Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

305results about "Magnetostrictive devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetostrictive actuator of a medical ultrasound transducer assembly, and a medical ultrasound handpiece and a medical ultrasound system having such actuator

ActiveUS8487487B2Efficiently sculpt teeth or remove boneLow powerUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonographyUltrasonic sensor

Owner:CILAG GMBH INT

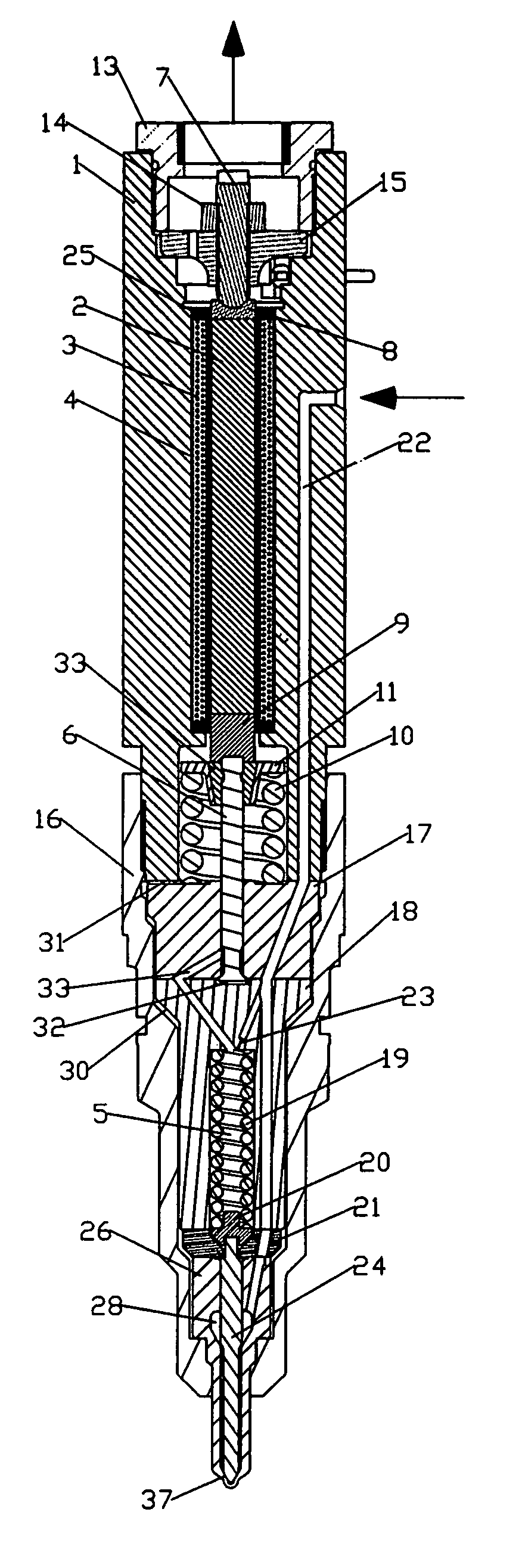

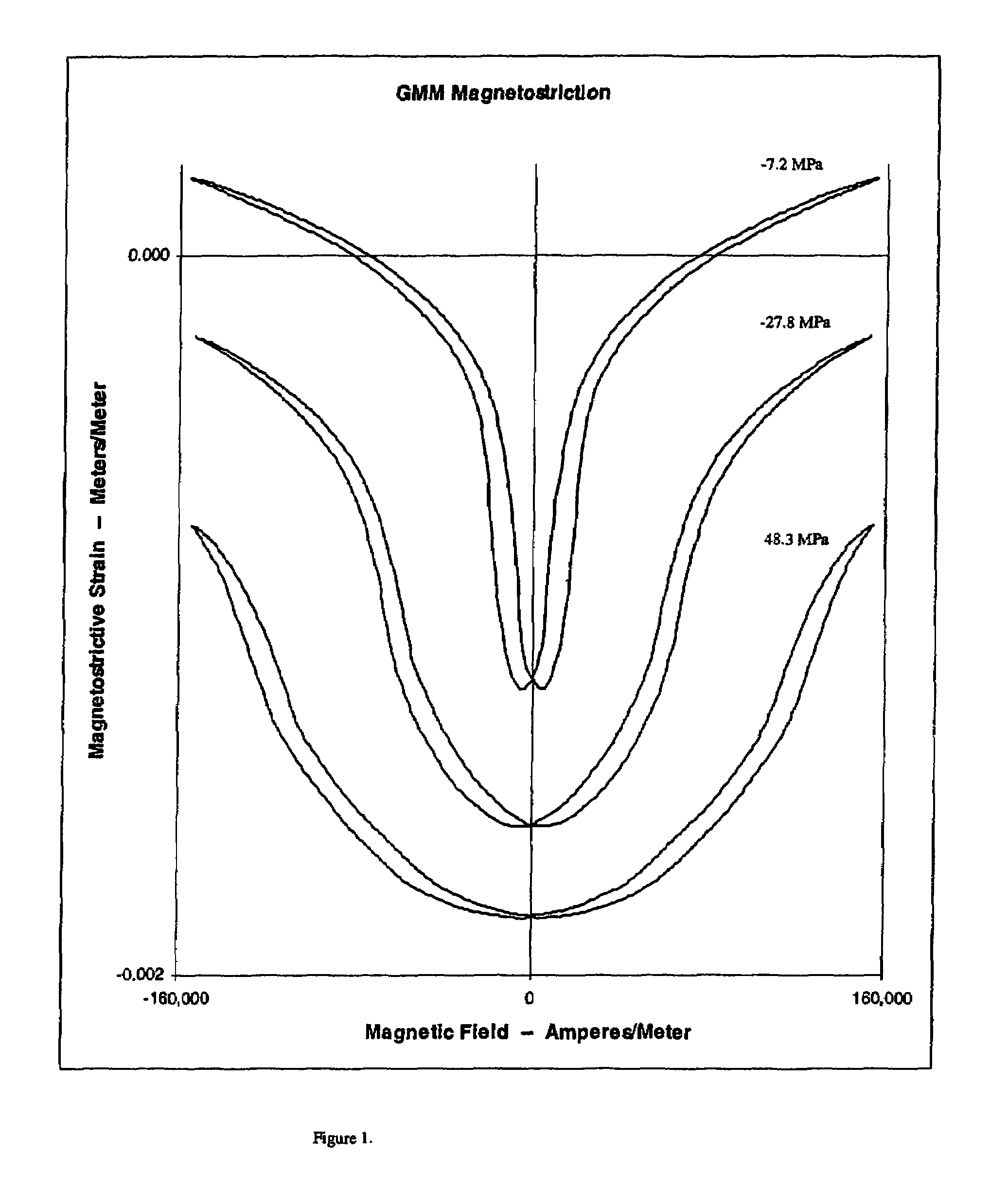

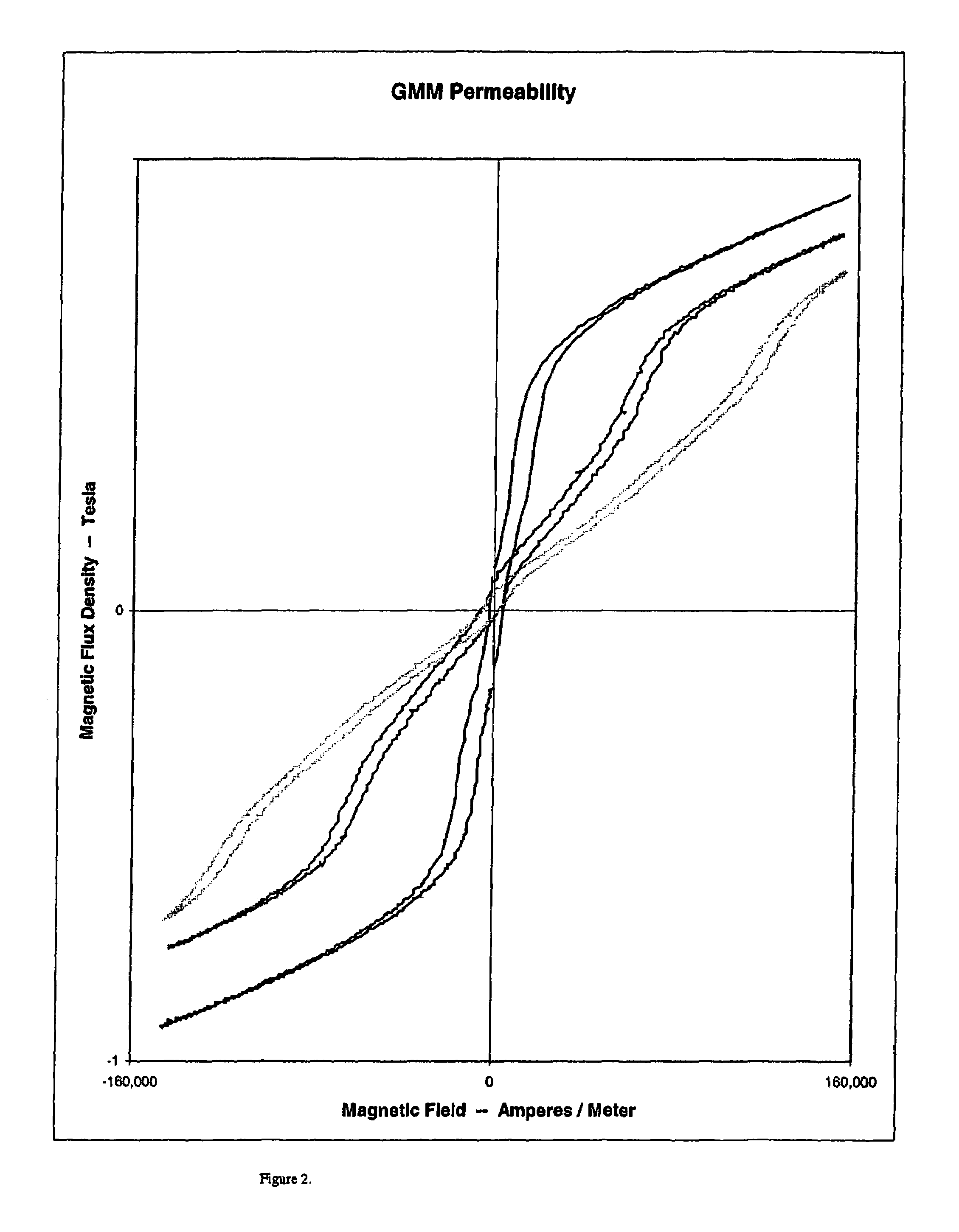

Very high speed rate shaping fuel injector

ActiveUS7255290B2Simple processMinimize formationOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesParticulatesCombustion chamber

Owner:QUANTUM CONTROL WORKS L C

Hybrid electric linear actuator

InactiveUS6982502B1Piezoelectric/electrostriction/magnetostriction machinesMechanical actuated clutchesElectric machinePermanent magnet synchronous motor

A hybrid linear actuator features a central load shaft on which a plurality of solid-state magnetostrictive thrusters are positioned in operative relation to electric motors of a permanent magnet synchronous type to impart linear thrust force to the load shaft through clutch units also positioned thereon and under control of force and stroke amplification of output force from motor shafts projecting from the motors.

