Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about "Fuel injection with piezoelectric/magnetostrictive elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

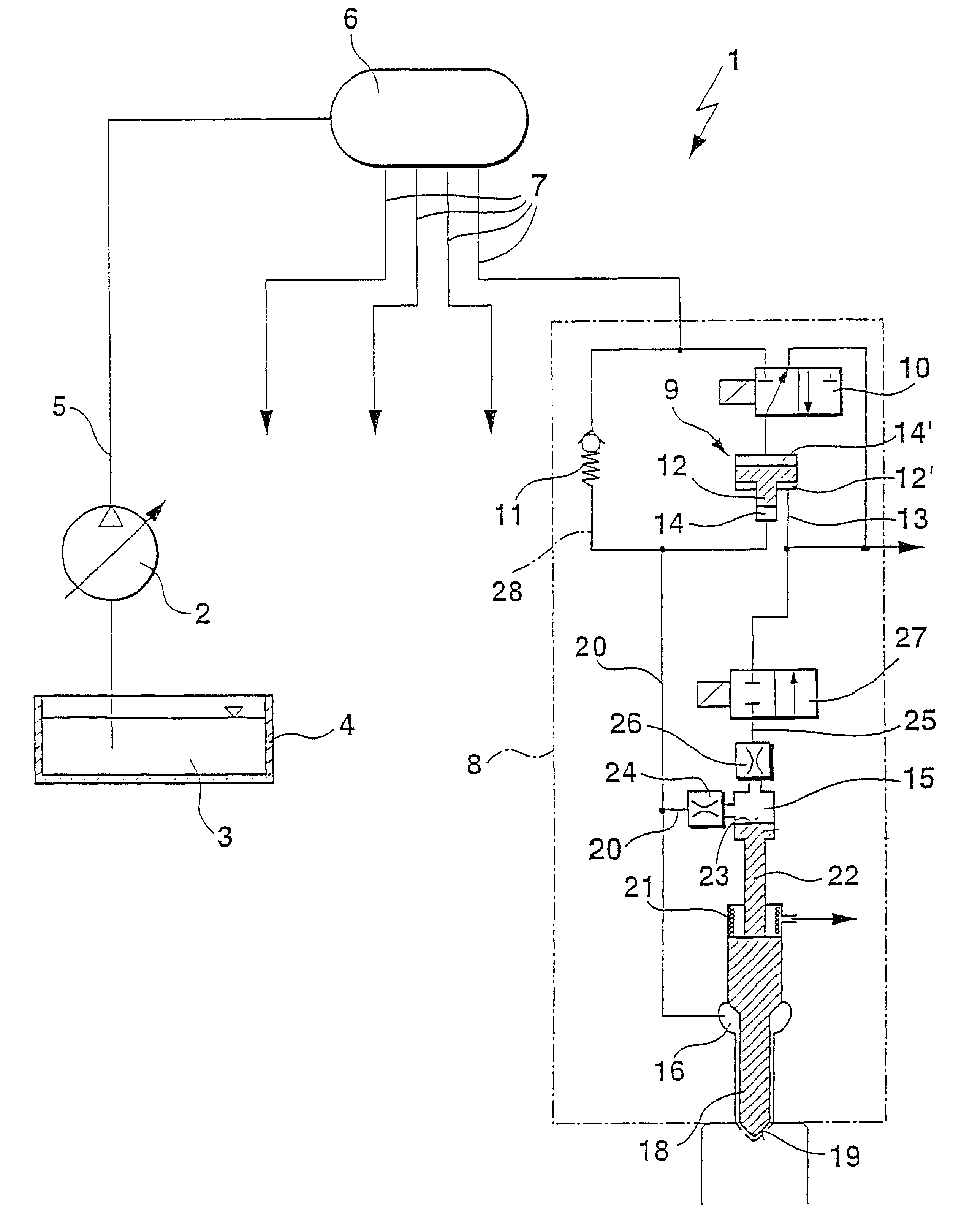

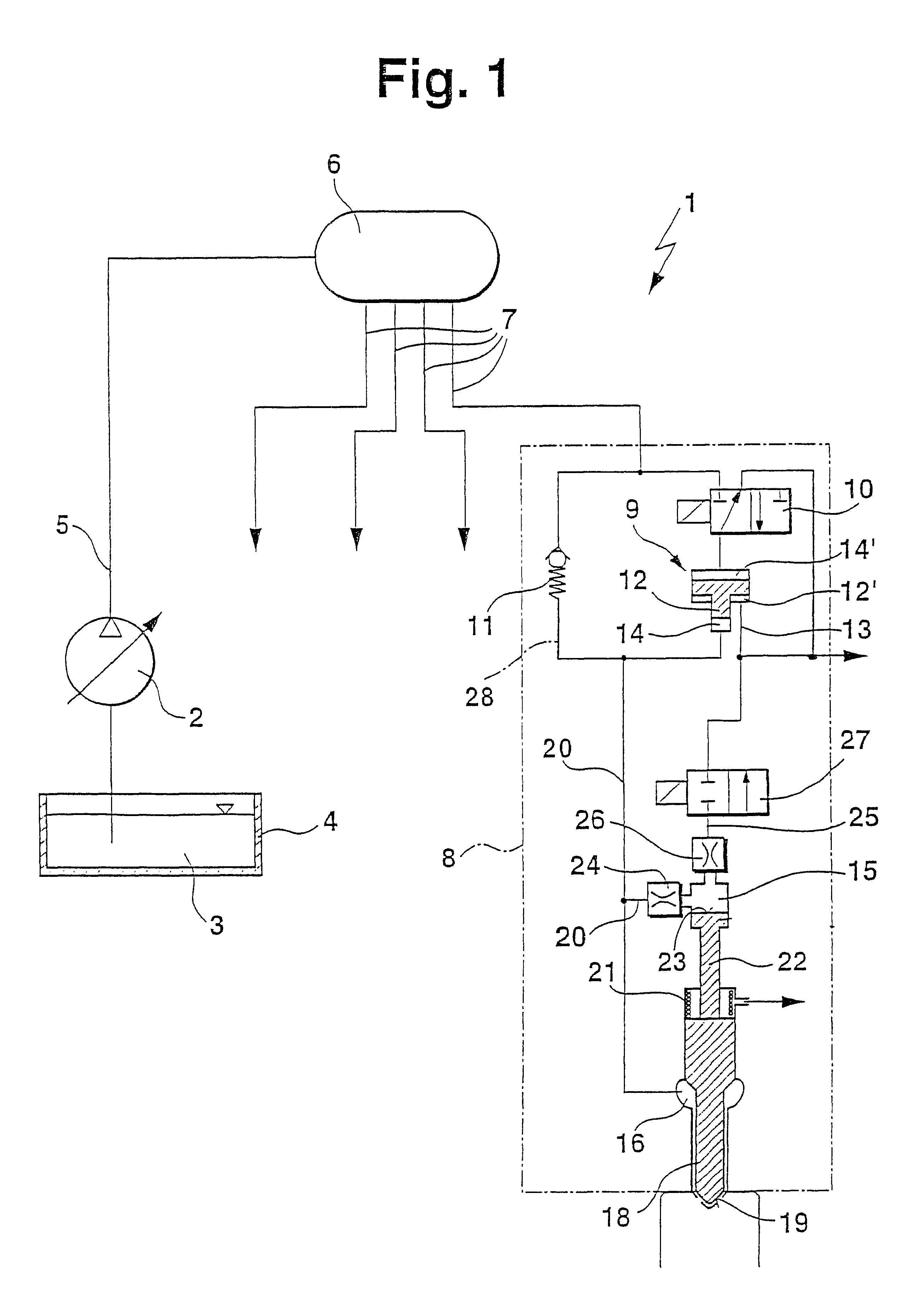

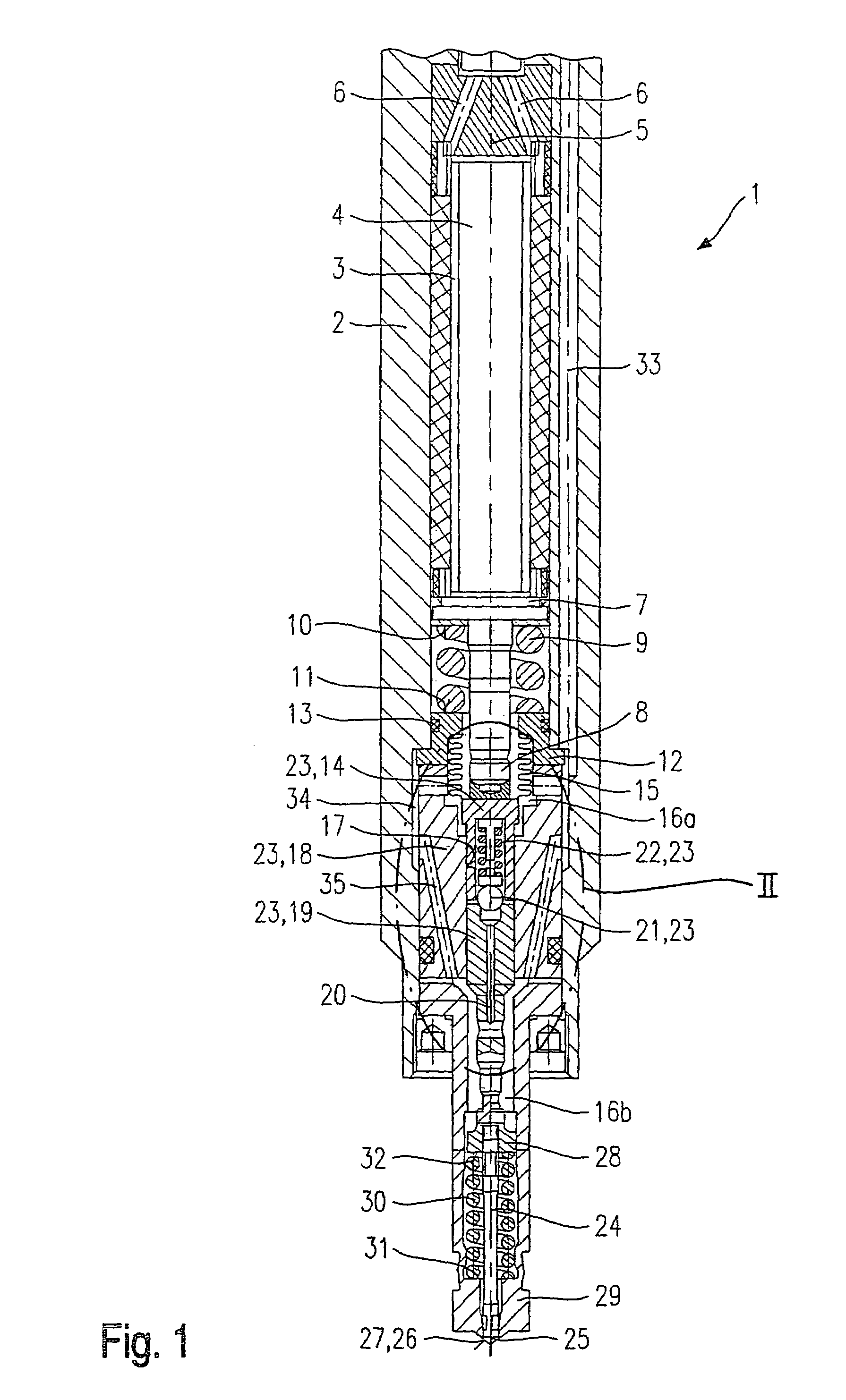

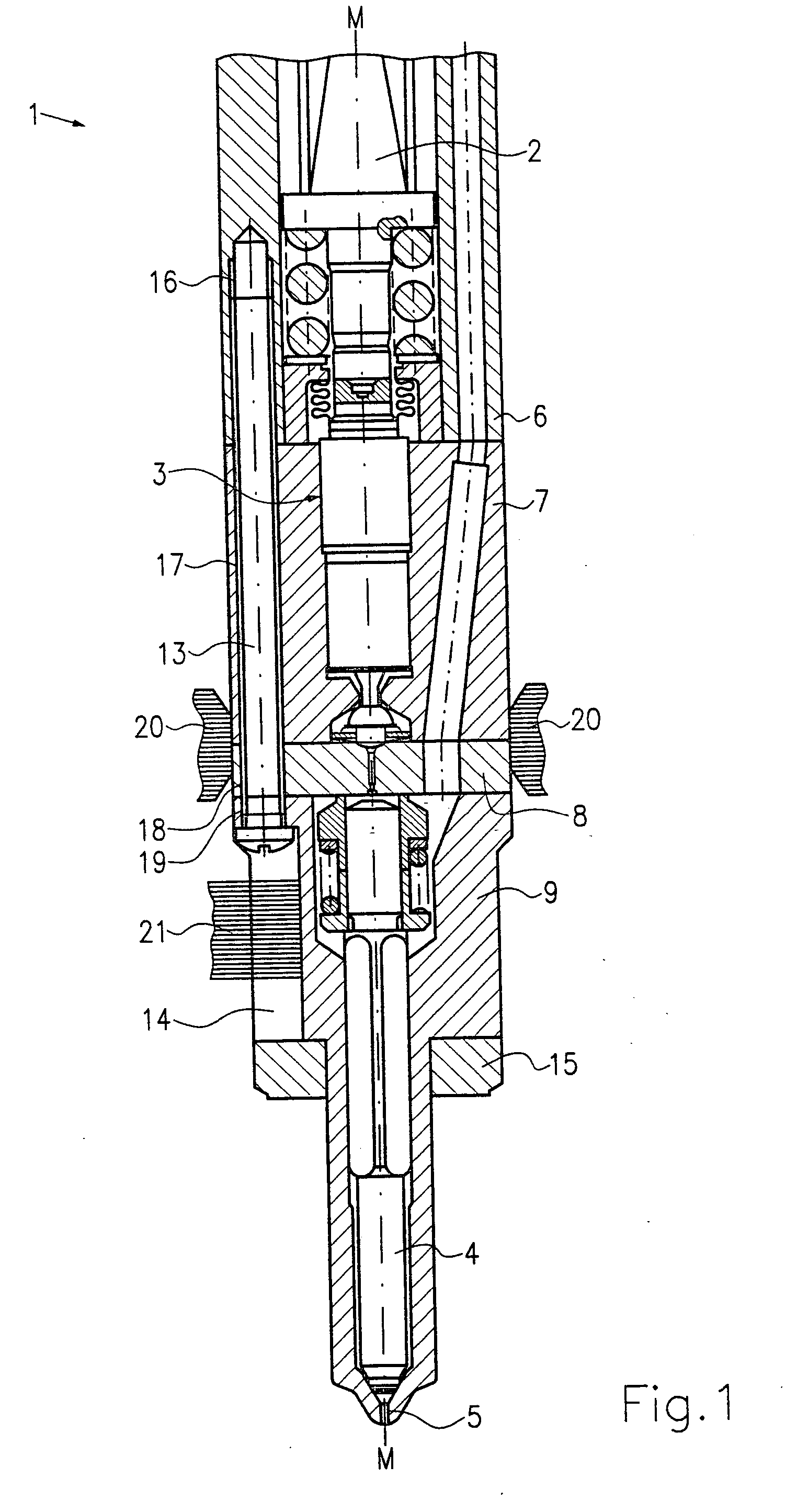

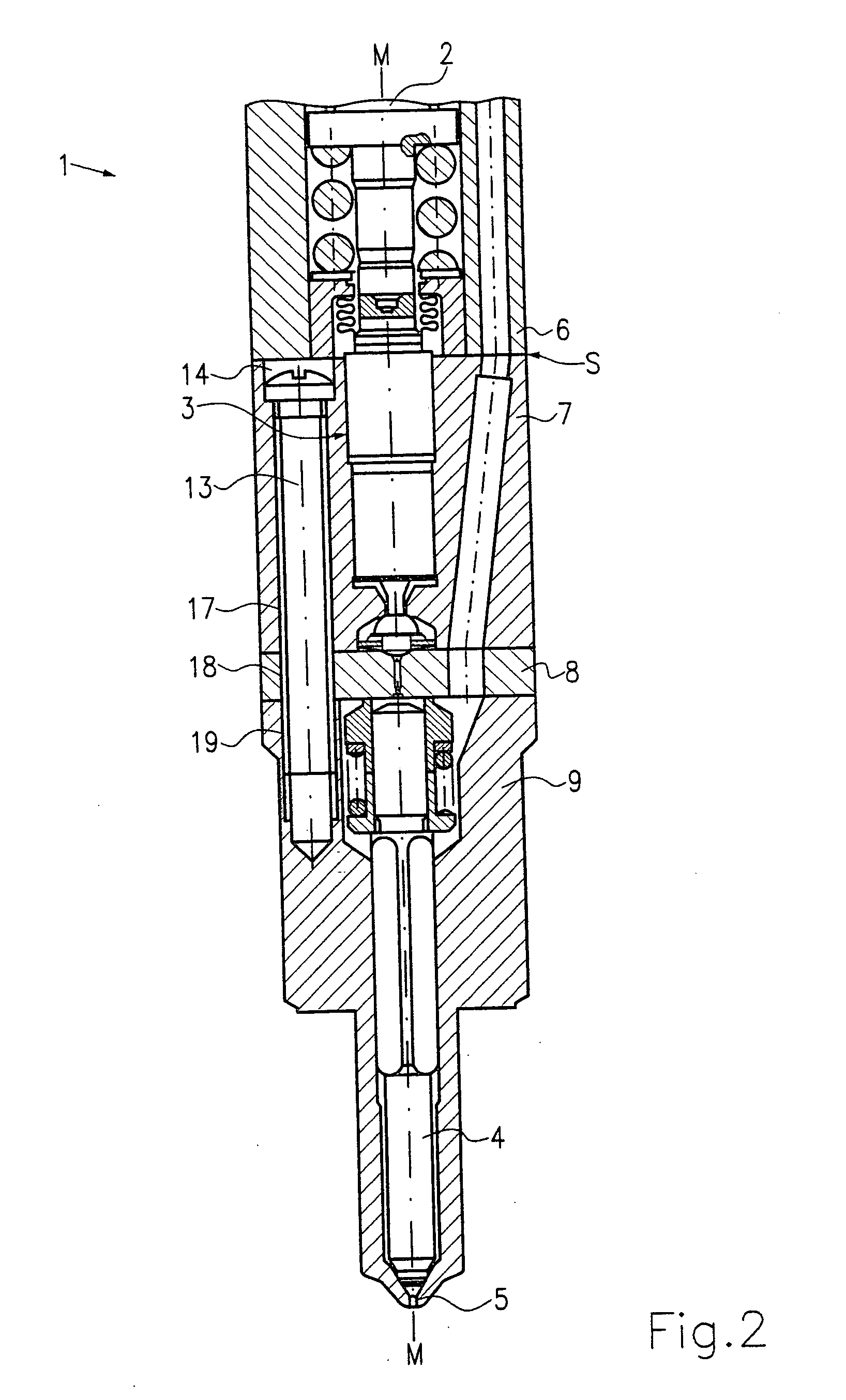

Fuel injection system which uses a pressure step-up unit

InactiveUS6453875B1Increase flexibilityIncrease injection pressureFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesEngineeringPiston

A fuel injection system has a pressure step-up unit, disposed between a pressure storage chamber and a nozzle chamber, whose pressure chamber communicates with the nozzle chamber via a pressure line. A bypass line connected to the pressure storage chamber is also provided. The bypass line communicates directly with the pressure line. The bypass line can be used for pressure injection and is disposed parallel to the pressure chamber, so that the bypass line is open regardless of the motion and position of a displaceable piston element in the pressure step-up unit. This enhances the flexibility of injection.

Owner:ROBERT BOSCH GMBH

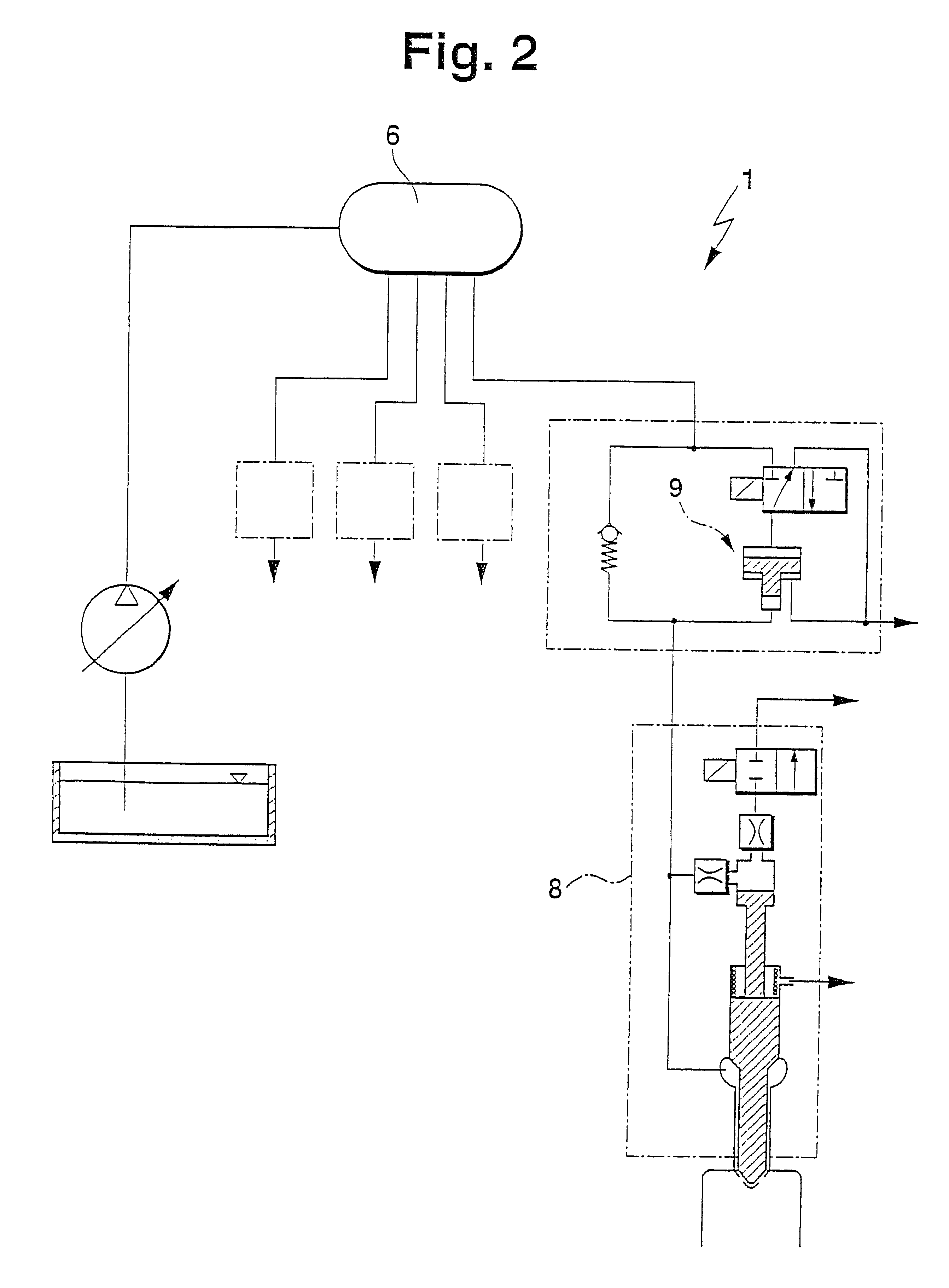

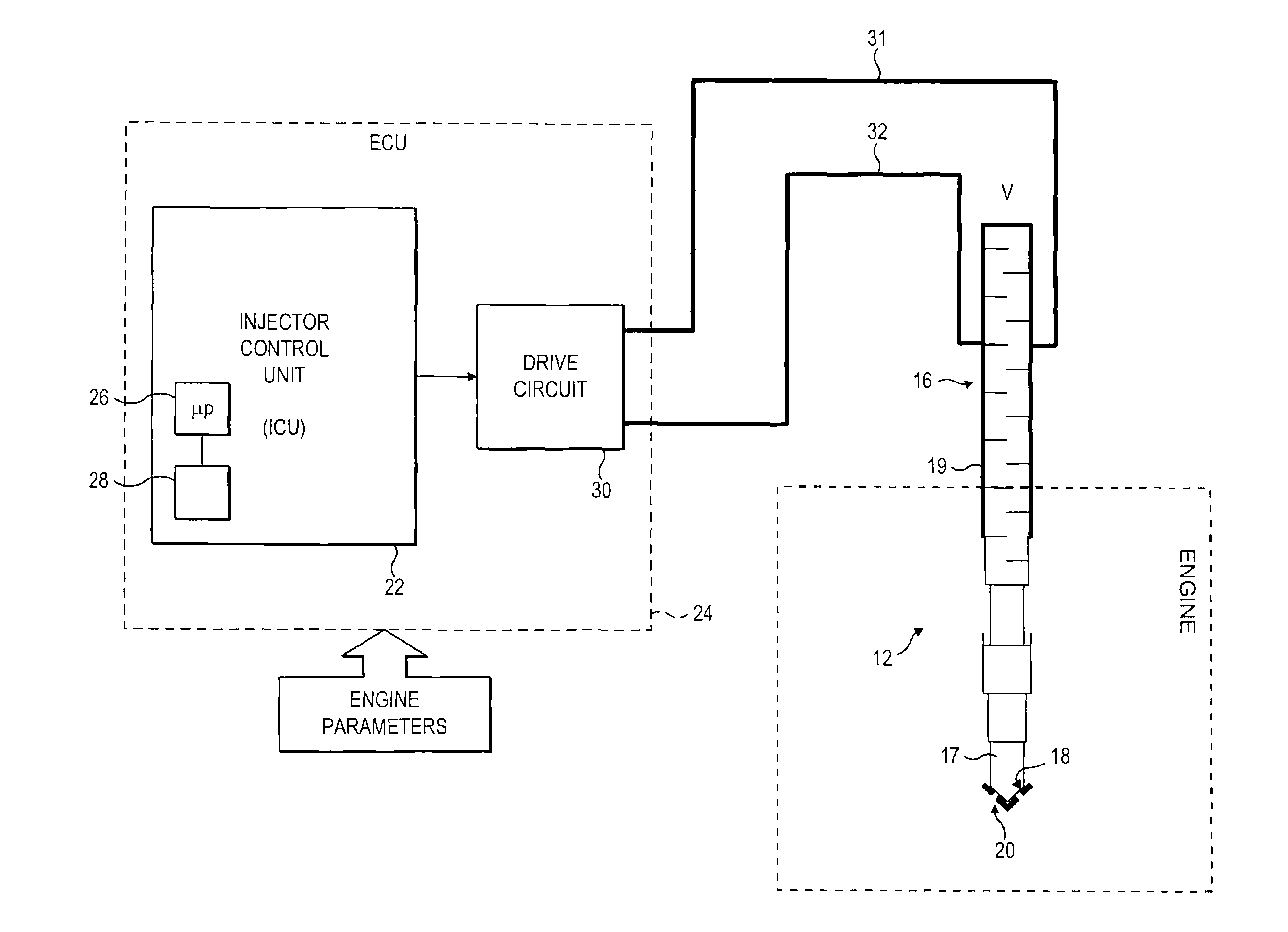

Fuel injector and method for controlling fuel injectors

InactiveUS20090038589A1Low costAccurate predictionElectrical controlInternal combustion piston enginesControl signalInternal combustion engine

