Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5934results about How to "Reduce downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

Carbonitride coated component of semiconductor processing equipment and method of manufacturing thereof

InactiveUS20020094378A1High purityIncrease resistanceCellsElectric discharge tubesCorrosion resistantMetallurgy

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a carbonitride containing surface and process for manufacture thereof.

Owner:LAM RES CORP

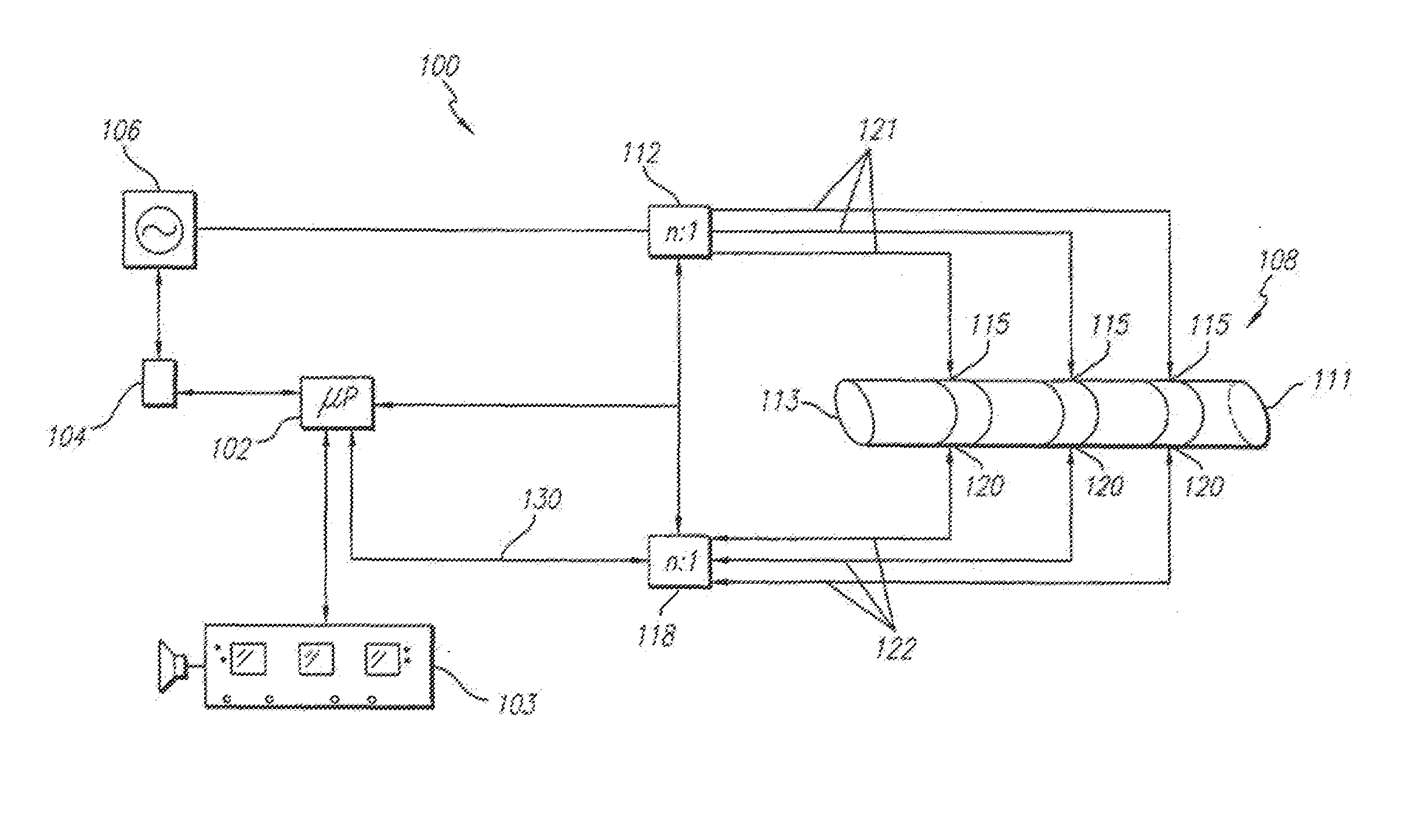

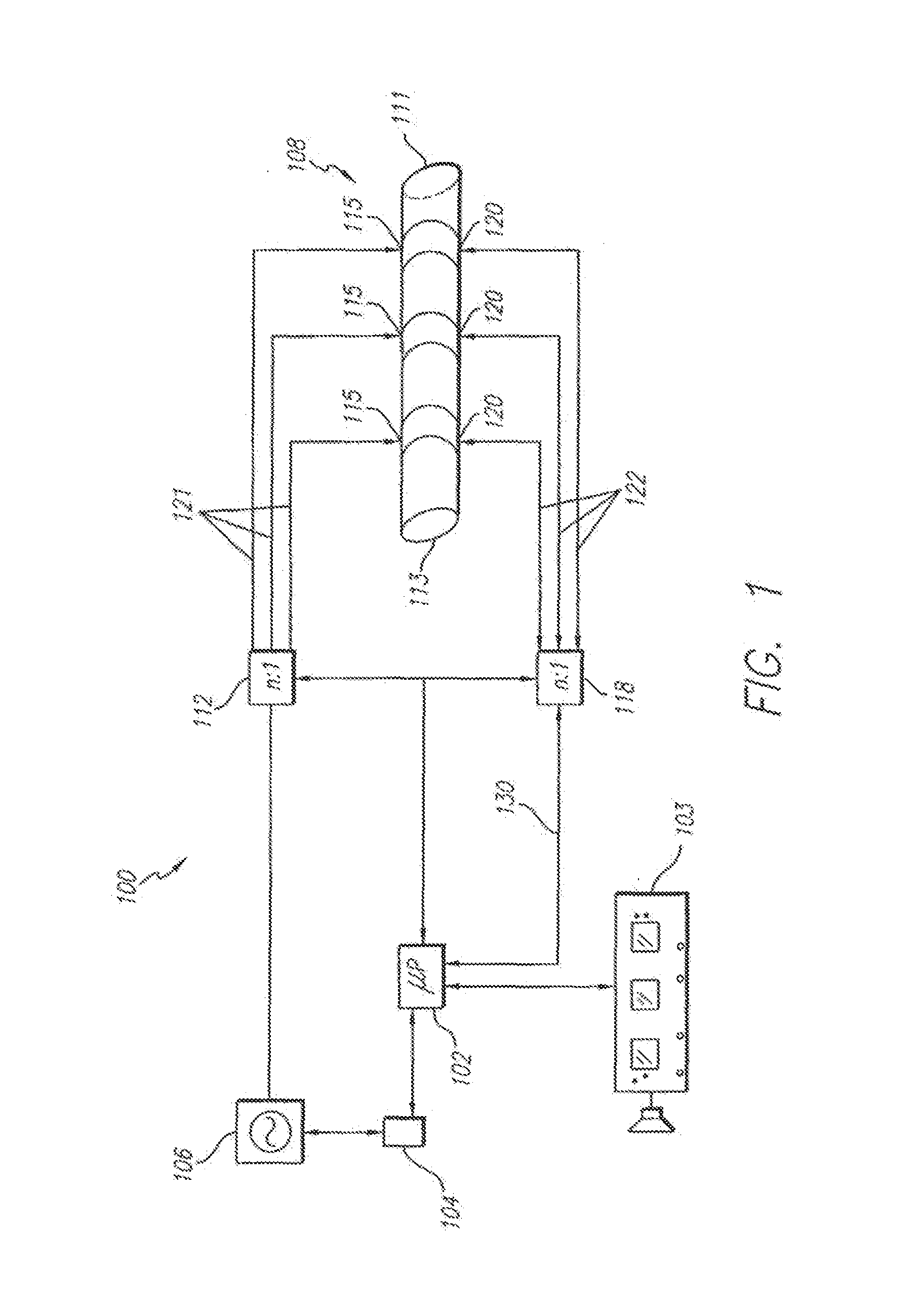

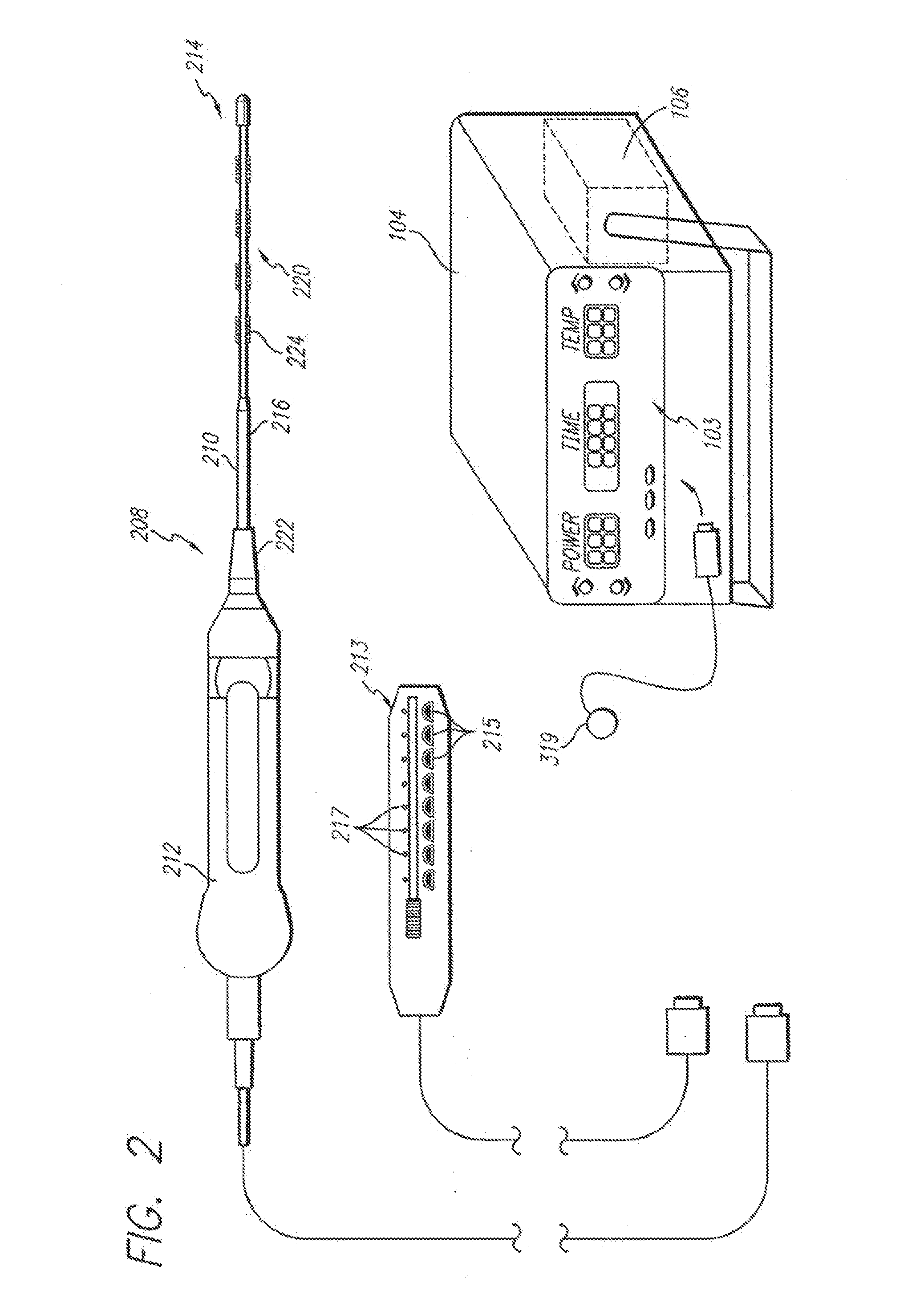

Systems and methods for controlling power in an electrosurgical probe

InactiveUS7582084B2Avoid problemsAccelerated programControlling energy of instrumentSurgical instruments for heatingControl powerCharring

Systems and methods for controlling the power supplied to an electrosurgical probe. The systems and methods may be used to monitor electrode-tissue contact, adjust power in response to a loss of contact, and apply power in such a manner that charring, coagulum formation and tissue popping are less likely to occur.

Owner:BOSTON SCI SCIMED INC

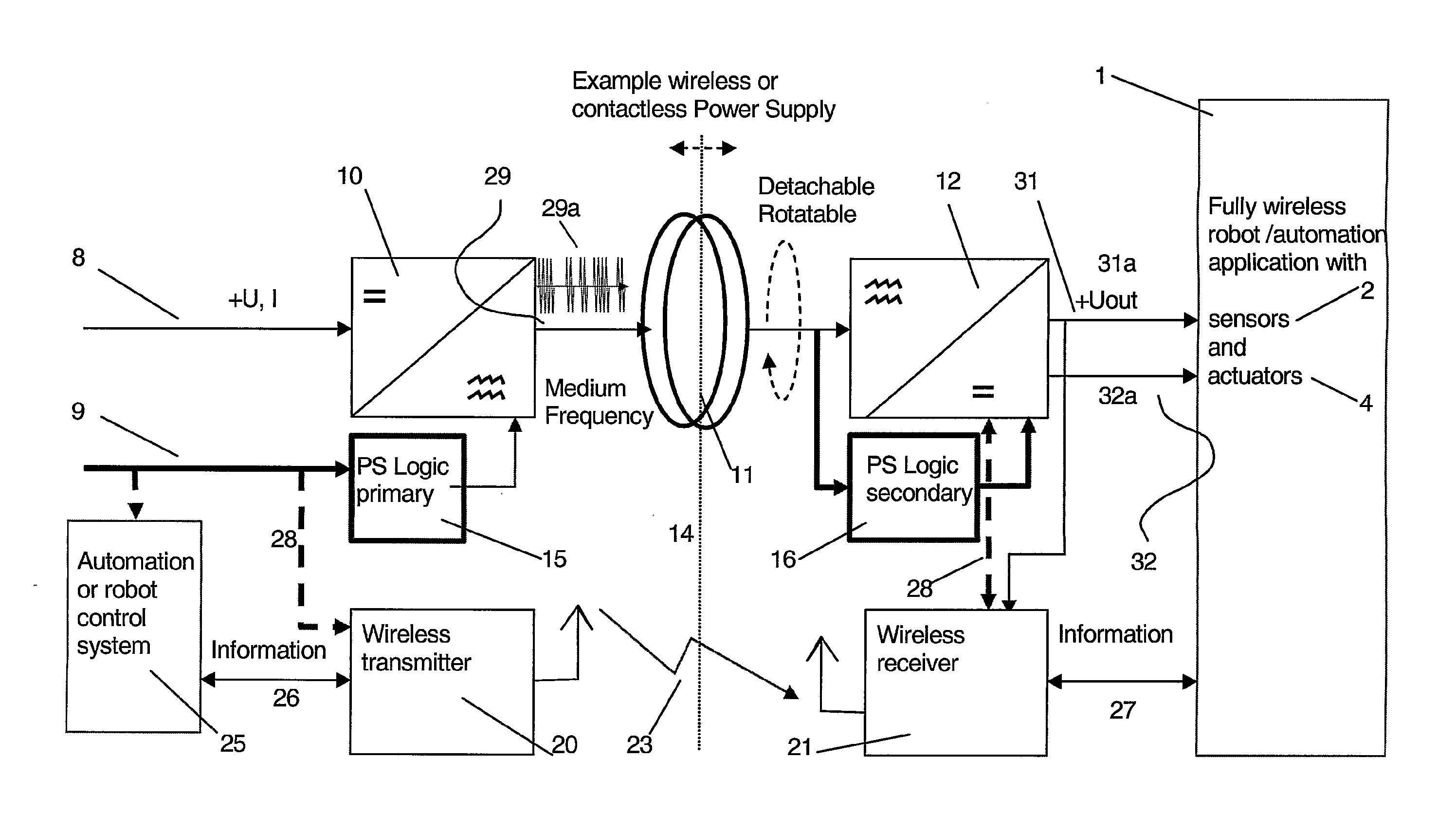

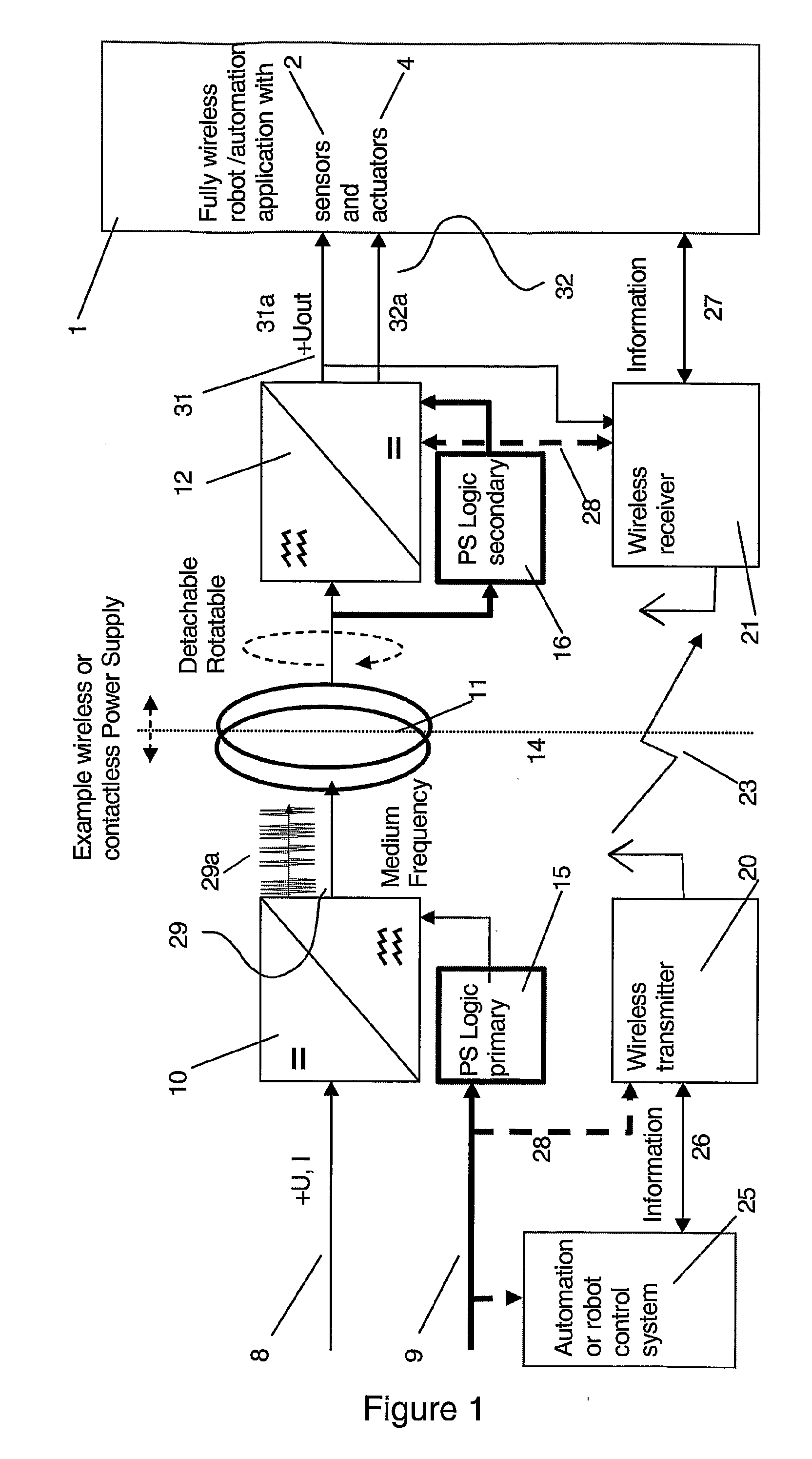

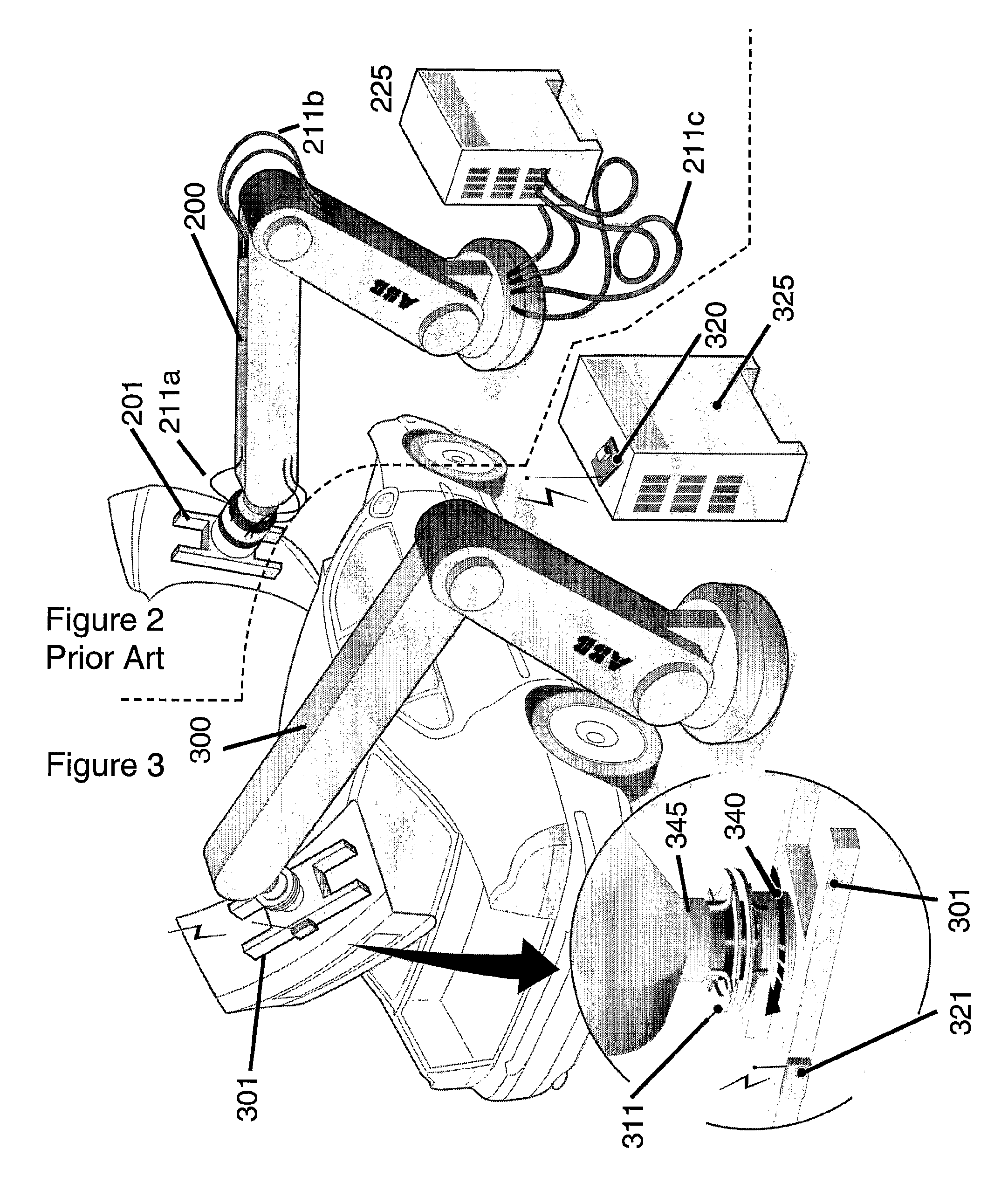

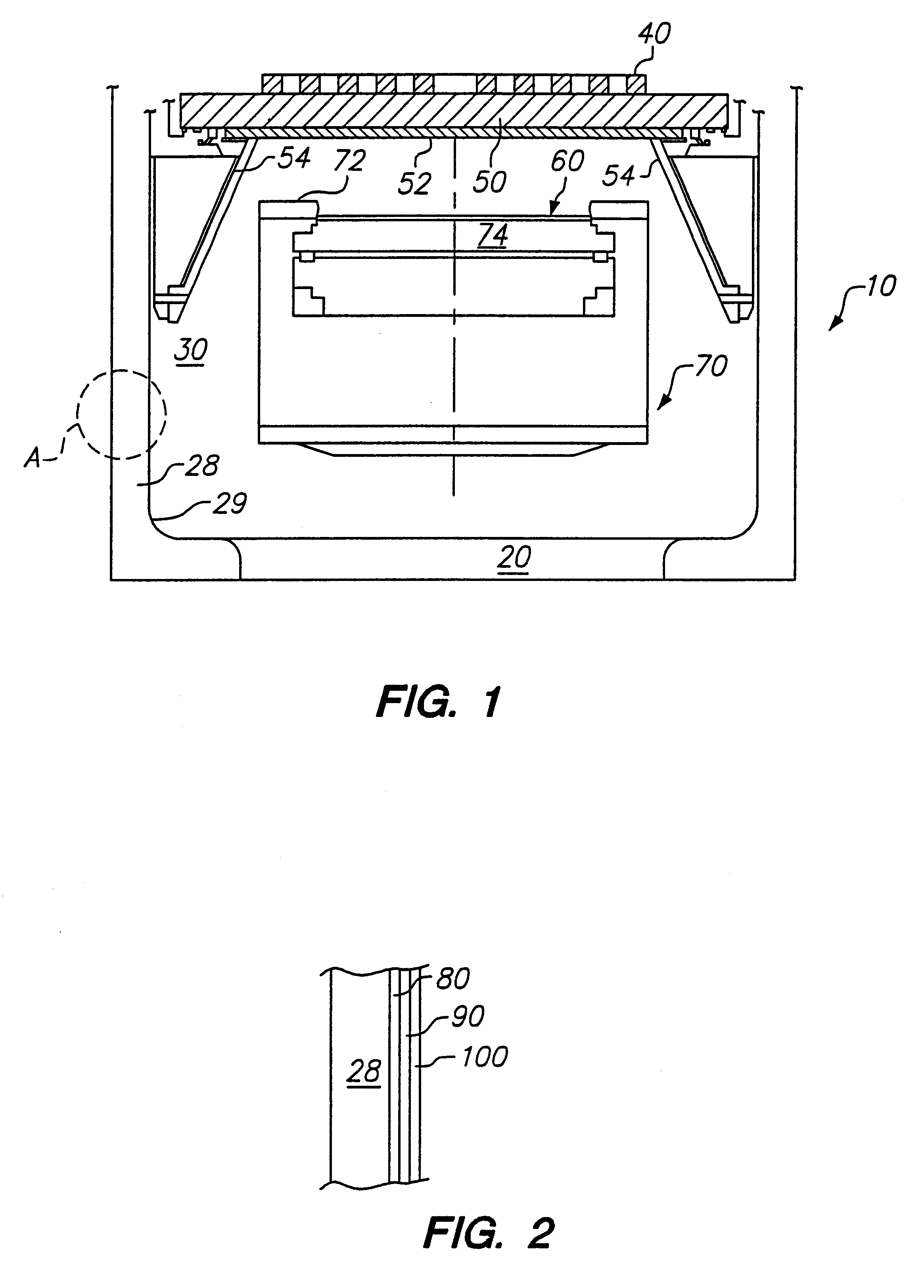

Tool for an Industrial Robot

InactiveUS20070276538A1Speeding up changeReduce downtimeSingle-phase induction motor startersProgramme-controlled manipulatorWireless controlIndustrial robotics

A robot or manipulator including a wireless power supply and a wireless communication device. One or more actuators on the robot tool may be wirelessly powered and wirelessly controlled. The robot tool may have one or more wireless communication members for transmission of data from sensors on the tool. The power supply includes a primary power supply member and secondary power supply member. Tool changes may be carried out automatically by the robot. In other aspects of the invention a method, a control system and a computer program for carrying out the method are described.

Owner:ABB RES LTD

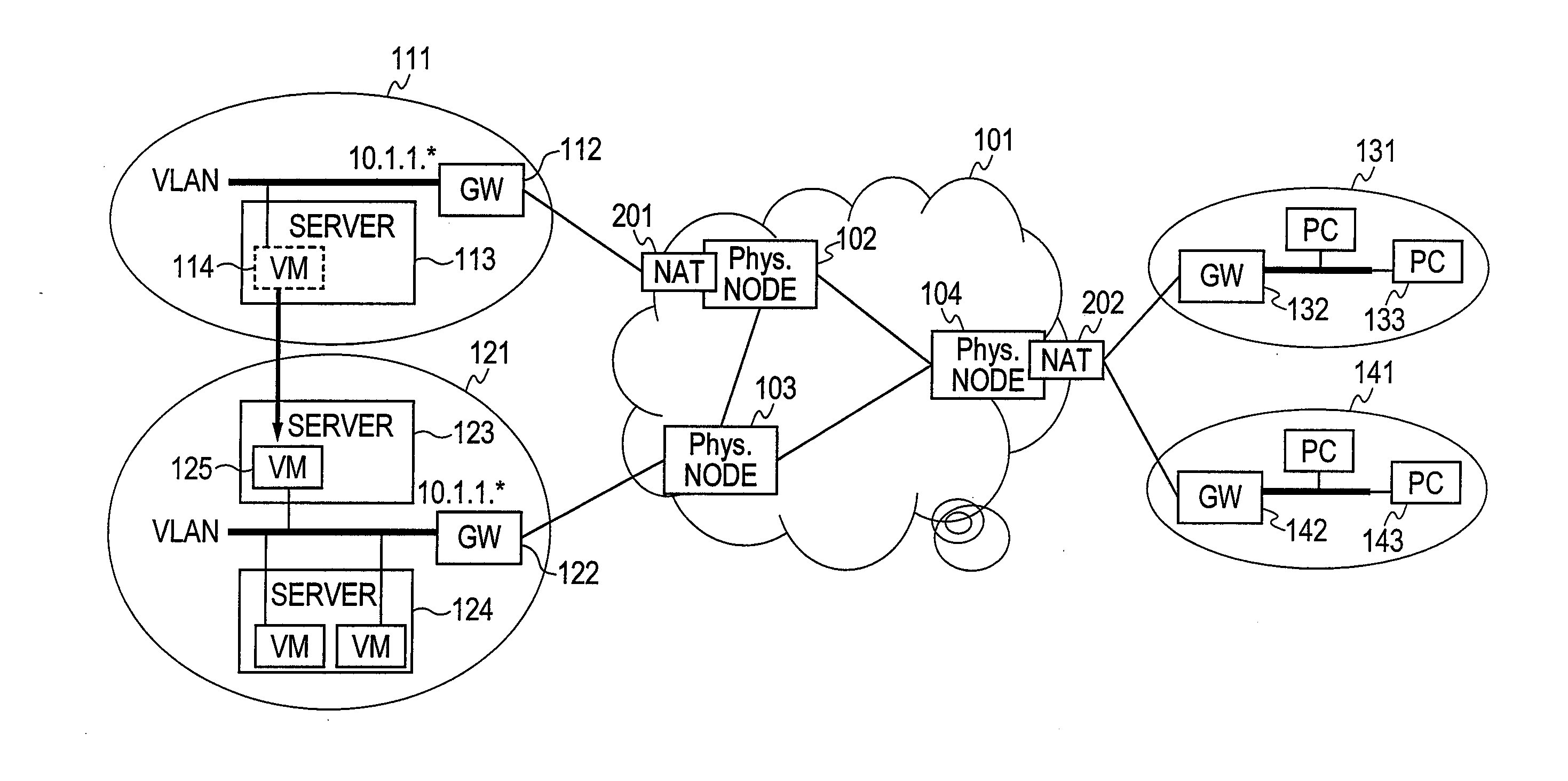

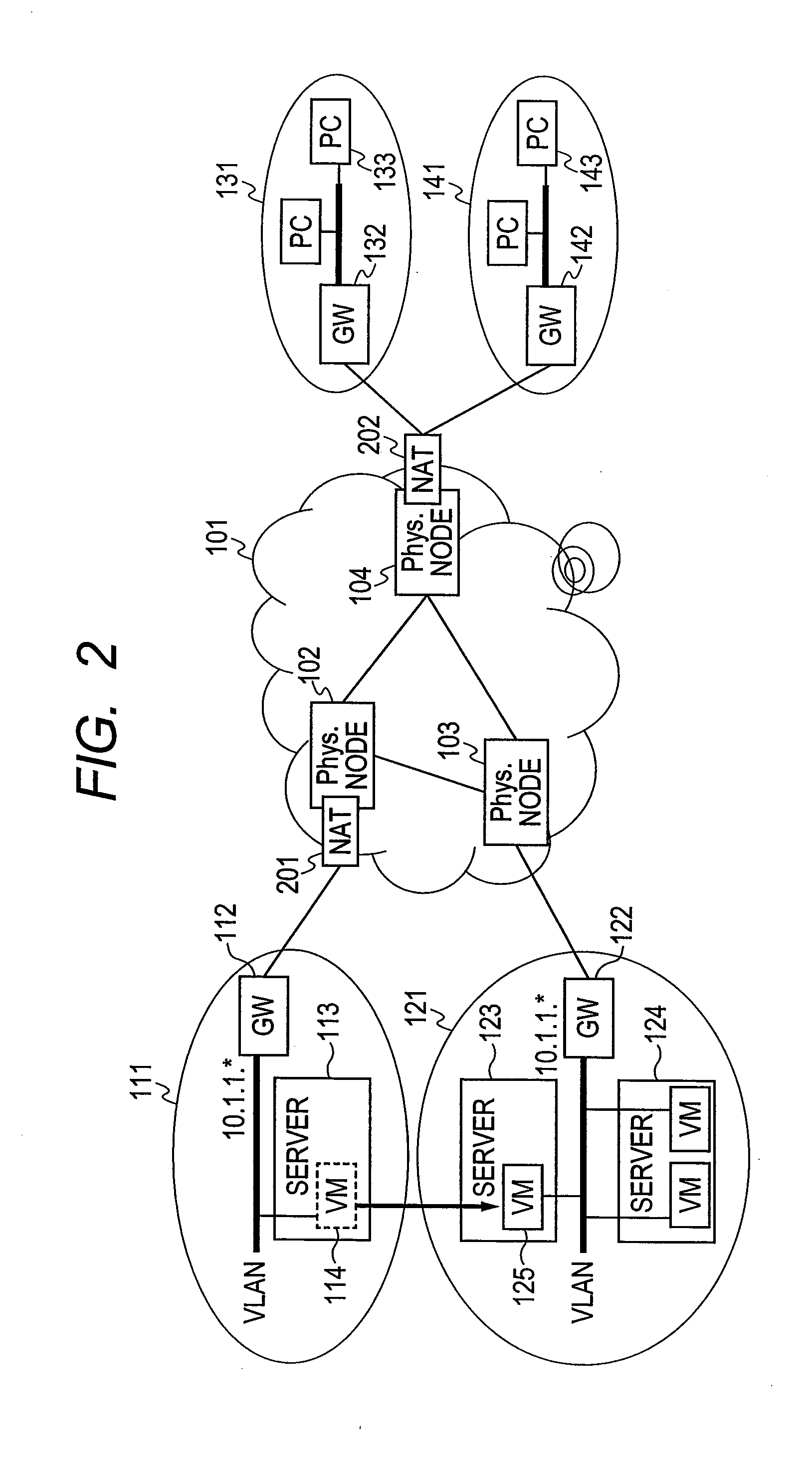

Method and system of virtual machine migration

ActiveUS20110246669A1Reduce downtimeEnergy efficient ICTResource allocationVirtual machineCountermeasure

In cooperation between each data center and a WAN, virtual machine migration is carried out without interruption in processing so as to enable effective power-saving implementation, load distribution, or fault countermeasure processing. Each node located at a boundary point between the WAN and another network is provided with a network address translation (NAT) function that can be set dynamically to avoid address duplication due to virtual machine migration. Alternatively, each node included in the WAN is provided with a network virtualization function; and there are implemented a virtual network connected to a data center for including a virtual machine before migration, and a virtual network connected to a data center for including the virtual machine after migration, thereby allowing coexistent provision of identical addresses. Thus, the need for changing network routing information at the time of virtual machine migration can be eliminated, and a setting change for migration accomplished quickly.