Owner:TOYOTA JIDOSHA KK +1

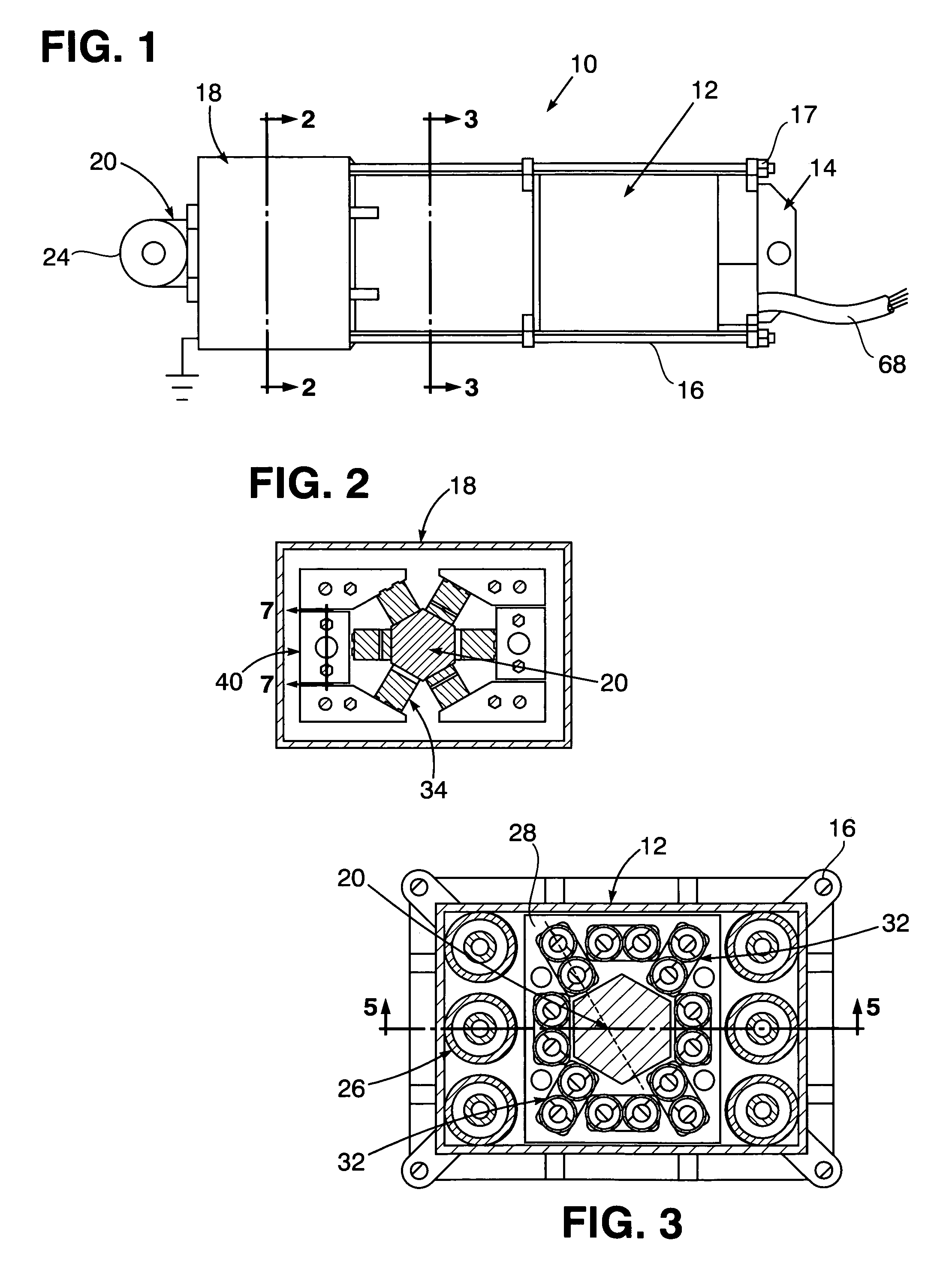

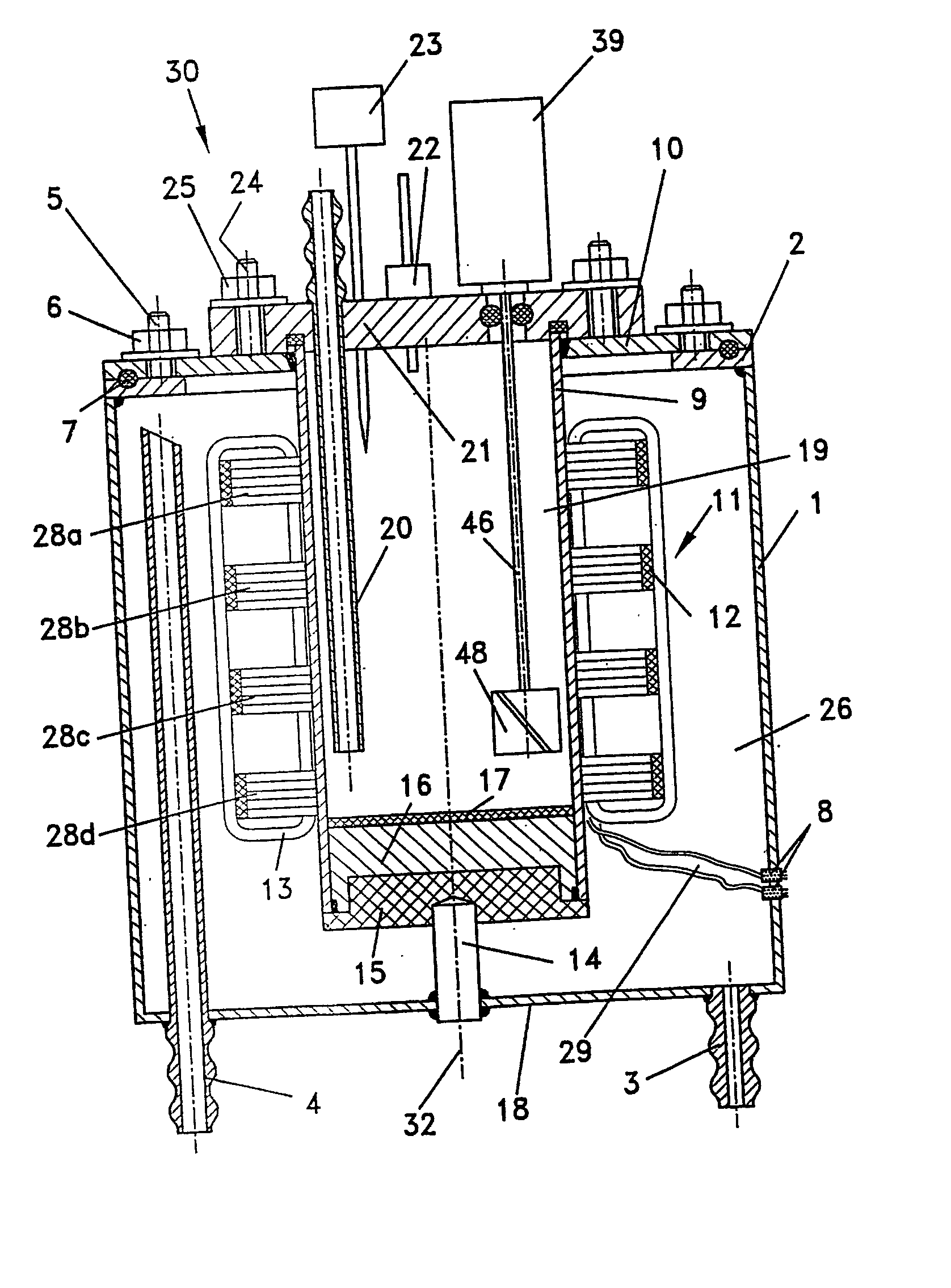

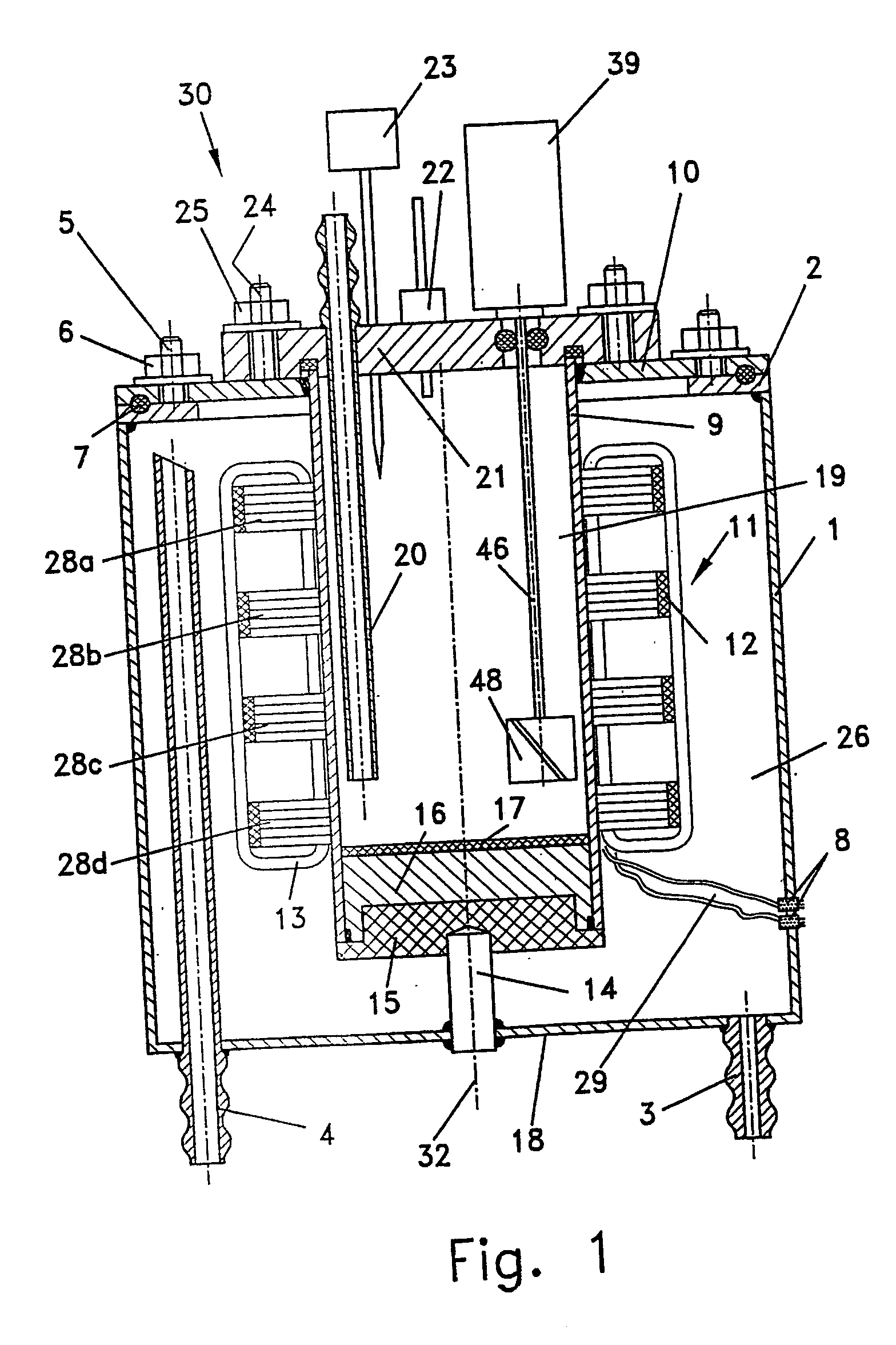

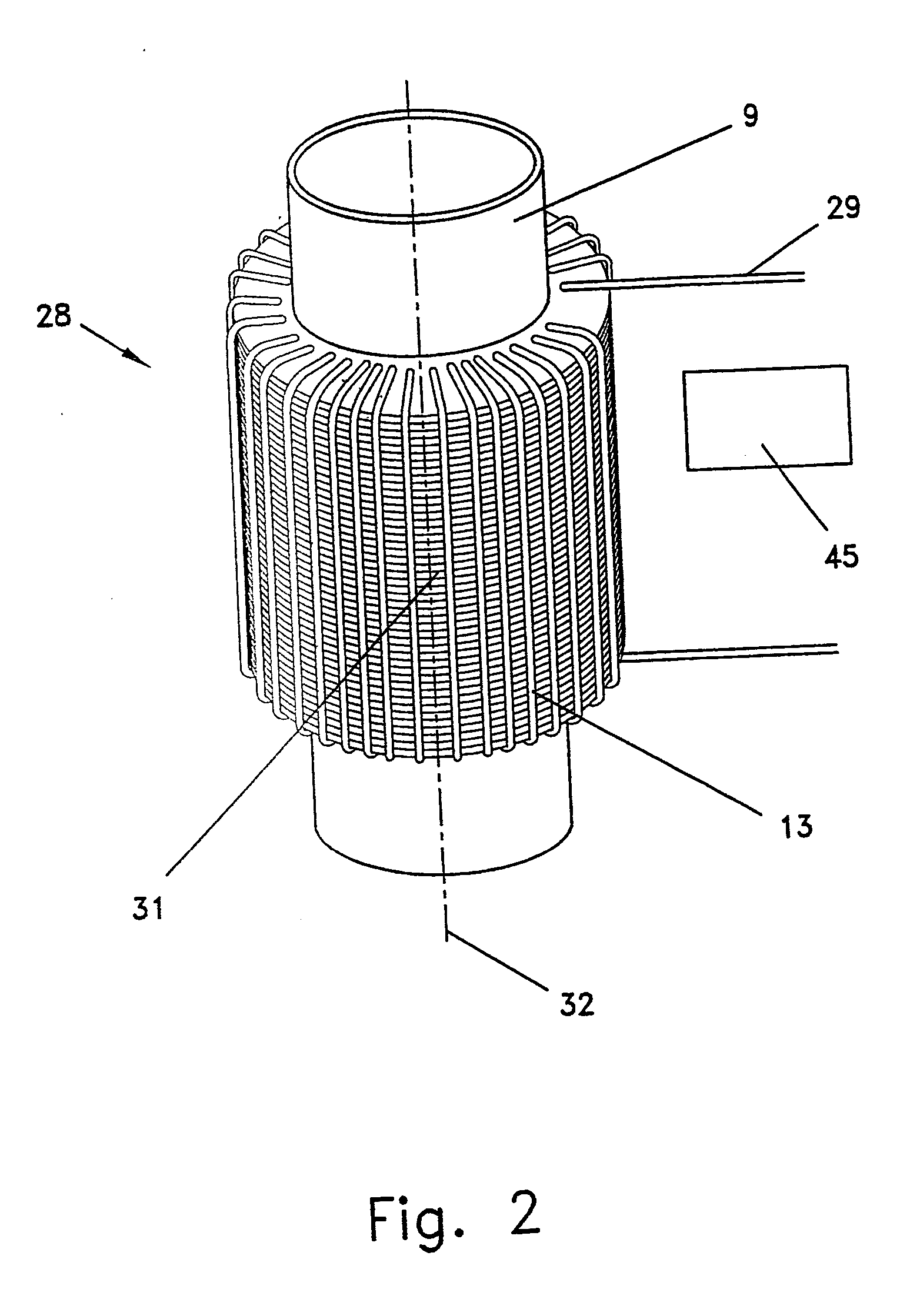

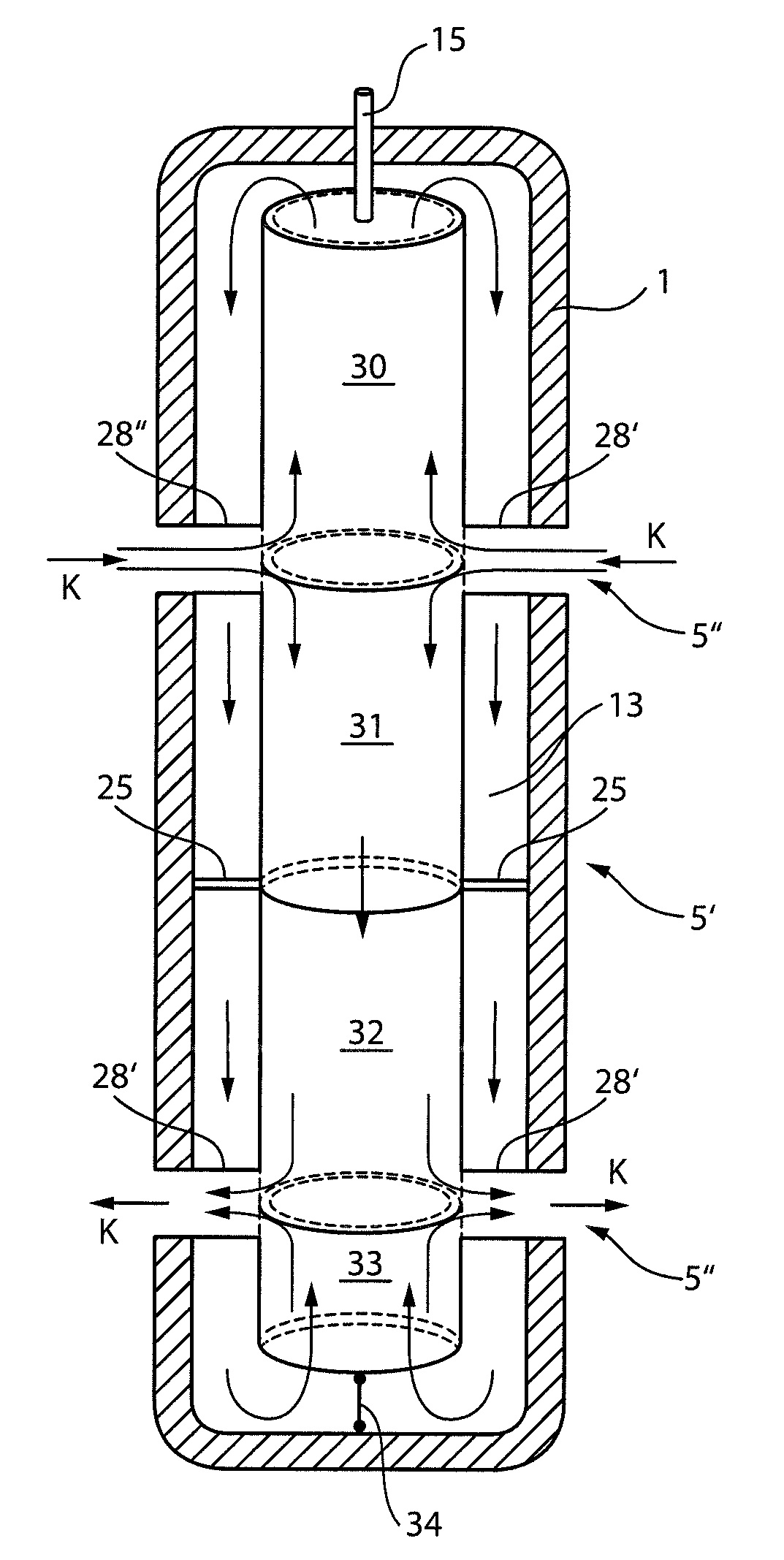

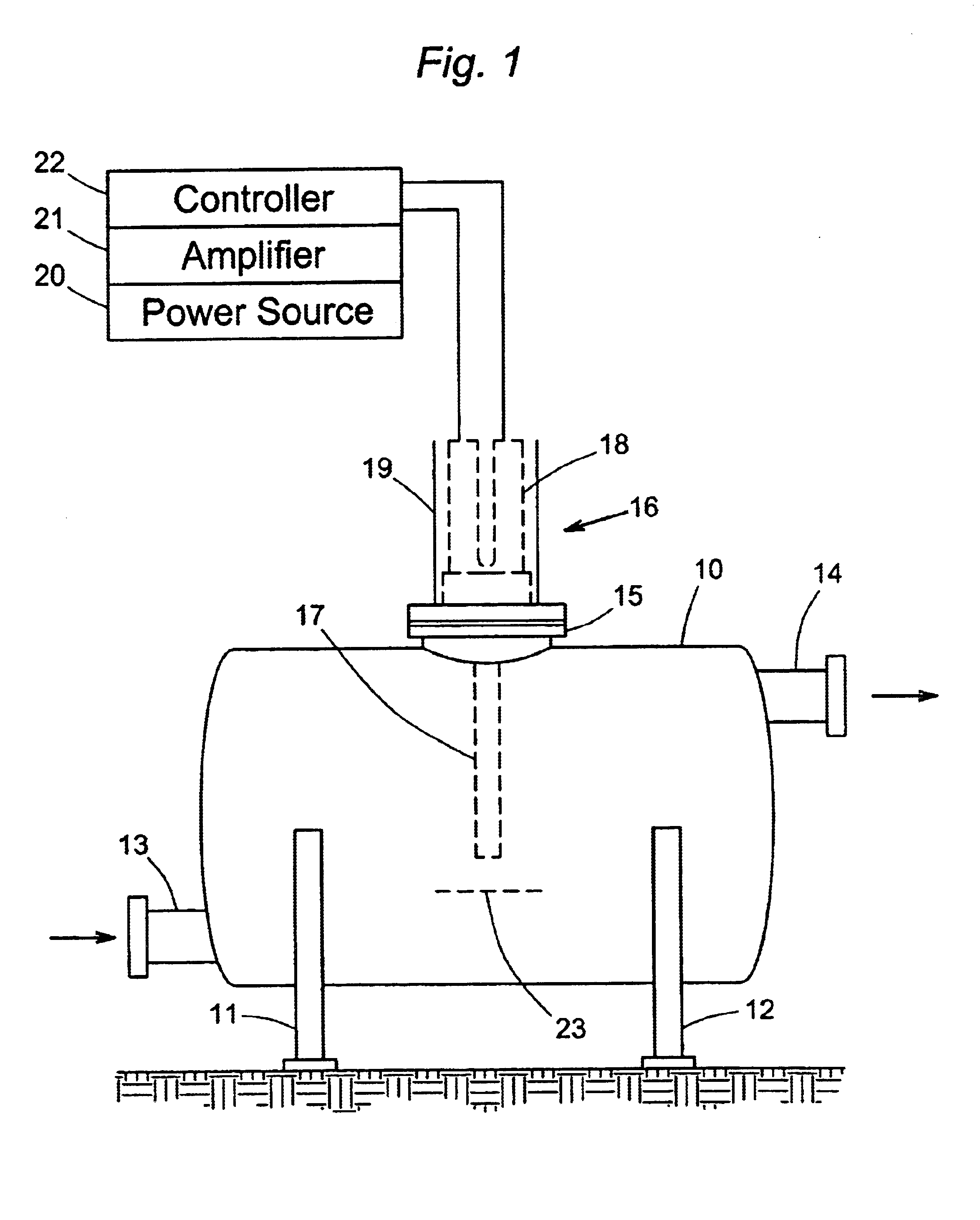

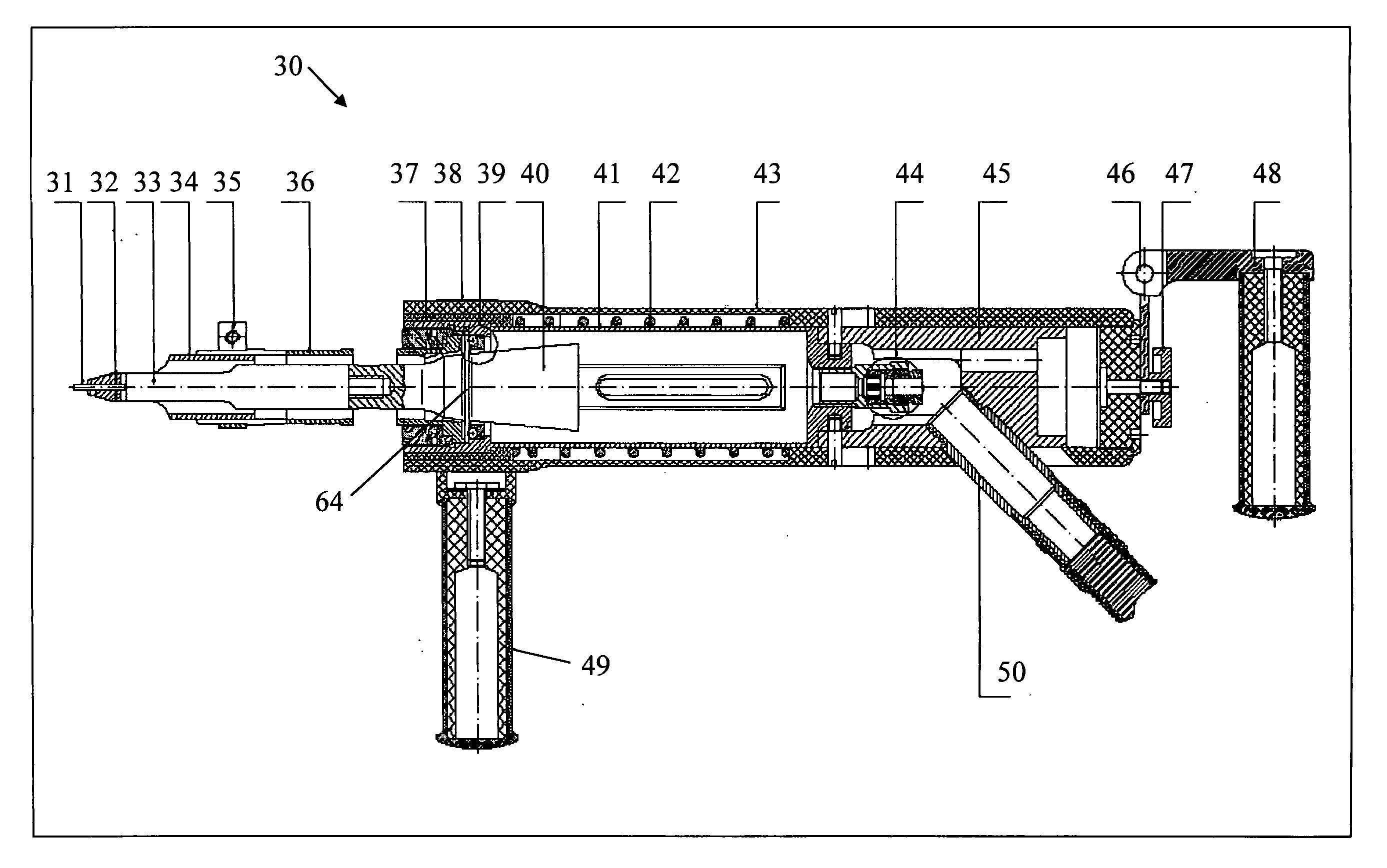

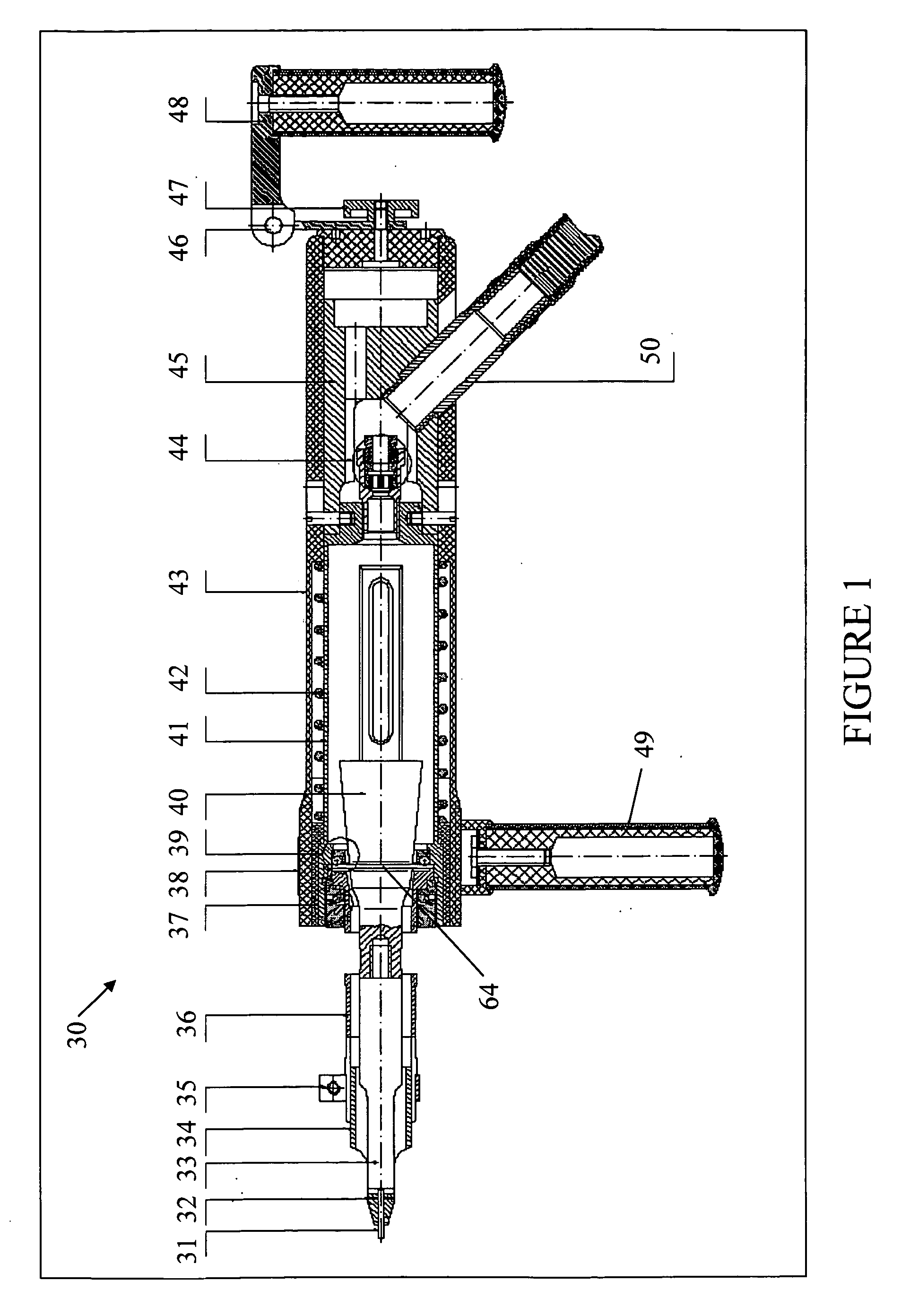

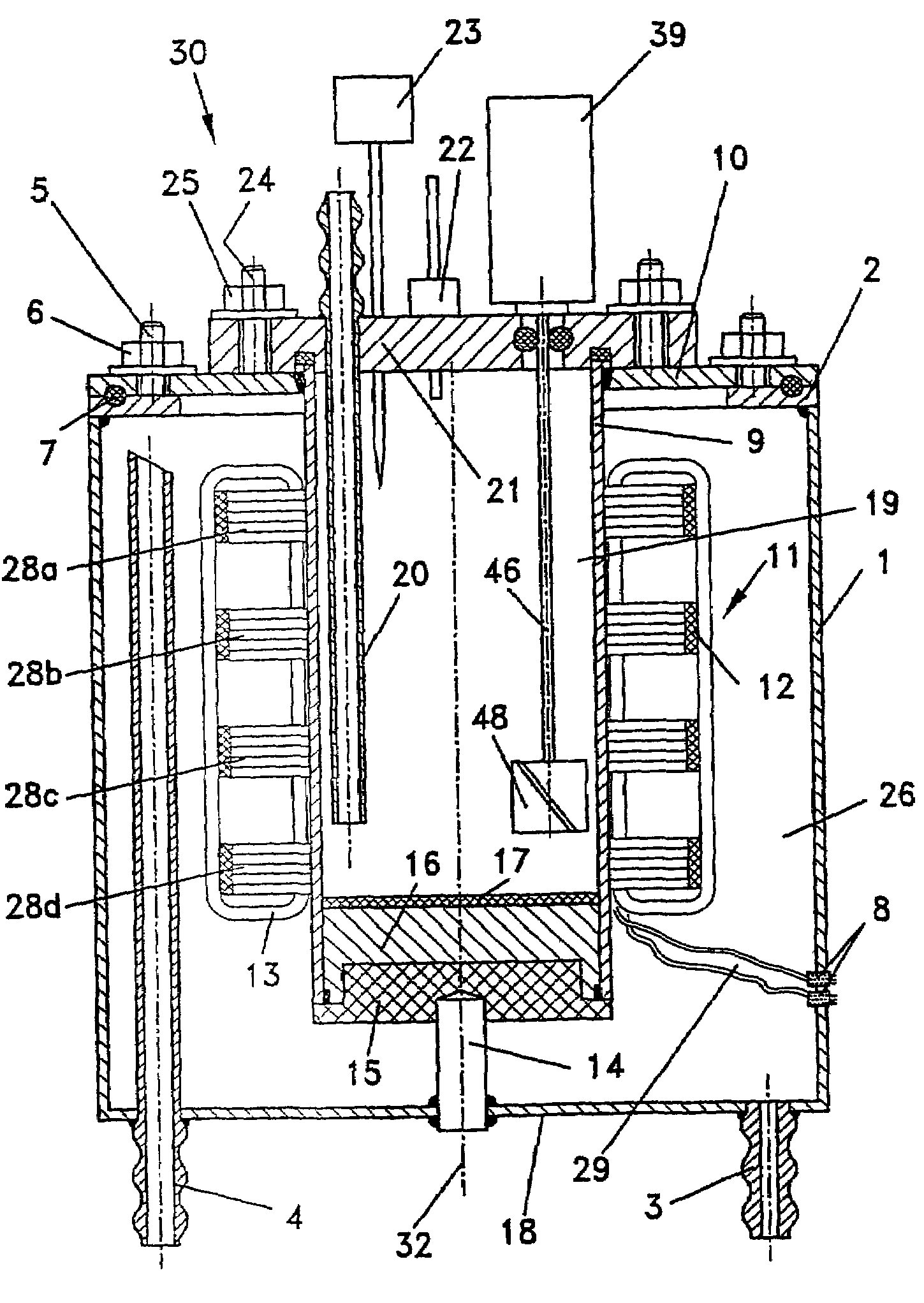

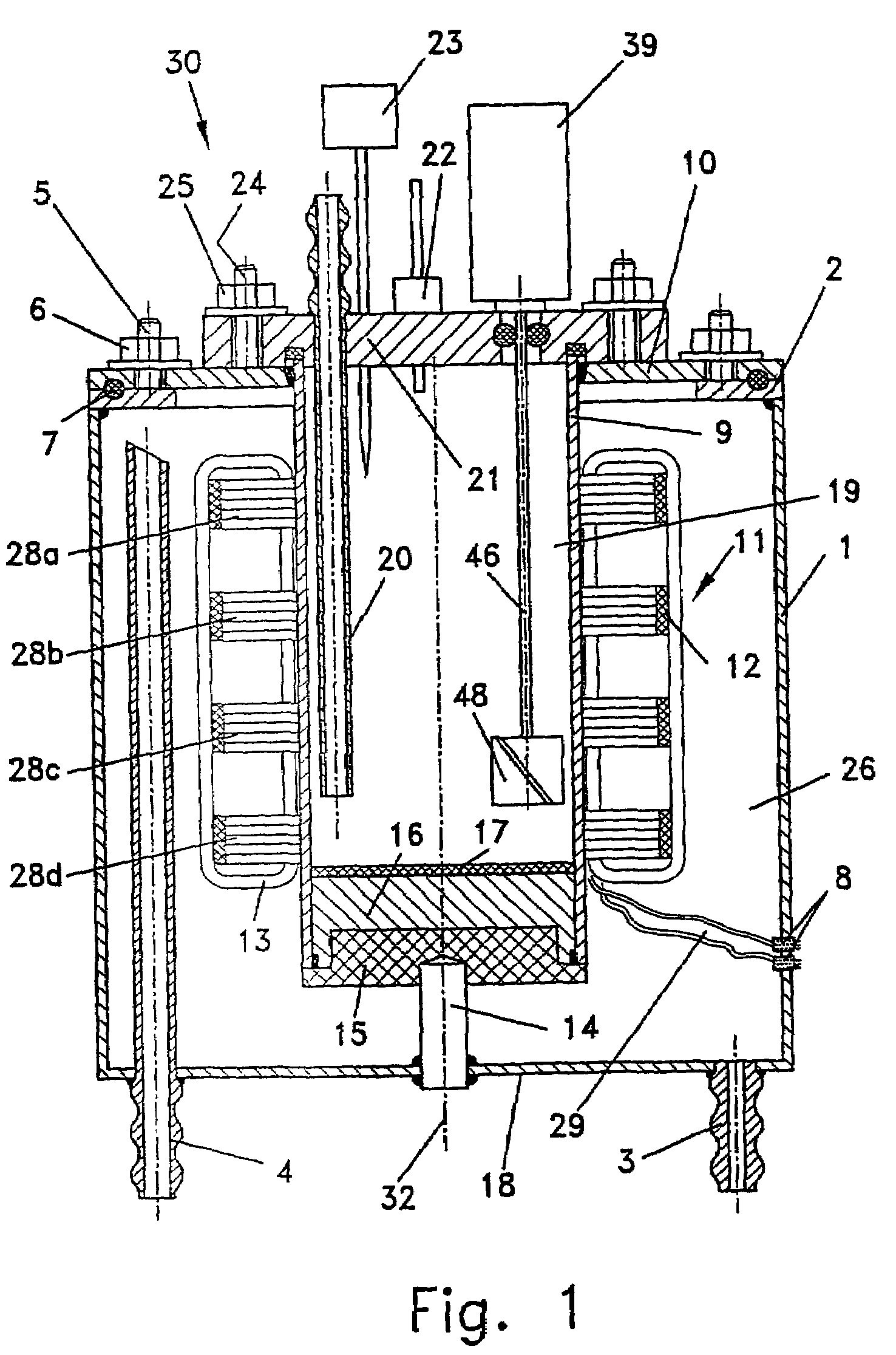

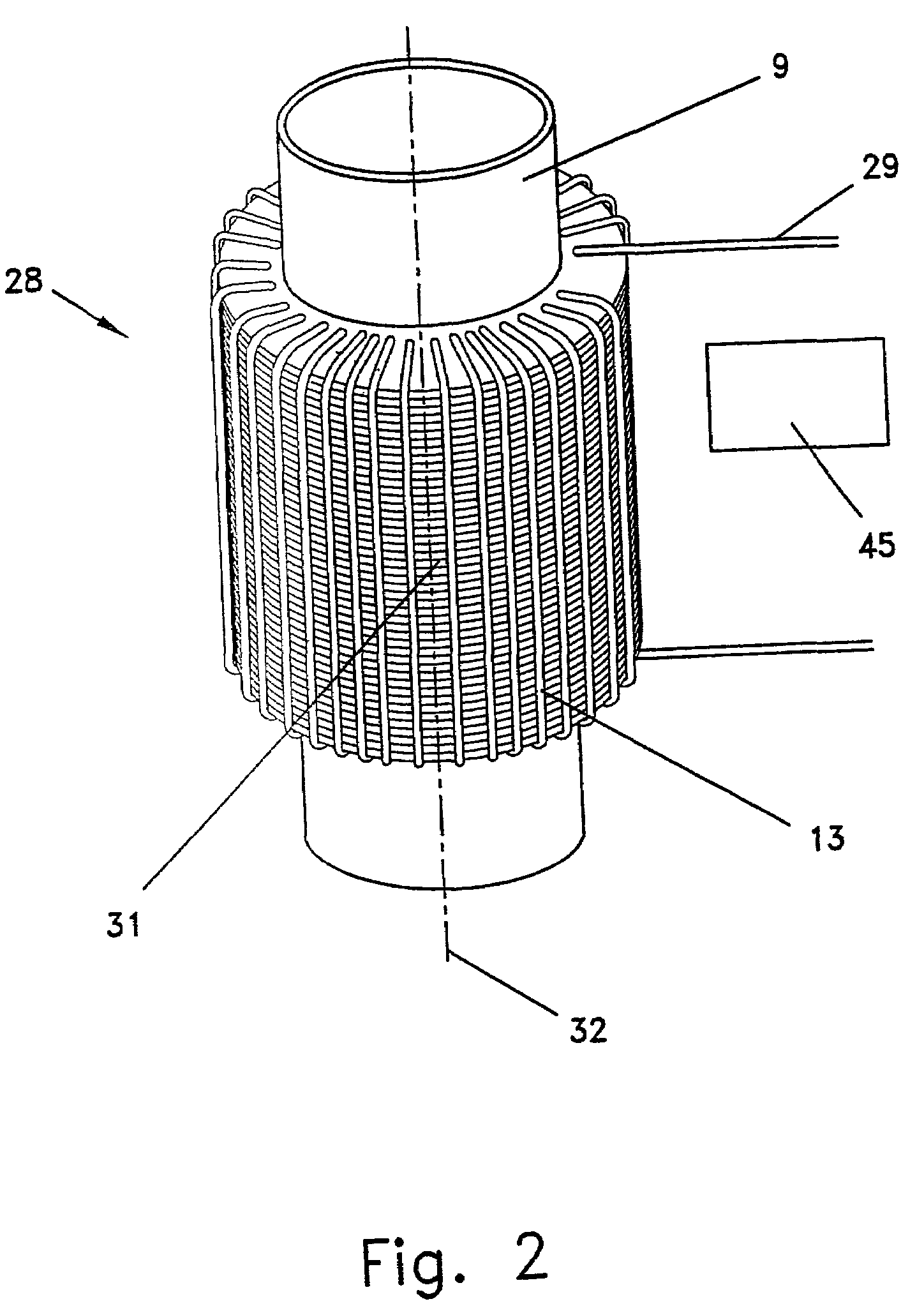

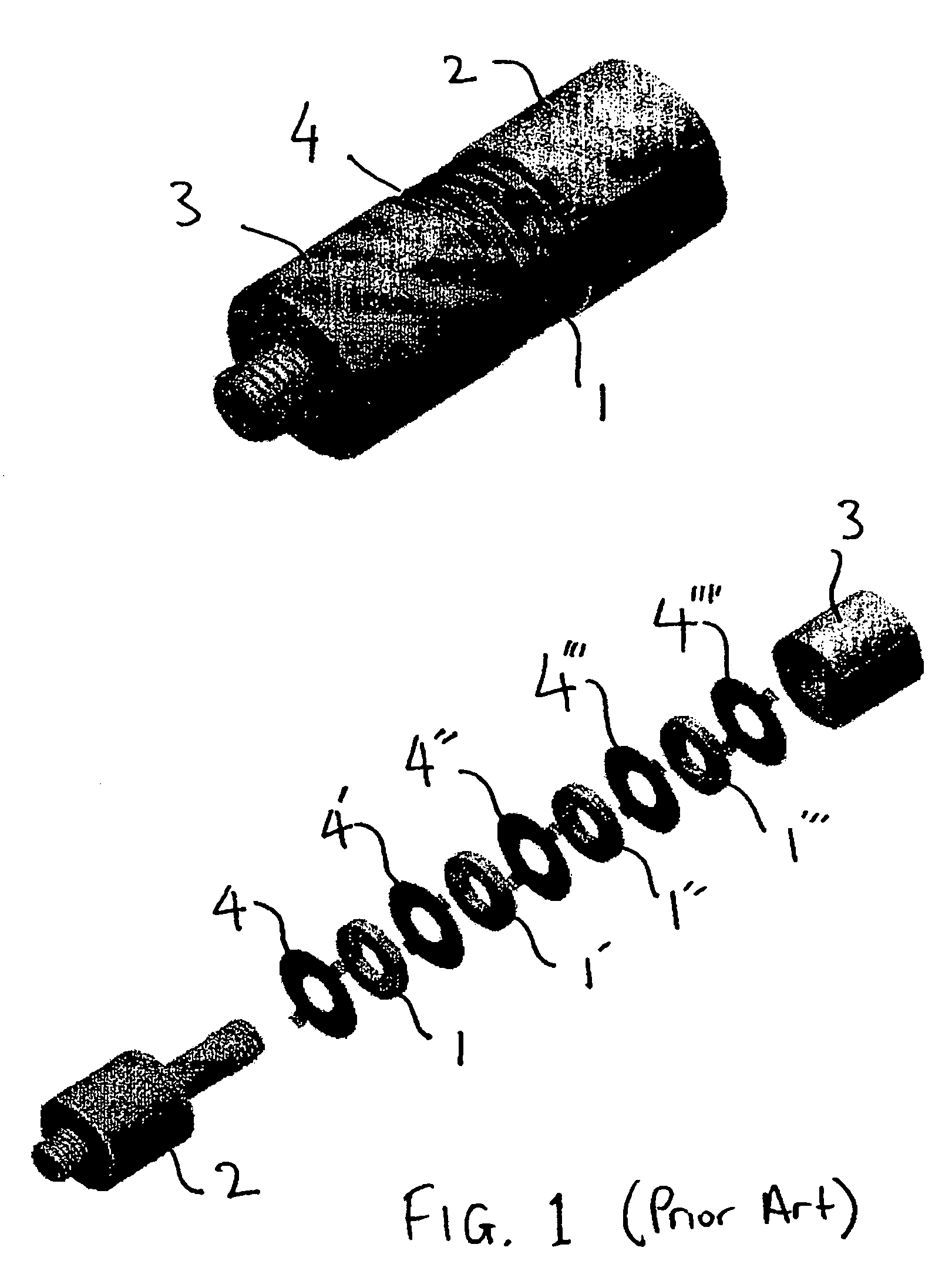

Ultrasonic reactor and process for ultrasonic treatment of materials

InactiveUS20050260106A1Shaking/oscillating/vibrating mixersTransportation and packagingCavitationTransducer

An ultrasound reactor (30) having a reactor body (1), a reactor tube (9) disposed within the reactor body and a magnetostrictor transducer (11) comprising at least one annular element (28a-d) concentric with, and mounted to an external wall of said tube and a process for ultrasonic treatment of a reaction material are disclosed. The transducer is mounted on the reactor tube in such a way so as to transmit ultrasound radiation to the interior of the tube and to induce an upwardly flowing cavitation stream whose longitudinal axis substantially coincides with a longitudinal axis of said tube, causing physical changes to the reaction material.

Owner:NANO SIZE

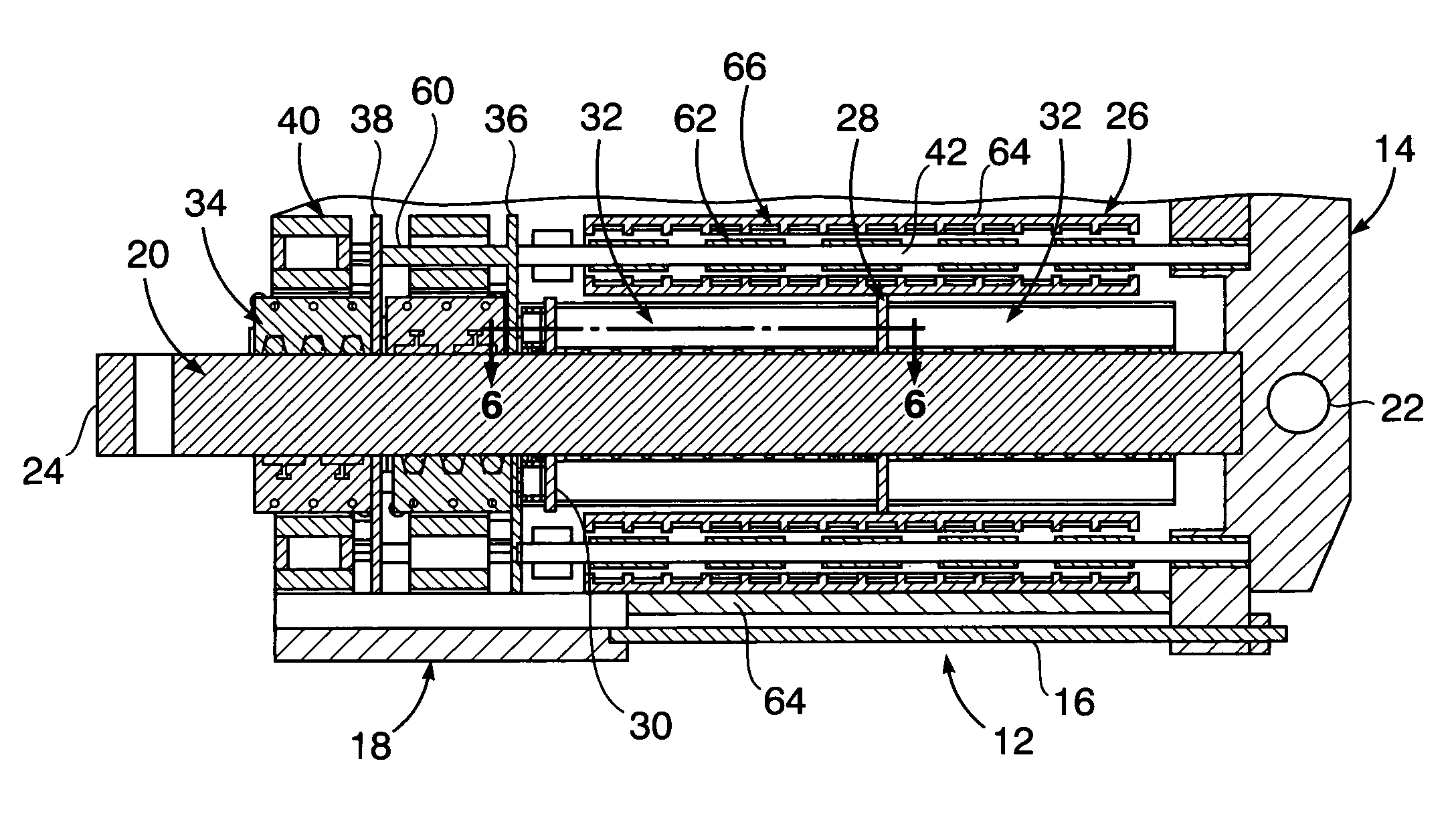

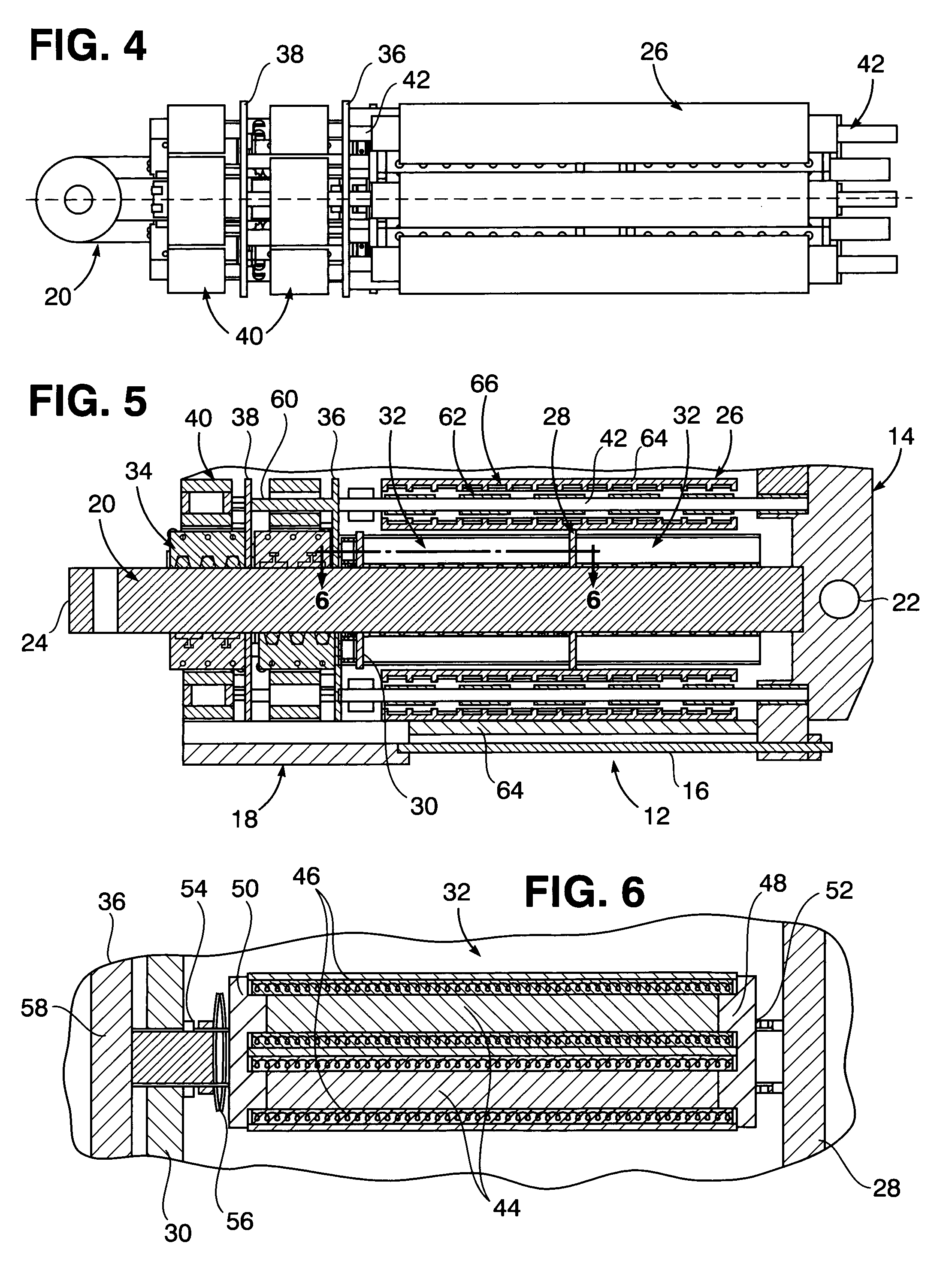

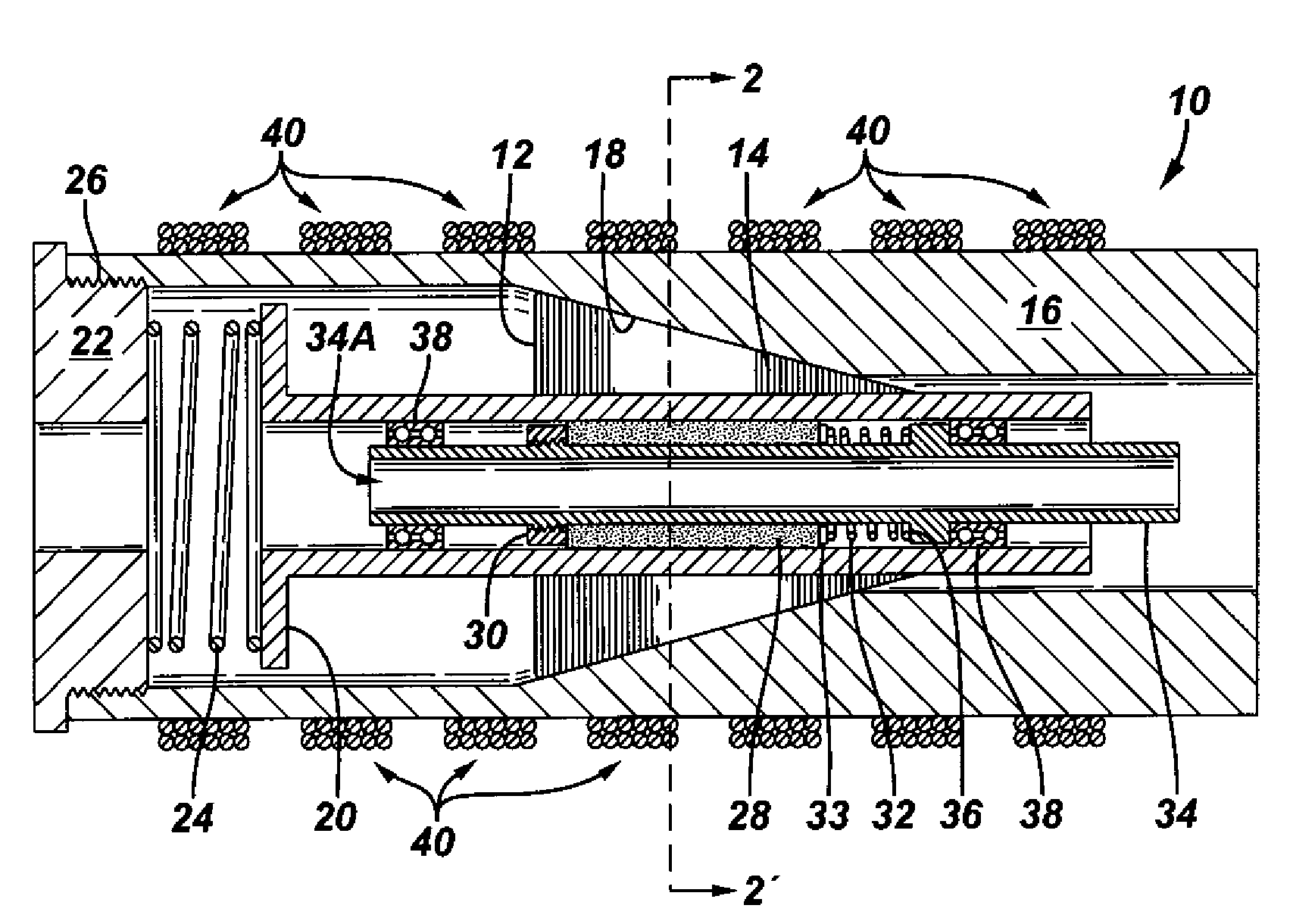

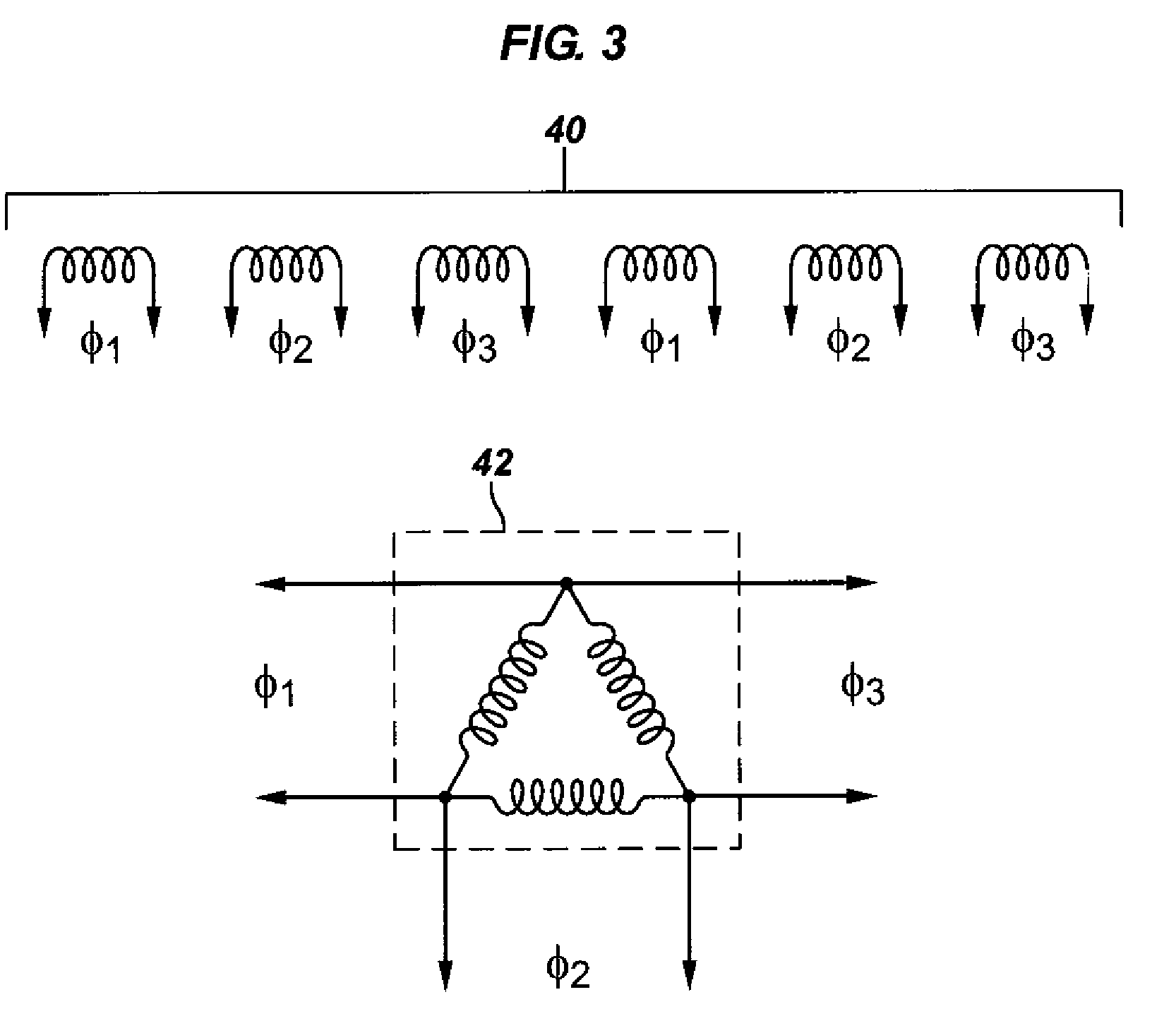

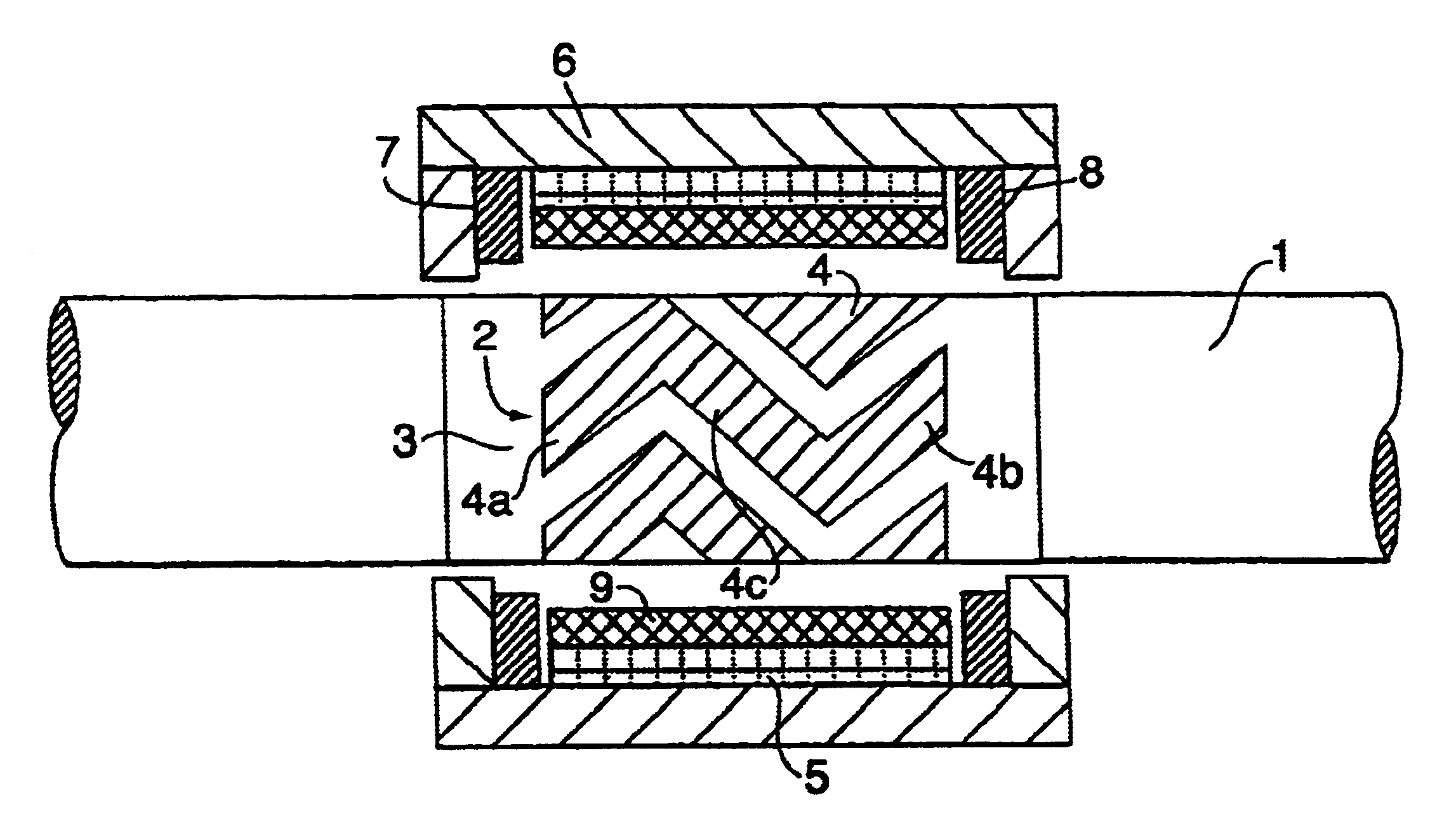

Linear actuator using magnetostrictive power element

InactiveUS7675253B2Piezoelectric/electrostriction/magnetostriction machinesFluid removalLateral compressionLinear actuator

A linear actuator includes a substantially cylindrical magnetostrictive element disposed in a housing. A retainer is cooperatively engaged with the housing and an exterior of the magnetostrictive element such that relaxed portions of the magnetostrictive element are frictionally retained in the retainer. An actuator rod is functionally coupled to one longitudinal end of the magnetostrictive element. A biasing device is disposed between the housing and the retainer to maintain the retainer in lateral compression. The actuator includes magnets arranged to induce peristaltic motion in the magnetostrictive element.

