Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3642results about "Low pressure fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

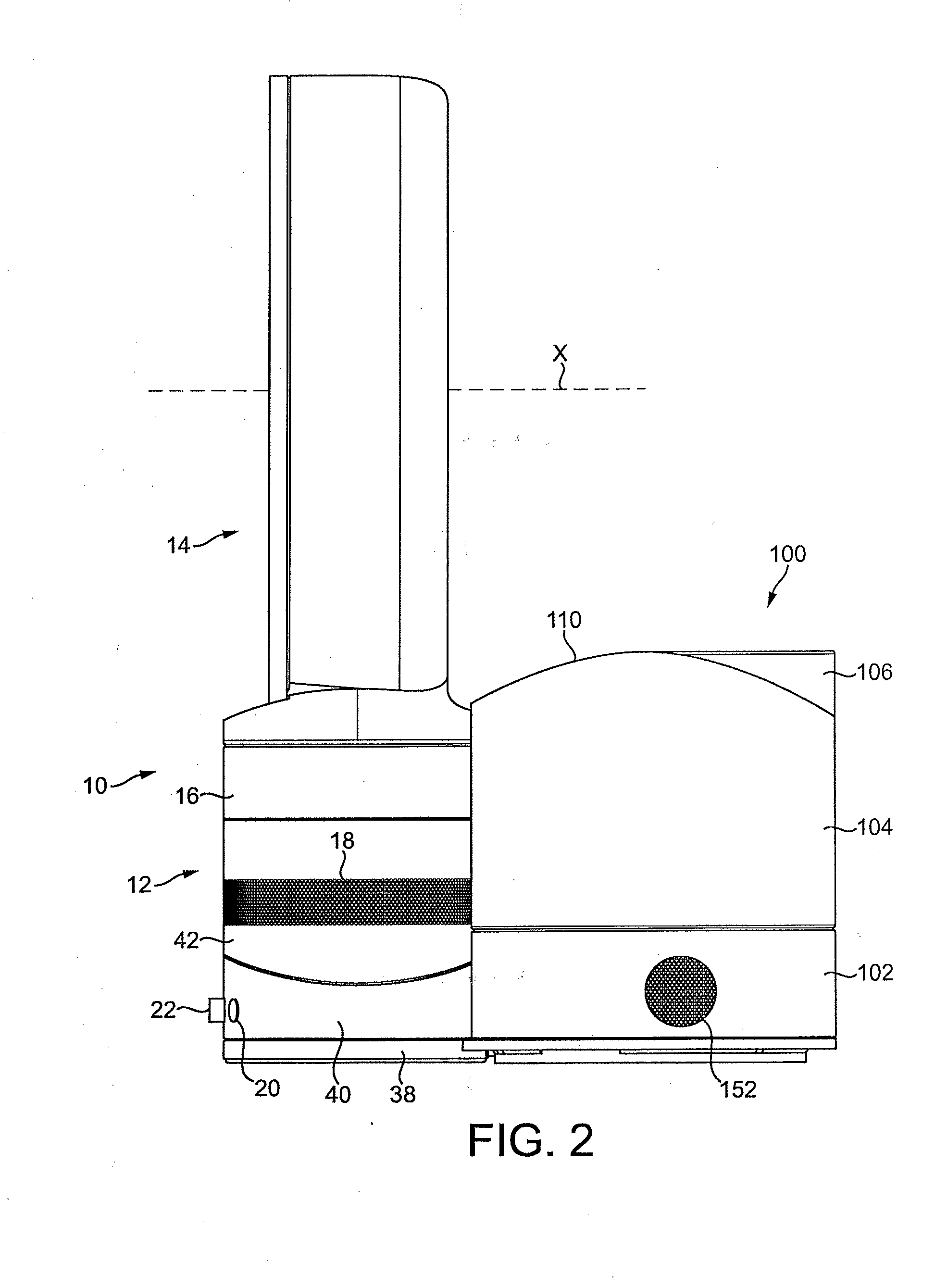

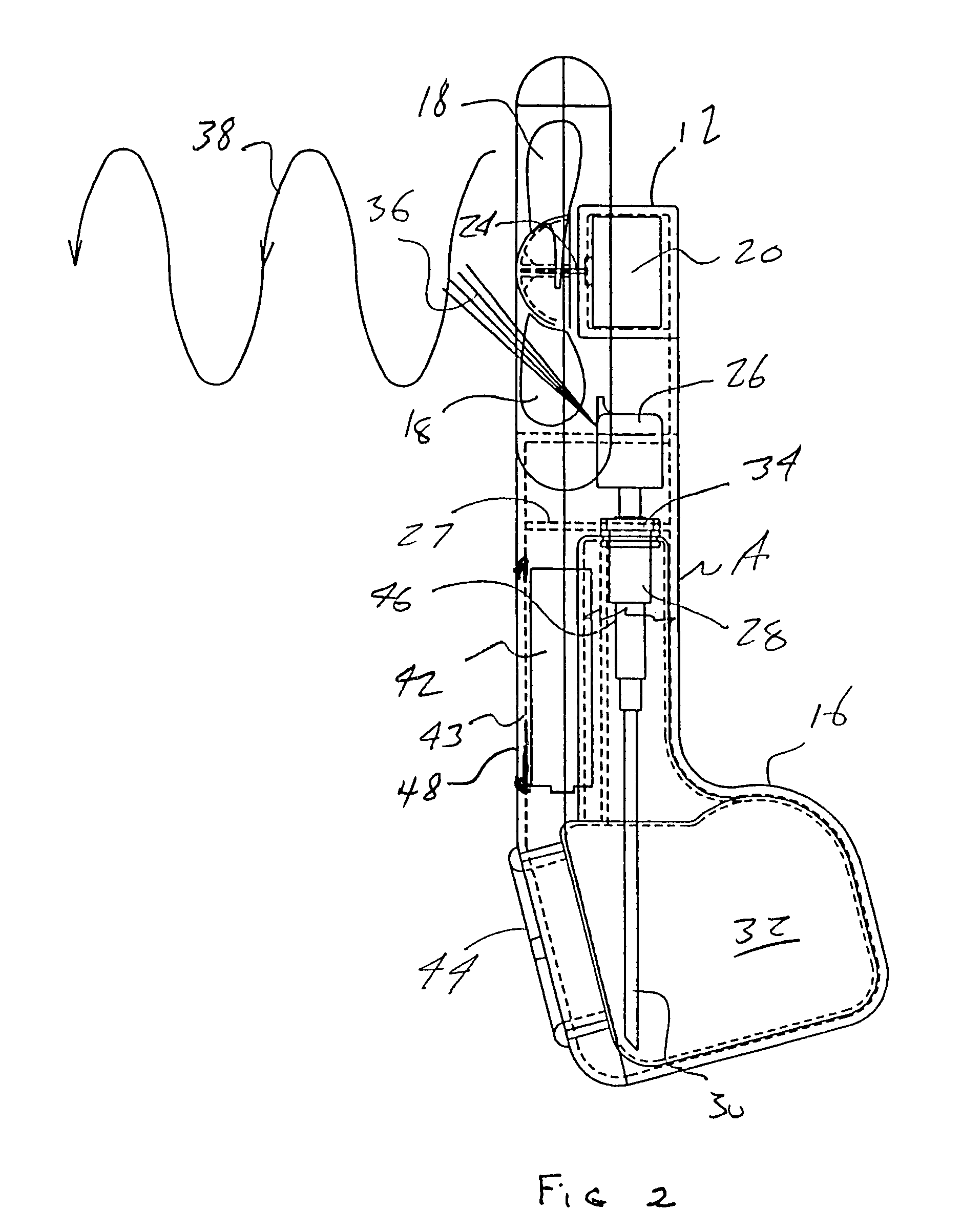

Artificial smoke cigarette

InactiveUS7845359B2Reduced health consequenceEasy to useRespiratorsUsing liquid separation agentUltrasonic nebulizersSmoke Emission

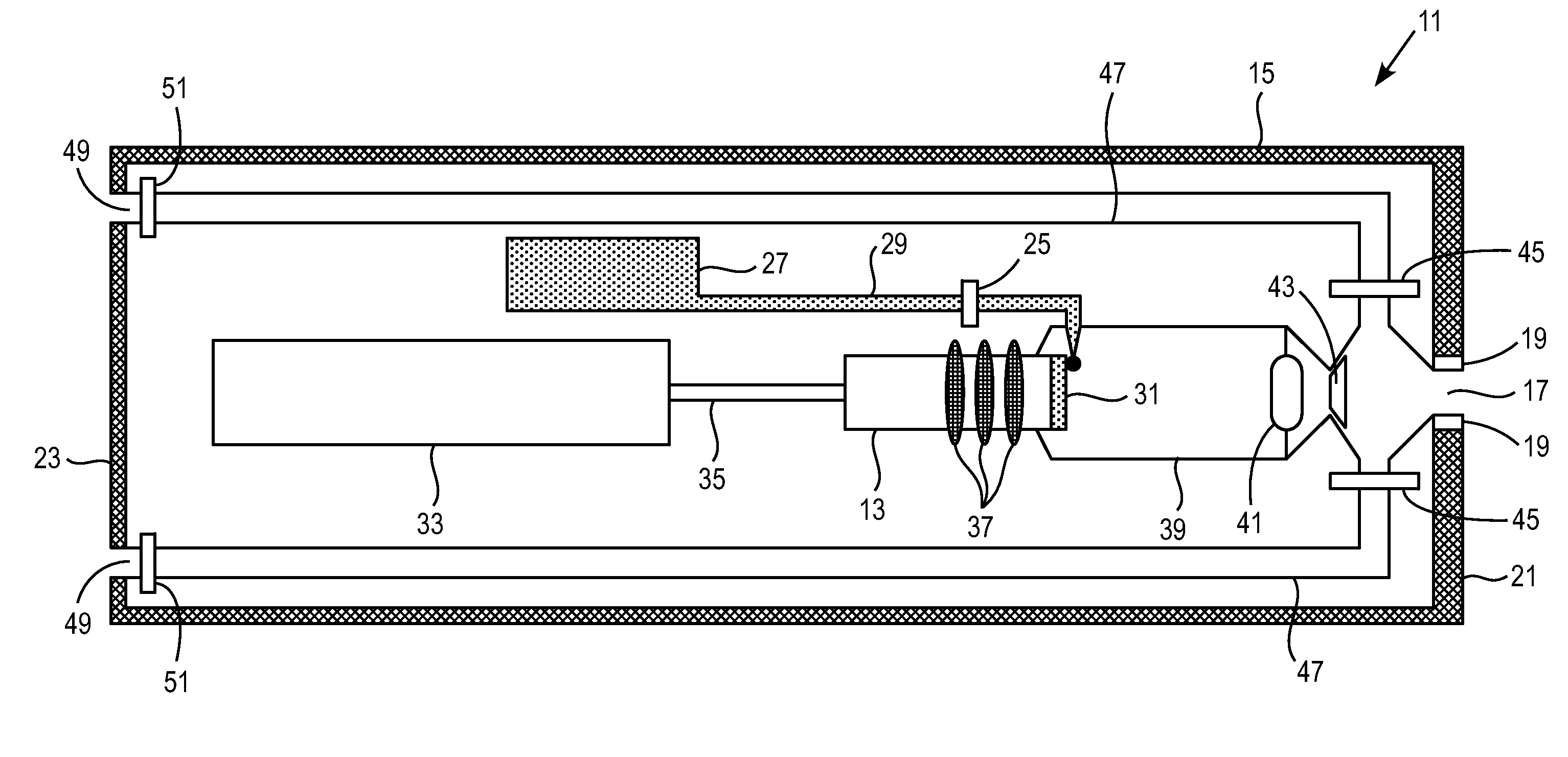

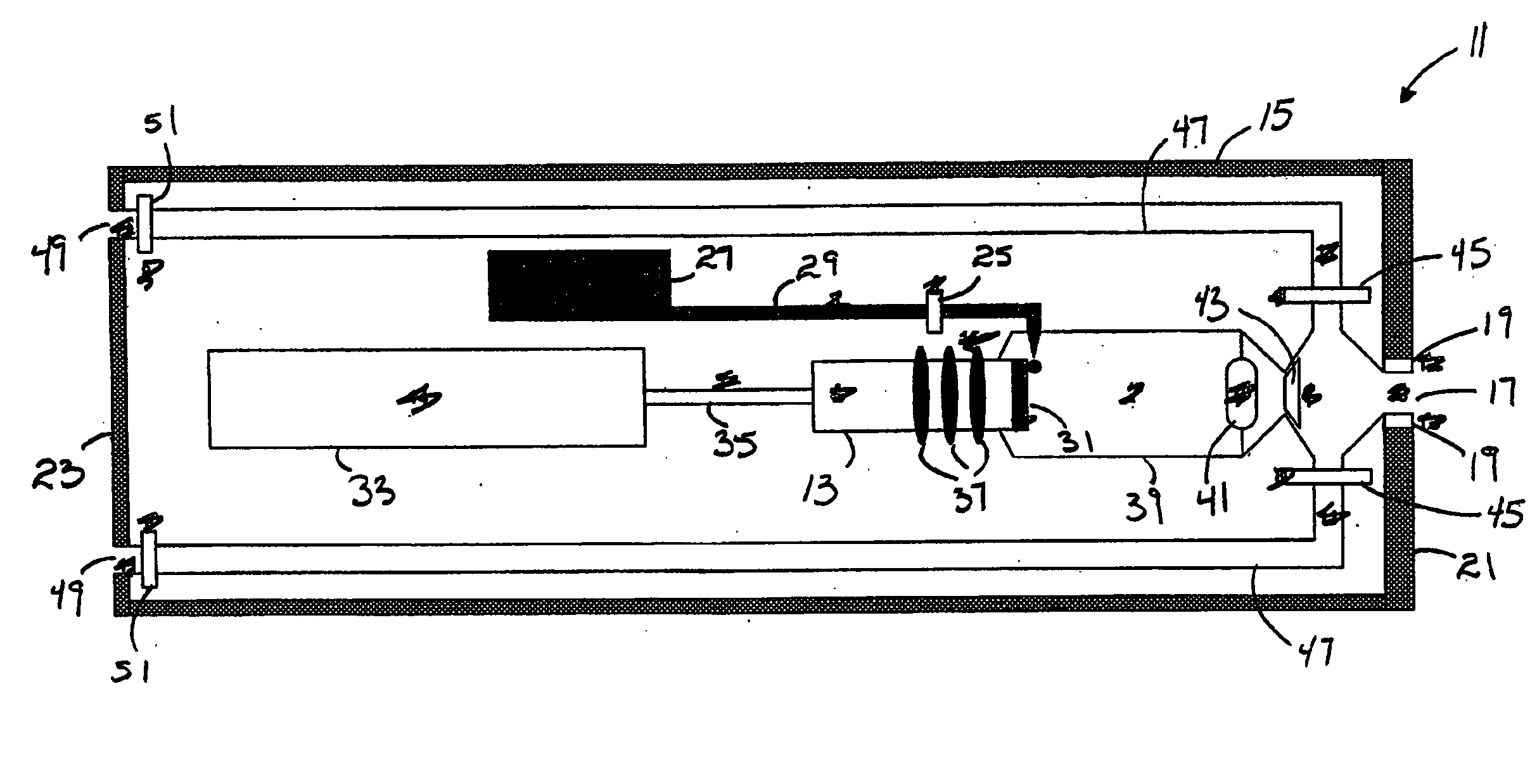

An artificial cigarette, inhaler or other nebulizer device may include a housing, an air passage into the housing, a fog generator chamber within the housing connected to the air passage, a liquid source connected to the fog generating chamber, and a fog generator within the fog generating chamber for receiving liquid from the liquid source and creating an aerosol. The fog generator may be an ultrasonic nebulizer and / or a pneumatic nebulizer.

Owner:DENAIN PIERRE +1

Artificial smoke cigarette

InactiveUS20080230052A1Reduced adverse health consequenceEasy to useRespiratorsUsing liquid separation agentUltrasonic nebulizersEngineering

An artificial cigarette, inhaler or other nebulizer device may include a housing, an air passage into the housing, a fog generator chamber within the housing connected to the air passage, a liquid source connected to the fog generating chamber, and a fog generator within the fog generating chamber for receiving liquid from the liquid source and creating an aerosol. The fog generator may be an ultrasonic nebulizer and / or a pneumatic nebulizer.

Owner:DENAIN PIERRE +1

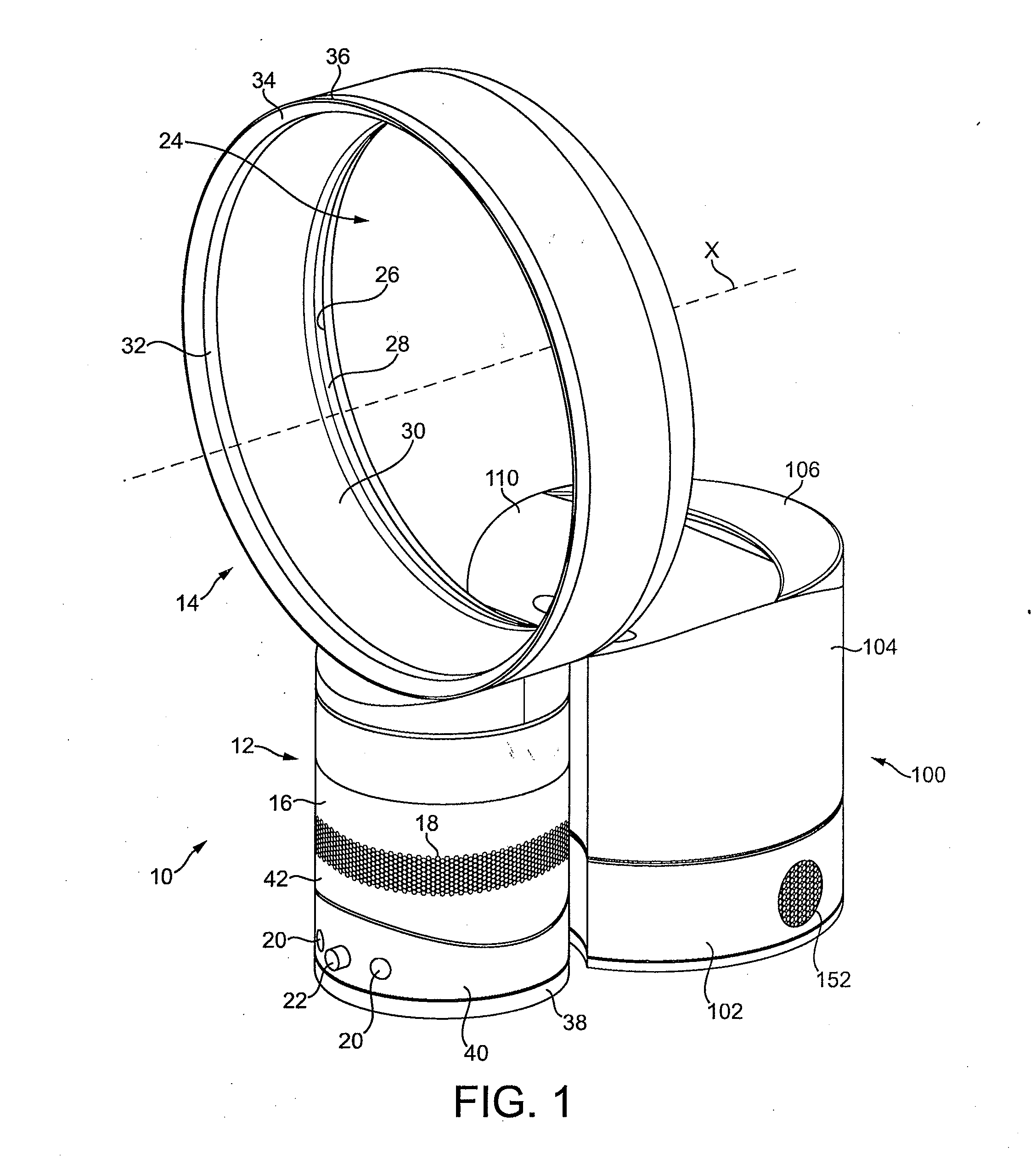

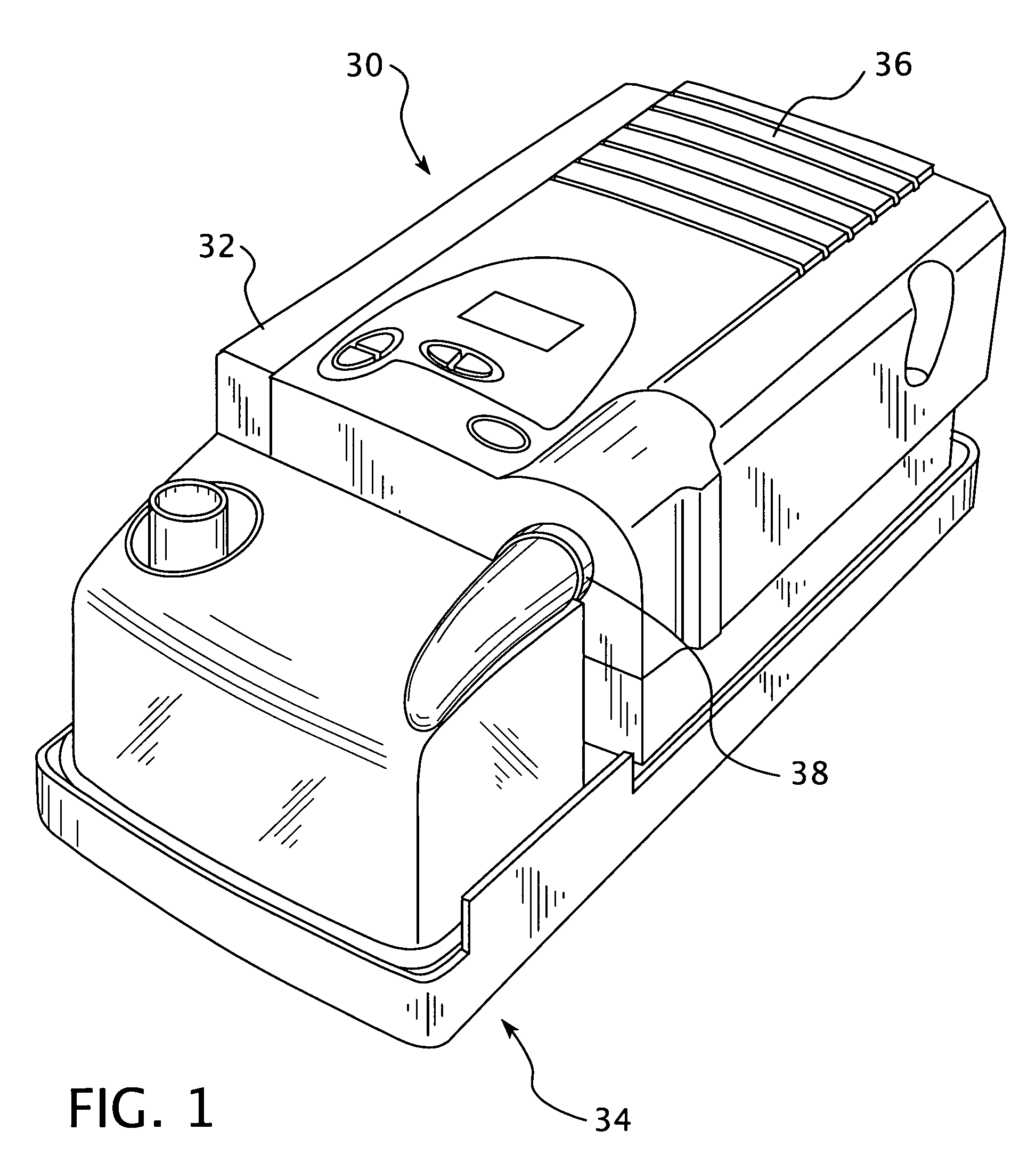

Humidifying apparatus

InactiveUS20100225012A1Rapid rise in relative humidityReduce the amount requiredFlow mixersSpace heating and ventilationEngineeringAirflow

Humidifying apparatus includes a humidifier for emitting moist air into an external environment, and a fan assembly for generating an air current within the external environment for conveying the emitted moist air away from the humidifier. The fan assembly includes a device for creating an air flow and a nozzle comprising an interior passage for receiving the air flow and a mouth for emitting the air flow. The humidifier is located behind nozzle, the nozzle extending about and defining an opening through which both air from outside the nozzle and the moist air emitted from the humidifier are drawn by the air flow emitted from the mouth.

Owner:DYSON TECH LTD

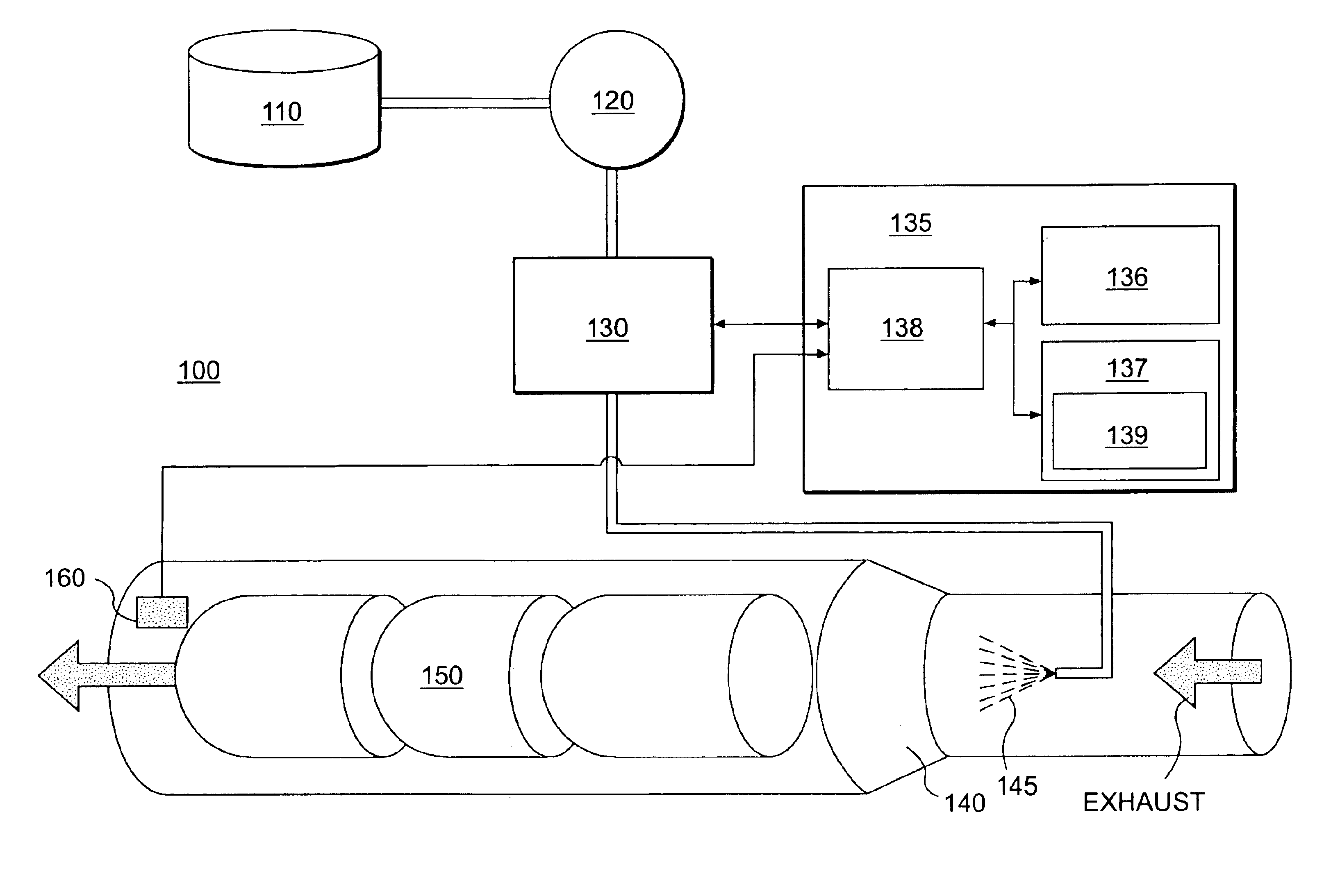

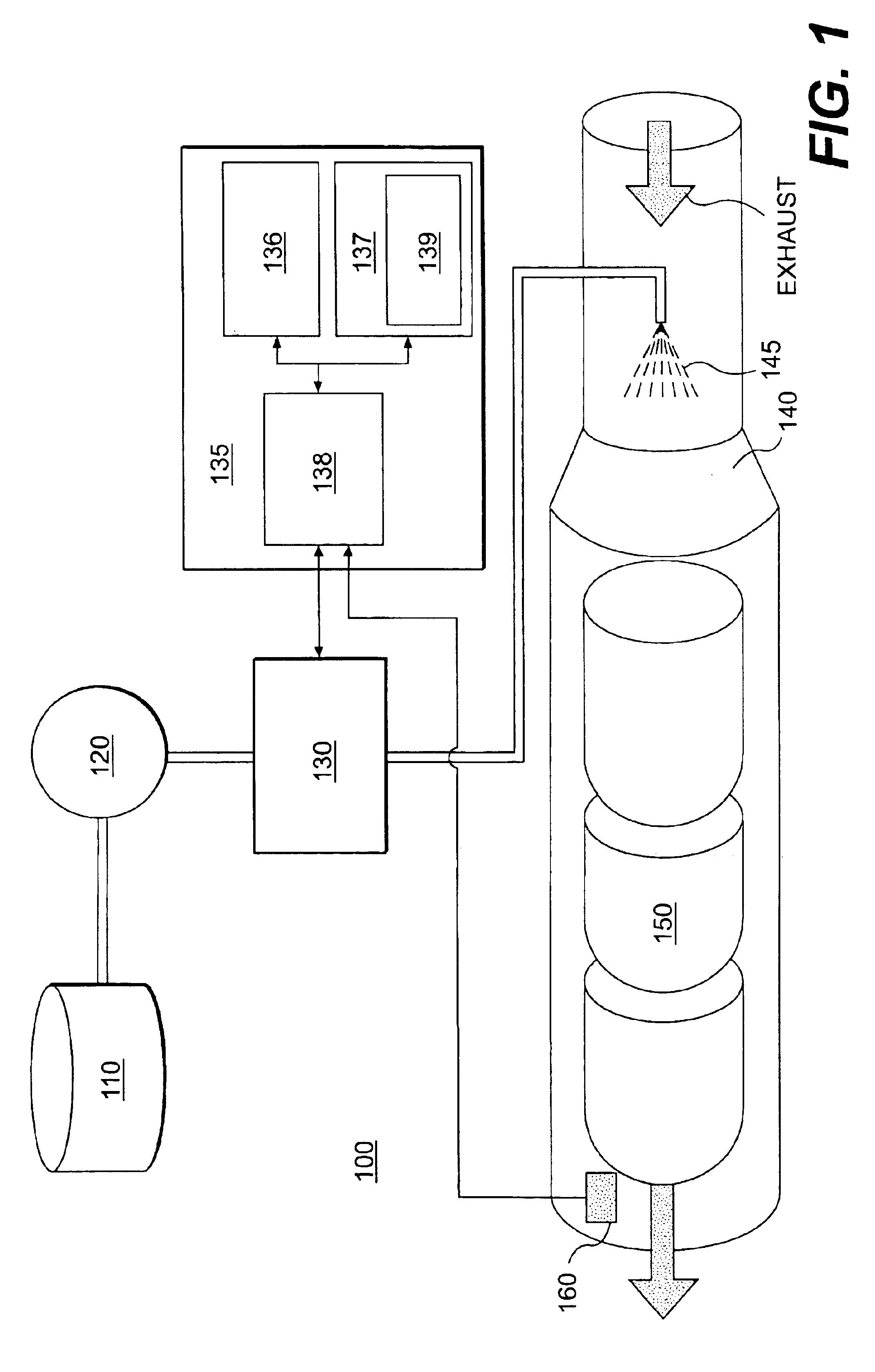

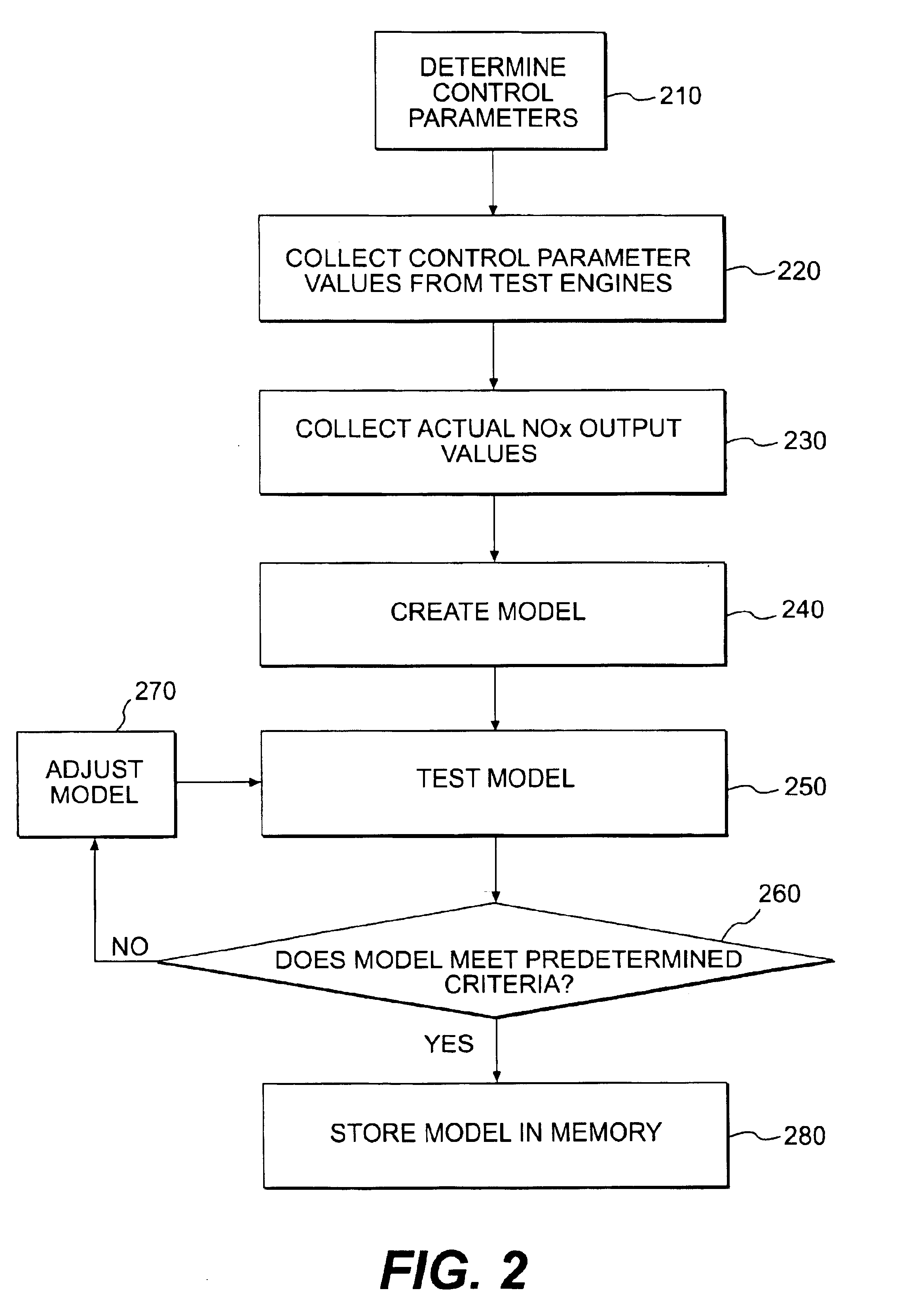

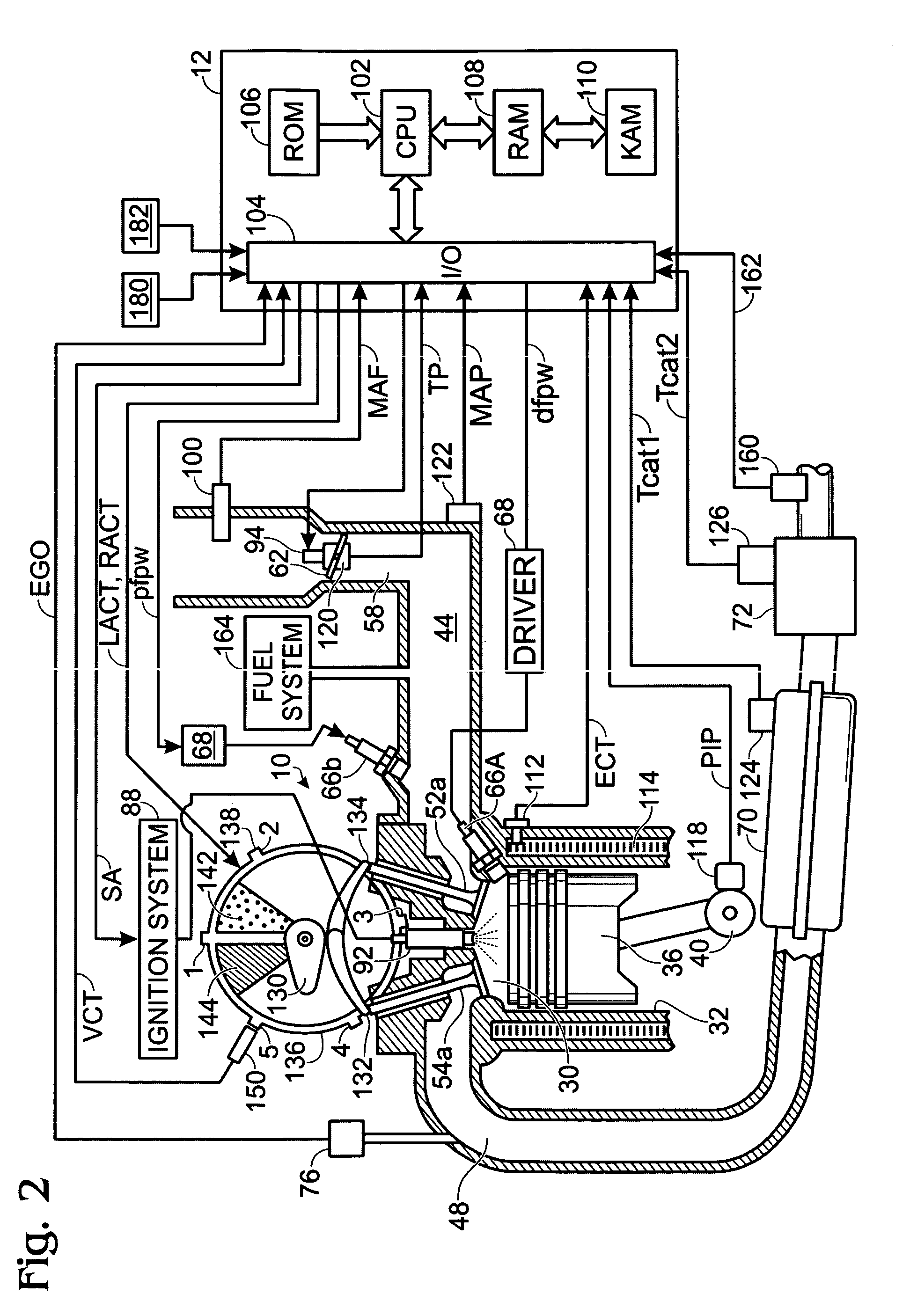

NOx emission-control system using a virtual sensor

InactiveUS6882929B2Reduce nitrogen oxide emissionsInternal combustion piston enginesDigital data processing detailsAmbient humidityControl system

A method and system may be provided to perform a process for controlling NOx emissions of an target engine. In one embodiment of the invention, the process may include determining predicted NOx values based on a model reflecting a predetermined relationship between control parameters and NOx emissions, wherein the control parameters include ambient humidity, manifold pressure, manifold temperature, fuel rate, and engine speed associated with the engine. Further, the process may include adjusting the model based on a determination of whether the predicted NOx values meet a predetermined criteria associated with actual NOx values. The adjusted model may be stored in a memory associated with the engine whereby NOx emissions exhausted from the engine may be reduced based on virtual NOx emission values determined from the adjusted model.

