Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1383results about How to "Avoid volatility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

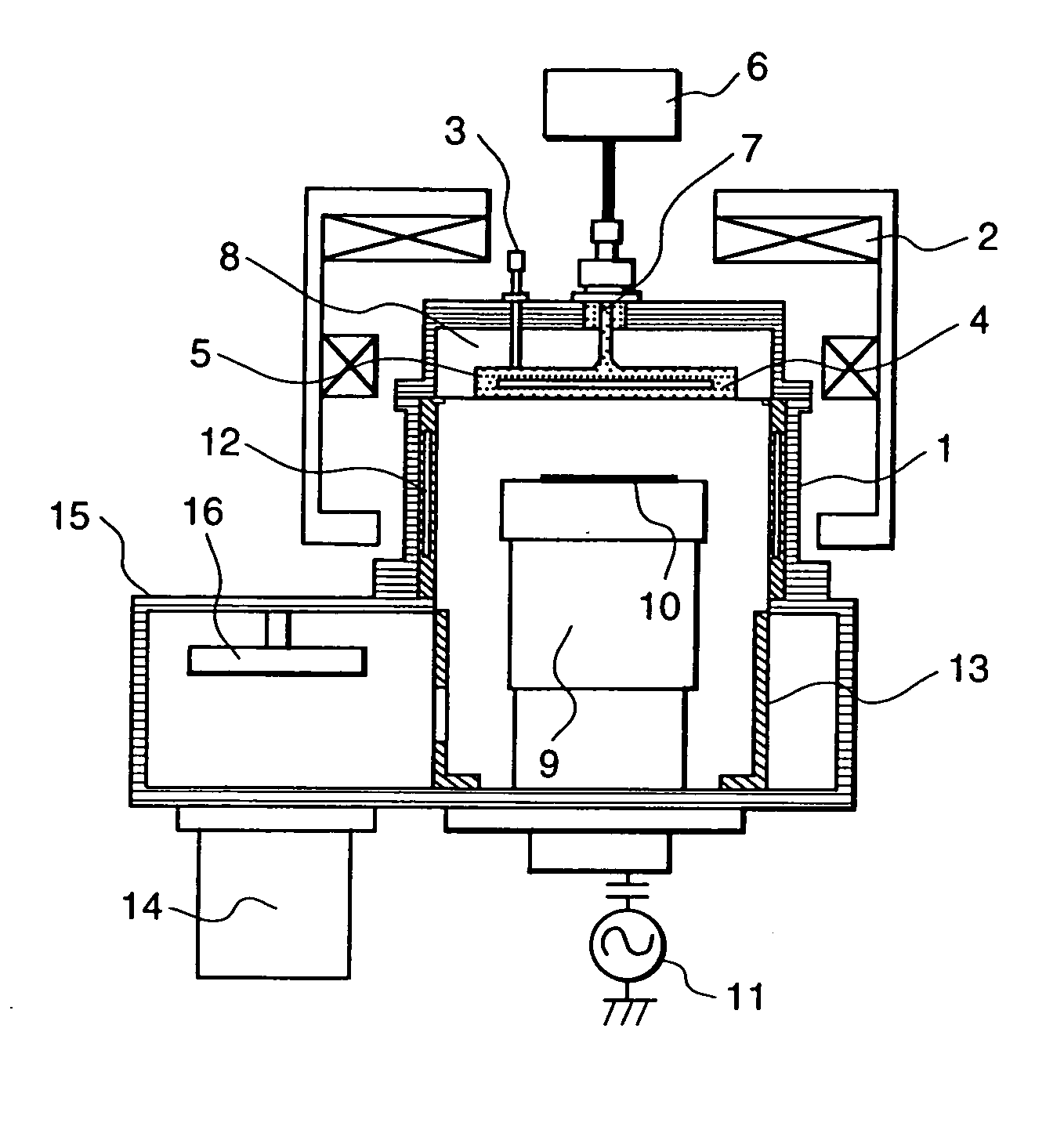

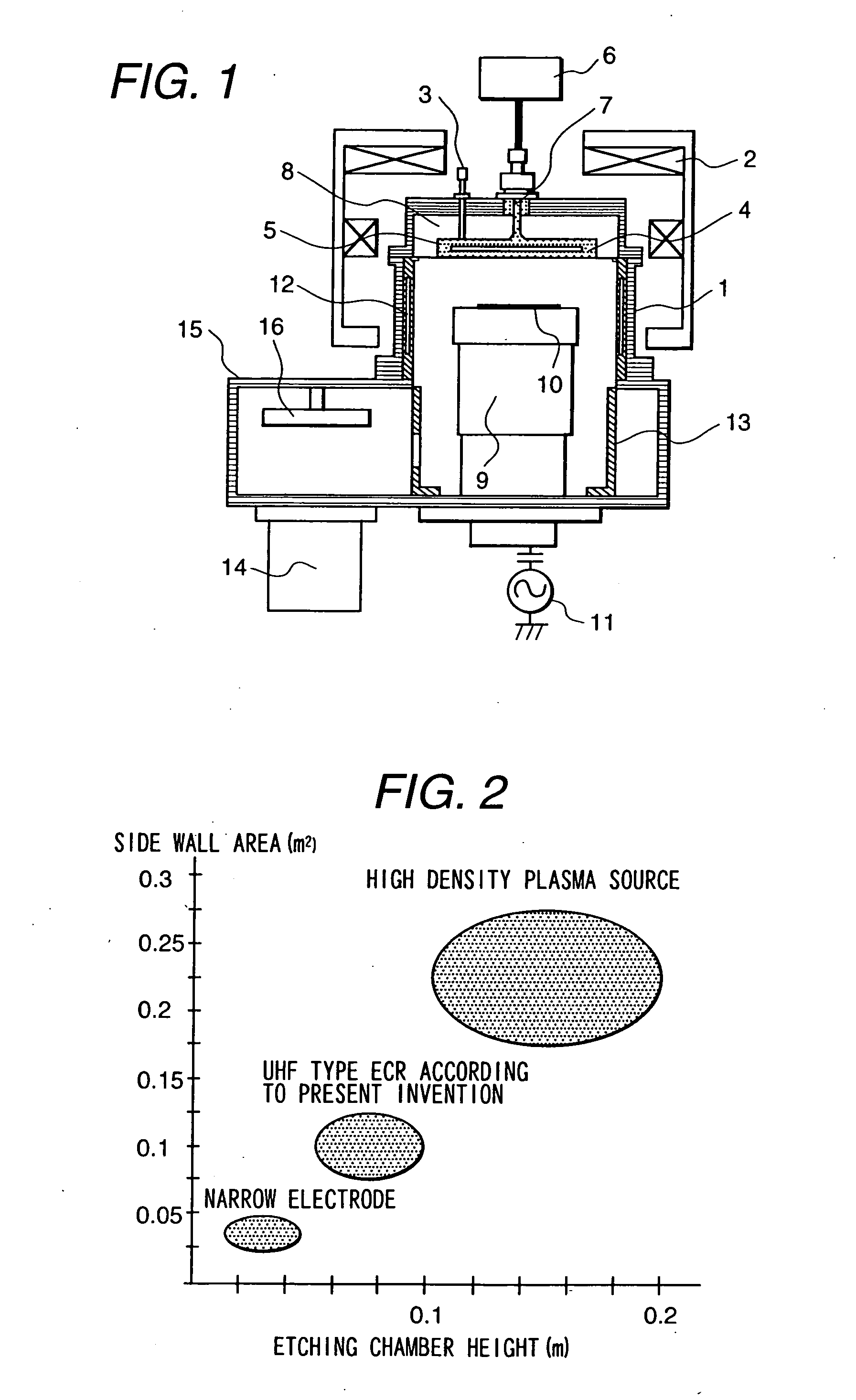