Owner:SCHLUMBERGER TECH CORP

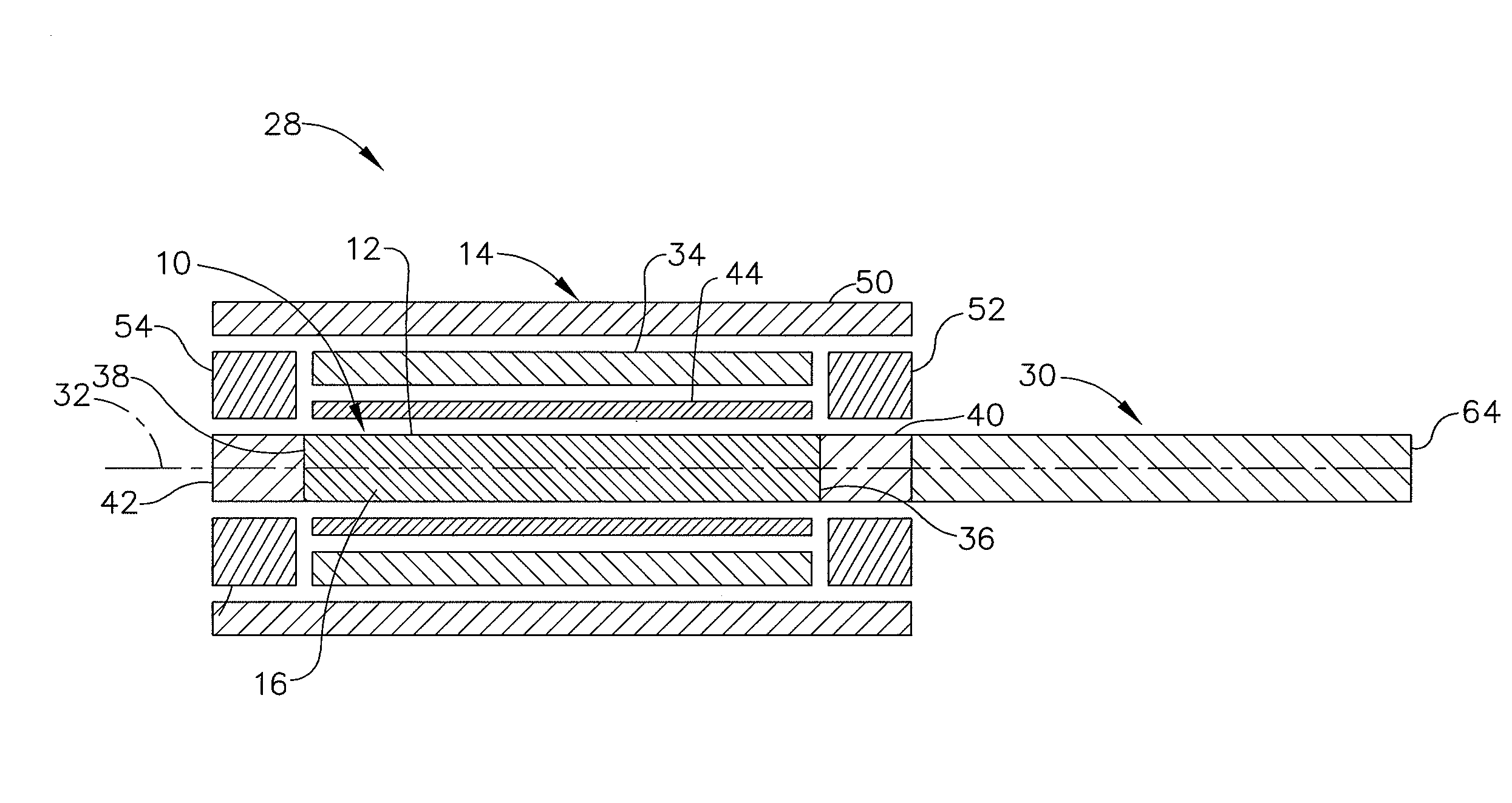

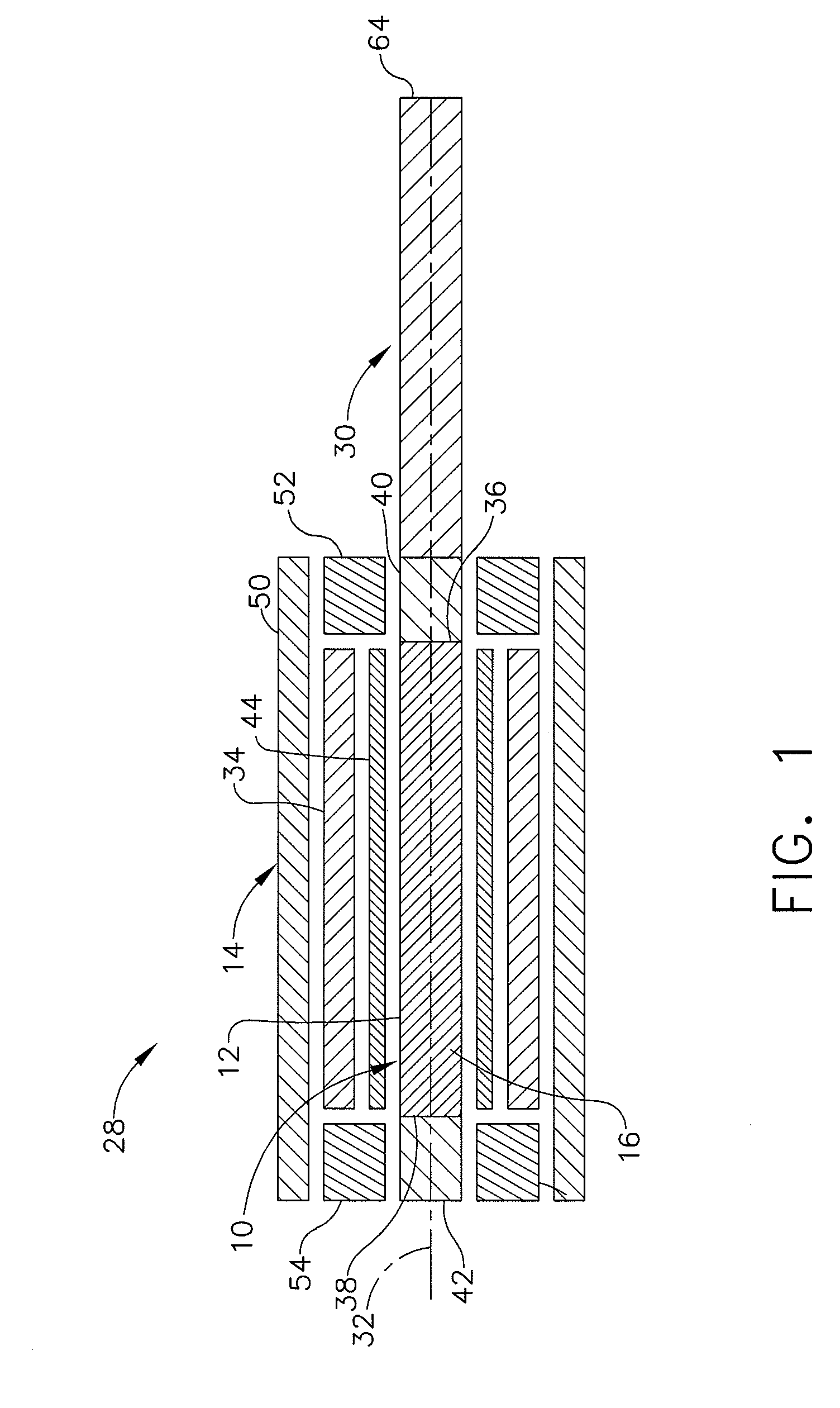

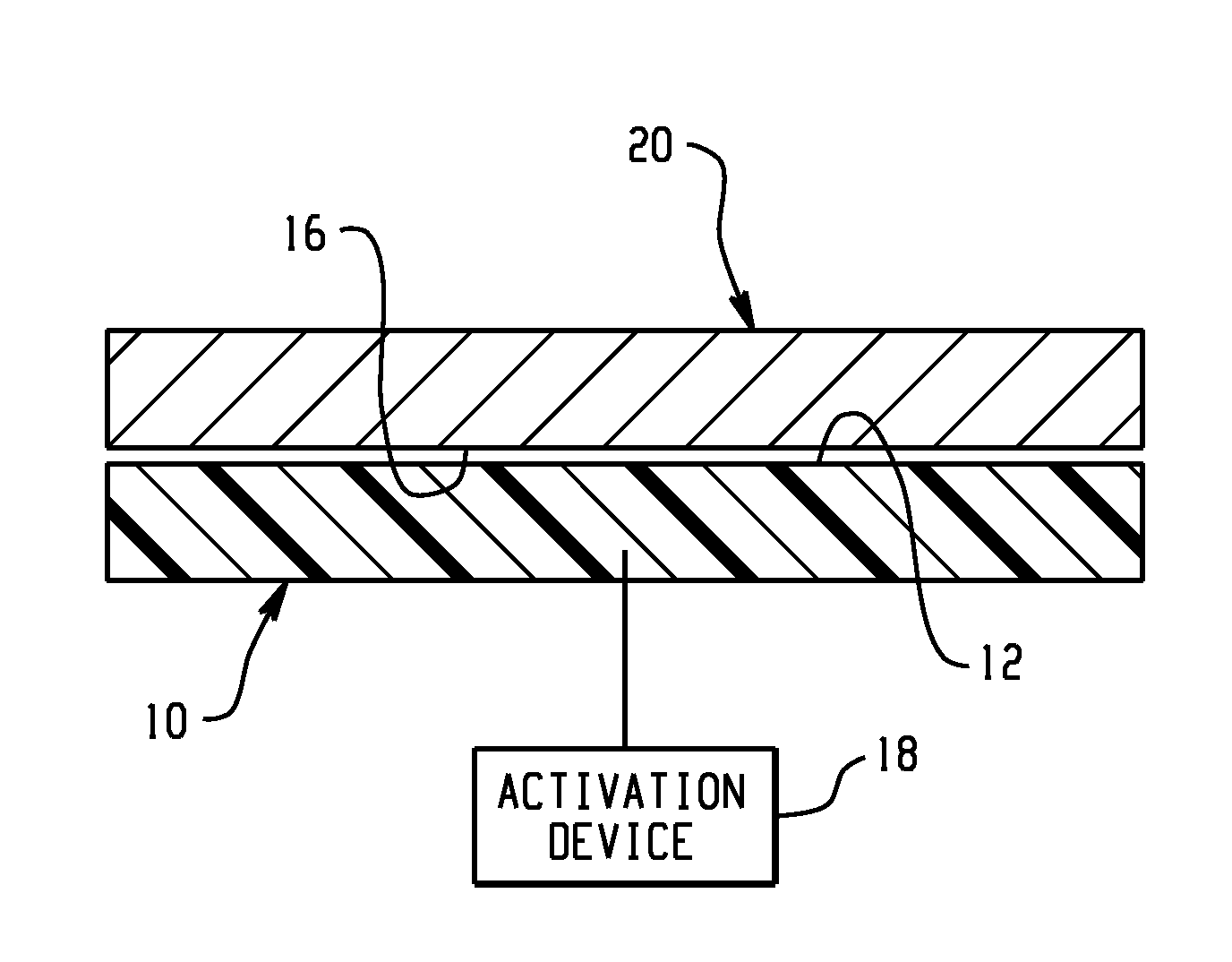

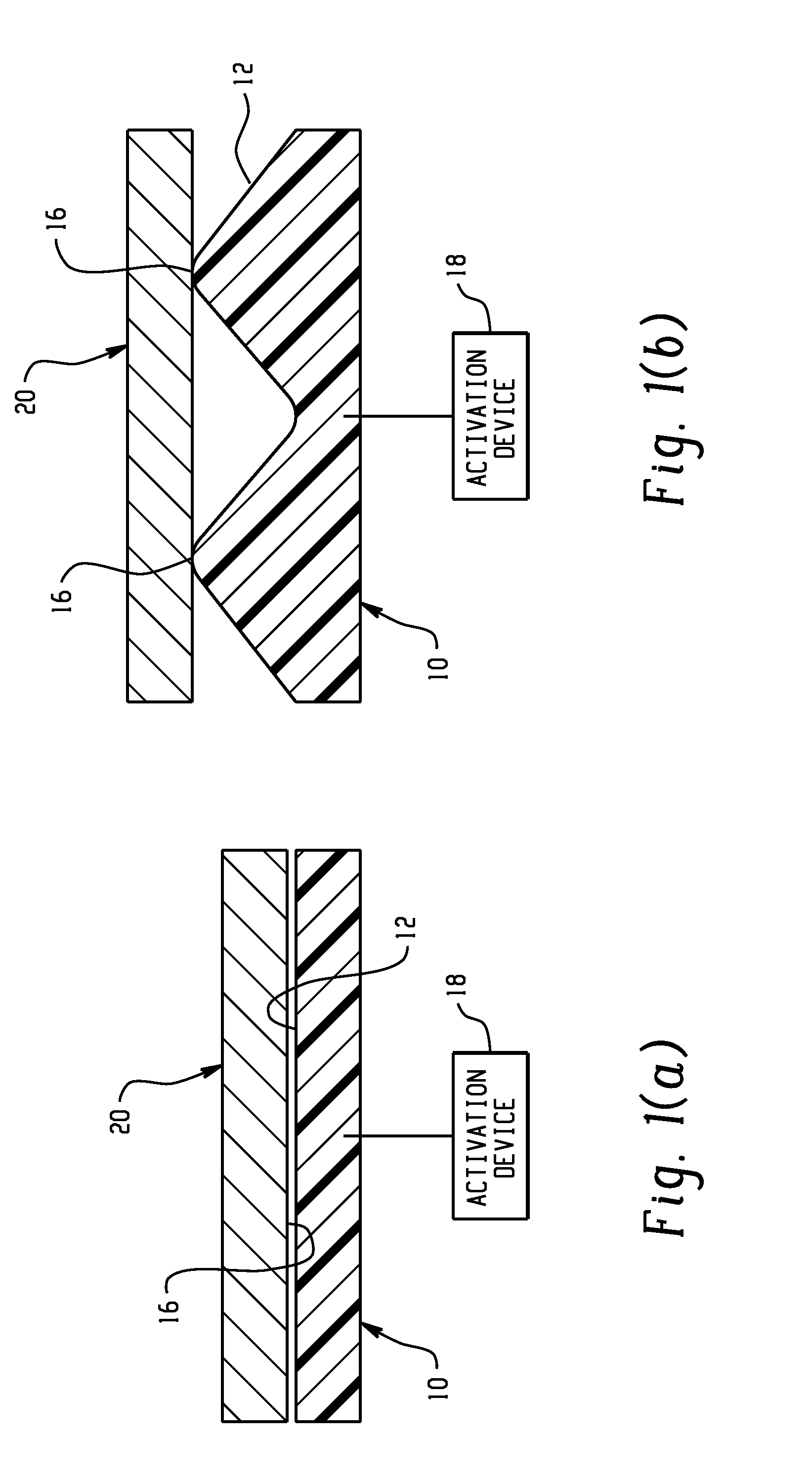

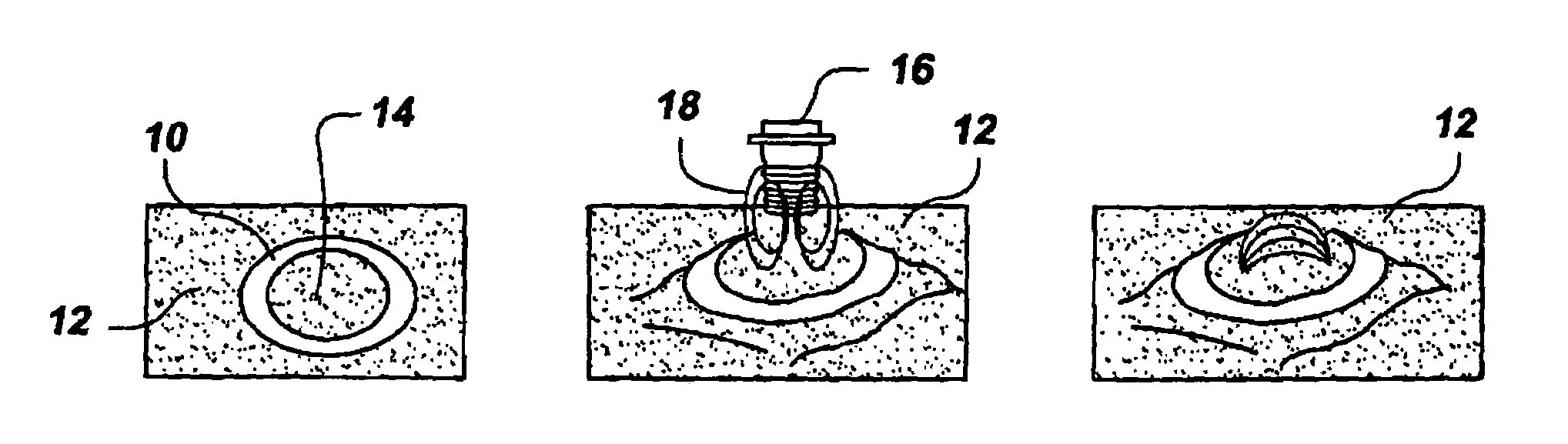

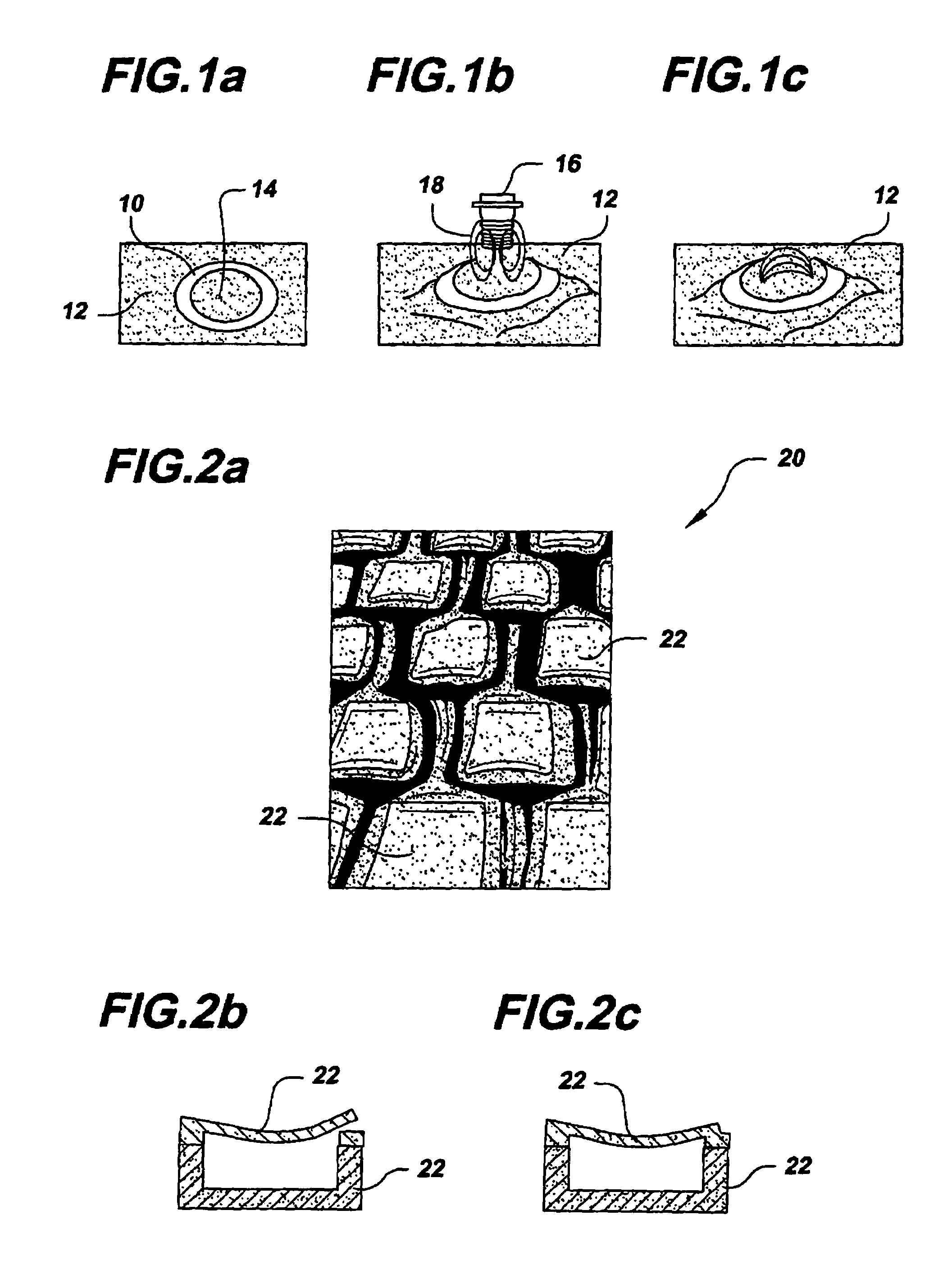

Active material based bodies for varying frictional force levels at the interface between two surfaces

A device for selectively controlling and varying a frictional force level at an interface between two bodies, includes a first contact body having at least one surface, a second contact body having at least one surface in physical communication with the first contact body, and an active material in operative communication with a selected one or both of the first contact body and the second contact body, wherein the active material is configured to undergo a change in a property upon receipt of an activation signal wherein the change in a property is effective to change the frictional force level at the interface between the at least one surface of the first contact body and the at least one surface of the second contact body.

Owner:GM GLOBAL TECH OPERATIONS LLC

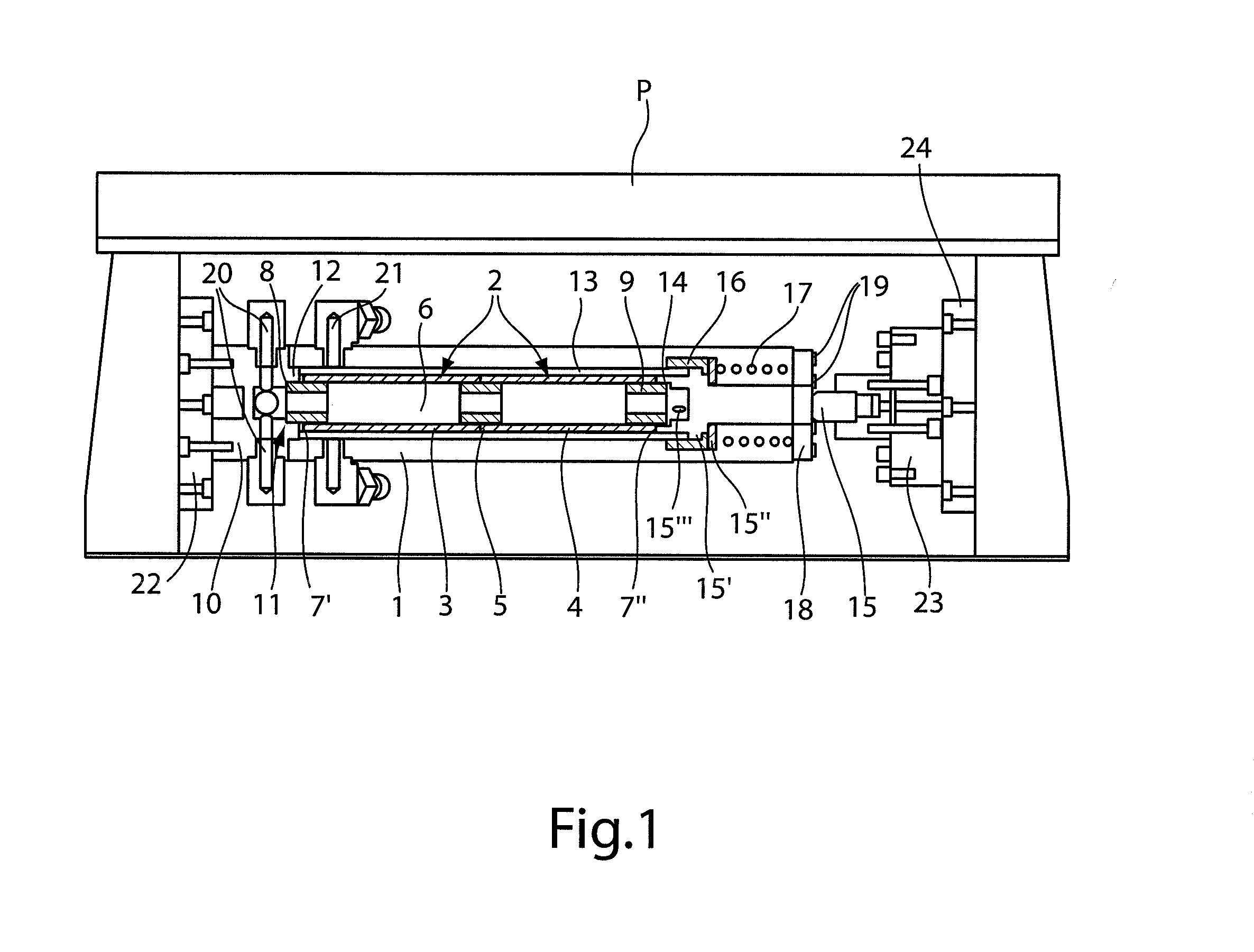

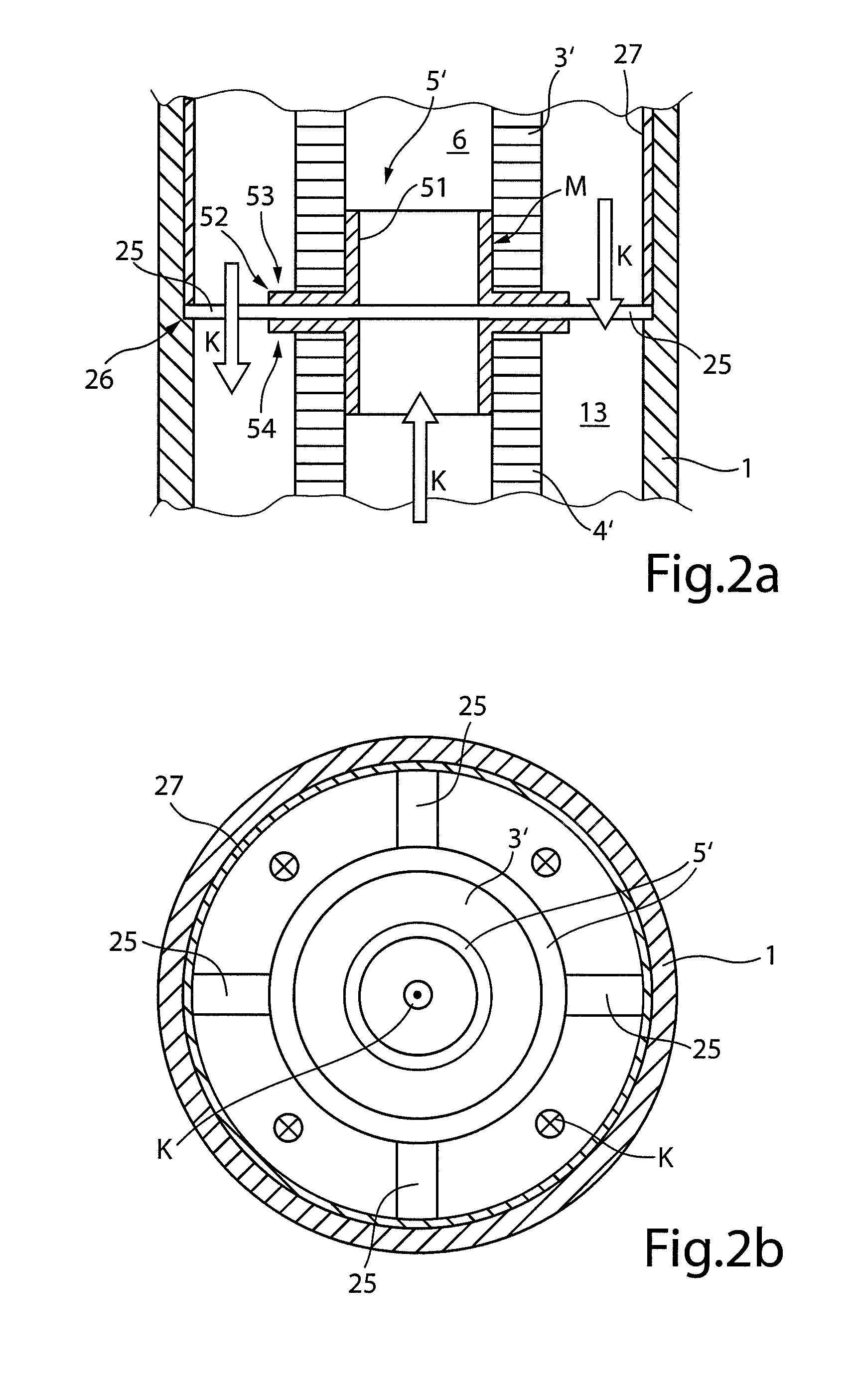

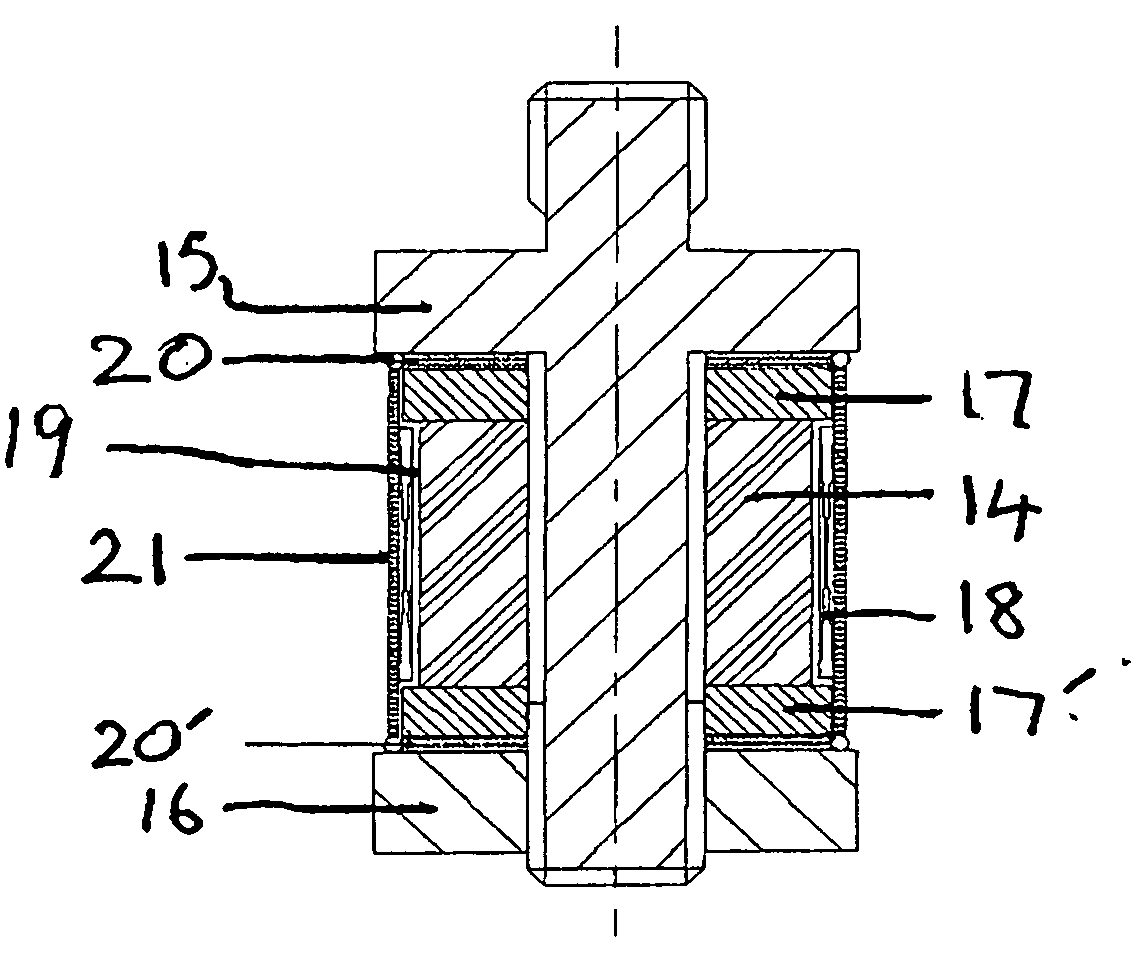

Actuating drive and method for cooling a solid body actuator housed in an actuating drive with an actuating element

InactiveUS20150221854A1Avoid lostLoss of coolant is avoidedPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive device detailsEngineeringActuator

The invention ris an actuating drive for deflecting an actuating element by a solid body actuator (2) which, when an electrical voltage or an alternating magnetic field is applied, experiences a length change. A housing (1) encloses the solid body actuator to define an interspace (13) in a fluid-tight manner. Furthermore, the solid body actuator includes a hollow duct (6) having one end connected to a first hollow conduit (20) passing through the housing and the other end opening into the interspace. The interspace is additionally connected in a fluid-tight manner to a second hollow conduit (21) passing through the housing.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