Owner:CATERPILLAR INC

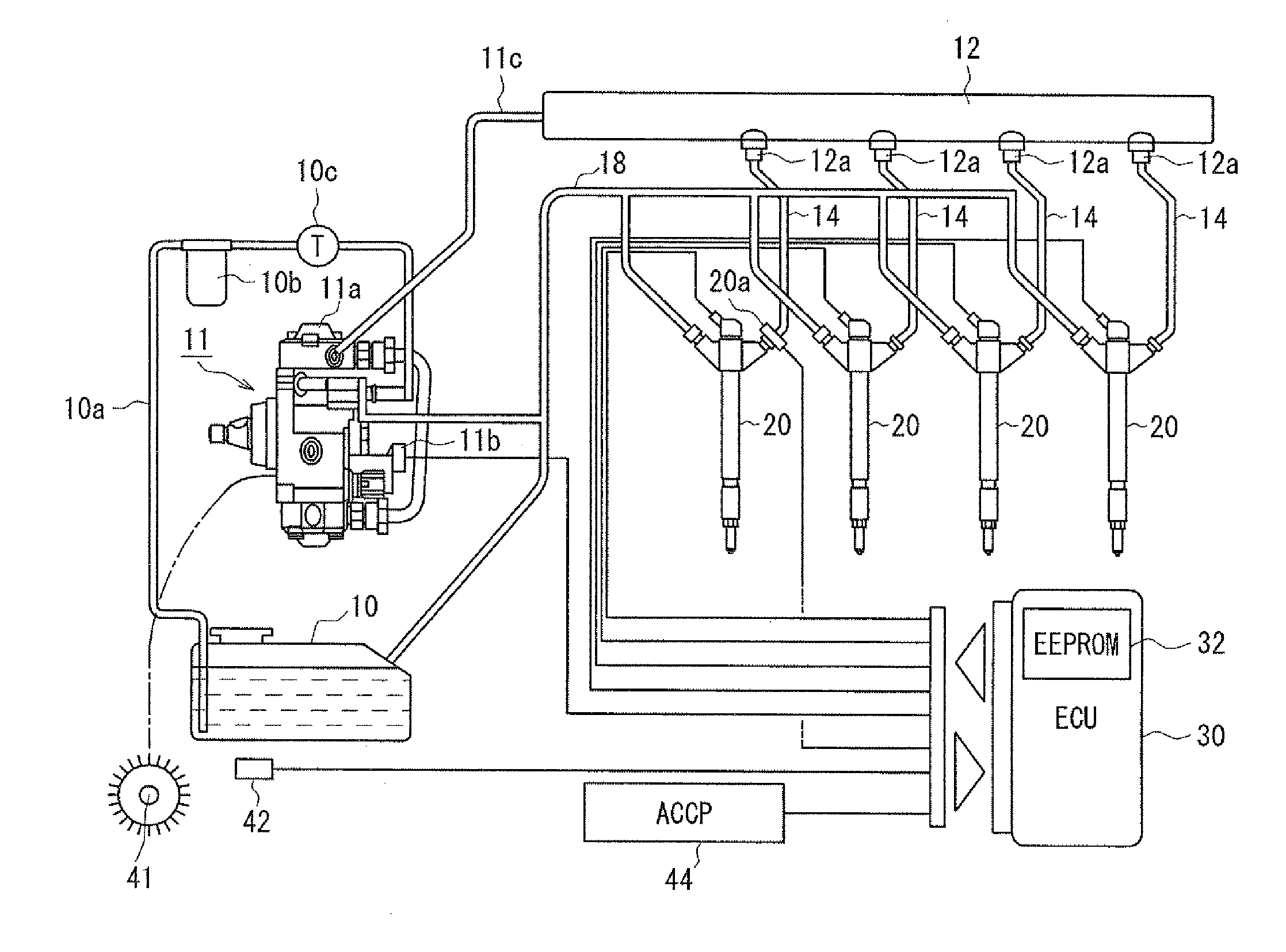

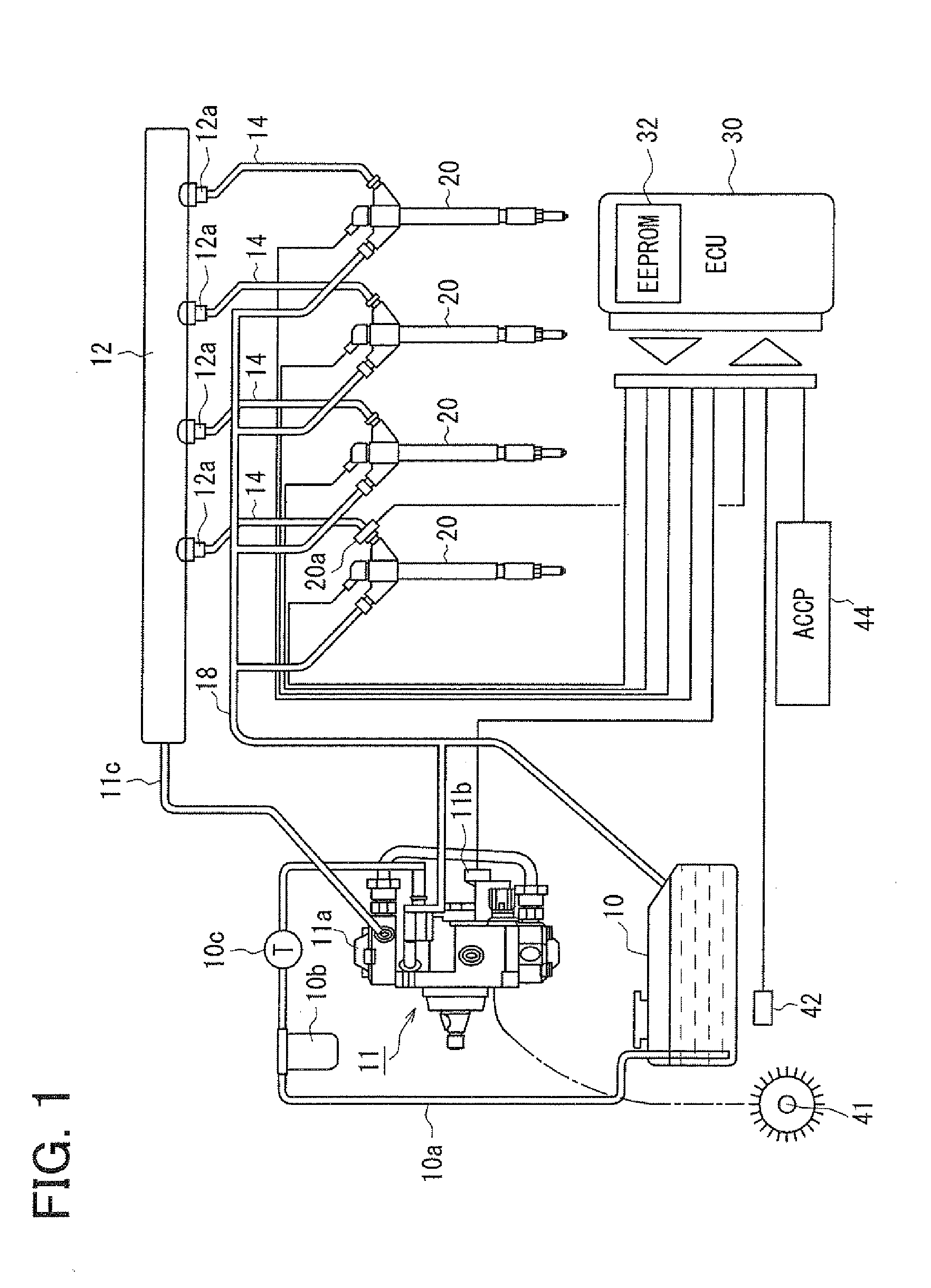

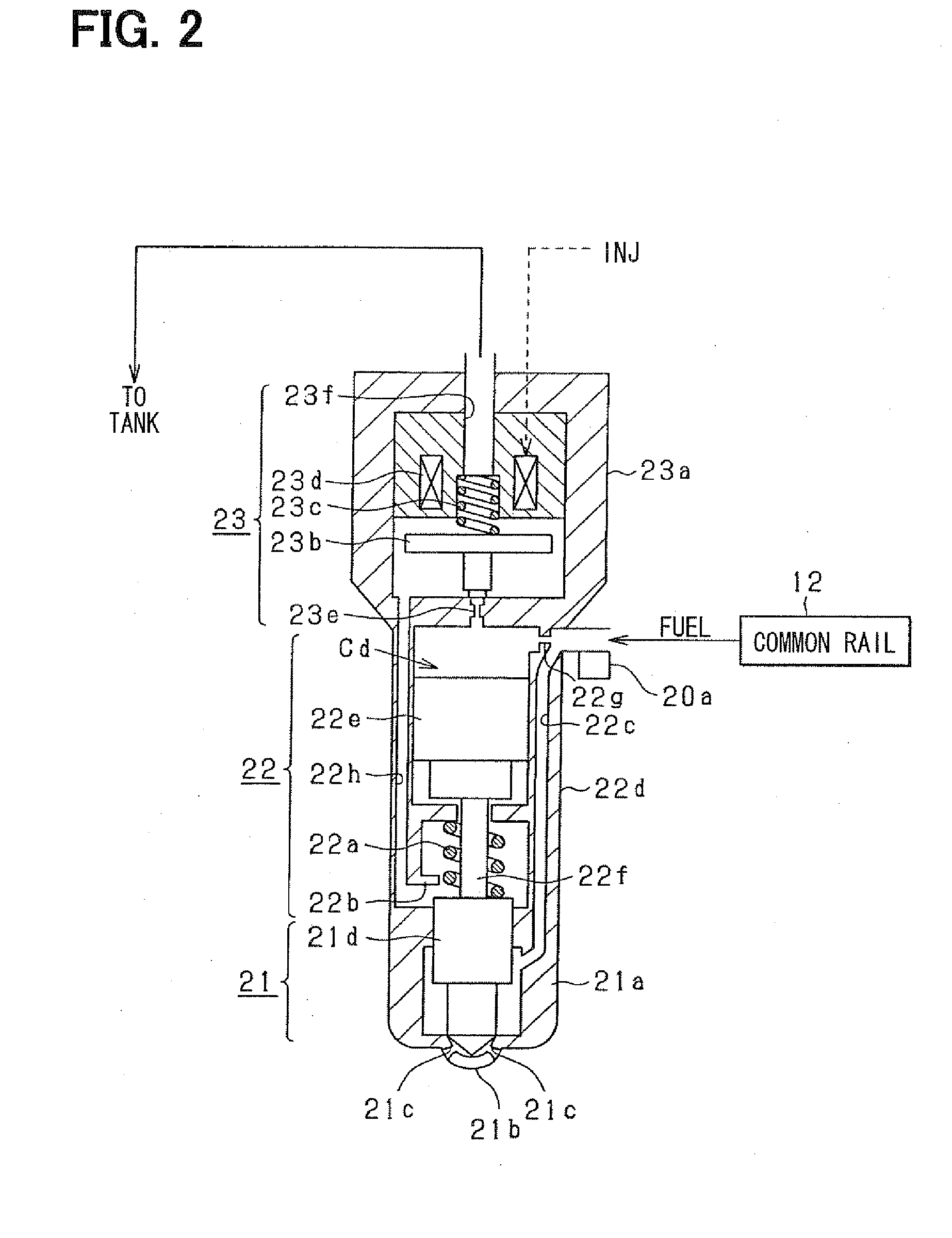

Fuel injection device and adjustment method thereof

ActiveUS20080228374A1Improve accuracyAccurate inductionInternal-combustion engine testingElectrical controlCommon railForce sensor

A fuel injection device (fuel supply system) of a common rail type fuel injection system for an engine includes a pressure sensor disposed in a fuel inlet of an injector for measuring a fuel pressure at a position where the sensor is disposed and an ECU for sensing various kinds of pressure fluctuations associated with the injection including a pressure leak due to an injection operation of the injector and waving characteristics due to actual injection thereof based on sensor outputs from the pressure sensor. The ECU serially obtains the sensor outputs from the pressure sensor at intervals of 20 μsec.

Owner:DENSO CORP

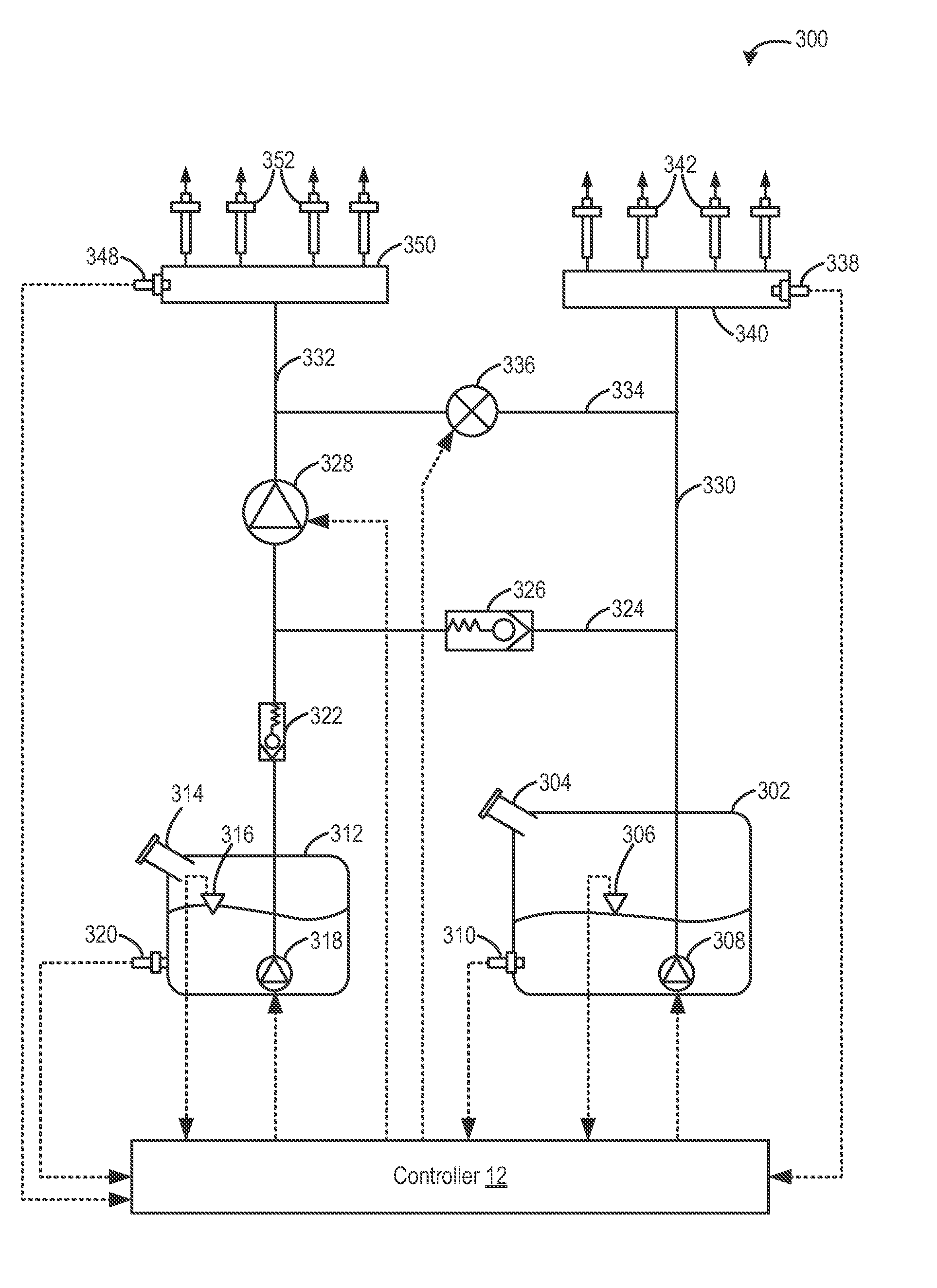

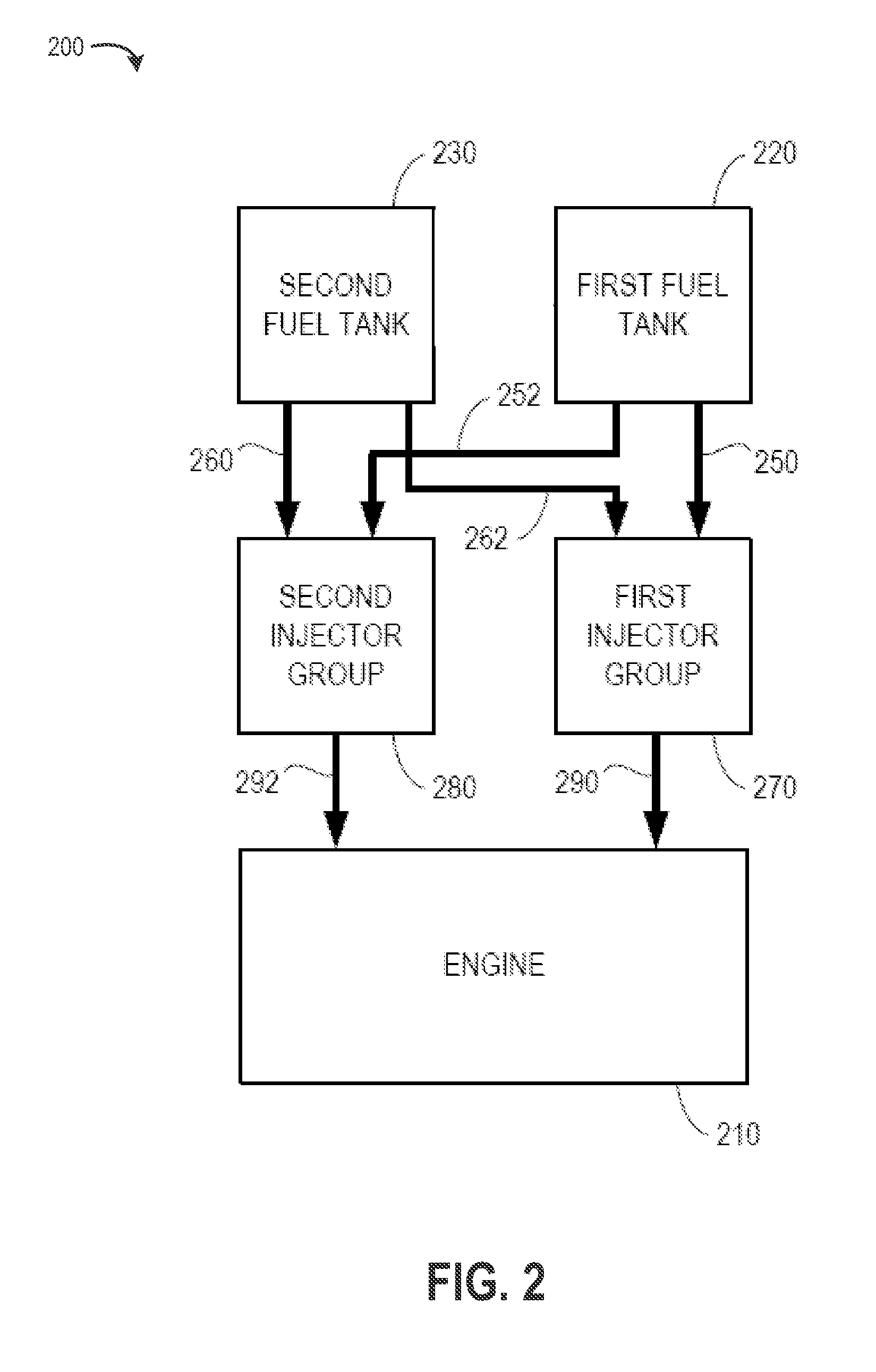

Fuel system for a multi-fuel engine

InactiveUS20120048242A1Reducing high pressure pump degradationReduce degradationElectrical controlInternal combustion piston enginesFuel typeHigh pressure

Methods and systems are provided for operating an engine fuel system including fuels of different fuel types. A first fuel type is delivered for port injection upon circulation through a high pressure pump when direct injection of a fuel is not requested to cool and / or lubricate the high pressure pump.

Owner:FORD GLOBAL TECH LLC

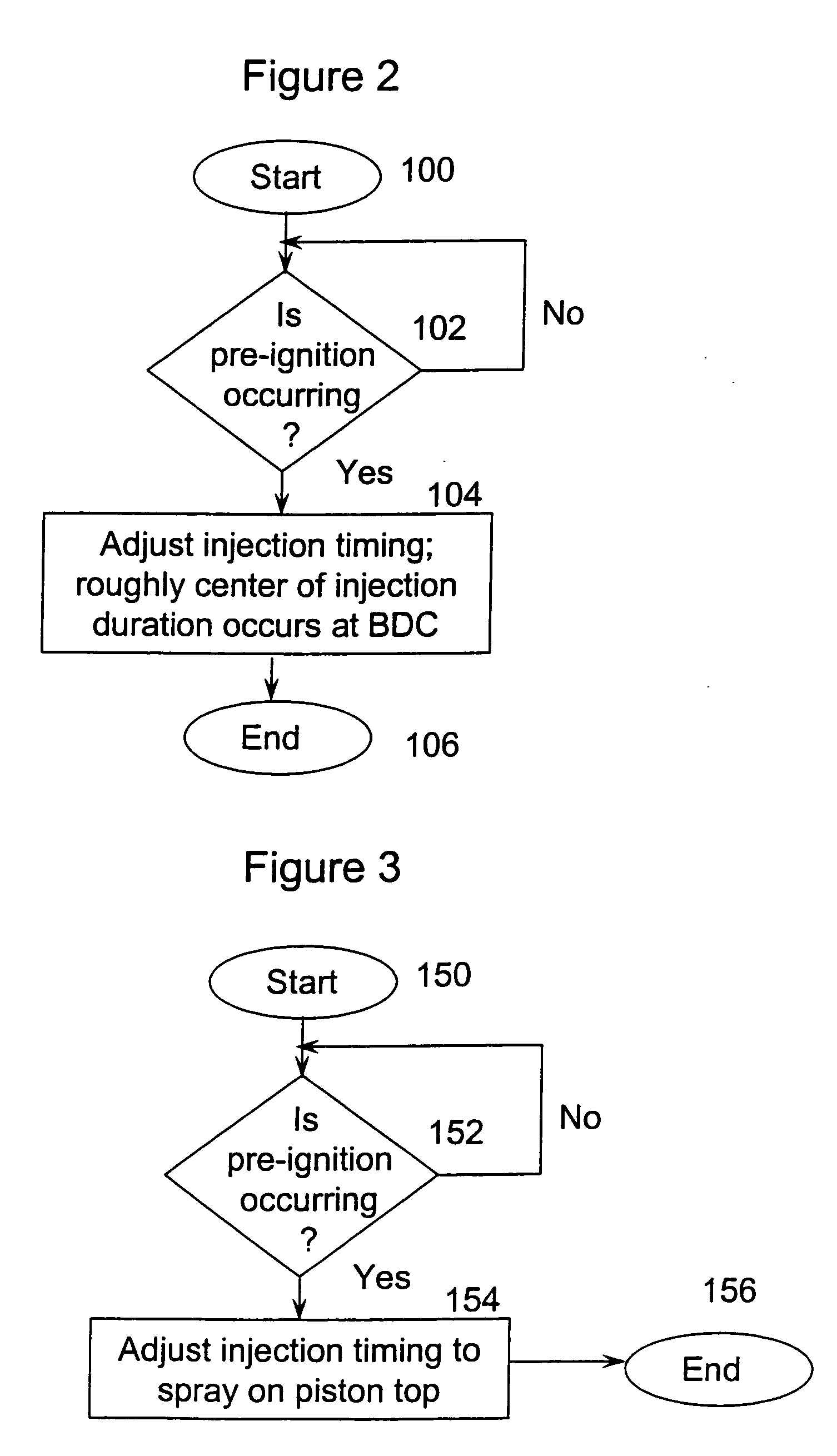

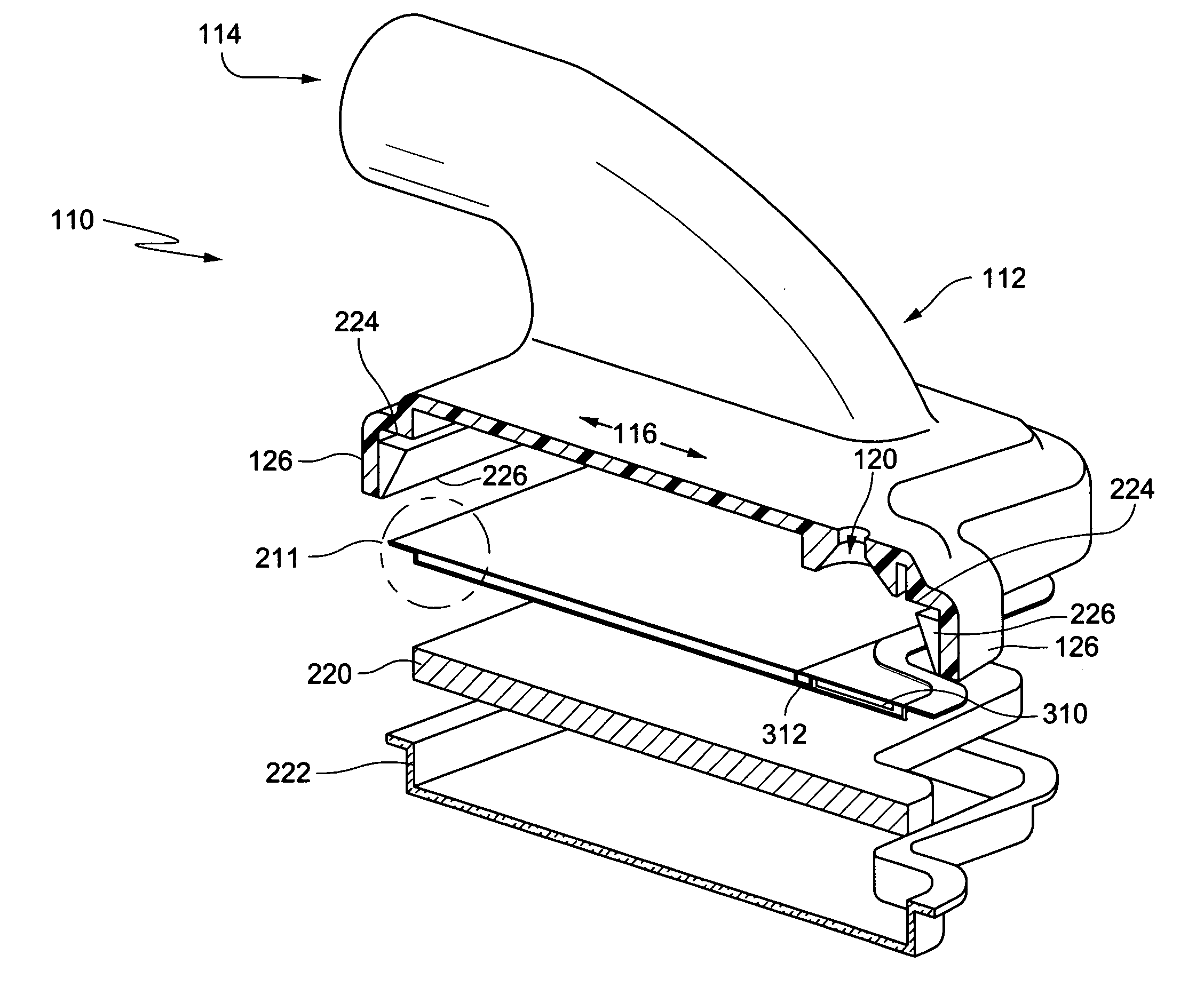

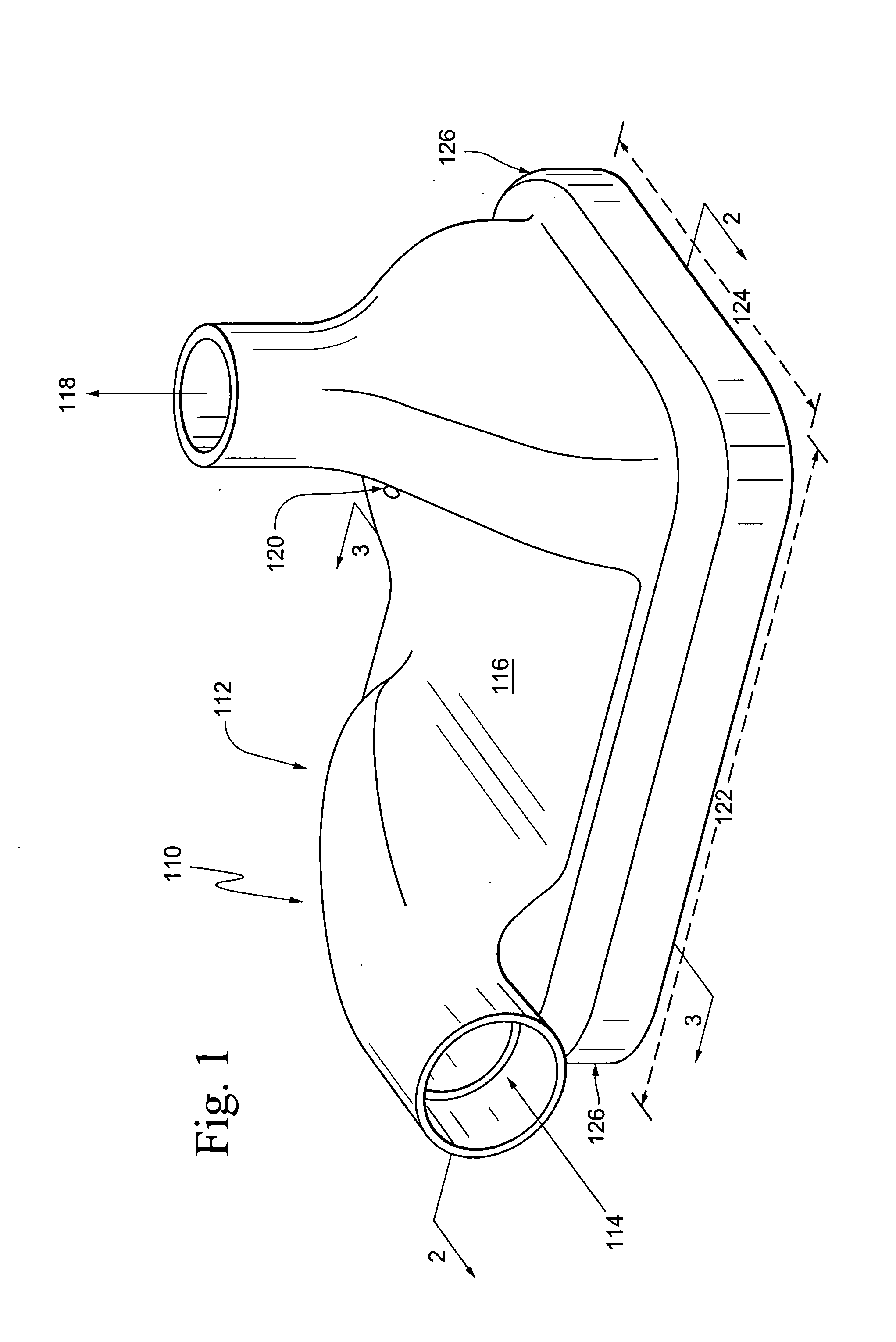

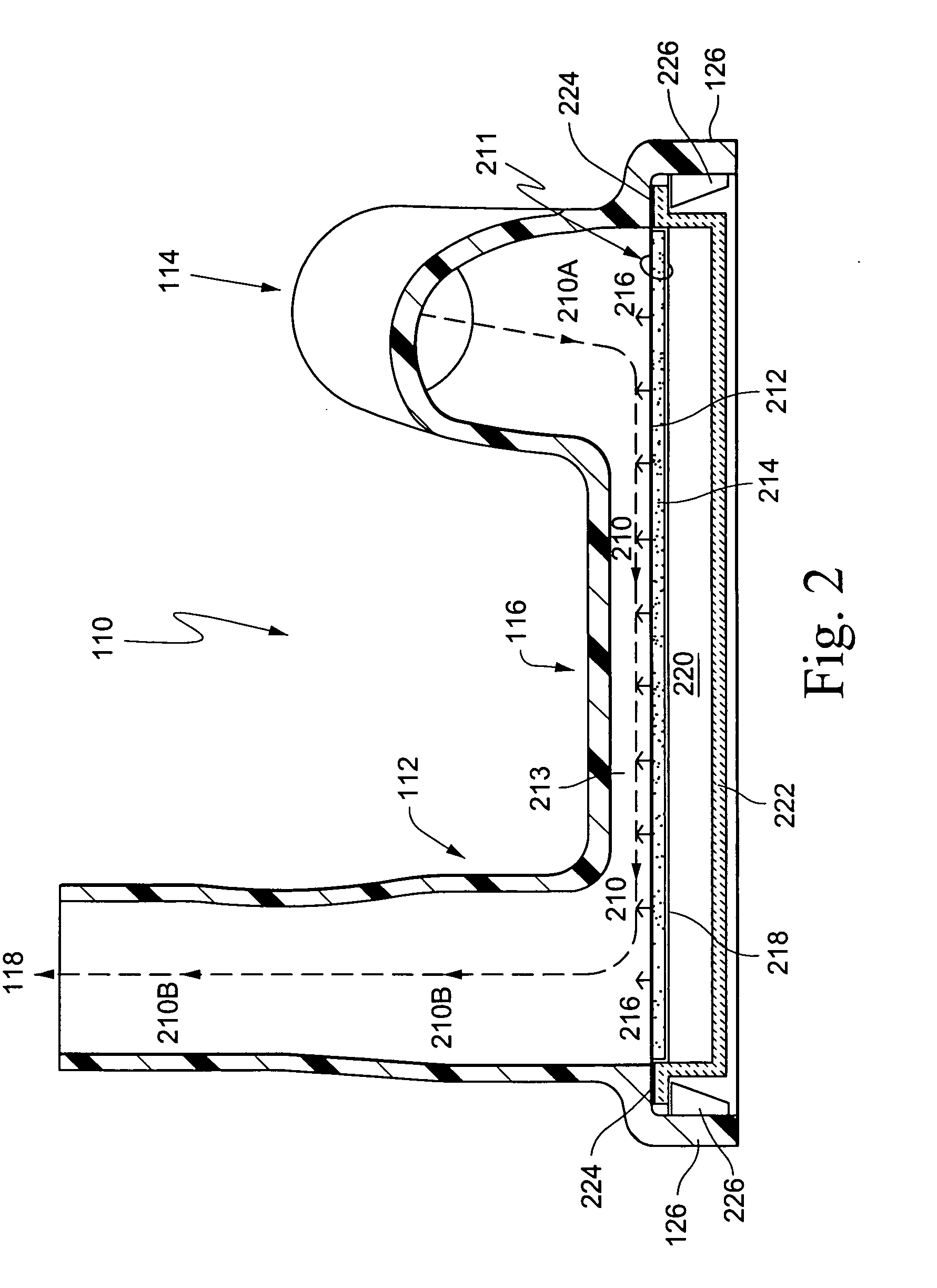

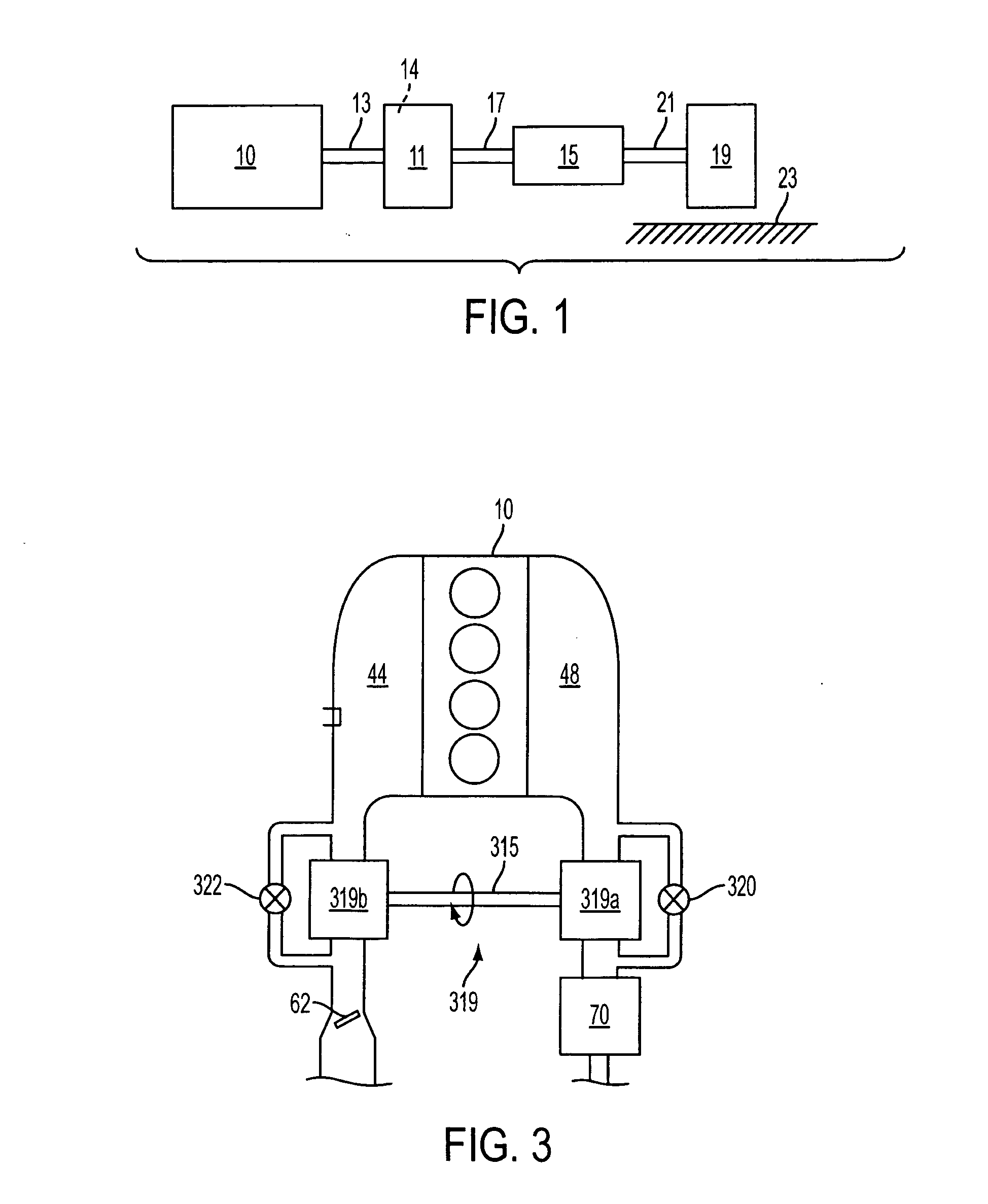

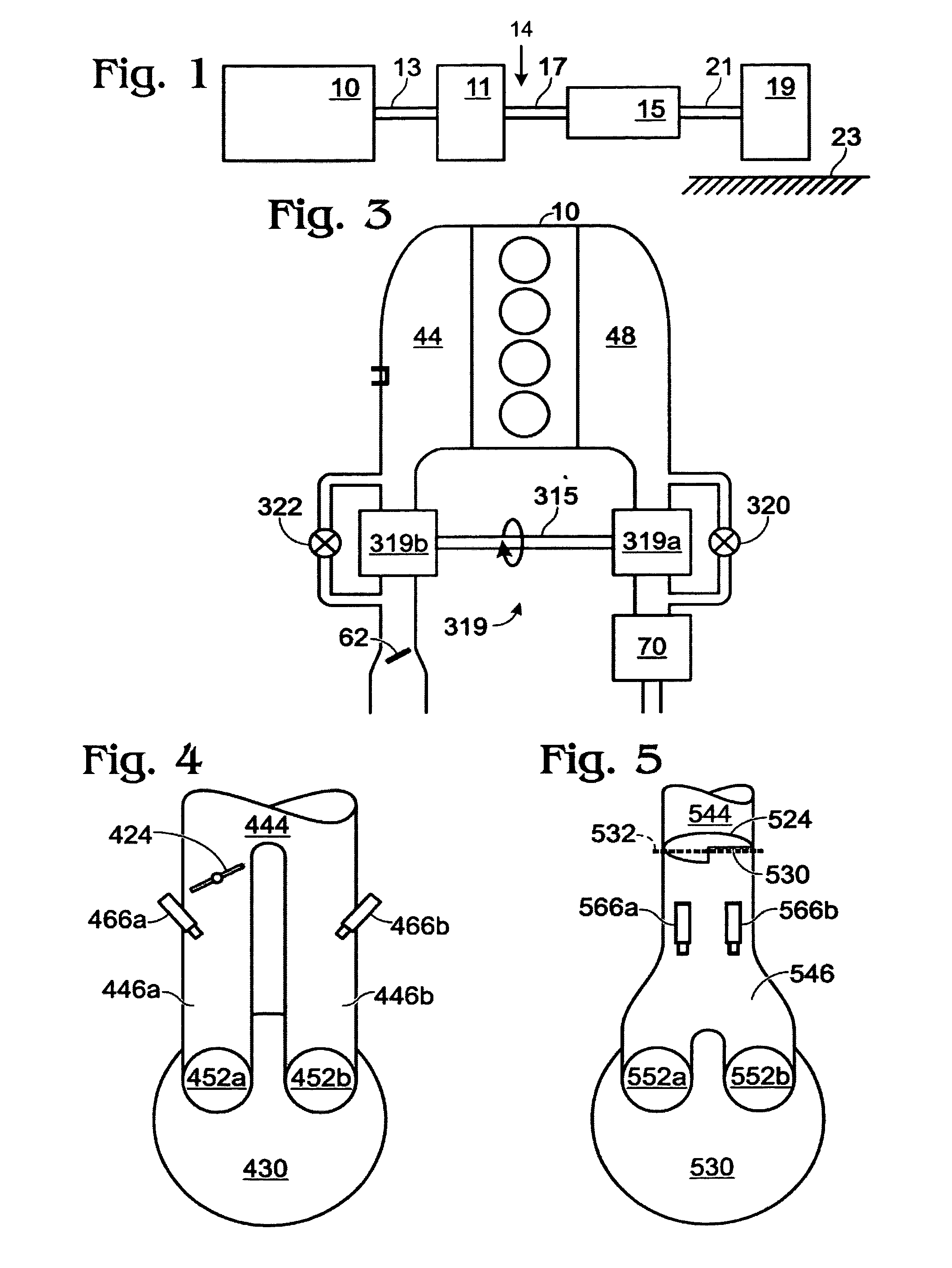

System and method to pre-ignition in an internal combustion engine

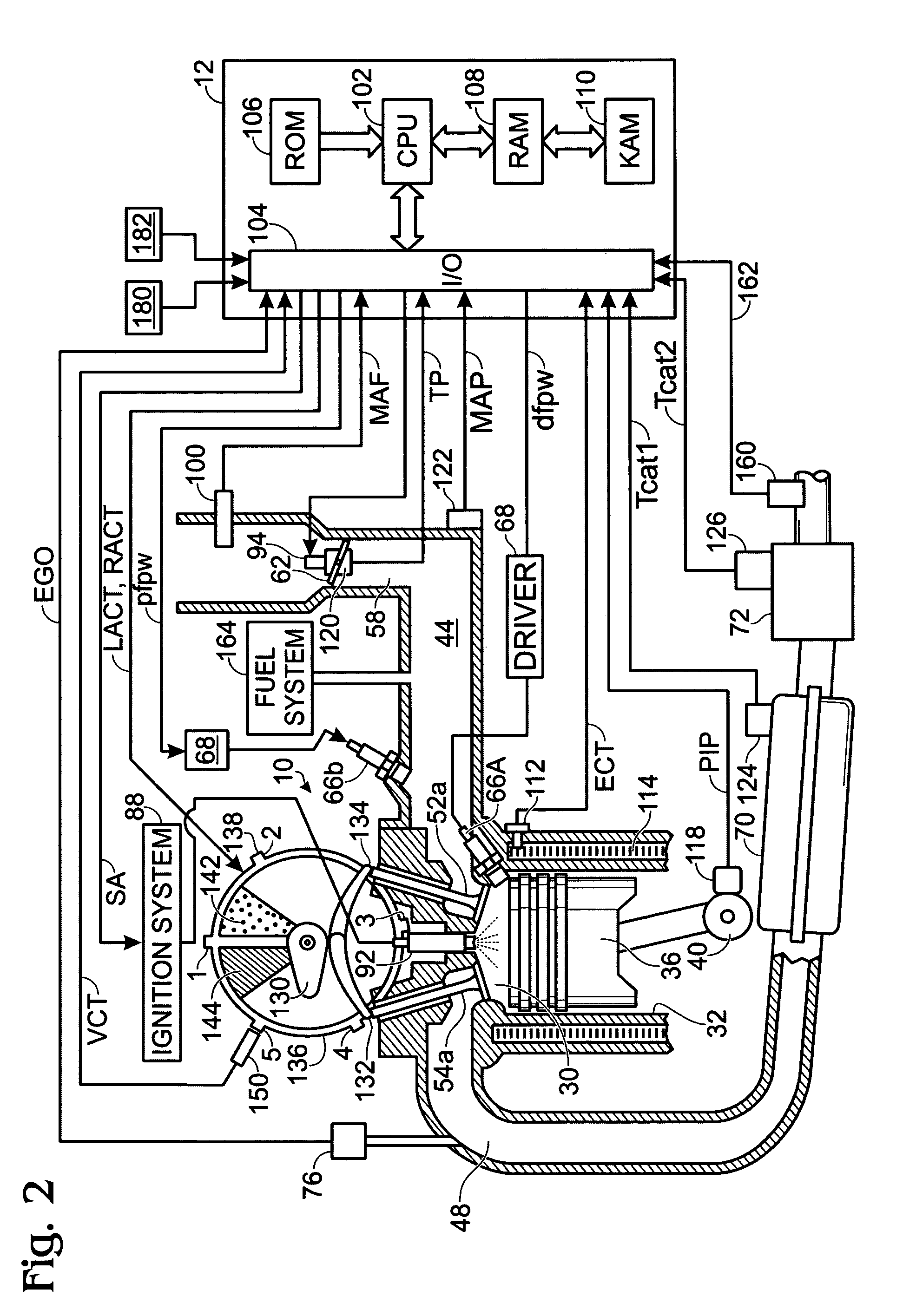

ActiveUS7178503B1Mitigate pre-ignitionReduce air densityAnalogue computers for vehiclesElectrical controlCombustion chamberAlcohol fuel

An engine system and method are disclosed for controlling pre-ignition of an alcohol fuel. In one embodiment, the fuel injection timing is adjusted to cause the fuel to avoid combustion chamber surfaces. In another embodiment, the fuel injection timing is adjusted to spray the fuel directly onto the piston surface to cool the piston. Also disclosed is a cylinder cleaning cycle in which engine knock is purposely caused for one to hundreds of engine cycles by adjusting the fuel content away from alcohol toward gasoline. Further measures to cause knock which are disclosed: adjusting spark timing, intake boost, exhaust gas fraction in the cylinder, cam timing, and transmission gear ratio.

