Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7119results about How to "Simplify the assembly process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

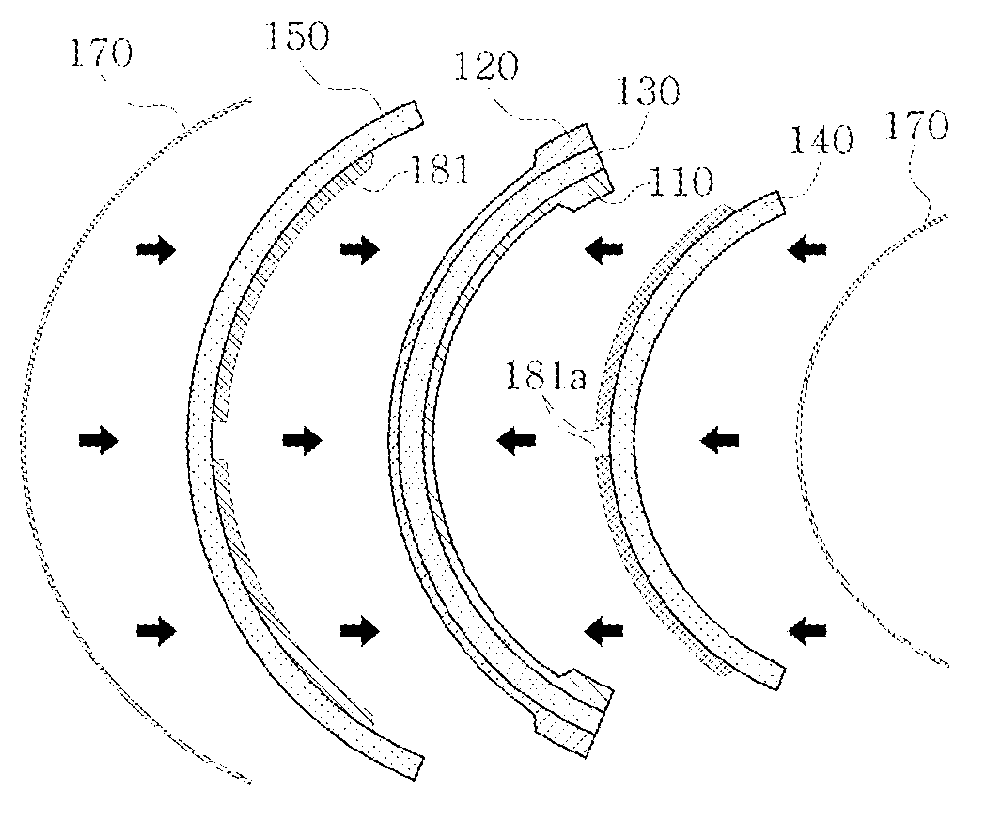

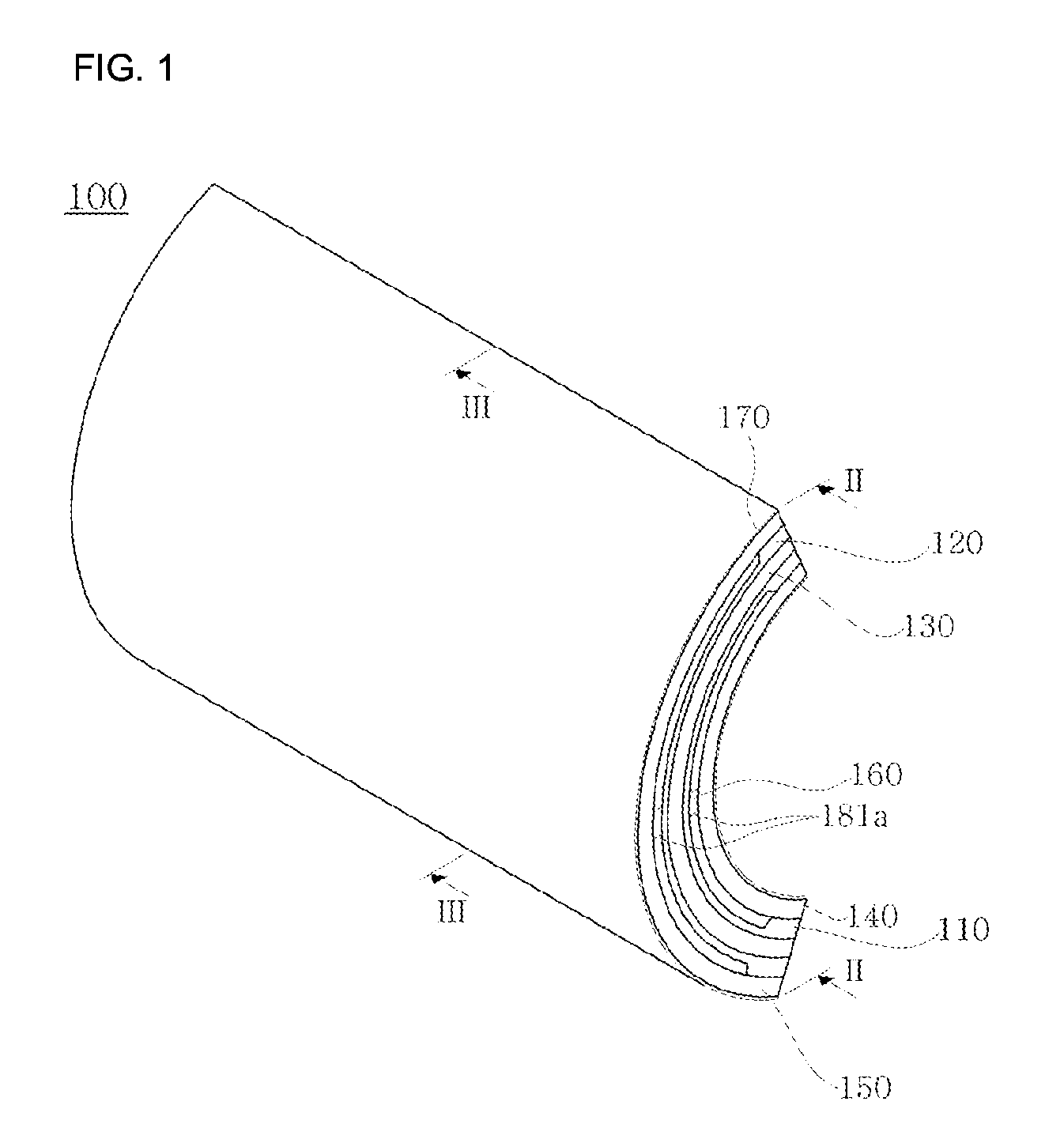

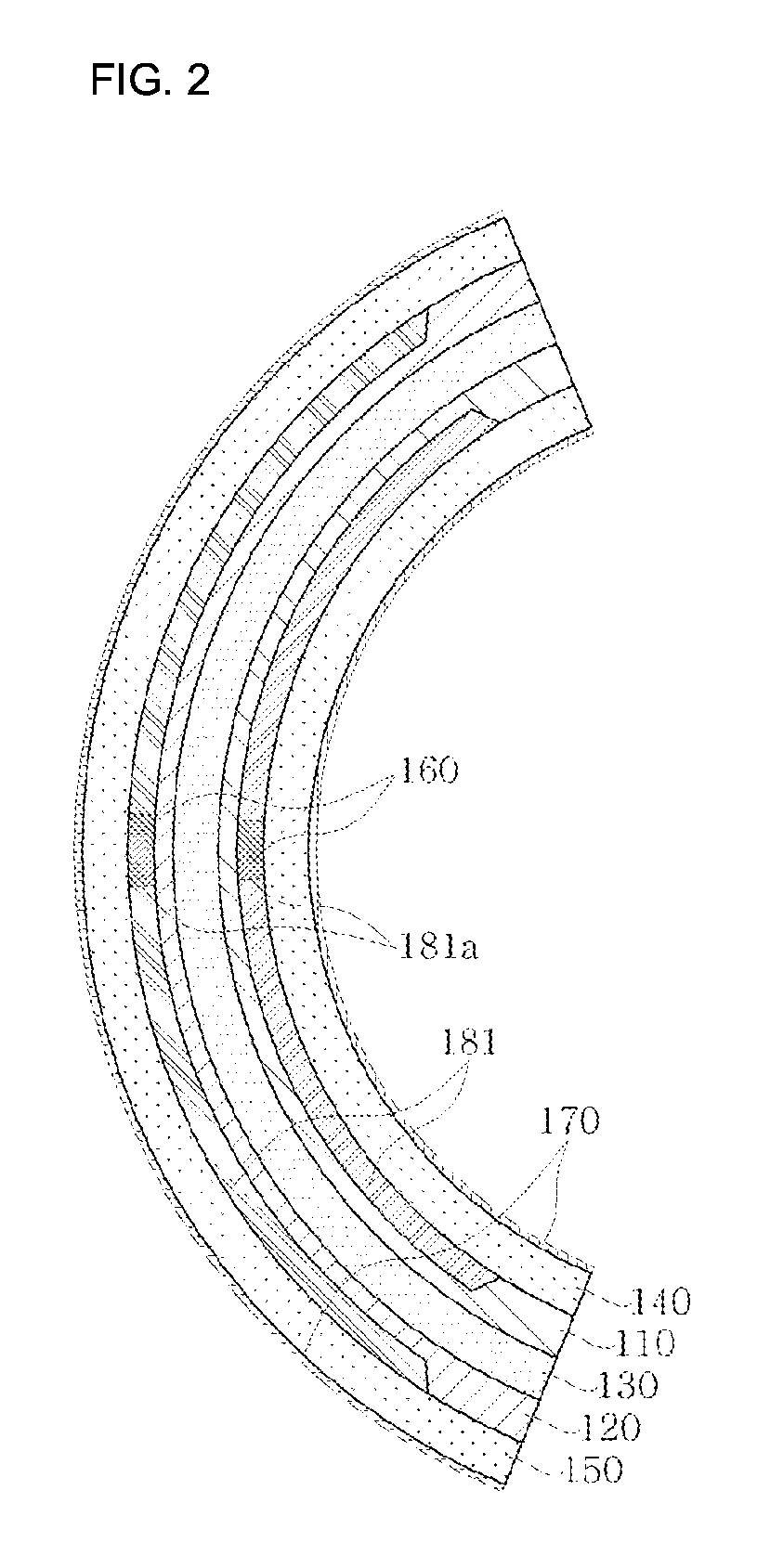

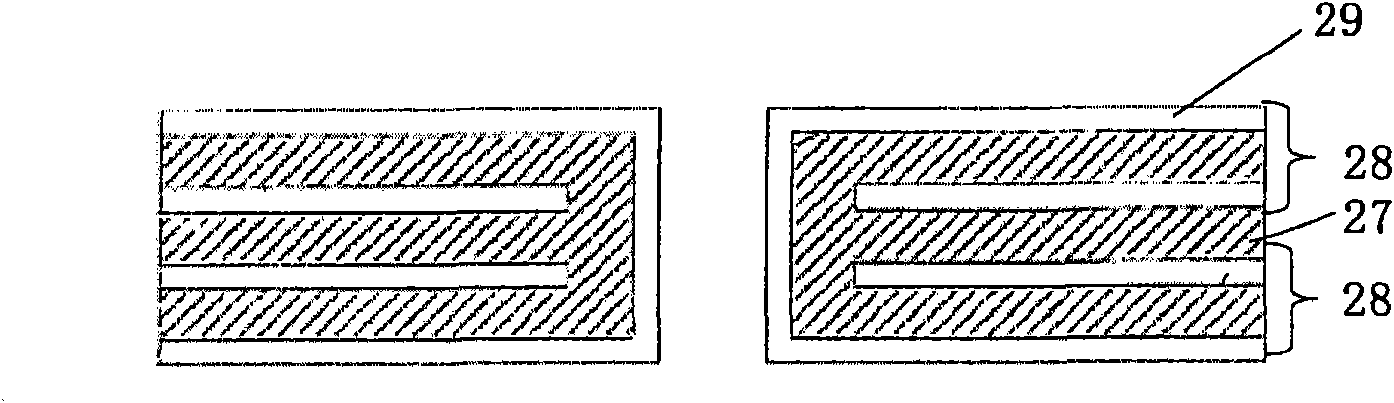

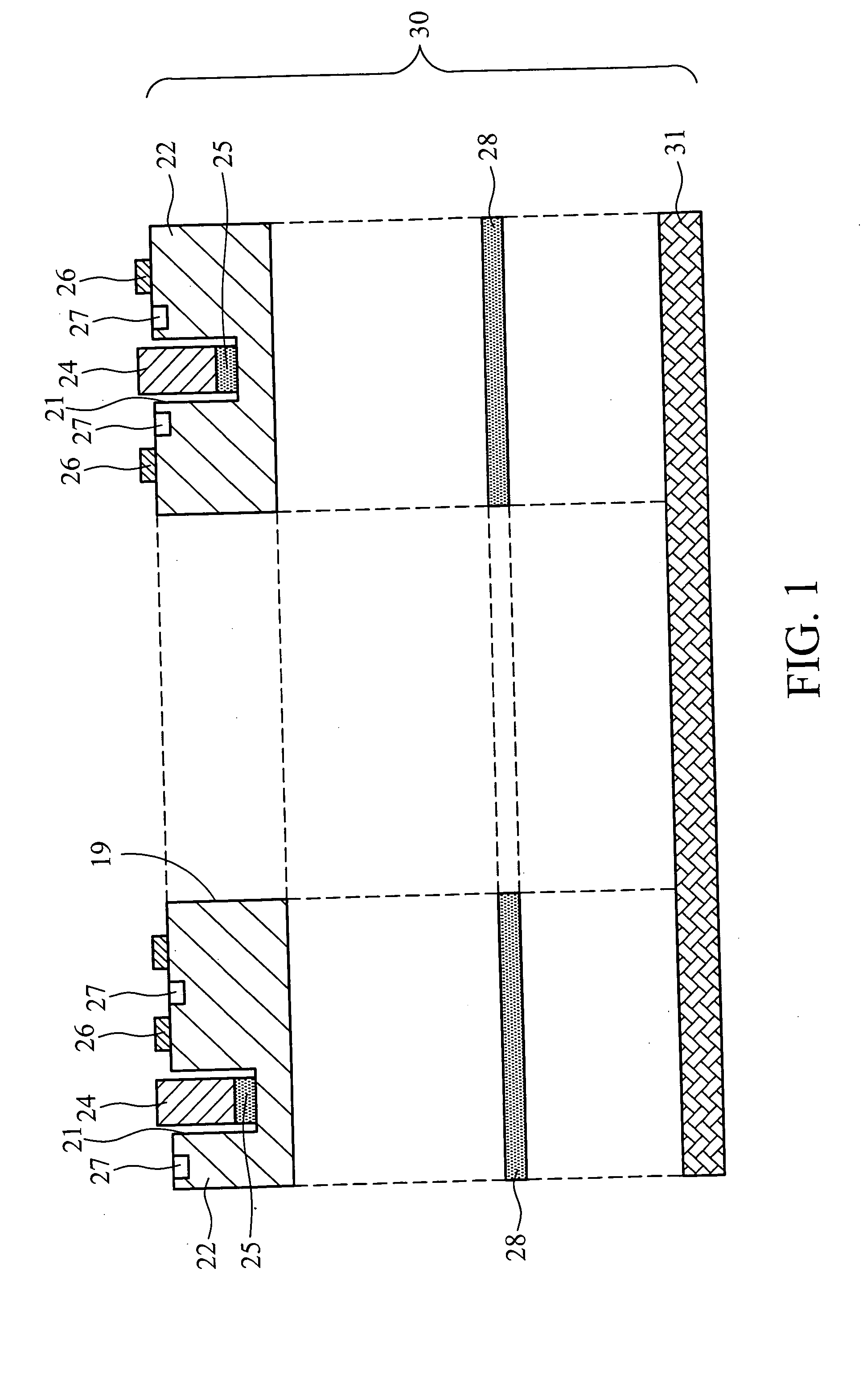

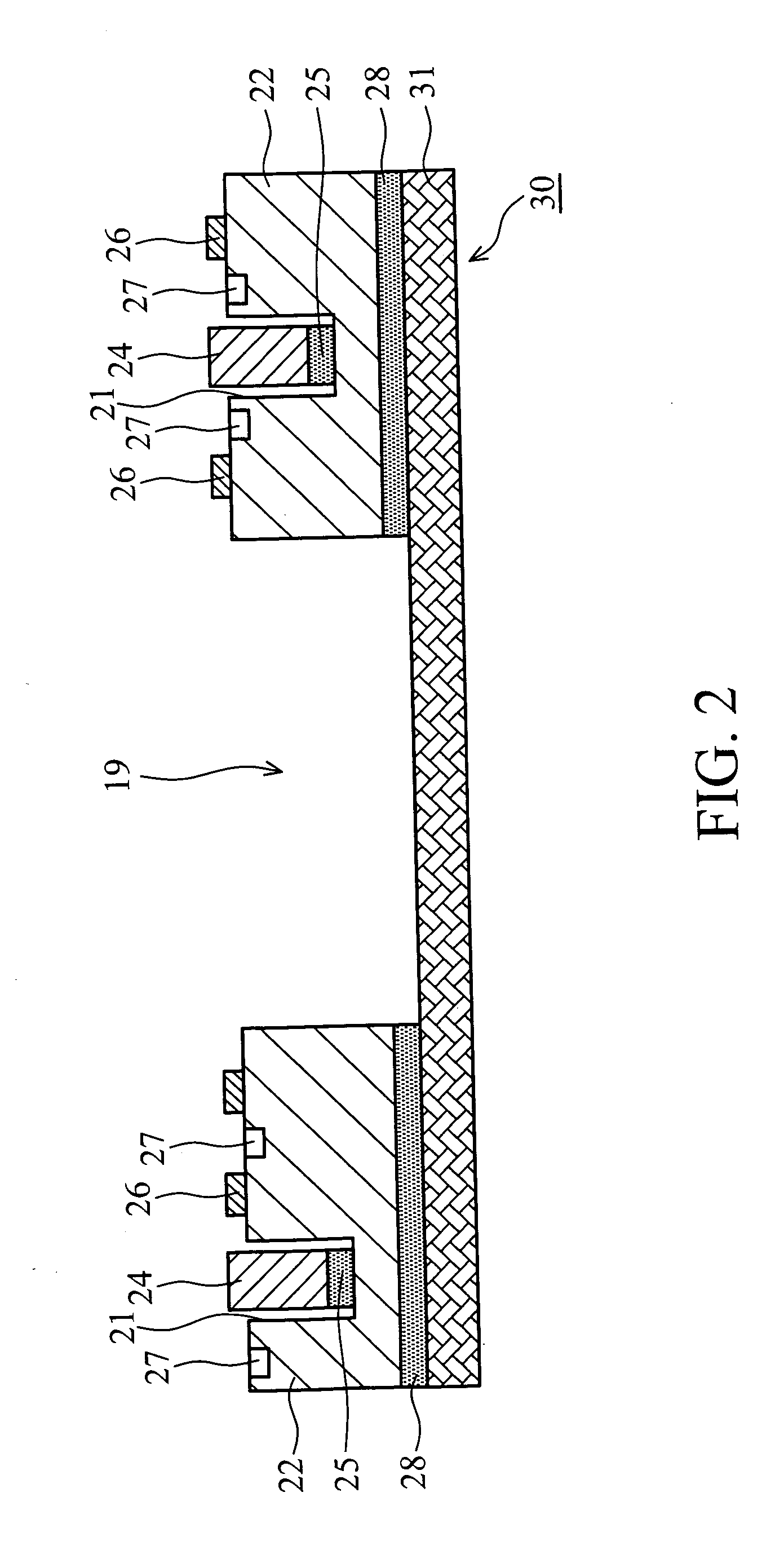

Curved-surface display panel fabrication method, curved-surface display panel using same, and multi-image display device using same

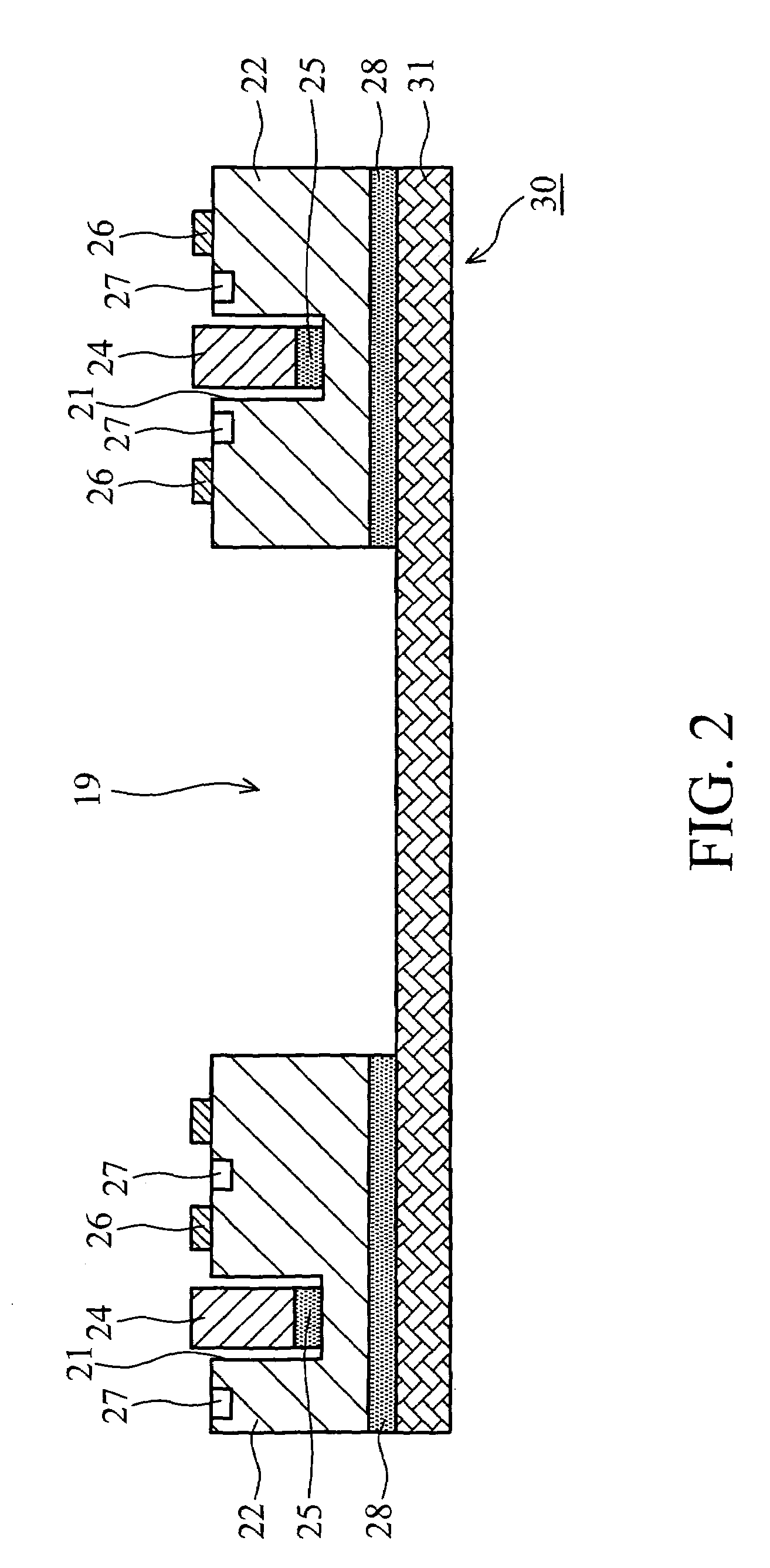

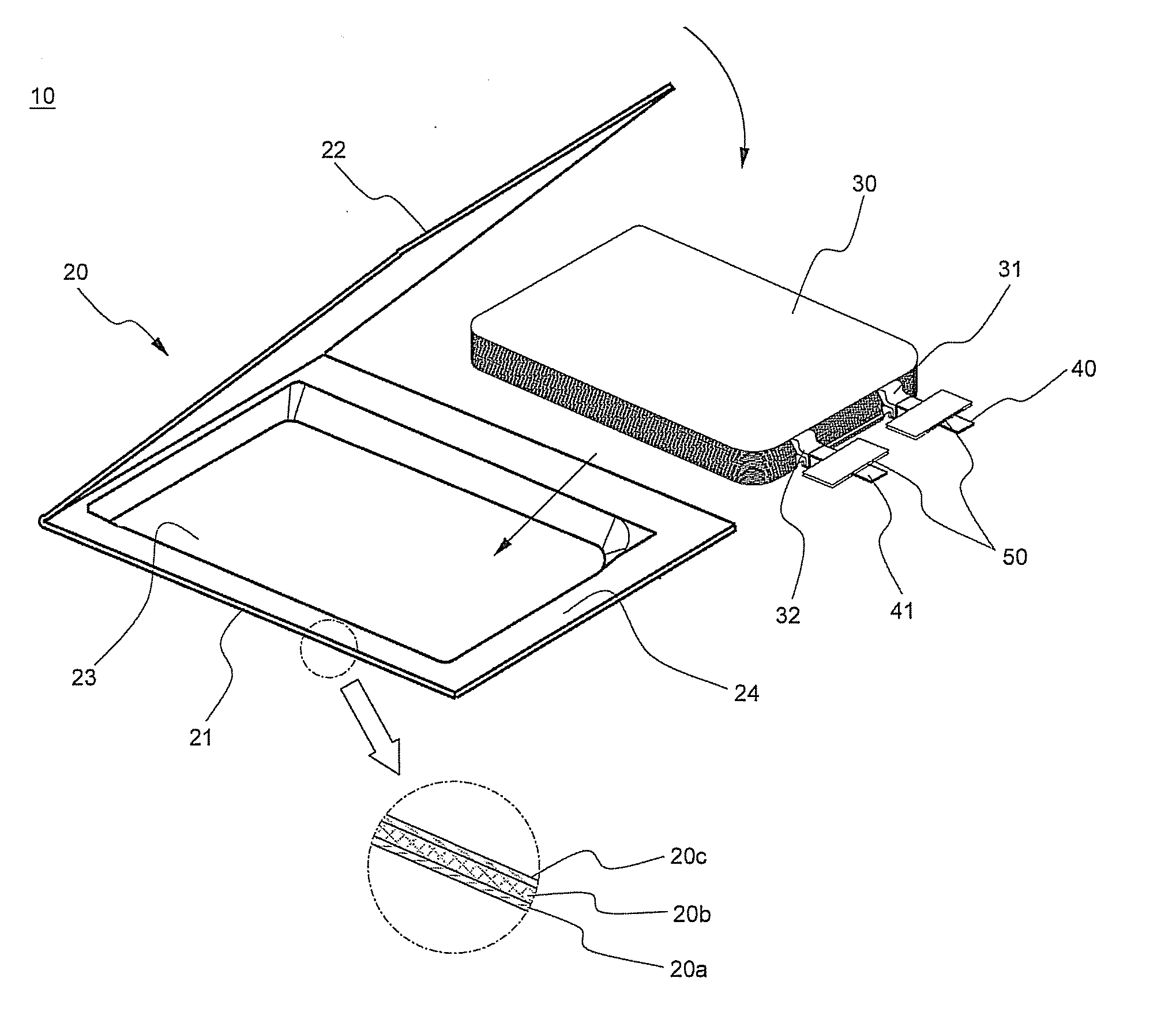

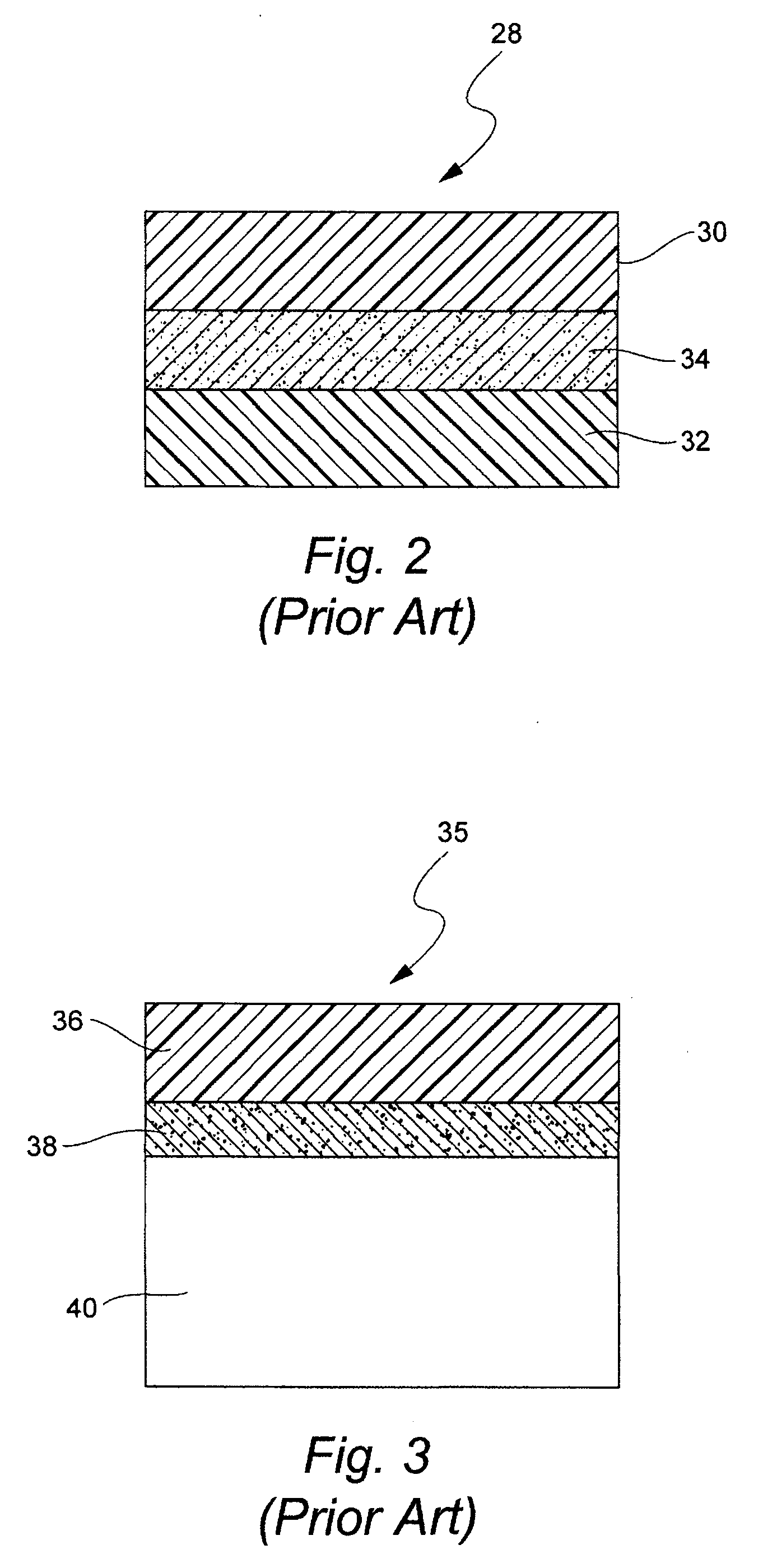

ActiveUS8982545B2Reduce thicknessSimple processDigital data processing detailsVessels or leading-in conductors manufactureSurface displayMulti-image

A curved-surface display panel fabrication method for fabricating a curved-surface display panel using a flat display panel having a first substrate and a second substrate includes: paring partially outer surfaces of the first substrate and the second substrate so as to reduce thicknesses thereof to a predetermined thickness; bending the pared flat display panel to a desired curved shape; attaching a first guide member which has a shape corresponding to the desired curved shape to the first substrate with a predetermined gap from the pared outer surface thereof and attaching a second guide member with has a shape corresponding to the desired curved shape to the second substrate with a predetermined gap from the pared outer surface thereof; and forming light transmitting reinforcing layers respectively in a space between the first guide member and the first substrate and a space between the second guide member and the second substrate.

Owner:TOVIS

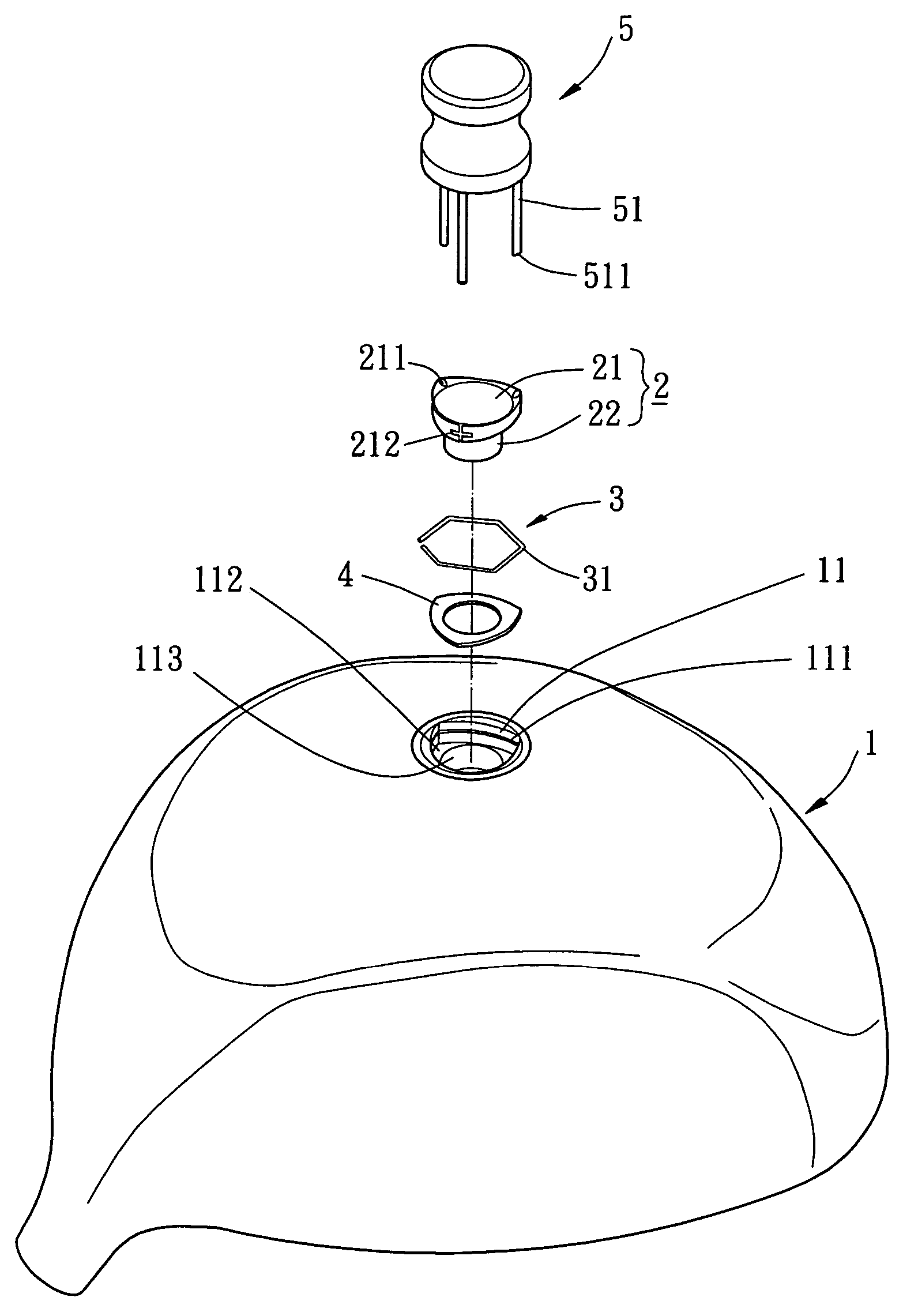

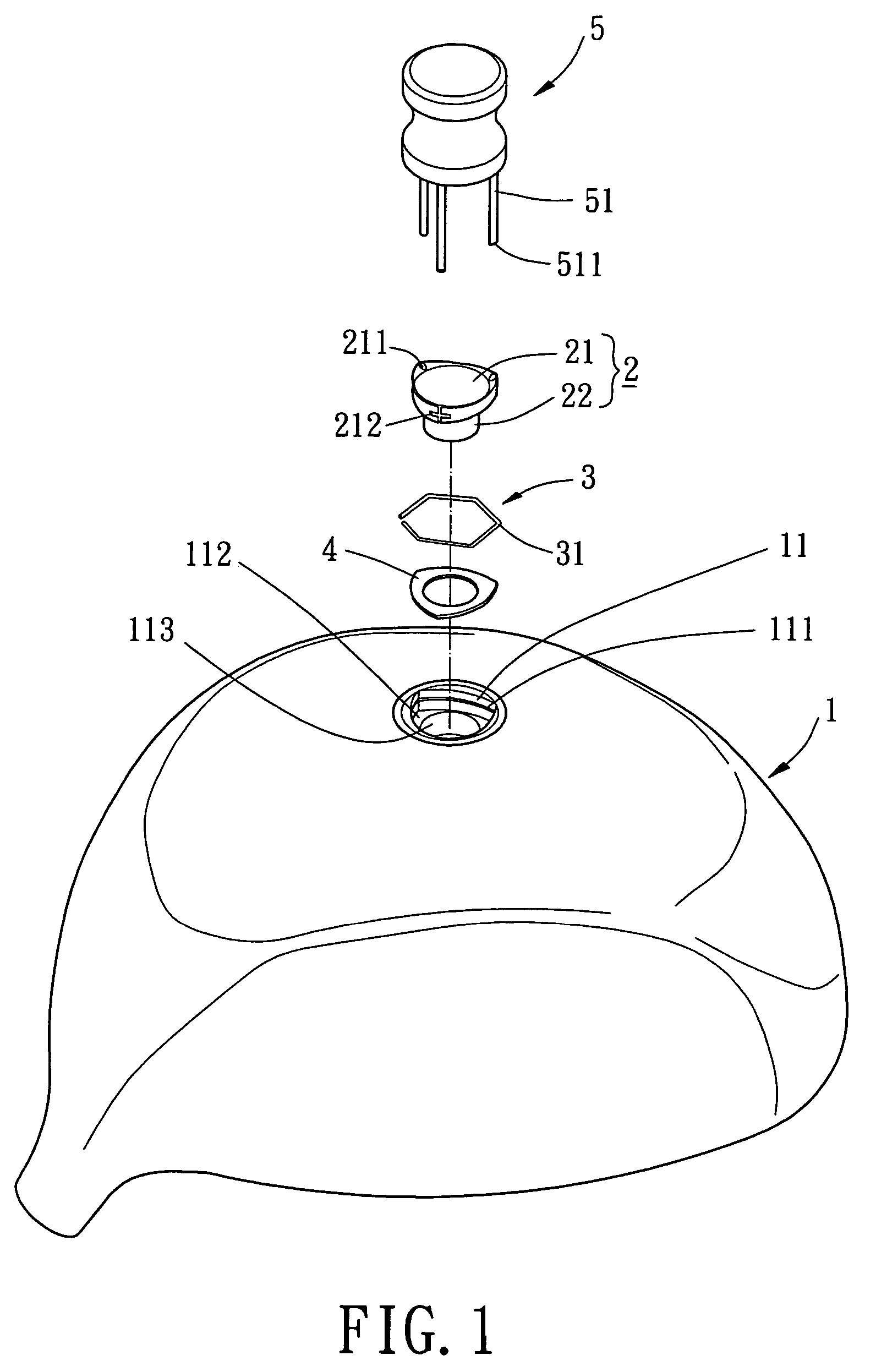

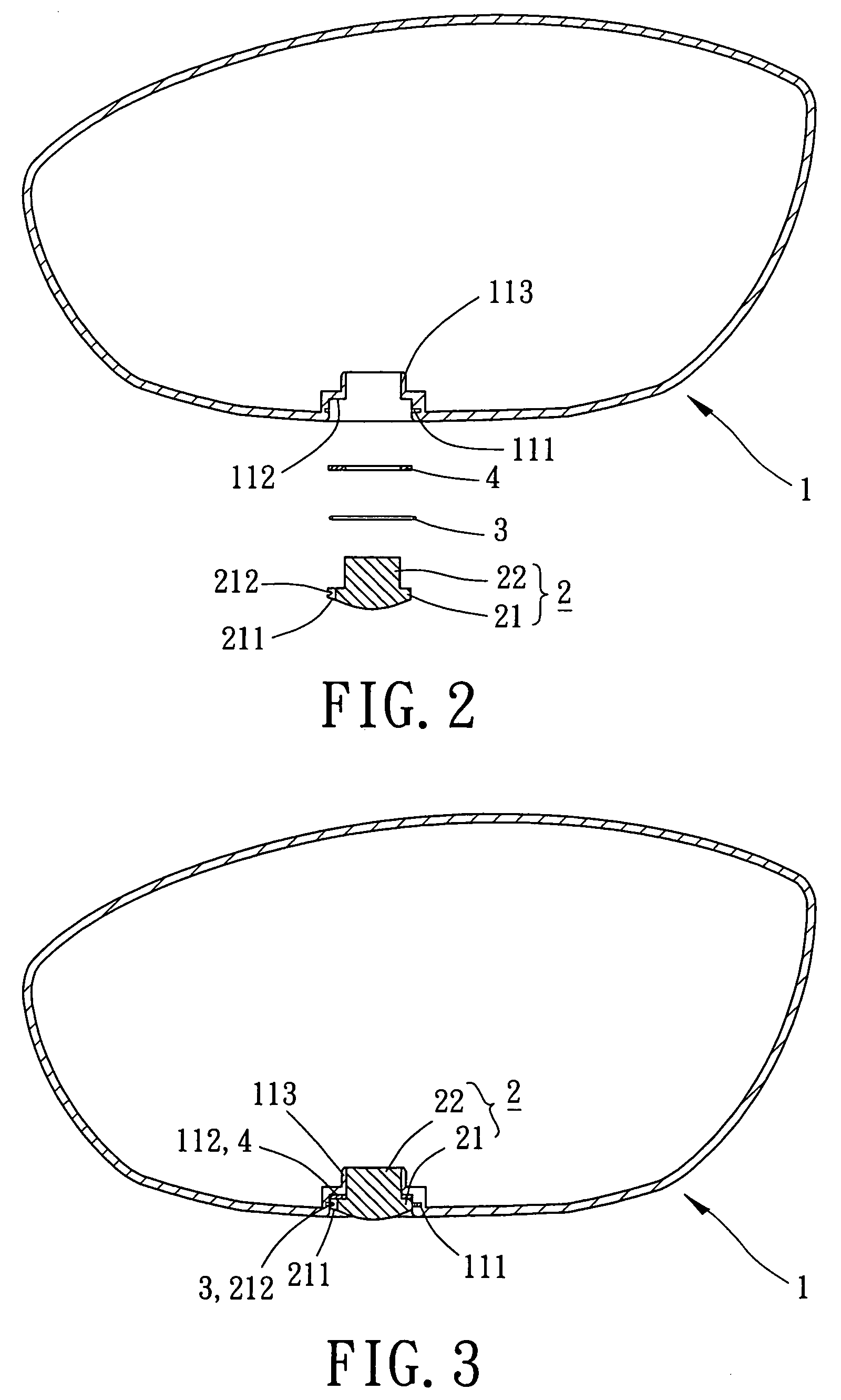

Weight assembly for golf club head

InactiveUS7294065B2Easy to adjustSimplify the assembly processGolf clubsRacket sportsEngineeringGolf Ball

A golf club head includes a body, a weight, and a positioning resilient member. The body includes an engaging seat having a perimeter wall and a perimeter groove defined in the perimeter wall. The weight is mounted in the engaging seat, and includes a main body having a perimeter wall with a plurality of latching grooves corresponding to the perimeter groove of the engaging seat. The positioning resilient member is initially mounted in the perimeter groove of the engaging seat prior to receiving the weight. The positioning resilient member includes at least one engaging point pressing against a perimeter bottom wall of the perimeter groove. The positioning resilient member is further engaged in the latching grooves of the weight to thereby resiliently retain the weight in the engaging seat when assembled.

