Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4955results about "Fuel injecting pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

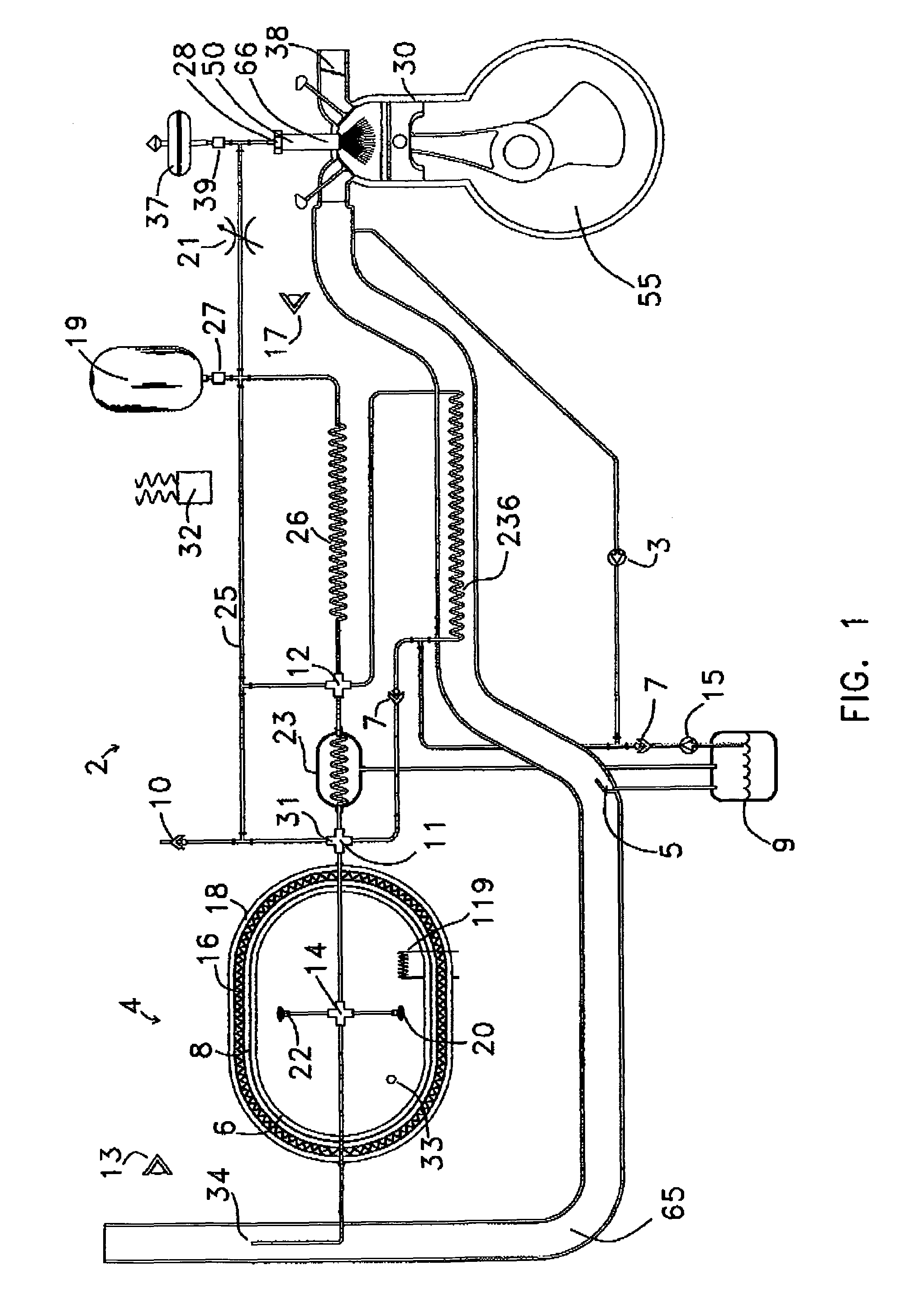

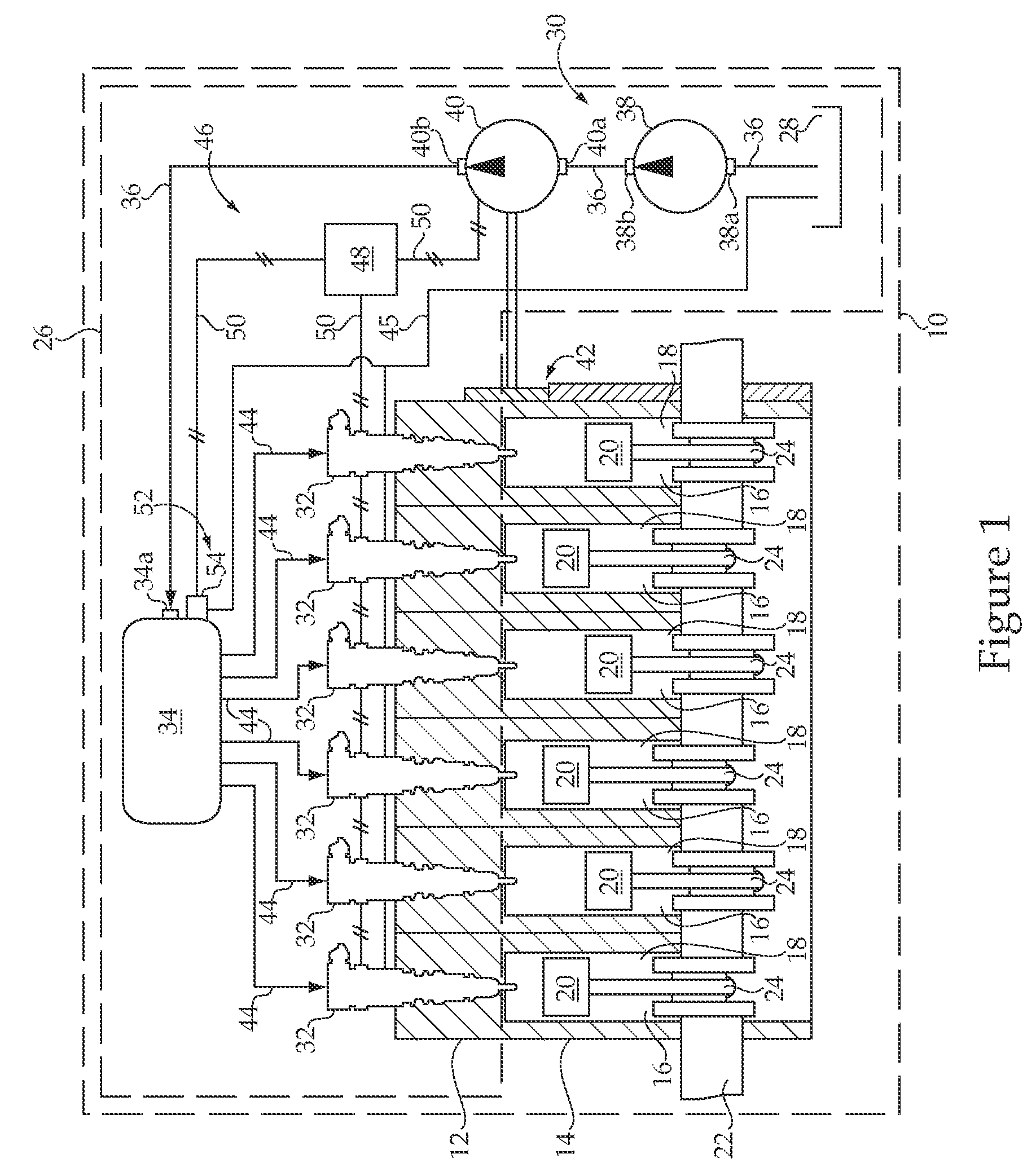

Multifuel storage, metering and ignition system

A system for safe storage and efficient utilization of a variety of fuel selections that range in composition and phase from cryogenic mixtures of solids and liquids to elevated temperature gases is provided for unique applications with various types of heat engines and fuel cells including hybridized combinations.