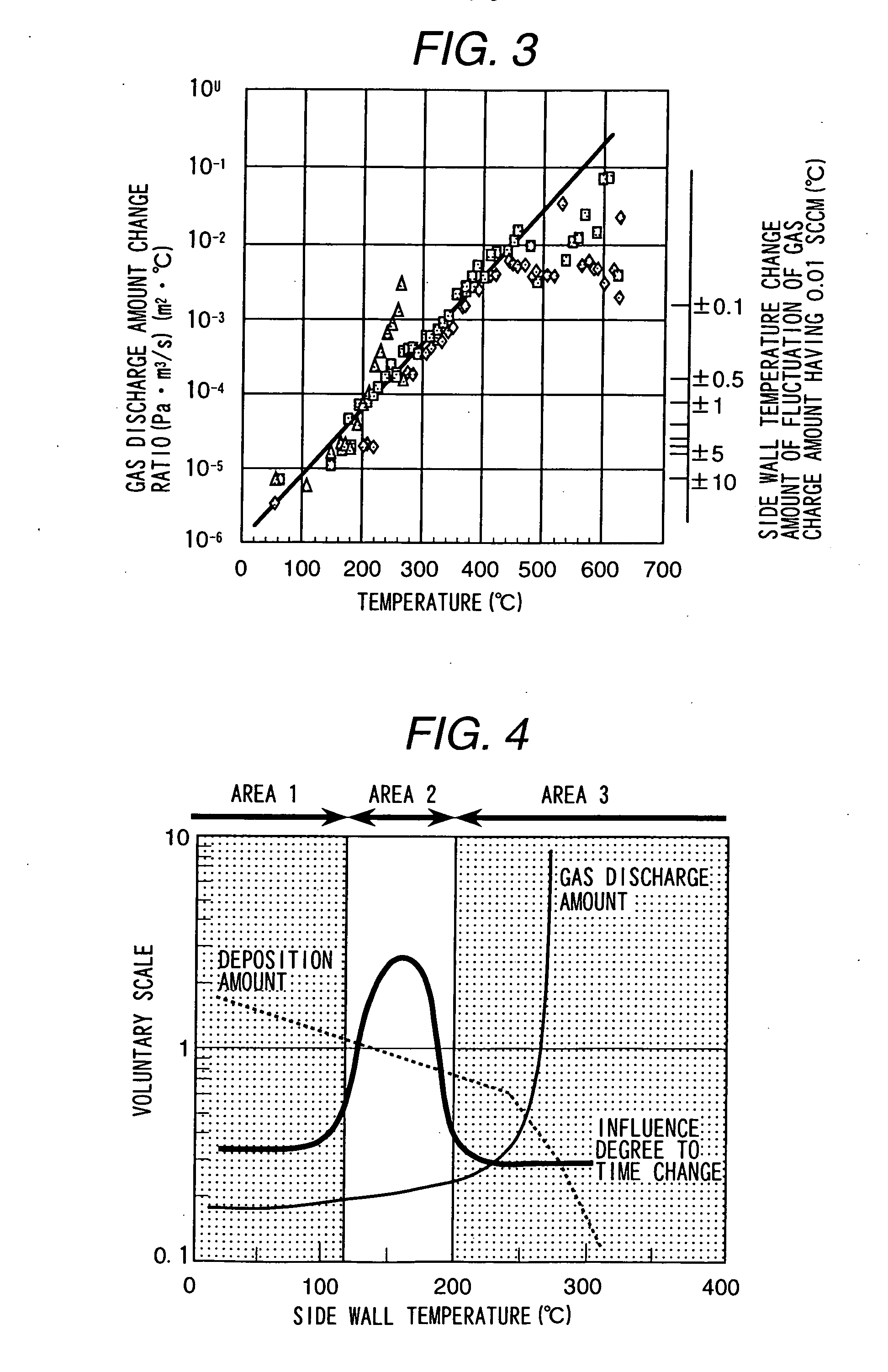

Plasma processing apparatus and a plasma processing method

