Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

761results about How to "Improve material performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of forming crystallographically stabilized doped hafnium zirconium based films

ActiveUS20080233288A1Improve material propertiesImprove material performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRare-earth elementDopant

A method is provided for forming doped hafnium zirconium based films by atomic layer deposition (ALD) or plasma enhanced ALD (PEALD). The method includes disposing a substrate in a process chamber and exposing the substrate to a gas pulse containing a hafnium precursor, a gas pulse containing a zirconium precursor, and a gas pulse containing one or more dopant elements. The dopant elements may be selected from Group II, Group XIII, silicon, and rare earth elements of the Periodic Table. Sequentially after each precursor and dopant gas pulse, the substrate is exposed to a gas pulse containing an oxygen-containing gas, a nitrogen-containing gas, or an oxygen- and nitrogen-containing gas. In alternative embodiments, the hafnium and zirconium precursors may be pulsed together, and either or both may be pulsed with the dopant elements. The sequential exposing steps may be repeated to deposit a doped hafnium zirconium based film with a predetermined thickness.

Owner:TOKYO ELECTRON LTD

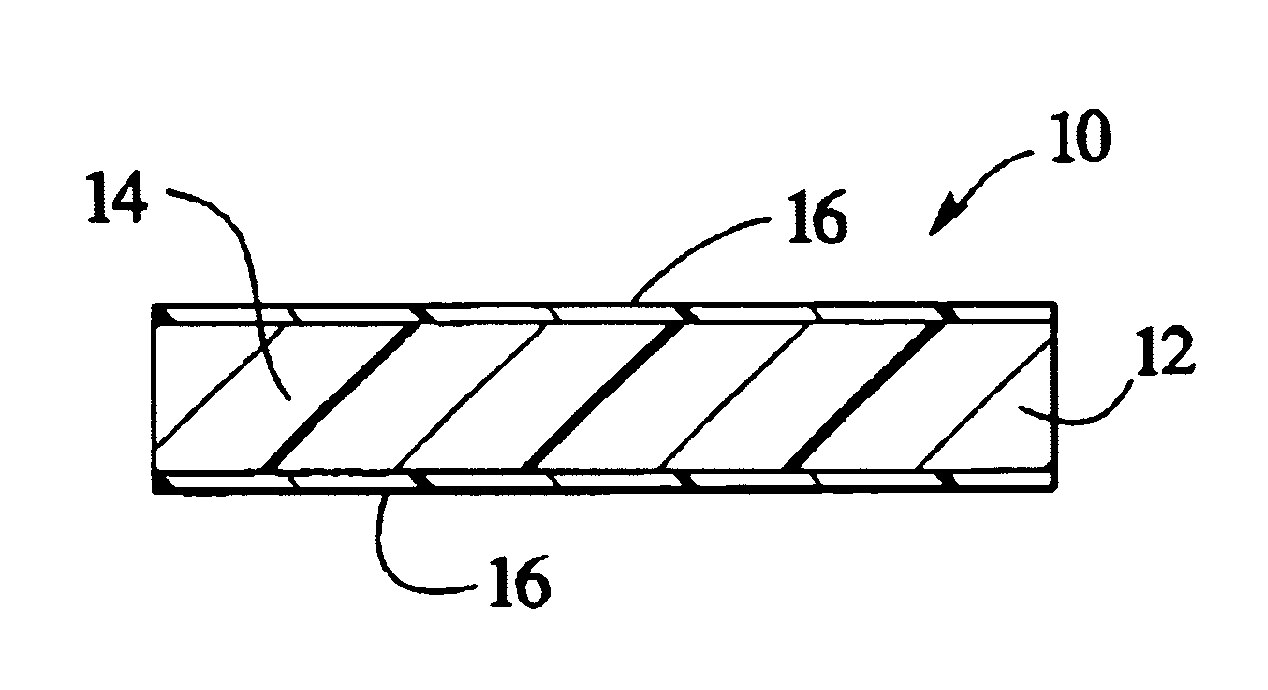

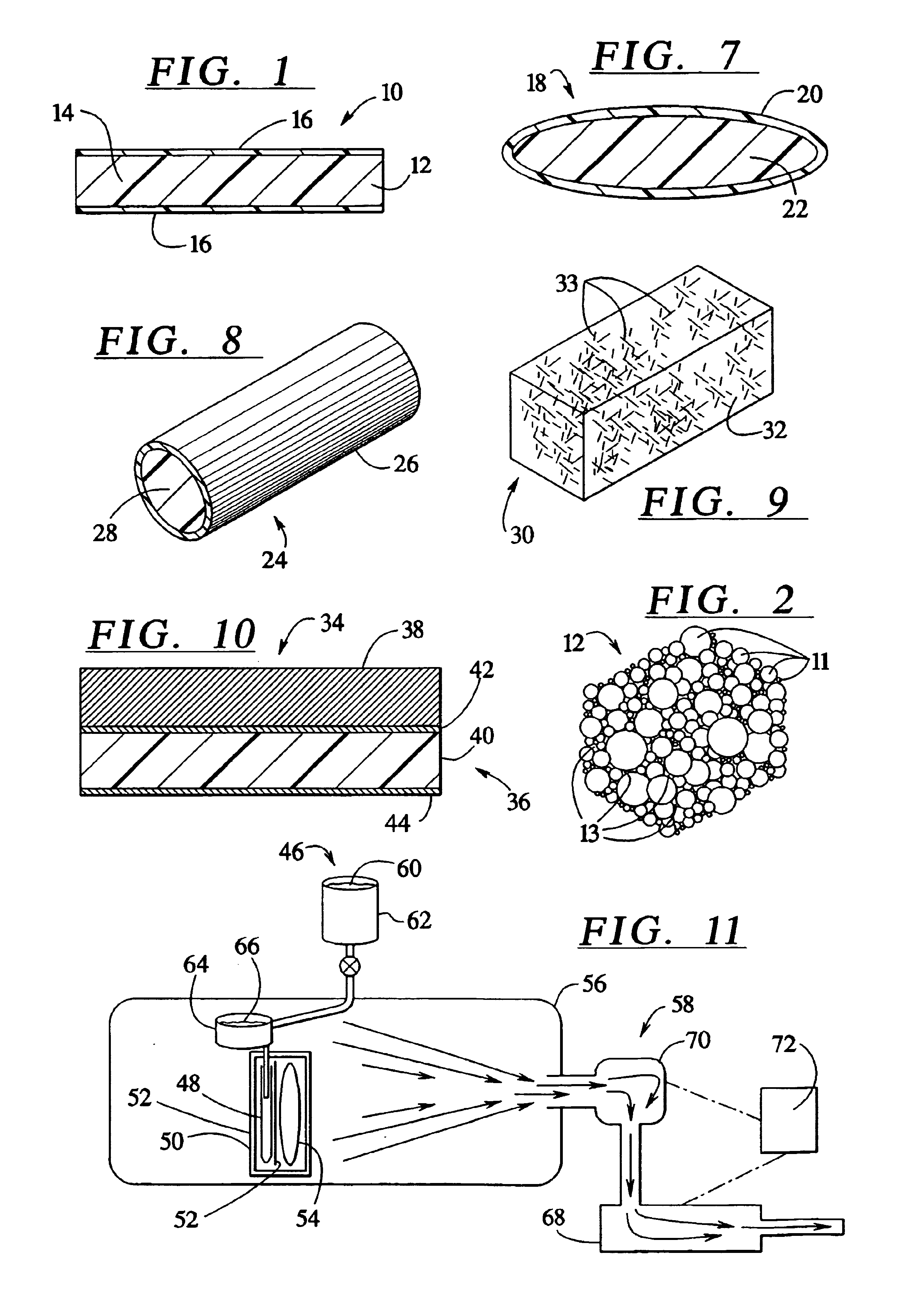

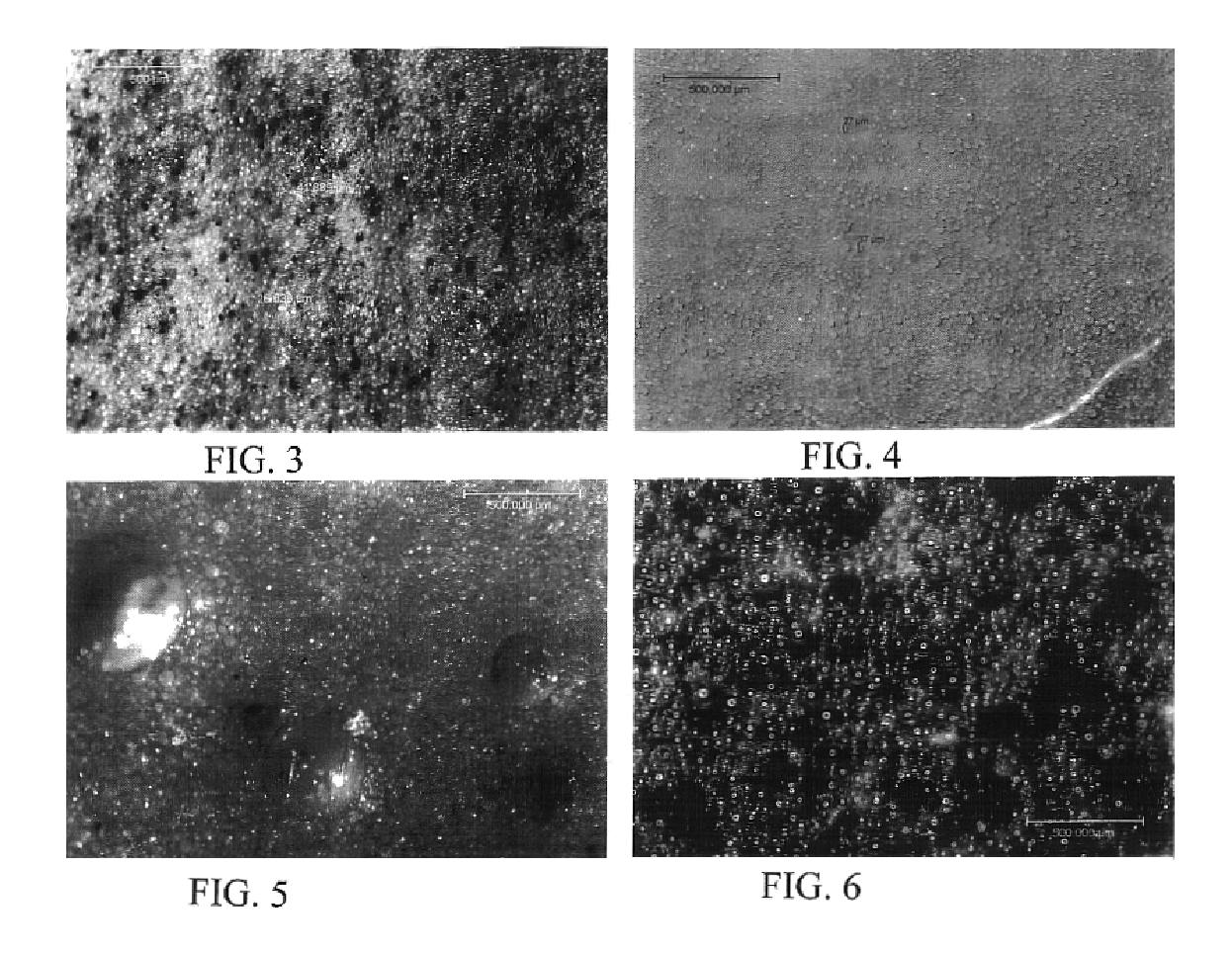

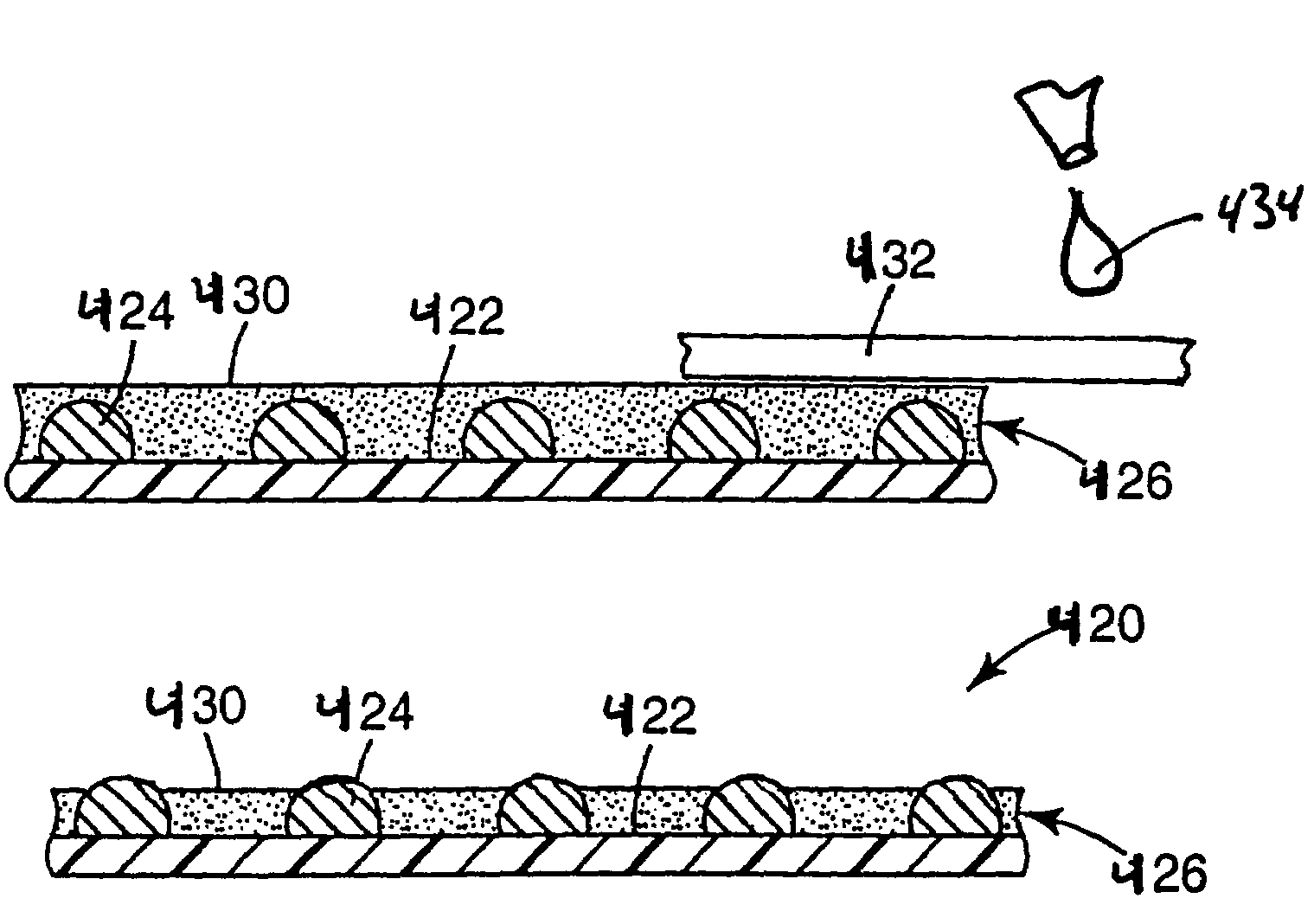

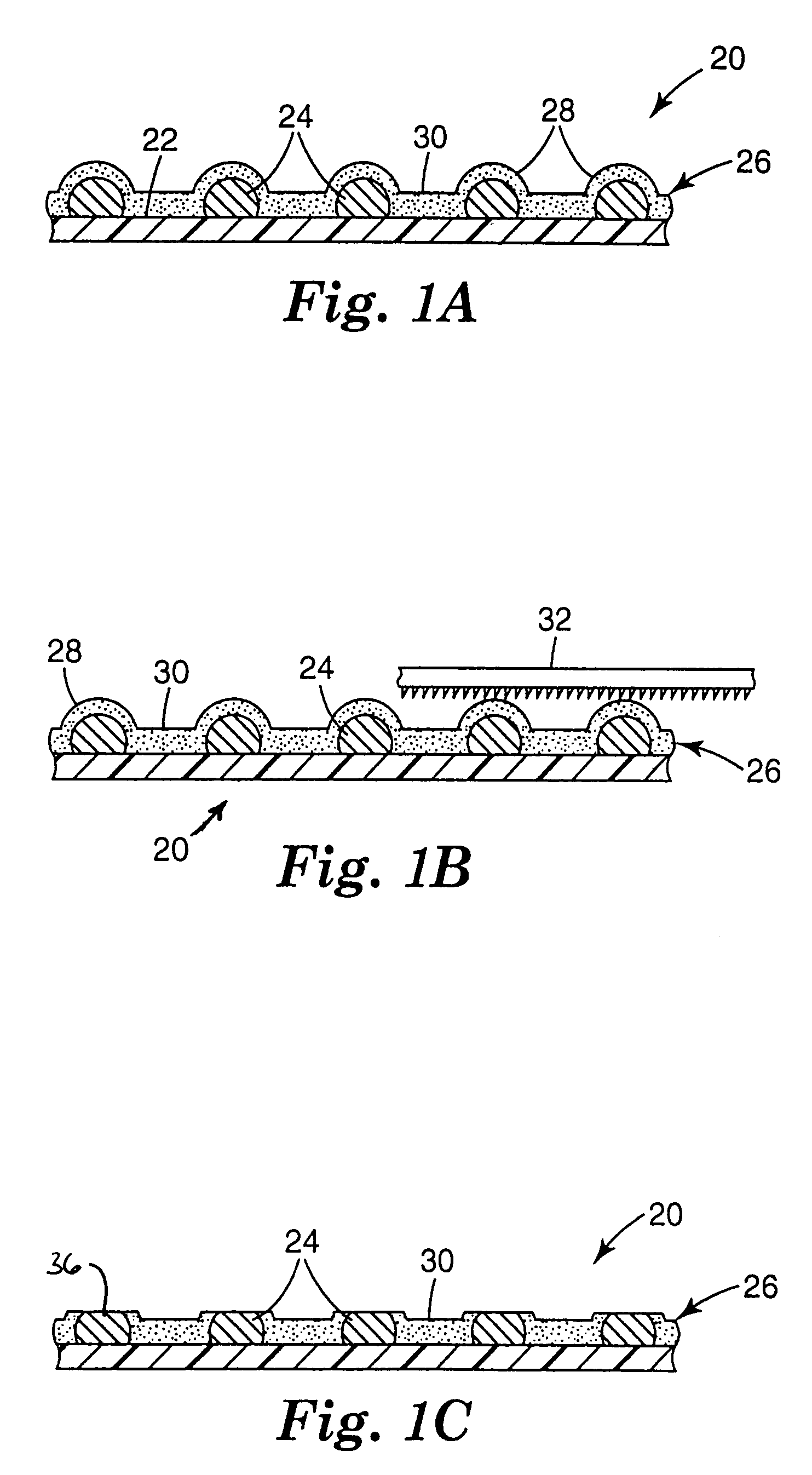

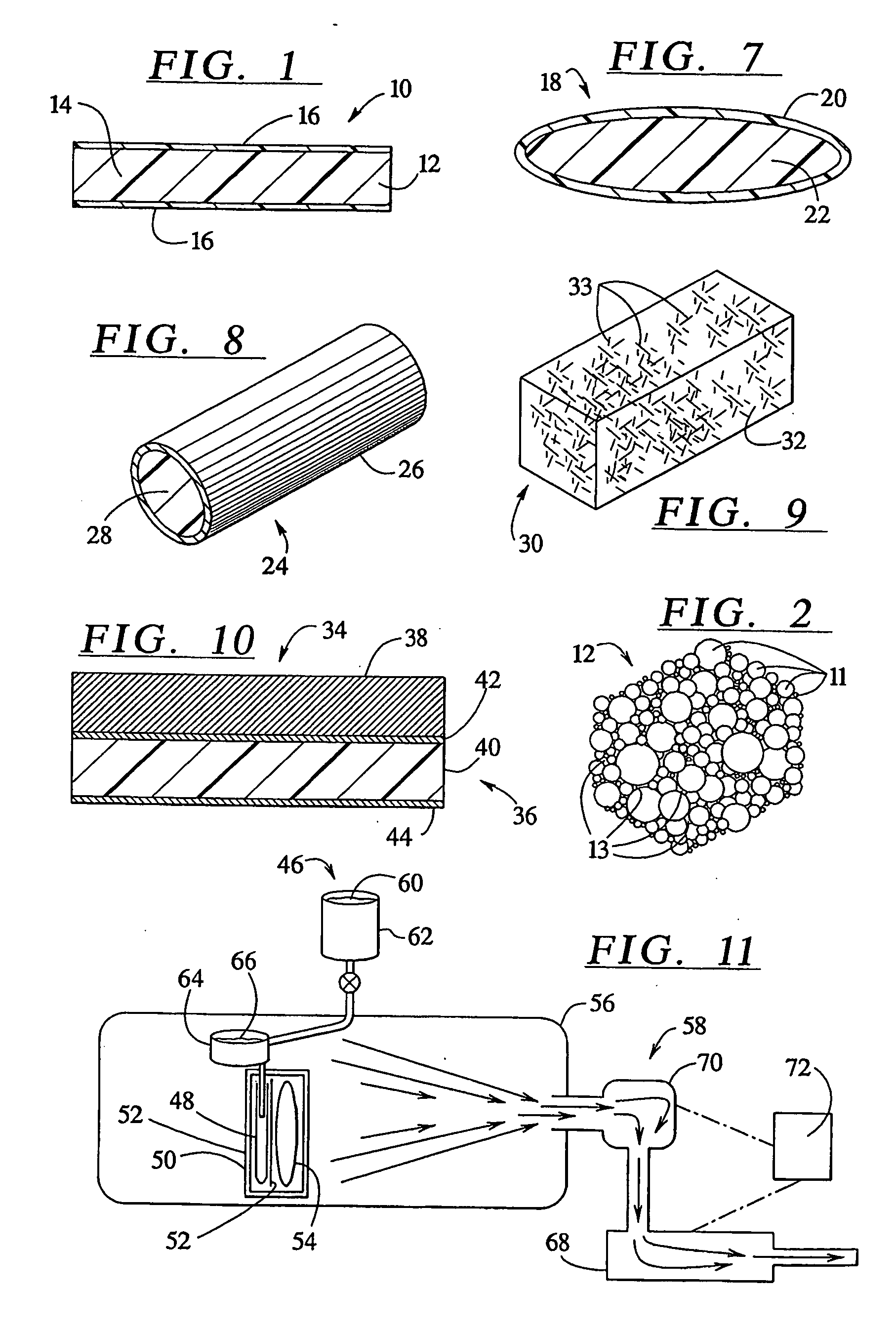

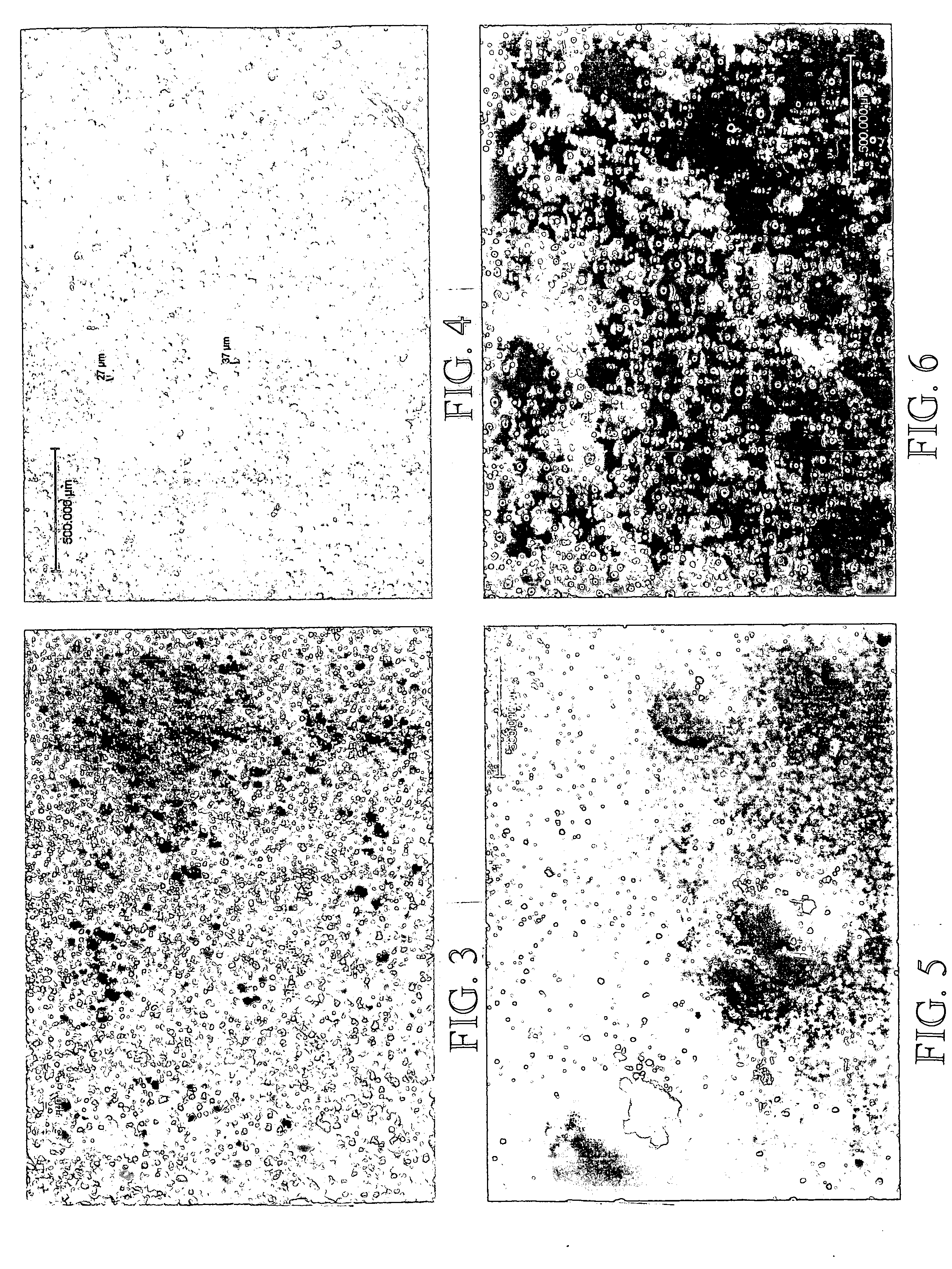

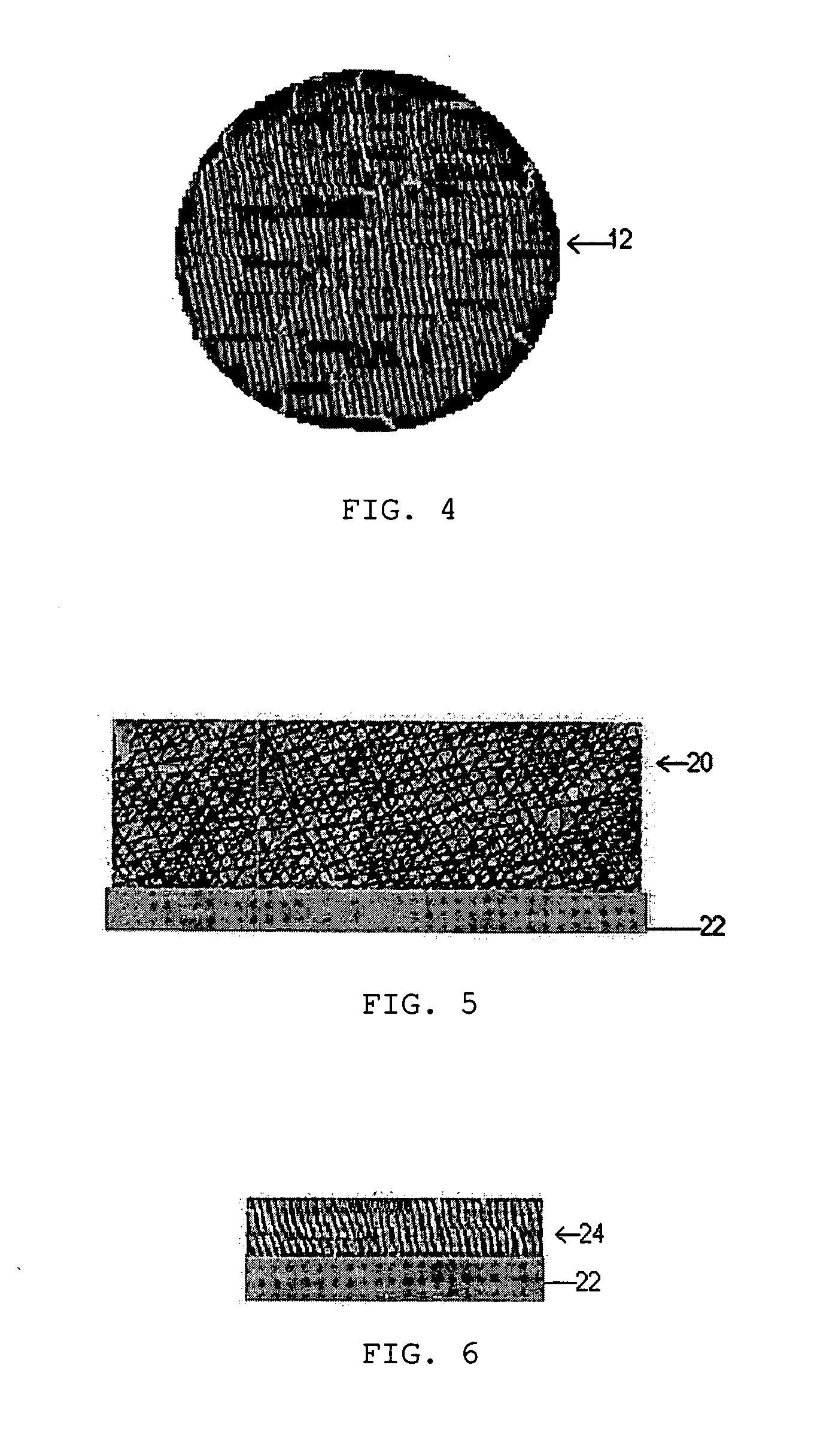

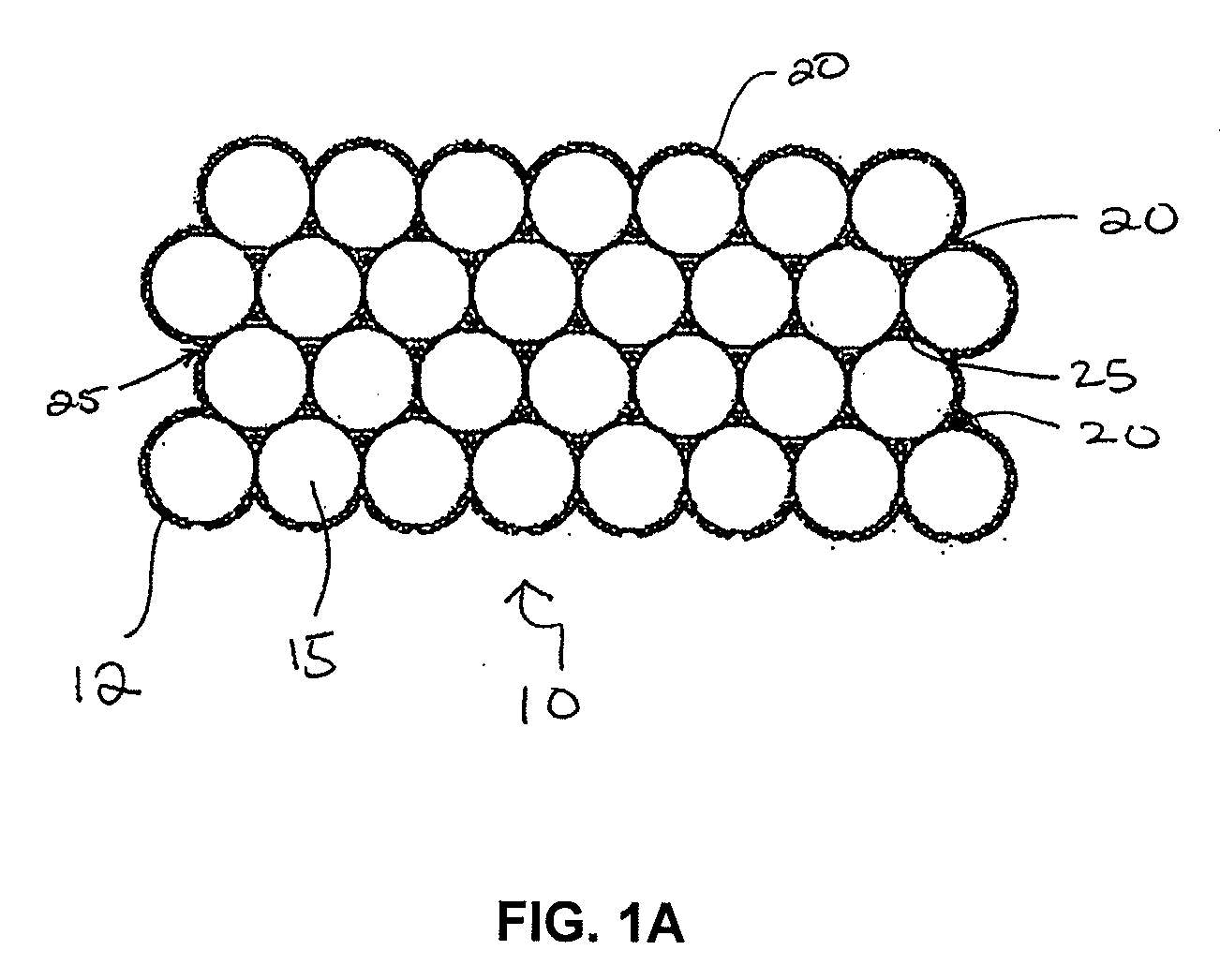

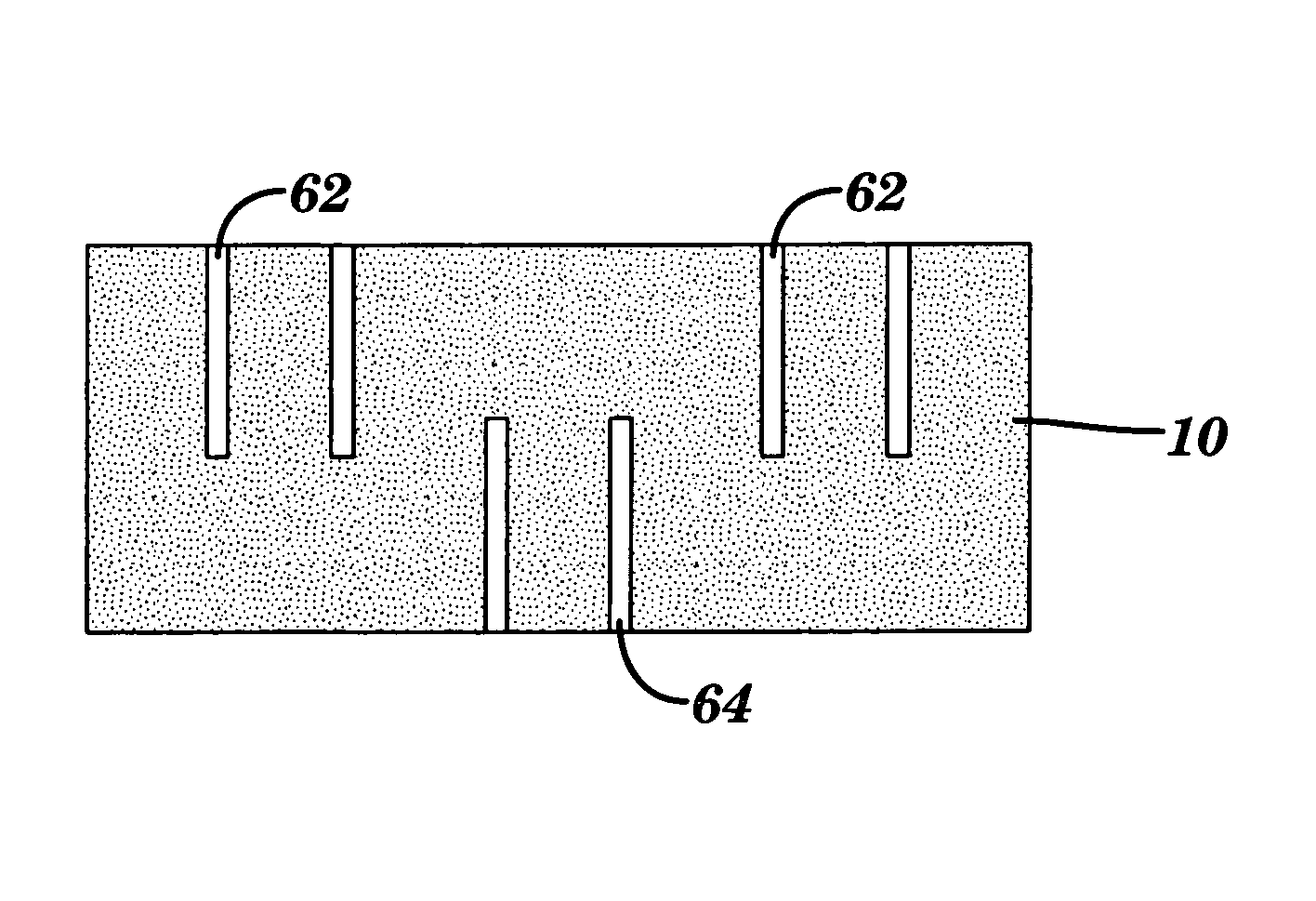

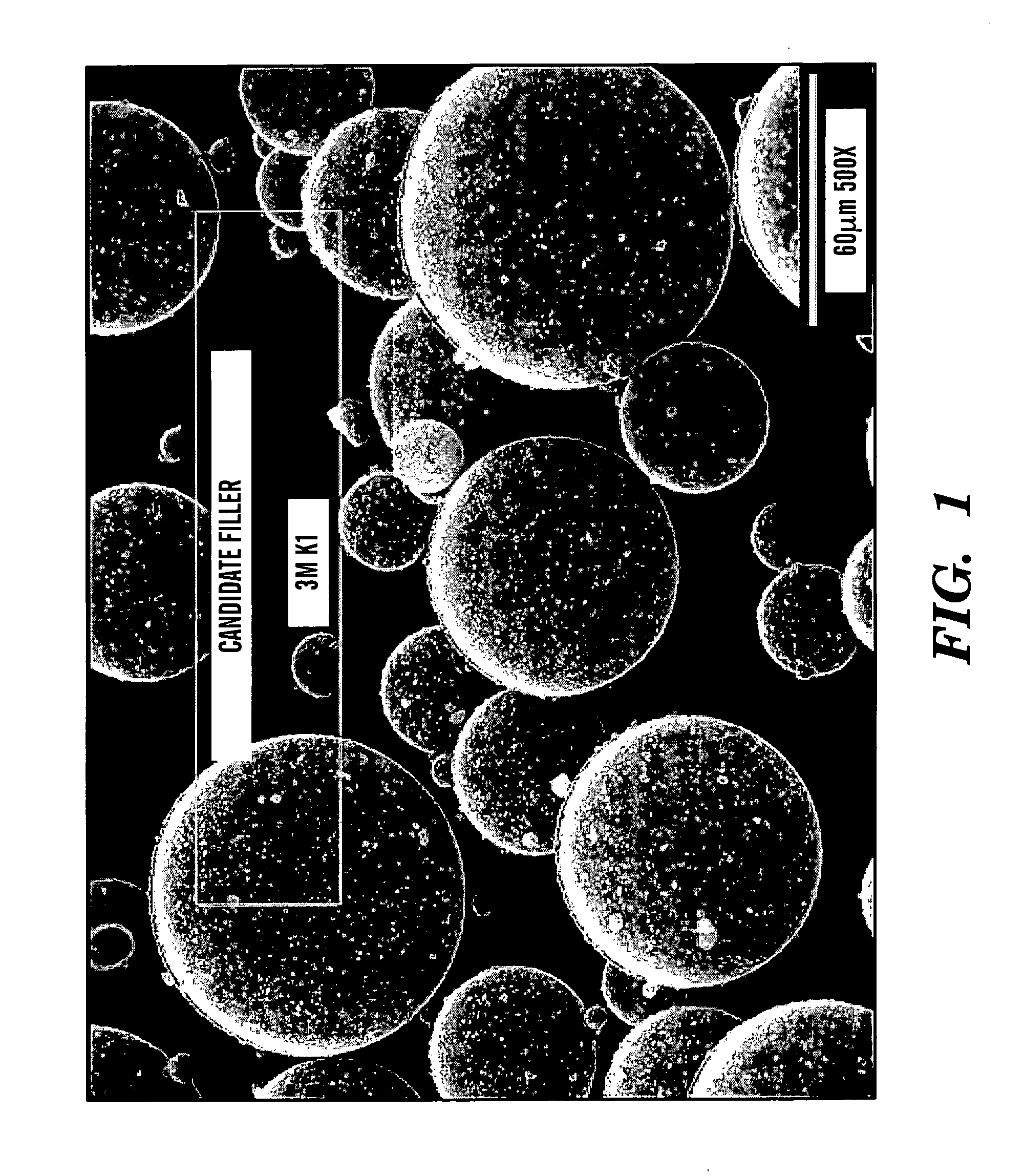

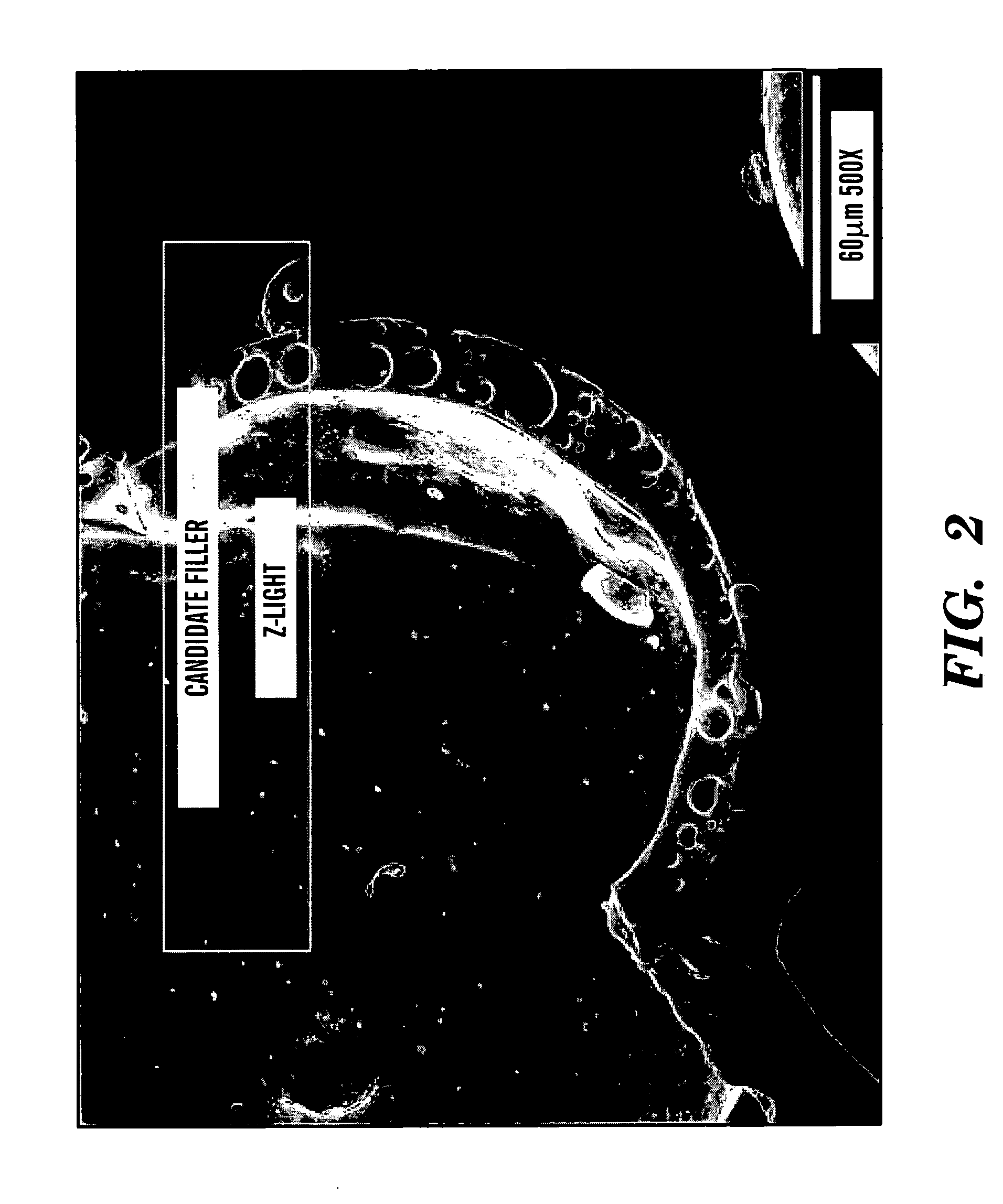

Composite materials

InactiveUS7037865B1Remarkable strength and other propertyImprove material performanceSynthetic resin layered productsCellulosic plastic layered productsFiberHigh density

New composite materials having a high density of small particles, such as hollow microspheres, in a matrix material are disclosed. The microspheres are densely packed in the matrix material such that adjacent microspheres are positioned in contact with each other or very close together. Fiber flanking may be provided on the opposite sides of a layer of a core of composite material having the small particles and matrix material. Also disclosed are methods of making and using the composite materials.

Owner:JAMES HARDIE TECH LTD

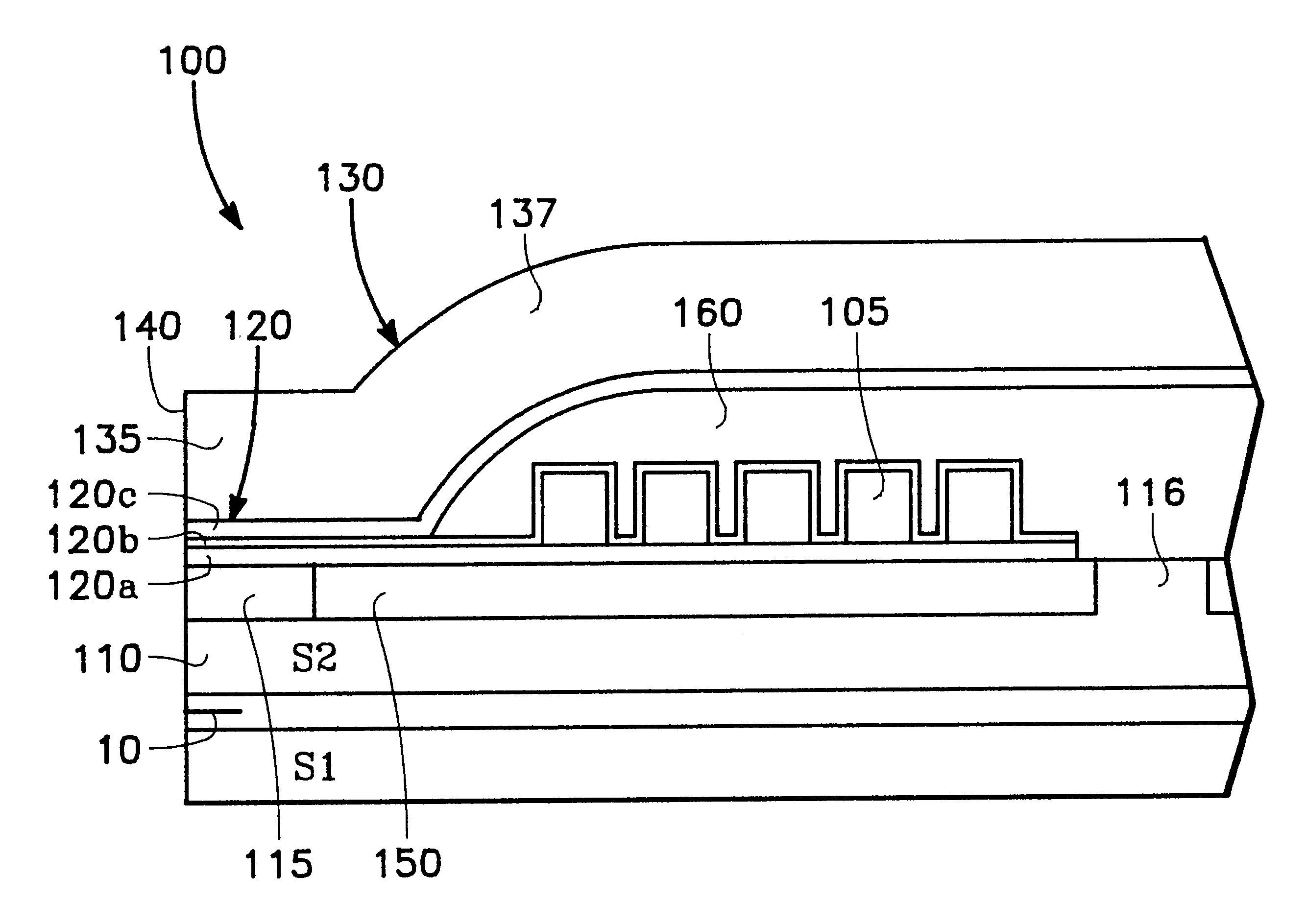

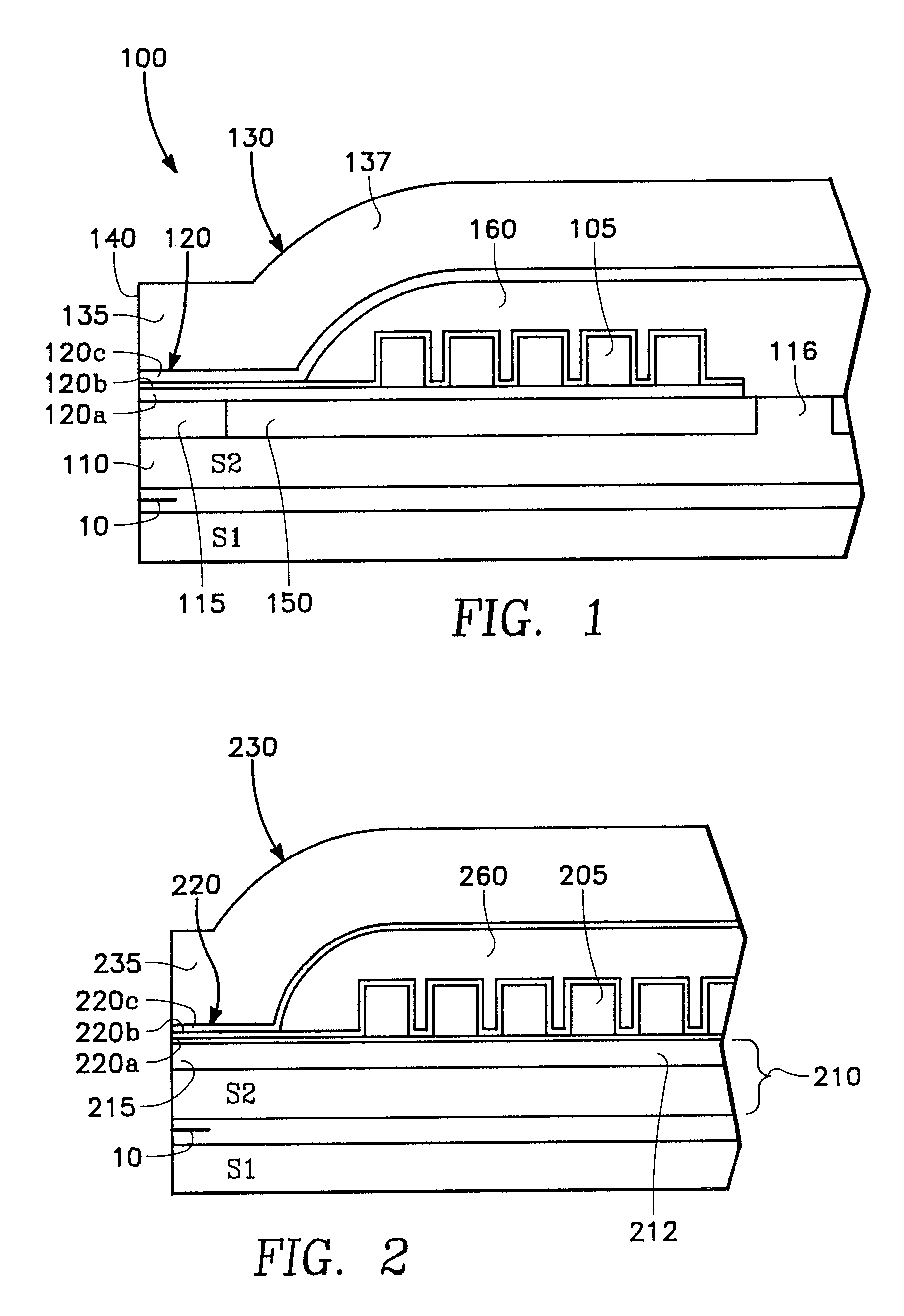

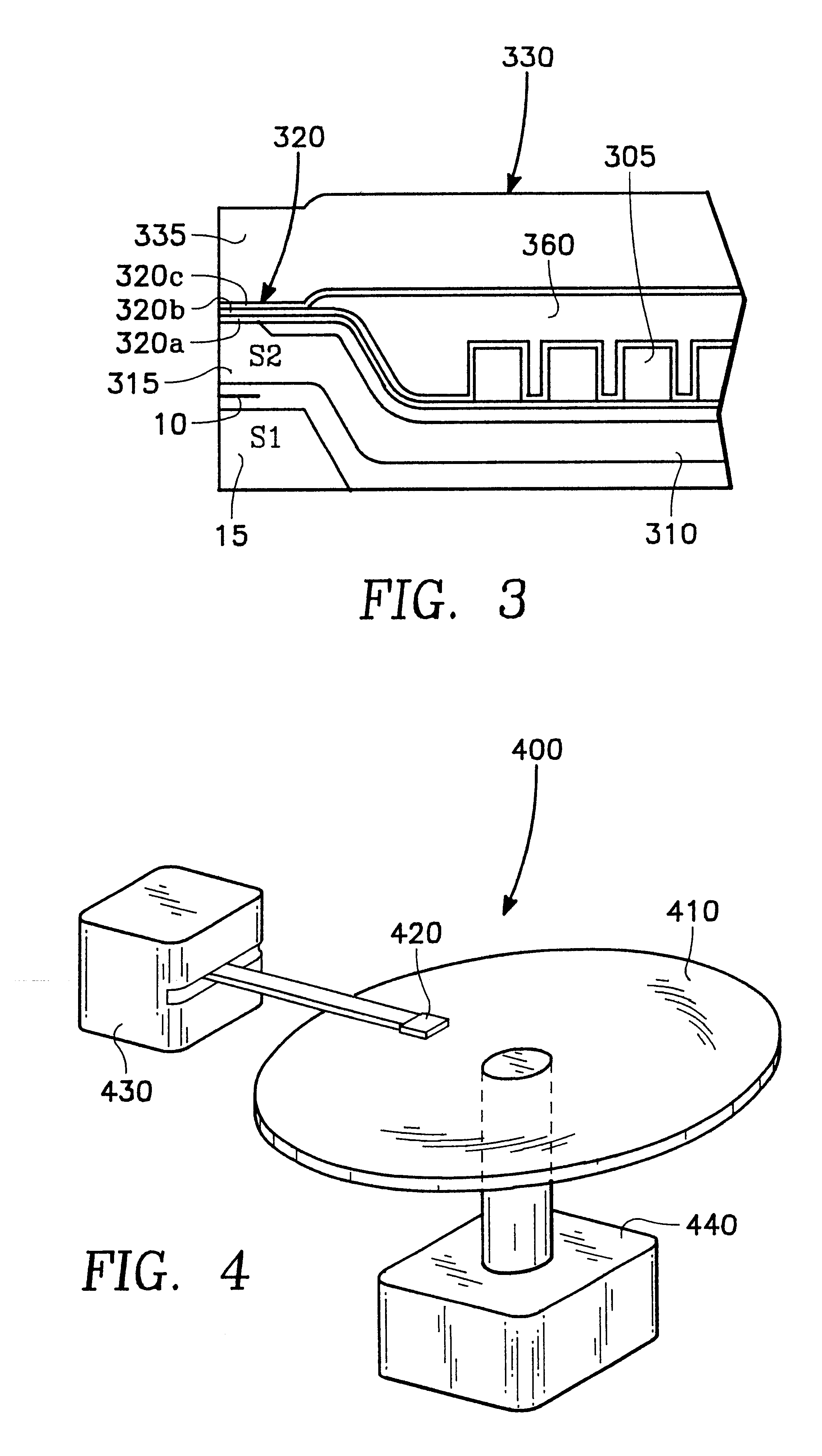

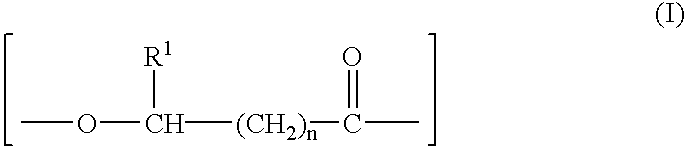

Thin film writer with multiplayer write gap

InactiveUS6724569B1Easy to controlControl performanceConstruction of head windingsManufacture head surfaceElectrical conductorLower pole