Owner:FORD GLOBAL TECH LLC

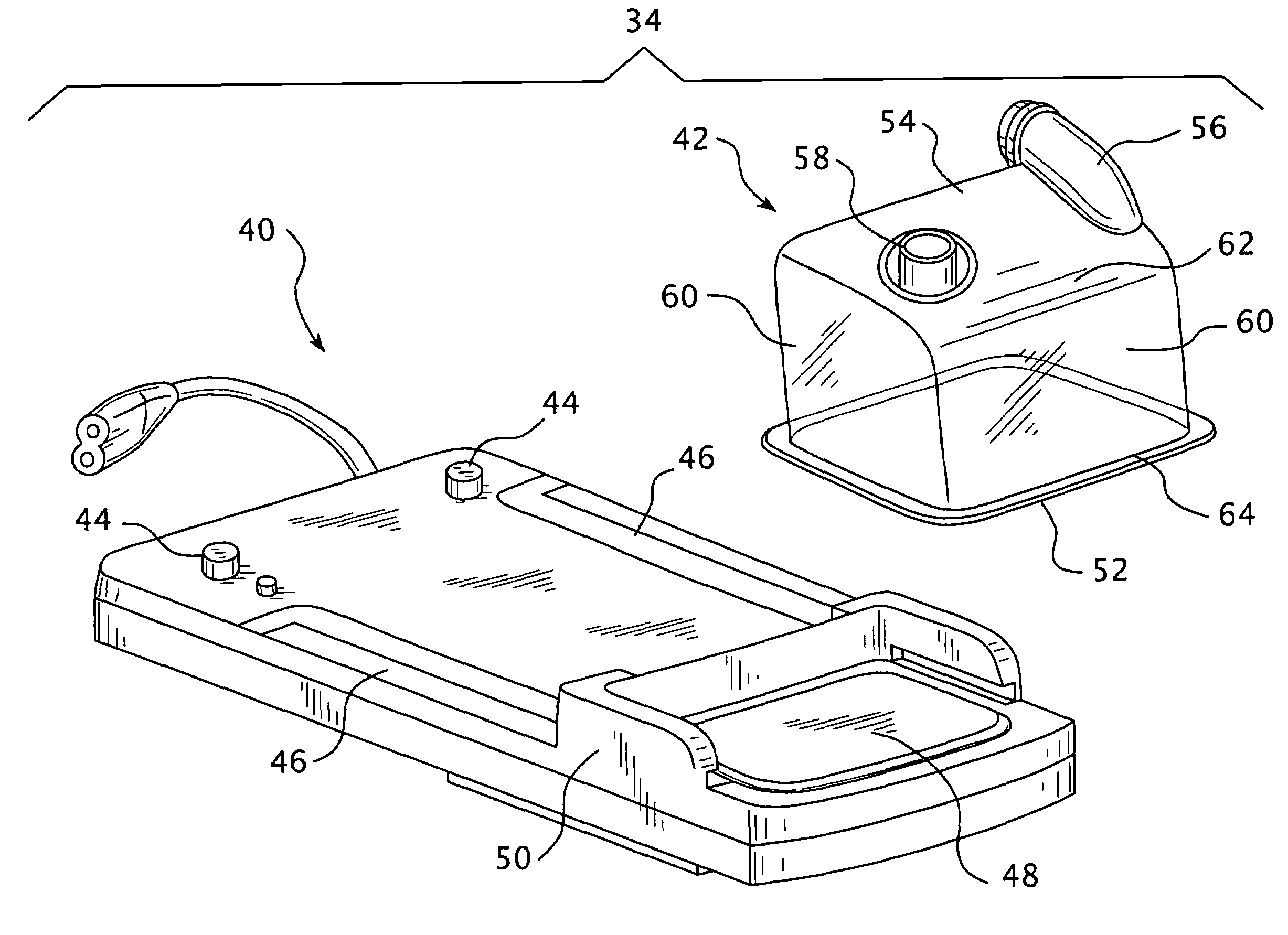

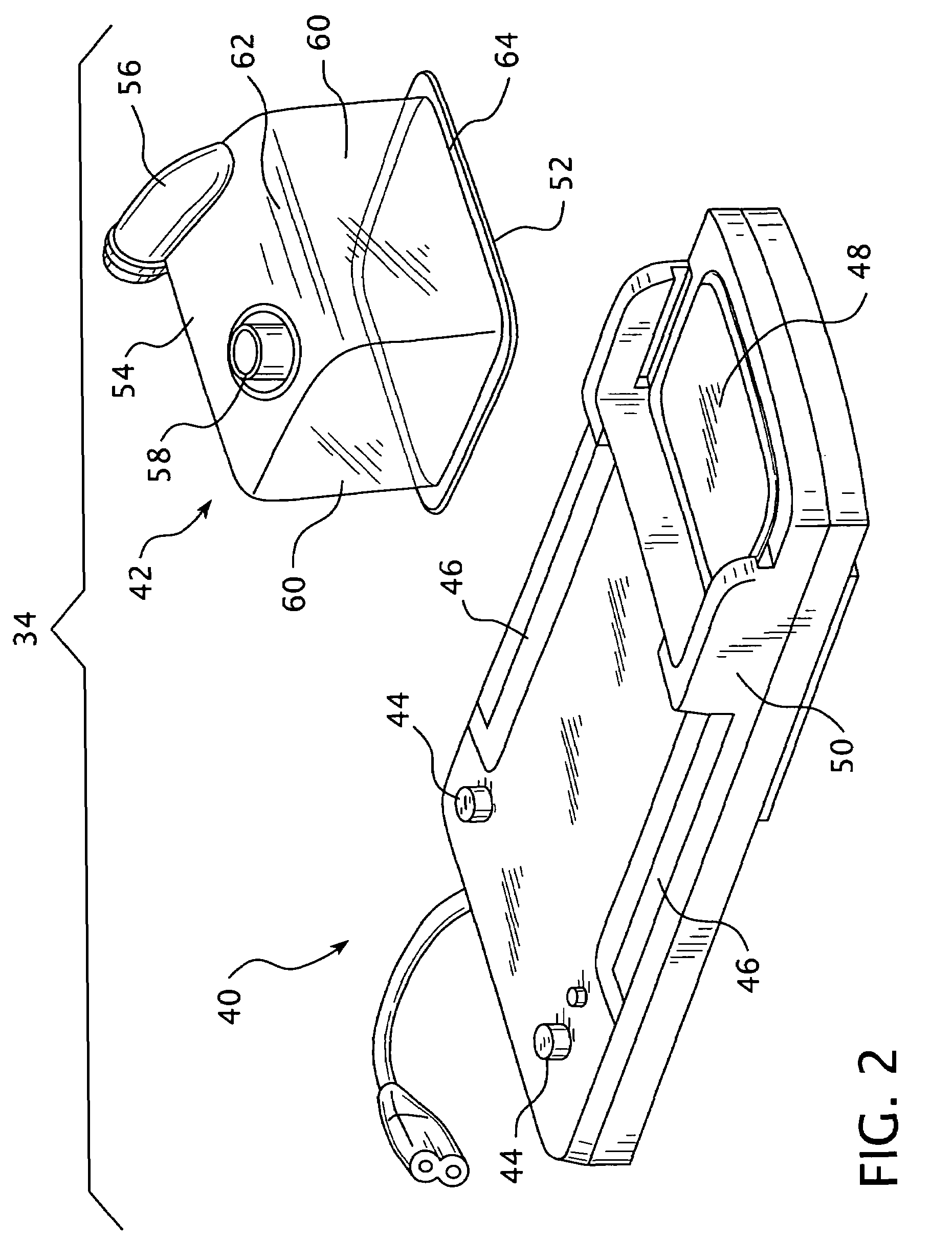

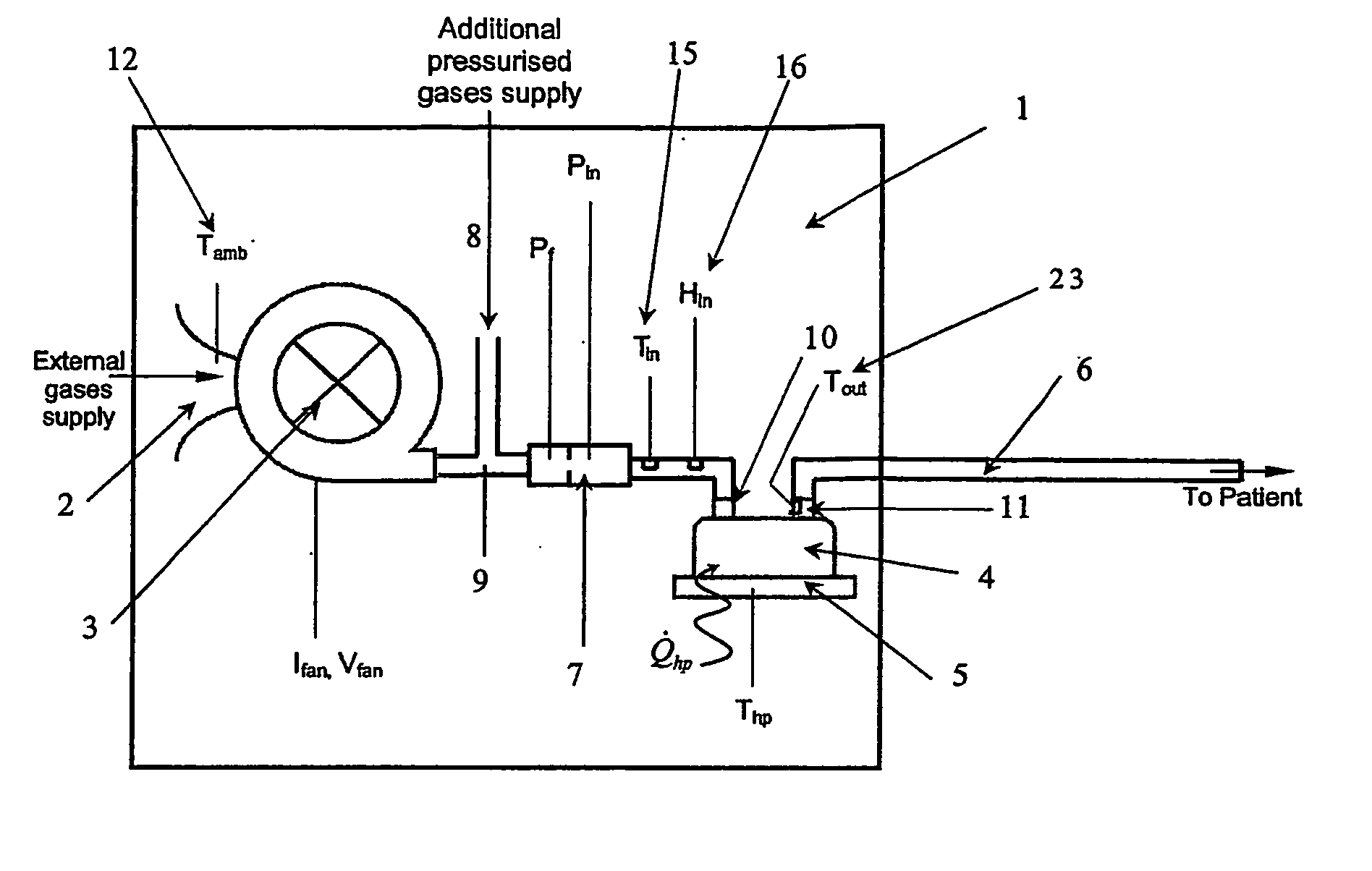

Removable and/or replaceable humidifier

ActiveUS20090000620A1Improved vaporizationUsing liquid separation agentMedical devicesWater vaporEngineering

Humidifier apparatus for a respiratory apparatus includes a housing providing a gas flow path, a heater apparatus, and a water supply distribution member configured and arranged to deliver water vapour to the gas flow path. The water distribution member is provided to the housing and in thermal communication with the heater apparatus.

Owner:RESMED LTD

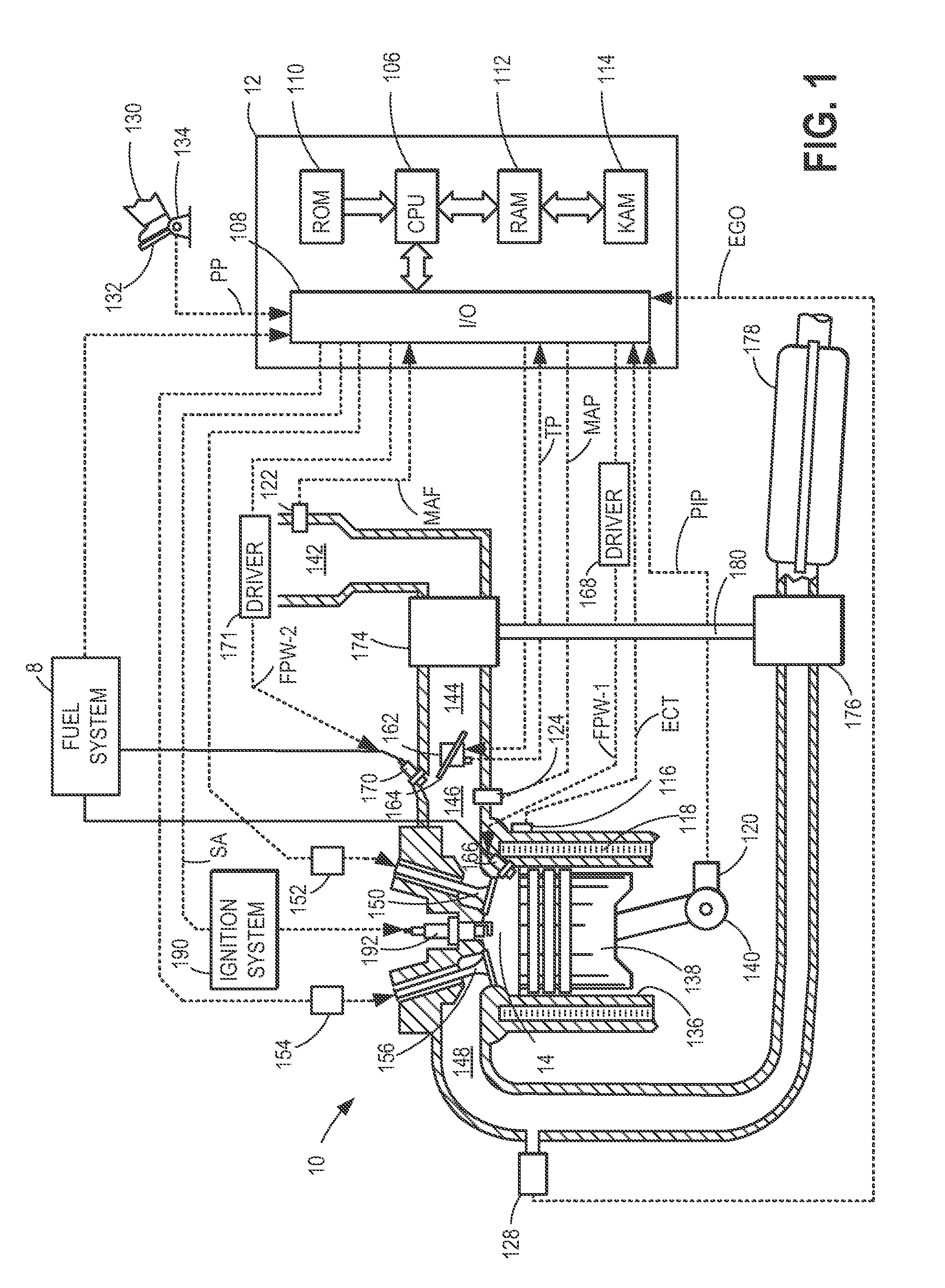

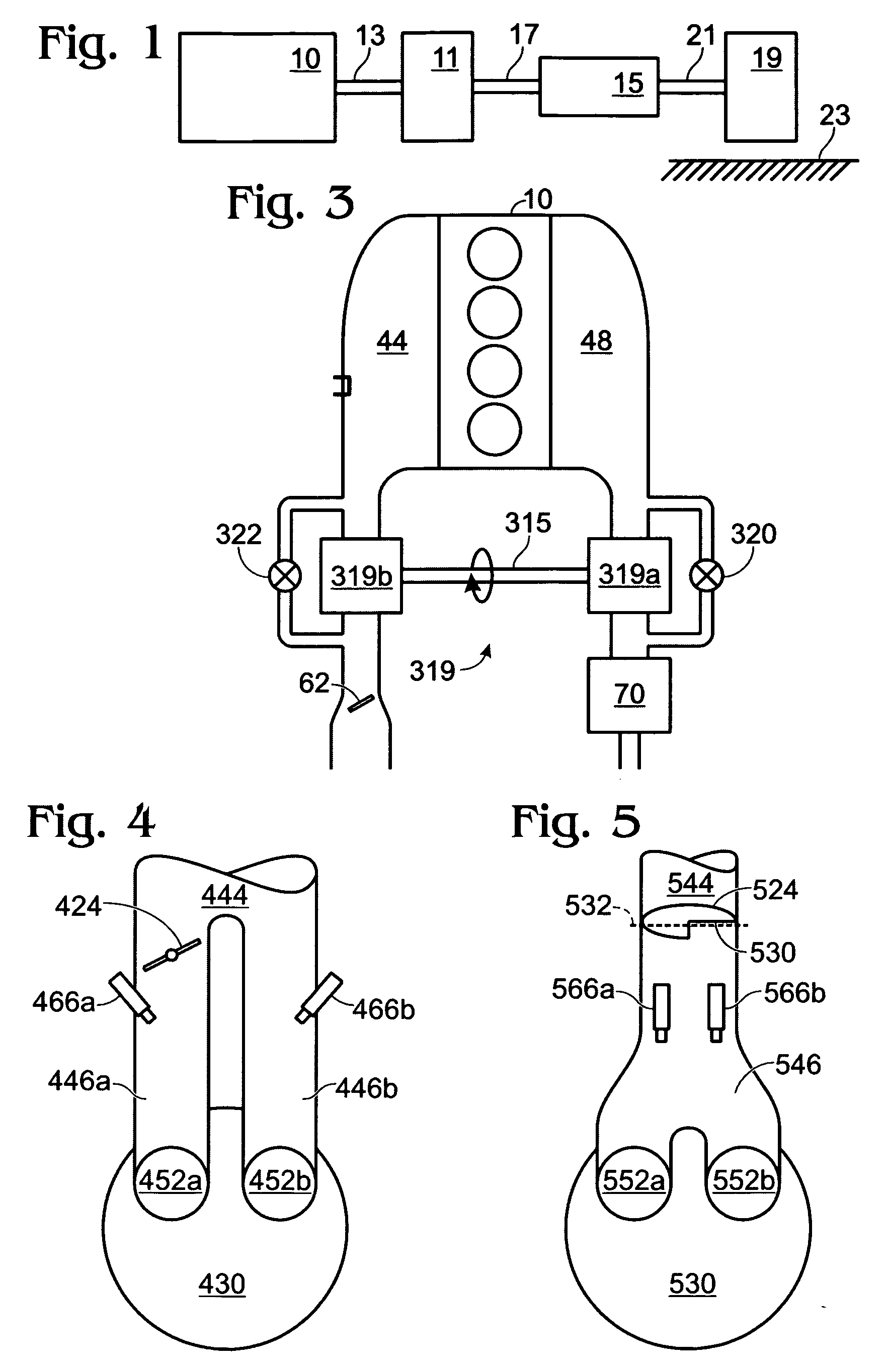

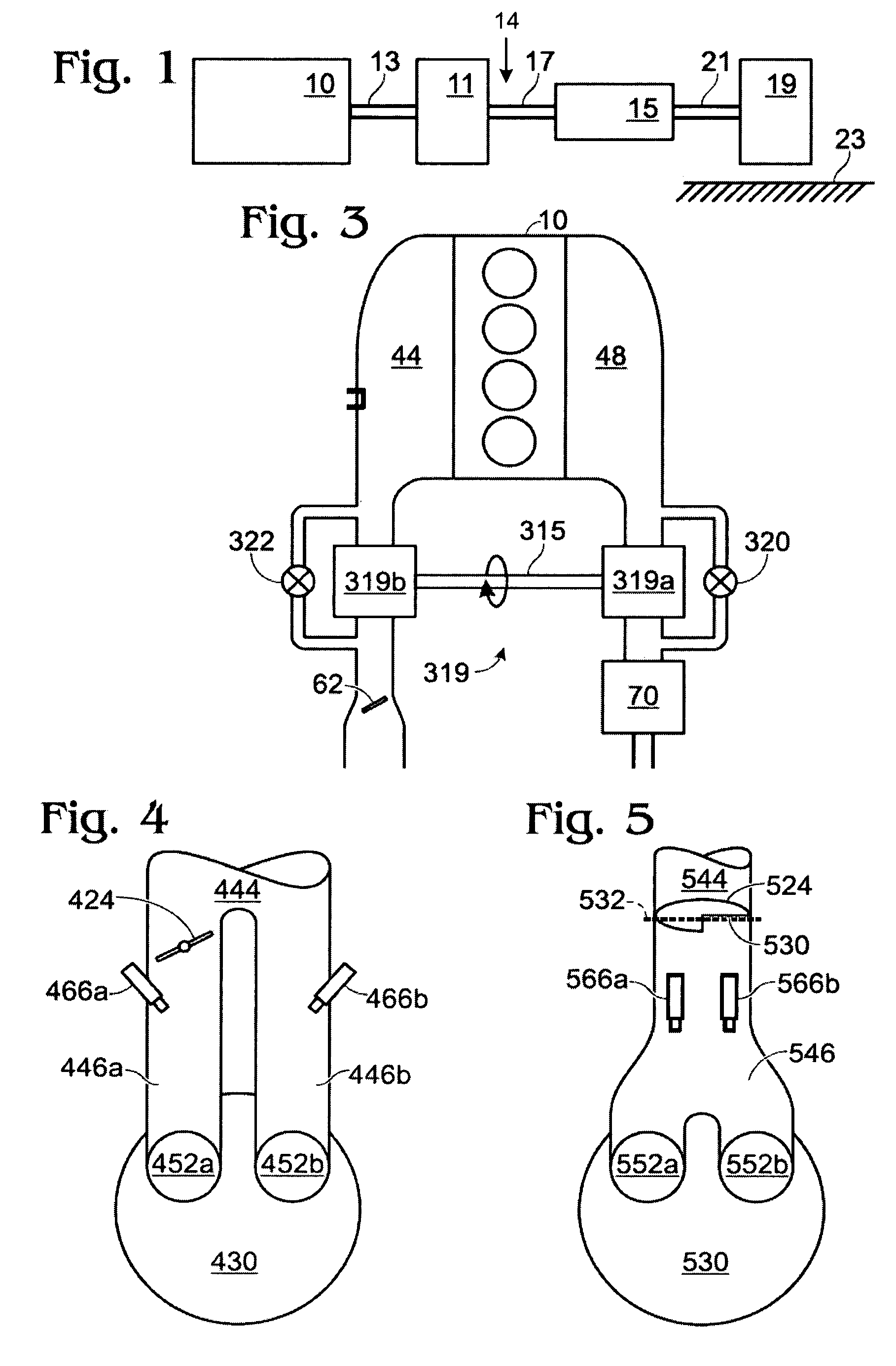

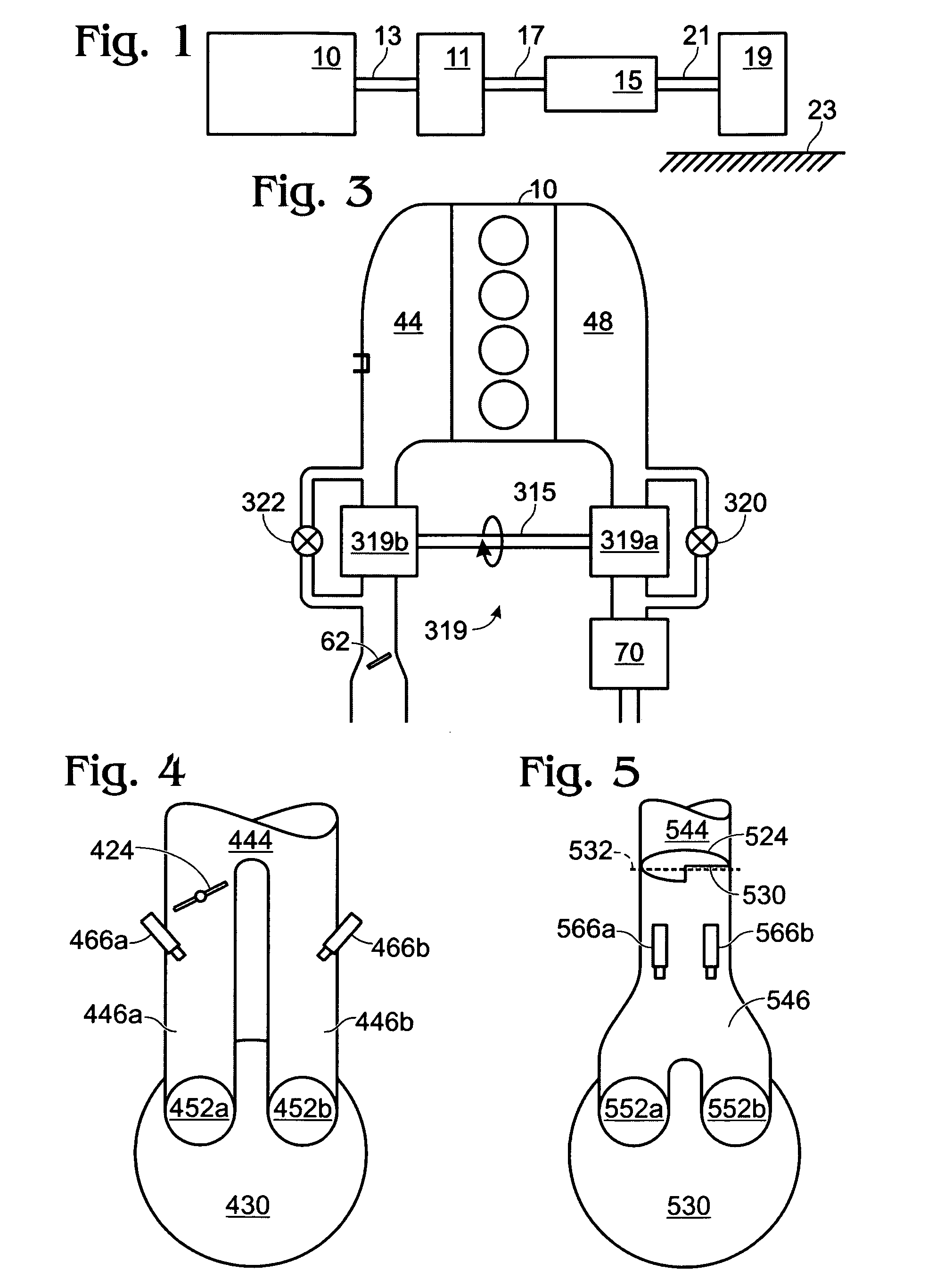

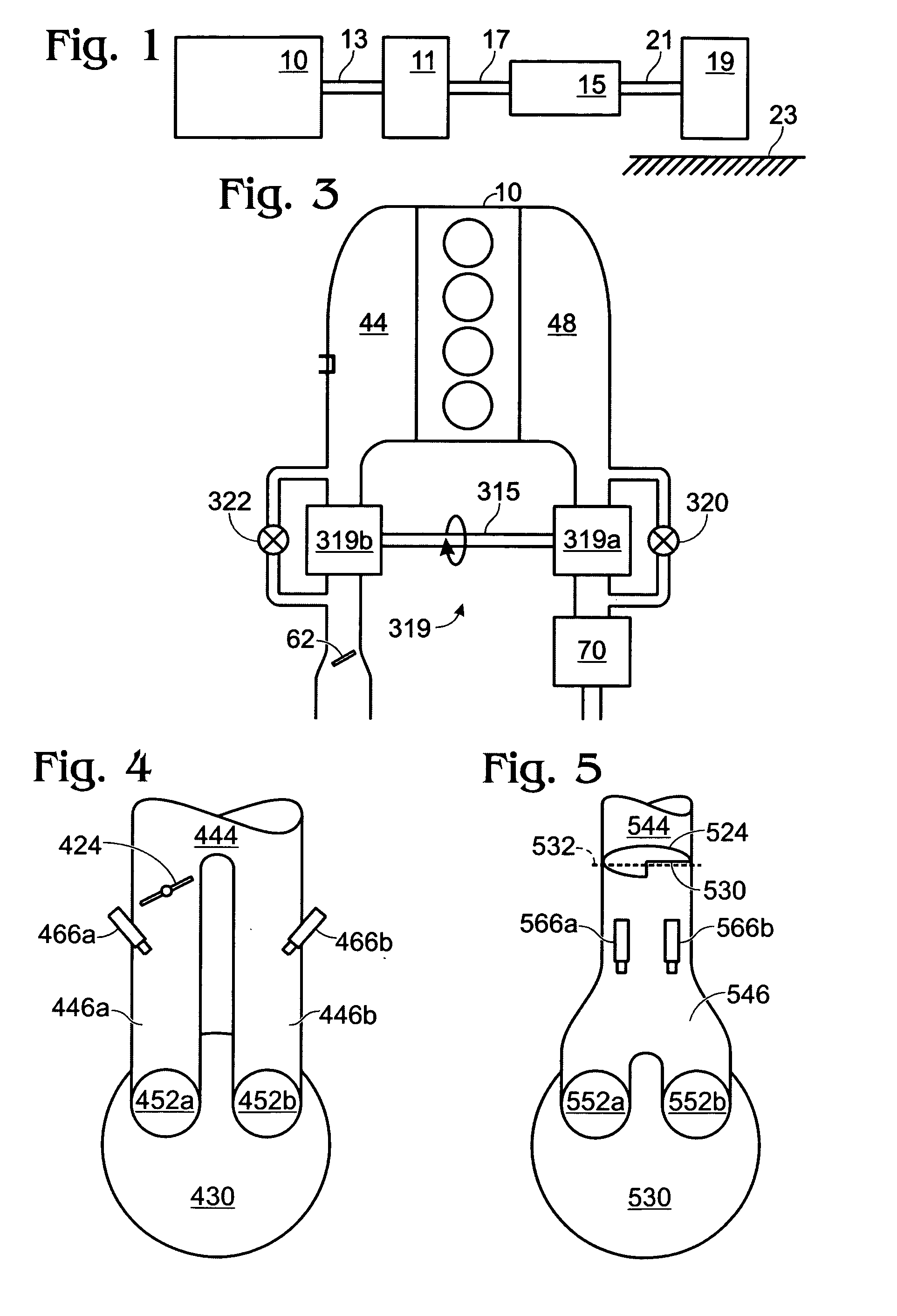

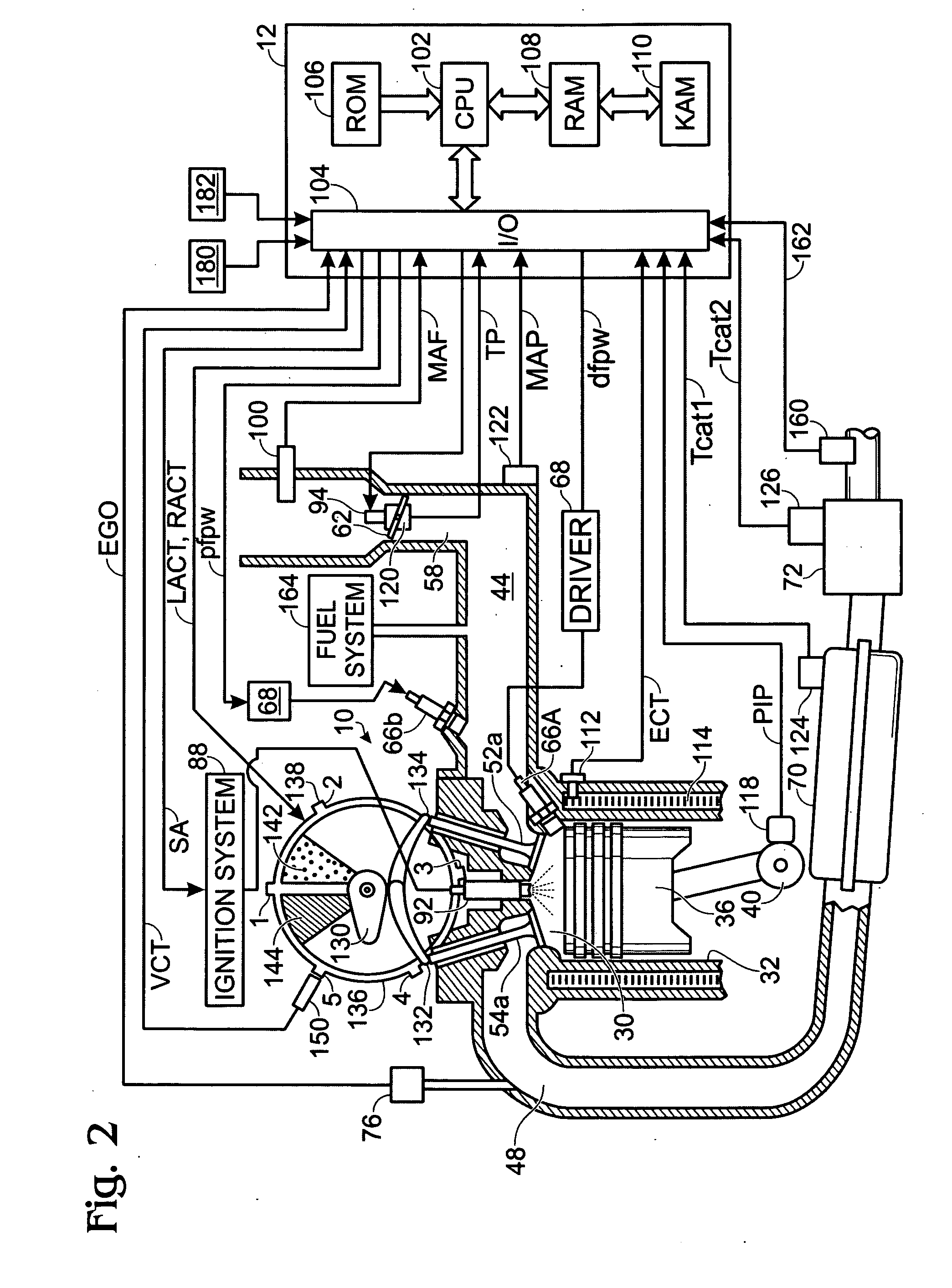

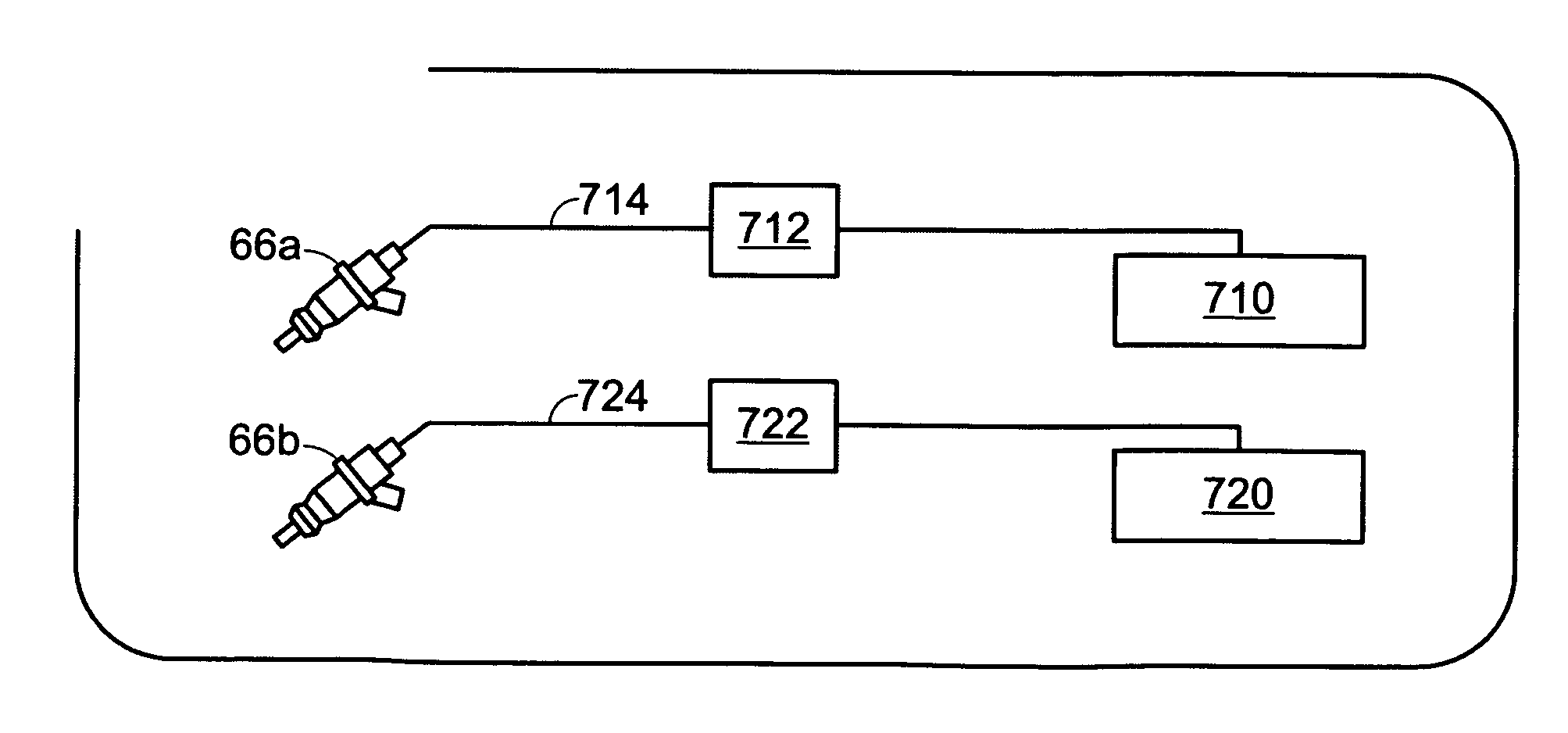

Event based engine control system and method

A system for an engine of a vehicle, comprising of a cylinder of the engine; a first injector configured to inject a first substance to said cylinder; a second injector configured to inject a second substance to said cylinder; and a controller configured to perform injection from said first and second injector in response to a number of combustion events from an engine start.