Owner:FUSHENG IND CO LTD

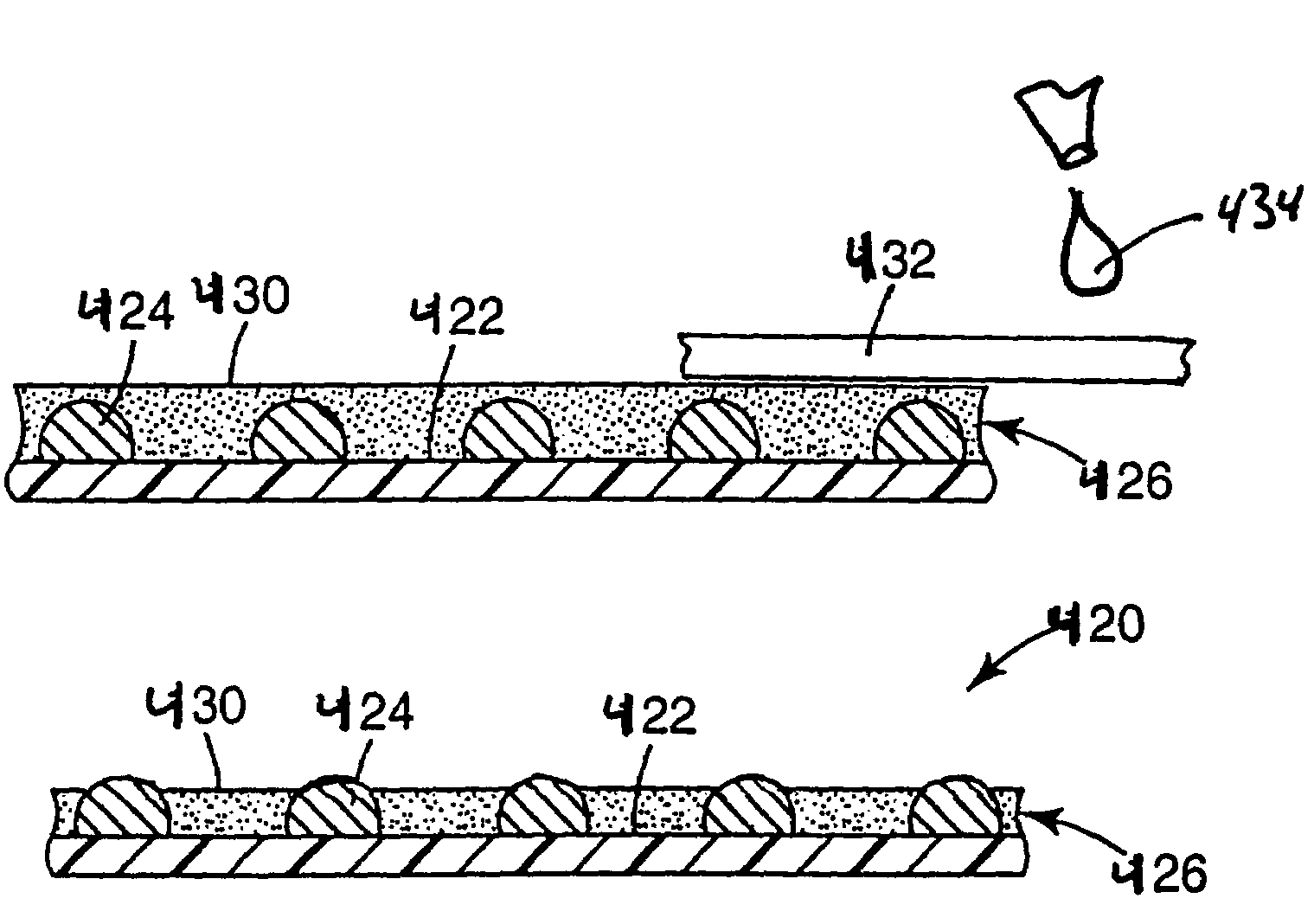

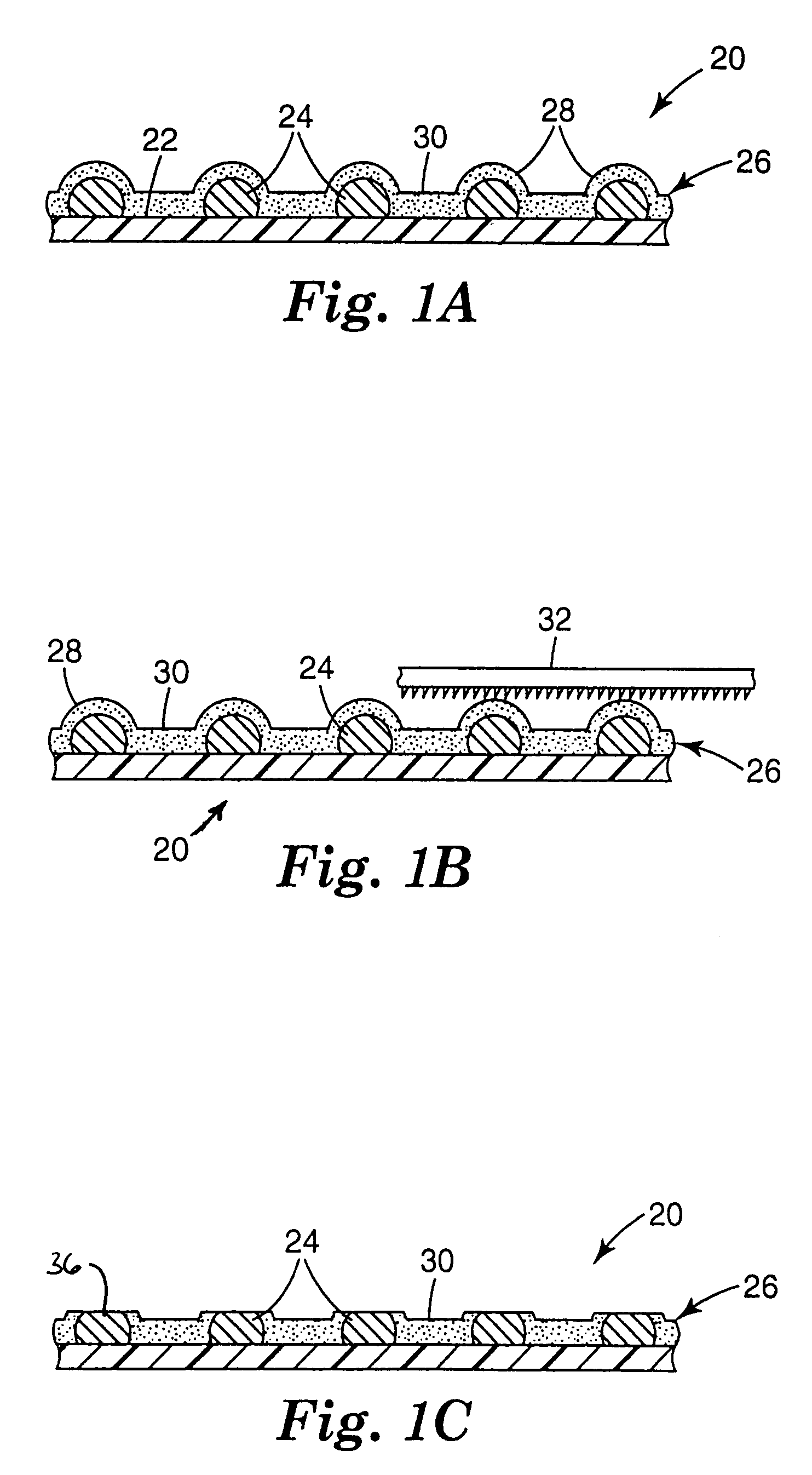

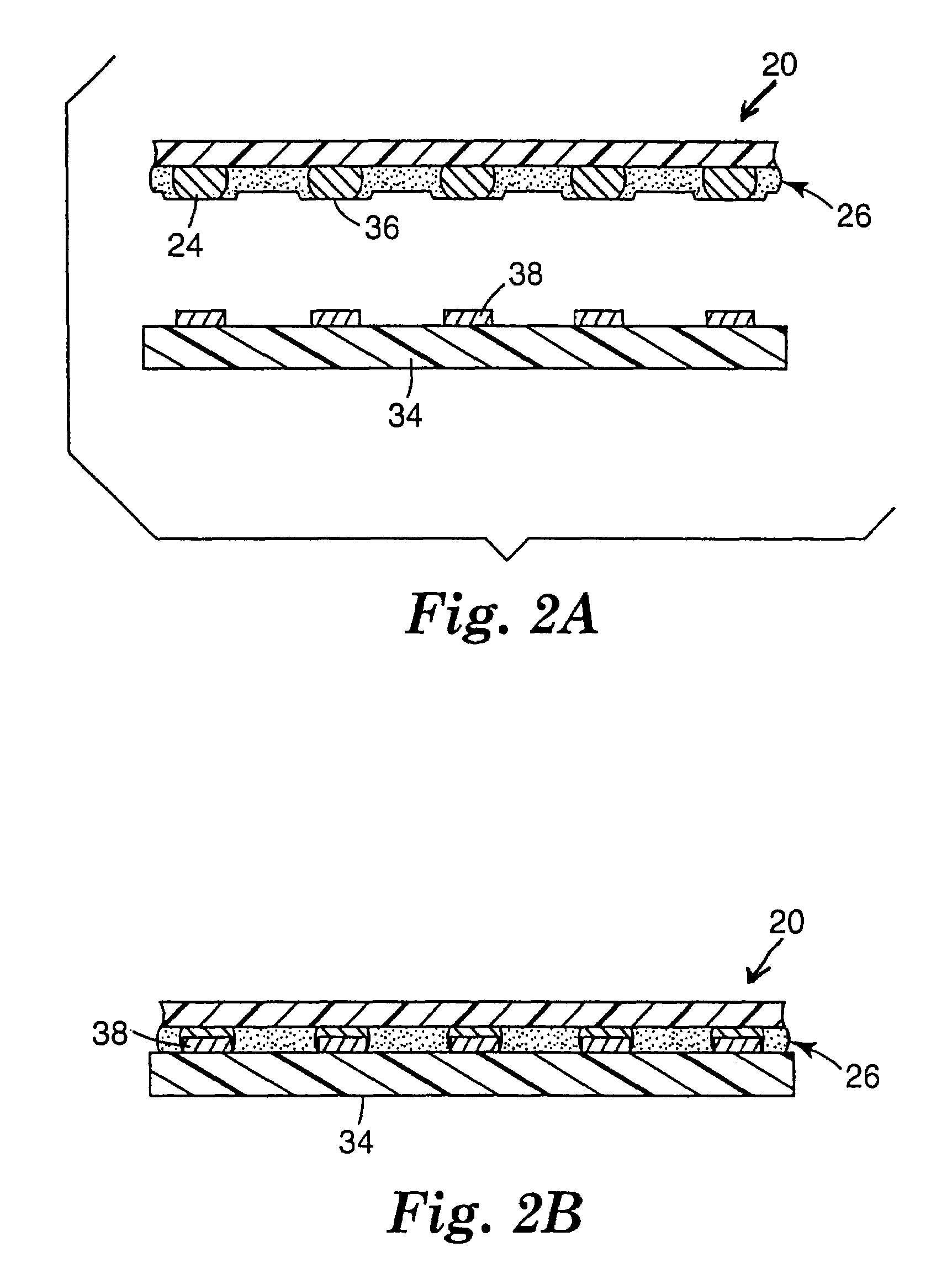

Solvent assisted burnishing of pre-underfilled solder bumped wafers for flipchip bonding

InactiveUS7170185B1Simplify flip-chip assembly processLower assembly costsSemiconductor/solid-state device detailsSolid-state devicesAdhesiveElectrical connection

The present invention relates to a method for connecting an integrated circuit chip to a circuit substrate. The method includes the step of pre-applying adhesive directly to a bumped side of an integrated circuit chip. The method also includes the steps of removing portions of the adhesive from the tips of the solder bumps to expose a contact surface, and pressing the bumped side of the integrated circuit chip, which has previously been coated with adhesive, against the circuit substrate such that the bumps provide an electrical connection between the integrated circuit chip and the circuit substrate. The adhesive is removed from the tips of the solder bumps using a solvent assisted wiping action. The pre-applied adhesive on the chip forms a bond between the integrated circuit chip and the circuit substrate.

Owner:3M INNOVATIVE PROPERTIES CO

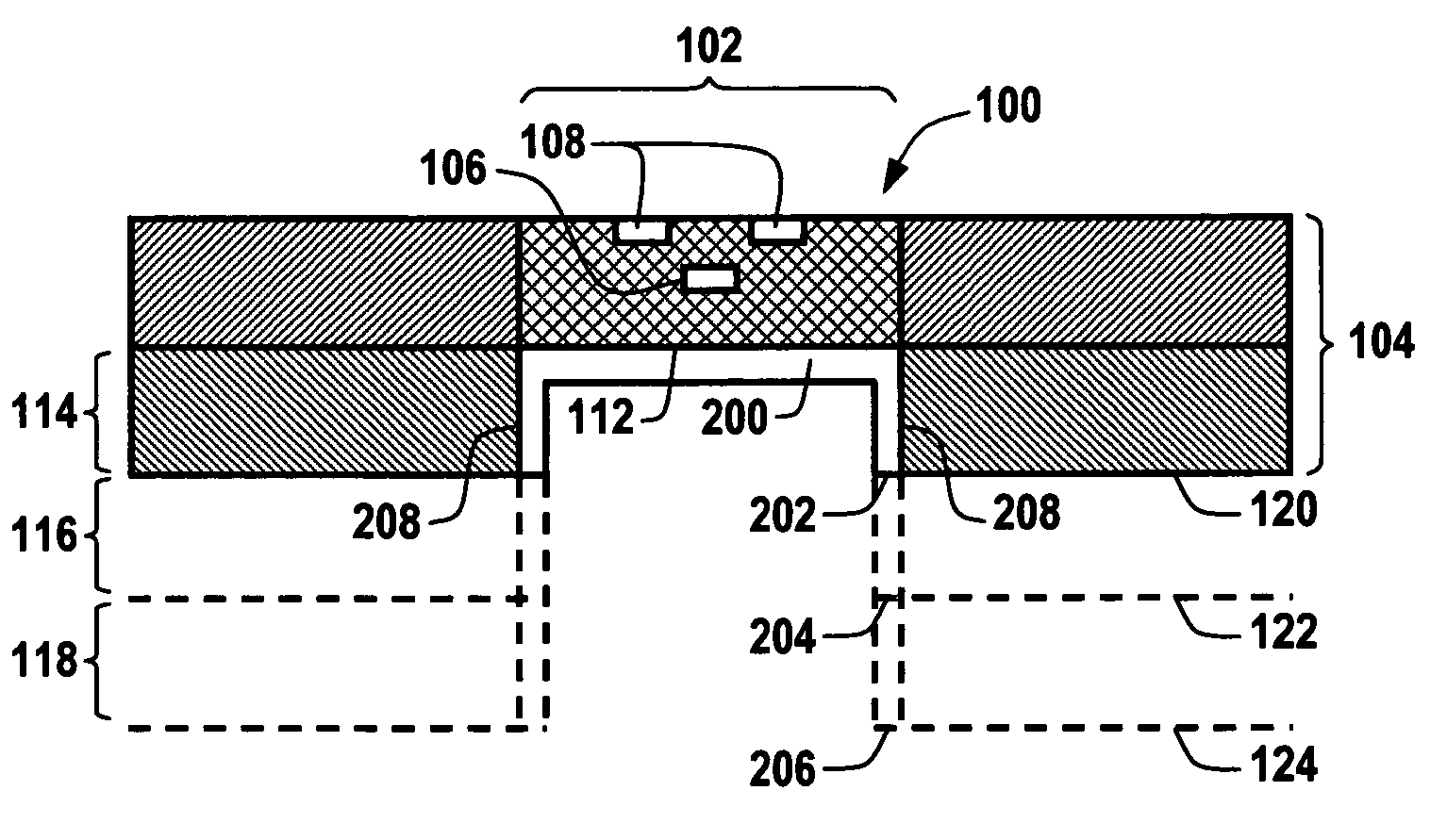

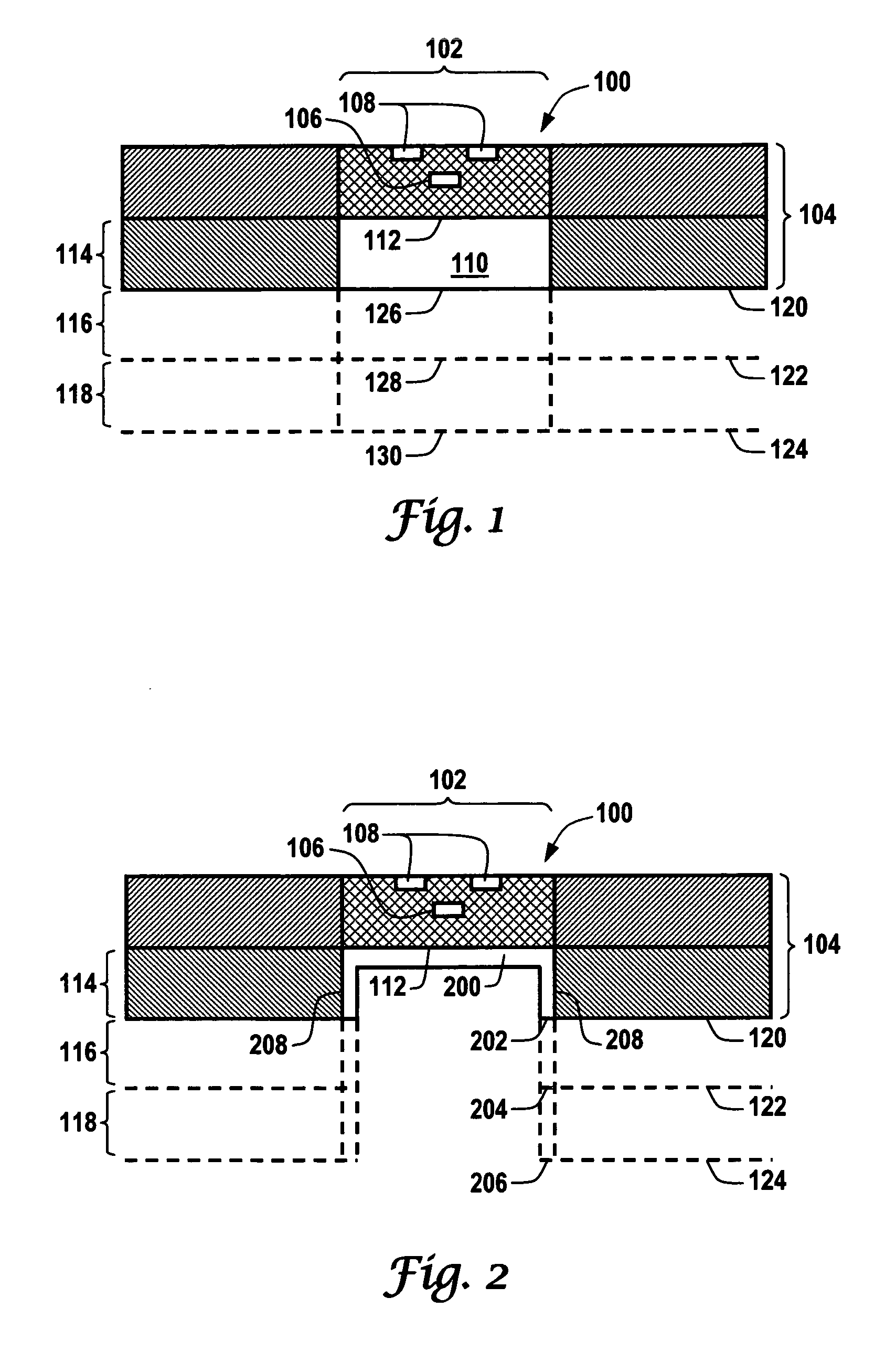

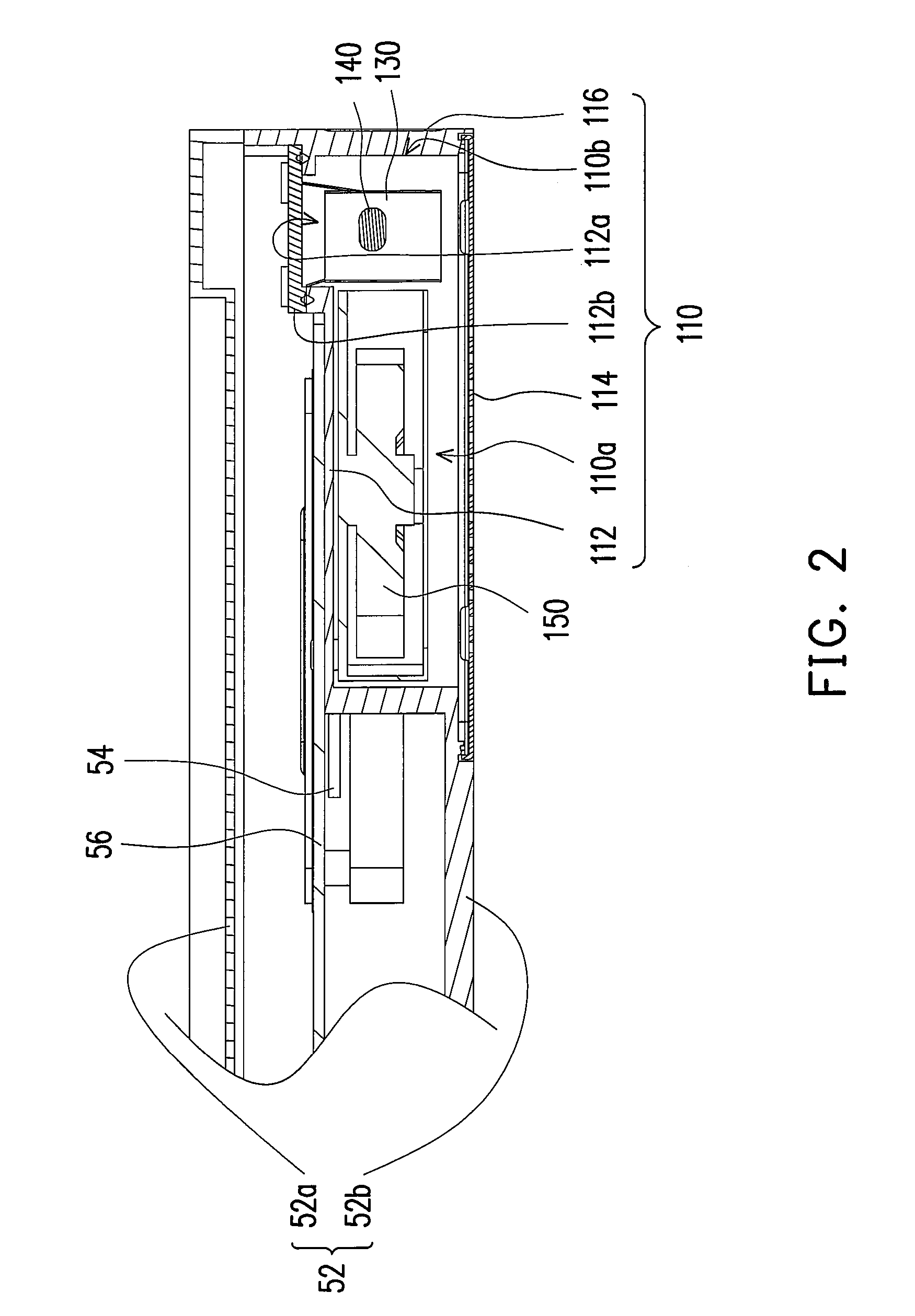

System, method and apparatus for improved electrical-to-optical transmitters disposed within printed circuit boards

InactiveUS20050046011A1Simple and reliable processAdded fabricationCircuit optical detailsSemiconductor/solid-state device detailsCommunications systemConductive materials

The present invention provides a system, method and apparatus for improved electrical-to-optical transmitters (100) disposed within printed circuit boards (104). The heat sink (110, 200) is a thermal conductive material disposed within a cavity (102) of the printed circuit board (104) and is thermally coupled to a bottom surface (112) of the electrical-to-optical transmitter (100). A portion of the thermal conductive material extends approximately to an outer surface (120, 122 or 124) of a layer (114, 116 or 118) of the printed circuit board (104). The printed circuit board may comprise a planarized signal communications system or an optoelectronic signal communications system. In addition, the present invention provides a method for fabricating the heat sink wherein the electrical-to-optical transmitter disposed within a cavity of the printed circuit board is fabricated. New methods for flexible waveguides and micro-mirror couplers are also provided.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

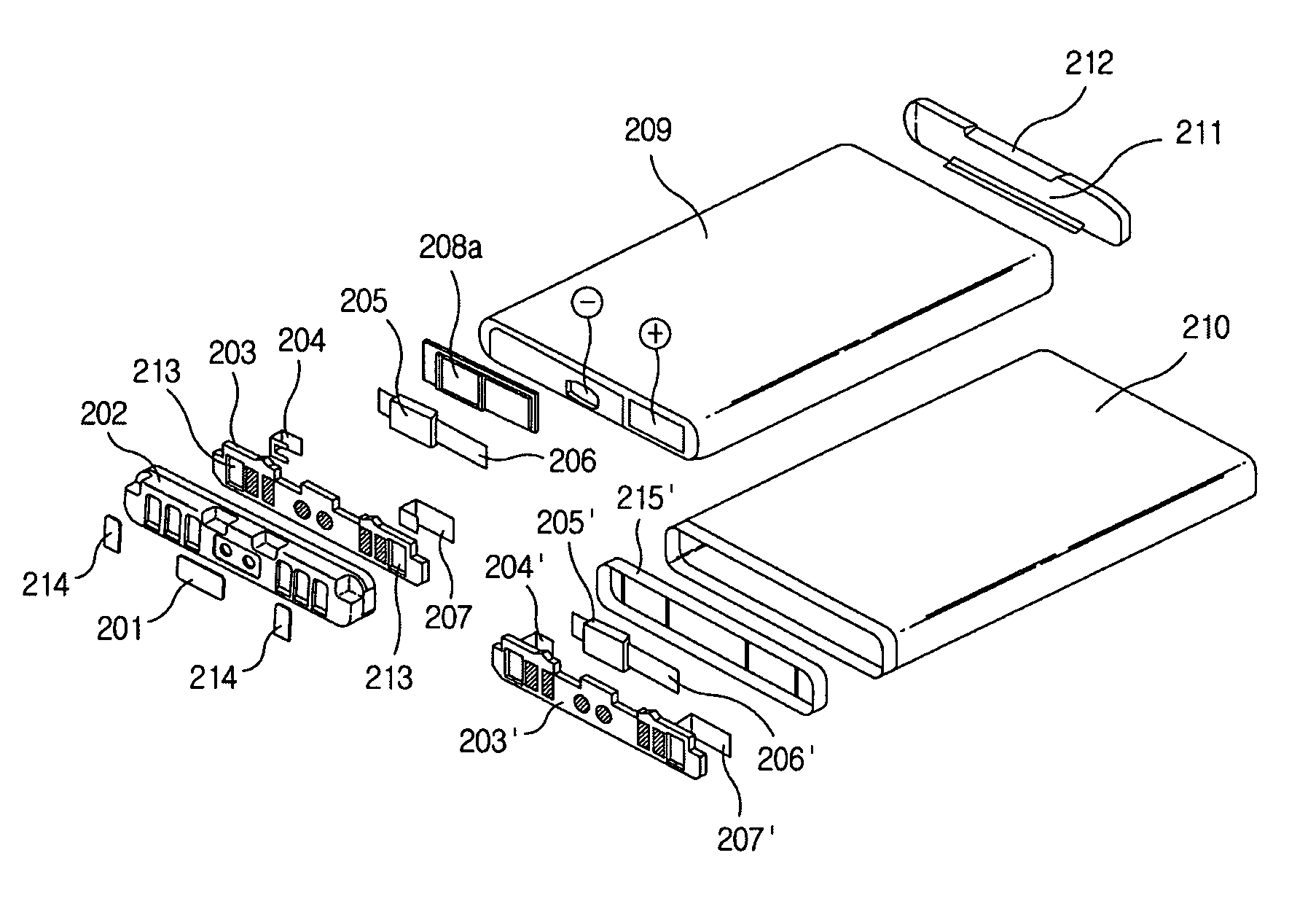

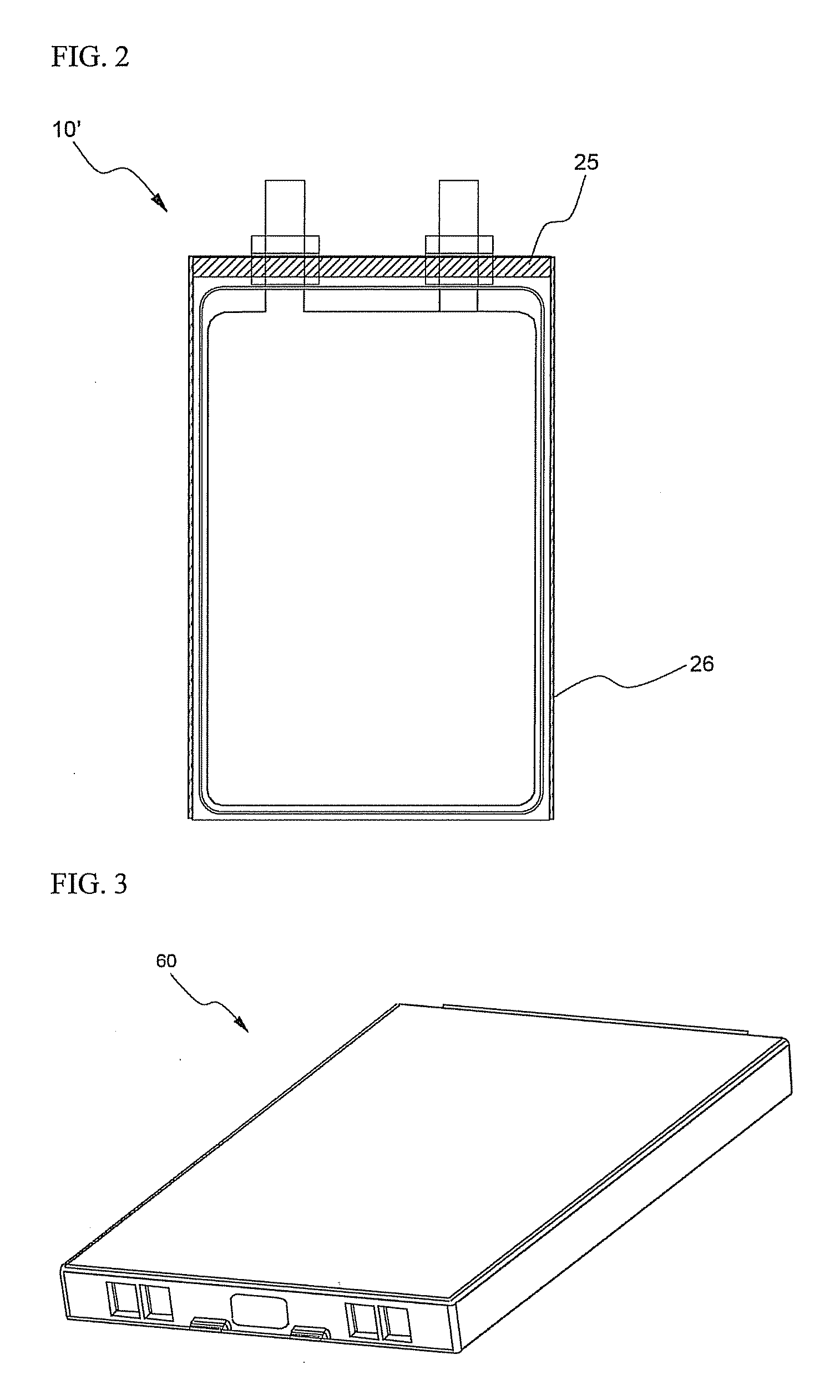

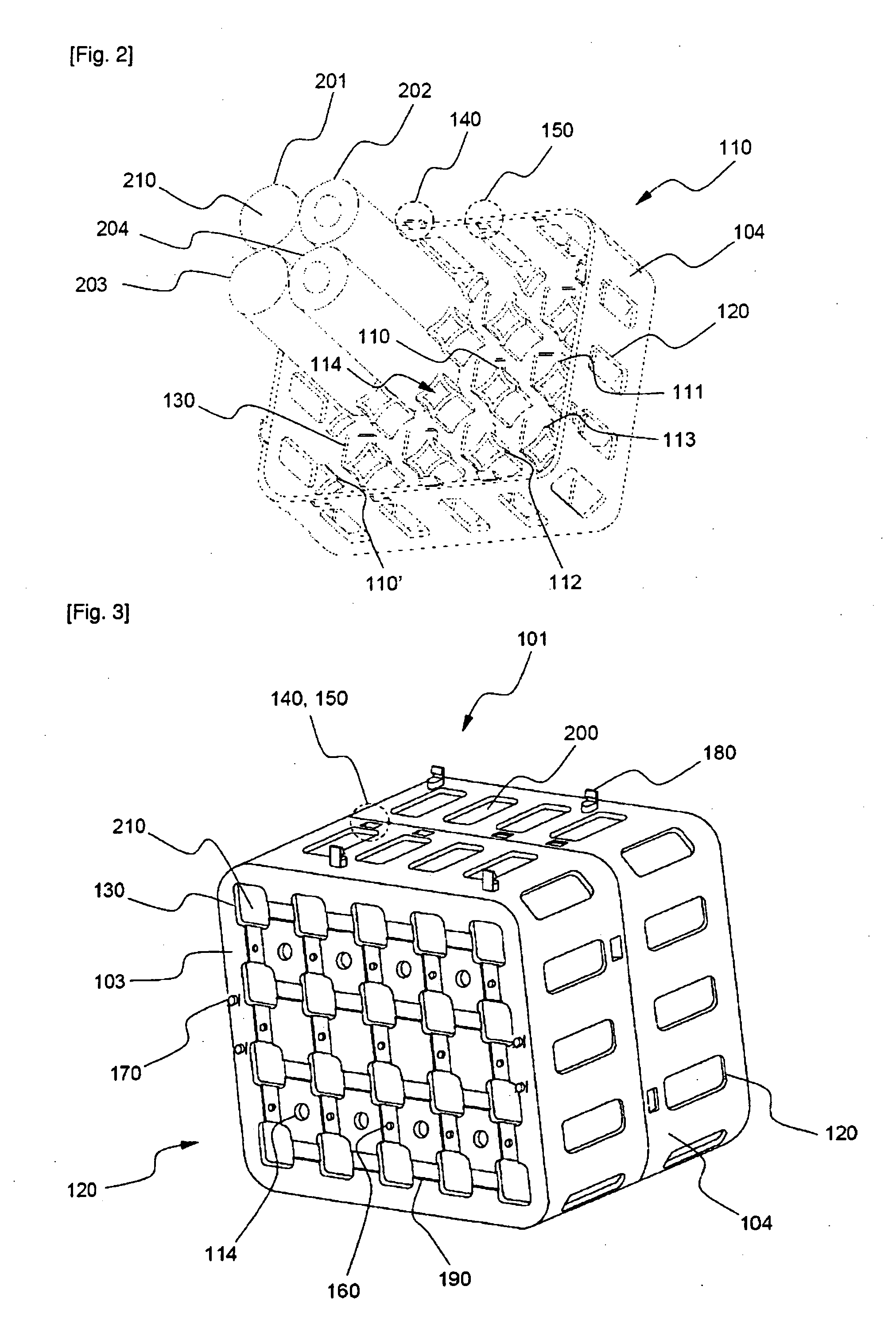

Battery pack of improved structure

ActiveUS20050208346A1Small sizeImprove workabilitySmall-sized cells cases/jacketsCells structural combinationManufacturing cost reductionProduction rate

A battery pack comprising a battery cell having electrode terminals formed on an upper surface of the battery cell, and a protective circuit module (PCM) block mounted on the battery cell, wherein one or more connecting holes for electrical connection between the battery cell and the PCM block are perforated through the PCM block such that a connecting portion between the battery cell and the PCM block is exposed to the outside of the upper surface of the battery cell. The battery pack is lighter, compacter and miniaturized, thereby allowing an electronic device employing the battery pack to be reduced in an overall size, enhancing workability through a simplified assembling process, reducing manufacturing costs through reduction of the number of components, and enhancing productivity through reduction of the number of operating steps by eliminating additional installation steps.

