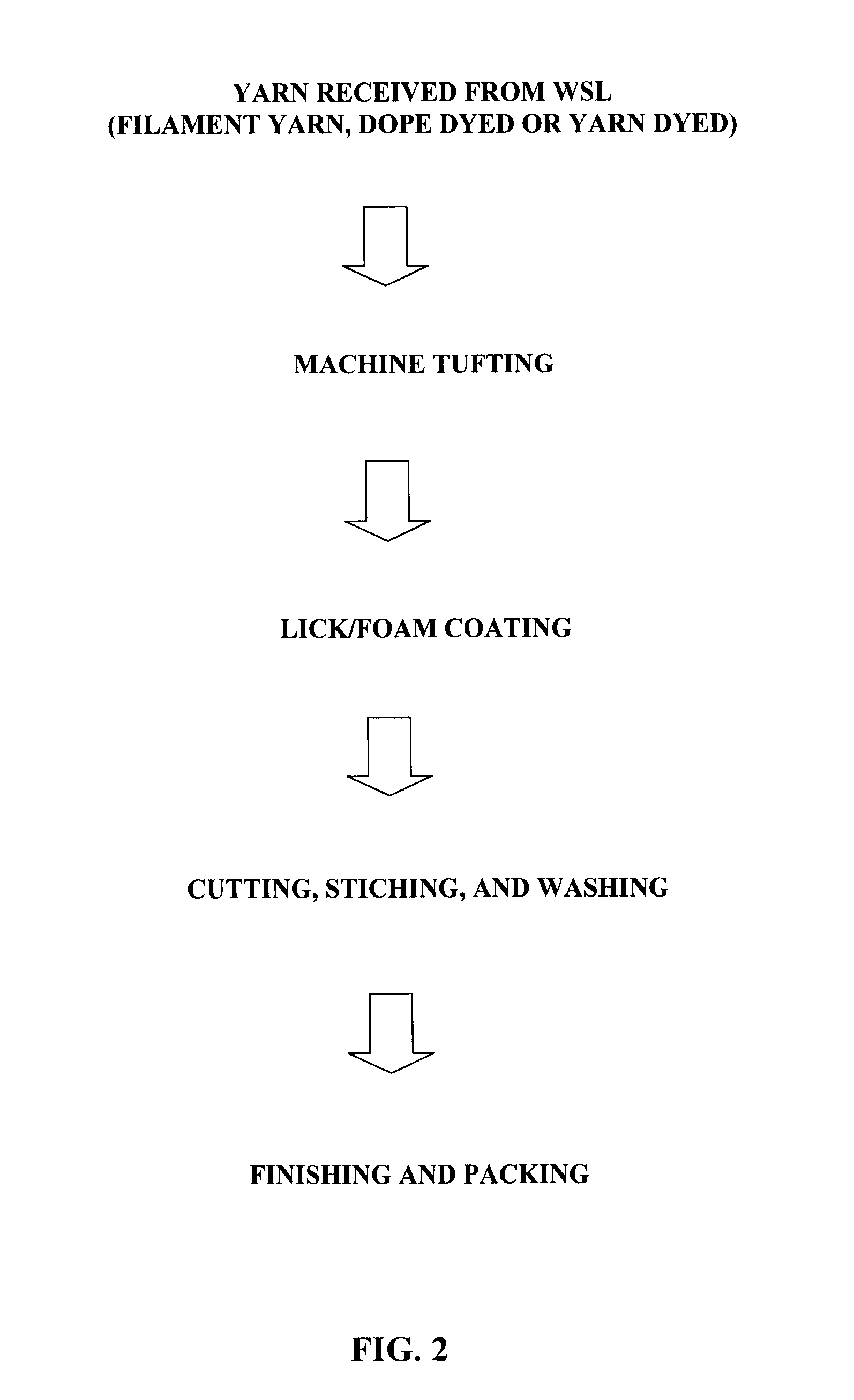

A process for making a Drylon rug is disclosed, wherein the said process comprises use of dope dyed, micro-denier filament, cabled and heat set polyester yarn or micro denier filament, cabled heat set dyed with antimicrobial treatment for tufting of rugs, thereby eliminating the process of batch dyeing after the formation of rugs and further ensuring that the rugs are bleach safe, quick drying, anti microbial and stain resistant. The present invention also discloses Drylon rugs as manufactured using yarns of invention. Further, the present invention discloses the process for manufacture of Drylon yarns.

Owner:WELSPUN GLOBAL BRANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com