Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about "Creels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

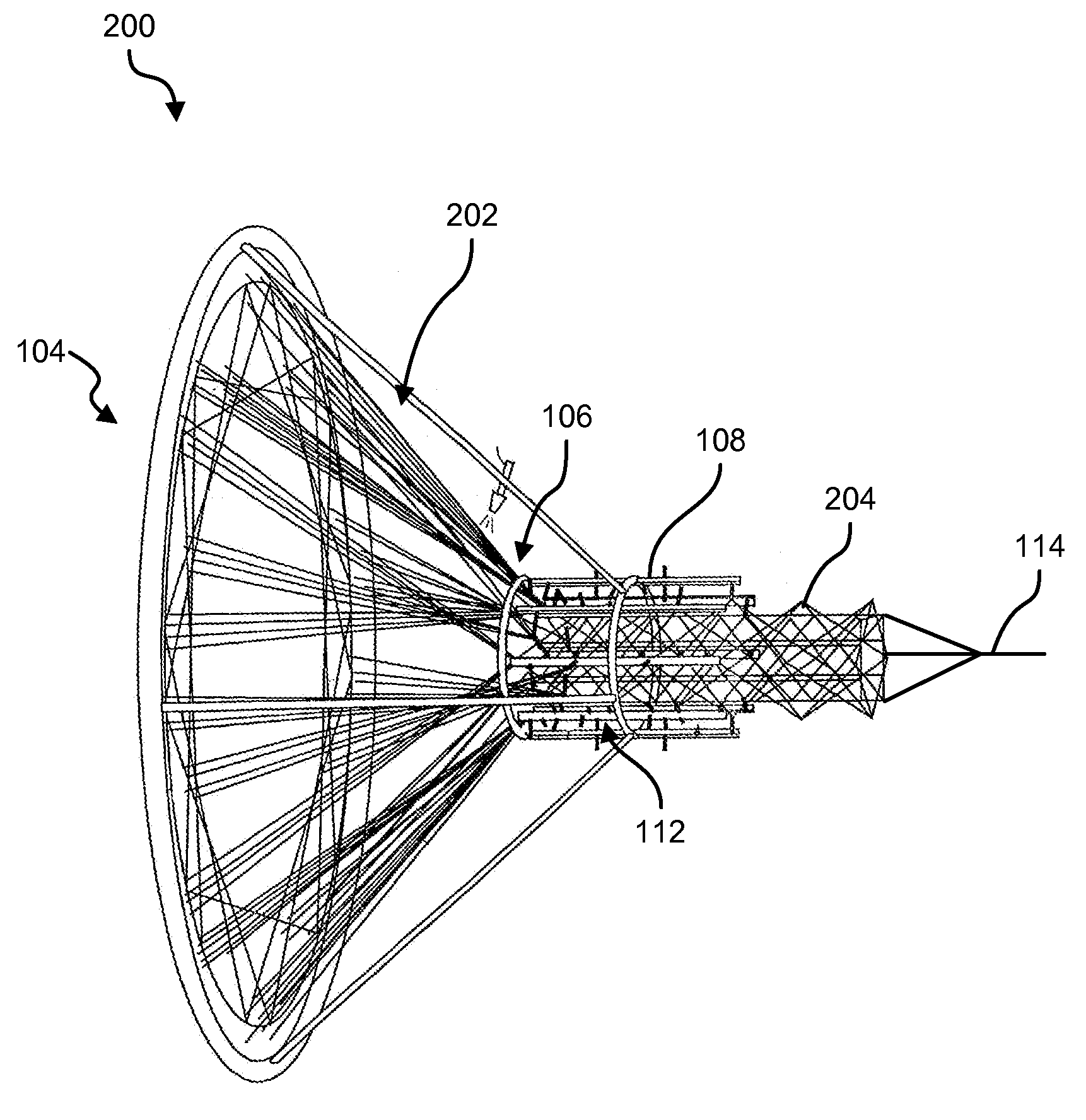

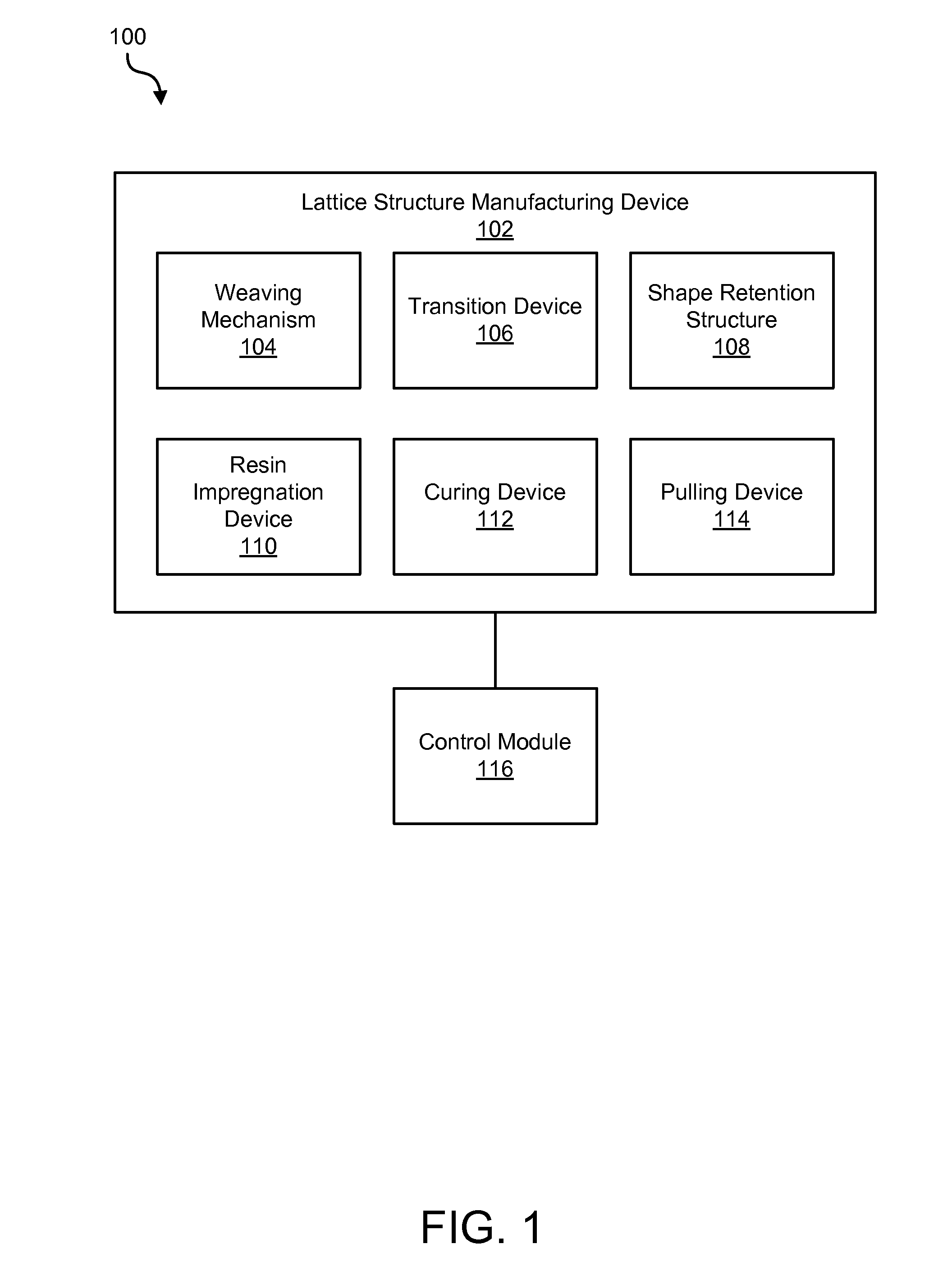

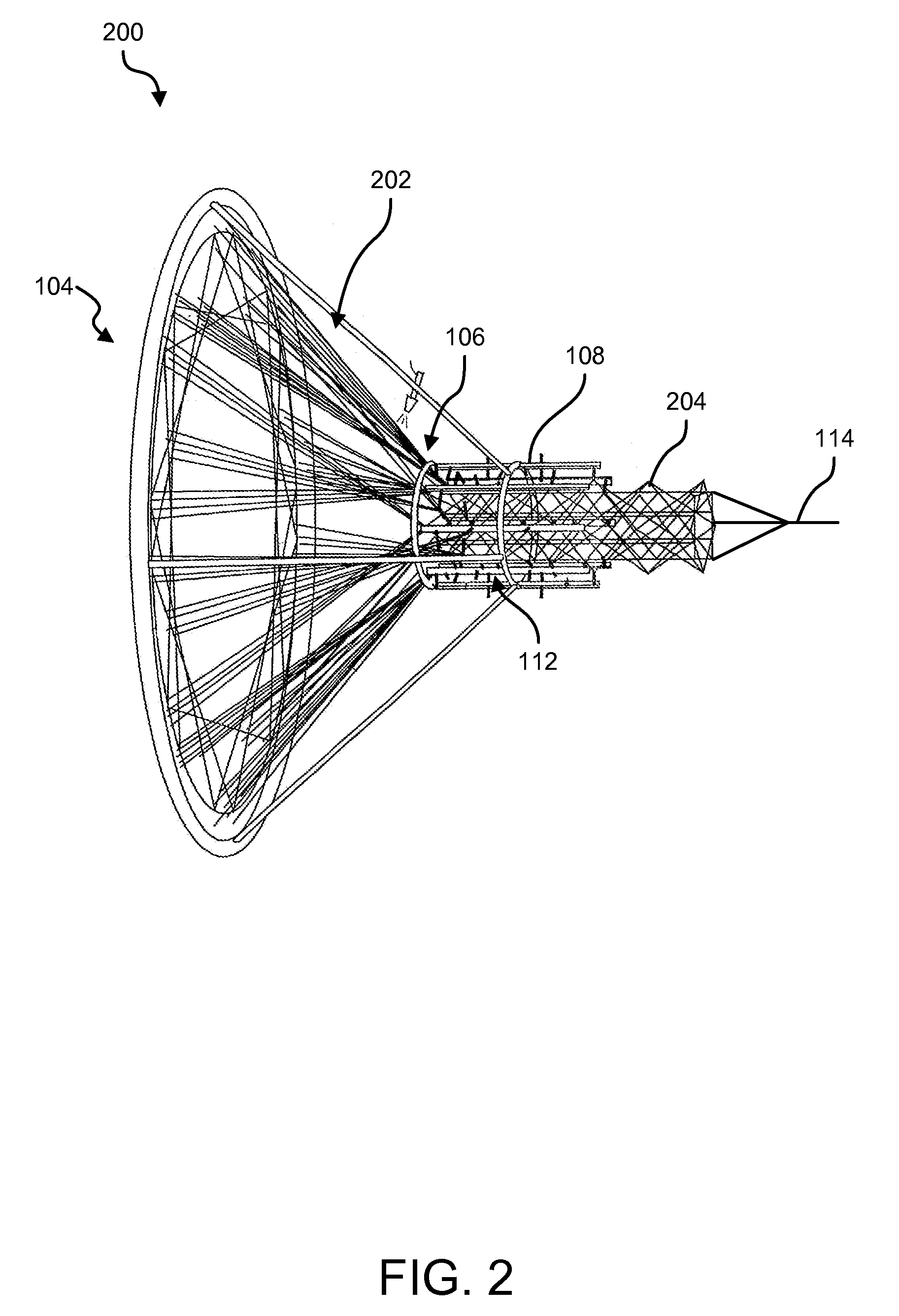

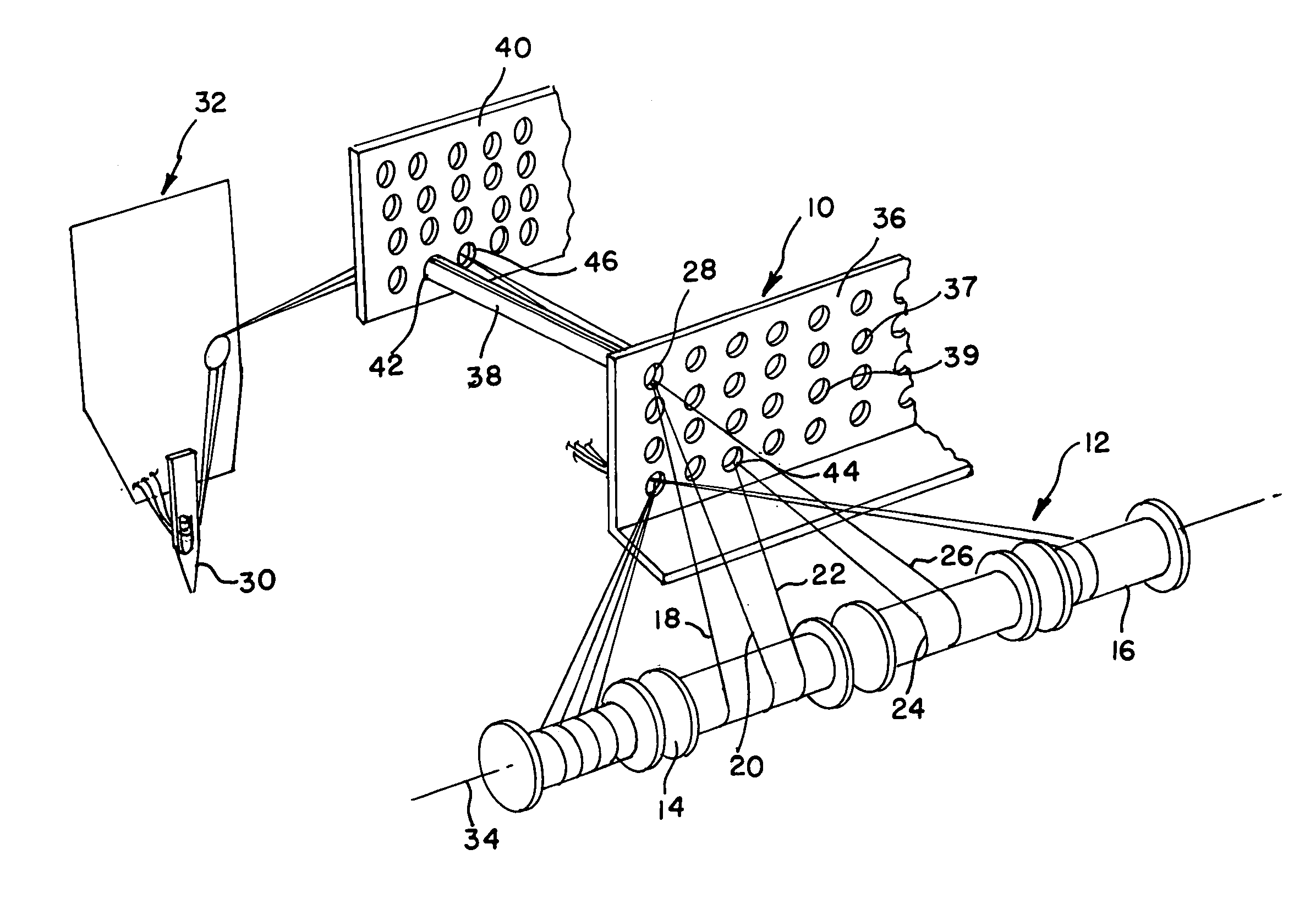

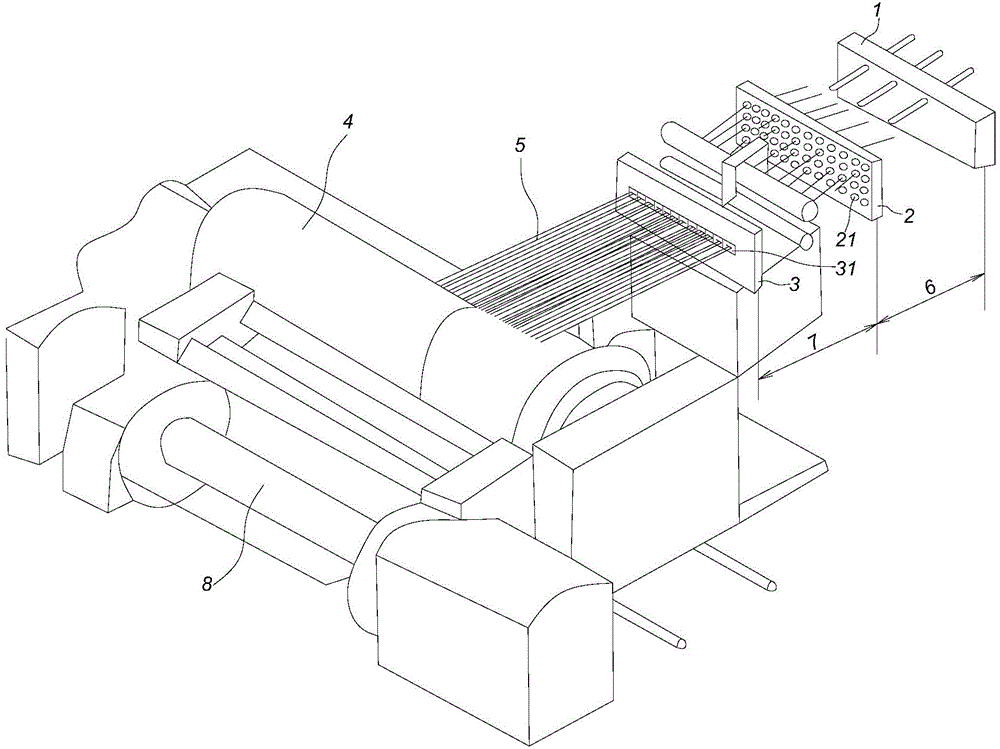

Apparatus, System, and Method for Filamentary Composite Lattice Structure Manufacturing

An apparatus, system, and method are disclosed for the manufacture of composite lattice structures comprising a weaving mechanism 104 configured to position fibers in a lattice structure, the weaving mechanism 104 comprising one or more bobbins 304, each one or more bobbin 304 configured to carry fiber and a plurality of horn gears 302 configured to move the one or more bobbins 304 across the face of the weaving mechanism 104 to control the position of the fiber carried by the one or more bobbins 304 in the lattice structure, and a shape retention structure 108 configured to hold the fibers in lattice structure. Beneficially, such an apparatus, system, and method would automate the process of manufacturing composite lattice structures and reduce the costs associated with the existing methods for manufacturing such structures.

Owner:BRIGHAM YOUNG UNIV

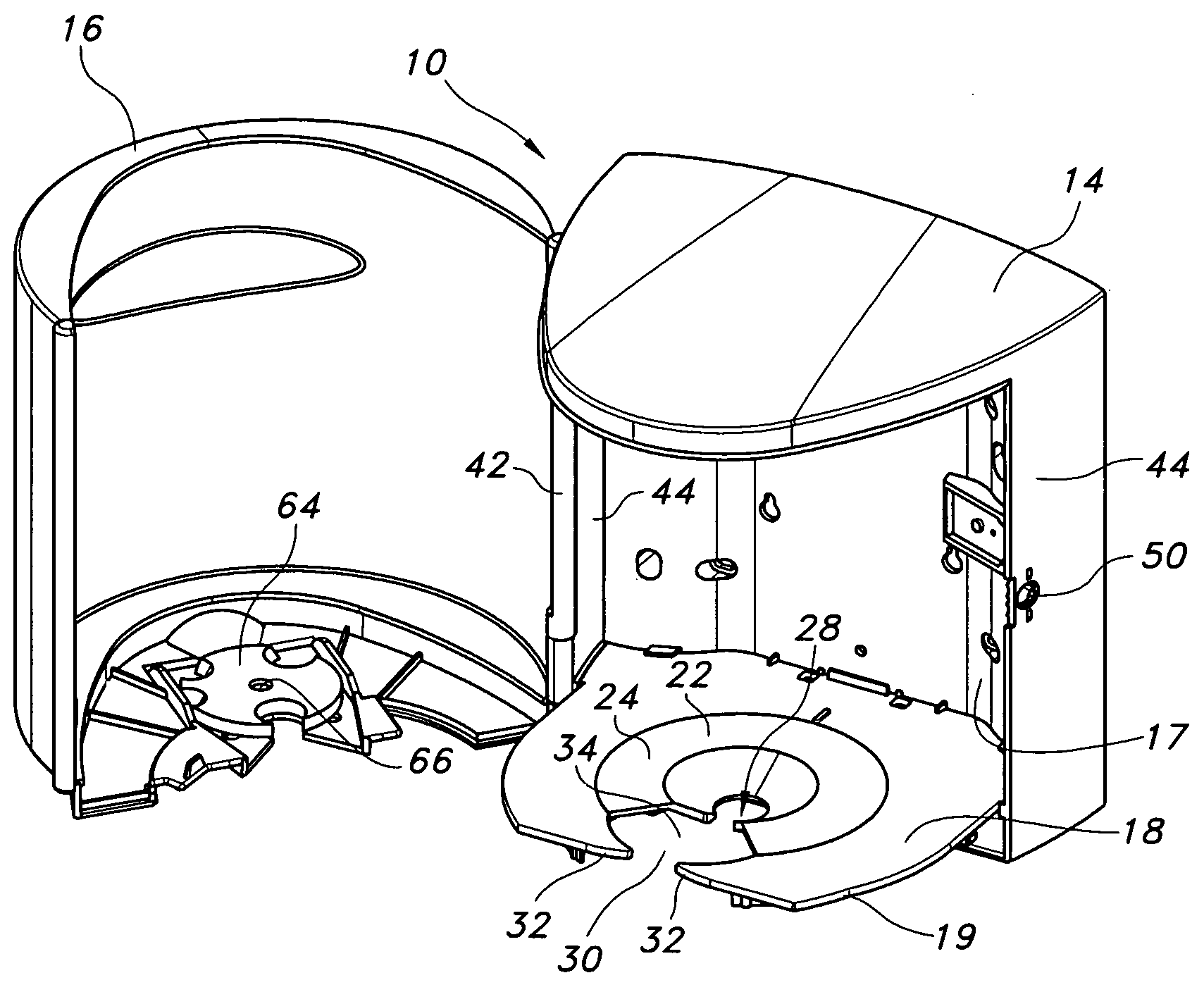

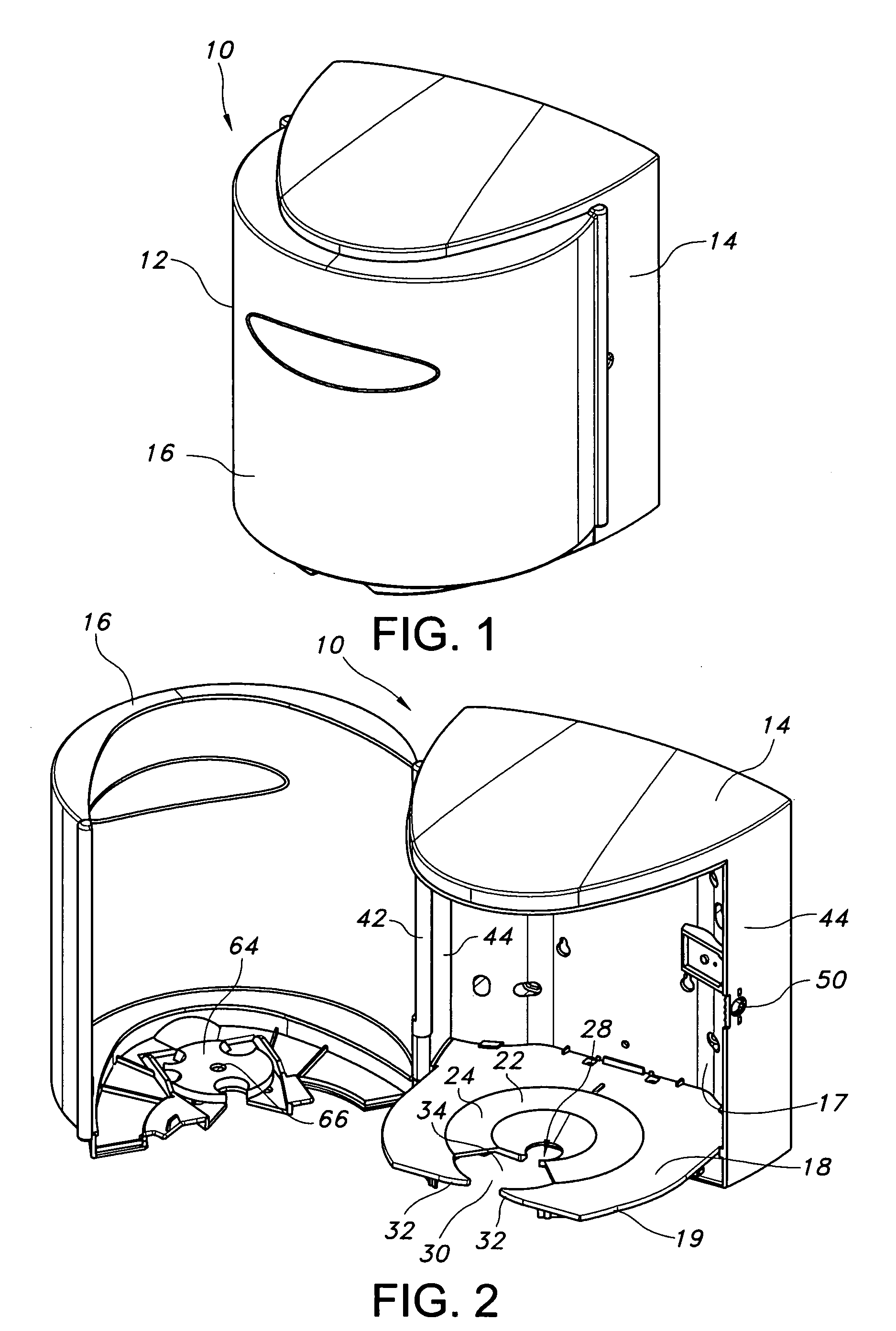

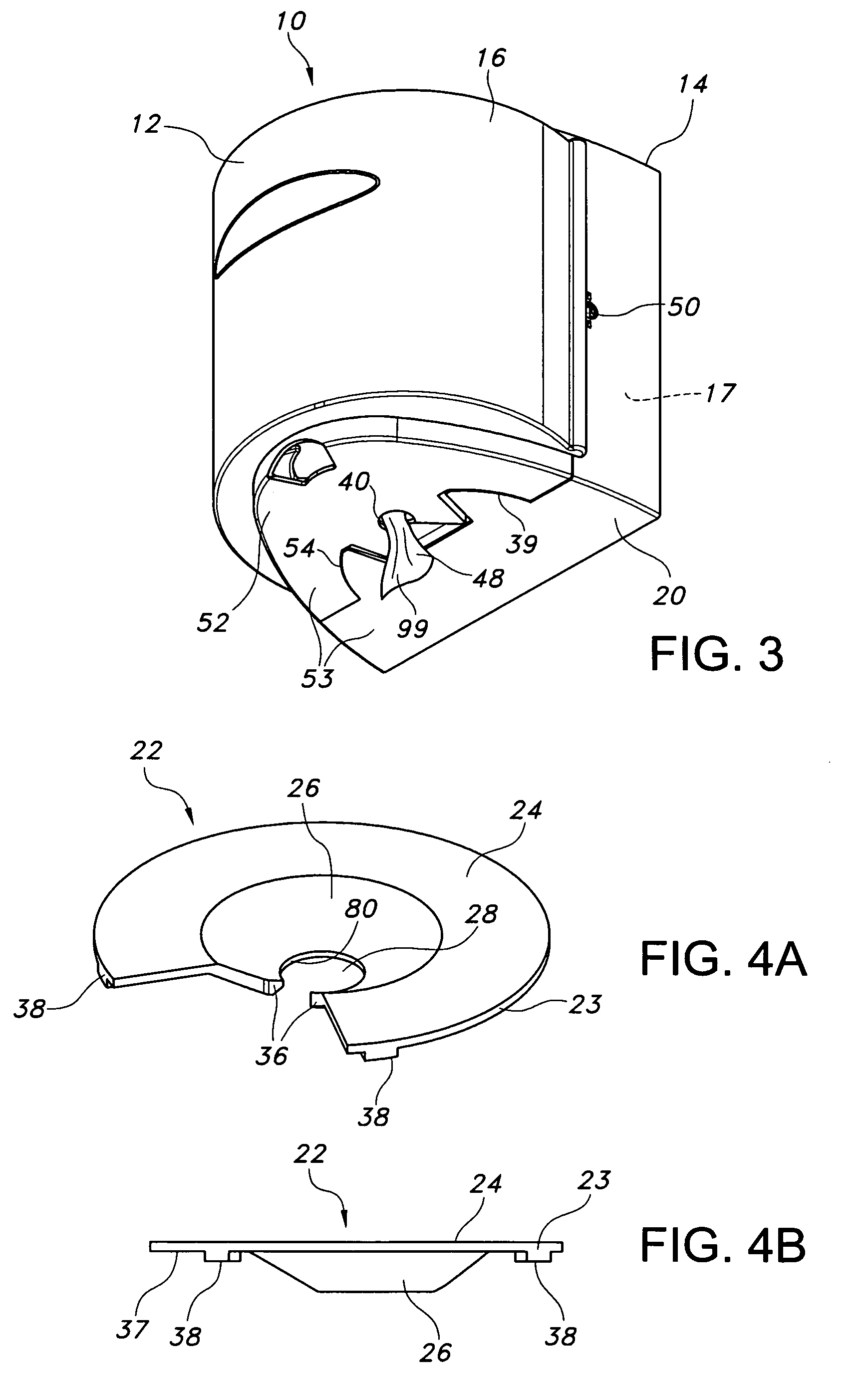

Dispenser for sheet material

A dispenser adapted to dispense sheet material therefrom is provided and includes a housing including a base and a cover. The base includes a platform configured to support sheet material. The platform includes a dispensing disk and the platform has an outer perimeter intersected by a slot thereby providing an opening into the platform and dispensing disk. The housing is formed to include an exit port spaced apart from the platform and dispensing disk. The cover includes a rotatable disk having a plurality of user interchangeable dispensing slots of differing diameters intersecting an outer periphery of the rotatable disk. Sheet material positioned on the platform flows through the dispensing opening of the dispensing disk and through a selected one of the plurality of dispensing slots. The selected one of the plurality of dispensing slots is aligned with the exit port. The sheet material disposed in the dispenser flows between the opening in the dispensing disk, through at least one space, through the selected one of the plurality of dispensing slots and through the exit port to be dispensed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Elastic thread supply device

Owner:UNI CHARM CORP

Multiend package of multifilament polyester bicomponent yarn

Included are multiend packages of multicomponent yarns, where the yarn is separable into individual ends upon unwinding. The multicomponent yarn may be a bicomponent yarn, such as a yarn including compositionally different polyesters in a side-by-side or eccentric sheath-core configuration. Uses of such multiend packages are also included.

Owner:INVISTA NORTH AMERICA R L

Elastic thread supply device

An elastic thread supply device including a tension controller configured to control the stress acting upon an elastic thread drawn from an elastic thread package, and a drive roll configured to supply the elastic thread dispensed from the tension controller to a processing line. The drive roll operates at a supply velocity slower than a conveyance velocity of a web, and increases or decreases the supply velocity depending on the fluctuation in the conveyance velocity.

