Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

693results about How to "Improve overall performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

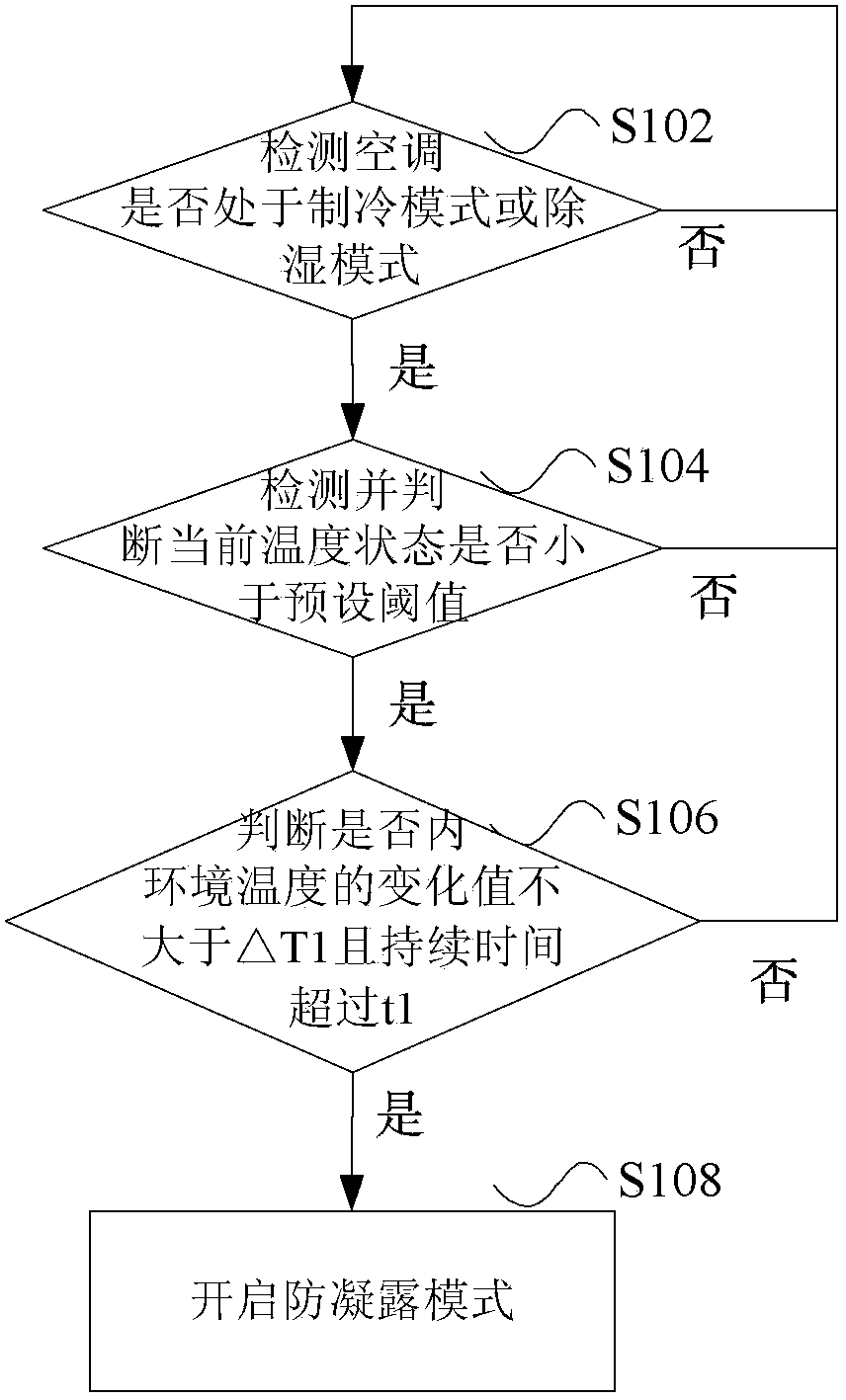

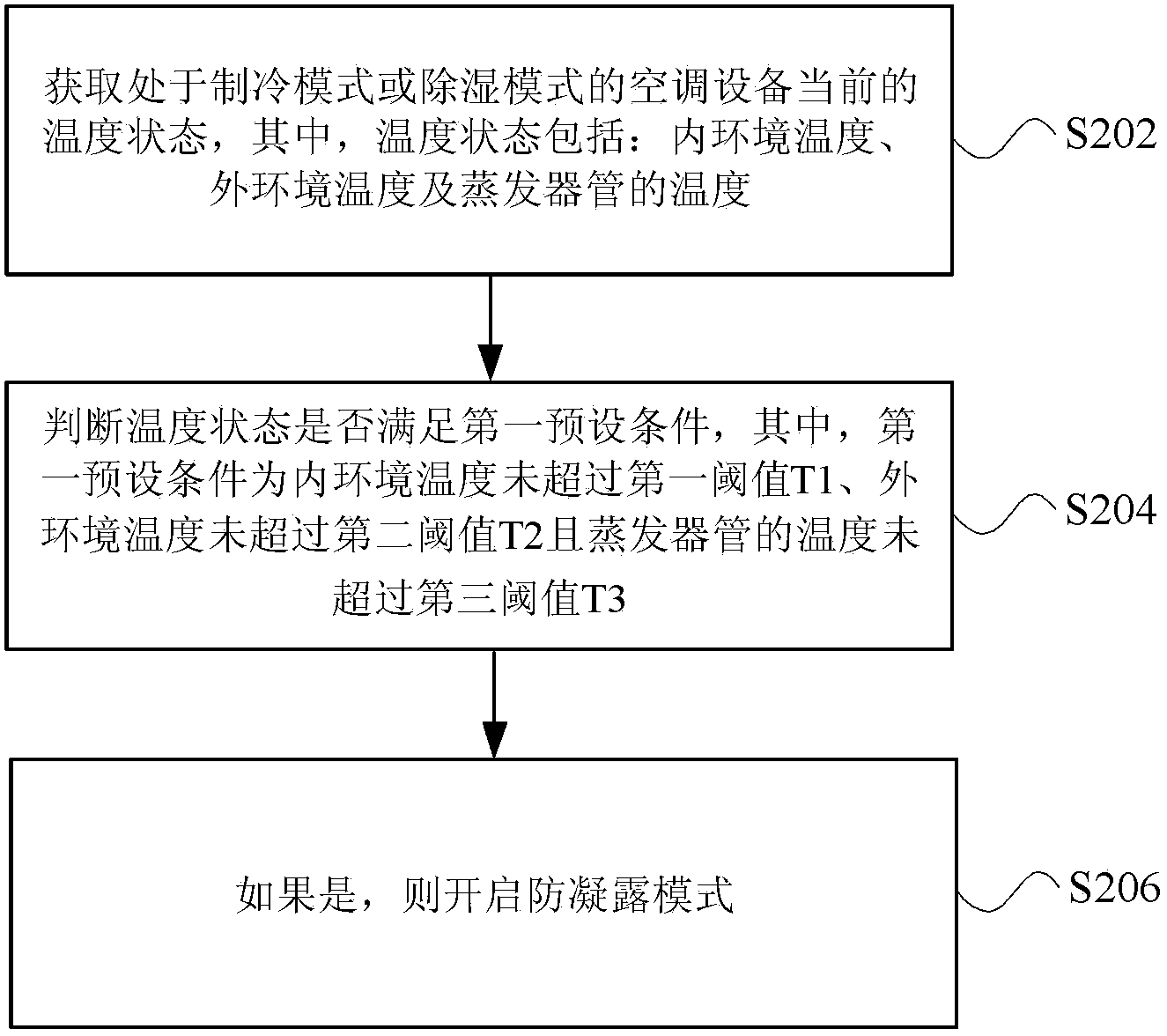

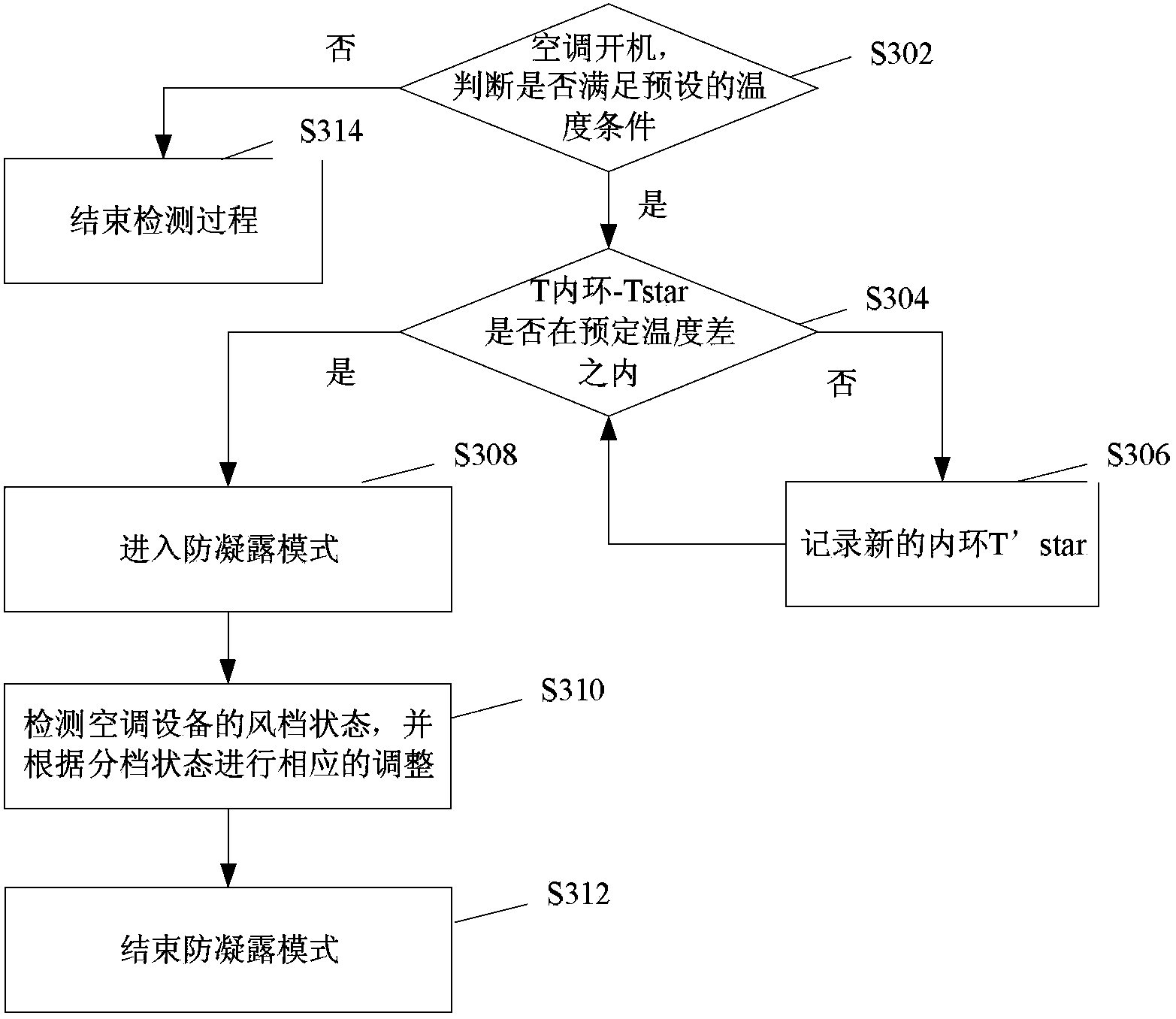

Method and device for preventing air conditioner from condensing

ActiveCN103453616ASave resourcesImprove overall performanceCondensate preventionSpace heating and ventilation safety systemsElectrical and Electronics engineeringEngineering

Owner:GREE ELECTRIC APPLIANCES INC

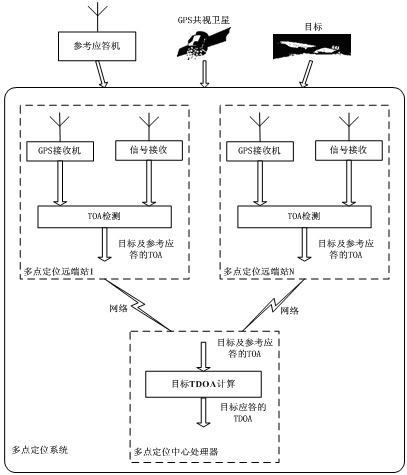

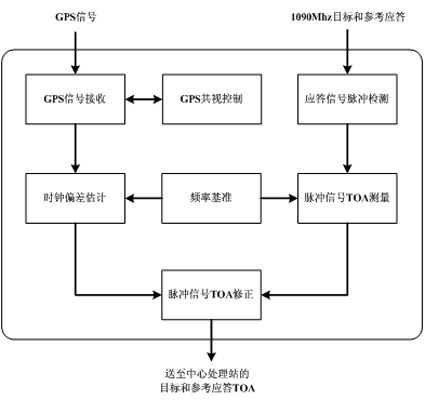

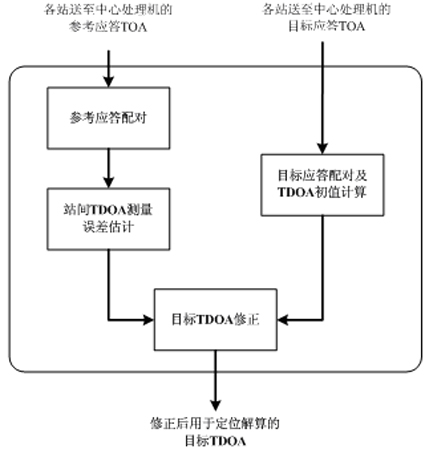

High-precision distributed pulse signal time difference of arrival detection system

ActiveCN102023290AReduce target positioning errorImprove overall performancePosition fixationSatellite radio beaconingTime of arrivalMultilateration

The invention discloses a high-precision distributed pulse signal time difference of arrival (TDOA) detection system. The system consists of a time of arrival (TOA) detection module in a multi-point positioning distant station and a target TOA calculation module in a multi-point positioning central processing station; and the system synchronously corrects time delay errors of a system time synchronization signal processing channel and a target signal processing channel by adopting a method combining global position system (GPS) common-view technology and reference responder synchronization error correction, and corrects TOA measurement errors and TDOA measurement errors in real time by using multiple filter and tracking algorithms. The system makes up the defects of single mode, and realizes high-precision distributed pulse signal TDOA detection so as to reduce the target positioning errors and improve the integral performance of a multi-point positioning system.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

