Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

747 results about "Piezoelectric composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

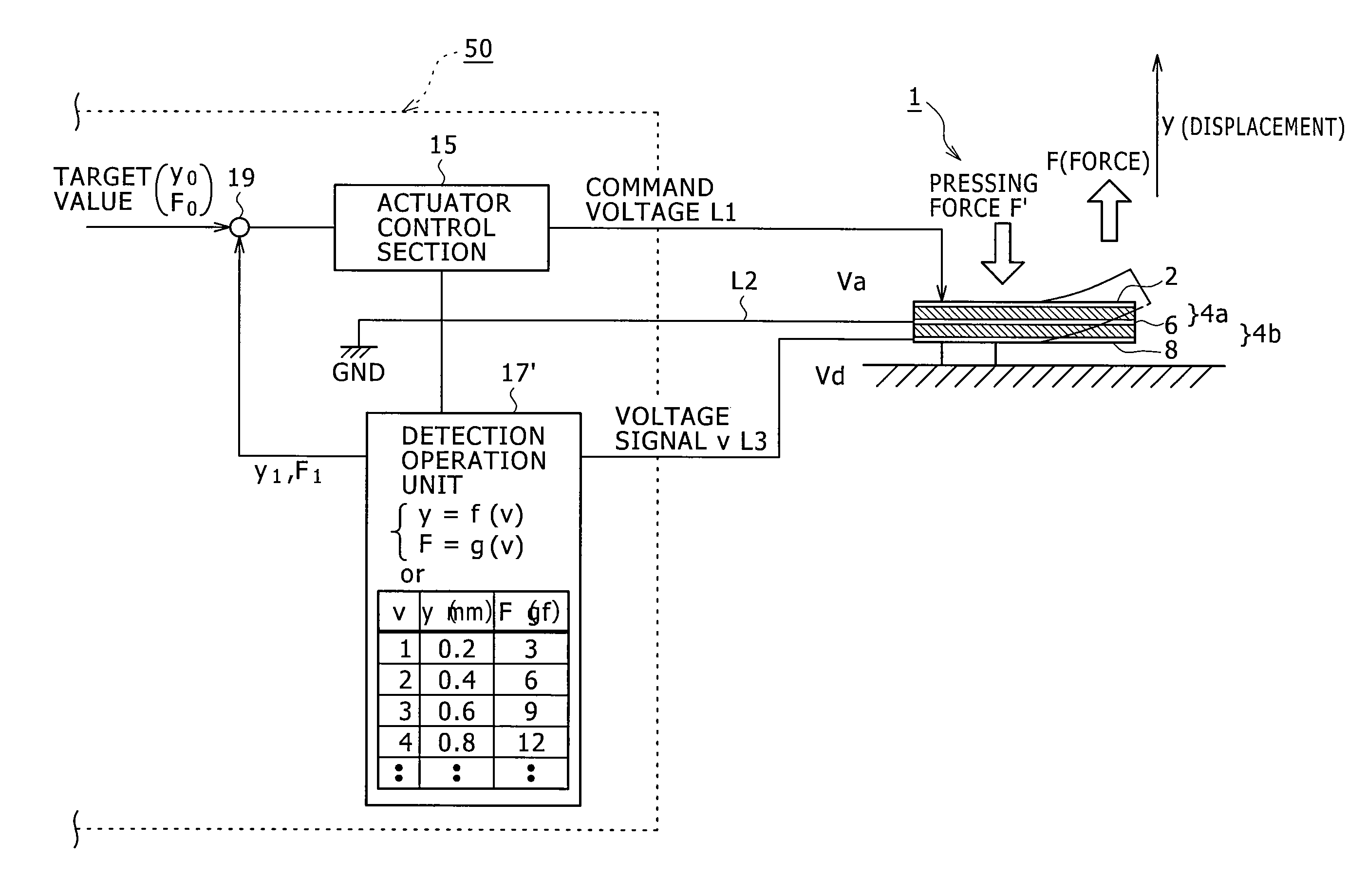

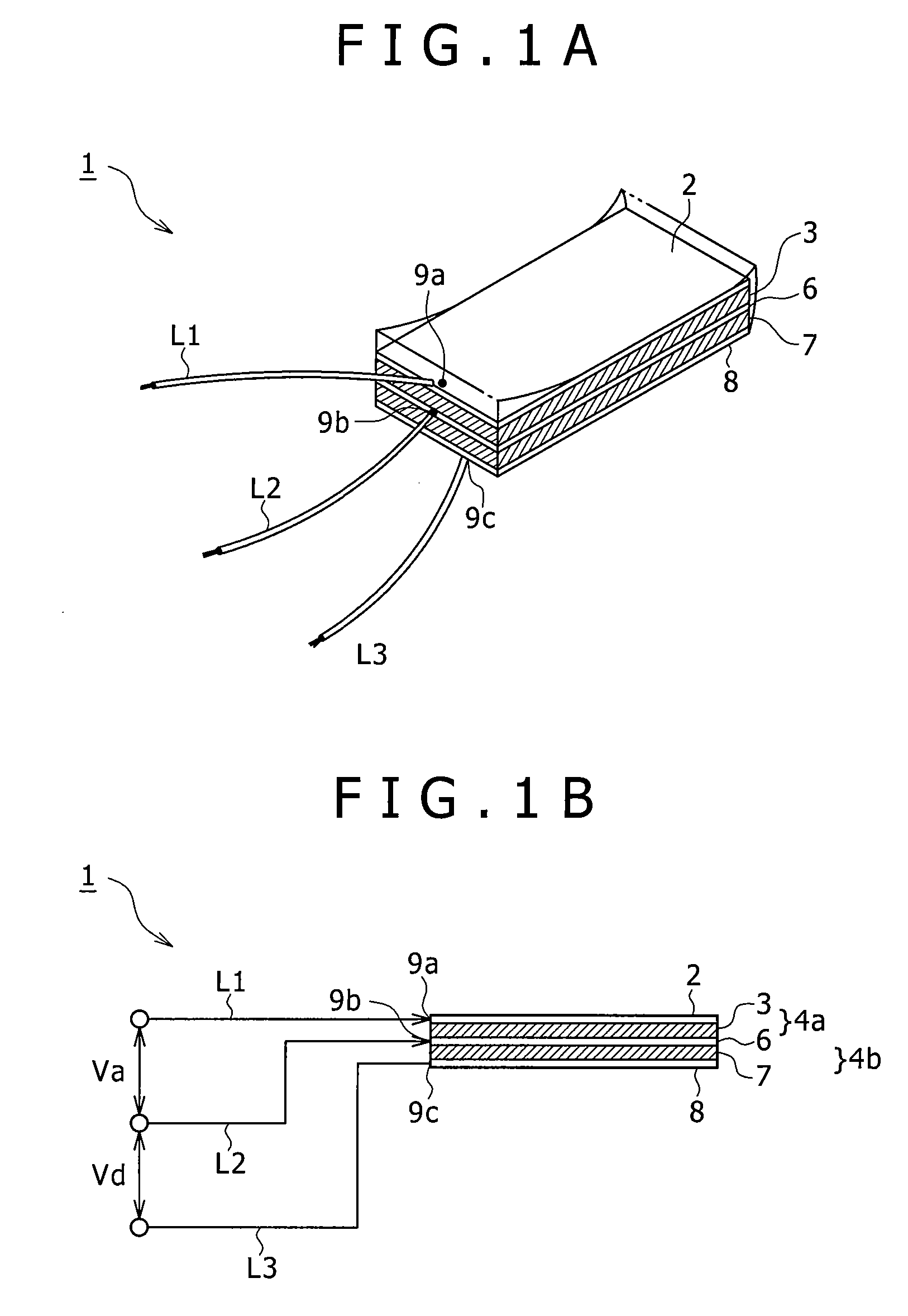

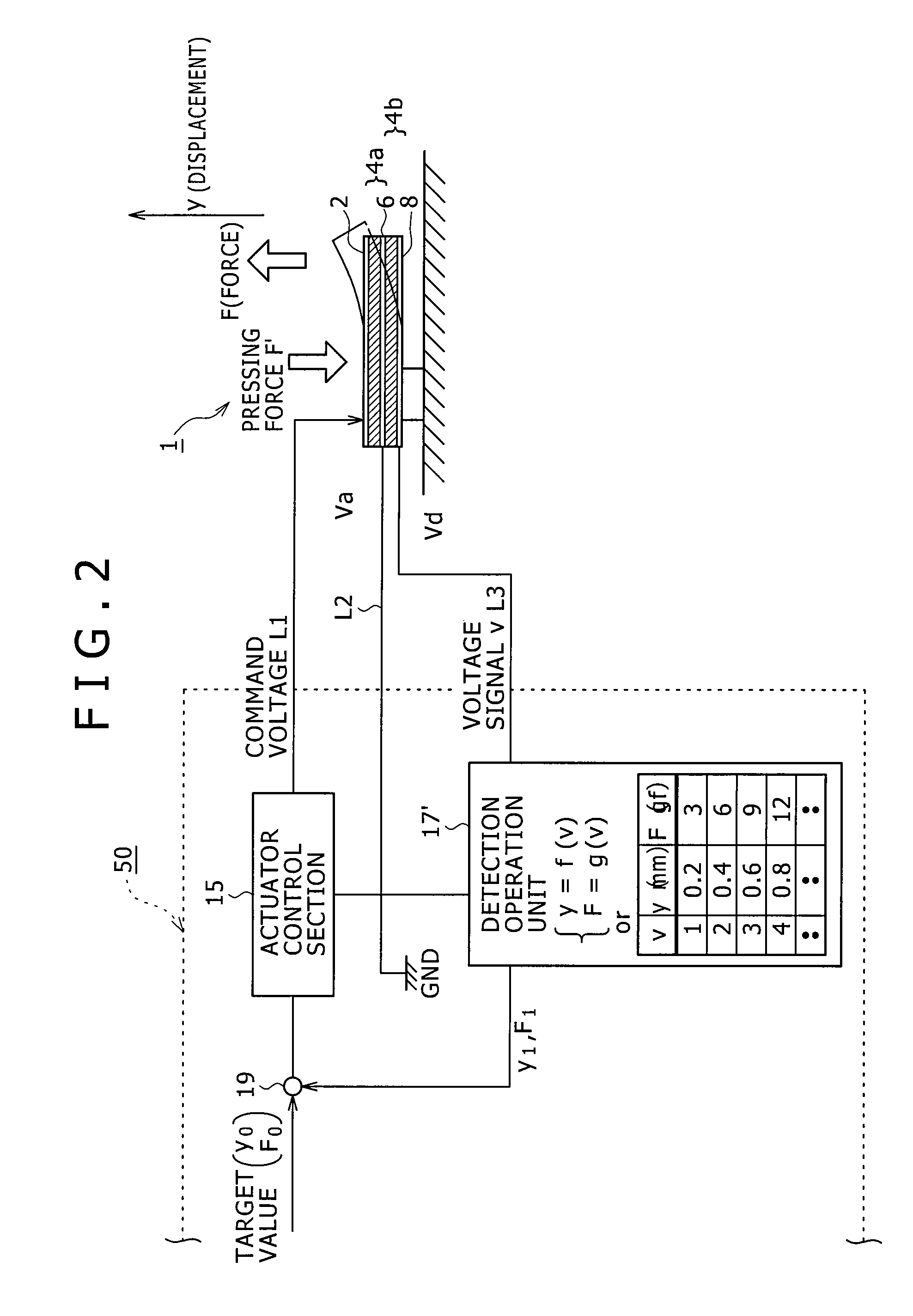

Piezoelectric composite device, method of manufacturing same, method of controlling same, input-output device, and electronic device

InactiveUS20060028095A1MorePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

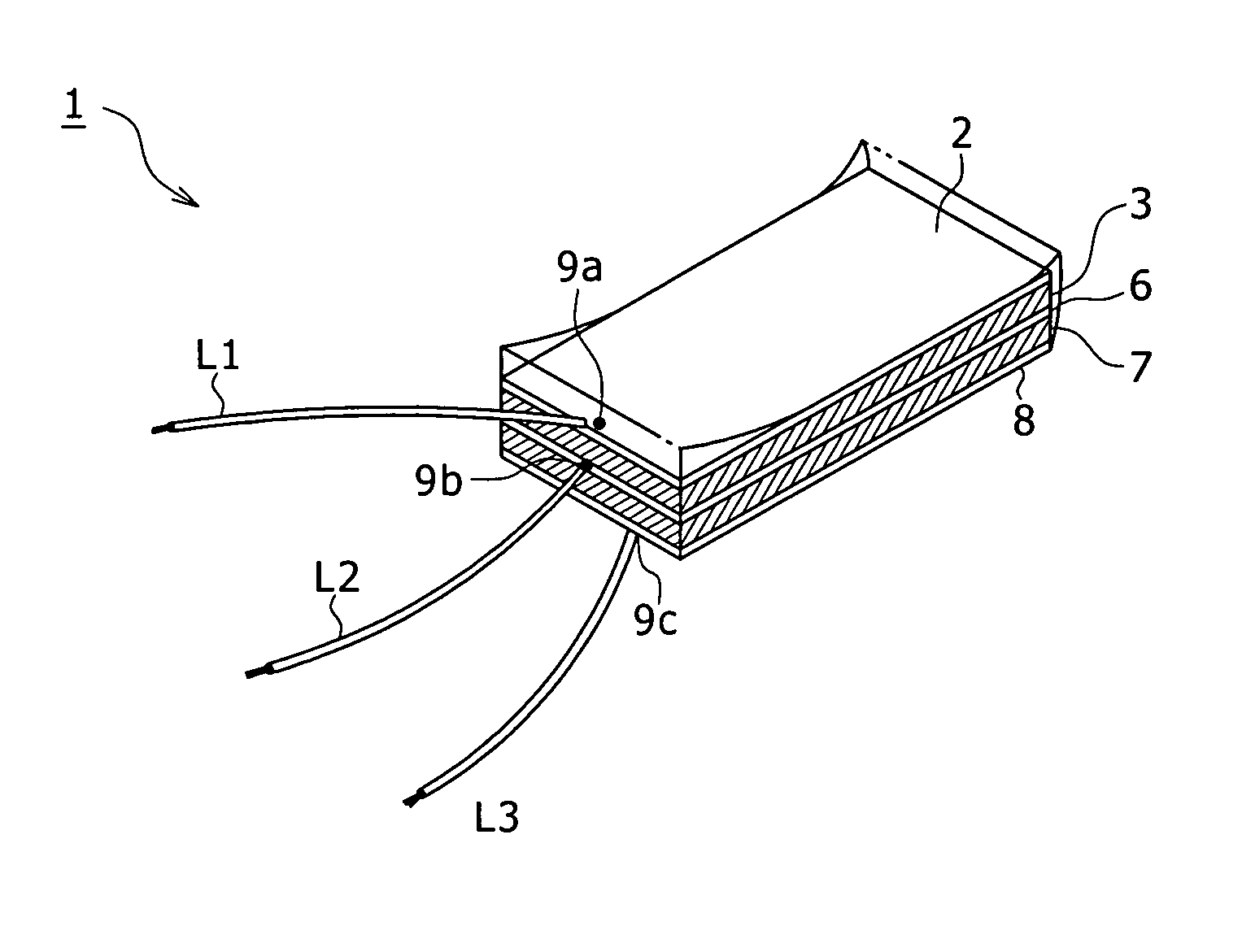

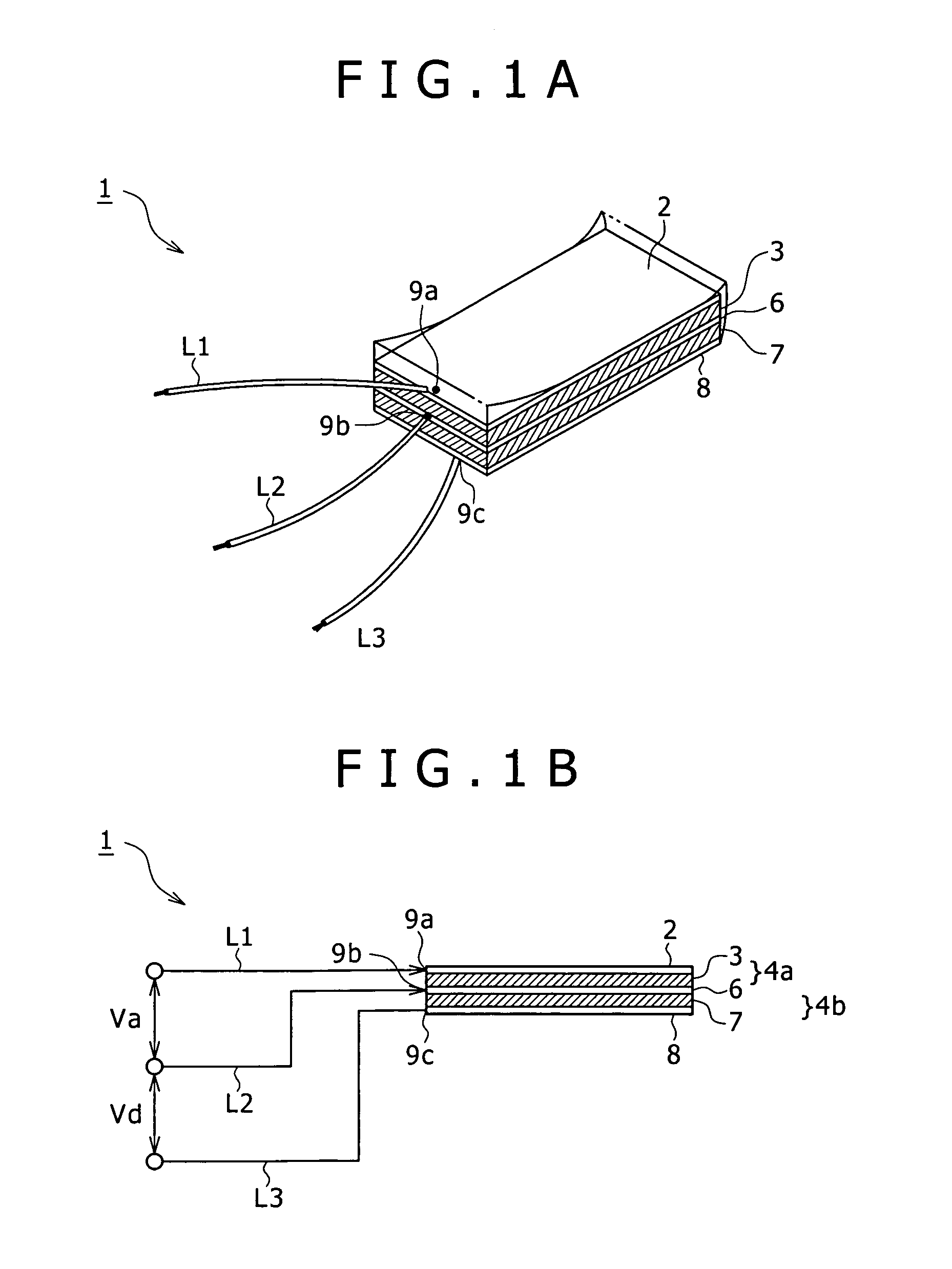

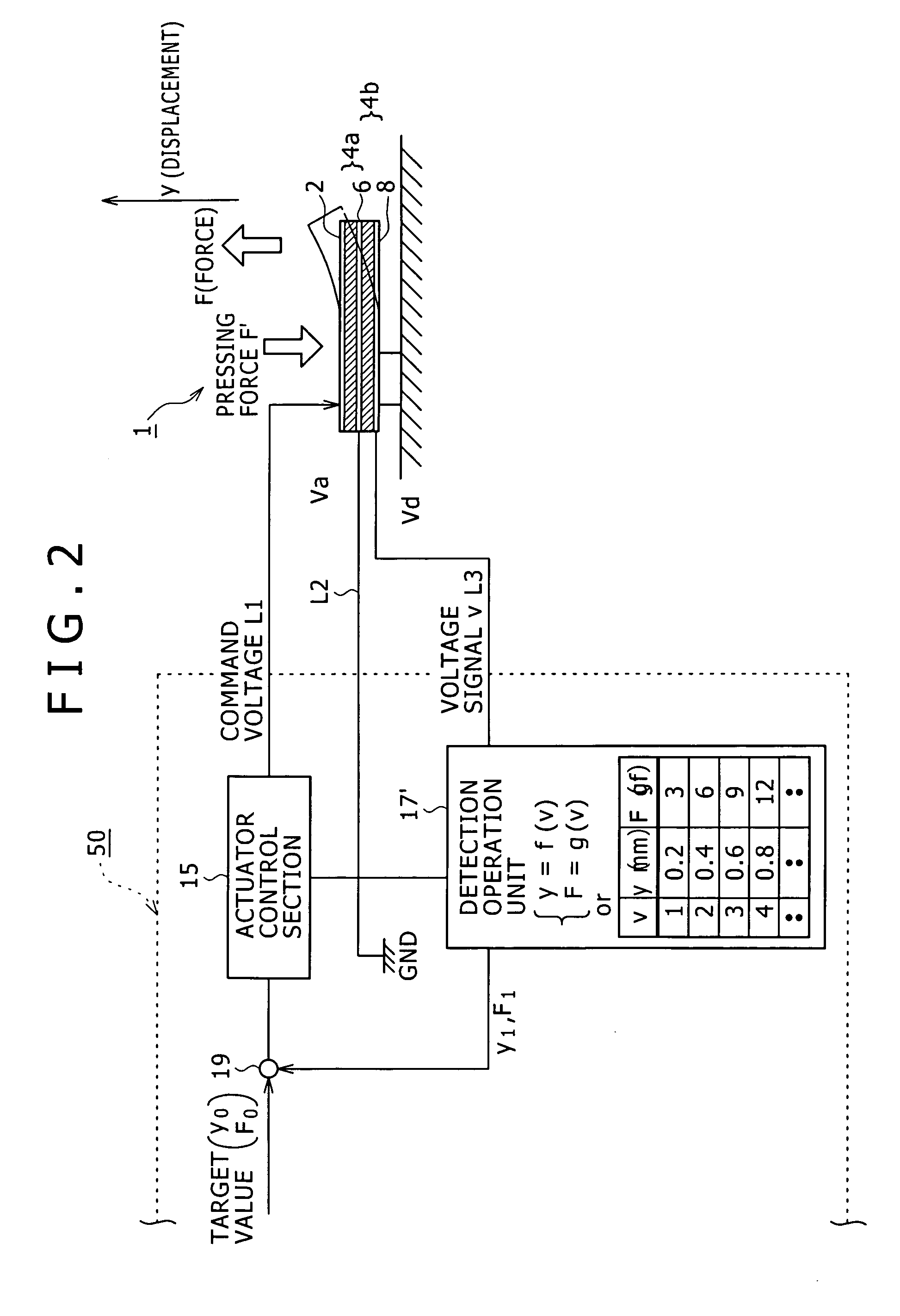

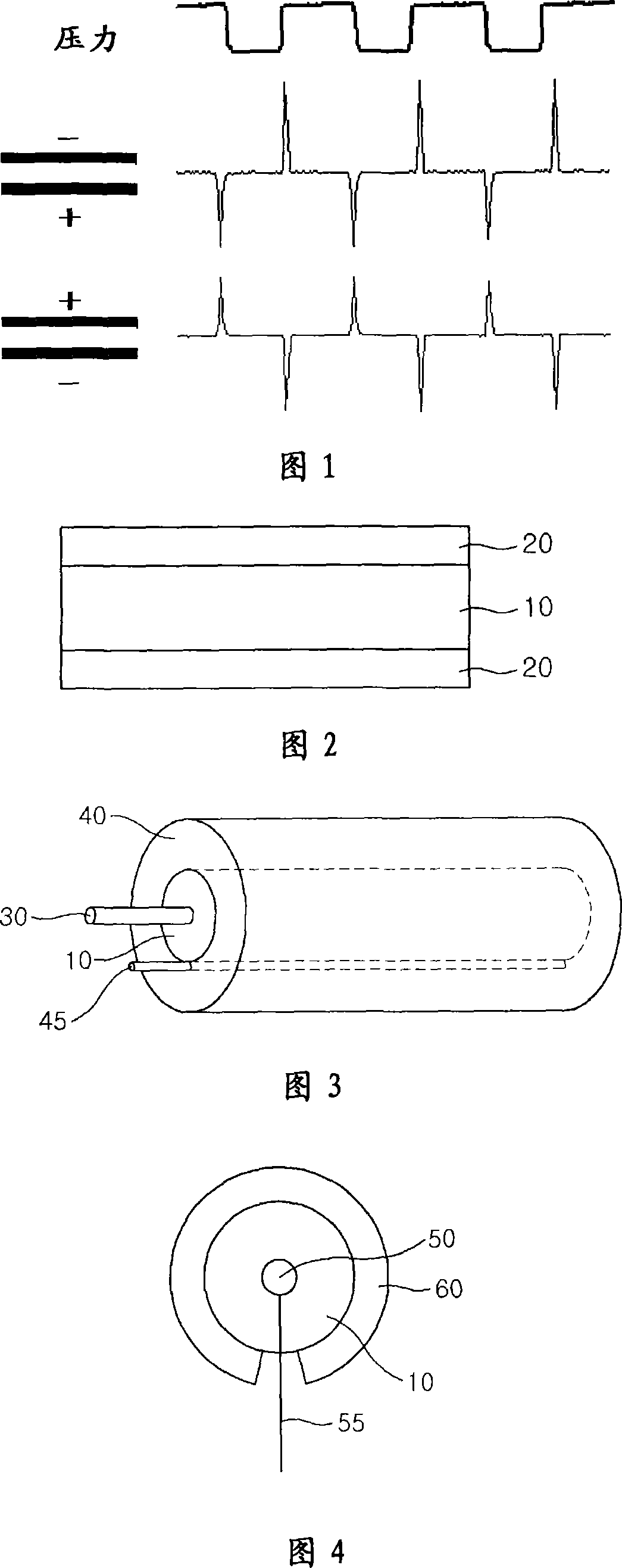

Disclosed herein is a piezoelectric composite device including: a feeding electrode; a common electrode; a signal detecting electrode; a first piezoelectric element joined between the feeding electrode and the common electrode; and a second piezoelectric element joined between the common electrode and the signal detecting electrode; a predetermined voltage being supplied between the feeding electrode and the common electrode; and a force detection signal based on an external force being extracted from the detecting electrode.

Owner:SONY CORP

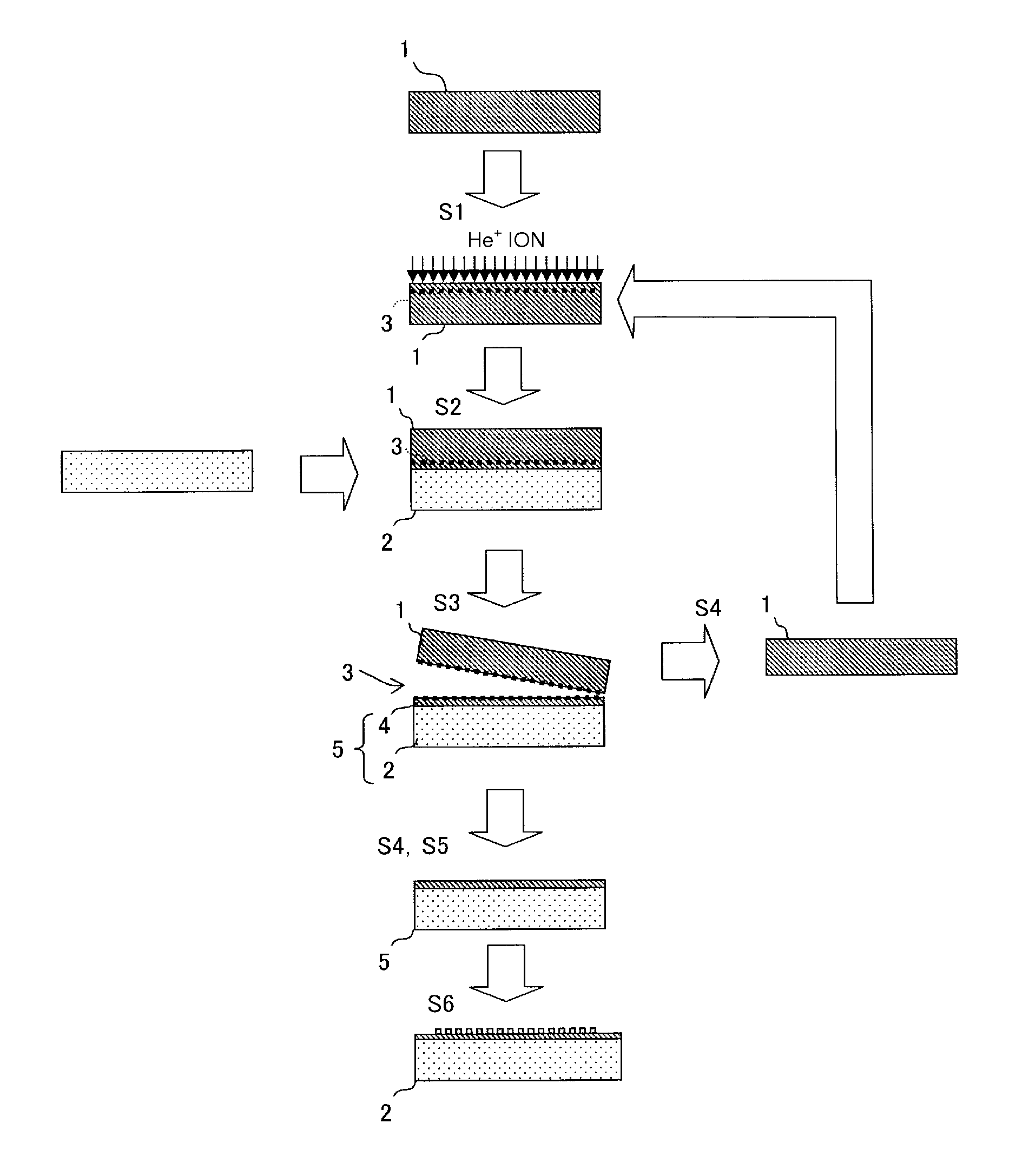

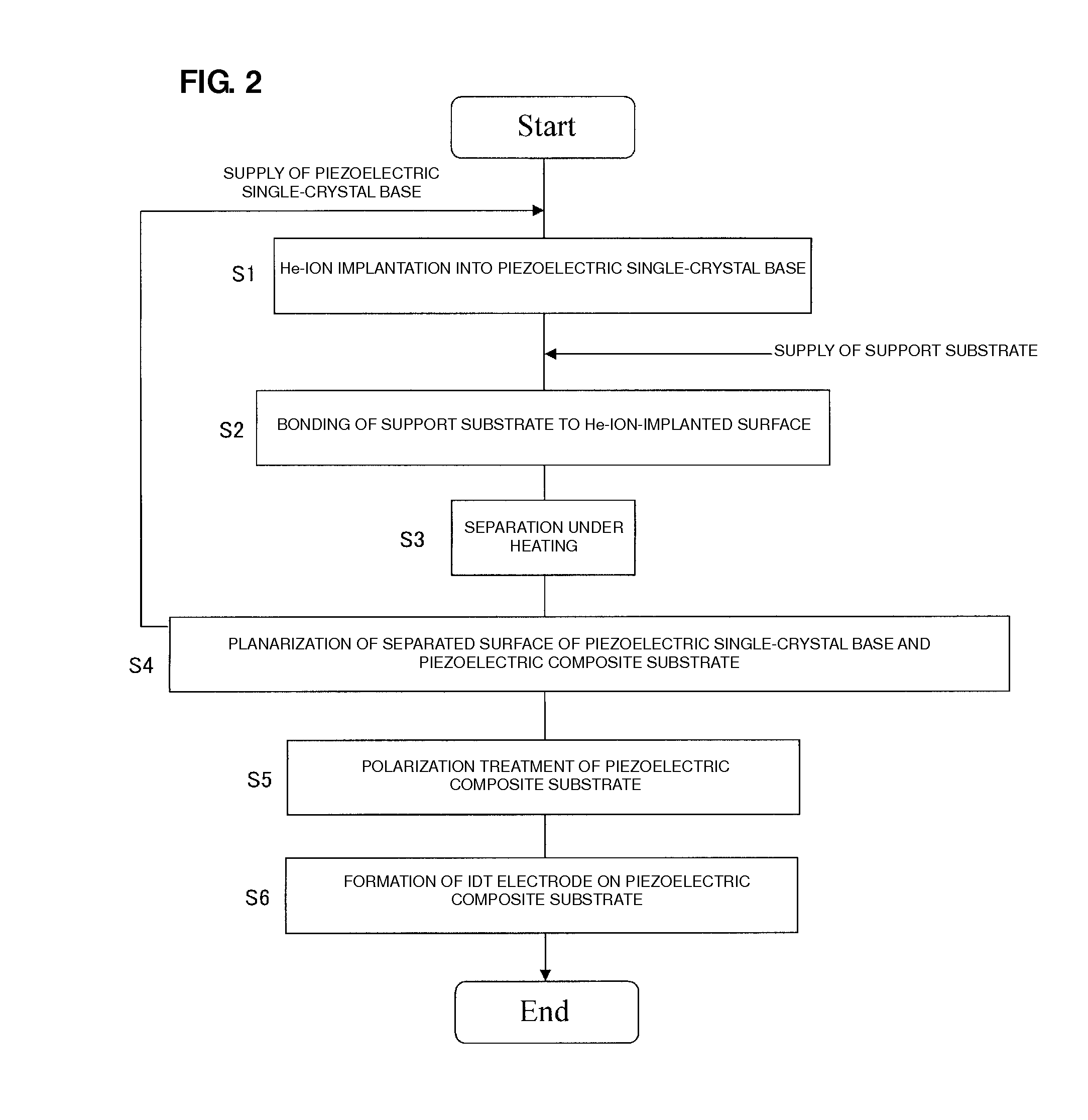

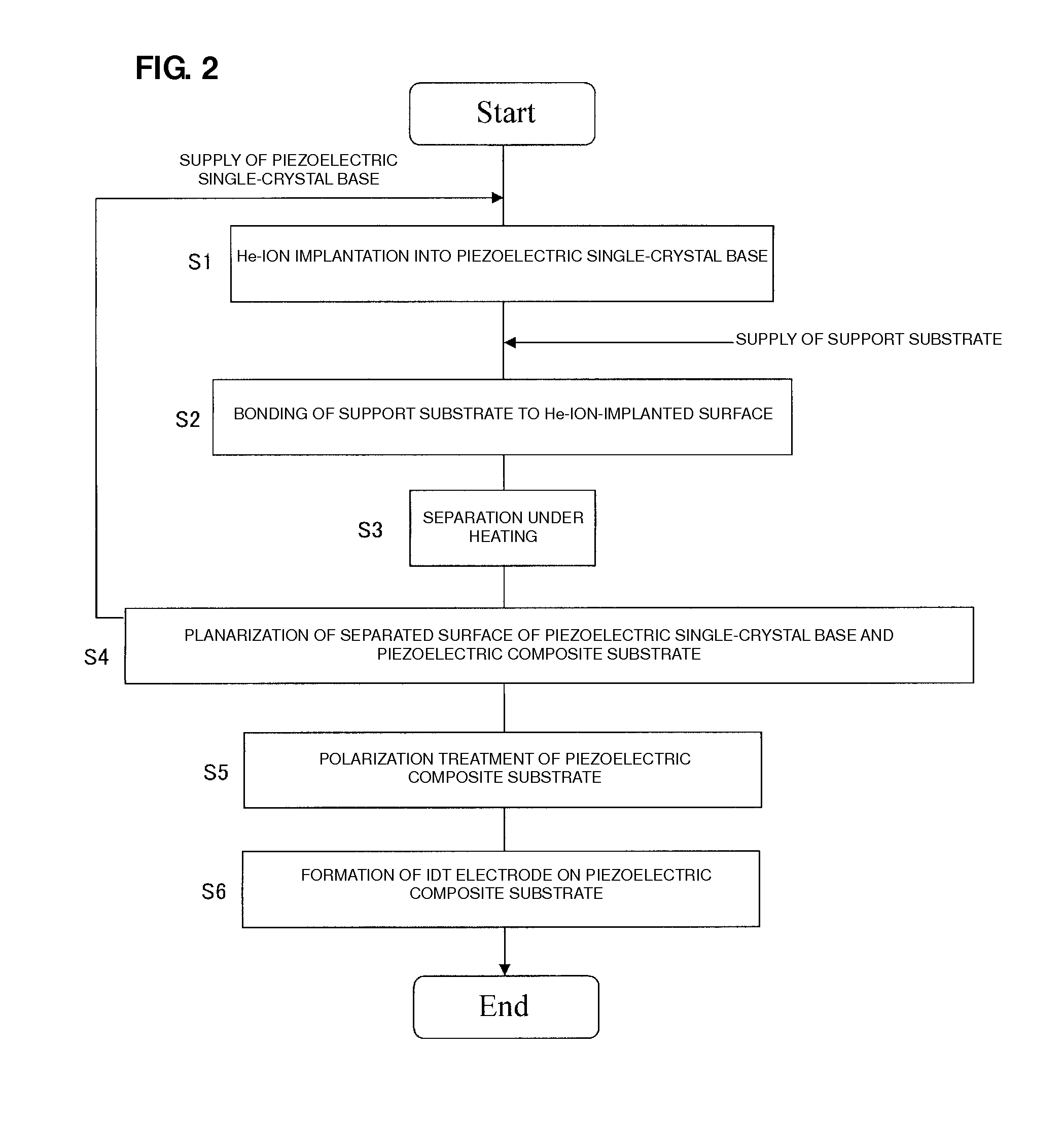

Method for producing piezoelectric composite substrate

ActiveUS8932686B2Improve utilization efficiencyUniform thicknessAfter-treatment detailsImpedence networksSingle crystalPiezoelectric composite