Owner:HITACHI LTD

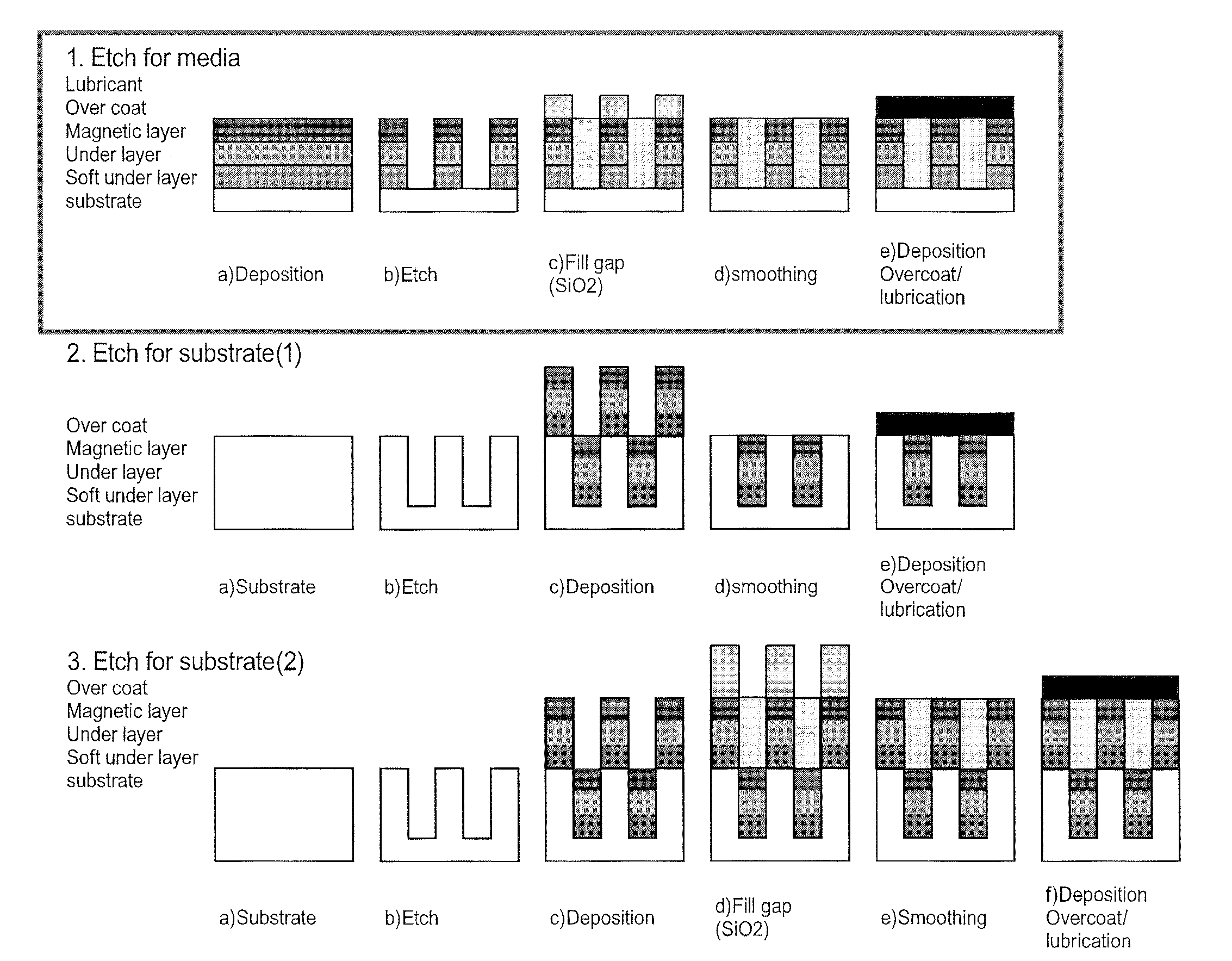

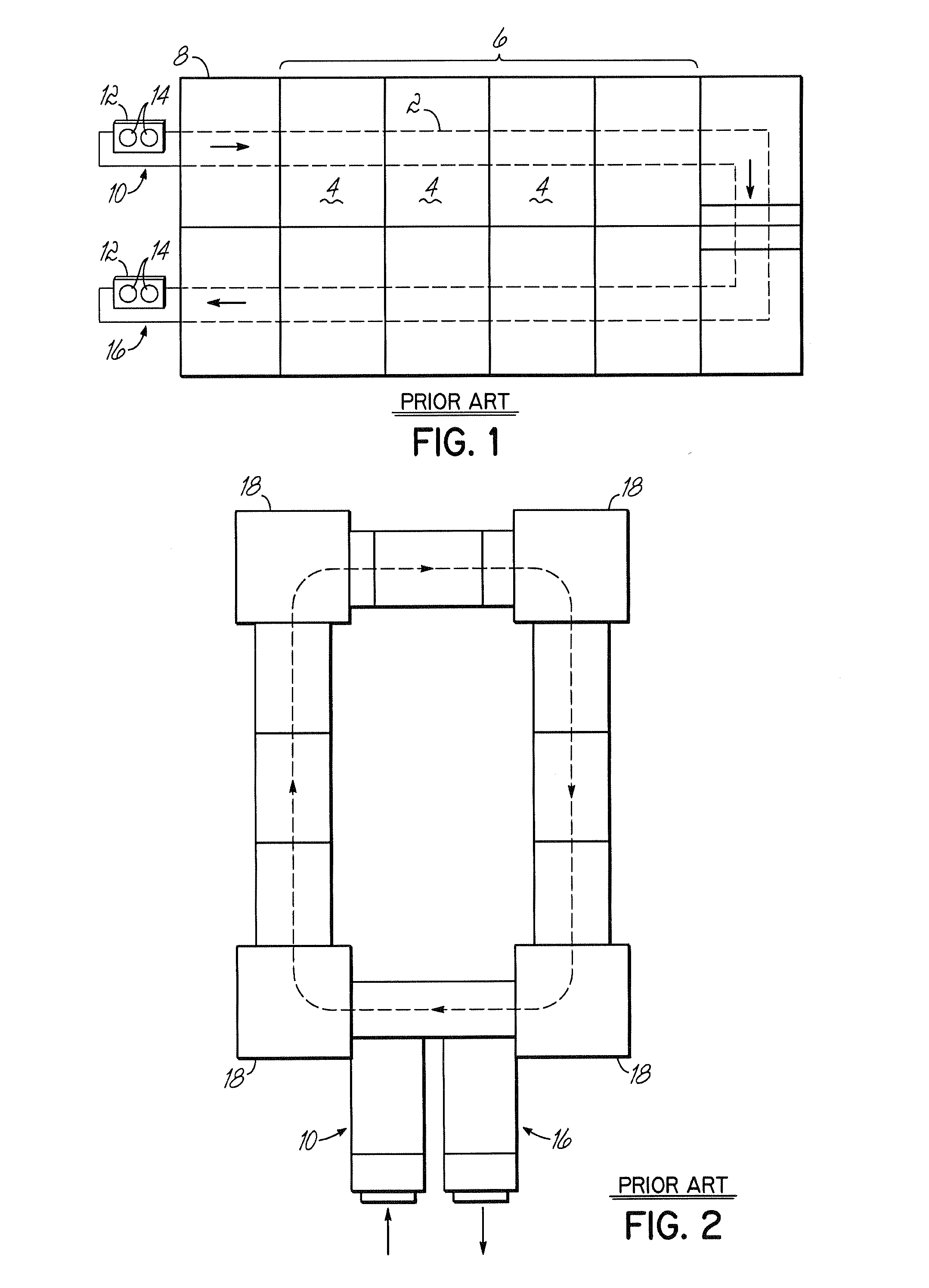

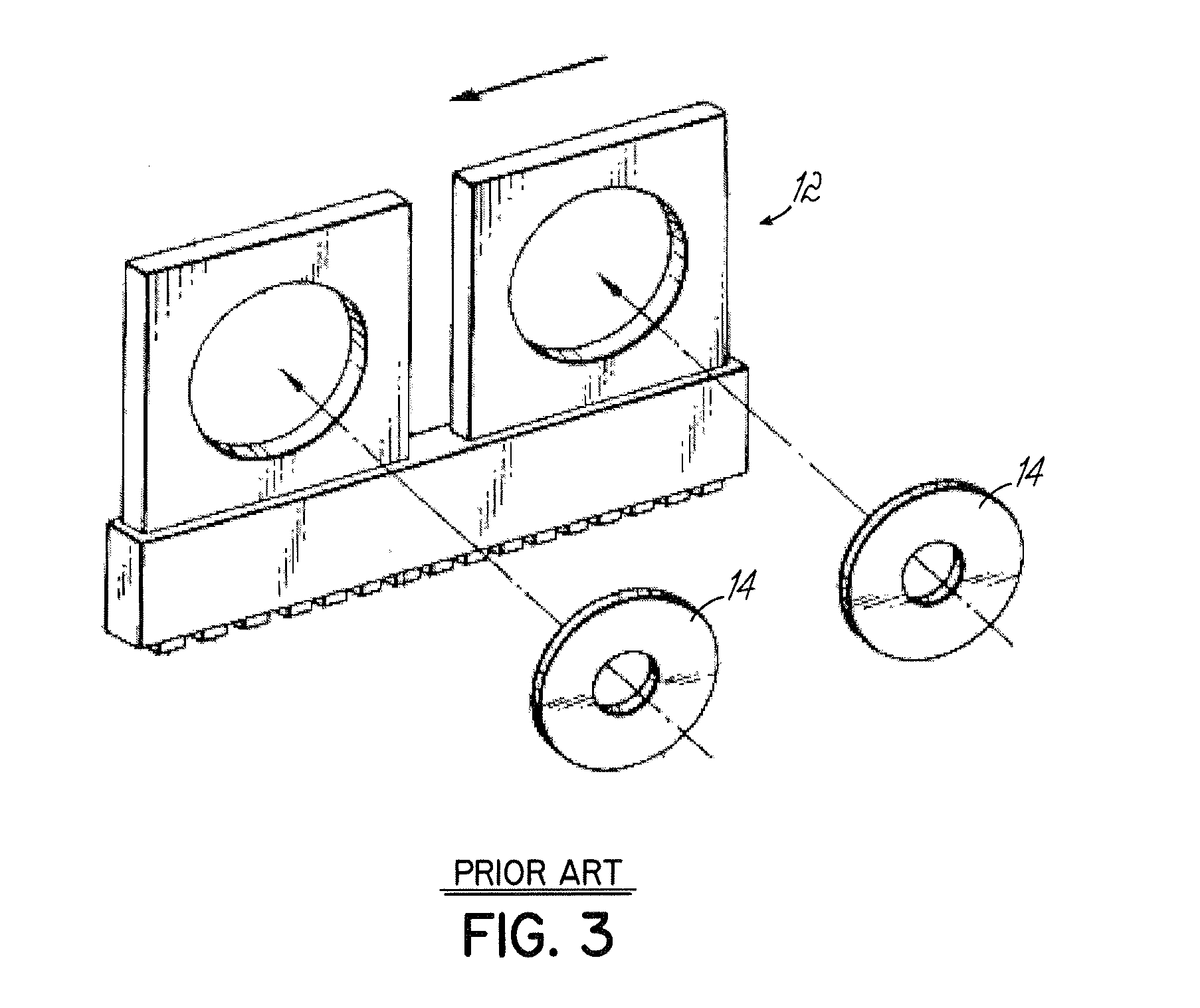

System for Fabricating a Pattern on Magnetic Recording Media

InactiveUS20120223048A1Easy to useReduce system footprintLiquid surface applicatorsDecorative surface effectsHard disc driveMagnetic media

An inline processing system for patterning magnetic recording layers on hard discs for use in a hard disc drive. Discs are processed on both sides simultaneously in a vertical orientation, in round plate-like holders called MDCs. A plurality (as many as 10) discs are held in a dial carrier of the MDC, and transferred from one process station to another. The dial carrier of the MDC may be rotated and / or angled at up to 70° from normal in each process station, so that one or a plurality of process sources may treat the discs simultaneously. This configuration provides time savings and a reduction in the number and size of process sources needed. A mask enhancement process for patterning of magnetic media, and a filling and planarizing process used therewith, are also disclosed.