Owner:ADVANCED GREEN INNOVATIONS LLC +1

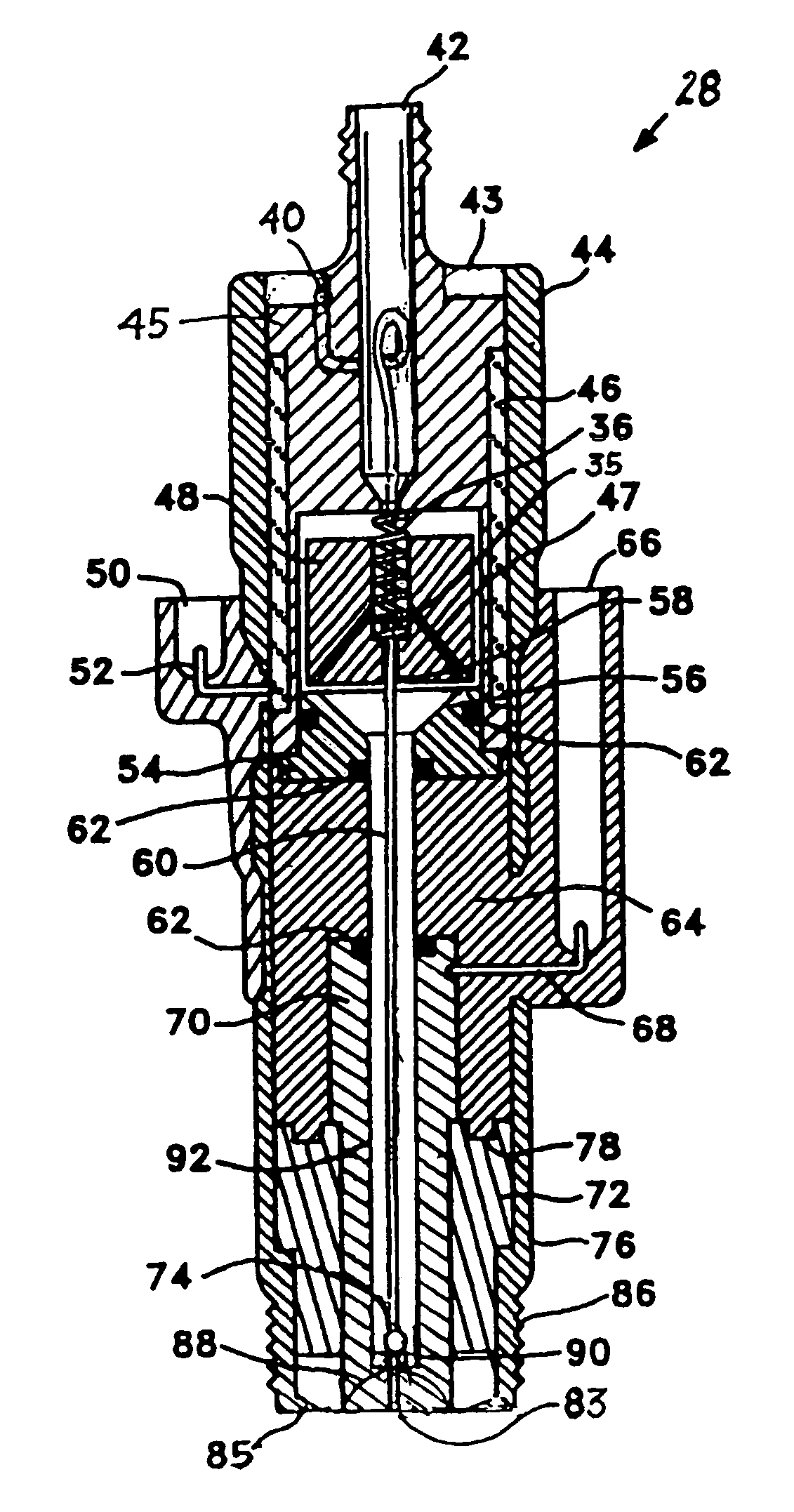

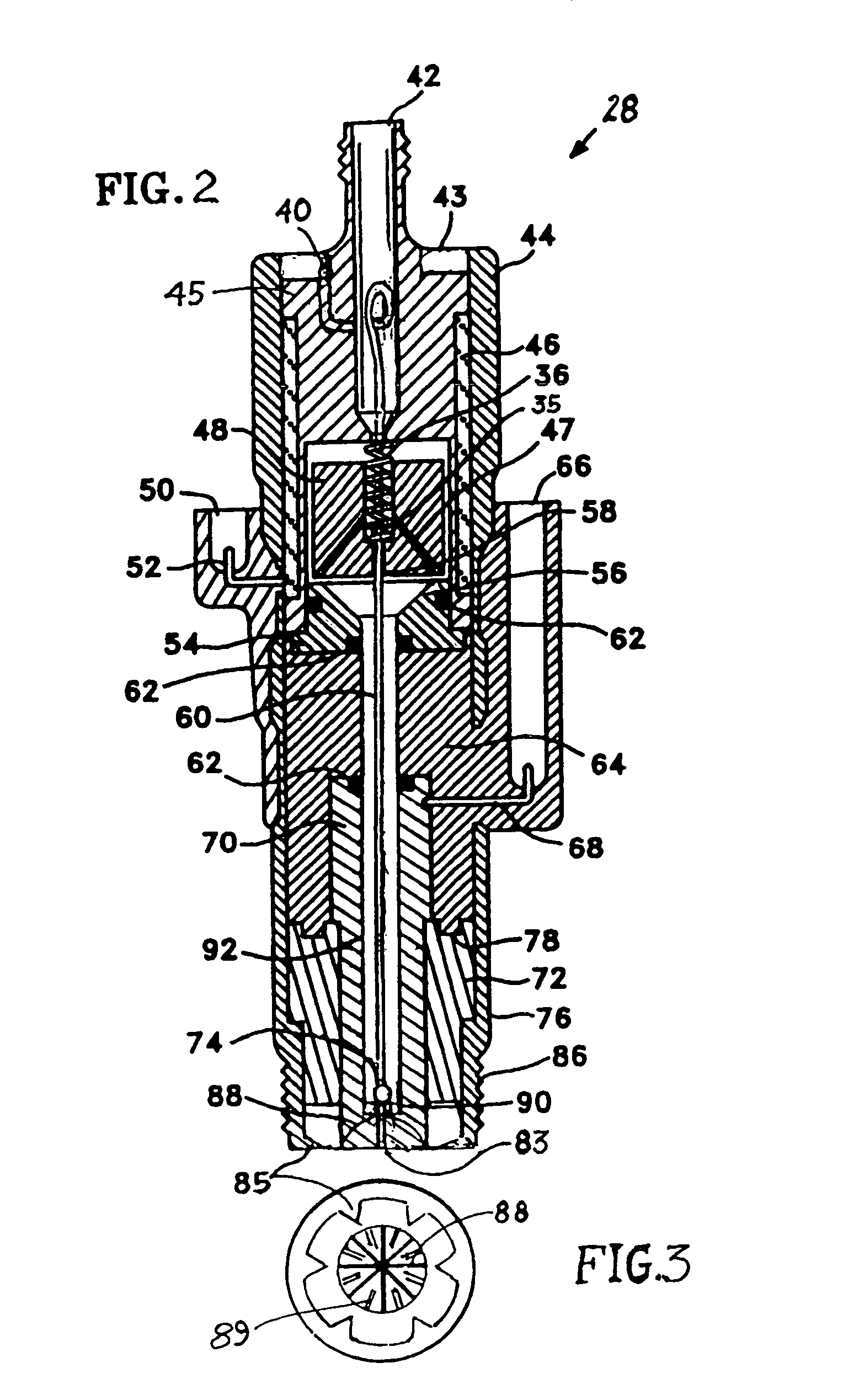

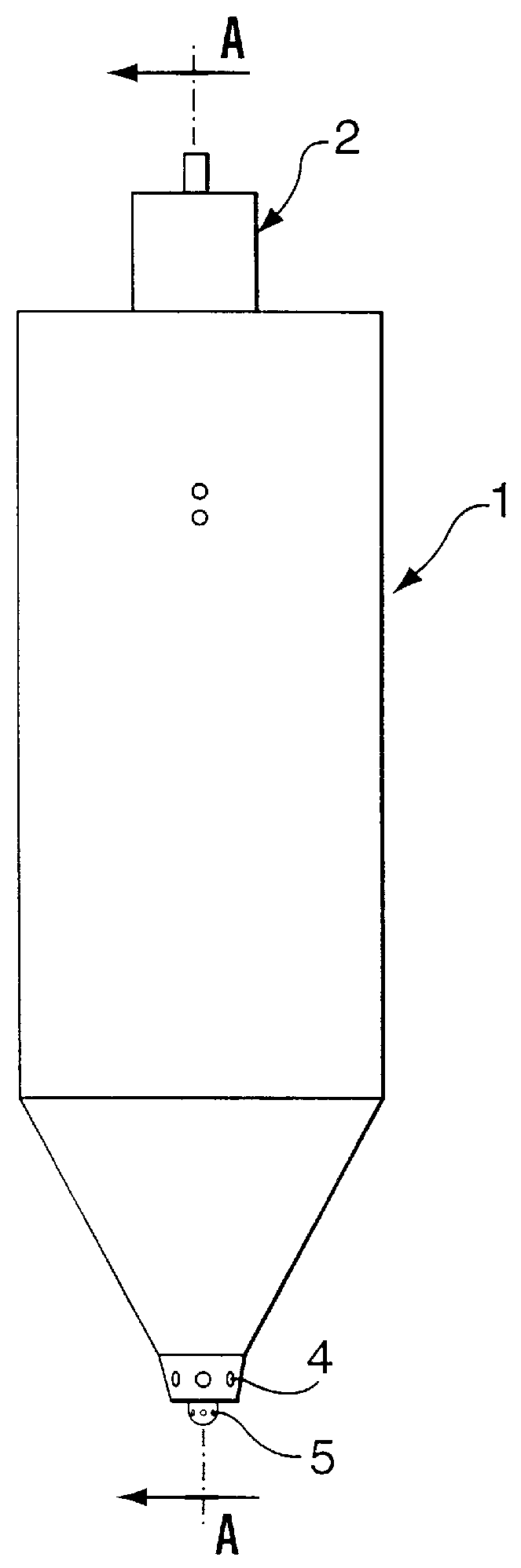

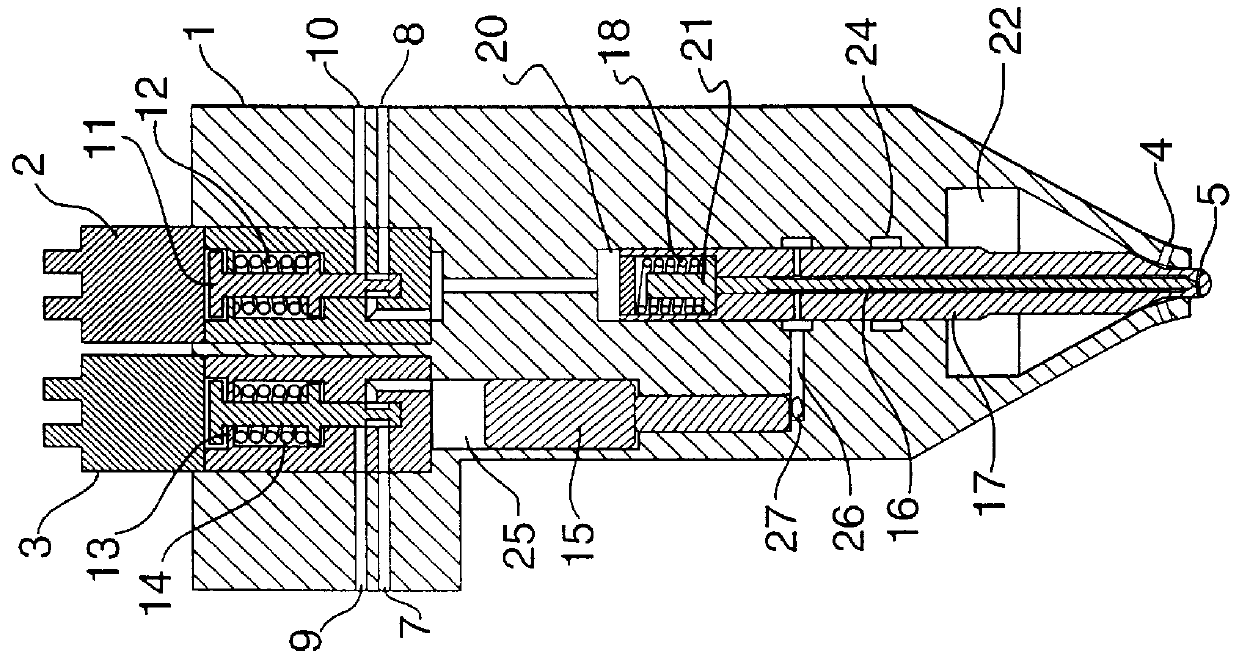

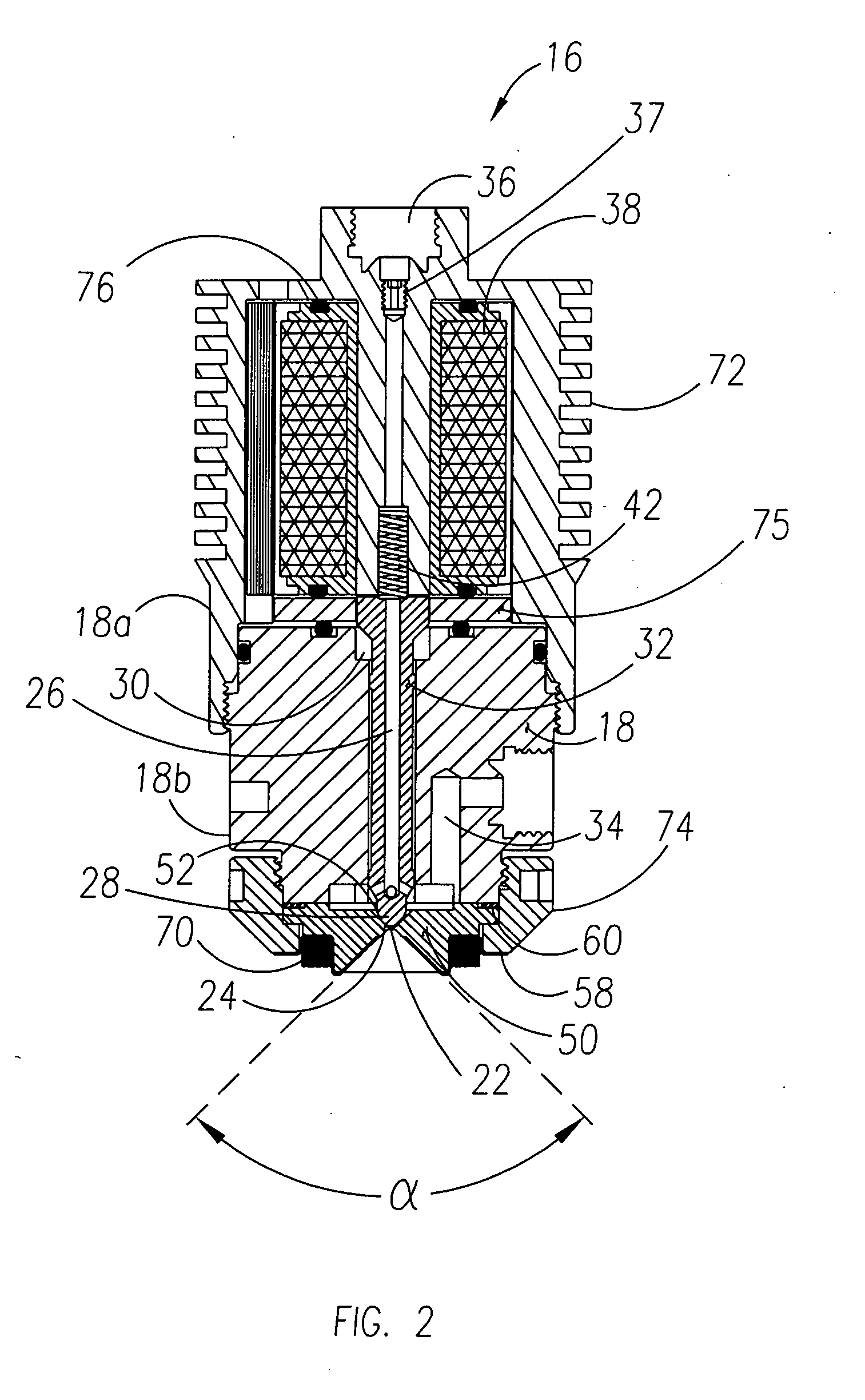

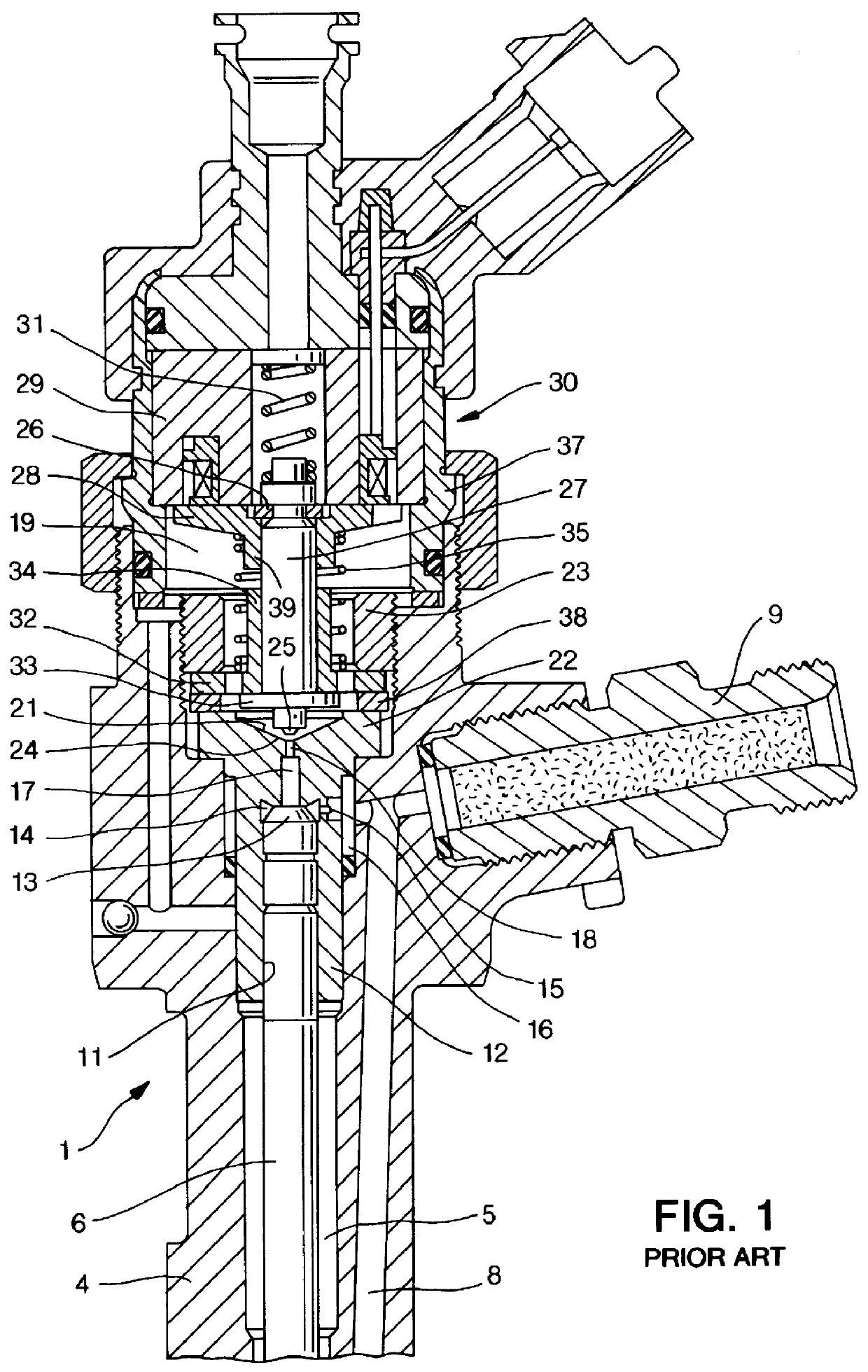

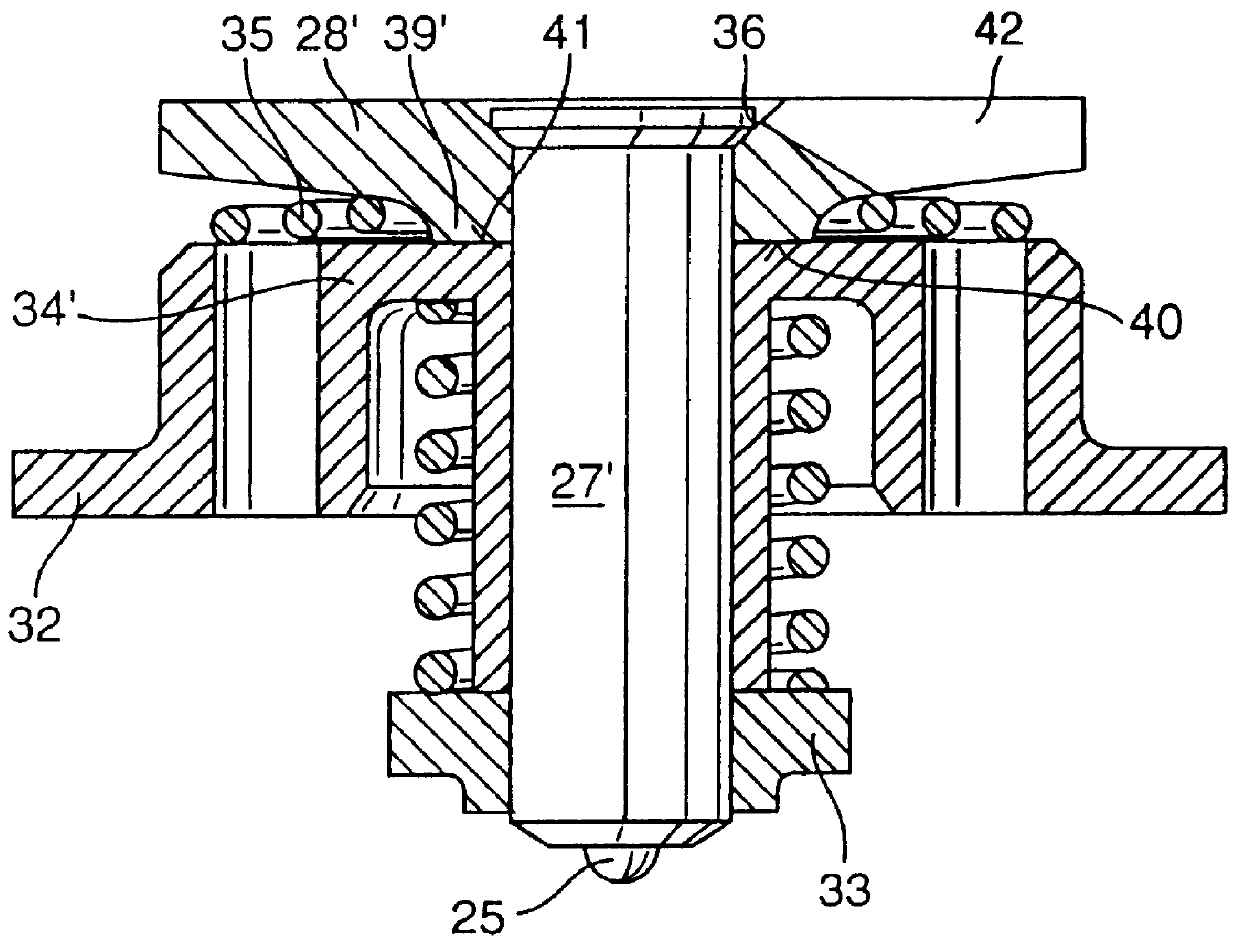

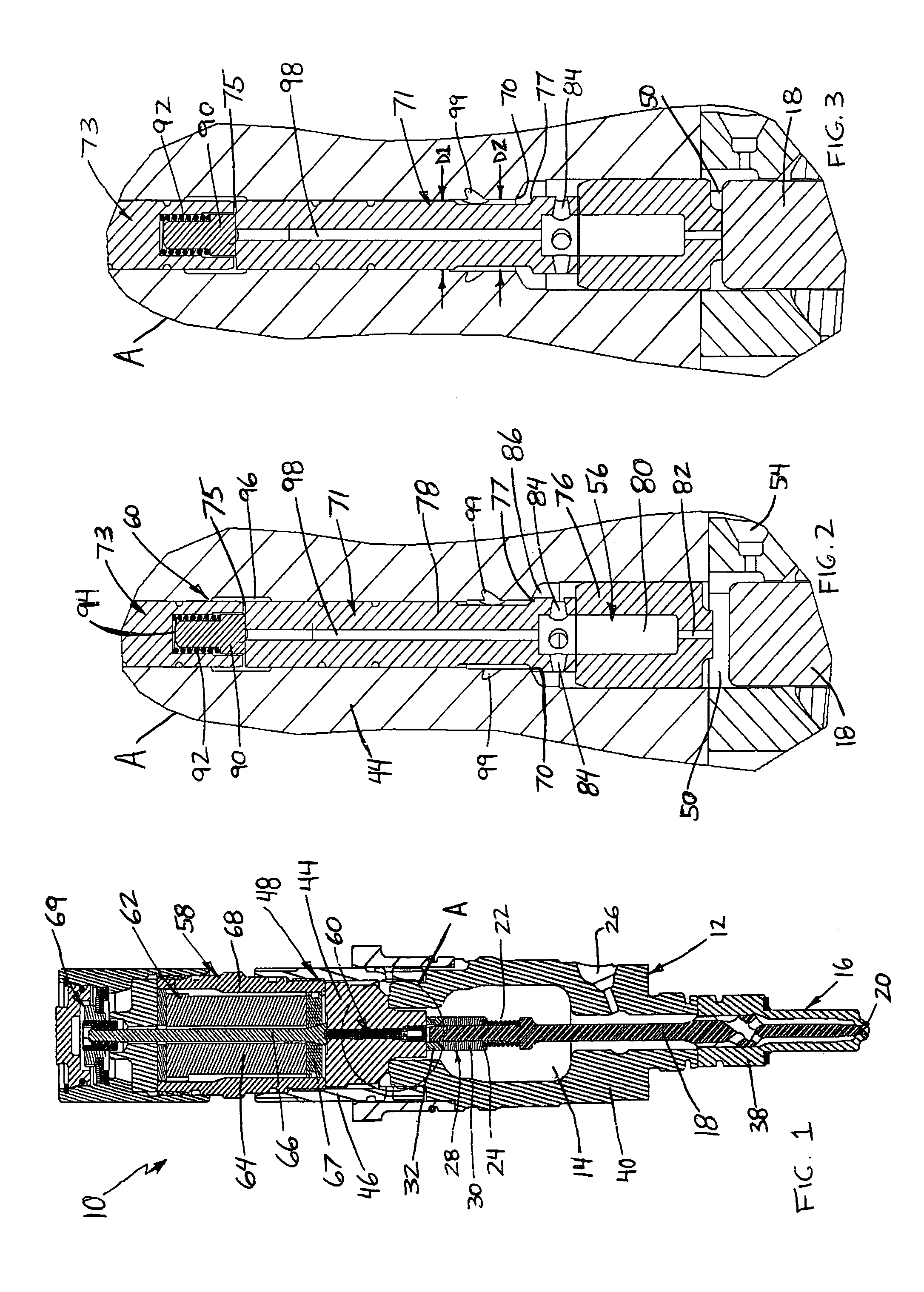

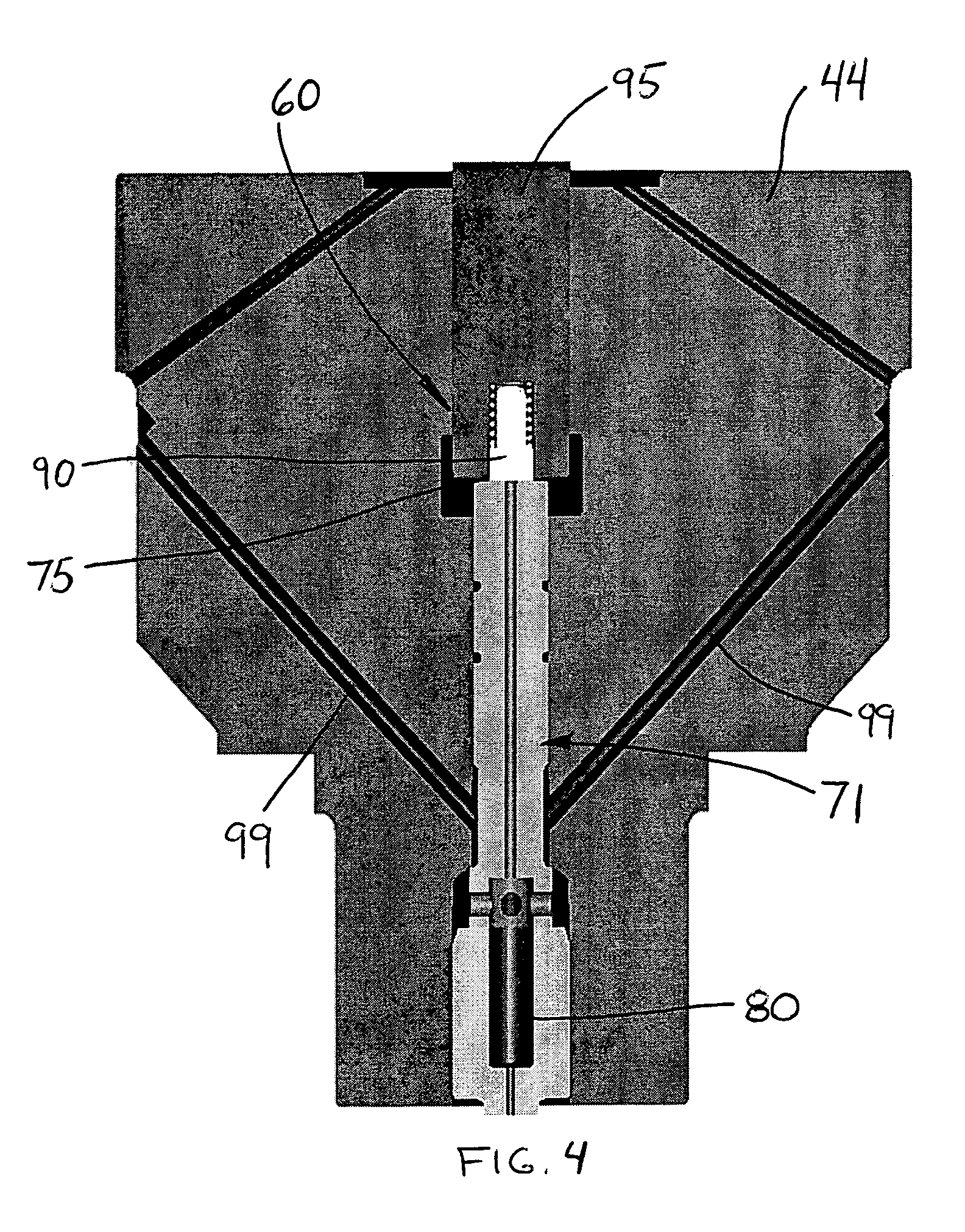

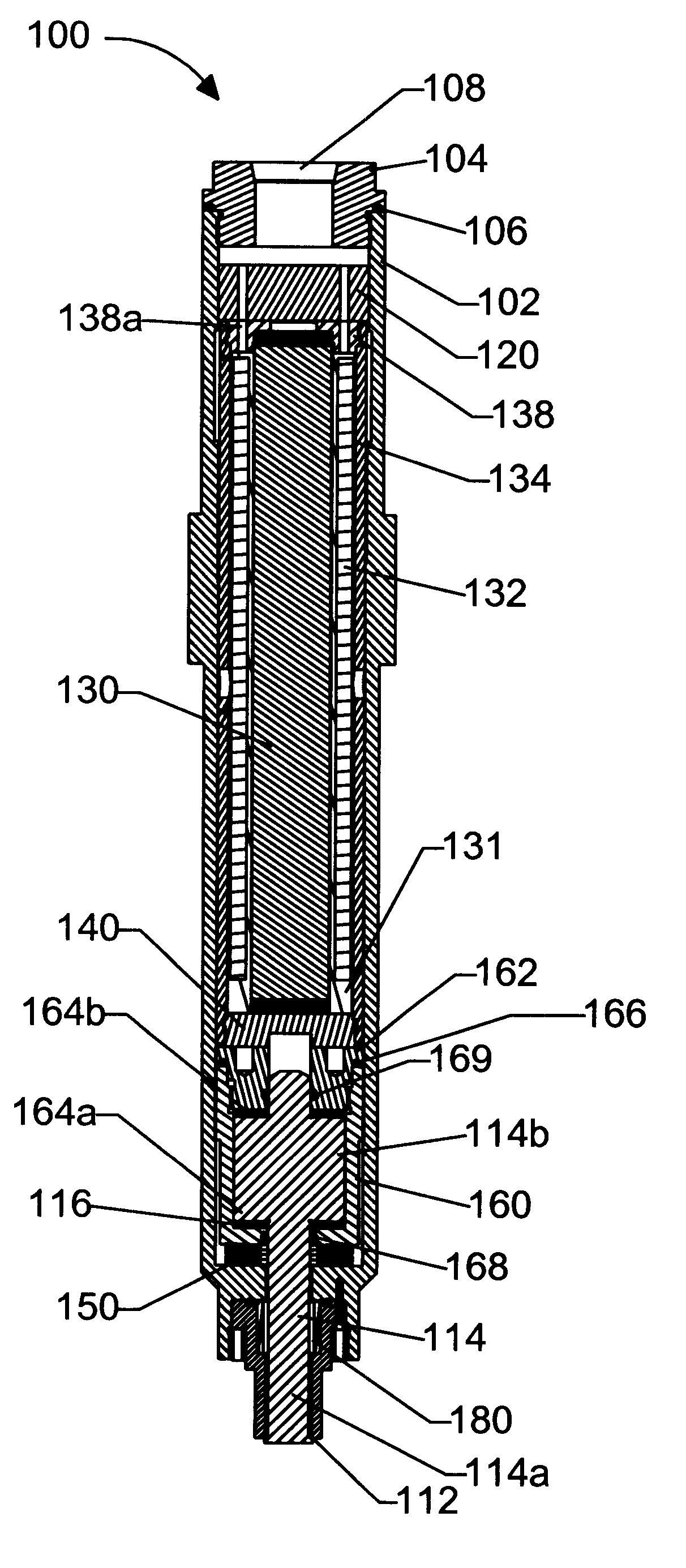

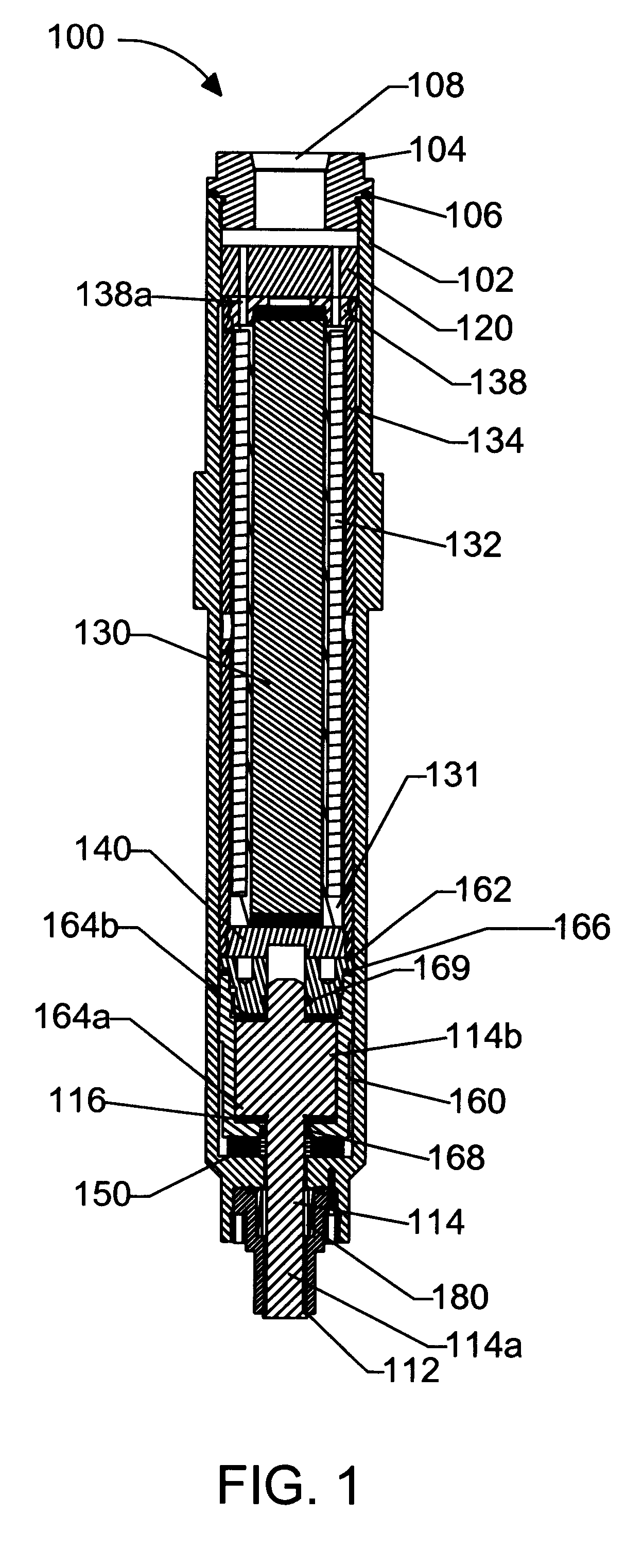

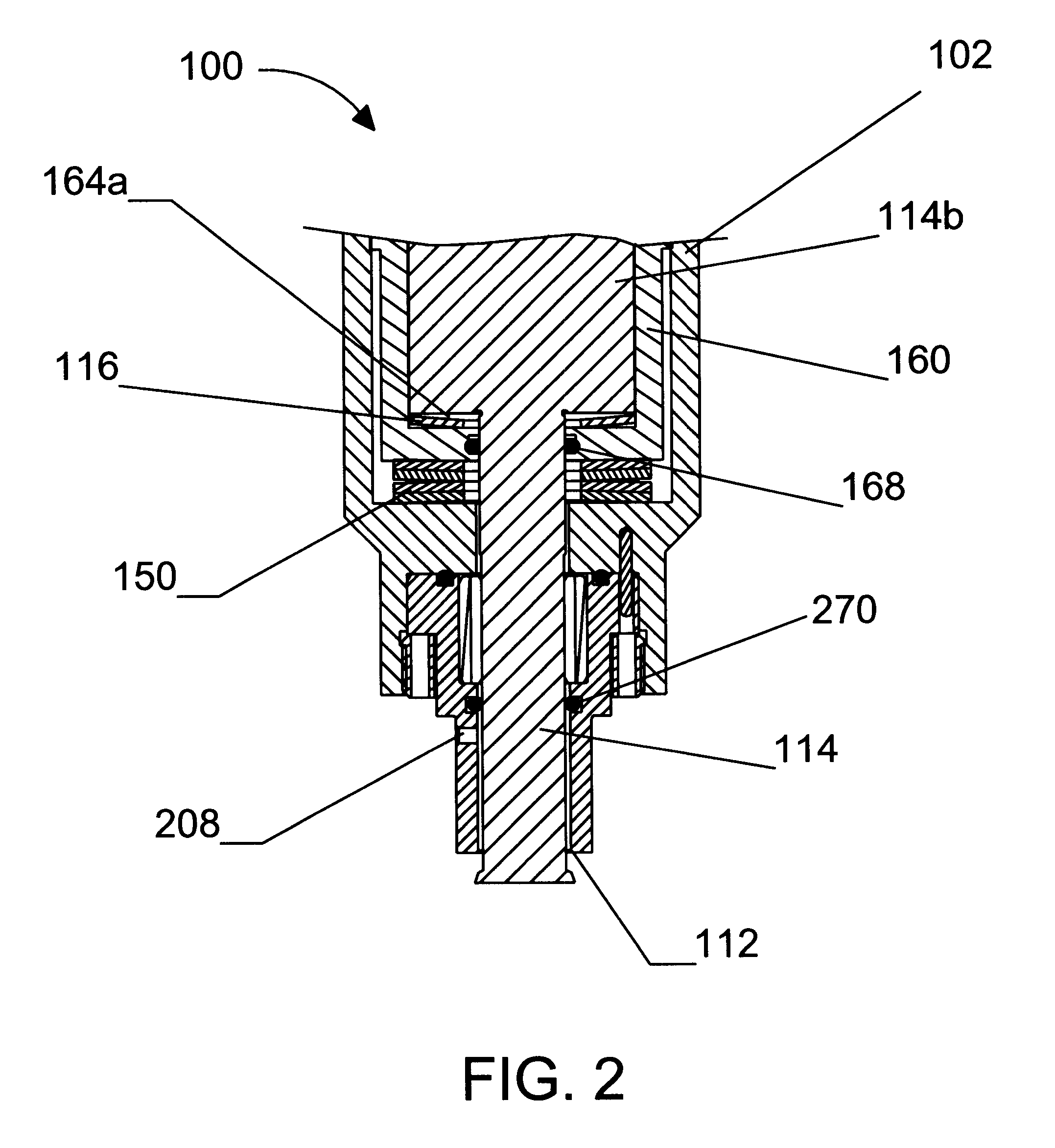

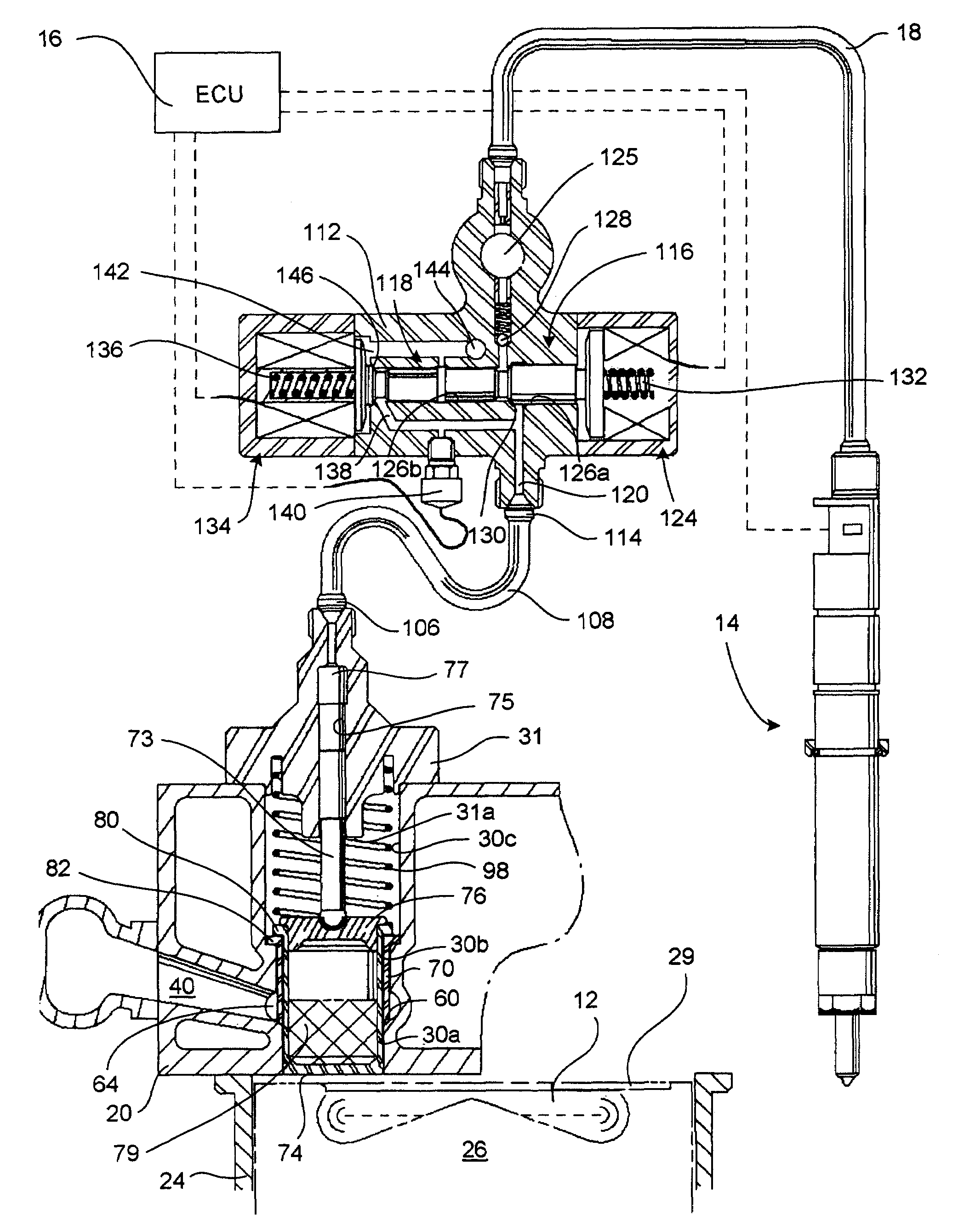

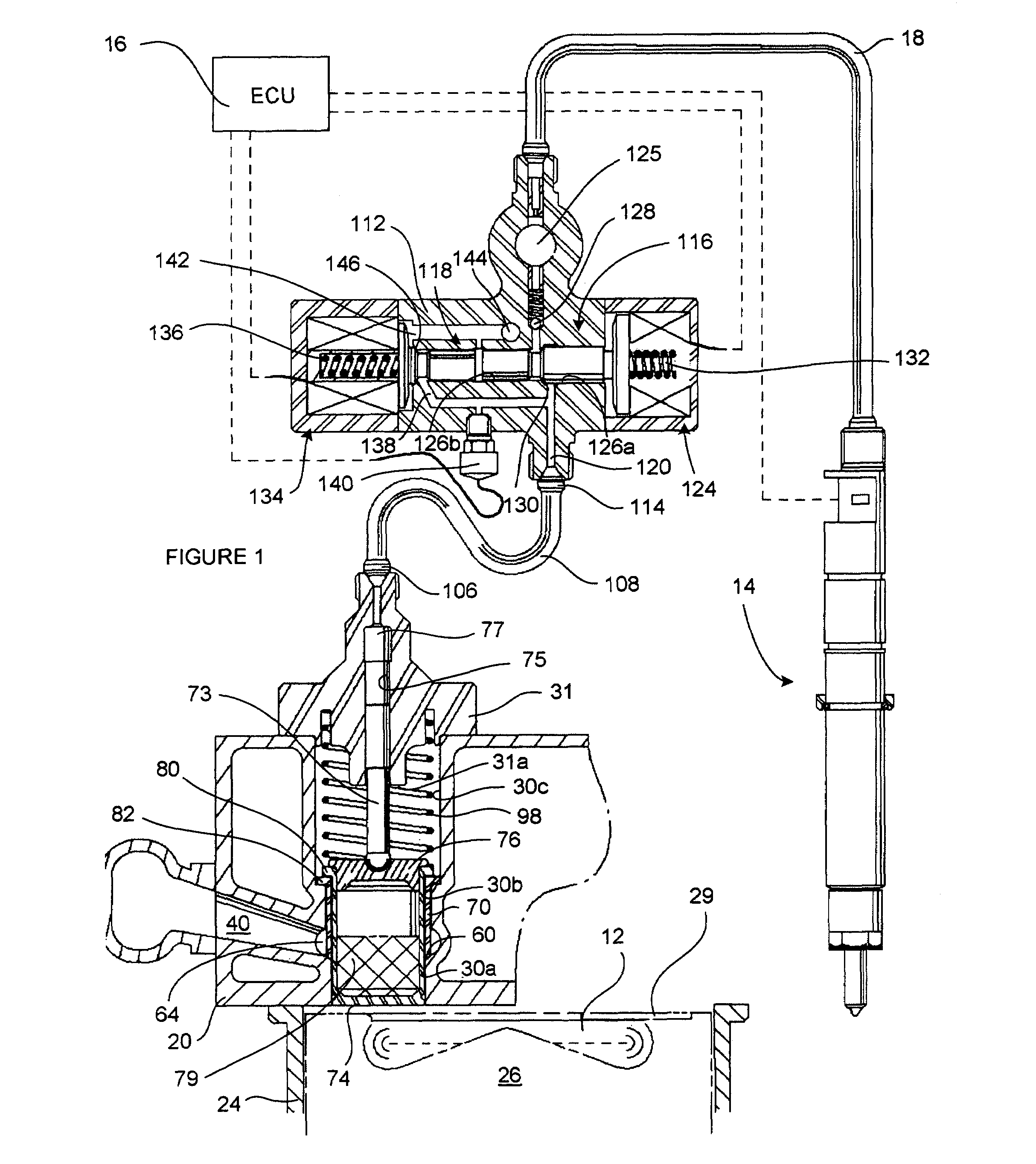

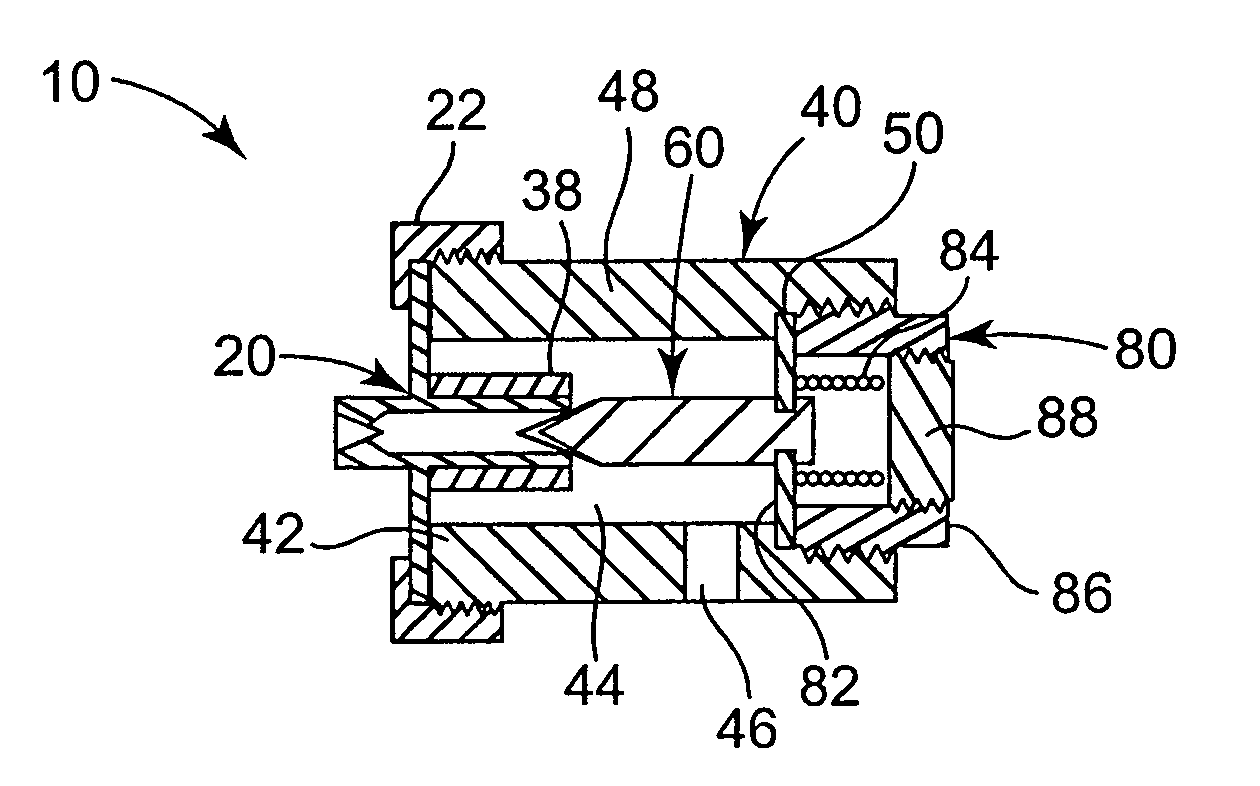

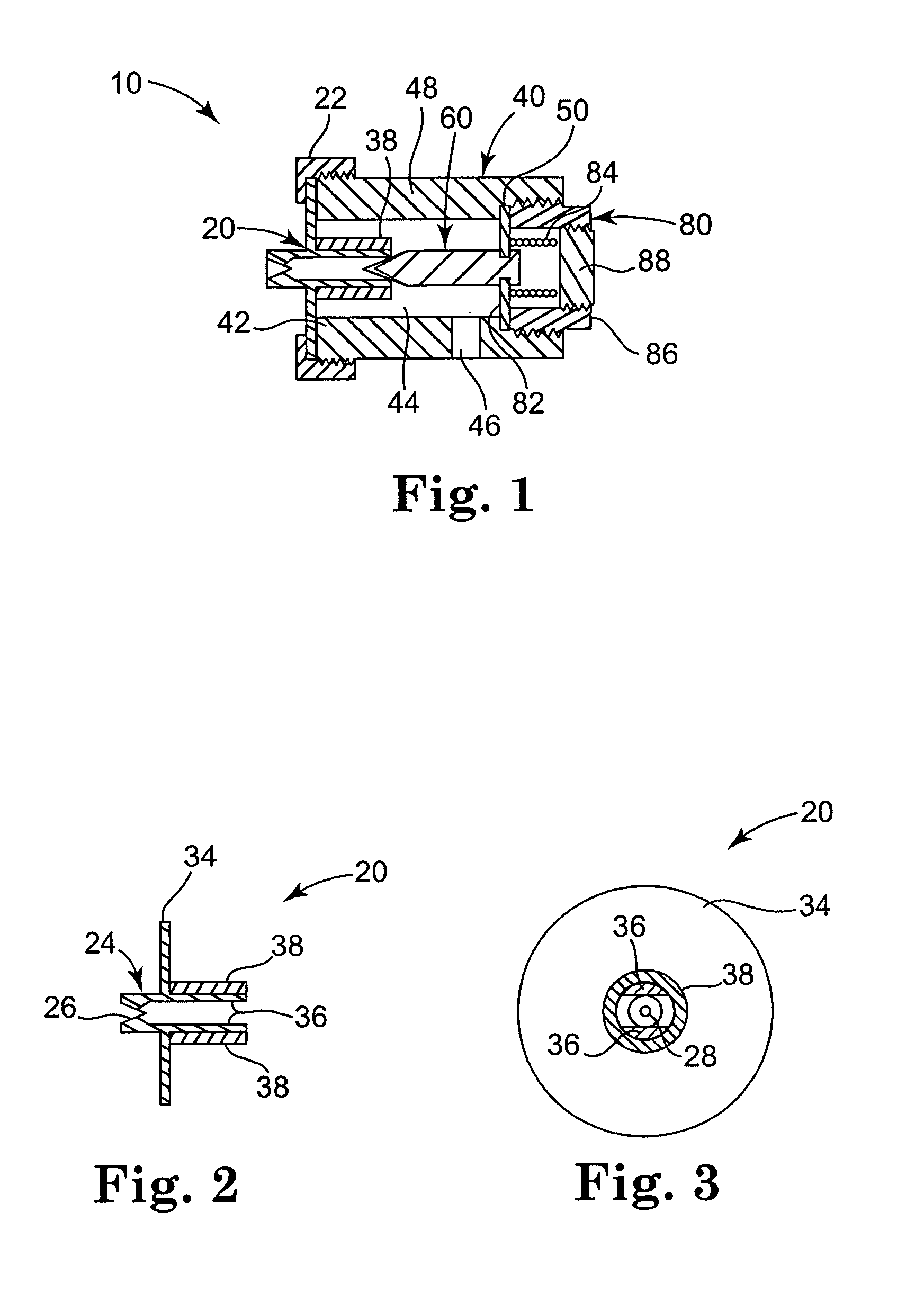

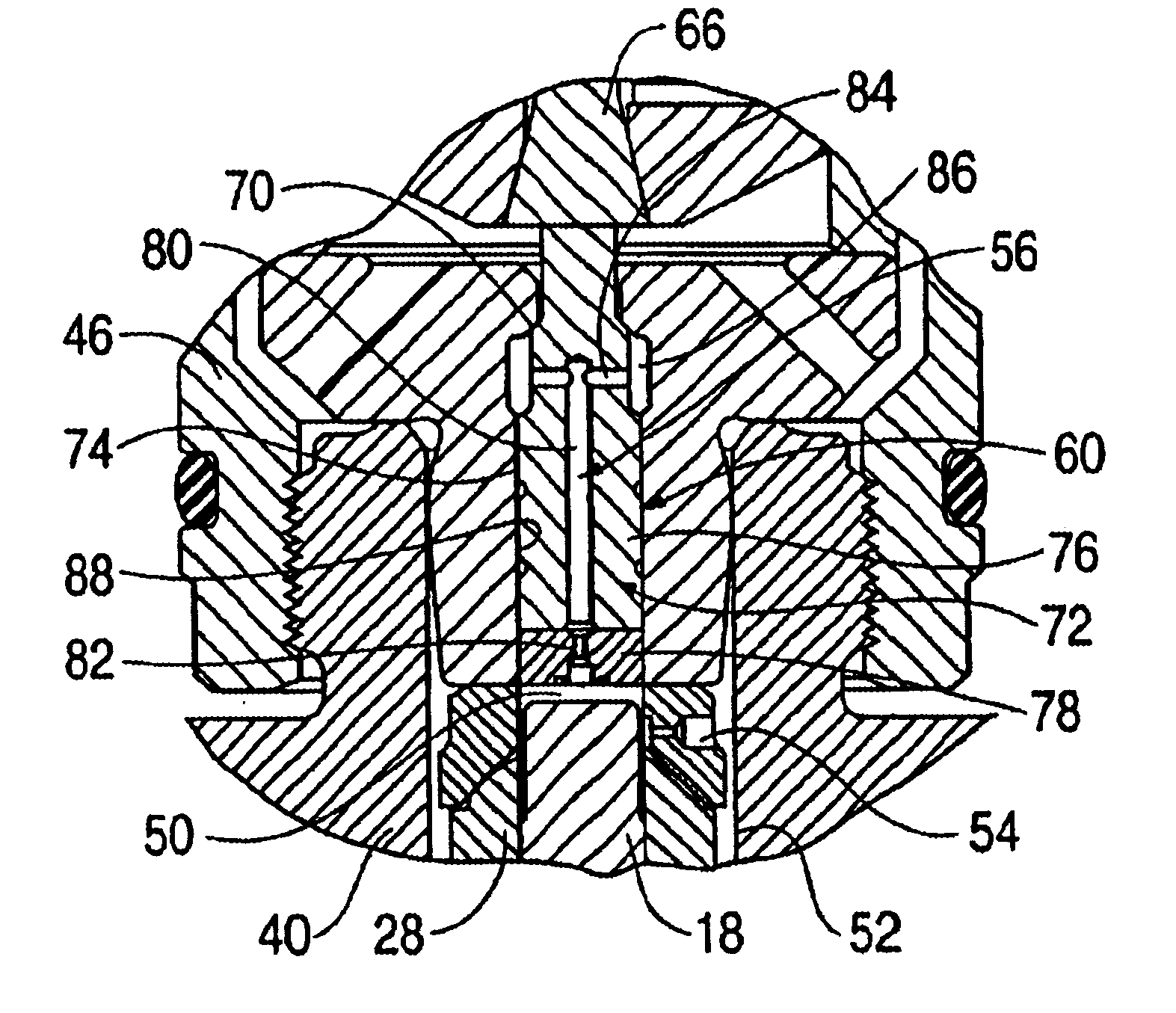

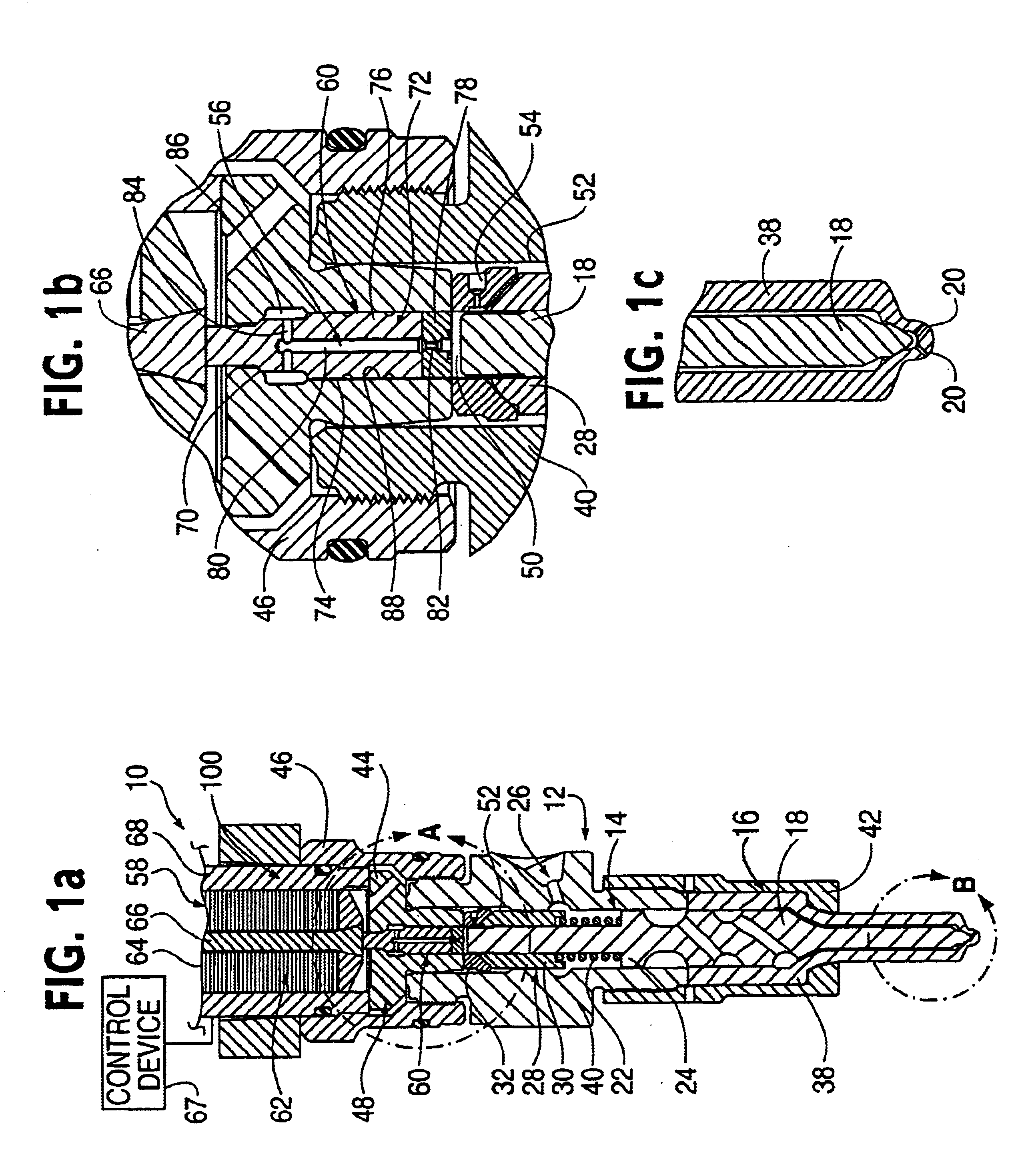

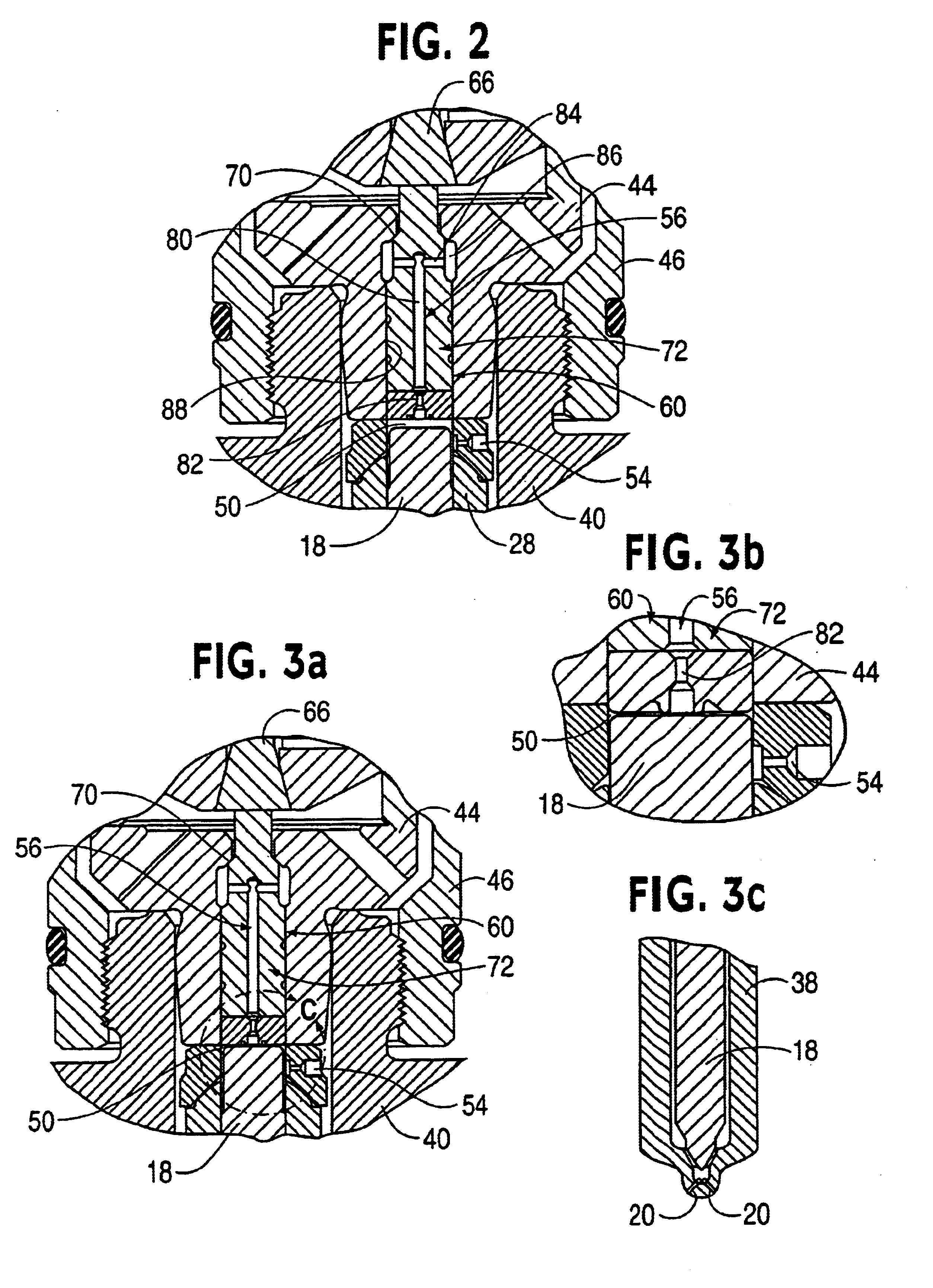

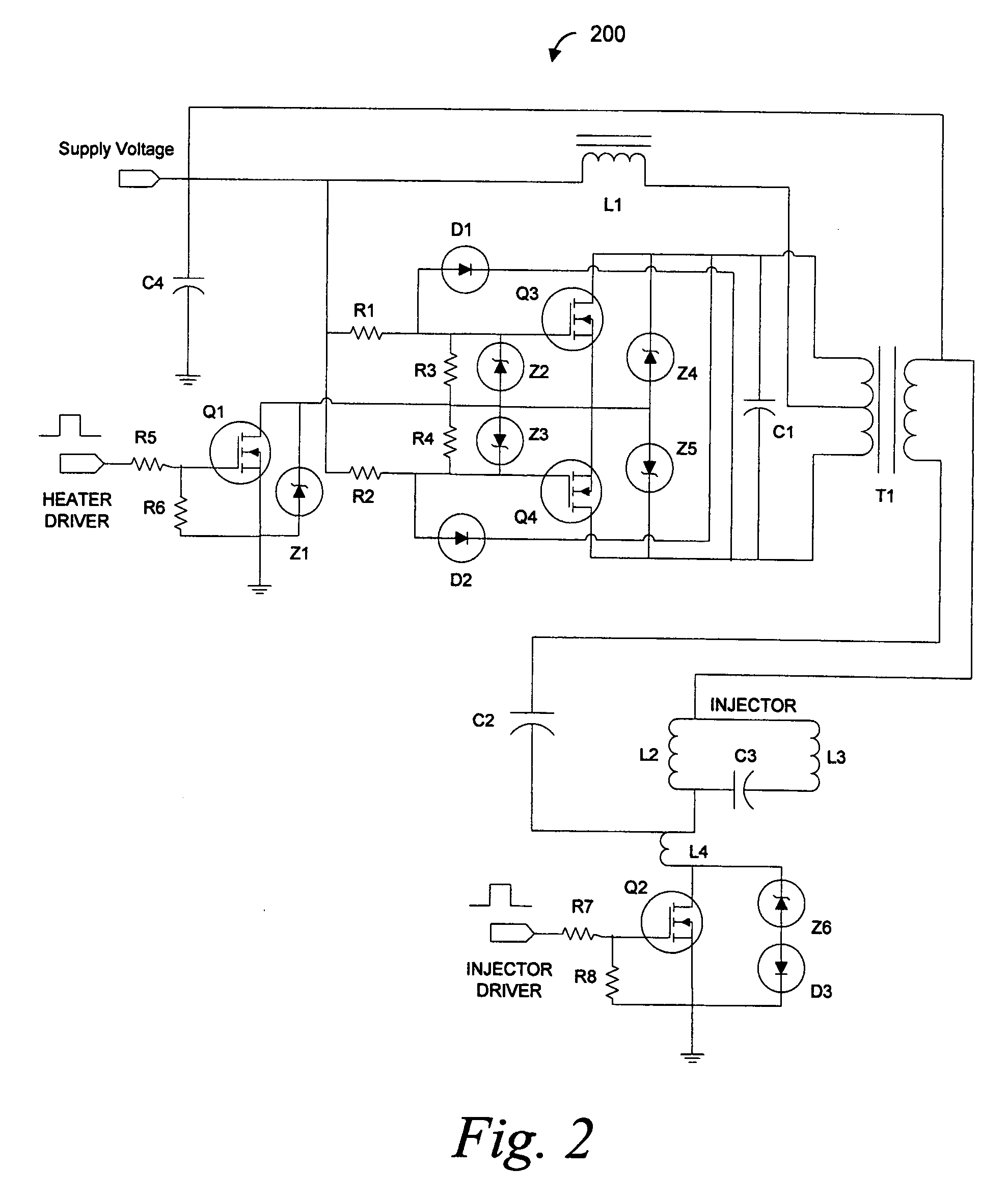

Gaseous and liquid fuel injector

A hydraulically actuated dual fuel injector for an internal combustion engine. More particularly, the application pertains to a hydraulically actuated injector for injecting controlled quantities of a first fuel and of a second fuel into an internal combustion diesel engine at different times. A dual fuel injector comprising: (a) an injector body; (b) an inlet port in the injector body for enabling pressurized hydraulic fluid from a hydraulic fluid source to be introduced into the interior of the injector body, the hydraulic fluid being of sufficient pressure to maintain injection valves in the injector body in a closed position until actuated; (c) a first inlet port in the injector body for enabling a first fuel to be introduced into the interior of the injector body; (d) a first injection valve in the injector body connected to the second inlet port for controlling injection of the first fuel from the injector through a first fuel ejection port; (e) a second inlet port in the injector body for enabling a second fuel to be introduced into the interior of the injector body; (f) a second injection valve in the injector body connected to the second inlet port for controlling injection of the second fuel from the injector through a second fuel ejection port; (g) a first control valve which causes the hydraulic fluid to actuate the first injection valve; (h) a second control valve which causes the hydraulic fluid to actuate the second injection valve; (i) a metering device in the injector body for metering the amount of first fuel injected by the first injection valve; and (j) a seal in the injector body which prevents leakage of the second fuel into the first fuel.