Embodiments in accordance with the thin film write head of the present invention have a lower pole structure, an upper pole structure, and a multilayer write gap extending from an air bearing surface between the upper and lower pole structures. In preferred embodiments, the write gap comprises at least two of: (a) a first layer covering a lower pole tip portion of the lower pole structure, (b) a second layer covering turns of a semiconductor winding, or (c) a third layer covering a winding insulation stack. In more preferred embodiments, the write gap is formed of the first, the second, and the third write gap layers. An advantage of a write head with a multilayer write gap is that it allows better control of write gap thickness. As such, loss of write gap thickness can be compensated for by deposition of the second write gap layers, or by deposition of the third write gap layer. Some embodiments have one or more additional advantages in providing increased corrosion prevention, improving the integrity of conductor insulation, and / or improving the top pole magnetic material characteristics.

Owner:WESTERN DIGITAL TECH INC

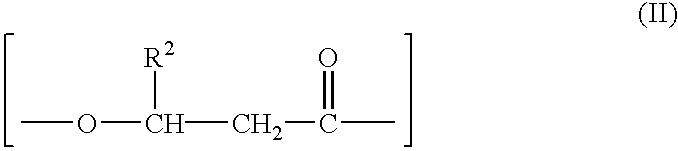

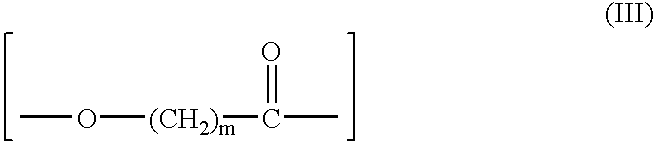

Fibers comprising polyhydroxyalkanoate copolymer/polylactic acid polymer or copolymer blends

InactiveUS6905987B2Improve material performancePersonal careSynthetic resin layered productsFiberPolymer chemistry

Environmentally degradable melt spun fibers comprising a polyhydroxyalkanoate copolymer and a polylactic acid polymer or copolymer are disclosed. A preferred configuration of the present invention is directed to environmentally degradable fibers comprising a sheath / core structure where the core comprises a biodegradable polyhydroxyalkanoate copolymer and the sheath comprises a polymer or copolymer of polylactic acid. Nonwoven webs and disposable articles comprising the environmentally degradable fibers are also disclosed.

Owner:DANIMER IPCO LLC

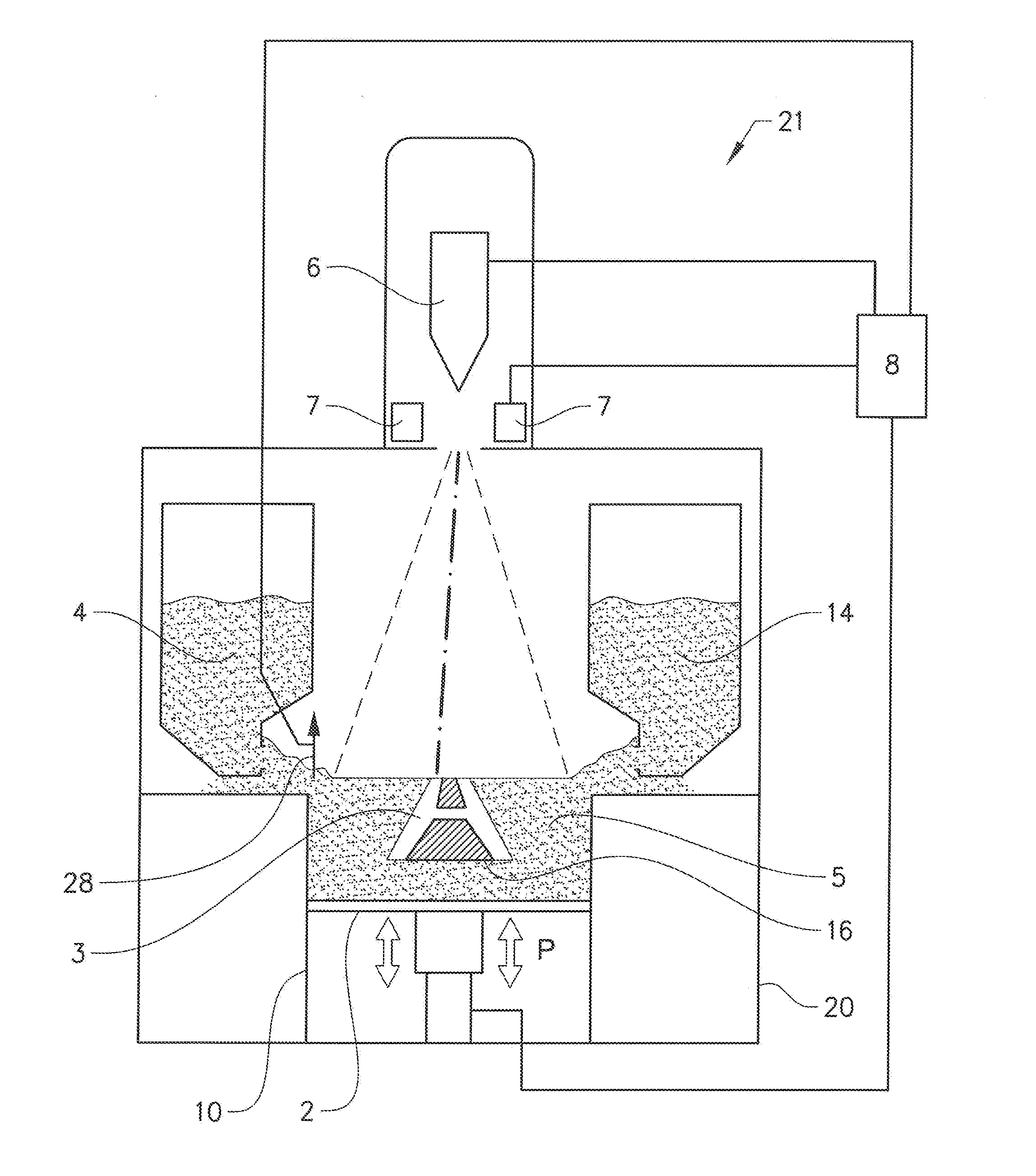

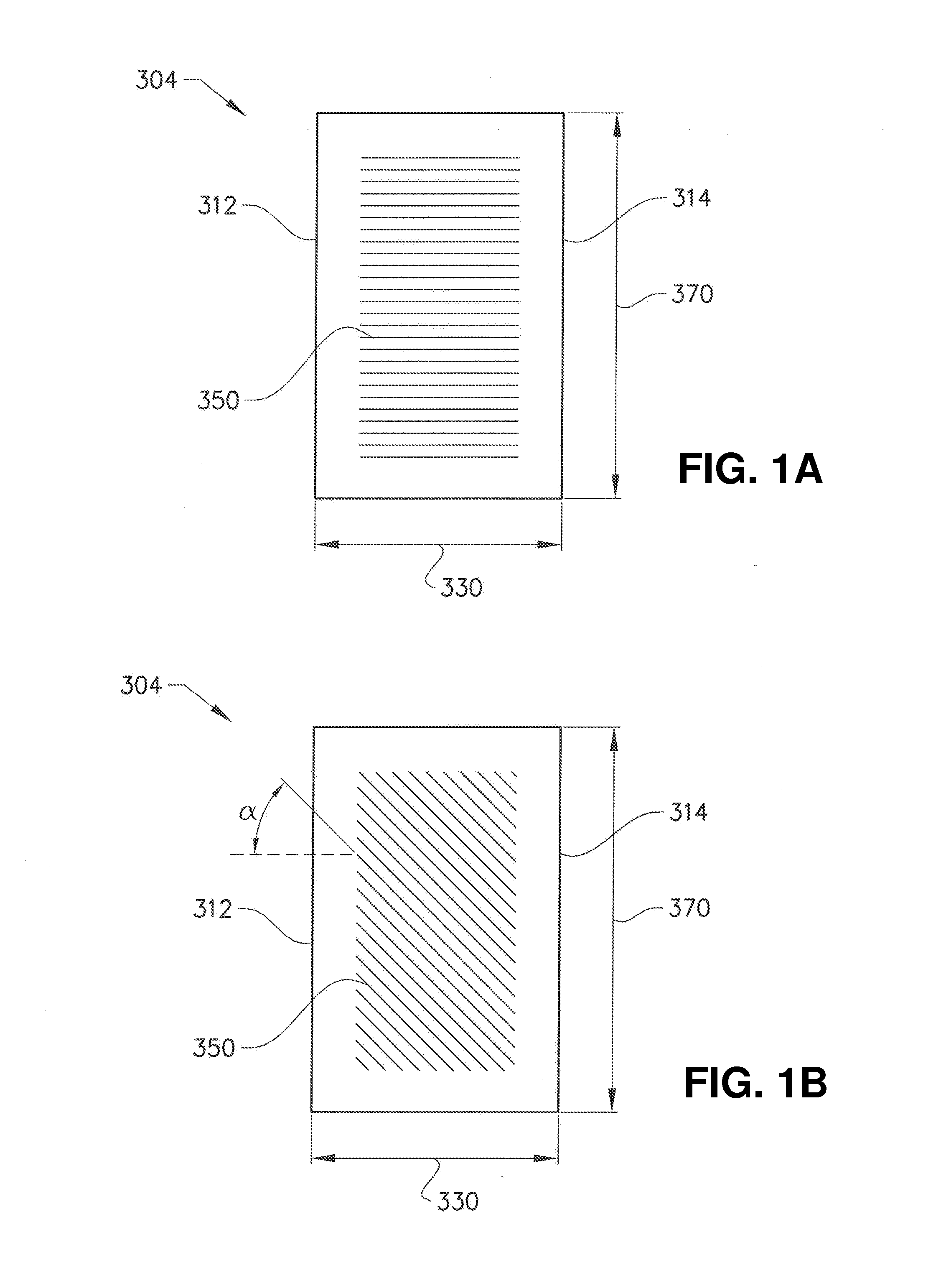

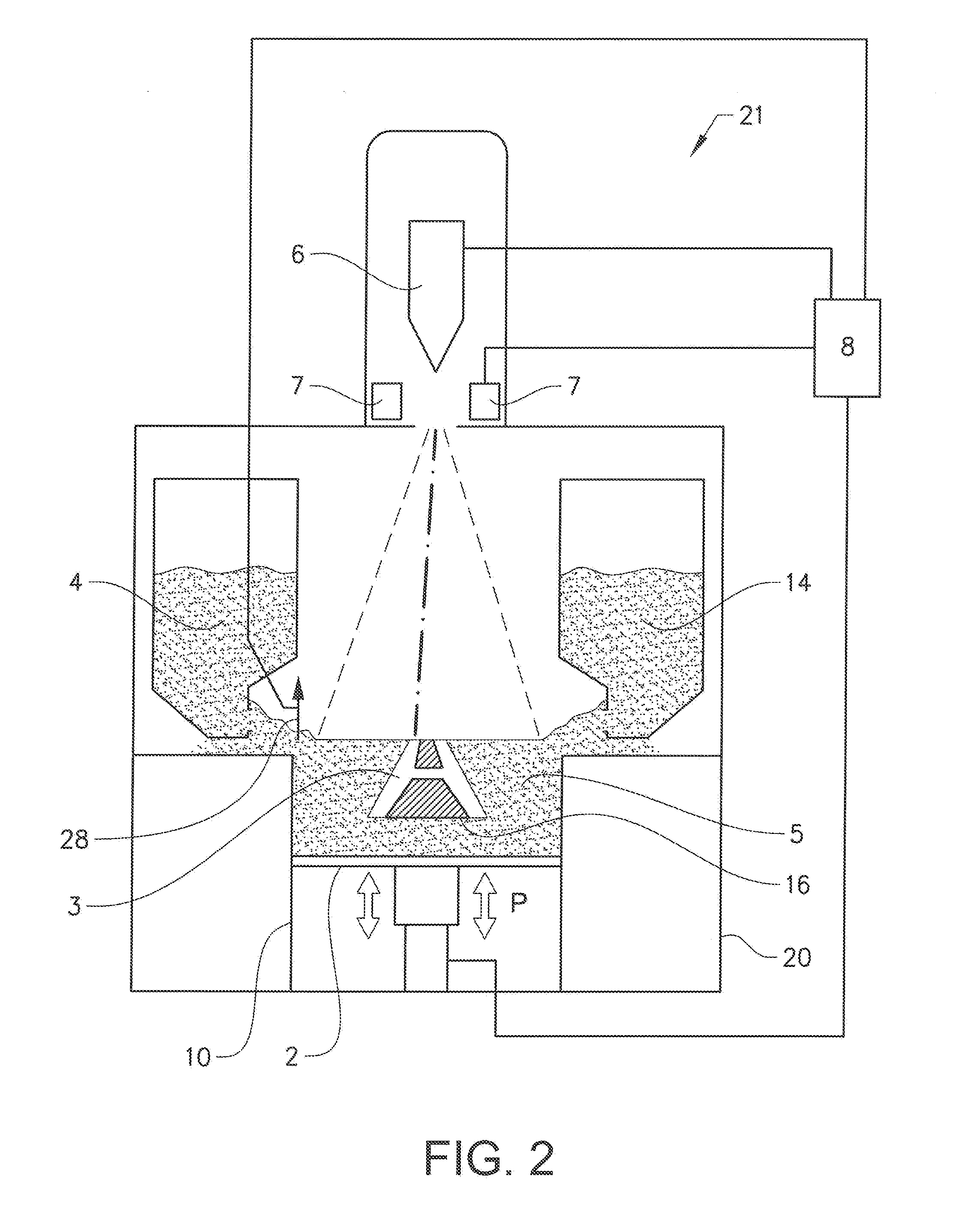

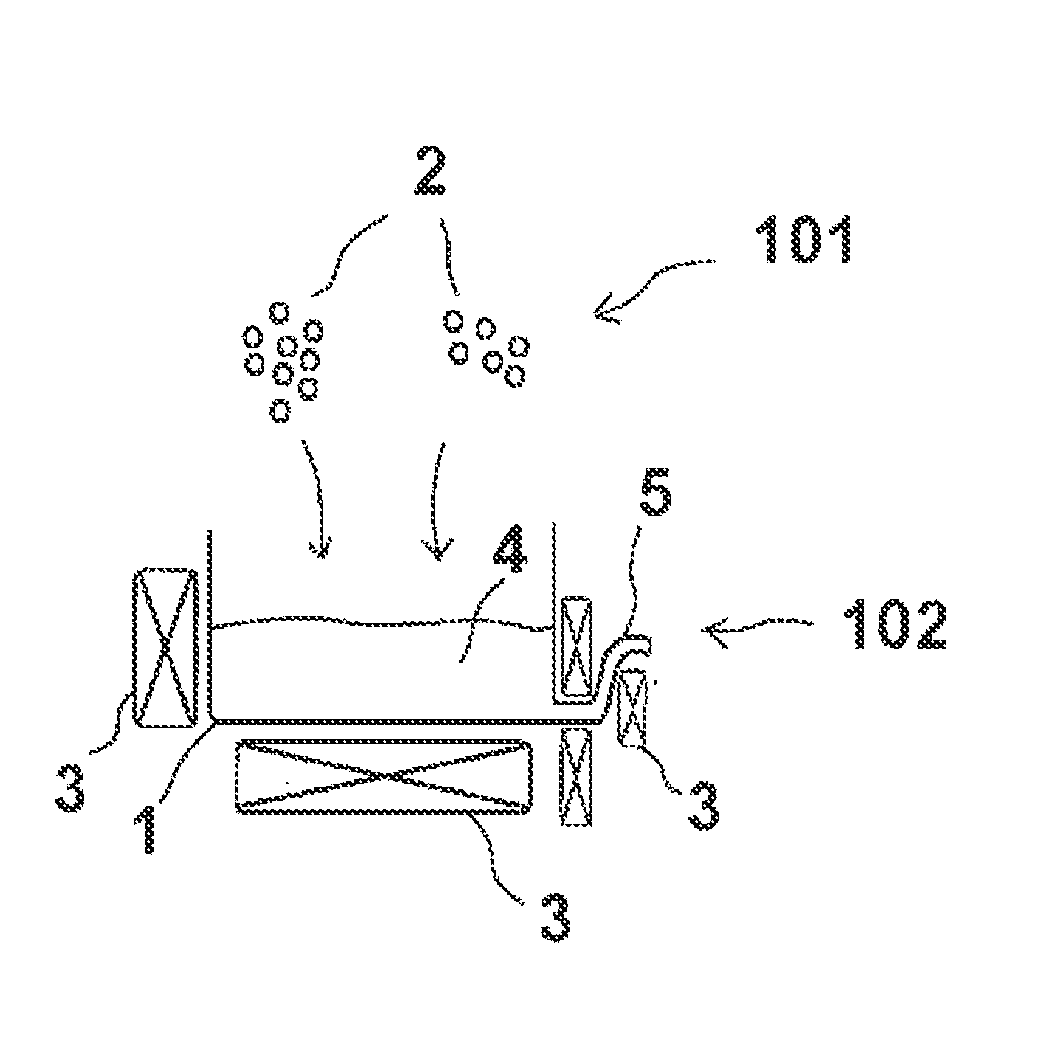

Method and apparatus for forming a three-dimensional article

ActiveUS20140314609A1Improve compactionIncrease flexibilityAdditive manufacturing apparatusElectric discharge tubesMetallurgyDistributor

An apparatus for forming at least one three-dimensional article by fusing parts of a powder bed layer-wise. The apparatus comprising a powder distributor and an energy beam for fusing the powder layer. Said powder distributor comprises a first part being an elongated rod provided movable at a predetermined distance above the powder bed and with its central axis in parallel with a top surface of said work table and second part being a metal foil having at least a first and a second opposite edge portions. Said metal foil is provided between said elongated rod and said work table, said first and second opposite edge portions are attached to said elongated rod so that a distance between said first and second edge portions is smaller than the distance between said first and second edge portions of said metal foil when said metal foil is in a flat position.