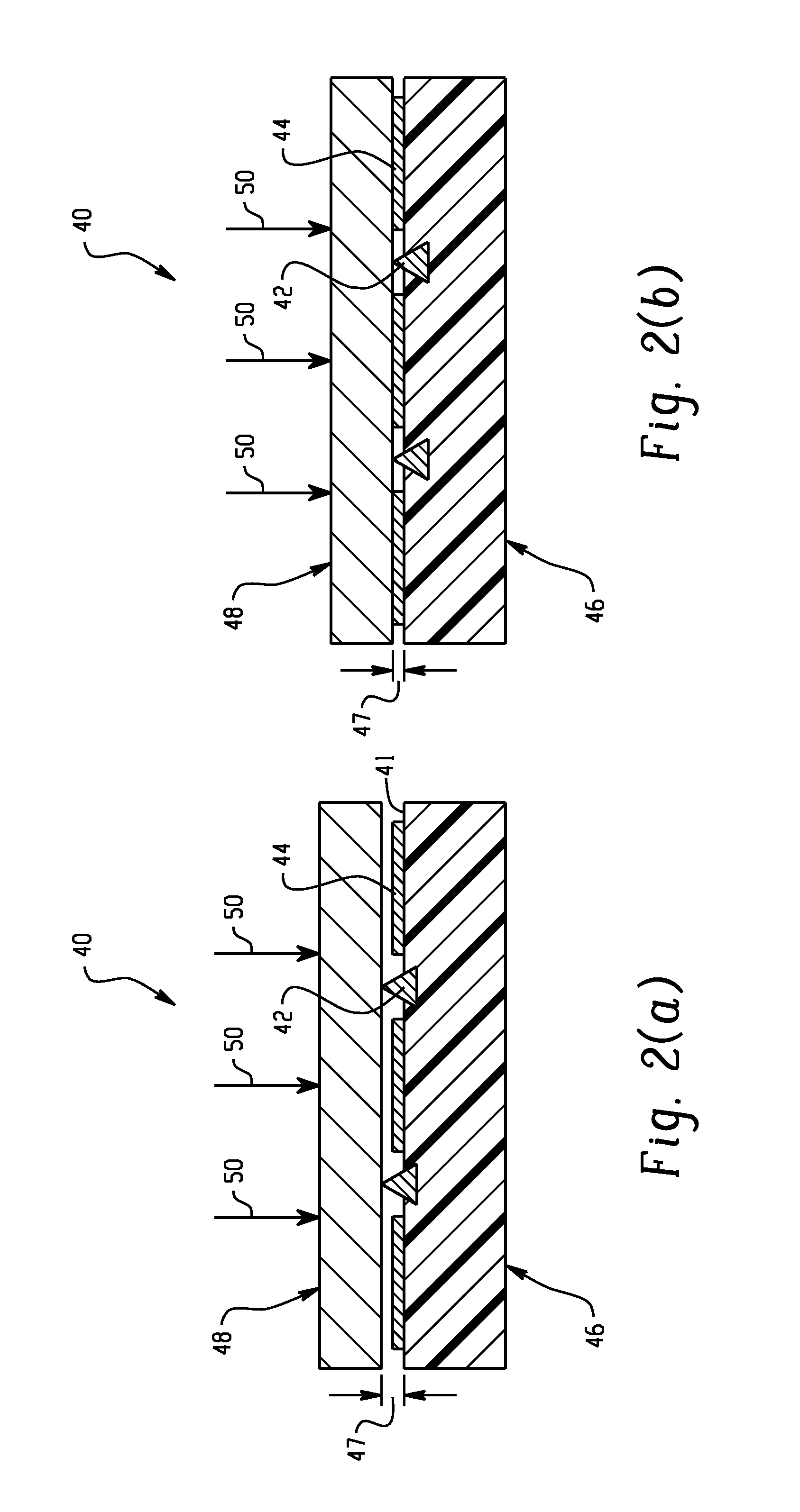

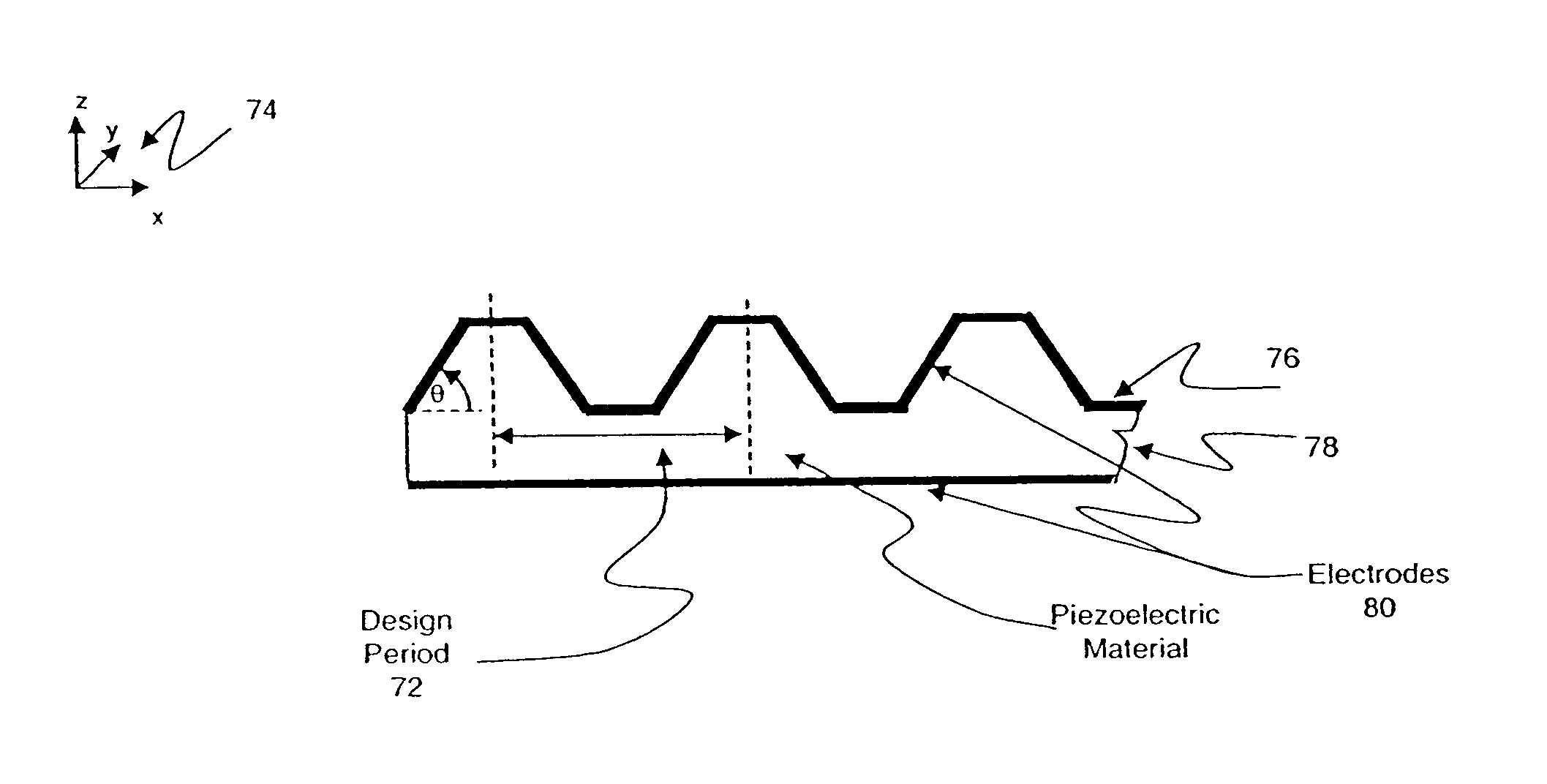

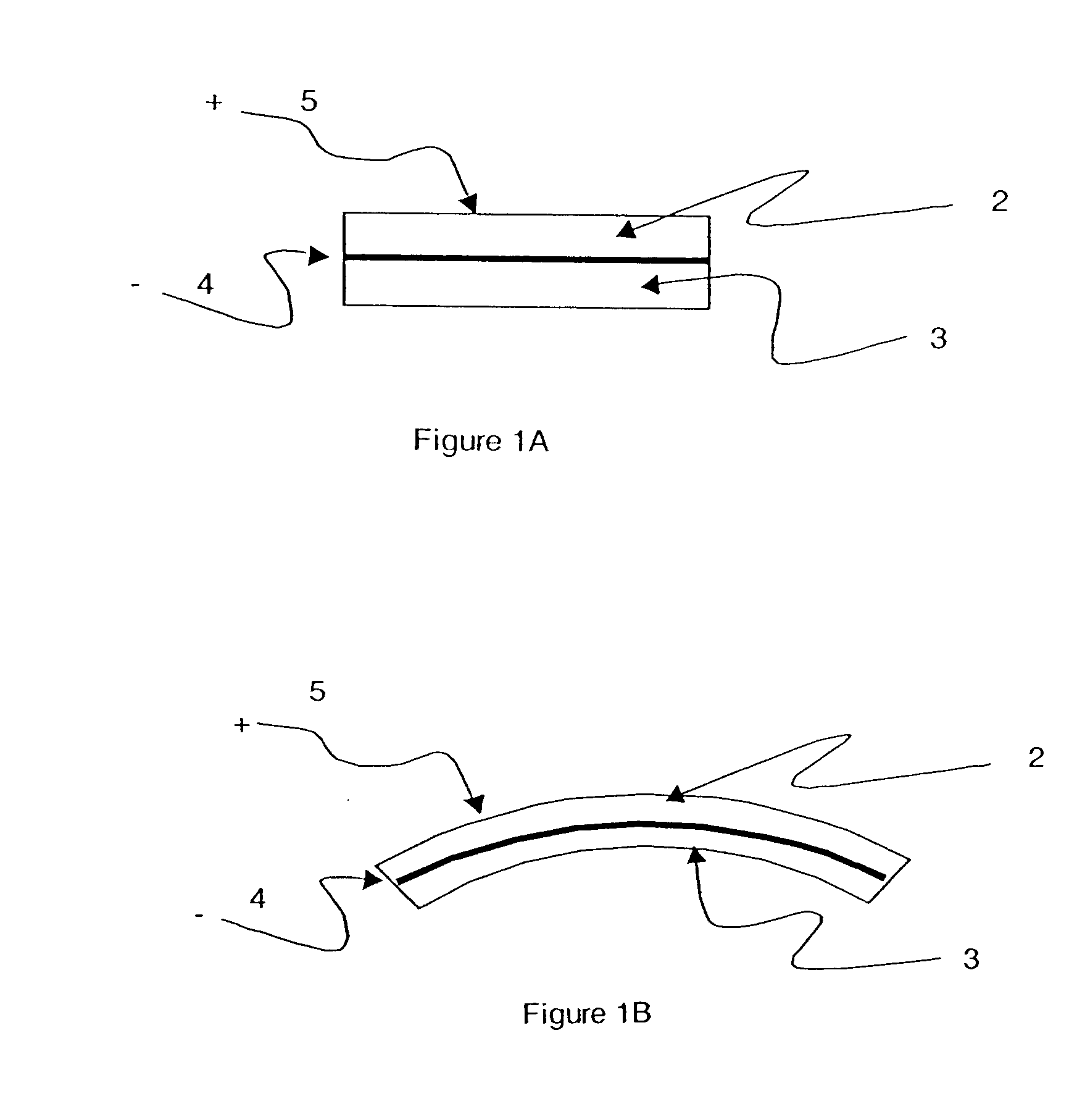

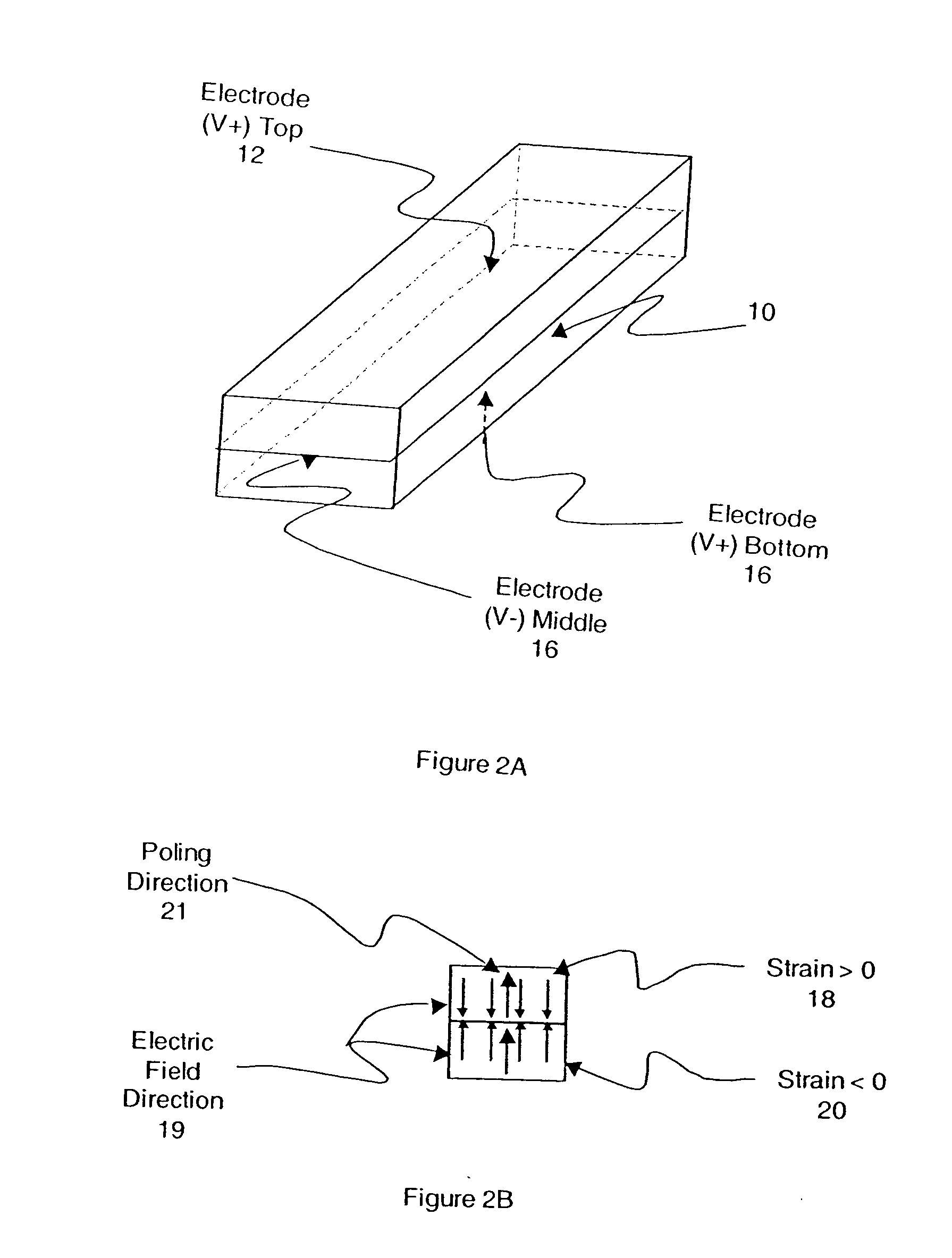

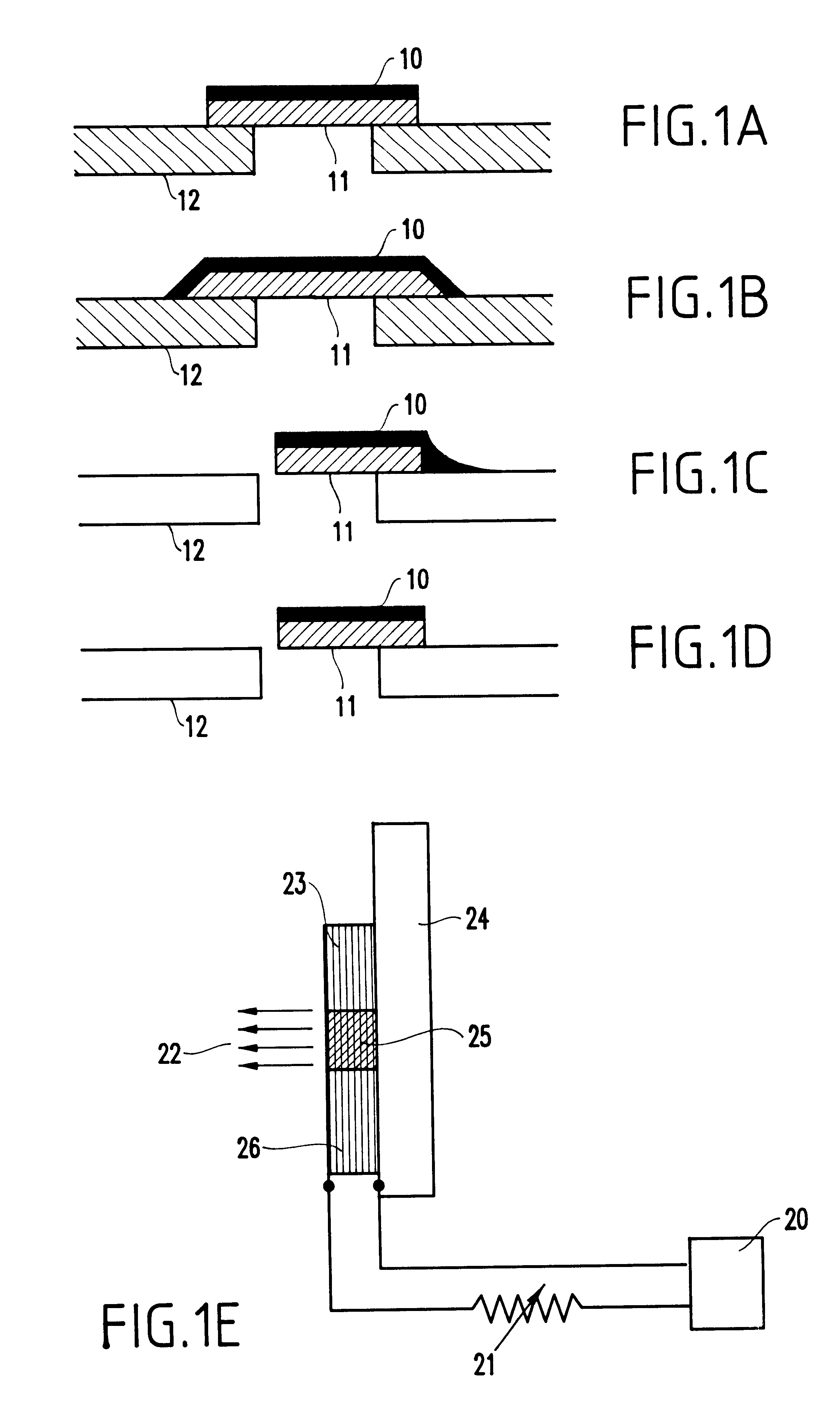

Bending actuators and sensors constructed from shaped active materials and methods for making the same

InactiveUS20040056567A1Increase stiffnessMagnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrode placementUniform field

Bender devices are demonstrated by developing non-uniform fields within a homogeneous, non-planar single slab active member material of non-uniform thickness through geometrical constraints and electrode placement. Single slab actuators are demonstrated for semiconductor designs including MEMS applications. Single slab bender periodic designs are demonstrated to be well suited for MEMS fabrication. Shaped actuators having a topological pattern formed across at least one portion are demonstrated to induced strain at the patterned portion of the actuator, causing the patterned portion to flare into open and close positions upon application of an external field. Voltage transformers, spark generators, power sources, and sensors are developed using the non-planar, homogeneous, single slab active member material of non-uniform thickness. Last, semiconductor process design techniques are demonstrated for periodic and other non-planar single slab actuators.

Owner:MONODRIVE

High-power ultrasound generator and use in chemical reactions

InactiveUS6897628B2Reaction be enhancedHigh yieldPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationChemical reactionEngineering

Ultrasound for use in promoting a chemical reaction is generated by an electromagnet formed from a pair of magnetostrictive prongs wound with coils that are oriented to produce an oscillating magnetostrictive force when an oscillating voltage is applied, in conjunction with a sensing electromagnet of magnetostrictive material that is arranged to receive the vibrations generated by the driving electromagnet and produce internal magnetic field changes due to the reverse magnetostrictive effect. These field changes generate voltages that are representative of the amplitude of the oscillating magnetostrictive force. The generated voltage is compared to a target value in a control circuit that adjusts the applied oscillating voltage accordingly. The oscillations in the prongs of the electromagnet are transmitted to an ultrasonic horn that is immersed in the reaction medium to provide direct contact with the reaction mixture.

Owner:NOKIA CORP +1

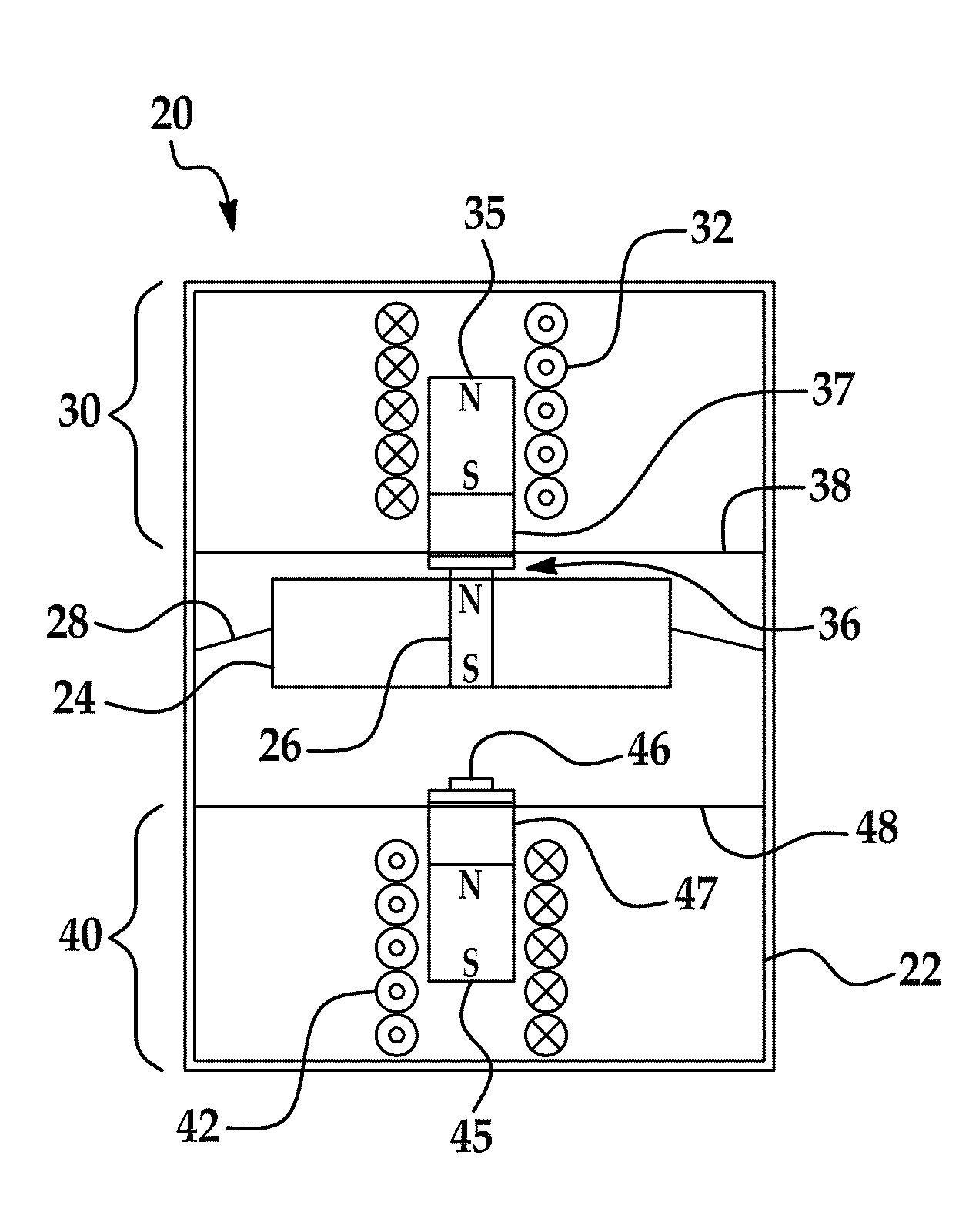

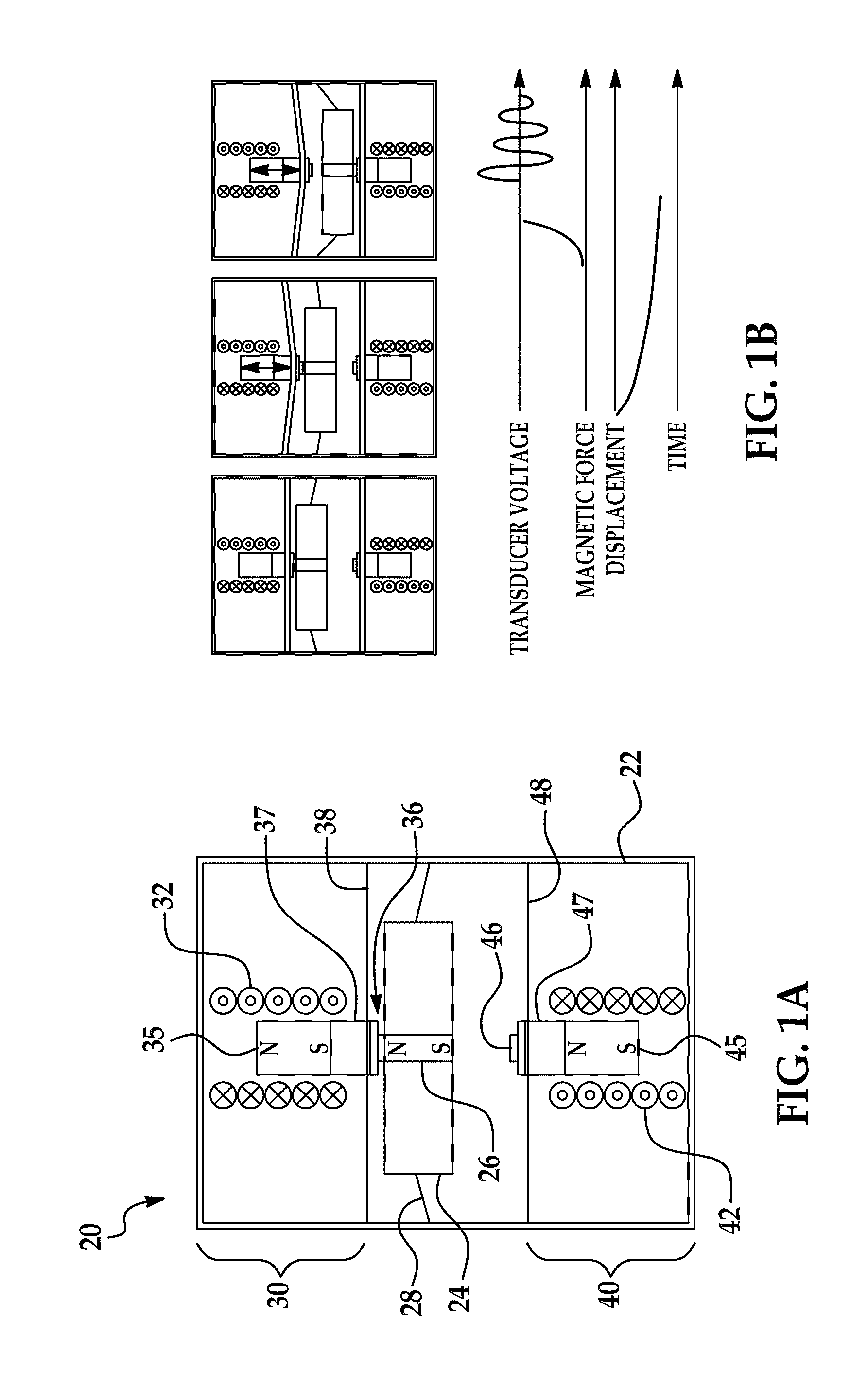

Increased frequency power generation using low-frequency ambient vibrations

ActiveUS20110140577A1Restrict movementPiezoelectric/electrostriction/magnetostriction machinesMechanical energy handlingInertial massReciprocating motion

An increased frequency power generator that includes a pair of transducers located on opposite sides of a suspended inertial mass. Magnetic attraction is used to couple the mass to each of the two transducers in alternating fashion in response to vibration and other movement externally imparted on the generator. Each transducer includes a suspended magnetic element that couples and decouples to the inertial mass as it reciprocates in the housing due to the applied external moving force. As the inertial mass decouples from one transducer on its way to magnetically connecting to the other transducer, the decoupled suspended magnetic element oscillates at a frequency greater than the imparting force, thereby generating electrical power.

Owner:RGT UNIV OF MICHIGAN

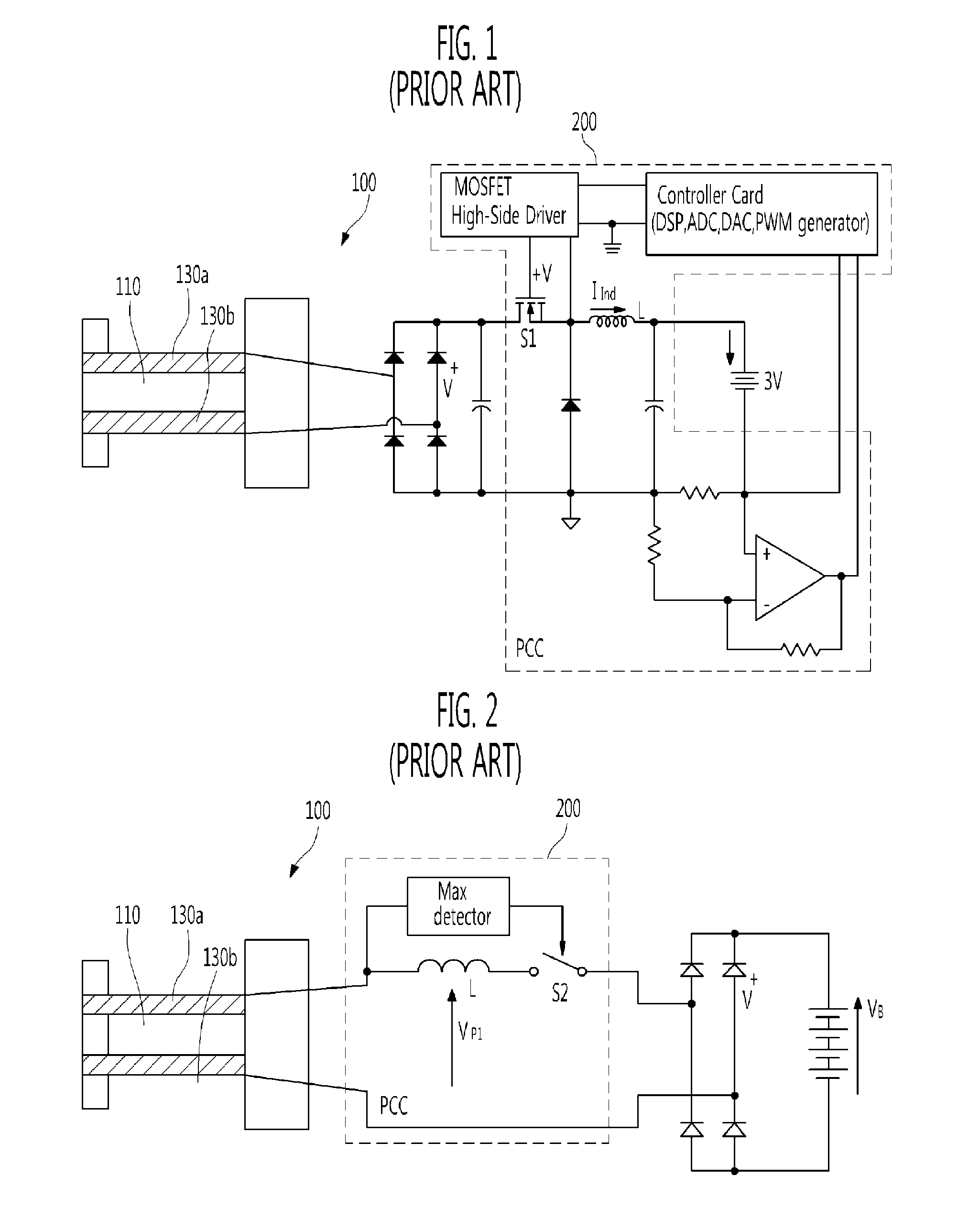

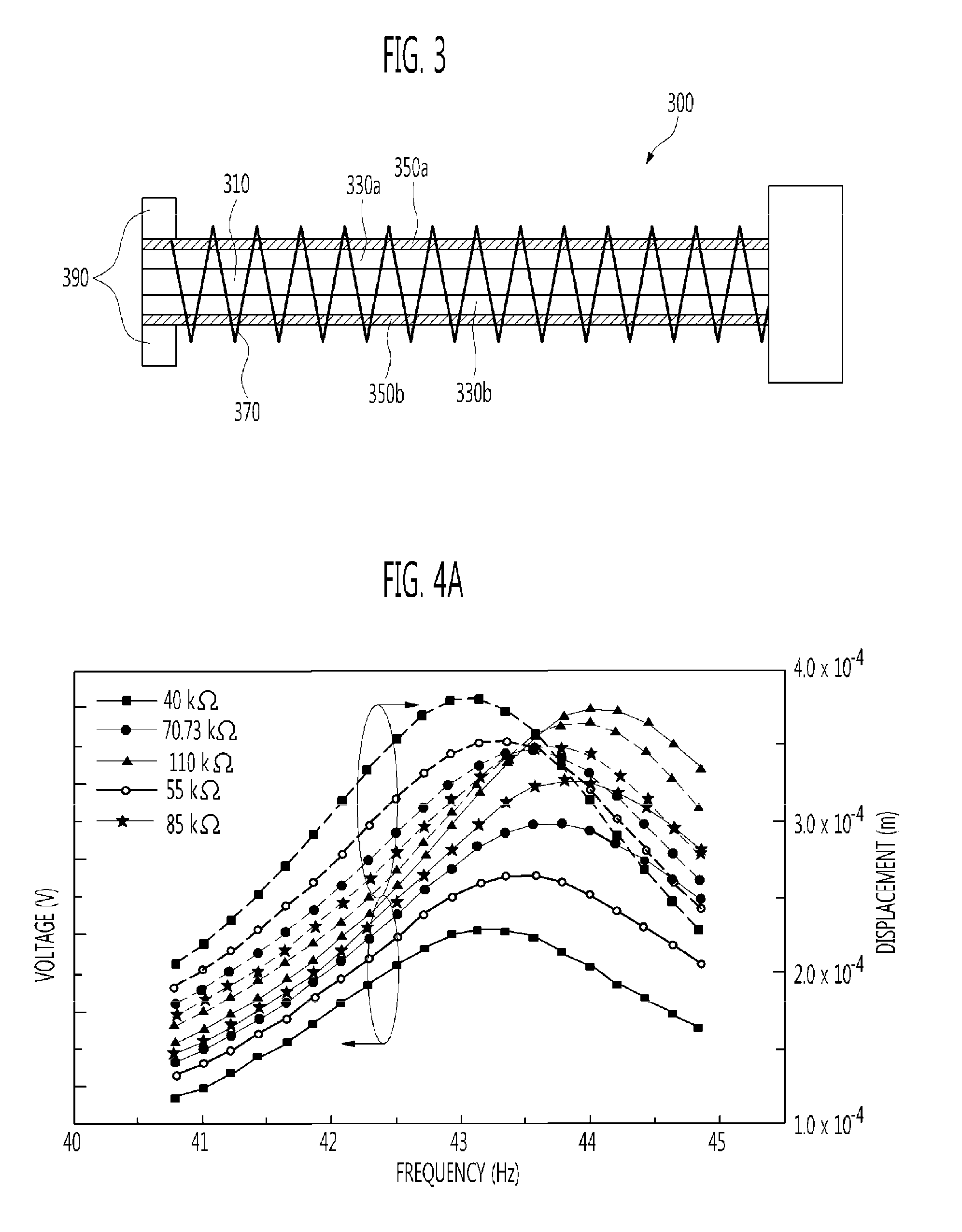

Apparatus employing piezoelectric energy harvester capable of generating voltage to drive power conditioning circuit and method of manufacturing the same

InactiveUS8330334B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesElectricityEnergy harvester

Provided are a piezoelectric energy harvester and a method of manufacturing the same. The piezoelectric energy harvester is configured to obtain primary voltage from a piezoelectric layer vibrated to generate voltage and secondary voltage from a magnetostrictive layer vibrated to induce a change in magnetic field and a coil surrounding the magnetostrictive layer. Thus, it is possible to obtain sufficient voltage to drive a power conditioning circuit (PCC).