Owner:WESTPORT POWER

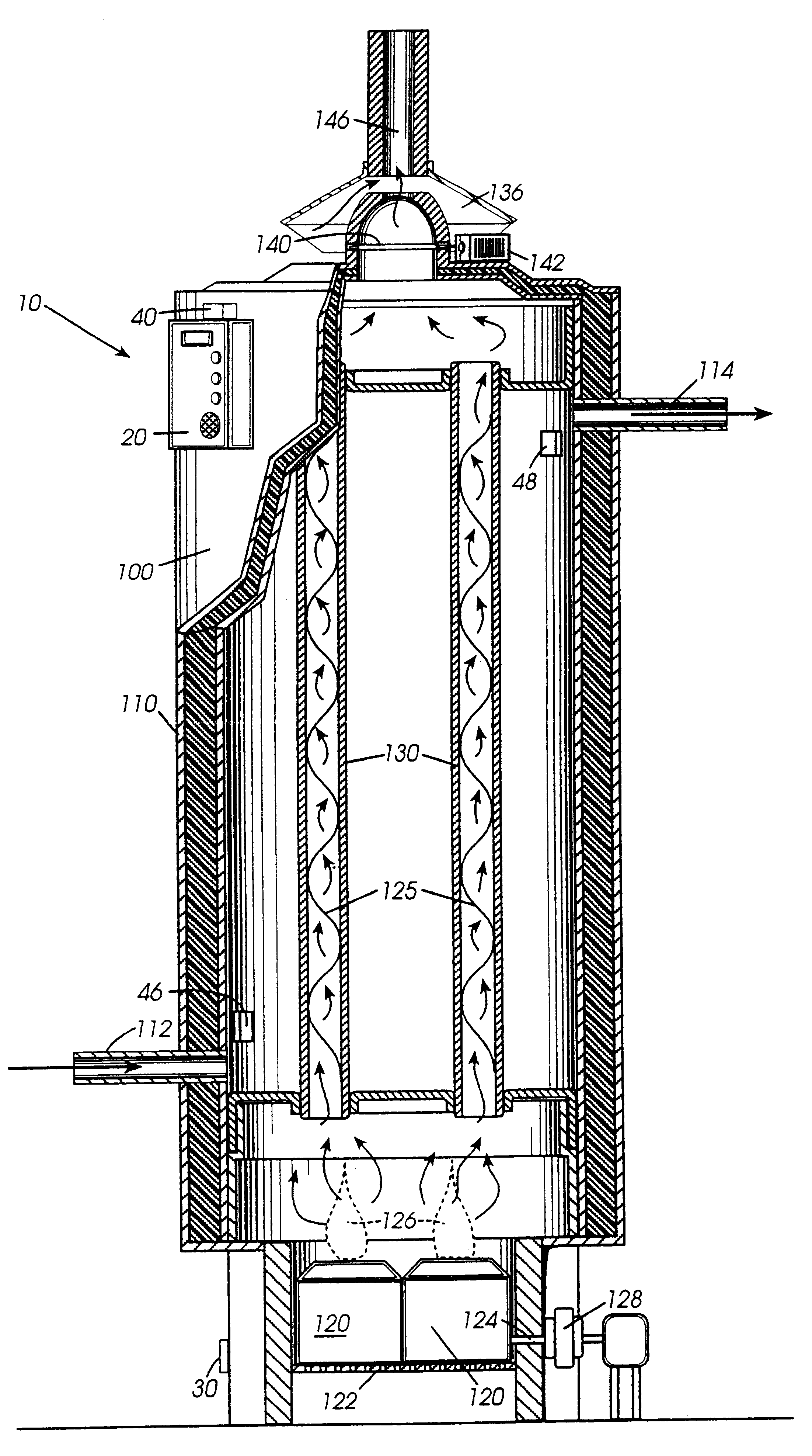

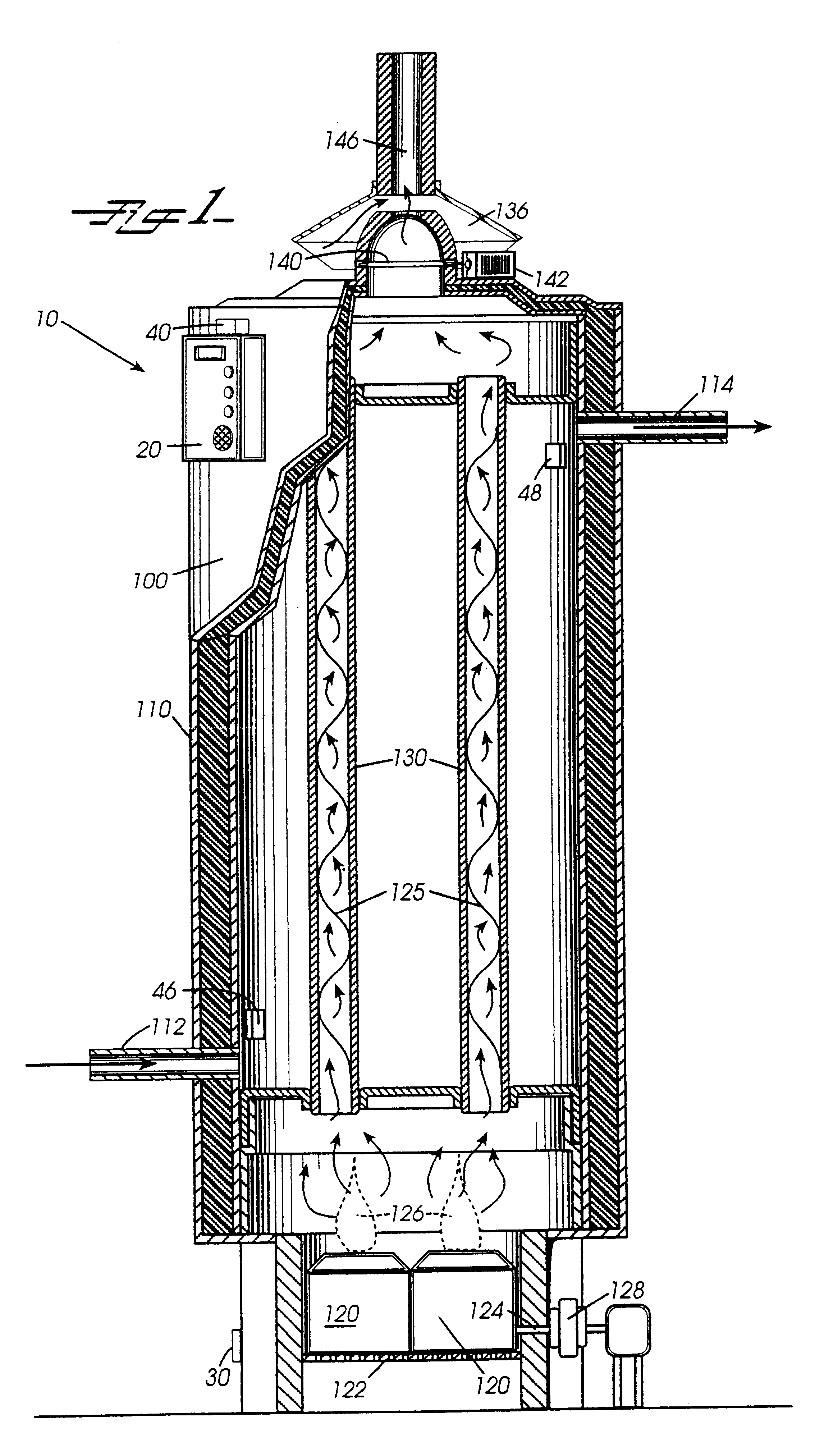

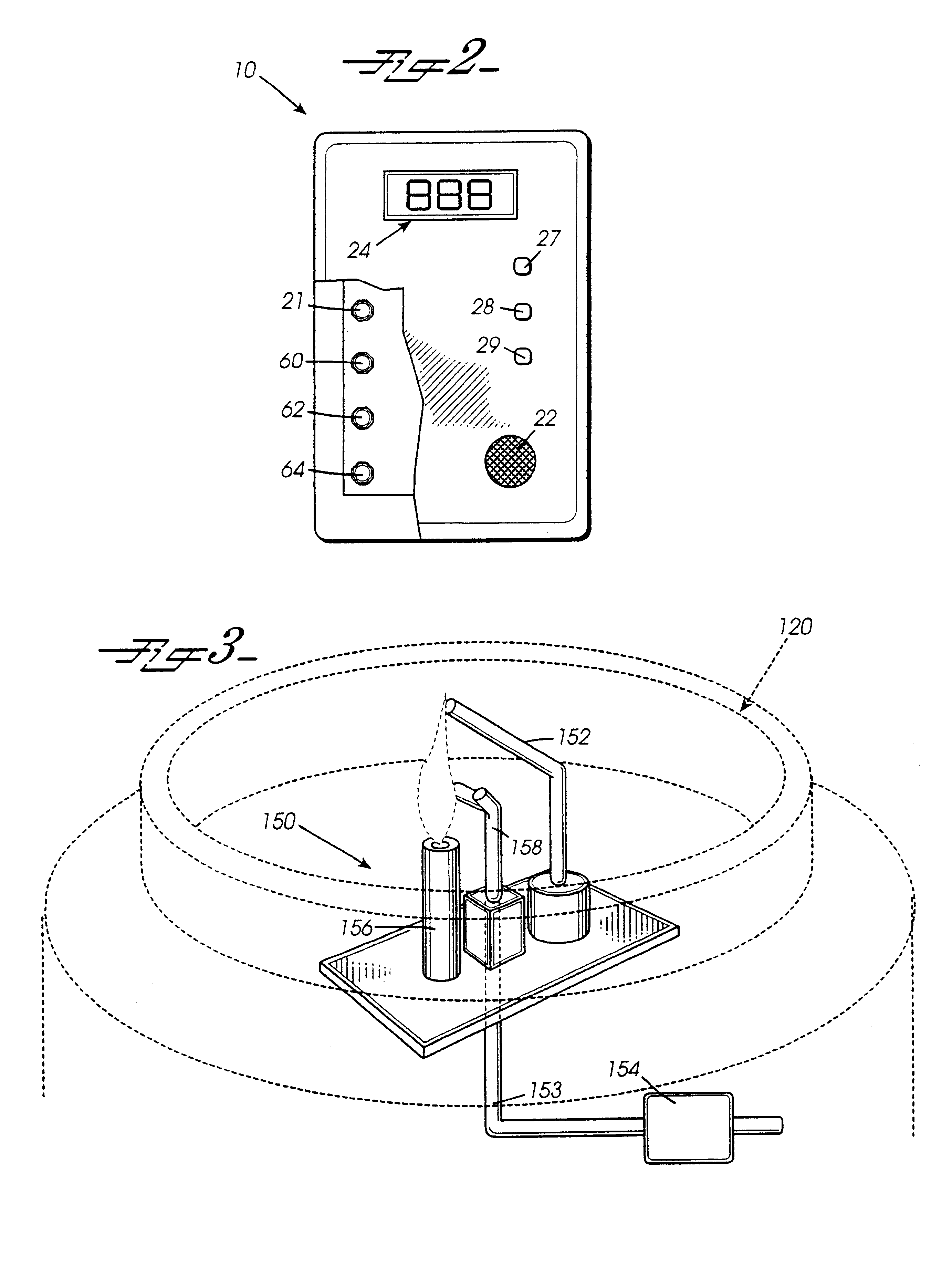

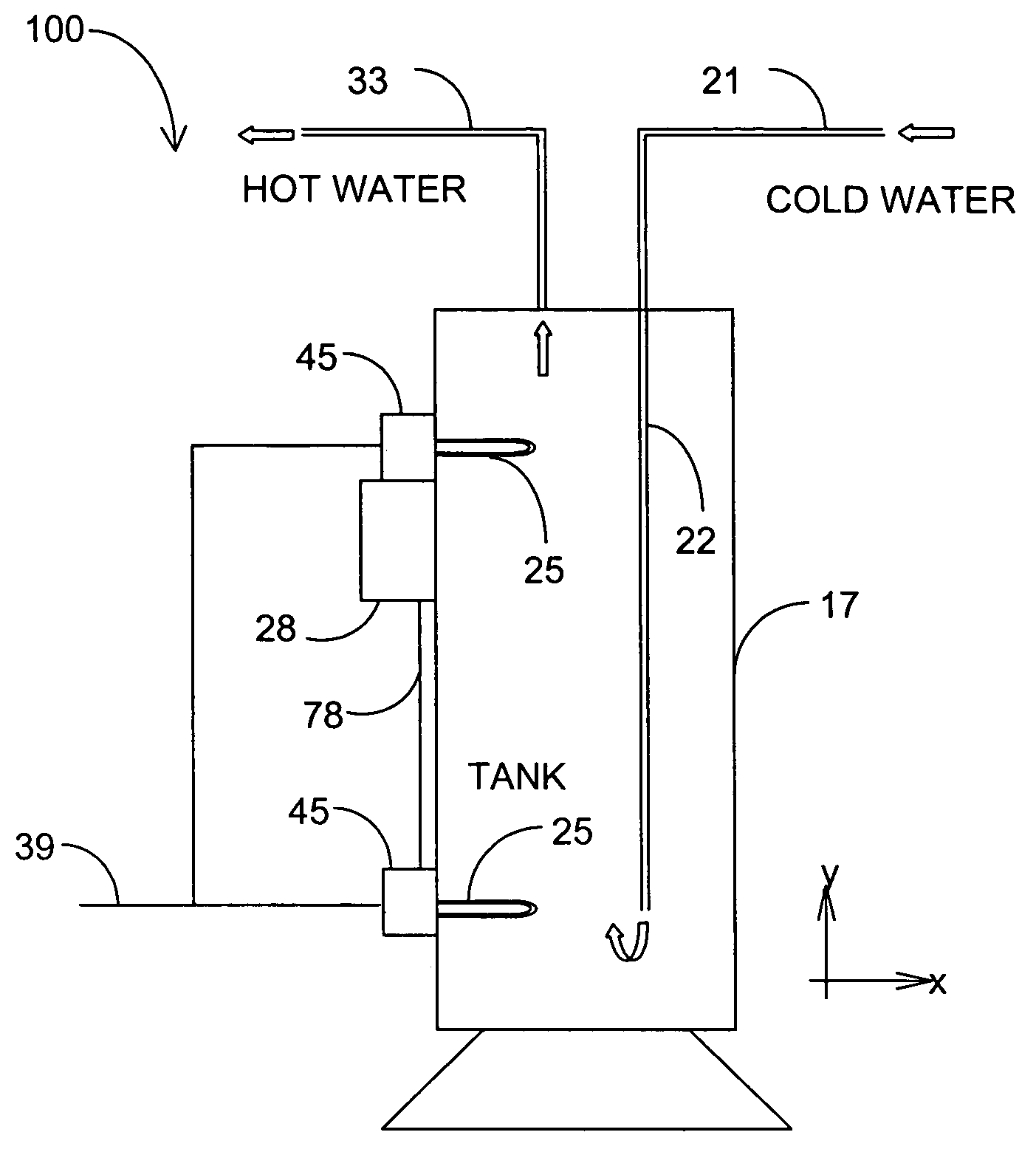

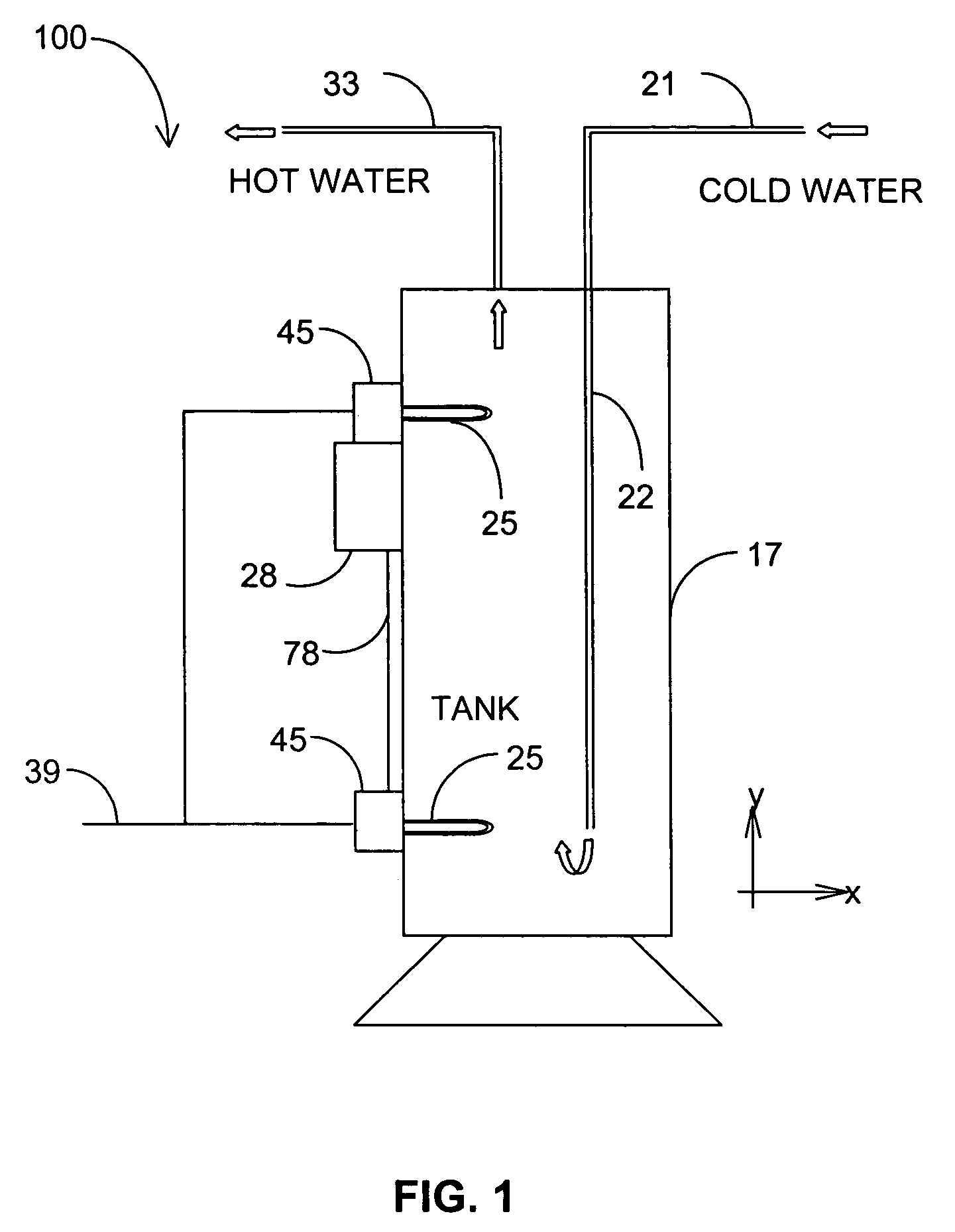

Control system for a water heater

InactiveUSRE37745E1Detect presenceHarmful and dangerousMachines/enginesFuel injecting pumpsCombustorControl system

A multi-function controller for a water heater is advanced comprising a control panel and a plurality of sensors that monitor a variety of functions that impact the operation of a water heater. A flammable gas sensor, placed in proximity to the air intake, detects the presence of an unsafe concentration of gas and issues a signal to the control panel, which subsequently discontinues the operation of the burners. Detection of a blocked vent pipe is achieved by a carbon monoxide sensor placed near the draft hood. The control panel is equipped with circuitry which monitors usage of the heater for a specified time period to develop a pattern of use. Subsequent to the monitoring period, the controller will activate the burners a predetermined time prior to an anticipated period of high use. During periods of low use, the controller will decrease the temperature to which the water is to be heated, thereby resulting in a more efficient heater. Non-volatile memory records data from the sensors so that the operation status of the heater may be ascertained subsequent to a power outage. The control panel contains a plurality of visual alarms, each of which corresponds to a sensor. Consequently, repair and maintenance are simplified because the cause of a malfunction is quickly recognized.

Owner:AOS HLDG CO

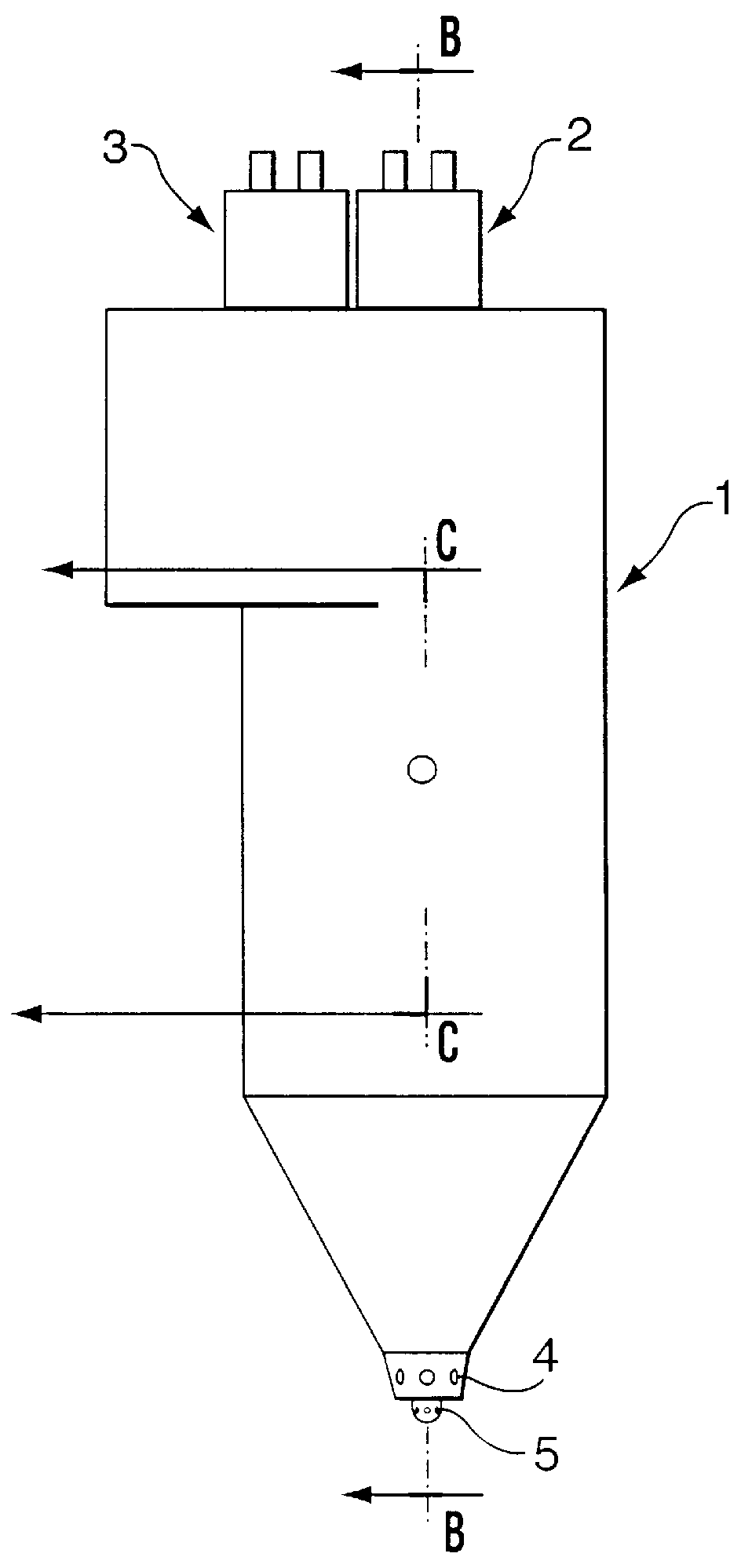

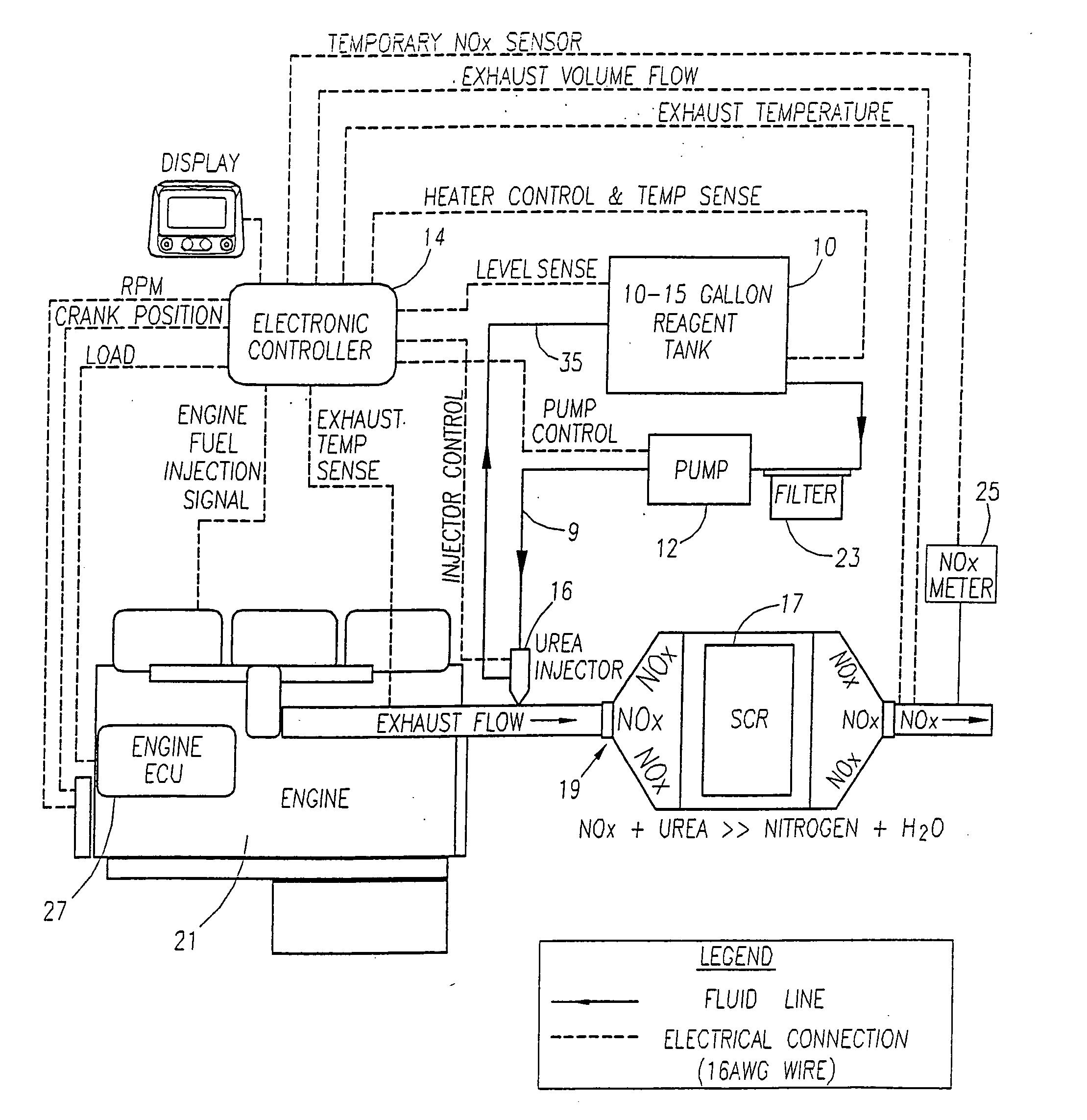

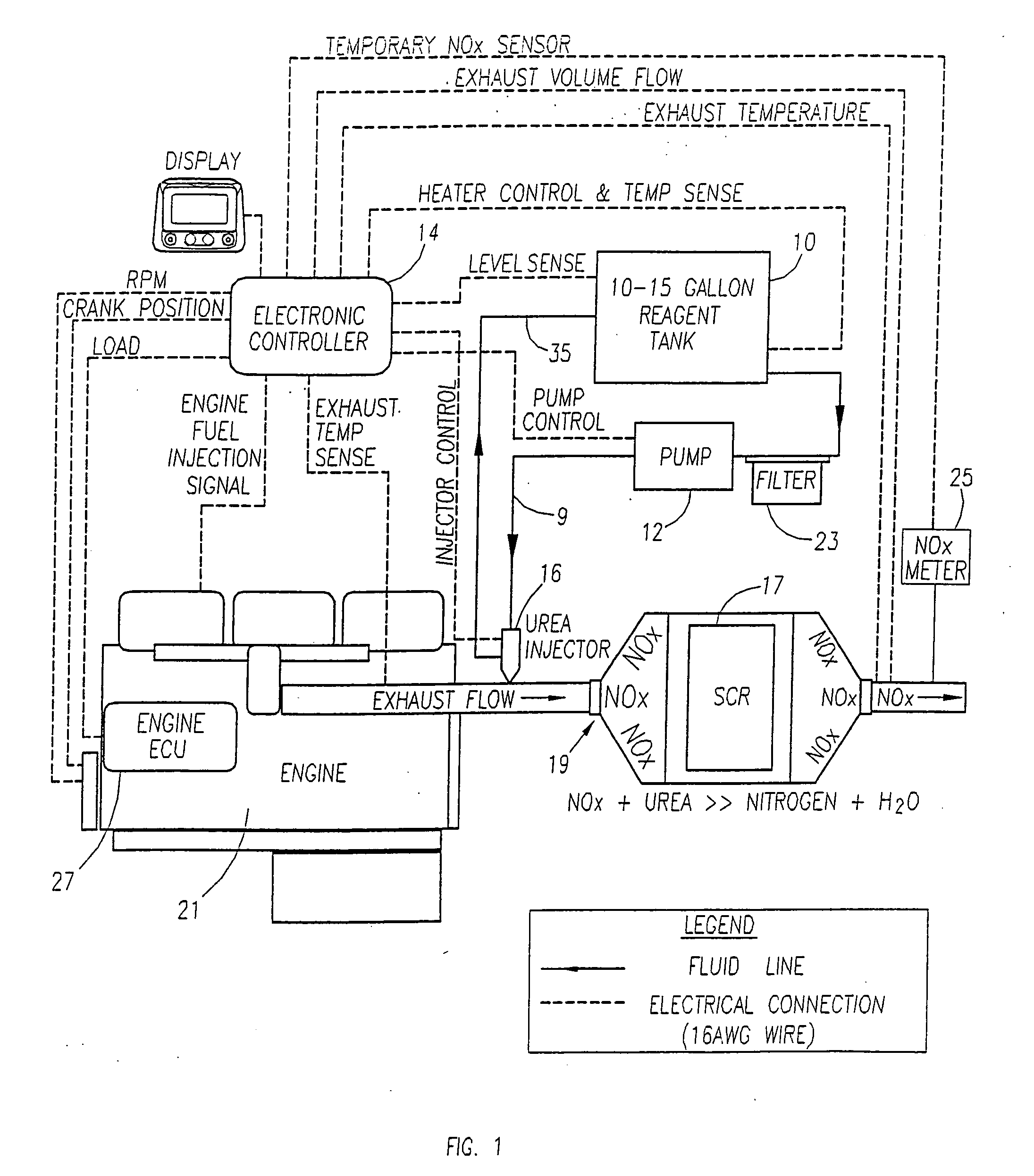

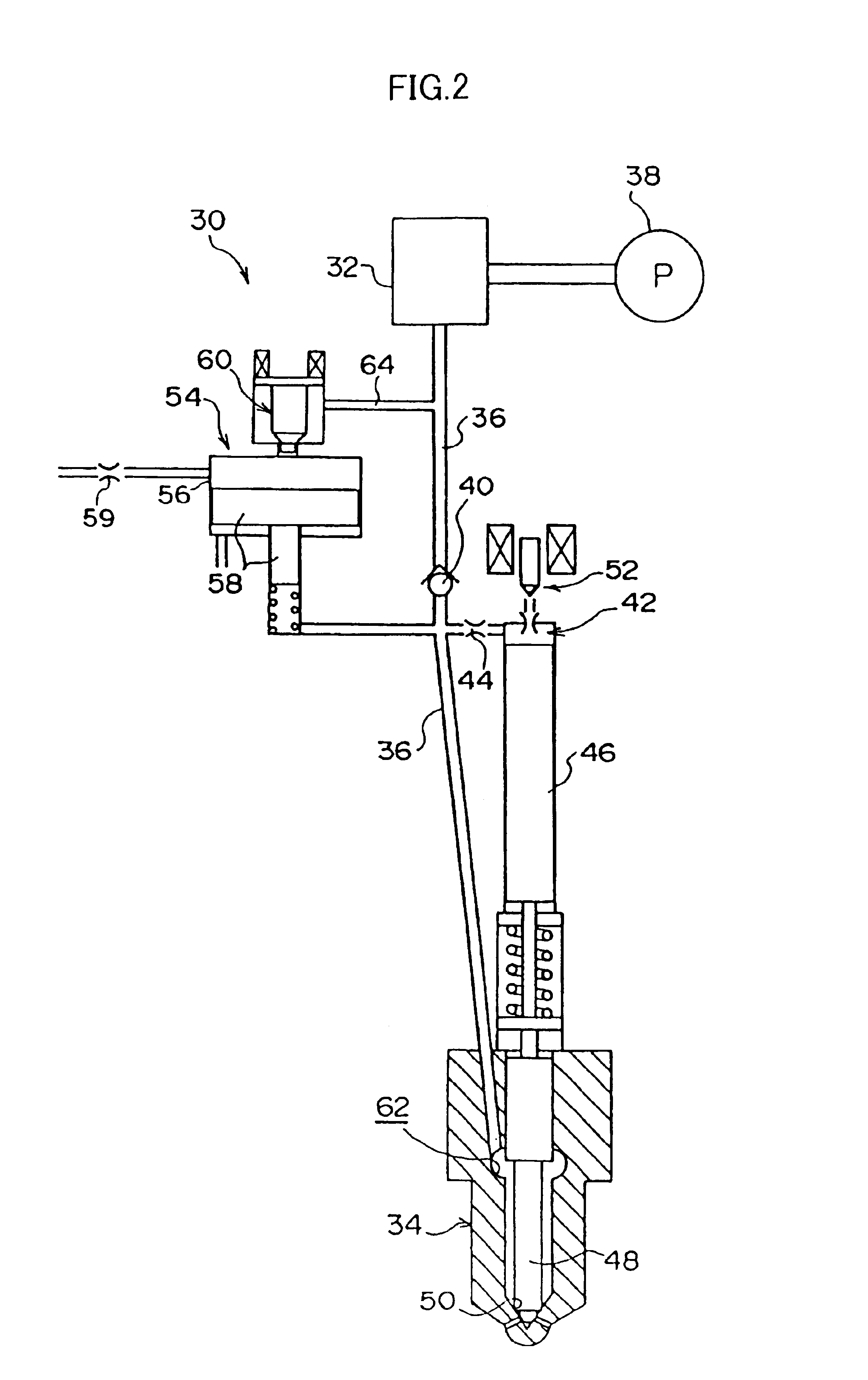

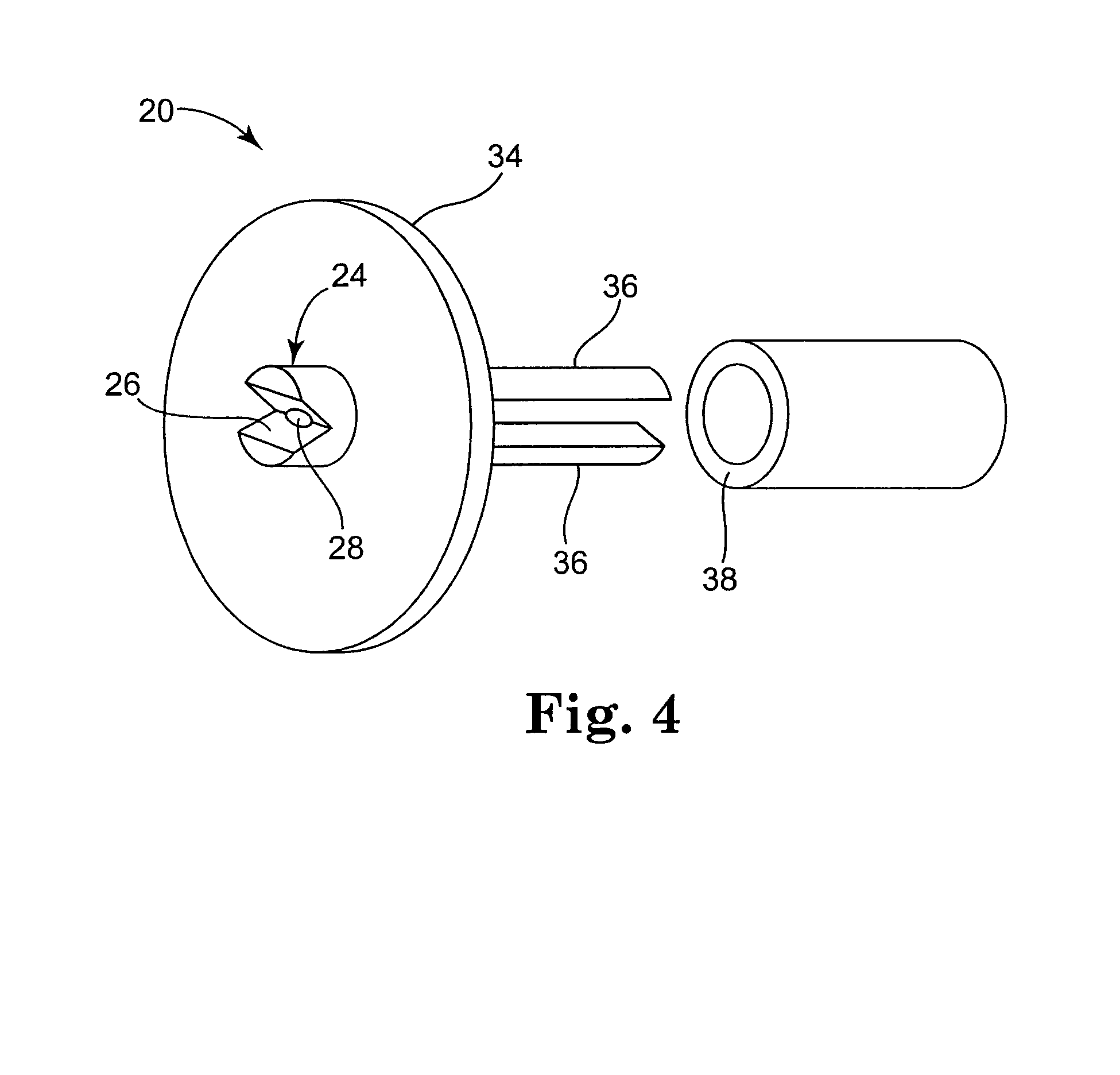

Methods and apparatus for injecting atomized fluid

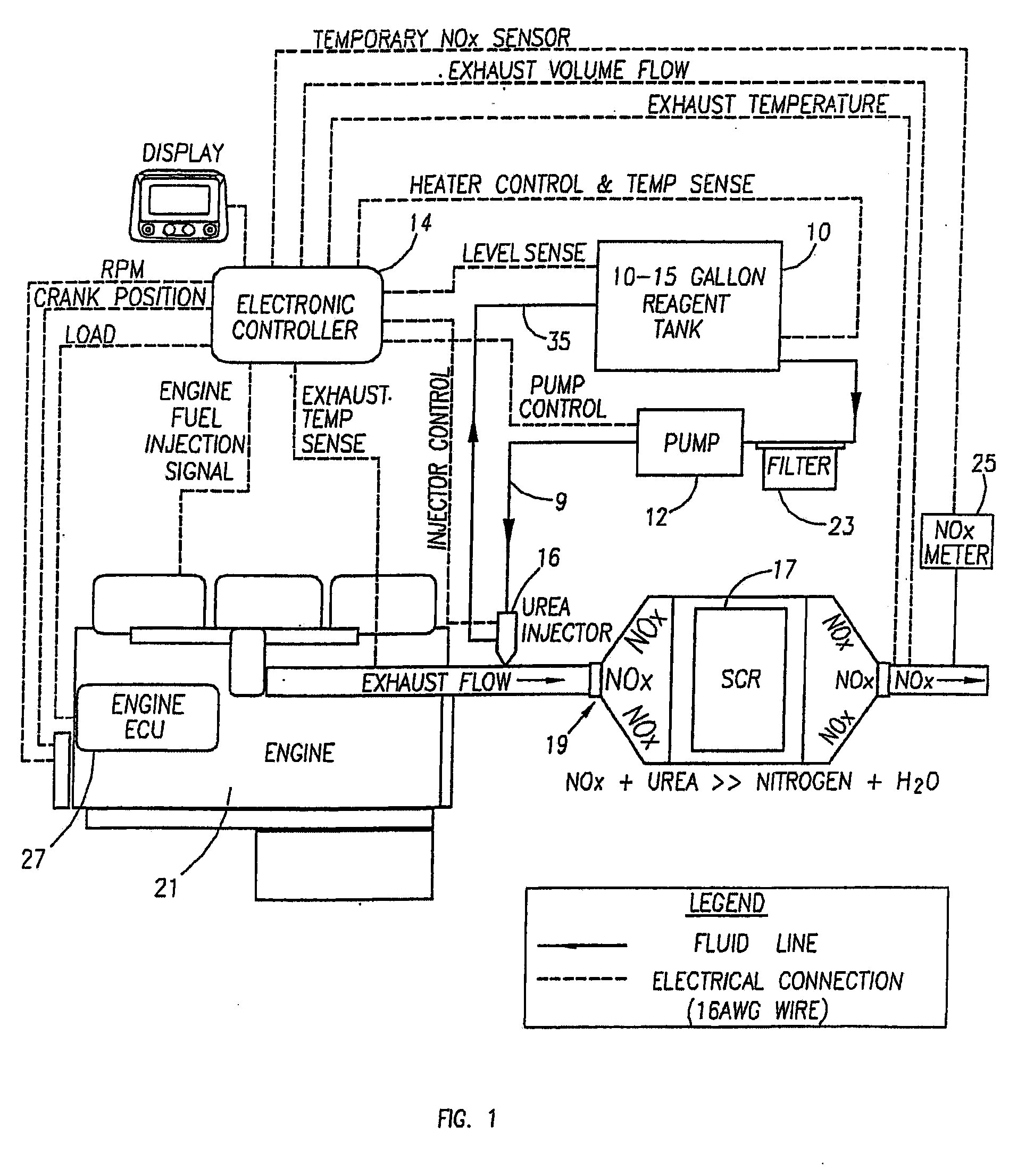

ActiveUS20050235632A1Reduce oxide of nitrogen (NOx) emissionImprove performanceInternal combustion piston enginesExhaust apparatusDiesel engineNOx

