Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1176results about "Machining electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

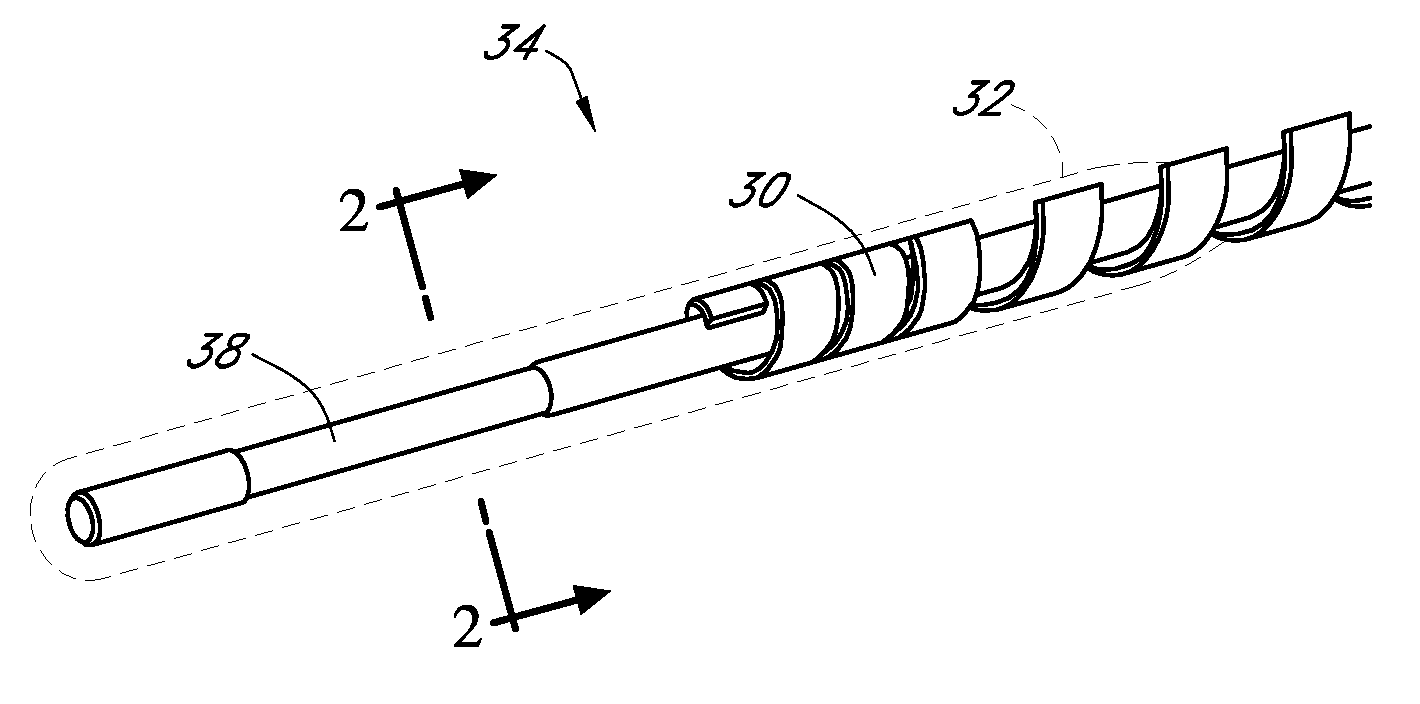

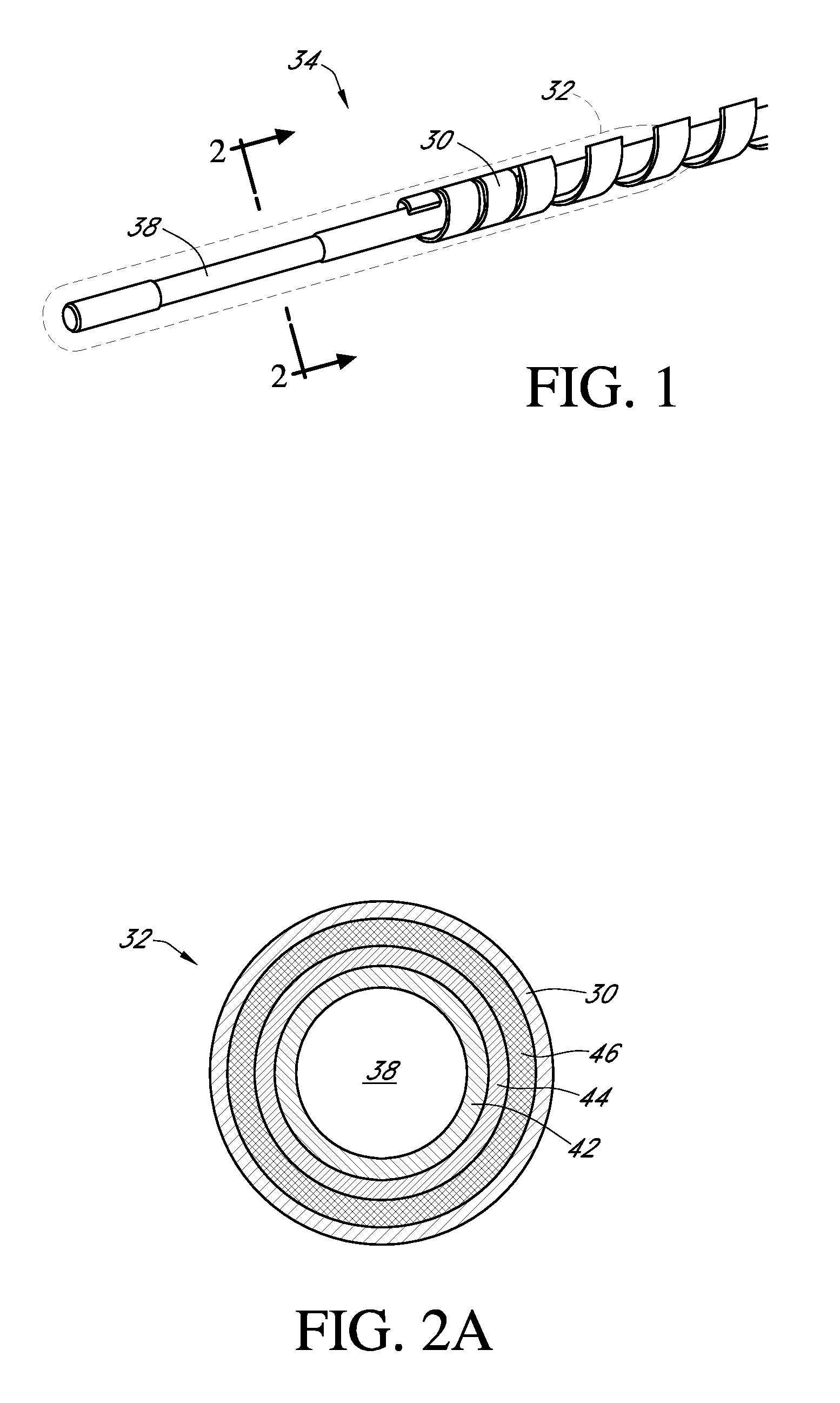

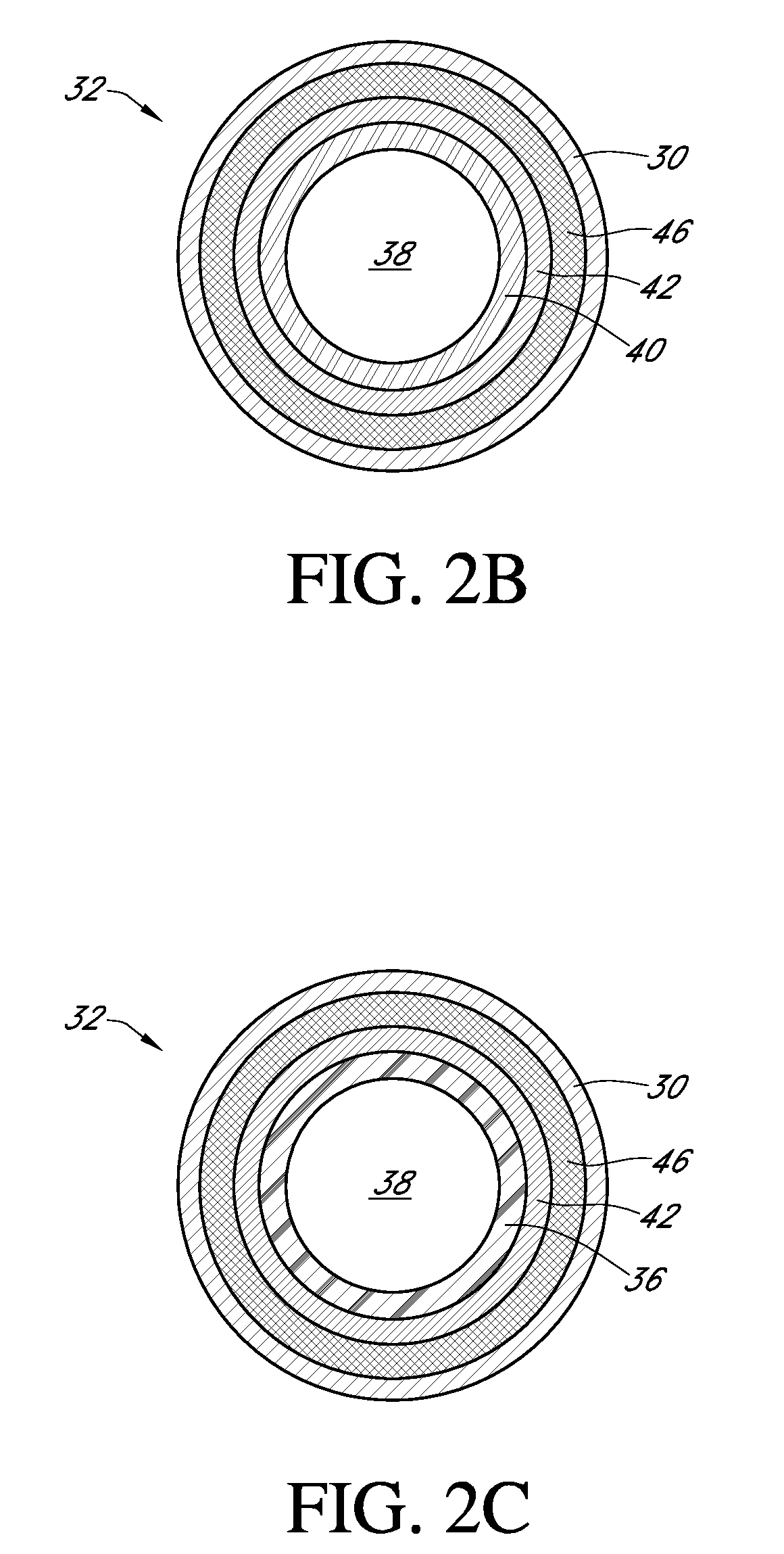

Polymer membranes for continuous analyte sensors

InactiveUS20100096259A1Machining electrodesMicrobiological testing/measurementContinuous measurementAnalyte

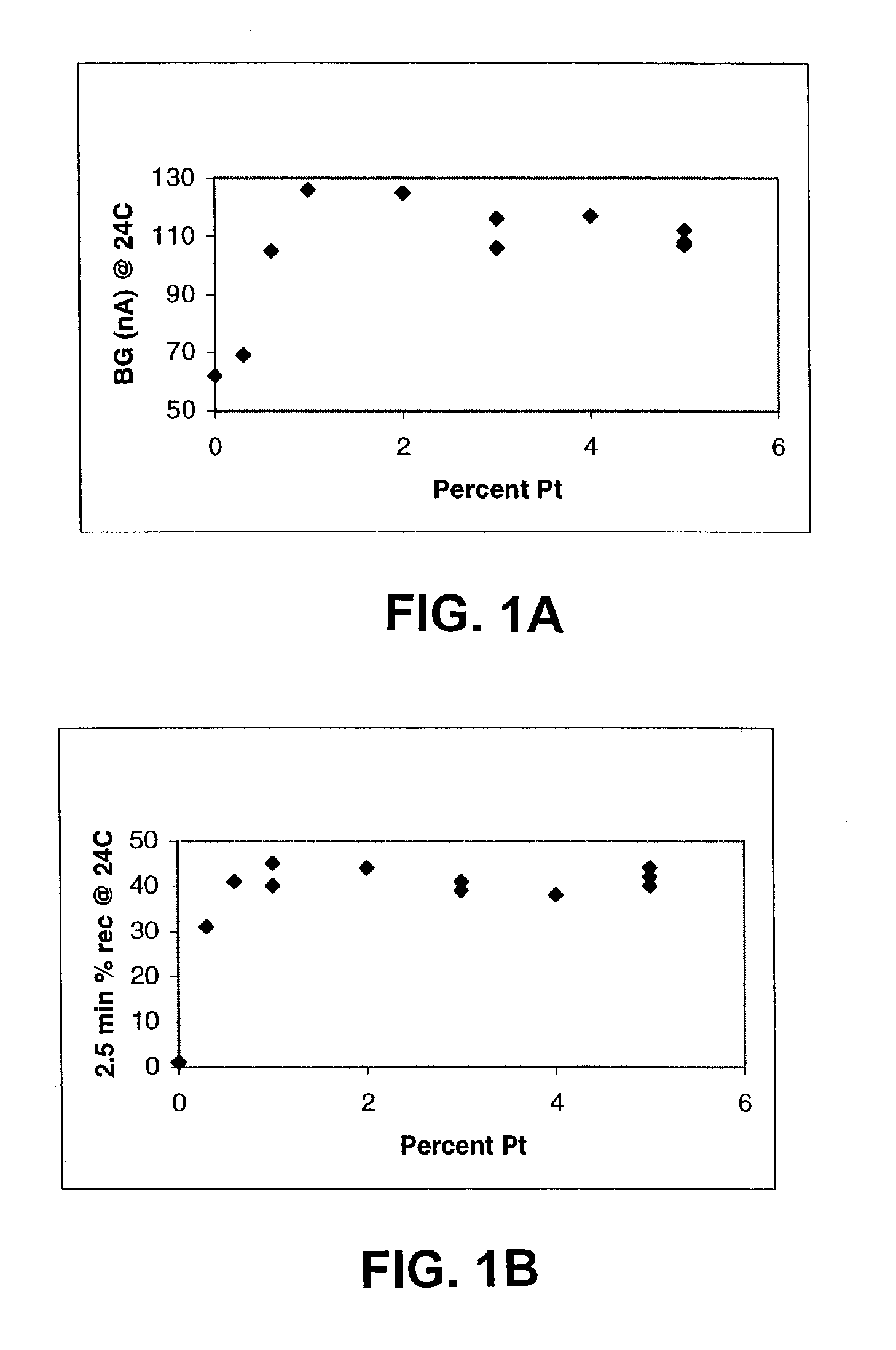

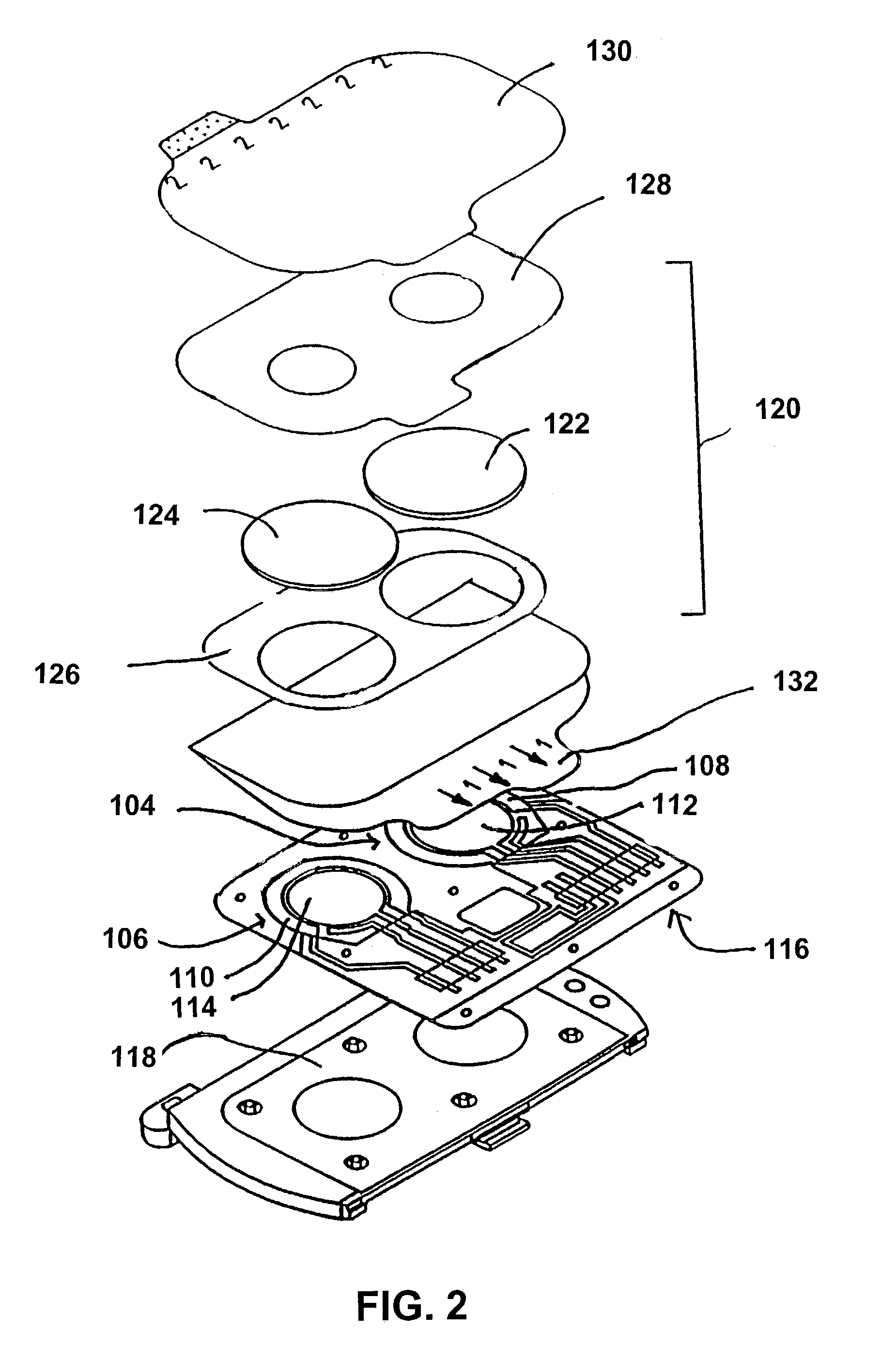

Devices and methods are described for providing continuous measurement of an analyte concentration. In some embodiments, the device has a sensing mechanism and a sensing membrane that includes at least one surface-active group-containing polymer and that is located over the sensing mechanism. The sensing membrane may have a bioprotective layer configured to substantially block the effect and / or influence of non-constant noise-causing species.

Owner:DEXCOM

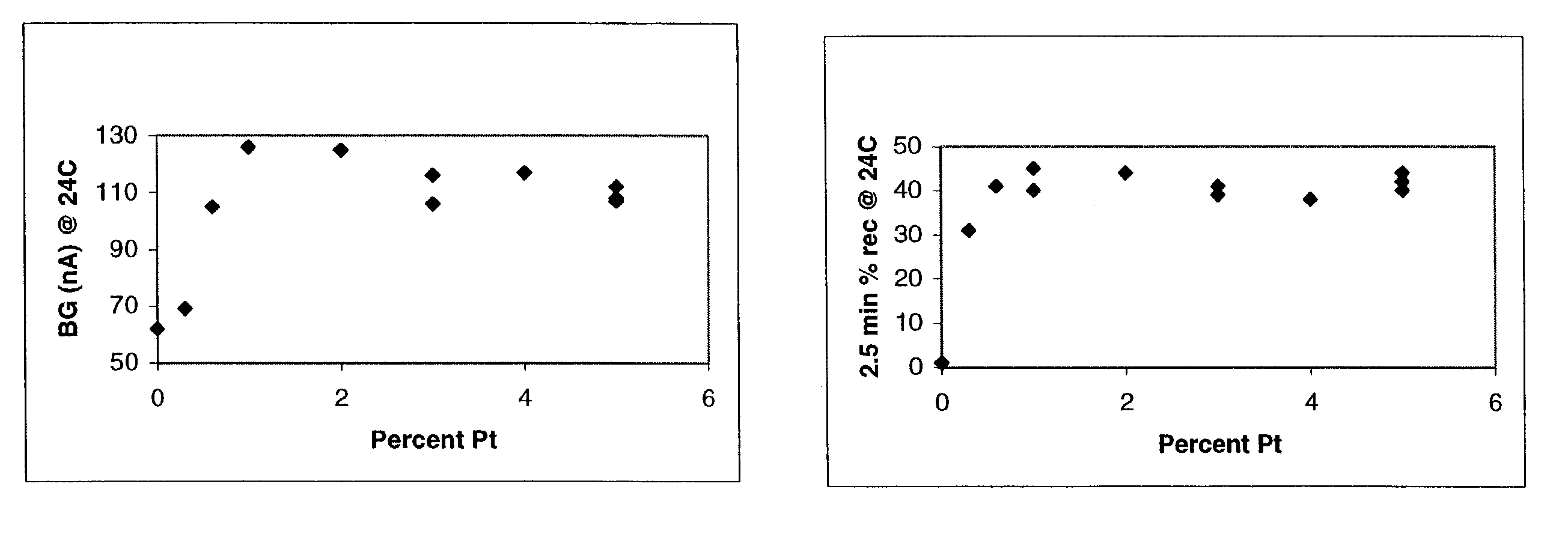

Highly catalytic screen-printing ink

ActiveUS7018568B2Easy to produceConductive layers on insulating-supportsConductive materialConductive polymerPrinting ink

The invention is directed to conductive polymer compositions, catalytic ink compositions (e.g., for use in screen-printing), electrodes produced by deposition of an ink composition, methods of making, and methods of using thereof. An exemplary ink material comprises platinum black and / or platinum-on-carbon as the catalyst, graphite as a conducting material, a polymer binding material, and an organic solvent. The polymer binding material is typically a copolymer of hydrophilic and hydrophobic monomers. The conductive polymer compositions of the present invention can be used, for example, to make electrochemical sensors. Such sensors can be used in a variety of analyte monitoring devices to monitor analyte amount or concentrations in subjects, for example, glucose monitoring devices to monitor glucose levels in subjects with diabetes.

Owner:LIFESCAN IP HLDG LLC +1

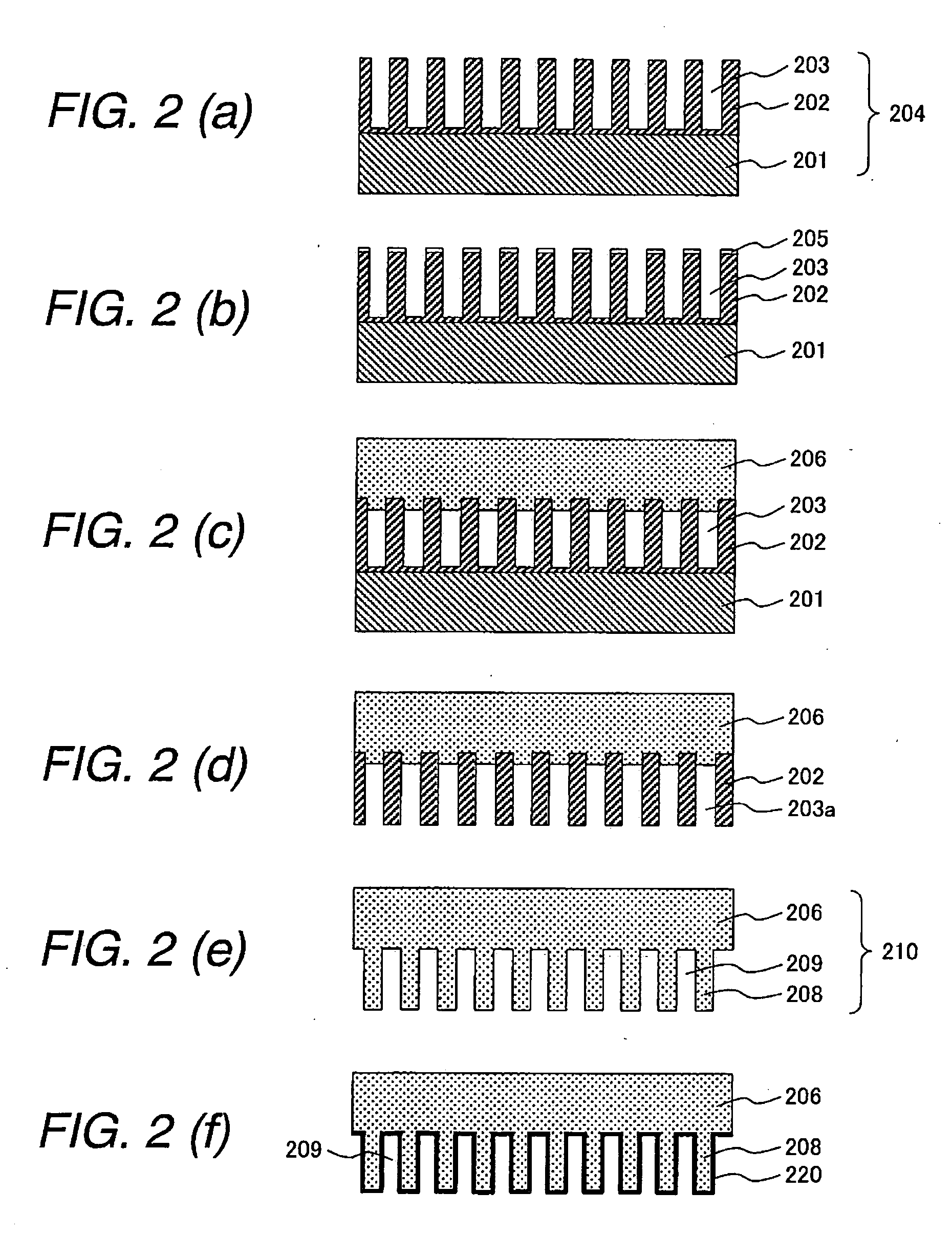

Release system for electrochemical cells

InactiveUS20110068001A1Active material electrodesElectrical-based machining electrodesEngineeringElectrochemical cell

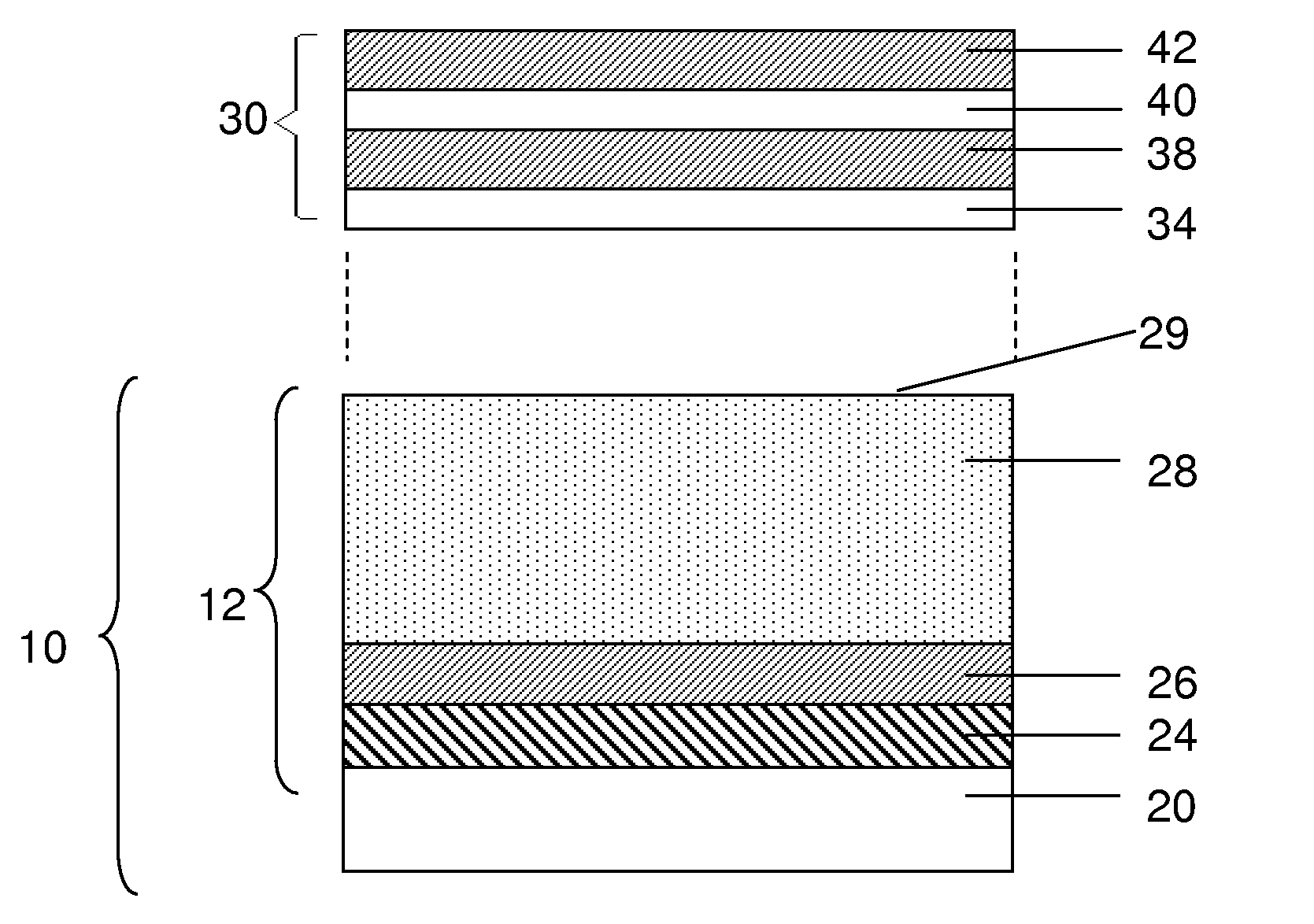

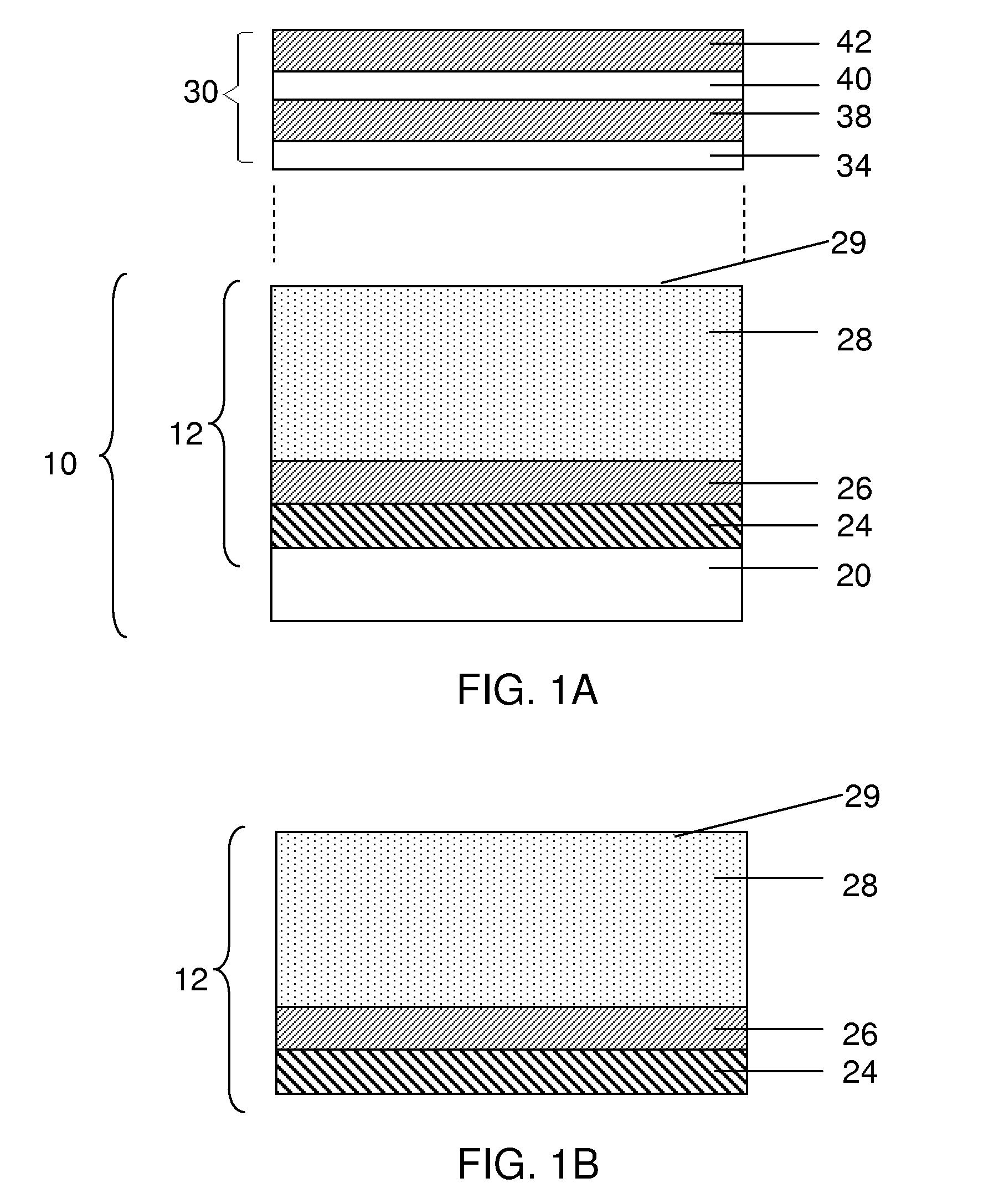

Electrochemical cells, and more specifically, release systems for the fabrication of electrochemical cells are described. In particular, release layer arrangements, assemblies, methods and compositions that facilitate the fabrication of electrochemical cell components, such as electrodes, are presented. In some embodiments, methods of fabricating an electrode involve the use of a release layer to separate portions of the electrode from a carrier substrate on which the electrode was fabricated. For example, an intermediate electrode assembly may include, in sequence, an electroactive material layer, a current collector layer, a release layer, and a carrier substrate. The carrier substrate can facilitate handling of the electrode during fabrication and / or assembly, but may be released from the electrode prior to commercial use.