Owner:UNI CHARM CORP

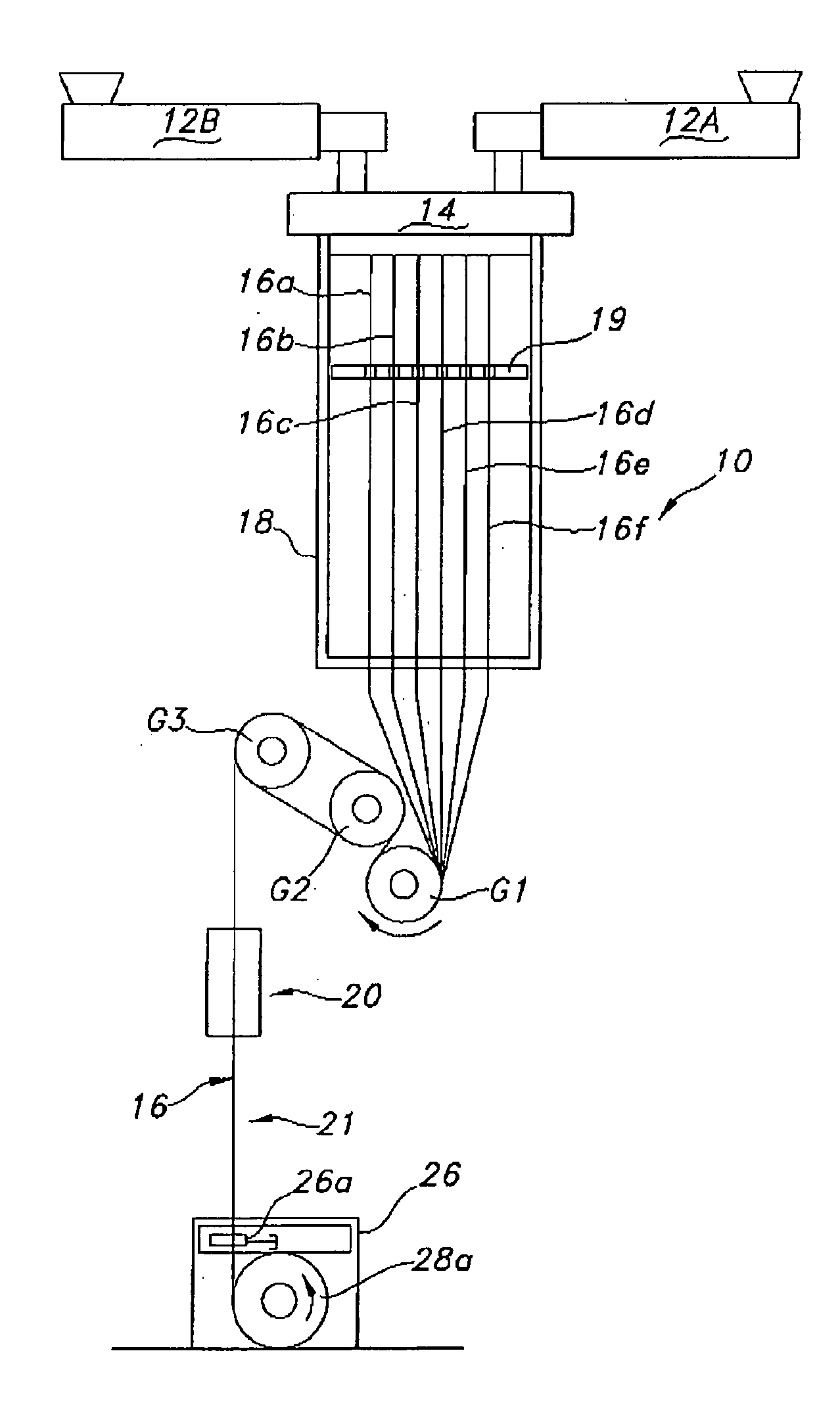

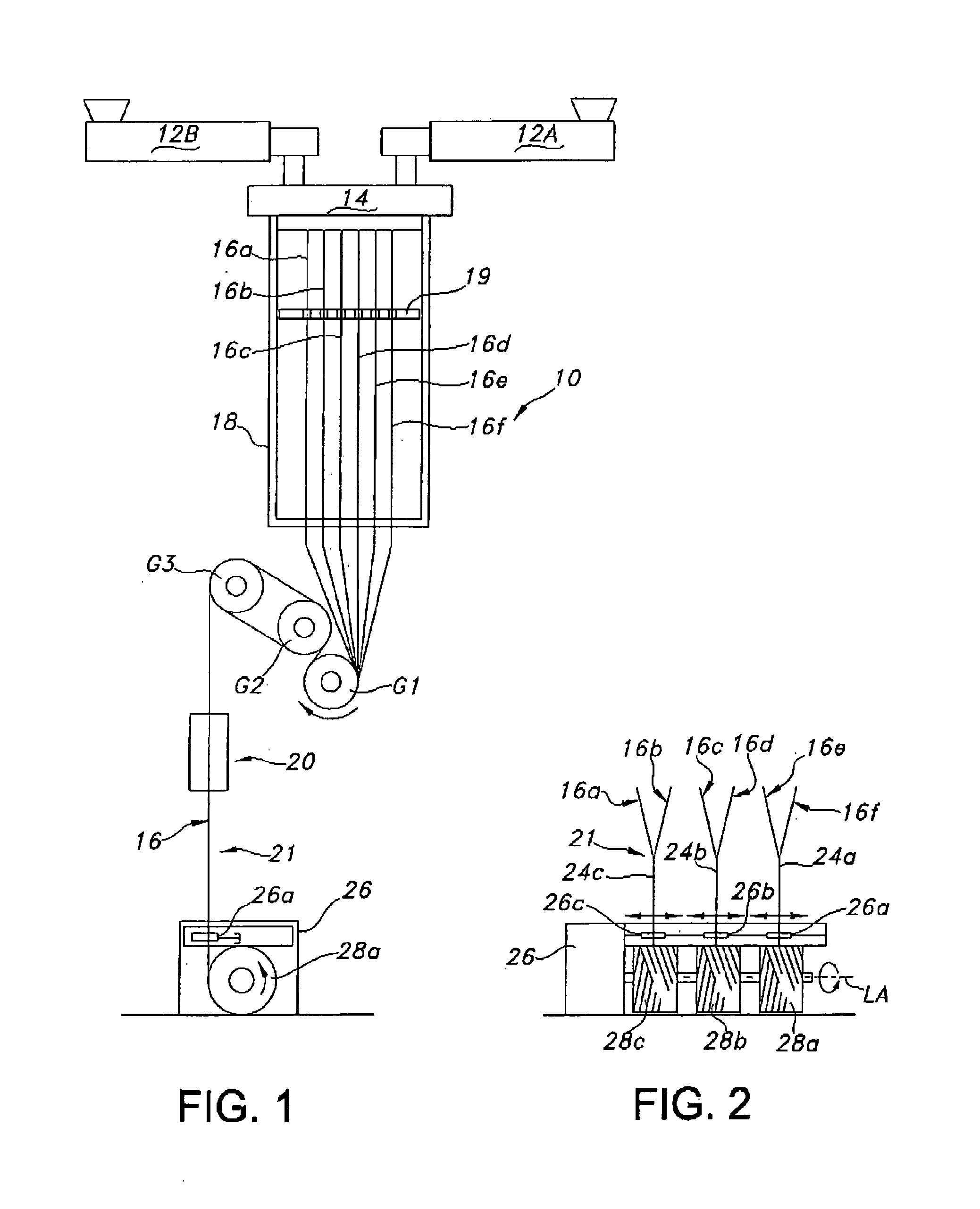

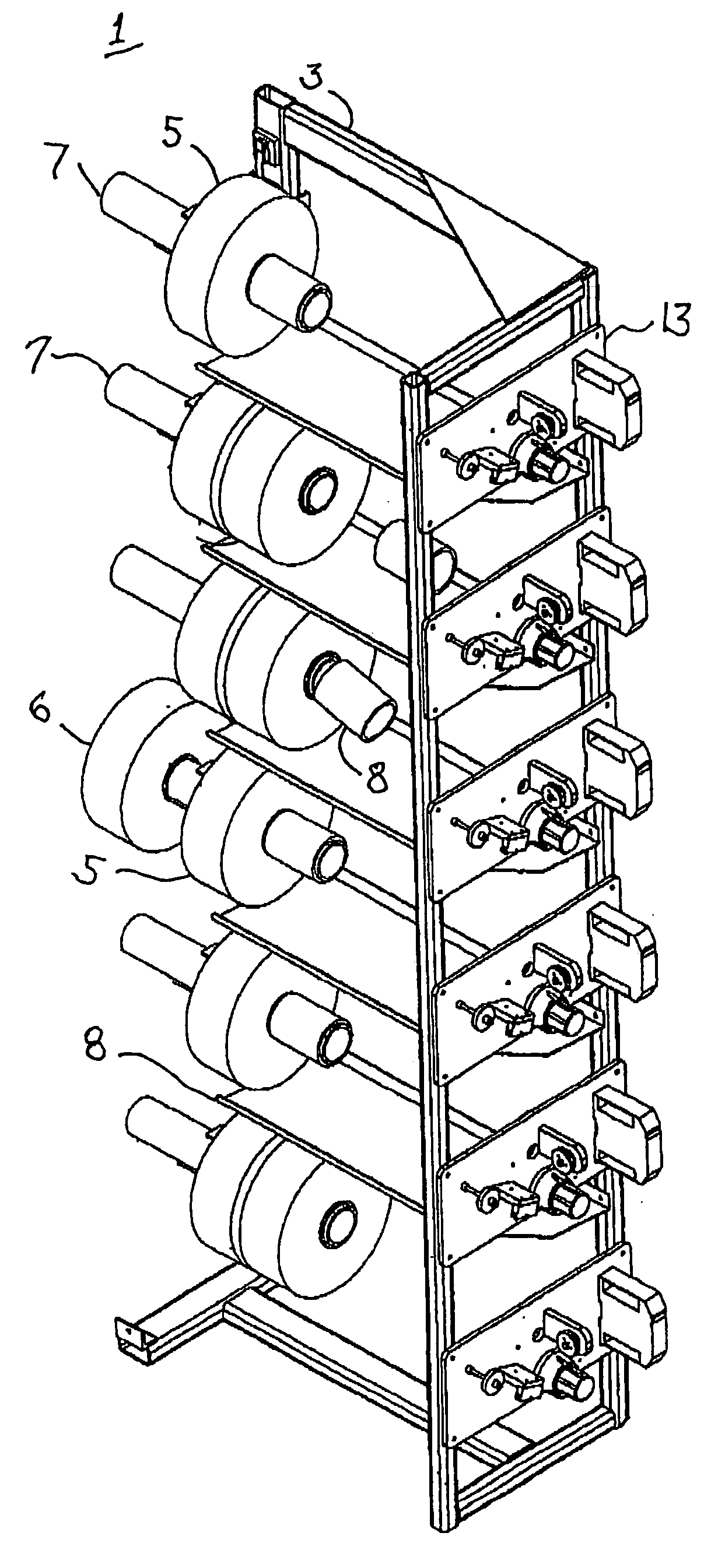

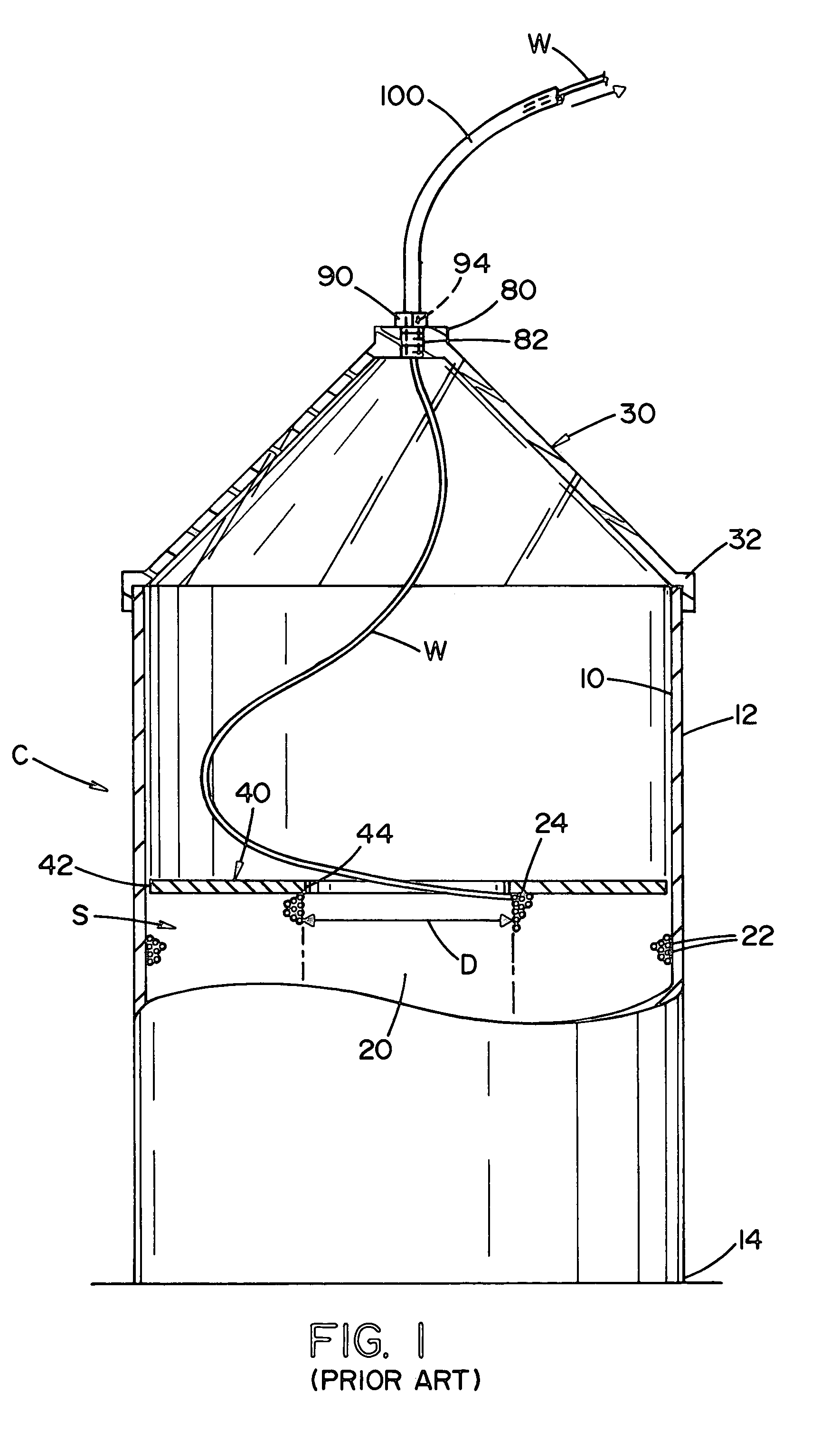

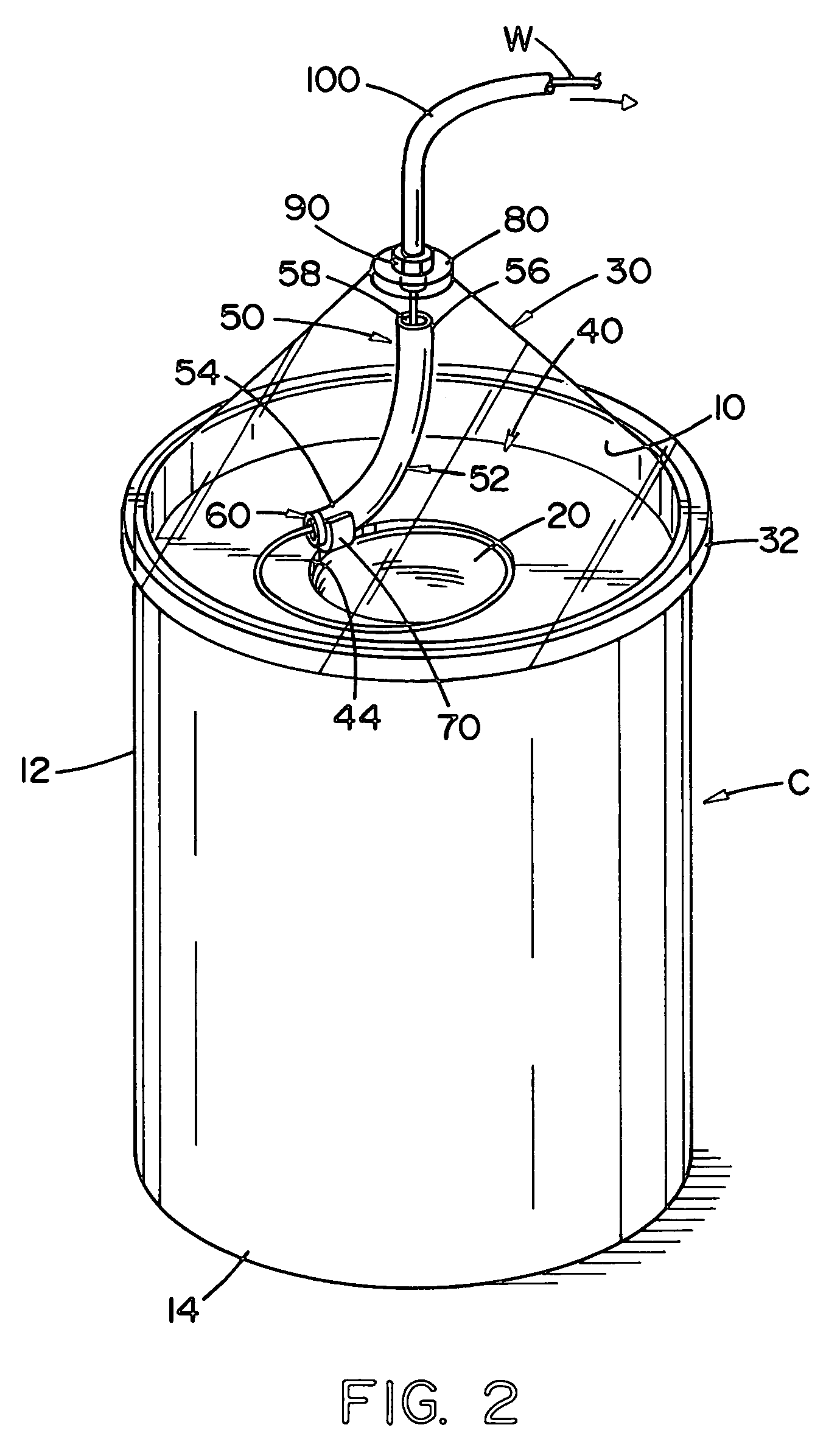

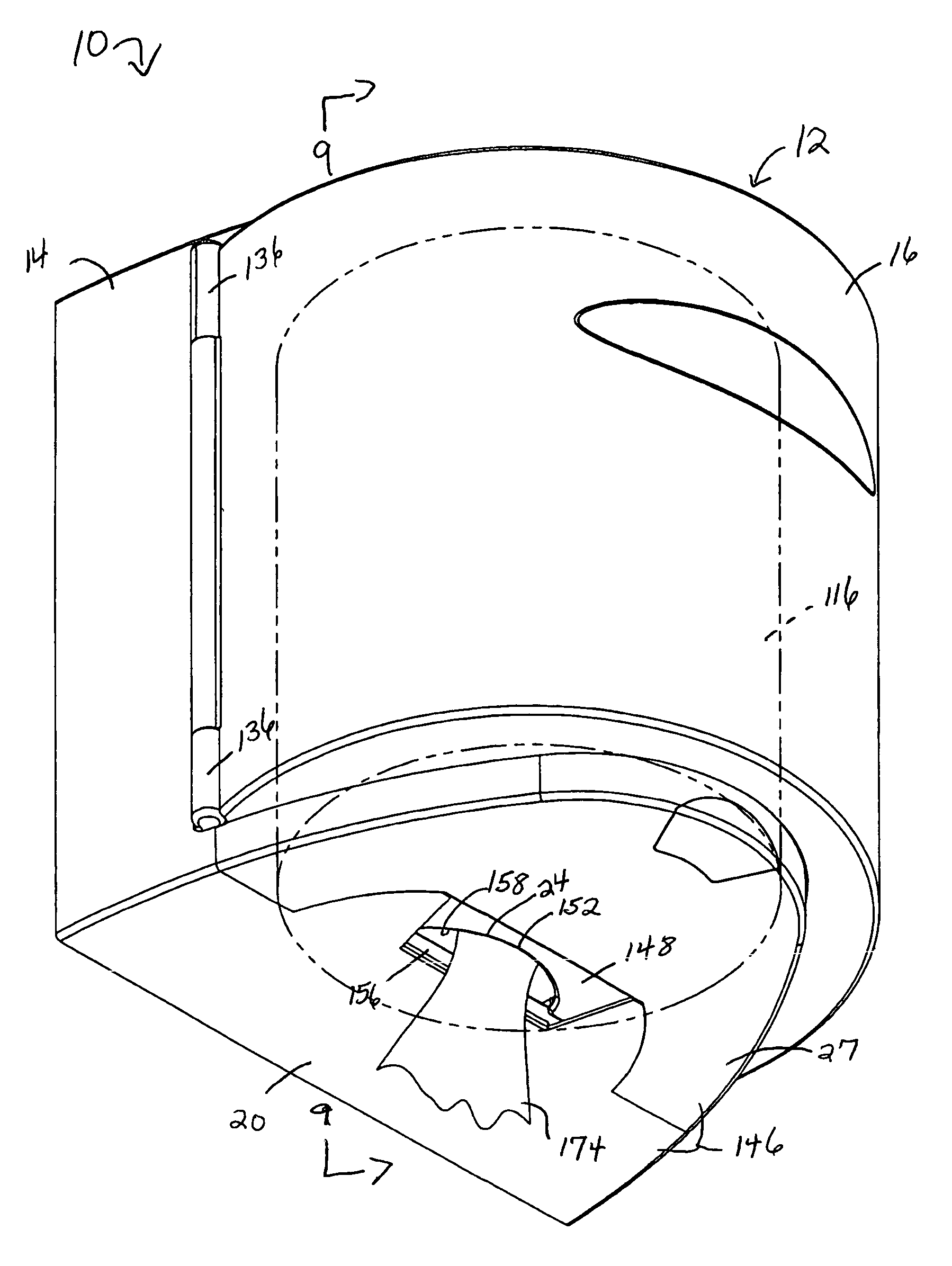

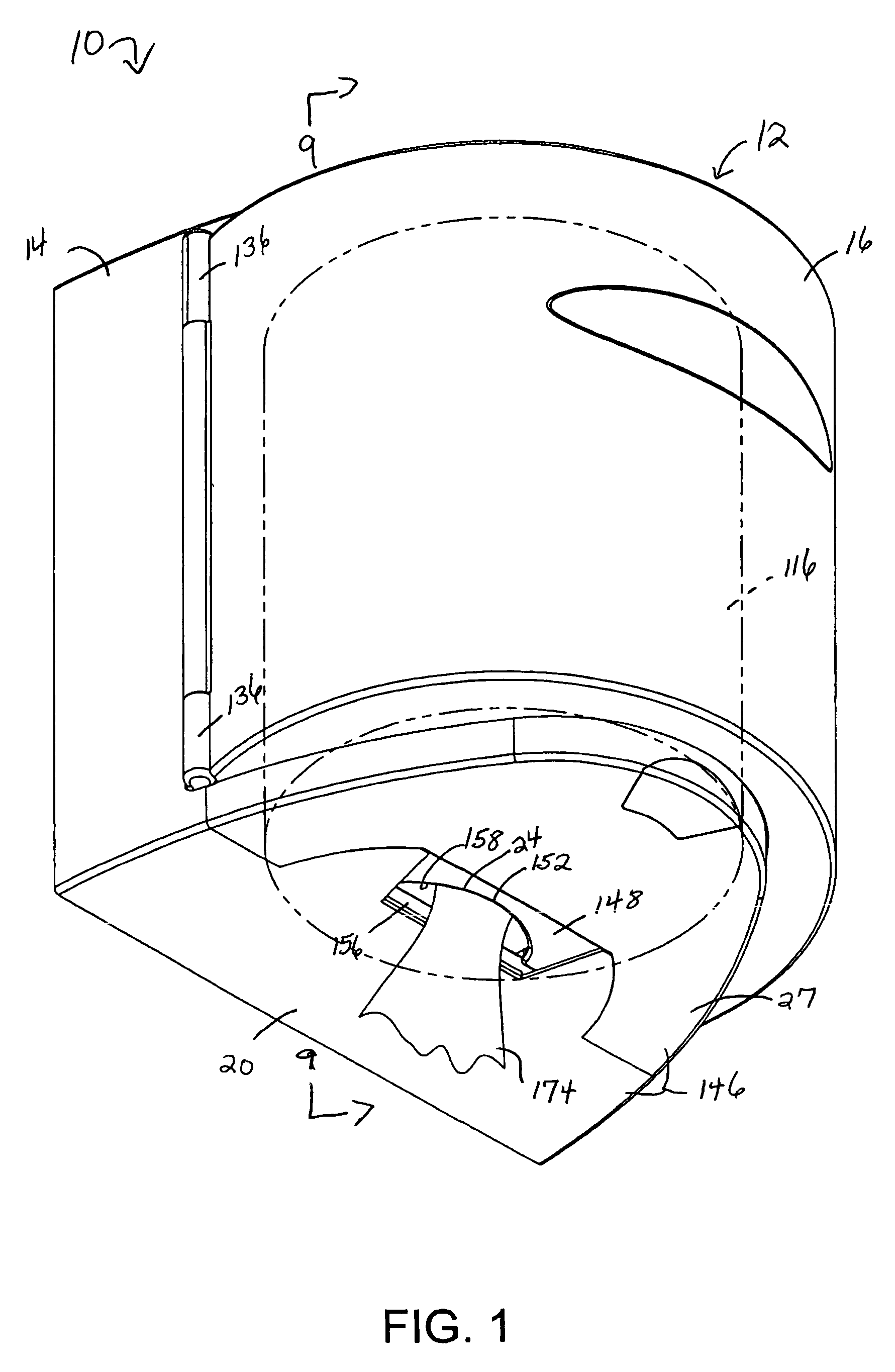

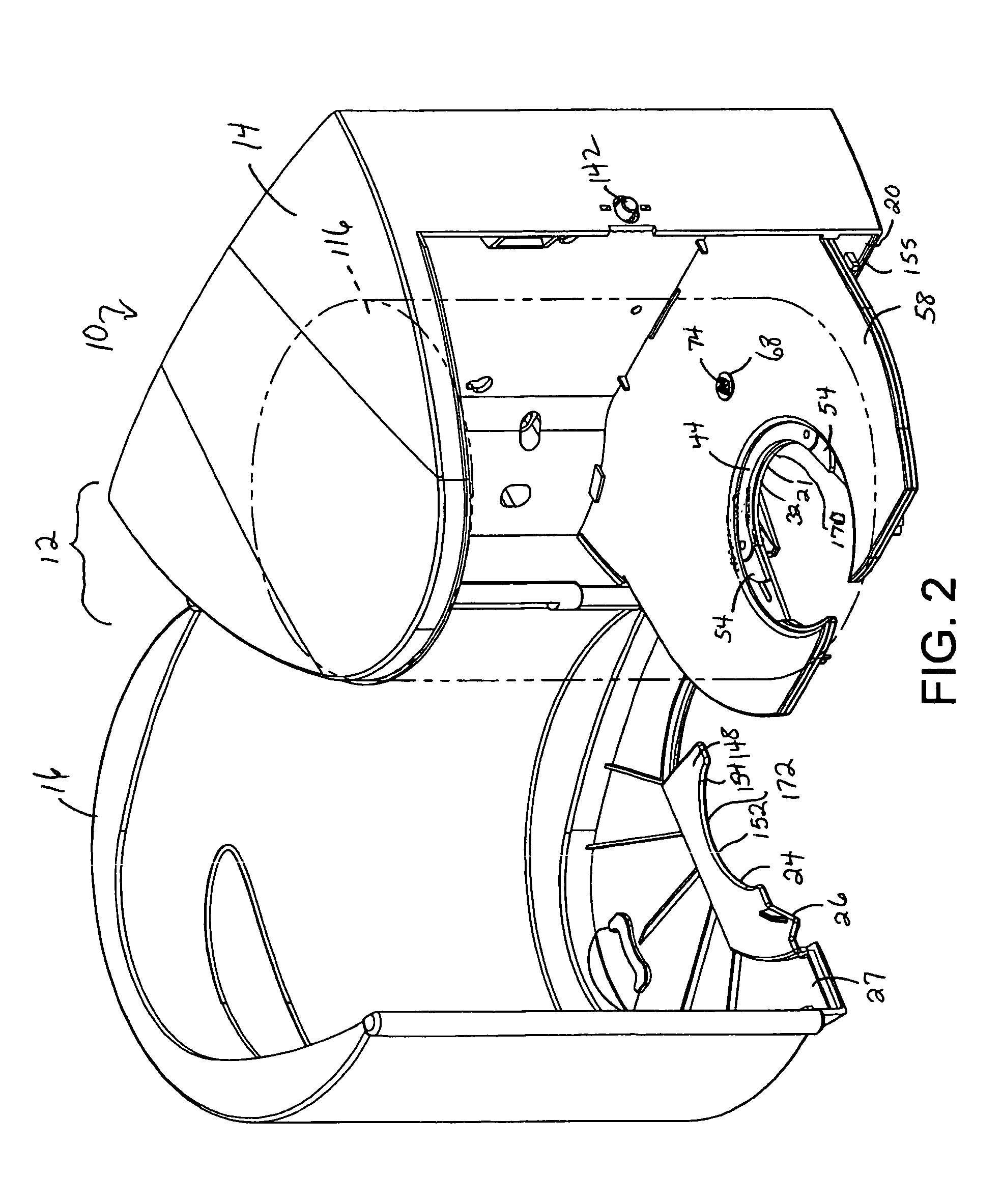

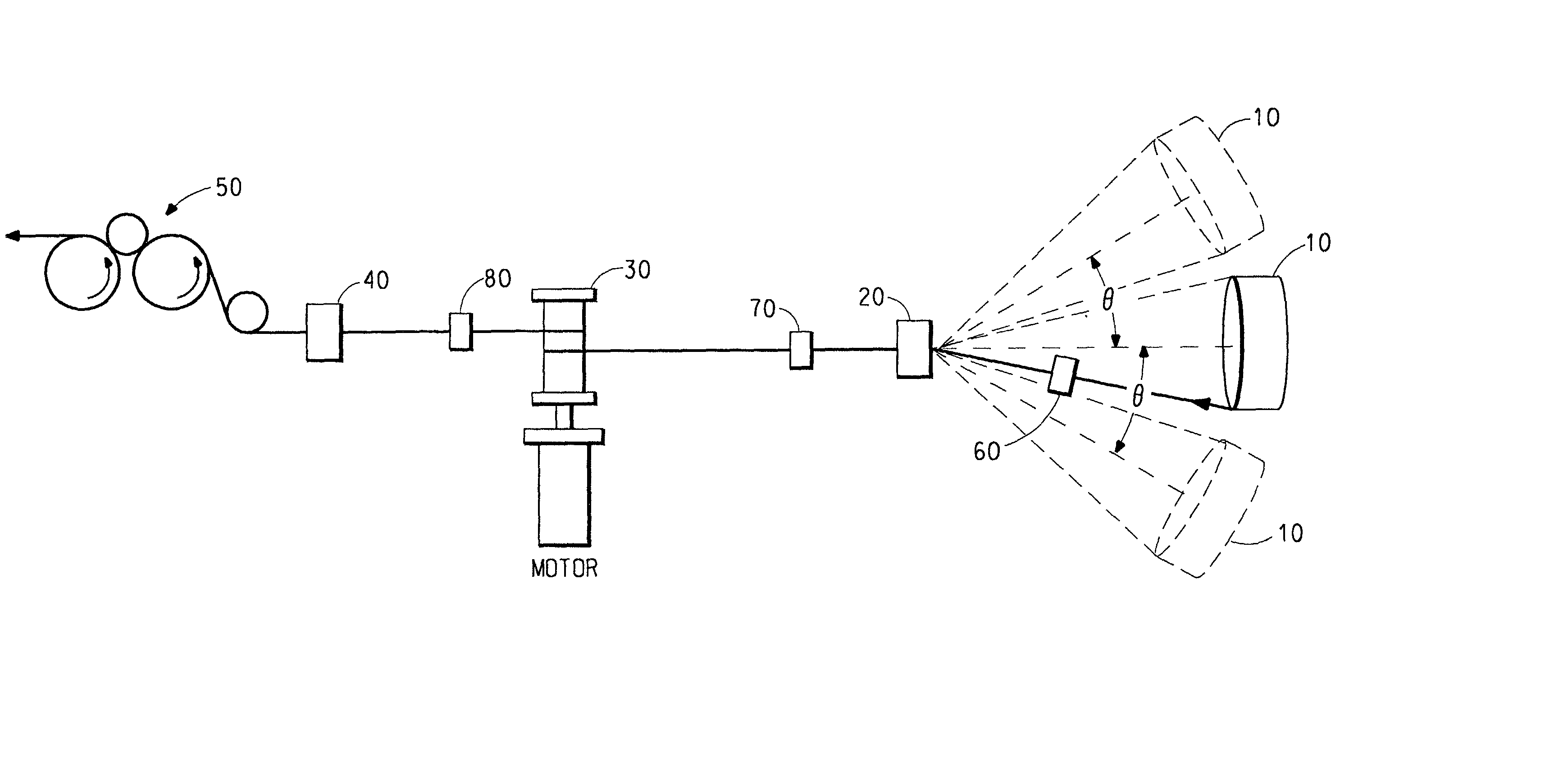

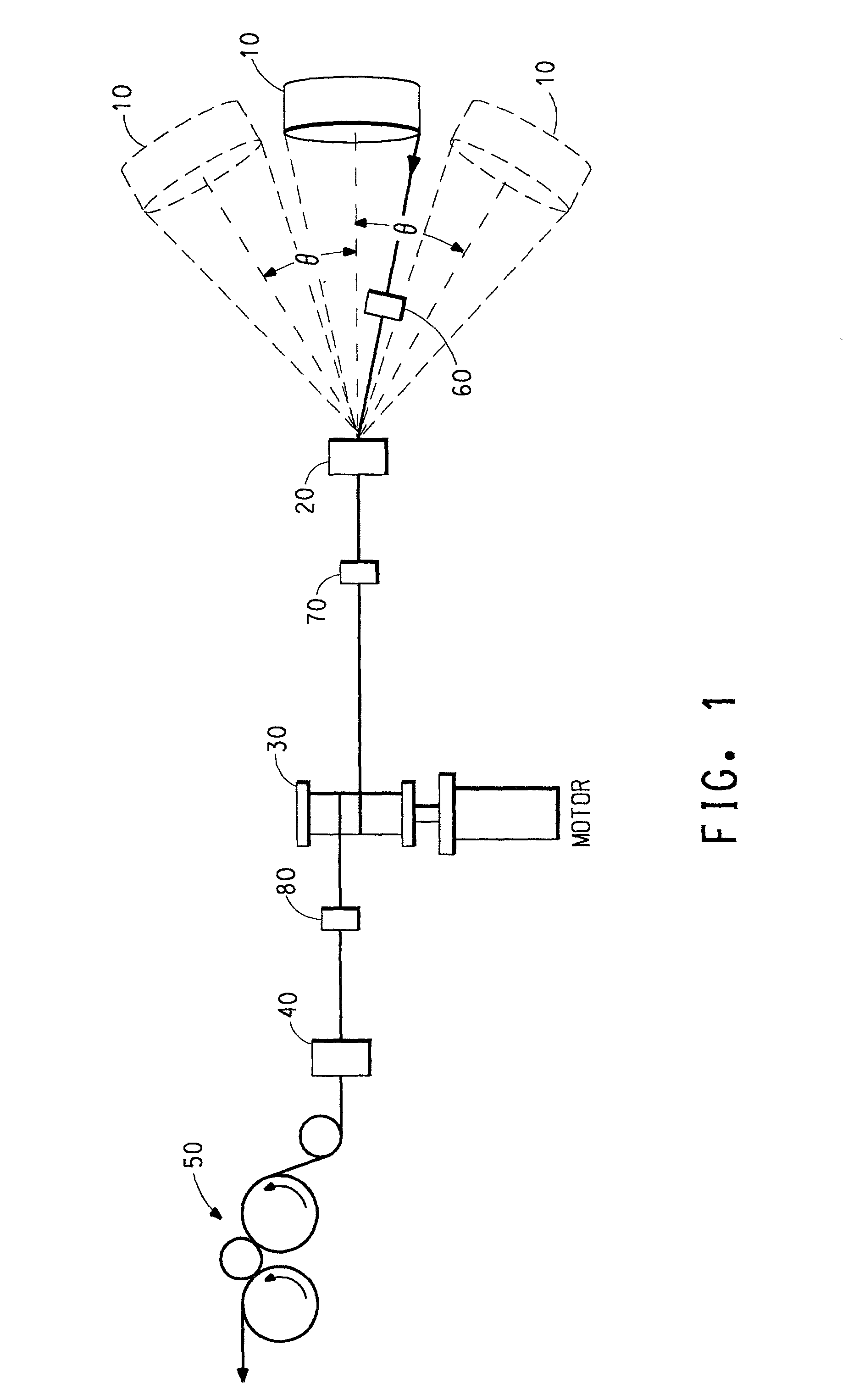

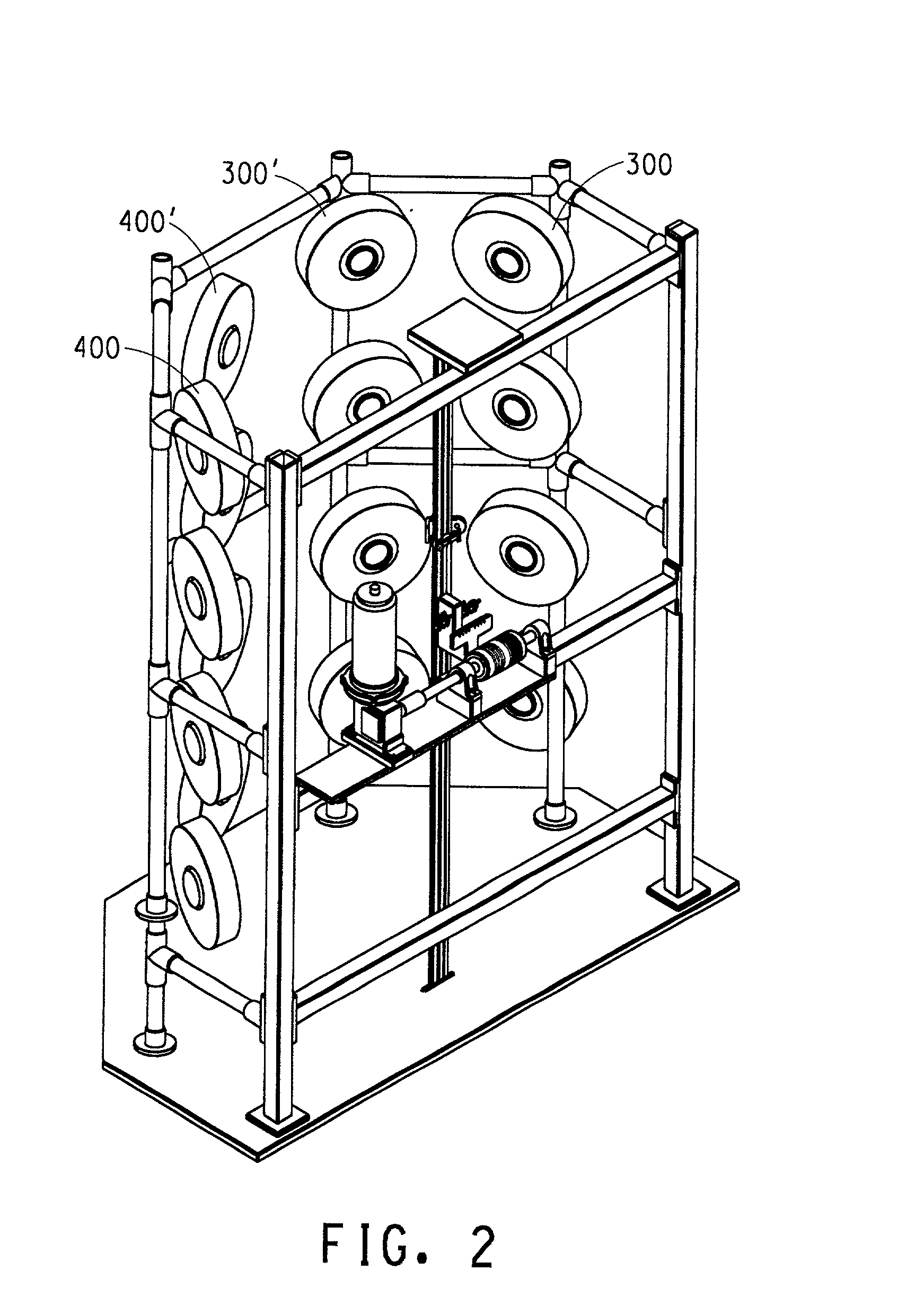

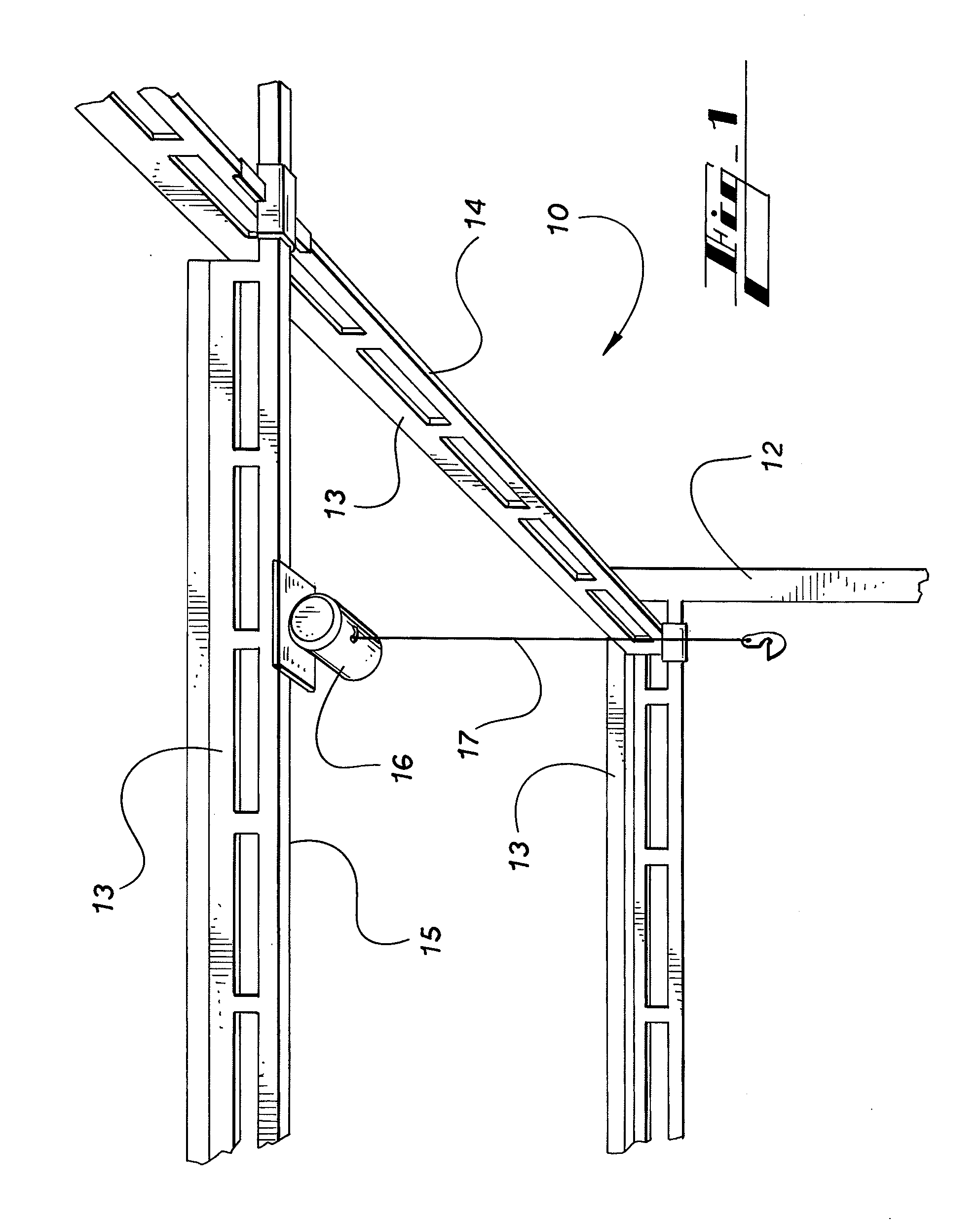

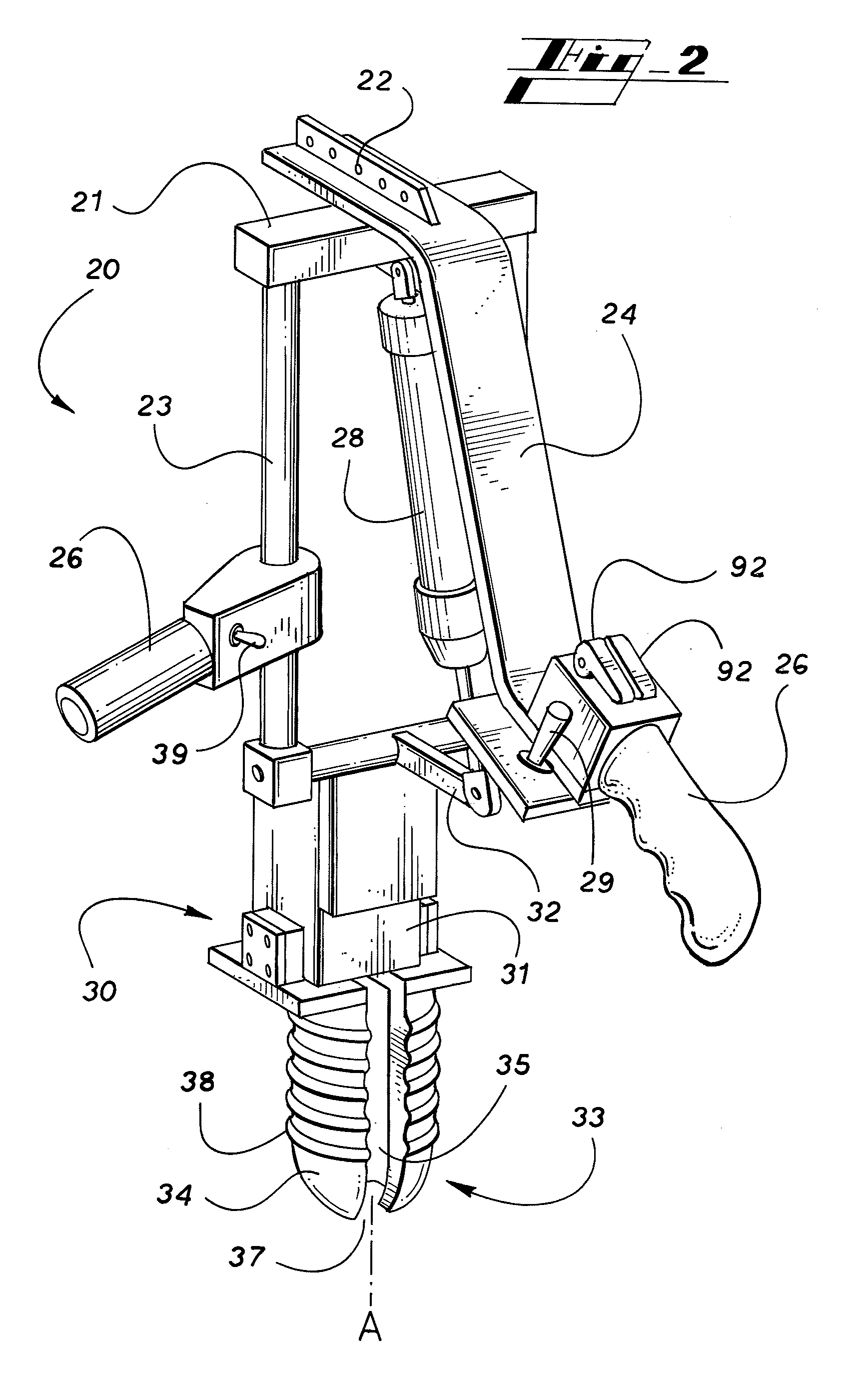

Compact single mandrel creel for over end take-off thread delivery

InactiveUS20070084960A1Fast and reliable methodIncrease the number ofLoomsFilament handlingFiberSmall footprint

The present invention compact creel using the OETO method that accommodates an increased number of packages in a relatively small footprint while providing a straight in-line delivery path in which fiber bends and changes in direction are minimized. In addition, the present invention is a system, apparatus and method for tension control in a fiber feeding system that provides a fast and reliable method for feeding high tack elastomeric thread or fiber from a package to a manufacturing process. Furthermore, the present invention provides a method and apparatus for changing packages on a creel without interrupting the manufacturing process. In particular, the compact creel of the present invention provides for continuous operation of unwinding and fiber delivery by allowing a standby package to be loaded on the same mandrel as an active package that is presently being unwound.