A fuel injector for an internal combustion engine, the fuel injector comprising an injector body, a fuel supply passage defined in the injector body, the fuel supply passage containing fuel under high pressure in use of the injector, a pressure sensor for measuring the pressure of fuel in the passage in use, wherein the pressure sensor is situated within the injector body and is separated from fuel in the passage in use, and a method of fuel injection, comprising constructing an hydraulic behaviour profile by fuel pressure measurement, using the hydraulic behaviour profile to predict fuel pressure that will prevail in a fuel injector during an injection event, and supplying a control signal to the fuel injector to control the amount of fuel injected during the injection event in accordance with the predicted fuel pressure. By predicting the fuel pressure that will prevail during an injection event, the fuel delivered during the injection event can be accurately controlled.

Owner:DELPHI TECH IP LTD

Fuel injector and method for controlling fuel injectors

InactiveUS7552717B2Expensive to fabricateReduced risk of mechanical failureElectrical controlInternal combustion piston enginesControl signalInternal combustion engine

A fuel injector for an internal combustion engine, the fuel injector comprising an injector body, a fuel supply passage defined in the injector body, the fuel supply passage containing fuel under high pressure in use of the injector, a pressure sensor for measuring the pressure of fuel in the passage in use, wherein the pressure sensor is situated within the injector body and is separated from fuel in the passage in use, and a method of fuel injection, comprising constructing an hydraulic behavior profile by fuel pressure measurement, using the hydraulic behavior profile to predict fuel pressure that will prevail in a fuel injector during an injection event, and supplying a control signal to the fuel injector to control the amount of fuel injected during the injection event in accordance with the predicted fuel pressure. By predicting the fuel pressure that will prevail during an injection event, the fuel delivered during the injection event can be accurately controlled.

Owner:DELPHI TECH IP LTD

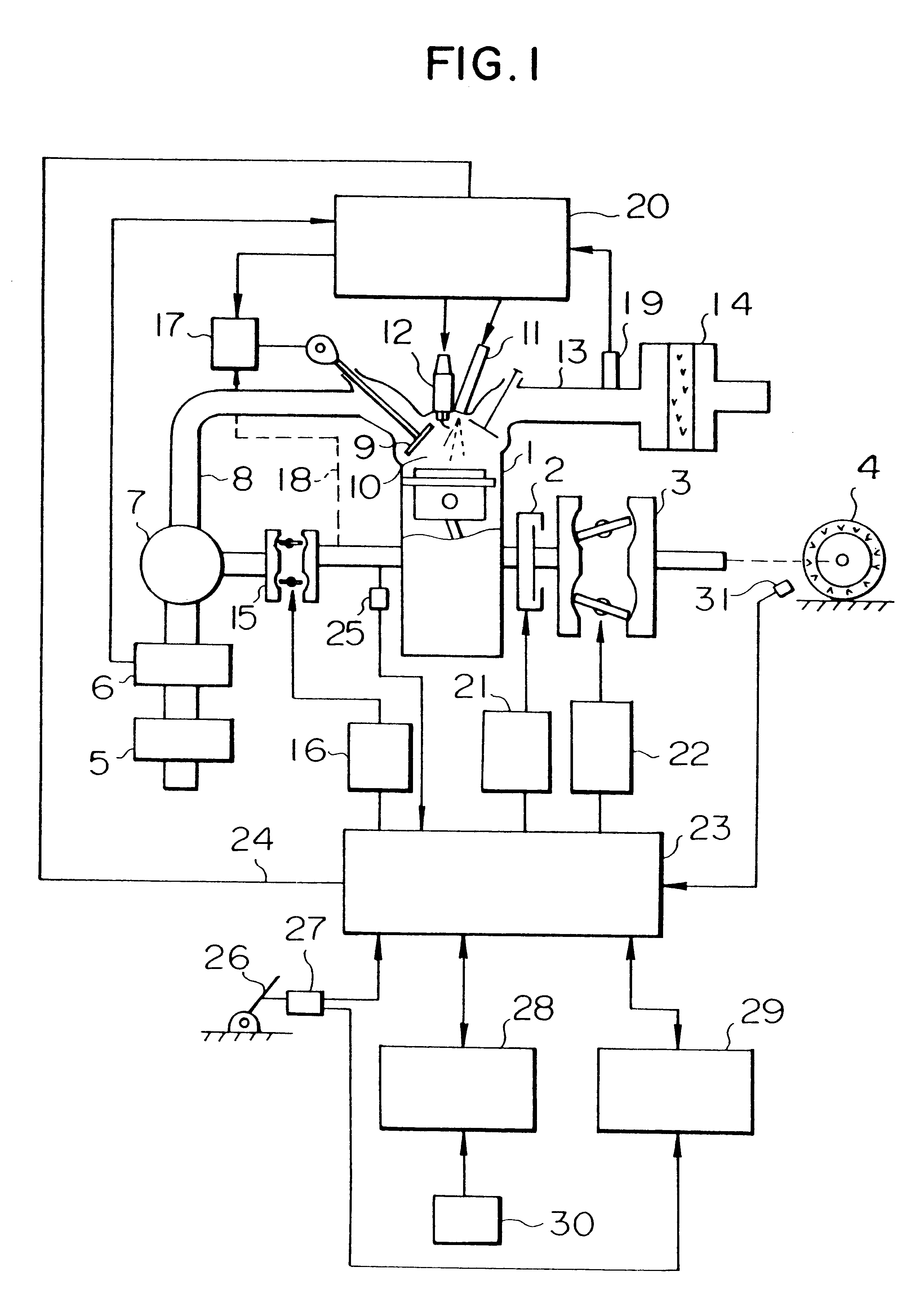

Control apparatus for drive system

InactiveUS6516264B2Improve acceleration performanceImprove fuel economy performanceElectrical controlInternal combustion piston enginesControl theoryAir–fuel ratio

A drive system composed of an engine and a transmission is controlled in accordance with a desired wheel toque corresponding to a position of an accelerator, and a present vehicle speed in such a way that a speed ratio of the transmission is determined in consideration with torque factors such as an air-fuel ratio on the engine side, thereby it possible to optimize the control in order to reduce the emission of exhaust substance such as NOx and to enhance the acceleration performance and the fuel economy.

Owner:HITACHI LTD

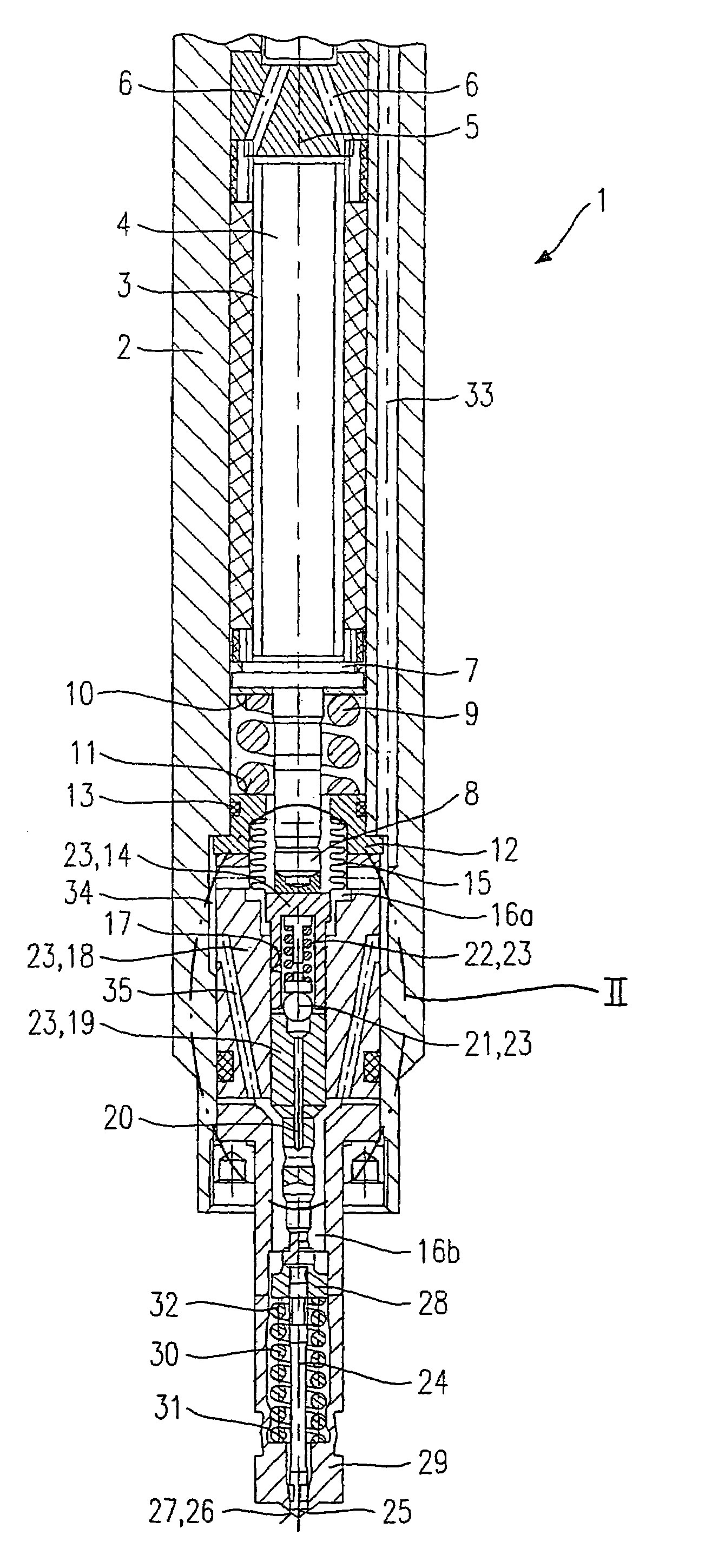

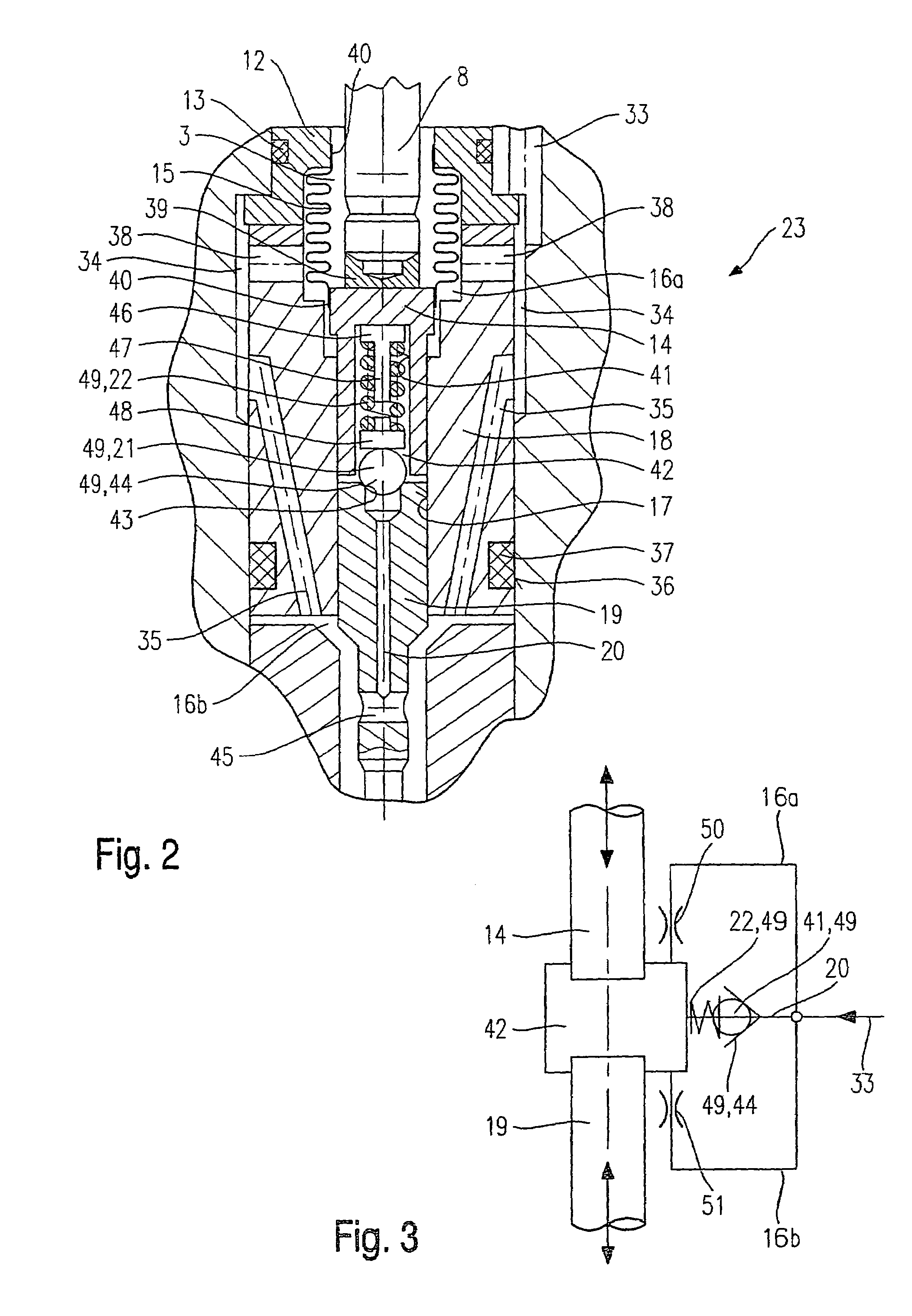

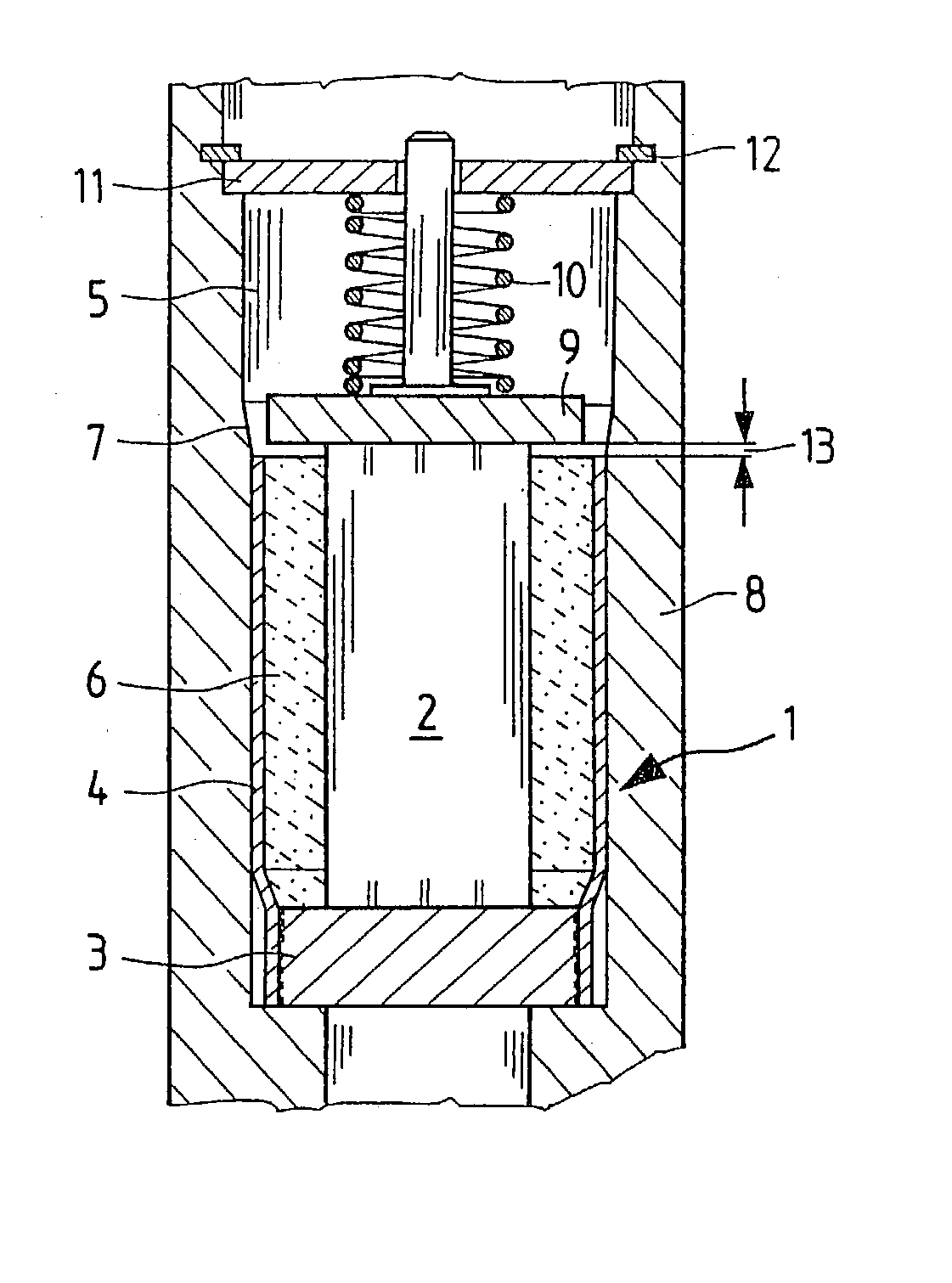

Fuel injection valve

InactiveUS7073730B2Increase volumeQuick refillMovable spraying apparatusSpray nozzlesCombustionMagnetostrictive actuator

A fuel injector, in particular a fuel injector for fuel-injection systems of internal combustion engines, including a piezoelectric or magnetostrictive actuator, actuates a valve-closure member formed on a valve needle via a hydraulic coupler, the valve-closure member cooperating with a valve-seat surface to form a valve-sealing seat. The coupler includes a master piston and a slave piston which are connected to a pressure chamber, and at least one coupler-spring element which in each instance produces a prestressing force on the master piston, counter to a working direction, and on the slave piston, in a working direction. The pressure chamber of the coupler is connected to a fuel inflow in the flow-through direction to the pressure chamber via an inflow bore and a check valve.

Owner:ROBERT BOSCH GMBH

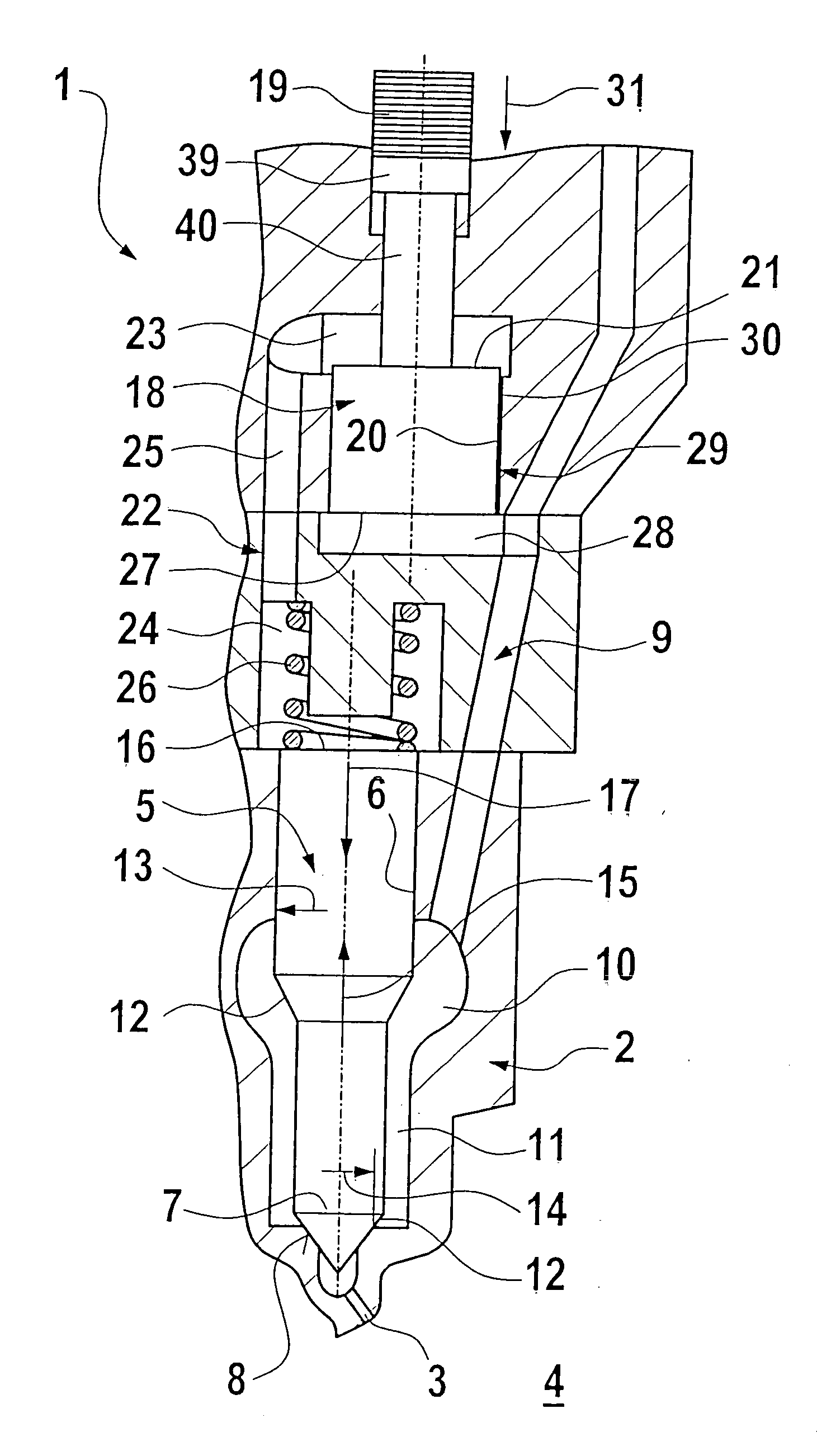

Injection nozzle for internal combustion engines

InactiveUS20060032940A1Fuel injection with piezoelectric/magnetostrictive elementsMachines/enginesCombustionEngineering

An internal combustion engine having a nozzle body equipped with at least one injection opening and a nozzle needle guided in a needle guide and is able to control the injection of fuel through the at least one injection opening. A control piston drive-coupled to an actuator has a first control surface, if the nozzle needle has a compensator surface that is hydraulically coupled to the first control surface via a first hydraulic path, and a second hydraulic path is able to hydraulically couple the first control surface to a supply line that supplies highly pressurized fuel to the at least one injection opening.