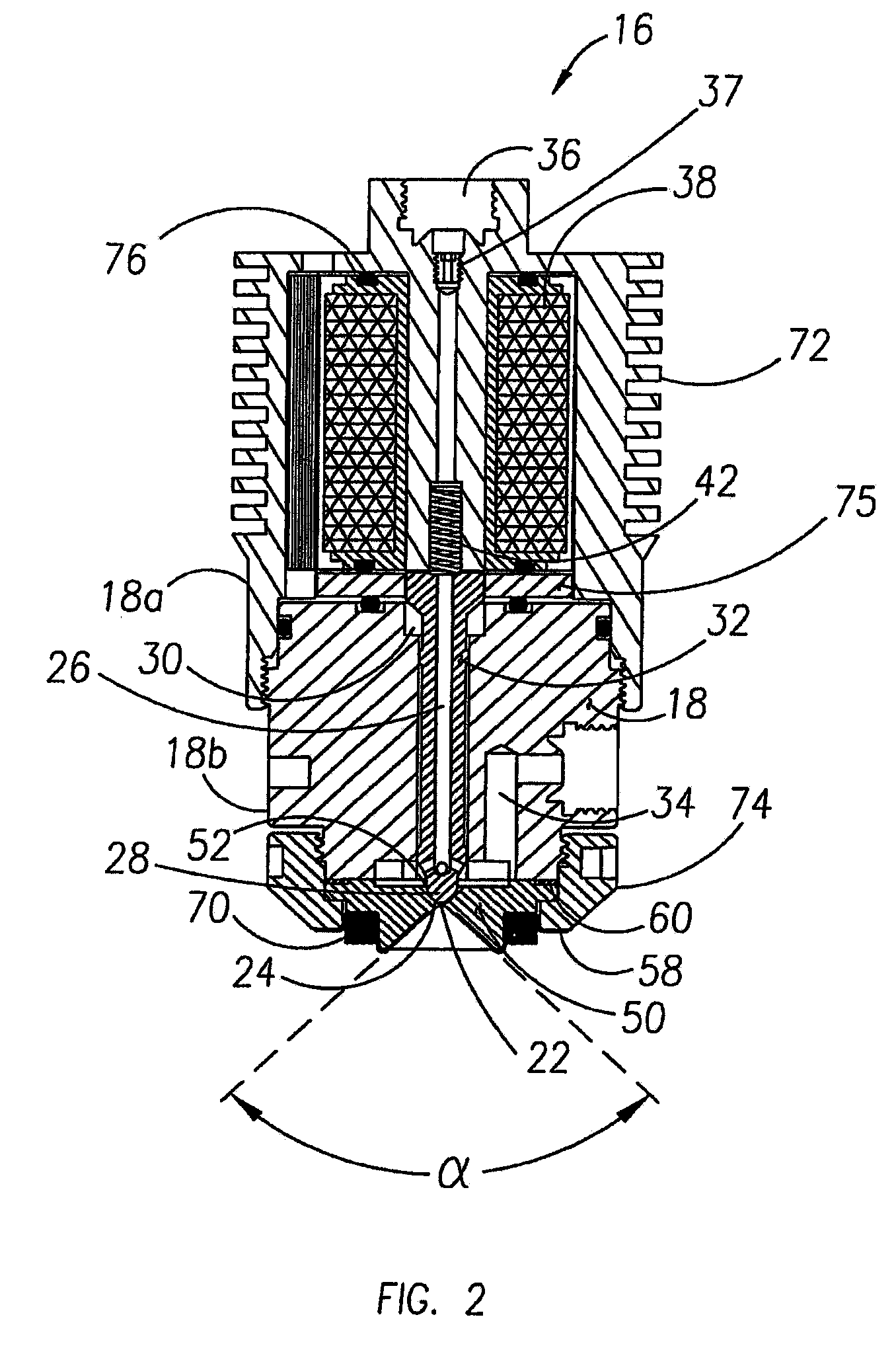

The present invention provides methods and apparatus for injecting fluid, such as an aqueous urea solution, into an exhaust stream in order to reduce oxides of nitrogen (NOx) emissions from diesel engine exhaust The present invention uses mechanical spill return atomization techniques to produce droplets approximately 50 μm SMD (Sauter mean diameter) or smaller. This size range is appropriate to allow urea to react into ammonia within the residence time associated with an on-road diesel engine. This effect is achieved through the use of a whirl plate having a plurality of whirl slots surrounding an exit orifice of the injector, which produce a high velocity rotating flow in the whirl chamber. When the rotating flow of fluid is passed through the exit orifice into an exhaust stream, atomization occurs from a combination of centrifugal force and shearing of the fluid by air as it jets into the exhaust stream.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

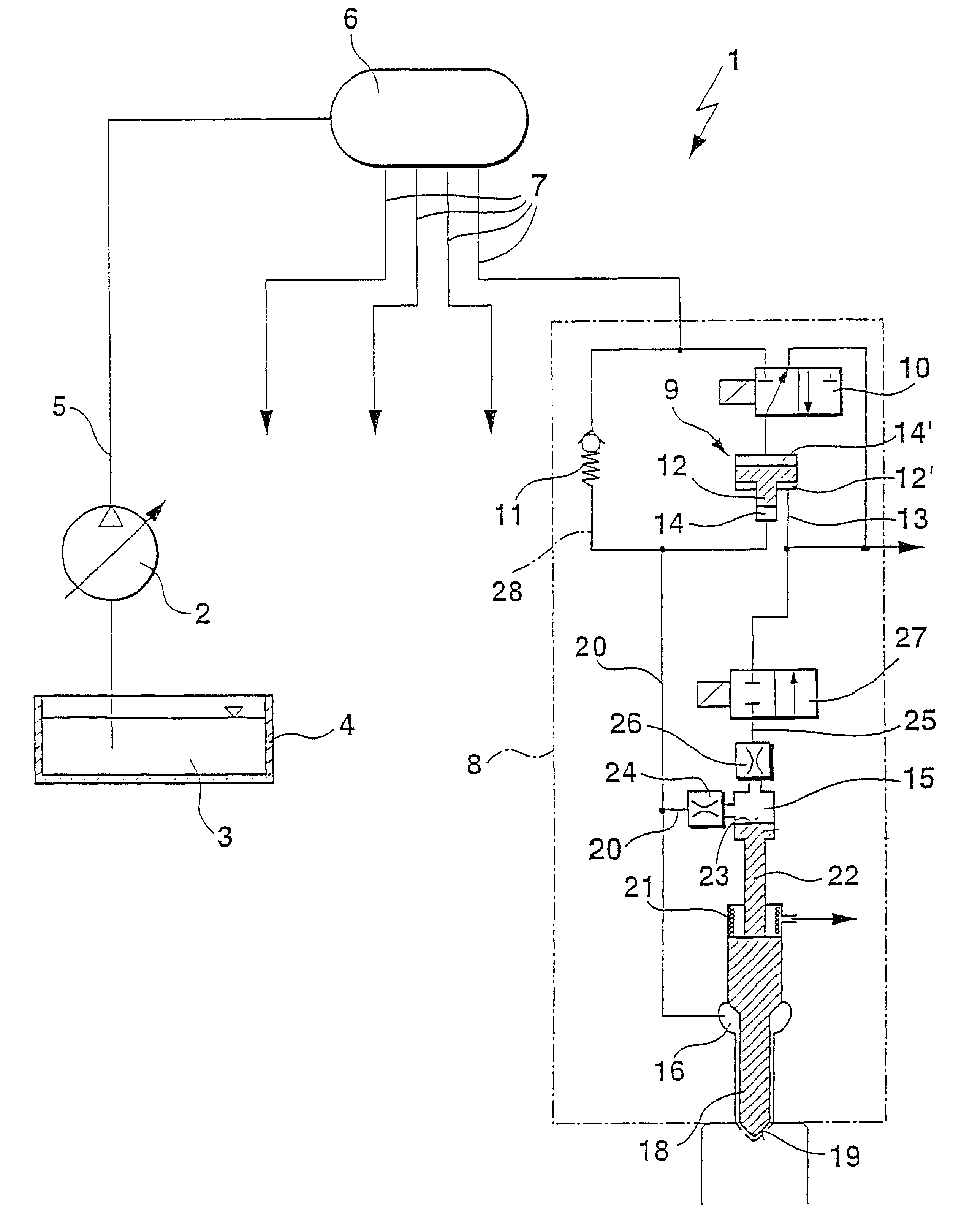

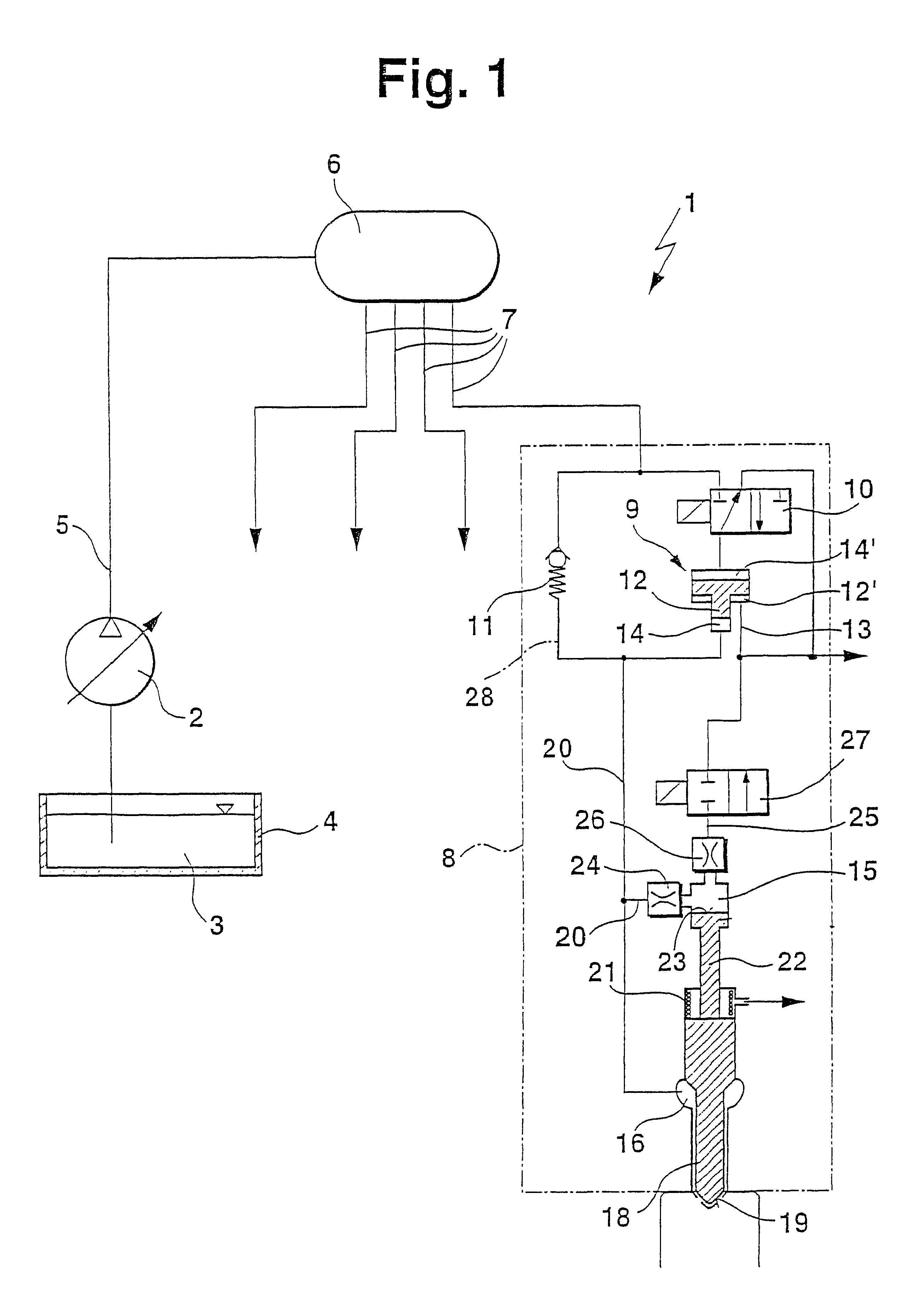

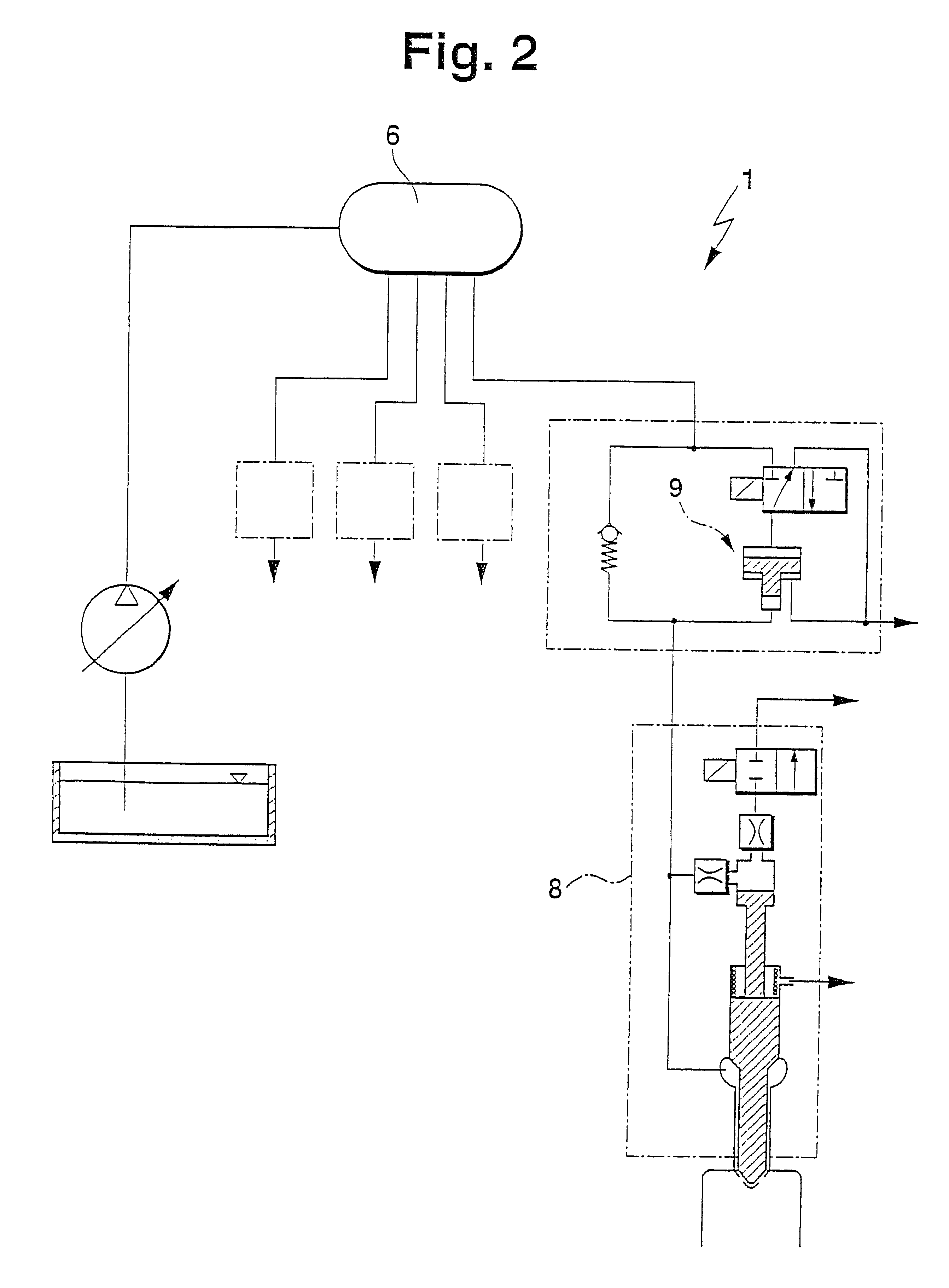

Fuel injection system which uses a pressure step-up unit

InactiveUS6453875B1Increase flexibilityIncrease injection pressureFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesEngineeringPiston

A fuel injection system has a pressure step-up unit, disposed between a pressure storage chamber and a nozzle chamber, whose pressure chamber communicates with the nozzle chamber via a pressure line. A bypass line connected to the pressure storage chamber is also provided. The bypass line communicates directly with the pressure line. The bypass line can be used for pressure injection and is disposed parallel to the pressure chamber, so that the bypass line is open regardless of the motion and position of a displaceable piston element in the pressure step-up unit. This enhances the flexibility of injection.

Owner:ROBERT BOSCH GMBH

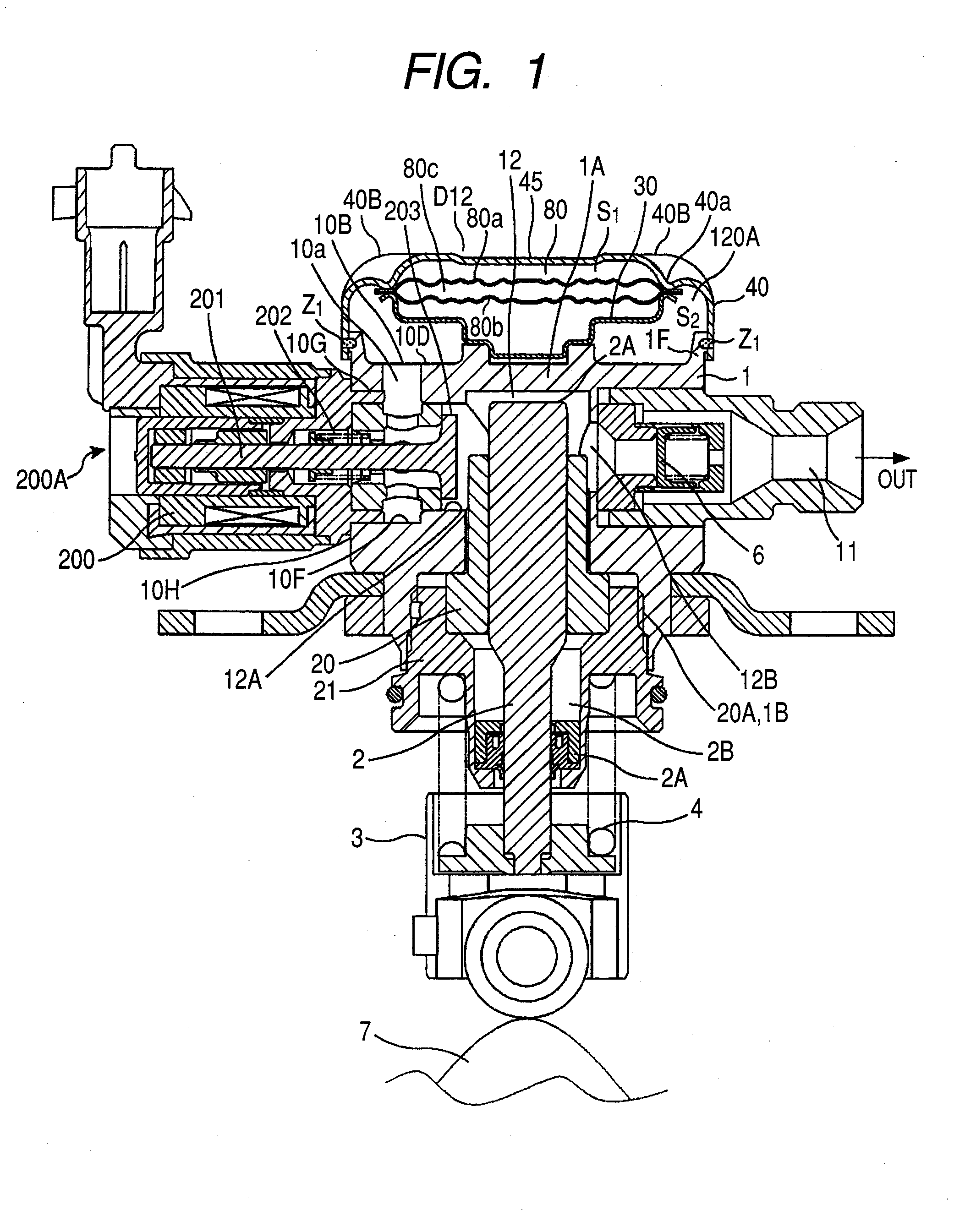

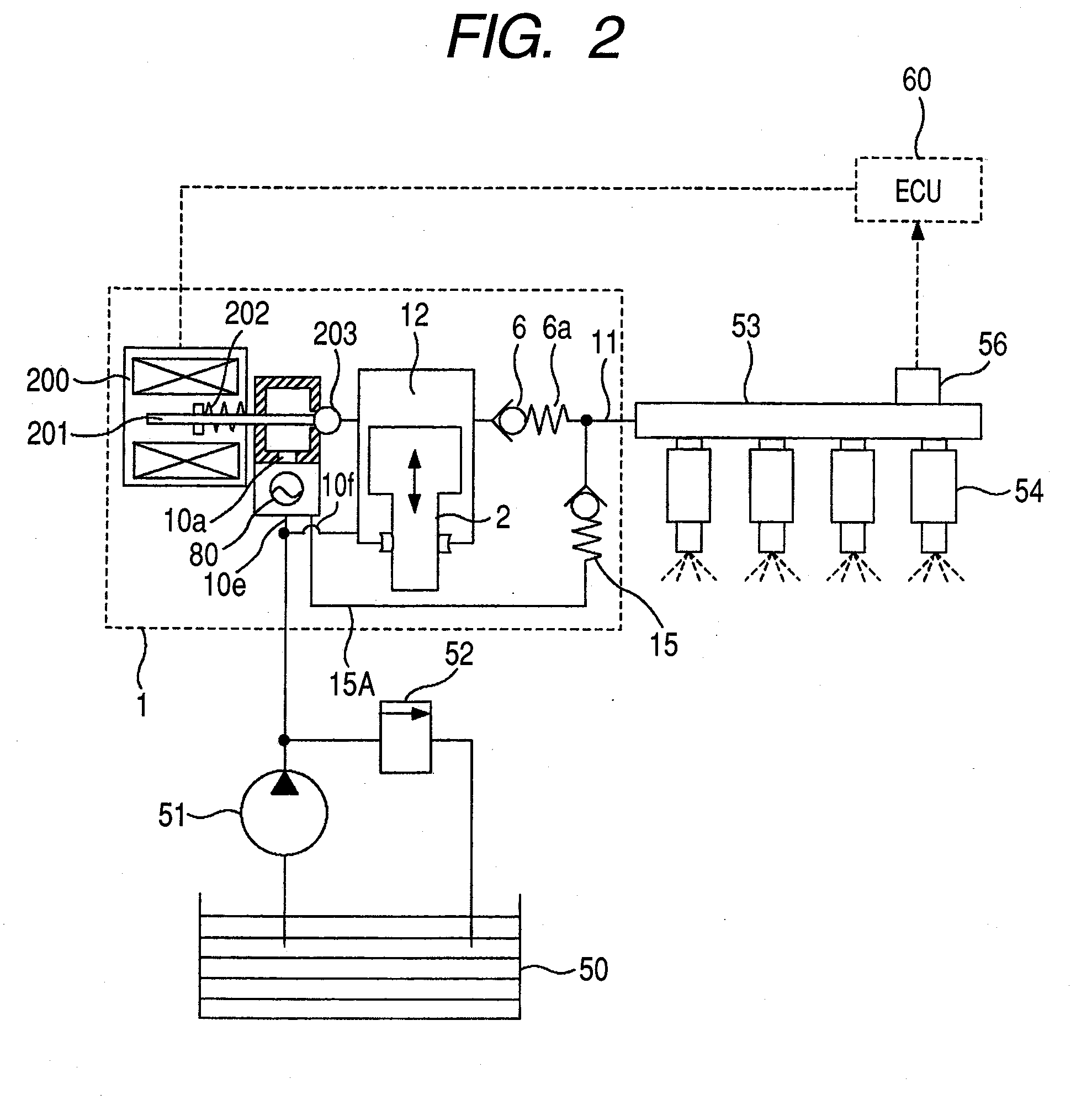

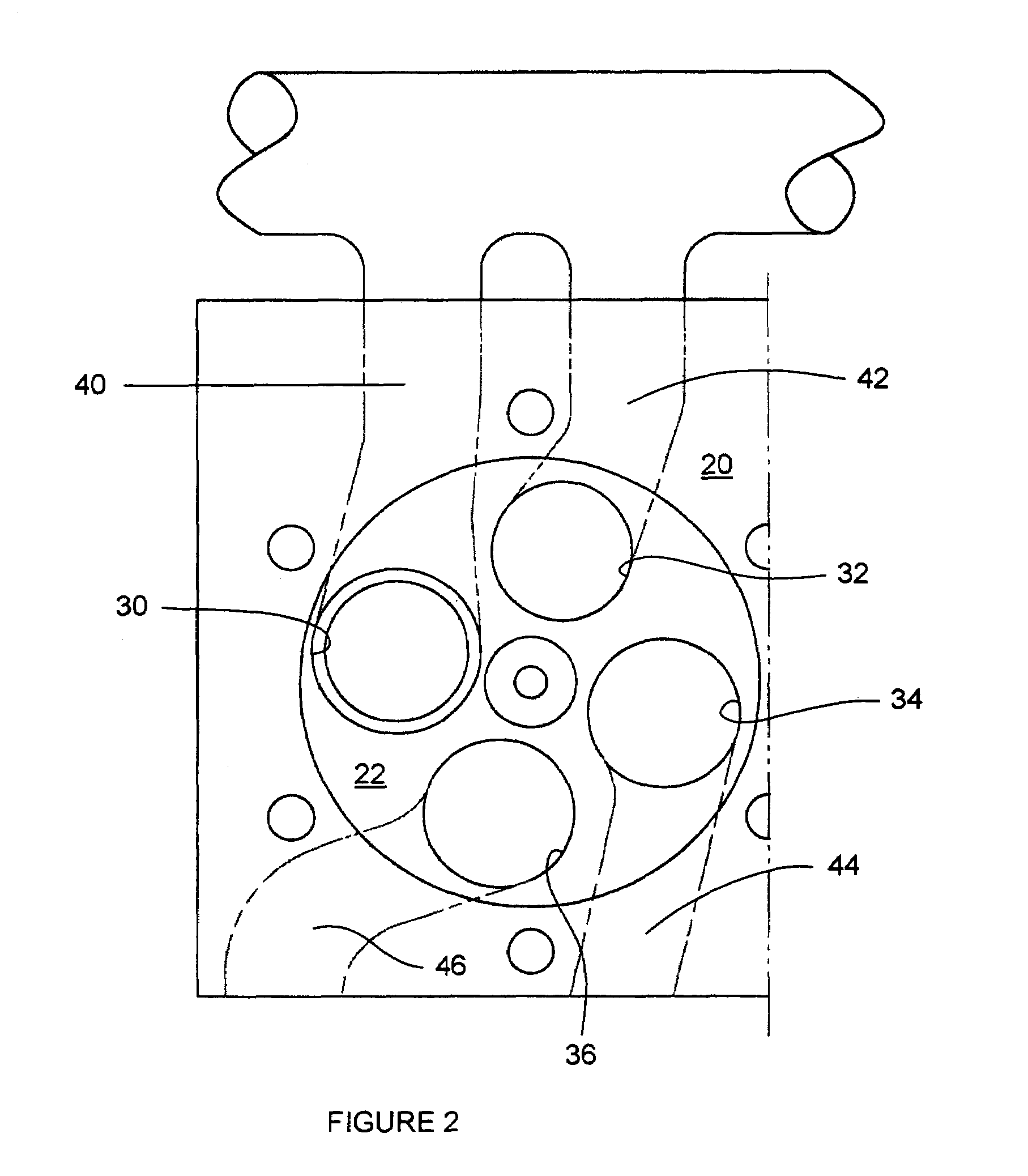

Fluid Pressure Pulsation Damper Mechanism and High-Pressure Fuel Pump Equipped with Fluid Pressure Pulsation Damper Mechanism

ActiveUS20080289713A1Necessary stiffnessIncrease fluid pressurePipe elementsFuel injecting pumpsHermetic sealEngineering

A fluid pressure pulsation damper mechanism comprising: a metal damper having two metal diaphragms joined together with a hermetic seal for forming a sealed spacing filled with a gas between the two metal diaphragms, an edge part at which are overlapped along outer peripheries thereof; a main body having a damper housing in which the metal damper is accommodated; and a cover attached to the main body to cover the damper housing and isolate the damper housing from an outside air, the metal damper being held between the cover and the main body; wherein the cover is further comprising: a metal plate for making the cover, a peripheral edge of the cover being joined to the main body, a plurality of inner convex curved parts extending toward the main body and a plurality of outer convex curved parts extending in a direction away from the main body, and a plurality of the inner convex curved parts and a plurality of the outer convex parts being disposed alternately inside the peripheral edge of the cover at which the cover is joined to the main body; wherein the cover is attached to the main body, ends of the plurality of inner convex curved parts touch one side of the edge part of the metal damper, which are outwardly formed in radial directions of a part including the sealed spacing in the metal damper; and the metal damper is held between the cover and a metal damper holding part of a holding member placed on the main body.

Owner:HITACHI LTD

Common rail fuel pump with combined discharge and overpressure relief valves

ActiveUS20110126804A1Reduce system costIncrease flexibilityCheck valvesEqualizing valvesCommon railPump chamber

A high pressure piston fuel pump having a discharge check valve between the pumping chamber and a pressurized fuel reservoir and a pressure relief valve between the fuel reservoir and a passageway in the housing, wherein the discharge check valve and the pressure relief valve are contained within a single fitting assembly affixed at the pump housing. A first end flow passage is in fluid communication with the pumping chamber and provides an inlet to the discharge check valve and an outlet from the pressure relief valve. A second end flow passage is in fluid communication with the fuel reservoir and provides an outlet for the discharge check valve and an inlet for the pressure relief valve. Advantages include the ability to pre-test the outlet check and pressure relief prior to assembly into the pump housing, and improved flexibility of the outlet fitting location.

Owner:STANDYNE INC

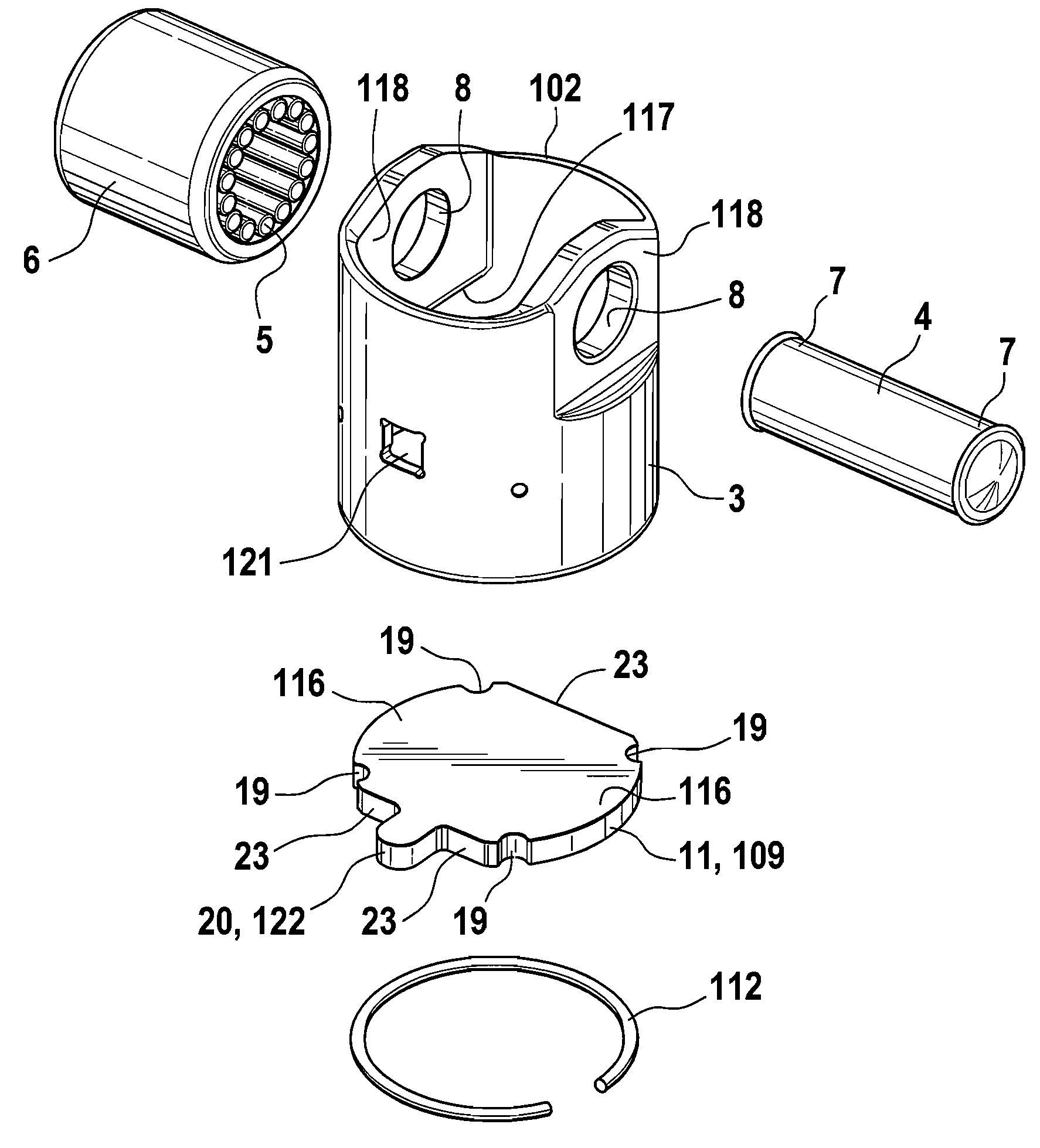

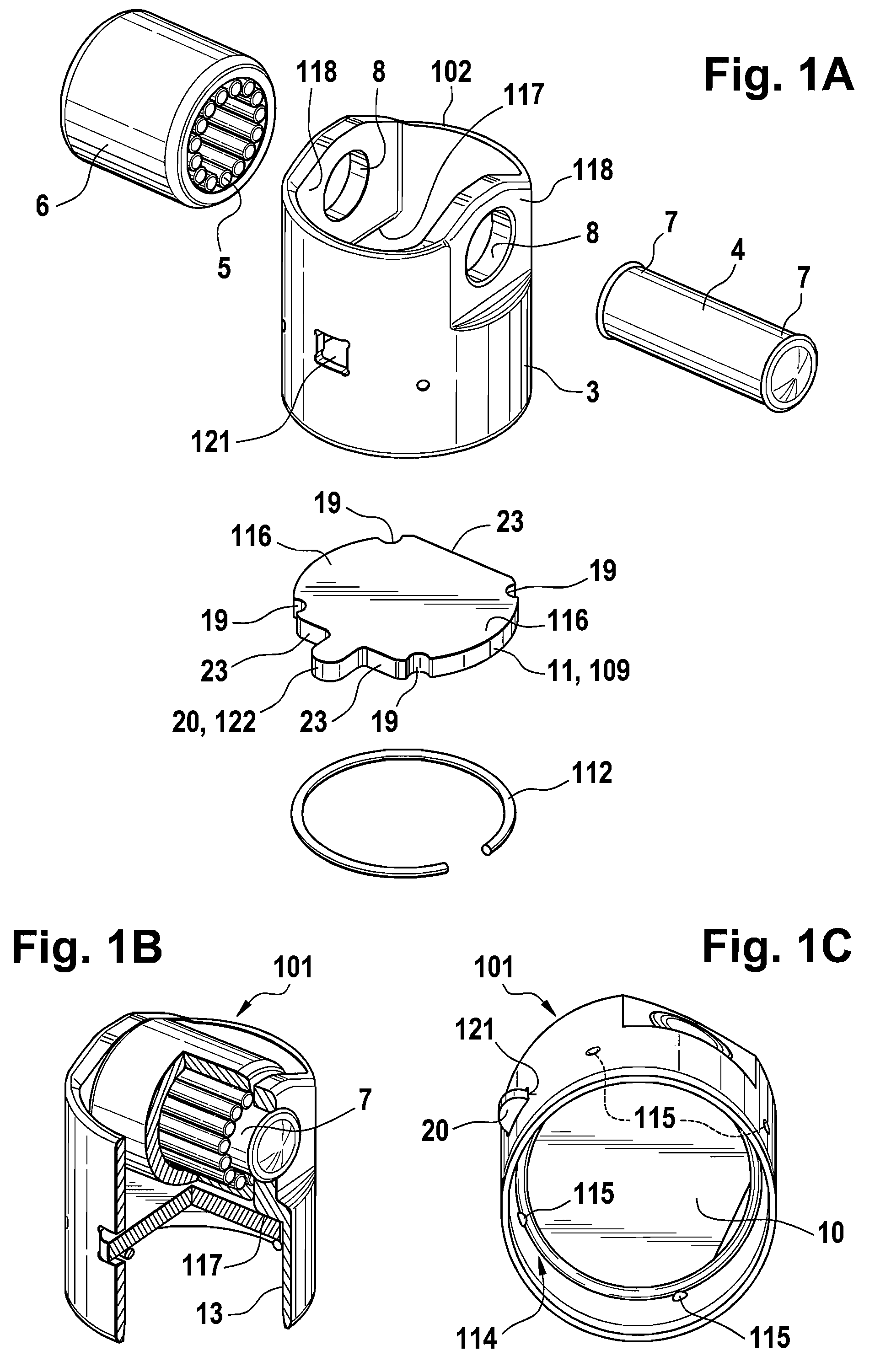

Mechanical tappet in particular for a fuel pump of an internal combustion engine

InactiveUS7793583B2High potential lightweight constructionSave on high costsValve arrangementsEngine sealsInternal combustion engineTappet

A mechanical tappet (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001) is provided, in particular for actuating the lifting of a pump piston (39) of a fuel pump of an internal combustion engine, with a sleeve-shaped tappet housing (102, 202, 302, 402, 502, 602, 702, 902, 1002) constructed as a shaped sheet-metal part and with a driving roller (6) supported so that it can rotate. Here, a bolt (4) supports the driving roller so that it is centered, and end sections (7) of the bolt projecting from the driving roller are supported in bolt eyes (8) of the tappet housing.