Owner:LG ENERGY SOLUTION LTD

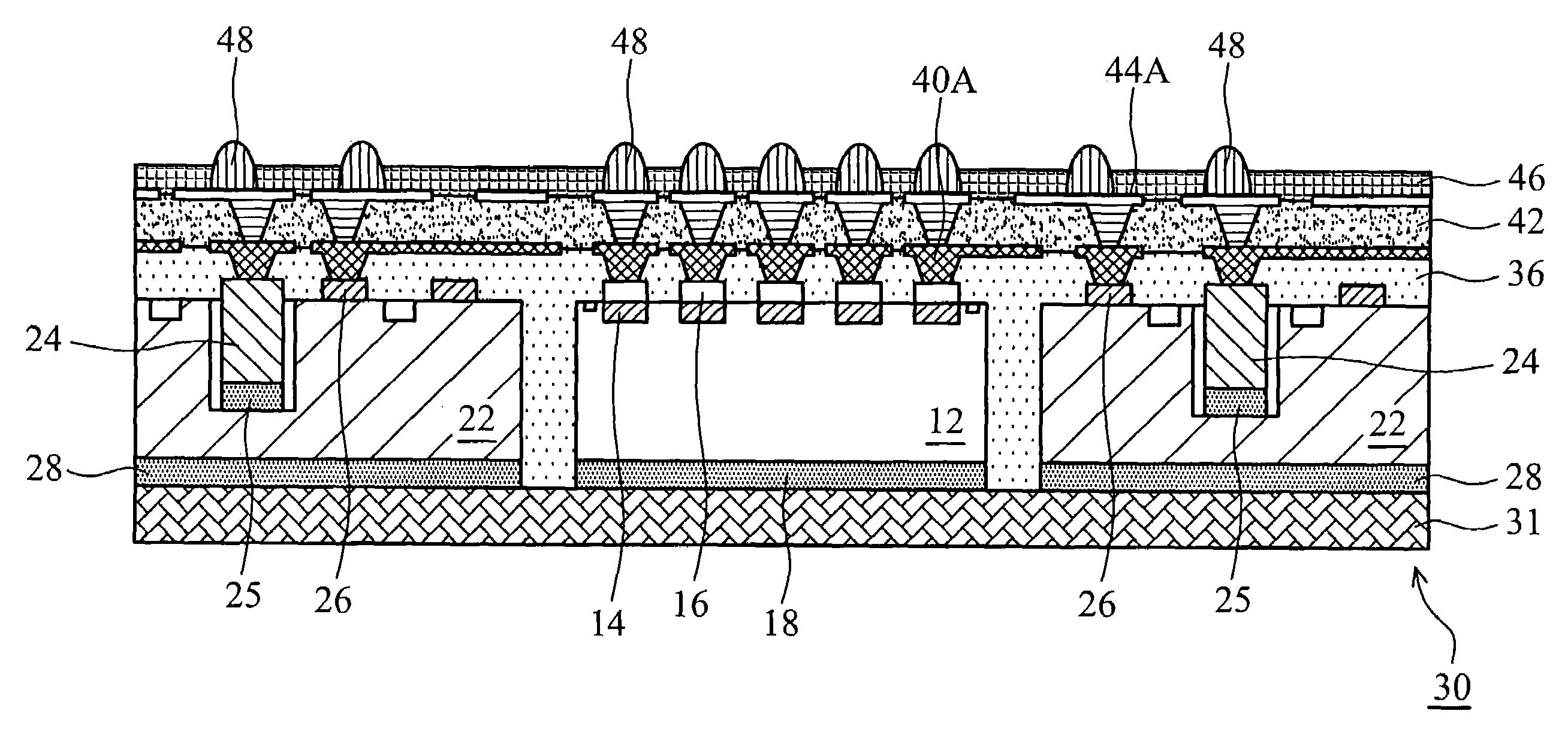

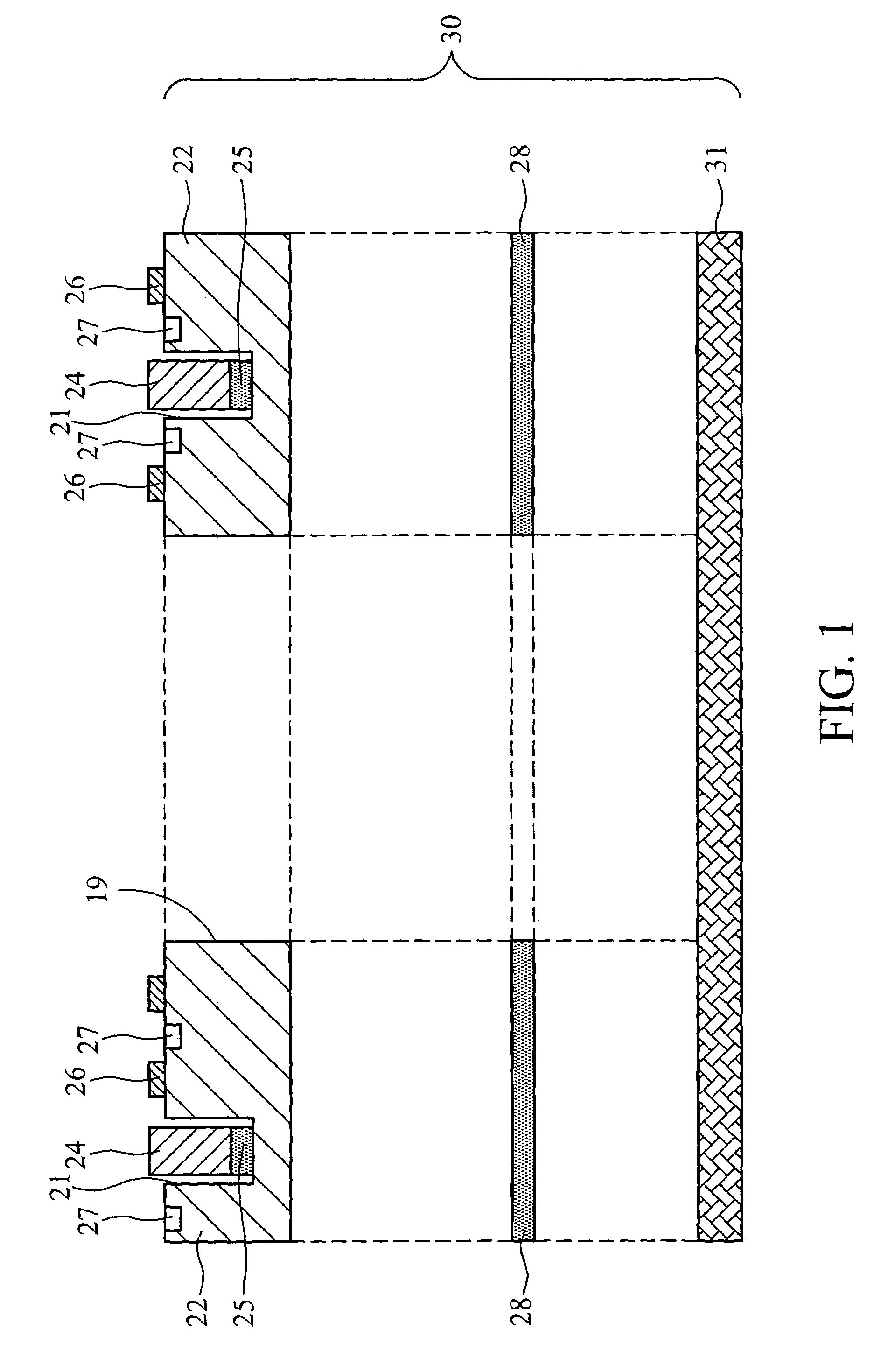

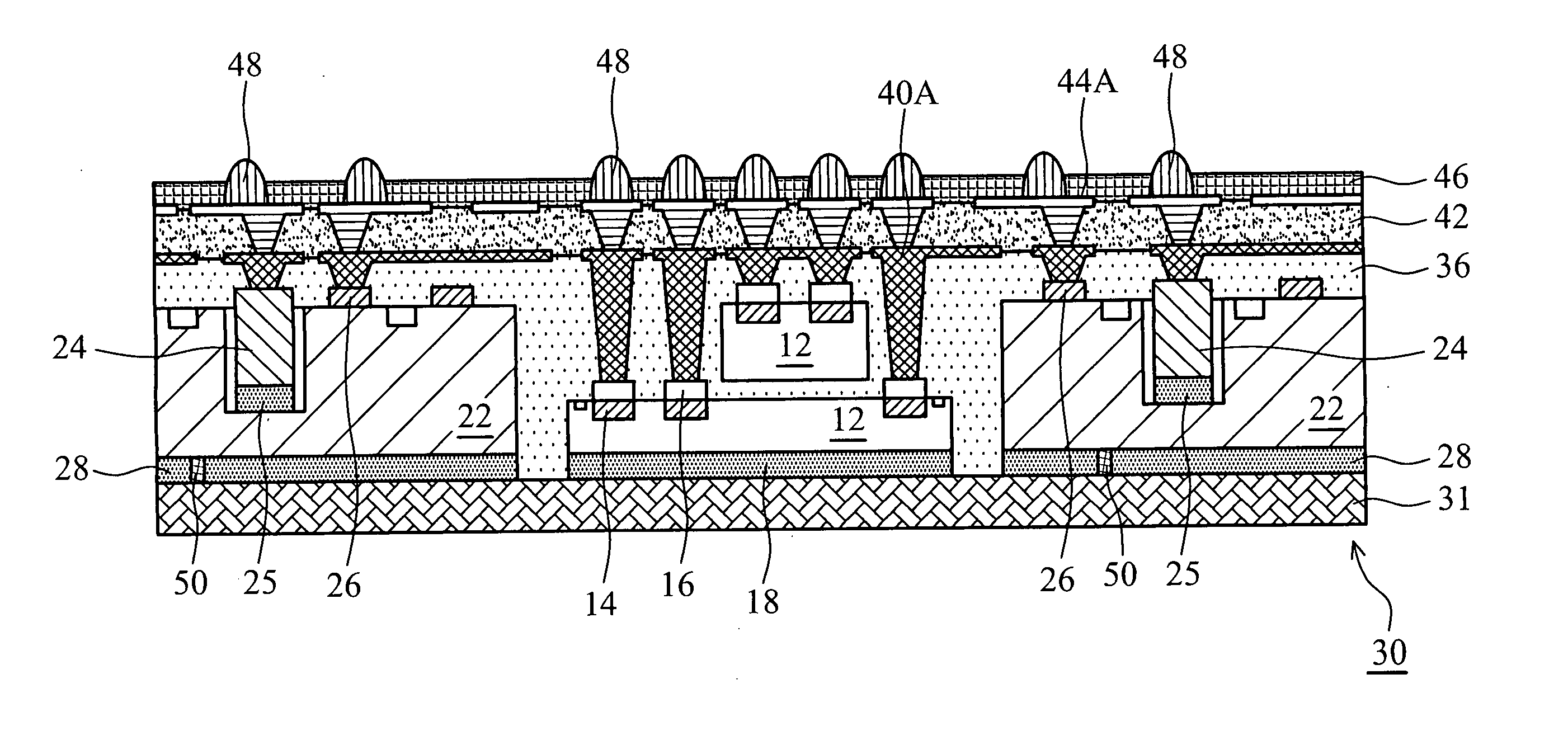

Module board having embedded chips and components and method of forming the same

InactiveUS6972964B2Simplify the assembly processReduce processing costsSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

A module board has embedded chips and components. A substrate has at least one large cavity and at least one small cavity, in which the large cavity passes through the substrate and a passive component is set in the small cavity. A heat-dissipation sheet is set at the bottom of the substrate. A first adhesion layer bonds the bottom of the substrate to the heat-dissipation sheet. At least one IC chip is fixed in the large cavity of the substrate by a second adhesion layer. A dielectric filling layer covers the entire surface of the module board and fills all gaps, in which the dielectric filling layer has a plurality of micro vias to expose partial areas of the IC chip, the passive component and the substrate. At least one wiring pattern layer is formed on the dielectric filling layer and provide electrical connection among the IC chip, the passive component, and the substrate.

Owner:VIA TECH INC

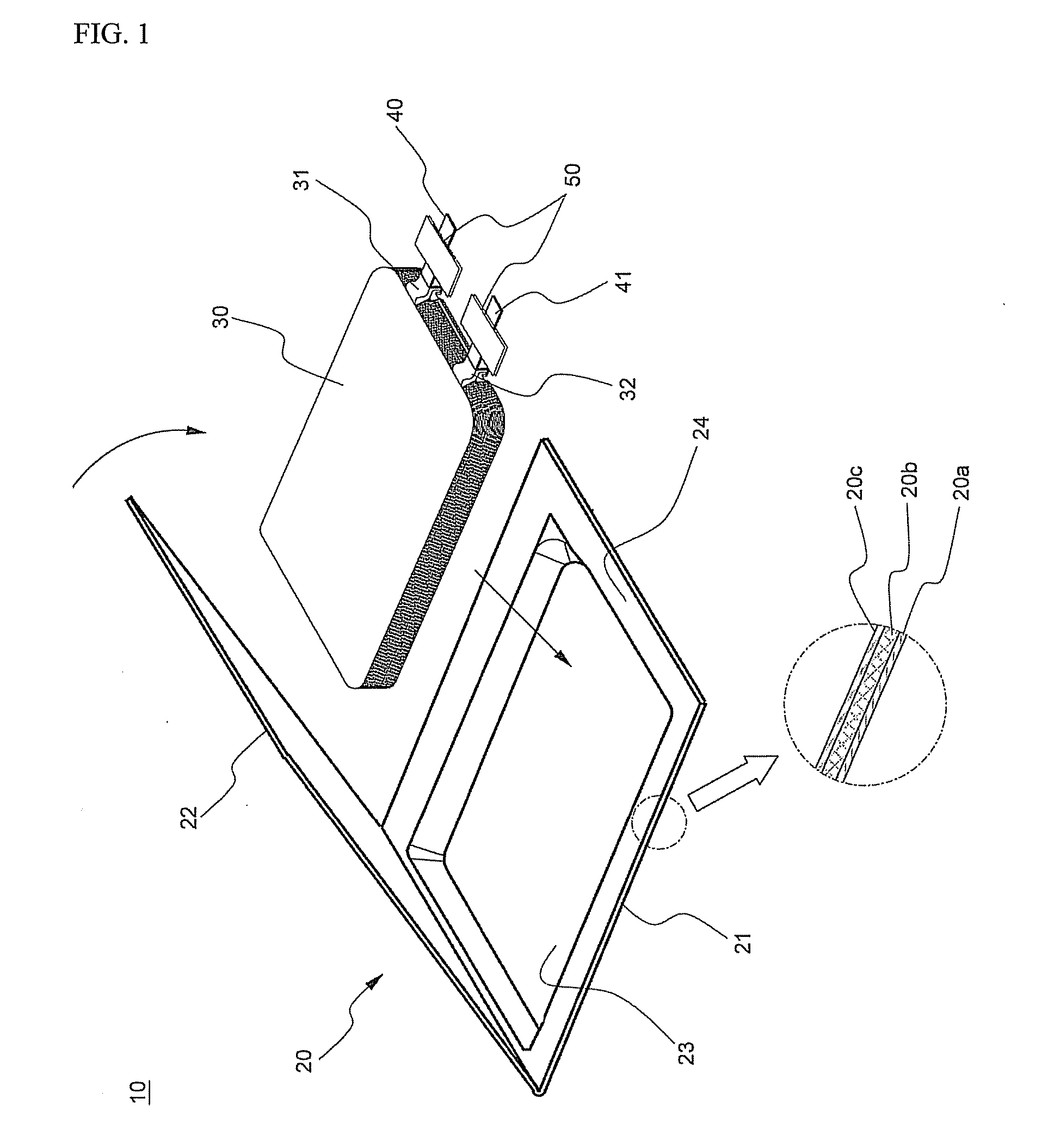

Small battery pack employing PCM on side sealing part

InactiveUS20070264535A1Enhanced couplingAvoid introducingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringHigh intensity

Disclosed herein is a battery pack constructed such that a battery case, in which an electrode assembly is mounted, is made of a laminate sheet having high strength, side sealing parts of the battery case are formed in a specific shape, and a protection circuit module (PCM) is located in the inner space of at least one of the side sealing parts. The side sealing parts in themselves are used as a structure to decide the external shape of the battery pack, and, at the same time, are used as spaces for mounting the PCM therein. Consequently, it is possible to construct the battery pack without using additional pack sheathing members, to simplify the assembly process of the battery pack, and to manufacture the battery pack in a thinner and more compact structure with the reduced manufacturing costs. Furthermore, the PCM is located at either side of the battery cell while the PCM is spaced apart from electrode terminals. Consequently, the battery pack exhibits high safety against external impacts, such as dropping of the battery pack.

Owner:LG CHEM LTD

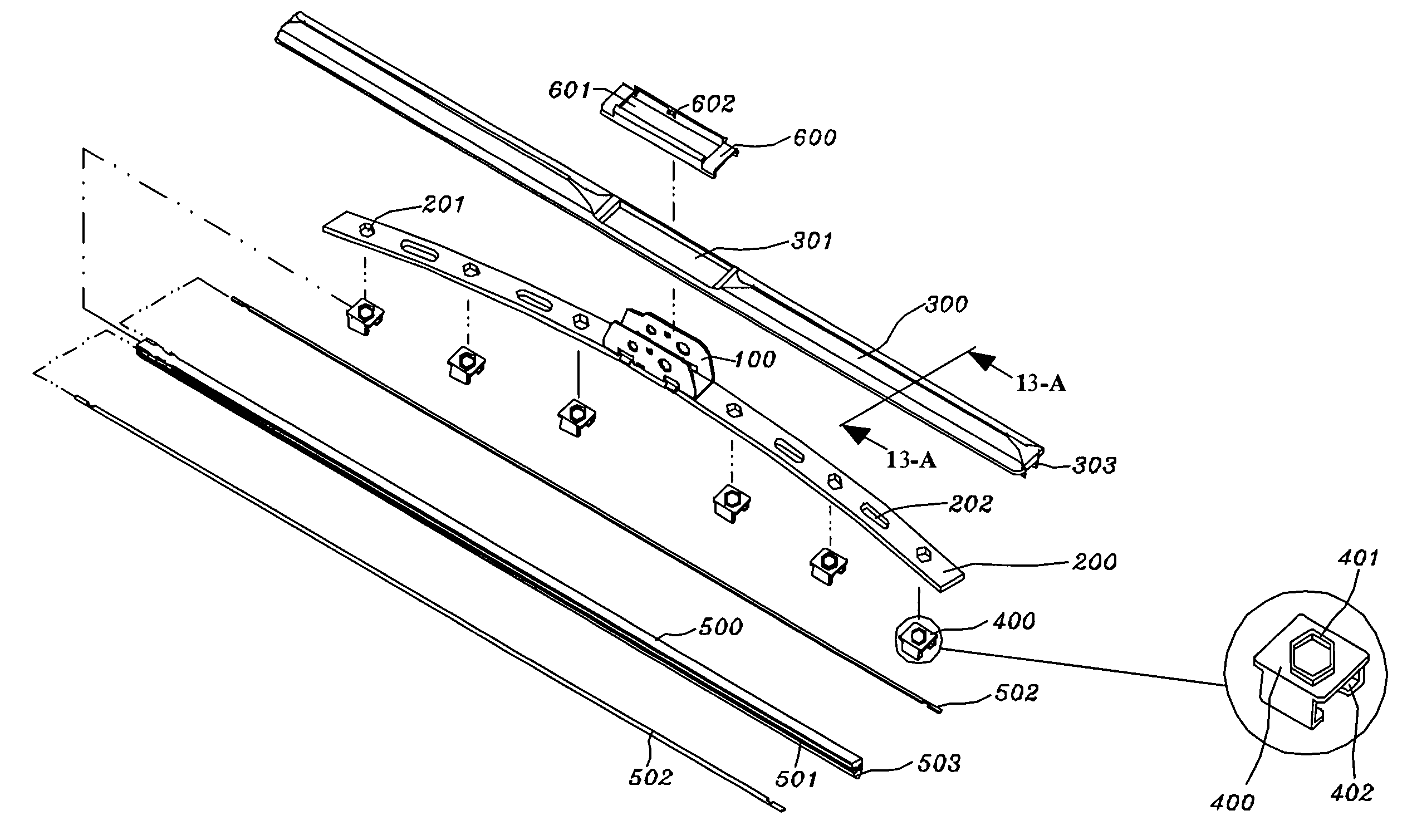

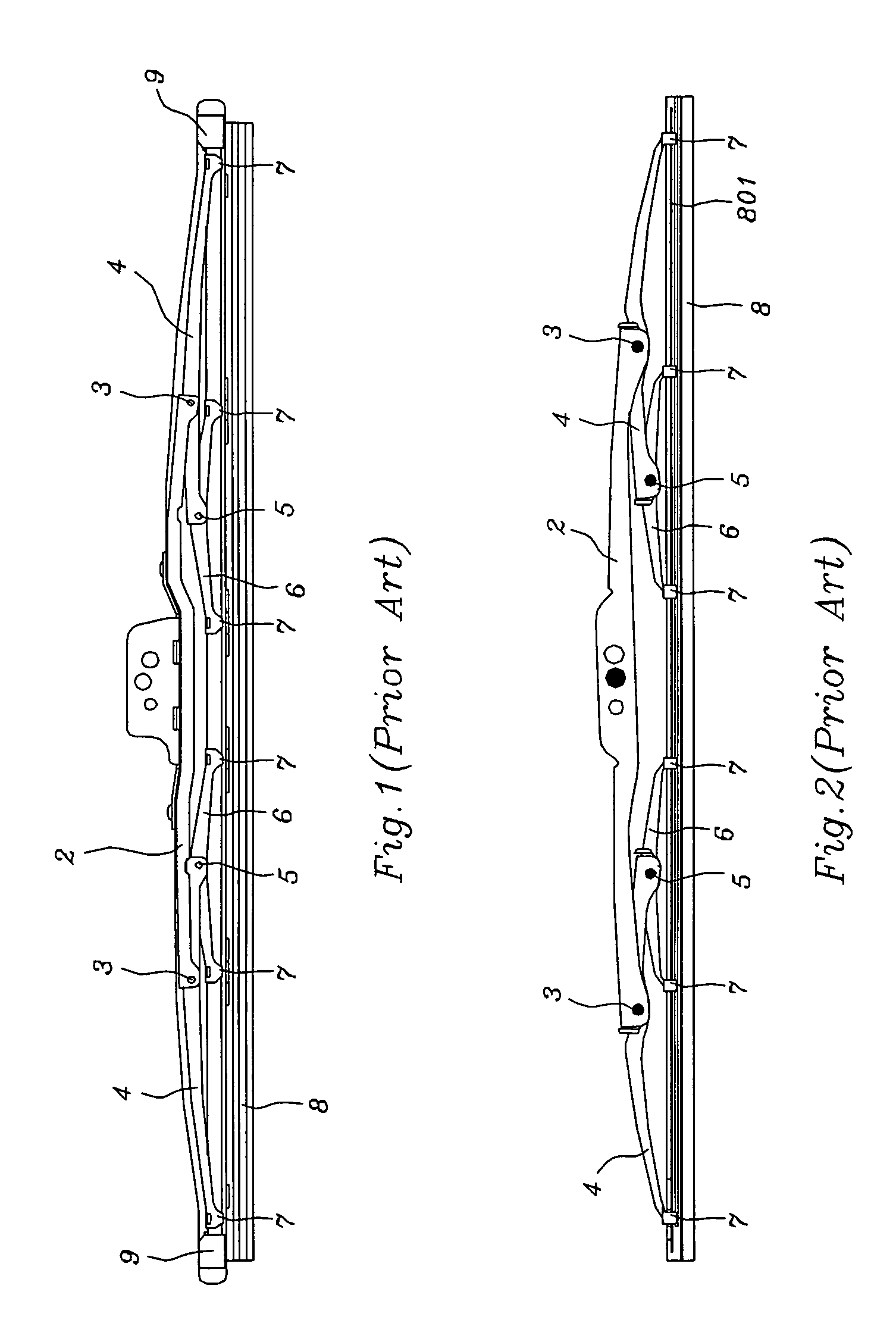

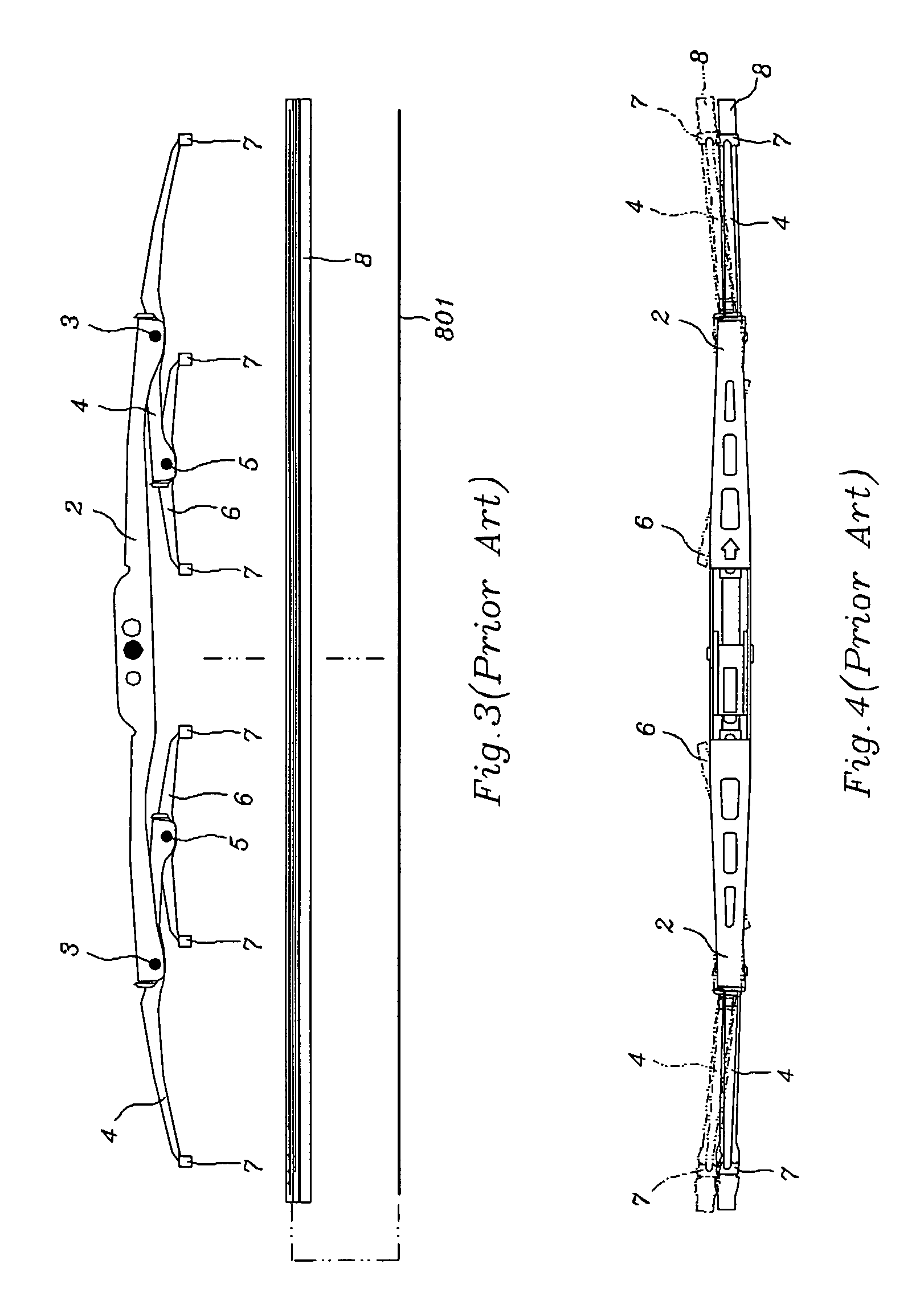

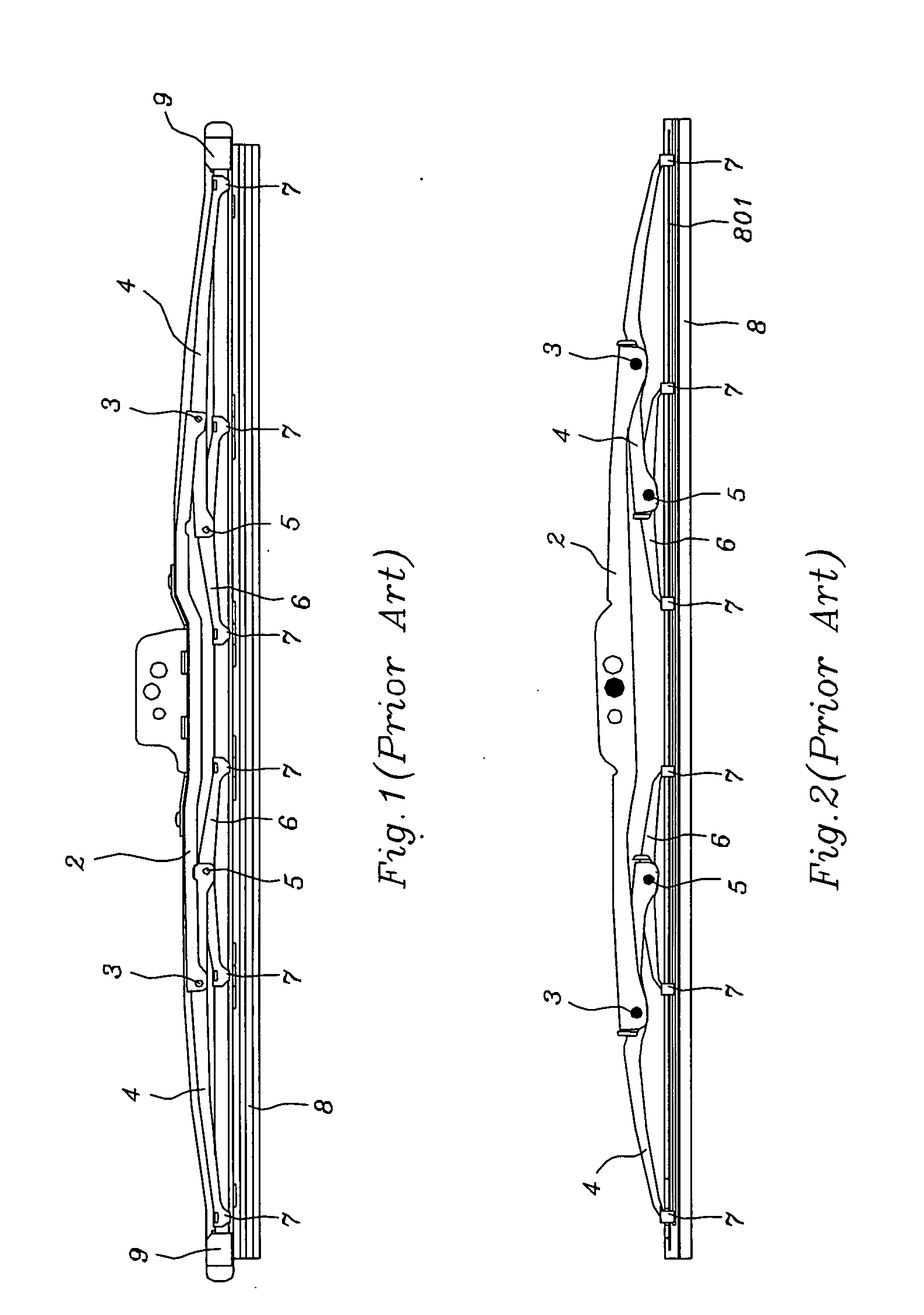

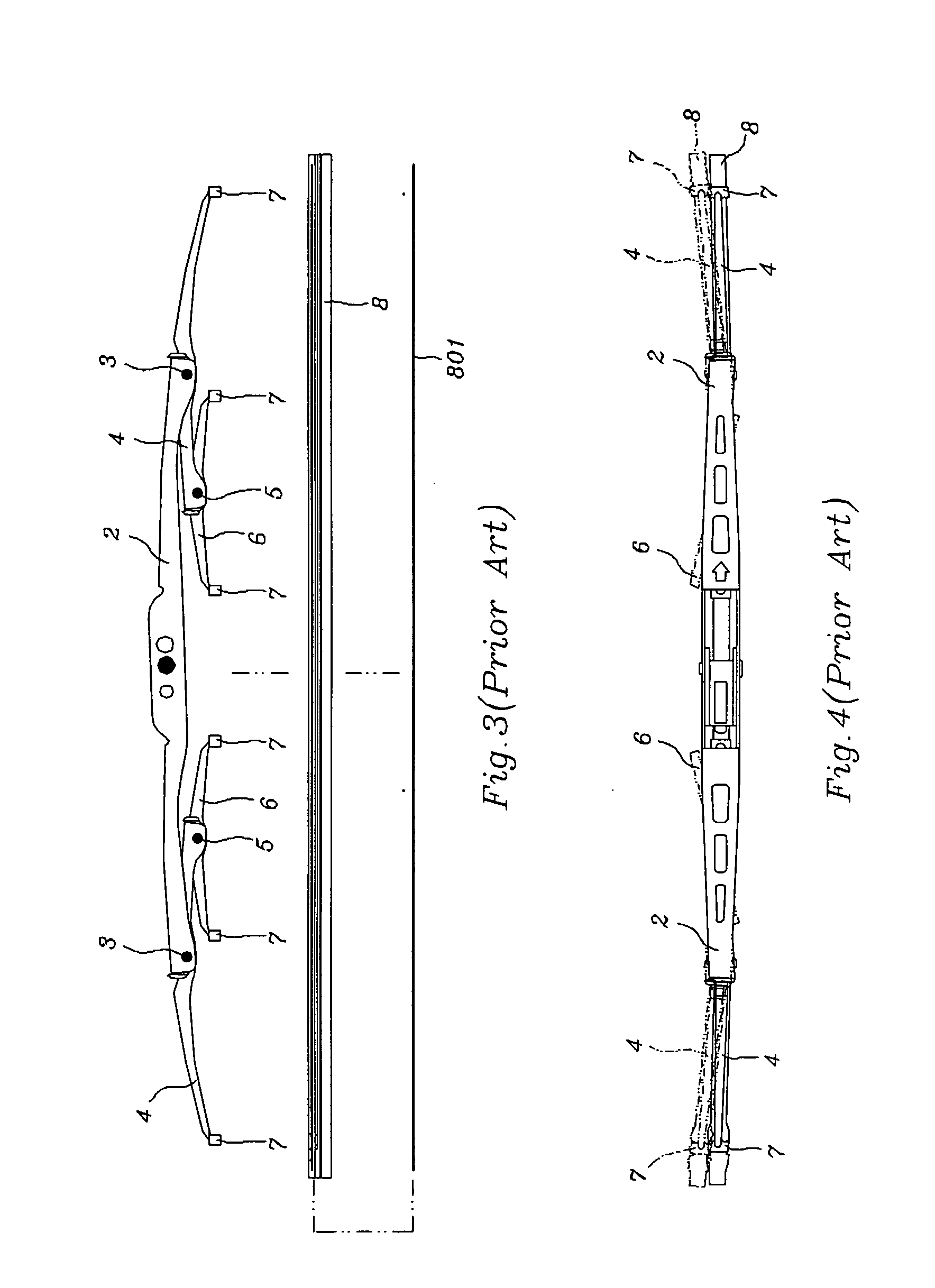

Windshield wiper structure for vehicles

InactiveUS7150066B1Improve scraping effectExtended service lifeWindow cleanersVehicle cleaningEngineeringCircular segment

A windshield wiper structure for vehicles includes a truss saddle, a bow elastic stripe, a cover body, some detachable clamping devices, a strip scraper and a frame cover. Hollow pressure adjusting vents are created on said bow elastic stripe in order to keep nearly the same elasticity at every section of said bow elastic stripe. Hence, force can be equalized in every portion of the whole wiper thereby achieving even pressure distribution. As a result, the contact between the strip scraper and the windshield glass is uniformly tight and hermetic to enhance the scraping effect of the windshield wiper as the effect of prolonging service-lifetime while reducing expenses associated with wiper replacement, thereby providing enhanced economy and environmental protection.