Owner:VEECO INSTR

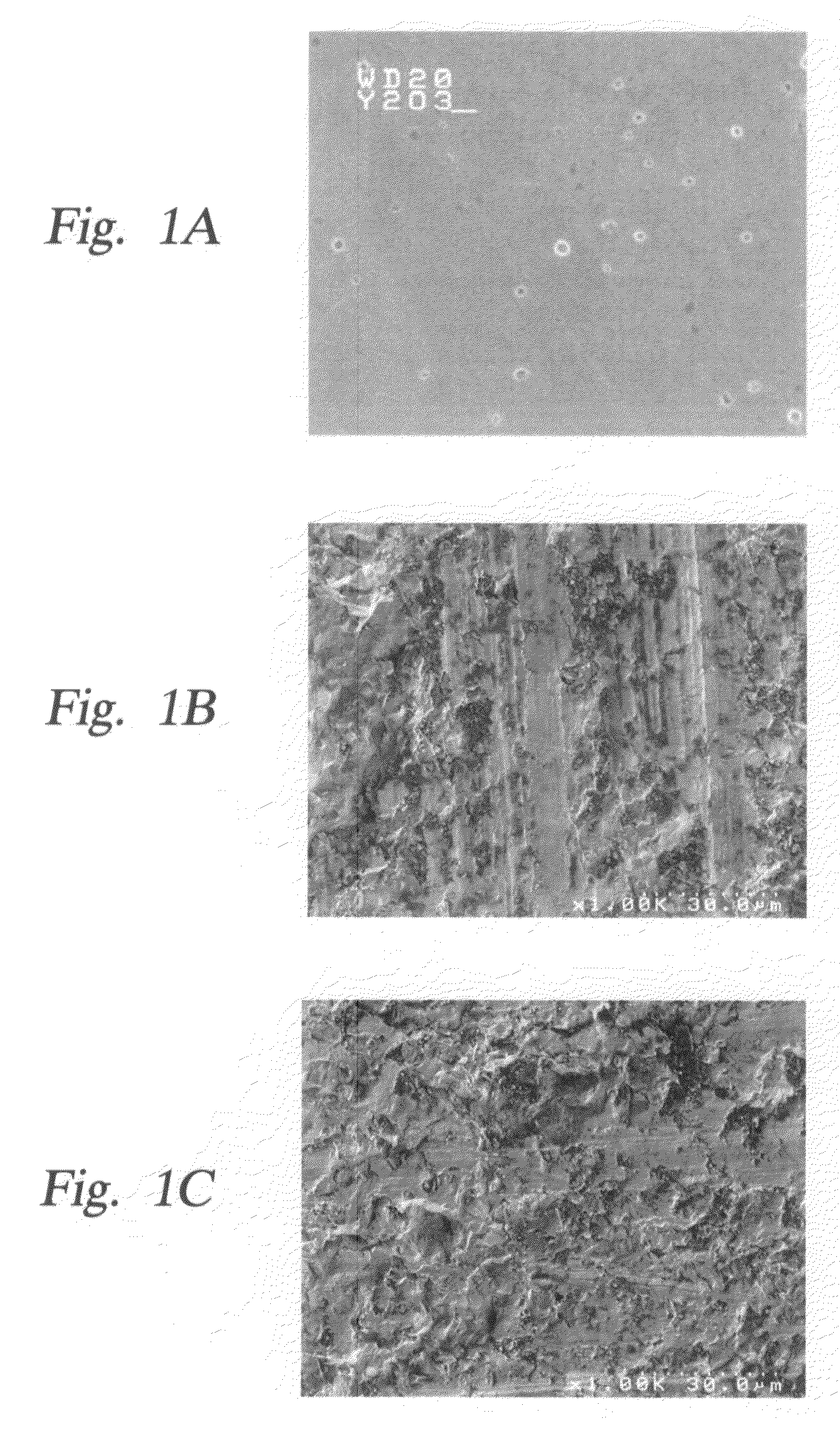

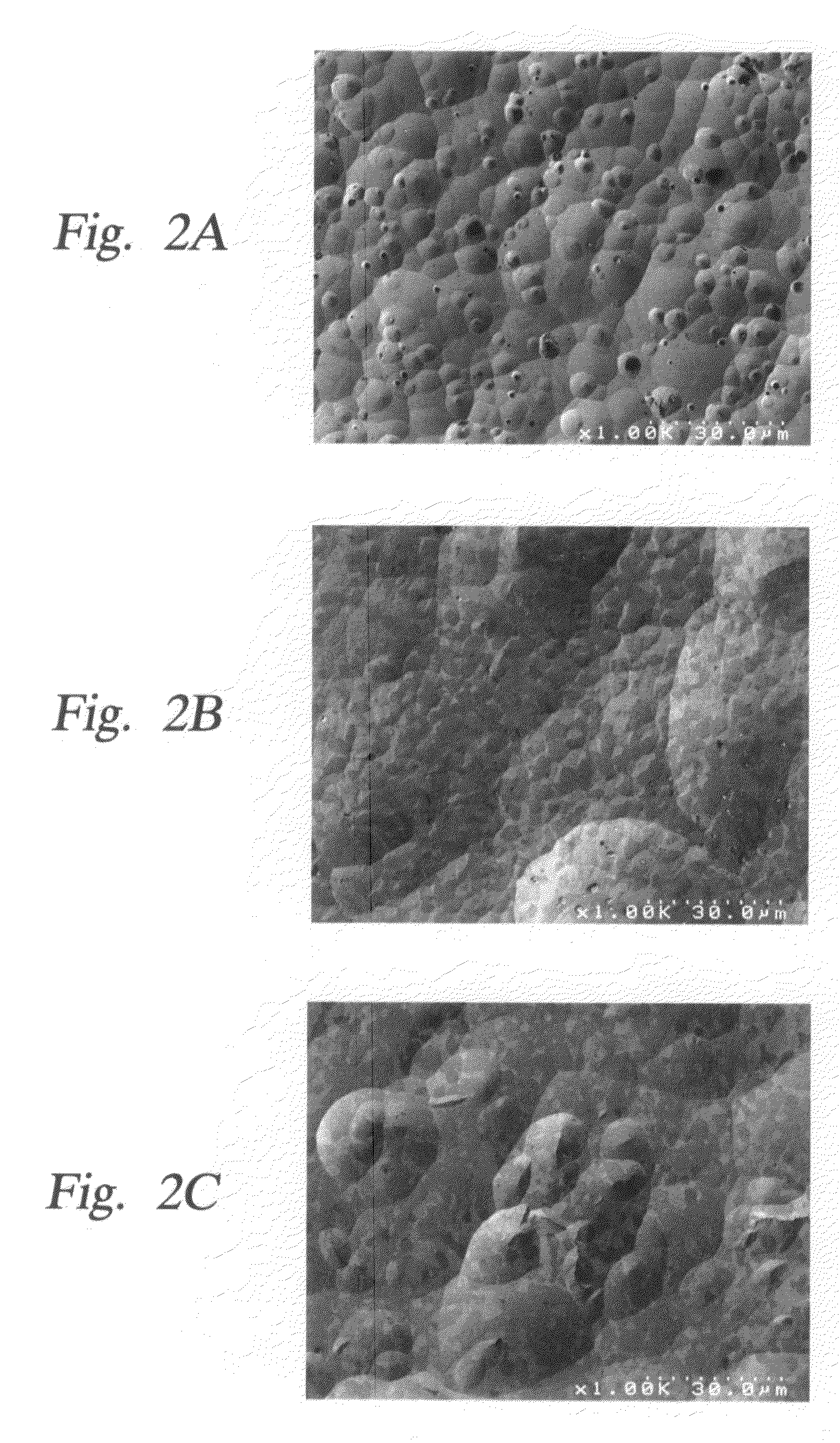

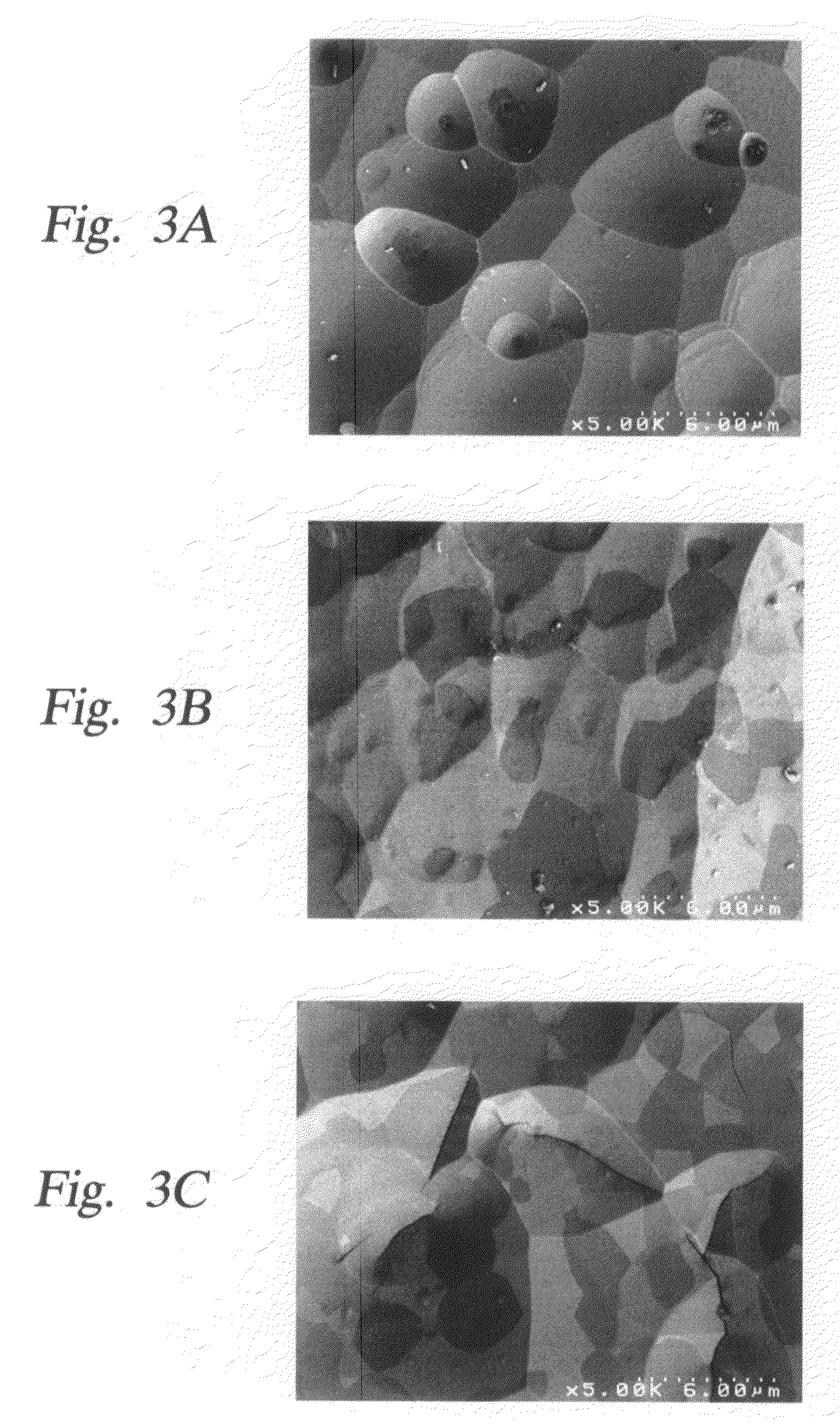

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

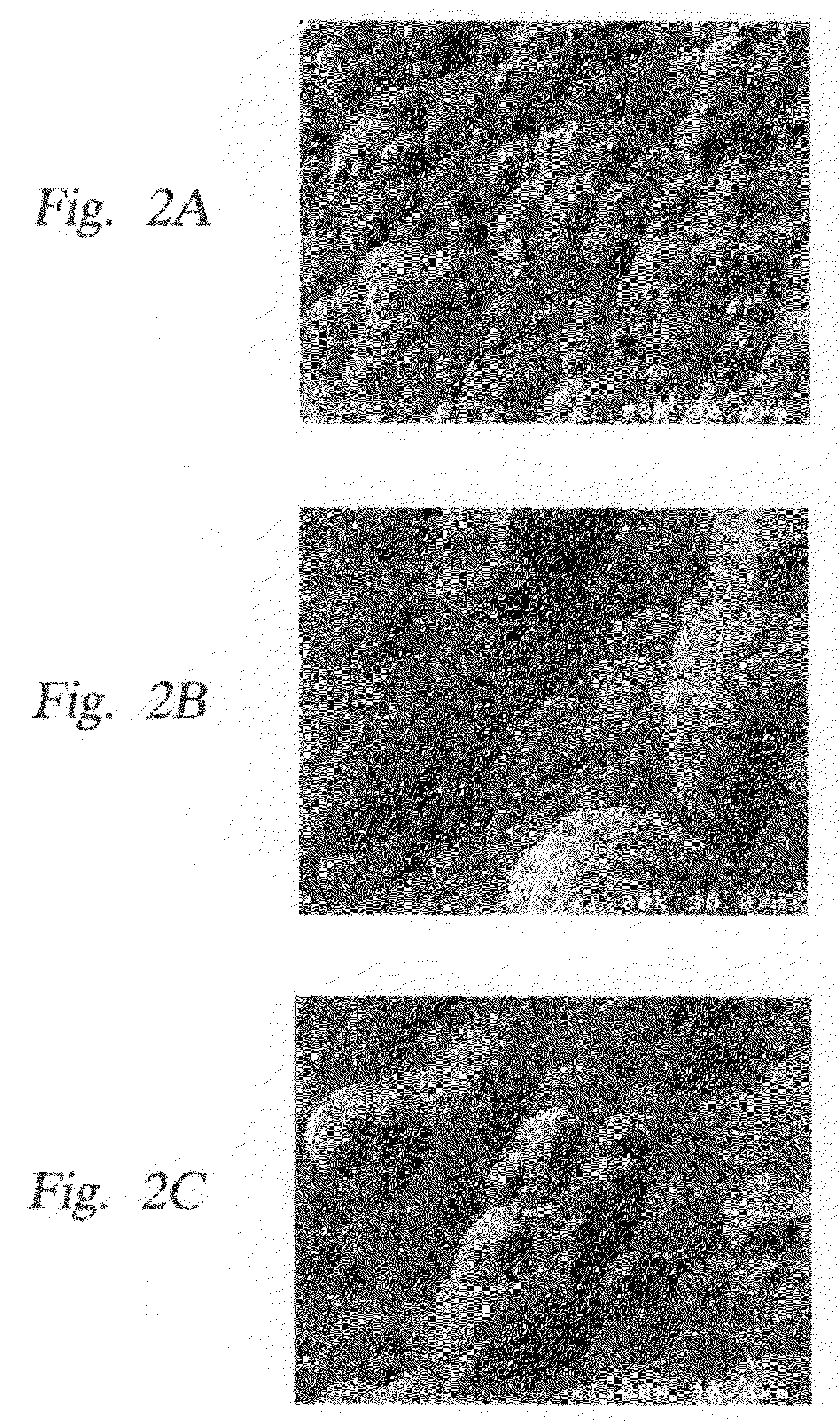

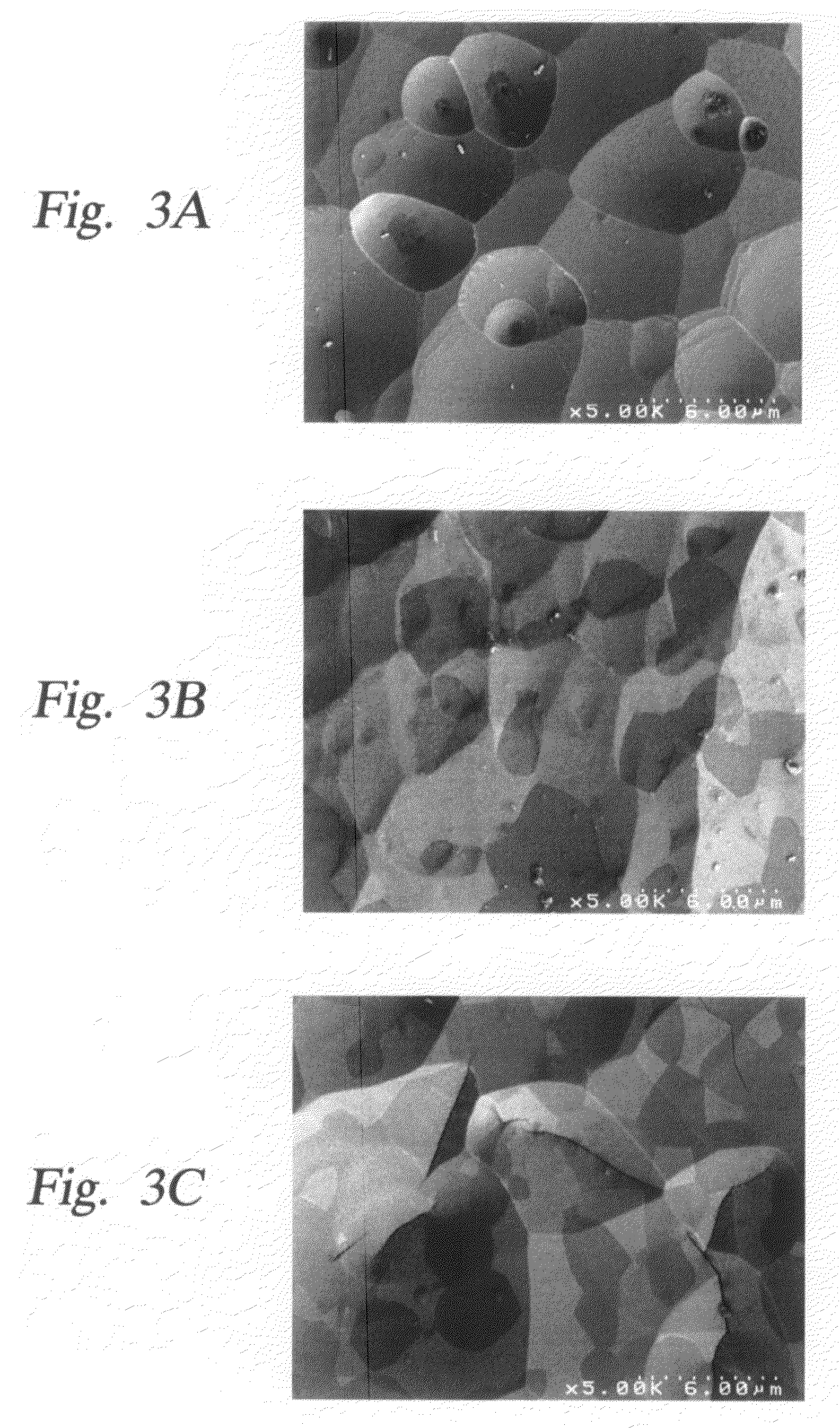

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

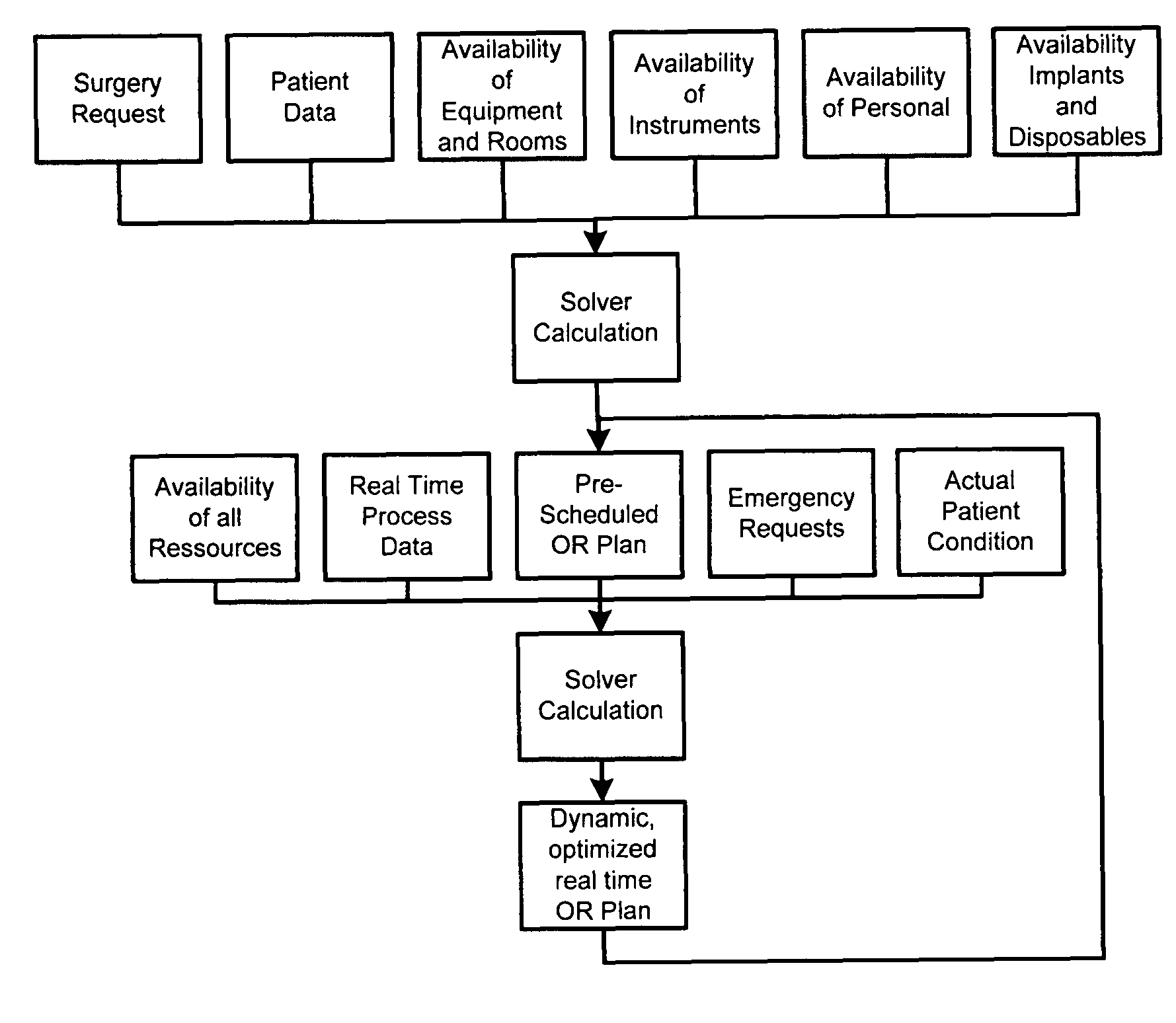

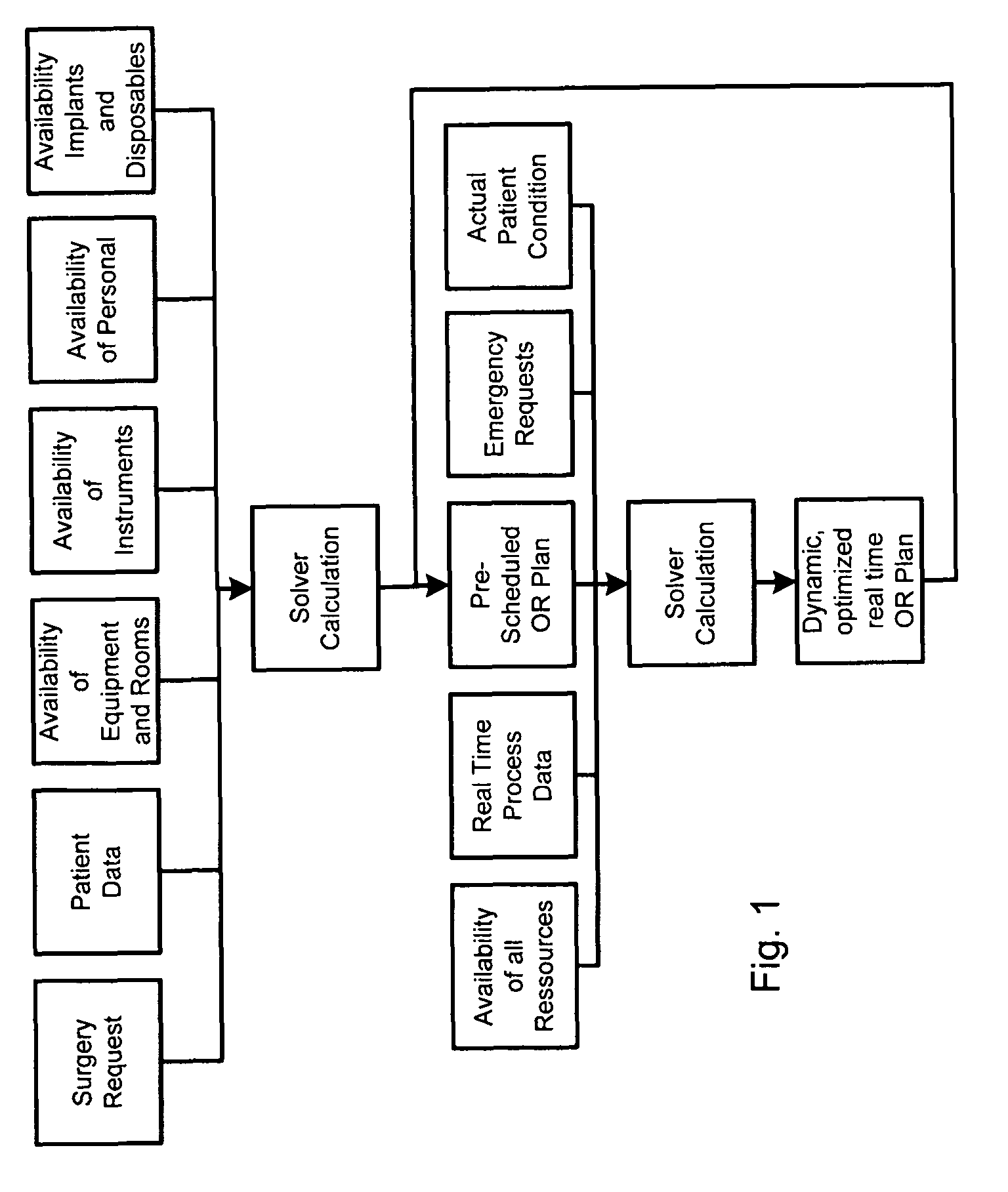

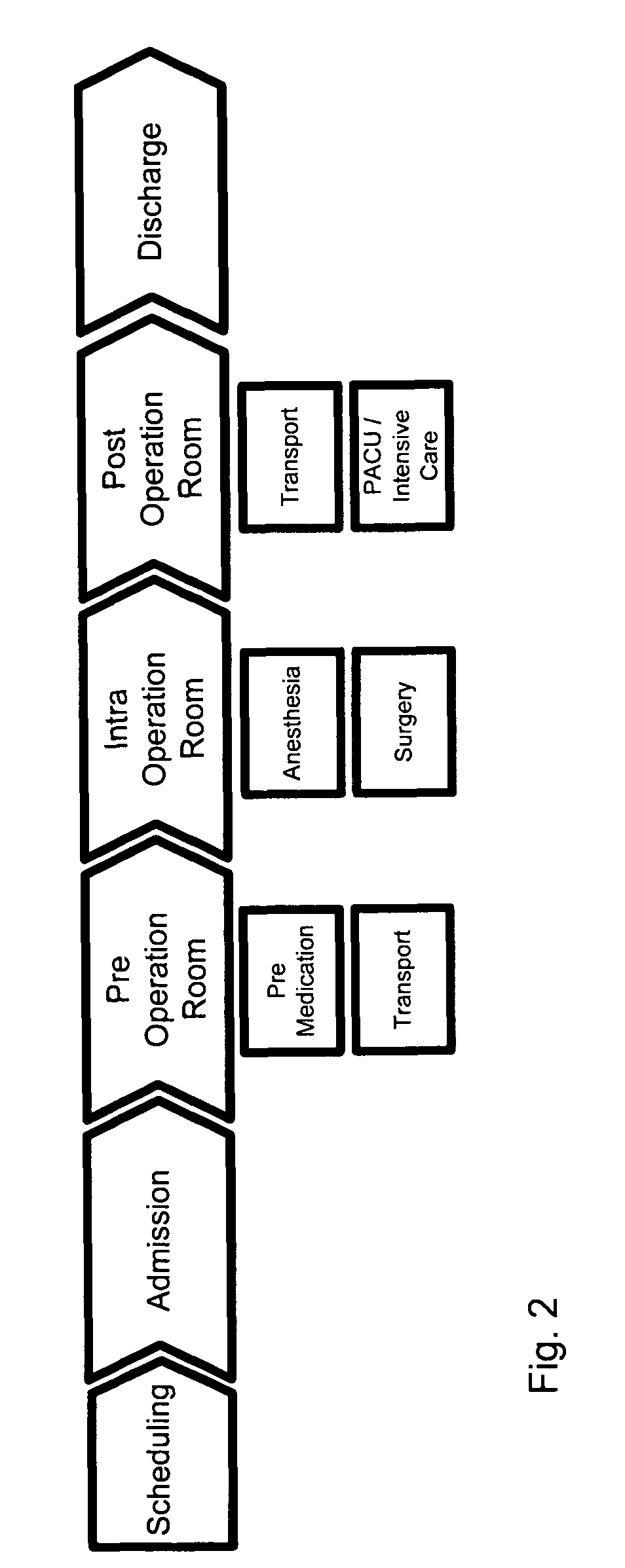

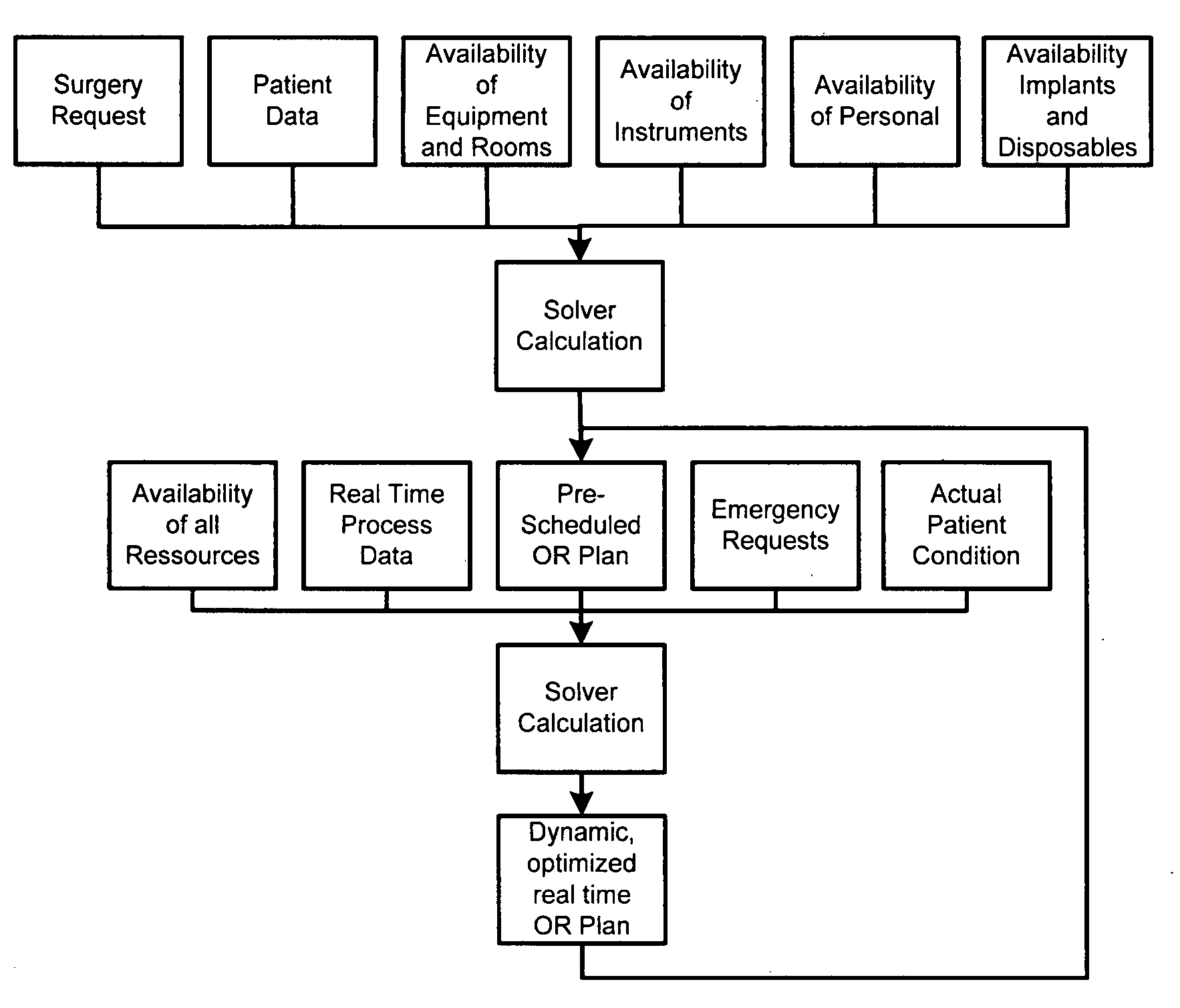

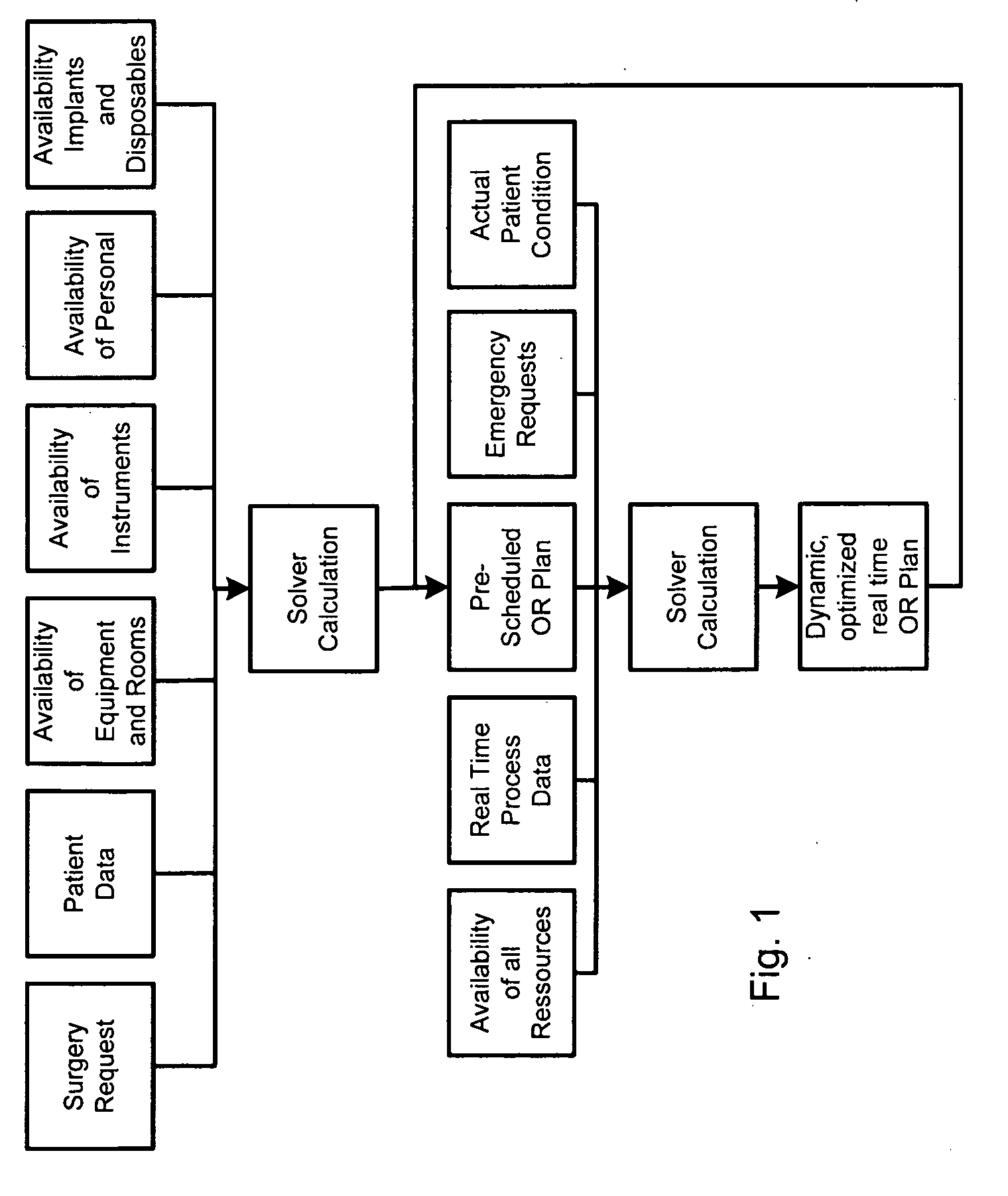

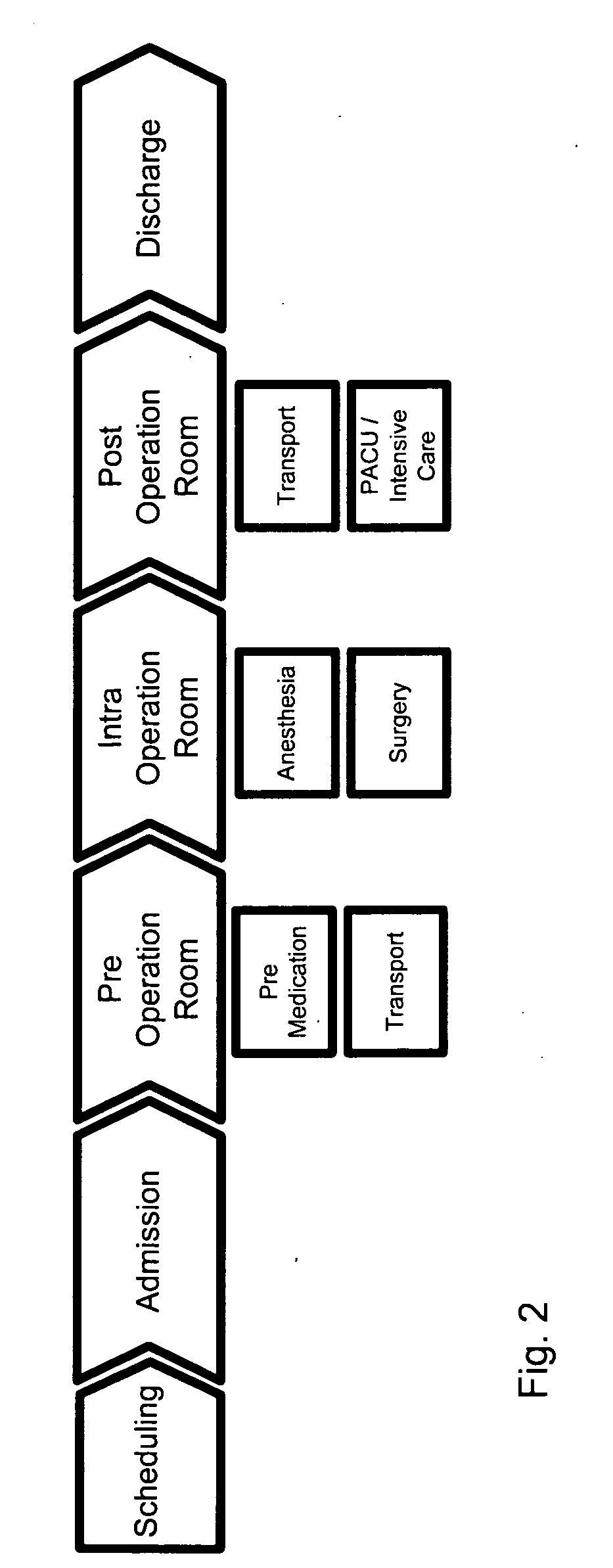

Method and system for management of operating-room resources

ActiveUS8452615B2Improve overall utilizationReduce operating costsMechanical/radiation/invasive therapiesOffice automationProgram planningOperating theatres

Owner:KARL STORZ GMBH & CO KG

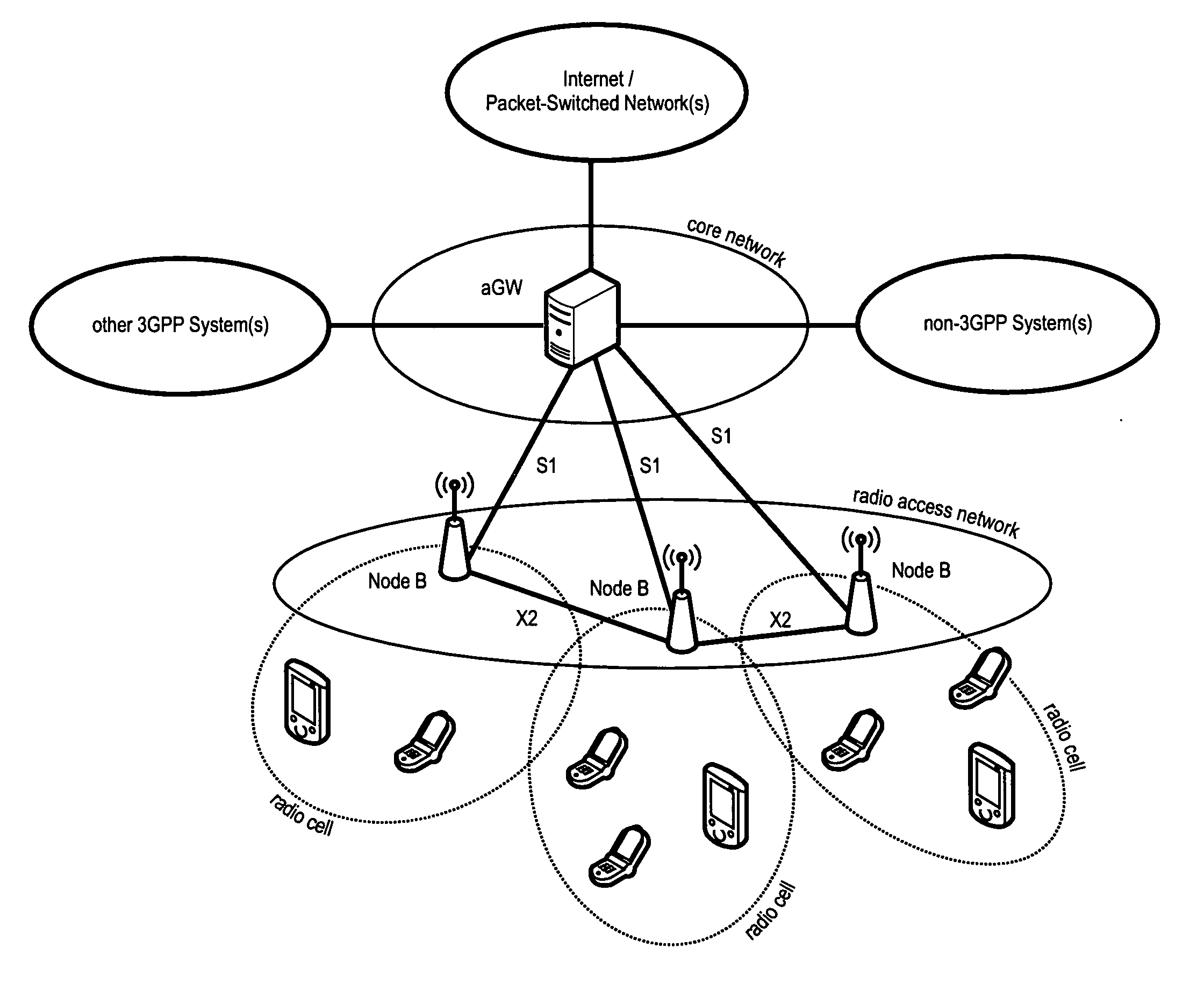

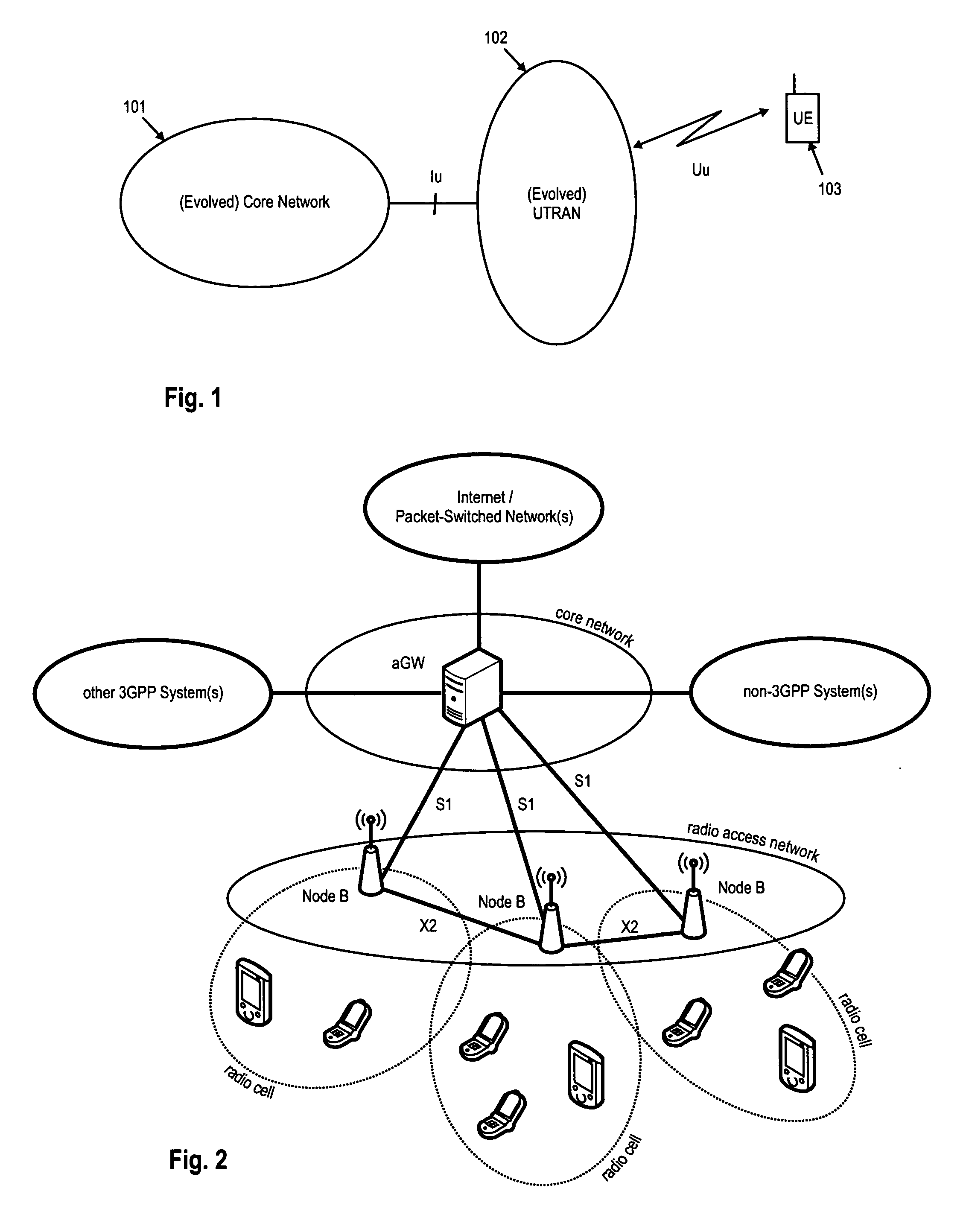

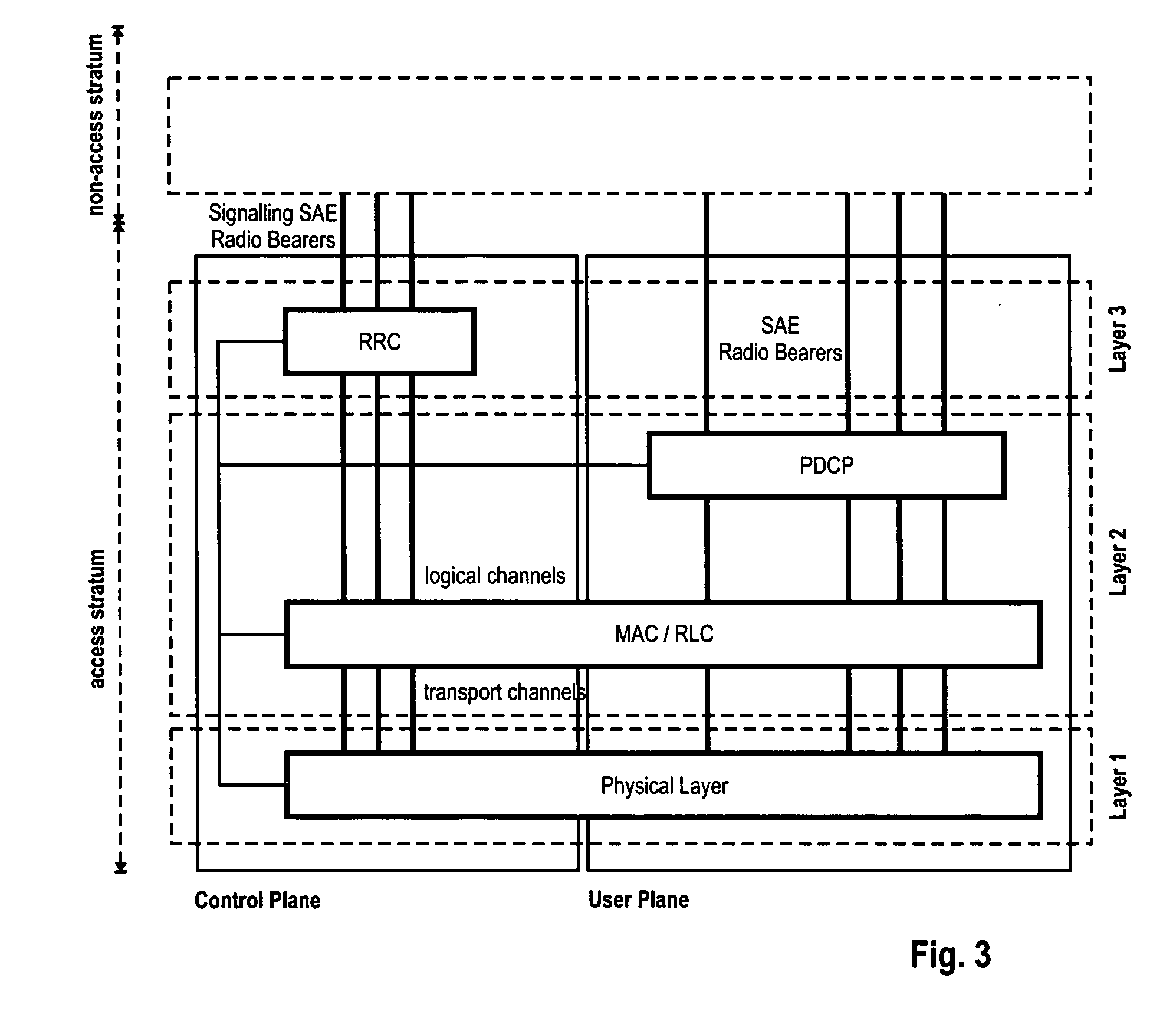

Transmission and reception of system information upon changing connectivity or point of attachment in a mobile communication system

InactiveUS20100022250A1Reduce downtimeIncrease flexibilityAssess restrictionOrthogonal multiplexCell specificMobile communication systems

Method for informing a mobile terminal on target cell-specific system information to facilitate a mobility procedure such as handover or cell reselection in a mobile communication network. Further a radio resource control apparatus, a mobile terminal and a system comprising the radio resource control apparatus and the mobile terminal are provided. The invention suggests improvements to current mobility procedures so as to reduce the interruption time implied by the procedures. More specifically, it is proposed to include at least one pointer to target cell-specific system information to a control message, such as a handover indication or connection release message, pointing the mobile terminal to system information in the target cell relevant for system access and / or to perform mobility procedures. Further, a portion of the target cell-specific system information may also be comprised in the control message.

Owner:PANASONIC CORP

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS7696117B2Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

Method of reducing the erosion rate of semiconductor processing apparatus exposed to halogen-containing plasmas

InactiveUS20080264564A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article useful in semiconductor processing, which is resistant to erosion by halogen-containing plasmas. The ceramic article is formed from a combination of yttrium oxide and zirconium oxide. In a first embodiment, the ceramic article includes ceramic which is formed from yttrium oxide at a molar concentration ranging from about 90 mole % to about 70 mole %, and zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %. In a second embodiment, the ceramic article includes ceramic which is formed from zirconium oxide at a molar concentration ranging from about 96 mole % to about 94 mole %, and yttrium oxide at a molar concentration ranging from about 4 mole % to about 6 mole %.