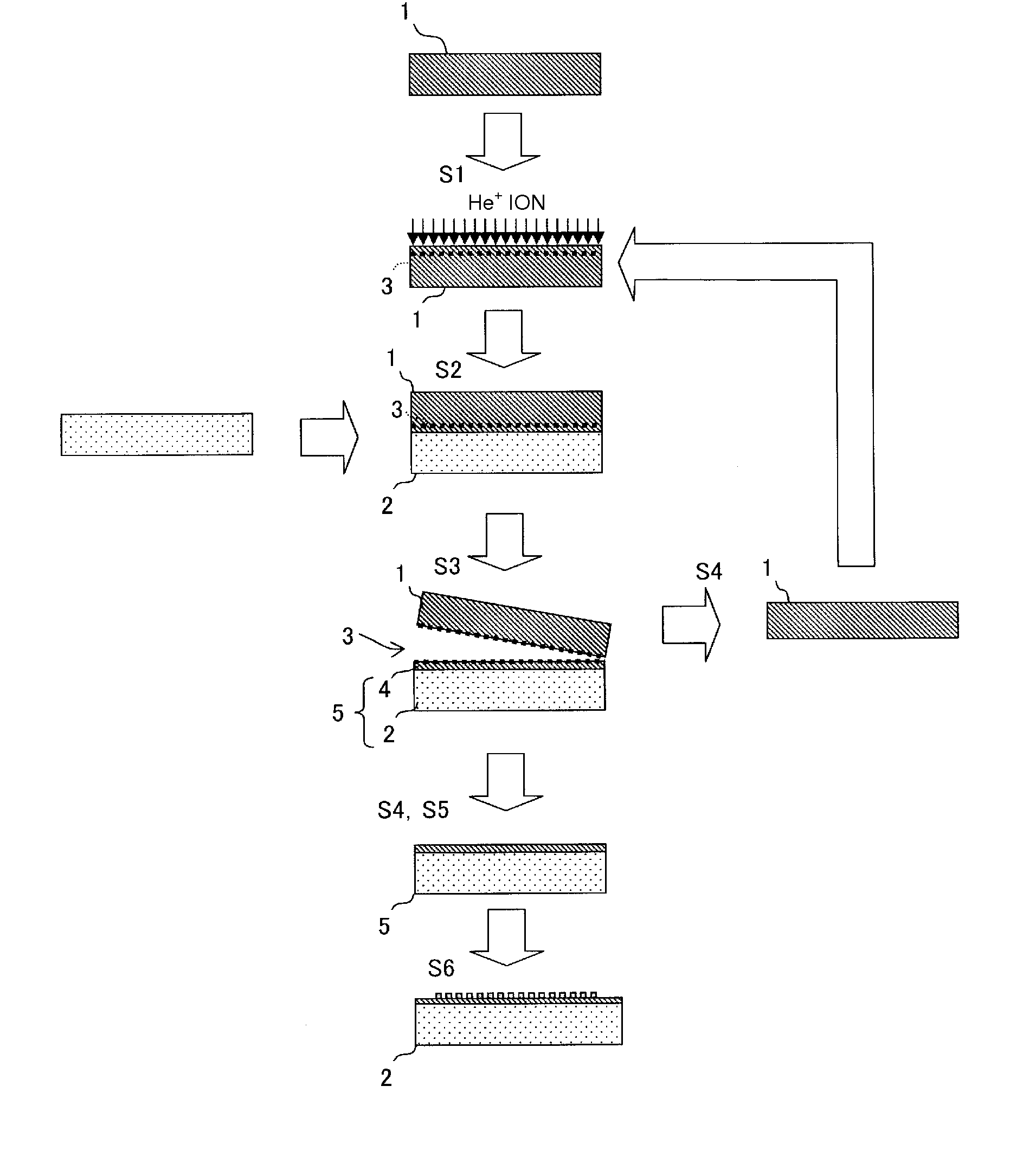

A method for producing a piezoelectric composite substrate having a single-crystal thin film of a piezoelectric material includes an ion-implantation step and a separation step. In the ion-implantation step, He+ ions are implanted into the single-crystal base made of the piezoelectric material to form localized microcavities in a separation layer located inside the single-crystal base and apart from a surface of the single-crystal base. In the separation step, the microcavities formed in the ion-implantation step are subjected to thermal stress to divide the separation layer of the piezoelectric single-crystal base, thereby detaching the single-crystal thin film.

Owner:MURATA MFG CO LTD

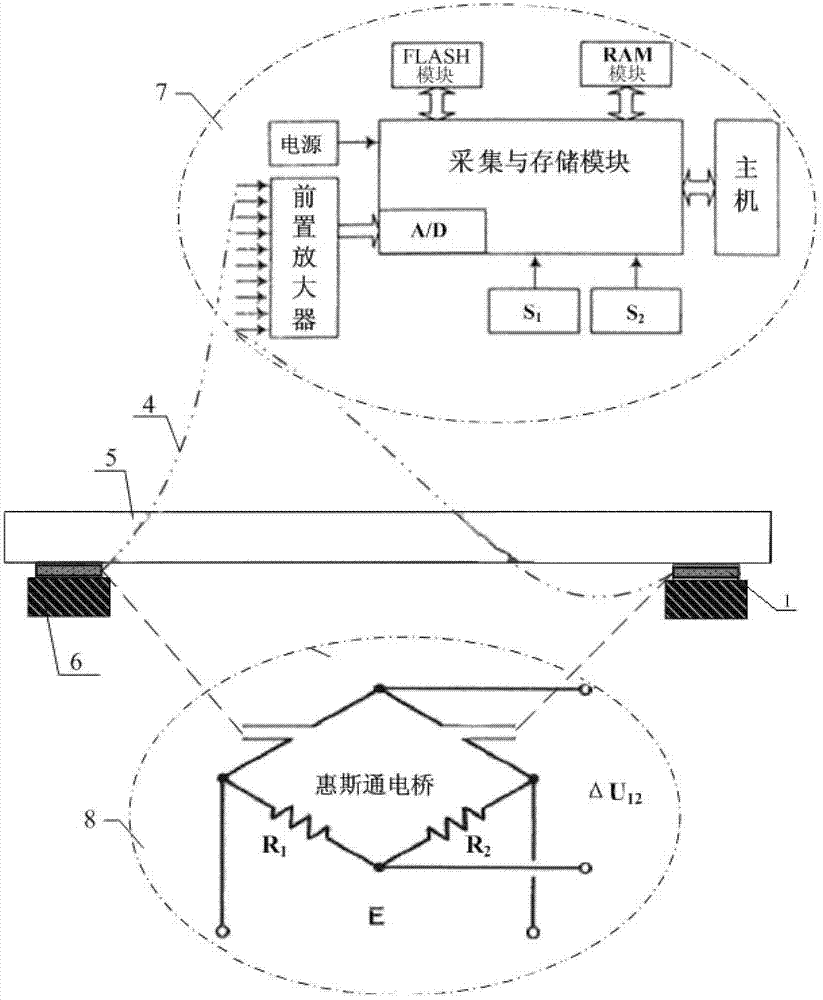

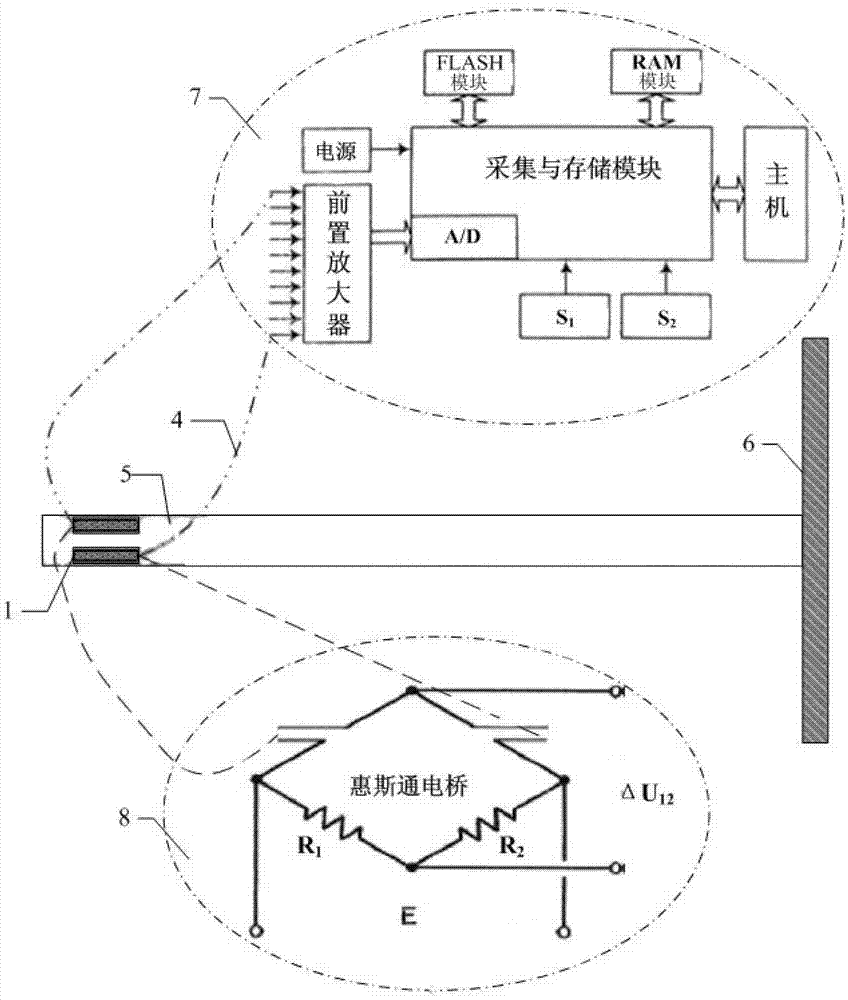

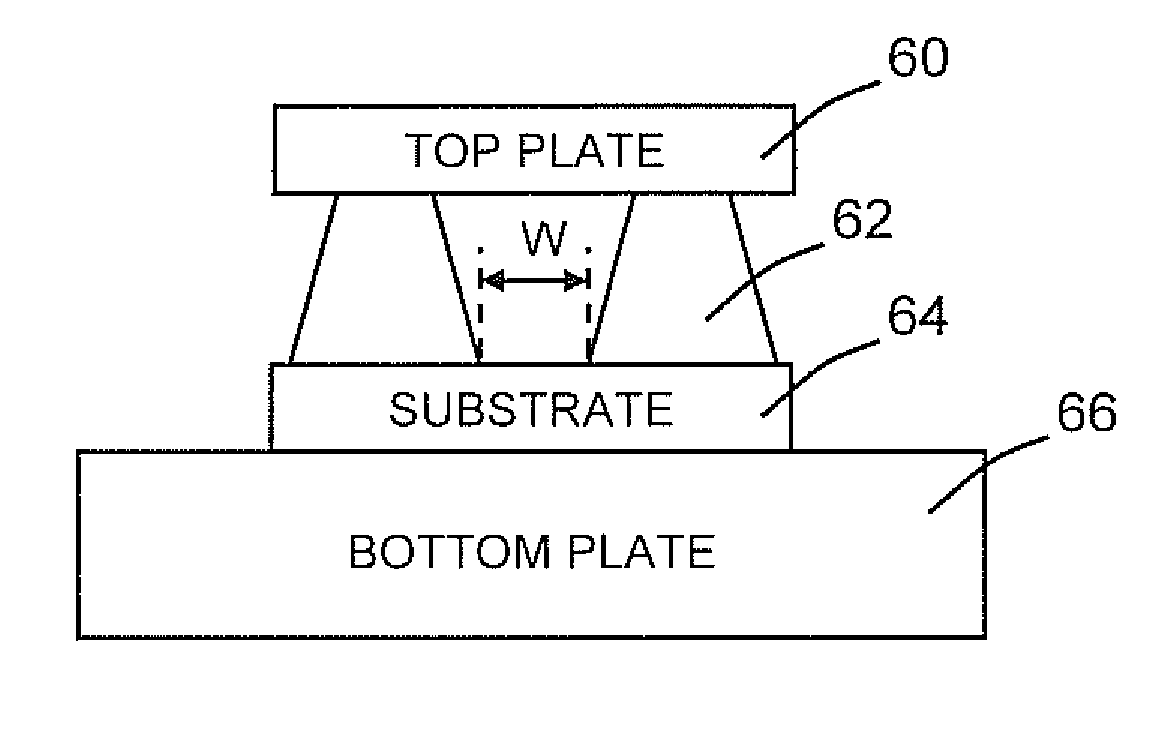

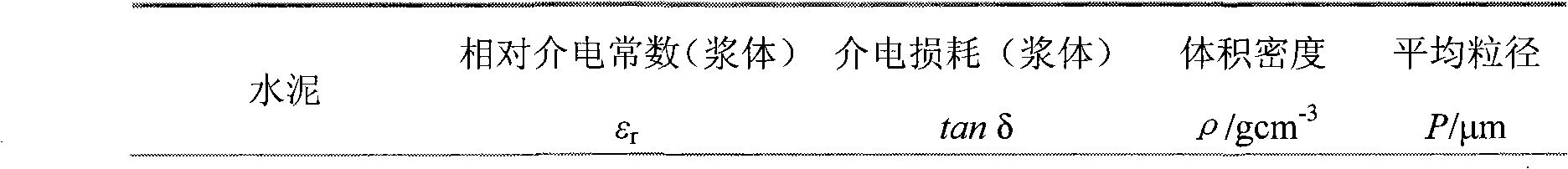

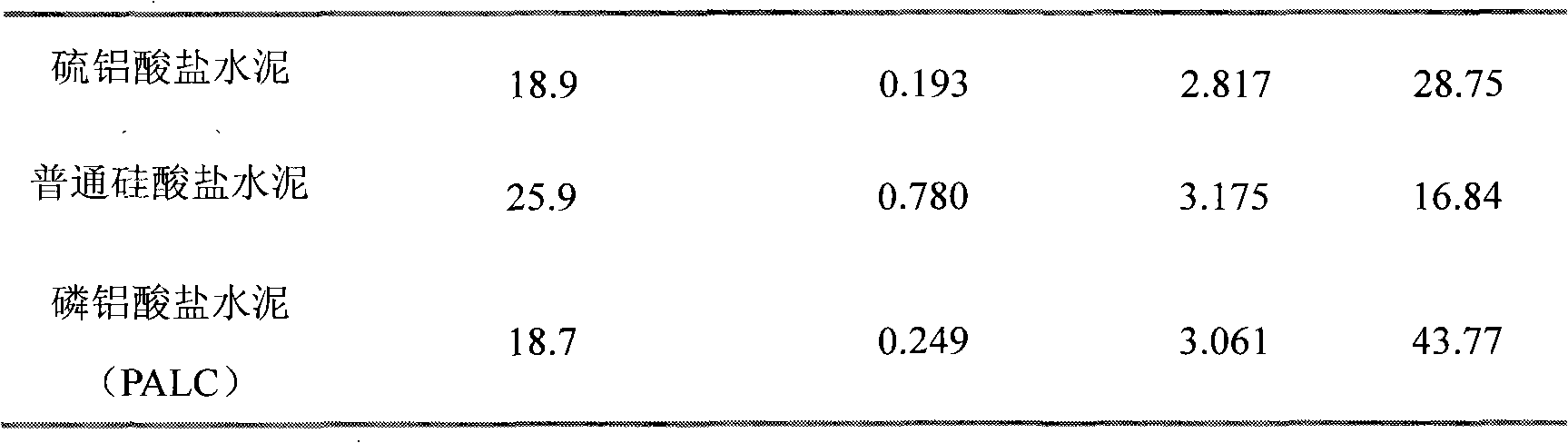

Piezoresistance/piezoelectric composite material, manufacturing method of material, sensor utilizing material and manufacturing method of sensor

InactiveCN102924020AImprove structural toughnessGood compatibilityConverting sensor output electrically/magneticallyFiberBridge deck

The invention relates to a piezoresistance / piezoelectric material system and production and application methods of the piezoresistance / piezoelectric material system. The piezoresistance / piezoelectric composite material comprises the following components in parts by weight: 100 parts of cement, 105-500 parts of micro / nano grade piezoelectric ceramic powder body, 10-30 parts of fly ash, 15-50 parts of water, 0.01-2 parts of super plasticizer, 0.1-10 parts of toughness fiber and 0.01-15 parts of conductive fillers. A sensor utilizing the piezoresistance / piezoelectric composite material comprises a piezoresistance / piezoelectric composite material layer, wherein the upper surface and the lower surface of the piezoresistance / piezoelectric composite material layer are respectively provided with one electrode, the piezoresistance / piezoelectric composite material layer and the electrodes are coated in a package shell, the upper electrode and the lower electrode are connected by an electromagnetic shielding wire passing through the package shell, and the sensor is arranged between a bracket and a support bridge deck unit or is embedded in the support bridge deck unit. The sensor utilizing the material, disclosed by the invention, has intrinsic structure toughness and synchronous monitoring capability of covering a whole-frequency-domain static / dynamic traffic and structure parameters.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

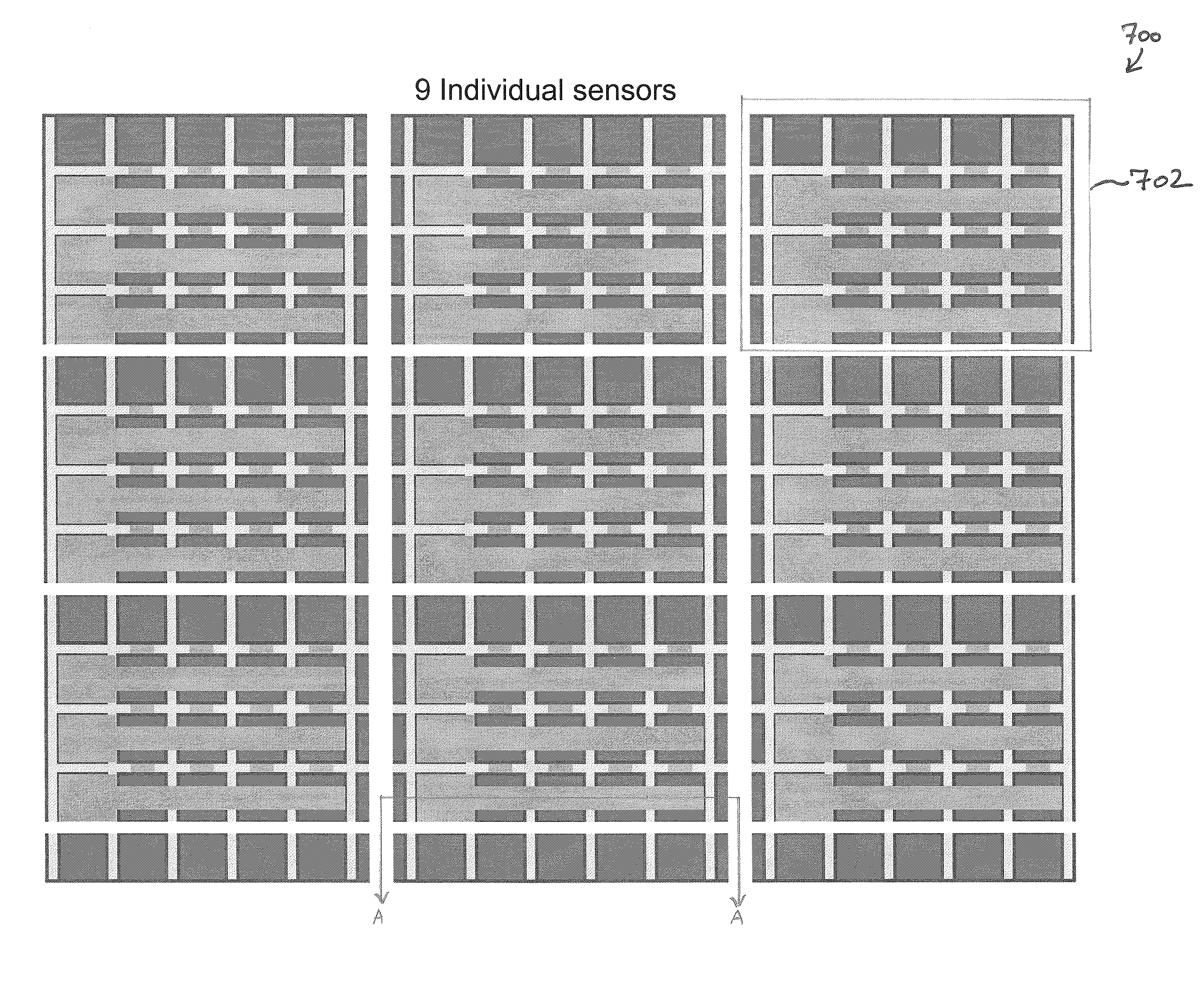

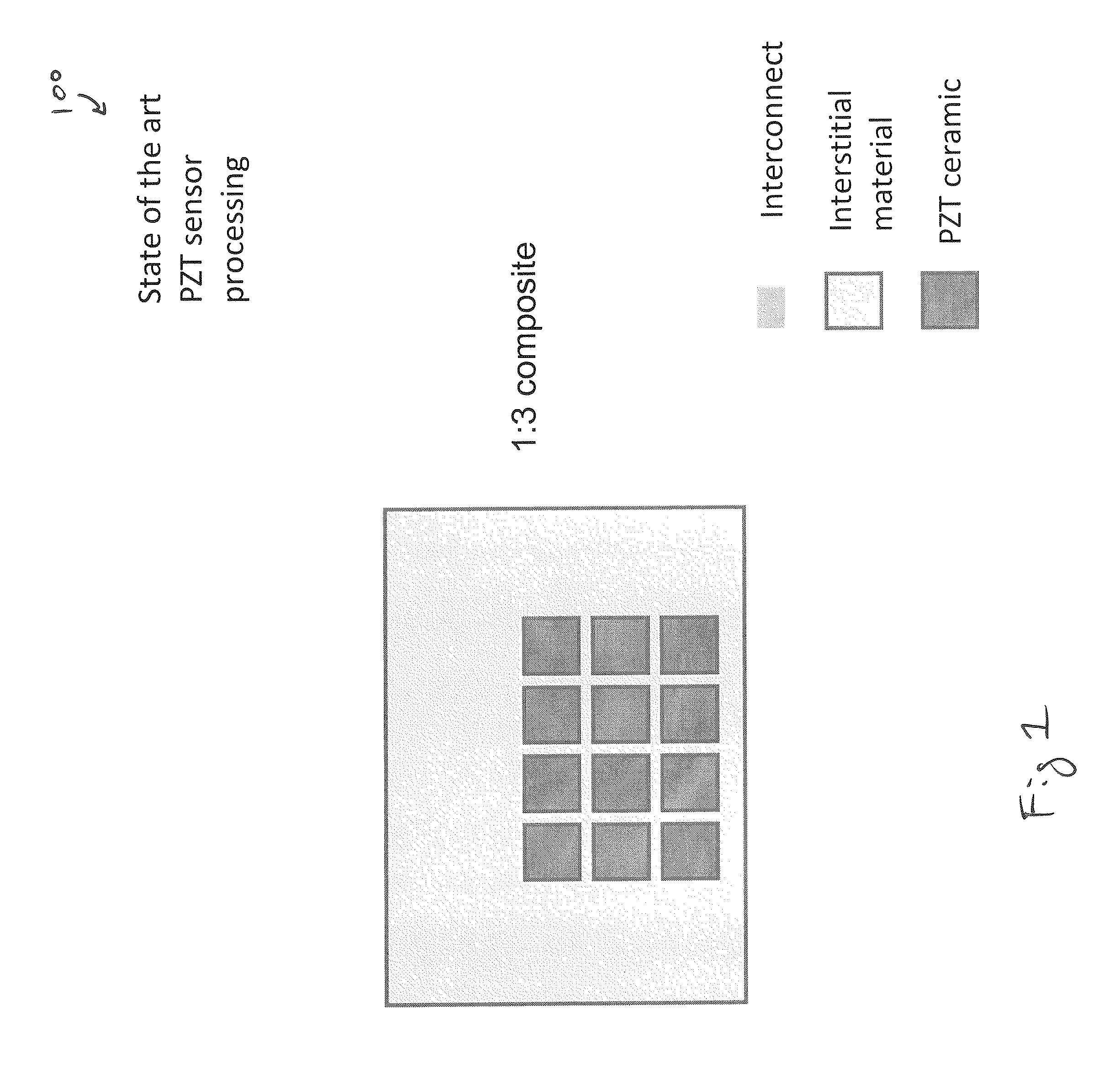

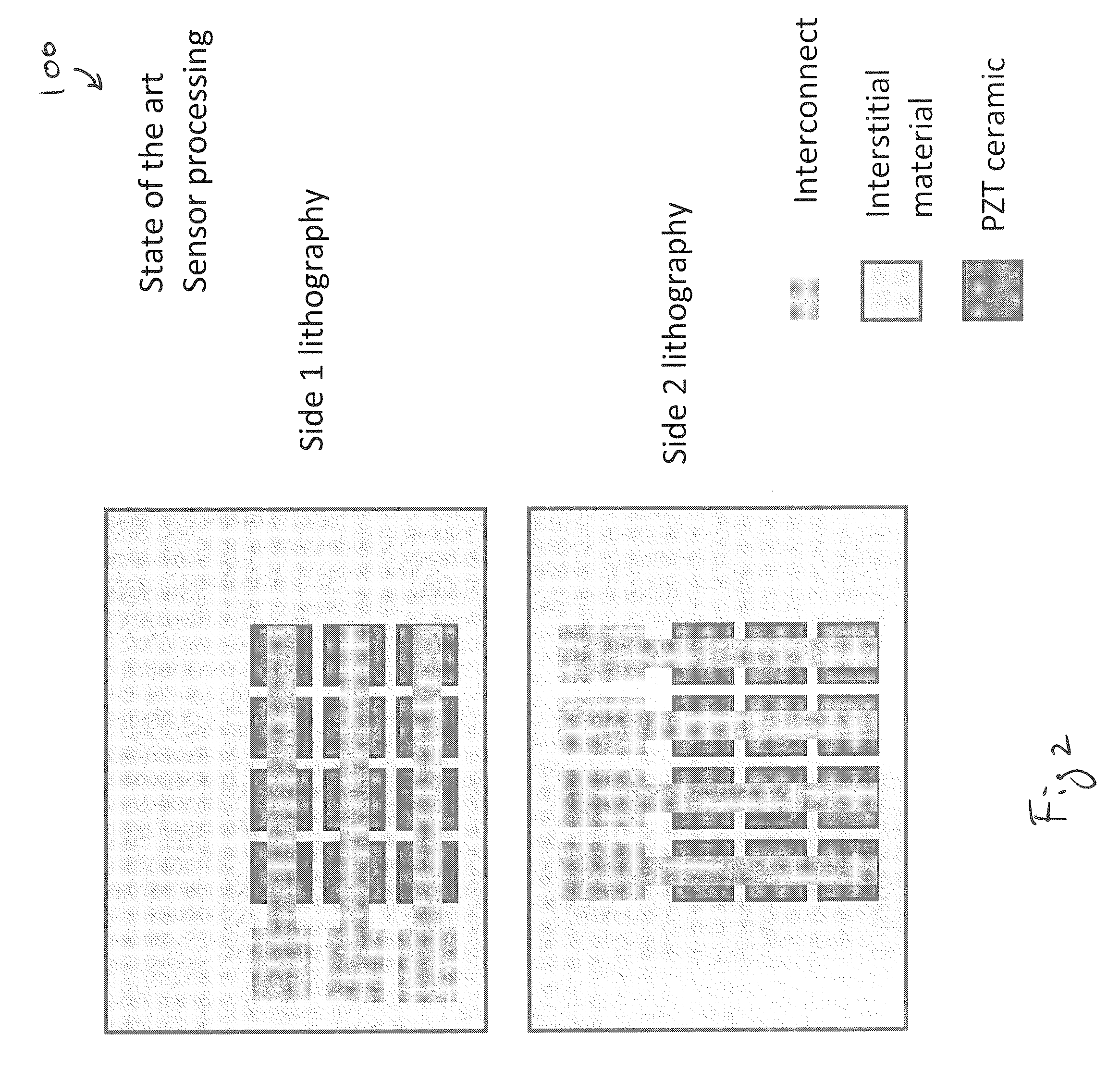

Sea of Pillars

InactiveUS20100239751A1Piezoelectric/electrostrictive device manufacture/assemblySolid-state devicesMultiple sensorEngineering

Provided is a method for manufacturing multiple devices on a single piezoelectric composite substrate. The piezoelectric composite substrate is significantly larger than a size required for a single device, thus multiple sensors can be simultaneously fabricated from the same piezoelectric composite substrate.