Owner:ROBERT BOSCH GMBH

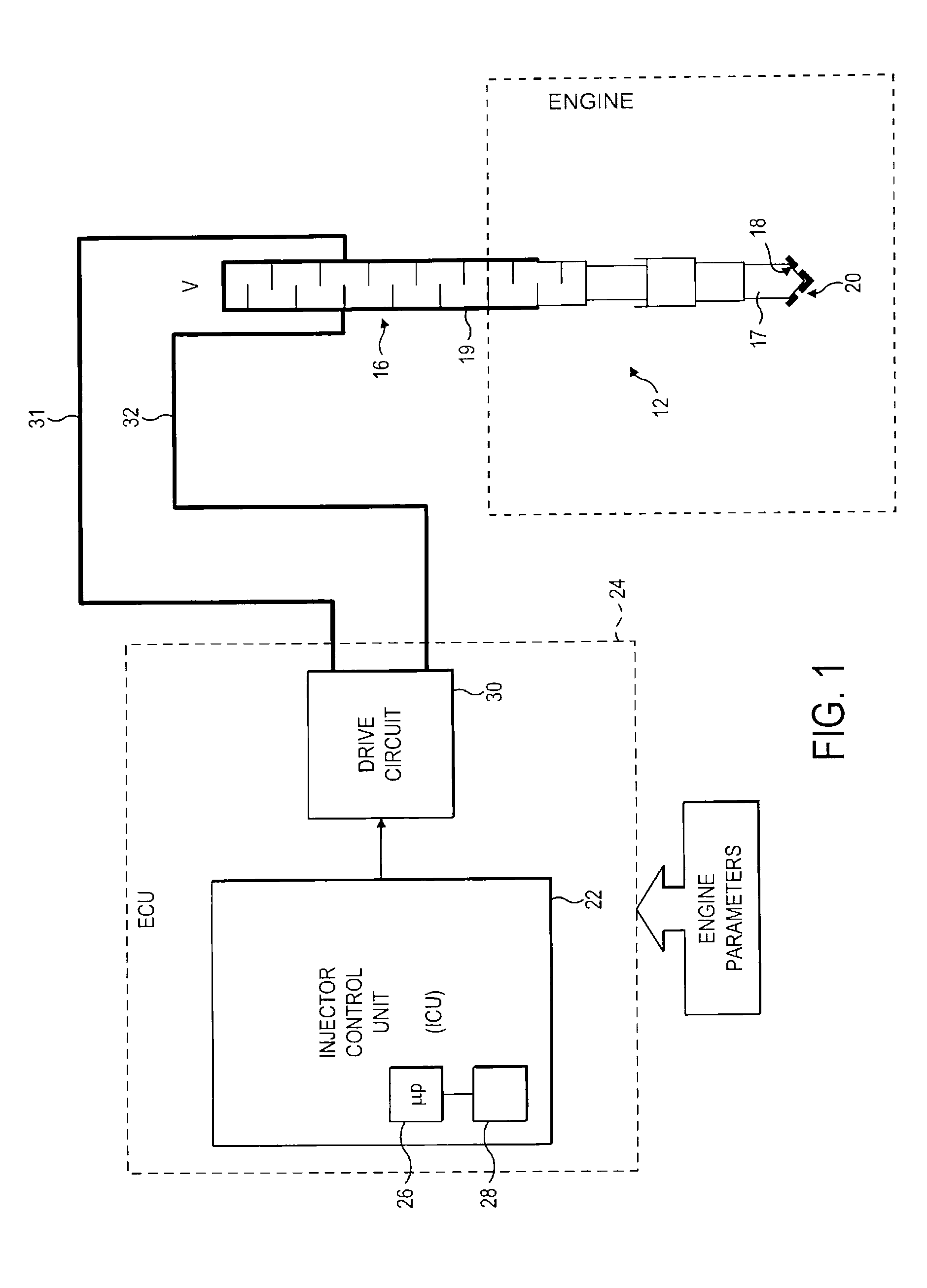

Detection of faults in an injector arrangement

InactiveUS20090314073A1Obtained is robustThe result is accurateInternal-combustion engine testingElectrical controlDelayed periodsPiezoelectric actuators

A method of identifying an individual short circuit fuel injector, within an injector bank of an engine comprising a plurality of fuel injectors. Each fuel injector has a piezoelectric actuator and an associated injector select switch forming part of an injector drive circuit. The method comprises: (i) charging all of the piezoelectric actuators of the plurality of fuel injectors within the injector bank during a charge phase; (ii) at the end of the charge phase waiting for a delay period; and (iii) subsequently closing an injector select switch of a fuel injector to select said fuel injector. The method further comprises: (iv) determining a stack voltage present on terminals of the piezoelectric actuator of the selected fuel injector and storing the stack voltage in a data store. The stack voltage is indicative of an amount of charge present on the selected injector at the end of the delay period. The method further comprises (v) repeating steps (i) to (iv) for each fuel injector in the injector bank in turn; and (vi) identifying the individual short circuit fuel injector as being the injector which has discharged beyond a predetermined voltage drop limit during the delay period. The method also comprises generating a short circuit fault signal for the identified fuel injector.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