Owner:APPLIED MATERIALS INC

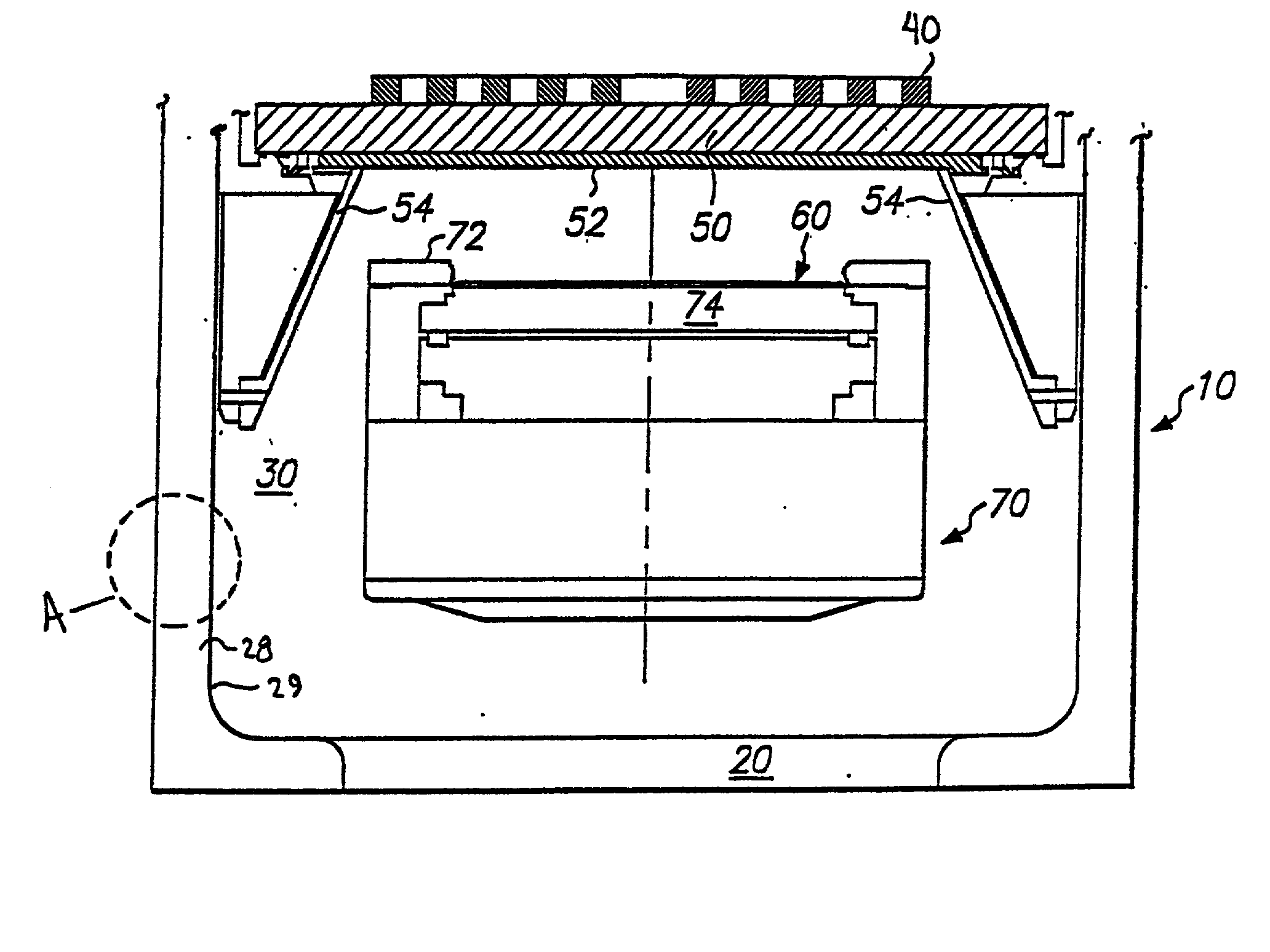

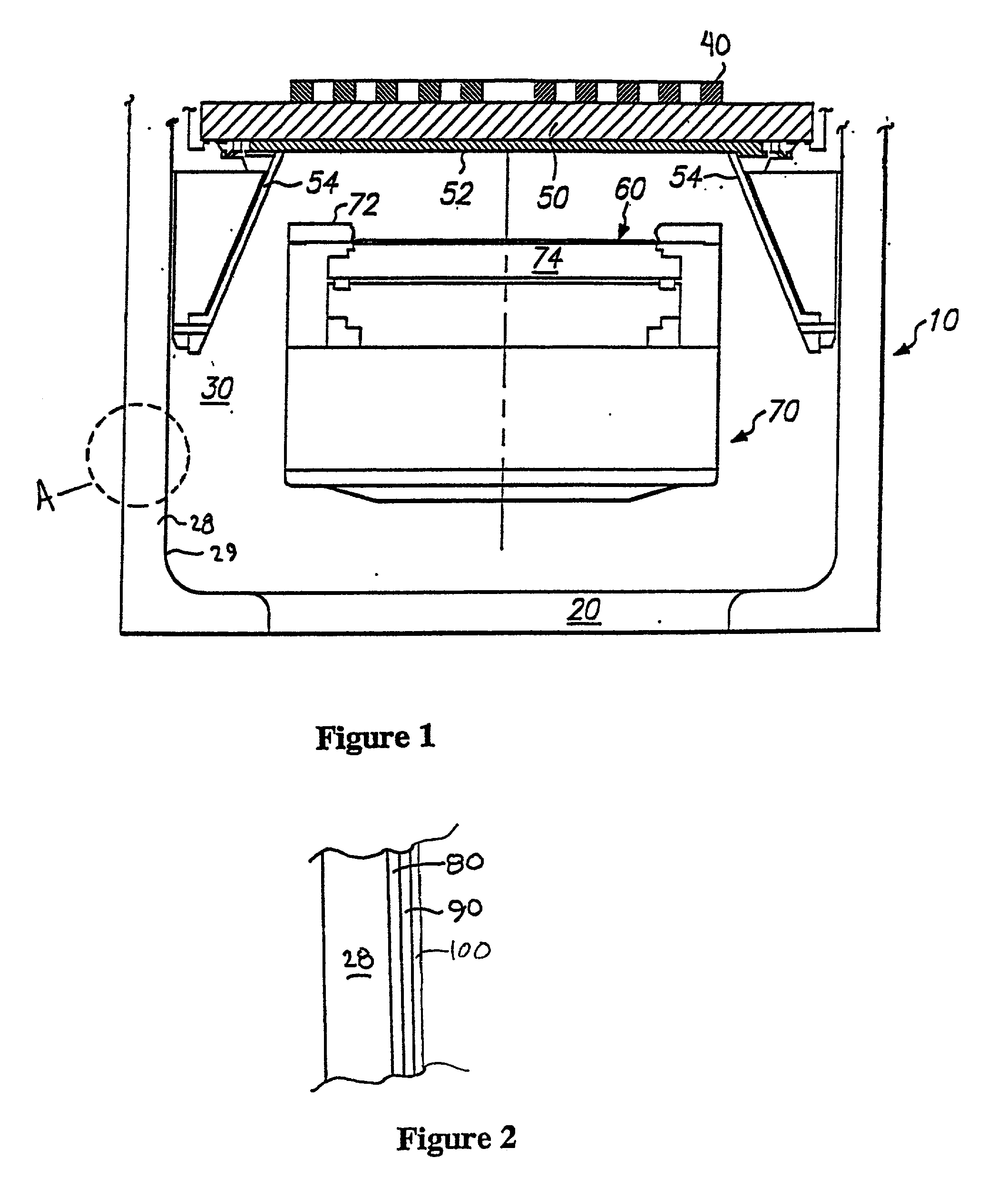

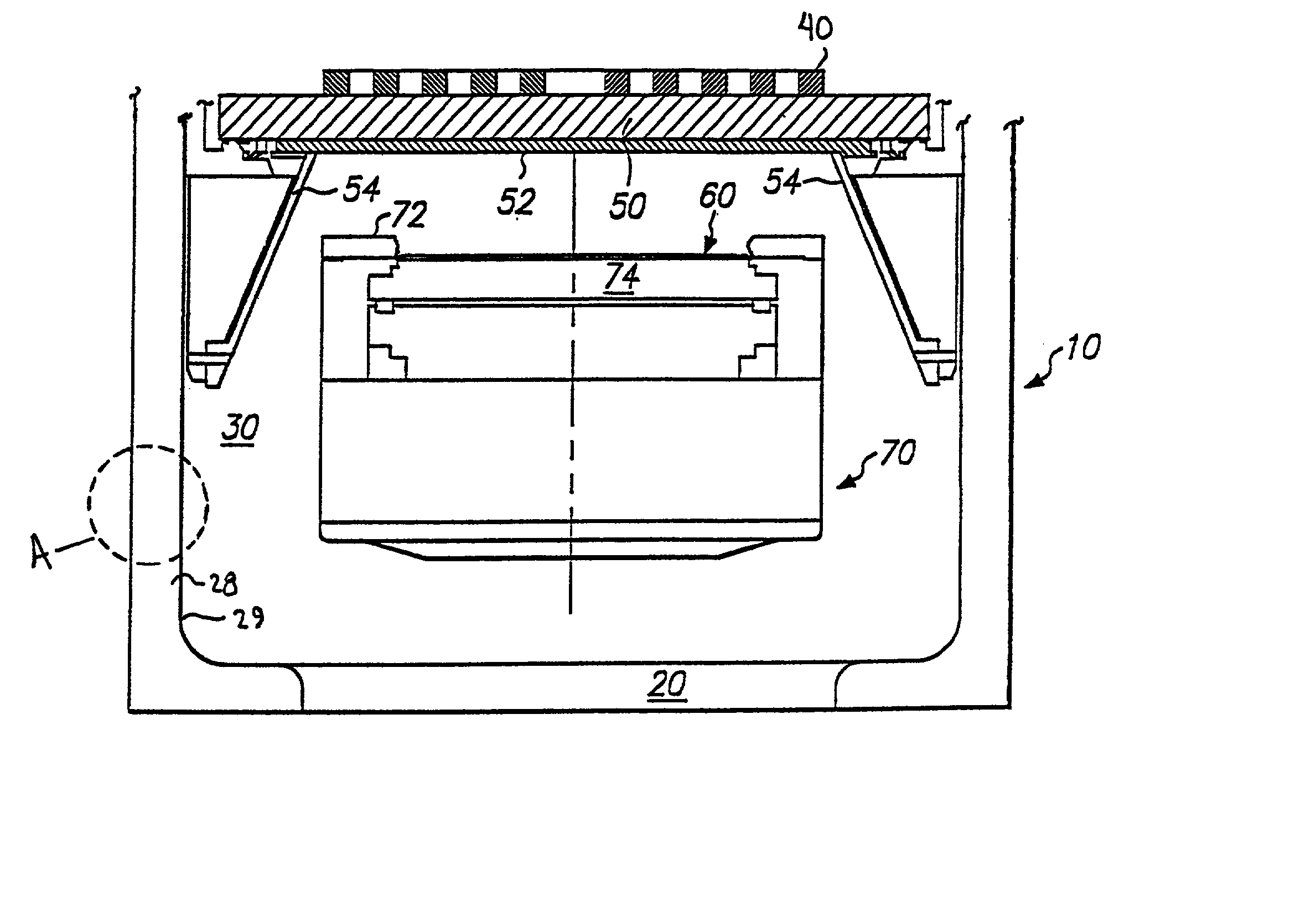

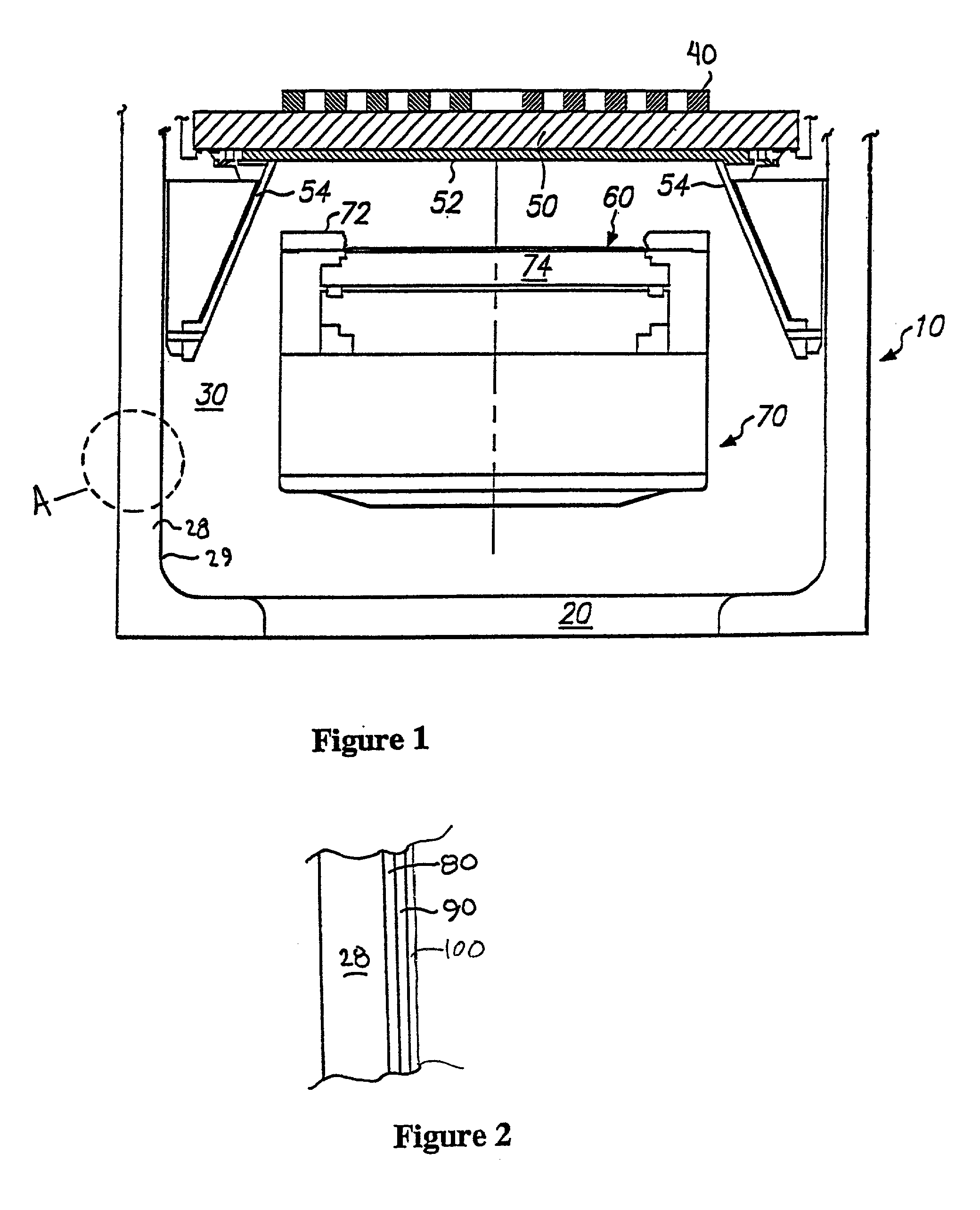

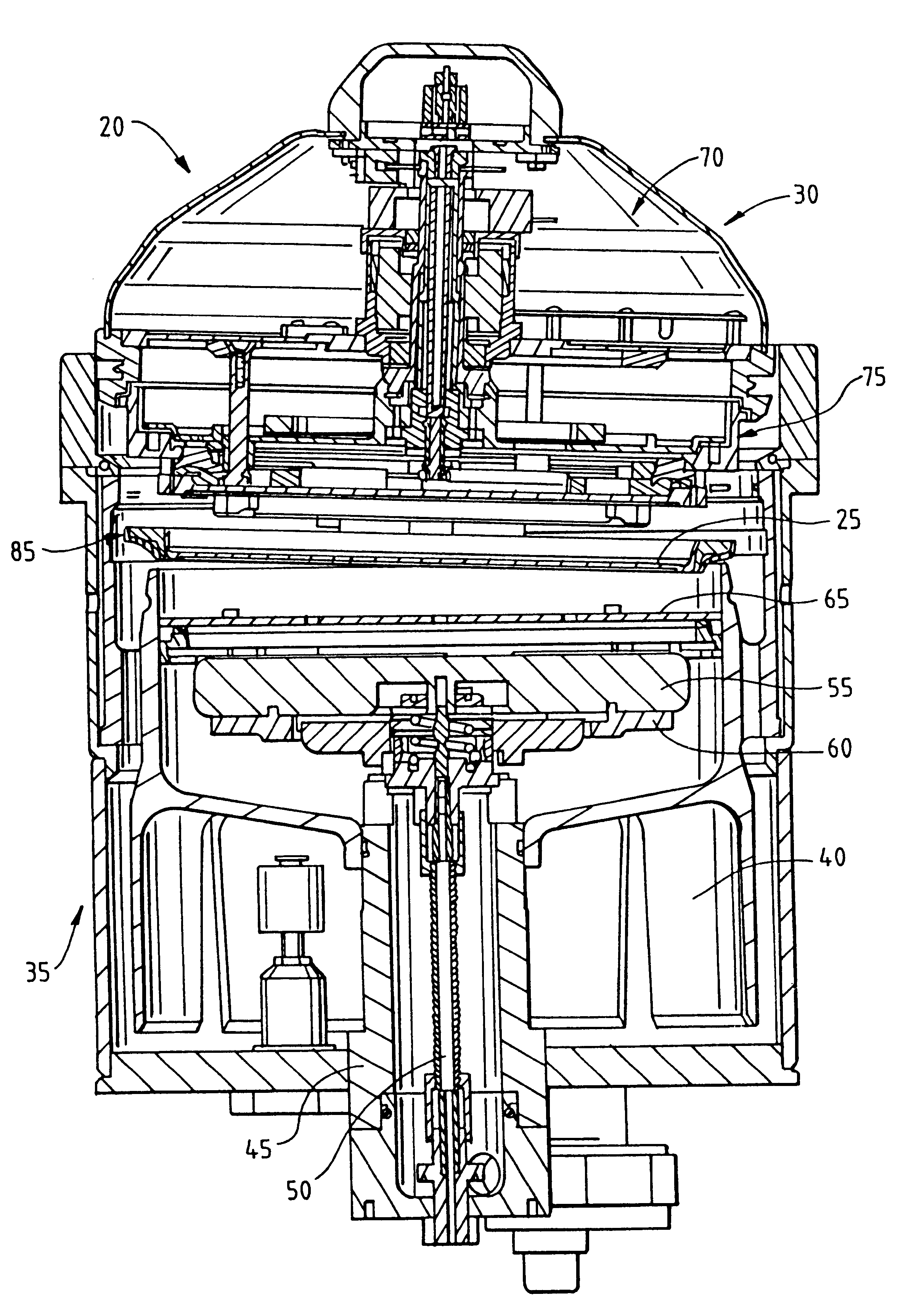

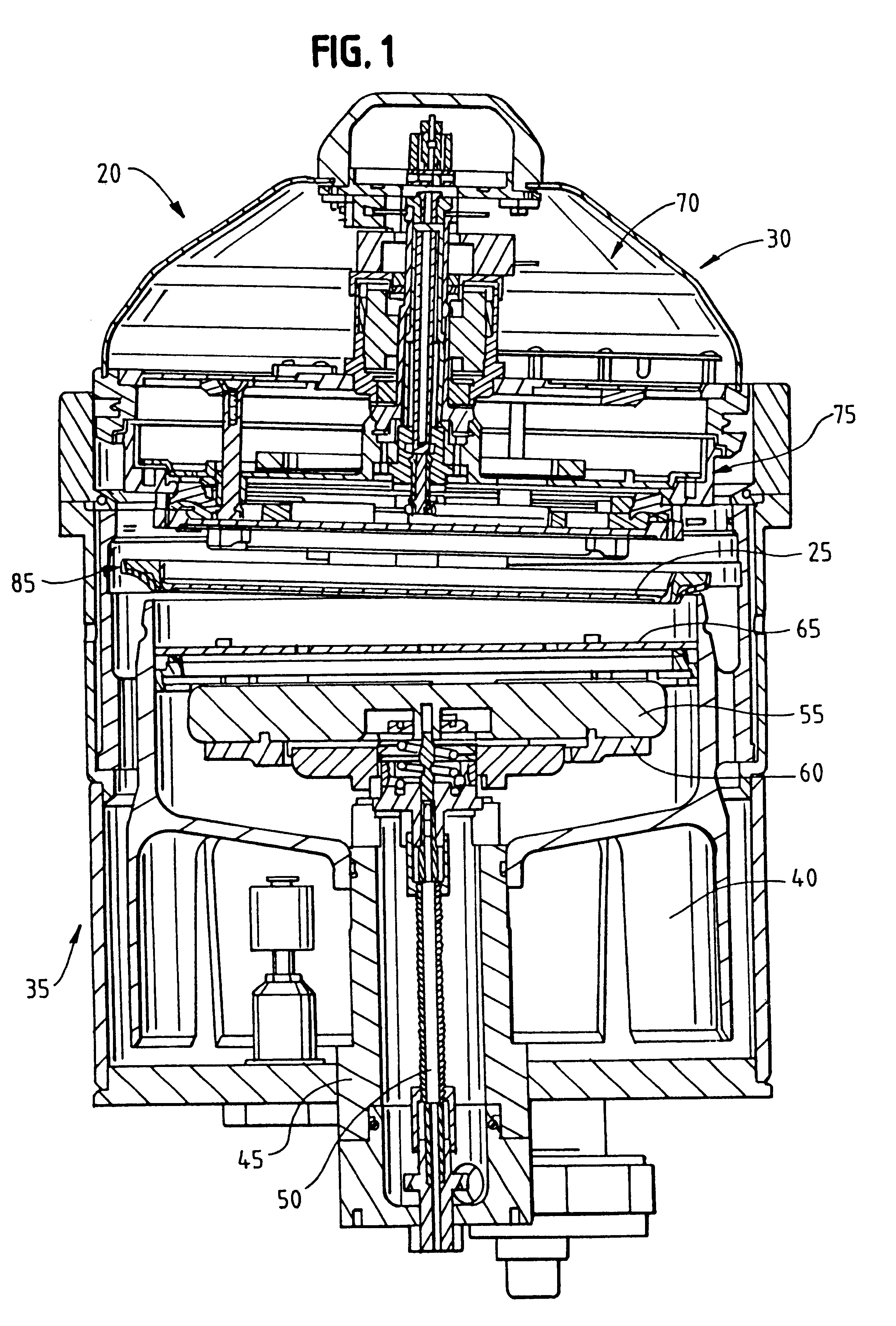

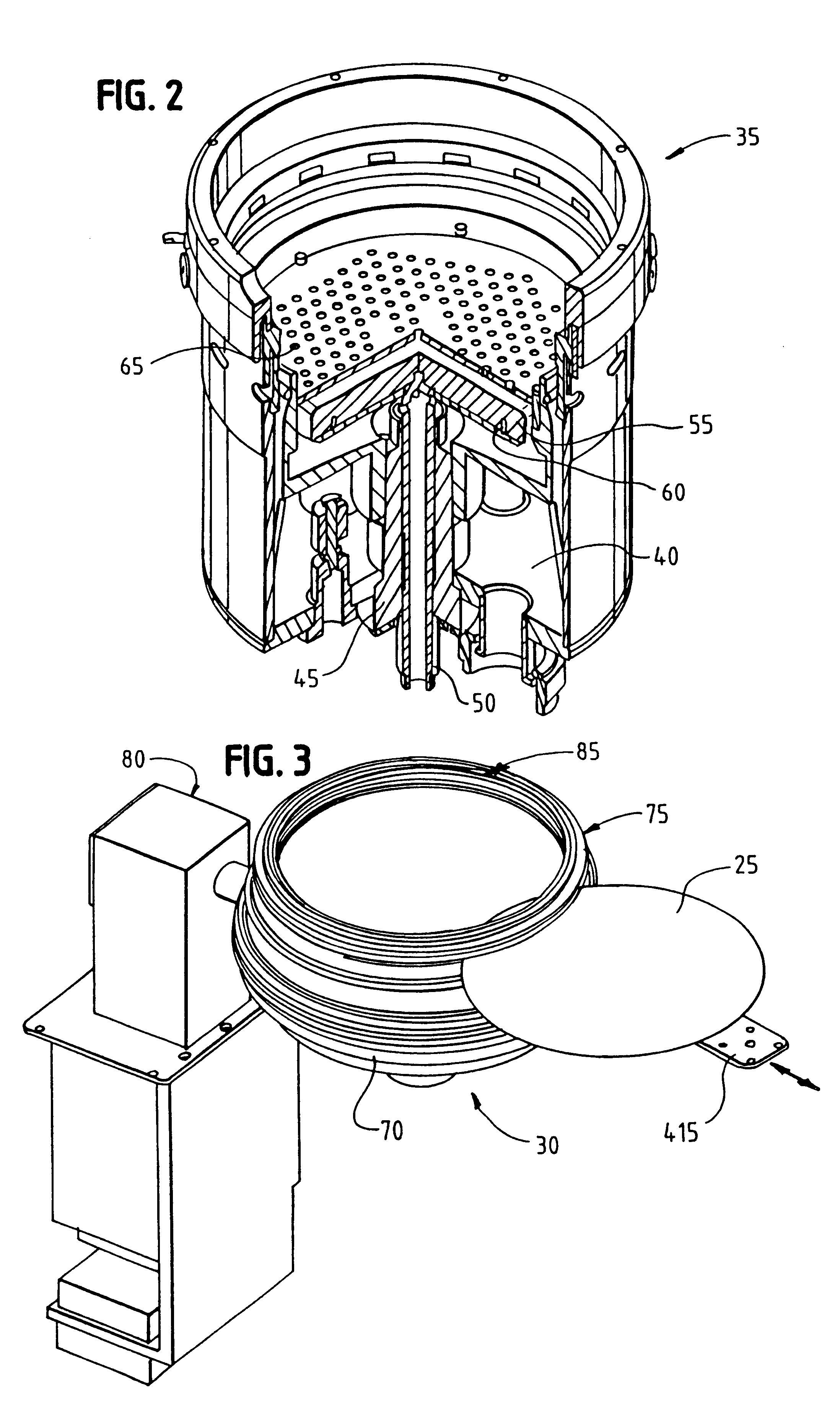

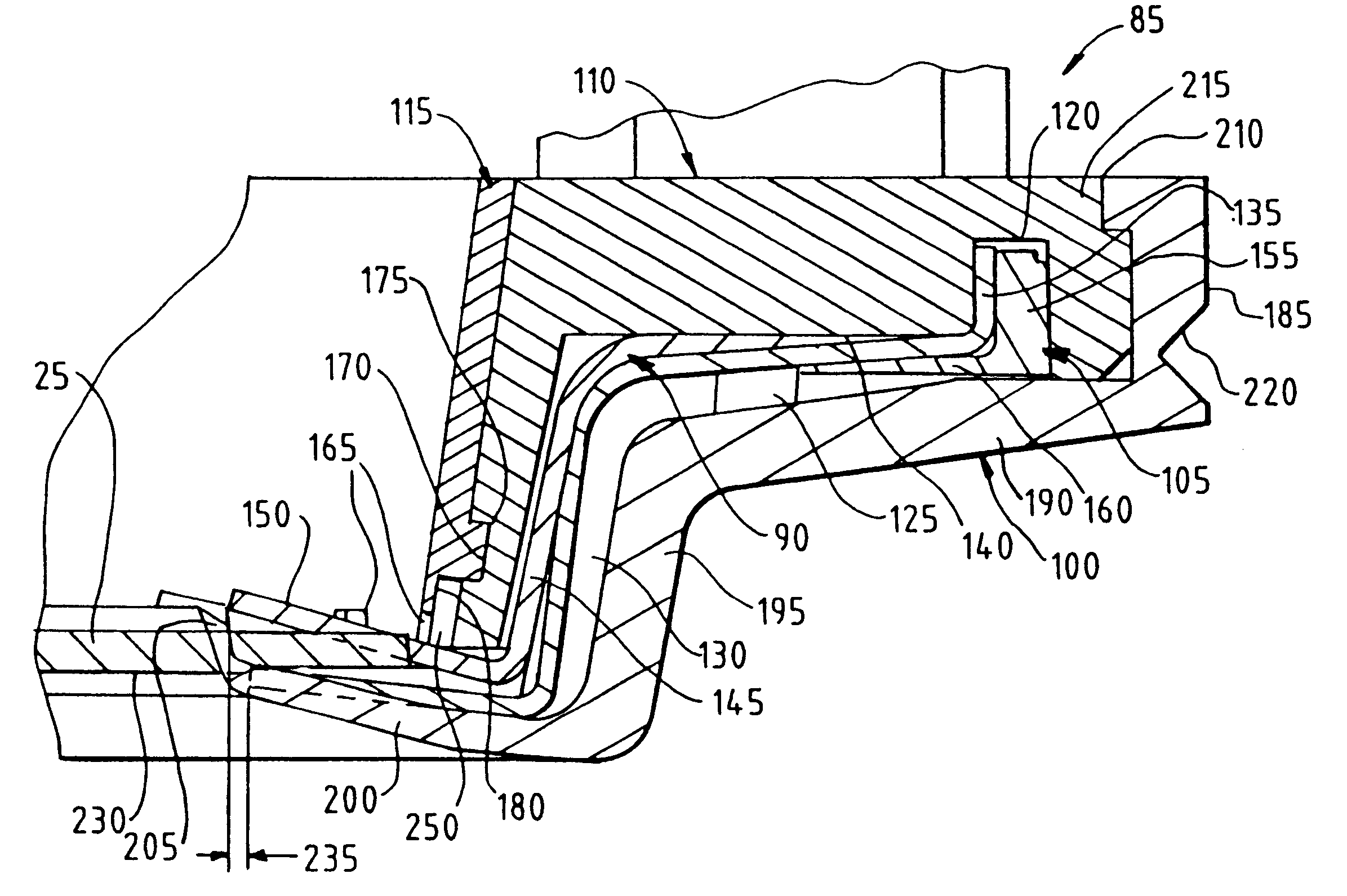

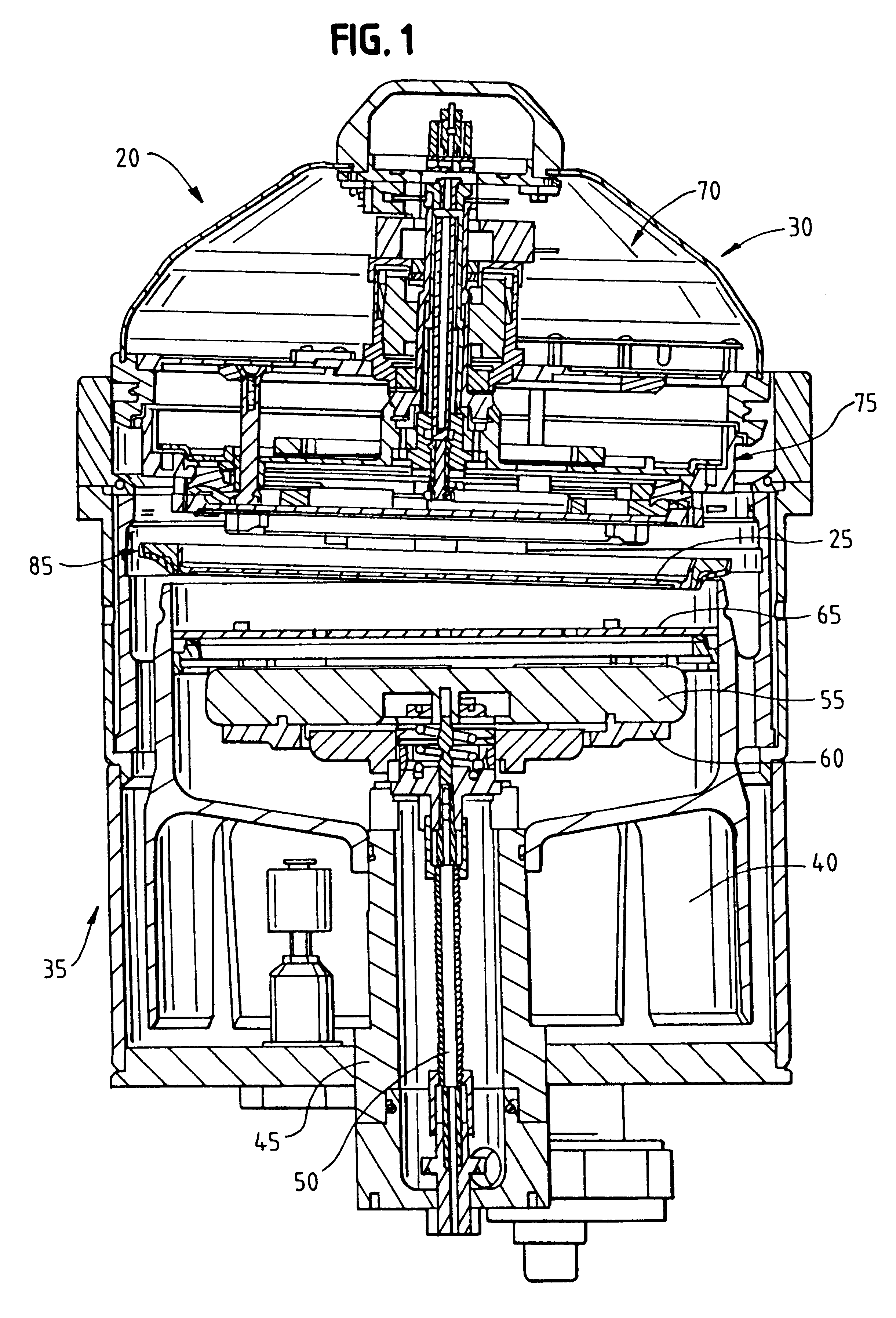

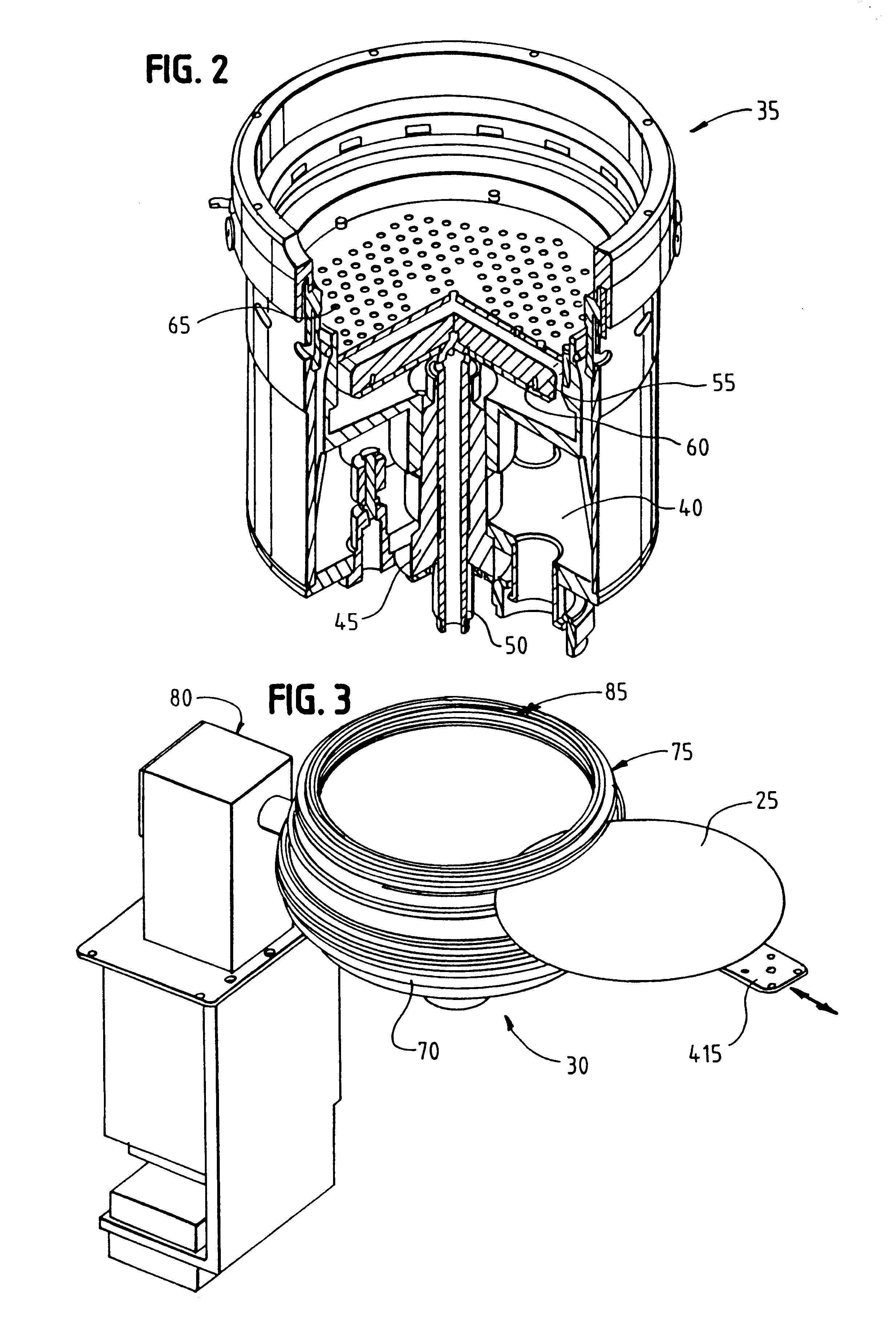

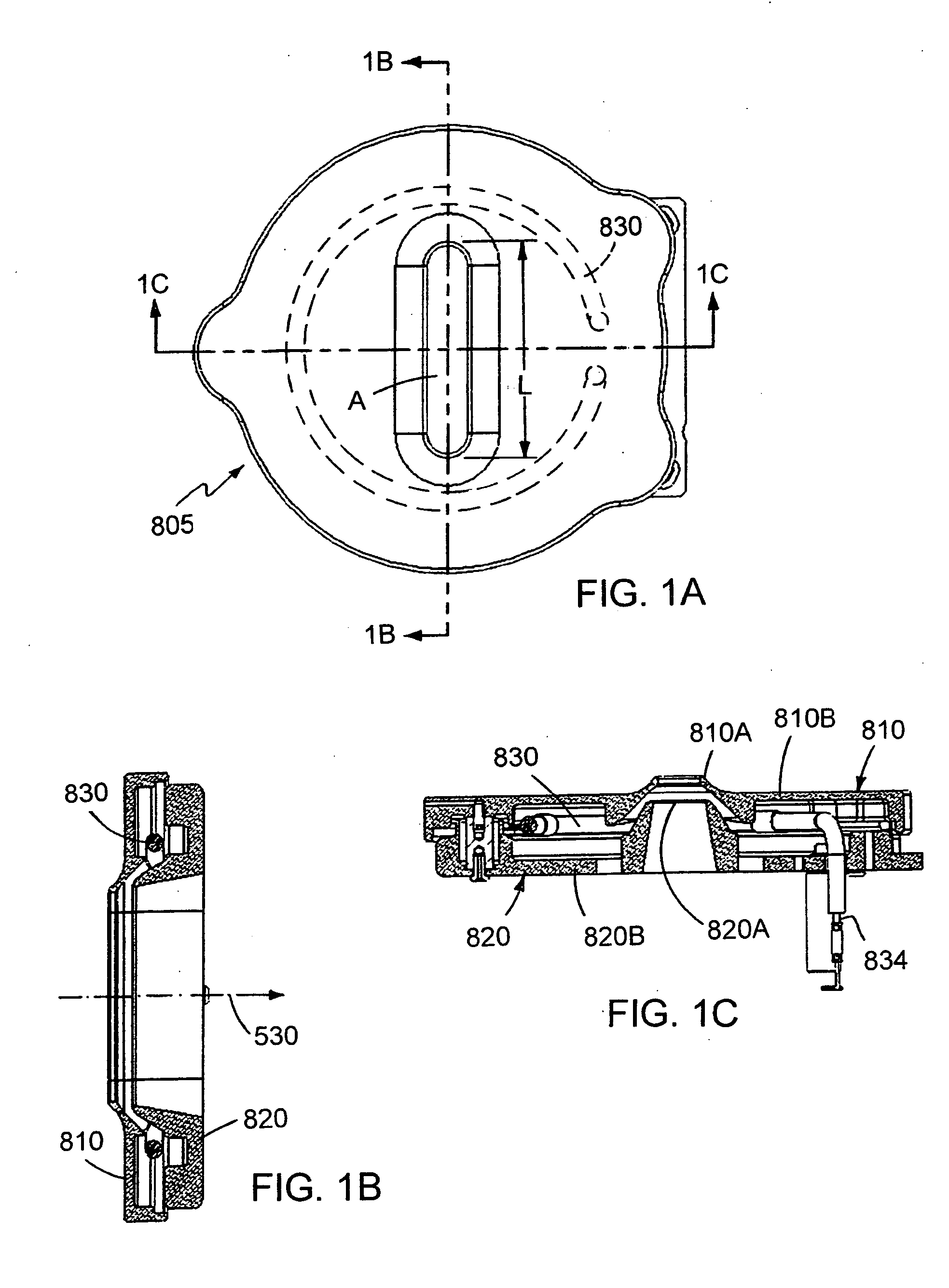

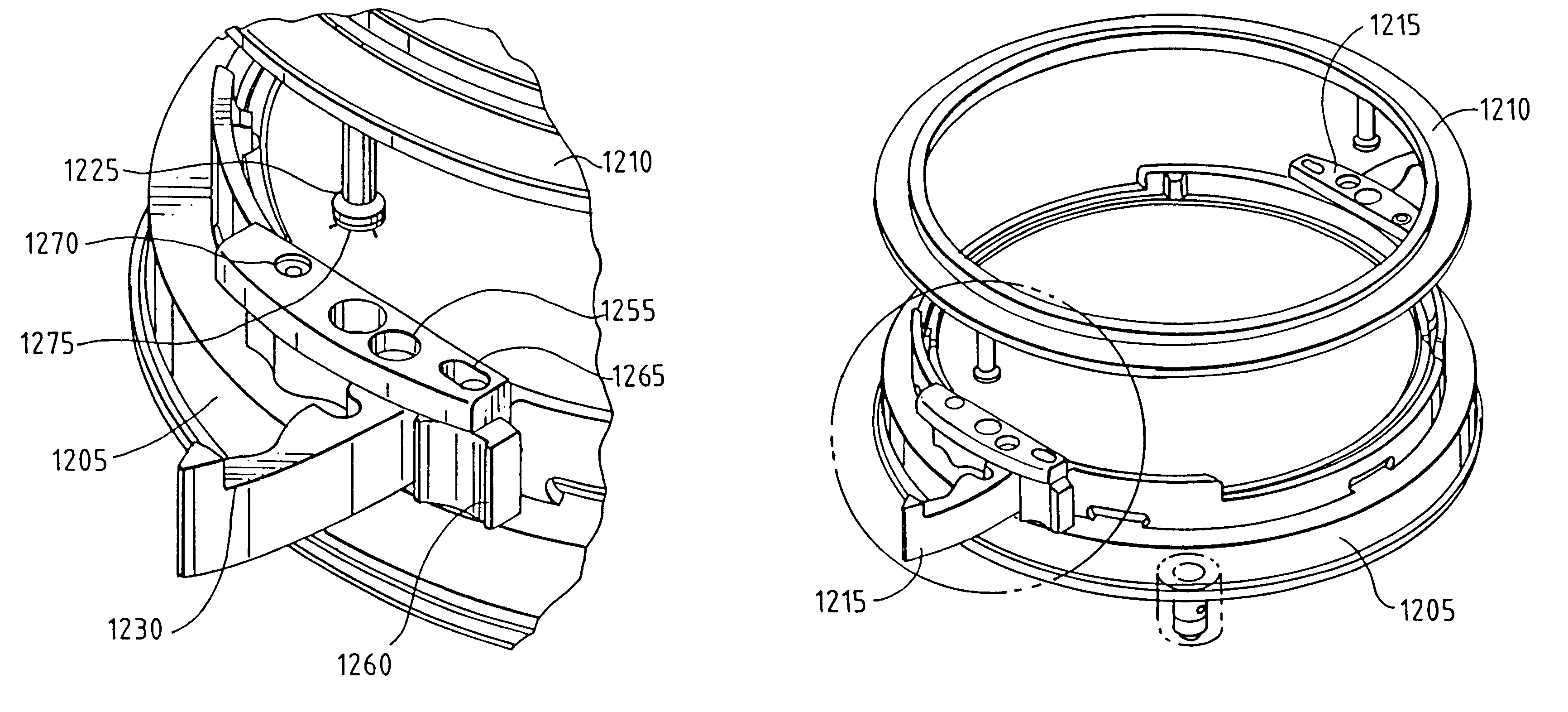

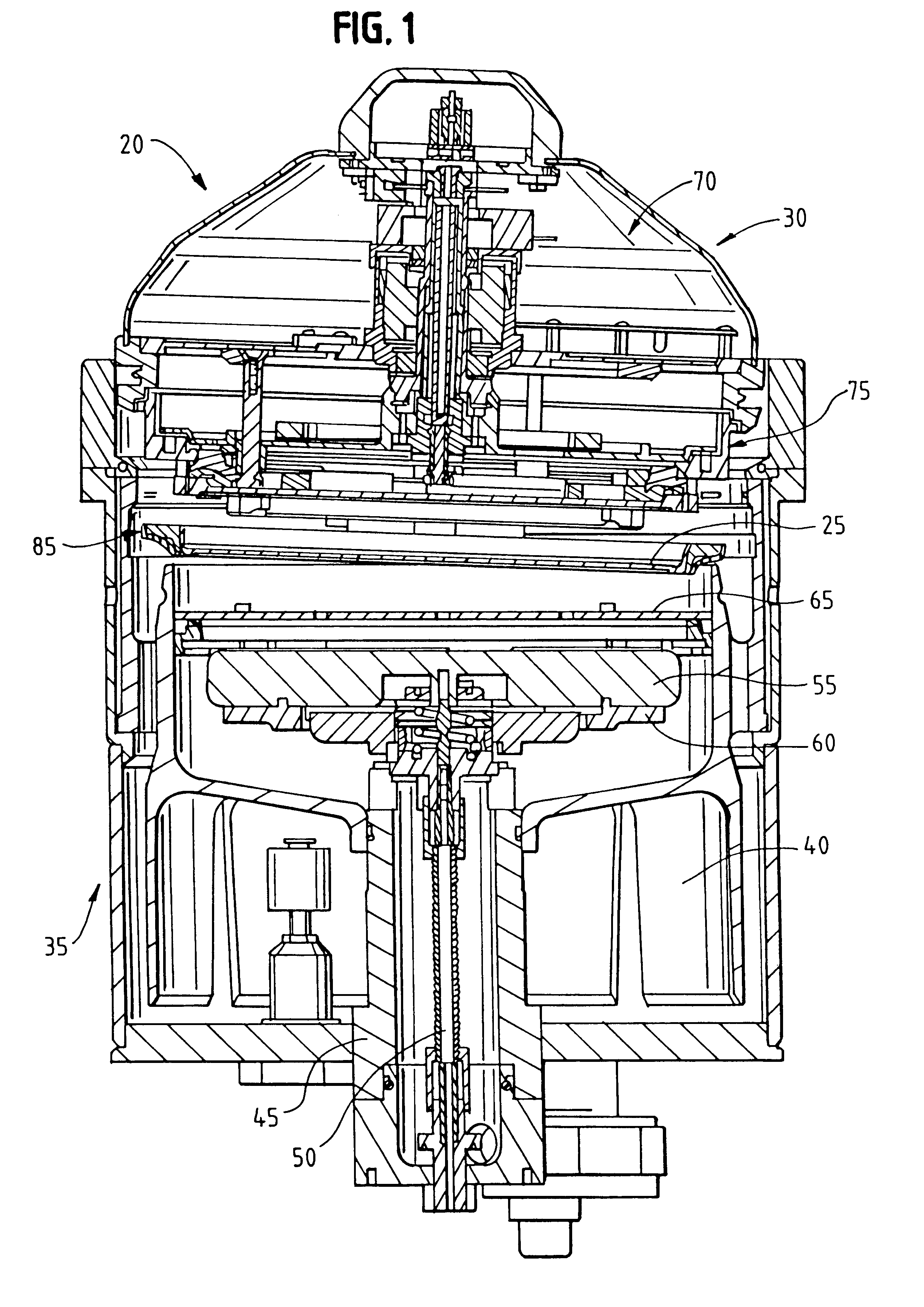

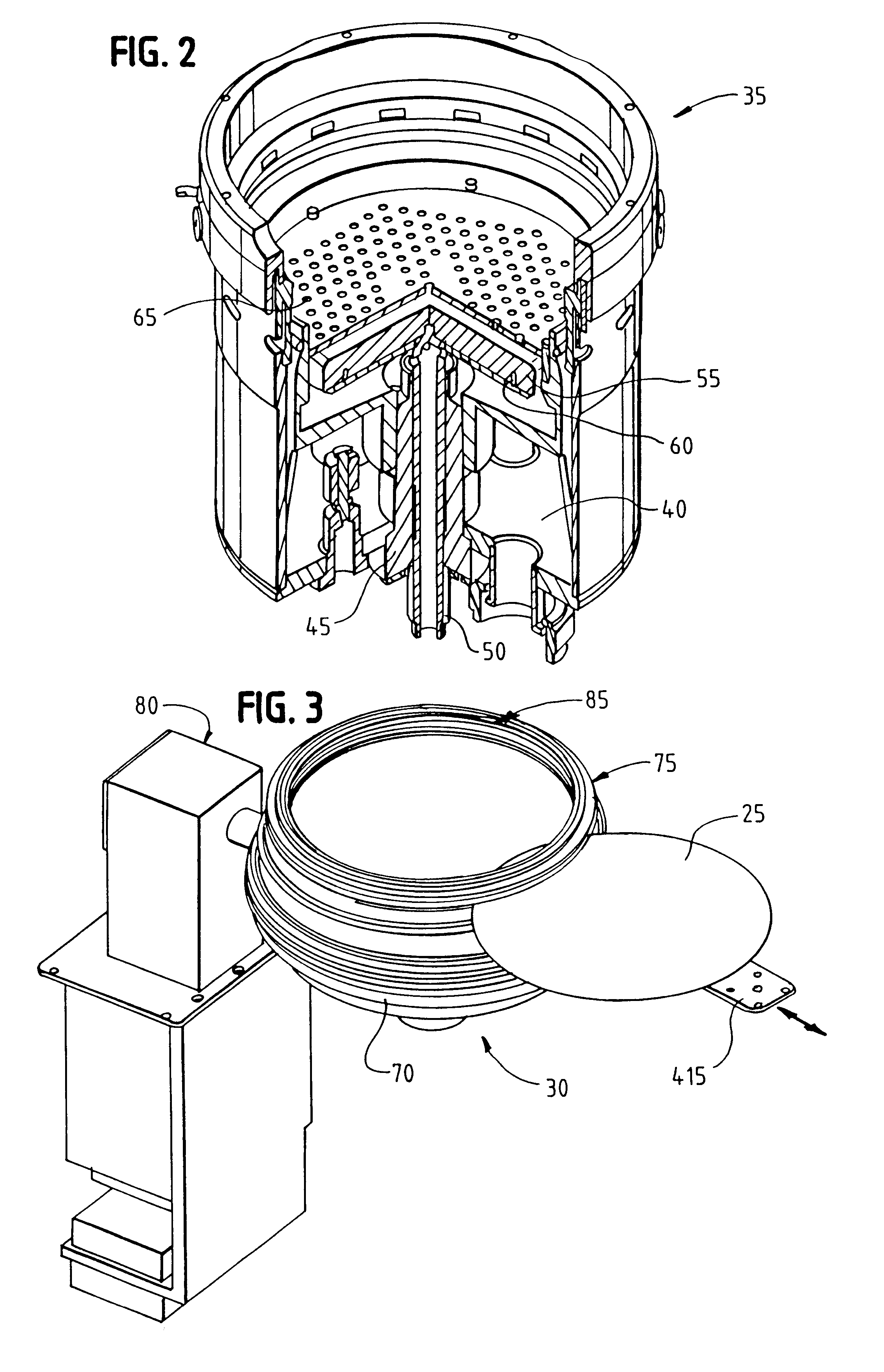

Methods and apparatus for processing the surface of a microelectronic workpiece

InactiveUS6309524B1Reduce the risk of contaminationReduce downtimeCellsTanksEngineeringMechanical engineering

A reactor for plating a metal onto a surface of a workpiece is set forth. The reactor comprises a reactor bowl including an electroplating solution disposed therein and an anode disposed in the reactor bowl in contact with the electroplating solution. A contact assembly is spaced from the anode within the reactor bowl. The contact assembly includes a plurality of contacts disposed to contact a peripheral edge of the surface of the workpiece to provide electroplating power to the surface of the workpiece. The contacts execute a wiping action against the surface of the workpiece as the workpiece is brought into engagement therewith. The contact assembly also including a barrier disposed interior of the plurality of contacts. The barrier includes a member disposed to engage the surface of the workpiece to assist in isolating the plurality of contacts from the electroplating solution. In one embodiment, the plurality of contacts are in the form of discrete flexures while in another embodiment the plurality of contacts are in the form of a Belleville ring contact. A flow path may be provided in the contact assembly for providing a purging gas to the plurality of contacts and the peripheral edge of the workpiece. The purging gas may be used to assist in the formation of the barrier of the contact assembly. A combined electroplating / electroless plating tool and method are also set forth.