Owner:SCHAEFFLER TECH AG & CO KG

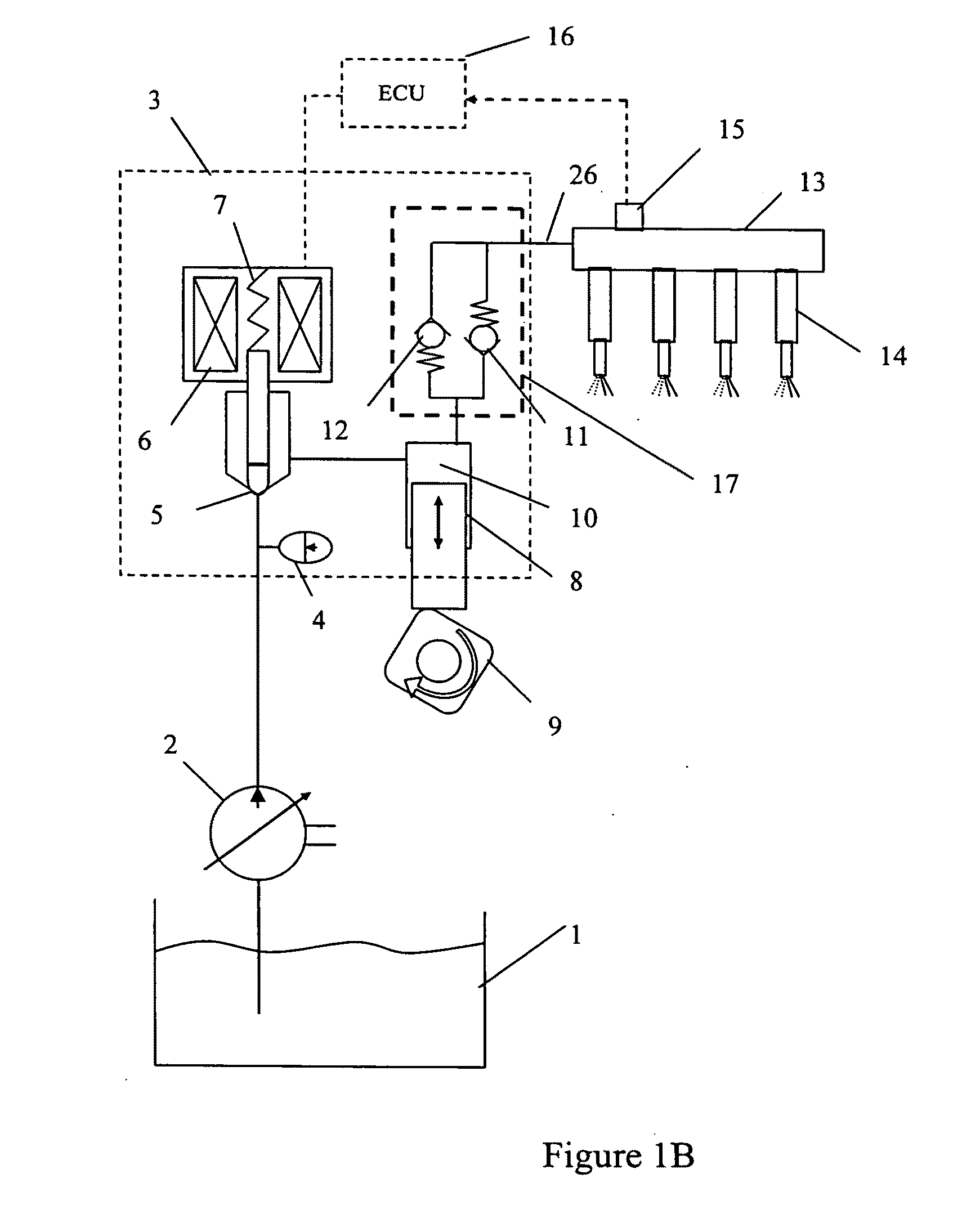

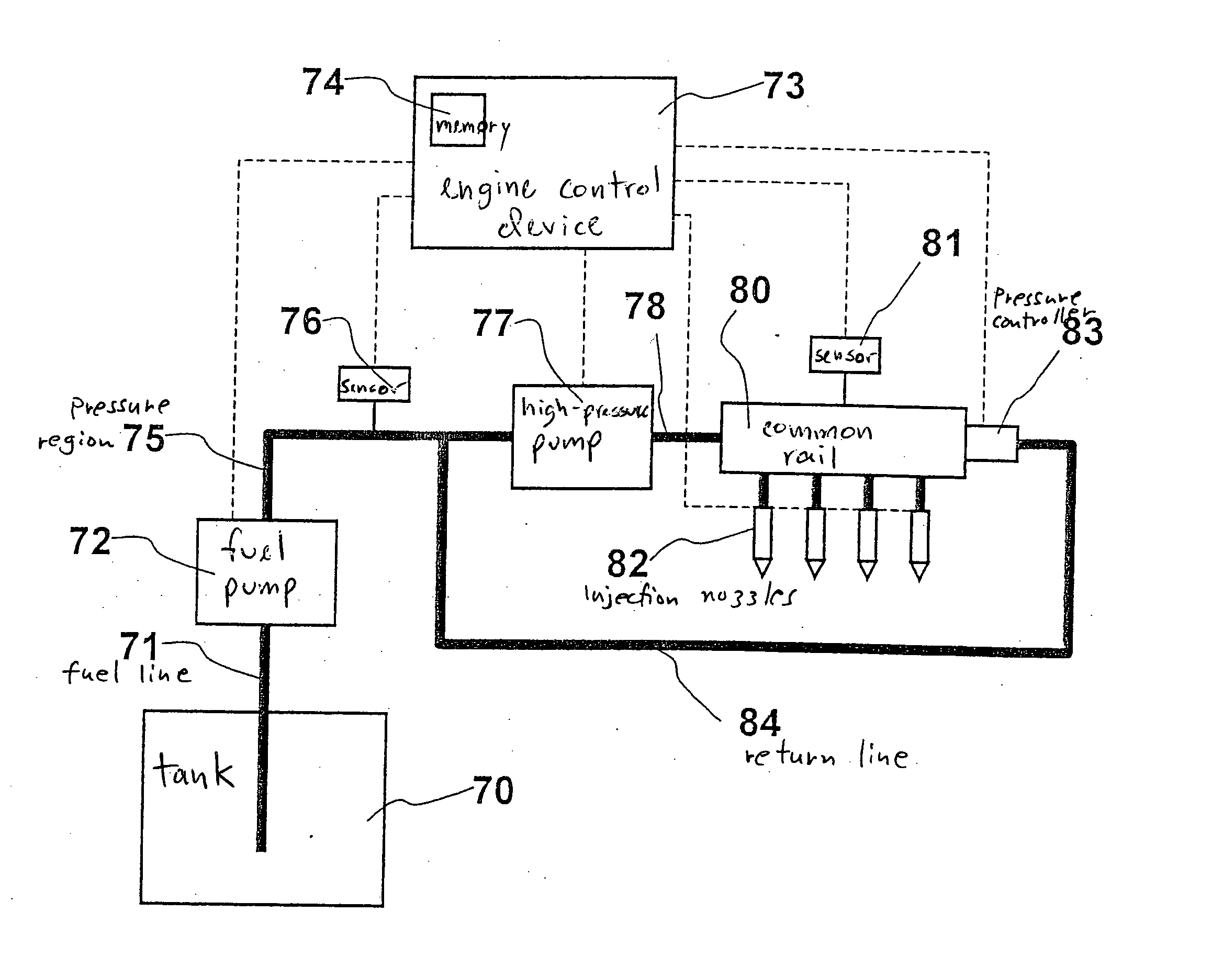

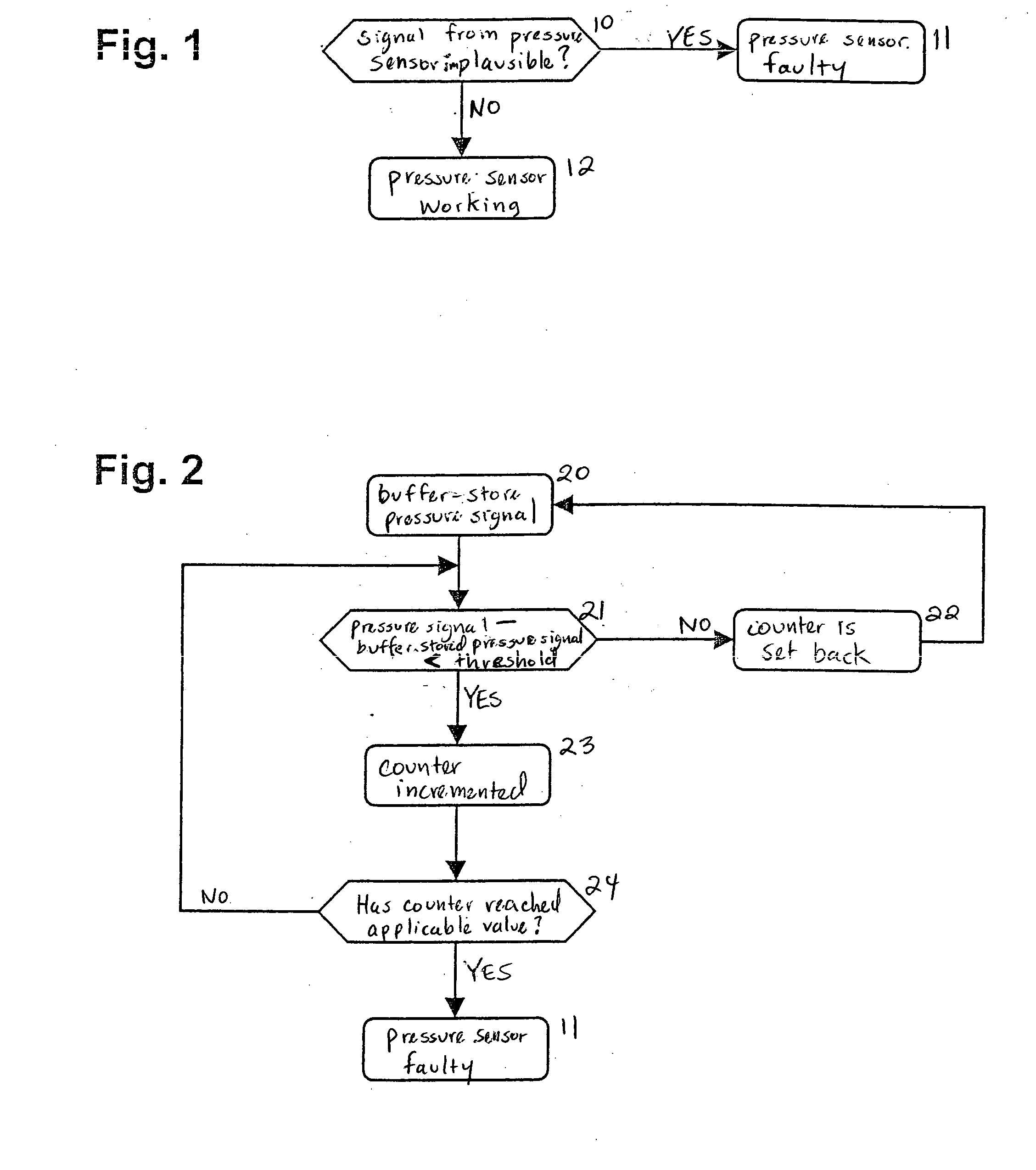

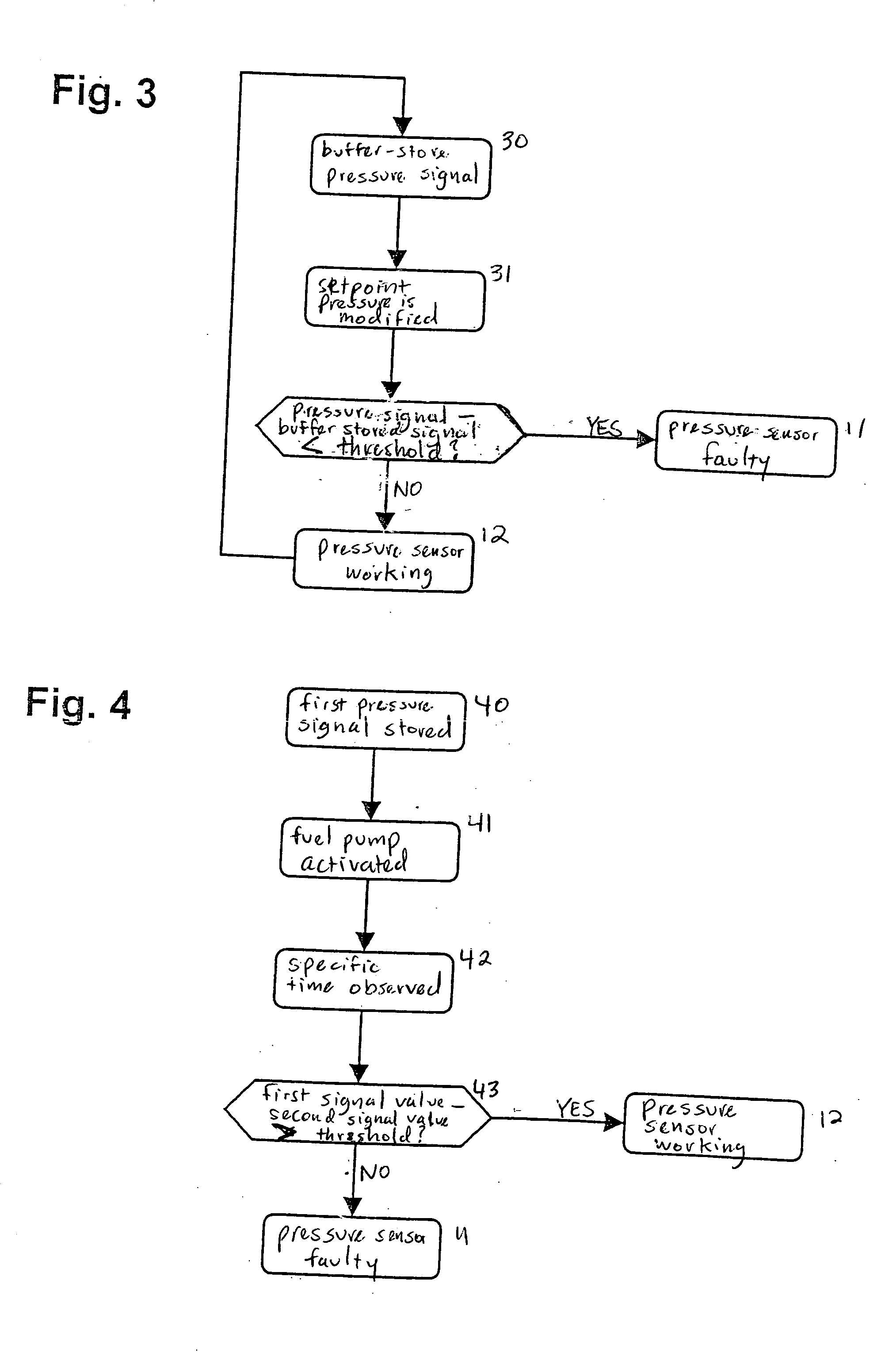

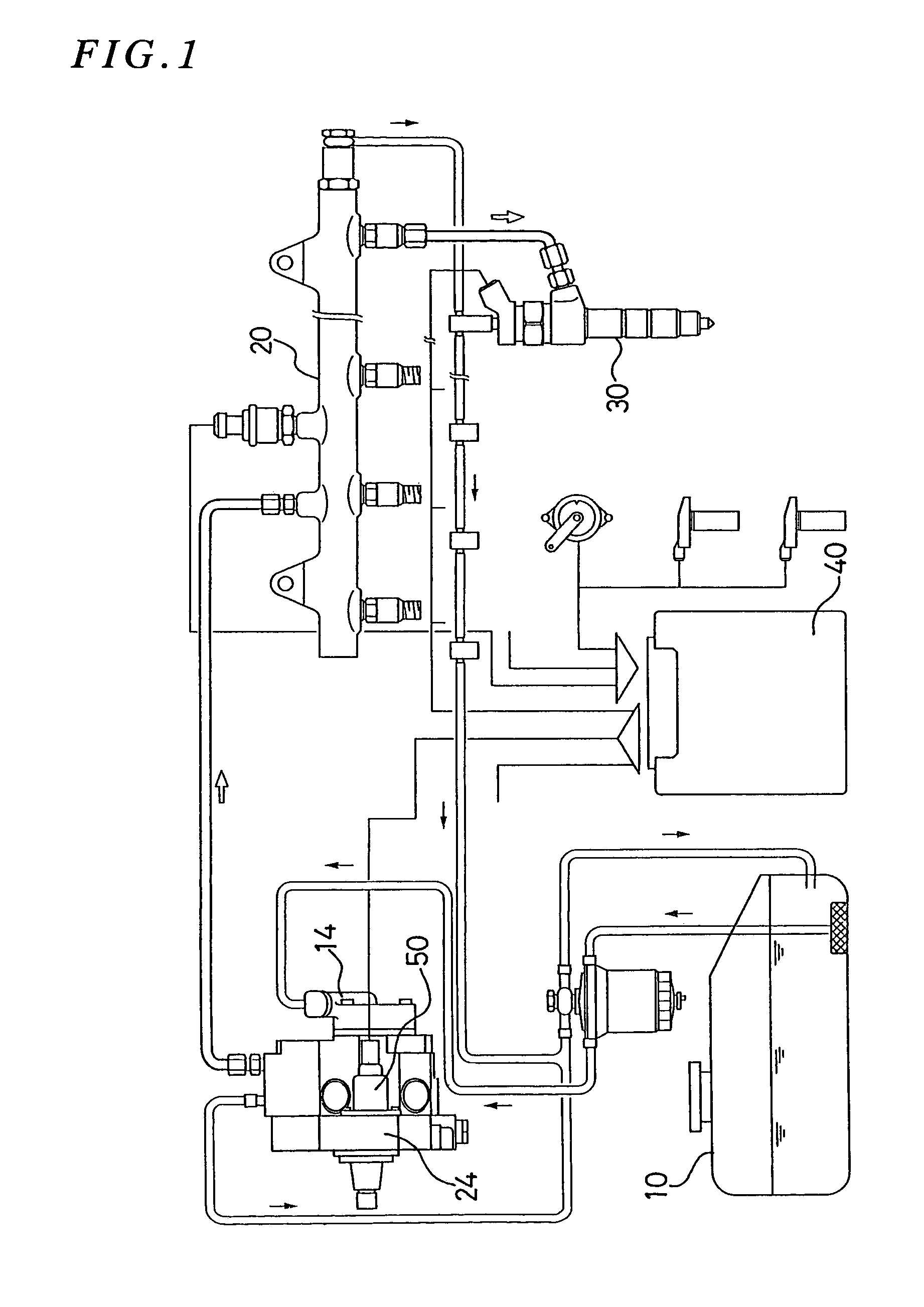

Method for operating a fuel supply system for an internal combustion engine in a motor vehicle

InactiveUS20050005912A1Reliable diagnosisCost-effectiveElectrical controlEngine testingInternal combustion engineMotorized vehicle

A method for operating a fuel-supply system for an internal combustion engine of a motor vehicle is provided, the fuel-supply system having a fuel-storage tank, a fuel pump and a pressure sensor, the fuel pump supplying fuel from the fuel-storage tank to a pressure region, the pressure sensor being arranged in the pressure region, and the pressure sensor generating a signal representing the pressure in the pressure region.

Owner:ROBERT BOSCH GMBH

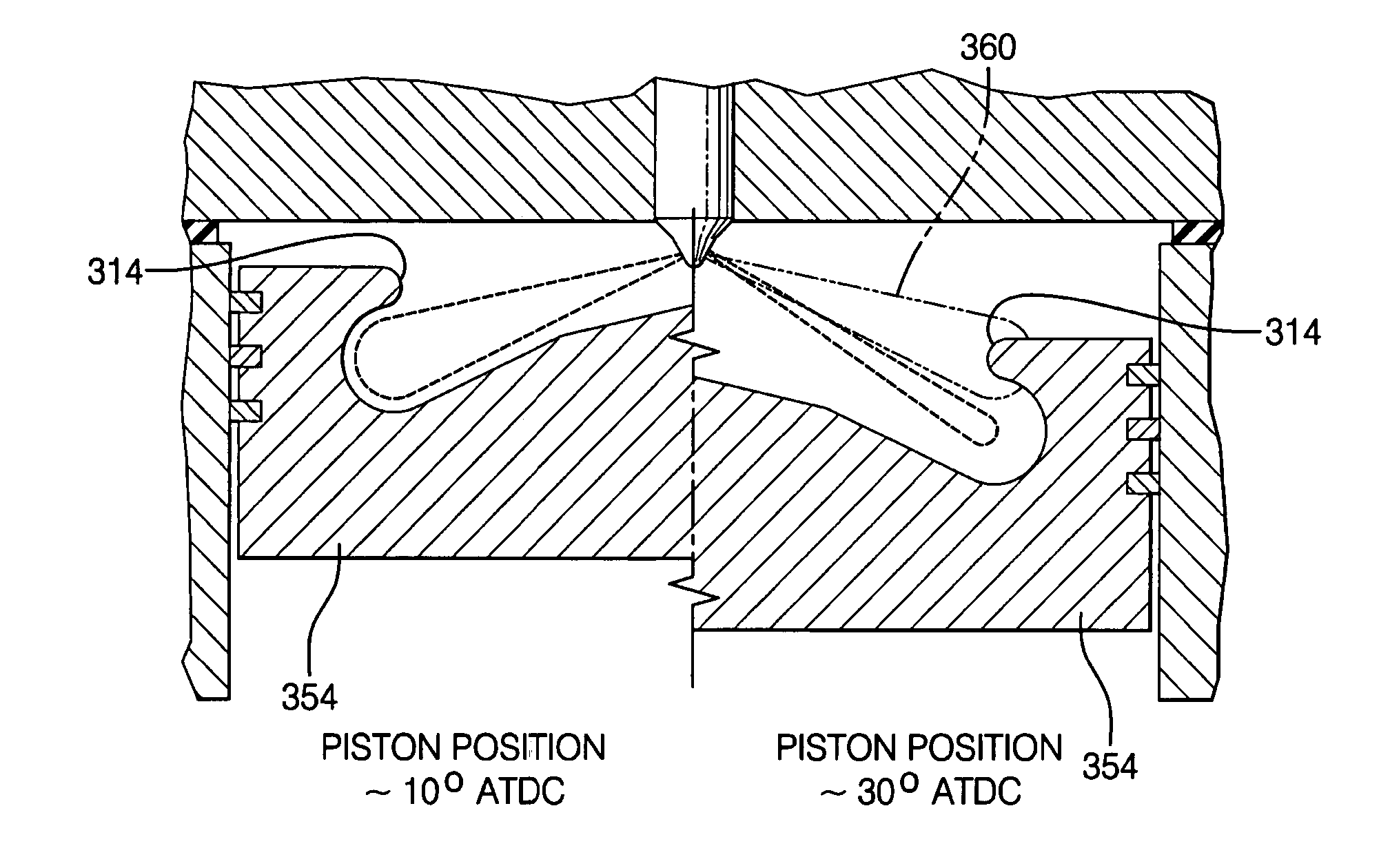

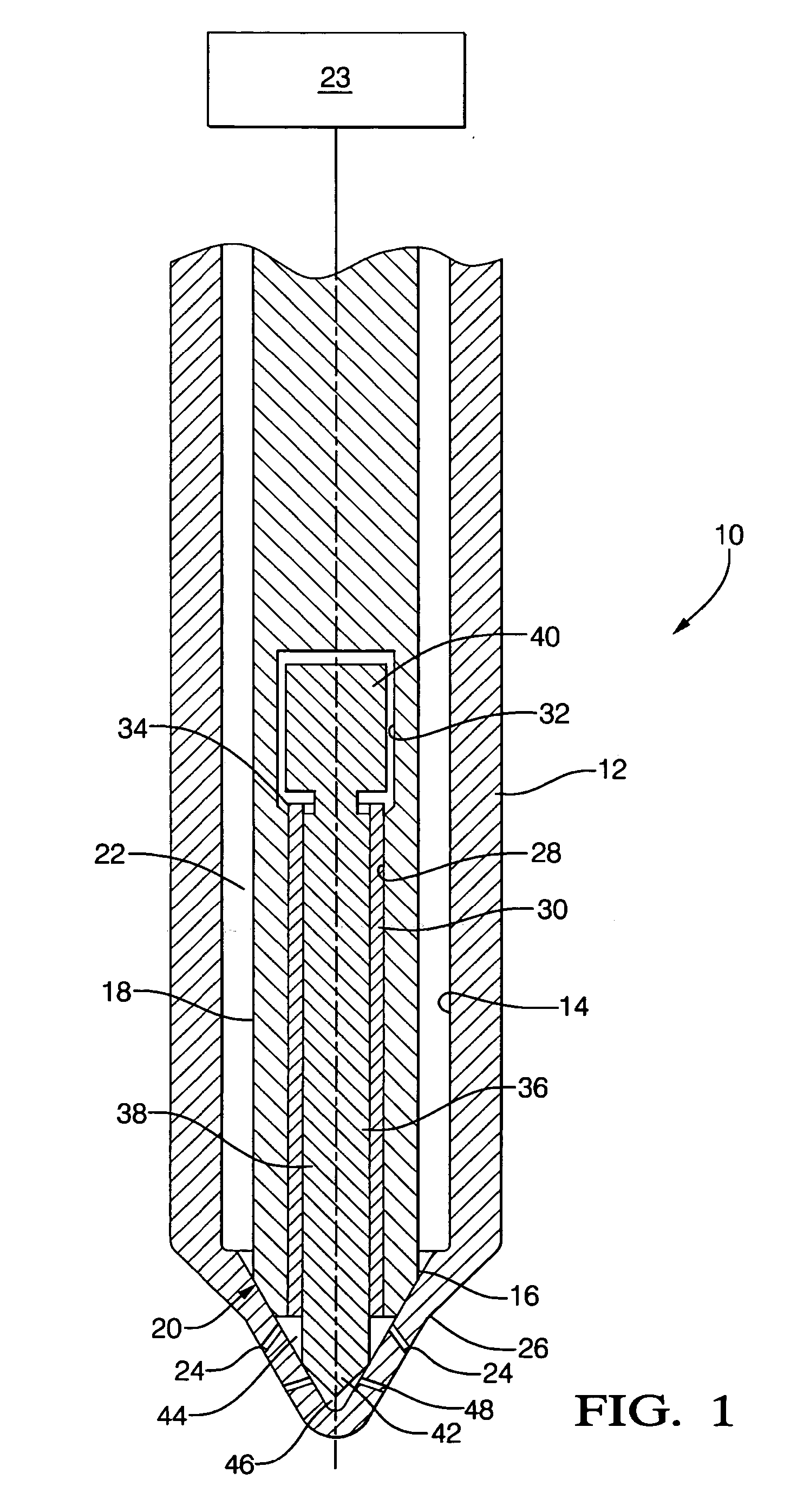

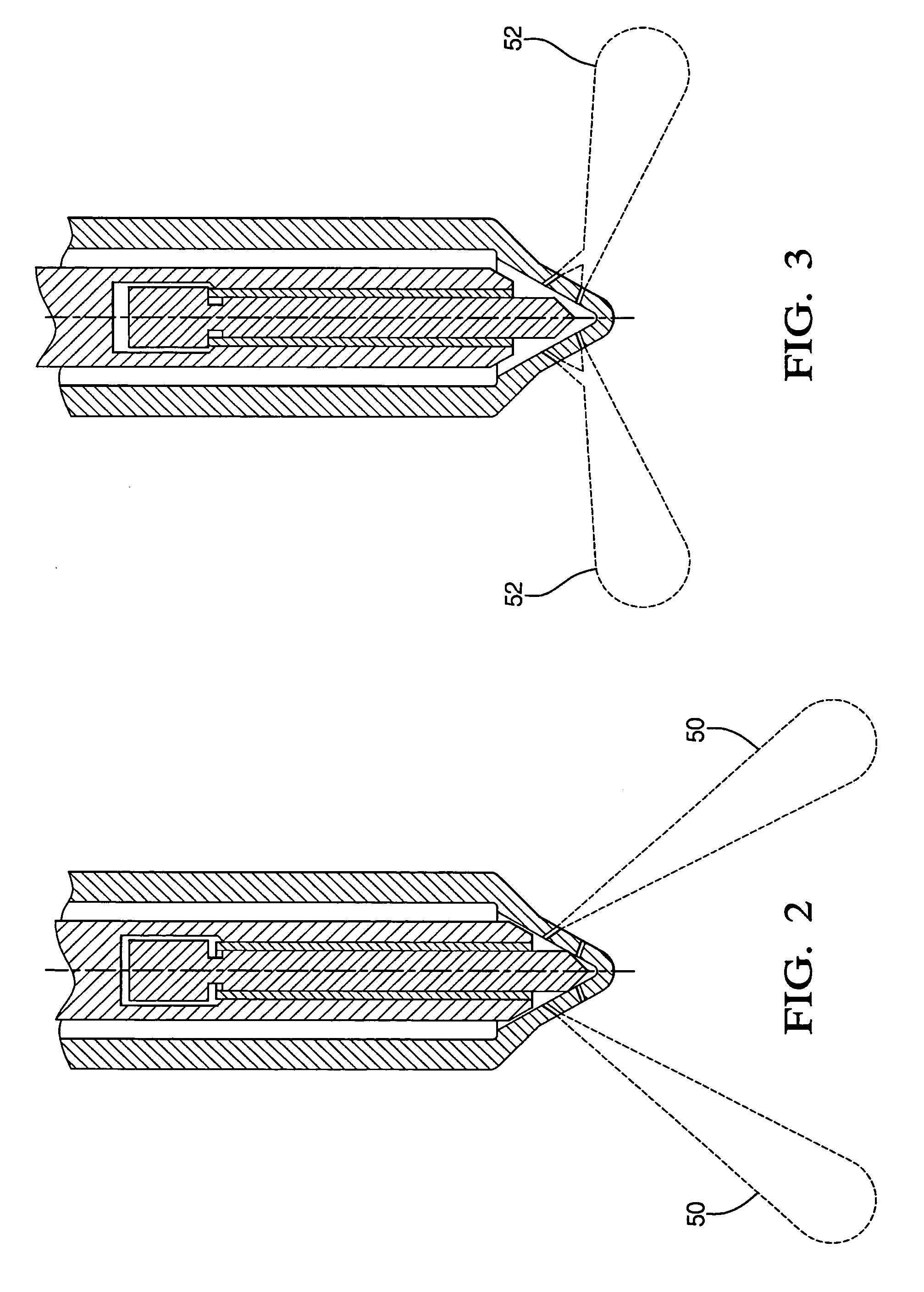

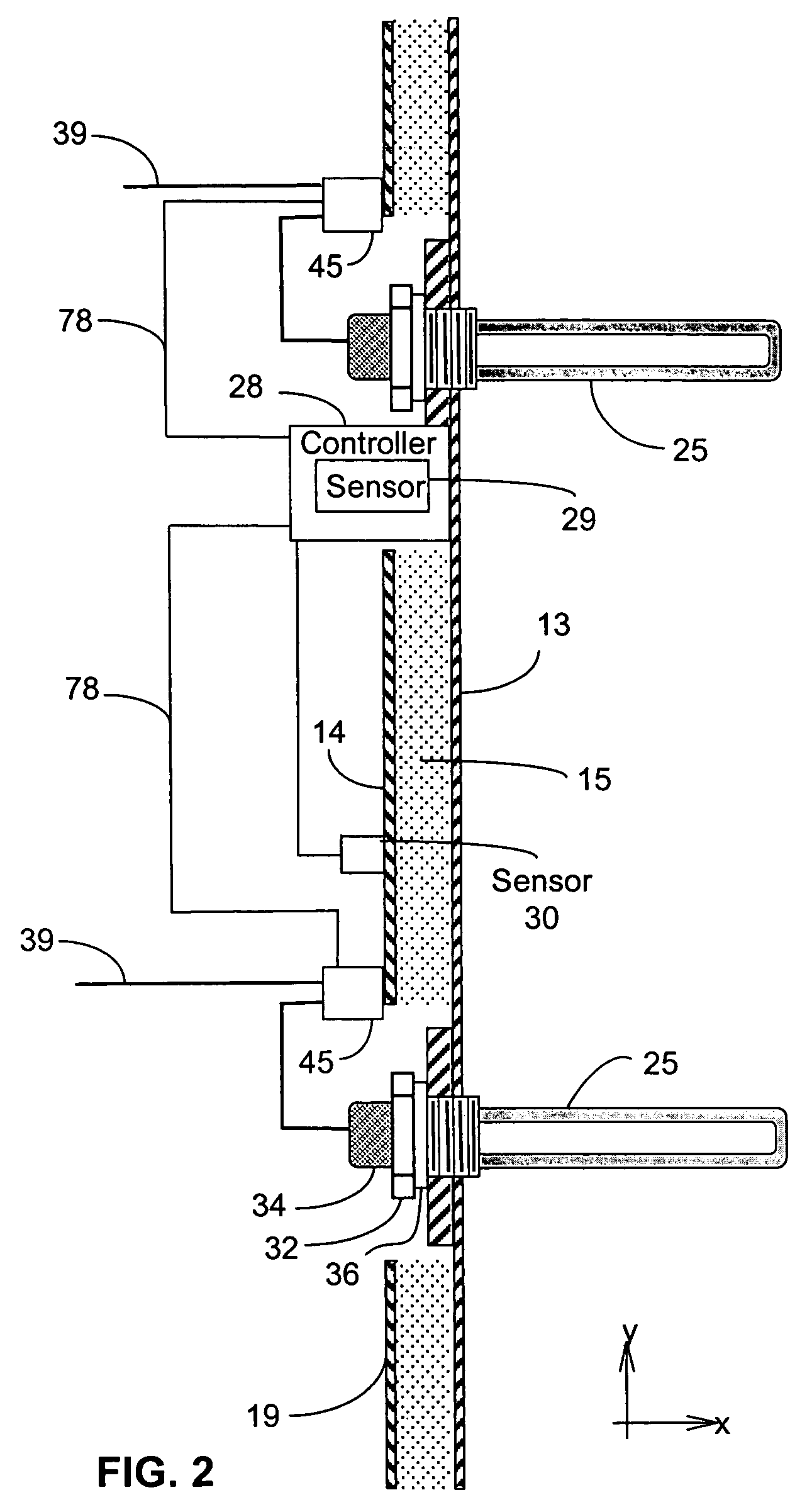

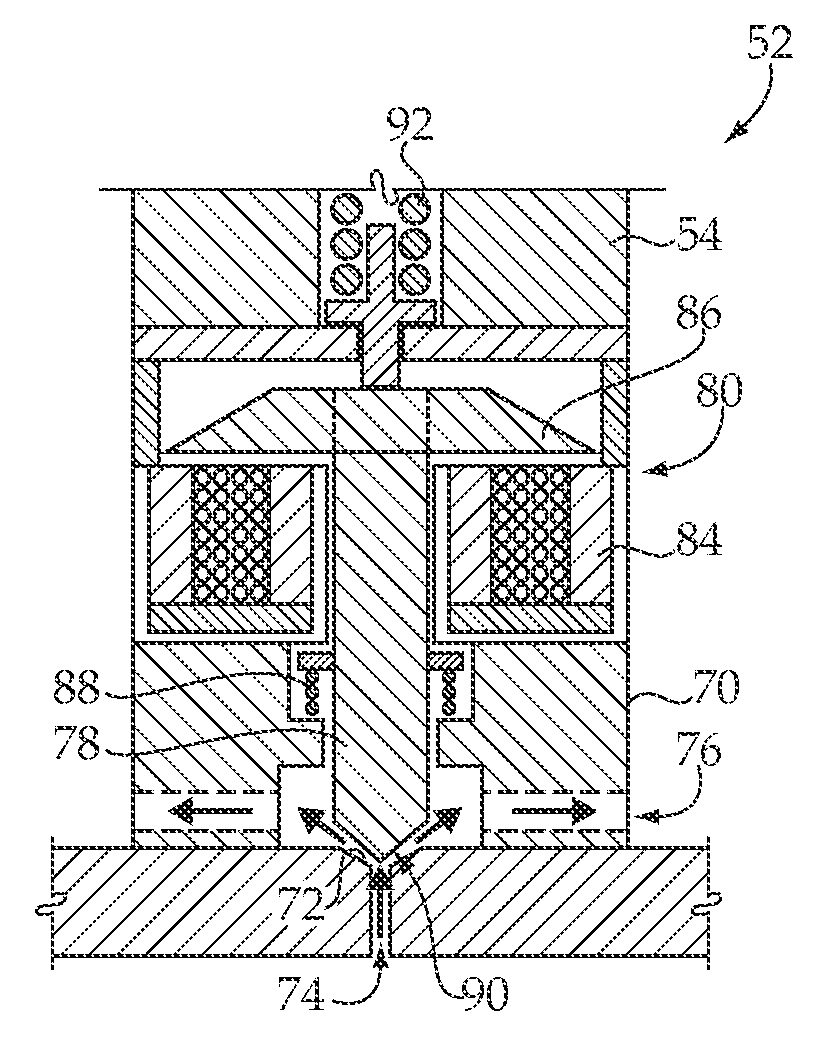

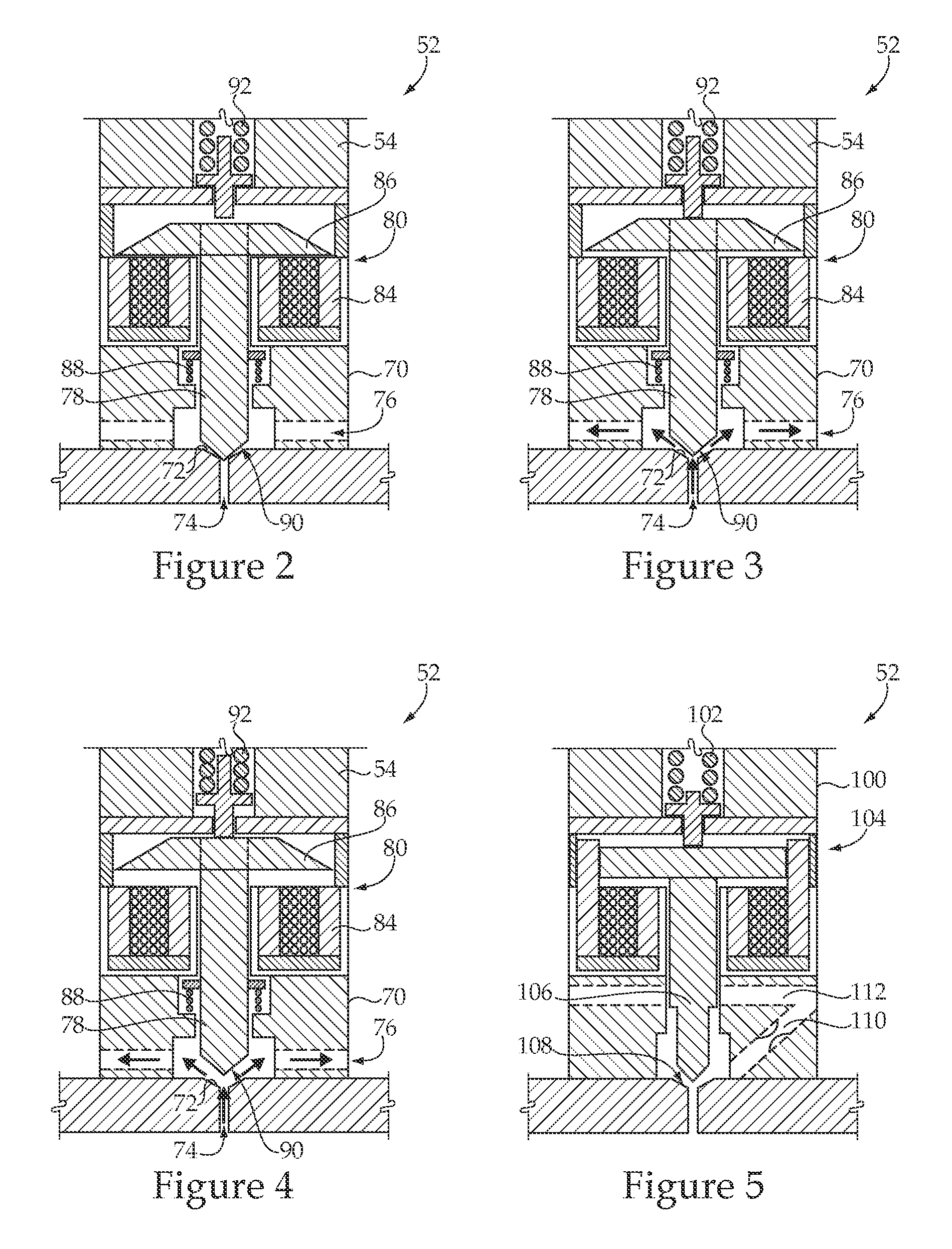

Apparatus and method for mode-switching fuel injector nozzle

InactiveUS20050224606A1Prevent penetrationElectrical controlInternal combustion piston enginesCombustionInjector nozzle

A fuel injector nozzle and method for dispersing fuel during a normal combustion operation and a supplemental combustion operation, the fuel injector nozzle comprising: a plurality of first outlet openings configured to disperse fuel in a first arrangement; and a plurality of second outlet openings configured to collide with the fuel passing through the plurality of first openings to disperse fuel in a second arrangement, wherein either the first or second arrangement is selected by the position of the piston.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

