Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

511results about "Tufting apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

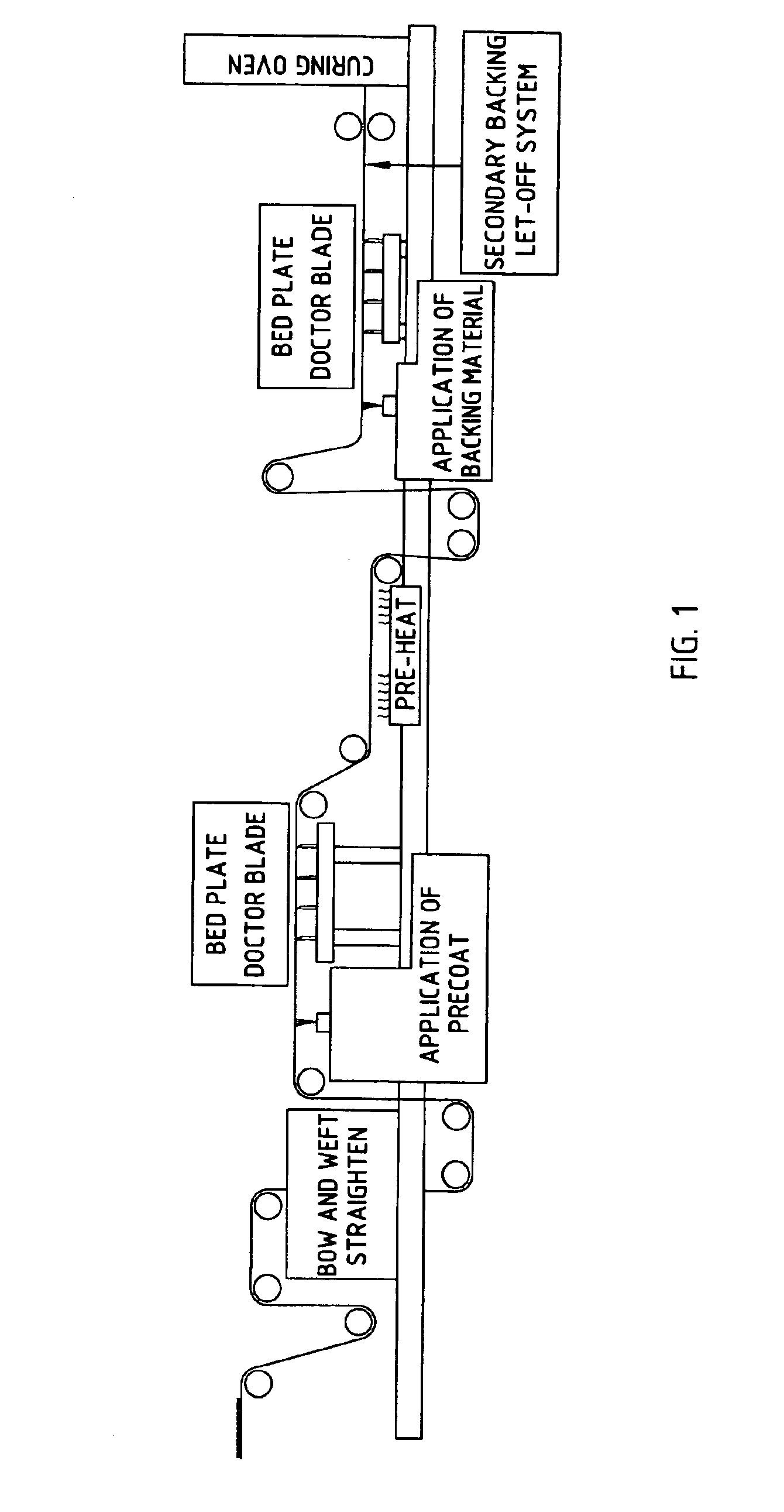

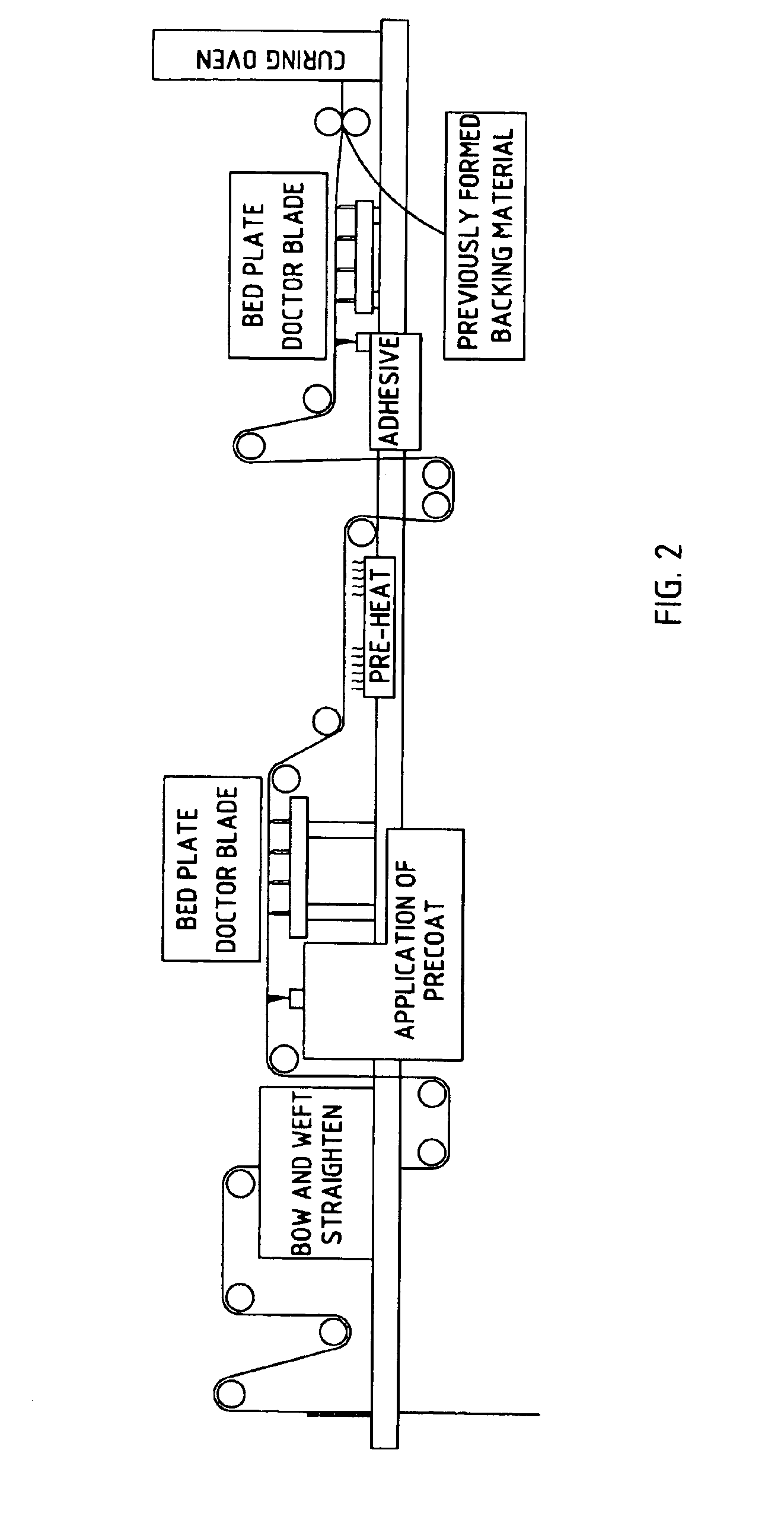

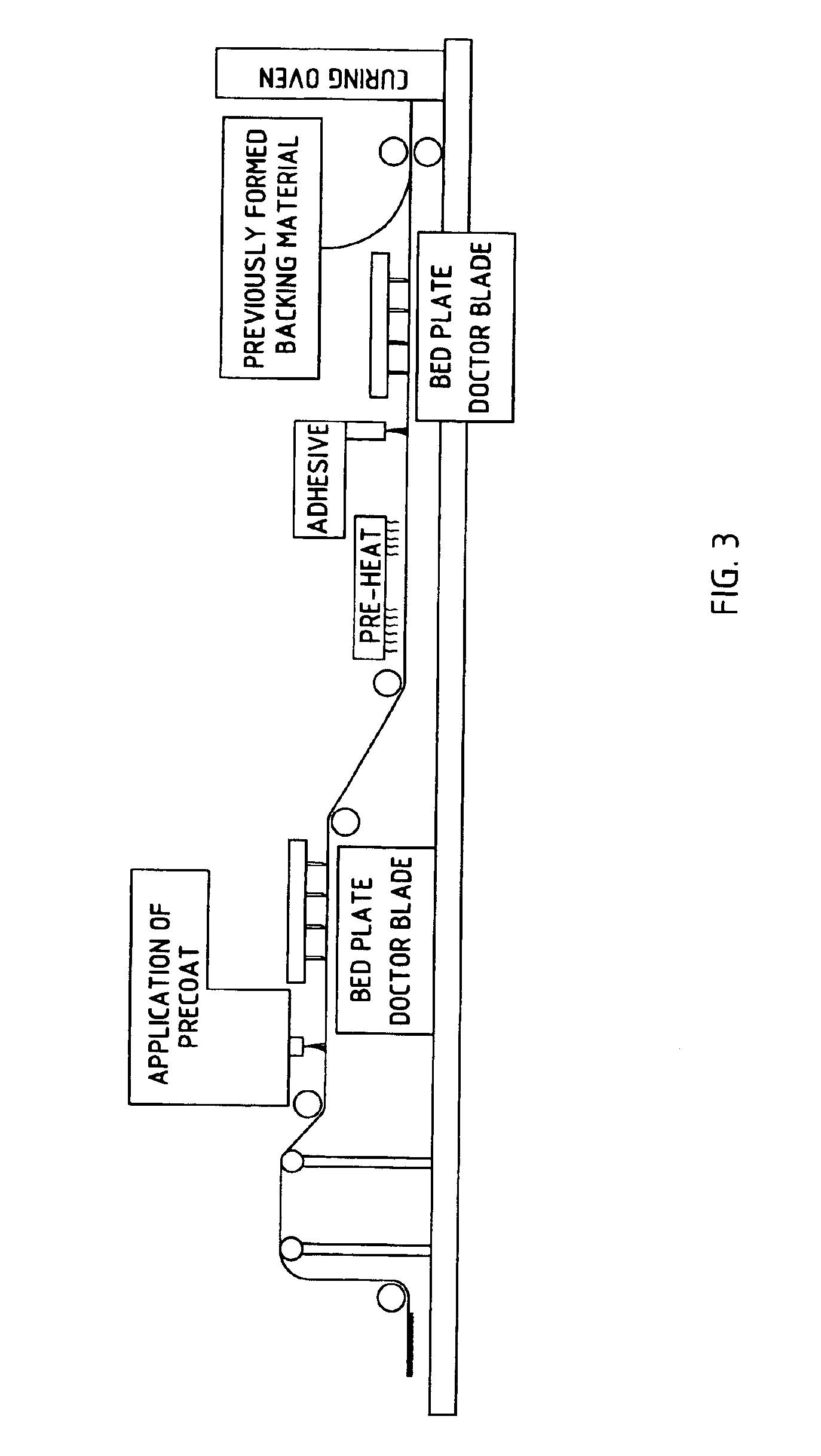

Method of producing a bio-based carpet material

The present invention includes a method for making a bio-based carpet material by providing tufts, a backing, a pre-coat, and a backing material wherein the pre-coat includes the reaction product of a pre-coat A-side having a pre-coat isocyanate and a pre-coat B-side and the backing material includes the reaction product of a backing material A-side having a backing material B-side. The pre-coat B-side and the backing material B-side may include a petroleum based polyol; a vegetable oil, cross-linker, and a catalyst; or a transesterified polyol.

Owner:RHINO LININGS CORP +1

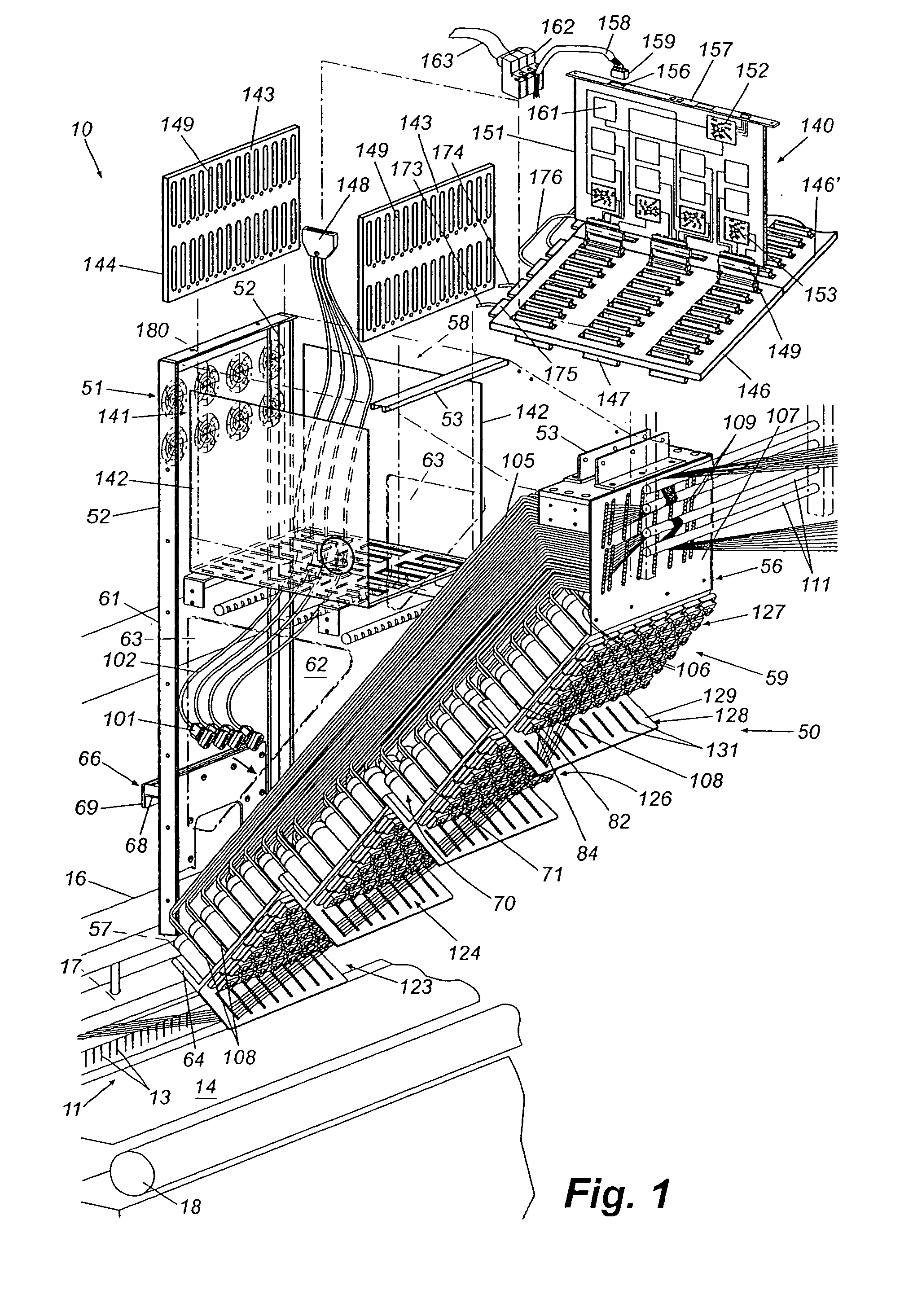

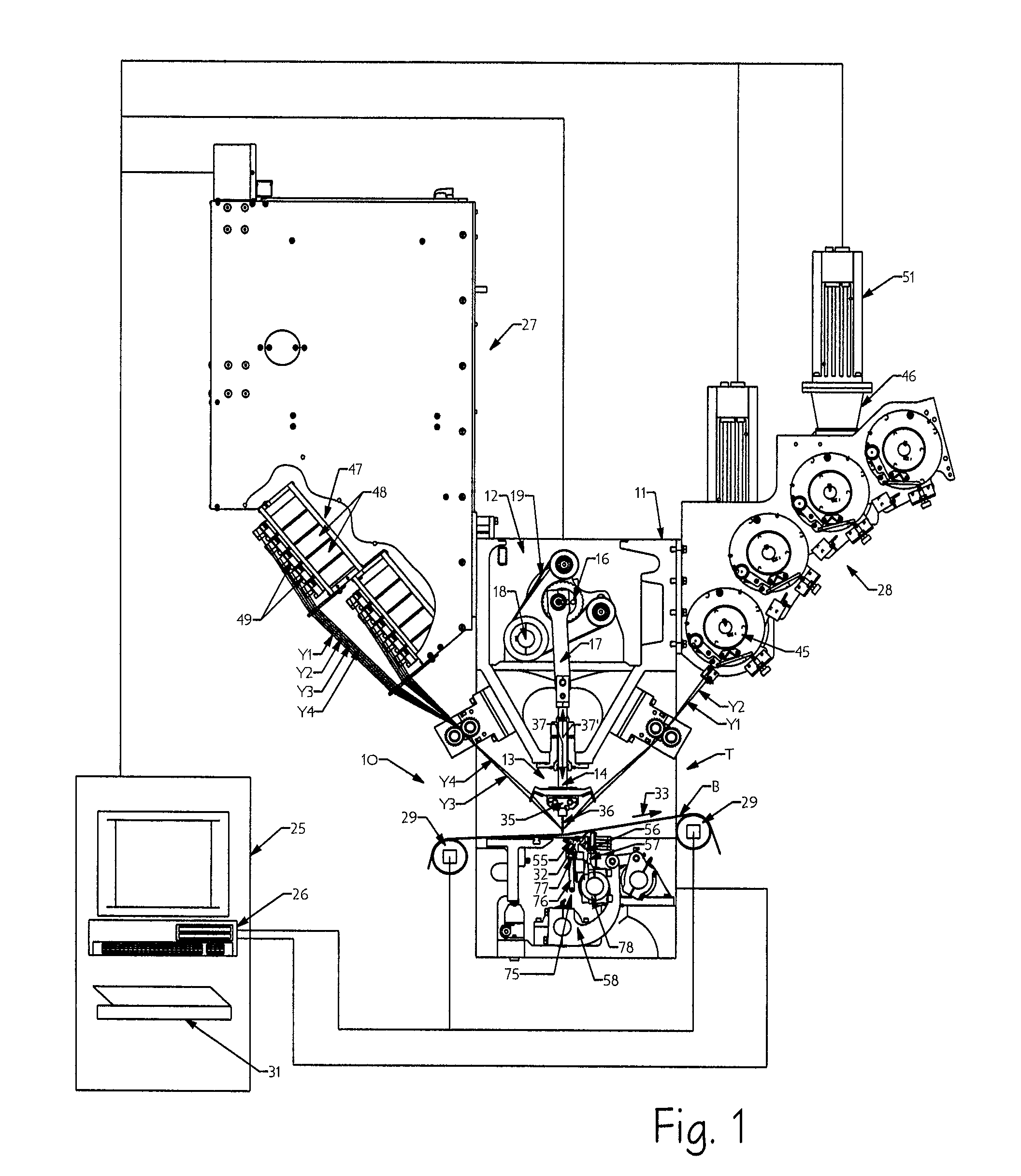

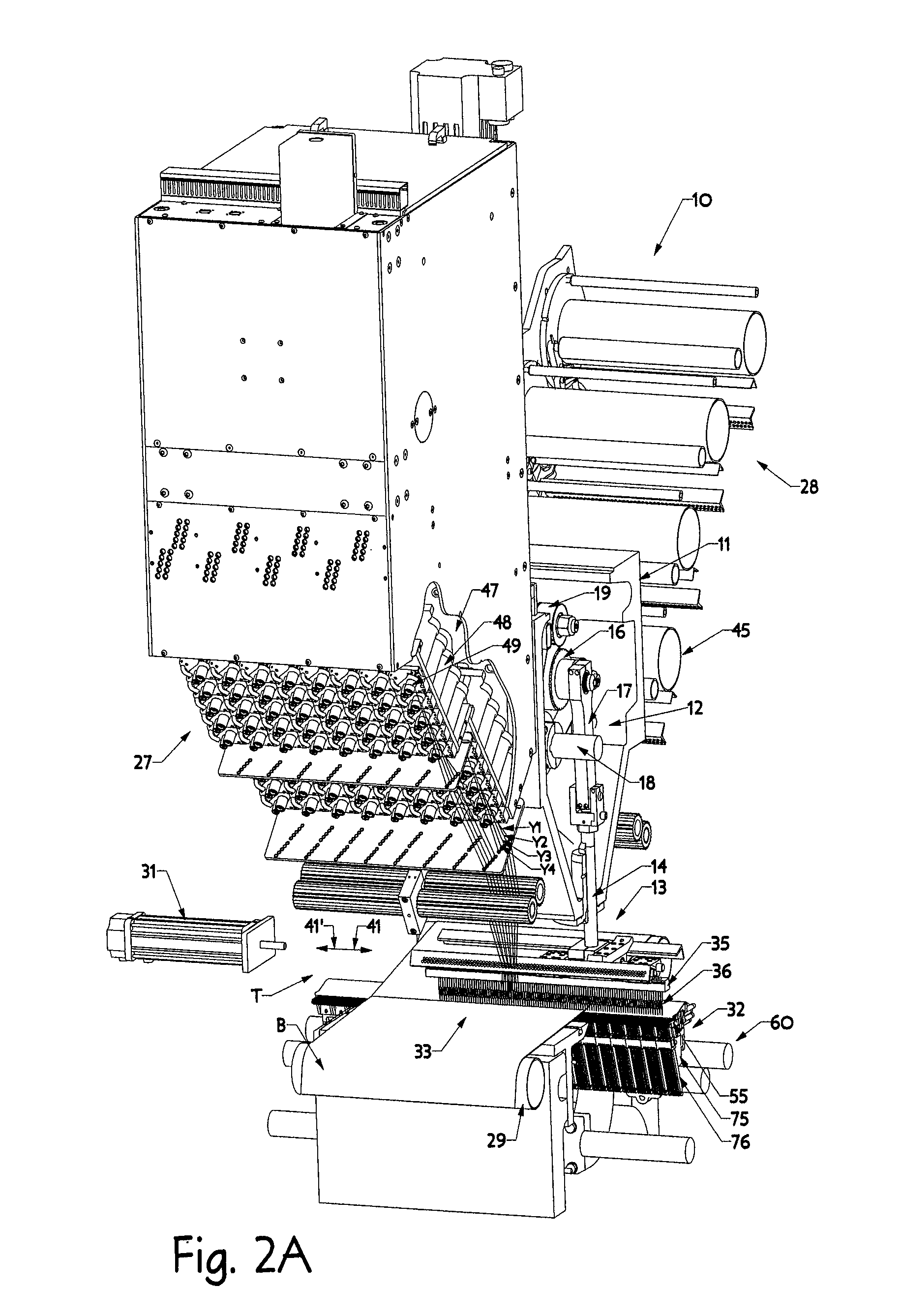

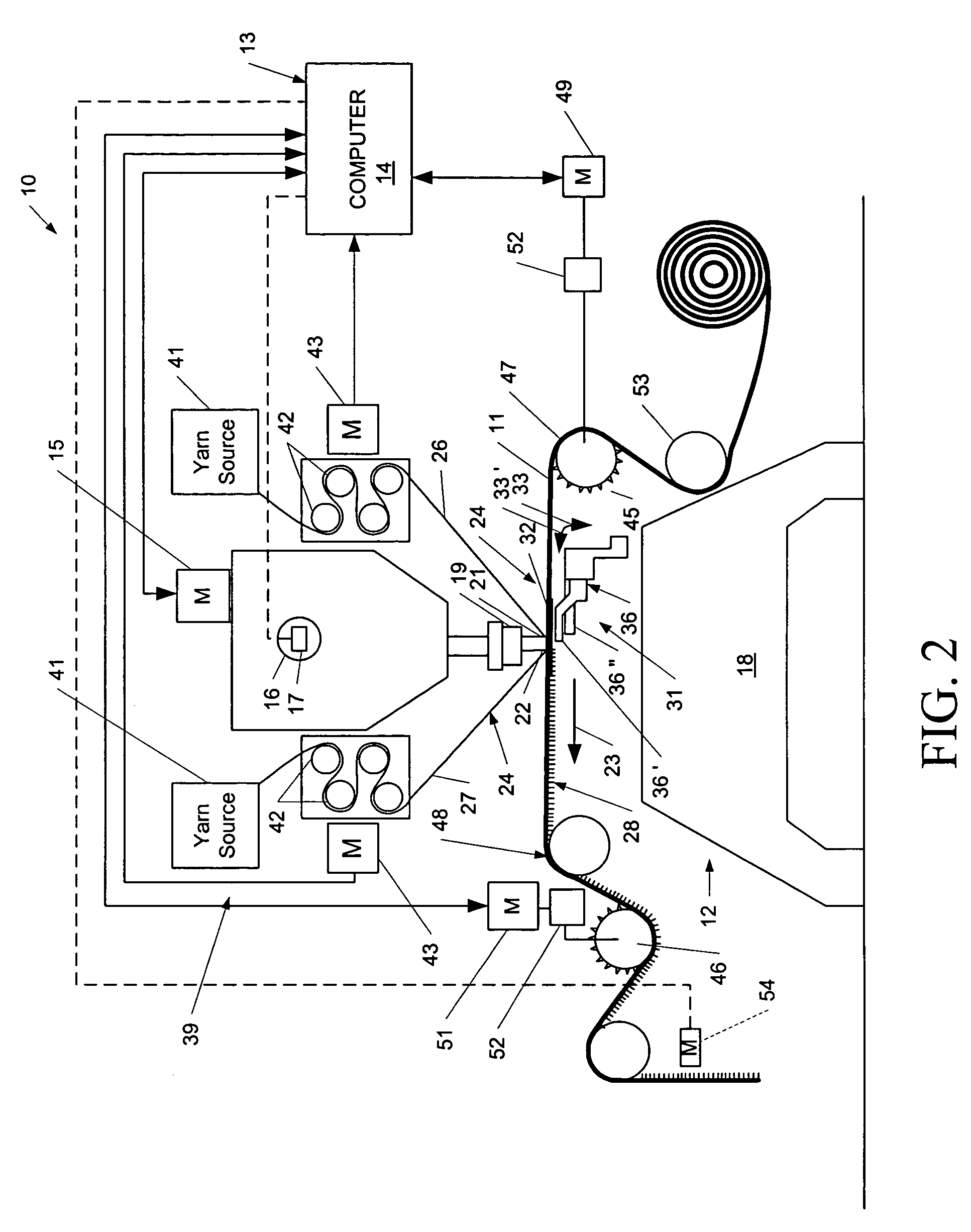

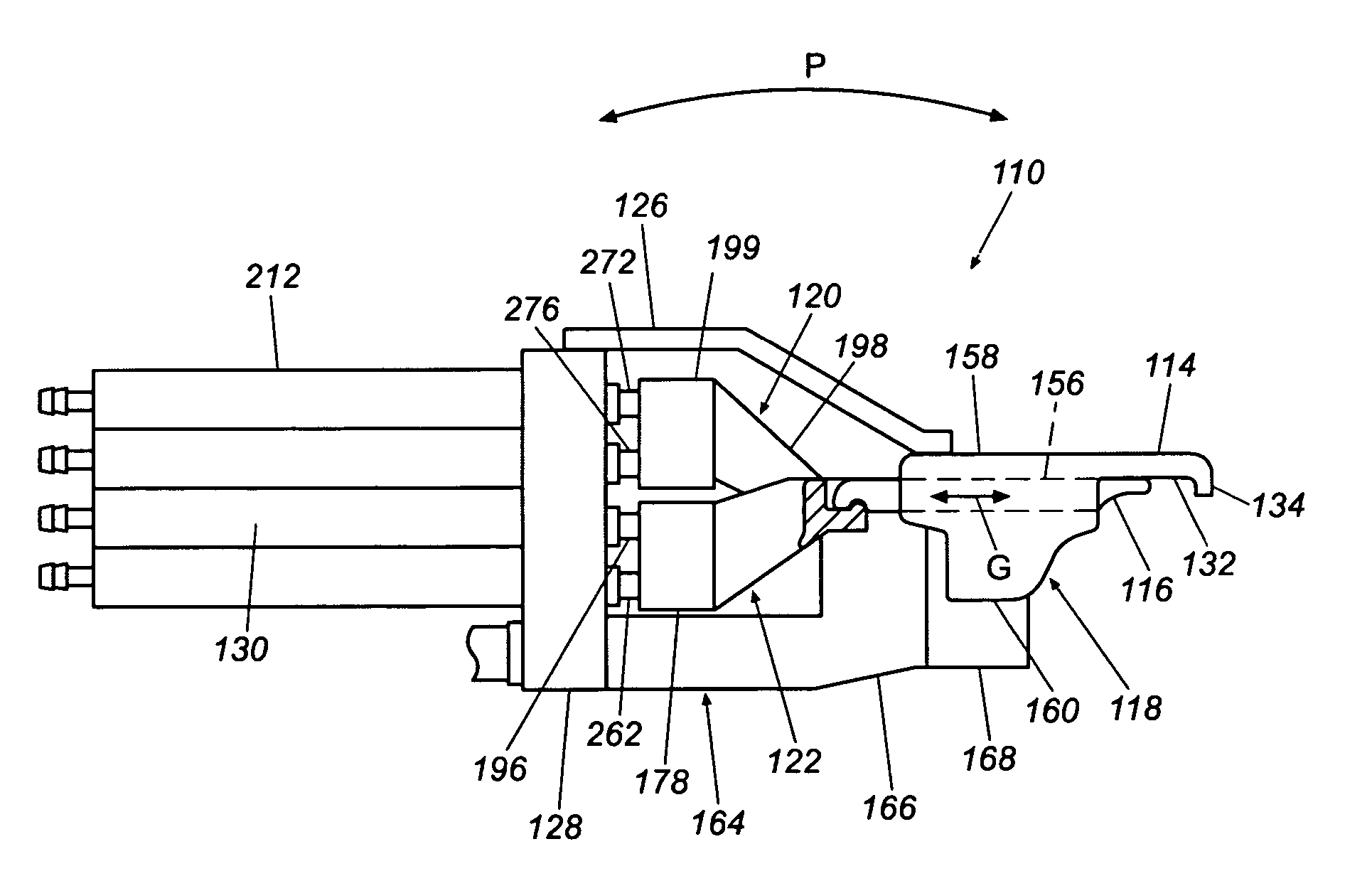

Yarn feed system for tufting machines

InactiveUS7096806B2Improve precisionEasy to controlTufting apparatusYarnElectrical and Electronics engineering