Owner:ELECTRONICS & TELECOMM RES INST

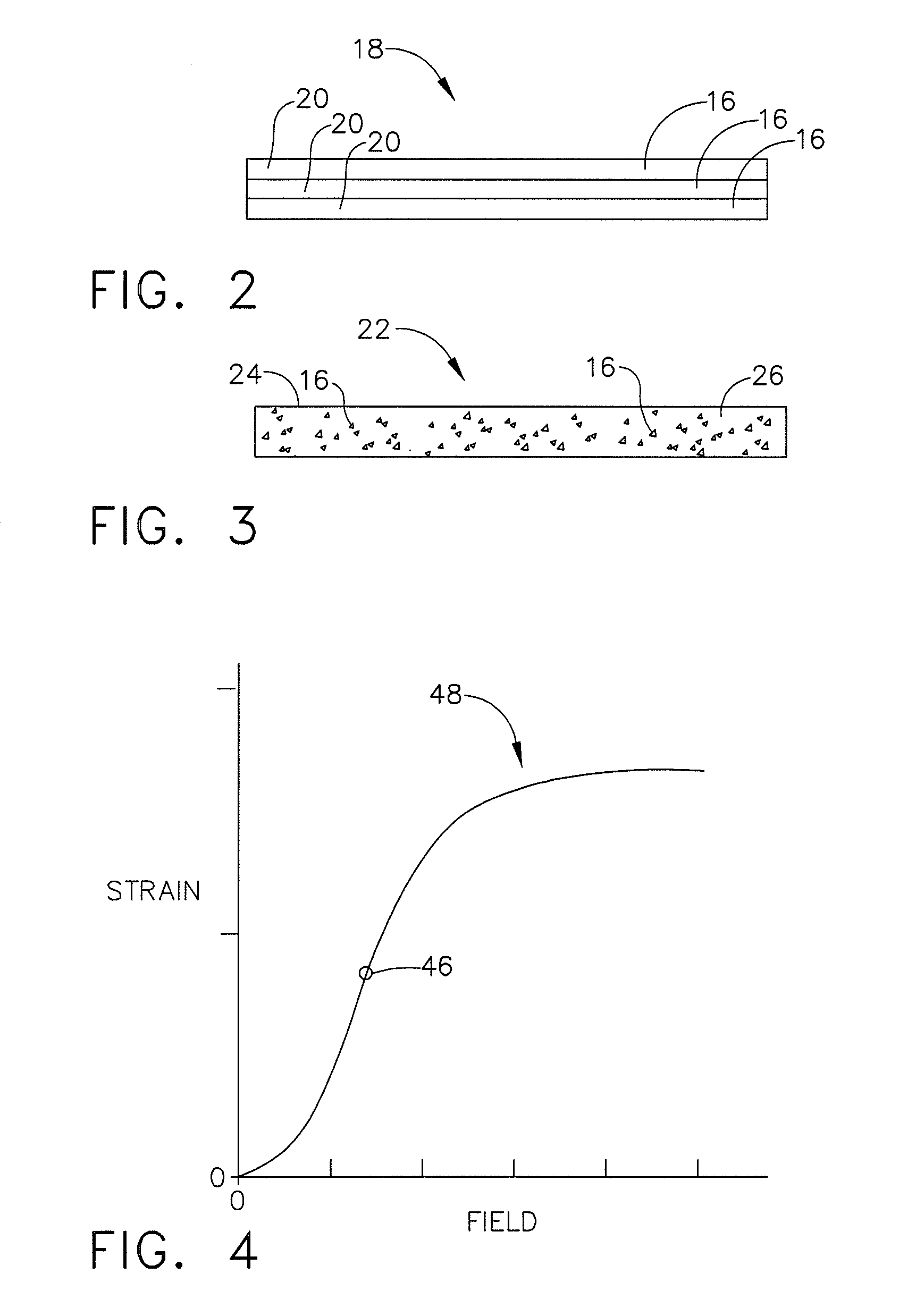

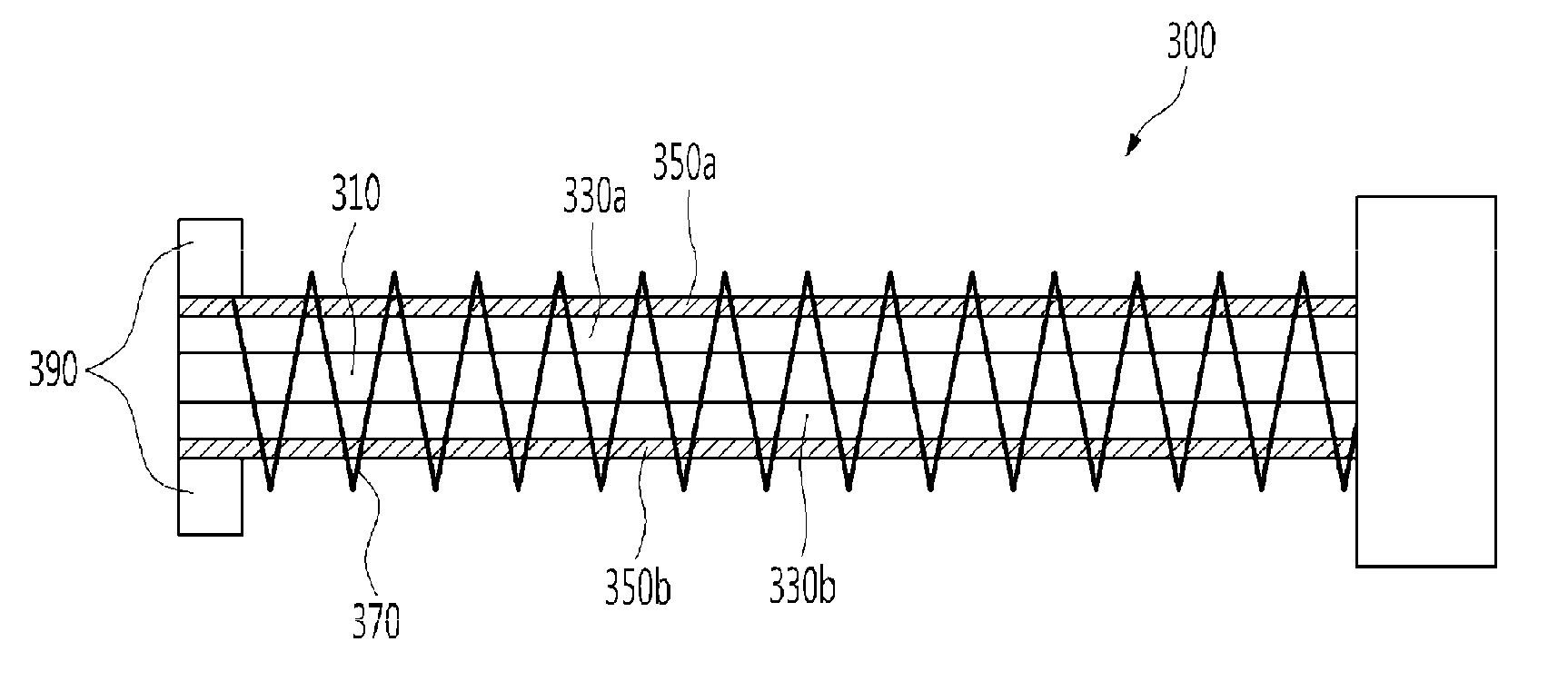

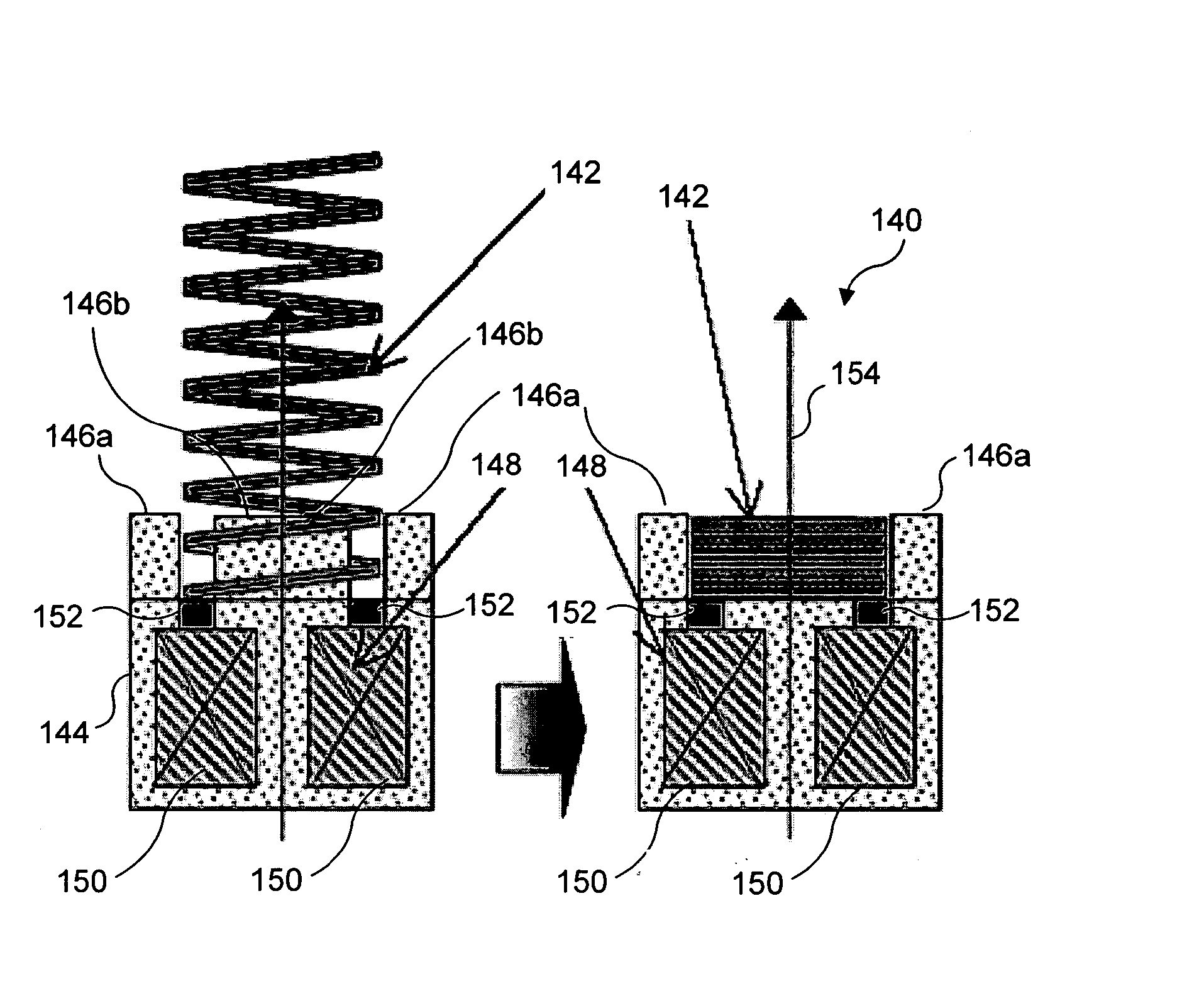

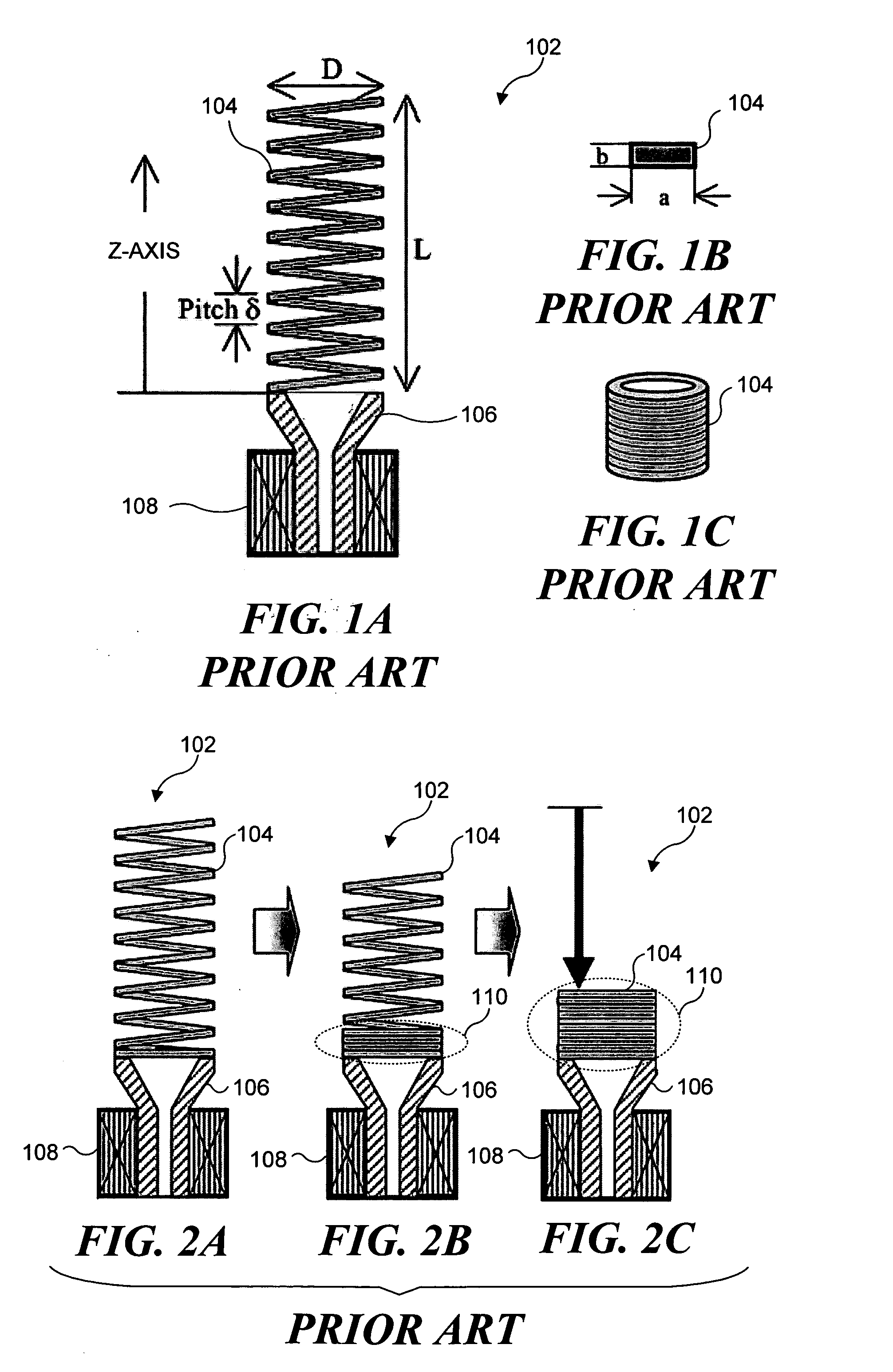

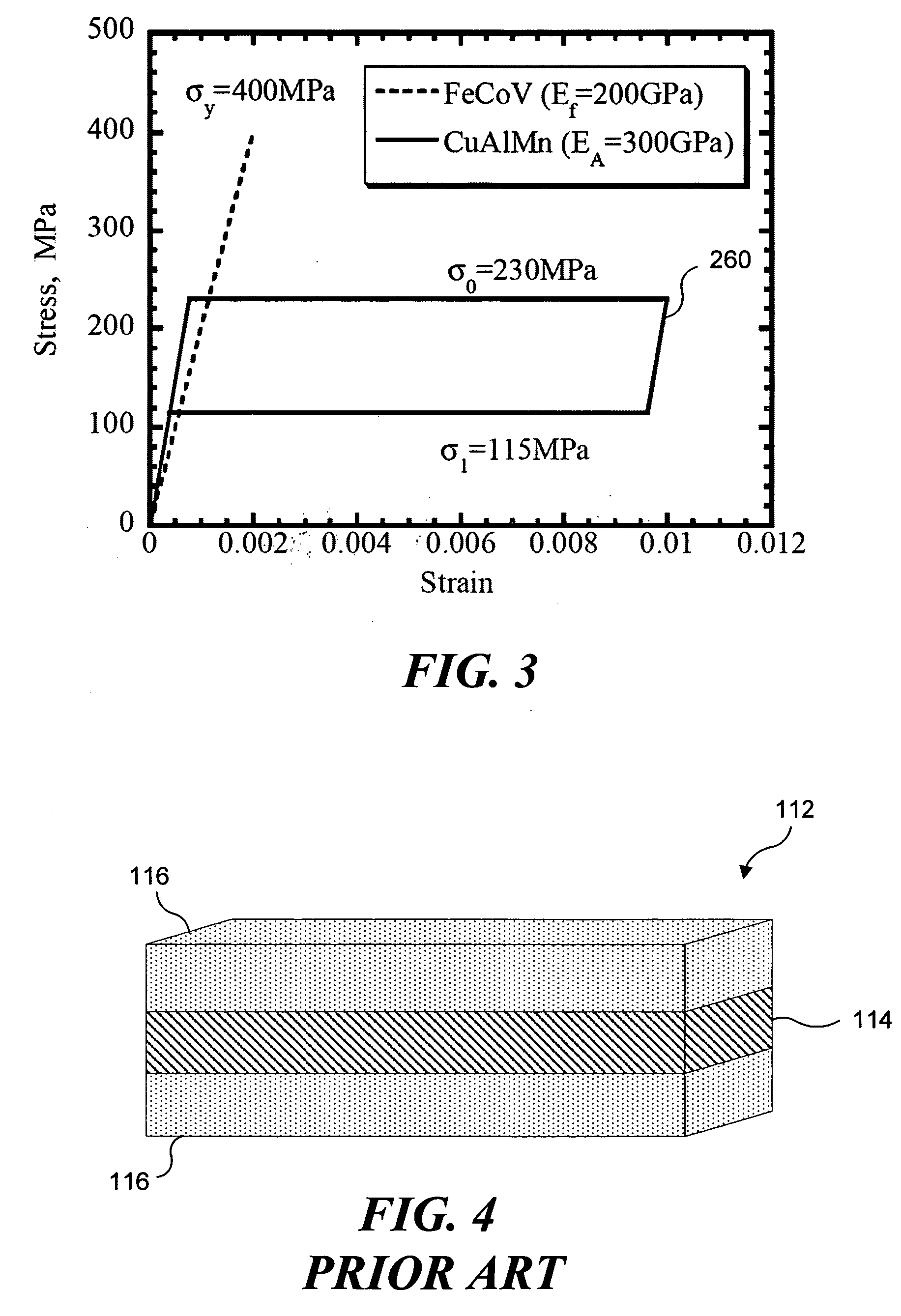

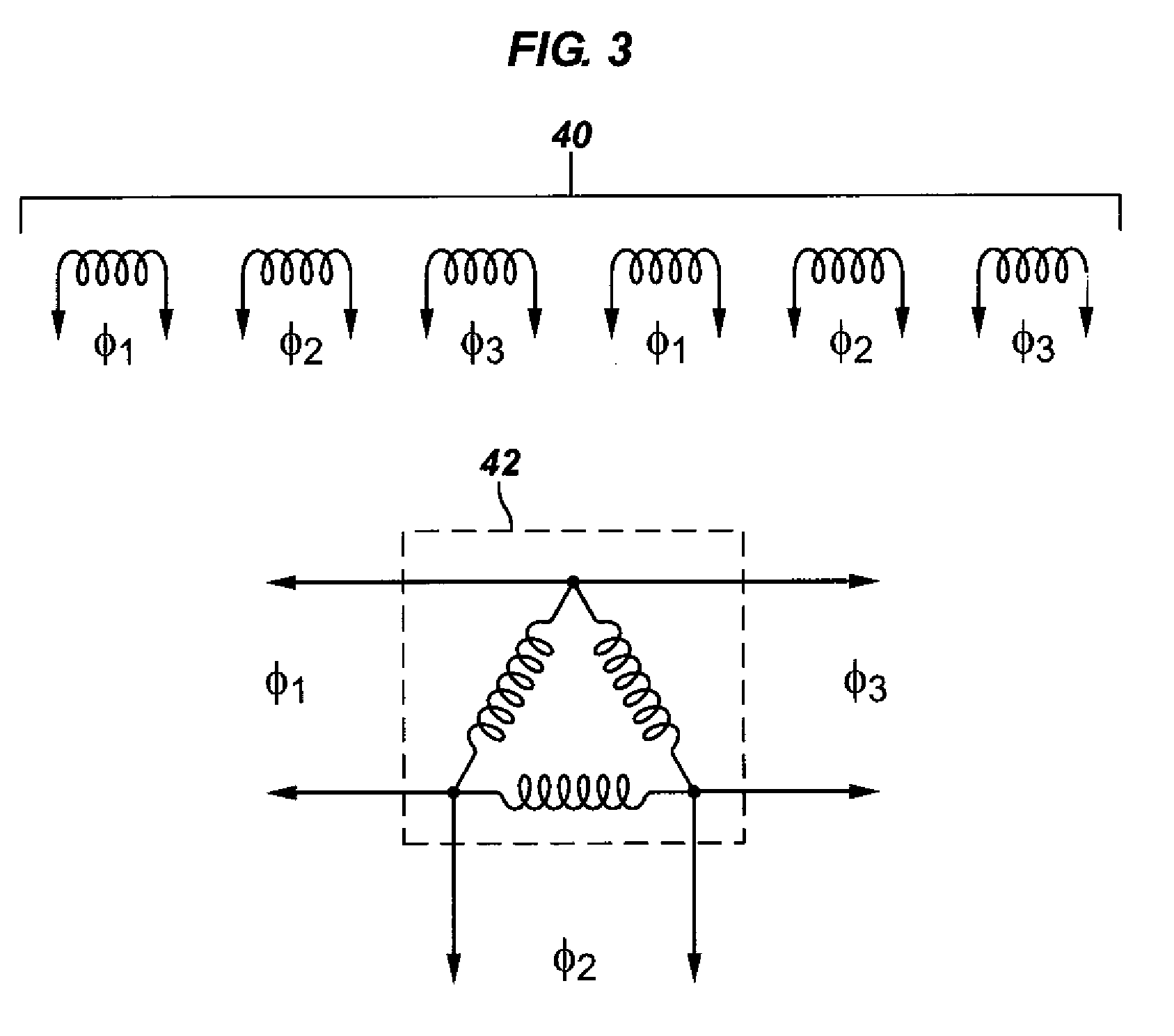

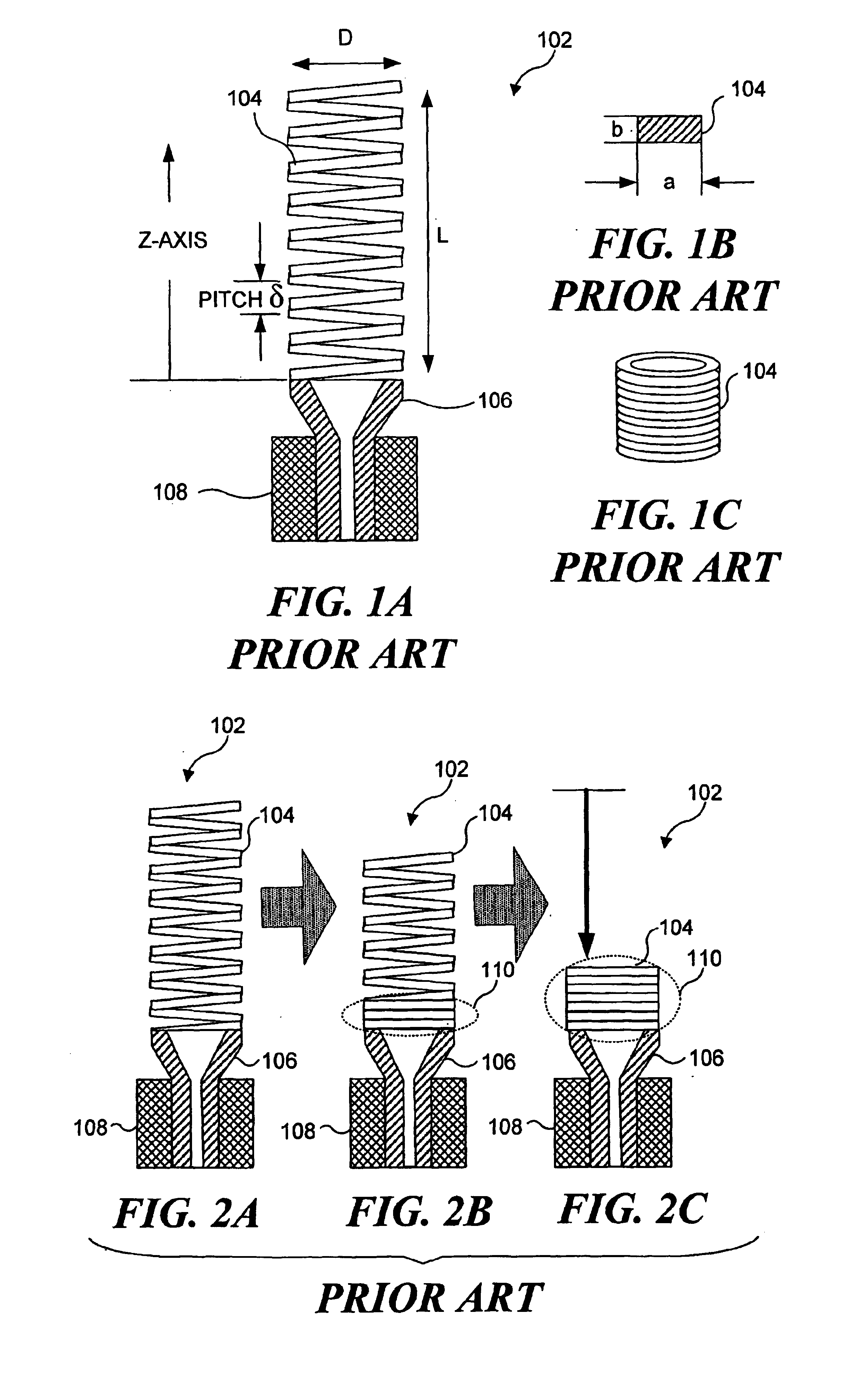

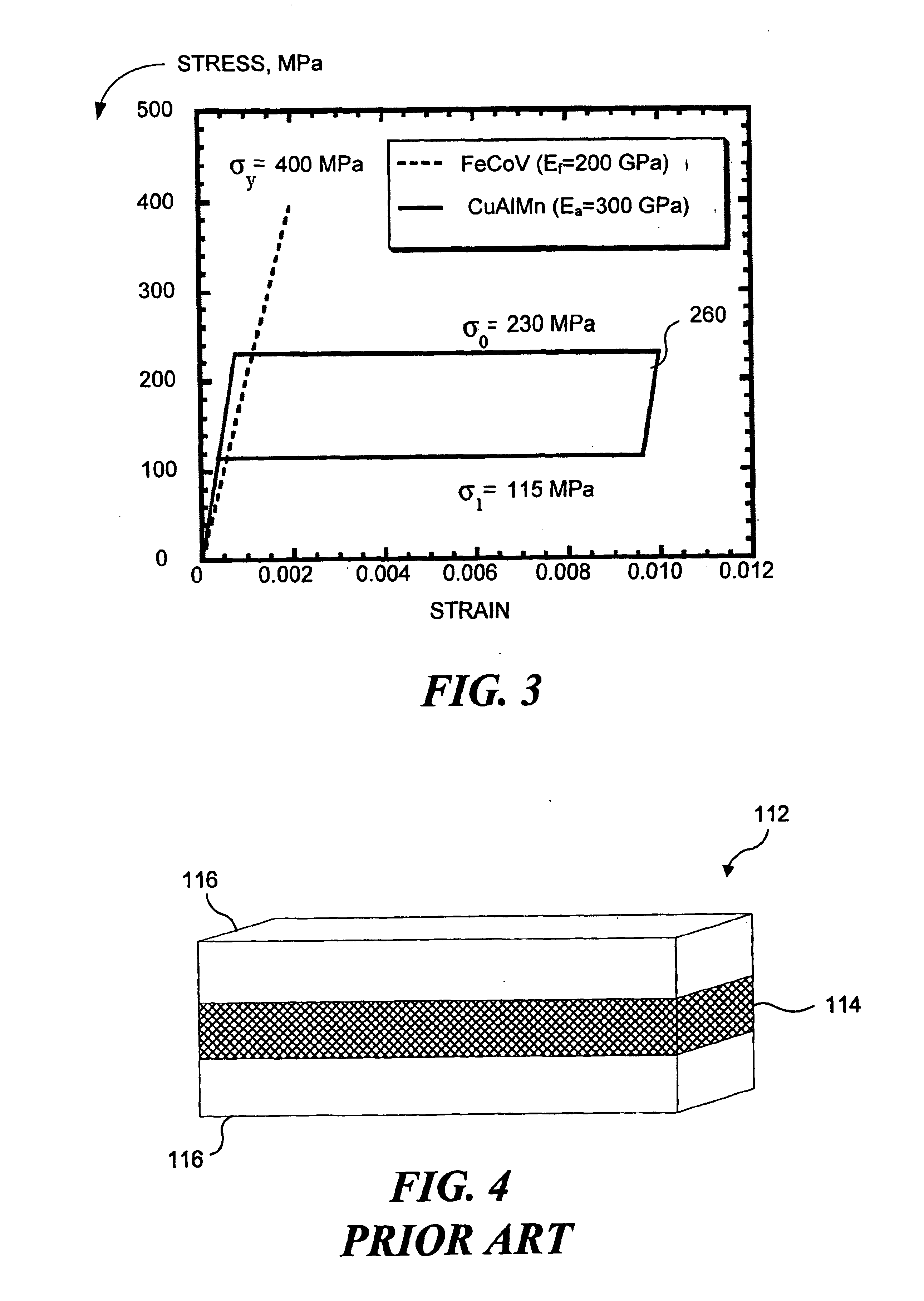

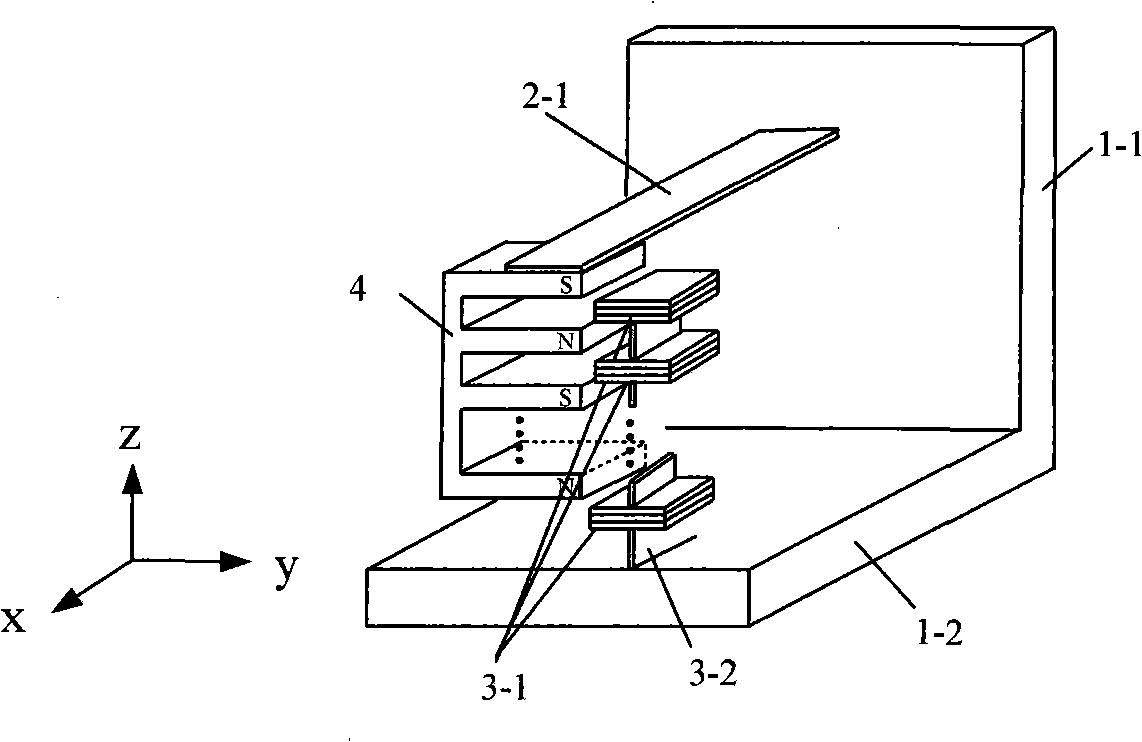

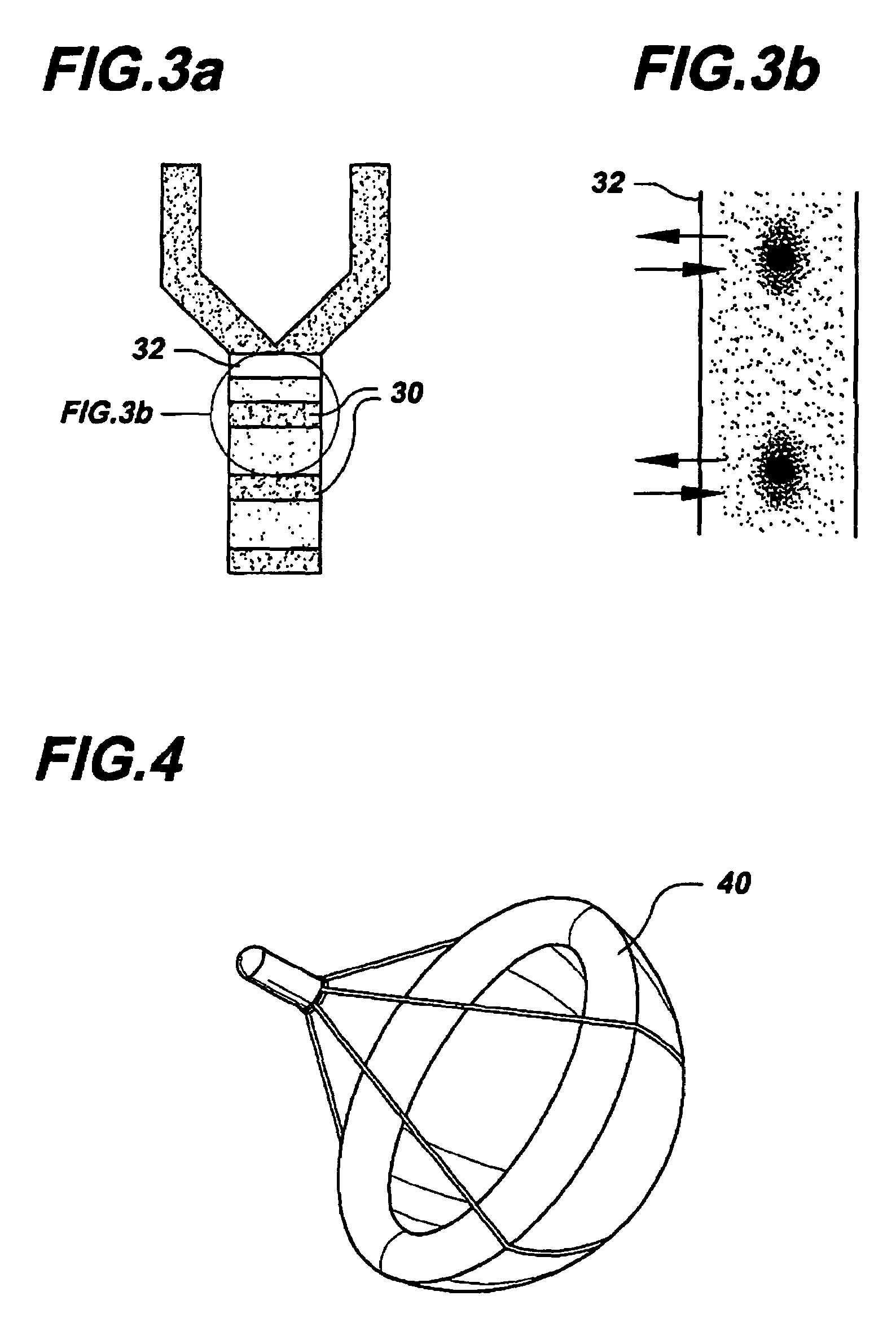

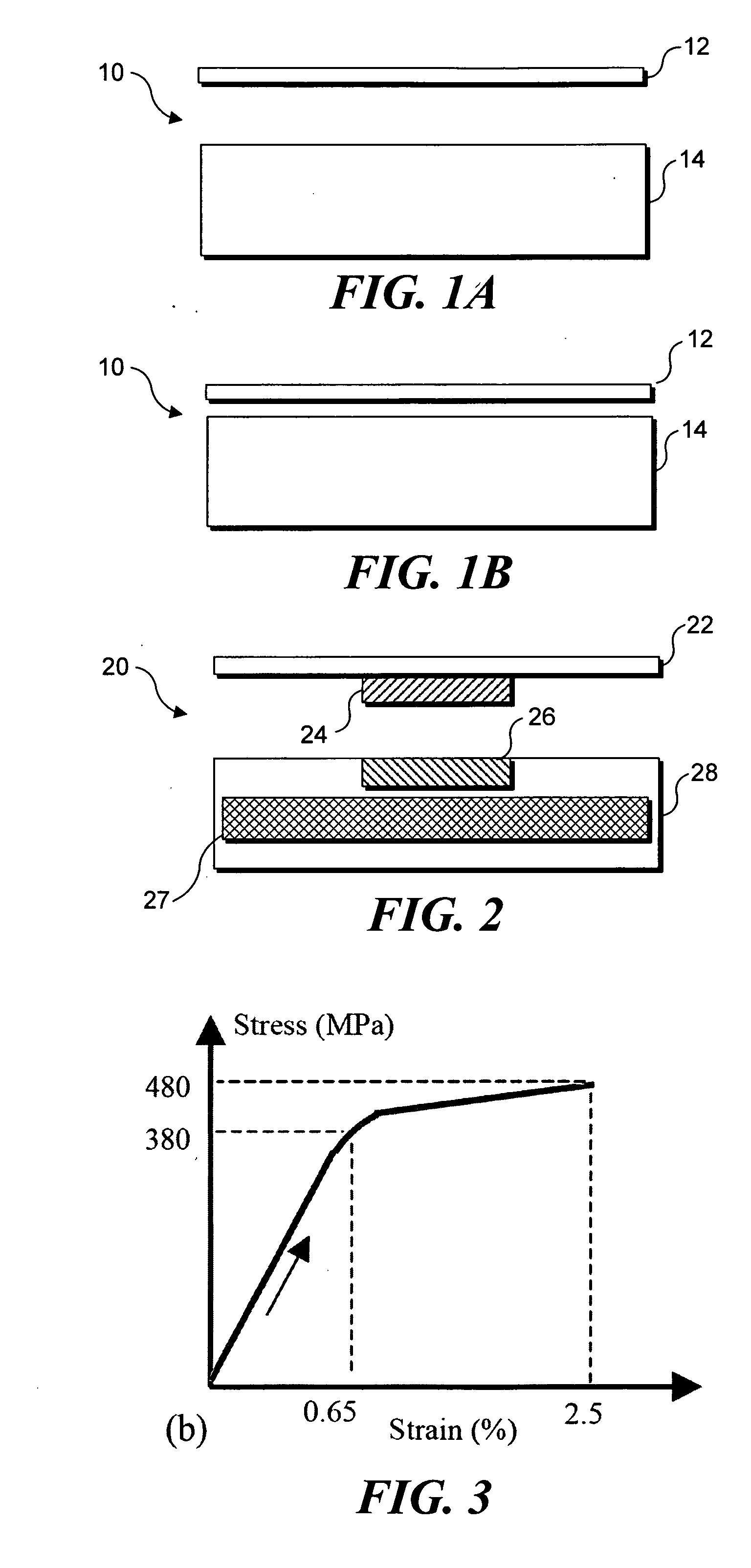

Design of ferromagnetic shape memory alloy composites and actuators incorporating such materials

InactiveUS20050001367A1Operating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesShape-memory alloyAlloy composite

The present invention employs an optimized cross-sectional shape for a ferromagnetic shape memory alloy (FSMA) composite that is used in a spring-type actuator, an improved hybrid magnetic trigger for use in FSMA based actuators, an a FSMA composite based spring type actuator, an a FSMA based spring type actuator including a stack of triggering units and FSMA springs, a FSMA composite based torque actuator. The invention also includes a model that can be employed to evaluate different materials being considered as components a FSMA for a FSMA composite used in either a FSMA based torque actuator or a FSMA spring actuator.

Owner:UNIV OF WASHINGTON

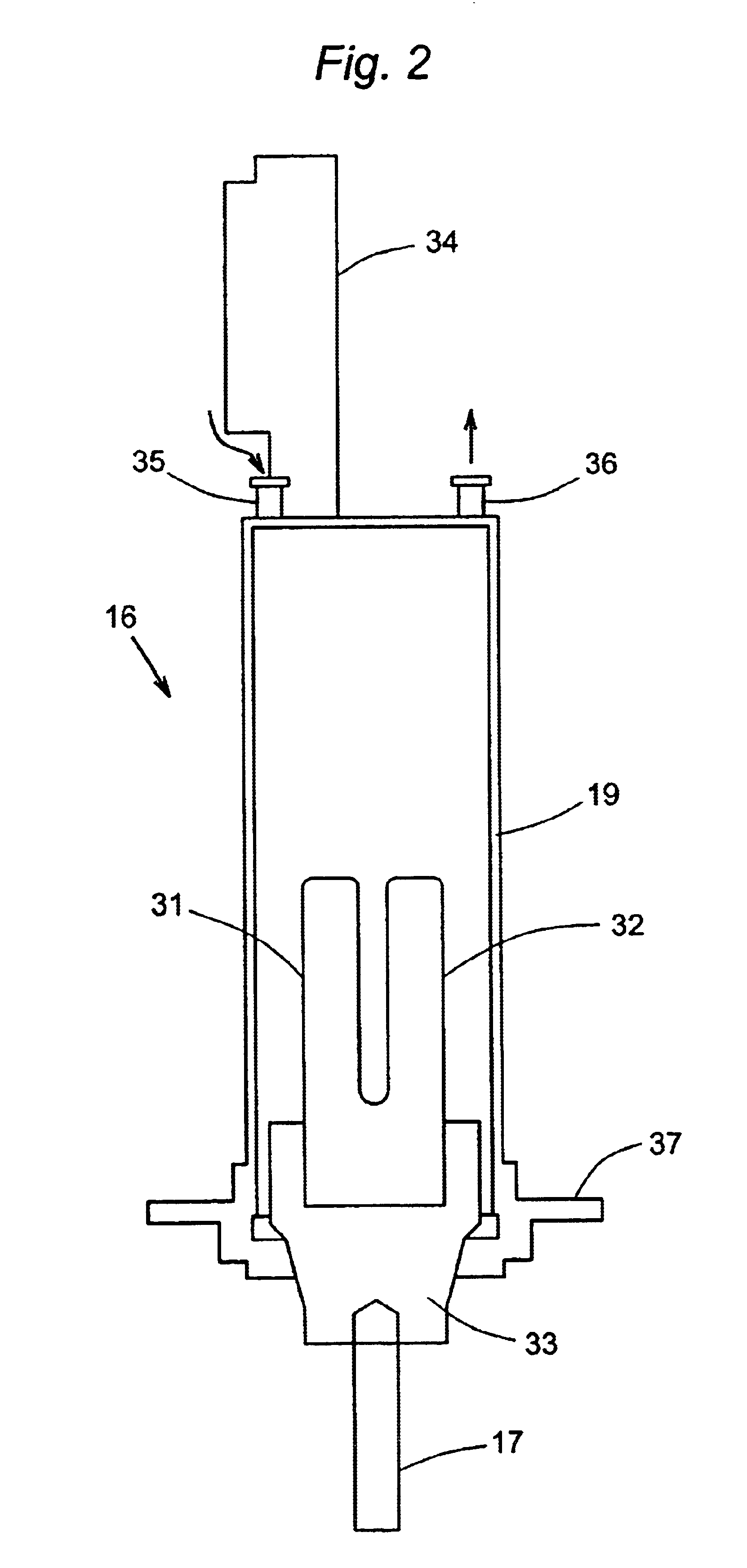

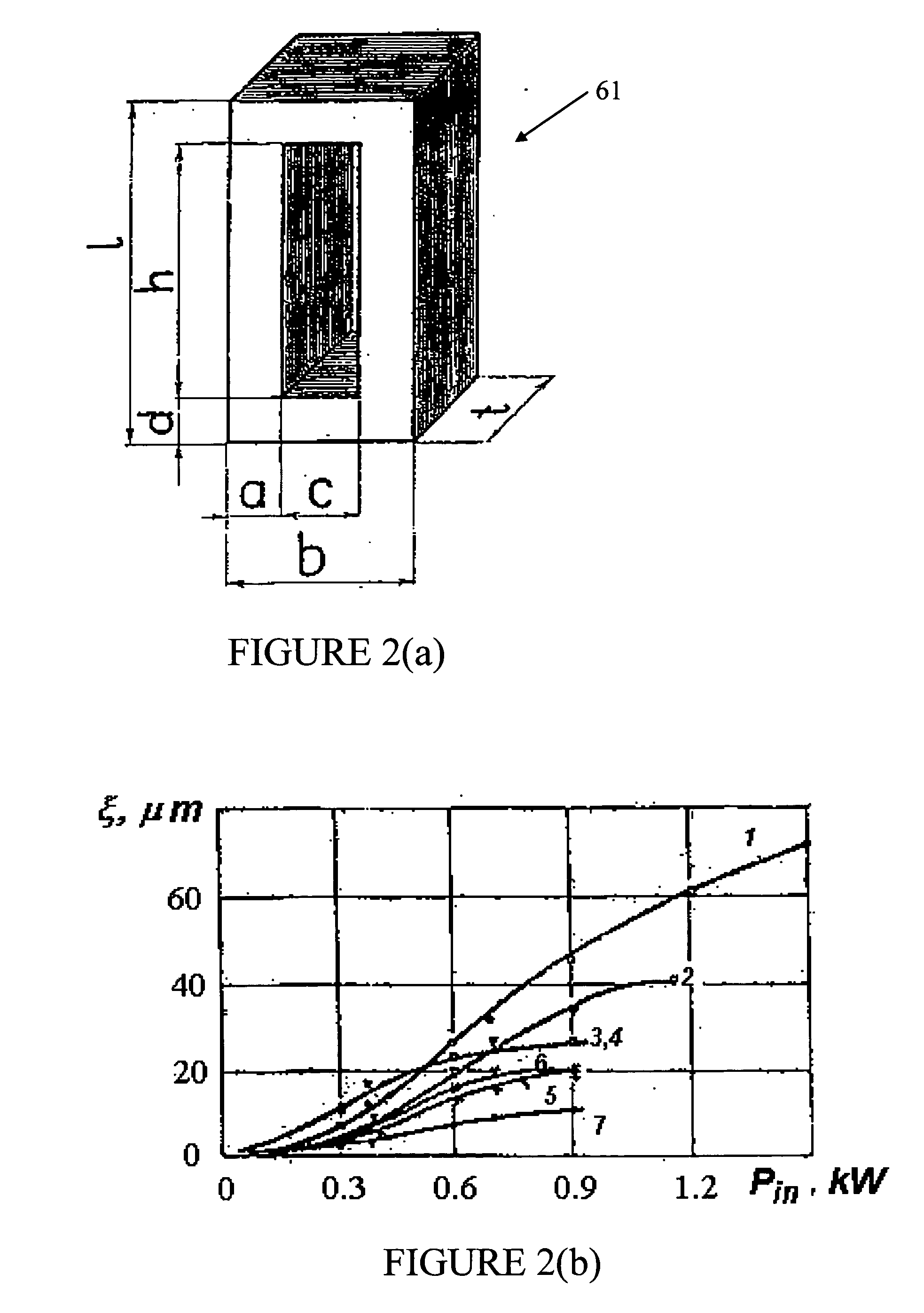

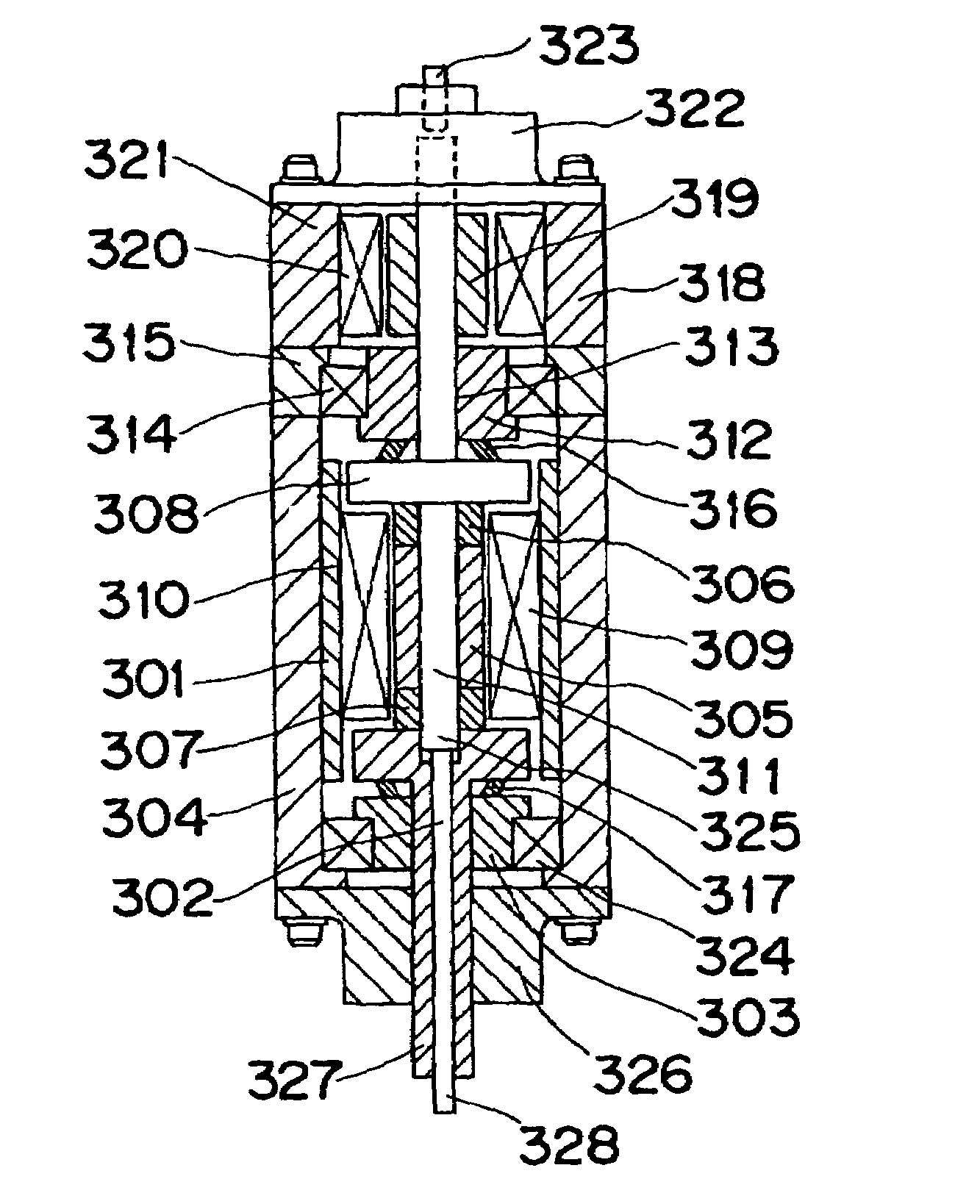

Oscillating system and tool for ultrasonic impact treatment

ActiveUS20070040476A1Increase heightRelieve stressPiezoelectric/electrostriction/magnetostriction machinesPortable percussive toolsFull scaleUltrasonic impact treatment

Devices including a magnetostrictive transducer, an oscillating system and a tool for ultrasonic impact treatment of constructions, construction units and components of machines and mechanisms are disclosed. The invention provides high reliability of magnetostrictive transducers, oscillating systems and their components, tools and their parts affected by simultaneous action of static, dynamic and impact load on a work surface, high stability of characteristics and interchangeability thereof under conditions of small-scale, full-scale and mass production. The invention also includes design solutions with the use of new methods of the realization and manufacturing technique of the above.