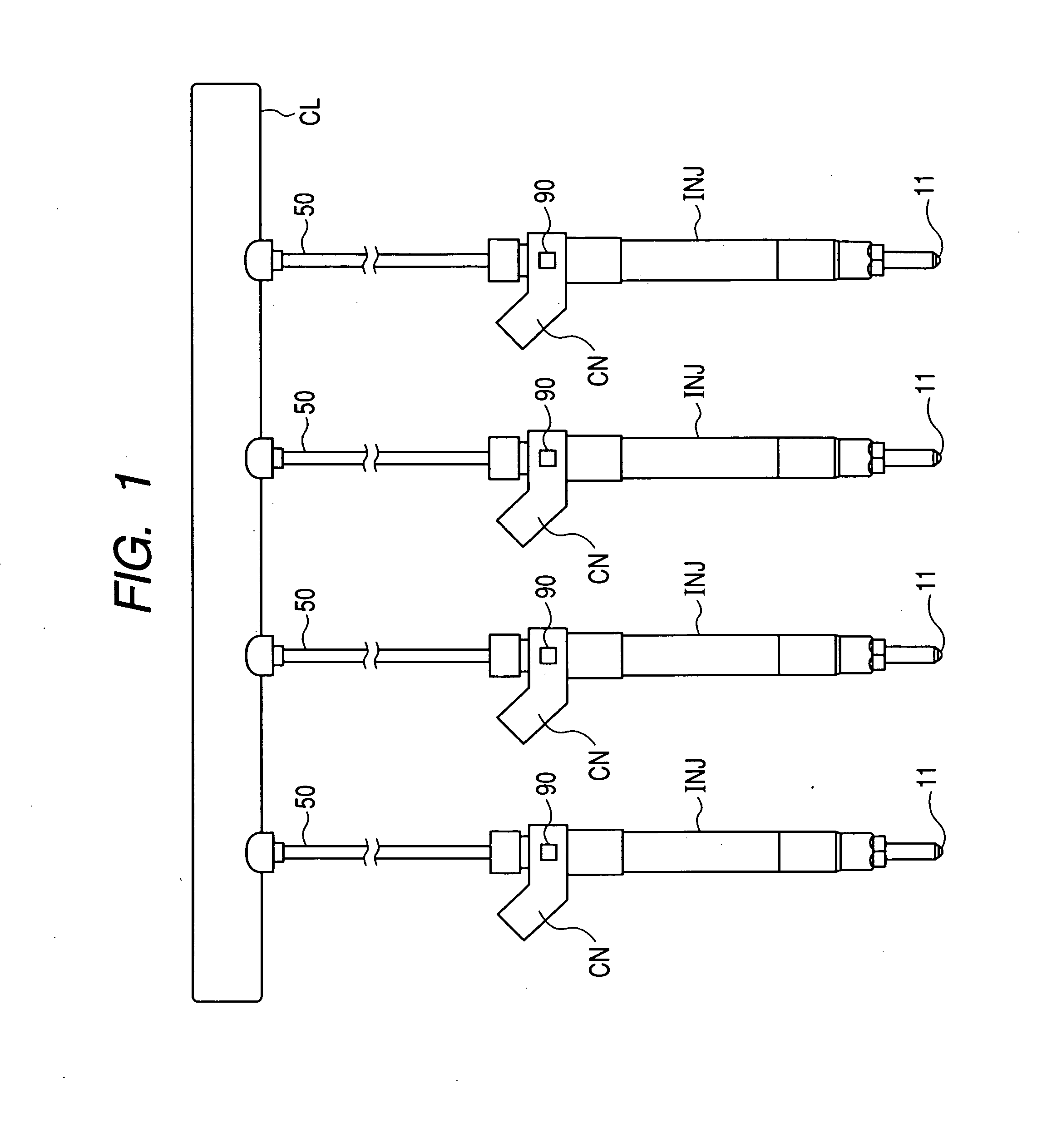

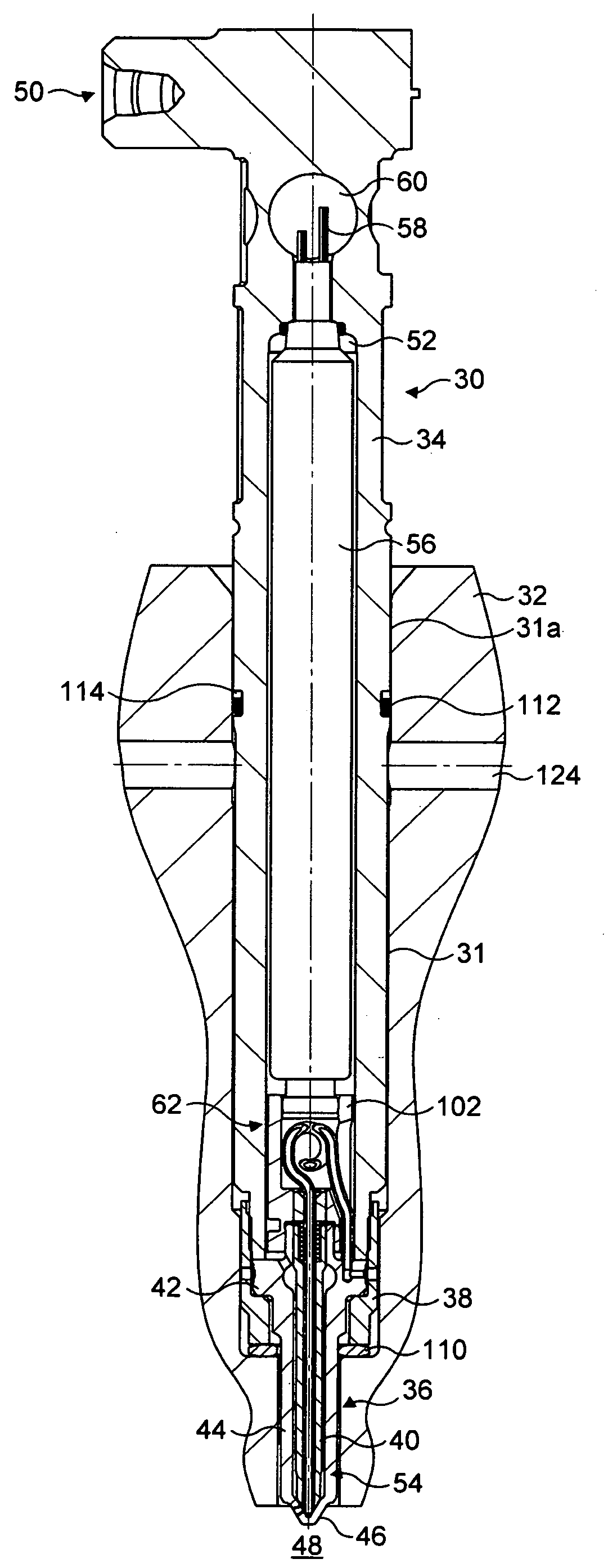

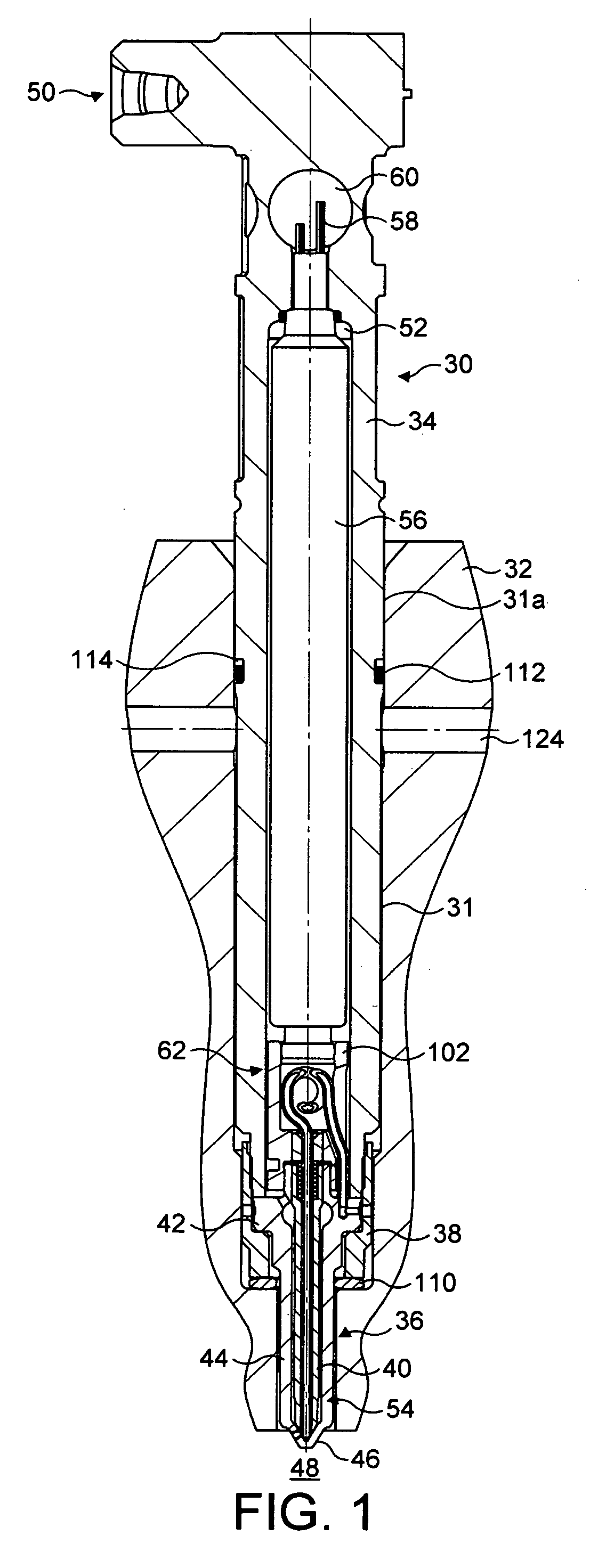

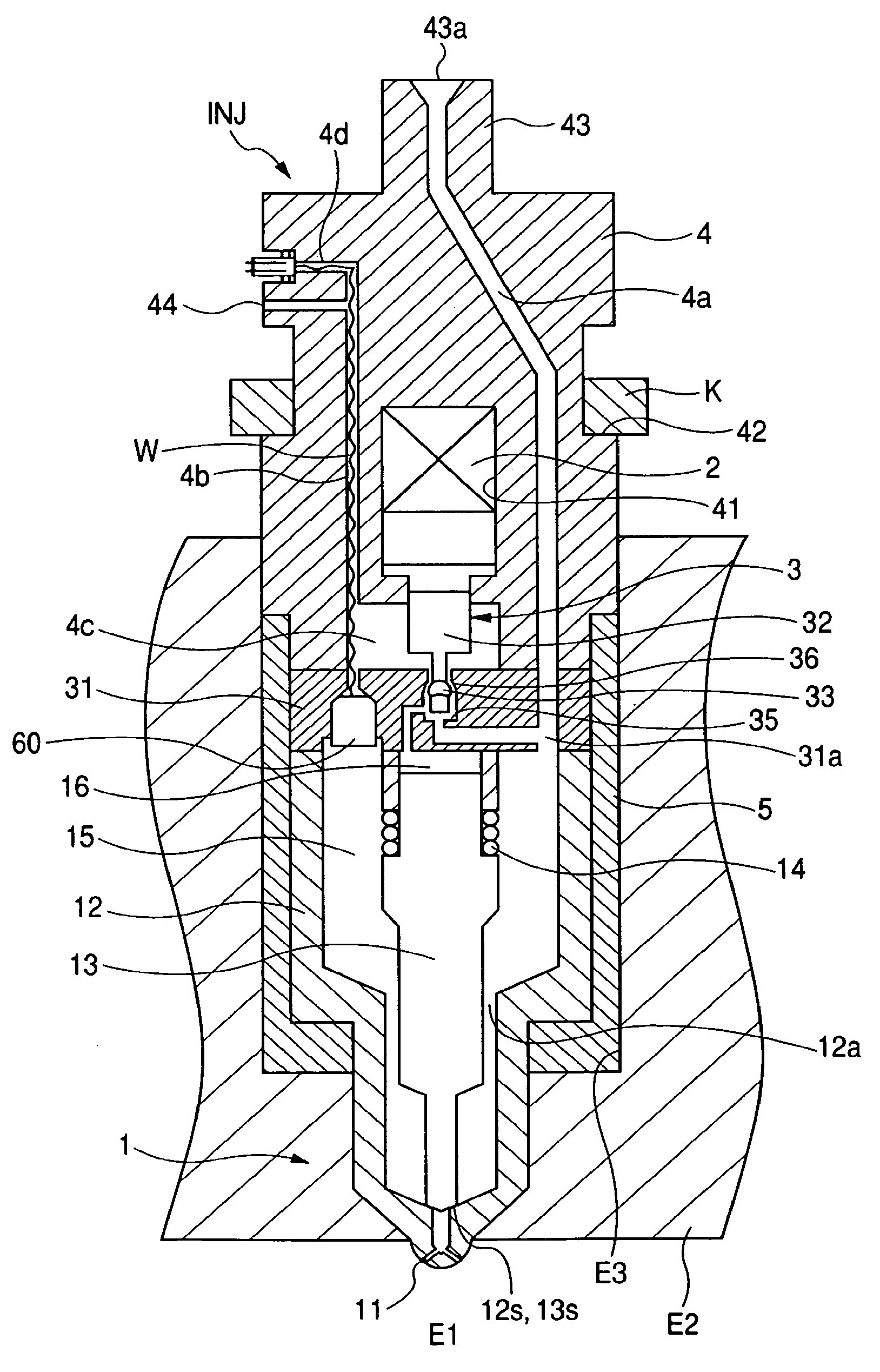

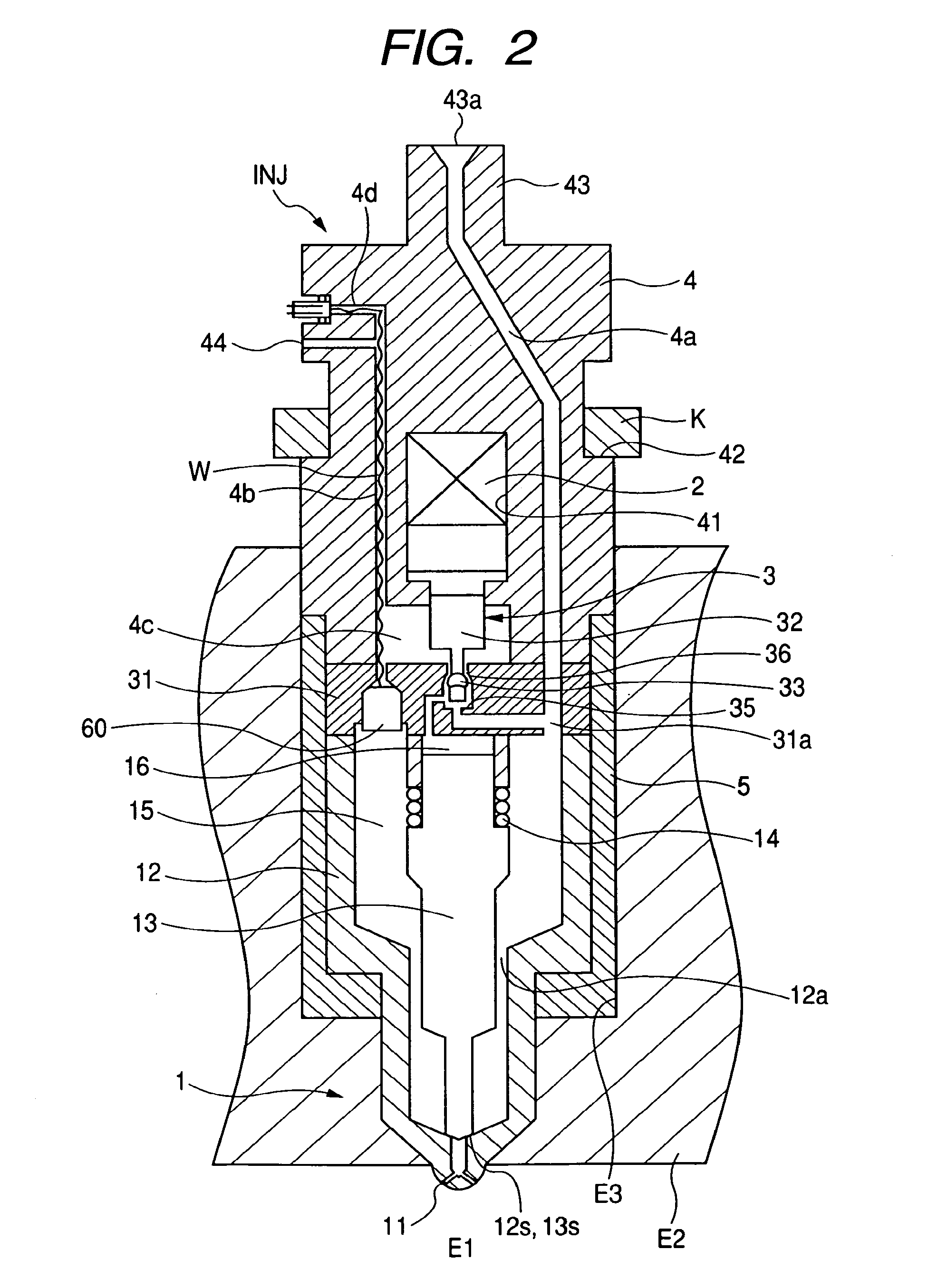

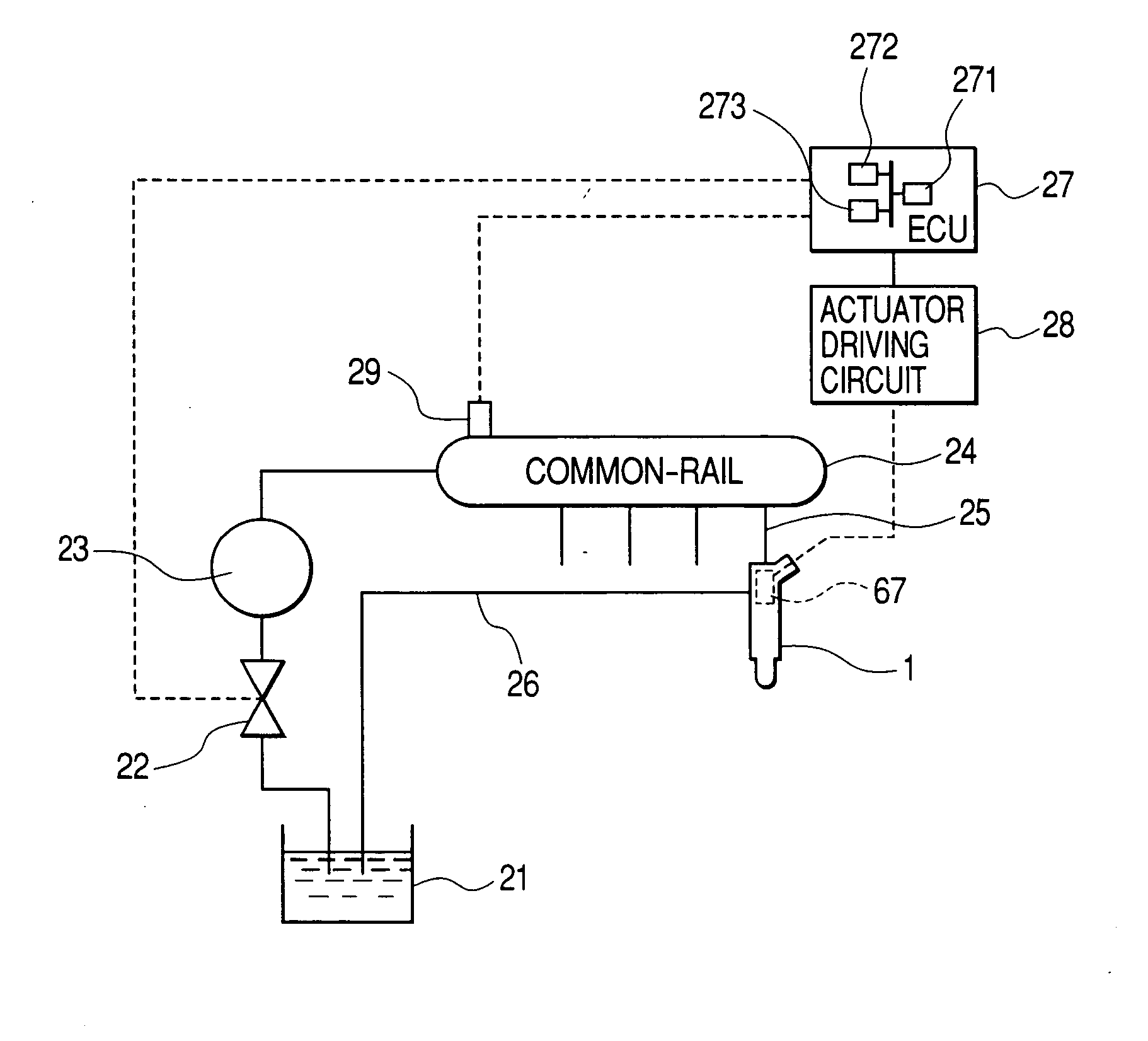

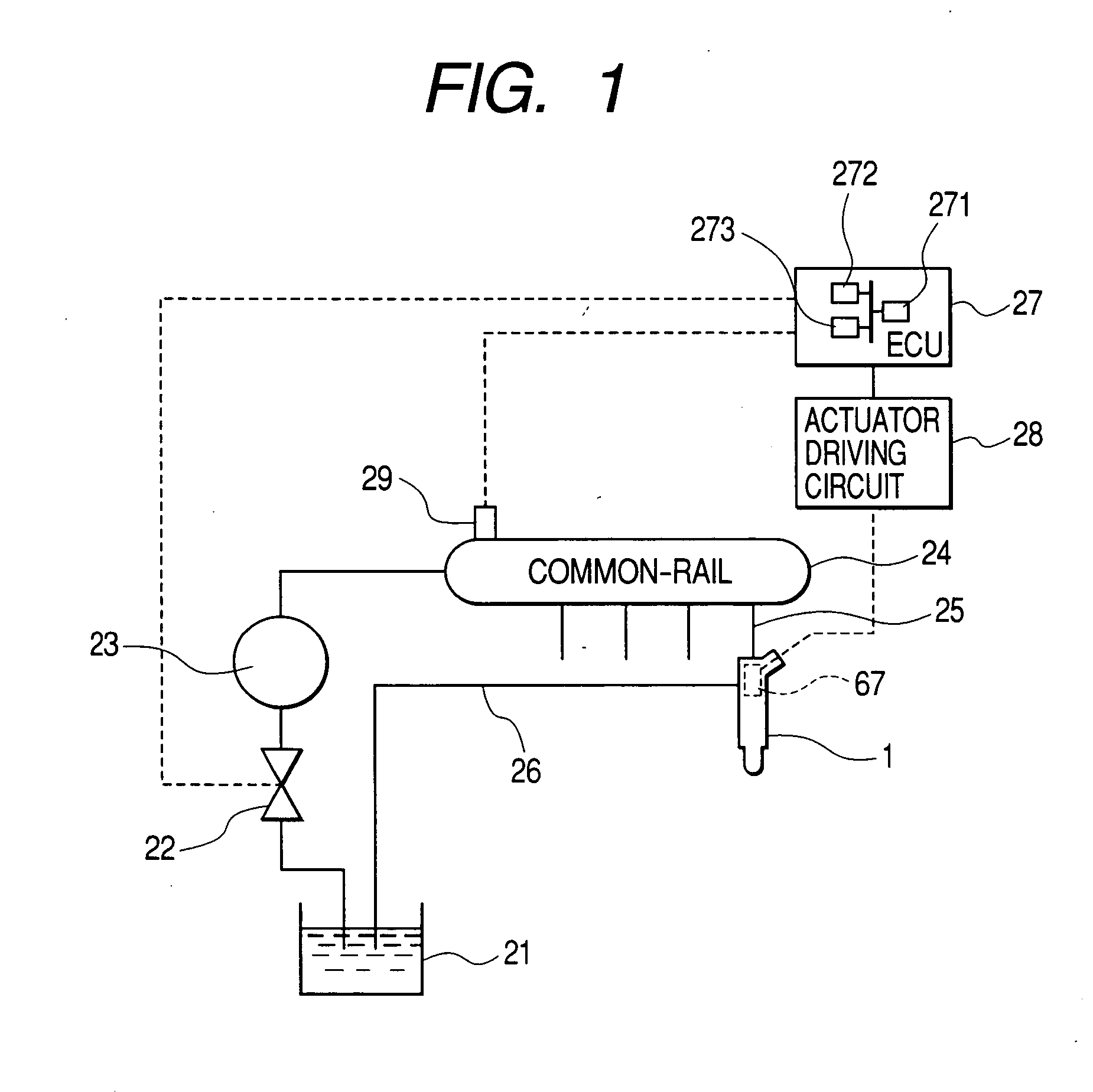

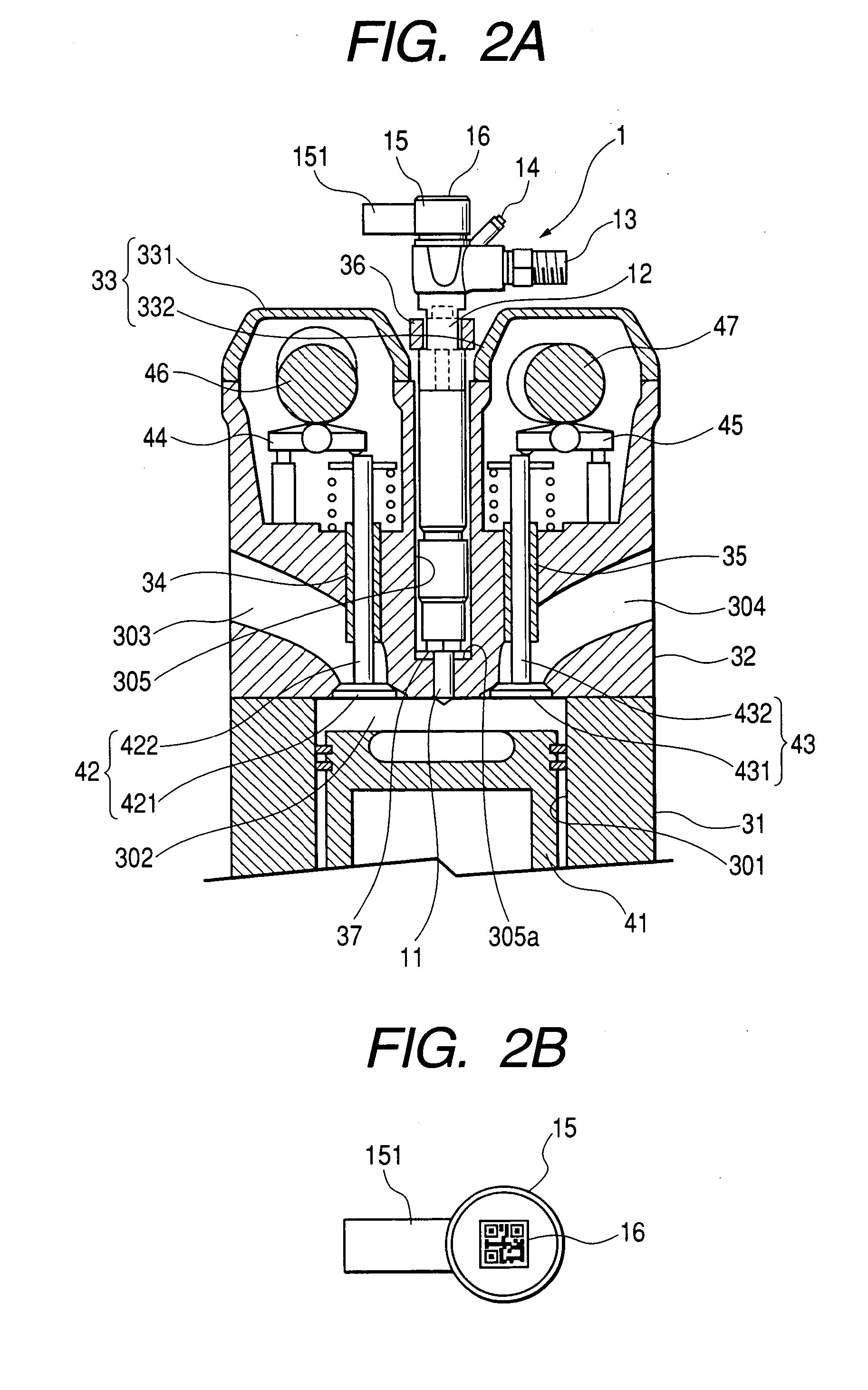

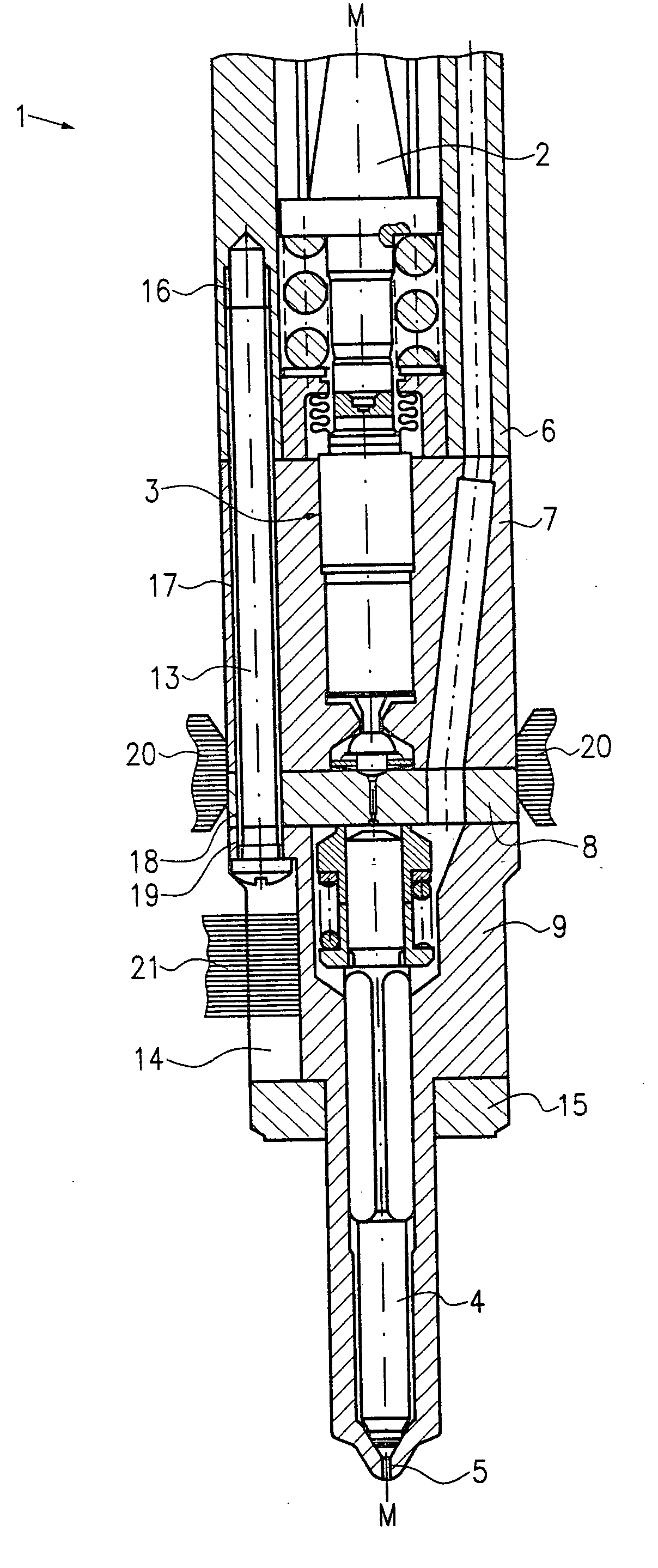

Fuel injector with built-in fuel pressure sensor

ActiveUS20090248276A1Improve accuracyElectrical controlDigital data processing detailsInternal combustion engineFuel supply

A fuel injector for an internal combustion engine is provided which has a fuel supply path and a nozzle chamber. The fuel supply path extends a spray hole. The nozzle chamber is defined in the fuel supply path. A nozzle is disposed within the nozzle chamber to establish or block a fluid communication between the fuel supply path and the spray hole. A fuel pressure sensor is installed in the fuel injector so as to be exposed to the fuel in the nozzle chamber. Specifically, the fuel pressure sensor is located closer to the spray hole than a prior art structure in which the fuel pressure sensor is installed in a fuel supply pipe, thus resulting in increased accuracy in measuring a change in pressure of the fuel arising from the spraying of the fuel from the spray hole.

Owner:DENSO CORP

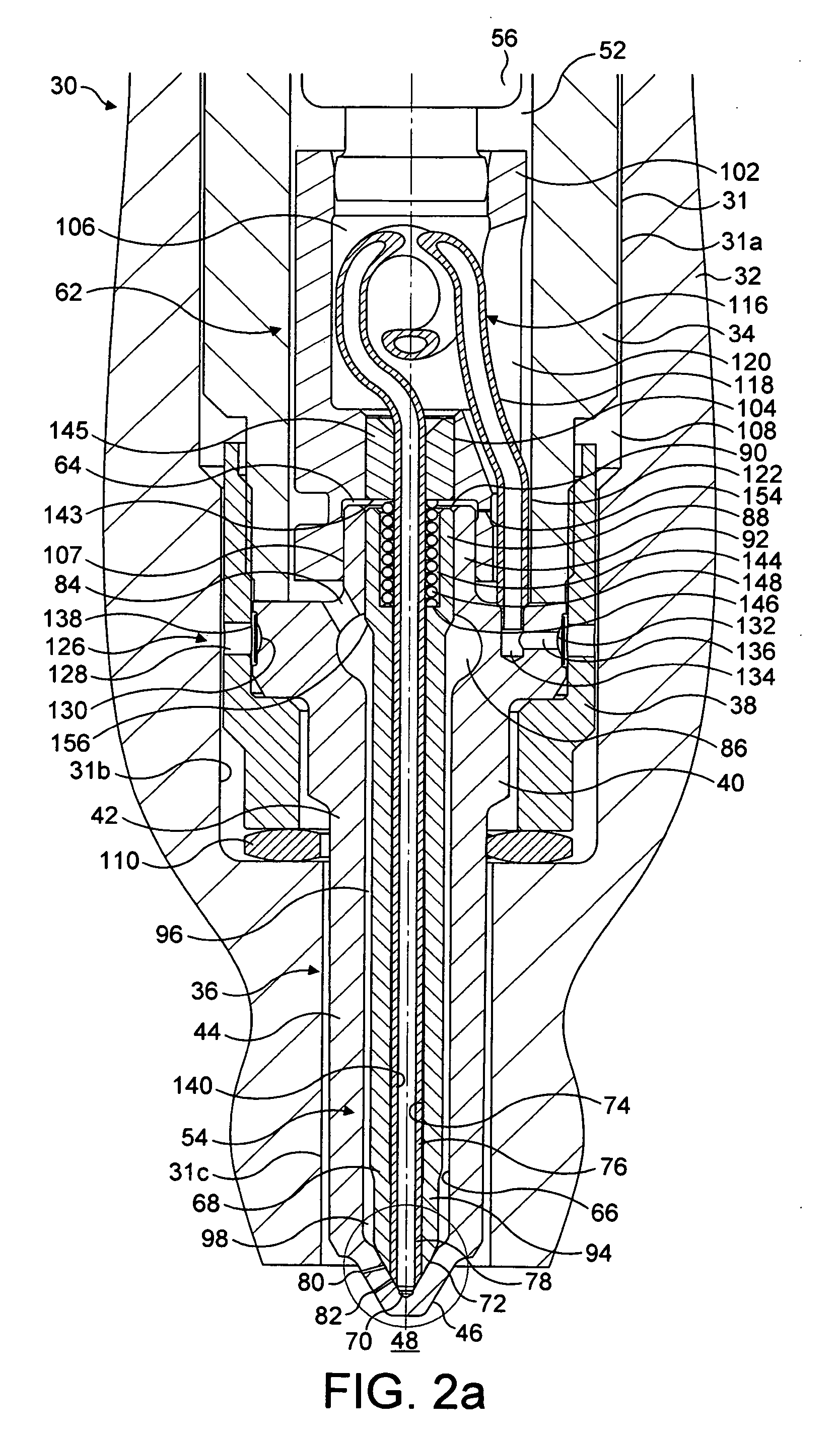

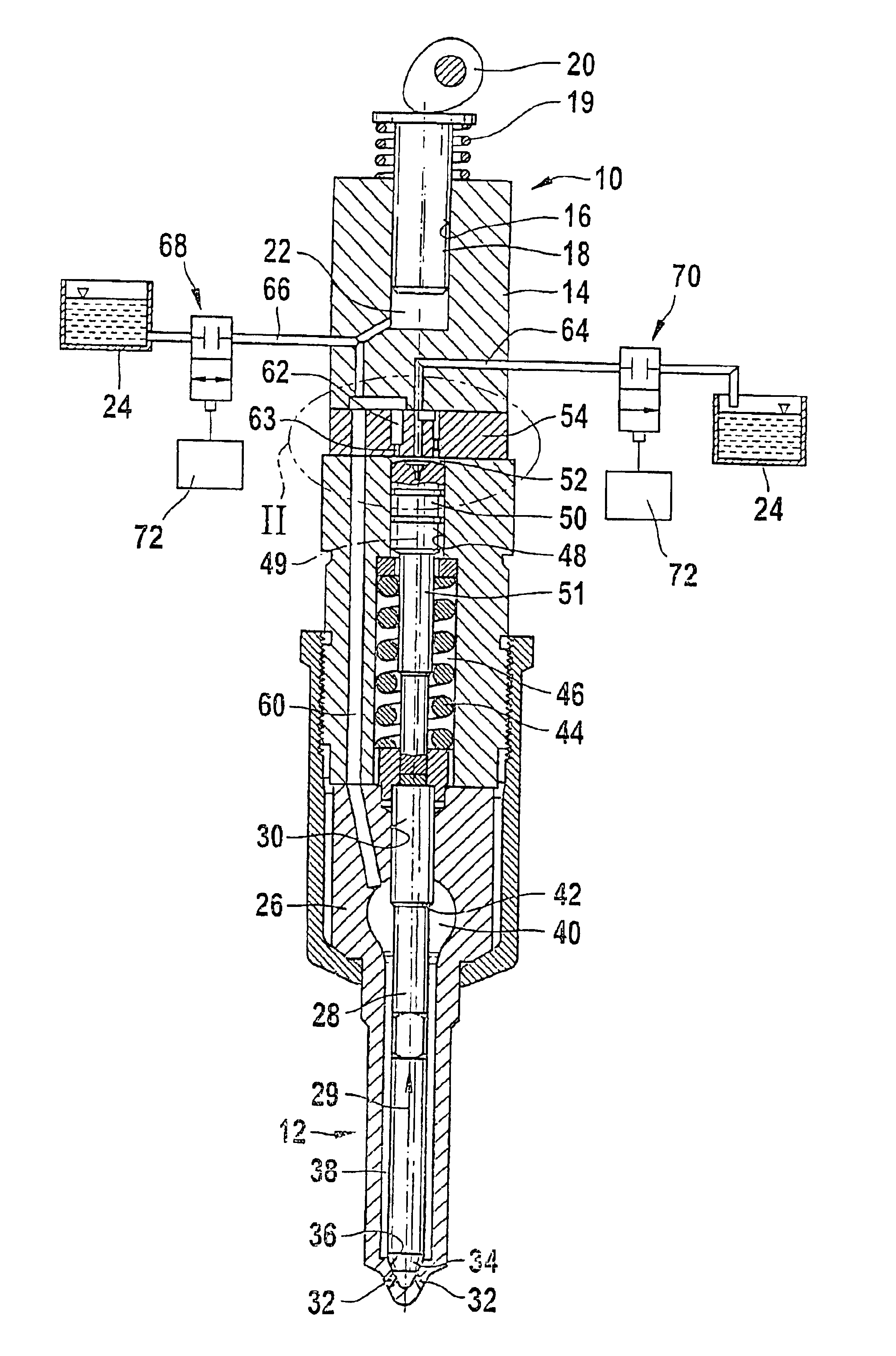

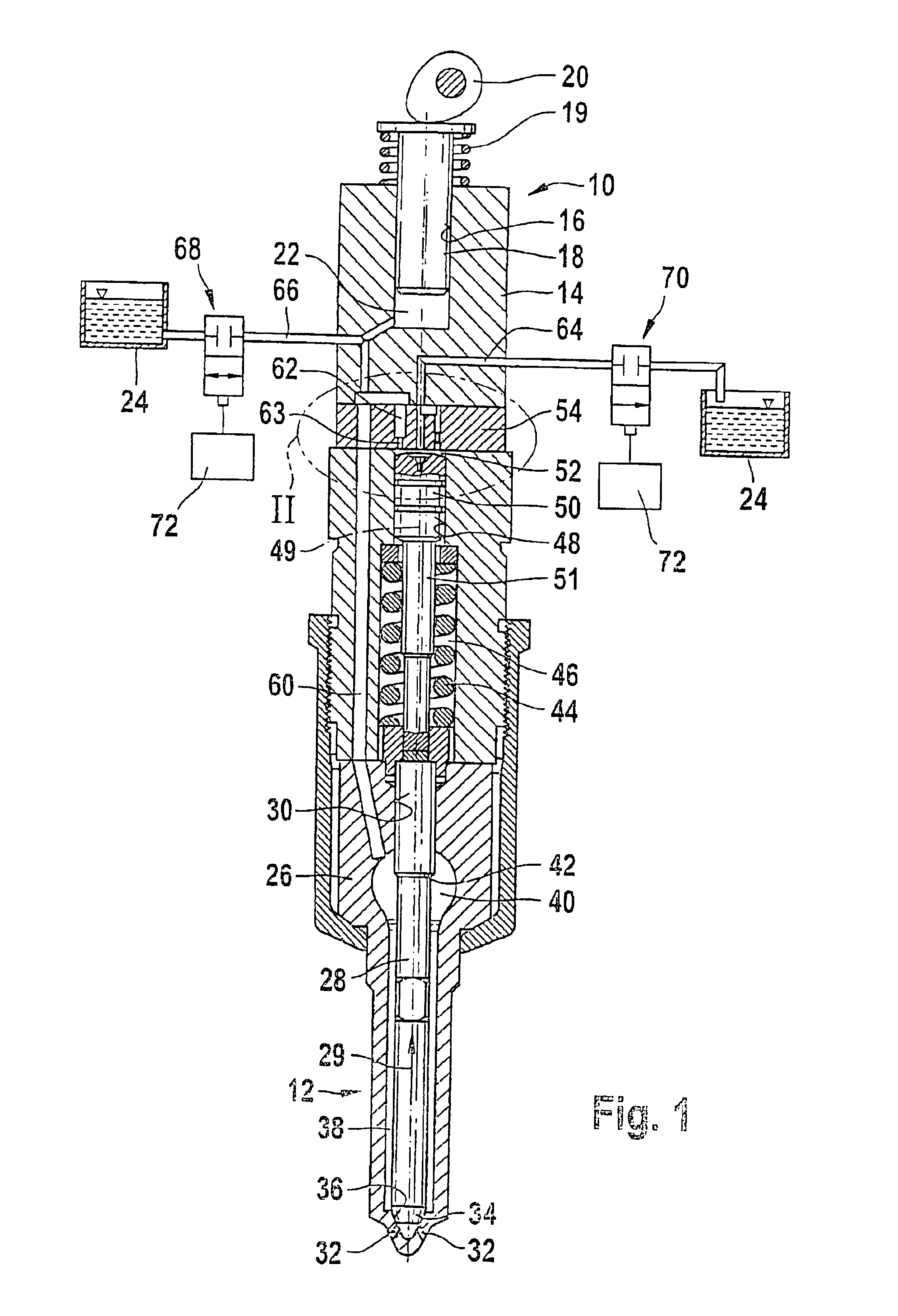

Fuel injecton apparatus

InactiveUS20040237930A1Combustion enginesFuel injection with piezoelectric/magnetostrictive elementsLiquid fuelControl valves

A fuel injection device is provided which can inject fuel by very high injection pressure and can realize favorable combustion and exhaust characteristics, and moreover, enables performance of fuel injection with arbitrary fuel injection patterns. In the fuel injection device 30, the protrusion 61 is provided at a distal end portion of the piston control valve 60 which is provided at the pressure intensifier 54, can change a practical opening area of the fuel flow path 57 to the cylinder 56 in accordance with movement of the piston control valve 60, and can control inflow amounts of liquid fuel that is flowed into the cylinder 56 by the piston control valve 60 (does orifice control). Thus, control of injection rates and injection pressures of fuel that is injected from the fuel injection nozzle 34 is enabled, and fuel injection patterns can be realized with an extremely high degree of freedom.