Owner:SION POWER CORP

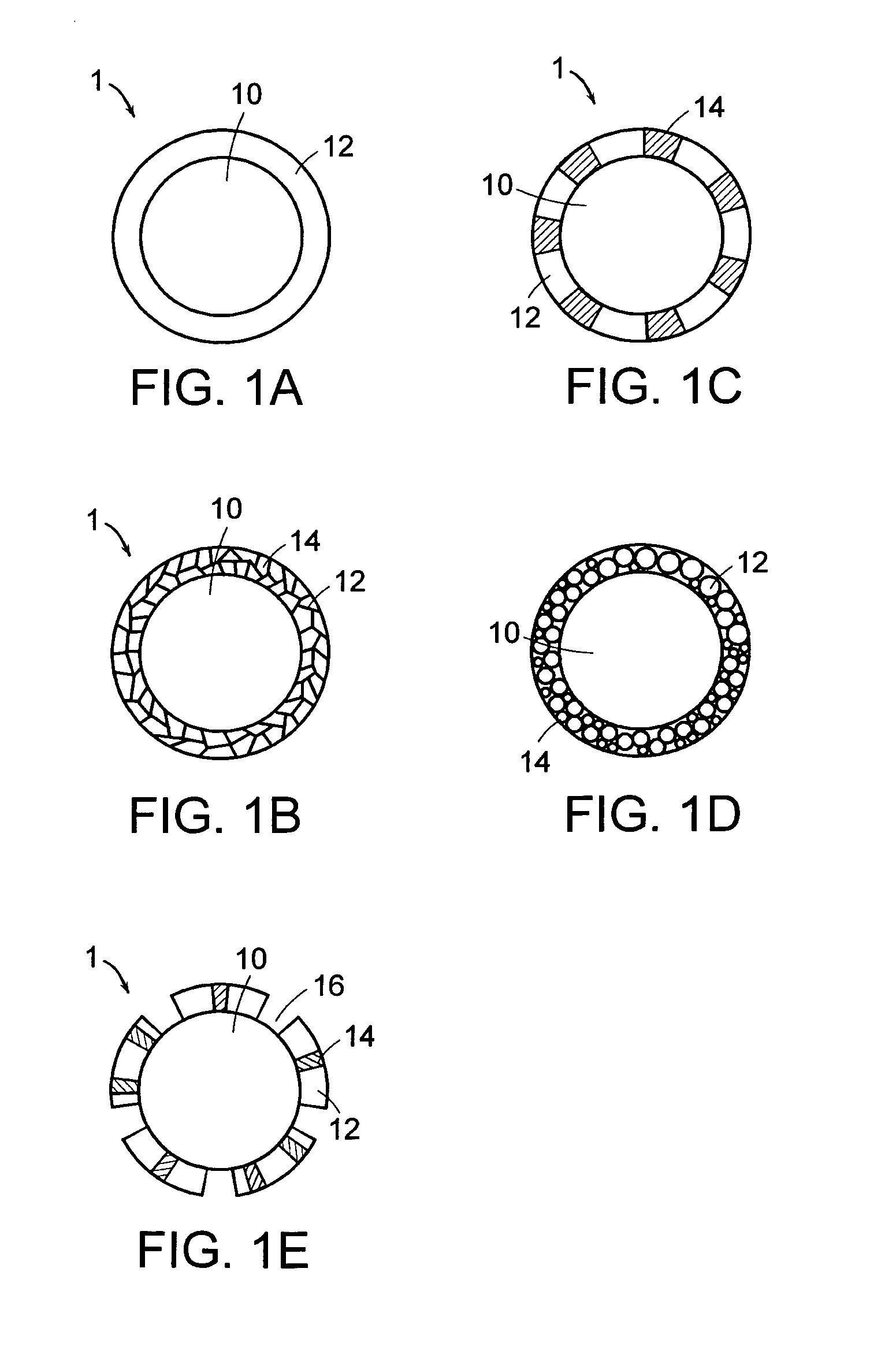

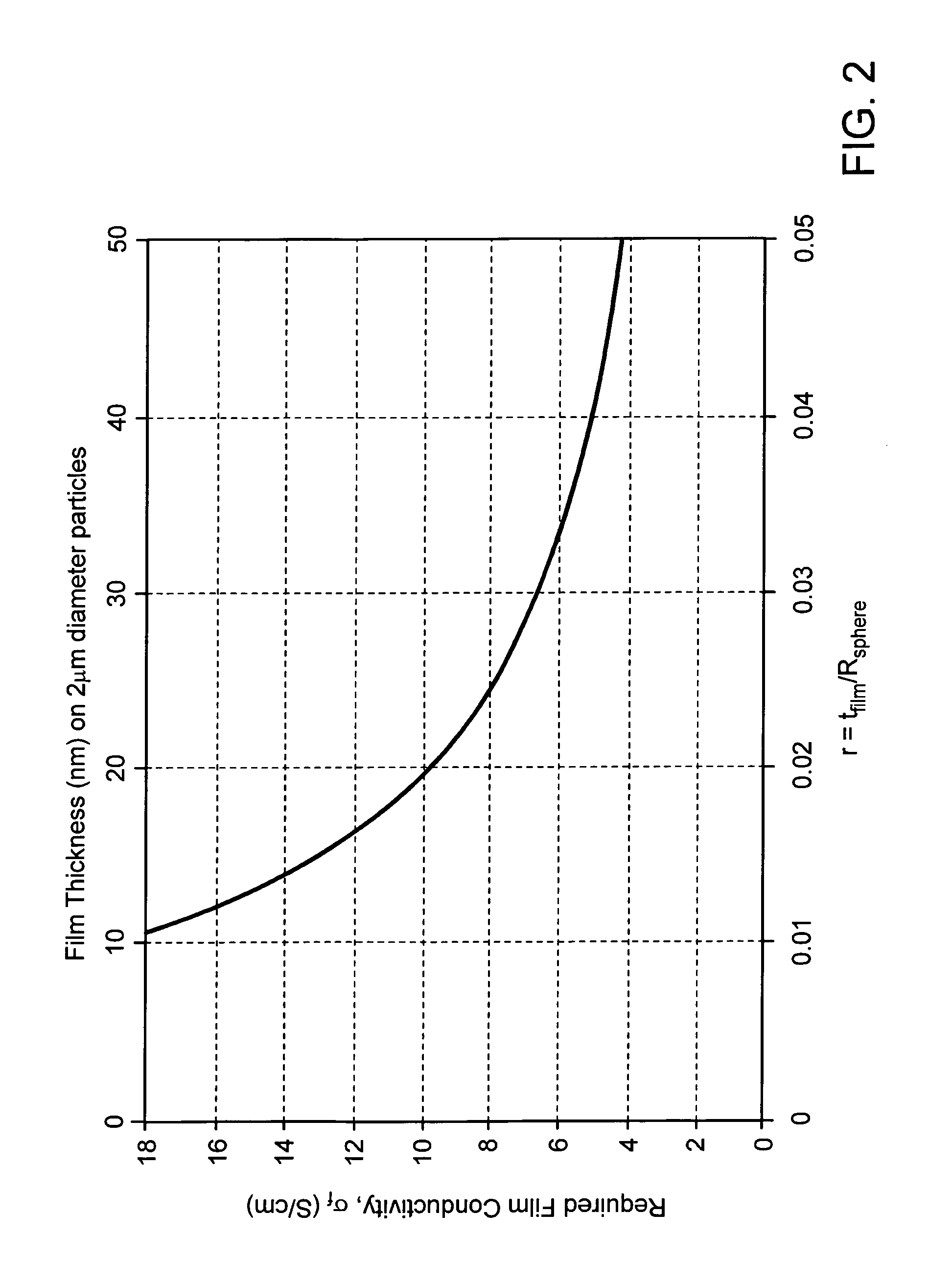

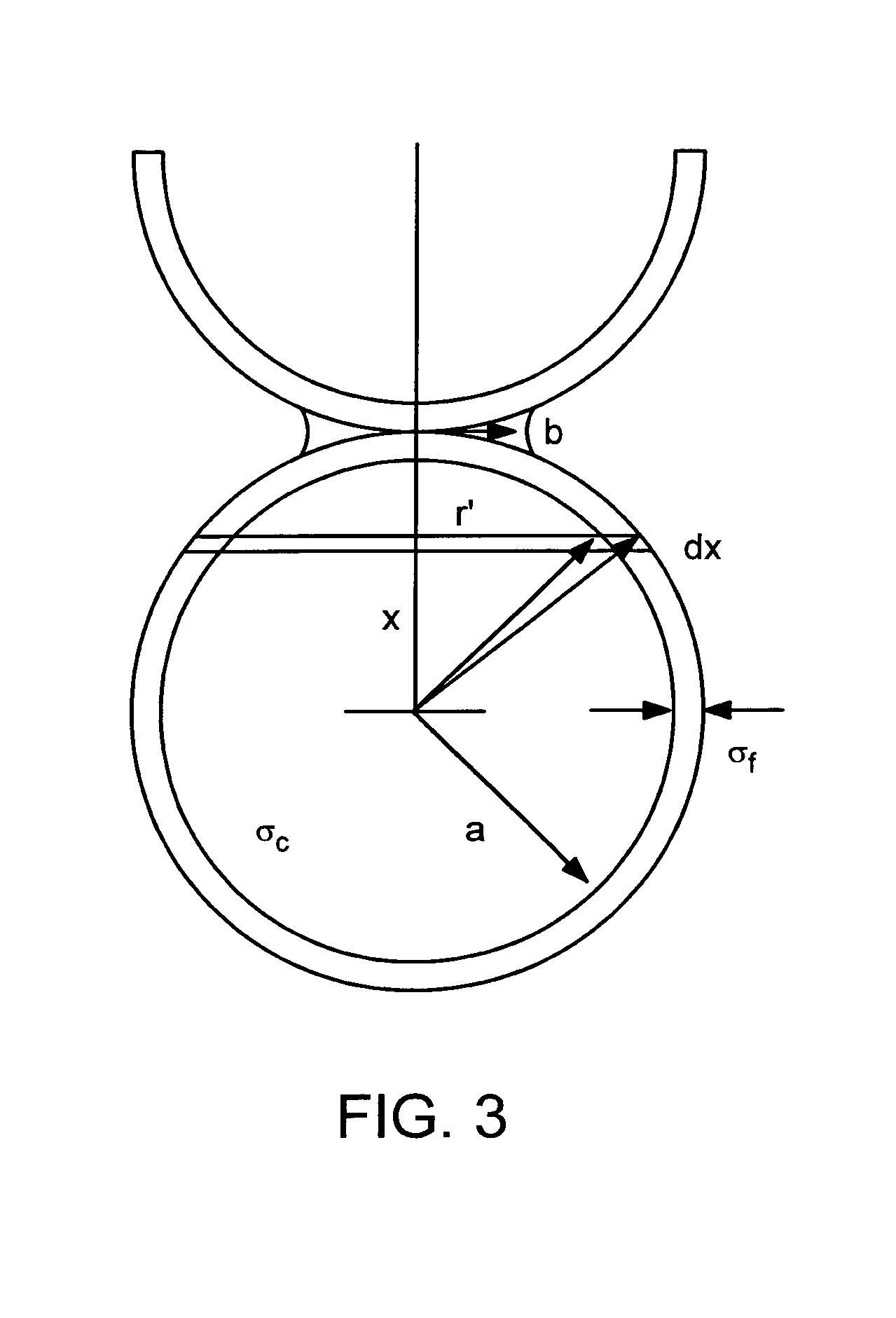

Coated electrode particles for composite electrodes and electrochemical cells

InactiveUS7087348B2Precise positioningImprove conductivityMachining electrodesHybrid capacitor electrodesComposite electrodeRefractive index

Electrodes for use in electrochemical devices are disclosed. More particularly coated electrode particles for use in solid electrochemical cells and materials and systems for improving electronic conductivity and repulsive force characteristics of an electrode network are disclosed. An article containing a plurality of distinct first particles that form an electrode network in which the distinct first particles are coated with a system of electrically conductive material is also disclosed. In some embodiments, the coating layer also includes a low refractive index material. In some embodiments, the coating layer of the electroactive material includes a plurality of second particles.

Owner:A123 SYSTEMS LLC

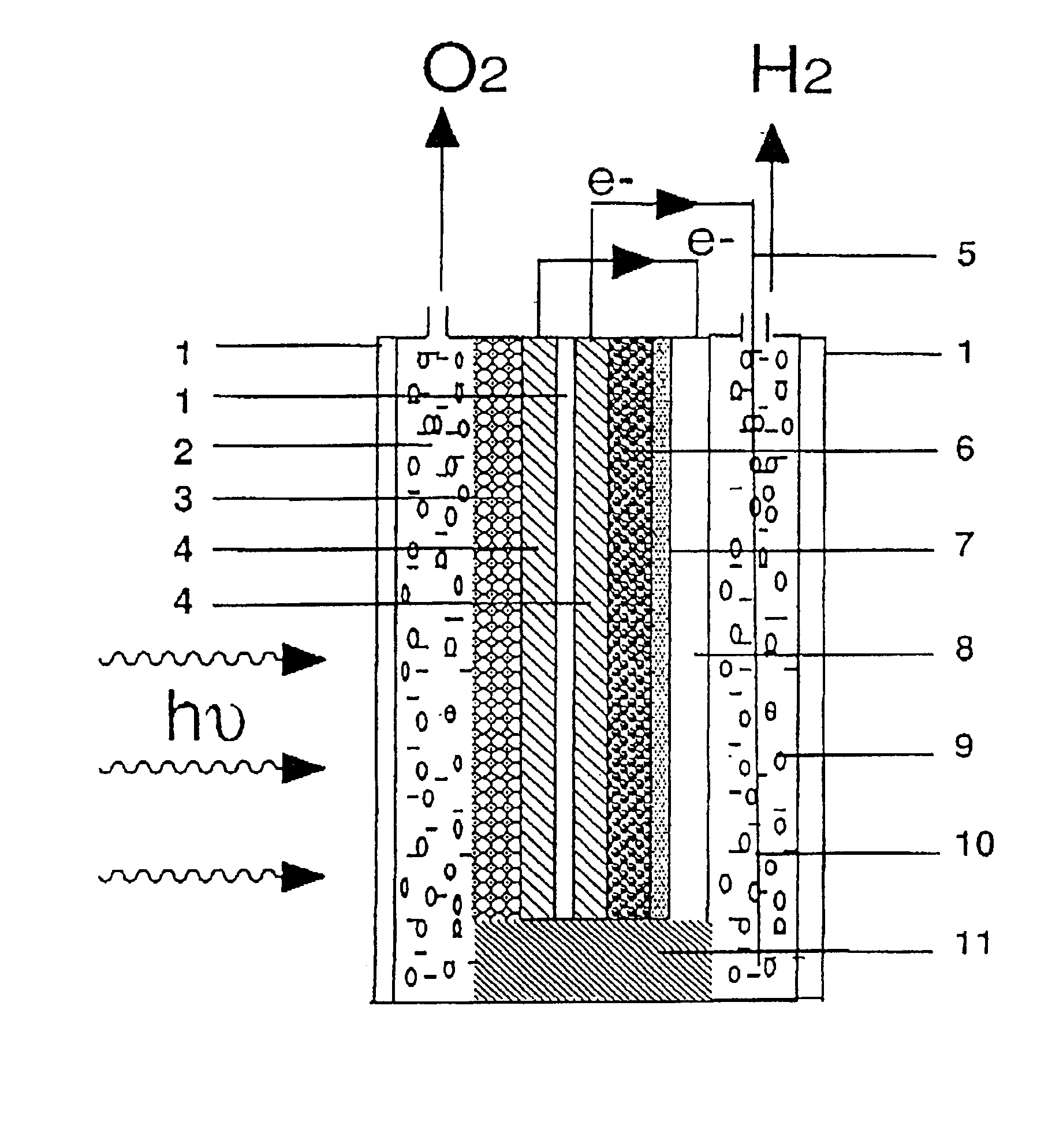

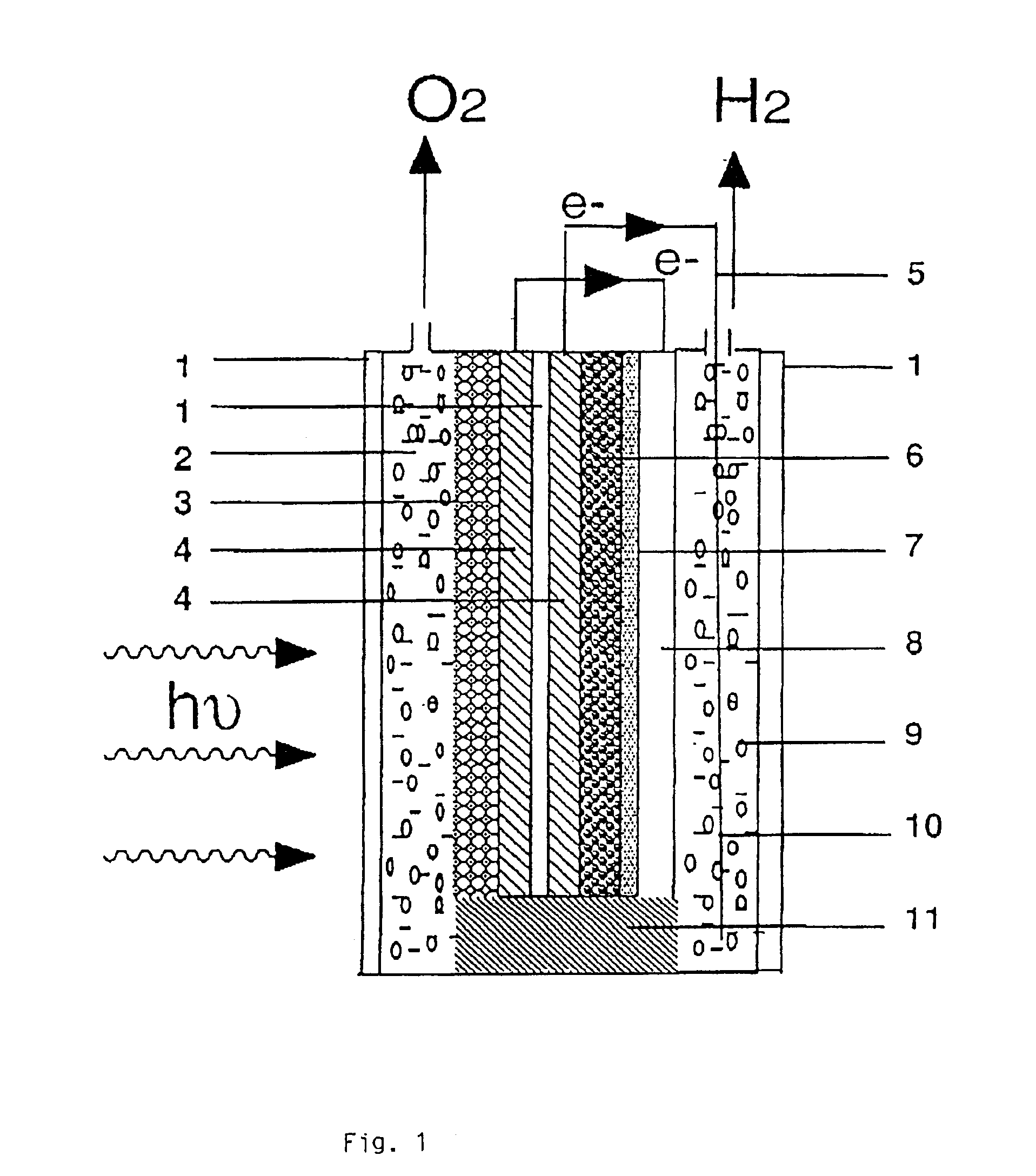

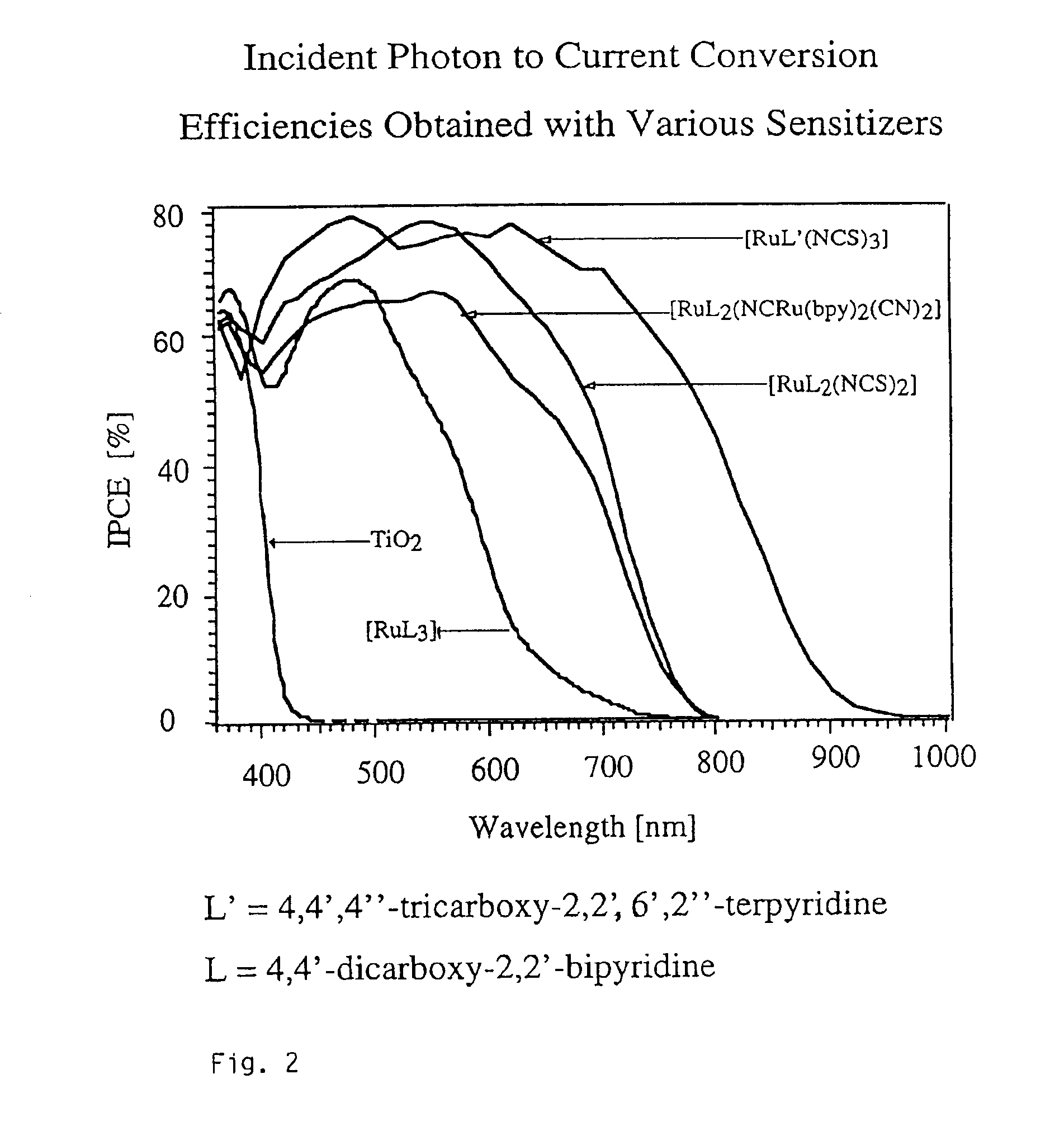

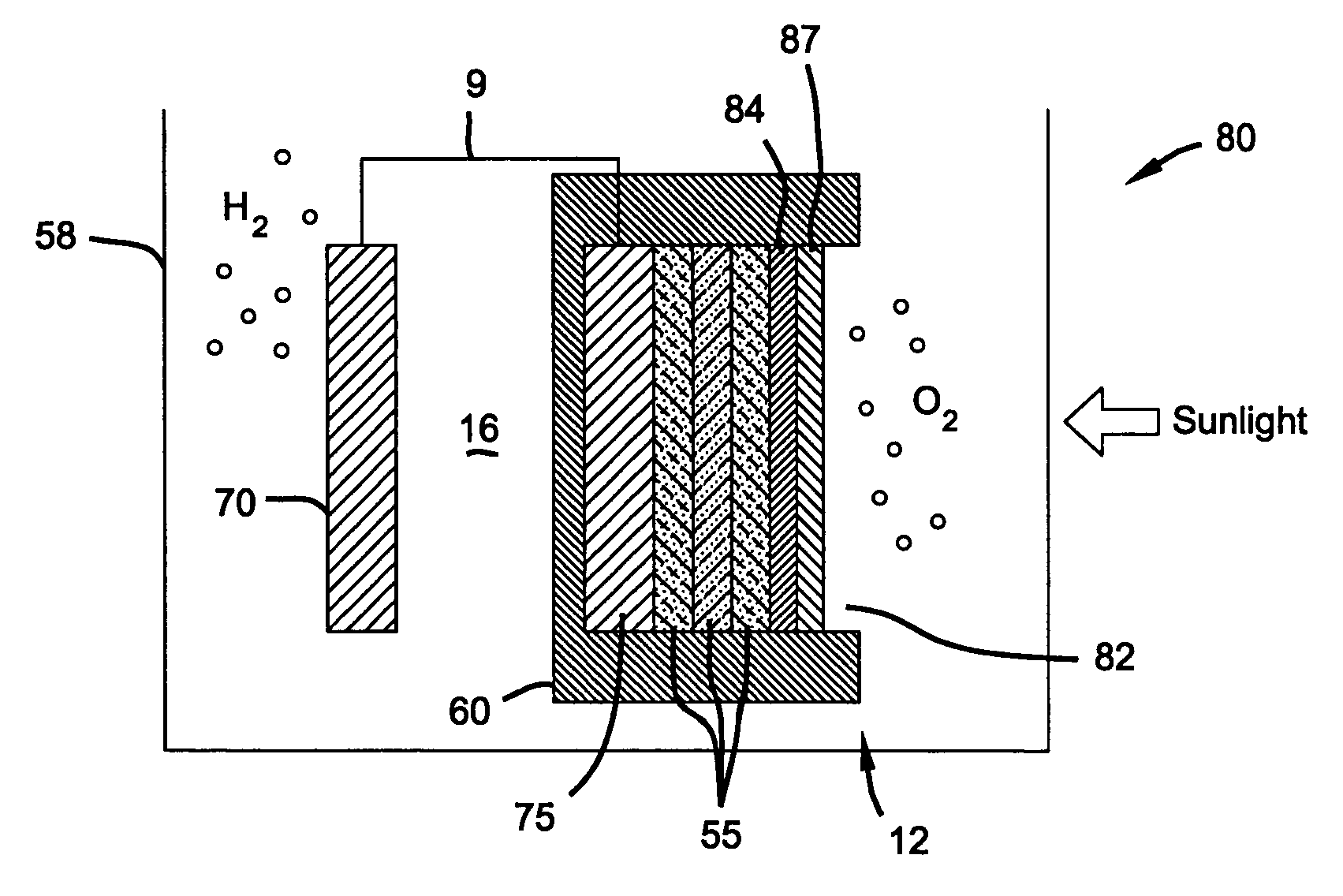

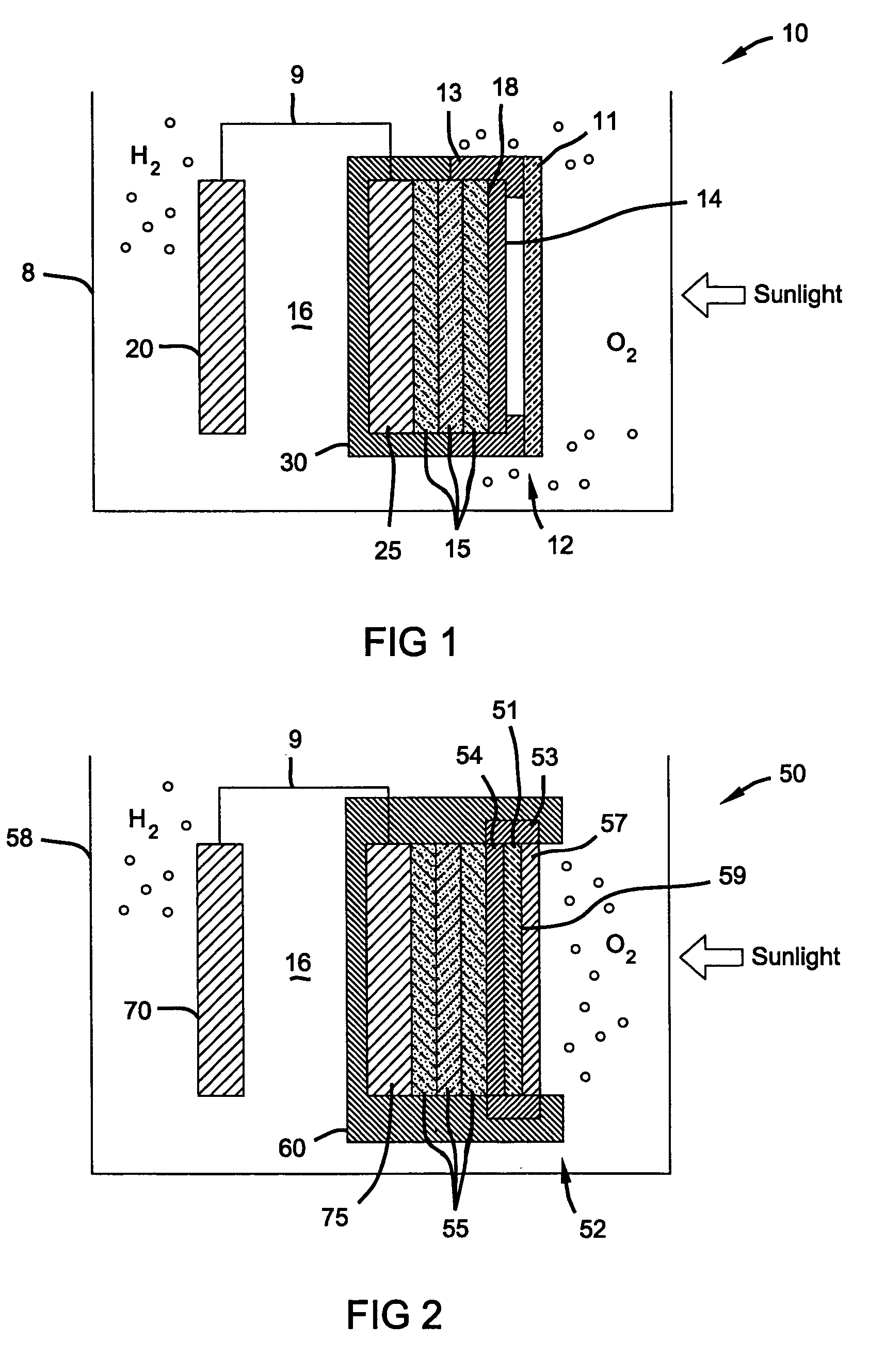

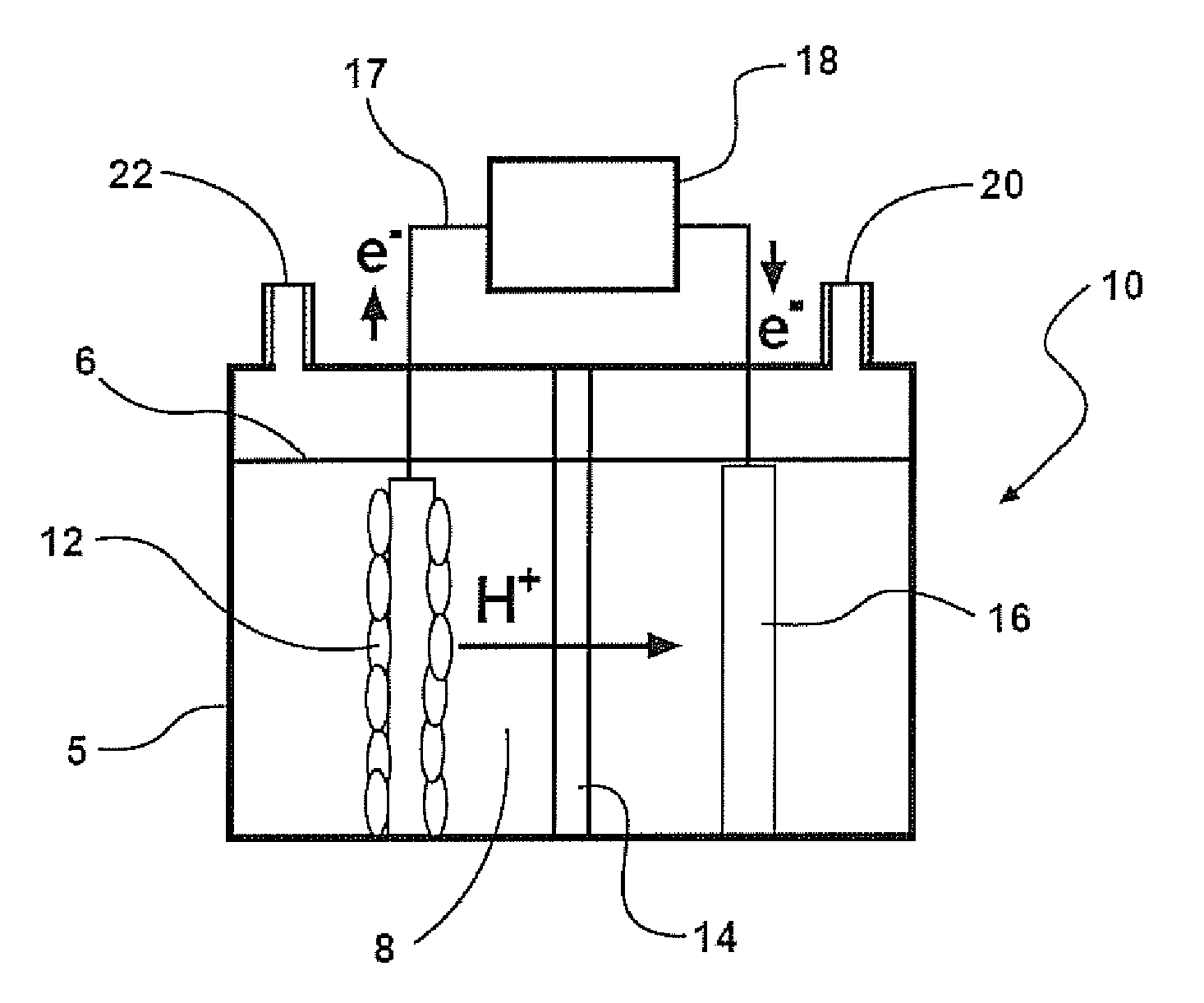

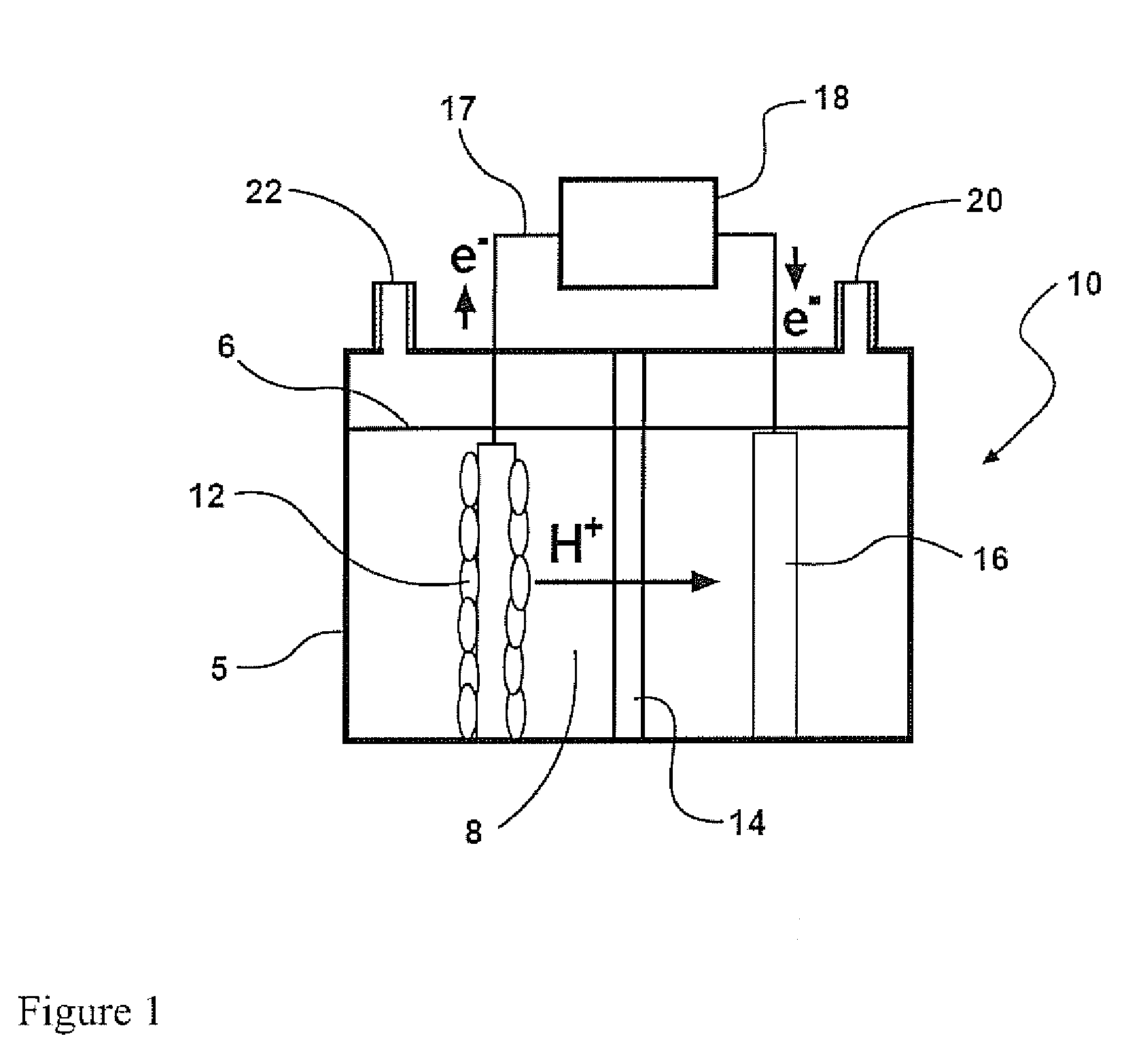

Tandem cell for water cleavage by visible light

A tandem cell or photoelectrochemical system for the cleavage of water to hydrogen and oxygen by visible light has two superimposed photocells, both cells being connected electrically. The photoactive material in the top cell is a semiconducting oxide placed in contact with an aqueous solution. This semiconducting oxide absorbs the blue and green part of the solar emission spectrum of a light source or light sources and generates with the energy collected oxygen and protons from water. The not absorbed yellow and red light transmits the top cell and enters a second photocell, the bottom cell, which is mounted, in the direction of the light behind, preferably directly behind the top cell. The bottom cell includes a dye-sensitized mesoporous photovoltaic film. The bottom cell converts the yellow, red and near infrared portion of the sunlight to drive the reduction of the protons, which are produced in the top cell during the photo catalytic water oxidation process, to hydrogen.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Anode catalyst for fuel cells with polymer electrolyte membranes

A platinum / ruthenium alloy catalyst that includes finely dispersed alloy particles on a powdery, electrically conductive carrier material. The catalyst is particularly resistant to carbon monoxide poisoning when the alloy particles display mean crystallite sizes of 0.5 to less than 2 nm.

Owner:EVONIK DEGUSSA GMBH

Diagnostic devices and apparatus for the controlled movement of reagents without membranes

InactiveUS20050112782A1Change physical propertiesImmobilised enzymesBioreactor/fermenter combinationsControl flowTime gating

The assay devices, assay systems and device components of this invention comprise at least two opposing surfaces disposed a capillary distance apart, at least one of which is capable of immobilizing at least one target ligand or a conjugate in an amount related to the presence or amount of target ligand in the sample from a fluid sample in a zone for controlled fluid movement to, through or away the zone. The inventive device components may be incorporated into conventional assay devices with membranes or may be used in the inventive membrane-less devices herein described and claimed. These components include flow control elements, measurement elements, time gates, elements for the elimination of pipetting steps, and generally, elements for the controlled flow, timing, delivery, incubation, separation, washing and other steps of the assay process.