Owner:APPLIED MATERIALS INC

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS6537429B2High purityIncrease resistanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingSemiconductorPlasma chamber

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

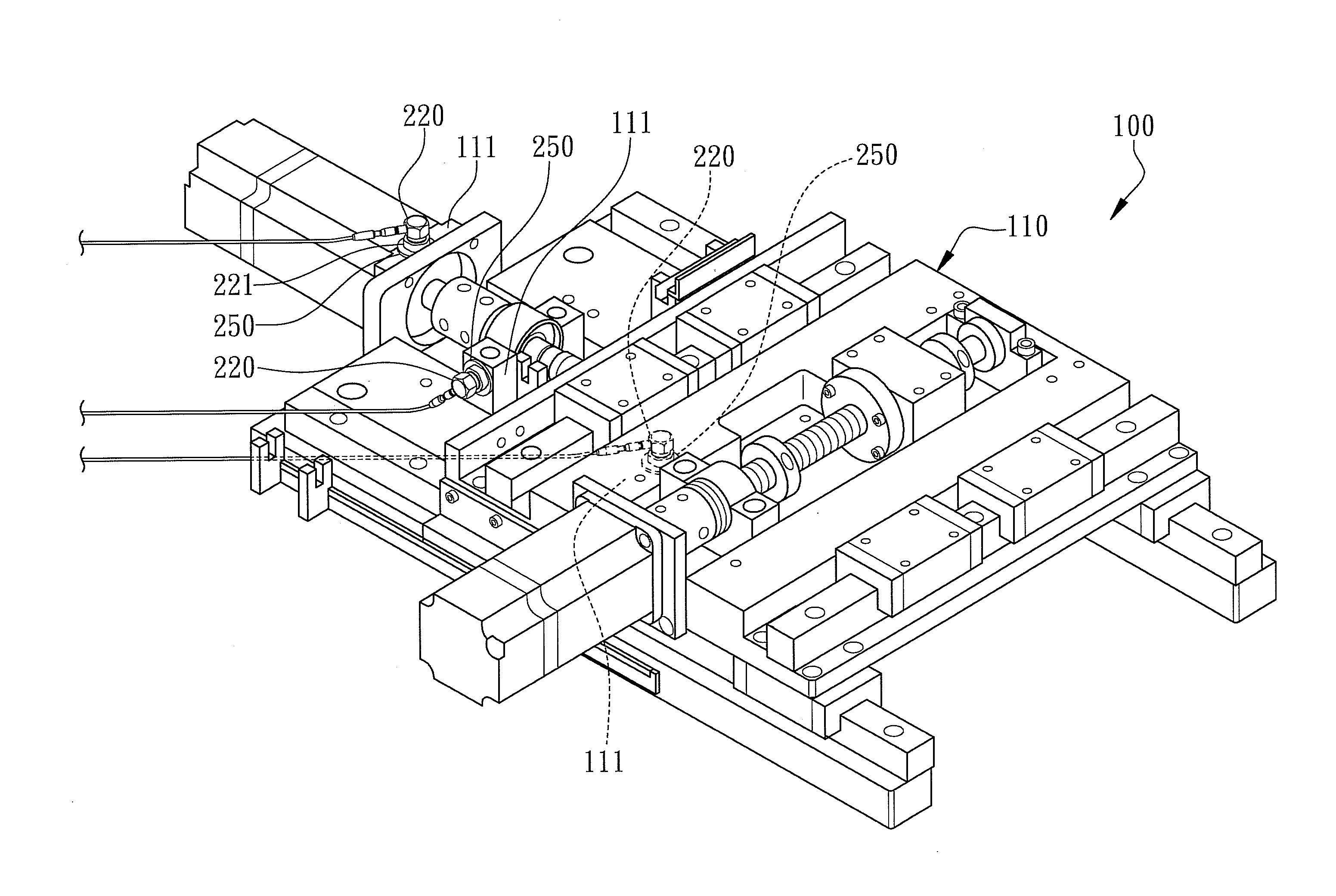

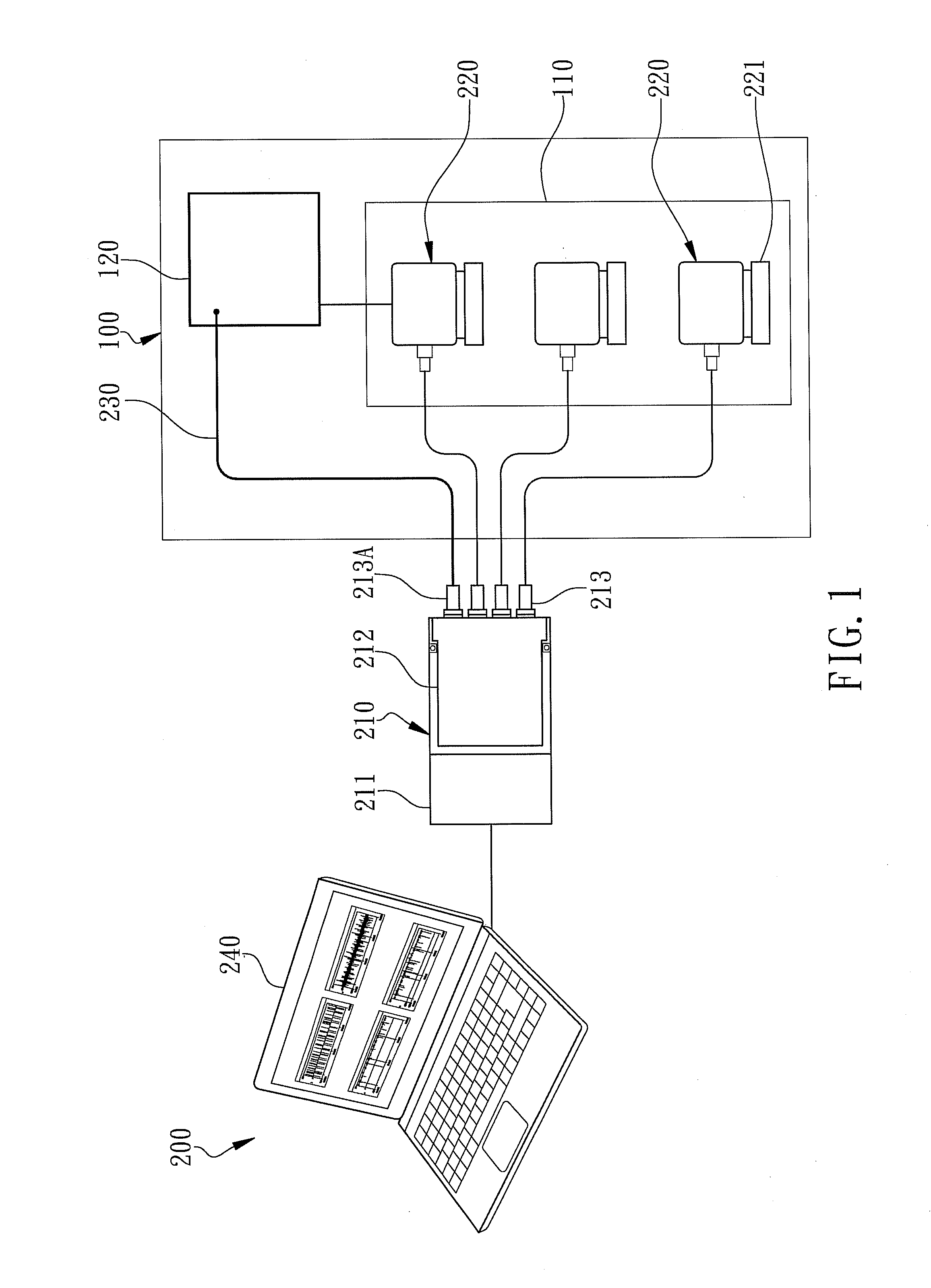

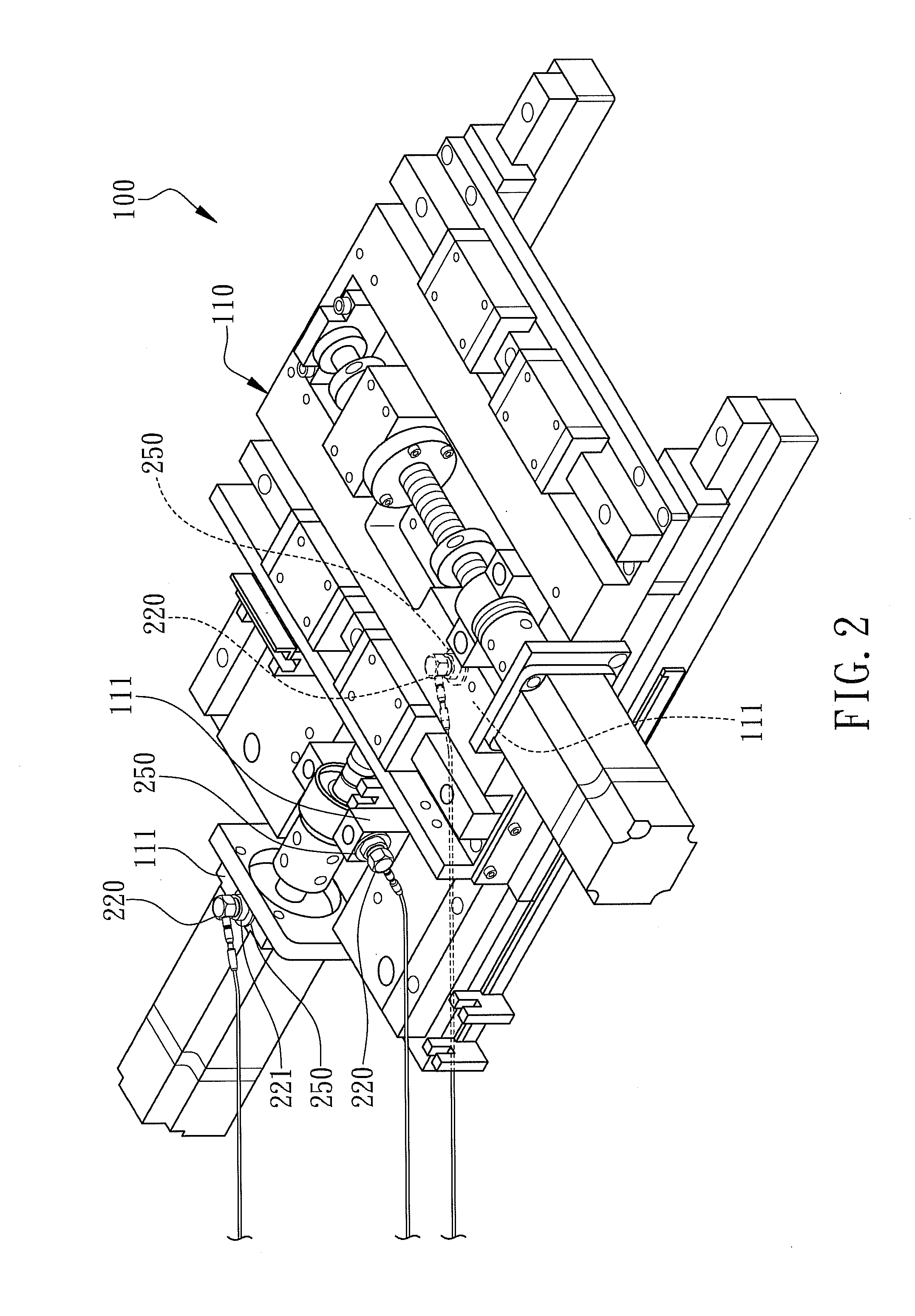

Controlling device and method for abnormality prediction of semiconductor processing equipment

InactiveUS20120239317A1Reducing down timeObstruction is producedFlow propertiesProcessing detected response signalSpectrum analyzerRepair time

Disclosed in this invention is a controlling device for abnormality prediction of semiconductor processing equipment. The controlling device includes a multiplexer connecting a plurality of vibration sensors to a spectrum analyzer. Therein, the vibration sensors are non-destructively installed to a variable-frequency rotating mechanism inside the semiconductor processing equipment. The multiplexer includes an adapter and at least a modularized multi-channel connecting assembly plugged into the adapter where the number of the connected vibration sensors is less than the number of the signal connecting terminals of the multiplexer so that at least one terminal is unconnected with the vibration sensors. Additionally, a control signal wire connects the unconnected terminal to a corresponding controller of the variable-frequency rotating element. The vibration spectrum analyzer is configured to record and collect both vibration signals and control signals where these signals are transformed into time-domain waveforms to track the lifetime of the equipment, to predict the failure of the equipment, and to reduce equipment down time, parts waiting time, and equipment repair time of the semiconductor processing equipment.

Owner:POWERTECH TECHNOLOGY

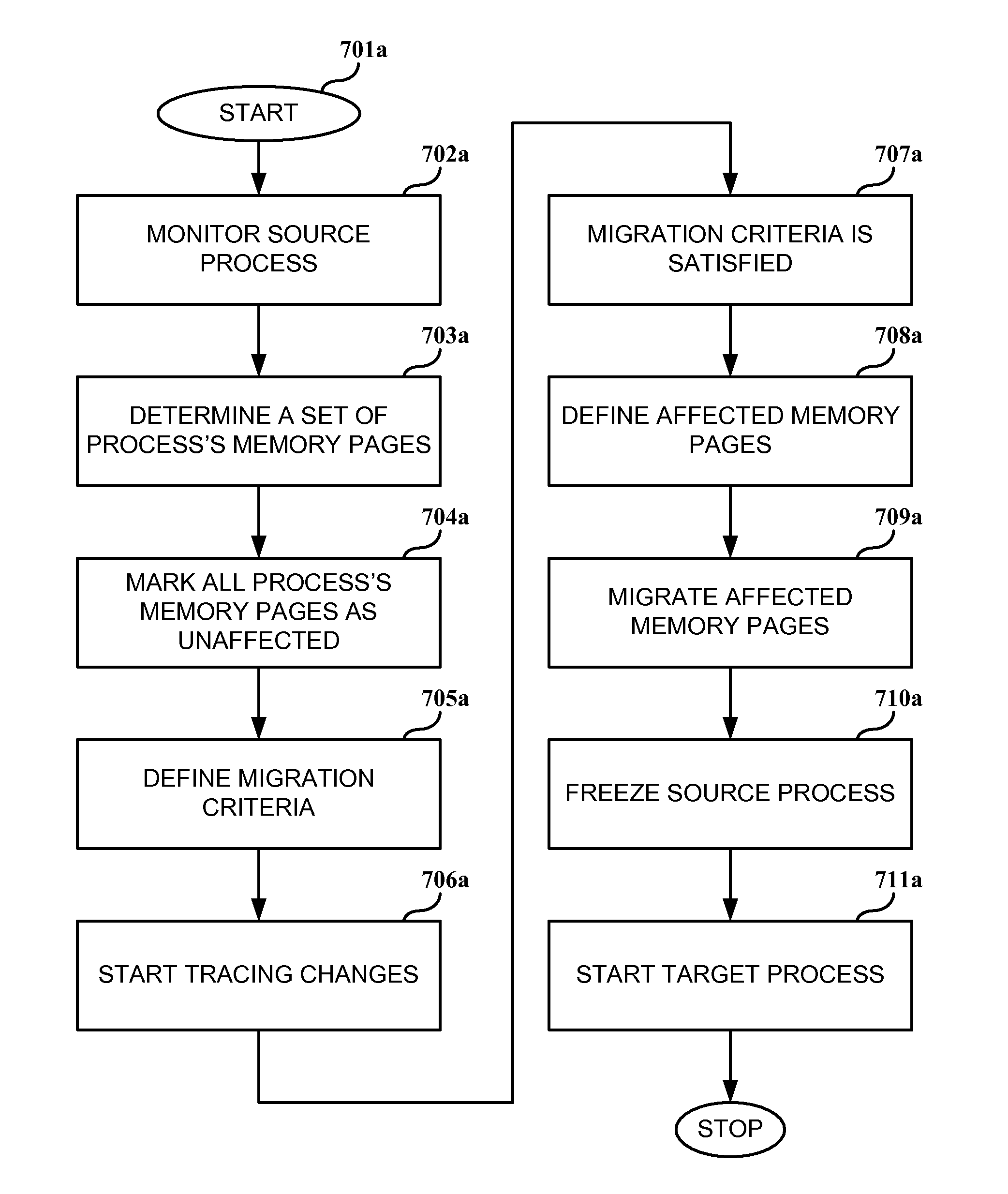

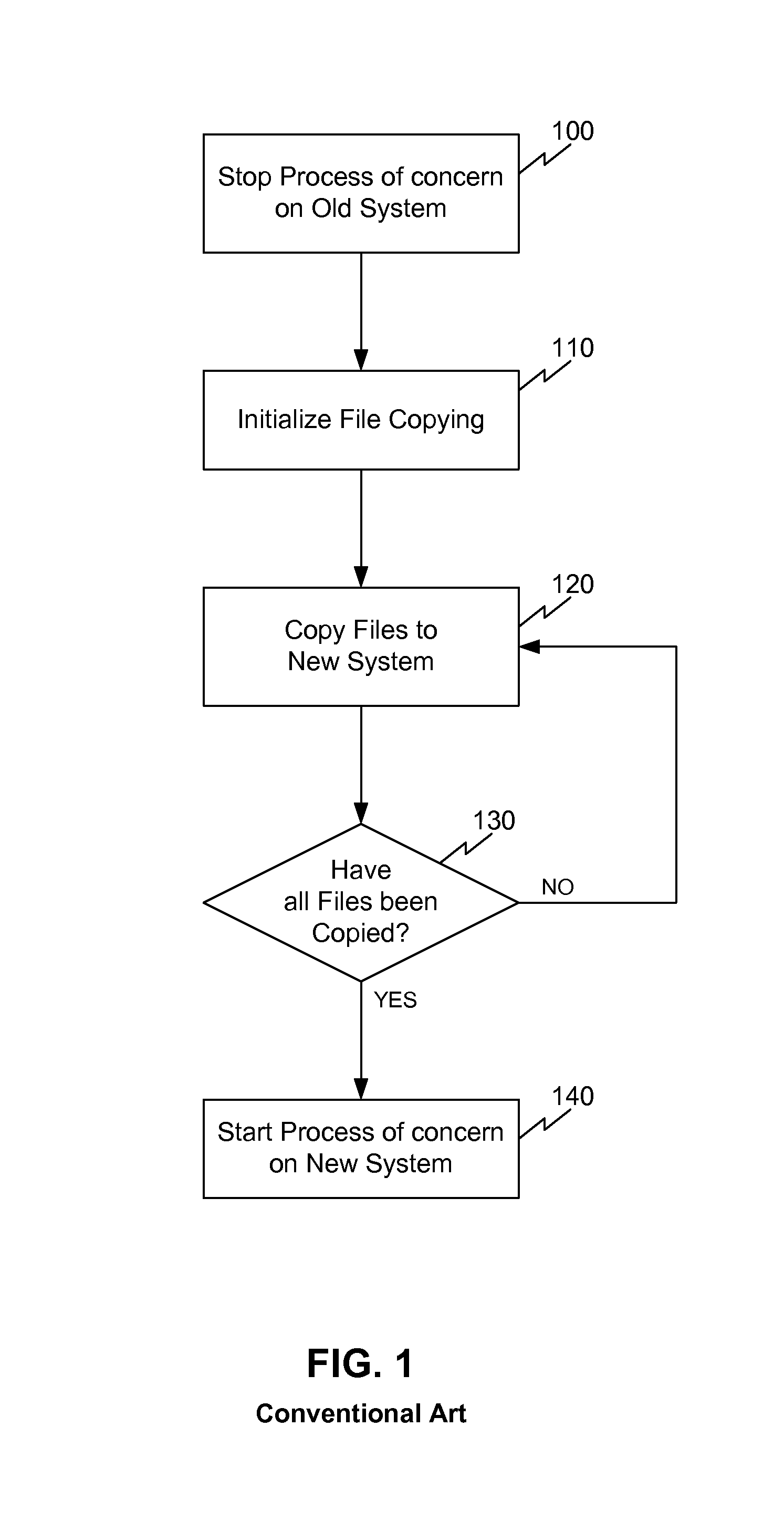

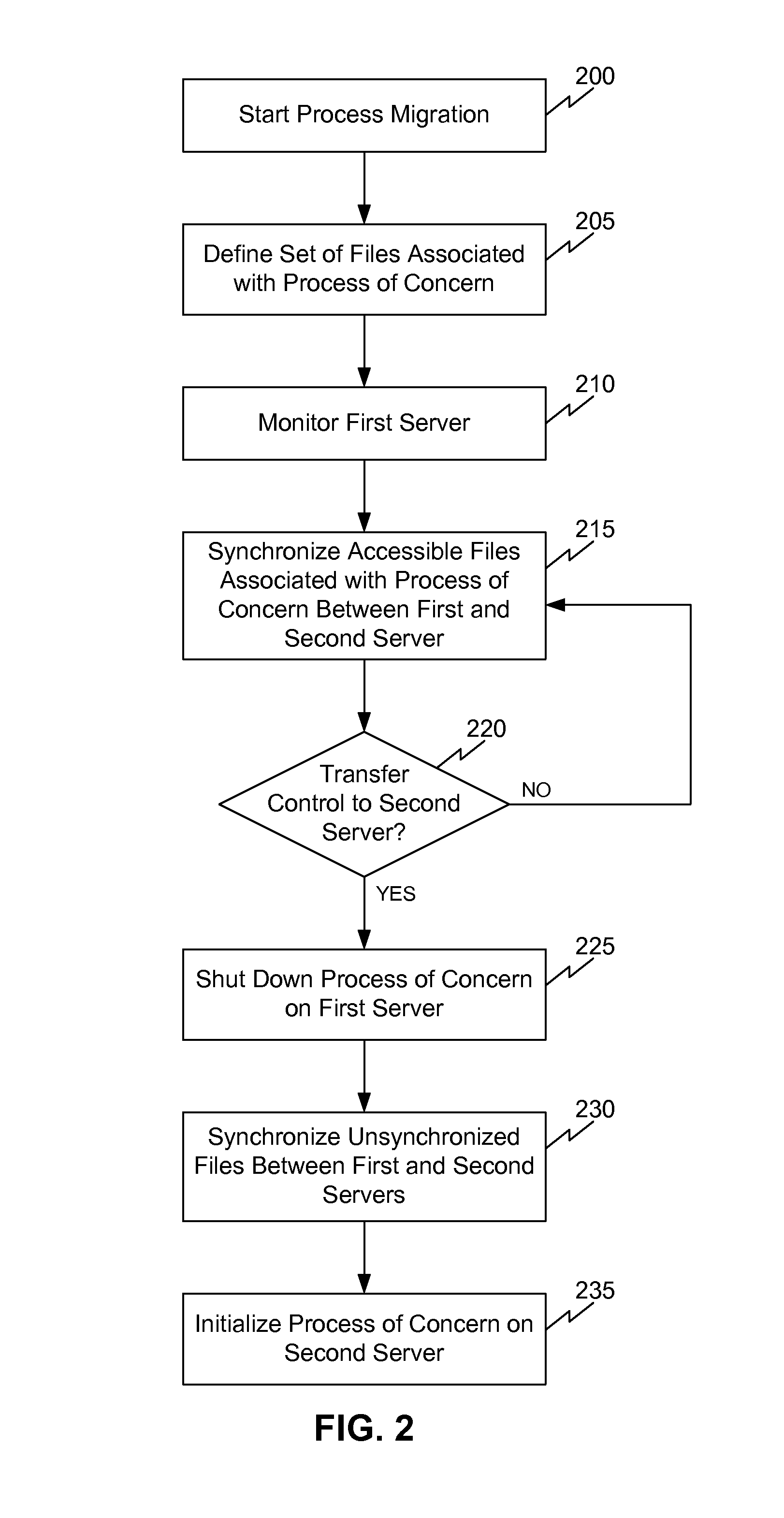

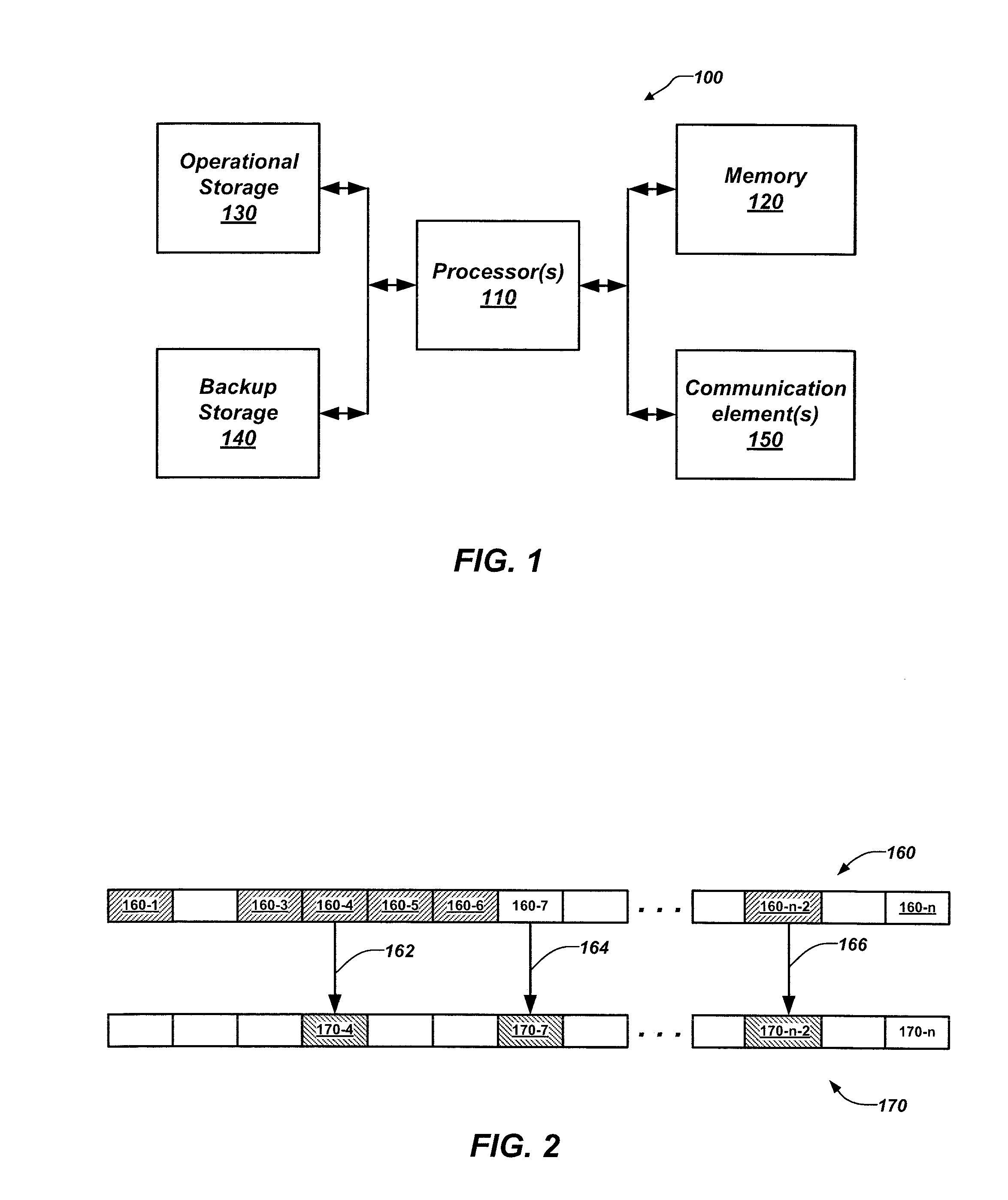

System, method and computer program product for process migration with planned minimized down-time

ActiveUS8069218B1Reduce downtimeGood synchronizationDigital computer detailsProgram controlData synchronizationProgram planning

A system, computer program product and method for a running process migration with planned minimized down-time. The method facilitates fast and efficient process migration by performing background data synchronization prior to actual process migration. The service slowdown is reduced by employing two-stage transfer method. During a first stage the service, being executed on the original machine, does not stop and all the available data required by this process is being copied. After the first stage is completed the service continues to be executed without an interruption, while the most of the data associated with the service process is already transferred to the new machine. During the second stage the execution of the service on the first machine is stopped. The files, which were not available during the first stage, are now copied. Then the execution of service is started on the second machine. The down-time is reduced to the duration of the second stage.

Owner:VIRTUOZZO INT GMBH

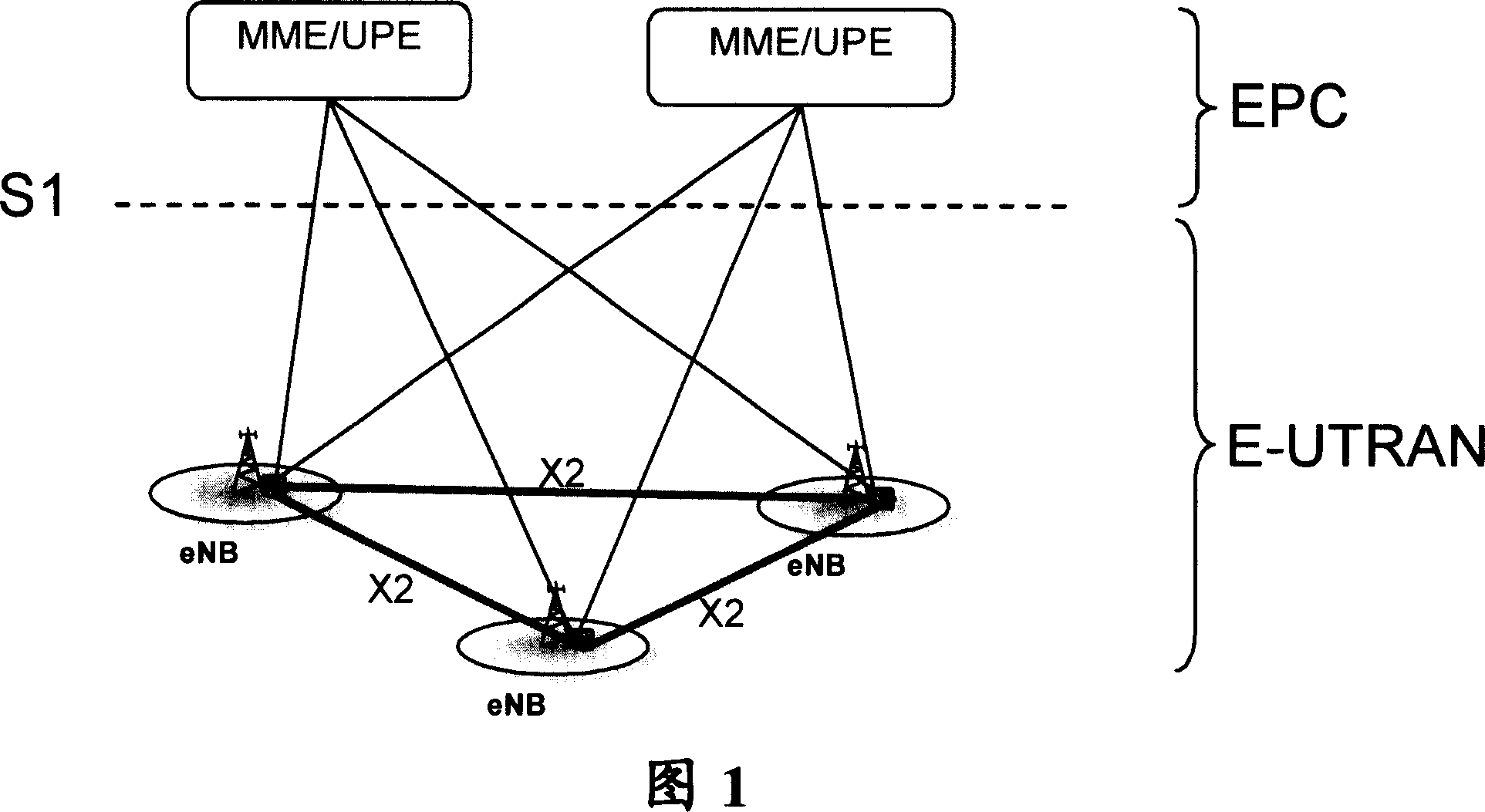

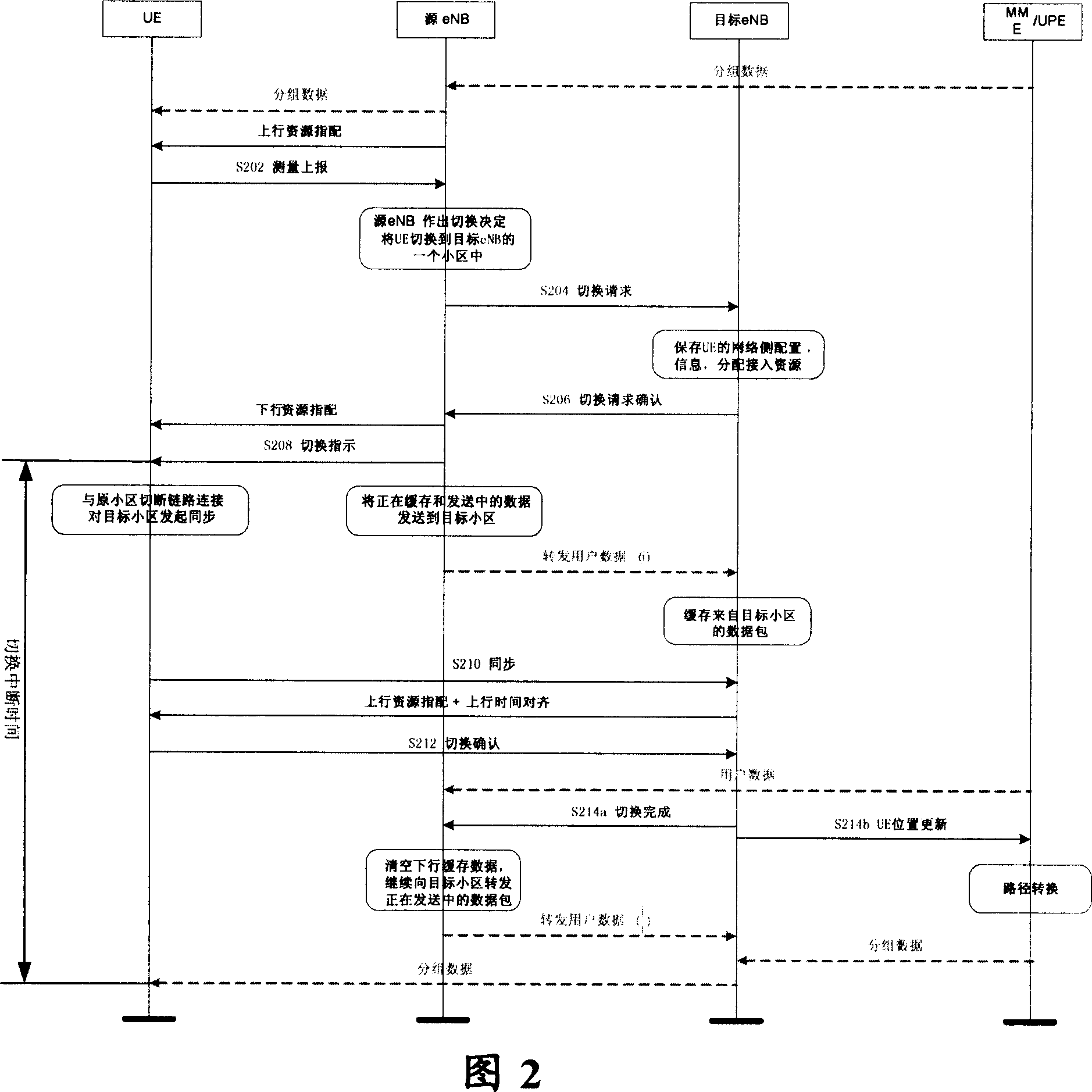

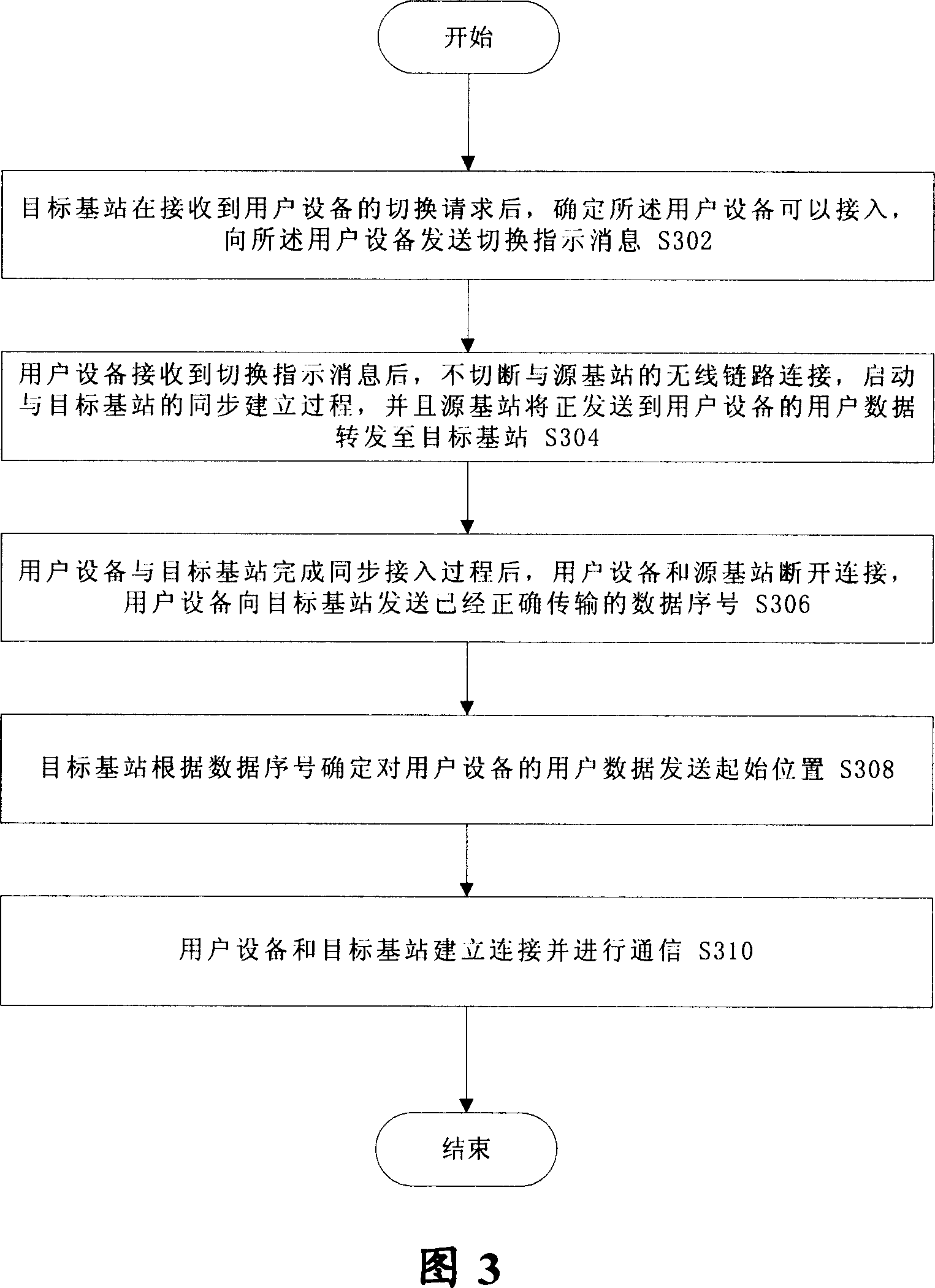

Switchover control method

InactiveCN101048001AAvoid redundant wasteReduce downtimeRadio/inductive link selection arrangementsData switching networksHandoff controlData transmission

The invention provides a wide range of switching control methods, in which, one of the switching control method includes the following steps: Step S302, the target base station determines to access to the user-equipment and sends switching instructions to referred user-equipment when receiving request for switching from user-equipment. Step S304, when the user-equipment receives the request for switching, without cutting off the source of the wireless link connecting of source base station, the user-equipment launches the same synchronizing establishing process with the target base station, and the source base station transmits the transmitting user-data to the target base station. Step S306, the user-equipment cuts off the connection with the source base station after their synchronous access process, the user-equipment sends the transmitted correct serial number to the target base station. Step S308, the target base station determines the starting position of data transmission the user-equipment. Step S310, the user-equipment and the target base station establish connection and communication.

Owner:SHENZHEN TINNO MOBILE TECH CO LTD

Methods and apparatus for processing the surface of a microelectronic workpiece

InactiveUS6309520B1Reduce riskReduce downtimeMachining electrodesCellsElectroless platingEngineering

A reactor for plating a metal onto a surface of a workpiece is set forth. The reactor comprises a reactor bowl including an electroplating solution disposed therein and an anode disposed in the reactor bowl in contact with the electroplating solution. A contact assembly is spaced from the anode within the reactor bowl. The contact assembly includes a plurality of contacts disposed to contact a peripheral edge of the surface of the workpiece to provide electroplating power to the surface of the workpiece. The contacts execute a wiping action against the surface of the workpiece as the workpiece is brought into engagement therewith The contact assembly also including a barrier disposed interior of the plurality of contacts. The barrier includes a member disposed to engage the surface of the workpiece to assist in isolating the plurality of contacts from the electroplating solution. In one embodiment, the plurality of contacts are in the form of discrete flexures while in another embodiment the plurality of contacts are in the form of a Belleville ring contact. A flow path may be provided in the contact assembly for providing a purging gas to the plurality of contacts and the peripheral edge of the workpiece. The purging gas may be used to assist in the formation of the barrier of the contact assembly. A combined electroplating / electroless plating tool and method are also set forth.