Owner:FORD GLOBAL TECH LLC

System and method for engine fuel blend control

A system for an engine, comprising of a cylinder located in the engine, a fuel delivery system for varying relative delivery amounts of a first and second injection type into said cylinder, and a controller configured to adjust a parameter affecting flow through the engine in response to said relative delivery amounts of said first and second injection type.

Owner:FORD GLOBAL TECH LLC

Molded water chamber base plate for use in a humidifier and ventilator assembly

A molded base plate for use in a humidifier and ventilation assembly is disclosed. The base plate is connected to a cover which forms the water chamber of the humidifier. A thermally conductive material is used in the molding process of the base plate so that heat applied to the base plate is conducted into the water.

Owner:RIC INVESTMENTS LLC

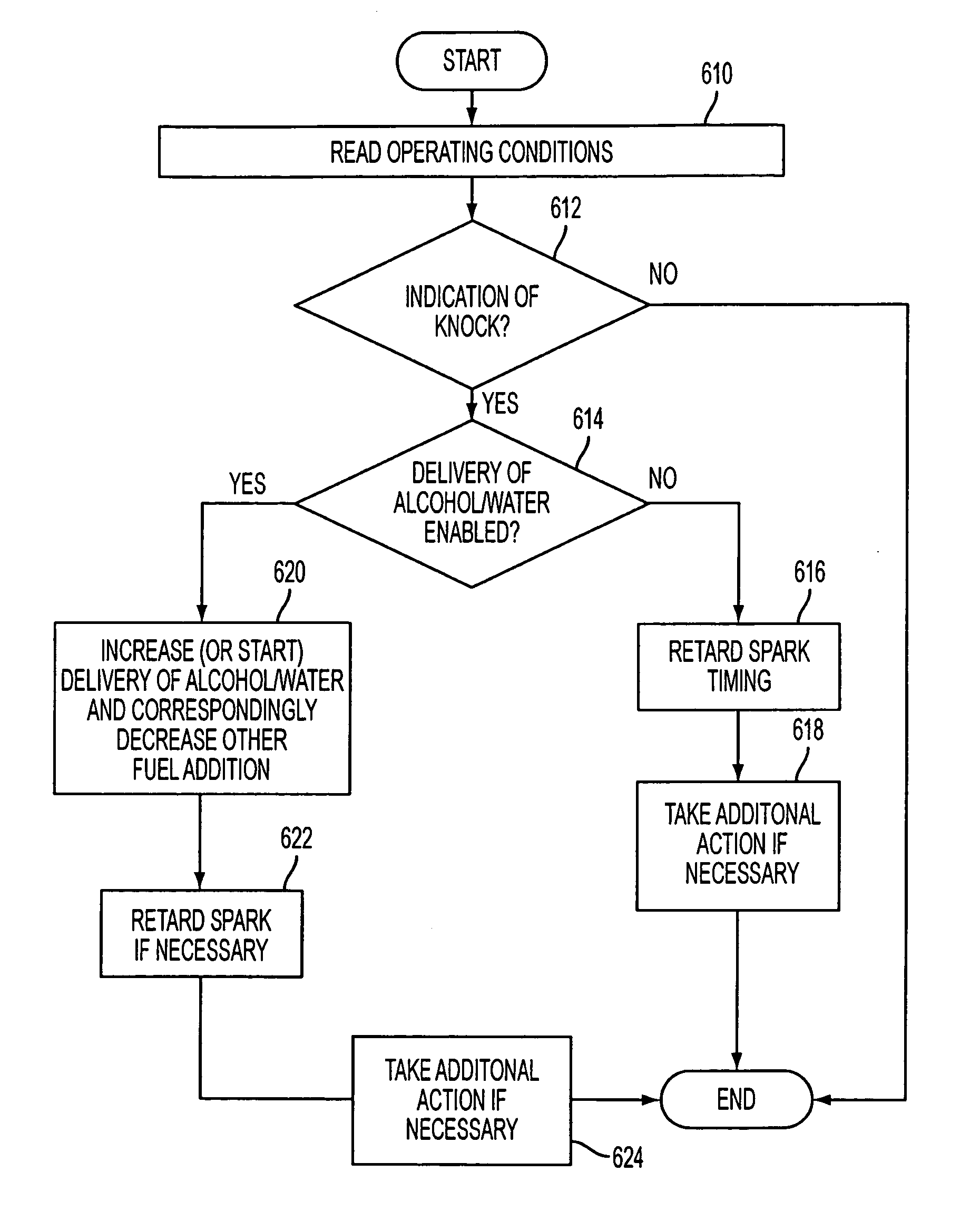

Control for alcohol/water/gasoline injection

ActiveUS20070119391A1Low costImprove charge cooling effectInternal combustion piston enginesNon-fuel substance addition to fuelAlcoholGasoline

Owner:FORD GLOBAL TECH LLC

Method for controlling injection timing of an internal combustion engine

InactiveUS7278396B2Reduce mixEmission reductionElectrical controlInternal combustion piston enginesExternal combustion engineIgnition timing

A method to control injection timing for an internal combustion engine having a plurality of injectors in at least a cylinder, the method comprising of injecting a first fuel amount to at least a cylinder of an internal combustion engine from a first injector, injecting a second fuel amount fuel to said cylinder from a second injector, and adjusting the timing between starting or ending injection of said first fuel amount, and starting or ending of said second fuel amount in response to an operating condition of said engine.

Owner:FORD GLOBAL TECH LLC

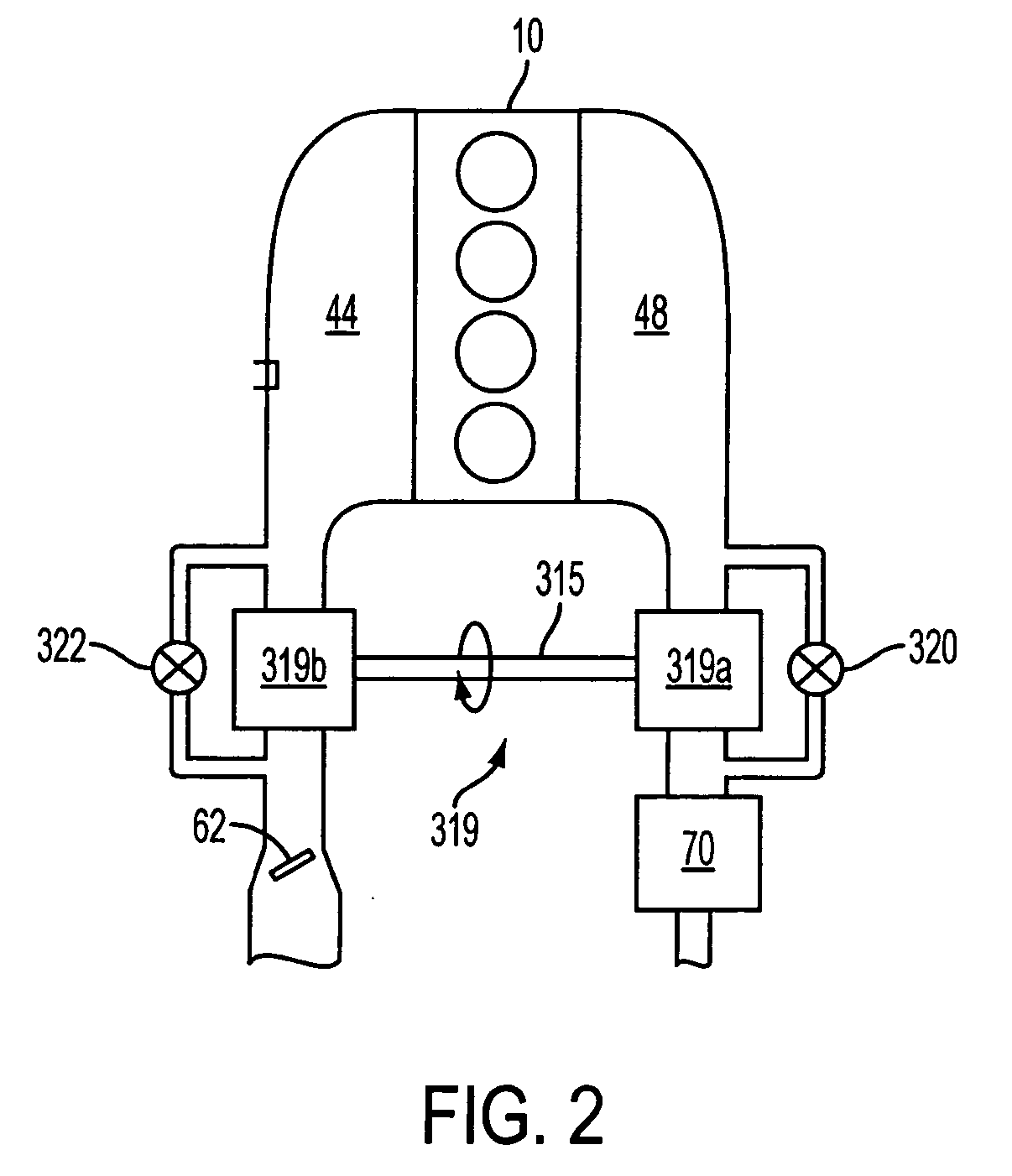

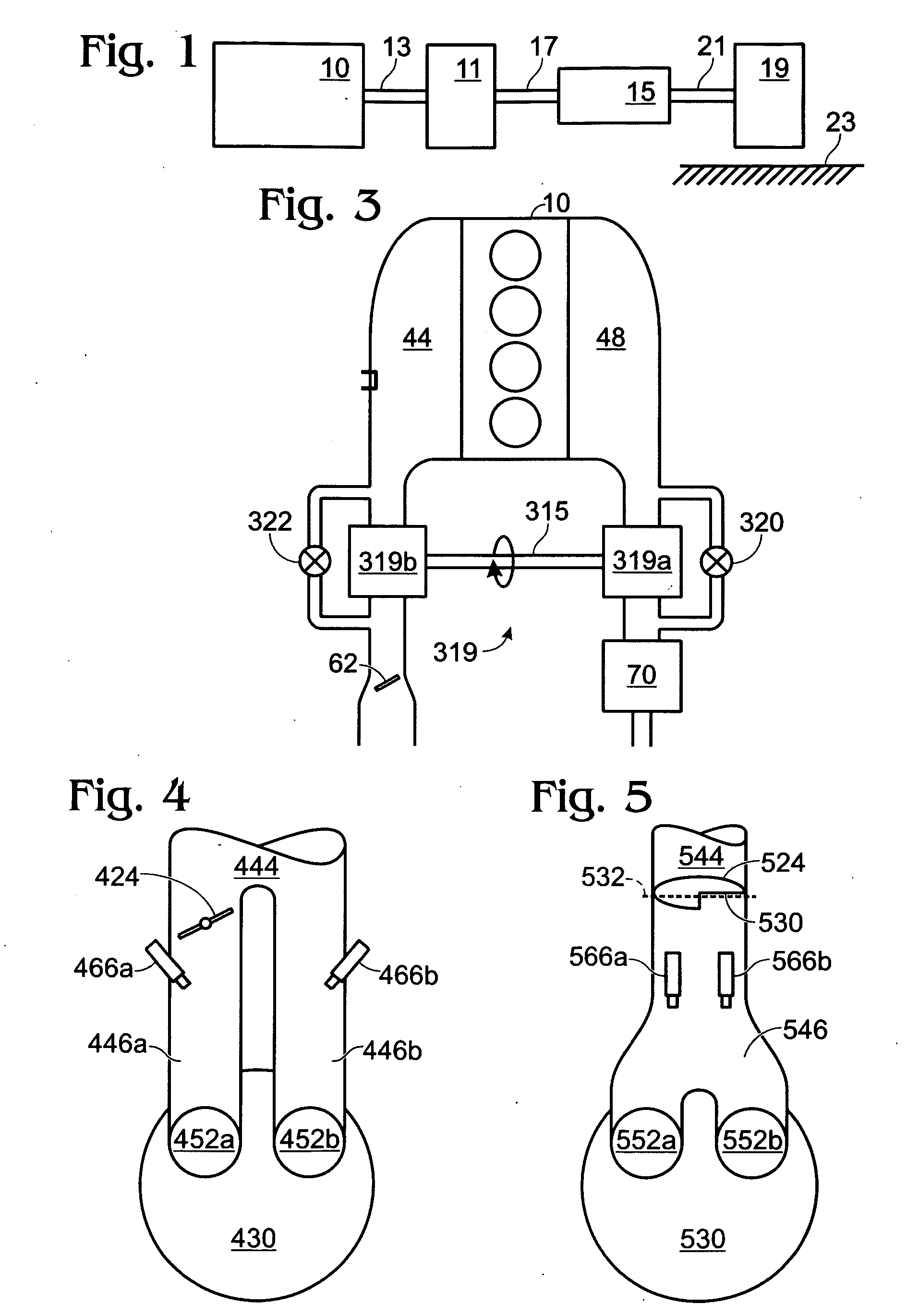

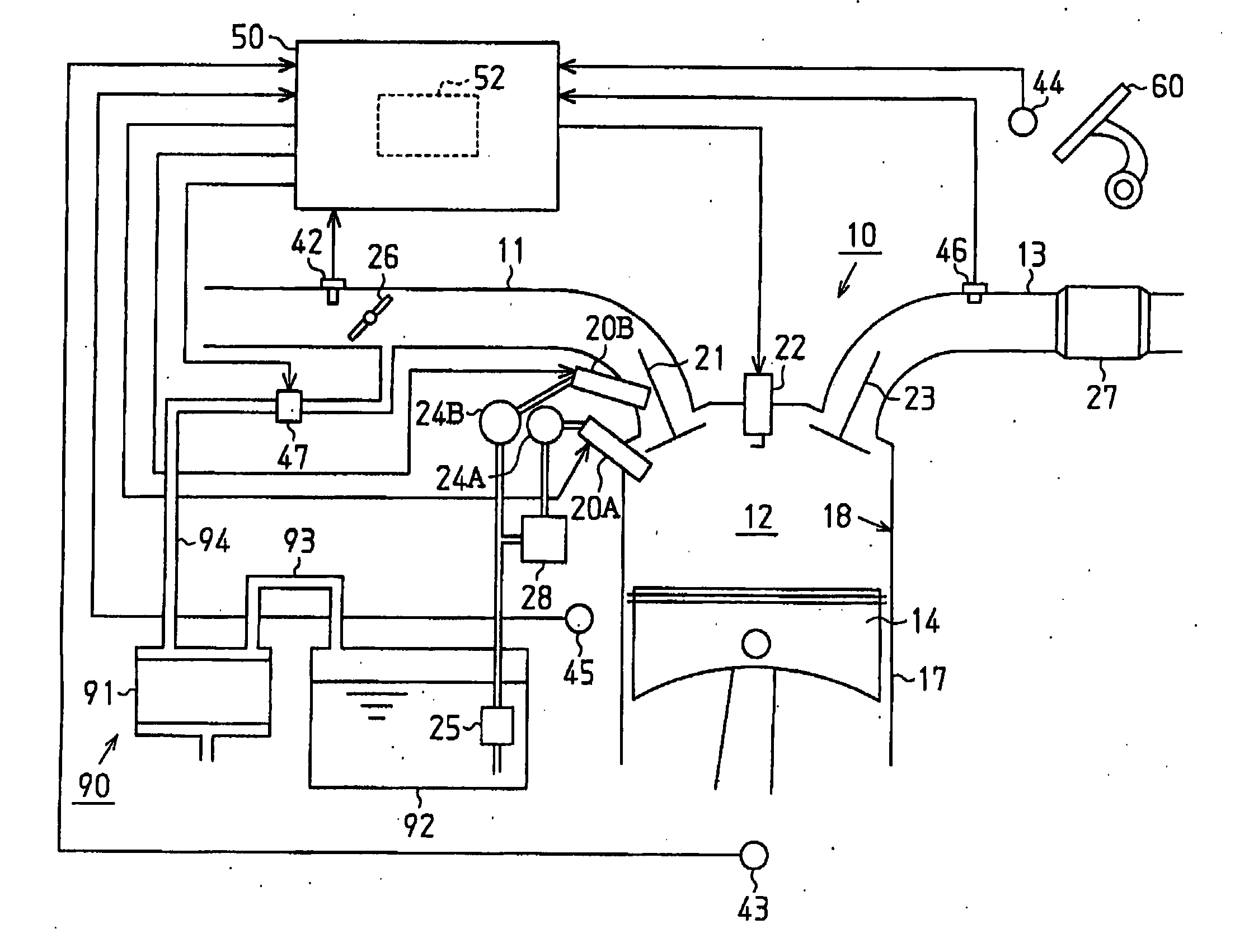

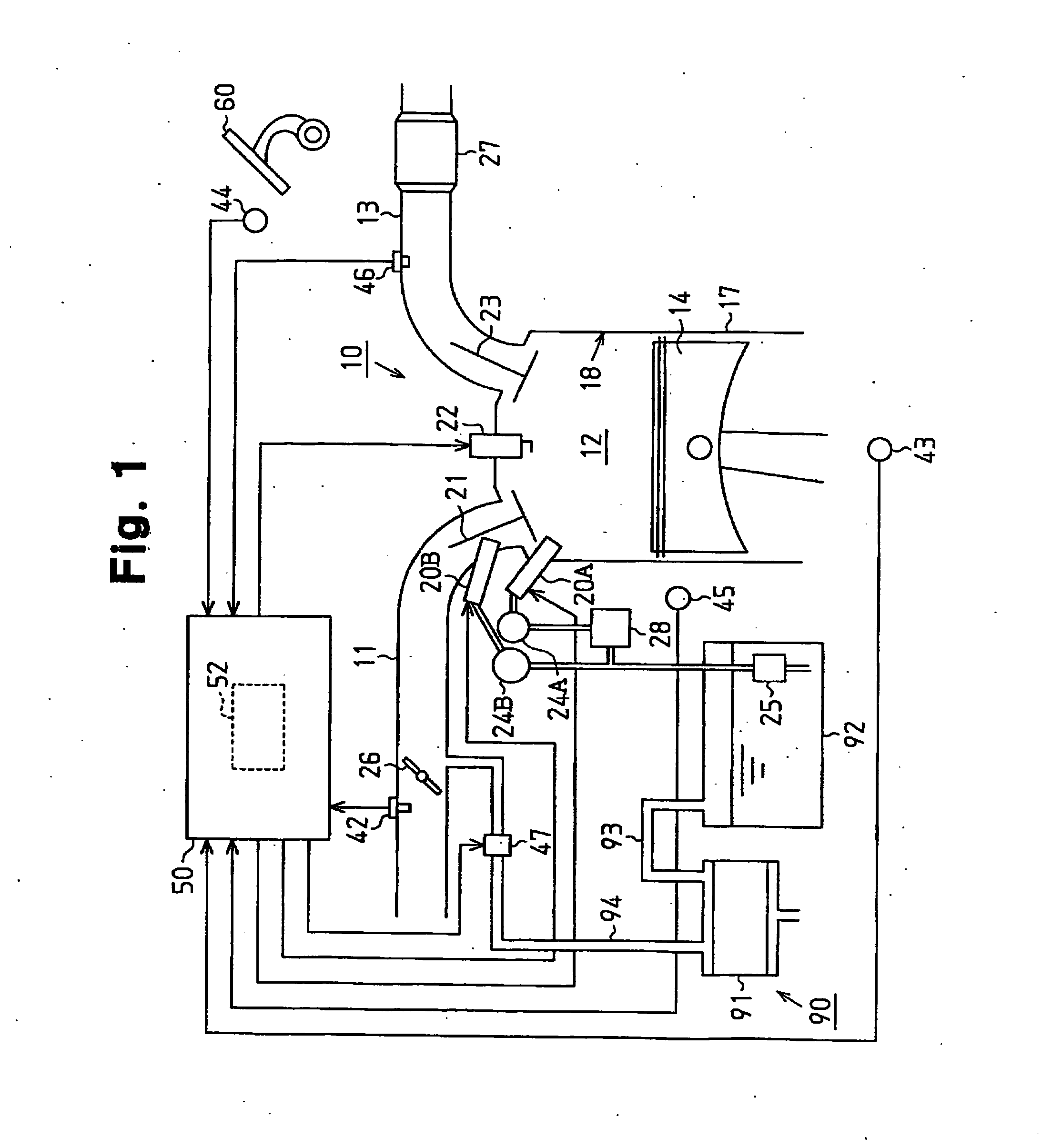

Engine with water and/or ethanol direct injection plus gas port fuel injectors

Owner:FORD GLOBAL TECH LLC

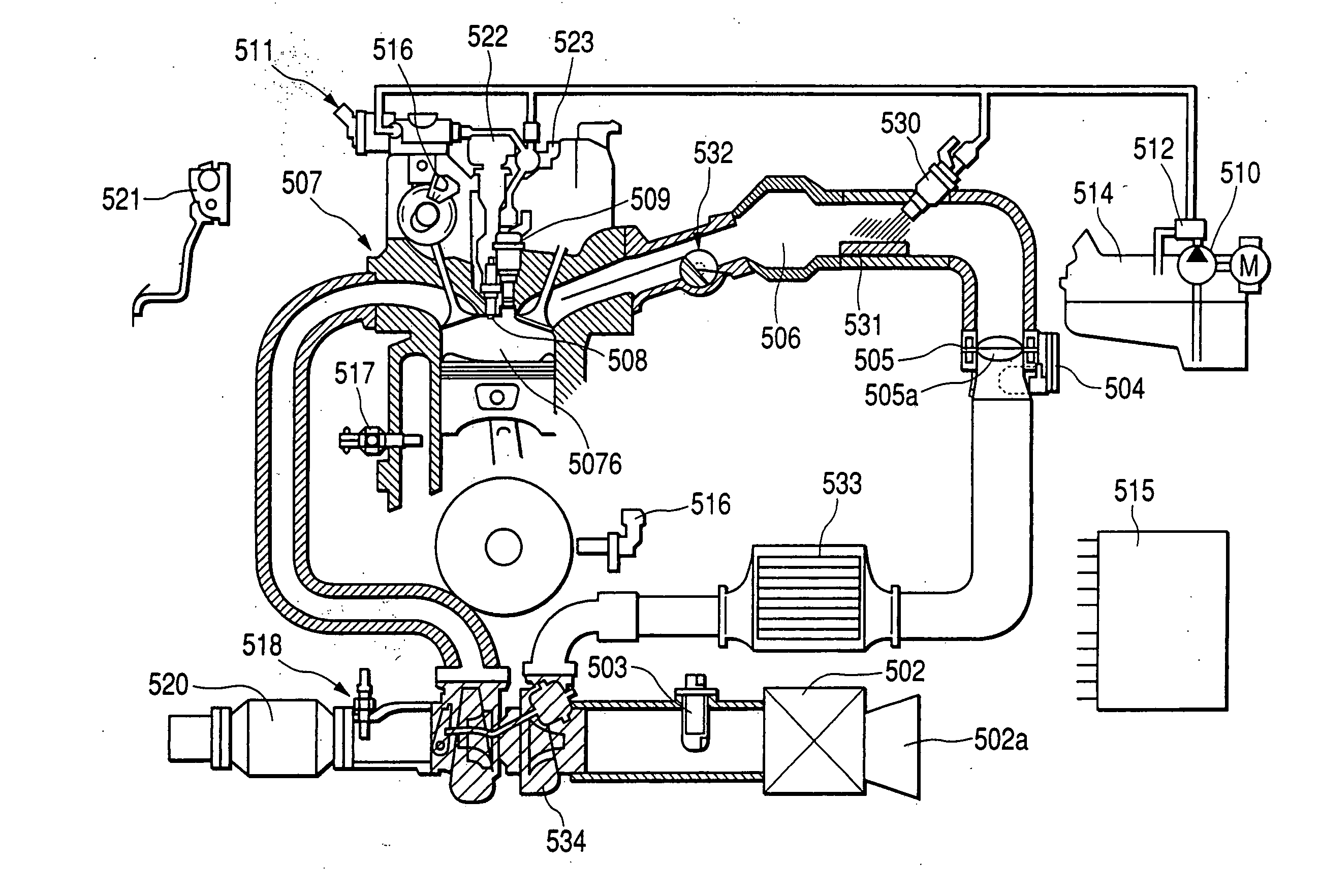

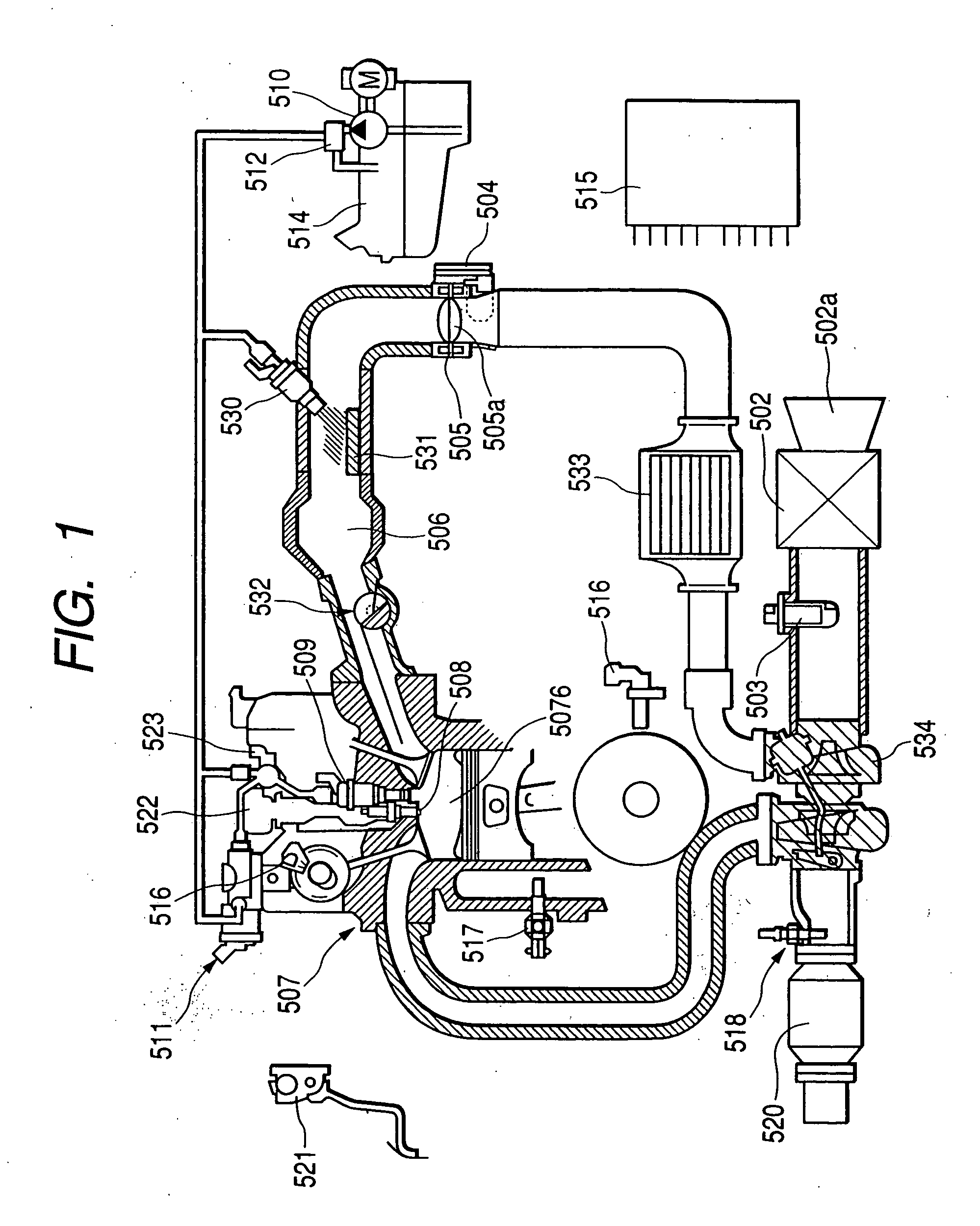

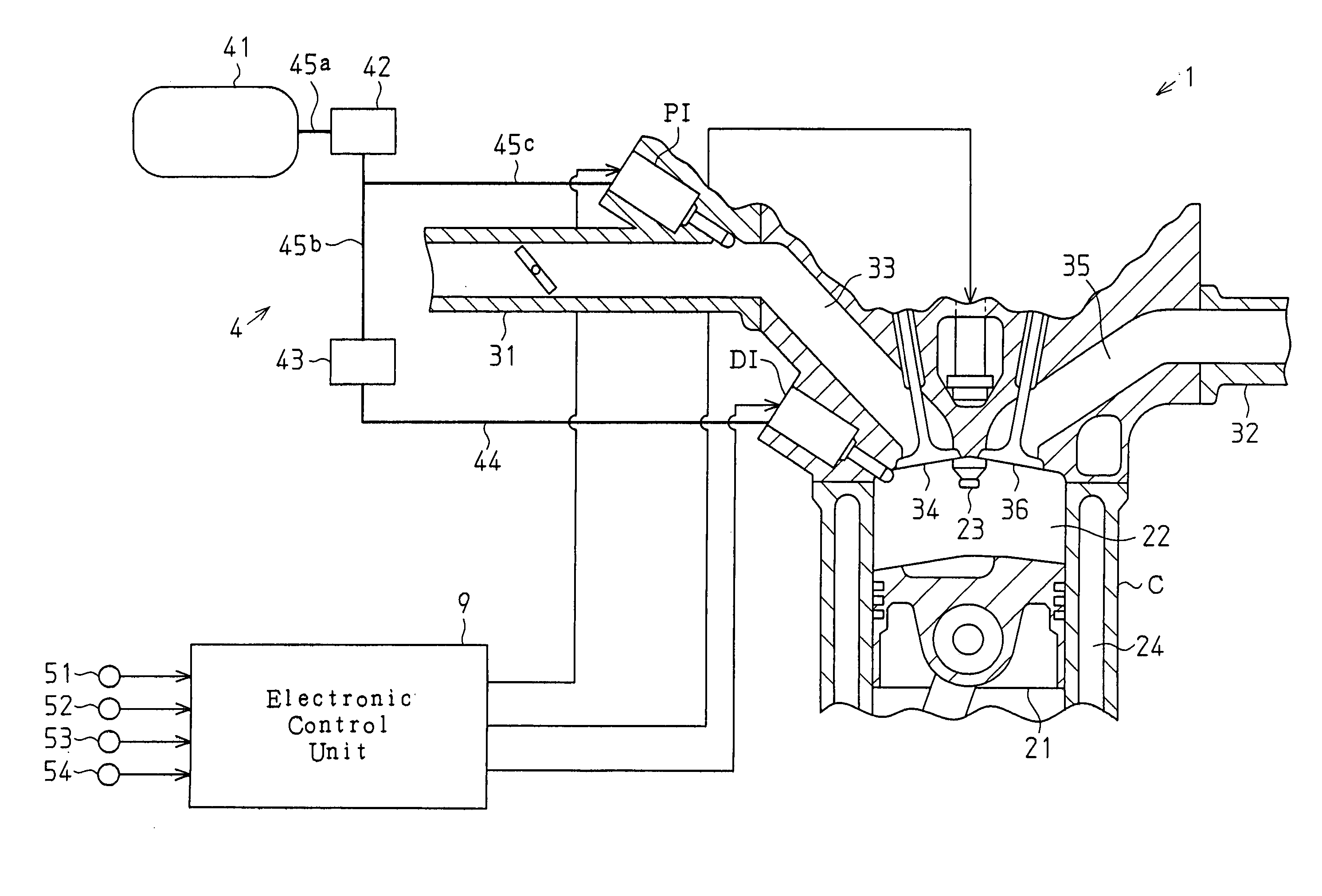

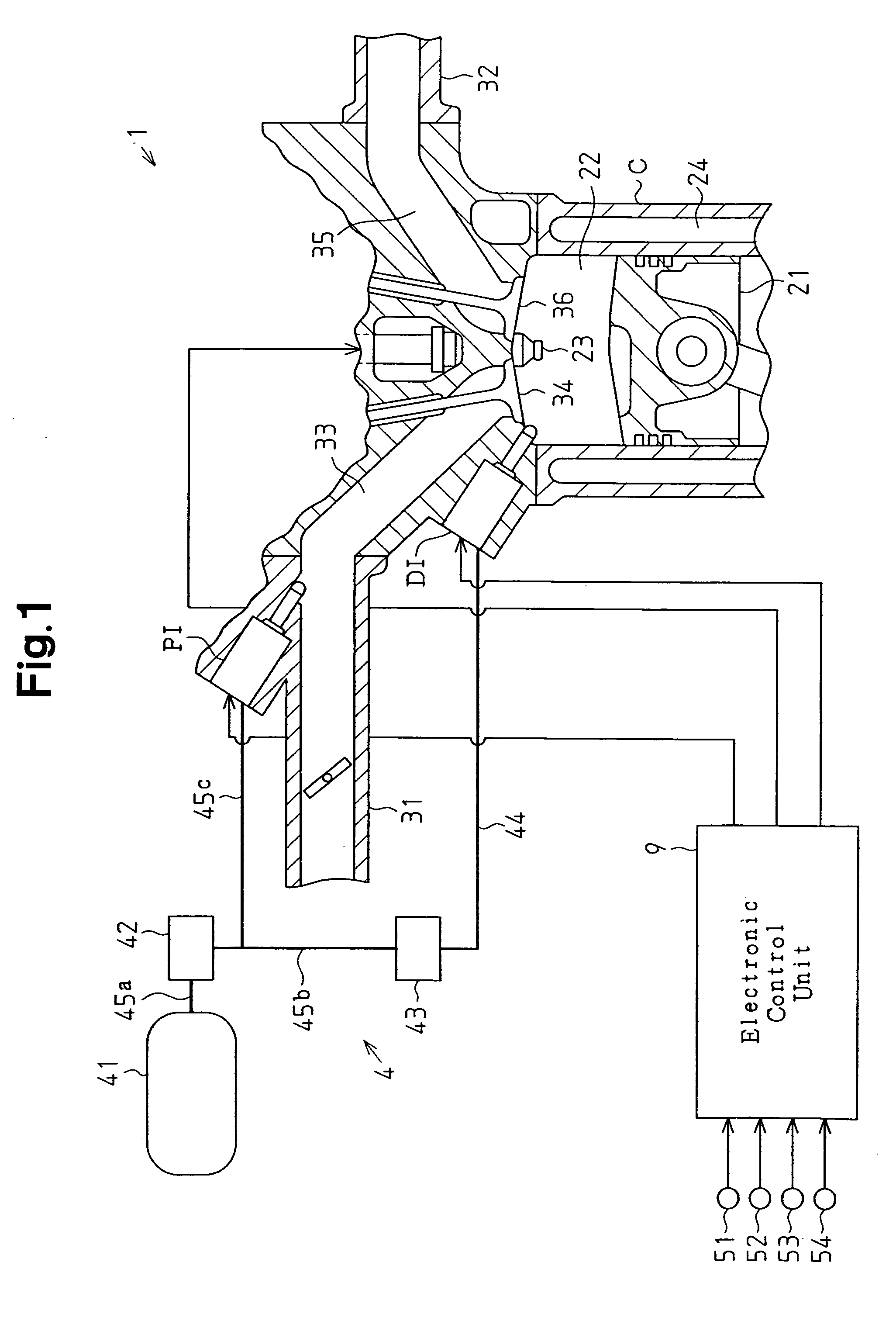

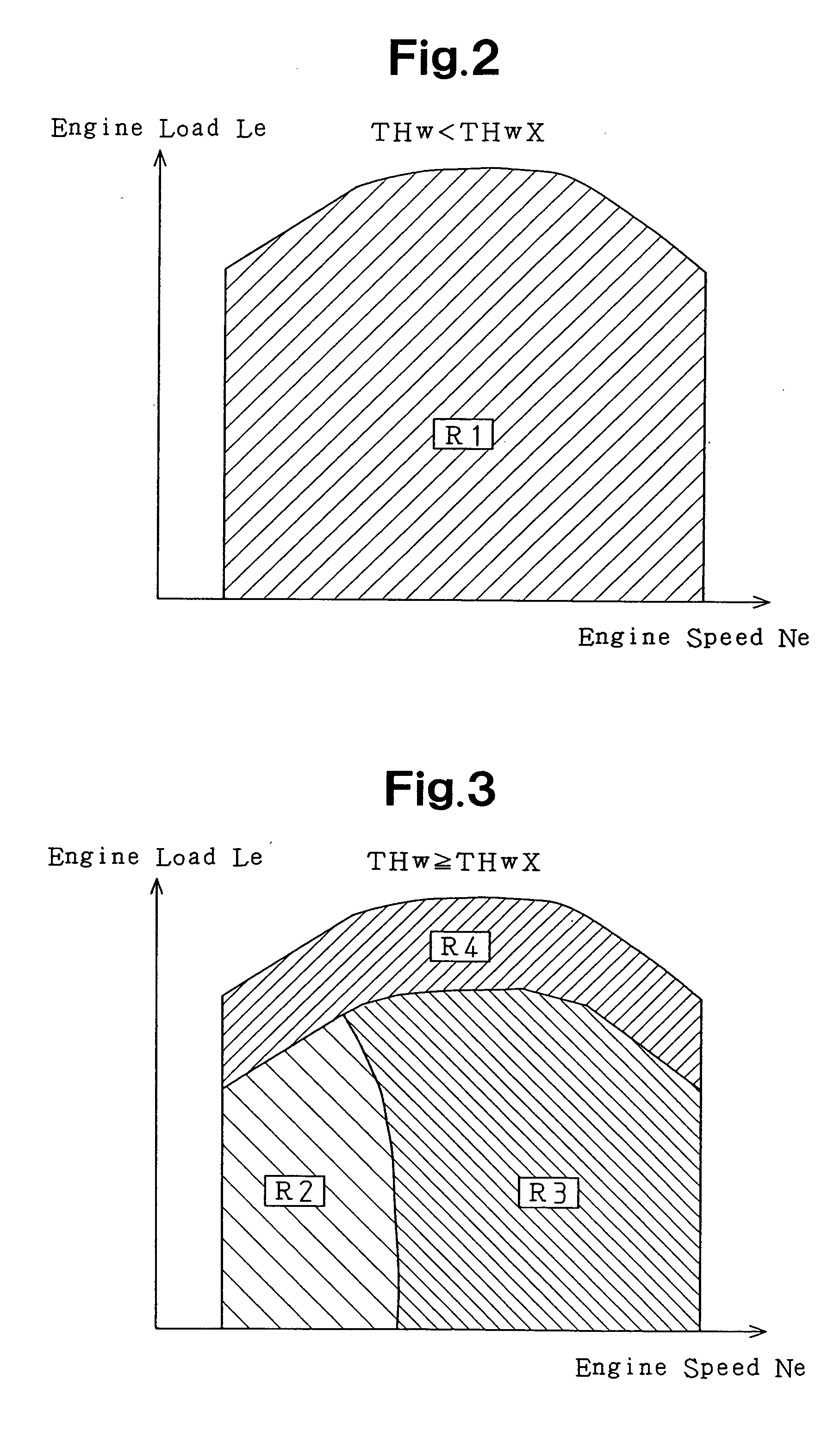

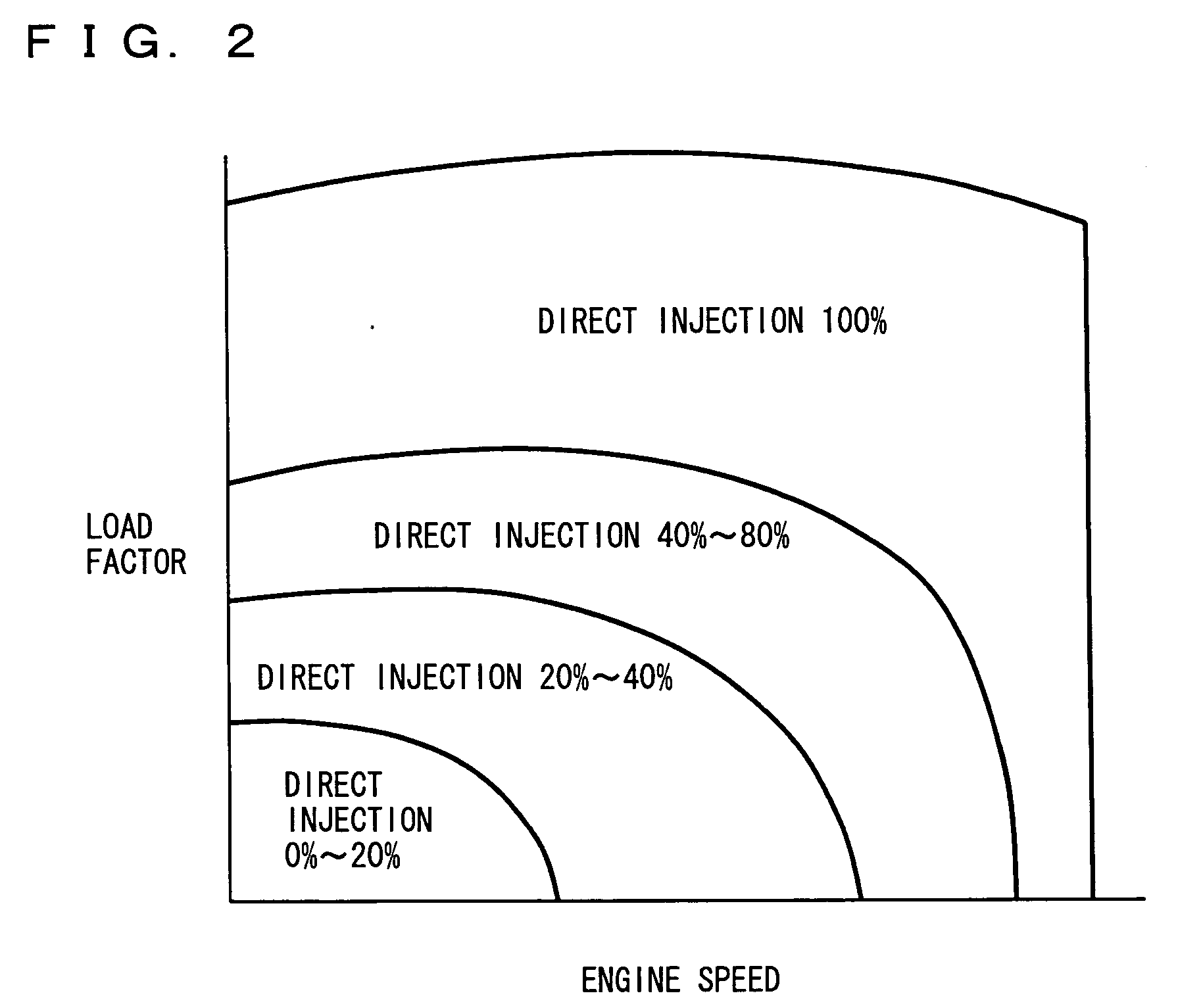

Fuel supply system and fuel supply method for in-cylinder direct fuel injection engine

InactiveUS20050066939A1Increase productionHigh outputElectrical controlInternal combustion piston enginesFuel supplyFuel injection

To offer a fuel supply system and fuel supply method for direct injection engine that realizes higher output. In a fuel supply system for direct injection engine of the present invention, equipped with a primary fuel injector that injects fuel directly into the cylinder of the direct injection engine and supercharger that increase the intake air quantity of the engine, a secondary fuel injector is installed in addition to the primary fuel injector. In a specified engine load area, fuel is supplied using the primary fuel injector and secondary fuel injector. Even though the fuel quantity injected from the primary fuel injector into the cylinder is limited, the fuel supply system for direct injection engine constructed as above can increase the engine output because the fuel insufficiency can be supplied by the secondary fuel injector.