Owner:BIOSITE INC

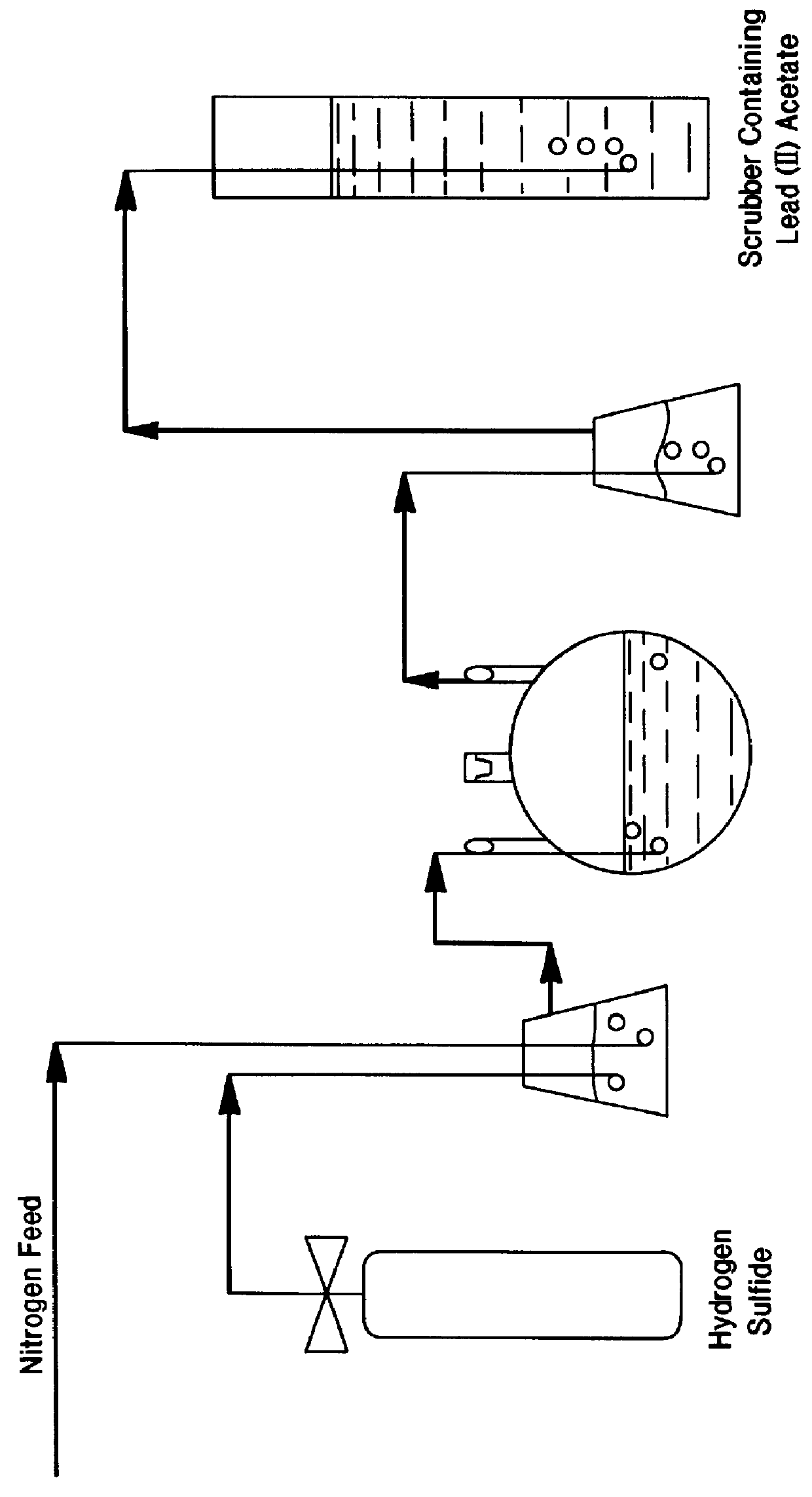

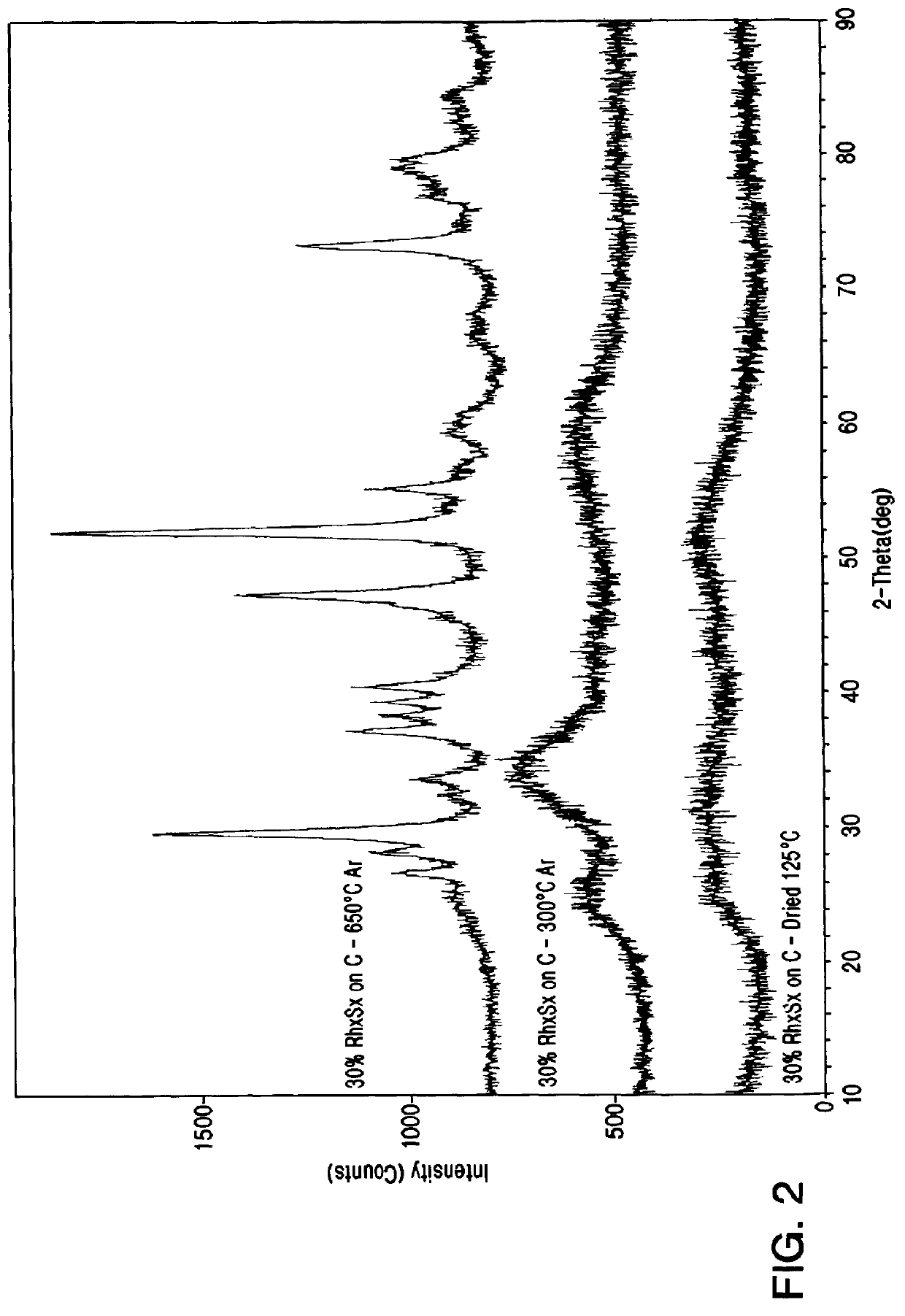

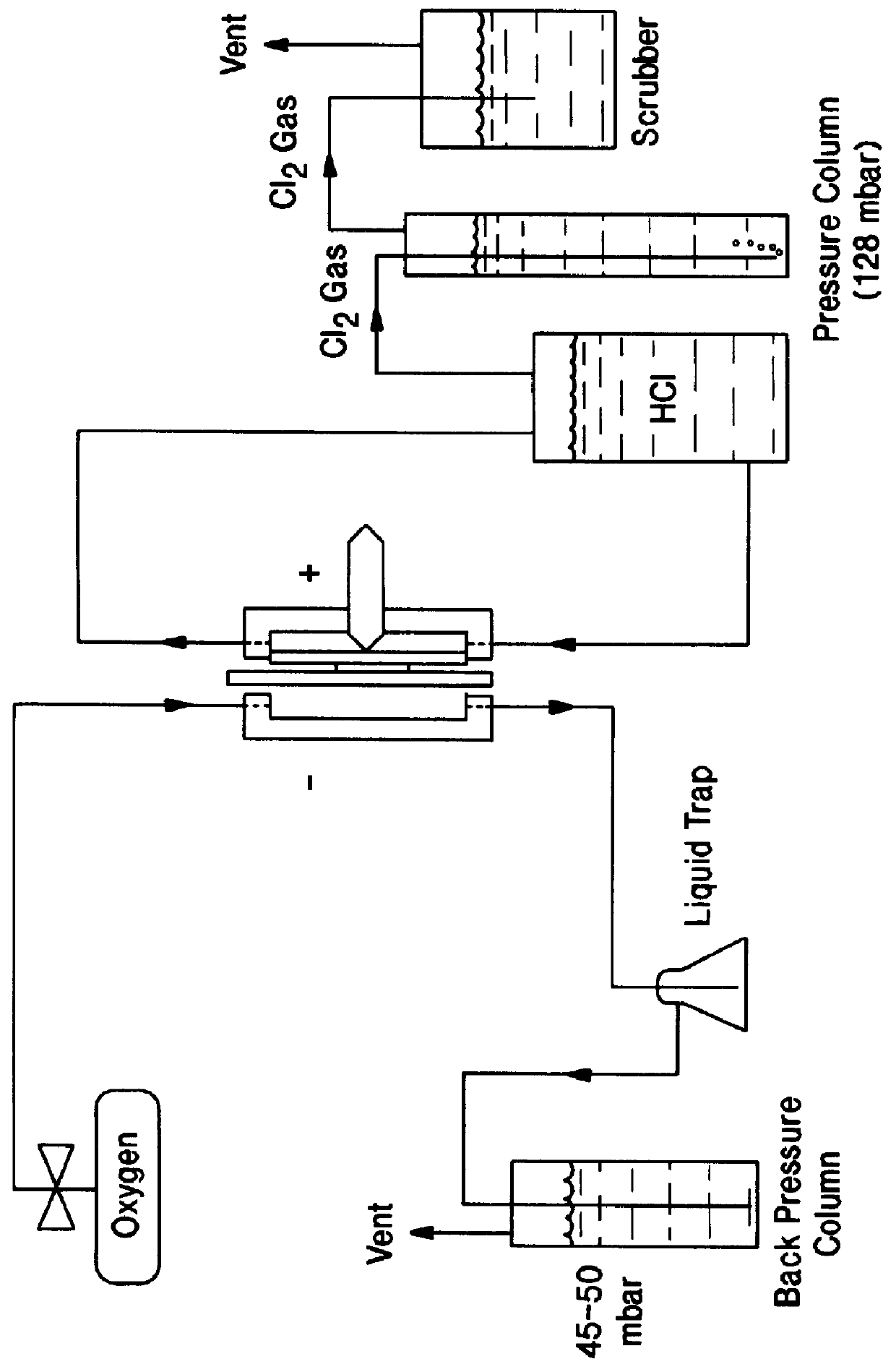

Rhodium electrocatalyst and method of preparation

The invention relates to a novel rhodium sulfide catalyst for the reduction of oxygen in industrial electrolyzers. The catalyst is highly resistant towards corrosion and poisoning by organic species, thus resulting particularly suitable for use in aqueous hydrochloric acid electrolysis, when technical grade acid containing organic contaminants is employed.

Owner:DE NORA SPA

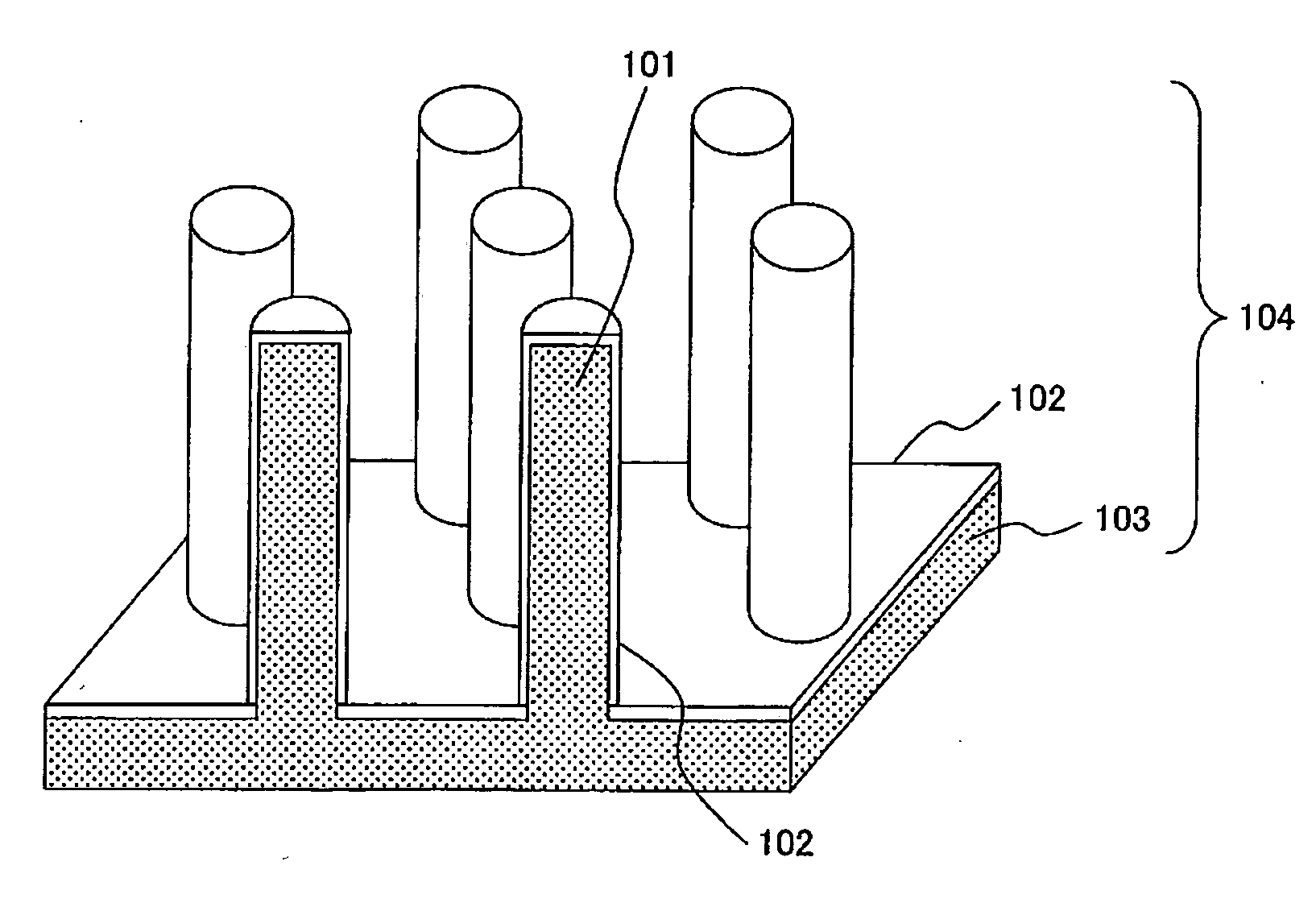

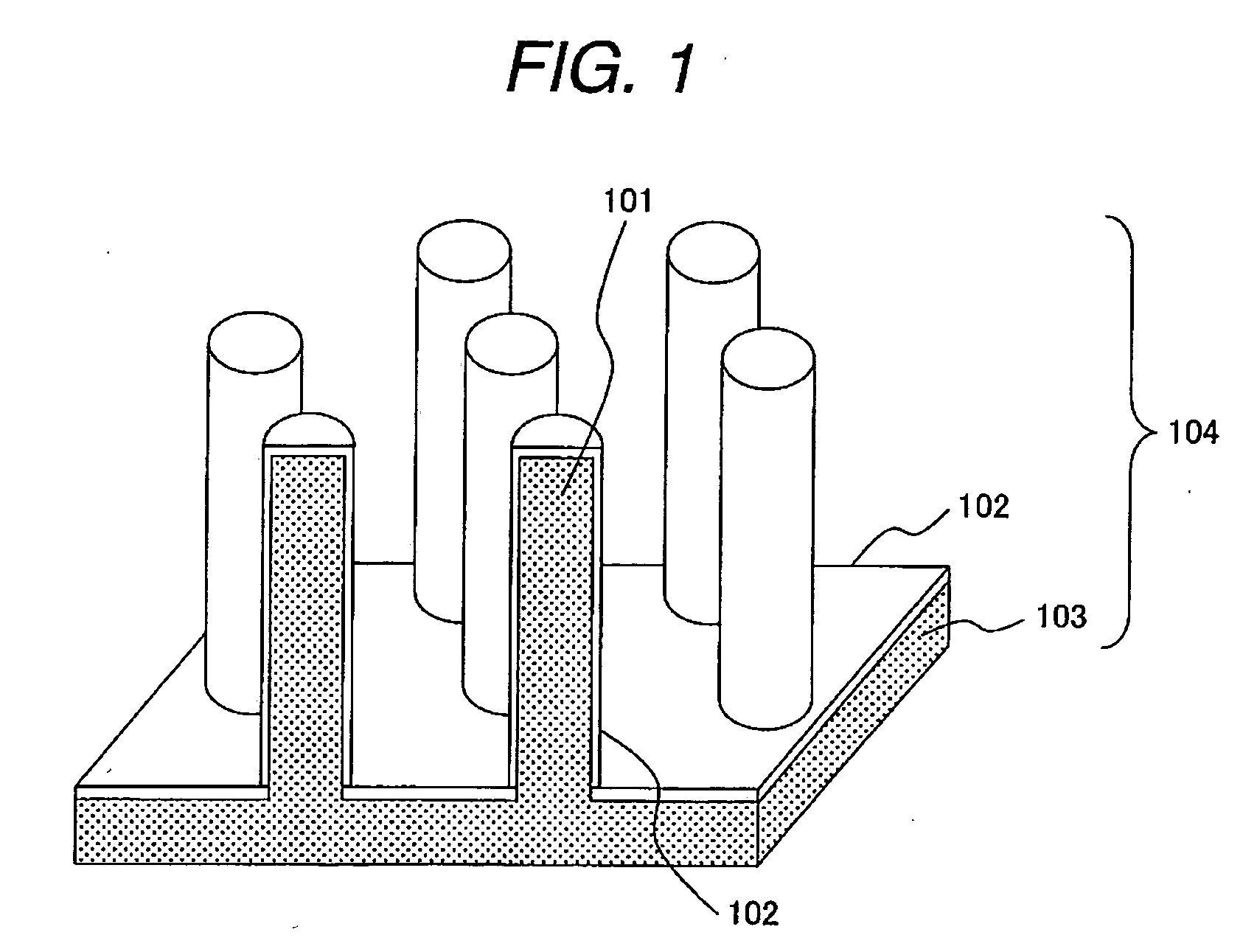

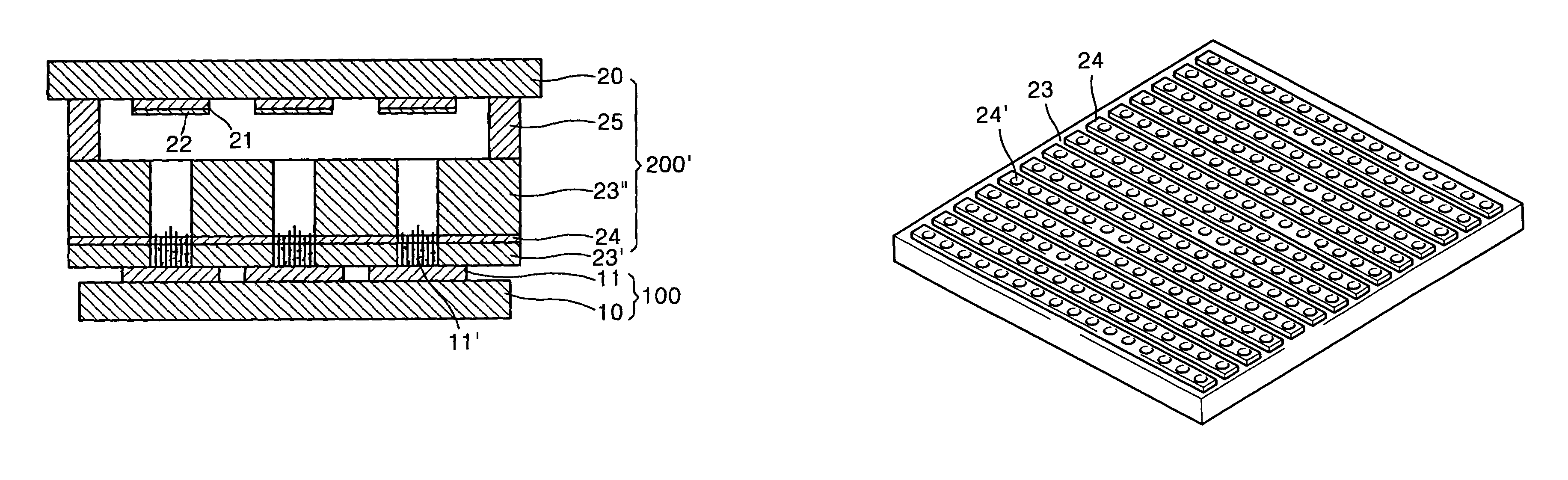

Electrode for use in electrochemical device, solid electrolyte/electrode assembly, and production method thereof

InactiveUS20070059584A1Resistance of electrodeHigh capacity densityMachining electrodesElectrolytic inorganic material coatingNano sizeNanometre

In an electrode in electrochemical device, particularly an anode lithium ion secondary battery, a cathode for use in alkali storage battery, an electrode for use in fuel cell, or a capacitor electrode, a metal structure has nano size micro-pillars is constructed with an electrode active material being formed on the surface of the metal structure. The metal structure having nano size micro-pillars can be formed, for example, by forming a metal layer as an electrode material by plating to the surface of a substrate having pores and then removing the substrate by dissolution, the metal filled in the pores of the substrate to form a group of micro-pillars. And the active material can be formed by depositing metal by plating. Since the active material is in direct contact with the conductive skeleton, the conducting agent for connecting the active materials to each other may not be added at all.