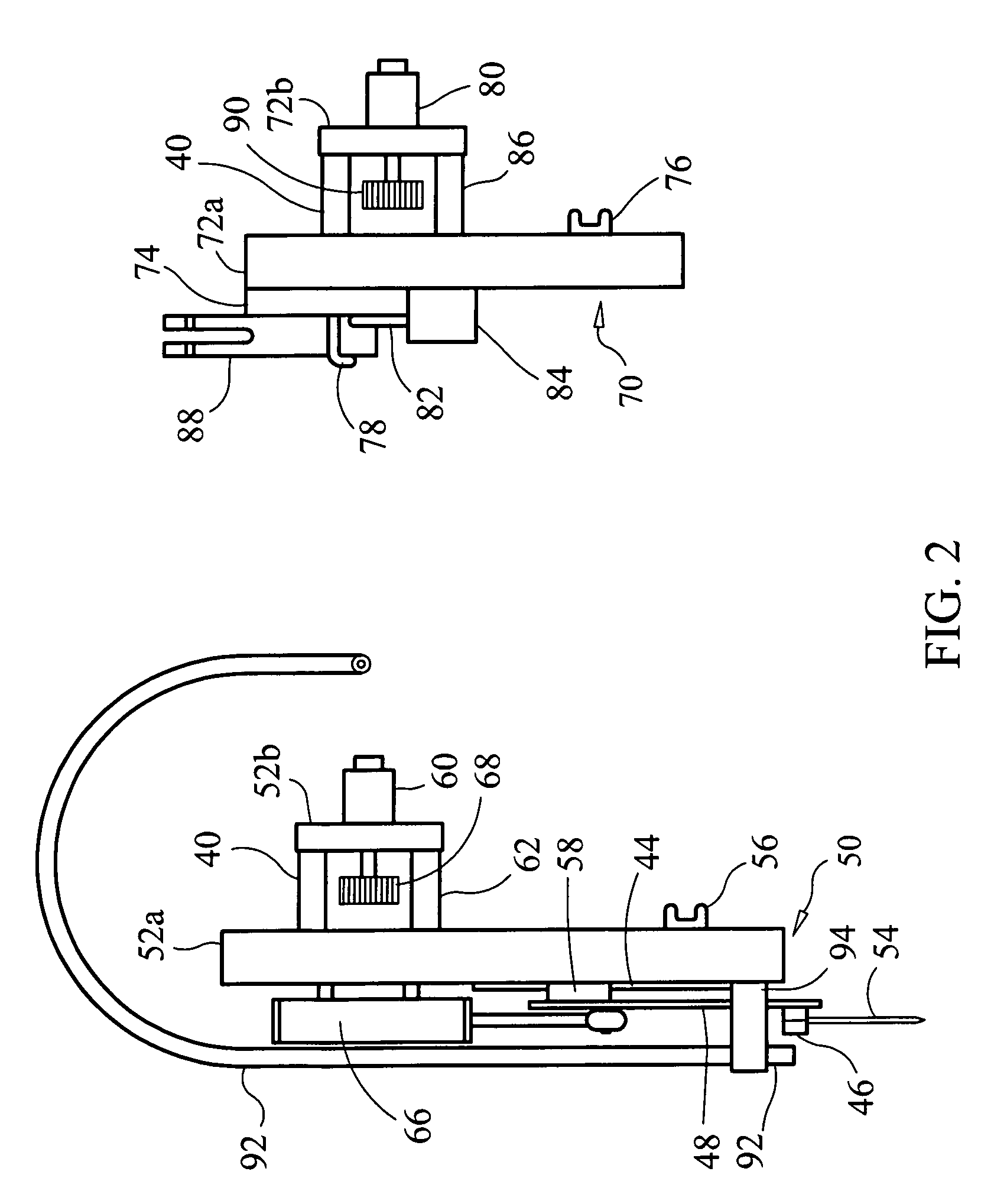

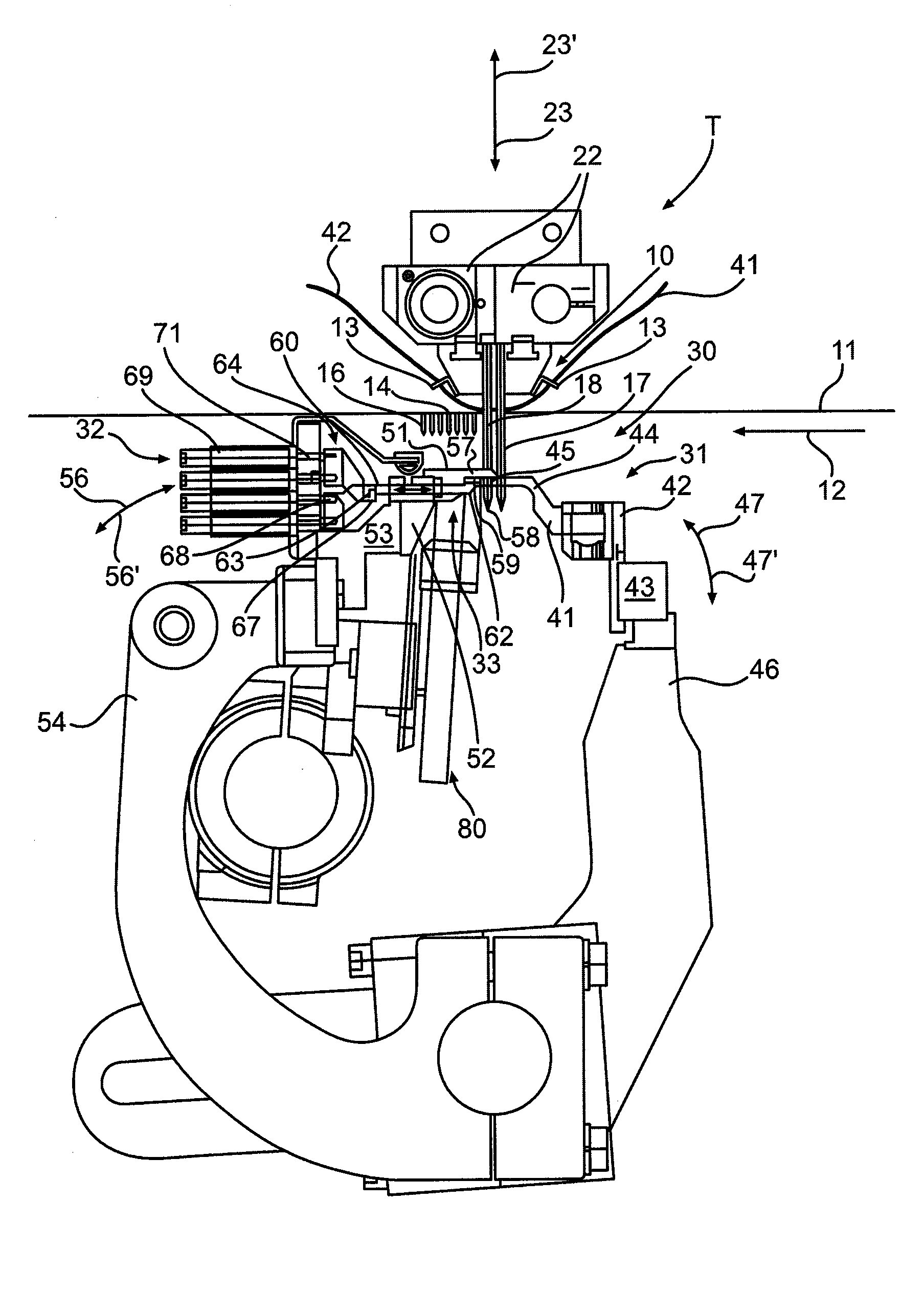

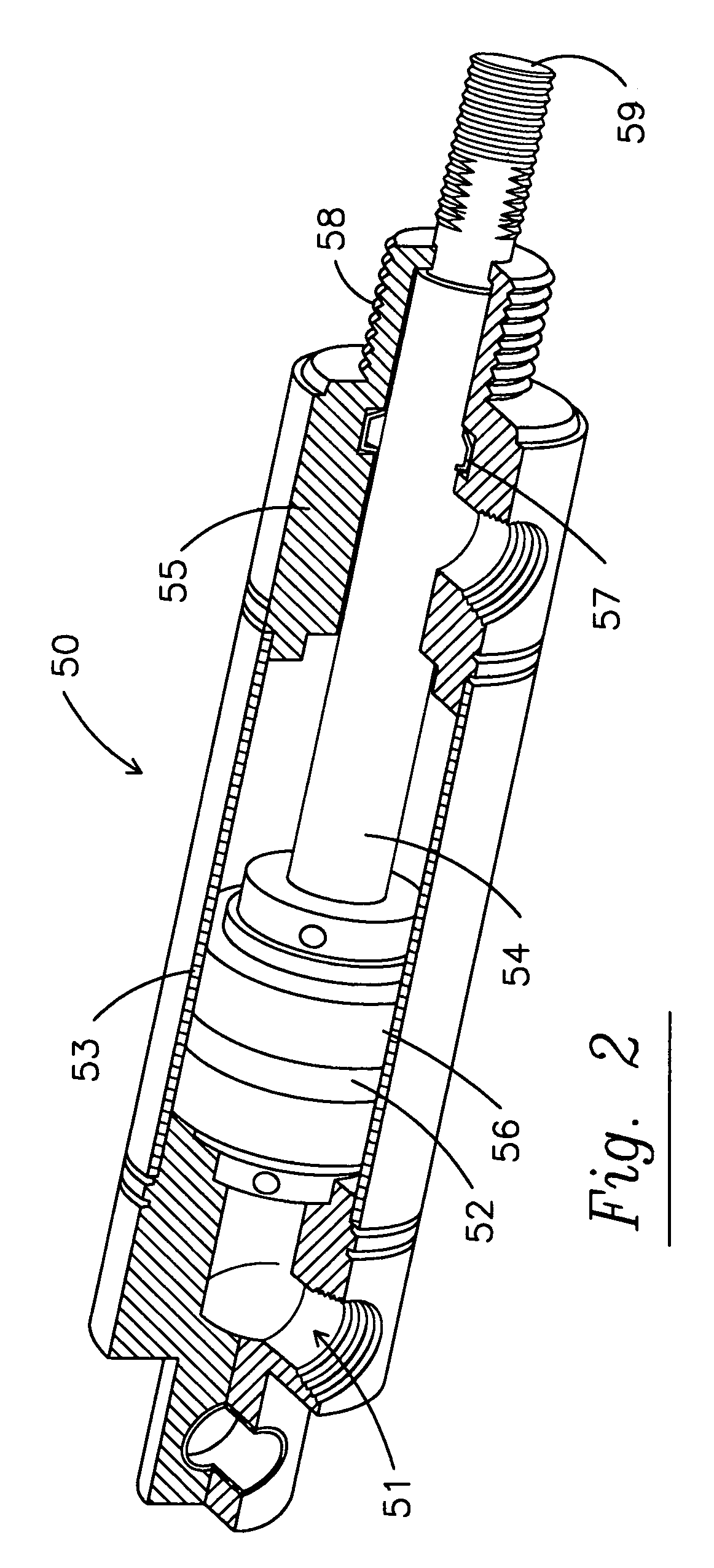

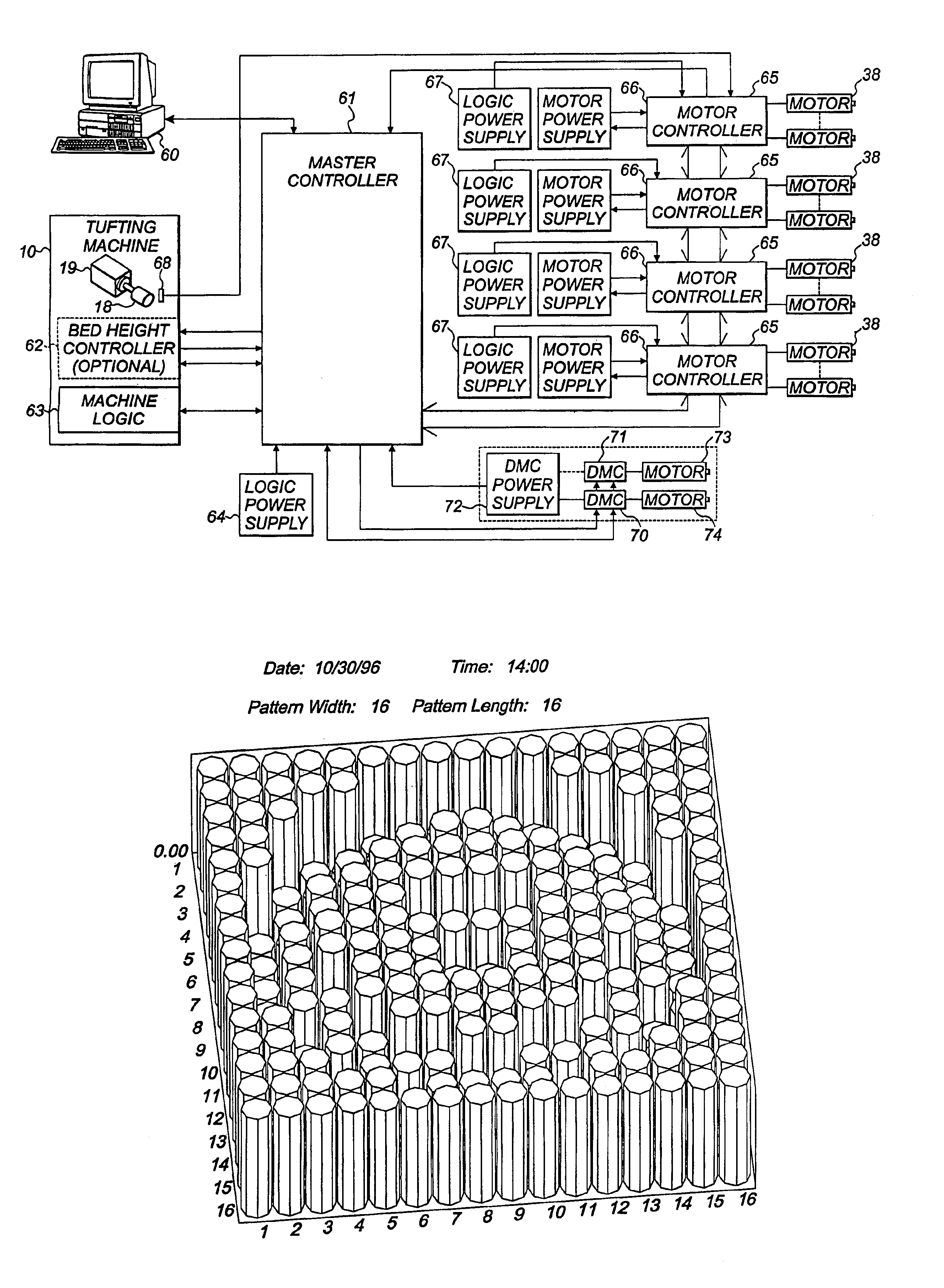

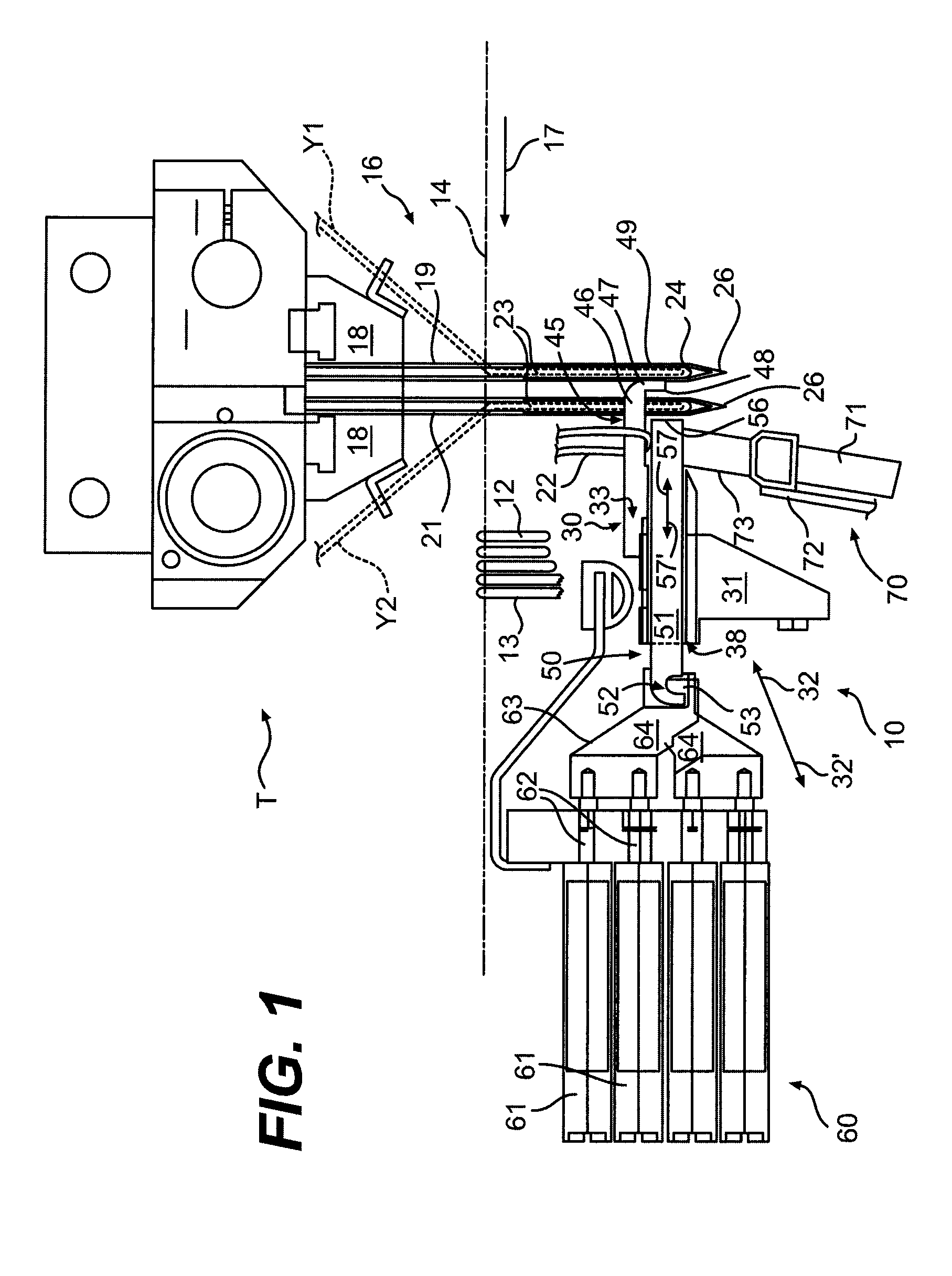

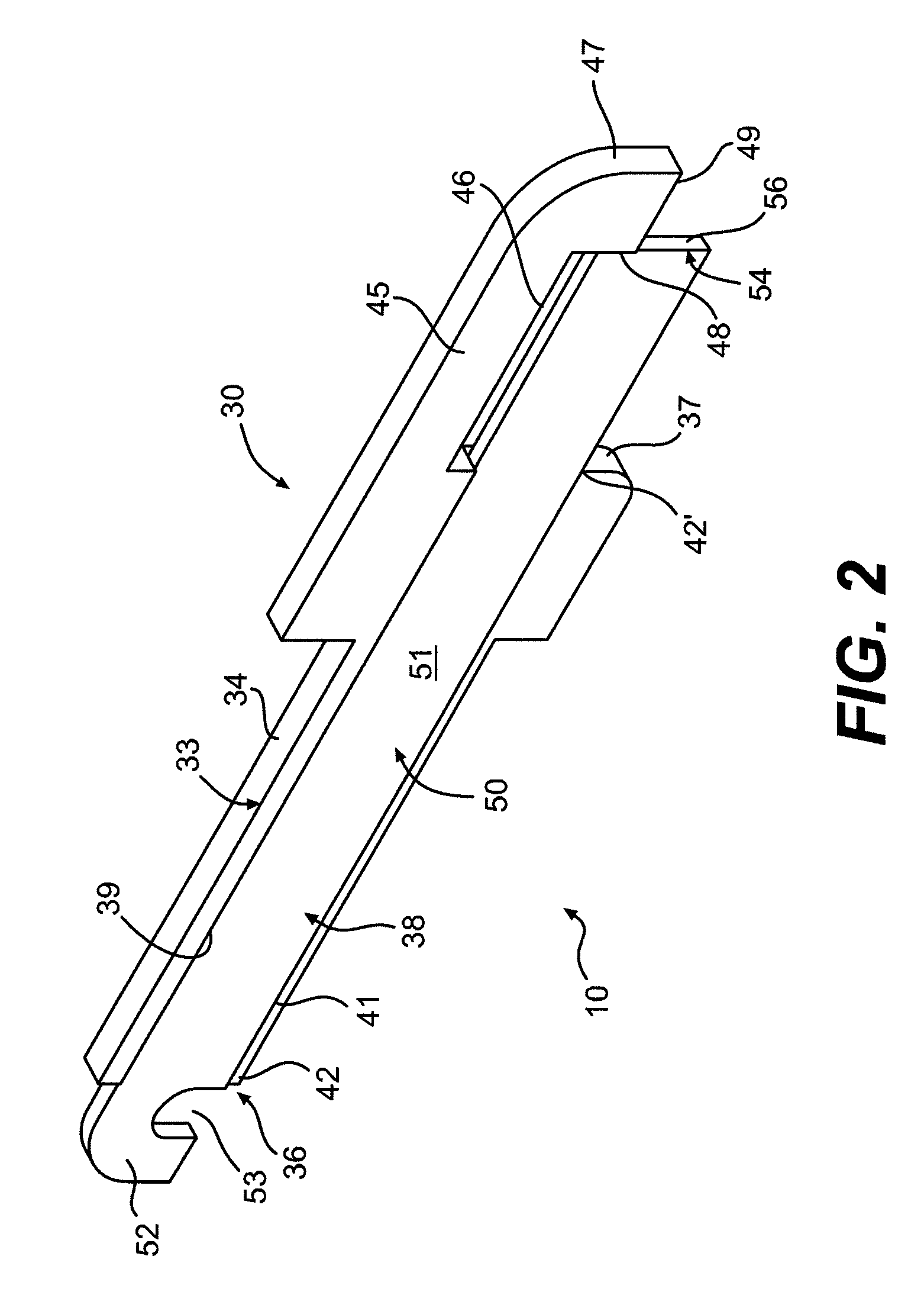

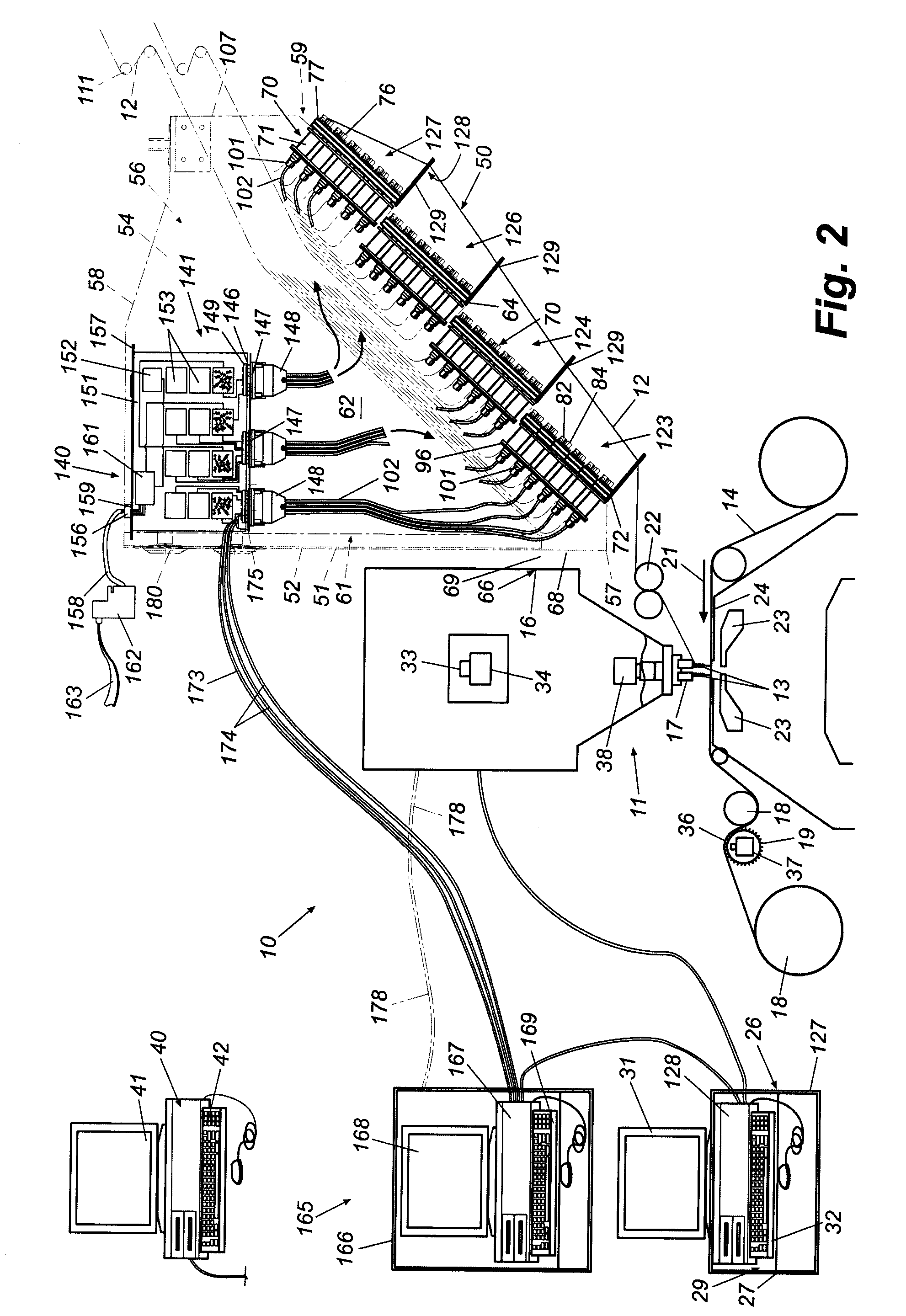

A yarn feed system, enabling the control of individual yarns to the needles of a tufting machine, and which system can be manufactured as a substantially standardized unit or attachment that can be removably mounted to a tufting machine. The yarn feed unit includes a series of yarn feed devices for feeding each of the yarns to the needles of the tufting machine, and a series of yarn feed controllers that monitor and control the operation of the yarn feed devices to control the feeding of the yarns to the needles according to programmed pattern instructions.