Owner:INVISTA NORTH AMERICA R L

Multiple yarn delivery to a single needle method and apparatus

A textile machine receives a plurality of yarn strands from a yarn supply. A header receives the yarn strands where multiple strands are combined for joint direction to the textile machine. Beams with multiple yarn strands wrapped thereon preferably function as the yarn supply and the header may direct through yarn tubes to a staging header for use by the textile machine. The textile machine is preferably a tufting machine and multiple yarn strands are received by at least one needle of the tufting machine.

Owner:MILLIKEN & CO

Anti-twisting type sectional warping machine

The invention discloses an anti-twisting type sectional warping machine. The anti-twisting type sectional warping machine comprises a bobbin creel, a yarn fixing rack, a yarn distributing device and a drum, wherein the bobbin creel comprises a rack, yarn guiders, a flexible cover and yarn cone shafts; yarn cones are placed on the yarn cone shafts; the yarn cone shafts are fixed on the rack; each yarn cone shaft is provided with the corresponding yarn guider; and the flexible cover is fixed on the rack and covers the yarn cones. The anti-twisting type sectional warping machine is simple in structure; the circumstance that warp yarns are twisted together and are knotted in a warping process is avoided effectively; and the warping efficiency is improved.

Owner:佛山市三水三强塑胶有限公司

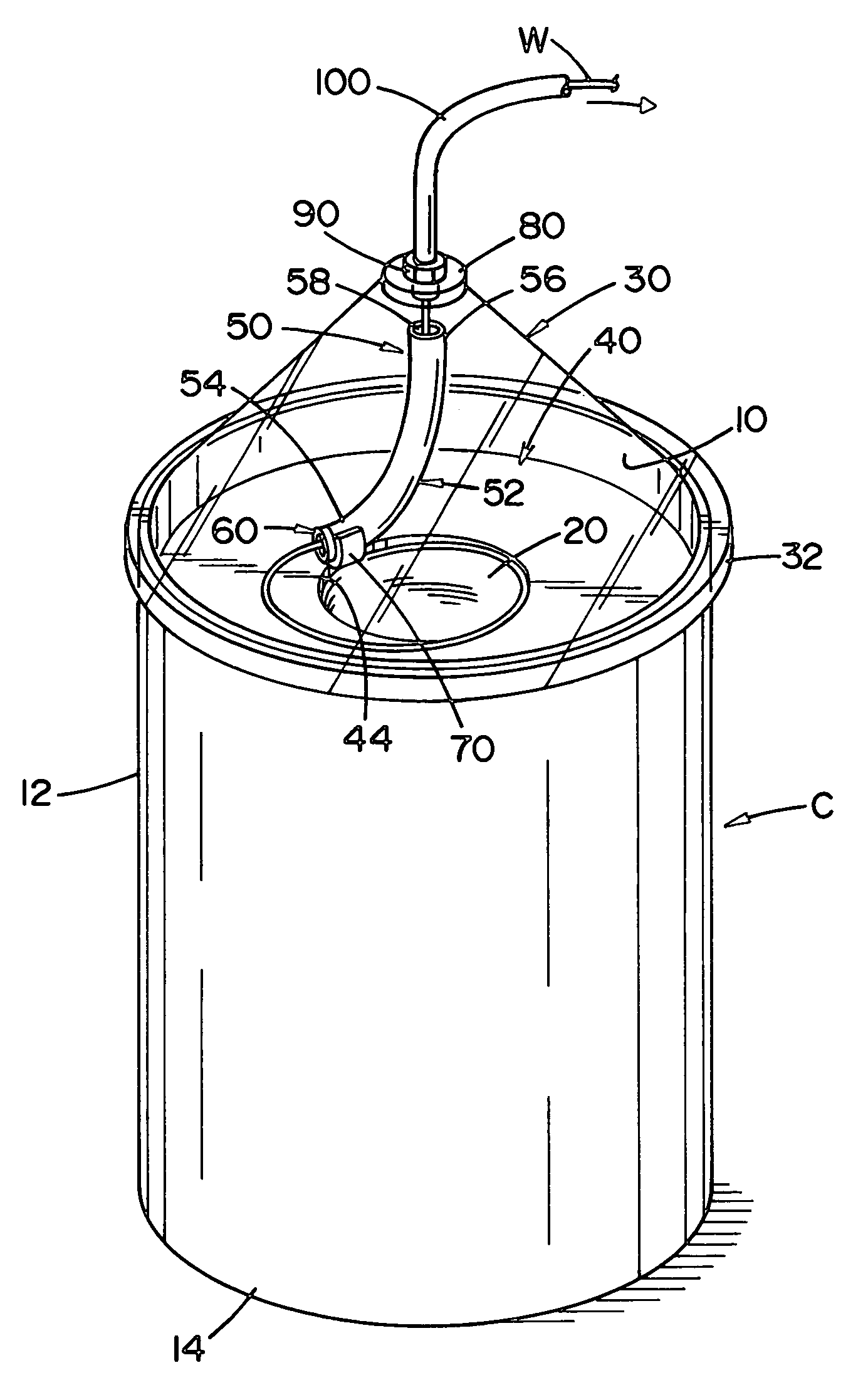

Floating liner

A floating liner for a container of welding wire which floating liner includes a tube having two ends and a passageway extending between the two ends. The floating liner is unsupported between the top of the container and the retaining ring. The floating liner is designed to provide structural support to the wire and added stiffness or rigidity to the wire to inhibit buckling of the wire, knot formation in the wire that can form between the retaining ring and the top of the container. The floating liner has a weight profile that causes one end of the tube to at least partially float above the top surface of a layer of welding wire or retaining ring in the container as the welding wire is paid out of the container.

Owner:LINCOLN GLOBAL INC

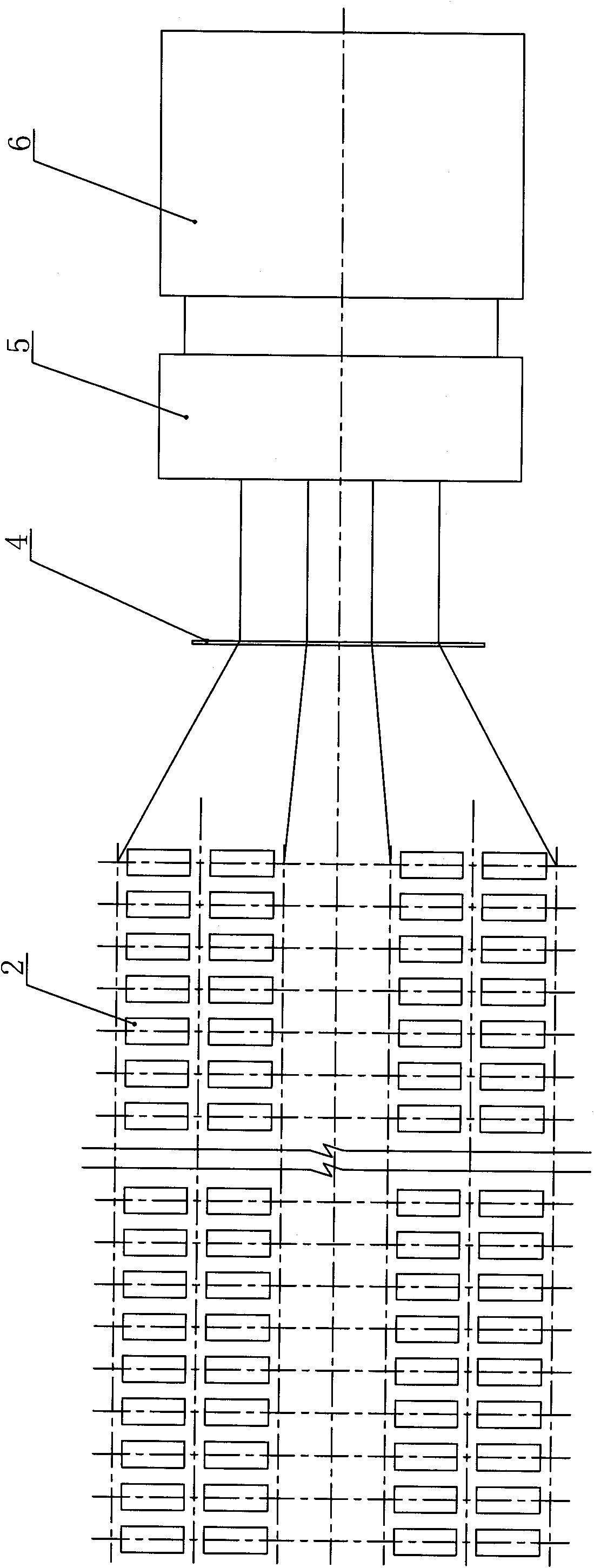

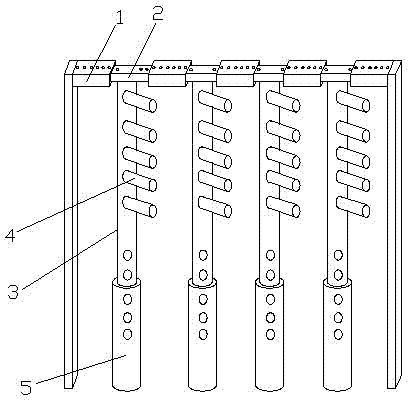

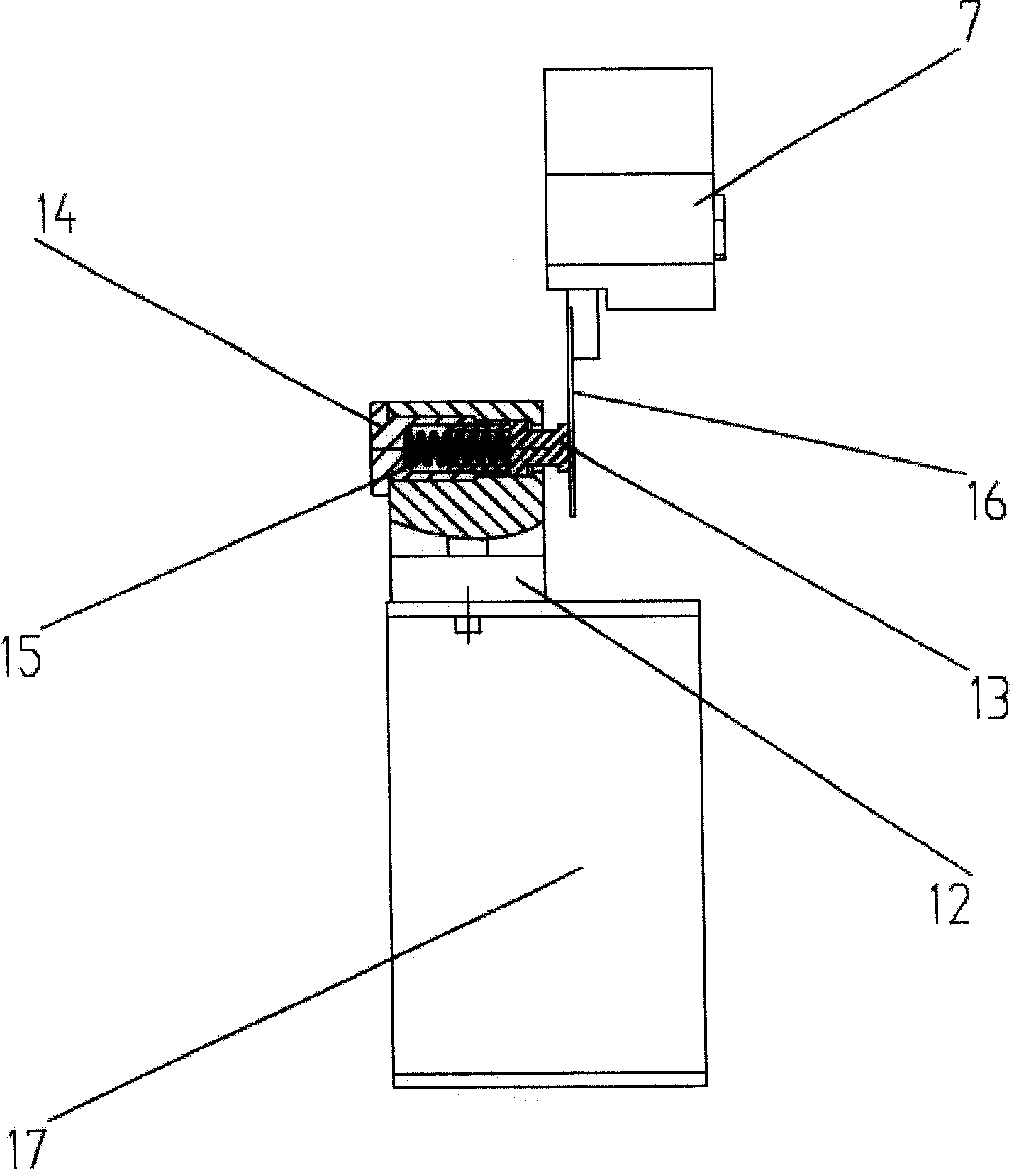

Carbon fibre bobbin creel

The invention discloses a carbon fibre bobbin creel in the field of textile machinery, which comprises a frame, a spindle blade and a carbon fibre bobbin, wherein the spindle blade is arranged on the frame; the carbon fibre bobbin is sleeved on the spindle blade; each spindle blade and each carbon fibre bobbin are distributed on the frame in an array; fixed and movable friction plates engaged with each other are arranged outside an inner end plate of the carbon fibre bobbin; a first rubber layer is arranged between the fixed friction plate and the frame; a second rubber layer is arranged between the movable friction plate and the inner end plate of the carbon fibre bobbin and adhered to the inner end plate of the carbon fibre bobbin; the first rubber layer is adhered to the frame; the end of the spindle blade is provided with a tension spring and a nut; and a silk guide plate is arranged every five carbon fibre bobbins and provided with an aluminium oxide guide groove. The bobbin on each spindle blade of the bobbin creel can automatically provide tension force for the carbon fibre and adjust the tension force according to the thickness of the carbon fibre bundle; and the carbon fibre led out has basically the same tension force and less wearing.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

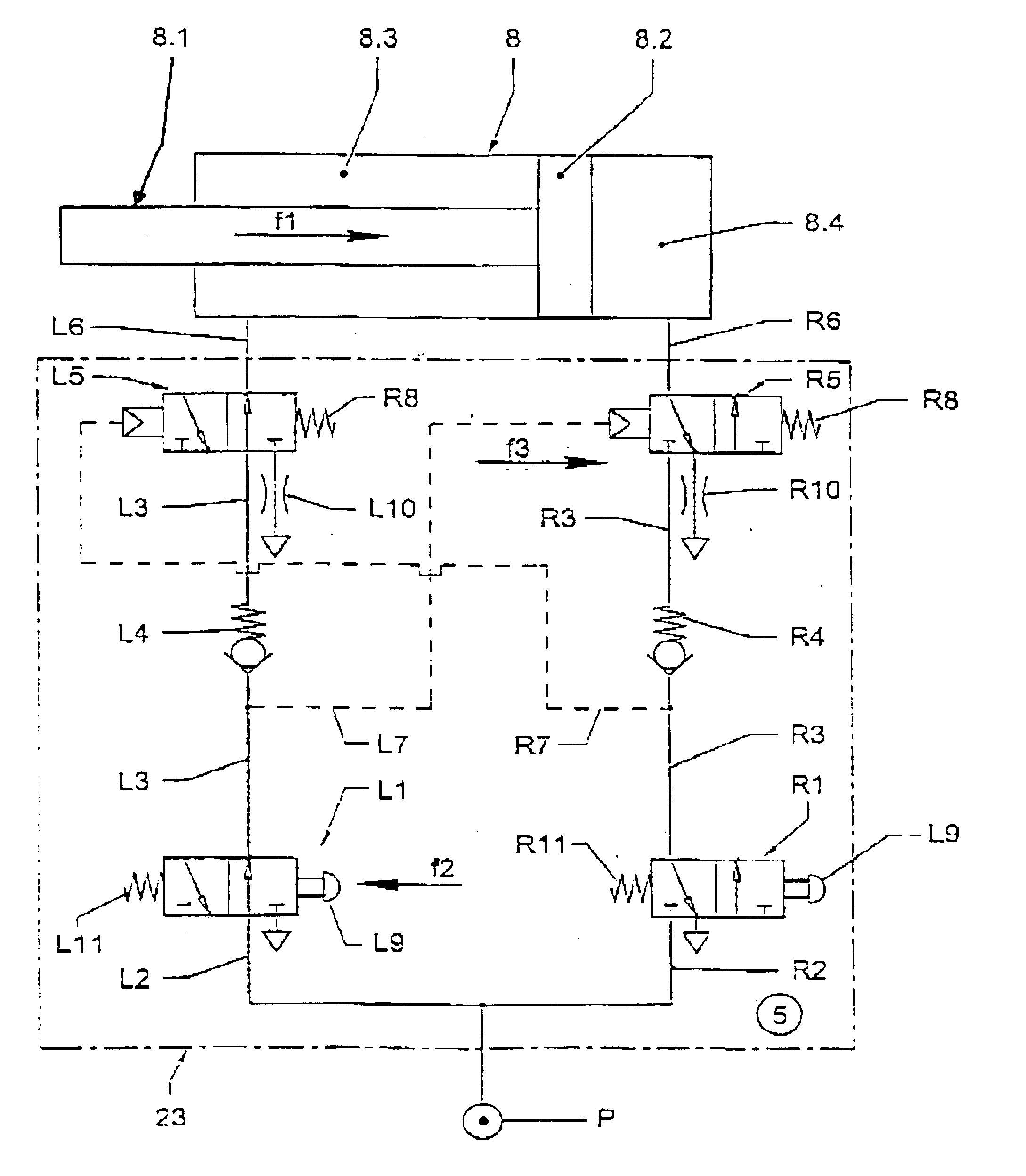

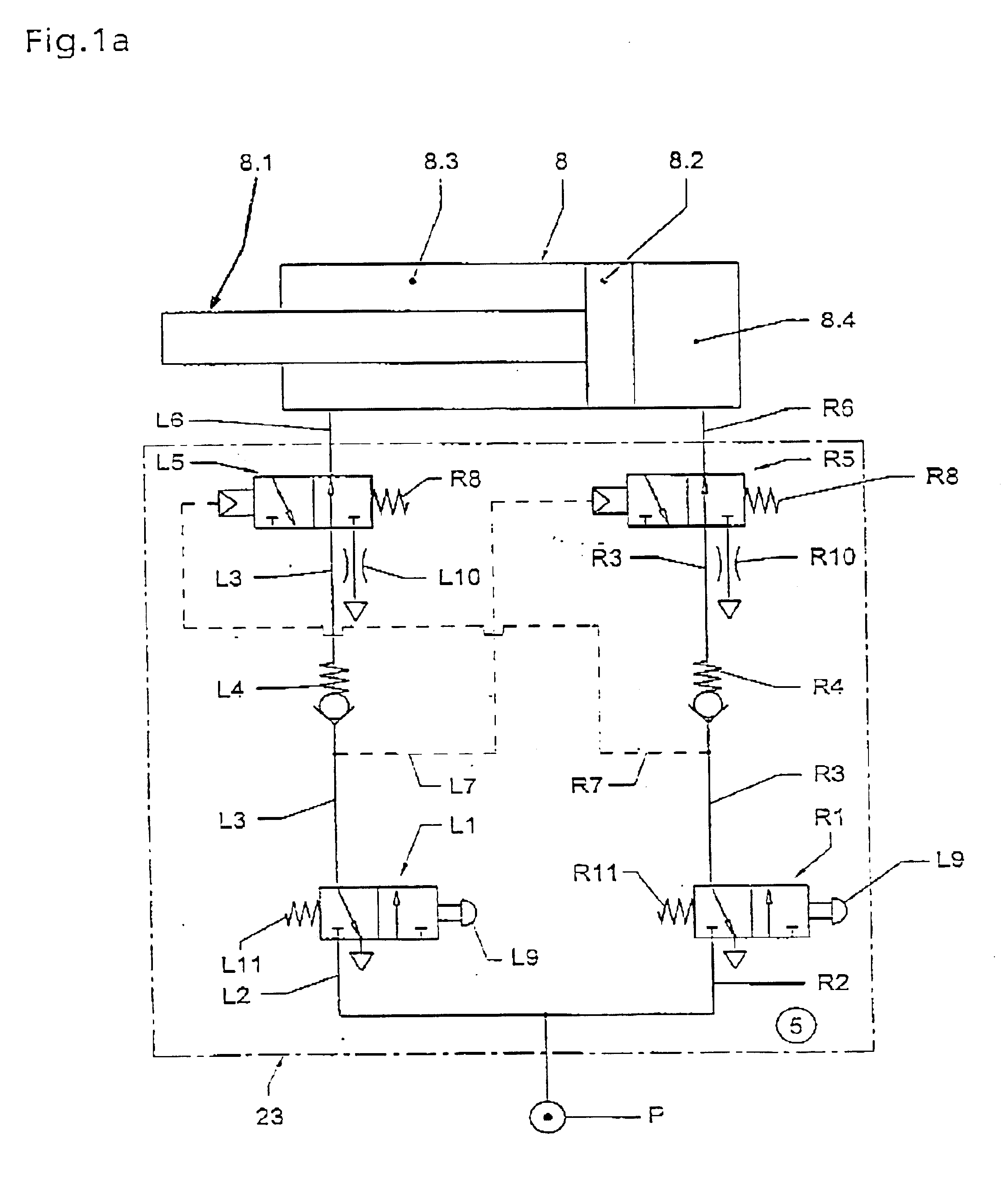

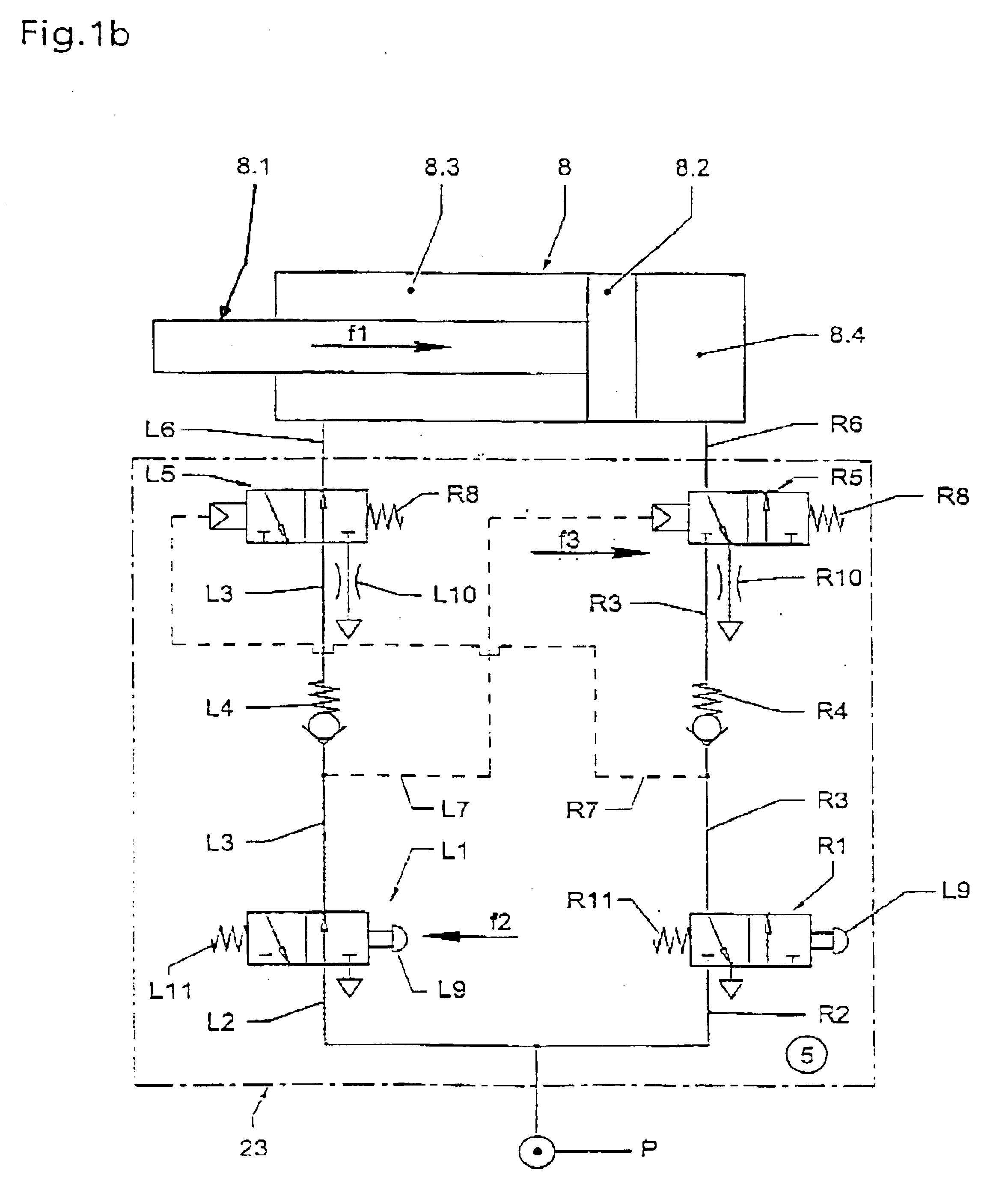

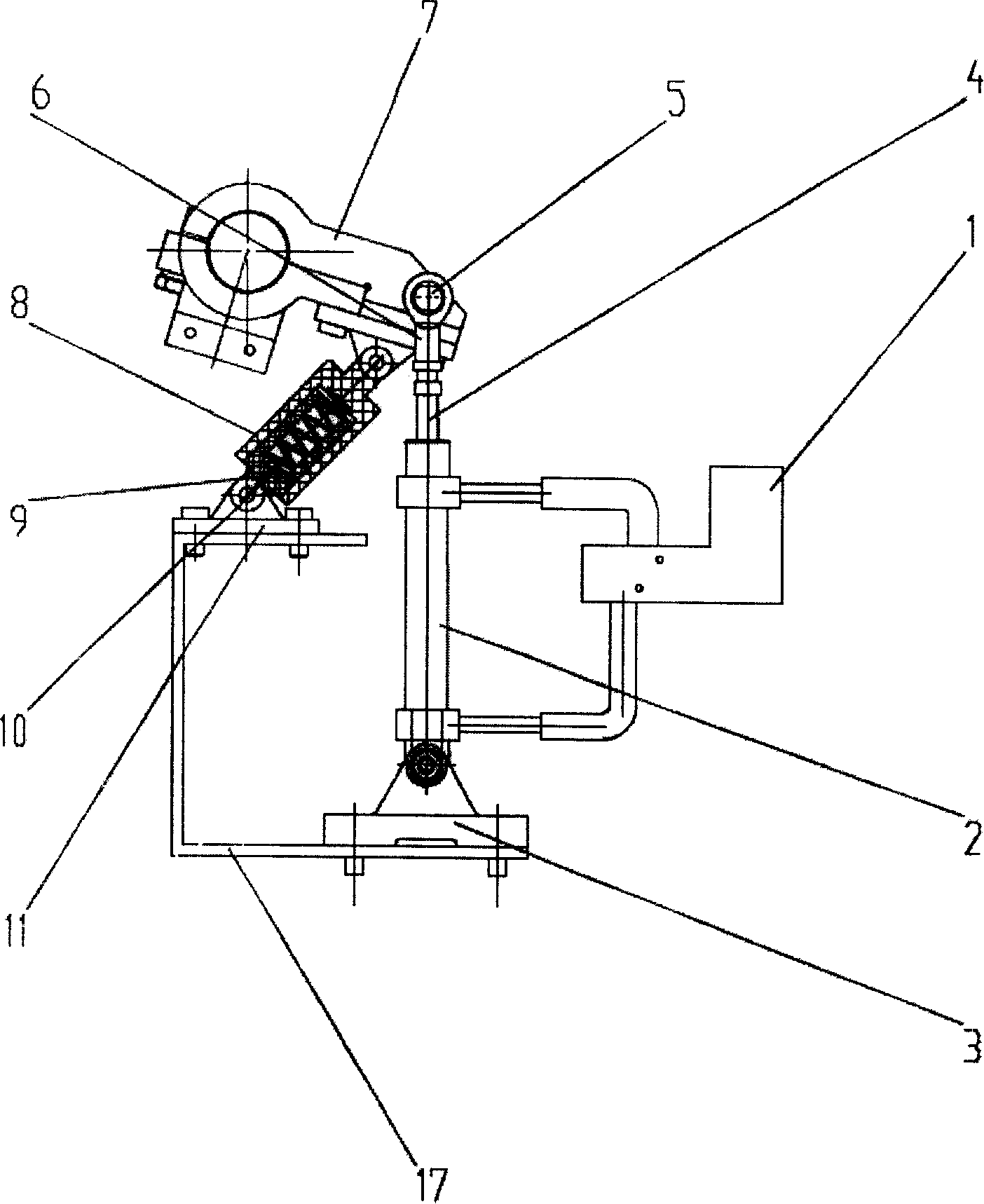

Actuating valve for bidirectional pneumatic cylinder and use of such actuating valve for bobbin creels controlled by pneumatic cylinders

InactiveUS6848641B2Reduce decreaseCompact configurationServomotor componentsServomotorsBobbinControl line

An actuating valve has two relay valves connected to a compressed air source and a pneumatic cylinder with two pressure chambers. When one relay valve is actuated, one pressure chamber is pressure-loaded and the other is relieved. Two 3 / 2 port directional control valves are arranged upstream of the pneumatic cylinder. Two check valves are positioned in branch lines connecting the relay valves and the directional control valves. A control line connects the branch line to the other directional control valve, respectively. The directional control valves are moveable between a first position allowing compressed air to pass and a pressure relief position. When the relay valves are inactive, the directional control valves are in the first position and the relay valves are in a venting position for the branch lines. When one relay valve is actuated, it assumes a position allowing passage of air to the branch line connected to it.