Owner:SONAVATION INC

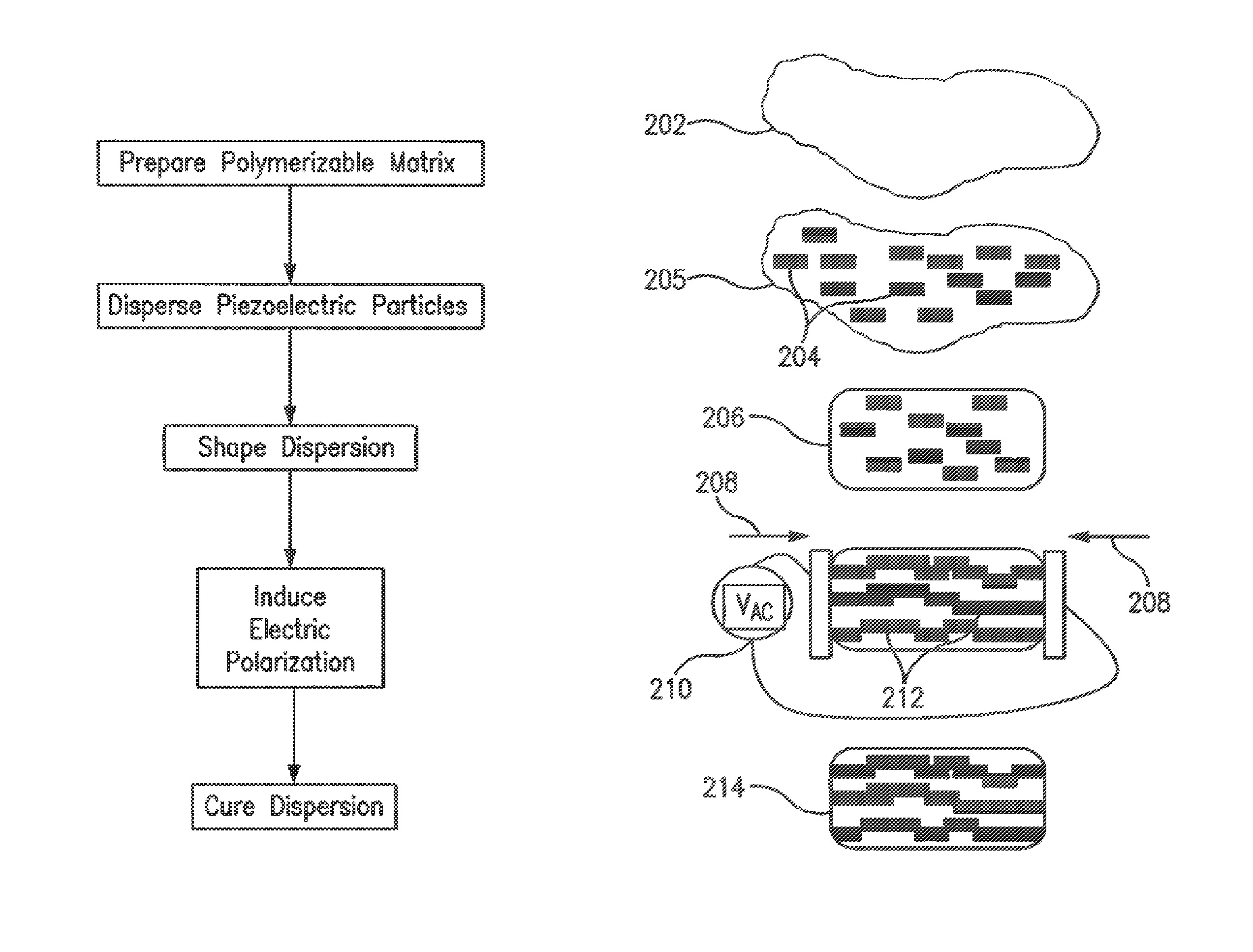

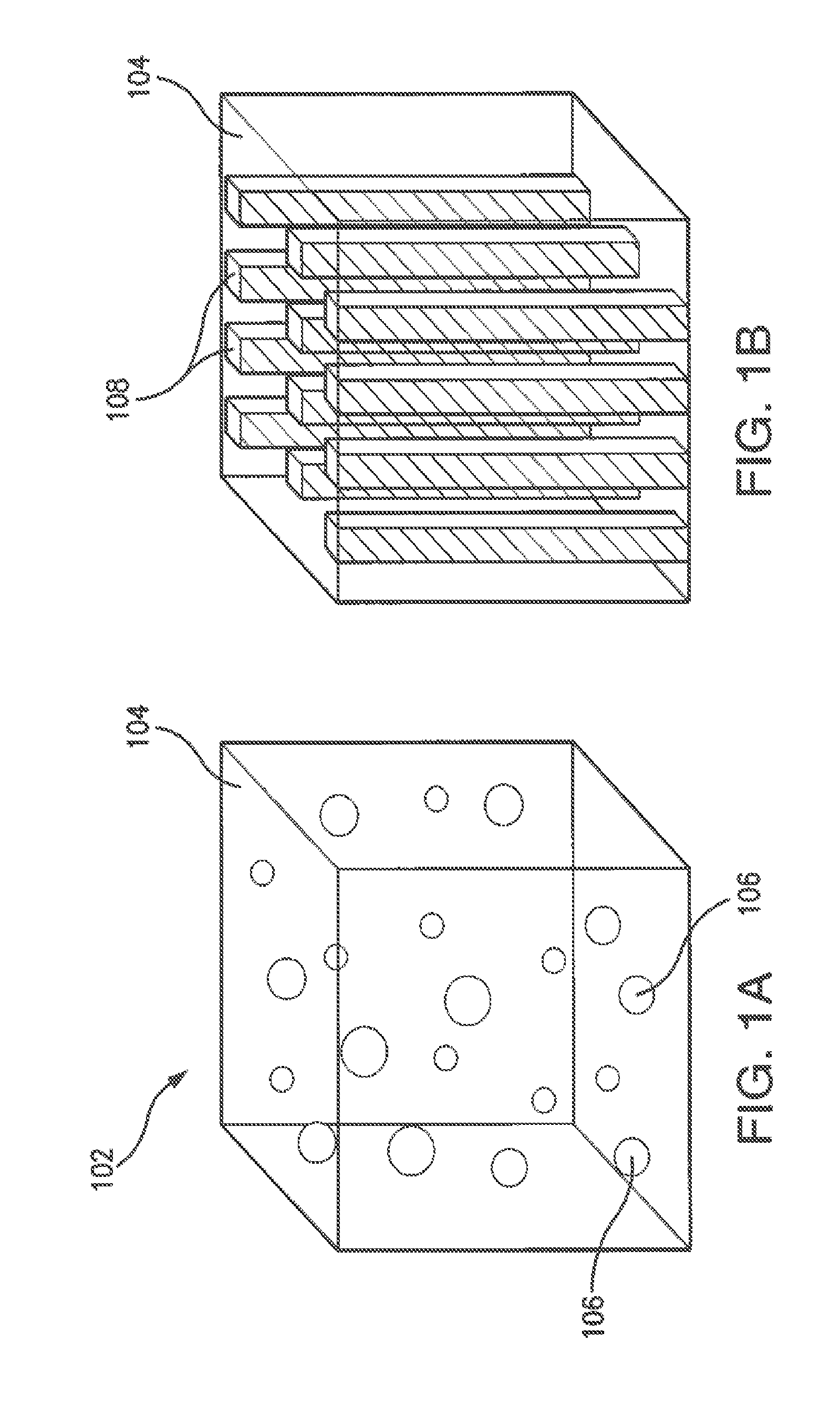

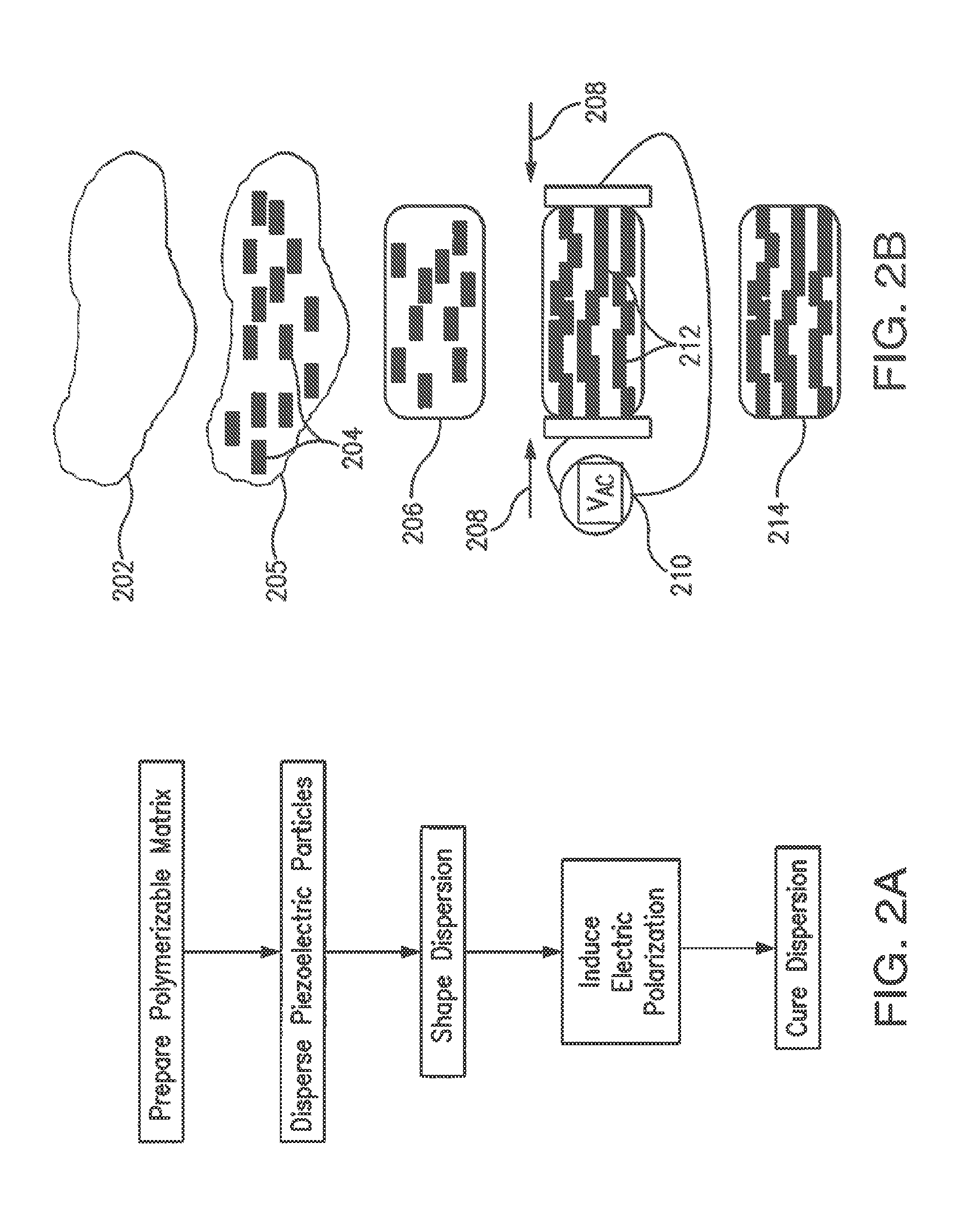

Piezoelectric composites and methods of making

InactiveUS20150134061A1Bone implantPiezoelectric/electrostrictive device material selectionThermoplasticMedicine

There is a need for methods that can produce piezoelectric composites having suitable physical characteristics and also optimized electrical stimulatory properties. The present application provides piezoelectric composites, including tissue-stimulating composites, as well as methods of making such composites, that meet these needs. In embodiments, methods of making a spinal implant are provided. The methods suitably comprise preparing a thermoset, thermoplastic or thermoset / thermoplastic, or copolymer polymerizable matrix, dispersing a plurality of piezoelectric particles in the polymerizable matrix to generate dispersion, shaping the dispersion, inducing an electric polarization in the piezoelectric particles in the shaped dispersion, wherein at least 40% of the piezoelectric particles form chains.

Owner:UNIVERSITY OF KANSAS

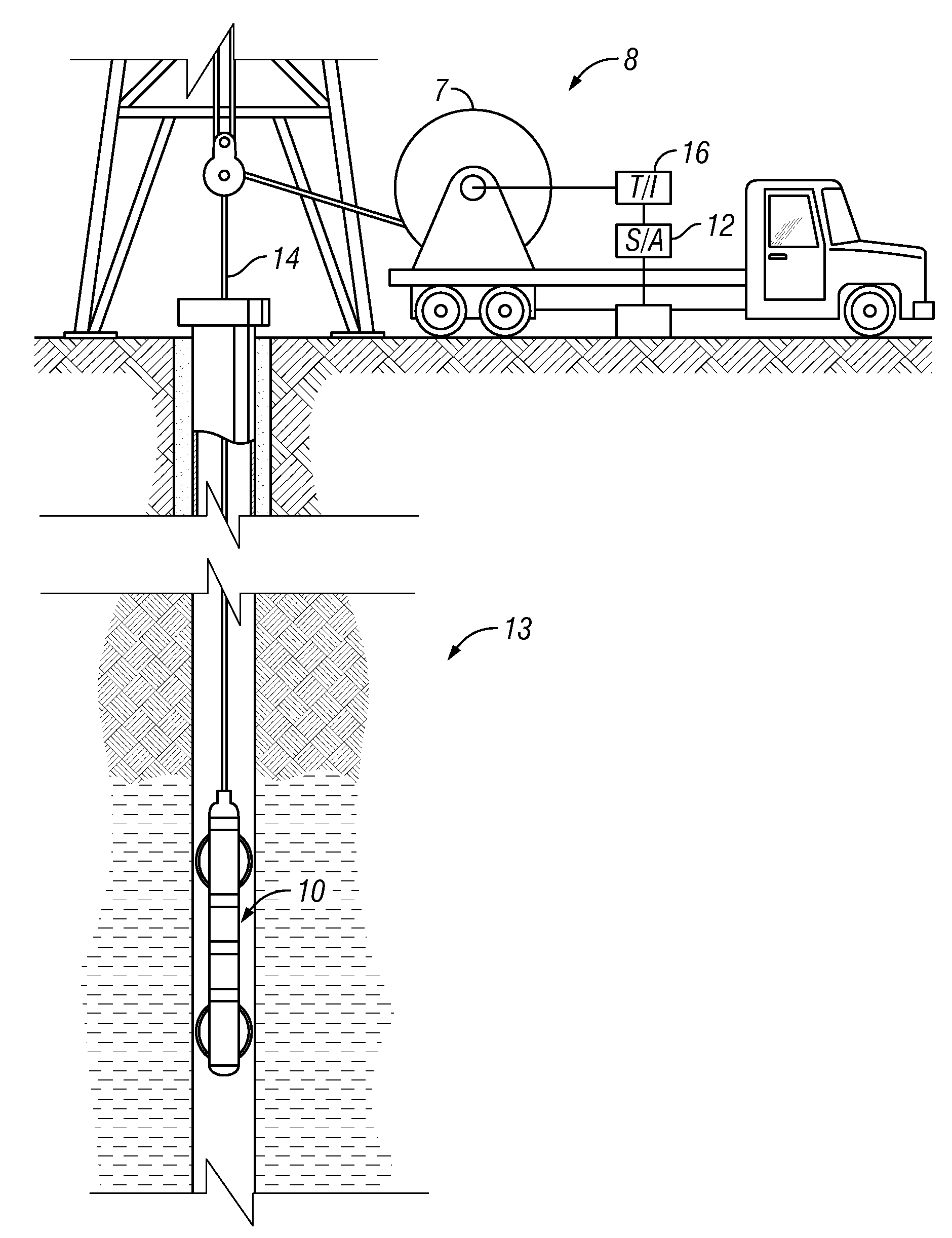

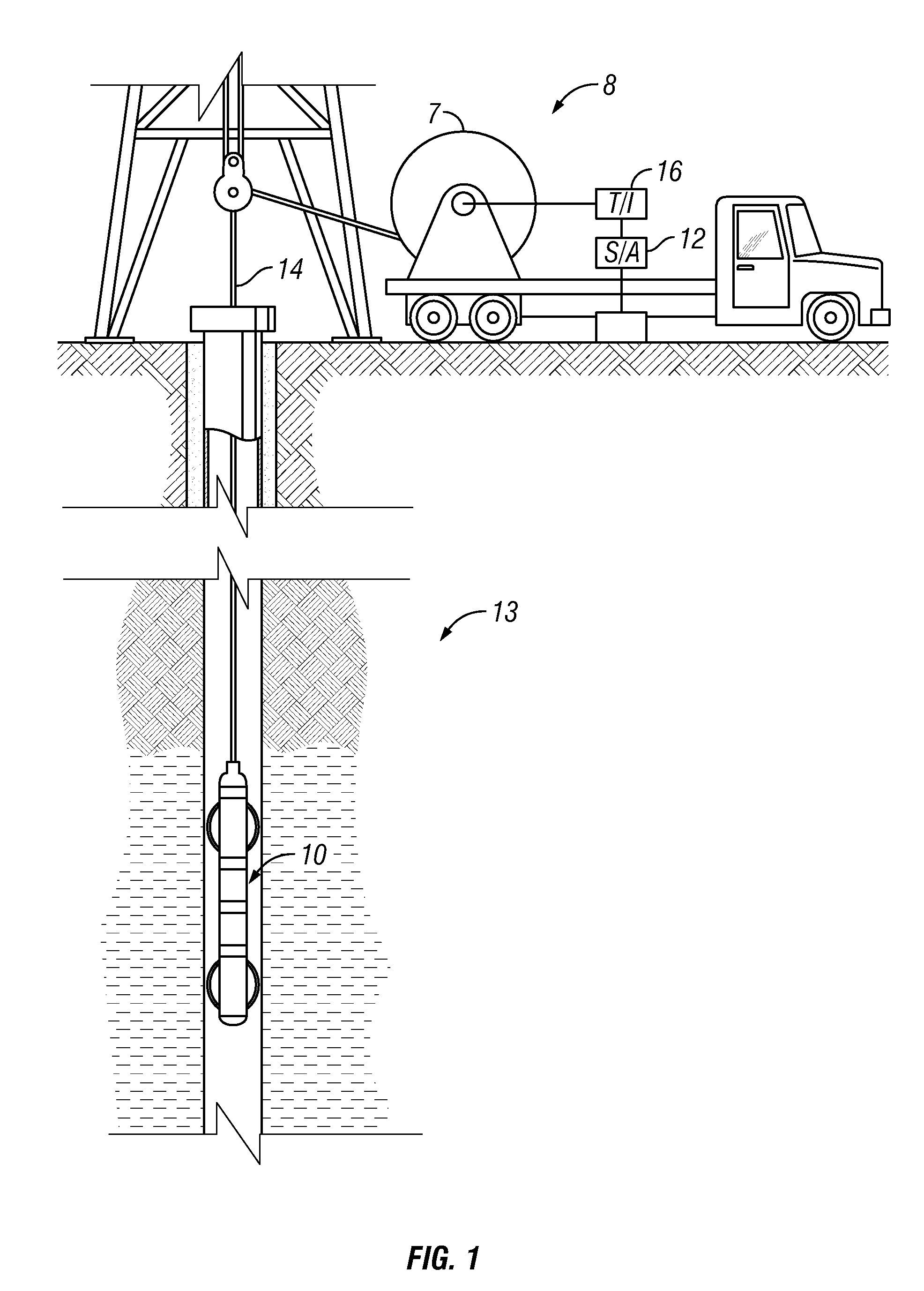

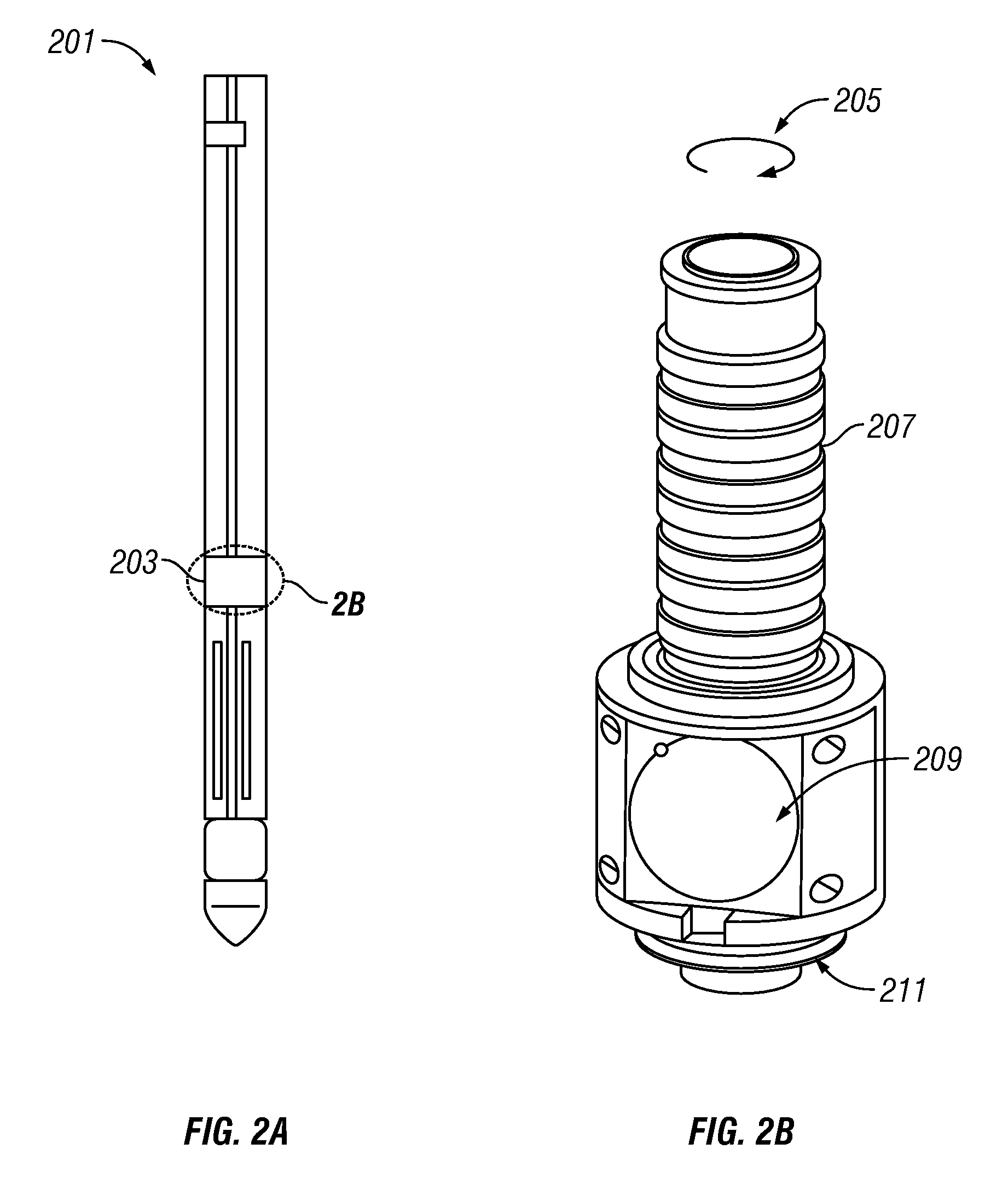

Composite Transducer for Downhole Ultrasonic Imaging and Caliper Measurement

ActiveUS20090213690A1Piezoelectric/electrostrictive transducersSeismic signal receiversSonificationUltrasonic imaging

A transducer assembly for downhole imaging includes a 1-3 Piezoelectric composite transducer of high Q ceramic rods in a polymer matrix. The assembly also includes a Teflon® window, a fluid-filled cavity adjacent to the window, and impedance matching material between the composite transducer and the fluid. The transducer is positioned to reduce the reverberation time.

Owner:BAKER HUGHES INC

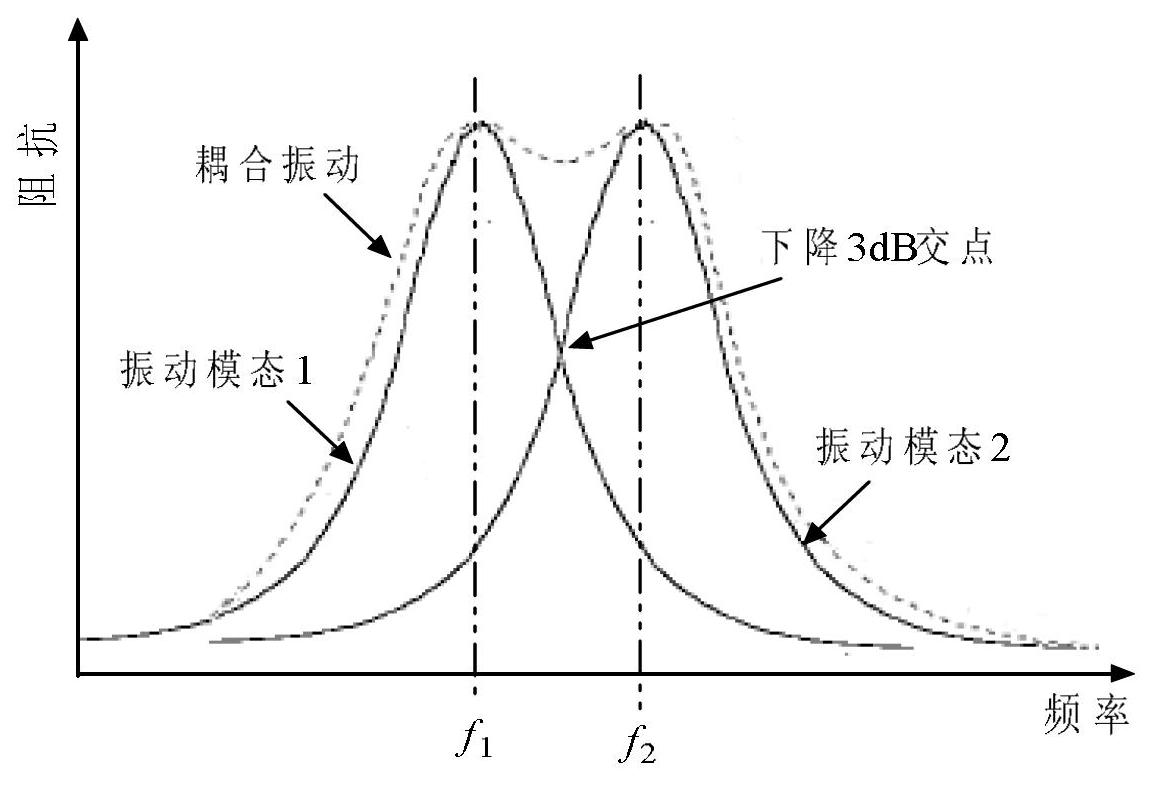

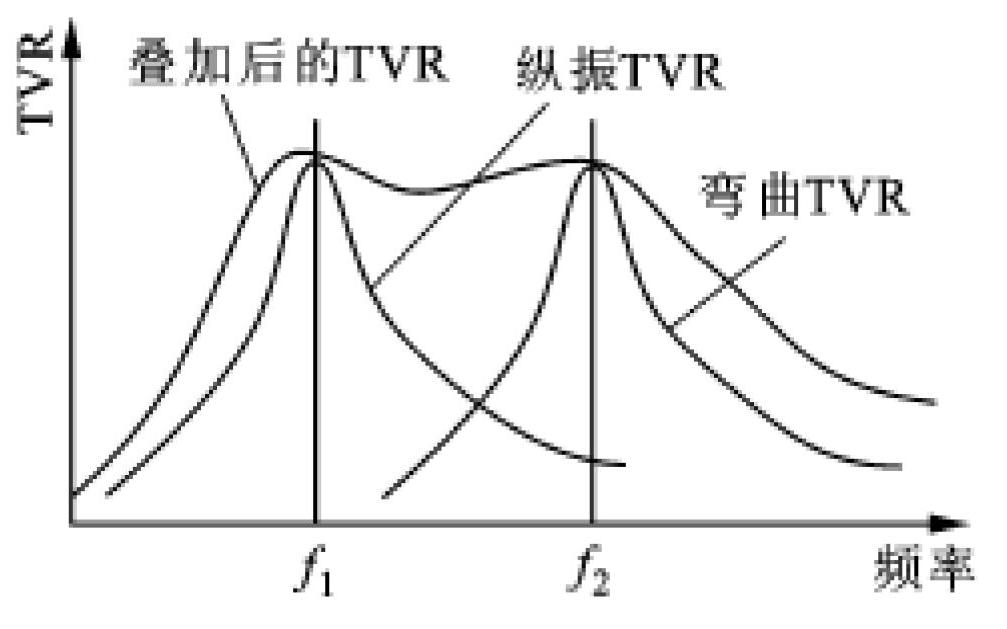

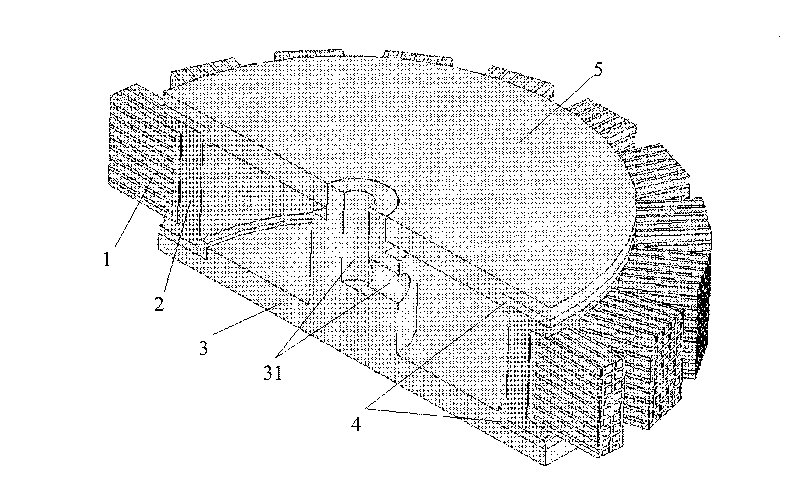

Multimode broadband circular array transducer

ActiveCN102662166AHigh bandwidthGuaranteed Emission EfficiencyWave based measurement systemsElectricityBroadband

The invention discloses a multimode broadband circular array transducer, which comprises a piezoelectric composite material cambered base array, a decoupling material, a back lining, a shell, a matching layer, a water sealing joint and a cable, wherein the piezoelectric composite material cambered base array is formed by uniformly arranging a plurality of piezoelectric composite material base elements; the decoupling material is filled between the piezoelectric composite material base elements, so that a circular sensitive element is formed; the back lining is tightly attached to the inner side of the circular sensitive element; the shell supports and encircles the sensitive element and the back lining; the matching layer is poured on the outer side of the sensitive element; electrodes are arranged on the upper surfaces and the lower surfaces of the piezoelectric composite material base elements, so that positive electrodes and negative electrodes are led out by wires; wire holes are formed in the back lining, so that the wires pass through the wire holes; a wire outlet is formed on the shell; the water sealing joint seals the wire outlet; and the wires are connected with the cable in the water sealing joint. The transducer has the characteristics of high frequency, high sensitivity, broadband and large directive opening angle.

Owner:常州市深海回声声学科技有限公司

Epoxide resin based piezoelectric composite damping material and method for preparing the same

The invention introduces an epoxy resin-based piezoelectric and composite damping material and a preparation method thereof, which comprises the following materials by weight portion: 100 portions of epoxy resin, 30 portions to 220 portions of piezoelectric ceramic powder, 0.5 portion to 5 portions of graphitized carbon black and 30 portions to 120 portions of curing agent. After being mixed, dispersed and added with the curing agent to be evenly blended and then poured, cured and shaped, the piezoelectric and composite material can be polarized in an HVDC oil-bath electric field and has good damping property (tan Delta is not less than 0.3) in a wide-temperature range (10 to 100 DEG C) and can also be applied in projects as free damping material as well as in an intelligent vibration and noise reduction system. In addition, the piezoelectric and composite material can be made into damping paint, putty, slurry and potting adhesive and poured into various section materials to be used in vibration and noise reduction projects in the fields such as vehicles, industrial machinery, civil construction, household appliances, precision instruments, military equipment, etc.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Piezoelectric composite device, method of manufacturing same, method of controlling same, input-output device, and electronic device

InactiveUS20060238069A1MorePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

Disclosed herein is a piezoelectric composite device including: a feeding electrode; a common electrode; a signal detecting electrode; a first piezoelectric element joined between the feeding electrode and the common electrode; and a second piezoelectric element joined between the common electrode and the signal detecting electrode; a predetermined voltage being supplied between the feeding electrode and the common electrode; and a force detection signal based on an external force being extracted from the detecting electrode.