Owner:ARCAM AB

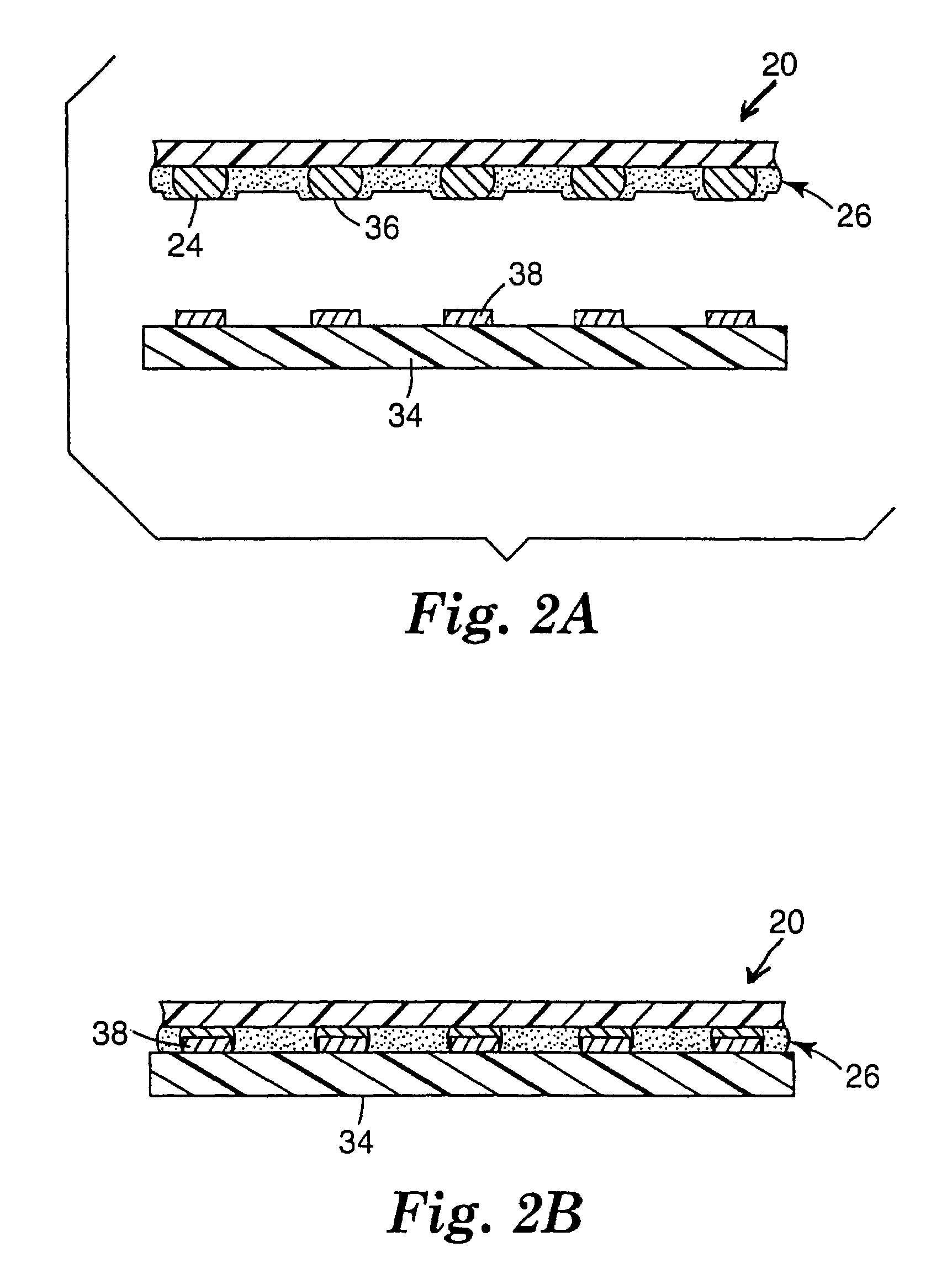

Solvent assisted burnishing of pre-underfilled solder bumped wafers for flipchip bonding

InactiveUS7170185B1Simplify flip-chip assembly processLower assembly costsSemiconductor/solid-state device detailsSolid-state devicesAdhesiveElectrical connection

The present invention relates to a method for connecting an integrated circuit chip to a circuit substrate. The method includes the step of pre-applying adhesive directly to a bumped side of an integrated circuit chip. The method also includes the steps of removing portions of the adhesive from the tips of the solder bumps to expose a contact surface, and pressing the bumped side of the integrated circuit chip, which has previously been coated with adhesive, against the circuit substrate such that the bumps provide an electrical connection between the integrated circuit chip and the circuit substrate. The adhesive is removed from the tips of the solder bumps using a solvent assisted wiping action. The pre-applied adhesive on the chip forms a bond between the integrated circuit chip and the circuit substrate.

Owner:3M INNOVATIVE PROPERTIES CO

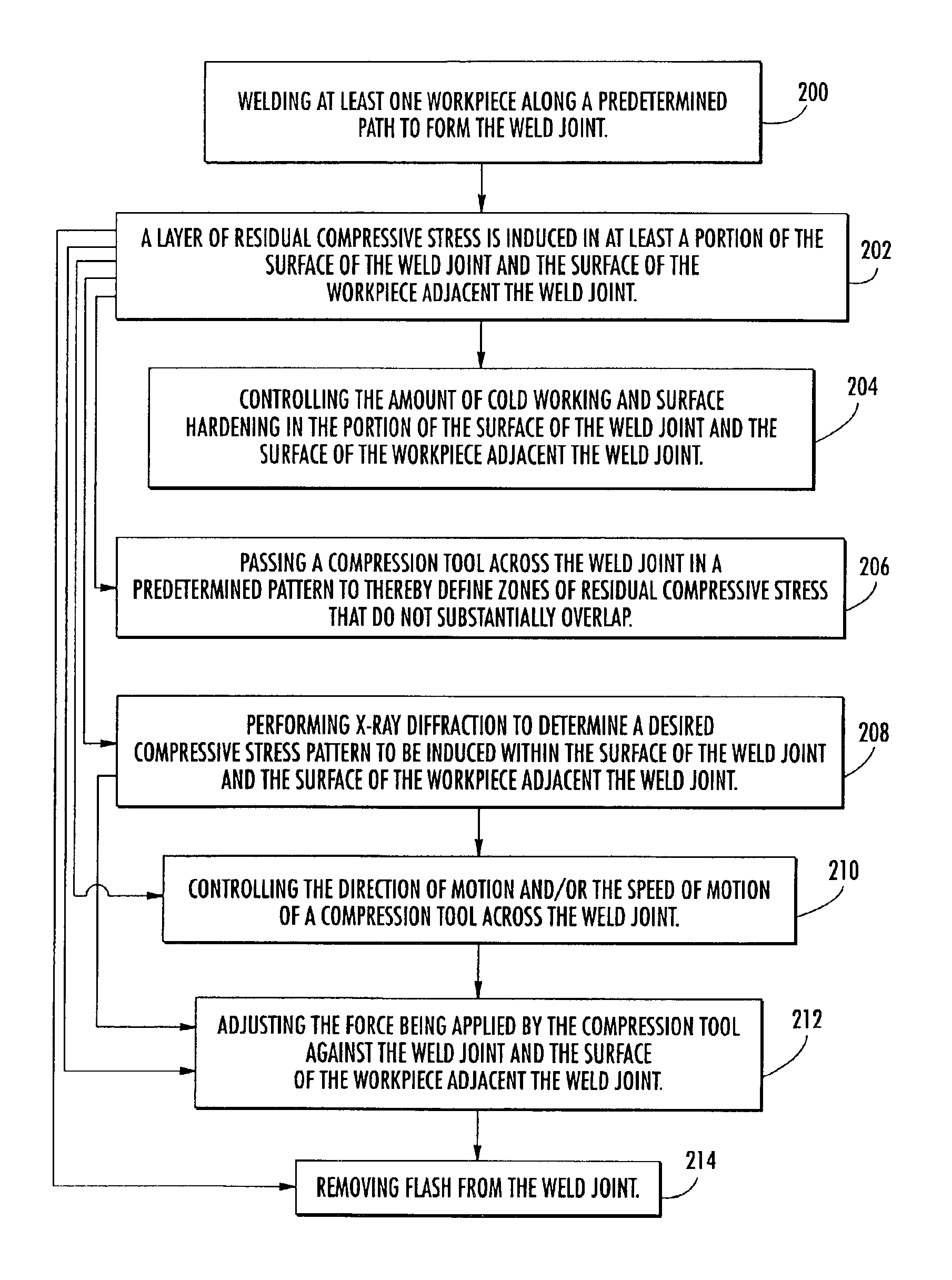

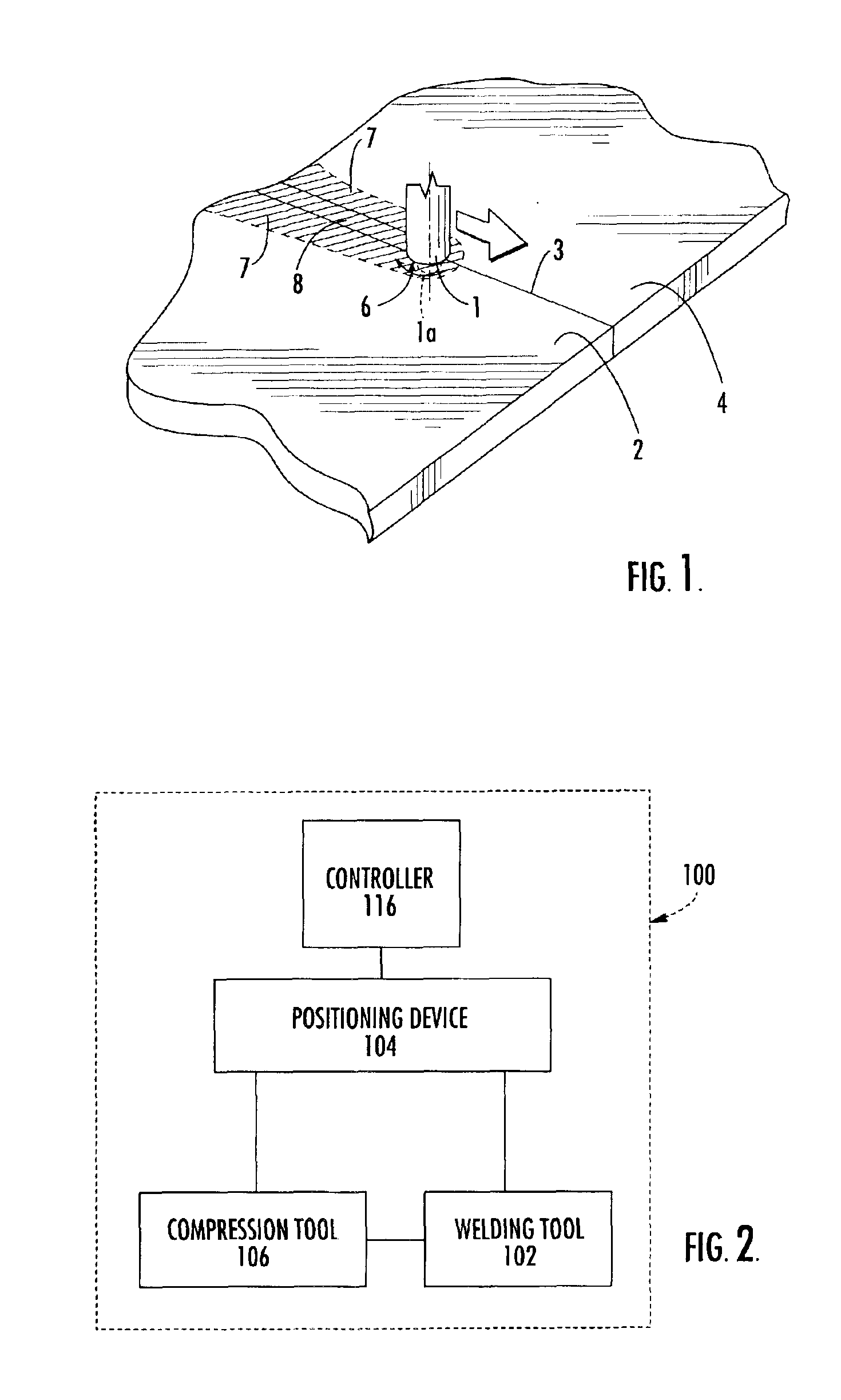

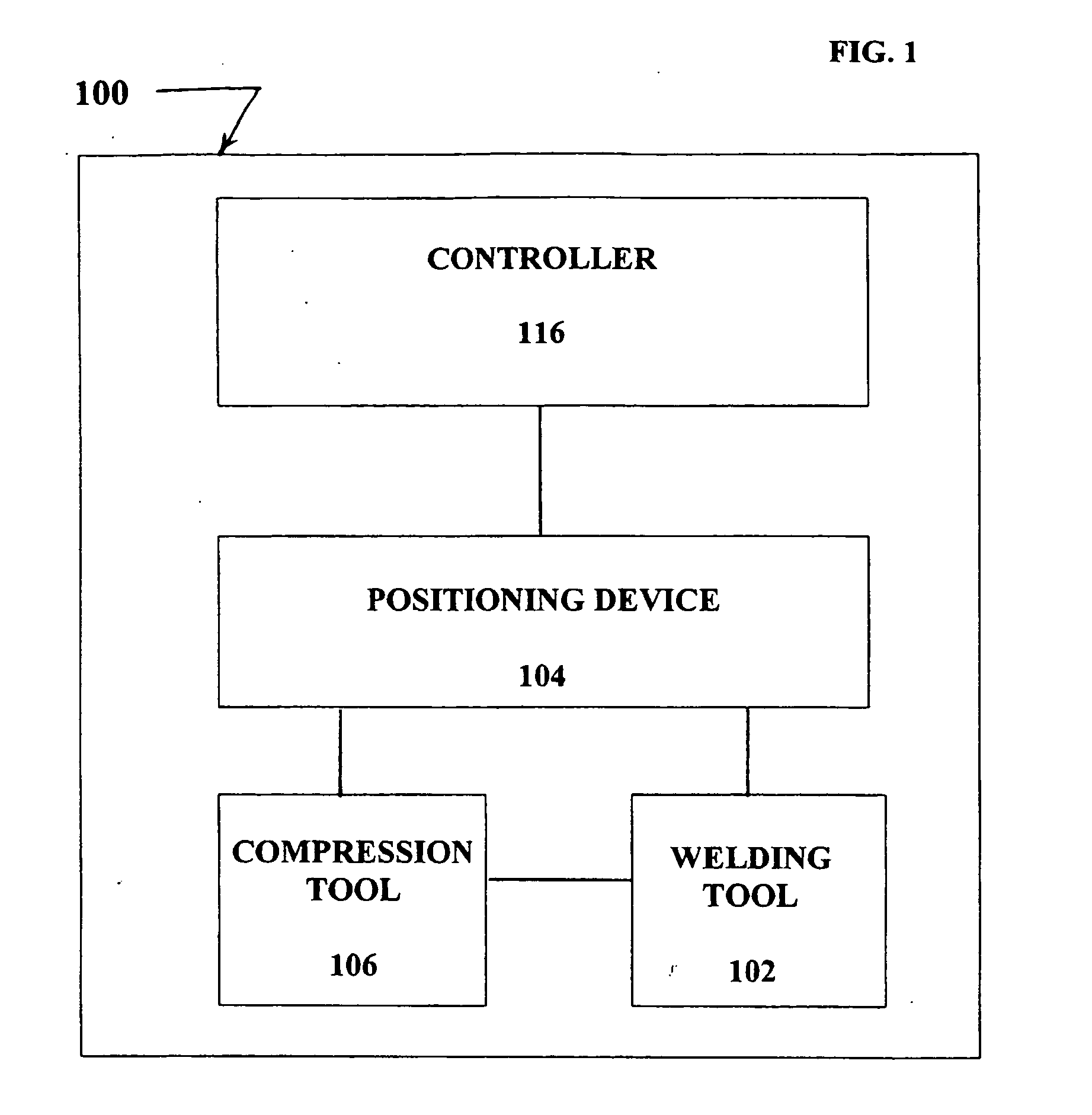

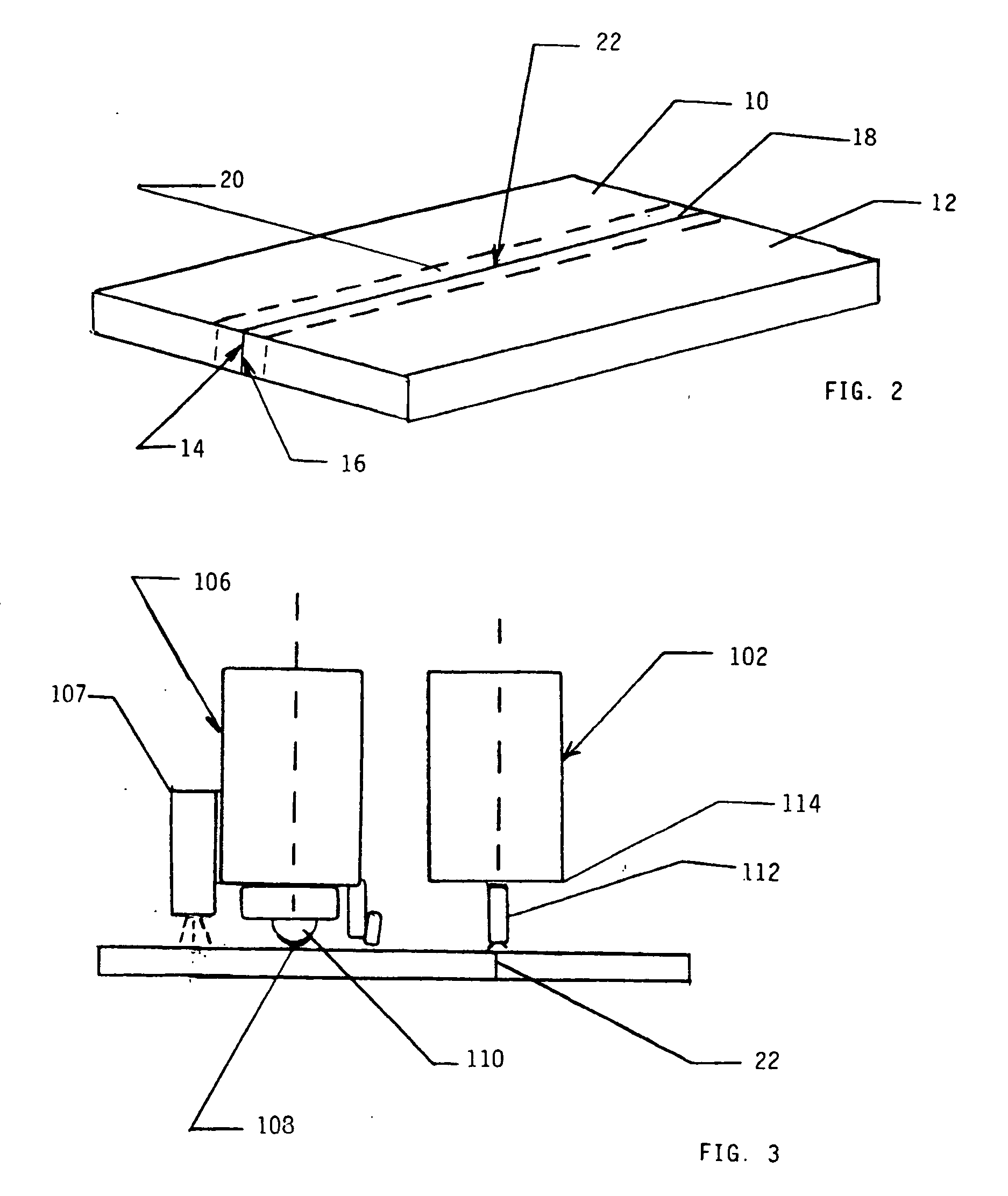

Apparatus and method for forming weld joints having compressive residual stress patterns

InactiveUS6926970B2Improve material propertiesHigh surface finishWelding/cutting auxillary devicesBurnishing machinesUltimate tensile strengthMechanical engineering

The welding apparatus and associated method are provided. The welding apparatus includes a welding tool for forming a weld joint along the surface of at least one workpiece. The welding apparatus also includes a compression tool for selectively inducing a layer of residual compressive stress in at least a portion of the surface of the weld joint and the surface of the at least one workpiece to thereby improve the material properties of the workpiece, including corrosion resistance and fatigue strength.