Owner:CARD MONROE

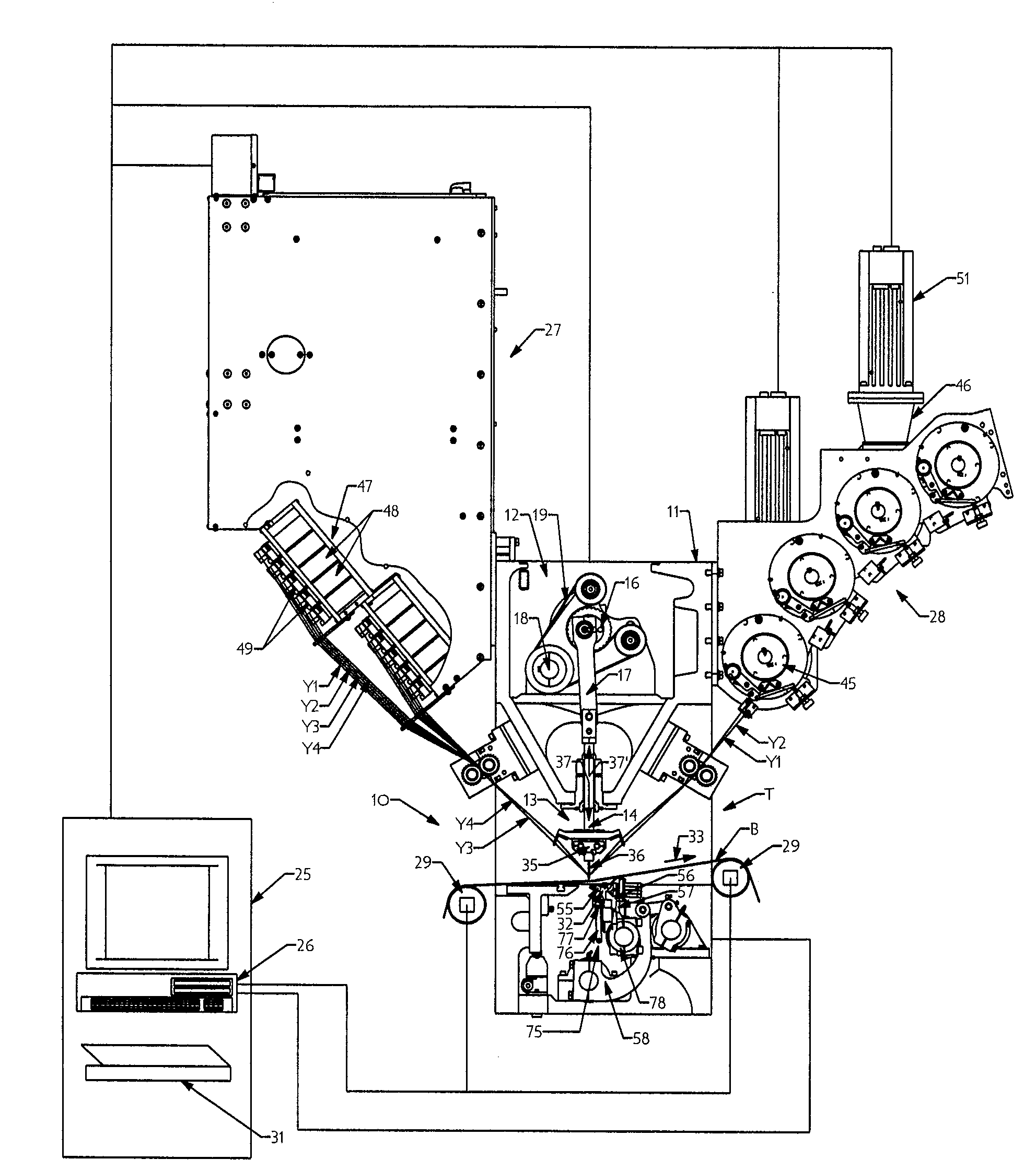

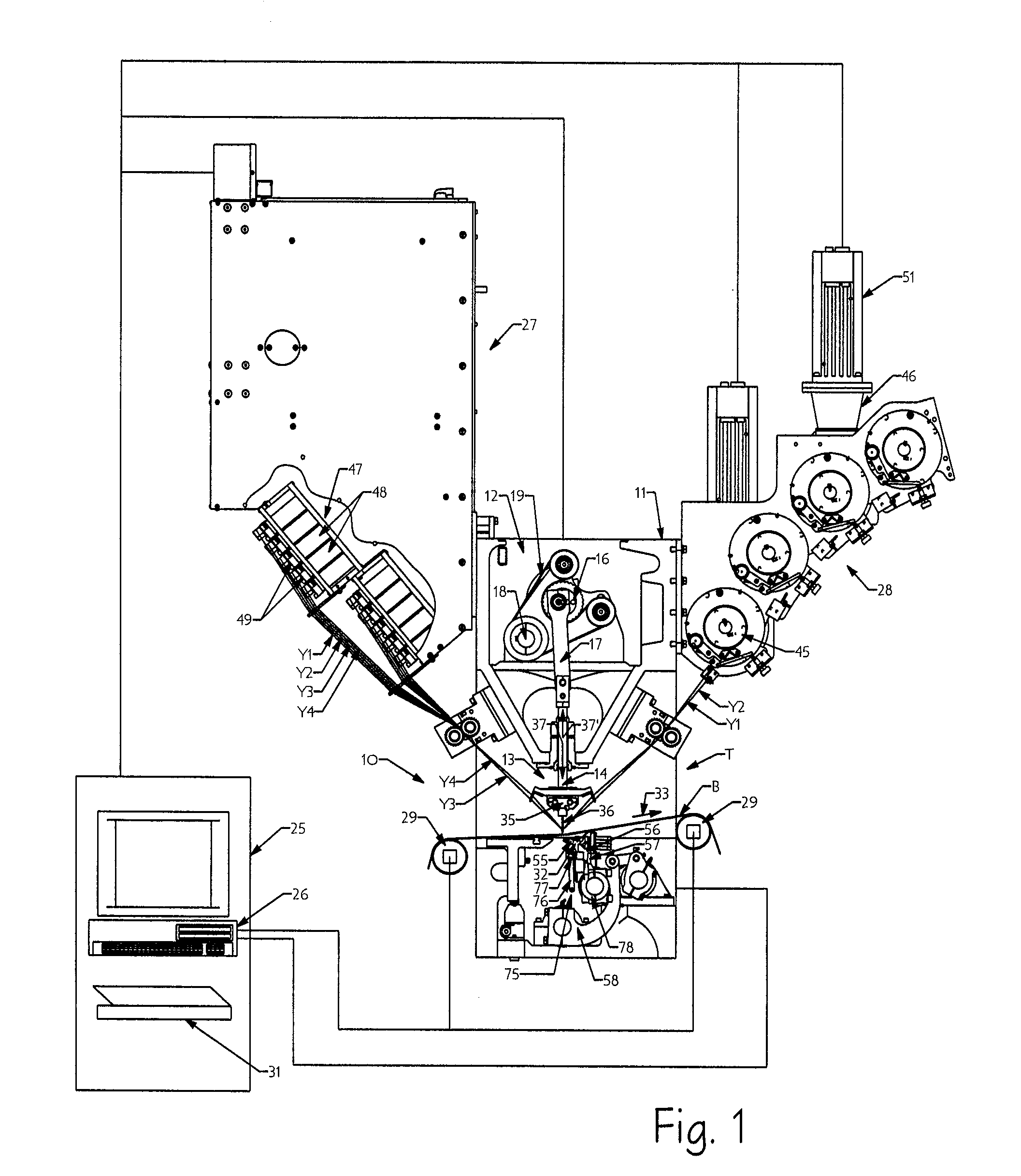

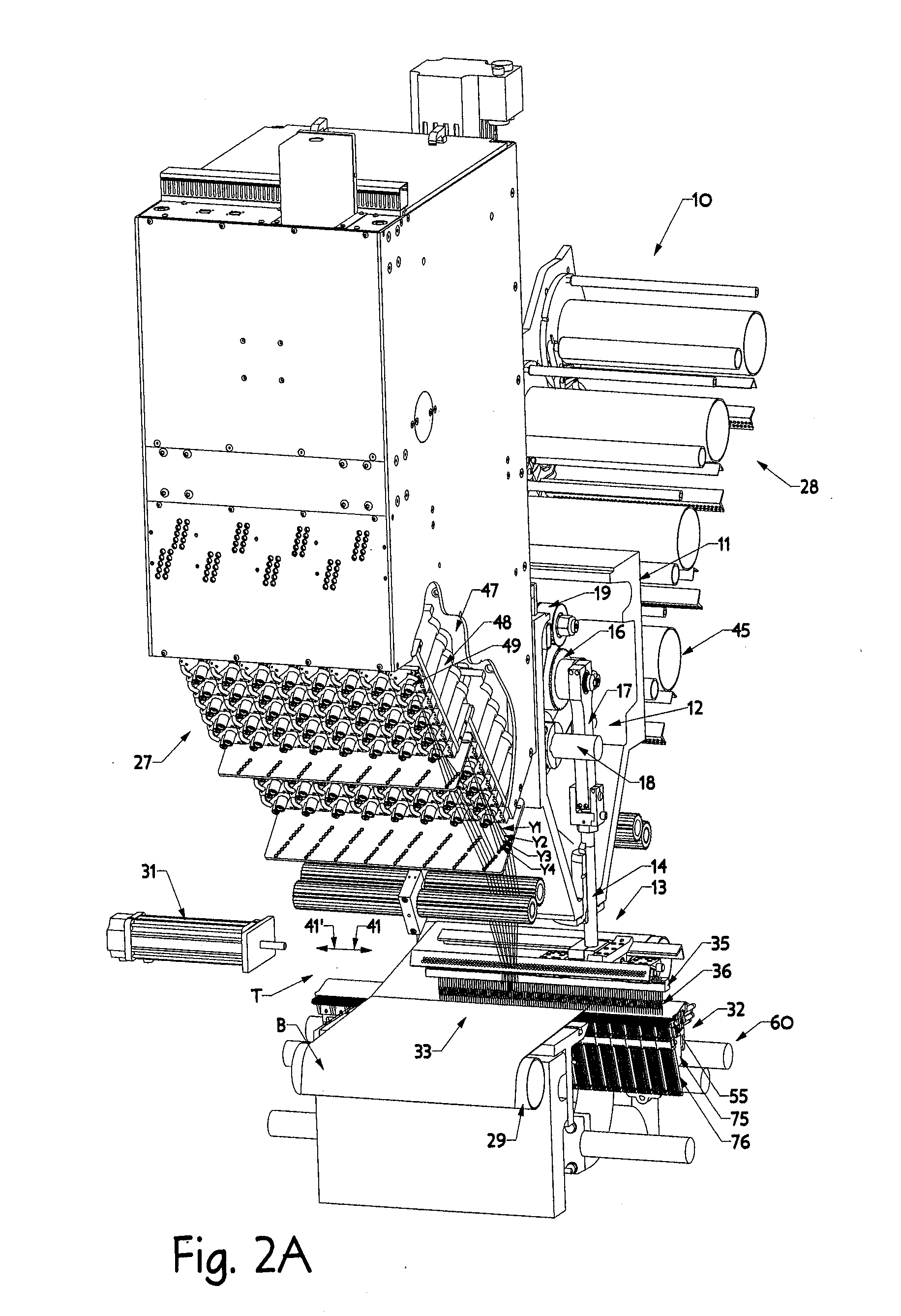

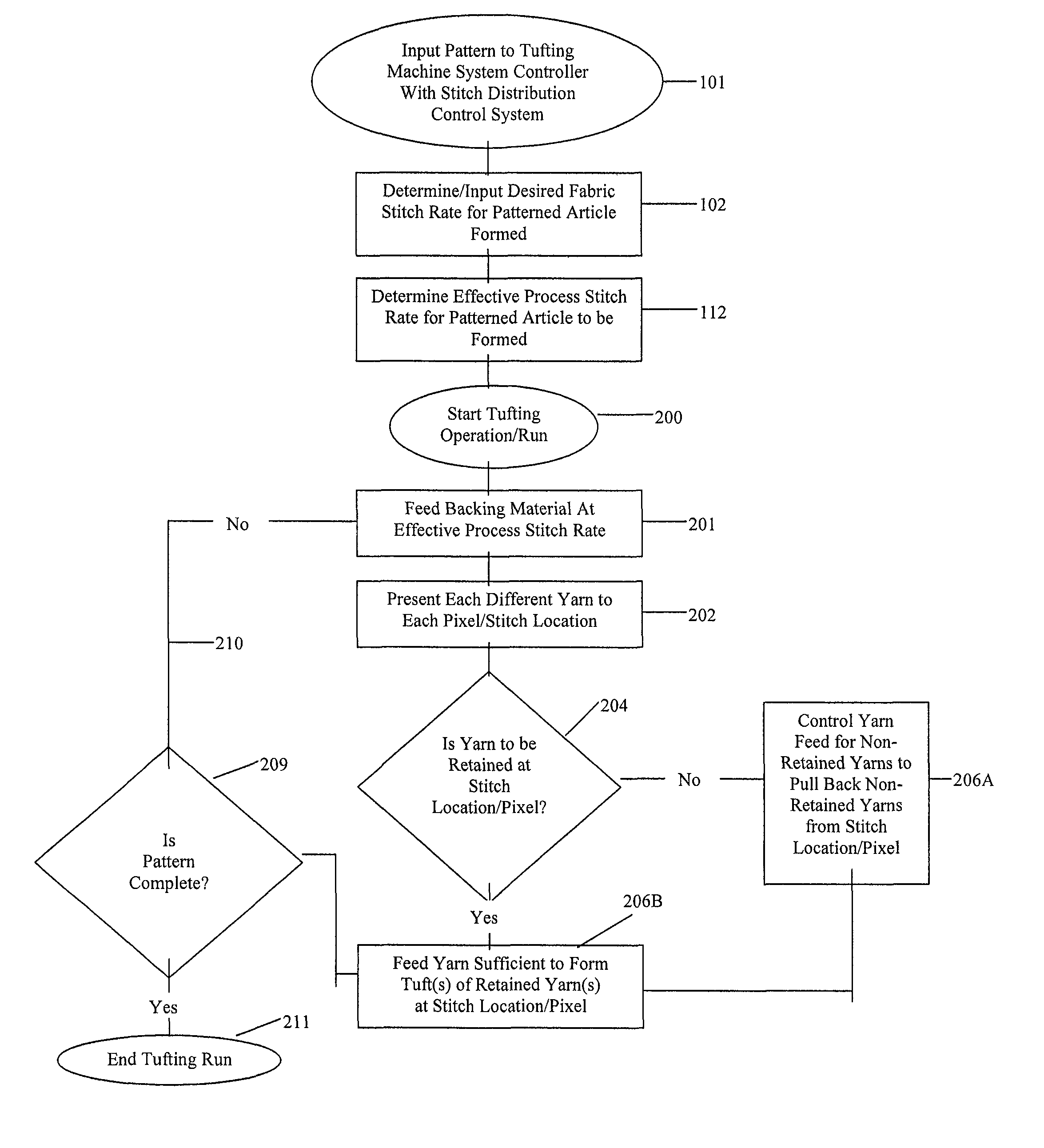

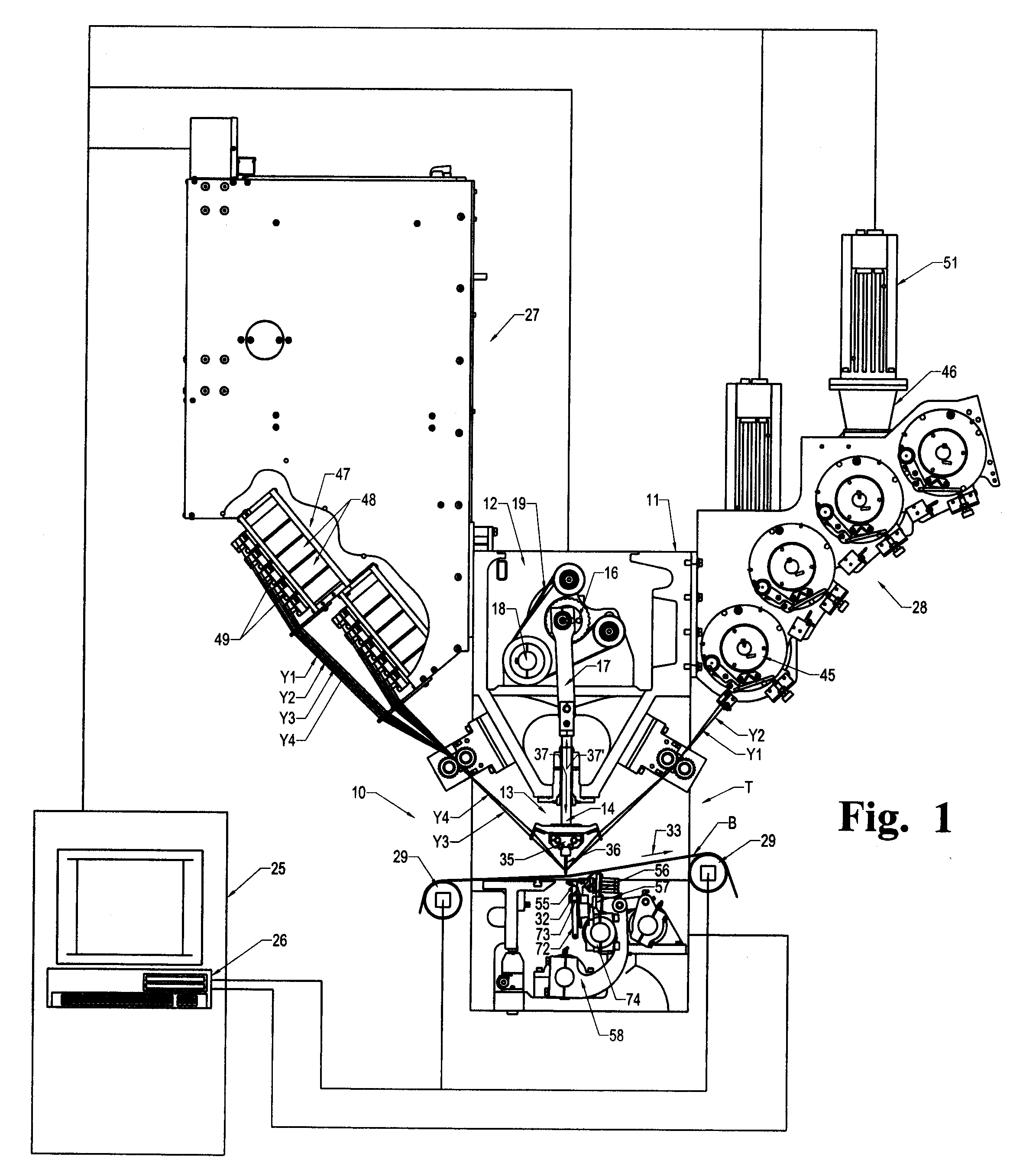

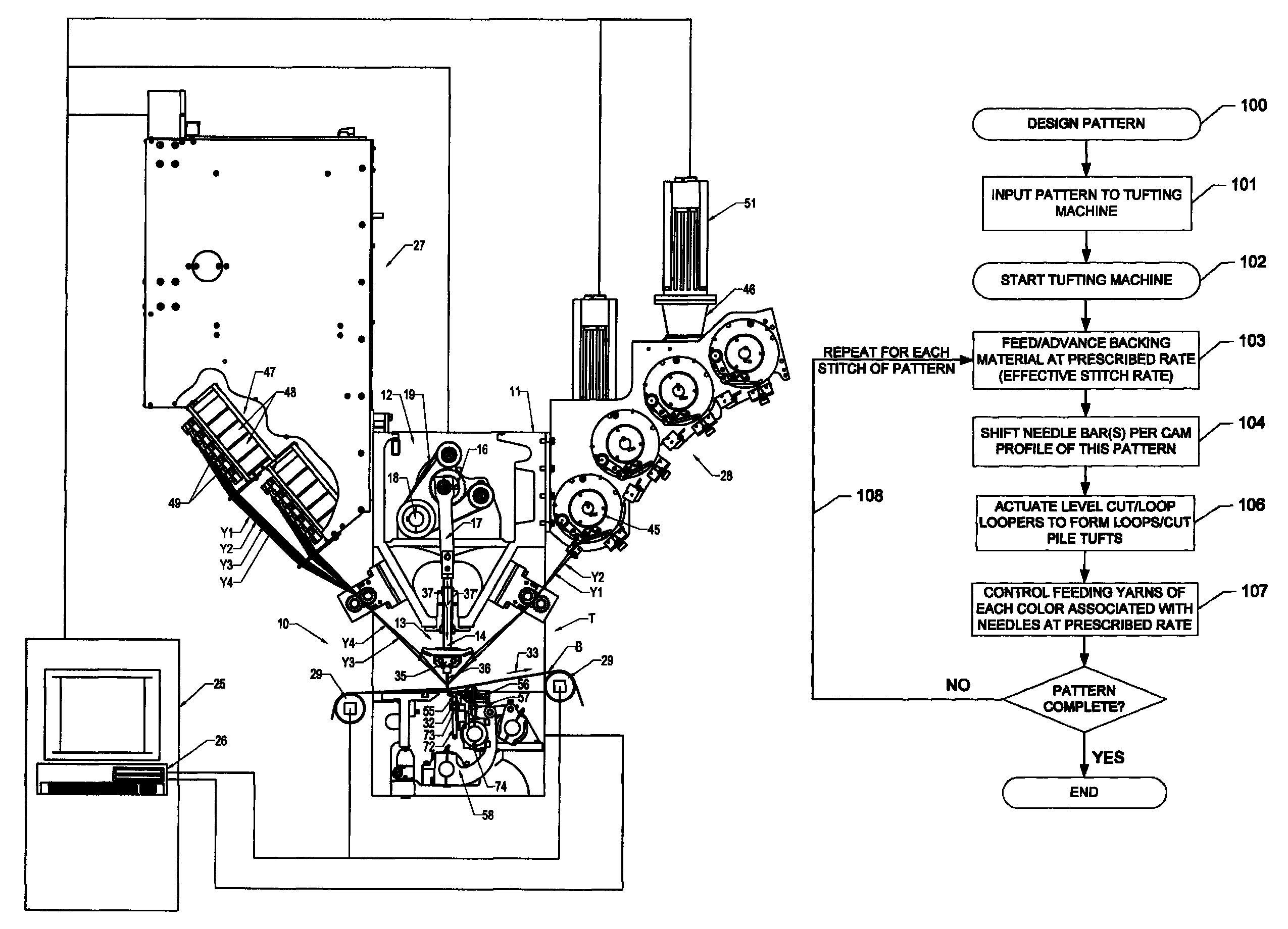

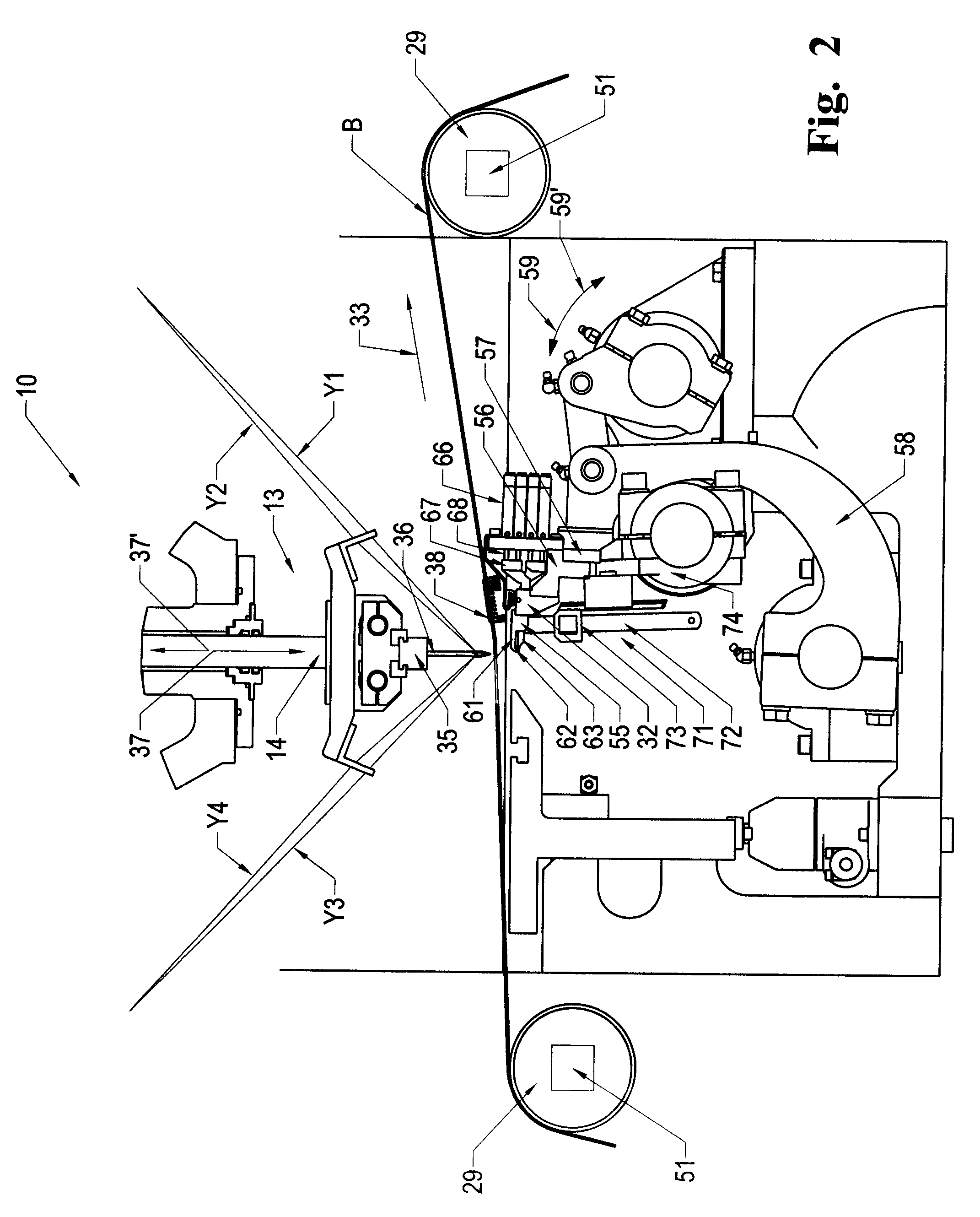

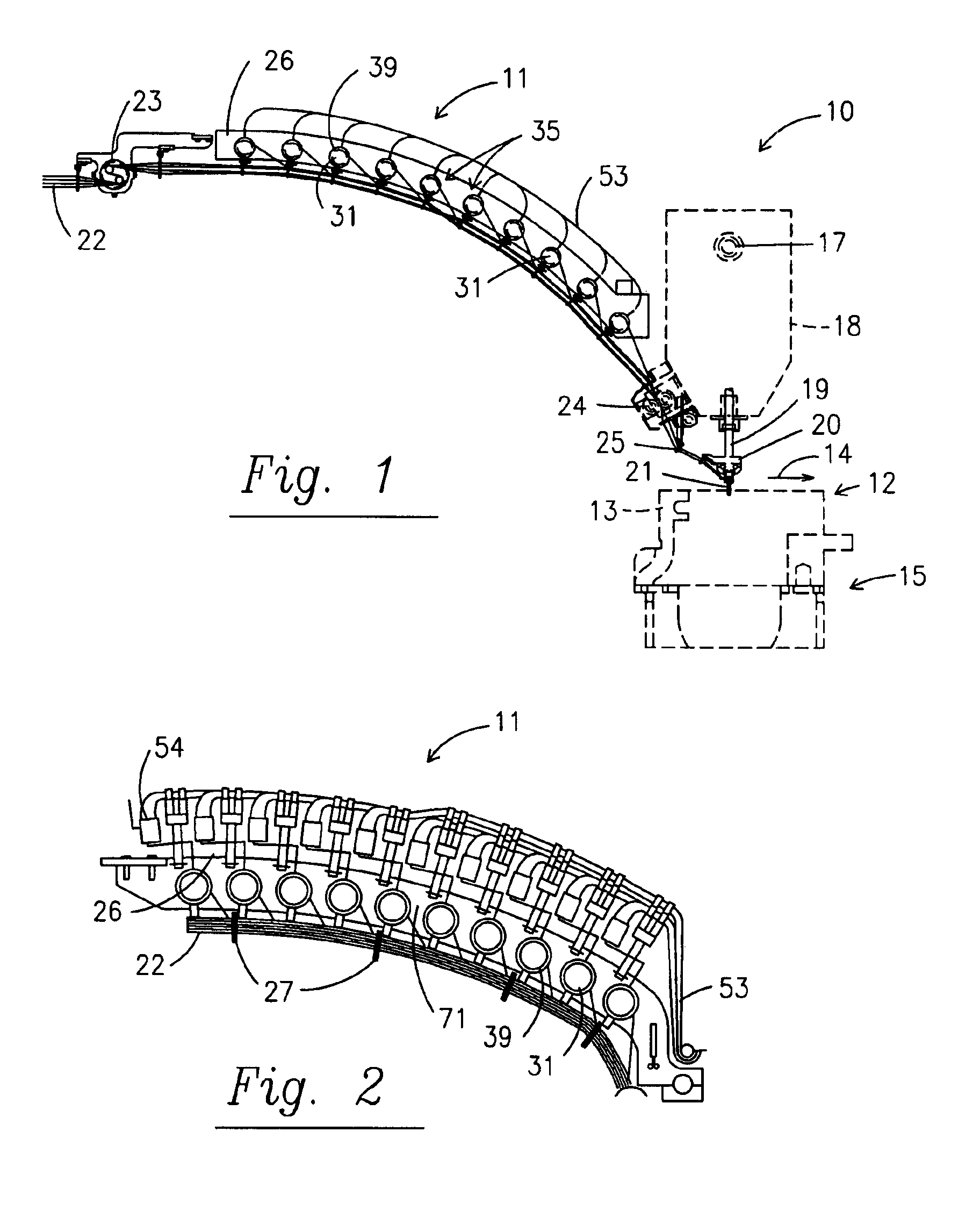

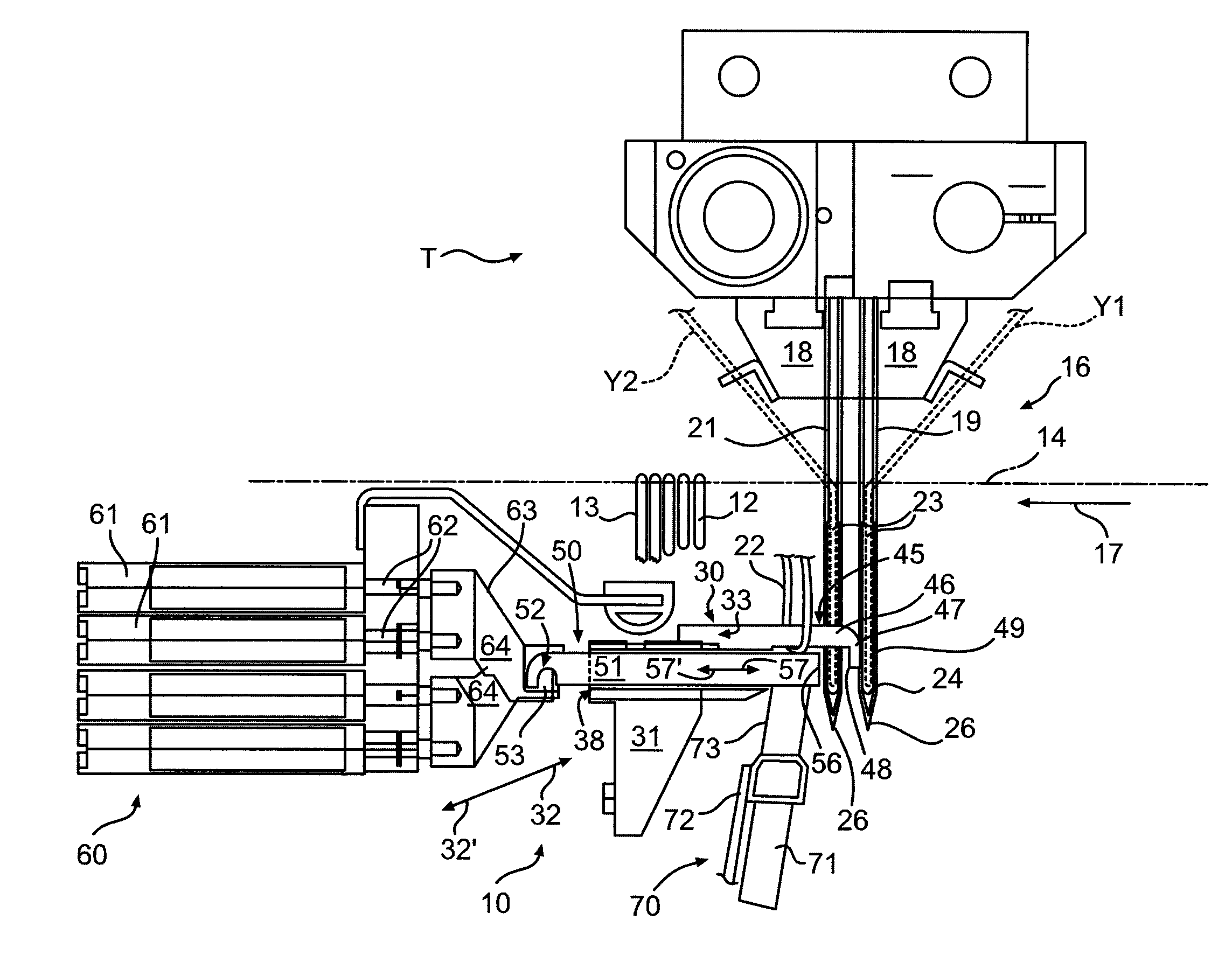

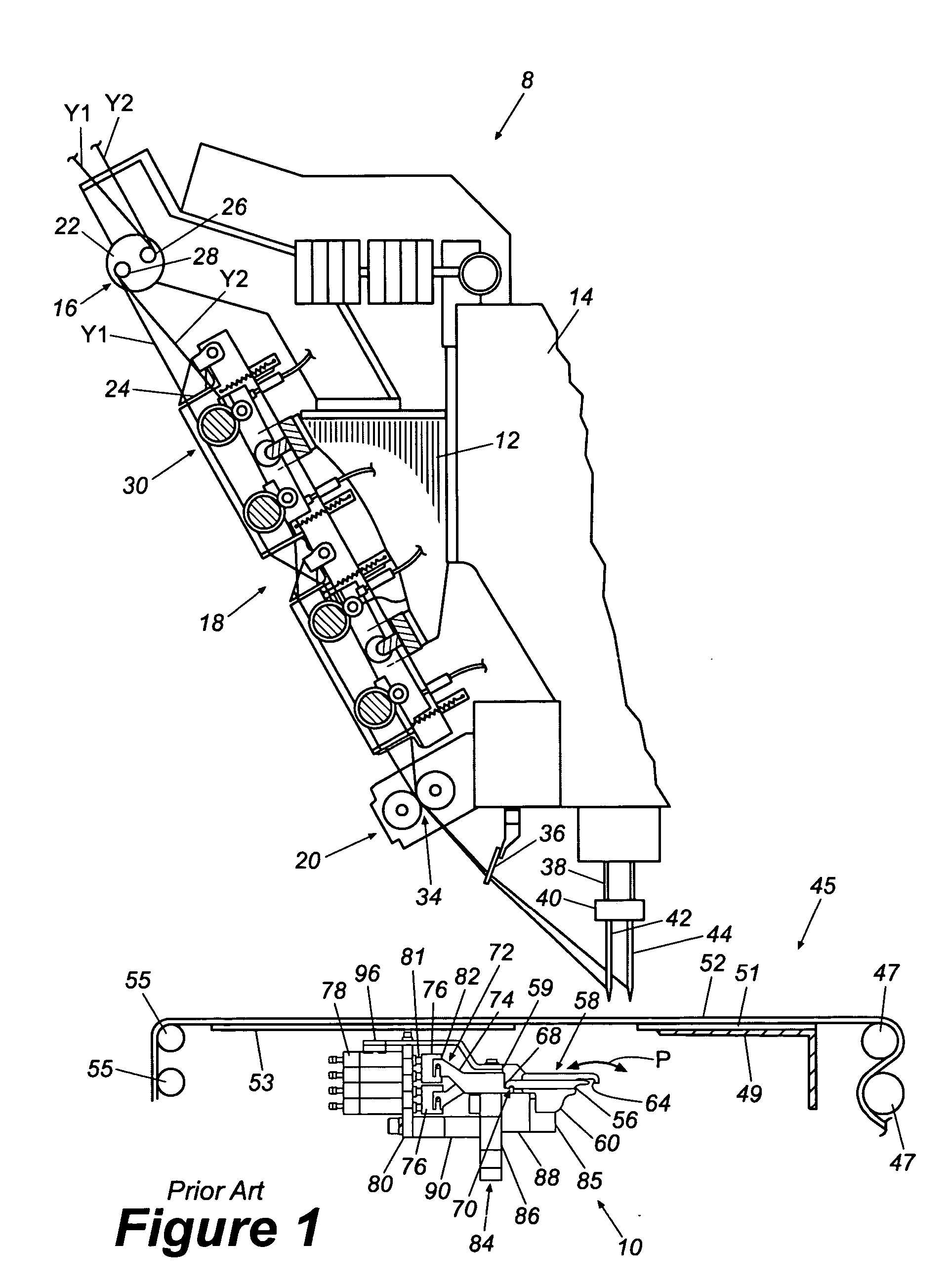

Stitch distribution control system for tufting machines

ActiveUS20090260554A1Sufficient enhanced densityHigh selectivityTufting apparatusYarnDistribution control

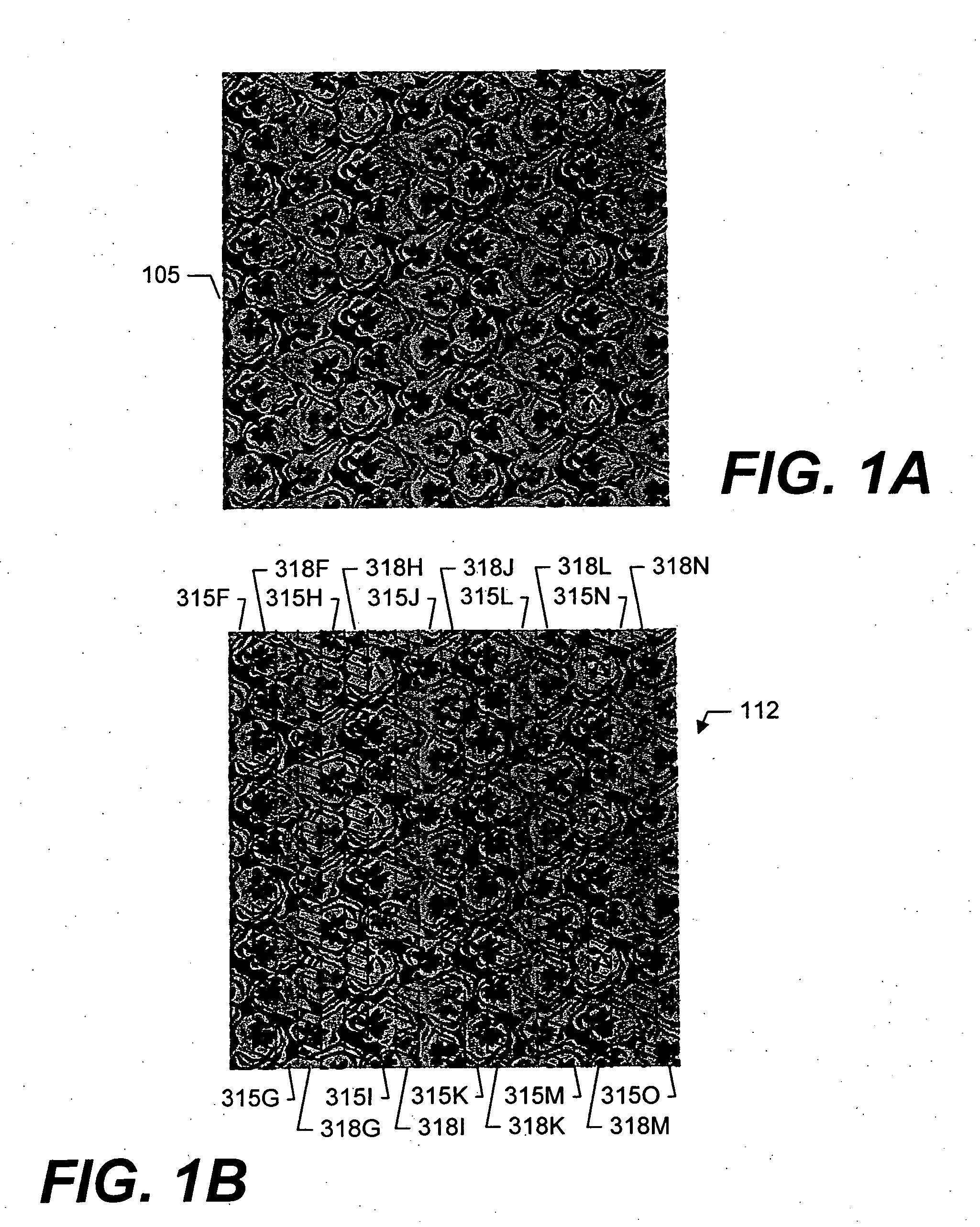

A stitch distribution control system for a tufting machine for controlling placement of yarns being fed to the needles of the tufting machine by yam feed mechanisms to form a desired pattern. A backing material is fed through the tufting machine at an increased stitch rate as the needles are shifted according to calculated pattern steps. A series of loopers or hooks engage and pick loops of yarns from the needles. The yarn feed mechanisms further can be controlled so that selected loops of yarns can be back-robbed so as to be hidden from view in the finished patterned tufted article.