Owner:HUANG SHIH HSIEN

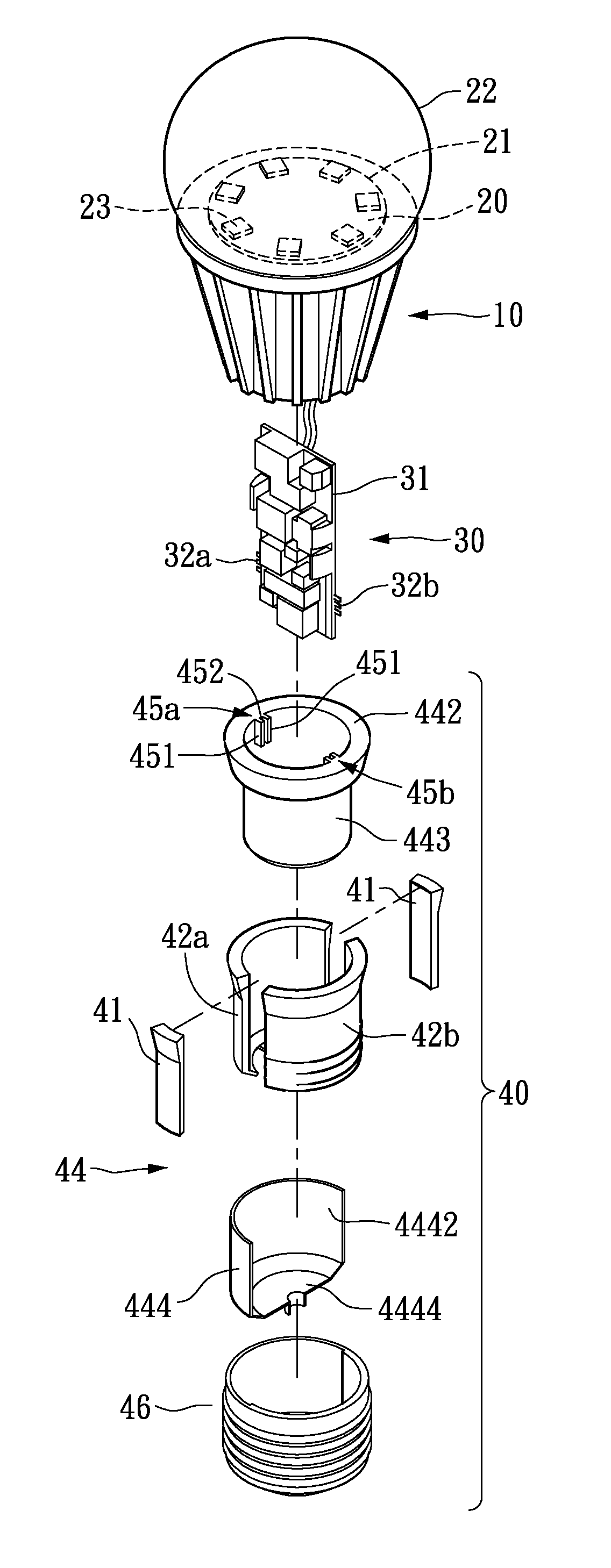

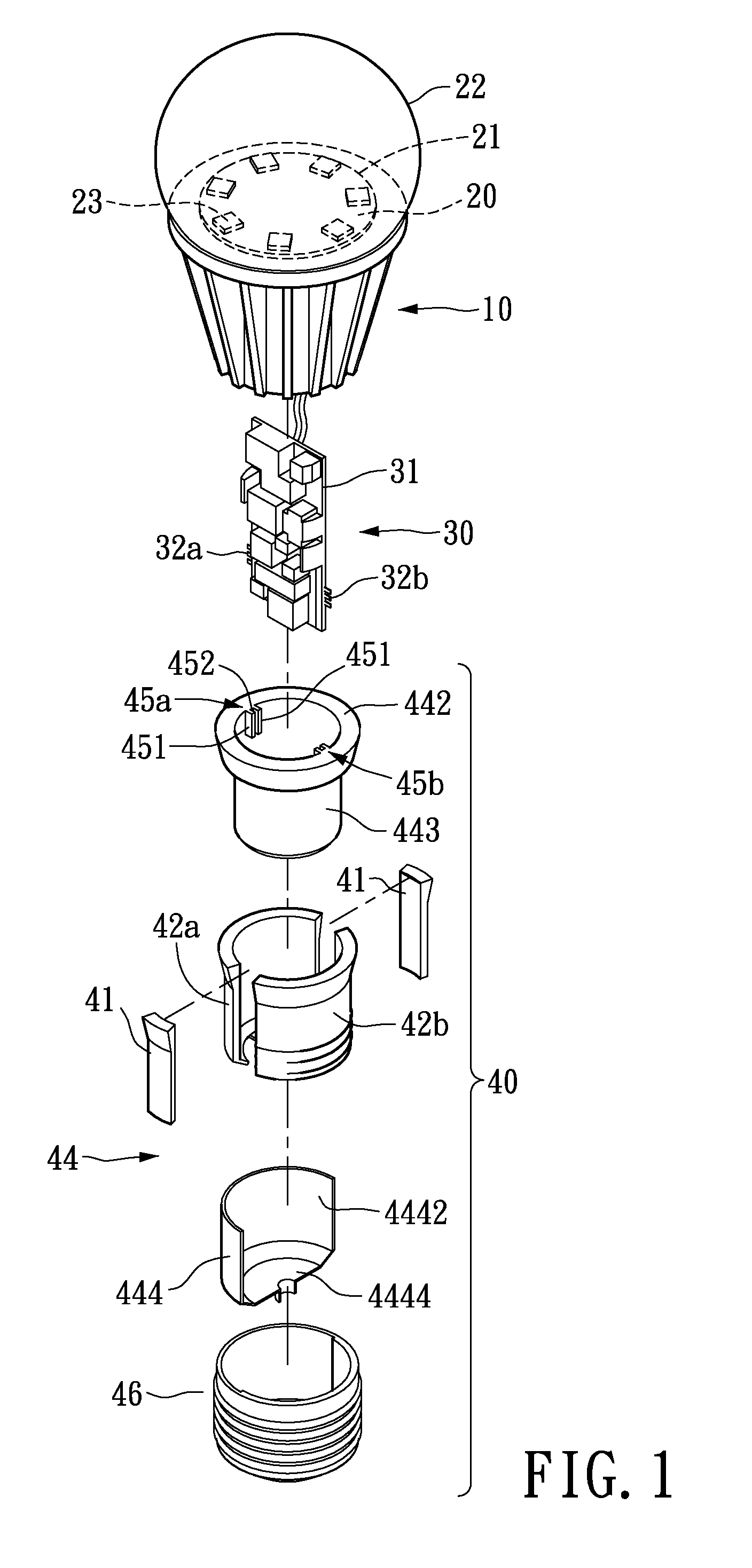

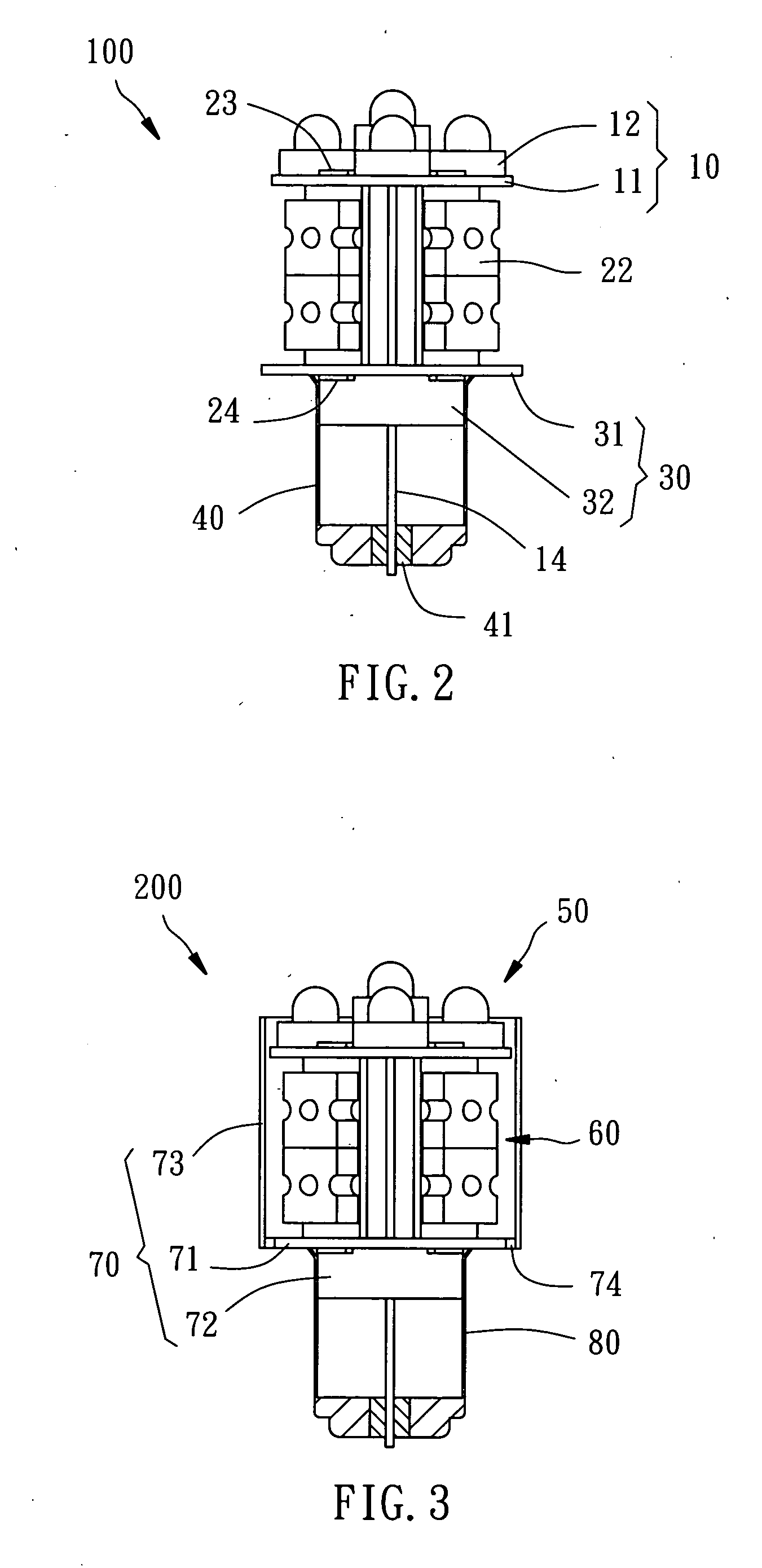

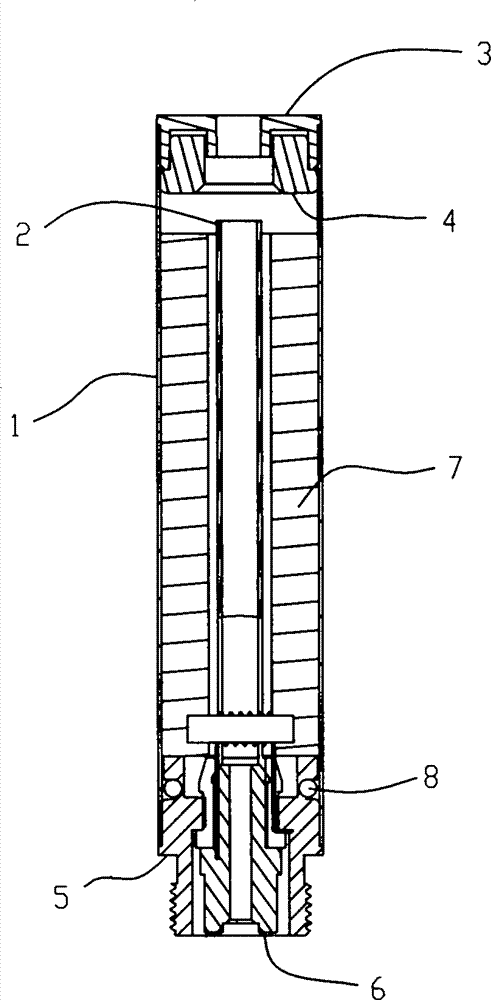

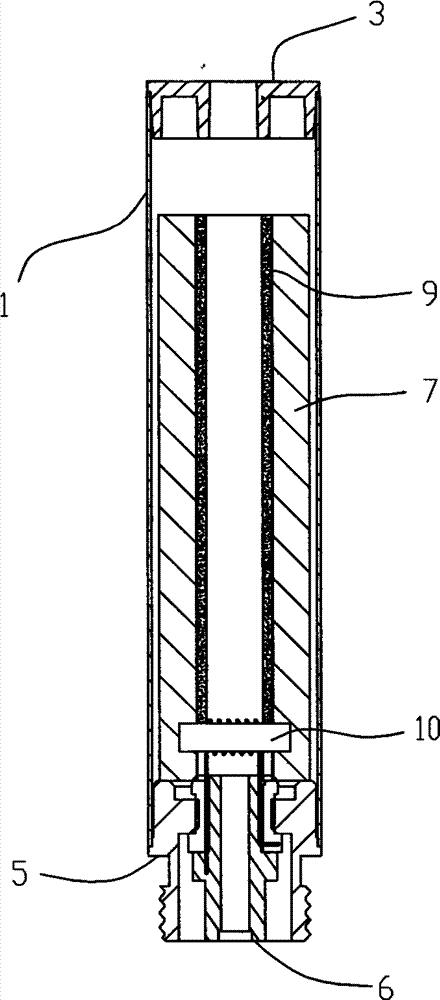

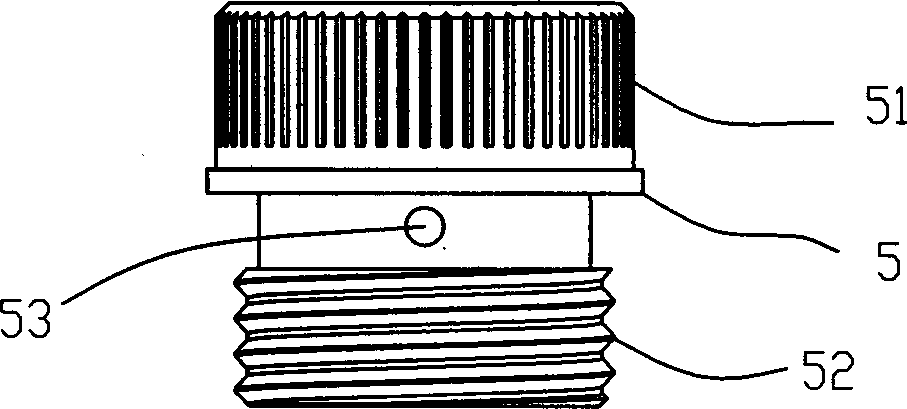

Illumination device

ActiveUS8696168B2Simplify the assembly processImprove cooling effectPoint-like light sourceLighting support devicesElectrical connectionEngineering

An illumination device having enhanced thermal dissipating capacity is provided. The illumination device includes a heat sink, an LED module, a cover, an LED driver, and a lamp base. The LED module is disposed at one end of the heat sink. The cover covers the LED module. The LED driver is in connection with the LED module, and includes a circuit board and at least one electrical contact member disposed on the circuit board. The lamp base is connected to the other end of the heat sink, and comprises an insulating unit, a first electrode, a second electrode and at least one contact port. The contact port is arranged on the lateral interior of the insulating unit, so that the electrical contact member of the LED driver may establish electrical connection with the lamp base.

Owner:LITE ON TECH CORP +1

Radiopaque embedded into desiccant for implantable medical device

InactiveUS20120065500A1Simplify the assembly processRule out the possibilitySurgeryProsthesisDesiccantEngineering

A molded desiccant article for placement in an implantable medical device includes an affixed radiopaque marker. The radiopaque marker may serve to provide information regarding the make and model of the device or may be used for purposes of determining whether the desiccant was placed in the device.

Owner:MEDTRONIC INC

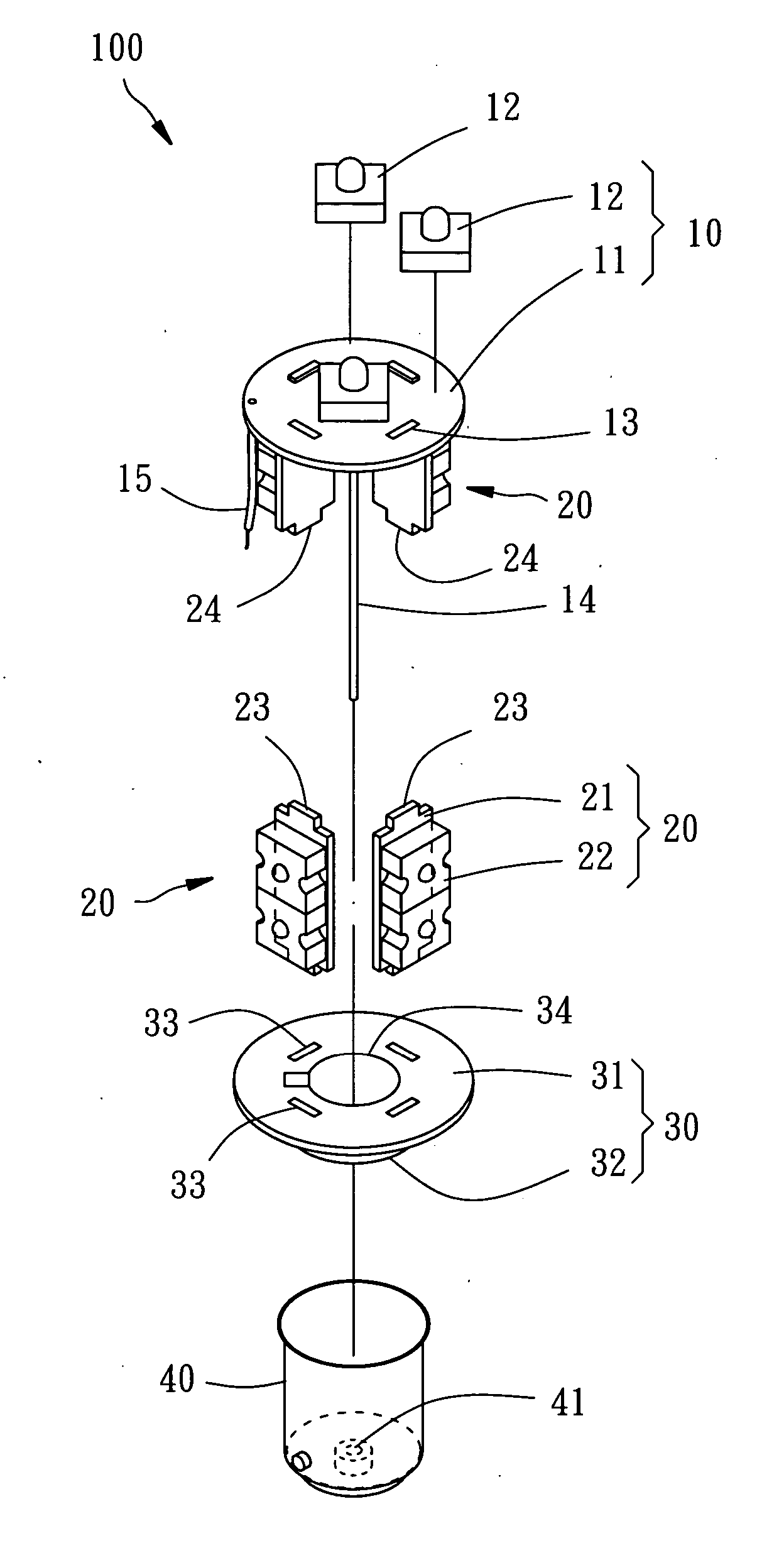

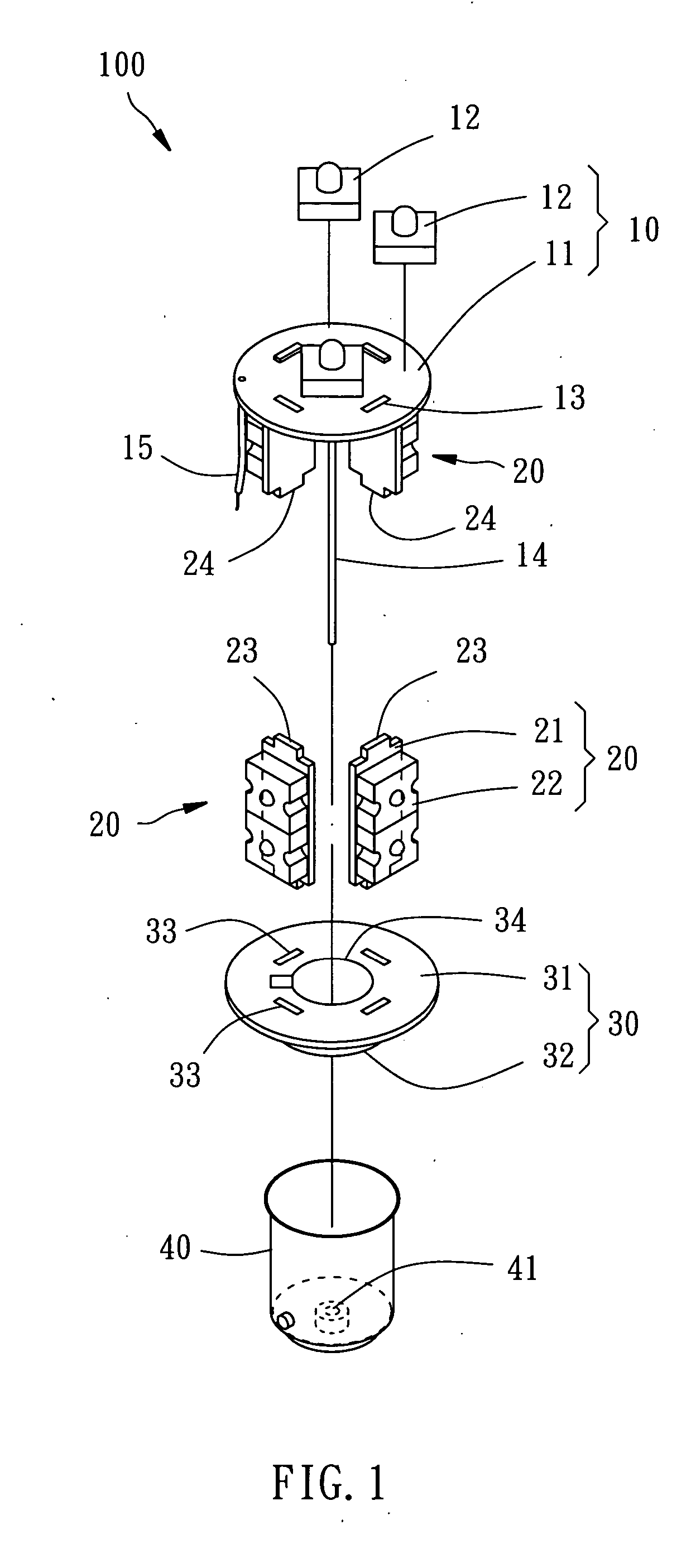

Bulb with light emitting diodes

InactiveUS20070097678A1Simple assembly processSimplify the assembly processLighting support devicesPoint-like light sourceEngineeringLight-emitting diode

A bulb includes a top light-emitting module having a top circuit board and light emitting diodes (LEDs). The top circuit board has first lock slots and wires electrically connected to the LEDs respectively. Vertical light-emitting modules have a vertical circuit board with a first coupling portion and a second coupling portion and LEDs respectively. The first coupling portions are inserted into the first lock slots of the top light-emitting module. A positioning base has a positioning plate and a coupling portion. The positioning plate has second lock slots to engage the second coupling portions respectively. The positioning base has a through hole through the positioning plate and the coupling portion for the wires passing through. A cap is fixed to the coupling portion of the positioning base, and the wires through the through hole are electrically connected to a bottom of the cap.

Owner:YANG SHENG LI

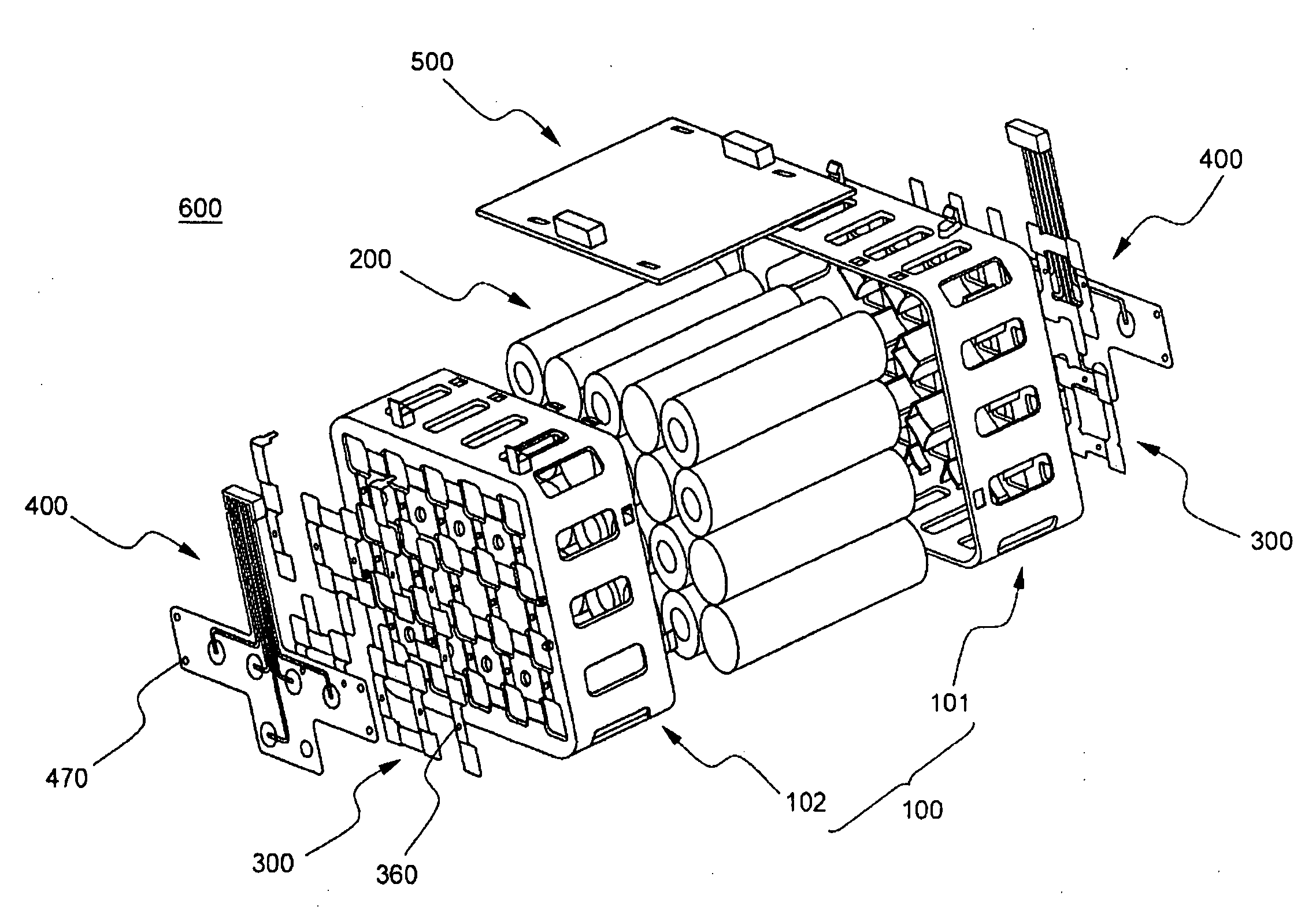

Battery pack case

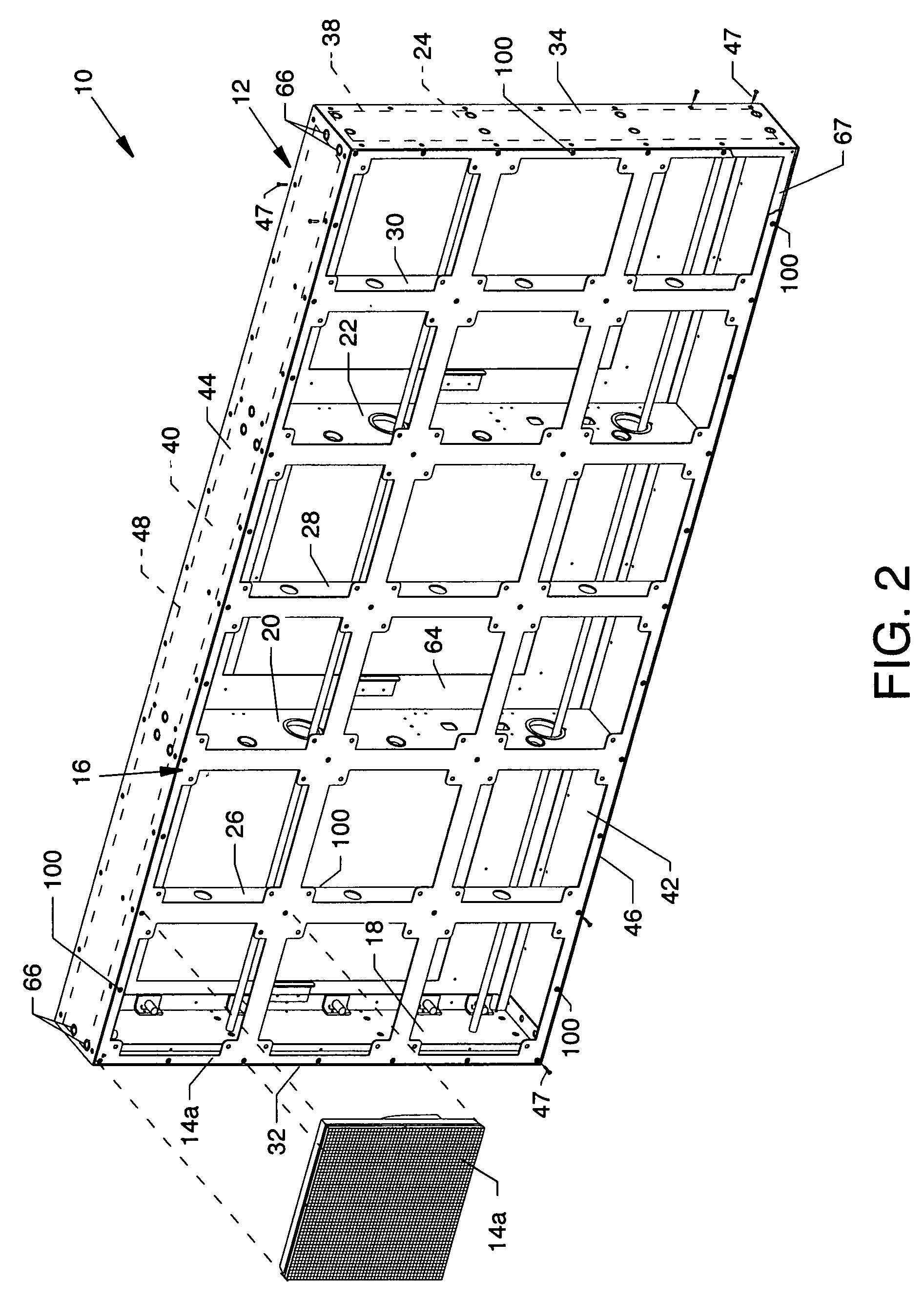

ActiveUS20100047676A1Improve structural stabilitySimplify the assembly processPrimary cell to battery groupingFinal product manufactureEngineeringBattery cell

Disclosed herein are a pack case constructed in a structure in which a plurality of battery cells are mounted in the pack case to electrically connect the battery cells with each other, wherein the pack case includes an upper case and a lower case constructed in a hollow structure in which the upper case and the lower case are coupled with each other while the battery cells are mounted between the upper case and the lower case, each case is integrally provided at the inner part thereof with a plurality of spacers for supporting the battery cells, and each case is provided at the outer part thereof with a plurality of ventilation openings which communicate with the interior of each case, and a battery pack including the pack case. The pack case according to the present invention has effects in that a plurality of battery cells are stably mounted in the pack case in a compact structure through a simple assembly process, heat generated from the battery cells is effectively removed during the charge and discharge of the battery cells, and an additional safety unit, such as a detection member and / or a protection circuit module, is easily mounted to the pack case.