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

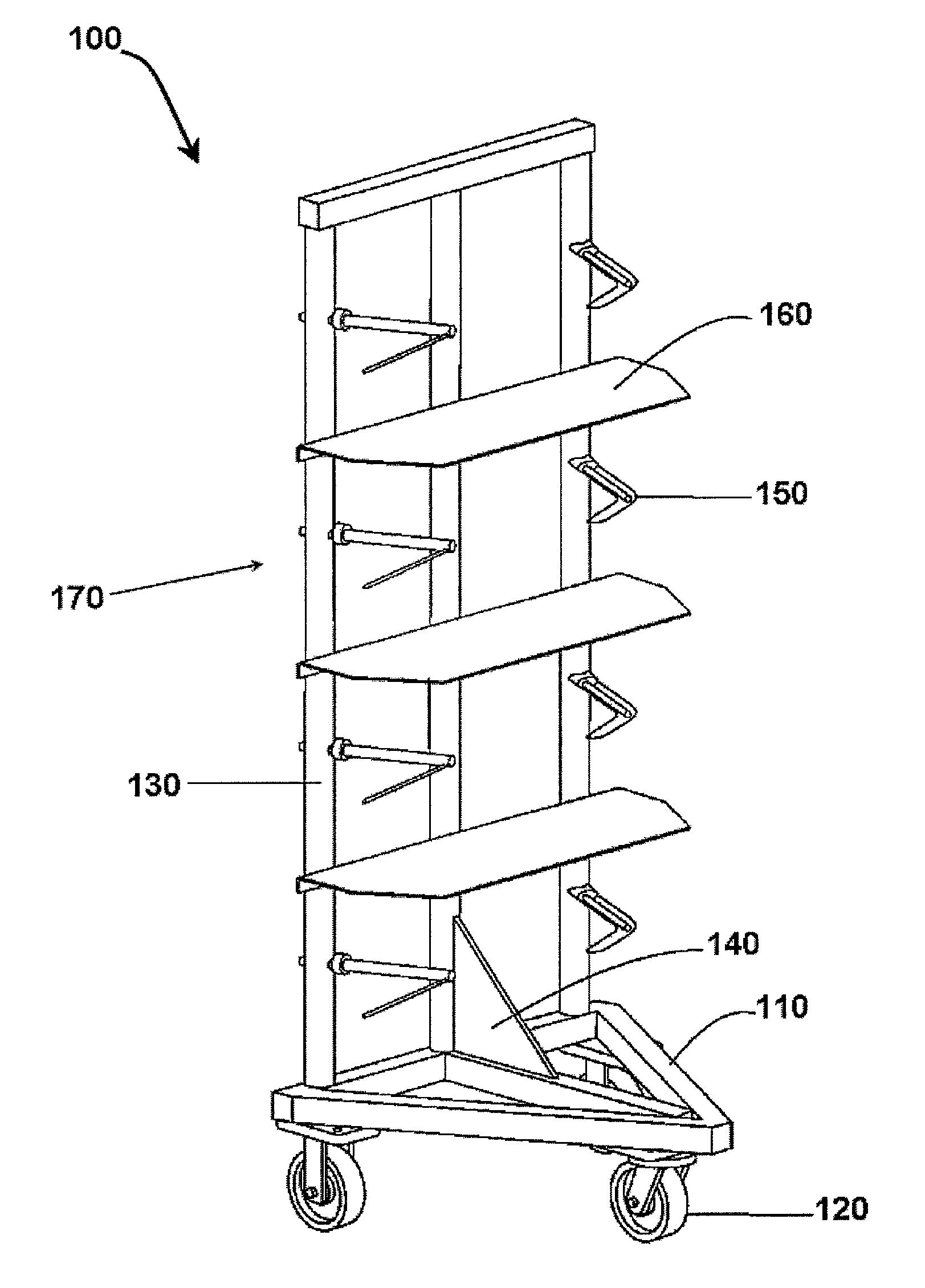

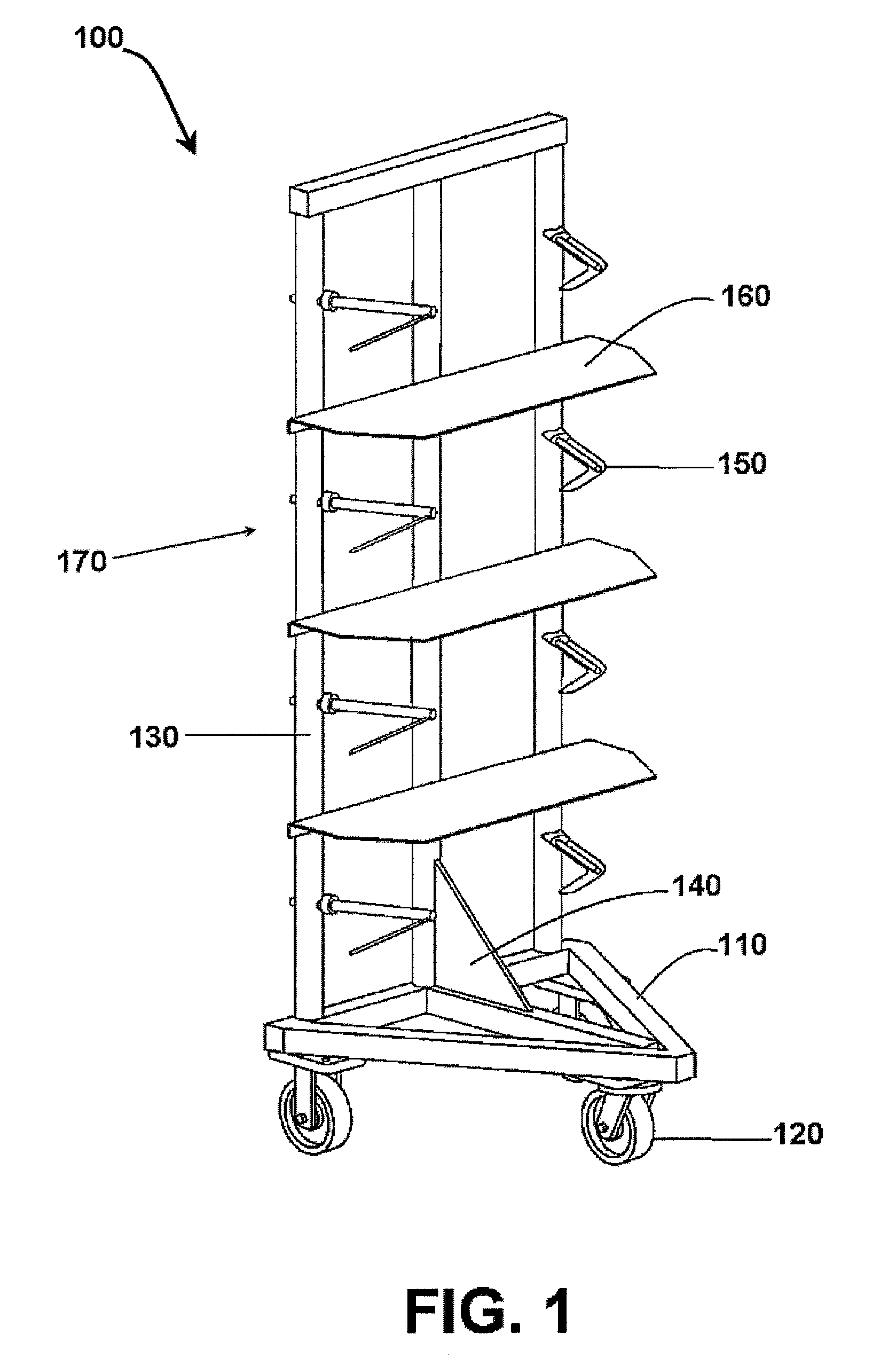

Portable Creels With Insertable Yarn Trays and Improved Headers and Yarn Handling Methods

Creels having frames configured to receive one or more trays of yarn packages. The trays of yarn packages are removable from the frame and can be loaded with packages of yarn when not inserted into the frame. Separately loading trays with yarns can simplify and provide other benefits with respect to the process of loading a creel with yarn packages. Also disclosed is an assembly that is positioned with respect to a detachable header and a stationary header on a creel and that comprises an air flow unit that causes yarns to move through to an alignment mechanism that aligns the yarns for attachment to yarns already feeding into a tufting machine.

Owner:INTERFACE INC

Dispenser for sheet material

Owner:KIMBERLY-CLARK WORLDWIDE INC

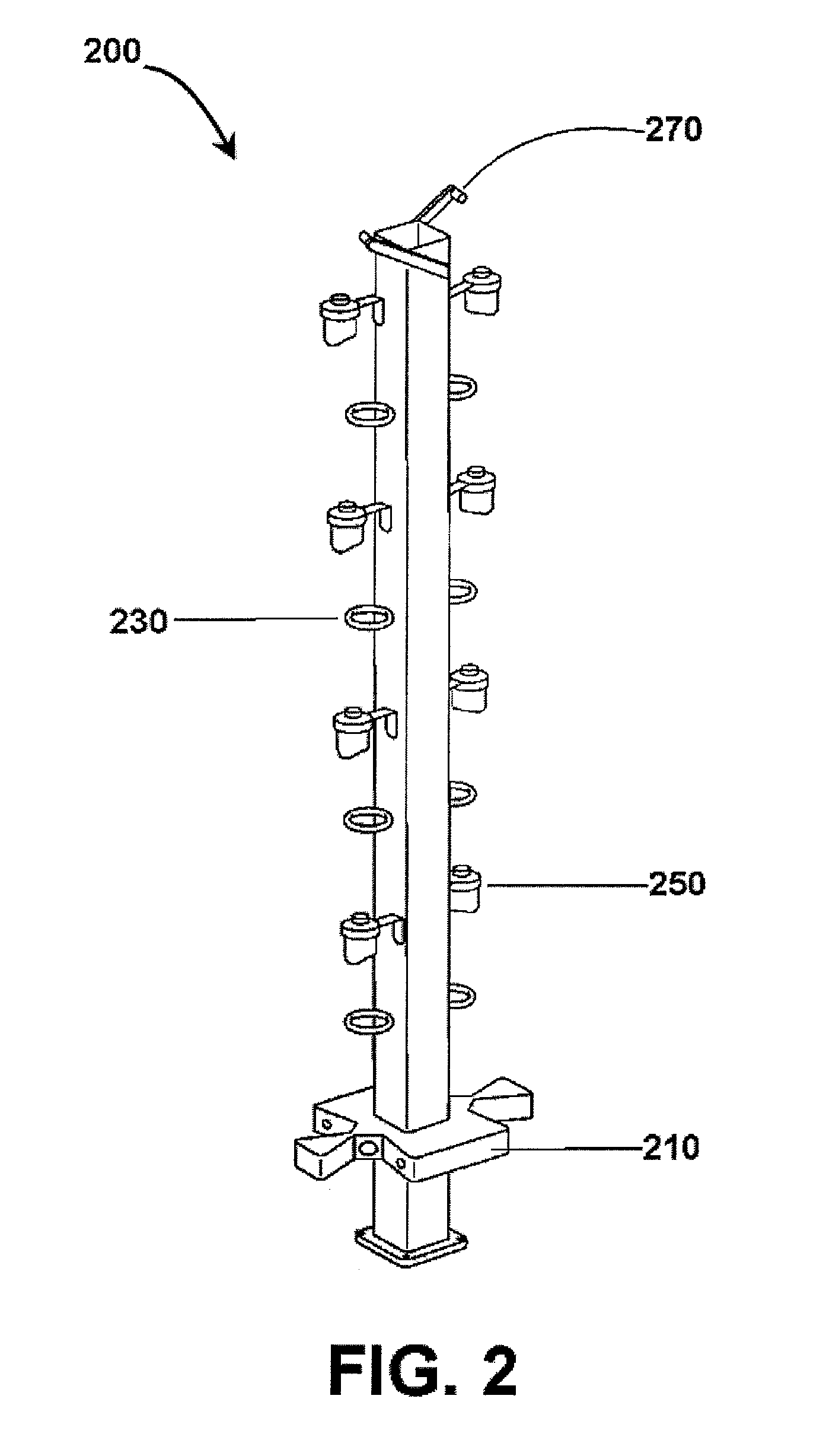

Yarn package supporting bracket for use on a creel

A yarn package supporting bracket for use on a creel and attached to the creel for swiveling between a yarn feeding position and a yarn package loading position. The bracket has a magnet and the creel has a magnetically attractable portion with the magnet and magnetically attracted portion having flat surfaces that are in flush contact when the bracket is in yarn feeding position to releaseably fix by magnetic force the bracket and yarn package in the yarn feeding position.

Owner:ZOLLINGER RICHARD V

Mobile creel

A mobile creel for organizing yarn packages and directing yarn is disclosed. In one aspect, the mobile creel has a plurality of support frames and an upright creel docking post. The front portion of the base of each support frame can be configured for engagement with the lower portion of the upright creel docking post. The creel docking post can simultaneously engage one, two, three, or four support frames.

Owner:COLUMBIA INSURANCE CO

Modular creel

A portable creel for organizing yarn packages and directing yarn to a tufting machine. A portable creel provides flexibility for carpet manufactures in that operators can pre-load portable creels with yarn packages for future runs and move them into position when needed. In one aspect, the portable creel comprises an outer frame and a movable inner frame. The inner frame is configured to hold a plurality of yarn packages and the outer frame comprises a plurality of tubes configured to direct the yarn from the yarn packages to a header. The header, in turn, directs the yarn from the portable creel to specific portions of a tufting machine.

Owner:COLUMBIA INSURANCE CO

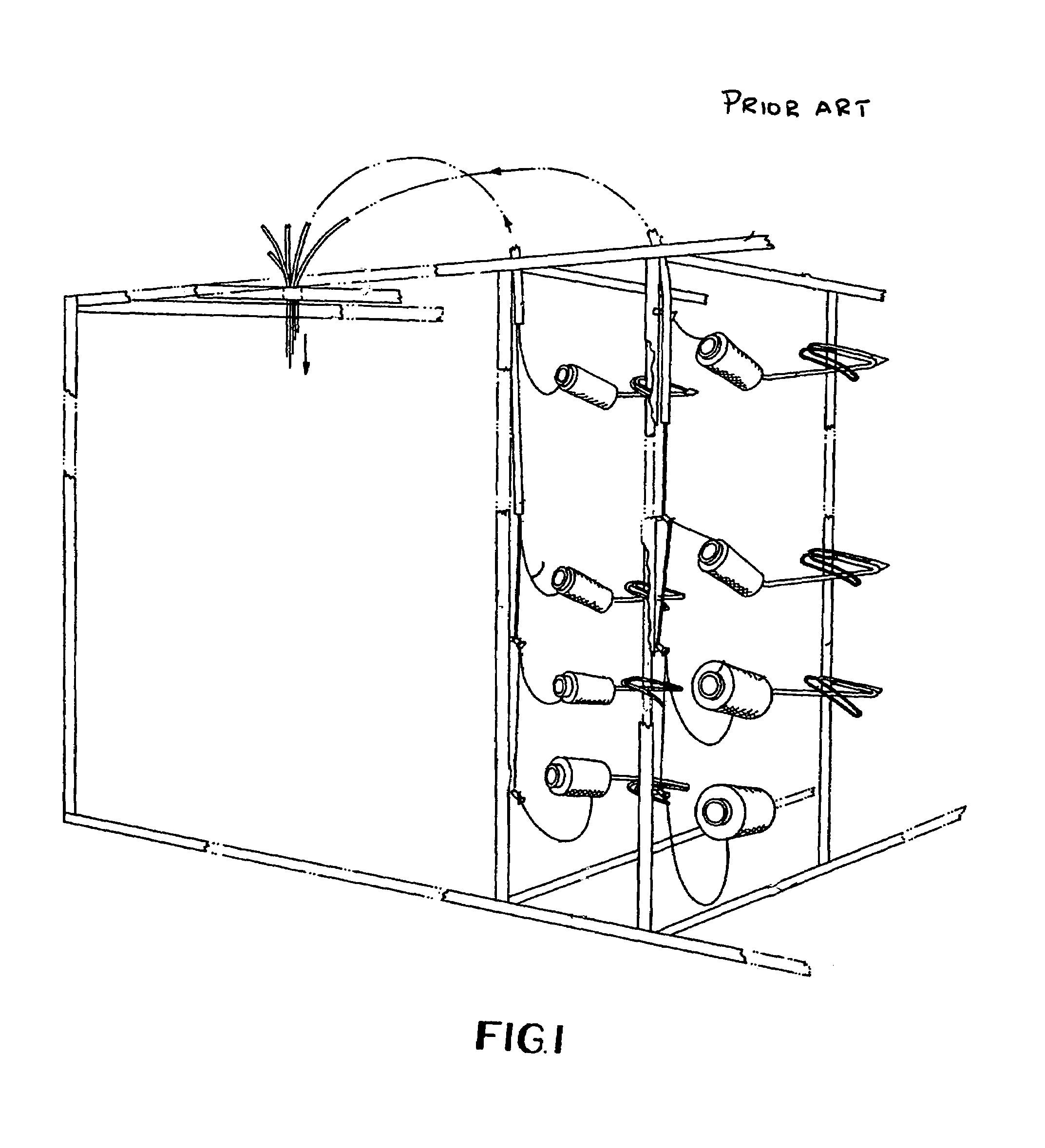

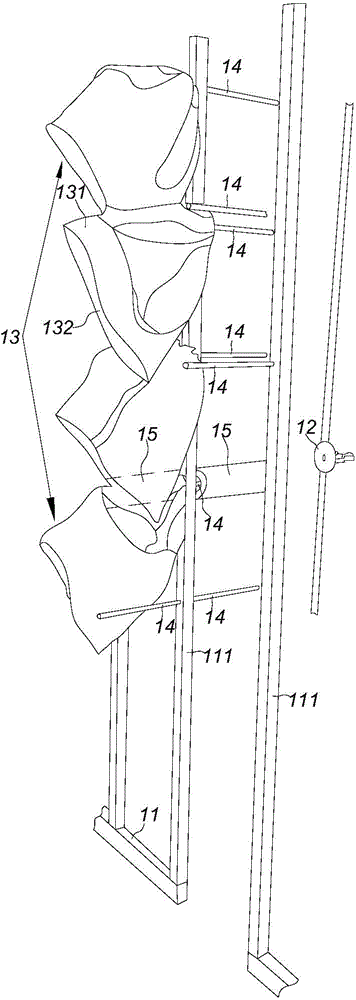

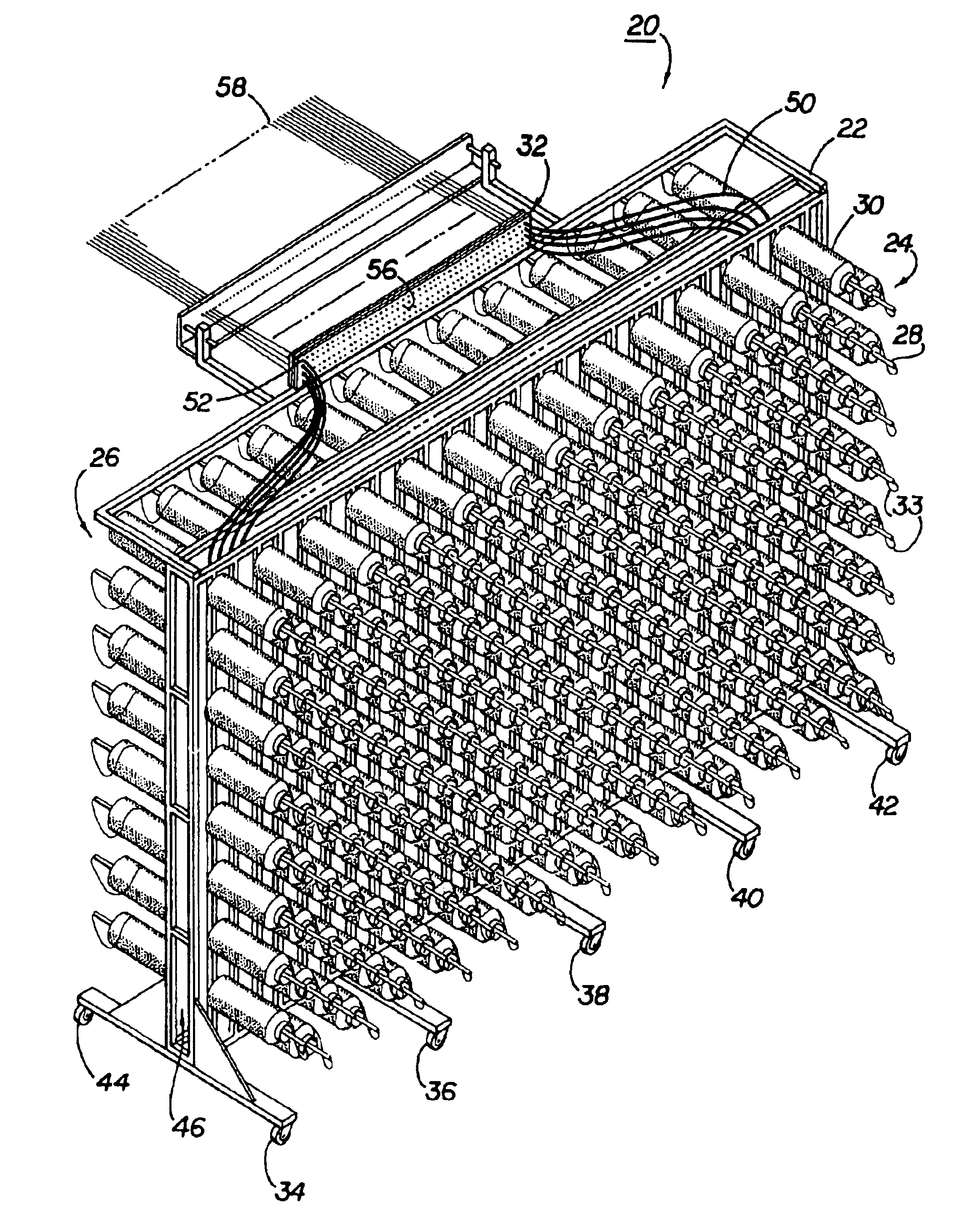

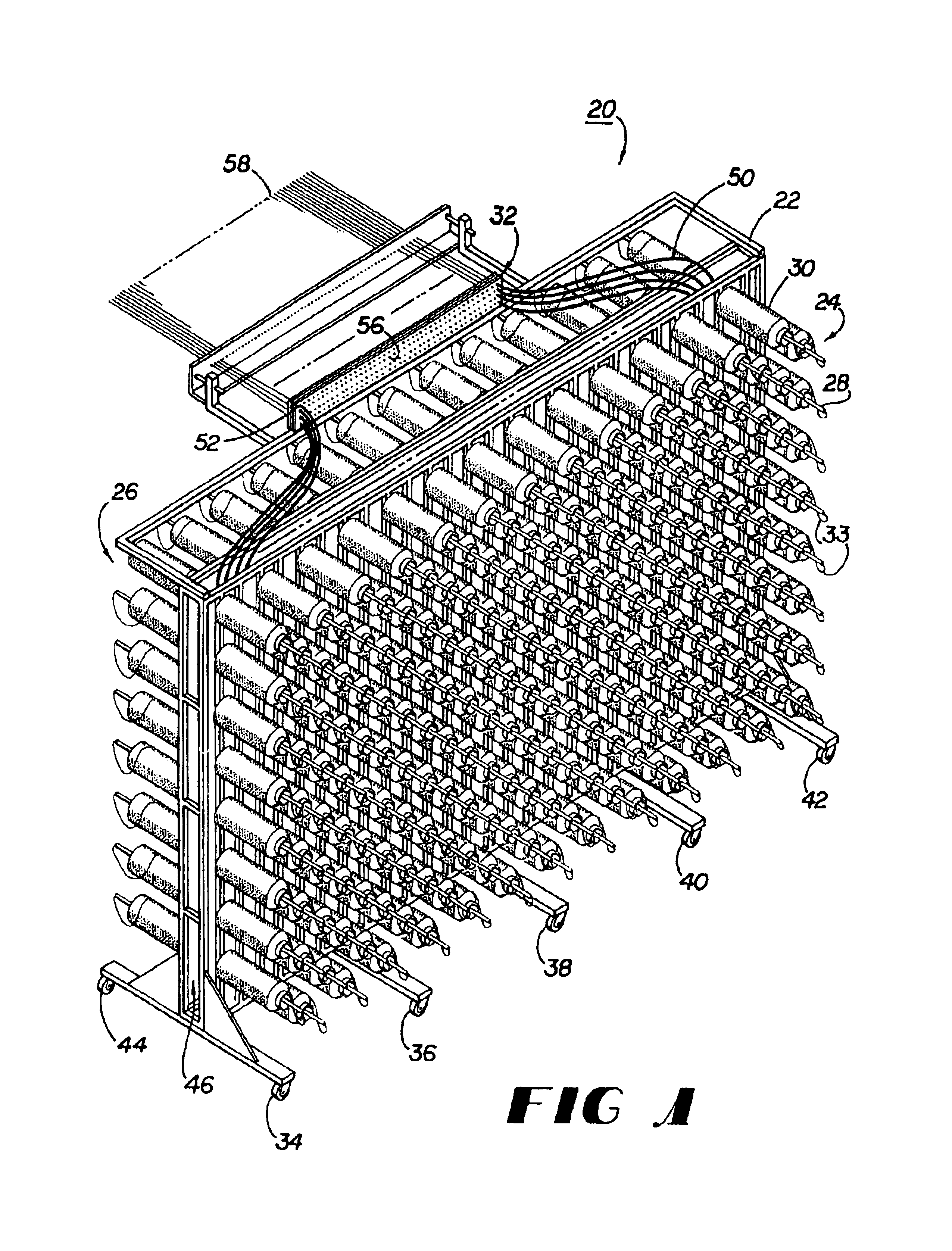

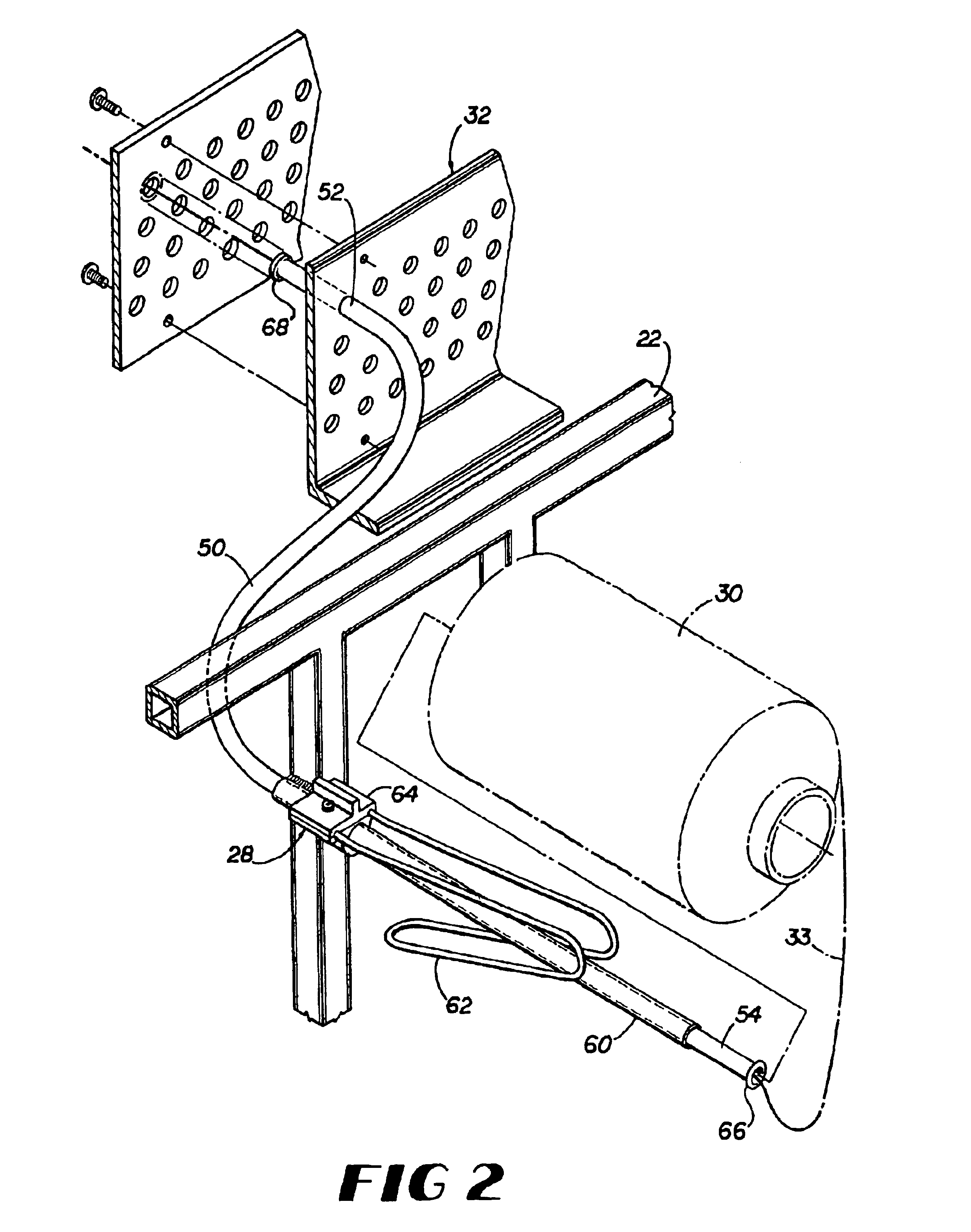

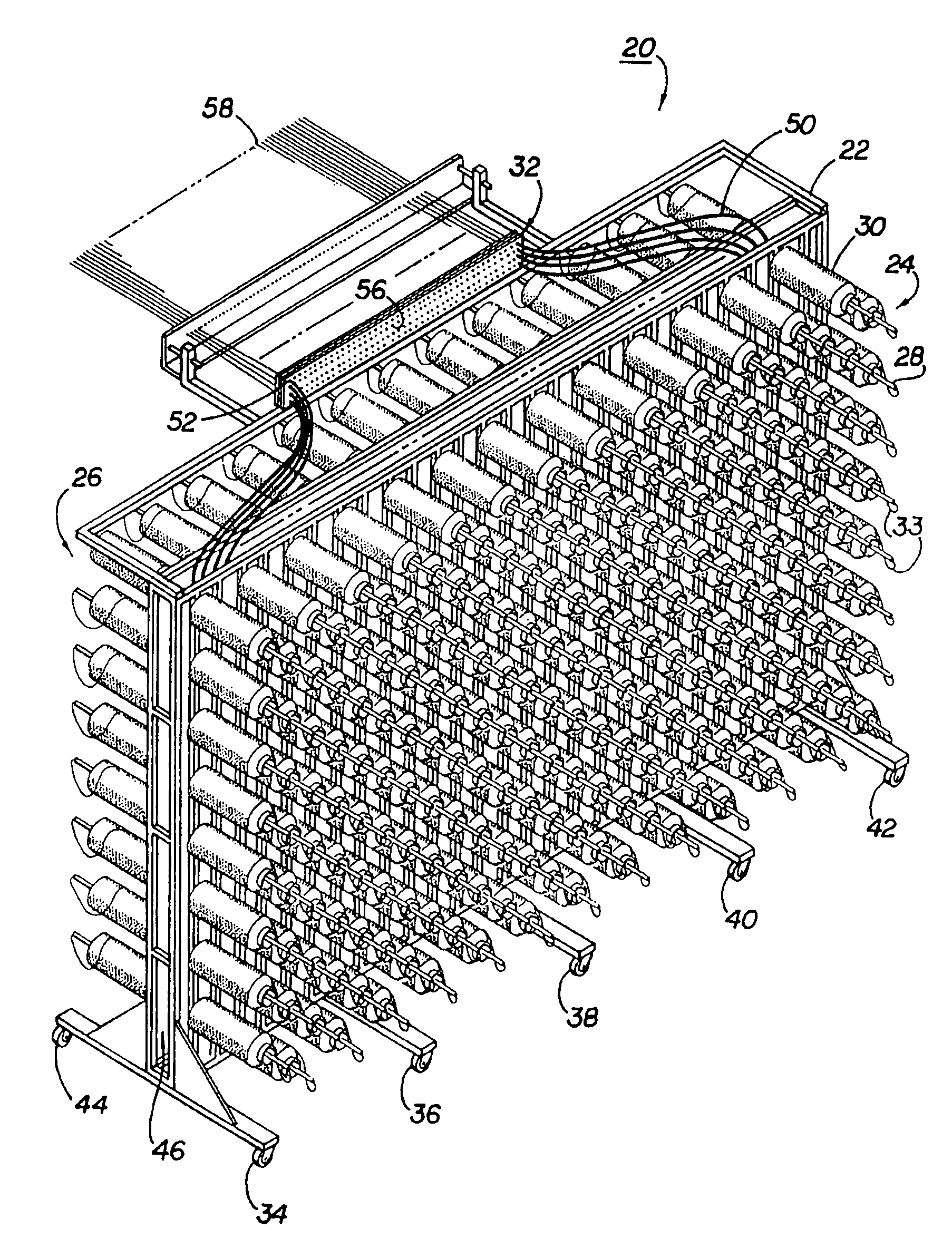

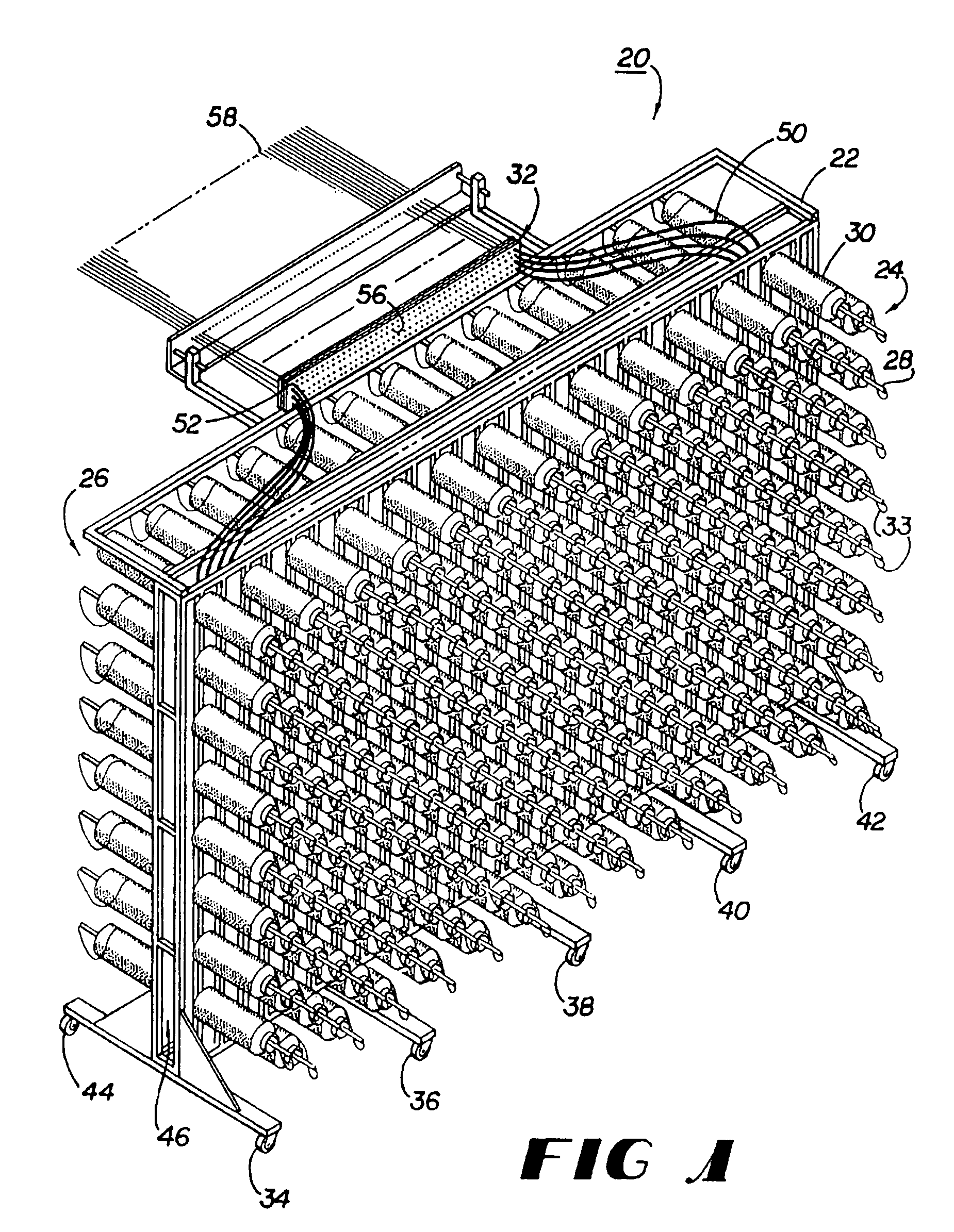

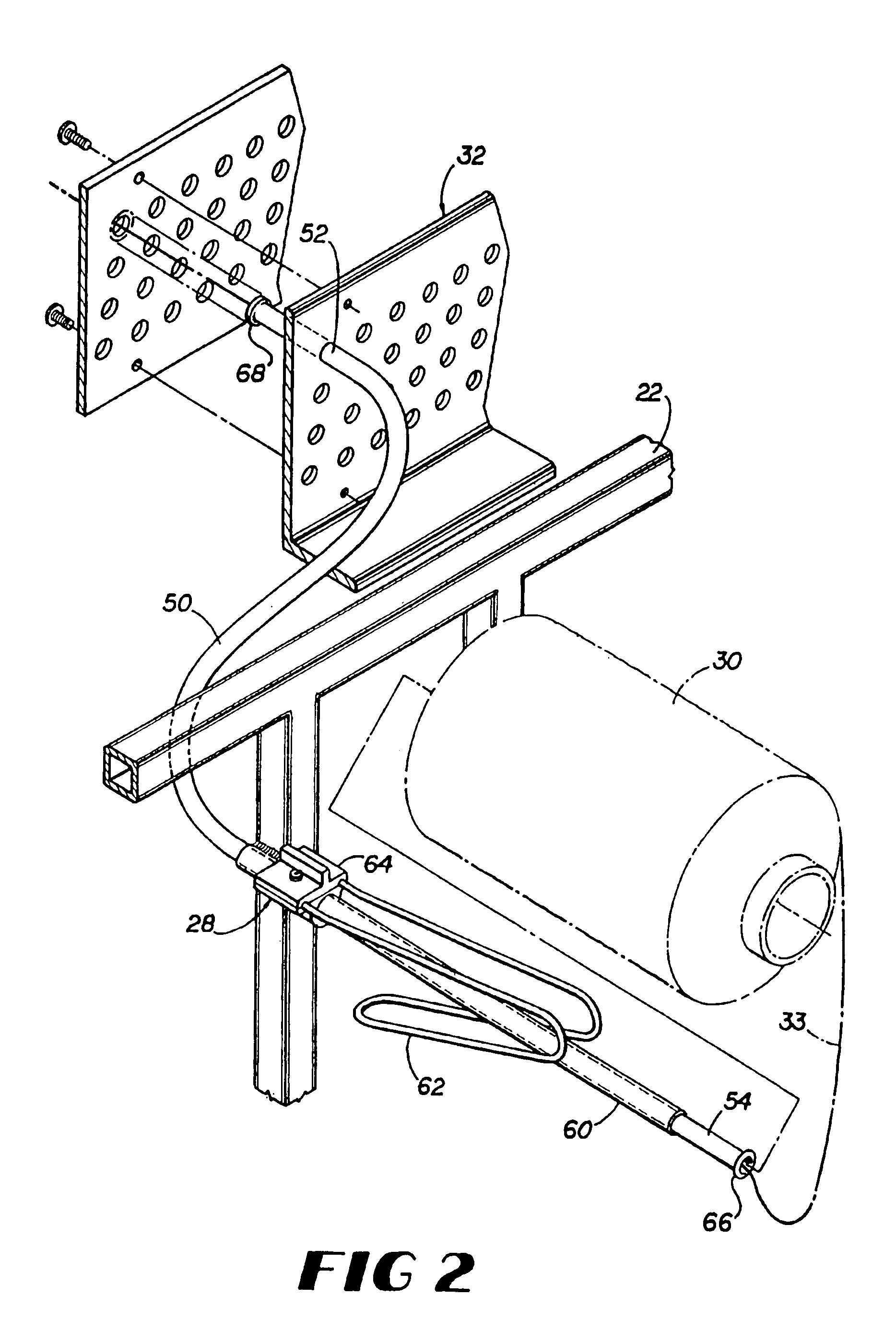

Compact creel

InactiveUS7004415B2Reduces yarn wasteImprove finished product qualityTufting apparatusFilament handlingYarnBobbin

A highly mobile, compact creel that utilizes frames for holding yarn packages (or bobbins) for feeding yarn to a tufting machine. Each frame includes holders affixed to the frame for holding yarn packages facing front and back, a header attachable to the frame for directing yarn from the yarn packages to the tufting machine, and anti-static flexible tubing for leading yarn from the holders to the header. The header provides for aligning all the yarn ends in the same plane to join them to ends already threaded into the tufting machine. An optional frame overlay upright having a ring affixed thereto and strands threaded through the ring prevents yarn from upper yarn packages from falling onto tubes holding lower yarn packages causing yarn entanglement.