Owner:APPLIED ULTRASONICS INT PTY LTD

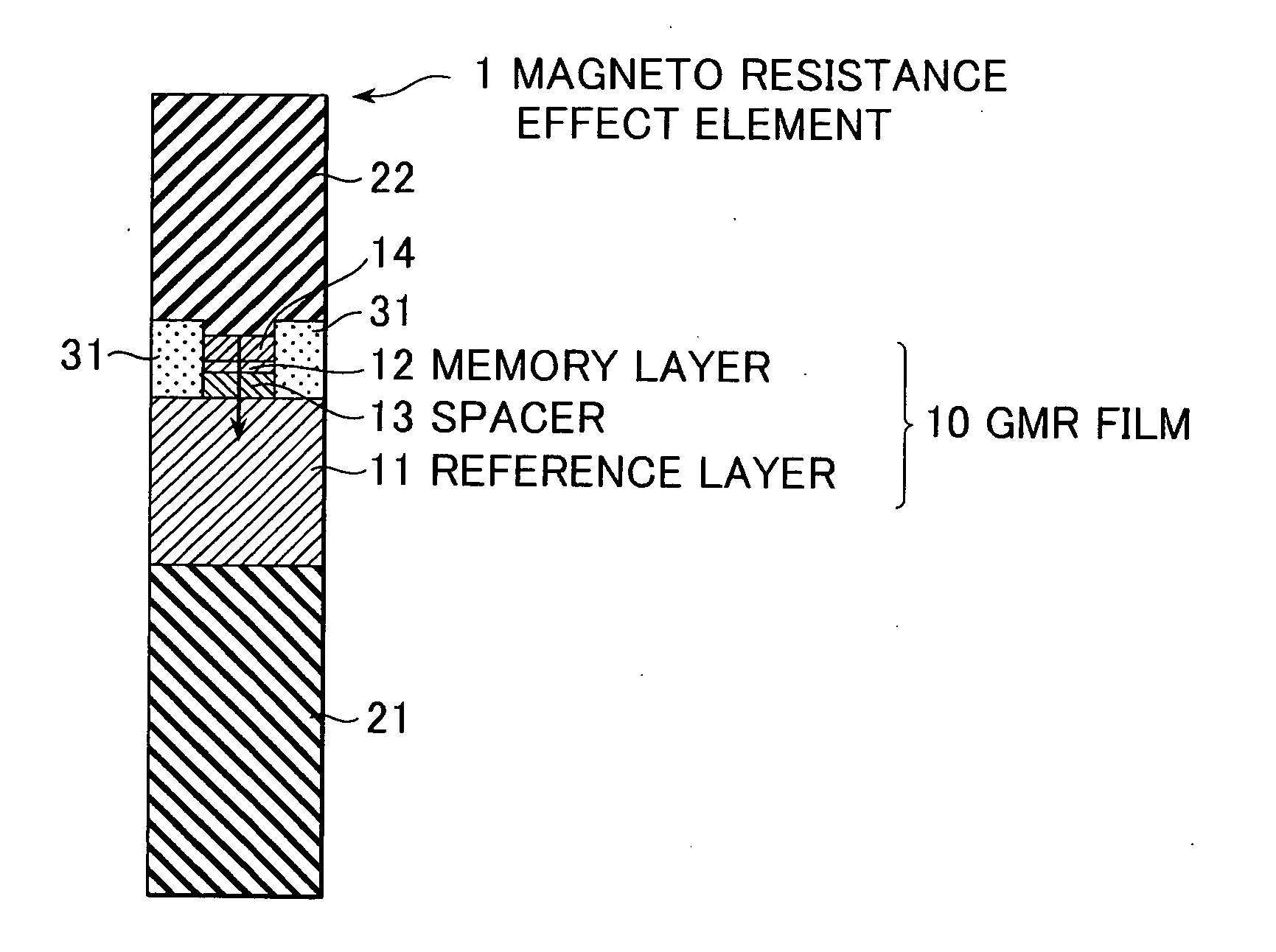

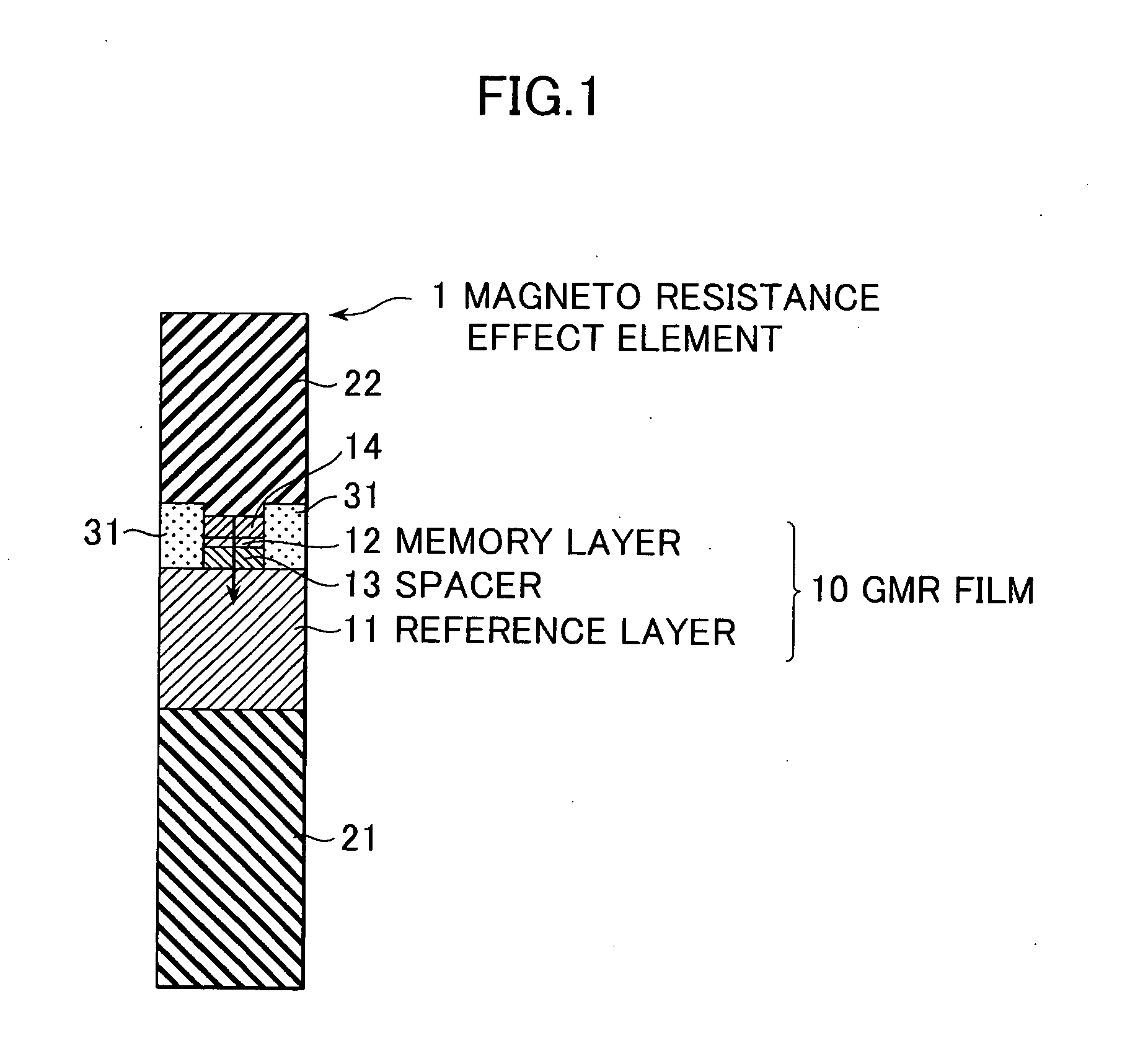

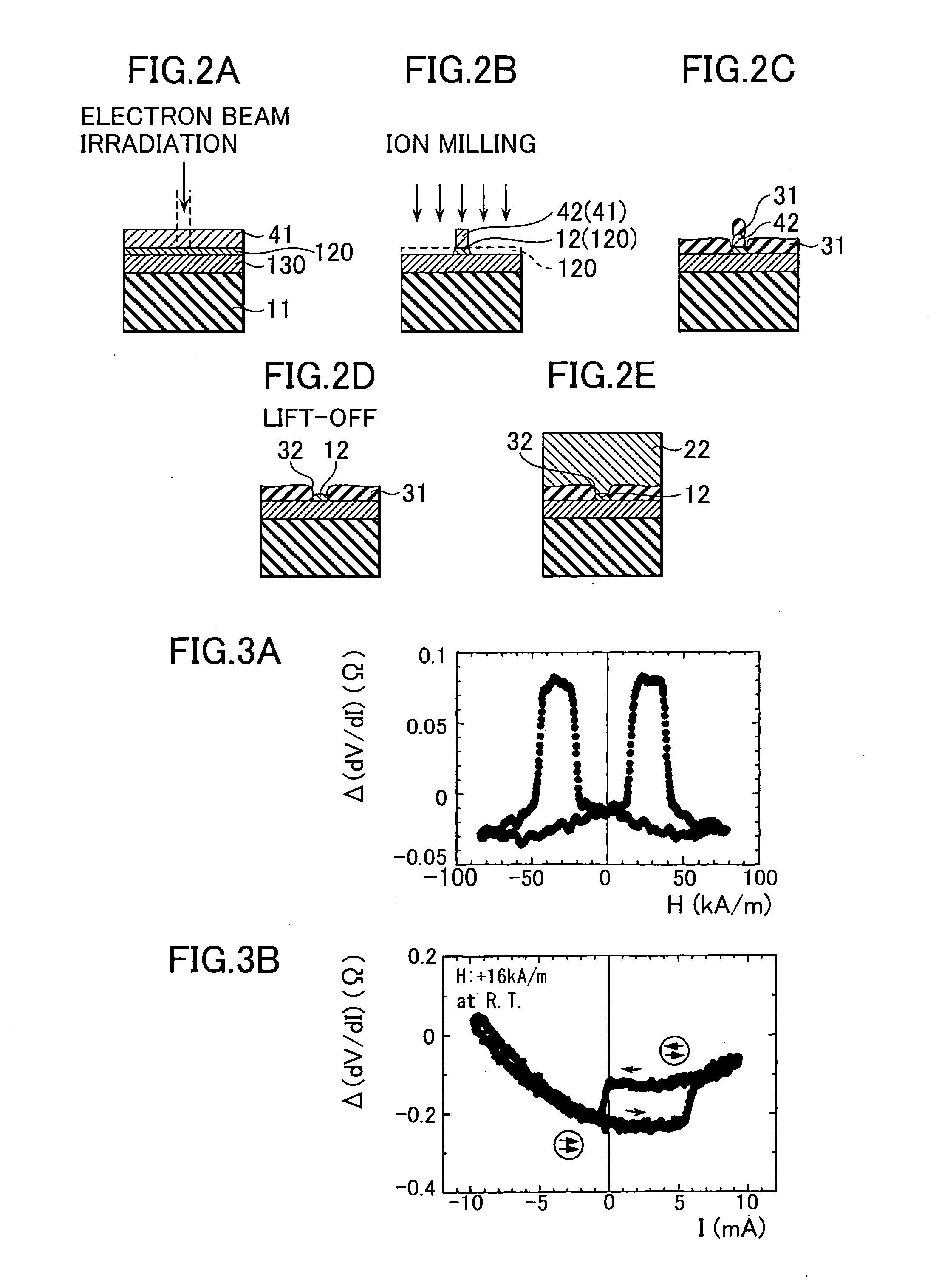

Magnetoresistance effect element, method of manufacture thereof, magnetic storage and method of manufacture thereof

ActiveUS20050057992A1Enabling a spin-transfer magnetization switchingLow densityNanomagnetismNanoinformaticsSwitched currentMagnetic storage

The present invention is aimed at enabling a spin-transfer magnetization switching in the random access magnetic memory by reducing a switching current density in the spin-transfer magnetization switching to an order smaller than 10 MA / cm2 and without causing breakdowns neither in the memory element which uses a TMR film nor in the element selection FET. The memory layer in the magnetoresistance effect element comprises a magnetic film having a value of saturation magnetization in a range from 400 kA / m to 800 kA / m. The memory layer comprises a magnetic film which contains one or more magnetic elements selected from the group of, for example, cobalt, iron and nickel, and which further contains a non-magnetic element. The non-magnetic element is contained at a ratio of, for example, 5 at % or more and less than 50 at %. A memory layer 12 in the memory cell has a dimension less than 200 nmφ.

Owner:SONY CORP

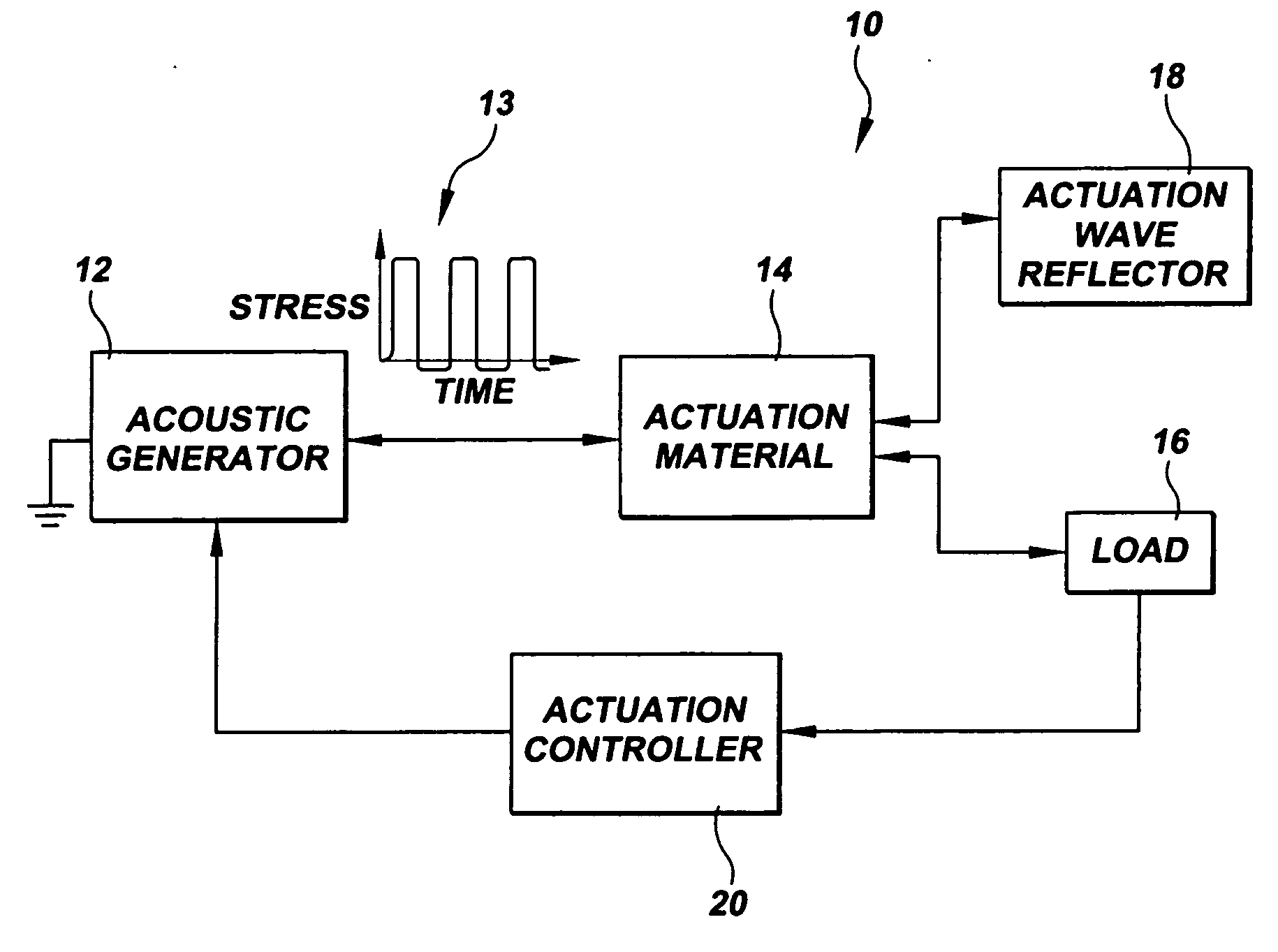

Acoustic pulse actuator

InactiveUS20060236777A1Analysing solids using sonic/ultrasonic/infrasonic wavesMechanical vibrations separationActuatorAcoustics

The invention provides an acoustic actuator, including an acoustic stress wave generator and an actuation material operatively positioned relative to the acoustic stress wave generator for delivery of acoustic stress waves from the generator to the actuation material.

Owner:MASSACHUSETTS INST OF TECH

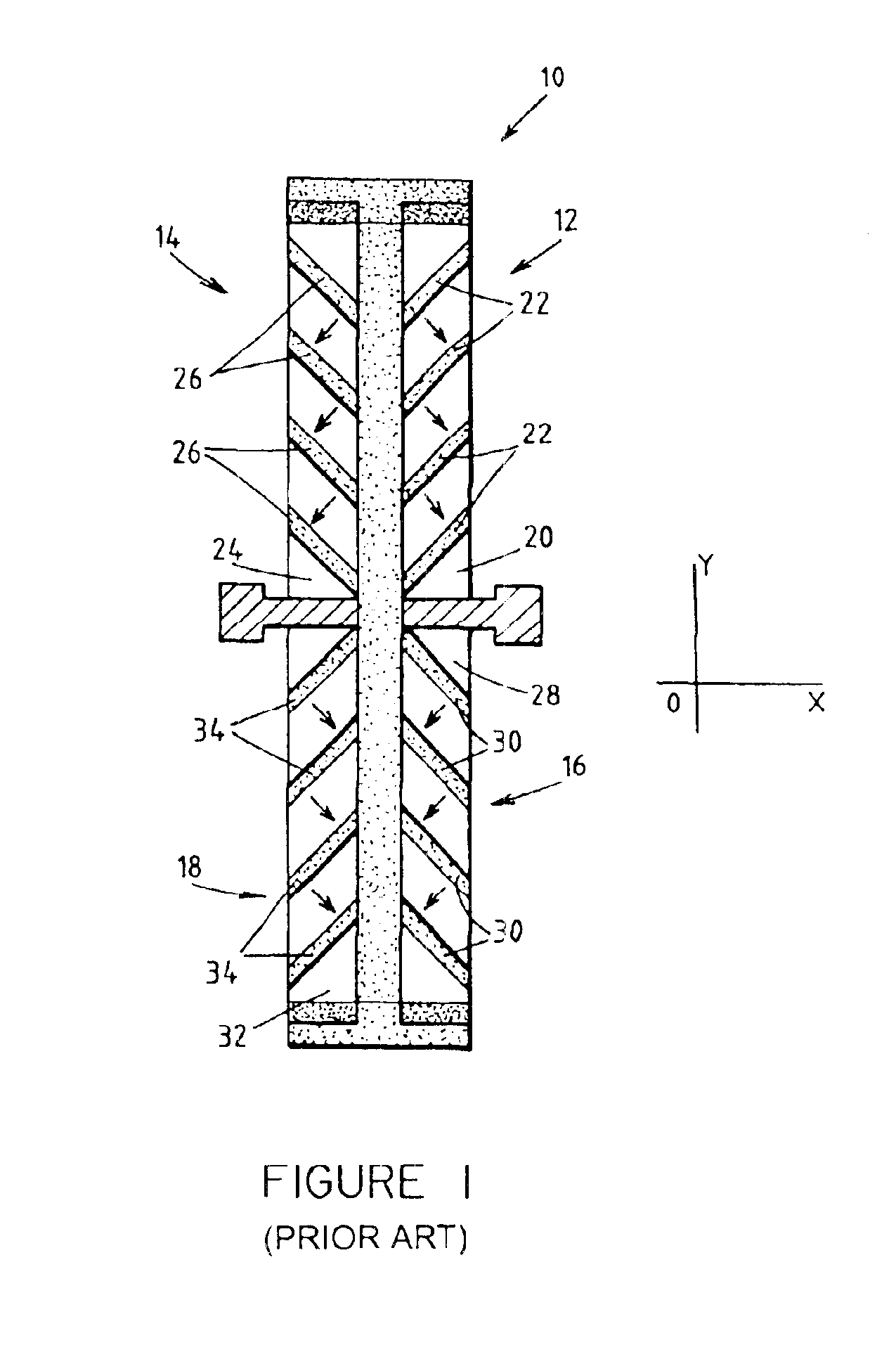

Linear actuator using magnetostrictive power element

InactiveUS20080111431A1Piezoelectric/electrostriction/magnetostriction machinesDirectional drillingLateral compressionLinear actuator

A linear actuator includes a substantially cylindrical magnetostrictive element disposed in a housing. A retainer is cooperatively engaged with the housing and an exterior of the magnetostrictive element such that relaxed portions of the magnetostrictive element are frictionally retained in the retainer. An actuator rod is functionally coupled to one longitudinal end of the magnetostrictive element. A biasing device is disposed between the housing and the retainer to maintain the retainer in lateral compression. The actuator includes magnets arranged to induce peristaltic motion in the magnetostrictive element.

Owner:SCHLUMBERGER TECH CORP

Torque sensor

InactiveUS6701793B2Simple to provideAvoid poor resultsWork measurementTorque measurementSurface patternEngineering

The present invention relates to a magnetostrictive sensor for measuring a torque in a shaft. The sensor comprises at least one active magnetostrictive region on the shaft, a surface pattern in the magnetostrictive region such that it obtains anisotropic properties, a first means arranged to generate a magnetic field varying in time in the magnetostrictive region and a second means arranged to sense variation in the permeability in the magnetostrictive region. Said magnetostrictive region comprises a first layer of a magnetostrictive material which is provided on the surface of the shaft and that said surface pattern is formed by a second layer of a non-magnetostrictive material comprising a low resistivity.

Owner:ABB (SCHWEIZ) AG

Design of ferromagnetic shape memory alloy composites and actuators incorporating such materials

InactiveUS7104056B2Piezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionShape-memory alloyAlloy composite

The present invention employs an optimized cross-sectional shape for a ferromagnetic shape memory alloy (FSMA) composite that is used in a spring-type actuator, an improved hybrid magnetic trigger for use in FSMA based actuators, an a FSMA composite based spring type actuator, an a FSMA based spring type actuator including a stack of triggering units and FSMA springs, a FSMA composite based torque actuator. The invention also includes a model that can be employed to evaluate different materials being considered as components a FSMA for a FSMA composite used in either a FSMA based torque actuator or a FSMA spring actuator.

Owner:UNIV OF WASHINGTON

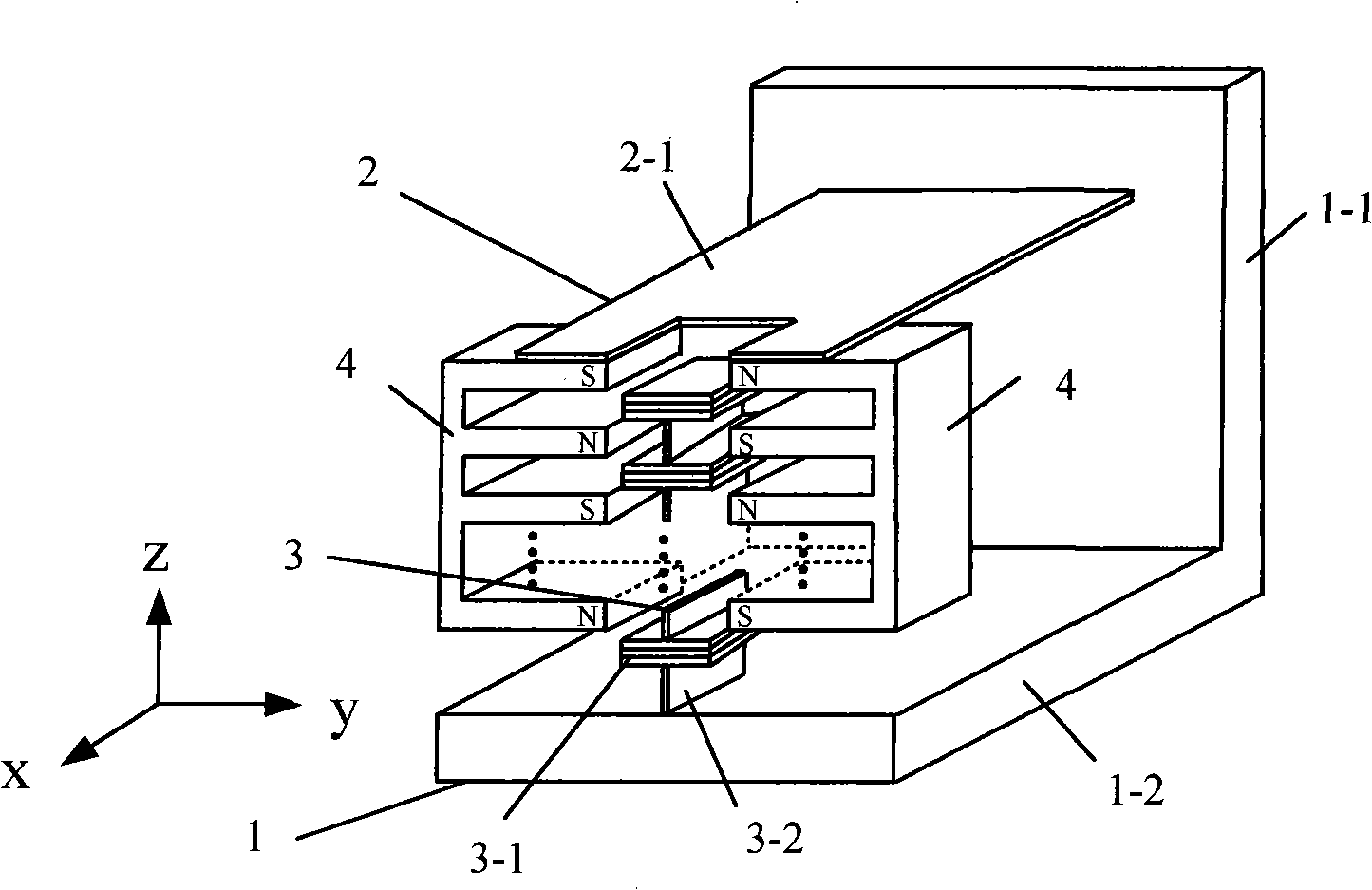

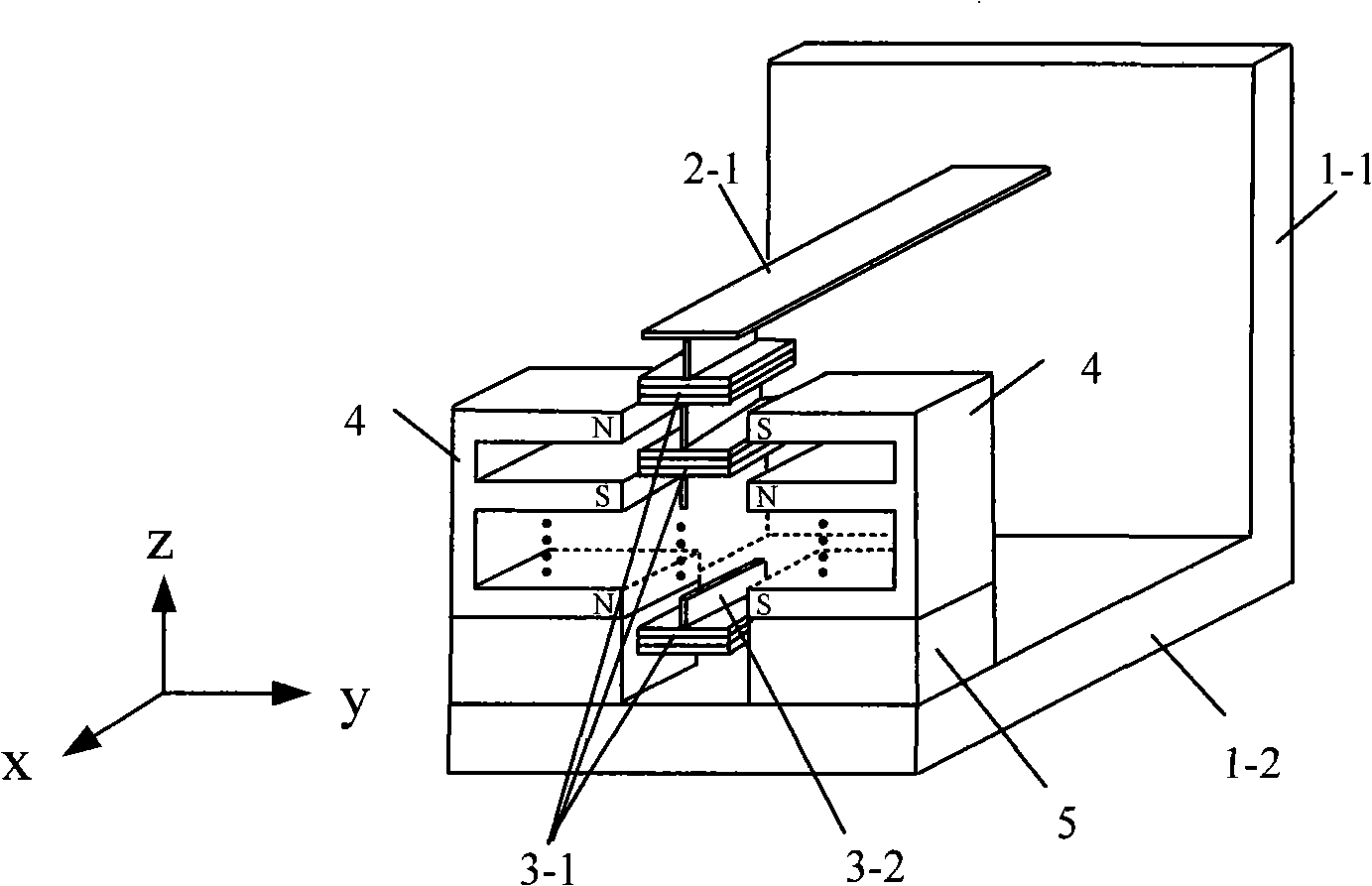

Vibration energy collector with piezomagnetic/piezoelectric composite energy conversion structure

InactiveCN101404468AHigh magnetoelectric conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive devicesElectricityReciprocating motion

The invention discloses a vibrational energy collecting device adopting a piezomagnetic / piezoelectric compound transduction structure. The device comprises a supporting mechanism, a piezomagnetic / piezoelectric compound magneto-electricity transducer, a permanent magnet magnetic circuit and an elastic mechanism; wherein, the piezomagnetic / piezoelectric compound magneto-electricity transducer is arranged in the space of the air gap field of the permanent magnet magnetic circuit; one of the piezomagnetic / piezoelectric compound magneto-electricity transducer and the permanent magnet magnetic circuit is elastically connected with the supporting mechanism by the elastic mechanism and can do reciprocating movement along with the mechanism while the other is fixed on the base of the supporting mechanism; namely, the piezomagnetic / piezoelectric compound magneto-electricity transducer is fixed on the base while the permanent magnet magnetic circuit is connected with the supporting mechanism by the elastic mechanism, or the piezomagnetic / piezoelectric compound magneto-electricity transducer is connected with the supporting mechanism by the elastic mechanism while the permanent magnet magnetic circuit is fixed on the base by non-permeability magnetic material. The invention has the beneficial effect that the invention provides a self-energized device which is applicable to weak vibration and has higher magnetoelectricity conversion efficiency.

Owner:CHONGQING UNIV

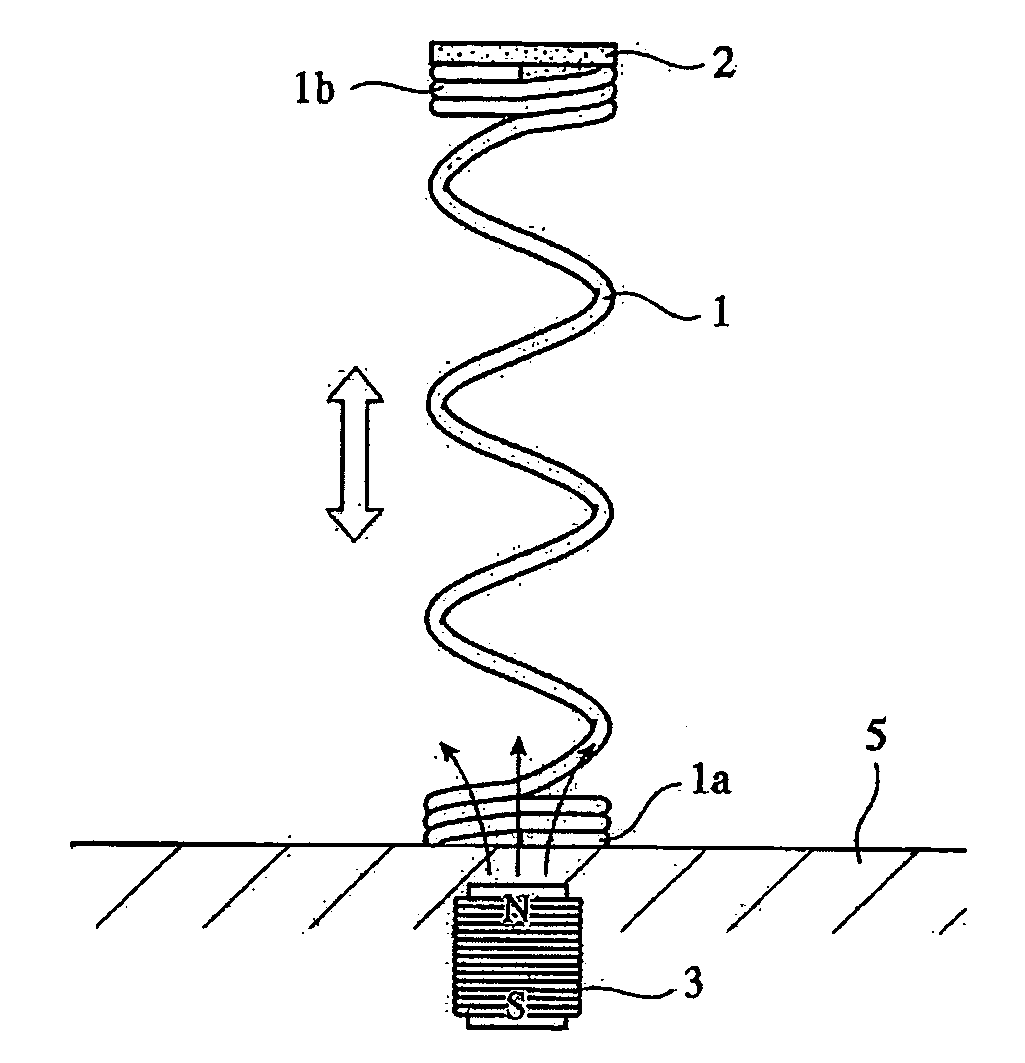

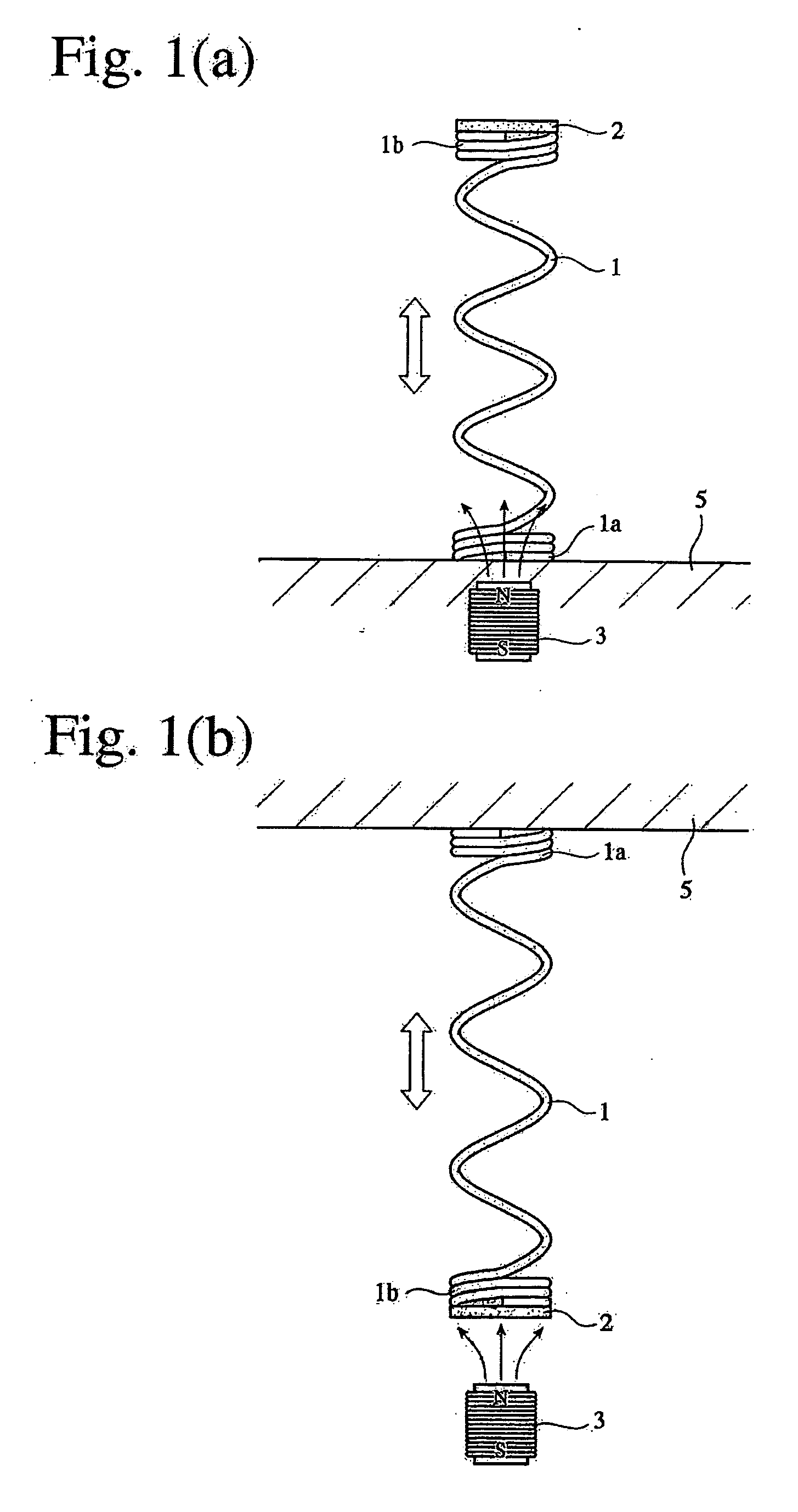

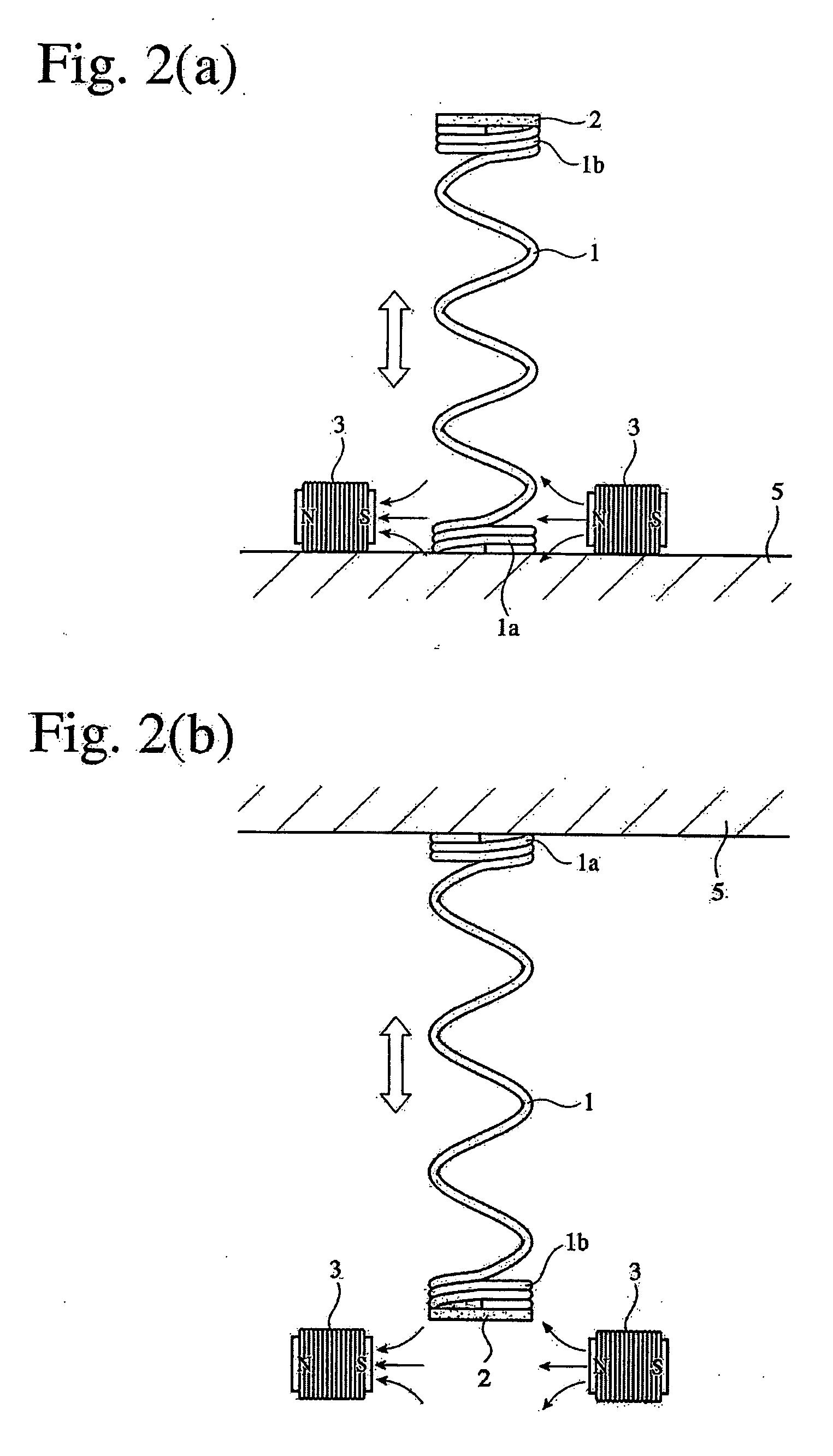

Actuator

InactiveUS20060044093A1Large displacementLarge outputDynamo-electric machinesMagnetostrictive devicesEngineeringActuator

An actuator has a resilient shape memory member 1 with superelasticity, a magnetic body 2, and a magnetic field generator 3. At least one of the magnetic body 2 and the magnetic field generator 3 is fixed to the resilient shape memory member 1 such that one of the magnetic body 2 and the magnetic field generator 3 is stationary while the other is movable, whereby the movable member is moved by a magnetic field provided from the magnetic field generator 3.