Owner:HITACHI CABLE

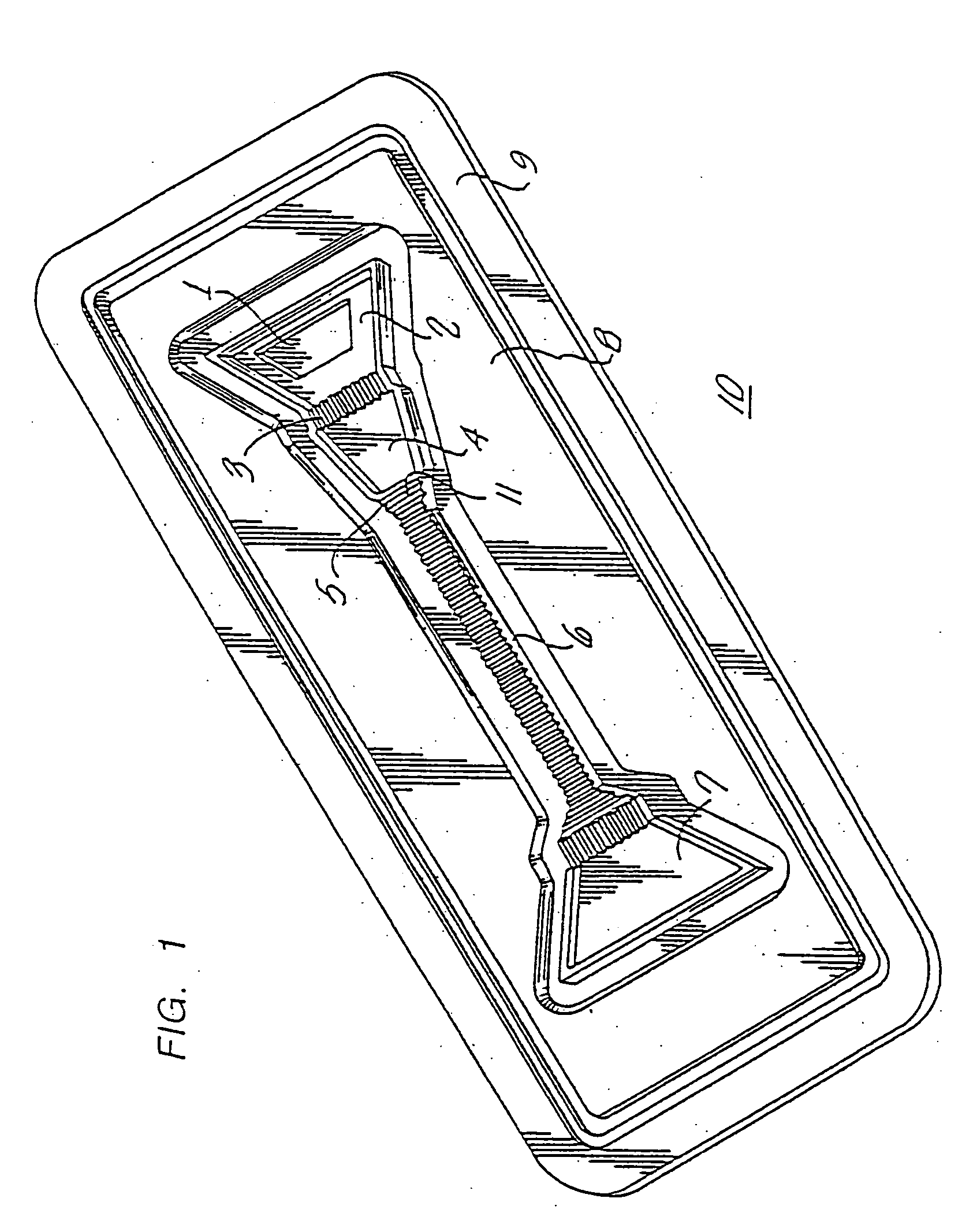

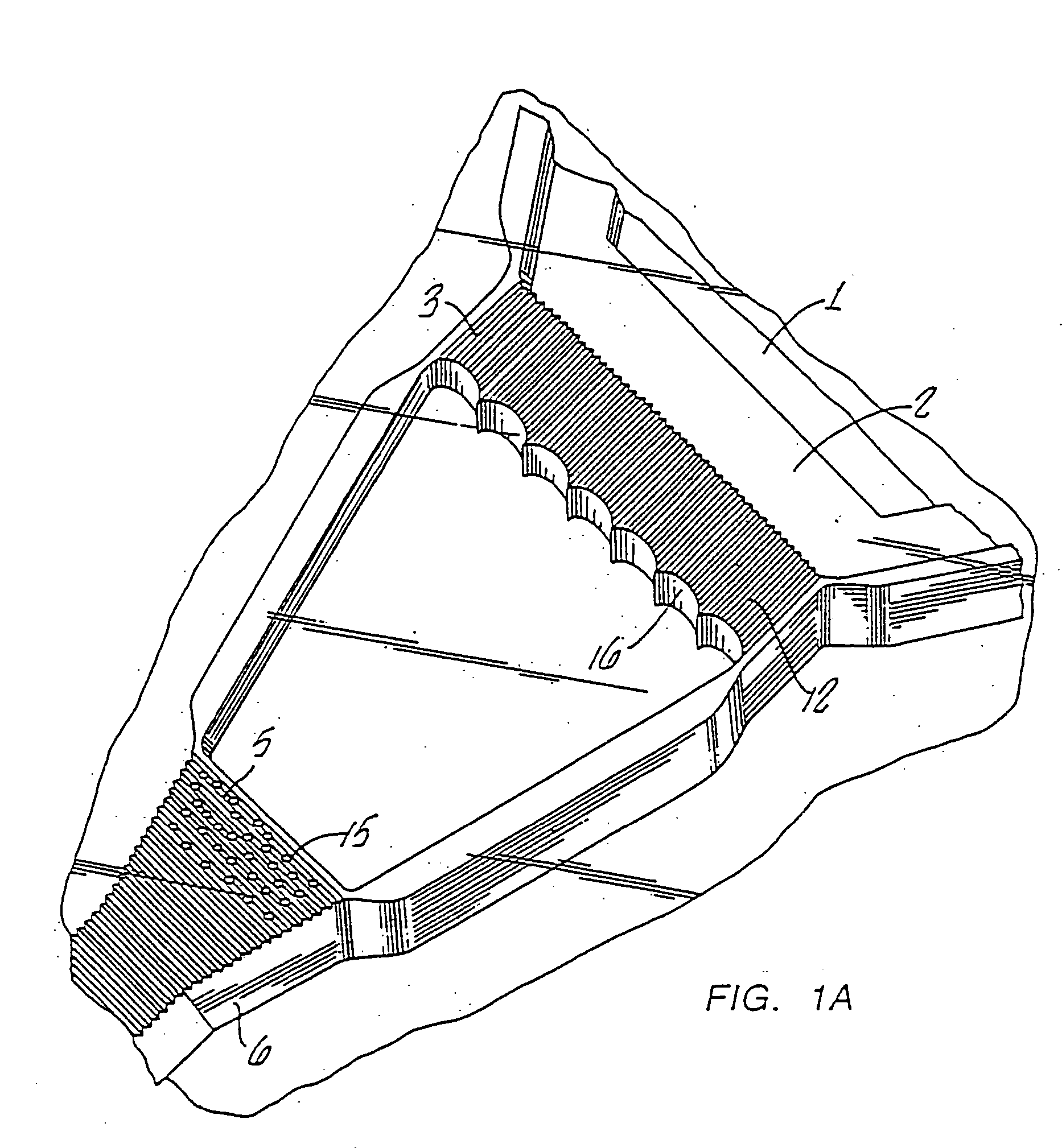

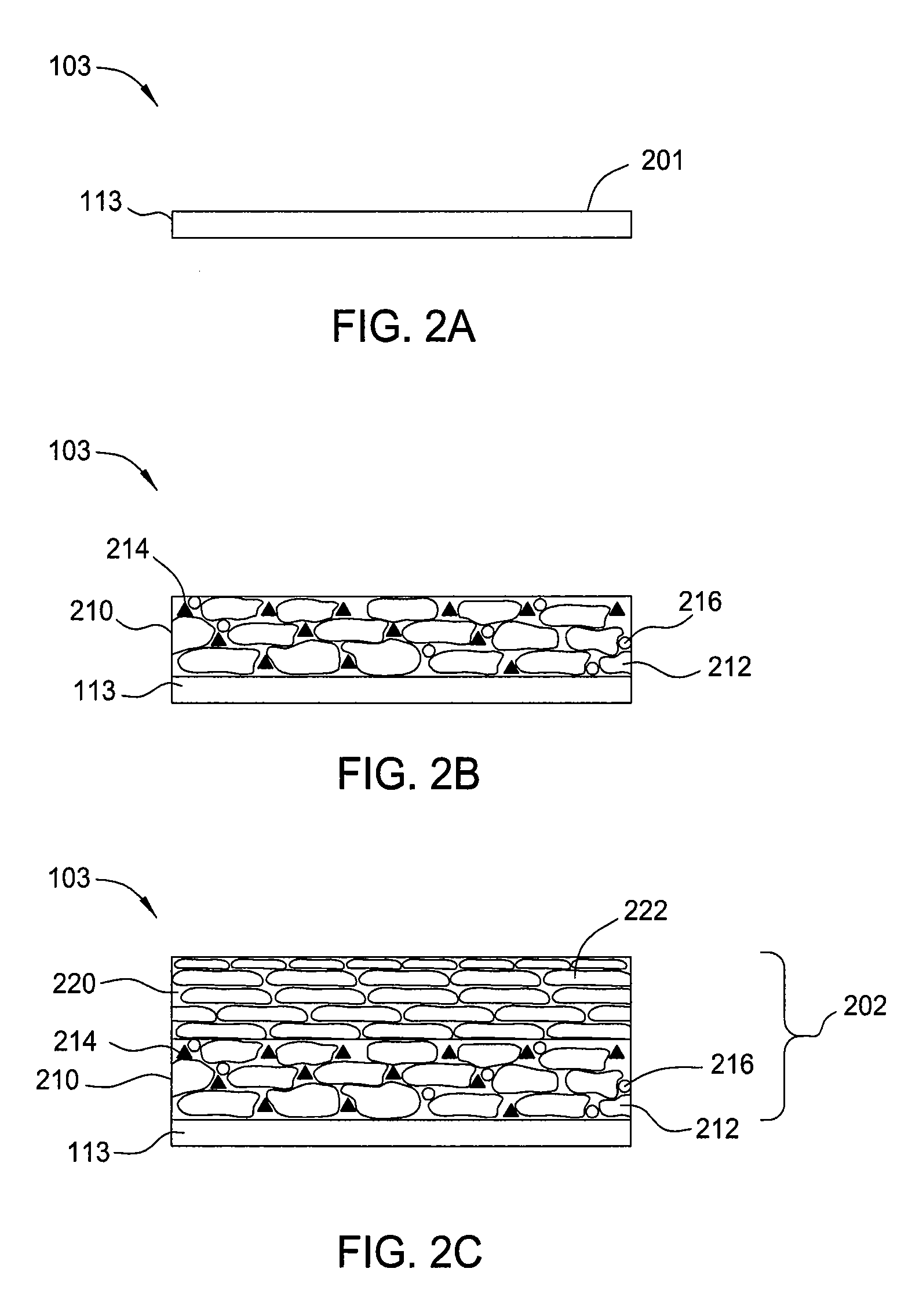

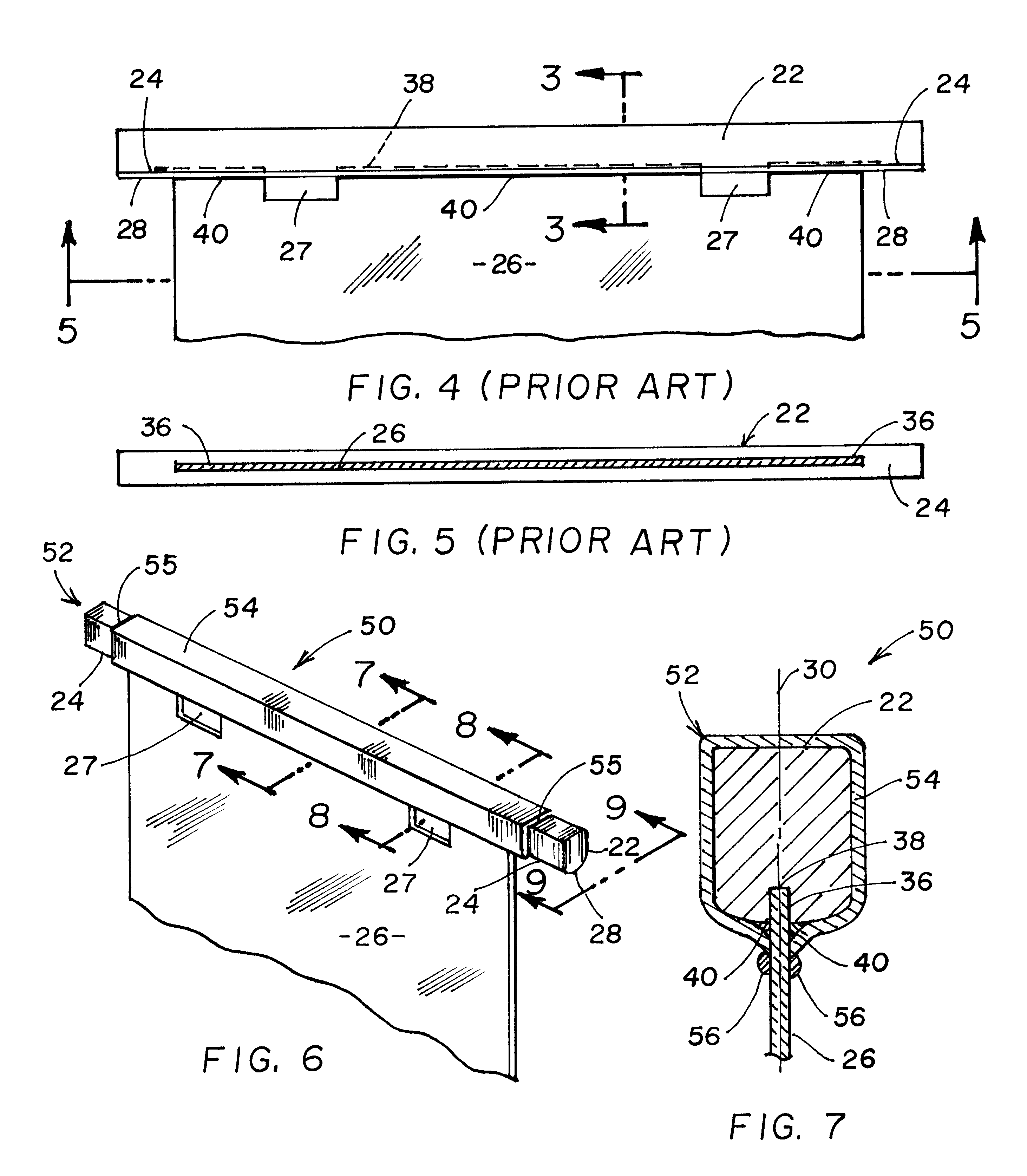

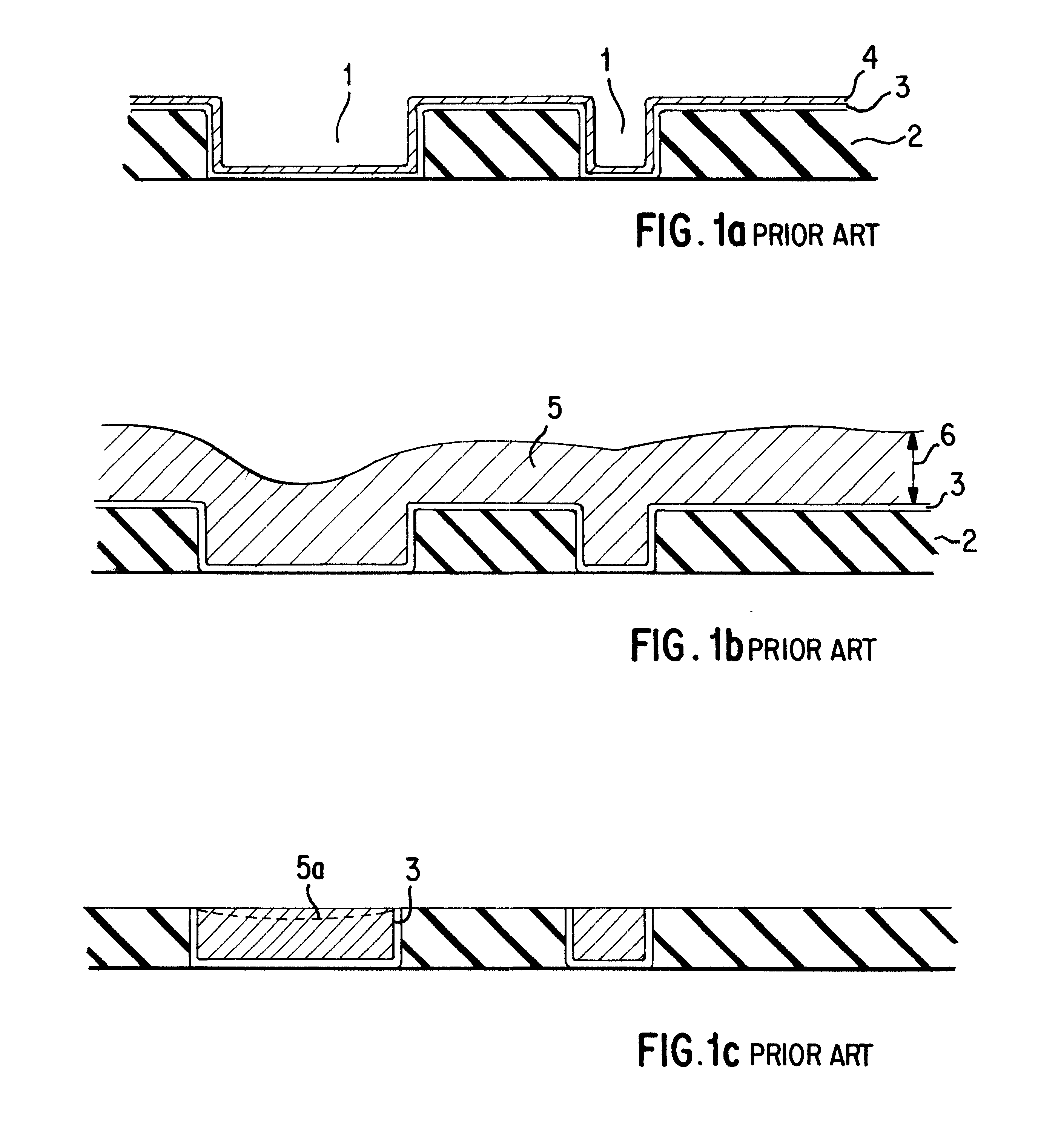

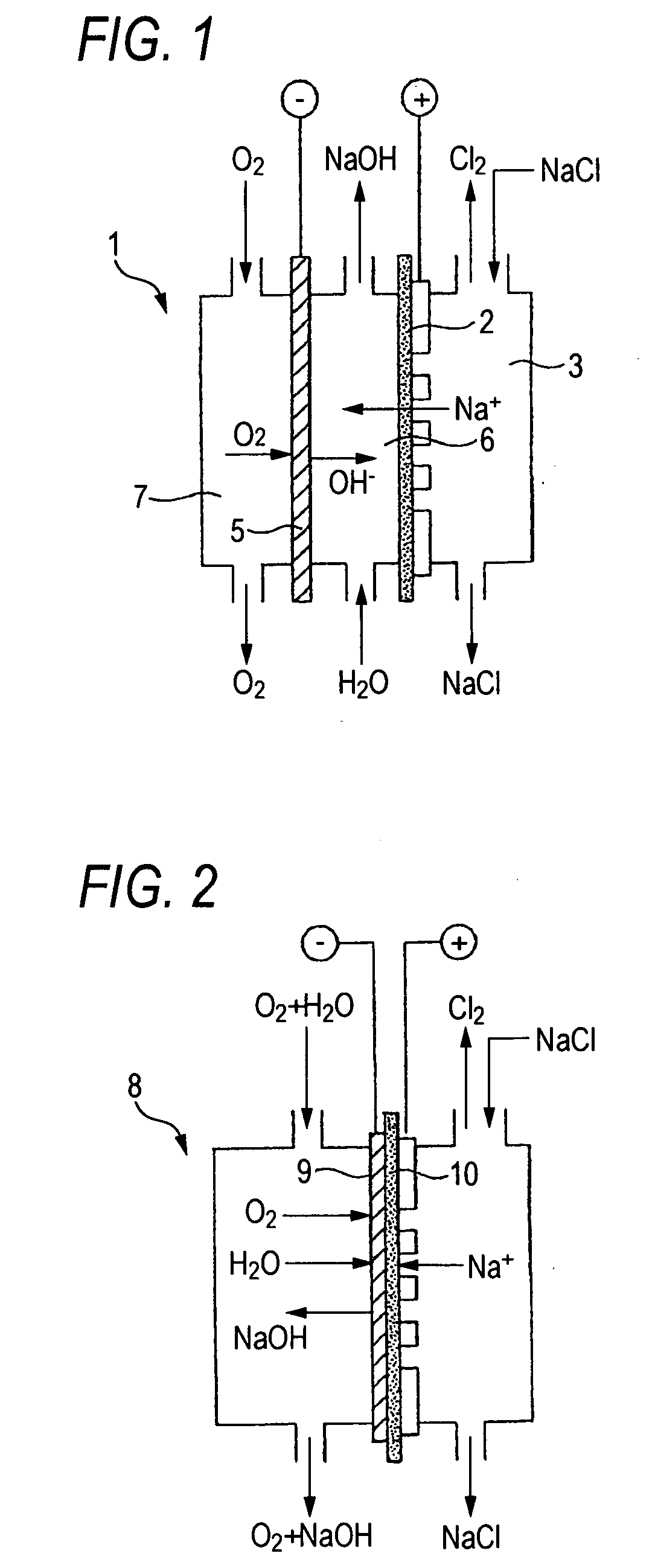

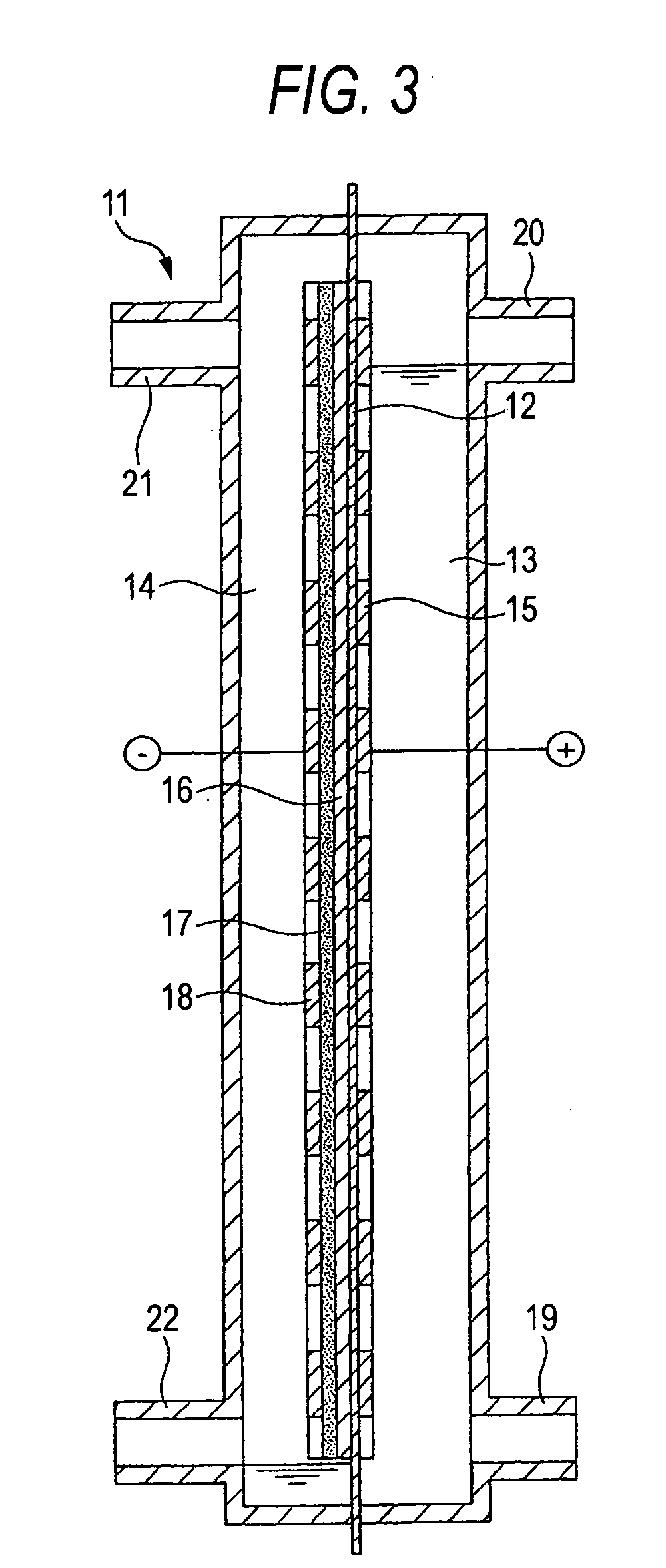

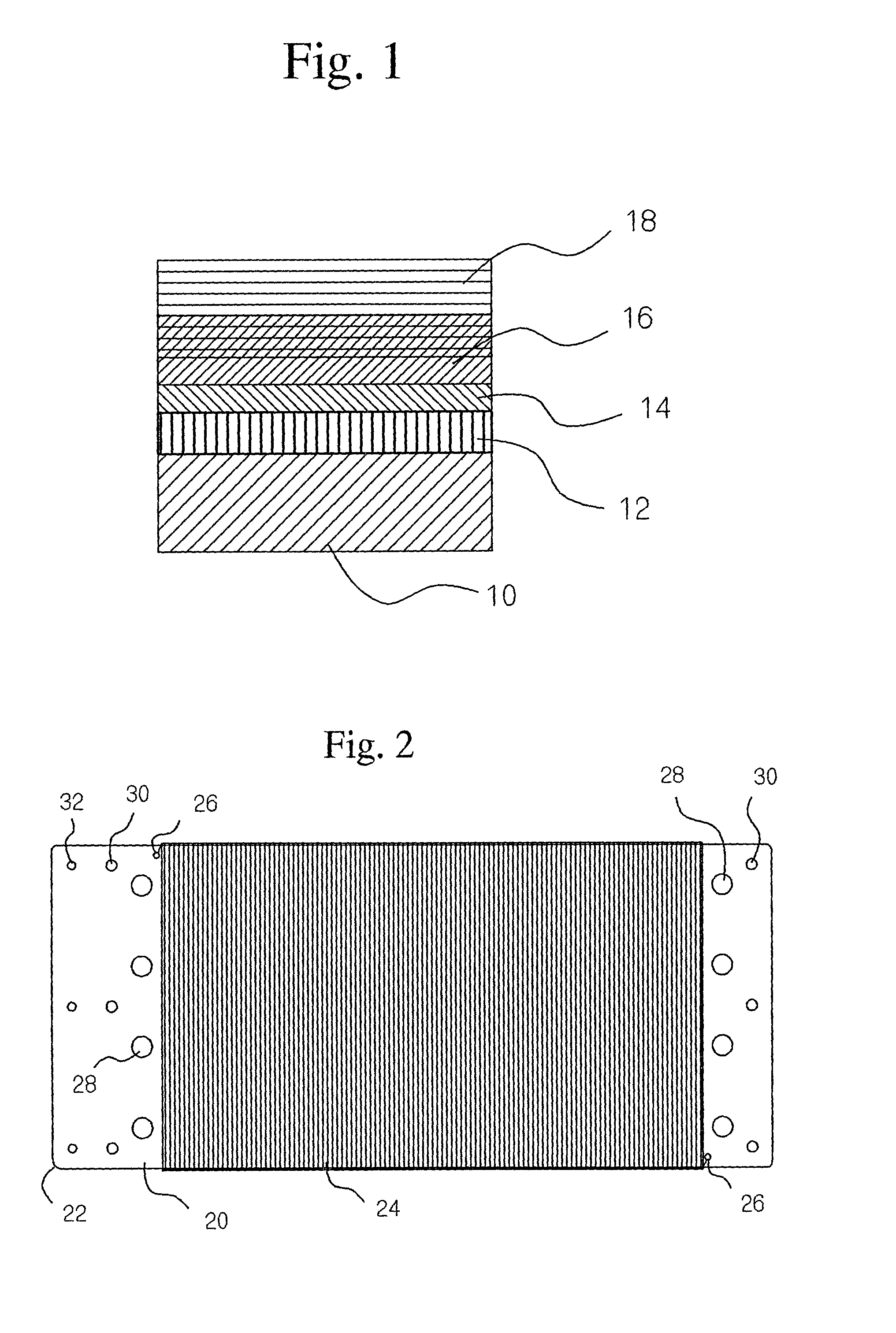

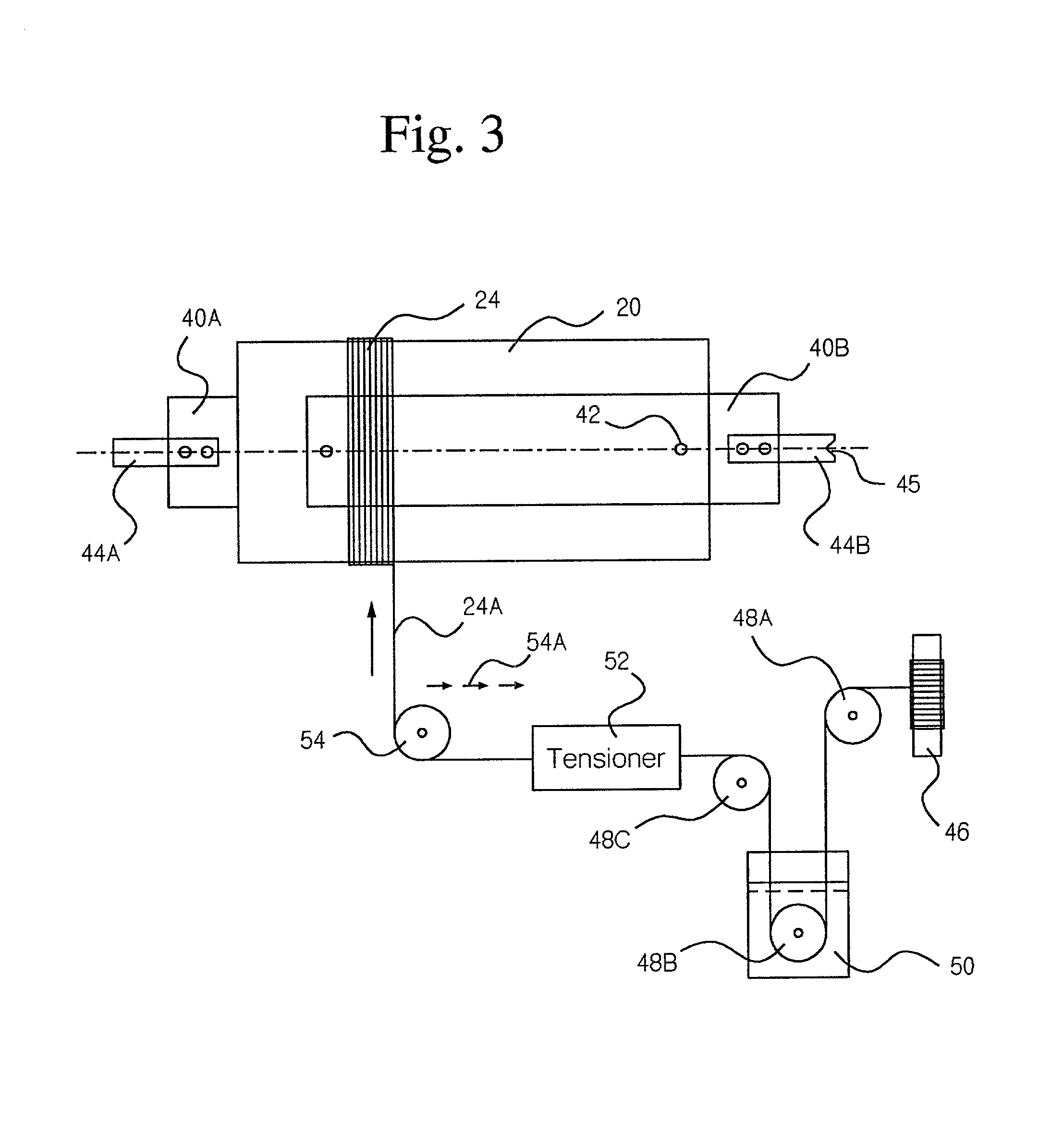

Structures and methods of manufacture for gas diffusion electrodes and electrode components

InactiveUS6103077AReduce in quantityStructure moreMachining electrodesSolid electrolytesAlkaline fuel cellFluid electrolytes

Gas Diffusion Electrodes (GDES) play a pivotal role in clean energy production as well as in electrochemical processes and sensors. These gas-consuming electrodes are typically designed for liquid electrolyte systems such as phosphoric acid and alkaline fuel cells, and are commercially manufactured by hand or in a batch process. However, GDEs using the new electrolytes such as conductive polymer membranes demand improved electrode structures. This invention pertains to GDEs and gas diffusion media with new structures for systems using membrane electrode assemblies (MEAs), and automated methods of manufacture that lend themselves to continuous mass production Unexpected improvements in gas and vapor transport through the electrode are realized by incorporating a new dispersion process in the construction, reformulating the applied mix with solution additives, and creating a novel coating structure on a conductive web. Furthermore, combining these changes with a judicious choice in coating methodology allows one to produce these materials in a continuous, automated fashion.

Owner:IND DE NORA SPA

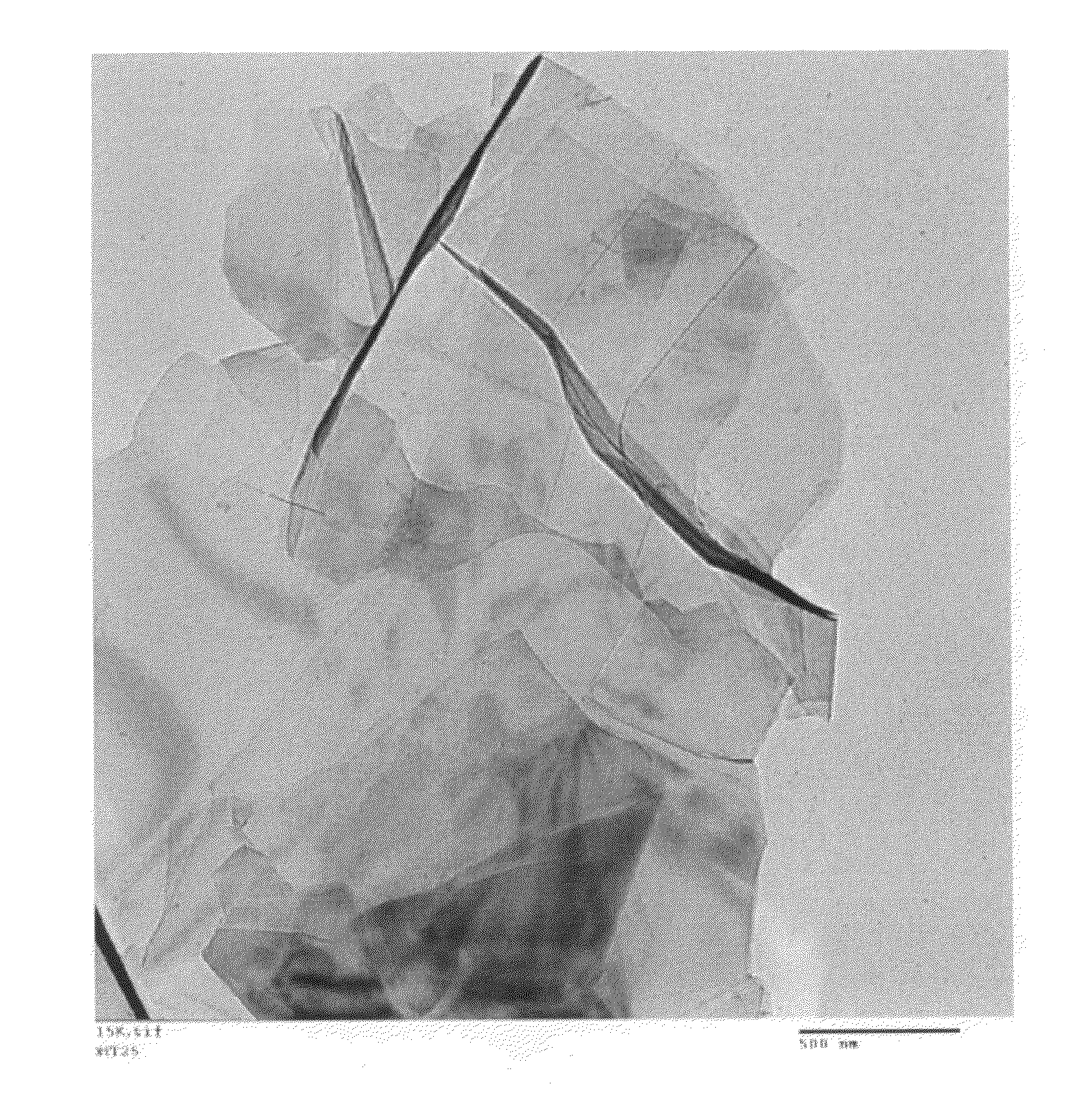

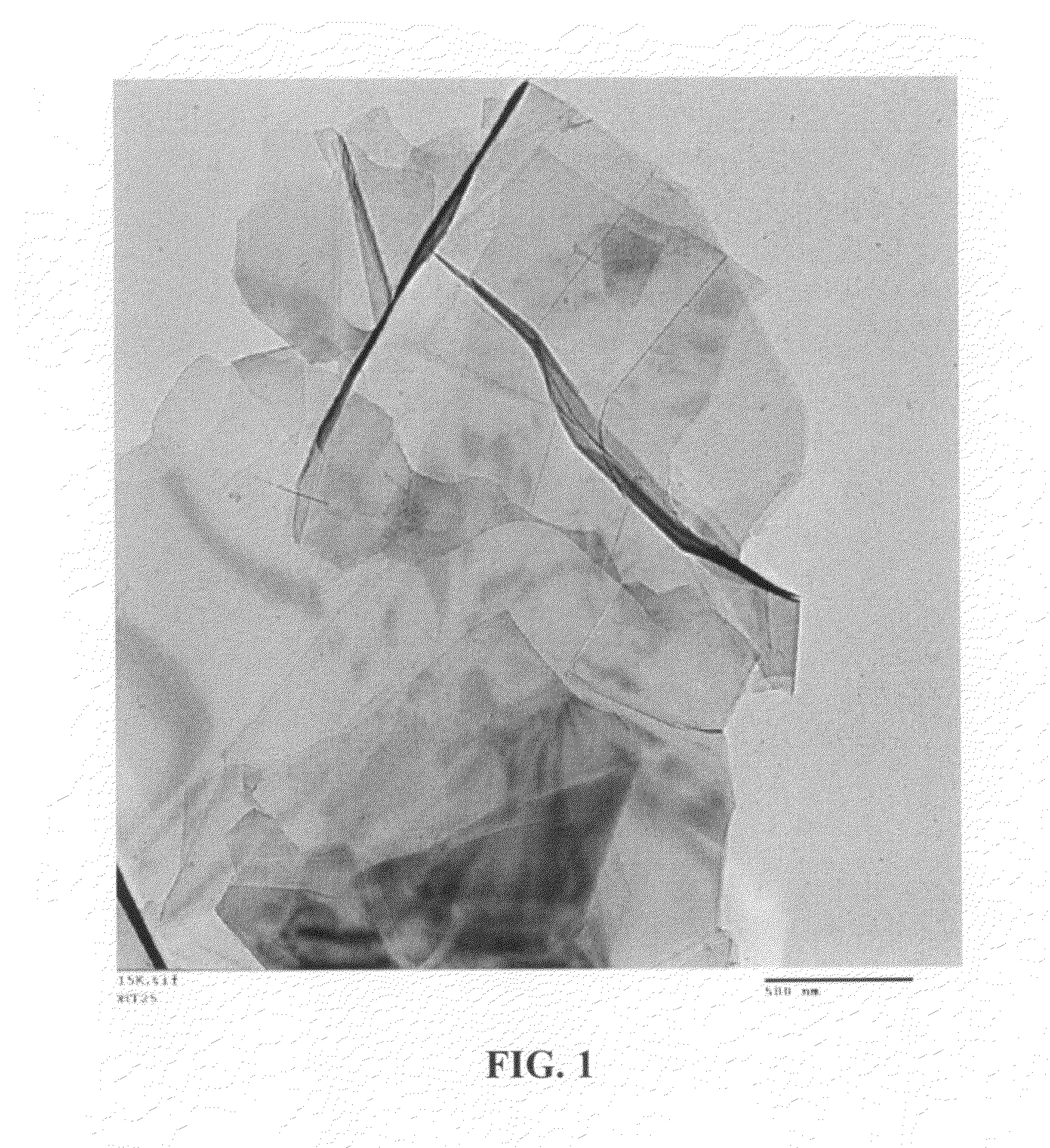

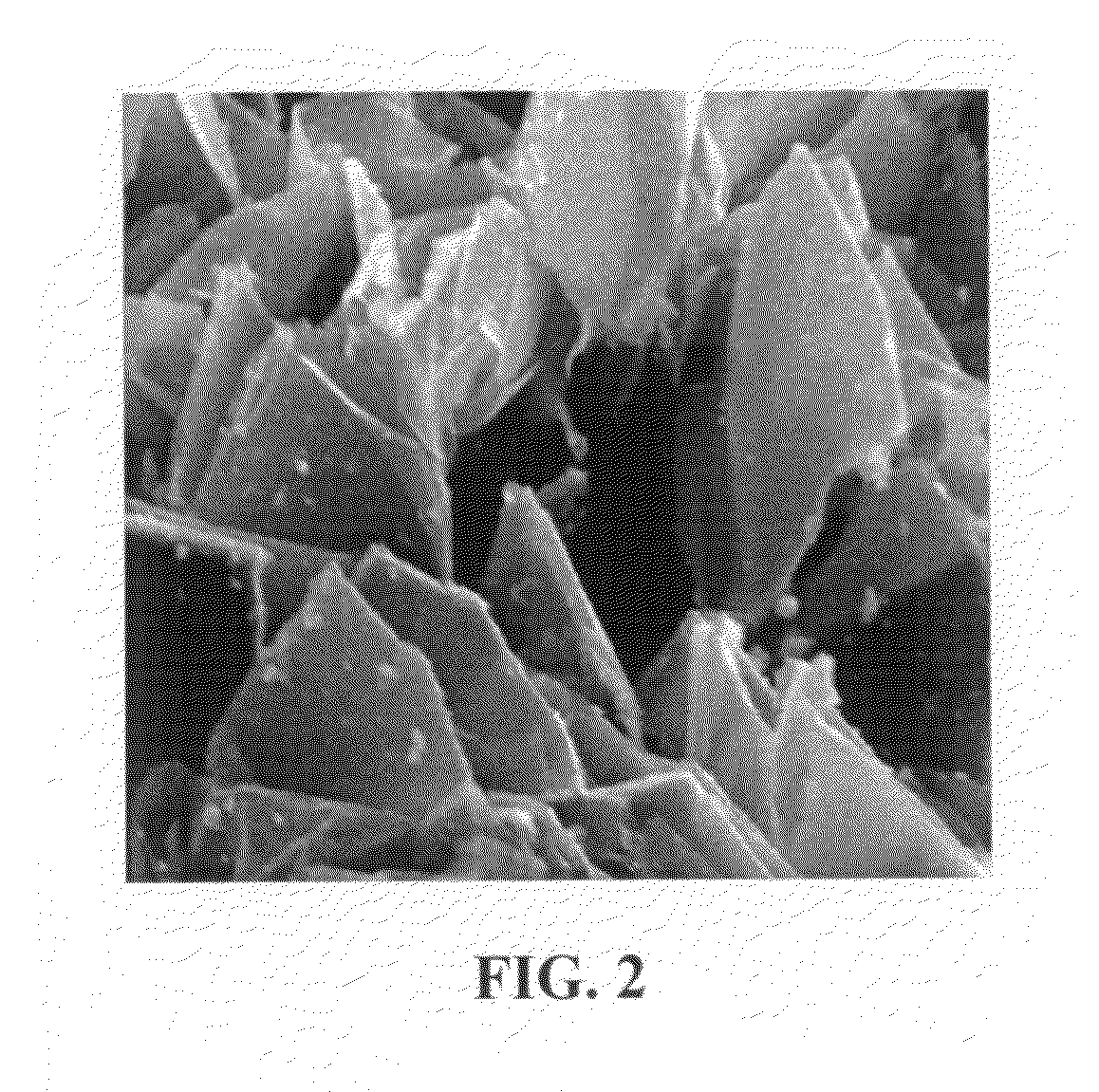

Spacer-modified nano graphene electrodes for supercapacitors

ActiveUS20110157772A1Increase surface areaMaterial nanotechnologyLiquid electrolytic capacitorsCapacitanceSupercapacitor

A surface-modified nano graphene platelet (NGP), comprising: (a) a nano graphene platelet having a thickness smaller than 10 nm; and (b) discrete, non-continuous, and non-metallic bumps or nodules bonded to a surface of the graphene platelet to serve as a spacer. When multiple surface-modified NGP sheets are stacked together to form an electrode, large numbers of electrolyte-accessible pores are formed, enabling the formation of large amounts of double layer charges in a supercapacitor, which exhibits an exceptionally high specific capacitance.

Owner:NANOTEK INSTR GRP LLC

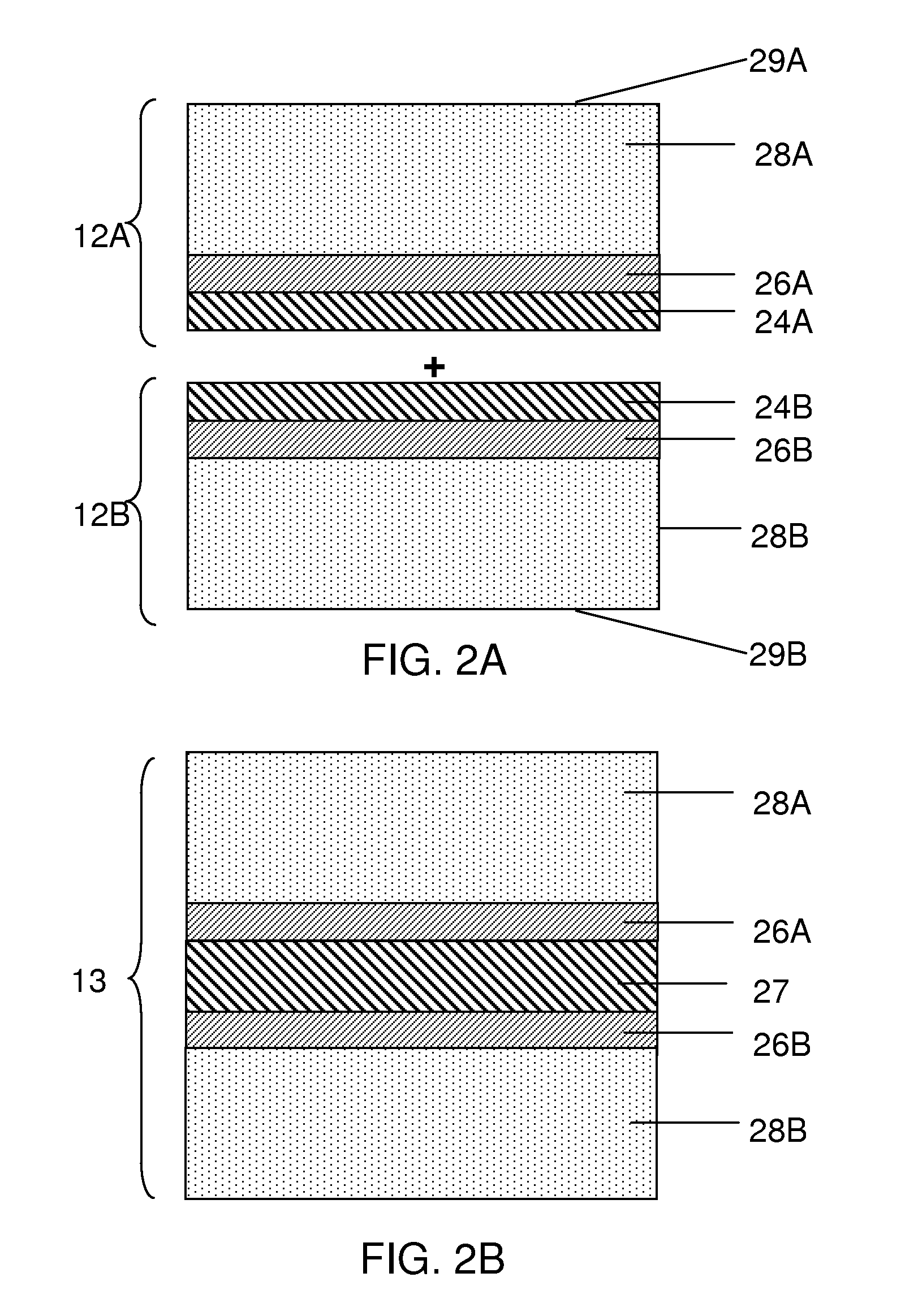

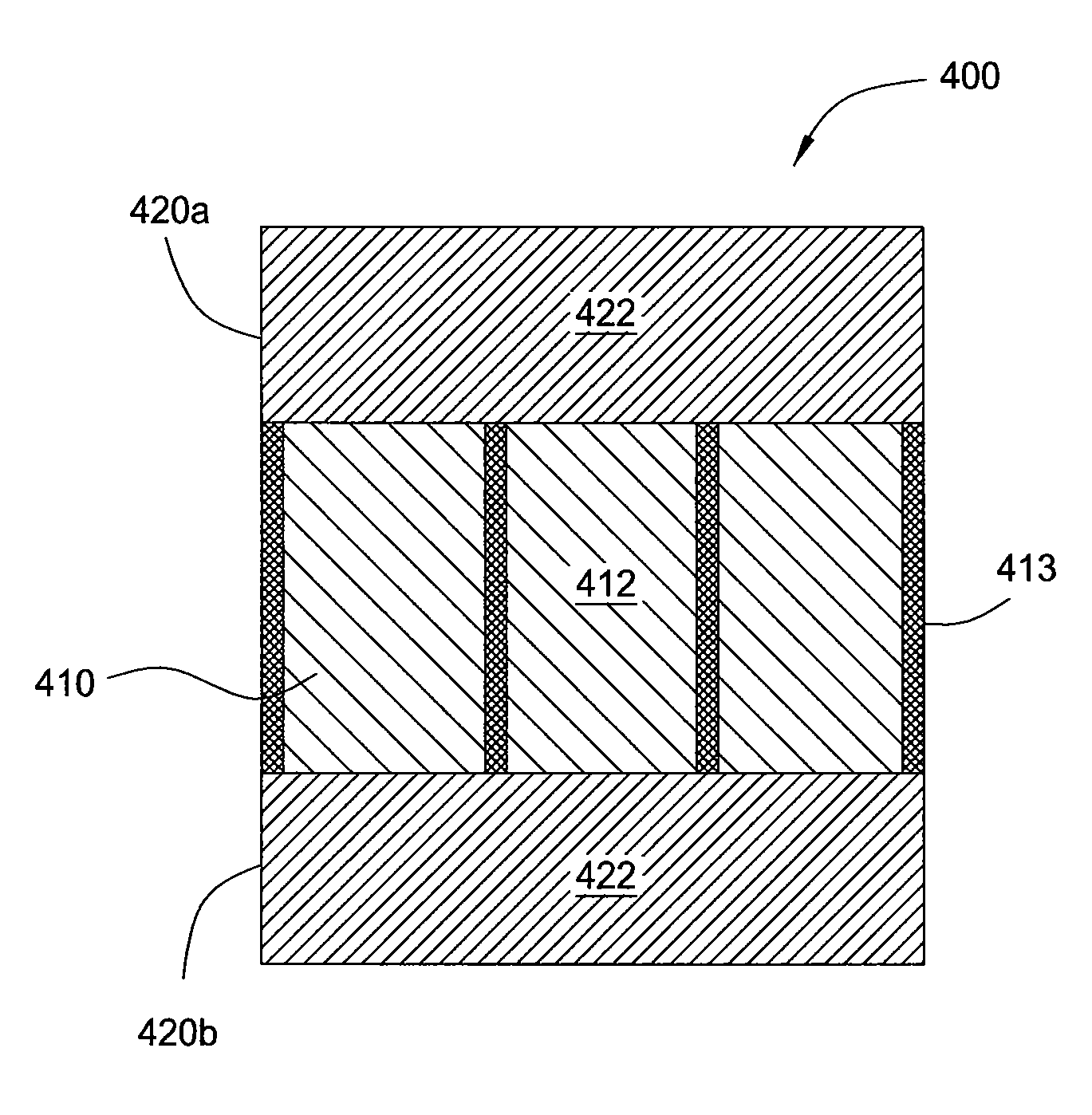

Graded electrode technologies for high energy lithium-ion batteries

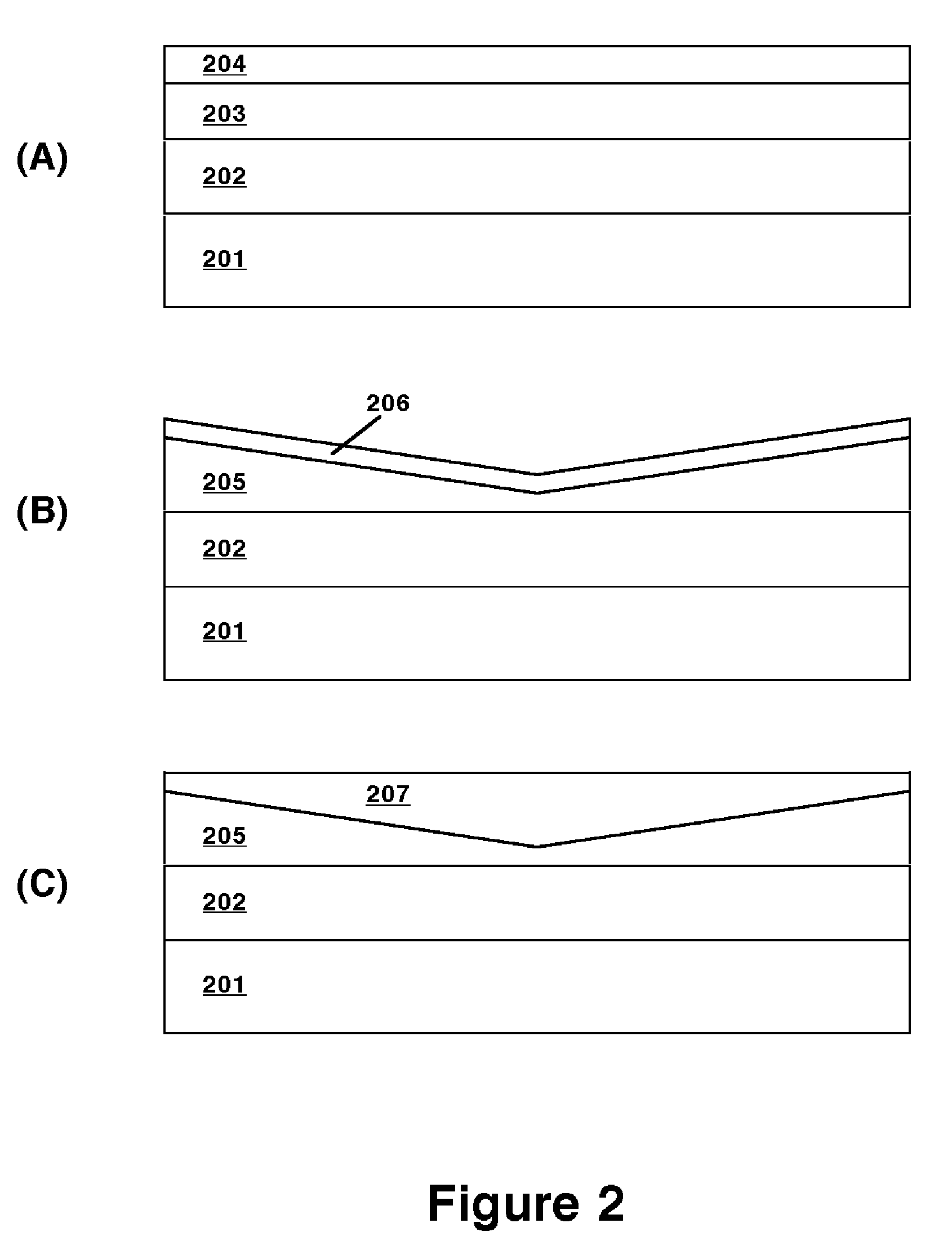

InactiveUS20110168550A1Reduce separator material costEasy to manufactureMachining electrodesElectrode carriers/collectorsProduction rateElectrical battery

Embodiments described herein provide methods and systems for manufacturing faster charging, higher capacity energy storage devices that are smaller, lighter, and can be more cost effectively manufactured at a higher production rate. In one embodiment, a graded cathode structure is provided. The graded cathode structure comprises a conductive substrate, a first porous layer comprising a first cathodically active material having a first porosity formed on the conductive substrate, and a second porous layer comprising a second cathodically active material having a second porosity formed on the first porous layer. In certain embodiments, the first porosity is greater than the second porosity. In certain embodiments, the first porosity is less than the second porosity.