Owner:CARD MONROE

Stitch distribution control system for tufting machines

ActiveUS8359989B2High selectivityEnable formationProgramme-controlled sewing machinesTufting apparatusYarnDistribution control

Owner:CARD MONROE

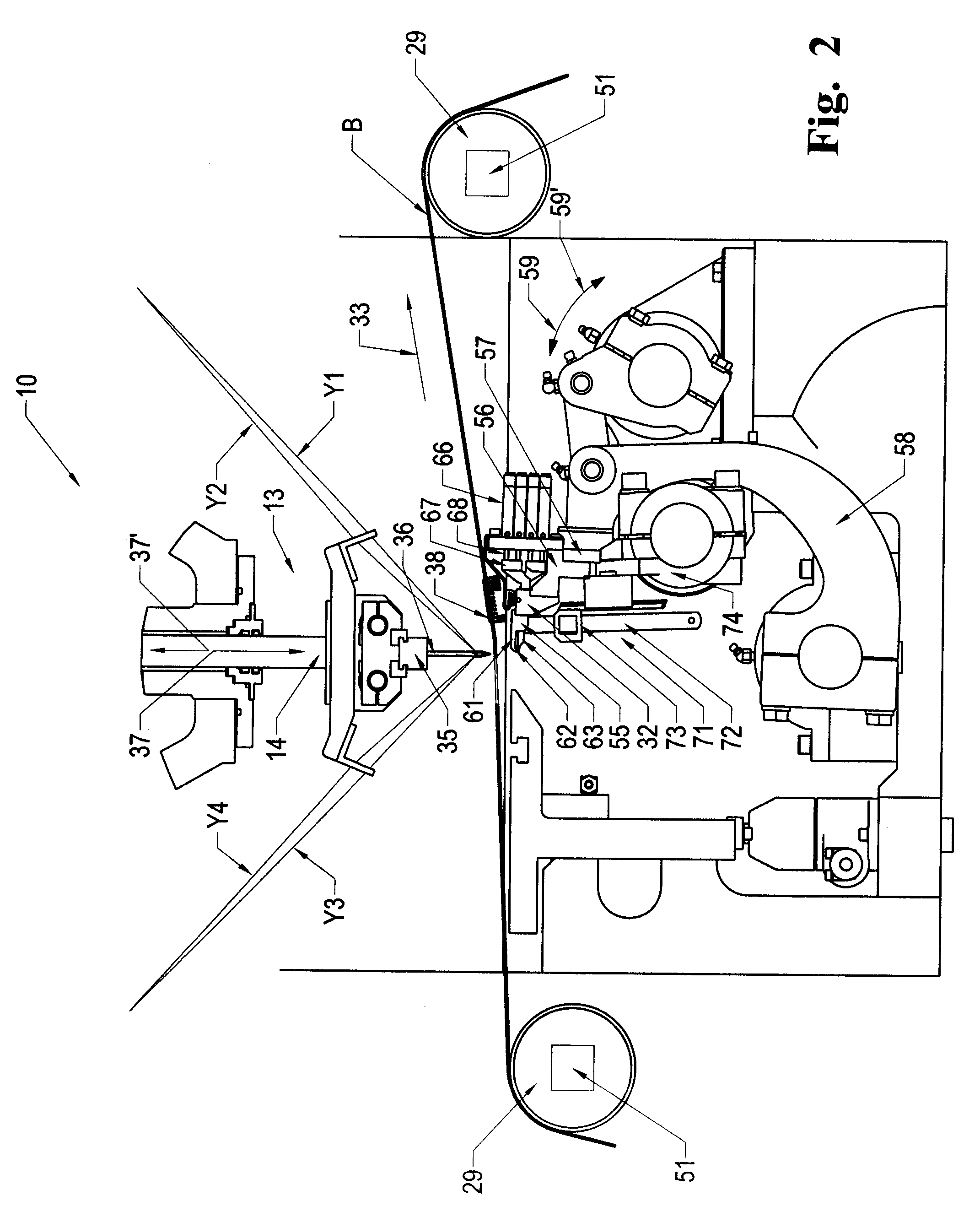

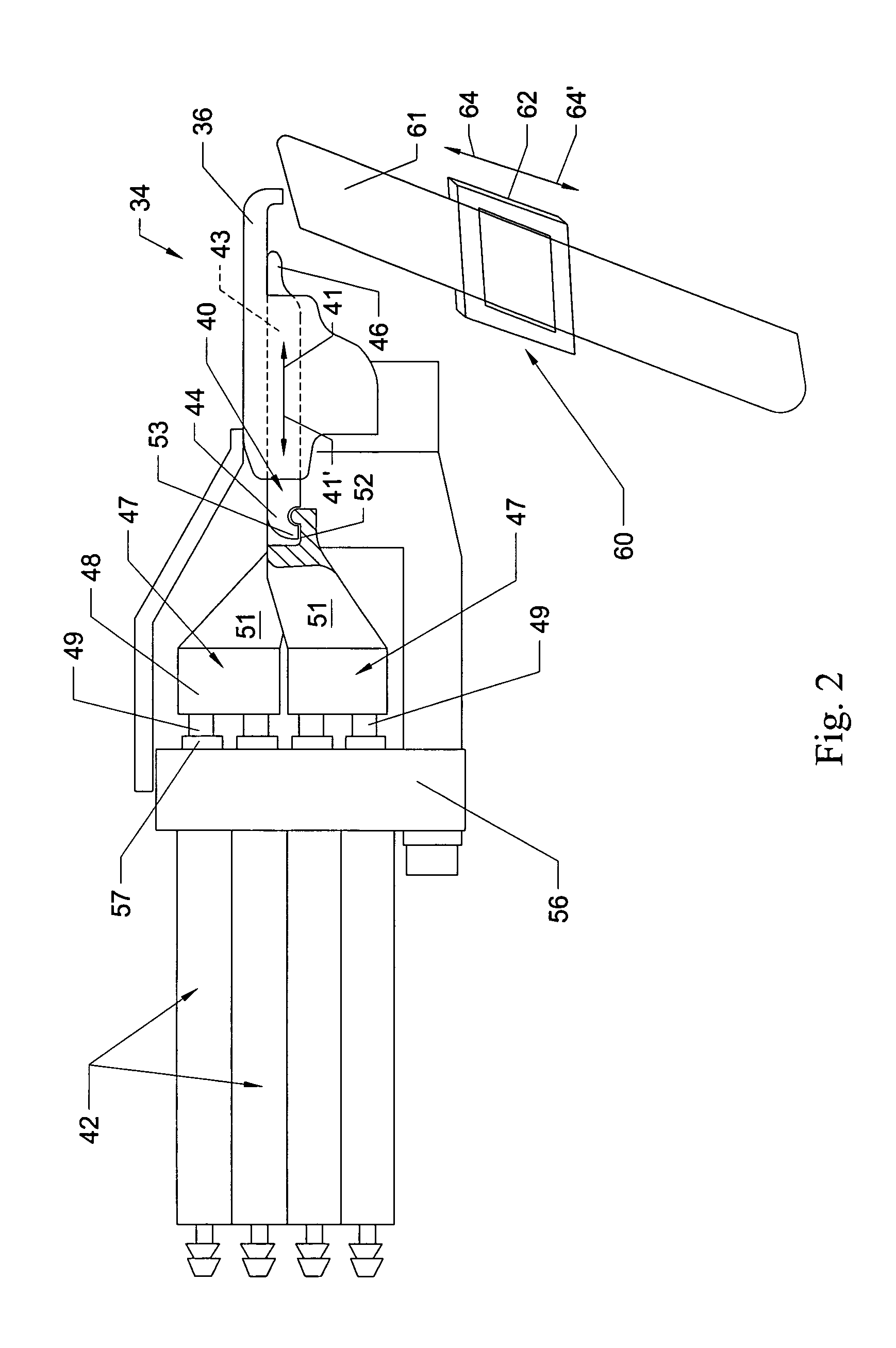

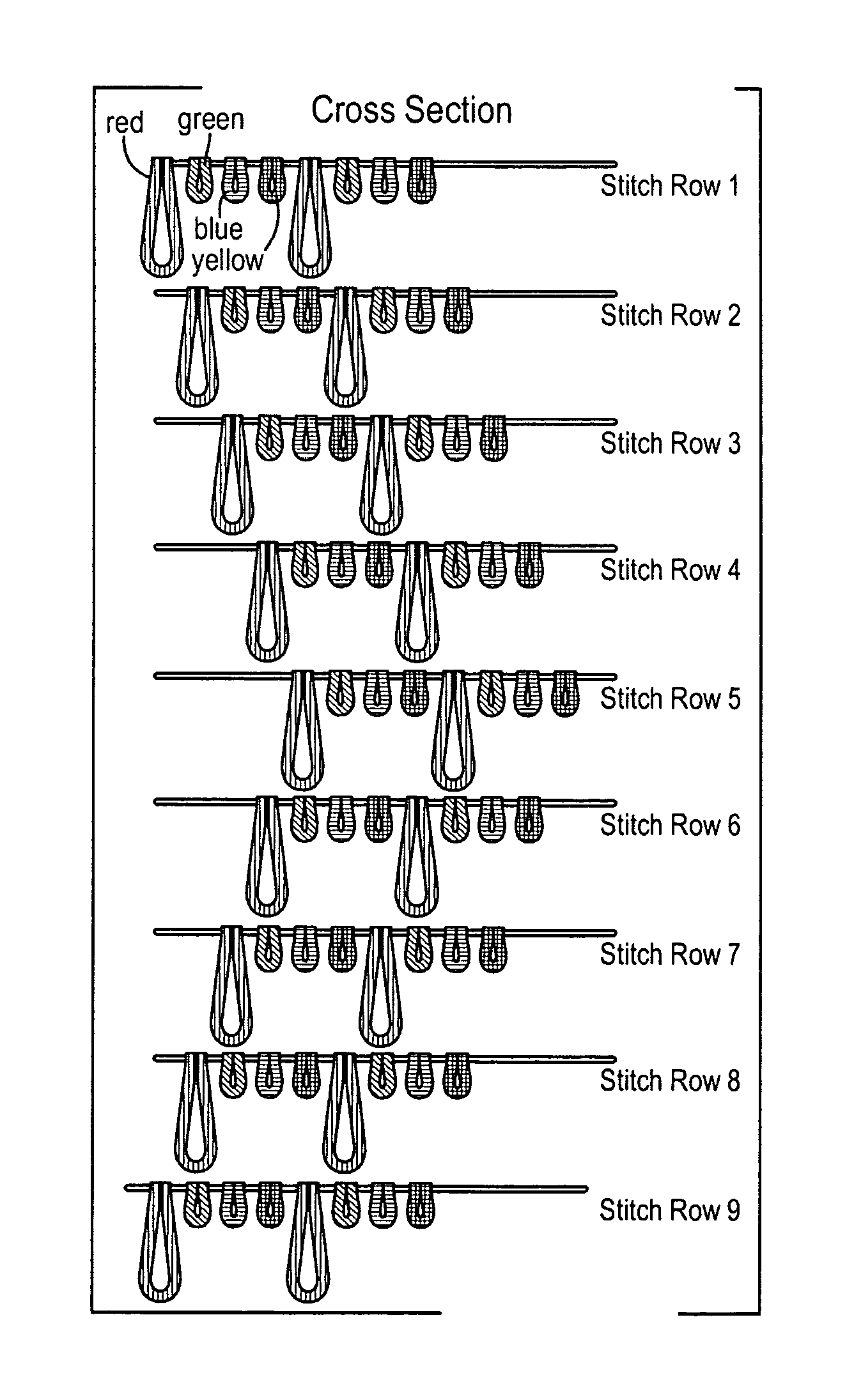

Yarn color placement system

A yarn color placement system for a tufting machine including a series of different color yarns being fed to the needles of the tufting machine by yarn feed mechanisms. A backing material is fed through the tufting machine at an increased stitch rate as the needles are shifted according to the programmed pattern steps. A series of level cut loop loopers or hooks engage and pick loops of yarns from the needles, with the clips of the level cut loop loopers or hooks being selectively actuated to form cut pile tufts, while the remaining loops of yarns can be back-robbed so as to be hidden from view in the finished patterned tufted article.