Owner:HONDA MOTOR CO LTD

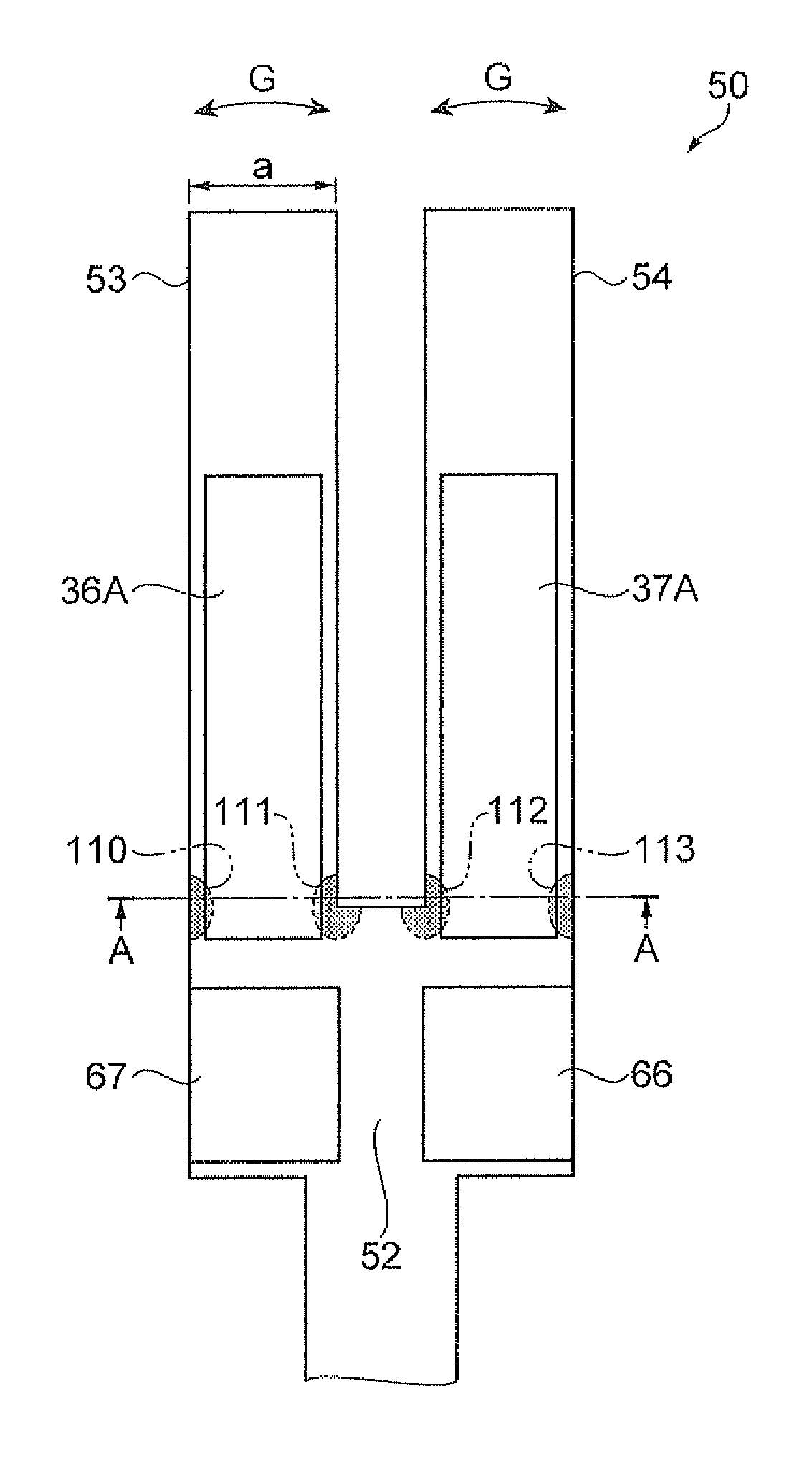

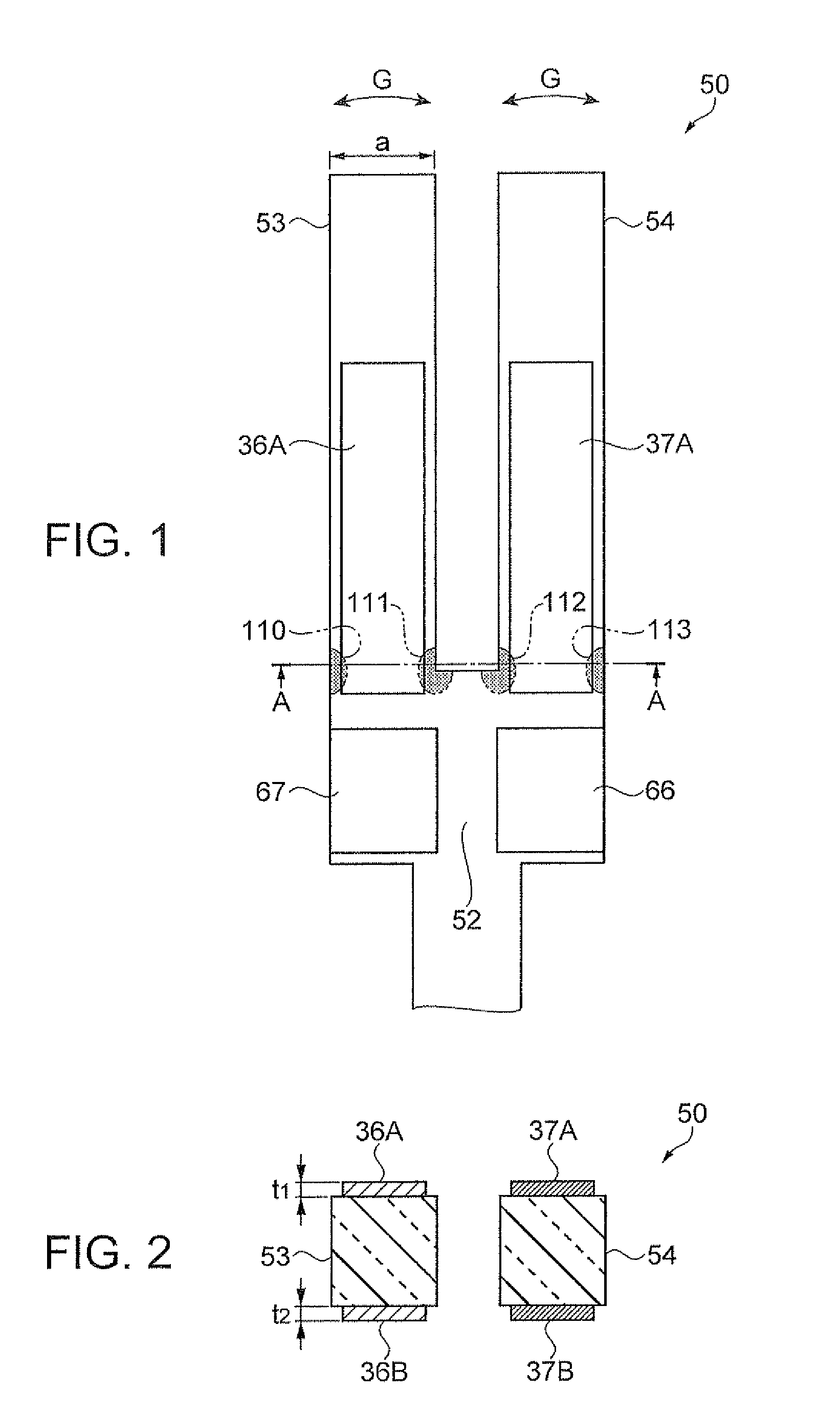

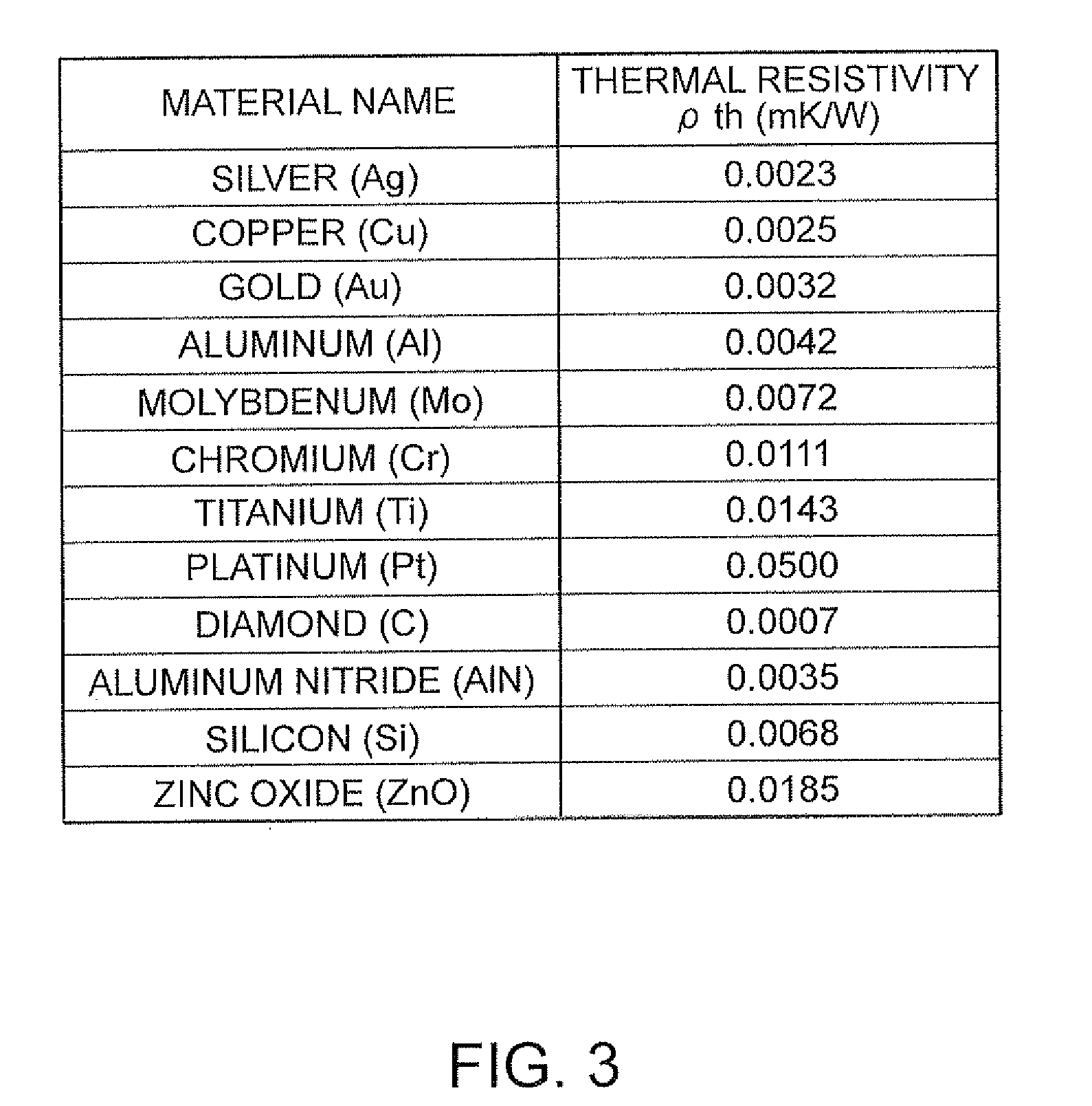

Flexural vibration piece and oscillator using the same

InactiveUS20100244989A1Reduction in Q value can be suppressedEfficient executionPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThermal conductivityPhysics

A flexural vibration piece includes: a flexural vibrator that has a first region on which a compressive stress or a tensile stress acts due to vibration and a second region having a relationship in which a tensile stress acts thereon when a compressive stress acts on the first region and a compressive stress acts thereon when a tensile stress acts on the first region, and performs flexural vibration in a first plane; and a heat conduction path, between the first region and the second region, that is formed of a material having a thermal conductivity higher than that of the flexural vibrator and thermally connects between the first region and the second region, wherein when m is the number of heat conduction paths, ρth is the thermal resistivity of the heat conduction path, ρv is the thermal resistivity of the flexural vibrator, tv is the thickness of the flexural vibrator in, a direction orthogonal to the first plane, and tth is the thickness of the heat conduction path, a relationship of tth≧(1 / m)×tv×(ρth / ρv) is satisfied.

Owner:SEIKO EPSON CORP

Ultrasonic reactor and process for ultrasonic treatment of materials

InactiveUS7504075B2Shaking/oscillating/vibrating mixersPiezoelectric/electrostriction/magnetostriction machinesCavitationTransducer

An ultrasound reactor (30) having a reactor body (1), a reactor tube (9) disposed within the reactor body and a magnetostrictor transducer (11) comprising at least one annular element (28a-d) concentric with, and mounted to an external wall of said tube and a process for ultrasonic treatment of a reaction material are disclosed. The transducer is mounted on the reactor tube in such a way so as to transmit ultrasound radiation to the interior of the tube and to induce an upwardly flowing cavitation stream whose longitudinal axis substantially coincides with a longitudinal axis of said tube, causing physical changes to the reaction material.

Owner:NANO SIZE

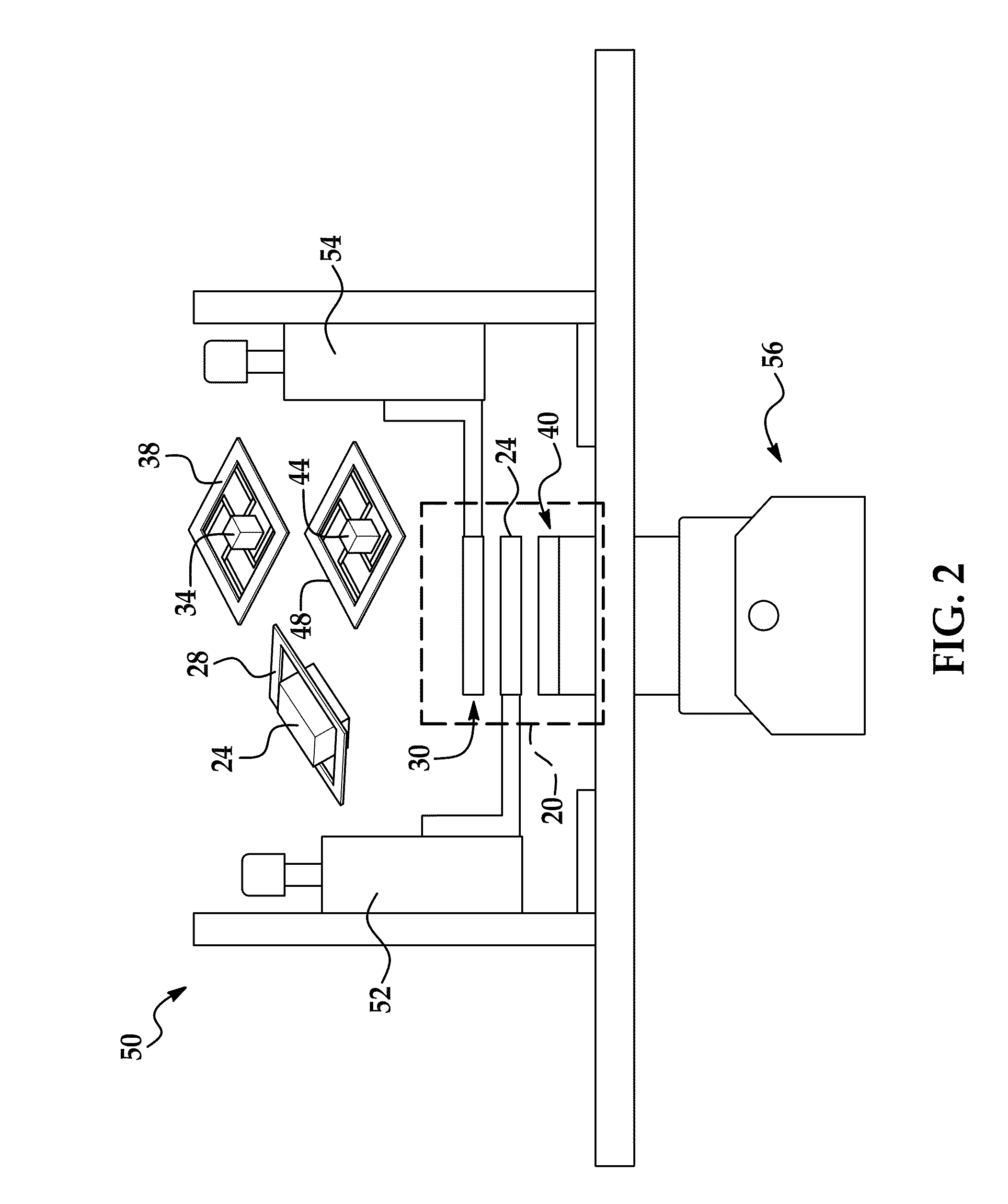

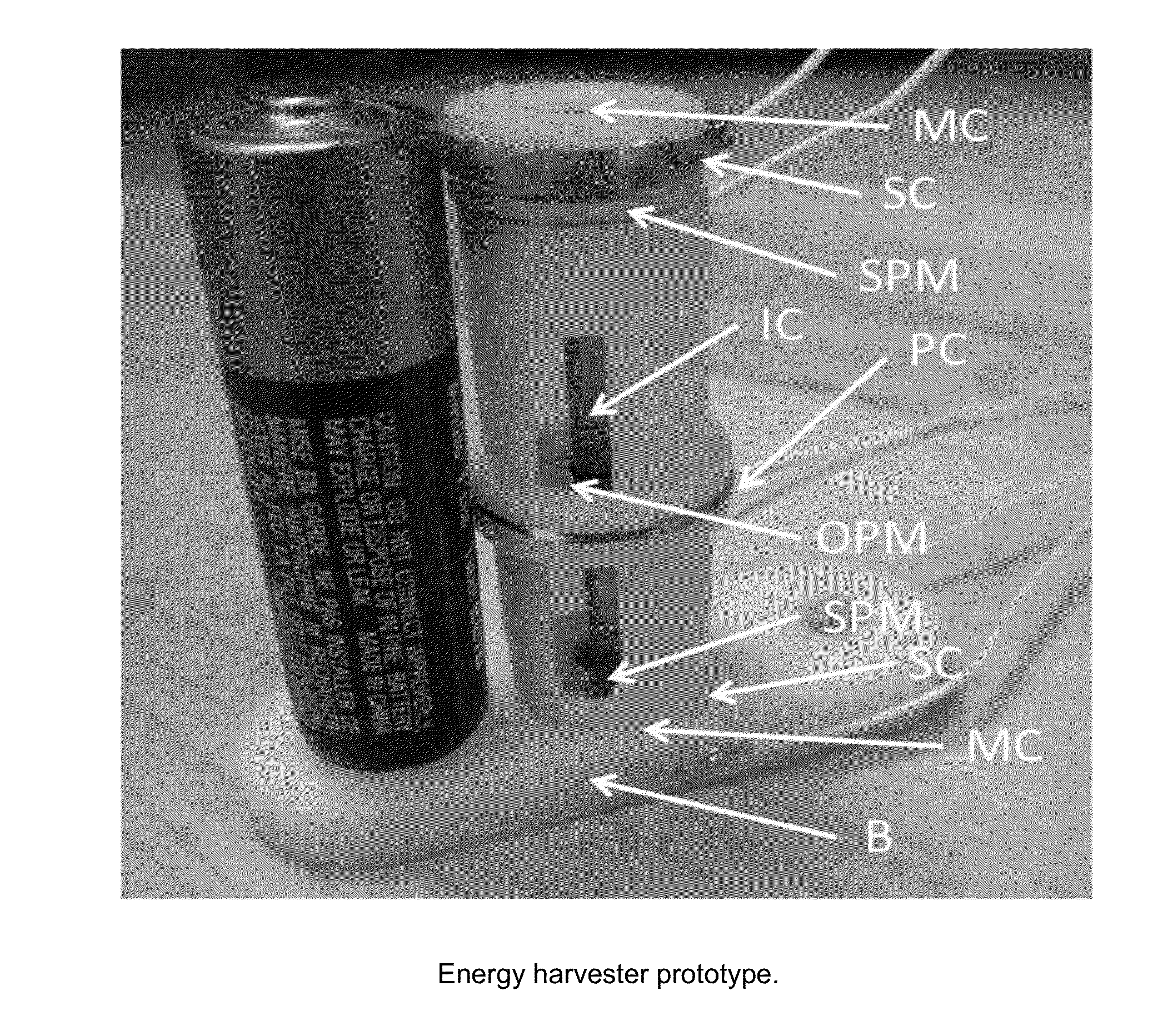

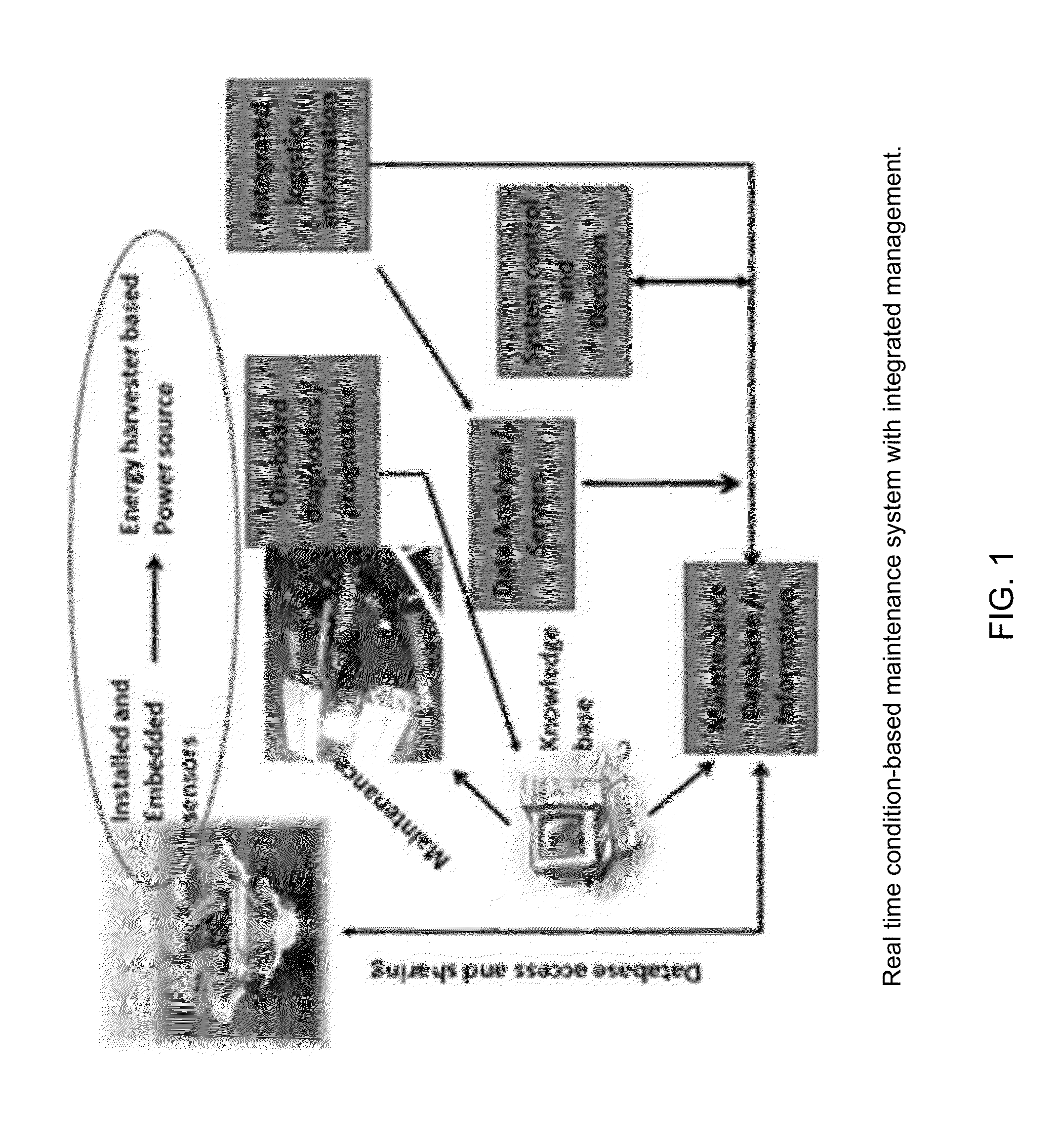

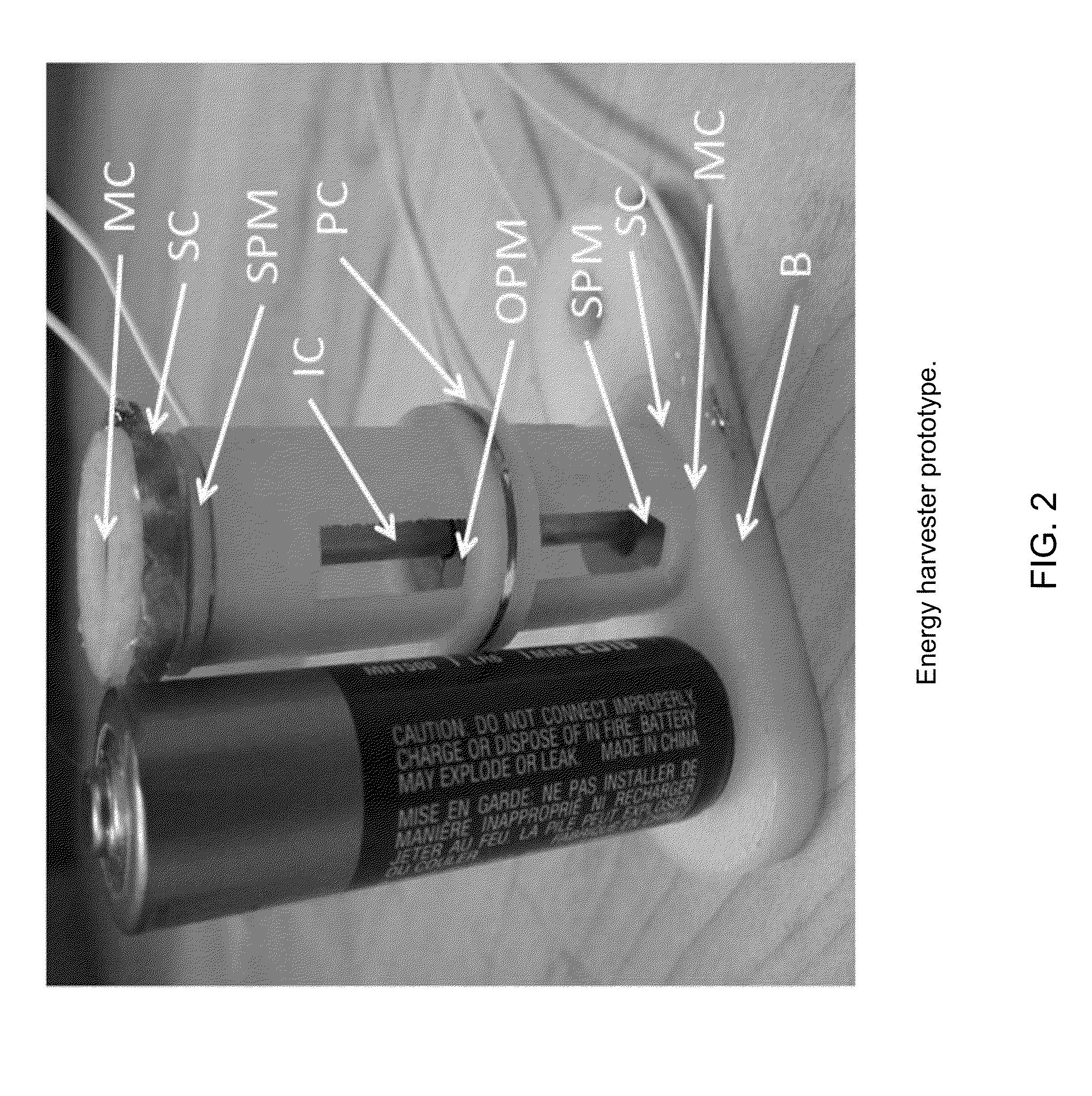

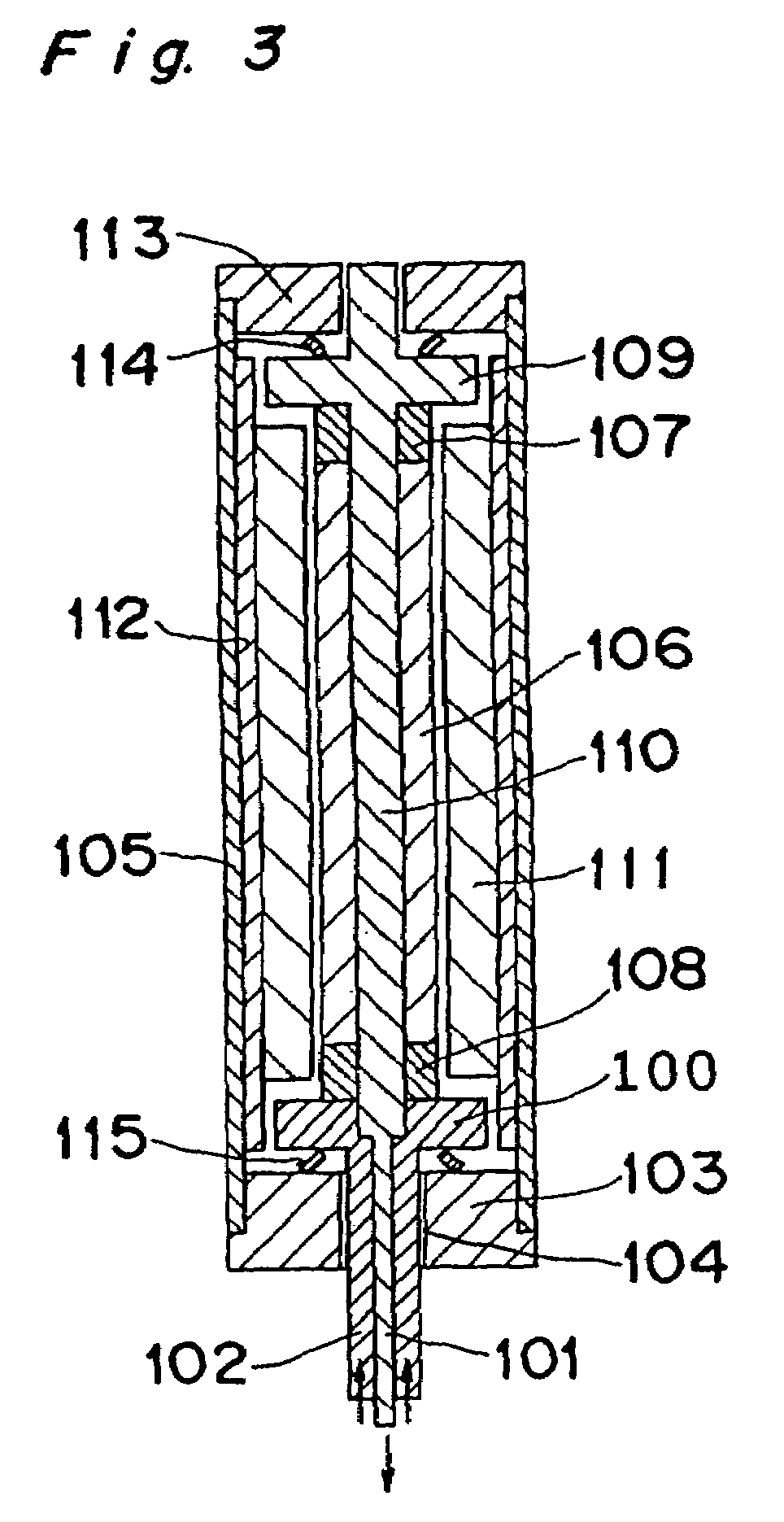

Multimodal vibration harvester combining inductive and magnetostrictive mechanisms

ActiveUS20130193693A1Minimal costImprove power densityPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesEnergy harvesterEngineering

Multi-Mechanism Energy Harvesters (MMEHs) combining magnetostrictive and inductive mechanisms with a shape and size similar to an AA battery. Included are MMEHs with (a) an inductive mode: a cylindrical tube, a rod lengthwise within the tube, permanent magnets with opposing polarities at opposing ends of the tube, an annular oscillatory magnet in the tube and between the magnets and around the rod; and a primary coil around the tube and oscillatory magnet, such that relative movement between the magnet and coil induces electrical current in the coil; and (b) a magnetostrictive mode comprising: piezoelectric cymbal transducers on opposing ends of the tube and comprising a magnetostrictive material surrounded by a secondary coil, such that movement of the magnetostrictive material induces voltage in the secondary coil. During use, electrical energy can be harvested from the relative motion between the magnet and coil and from the magnetostrictive material.

Owner:VIRGINIA TECH INTPROP INC

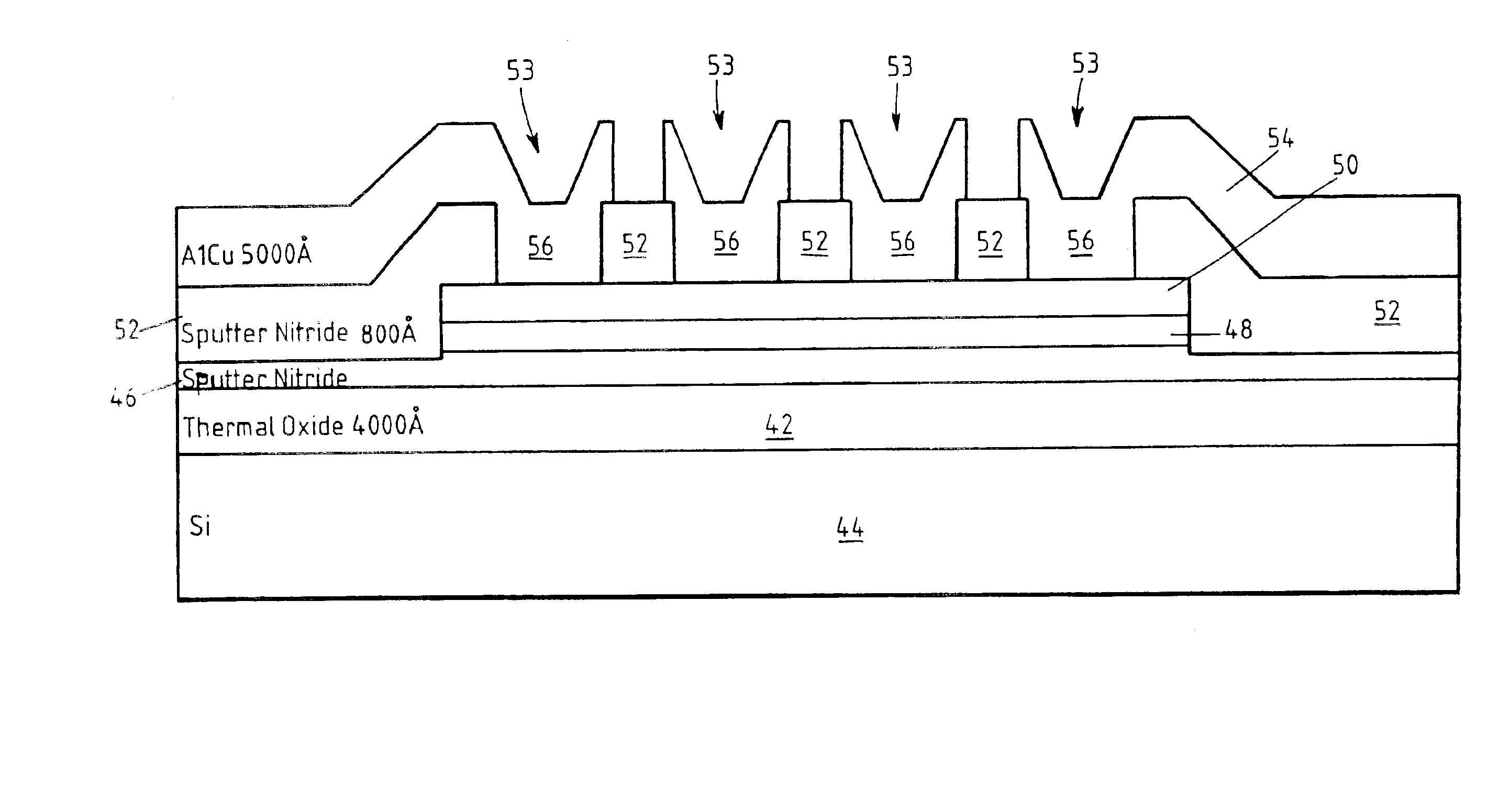

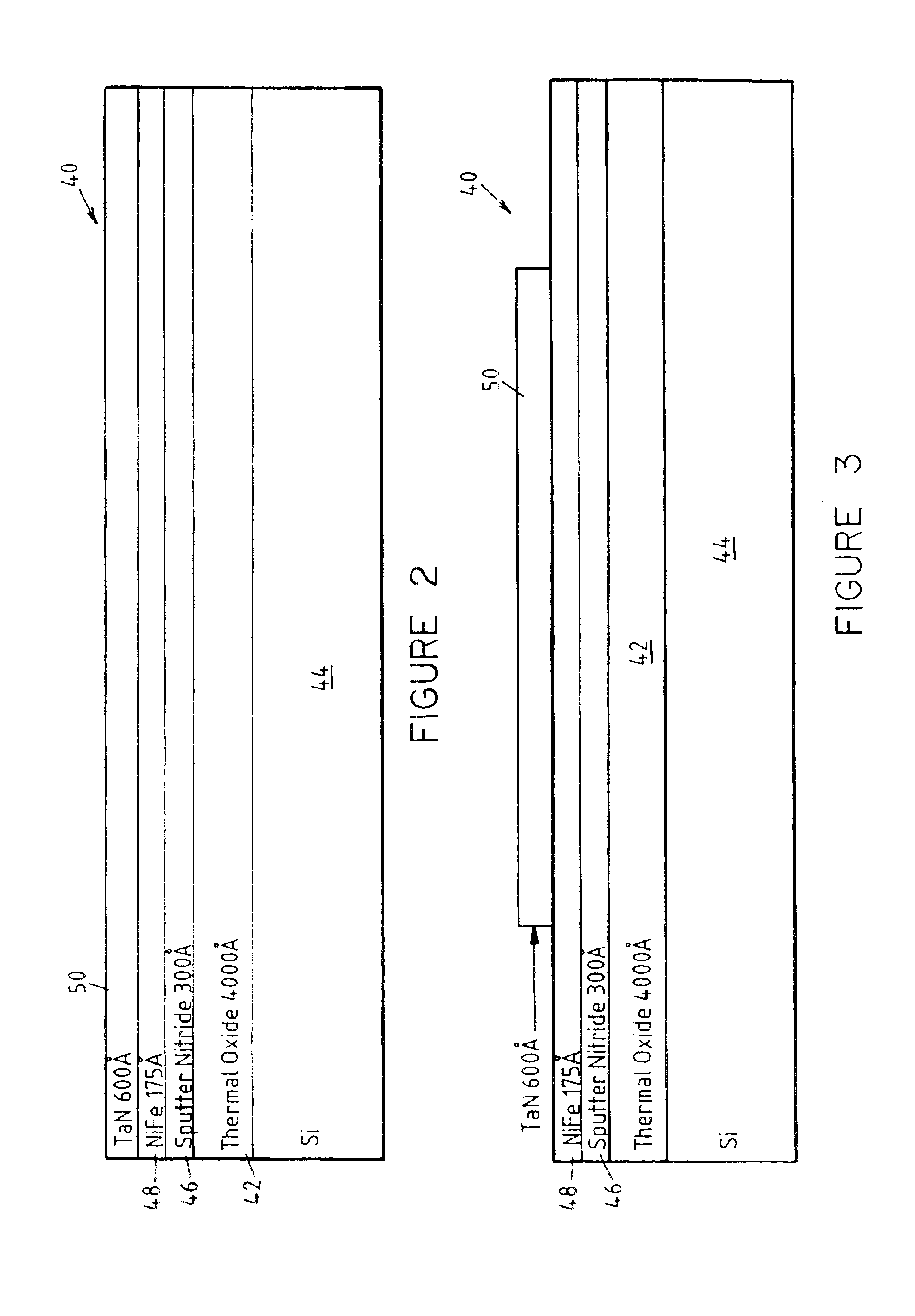

Barber pole structure for magnetoresistive sensors and method of forming same

InactiveUS6850057B2Piezoelectric/electrostrictive device manufacture/assemblyMagnetic field measurement using galvano-magnetic devicesEtchingConductive materials

A method of making a magnetorestrictive sensor involves the deposition of a magnetorestrictive strip over a substrate, the deposition of an insulating layer over the magnetorestrictive strip, the etching of barber pole windows through the insulating layer, the deposition of a conductive material over the insulating layer and into the barber windows, and the etching away of the conductive material between the barber pole windows so as to form barber poles. In this manner, the formation of the barber poles is controlled by the windows formed in the insulating layer.