Owner:APPLIED MATERIALS INC

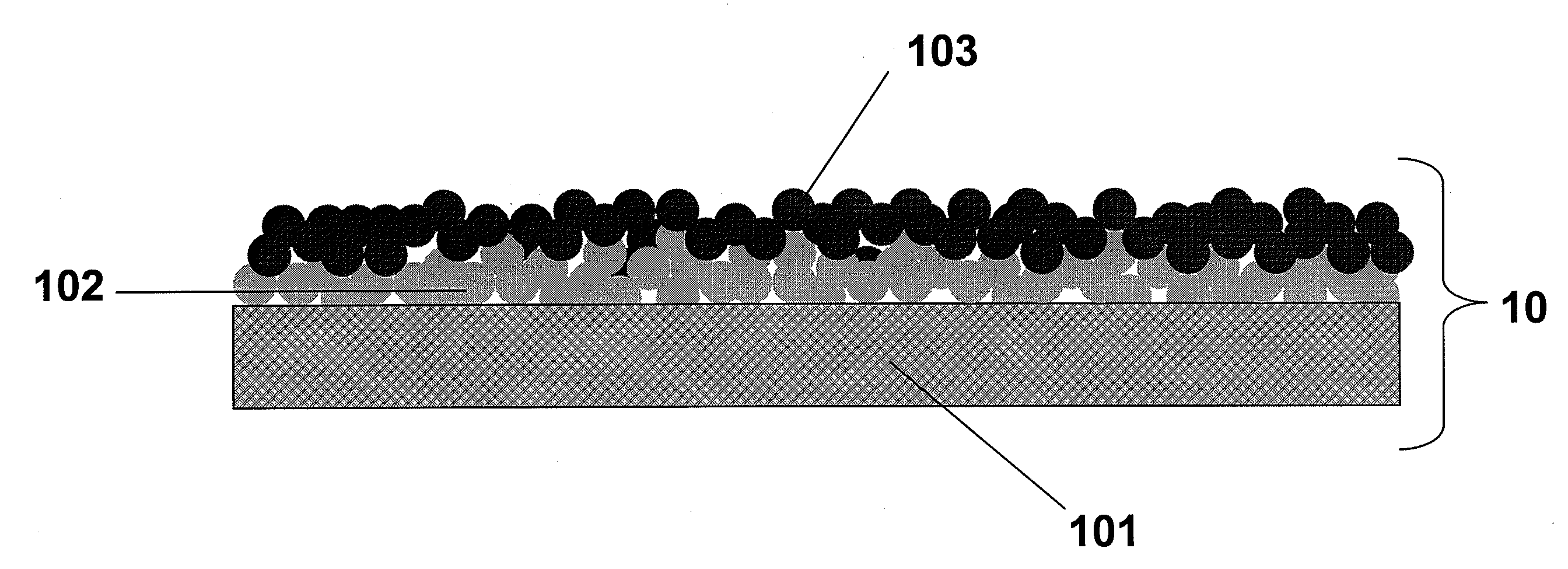

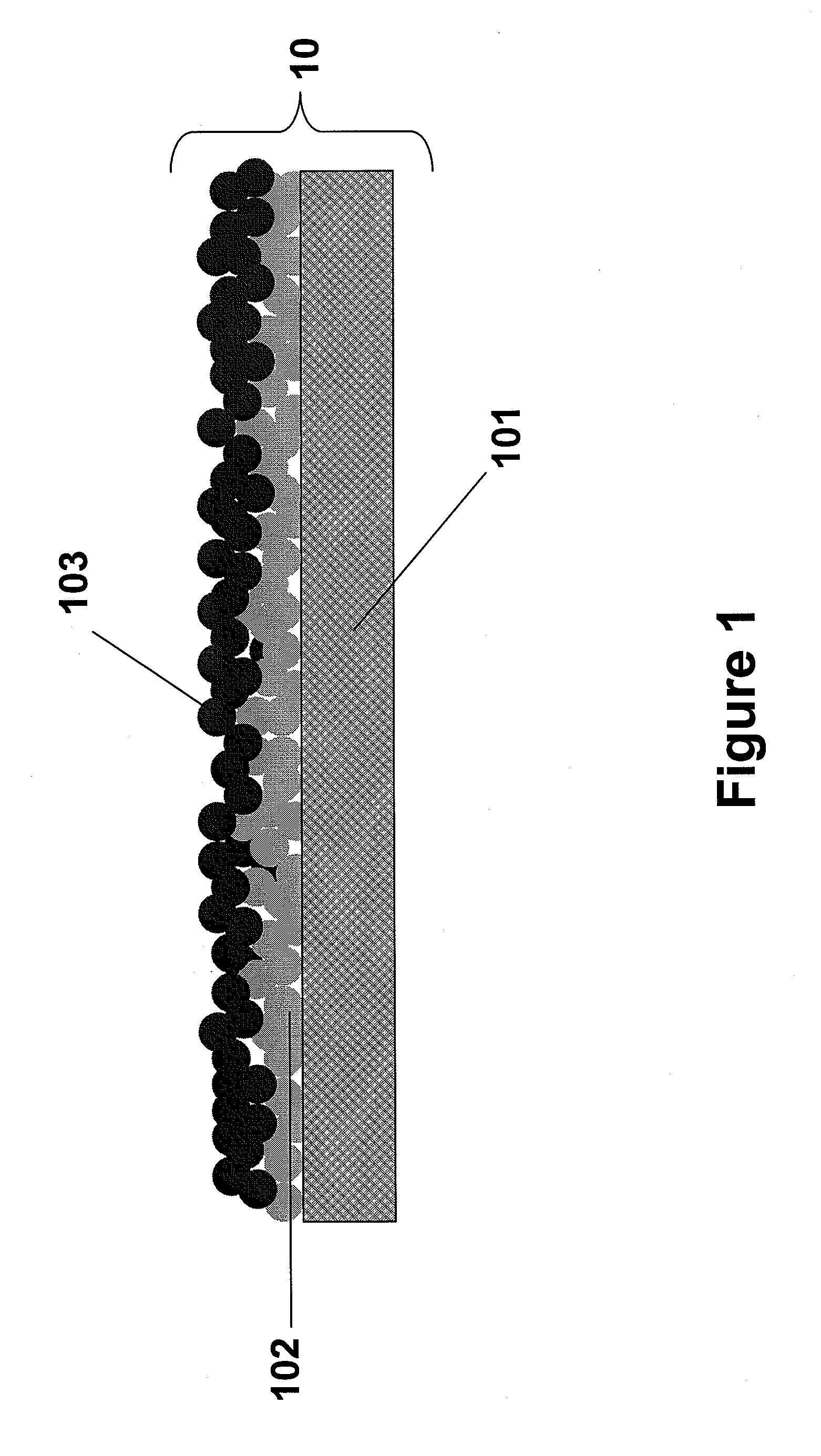

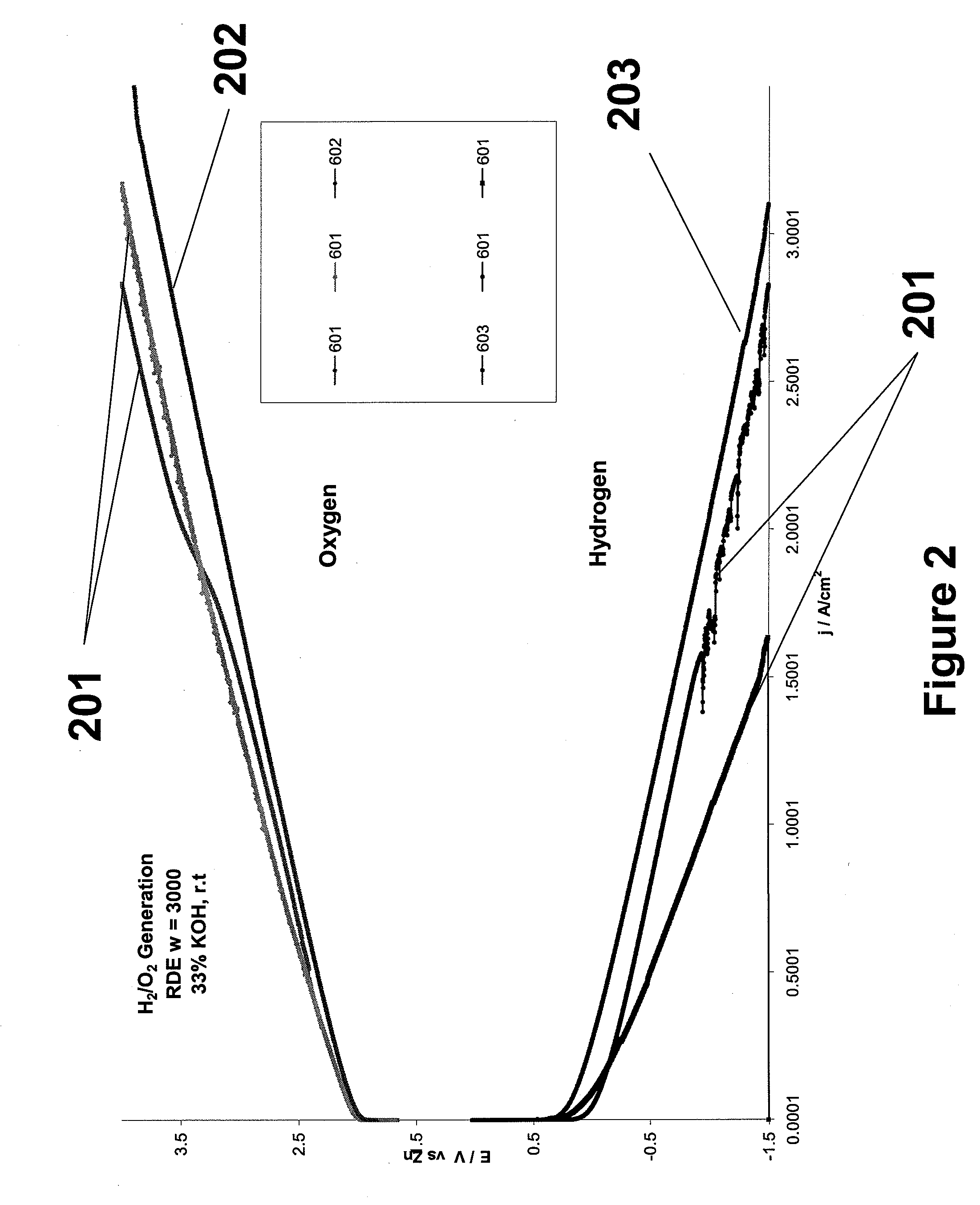

Nanoparticle coated electrode and method of manufacture

InactiveUS20090092887A1Increase surface areaFirmly connectedMachining electrodesMultiple component coatingsElectrolysisFuel cells

An electrode comprising a primary and secondary metal nanoparticle coating on a metallic substrate is prepared by dispersing nanoparticles in a solvent and layering them onto the substrate, followed by heating. The enhanced surface area of the electrode due to the catalytic nanoparticles is dramatically enhanced, allowing for increased reaction efficiency. The electrode can be used in one of many different applications; for example, as an electrode in an electrolysis device to generate hydrogen and oxygen, or a fuel cell.

Owner:BRICOLEUR PARTNERS LP

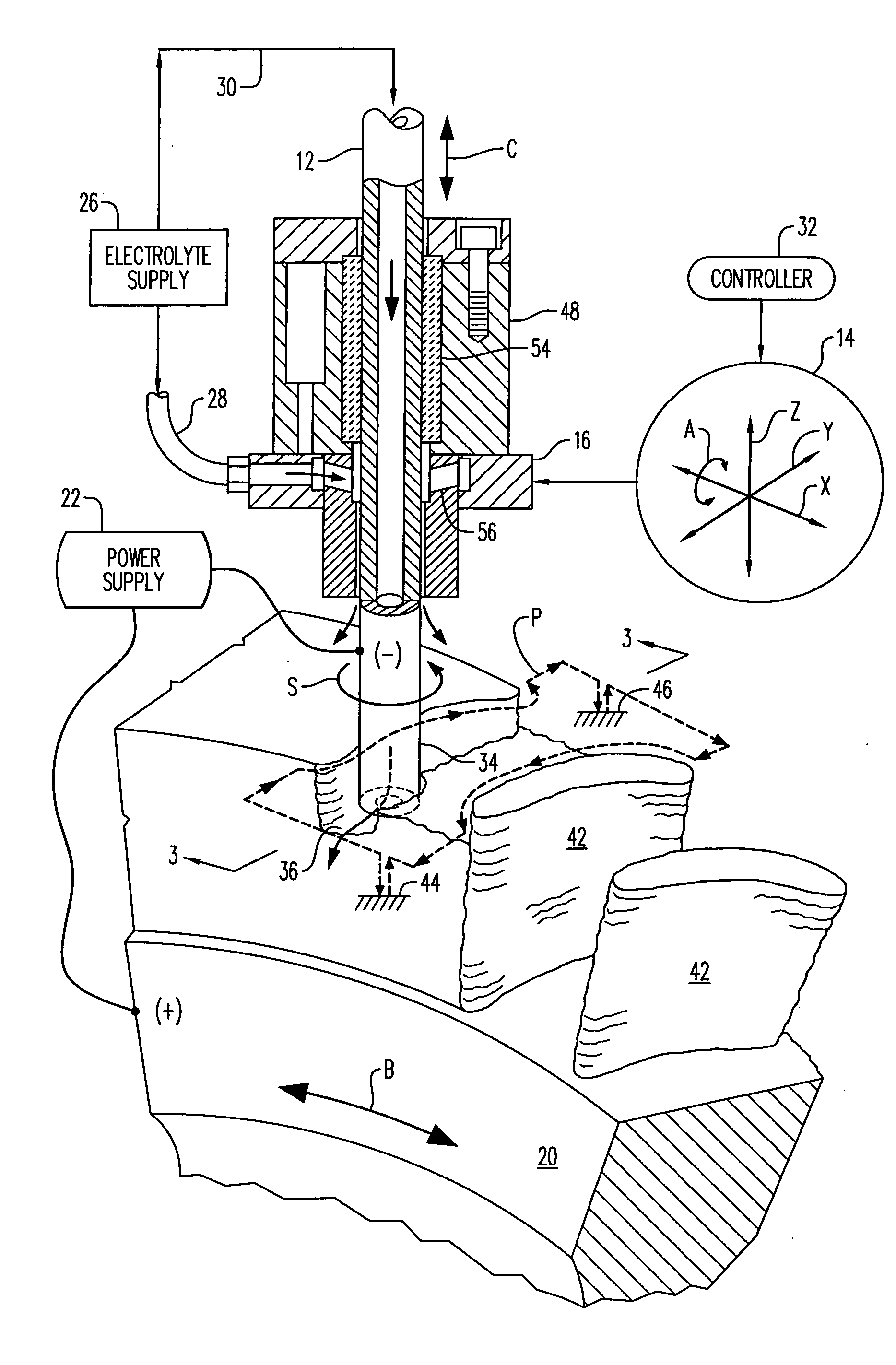

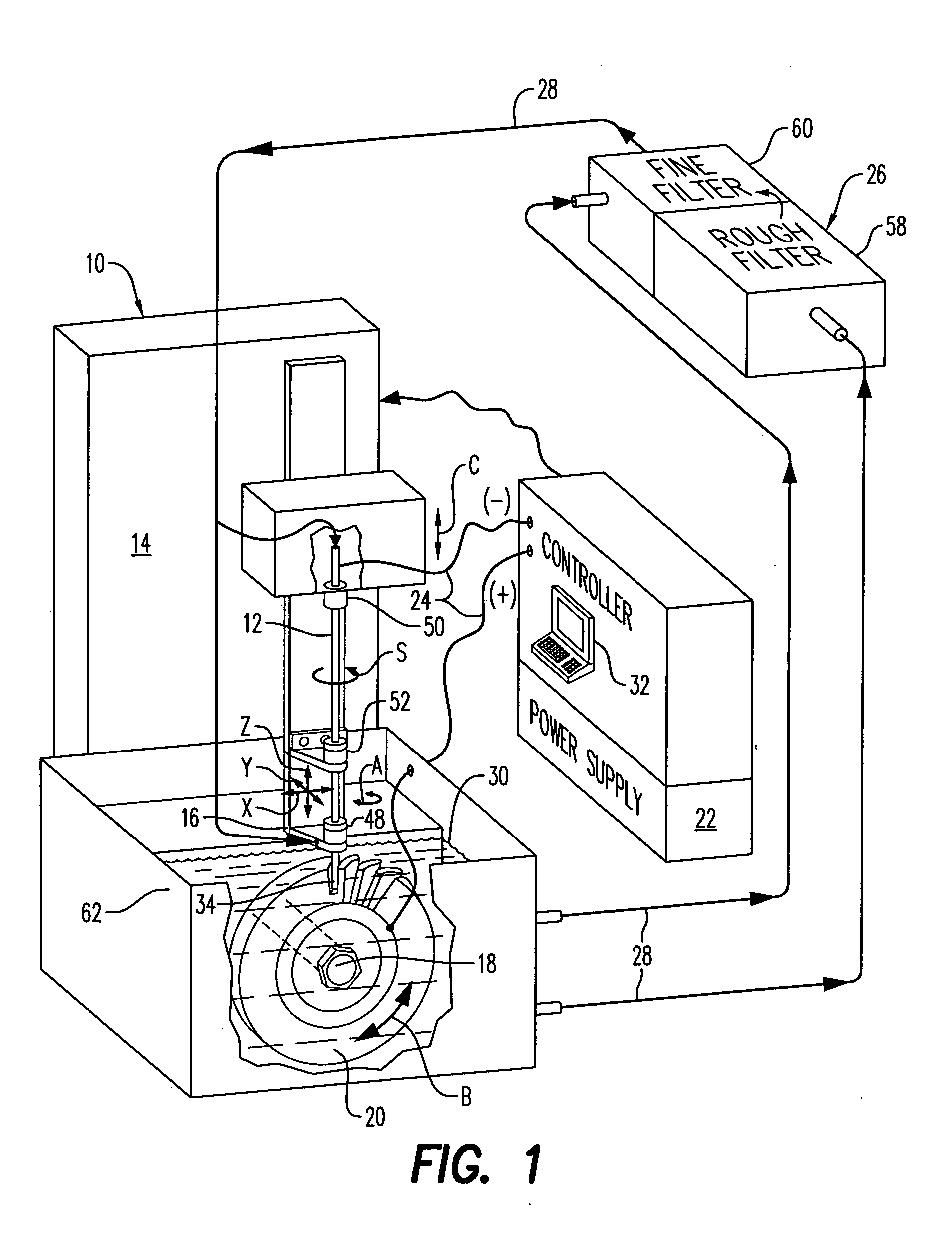

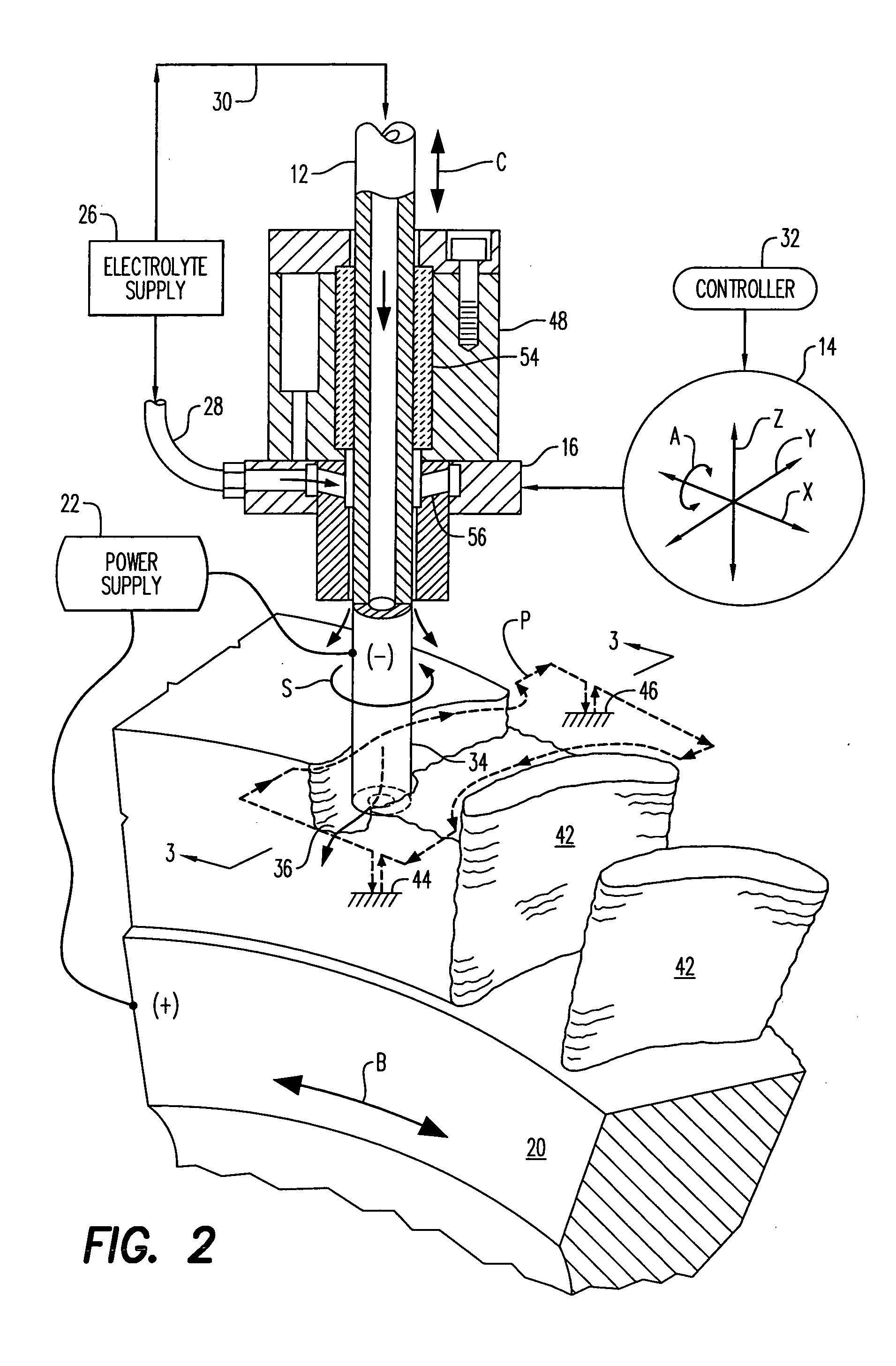

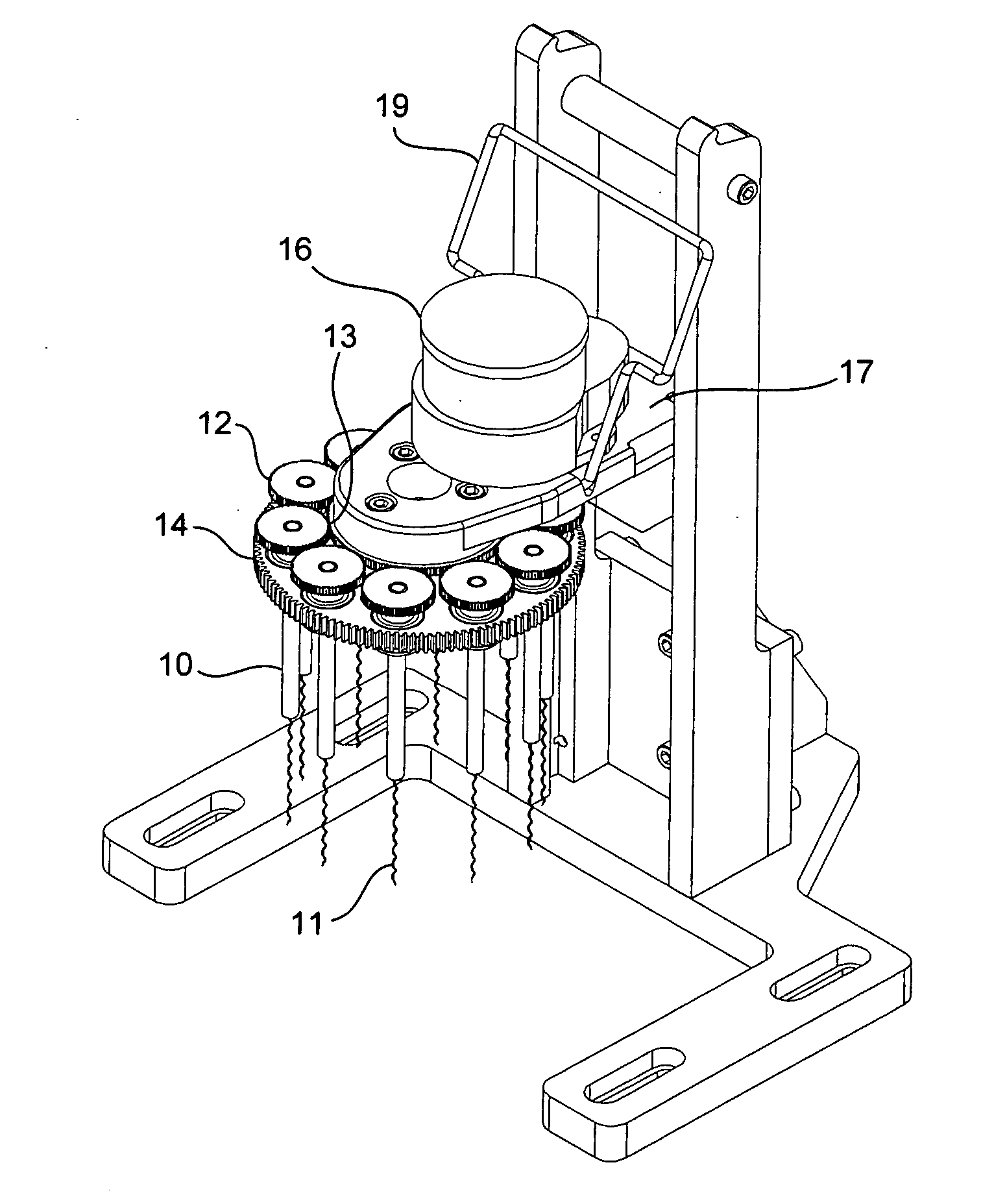

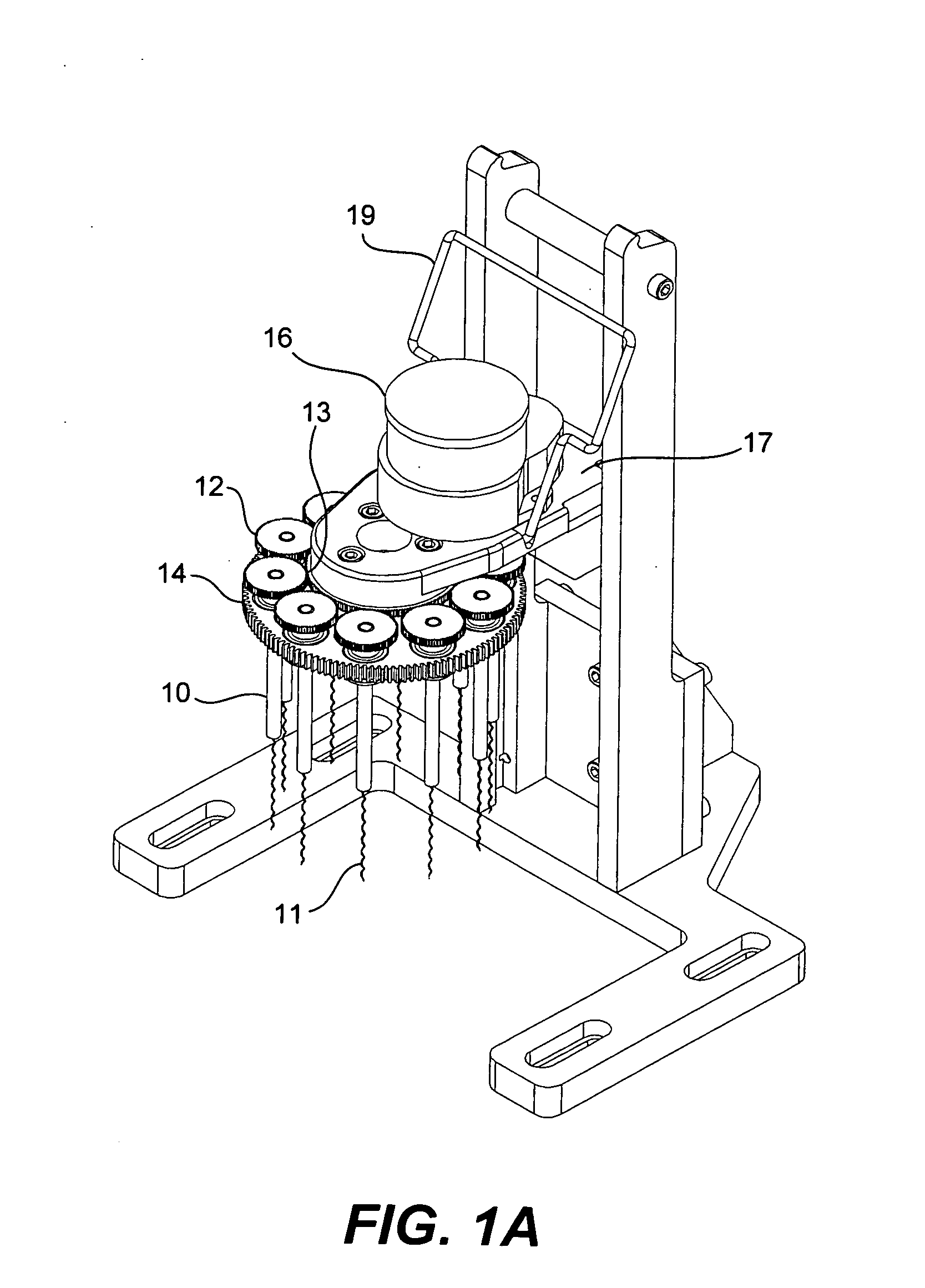

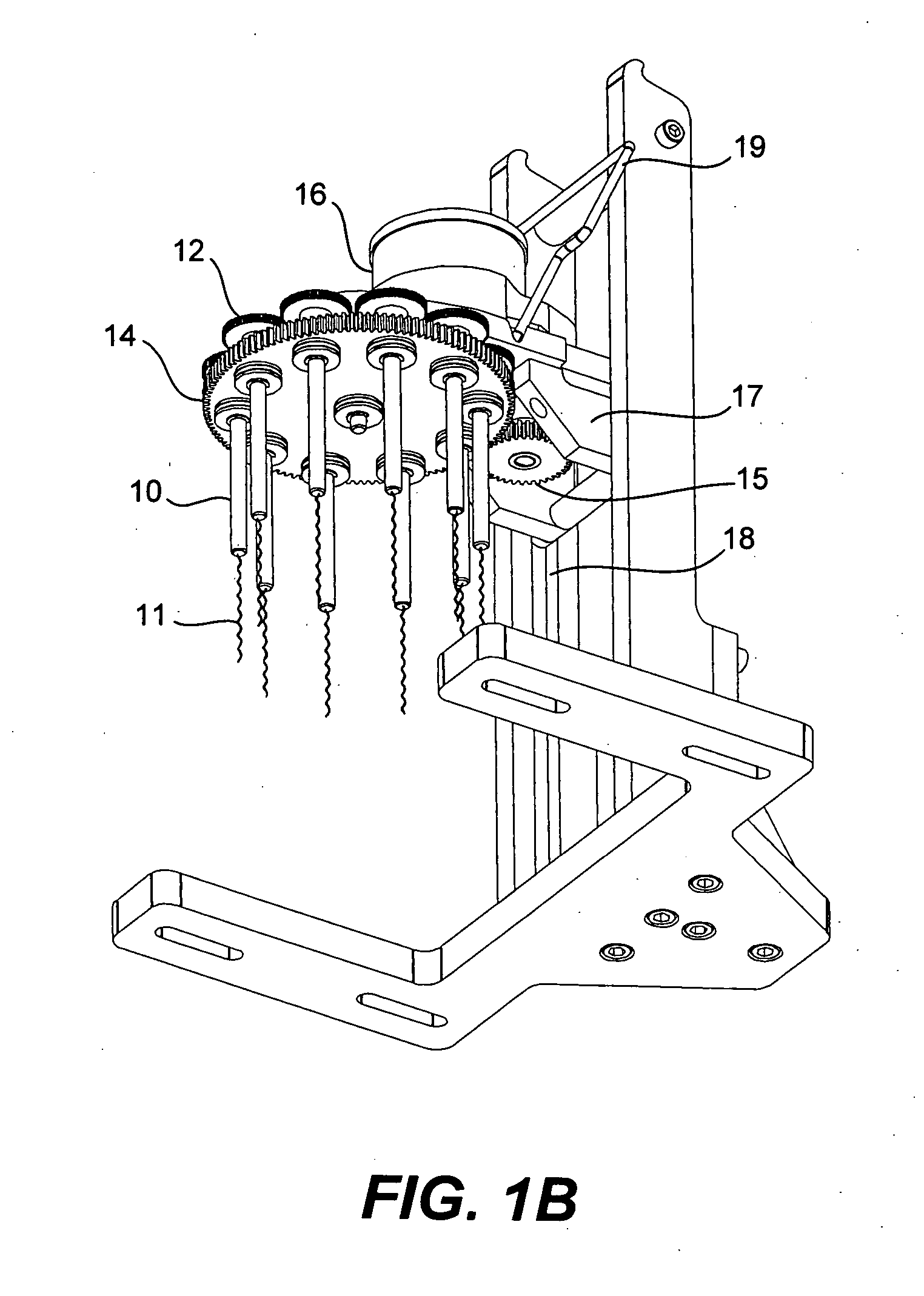

Distributed arc electroerosion

InactiveUS20050247569A1Easy to processMachining electrodesElectrolysis componentsElectricityEngineering

An electroerosion apparatus includes a tubular electrode supported in a tool head in a multiaxis machine. The machine is configured for spinning the electrode along multiple axes of movement relative to a workpiece supported on a spindle having an additional axis of movement. A power supply powers the electrode as a cathode and the workpiece as an anode. Electrolyte is circulated through the tubular electrode during operation. And, a controller is configured to operate the machine and power supply for distributing multiple electrical arcs between the electrode and workpiece for electroerosion thereof as the spinning electrode travels along its feedpath.