Owner:SURFACE TECH HLDG +1

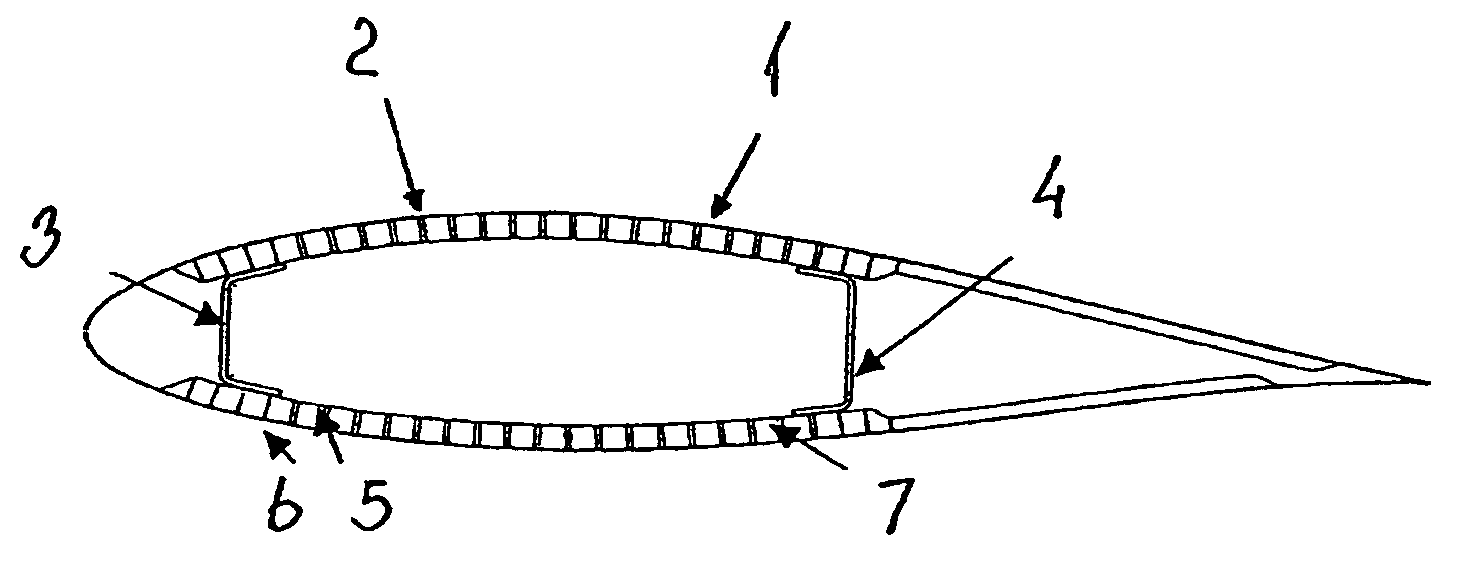

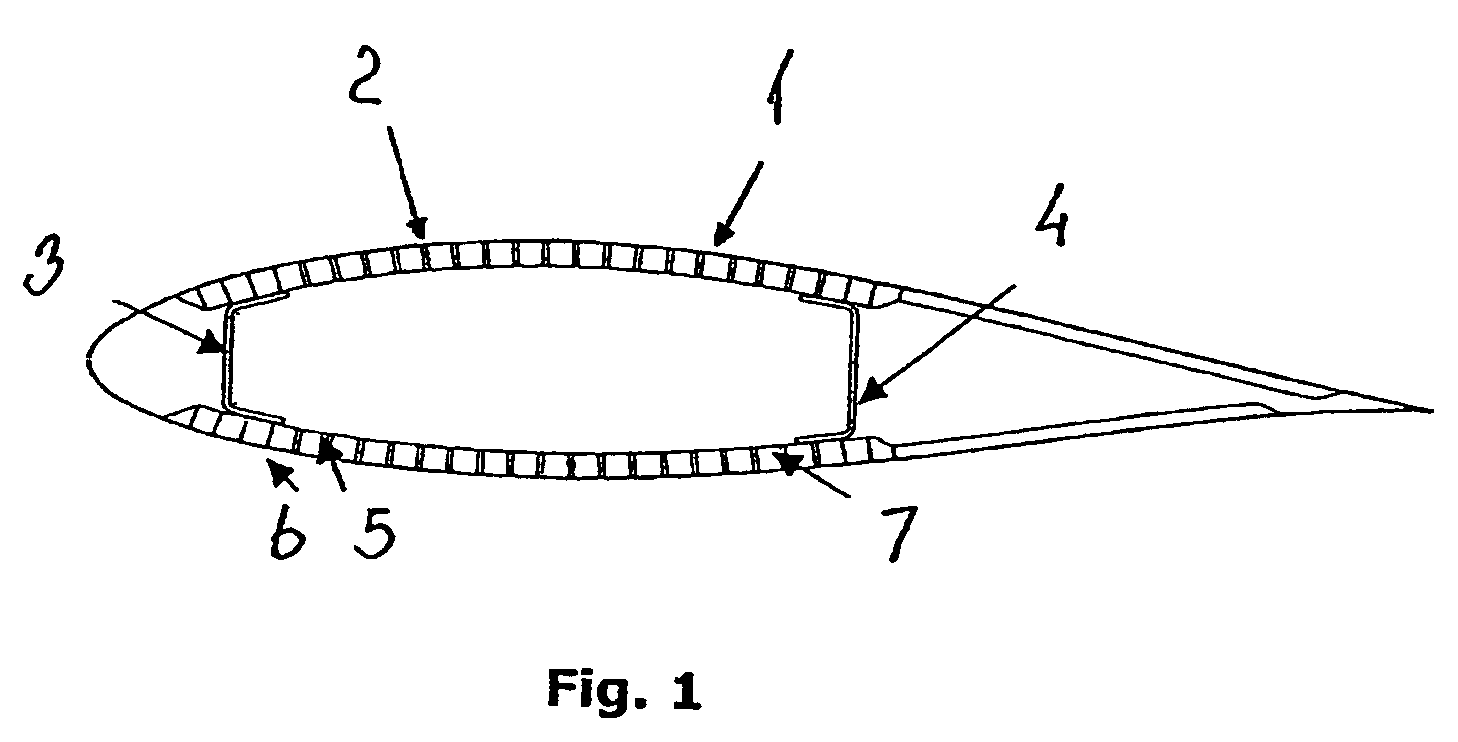

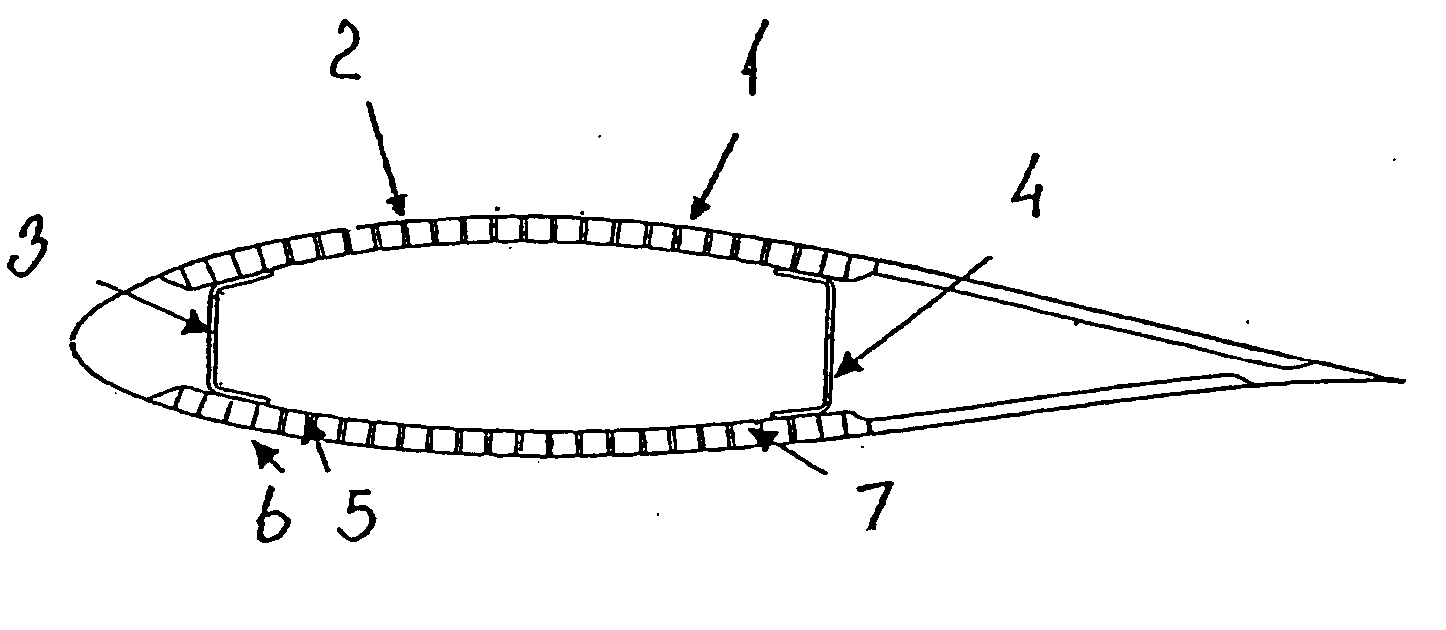

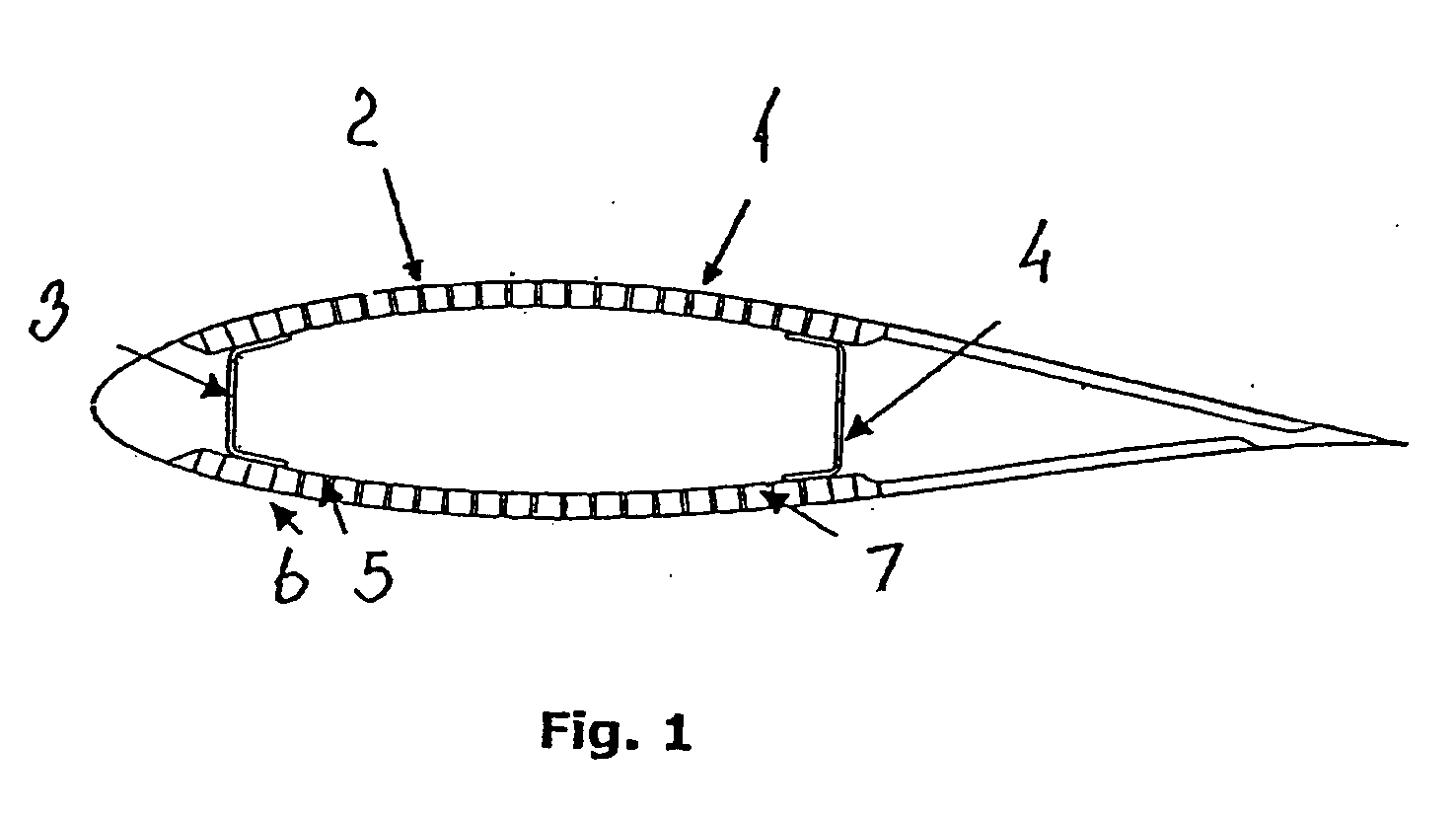

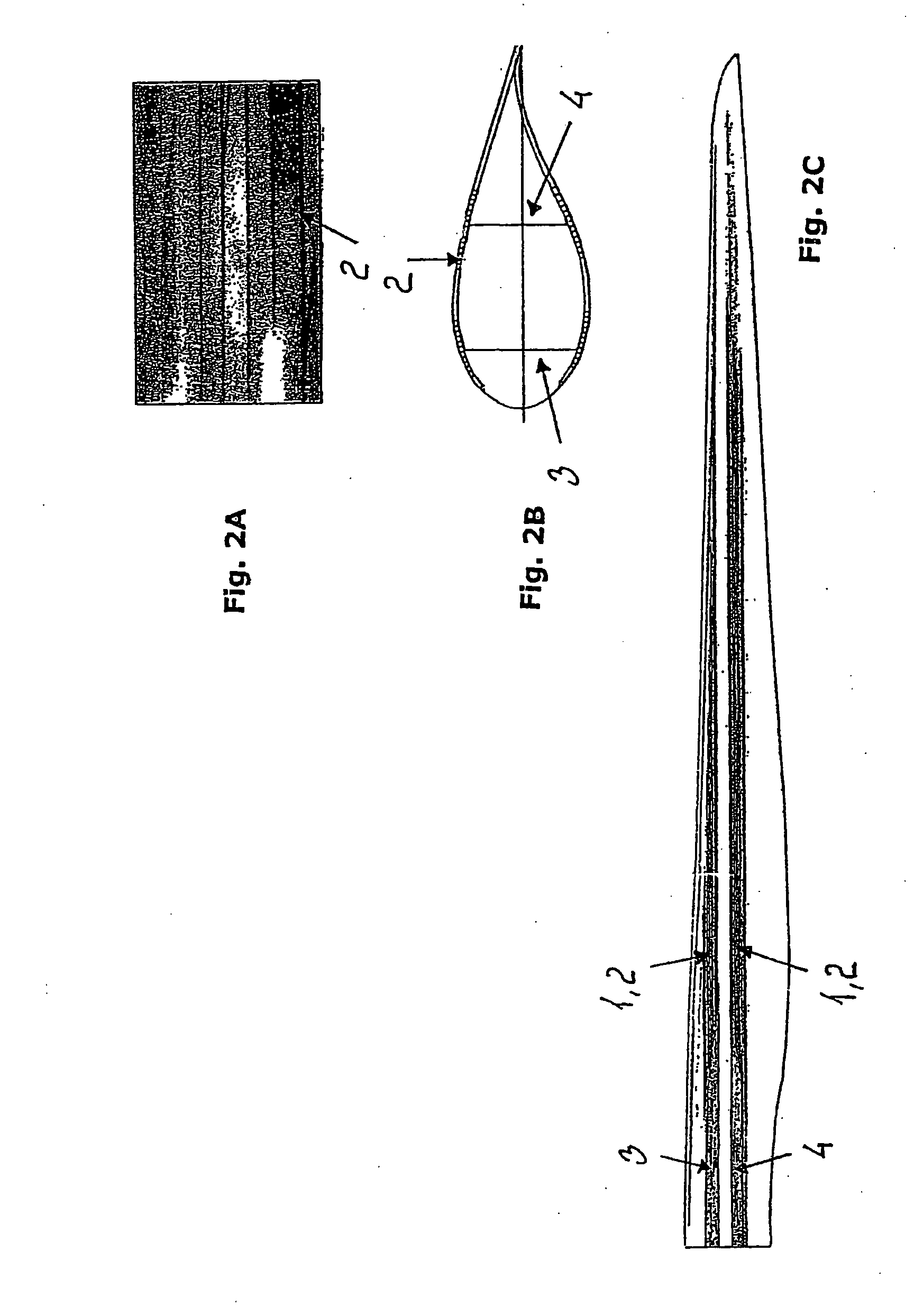

Wind turbine blade

InactiveUS7198471B2Save materialSave weightFinal product manufactureBlade accessoriesCarbon fibersTurbine blade

The invention relates to a wind turbine blade comprising a number of pre-fabricated strips arranged in a sequence along the outer periphery. The strips consist of a fibrous composite material, preferably carbon fibres, and consist of a wooden material, preferably plywood or wooden fibres held in a cured resin. The advantage is that it is possible to manufacture blades for wind turbines which are very stiff and generally have a high strength, but which nevertheless are easy to manufacture and also is much cheaper to manufacture compared to conventional manufacturing techniques. The invention also relates to methods for manufacturing prefabricated strips and for manufacturing wind turbine blades.

Owner:VESTAS WIND SYST AS

Composite materials

InactiveUS20060269738A1Remarkable strength and other propertyImprove material performanceLayered productsWoven fabricsFiberHigh density

New composite materials having a high density of small particles, such as hollow microspheres, in a matrix material are disclosed. The microspheres are densely packed in the matrix material such that adjacent microspheres are positioned in contact with each other or very close together. Fiber flanking may be provided on the opposite sides of a layer of a core of composite material having the small particles and matrix material. Also disclosed are methods of making and using the composite materials.

Owner:JAMES HARDIE TECH LTD

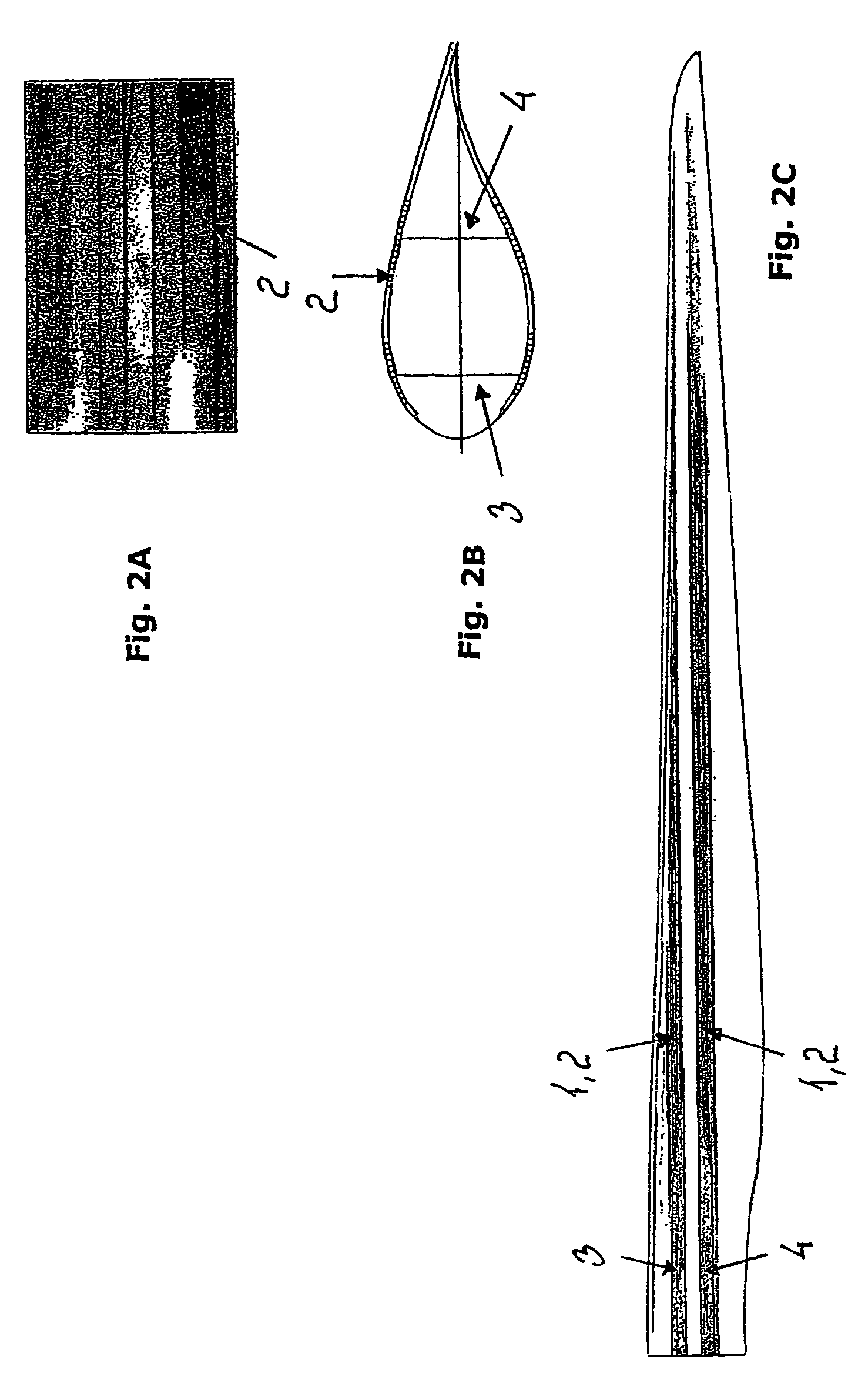

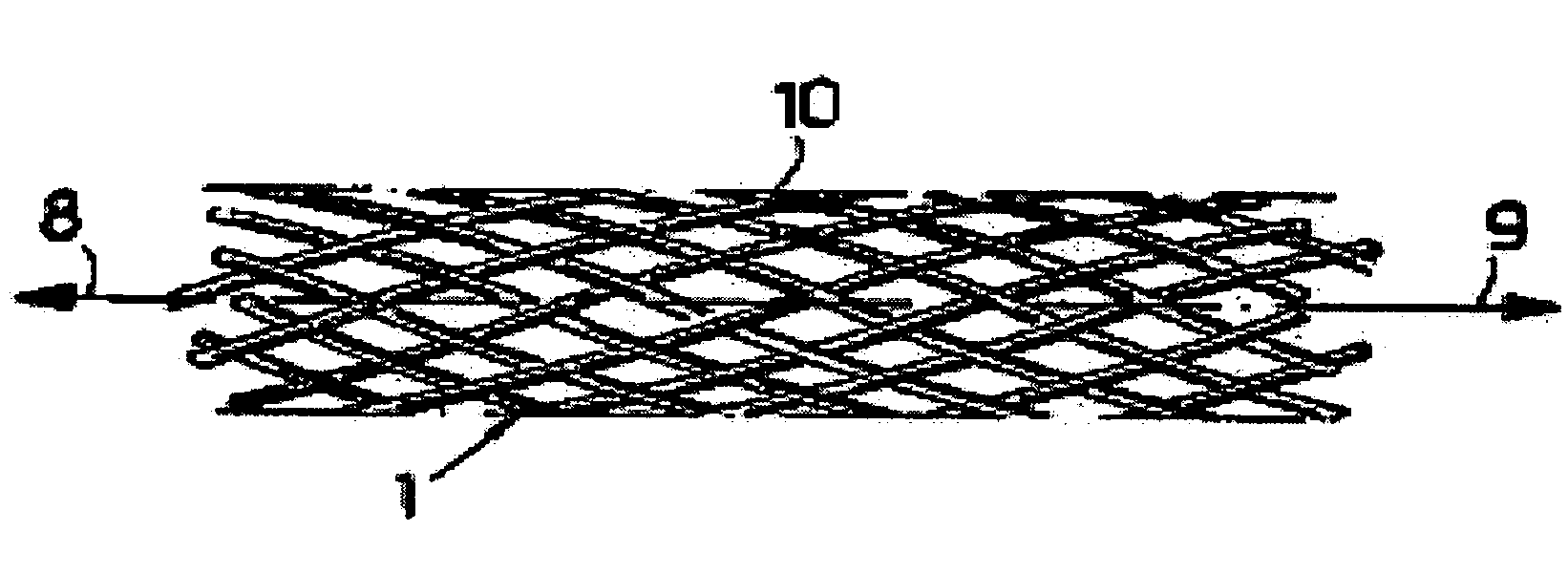

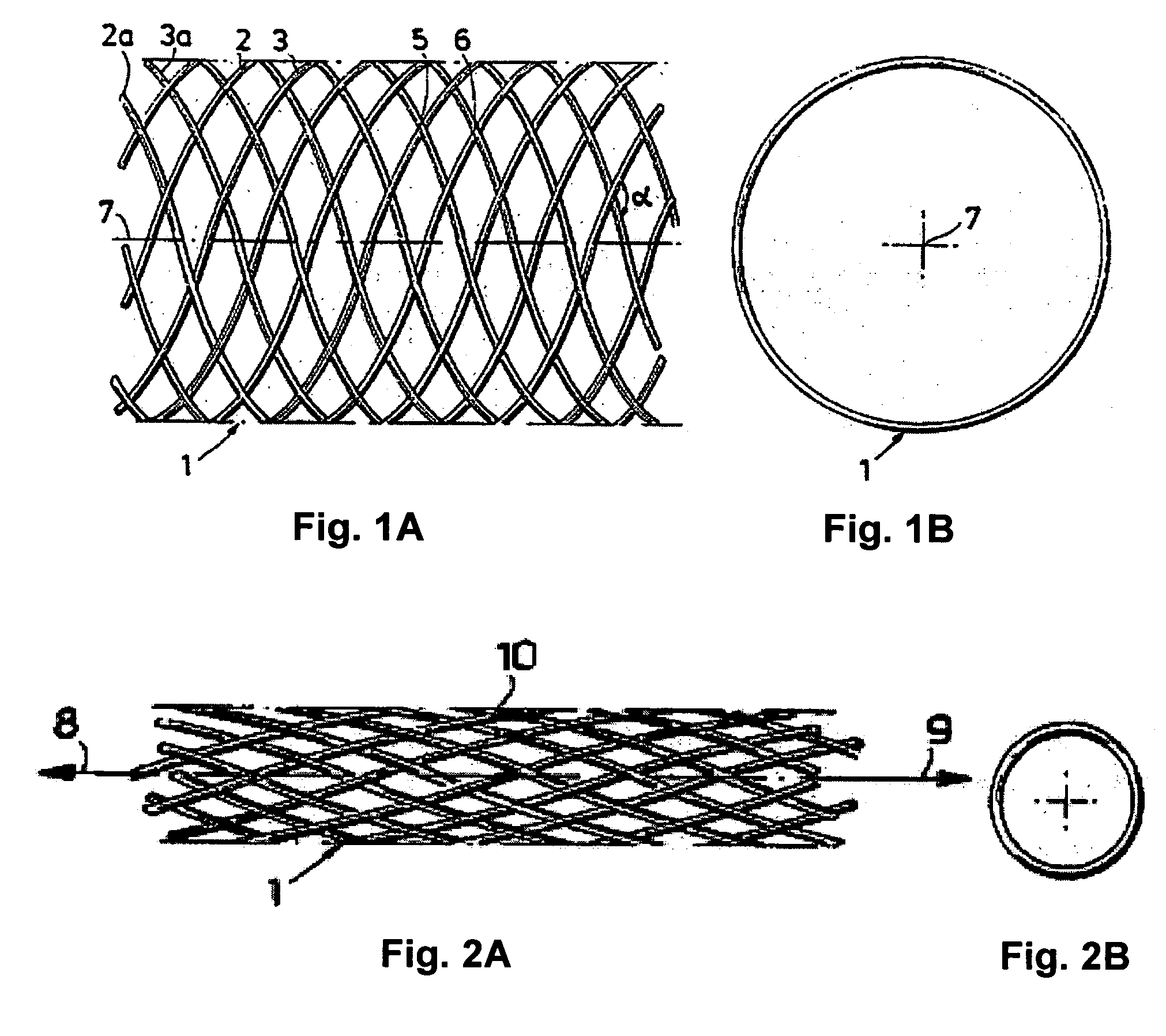

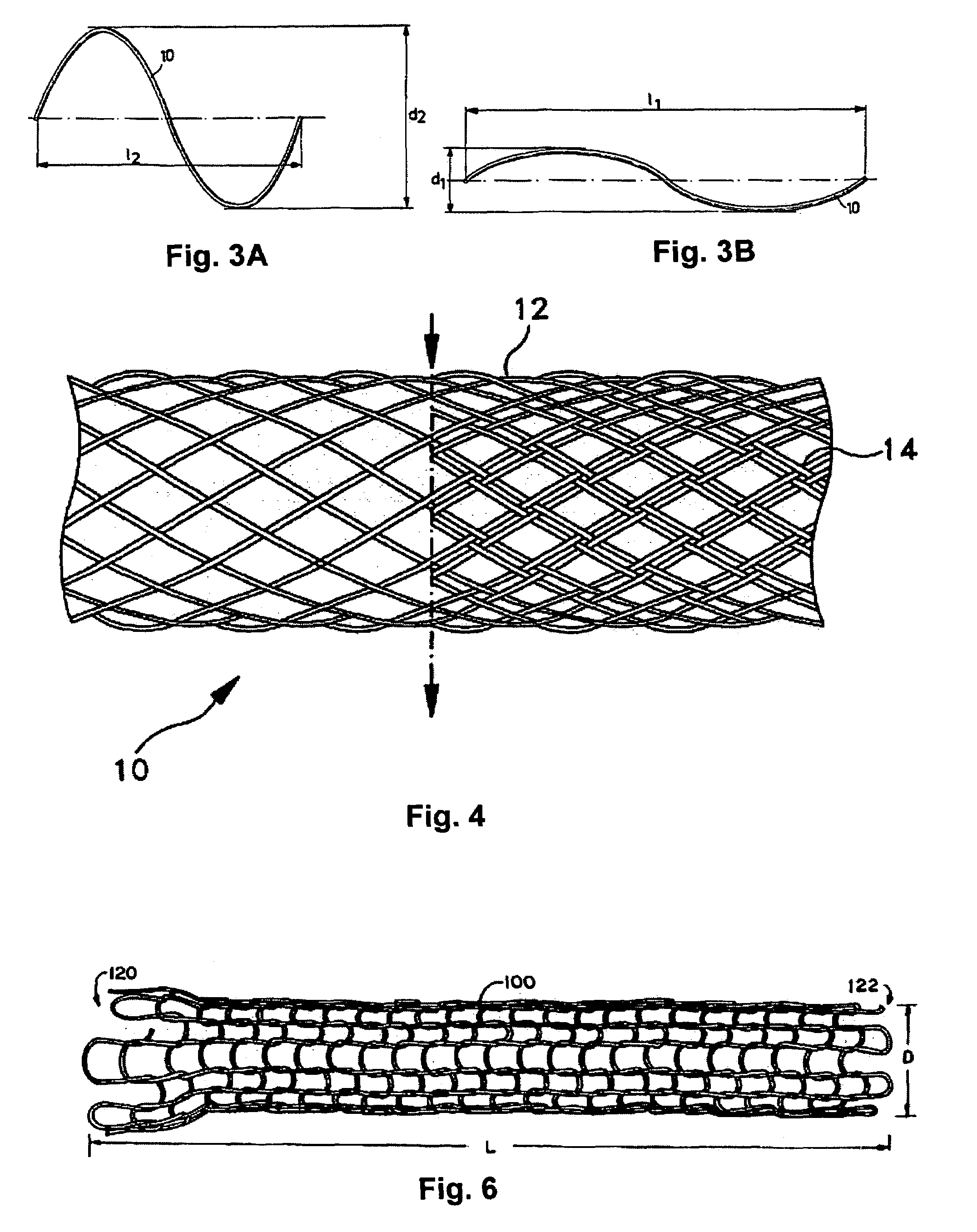

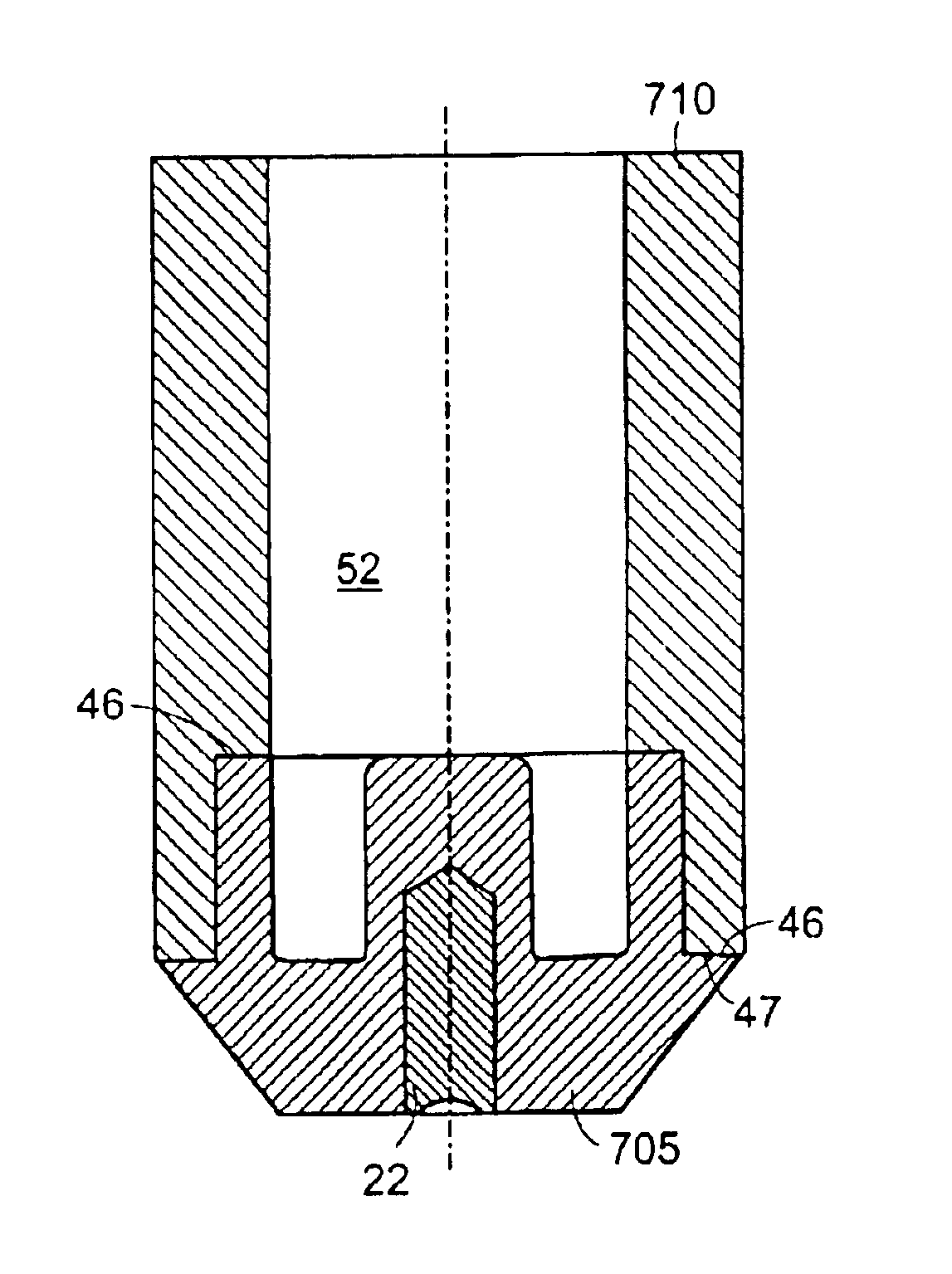

Bioabsorbable stents with reinforced filaments

ActiveUS7594928B2Improve material performanceIncrease radial forceStentsSurgeryBioabsorbable stentPolymer

According to an aspect of the present invention, a stent is provided, which contains at least one filament that has a longitudinal axis and comprises a bioabsorbable polymeric material. Polymer molecules within the bioabsorbable polymeric material are provided with a helical orientation which is aligned with respect to the longitudinal axis of the filament. The stent is at least partially bioabsorbed by a patient upon implantation or insertion of the stent into the patient.

Owner:BOSTON SCI SCIMED INC

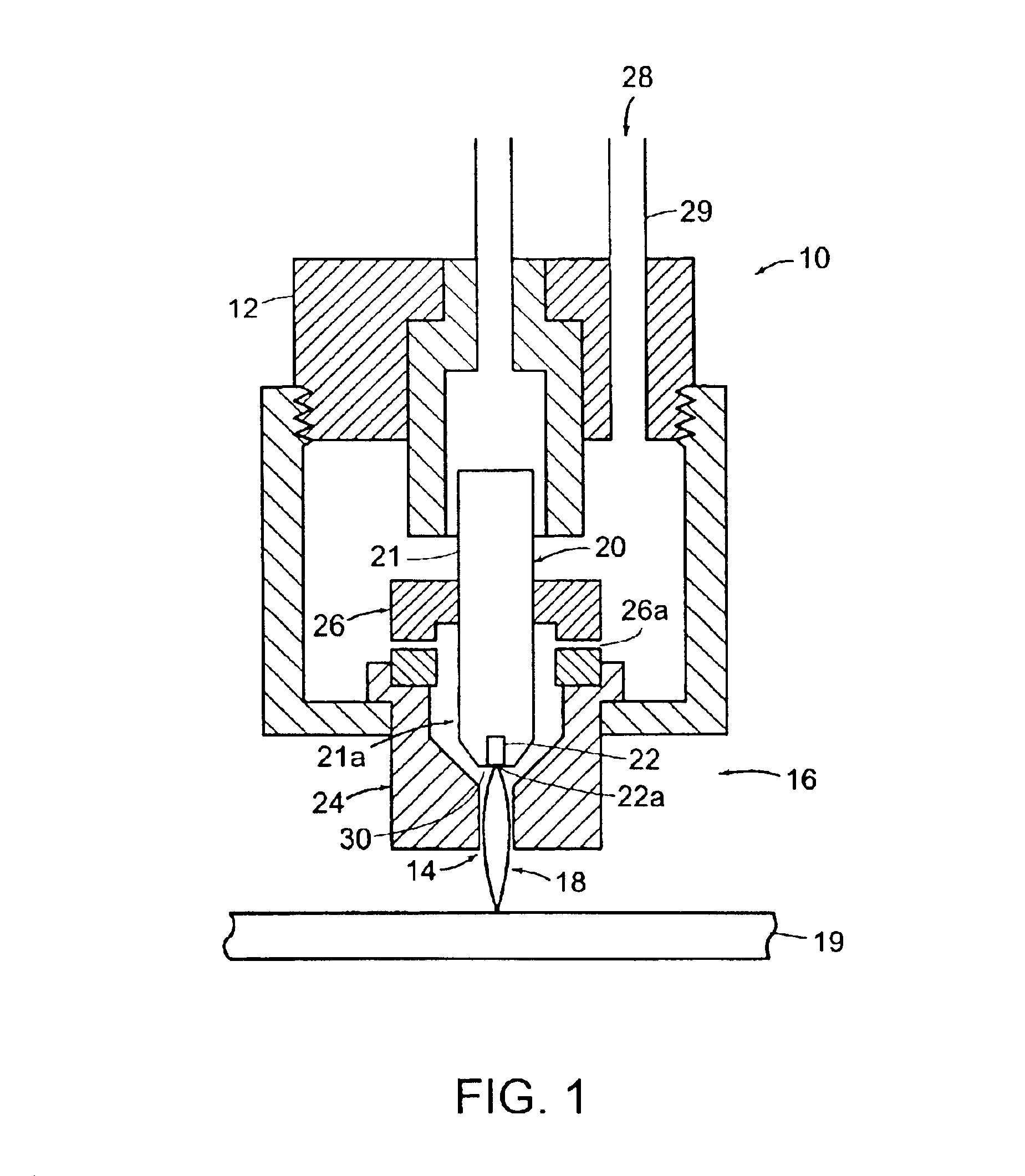

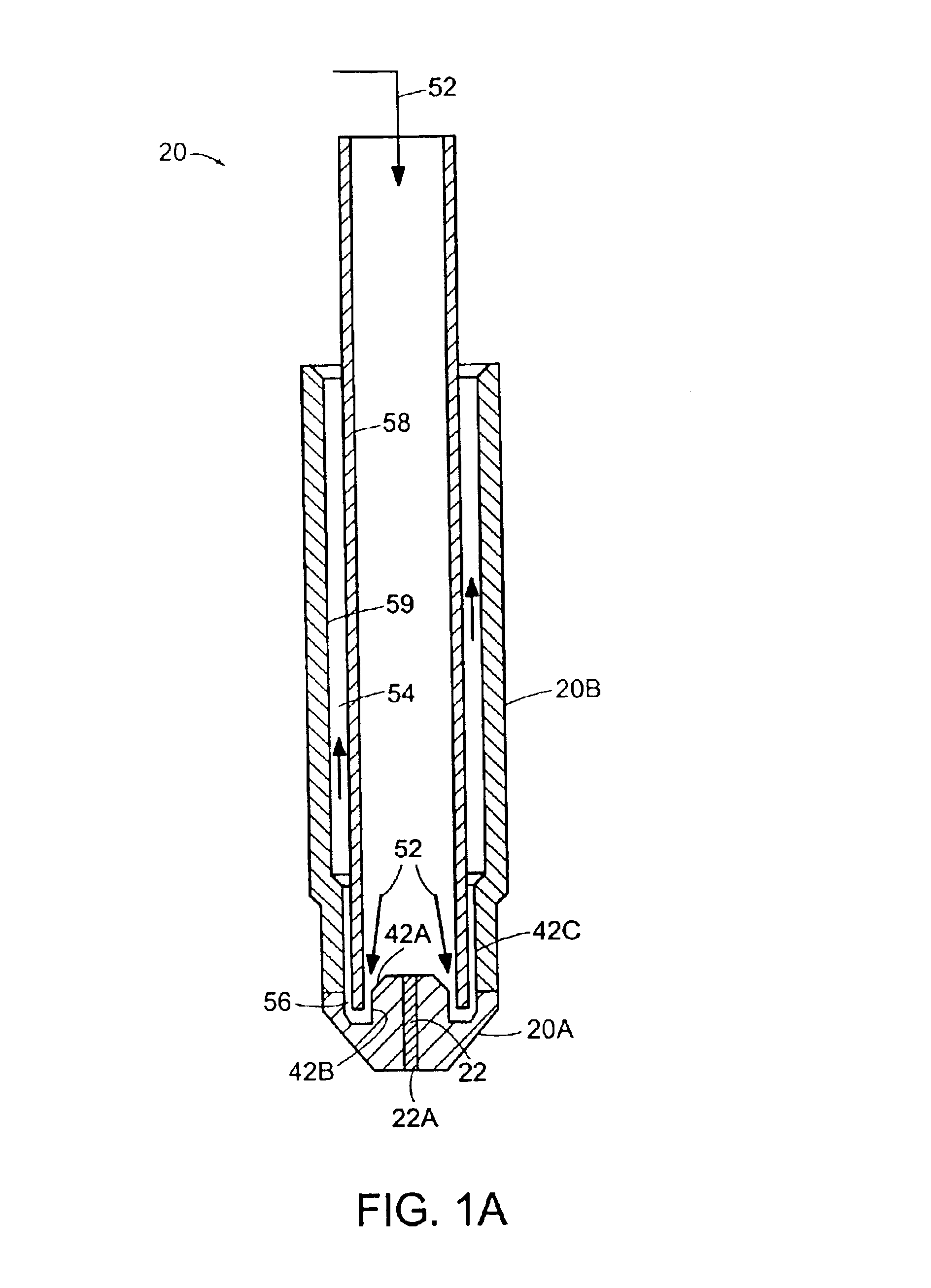

Composite electrode for a plasma arc torch

InactiveUS6841754B2Improve heat transfer performanceImprove thermal conductivityElectric discharge heatingArc welding apparatusMetallic materialsCopper electrode

A plasma arc torch that includes a torch body having a nozzle mounted relative to a composite electrode in the body to define a plasma chamber. The torch body includes a plasma flow path for directing a plasma gas to the plasma chamber in which a plasma arc is formed. The nozzle includes a hollow, body portion and a substantially solid, head portion defining an exit orifice. The composite electrode can be made of a metallic material (e.g., silver) with high thermal conductivity in the forward portion electrode body adjacent the emitting surface, and the aft portion of the electrode body is made of a second low cost, metallic material with good thermal and electrical conductivity. This composite electrode configuration produces an electrode with reduced electrode wear or pitting comparable to a silver electrode, for a price comparable to that of a copper electrode.