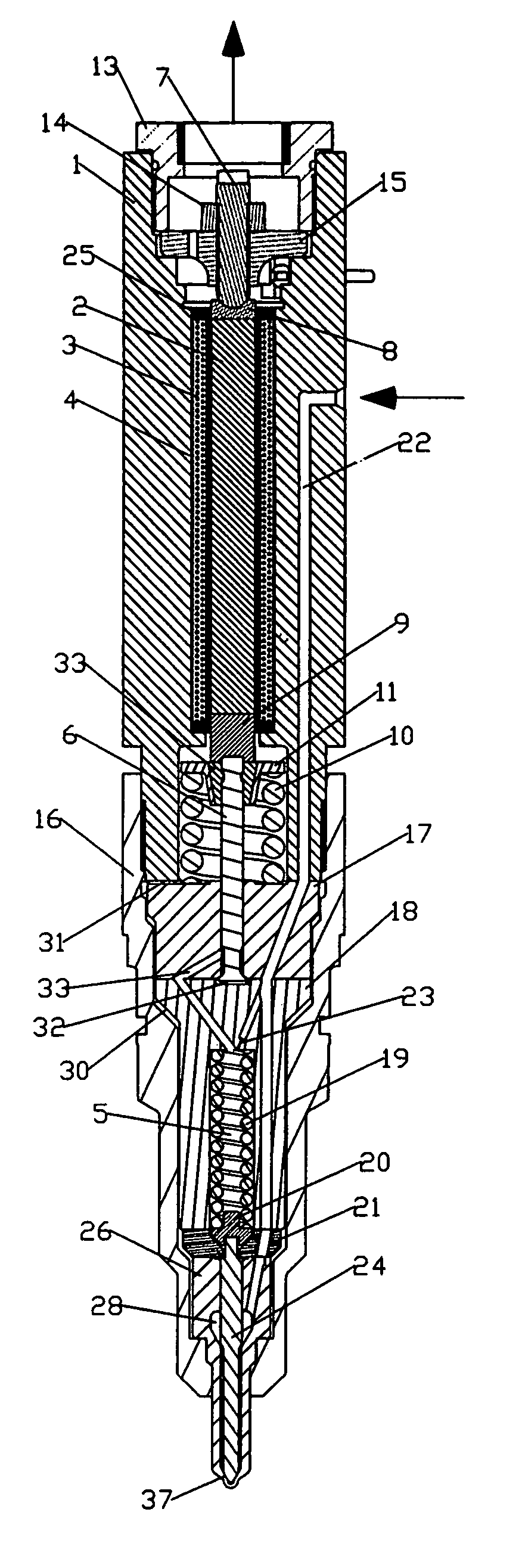

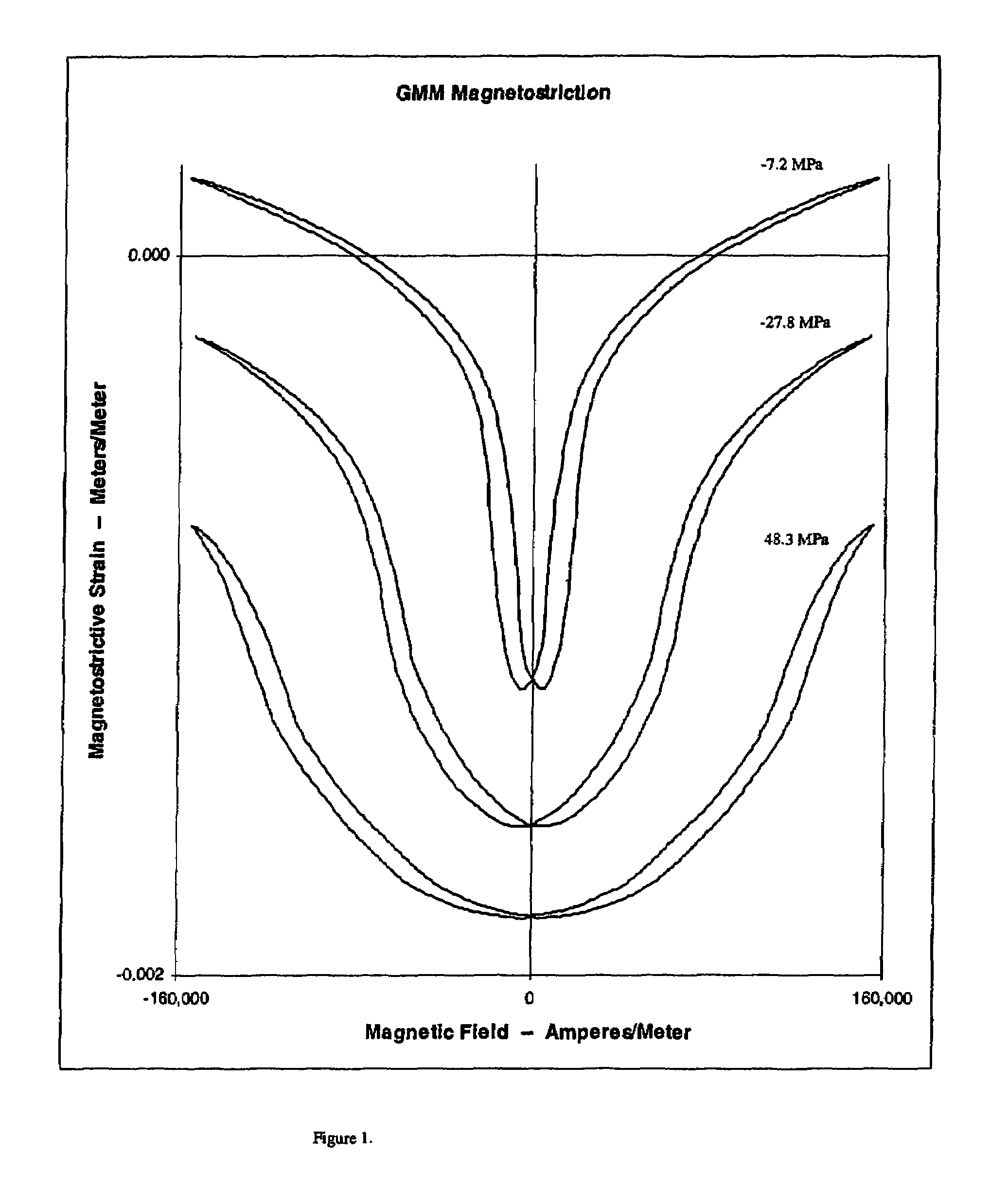

Very high speed rate shaping fuel injector

ActiveUS7255290B2Simple processMinimize formationOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesParticulatesCombustion chamber

Owner:QUANTUM CONTROL WORKS L C

Piezoelectric element and injector using the same

InactiveUS6845920B2Good heat dissipationHighly compactPiezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusHigh humidityInorganic materials

Owner:DENSO CORP

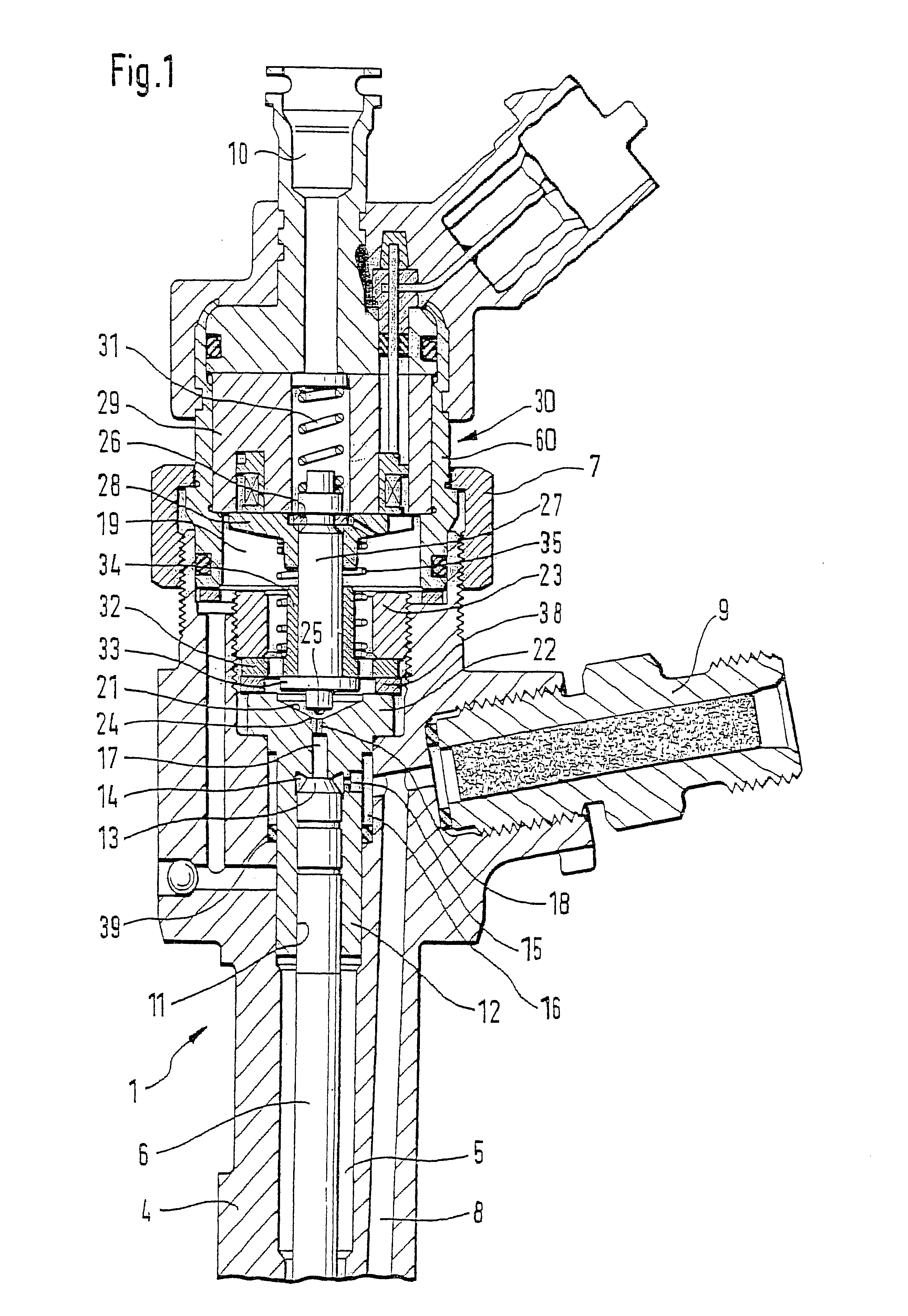

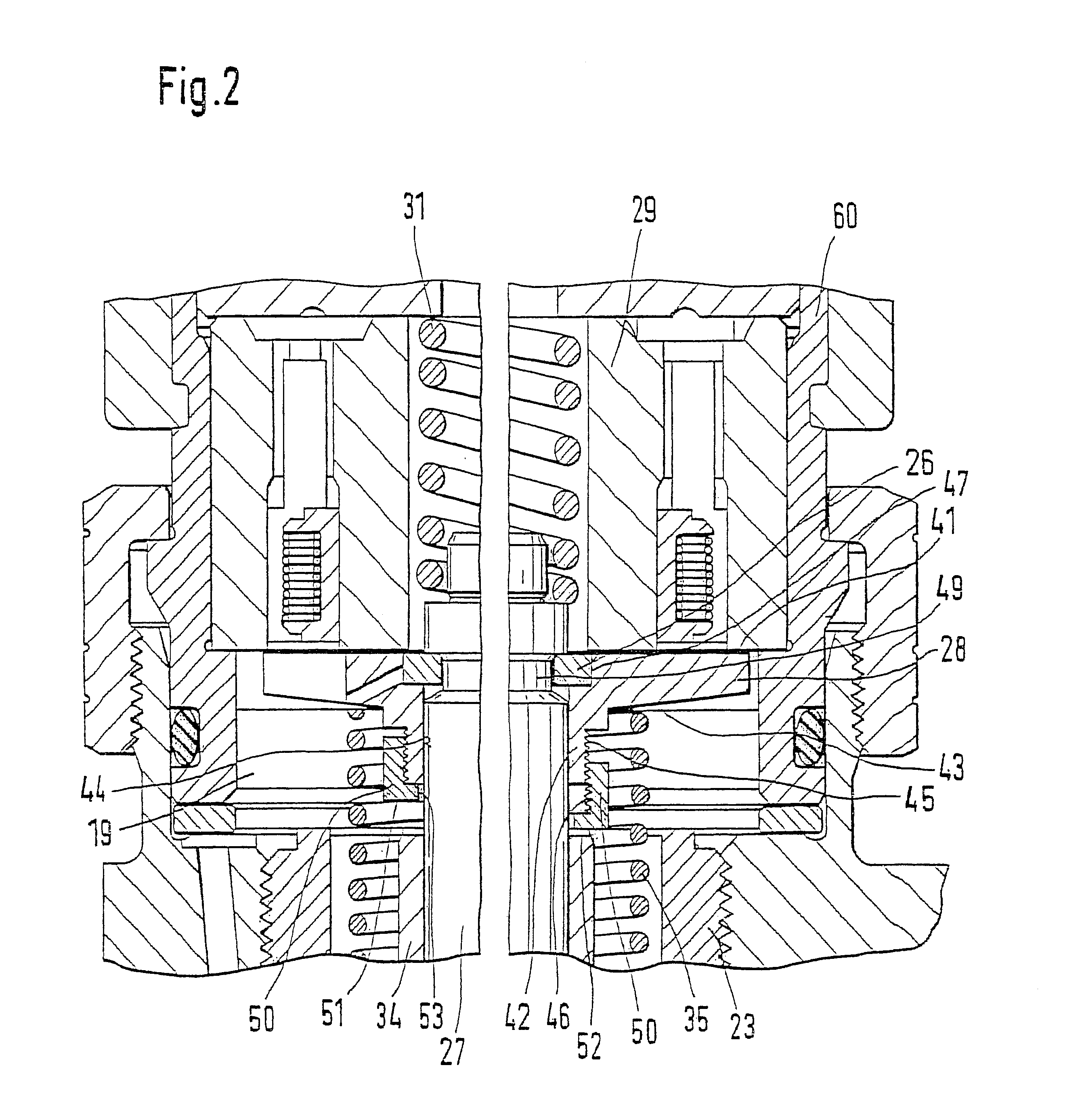

Solenoid valve for an electrically controlled valve

InactiveUS6161813APrevent reverberationOperating means/releasing devices for valvesFluid pressure injection controlCommon railSolenoid valve

PCT No. PCT / DE97 / 02723 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Nov. 20, 1997 PCT Pub. No. WO98 / 38426 PCT Pub. Date Sep. 3, 1998A solenoid valve comprising a magnet armature which is embodied as having multiple parts and has an armature disk and an armature bolt. The magnet armature is guided in a slider. A damping device is provided in order to prevent post-pulse oscillation of the armature after a closing of the solenoid valve. The required short switching times of the solenoid valve can be exactly maintained with a device of this kind. The solenoid valve is designated for use in injection systems with a common rail.

Owner:ROBERT BOSCH GMBH

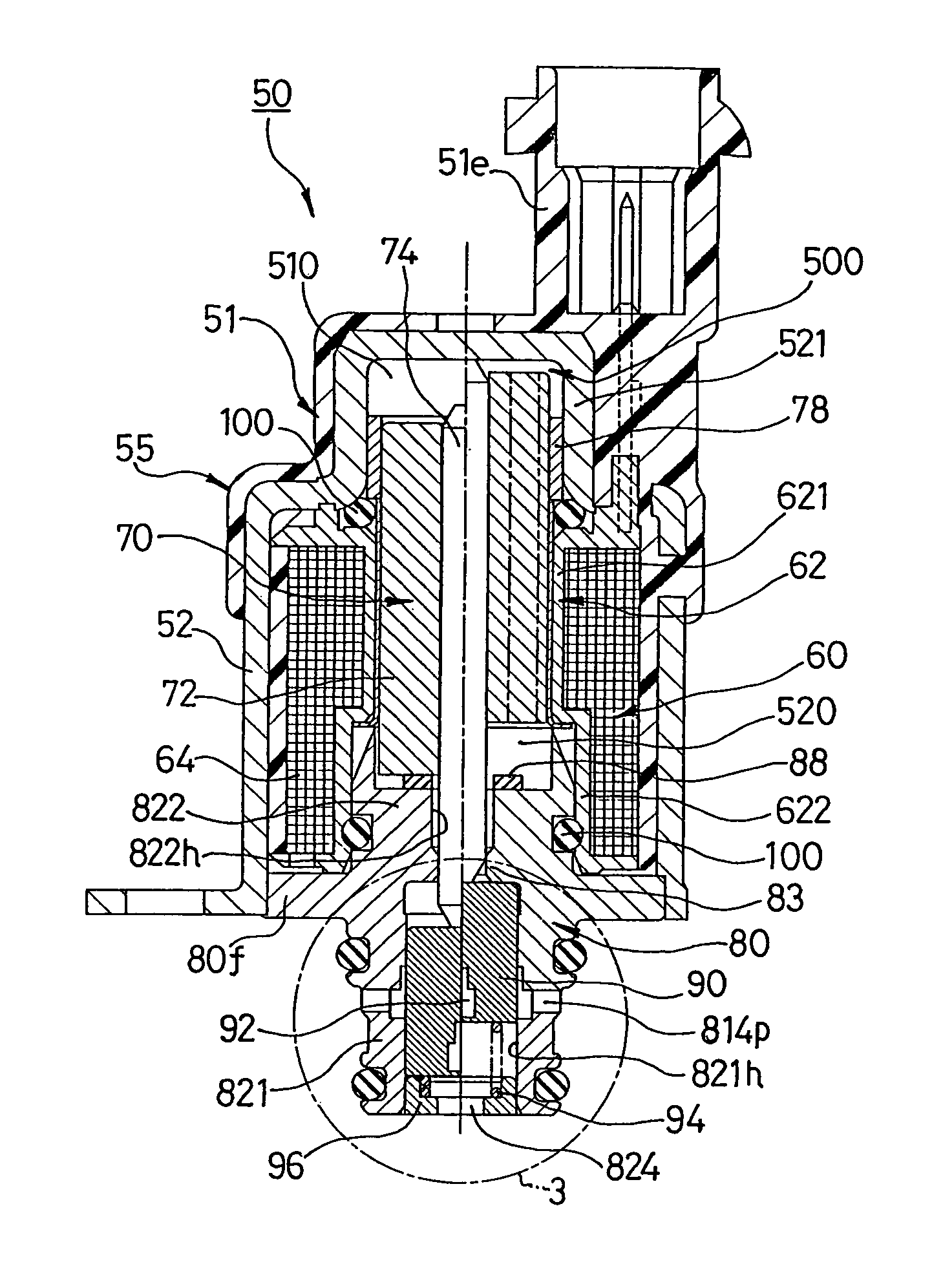

Fuel injector with piezoelectric actuator preload

ActiveUS7140353B1Meet the requirementsEasy to controlMovable spraying apparatusSpray nozzlesPiezoelectric actuatorsEngineering

An piezoelectric actuated injector is provided which includes a nozzle valve element, a control volume, and an injection control valve including a control valve member for controlling fuel flow from the control volume so as to control nozzle valve movement. Importantly, the injector includes a preload chamber positioned along an injection control valve member for receiving high pressure fuel. The high pressure fuel acts on the injection control valve member to apply a preload force to supply a preload force to the stack of piezoelectric elements thereby ensuring more accurate control over fuel injection timing and metering.

Owner:CUMMINS INC

System and method for preventing overheating of water within a water heater tank

A water heating system has a tank, a first heating element, a first temperature sensor, and a controller. The first heating element is mounted on the tank, and the controller is electrically coupled to the first temperature sensor. The controller is configured to detect a stacking condition based on the first temperature sensor and to disable the first heating element in response to detection of the stacking condition.

Owner:A O SMITH

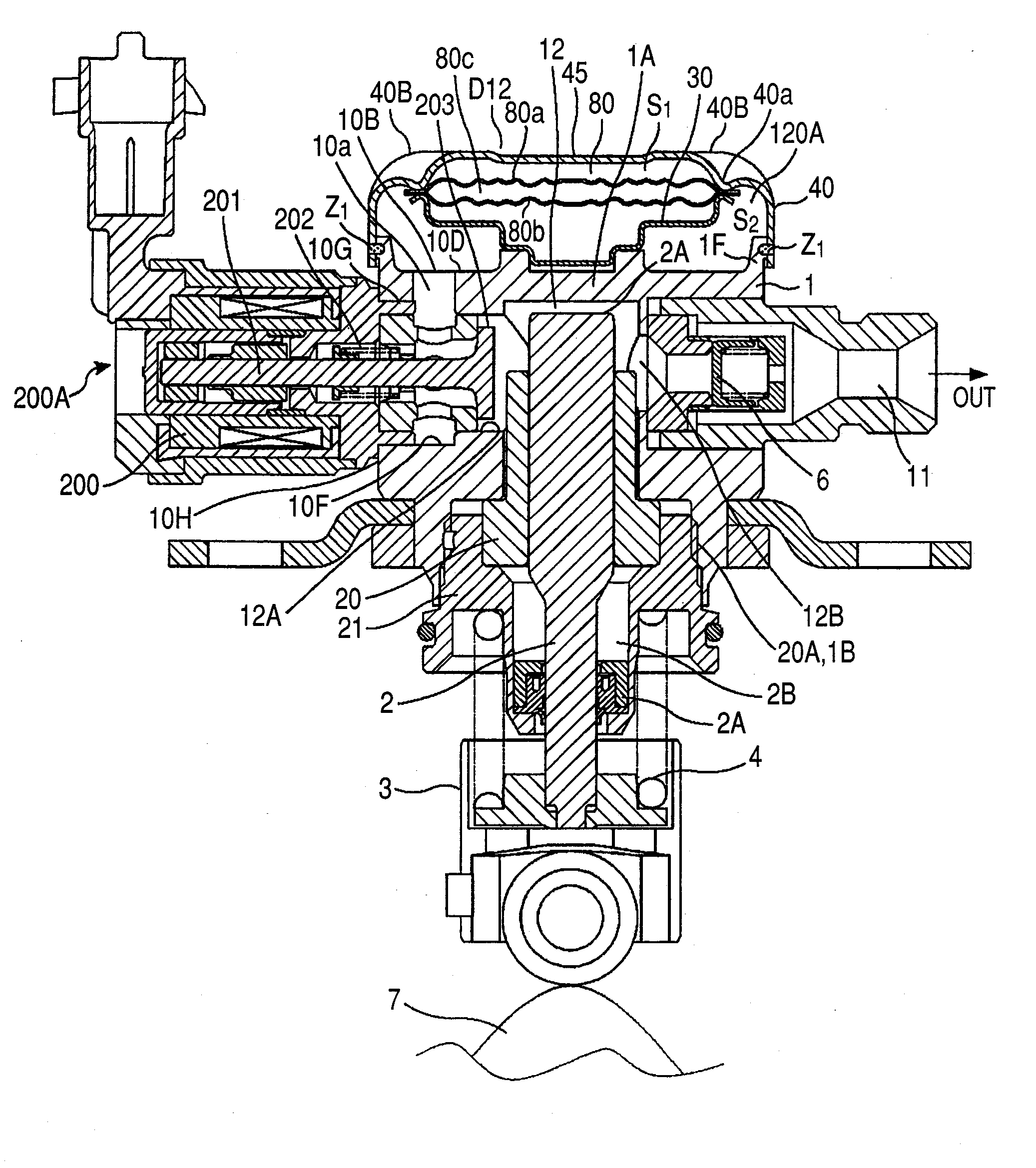

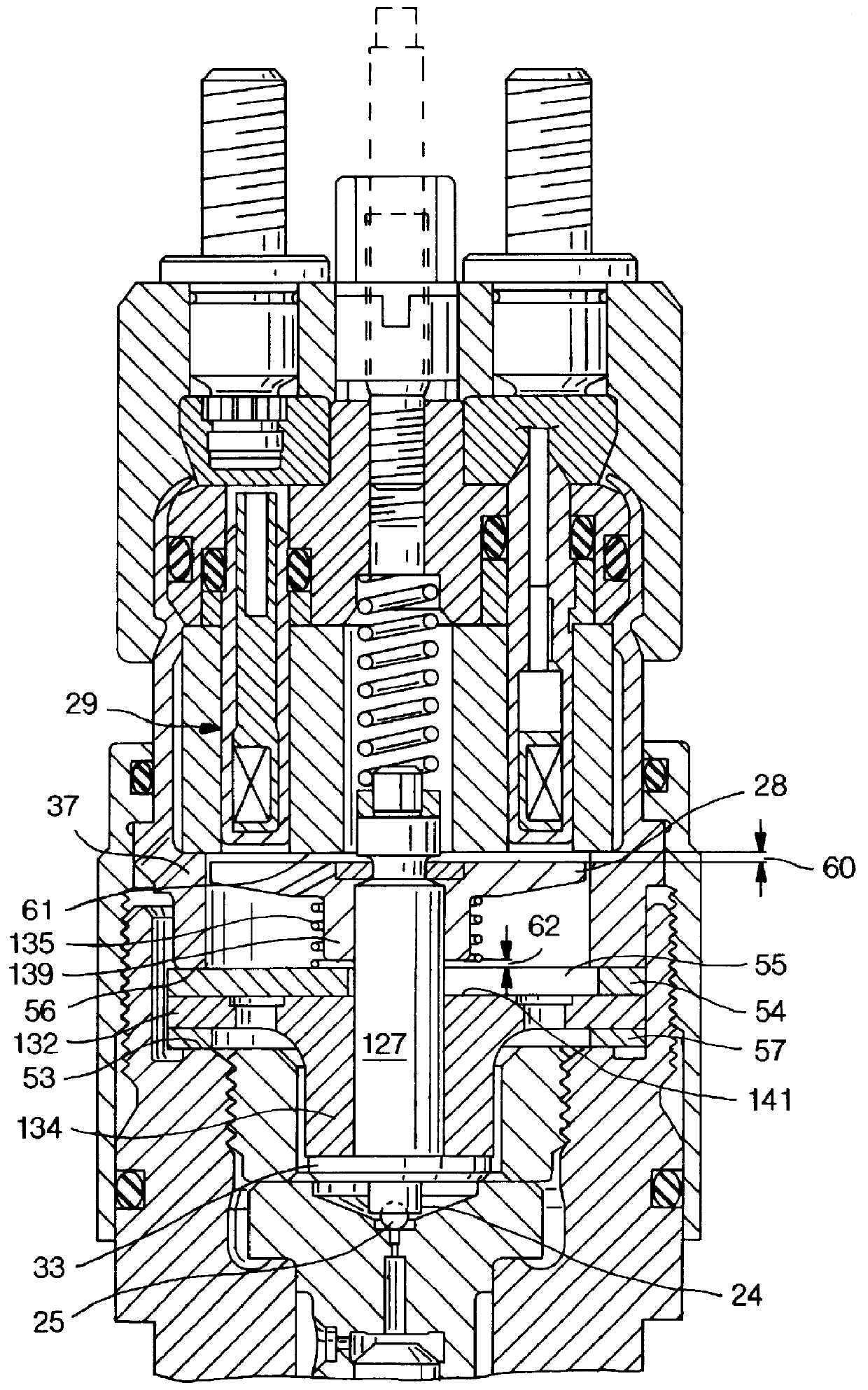

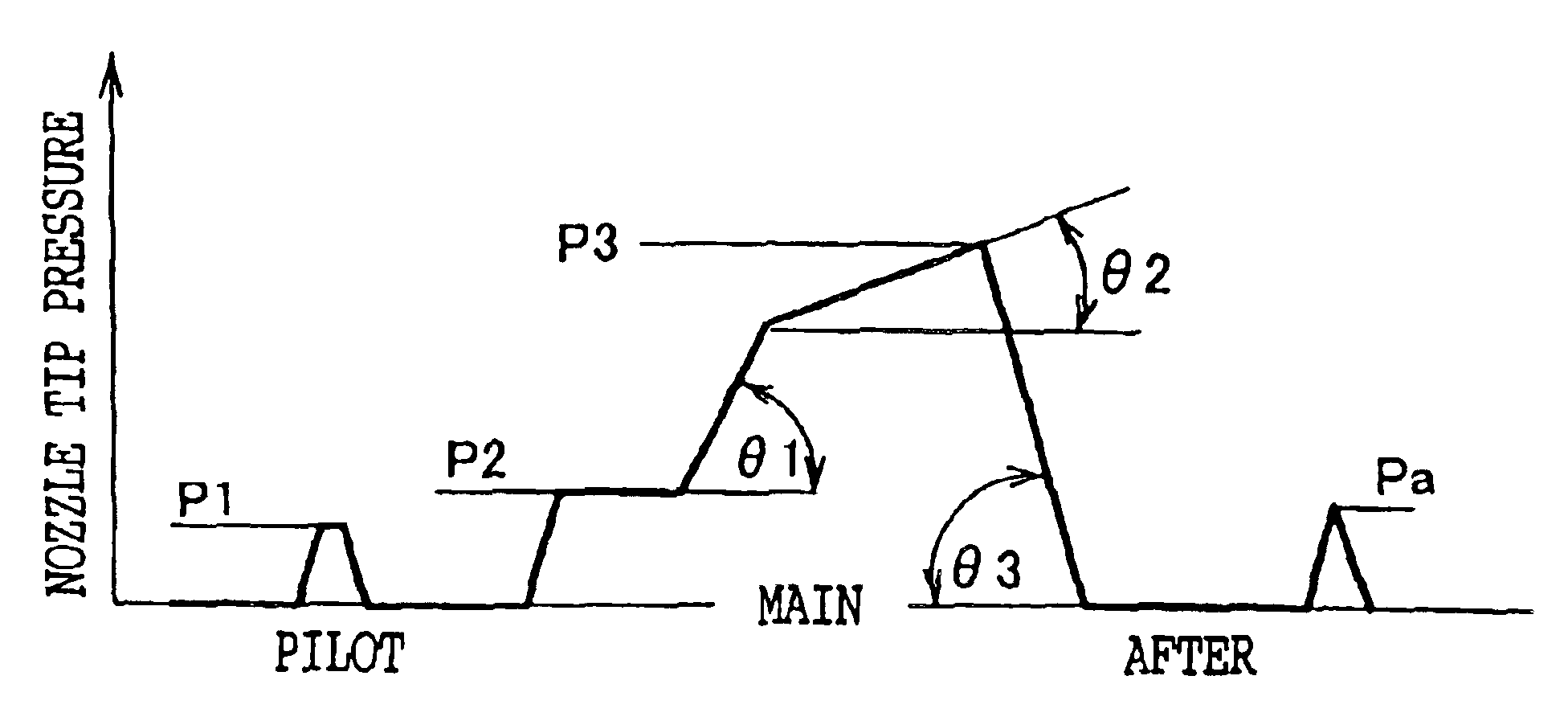

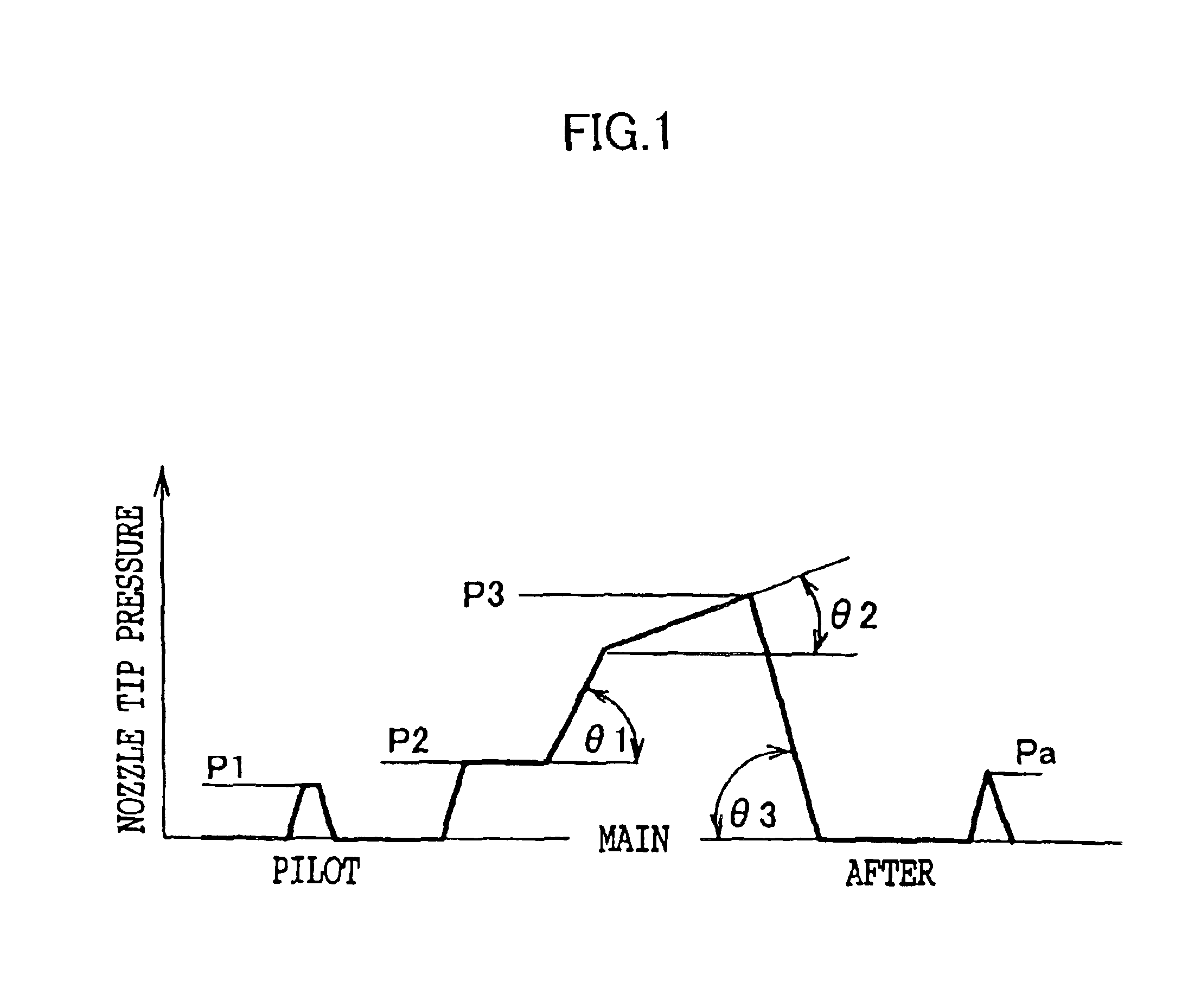

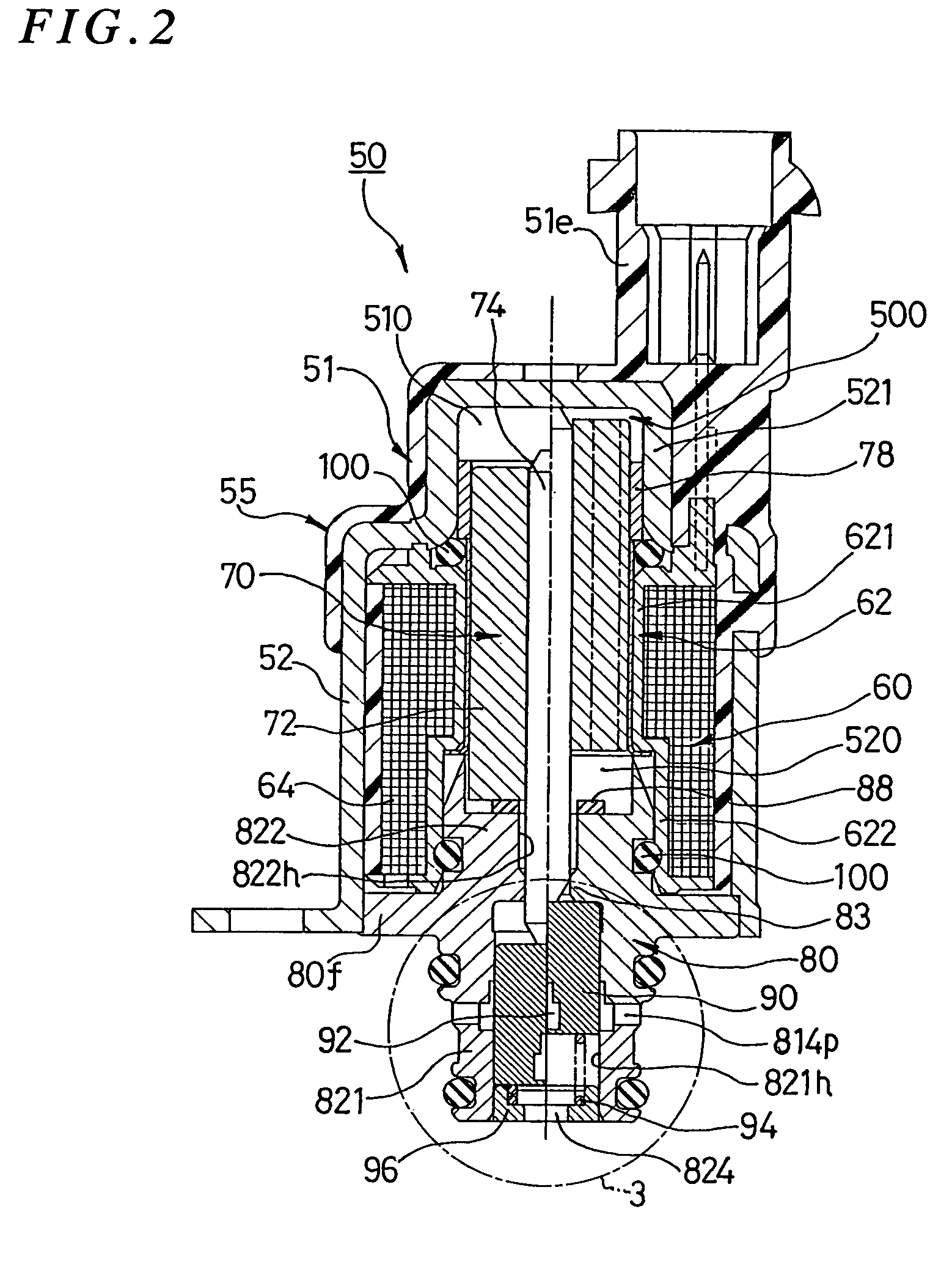

Fuel injection method in fuel injector

InactiveUS6904893B2Increase freedomRealize the structureElectrical controlInternal combustion piston enginesPhase differenceEngineering

In fuel injector including an accumulator and an intensifier, fuel is injected such that an injection control valve and a piston control valve are individually controlled, an operational phase difference therebetween is regulated, and at least one of a maximum injection pressure, a rate of increase of an injection pressure at the start of an increase of pressure, a rate of decrease of the injection pressure at the completion of injection, a pilot injection pressure, and an after injection pressure of fuel injected from a fuel injection nozzle is arbitrarily changed. Namely, a pressure during a movement from a base common rail pressure of the accumulator to a static maximum pressure statically determined by an operation of the intensifier is positively used as a control factor of injection, whereby a fuel injection pattern can be implemented with an extremely high degree of freedom.