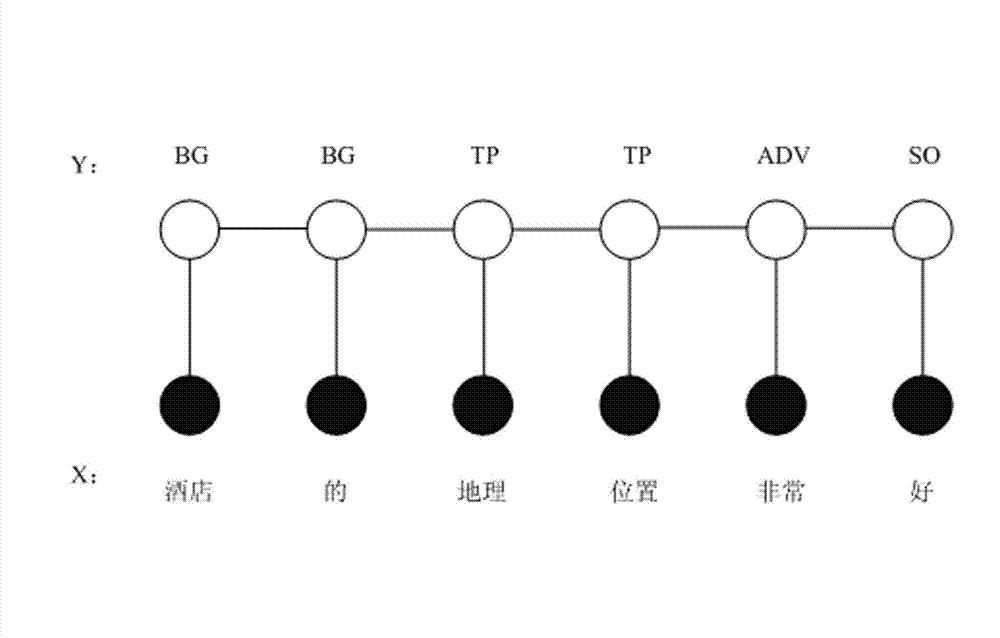

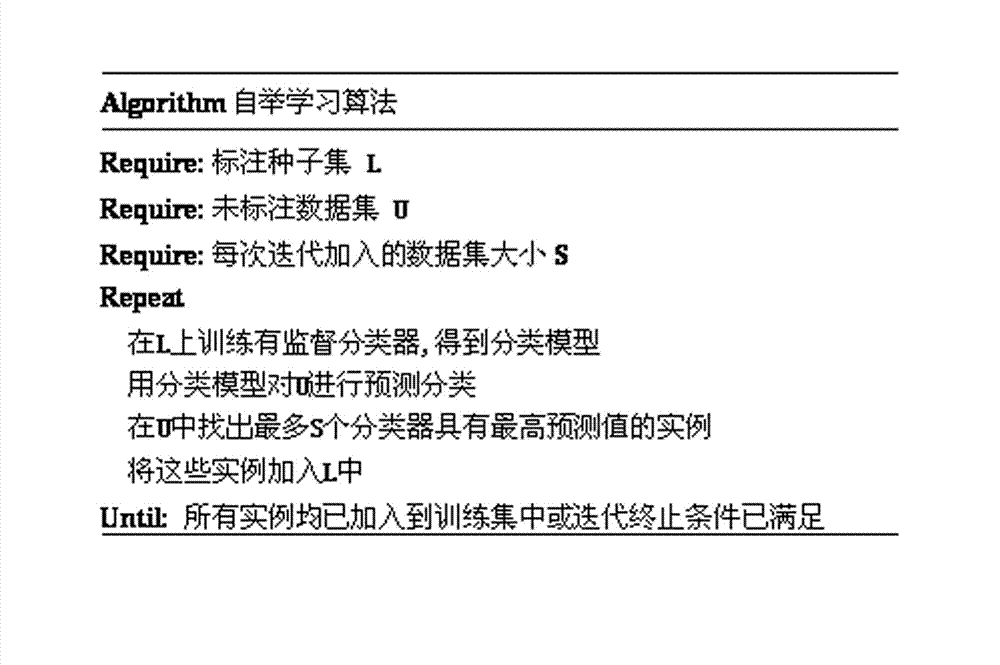

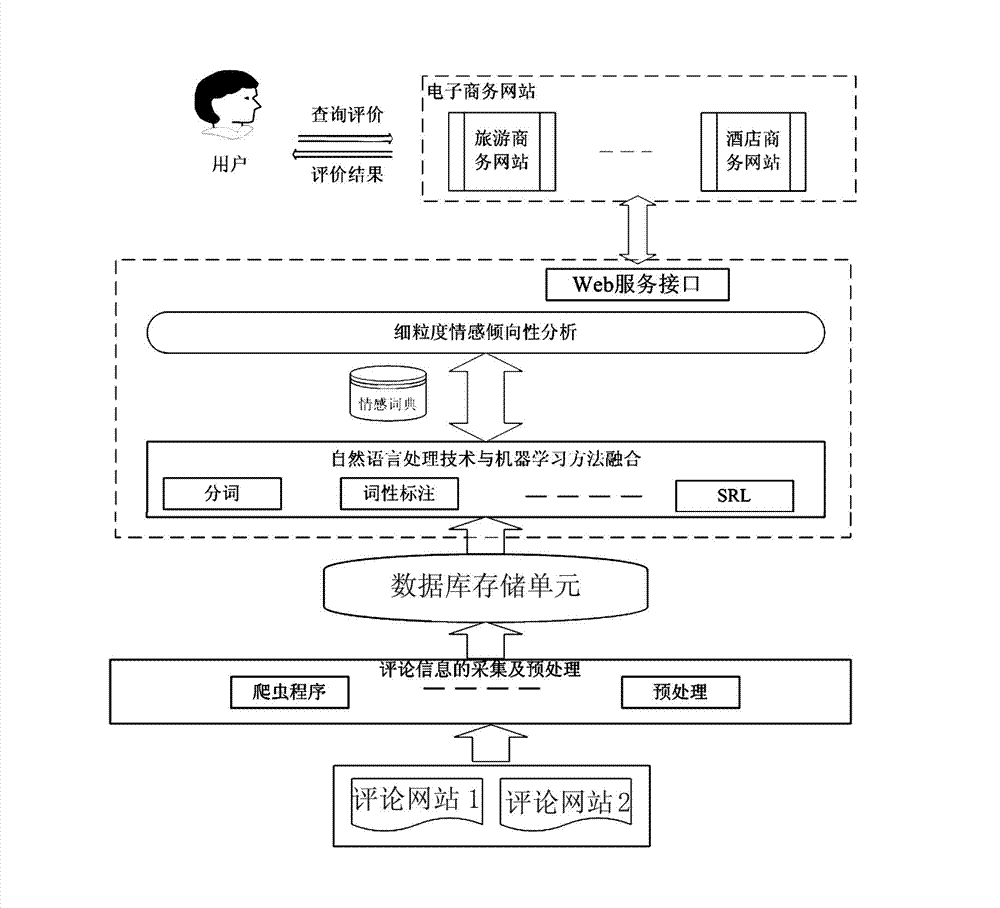

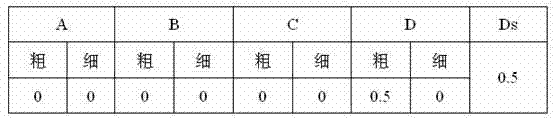

Text fine granularity sentiment analysis method and text fine granularity sentiment analysis device

ActiveCN103049435AImprove overall performanceImprove accuracySpecial data processing applicationsData processingTheoretical computer science

The invention discloses a text fine granularity sentiment analysis method. The text fine granularity sentiment analysis method includes the steps: performing sentiment word orientation intensity quantitative calculation; performing combined recognition of evaluation object attributes and sentiment expression elements thereof; and performing fine granularity attribute classification and sentiment calculation. The invention further discloses a text fine granularity sentiment analysis device which comprises a comment data acquiring and preprocessing module, a data processing module, a data analysis module and an information display module. The text fine granularity sentiment analysis method adopting the three steps has the advantages that accuracy rate is increased by nearly 30% by the aid of the sentiment word orientation intensity quantitative calculation step; the step of combined recognition of the evaluation object attributes and the sentiment expression elements thereof aims at the specific sentiment analysis application fields, and combined recognition accuracy rate is above 80%; and integral performance of sentiment calculation can be increased above 2.5% by the step of fine granularity attribute classification and sentiment calculation.

Owner:杭州脑壳顶科技有限公司

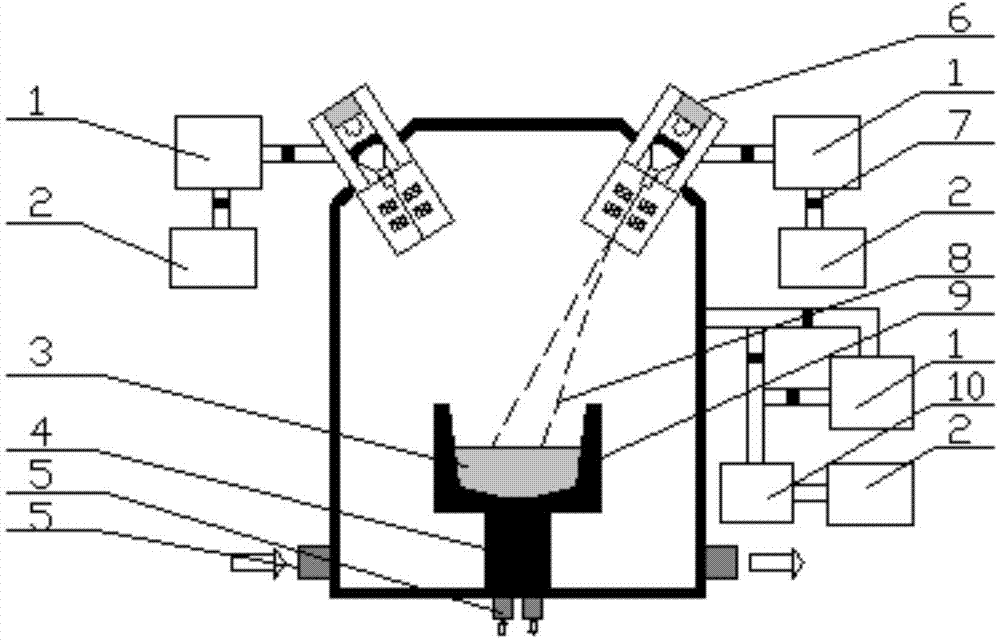

Method for preparing high-performance doped diamond-like film

InactiveCN101748381AImprove overall performanceImprove performanceChemical vapor deposition coatingIon beam depositionPhysics

The invention discloses a method for preparing a high-performance doped diamond-like film. The method is characterized by comprising the following steps: firstly, utilizing ultrasonic cleaning technology to remove a polluted layer on the surface of a substrate; utilizing ion beam assisted deposition technology to prepare a gradient transition layer; and finally utilizing ion beam deposition and magnetron sputtering to synthesize a multi-element doped DLC film, wherein except any one of carbonaceous gases, such as methane, acetylene, benzene, ethanol, acetone and the like, any gas containing non-carbon elements, such as silicon hydride, boron hydride, phosphorane, carbon tetrafluoride and the like, is simultaneously introduced, and a metal sputtering source is opened for the doping of metal elements. The method has the advantages of synthesizing the multi-element doped DLC film which is simultaneously doped with the metal elements and the nonmetal elements, fully developing the complementary advantages of the doped metal elements and the doped nonmetal elements and remarkably improving the combination properties of the DLC film.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

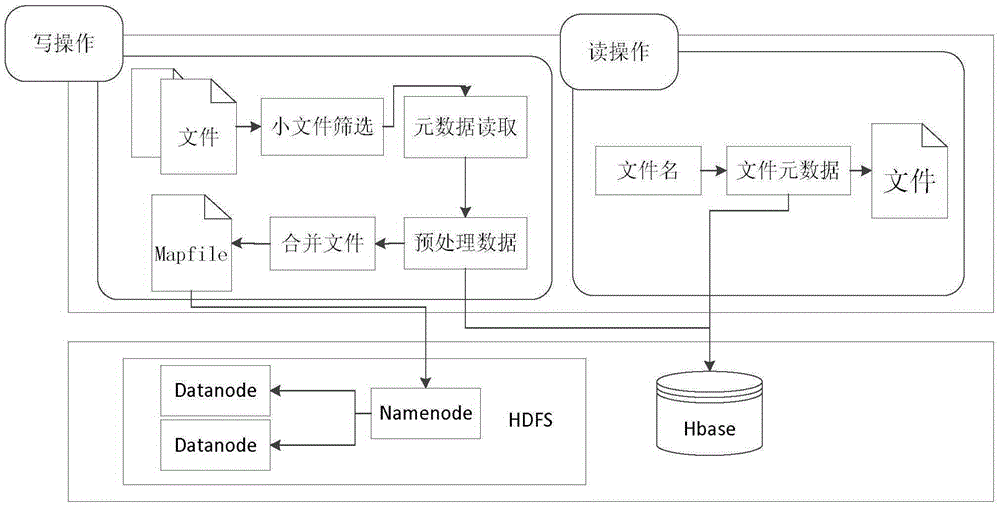

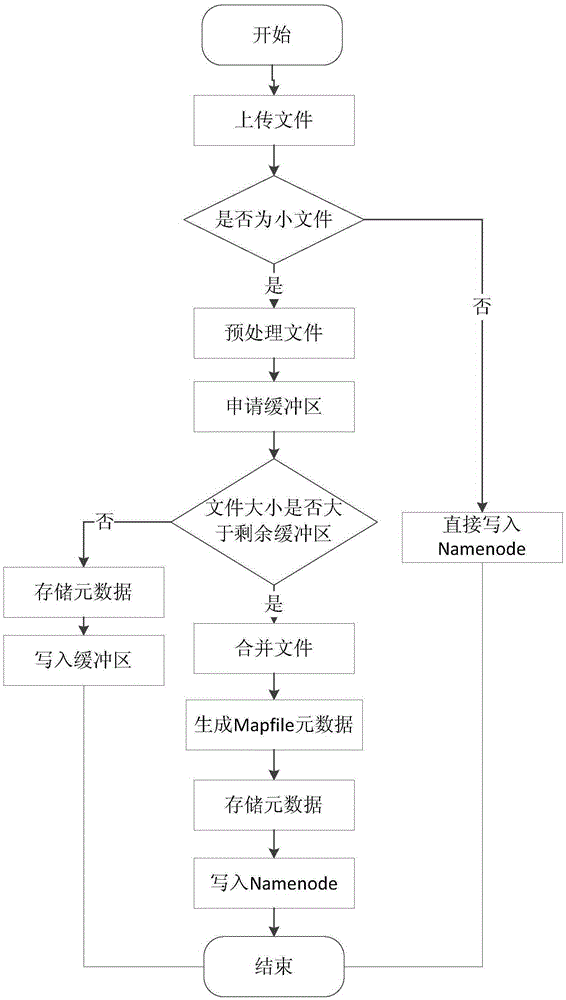

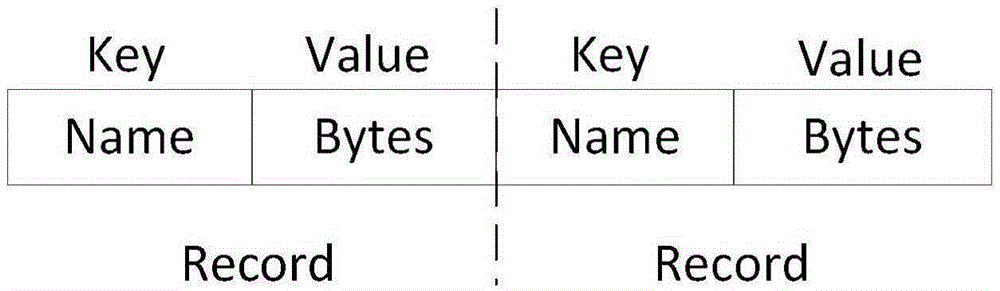

Mass small file processing method based on HDFS

InactiveCN105404652AImprove write and read efficiencyImprove overall performanceSpecial data processing applicationsDistributed File SystemMetadata

The invention provides a mass small file processing method based on an HDFS (Hadoop Distributed File System). The method comprises the following steps of generating a file ID (Identifier) through small file filtration and metadata reading to complete preprocessing on files; opening up a memory cache region; building a file uploading queue; performing time-delay storage on the files; merging the small files into a Mapfile file of a <key, value> structure in the cache region to be stored; storing file metadata into a distributive database Hbase, wherein the Hbase realizes the persistence in the HDFS; expressing the file status by a Status flag bit to complete operations such as fast reading of the small files of the cache region and Mapfile fragment merging, so that the real-time insert update and delete operation of the HDFS on the small files can be supported. The method has the advantages that the reading efficiency of the HDFS on the small files is improved, so that the system supports the real-time update operation on the small files, and the integral performance of the system is improved.