Owner:HITACHI LTD

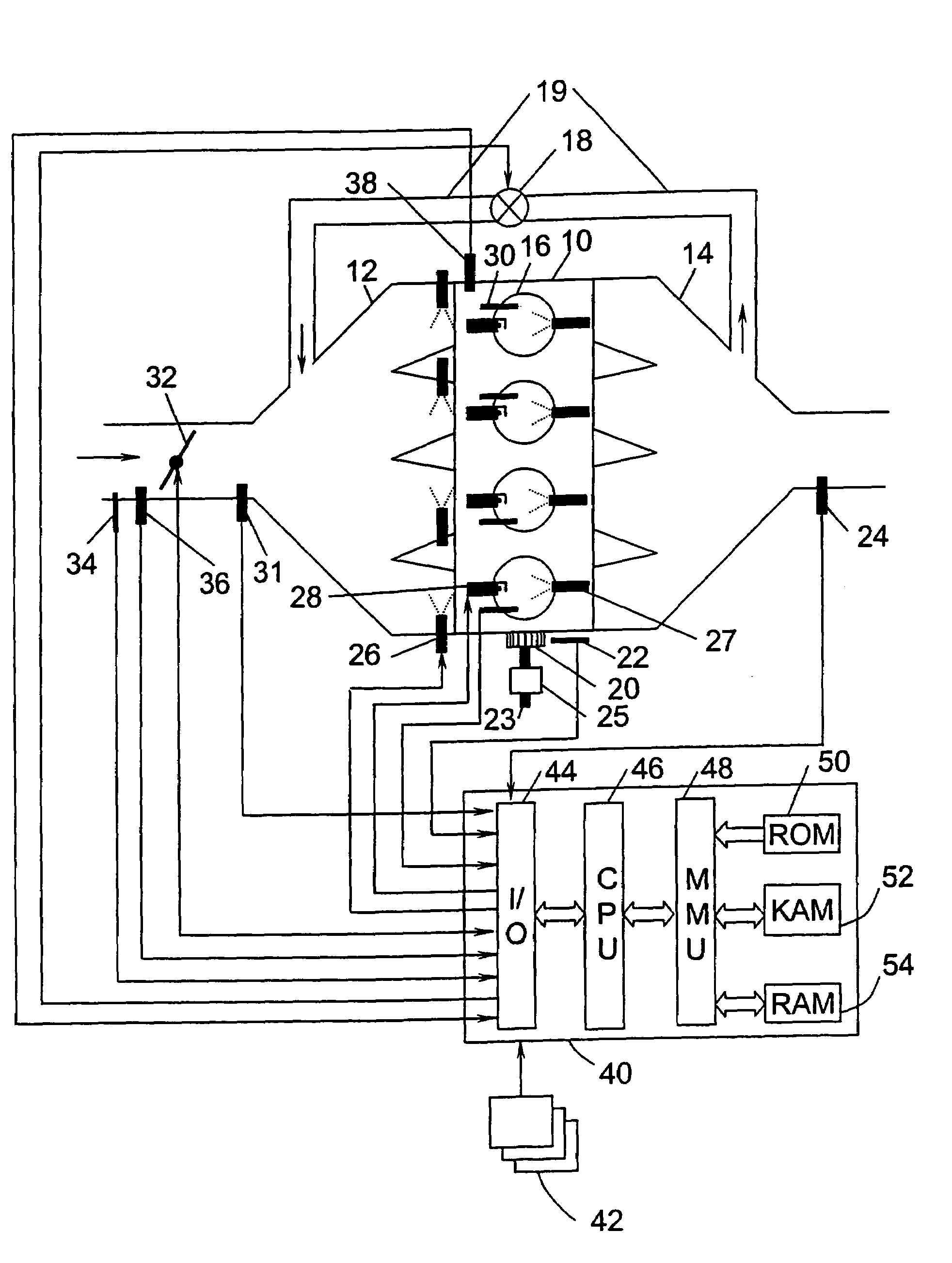

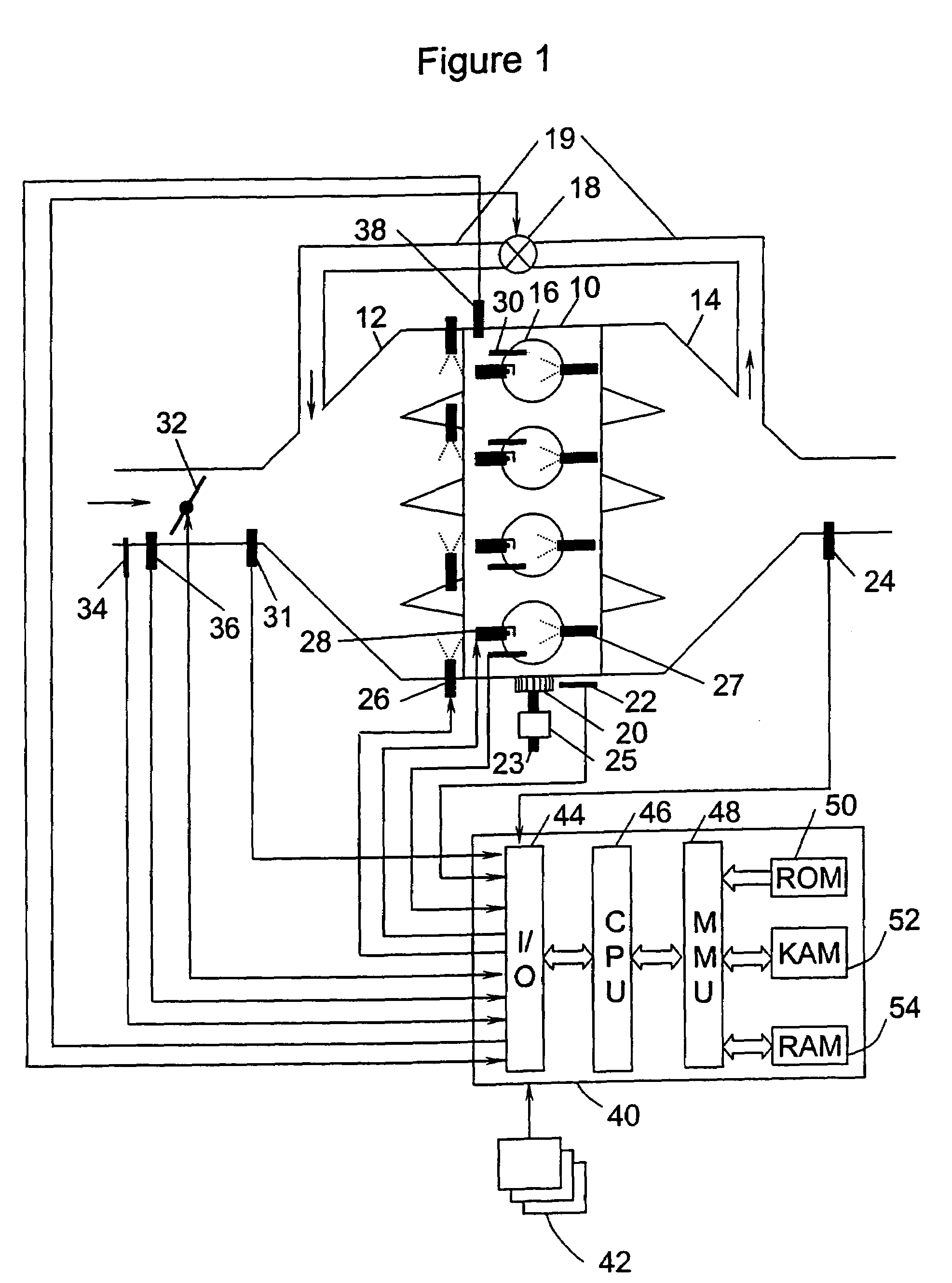

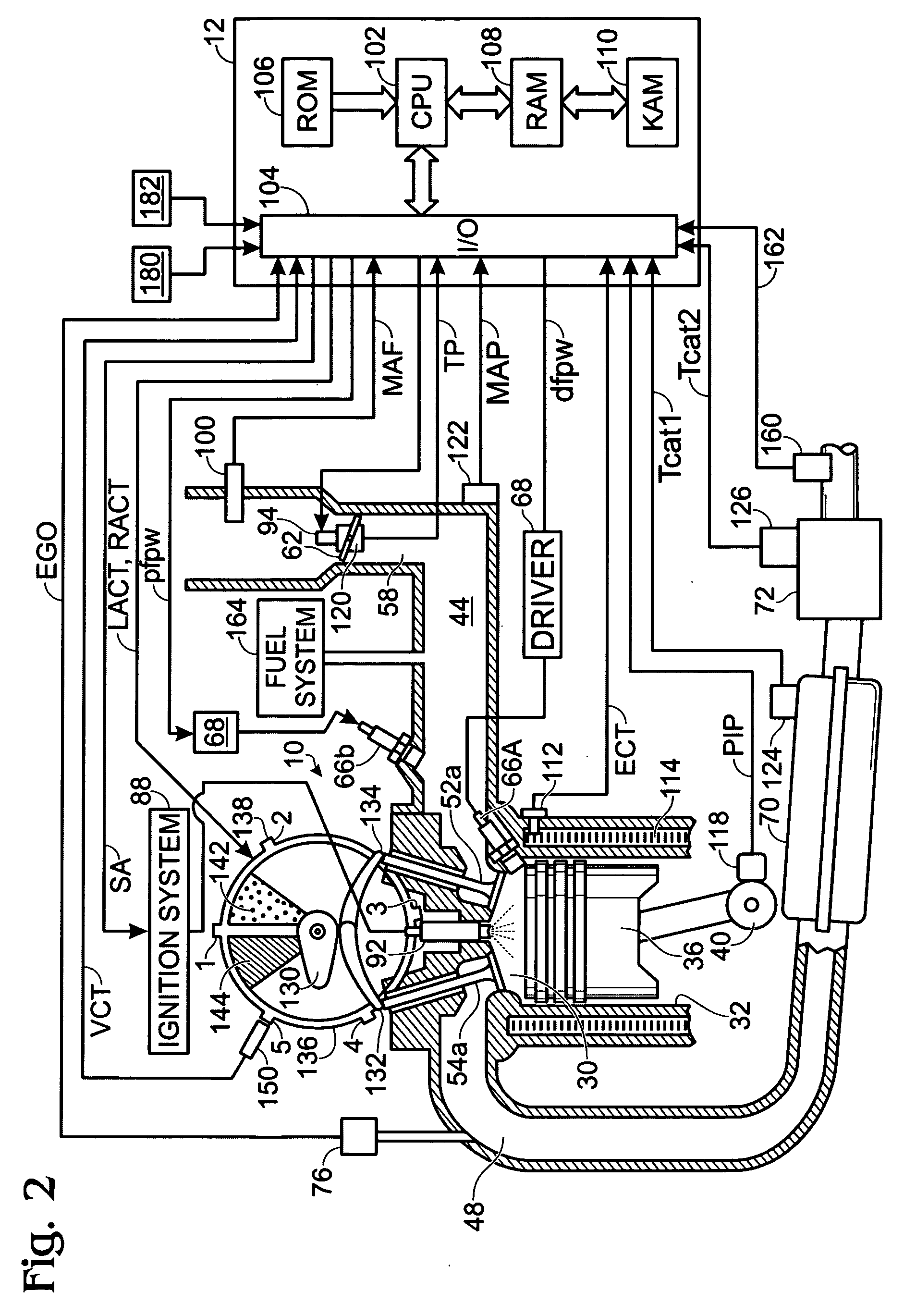

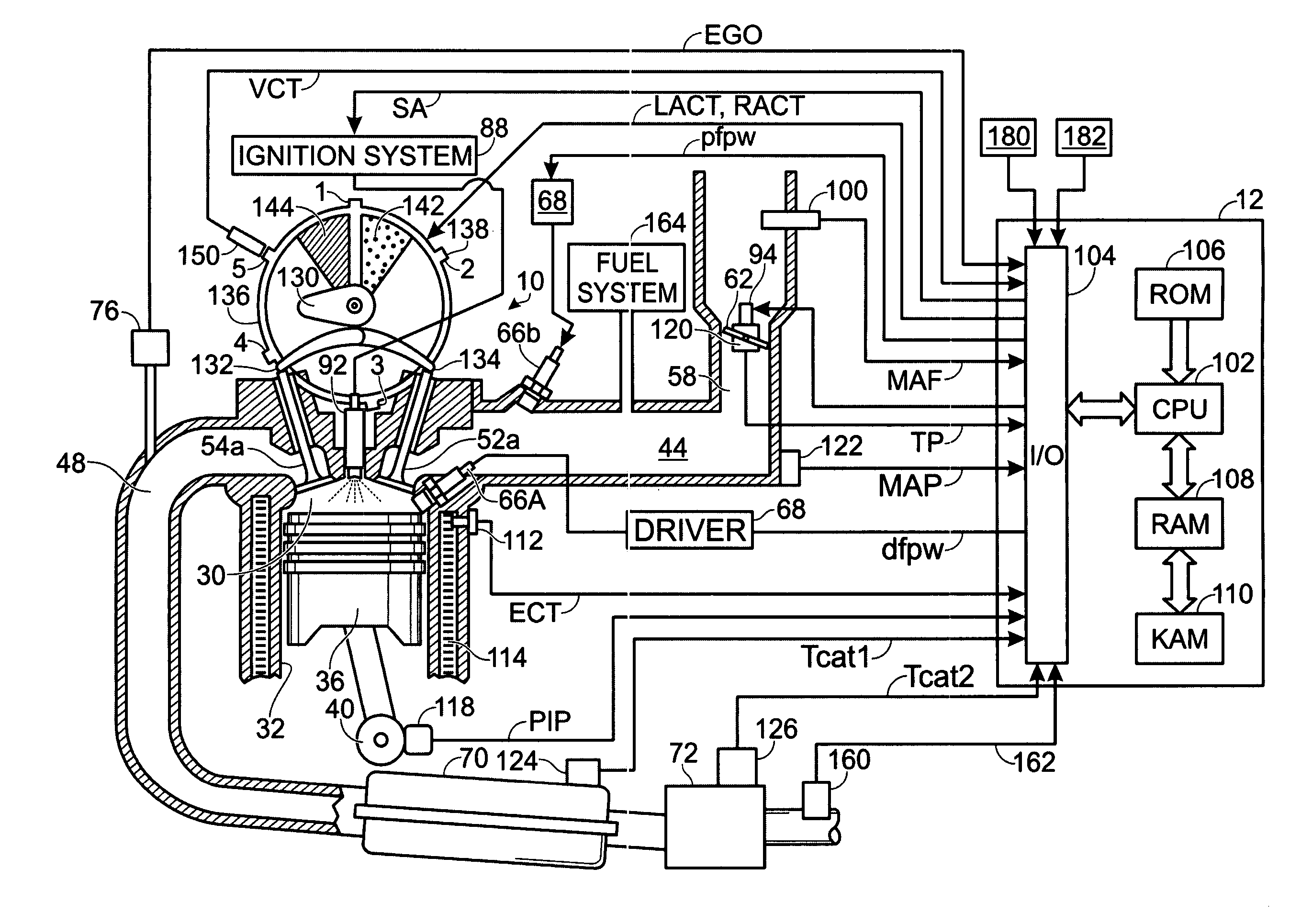

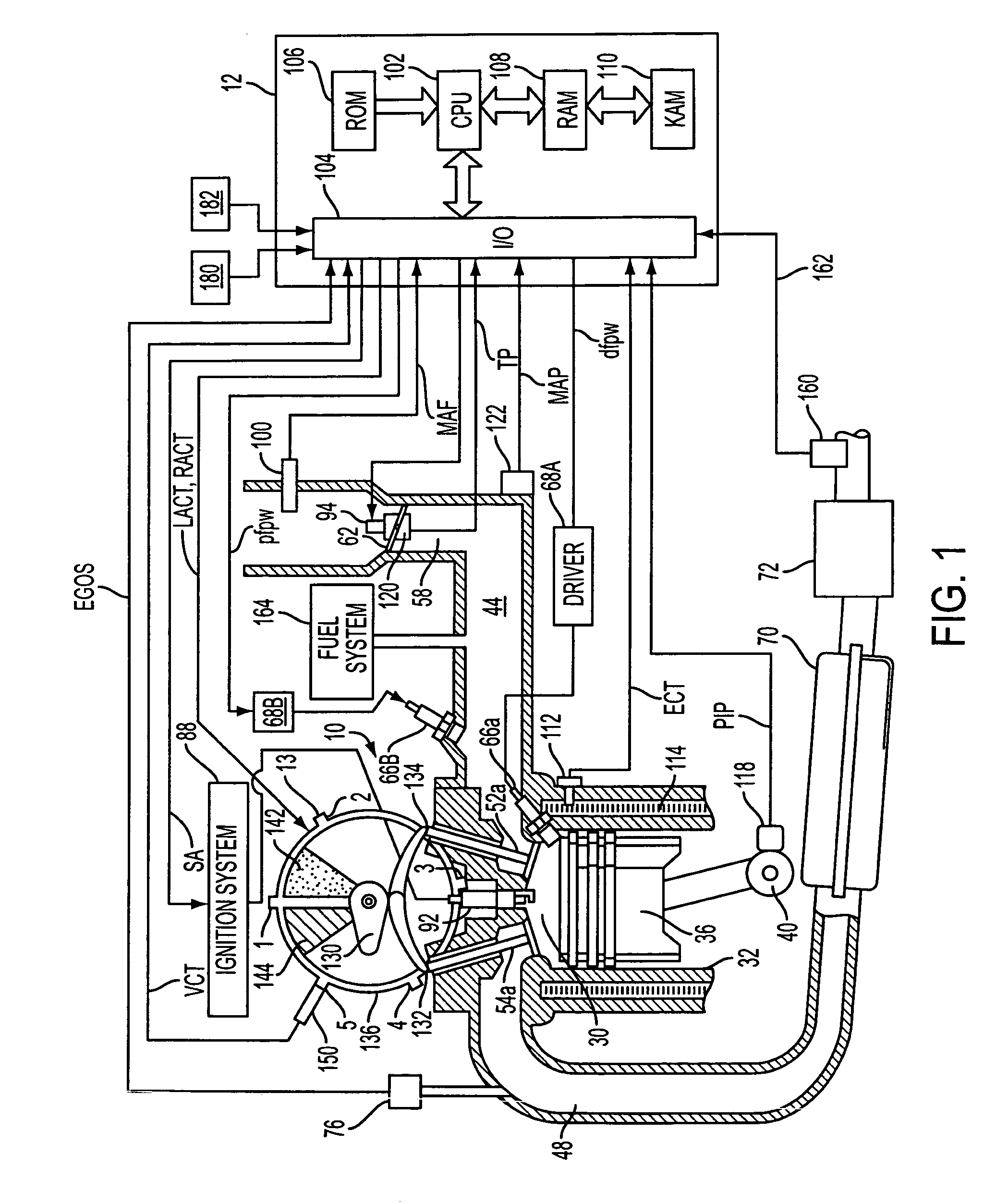

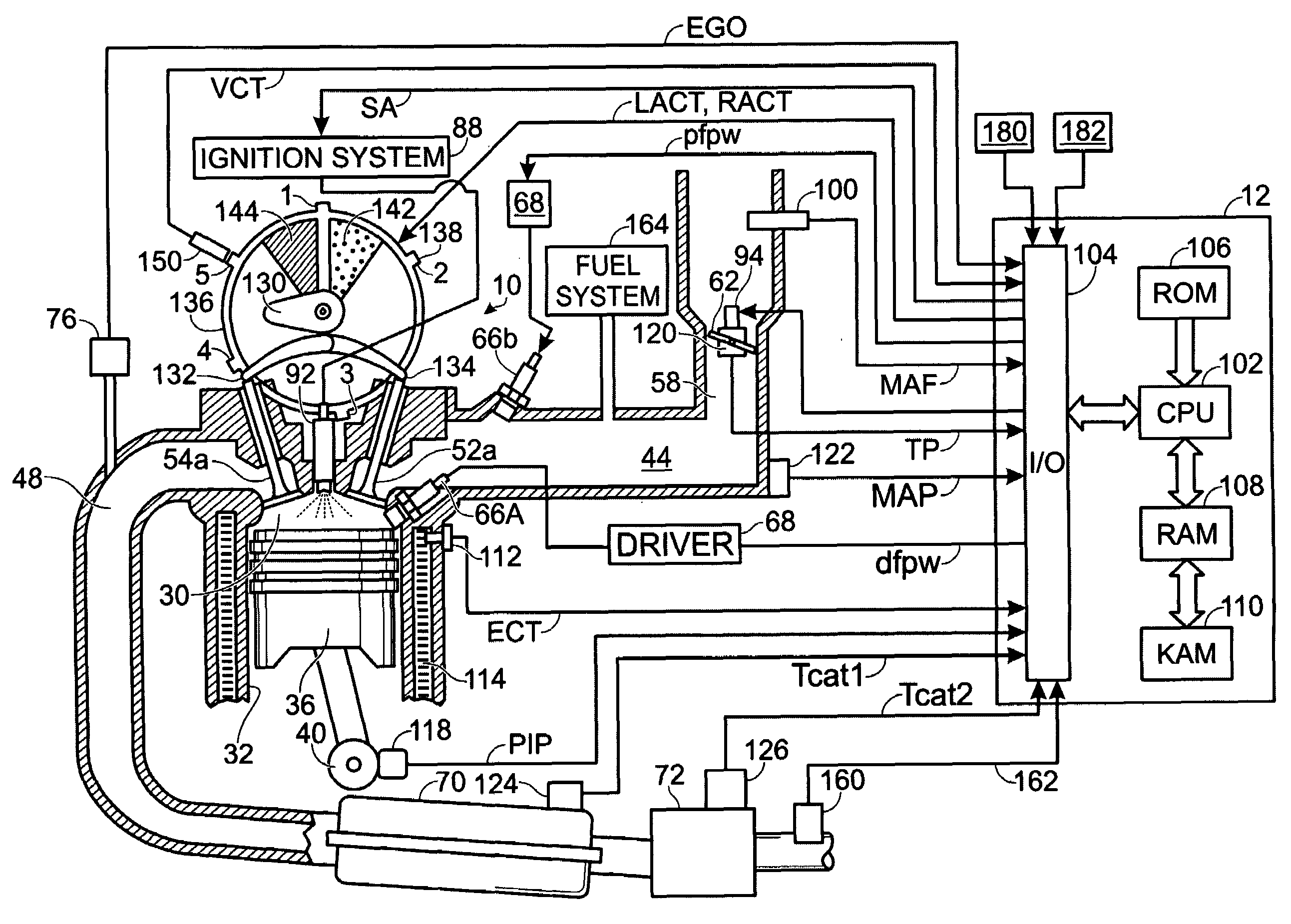

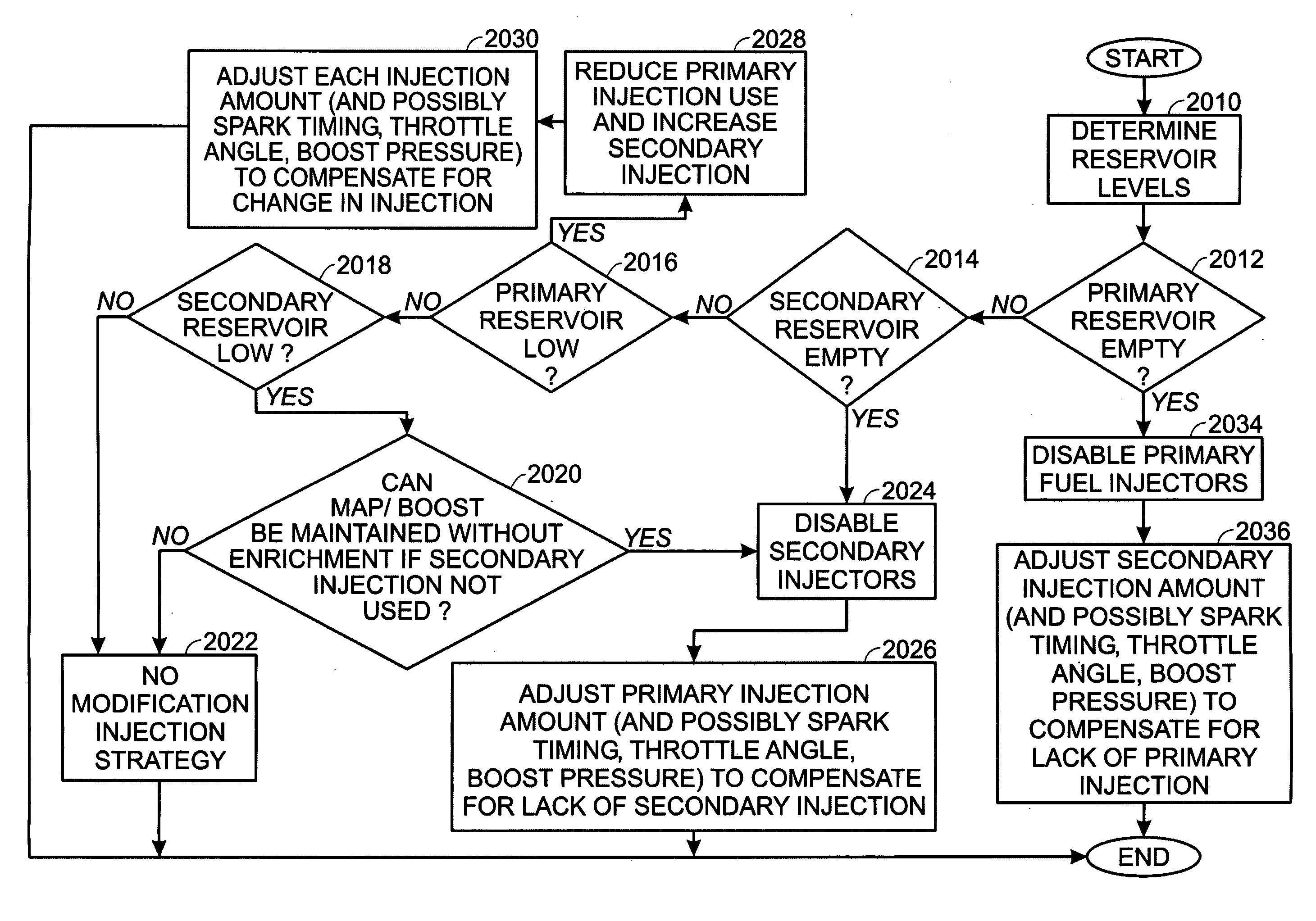

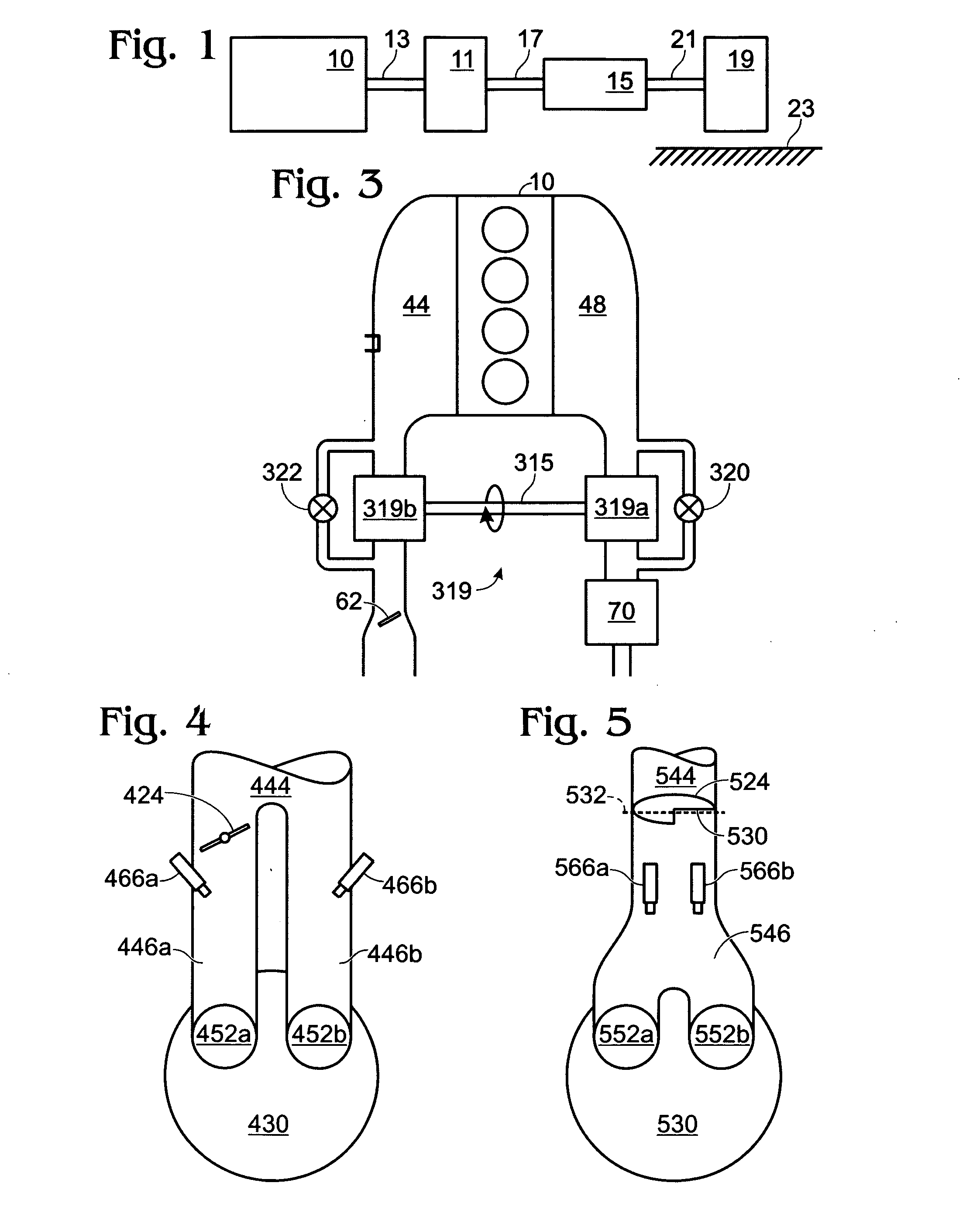

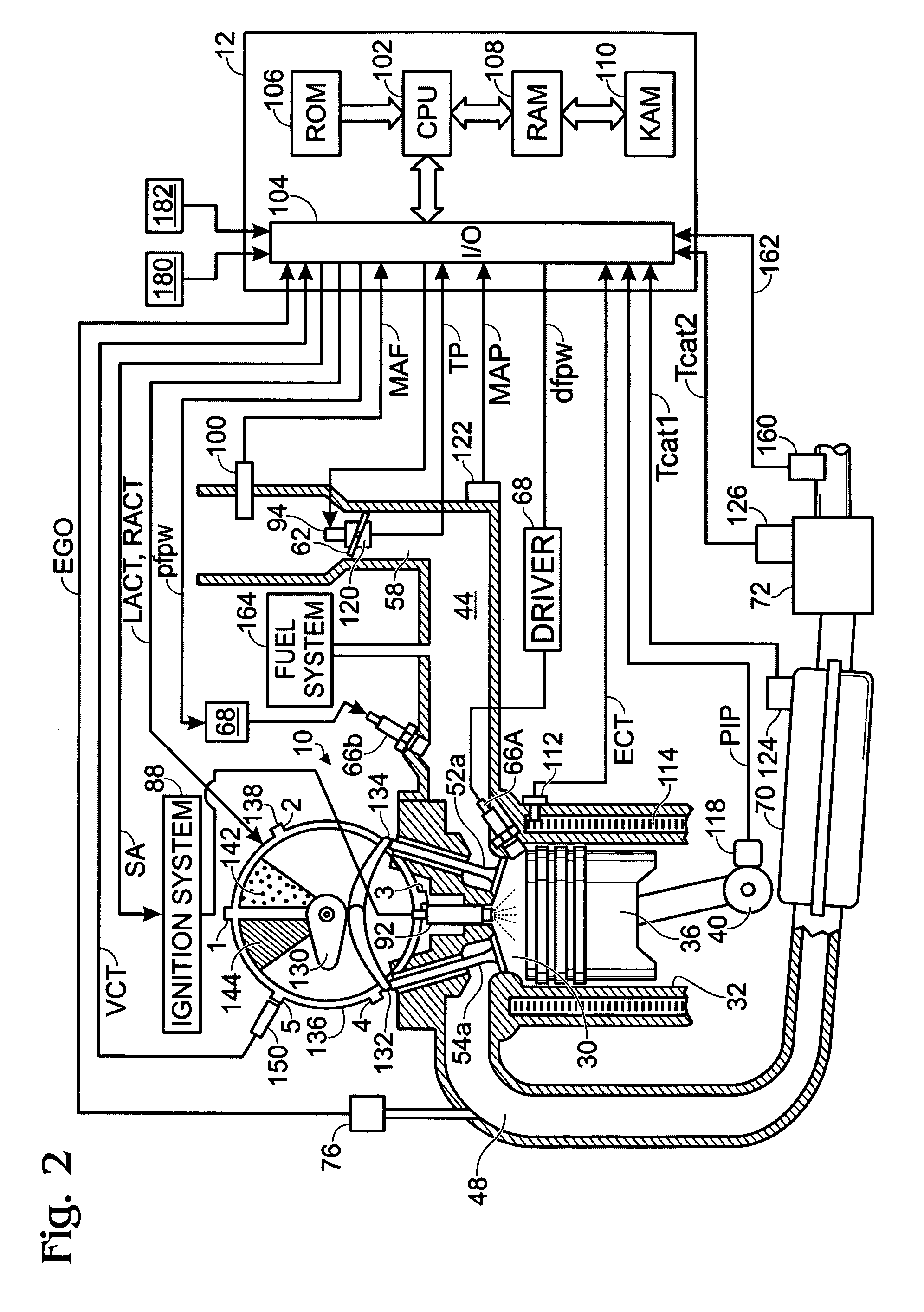

Control strategy for engine employing multiple injection types

ActiveUS20070215110A1Improve engine performanceLow costElectrical controlInternal combustion piston enginesMultiple injectionAutomotive engineering

A system for an engine, comprising a cylinder, a first injection subsystem for injecting a first substance into the cylinder, a second injection subsystem for injecting a second substance into the cylinder, and an electronic engine controller configured to control a plurality of operating parameters of the engine, where the electronic engine controller is configured to cause variation of at least one of the operating parameters in response to a shortfall condition of the second injection subsystem.