Owner:GENERAL ELECTRIC CO

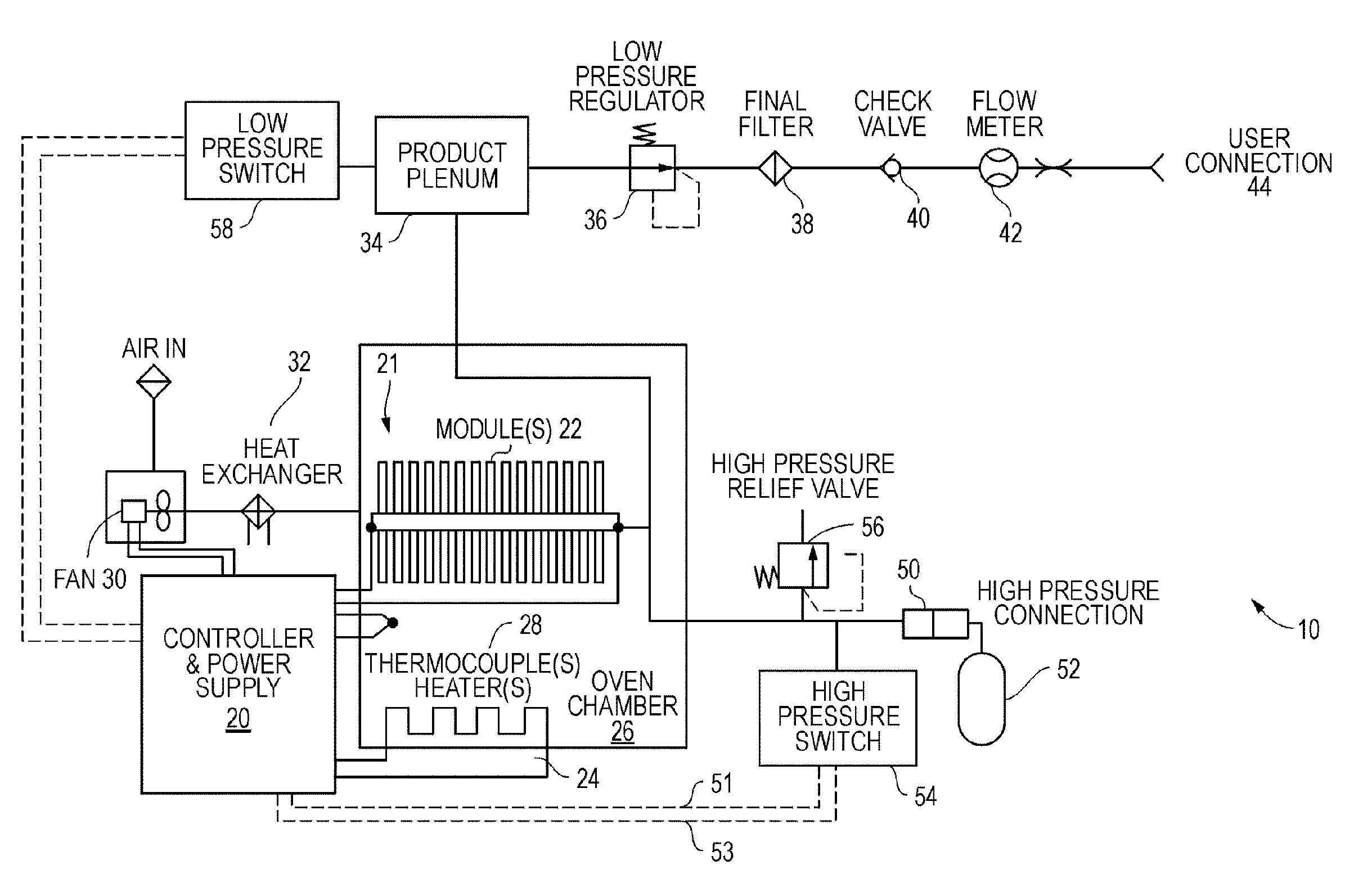

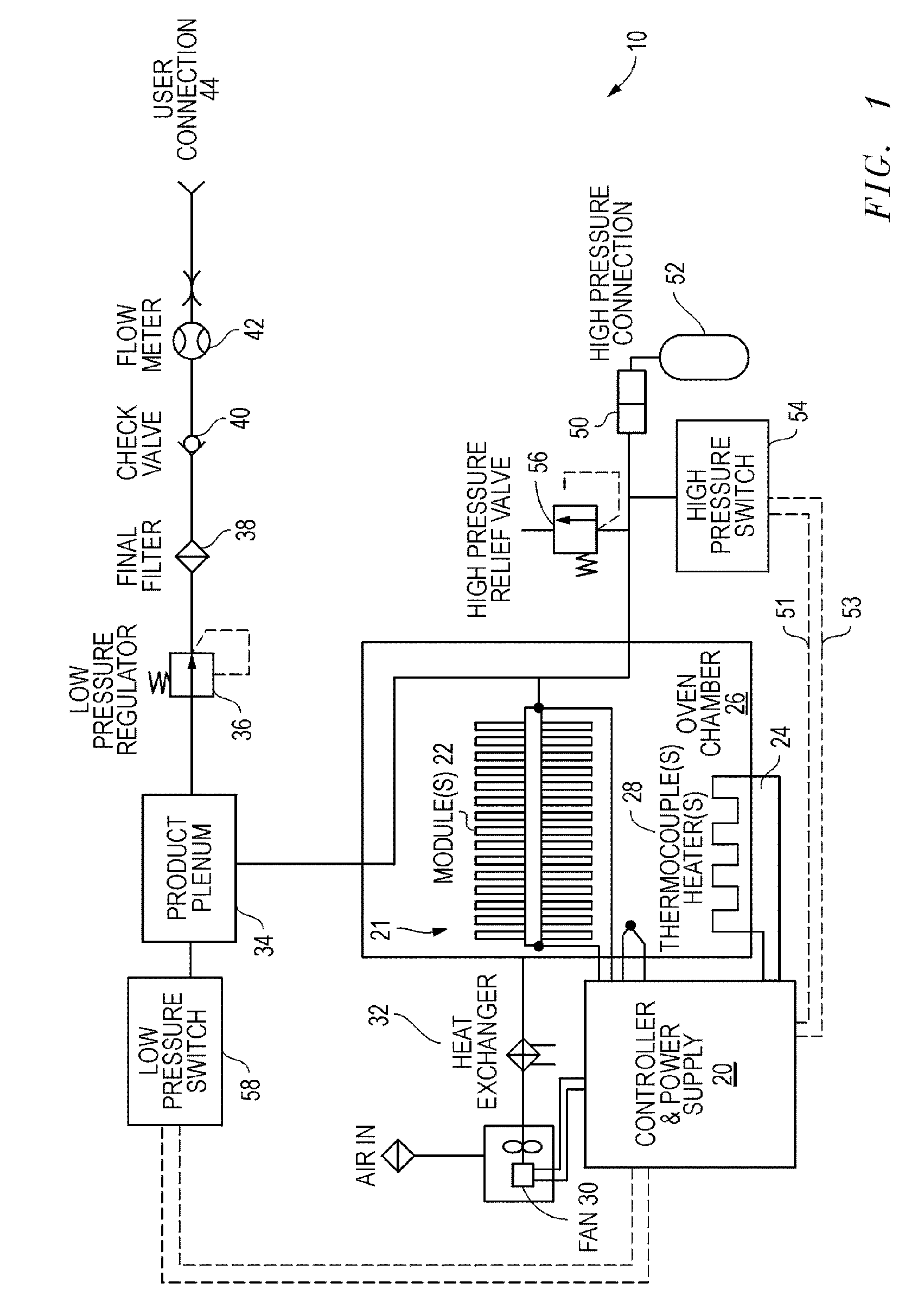

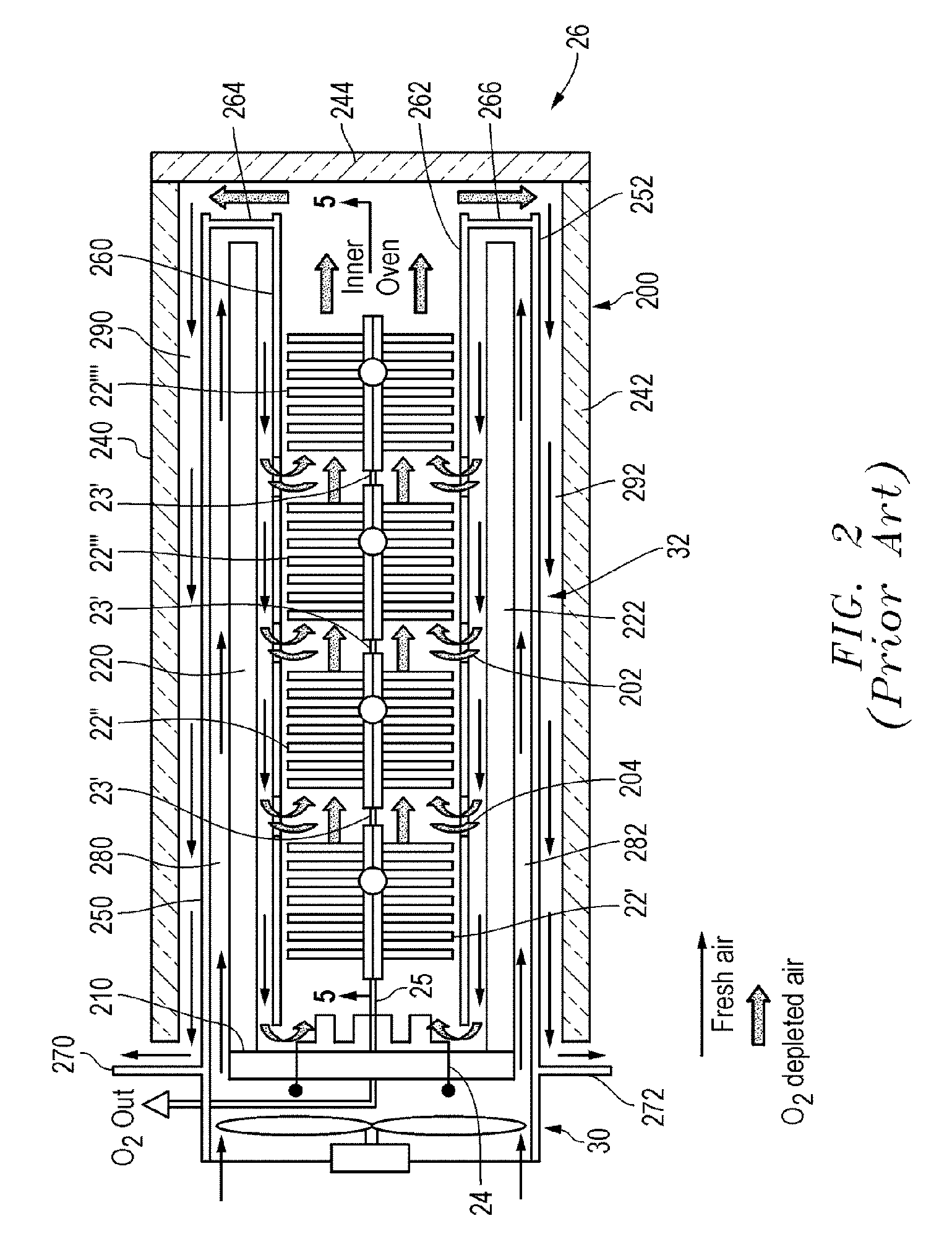

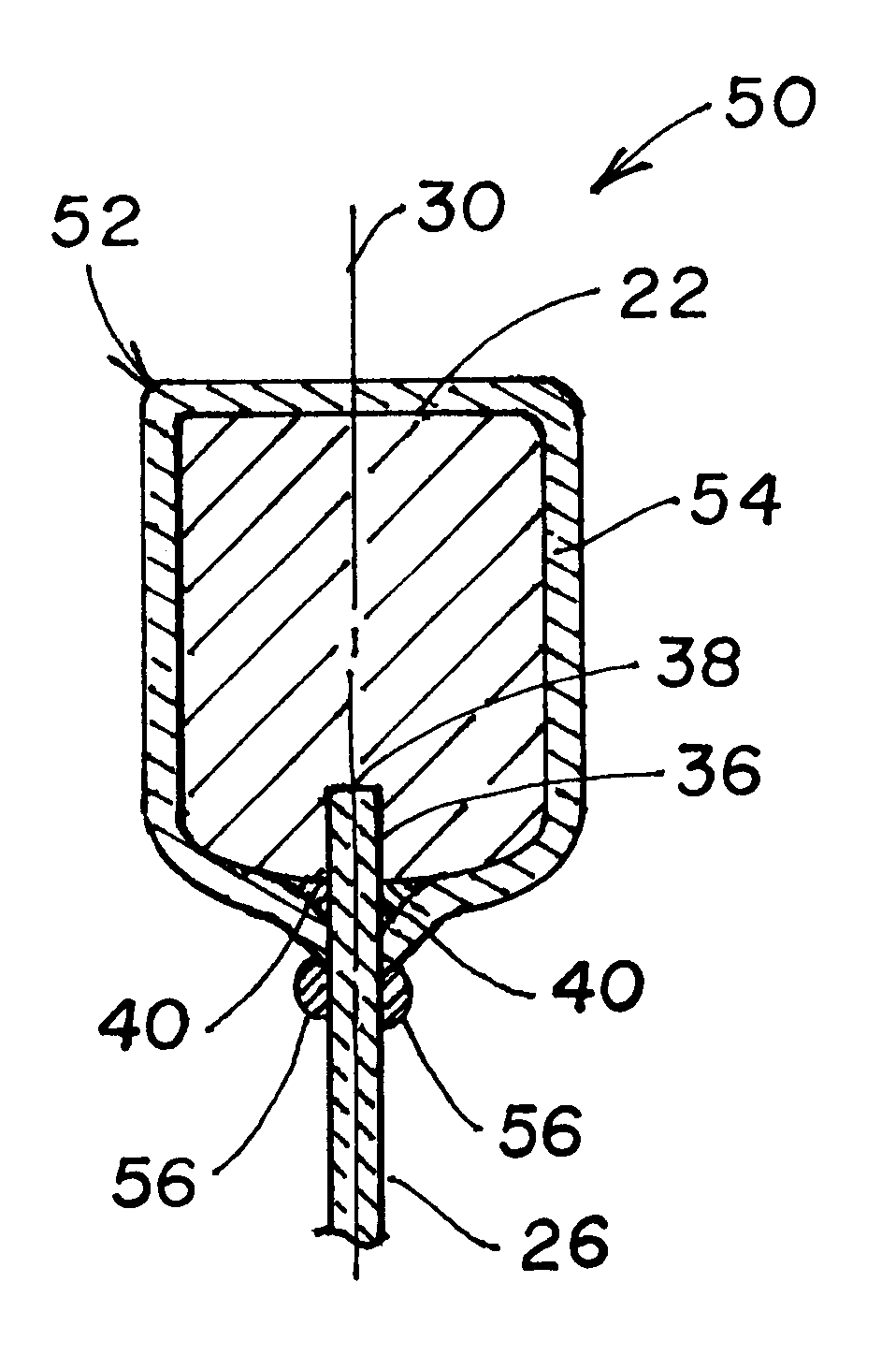

Electrochemical oxygen generator module assembly

ActiveUS20060175194A1Improve oxygen production performanceIncrease capacityPhotography auxillary processesElectrical-based machining electrodesInterior spaceEngineering

An ionically conductive ceramic element includes a central unit (703). The central unit (703) is composed of a plurality of integrated manifold and tube modules (IMAT) (22) joined end to end along a central axis (A). Each IMAT module (22) has a tube support portion (804) and a plurality of tubes (802) extending from the first surface (803). The tubes (802) each have a closed end (805) and an open end. The second surface (807) is at least partially open to the atmosphere. The open ends of the tubes (802) are open to the atmosphere through the second surface (807). An interior space (830) is formed in the interior of the IMAT (22) for collecting a desired product gas. A collection tube (710) is operable joined with a first end (714) of the central unit (703) for transporting the desired product gas collected in the interior space (730) of the connected IMAT modules (22).

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

Steel-clad cathode for electrolytic refining of copper

InactiveUS6569300B1Simplify the assembly processEnsure durabilityCellsMachining electrodesElectrical connectionCopper

An electrolytic cathode consists of a solid copper hanger bar and a stainless-steel mother plate attached to a receiving groove in the underside of the hanger bar. In the preferred embodiment of the invention, the entire length of connection is welded, thereby establishing a large boundary surface for good electrical conductance. The solid hanger bar further includes a cladding of stainless steel wrapped over the copper bar and the upper portion of the mother plate, leaving only the ends of the copper bar exposed for electrical connection with conventional bus-bars. The lower edges of the cover are attached to the mother plate by a steel-to-steel weld that produces a strong and durable connection. The lateral edges of the cover are also connected to the copper bar by a conventional copper weld that completely seals the cover over the copper bar, thereby preventing contamination from the electrolytic solution. The cover is then welded to the mother plate and sealed around the copper bar. The heat produced by the welding process, which causes the steel cladding material to expand during welding, is used to improve the tightness of the fit between the cover and the copper bar as a result of the cover's shrinkage occurring during cooling.

Owner:SAMUEL SON & CO USA INC

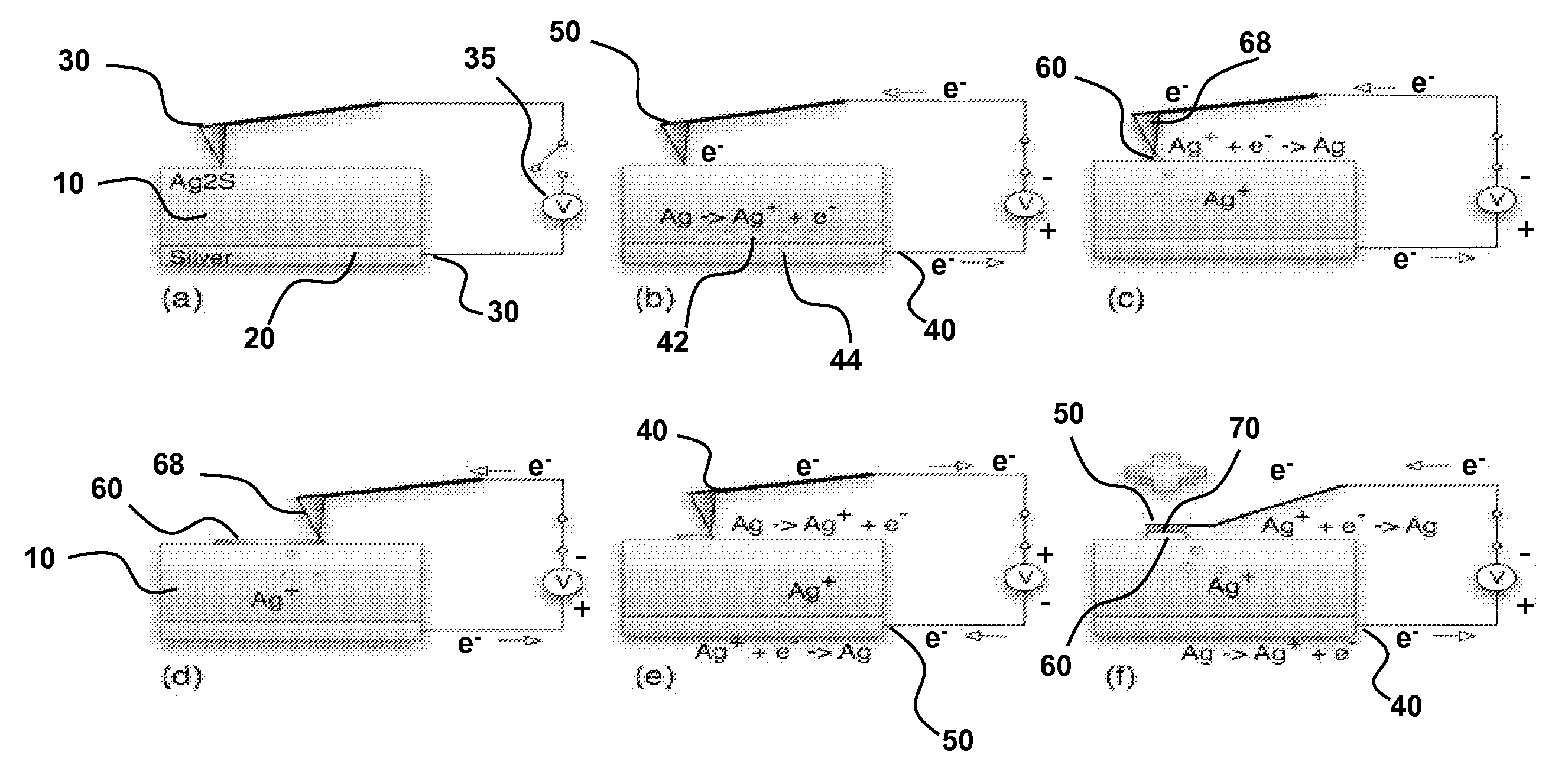

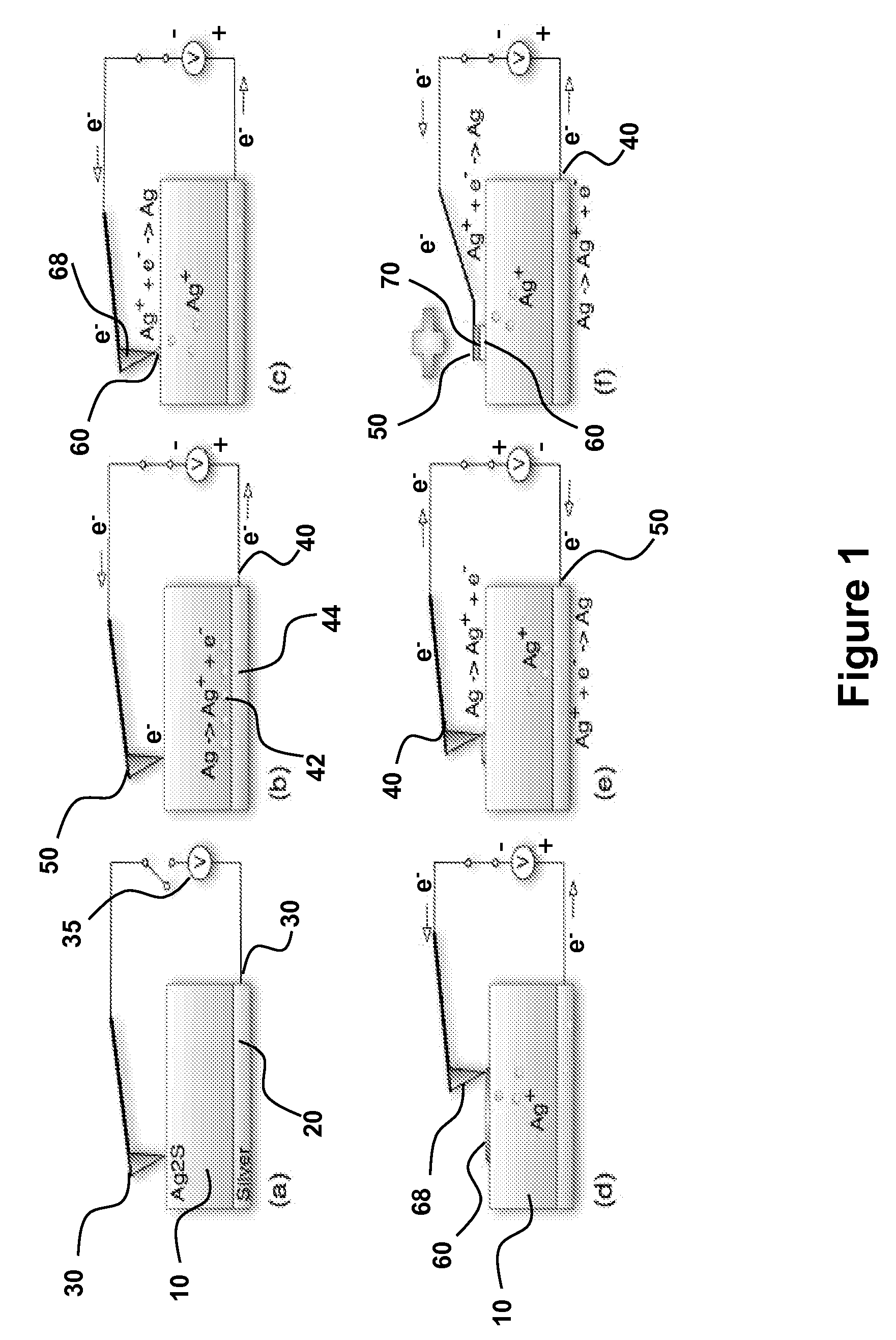

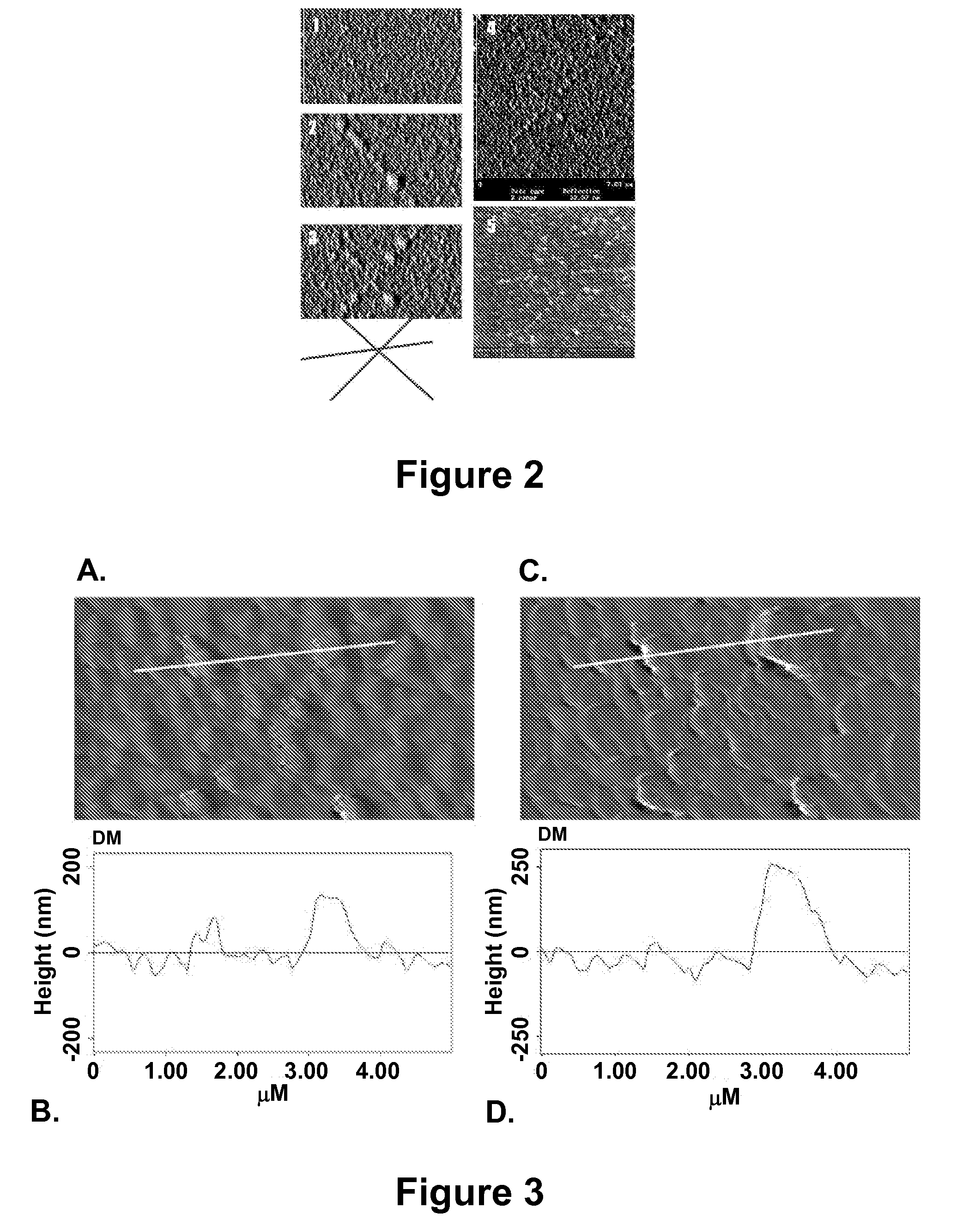

Direct Nanoscale Patterning of Metals Using Polymer Electrolytes

InactiveUS20090050487A1Improve throughputRobust and commercially attractive manufacturing pathwayMachining electrodesMaterial nanotechnologySpatial OrientationsElectrical conductor

Disclosed herein are electrochemical fabrication platforms for making structures, arrays of structures and functional devices having selected nanosized and / or microsized physical dimensions, shapes and spatial orientations. Methods, systems and system components use an electrochemical stamping tool such as solid state polymeric electrolytes for generating patterns of relief and / or recessed features exhibiting excellent reproducibility, pattern fidelity and resolution on surfaces of solid state ionic conductors and in metal. Electrochemical stamping tools are capable high throughput patterning of large substrate areas, are compatible with commercially attractive manufacturing pathways to access a range of functional systems and devices including nano- and micro-electromechanical systems, sensors, energy storage devices, metal masks for printing, interconnects, and integrated electronic circuits.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

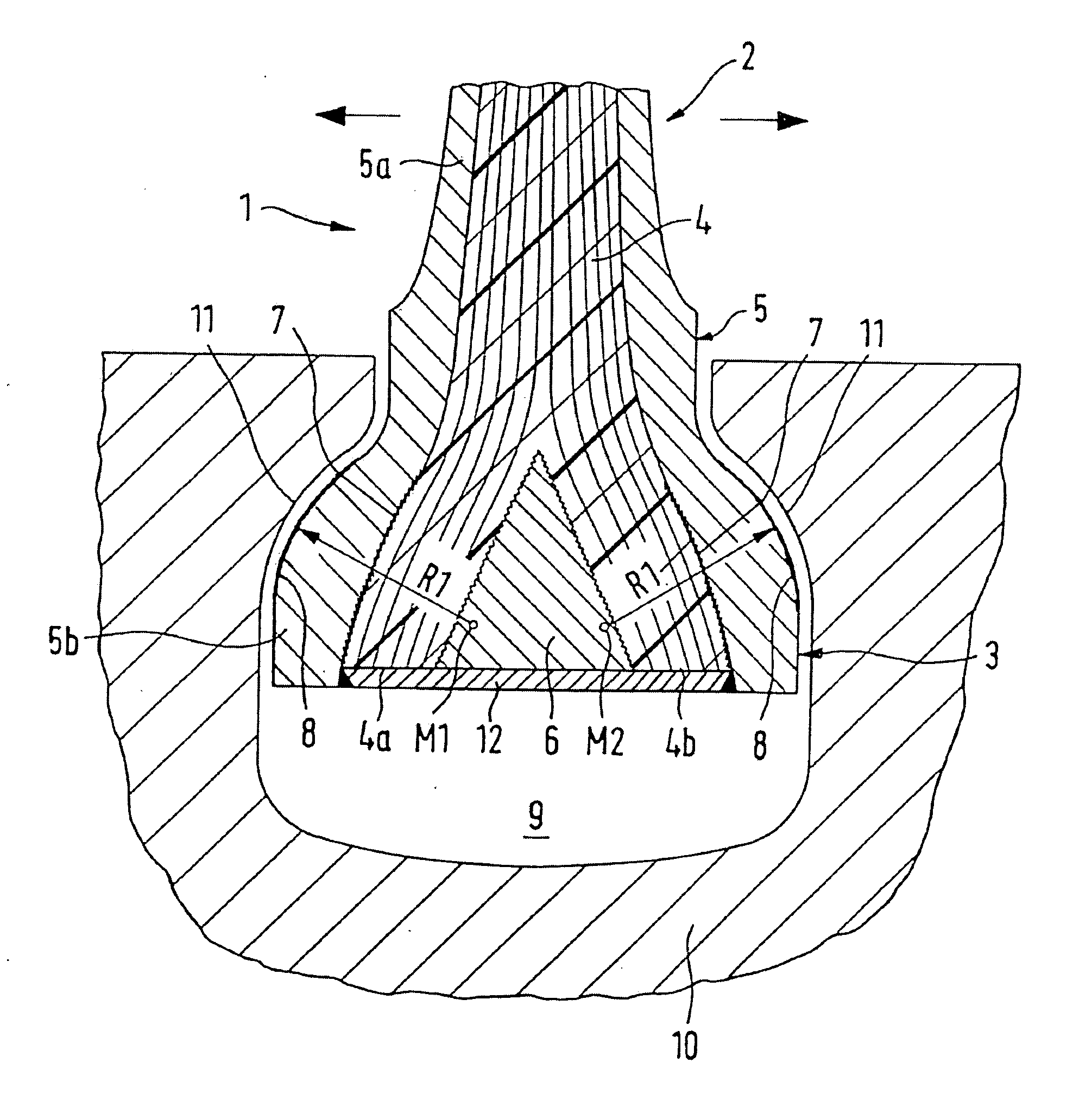

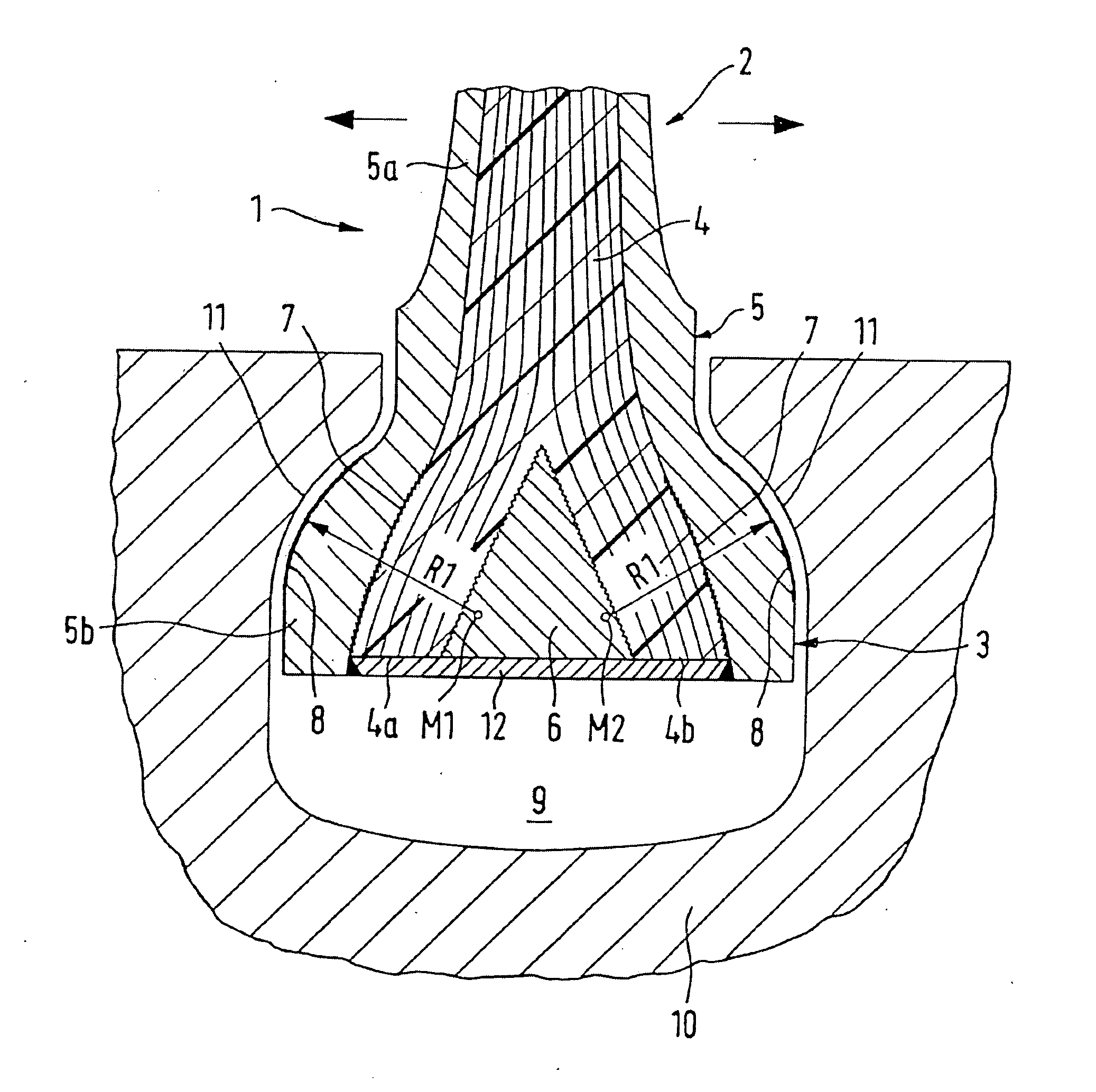

Compressor blade root for engine blades of aircraft engines

InactiveUS20050084379A1Taking up and transferring high forceEasy to usePropellersPump componentsMicro structureMetallic enclosure