Owner:TOYOTA JIDOSHA KK

Fuel injector

InactiveUS20090134246A1High thermal efficiencyEmission reductionInternal combustion piston enginesMovable spraying apparatusEngineeringInternal combustion engine

A fuel injector for use in an internal combustion engine, comprising a nozzle body being provided with a nozzle bore and at least one set of one or more outlets for fluid, an outer valve member received within the nozzle bore and being engageable with a first seating region of the nozzle body to control the flow of a first fluid from a first delivery chamber, the outer valve member being provided with an outer valve bore, and an inner valve member received within the outer valve bore and being engageable with a second seating region of the nozzle body to control the flow of a second fluid from a second delivery chamber. In various embodiments, the fuel injector can be arranged to allow the first and second fluids to be injected separately and / or together. In one embodiment, the first and second fluids can be mixed within the injector before injection.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

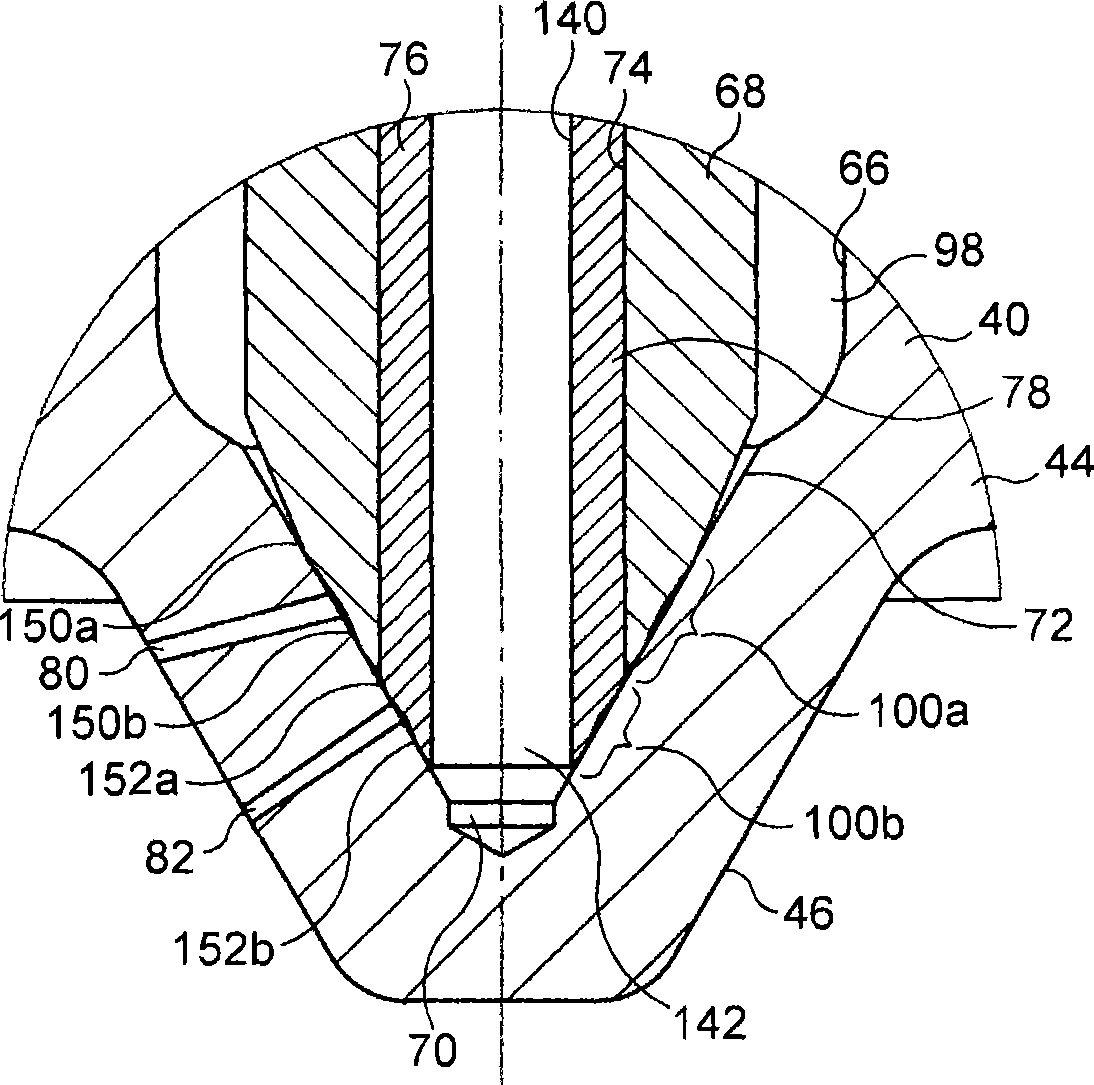

Fuel injector

InactiveCN101487433AOptimizing Spray PatternsHigh viscosityInternal combustion piston enginesEngine controllersInternal combustion engineInjector

The invention relates to a fuel injector for use in an internal combustion engine, comprising a nozzle body (40) being provided with a nozzle bore (66) and at least one set of one or more outlets for fluid, an outer valve member (68) received within the nozzle bore (66) and being engageable with a first seating region (100a) of the nozzle body (40) to control the flow of a first fluid from a first delivery chamber (98), the outer valve member (68) being provided with an outer valve bore (74), and an inner valve member (76) received within the outer valve bore (74) and being engageable with a second seating region (100b) of the nozzle body (40) to control the flow of a second fluid from a second delivery chamber (142). In various embodiments, the fuel injector can be arranged to allow the first and second fluids to be injected separately and / or together. In one embodiment, the first and second fluids can be mixed within the injector before injection.

Owner:DELPHI TECH HLDG SARL

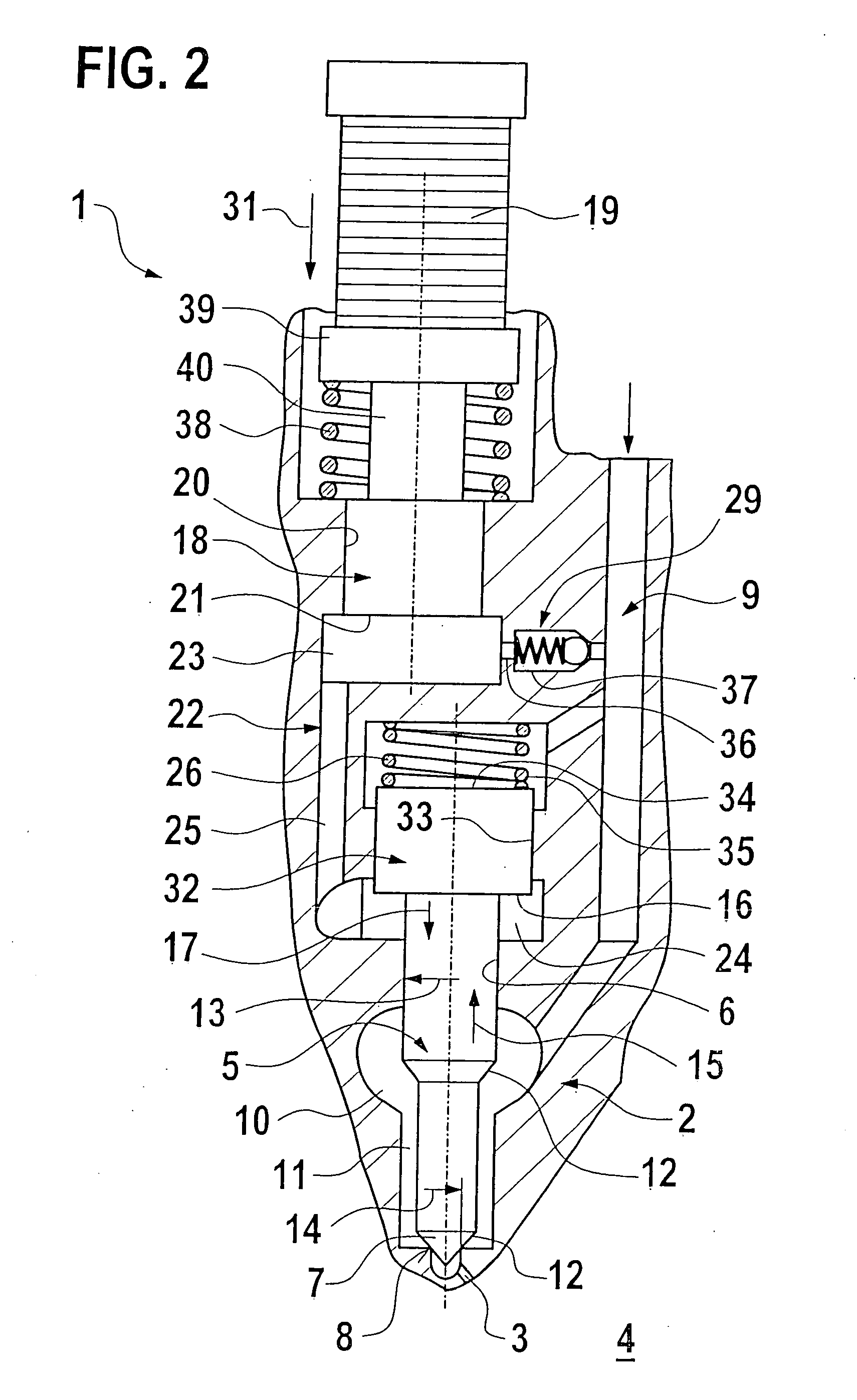

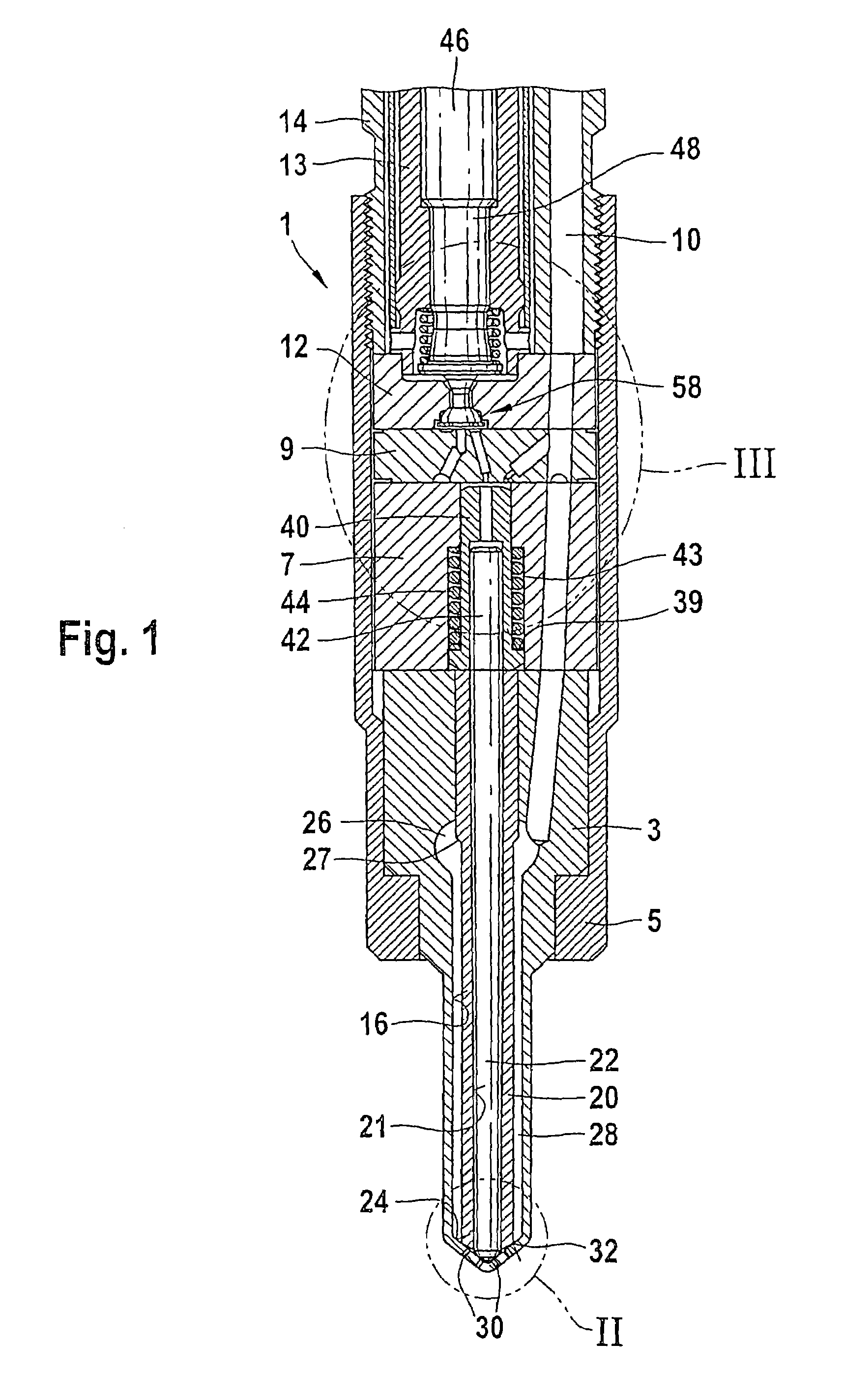

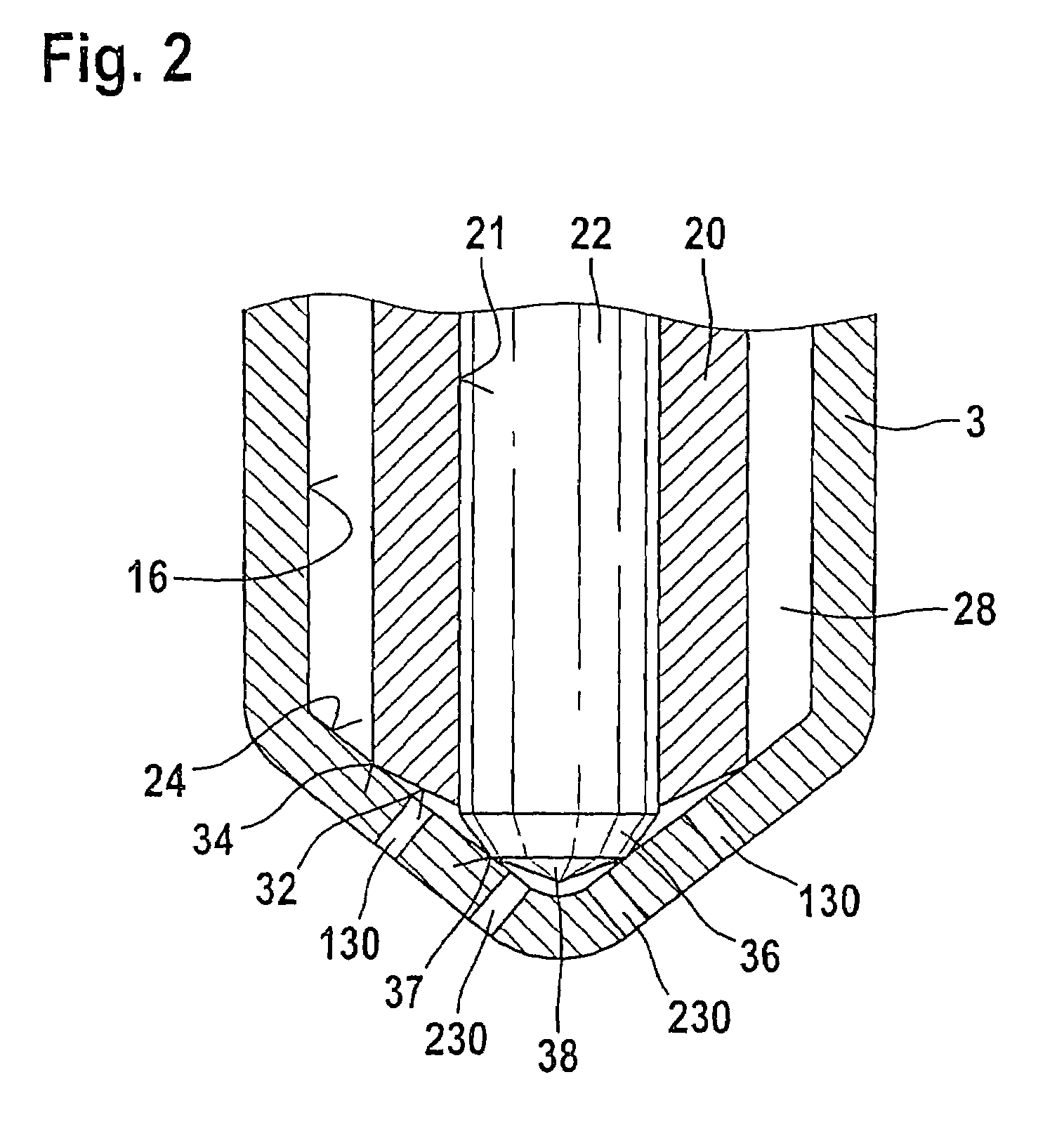

Fuel injection valve for internal combustion engines

InactiveUS20040129804A1Reduce pressureEasy to controlSpray nozzlesFuel injection with piezoelectric/magnetostrictive elementsInjection pressureCombustion

A fuel injection valve for internal combustion engines, having a housing (1) in which an outer valve needle (20) and an inner valve needle (22) guided in it are disposed in a bore (16). The outer valve needle (20), by a longitudinal motion, controls an outer row (130) of injection openings, and the inner valve needle (22), likewise by means of a longitudinal motion, controls an inner row (230) of injection openings, to which rows (130; 230) of injection openings fuel is delivered at an injection pressure through a high-pressure conduit (10) embodied in the housing (1). A control pressure chamber (52) is embodied in the housing (1); it can be made to communicate with the high-pressure conduit (10), and by means of its pressure, a closing force is exerted at least indirectly on the inner valve needle (22). The high-pressure conduit (10) communicates with a control chamber (50), by whose pressure a closing force is exerted at least indirectly on the outer valve needle (20), and the control chamber (50) communicates with the control pressure chamber (52). A control valve (58) is disposed in a housing (1), and by means of the control valve, the control chamber (50) can be made to communicate with a leak fuel chamber (78) (<cross-reference target="DRAWINGS">FIG. 1< / CROSS-REFERENCE>).

Owner:ROBERT BOSCH GMBH

Fuel injection valve for internal combustion engines

InactiveUS7051958B2Reduce pressureEasy to controlSpray nozzlesFuel injection with piezoelectric/magnetostrictive elementsInjection pressureCombustion

A fuel injection valve for internal combustion engines, having a housing in which an outer valve needle and an inner valve needle guided in it are disposed in a bore. The outer valve needle controls an outer row of injection openings, and the inner valve needle controls an inner row of injection openings, to which rows of injection openings fuel is delivered at an injection pressure through a high-pressure conduit embodied in the housing. A control pressure chamber in the housing can be made to communicate with the high-pressure conduit, and by means of its pressure, a closing force is exerted at least indirectly on the inner valve needle. The high-pressure conduit communicates with a control chamber, by whose pressure a closing force is exerted at least indirectly on the outer valve needle, and the control chamber communicates with the control pressure chamber. A control valve is disposed in a housing, and by means of the control valve, the control chamber can be made to communicate with a leak fuel chamber.

Owner:ROBERT BOSCH GMBH

Fuel injection device for an internal combustion engine

InactiveUS6892955B2Low-pressure fuel injectionFuel injection with piezoelectric/magnetostrictive elementsEngineeringControl valves

Owner:ROBERT BOSCH GMBH

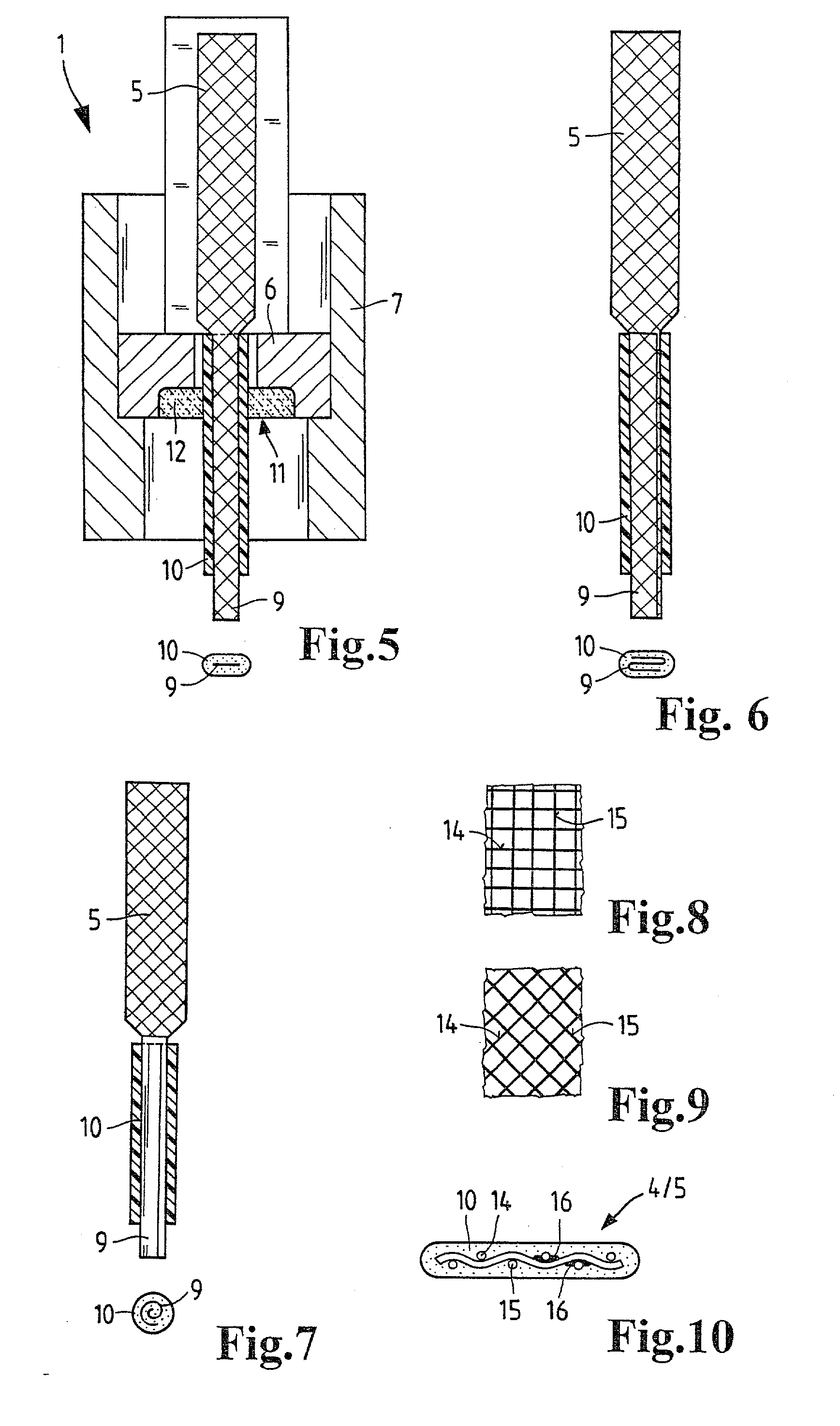

Piezoelectric actuator

InactiveUS20020135275A1Piezoelectric/electrostriction/magnetostriction machinesFuel injection with piezoelectric/magnetostrictive elementsMechanical componentsPiezoelectric actuators

A piezoelectric actuator, for instance for actuating a mechanical component, is proposed that has a multilayer structure of piezoelectric layers and disposed between them inner electrodes (2, 3) and an alternate-side lateral contacting of the inner electrodes (2, 3) via outer electrodes (4, 5). The outer electrodes (4, 5) are applied in network- or fabric-like fashion, each distributed over one side face, and are contacted at least at some points to the respective inner electrodes (2, 3). The outer electrodes (4, 5) are lengthened past the multilayer structure of piezoelectric layers in such a way that the delivery of the electrical voltage takes place at the extensions (8, 9).