Owner:MARUYAMA SHIGEAKI +2

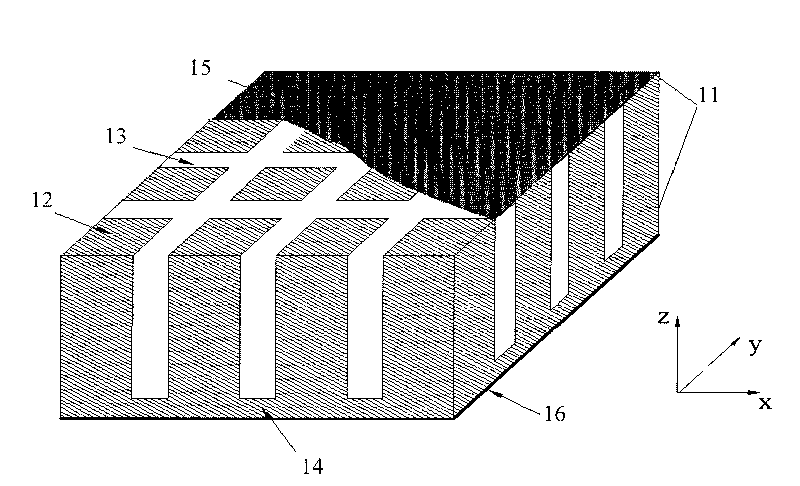

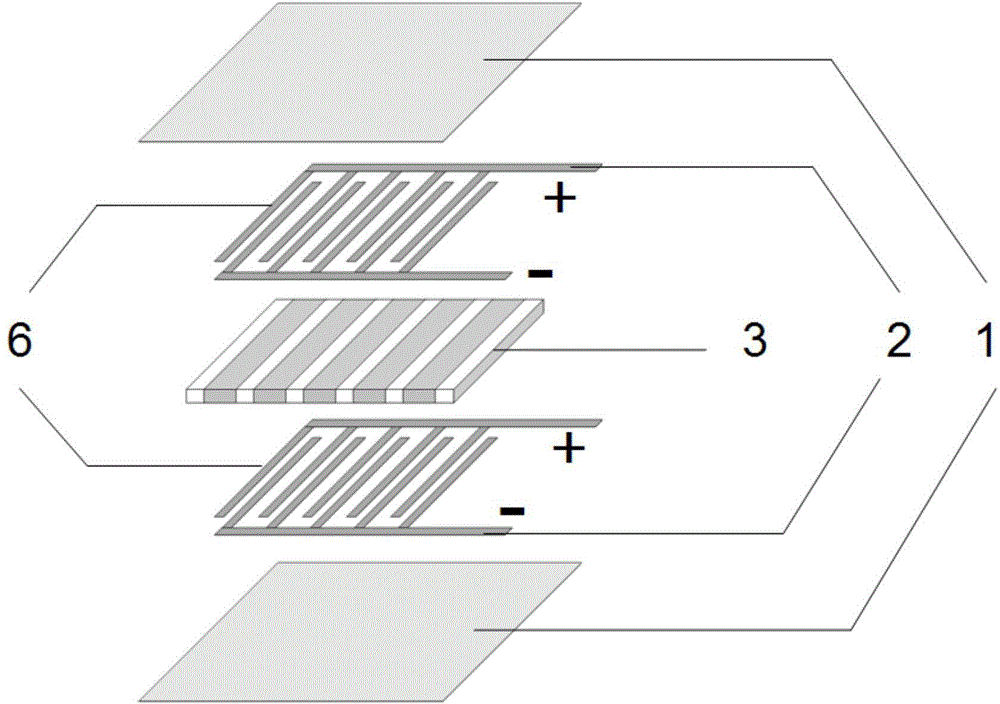

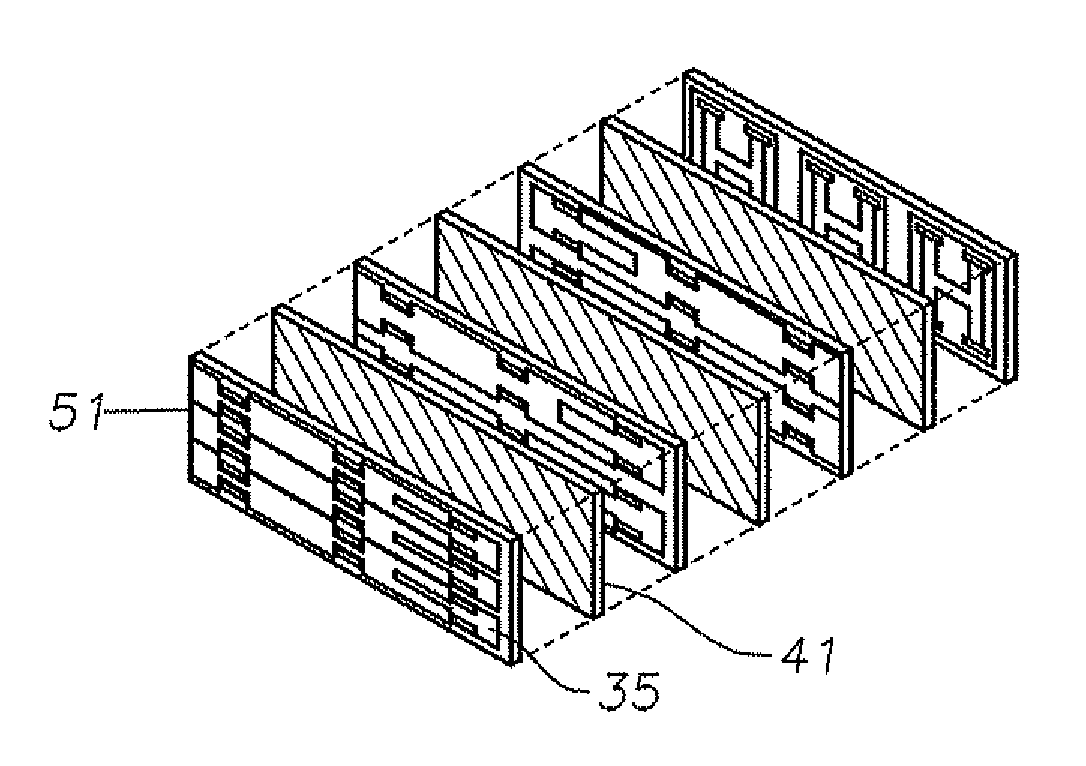

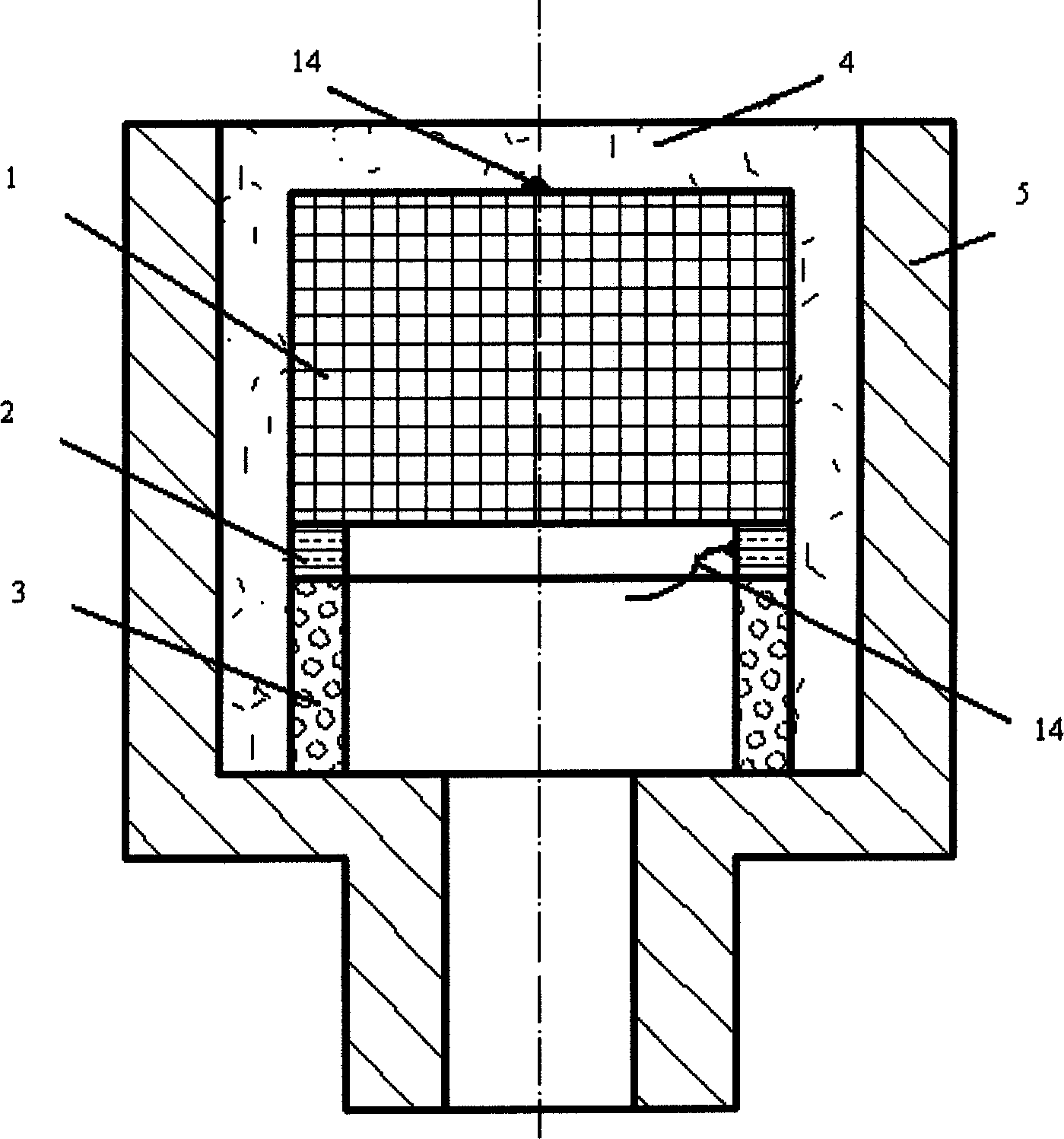

Multi-element piezoelectric composite material and preparation method and application thereof

ActiveCN102427110ASimple preparation processImprove performancePiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionPiezoelectric compositePolymer composite materials

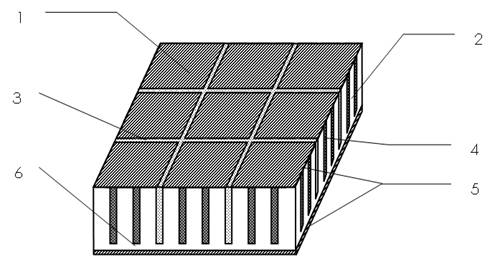

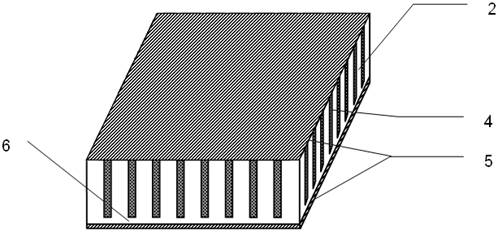

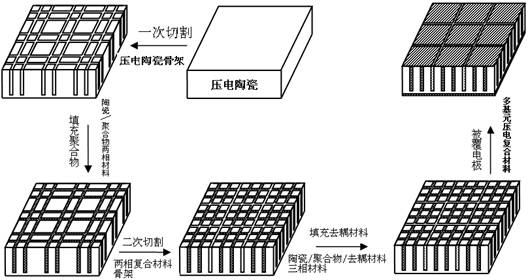

The invention discloses a multi-element piezoelectric composite material and a preparation method. The multi-element piezoelectric composite material is a 1-3-2 type composite material consisting of a piezoelectric ceramic / polymer composite material and a decoupling material, wherein the piezoelectric ceramic / polymer composite material takes piezoelectric ceramic as a skeleton and a polymer as a base body and is attached with an upper electrode and a lower electrode, the piezoelectric ceramic skeleton comprises a substrate and a piezoelectric ceramic column connected to the substrate, the decoupling material is filled in the piezoelectric ceramic / polymer composite material, the piezoelectric ceramic / polymer composite material is divided into a plurality of units of the same structure by the decoupling material, and the upper electrodes of all elements are discontinuous. Through the adding of the decoupling material, the whole composite material is divided into a plurality of units. The preparation technology is simple. The obtained multi-element material has excellent property, good consistency, low coupling and wide application prospect in the field of transducers.

Owner:UNIV OF JINAN

Method for producing piezoelectric composite substrate

ActiveUS20100108248A1Improve utilization efficiencyUniform thicknessAfter-treatment detailsLamination ancillary operationsSingle crystalPiezoelectric composite

A method for producing a piezoelectric composite substrate having a single-crystal thin film of a piezoelectric material includes an ion-implantation step and a separation step. In the ion-implantation step, He+ ions are implanted into the single-crystal base made of the piezoelectric material to form localized microcavities in a separation layer located inside the single-crystal base and apart from a surface of the single-crystal base. In the separation step, the microcavities formed in the ion-implantation step are subjected to thermal stress to divide the separation layer of the piezoelectric single-crystal base, thereby detaching the single-crystal thin film.

Owner:MURATA MFG CO LTD

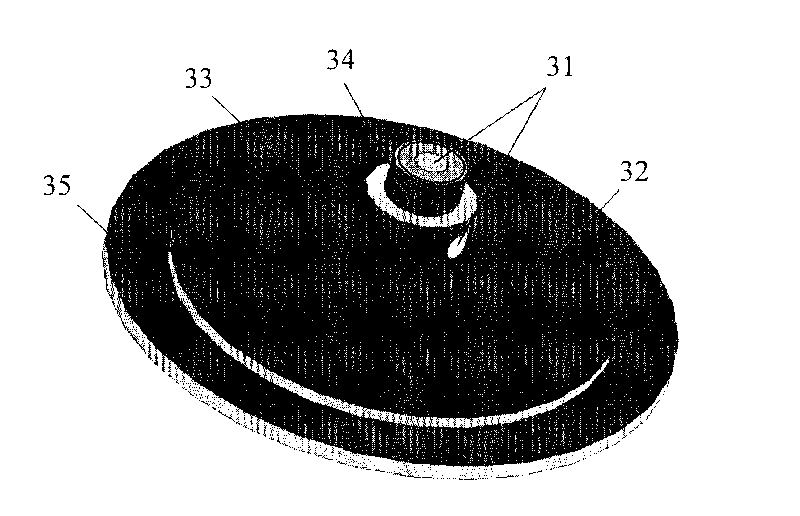

Cascade and parallel piezoelectric composite material-based cylindrical transducer

InactiveCN101715157ABandwidthHigh sensitivityTransducers for subaqueous useElectromechanical coupling coefficientEngineering

The invention discloses a cascade and parallel piezoelectric composite material-based cylindrical transducer, which comprises a support with an underpan, an annular backing, an end cover and a plurality of wafers, wherein the wafers are cascade and parallel piezoelectric composite wafers, are uniformly arranged on the outer side of the annular backing along the periphery and are polarized along the radial direction of the ring; insulating washers are cushioned on and under a tubular sensitive element consisting of the backing and the wafers; the tubular sensitive element is sleeved and fastened on the underpan of the support; and the end cover is fixed at the upper end of the support and on the insulating washer on the sensitive element. The transducer adopts a multi-wafer annular array as the sensitive element, the vibration of the wafers adopts a thickness model, the working frequency is higher than the radial vibration frequency of a round tube, and the high-frequency sound wave emission can be realized; moreover, because the wafers are mode of the cascade and parallel composite material, the electro-mechanical coupling factor of the composite material is high, the frequency band thereof is broad, and the transducer has high sensitivity and broad working frequency band; therefore, the transducer has the characteristics of high frequency, high sensitivity, broad band and level omnidirection.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Piezo-electric composite sensor

InactiveCN101194376AExcellent piezoelectric propertiesExcellent dielectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionProduction rateConductive polymer

The present invention provides a piezoelectric composite sensor comprising a piezoelectric material layer formed of a piezoelectric composite obtained by mixing piezoelectric material powder with a polymer, and electrodes formed of a conductive composite or conductive polymer obtained by mixing conductive filling particles with a polymer matrix and formed on both surfaces of the piezoelectric material layer. The piezoelectric composite sensor of the present invention has advantages of superior piezoelectric and dielectric properties, high mechanical strength, improved reliability and process flexibility, a simplified process and reduced process costs, and improved productivity.

Owner:ATSUDEN

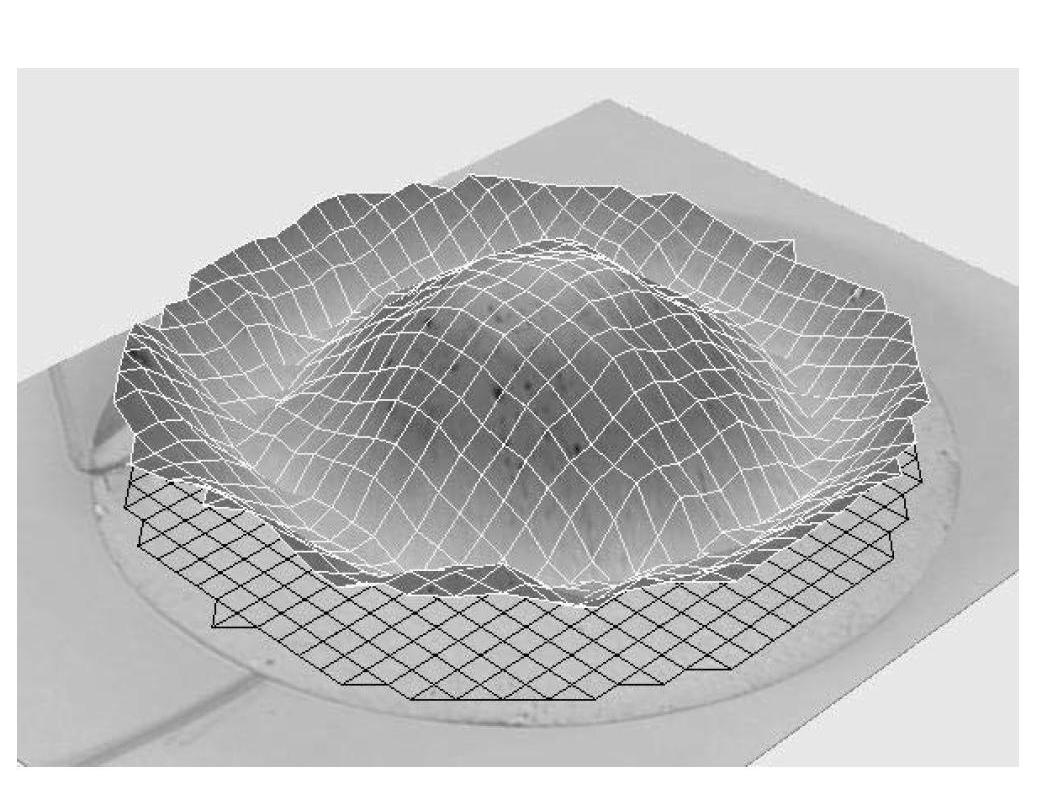

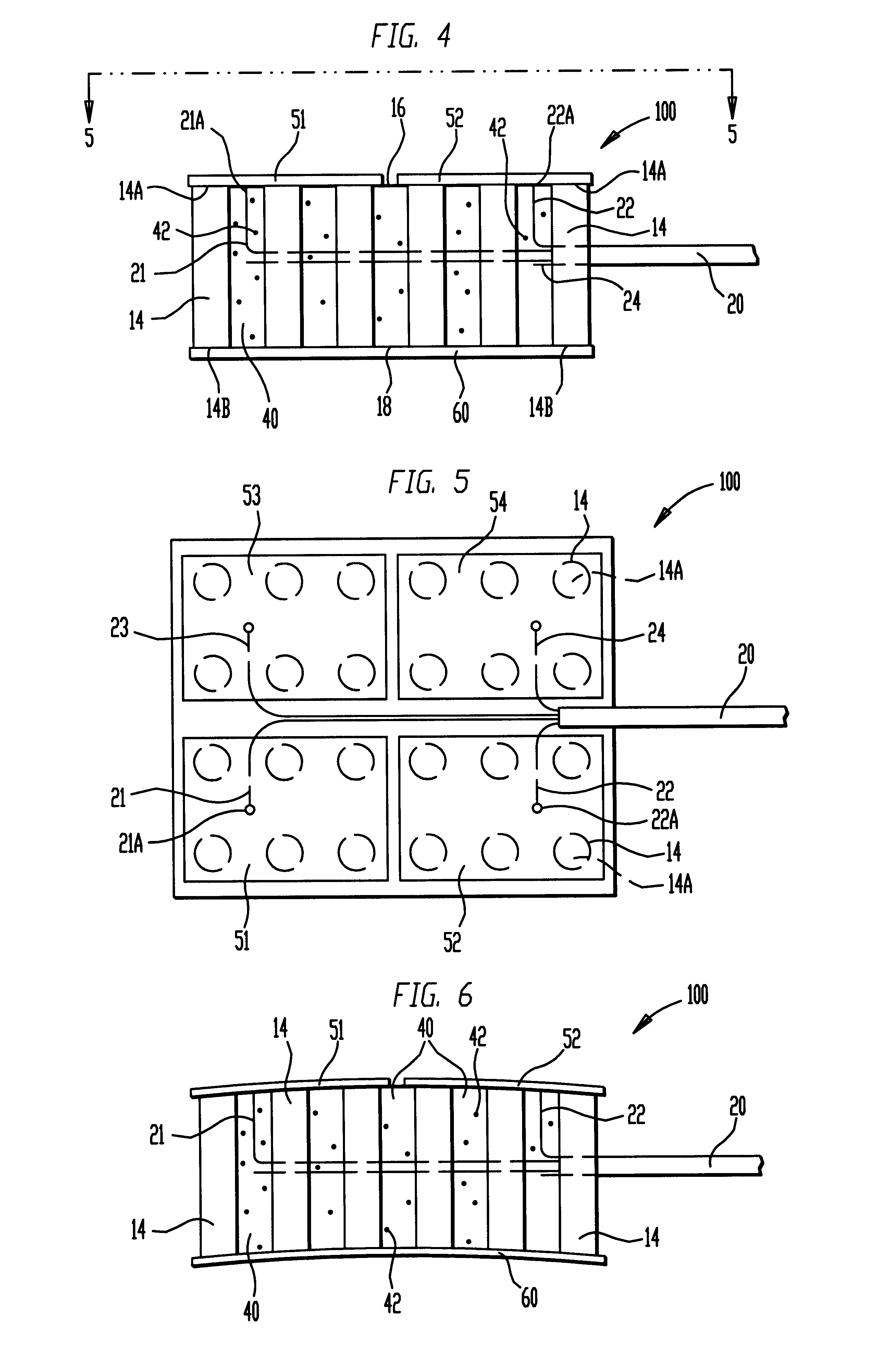

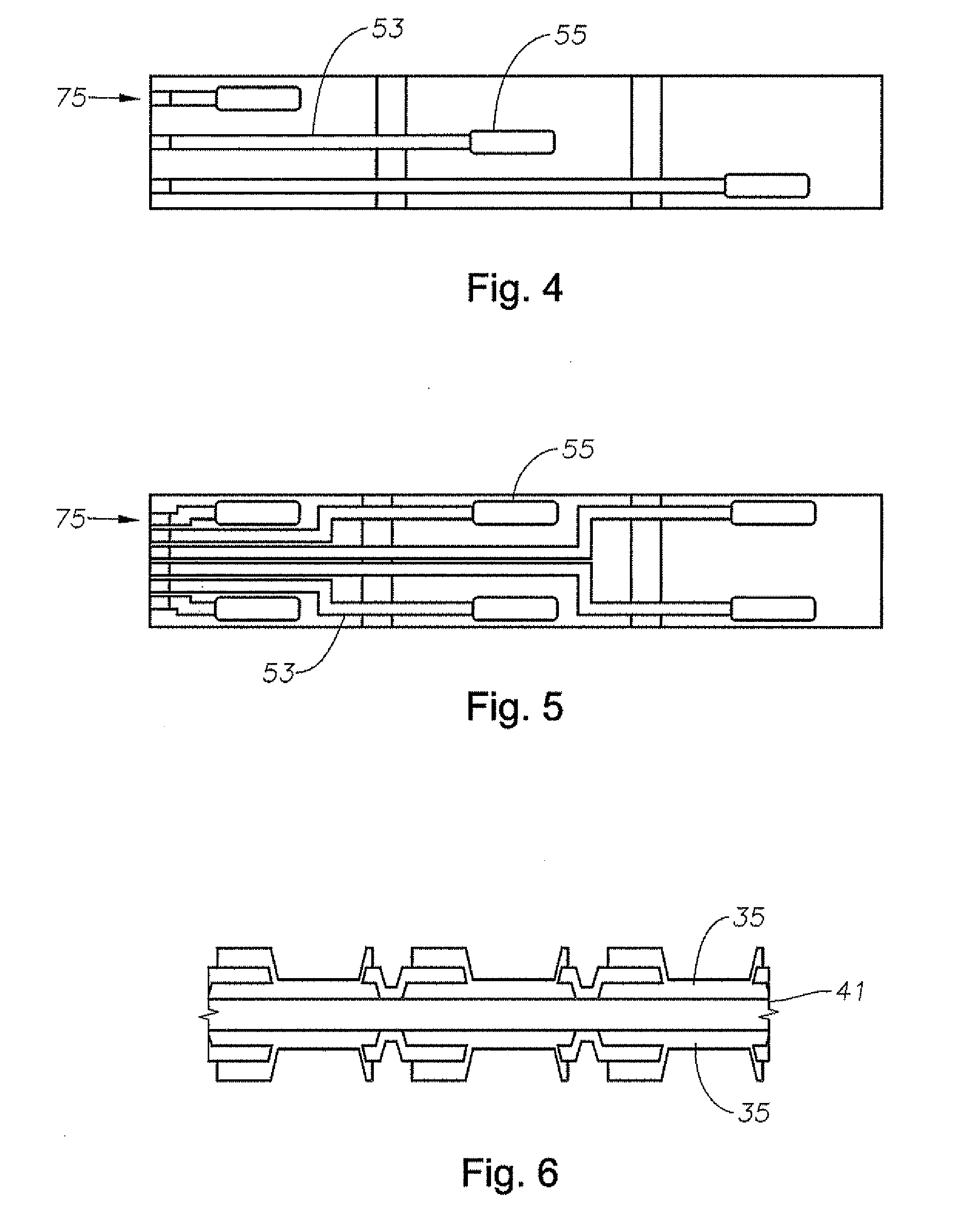

Shaped piezoelectric composite transducer

InactiveUS6255761B1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringPiezoelectric composite

A piezoelectric composite transducer and method for making same are disclosed. A block of piezoelectric material has a common base and a plurality of uniform-length rods extending from the common base in a parallel spaced-apart fashion to define an array. A first surface region is defined at outboard ends of the rods and a side region is defined about the periphery of the array. Electric conductors extend through the side region, are routed parallel to the first surface region, and are then led substantially parallel to the rods to the first surface region. Spaces between the rods are filled up to the first surface region with a viscoelastic material. The common base of the block is then removed such that a second surface region parallel and opposite to the first surface region is defined. Electrodes are deposited at the first surface region to be in contact with the rods and in electrical contact with the electric conductors. A ground electrode is deposited at the second surface region to be in contact with the rods. The resulting piezoelectric composite transducer can be heated and shaped to conform to complex curves.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

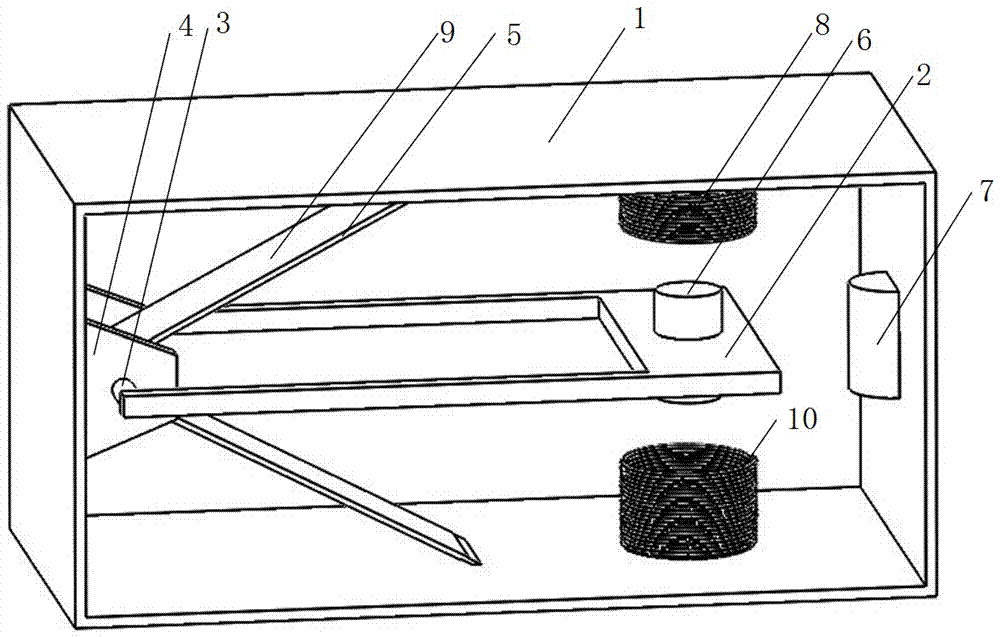

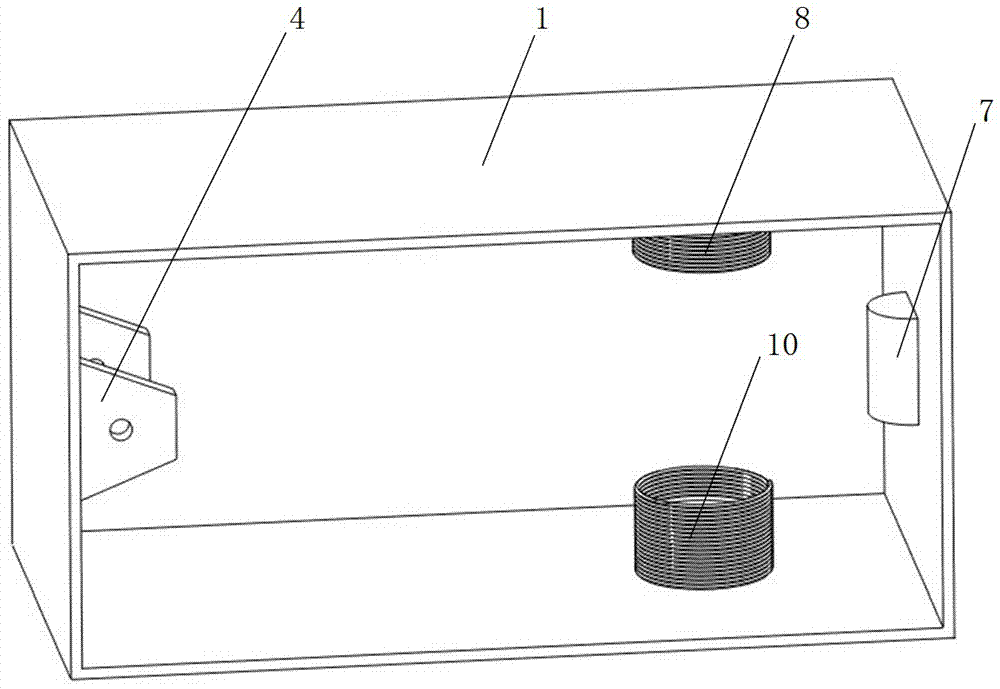

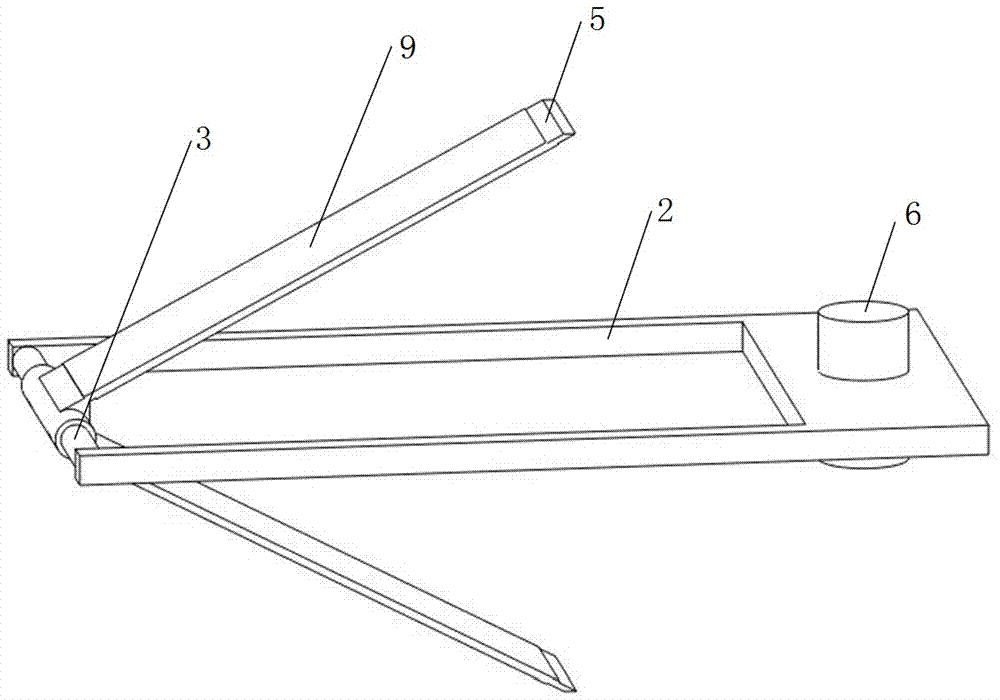

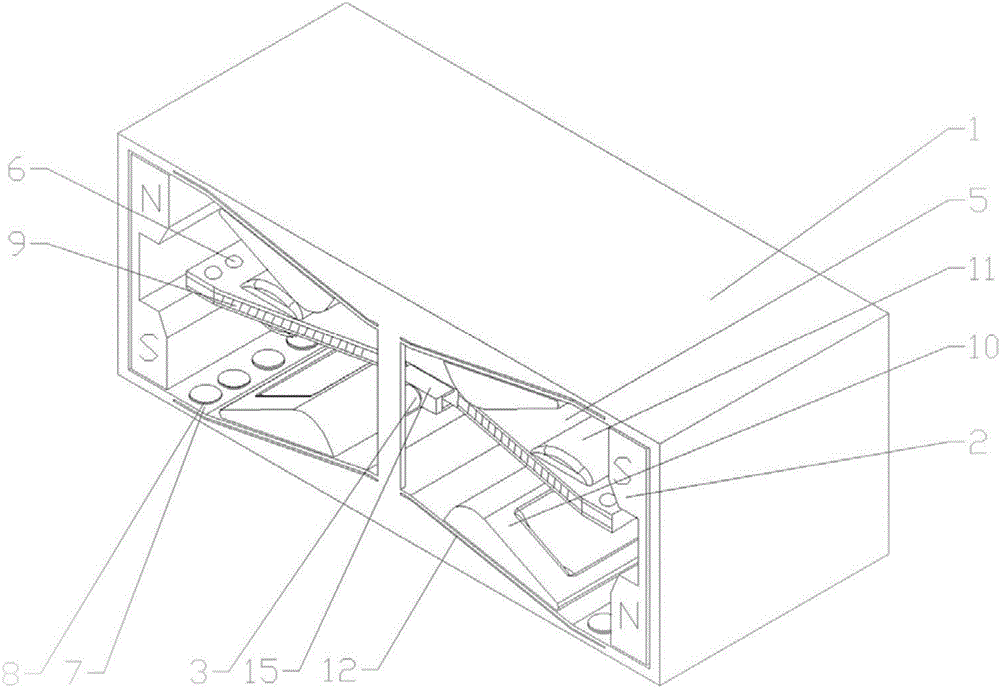

Spring leaf-type bistable electromagnetic piezoelectric composite energy collecting device

ActiveCN106899233AHigh utilization rate of space structureImprove energy harvesting efficiencyPiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesElectricityNatural state

The present invention relates to a spring leaf-type bistable electromagnetic piezoelectric composite energy collecting device, including a static mechanism and a movable mechanism. The static mechanism comprises a housing, and the housing is internally provided with a bearing bearer, a fixed magnet, an upper coil and a lower coil. The movable mechanism comprises a pendulum frame, a spring piece and a vibration magnet and a spring piece is a V-shaped or U-shaped sheet. In the natural state, the upper and lower ends of the spring piece are in contact with the inner top wall and the inner bottom wall of the housing respectively. The vibration magnet and the fixed magnet are magnetized in the axial direction and repel each other. Under the action of external vibration excitation, the swinging of the pendulum frame drives the rotation of a rotating shaft, and then the spring piece and a piezoelectric element are deformed and the electric charge is generated. The electric energy is outputted through an electrode terminal lead. When the vibration magnet on the pendulum frame swings up and down, the magnetic field around the magnet also moves, the coil in the magnetic field cuts the magnetic induction lines and generates induced current, and the current is output through the lead.