Owner:SEMITOOL INC

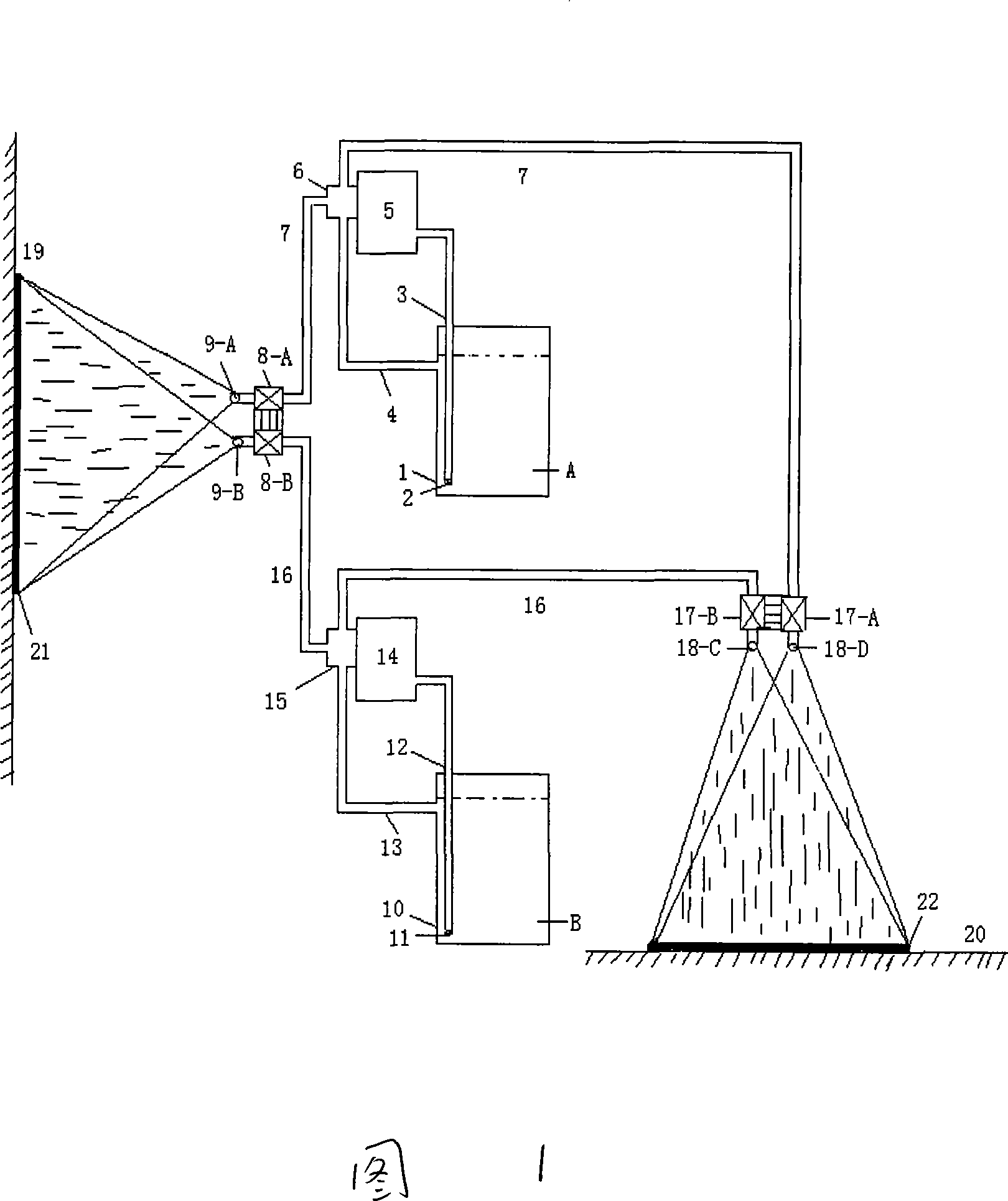

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

Apparatus for depositing a multilayer coating on discrete sheets

ActiveUS20050239294A1Reduce downtimeEasy to operateSolid-state devicesVacuum evaporation coatingTemperature controlEngineering

A tool for depositing multilayer coatings onto a substrate. In one configuration, the tool includes a includes an in-line organic material deposition station operating under at least one of a pressure or temperature controlled environment. In another, it further is of a hybrid design that incorporates both in-line and cluster tool features. In this latter configuration, at least one of the deposition stations is configured to deposit an inorganic layer, while at least one other deposition station is configured to deposit an organic layer. The tool is particularly well-suited to depositing multilayer coatings onto discrete substrates, as well as to encapsulating environmentally-sensitive devices placed on the flexible substrate.

Owner:SAMSUNG DISPLAY CO LTD

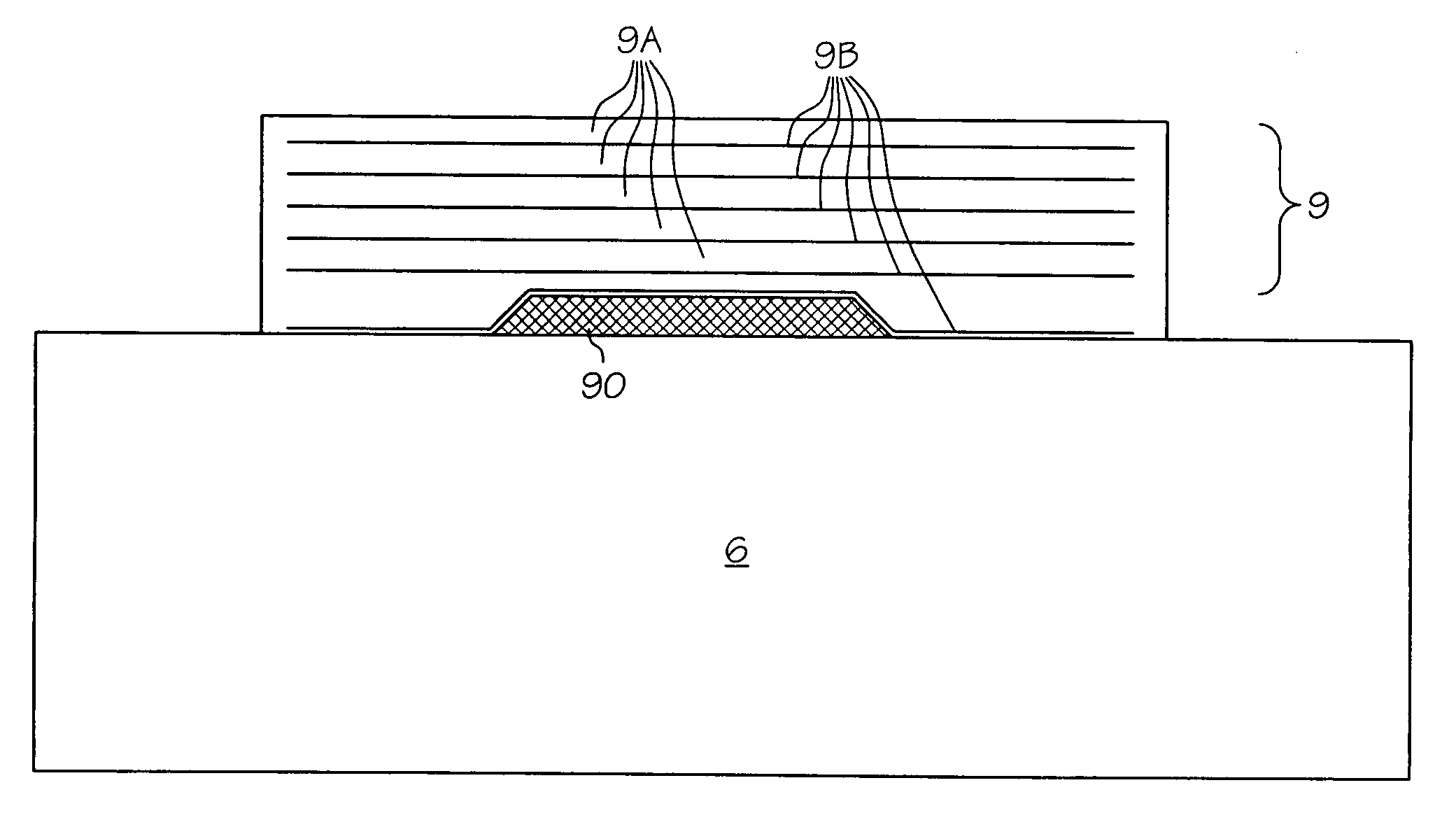

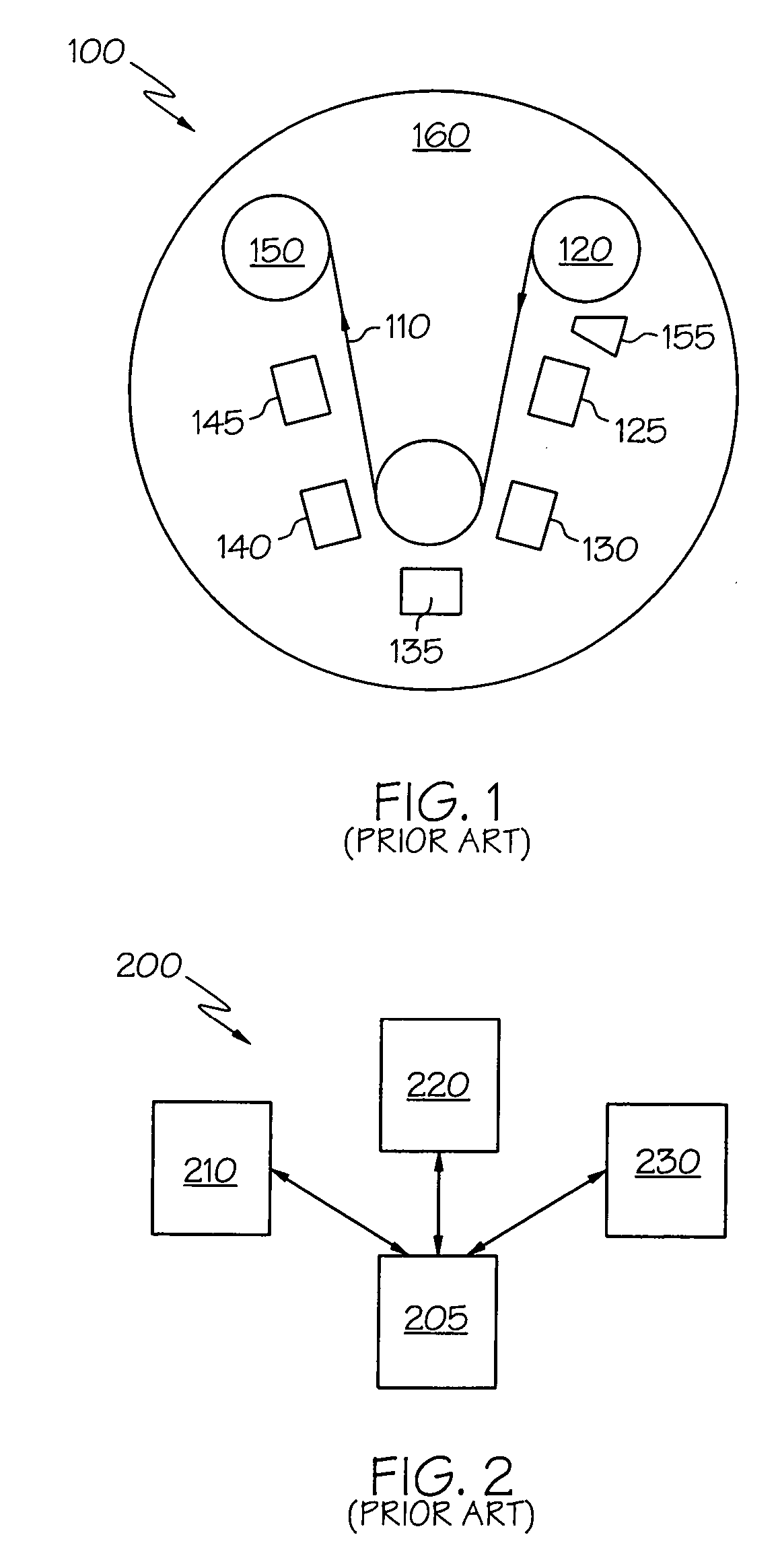

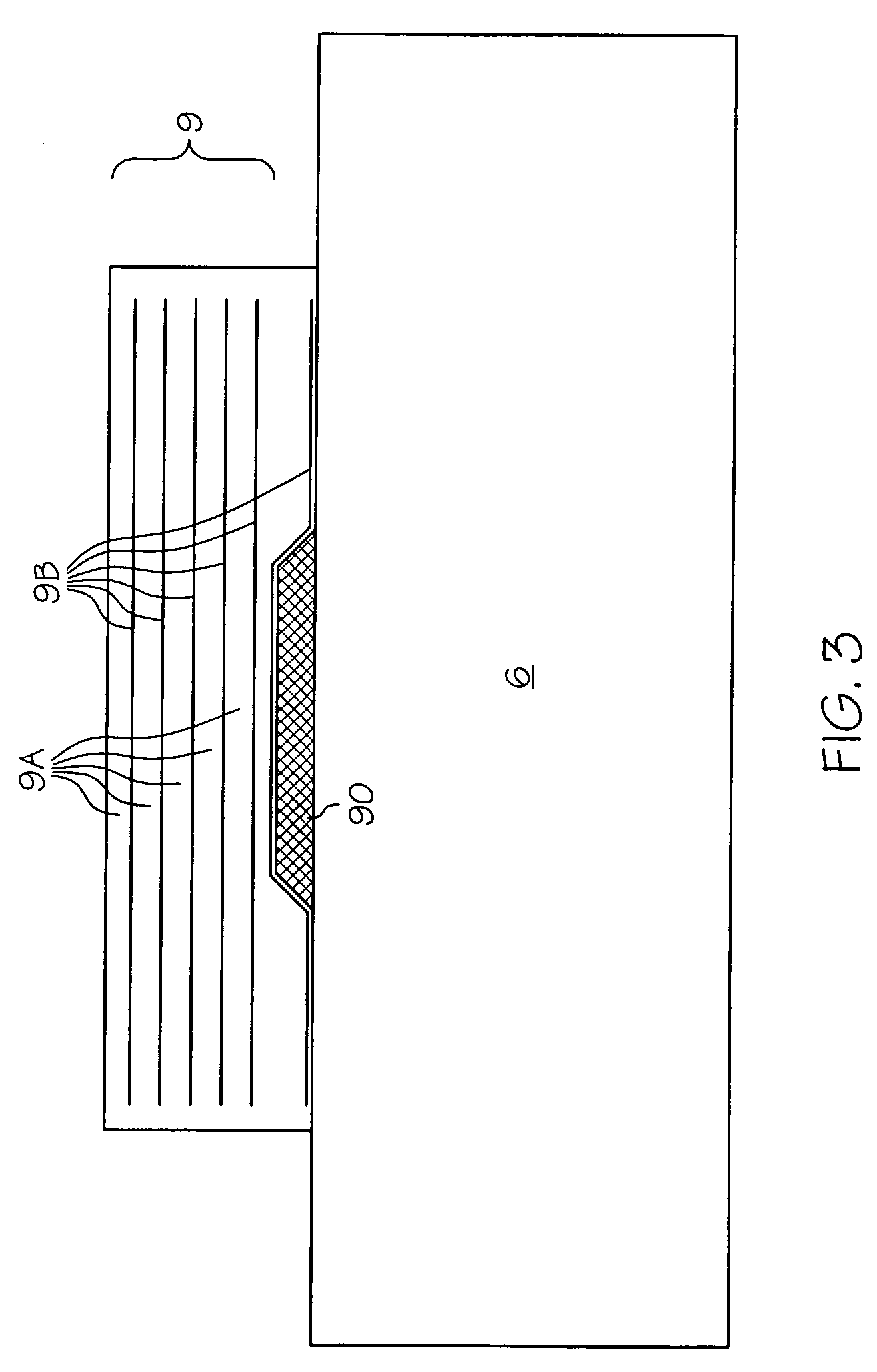

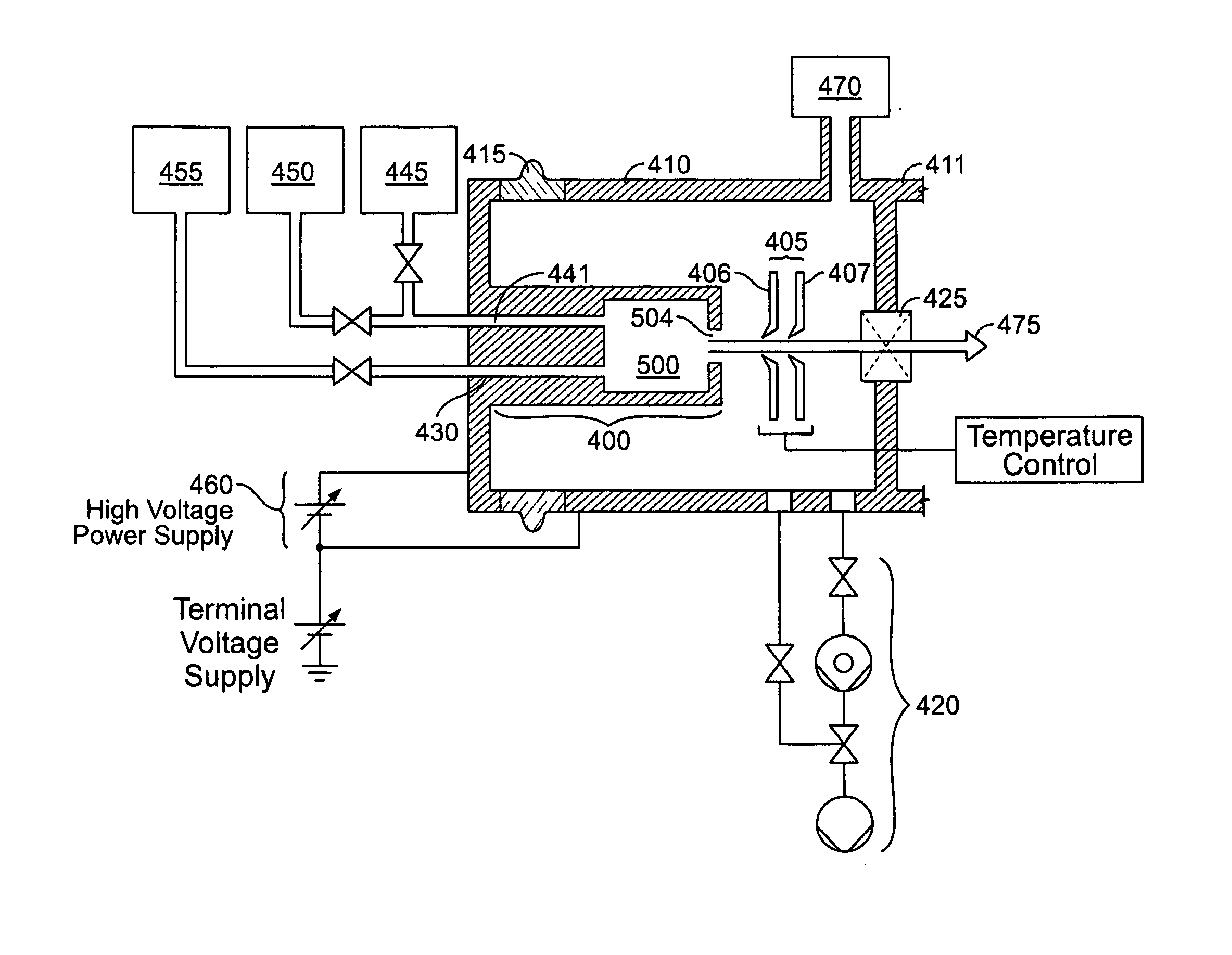

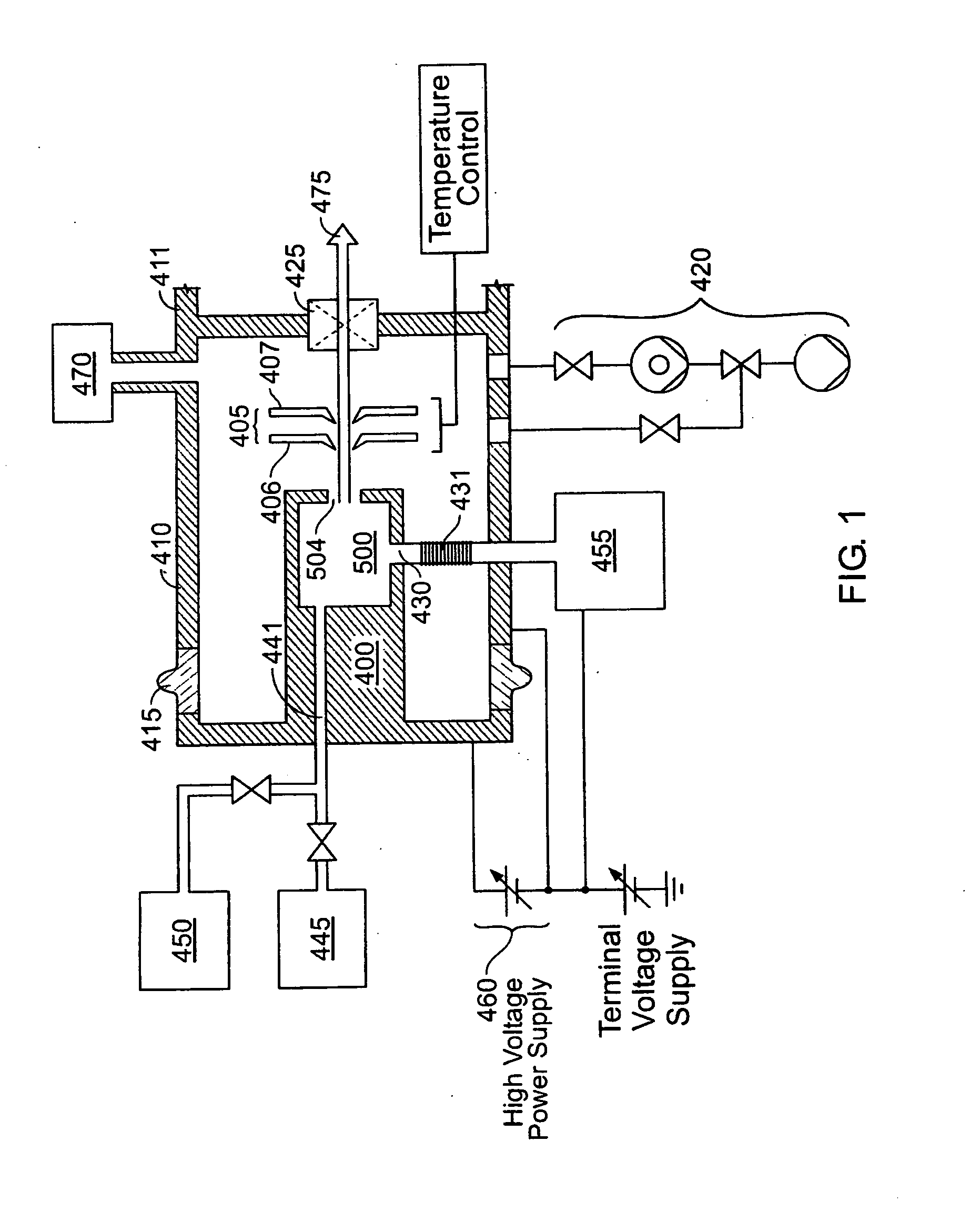

Method and apparatus for extracting ions from an ion source for use in ion implantation

InactiveUS20060272775A1Avoid unstable operationMaintain dimensional stabilityVacuum evaporation coatingSemiconductor/solid-state device manufacturingRemote plasmaActive cooling

Thermal control is provided for an extraction electrode of an ion-beam producing system that prevents formation of deposits and unstable operation and enables use with ions produced from condensable vapors and with ion sources capable of cold and hot operation. Electrical heating of the extraction electrode is employed for extracting decaborane or octadecaborane ions. Active cooling during use with a hot ion source prevents electrode destruction, permitting the extraction electrode to be of heat-conductive and fluorine-resistant aluminum composition. The service lifetime of the system is enhanced by provisions for in-situ etch cleaning of the ion source and extraction electrode, using reactive halogen gases, and by having features that extend the service duration between cleanings, including accurate vapor flow control and accurate focusing of the ion beam optics. A remote plasma source delivers F or Cl ions to the de-energized ion source for the purpose of cleaning deposits in the ion source and the extraction electrode. These techniques enable long equipment uptime when running condensable feed gases such as sublimated vapors, and are particularly applicable for use with so-called cold ion sources and universal ion sources. Methods and apparatus are described which enable long equipment uptime when decaborane and octadecaborane are used as feed materials, as well as when vaporized elemental arsenic and phosphorus are used, and which serve to enhance beam stability during ion implantation.

Owner:SEMEQUIP

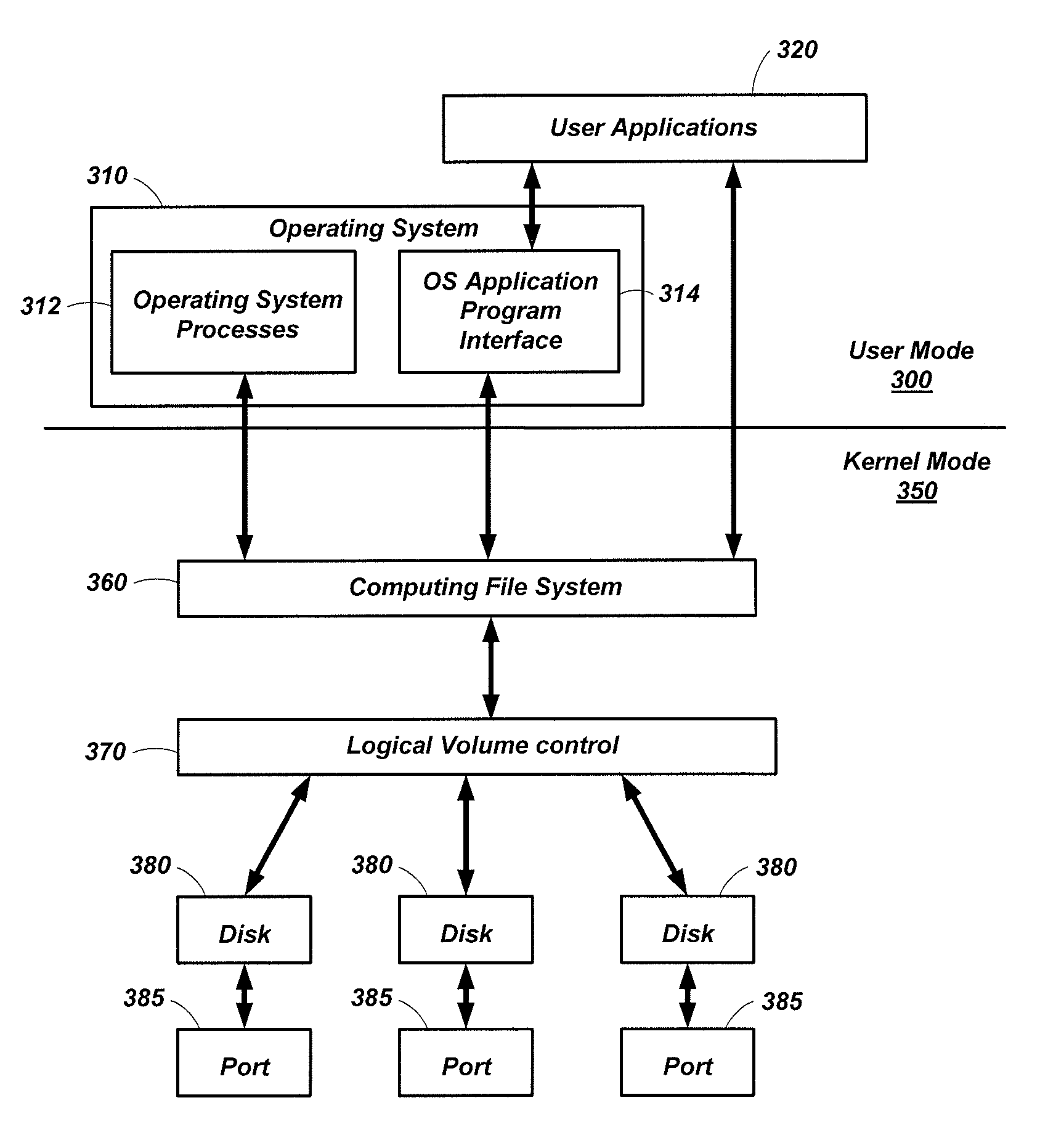

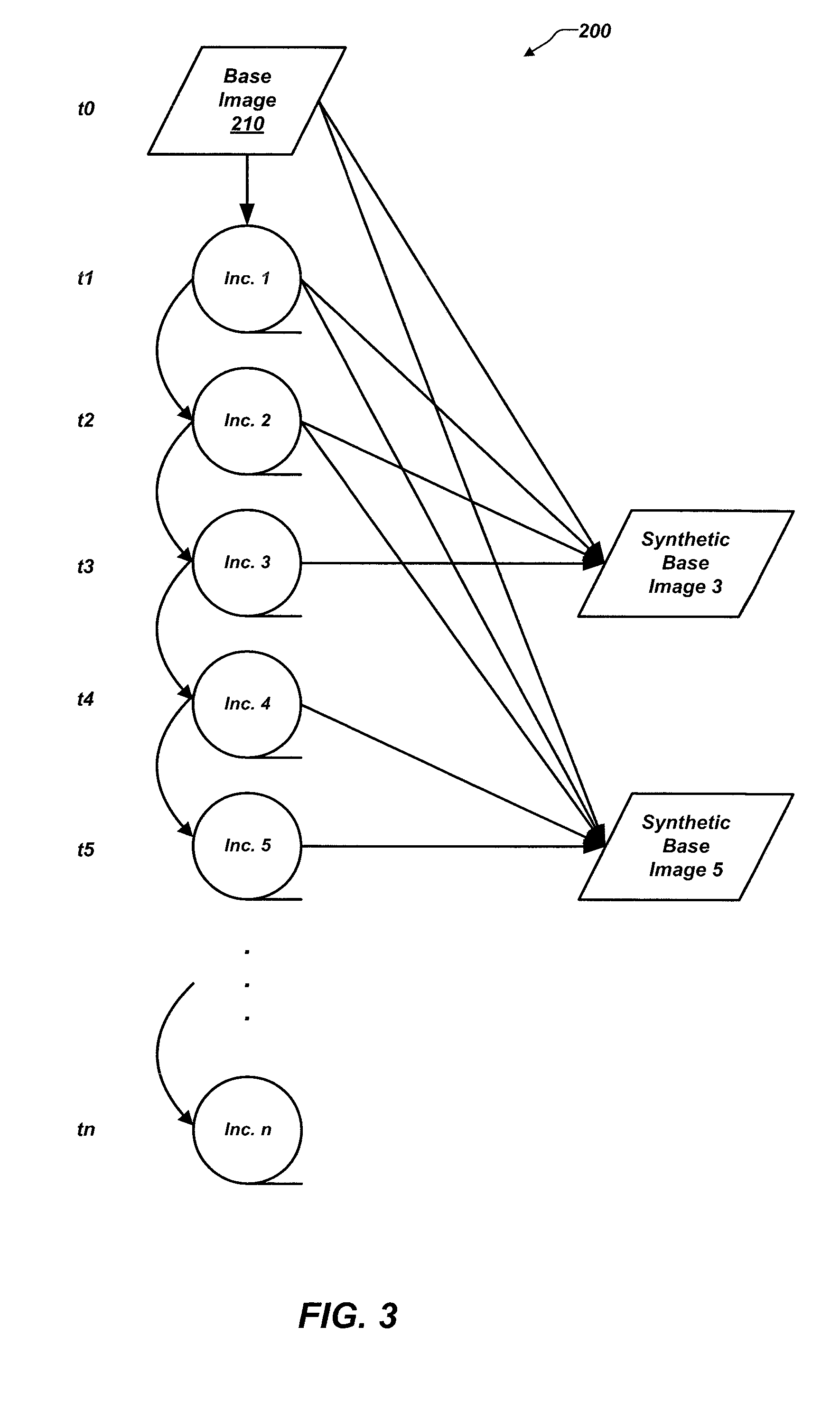

Systems, methods, and computer-readable media for backup and restoration of computer information

ActiveUS20110218966A1Reduce downtimeDigital data information retrievalMemory loss protectionFile systemPublic access

A computer creates a full backup of a target volume by copying sectors of the target volume. Incremental backups are created by copying modified sectors that have changed since a preceding backup. Public accesses to a restore volume are prevented by modifying a volume boot record (VBR) of the restore volume to prevent file systems from recognizing the restore volume or by filtering public accesses while allowing private block accesses to the restore volume. Sector data are copied from the backup files to the restore volume while the public accesses are being prevented. The restore can begin, using previously created backup files, while the backup is still in process creating new incremental backups for the target volume. The restore volume is finalized after restoring the full or any number of incremental backups by restoring the VBR to indicate the restore volume is valid or stopping the filtering of public accesses.

Owner:STORAGECRAFT TECH CORP

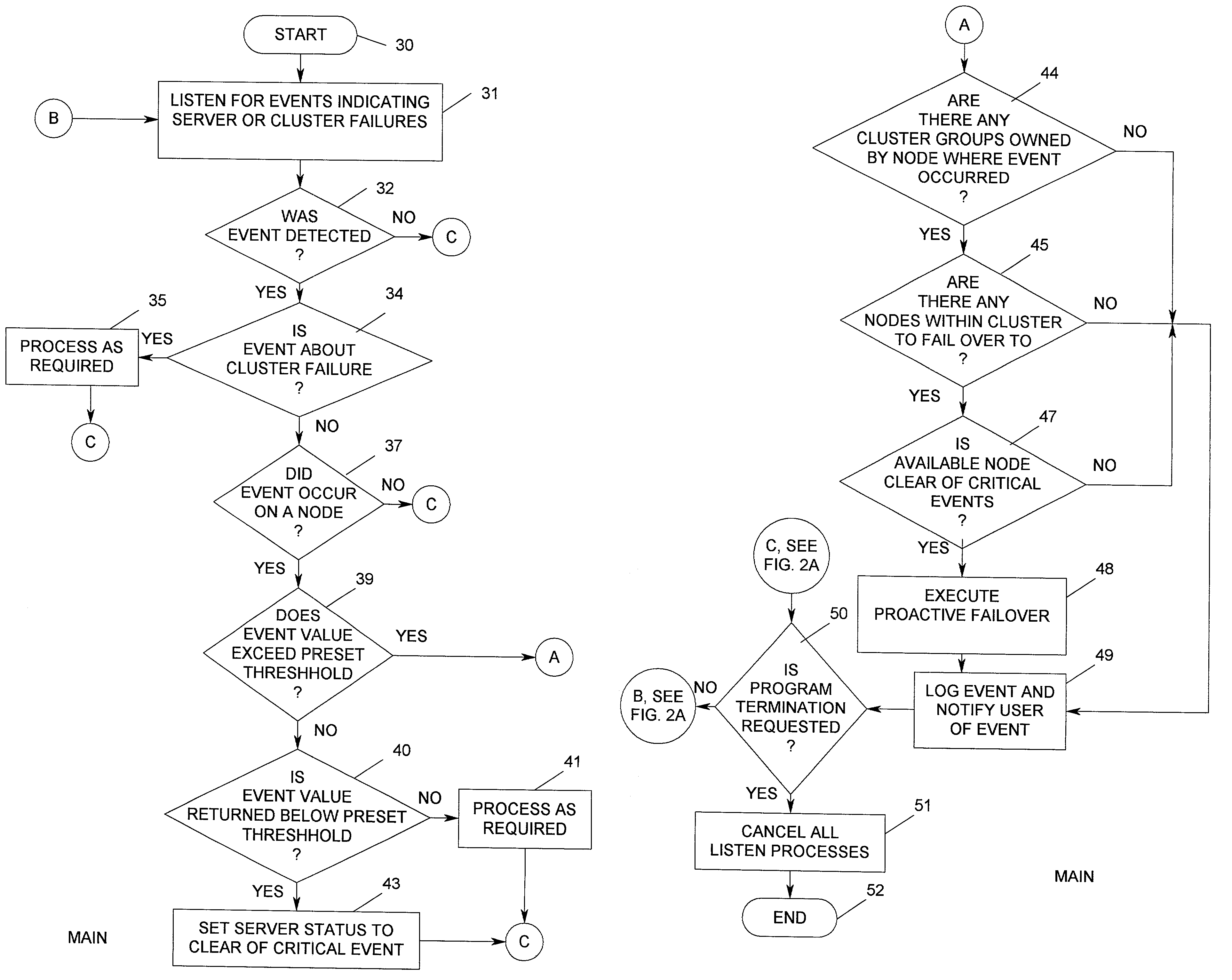

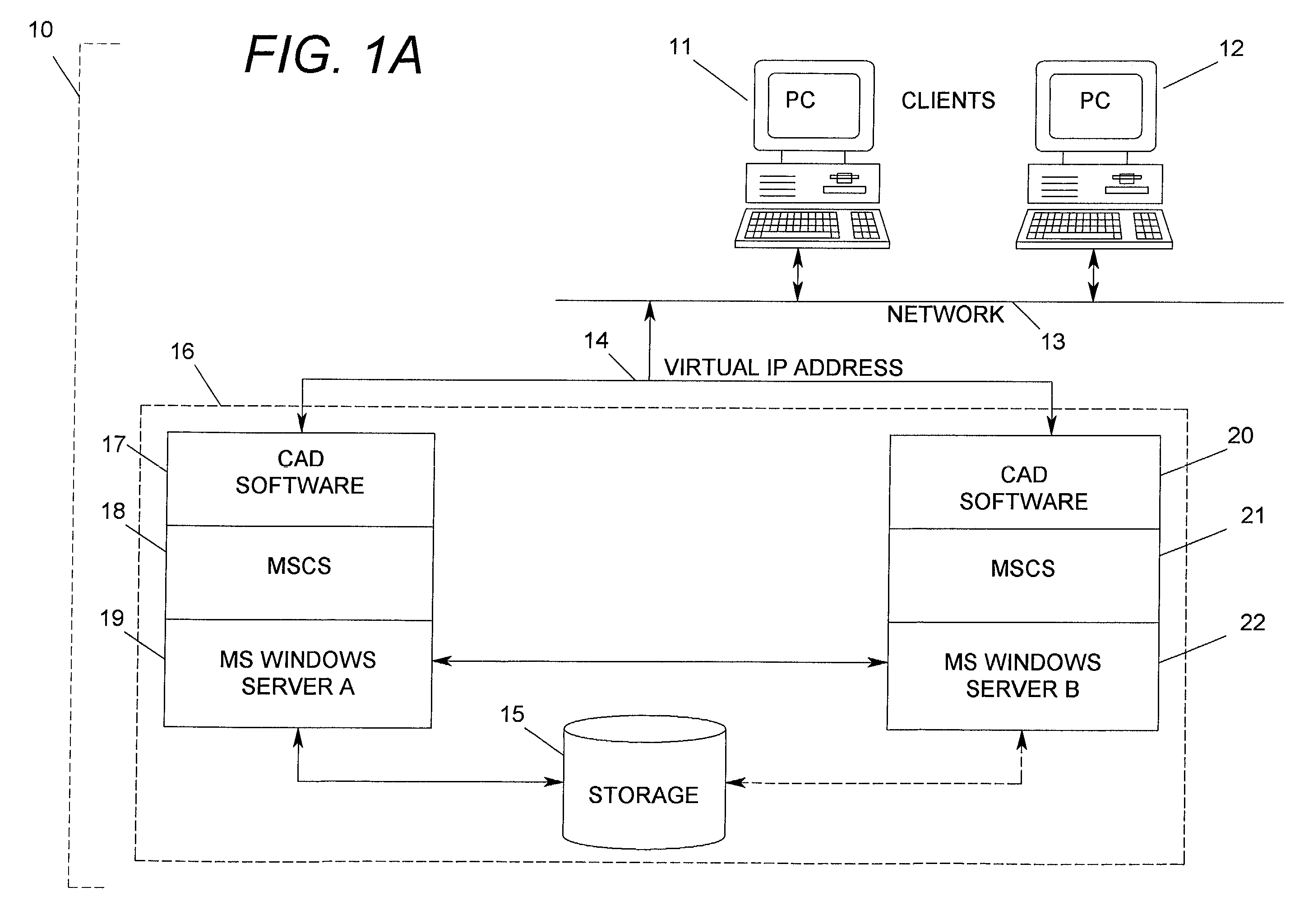

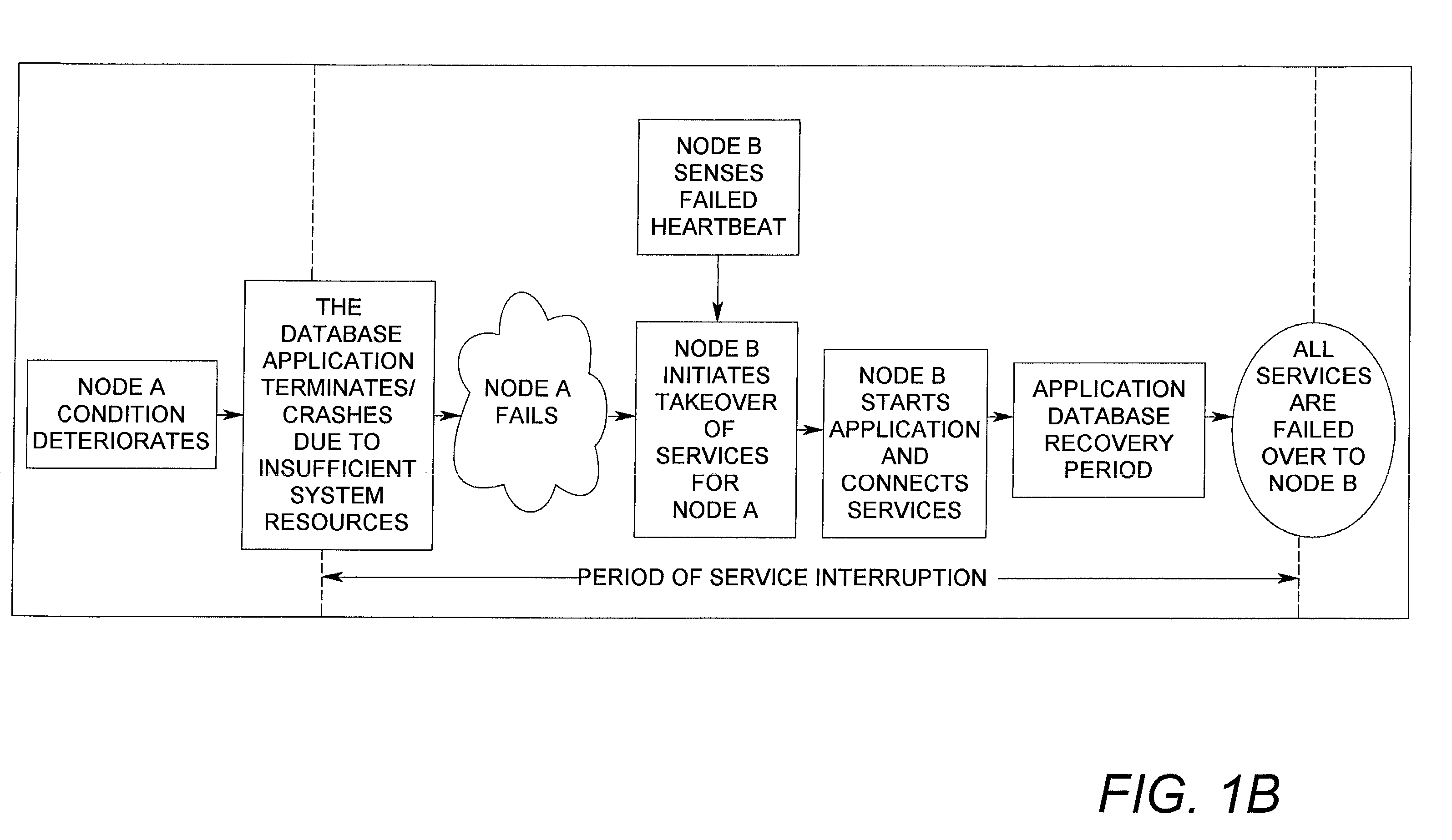

Proactive method for ensuring availability in a clustered system

The method of the present invention is useful in a computer system including at least two server nodes, each of which can execute clustered server software. The program executes a method for monitoring failure situations to reduce downtime. The method includes the step of detecting an event causing one of the failure situations, and then the method determines if the event affects one of the server nodes. If it is determined the event does affect one of the server nodes, the method then determines if the event exceeds a threshold value. If it is determined the event exceeds a threshold value, the method executes a proactive failover. If the event is not specific to a cluster node, but indicates an impending or actual failure of the cluster software, the method identifies and initiates an appropriate action to fix the condition or provide a workaround (if available) that will preempt an impending failure of the cluster system or would enable a restarting of a failed cluster software.