Owner:HYPERTHERM INC

Method for producing zirconia-reinforced alumina grains, in particular abrasive grains, and grains produced by such method

ActiveUS20130283705A1Cost effective productionImprove material performanceMaterial nanotechnologyPigmenting treatmentThin layerMaterials science

Method for producing zirconia-reinforced Al2O3 grains, including at least the following steps: inductively melting a starting mixture to form a eutectic melt made of alumina and zirconia; applying the eutectic melt as a thin layer material, the thin layer material being quenched; and removing the thin layer material. In this manner abrasive grains can be formed directly or the thin layer material can be classified when it is broken into abrasive grains, the grains are polycrystalline without amorphous glass phases as an alumina matrix having zirconia precipitations, and at least some of the zirconia precipitations can be formed in the nanoscale range.

Owner:VSM VEREINIGTE SCHMIRGEL- UND MASCHINEN-FABRIKEN

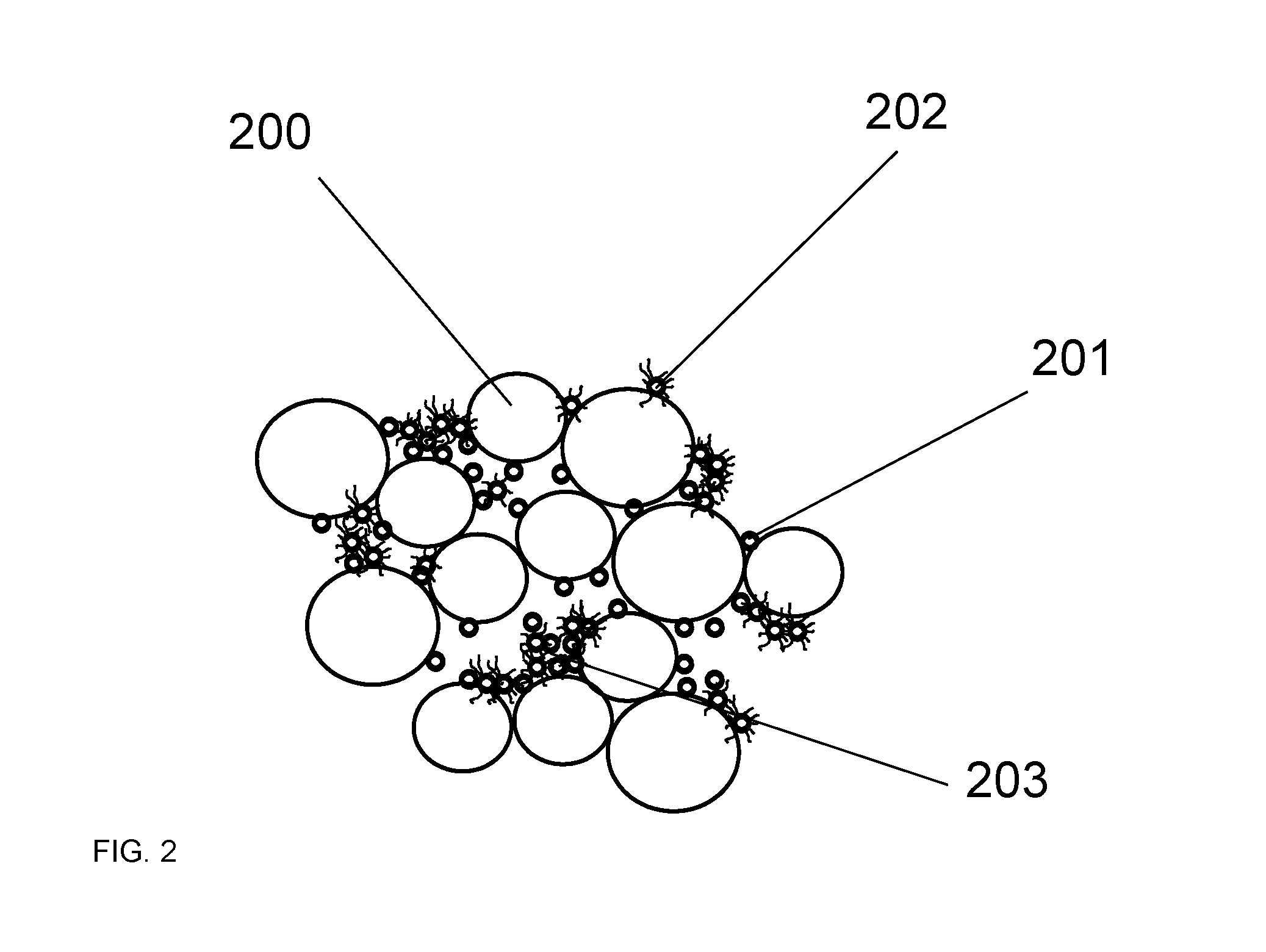

Nanostructured composite reinforced material

ActiveUS20120177905A1Maximum performanceImprove material performanceMaterial nanotechnologyAnimal housingDecrease weightAlloy

A family of materials wherein nanostructures and / or nanotubes are incorporated into a multi-component material arrangement, such as a metallic or ceramic alloy or composite / aggregate, producing a new material or metallic / ceramic alloy. The new material has significantly increased strength, up to several thousands of times normal and perhaps substantially more, as well as significantly decreased weight. The new materials may be manufactured into a component where the nanostructure or nanostructure reinforcement is incorporated into the bulk and / or matrix material, or as a coating where the nanostructure or nanostructure reinforcement is incorporated into the coating or surface of a “normal” substrate material. The nanostructures are incorporated into the material structure either randomly or aligned, within grains, or along or across grain boundaries.

Owner:UT BATTELLE LLC +1

3D infiltration method

ActiveUS20160303762A1High component strengthHigh strengthAdditive manufacturing apparatusCeramic shaping apparatusMaterial systemComposite material

The invention relates to a method for producing three-dimensional molded parts in two method steps and infiltrating the molded part, as well as a material system.

Owner:VOXELJET AG

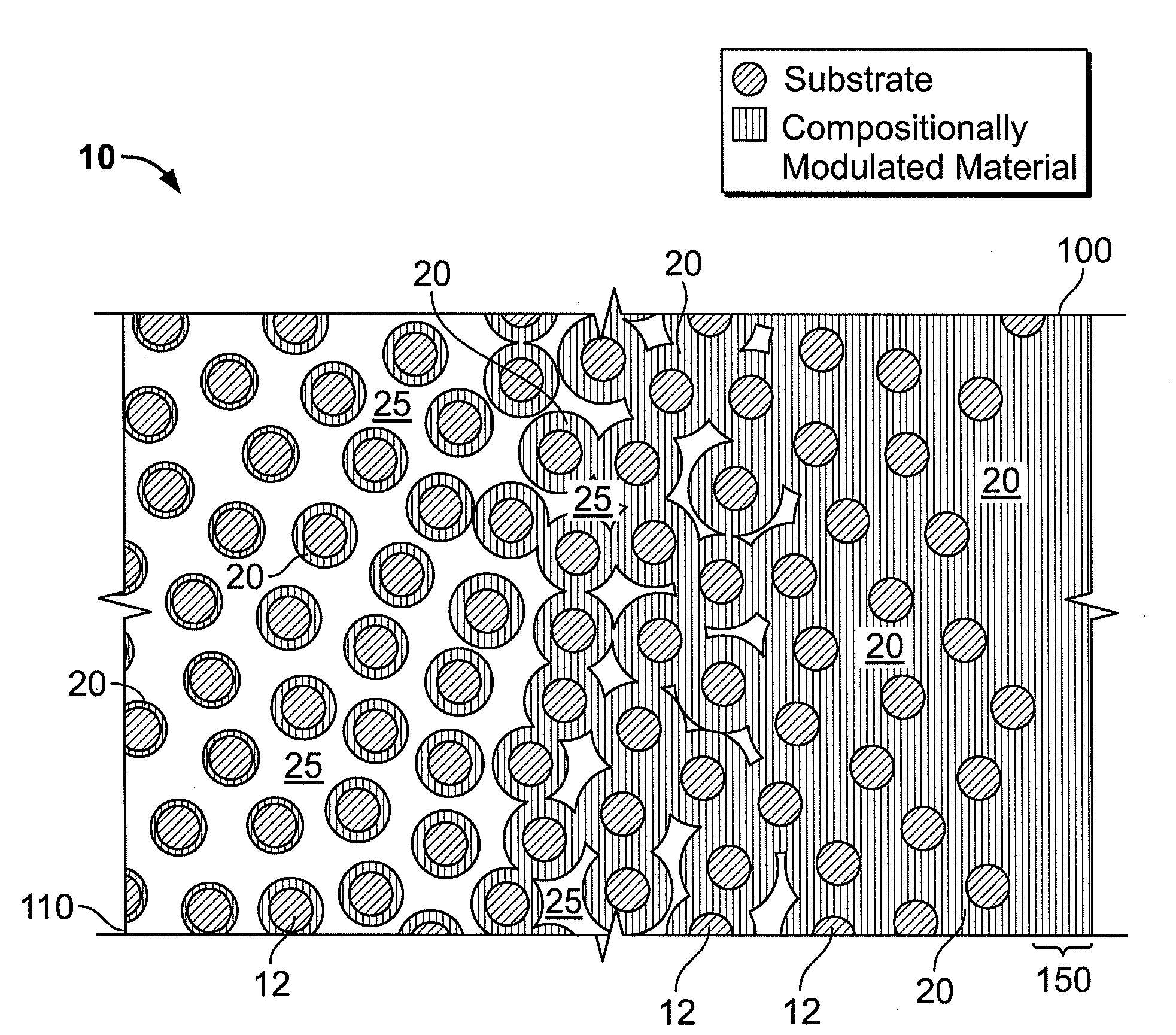

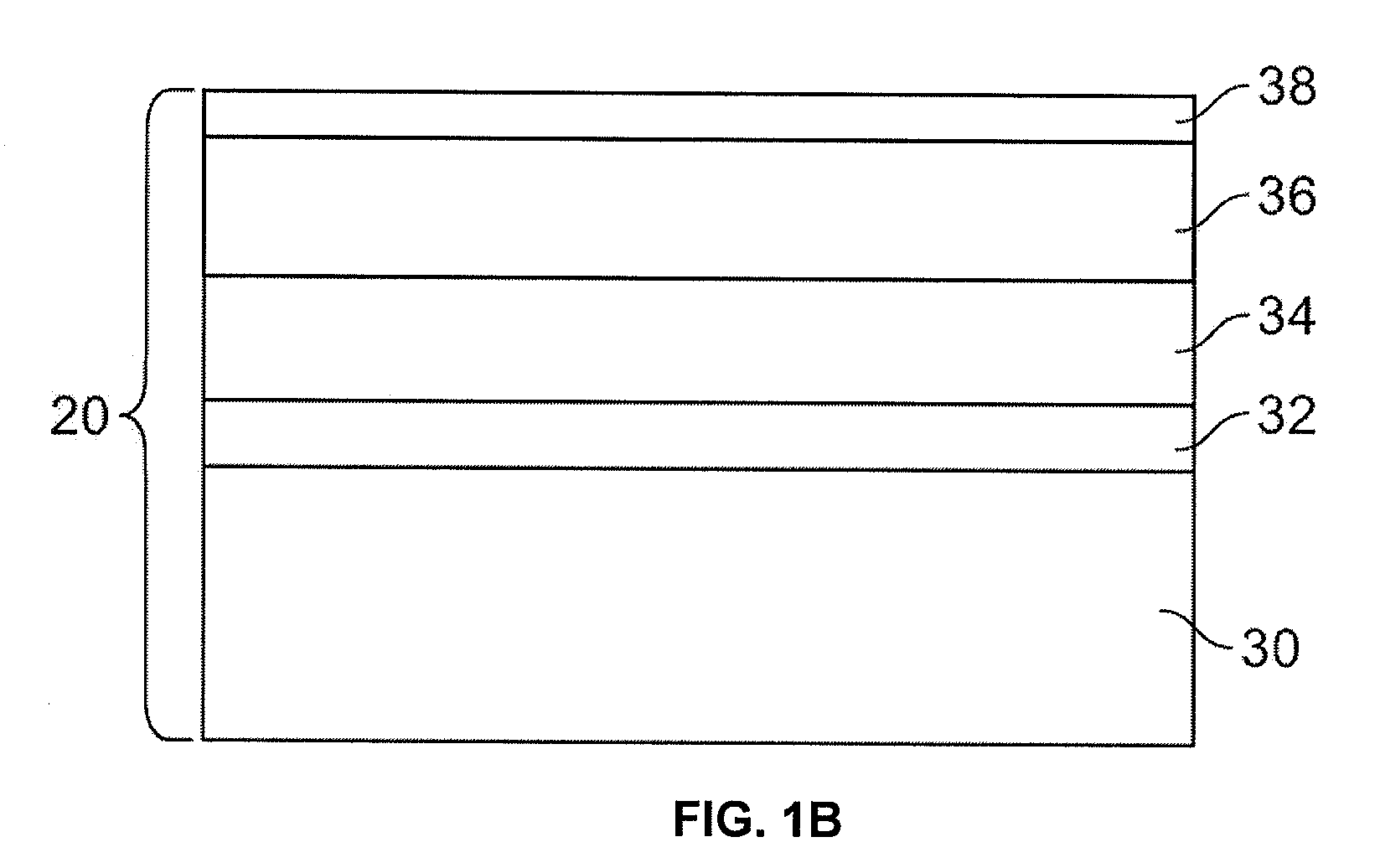

Compositionally modulated composite materials and methods for making the same

ActiveUS20090130425A1Easy to depositImprove material performanceArmourElectrolytic coatingsPorous substrateSports equipment

A light-weight composite material with enhanced structural characteristics includes, in one embodiment, a compositionally modulated nanolaminate coating electrically deposited into an open, accessible void structure of a porous substrate. As a result of including a nanolaminate within the void structure, the composite can include a greater amount of nanolaminate material per unit volume than can be achieved by depositing a nanolaminate material solely on a two-dimensional surface. In addition, the nanolaminate material as well as other material electrodeposited to form the composite is compositionally modulated so that discontinuities between layers are minimized and potentially eliminated. The light-weight but structurally enhanced composite material can be used in a number of different applications including, but not limited to, ballistic applications (e.g., armor panels or tank panels), automotive protection applications (e.g., car door panels, racing shells) and sporting equipment applications (e.g., golf club shafts and tennis racket frames).

Owner:MODUMETAL LLC

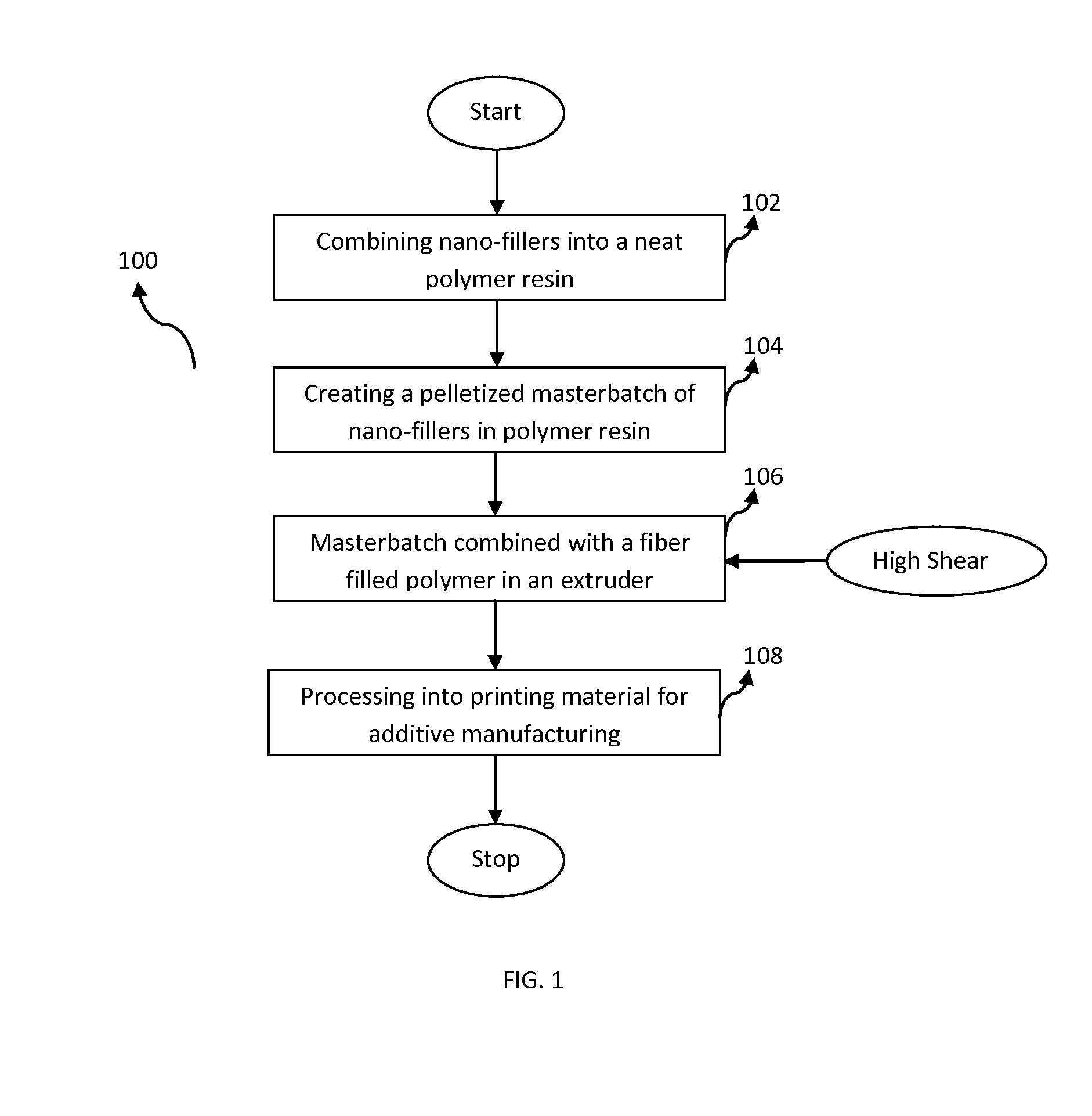

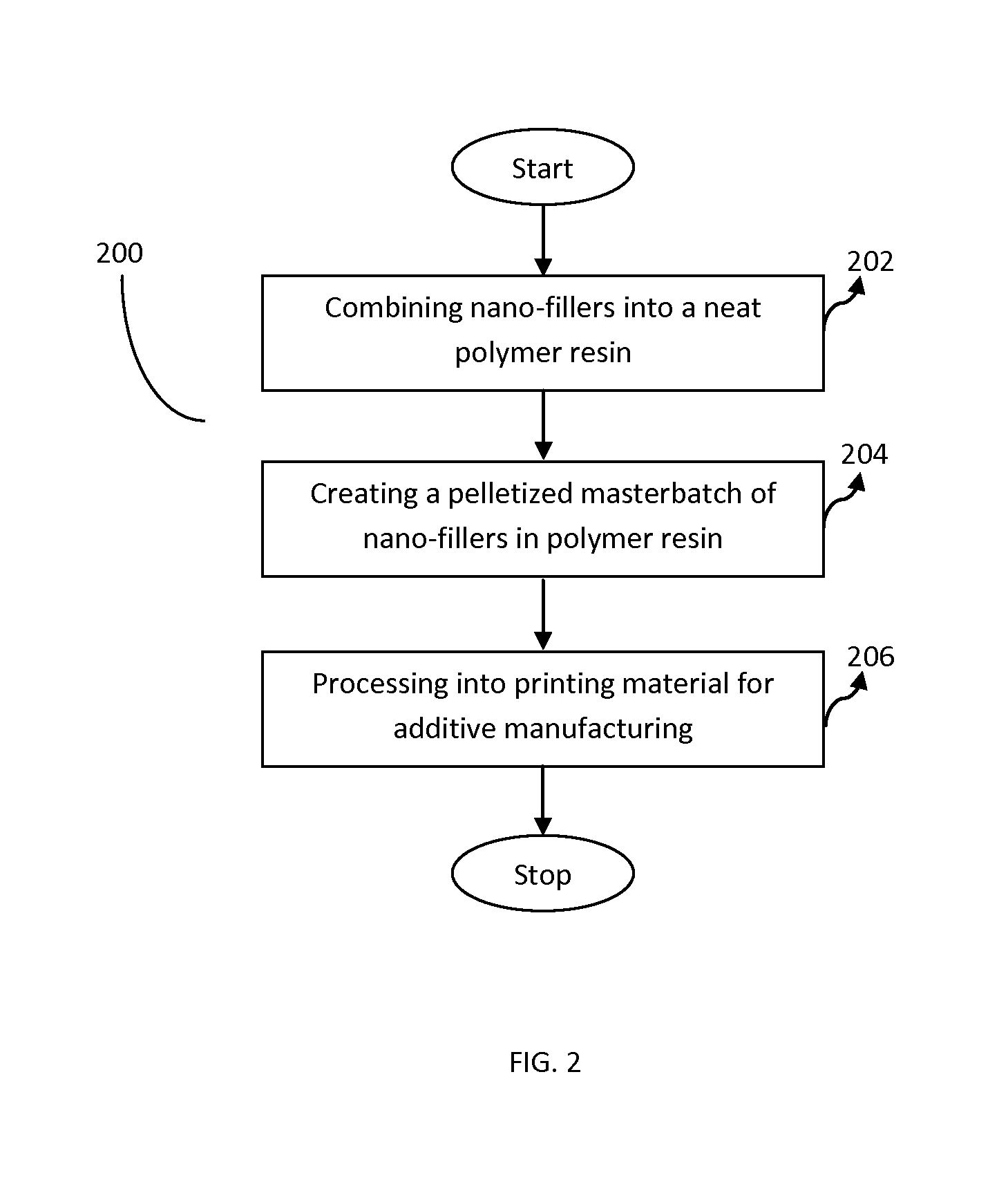

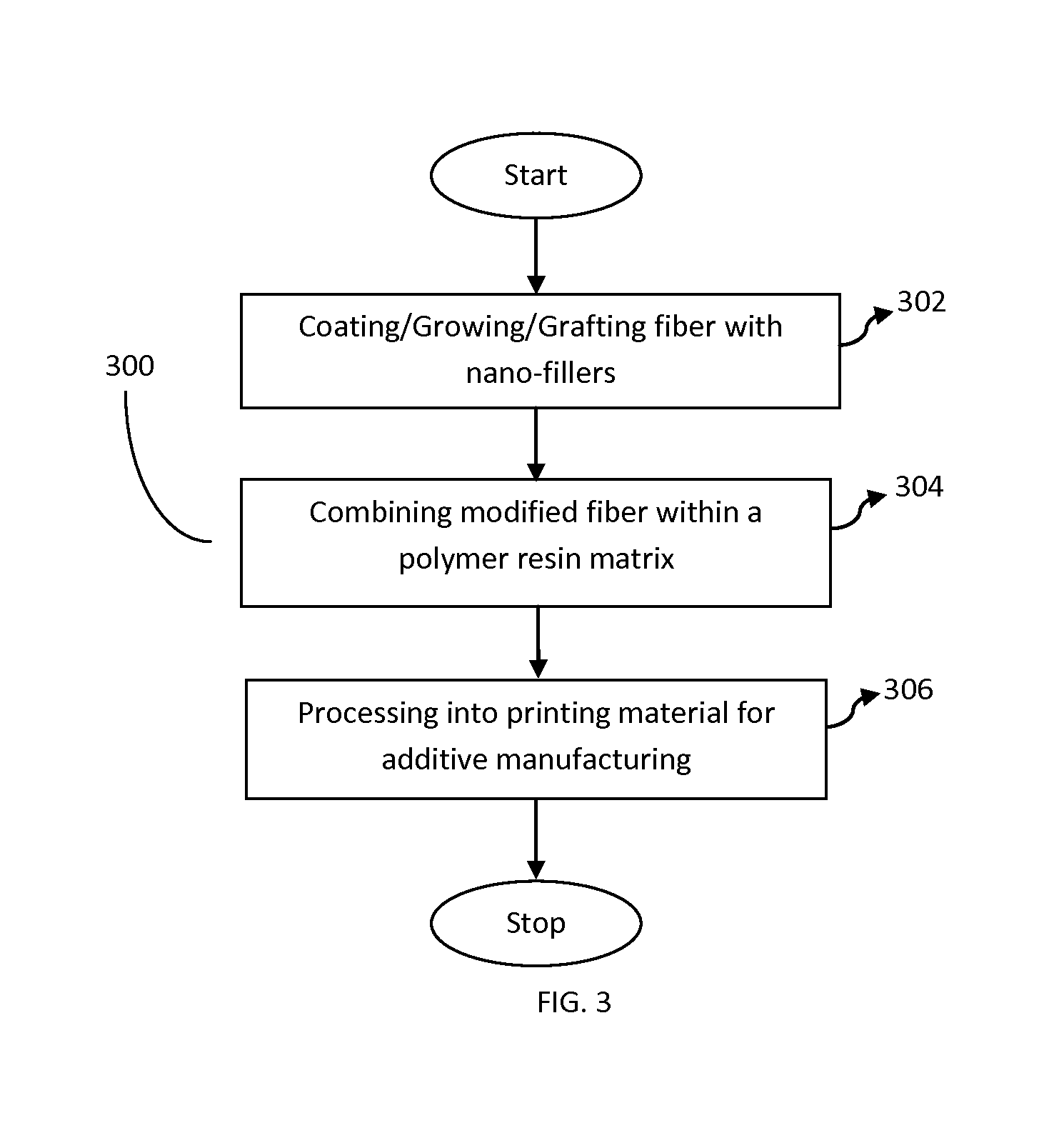

Method to manufacture polymer composite materials with nano-fillers for use in addtive manufacturing to improve material properties

ActiveUS20160297935A1Improved propertyImprove material propertiesAdditive manufacturing apparatusCarbon nanotubeAdvanced manufacturing

Methods for producing 3D printing composite polymer materials for use in additive manufacturing processes are provided. The methods result in enhancing the material properties of the printing material by providing a uniform and smooth surface finish of the printing material and the nozzle extrudate for additive manufacturing processes, such as Fused Filament Fabrication. The method includes implementing impregnation techniques for combining carbon nanotubes or other nano-fillers, a polymer resin and a fiber material to produce a polymer material that can be processed into a printing material. Further, the method may include combining the carbon nanotubes or other nano-fillers and the polymer resin to form a masterbatch that may be further combined with the fiber material through an extrusion process. The method results in a printing material with enhanced material properties and smooth surface finish for the printing material and resulting nozzle extrudate for Fused Filament Fabrication.