Owner:LG ENERGY SOLUTION LTD

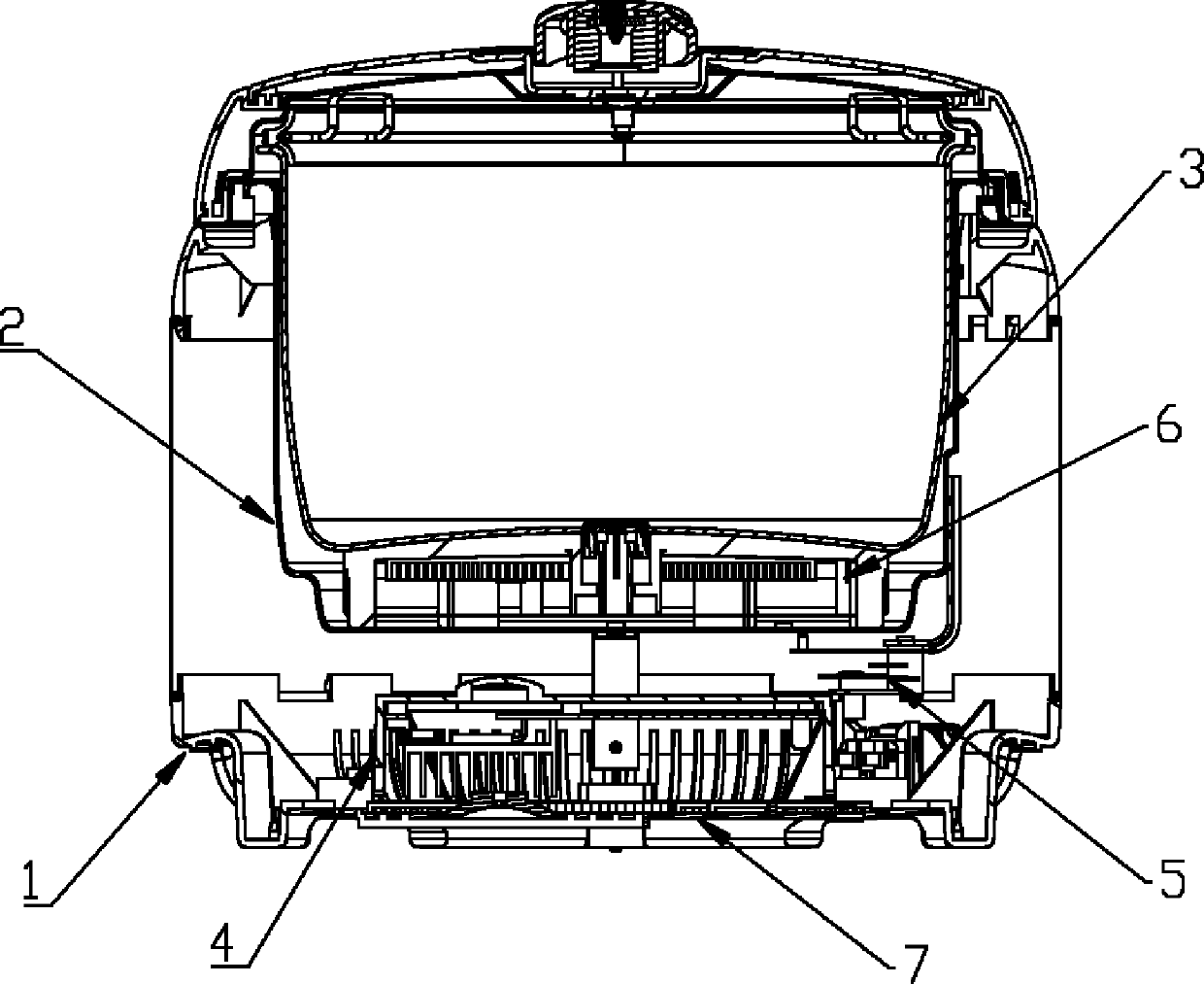

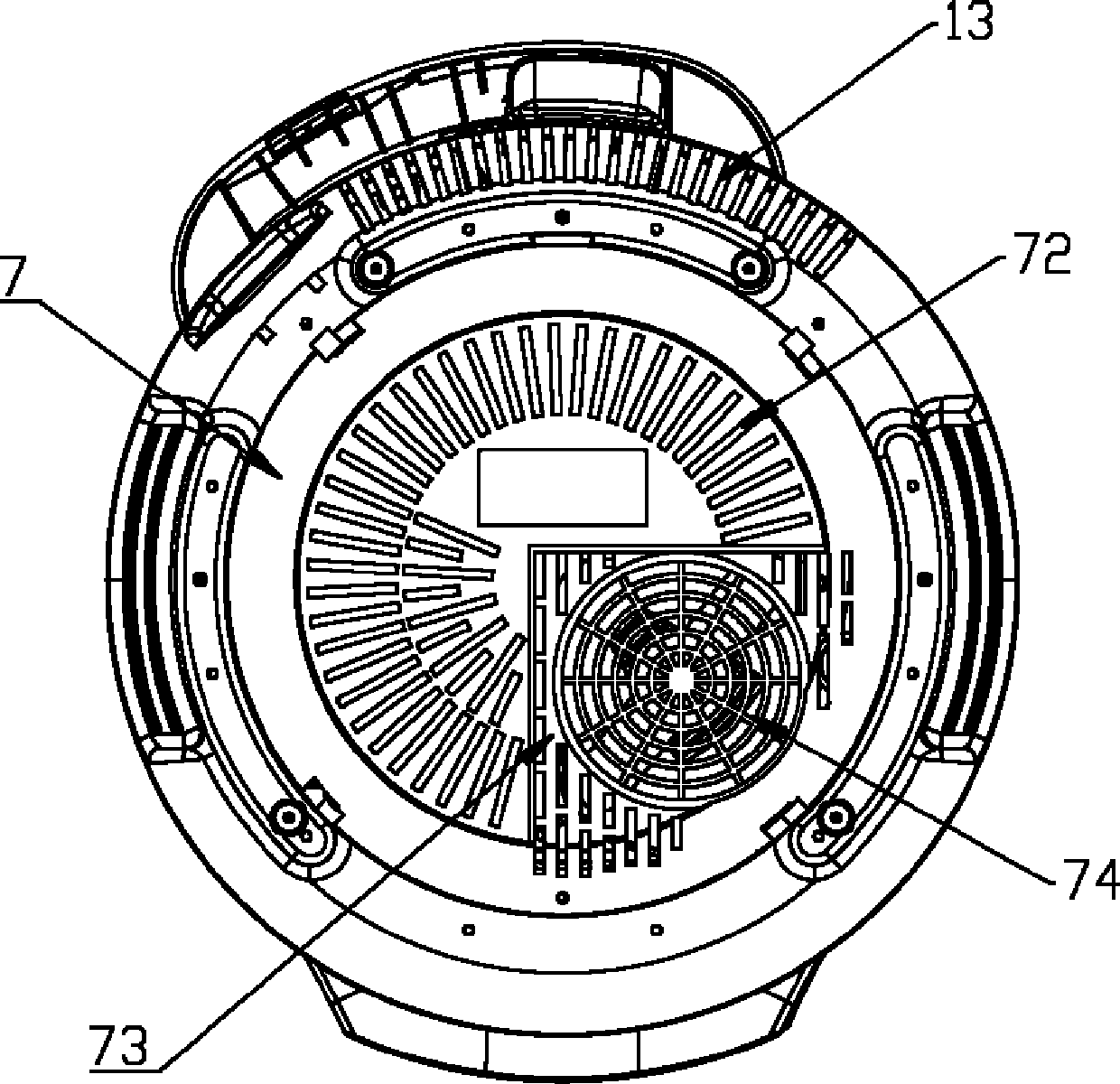

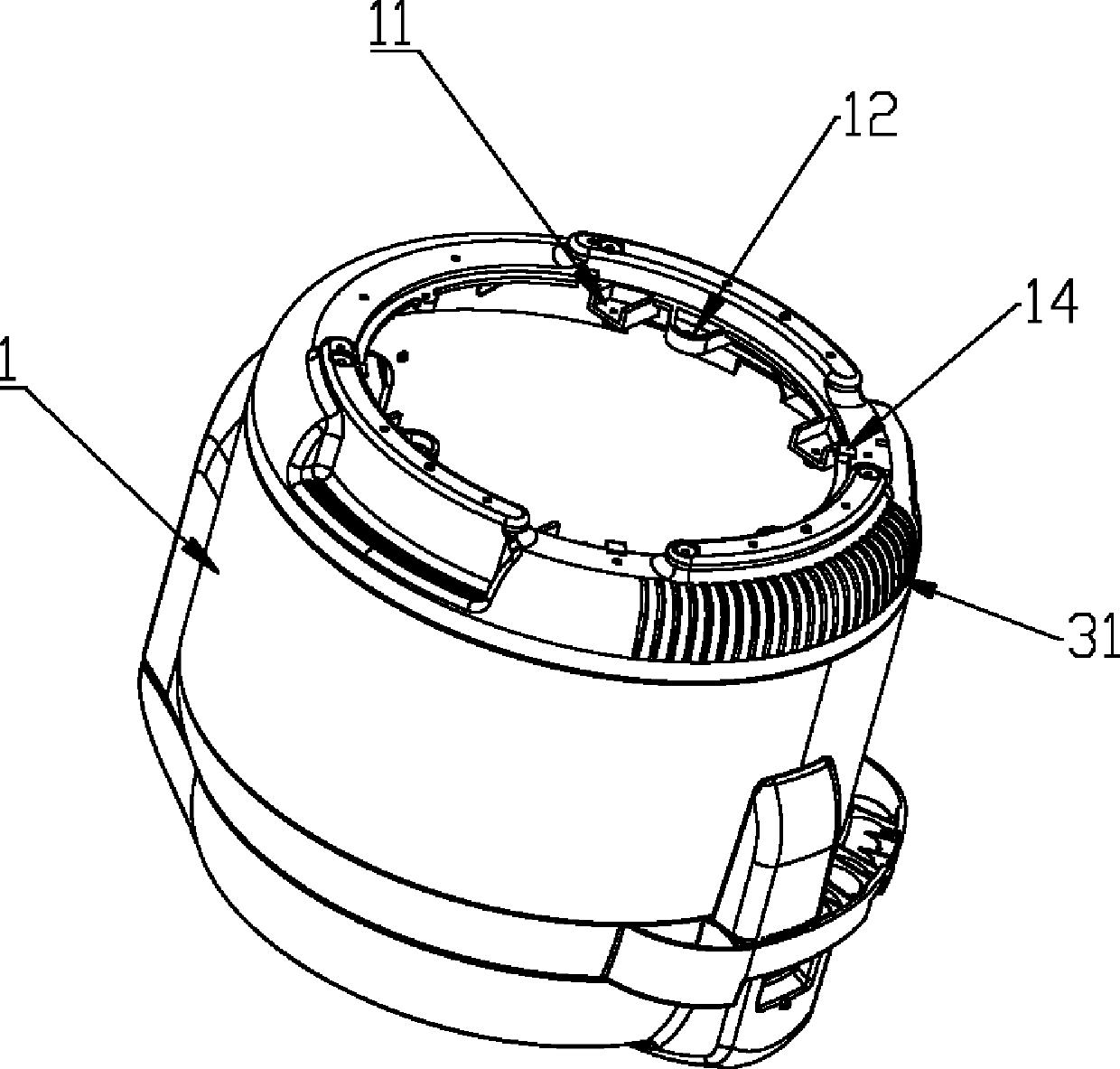

Electromagnetic electric-pressure cooker

InactiveCN103445669AGood for heat dissipationOptimize heat dissipation structureCooking vesselsPhysicsEngineering

The application of the invention relates to the technical field of electric-pressure cookers, in particular to an electromagnetic electric-pressure cooker. The electromagnetic electric-pressure cooker comprises a base, a bottom cap, an outer cover and a liner, wherein a power supply box is arranged in the base, an electromagnetic heating plate is arranged betweenthe outer cover and the liner, a fan and a heat sink are arranged in the power supply box, a funnel-shaped air guiding opening is arranged in the power supply box, the fan is arranged above the air guiding opening, and the heat sink is tightly leaned against the fan; the electromagnetic heating plate comprises a coil plate, a magnetism-isolating plate and a sensor assembly, an annular large winding area formed by a plurality of concentrically arranged coil slots is formed in an inner cavity of the coil plate and is divided into a plurality of small winding areas and ventilating slots, the small winding areas and the ventilating slots are arranged alternatively, and the slot bottoms of the ventilating slots are lower than the slot bottoms of the coil slots. Compared with the prior art, the electromagnetic electric-pressure cooker disclosed by the application of the invention has the advantages that the heat dissipation structure of the whole electric-pressure cooker is optimized, the whole heat dissipation performance is reinforced, the structure of the electromagnetic heating plate is simplified, and the manufacturing and assembling processes are simpler.

Owner:GUANGDONG LUBY ELECTRONICS

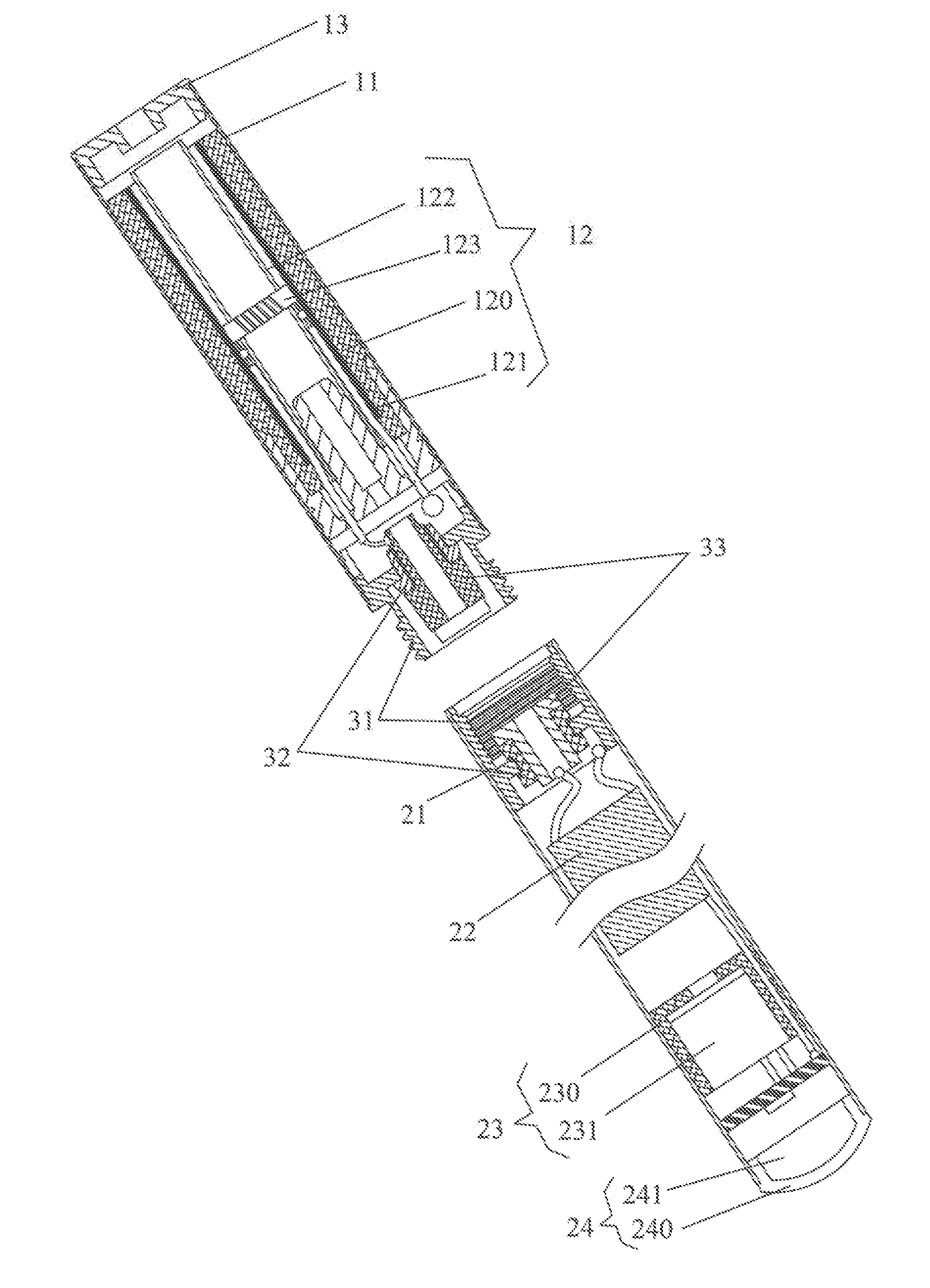

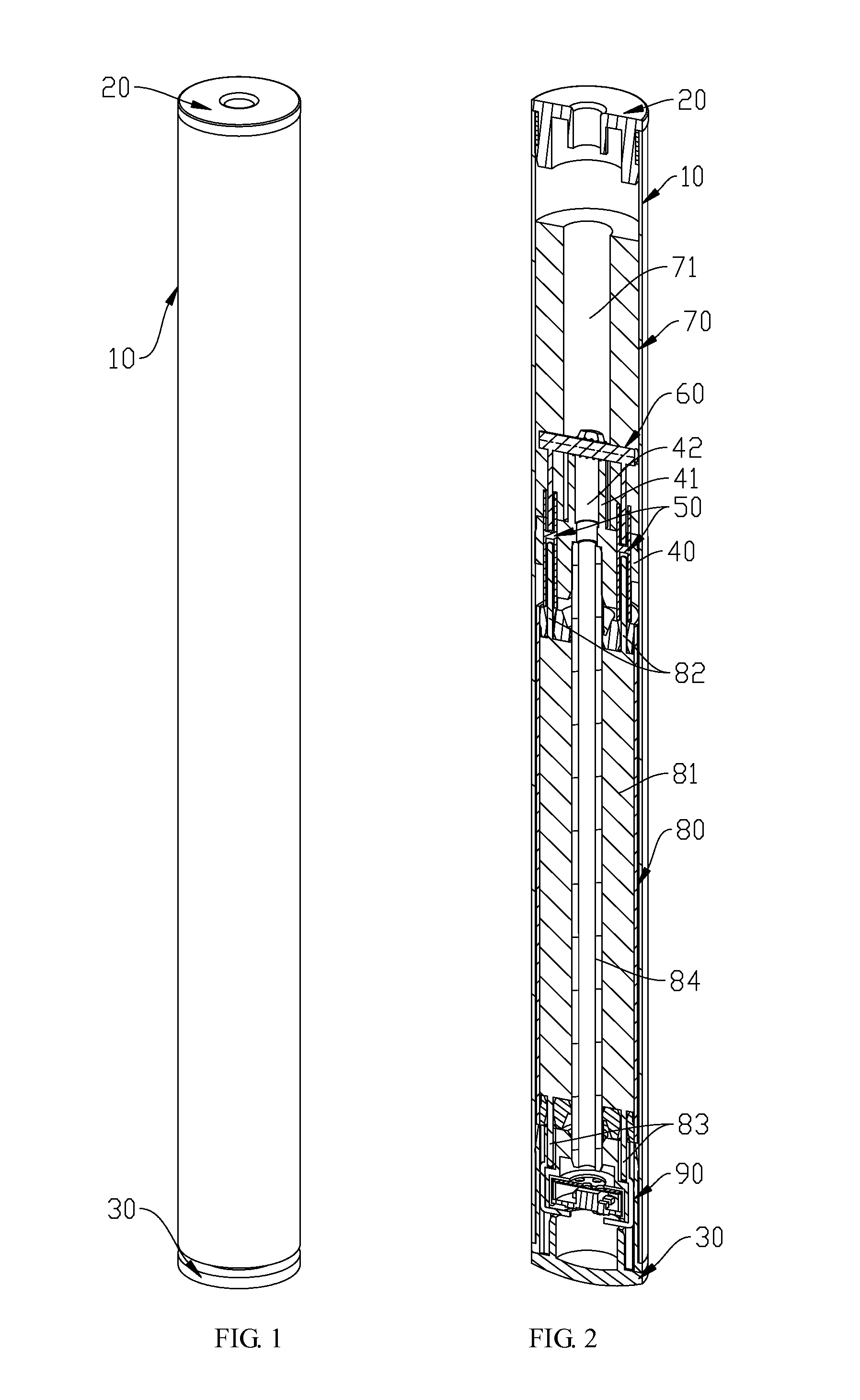

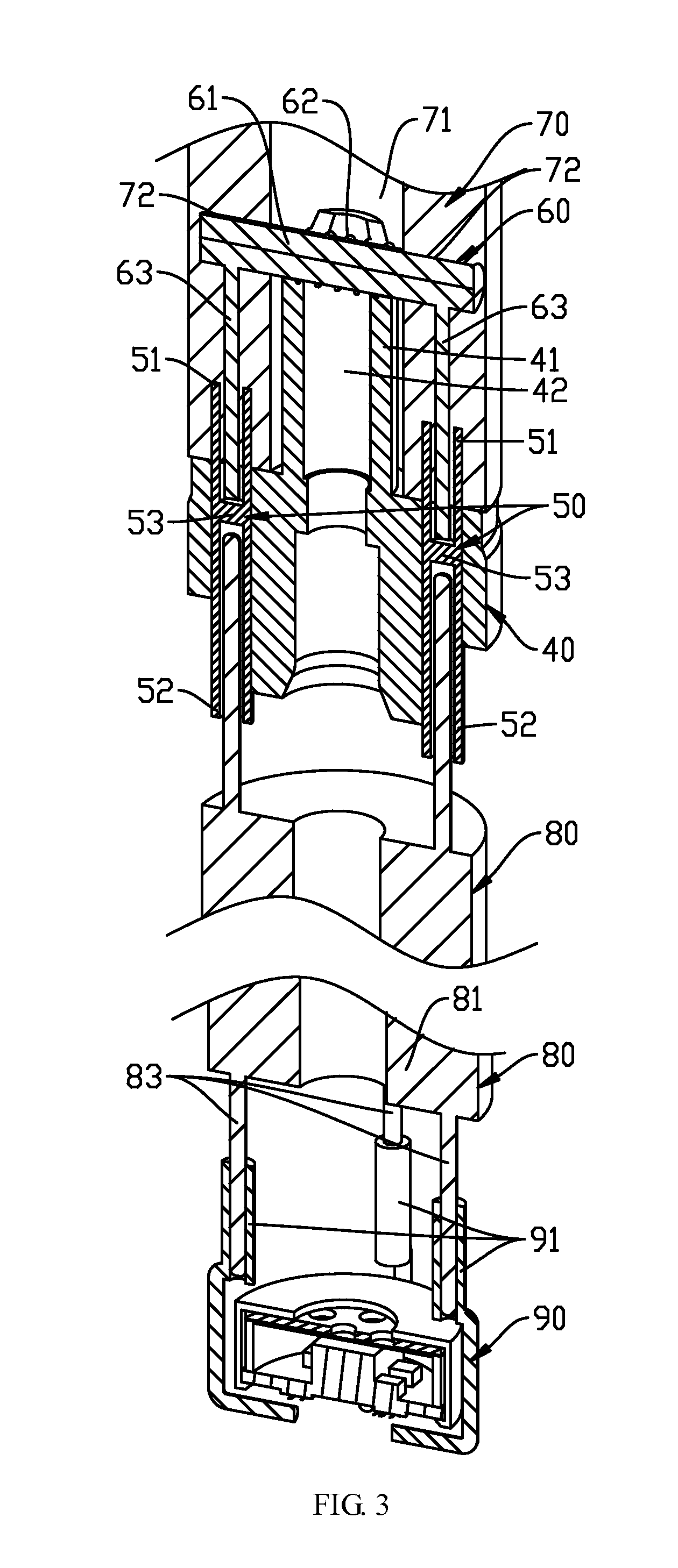

Electronic cigarette and assembly method of atomizer thereof

InactiveUS20150196056A1Simple assemblyHigh efficiencyElectric heatingTobacco pipesCost savingsEngineering

An electronic cigarette and a method for assembling an atomizer thereof. The electronic cigarette comprises a suction rod (10) and a power supply rod (20). The suction rod (10) comprises a suction tube (11) and an atomizer (12) disposed in the suction tube (11) and used for generating smoke. The atomizer (12) comprises an air pipe (122) and a heating assembly (123). The air pipe (122) is provided with a through hole (100) along a radial direction used for accommodating and fixing the heating assembly (123). The air pipe (122) is also provided with a notch (200) which has a bottom communicating with the through hole (100) and is used for assembling the heating assembly. By disposing a notch (200) which has a bottom communicating with the through hole (100) and is used for assembling the heating assembly (123) on the air pipe (122), technical effects of simple assembly, high efficiency, stable quality and cost saving are achieved.

Owner:KIMREE HI TECH

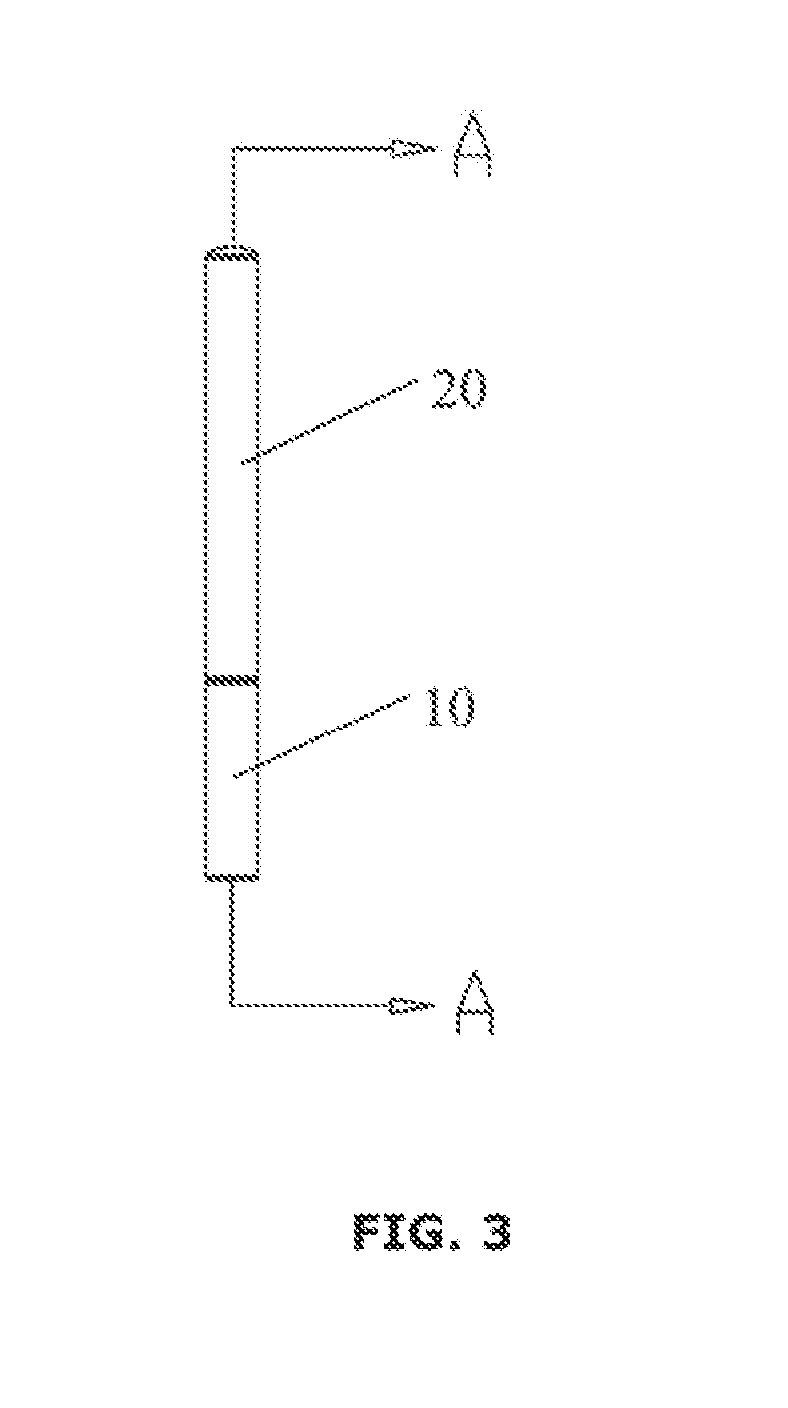

Electronic cigarette and method for assembling electronic cigarette

ActiveUS20160150823A1Simplify the assembly processEasy to assembleTobacco pipesTobacco devicesEngineeringStructural engineering

An electronic cigarette and a method for assembling the electronic cigarette are provided. The electronic cigarette includes an atomizer device mounting base, at least one conductive pipe, an atomizer device, and a battery device. The conductive pipe includes a first open end, a second open end, and a partition wall disposed within the middle of the conductive pipe to separate the first open end from the second open end. The atomizer device includes a first pluggable member being inserted into and electrically connected to the first open end. The battery device includes a second pluggable conductive member being inserted into and electrically connected to the second open end. When assembled, the atomizer device, the atomizer deice mounting base, and the battery device can be connected together by employing an insertion method directly, thus the assembly process can be simplified, and the leakage of the liquid solution can be prevented.

Owner:SHENZHEN SMOORE TECH LTD

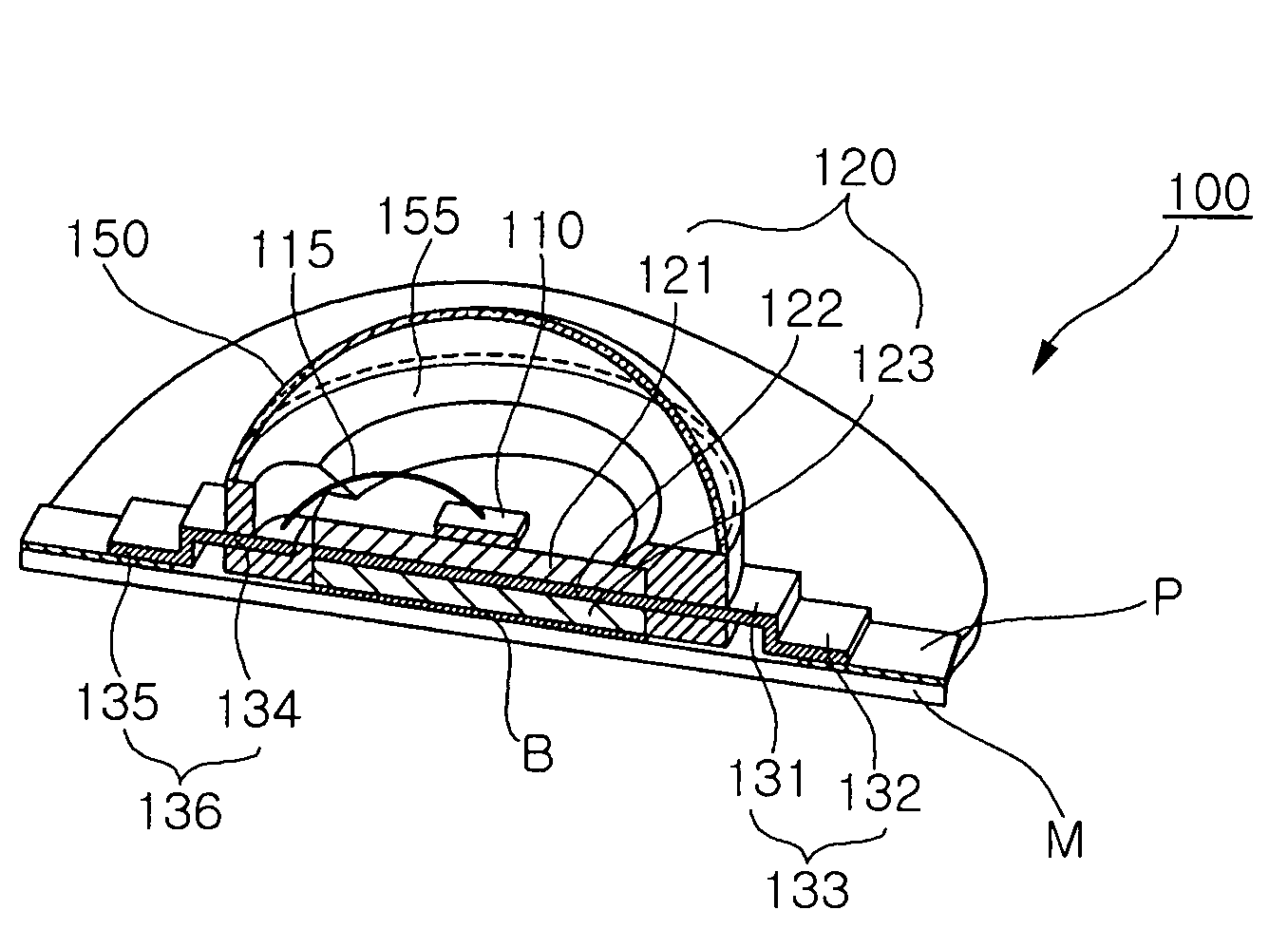

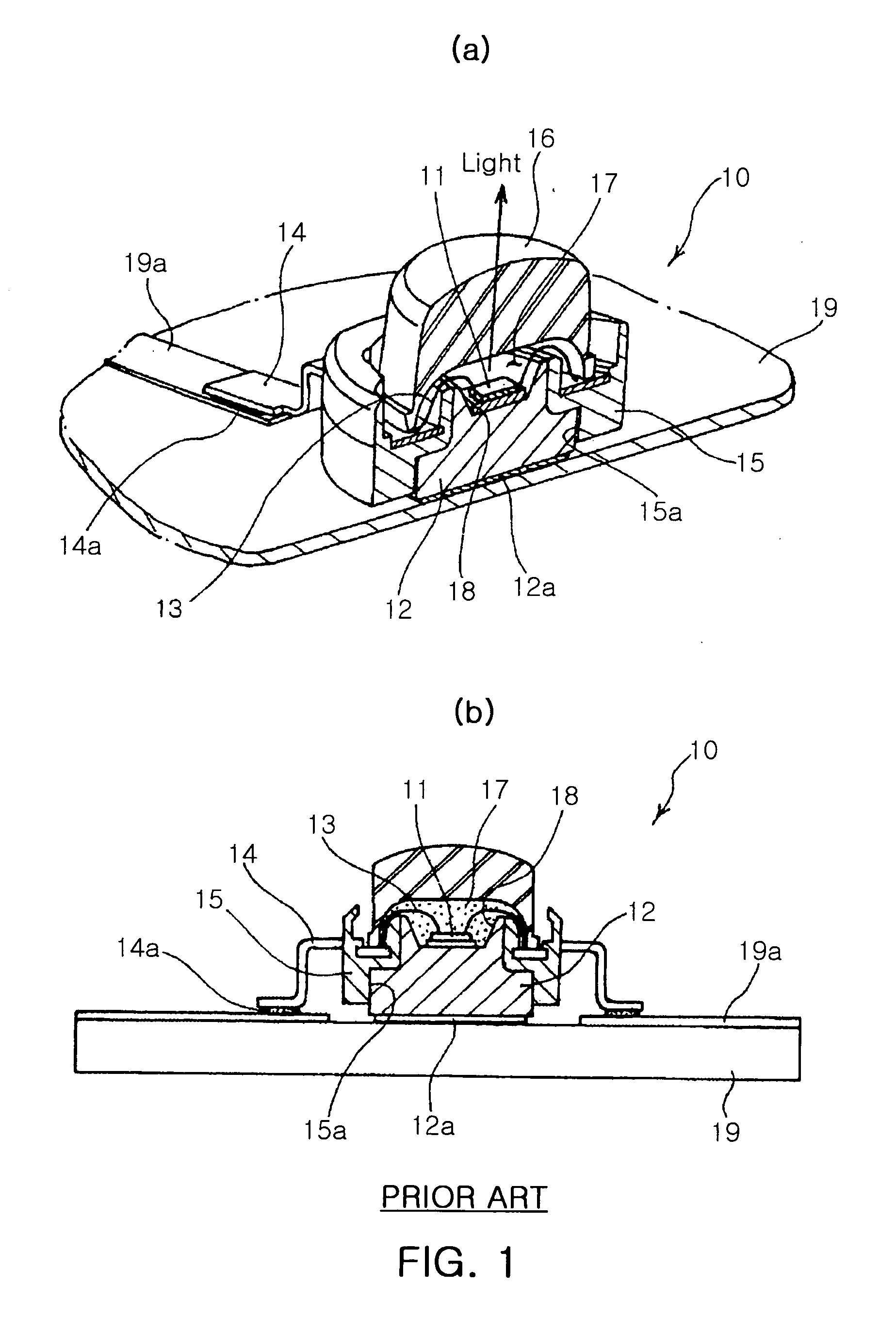

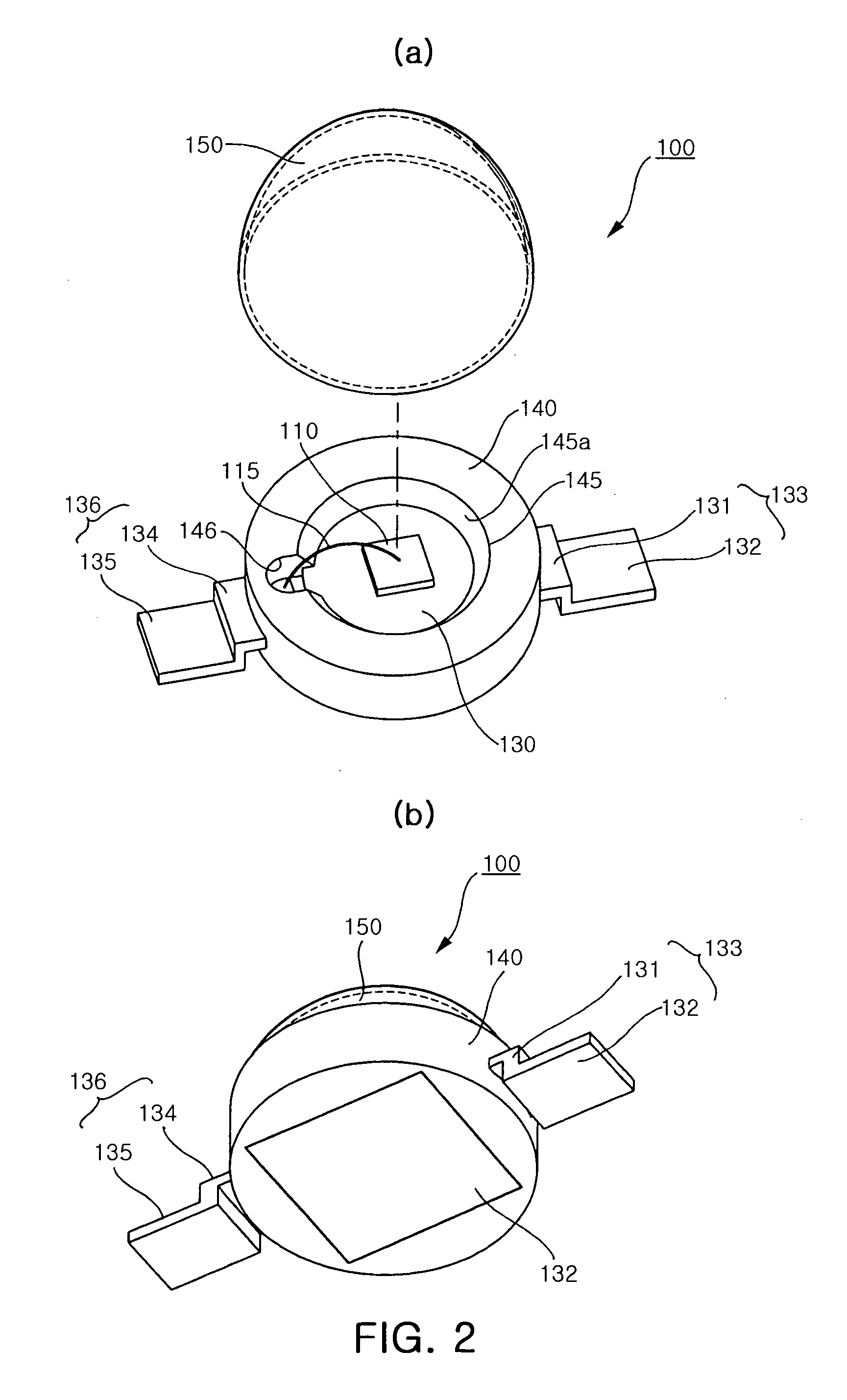

High power light emitting diode package and fabrication method thereof

InactiveUS20060267036A1Reduce numberSimplify assembly processSemiconductor/solid-state device detailsSolid-state devicesHeat conductingMetal

The invention relates to a high power LED package and a fabrication method thereof. The LED package includes a light emitting part for generating light in response to power applied, a heat conducting member with the light emitting part mounted thereon, a lead part for electrically connecting the light emitting part and a board, and a mold part for integrally fixing the heat conducting member and the lead part. The heat conducting member is composed of at least two metal layers in a height direction, and the lead part includes at least one first lead extended out of the heat conducting member and at least one second lead separated from the heat conducting member. The invention allows integration of two components into a single one, reducing the number of components and simplifying the assembly process, thereby reducing the manufacturing costs.