Owner:HOHAI UNIV

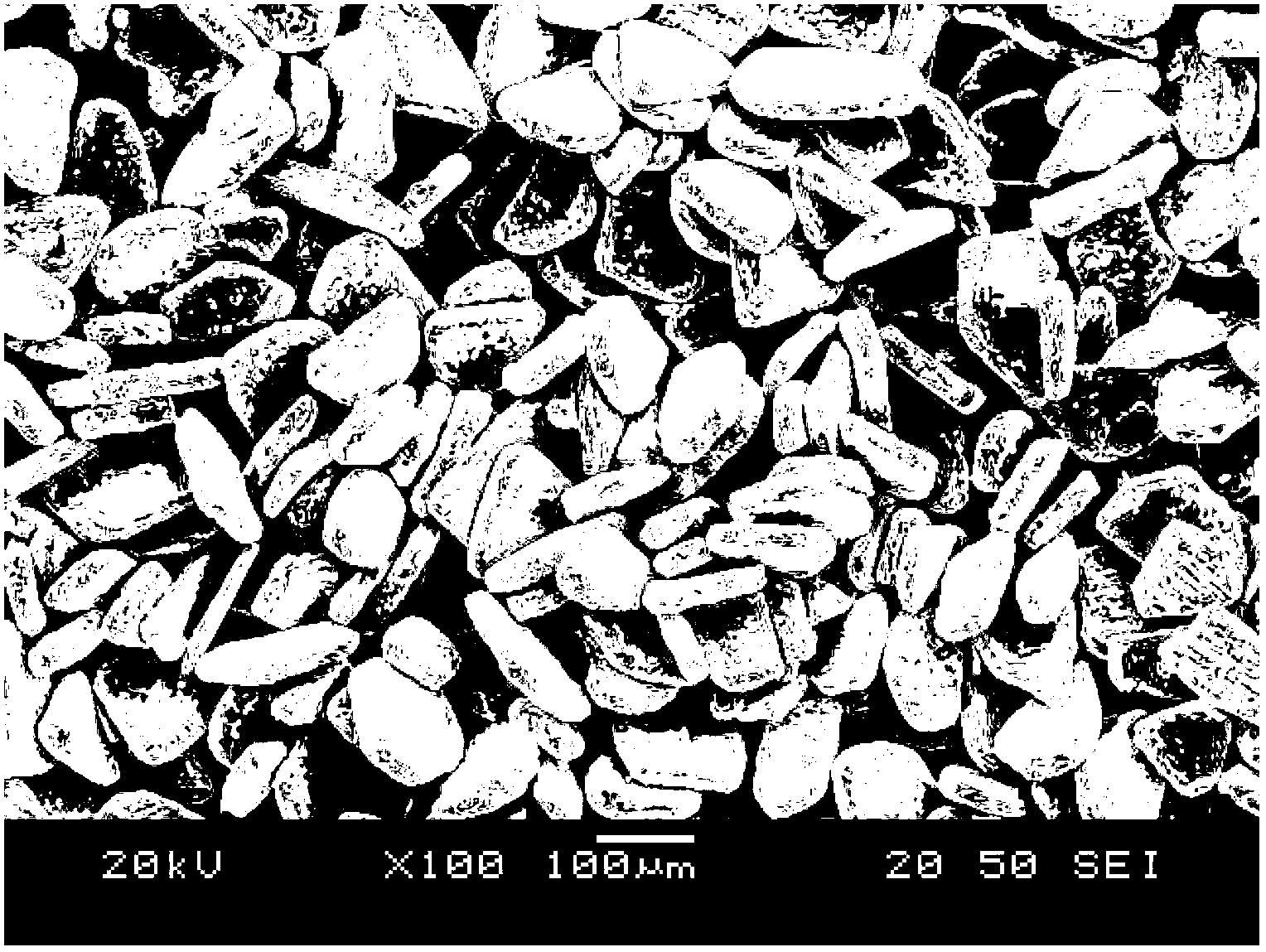

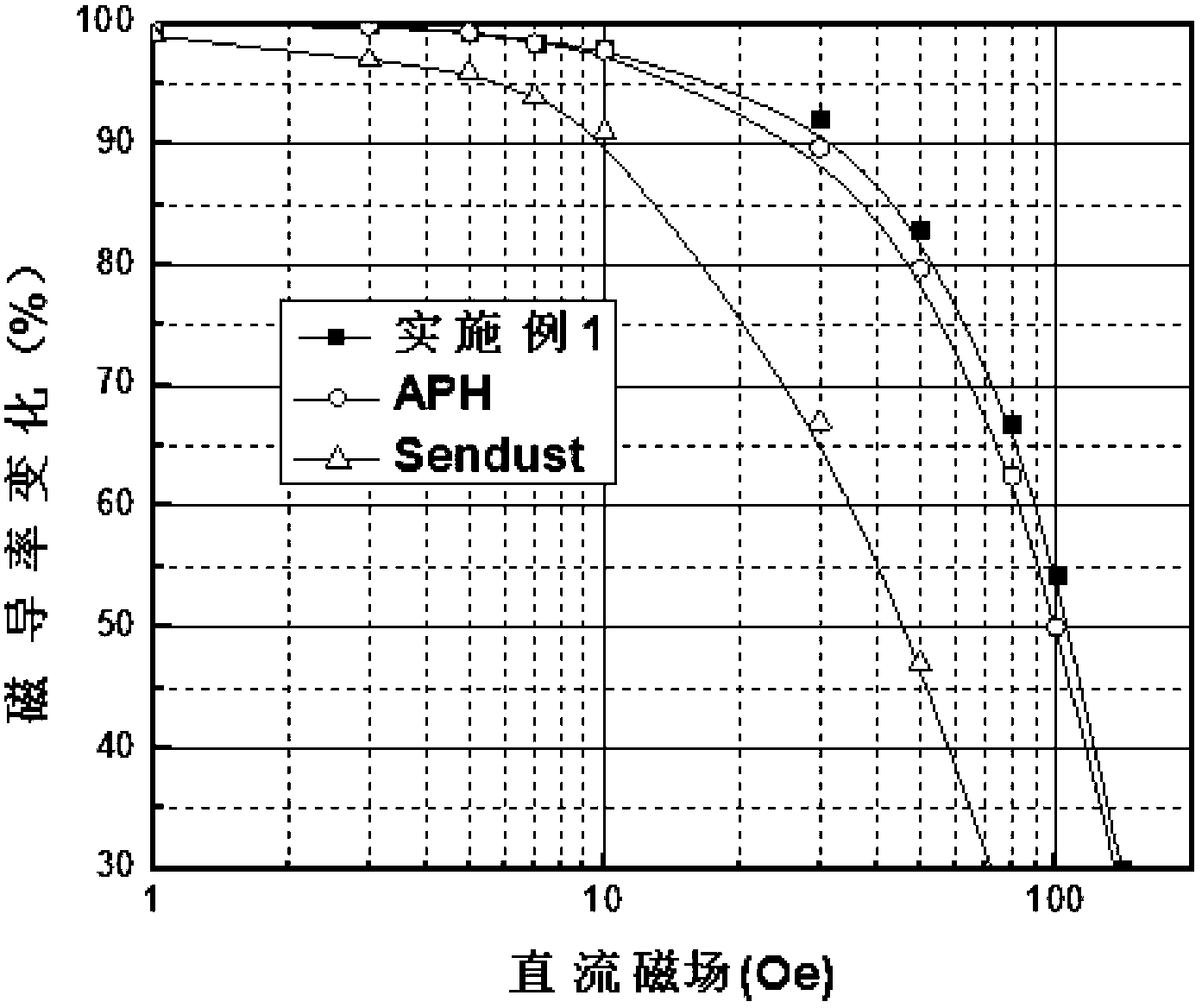

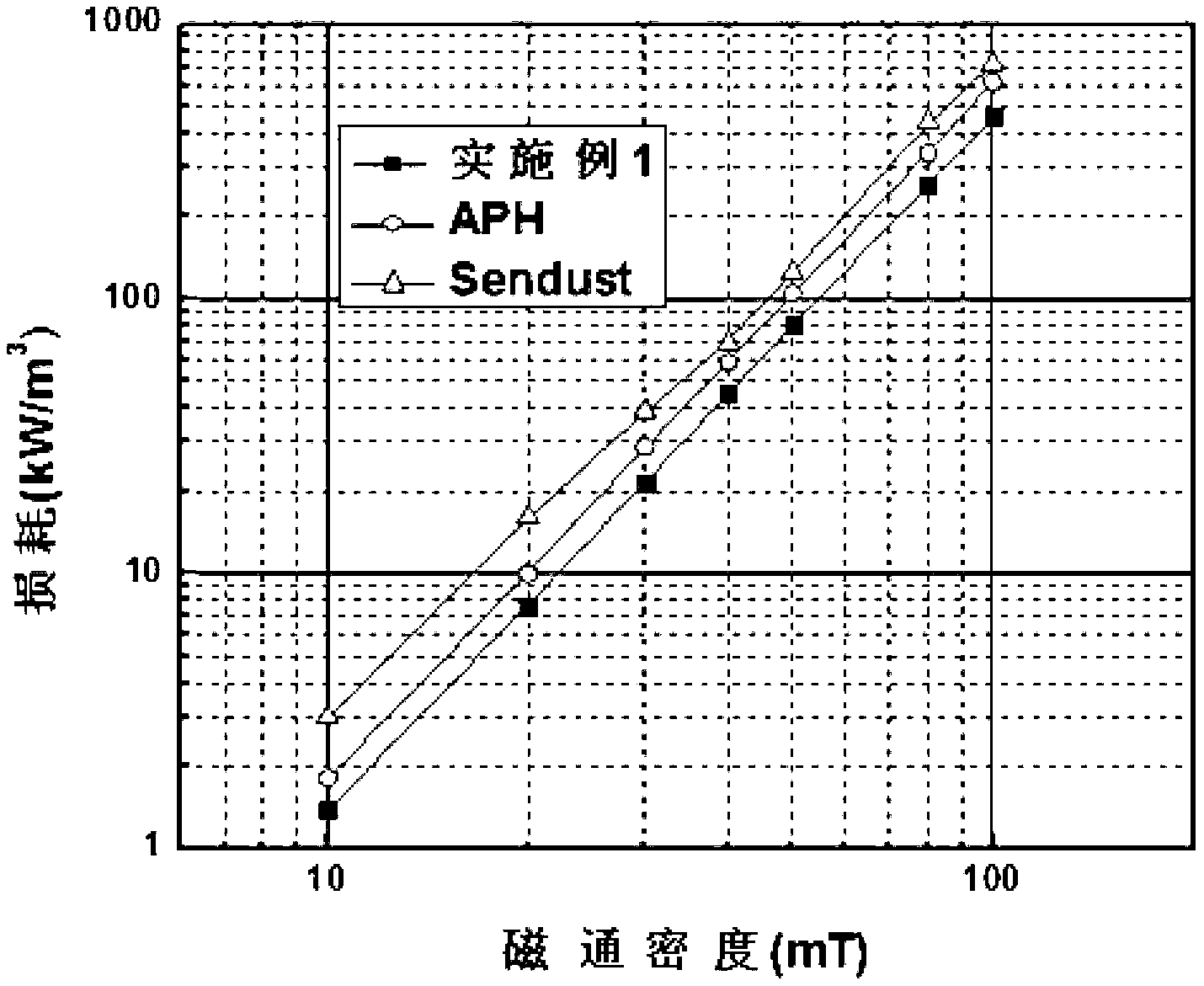

Preparation method of mu90 high-permeability Fe-based amorphous magnetic powder core

InactiveCN103219119AExcellent DC bias characteristicsHigh permeabilityInorganic material magnetismQuenchingMagnetic powder

The invention belongs to the field of Fe-based soft magnetic materials and particularly relates to a preparation method of a mu90 high-permeability Fe-based amorphous magnetic powder core. The preparation method comprises the steps of conducting preheating treatment to Fe-based amorphous ribbon which is prepared by adopting a single-roller rapid quenching method; crushing the amorphous ribbon by adopting a mechanical milling and air-current milling combination method; screening amorphous powder to obtain Fe-based amorphous powder with grain size being less than 100-mesh; conducting passivation and insulation treatment to the screened Fe-based amorphous powder, then mixing the Fe-based amorphous powder with adhesive and conducting coating granulation; molding the granulated coated powder to obtain the Fe-based amorphous magnetic powder core; and conducting stress relief annealing to the molded magnetic powder core. The Fe-based amorphous magnetic powder core which is prepared by adopting the method provided by the invention has high permeability and excellent loss and biasing characteristic.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Bamboo powder filled biomass-based resin composite material and preparation method thereof

ActiveCN101602882AImprove interfacial compatibility and bond strengthImprove overall performanceBiomassResin composite

The invention discloses a bamboo powder filled biomass-based resin composite material comprising the following components in part by weight: 20-60 parts of bamboo powder, 40-80 parts of biomass-based resin, 0.8-5 parts of resin acceptor, 0.2-0.6 part of antioxidant and 0.1-0.7 part of ultraviolet absorbent. The invention also discloses a preparation method of the composite material. Compared with the prior art, the invention has the advantages that waste bamboo powder is used as raw material, the hydrophilic and oleophobic bamboo powder is coupled with the oleophylic and lyophobic biomass-based resin by the resin acceptor, and thus the compatibility and the cohesional strength of interfaces of the bamboo powder and the biomass-based resin are improved. The composite material can be widely applied to the fields of automobile interior parts, traffic road blocks, food bags, preservative films, disposable tablecloth, disposable lunch boxes, flowerpots, knives and forks, and the like.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

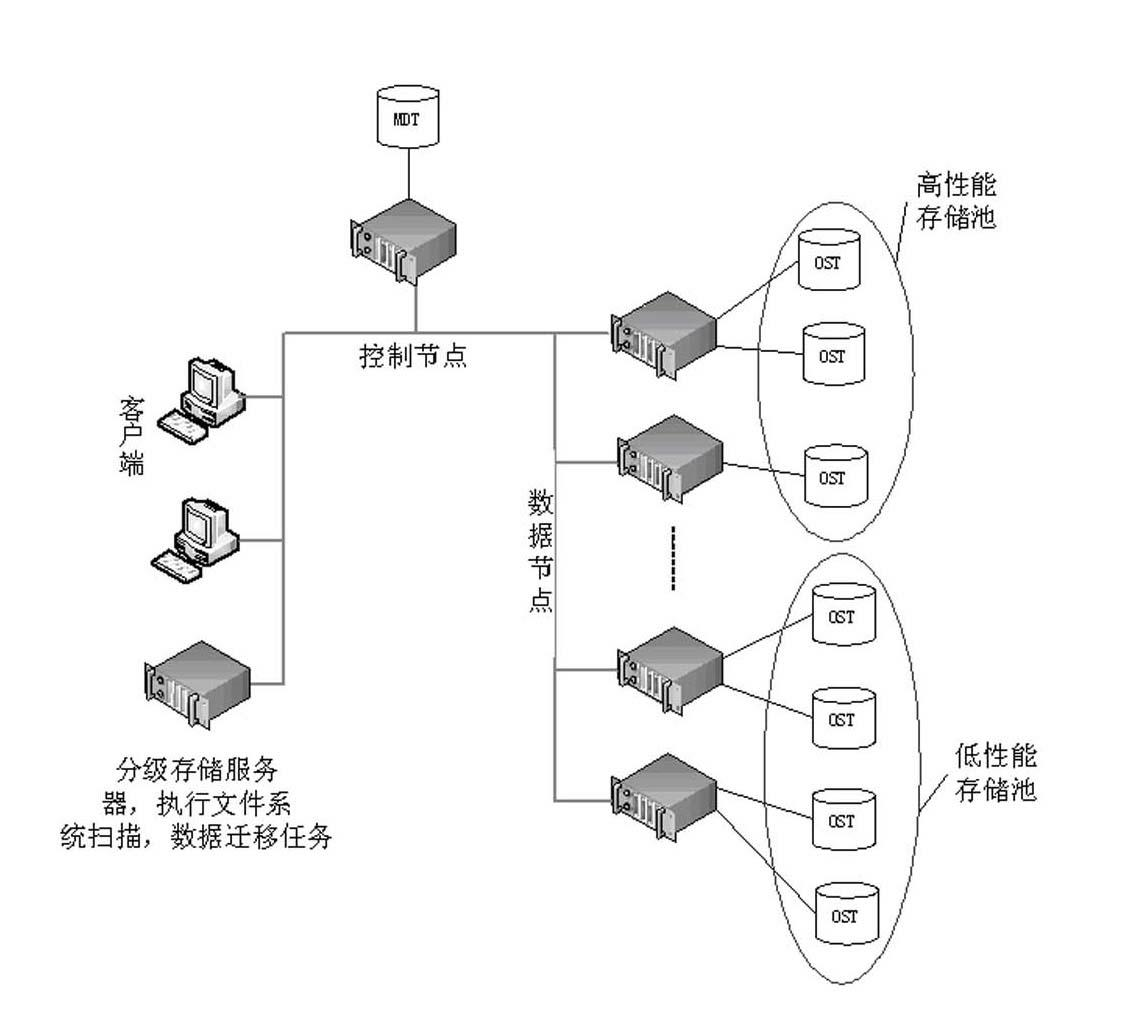

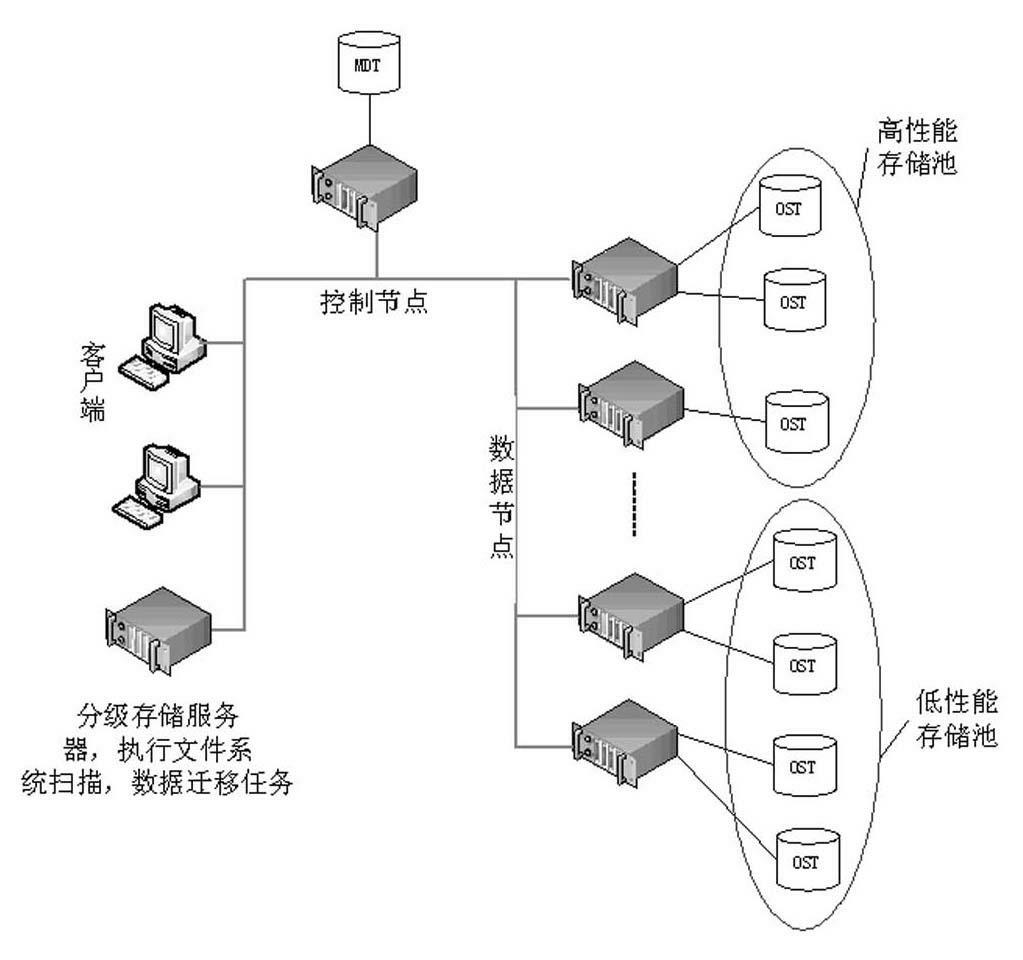

A method for online hierarchical storage of data in a cluster storage system

ActiveCN102291450AReduce storage costsImprove overall performanceTransmissionAccess frequencySoftware

The invention provides a data online hierarchical storage method in a cluster storage system. Data has a life cycle, and particularly has different meanings in different periods; a cluster storage system stores mass data; however, only 20% of the mass data is key data at high access frequency, and 80% of the mass data is non-key data at low access frequency that the non-key data is generally not accessed in one month or even one year; and the mass data stored in the cluster storage system is classified for storage according to the data access frequency and the characteristic that data has a life cycle so as to save the storage cost. According to the invention, different storage pools are established in the cluster storage system based on the life cycle of data, online hierarchical storage in the cluster storage system is realized by use of scanning software and migration software, thereby saving the storage cost and improving the overall performance of the system.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Aluminum alloy special-shaped member equivalent temperature precision forging technique method

ActiveCN101185954AImprove overall performanceIncreased internal densityForging/hammering/pressing machinesHeat treatment process controlEquivalent temperatureFiber

The invention relates to a constant temperature fine-forging technique process used for the aluminum alloy parts with different shapes. The invention is mainly characterized in that constant temperature blank forging, die pre-forging, corrode-washing, fine forging of dies, heat treatment and re-corrode washing, etc. processes are adopted under a given temperature to enlarge the internal density of the parts and optimize the fiber direction and distribution of the inner construction of the parts, so as to enhance the strength and improve the appearance quality of the parts. The invention can enhance machining efficiency, reduce machining cost and conserve precious materials. The invention can enhance the compound capability of the materials of parts.

Owner:HENAN COSTAR GRP CO LTD

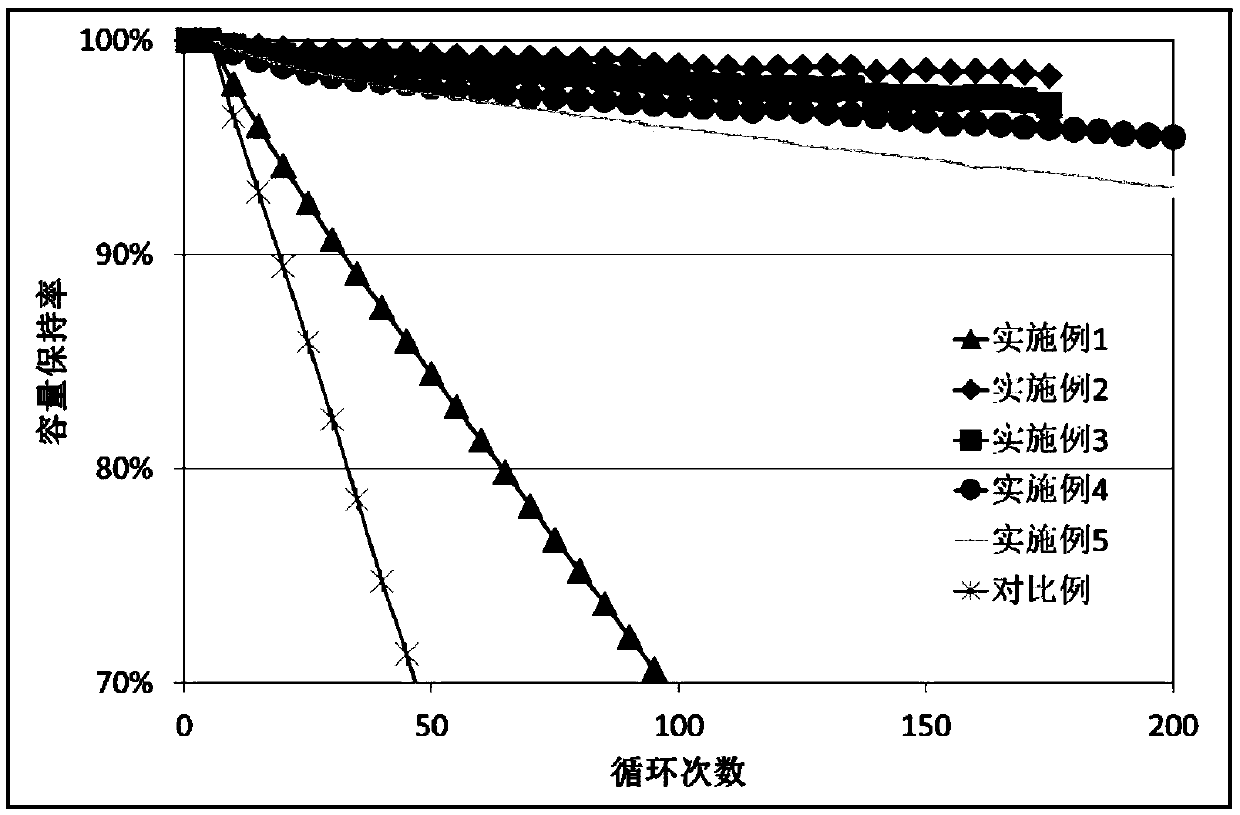

Modified composite material containing silicon-based material, preparation method thereof and use thereof in lithium ion battery

InactiveCN109103441AImprove overall performanceStable electrode structureNegative electrodesSecondary cellsSolventCharge and discharge

The invention discloses a modified composite material containing a silicon base material, which comprises a silicon base core and a polymer cladding layer covering the surface of the core, and a preparation method and use thereof in a lithium ion battery. The method comprises the steps of : 1) adding a polymer into a liquid solvent and dispersing to obtain a slurry; 2) adding a silicon-based material or a mixture of that silicon-based material and the carbon material into the slurry and mixing the solid and liquid; 3) removing the solvent to obtain a modified composite material containing a silicon-based material. As the polymer coat layer is introduced on the surface of the silicon base core, so that the electrolyte can be isolated and the side reaction of the electrolyte on the surface of the silicon base core can be prevented; the method can also improve the crushing, electrode pulverization and peeling of the silicon-based negative electrode material in the process of processing and using, and reduce the electrode crushing and peeling caused by the huge volume expansion of the silicon-based material in the process of charging and discharging, so as to achieve the purpose of stabilizing the electrode structure and improving the cell cycle performance.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

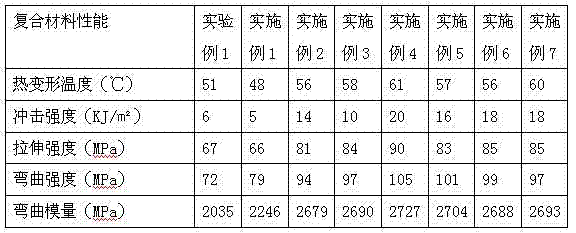

Nylon 6 with high performance and low melting-point and preparation method thereof

The invention discloses nylon 6 with high performance and low melting-point and preparation method thereof. The nylon 6 is mainly prepared from common nylon 6, LiCl, epoxy resin and other auxiliaries. In comparison with the existing technology, the invention better lowers the melting point of the nylon 6; moreover, the epoxy resin is added to perform mutual exchange reaction with the nylon 6 such that nylon 6 with high strength, high impact, high resistance and low melting-point can be obtained without adding glass fiber. The comprehensive performance of the nylon is largely raised. The preparation technology provided by the invention is simple, and is suitable to be applied in mass production.