Owner:INTERFACE INC

Assembly type bobbin creel

The invention discloses an assembly type bobbin creel which comprises a transverse beam, bobbin inserting rods and vertical supporting rods. The transverse beam is composed of a plurality of first transverse plates and a plurality of second transverse plates. The first transverse plates and the second transverse plates are all of frame structures and provided with threaded holes, the first transverse plates are connected with the adjacent second transverse plates in a sleeved mode through the threaded holes and threaded pieces, the bobbin inserting rods are fixedly connected to the second transverse plates and respectively provided with a plurality of bobbin inserting spindles, the bobbin inserting rods and the vertical supporting rods are respectively provided with a plurality of threaded holes and connected in a sleeved mode. According to the assembly type bobbin creel, the distances between the adjacent bobbin inserting rods can be adjusted, the heights of the bobbin inserting rods can also be adjusted, disassembly and assembly are convenient to achieve, and convenience is brought to encasement carrying. In addition, if any part of the transverse beam, the vertical supporting rods and the bobbin inserting rods of the bobbin creel is damaged, replacement is conveniently achieved, the bobbin creel is not required to be overall replaced, and cost is saved.

Owner:JIANGSU GOLD IRON MAN AUTOMATION TECH

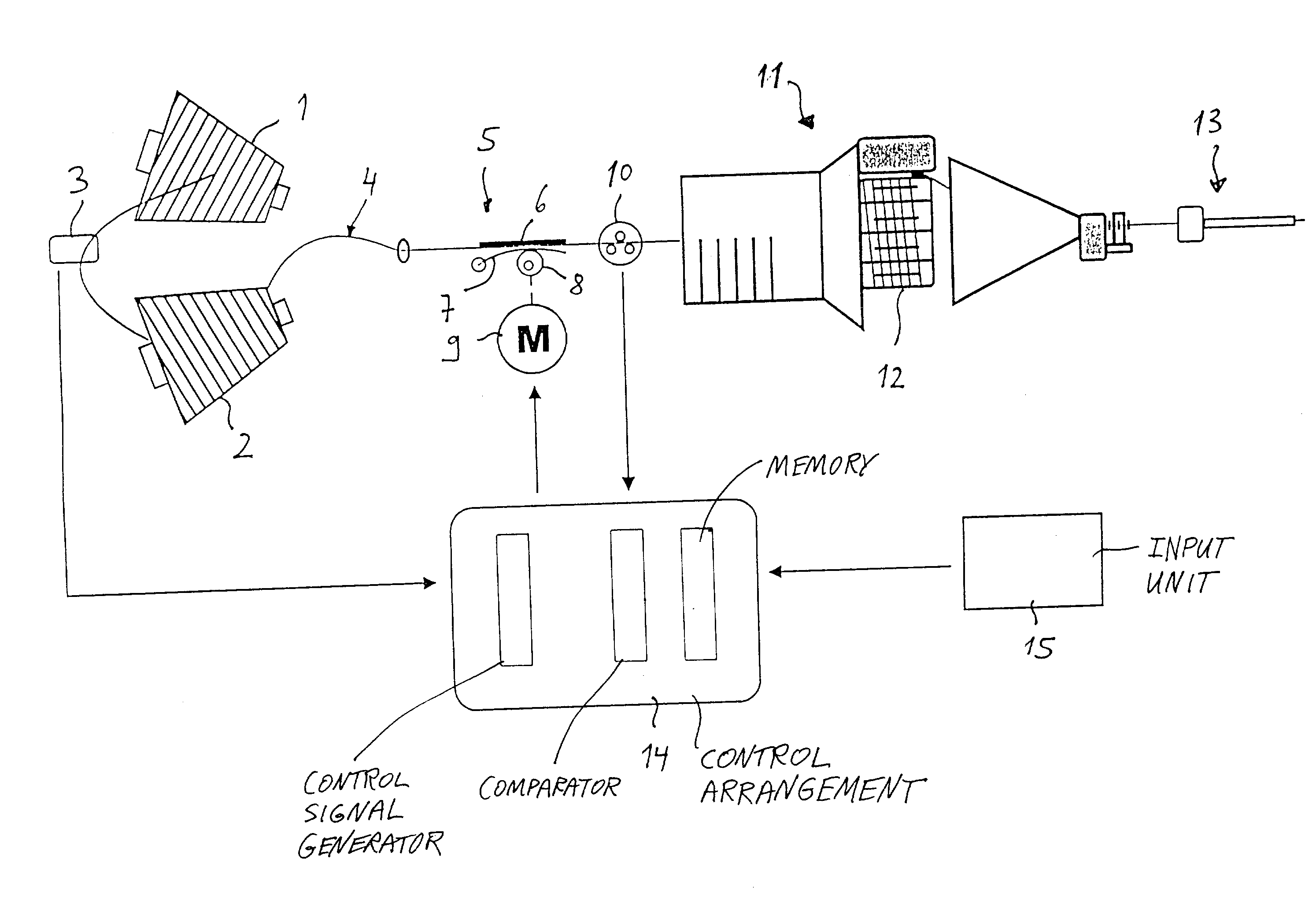

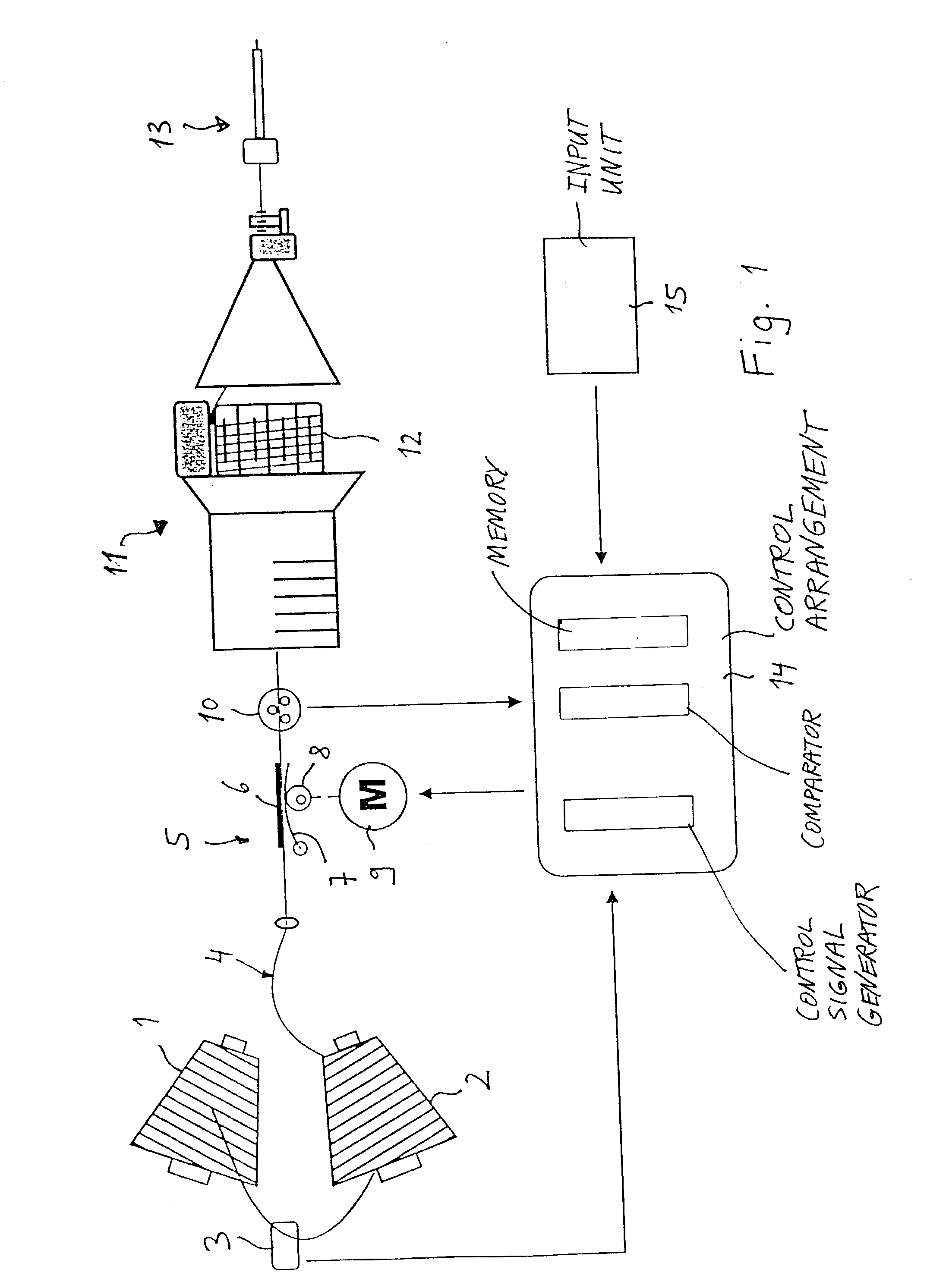

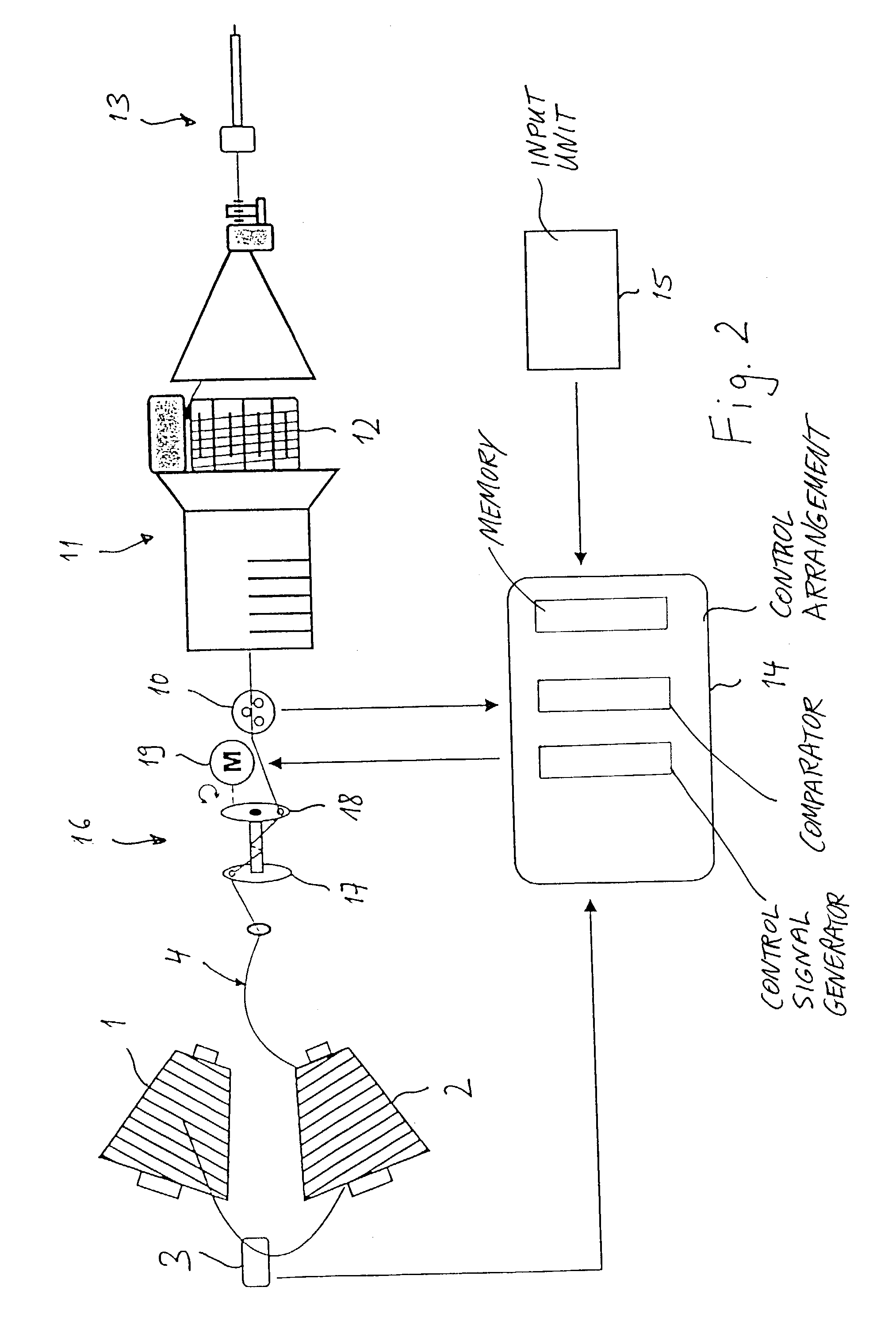

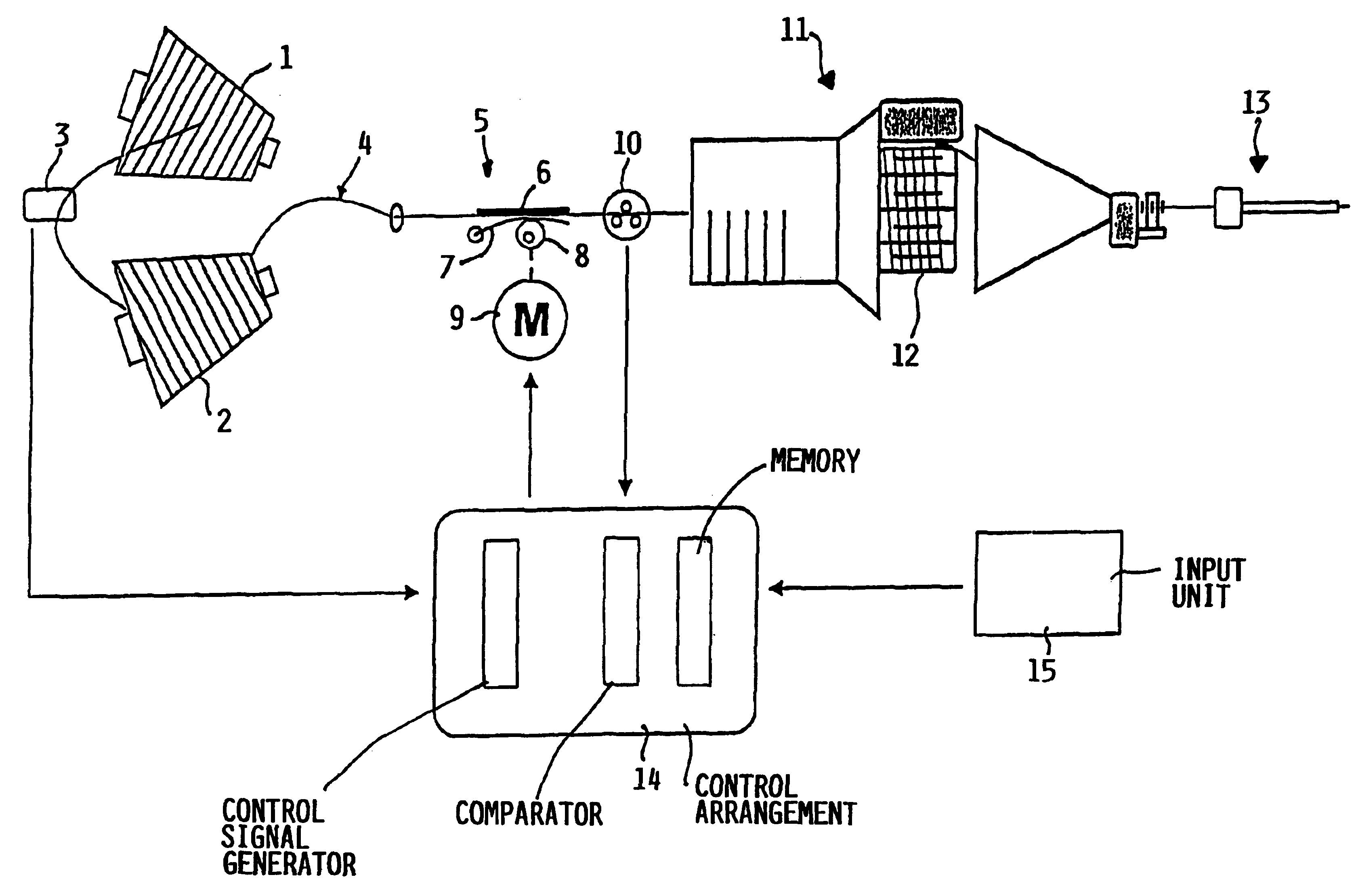

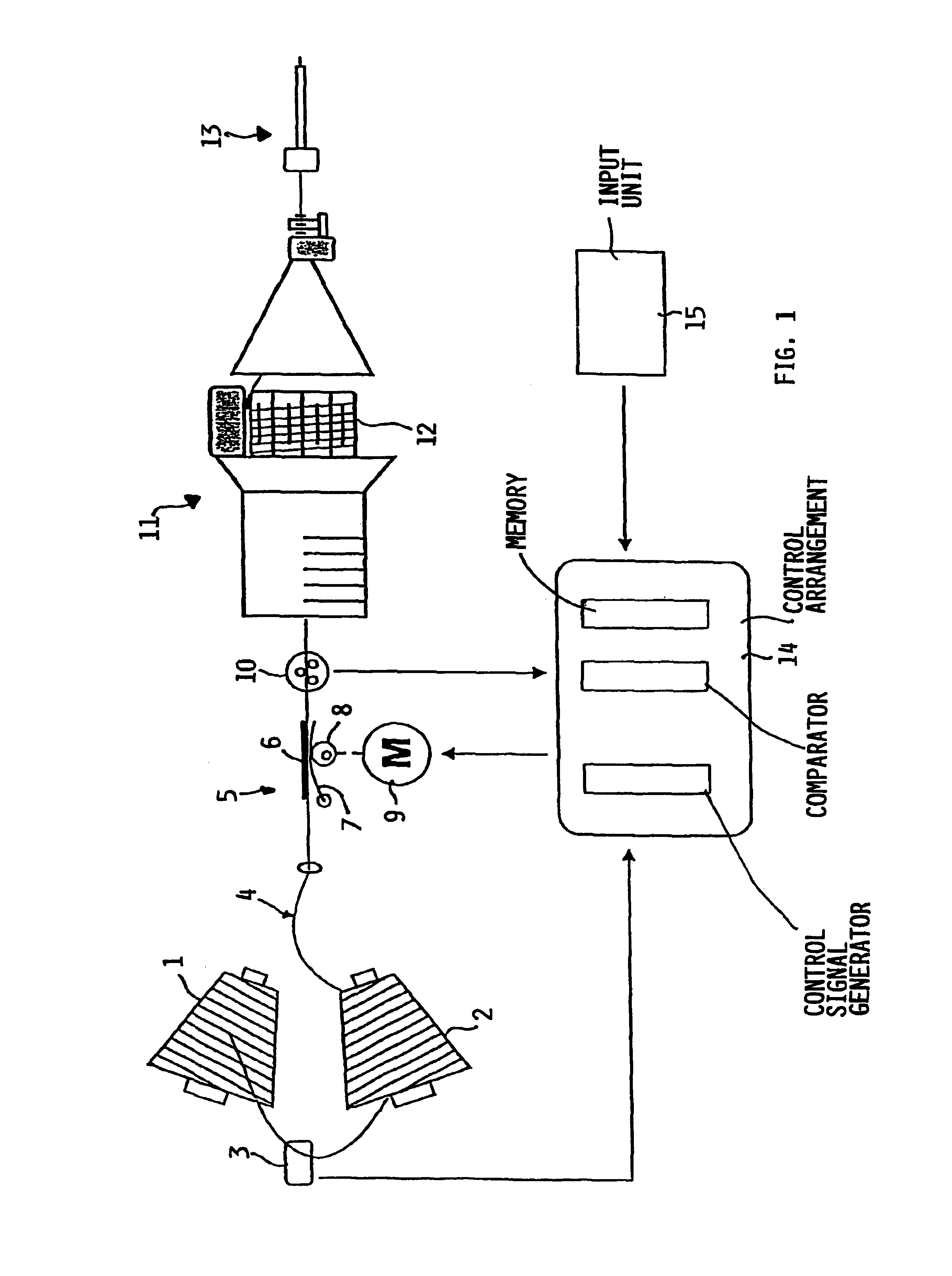

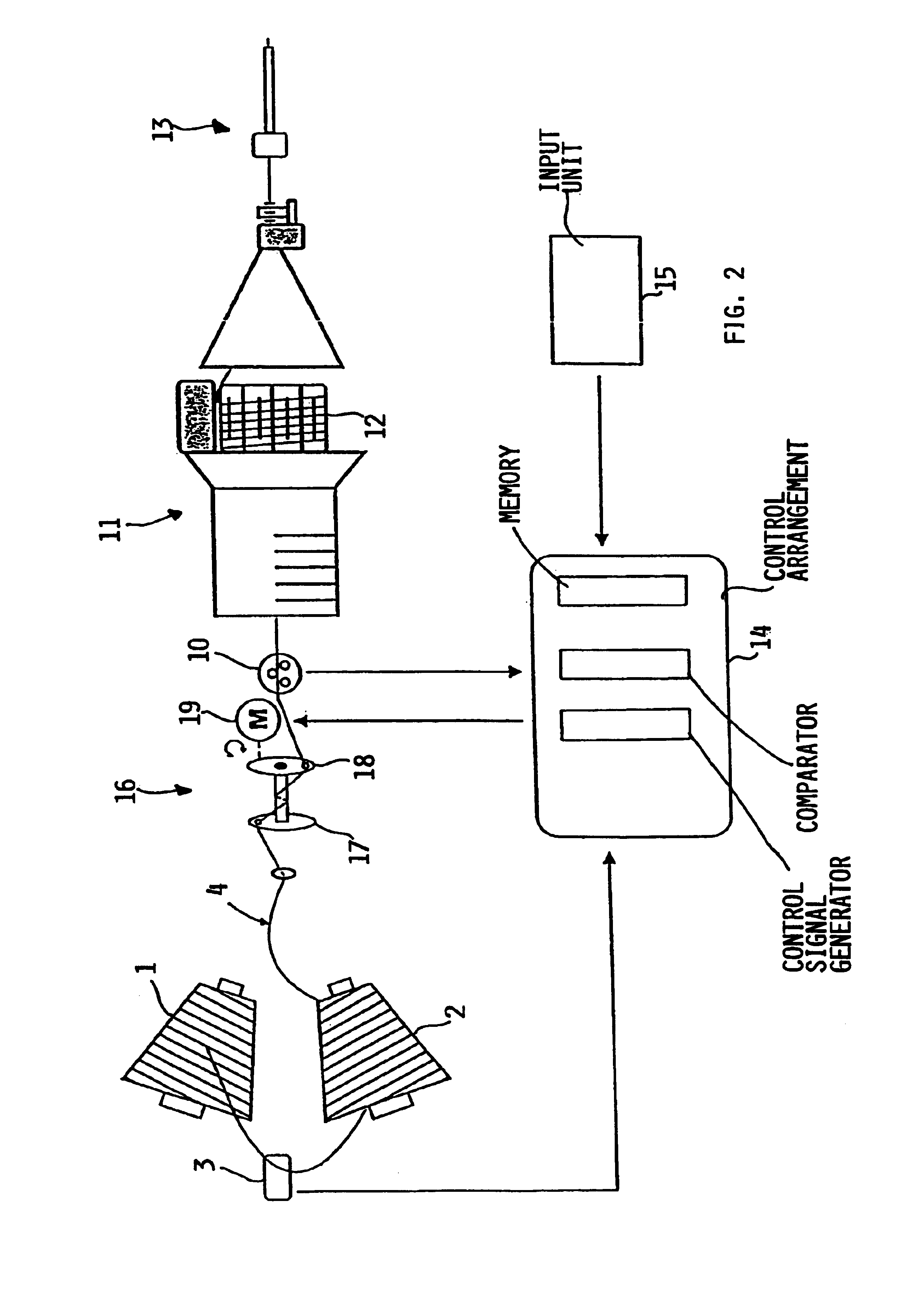

Method and apparatus for variably braking the weft thread between a supply spool and a thread store in a loom

A supply spool supplies a weft thread through an adjustable actuated thread brake and a thread tension sensor to a weft thread accumulator, from which an accumulated insertion length of the thread is provided to a weft insertion device. The tension sensor provides a measured actual thread tension signal to a control arrangement, which compares the actual tension to a selected rated tension, and, dependent on the deviation therebetween, provides a control signal to an actuator of the thread brake, so that the actual thread tension constantly corresponds to the selected rated tension. Another sensor provides a signal indicating a change from an empty spool to a full spool. Responsive thereto, the control arrangement actuates the thread brake to an adjustable starting brake setting as a coarse adjustment. Then the self-regulating fine adjustment is continued. A constant winding tension and thread accumulation length are achieved in the thread accumulator.