Owner:HEFEI UNIV OF TECH

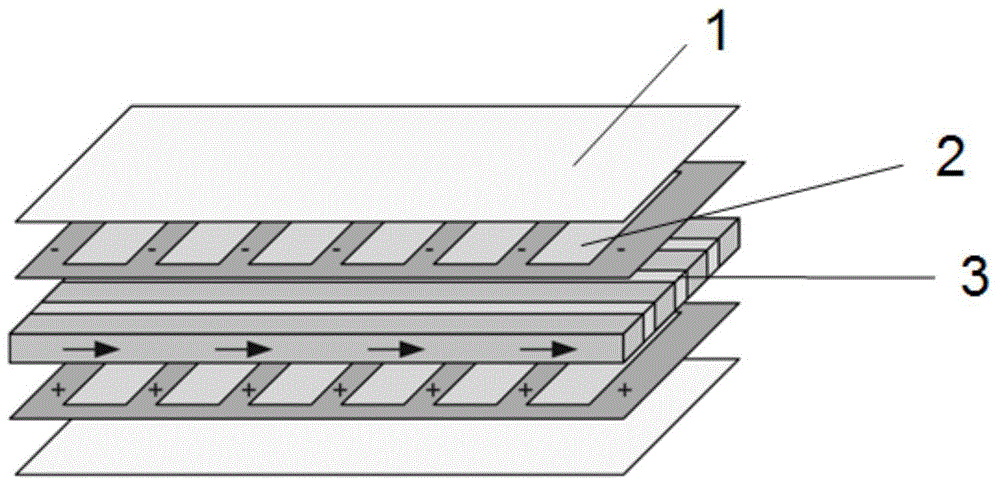

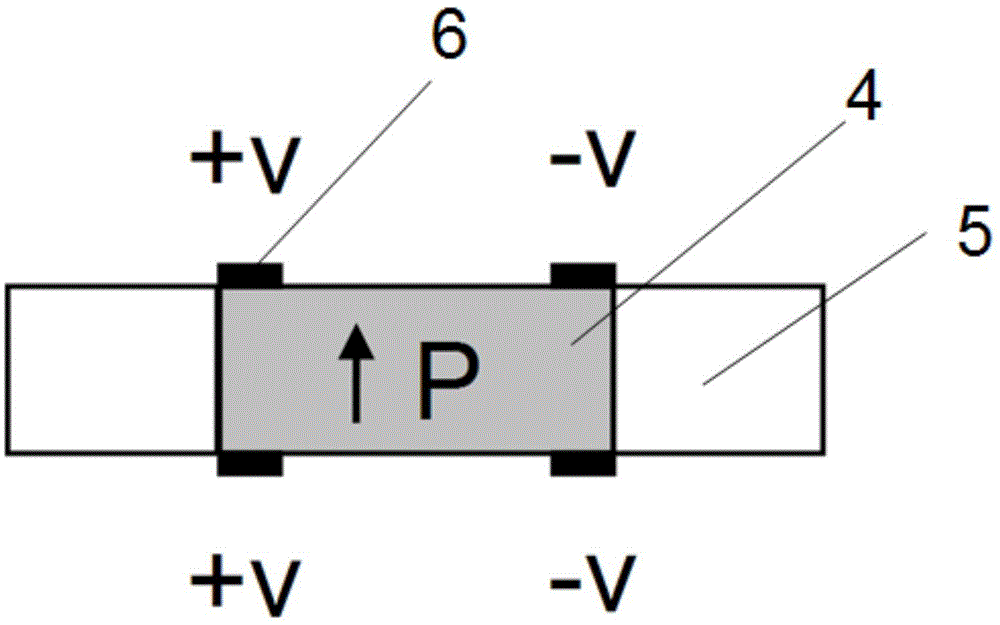

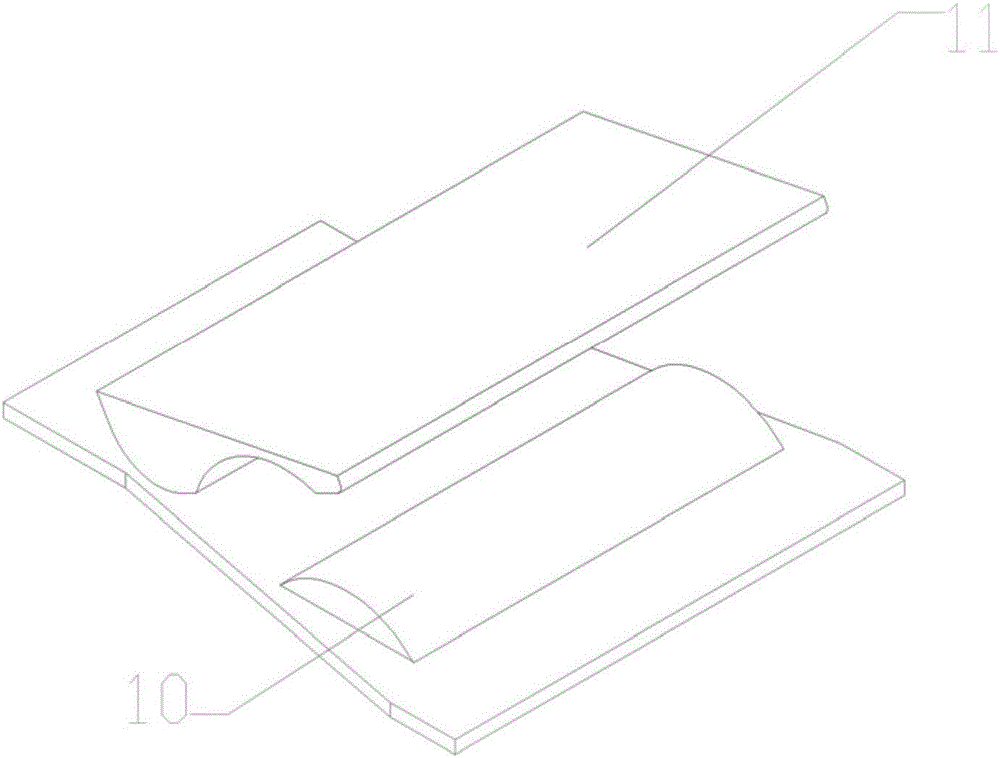

Shearing-type piezoelectric composite material

ActiveCN104821372ALow working voltageReduced Polarization VoltagePiezoelectric/electrostrictive device material selectionEpoxyOptoelectronics

The invention discloses a shearing-type piezoelectric composite material. The outermost two layers of the composite material structure are flexible insulated thin films, the middle layer is a piezoelectric phase / epoxy resin composite layer, and interdigital electrodes are arranged between the middle layer and the flexible insulated thin films; the positive electrode finger parts and the negative electrode finger parts of the interdigital electrodes are arranged alternatively at equal distances, and the upper interdigital electrode and the lower interdigital electrode are in mirror symmetry and aligned; the finger parts of the interdigital electrodes are parallel to the piezoelectric phase of the piezoelectric phase / epoxy resin composite layer, and the electrode finger parts are located on the upper surface and the lower surface of the edge of the piezoelectric phase and epoxy resin joining surface; and the piezoelectric phase polarization direction is a direction vertical with the composite layer plane. The sheet piezoelectric composite material provided by the invention is thin in thickness, compact in structure, can fit a curved surface structure, can realize a certain degree of flexible deformation, and can be made into a driver, a sensor and the like.

Owner:CENT SOUTH UNIV

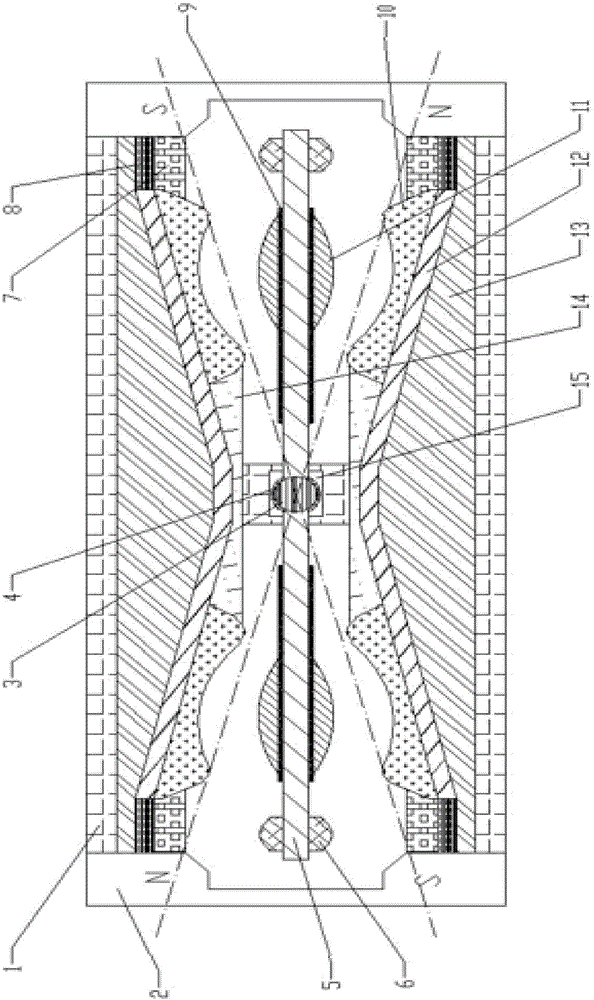

Electromagnet-friction piezoelectric composite energy harvester

ActiveCN106849599AReduce lossHigh vibration frequencyPiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesCantilevered beamEnergy technology

The invention relates to an electromagnet-friction piezoelectric composite energy harvester and belongs to the technical fields of micro-electro-mechanical systems and micro energy. Permanent magnets are placed on the two sides in a shell of the harvester, a rotary shaft is connected with the shell through a bearing, a cantilever beam in an internal dent shape is fixedly connected to the rotary shaft, and the two ends of the cantilever beam are fixedly connected with hemispherical mass blocks respectively. Piezoelectric ceramics coated with a buffer layer are installed in the shell, a coil is wound around the cantilever beam, a second friction layer is attached to the exterior of the coil, and a first friction layer, a flexible piezoelectric material and an insulated filling layer are sequentially arranged on the corresponding positions between the second friction layer and the shell. Harvested energy is output through external lines of a first electrode layer and a second electrode layer, the first electrode layer is connected with the flexible piezoelectric material and the first friction layer, and the second electrode layer is located on the upper portion of the rotary shaft, and connected with the coil and the second friction layer through wires. The electromagnet-friction piezoelectric composite energy harvester has the advantages that vibrational energy is converted into electric energy, the output energy is amplified in a summed mode, and the energy conversion efficiency of the harvester is further improved.

Owner:JILIN UNIV

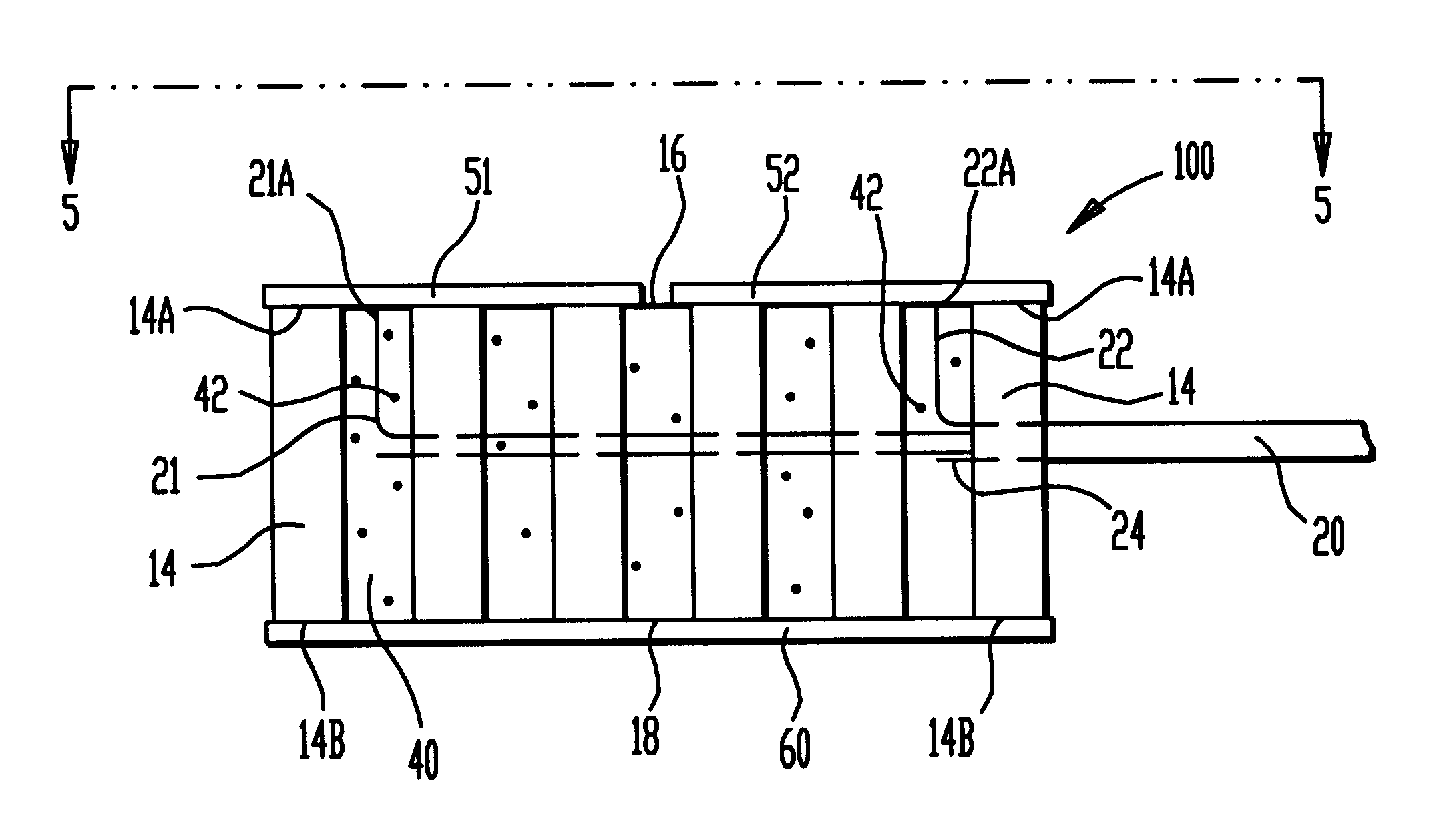

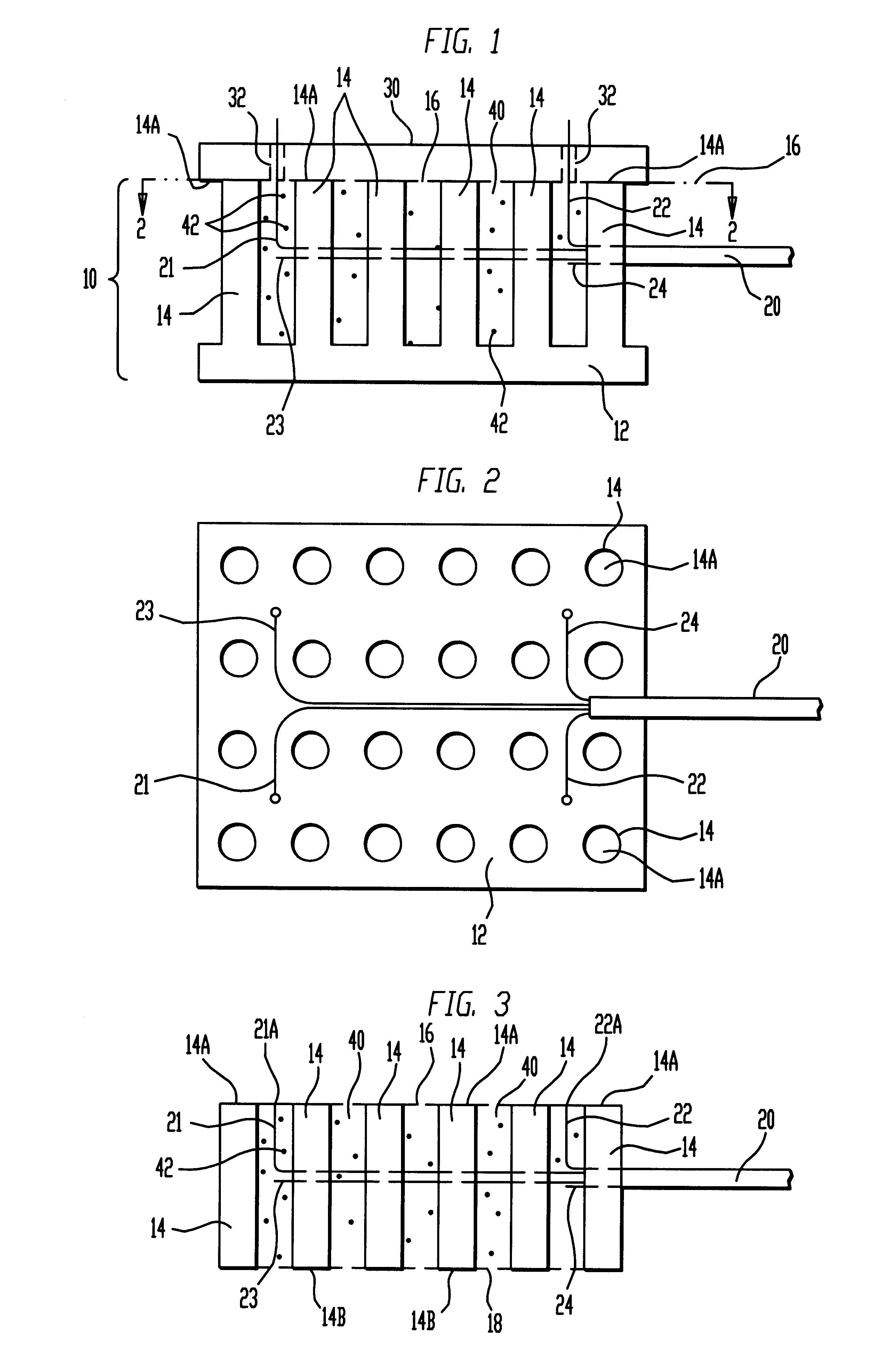

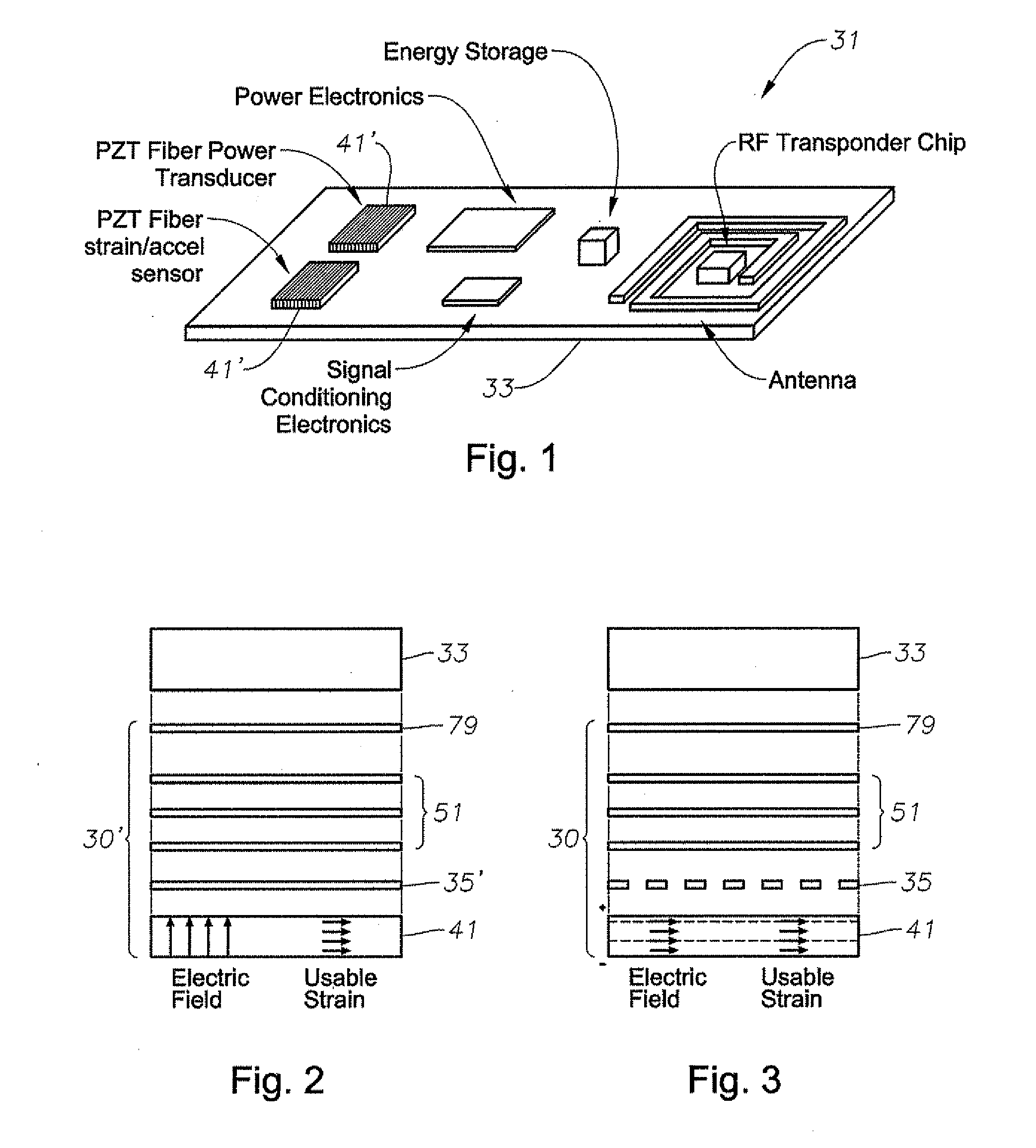

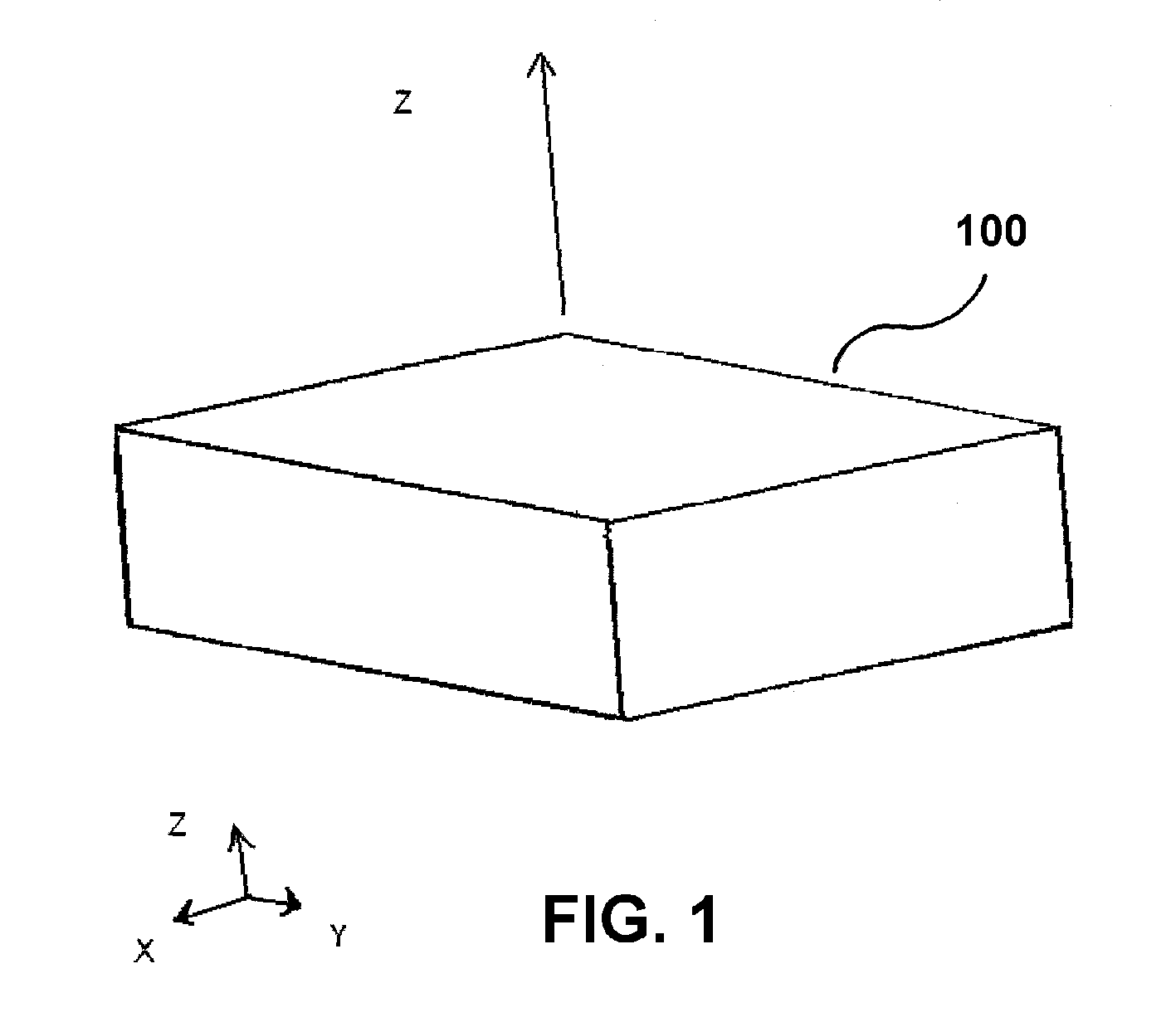

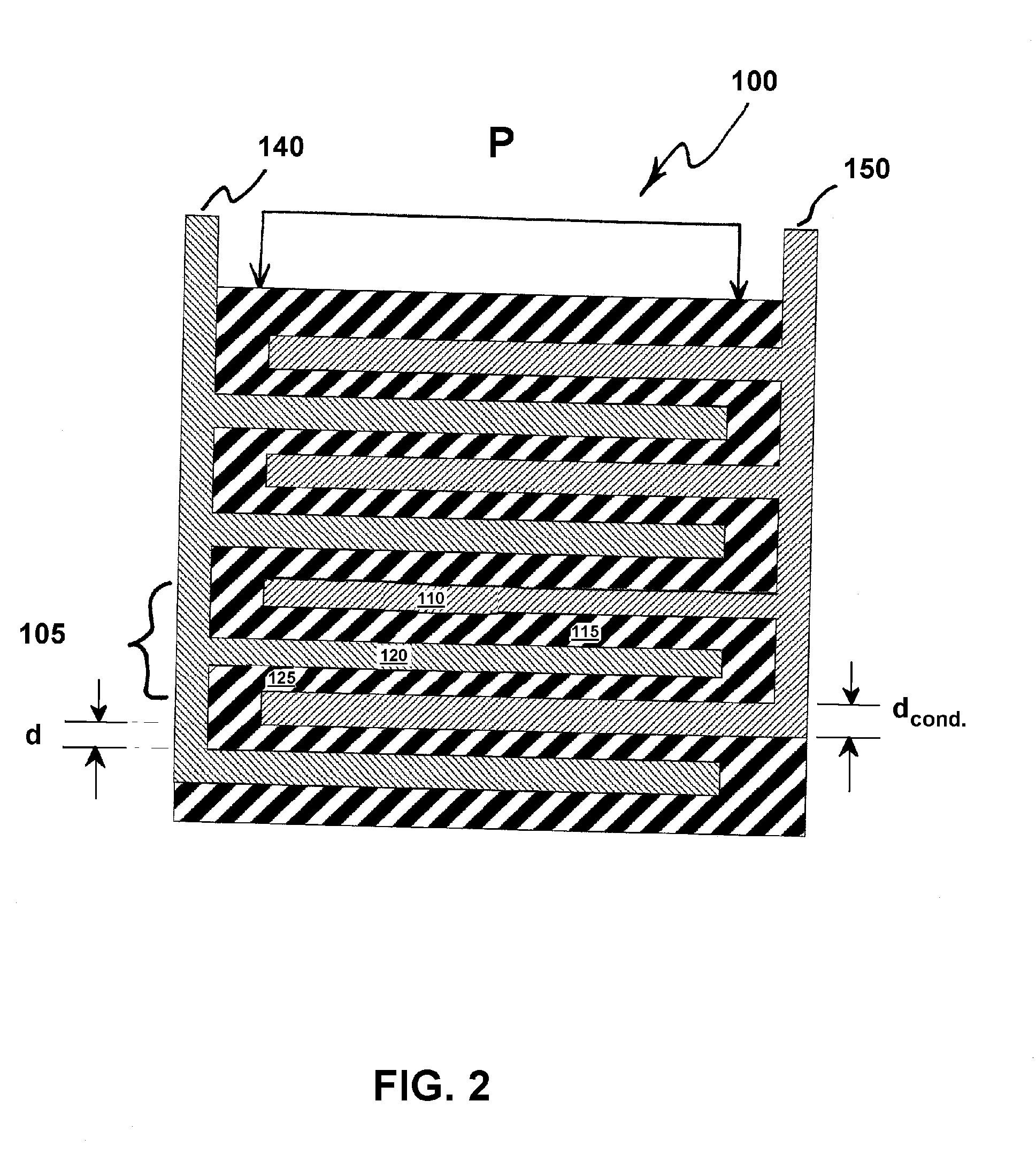

Piezoelectric composite apparatus and related methods

ActiveUS20080143216A1Increase temperatureFacilitate high outputMaterial analysis using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorPiezoelectric composite

A piezoelectric planar composite apparatus to provide health monitoring of a structure and associated methods are provided. The piezoelectric planar composite apparatus includes a piezoelectric electric material layer, multiple electrodes positioned in electrical contact with the piezoelectric material layer, and multiple sets of electrode interconnect conductors each positioned in electrical contact with a different subset of the of the electrodes and positioned to form multiple complementary electrode patterns. Each of the complementary electrode patterns is positioned to form an electric field having an electric field axis oriented along a different physical axis from that of an electric field formed by at least one other of the complementary electrode patterns. The interconnect conductors can be distributed over several electrode interconnect conductor carrying layers to enhance formation of the different complementary electrode patterns.