Owner:贵州凯科特材料有限公司

Bus transfer method based on weighted directed network model

InactiveCN102880642AImprove efficiency and convenienceImprove overall performanceRoad vehicles traffic controlSpecial data processing applicationsNetwork modelBreadth-first search

The invention discloses a bus transfer method based on a weighted directed network model. The method comprises the following steps of: regardless of influence of a plurality of bus lines in the same road section on traffic, constructing an unweighted directed network model of a bus system; in consideration of the influence of a plurality of bus lines in the same road section on the traffic, constructing a weighted directed network model of the bus system; applying a breadth-first search algorithm to an unweighted directed network, and calculating a set R of shortest paths from a start station Vstart to a destination station Vend; and applying a weighted directed network, calculating path characteristic time coefficients of each shortest path in the set R of the shortest paths, and setting a path with the minimum path characteristic time coefficient as an optimal path. By adoption of the bus transfer method, the average waiting time of bus transfer can be effectively shortened, and selected traveling paths are optimized, so bus transfer efficiency and convenience are improved.

Owner:ZHEJIANG UNIV OF TECH

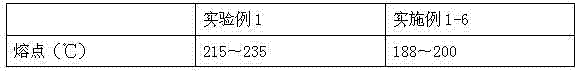

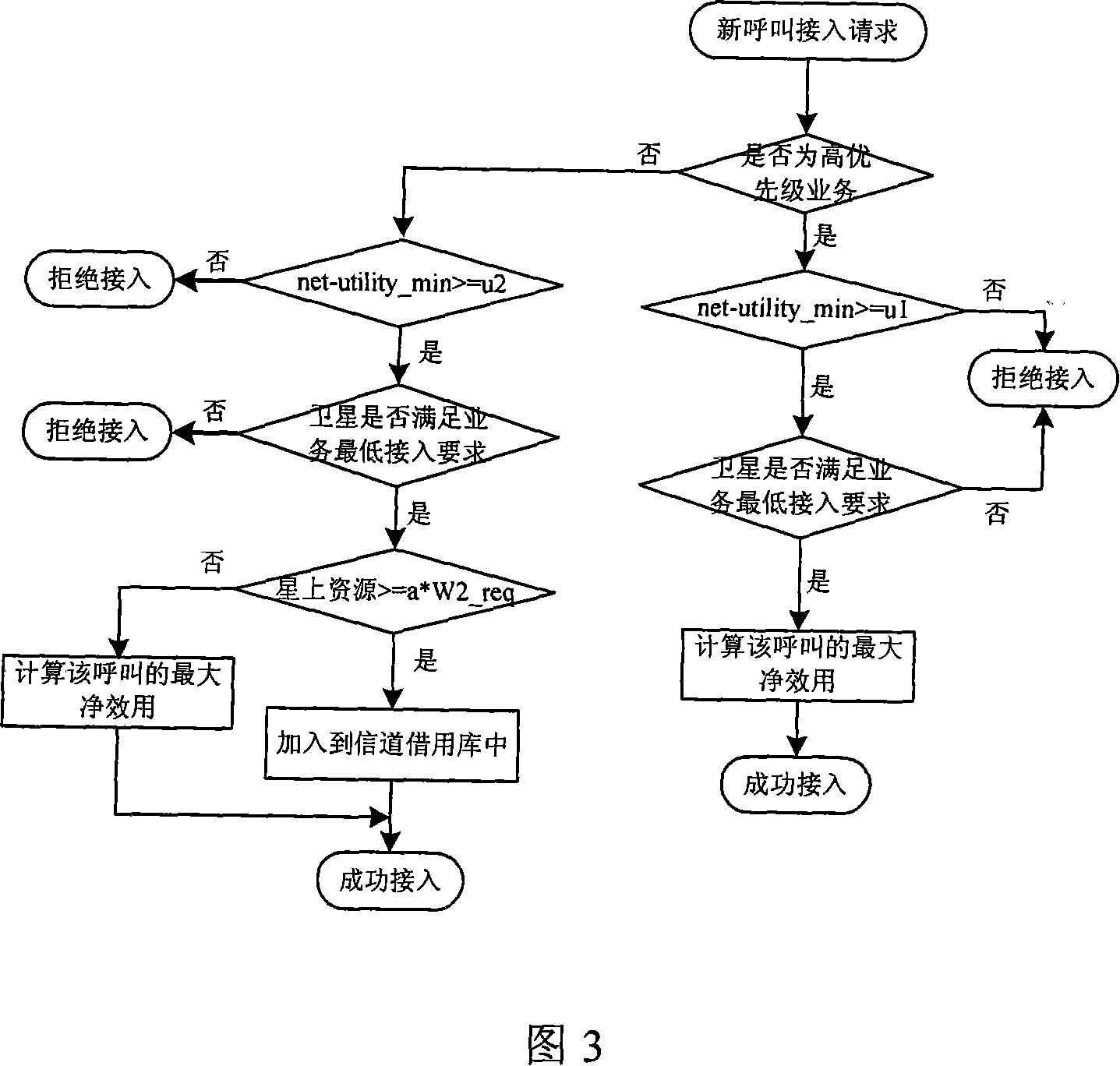

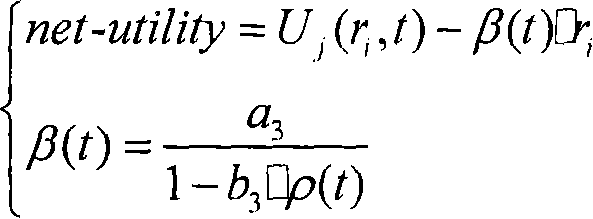

A satellite call access control method

InactiveCN101106417AImprove onboard resource utilizationImprove overall performanceRadio/inductive link selection arrangementsRadio transmission for post communicationCall blockingSatellite

An on-board call access control method is characterized in that for access request, firstly judge the type of call: if a switching call, determine the switching call service is low-priority or high-priority, and implement the switching call request access process on the low-priority or the high-priority call service; if a new call, determine the new call service is low-priority or high-priority, and implement the new call request access process on the low-priority or the high-priority call service. Under the circumstances of ensuring the indexes of handoff failure probability of satellite systems, the new call-blocking probability, the link bandwidth utilization and so on, the invention fully considers the satisfaction of users and the influence of network-load changes on the system performances, effectively ensures the QOS requirement of mobile satellites, and improves comprehensive properties and robustness of satellite systems.

Owner:BEIHANG UNIV

Sweetmuscat wine and brewing process thereof

The invention aims at providing sweet muscat wine which uses muscat grapes as a raw material, is rosy in appearance color, is clear and transparent, typical, rich, fresh and elegant in aroma, mellow and full in taste, smooth in wine body, balanced in taste, lasting in aftertaste and high in alcohol degree and a brewing process thereof, belonging to the technical fields of wines. The technical scheme is as follows: the brewing process of the sweet muscat wine adopts a segmented fermentation method,an impregnation process and a fermentation process are not fully synchronized, the impregnation is performed for a fixed time of 96h in an alcohol fermentation process I, peel and pomace are separated and then an alcohol fermentation process II is performed, and the impregnation time length is fixed and appropriate.

Owner:山西戎子酒庄有限公司

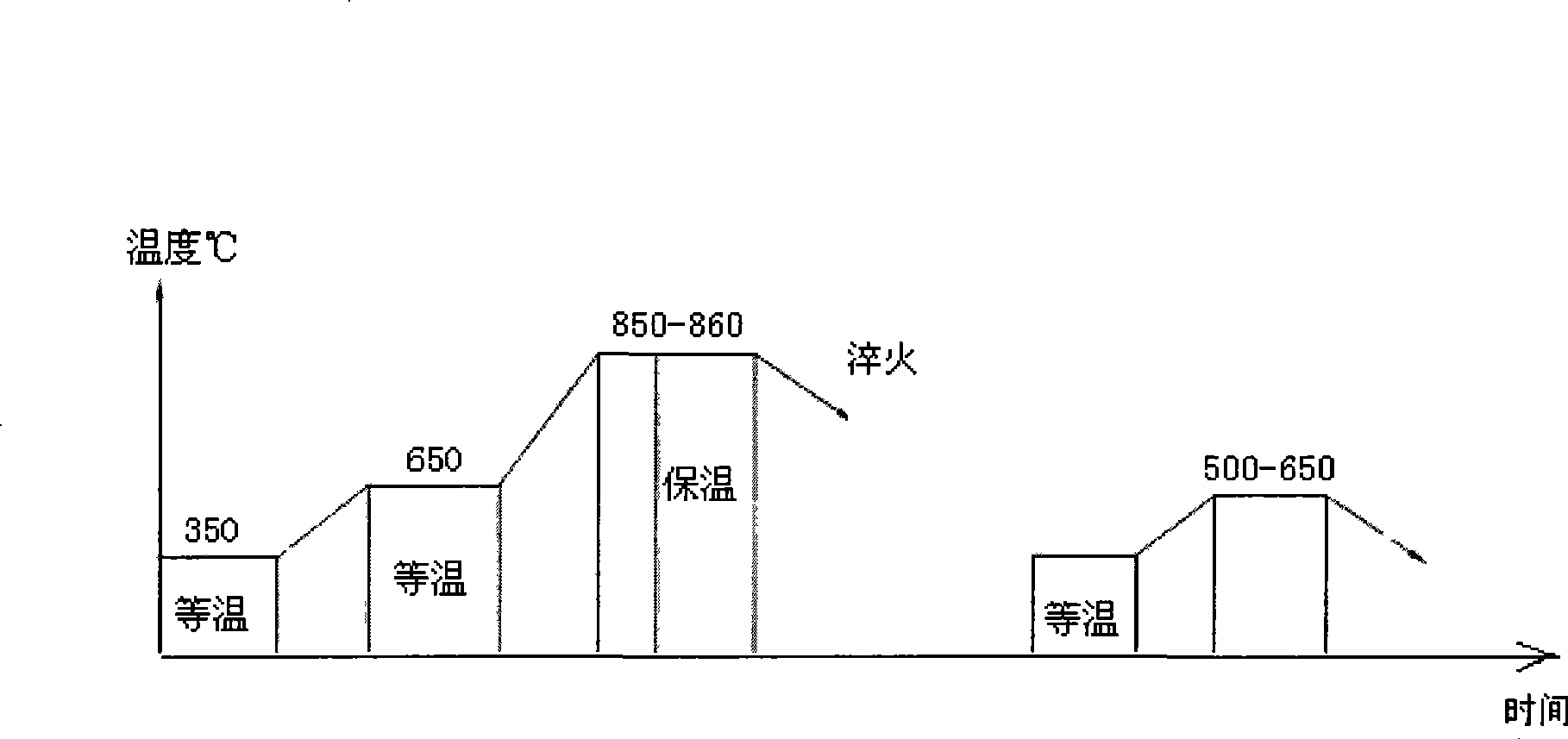

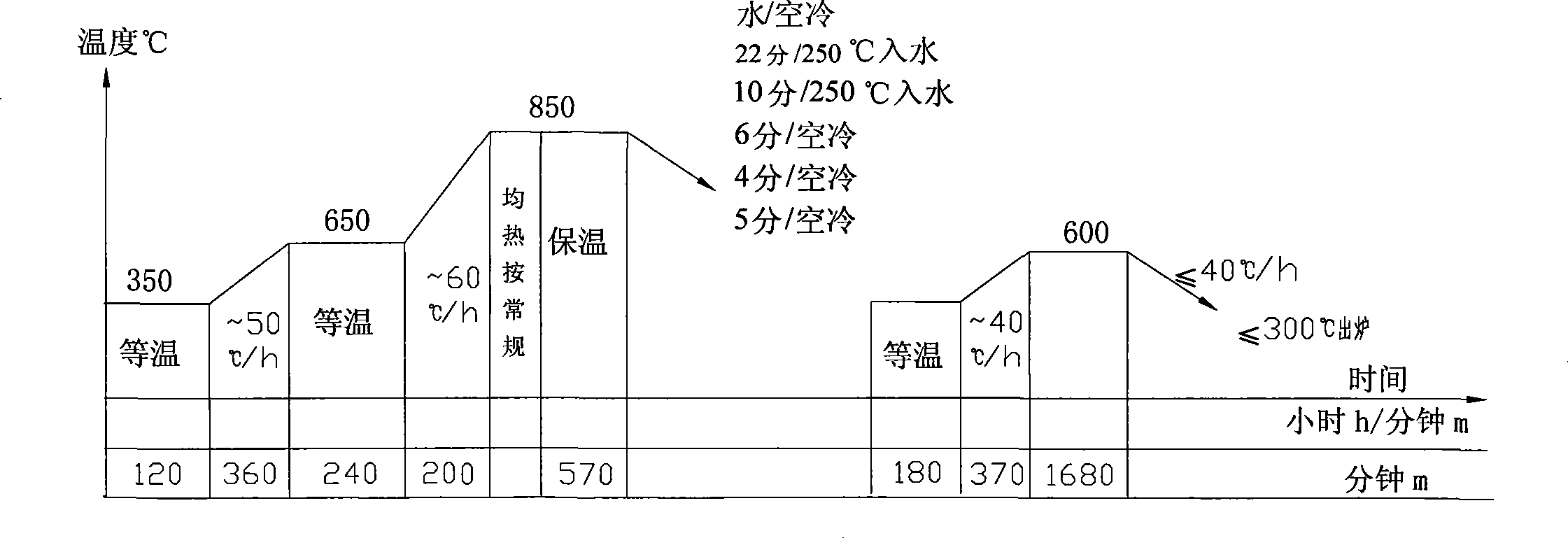

Water quenching and air cooling modified treatment technology of 42CrMo material

InactiveCN101363070APrevent cold crackingImprove overall performanceHeat treatment process controlQuenchingAir cooling

The invention discloses a hardening and tempering and quenching treatment process of a large 42CrMo forged piece, which comprises the steps of heating up, heat preservation, quenching, high temperature tempering, etc. Quenching is carried out by a water quenching and air cooling method. The process comprises the following specific steps: when quenching, the forged piece is cooled in water for a certain time, and then is taken out for air cooling and buffer; when the surface temperature returns to 200-300 DEG C, the forged piece is put into water for water cooling again, and then is taken out for air cooling and buffer; after a plurality of cycles of water cooling and air cooling, the temperature of the forged piece is stable and not over 300 DEG C, the quenching process is completed. The treatment process provides the hardening and tempering scheme of the forged piece under the quenching condition without an oil groove, quenching oil, and the like, and improves the comprehensive properties of the forged piece.