Owner:LINDAUER DORNIER GMBH

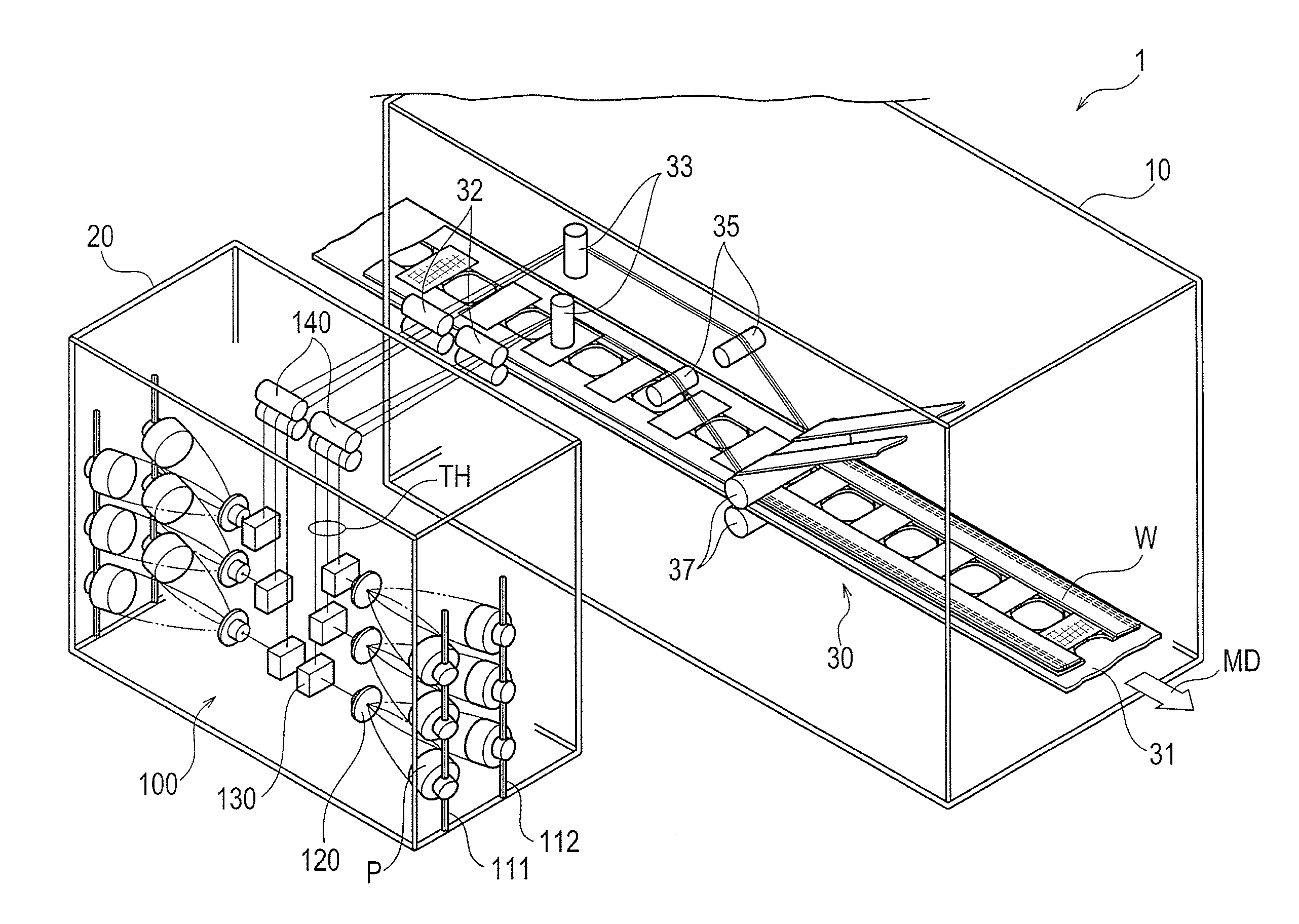

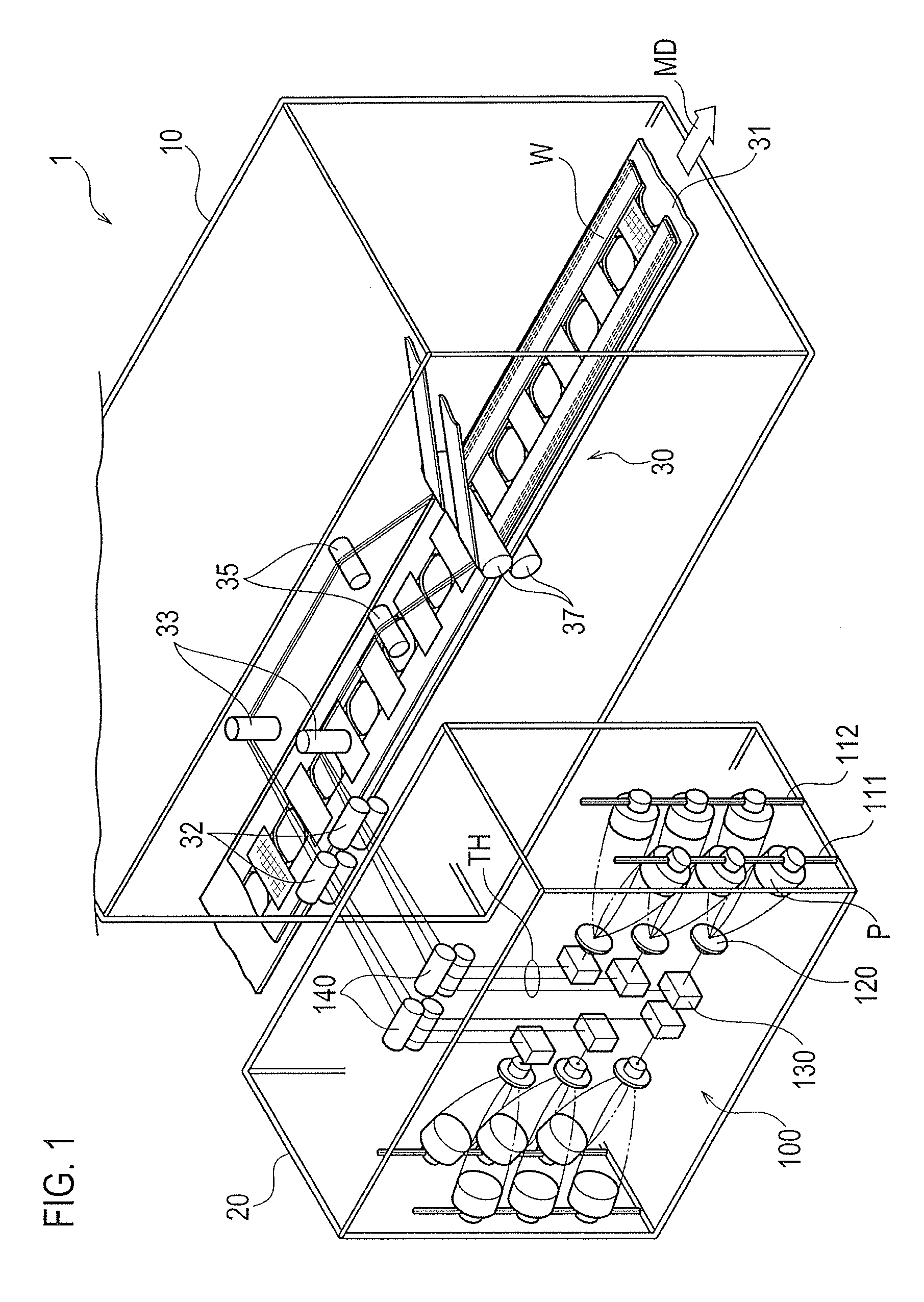

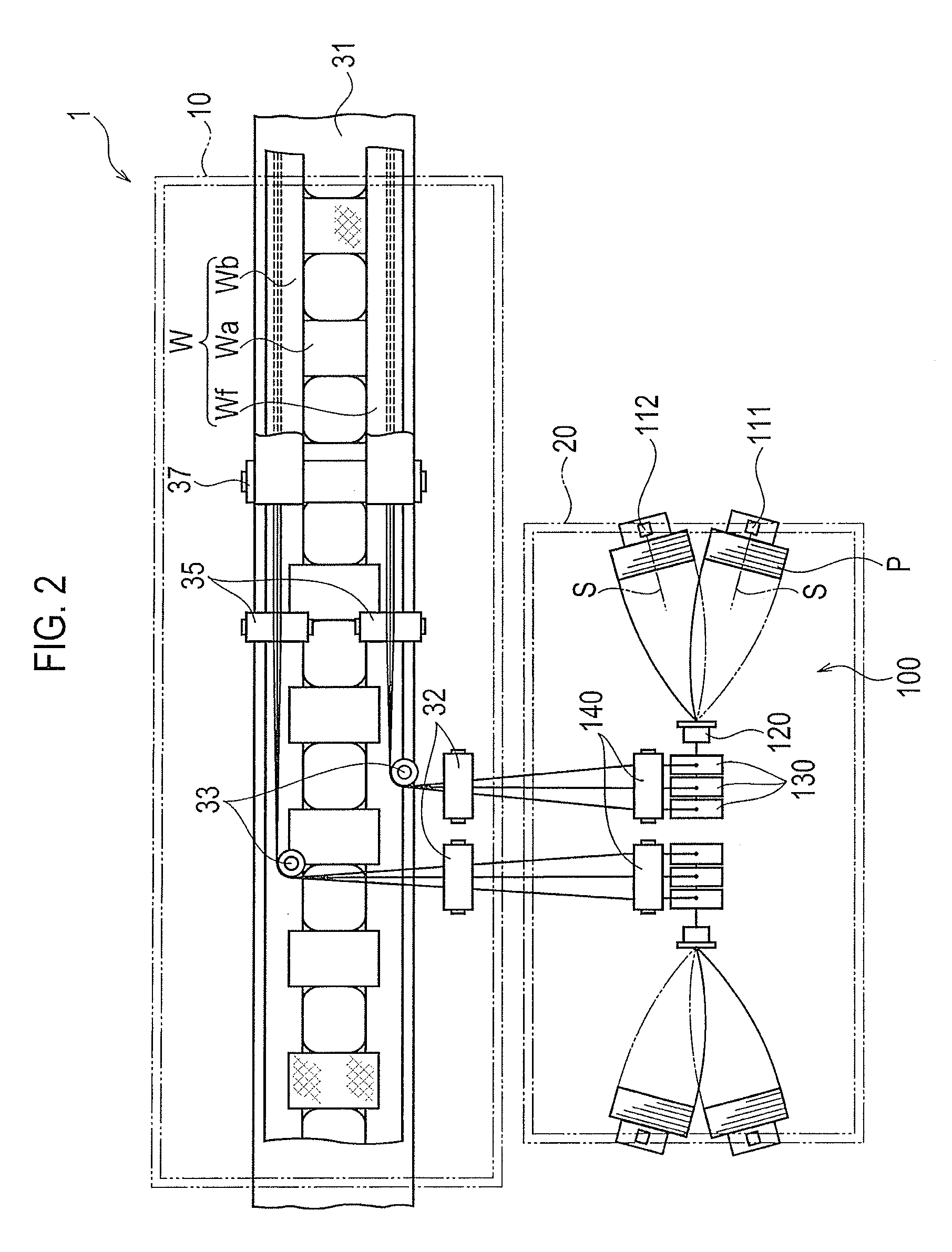

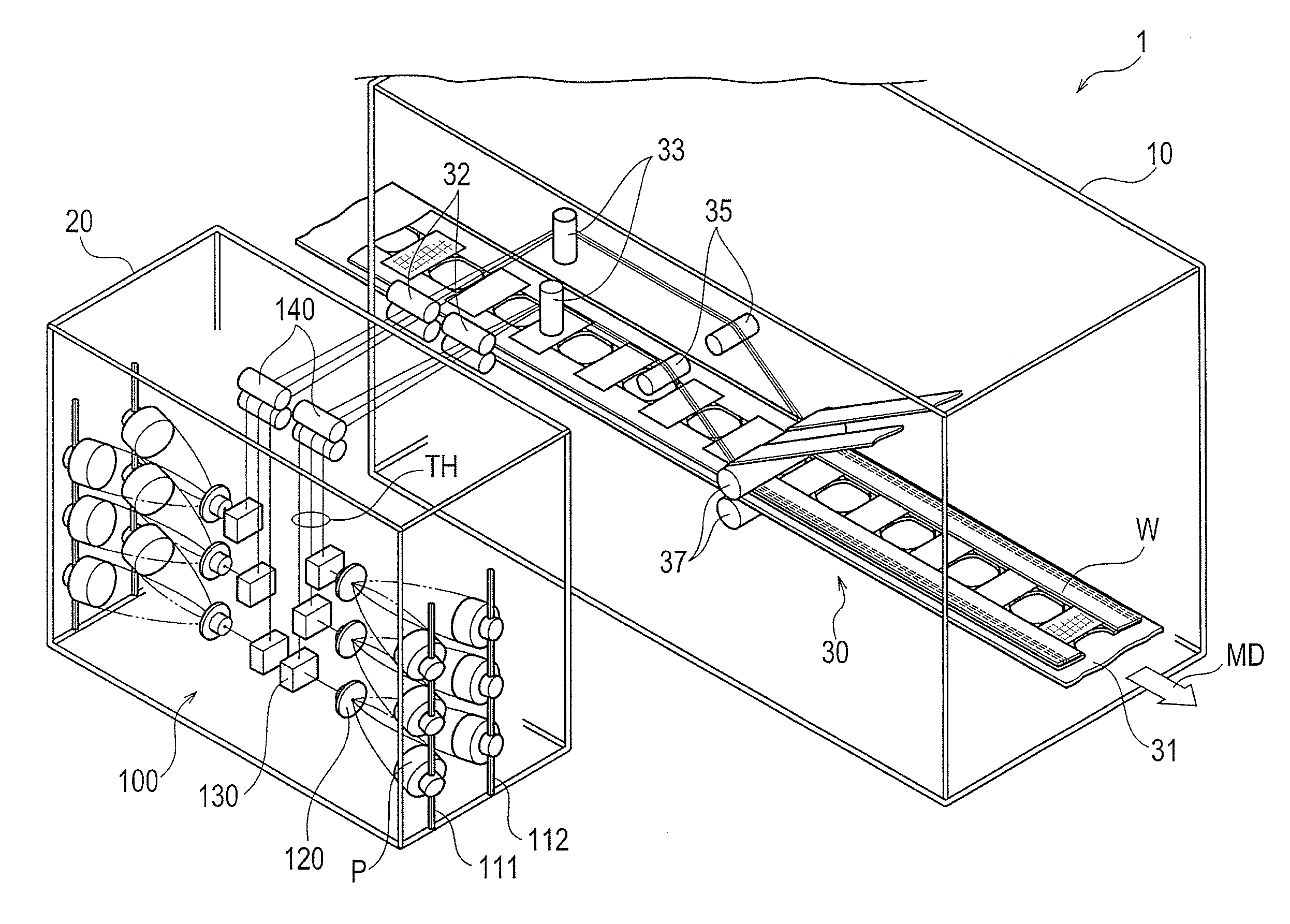

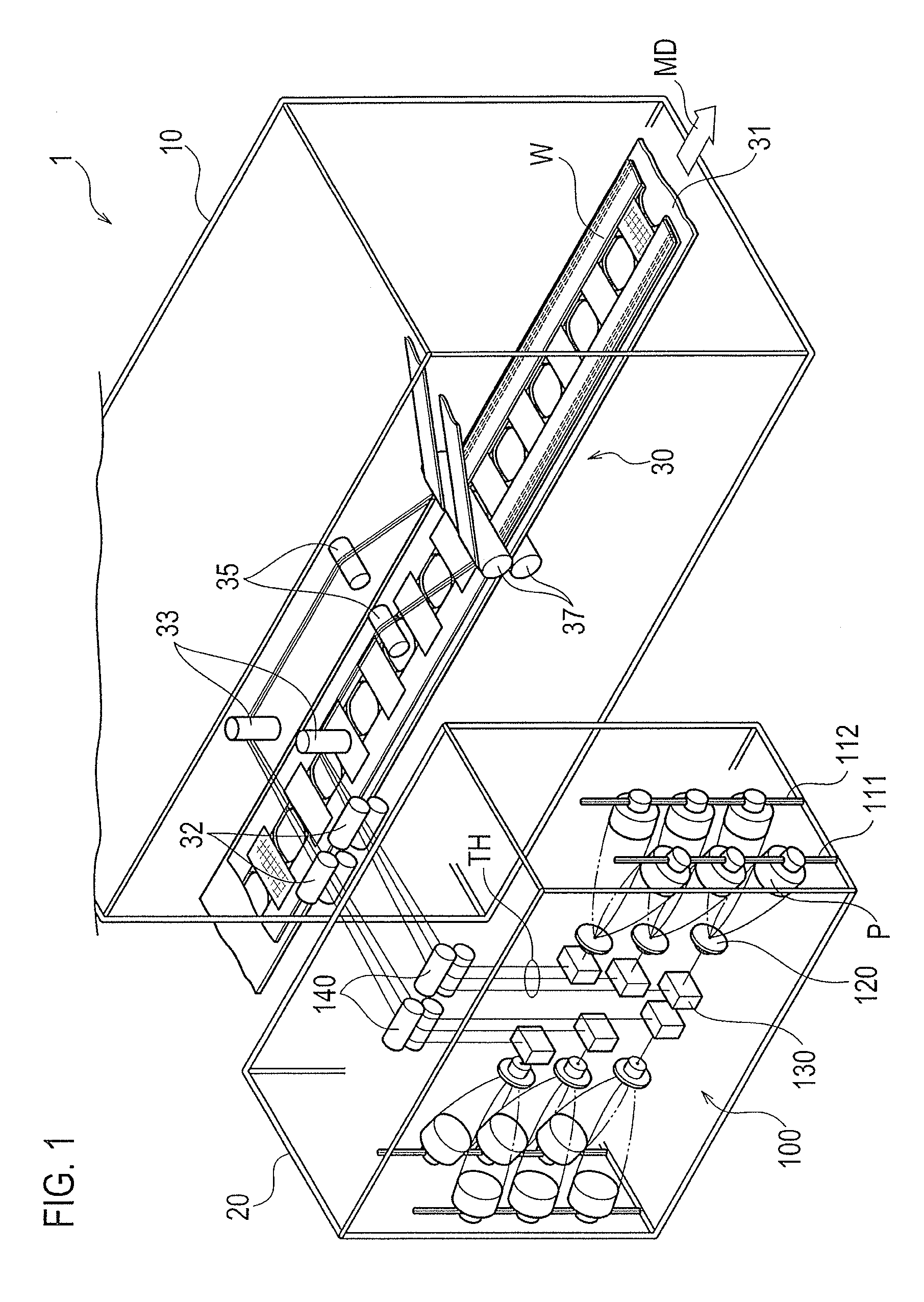

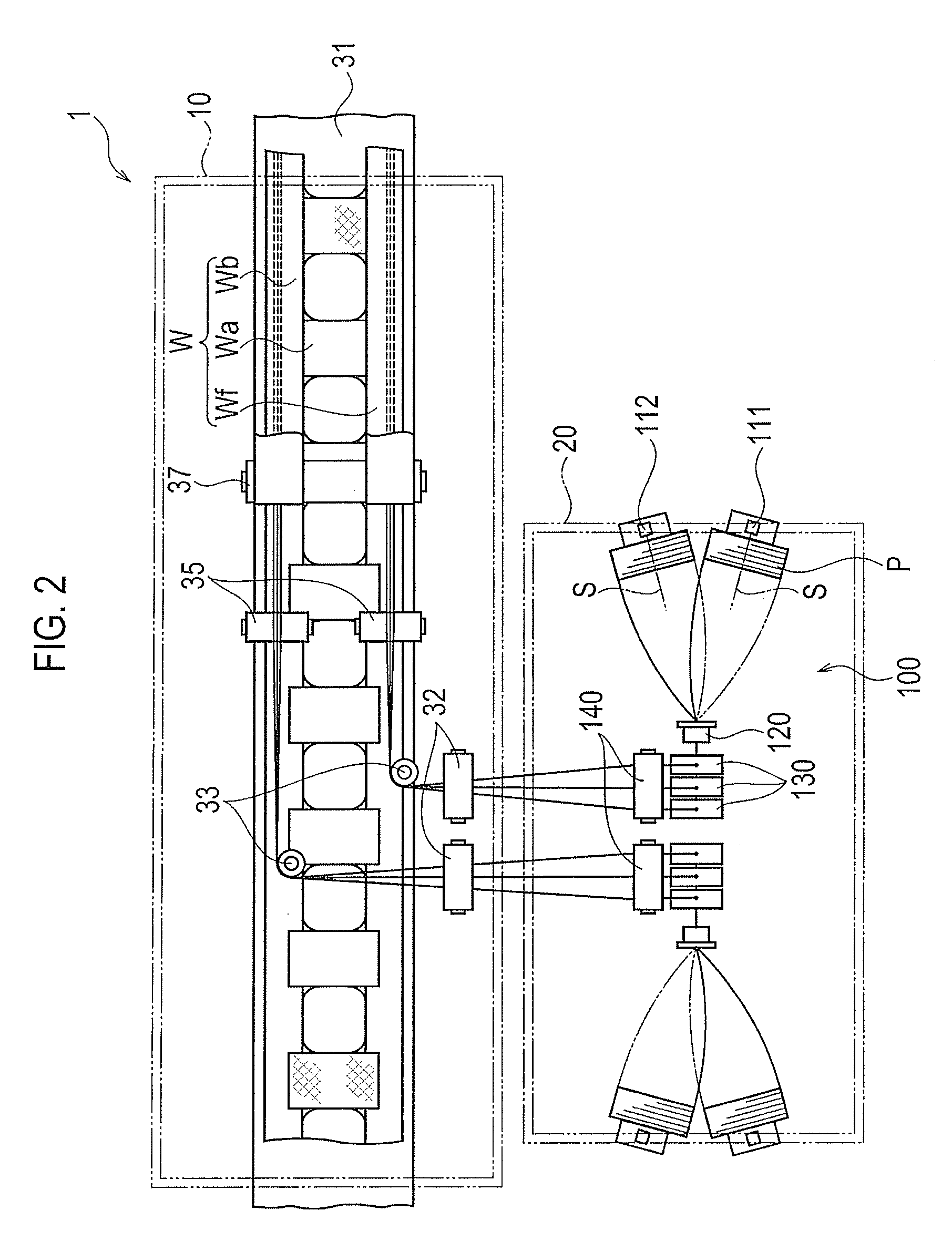

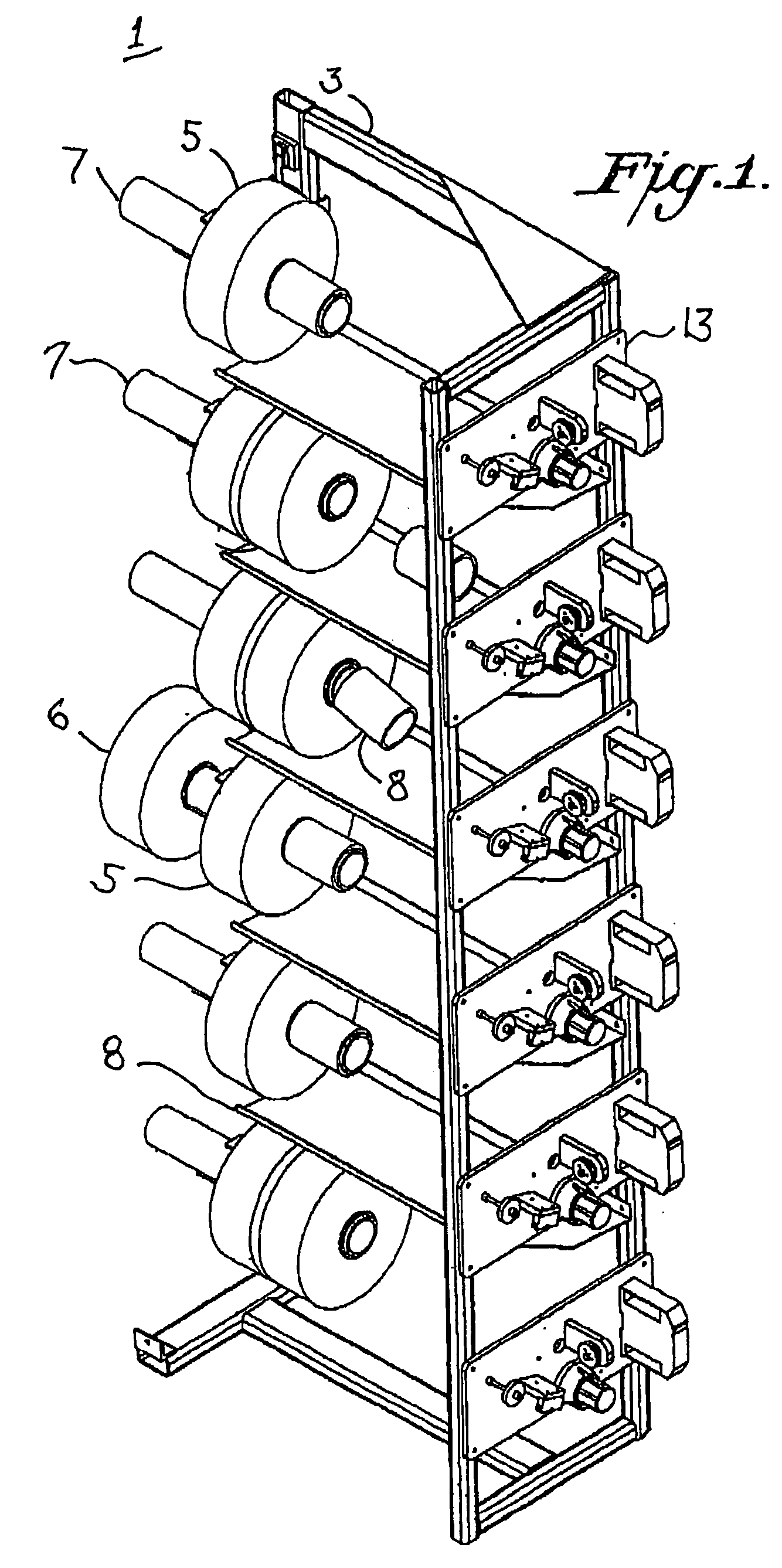

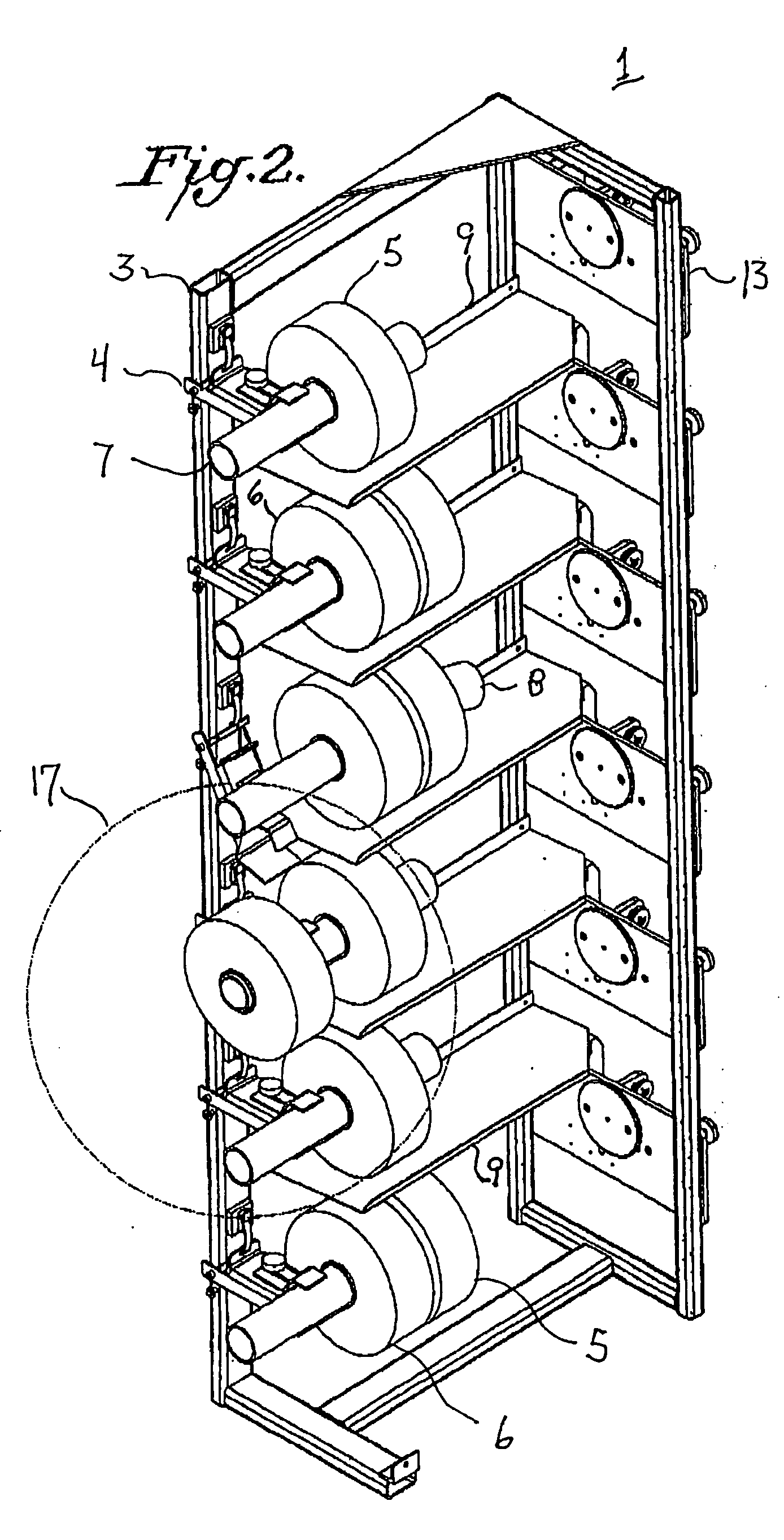

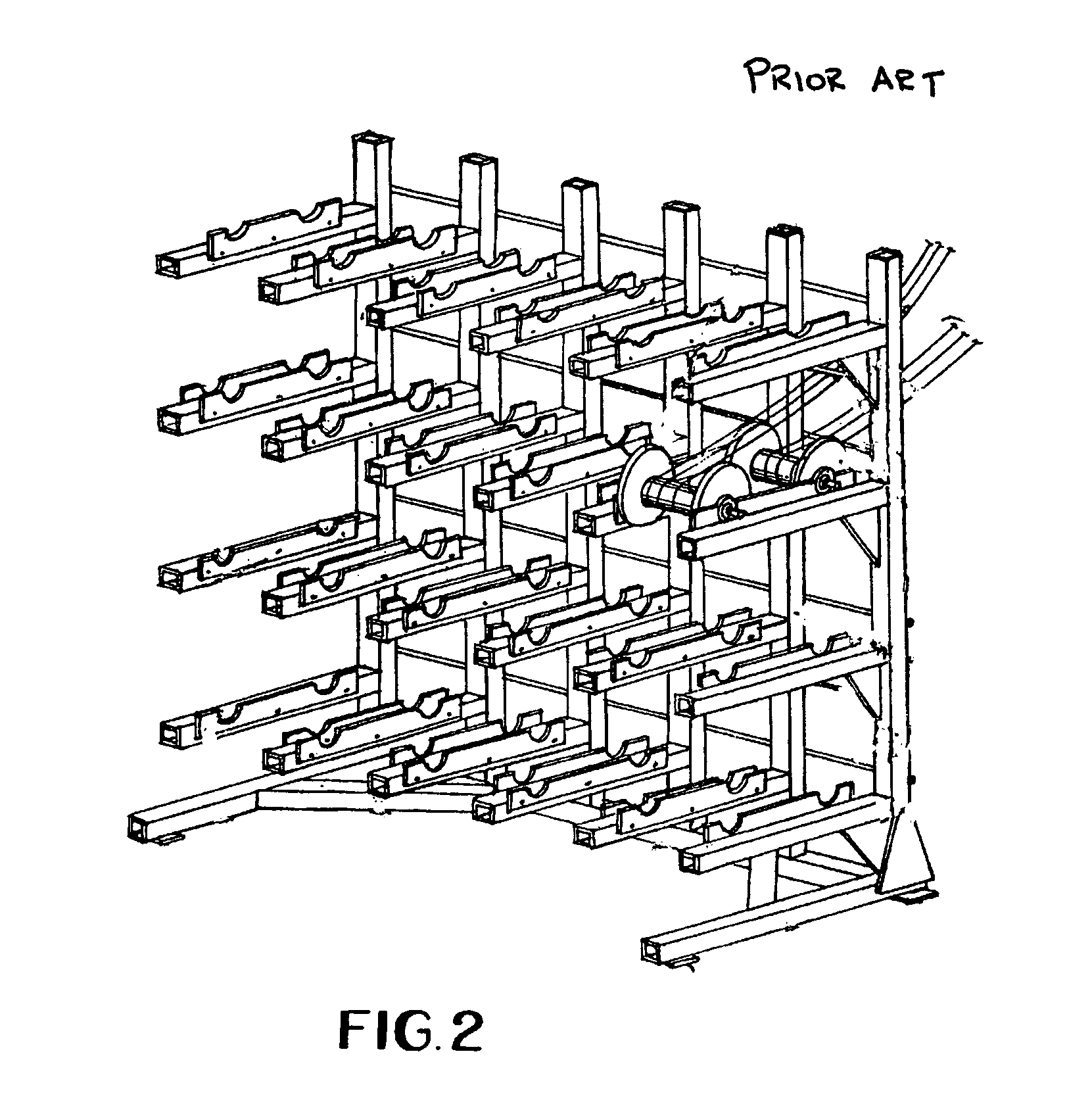

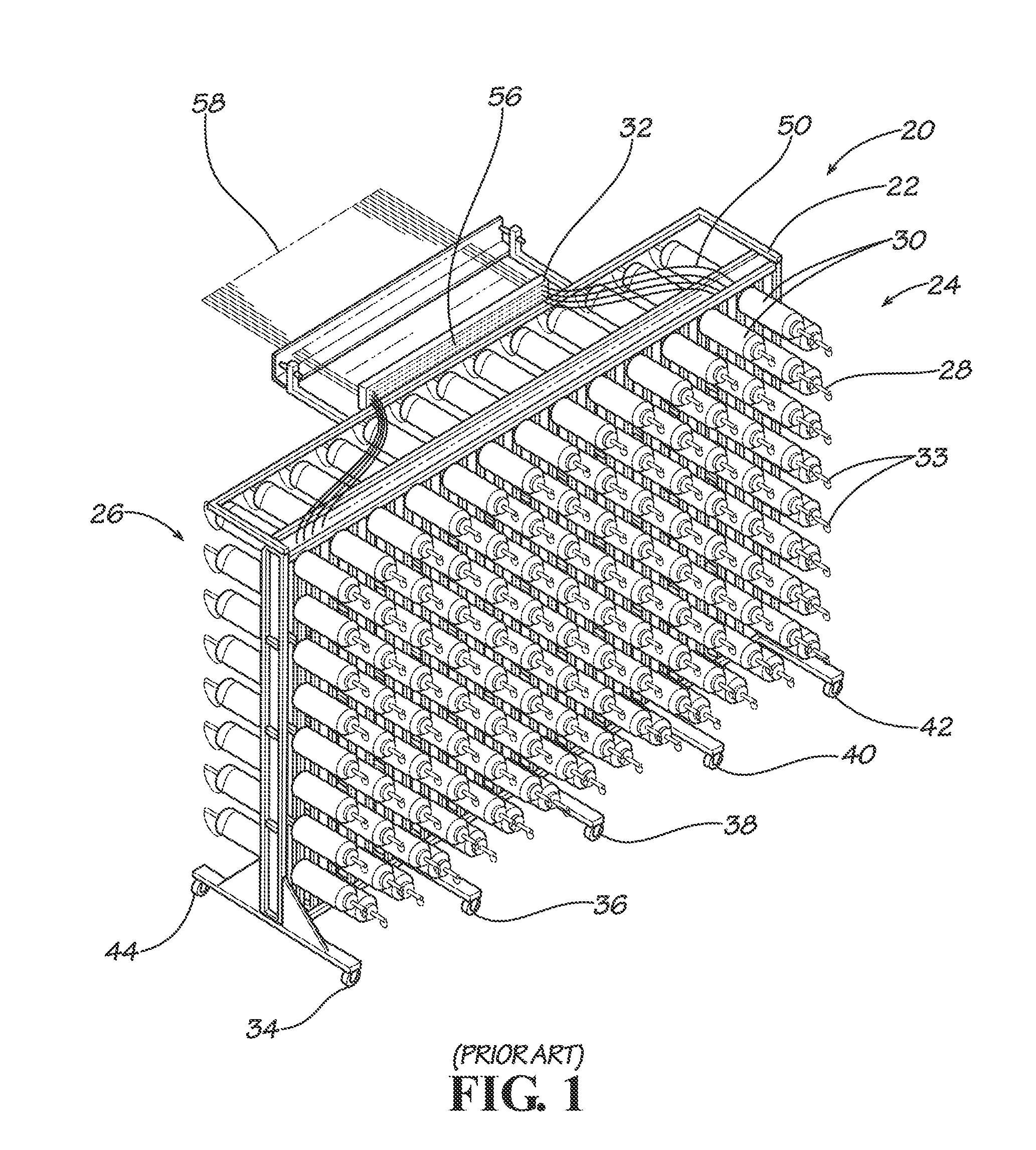

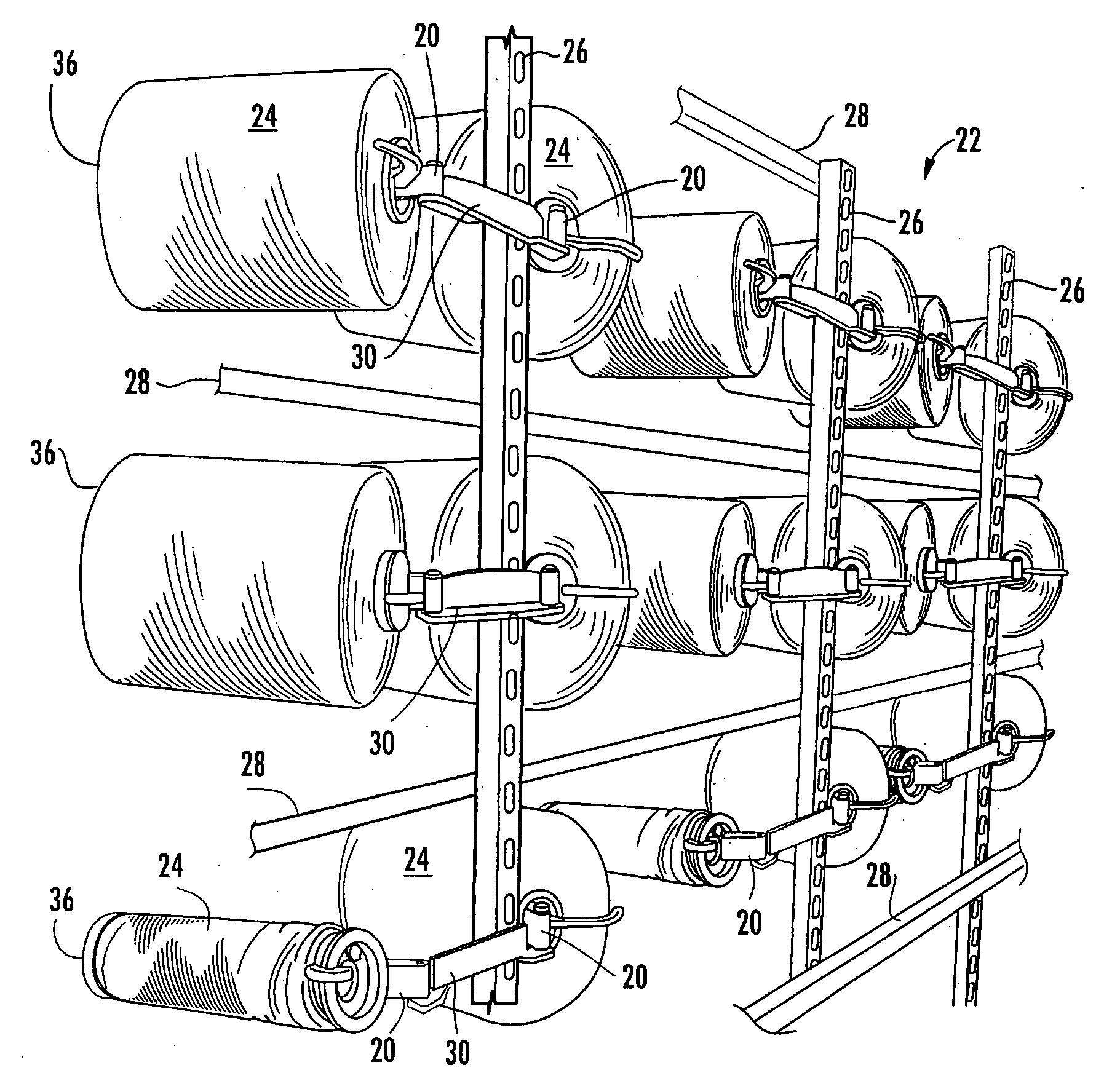

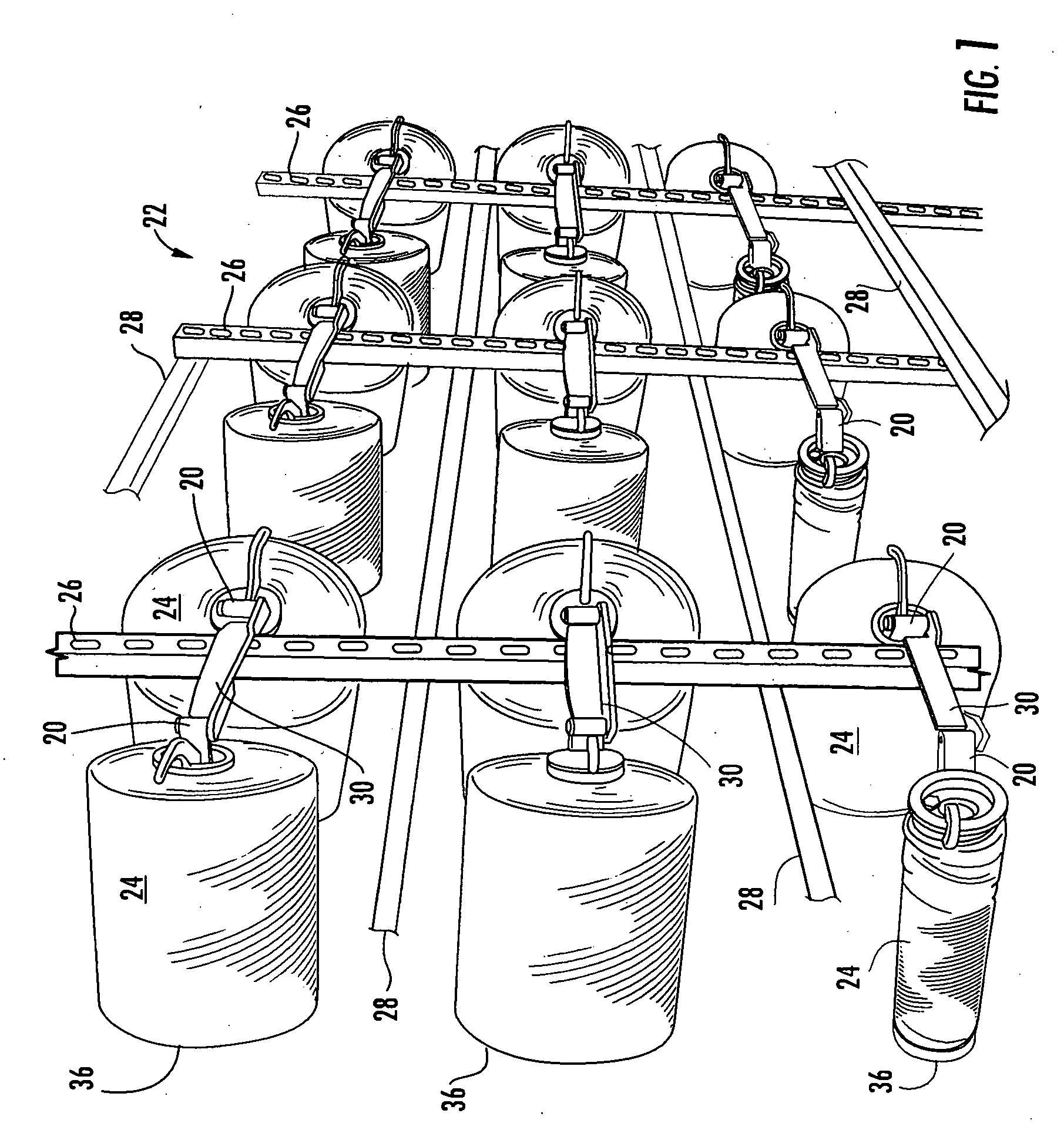

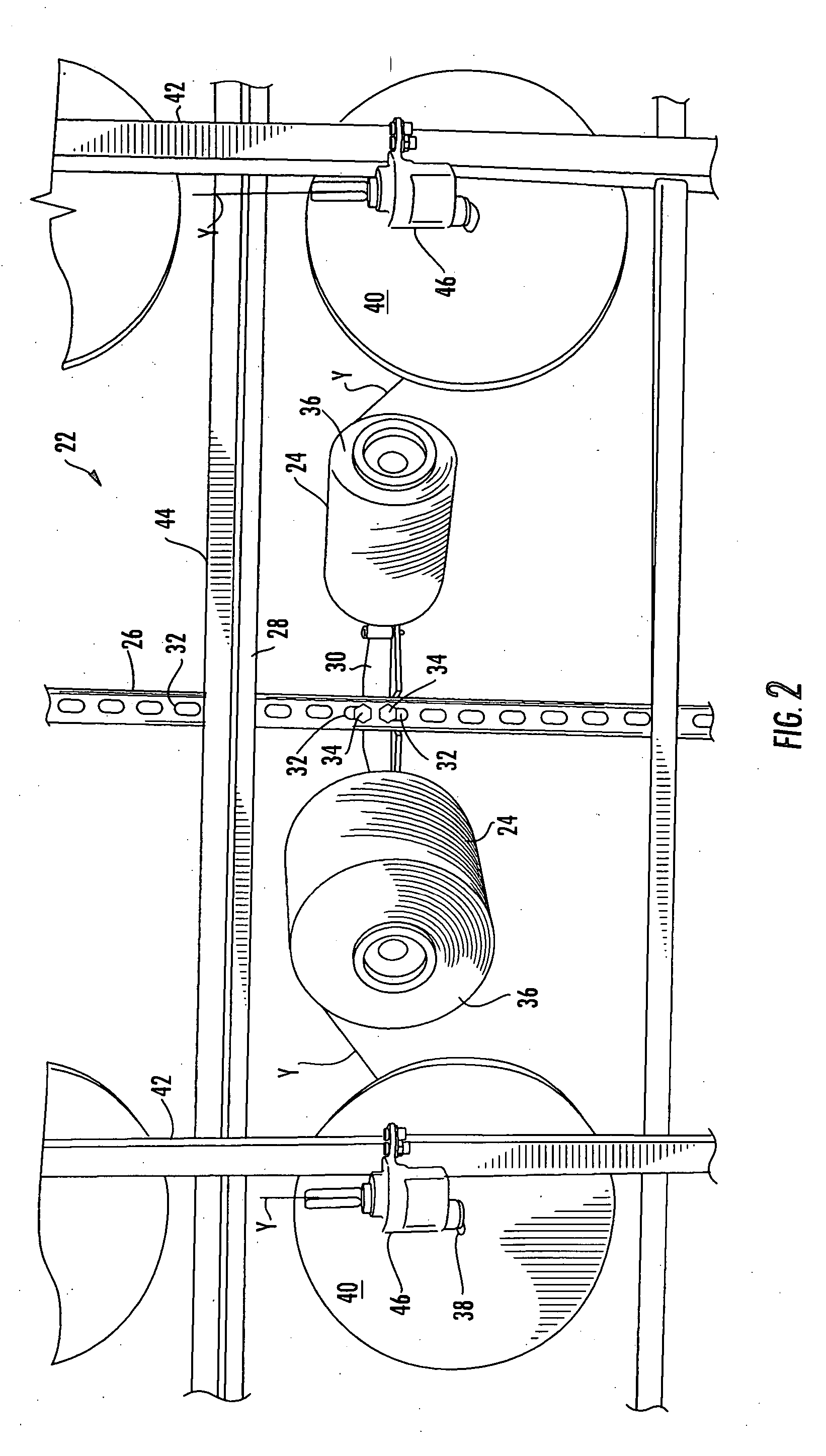

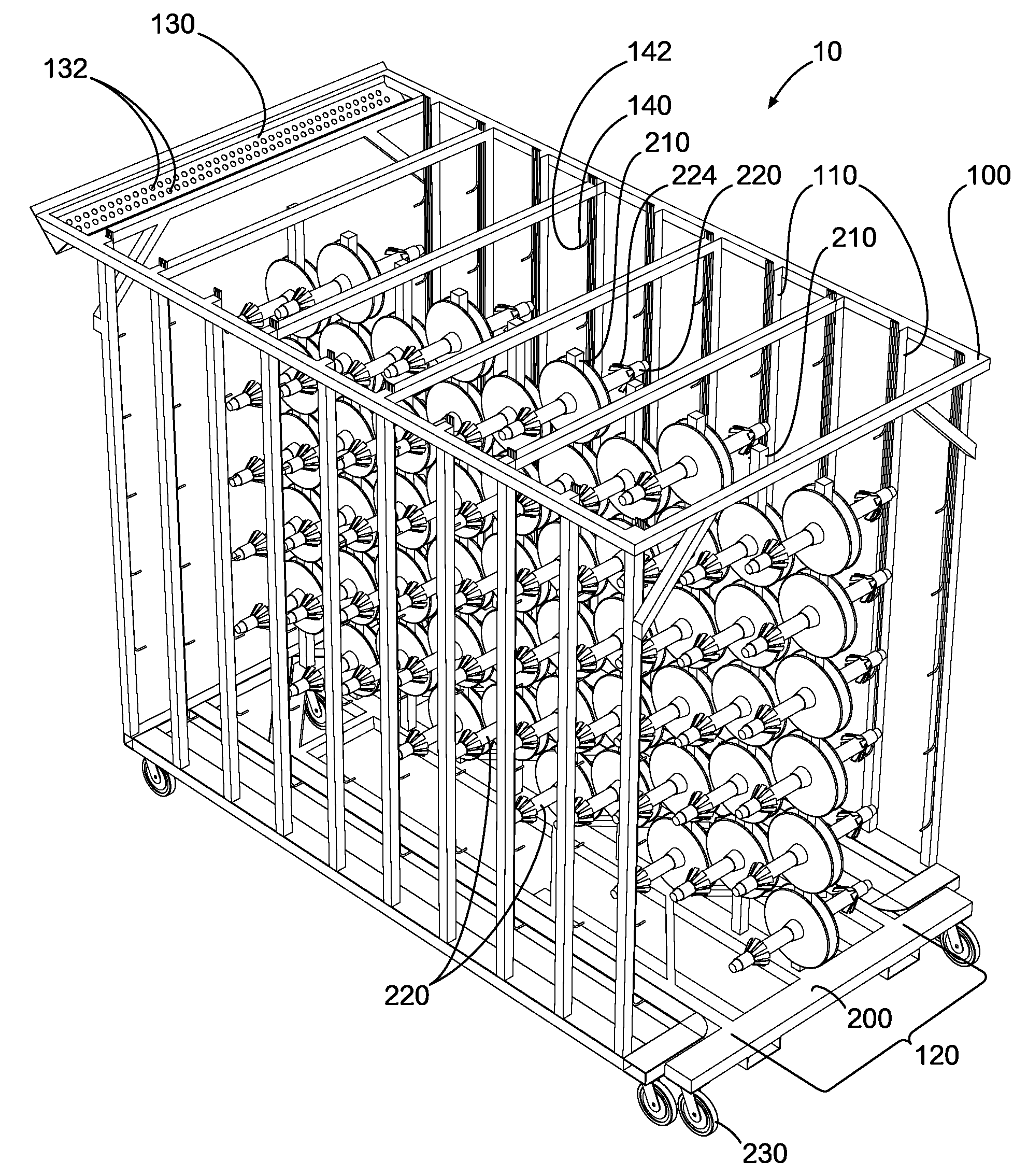

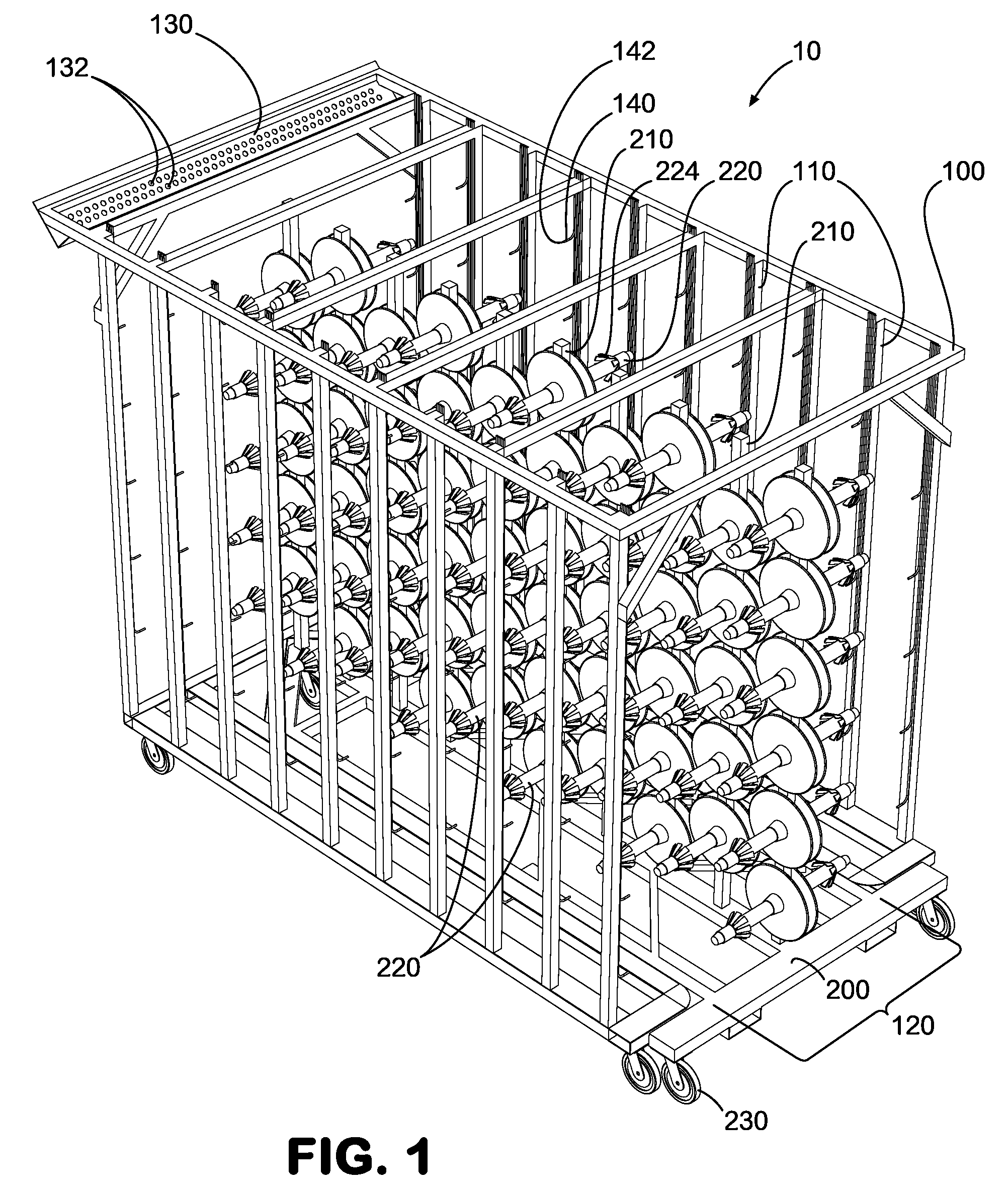

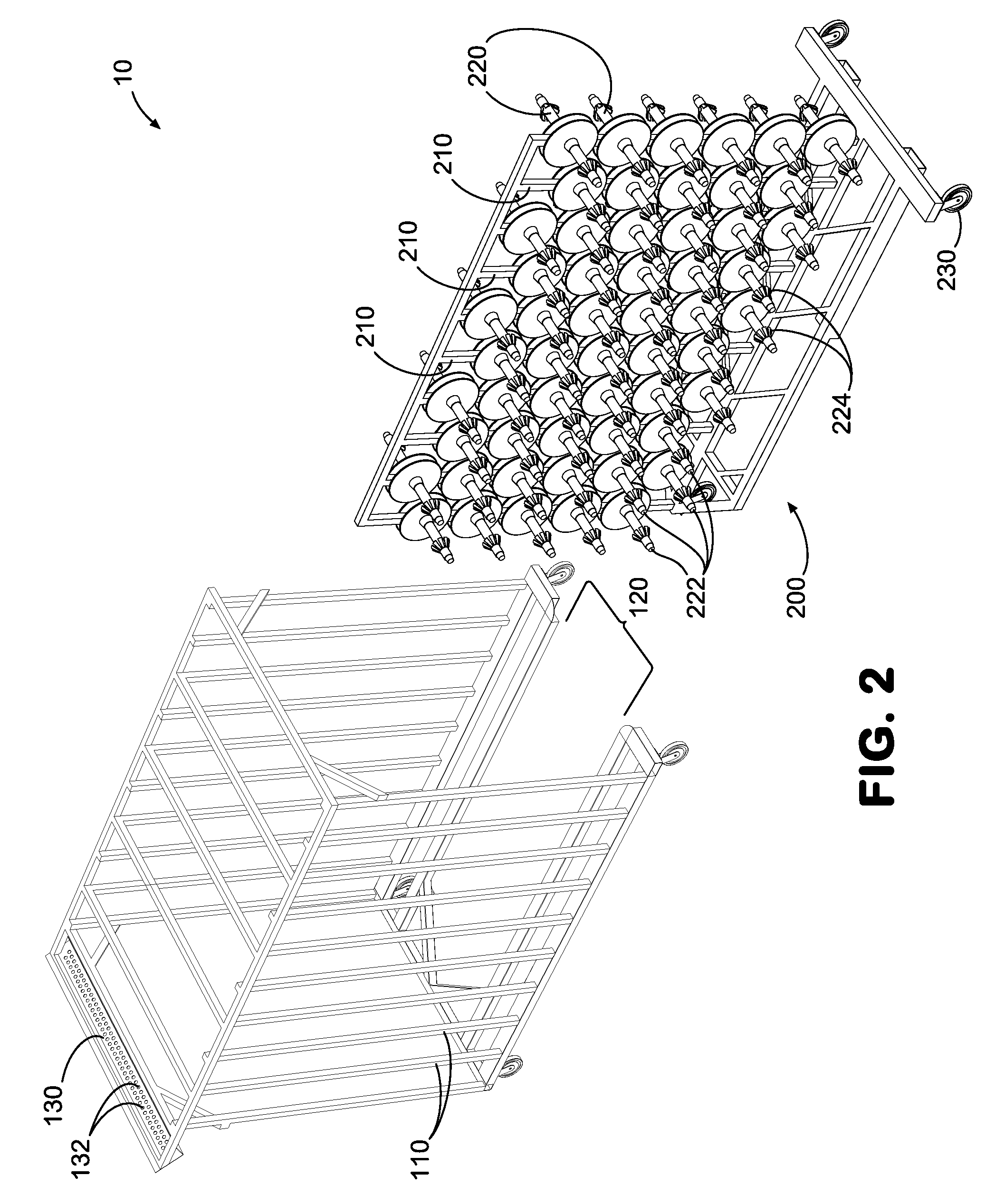

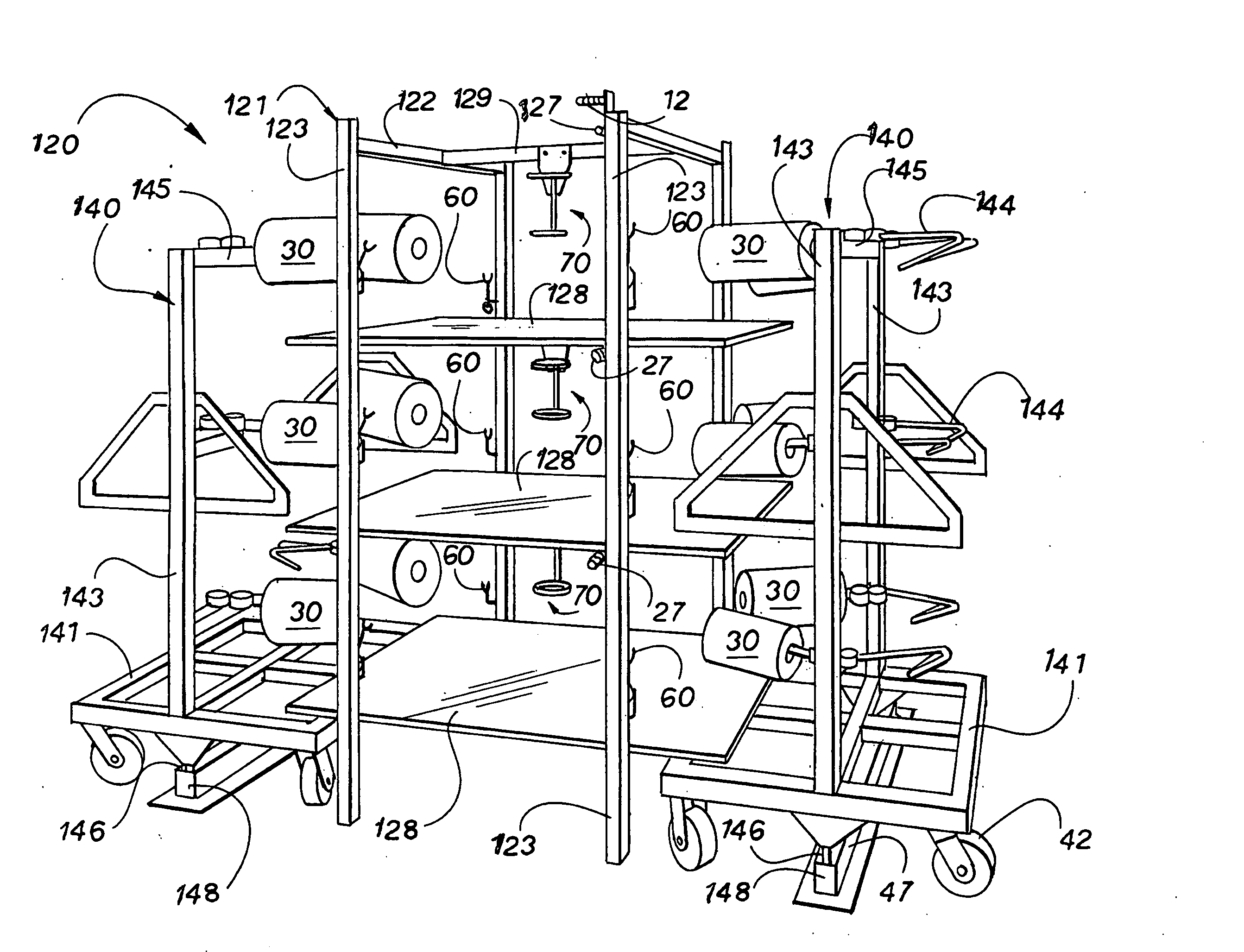

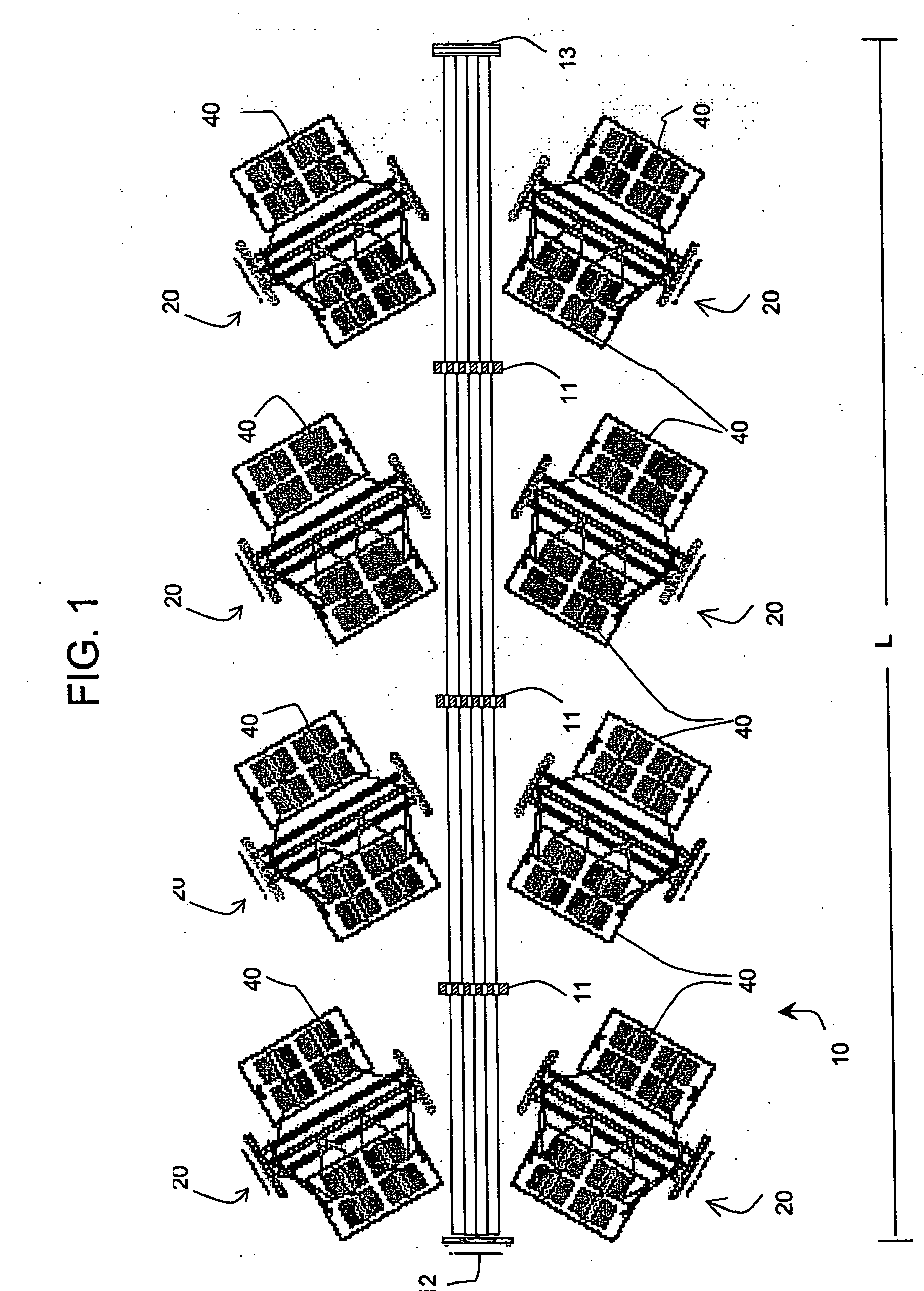

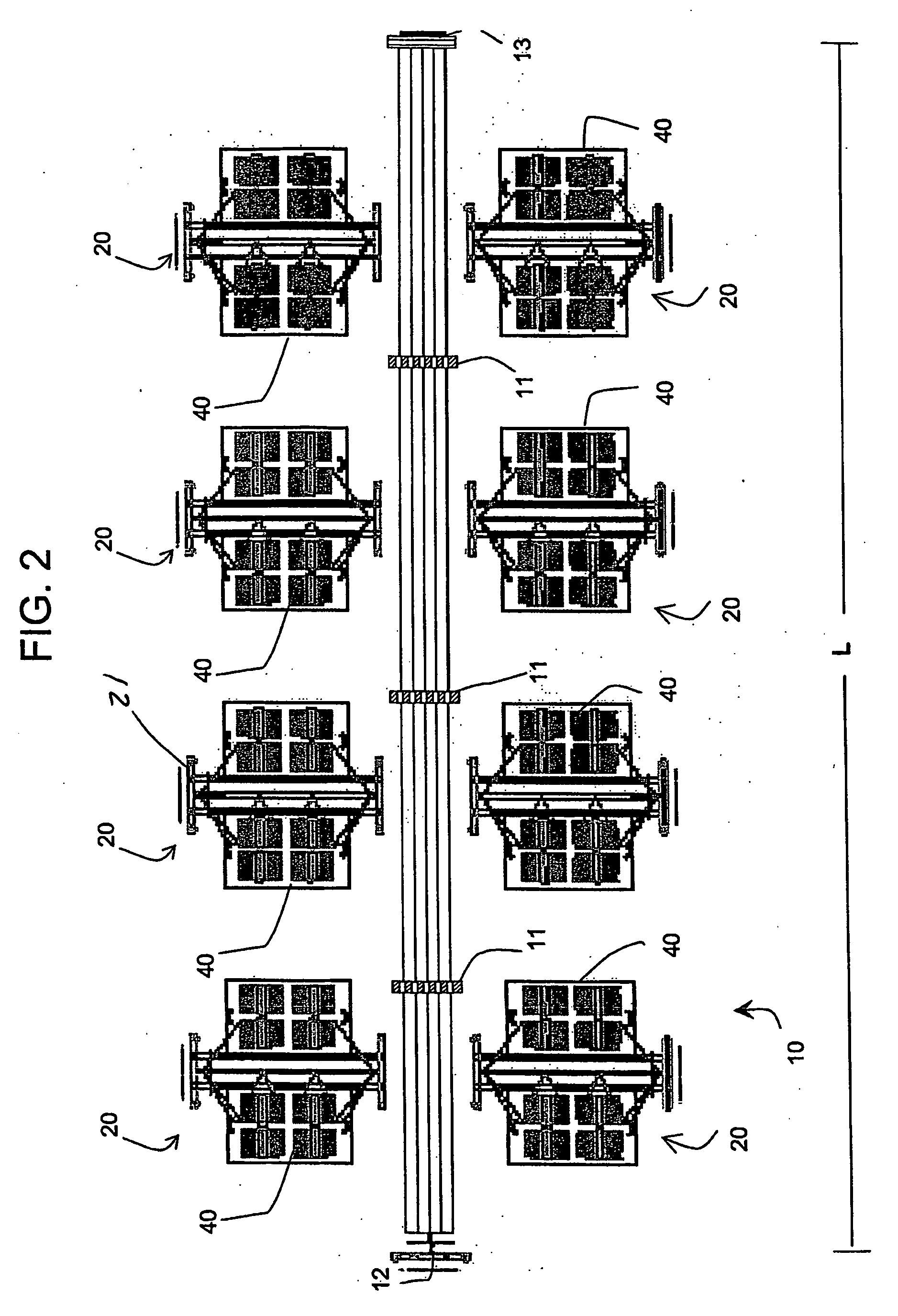

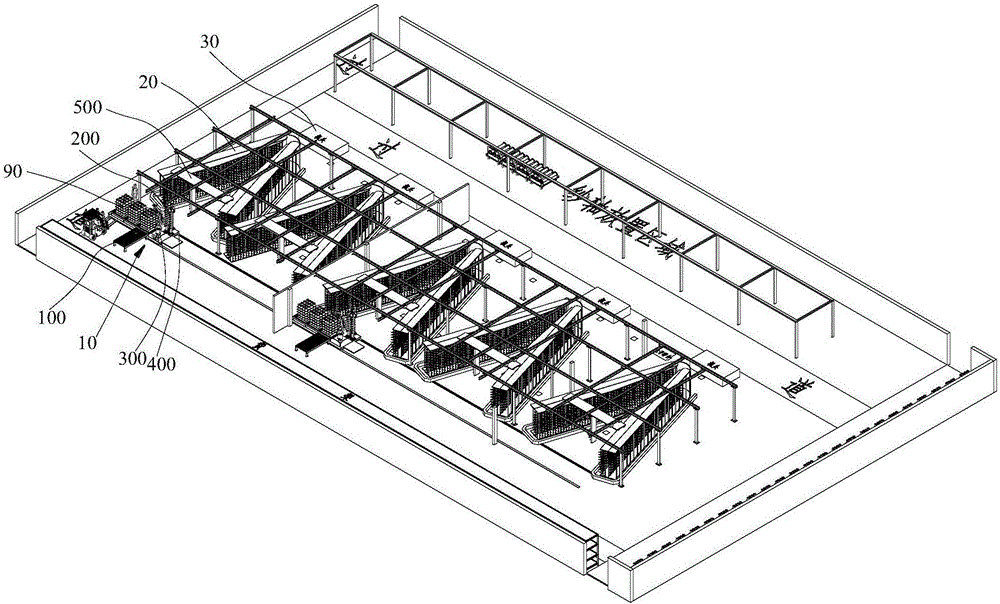

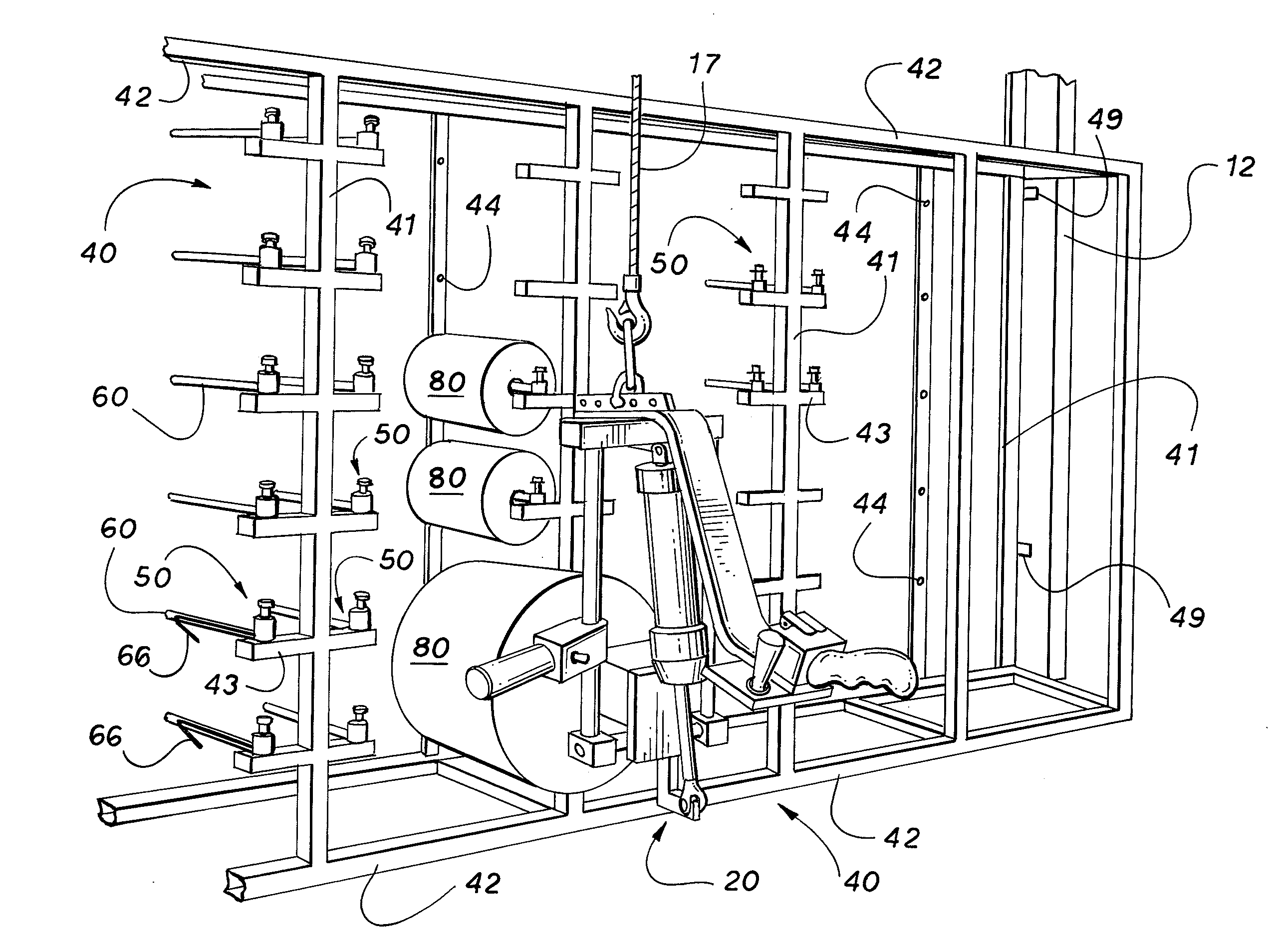