Owner:FORD GLOBAL TECH LLC

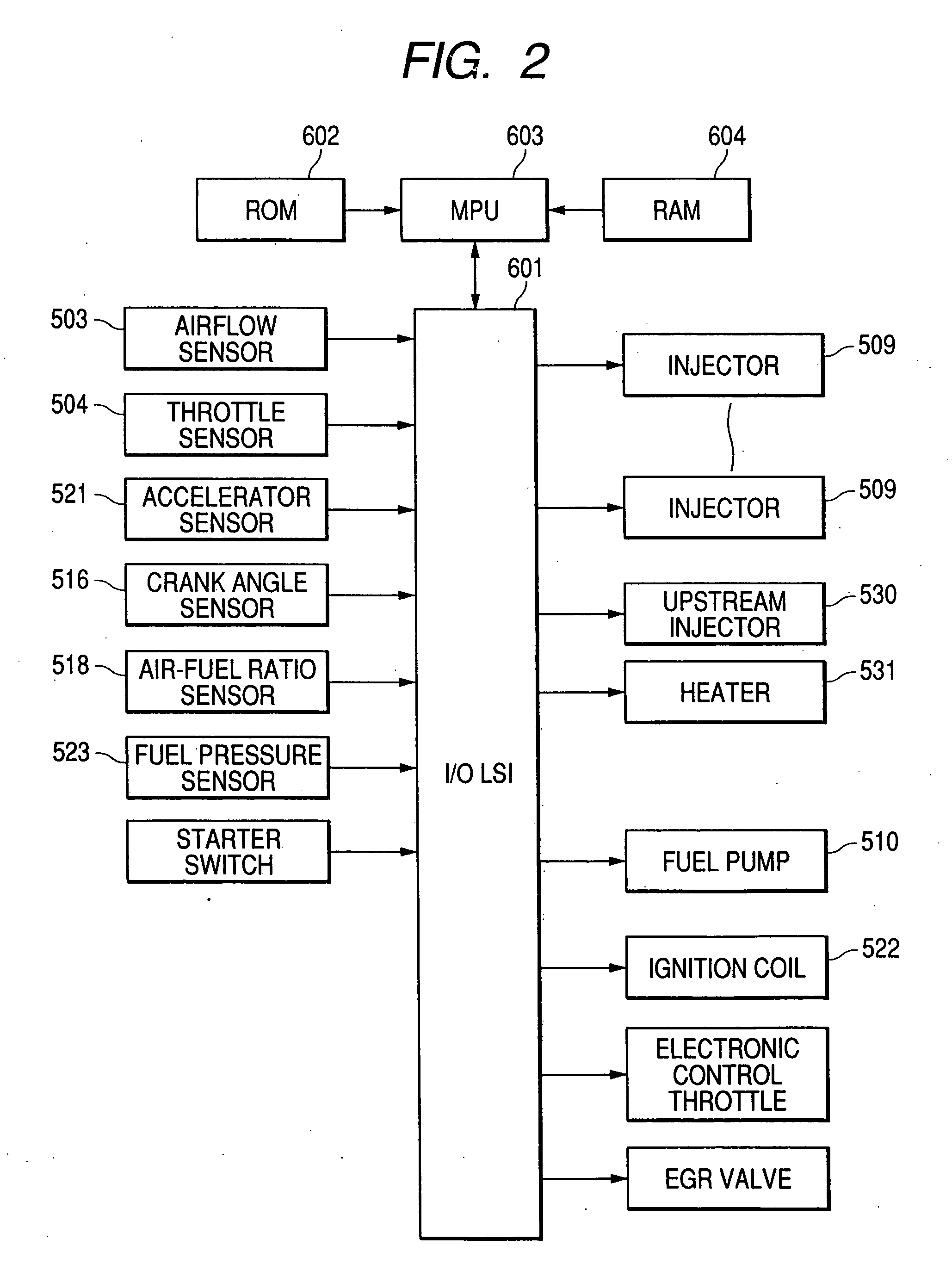

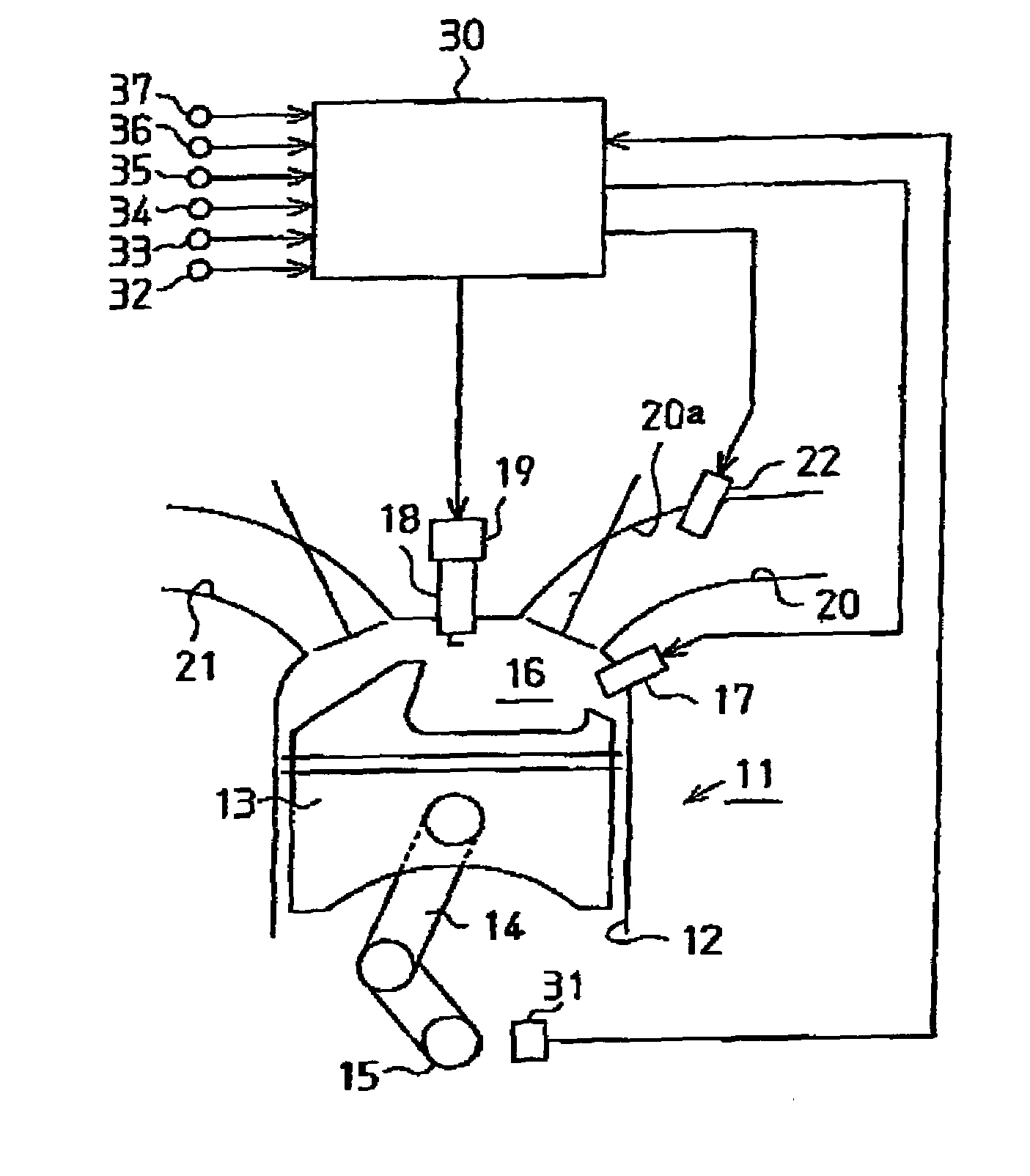

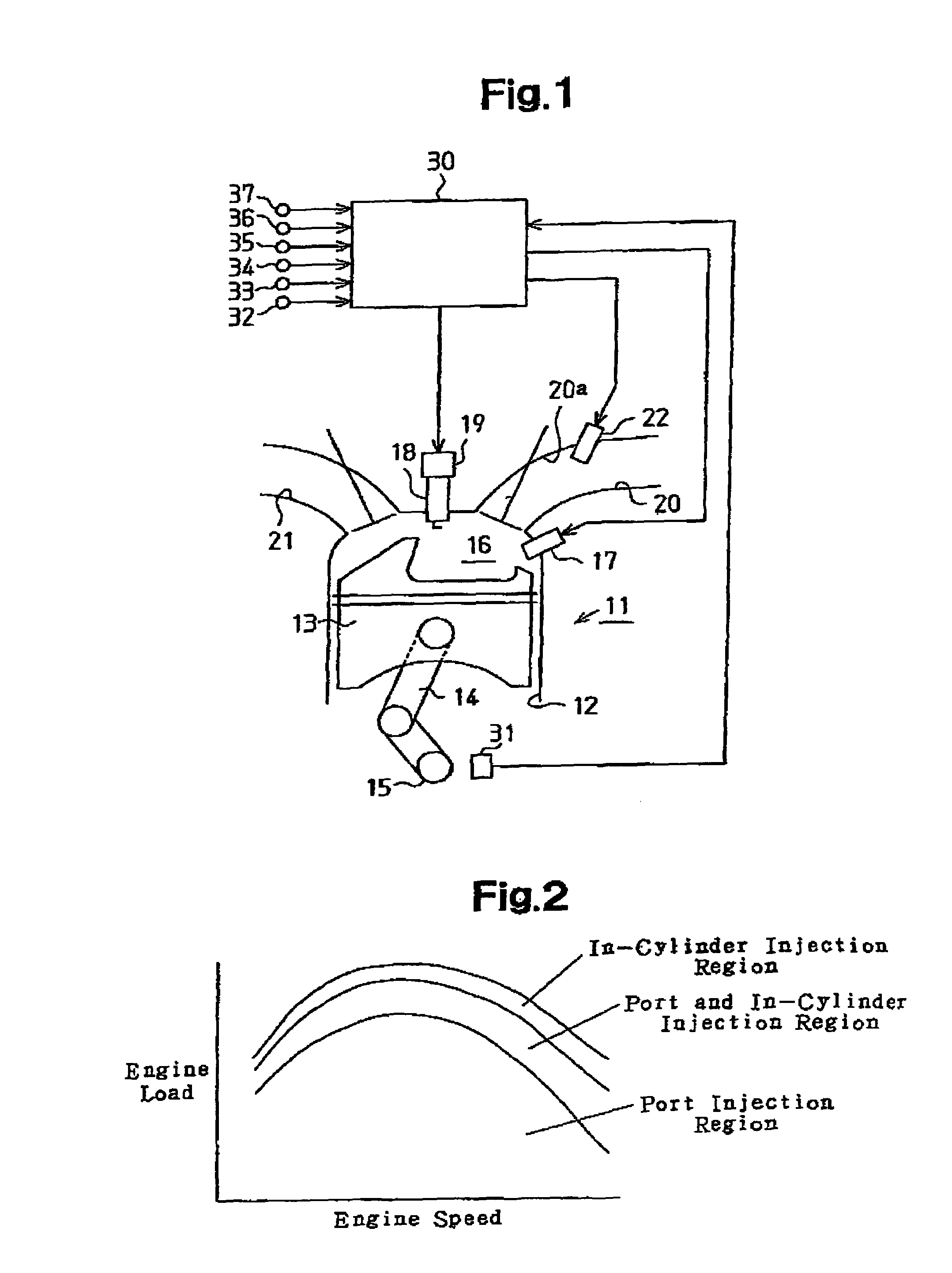

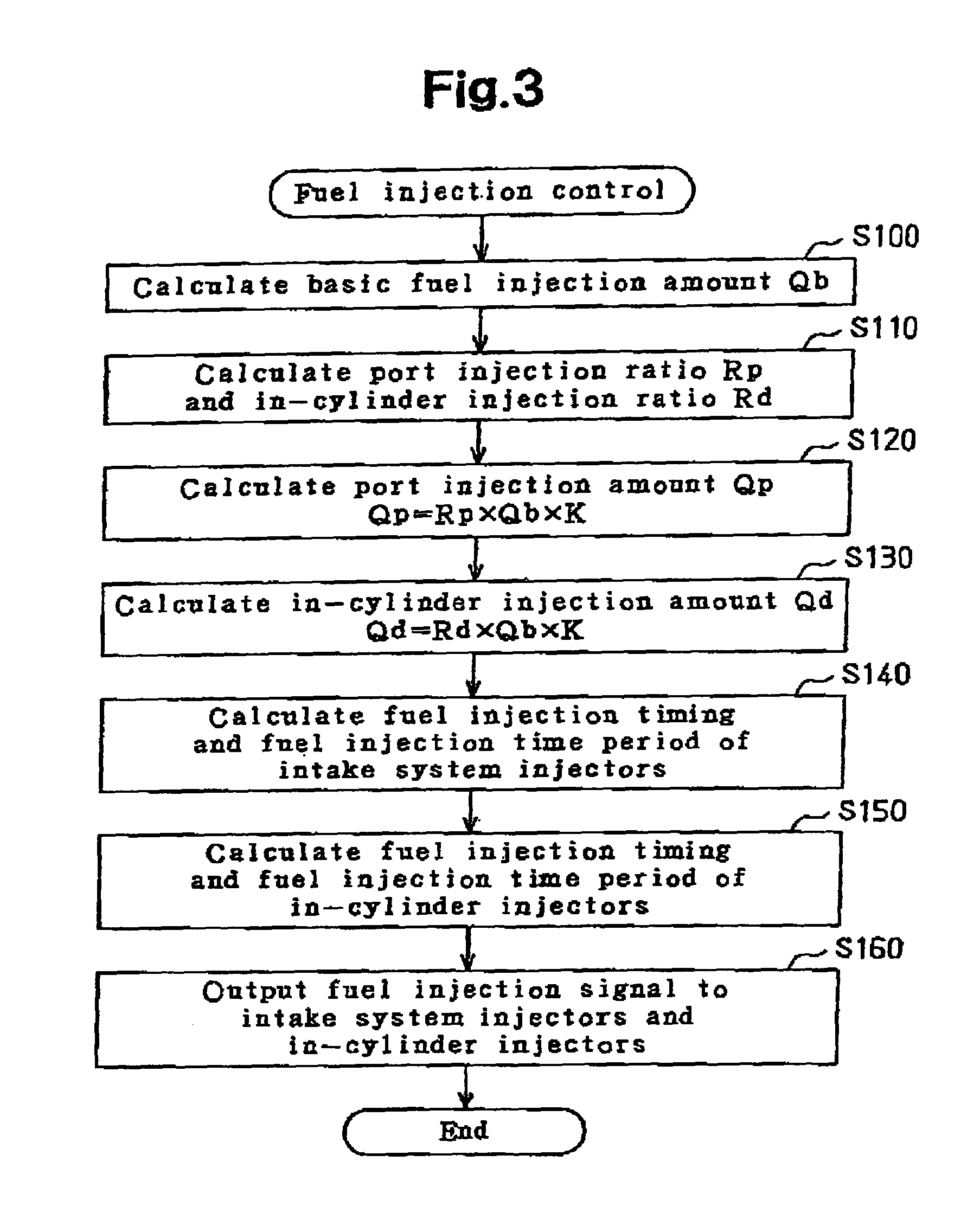

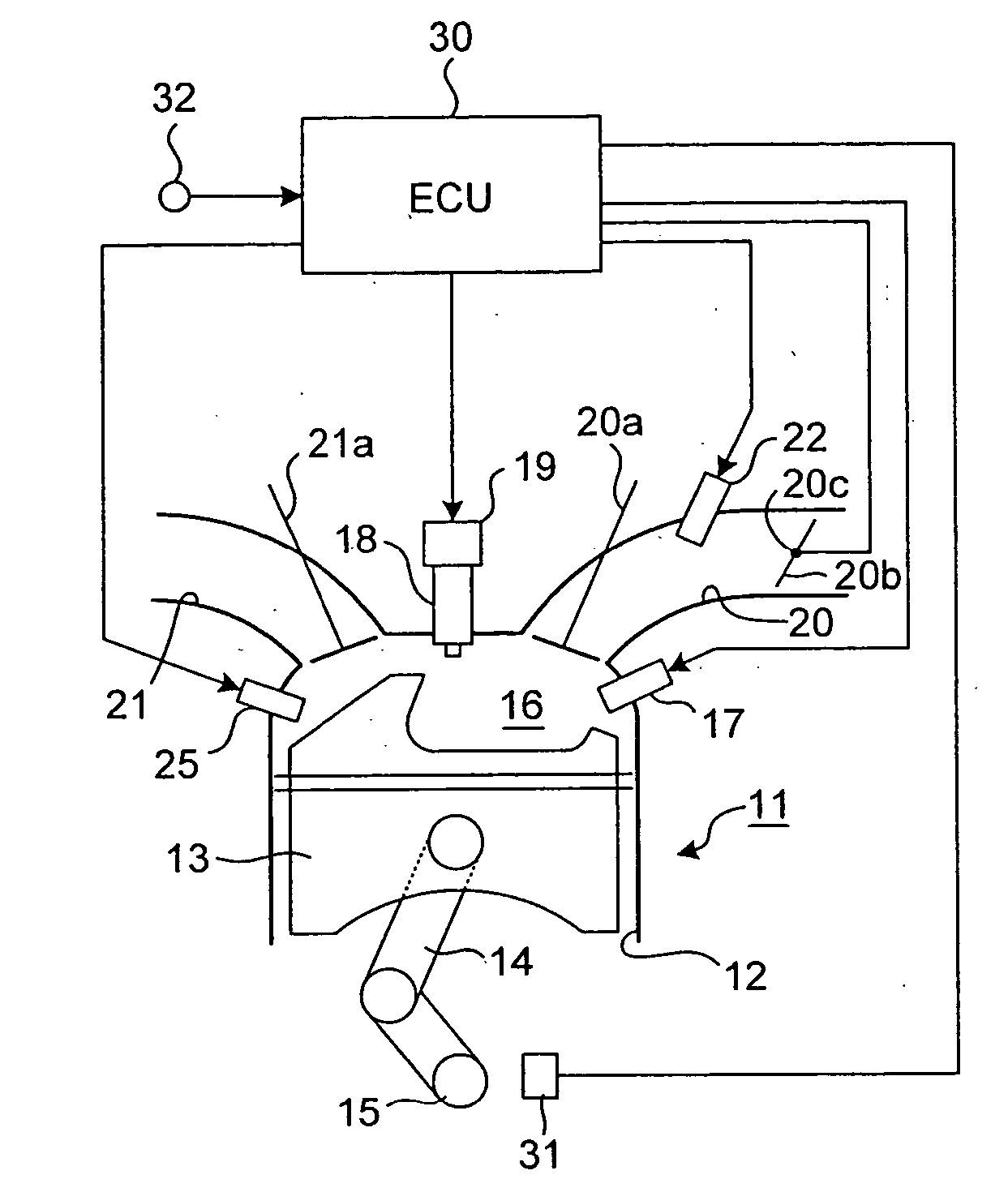

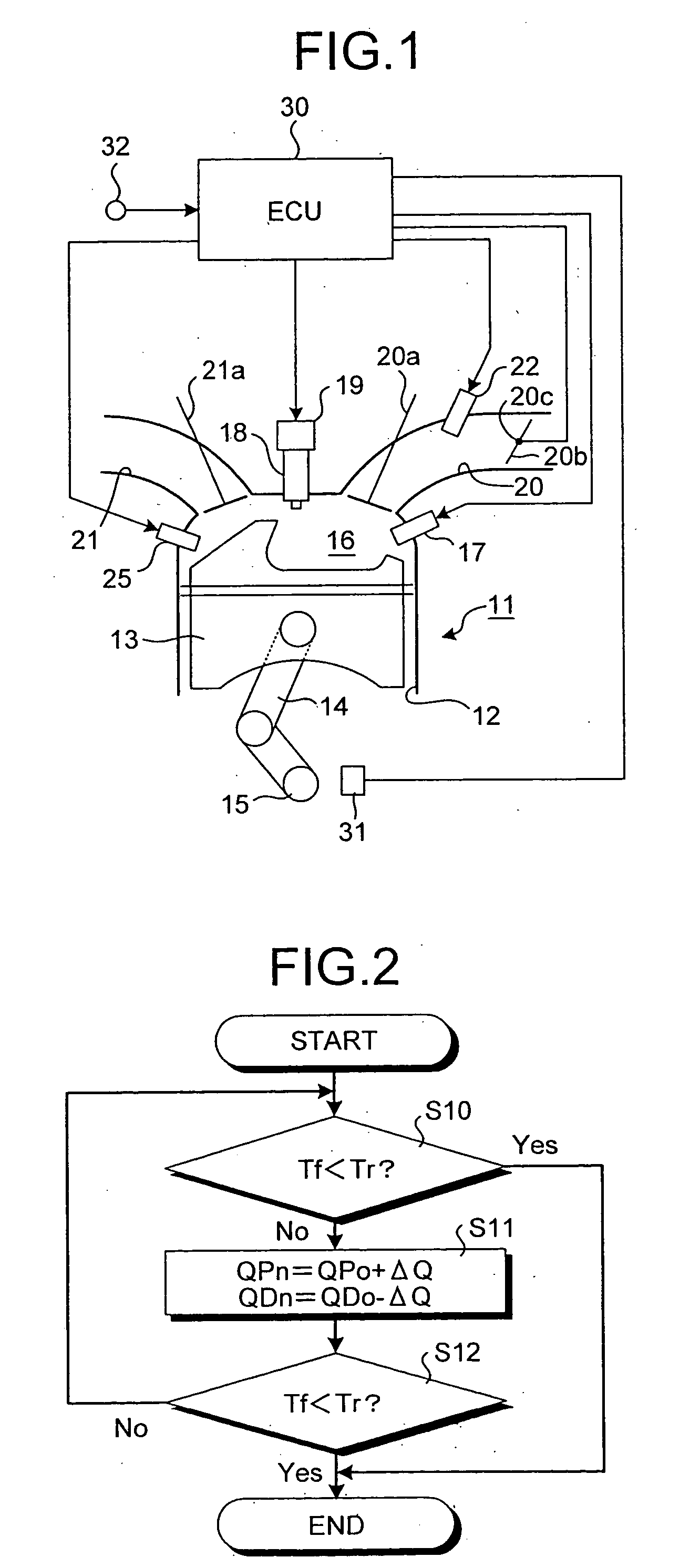

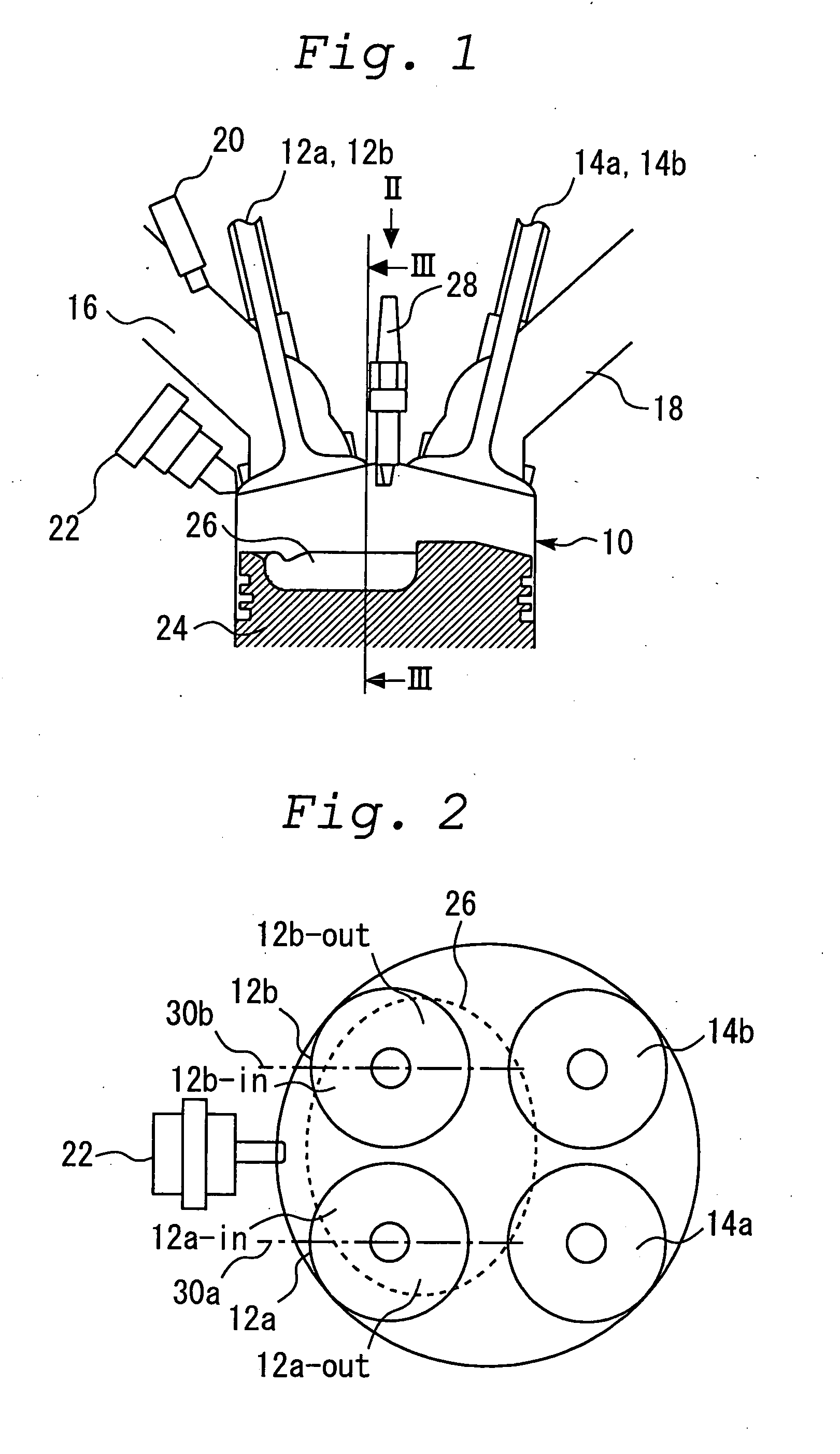

Apparatus and method for controlling fuel injection in internal combustion engine

InactiveUS7082926B2Favorable engine startabilityElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

An internal combustion engine includes an in-cylinder injector for injecting fuel into a combustion chamber of the engine and an intake system injector for injecting fuel into an intake system connected to the combustion chamber. In a starting state of the engine, an electronic control unit (ECU) causes the in-cylinder injector to perform only the initial injection to the combustion chamber, and causes the intake system injector to perform fuel injections after the initial injection. As a result, favorable engine startability is ensured, and the emission of unburned components is suppressed in the engine starting state.

Owner:TOYOTA JIDOSHA KK

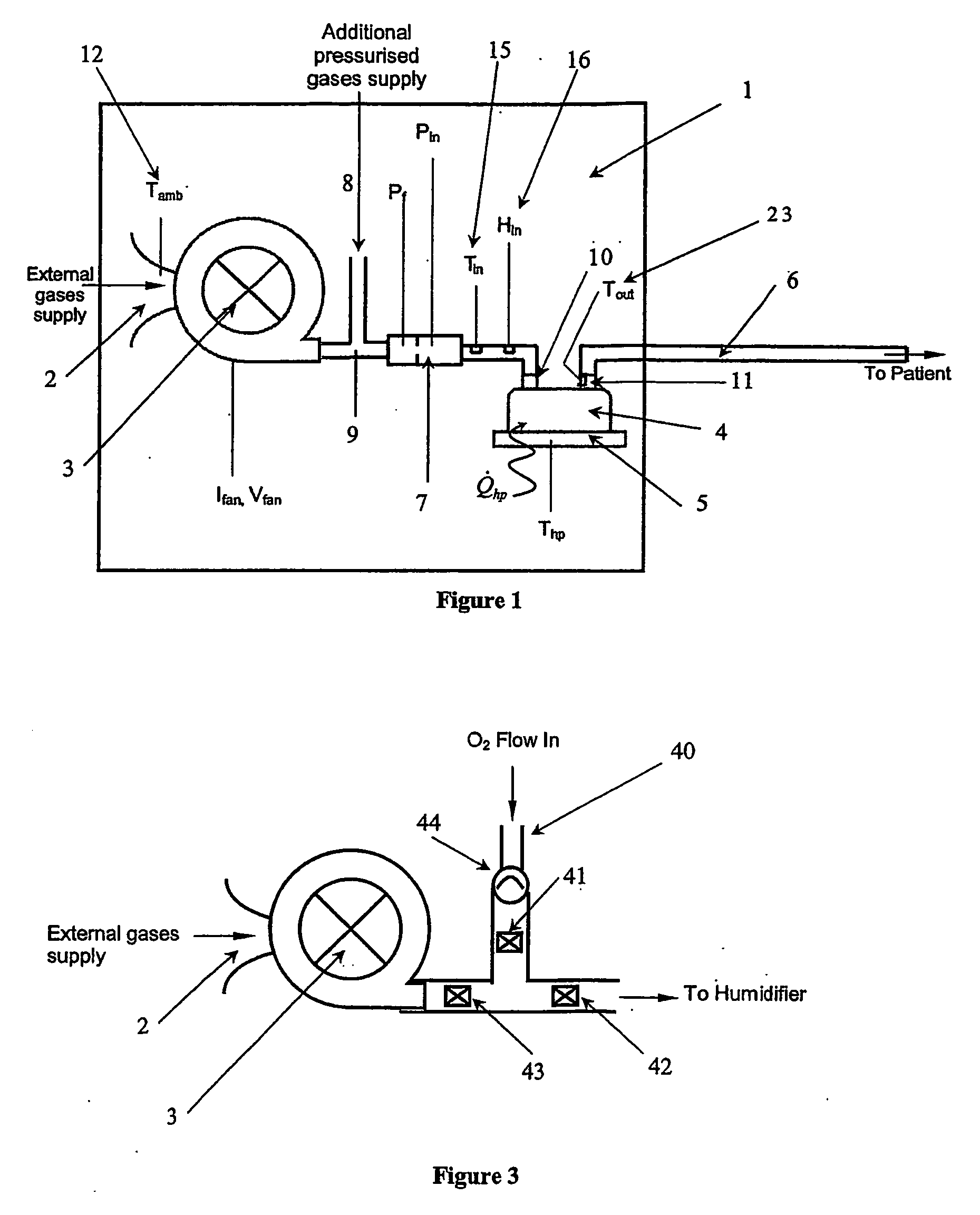

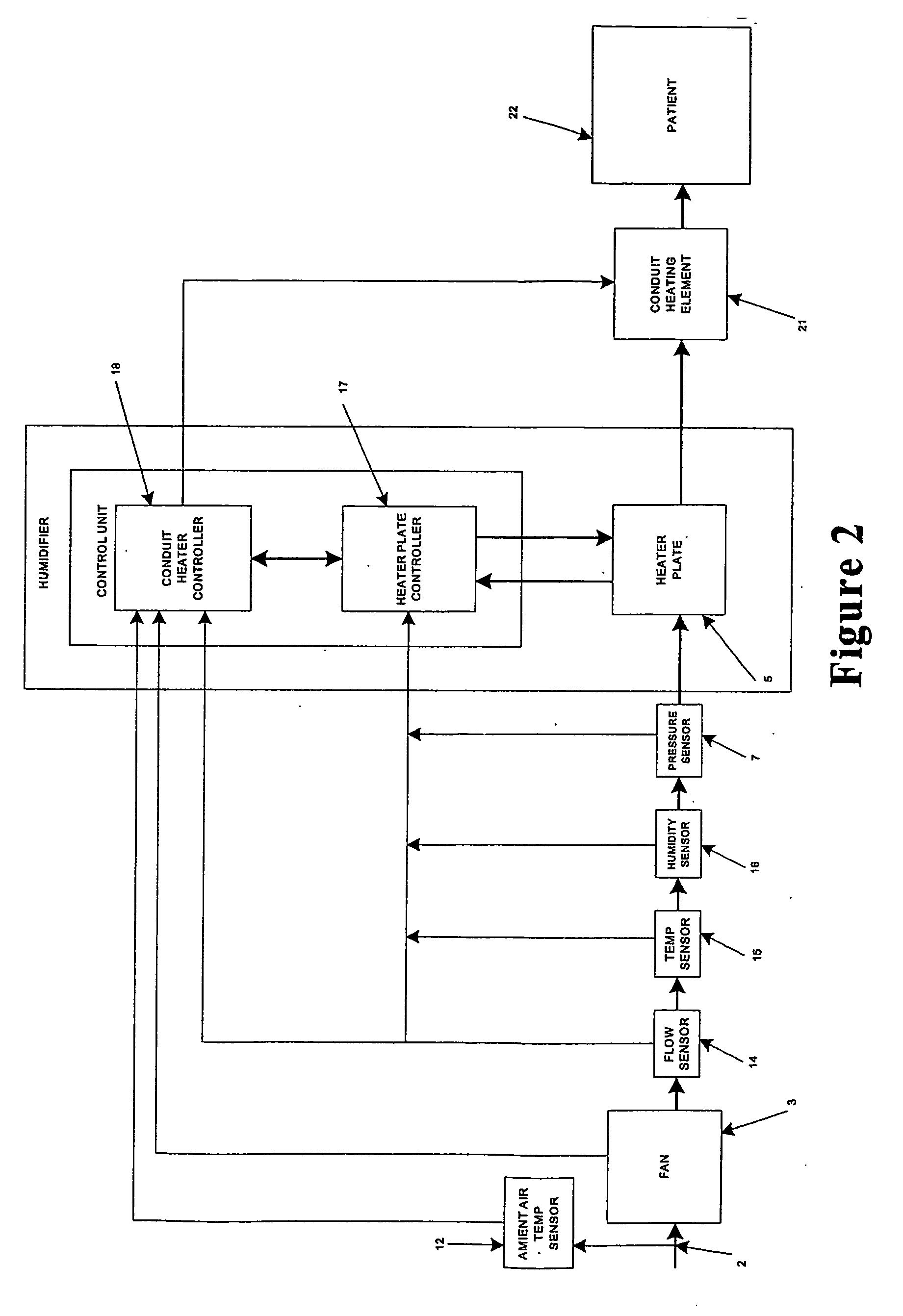

Humidification system

ActiveUS20060113690A1Eliminate needUsing liquid separation agentMedical devicesMarine engineeringHumidity

Breathing assistance apparatus including humidifier (4) and heated conduit (6) adapted to deliver humidified gases at desired and accurate level of humidity to patient. Humidifier includes controller (18) that delivers flow rate, temperature and humidity of gases and then determines required power input to deliver gases as required. Need for external sensors is dispensed with providing simple and less bulky apparatus.

Owner:FISHER & PAYKEL HEALTHCARE LTD

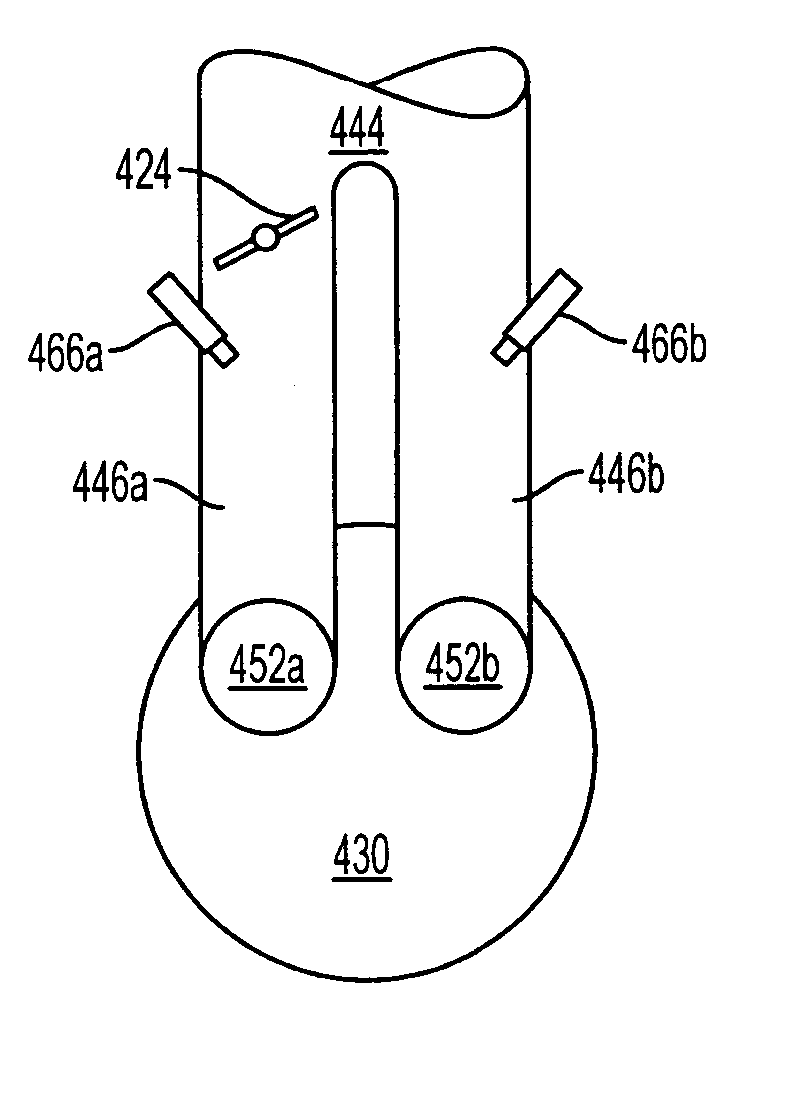

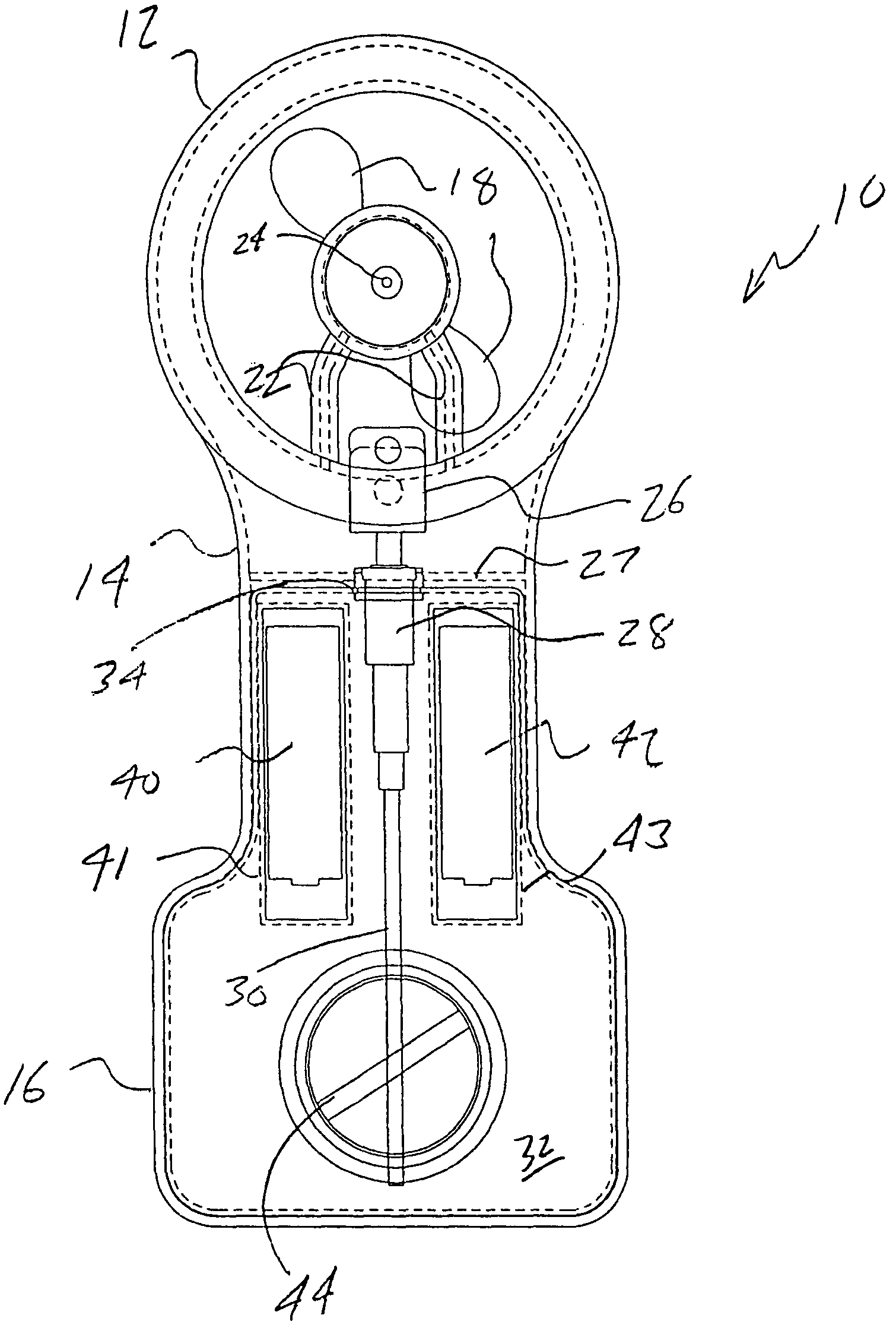

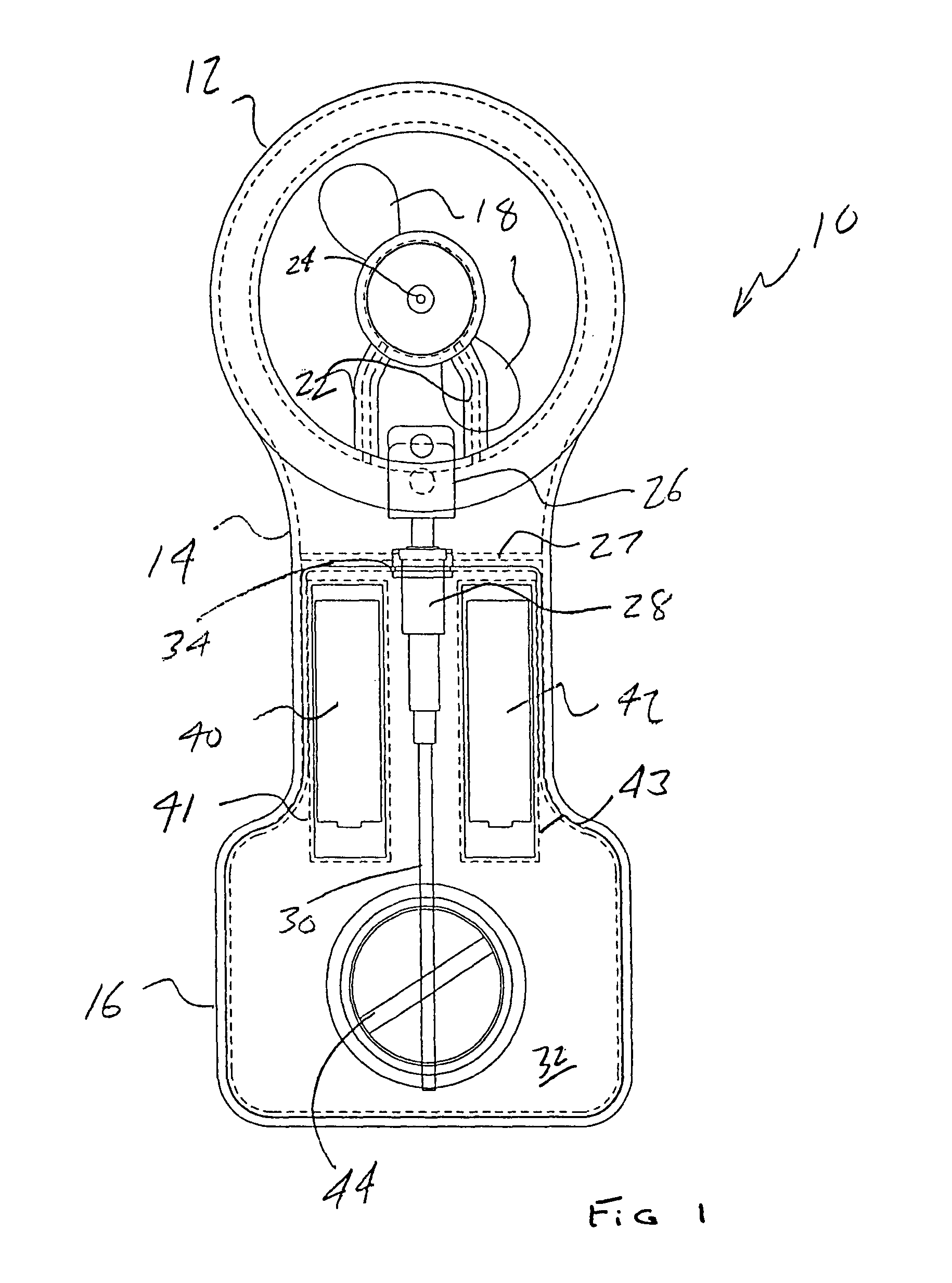

Handheld water misting fan with improved air flow

The present invention is directed to an improved handheld water misting fan device wherein the power source compartment is positioned within the device at a location remote from the fan motor thereby to remove any structure from the area bounded by the fan shroud. The relocation of the power source compartment leaves the area bounded by the shroud substantially unobstructed thereby to improve air flow. The device is formed in a dog bone shaped configuration to provide a narrow handle section for improved grippability, and an enlarged fluid reservoir at the lower end thereof for greater reservoir capacity.