Owner:SAMSUNG ELECTRONICS CO LTD

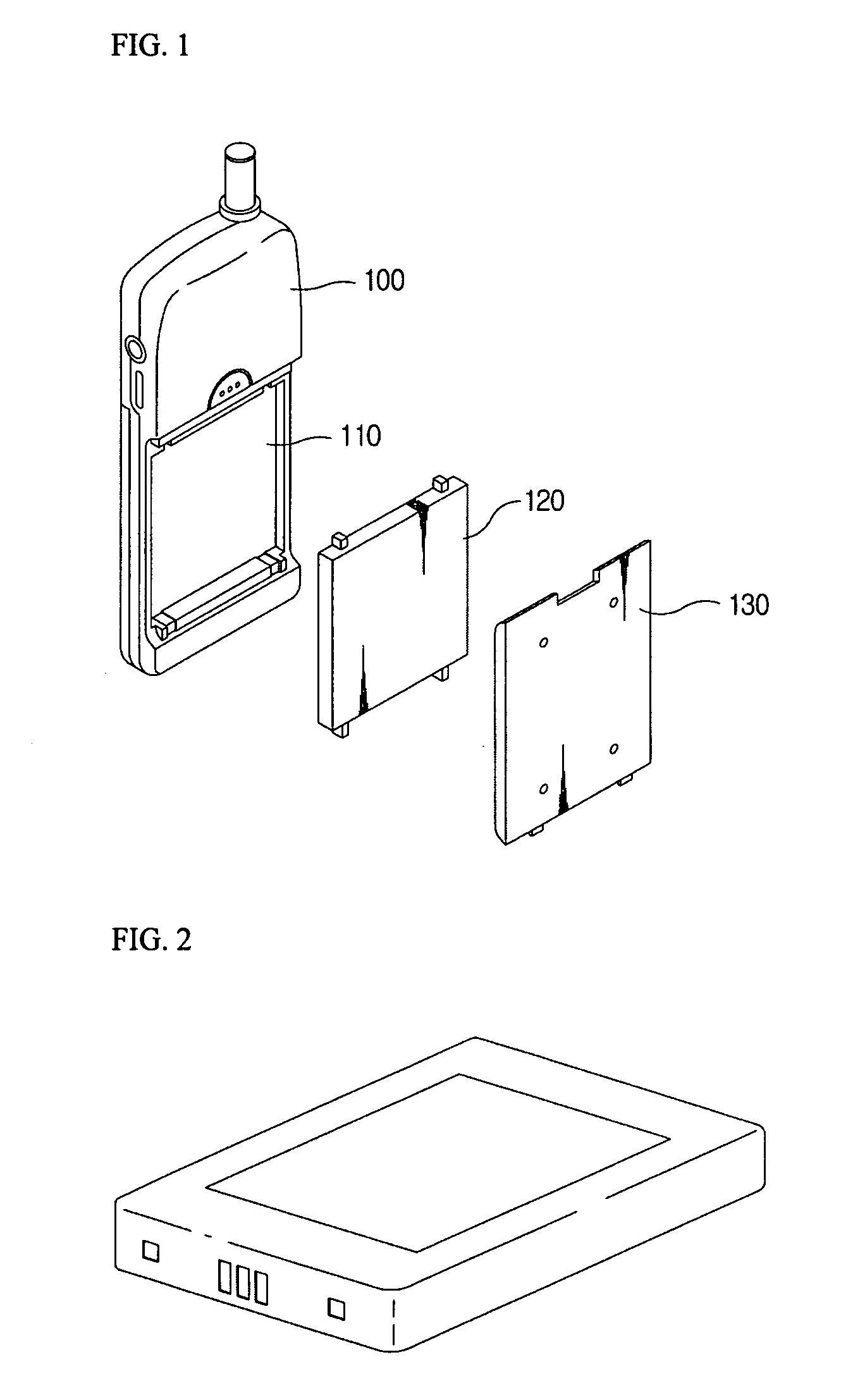

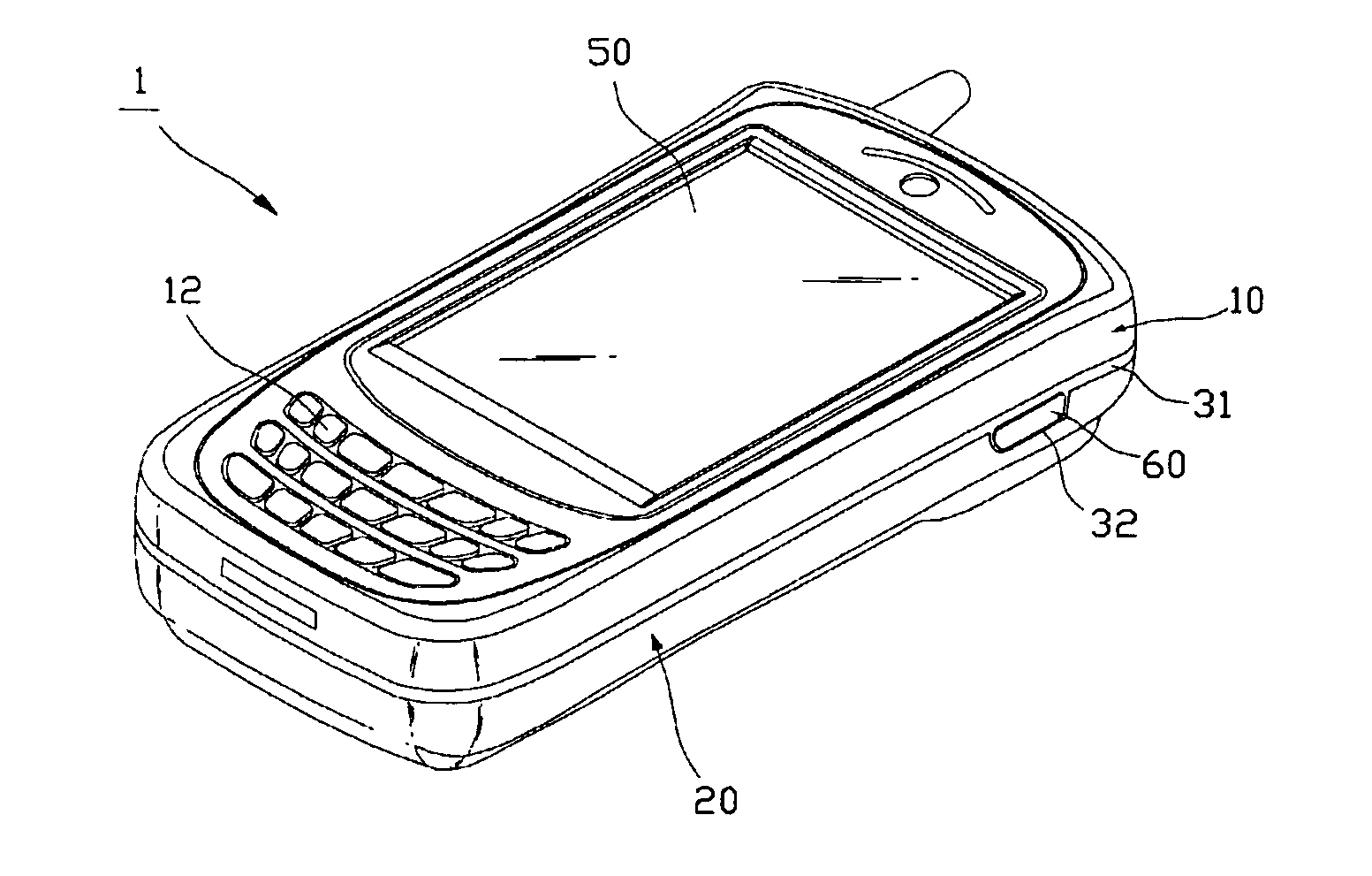

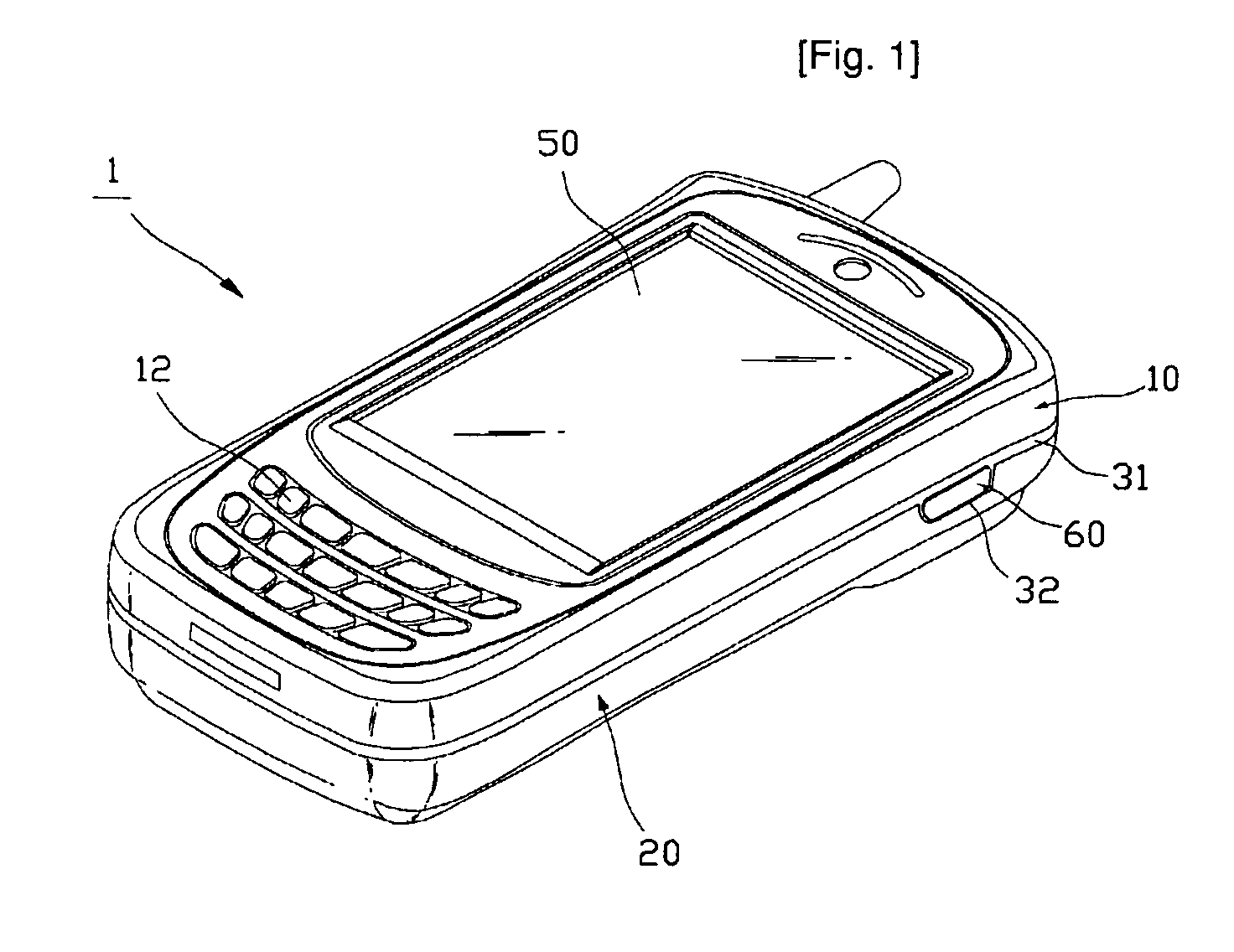

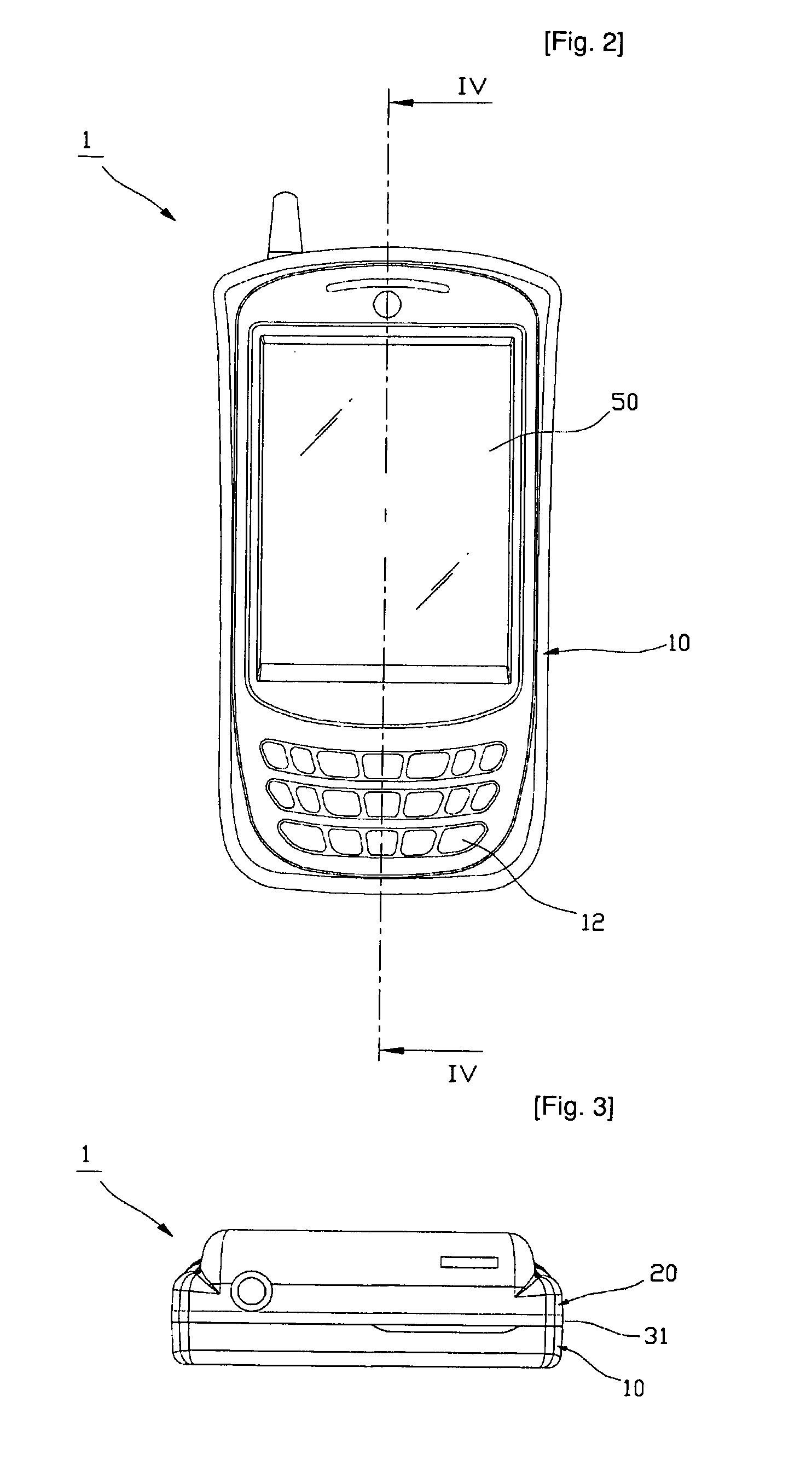

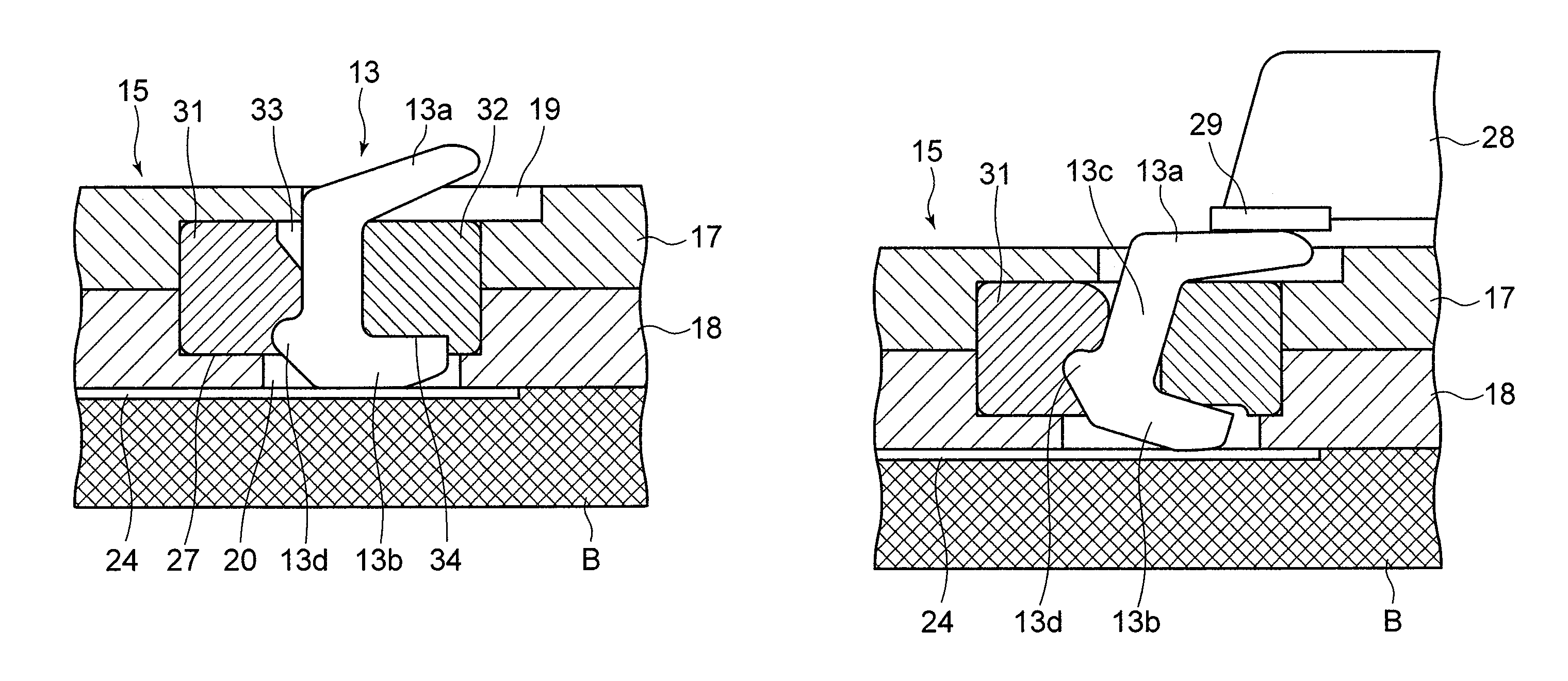

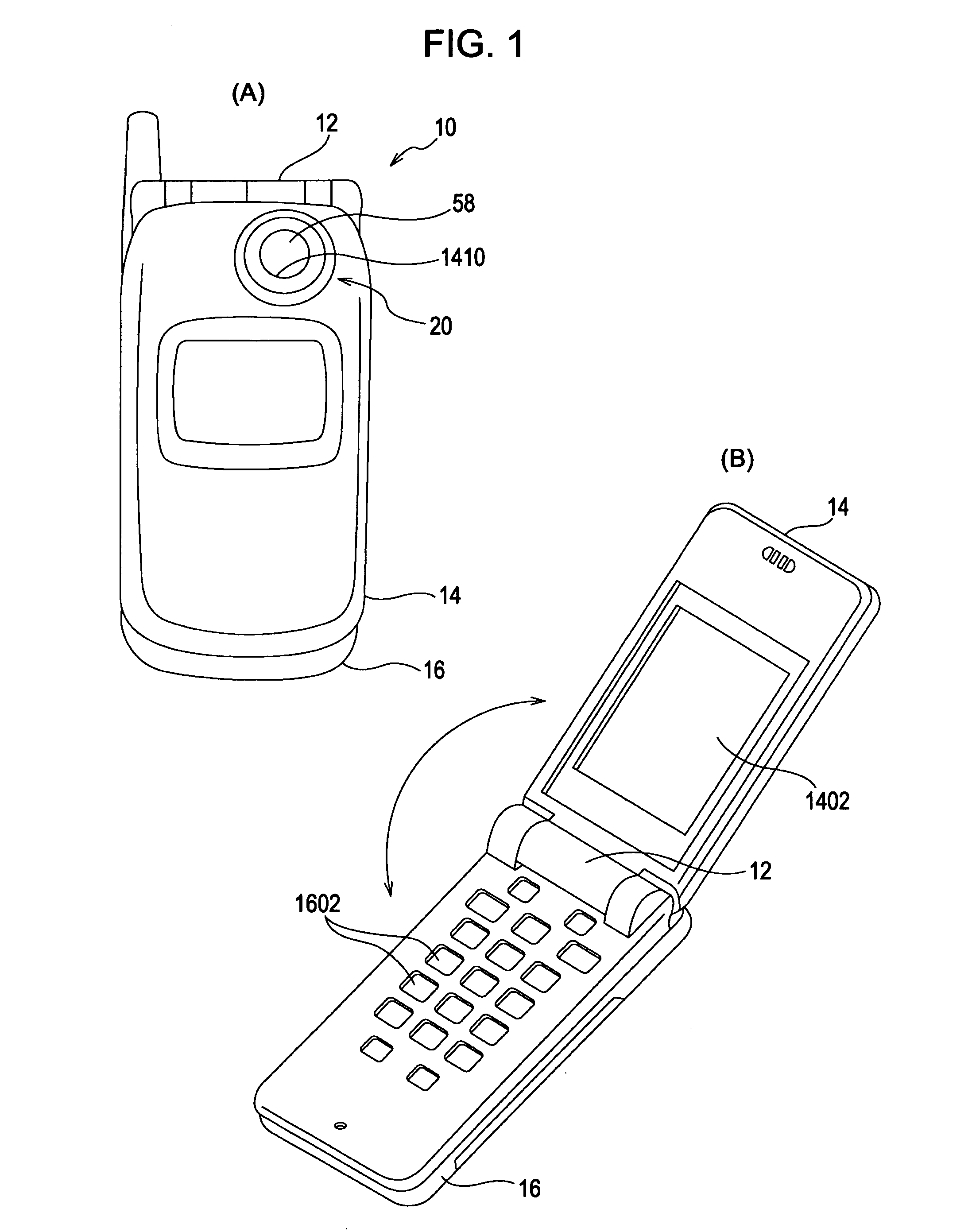

Mobile terminal

ActiveUS20090291709A1Simple structureSimplify the assembly processDigital data processing detailsDigital computer detailsEngineeringSynthetic resin

A mobile terminal includes an upper casing having at least one exposure opening formed by penetrating a predetermined area thereof, a lower casing coupled to the upper casing to face each other and having an accommodation space formed therein and capable of accommodating an internal part assembly including a printed circuit board, and a middle frame arranged between the upper casing and the lower casing and coupled to the upper casing and the lower casing, and supporting installation parts electrically connected to the internal part assembly and installed such that at least part thereof is exposed to the outside through the exposure opening. A resin mold waterproof ring which is injection molded of synthetic resin having elasticity to have a predetermined width along at least part of an edge portion of the middle frame is integrally coupled to the middle frame and, when the upper casing, the lower casing, and the middle frame are coupled one another, the resin mold waterproof ring is pressed by the upper casing and the lower casing to seal a gap between the upper casing and the lower casing.

Owner:BLUEBIRD

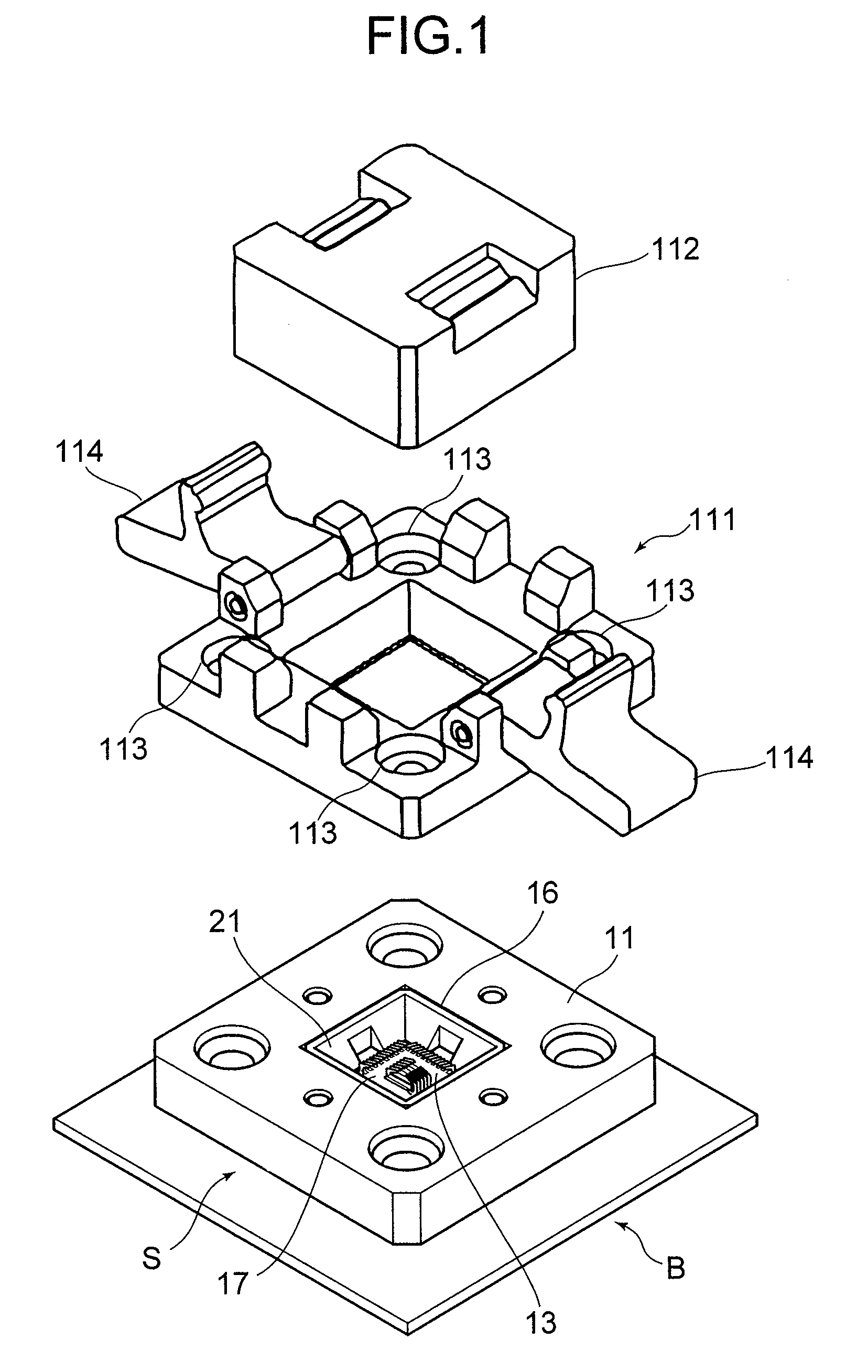

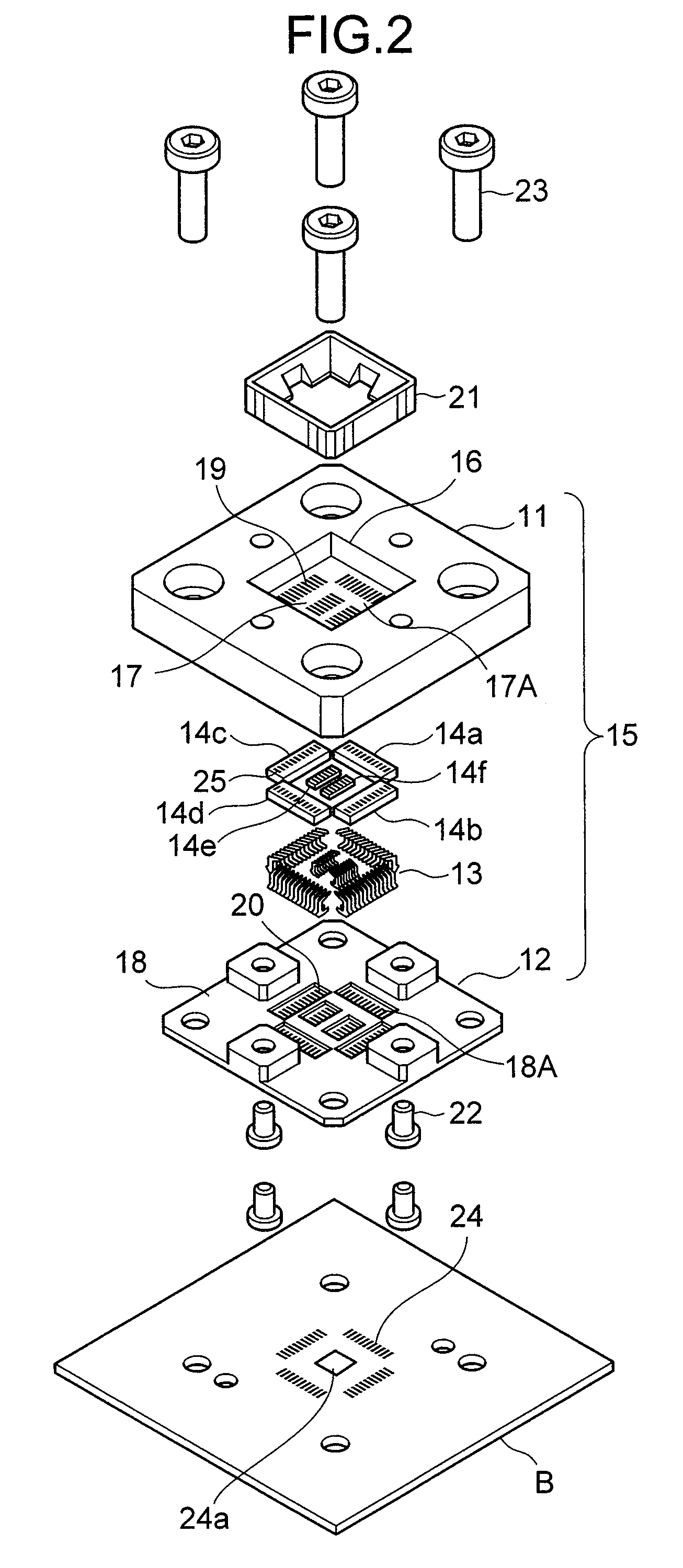

IC socket to be mounted on a circuit board

InactiveUS7632106B2Reduce the overall heightEasily down-sizedElectrical measurement instrument detailsSecuring/insulating coupling contact membersContact pressureRestoring force

The configuration comprises a base board to be mounted a circuit board, with an IC receiving concave place and a resilient member receiving area, having an upper wall and a lower wall surrounding the resilient member receiving area, the upper wall provided with a first slot for contact and the lower wall provided with a second slot, a contact comprising a first contact portion on which a lead of the IC is loaded, a second contact portion coming into contact with a circuit lead of the circuit board, a contact main body communicating the first contact portion with the second contact portion, and a compressing portion protruding from the rear of the contact main body, the resilient member receiving area receiving the resilient member of integral structure, set in the resilient member receiving area, in which a plurality of contacts are implanted, wherein the compressing portion compresses the resilient member in order that a contact pressure can be obtained for the contact to the IC lead and the circuit lead by means of a restoring force of the resilient member.