Owner:GOOGLE LLC

Aparatus for processing the surface of a microelectronic workpiece

InactiveUS6303010B1Reduce the risk of contaminationReduce downtimeCellsTanksEngineeringMechanical engineering

A reactor for plating a metal onto a surface of a workpiece is set forth. The reactor comprises a reactor bowl including an electroplating solution disposed therein and an anode disposed in the reactor bowl in contact with the electroplating solution. A contact assembly is spaced from the anode within the reactor bowl. The contact assembly includes a plurality of contacts disposed to contact a peripheral edge of the surface of the workpiece to provide electroplating power to the surface of the workpiece. The contacts execute a wiping action against the surface of the workpiece as the workpiece is brought into engagement therewith The contact assembly also including a barrier disposed interior of the plurality of contacts. The barrier includes a member disposed to engage the surface of the workpiece to assist in isolating the plurality of contacts from the electroplating solution. In one embodiment, the plurality of contacts are in the form of discrete flexures while in another embodiment the plurality of contacts are in the form of a Belleville ring contact. A flow path may be provided in the contact assembly for providing a purging gas to the plurality of contacts and the peripheral edge of the workpiece. The purging gas may be used to assist in the formation of the barrier of the contact assembly. A combined electroplating / electroless plating tool and method are also set forth.

Owner:APPLIED MATERIALS INC

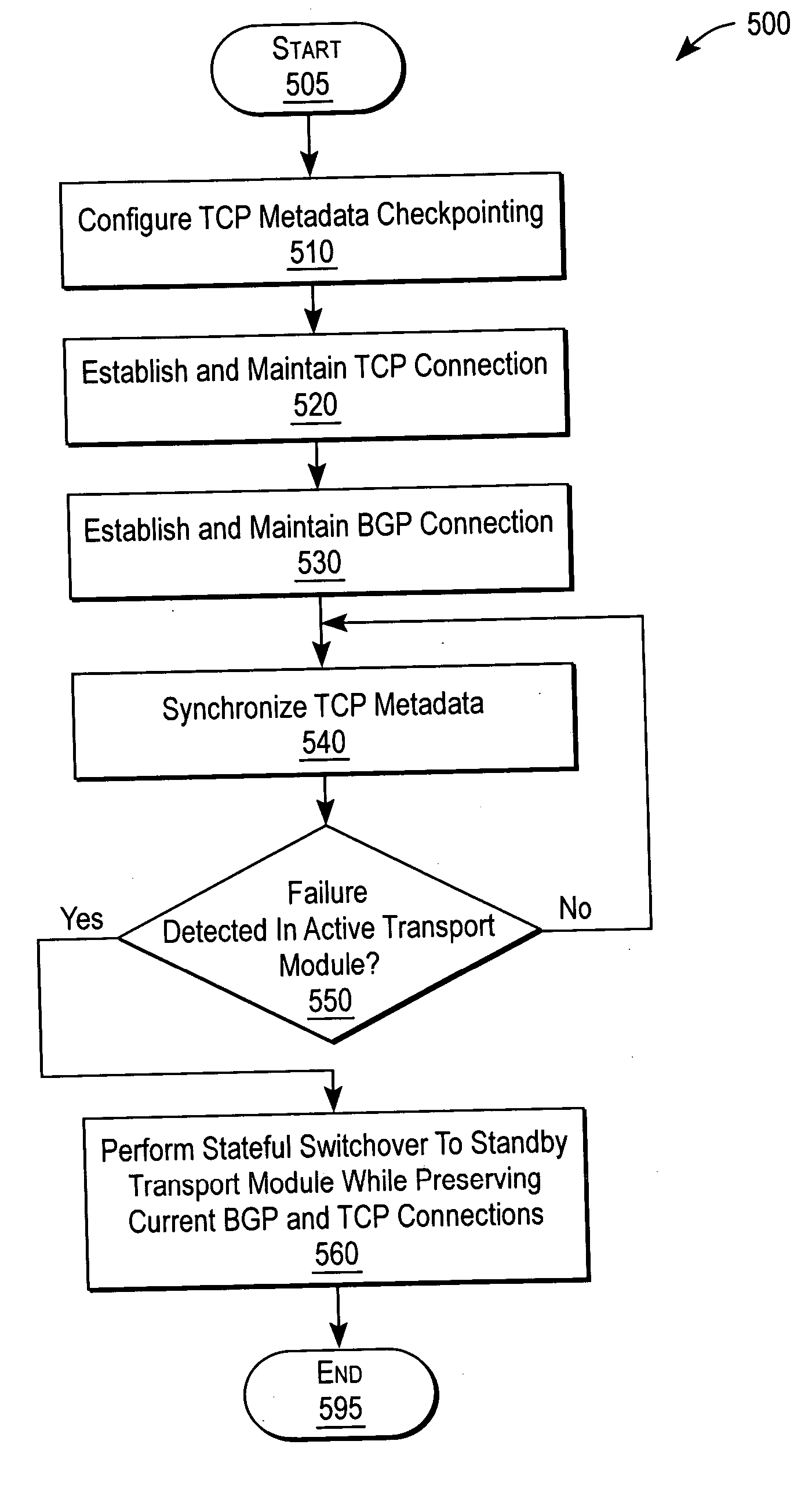

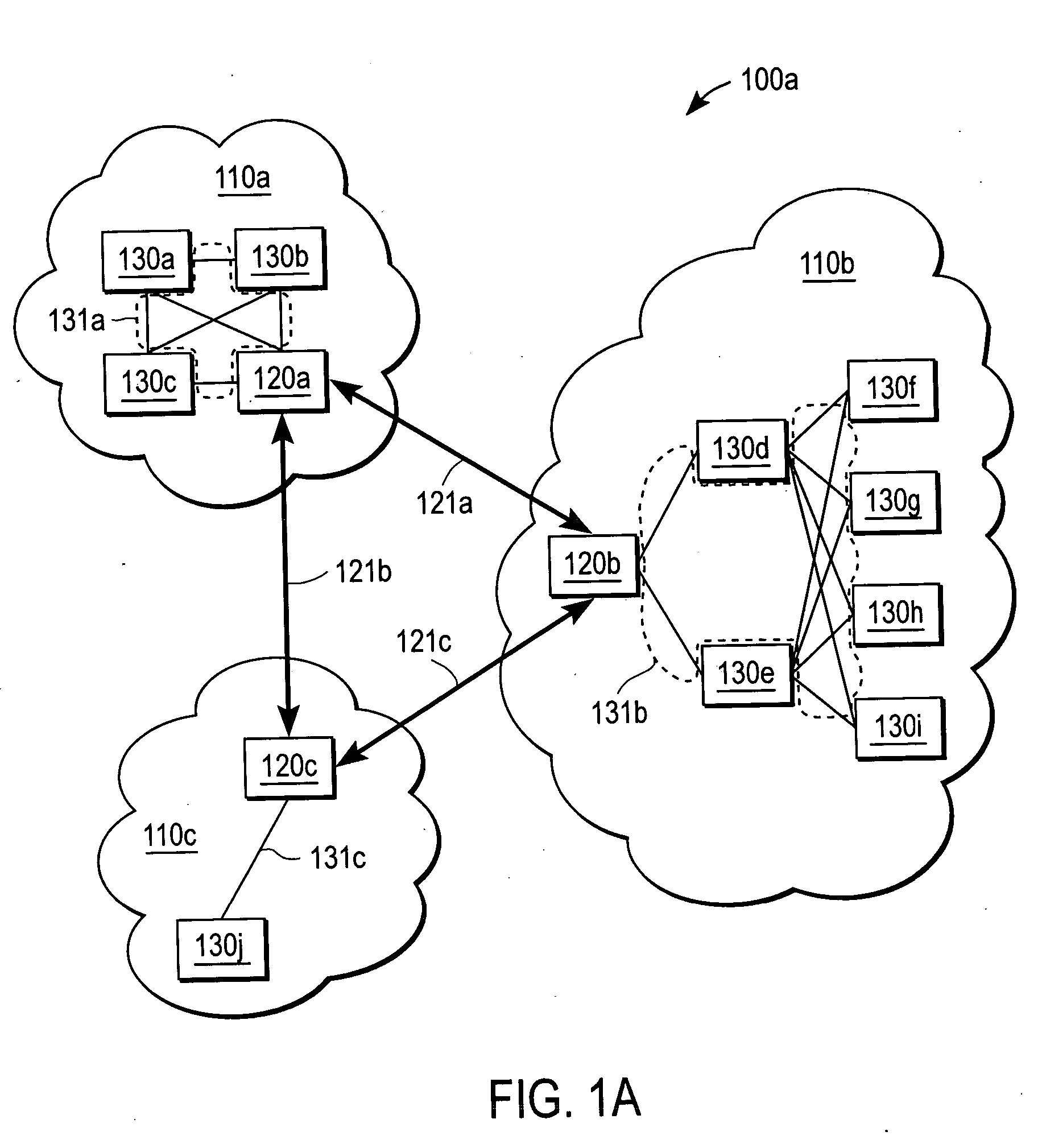

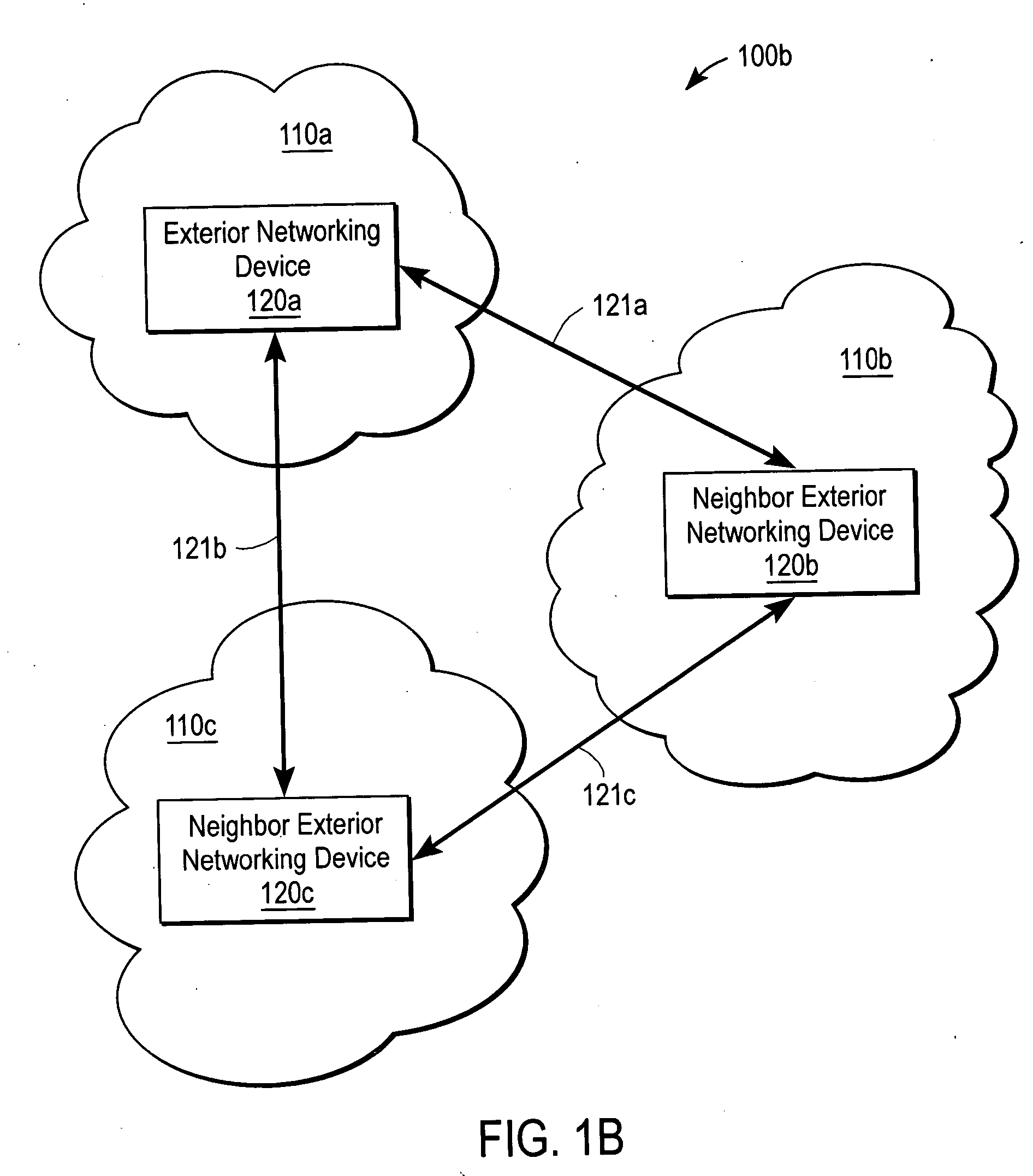

Cooperative TCP / BGP window management for stateful switchover

InactiveUS20060062142A1Less dataReduce downtimeError preventionTransmission systemsMetadataReal-time computing

A system and method for performing stateful switchover with reduced data, such as only metadata about a TCP window state. The metadata comprises a size of TCP packets used to send BGP messages, and which of those have been acknowledged by a neighbor networking device. The networking device comprises a BGP module to establish a BGP session between the networking device and a neighbor networking device. An active transport module within the networking device synchronizes with a standby transport module within the networking device by sending the metadata. A fault detector within the networking device initiates a stateful switchover from the active transport module to the standby transport module responsive to detecting a failure of a process and / or processor. The standby transport module uses the metadata to determine stateful metadata for preserving current BGP and TCP sessions of the networking device with dummy TCP packets having the same size ad sent TCP packets and containing safe BGP message data.

Owner:CISCO TECH INC

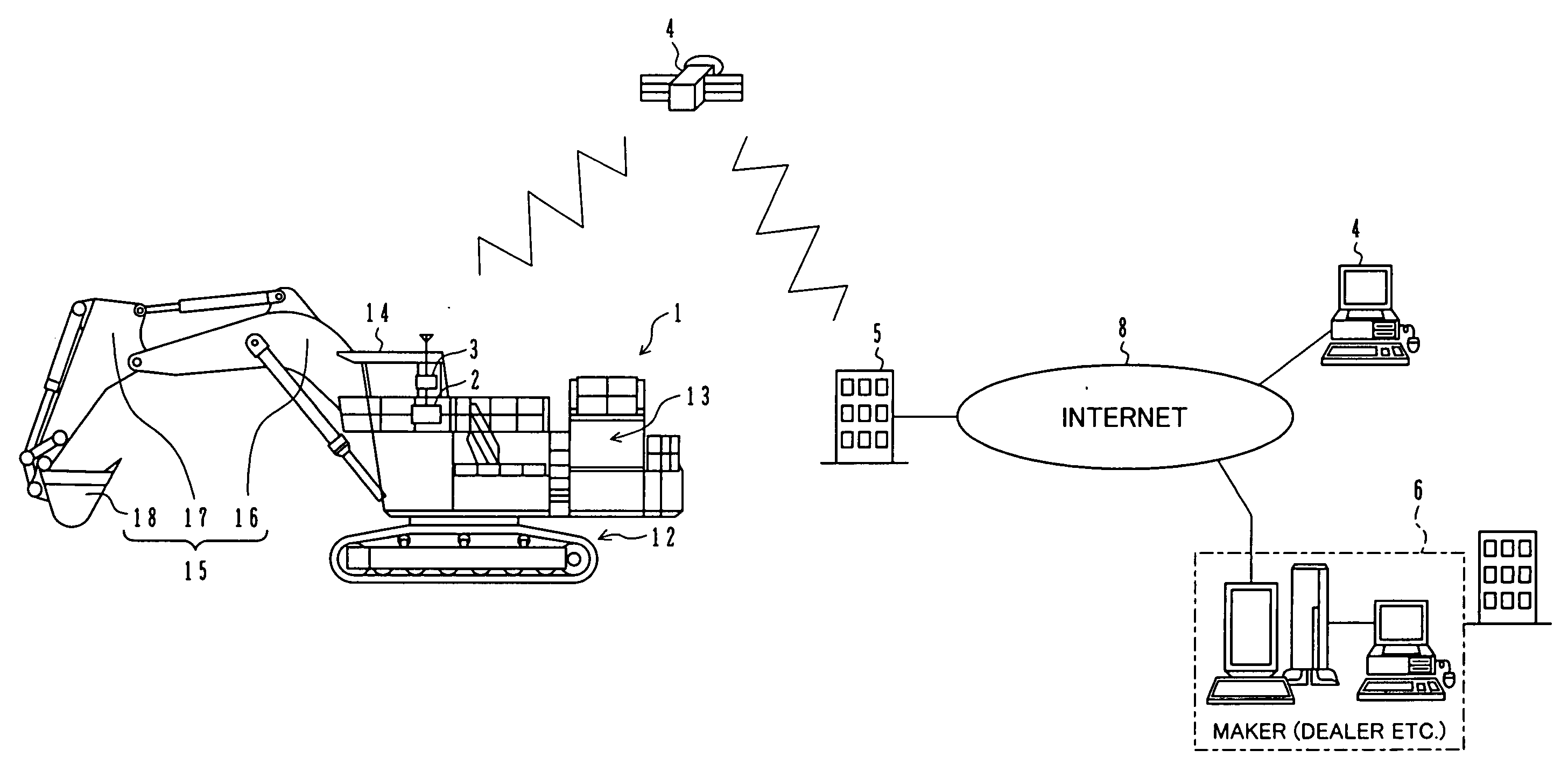

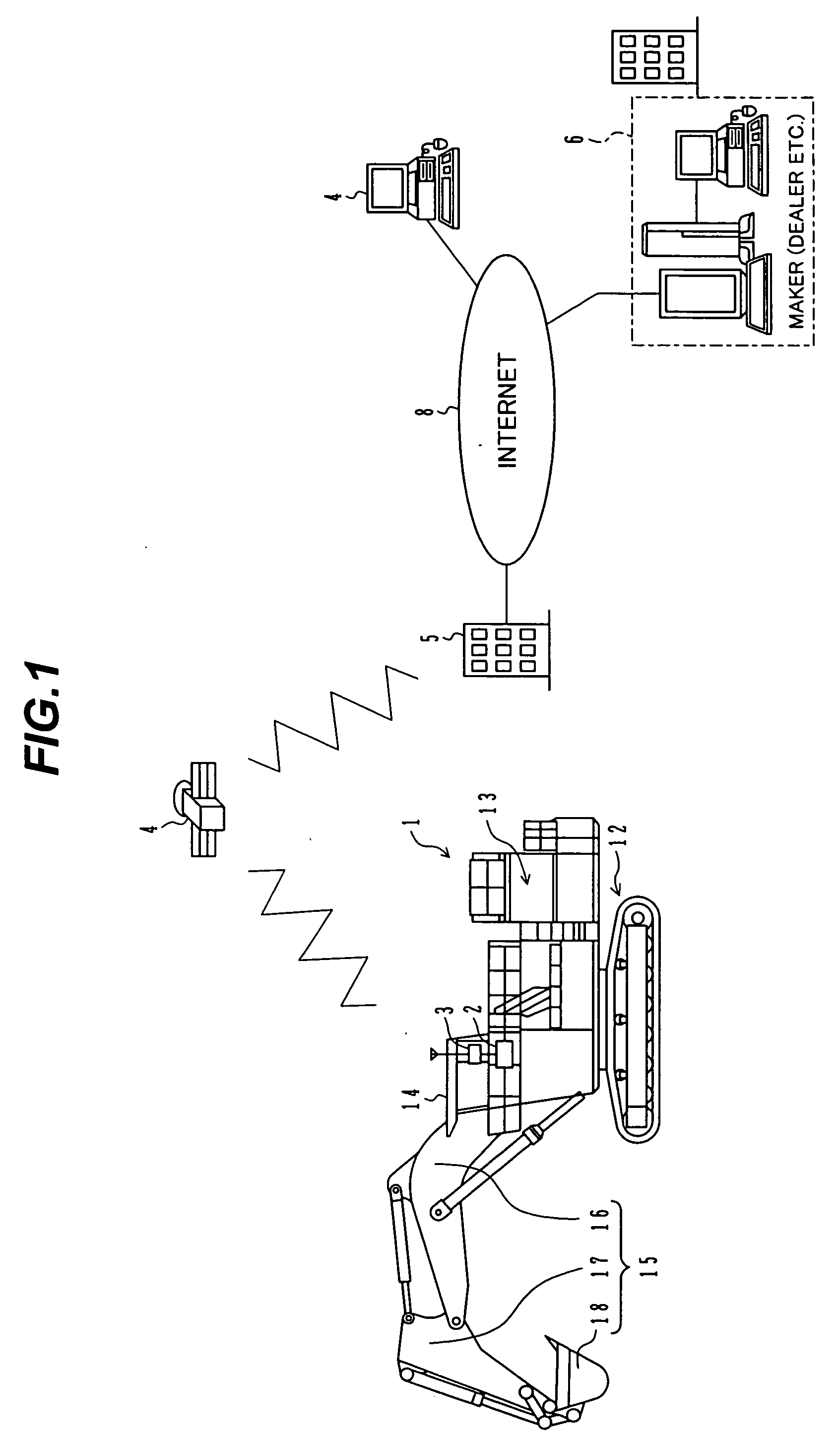

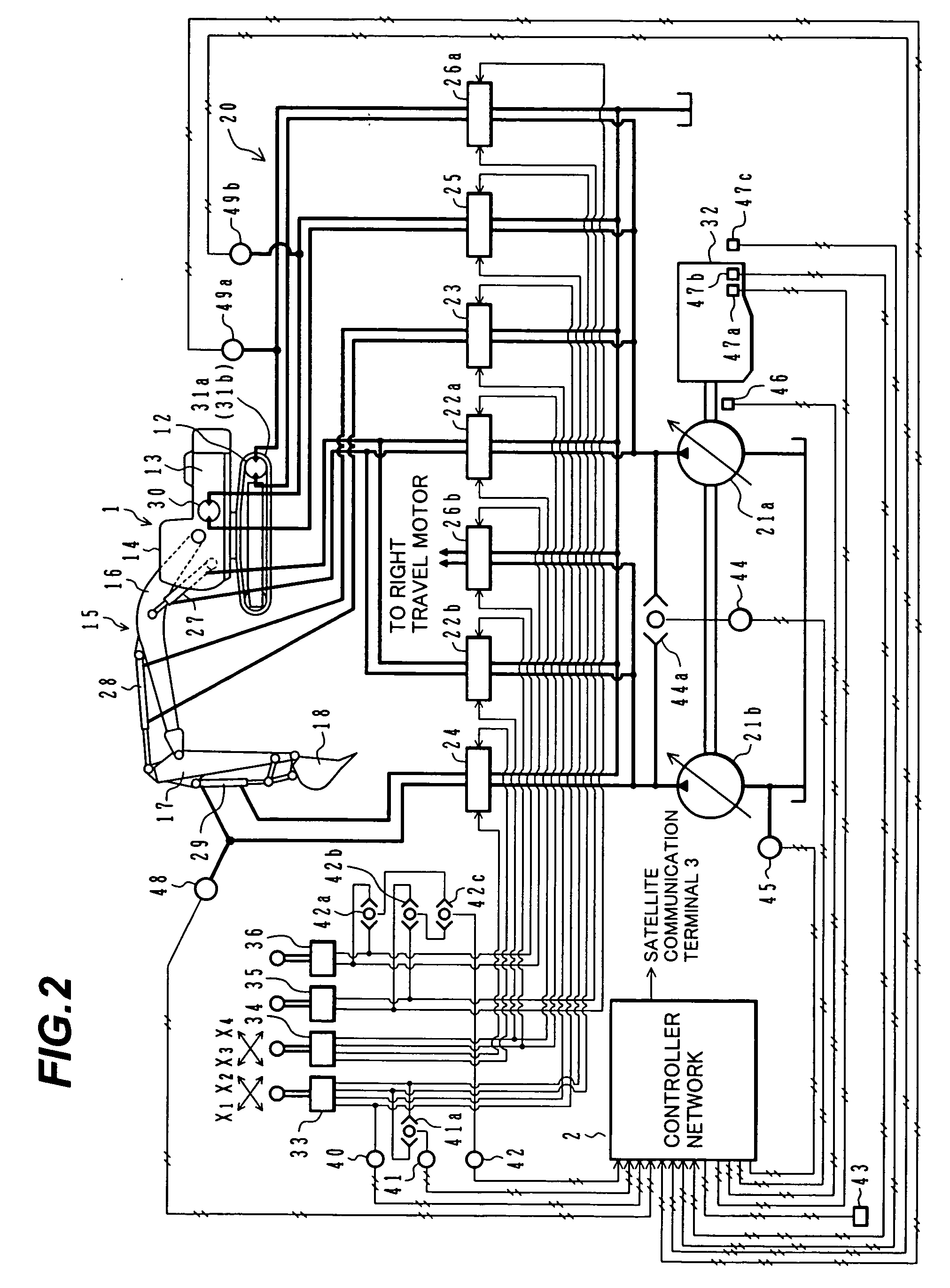

Operation information control device for construction machine and construction machine operation information control system provided with it

InactiveUS20060212203A1Drawback can be obviatedRestraining the drop in productivityVehicle testingData processing applicationsMachineOperational data store

A data recording unit 60 for managing operating situations of a hydraulic excavator 1 comprises a RAM 67 for taking in and storing plural kinds of operational information regarding the hydraulic excavator 1 as operational data, and a CPU 65 for extracting top priority operational data from among the plural kinds of operational data stored in the RAM 67, and transmitting the extracted data to the supervising side via satellite communication. Top priority data among the plural kinds of operational data of the hydraulic excavator, which may bring the hydraulic excavator into rest, can be presented to a supervisor of the hydraulic excavator, etc.