Owner:AREVO INC

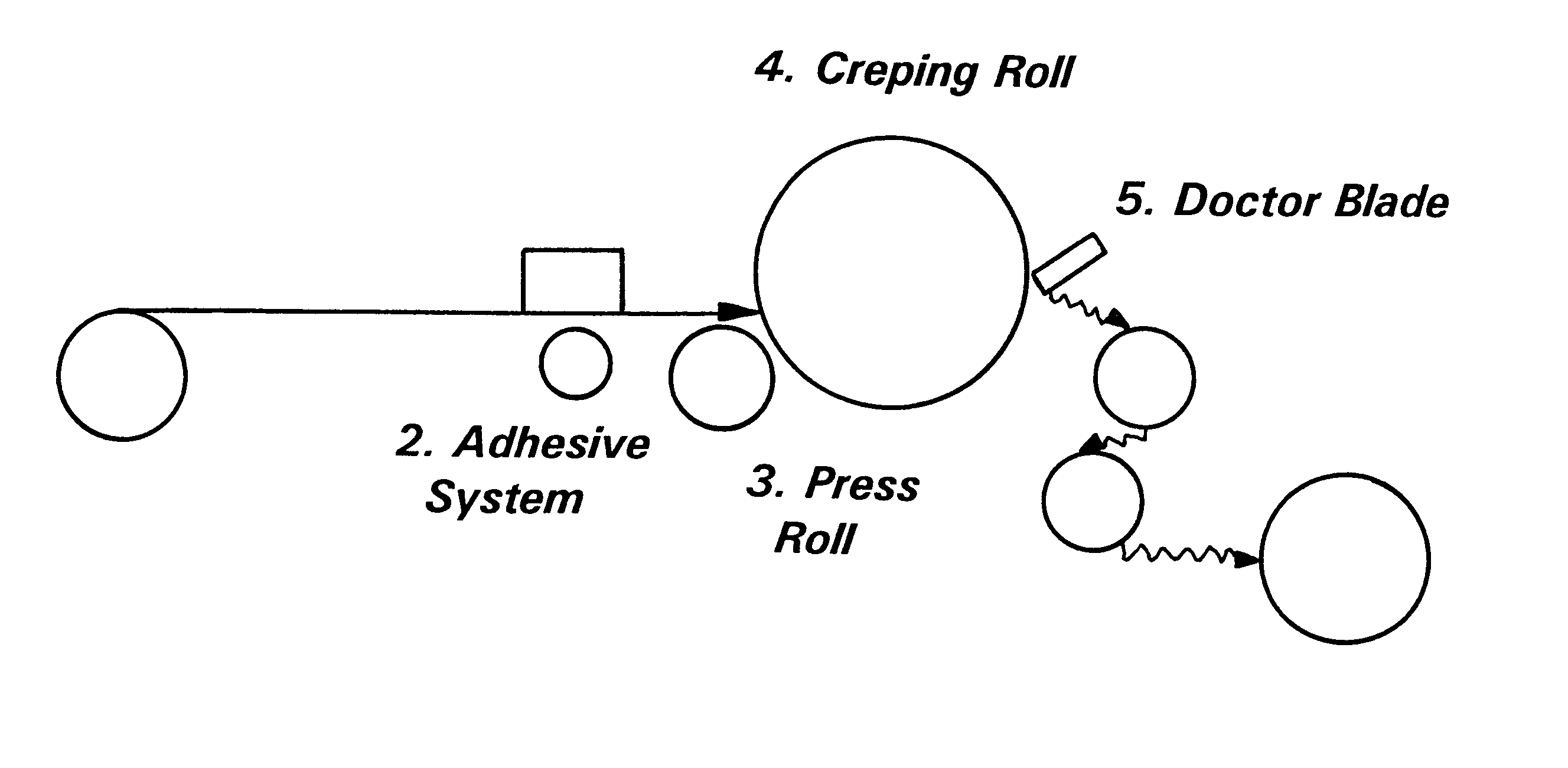

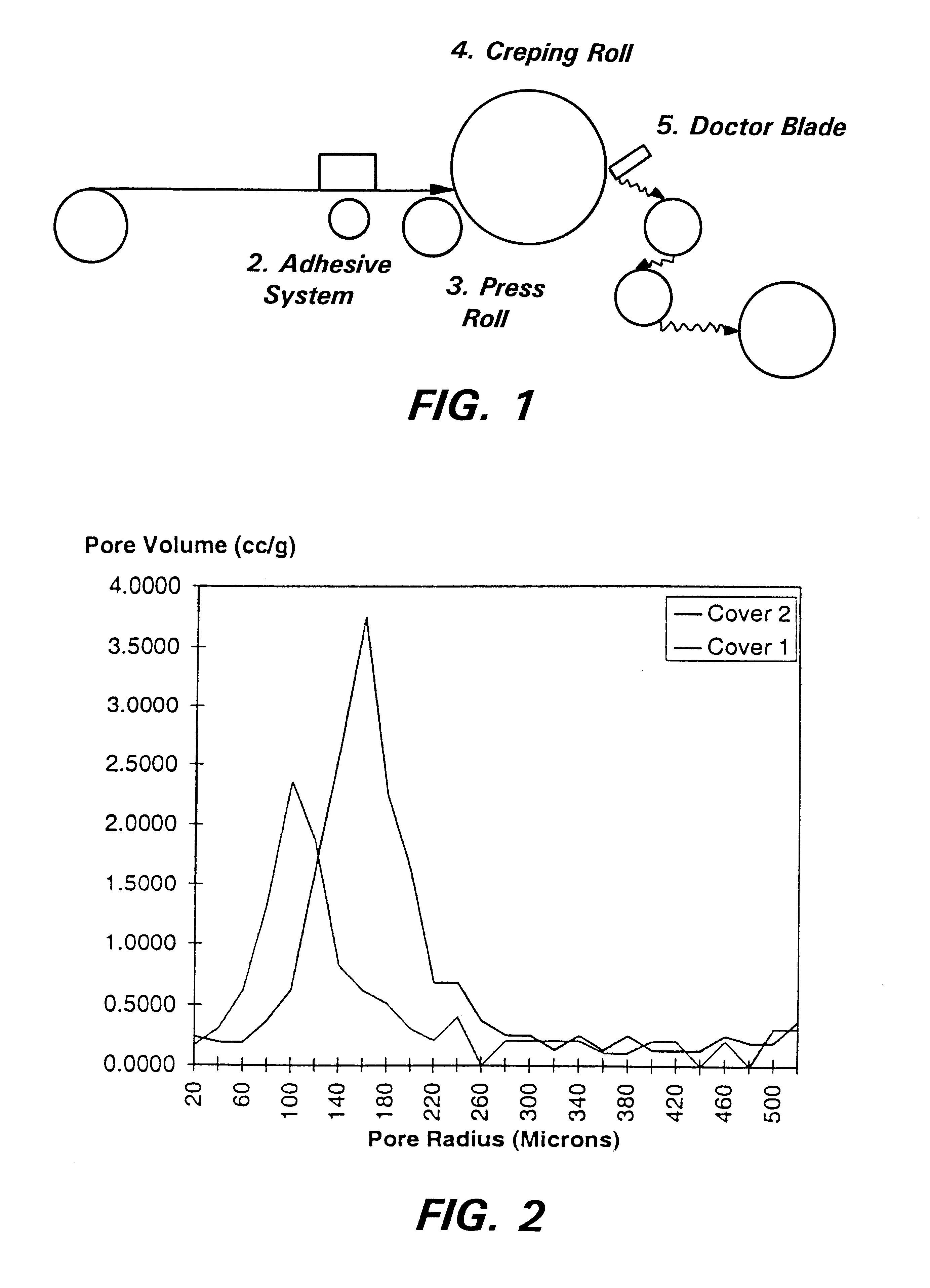

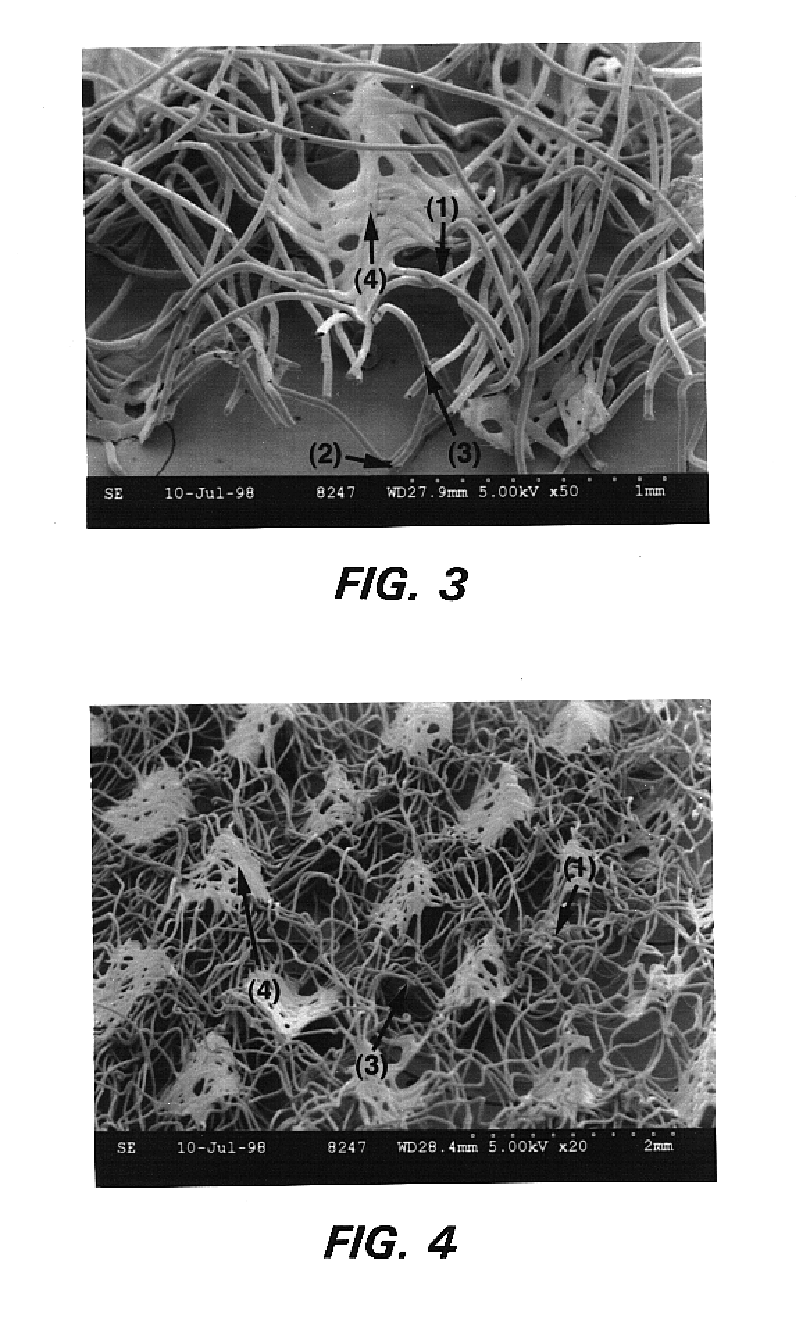

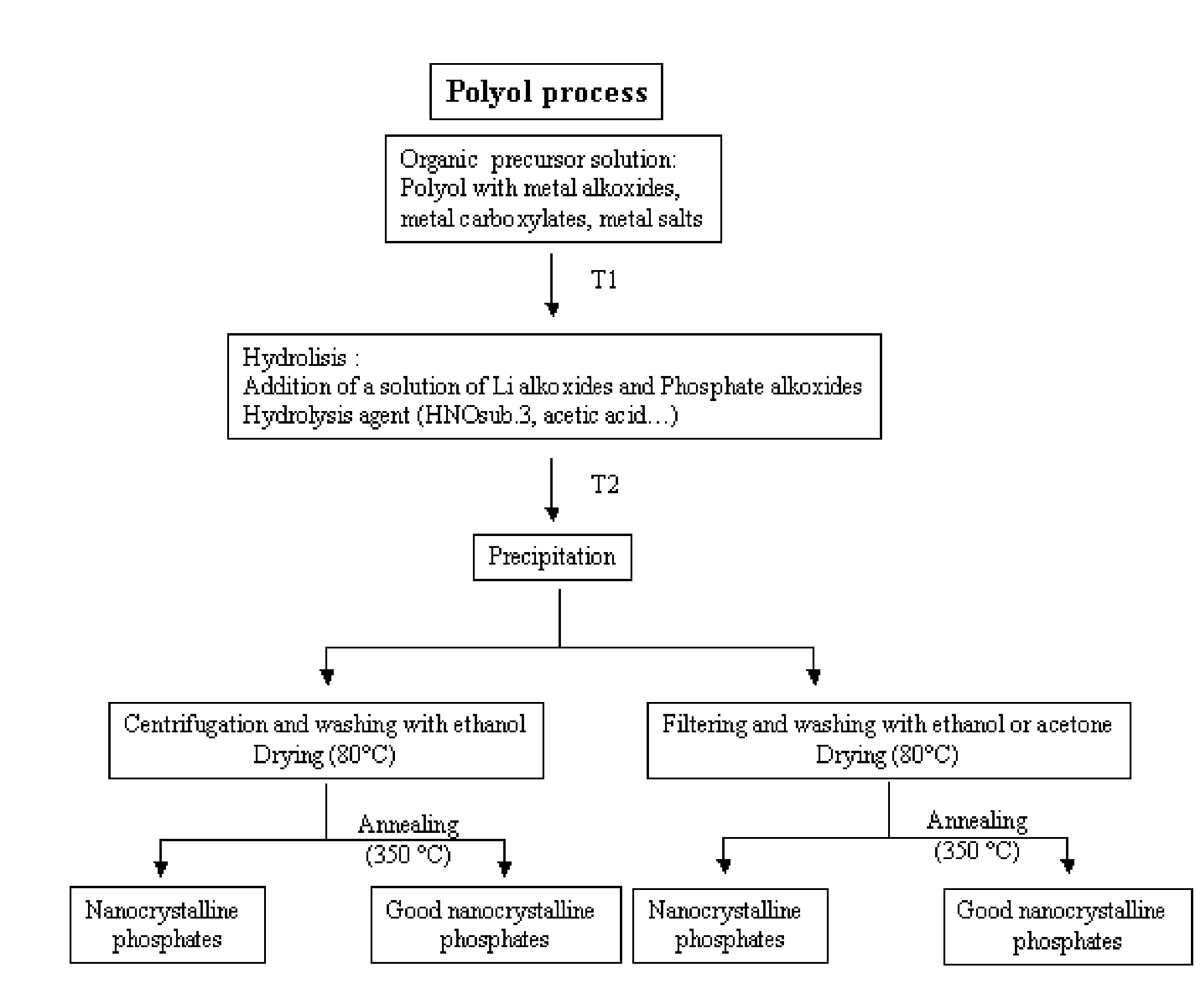

Creped materials

InactiveUS6838154B1Improve material performanceFluid handlingBaby linensWoven fabricsFiberEngineering

There is provided a resilient, three dimensional material having fibrous texture and appearance and capable of fluid handling. It consists of a top surface and a bottom surface wherein fiber-like elements typically extend from one surface to the other forming flat to undulating surfaces characterized by a multiplicity of interconnected fluid passageways. Deformed, discontinuous film-like or encapsulated regions connect fiber-like elements and stabilize the material. The material of this invention is unique based on the three principle characteristics which are communicated in this application: 1) ff(ψ)<0.87, 2) SA / VV<186 cm2 / cm3, and 3) caliper<0.150 inches. This material is useful for a number of purposes, such as for use as a liner for personal care products like diapers, absorbent underpants, swim wear, feminine hygiene products, adult incontinence products and the like. The properties of the material may be tailored within the ranges of this invention to deliver optimal material performance for use in specific personal care products.

Owner:KIMBERLY-CLARK WORLDWIDE INC

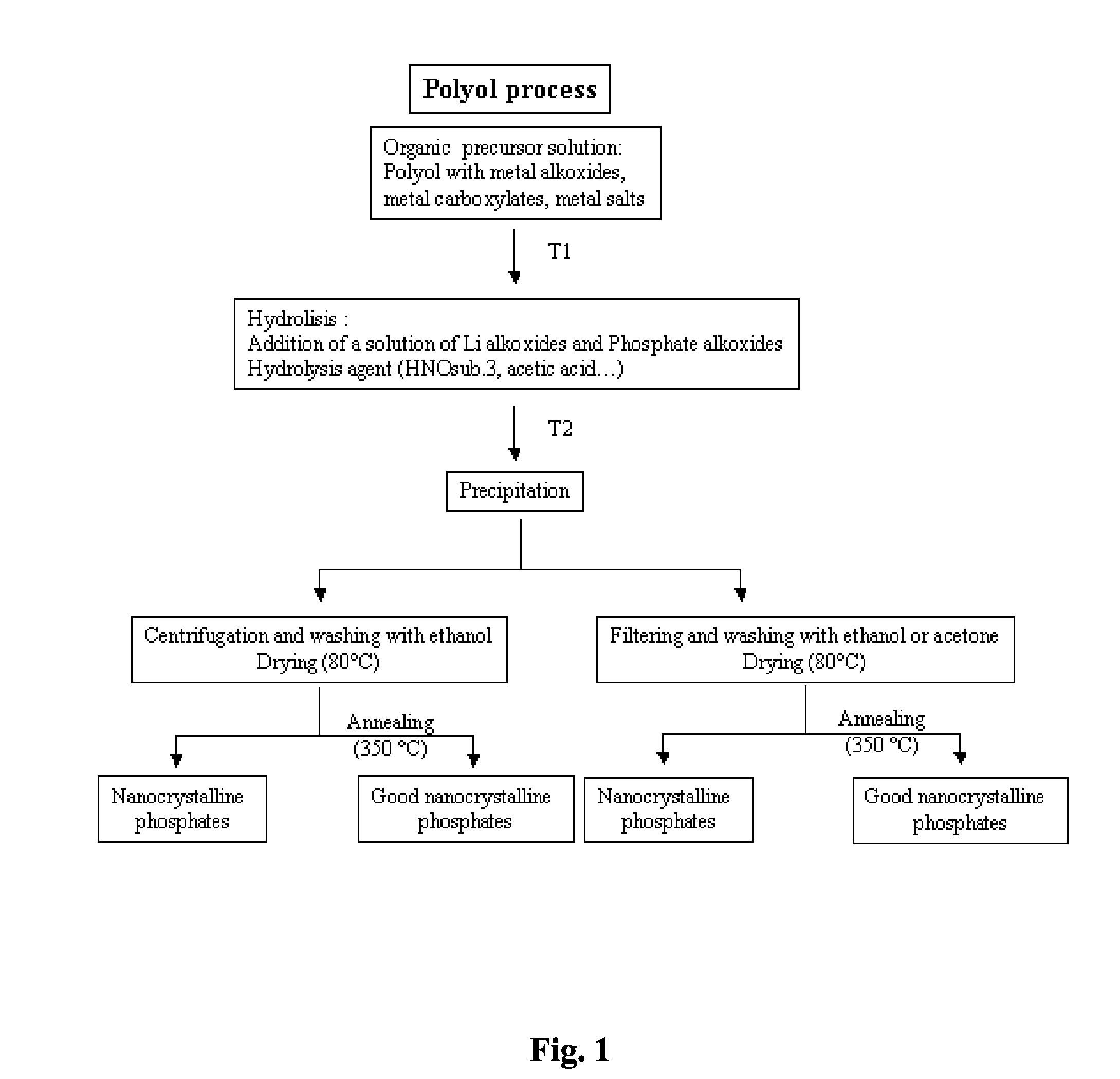

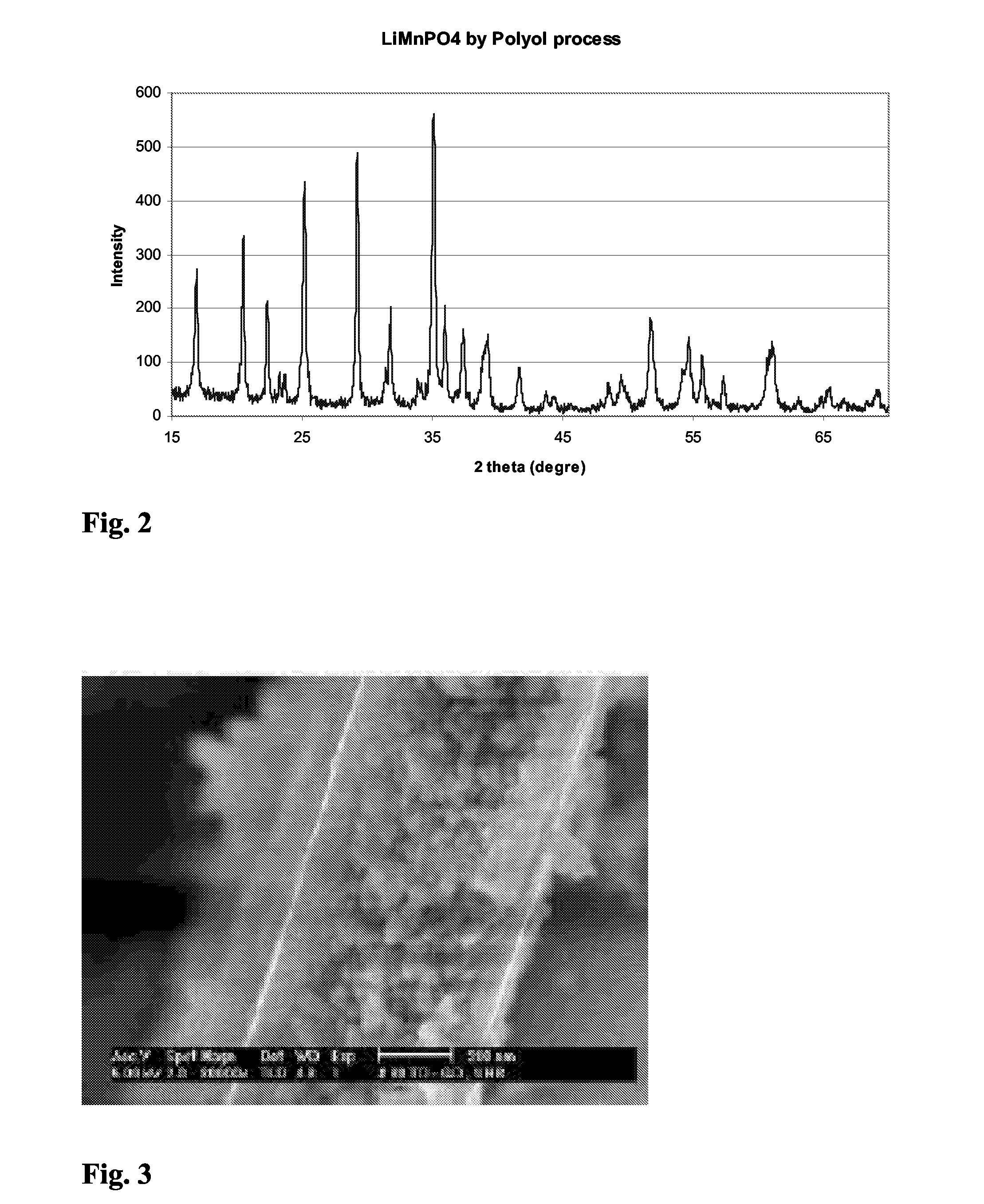

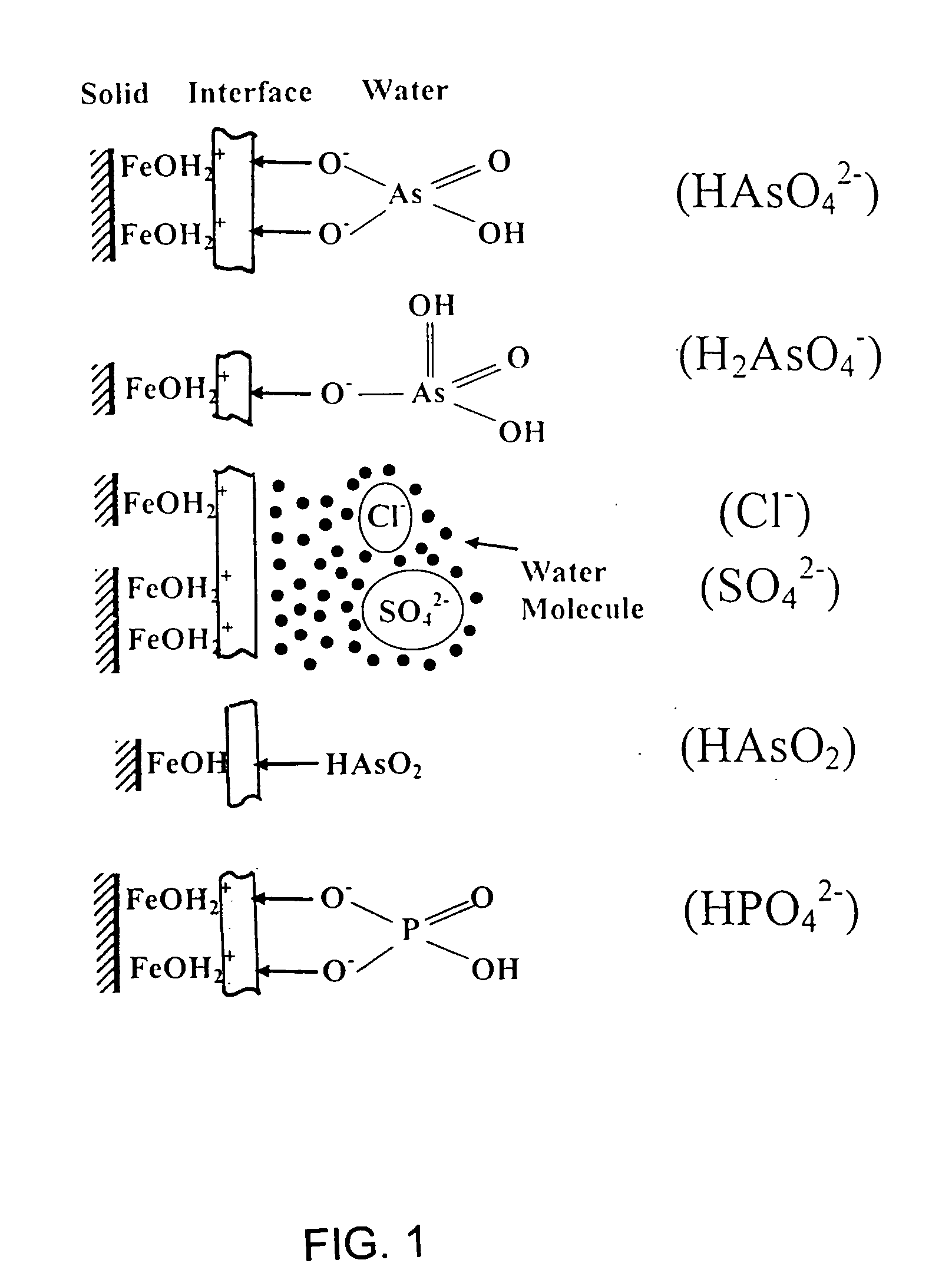

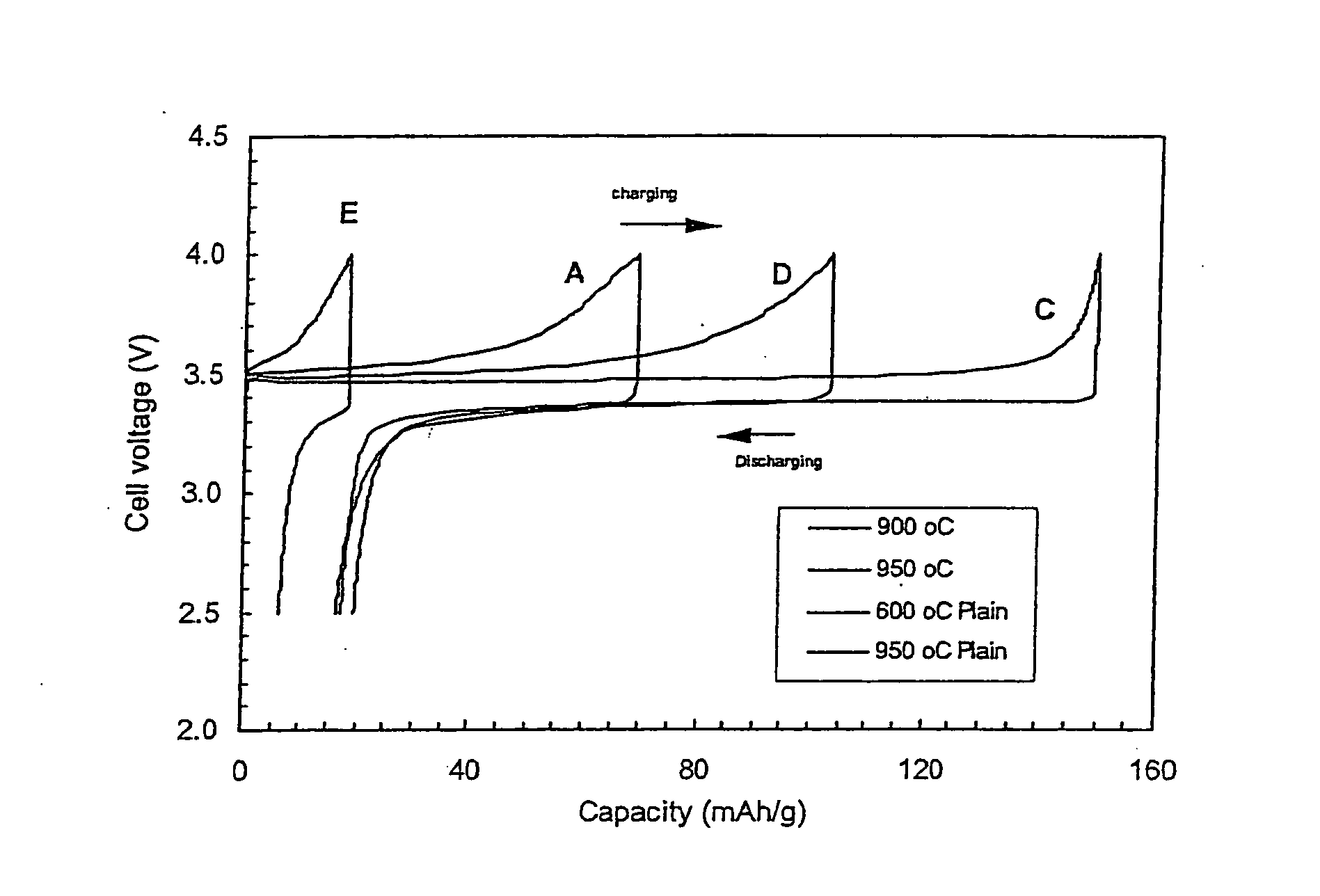

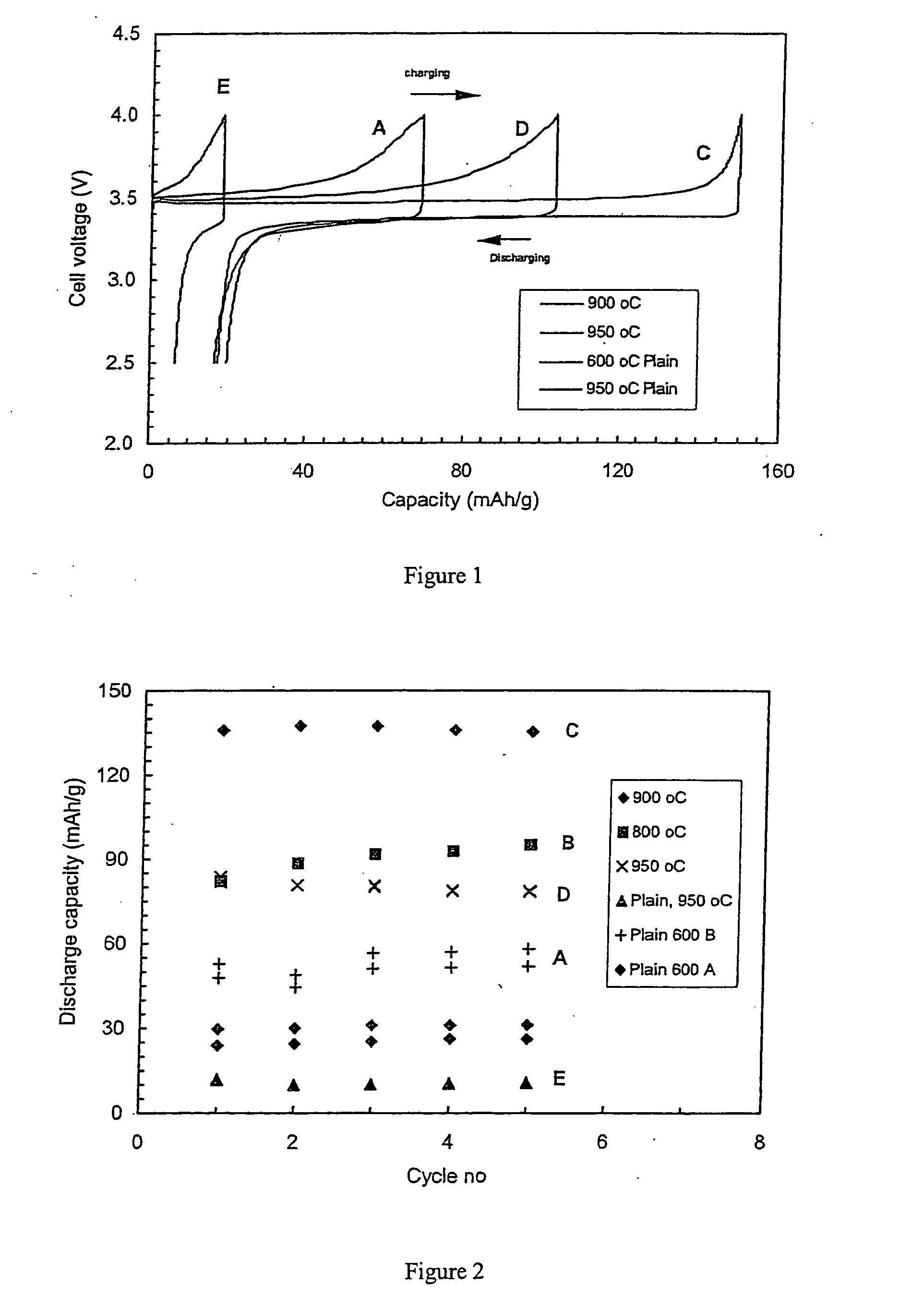

Synthesis of nanoparticles of lithium metal phosphate positive material for lithium secondary battery

InactiveUS20090186275A1Improve material performanceImprove electrochemical performanceNon-metal conductorsPhosphatesPhosphateLithium metal

Novel process for the preparation of finely divided, nano-structured, olivine lithium metal phosphates (LiMPO.sub.4) (where metal M is iron, cobalt, manganese, nickel, vanadium, copper, titanium and mix of them) materials have been developed. This so called Polyol” method consists of heating of suited precursor materials in a multivalent, high-boiling point multivalent alcohol like glycols with the general formula HO—(—C2H4O—).sub.n-H where n=1-10 or HO—(—C3H6O—).sub.n.-H where n=1-10, or other polyols with the general formula HOCH2—(—C3H5OH—).sub.n-H where n=1-10, like for example the tridecane-1,4,7,10,13-pentaol. A novel method for implementing the resulting materials as cathode materials for Li.-ion batteries is also developed.

Owner:DOW GLOBAL TECH LLC

Syndet bar soap having an acidifying agent

InactiveUS6559110B1Enhance and provide antimicrobial propertyInhibiting survival and growthCosmetic preparationsHair removalChemistrySOAP

A bar soap preparation having enhanced antibacterial and microbial properties which contains between 0.1 weight % and 95 weight % of at least one anionic surfactant; and at least one acidifying agent present in an amount sufficient to impart a pH of below 5.0. The bar soap provides microbial protection resulting from its rapid microbicidal action.

Owner:MICROCIDE

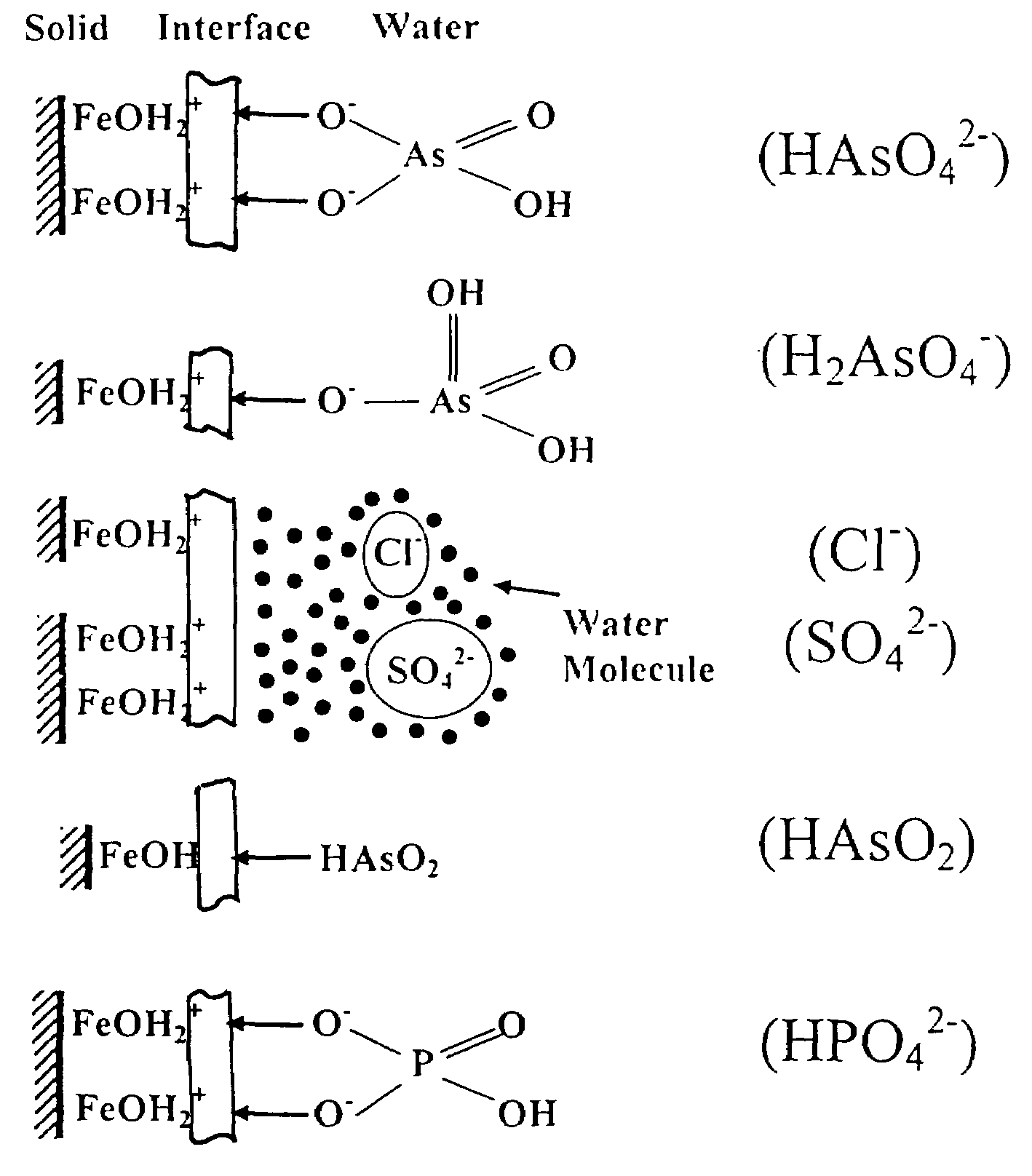

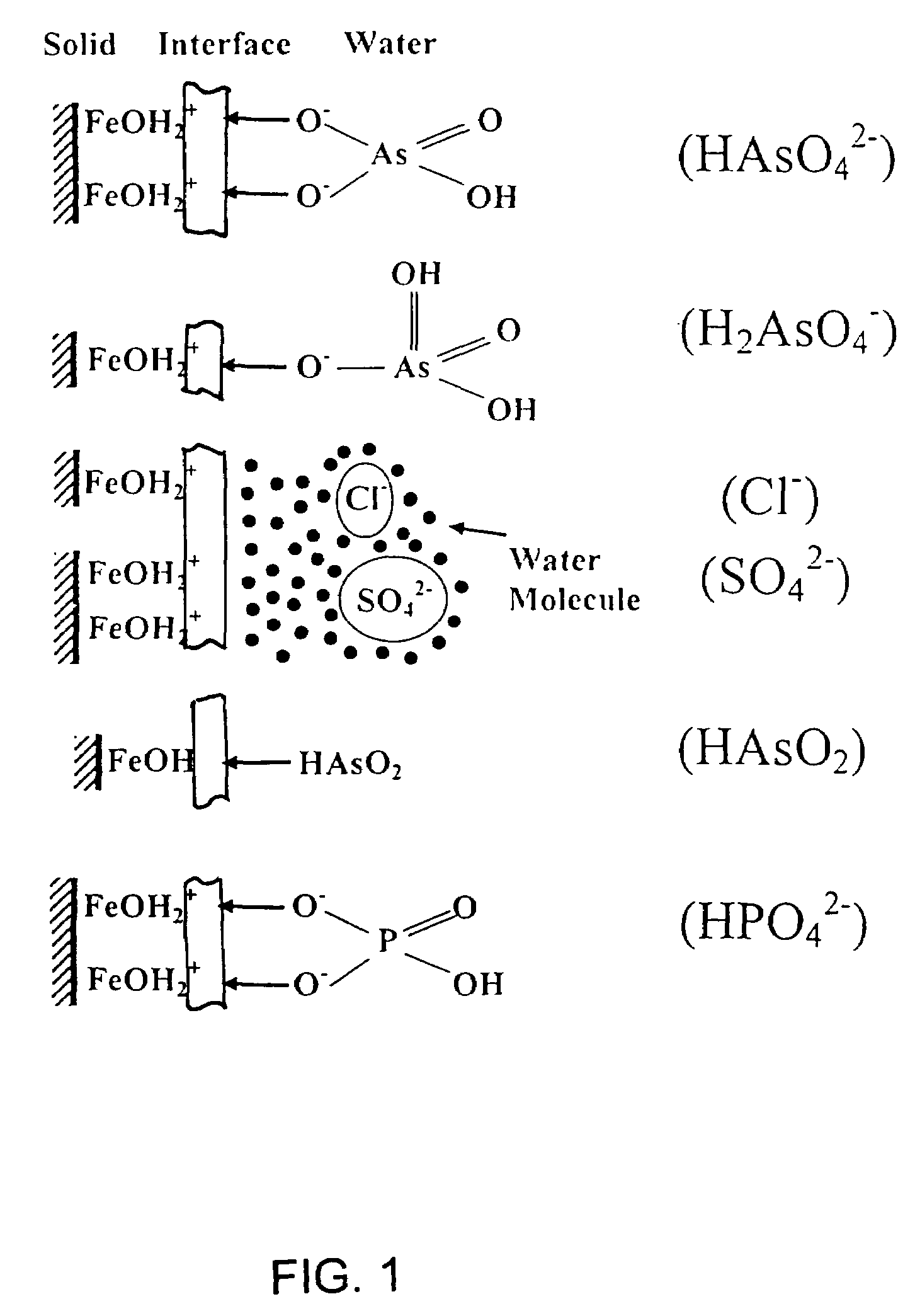

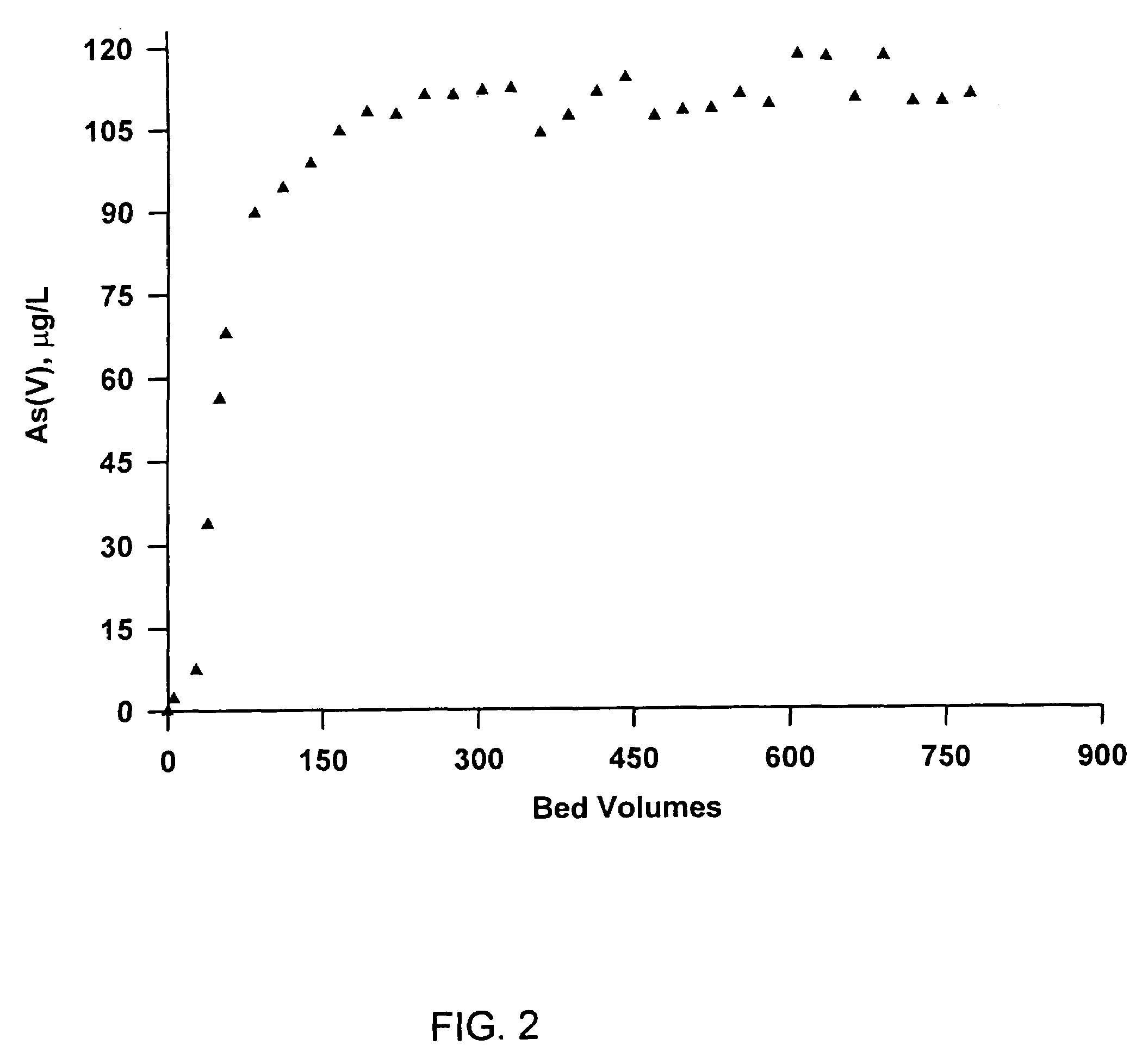

Method of manufacture and use of hybrid anion exchanger for selective removal of contaminating ligands from fluids

ActiveUS20050156136A1Reduce needSuperior material propertyOther chemical processesWater contaminantsArsenatePhosphate

Polymeric anion exchangers are used as host materials in which hydrated Fe(III) Oxides (HFO) are irreversibly dispersed within the exchanger beads. Since the anion exchangers have positively charged quaternary ammonium functional groups, anionic ligands such as arsenates, chromates, oxalates, phosphates, phthalates can permeate in and out of the gel phase and are not subjected to the Donnan exclusion effect. Consequently, anion exchanger-supported HFO micro particles exhibit significantly greater capacity to remove arsenic and other ligands in comparison with cation exchanger supports. Loading of HFO particles is carried out by preliminary loading of the anion exchange resin with an oxidizing anion such as MnO4− or OCl−, followed by passage of a Ferrous Sulfate solution through the resin.