Owner:YAMAICHI ELECTRONICS

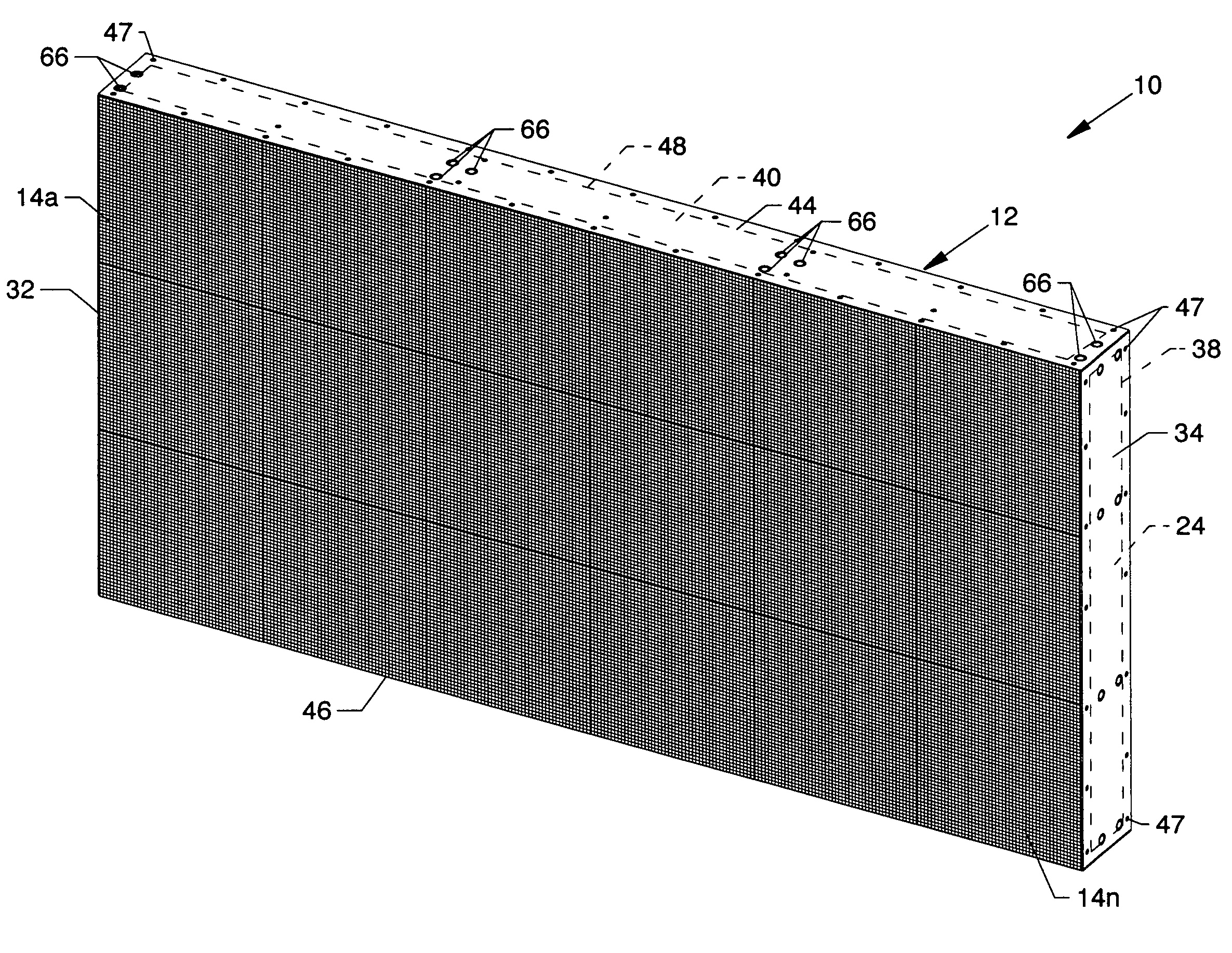

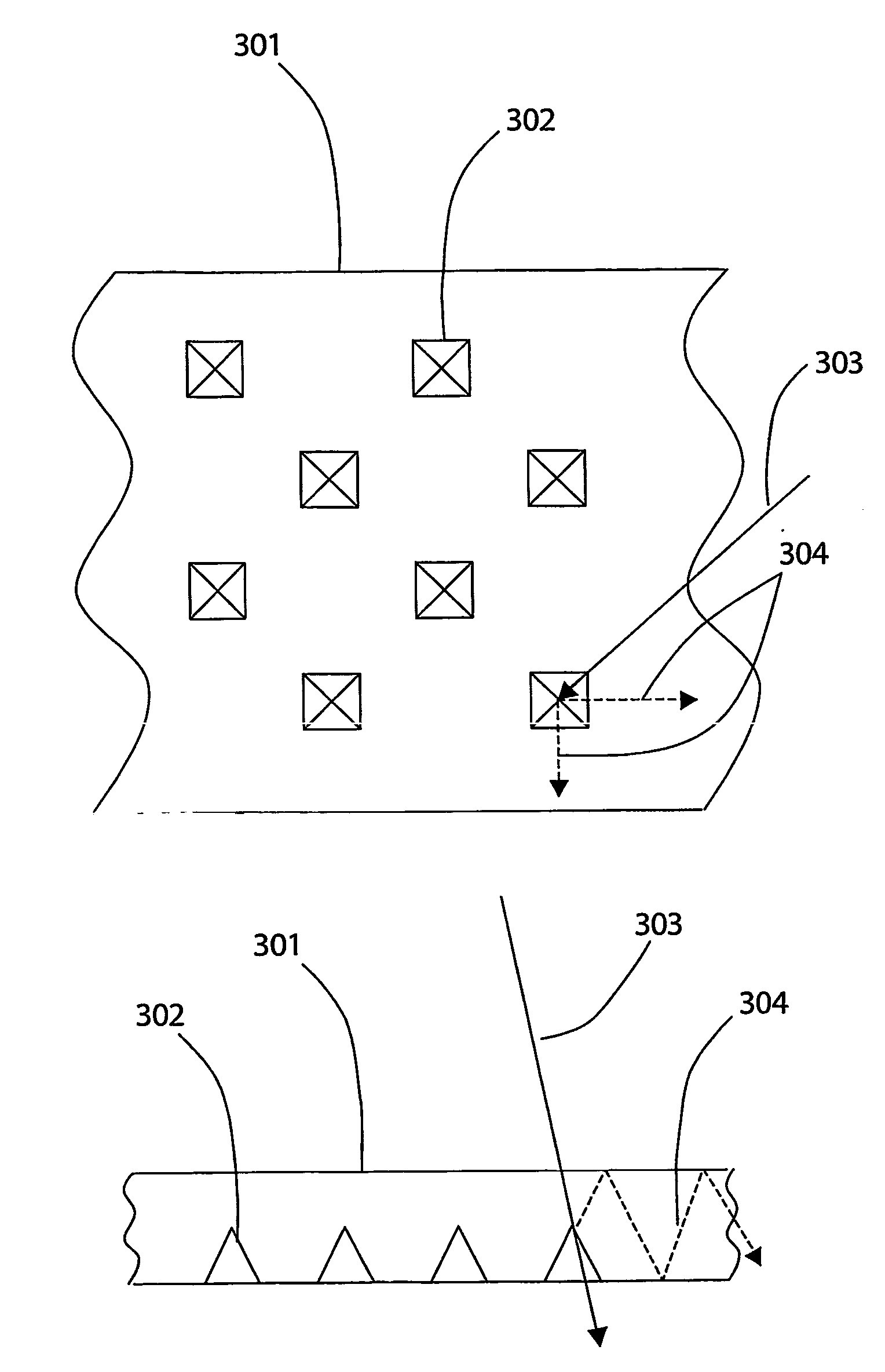

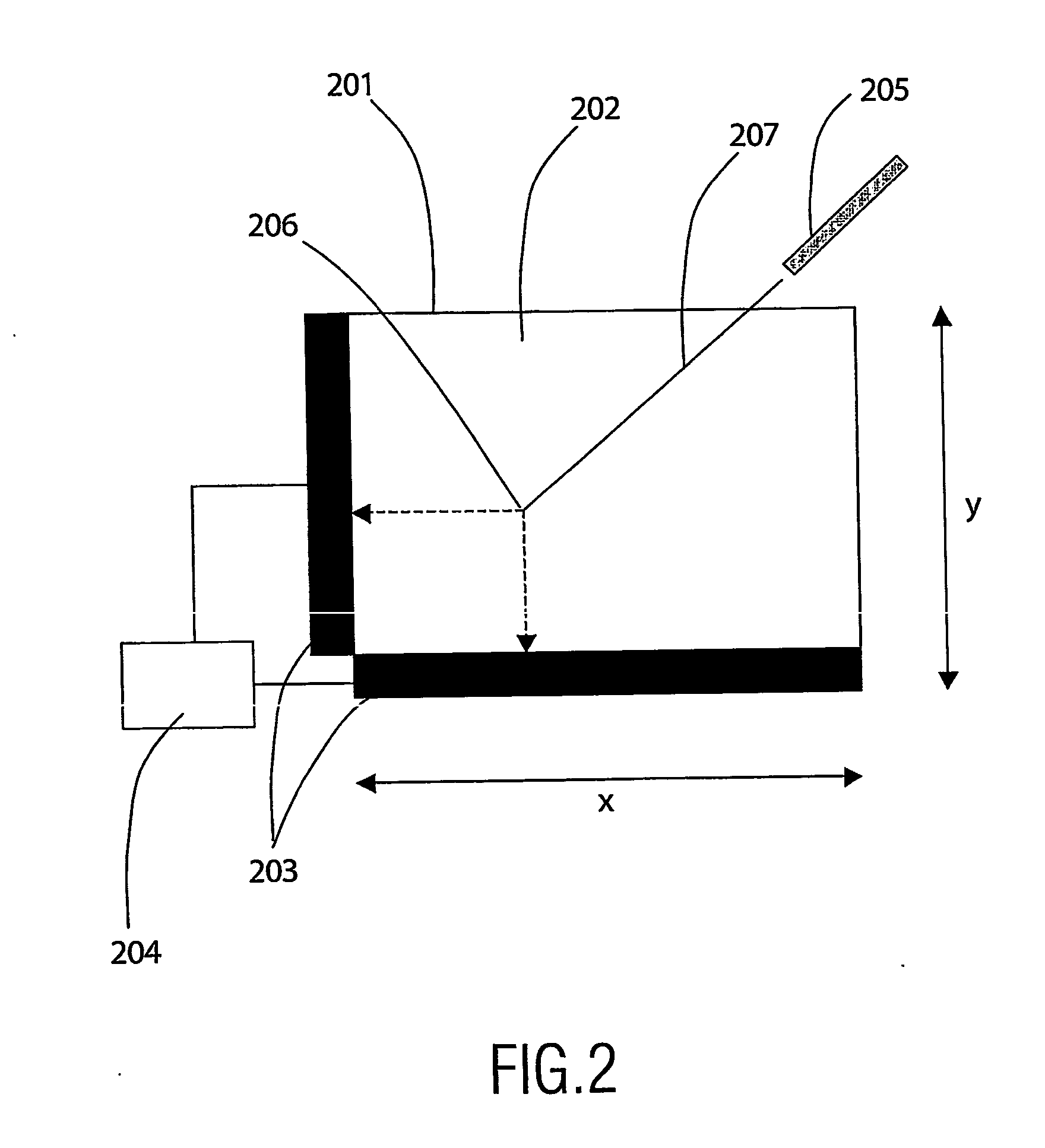

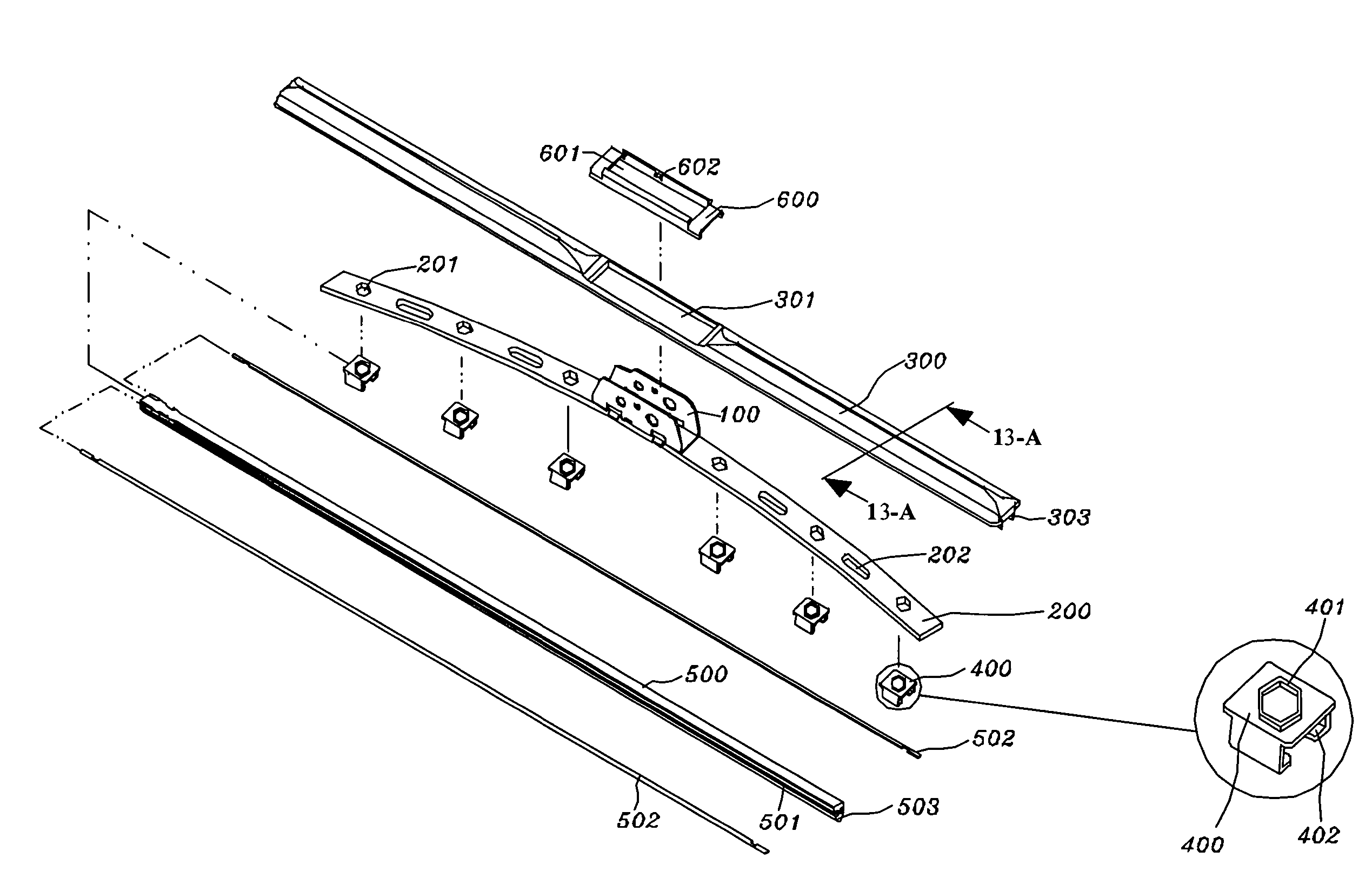

Coordinate detection system for a display monitor

InactiveUS20060290684A1High selectivityEasy to assembleMechanical apparatusCathode-ray tube indicatorsLight guideOptoelectronics

The present invention relates to an apparatus for detecting an input position on a screen of a display monitor. The apparatus comprises a light guiding layer (301) having an optical structure such that a fraction (304) of the light (303) incident on the layer (301) from the apparatus' exterior is confined in the layer (301). The incident light (303) is emitted by a remote input device, operable by a user, for interacting with the apparatus. The remote input device is, for example, a laser pointer (205). Light detecting means (803) in the apparatus detects the light (304) confined in the layer (301). It is thus possible to determine the input position (206) where the light (207) from the input device enters the layer (301).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

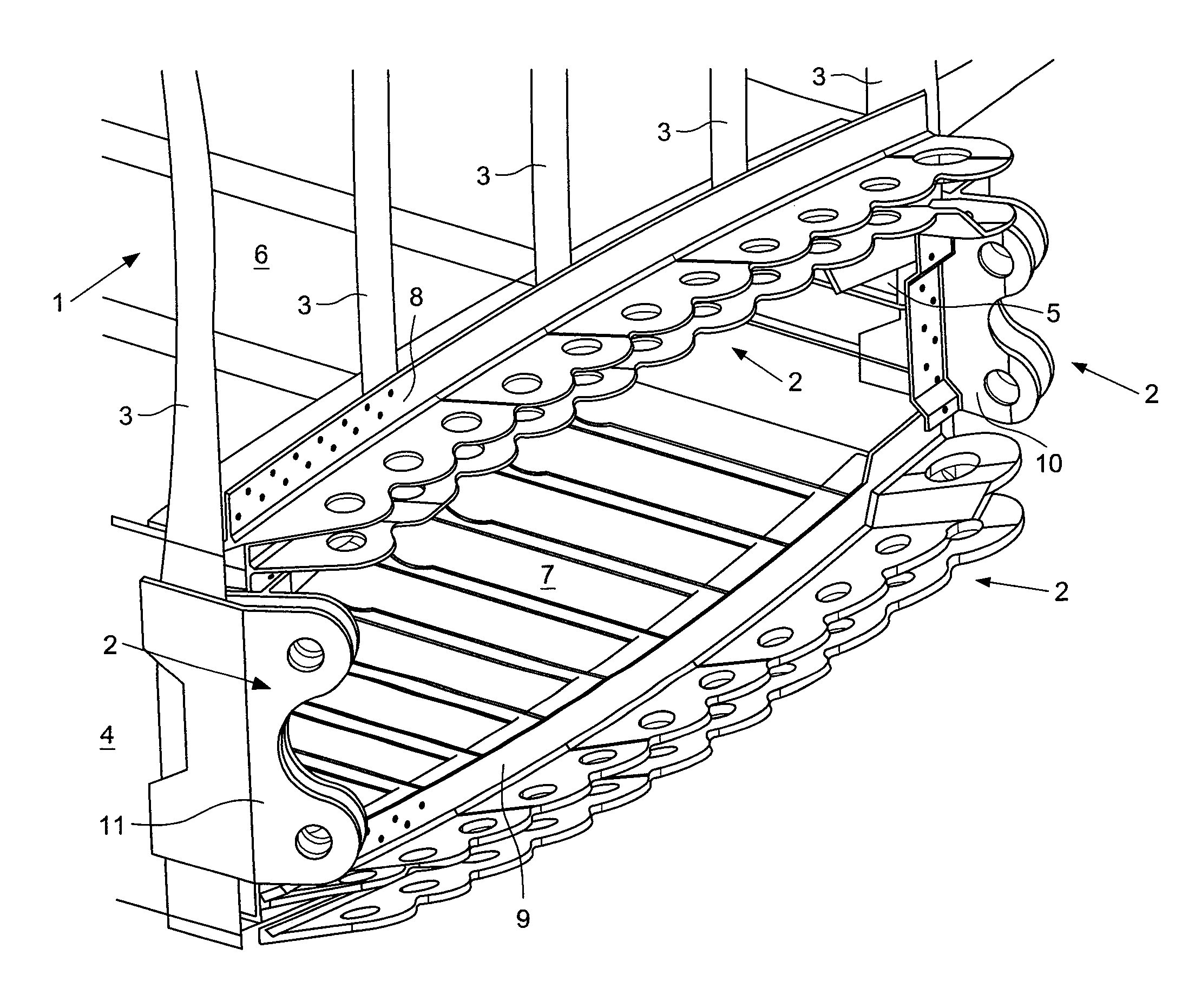

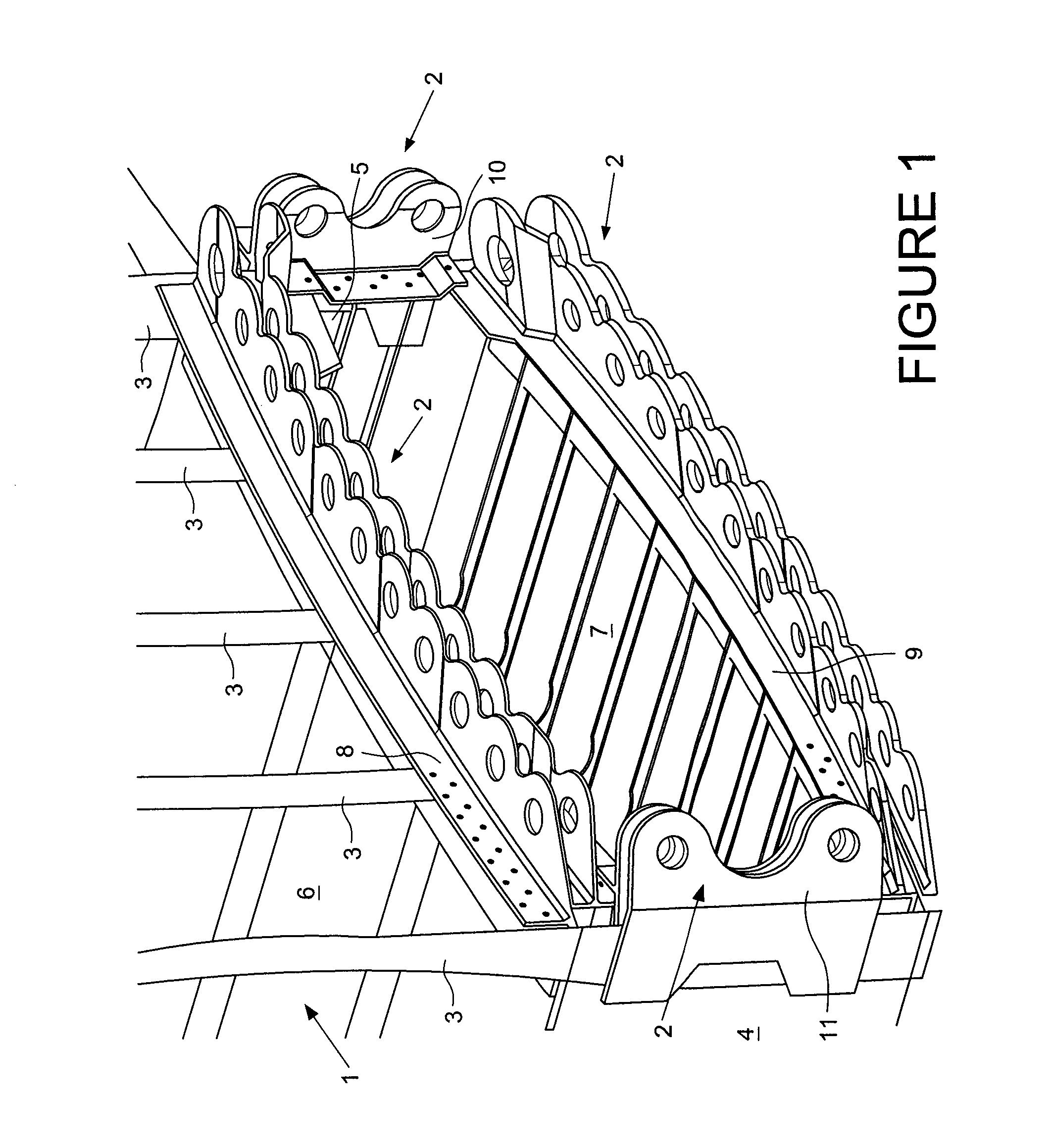

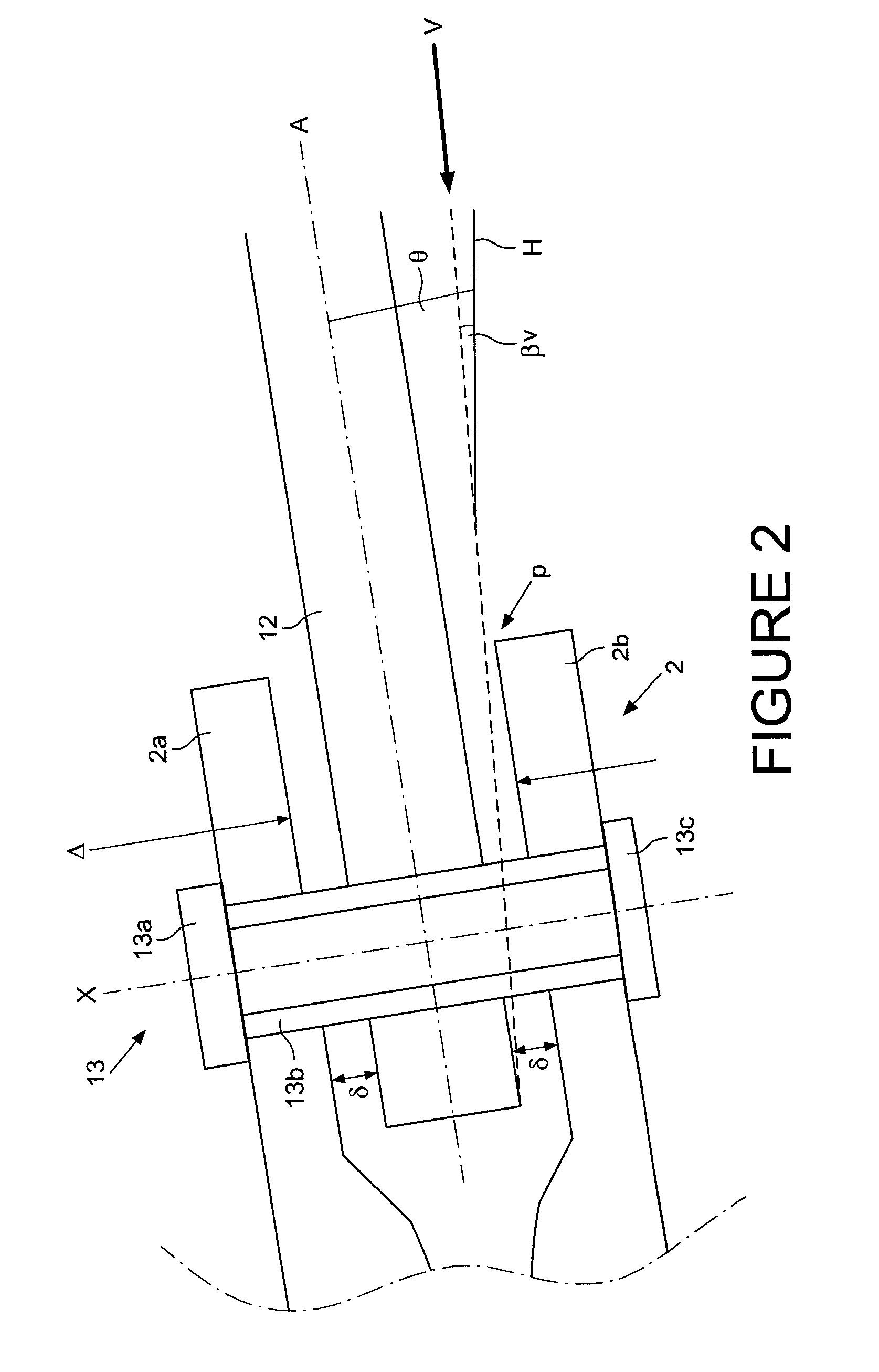

Aircraft joint

InactiveUS20110089292A1Simplify the assembly processReduce in quantityFuselage framesAircraft stabilisationFuselageAirplane

A method of joining a wing to an aircraft fuselage by forming a series of pinned lug joints between a fuselage side and a wing side of a wing box structure. The joint forming process includes providing a single row of lugs on one side of the joint to be formed, and providing a respective double row of lugs on the other side of the joint to be formed. A gap between opposing lugs of the double row varies along the row. The wing side and the fuselage side of the wing box structure are brought together such that the lugs of the single row are located within the respective gaps between opposing lugs of the double row, and the lugs are pinned to form the series of pinned lug joints. Also, a joint formed by the method.

Owner:AIRBUS OPERATIONS LTD

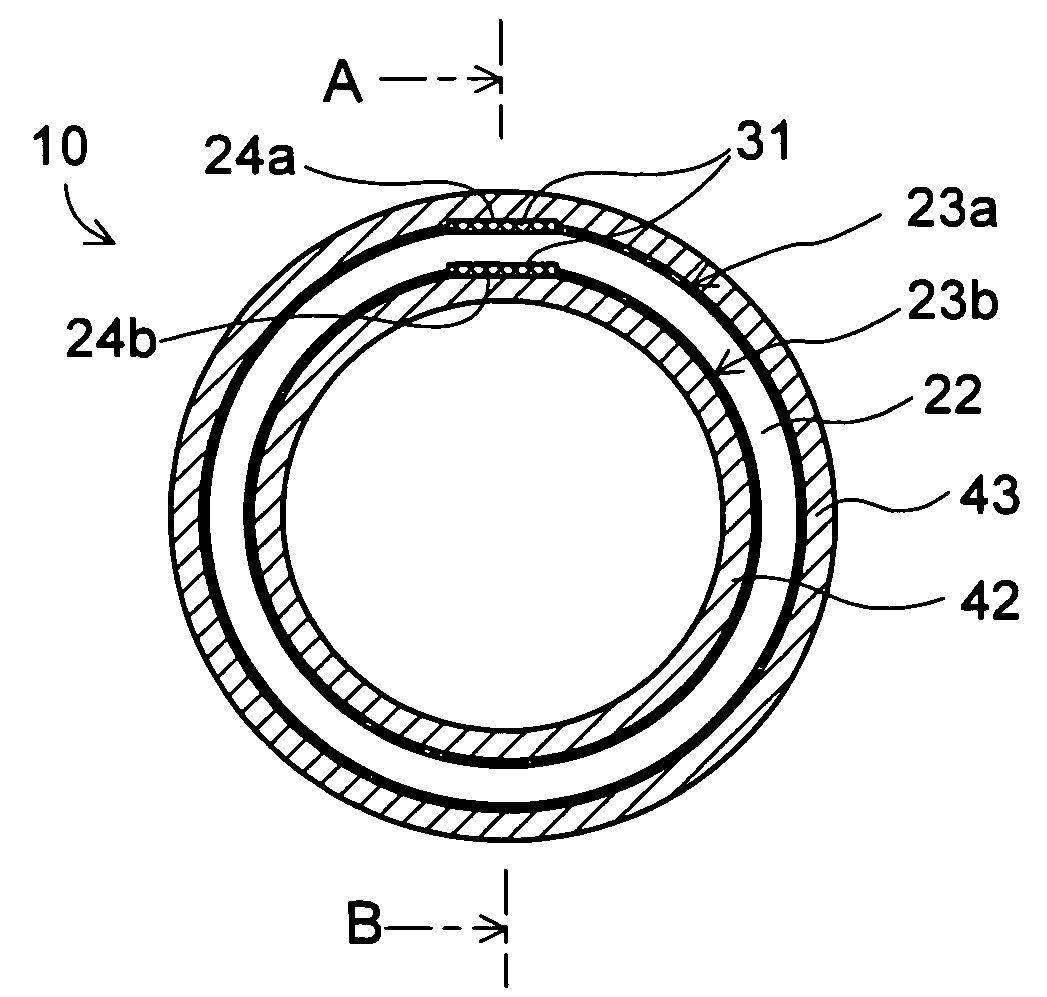

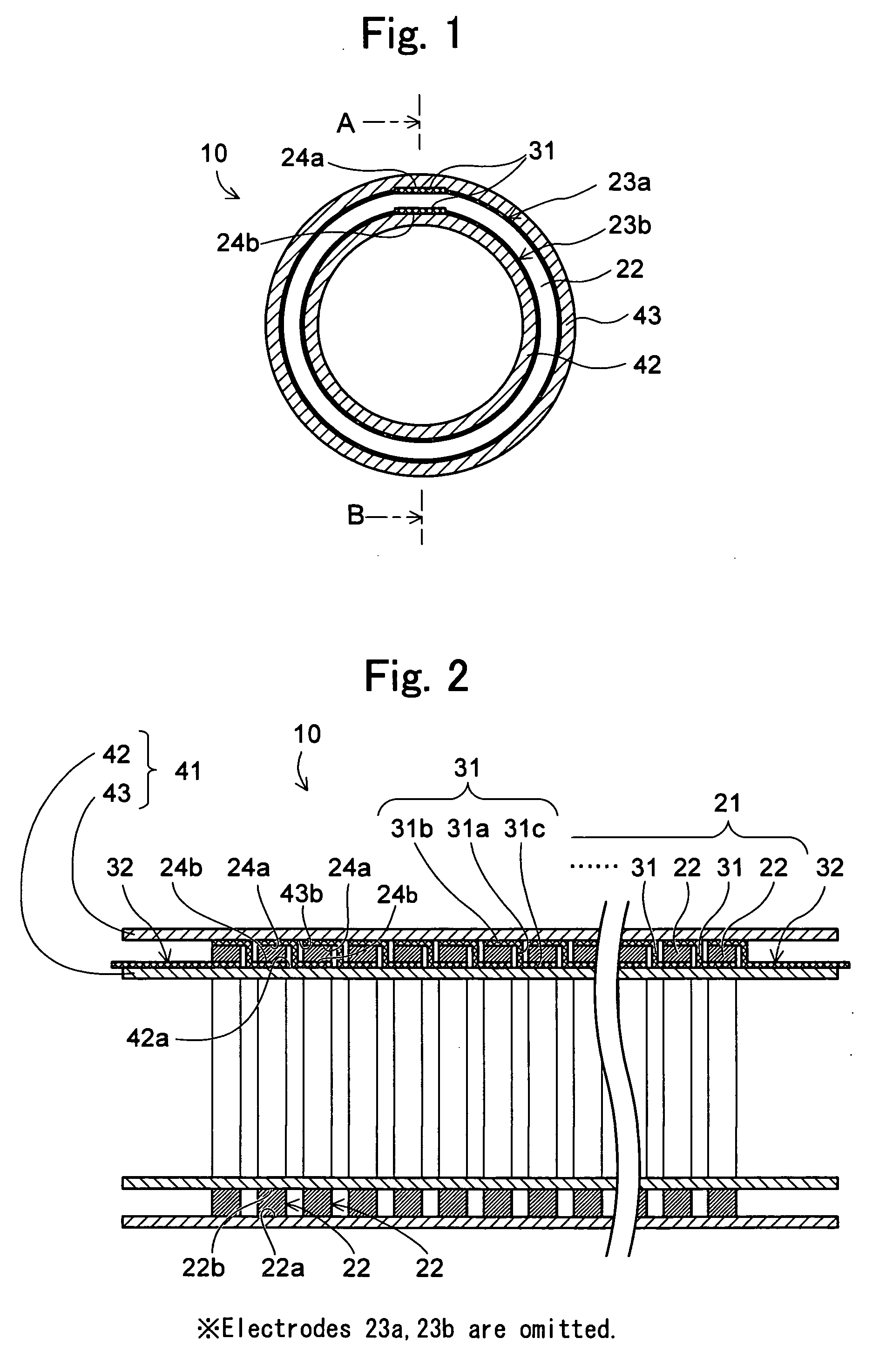

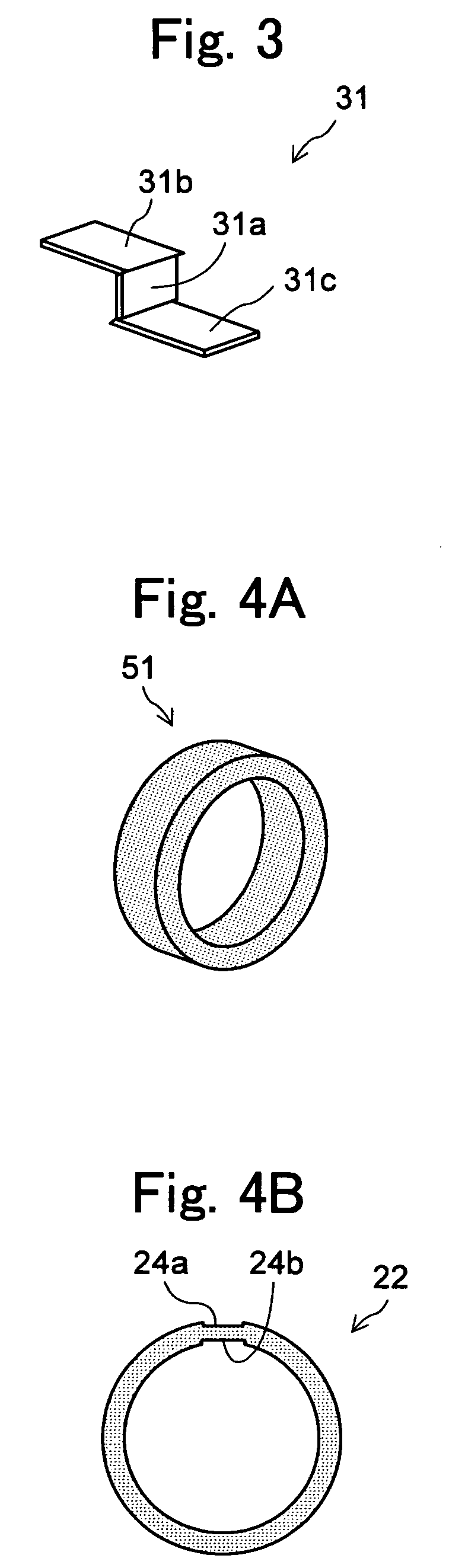

Thermoelectric Conversion Module

InactiveUS20090133734A1Simple structureShorten the timeThermoelectric device with peltier/seeback effectGenerators/motorsTemperature differenceEngineering

To provide a thermoelectric conversion module enabling cost reduction by reducing time and work required for assembly, and so on. A thermoelectric conversion module 10 comprises a tubular element unit 21 having a plurality of ring-like thermoelectric elements 22 coaxially arranged with air as an insulator sandwiched inbetween, wherein the ring-like thermoelectric element 22 is covered approximately entirely with electrodes 23a, 23b at its outer circumference surface 22a and inner circumference surface 22b, respectively, and generates electricity by temperature difference between the outer circumference surface 22a and the inner circumference surface 22b, a lead wire 31 electrically connecting the electrode 23a covered on the outer circumference surface 22a of one ring-like thermoelectric element 22 among the plurality of ring-like thermoelectric elements 22 to the electrode 23b covered on the inner circumference surface 22b of another ring-like thermoelectric element 22 adjacent to this one ring-like thermoelectric element 22, and a doubled cylindrical support unit 41 consisting of a SUS tube 42 whose outer circumference surface 42a supports the tubular element unit 21 and a SUS tube 43 whose inner circumference surface 43b supports the tubular element unit 21.

Owner:UNIVERSAL ENTERTAINMENT CORP

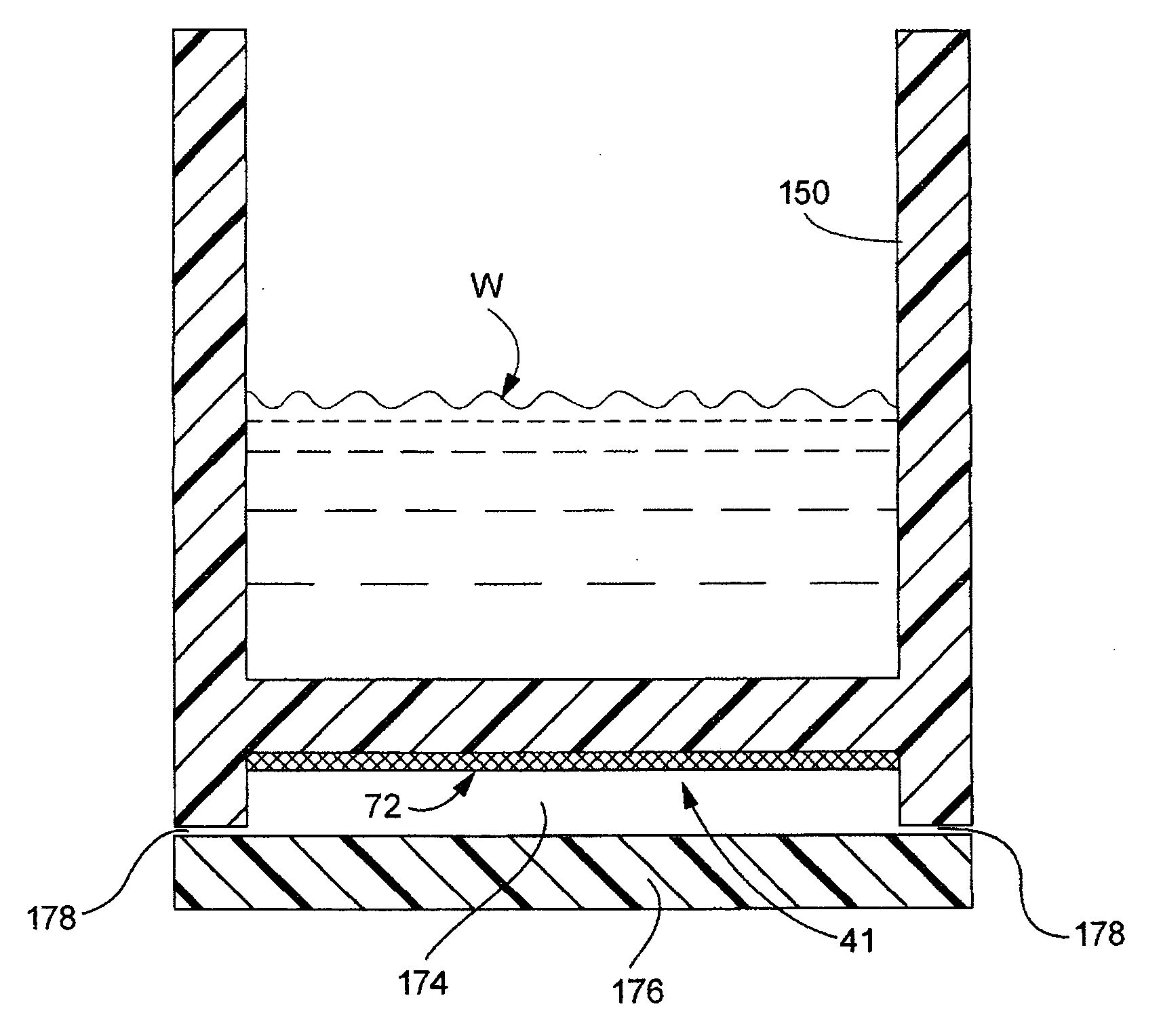

Electrical heater with particular application to humidification and fluid warming

ActiveUS20100147299A1Reduced number of partSimplify the assembly processRespiratorsLighting and heating apparatusElectricityBreathing gas

A humidifier includes a tub configured to contain a supply of water and a heater including a first polymer film having an electrically conductive circuit provided upon a surface. The first polymer film is electrically insulating and the tub is formed of molded resin and the heater is molded at least partially within the resin. A respiratory apparatus for delivering a flow of breathable gas to a patient includes the humidifier. A method of humidifying a flow of pressurized breathable gas includes passing the flow of pressurized breathable gas over a supply of water contained in a tub. The tub is formed of molded resin and a heater including a first polymer film having an electrically conductive circuit on a first surface is molded at least partially within the resin.

Owner:RESMED LTD

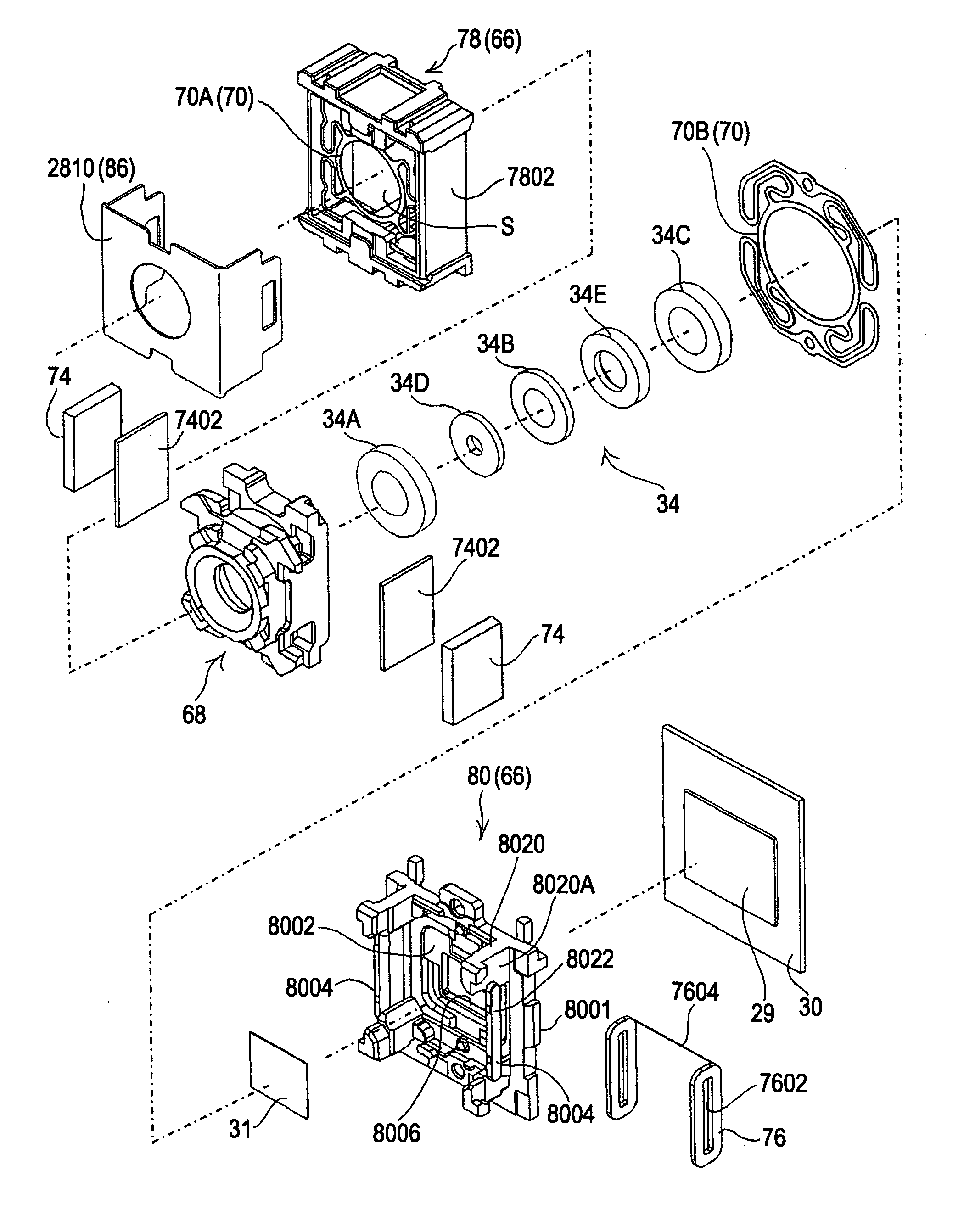

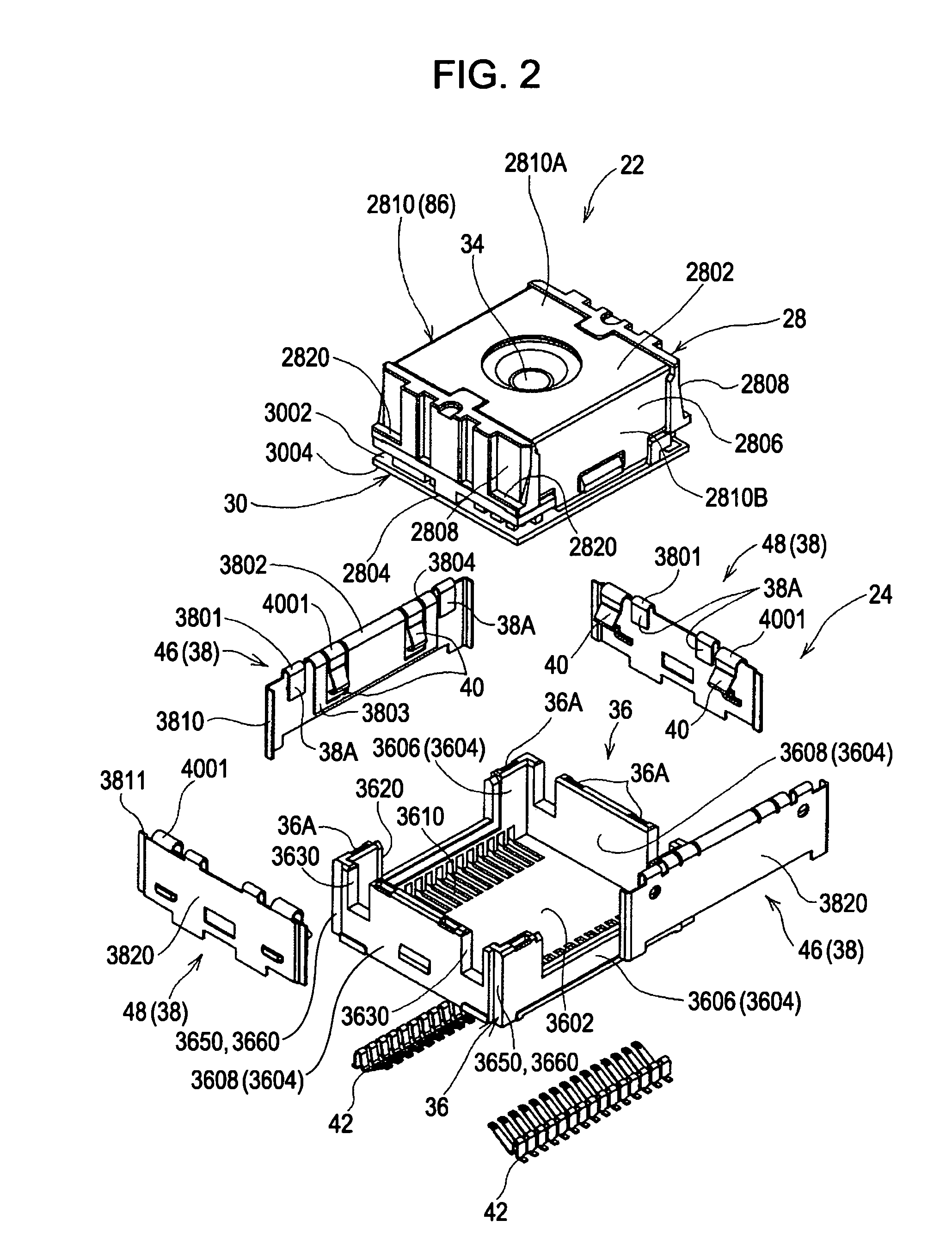

Camera module

InactiveUS20100150545A1Simplify the assembly processLow costTelevision system detailsColor television detailsOptical axisCamera module

A camera module advantageous in simplifying an assembly process is provided. A camera module 22 includes a barrel unit 66 having a housing space S; a lens holding unit 68 which holds an imaging optical system 34, which is housed in the housing space S, and which is supported such that the lens holding unit 68 is movable along an optical axis of the imaging optical system 34; an image pickup element 29 which is disposed in the barrel unit 66 and which picks up an object image guided by the imaging optical system 34; and a driving unit 72 which moves the lens holding unit 68 along the optical axis of the imaging optical system 34. The barrel unit 66 includes an inner barrel 80 in which the housing space S is formed and an outer barrel 78 disposed outside the inner barrel 80. A retaining plate 86 includes a front plate portion 86A and two side plate portions 86B. The retaining plate 86 clamps the inner barrel 80 and the outer barrel 78 in the optical axis direction in the state in which the front plate portion 86A retains a front end of the outer barrel 78 and distal ends of the two side plate portions 86B retain the rear end-face wall 8002.