Owner:ROLLS ROYCE DEUT LTD & CO KG

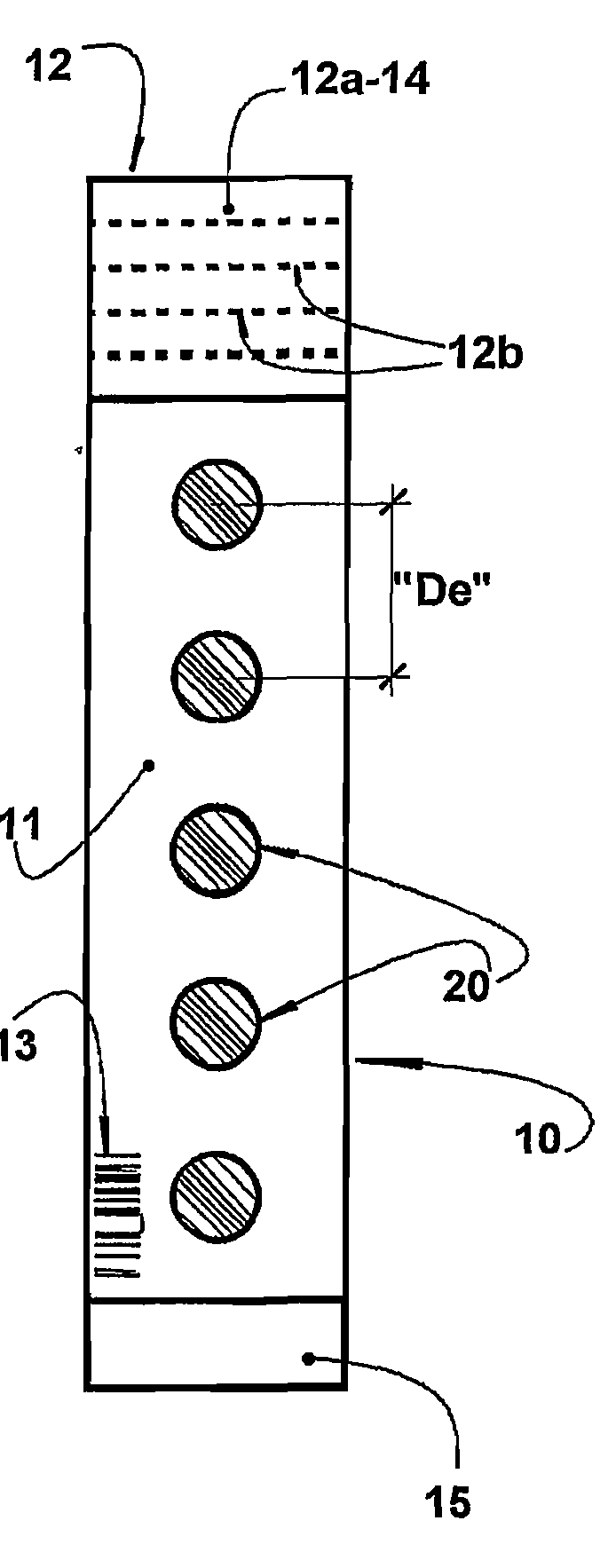

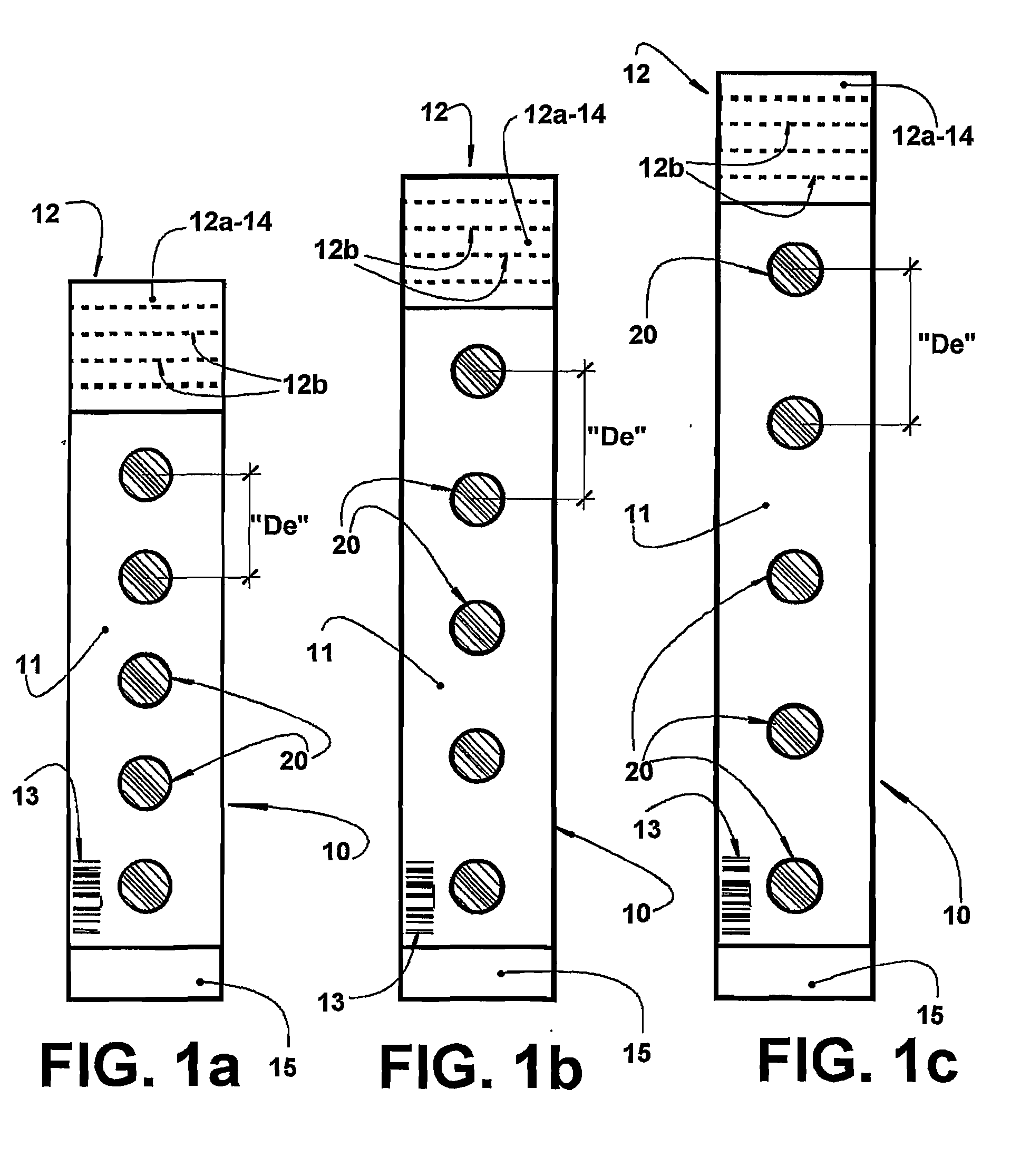

Electrode assembly for electrical impedance tomography

InactiveUS20090084674A1Machining electrodesDiagnostic recording/measuringElectrical resistance and conductanceElectrical impedance tomography

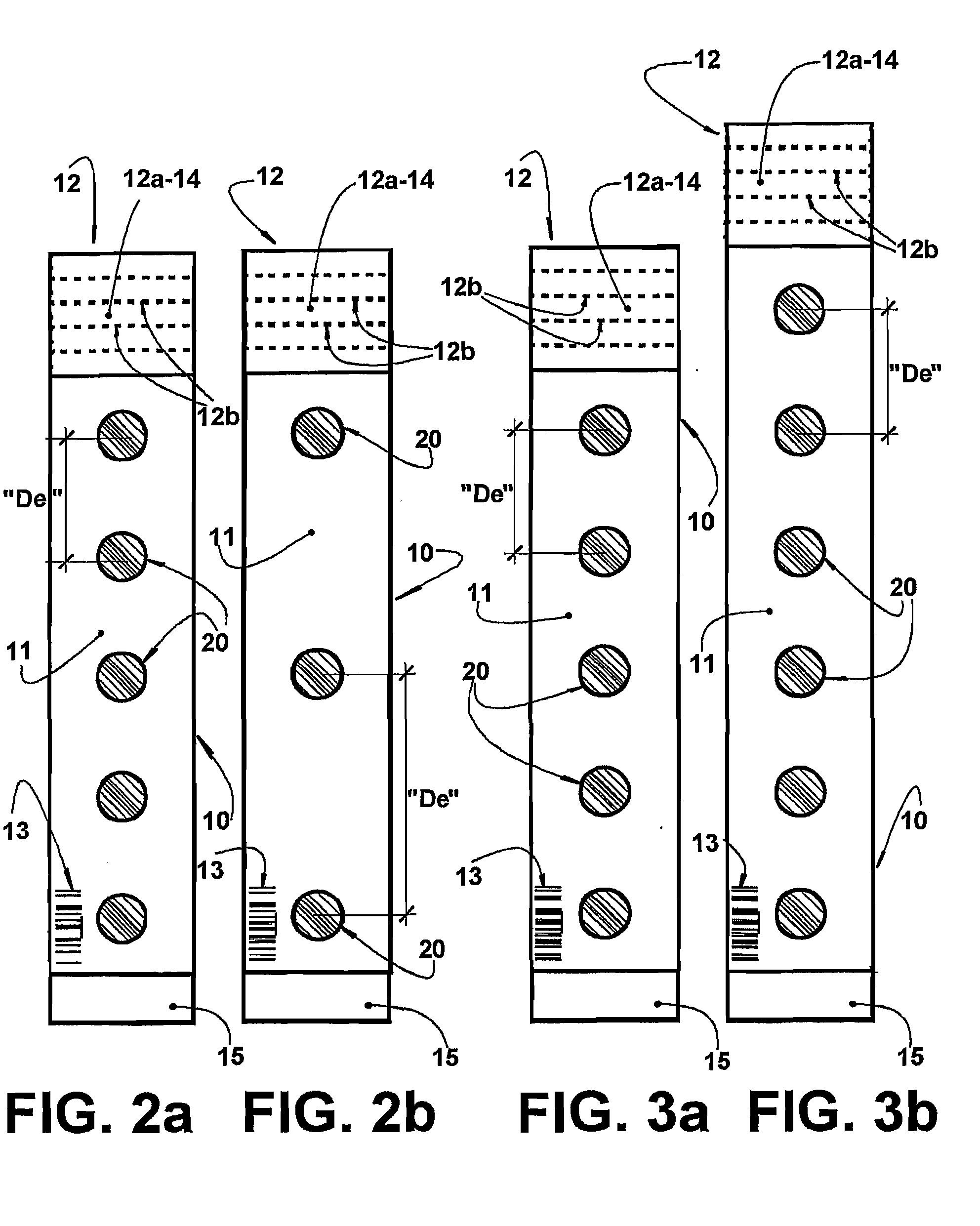

An electrode assembly for electrical impedance tomography comprising a plurality of different electrode modules, each containing a support strap made of a flexible material that presents a reduced longitudinal deformability and carrying a predetermined number of electrodes, each support strap being dimensioned to be seated and retained onto a respective extension portion of a body segment of a patient. Each electrode module presents the number of electrodes and a distance ‘De’ between each two consecutive electrodes predetermined as a function of a specific operational pattern to be obtained from each electrode module. The assembly can further comprise an electrical conducting cable having an end connected to a monitoring apparatus and a free end provided with a connector to be coupled to a respective electrode of an electrode module.

Owner:TIMPEL MEDICAL BV

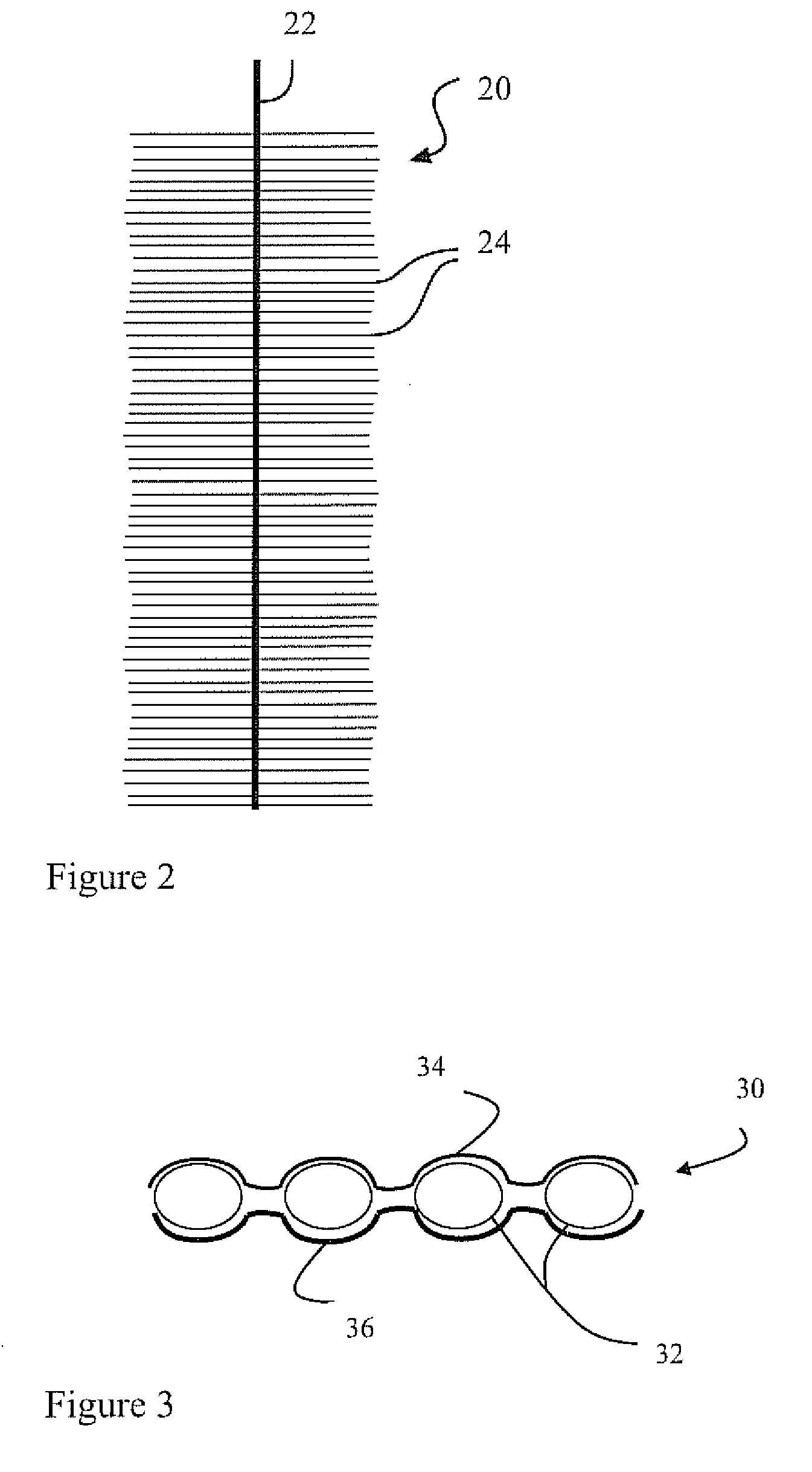

Electrode with transparent series resistance for uniform switching of optical modulation devices

InactiveUS7317566B2Improves switching uniformityIncrease resistanceMachining electrodesMultiplier circuit arrangementsElectrical resistance and conductanceElectrical conductor

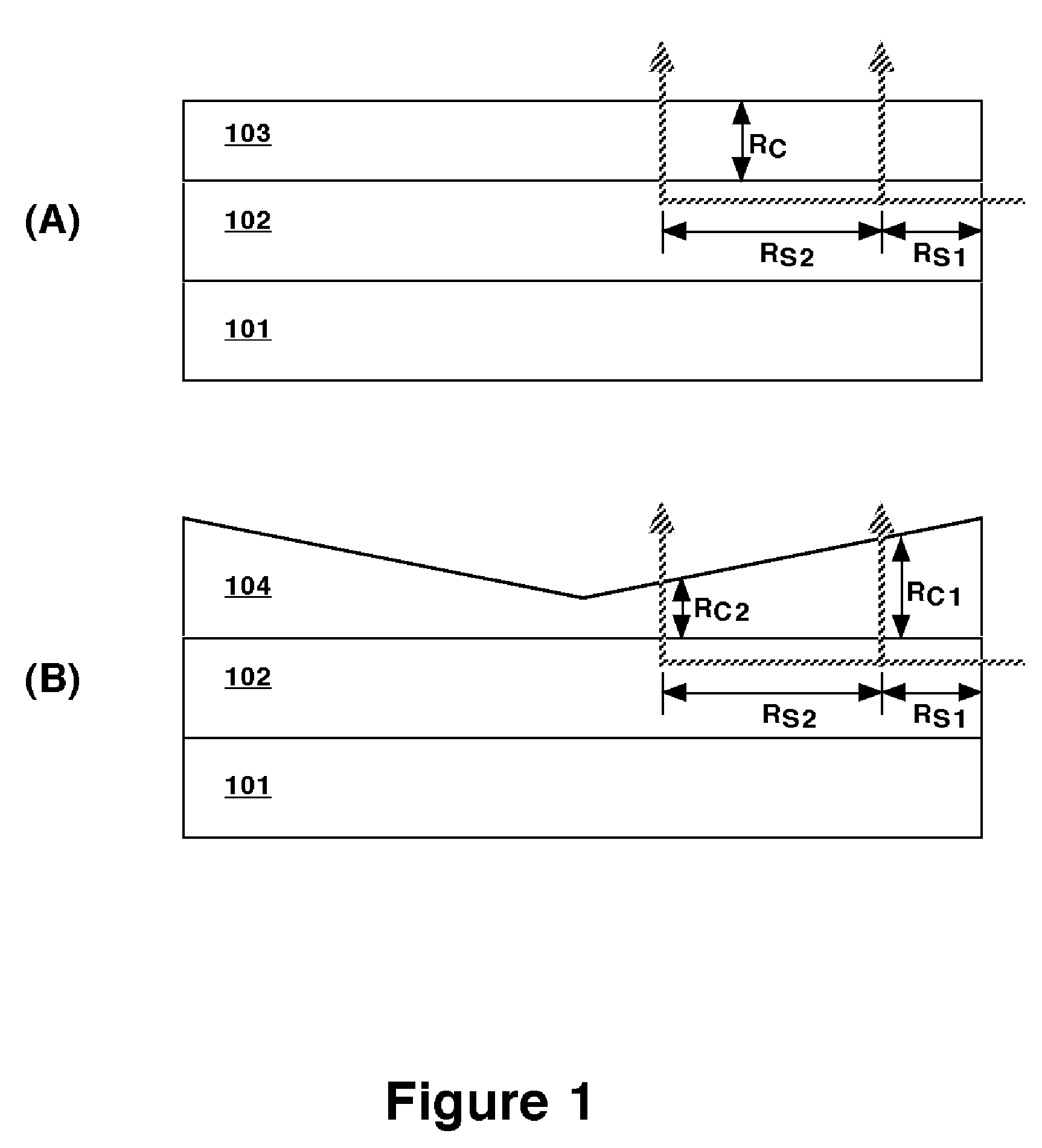

Switching uniformity of an optical modulation device for controlling the propagation of electromagnetic radiation is improved by use of an electrode comprising an electrically resistive layer that is transparent to the radiation. The resistive layer is preferably an innerlayer of a wide-bandgap oxide sandwiched between layers of indium tin oxide or another transparent conductor, and may be of uniform thickness, or may be graded so as to provide further improvement in the switching uniformity. The electrode may be used with electrochromic and reversible electrochemical mirror (REM) smart window devices, as well as display devices based on various technologies.

Owner:TELEDYNE SCI & IMAGING

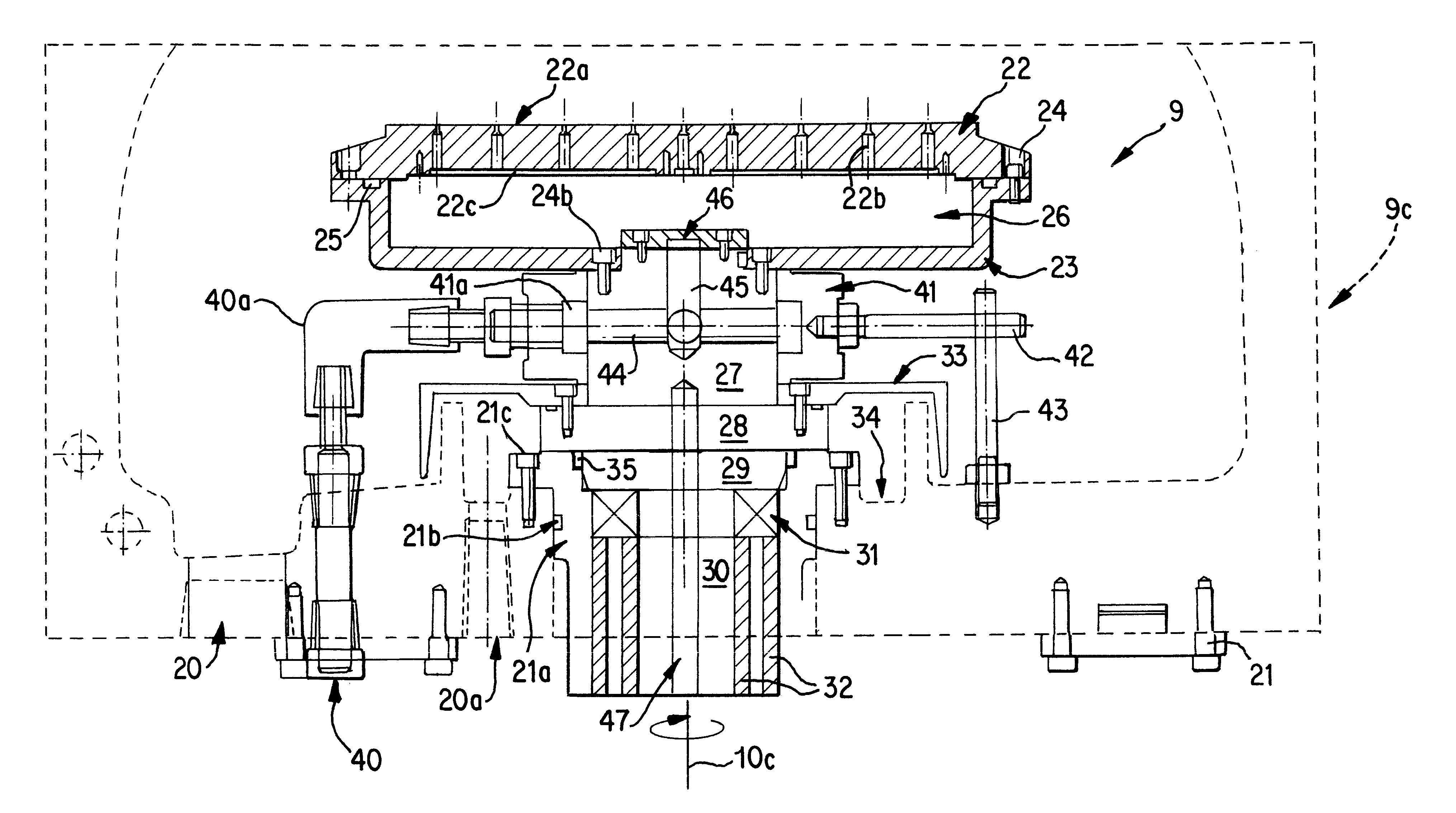

Anode assembly for plating and planarizing a conductive layer

A particular anode assembly can be used to supply a solution for any of a plating operation, a planarization operation, and a plating and planarization operation to be performed on a semiconductor wafer. The anode assembly includes a rotatable shaft disposed within a chamber in which the operation is performed, an anode housing connected to the shaft, and a porous pad support plate attached to the anode housing. The support plate has a top surface adapted to support a pad which is to face the wafer, and, together with the anode housing, defines an anode cavity. A consumable anode may be provided in the anode cavity to provide plating material to the solution. A solution delivery structure by which the solution can be delivered to said anode cavity is also provided. The solution delivery structure may be contained within the chamber in which the operation is performed. A shield can also be mounted between the shaft and an associated spindle to prevent leakage of the solution from the chamber.

Owner:NOVELLUS SYSTEMS

Photoelectrochemical device and electrode

In one aspect, the invention provides a photoelectrochemical (PEC) electrode or photoelectrode for use in splitting water by electrolysis. The photoelectrode has an electrically conductive surface in contact with an electrolyte solution. This surface is a doped tin oxide layer, which is in electrical contact with the semiconductor solar cell material of the PEC photoelectrode. In a variation of the present invention, another layer of metal oxide having transparent, anti-reflective, and conductive properties is disposed between the doped tin oxide layer and the semiconductor material.

Owner:GM GLOBAL TECH OPERATIONS LLC

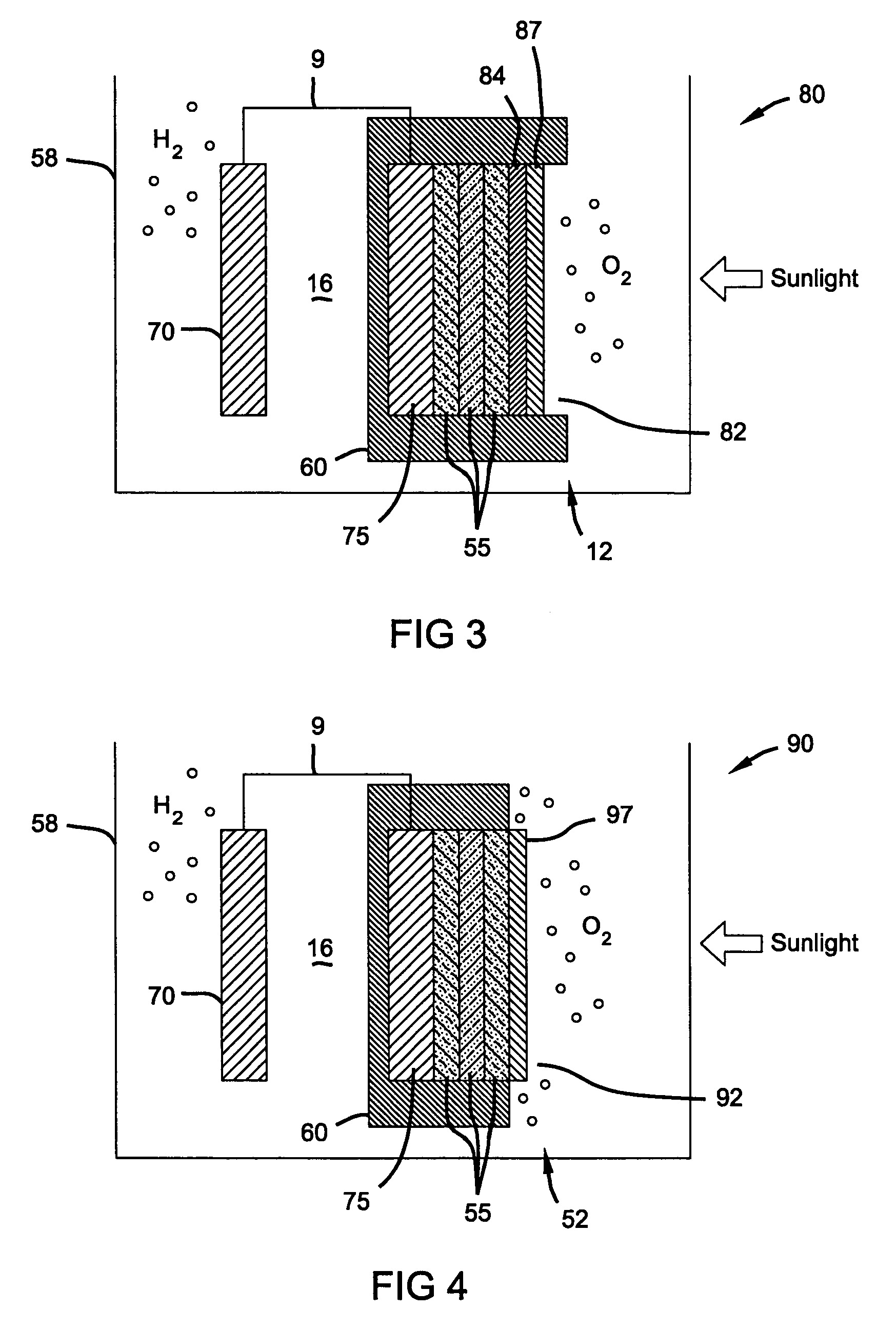

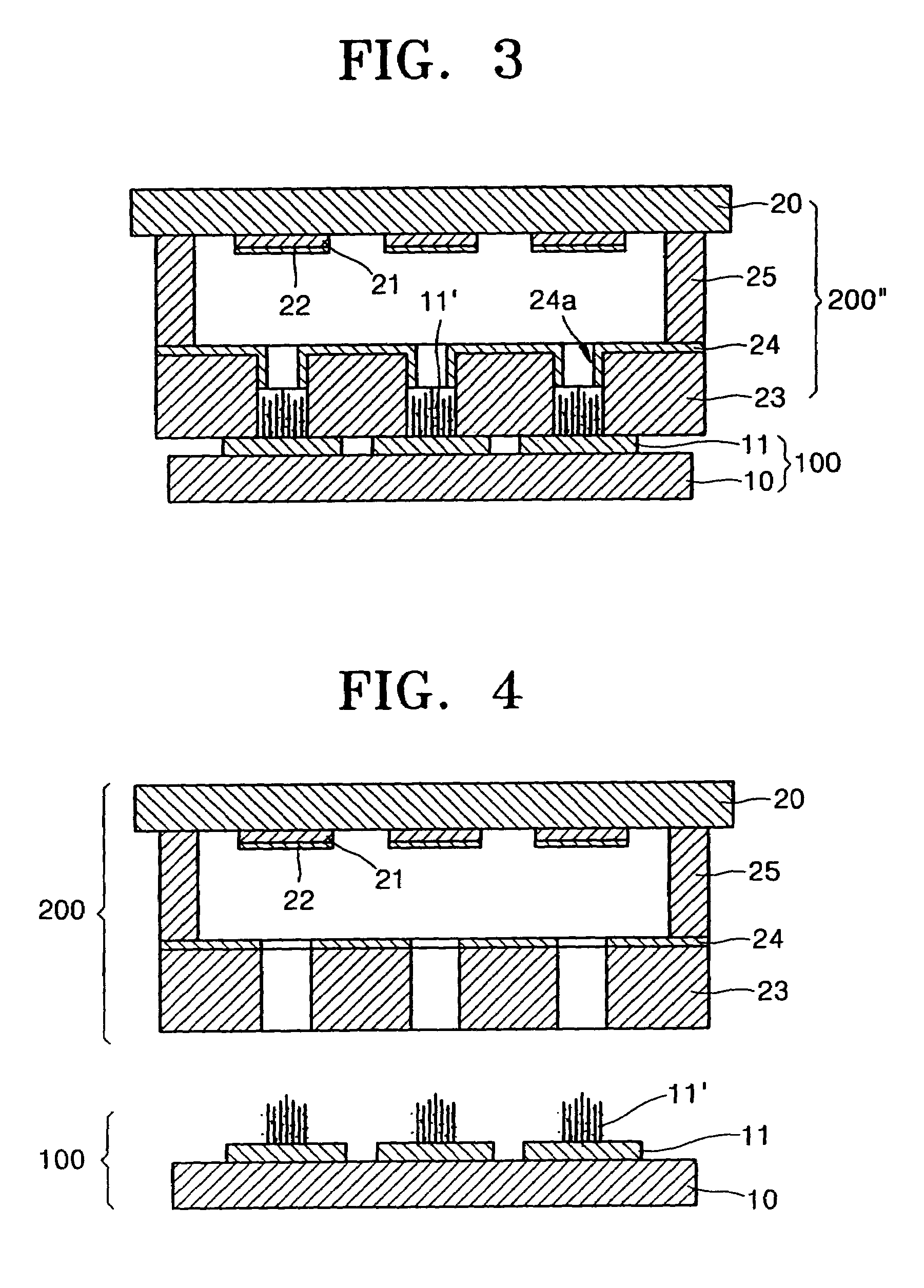

Field emission array with carbon nanotubes and method for fabricating the field emission array

InactiveUS6976897B2Simple film formationTube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersPhosphorCarbon nanotube

A field emission array adopting carbon nanotubes as an electron emitter source, wherein the array includes a rear substrate assembly including cathodes formed as stripes over a rear substrate and carbon nanotubes; a front substrate assembly including anodes formed as stripes over a front substrate with phosphors being deposited on the anodes, a plurality of openings separated by a distance corresponding to the distance between the anodes in a nonconductive plate, and gates formed as stripes perpendicular to the stripes of anodes on the nonconductive plate with a plurality of emitter openings corresponding to the plurality of openings. The nonconductive plate is supported and separated from the front substrate using spacers. The rear substrate assembly is combined with the front substrate assembly such that the carbon nanotubes on the cathodes project through the emitter openings.

Owner:SAMSUNG SDI CO LTD

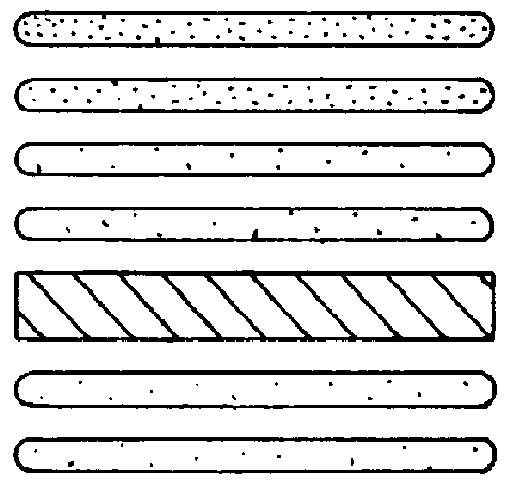

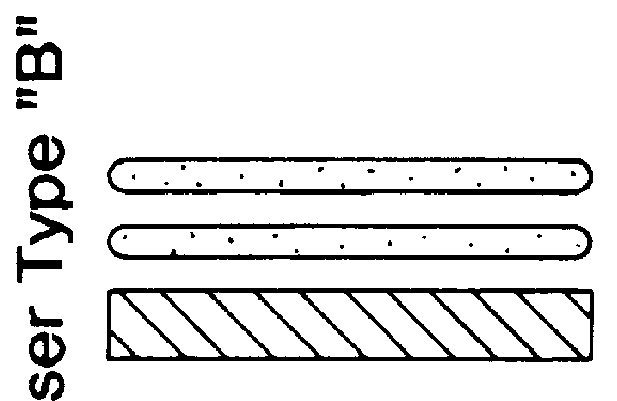

Multi-layer non-carbon metal-based anodes for aluminum production cells and method

InactiveUS6077415AImprove electrochemical activitySolution to short lifeMachining electrodesIsotope separationElectrical batteryOxygen ions

A composite, high-temperature resistant, non-carbon metal-based anode of a cell for the electrowinning of aluminium comprises a metal-based core structure of low electrical resistance, for connecting the anode to a positive current supply, coated with a series of superimposed, adherent, electrically conductive layers. These layers consist of at least one layer on the core structure constituting a barrier substantially impervious to monoatomic oxygen and molecular oxygen; one or more intermediate, protective layers on the oxygen barrier layer which remain inactive in the reactions for the evolution of oxygen gas; and an electrochemically active layer for the oxidation reaction of oxygen ions present at the anode / electrolyte interface into nascent monoatomic oxygen, as well as for subsequent reaction for the formation of gaseous biatomic oxygen. The active layer on the outermost intermediate layer is slowly consumable during electrolysis and protects the intermediate protective layer by inhibiting its dissolution into the electrolyte.