Owner:CARD MONROE

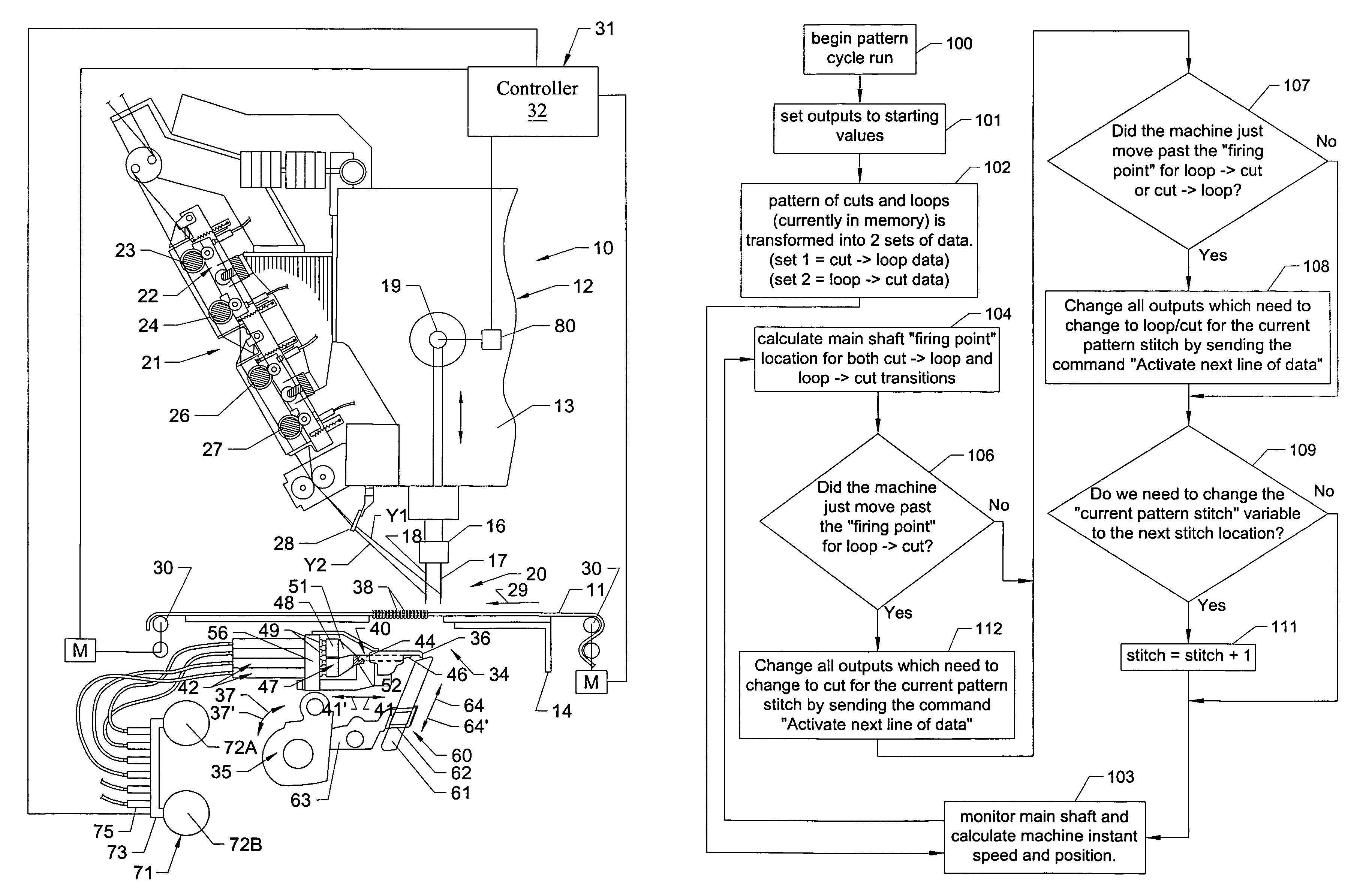

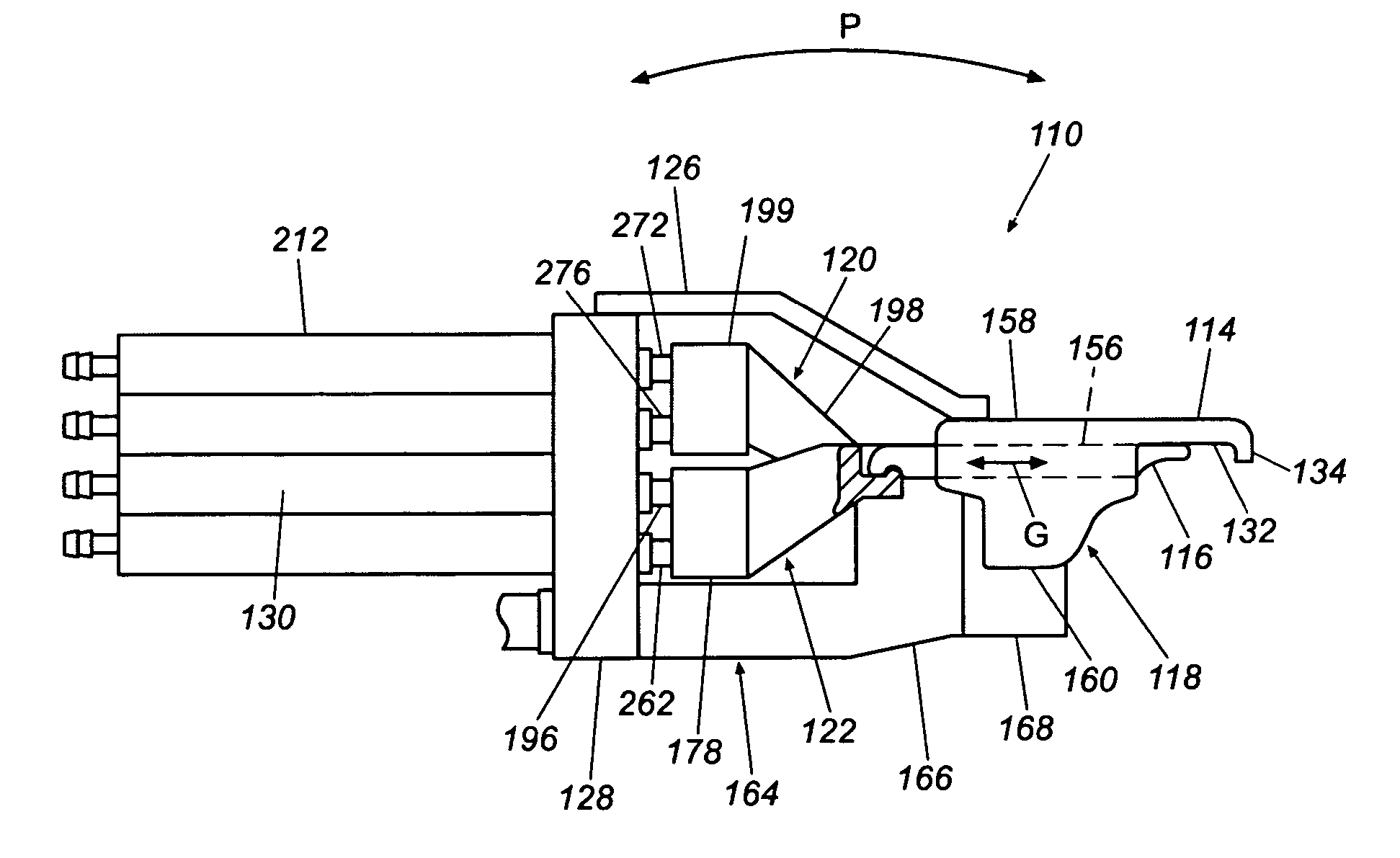

Control assembly for tufting machine

A tufting machine and a method of controlling a tufting machine for forming cut and loop pile tufts of yarns in a backing material that includes a hook assembly having a series of hooks / loopers and a series of clips independently moveable between extended and retracted positions. The movement of the clips between their extended and retracted positions is selectively activated to cause transitions from cut pile tufts to loop pile tufts and loop pile tufts to cut pile tufts according to programmed pattern information.

Owner:CARD MONROE

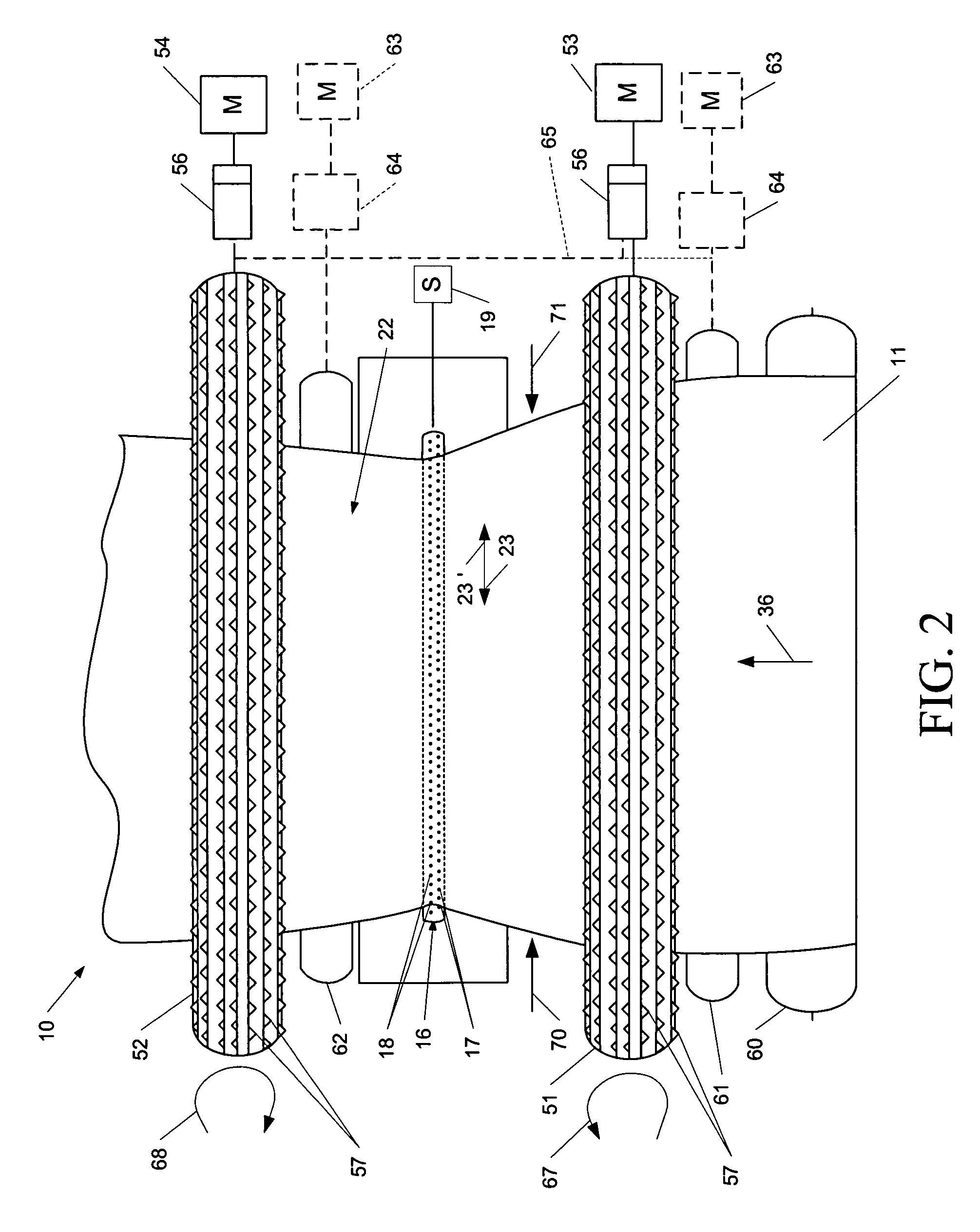

System and method for pre-tensioning backing material

ActiveUS7216598B1Compensation differenceMisalignment problemTufting apparatusMachine controlControl system

A tufting machine control system for controlling the tension applied to a backing material as it enters the tufting zone of the tufting machine, including a pair of driven backing feed rolls for feeding the backing material. The drive motors for the backing feed rolls are monitored by the control system and are adjusted to control the amount of tension applied to the backing material as it enters the tufting zone of the tufting machine.