Owner:ROBERT BOSCH GMBH

Fuel injection valve for internal combustion engines

InactiveUS6732949B1Avoid excessive wearEasy to useOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesCombustionPiezoelectric actuators

A fuel injection valve has a valve body and a valve member axially movable within the valve body. The opening stroke of the valve member is limited by a stroke stop face provided on a control piston which surrounds the valve member. A control chamber, which may be filled with fuel, is located at one end of the control piston. At a certain pressure in the control chamber, the control piston moves from a first to a second stroke position to limit the opening stroke motion of the valve member. Part of the control piston is embodied as a piezoelectric actuator which, when supplied with electric current, changes its axial length to further vary the stroke of the valve member.

Owner:ROBERT BOSCH GMBH

Fuel injector

InactiveUS6948667B2Improve sealingQuick refillMovable spraying apparatusSpray nozzlesCombustionExternal combustion engine

A fuel injector, in particular a fuel injector for fuel-injection systems of internal combustion engines, having a piezoelectric or magnetostrictive actuator, has a coupler with a master piston and a slave piston which are connected to a pressure chamber. The pressure chamber is filled with an hydraulic fluid, and a coupler spring presses apart the master piston and the slave piston. The pressure chamber is connected to an actuator chamber via a check valve whose blocking direction faces the pressure chamber. The actuator chamber is sealed from a fuel chamber via a movable membrane.

Owner:ROBERT BOSCH GMBH

Fuel injector

InactiveUS20090277423A1Reduce disadvantagesLow costMovable spraying apparatusSpray nozzlesControl roomInternal combustion engine

A fuel injector for use in an internal combustion engine comprises a first valve member and a second valve member, an injection control chamber for fuel, and a set of nozzle outlets; wherein actuation of the second valve member controls the fuel pressure within the injection control chamber, and actuation of the first valve member is regulated by the fuel pressure within the injection control chamber; and wherein the fuel injector is arranged such that actuation of the second valve member establishes a fuel flow path between the injection control chamber and the set of nozzle outlets. The first valve member may be provided with a first valve bore within which the second valve member is received. An injection nozzle and a method of operating a fuel injector are also described.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

Fuel injection device

InactiveUS6880527B2Low pressure boosting ratioHighly dynamic pressure buildupFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesCombustionEngineering

A fuel injection system for internal combustion engines includes an injector supplied from a high-pressure fuel source and with a pressure booster device, in which the closing piston can be acted upon by fuel pressure to attain a force exerted on the closing piston in the closing direction, and in which the closing pressure chamber and the return chamber of the pressure booster device are formed by a common closing pressure return chamber, and all the portions of the closing pressure return chamber communicate with one another permanently for exchanging fuel, so that despite a low pressure boost by the pressure booster device, a relatively low injection opening pressure is attainable.

Owner:ROBERT BOSCH GMBH

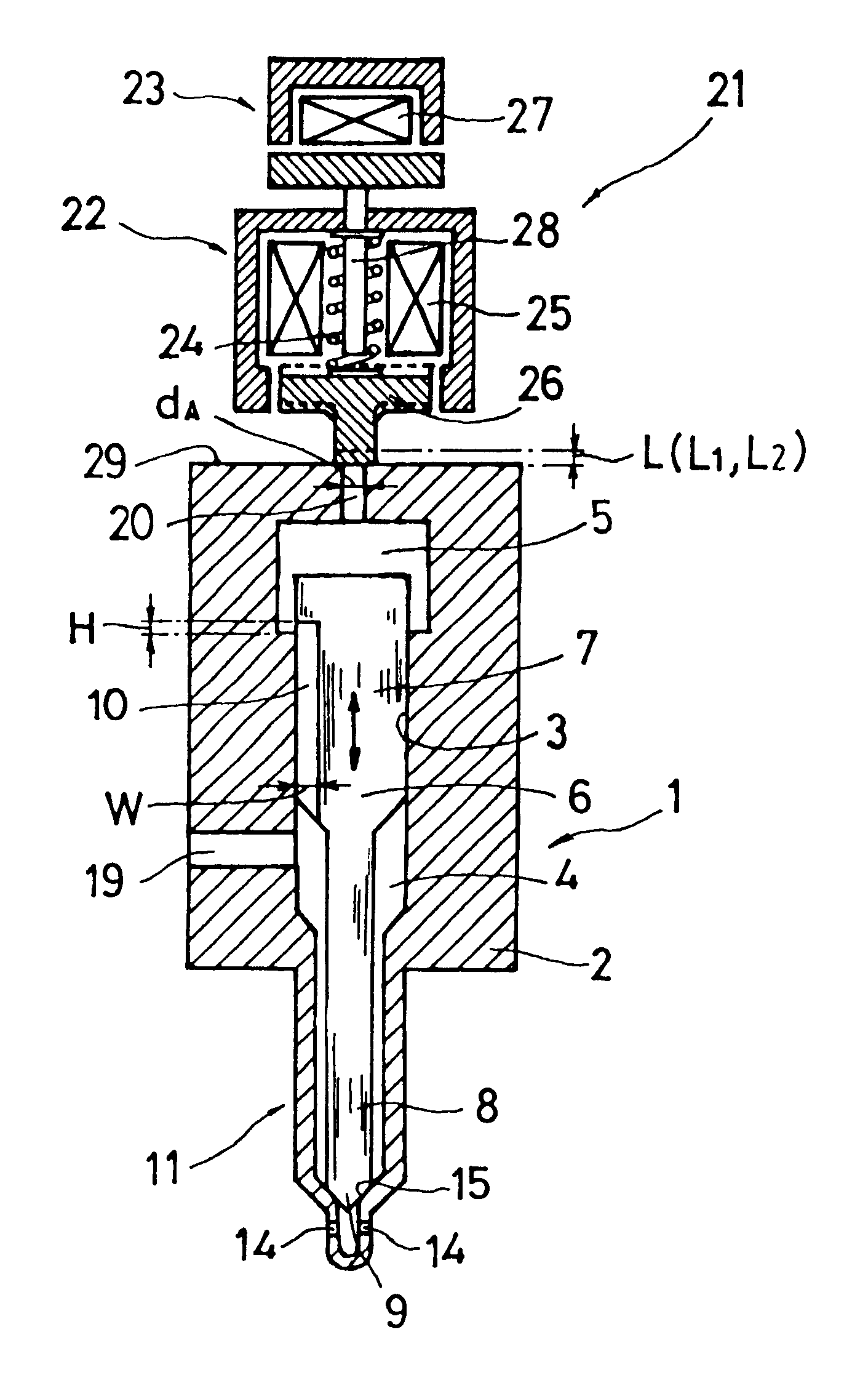

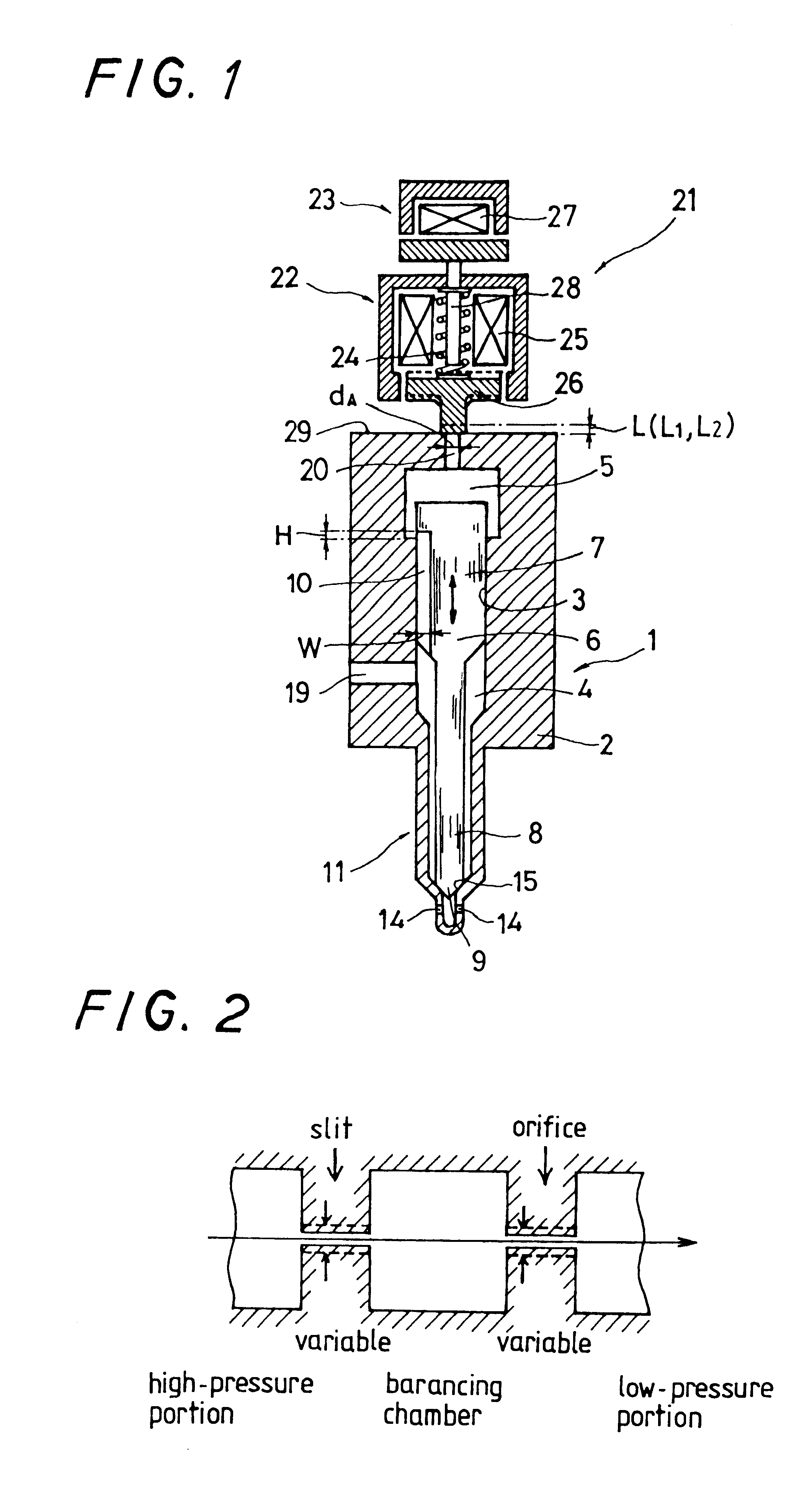

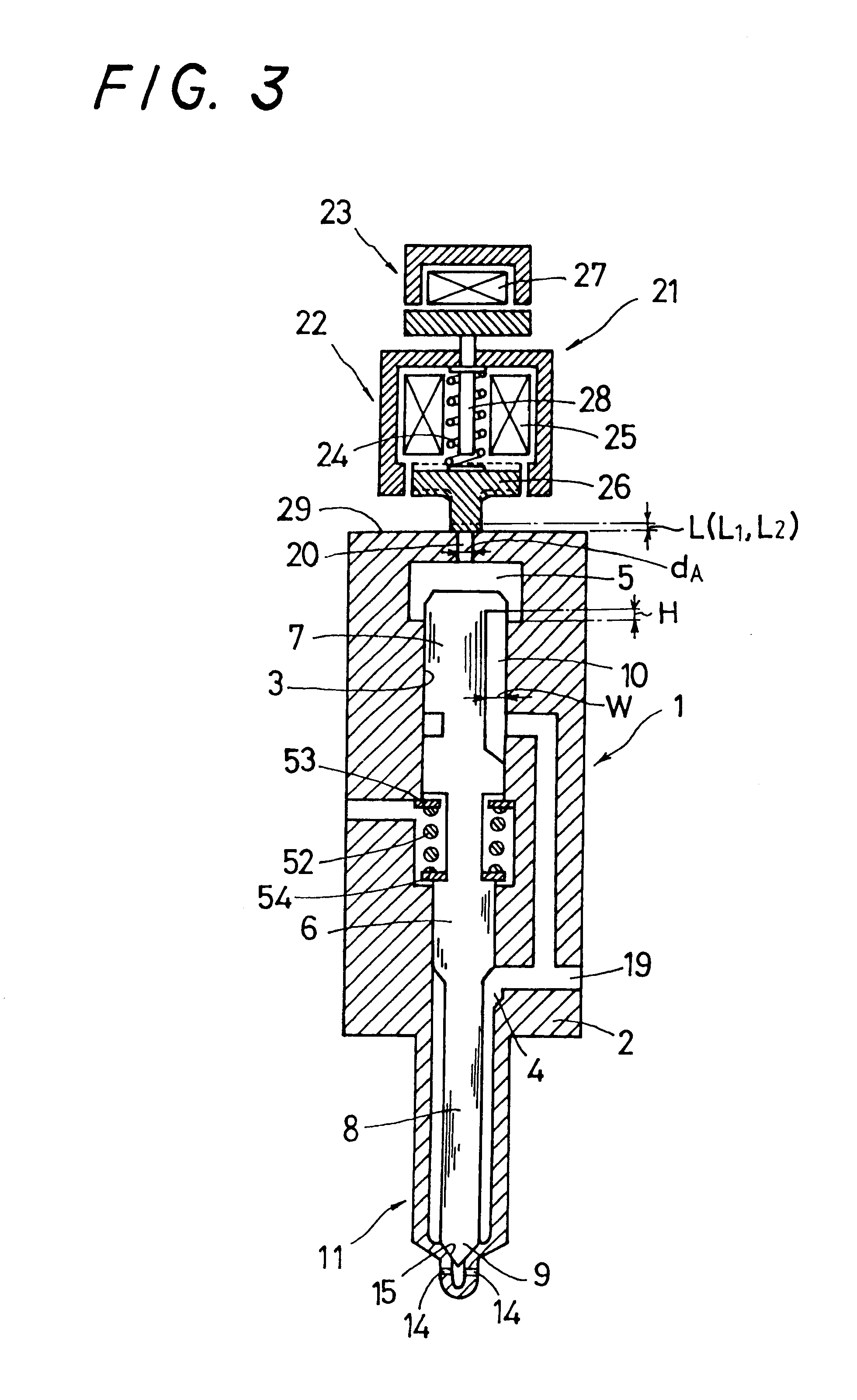

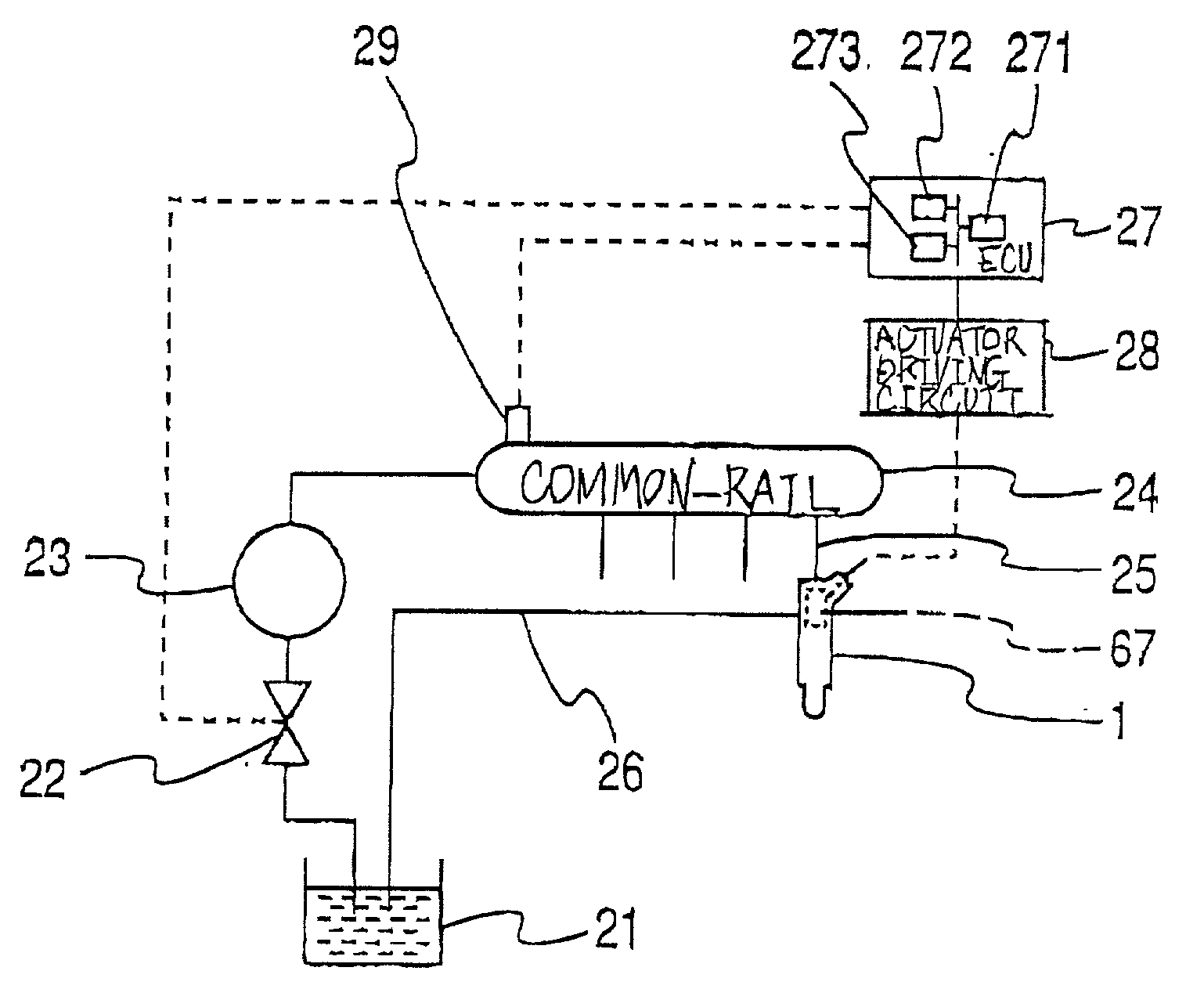

Accumulating fuel injection apparatus

InactiveUSRE37633E1Increase the opening areaLow fuel pressureElectrical controlFuel injection with piezoelectric/magnetostrictive elementsInjection portSolenoid valve

This accumulating fuel injection apparatus is provided with a needle valve 6 adapted to open and close an injection nozzle 11 having injection ports 14 in a lower end portion thereof, a balancing chamber 5 formed in a casing 2 so as to apply a fuel pressure to a head portion of the needle valve 6, a supply passage including a slit 10 and used for supplying a fuel from a fuel supply port 19 to the balancing chamber 5, a discharge passage 20 comprising an orifice for discharging the fuel from the balancing chamber 5, and a solenoid valve 22 adapted to open and close the discharge passage 20, the lift of a valve disc 26 of the solenoid valve 22 is controlled by a lift control means comprising a stopper 28 the position of which is controlled by a lift control mechanism 23. The opening area of the discharge passage 20 comprising an orifice increases and decreases in accordance with the lift of the valve disc 26, and the lift of the needle valve 6 is determined so that the opening area of the slit 10 facing the interior of the balancing chamber 5 increases and decreases correspondingly to the flow rate of the fuel passing through the discharge passage 20, the degree of opening of the injection nozzle 11 increasing and decreasing accordingly.