Owner:O2COOL

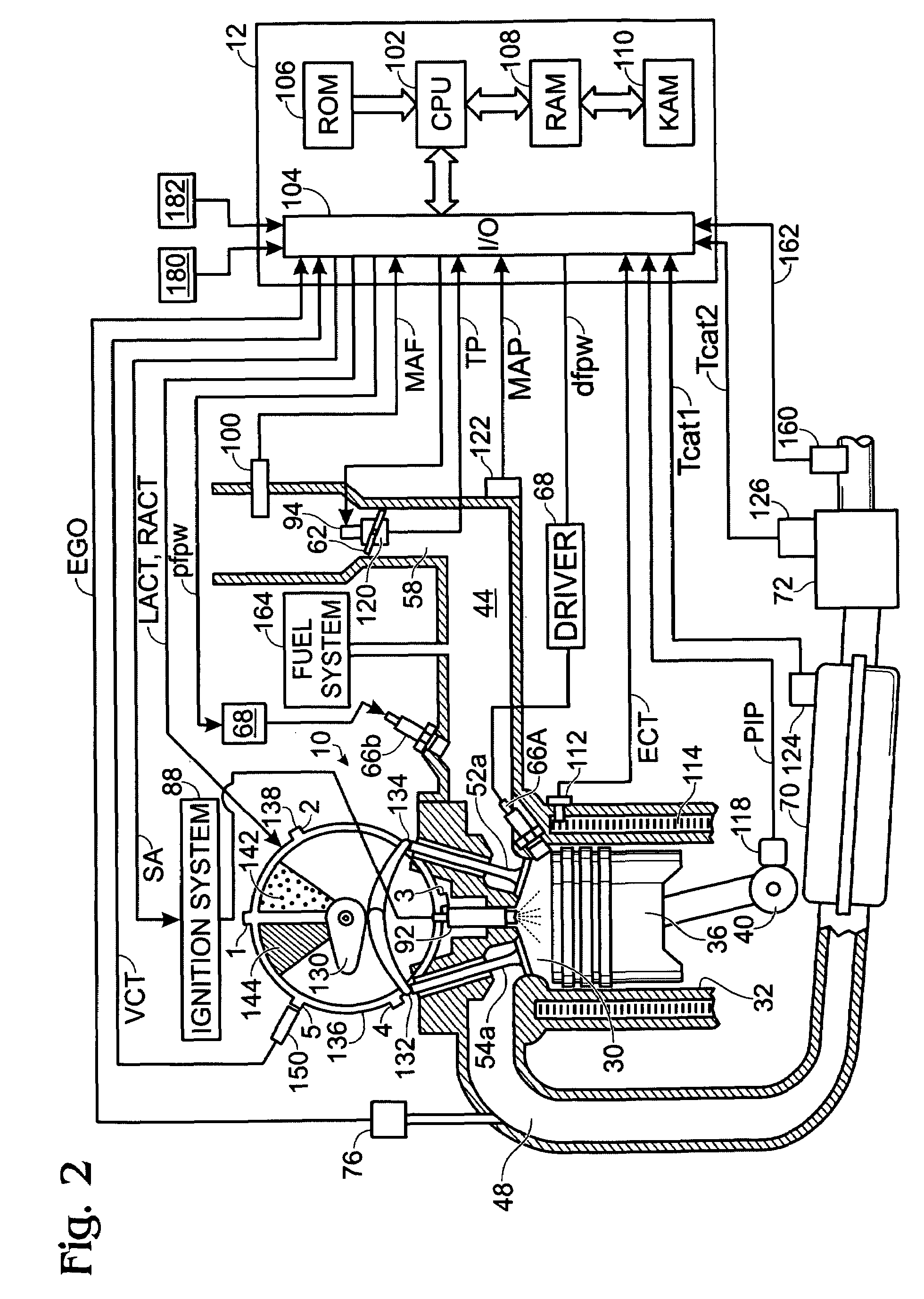

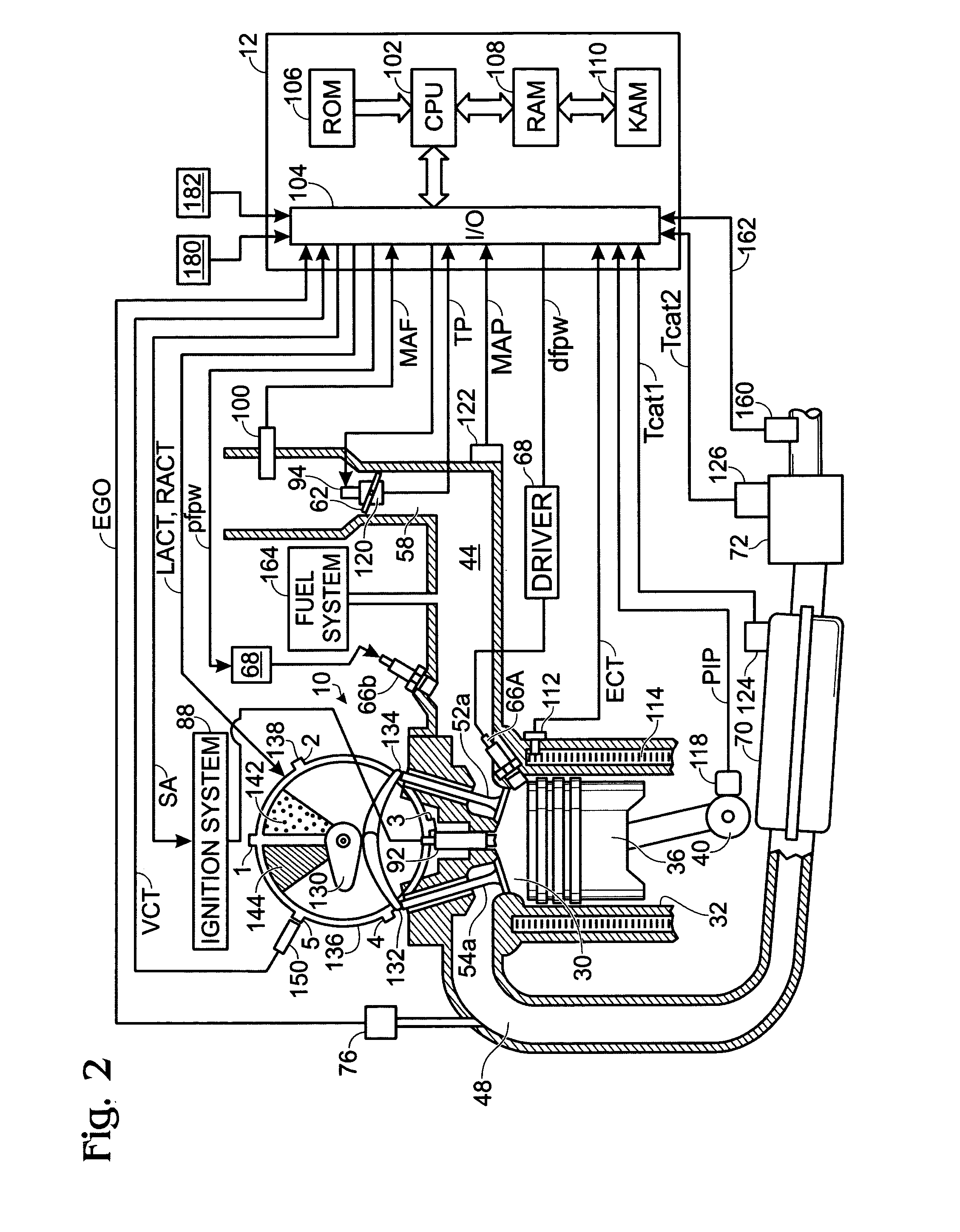

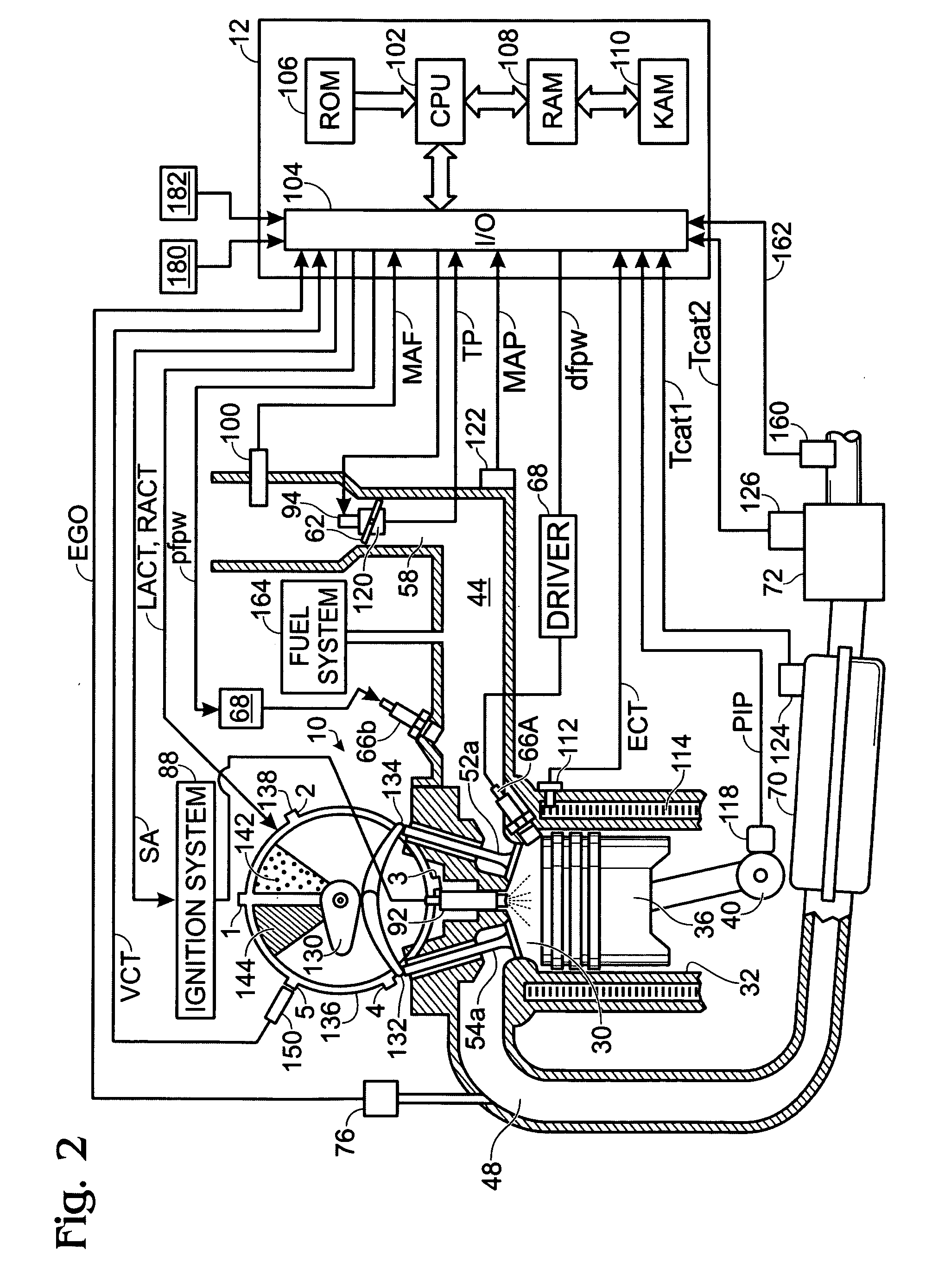

System and method for engine air-fuel ratio control

InactiveUS20070119415A1Improve engine performanceLow costElectrical controlNon-fuel substance addition to fuelOxygen sensorOperant conditioning

A method for operating an engine having a first injector for injecting a first fuel into a cylinder of the engine and a second injector for injection a second fuel into said cylinder of the engine, the engine further having at least an exhaust gas oxygen sensor, the method comprising of varying an amount of said first fuel injection in response to said sensor under a first operating condition, and varying an amount of said second fuel injection in response to said sensor under a second operating condition.

Owner:FORD GLOBAL TECH LLC

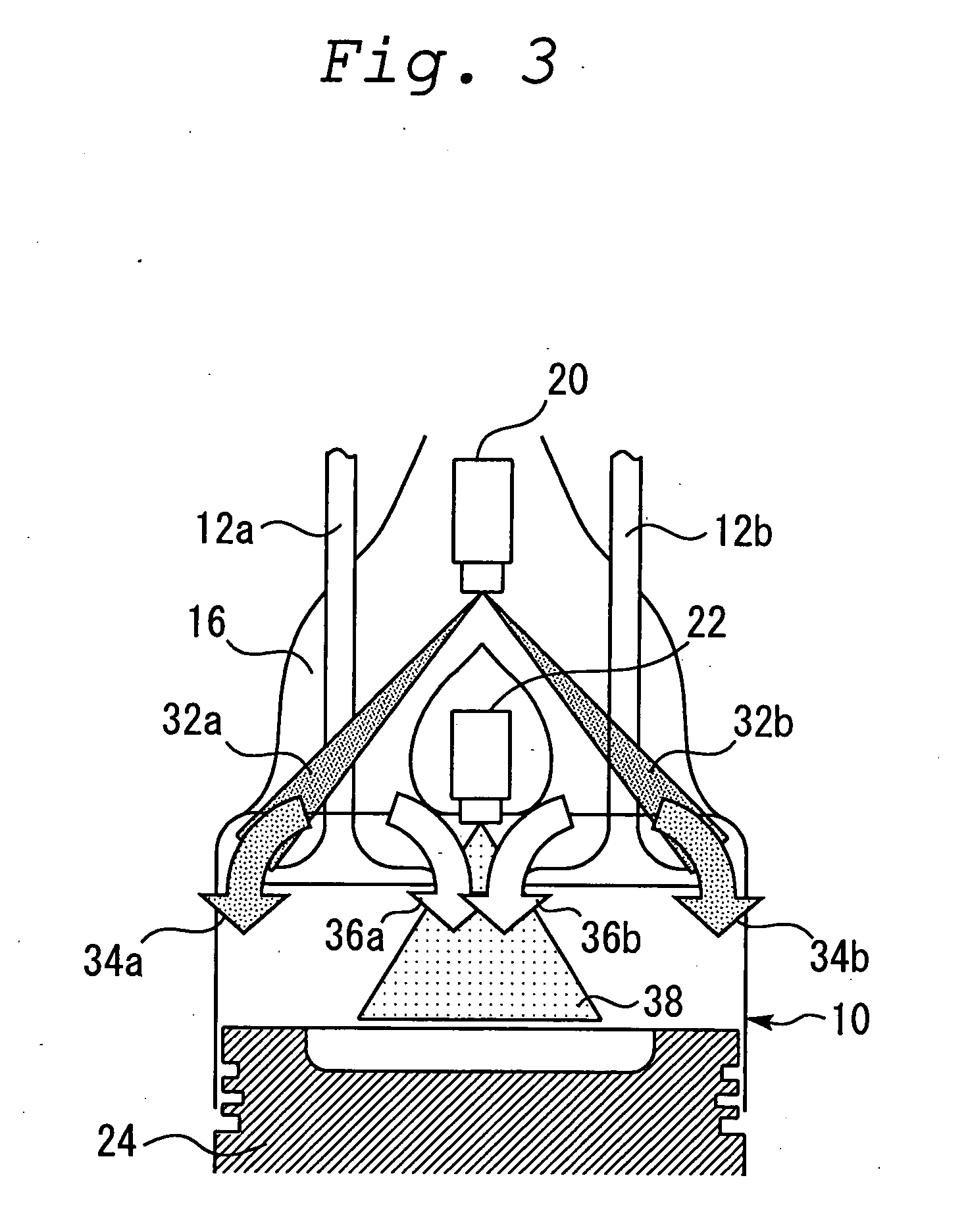

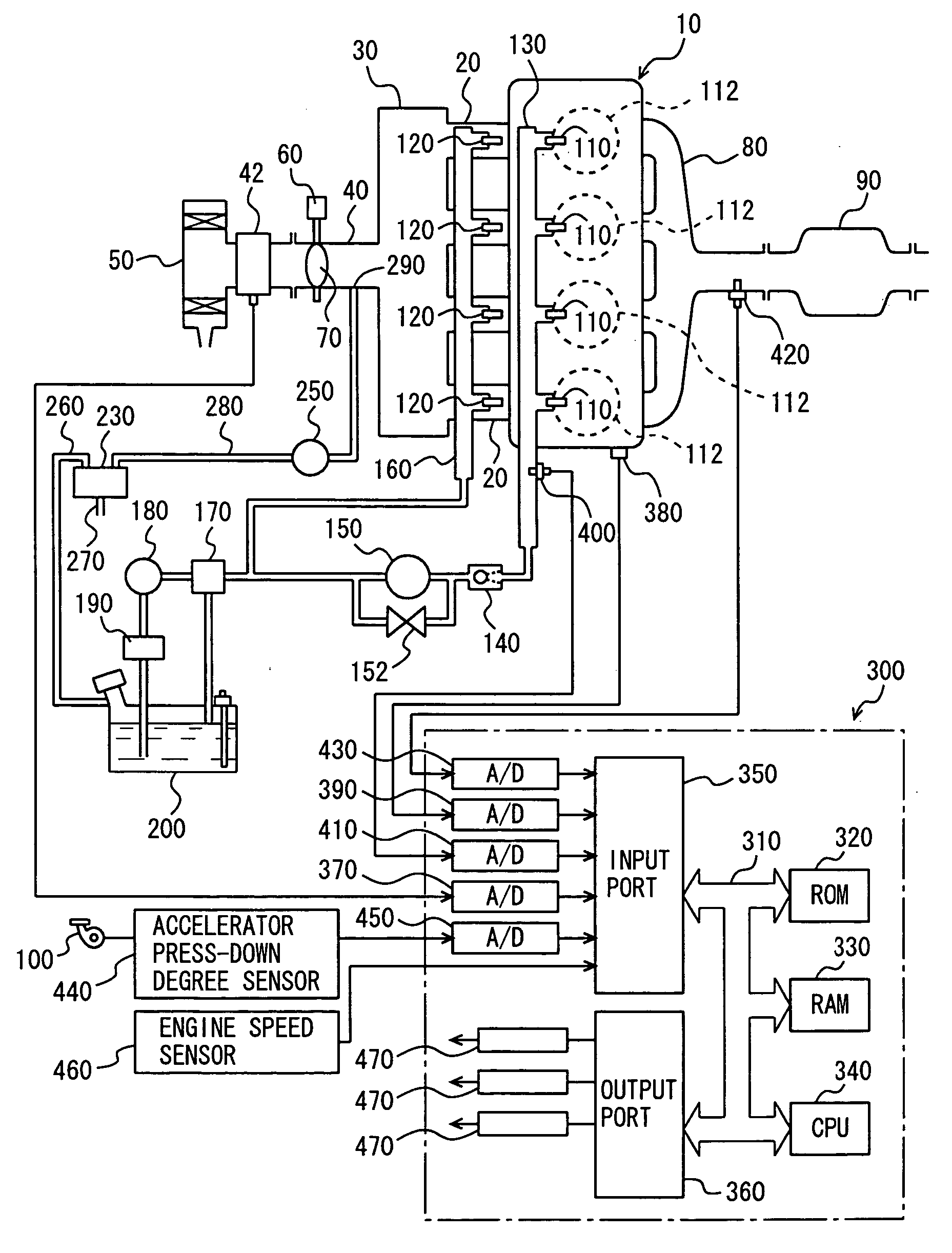

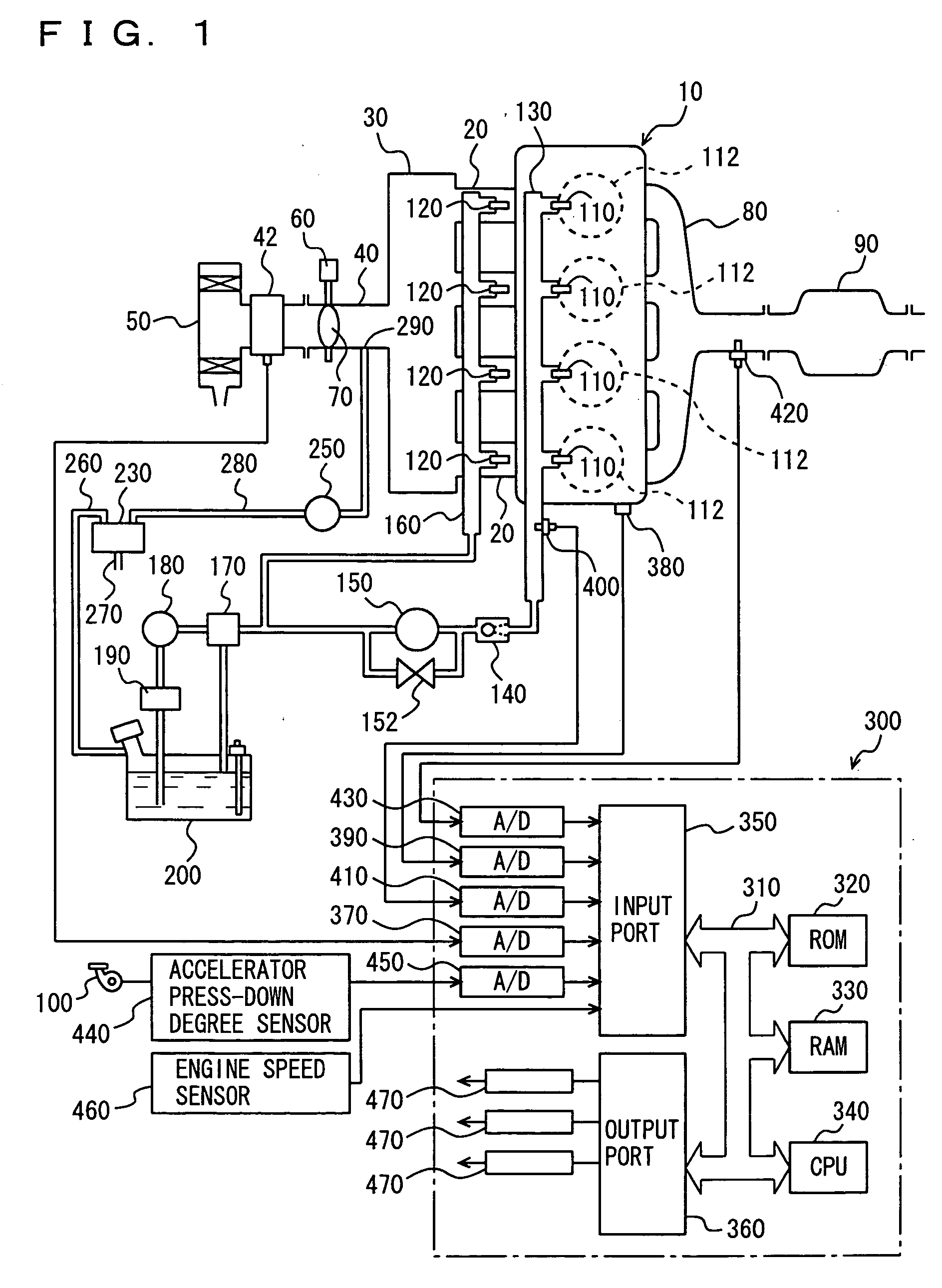

Fuel injection controller for engine

InactiveUS20050178356A1Lowering target speedAvoid procrastinationElectrical controlCombustion enginesFuel injectionInjector

A fuel injection controller for an engine having a direct injector for injecting fuel into a cylinder and an intake injector for injecting fuel into an intake passage. When the engine is idling, the controller reduces a target engine speed while preventing the engine from stalling. The fuel injection controller supplies fuel to the engine through the direct injector and the intake injector when the engine is idling. The electronic control unit determines if there is a possibility of the engine stalling when the engine is idling. When having determined that there is such a possibility, the electronic control unit increases the fuel injection amount of the direct injector.

Owner:TOYOTA JIDOSHA KK

System and method for controlling spark-ignition internal combustion engine

ActiveUS20050051135A1Reduce openingElectrical controlNon-fuel substance addition to fuelControl systemFuel injection

A control system controls a spark-ignition internal combustion engine. The spark-ignition internal combustion engine includes a cylinder, and a fuel injection valve arranged in the cylinder; and an intake port that communicates with the cylinder, and a fuel injection valve arranged in the intake port. Fuel is injected from both the fuel injection valves in at least a part of an operating range. If combustion fluctuations exceed a predetermined amount, in consideration of a preset proportion of fuels to be injected into the cylinder and the intake port, a proportion of fuel to be injected into the cylinder is decreased and a proportion of fuel to be injected into the intake port is increased.

Owner:TOYOTA JIDOSHA KK

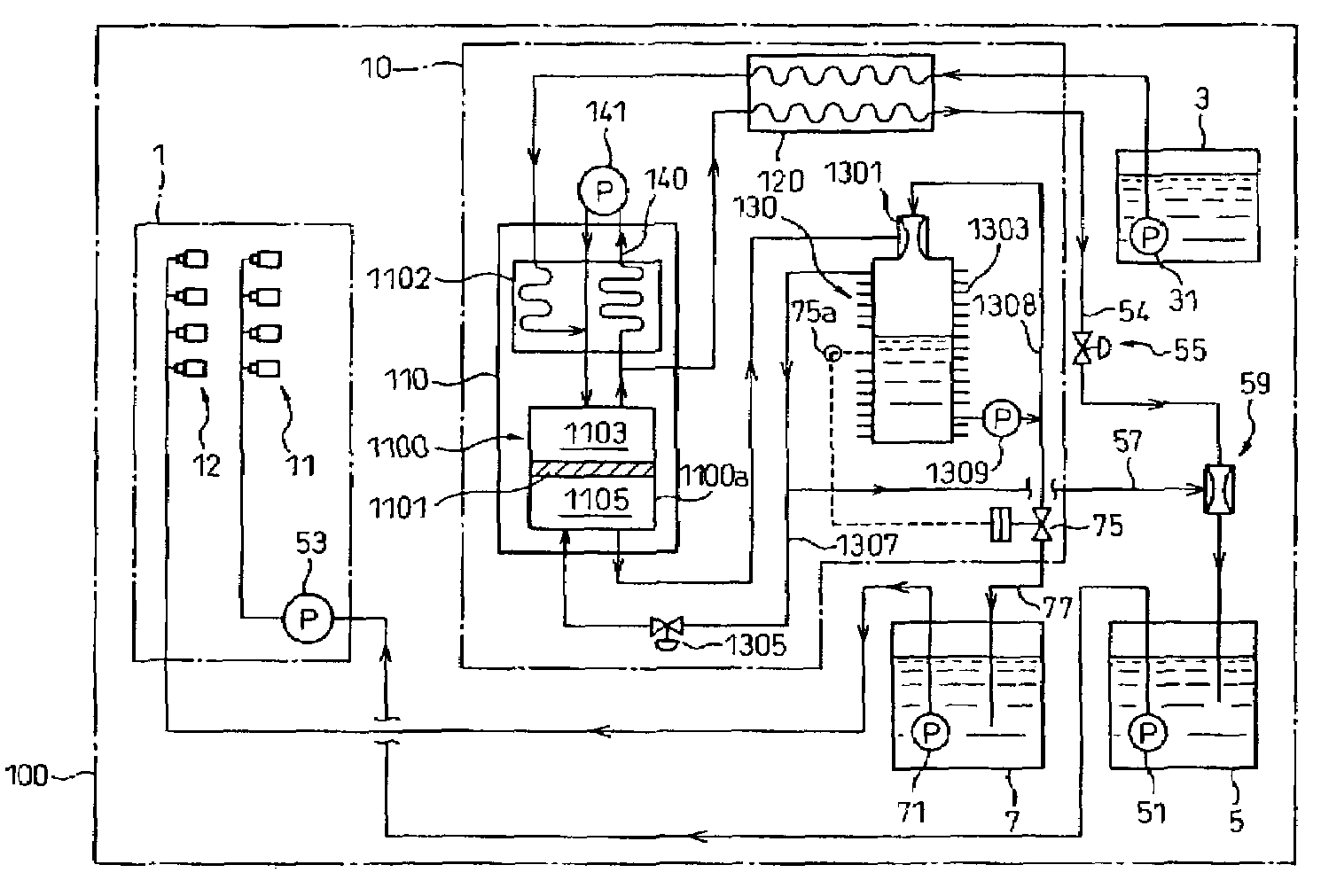

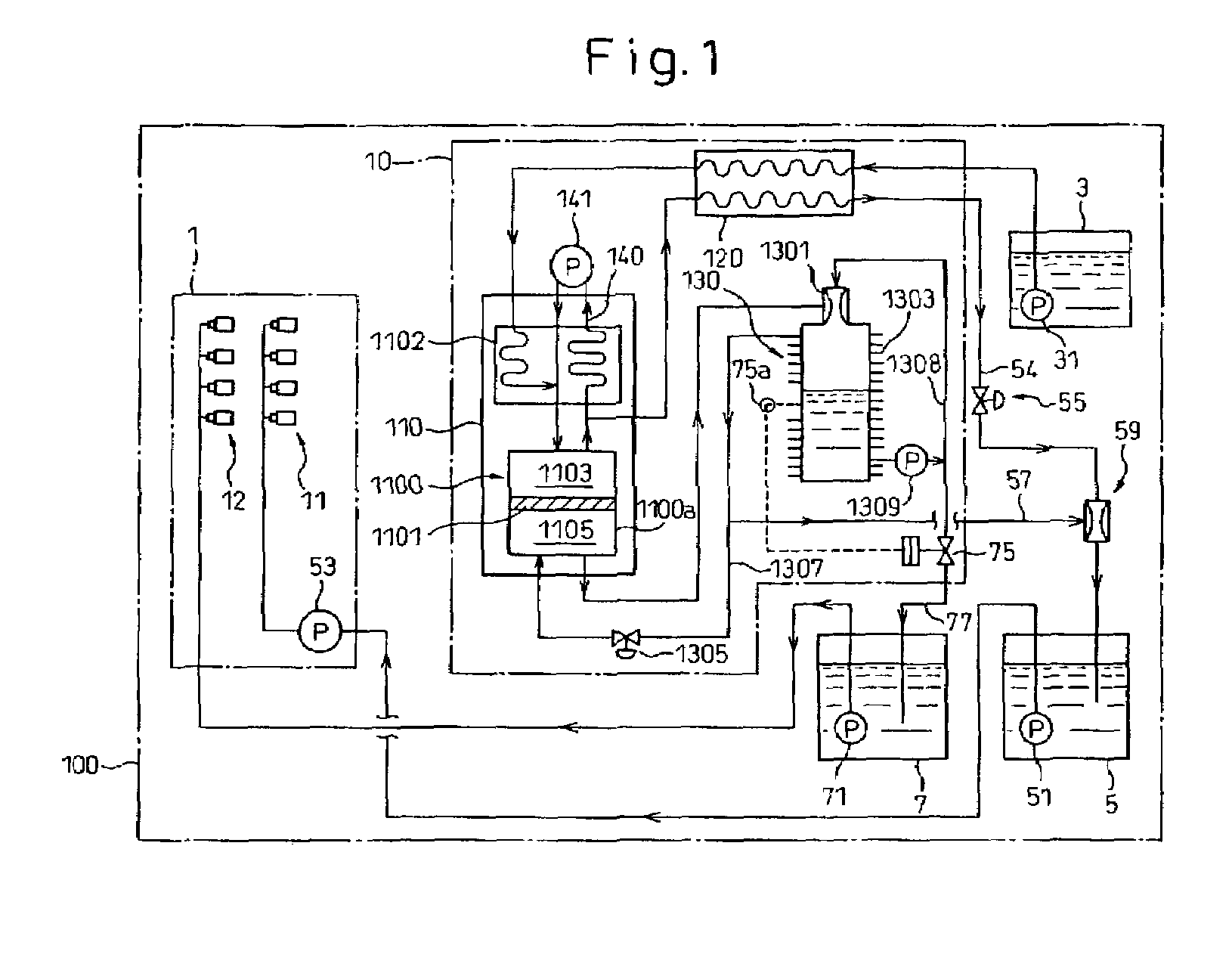

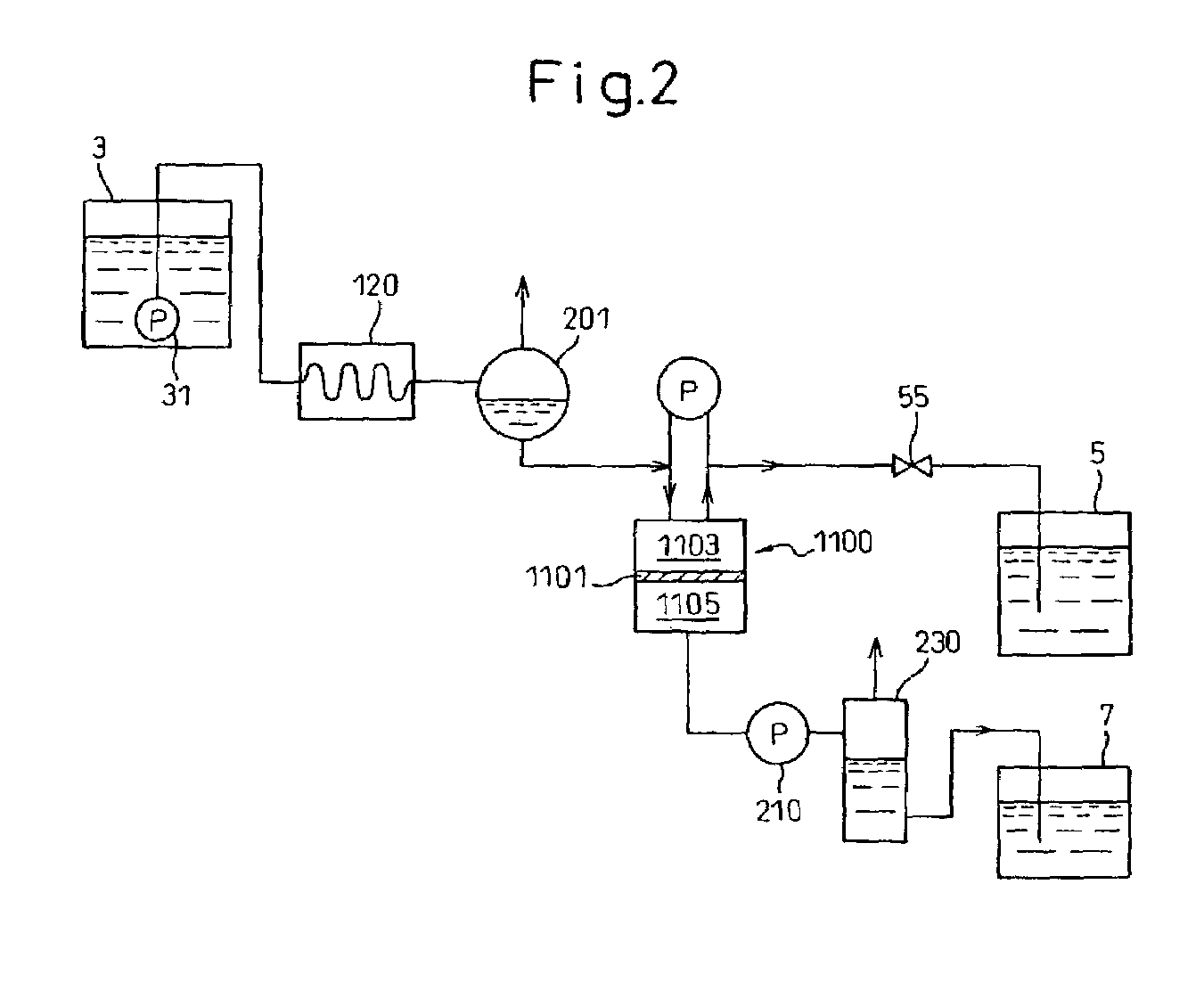

Onboard fuel separation apparatus for an automobile

InactiveUS6972093B2Increase volumeBoost octaneInternal combustion piston enginesUsing liquid separation agentVolatilesEngineering

An onboard fuel separation apparatus separates a material fuel (gasoline) into a high-octane fuel having a higher octane value than the material fuel and a low-octane fuel having a lower octane value than the material fuel using a separation membrane which selectively allows high-octane value components (such as aromatic components) permeate through the membrane. The apparatus increases the ratio of the amount of the high-octane value components permeating through the membrane to the amount of the high-octane value components contained in the material fuel by, (A) Controlling the temperature of the material fuel supplied to the membrane (B) Increasing partial pressure of the low-octane value components on the high-octane fuel side of the membrane and removing volatiles from the permeate, and (C) Bypassing volatiles in the material feed around the membrane.