Owner:LOCKHEED MARTIN CORP

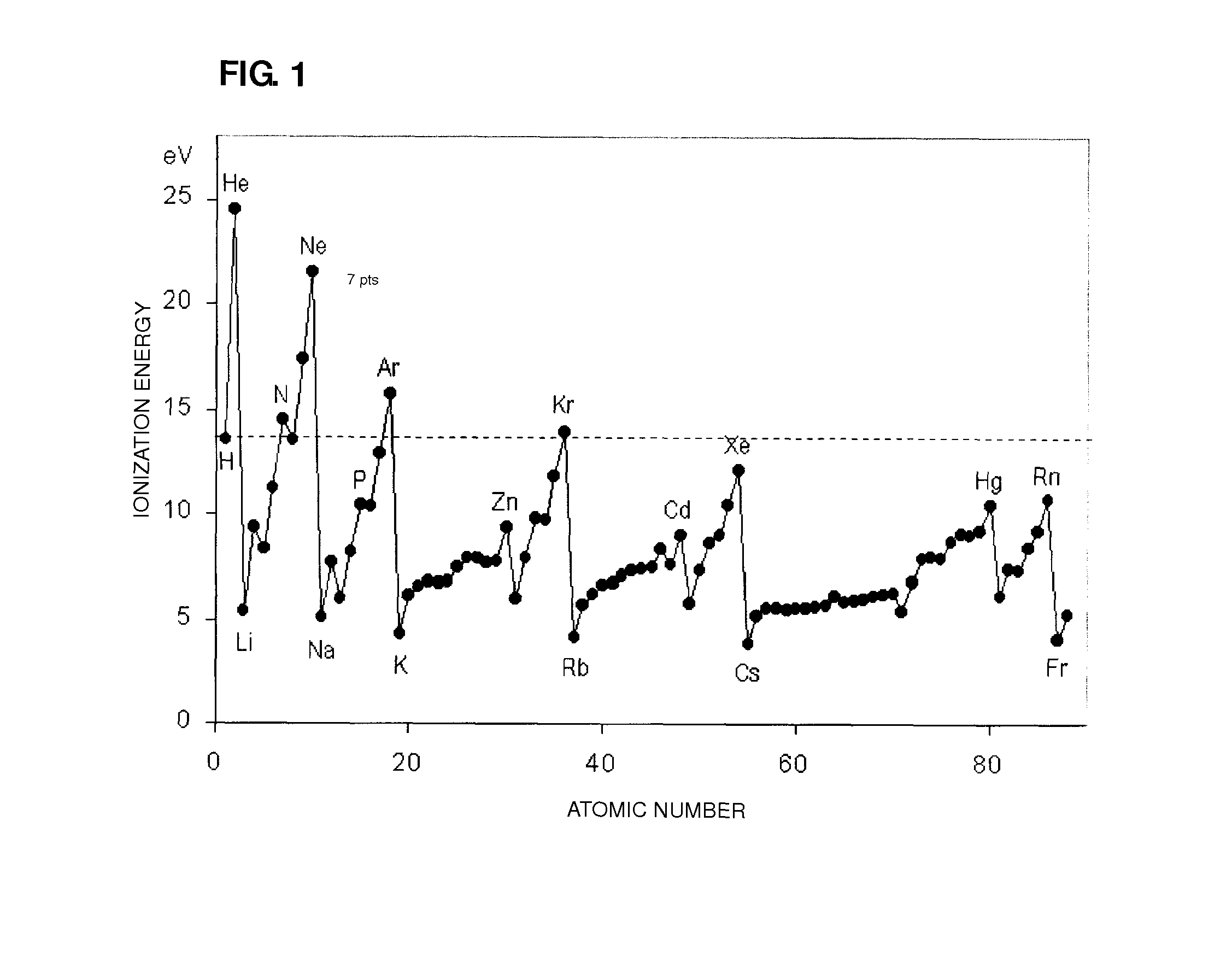

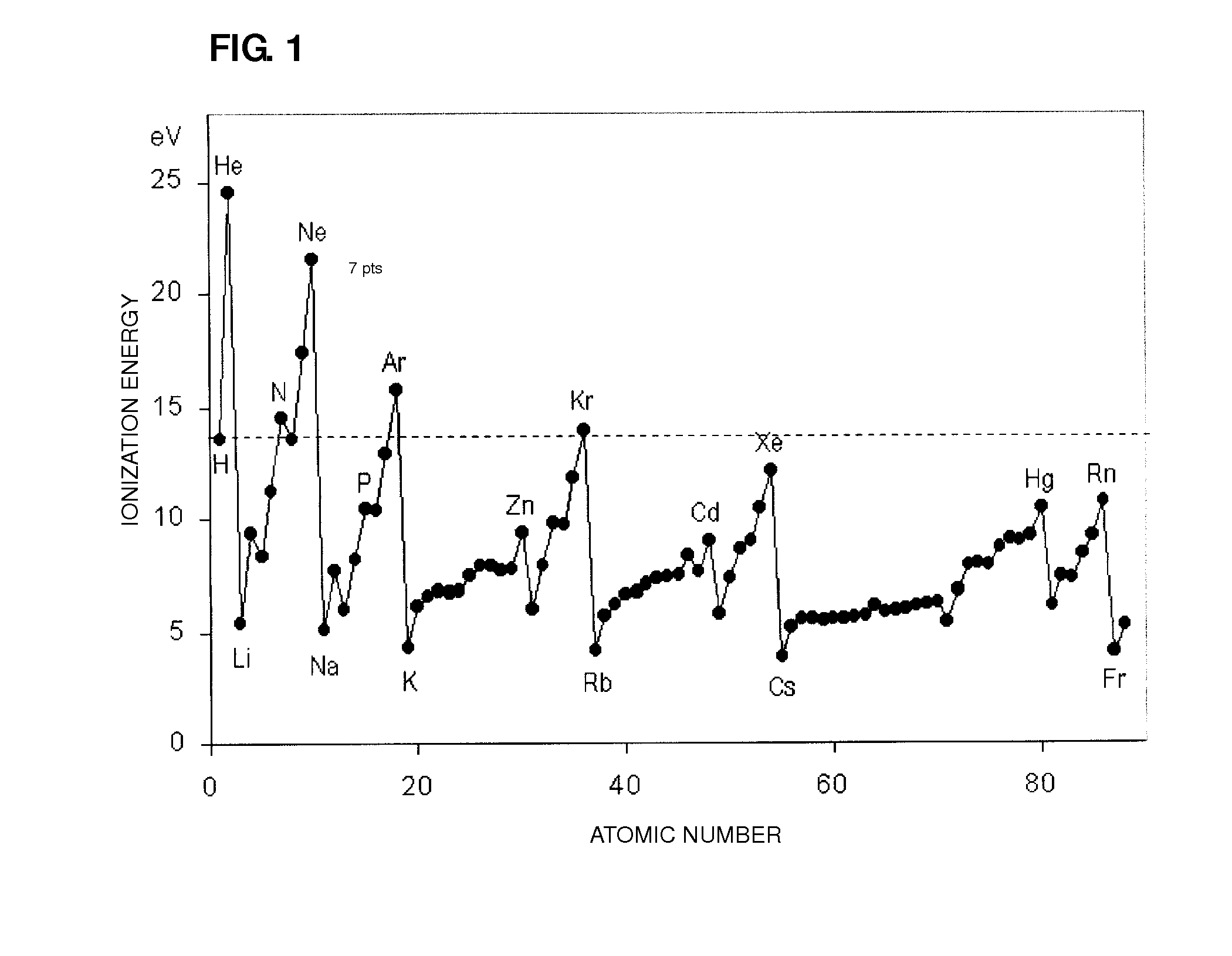

Piezoelectric Composite Material

InactiveUS20070138905A1High piezoelectric coefficientMaterial nanotechnologyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorWork function

A composition of matter having multiple layers of different conductors separated by thin layers of dielectric materials has a high piezoelectric coefficient when the conductors are metals having a significant difference in work function and the dielectric materials have a low elastic modulus when the metal layers are connected to form a capacitive circuit. Alternatively, when the conductors are semi-conductors they should have a significant difference in Fermi levels.

Owner:PHYSICAL LOGIC

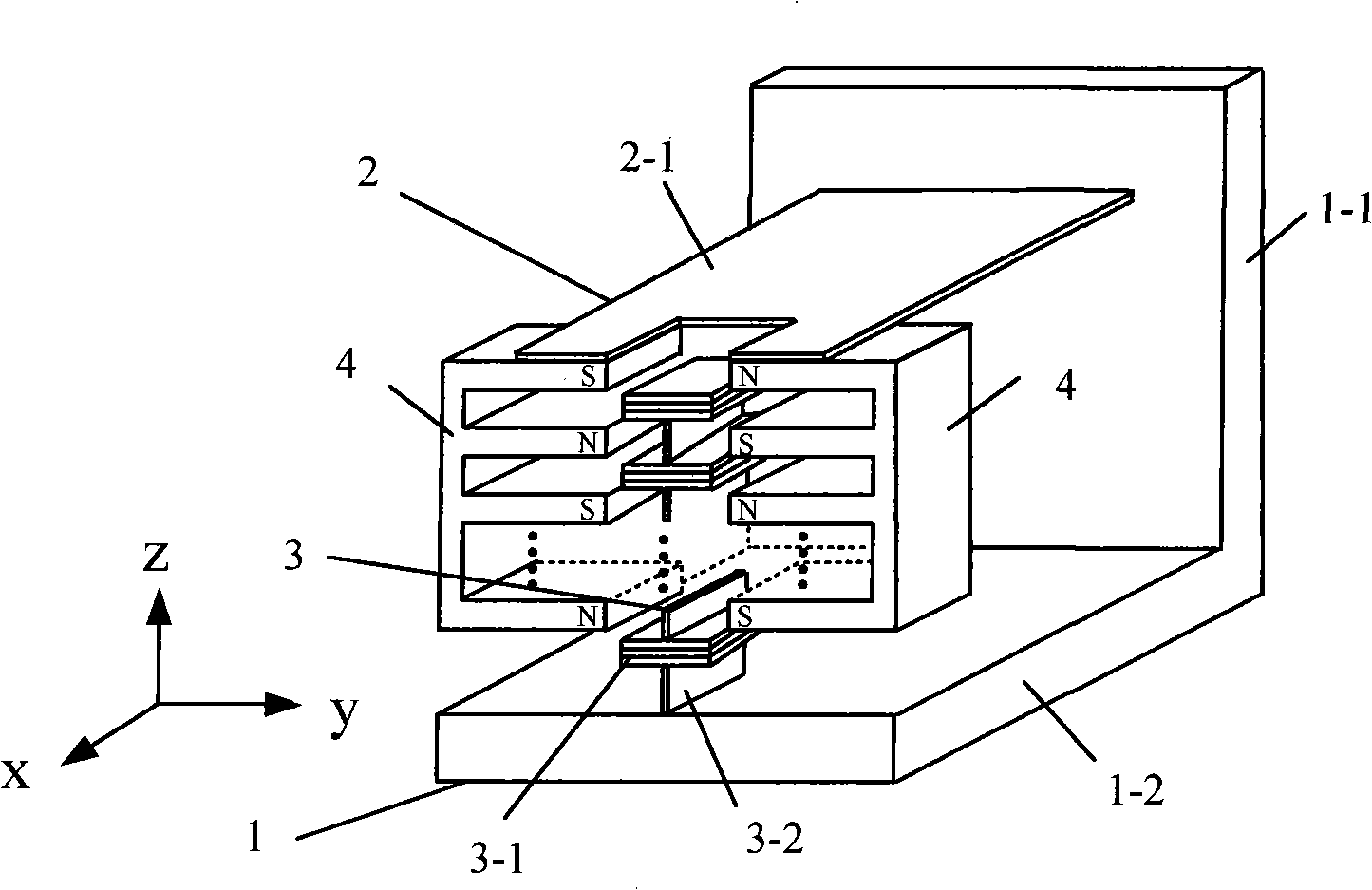

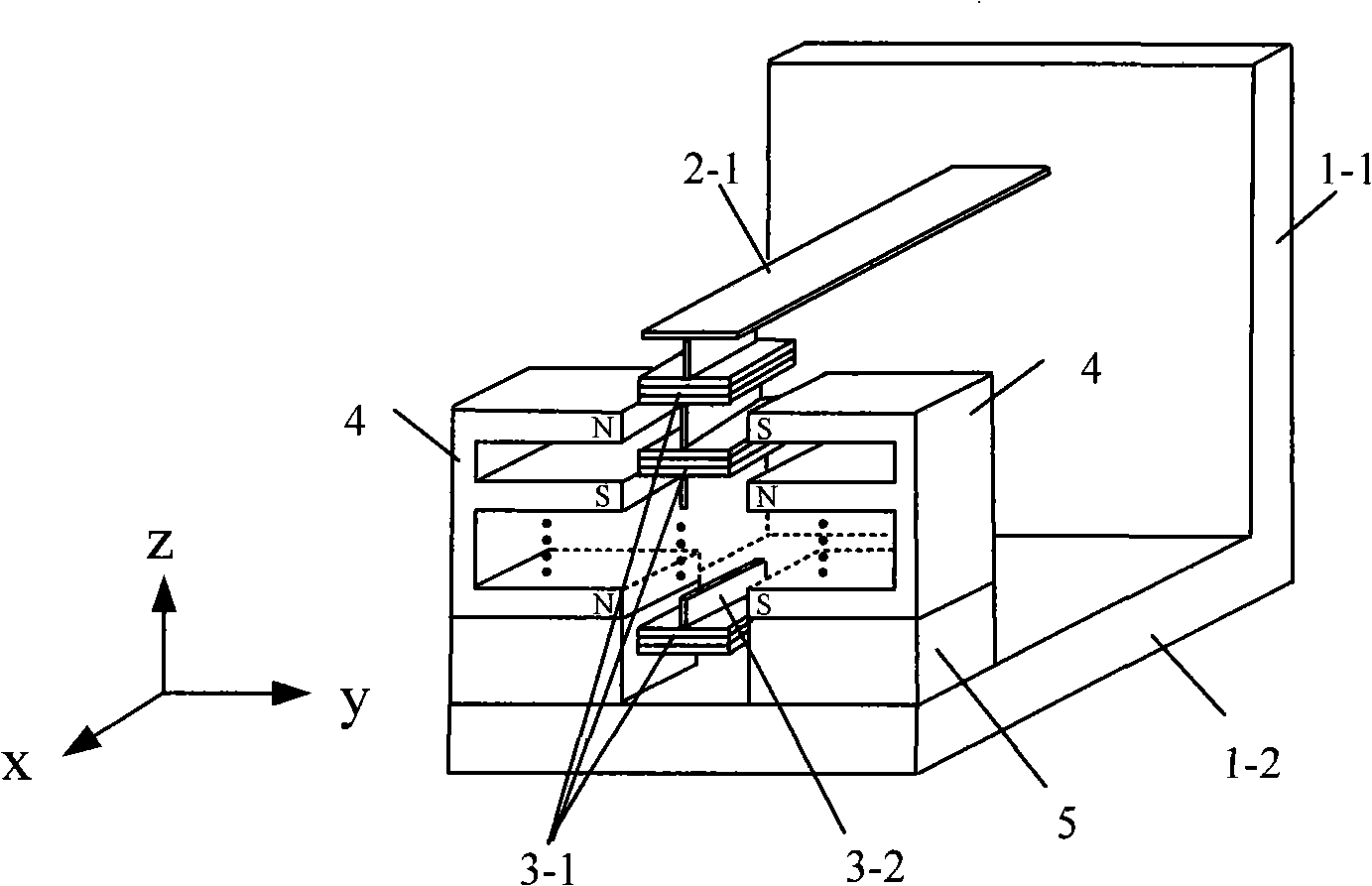

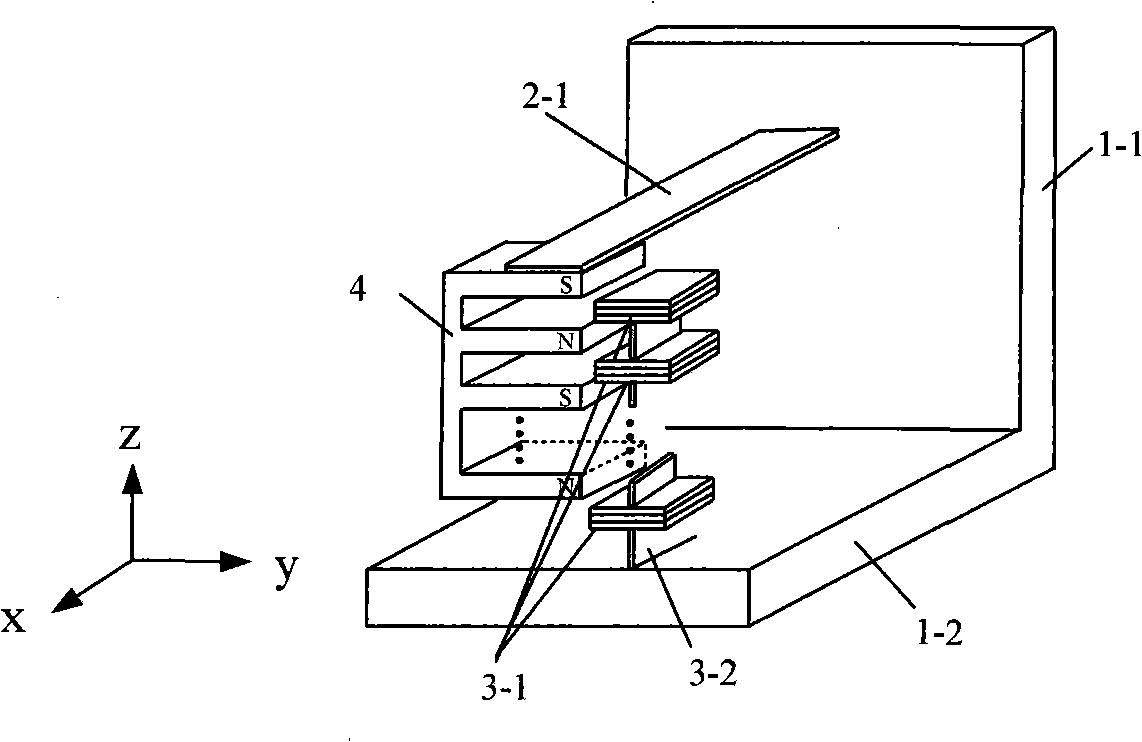

Vibration energy collector with piezomagnetic/piezoelectric composite energy conversion structure

InactiveCN101404468AHigh magnetoelectric conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive devicesElectricityReciprocating motion

The invention discloses a vibrational energy collecting device adopting a piezomagnetic / piezoelectric compound transduction structure. The device comprises a supporting mechanism, a piezomagnetic / piezoelectric compound magneto-electricity transducer, a permanent magnet magnetic circuit and an elastic mechanism; wherein, the piezomagnetic / piezoelectric compound magneto-electricity transducer is arranged in the space of the air gap field of the permanent magnet magnetic circuit; one of the piezomagnetic / piezoelectric compound magneto-electricity transducer and the permanent magnet magnetic circuit is elastically connected with the supporting mechanism by the elastic mechanism and can do reciprocating movement along with the mechanism while the other is fixed on the base of the supporting mechanism; namely, the piezomagnetic / piezoelectric compound magneto-electricity transducer is fixed on the base while the permanent magnet magnetic circuit is connected with the supporting mechanism by the elastic mechanism, or the piezomagnetic / piezoelectric compound magneto-electricity transducer is connected with the supporting mechanism by the elastic mechanism while the permanent magnet magnetic circuit is fixed on the base by non-permeability magnetic material. The invention has the beneficial effect that the invention provides a self-energized device which is applicable to weak vibration and has higher magnetoelectricity conversion efficiency.

Owner:CHONGQING UNIV

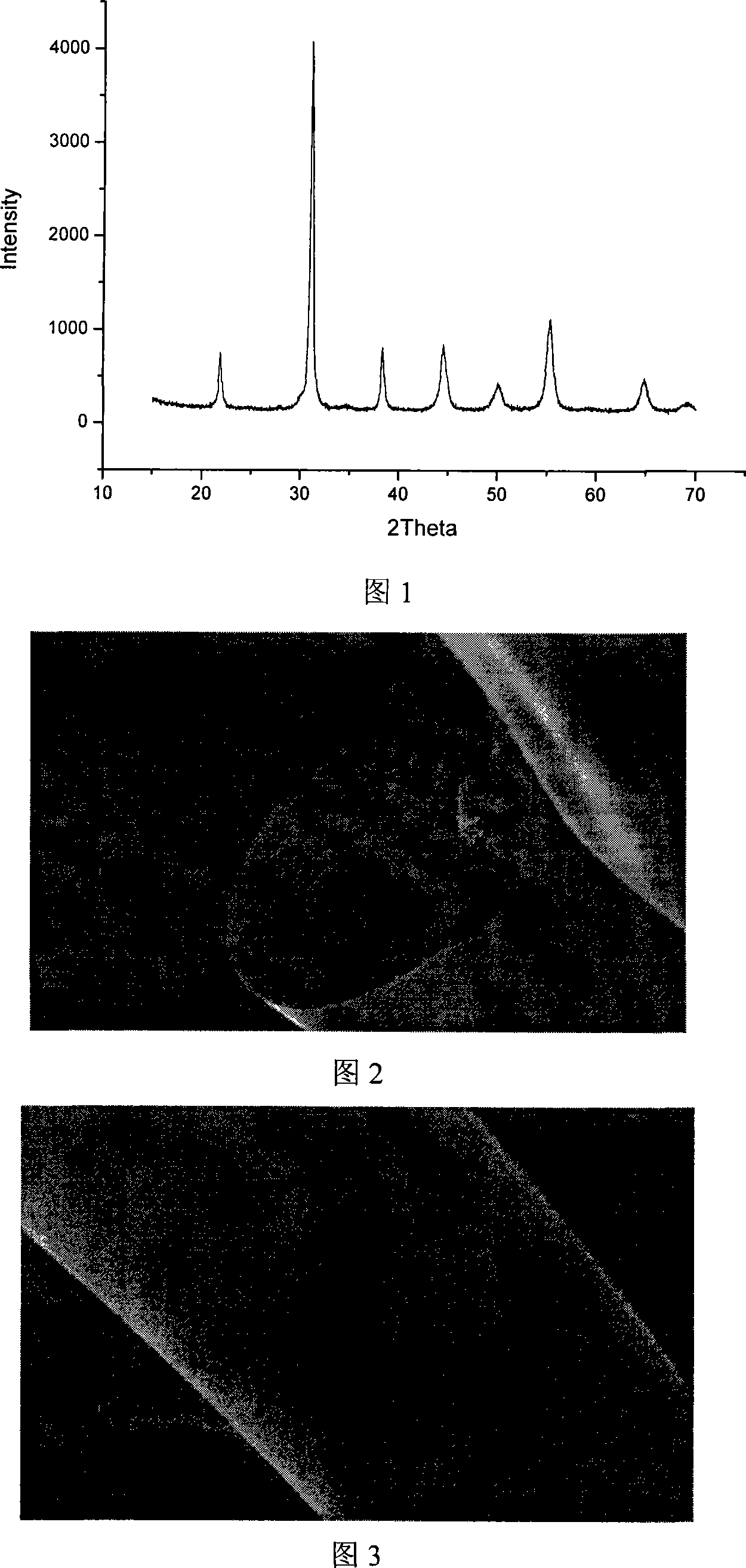

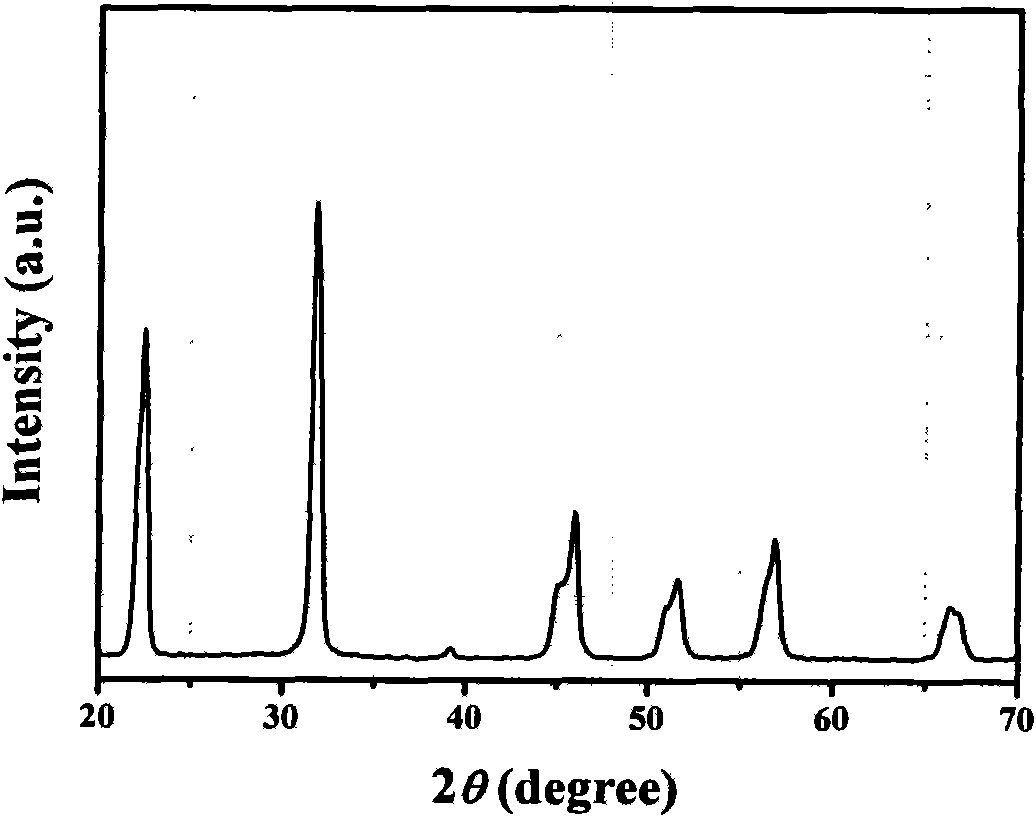

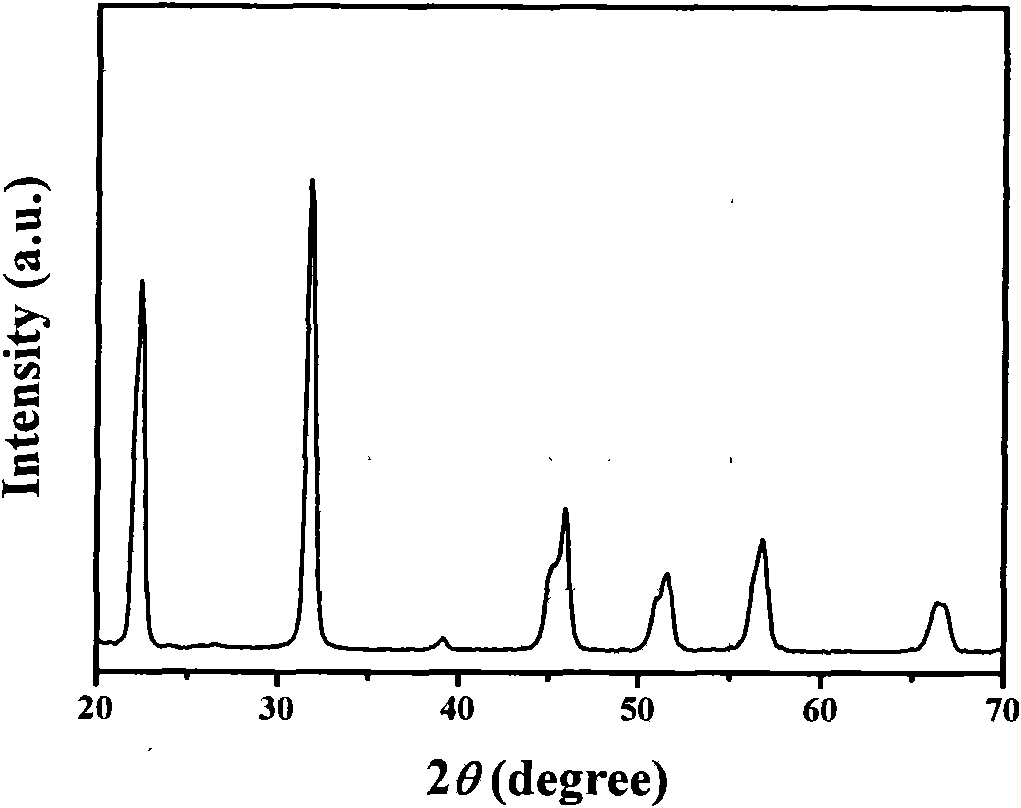

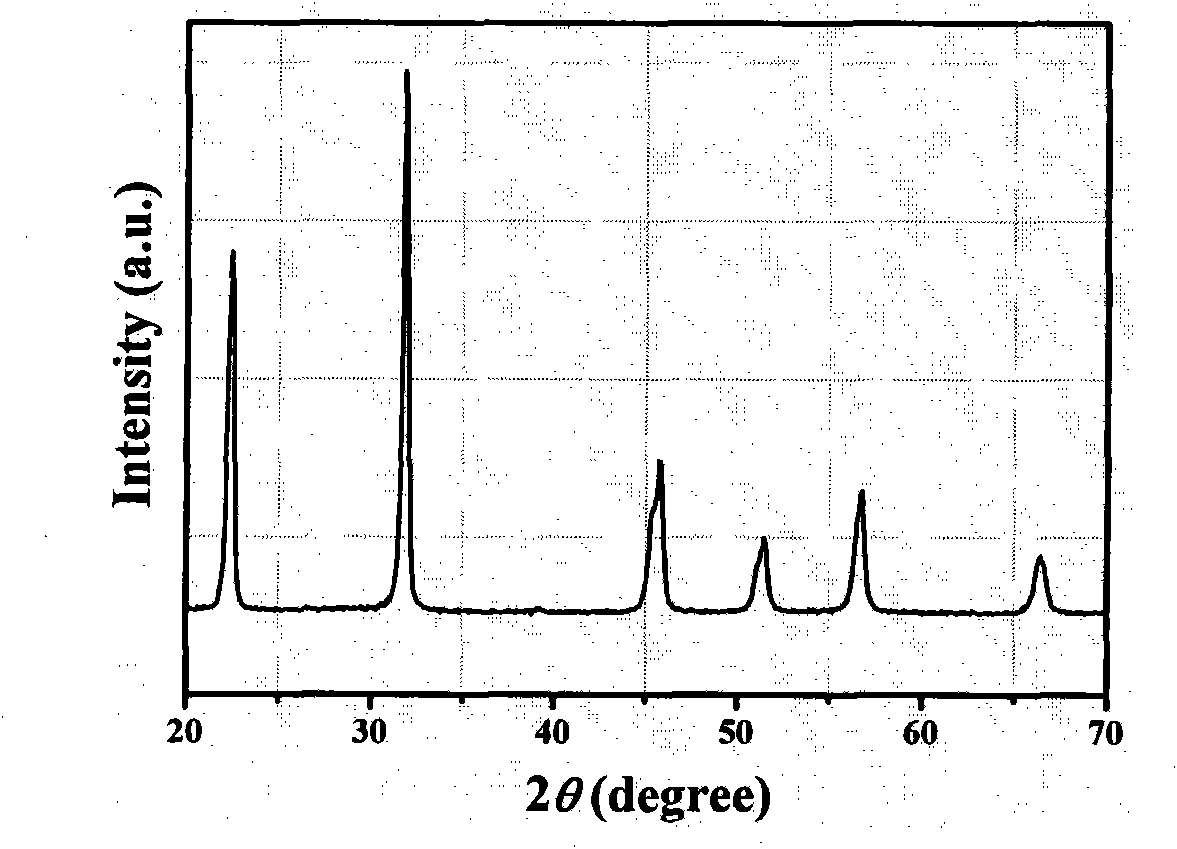

Method for preparing lead zirconate titanate ceramics fibre

The invention provides a preparation method of lead zirconate-titante ceramic fiber, which relates to a ceramic fiber. The fiber obtained with the diameter less than 30Mum and the length about 1cm has a single perovskite phase and comparatively high consistency and the invention can be a preparation method of lead zirconate-titante ceramic fiber of ceramic fiber for 1-3 piezoelectric composites. The preparation of lead zirconate-titante precursor solution is : lead acetate trihydrate is added into n-Butyl alcohol, complexing agent glacial acetic acid is added then; the mixture is heated, dissolved and cooled to obtain solution A; zirconium butoxide and titanium butoxide are poured into the n-Butyl alcohol in sequence to obtain the binary mixed solution of zirconium and titanium, and then acetyl acetone is added into the binary mixed solution and solution B is obtained after backflowing; the solution A and the solution B are mixed and the lead zirconate-titante precursor solution is obtained after backflowing. The preparation of lead zirconate-titante precursor sol is: the lead zirconate-titante precursor solution is steamed, concentrated and stirred, rod winding is carried out and the lead zirconate-titante precursor sol is obtained after concentration; lead zirconate-titante gel fiber is obtained through fiber drawing; after aging, the lead zirconate-titante gel fiber is dried and carried out by heat treatment.

Owner:XIAMEN UNIV

Lead-free piezoceramics-polymer piezoelectric composite material and preparation method thereof

InactiveCN101591461ASimple processMaterials are readily availablePiezoelectric/electrostrictive device manufacture/assemblySilicone oil bathPiezoelectric composite

The invention relates to a lead-free piezoceramics-polymer piezoelectric composite material and a preparation method thereof. The method comprises the following steps: preparing materials according to compositions in a chemical general formula (1-x)(LiaNabK1-a-b)(Nb1-cSbc)O3-xABO3-yM, taking analytically pure anhydrous carbonates or oxides as raw materials, and preparing ceramic powder by the conventional ceramic preparing process; performing mixing and ball-milling on the ceramic powder and polyvinylidene fluoride in a volume ratio of between 10:90 and 95:5; and drying, performing ultrasonic oscillation for 10 to 100 minutes, performing cold press molding on the mixed powder material by a tablet press, processing by heating through a muffle furnace, finally sputtering gold electrodes on the surface of the powder material, and performing polarization in a silicone oil bath at a temperature of between 80 and 130 DEG C for 10 to 120 minutes to prepare the potassium-sodium niobate-based lead-free piezoceramics-polymer piezoelectric composite material. The piezoelectric composite material has pure perovskite crystalline phase and no impurity phase to prove that the two have good solid solubility, and has good piezoelectric and dielectric properties.