Owner:MOLTECH INVENT

Cathodes for microbial electrolysis cells and microbial fuel cells

An apparatus is provided according to embodiments of the present invention which includes a reaction chamber having a wall defining an interior of the reaction chamber and an exterior of the reaction chamber; exoelectrogenic bacteria disposed in the interior of the reaction chamber; an aqueous medium having a pH in the range of 3-9, inclusive, the aqueous medium including an organic substrate oxidizable by exoelectrogenic bacteria and the medium disposed in the interior of the reaction chamber. An inventive apparatus further includes an anode at least partially contained within the interior of the reaction chamber; and a brush or mesh cathode including stainless steel, nickel or titanium, the cathode at least partially contained within the interior of the reaction chamber.

Owner:PENN STATE RES FOUND

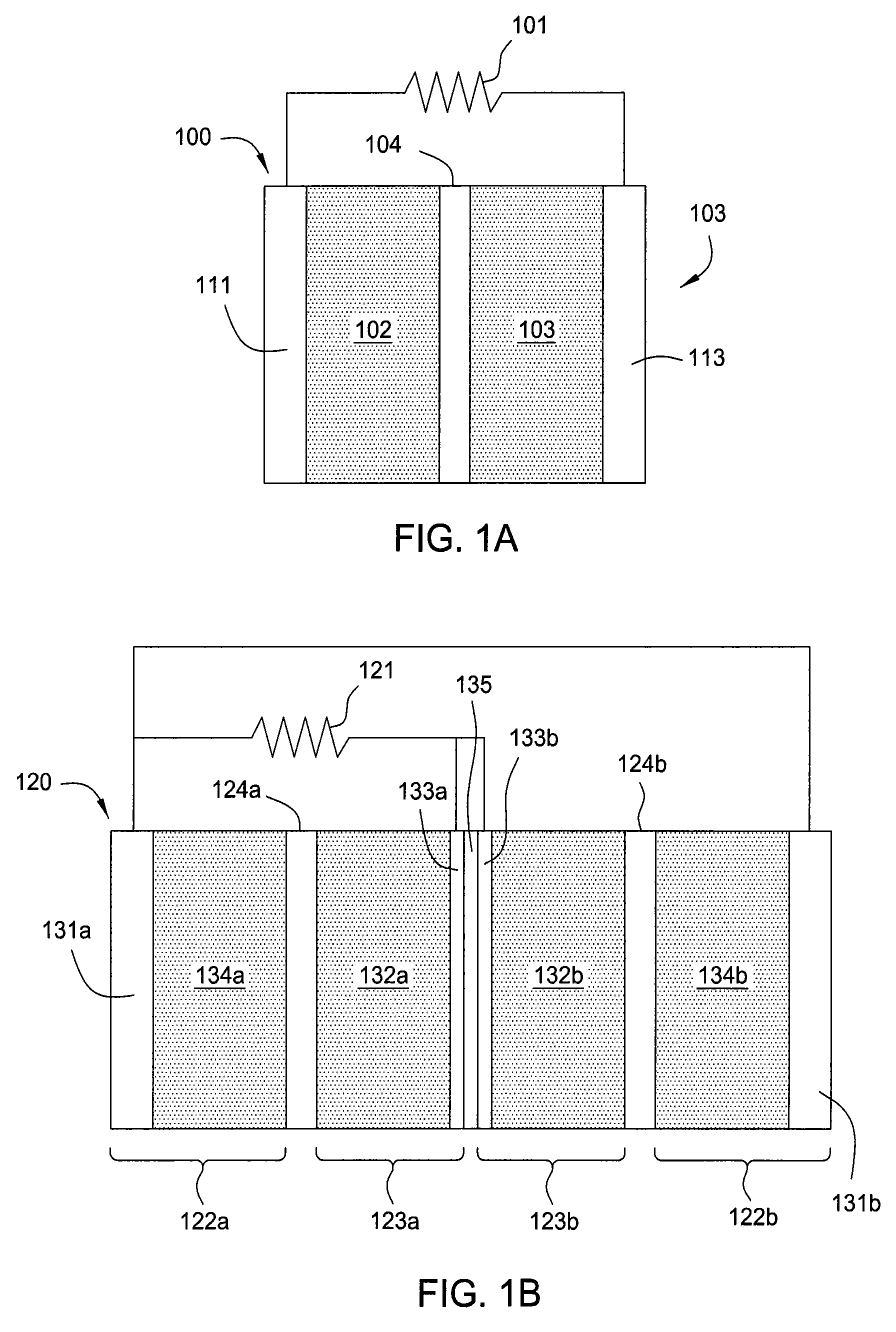

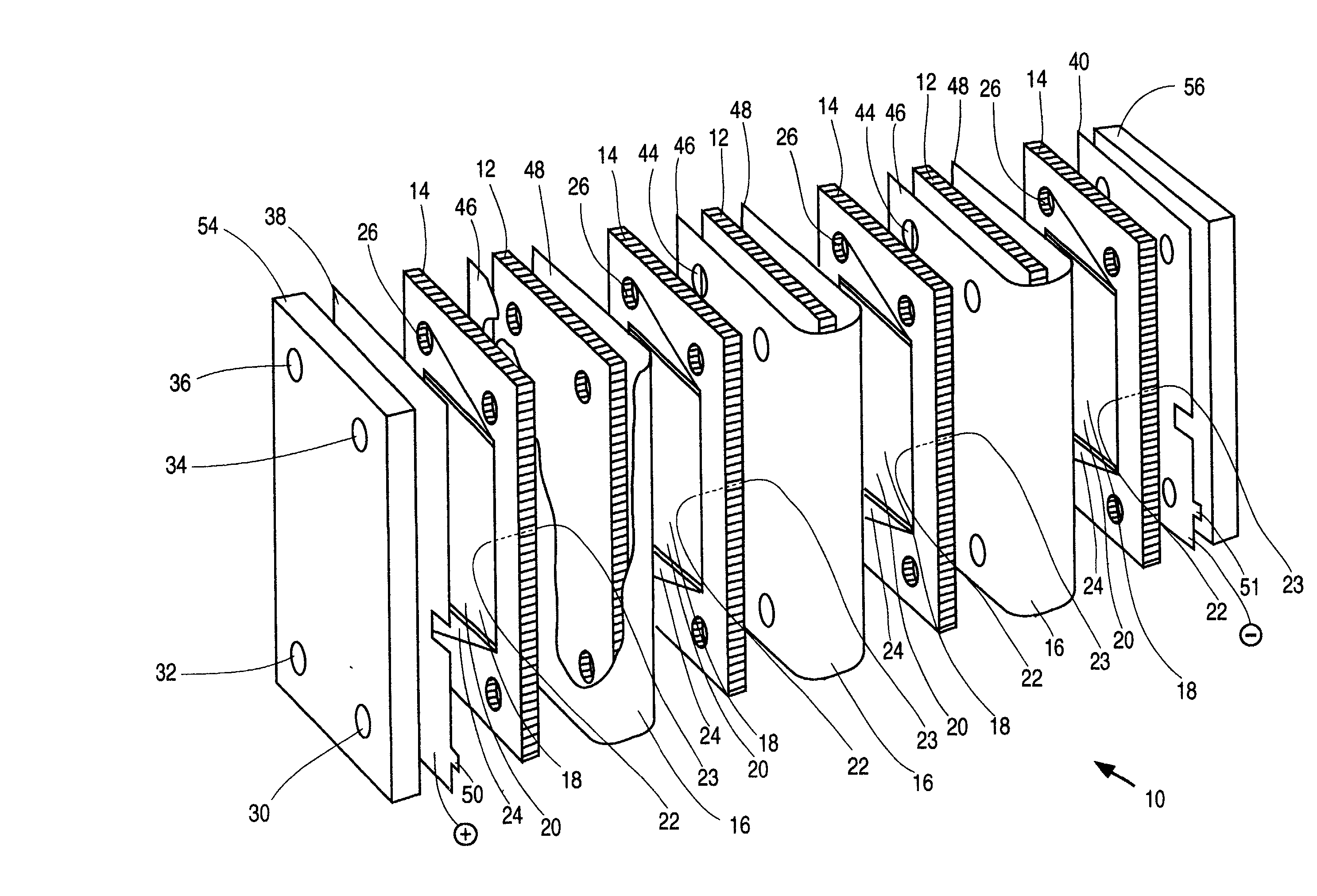

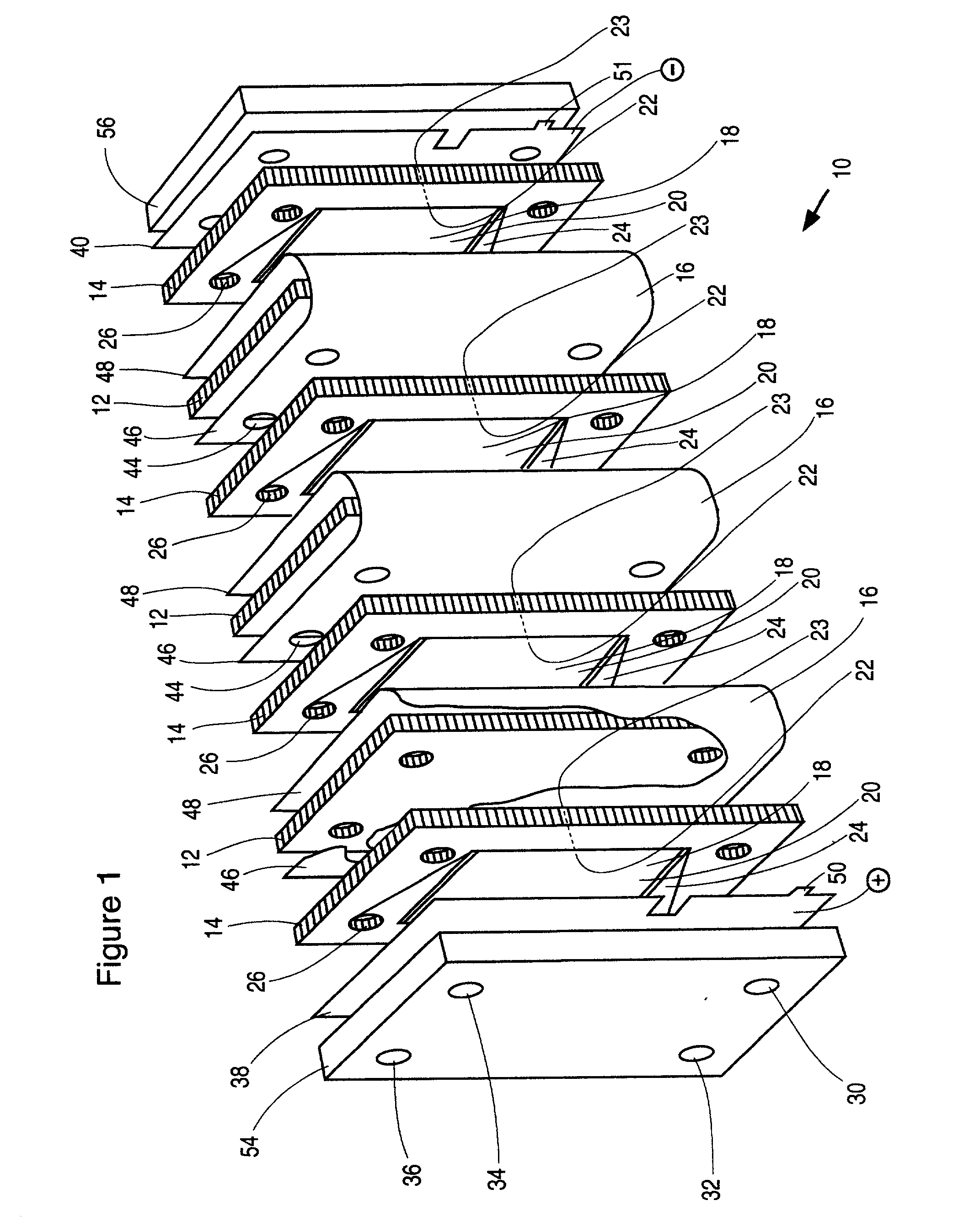

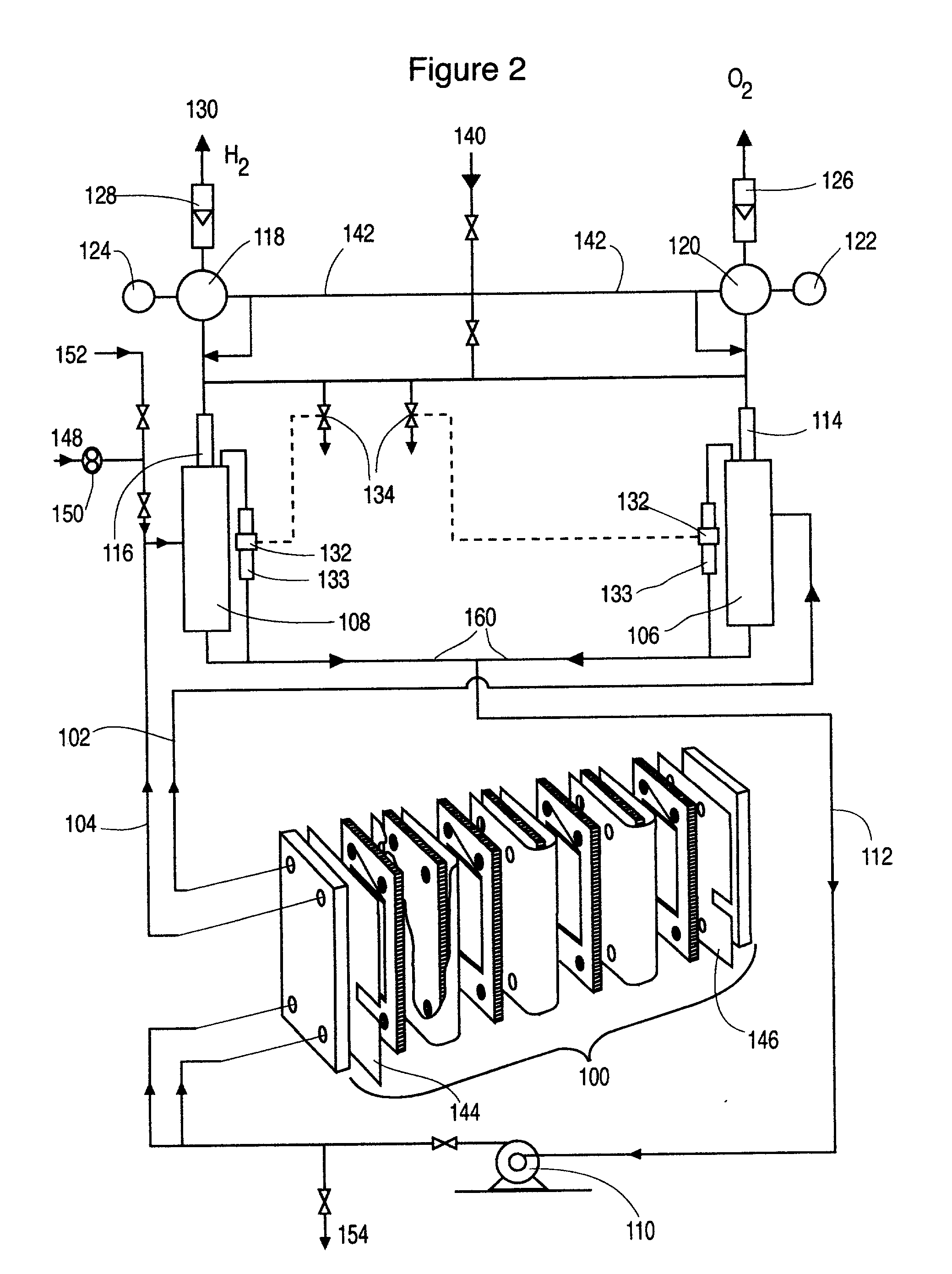

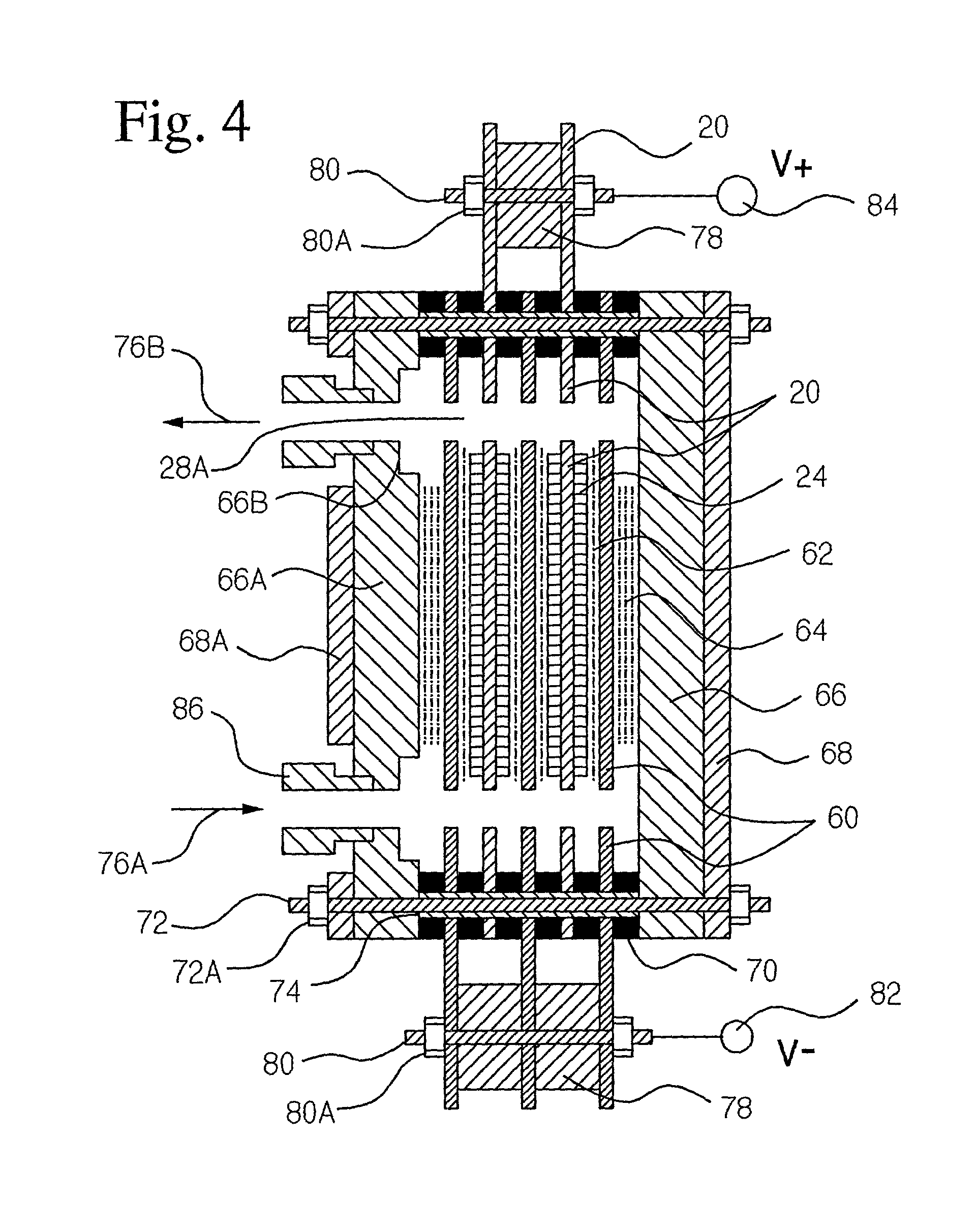

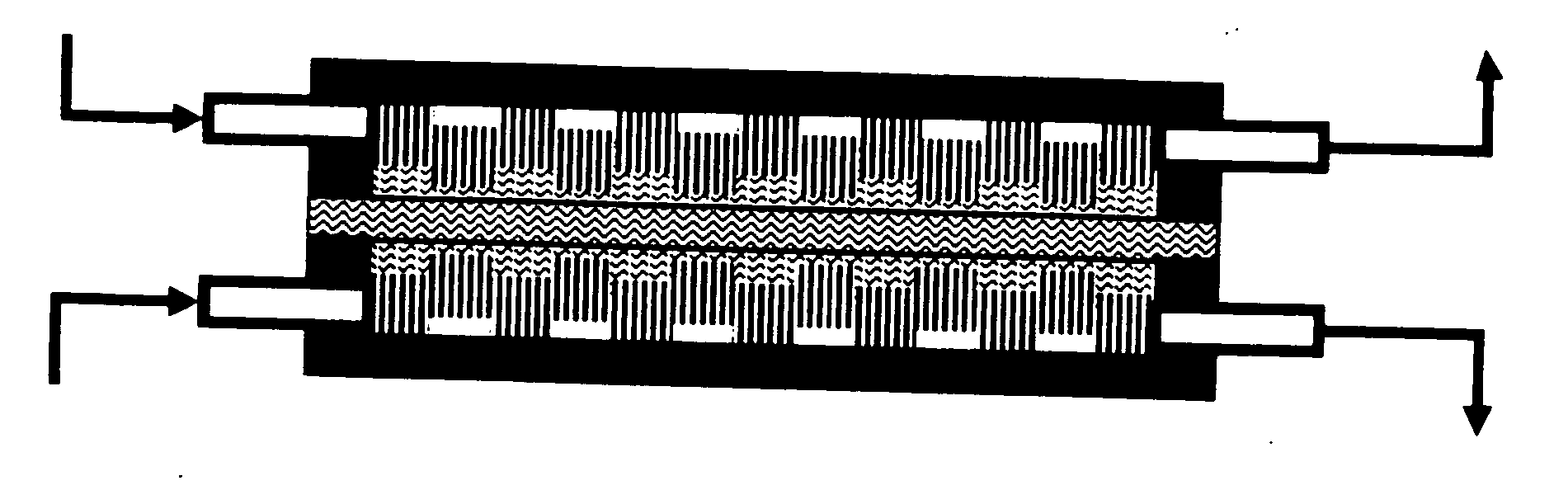

Electrochemical cell stacks

InactiveUS20020100681A1Minimal thicknessImprove security levelCellsMachining electrodesElectrical batteryConductive materials

An electrochemical cell stack comprising stack walls and a plurality of electrolytic cells within the stack walls, each cell comprising cell members selected from an anode a cathode; a membrane separator frame formed of a non-conductive material and having a frame first planar peripheral surface; a frame second planar peripheral surface; and a central portion defining a membrane-receiving aperture; a membrane within the aperture to provide an anolyte circulation chamber and a catholyte circulation chamber distinct one from the other within the frame, an impermeable cell end wall formed of a non-conductive material between the anode and cathode and the anodes and cathodes of adjacent cells of said stack; wherein each of said anode, said cathode, said separator frame and said end wall has a portion defining an anolyte flow inlet channel, a catholyte flow inlet channel, a spent anolyte channel and a spent catholyte channel; said anolyte flow inlet channel and said spent anolyte channel are in communication with said anolyte circulation chamber, said catholyte flow inlet channel and said spent catholyte channel are in communication with said catholyte circulation chamber. The cell stack is of greatly reduced footprint, operable at relatively high temperatures and pressures and which is stable under current load.

Owner:KIRK DONALD W +2

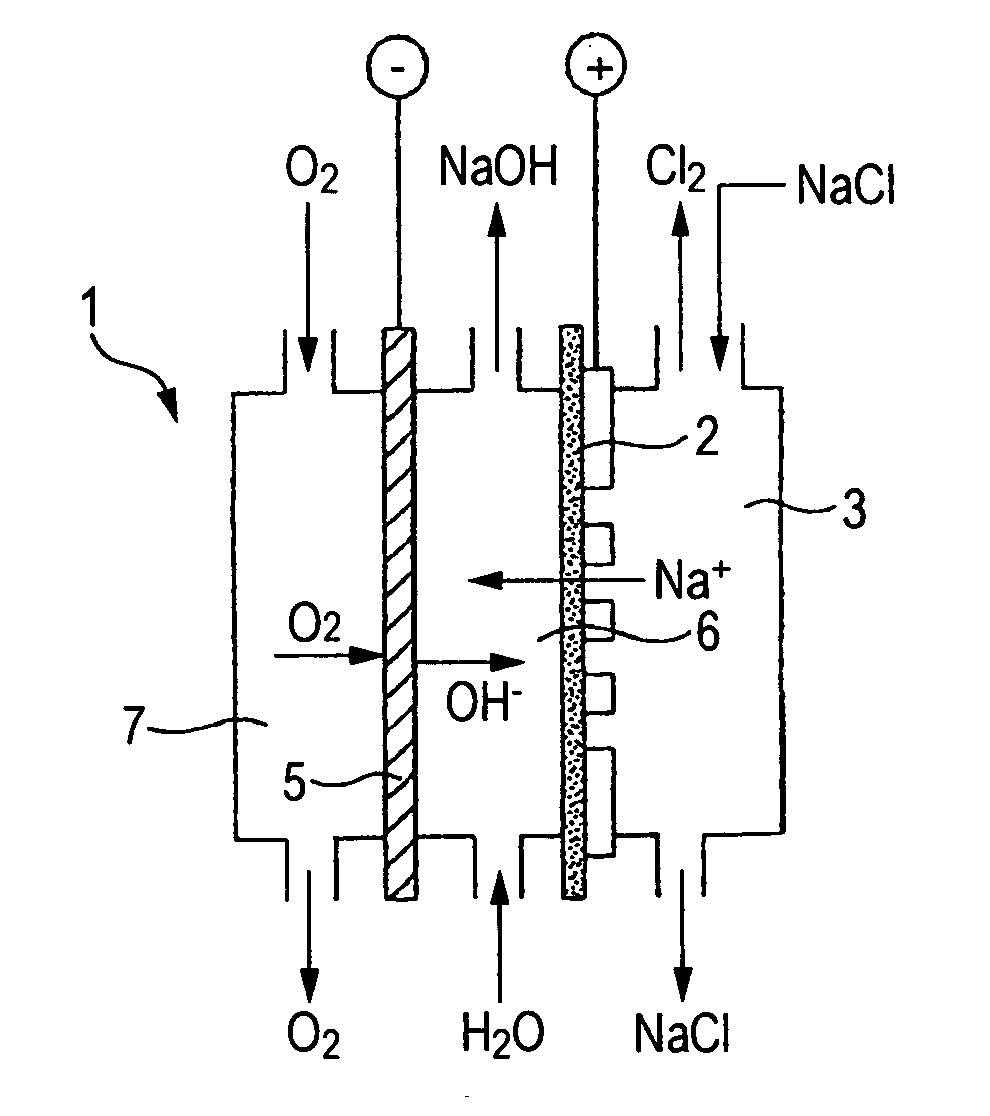

Gas diffusion electrode

InactiveUS20060175195A1High gas diffusionHigh densityMachining electrodesActive material electrodesGas diffusion electrodeNanotechnology

The present invention provides a gas diffusion electrode having: an electrode substrate; and a catalyst layer containing a hydrophilic catalyst and a hydrophobic binder, which is carried on the electrode substrate, wherein the electrode substrate contains at least one carbon material selected from a carbon cloth, a carbon paper, a foamed carbon material, and a sintered carbon material.

Owner:DE NORA PERMELEC LTD

Method and apparatus for electropolishing metallic stents

ActiveUS20070209947A1Machining electrodesElectrical-based machining electrodesInsertion stentEngineering

An apparatus and method are provided for simultaneously electropolishing a plurality of metallic stents. A plurality of elongated members on the apparatus are movably engaged with a plate such that movement of the plate relative to the elongated members causes each of the elongated members to rotate on its respective longitudinal axis when immersed in an electrolytic solution. A continuous cathode is located in close proximity to each of the elongated members when they are immersed in the electrolytic solution.

Owner:VIANT AS&O HLDG LLC +1

Electrode and electrochemical cell for water purification

An electrode with large active surface area is made by winding a Ti-fiber tow around a rectangular Ti-plate, and an electrocatalytic coating of three layers is applied. A precoat comprising a mixture of iridium dioxide and tantalum pentoxide is applied first, using a solution of the corresponding chloride salts in hydrochloric acid with some nitric acid added to inhibit corrosion of the metal. A sealing coat is then applied, comprising tin dioxide doped with antimony, in order to improve adhesion of the final oxide coat to the precoat. The third and final coat comprises particles of titanium dioxide doped with niobium in the +4 oxidation cemented with titanium dioxide that is doped with antimony. Anodes of this description are preferably assembled together with corrosion resistant cathodes in an alternating sequence, with a plastic coated fiber glass mesh placed between the anodes and cathodes to prevent short circuiting. When a sufficiently large voltage is applied across the cell, organic substances dissolved in the electrolyte will be oxidized.

Owner:WERES OLEH

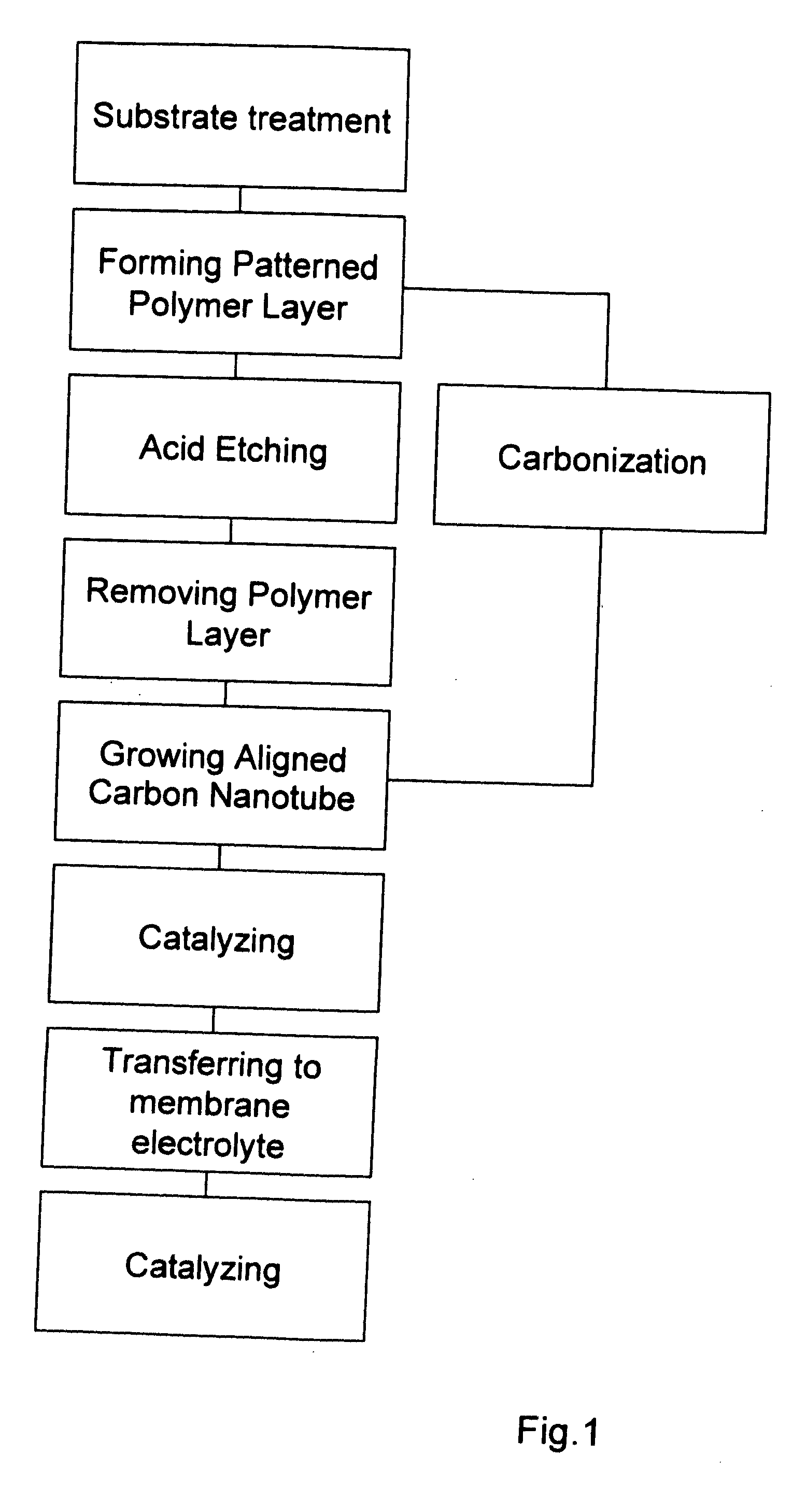

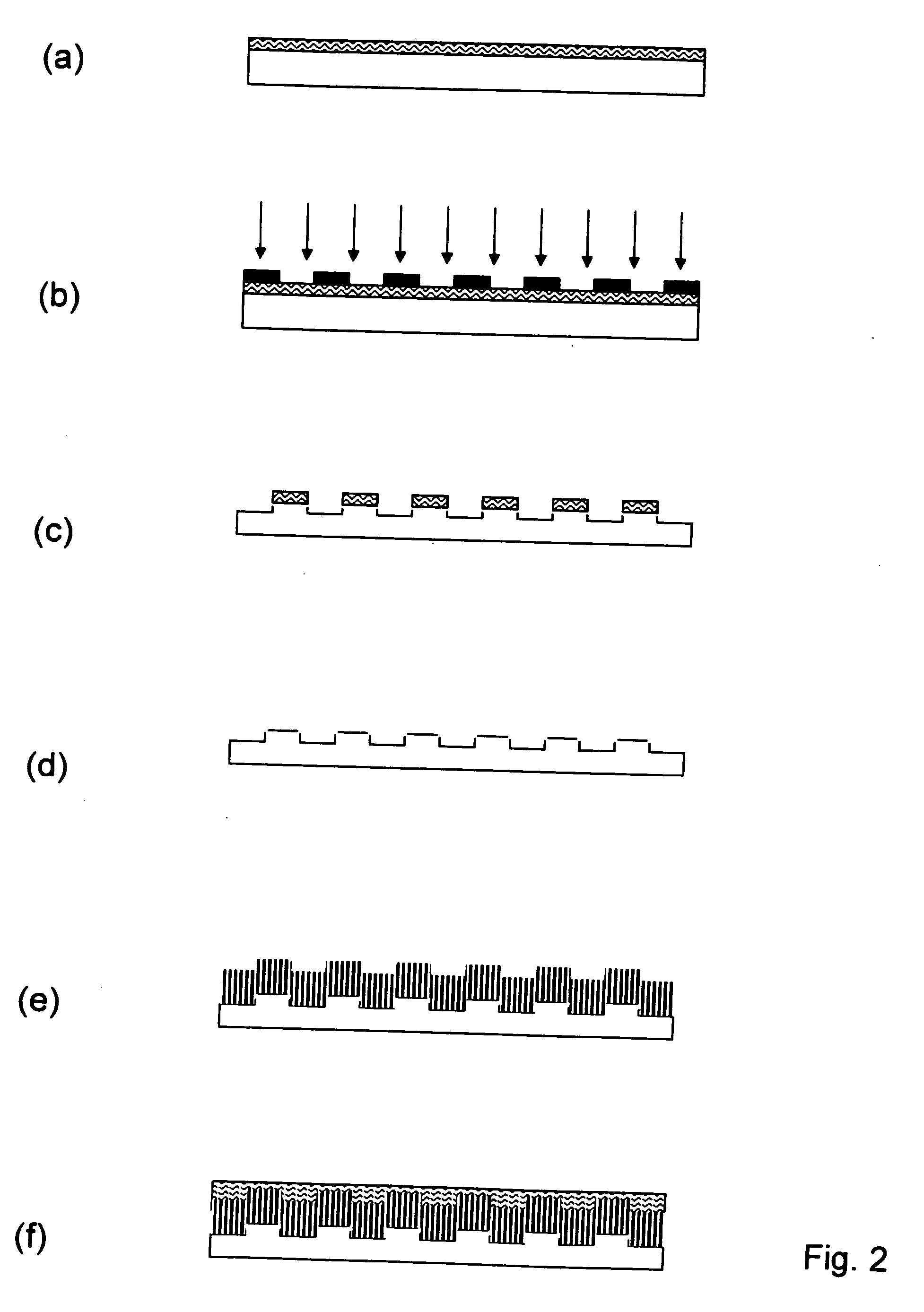

Method of fabricating electrode catalyst layers with directionally oriented carbon support for proton exchange membrane fuel cell

InactiveUS20060269827A1Simplify design and fabricationReduce usageMachining electrodesFinal product manufactureReaction temperatureNanotube

A method of making a membrane electrode assembly (MEA) having an anode and a cathode and a proton conductive membrane there between. A bundle of longitudinally aligned carbon nanotubes with a catalytically active transition metal incorporated in the nanotubes forms at least one portion of the MEA and is in contact with the membrane. A combination selected from one or more of a hydrocarbon and an organometallic compound containing an catalytically active transition metal and a nitrogen containing compound and an inert gas and a reducing gas is introduced into a first reaction zone maintained at a first reaction temperature for a time sufficient to vaporize material therein. The vaporized material is transmitted to a second reaction zone maintained at a second reaction temperature for a time sufficient to grow longitudinally aligned carbon nanotubes with a catalytically active transition metal incorporated throughout the nanotubes. The nanotubes are in contact with a portion of the MEA at production or being positioned in contact thereafter. Methods of forming a PEMFC are also disclosed.

Owner:UCHICAGO ARGONNE LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com