Owner:SHANGHAI HEAVY MACHINERY PLANT

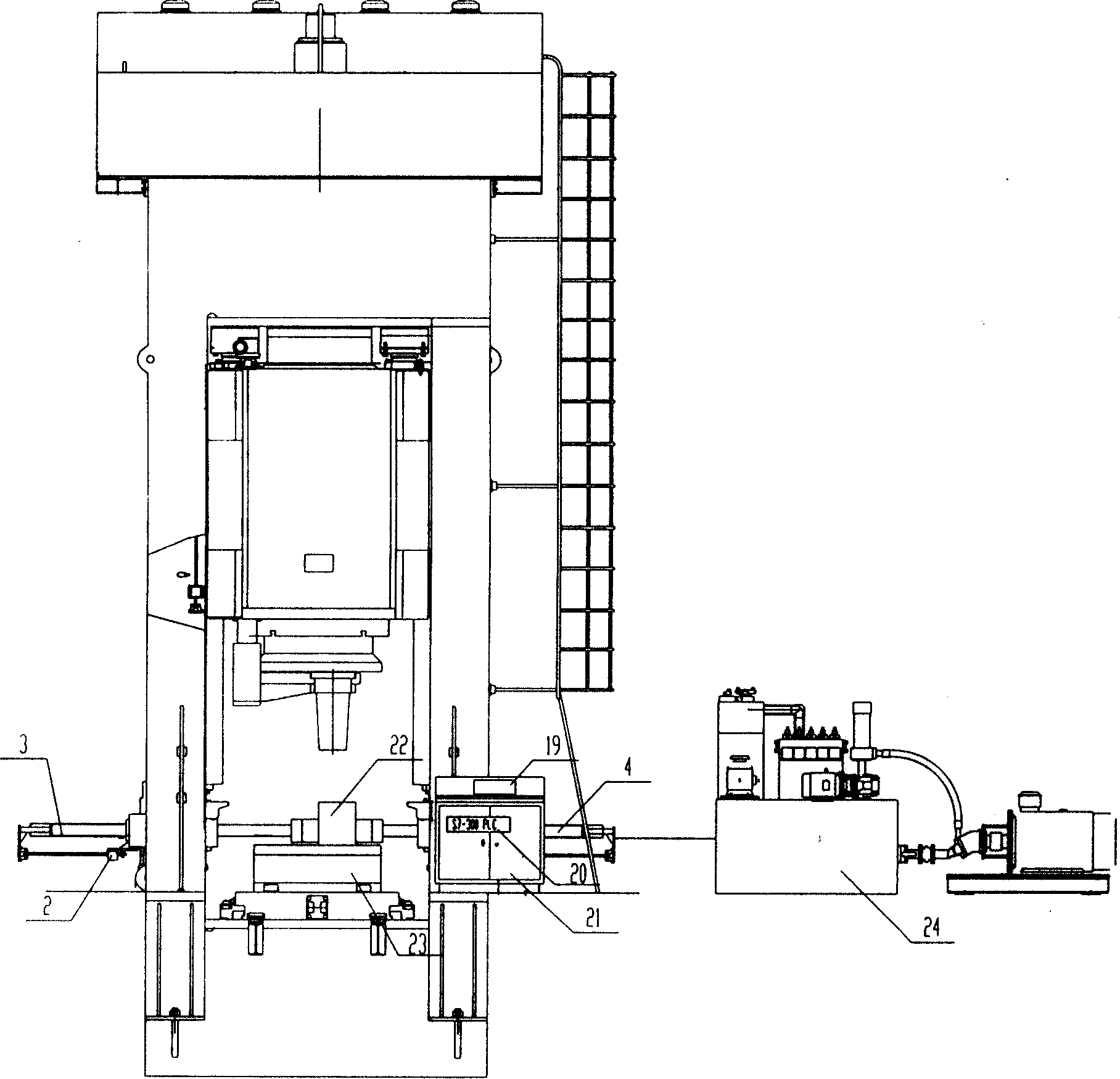

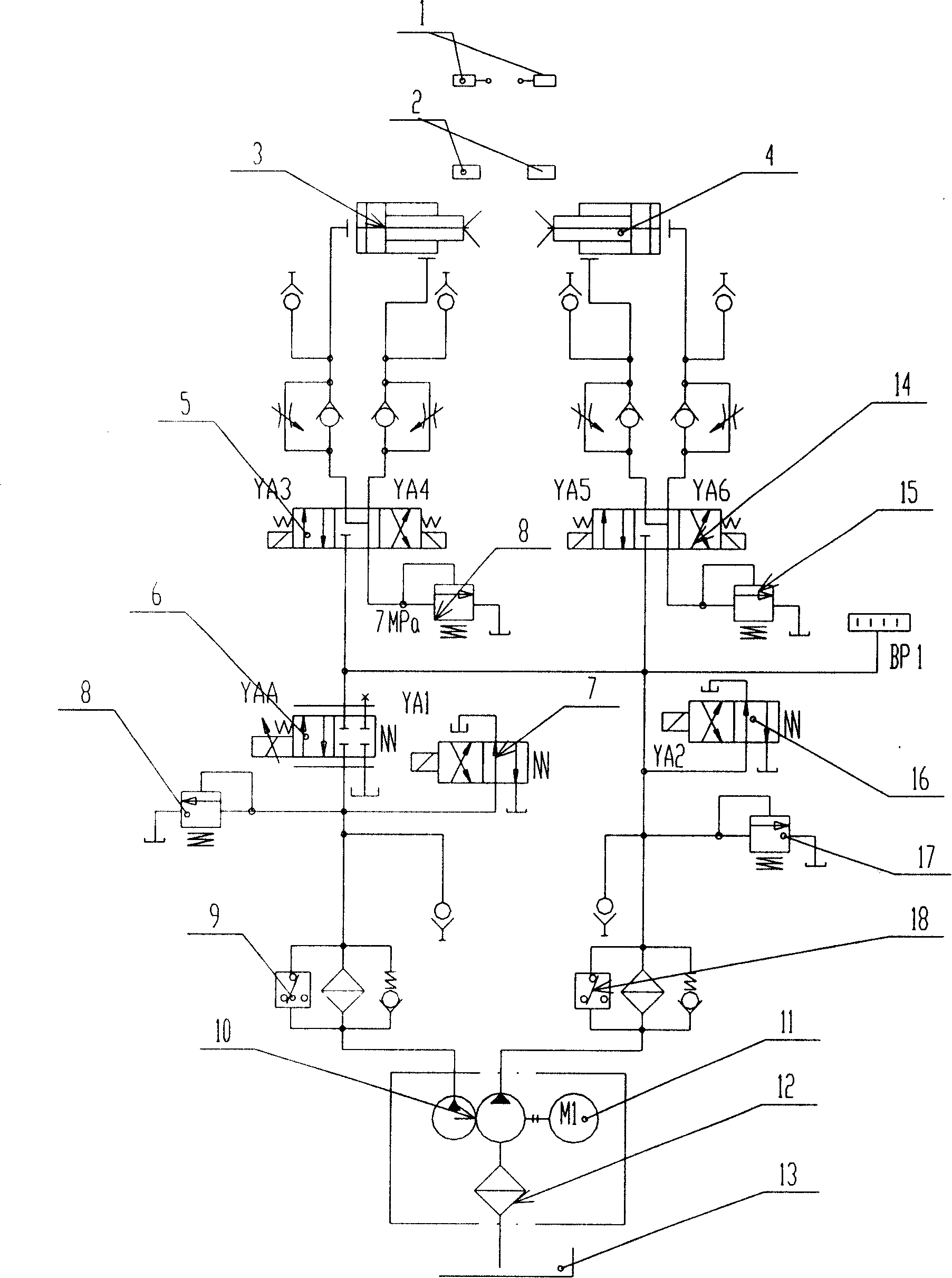

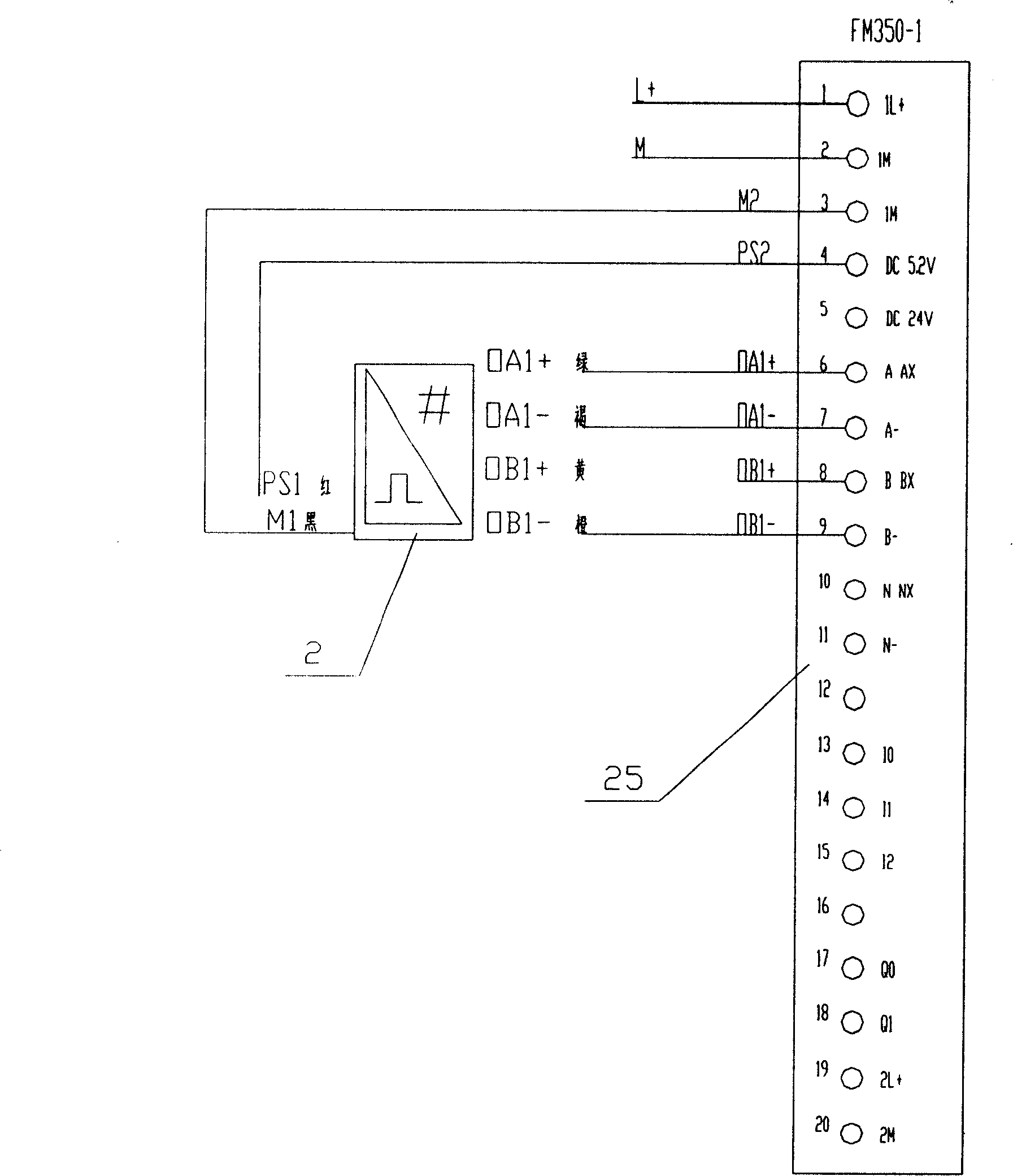

Numerically-controlled forging hydraulic press capable of realizing workpiece automatic centering

InactiveCN101164718AIncrease productivityImprove overall performanceForging press drivesTransducerDisplay device

The present invention relates to a numerically-controlled forging hydraulic press capable of implementing automatic alignment of workpiece, belonging to the field of hydraulic press technology. It includes the following several portions: hydraulic press machine frame, movable transverse beam, working table, display, electric controller and power mechanism. Said electric controller can be used for controlling power mechanism to drive hydraulic press machine frame and movable transverse beam, and the electric controller is connected with the display. It is characterized by that on the working table a workpiece alignment cylinder is mounted, on the alignment cylinder a motion transducer is mounted, the alignment cylinder is connected with power mechanism, and the motion transducer is connected with electric controller.

Owner:赵常海 +4

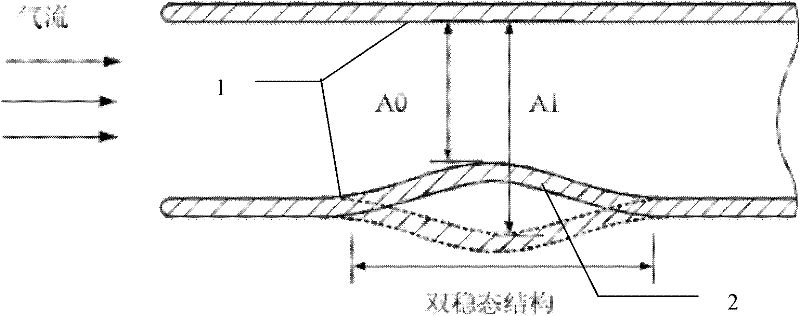

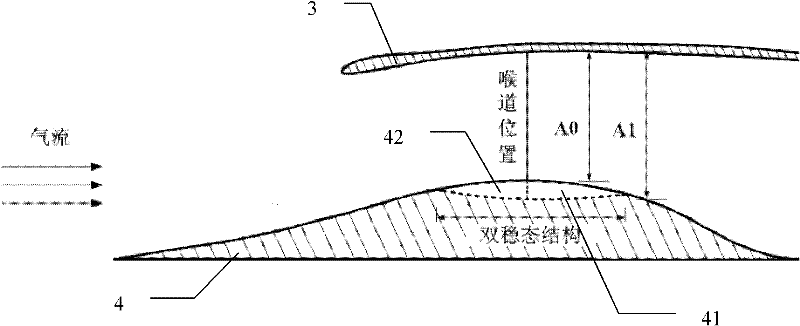

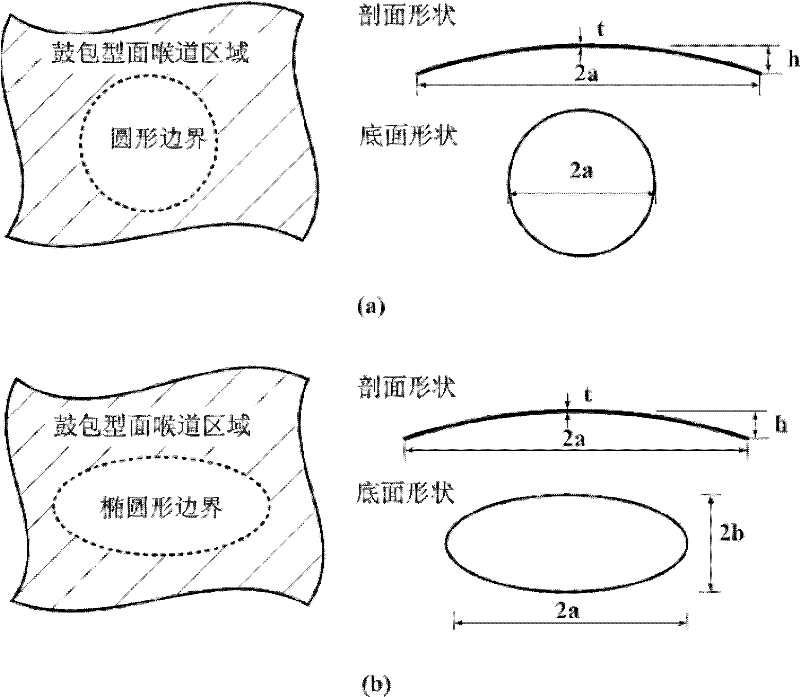

Bistable air inlet, its application as aircraft air inlet and design method of bistable air inlet

InactiveCN102518517ASolve non-adjustable problemsChanging throat areaGas turbine plantsJet propulsion plantsAirframeDesign methods

The invention discloses an aircraft air inlet with a bistable structure, and simultaneously relates to a design method of the bistable air inlet. The bistable structure area is designed differently according to different forms of aircraft air inlets. When an aircraft has an independent air inlet pipeline, the bistable structure can be arranged on the wall of the inlet pipeline; when the air inlet area of the aircraft is formed by an air inlet enclosure and an airframe bump profile, the bistable structure can be disposed in a bump area of the airframe bump profile. The design method designs the bistable structure area, and finally determines its structural parameters. The air inlet of the invention with a bistable and deformable structure realizes local concave-convex deformation of an air inlet, such as the compression profile of a bump air inlet, so that the throat area of the air inlet is changed, and the problem of an unadjustable compression profile of the bump air inlet is solved. Thus, under different flying states, the aircraft can have the optimal air inlet performance and inlet-engine matching property.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

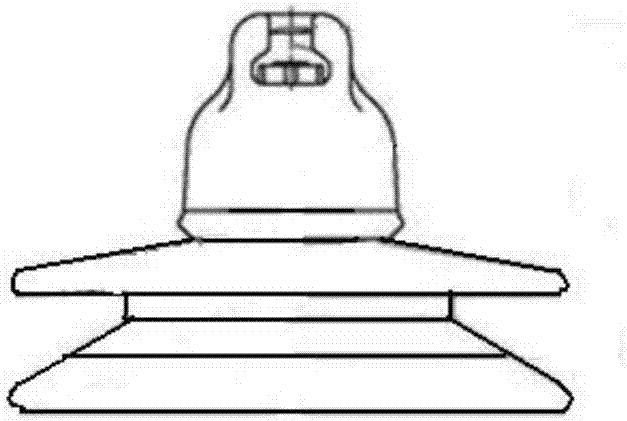

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

Smelting method of steel for hypoxia axle

ActiveCN102776323AImprove overall performanceImprove performanceProcess efficiency improvementElectric furnaceScrapElectric furnaces

The invention relates to a smelting method of steel for a hypoxia axle, which comprises the following steps that: I. smelting by using an electric furnace: scrap steel and pre-treated hot metal are added into the electric furnace, the oxygen blowing is carried out, and then a slagging material is added; the oxygen blowing is continuously carried out, and the eccentric bottom tapping of the electric furnace is adopted; a deoxidizer, ferroalloy and a slagging agent are added into a ladle before tapping; the hot metal is poured into the ladle; II. refining in a ladle furnace: before ladle refining, an Al wire is quickly fed for deoxy treatment; the ladle enters an LF(Ladle Furnace) station, Ar gas is blown from the bottom of the furnace, and calcium carbide is added; power is supplied to raise the temperature; reducing white slag is made in the ladle; Al powder and synthetic slag are added for diffusible desoxydation; in a white slag state, the time is kept within more than 15 minutes, the ladle goes out of an LF station; and III. VD (Vacuum Distillation) vacuum refining: the ladle enters a VD station; Ar gas is blown from the bottom under the high degree of vacuum; after VD treatment, an Al wire is fed; a covering agent is added; Ar gas is blown from the bottom, and soft stirring is carried out; the ladle goes out of the station; and steel is poured. According to the smelting method of steel for the hypoxia axle, the content of oxygen in the steel can be reduced to not more than 15 * 10<-6>.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for preparing solid-mold casting coating material for cast iron

ActiveCN103100658AImprove overall performanceHigh anti-sand sticking abilityFoundry mouldsFoundry coresCast ironCorundum

The invention discloses a method for preparing a solid-mold casting coating material for cast iron. According to the method, the solid-mold casting coating material is prepared from the following ingredients in parts by weight: 65-75 parts of quartz powder, 5-7 parts of wood ash, 10-12 parts of corundum powder, 10-12 parts of sodium bentonite, 4-6 parts of nano attapulgite, 1-2 parts of lignosulfonic acid, 2-4 parts of water glass, 2-4 parts of sodium borate, 5-7 parts of starch paste, 1.4-1.6 parts of silica sol, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder and 525-535 parts of water. The solid-mold casting coating material prepared by the method has excellent gas permeability and quick-drying performance in both high-temperature environments and low-temperature environments, thereby being capable of meeting the production requirements of large-sized cast parts.

Owner:XIANGFAN JINNAITE MACHINERY

Ternary doping modified SPEEK proton exchange membrane and preparation method

InactiveCN101908632AImprove overall performanceImprove proton conductivitySemi-permeable membranesCell component detailsIonYttrium

The invention relates to a ternary doping modified SPEKK proton exchange membrane and a preparation method thereof. The exchange membrane comprises the following components by mass percent: 80-98.5% of SPEEK with 40%-80% of sulfonation degree and 1.5-20% of ternary adulterant. The preparation method comprises the following steps: 1, adopting the SPEEK with medium sulfonation degree as a matrix material so as to overcome the over high water absorption and poor stability of the composite membrane of the SPEEK with over high sulfonation degree, and ensure that the composite membrane has a certain water absorption; 2, adopting a three ternary doping mode of ion liquid, rare-earth oxide yttrium oxide and phosphotungstic acid so as to enable the SPEEK substrate to act with the dopant materials so as to improve the combination property of the composite membrane; and 3, by the process of high temperature high-intensity magnetic field, enabling the dopant materials to be orientated under the action of a magnetic field to form a proton conduction passage to improve the proton conduction rate of the composite membrane.