Owner:SICHUAN UNIV

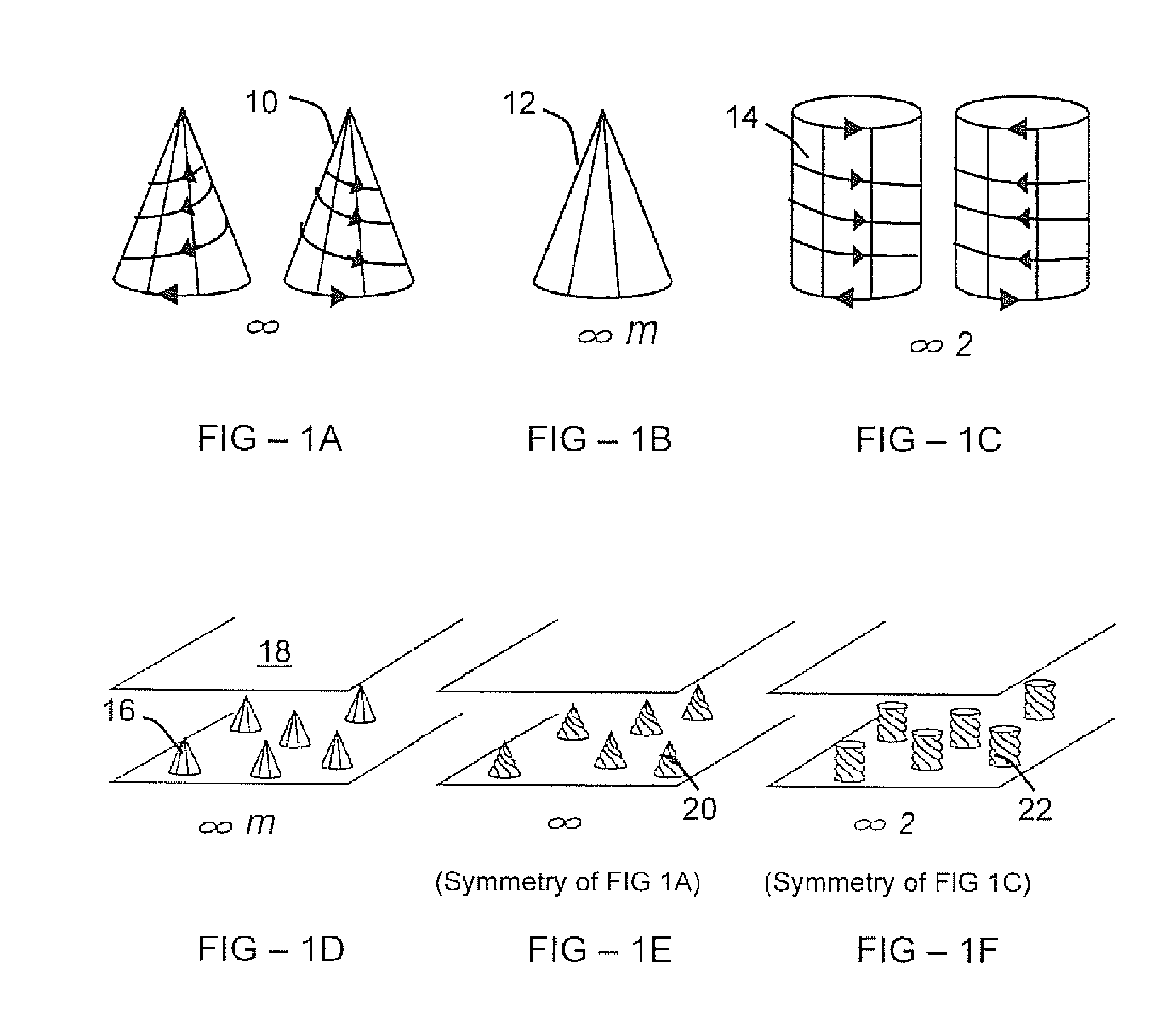

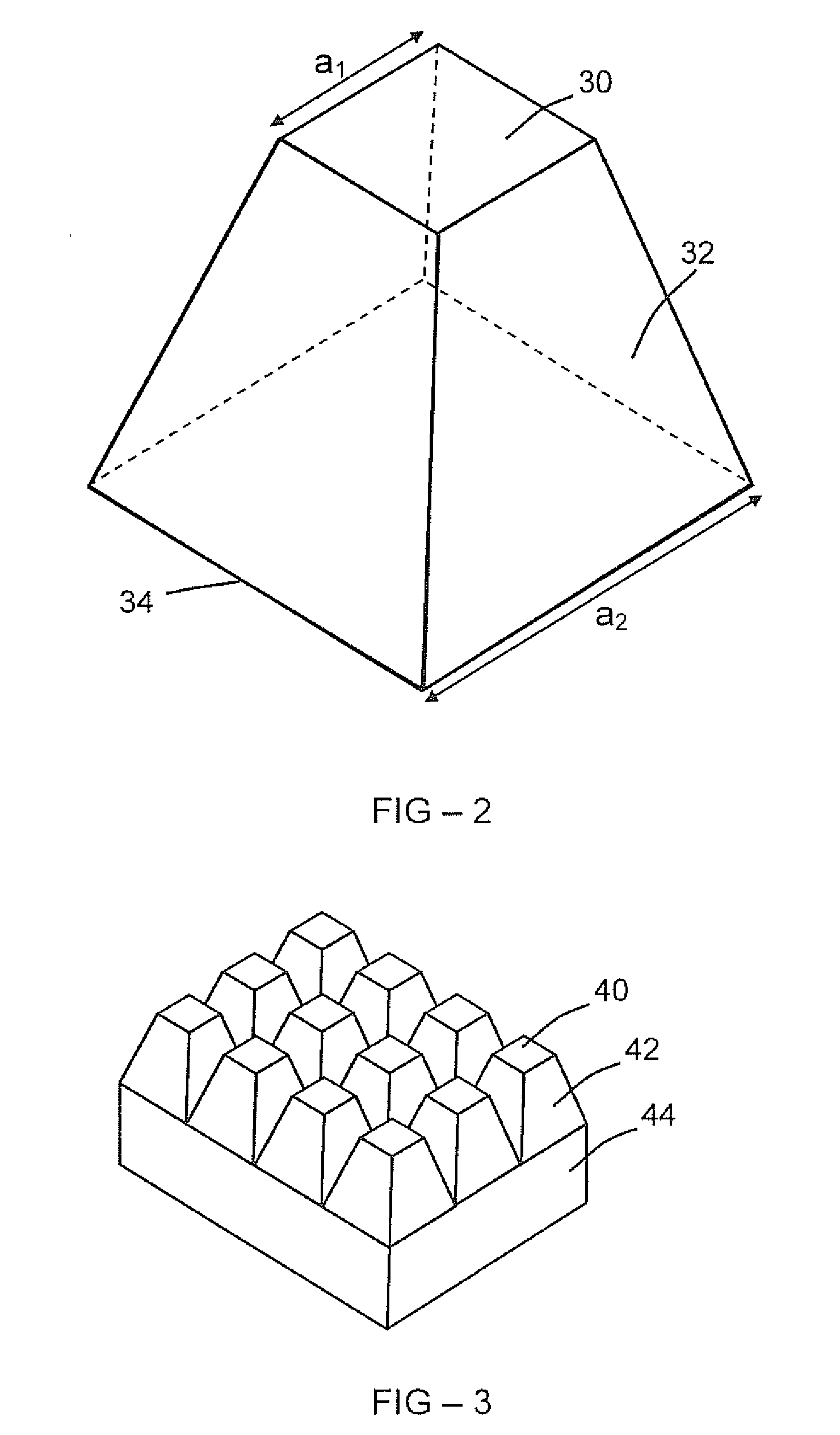

Flexoelectric - piezoelectric composite based on flexoelectric charge separation

InactiveUS20110006641A1Piezoelectric/electrostriction/magnetostriction machinesForce measurement using piezo-electric devicesElectricityCharge separation

An example flexoelectric-piezoelectric apparatus provides an electrical response to an applied force, and / or an actuation in response to an applied electric field, that originates from the flexoelectric properties of a component. For example, shaped forms within the apparatus may be configured to yield a stress gradient on application of the force, and the stress gradient induces the flexoelectric signal. A flexoelectric-piezoelectric apparatus can be substituted for a conventional piezoelectric apparatus, but does not require the use of a piezoelectric material. Instead, the response of the apparatus is due to the generation of stress gradients and / or field gradients.

Owner:PENN STATE RES FOUND

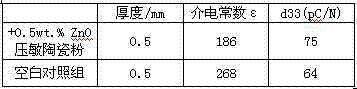

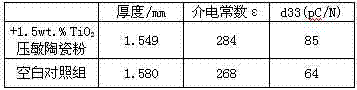

Piezoelectric composite material and preparation method thereof

The invention provides a piezoelectric ceramic, polyvinylidene fluoride (PVDF) and pressure-sensitive material three-phase composite material with high piezoelectric property. The pressure-sensitive material is added to a piezoelectric ceramic / PVDF piezoelectric composite material as an intermediate layer, so as to play a bridging role; the interfacial bonding properties of the piezoelectric ceramic and the PVDF are improved; coupling between the piezoelectric ceramic and the PVDF is increased; electron migration between ceramic particles is promoted; and the polarization voltage of a ceramic phase is improved. In addition, due to the nonlinear current-voltage characteristics of the pressure-sensitive material, when the pressure-sensitive material is added to the piezoelectric ceramic and PVDF composite material, the polarization-resistant voltage of the piezoelectric composite material is improved; and the overall piezoelectric property of the composite material is improved. Therefore, the piezoelectric composite material is simple in process, and low in cost; the piezoelectric composite film with excellent overall performance and large size can be prepared; and the piezoelectric composite material is expected to be applied to a piezoelectric touchpad, thus industrialized production is achieved.

Owner:SUZHOU PANT PIEZOELECTRIC TECH

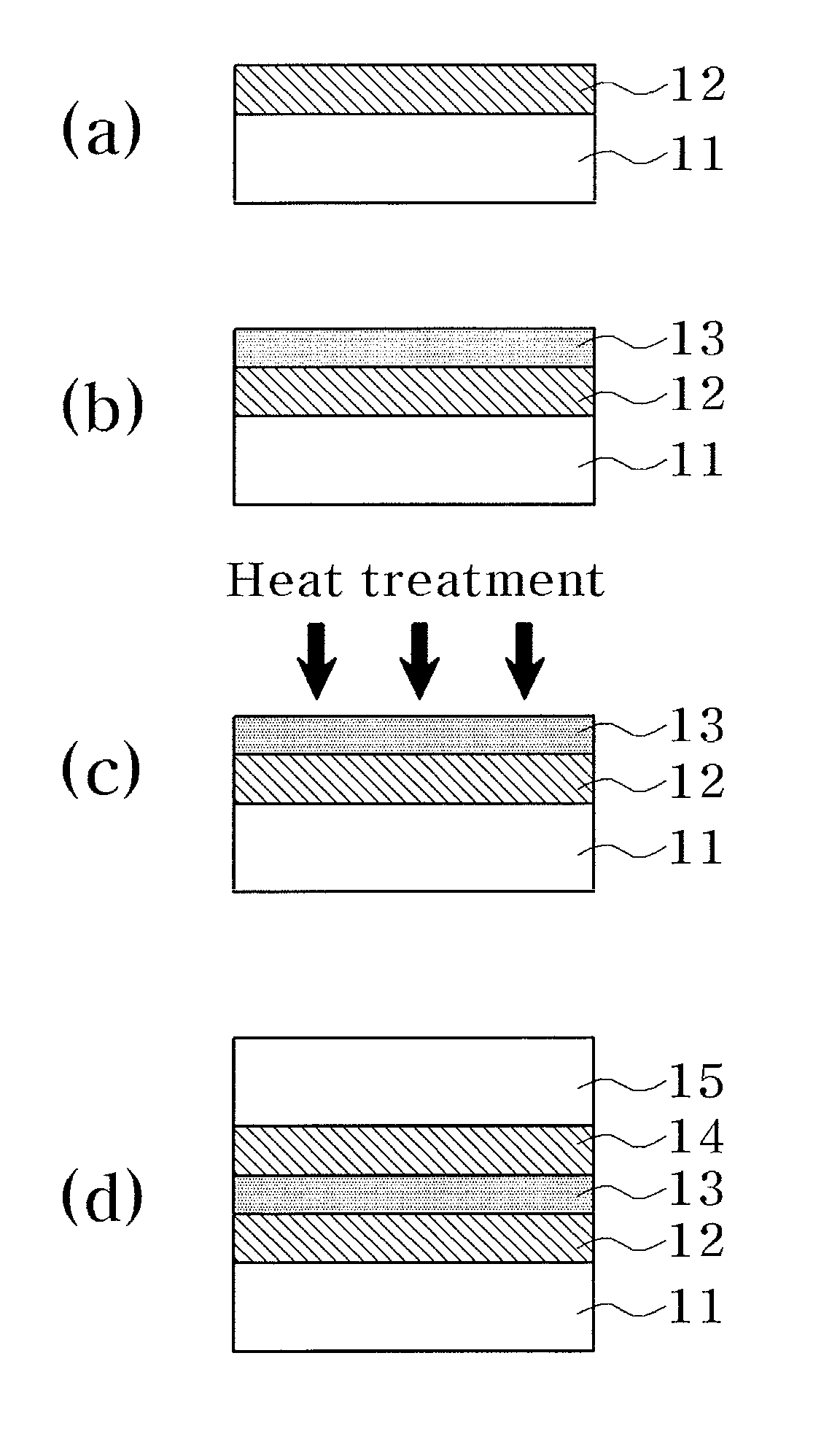

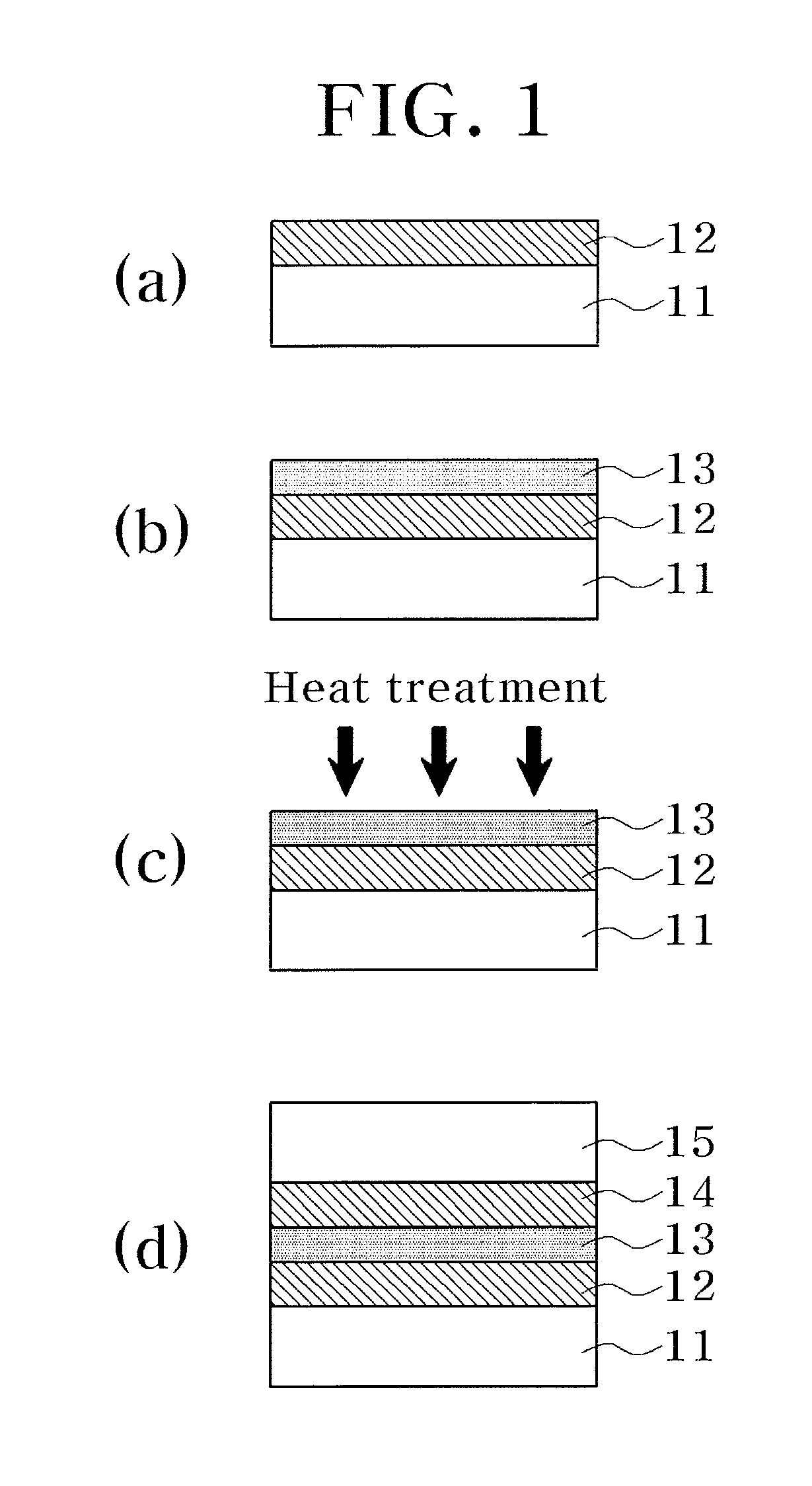

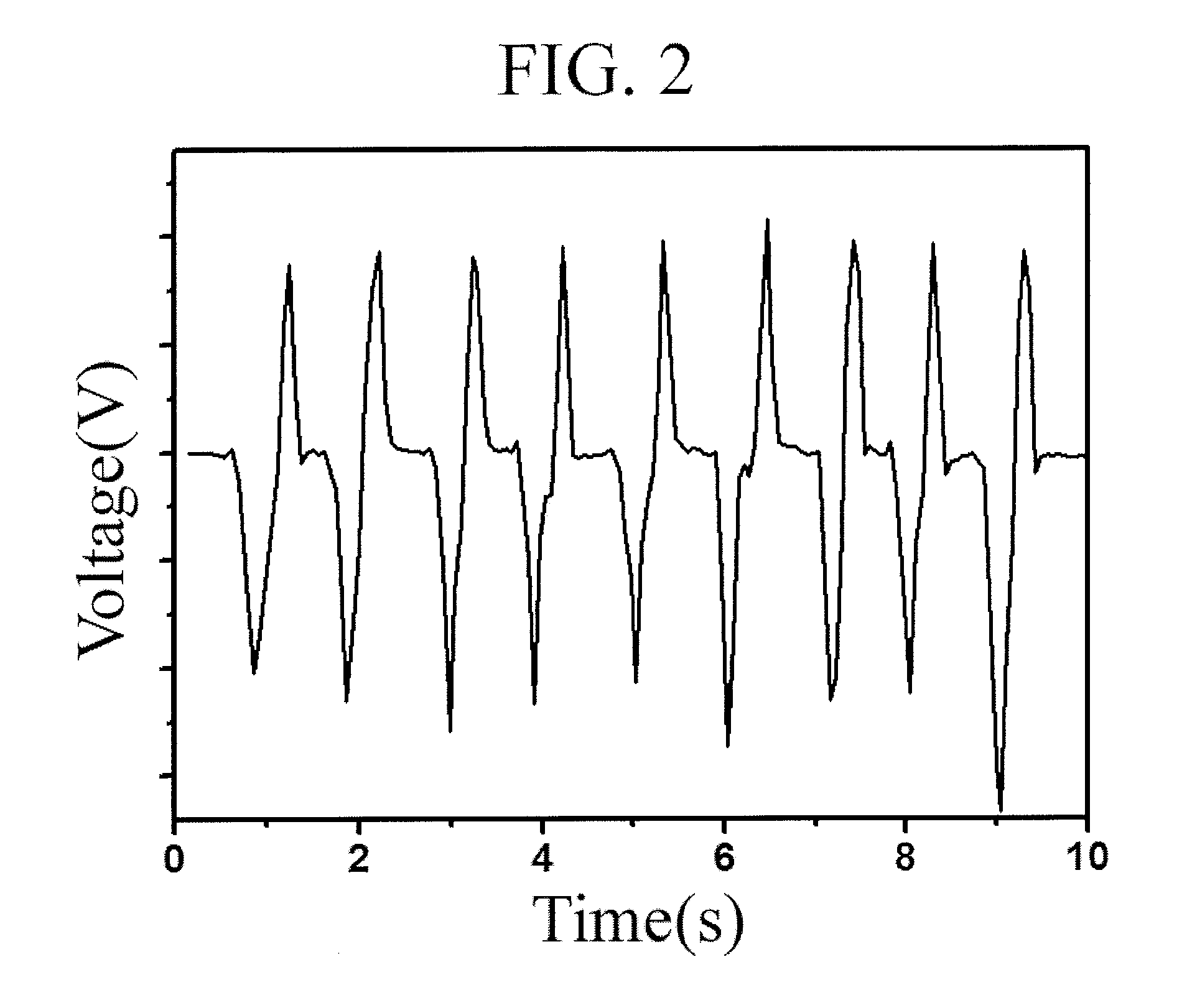

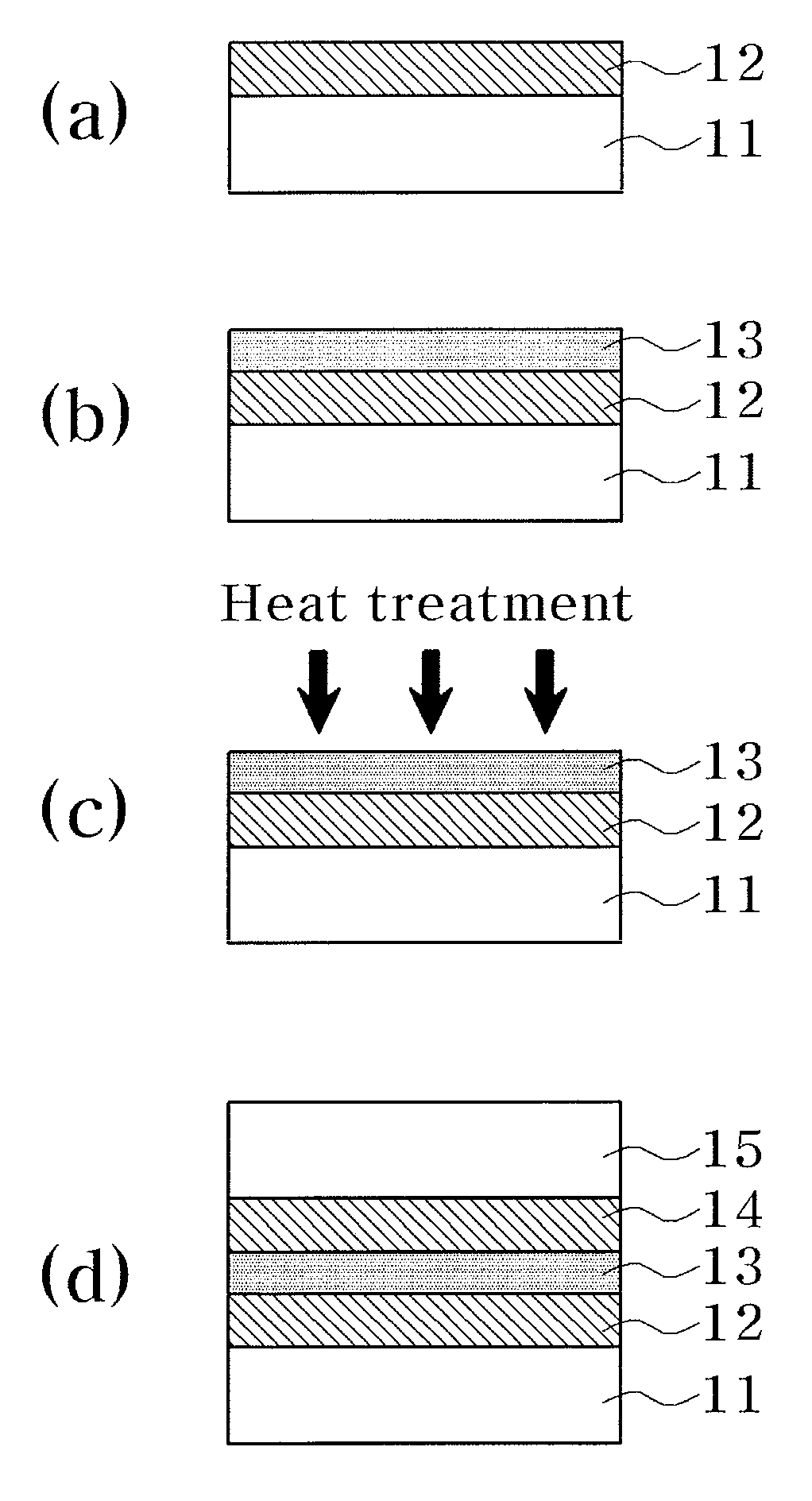

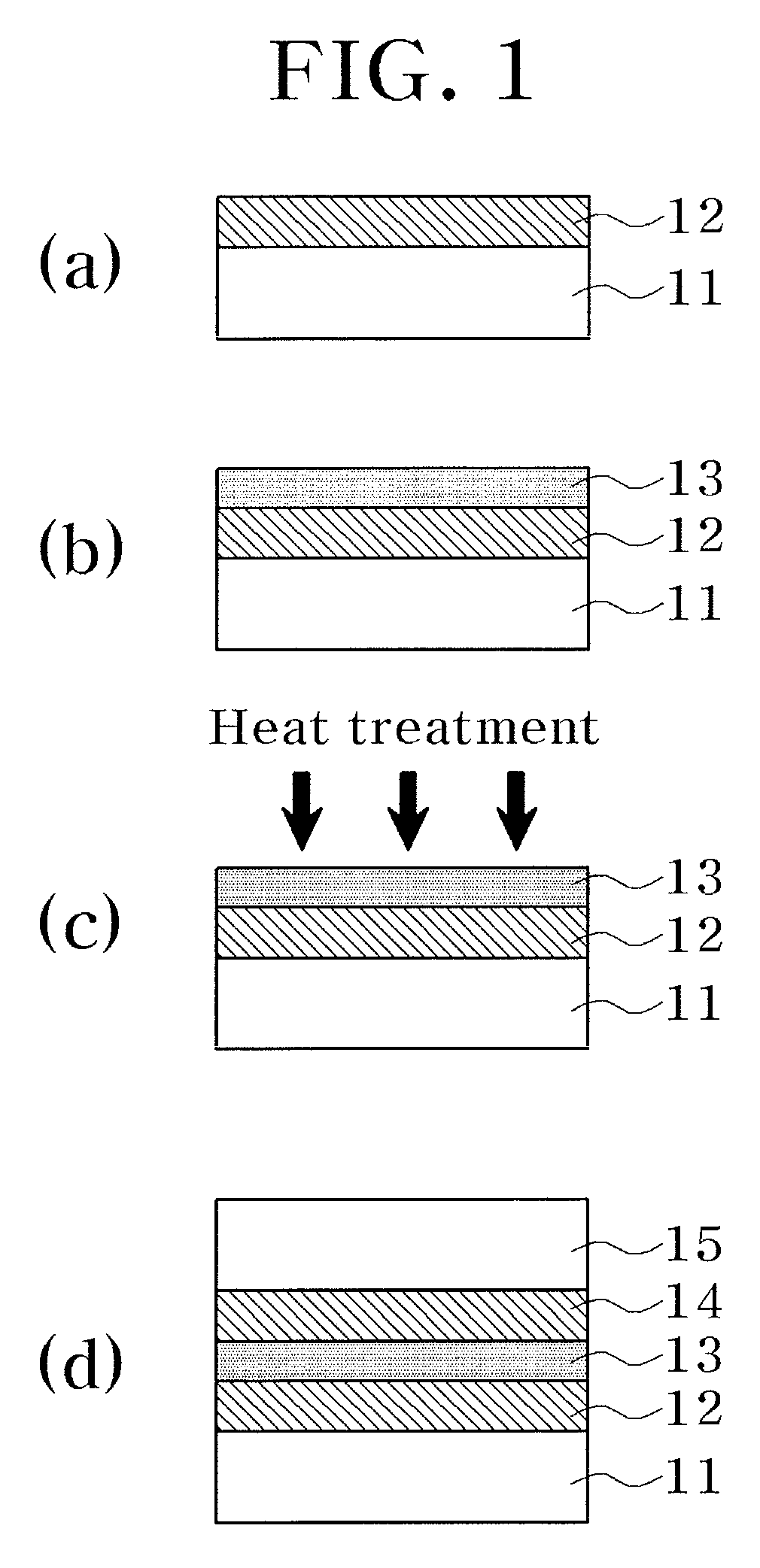

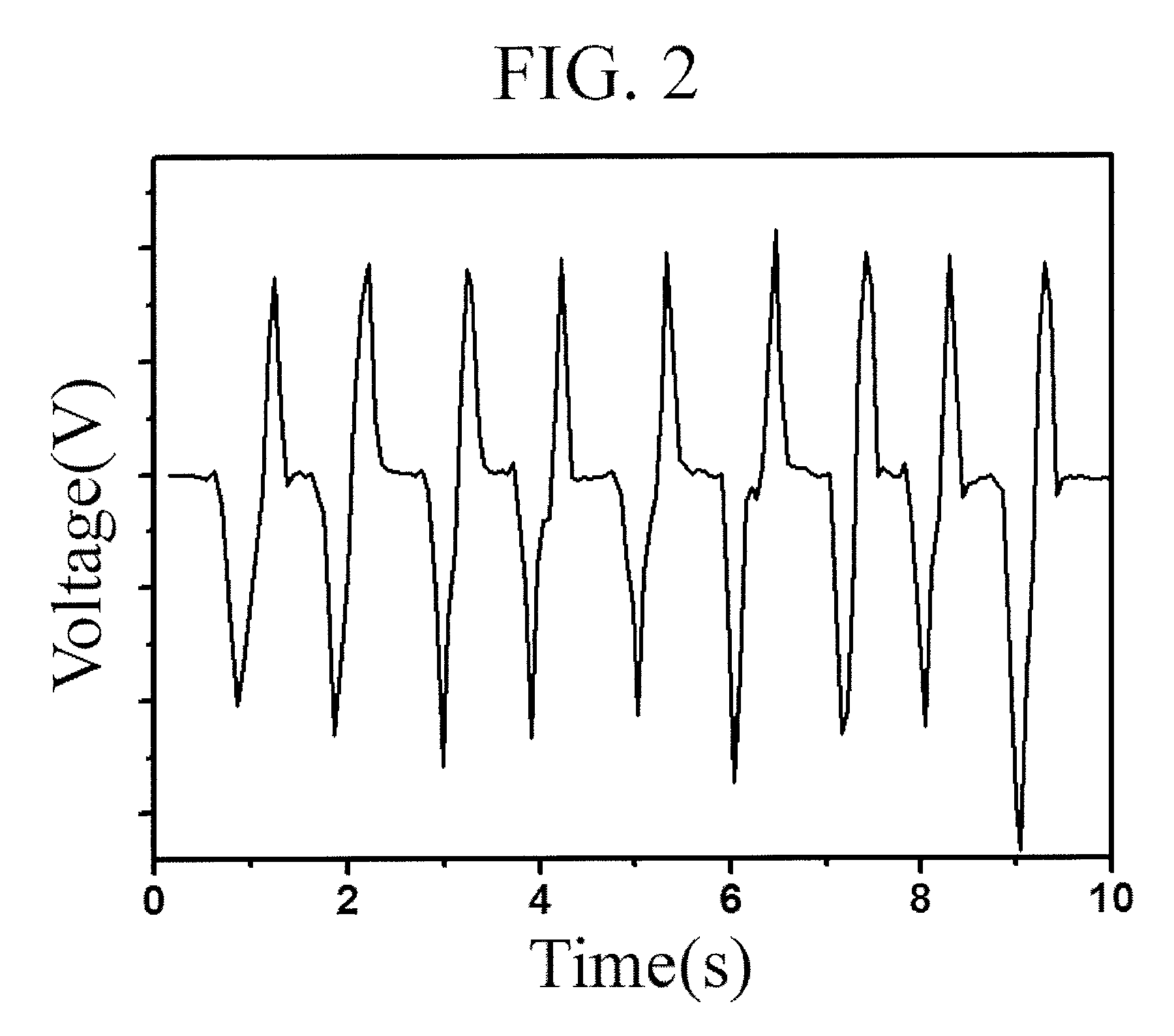

Method of manufacturing flexible piezoelectric energy harvesting device and flexible piezoelectric energy harvesting device manufactured by the same

ActiveUS20130334930A1Simple manufacturing processImprove efficiencyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricitySpins

Provided are a method of manufacturing a flexible piezoelectric energy harvesting device using a piezoelectric composite, and a flexible piezoelectric energy harvesting device manufactured by the same. The method of manufacturing the flexible piezoelectric energy harvesting device includes: forming a first electrode layer on a first flexible substrate; spin-coating a piezoelectric composite layer on the first electrode layer, wherein the piezoelectric composite layer is produced by mixing piezoelectric powder with polymer; performing heat treatment on the piezoelectric composite layer to harden the piezoelectric composite layer; and bonding a second flexible substrate with a second electrode layer on the hardened piezoelectric composite layer. Therefore, it is possible to simplify a manufacturing process and manufacture a high-performance flexible piezoelectric energy harvesting device having various sizes and patterns.