Owner:TOYOTA JIDOSHA KK

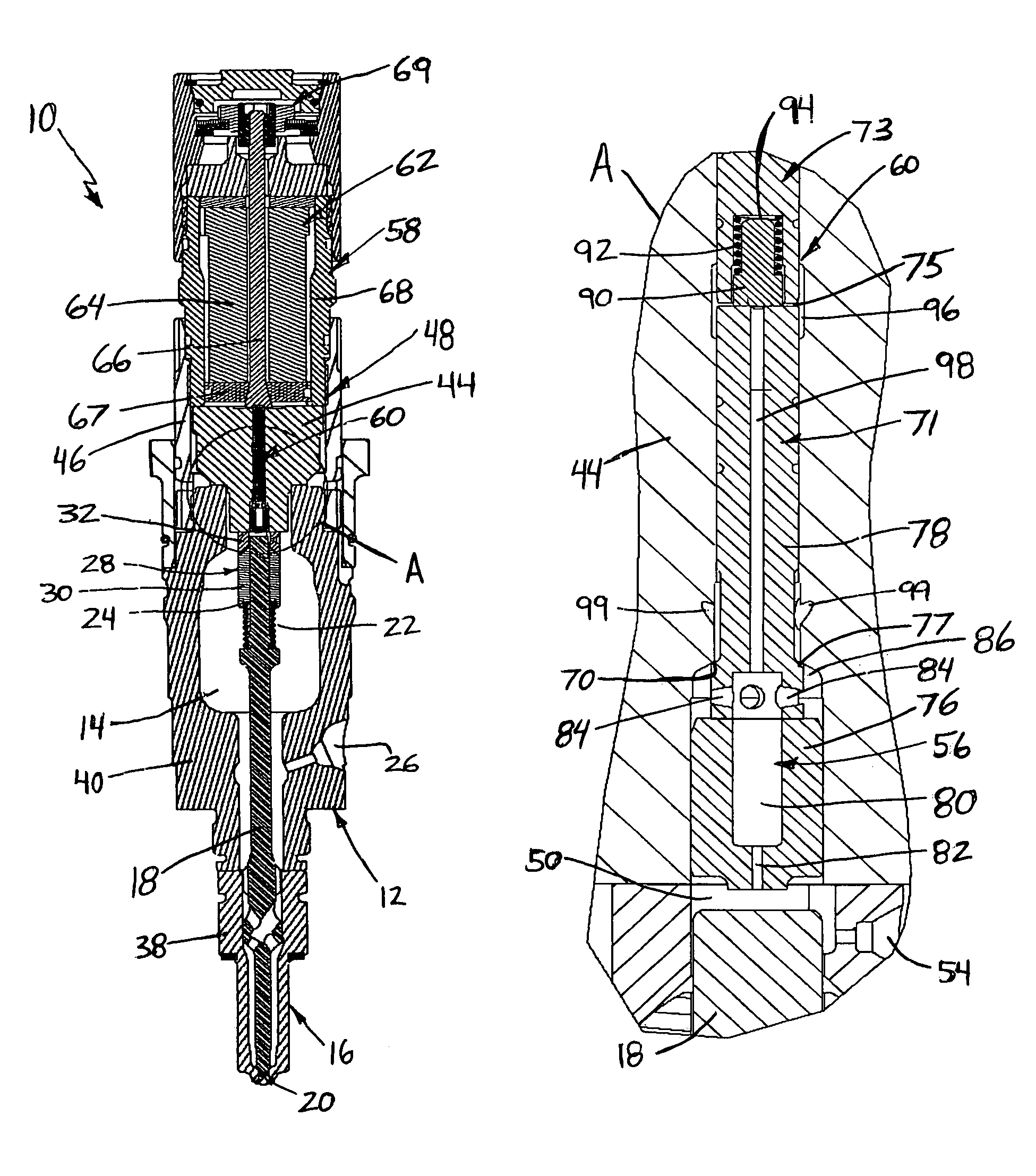

Directly actuated injection valve

InactiveUS6575138B2Reduce impactReduce wearElectrical controlInternal combustion piston enginesCombustion chamberEngineering

Owner:WESTPORT FUEL SYST CANADA INC

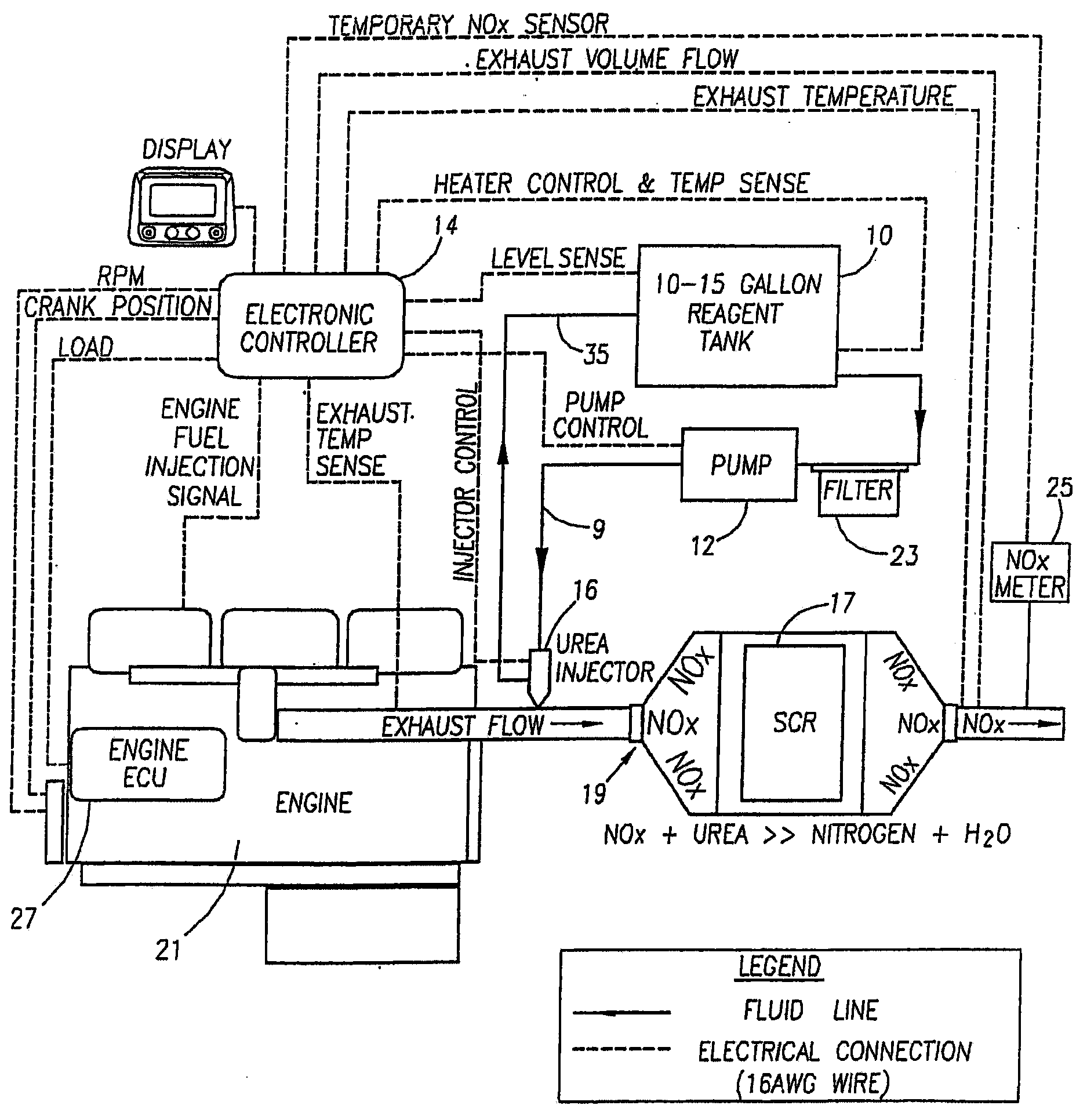

Method and apparatus for injecting atomized fluids

ActiveUS20090179087A1Emission reductionImprove performanceInternal combustion piston enginesExhaust apparatusEngineeringCentrifugal force

Methods and apparatus for injecting reagent, such as an aqueous urea solution, into an exhaust stream in order to reduce emissions from an engine exhaust. The present teachings can use a whirl plate having a plurality of whirl slots surrounding an exit orifice of an injector, which produce a high velocity rotating flow in the whirl chamber. When the rotating flow of reagent is passed through the exit orifice into an exhaust stream, atomization occurs from a combination of centrifugal force and shearing of the reagent by air as it jets into the exhaust stream.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Exhaust valve arrangement and a fuel system incorporating an exhaust valve arrangement

InactiveUS7533656B2Small diameterSecure attachmentMachines/enginesFuel injecting pumpsCombustion chamberExhaust valve

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

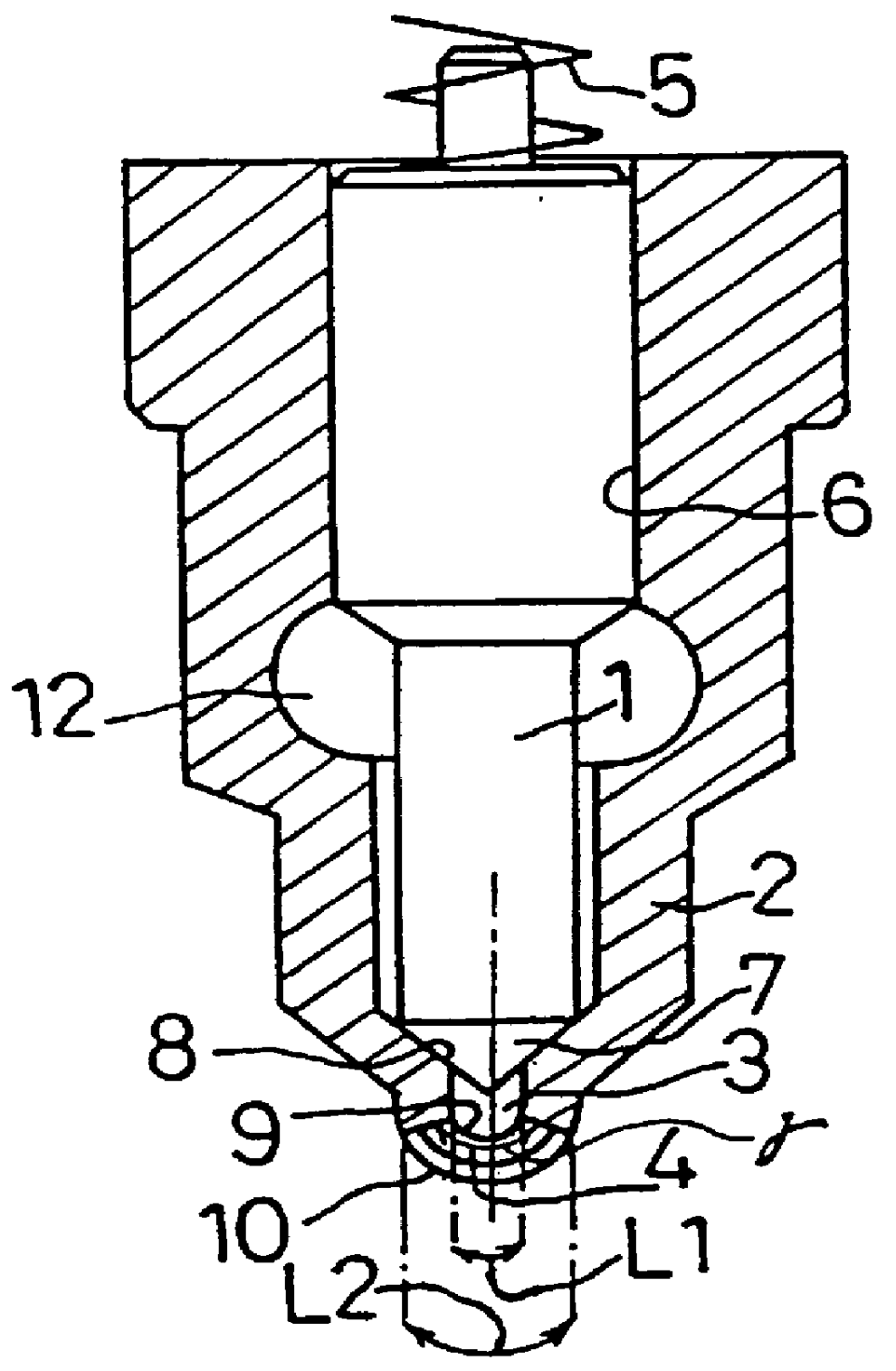

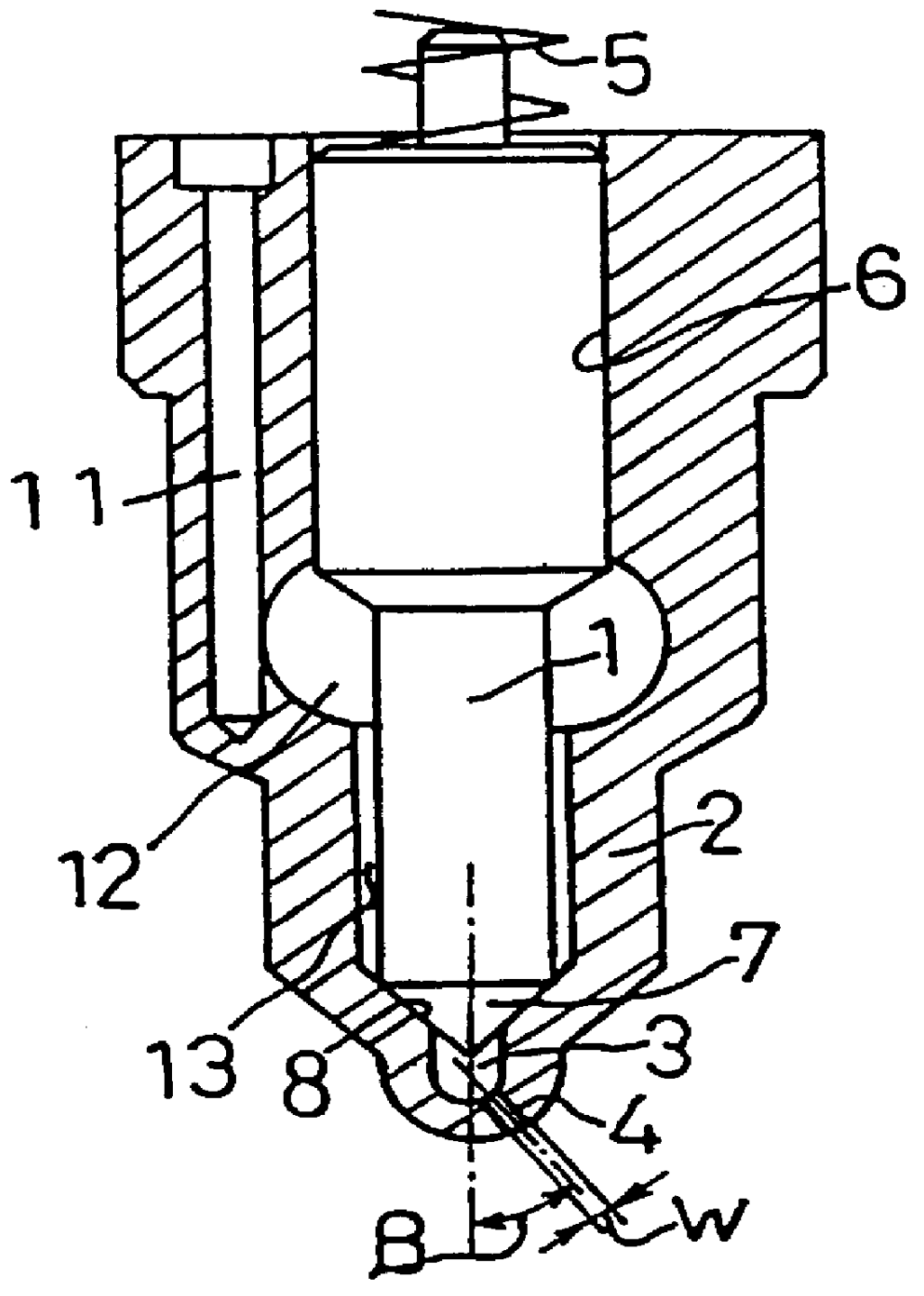

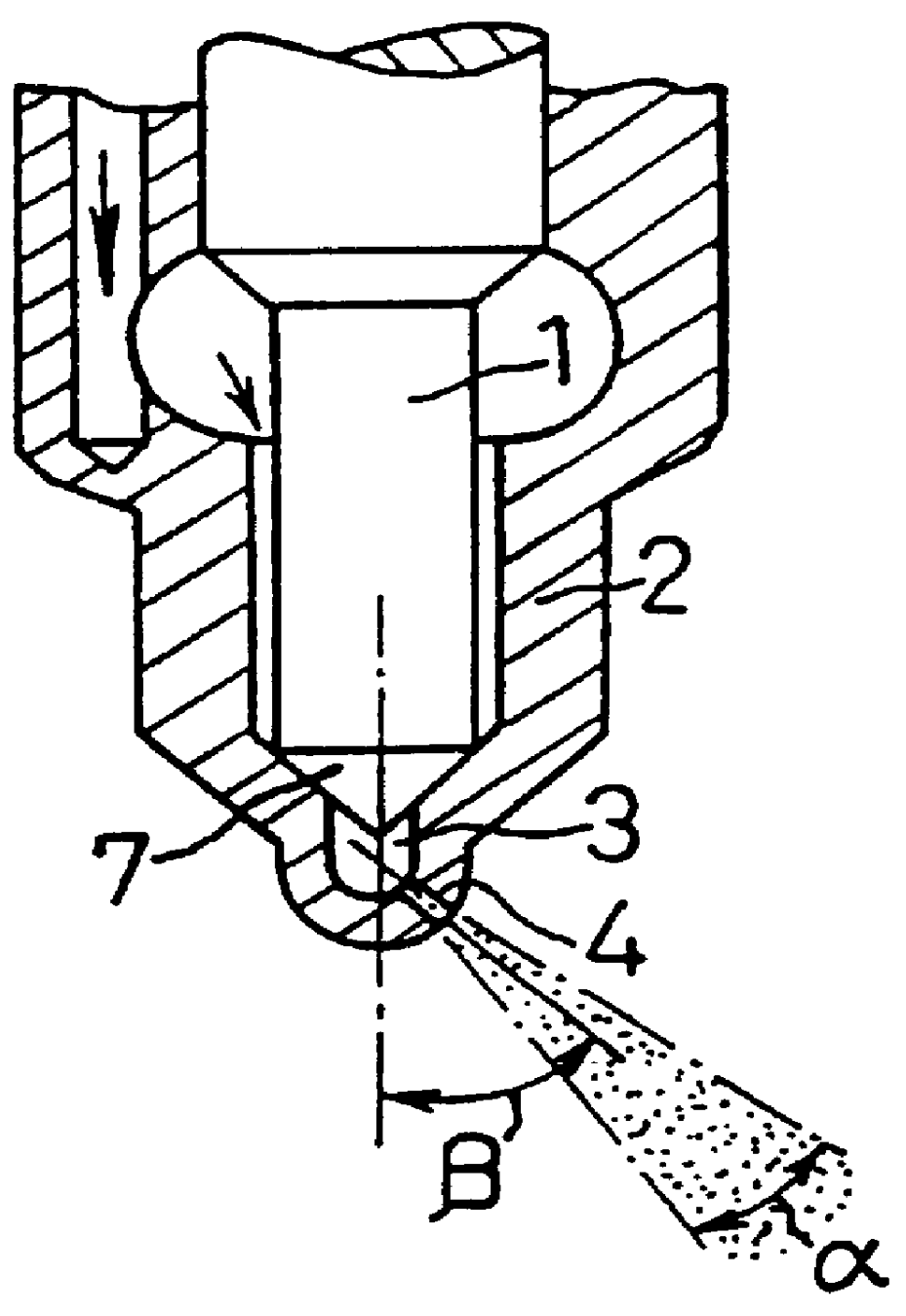

Fuel injection valve and nozzle

InactiveUS6045063AReduce traffic lossLower resistanceInternal combustion piston enginesSpray nozzlesEngineeringFuel injection

A fuel injector which is enabled to form a fuel spray efficiently and properly into a flat sector shape by improving the angle, dispersion and atomization of the spray and by optimizing the spray tip penetration. A slit-shaped nozzle outlet 4 is constructed such that its transverse walls from its inner end 9 to its outer end 10 have an included angle gamma of 20 to 180 degrees, such that an angle beta of 0 to 90 degrees is made between the axis of the fuel injector and the opening direction of the slit-shaped nozzle outlet 4, such that the nozzle outlet 4 is diverged outward from a plane joining the axis to the fuel injector and the inner end 9, and such that the opposite portions of the inner end 9 have a width W of 0.05 mm to 0.24 mm. By combining these constructions suitably, the fuel spray can be formed efficiently and properly into a flat sector shape thereby to improve the fuel injection characteristics.

Owner:TOYOTA CENT RES & DEV LAB INC

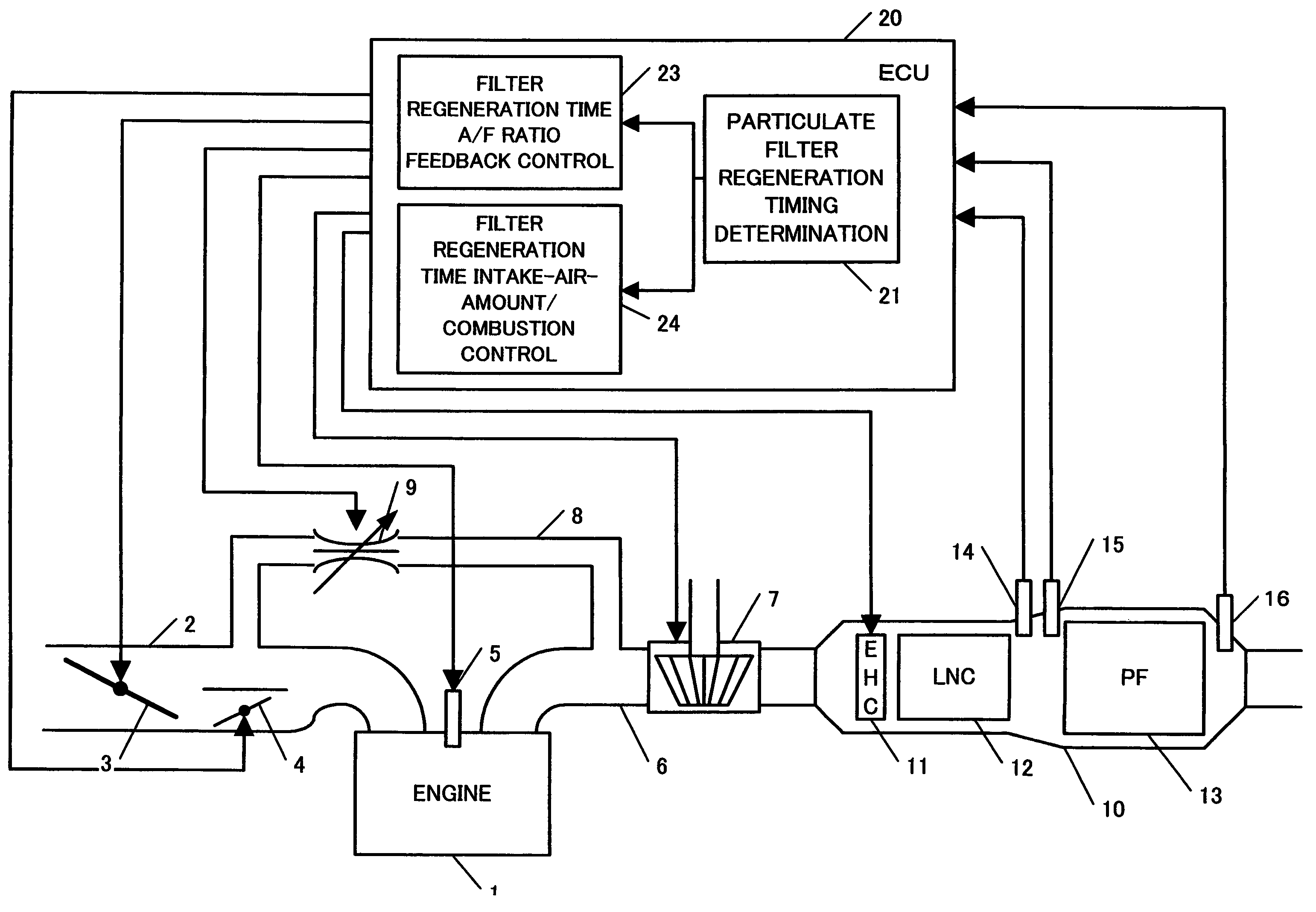

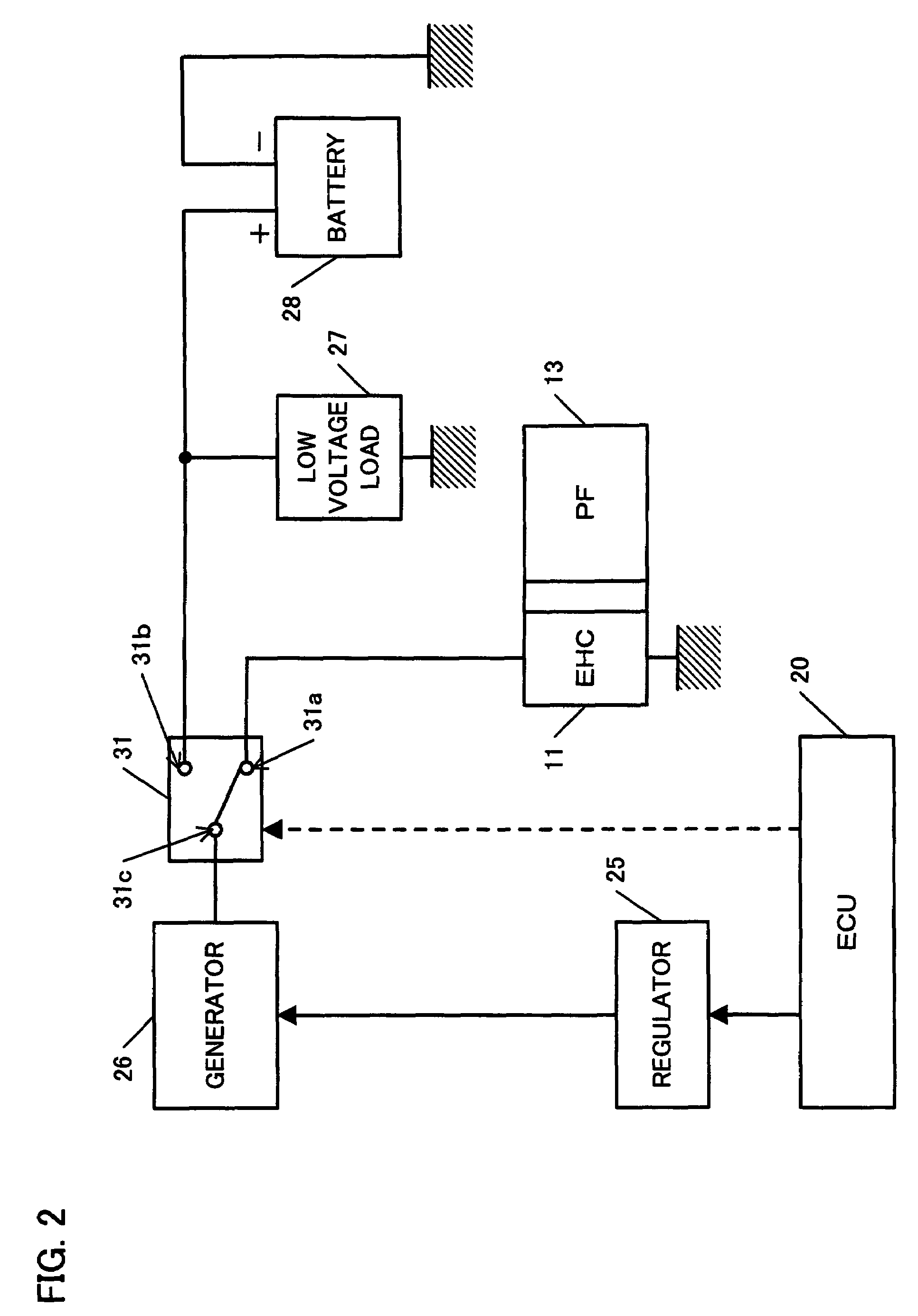

Exhaust gas purification device

InactiveUS7104051B2Emission is deterioratedInhibit deteriorationElectrical controlInternal combustion piston enginesParticulatesCombustion

The invention provides an exhaust gas purification device that can prevent deterioration of the emission during a regeneration process for a particular filter for trapping particulates contained in the exhaust gas.Particulate filter regeneration timing determining unit estimates the amount of particulates trapped by the particulate filter to determine the filter regeneration timing based on the estimated particular amount. In response to the regeneration timing determination, heating unit heats the particulate filter to raise an exhaust gas temperature, so that a particulate filter regeneration process starts. At this time, intake air amount reducing unit reduces the intake air amount to raise the exhaust gas temperature while combustion maintaining unit controls the combustion in the internal-combustion engine so as to be maintained in a desired condition.

Owner:HONDA MOTOR CO LTD

Nozzle with flow rate and droplet size control capability

A flexible, self-adjusting flow nozzle is provided, optimally configured for agricultural uses. The nozzle flexes automatically in response to changes in fluid pressure, thereby maintaining an optimal droplet size and spray area for a variety of flow rates. The self-adjusting characteristic of the nozzle allows for the creation of a fully or semi-automatic spray system. The fully automatic system uses a GPS receiver to compare actual geographic data against a predetermined flow plan for automatically making adjustments to flow rate in order to accommodate both speed changes and varying crop needs. The semi-automatic system uses a manually controlled flow rate but utilizes the self-adjusting capabilities of the spray nozzle.