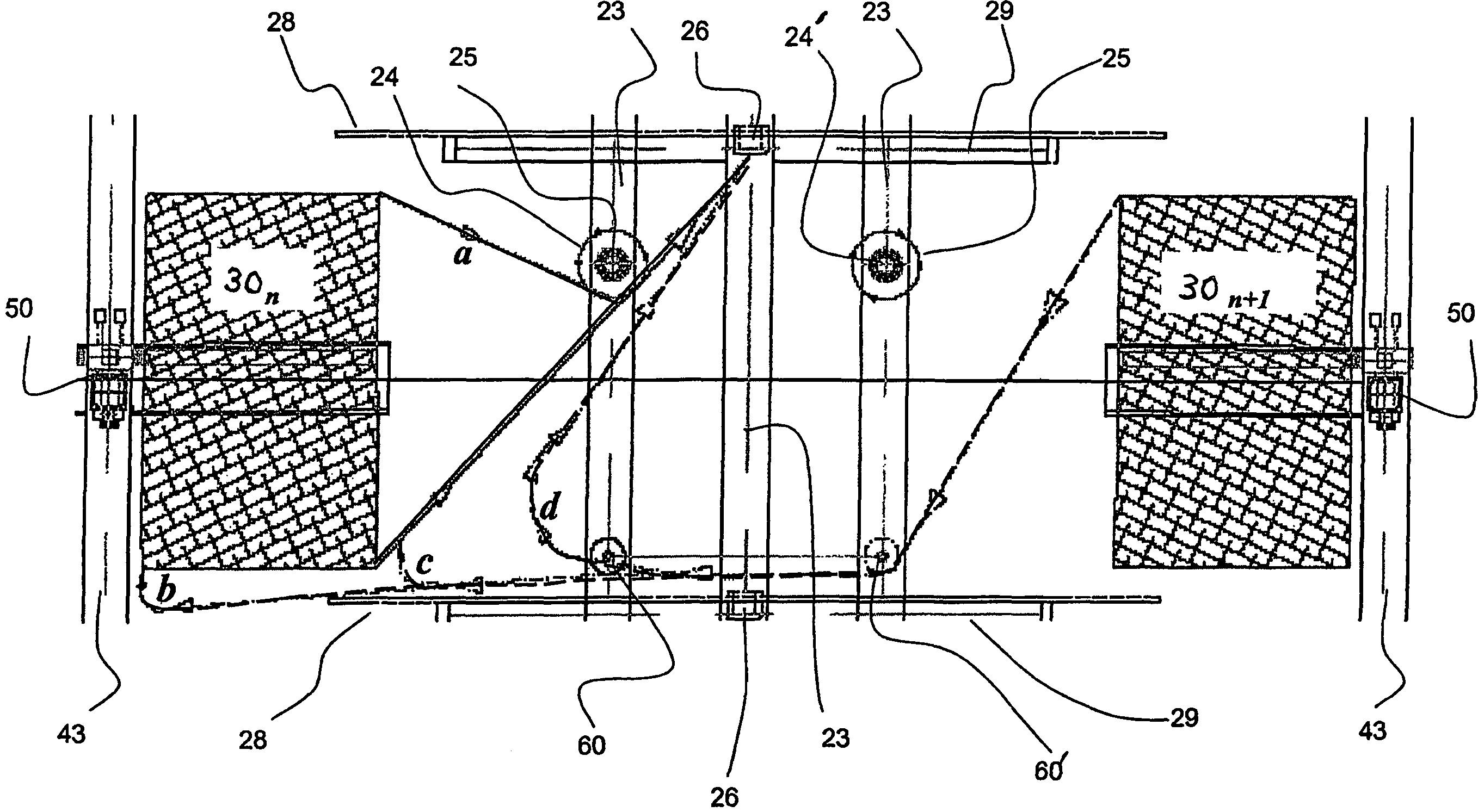

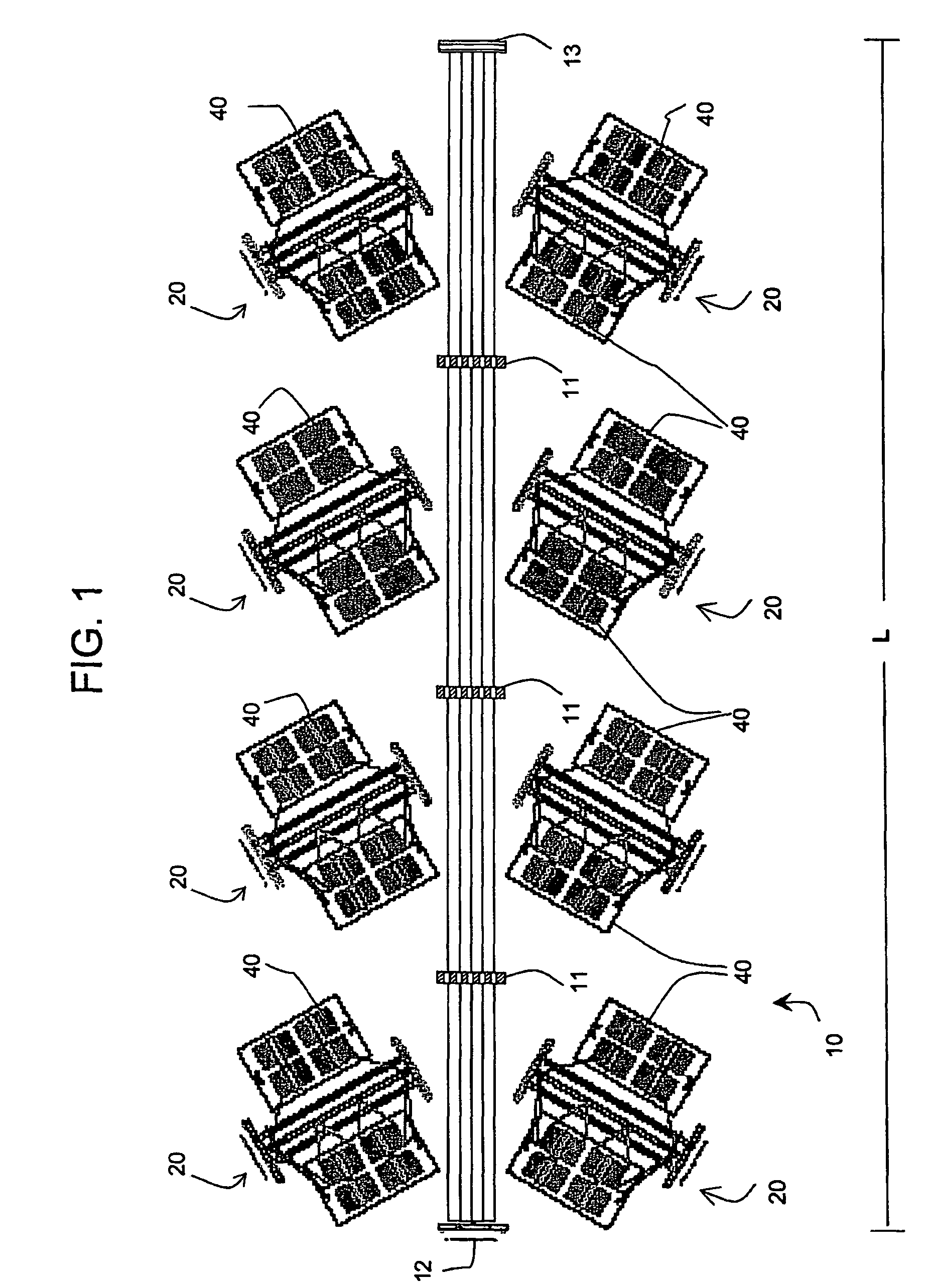

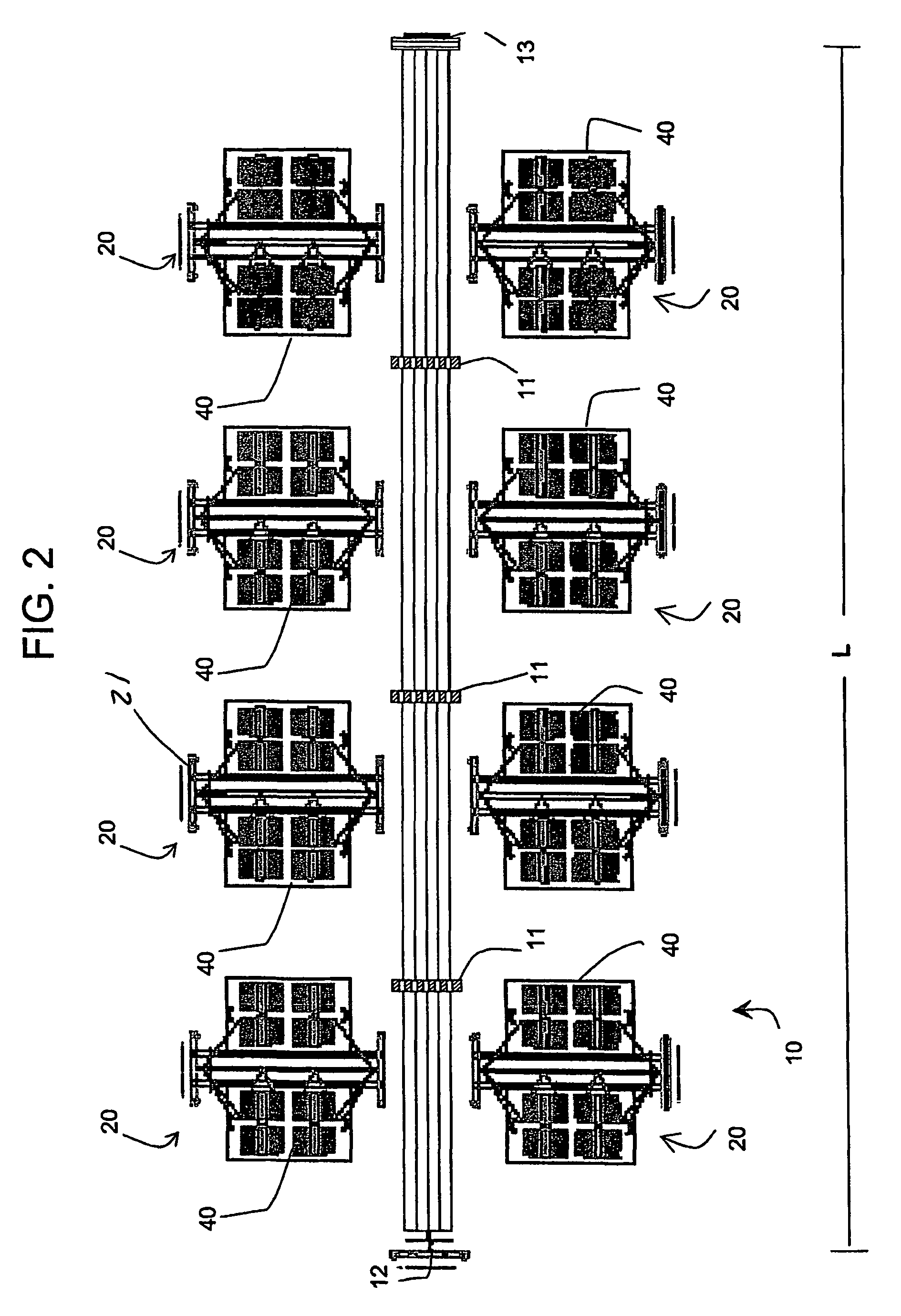

Creel Magazine Supply System and Method

InactiveUS20090101749A1Improve efficiencyReduce complexityFilament handlingCreelsEngineeringMechanical engineering

A creel magazine for continuously delivering packaged stranded material to a manufacturing process. A plurality of magazines linearly disposed in substantially parallel alignment are alternately supplied stranded materials fed to the manufacturing process from movable magazine cartridges supporting packages of stranded materials form either side of the magazine frame. The apparatus and method provide for sequential delivery of stranded materials from packages supported by cartridges at the sides of the magazines, intermediate replenishment of the depleted cartridges with cartridges loaded with replenished packages.