Owner:KOREA INST OF SCI & TECH

2-2 type cement base piezoelectric composite material

InactiveCN101538144AExcellent piezoelectric propertiesIncreased durabilitySilver inkPiezoelectric composite

The invention relates to a 2-2 type cement base piezoelectric composite material which belongs to an intelligent material in the civil engineering field. The composite material is manufactured by the following method: polarizing a cuboid piezoelectric ceramic block; using a slicer to sequentially cut out a series of piezoelectric ceramic pieces along the direction parallel to a piezoelectric ceramic polaxis and pouring cement according to a certain cement water ratio; after finishing the pouring, putting both a sample and a mould in a vacuum drying box for carrying out vacuum processing; putting the sample in a maintenance box for maintenance; and uniformly coating low-temperature conductive silver ink or plating an electrode on the two surfaces after two parallel surfaces are respectively sanded and polished so as to prepare the 2-2 type cement base piezoelectric composite material. The 2-2 type cement base piezoelectric composite material has the advantages of good piezoelectric performance and compatibility with concrete, integration of sensing and driving, good durability, simple preparation process, low cost, and the like.

Owner:UNIV OF JINAN

Transducer array and production thereof

InactiveCN1817486AAvoid Structural DefectsImprove performancePiezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationSynthetic aperture sonarTransducer

A transducer and its array for synthesizing different sonar devices are disclosed. Said transducer and its array are composed of 1-3-2 type composite piezoelectric chip(s), back liner, matching layer, casing, output lines, and electrically conductive locating coil between said chip and back liner. Its advantages are correct locating, no deformation and high stability.

Owner:PEKING UNIV

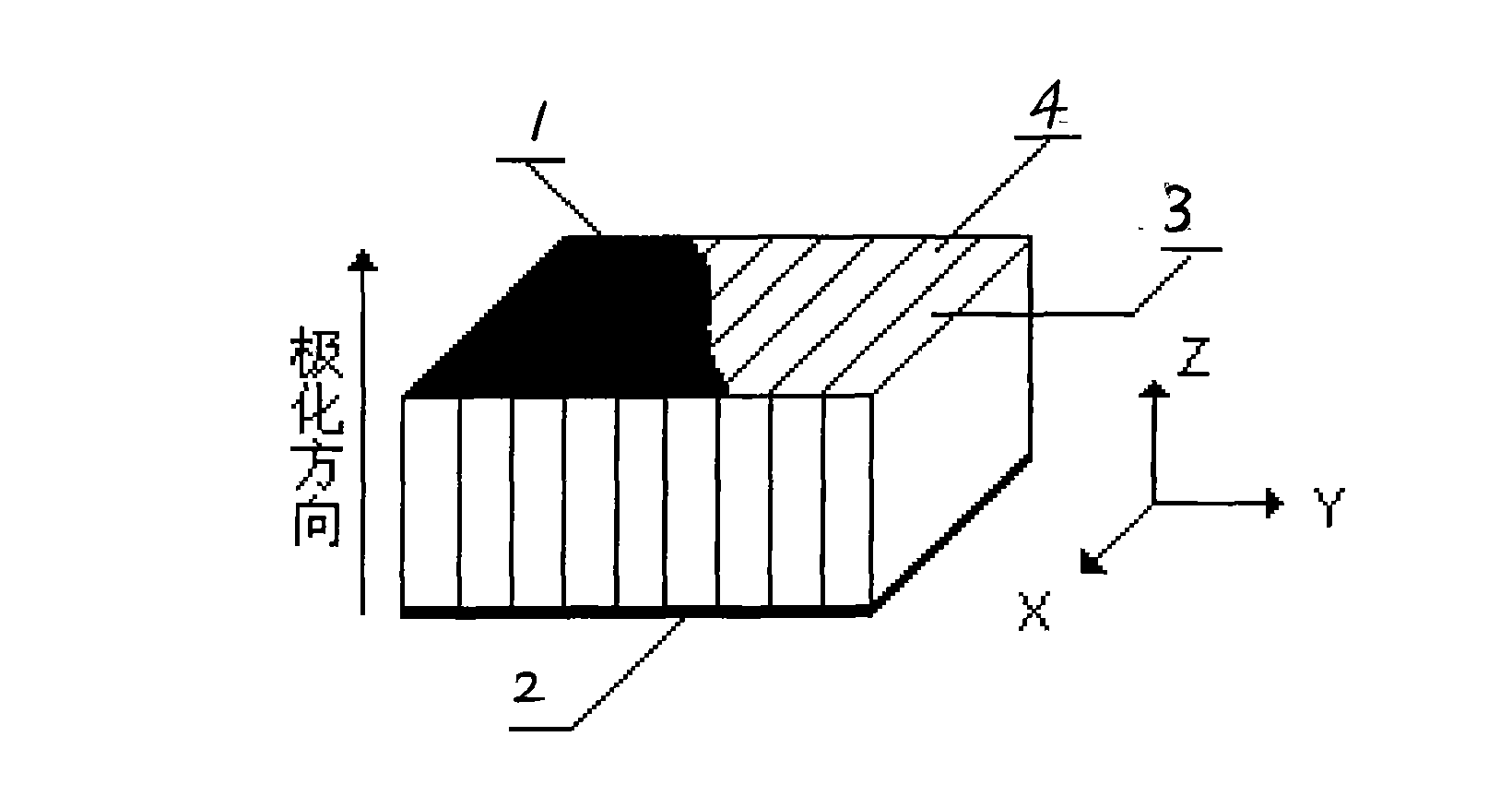

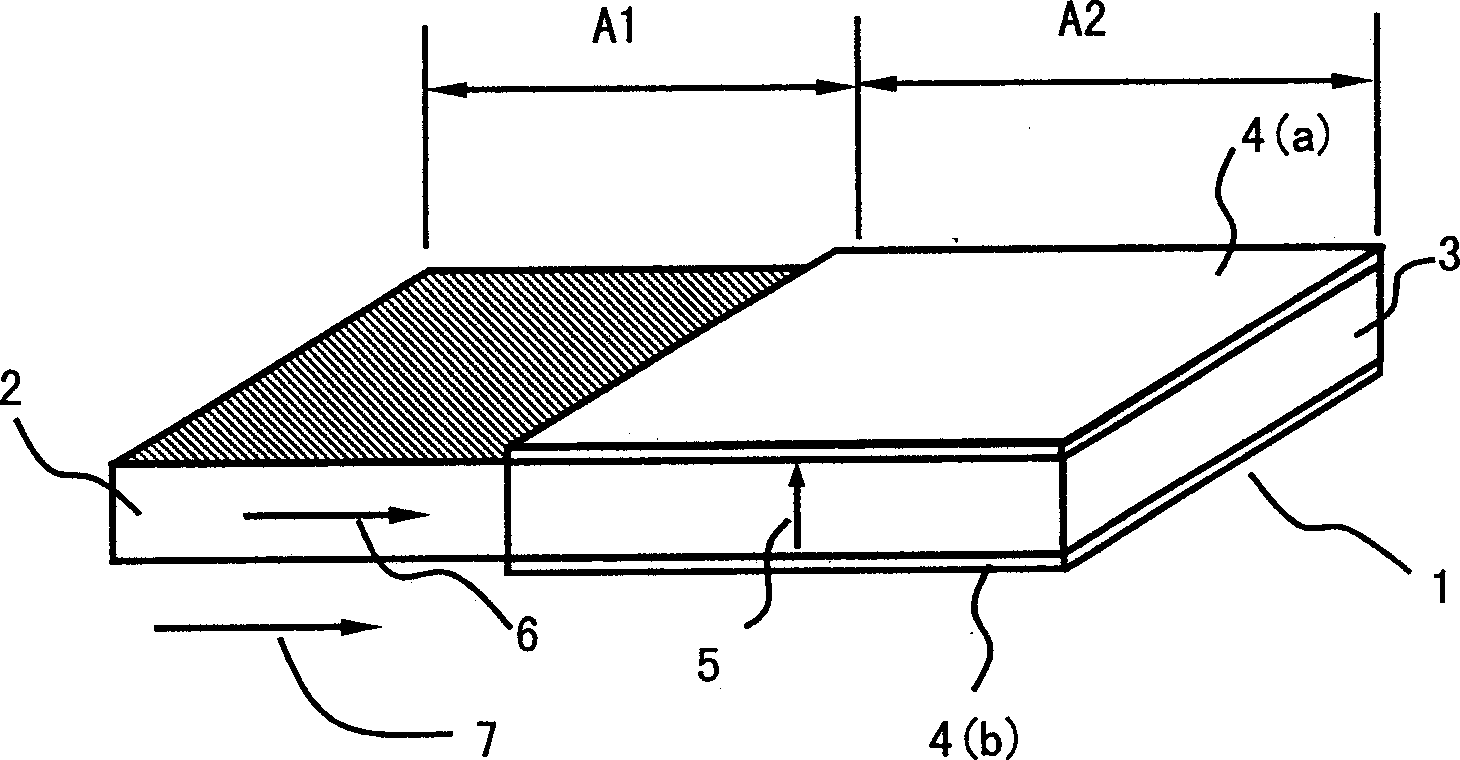

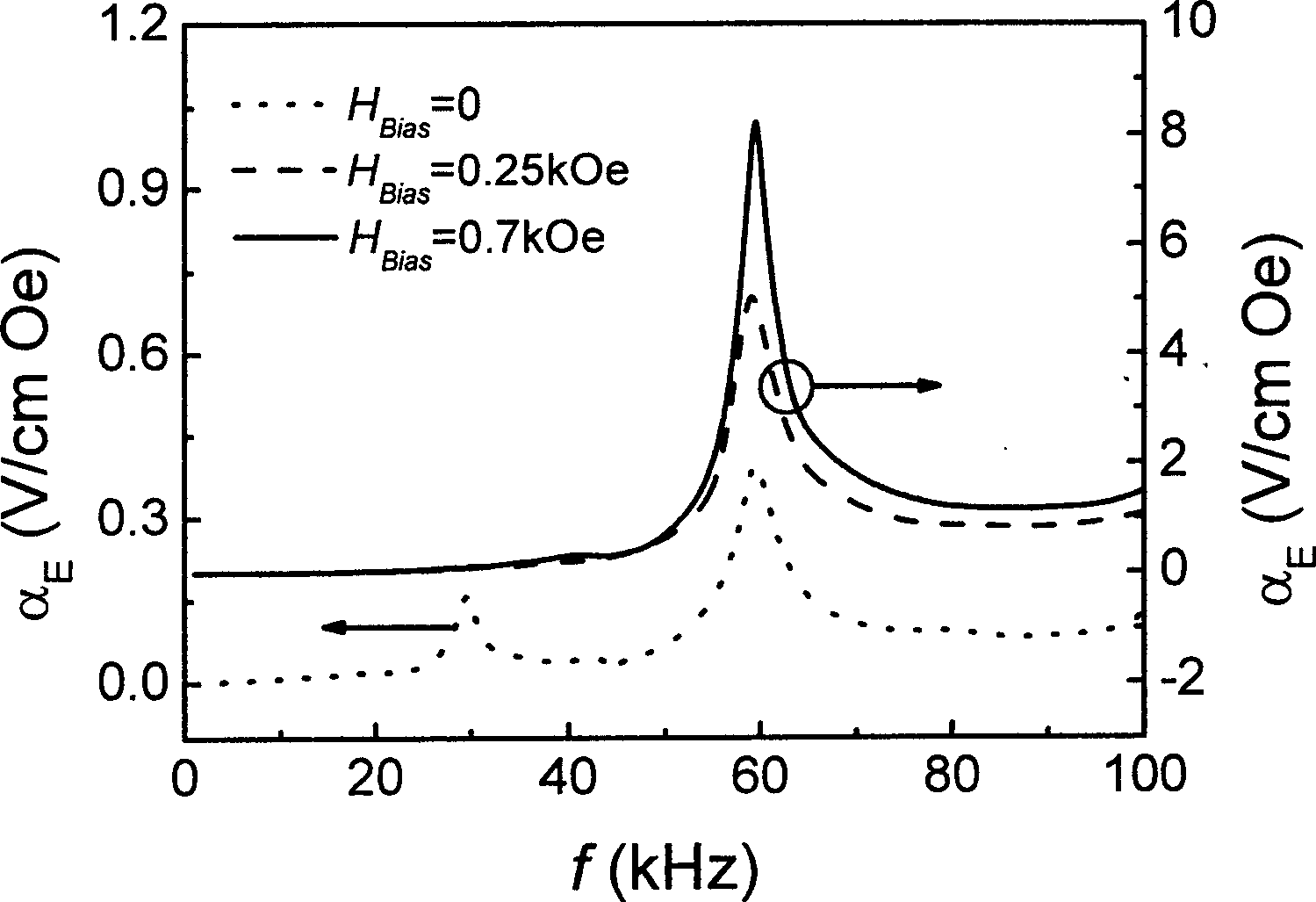

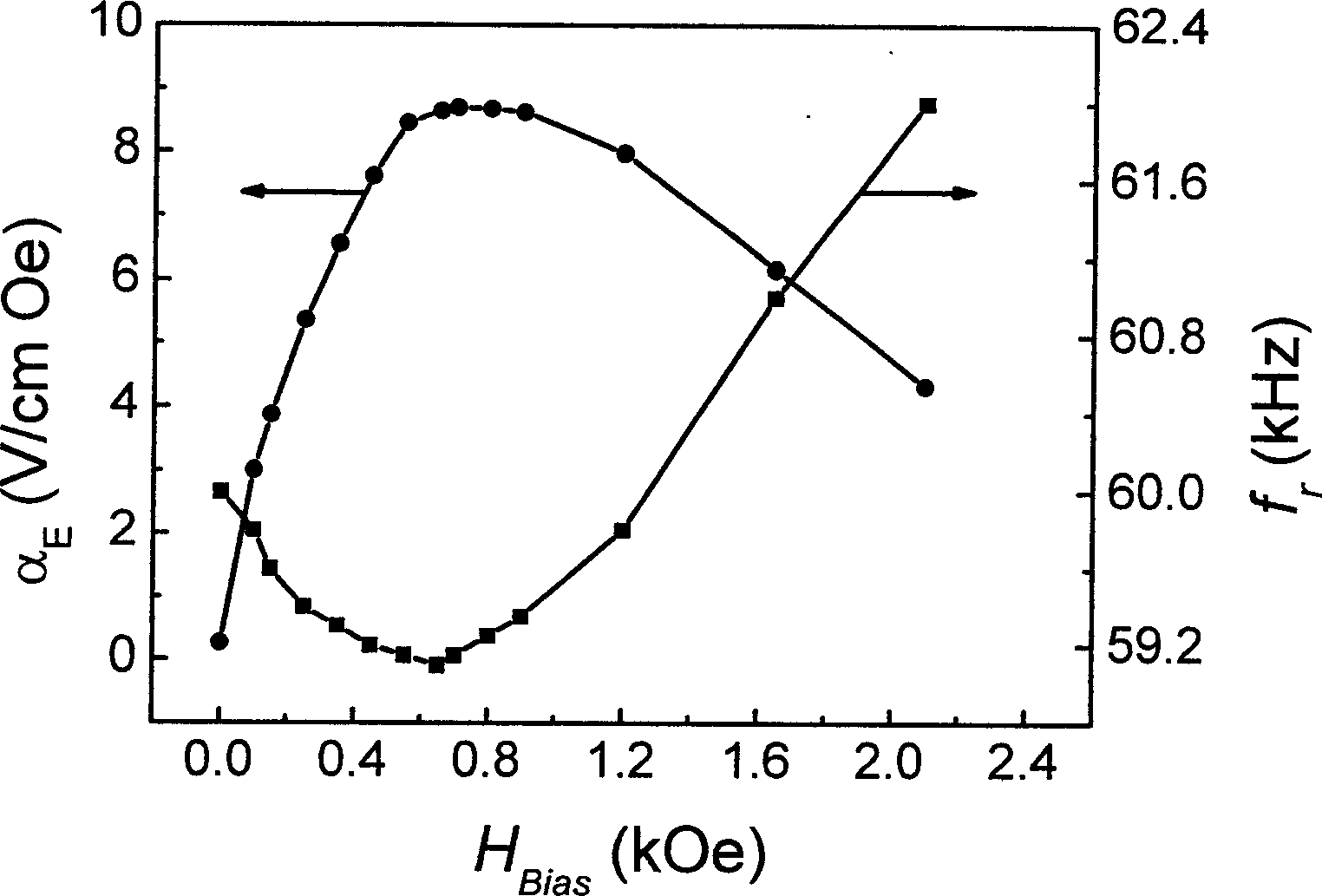

Magne to electric composite material and manufacturing method thereof

InactiveCN1489227AReduce lossImprove conversion efficiencyPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyResonanceAlloy

The magnetoelectricity composite material is a rectangle piece (1) divided into two areas A1 and A2 along longitudinal direction. A1 is made from magnetostrictive material, and A2 is made from piezodielectric material. A1 and A2 are combined through agglomerant. A pair of flat pole (4a and 4b) is in the A2 area. The piezodielectric material is polarized along thick direction. The said magnetostrictive material is magnetostrictive alloy, oxide or their composite material with polymer. The said piezodielectric material is piezoelectric ceramic or a composite material formed from piezoelectric ceramic and polymer. When dc magnetic biasing field and AC magnetic field with small signal are applied to rectangle piece 2 of magnetostrictive material along longitudinal direction, the rectangle piece (1) of magnetoelectricity generates resonance near to 60kHz, and voltage is output through rectangle piece 3 of piezodielectric composite material so as to realize magneto-electric coupling.

Owner:NANJING UNIV

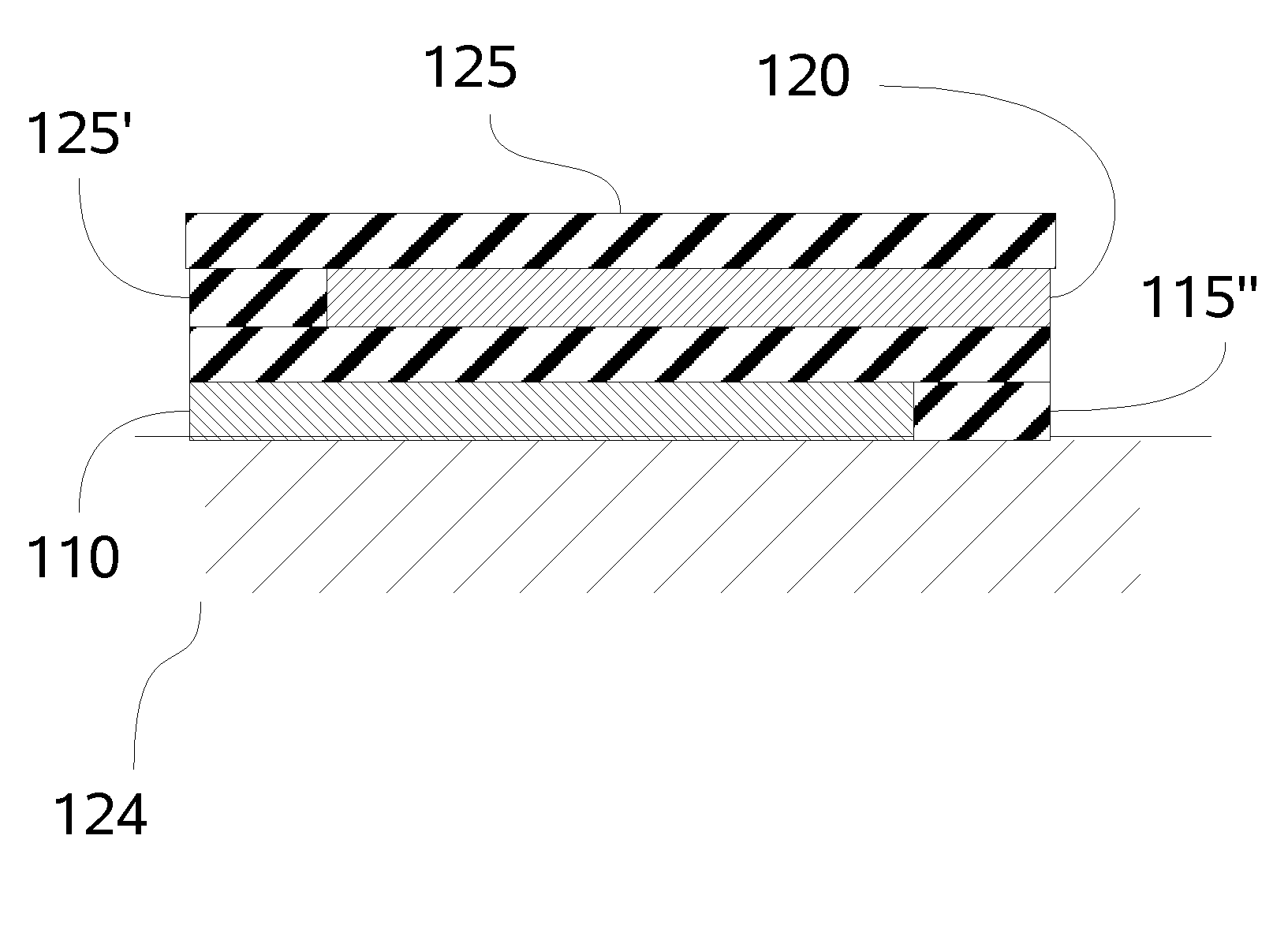

Method of manufacturing flexible piezoelectric energy harvesting device

InactiveUS9118000B2Simple manufacturing processImprove efficiencyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersPiezoelectric compositeMechanical engineering

Provided are a method of manufacturing a flexible piezoelectric energy harvesting device using a piezoelectric composite, and a flexible piezoelectric energy harvesting device manufactured by the same. The method of manufacturing the flexible piezoelectric energy harvesting device includes: forming a first electrode layer on a first flexible substrate; spin-coating a piezoelectric composite layer on the first electrode layer, wherein the piezoelectric composite layer is produced by mixing piezoelectric powder with polymer; performing heat treatment on the piezoelectric composite layer to harden the piezoelectric composite layer; and bonding a second flexible substrate with a second electrode layer on the hardened piezoelectric composite layer. Therefore, it is possible to simplify a manufacturing process and manufacture a high-performance flexible piezoelectric energy harvesting device having various sizes and patterns.

Owner:KOREA INST OF SCI & TECH

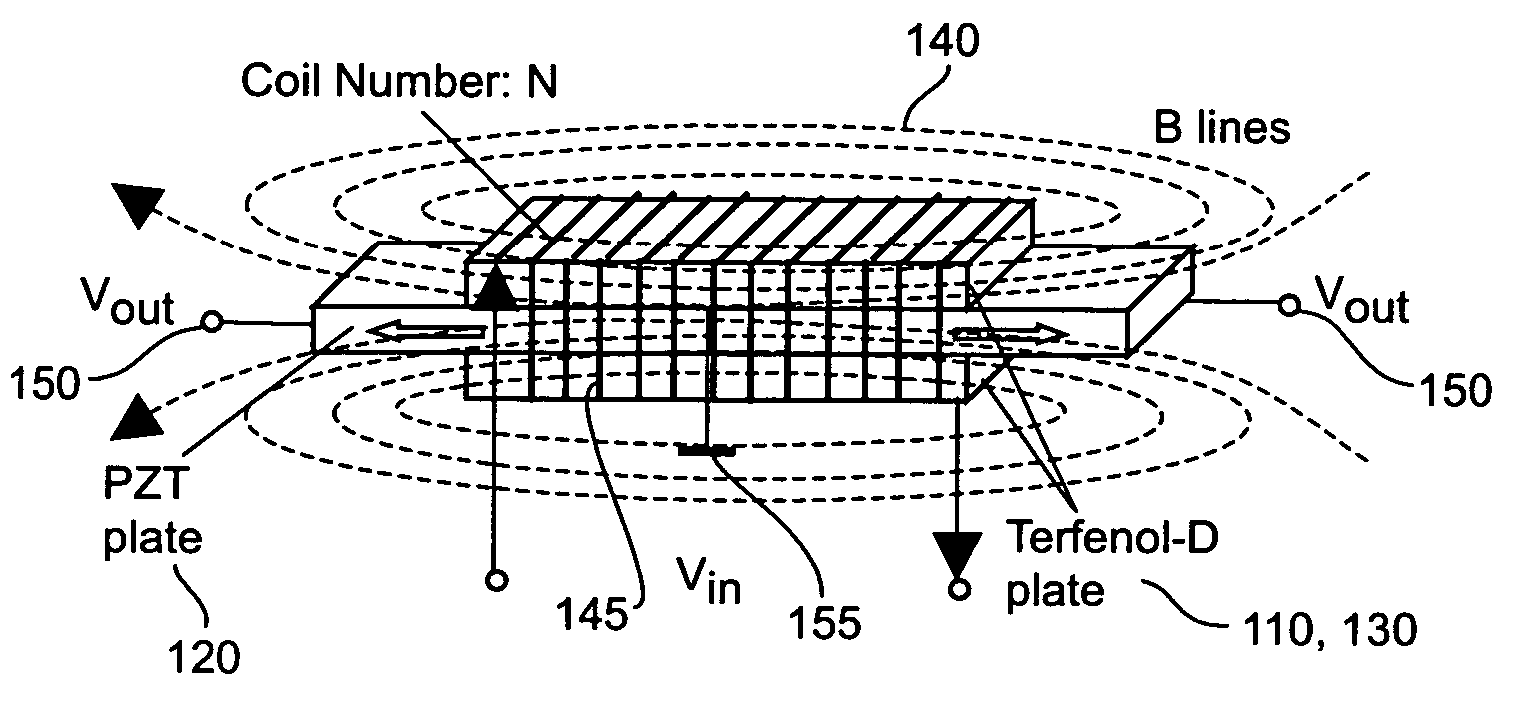

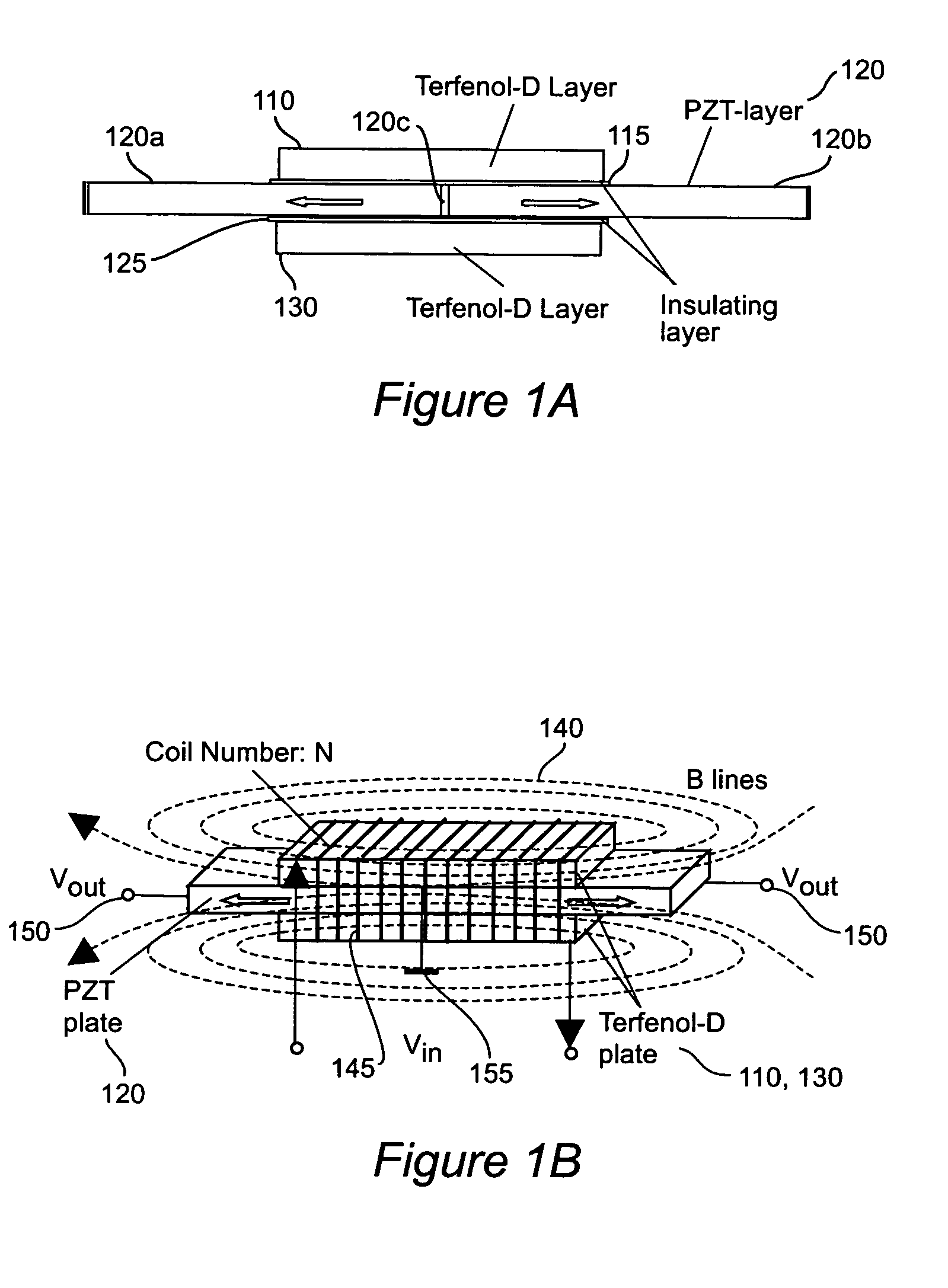

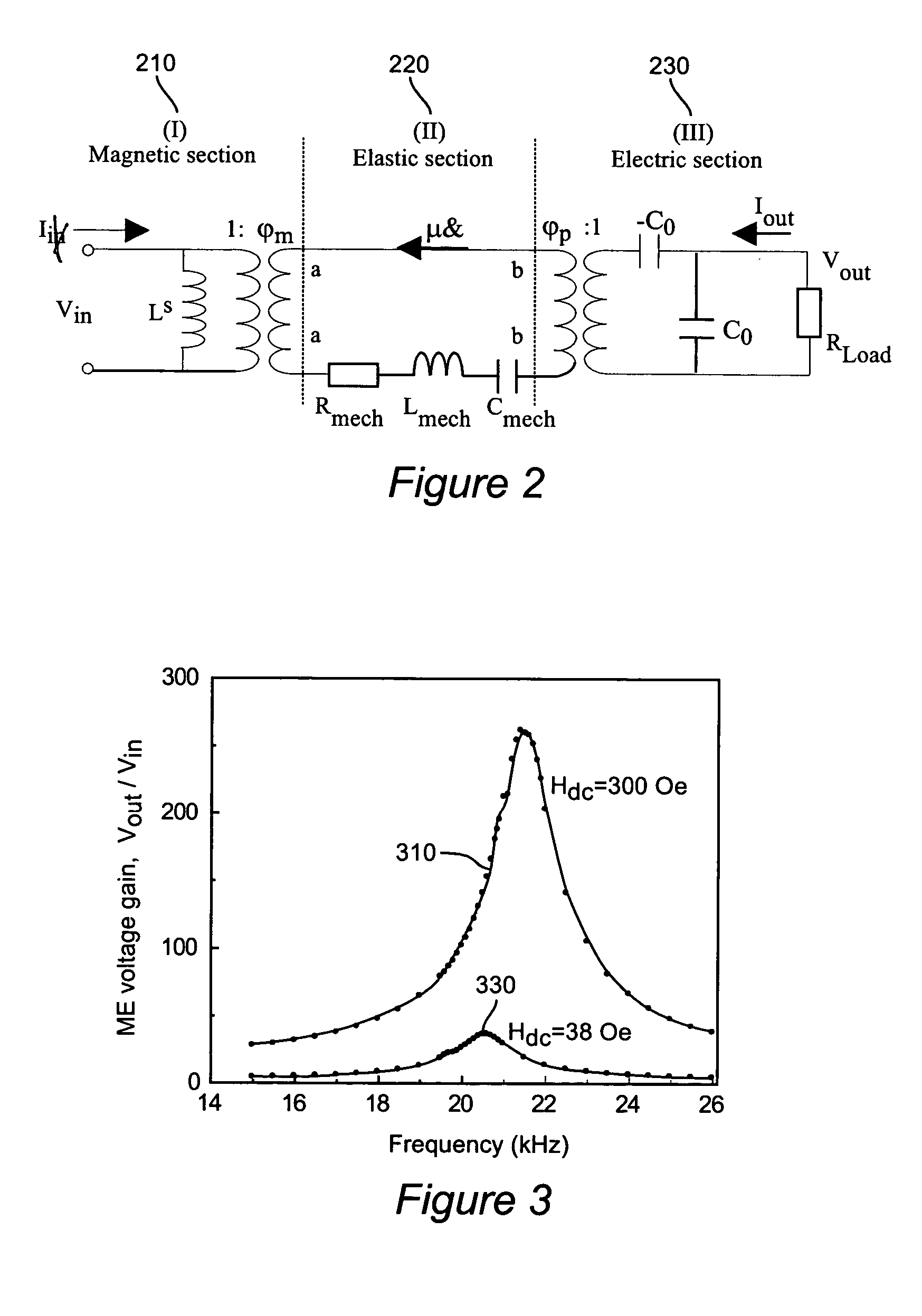

Method and apparatus for high voltage gain using a magnetostrictive-piezoelectric composite

InactiveUS7256532B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesHarmonicMechanical resonance

A method and apparatus attains high voltage gain by using a composite structure of an elastic section of piezoelectric layers bonded between magnetic and electric sections of magnetostrictive layers, with a harmonic magnetic field being applied along the layers at a mechanical resonance frequency of the composite structure, through coils around the laminate carrying current, such as to produce a continuity of both magnetic and electric flux lines, and achieving a high voltage output.

Owner:VIRGINIA TECH INTPROP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com