Owner:ISUZU MOTORS LTD +1

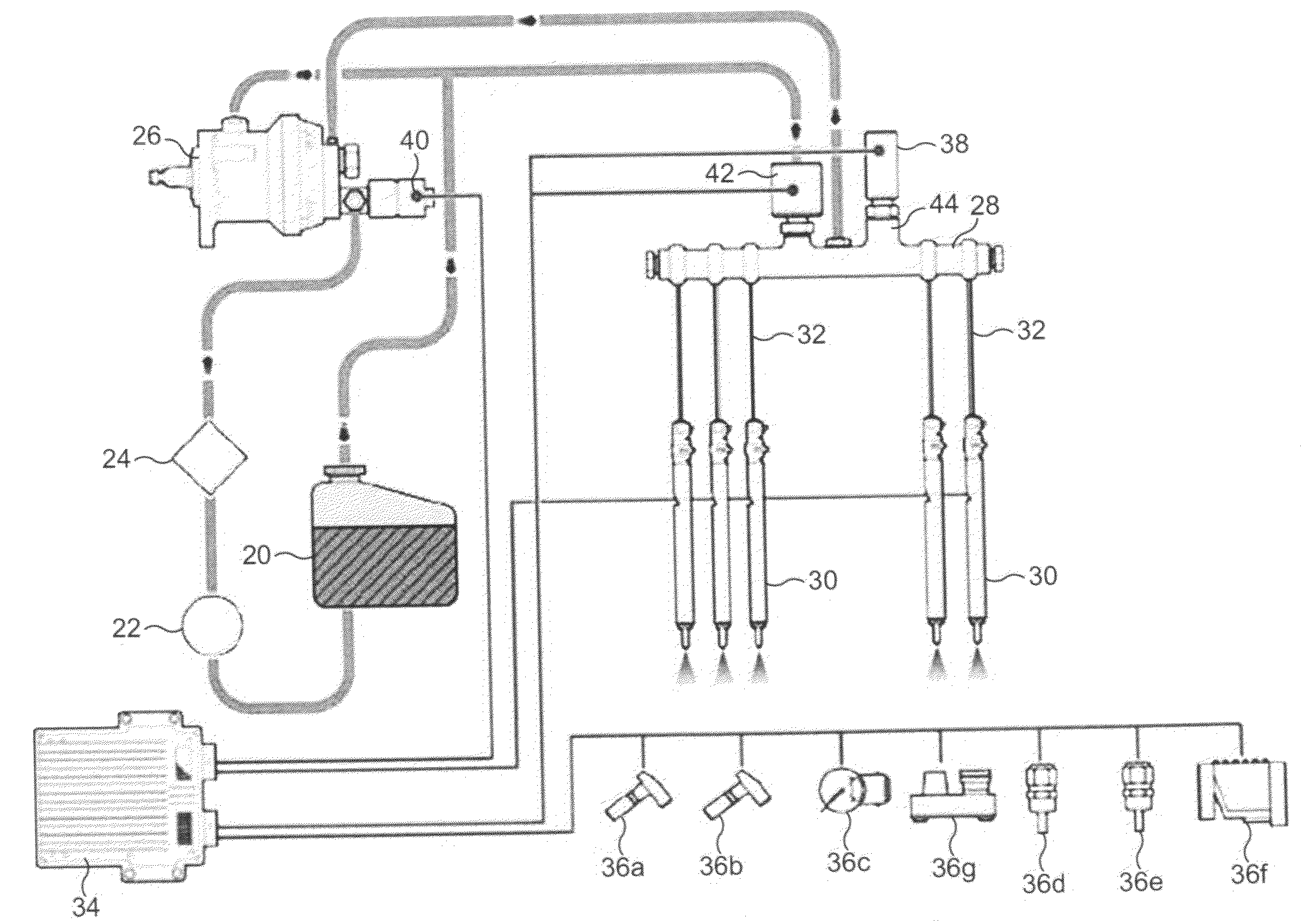

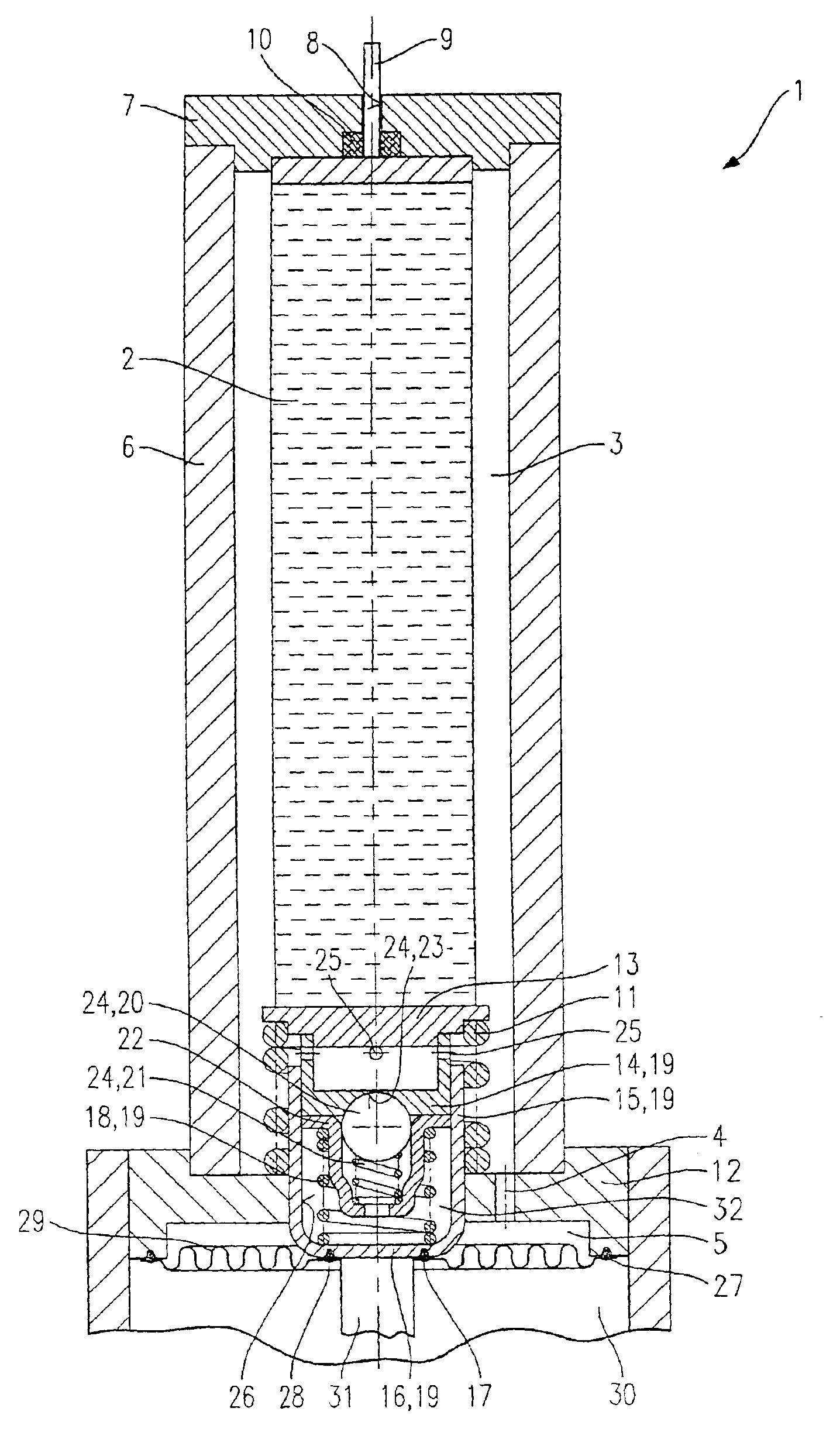

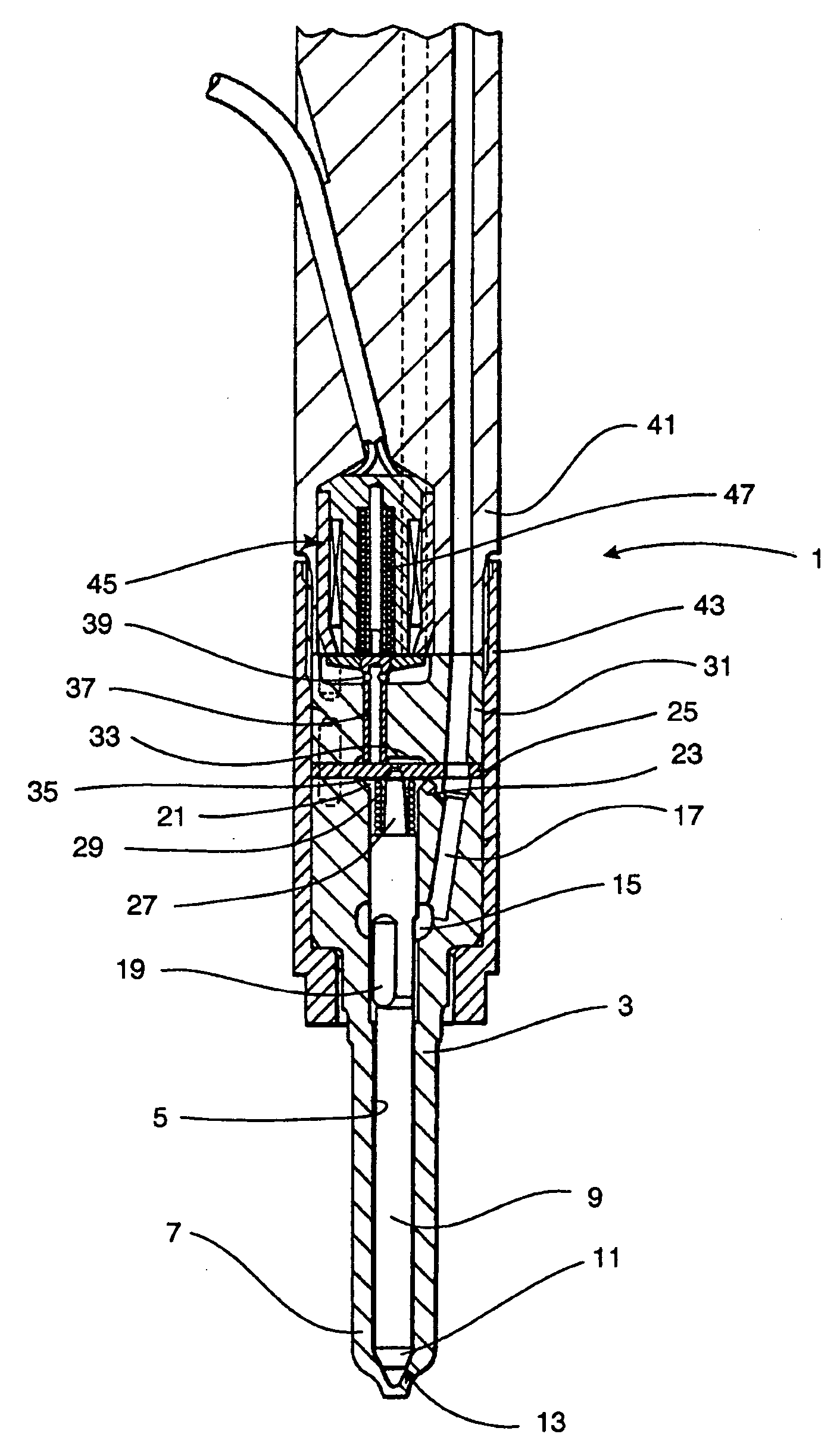

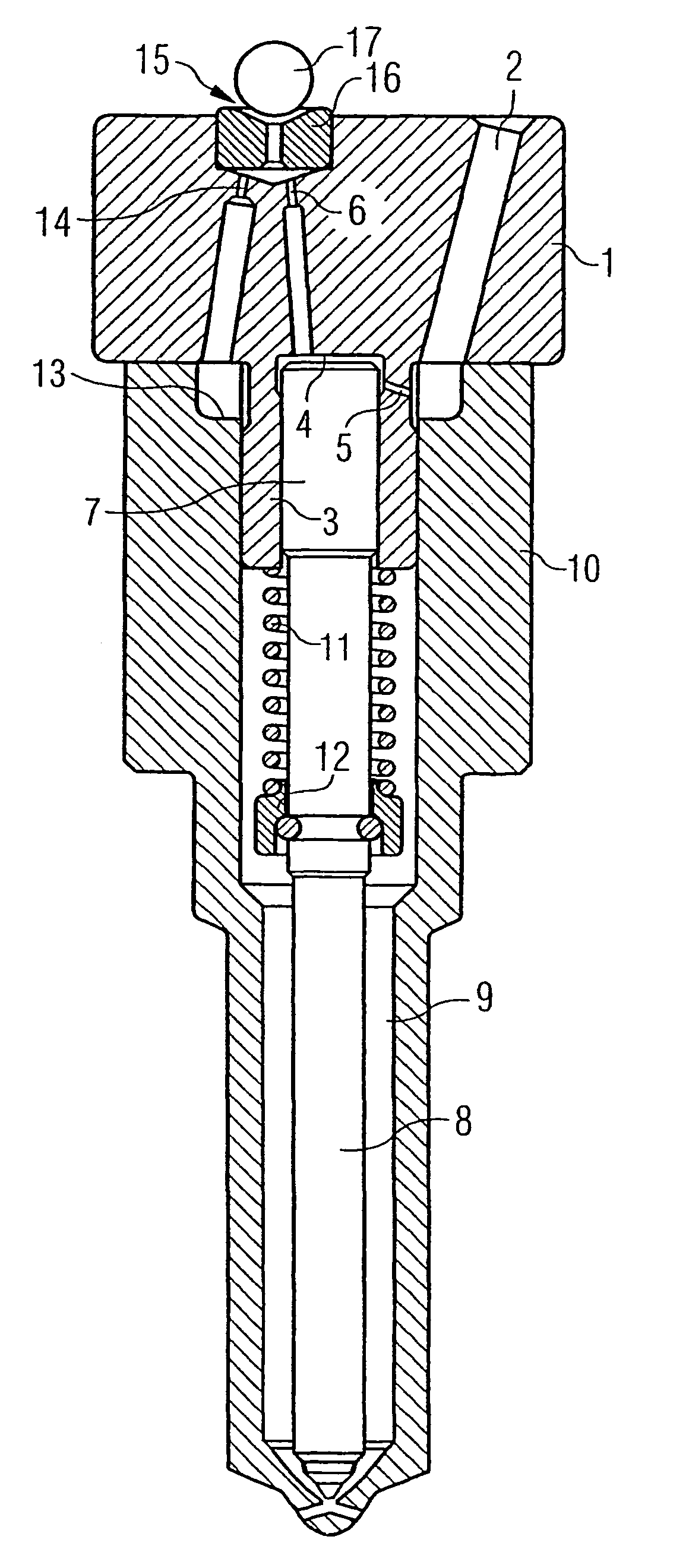

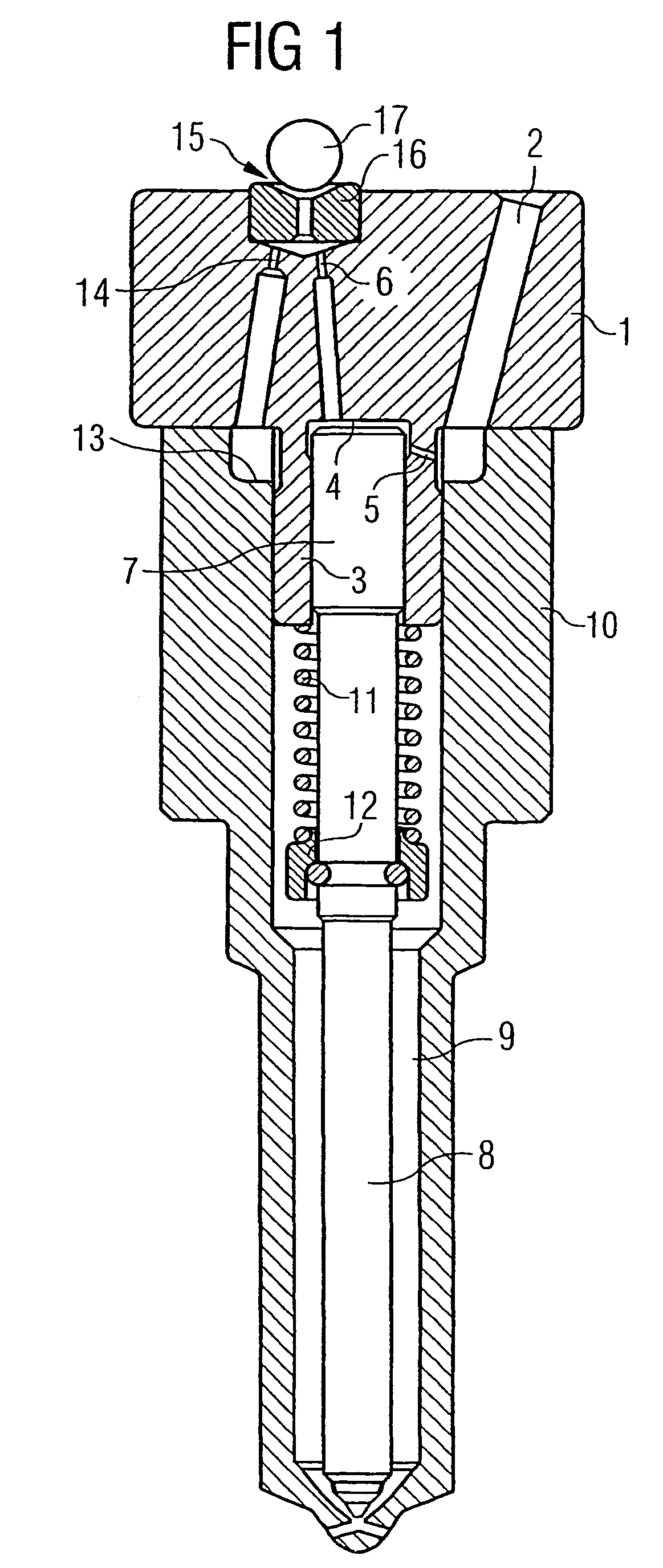

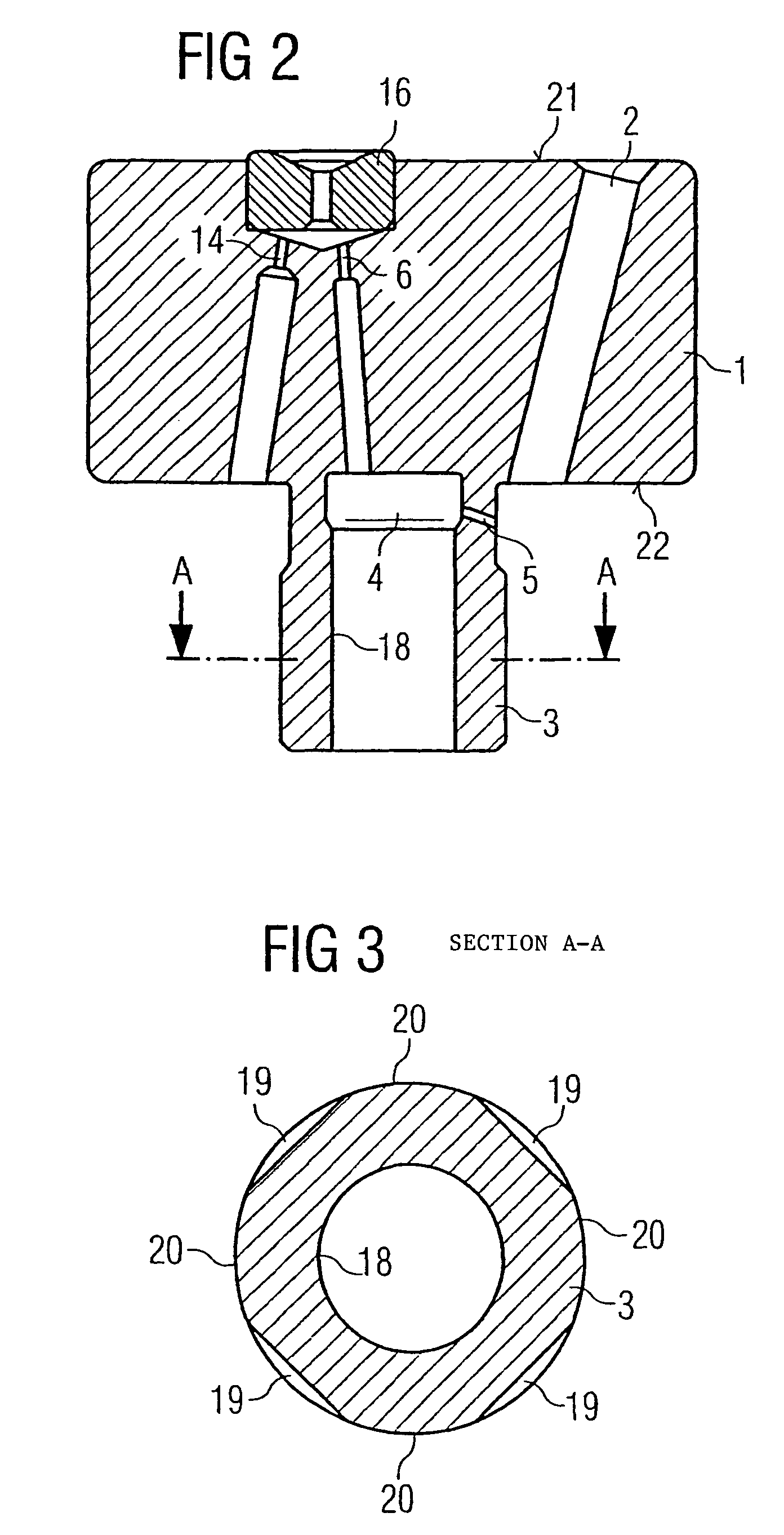

Control module for an injector of an accumulator injection system

InactiveUS6986474B2Improve accuracyHigh movement precisionFuel injection with piezoelectric/magnetostrictive elementsFluid pressure injection controlEngineeringControl room

A control module (1) for an injector of an accumulator injection system is used to control and guide a valve body (8). The control module comprises a high pressure supply line (2) for supplying fuel, and a guiding device (3) for guiding the valve body (8). A control room (4), an inlet throttle (5) and an outlet throttle (6) are also provided. The inlet throttle (5) connects the high pressure supply line (2) to the control chamber (4) and the outlet throttle (6) connects the control chamber (4) to a control valve (15). A control piston (7) is arranged in the control chamber (4), the end of the control piston opposite the control chamber (4) being connected to a high pressure region (9) on the valve body (8).

Owner:SIEMENS AG

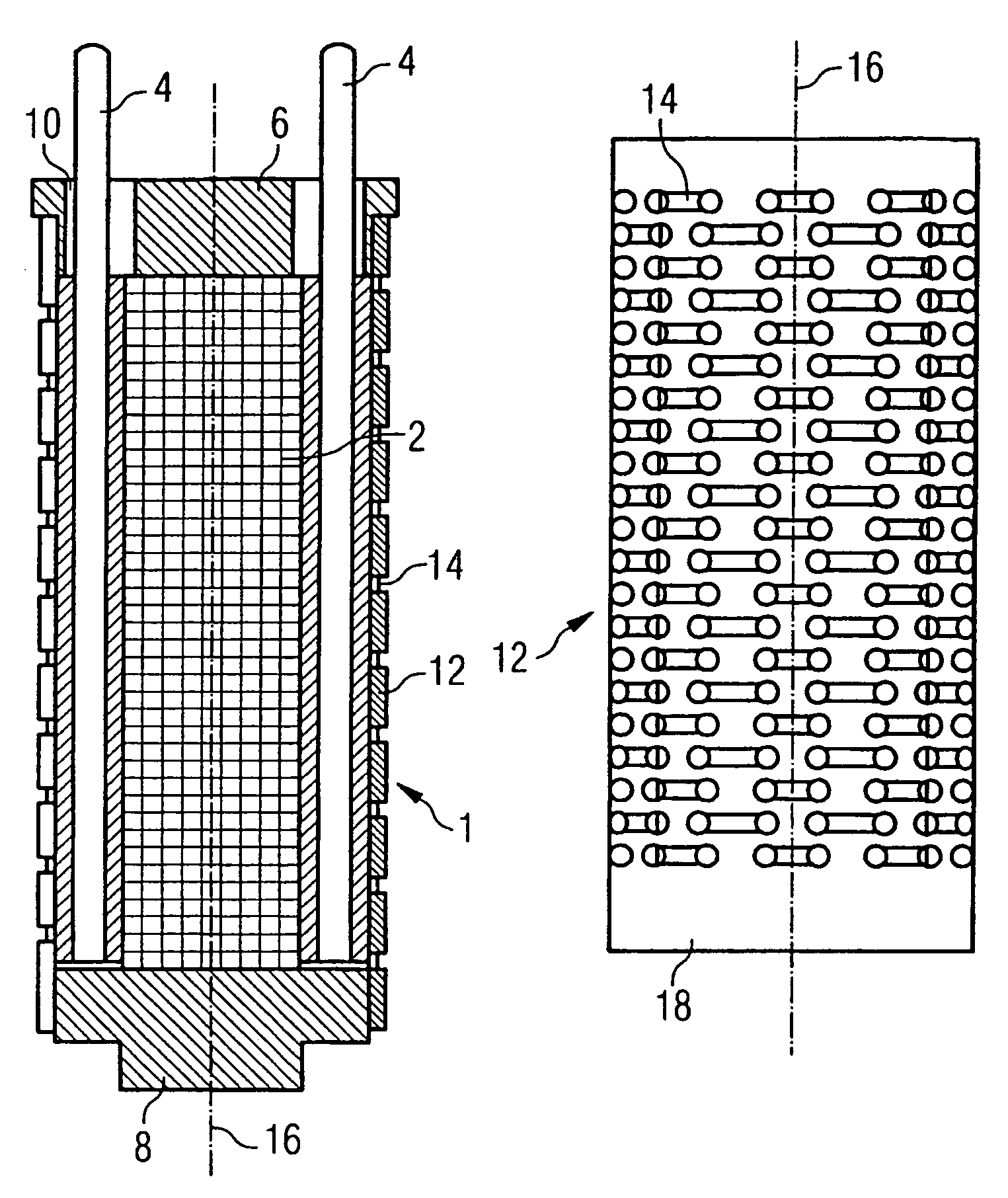

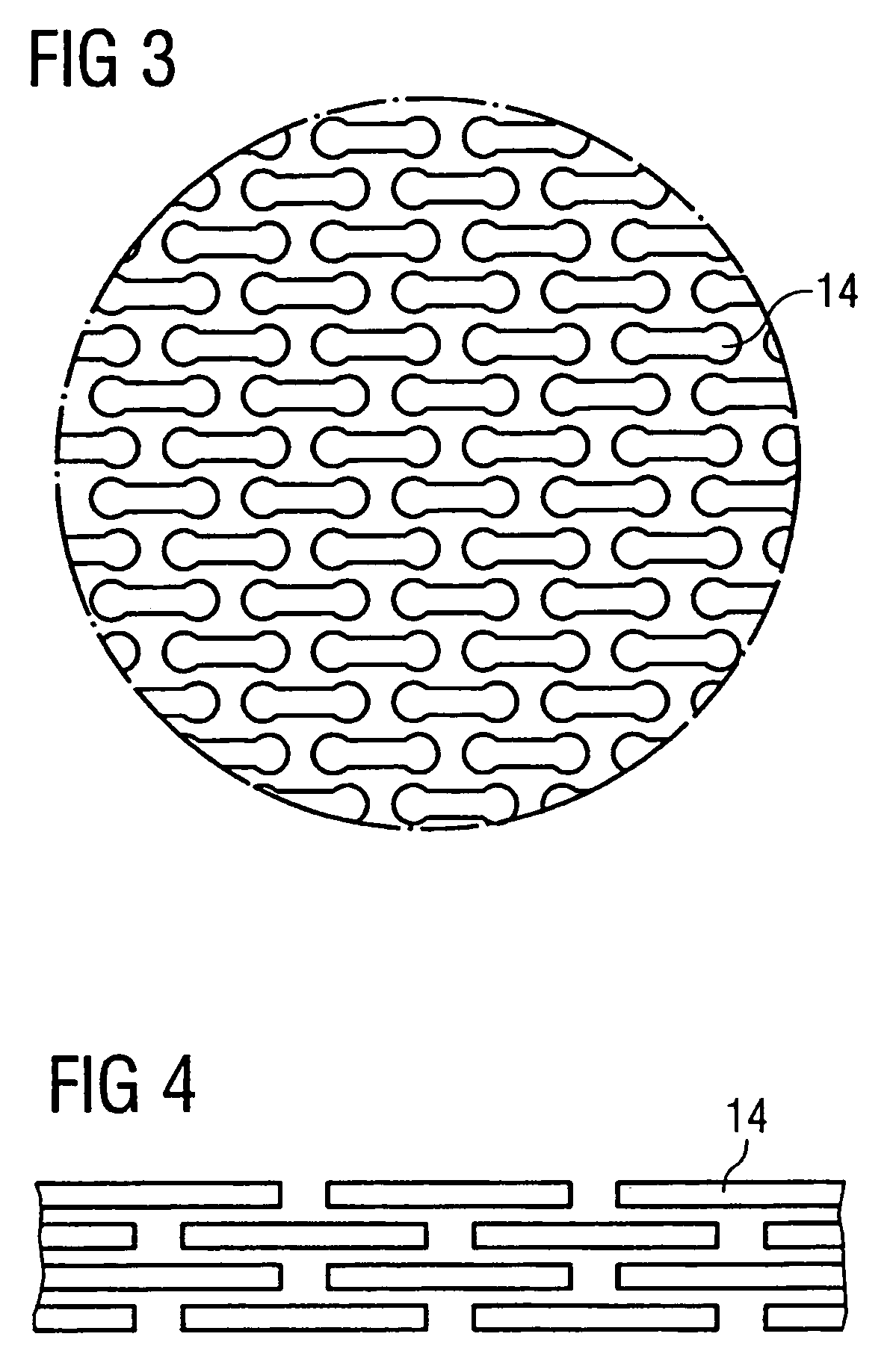

Method for producing a tubular spring and an actuator unit comprising one such tubular spring

InactiveUS7222424B2High strengthReduce the spring ratePiezoelectric/electrostriction/magnetostriction machinesSoldering apparatusPiezoelectric actuatorsLaser cutting

A method for producing a tubular spring (12) in the form of a cylindrical hollow body, especially for pre-tensioning a piezoelectric actuator element (2) of an actuator unit (1) of a fuel injector comprises the step of providing a thin-walled, solid-drawn steel tube with a plurality of regularly arranged longish recesses (14) by means of laser cutting. Thus, an actuator unit (1) comprises a piezoelectric actuator element (2) which is arranged in a thin-walled cylindrical hollow body, wherein the hollow body being elastically embodied and pre-tensioning the actuator element (2). Furthermore, the hollow body is a solid-drawn steel tube which is provided with a plurality of longish recesses (14).