Owner:ARUP K SENGUPTA

Hybrid anion exchanger for selective removal of contaminating ligands from fluids and method of manufacture thereof

ActiveUS7291578B2Improve material performanceImprove physical strengthOther chemical processesWater contaminantsPhosphateIon-exchange resin

Owner:ARUP K SENGUPTA

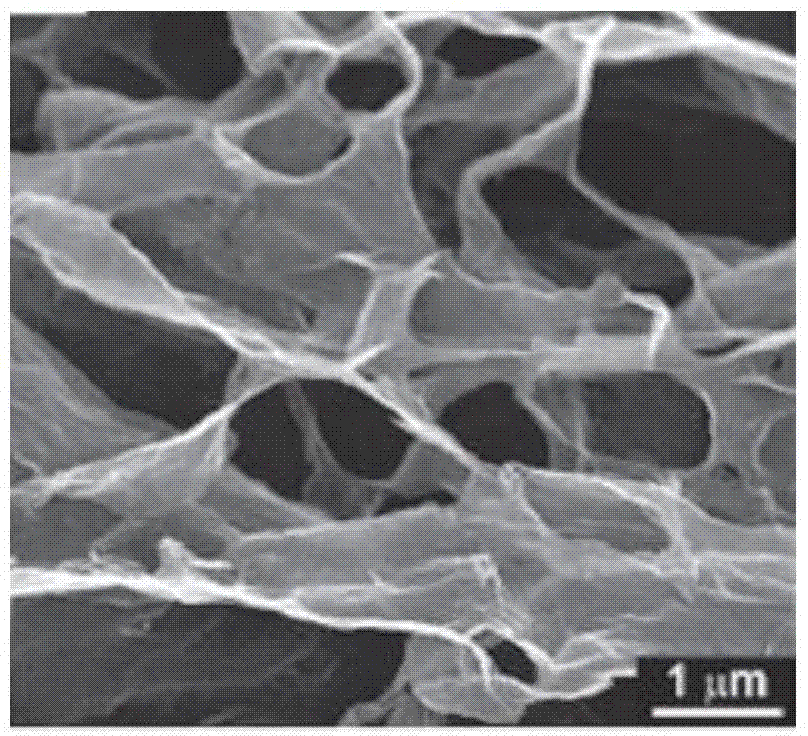

Preparation method for graphene aerogel

The invention discloses a preparation method for graphene aerogel. The method comprises the following steps: preparing an aqueous polyvinyl alcohol solution containing graphene oxide so as to obtain a graphene oxide dispersion liquid with a concentration of 1 to 10 mg / cm<3>; subjecting the graphene oxide dispersion liquid to freezing in the condition of no higher than minus 196 DEG C so as to obtain a frozen sample; subjecting the frozen sample to freezing and drying so as to obtain a frozen-dried sample; and subjecting the frozen-dried sample in an argon-hydrogen mixed gas environment to high-temperature reduction so as to obtain the required graphene aerogel, wherein the high-temperature reduction comprises the steps of burning at 350 to 450 DEG C for 2 to 3 hours and burning again at 900 to 1100 DEG C for 2 to 3 hours. The preparation method for the graphene aerogel provided by the invention adopts a liquid nitrogen freezing manner to obtain a graphene oxide aerogel precursor, the subsequent segmented high-temperature reduction process is combined, the frozen-dried sample undergoes high-temperature burning at different temperatures, polyvinyl alcohol is removed and graphene oxide is reduced at high temperature, so the graphene aerogel is finally obtained; meanwhile, the graphene aerogel obtained by using the method in the invention has stable structure, good homogeneity and stable material performance.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Process of making carbon-coated lithium metal phosphate powders

InactiveUS20070160752A1Improve material performanceThe process is simple and fastLiquid surface applicatorsCell electrodesLithium metalPhosphate

The present invention provides a process for making uniform carbon-coated LiMPO4 powders for use as a cathode material in lithium ion batteries. In one embodiment, the process comprises synthesizing a LiMPO4 powder. The process further comprises coating a carbonaceous coating on to the LiMPO4 powder to form a coated LiMPO4 powder. Additionally, the process comprises carbonizing the coated LiMPO4 powder.

Owner:CONOCOPHILLIPS CO

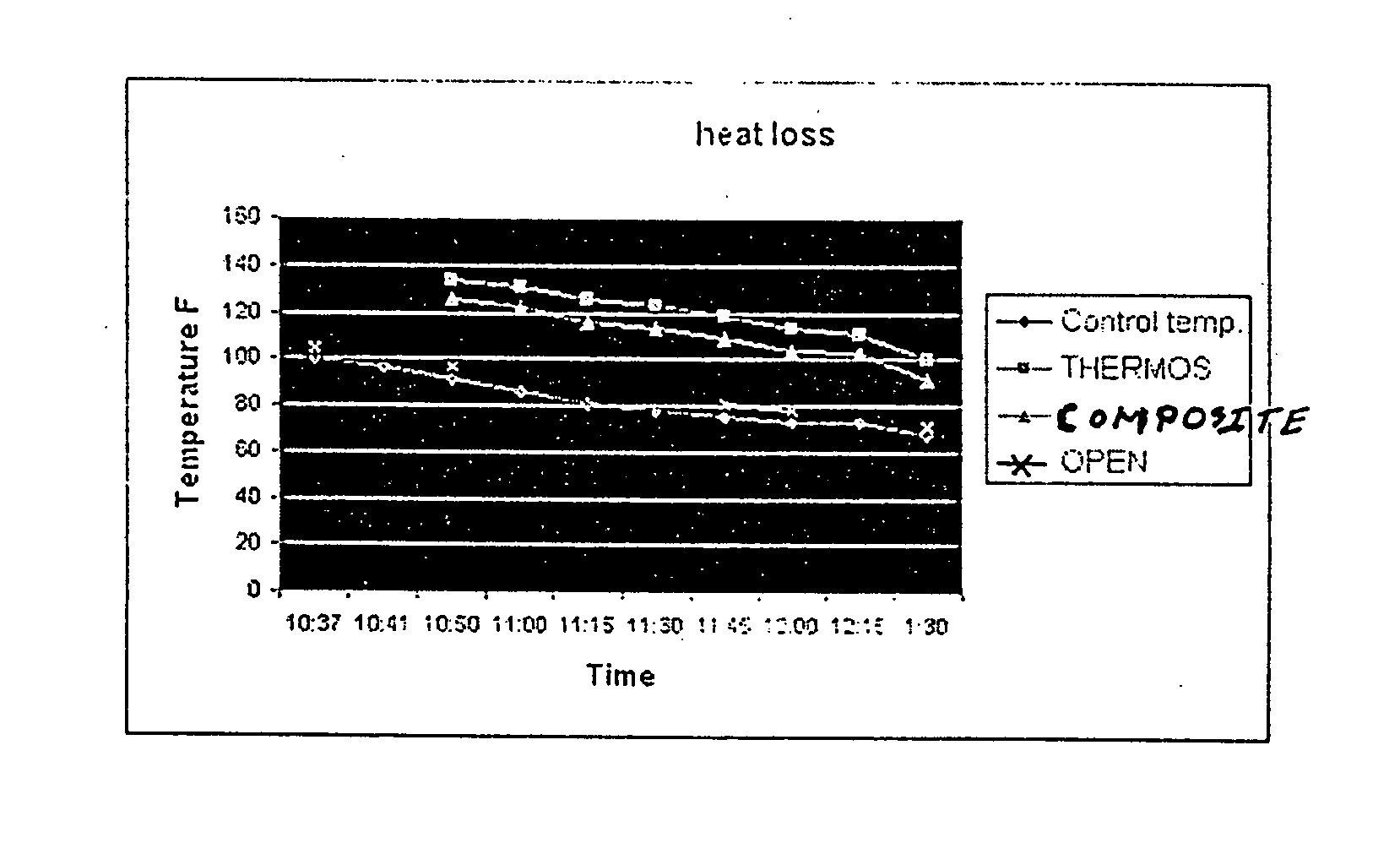

Process for enhancing material properties and materials so enhanced

InactiveUS7101607B2Overcome disadvantagesIncrease flexibilityMechanical working/deformationAdhesivesMaterials scienceAerogel

The present invention relates to a composite insulation material. The composite insulation material includes a syntactic foam component and a plurality of aerogel inserts. The present invention also relates to a method of making a composite insulation material. The present invention further relates to a method for enhancing the flexibility of a solid material.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Wind turbine blade

InactiveUS20070183888A1Improve material performanceReduce manufacturing costWind motor controlFinal product manufactureCarbon fibersTurbine blade

The invention relates to a wind turbine blade comprising a number of pre-fabricated strips arranged in a sequence along the outer periphery. The strips consist of a fibrous composite material, preferably carbon fibres, and consist of a wooden material, preferably plywood or wooden fibres held in a cured resin. The advantage is that it is possible to manufacture blades for wind turbines which are very stiff and generally have a high strength, but which nevertheless are easy to manufacture and also is much cheaper to manufacture compared to conventional manufacturing techniques. The invention also relates to methods for manufacturing prefabricated strips and for manufacturing wind turbine blades.

Owner:VESTAS WIND SYST AS

Method for producing macromolecule composite wood-plastic material by utilizing crop straw

The invention provides a process for producing high molecular composite wood-plastic materials by using straws of agricultural plants, belonging to a process for utilizing the straws of agricultural plants. The process is that the straws of agricultural plants are crushed and dried, then the achieved straw powder is processed soakage treatment, and then modified straw powder is achieved after being dried, further dry powder is achieved by processing high-speed mixing and cooling mixing to the modified straw powder and other raw materials of which the plastic is the main material, and then the dry powder is squeezed out to produce grains, the materials after producing grains are squeezed out and shaped, consequently high molecular composite wood-plastic materials are manufactured. Owing to the process of the high molecular composite wood-plastic materials, the sound adhesion between the plant fibers existed in the straw powder after being processed superficial treatment by a plurality of modifiers, and plastics can be truly realized and the perfect property of materials can be achieved.