Owner:SONY CORP

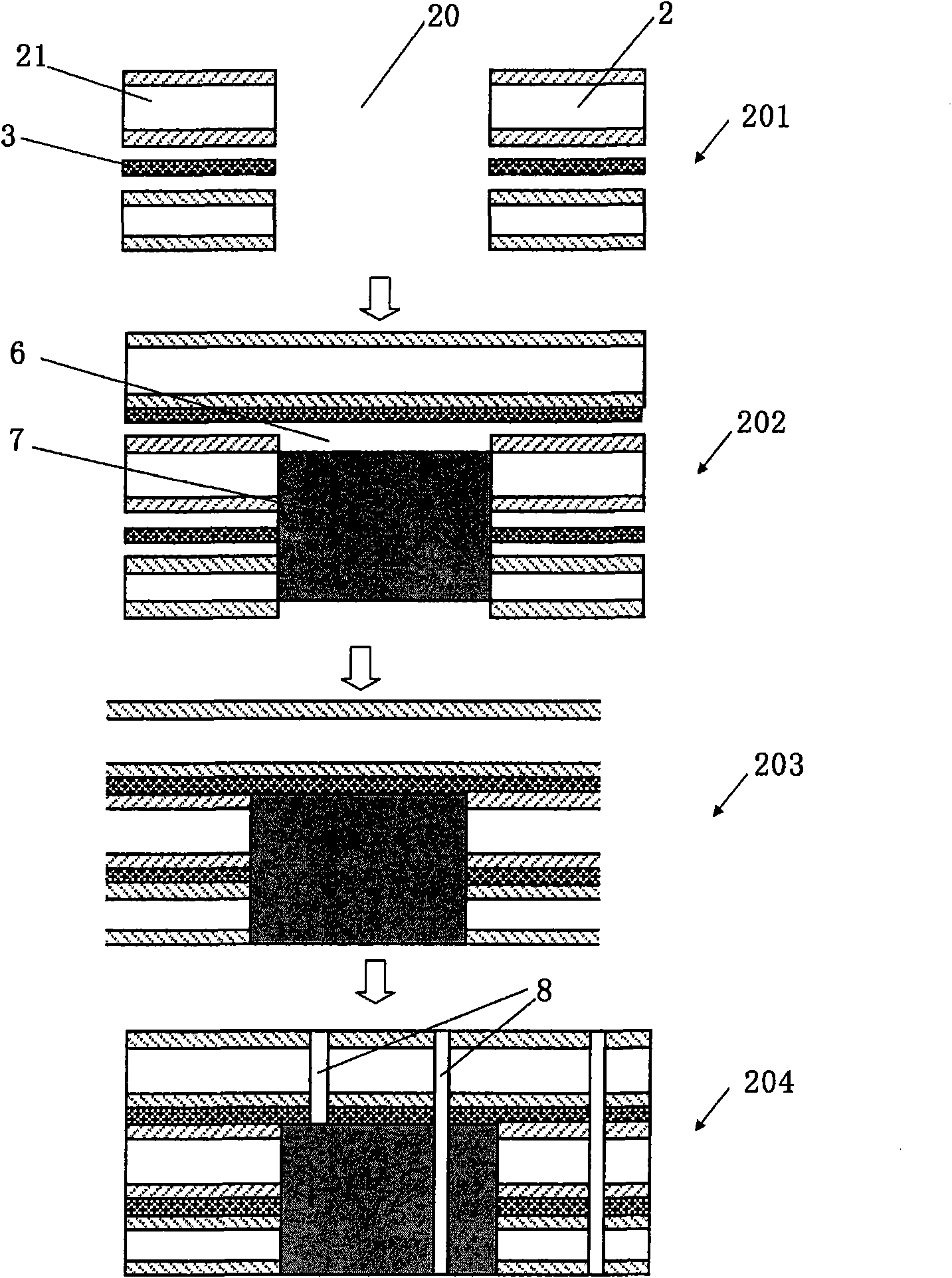

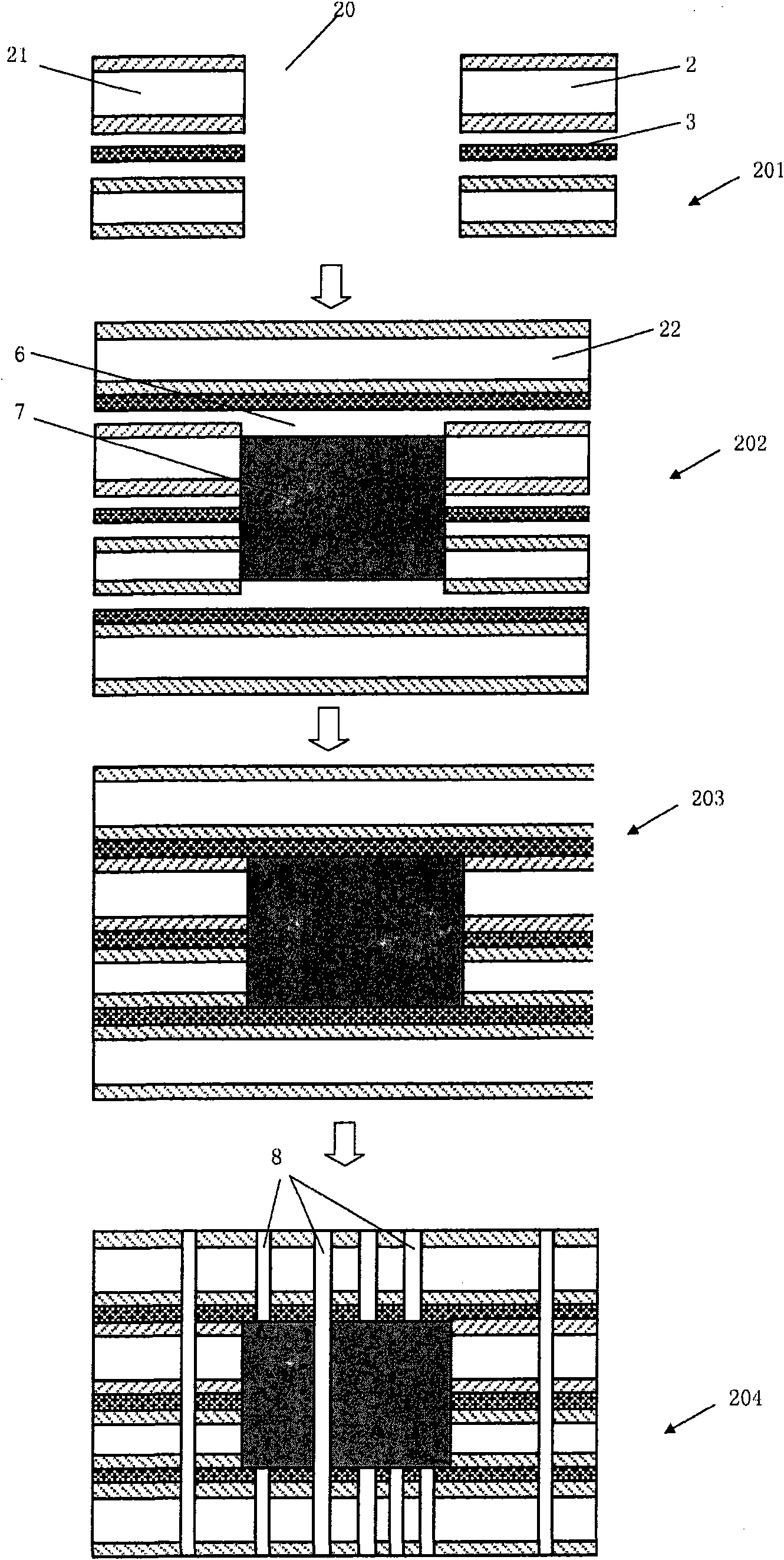

Multilayer circuit board, manufacture method thereof and communication equipment

InactiveCN101686611ASimplify the assembly processSemiconductor/solid-state device detailsPrinted circuit aspectsHeat conductingDielectric layer

The embodiment of the invention discloses a multilayer circuit board, a manufacture method thereof and communication equipment. The multilayer circuit board comprises at least one sub-board which is provided with step grooves to form a first sub-board and is stacked together with a dielectric layer, wherein the sub-board comprises the first sub-board; the first sub-board is placed in the mode of communicating the step grooves; a holding groove is formed after the step grooves are communicated; a heat-conducting block is placed in the holding groove; the dielectric layer is positioned between the sub-boards; the sub-boards stacked together, the dielectric layer and the heat-conducting block are pressed; and the sub-boards and the heat-conducting block which are pressed together are made into the multilayer circuit board. The process of assembling the heat-conducting block is simplified by embedding the heat-conducting block when the circuit board is pressed.

Owner:HUAWEI TECH CO LTD

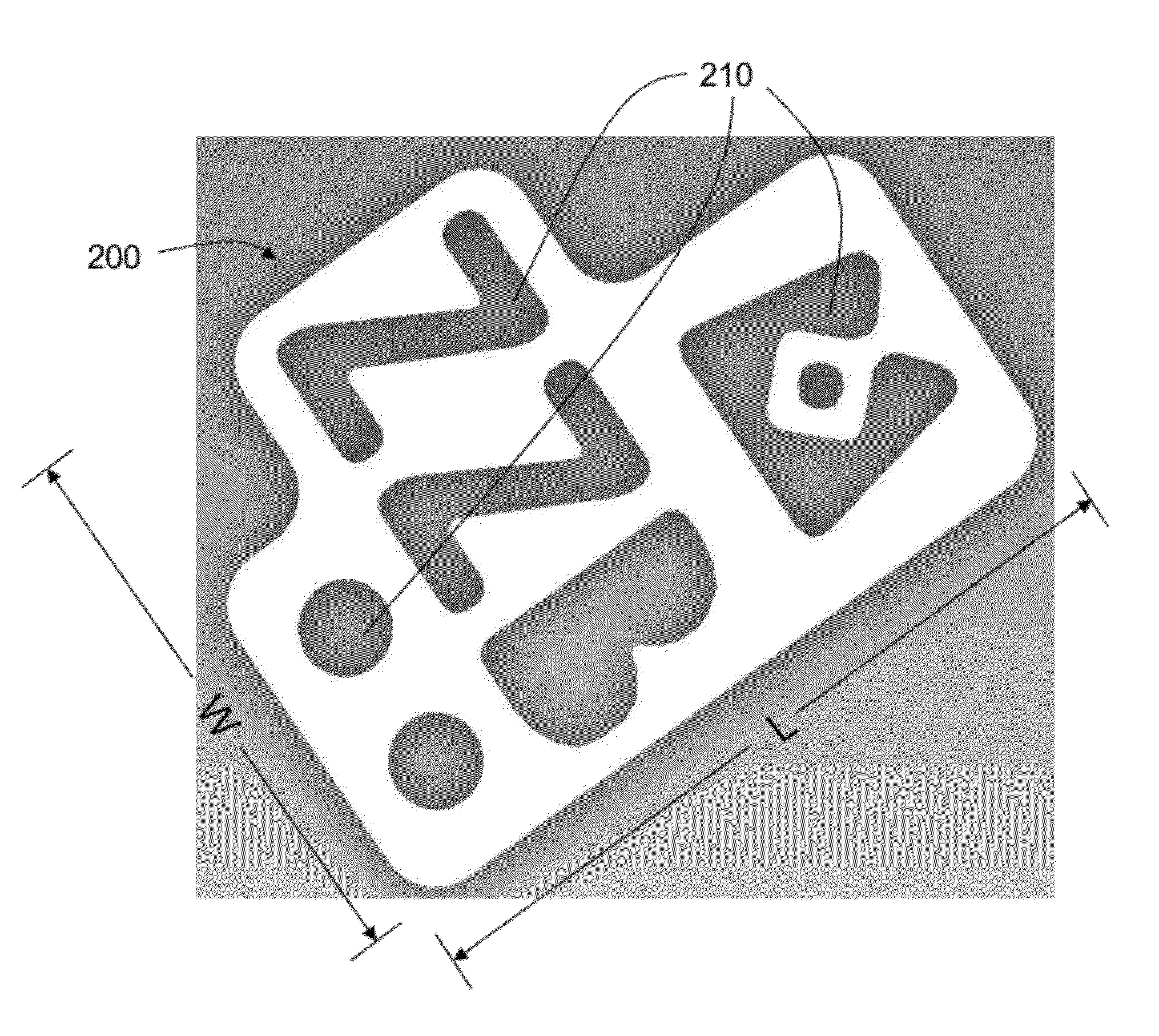

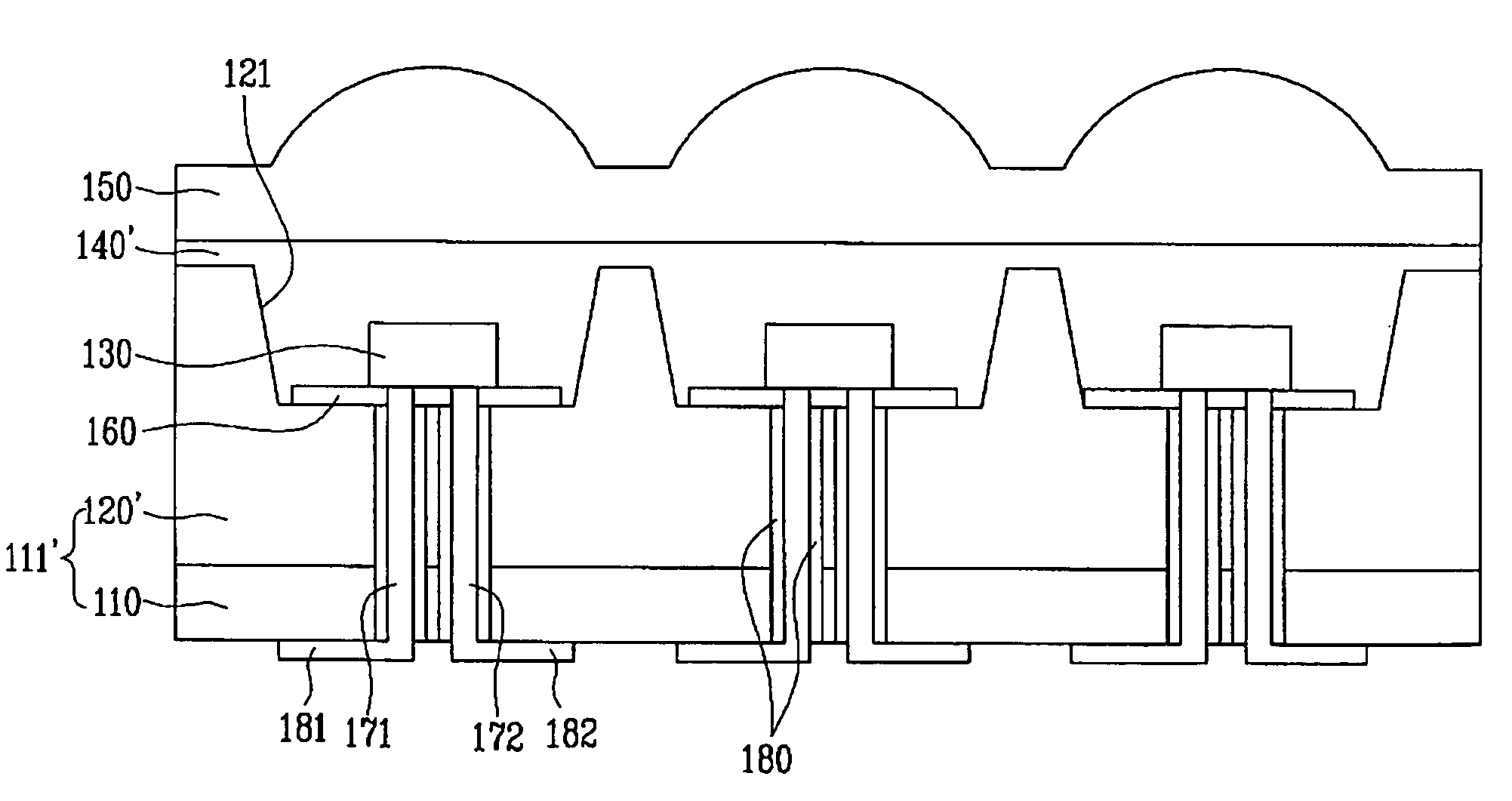

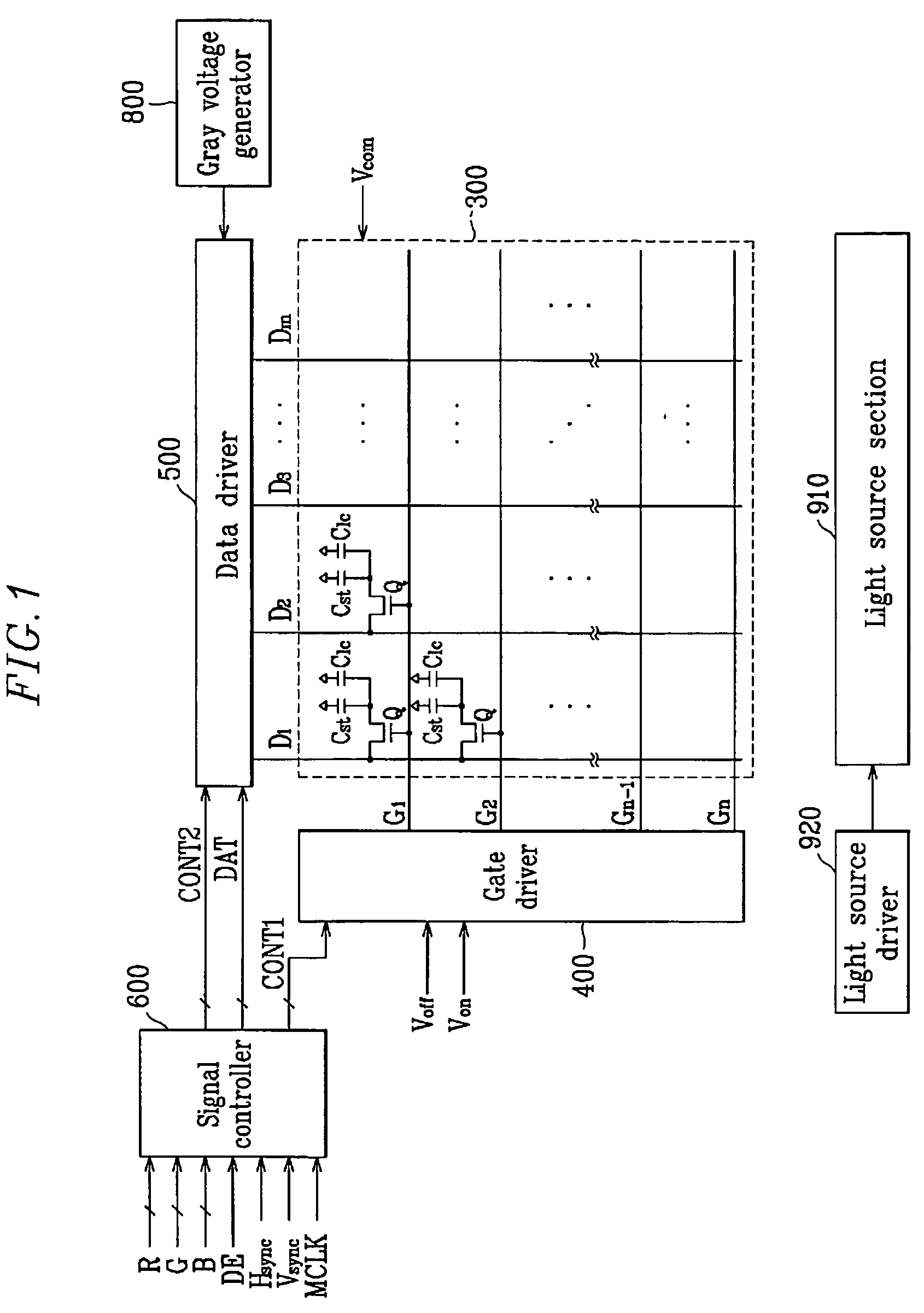

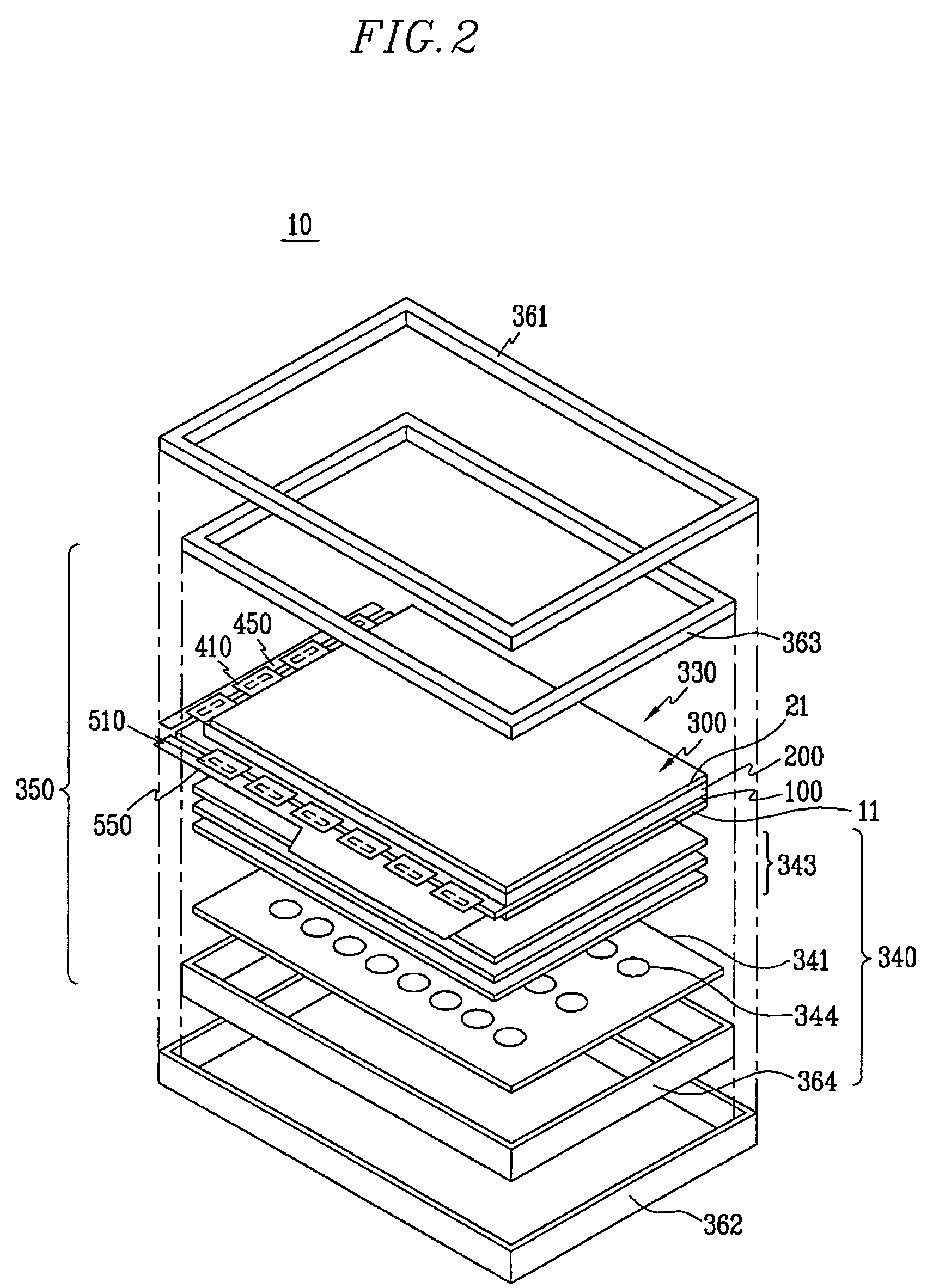

Two dimensional light source using light emitting diode and liquid crystal display device using the two dimensional light source

ActiveUS7436000B2Simplify the assembly processSemiconductor/solid-state device detailsPrinted circuit aspectsLiquid-crystal displayLight-emitting diode

A two-dimensional light source includes a base substrate having holes, wires disposed on a lower surface of the base substrate, a light emitting diode (LED) chip disposed on an upper surface of the base substrate, plugs that connect two electrodes of the LED chip to the wires through the holes, a buffer layer covering the LED chip, and an optical layer that is disposed on the buffer layer and has an optical pattern formed at a portion of the optical layer corresponding to the LED chip.

Owner:SAMSUNG DISPLAY CO LTD

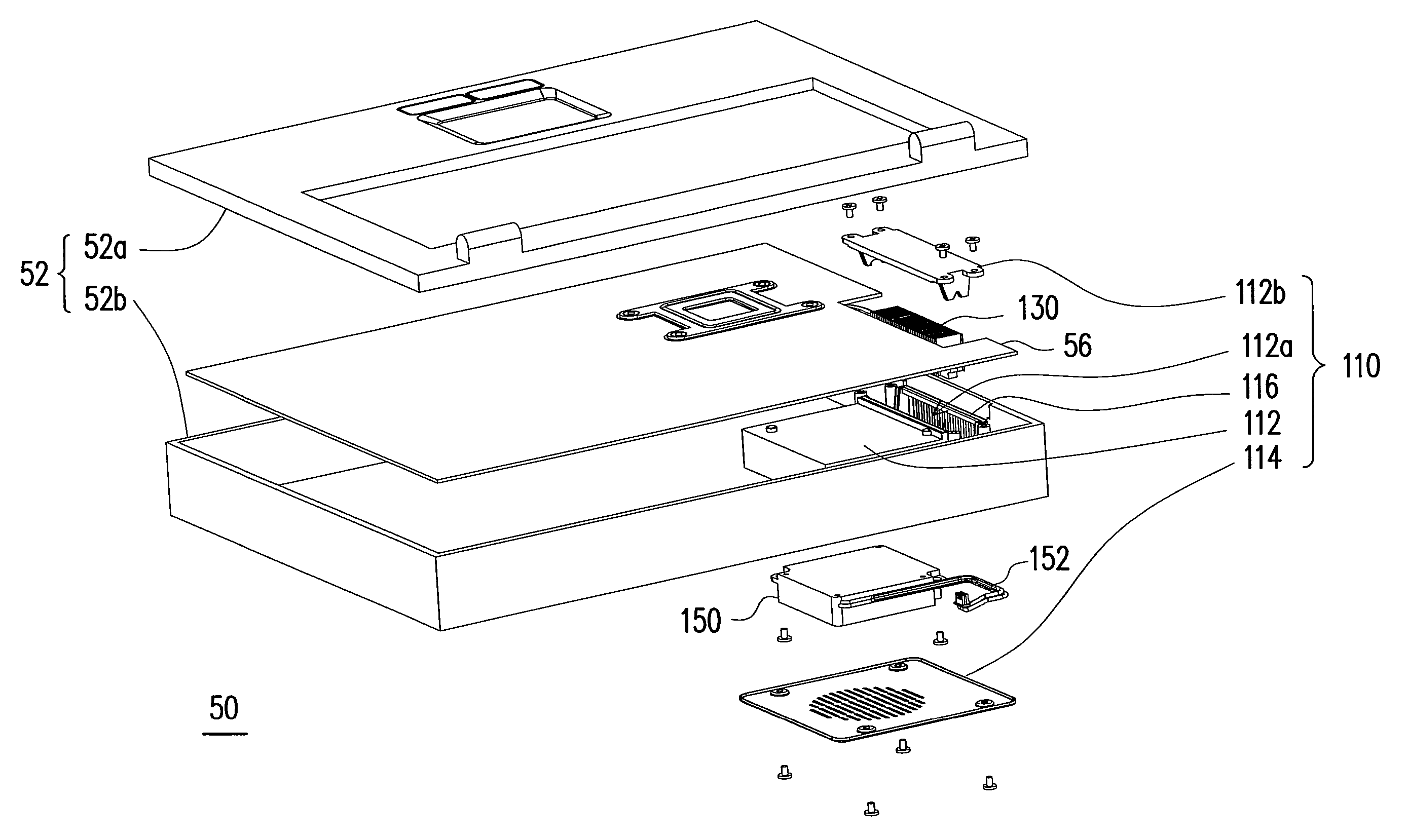

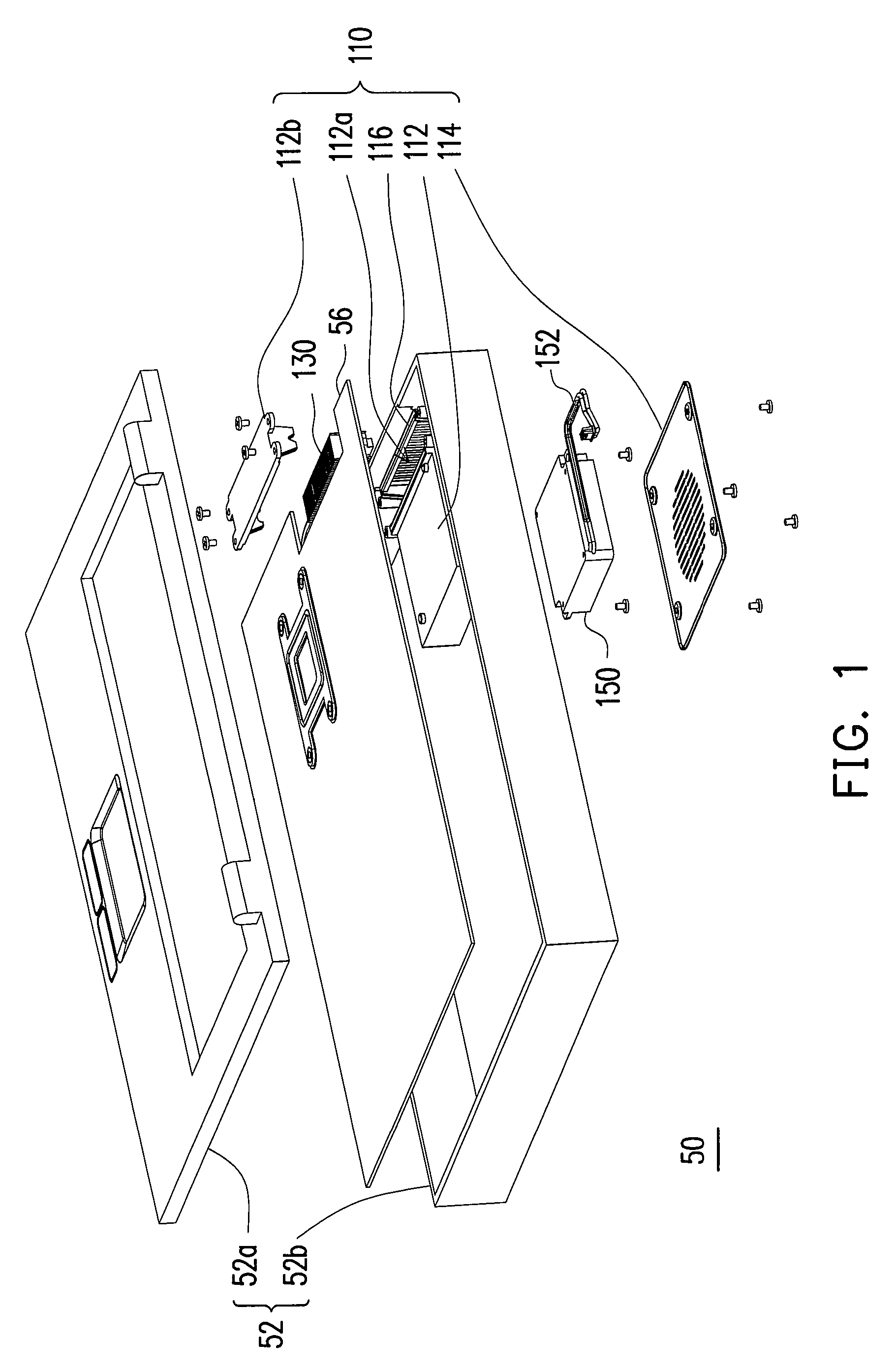

Waterproof thermal management module and portable

InactiveUS7336489B1Reduce thicknessSimplify the assembly processDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat pipe

Owner:COMPAL ELECTRONICS INC

Windshield wiper structure for vehicles

InactiveUS20060282972A1Improve scraping effectExtended service lifeWindow cleanersVehicle cleaningBand shapeEngineering

A windshield wiper structure for vehicles, comprises a truss saddle, a bow elastic stripe, a cover body, some detachable clamping devices, a strip scraper and a frame cover; wherein, some hollow pressure adjusting vents are created on said bow elastic stripe in order to keep nearly same elasticity at every sections of said bow elastic stripe. Hence, it can equilibrate force in every portions of whole wiper such that achieving in adjust-effect of even pressure distribution. Then, the contact between said strip scraper and the windshield glass is holistically even tight uniformly and hermetic closely to enhance the scraping effect of windshield wiper as well as the effect of prolonging service-lifetime with reducing expense in association with decreasing of replacing new product frequency in consequence of such even pressure distribution. Thus, it has more effect in economy and environmental protection.

Owner:HUANG SHIH HSIEN

Atomizer for electronic cigarette and electronic cigarette

ActiveCN102920028ASimple structureSimplify the assembly processTobacco pipesTobacco devicesGlass fiberElectronic cigarette

The invention discloses an atomizer for an electronic cigarette, and aims to provide the atomizer for the electronic cigarette, which is few in elements, simple in assembling process and low in cost. The implementation scheme is as follows: the atomizer for the electronic cigarette comprises an atomization sleeve, a suction nozzle cover, a thread bushing, an electrode retaining collar fixedly arranged in the thread bushing, an oil storage substance arranged in the atomization sleeve and a heating wire component, wherein an insulation ring is arranged between the thread bushing and the electrode retaining collar; the suction nozzle cover and the thread bushing are respectively in close fit with two ends of the atomization sleeve; two pins of the heating wire component are respectively connected with the thread bushing and the electrode retaining collar; the oil storage substance is formed by at least two layers with different densities; and the atomizer is exclusive of a glass fiber pipe. The invention further discloses an electronic cigarette comprising the atomizer.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Module board having embedded chips and components and method of forming the same

InactiveUS20050122698A1Reduce processing costsConvenient electricity testSemiconductor/solid-state device detailsSolid-state devicesHeat sinkEngineering

A module board has embedded chips and components. A substrate has at least one large cavity and at least one small cavity, in which the large cavity passes through the substrate and a passive component is set in the small cavity. A heat-dissipation sheet is set at the bottom of the substrate. A first adhesion layer bonds the bottom of the substrate to the heat-dissipation sheet. At least one IC chip is fixed in the large cavity of the substrate by a second adhesion layer. A dielectric filling layer covers the entire surface of the module board and fills all gaps, in which the dielectric filling layer has a plurality of micro vias to expose partial areas of the IC chip, the passive component and the substrate. At least one wiring pattern layer is formed on the dielectric filling layer and provide electrical connection among the IC chip, the passive component, and the substrate.

Owner:VIA TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com