Owner:CARD MONROE

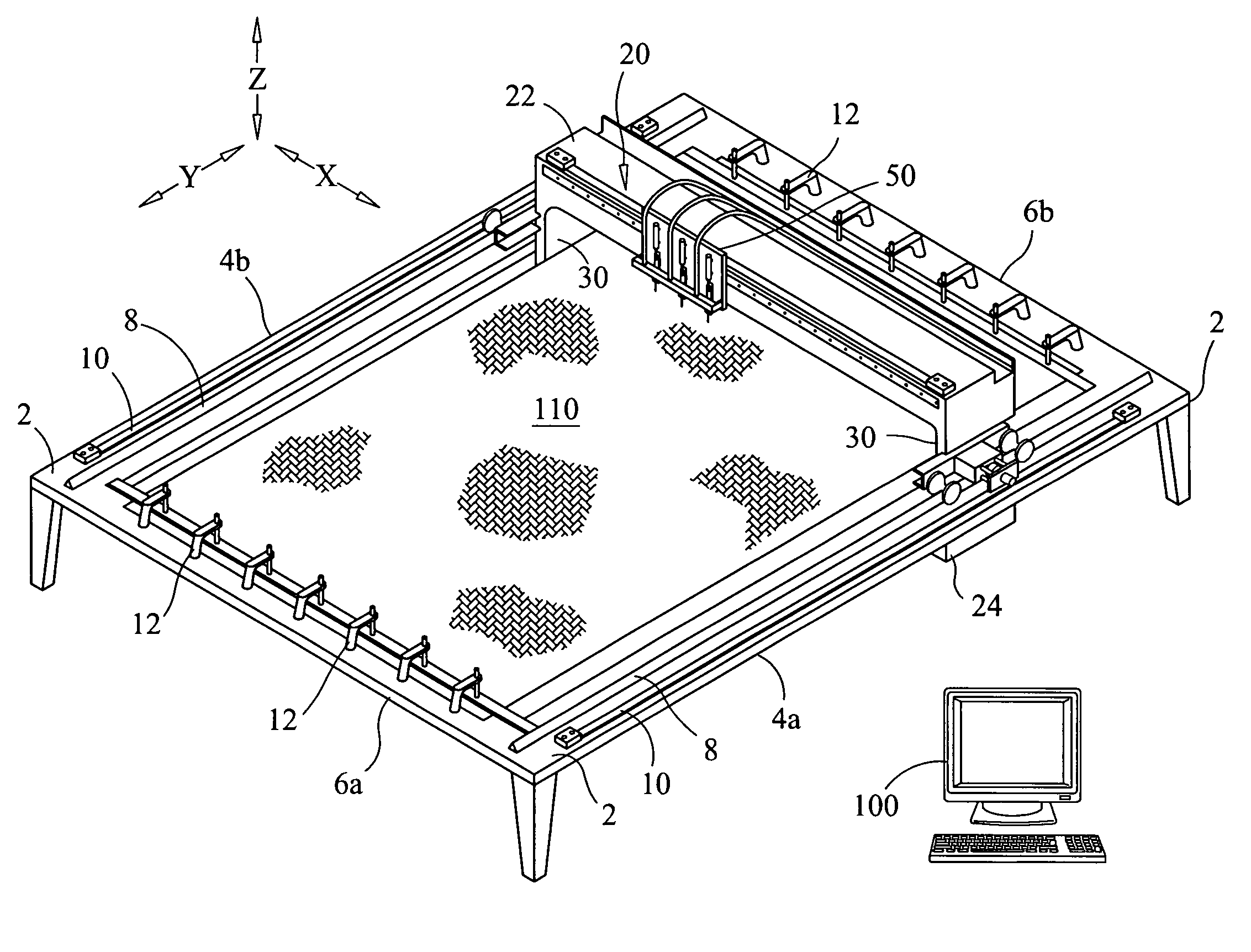

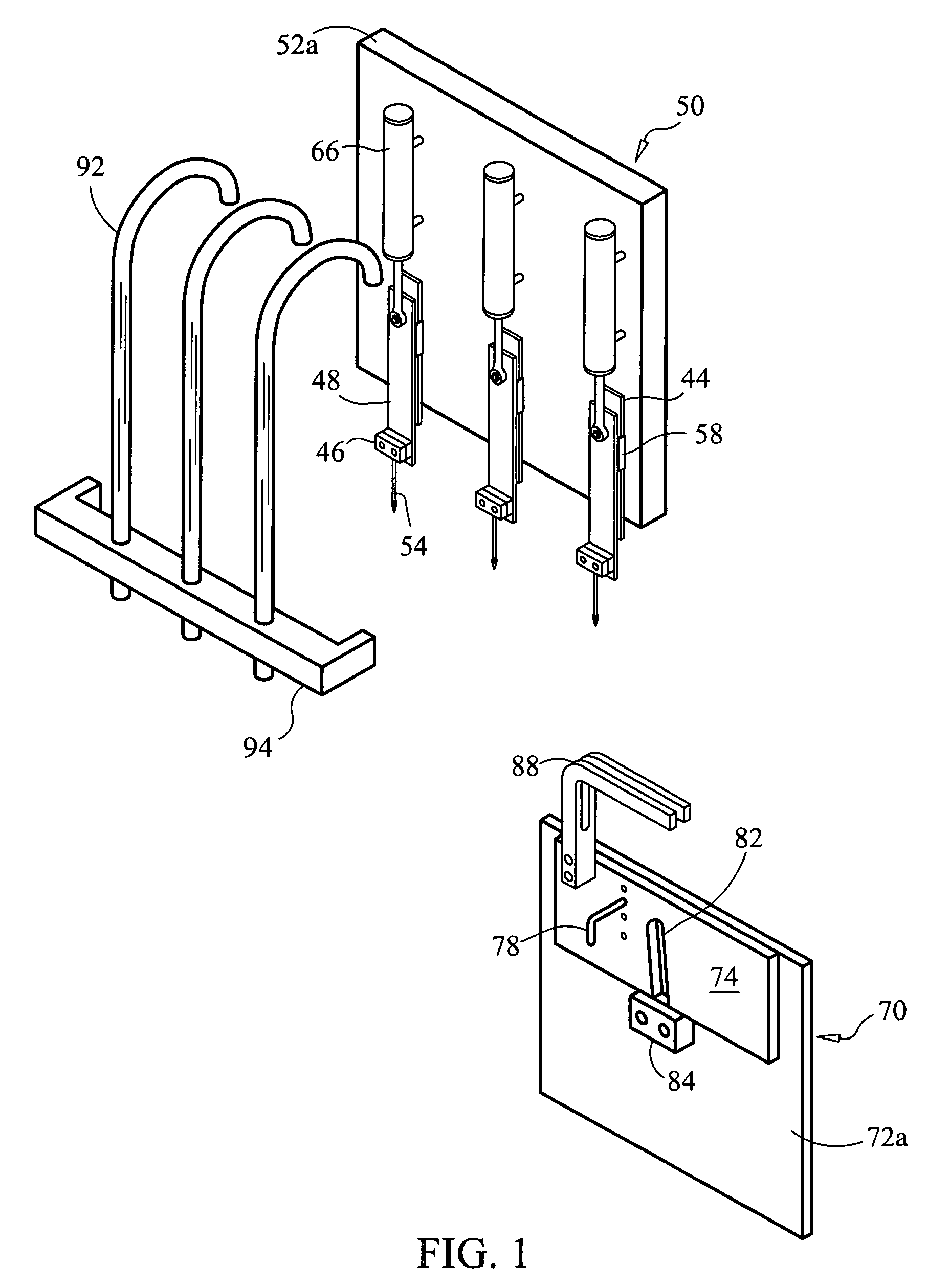

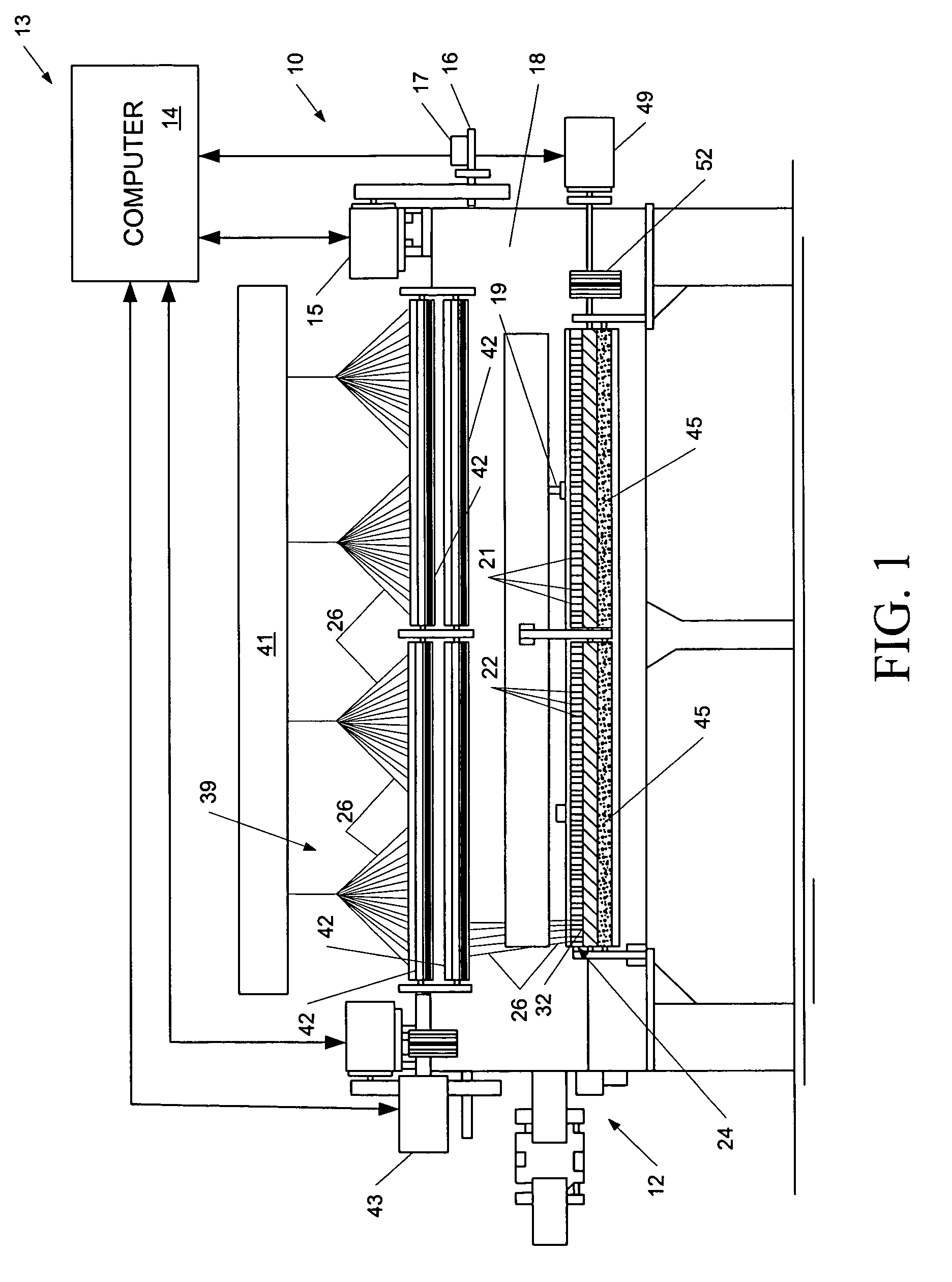

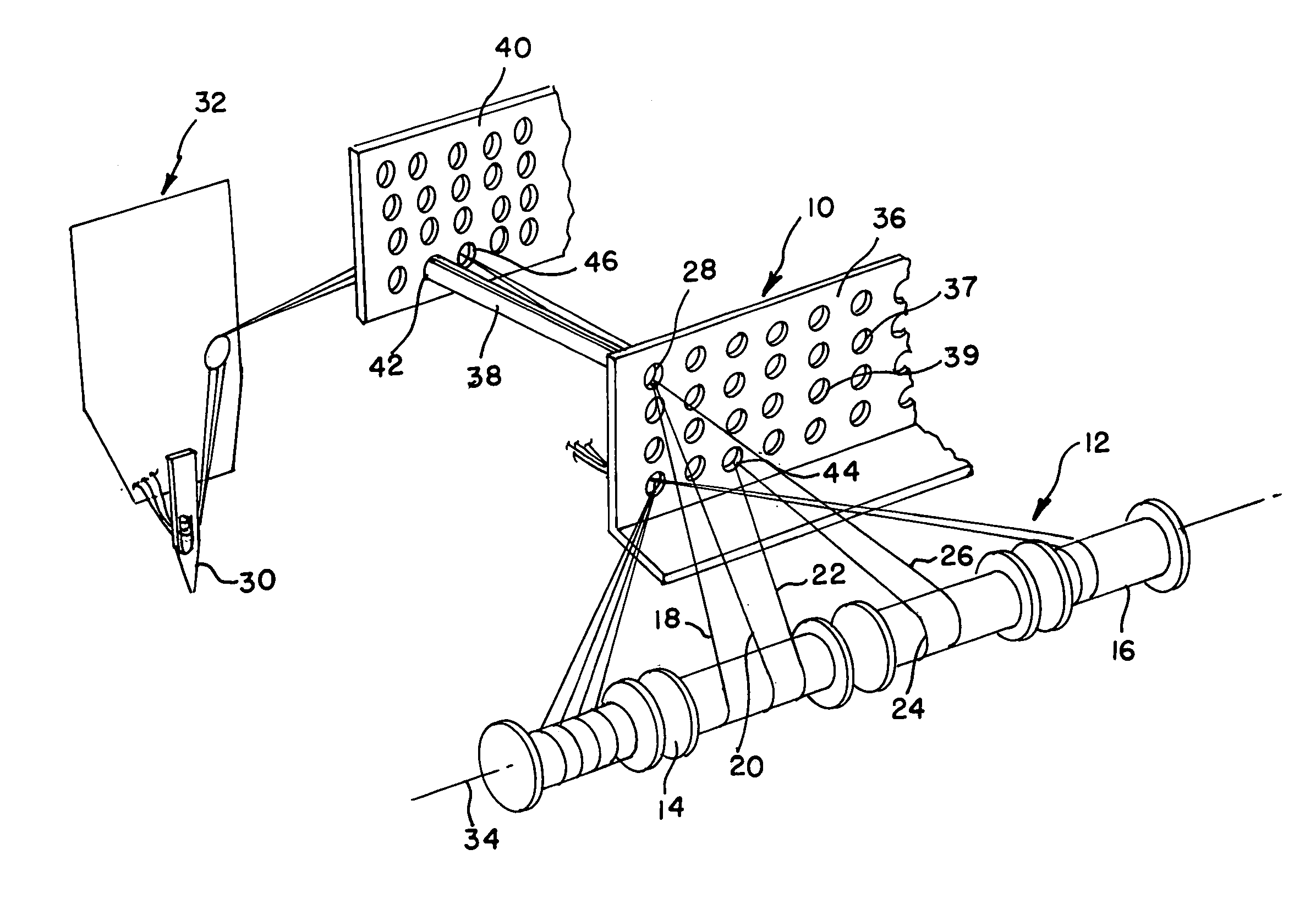

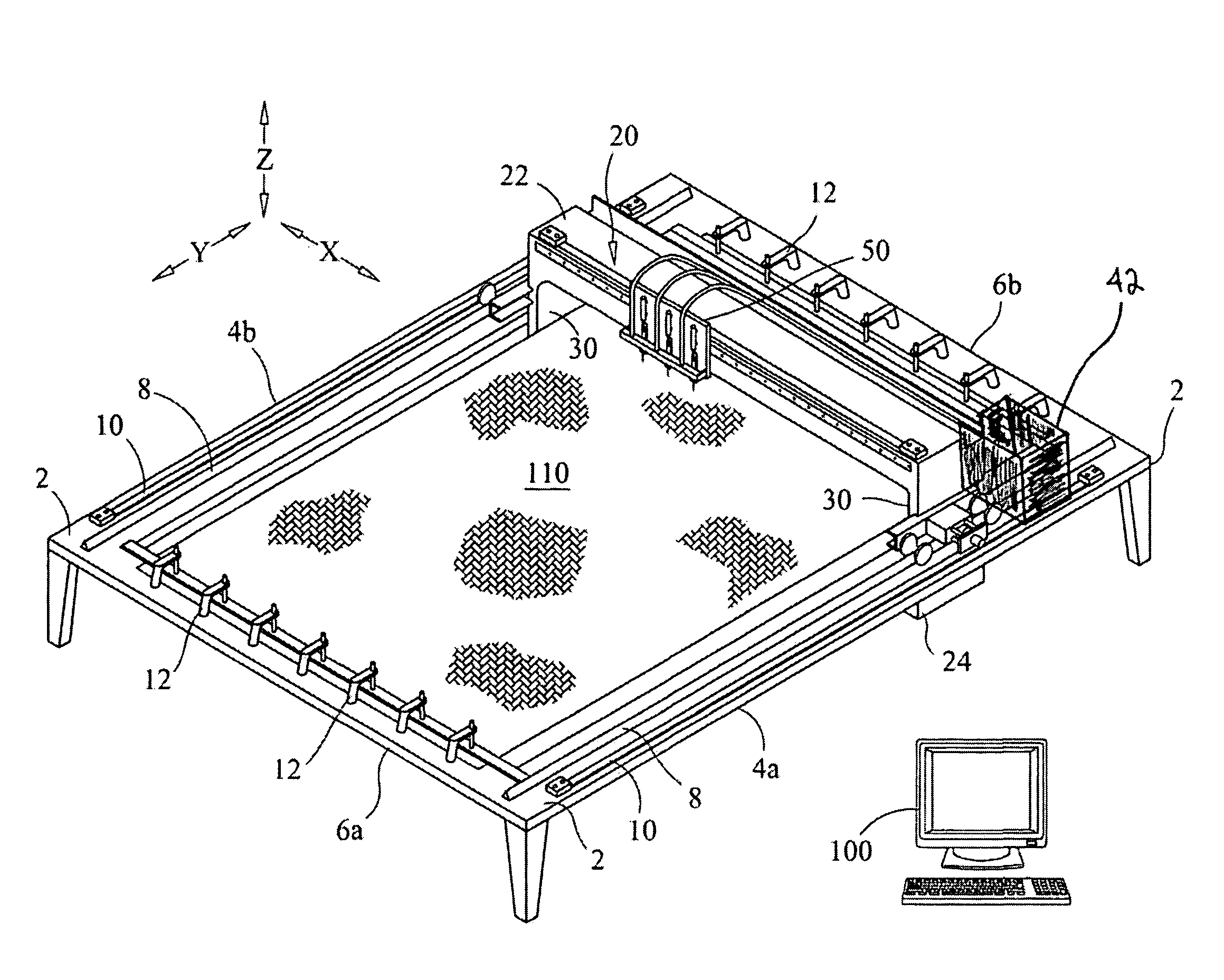

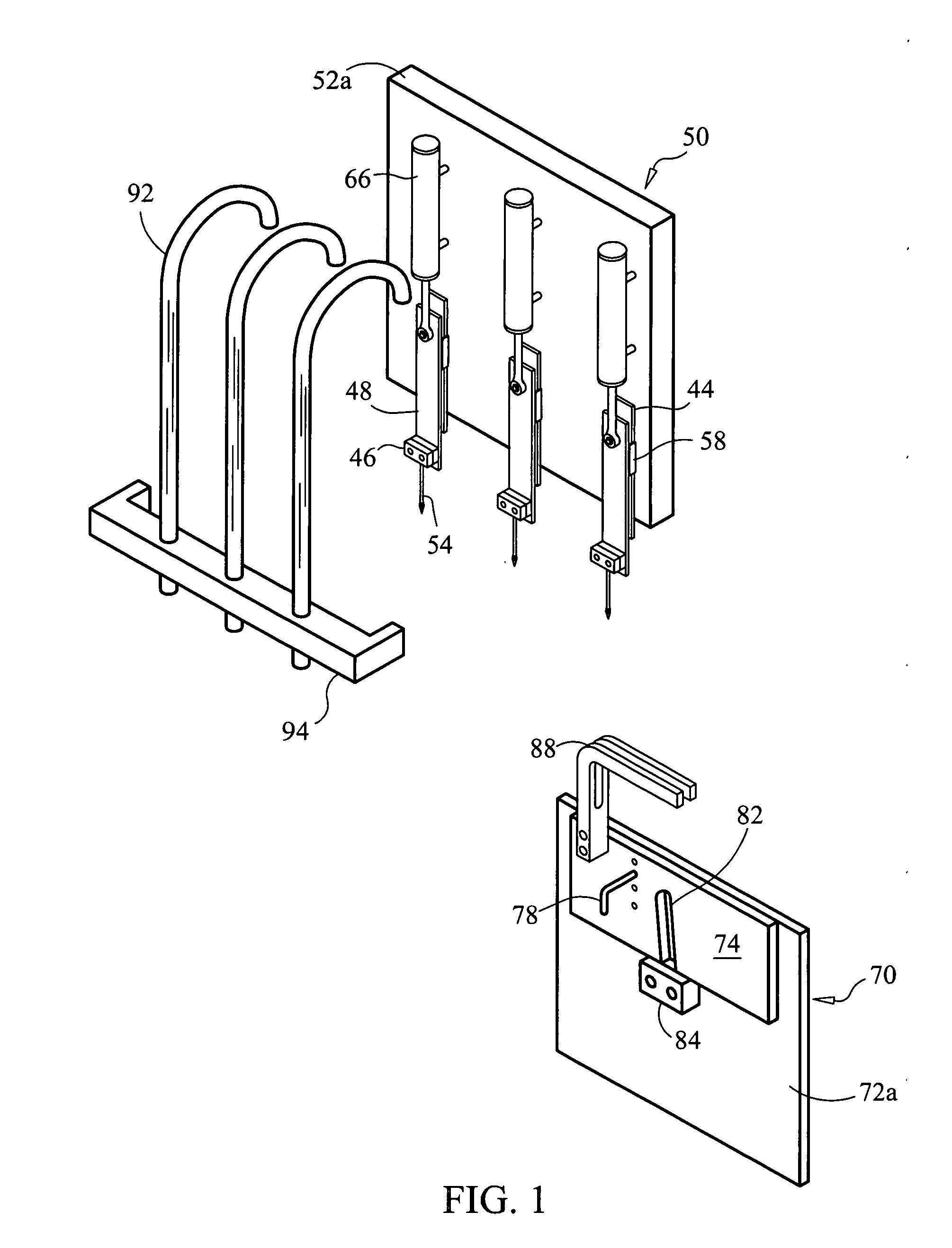

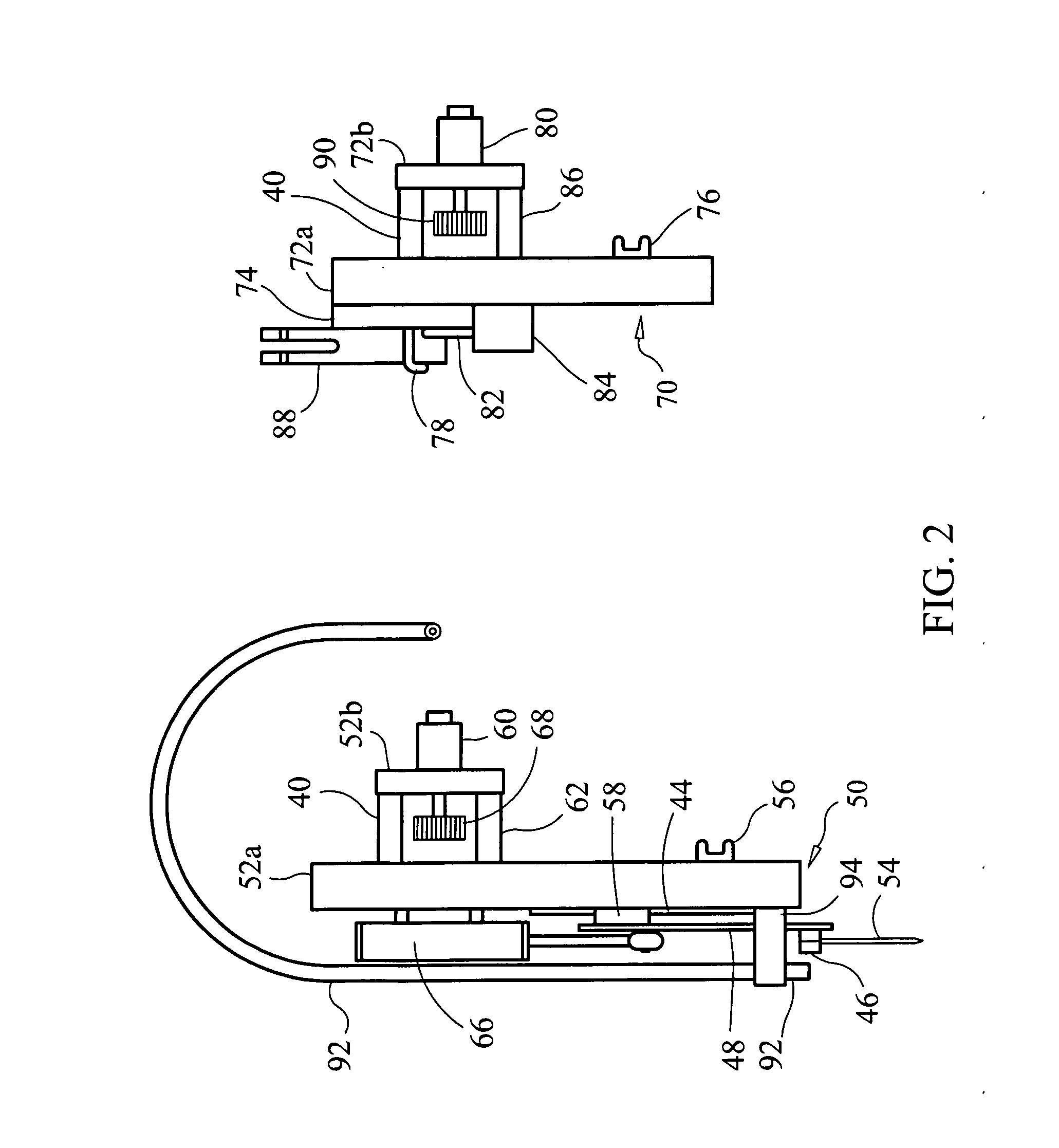

Tufting machine for producing athletic turf having a graphic design

ActiveUS7814850B2Reduce positioning accuracyEfficient constructionTufting apparatusSewing-machine control devicesGraphicsYarn

A tufting machine capable of producing individual articles of athletic turf bearing precise graphic patterns is disclosed. The machine includes a support frame to which a backing material is statically held, a tufting frame that spans above and below the backing and is computer-controlled to travel along the support frame, a yarn-inserting needle carriage disposed above the backing along the tufting frame and a yarn-catching looper carriage disposed below the backing along the tufting frame. The carriages are computer-controlled to asynchronously shift relative to each other as may be necessary for their individual yarn-inserting components and yarn-catching components to cooperate.

Owner:SIGNATURE BANK OF GEORGIA +1

Yarn color placement system

ActiveUS8141505B2Increased and denser effective process stitch rateHigh densityTufting apparatusYarnEngineering

A yarn color placement system for a tufting machine including a series of different color yarns being fed to the needles of the tufting machine by yarn feed mechanisms. A backing material is fed through the tufting machine at an increased stitch rate as the needles are shifted according to the programmed pattern steps. A series of level cut loop loopers or hooks engage and pick loops of yarns from the needles, with the clips of the level cut loop loopers or hooks being selectively actuated to form cut pile tufts, while the remaining loops of yarns can be back-robbed so as to be hidden from view in the finished patterned tufted article.

Owner:CARD MONROE

Method and apparatus for forming variable loop pile over level cut loop pile tufts

A tufting machine that includes spaced rows of needles of inserting yarns into a backing material. The needles are engaged by opposed loopers and level cut loop pile hooks that pass between one another so as to engage the opposite row of needles for forming cut pile and loop pile tufts of yarns in the backing material.

Owner:CARD MONROE

Gate apparatus for tufting loop and cut pile stitches

InactiveUS7222576B2Efficiently employedTufting apparatusLoop takersEngineeringMechanical engineering

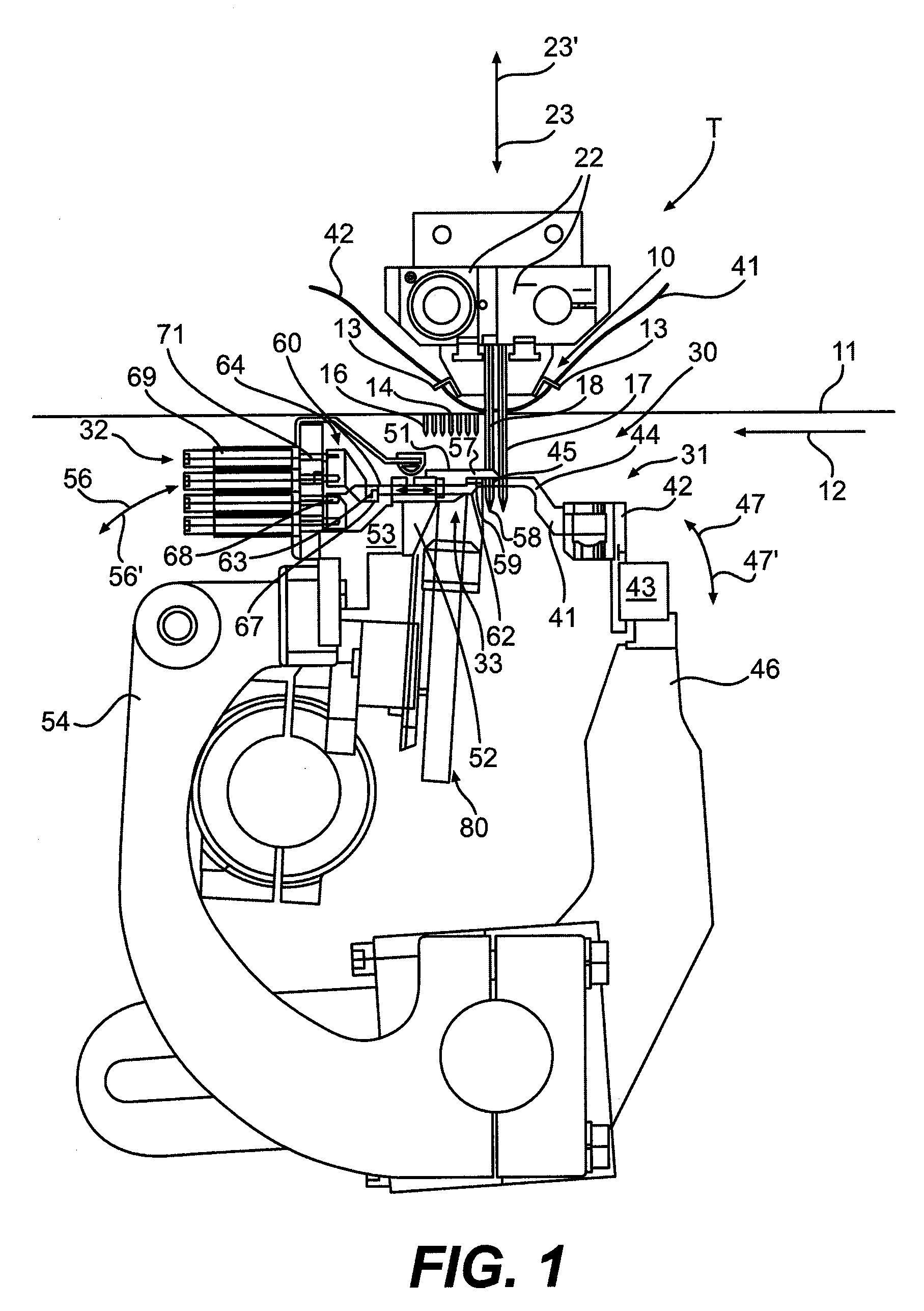

A gated looper apparatus has an array of individually mounted pressurizable air cylinders with piston rods acting against biased slider bars in communication with looper gates. Baising elements are mounted external of pneumatic cylinders about slider bars with protective ferules to provide greater responsiveness and ease of maintenance.

Owner:TUFTCO

Servo motor driven scroll pattern attachments for tufting machine with computerized design system and methods of tufting

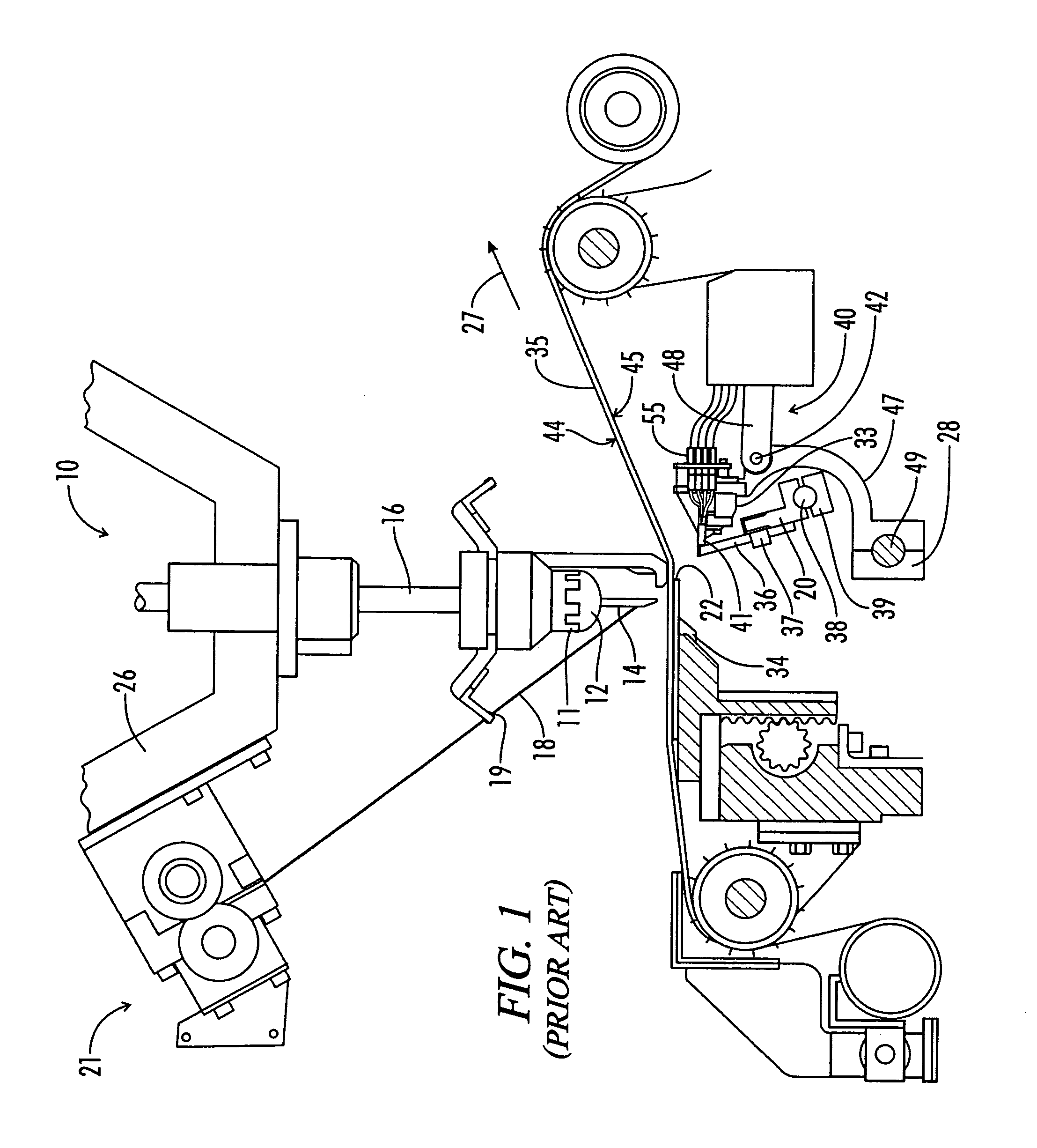

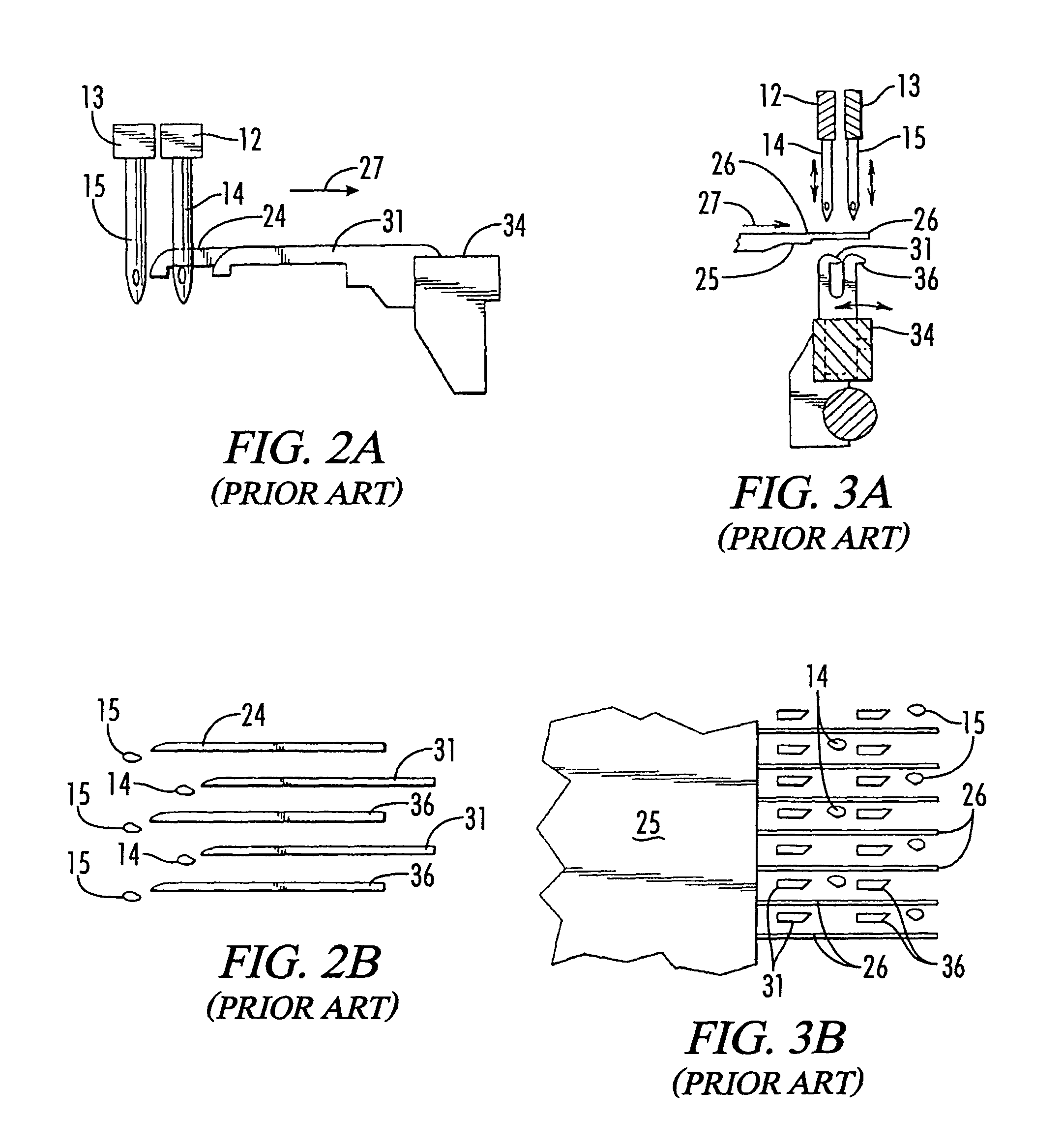

InactiveUS6877449B2Minimize the differenceEliminate needProgramme-controlled sewing machinesTufting apparatusYarnMotor drive

Owner:TUFTCO

Tufting machine and process for variable stitch rate tufting

A tufting machine as disclosed with a variable yarn feed mechanism and a method for tufting patterns with yarns from two rows of needles offset longitudinally from one another in a fashion that the different stitch lengths are selected in a fashion that the yarns from each row of needles are complementary to the other and maintain a consistent stitch density.