Owner:BUI QUY DUC

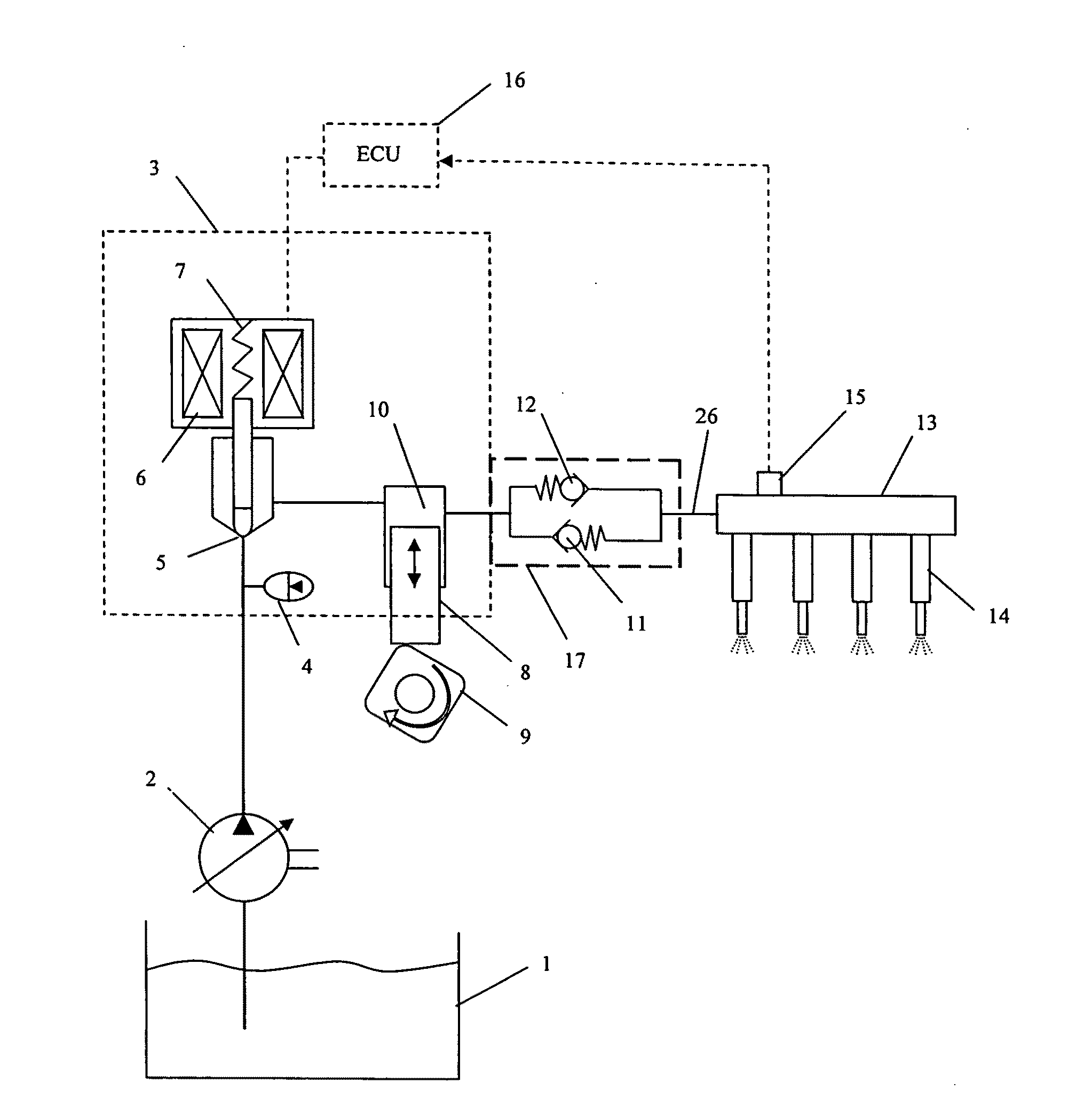

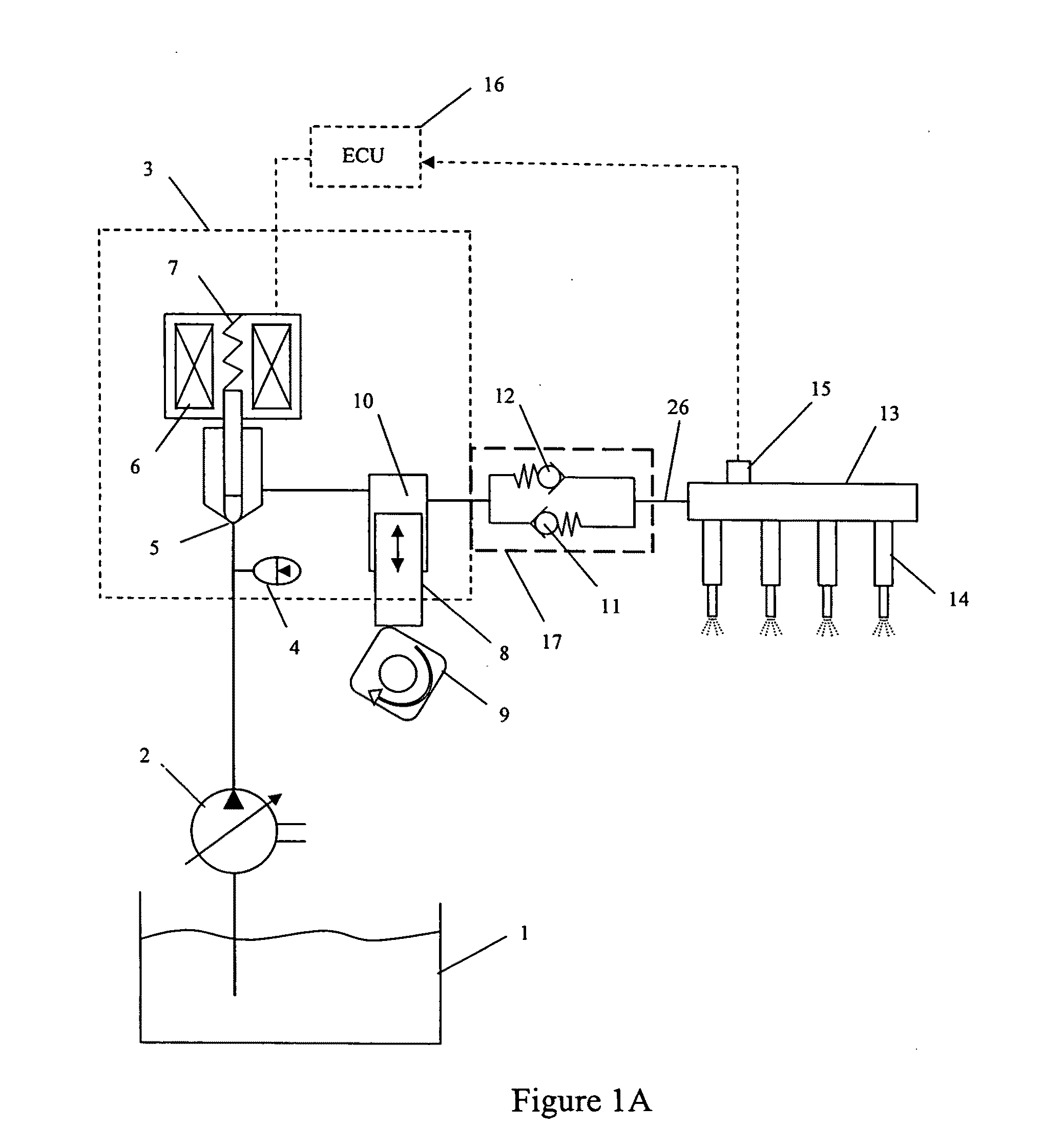

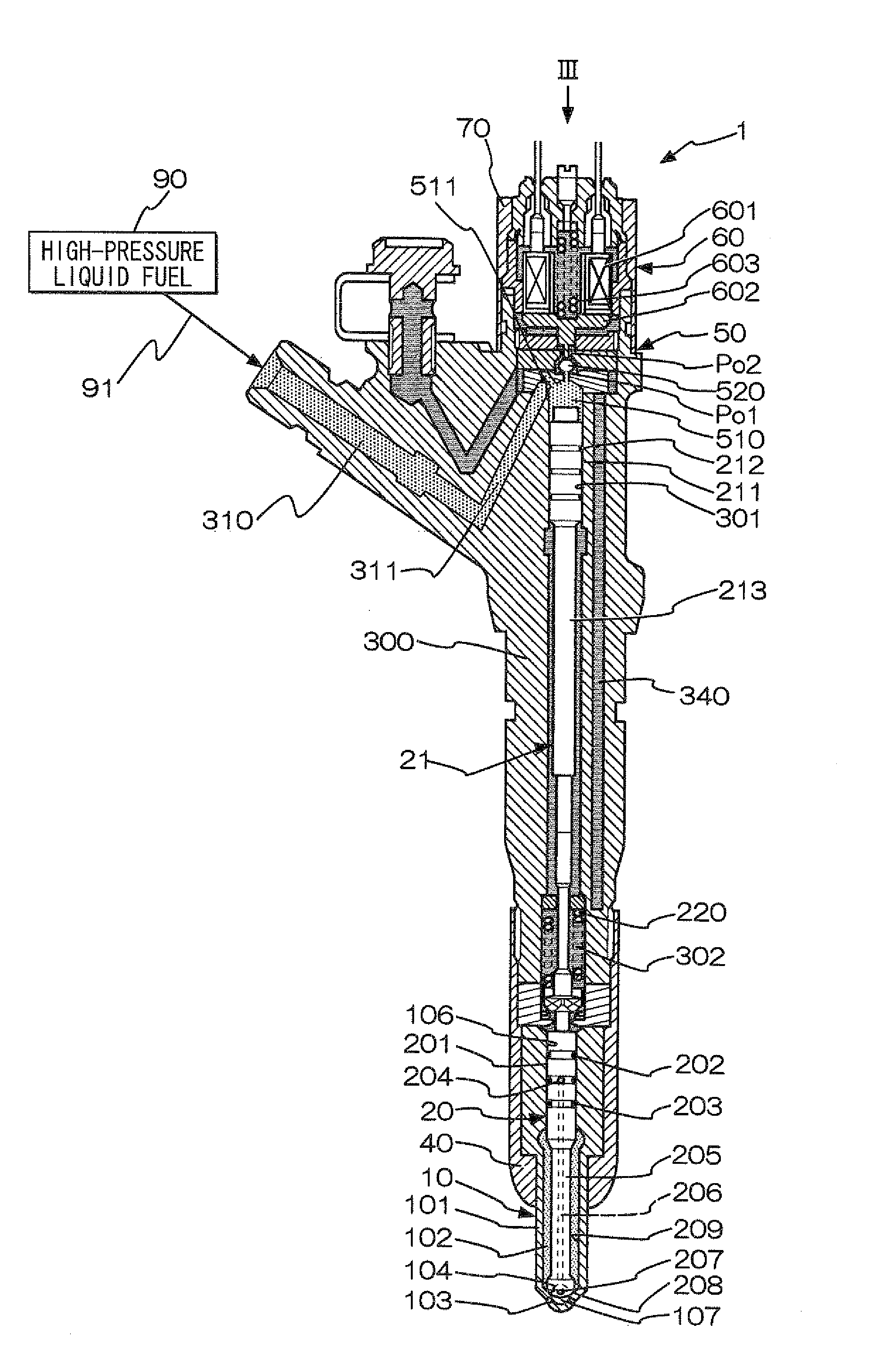

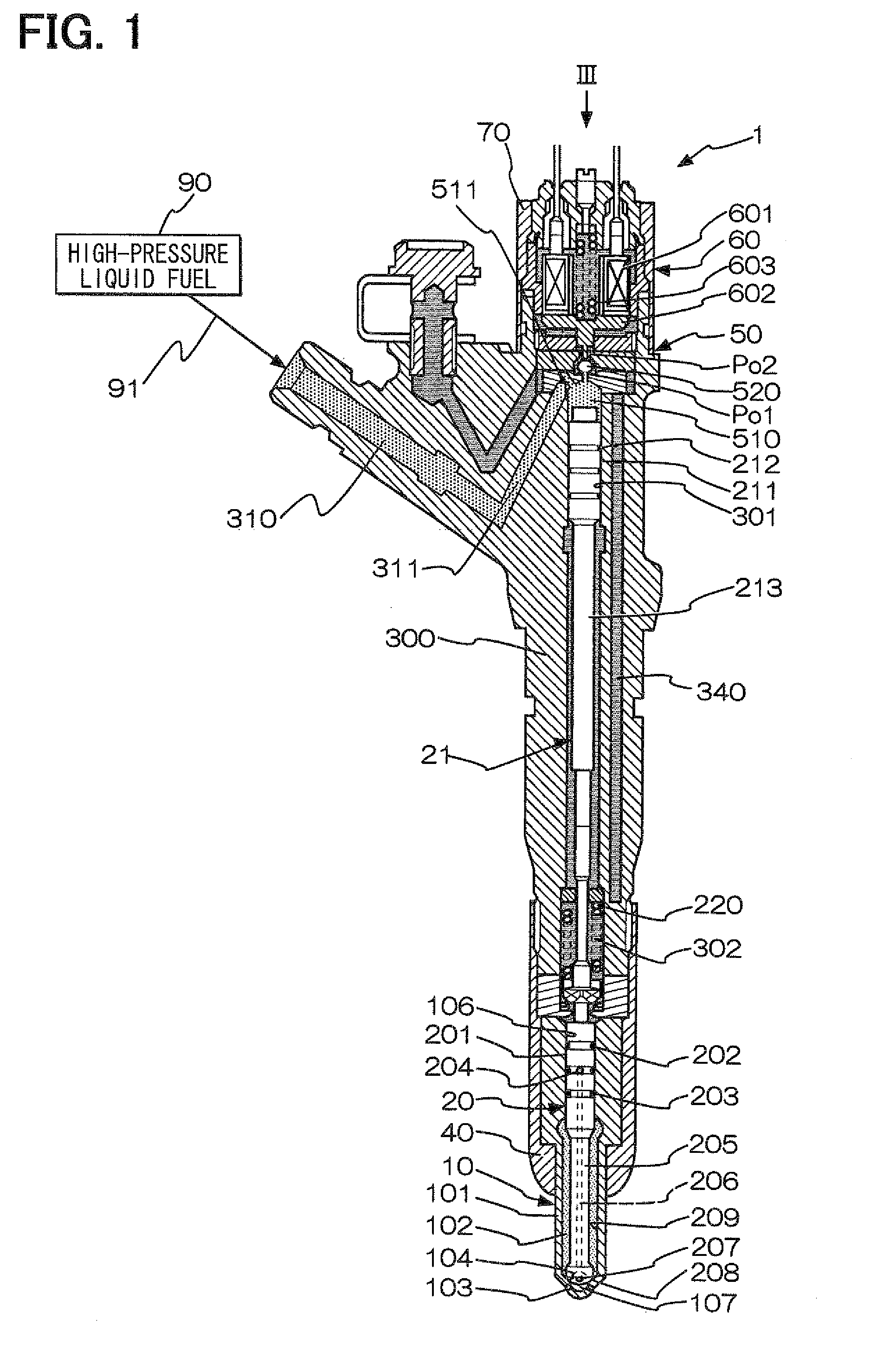

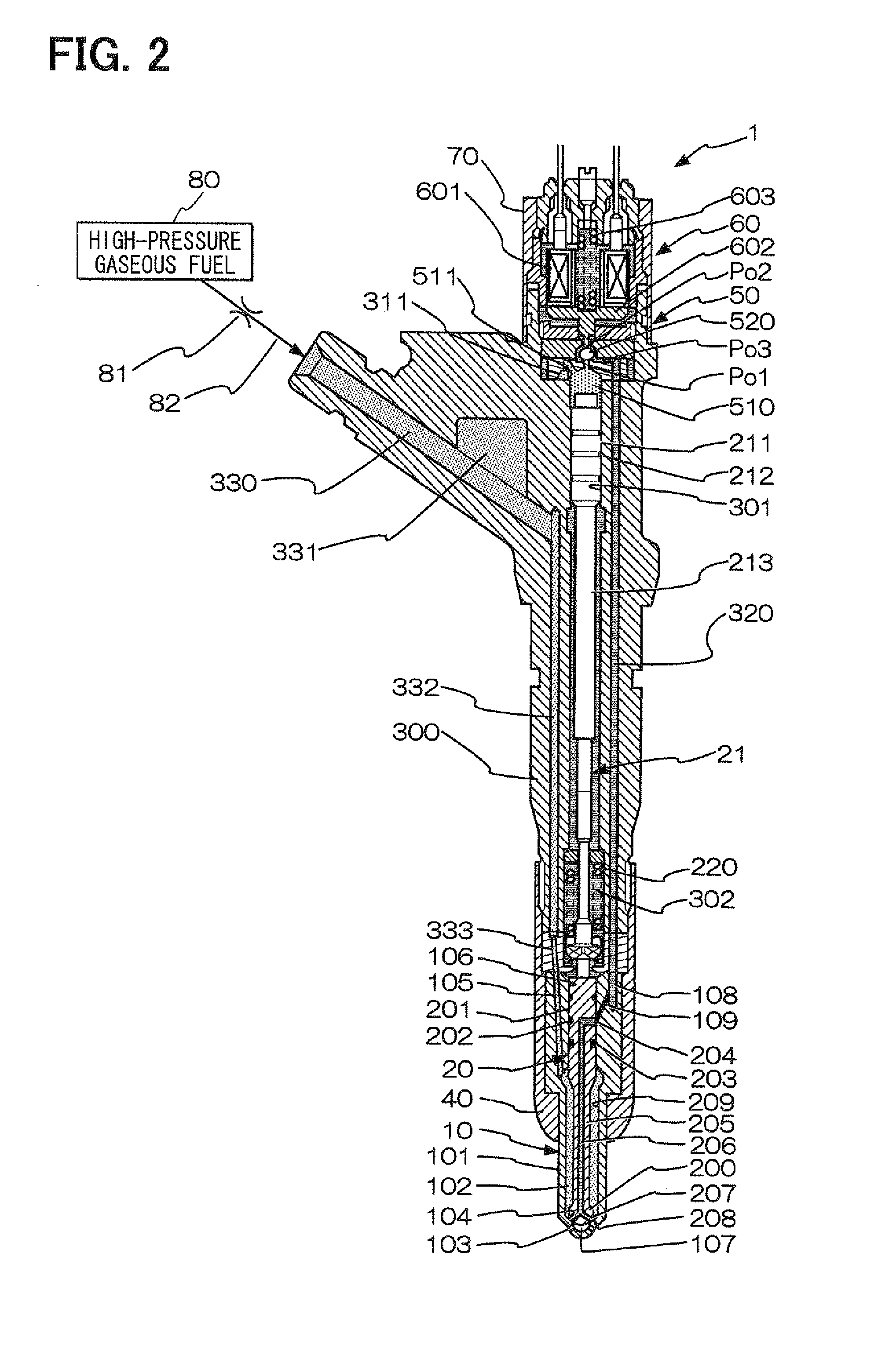

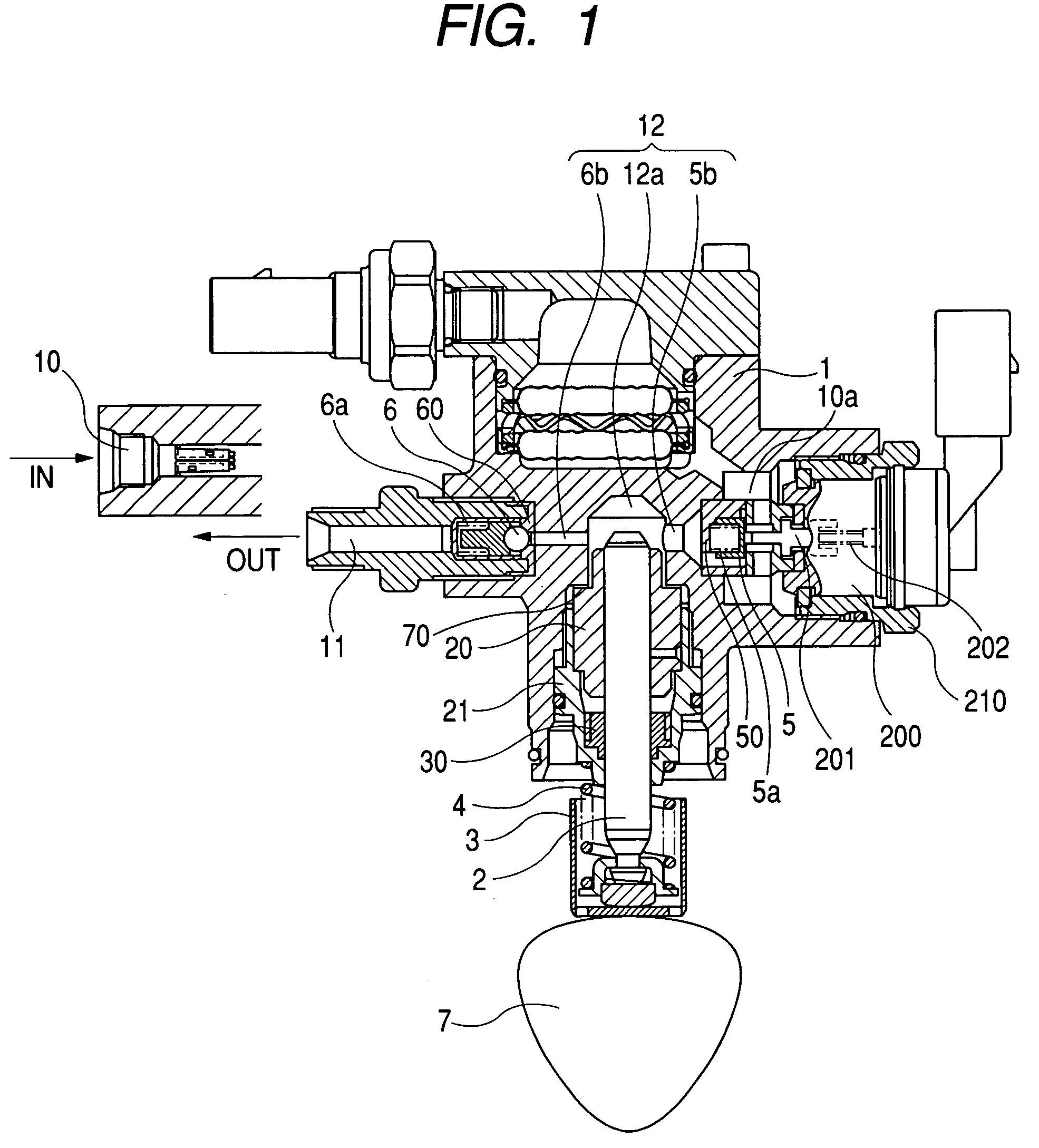

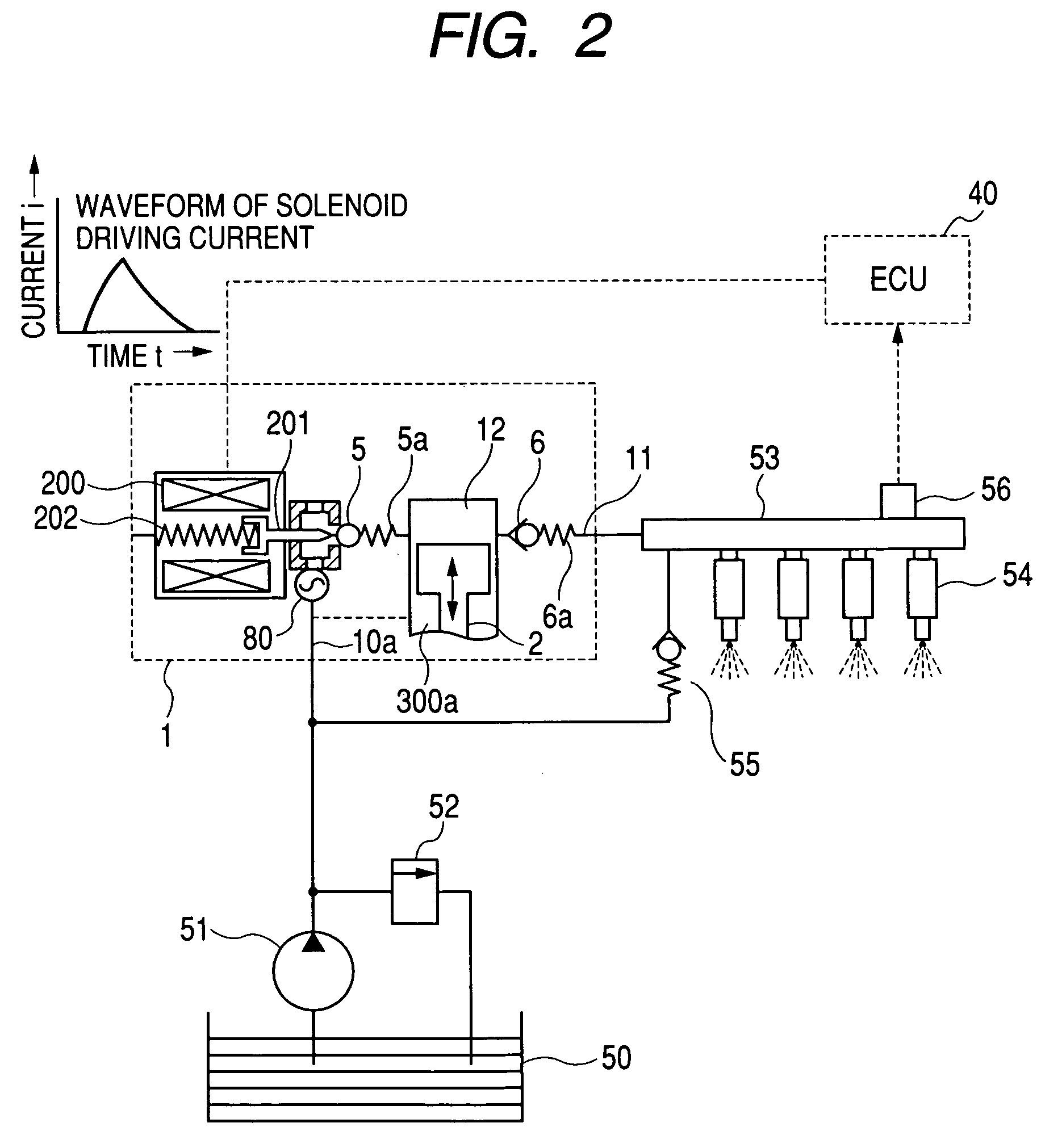

Gaseous fuel injector using liquid fuel as lubricant and pressure-transmitting medium

InactiveUS20090020631A1Improve flammabilityImprove responseInternal combustion piston enginesFuel supply apparatusElectricityPressure transmission

A fuel injector injects high-pressure gaseous fuel directly into a cylinder of an engine. A small amount of liquid fuel is used in the injector to lubricate sliding portions of the fuel injector in addition to utilizing it as a medium for transmitting driving force. The fuel injector includes a nozzle member having injection holes at its elongated end and a needle slidably disposed in an elongated center hole of the nozzle member. The needle is driven by pressure of the liquid fuel introduced into a control chamber to open or close the injection holes. The pressure in the control chamber is controlled by a switching valve which is in turn driven by an actuator such as an electromagnetic or piezoelectric actuator. The liquid fuel is injected together with the high-pressure gaseous fuel after lubricating the sliding portions between the nozzle member and the needle.

Owner:DENSO CORP

Pressure control in low static leak fuel system

A pressure relief valve includes a valve body having a valve seat fluidly positioned between an inlet and an outlet. A valve member is movable among a first position, a second position, and a third position. The valve member is in contact with the valve seat and fluidly blocks the inlet from the outlet at the first position. At the second position of the valve member, the inlet is fluidly connected to the outlet via a small flow area. The inlet is fluidly connected to the outlet via a large flow area when the valve member is at the third position. An electrical actuator is attached to the valve body and is operably coupled to move the valve member when energized. The valve member includes an opening hydraulic surface exposed to fluid pressure in the inlet when at the first position. A spring is operably positioned to bias the valve member toward the second position when the valve member is at the third position.

Owner:CATERPILLAR INC

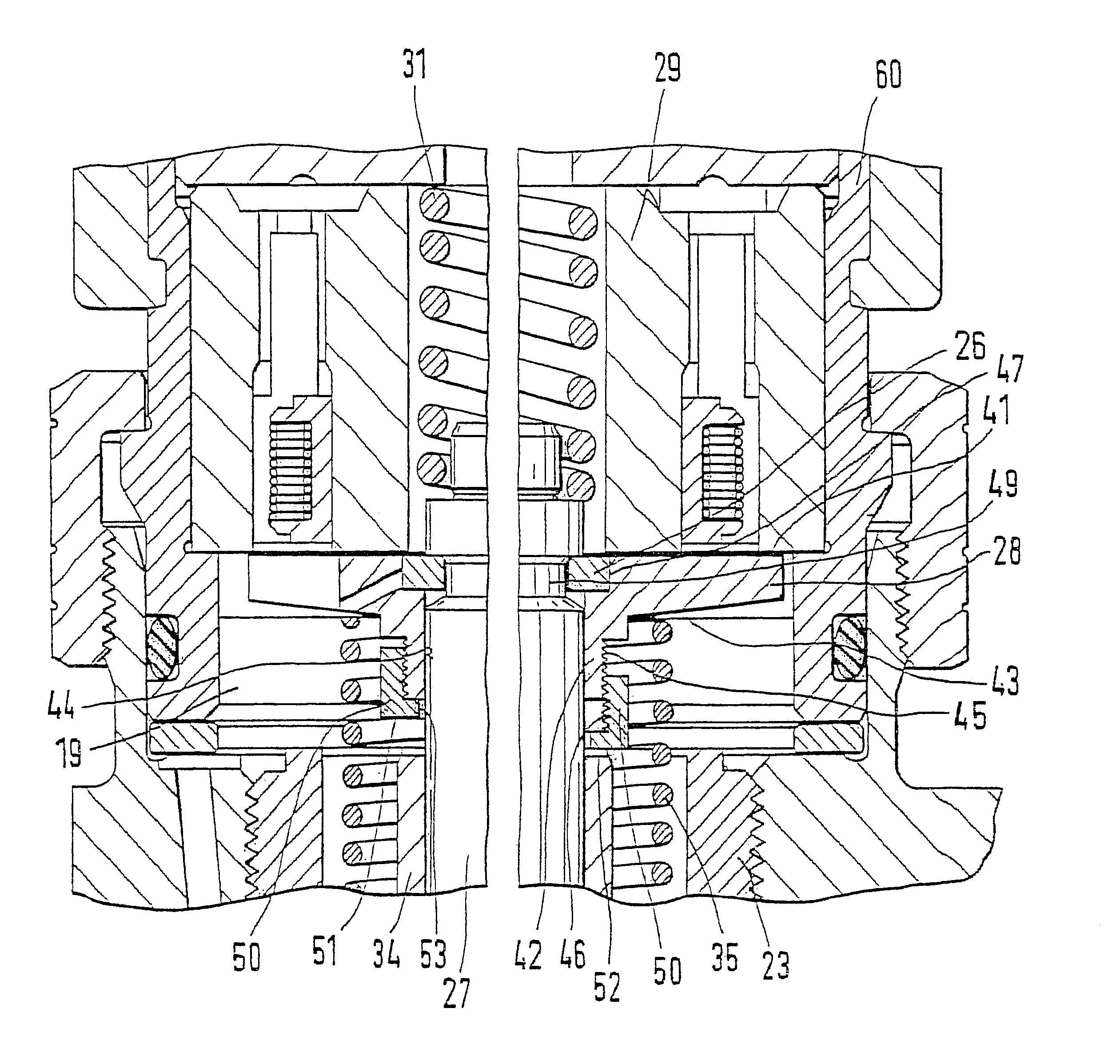

Solenoid valve for controlling a fuel injector of an internal combustion engine

InactiveUS6688579B2Easy to assembleAvoid disadvantagesOperating means/releasing devices for valvesFluid pressure injection controlInertial massSolenoid valve

A solenoid valve for controlling a fuel injector of an internal combustion engine having an electromagnet, a movable armature having an armature plate and an armature pin, and a control valve element which is moved with the armature and works together with a valve seat, for opening and closing a fuel drain channel of a control pressure chamber of the fuel injector, is provided. The armature plate is mounted on the armature pin so that it is movable by sliding under the effect of its inertial mass in the closing direction of the control valve element against the tension of a return spring acting on the armature plate. In order to be able to easily set the maximum slide path of the armature plate, an actuator is provided on the armature plate which is arranged on a section of the armature plate facing away from the electromagnet and is adjustable in the sliding direction of the armature plate relative to a face of the armature plate facing the electromagnet.

Owner:ROBERT BOSCH GMBH

Fluid flow rate control valve, anchor for mover and fuel injection system

InactiveUS7131426B2Large meritOperating means/releasing devices for valvesMachines/enginesEngineeringFuel injection

Owner:BOSCH CORP

Fuel injector with feedback control

InactiveUS6837221B2Minimize consumptionMeet the requirementsEngine testingMachines/enginesEngineeringControl valves

An injector is provided which includes a nozzle valve element, a control volume, and an injection control valve including a control valve member for controlling fuel flow from the control volume so as to control nozzle valve movement. Importantly, the injector includes a nozzle valve lift detecting device for detecting nozzle valve lift and providing a nozzle valve element lift feedback signal. Feedback signals are improved and control valve member oscillations are minimized by positioning a valve seat associated with the control valve member a spaced distance from the control volume, positioning a drain orifice such that the nozzle valve element restricts flow through a drain circuit when in an open position and extending the control valve member from the valve seat to the control volume to form an end wall of the control volume.

Owner:CUMMINS INC

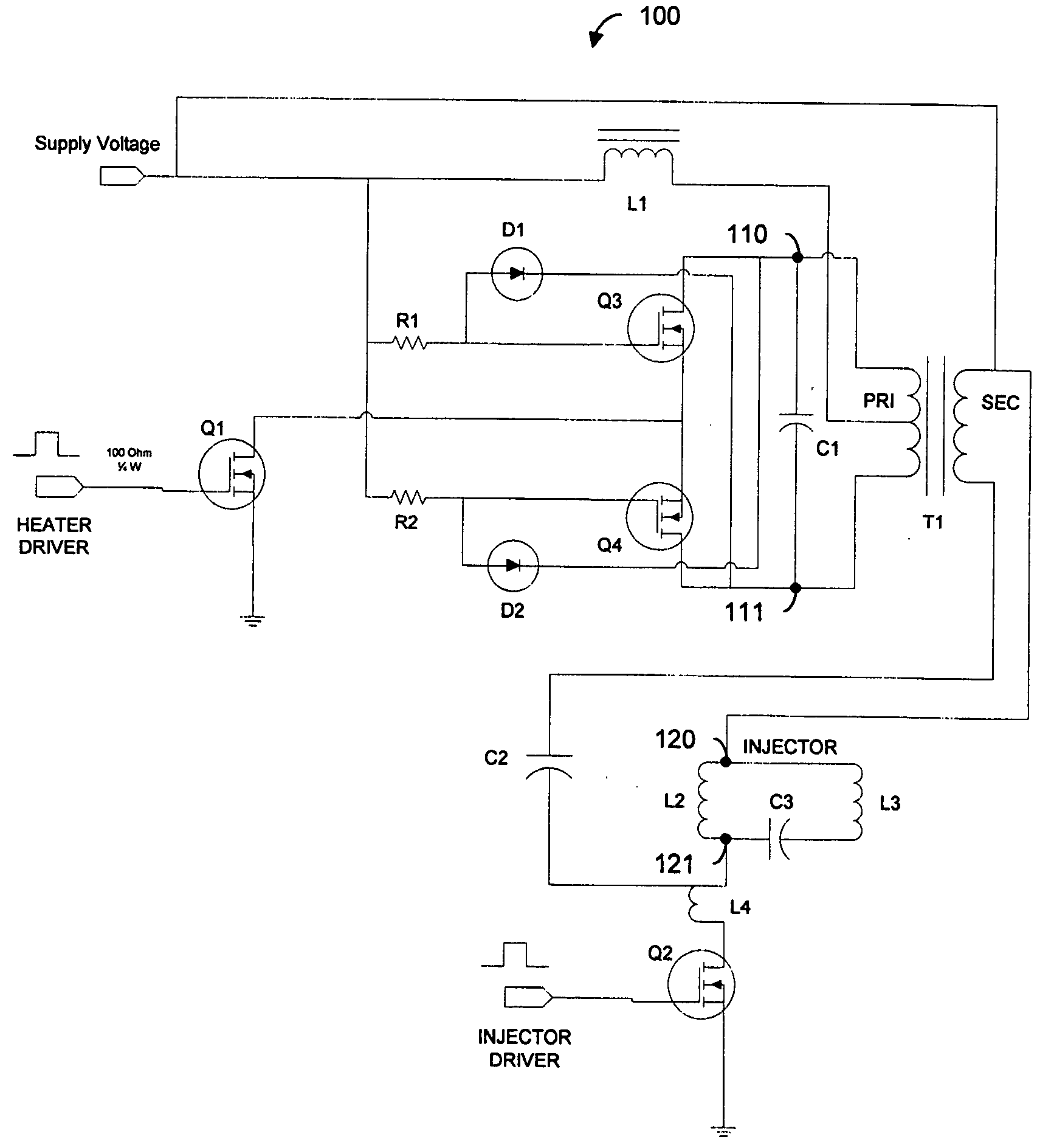

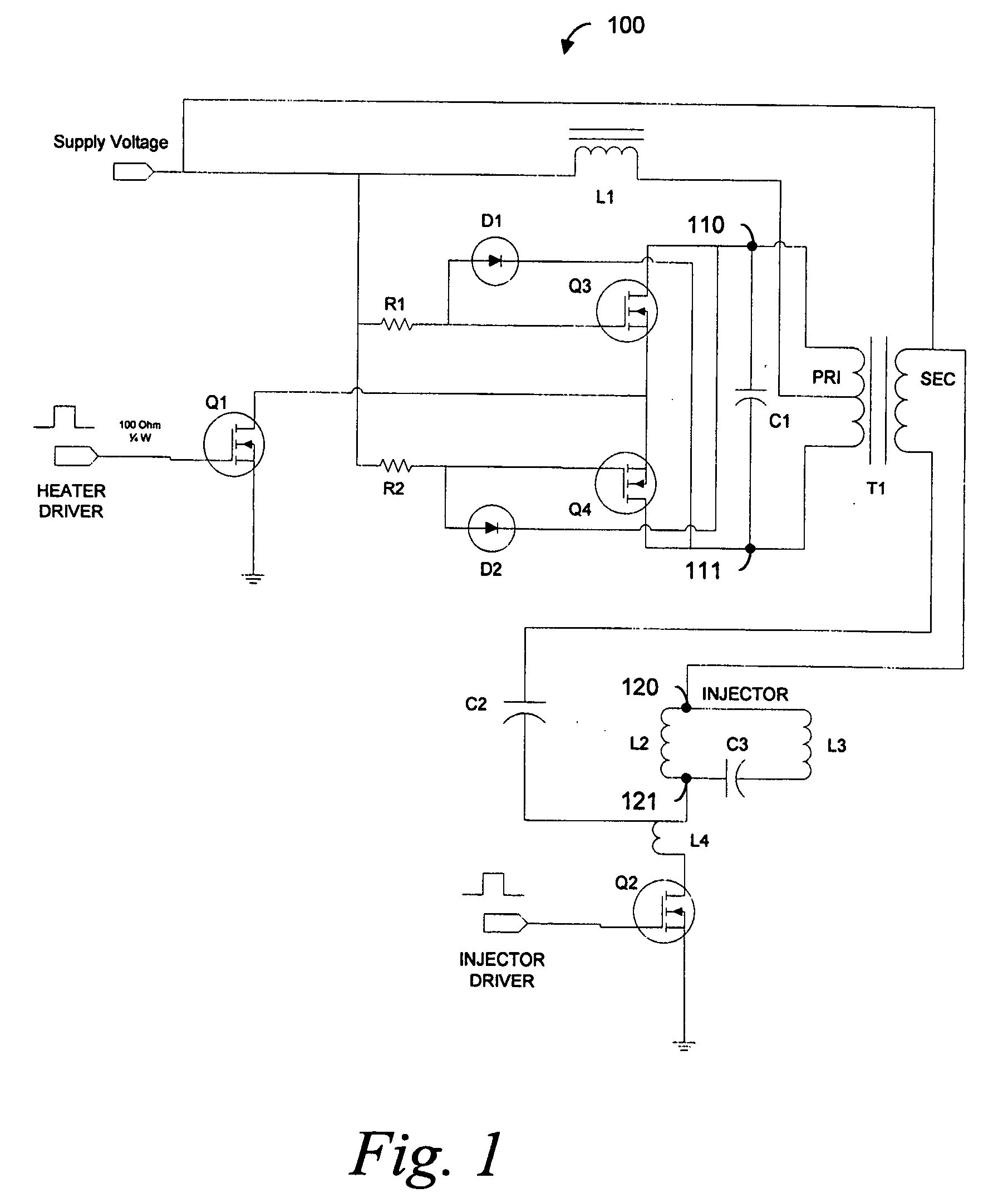

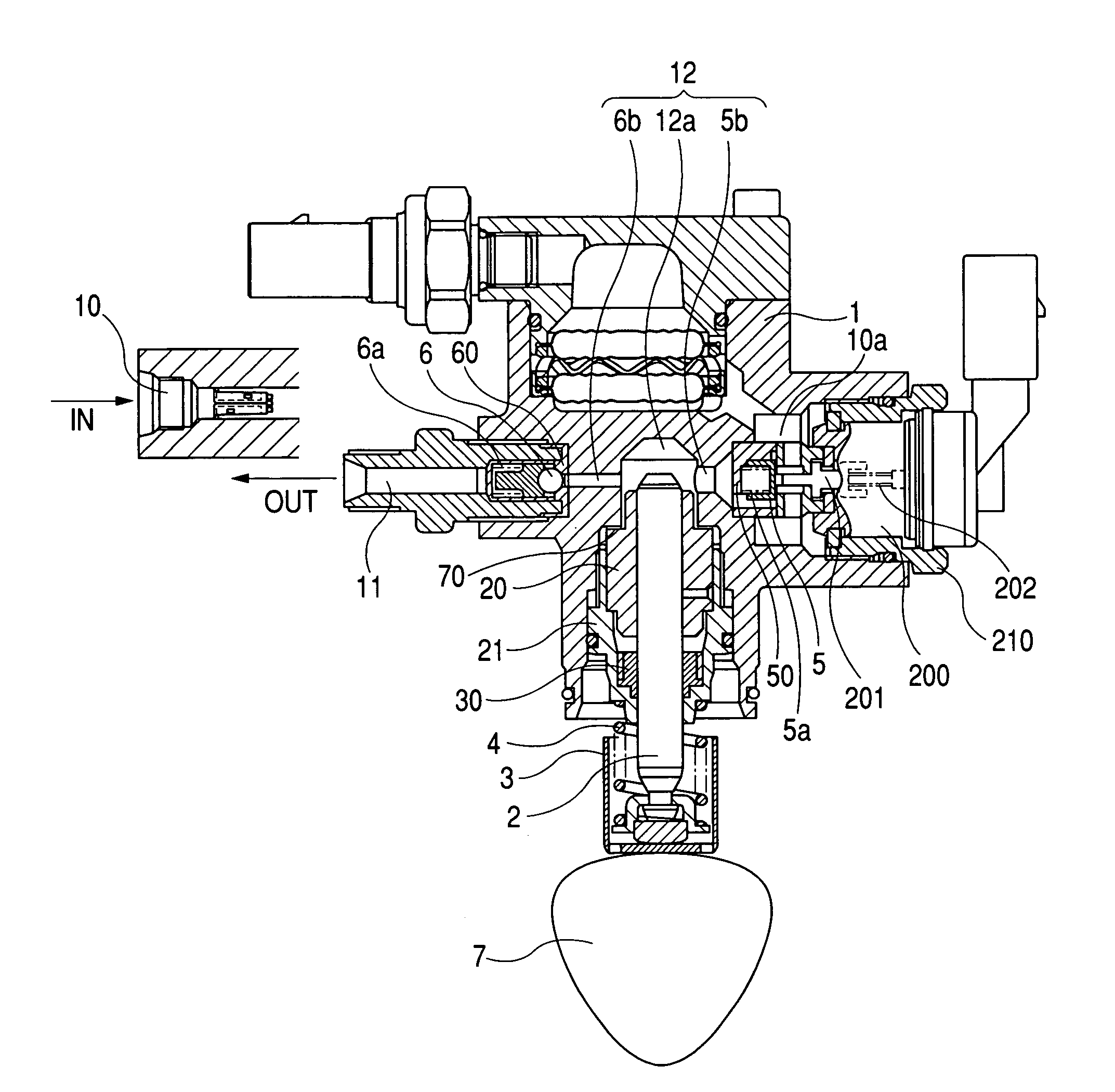

Constant current zero-voltage switching induction heater driver for variable spray injection

An electronic high frequency induction heater driver, for a variable spray fuel injection system, uses a zero-voltage switching oscillator that is impedance coupled to an imbedded multiple function signal separator and integrated with a conventionally implemented electronic fuel injector driver. The induction heater driver, upon receipt of a turn-on signal, multiplies a supply voltage through a self-oscillating series resonance, and couples the high frequency energy to a high pass filter such that the useful energy is utilized in an appropriate loss component so that fuel inside a fuel component is heated to a desired temperature.

Owner:VITESCO TECH USA LLC

Damper mechanism and high pressure fuel pump

ActiveUS7124738B2Increase in sizeReduce pressure pulsationFuel injecting pumpsFuel injection with sensorsEngineeringHigh pressure

To obtain a small and high performance damper mechanism which reduces pressure pulsation in low pressure-side fuel in the high pressure fuel pump in a high pressure fuel supply system or a high pressure fuel pump provided with the small and high performance damper mechanism.Two metal diaphragms are welded together over the entire circumference to obtain a metal diaphragm assembly (also referred to as “double metal diaphragm damper”). The whole or part of the portion of the metal diaphragm assembly other than the weld (for example, the portion inside the weld) is clamped by a pressing member and thereby the assembly is secured in a housing enclosure. The housing enclosure may be formed integrally with the body of a high pressure pump.

Owner:HITACHI ASTEMO LTD

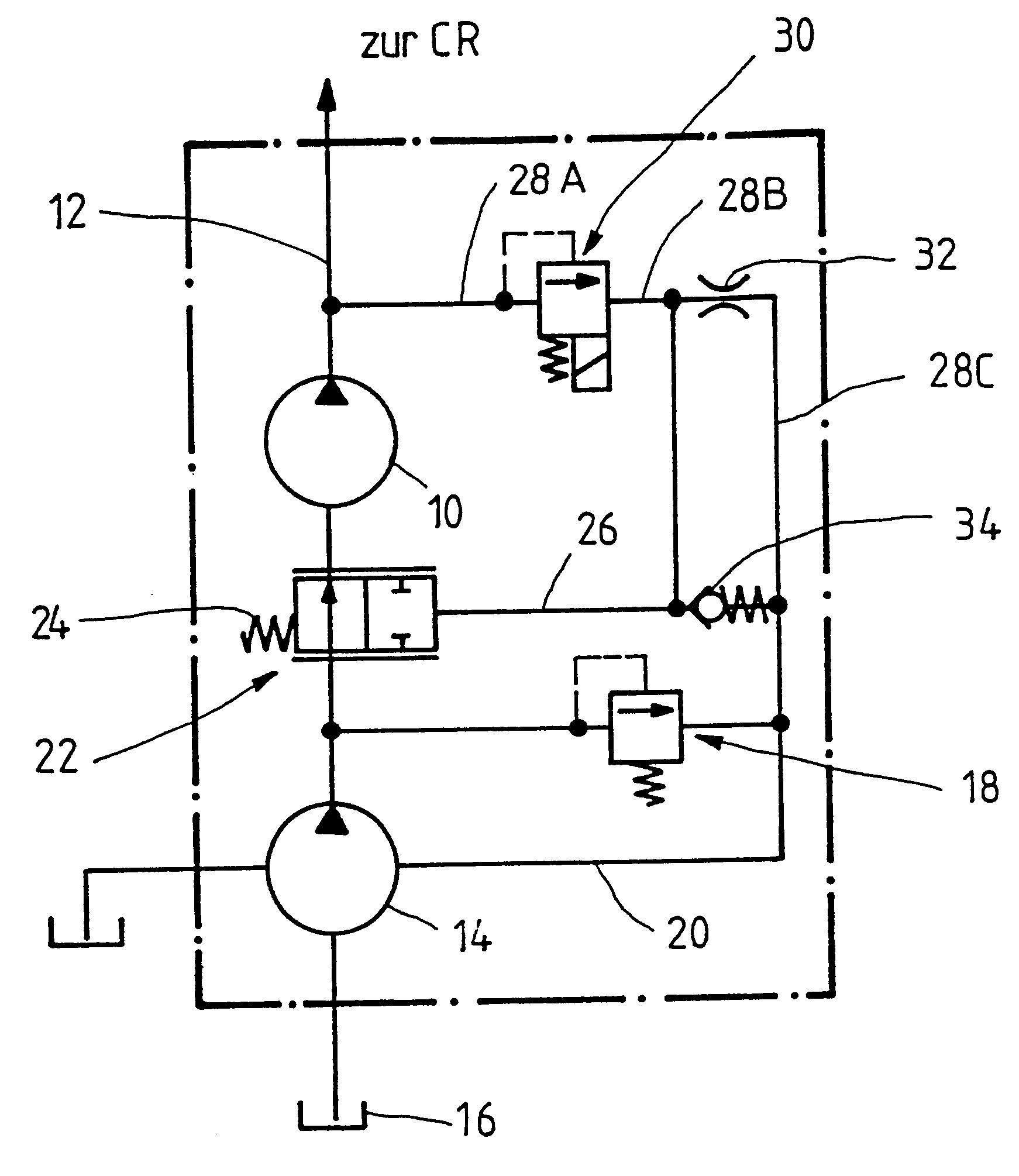

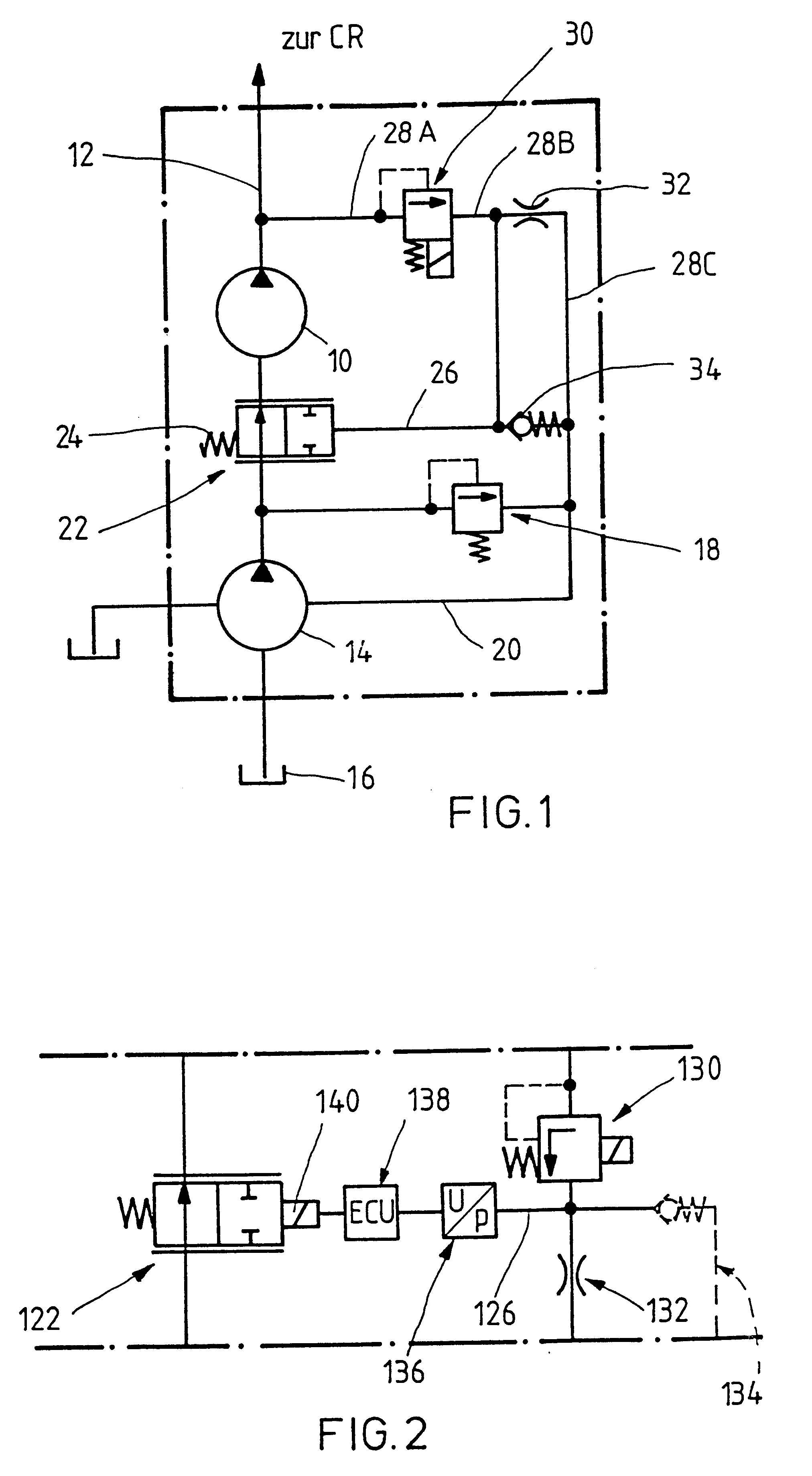

Control for a fluid pressure supply system, particularly for high pressure in a fuel injection system

InactiveUS6293253B1Control system can be kept considerably shorterReduce energy lossFluid parameterElectrical controlEngineeringThroughput

A control for a pressure fluid supply system is described, in particular for the high pressure in a fuel injection system, for example for an internal combustion Diesel engine, by means of which the pressure in a common high-pressure line supplied by a high-pressure pump, i.e. in the common rail, to which individual consumers are connected, is controlled in accordance with the instantaneous pressure fluid requirements. For adapting the pressure in the common high-pressure line to the pressure fluid requirements of the consumers, i.e. the injection nozzles, a device for limiting the amounts of fluids conveyed is associated with the high-pressure pump, which has at least on adjusting element which can be changed by means of an adjusting signal representing the instantaneous pressure fluid supply situation in the common rail. To avoid an elaborate pressure sensor device in the common rail and for the simultaneous improvement of the reaction behavior of the control, in particular when reducing the high pressure in the common rail, the adjusting signal is derived from the amount of fluid throughput in the delivery line of a pressure control valve connected to the common rail. The pre-conveying pressure or the pre-conveying amount available to the high-pressure pump is affected by means of this adjusting signal in the sense of a regulation of the pressure in the common rail.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com