Owner:AUTOMATED CREEL SYST

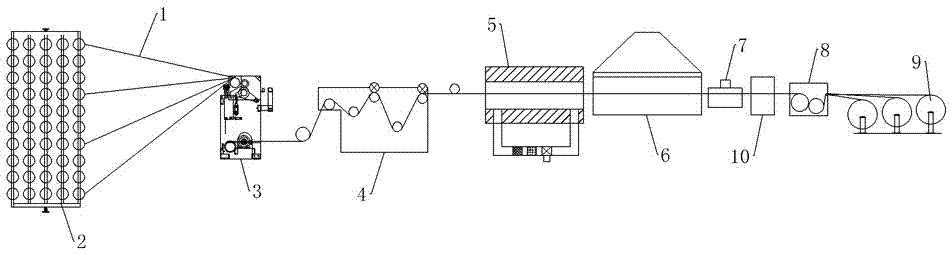

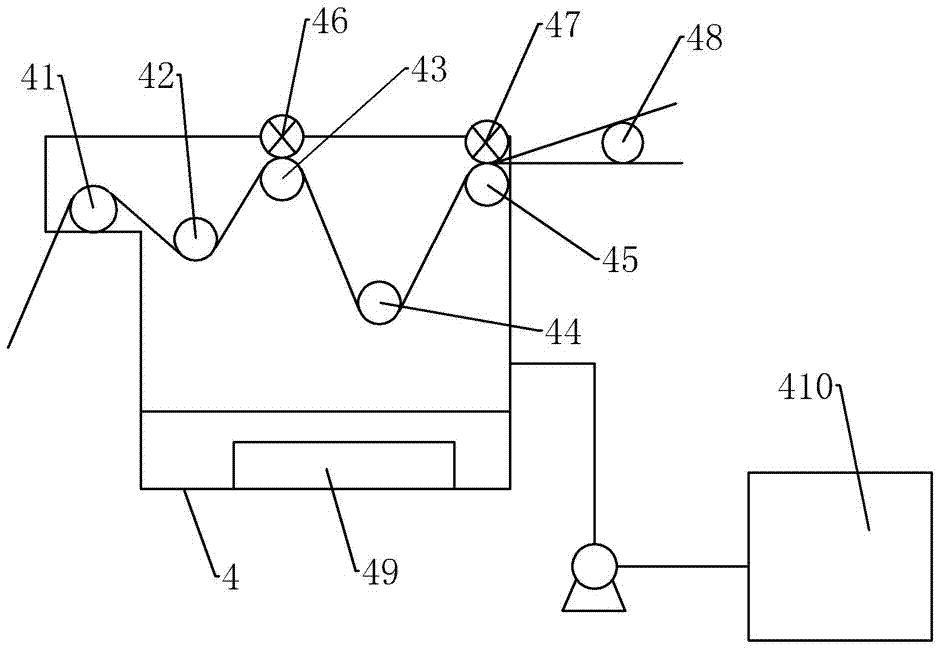

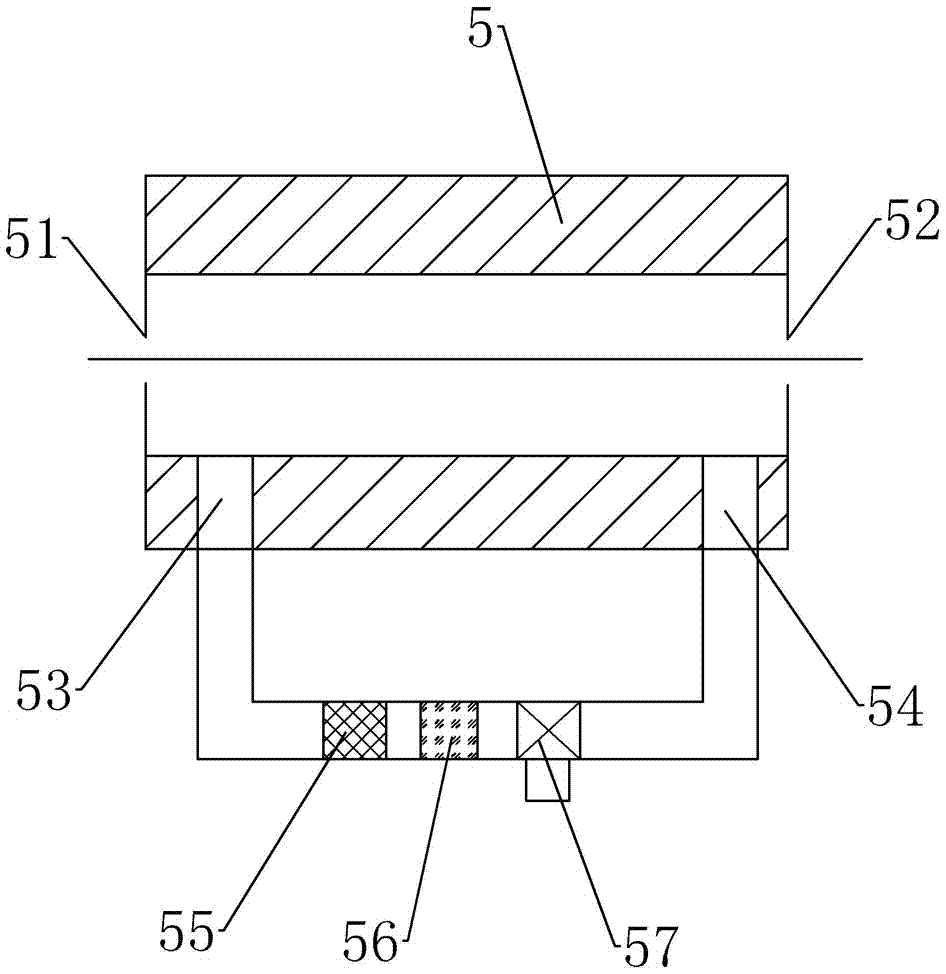

Aramid filament warping, sizing and drawing equipment

PendingCN107130381AAvoid markingsAvoid entanglementSucessive textile treatmentsCreelsBobbinStructural engineering

The invention discloses aramid filament warping, sizing and drawing equipment. The aramid filament warping, sizing and drawing equipment comprises a warping mechanism, a sizing mechanism and a re-beaming mechanism which are arranged along the advancing direction of aramid filaments sequentially, the warping mechanism comprises a bobbin creel, a destaticizing device and a tension frame, the sizing mechanism comprises a size box, a preheating oven, a drying room, a waxing device and a take-up device which are arranged along the advancing direction of the aramid filaments sequentially, a drawing roller is arranged on the inner side of a filament inlet of the size box, a first sizing roller, a second sizing roller, a third sizing roller and a fourth sizing roller are arranged in the size box along the advancing direction of the aramid filaments sequentially, a first squeezing roller is arranged at the top of the second sizing roller, and the re-beaming mechanism comprises a beam creel. The aramid filament warping, sizing and drawing equipment is applicable to processing the aramid filaments, is simple in structure, convenient to use and higher in working efficiency, and can achieve centralized control.

Owner:盐城市荣意来纺机有限公司

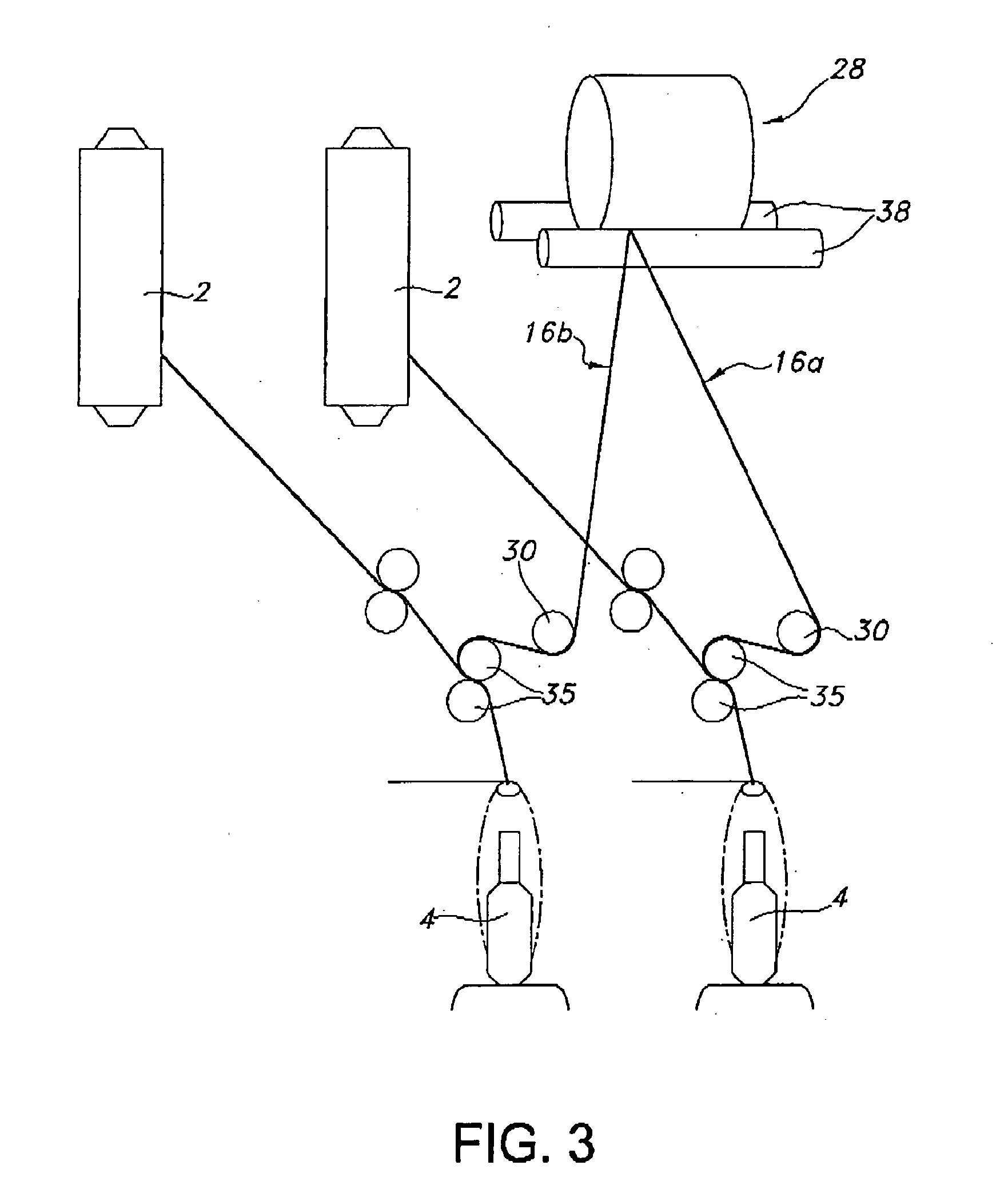

Unwinder for as-spun elastomeric fiber

The invention provides an over-end take off device (OETO) for unwinding elastomeric fiber. The invention further provides a method for unwinding elastomeric fiber for downstream processing.

Owner:THE LYCRA CO LLC

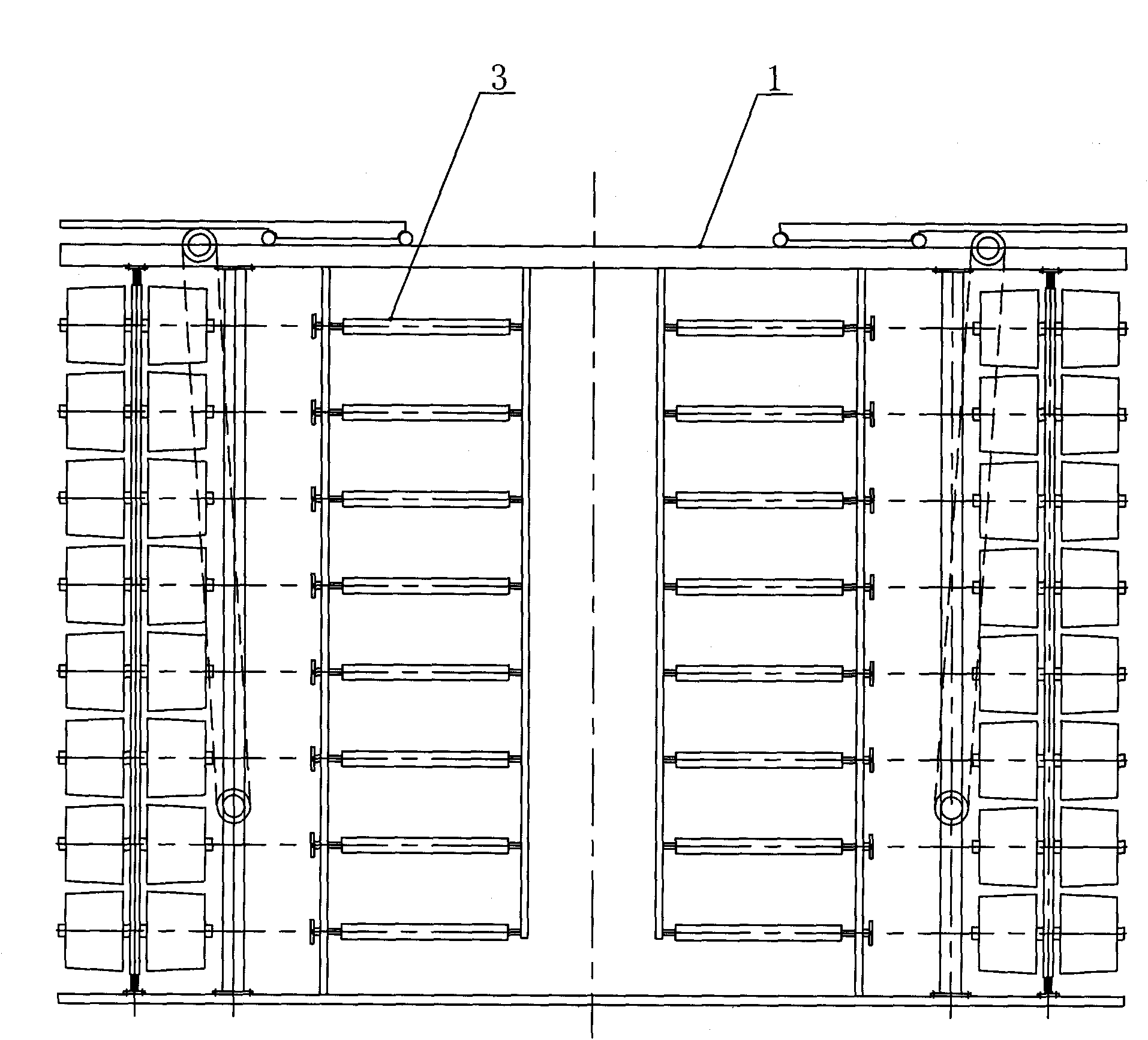

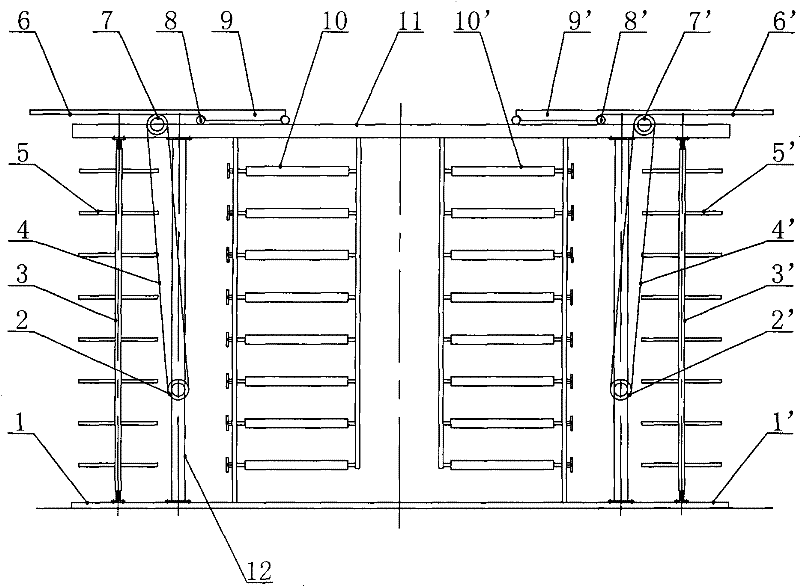

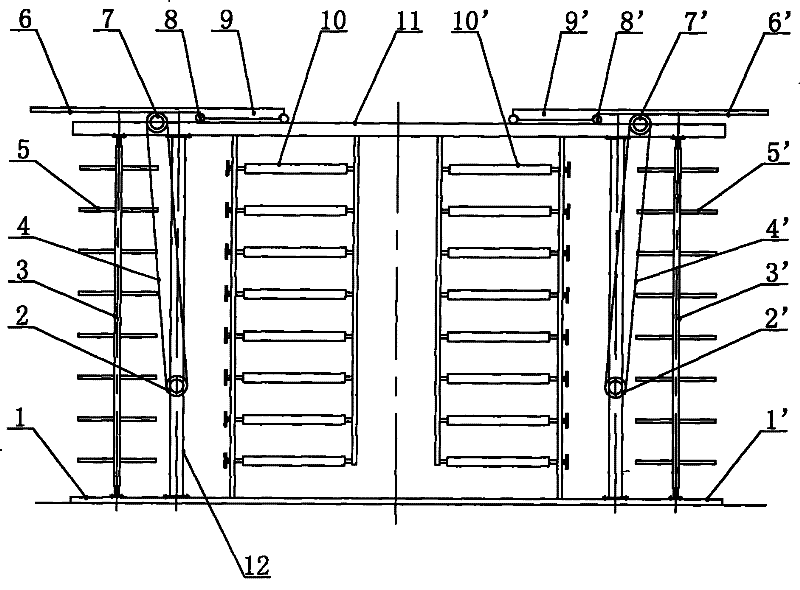

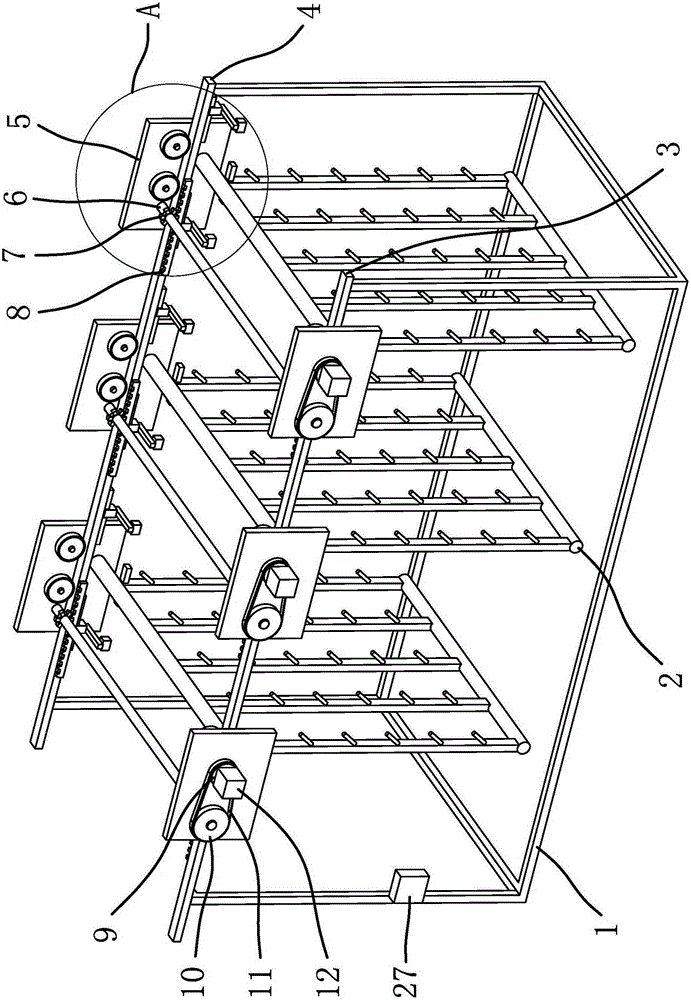

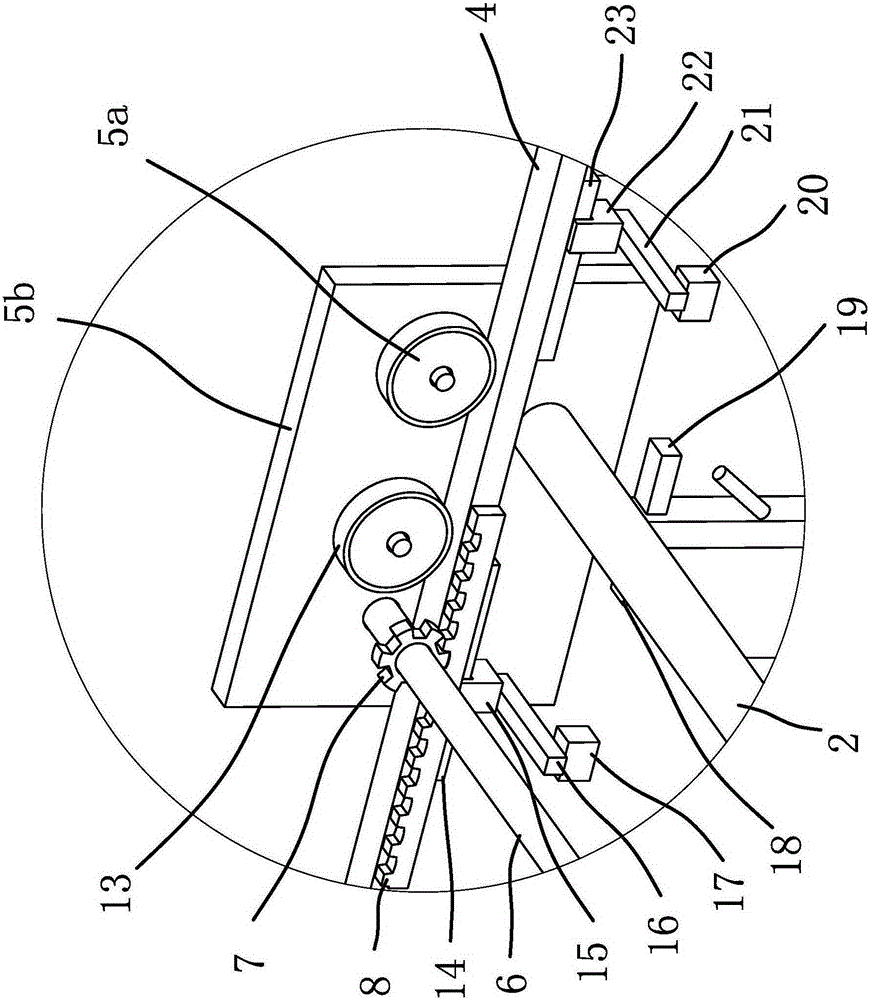

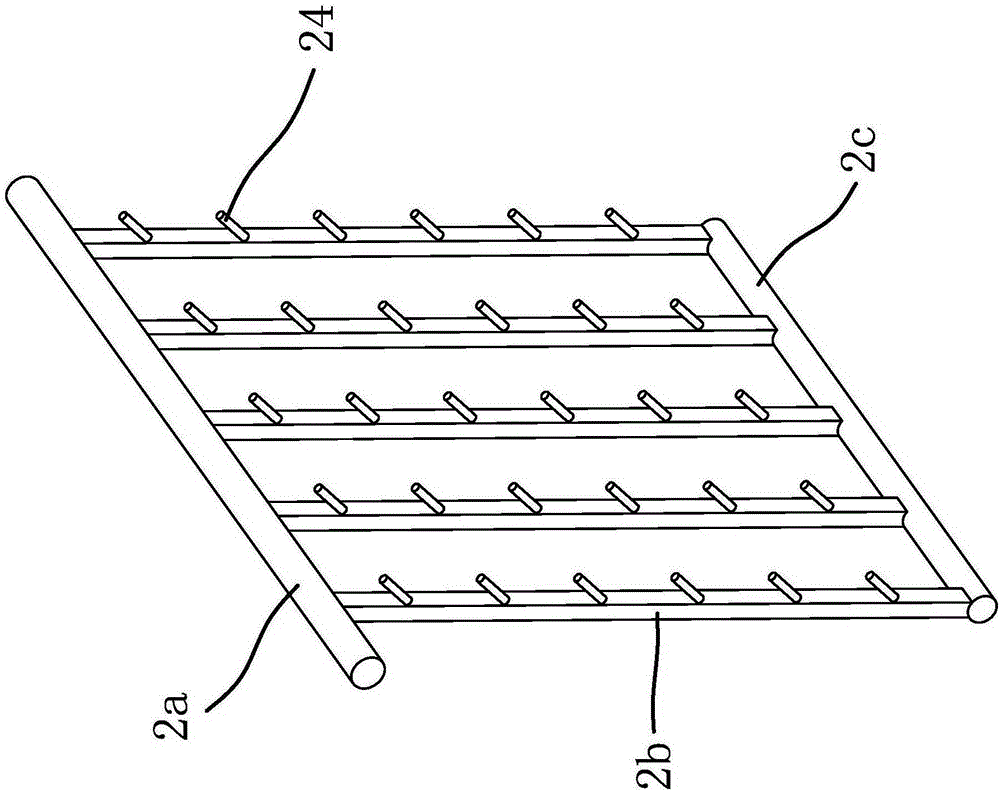

Double-array movable bobbin creel

The invention discloses a double-array movable bobbin creel, which belongs to the technical field of textile machinery. The double-array movable bobbin creel comprises a base, a vertical column which is connected onto the base and a beam which is connected to the top end of the vertical column, wherein the bobbin creel is symmetrically and respectively arrayed at the left and the right sides, a plurality of arrays are arranged from front to back, a plurality of static elimination rods are arranged at the middle part of a first array in front of the bobbin creel, the bobbin creel is provided with a movable device, the movable device comprises a rack, an idler wheel, an upper chain wheel and a lower chain wheel, and is used for moving the whole bobbin creel to the two sides or the middle part, a coaxial crank is arranged on the lower chain wheel, the lower chain wheel is connected with the upper chain wheel in a transmission way, the upper chain wheel is provided with a coaxial gear, the gear is meshed with the rack, and the idler wheel is positioned on a track on the upper surface of the beam; and the shaft of the upper chain wheel transfers from the first array to the last array. When a bobbin is wound, the crank on the lower chain wheel is forwards turned, the lower chain wheel rotates, the upper chain wheel rotates through the transmission of a chain, the gear which is coaxial with an upper chain also rotates for driving the rack of the movable device to move to the left, and the movable device drives the bobbin creel to move to the left too, so the space between the two arrays is increased.

Owner:苏祥

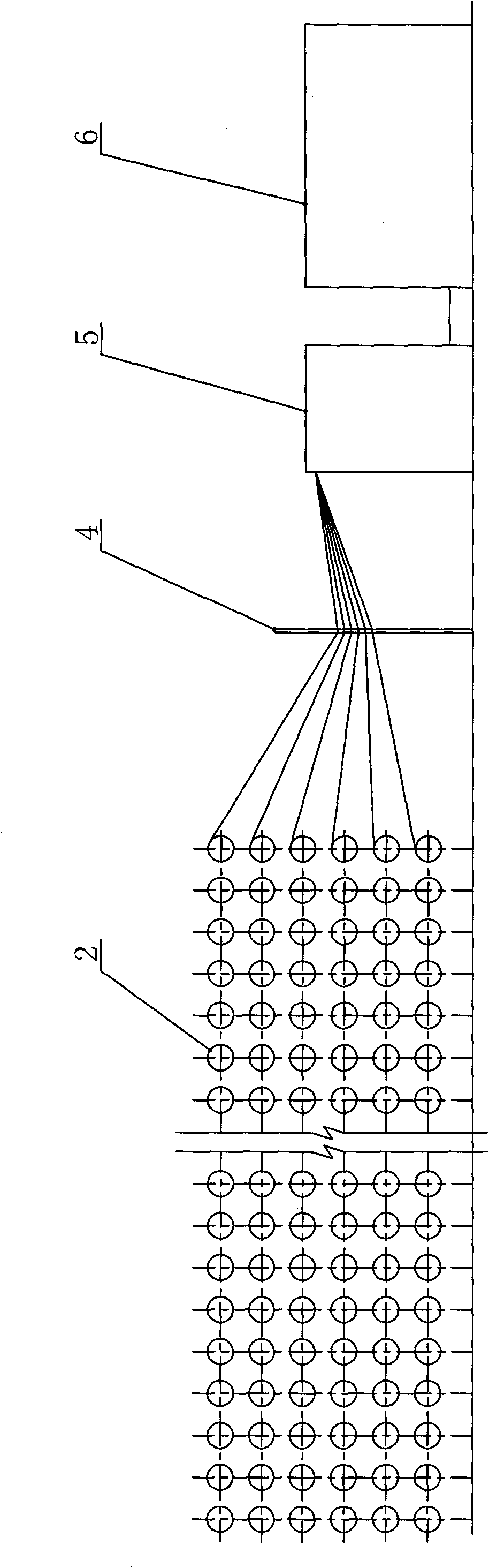

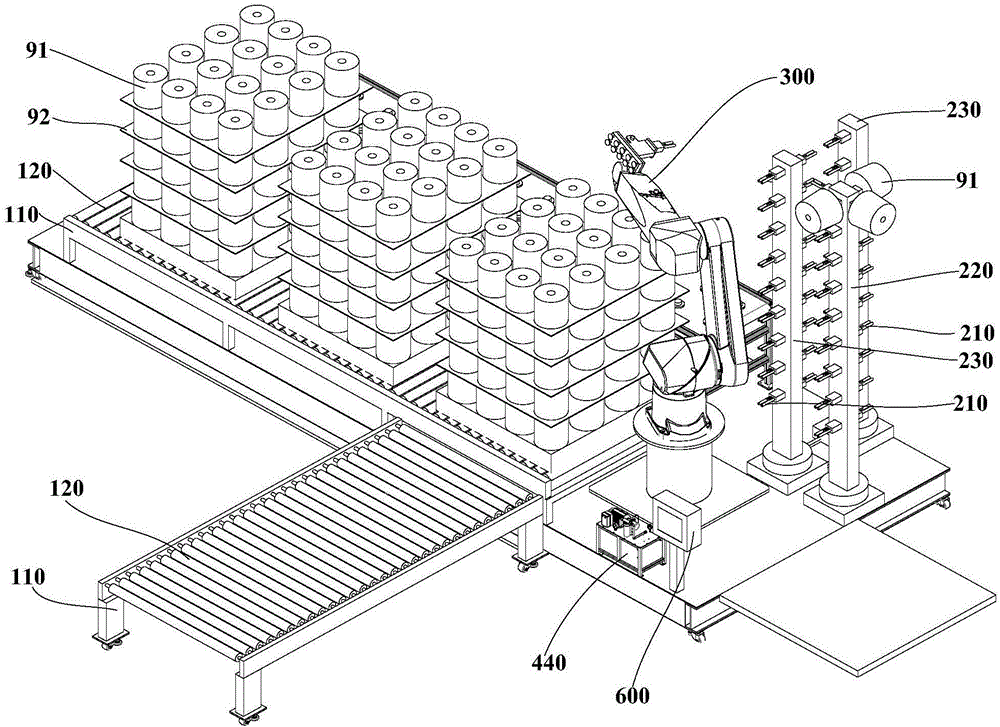

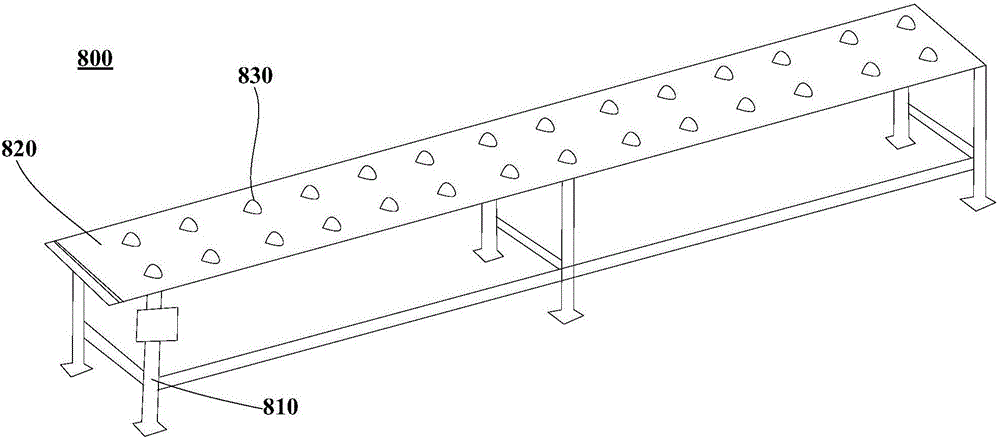

Beaming yarn loading system

The invention relates to a beaming yarn loading system. The beaming yarn loading system comprises a yarn storage mechanism, a transferring mechanism, a capturing mechanism, a feeding mechanism and a control mechanism. By means of the beaming yarn loading system and a beaming system with the beaming yarn loading system, yarn on cones loading can be automatically achieved on a creel, and the whole yarn loading process can be basically operated by the machine independently. The beaming yarn loading system has the advantages that the labor is saved, the working strength of workers is lowered, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Method and apparatus for variably braking the weft thread between a supply spool and a thread store in a loom

A supply spool supplies a weft thread through an adjustable actuated thread brake and a thread tension sensor to a weft thread accumulator, from which an accumulated insertion length of the thread is provided to a weft insertion device. The tension sensor provides a measured actual thread tension signal to a control arrangement, which compares the actual tension to a selected rated tension, and, dependent on the deviation therebetween, provides a control signal to an actuator of the thread brake, so that the actual thread tension constantly corresponds to the selected rated tension. Another sensor provides a signal indicating a change from an empty spool to a full spool. Responsive thereto, the control arrangement actuates the thread brake to an adjustable starting brake setting as a coarse adjustment. Then the self-regulating fine adjustment is continued. A constant winding tension and thread accumulation length are achieved in the thread accumulator.

Owner:LINDAUER DORNIER GMBH

Compact creel

InactiveUS7316366B2Reduces yarn wasteImprove finished product qualityTufting apparatusFilament handlingYarnBobbin

A highly mobile, compact creel that utilizes frames for holding yarn packages (or bobbins) for feeding yarn to a tufting machine. Each frame includes holders affixed to the frame for holding yarn packages facing front and back, a header attachable to the frame for directing yarn from the yarn packages to the tufting machine, and anti-static flexible tubing for leading yarn from the holders to the header. The header provides for aligning all the yarn ends in the same plane to join them to ends already threaded into the tufting machine. An optional frame overlay upright having a ring affixed thereto and strands threaded through the ring prevents yarn from upper yarn packages from falling onto tubes holding lower yarn packages causing yarn entanglement.

Owner:INTERFACE INC

Pivoting package support

InactiveUS20080173742A1Relieving musculo-skeletal stressEfficiencyFilament handlingCreelsYarnVertical axis

A yarn package support for a creel has a support arm that is pivotal about a vertical axis between a loading position and a use position. In the loading position, the package support arm is positioned to load a spool of stranded material, such as yarn or thread. In the use position, the spool and support arm are positioned so that the yarn may be feed into a weaving apparatus. The pivot arrangement permits a laborer to reposition the support arm in a single handed action.

Owner:AUTOMATED CREEL SYST

Elevator apparatus of pony roll support

InactiveCN101195452ALift up quickly and smoothlyAvoid left and right offsetFilament handlingCreelsBobbinBiochemical engineering

The invention provides a hoisting device for bobbin creels, which comprises a bobbin creel and a hoisting mechanism. The improvements of the hoisting device are that a fixing hole is arranged on the bobbin creel, one end of a connecting piece is fastened with the fixing hole by a built-in fitting, the other end of the connecting piece is connected with a lifting rod of the hoisting mechanism, and a connecting base of the hoisting mechanism is fixed on a base. A buffering mechanism is arranged between the base and the bobbin creel. The invention has the advantages of reasonable and simple structure, easy processing of main parts, convenient installation, operation and maintenance, improvement of production efficiency and low equipment failure rate. Besides, the invention can avoid oil leak problems, effectively improves yarn quality and has good application effect.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

Yarn stand of warping machine

The invention provides a yarn stand of a warping machine, belonging to the technical field of textiles. By adopting the yarn stand of warping machine, the technical problems that the distance between adjacent supports of the existing yarn stand cannot be automatically adjusted, the yarn stand is large in occupied space, the space utilization rate is low and the like are solved. The warping machine comprises an installation rack, wherein the installation rack is provided with an installation beam I and an installation beam II which are parallel to each other. The yarn stand comprises an upper beam, a lower beam, and a plurality of vertical rods, wherein the installation beam I and an installation beam II are respectively provided with sliding seats capable of sliding along the length direction, two ends of the upper beam are fixed on the sliding seats, each sliding seat comprises a sliding plate and a sliding wheel, the sliding wheel is rotatably connected to the sliding plate, the circumferential surface of the sliding wheel is propped against the upper surface of the installation beam I or an installation beam II, racks are fixed on the installation beam I and an installation beam II, gears meshed with the racks are arranged on the sliding plates, and the gears on the installation beam I and an installation beam II are connected by a transmission shaft and synchronously rotate. The yarn stand of warping machine has the advantages of high space utilization rate, and convenience in adjusting.

Owner:邓红梅 +2

Creel magazine supply system and method

InactiveUS7806360B2Improve efficiencyReduce complexityFilament handlingWarp knittingEngineeringMechanical engineering

A creel magazine for continuously delivering packaged stranded material to a manufacturing process. A plurality of magazines linearly disposed in substantially parallel alignment are alternately supplied stranded materials fed to the manufacturing process from movable magazine cartridges supporting packages of stranded materials form either side of the magazine frame. The apparatus and method provide for sequential delivery of stranded materials from packages supported by cartridges at the sides of the magazines, intermediate replenishment of the depleted cartridges with cartridges loaded with replenished packages.

Owner:AUTOMATED CREEL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com