Owner:HONEYWELL INT INC

Electromagnetostrictive actuator

InactiveUS7323960B2Increase freedomLiquid surface applicatorsOperating means/releasing devices for valvesEngineeringActuator

Owner:PANASONIC CORP

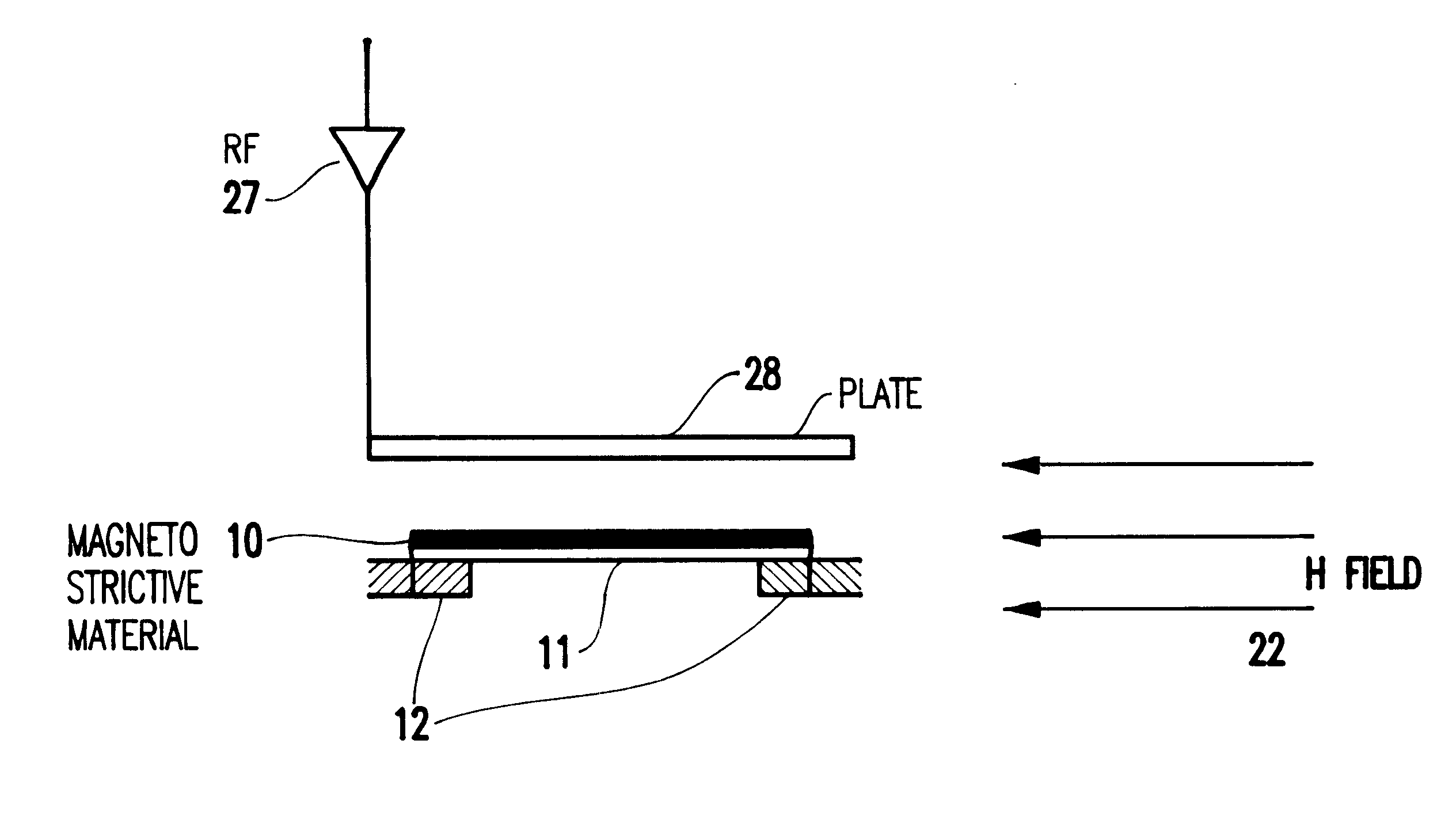

Magnetostrictive thin film actuator

InactiveUS7250839B2Well mixedValve arrangementsCosmonautic vehiclesMagnetostrictive actuatorEngineering

Owner:ENERGEN

Filter circuit including system for tuning resonant structures to change resonant frequencies thereof

InactiveUS6348846B1Resonant circuit auxillary power controlMultiple-port networksSemiconductor materialsSingle crystal

A structure (and method) for tuning a resonant structure, includes a resonant structure including either a predetermined material coating provided on either a bar or a cantilever, or a lightly doped single crystal semiconductor material, and a circuit for providing a variable field adjacent the resonant structure, with the length or at least one of the elastic constants of the resonant structure changing with the application of the variable magnetic or electric field, respectively, thereby to selectively tune the resonant structure.

Owner:TWITTER INC

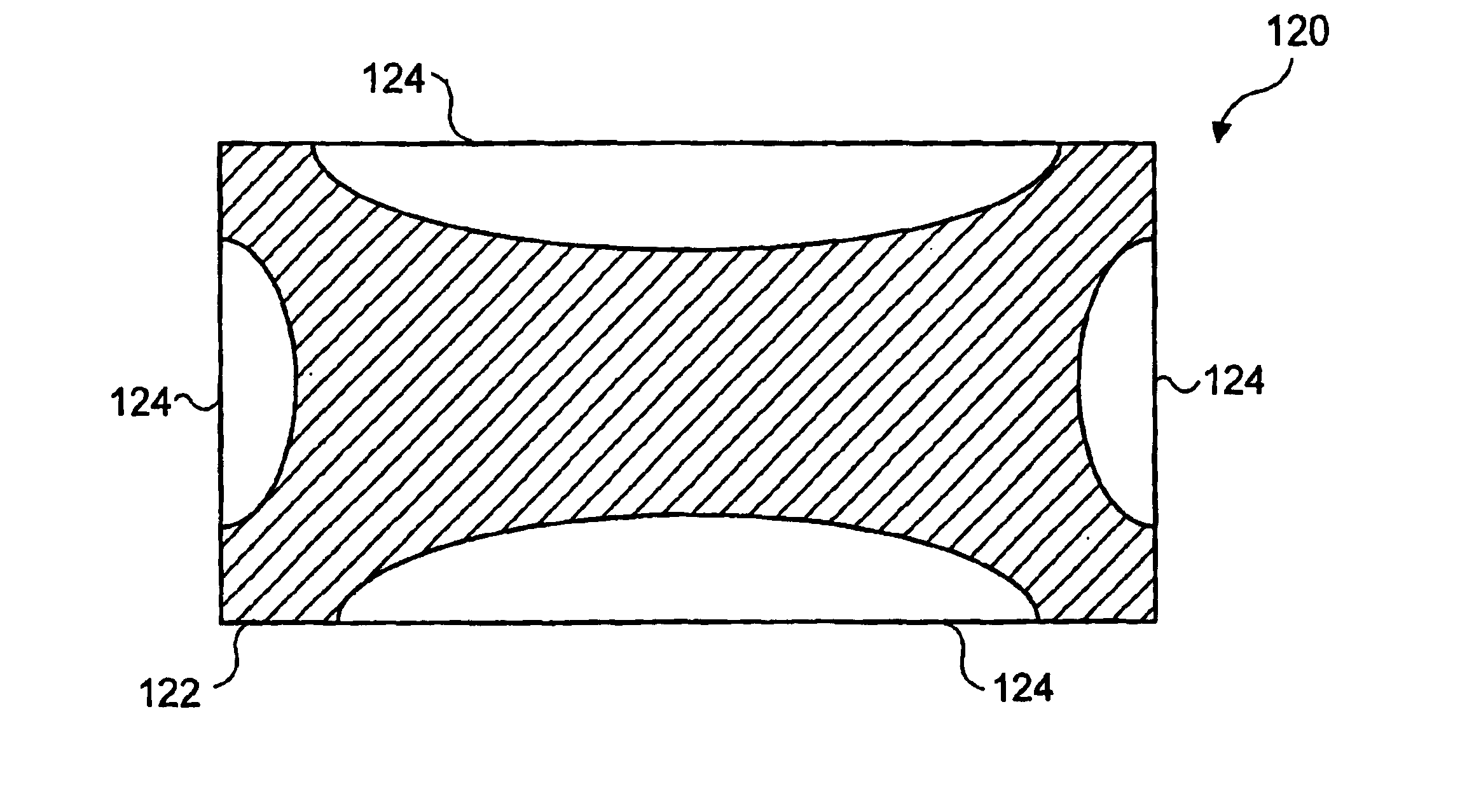

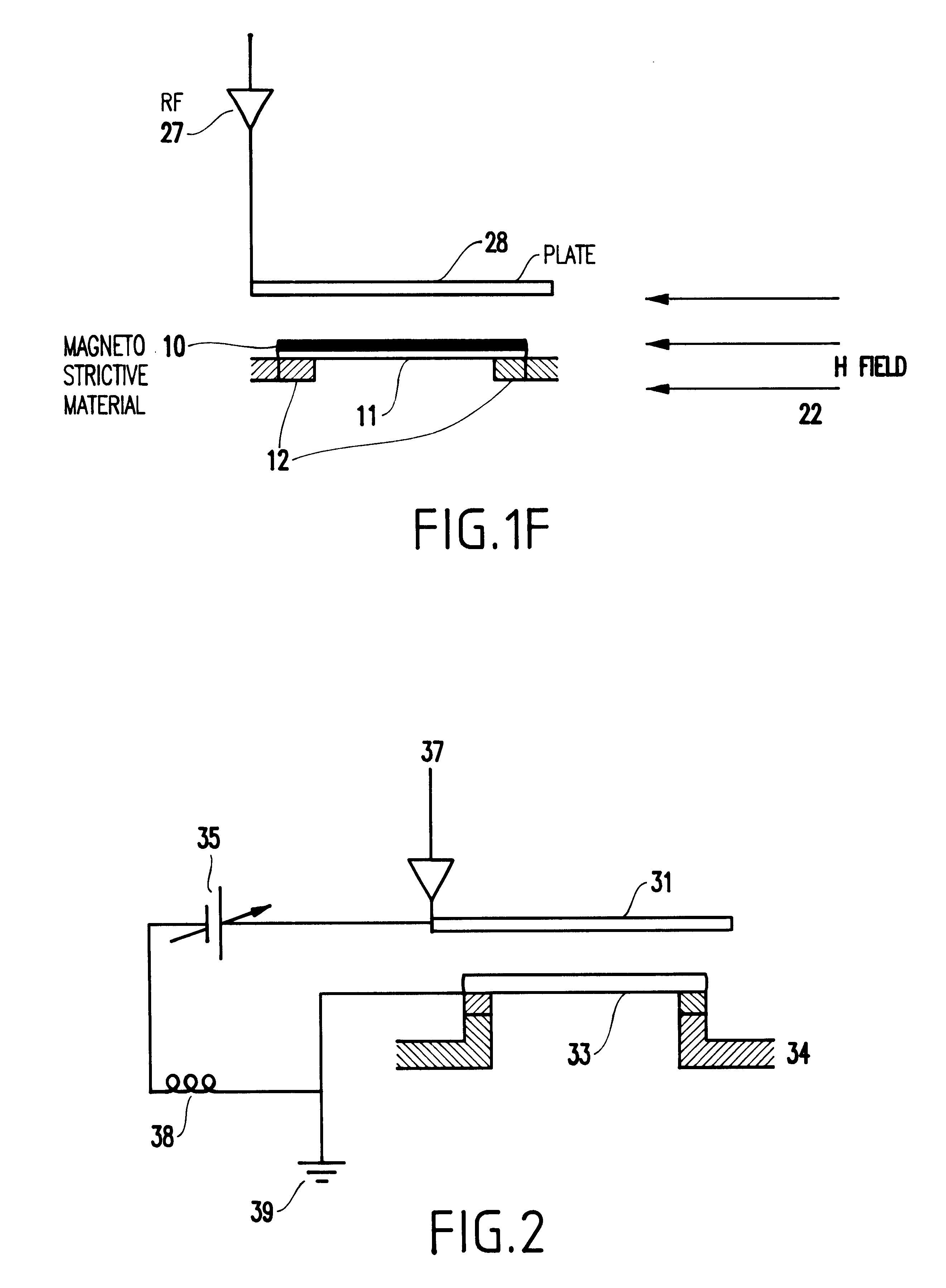

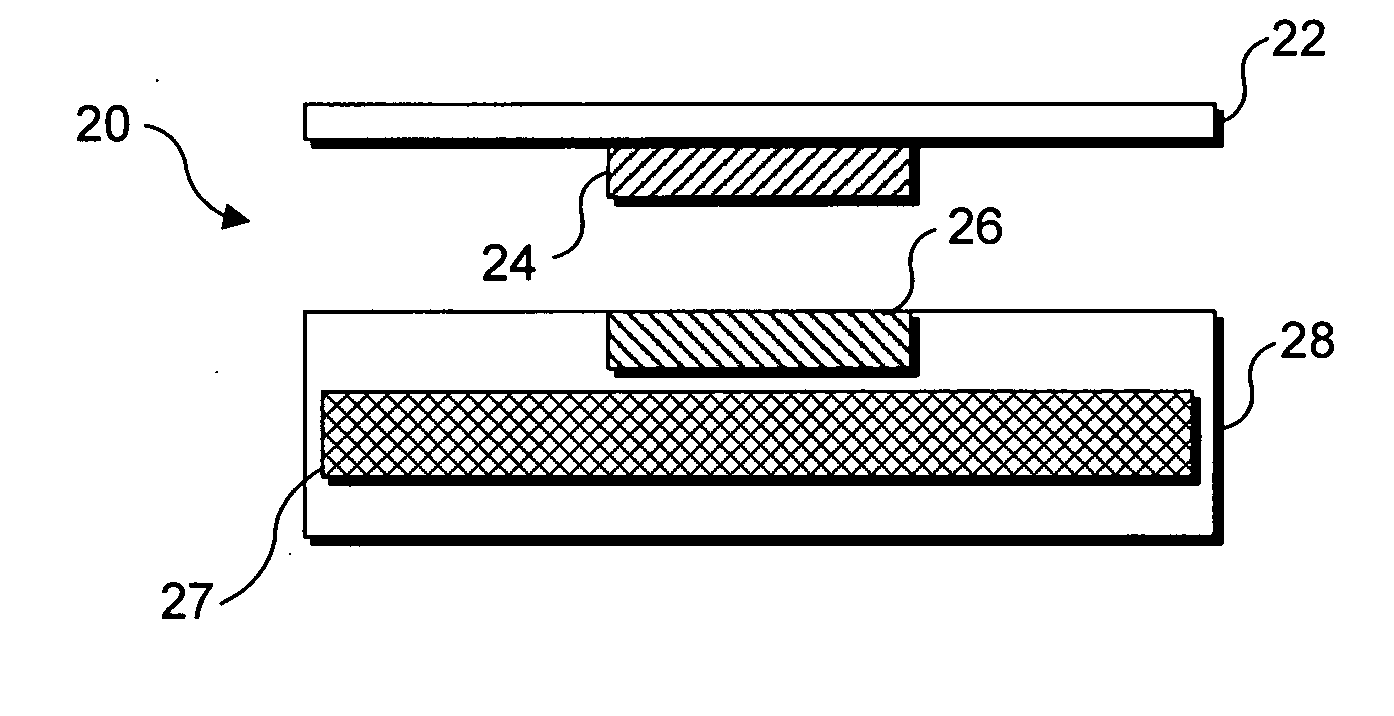

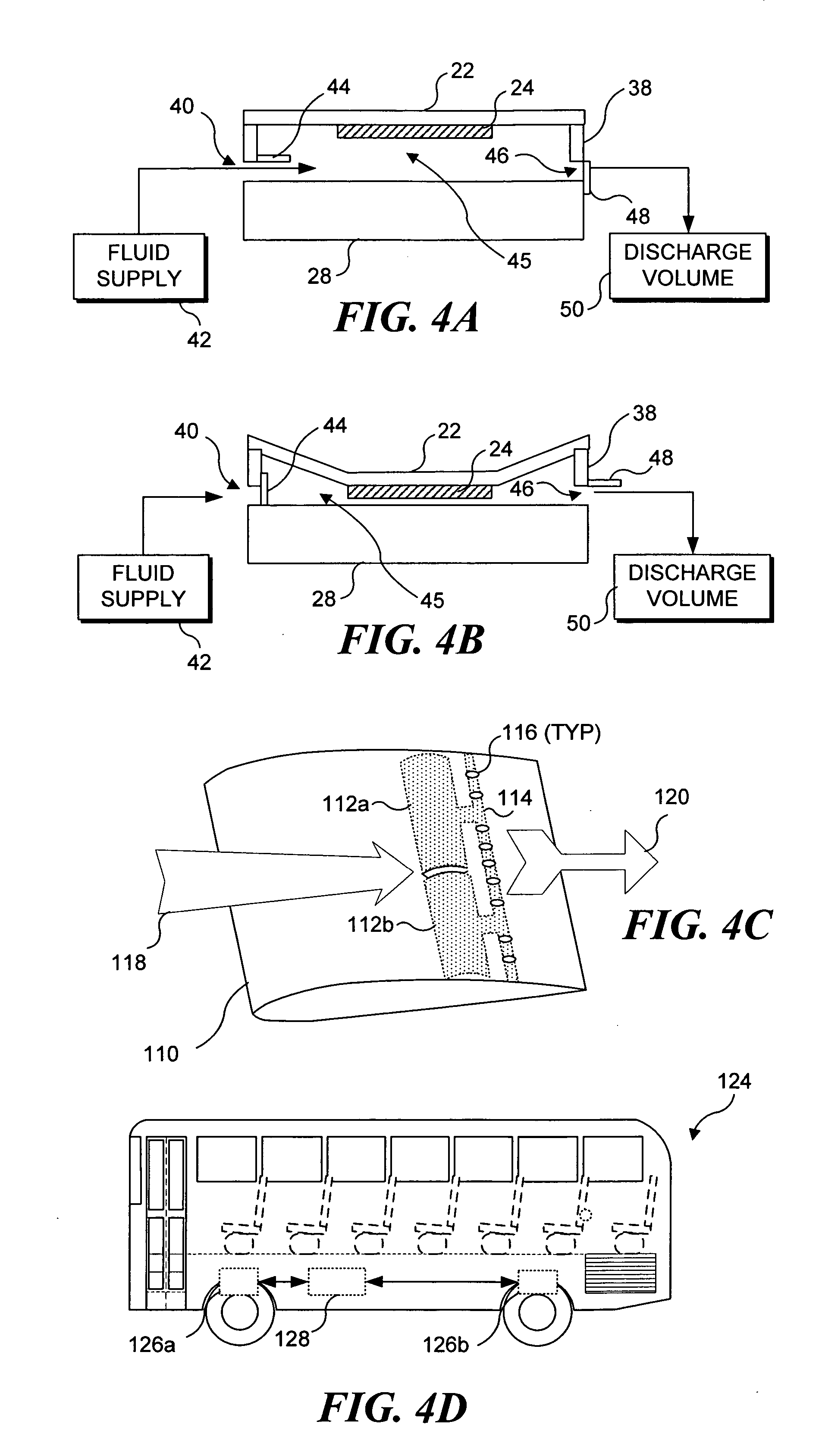

Design of membrane actuator based on ferromagnetic shape memory alloy composite for sythentic jet actuator

InactiveUS20070205853A1Rapid responseLarge deformationPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionMagnetic gradientShape-memory alloy

A membrane actuator includes a magnetically actuatable membrane and a magnetic trigger. The membrane includes a shape memory alloy (SMA), and the magnetic trigger is configured to induce a martensitic transformation in the SMA, to produce a larger force than would be achievable with non-SMA-based materials. Such a membrane actuator can be beneficially incorporated into a wide variety of devices, including fluid pumps, shock absorbing systems, and synthetic jet producing devices for use in an aircraft. The membrane / diaphragm can be formed from a ferromagnetic SMA, or a ferromagnetic material can be coupled with an SMA such that the SMA and the ferromagnetic material move together. A hybrid magnetic trigger, including a permanent magnet and an electromagnet, is preferably used for the magnetic trigger, as hybrid magnetic triggers are easy to control, and produce larger magnetic gradients than permanent magnets or electromagnets alone.

Owner:UNIV OF WASHINGTON

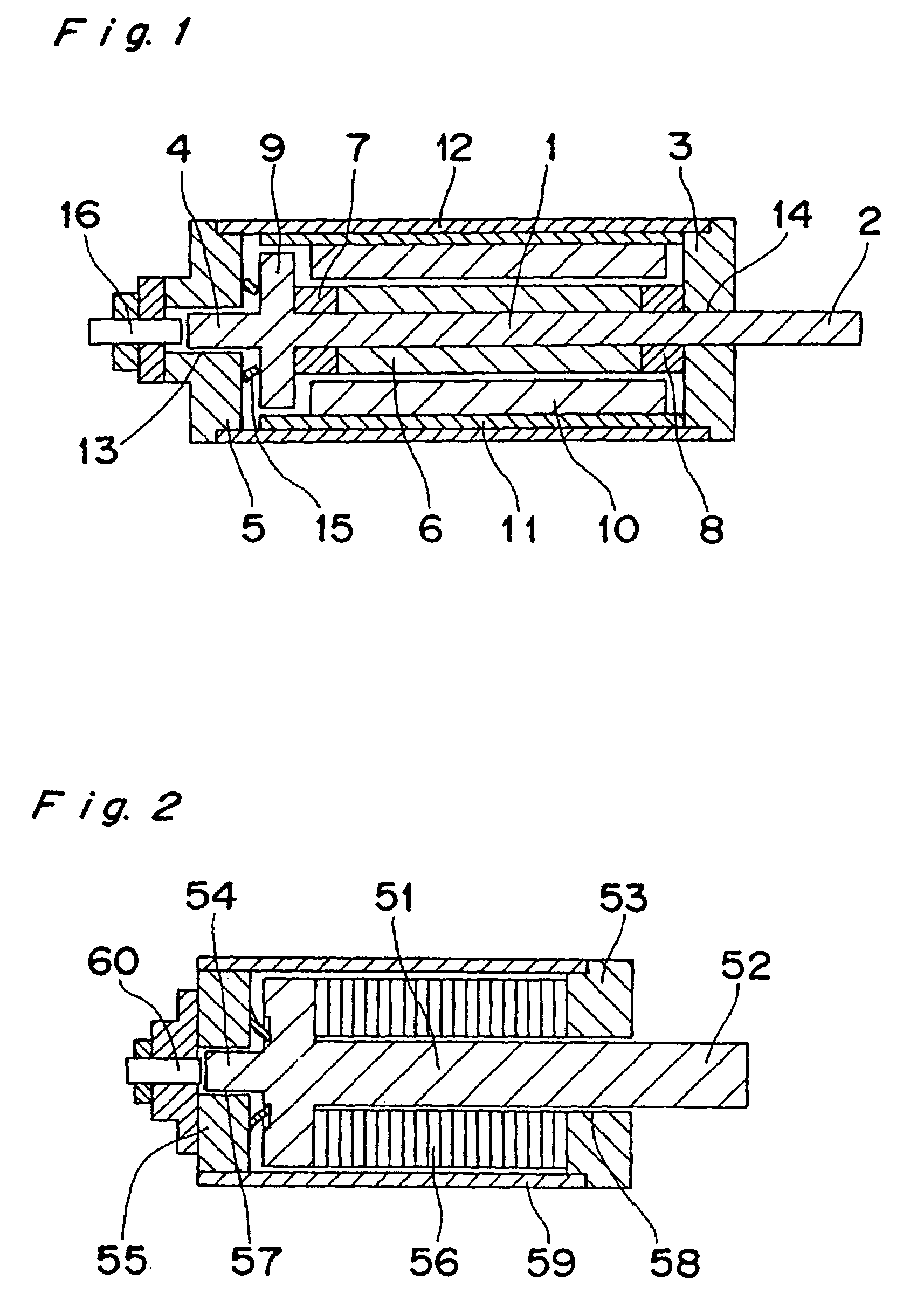

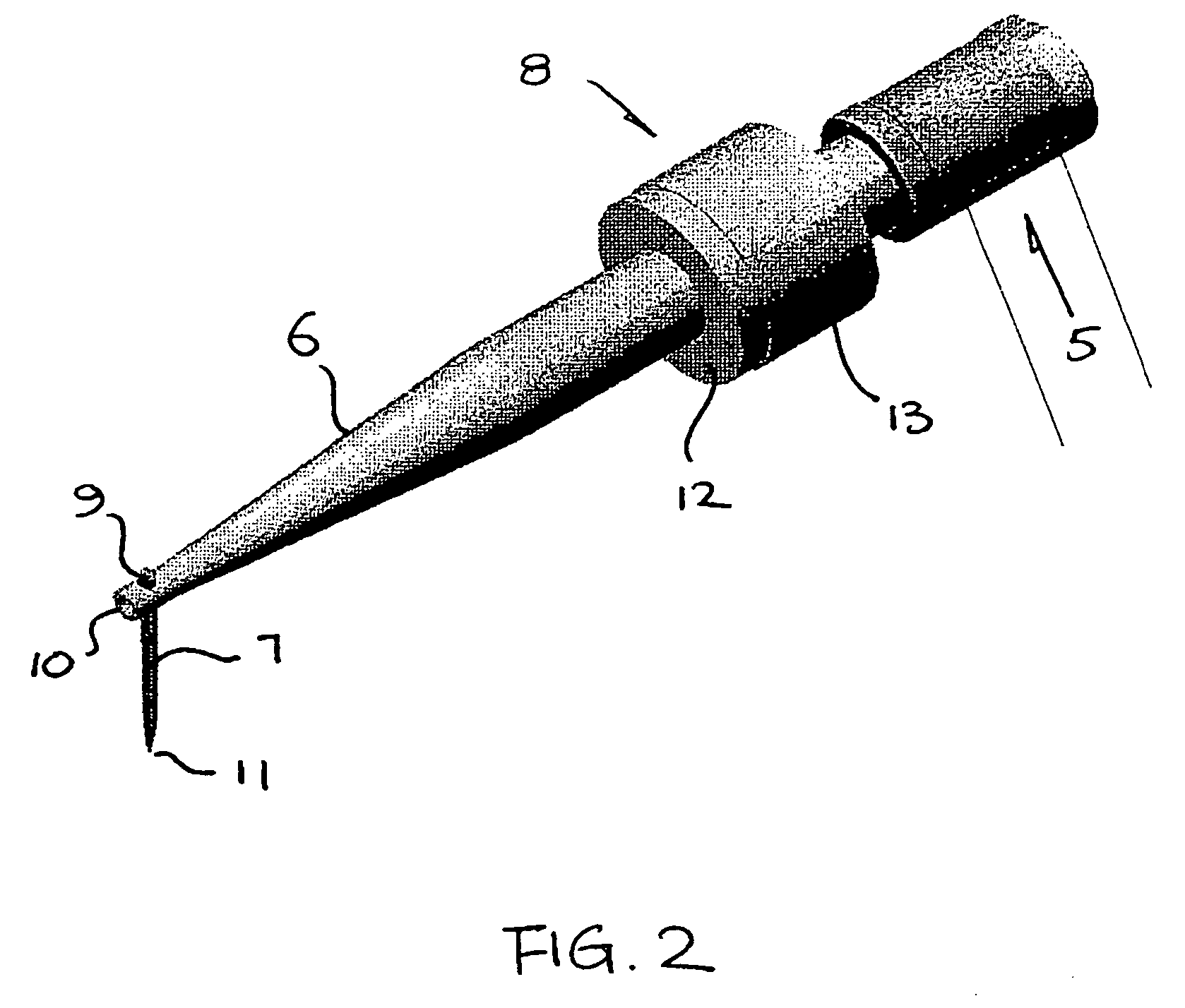

Driver for an ultrasonic transducer and an ultrasonic transducer

ActiveUS20050146231A1High Power Handling CapabilityImprove efficiencyPiezoelectric/electrostriction/magnetostriction machinesSolid-state devicesUltrasonic sensorBias field

An ultrasonic transducer driver has a giant magnetostrictive element, a fastener for holding the giant magnetostrictive element under mechanical pressure, a first field generator for providing a magnetic bias field, a second field generator for providing a magnetic drive field and a magnetic circuit for channelling the magnetic fields in the magnetostrictive element. An ultrasonic transducer for a bonding apparatus has a horn having a bonding tool at its smaller end and a mounting barrel adjoined onto it. The driver coupled to the larger end of the horn.

Owner:THE HONG KONG POLYTECHNIC UNIV

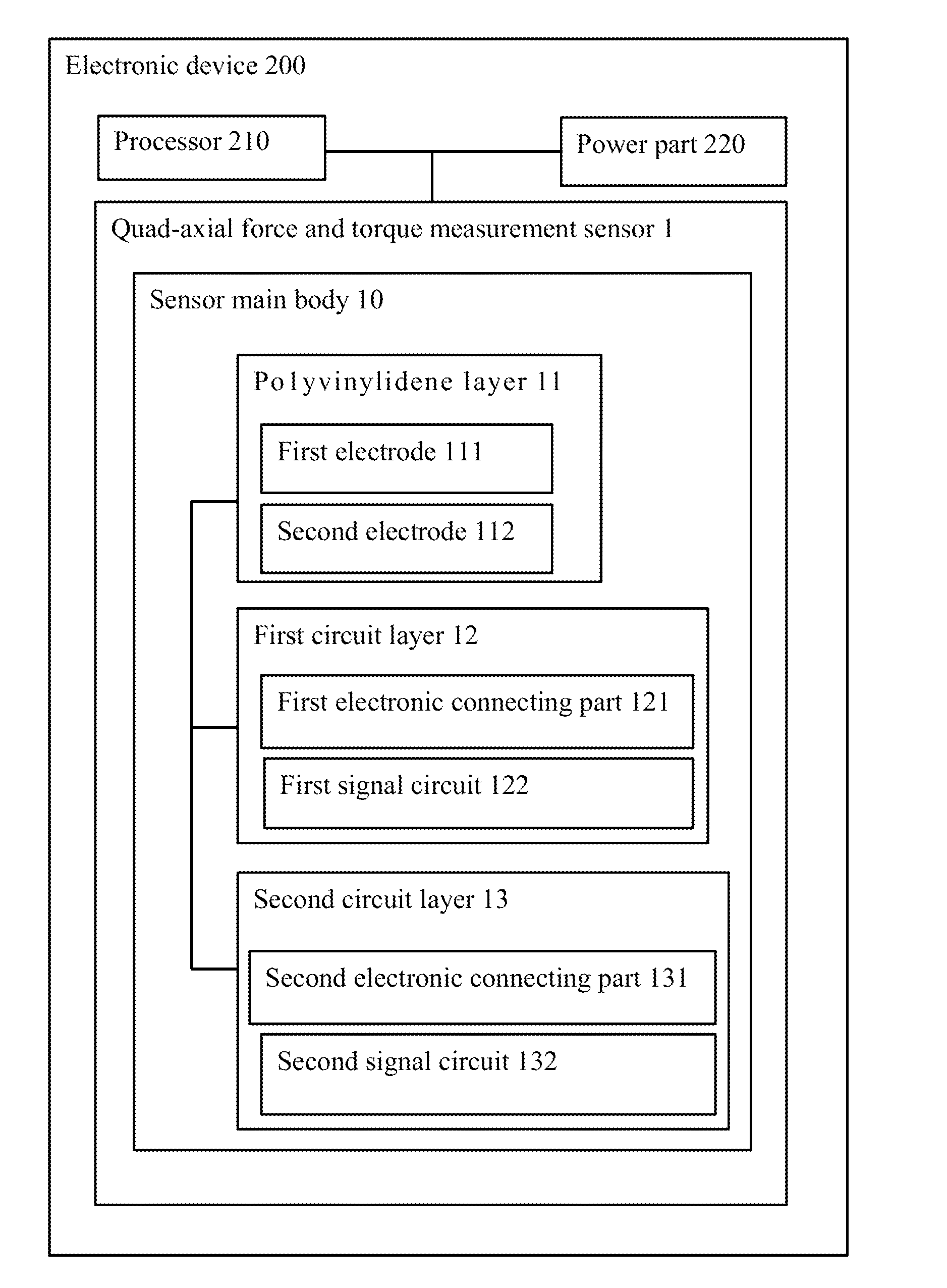

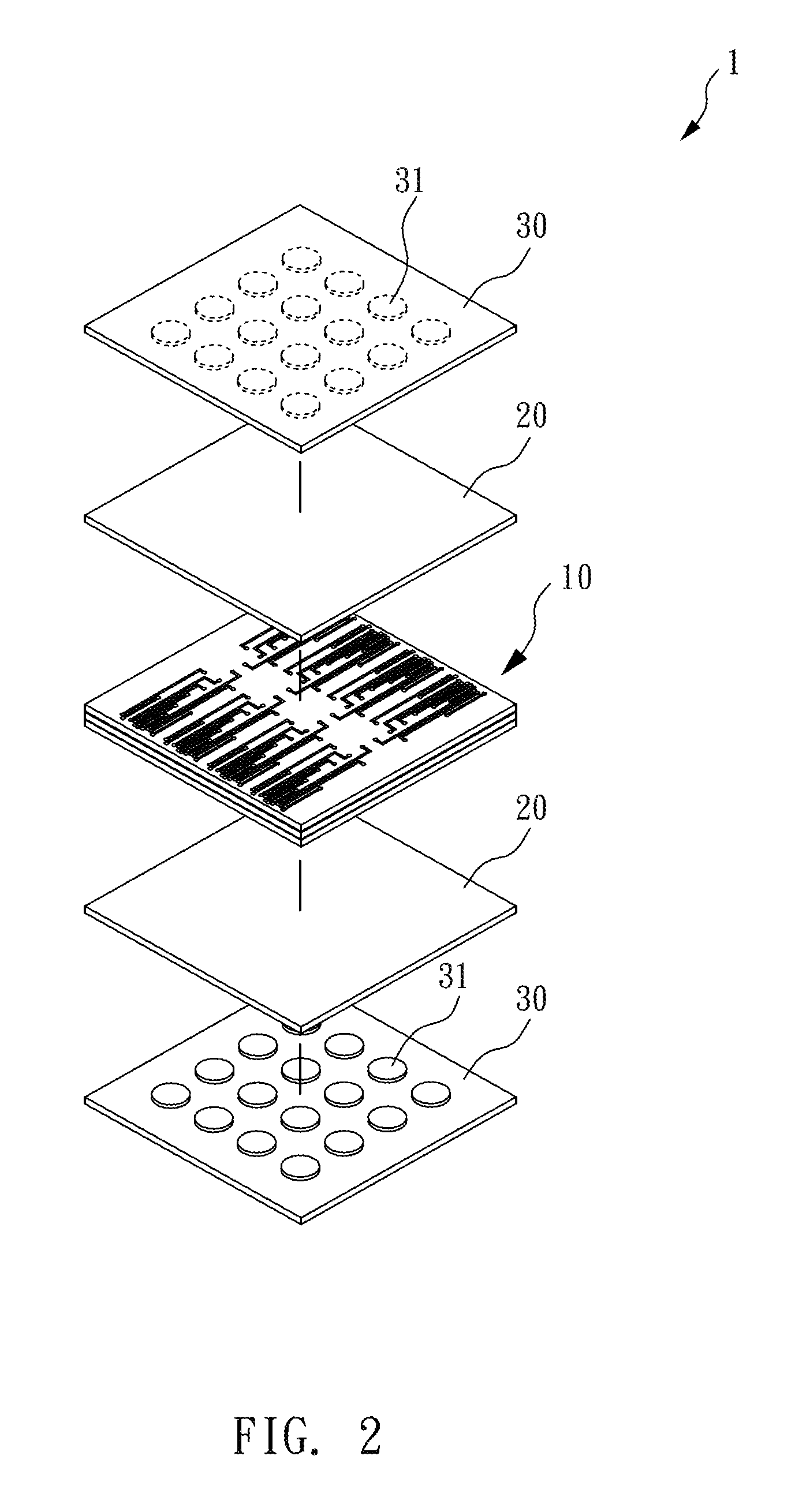

Electronic device and quad-axial force and torque measurement sensor thereof

ActiveUS9207134B2High sensitivityThin thicknessPiezoelectric/electrostrictive device manufacture/assemblyForce measurement using piezo-electric devicesElectricityAxial force

A quad-axial force and torque measurement sensor is disclosed in the invention. The quad-axial force and torque measurement sensor includes a sensor main body which includes a polyvinylidene layer, a first circuit layer, and a second circuit layer. The polyvinylidene layer is located between the first circuit layer and the second circuit layer. The polyvinylidene layer includes a first polyvinylidene layer surface, a second polyvinylidene layer surface, a plurality of first electrodes, a plurality of second electrodes and a plurality of third electrodes. The first electrodes are located on the first polyvinylidene layer surface. The second electrodes and third electrodes are located on the second polyvinylidene layer surface, and the third electrodes are located around each of the second electrodes.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com