Owner:NIHON KENKI CO LTD

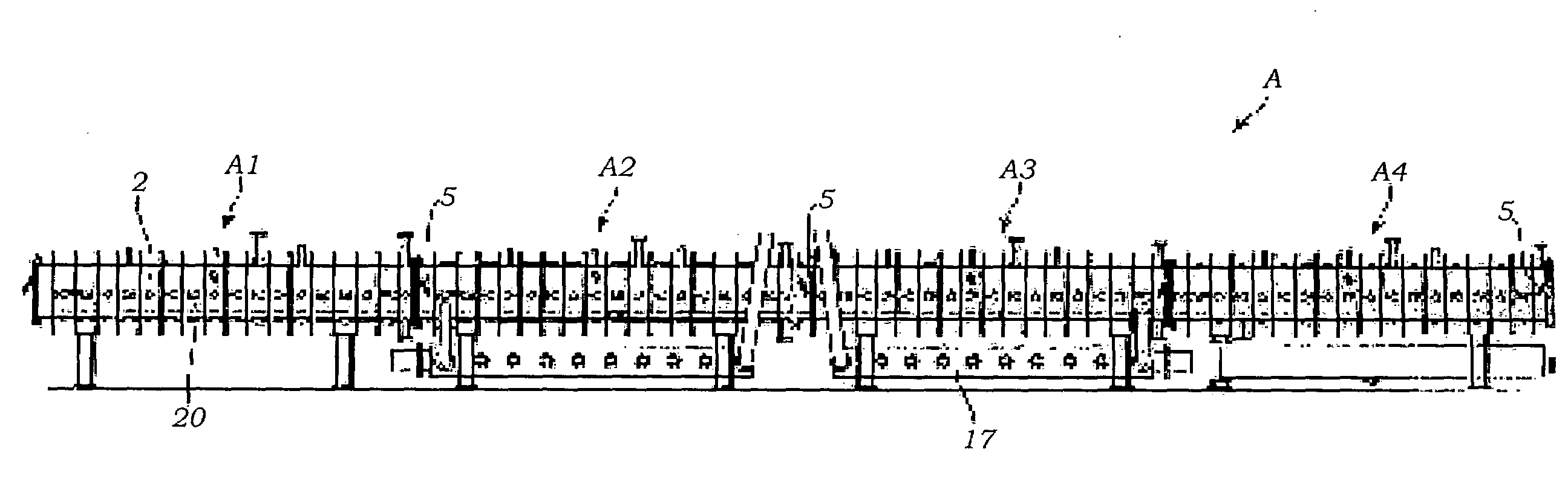

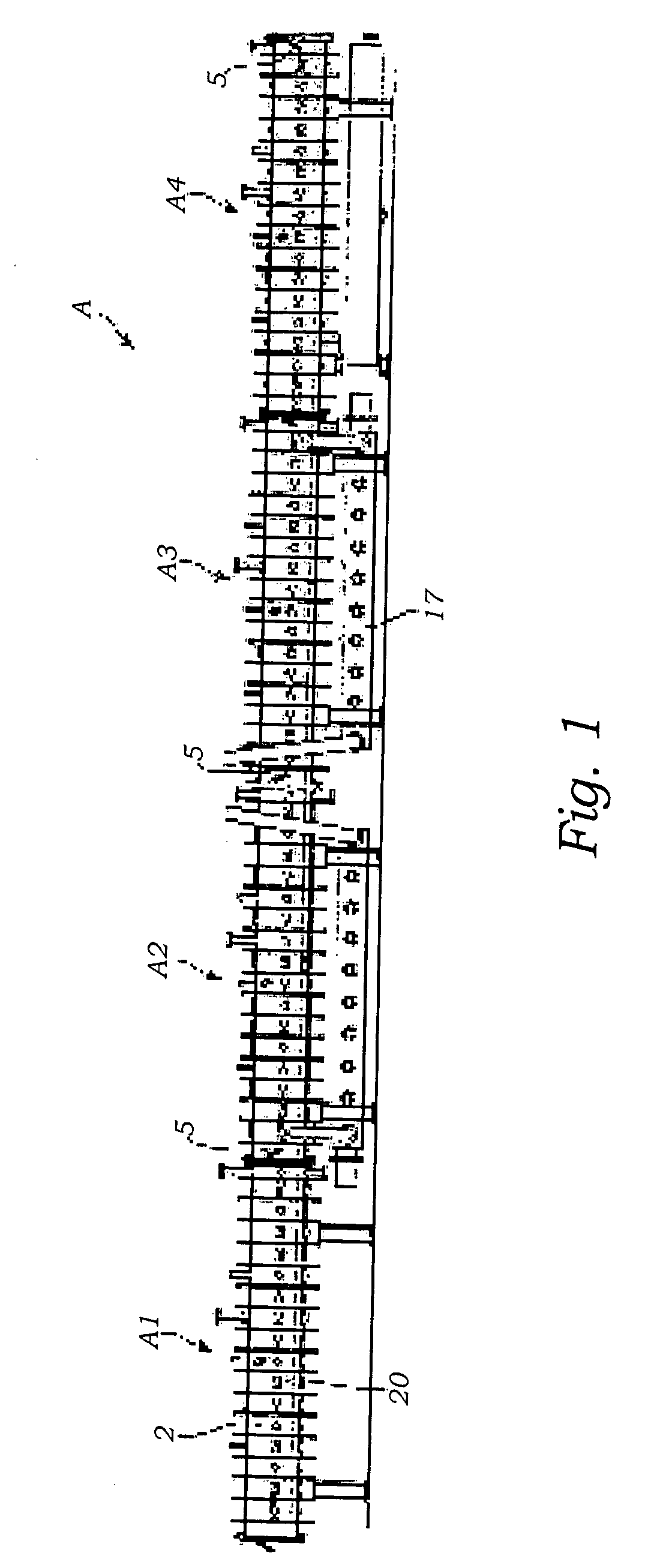

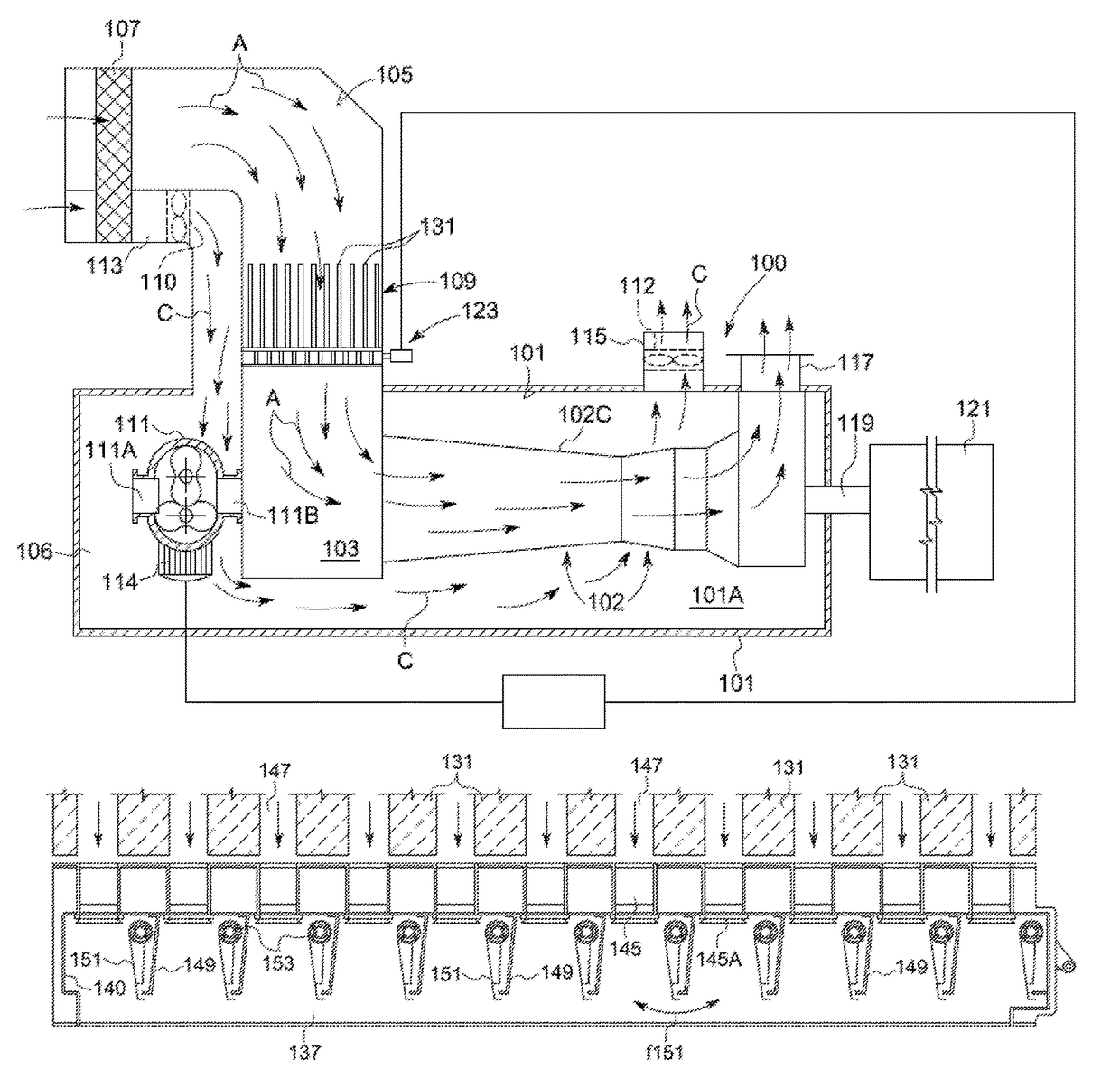

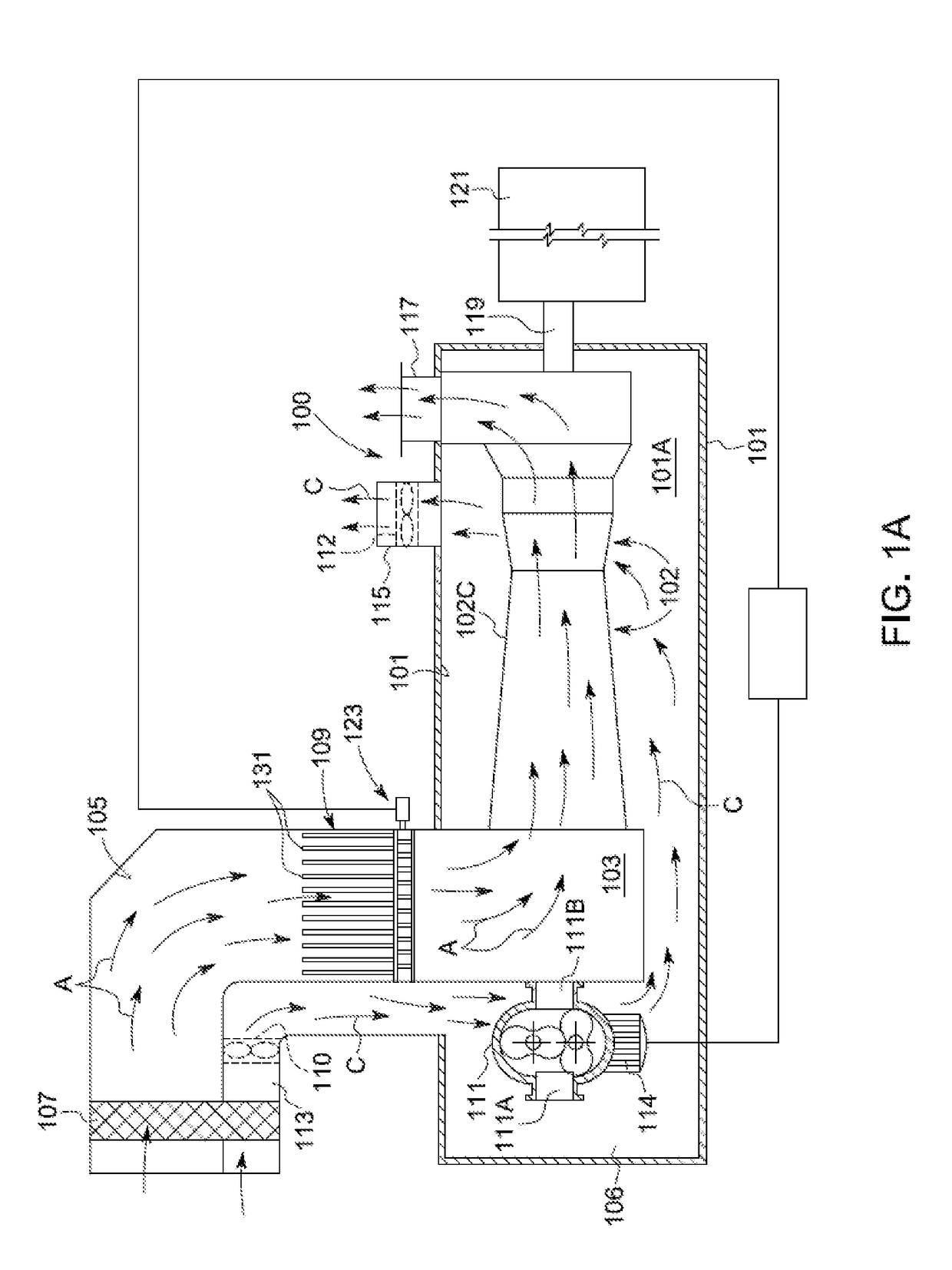

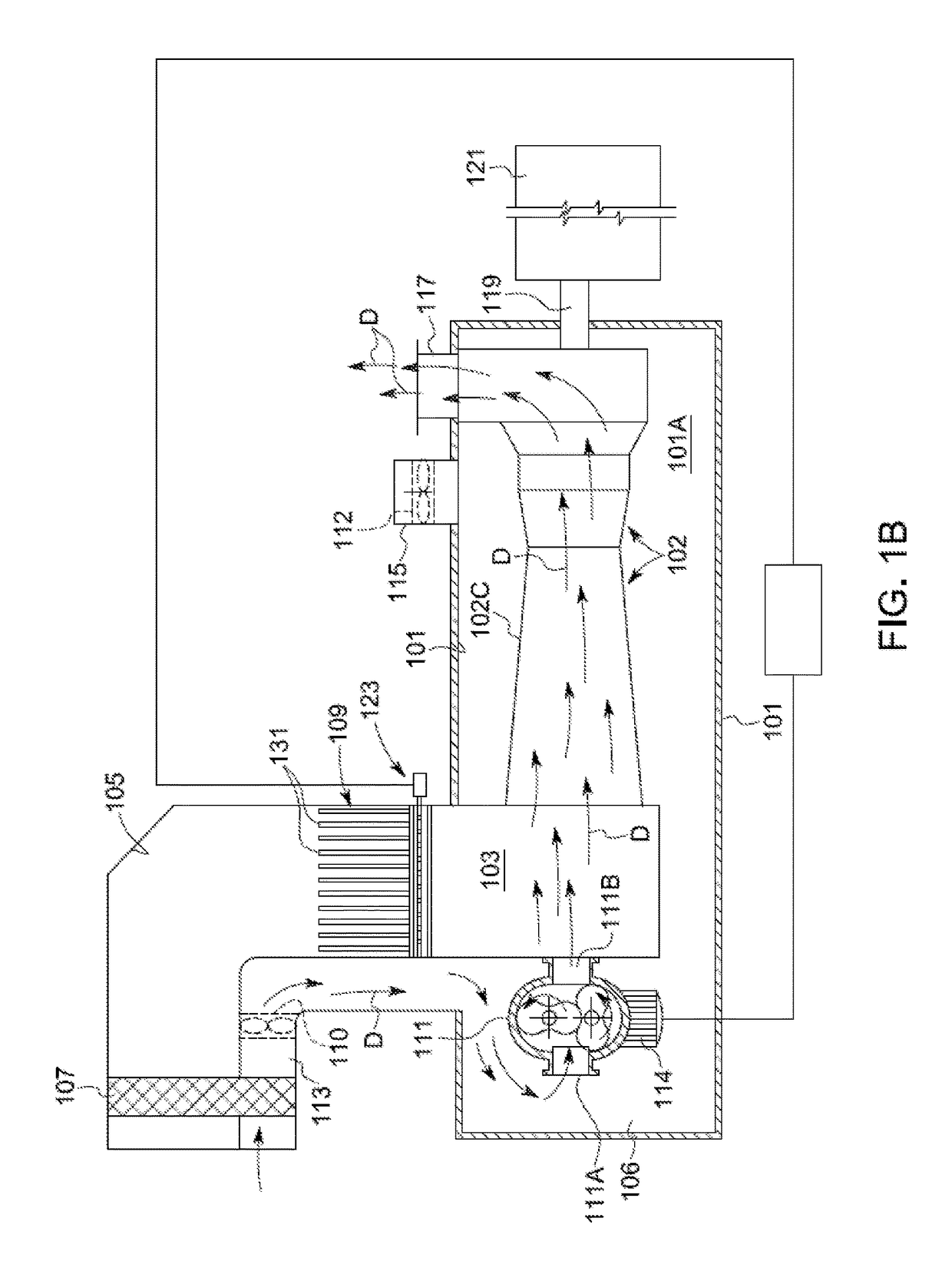

Tunnel for conditioning of products, especially for sterilization of food in prepackaged containers

ActiveUS20090283517A1Reduce maintenanceIncreases useful treatment capacityDough treatmentDisinfectionControl systemClosed loop

Tunnel is provided for conditioning of food products, especially for sterilization of food in containers or vessels of the heat-sealed type, in which the conditioning unit has: 1) an active temperature and pressure control system provided in at least one magnetron supported heating stage, which provides for balancing of the pressure within the heat-sealed vessels or containers; 2) a conveyor which conveys the heat-sealed vessels or containers through the stages along the conditioning unit which contains mechanisms that move the conveyor outside of the conditioning tunnel, and 3) doors operating like check valves that separate the conditioning stages, but still provide for continuous linear feed of products through conditioning tunnel. In preferred embodiment, the conditioning tunnel in includes a plurality temperature sensors, such as linear pyrometers for measuring the temperature of for mapping the temperature of products within the tunnel Moreover, preferably the conveyor is adjustable to move forward and rearward, and the magnetrons, which preferably operate at approximately 915 Mhz and 2400 Mhz, are adjustable to provide a controllable movement and amplitude. A controller is connected to the temperature sensors, conveyor and magnetrons to cause the conveyor to move products forward or rearward, or cause the magnetrons to move the magnetic field relative to the food products to more thoroughly and evenly cook the food products. Movement of the magnetron electromagnetic field and / or conveyor is controlled by software which utilizes the temperature and / or density measurements in a closed loop process to ensure uniform heating of the products.

Owner:MACKAY JEFFREY H +3

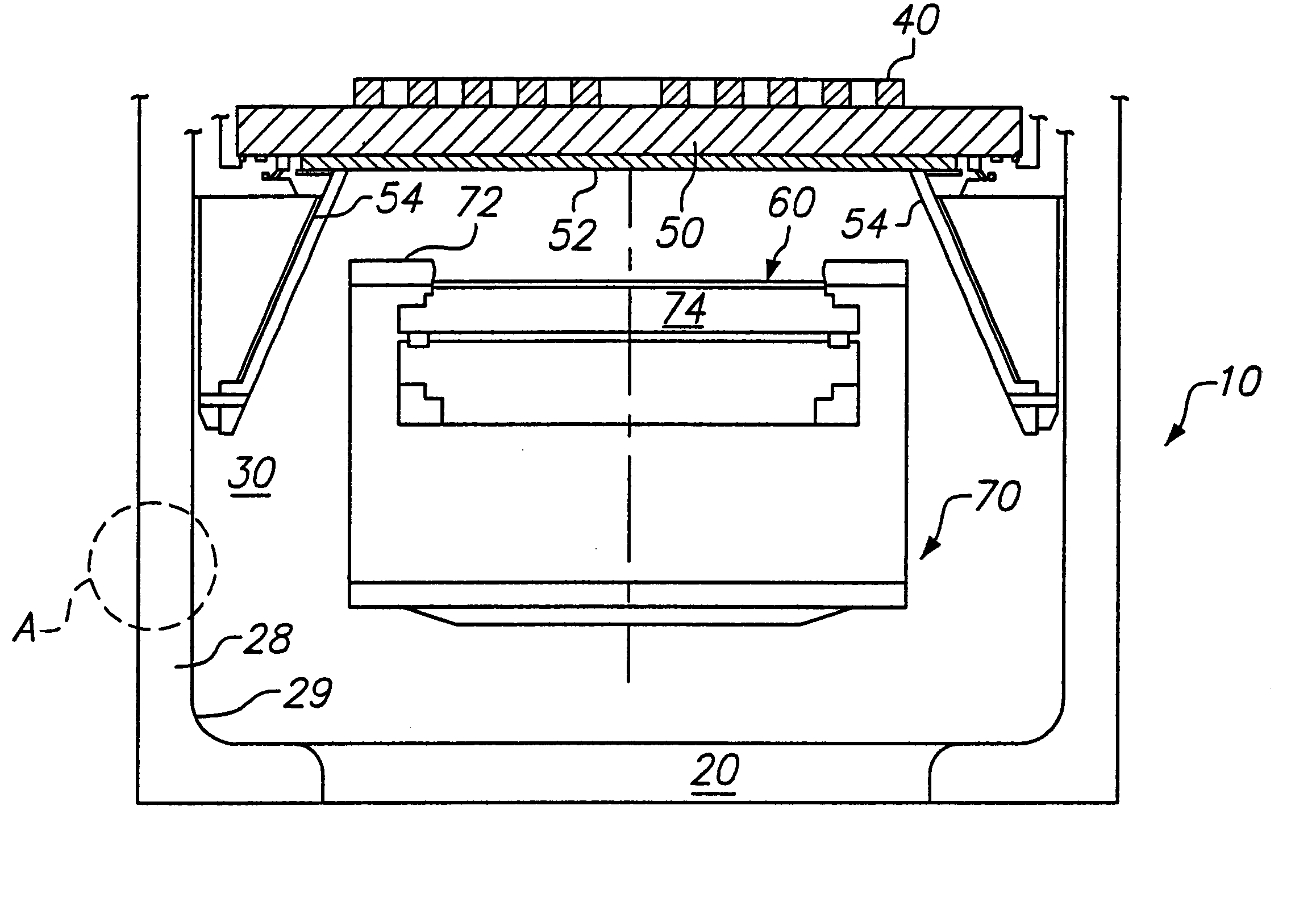

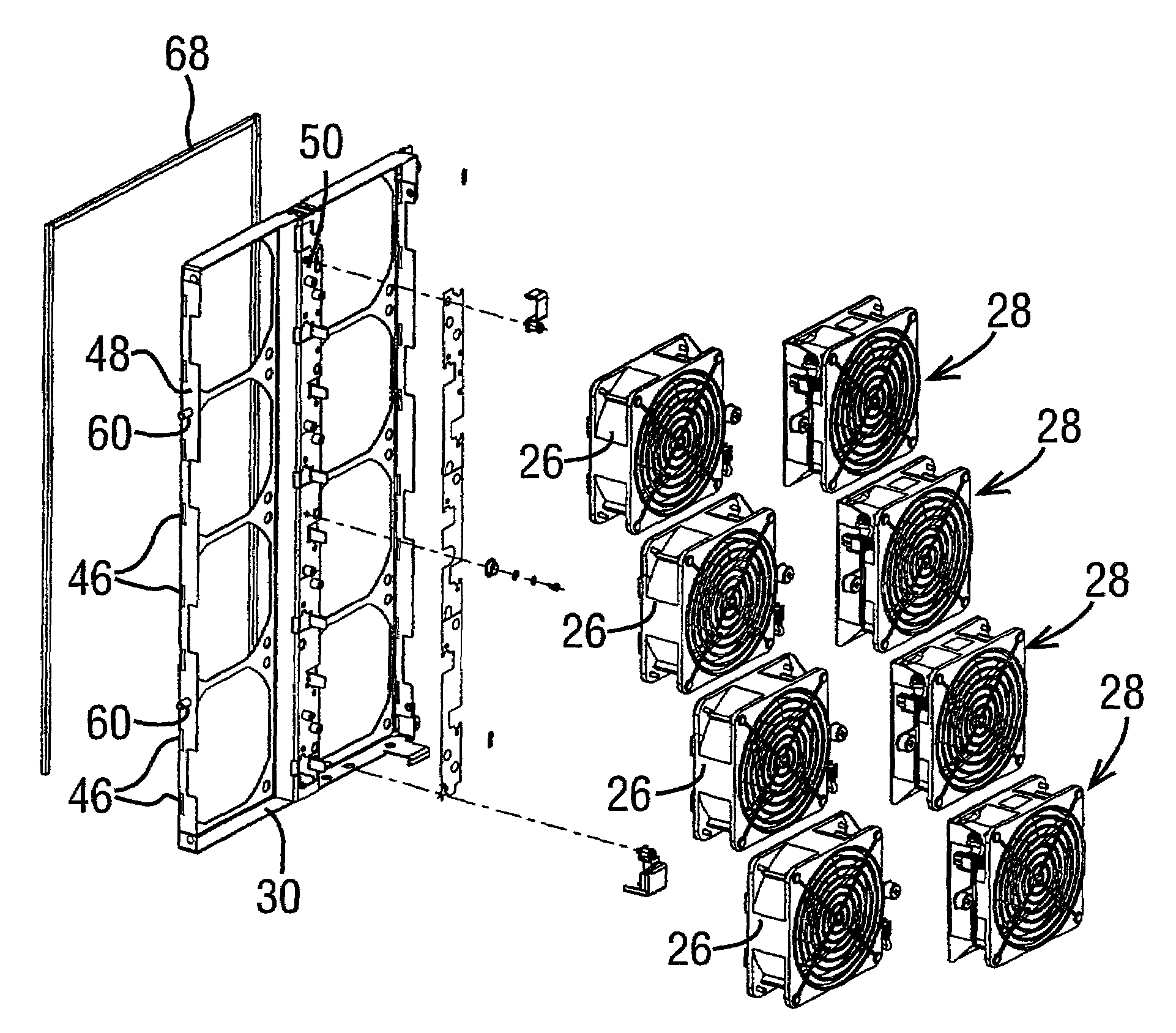

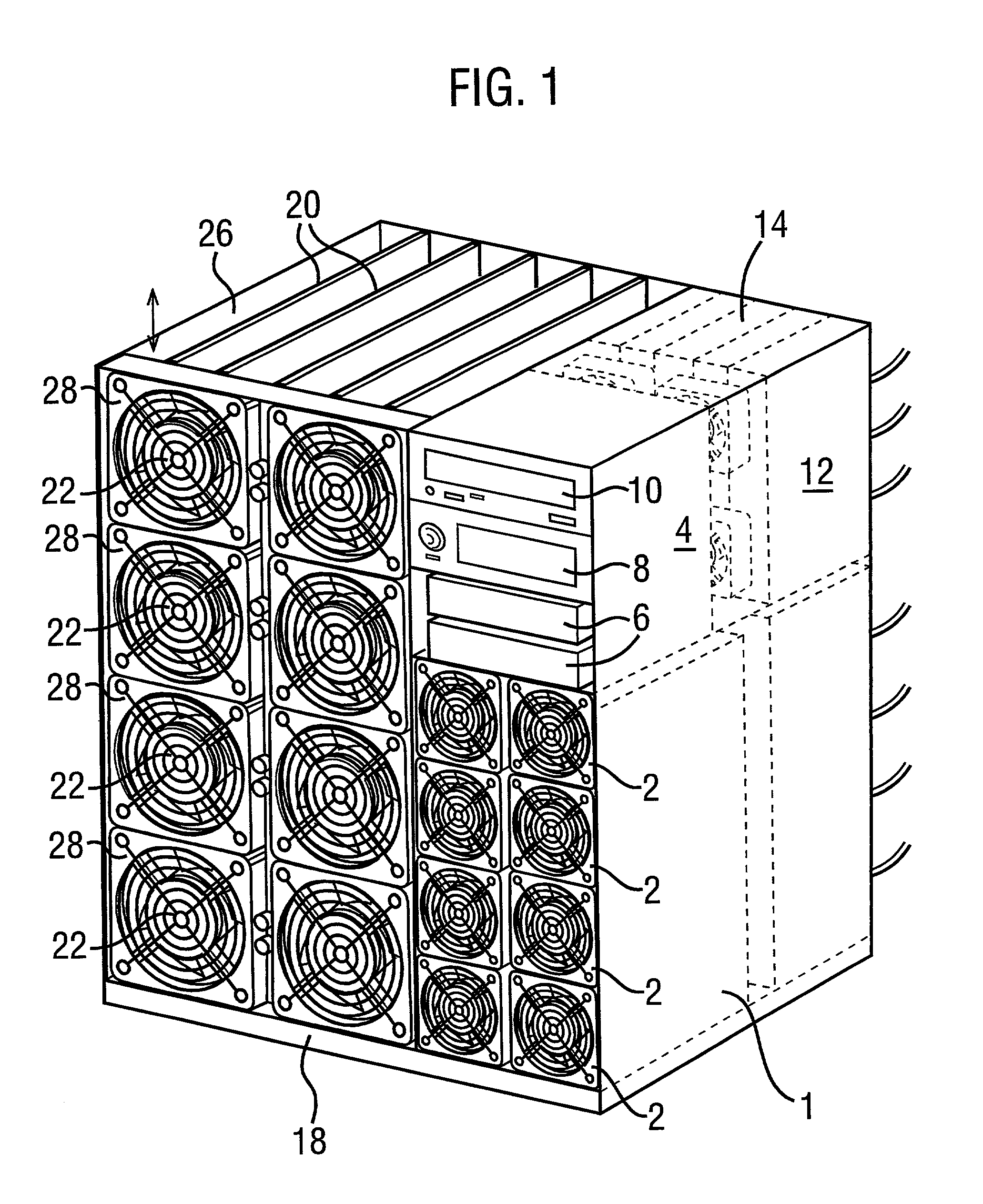

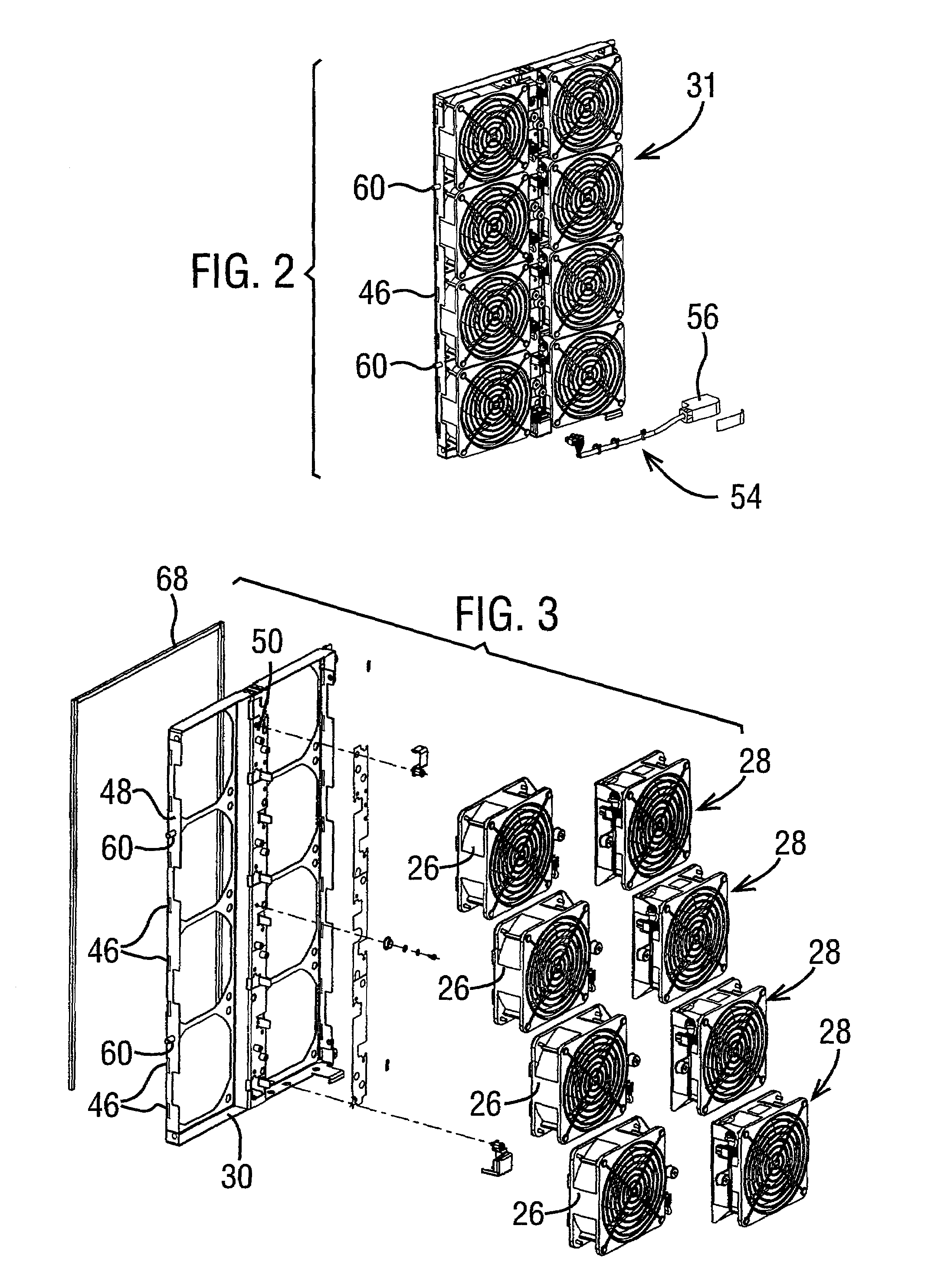

Electronics assembly

InactiveUS6961248B2Prevent and reduce bypass leakage of airReduce and prevent air leakageElectrically conductive connectionsPump componentsElectronic assembliesElectronics

A chassis for an electronics assembly comprises:(i) a frame (1); and(ii) a panel (31) located on a face of the frame, the panel comprising a plurality of cooling fans (22) and a holder (30) for the fans.The panel allows removal of individual fans from the panel and replacement of any fans while the panel is located on the frame, and the frame allows removal of the panel therefrom and replacement of the panel. The chassis thus allows replacement of any fans without the assembly being shut down, and also reduces downtime of the assembly if all the fans need replacing, for example for maintenance.

Owner:SUN MICROSYSTEMS INC

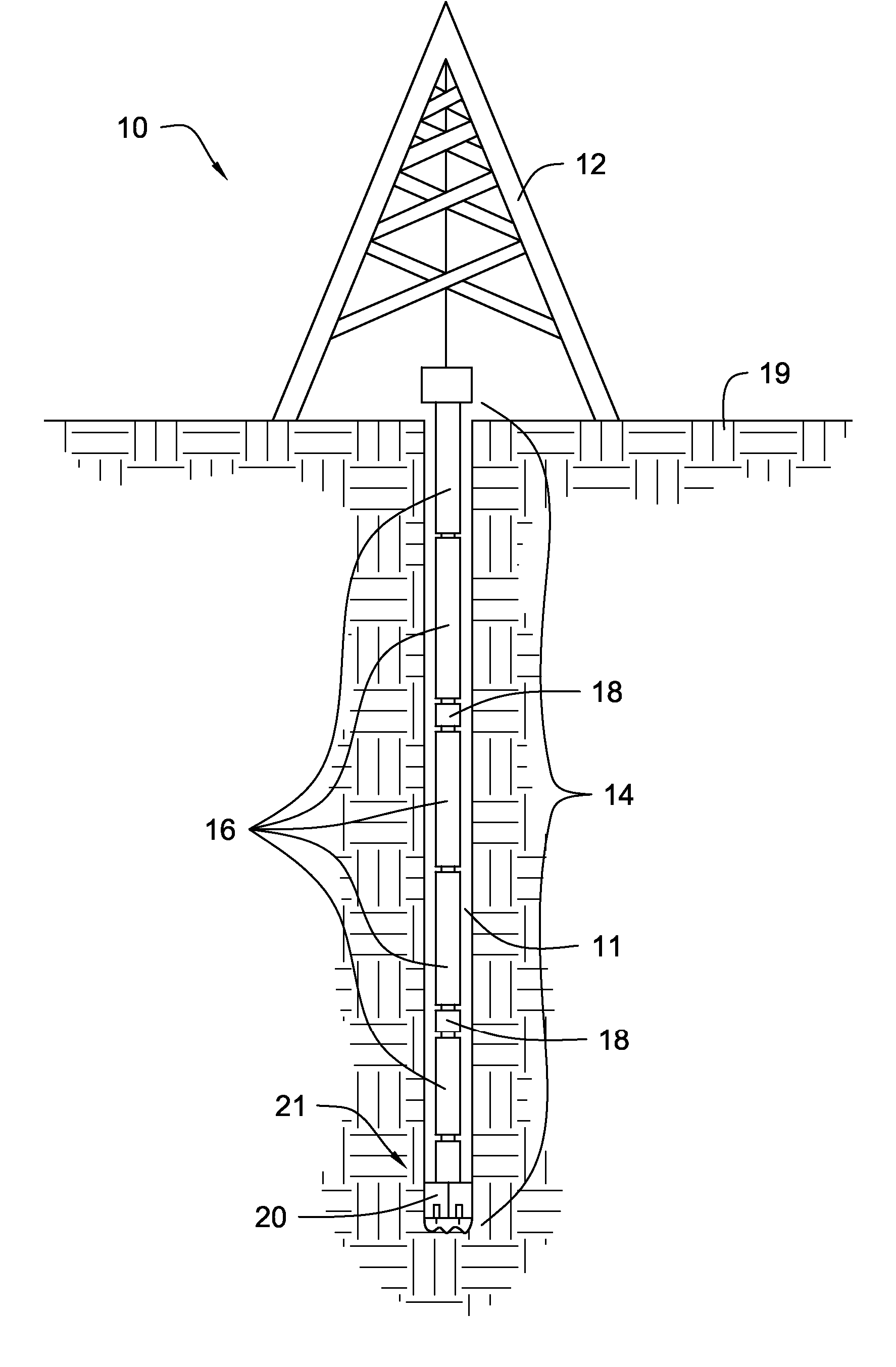

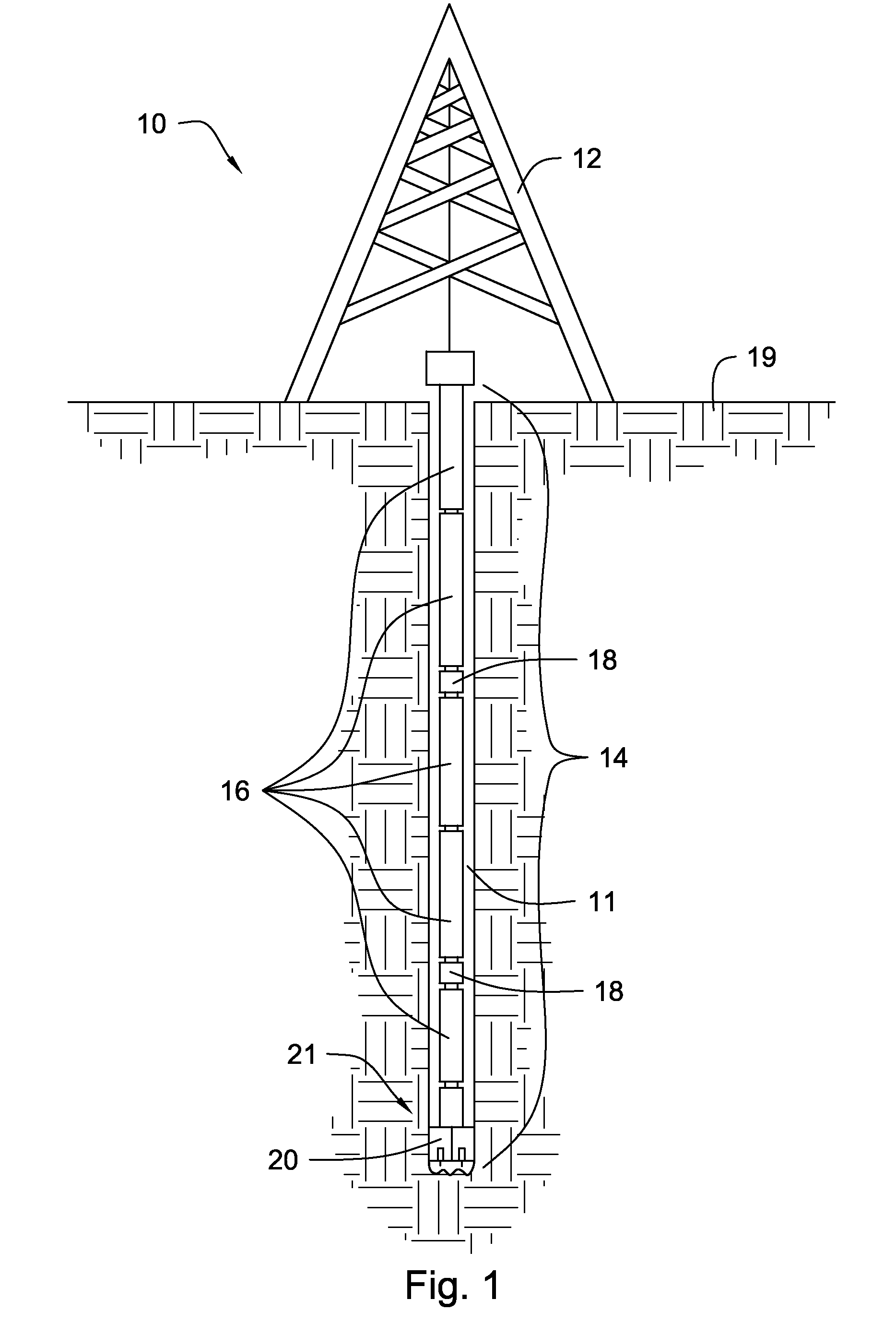

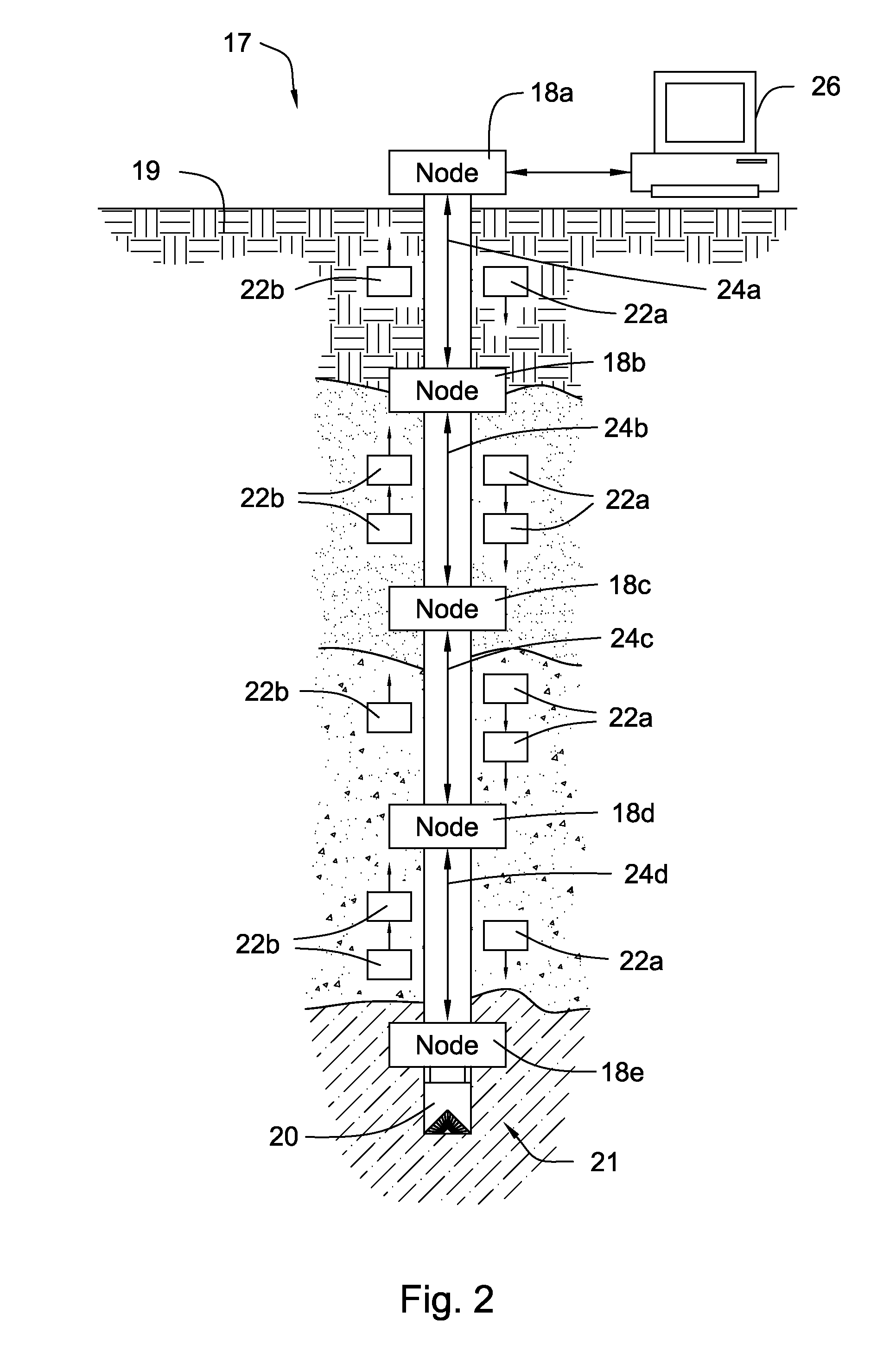

High-speed, Downhole, Cross Well Measurement System

InactiveUS20060221768A1Minimizing drill rig down timeIncrease speedSurveySeismology for water-loggingEngineeringSignal source

In one aspect of the invention, a high-speed measurement system has a first and a second well bore. A first and second plurality of network nodes is integrated into and spaced at intervals along the first and second well bore, respectively. A communications channel connects each plurality of network nodes forming a first and second downhole network. A signal source is in communication with the first downhole network and a signal receiver is in communication with the second downhole network; and a common clock source is in communication with both the signal source and the signal receiver over the first and second downhole networks, respectively. The signal source and signal receiver are synchronized with the clock source and the signal source is adapted to send a signal to the signal receiver through a subterranean formation.

Owner:SCHLUMBERGER TECH CORP

Device and method for gas turbine unlocking

ActiveUS9845730B2Shorten the timeReduce downtimePump componentsTurbine/propulsion engine coolingAviationCombustor

An aeroderivative gas turbine including an air intake plenum; a compressor with a compressor air intake in fluid communication with the air intake plenum; a combustor; a high pressure turbine; a power turbine. A forced air-stream generator is arranged in fluid communication with the air intake plenum. A shutter arrangement is provided in a combustion-air flow path, arranged and controlled to close the combustion-air flow path for pressurizing said air intake plenum by means of the forced air-stream generator to a pressure sufficient to cause pressurized air to flow through the aeroderivative air turbine.

Owner:NUOVO PIGNONE TECH SRL

Method and System for Management of Operating-Room Resources

ActiveUS20090125337A1Improve overall utilizationReduce operating costsMechanical/radiation/invasive therapiesData processing applicationsModularityPatient data

A computer-implemented method for managing operating-room resources in a hospital includes the steps of receiving at least one surgery request, identifying the resources required for surgery associated with the surgery request, capturing initial data on availability of the resources, capturing initial patient data, and establishing a pre-scheduled operating-room plan based on an initial optimization, and the further steps of capturing current data on availability of the resources, capturing current patient data and establishing a current operating-room plan based on a current optimization. A computer-based system for managing operating-room resources in a hospital and a modular computer-based system for managing operating-room related processes in a hospital are also disclosed.

Owner:KARL STORZ GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com