Owner:TUFTCO

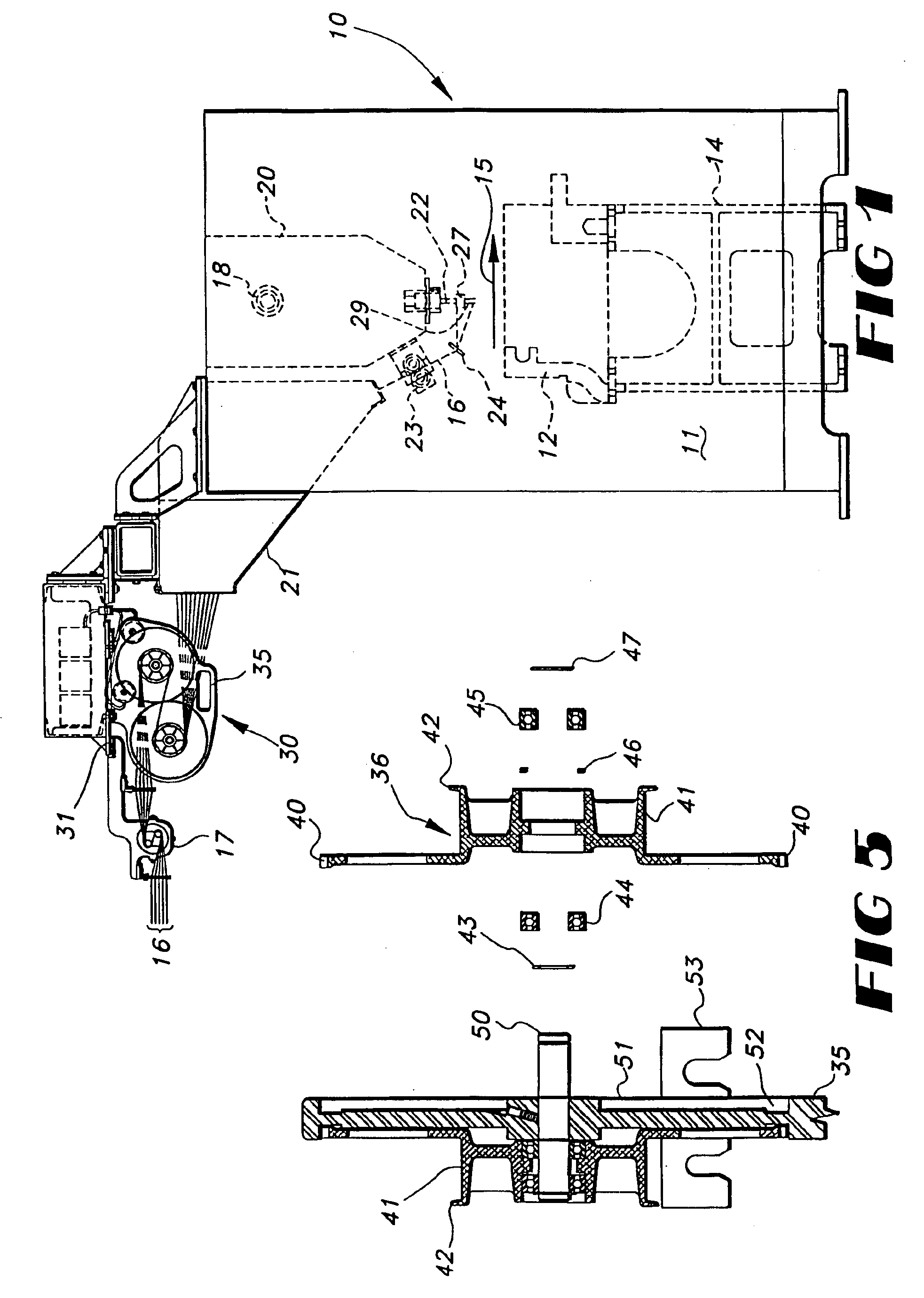

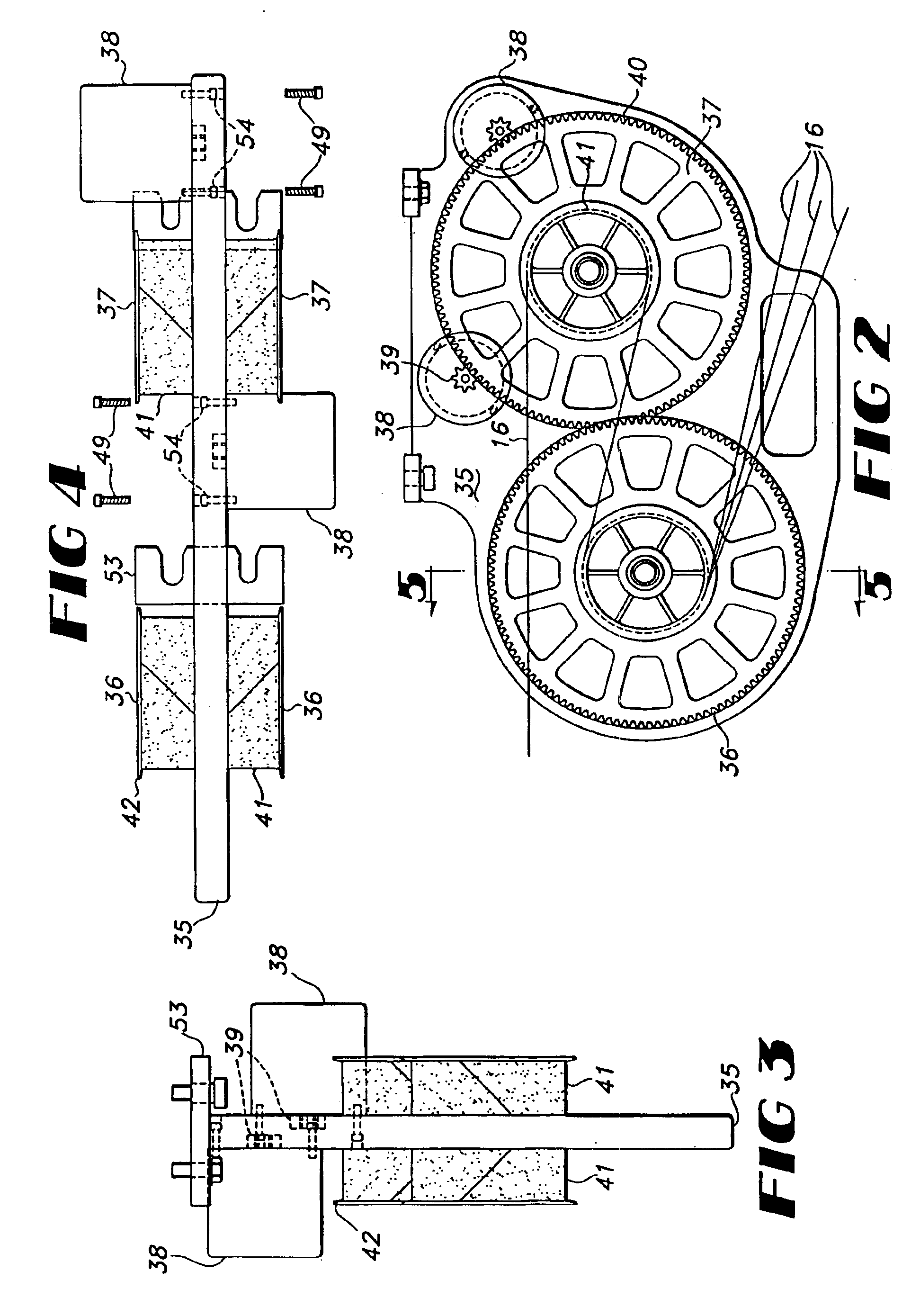

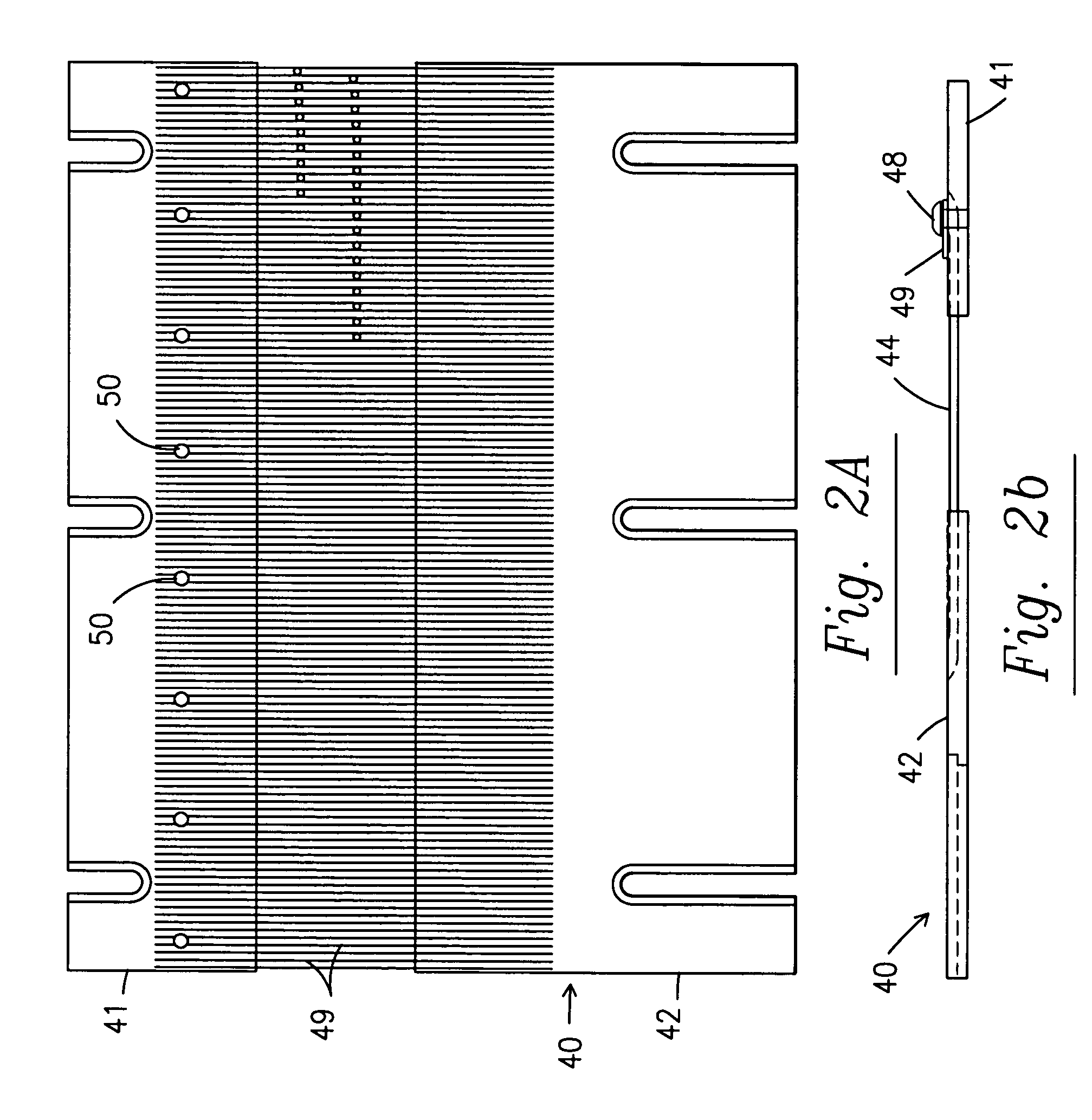

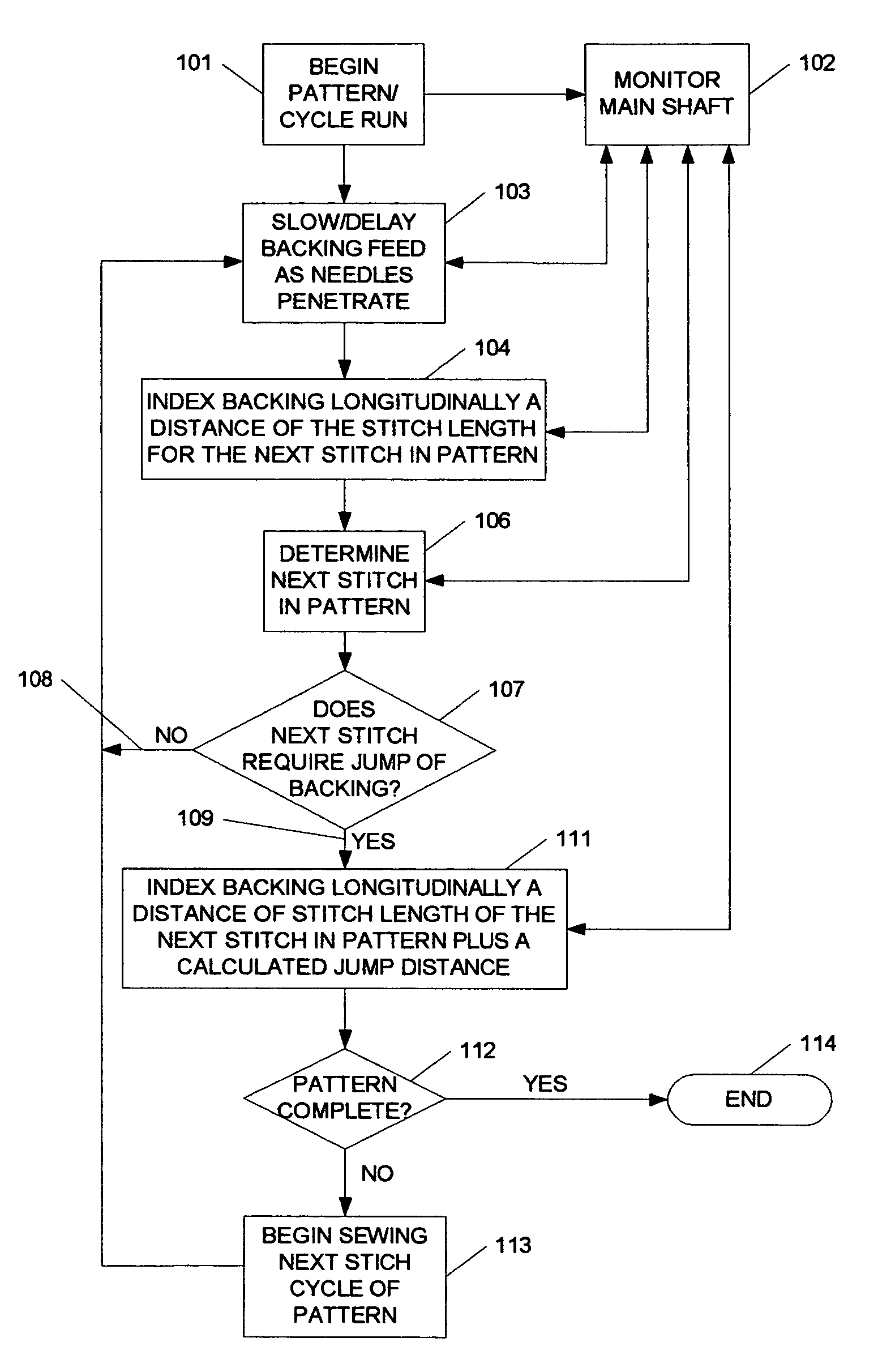

System and method for control of the backing feed for a tufting machine

ActiveUS7717051B1Further pattern effectsProgramme-controlled sewing machinesTufting apparatusMechanical engineeringTufting

Owner:CARD MONROE

Double end servo scroll and direct scroll driver pattern attachment for tufting machine

The present invention provides a double end yarn drive pattern attachment for tufting machines characterized by independent servo-motor control of yarn feed rolls capable of increased torque to carry multiple yarn ends on a single feed roll, thereby economically retaining many advantages of a single end pattern attachment. The improved attachment utilizes an intermediate gear to provide a relatively high torque drive adaptable between single and plural yarn pattern attachments.

Owner:TUFTCO

Level cut loop looper and clip assembly

A level cut loop looper or hook and clip for a tufting machine includes a looper body having a channel in which a clip is received. The clip is moved between extended and retracted positions by an actuator as the level cut loop looper or hook is reciprocated into engagement with a needle of the tufting machine, so as to selectively form cut and loop pile tufts in a backing material.

Owner:CARD MONROE

Method for Selective Display of Yarn in a Tufted Fabric With Double End Yarn Drives

A novel method of tufting carpets is provided to allow the use of four or more colors of yarn at sufficient stitch density to provide for a solid appearance of any of the selected colors at any location on the carpet, and utilizing natural tacking of rear yarns to minimize loose yarn on the backing.

Owner:TUFTCO

Tufting machine

A tufting machine for producing pile fabric having a pile height of approximately at least 50 mm has divider plates between adjacent needles to prevent yarn loops and especially the legs of cut loops from becoming trapped between an adjacent needle and its associated yarn feed. The divider plates may take the form of plates forming an extension of the fingers of the needle plate between each pair of which a needle reciprocates and may be mounted on a block on the bed plate beneath the needle plate, or may be plates upstanding from the hook bar.

Owner:SOC DINVESTMENT MOSELLE SA

Tufting machine with needle bar motor

InactiveUS6283052B1Optimization mechanismReduce in quantityTufting apparatusElectric machineryEngineering

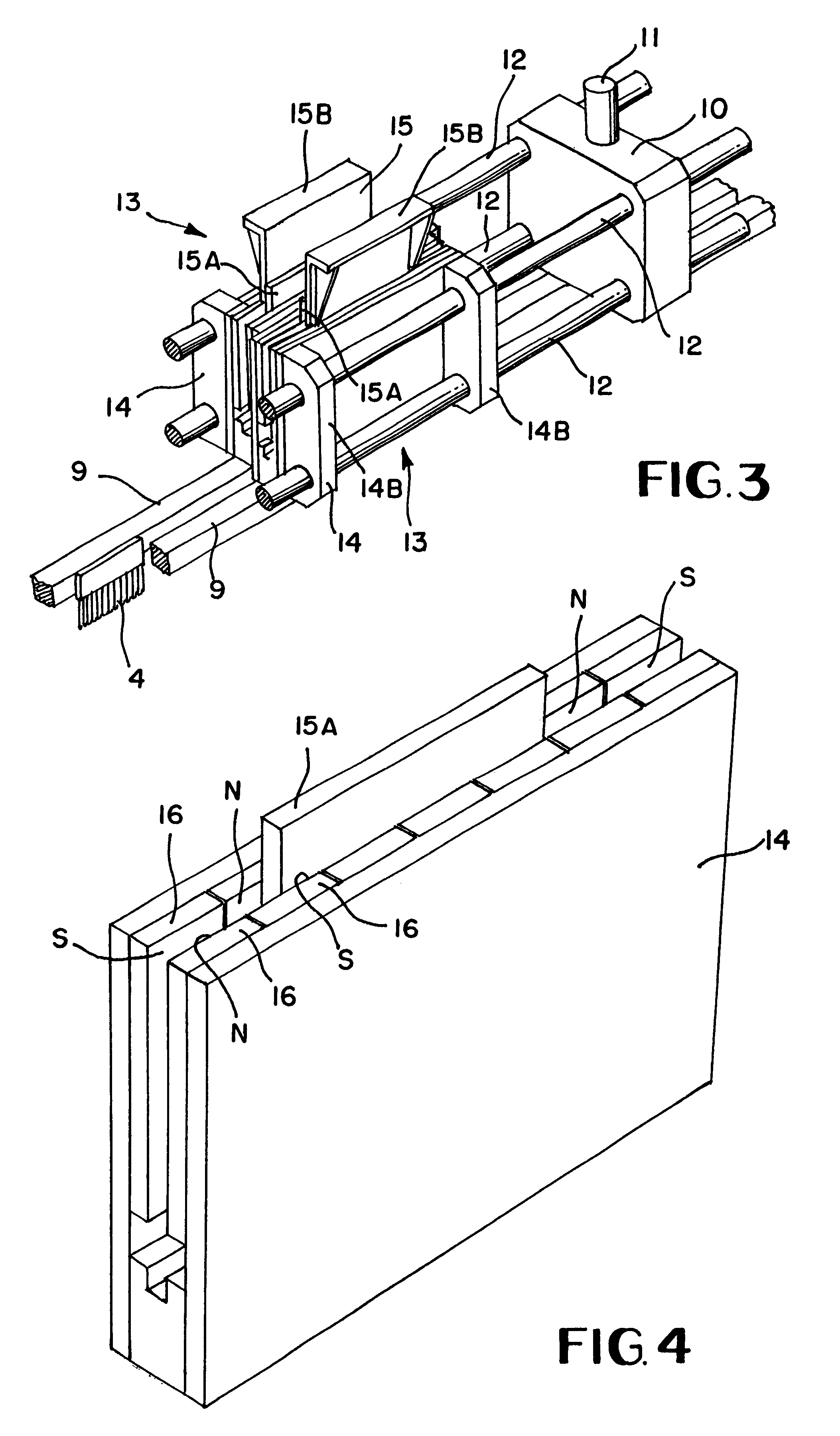

A tufting machine has a reciprocating needle bar which may be shifted laterally by a drive which includes at least one linear motor. Each linear motor has two major elements which may be coupled together electromagnetically. One of the elements is connected to a fixed portion of the tufting machine and another of the elements is connected to the needle bar. When electrical power is supplied to the motor, the element connected to the needle bar moves relatively to the other thereby moving the needle bar.

Owner:SOC DINVESTMENT MOSELLE SA

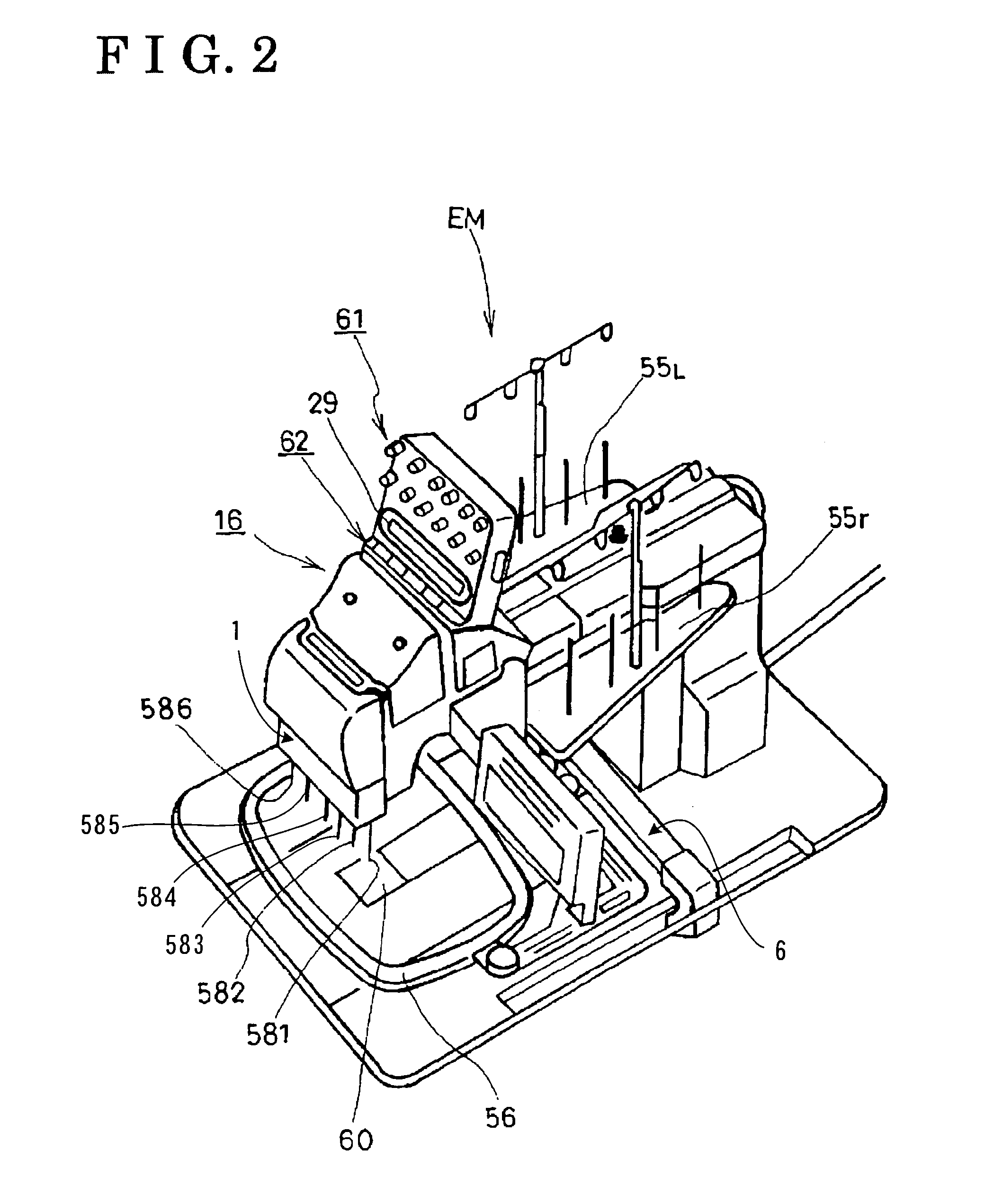

Embroidering system

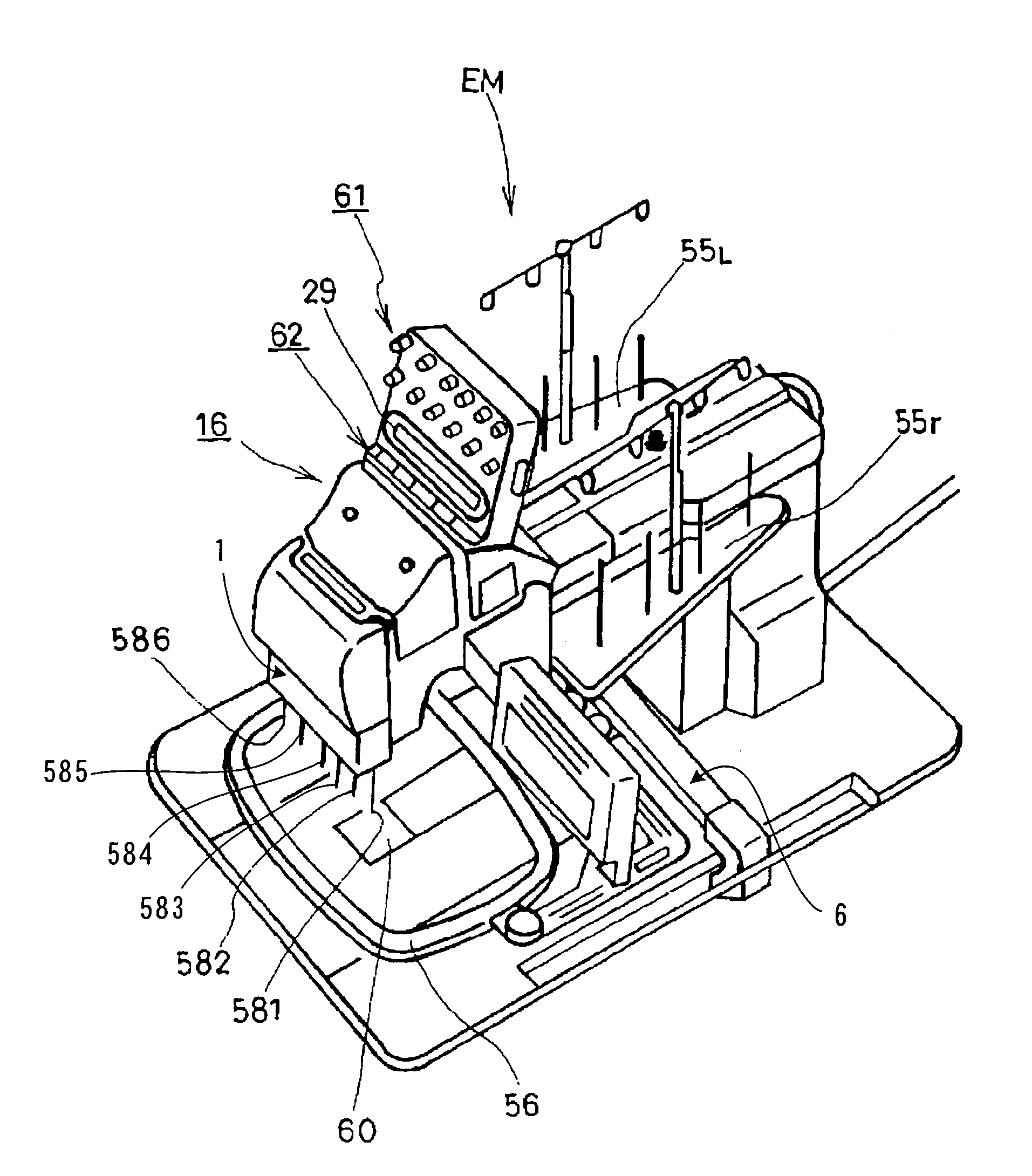

An embroidering system includes at least one embroidering machine having plural needles supplied with threads having different colors, and a control device for transmitting an embroidery data to the at least one embroidering machine so as to selectively drive the plural needles. The embroidery data is generated and memorized in the control device prior to being transmitted to the at least one embroidering machine. The embroidery data is corrected as required. It is preferable that the embroidery data is corrected as the basis for needle numbers for the respective needles and the colors of the threads supplied to the respective needles.

Owner:AISIN SEIKI KK

System and method for forming artificial/synthetic sports turf fabrics

A system and method for forming synthetic / artificial grass or turf products in which a series of tufts of artificial / synthetic grass filaments or yarns are formed in a backing material. The system generally will include spaced rows of needles mounted along a tufting zone and which are reciprocated through the backing to different penetration depths. A series of loopers and a series of hooks will be aligned with and will engage the needles in order to form cut and loop pile tufts of yarns having varying lengths in the backing material.