Owner:SHANGHAI UNIV

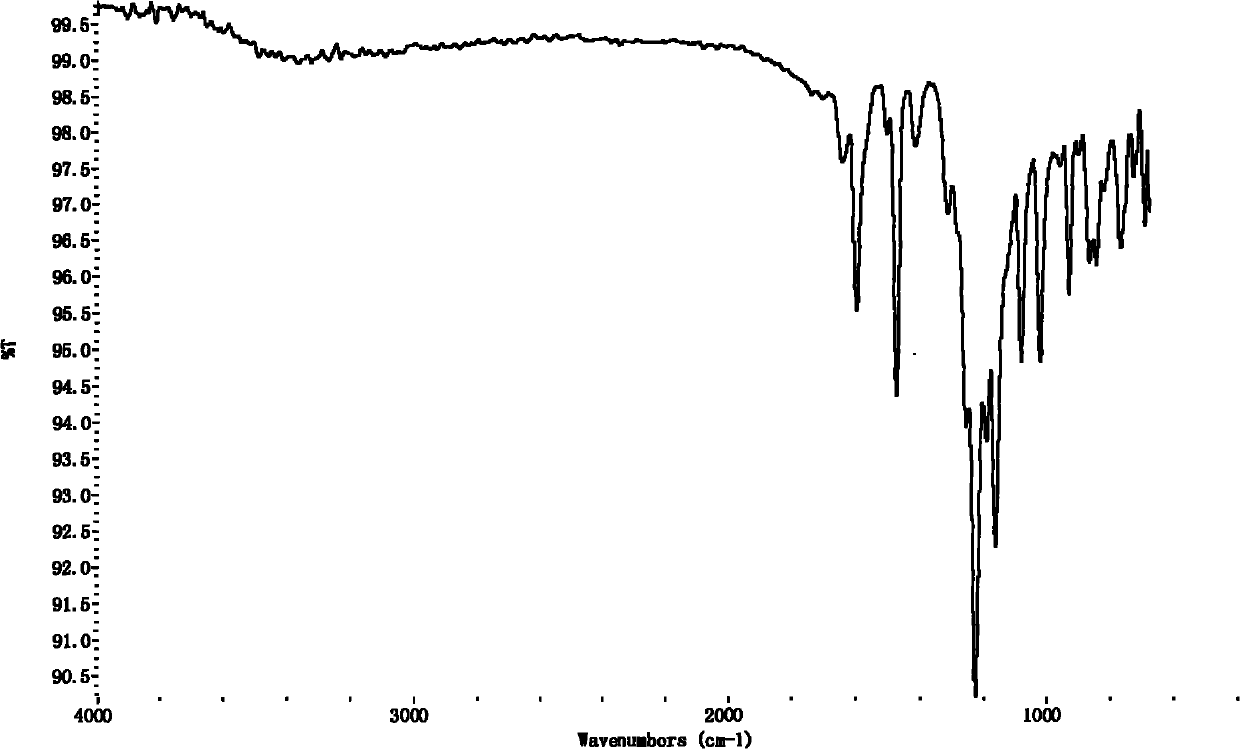

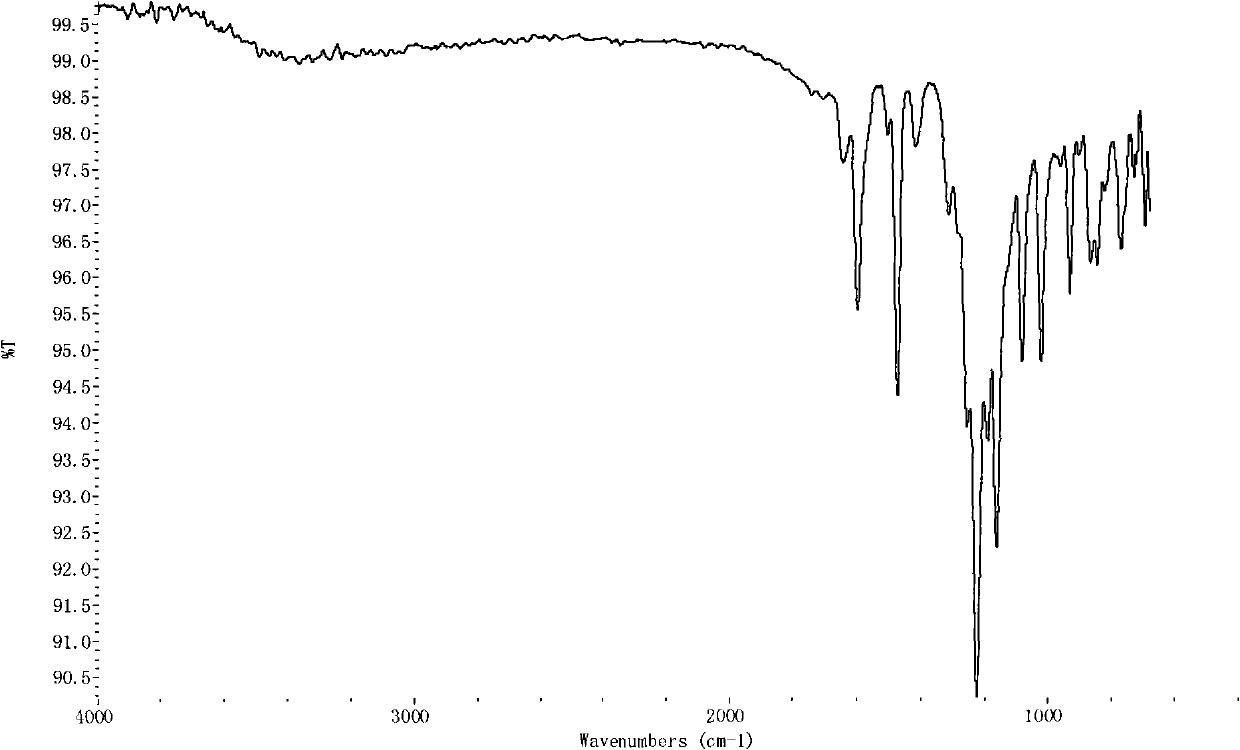

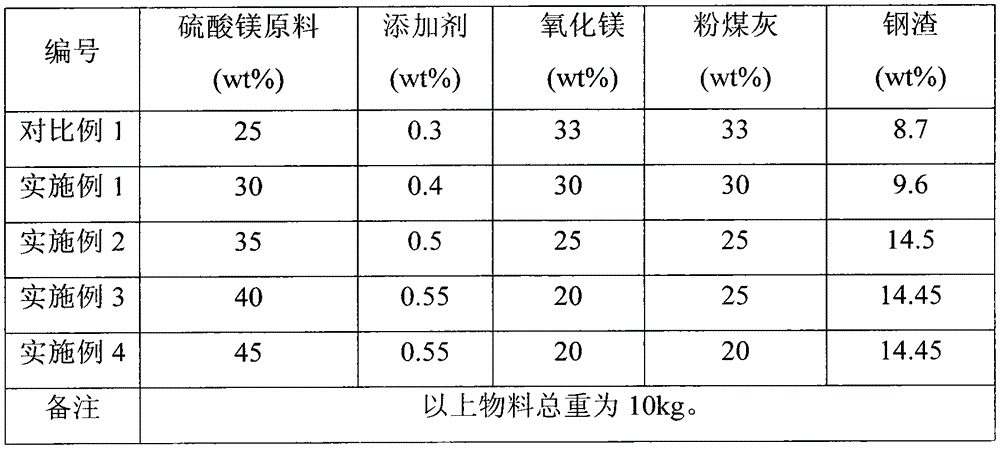

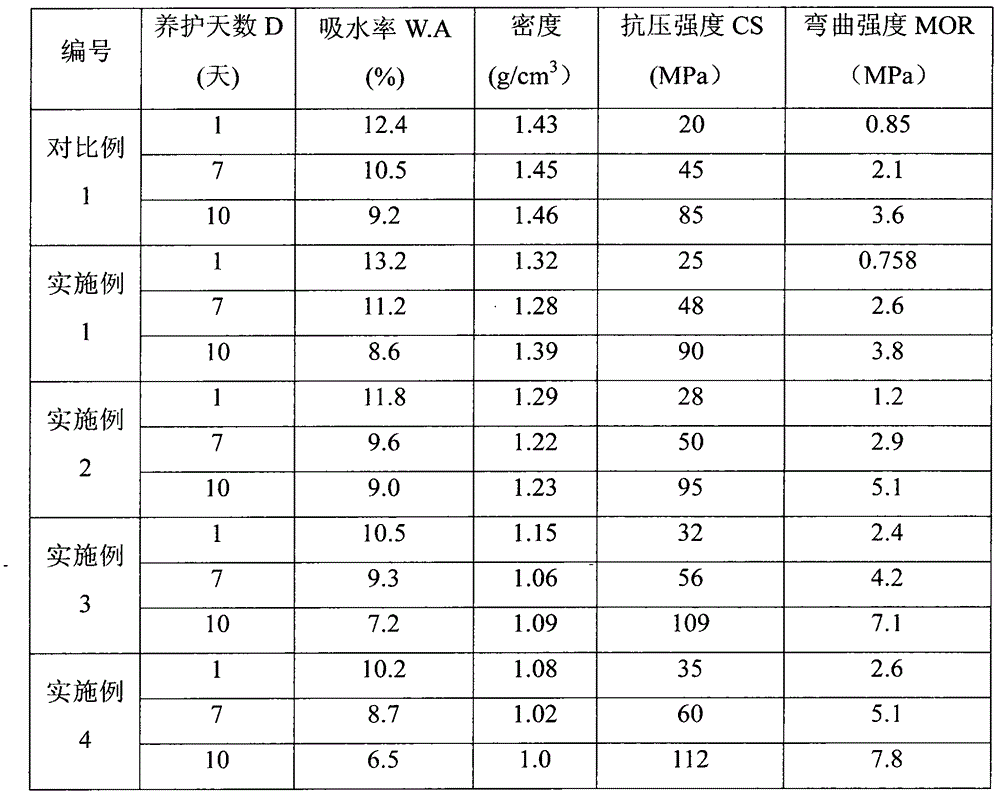

Cement and manufacturing method thereof

The invention discloses cement and a manufacturing method thereof, and in particular discloses cement taking magnesium sulfate as a main ingredient and a manufacturing method of the cement. The cement disclosed by the invention contains magnesium sulfate and magnesium oxide, wherein the weight ratio of magnesium sulfate to magnesium oxide is more than 0.9. By adopting the method disclosed by the invention, prejudices of the prior art are overcome, and the comprehensive performance of the cement is improved by greatly improving the content of magnesium sulfate in a cement formula. Moreover, a lot of industrial residues can be added into the cement produced by the method disclosed by the invention, and the main ingredient namely magnesium sulfate is prepared from waste liquid after desulfurization and belongs to desulfurization byproducts, so that the price of the cement is low, and the cost of magnesium sulfate cement is greatly reduced.