Owner:EXXON RES & ENG CO +1

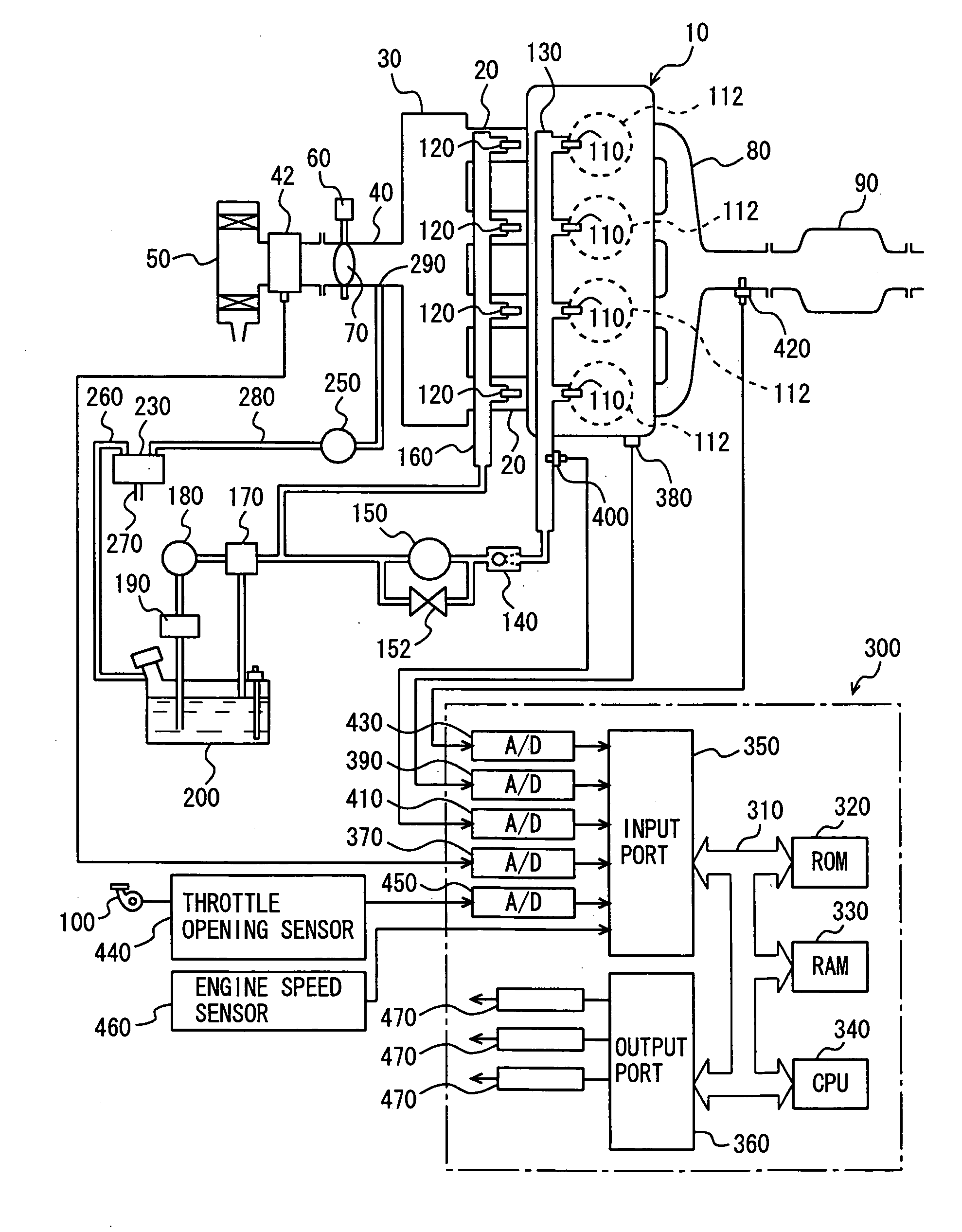

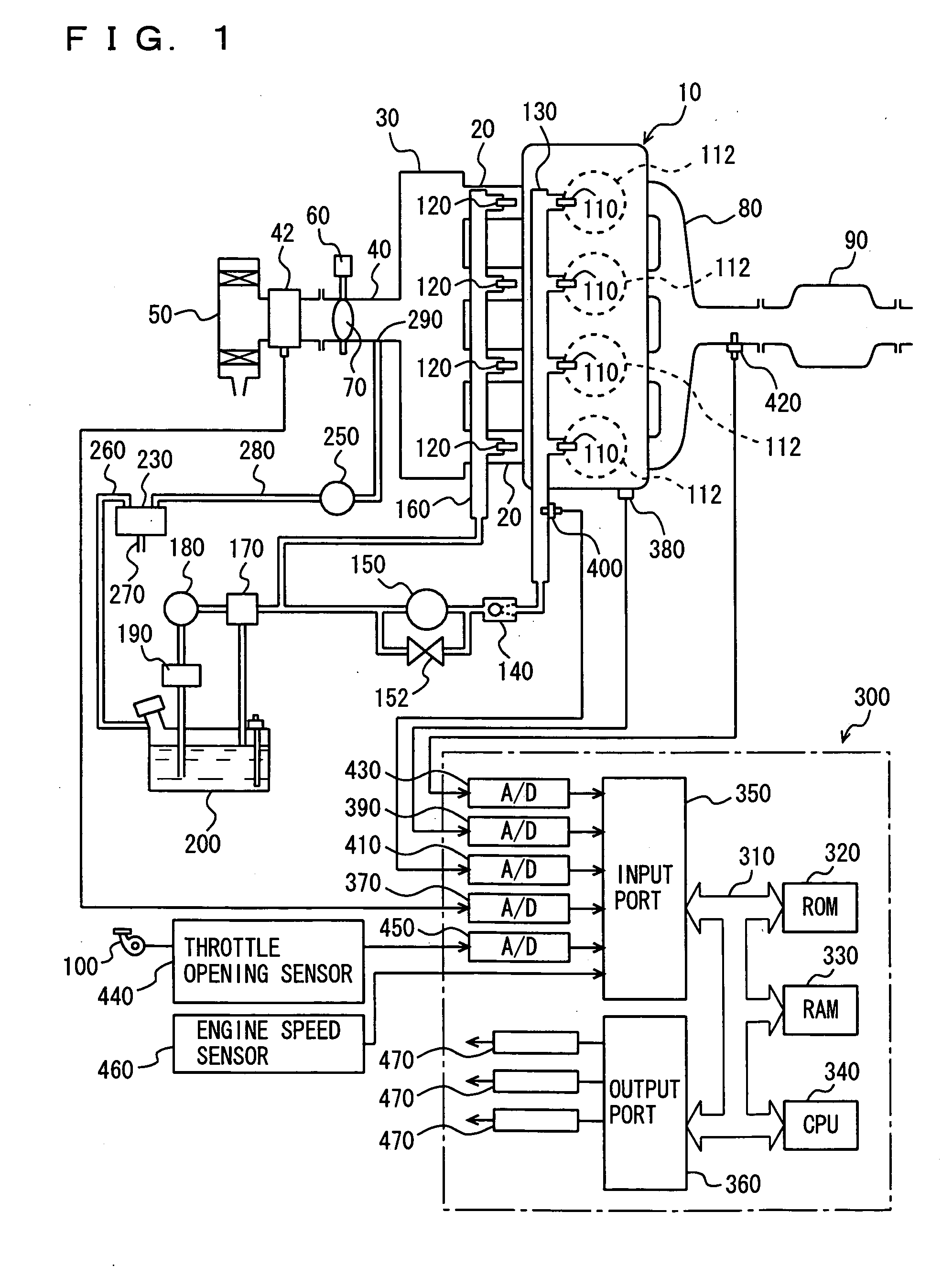

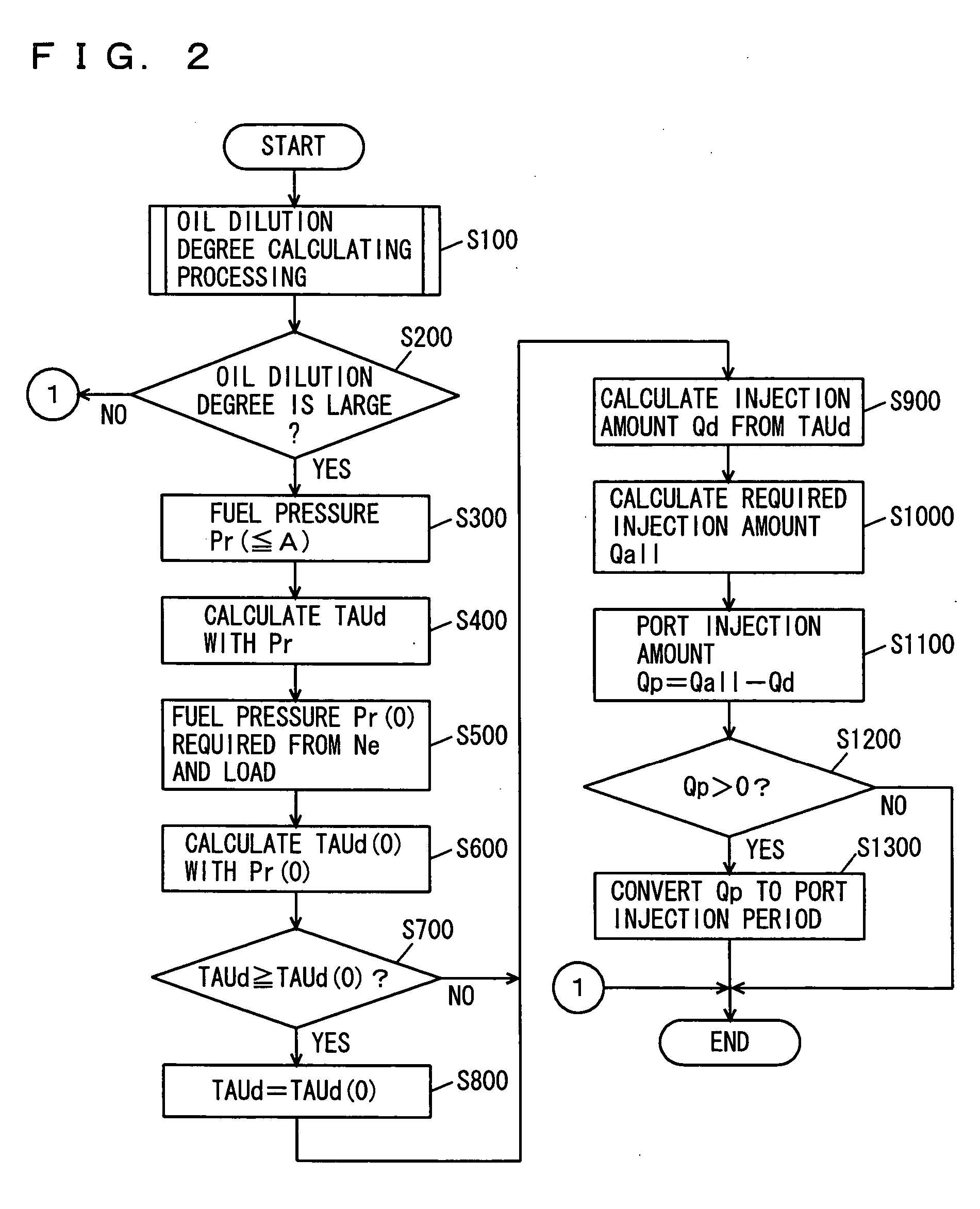

Control device of internal combustion engine

InactiveUS20060016429A1Without performance of internalElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

An engine ECU executes a program including a step of lowering a pressure of fuel supplied to an in-cylinder injector when it is determined that a degree of dilution of an oil with the fuel is large, a step of calculating a fuel injection period TAUd of the in-cylinder injector with a low fuel pressure, a step of calculating a fuel pressure Pr(0) of the in-cylinder injector required according to an engine speed and a load, a step of calculating a fuel injection period TAUd(0) of the in-cylinder injector with Pr(0), and a step of substituting TAUd(0) for TAUd when TAUd is equal to or larger than TAUd(0).

Owner:TOYOTA JIDOSHA KK

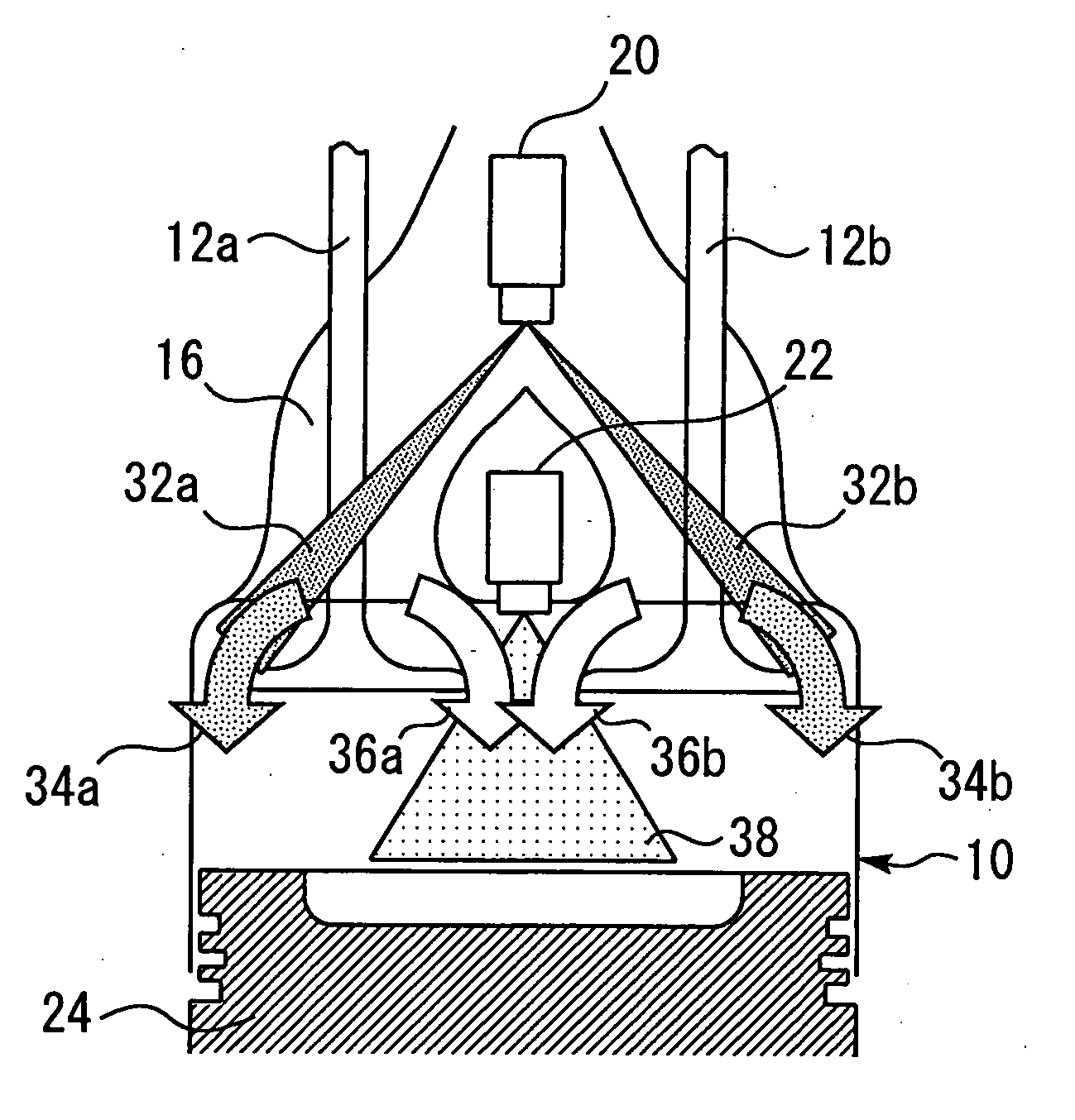

Spark ignition internal combustion engine

Each cylinder is provided with an ignition plug, two intake valves, an intra-cylinder fuel injector, and a port fuel injector. When homogeneous combustion is demanded, the intra-cylinder fuel injector and port fuel injector inject fuel on the same engine cycle. The port fuel injector is installed so that the amount of fuel directed toward outer regions of the intake valves is larger than that of fuel directed toward inner regions of the intake valves, thereby causing only fresh air to flow to regions near the inner regions of the intake valves.

Owner:TOYOTA JIDOSHA KK

Control device of internal combustion engine

ActiveUS20050274353A1Avoid volatilityLowering of of emissionElectrical controlCombustion enginesInlet manifoldFuel injection

When an injection sharing ratio r is neither 0 nor 1, an engine ECU executes a program including a step of calculating a purge reduction amount of an in-cylinder injector as fpg×r and calculating a purge reduction amount of an intake manifold injector as fpg×(1-r) when performing purge processing according to a current fuel injection sharing ratio of the injectors, and a step of calculating a correction fuel injection amount of the in-cylinder injector by raising the fuel injection amount to a minimum fuel injection amount, and calculating a correction fuel injection amount of the intake manifold injector by subtracting the raised amount from the fuel injection amount of the intake manifold injector when the fuel injection amount of the in-cylinder injector calculated by using the purge reduction amount is lower than the minimum injection amount.

Owner:TOYOTA JIDOSHA KK

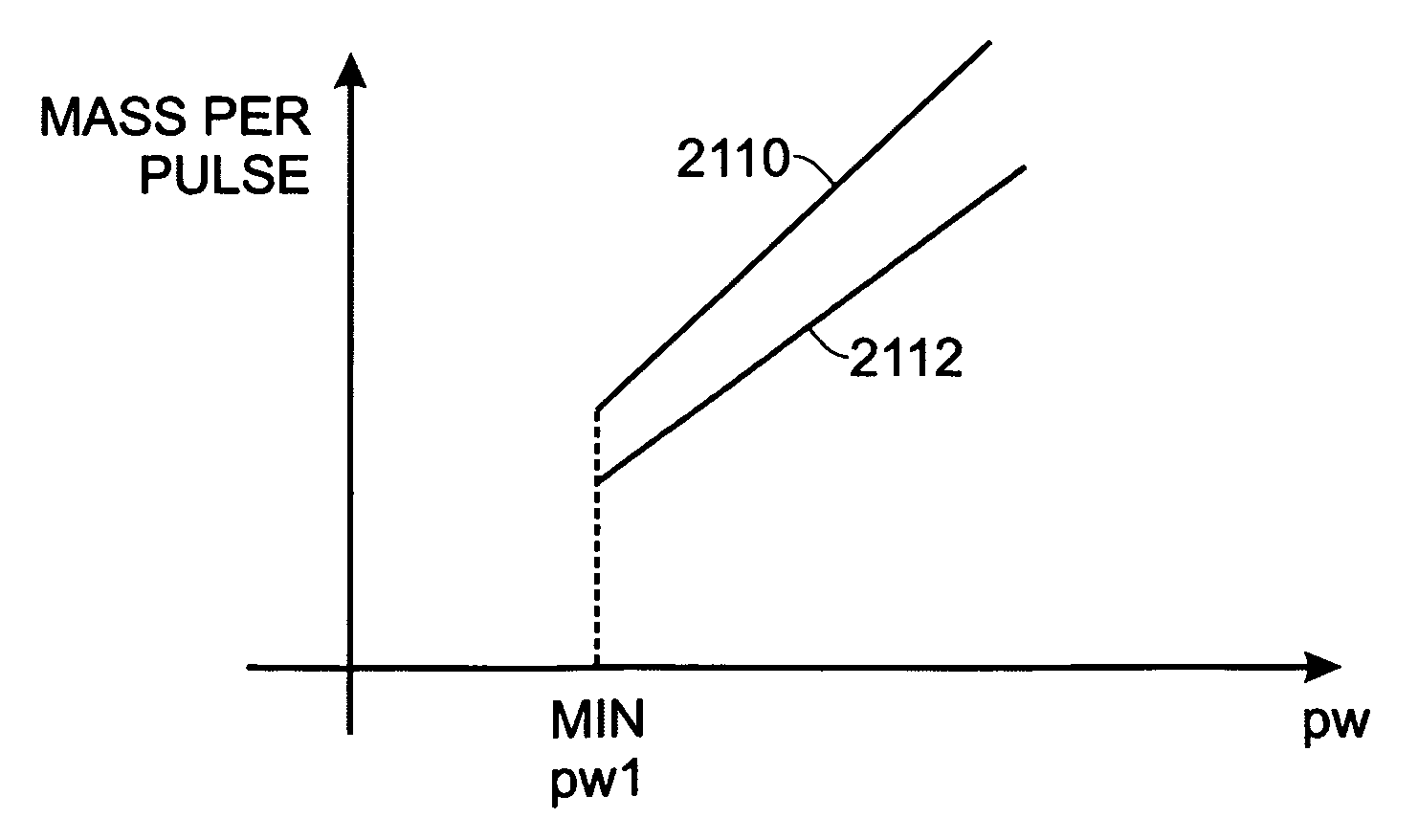

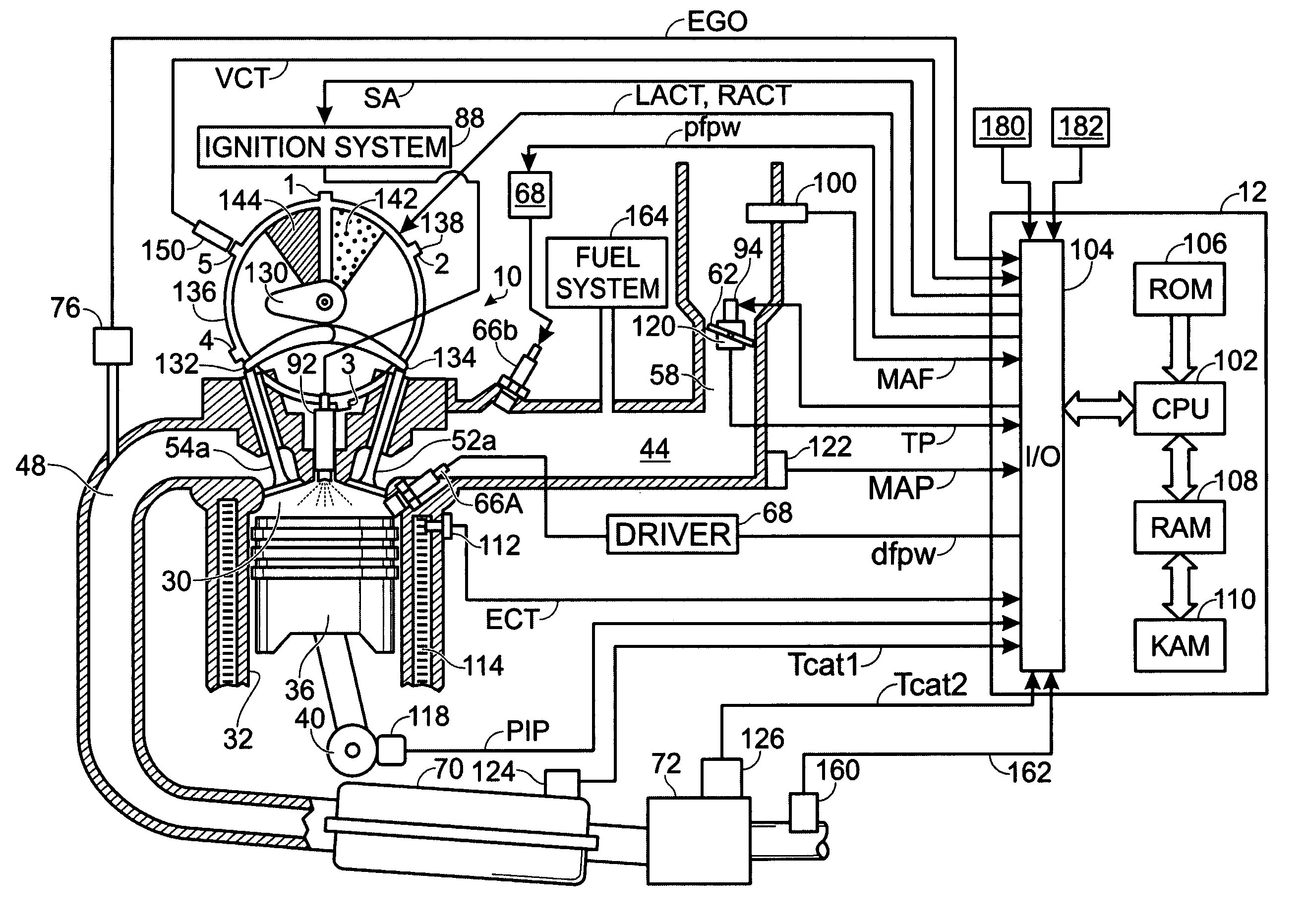

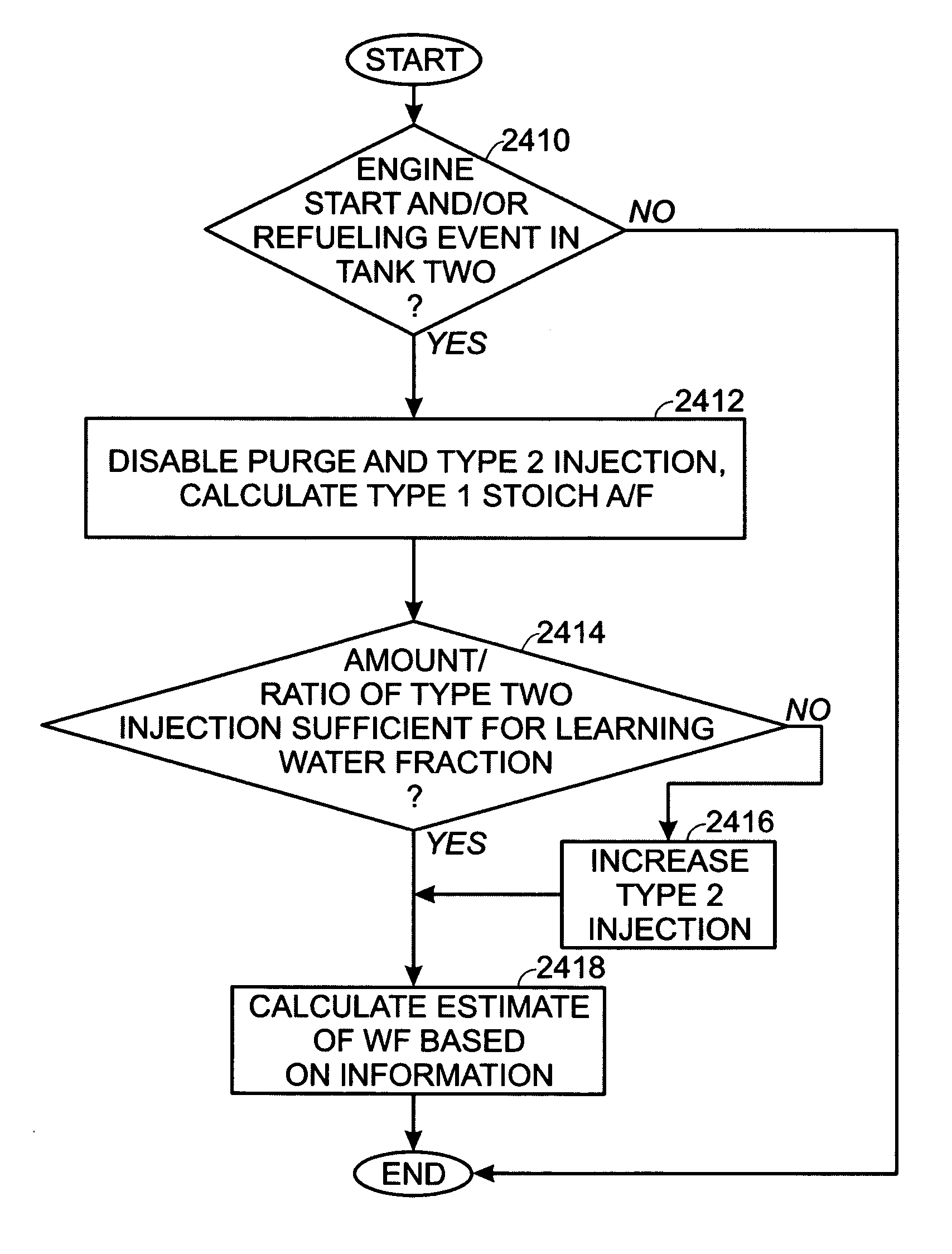

Fuel mass control for ethanol direct injection plus gasoline port fuel injection

ActiveUS20070119394A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesPort fuel injectionOperant conditioning

A system for an engine of a vehicle traveling on the road, comprising of a cylinder located in the engine, a delivery system configured to delivery fuel and a fluid to at least an engine cylinder of the while the vehicle is traveling on the road, said fluid containing at least some water, and a controller for varying an engine operating parameter based on an amount of water in said fluid, where said amount is determined based on an operating condition.

Owner:FORD GLOBAL TECH LLC

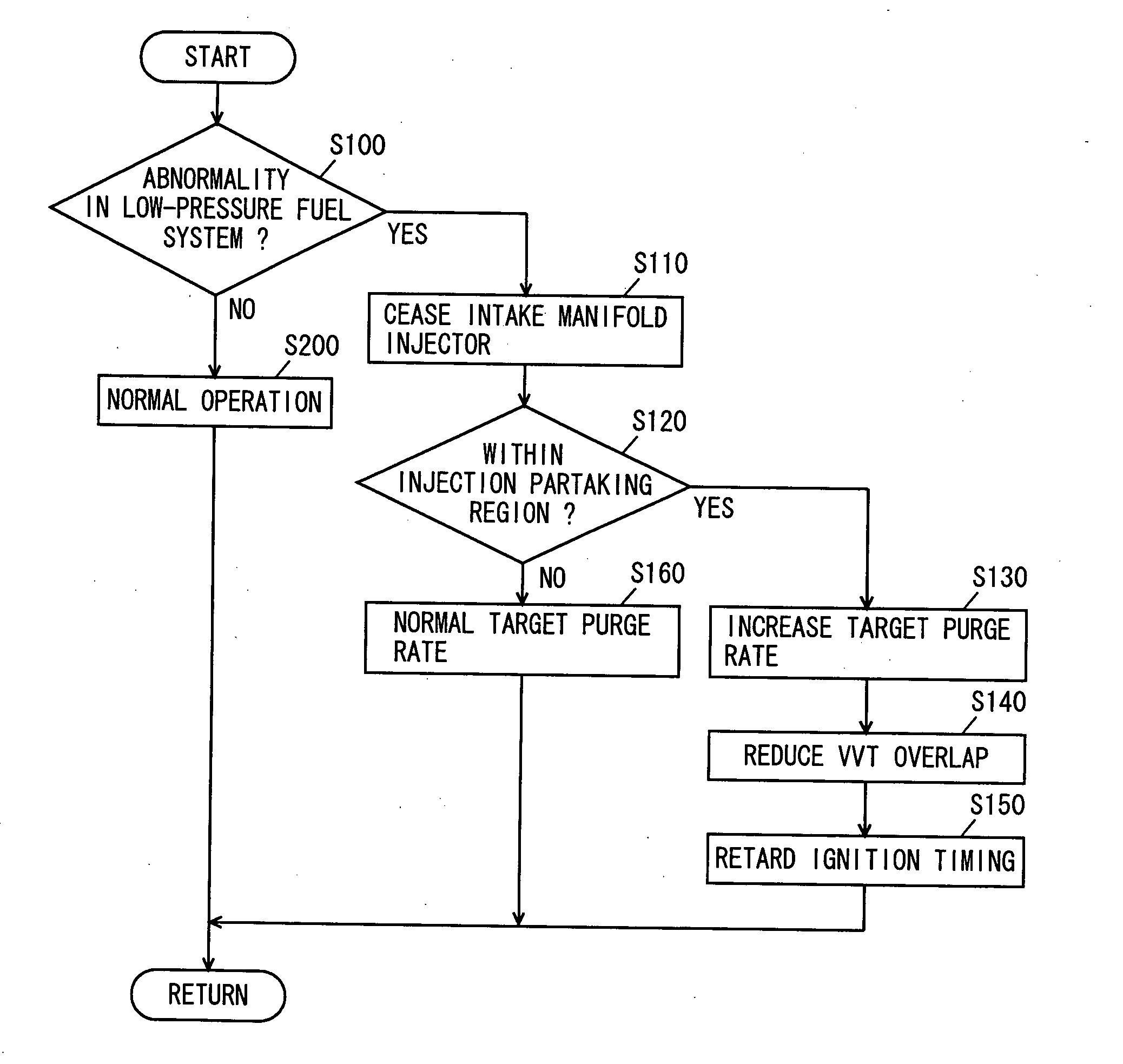

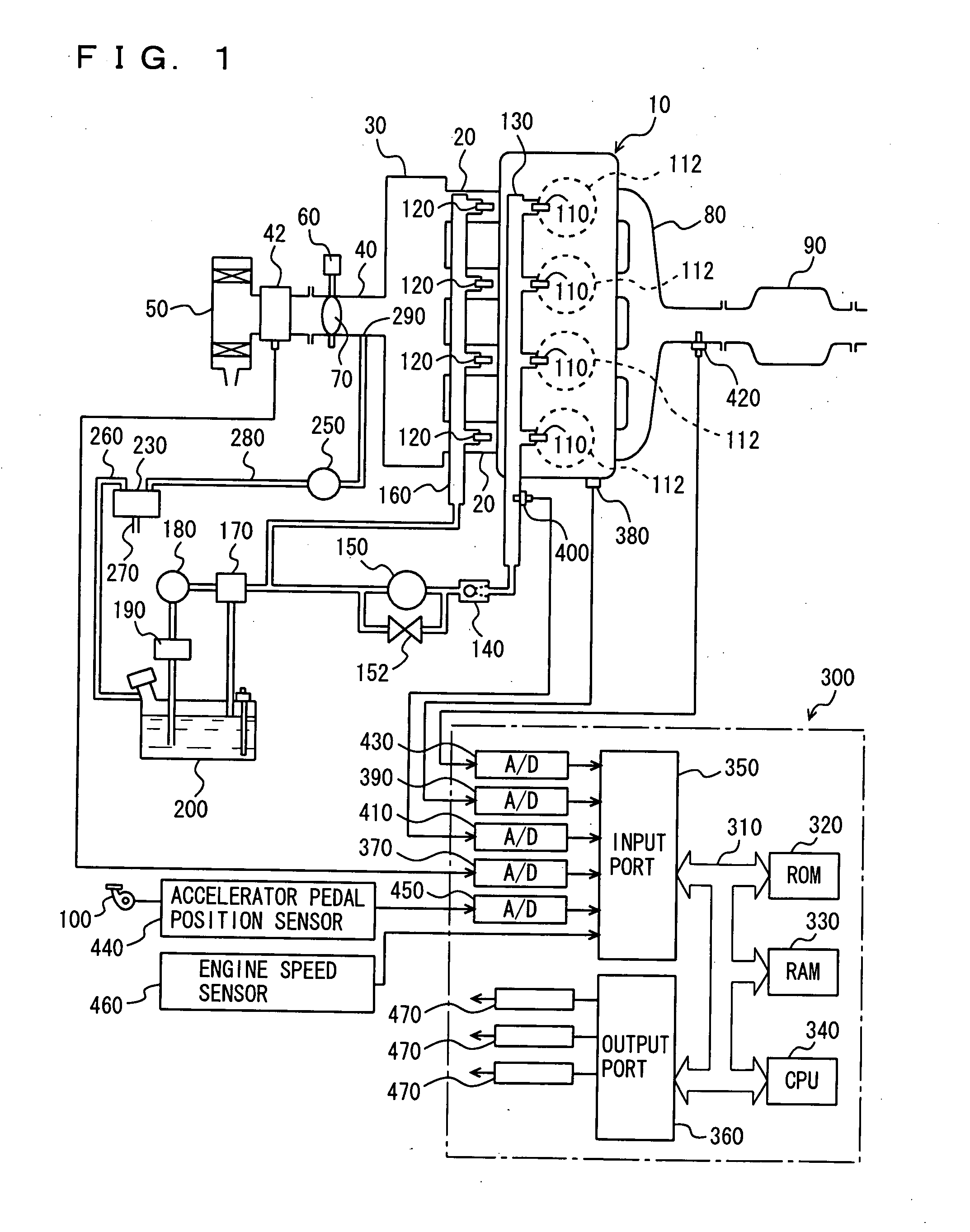

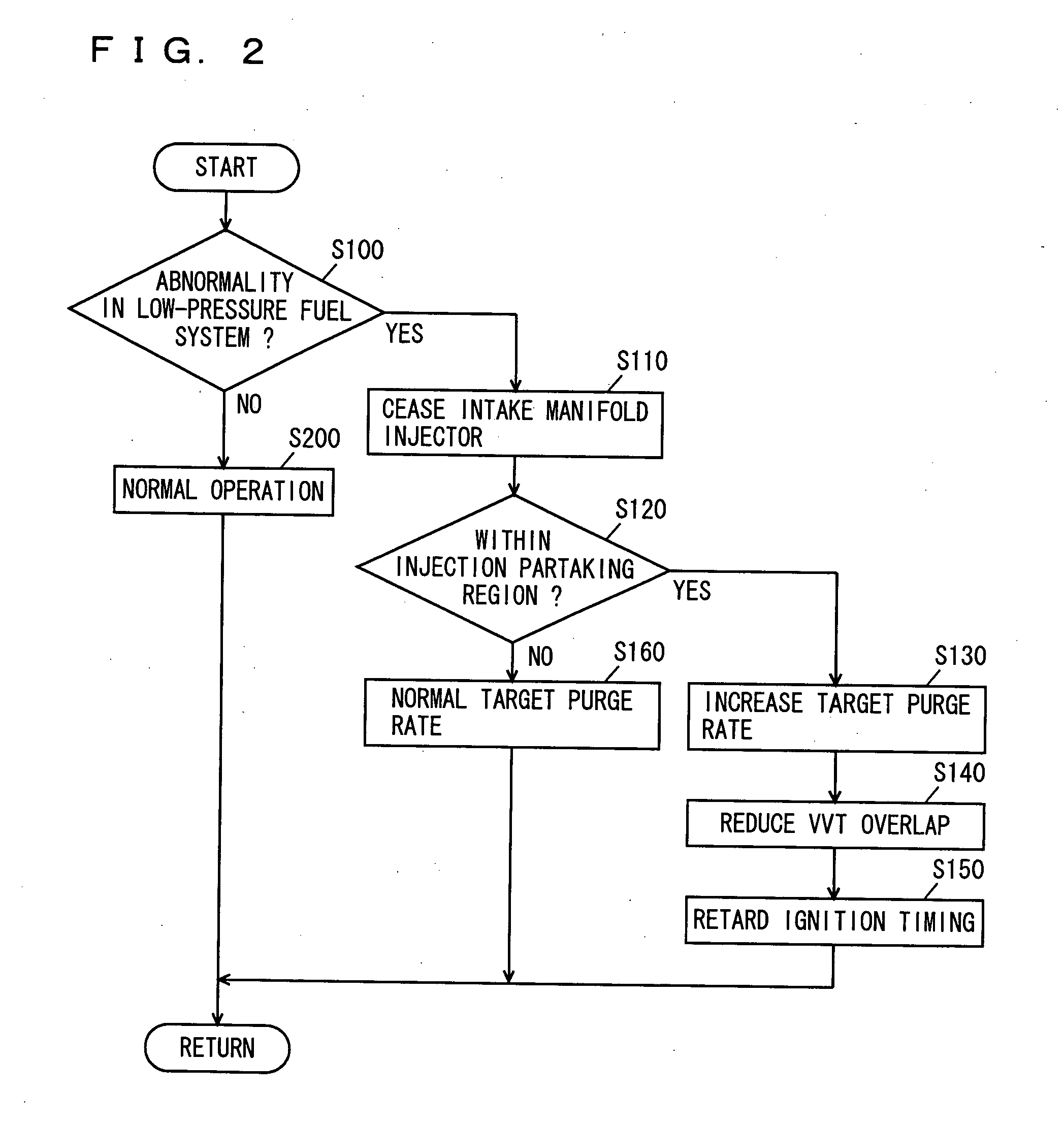

Control apparatus for internal combustion engine

InactiveUS20060090732A1Increasing purge rateVariation can be suppressedValve arrangementsElectrical controlIgnition timingInlet manifold

An engine ECU executes a program including the steps of: determining presence of abnormality in a low-pressure fuel system; ceasing an intake manifold injector when determination is made of abnormality in the low-pressure fuel system; increasing the target purge rate when the engine operation state attains an injection partaking state between an in-cylinder injector and an intake manifold injector; reducing the VVT overlap; and retarding the ignition timing.

Owner:TOYOTA JIDOSHA KK

System and method for engine with fuel vapor purging

ActiveUS20070119411A1Improve engine performanceLow costElectrical controlNon-fuel substance addition to fuelEngineeringFirst relationship

A method for controlling engine operation of an engine having a cylinder receiving fuel from a first and a second fuel injector, the first injector having a first relationship between a first input signal and a first amount of injected fuel, and the second injector having a second relationship between a second input signal and a second amount of injected fuel; the method comprising of varying injection from the first injector into the cylinder, varying injection from the second injector into the cylinder, purging fuel vapors from a fuel system into the cylinder, and adaptively learning said first and second relationships based on sensed operating conditions.

Owner:FORD GLOBAL TECH LLC

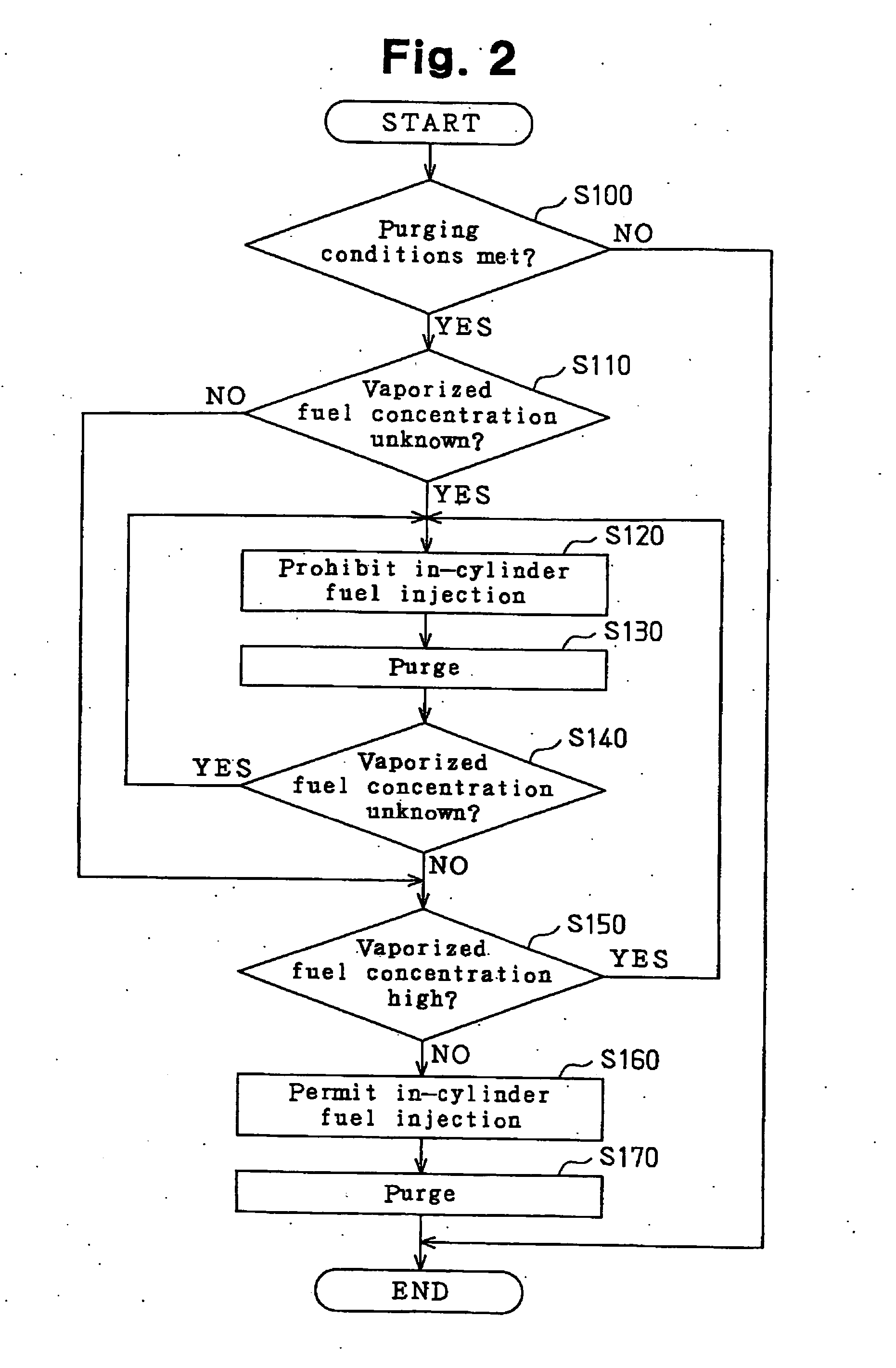

Fuel injection control apparatus for internal combustion engine

InactiveUS20050183698A1Suppressing hampering of engine combustionElectrical controlNon-fuel substance addition to fuelCombustionExternal combustion engine

An internal combustion engine includes a direct injector for injecting fuel directly into a combustion chamber of the engine, an intake passage injector for injecting fuel into an intake passage of the engine, and a vaporized fuel processing unit for purging purge gas containing a vaporized fuel into the intake passage. A fuel injection control apparatus includes a detecting section and an injection control section. The detecting section detects the amount of the vaporized fuel in the purge gas. The injection control section changes a fuel injection mode of at least one of the direct injector and the intake passage injector depending on the detected amount of the vaporized fuel. As a result, hampering of engine combustion due to purge gas is suppressed.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com