Owner:CARD MONROE

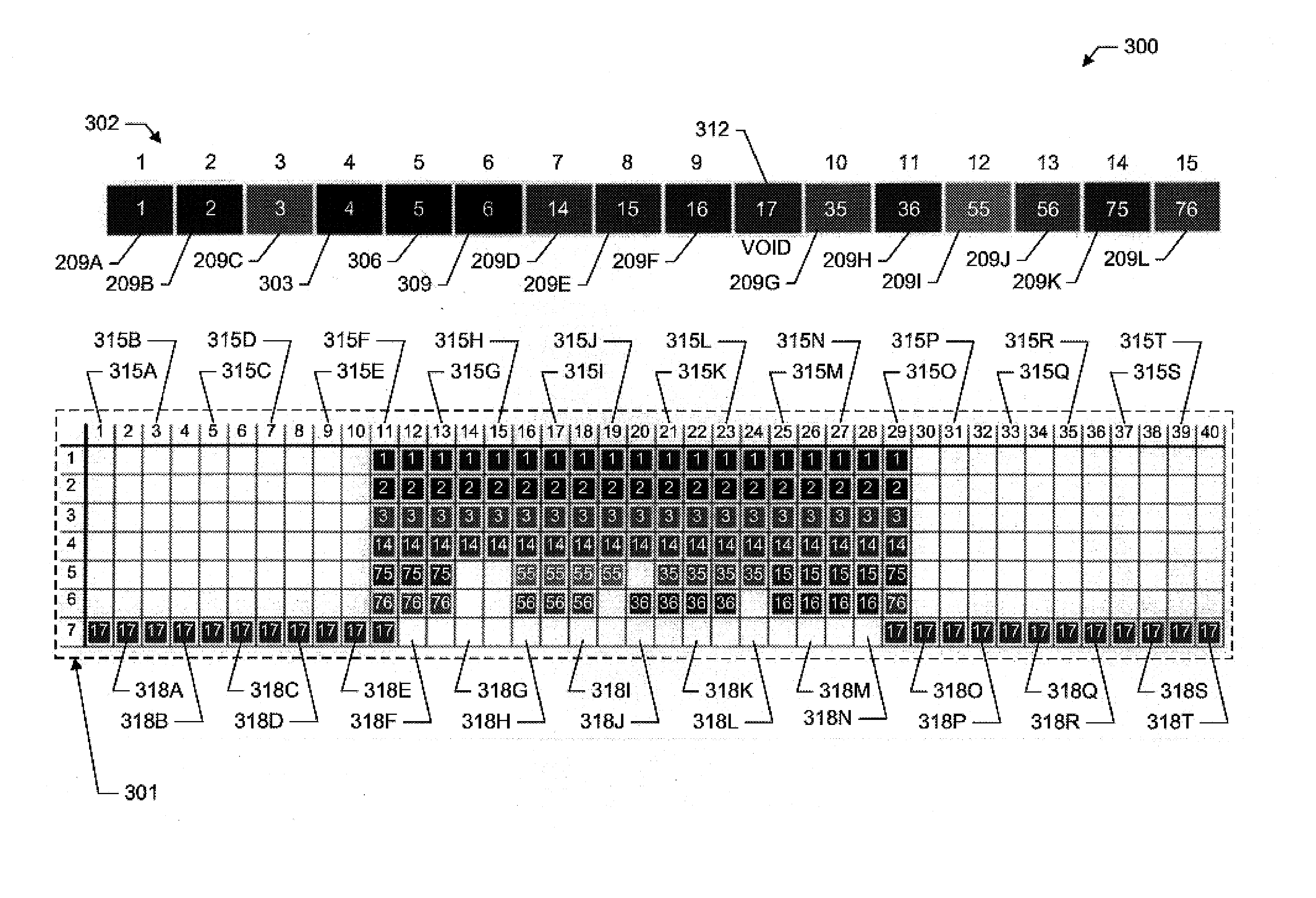

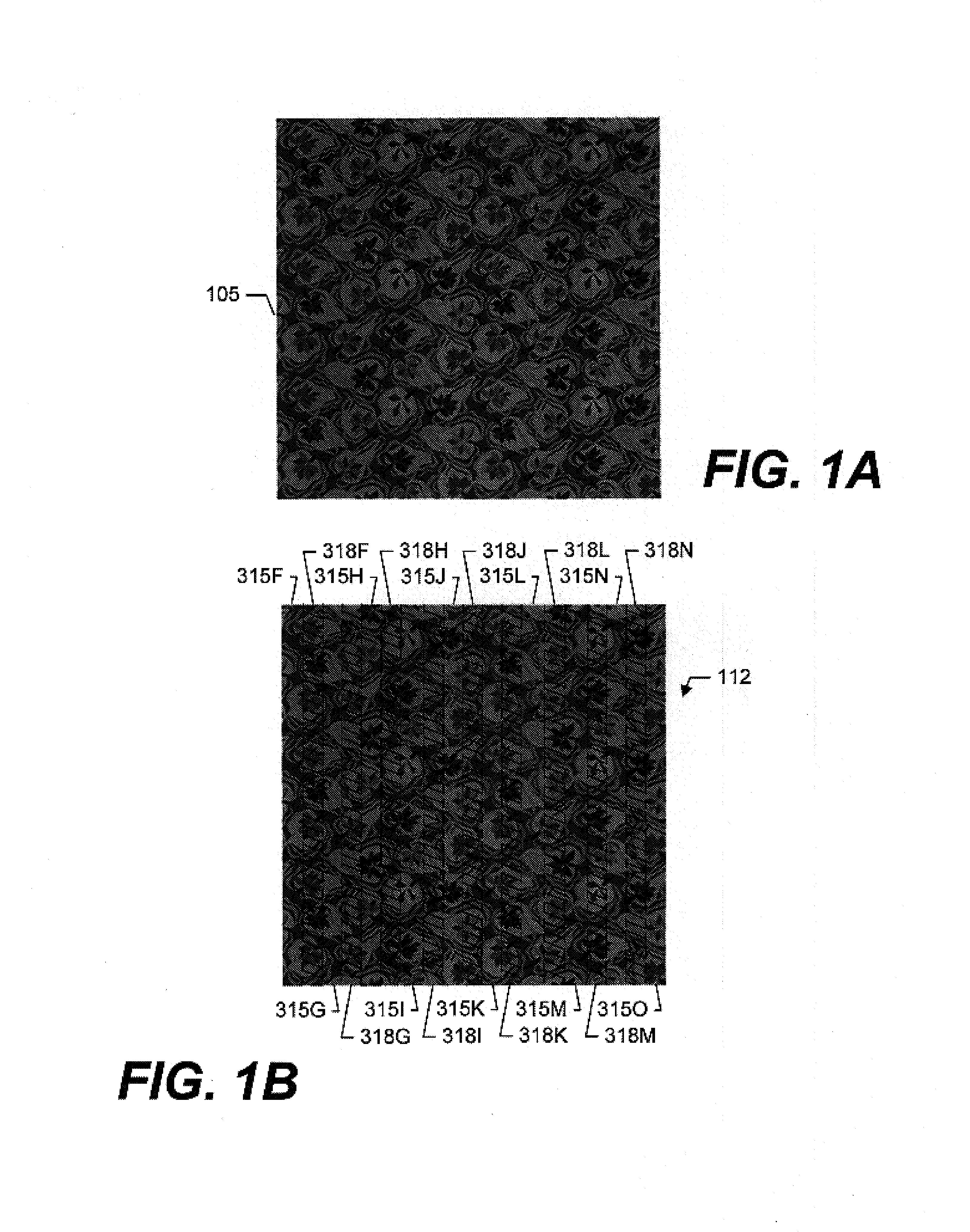

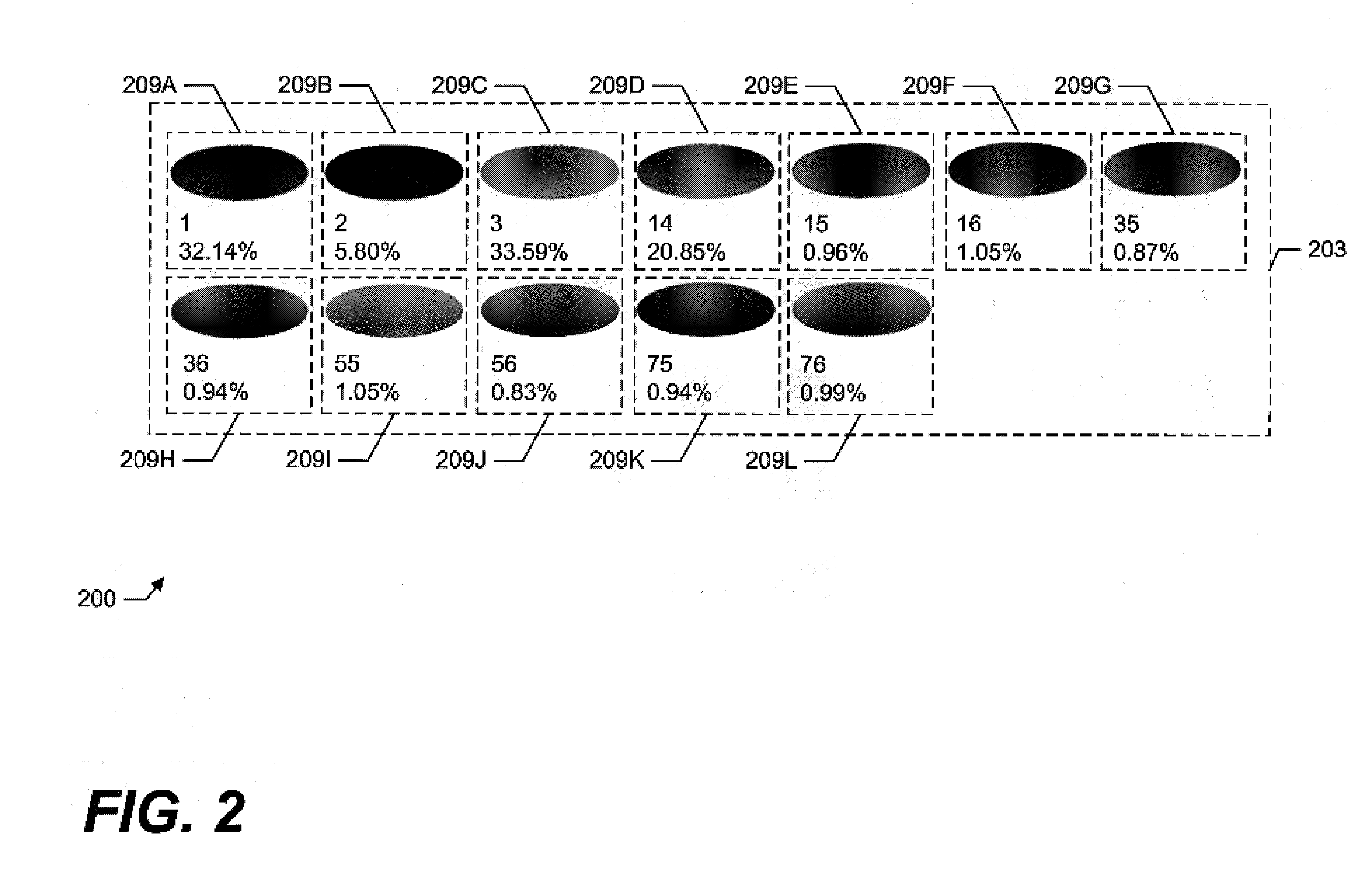

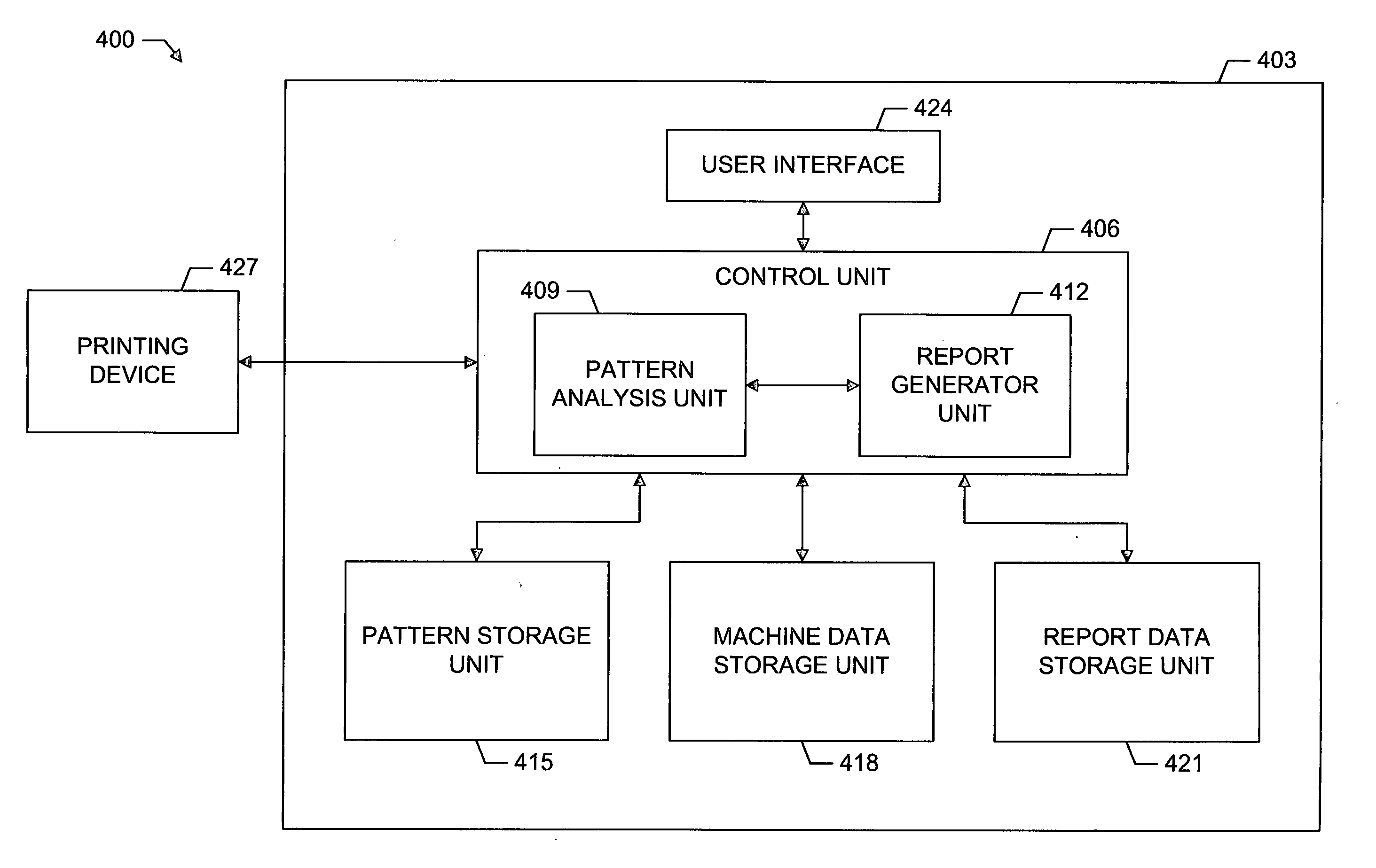

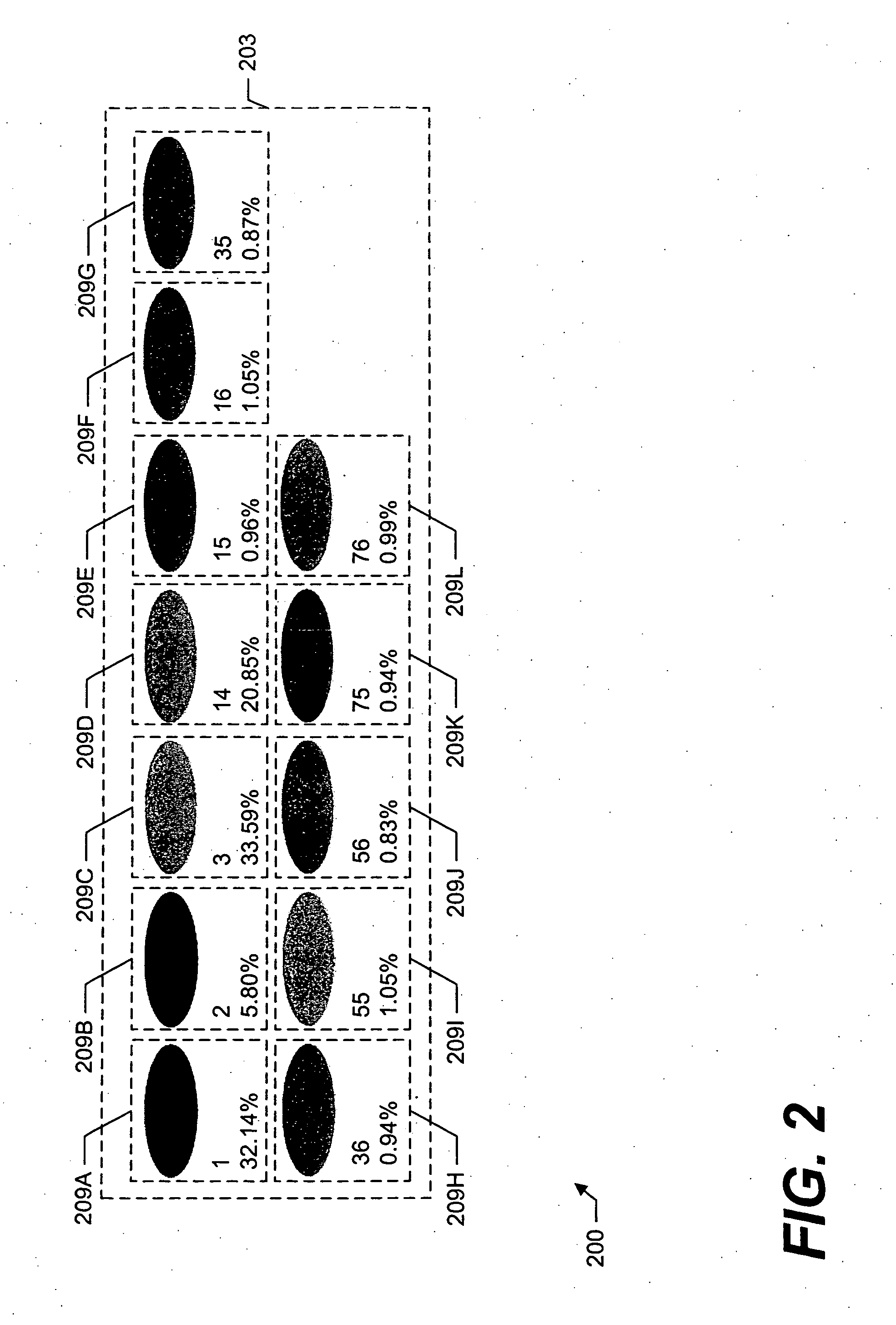

System and method of producing multi-colored carpets

A system and method for producing multi-colored carpets using a tufting machine. The present invention features a system and method for: providing a multi-colored pattern which is analyzed for validity with reference to a particular tufting machine; collecting parameters concerning a particular tufting machine; determining the colors of yarn to load with each needle of the particular tufting machine; and generating a report including a palette of colors used within the pattern, a chart indicating which color of yarns are used within each needle position, and a summary of the number of yarn cones needed to create a carpet of a predetermined size with the particular tufting machine.

Owner:ALADDIN MFG CORP +1

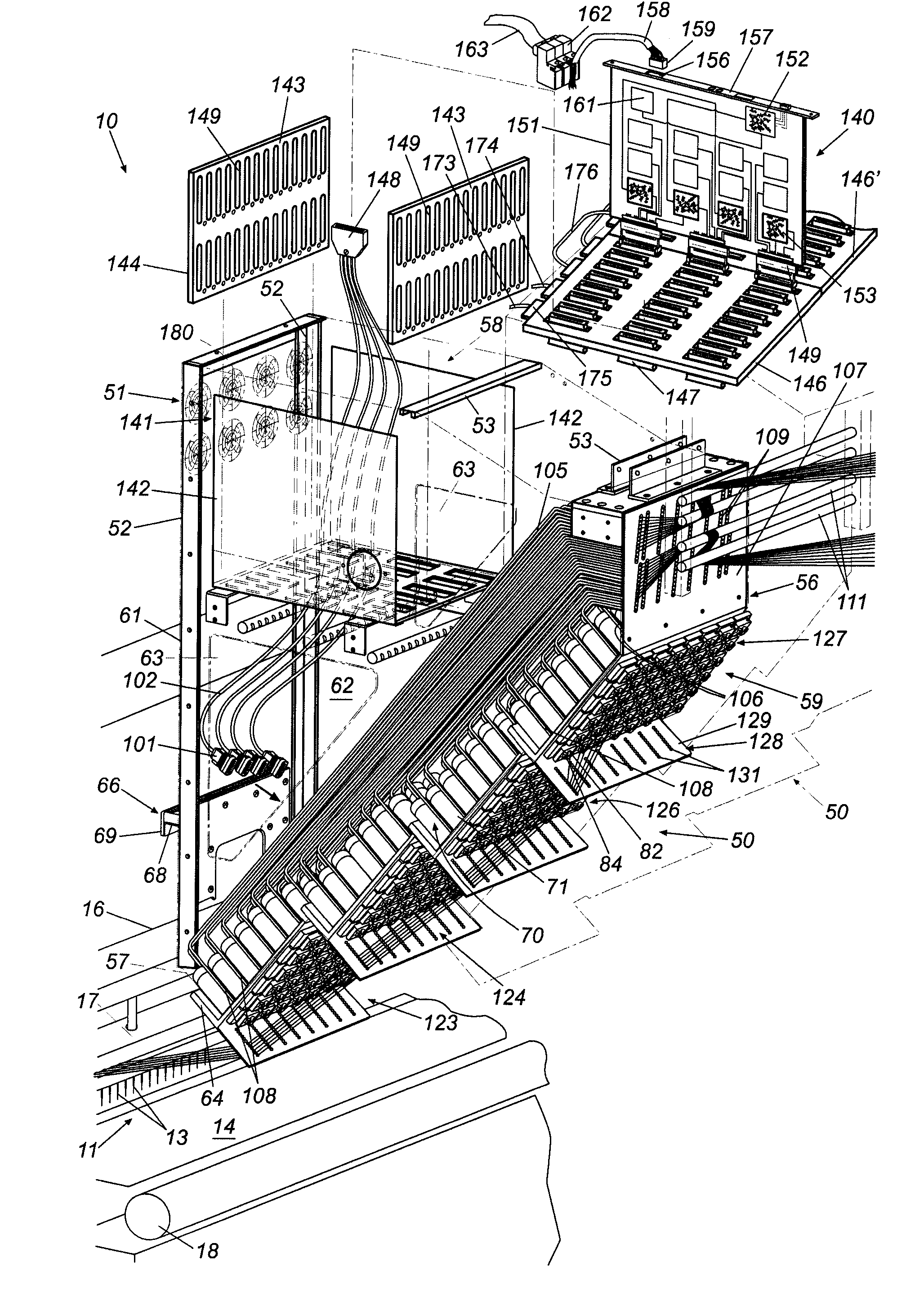

Yarn Feed System for Tufting Machines

InactiveUS20060272564A1Easy to controlImprove precisionTufting apparatusDigital differential analysersYarnEngineering

A yarn feed system, enabling the control of individual yarns to the needles of a tufting machine, and which system can be manufactured as a substantially standardized unit or attachment that can be removably mounted to a tufting machine. The yarn feed unit includes a series of yarn feed devices for feeding each of the yarns to the needles of the tufting machine, and a series of yarn feed controllers that monitor and control the operation of the yarn feed devices to control the feeding of the yarns to the needles according to programmed pattern instructions.

Owner:CARD MONROE

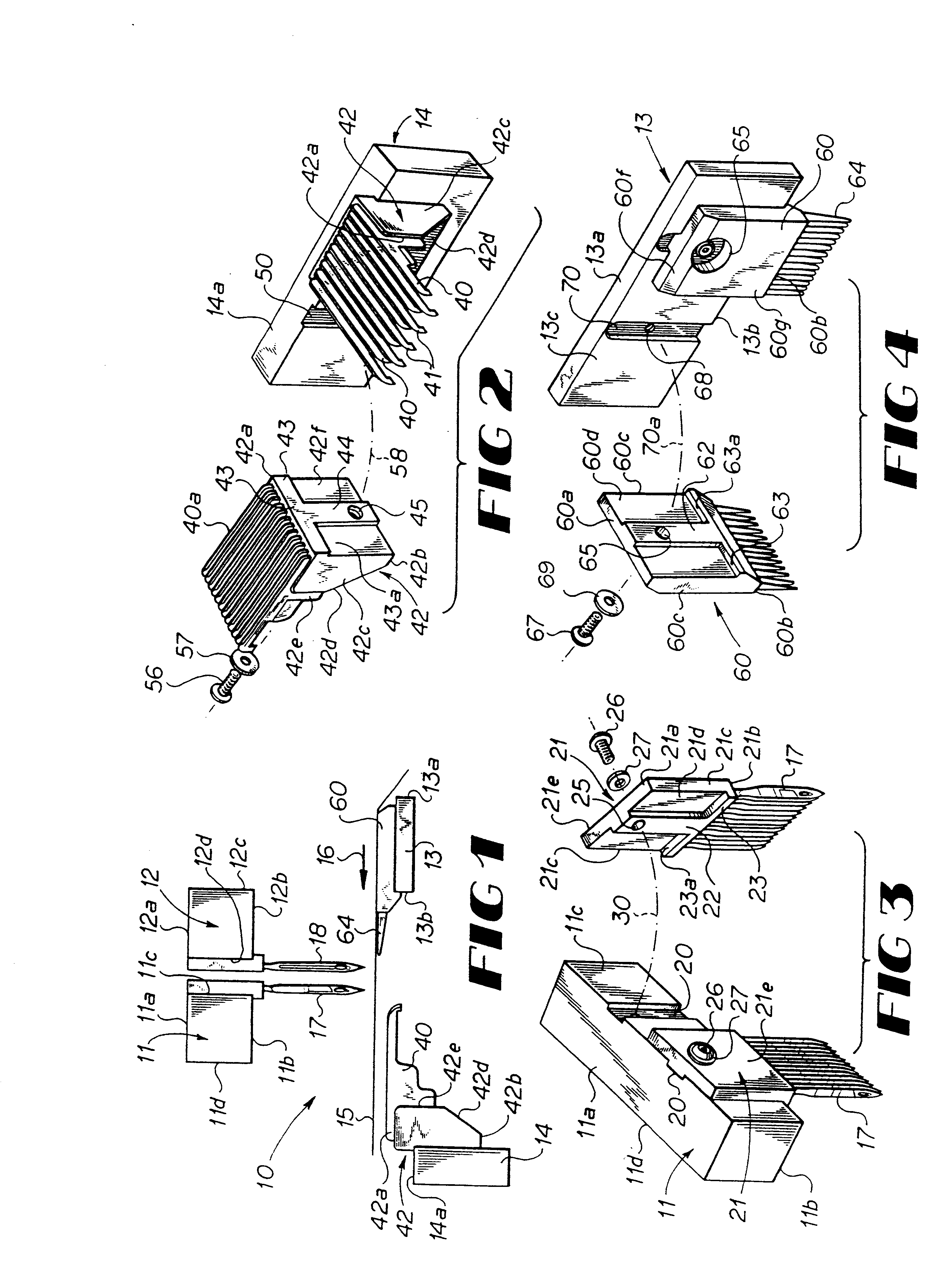

Tufting machine with self-aligning gauging modules

Symmetrical, modular blocks each having a plurality of fixed, equally spaced, gauging elements, namely loopers, needles, and reeds protruding therefrom, the blocks are positioned on the sides of the guide bars of a tufting machine, each guide bar having transverse channels at equally spaced intervals. These channels respectively receive guide bars of the blocks when the blocks are removably positioned on the sides of the guide bar. Bolts or screws secure the blocks in place on their guide bars so that their needles, loopers, and reeds are appropriately gauged and positioned for tufting action, protruding toward the tufting zone.

Owner:CARD MONROE

System and method of producing multi-colored carpets

A system and method for producing multi-colored carpets using a tufting machine. The present invention features a system and method for: providing a multi-colored pattern which is analyzed for validity with reference to a particular tufting machine; collecting parameters concerning a particular tufting machine; determining the colors of yarn to load with each needle of the particular tufting machine; and generating a report including a palette of colors used within the pattern, a chart indicating which color of yarns are used within each needle position, and a summary of the number of yarn cones needed to create a carpet of a predetermined size with the particular tufting machine.

Owner:ALADDIN MFG CORP +1

Multiple yarn delivery to a single needle method and apparatus

A textile machine receives a plurality of yarn strands from a yarn supply. A header receives the yarn strands where multiple strands are combined for joint direction to the textile machine. Beams with multiple yarn strands wrapped thereon preferably function as the yarn supply and the header may direct through yarn tubes to a staging header for use by the textile machine. The textile machine is preferably a tufting machine and multiple yarn strands are received by at least one needle of the tufting machine.

Owner:MILLIKEN & CO

Tufting machine for producing athletic turf having a graphic design

ActiveUS20080134949A1Reduce positioning accuracyEfficient constructionProgramme-controlled sewing machinesTufting apparatusYarnGraphics

A tufting machine capable of producing individual articles of athletic turf bearing precise graphic patterns is disclosed. The machine includes a support frame to which a backing material is statically held, a tufting frame that spans above and below the backing and is computer-controlled to travel along the support frame, a yarn-inserting needle carriage disposed above the backing along the tufting frame and a yarn-catching looper carriage disposed below the backing along the tufting frame. The carriages are computer-controlled to asynchronously shift relative to each other as may be necessary for their individual yarn-inserting components and yarn-catching components to cooperate

Owner:SIGNATURE BANK OF GEORGIA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com