Owner:中晶新材料有限公司

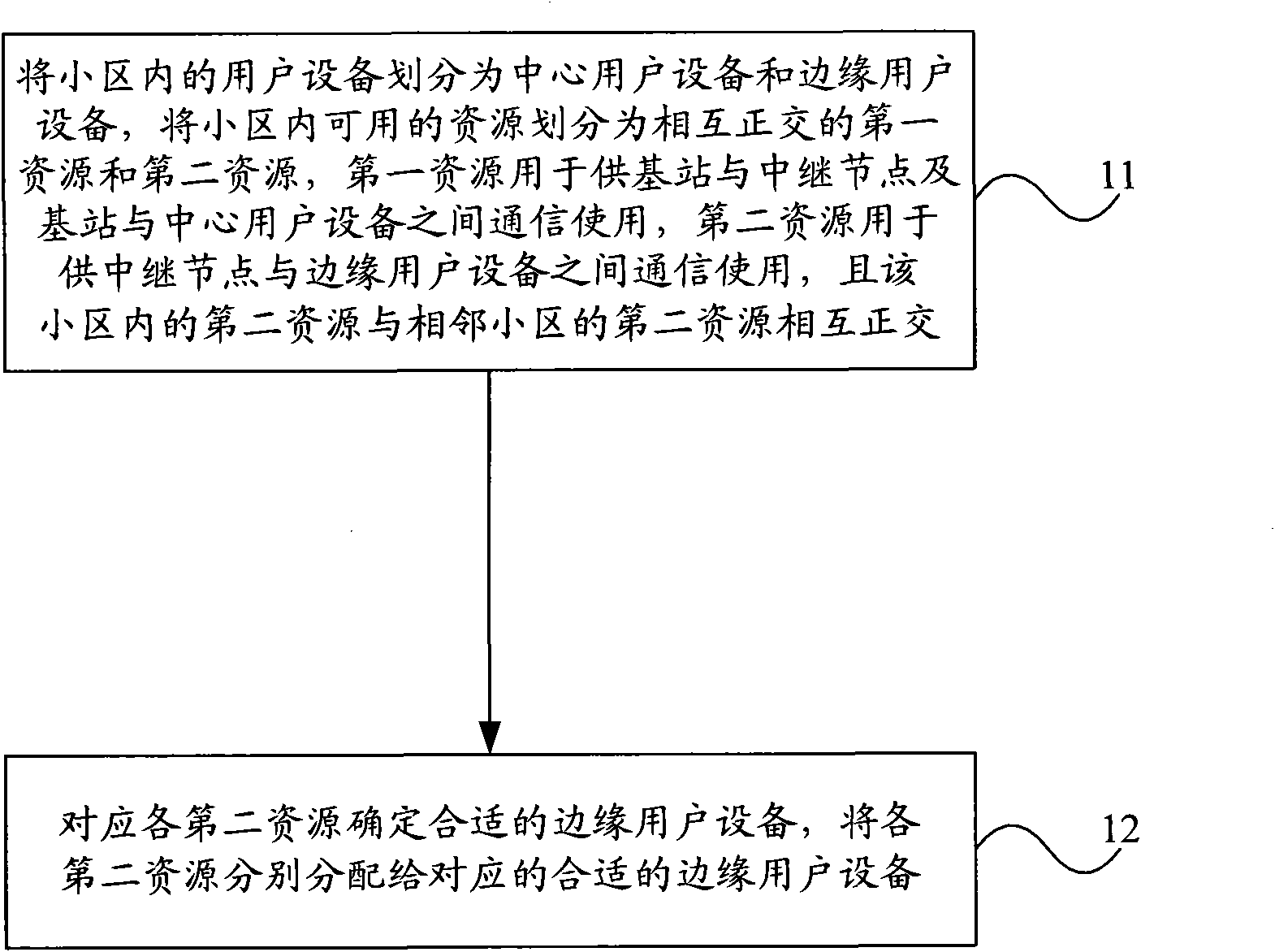

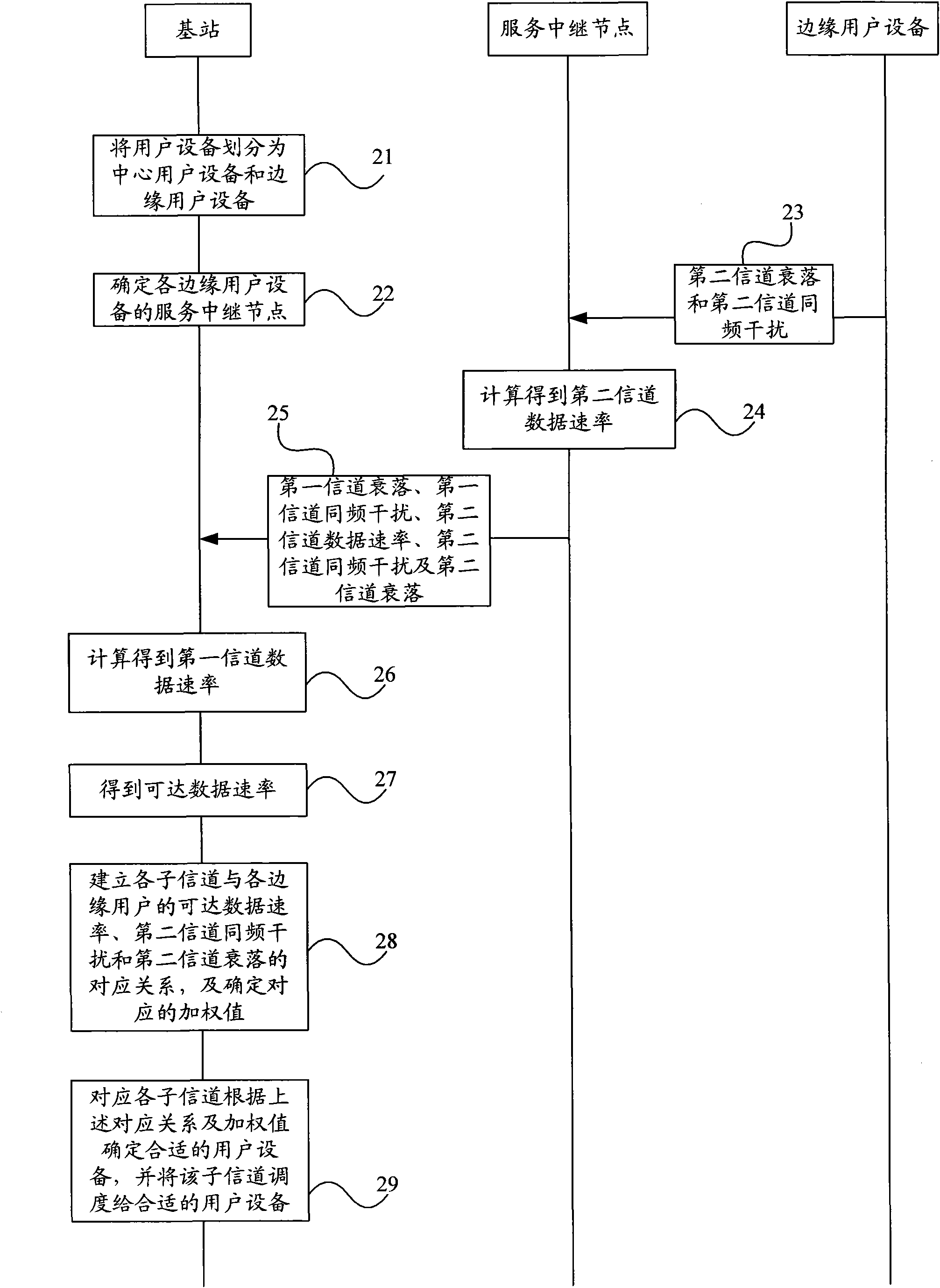

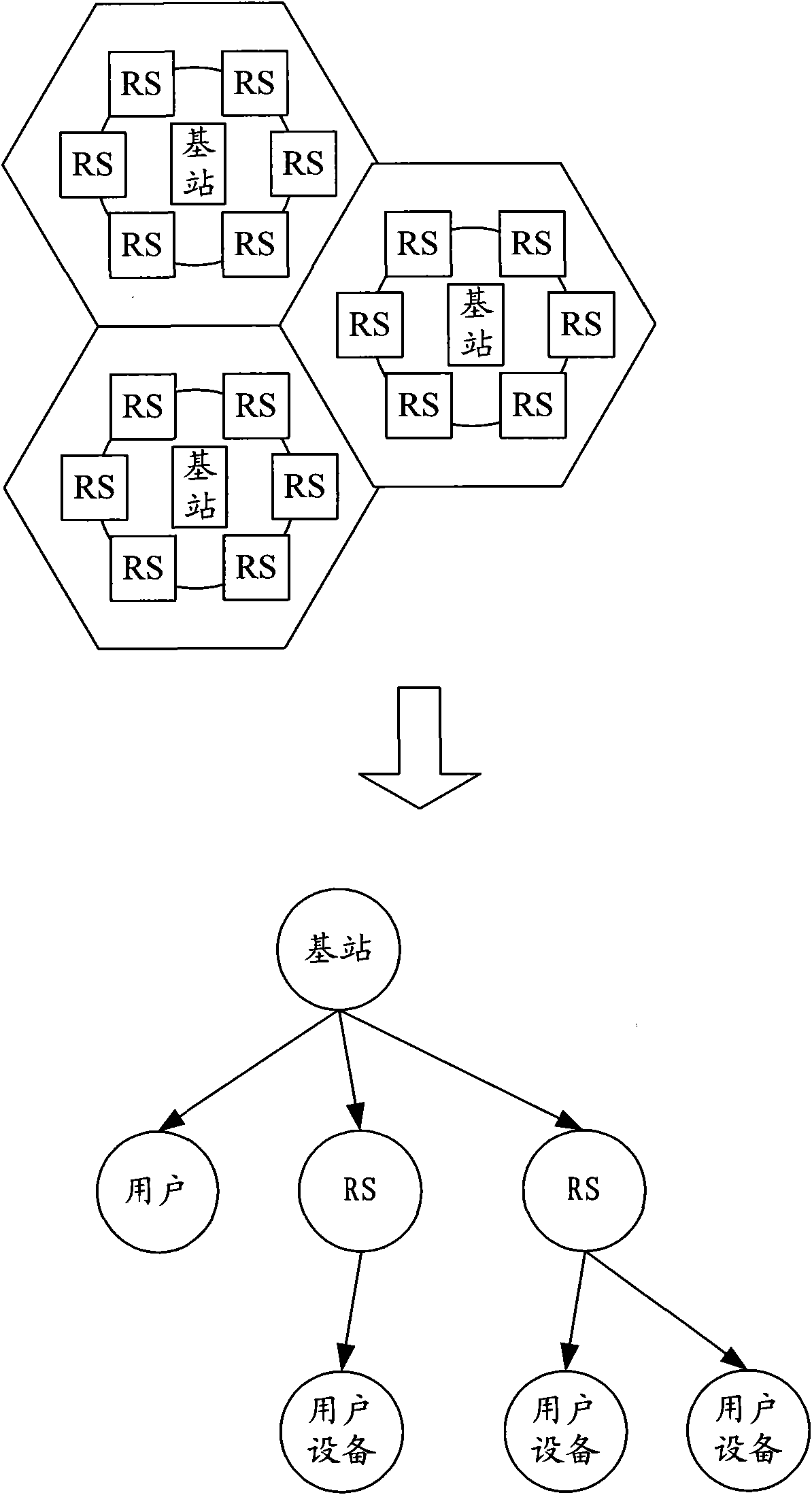

Interference suppression method of relay cellular network, base station and network system

ActiveCN101925185AAvoid interferenceImprove overall performanceNetwork topologiesCellular networkNetworked system

The invention discloses an interference suppression method of a relay cellular network, a base station and a network system. The method comprises the following steps of: dividing UE (User Equipment) in a district into center UE and edge UE and dividing available resources in the district into a first resource and a second resource which are mutually orthogonal, wherein the first resource is used for the communication between the base station and a relay node as well as between the base station and the center UE, the second resource is used for the communication between the relay node and the edge UE, and the second resource in the district and a second resource in an adjacent district are mutually orthogonal; and confirming suitable edge UE corresponding to the second resources and respectively allocating all the second resources to the corresponding suitable edge UE. The embodiment of the invention can effectively suppress the interference of the edge UE among the districts and improve the system performance of the relay cellular network.

Owner:HUAWEI TECH CO LTD +1

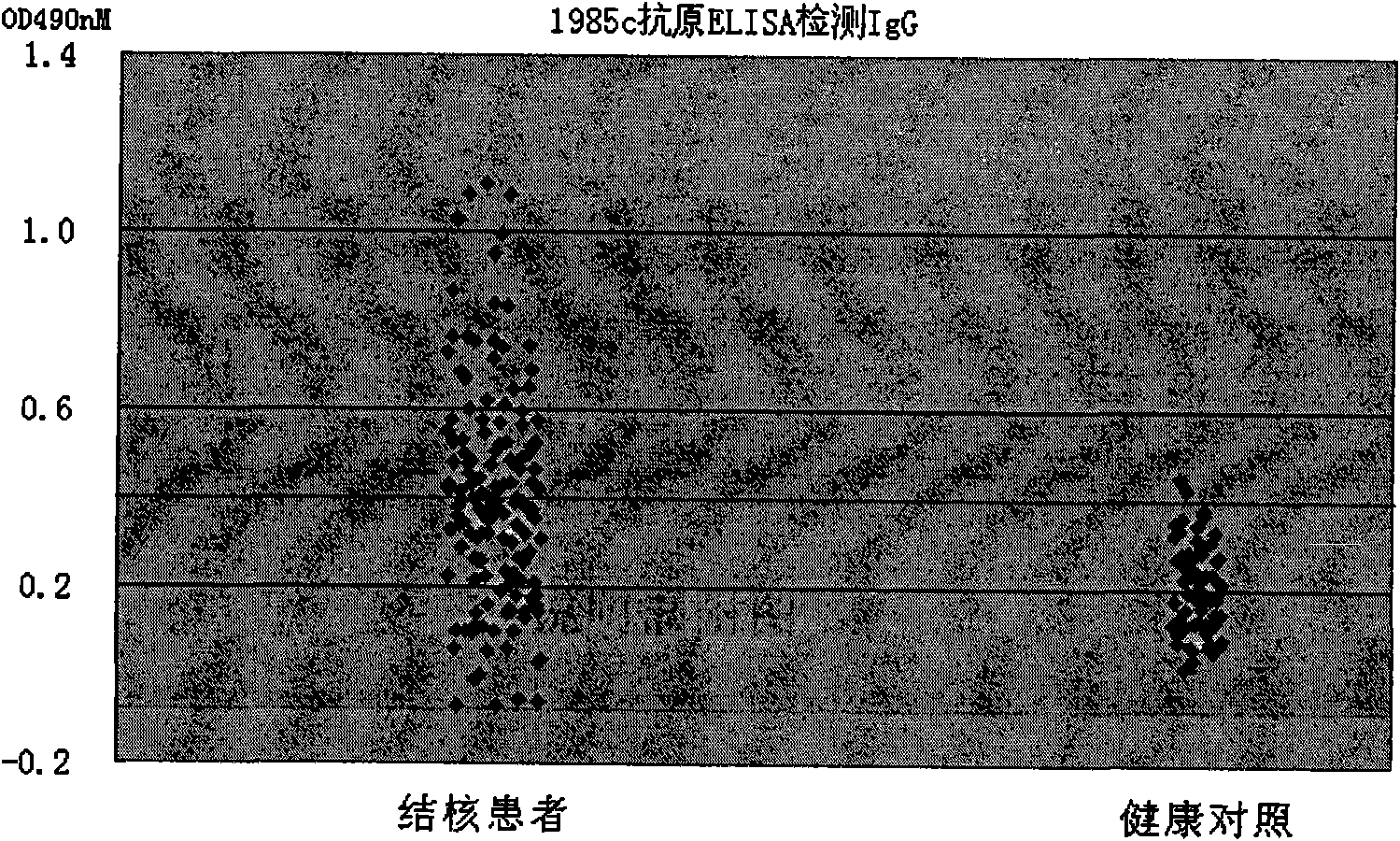

Diagnostic reagent of tuberculosis and kit

The invention belongs to the field of diagnostic reagents, and relates to a diagnostic reagent containing mycobacterium tuberculosis Rv1985c protein and a kit. The diagnostic reagent and the kit can perform rapid diagnosis on whether the blood or the body fluid of an experimenter is infected by the mycobacterium tuberculosis in the time periods from 15 minutes of an immune colloidal gold to 5 hours of ELISA. When the diagnostic reagent is used for the clinically-proved abortive tuberculosis, a Rv1985c antigen is used singly to detect that the sensitivity reaches 59 percent and the specificityreaches 96 percent; and when used together with other diagnostic antigens (such as a control antigen LAM / 38kDa), the diagnostic reagent can further improve the diagnostic sensitivity to 75 percent and has high clinical application values. The detection with the diagnostic reagent only needs a single blood serum sample, is simple and quick in test, needs no specialized laboratory equipment, is lowin cost, offers test results in the same day, and is very suitable for the detection of tuberculosis infection in extensive rural hospitals of villages and towns and under the condition of battlegrounds.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV +1

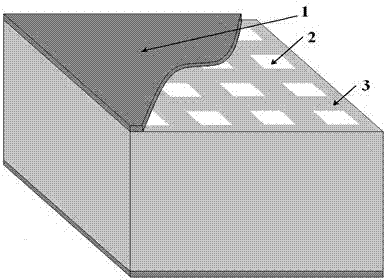

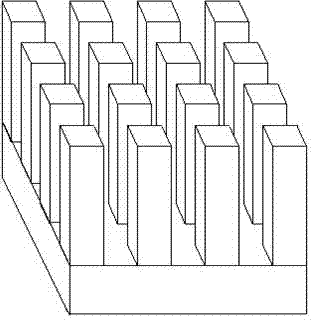

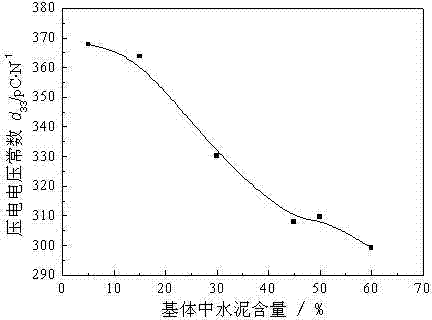

Type 1-3 polymer/cement based piezoelectric composite material and preparation method thereof

InactiveCN102260061AHigh bonding strengthImprove overall performancePiezoelectric compositeBonding strength

The invention discloses a type 1-3 polymer / cement-based piezoelectric composite material and a preparation method thereof. The material uses a mixture of polymer and cement as a matrix, and piezoelectric ceramics as a functional body, and the functional body is cut It is formed into multiple rows of vertical columns, and the surrounding and inside of the functional body are filled with matrix; wherein, the mass ratio of polymer to cement is 0.15~0.7:1, and the volume ratio of piezoelectric ceramics to matrix is 1~4:5. The flexibility, strength and bonding strength of the matrix and the functional phase of the polymer / cement-based piezoelectric composite material are obviously improved, and the overall performance of the composite material is improved. At the same time, the frequency bandwidth of polymer / cement-based piezoelectric composites is significantly increased, which broadens its application range, especially the polymer / cement-based piezoelectric composites have better compatibility with concrete, making them suitable for use in civil engineering structures. The field of health monitoring has broad application prospects.

Owner:UNIV OF JINAN

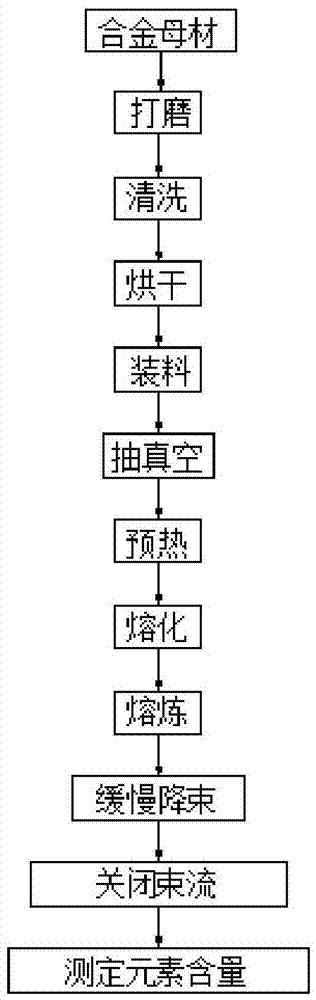

Method for improving purity of nickel-based superalloy

The invention relates to a method for improving the purity of nickel-based superalloy, which belongs to the field of alloy smelting. The method for improving the purity of nickel-based superalloy comprises the following process steps: increasing a beam to 200 mA at a speed of 1 mA / s under a vacuum degree of less than 0.05 Pa in the furnace body of an electron beam smelting device and a vacuum degree of less than 0.005 Pa of an electron gun body, and bombarding the beam onto a nickel-based superalloy substrate until the alloy is completely smelted; after the nickel-based superalloy substrate is completely smelted, continuing to increase the electron gun beam to 400 mA at a speed of 2 mA / s, adjusting the beam spot radius of the electron beam to 15*15, smelting the alloy for 5 minutes, and then cooling. According to the method, O, N and S in the alloy as well as harmful impurity elements such as As, Sb, Si, Pb and Bi can be greatly reduced, thus improving the purity of the alloy in the aspect of reducing the contents of the harmful elements, and then improving the comprehensive performance of the nickel-based superalloy.