Owner:VITESCO TECH GERMANY GMBH

Fuel injector with built-in fuel pressure sensor

ActiveUS8224554B2Improve accuracyDigital data processing detailsFluid pressure measurement by electric/magnetic elementsInternal combustion engineFuel supply

A fuel injector for an internal combustion engine is provided which has a fuel supply path and a nozzle chamber. The fuel supply path extends a spray hole. The nozzle chamber is defined in the fuel supply path. A nozzle is disposed within the nozzle chamber to establish or block a fluid communication between the fuel supply path and the spray hole. A fuel pressure sensor is installed in the fuel injector so as to be exposed to the fuel in the nozzle chamber. Specifically, the fuel pressure sensor is located closer to the spray hole than a prior art structure in which the fuel pressure sensor is installed in a fuel supply pipe, thus resulting in increased accuracy in measuring a change in pressure of the fuel arising from the spraying of the fuel from the spray hole.

Owner:DENSO CORP

Hydraulic control device, system and method for controlling actuator device

InactiveUS20020117149A1Stable controlSuppress mutationElectrical controlFuel injection with piezoelectric/magnetostrictive elementsEngineeringActuator

A supplying unit supplies energy to an actuator so that the supplied energy is kept therein, making displacement the actuator. An interrupting unit interrupts the supply of energy to cause the actuator to discharge the kept energy, making displacement the actuator. A converting unit is adapted to convert the displacement of the actuator corresponding to the kept energy into hydraulic pressure applied to the valve member, moving the valve member to open the low pressure port and close the high pressure port. The convert unit converts the displacement of the actuator corresponding to the discharged energy into hydraulic pressure applied to the valve member, moving the valve member to open the high pressure port and close the low pressure port. Energy which the actuator requires to move the valve member so as to close the high pressure port is larger than energy which the actuator requires to move the valve member so as to open the low pressure port.

Owner:DENSO CORP

Injector with a multilayer piezoelectric actuator

InactiveUS6371085B1Operating means/releasing devices for valvesSpray nozzlesPiezoelectric actuatorsCommon rail

An injector for common rail Diesel injection systems of motor vehicles, having a multilayer piezoelectric actuator which has a multilayer actuator body. The actuator body is prestressed on a face end by a prestressing device and is seated inside a center longitudinal bore of an injector housing. The injector is characterized in that the prestressing device have at least one cup spring, which in a prestressing movement engages the face end of the actuator body opposite an injector valve (V), as well as a force transmission member seated in the injector housing and axially movable therein, the transmission member transmits the spring force of the at least one cup spring to the face end, toward the valve, of the actuator body.

Owner:ROBERT BOSCH GMBH

Piezo actuator

InactiveUS20030168937A1Operating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesElastomerHeat conducting

A piezoelectric actuator (1) is proposed, in which a piezoelectric element (2) is present for subjecting an actuating element to a tensile or compressive stress. A sleeve (4; 20) is secured to a foot part (3), to which the piezoelectric element (2) is secured and by way of which the piezoelectric element (2) is kept centered in a housing (8) under mechanical prestressing, and this sleeve surrounds the piezoelectric element (2) in such a way as to stabilize it mechanically, at least in partial regions that are electrically insulated from the piezoelectric element. Between the sleeve (4; 20) and the piezoelectric element (2), a heat-conducting elastomer (6) is placed, and the sleeve (4; 20) comprises a heat-conducting material that is deformable within predetermined limits.

Owner:ROBERT BOSCH GMBH

Detection of faults in an injector arrangement

InactiveUS7966871B2Easily and quickly servicedReduce decreaseInternal-combustion engine testingElectrical controlDelayed periodsElectricity

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

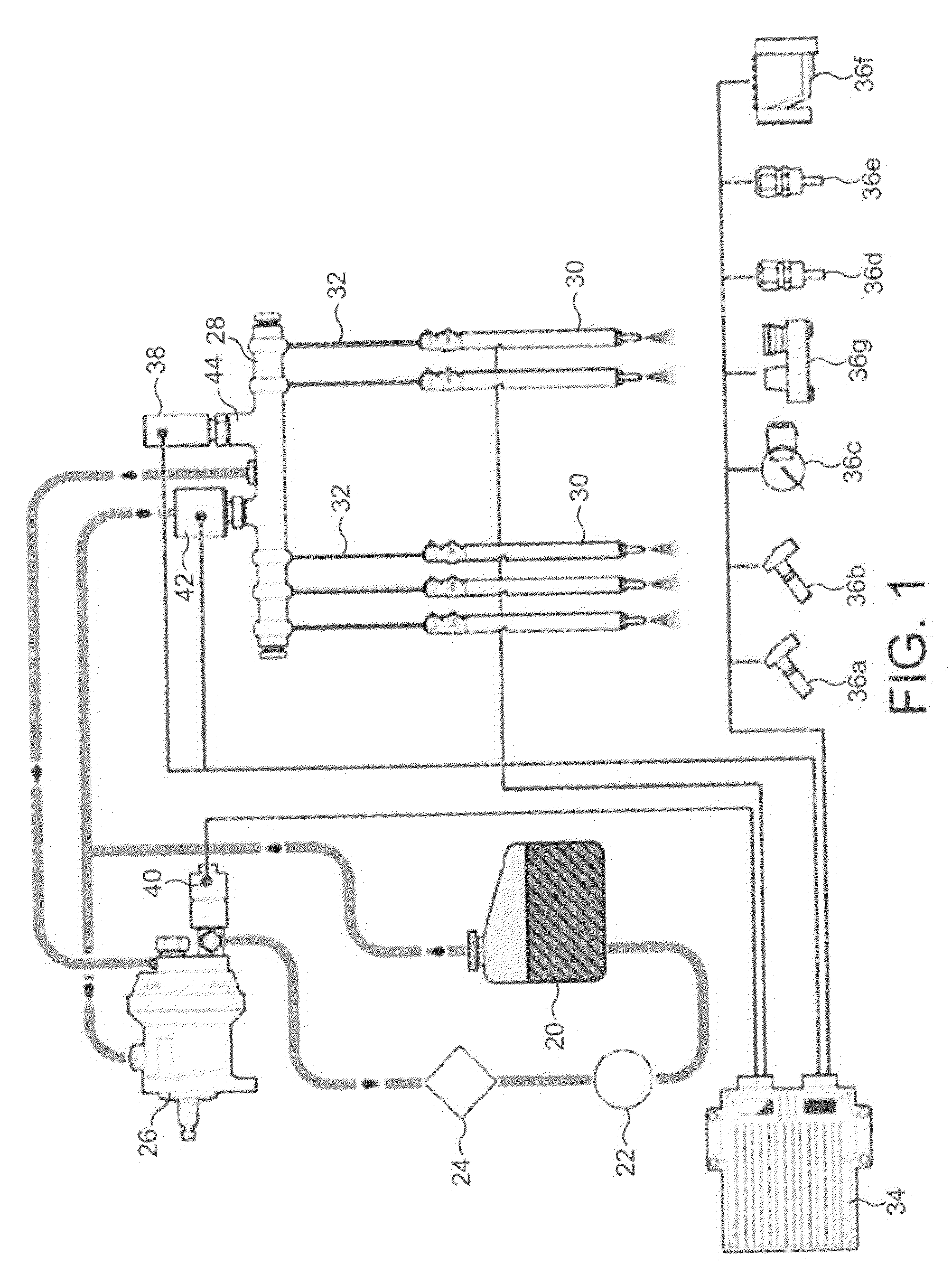

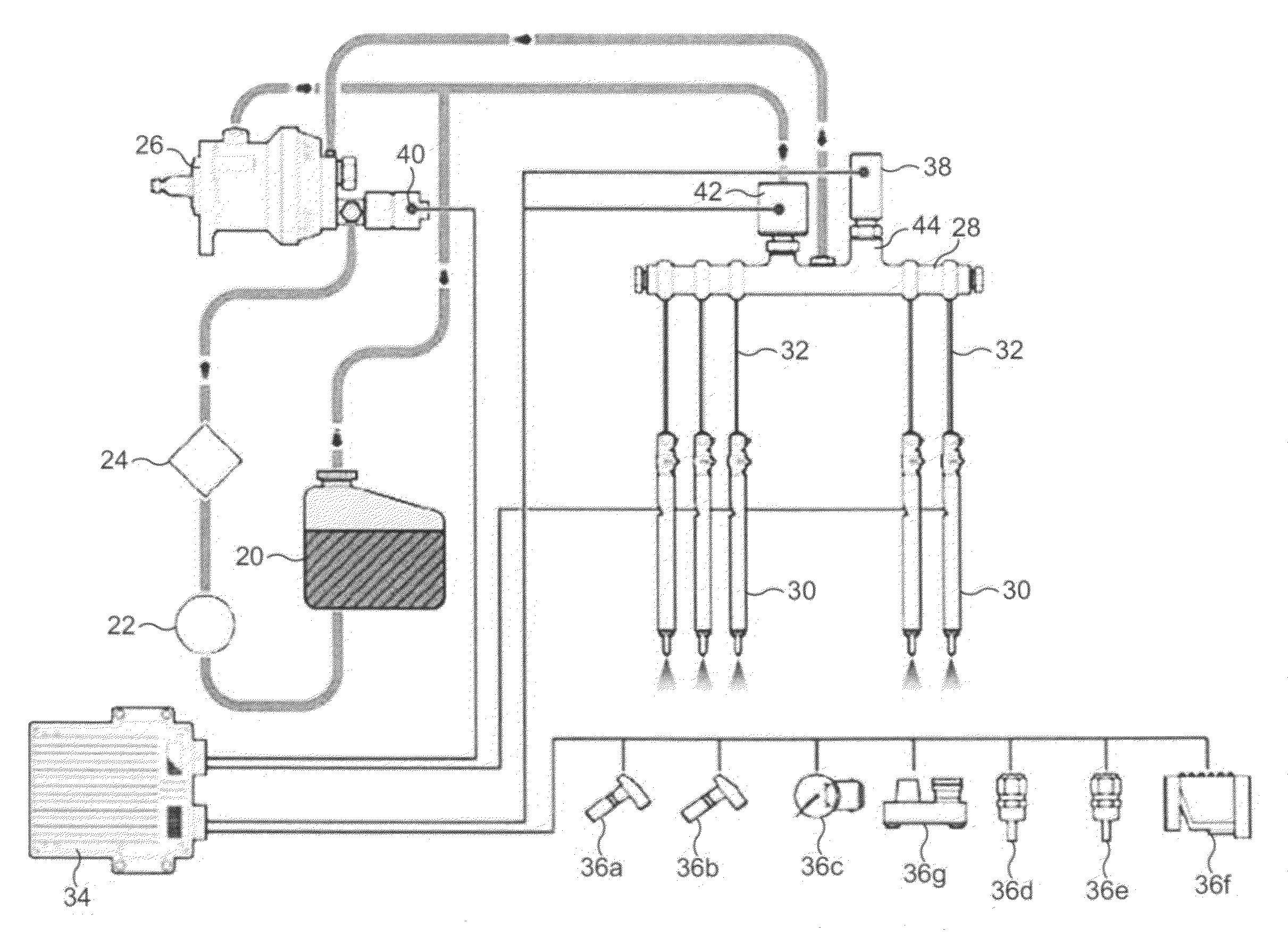

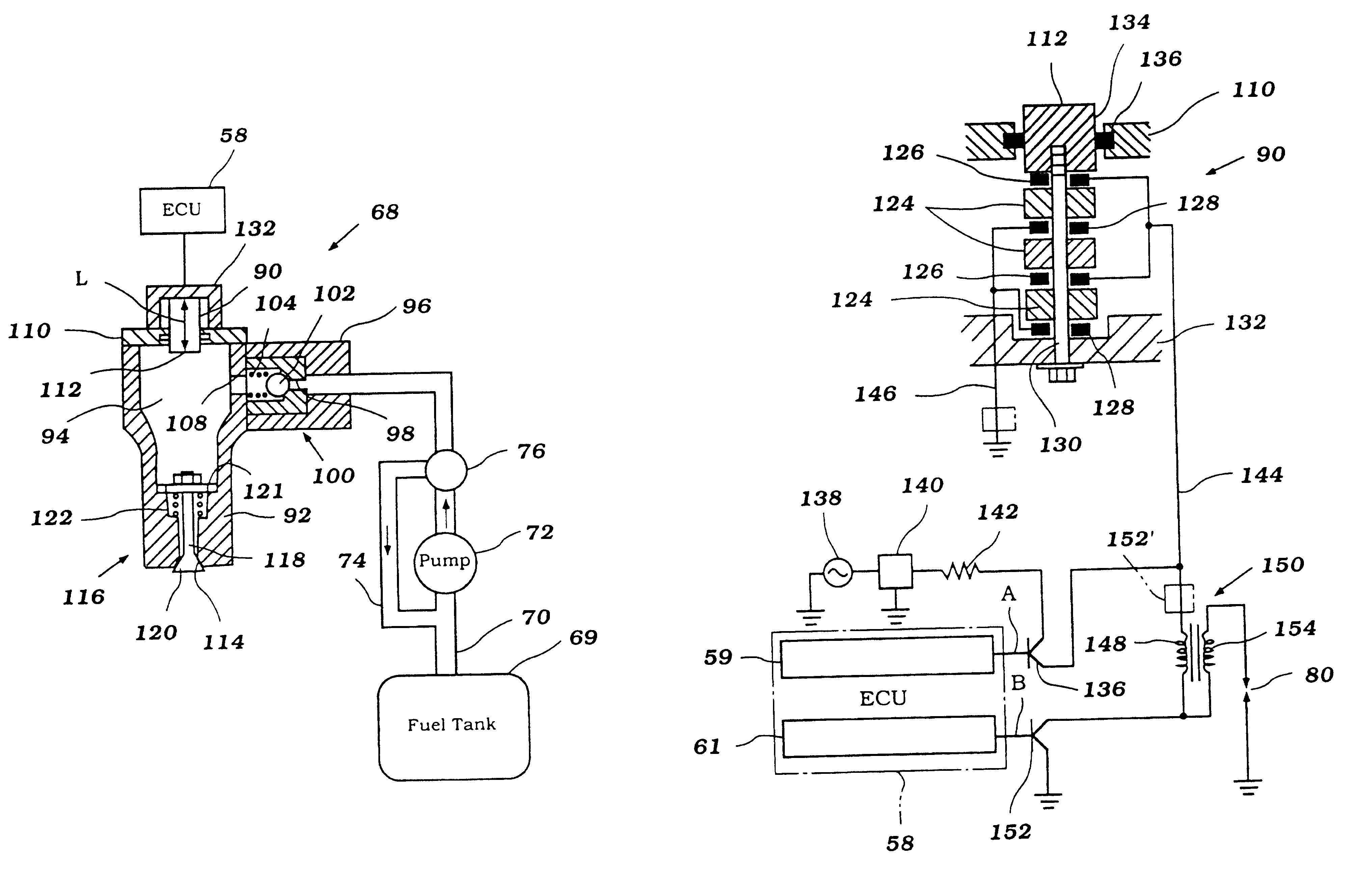

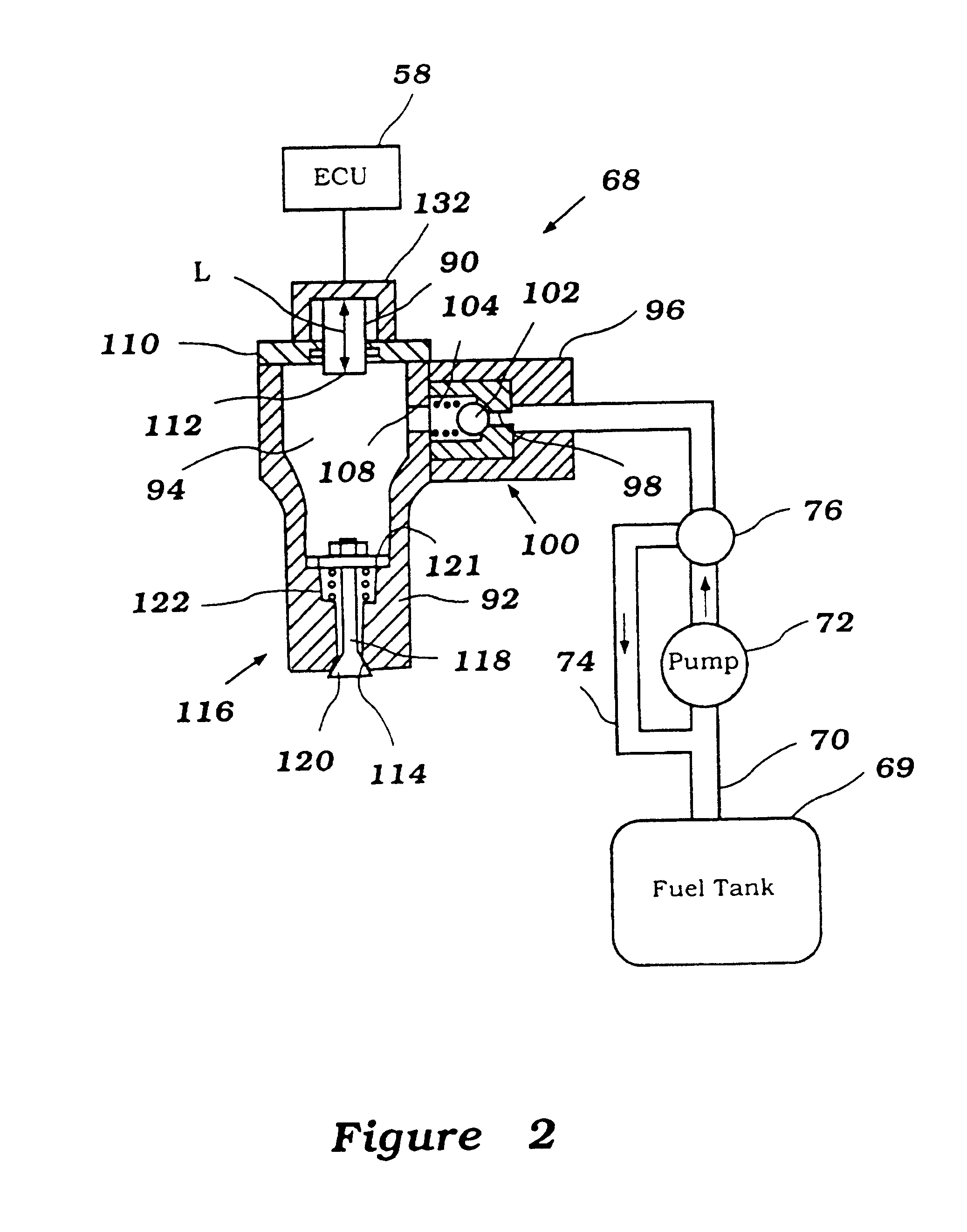

Fuel injection system

InactiveUS6293255B1Increase fluid pressureEasy to controlElectrical controlFuel injection with piezoelectric/magnetostrictive elementsPump chamberReciprocating motion

The present invention is an injection system including an injection device. The injection device includes a pumping chamber and an electrically operated device associated with the pumping chamber which, when energized, is capable of providing a rapid increase in localized fluid pressure in said pumping chamber without reciprocating a piston in a cylinder bore. A discharge port associated with the pumping chamber permits discharging of fluid displaced by the localized pressure increase. The injection system includes a circuit providing an energizing voltage to the electrically operated device, and a control for changing at least one characteristic of the energizing voltage selected from the group consisting of: the peak energizing voltage, the rate at which said energizing voltage increases, the rate at which said energizing voltage decreases, the duration of energization, and the frequency of energization.

Owner:YAMAHA MOTOR CO LTD

Hydraulic control device, system and method for controlling actuator device

InactiveUS20050077394A1Improve controllabilitySuppress mutationElectrical controlSpray nozzlesEngineeringActuator

A supplying unit supplies energy to an actuator so that the supplied energy is kept therein, making displacement the actuator. An interrupting unit interrupts the supply of energy to cause the actuator to discharge the kept energy, making displacement the actuator. A converting unit is adapted to convert the displacement of the actuator corresponding to the kept energy into hydraulic pressure applied to the valve member, moving the valve member to open the low pressure port and close the high pressure port. The convert unit converts the displacement of the actuator corresponding to the discharged energy into hydraulic pressure applied to the valve member, moving the valve member to open the high pressure port and close the low pressure port. Energy which the actuator requires to move the valve member so as to close the high pressure port is larger than energy which the actuator requires to move the valve member so as to open the low pressure port.

Owner:DENSO CORP

Fluid control valve

InactiveUS20040060998A1Reduce in quantityGood radial centeringOperating means/releasing devices for valvesMovable spraying apparatusFluid controlPiezoelectric actuators

The present invention relates to a valve for controlling fluids, which includes a valve member (4) that is actuatable via a piezoelectric actuator (2) and a hydraulic booster (3). The valve further includes a holder (6), a valve piece (7), a shim (8), and a nozzle body (9). The valve piece (7), the shim (8), and the nozzle body (9) are joined together via at least two screws (13), and the screws (13) are disposed radially to a center axis (M-M) of the valve. This makes both a simple design of the valve and economical assembly possible.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com