Owner:滨州华晨新型建材有限公司

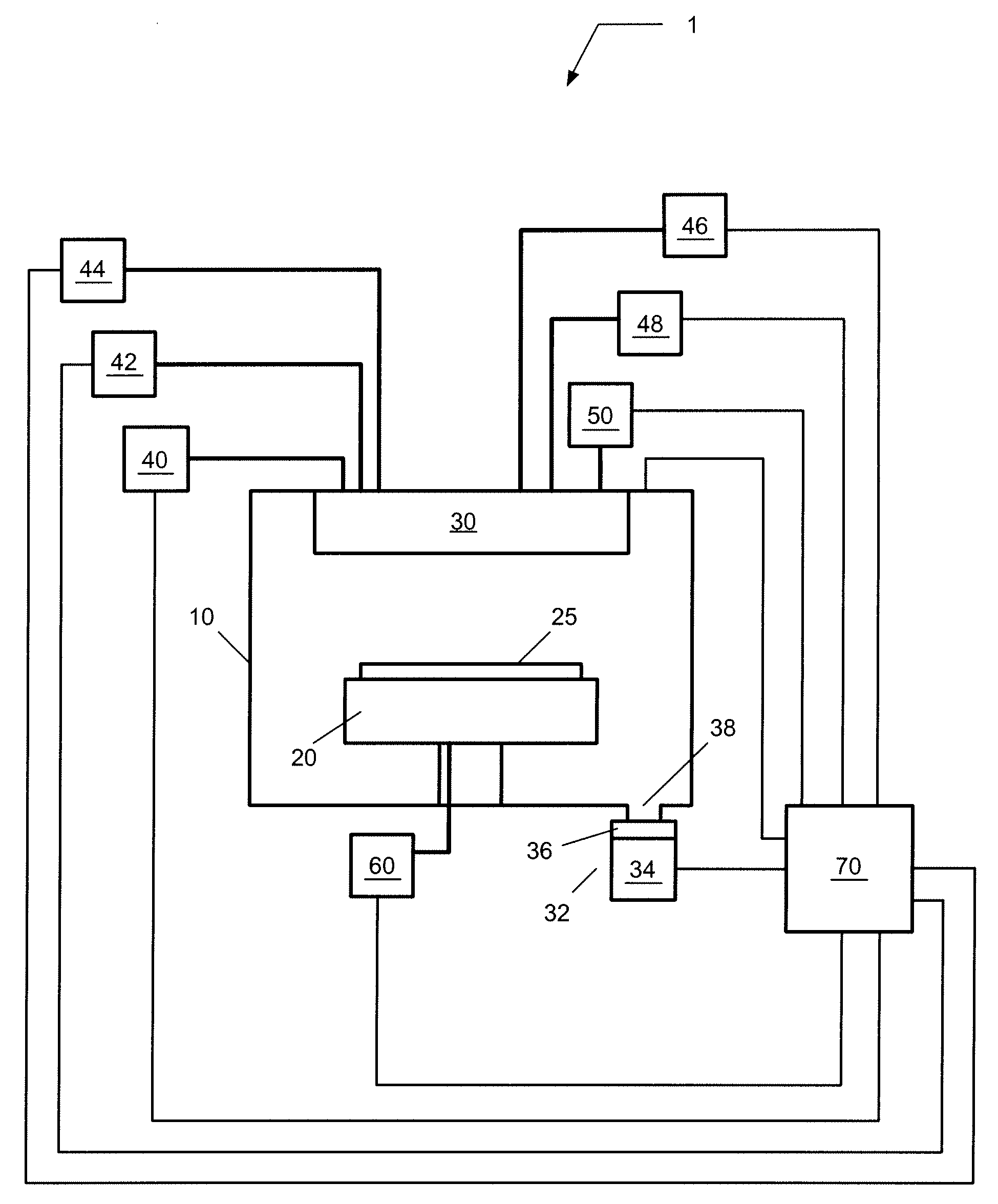

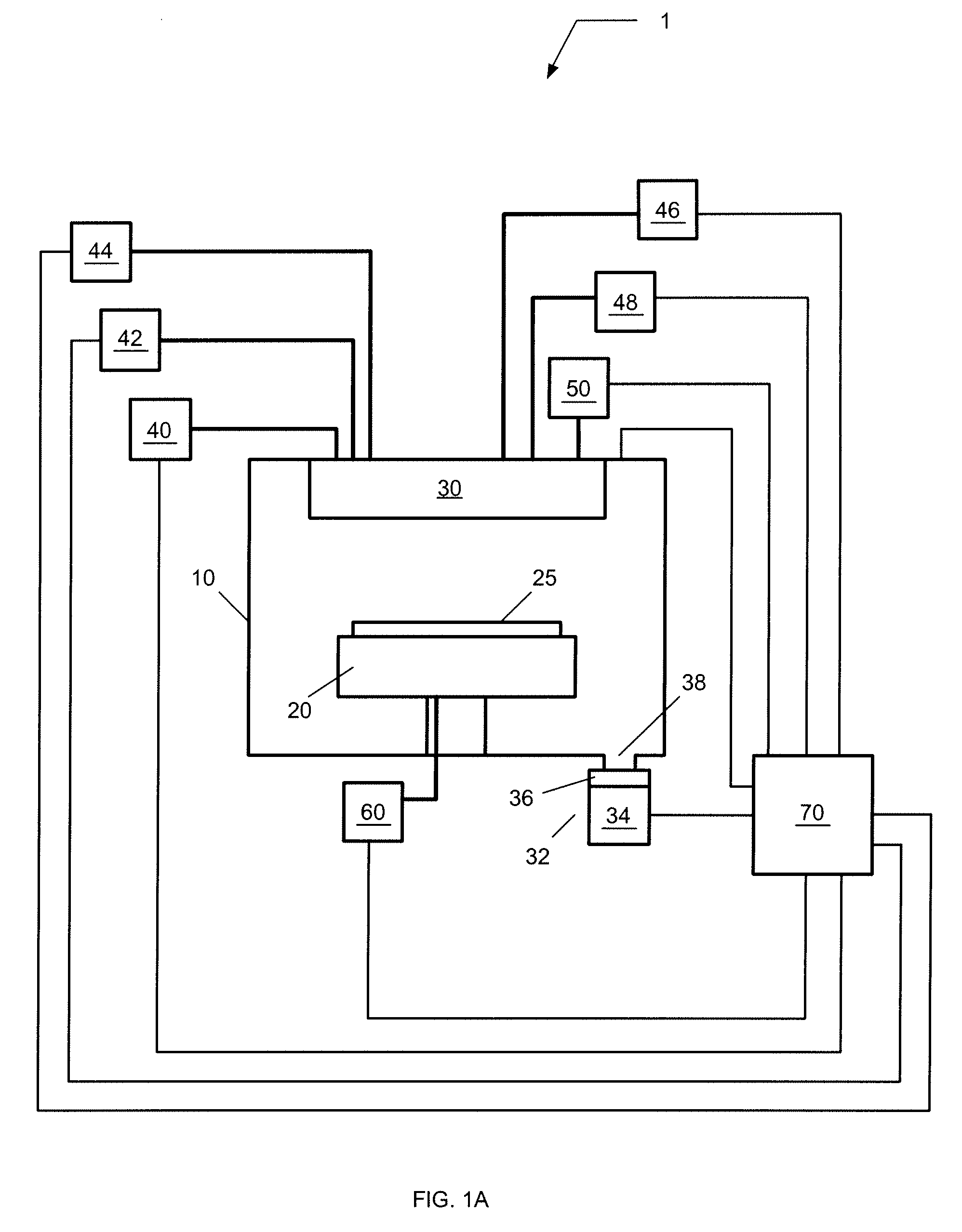

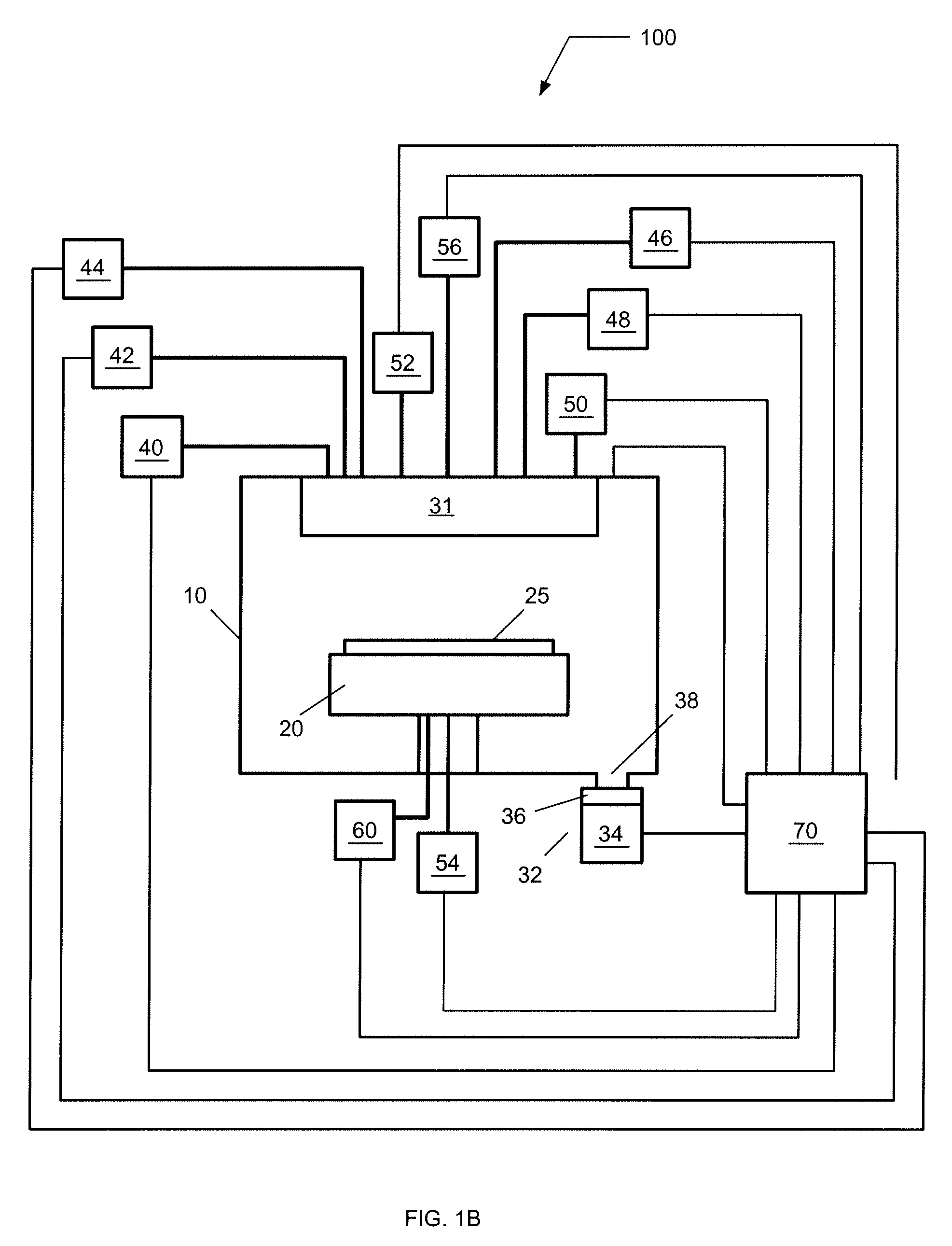

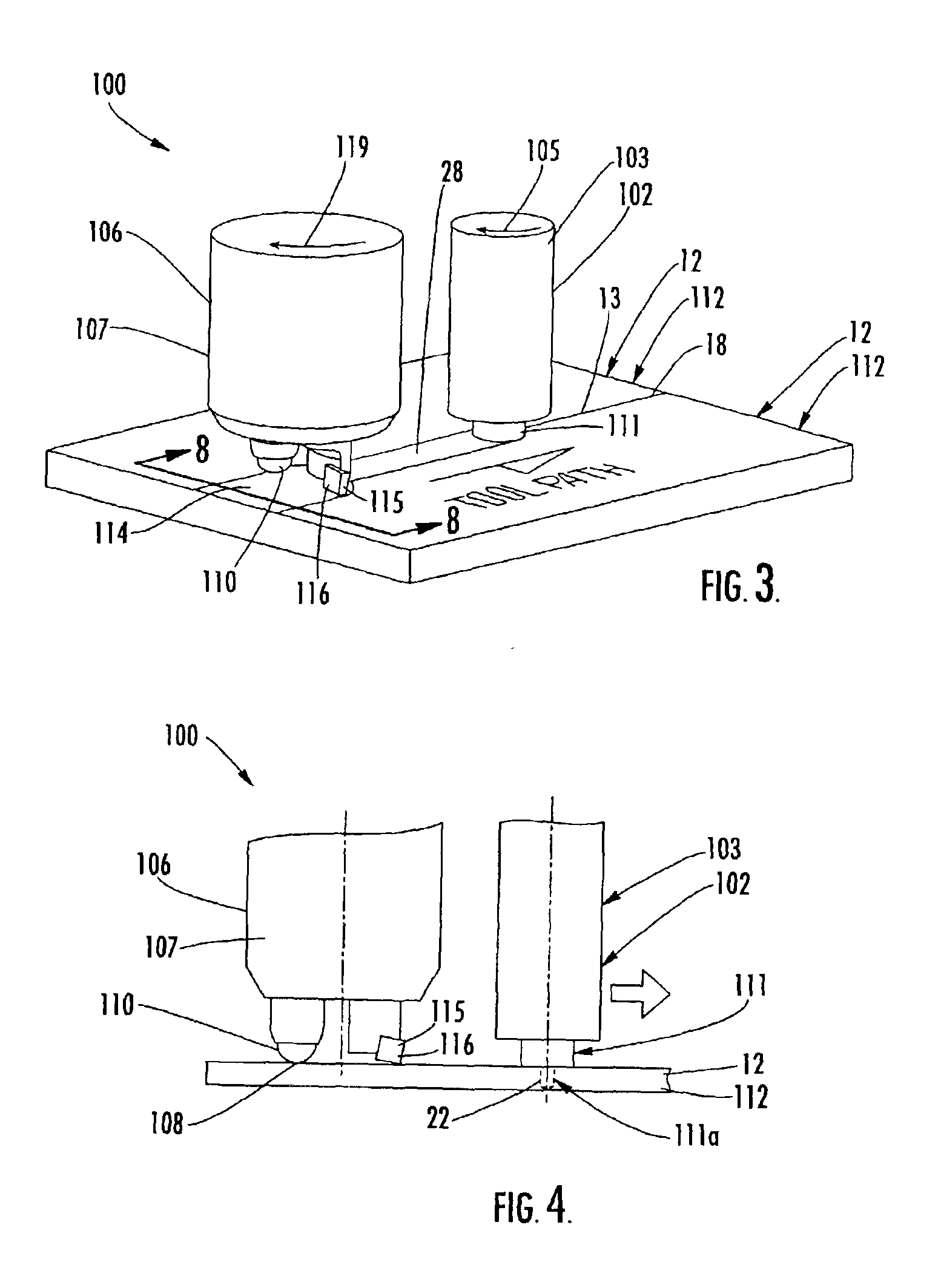

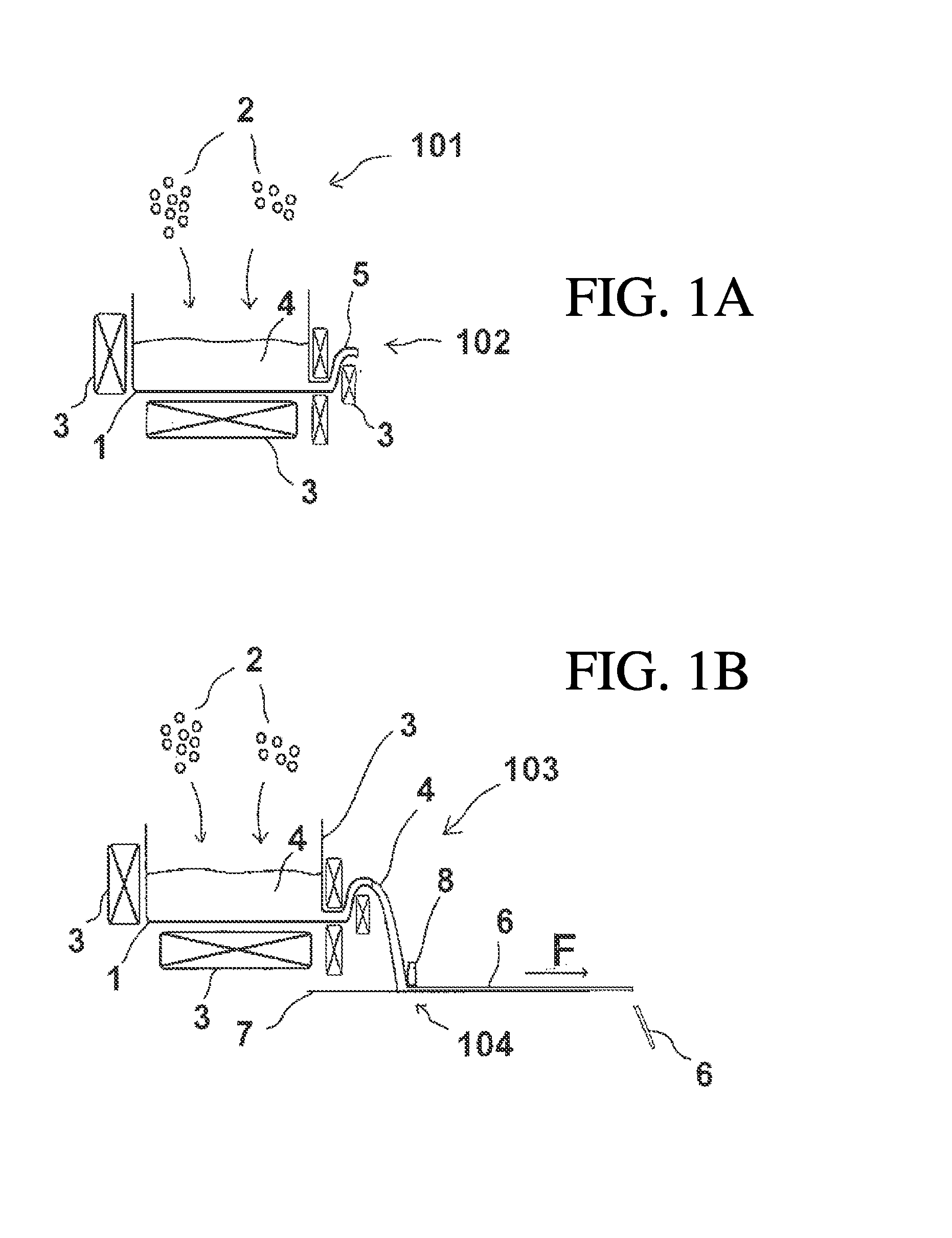

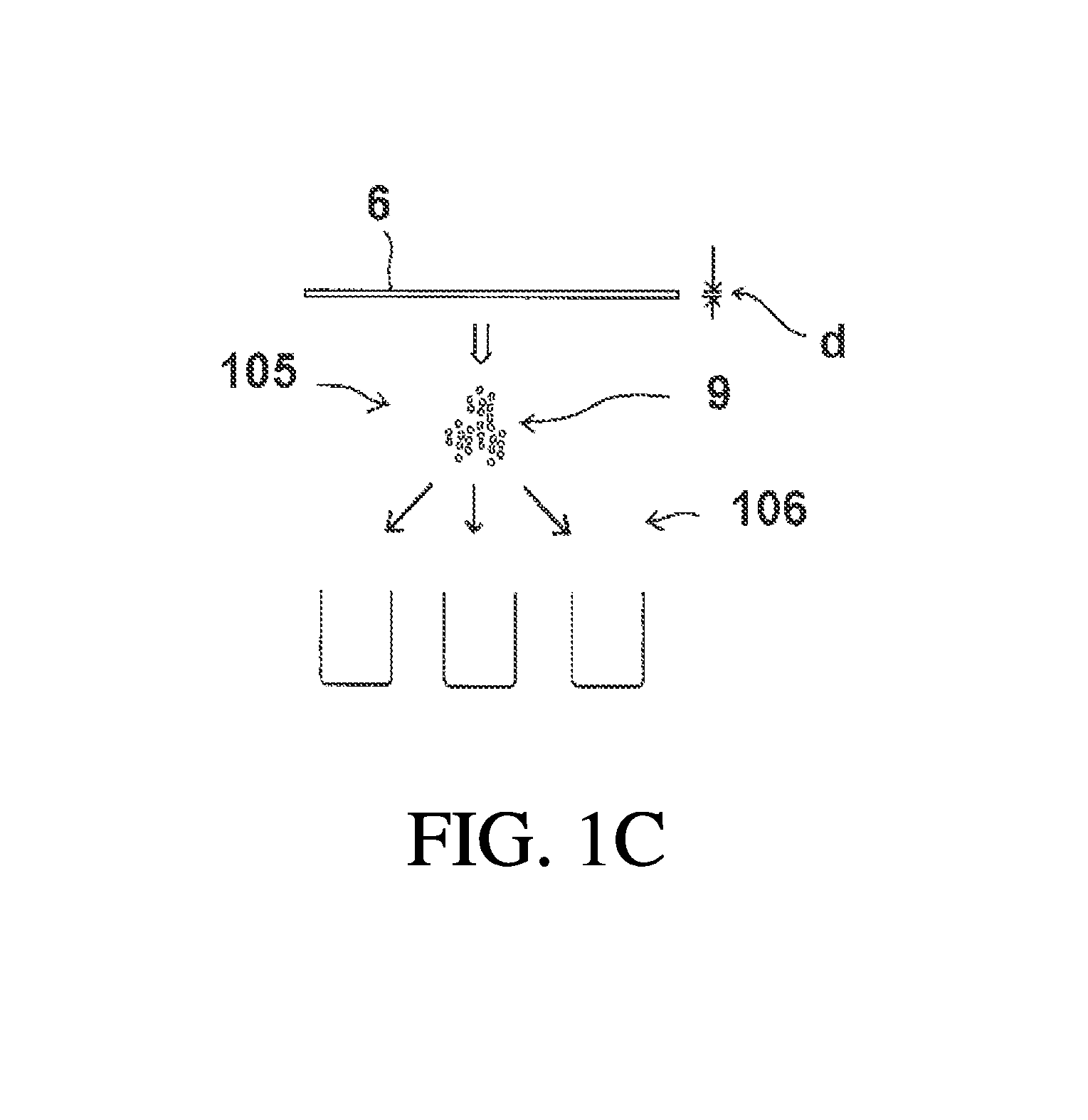

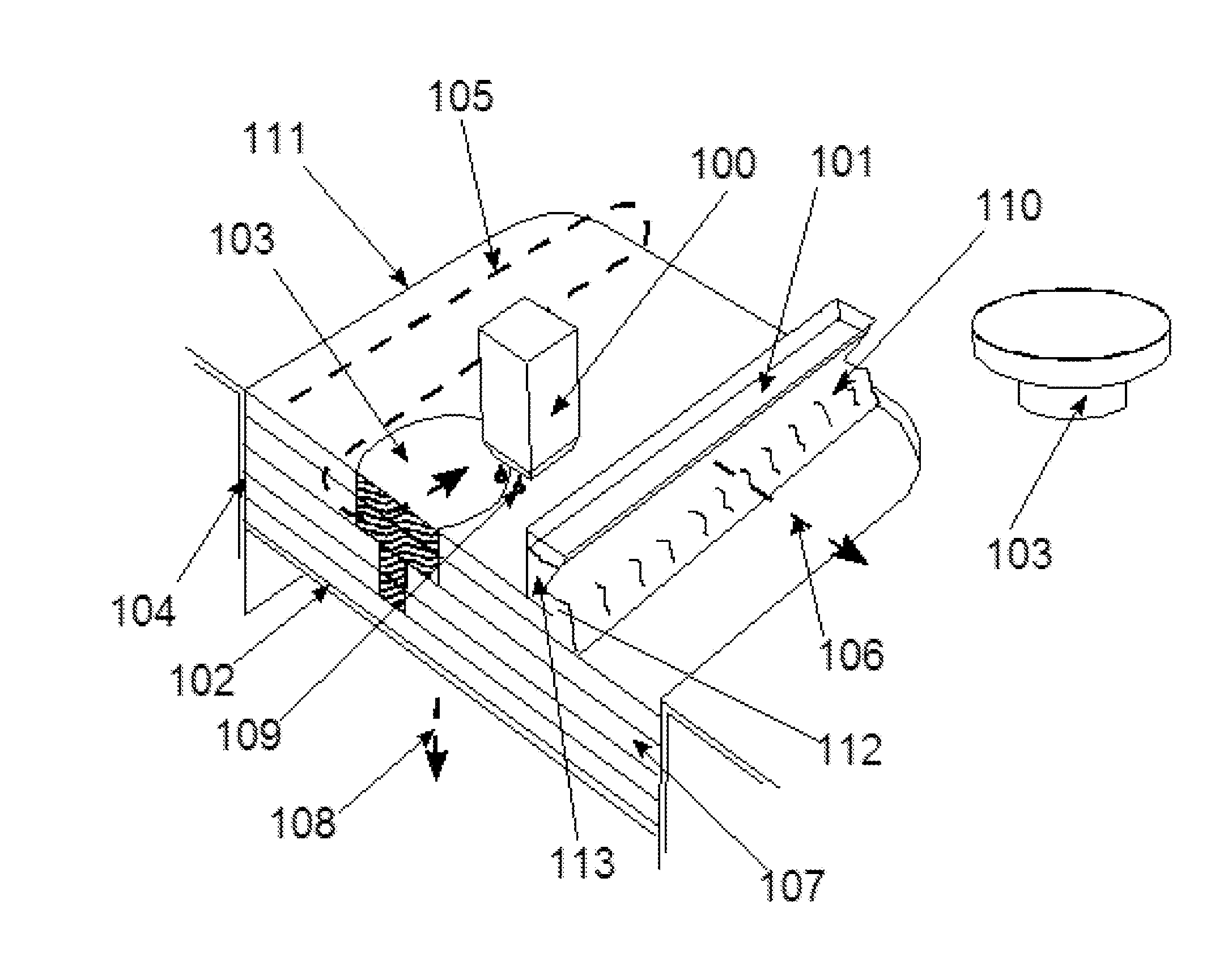

Apparatus and method for forming a weld joint having improved physical properties

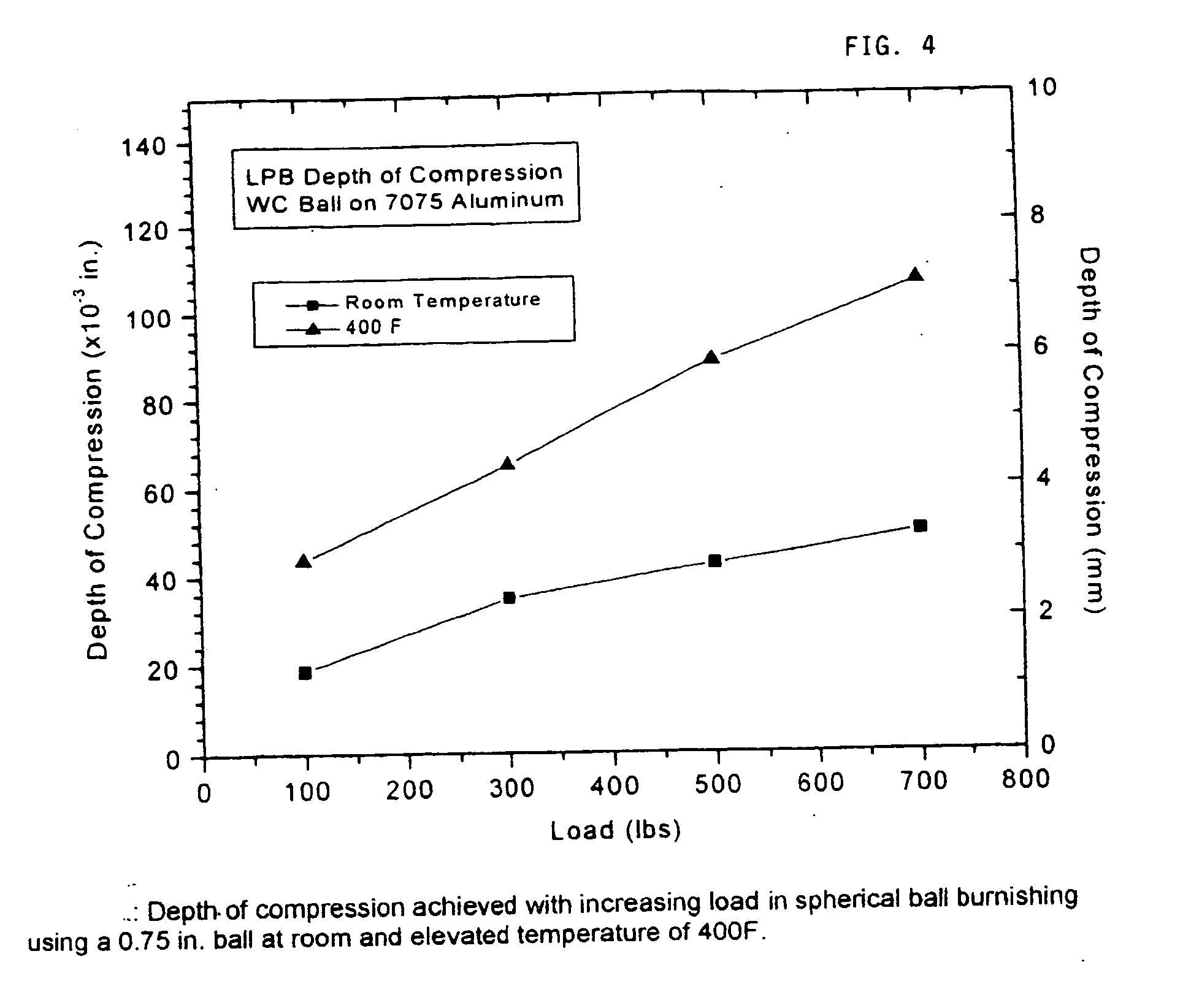

InactiveUS20050224562A1Improve material performanceDeep compressionArc welding apparatusFurnace typesHeat-affected zoneEngineering

The method and apparatus for performing the method of forming a weld joint of the present invention utilizes welding apparatus (100) having welded tool (102) and a compression tool (106) for inducing a layer of residual compressive stress along the surface of the weld line (18) and any heat affected regions with a controlled amount of cold working and surface hardening. In a preferred embodiment of the invention the compression tool (106) utilizes a single-point burnishing process to provide deep compression within the weld joint (20) with a minimal amount of cold working and surface hardening.

Owner:SURFACE TECH HLDG

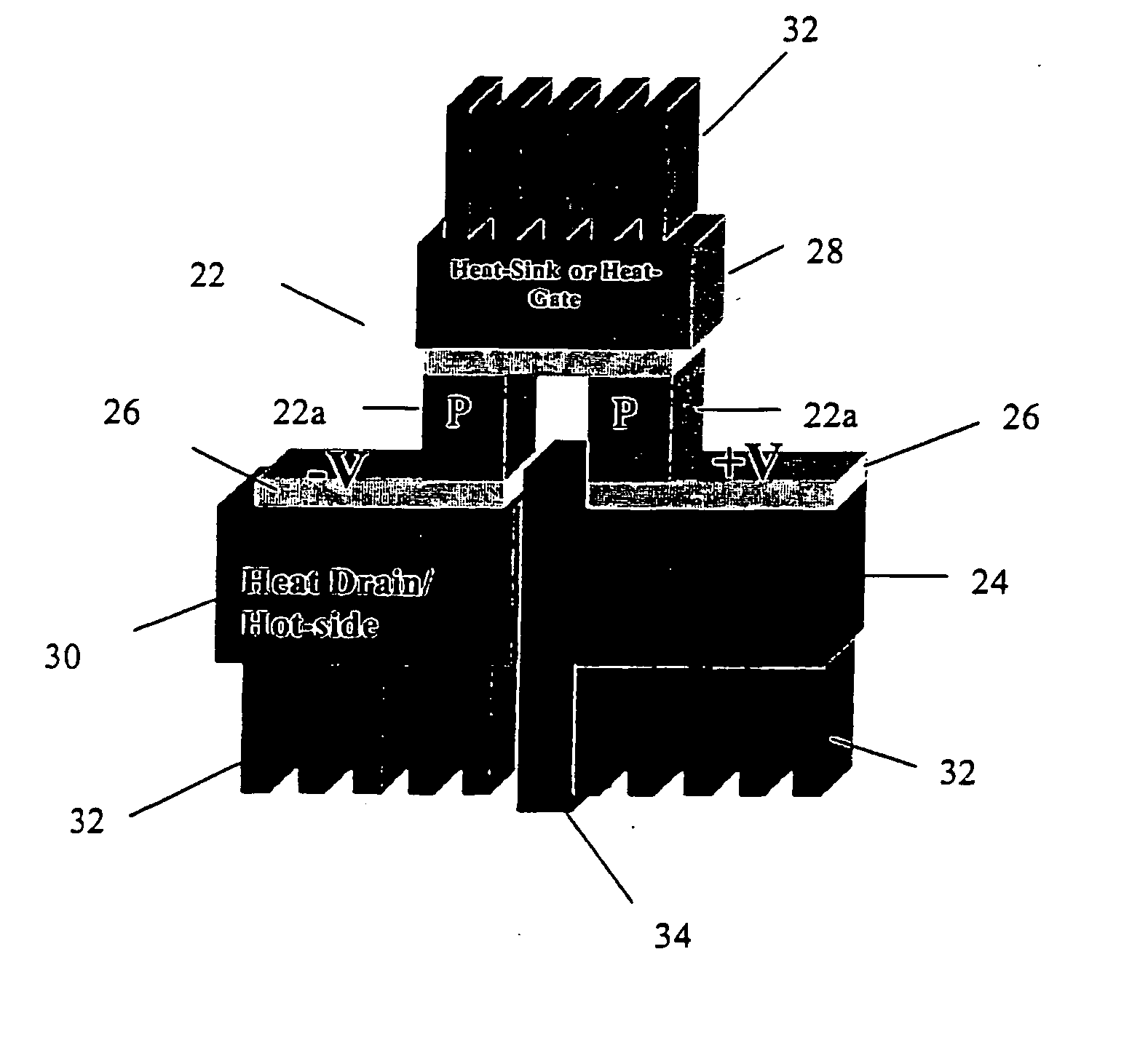

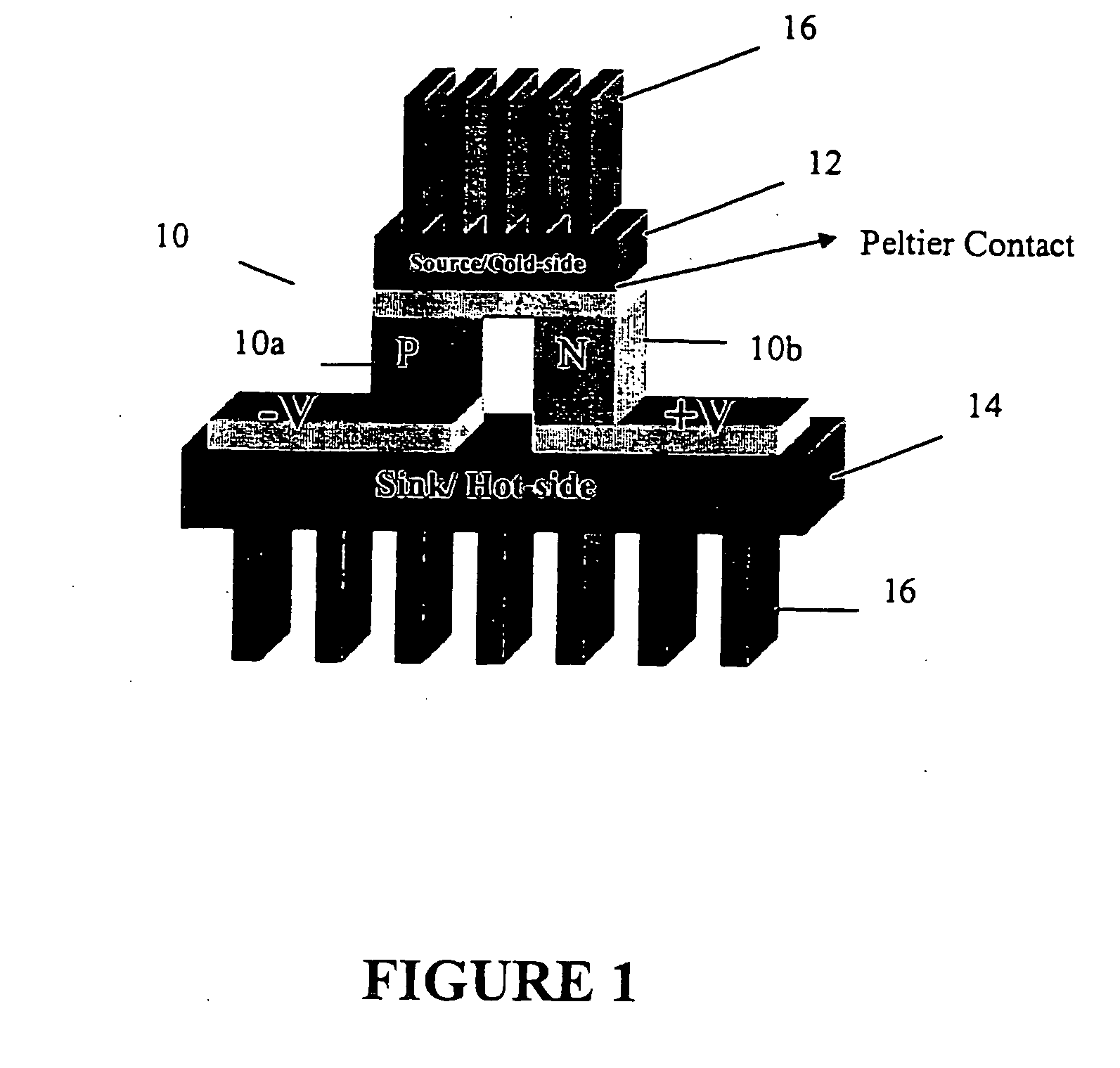

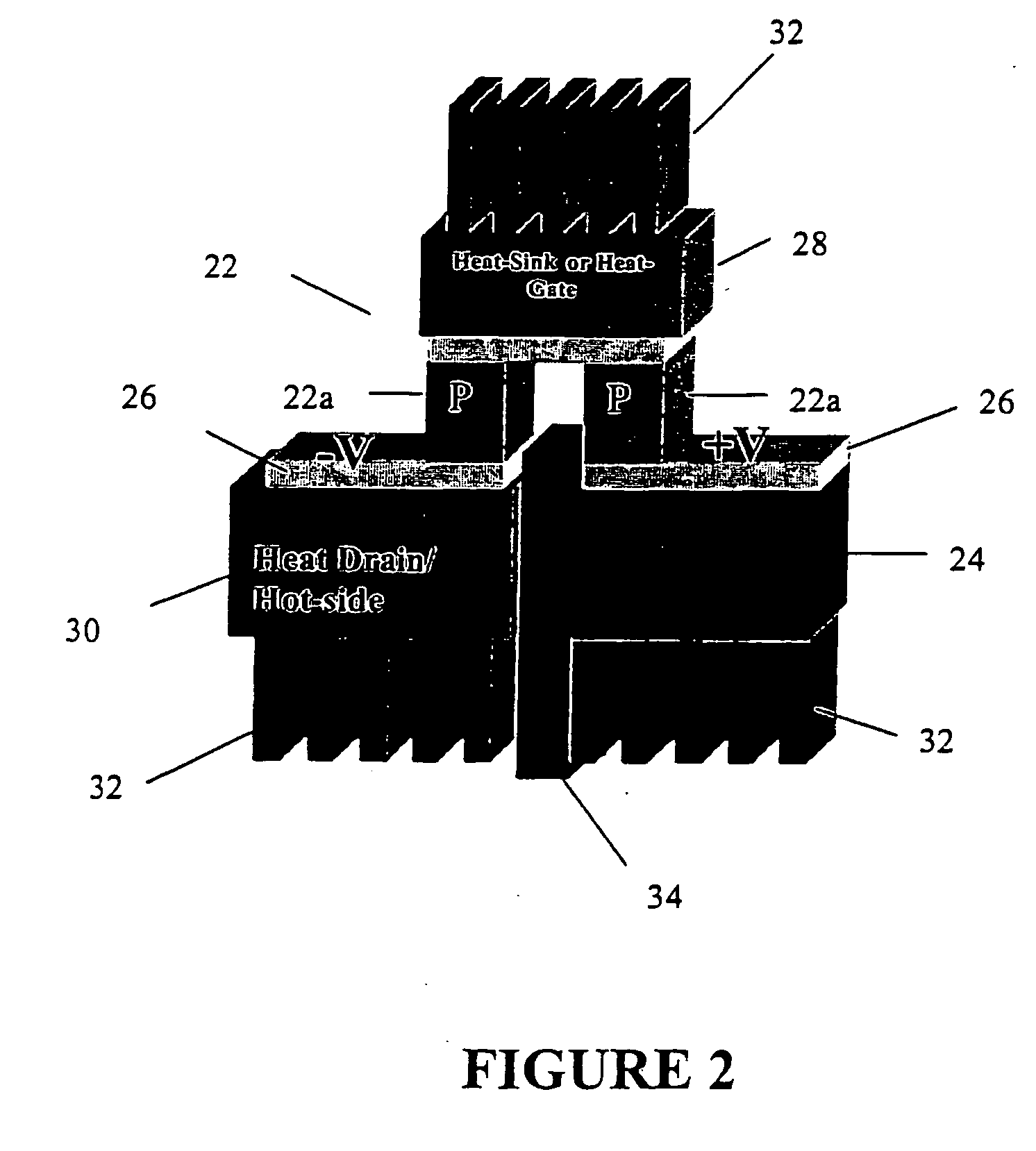

Trans-thermoelectric device

InactiveUS20060225773A1Reduce complexityImprove efficiencyThermoelectric device with peltier/seeback effectDomestic cooling apparatusElectrical resistivity and conductivityElectric energy

A thermoelectric device having at least one unipolar couple element (22) including two legs (22a) of a same electrical conductivity type. A first-temperature stage (24) is connected to one of the two legs. A second-temperature stage (28) is connected across the legs of the at least one unipolar couple element. A third-temperature stage (30) is connected to the other of the two legs. Methods for cooling an object and for thermoelectric power conversion utilize the at least one unipolar couple element to respectively cool an object and produce electrical power.

Owner:LAIRD THERMAL SYST INC

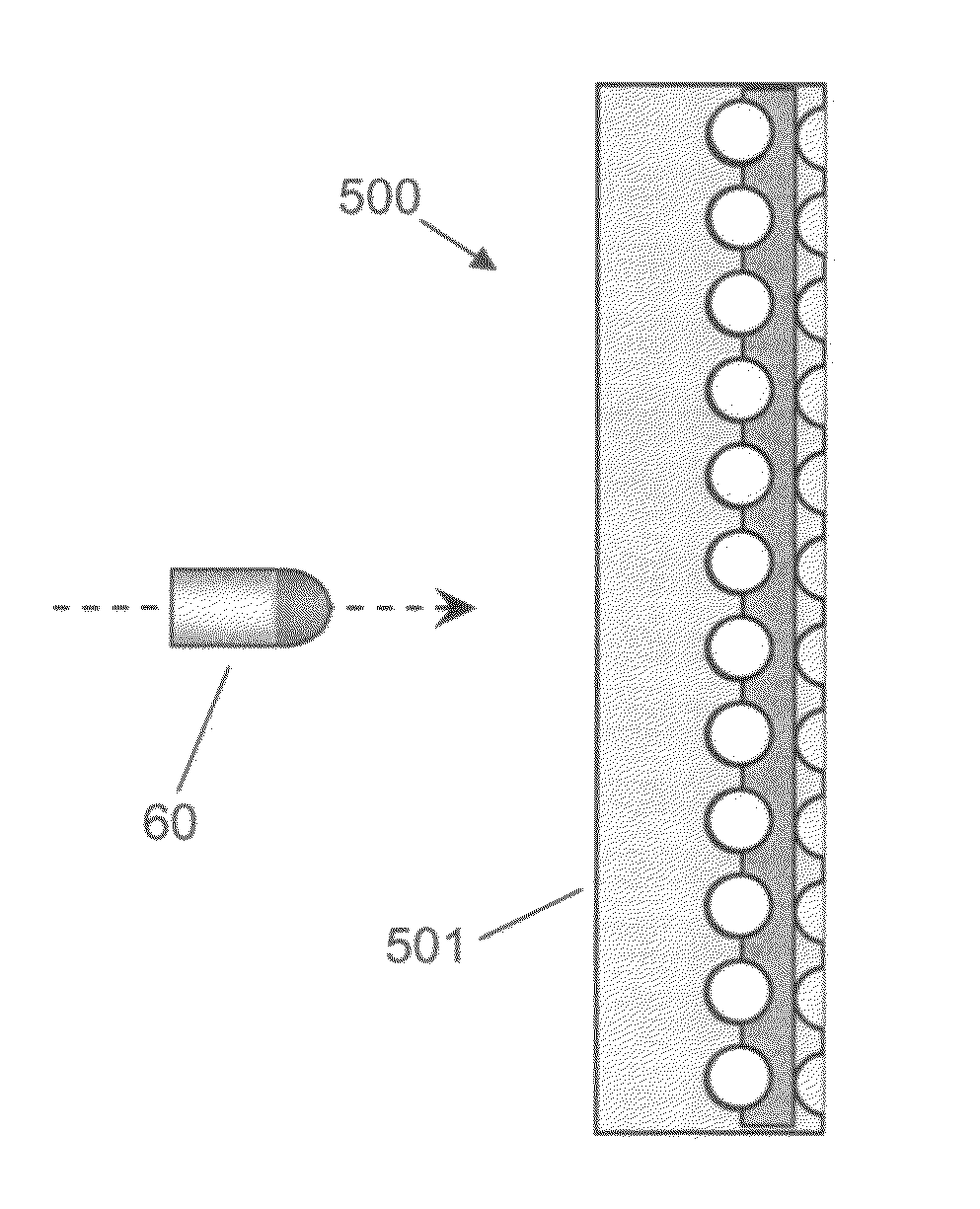

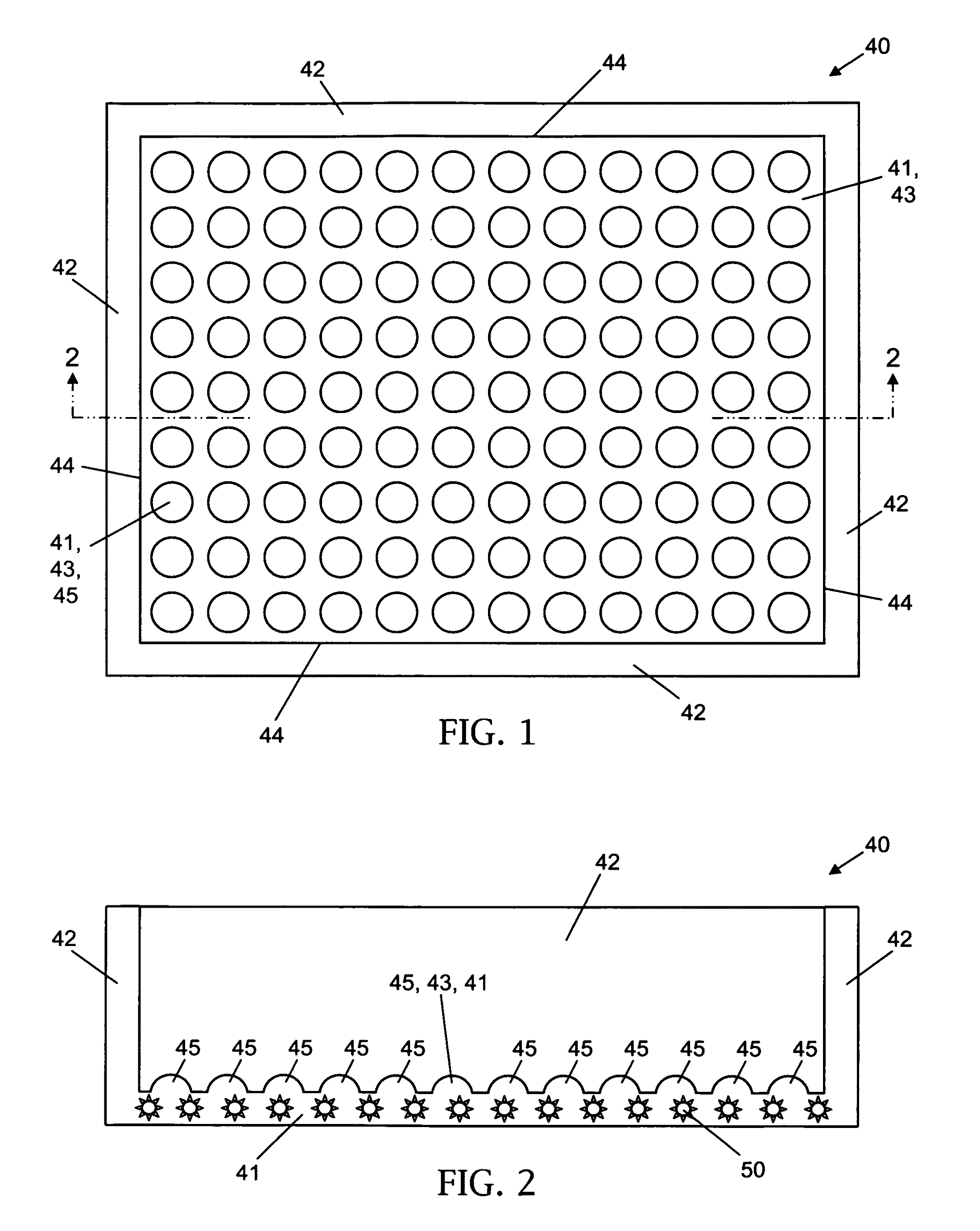

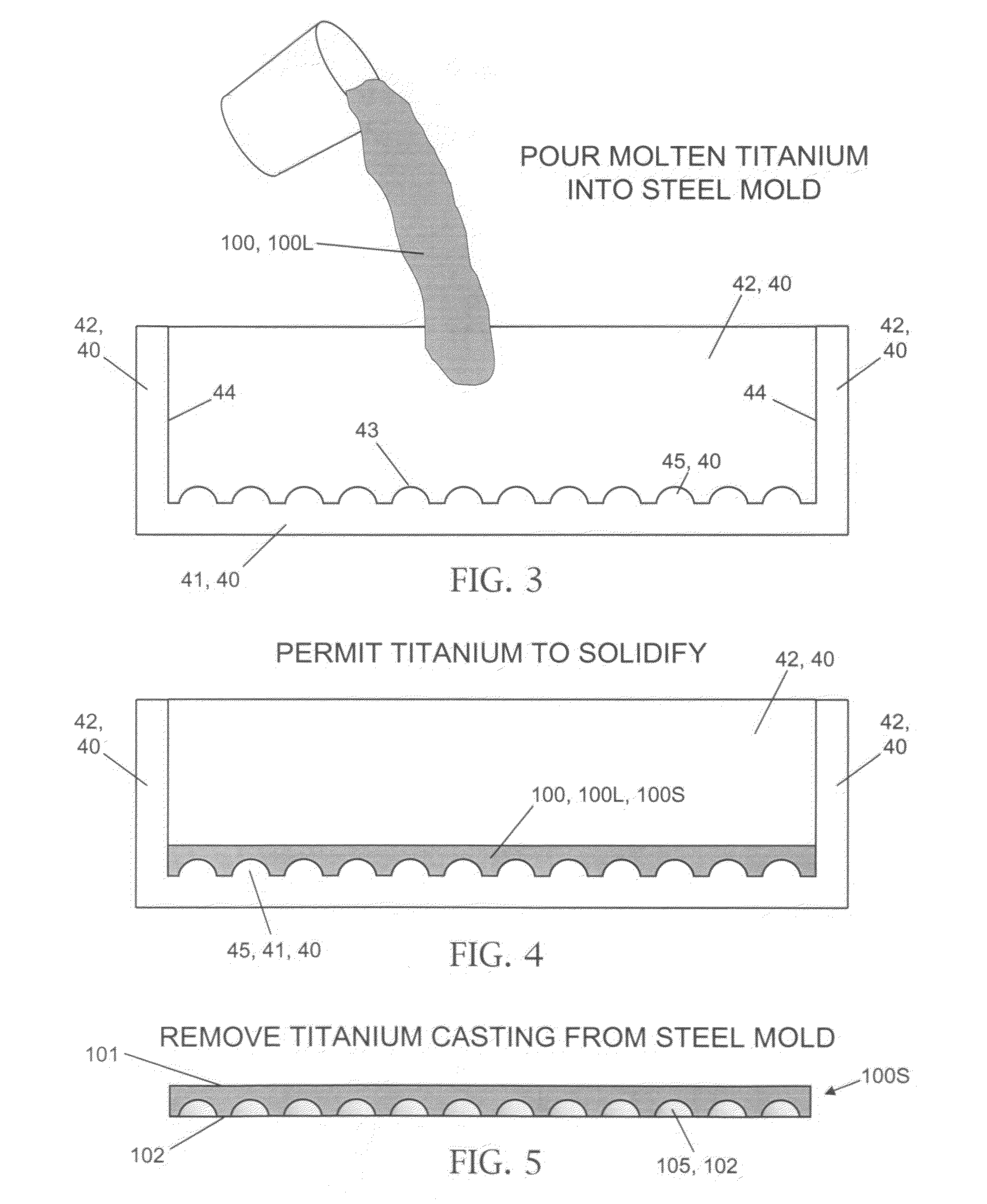

Composite armor having a layered metallic matrix and dually embedded ceramic elements

ActiveUS7833627B1Effective performance in resisting projectile impactEfficient and cost-effectiveSynthetic resin layered productsDomestic articlesMetallic materialsSpherical form

According to typical inventive practice, a first metallic material is poured into a mold including a bottom inside surface having regularly arrayed rises (truncated spherical convexities). The molten first metallic material cools and solidifies to include a surface correspondingly having regularly arrayed dents (truncated spherical concavities). The resultant “inner casting” is removed from and repositioned in the mold so that the inner casting's dent-laden surface faces upward. Ceramic spheres are placed in the dents. A second metallic material (having a higher melting point than the first metallic material) is poured into the mold with the inner casting and spheres in place. The molten second metallic material cools and solidifies as an “outer casting” surrounding the inner casting and the spheres. The resultant integral armor structure includes the inner casting, the outer casting, and the spheres, each sphere embedded partially in the inner casting and partially in the outer casting.

Owner:UNITED STATES OF AMERICA SEC OF THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCIP THE

Aluminum alloy special-shaped member equivalent temperature precision forging technique method

ActiveCN101185954AImprove overall performanceIncreased internal densityForging/hammering/pressing machinesHeat treatment process controlEquivalent temperatureFiber

The invention relates to a constant temperature fine-forging technique process used for the aluminum alloy parts with different shapes. The invention is mainly characterized in that constant temperature blank forging, die pre-forging, corrode-washing, fine forging of dies, heat treatment and re-corrode washing, etc. processes are adopted under a given temperature to enlarge the internal density of the parts and optimize the fiber direction and distribution of the inner construction of the parts, so as to enhance the strength and improve the appearance quality of the parts. The invention can enhance machining efficiency, reduce machining cost and conserve precious materials. The invention can enhance the compound capability of the materials of parts.

Owner:HENAN COSTAR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com