Owner:DALIAN UNIV OF TECH

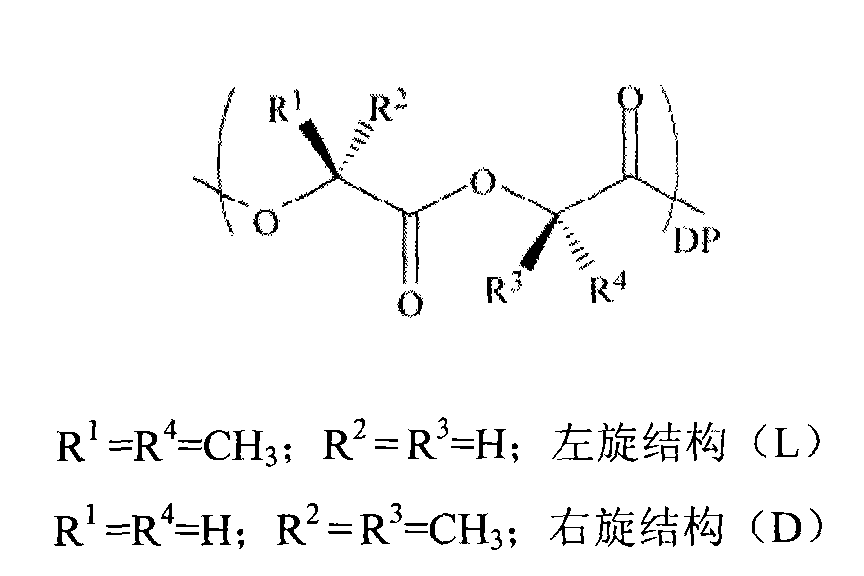

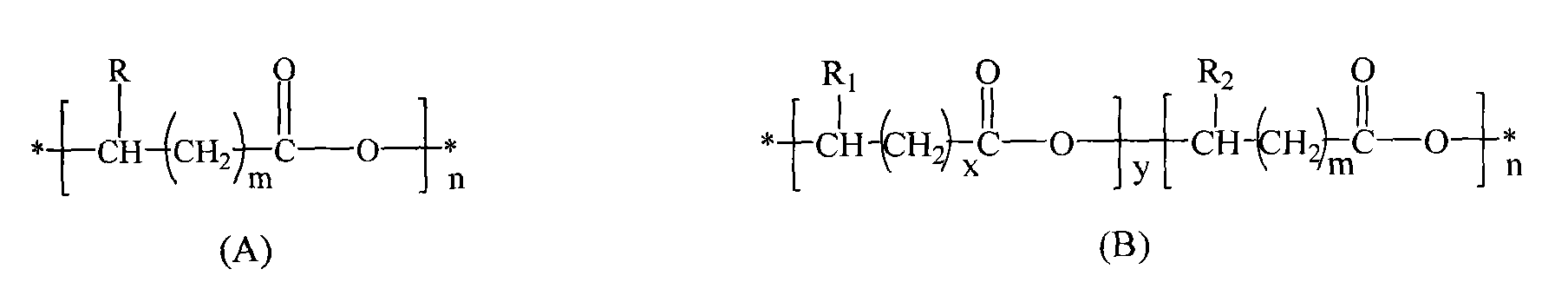

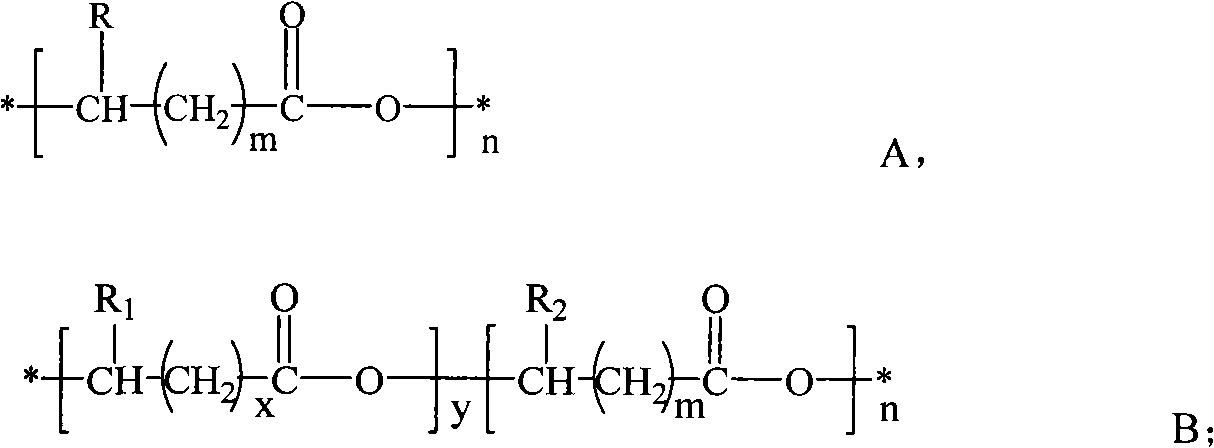

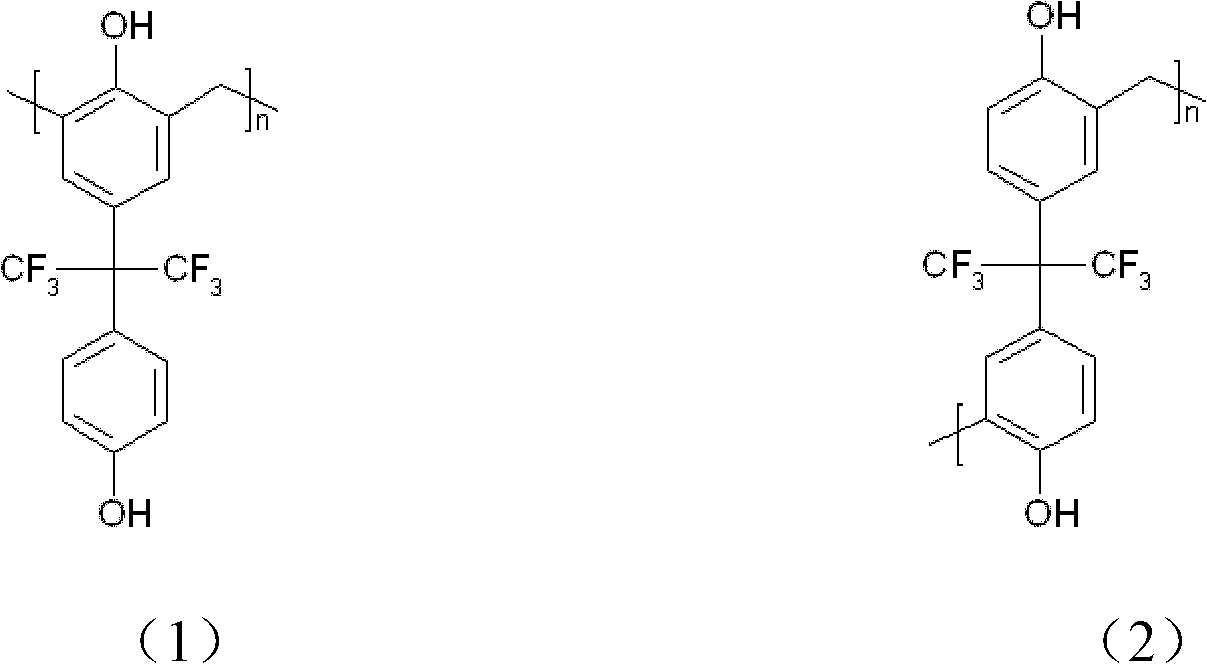

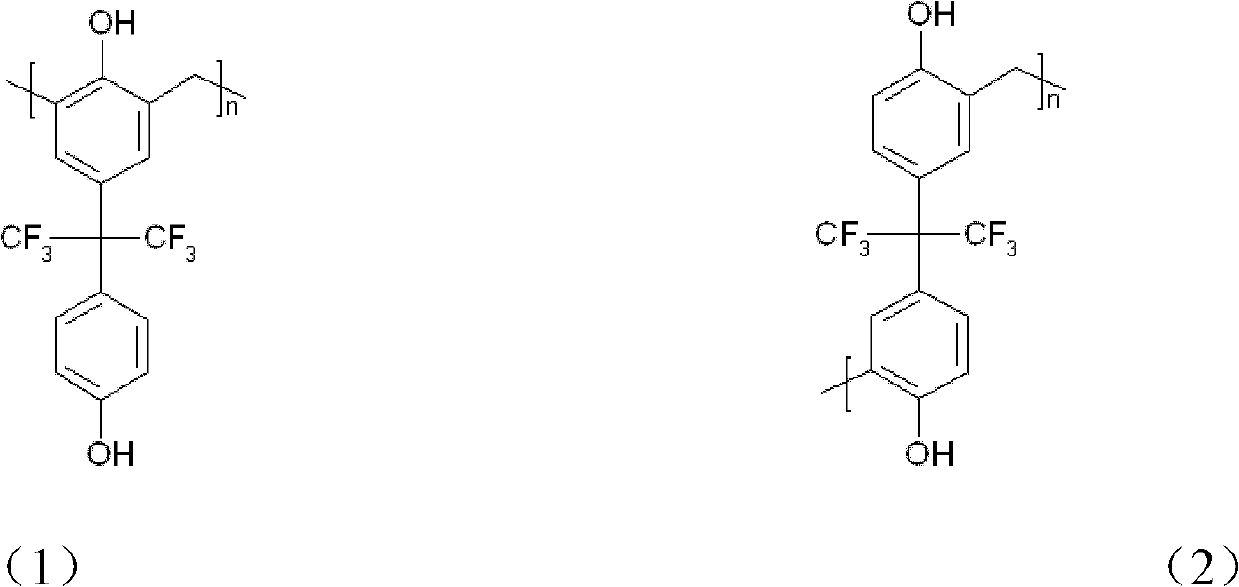

Fluorine-containing novolac resin and preparation method and application of fluorine-containing novolac resin

The invention discloses a fluorine-containing novolac resin, a preparation method of the fluorine-containing novolac resin and application of the fluorine-containing novolac resin, serving as a curing agent. The preparation method of the fluorine-containing novolac resin comprises the following step of performing a reaction of hexafluoro bisphenol A and solid paraformaldehyde by using organic acid as a catalyst to obtain the fluorine-containing novolac resin. The fluorine-containing novolac resin can be used as the curing agent to be cured with epoxide resin. High-content fluorine is induced into the curing agent, so that the comprehensive performance of an epoxide resin cured product is greatly promoted. A production process is controlled by adopting an acid catalysis method and a method of feeding paraformaldehyde serving as the raw material in batch. In the production process, the three wastes are not discharged, wherein a reaction solvent can be recycled. The production process is environmental-friendly. The structure of the fluorine-containing novolac resin is shown in the following formula (1) or (2).

Owner:ETERNAL CHEM (CHINA) CO LTD +1

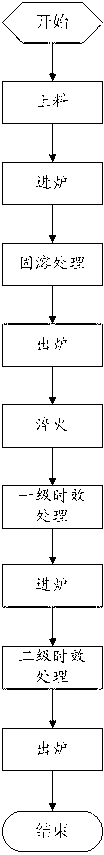

Aluminum alloy wheel heat treatment process

InactiveCN102912265AImprove overall performanceImprove plasticity and toughnessFurnace typesHeat treatment furnacesQuenchingSpoke

The invention discloses an aluminum alloy wheel heat treatment process comprising the steps of: loading, furnace feeding, solid solution treatment, discharging, quenching, primary aging treatment, feeding, secondary aging treatment, and discharging. During the solid solution treatment, a solid solution temperature is 540-550 DEG C, and a solid solution temperature maintenance time is 3.5-4.5h. During the primary aging treatment, the material is kept under room temperature for 24h. During the secondary aging treatment, the aging temperature is 115-125 DEG C, and an aging temperature maintenance time is 2.5-3.5h. With the aluminum alloy wheel heat treatment process provided by the invention, product comprehensive performance can be improved. On a basis that product hardness and tensile strength are ensured, product plasticity and toughness are substantially improved. Especially, impact toughness of the product is improved. With the process, impact strengths of thin spokes and wheels requiring lightweights can be greatly improved, such that requirements of high-requirement automotive main engine factories can be satisfied.

Owner:DARE TECH

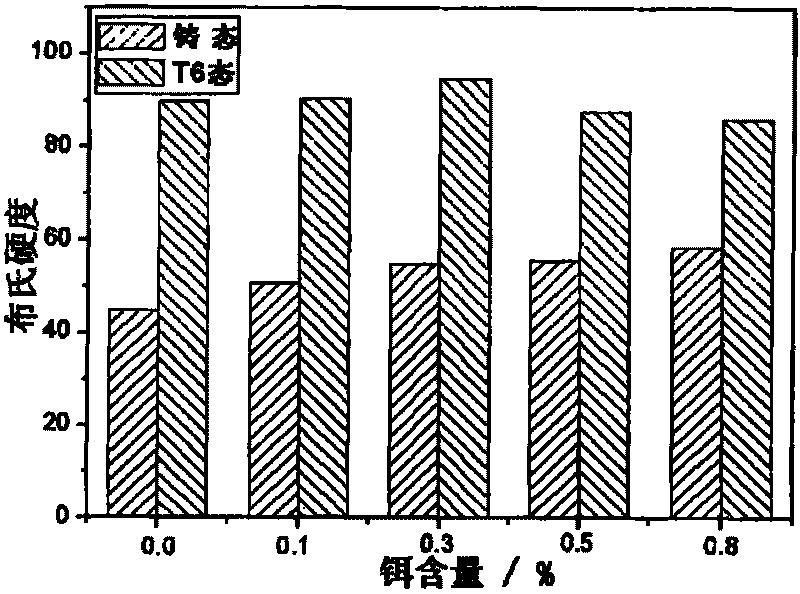

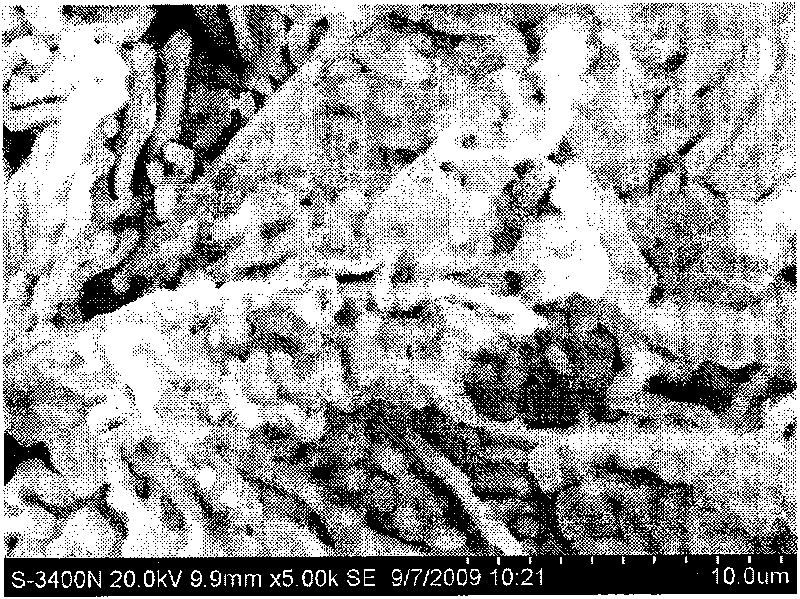

Al-Si-Mg-Er rare earth casting aluminium alloy

InactiveCN101705397AImprove overall performanceIncreased tensile strength and yield strengthMetal alloyAluminium alloy

The invention belongs to the technical field of metal alloy, and provides Al-Si-Mg-Er rare earth casting aluminium alloy which is characterized in that rare earth Er element accounting for 0.1-0.8% of the weight percent of final product is added into ZL101 alloy matrix. The ZL101 alloy comprises the following components by weight percent: 6.5-7.5 percent of Si, 0.25-0.45 percent of Mg and the balance of Al. As trace rare earth Er element is added, primary a-Al phase is thinned, eutectic silicon phase is changed into tiny coral shape from thick needle piece shape, the combination property of the alloy can be improved, the tensile strength and the yield strength are slightly enhanced compared with those of the alloy which has the original components and is not added with Er, and the elongation is 2 times higher than that thereof.

Owner:BEIJING UNIV OF TECH

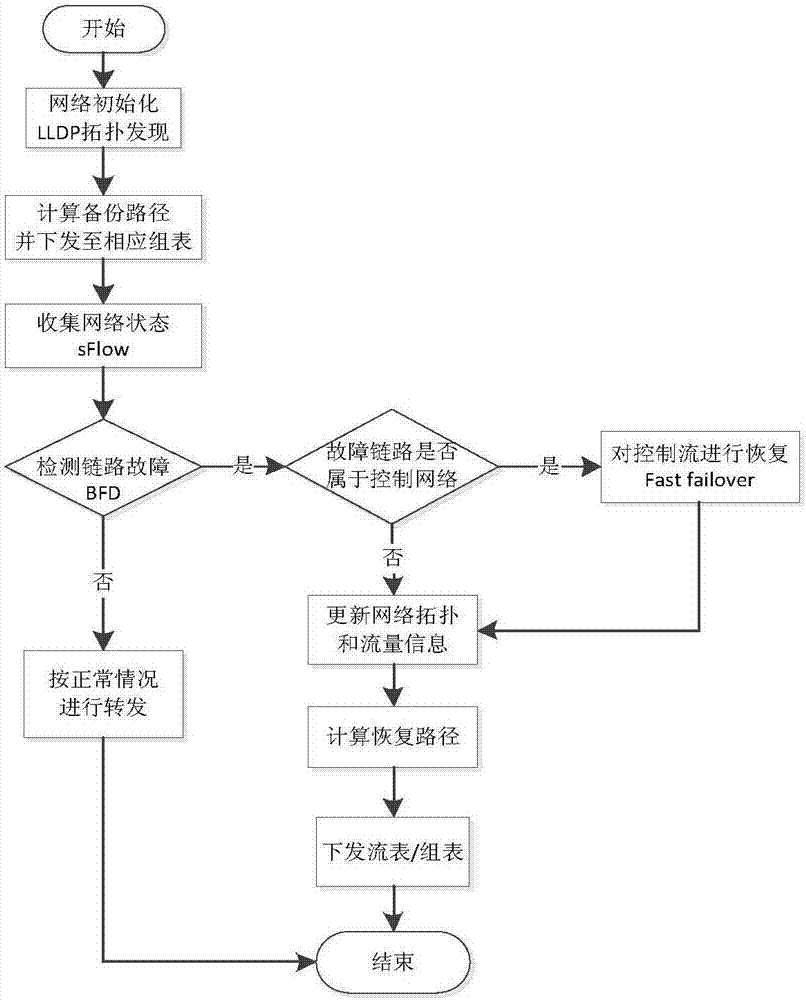

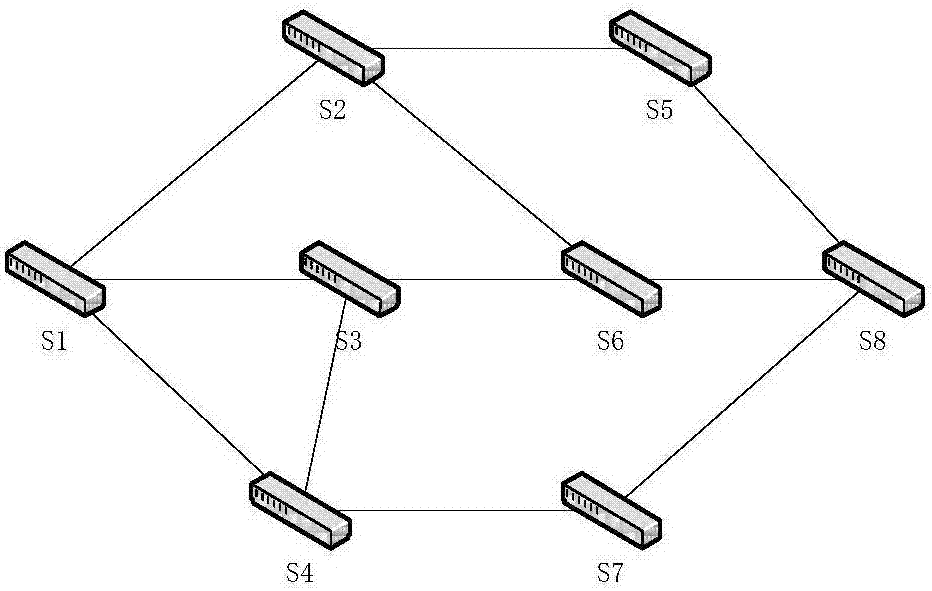

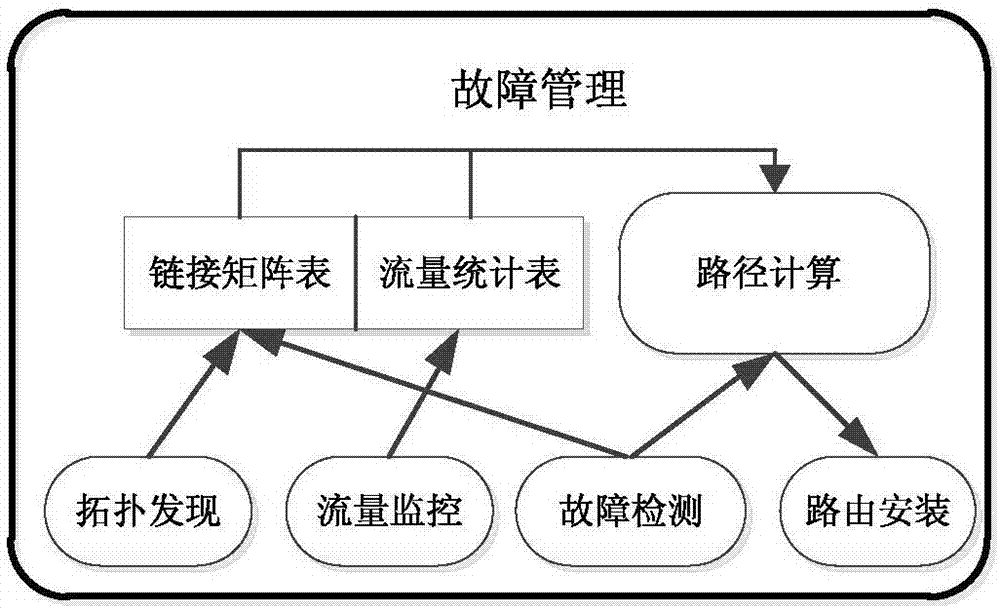

Software defined network link fault recovery method based on in-band control

ActiveCN107302496AImprove overall performanceAchieve recoveryData switching networksHigh level techniquesLink Layer Discovery ProtocolControl flow

The invention sets forth a software defined network (SDN) link fault recovery method based on in-band control, and belongs to the technical field of communication networks. Firstly, an SDN controller acquires the whole network topology by using an LLDP (Link Layer Discovery Protocol) and generates a control network, calculates a backup path for a link on the control network and transmits the path to a corresponding group table. Then, once the link has a fault, a switch sends fault information to the controller, the switch is triggered to feed real-time traffic information of the network back to the controller, and the controller updates the network topology and the traffic information. Finally, according to the current network topology and traffic information, the sum of resource consumption and feed of the path is calculated, thus an optimal recovery path is selected and a flow table is transmitted to the corresponding switch to realize recovery of the link fault. The system recovers control flow by adopting the backup path and adaptively recovers data flow in an in-band control network, thereby realizing reasonable allocation of link resources during fault recovery and improving the overall performance of the network.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com