InactiveUS20060157449A1Avoid volatilityElectric discharge tubesVacuum gauge using ionisation effectsElectron temperatureCountermeasure

Owner:TAKAHASHI KAZUE +3

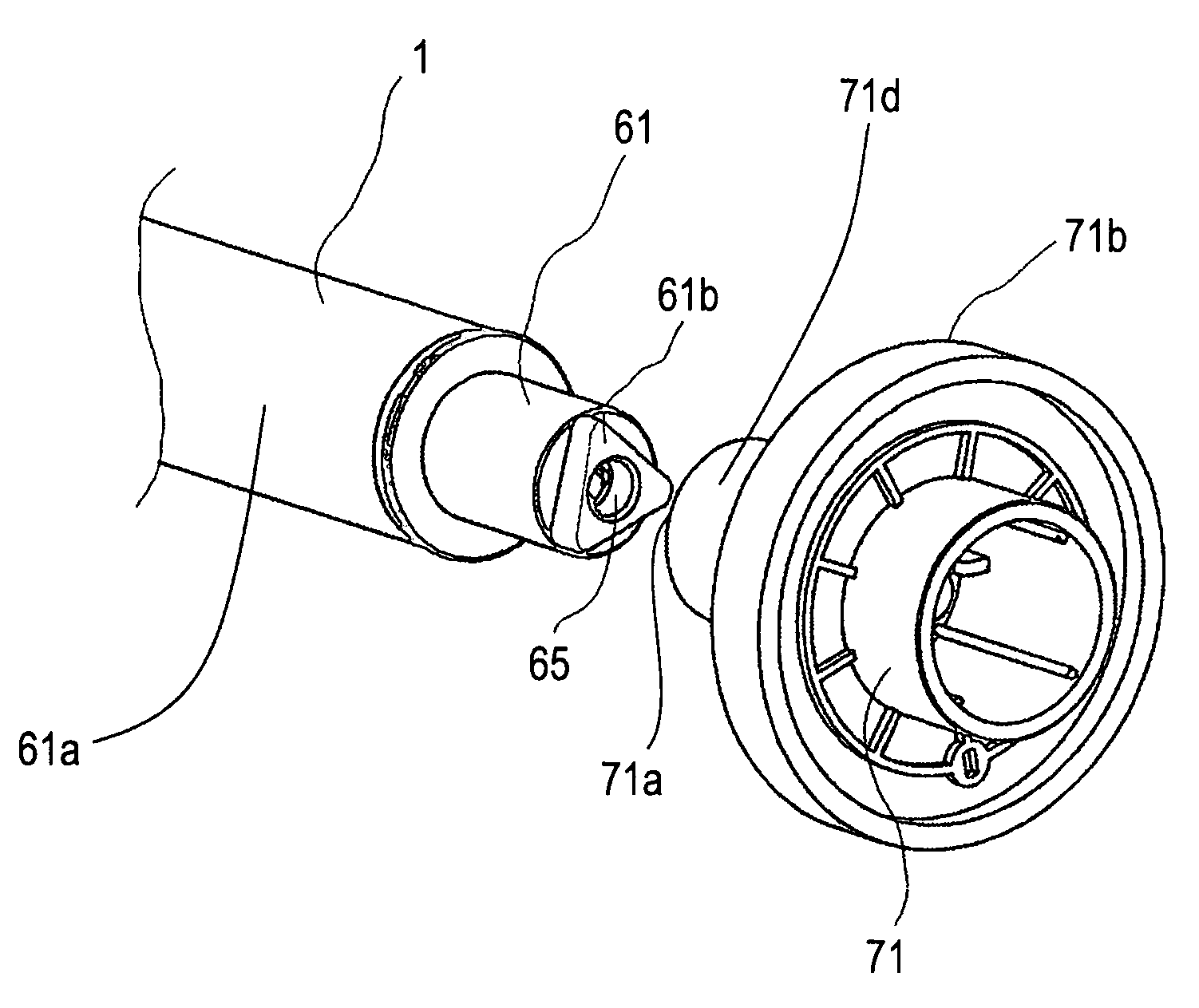

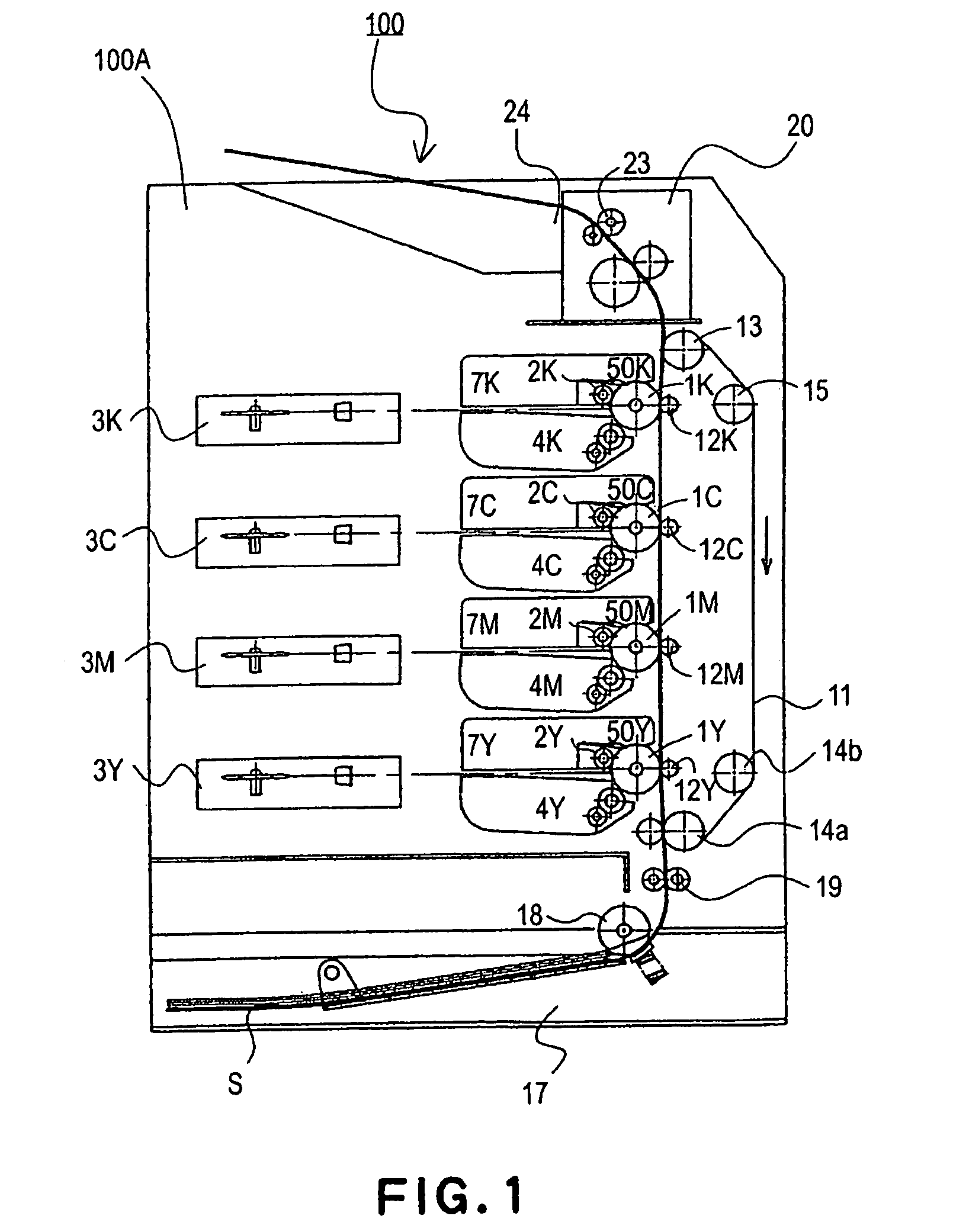

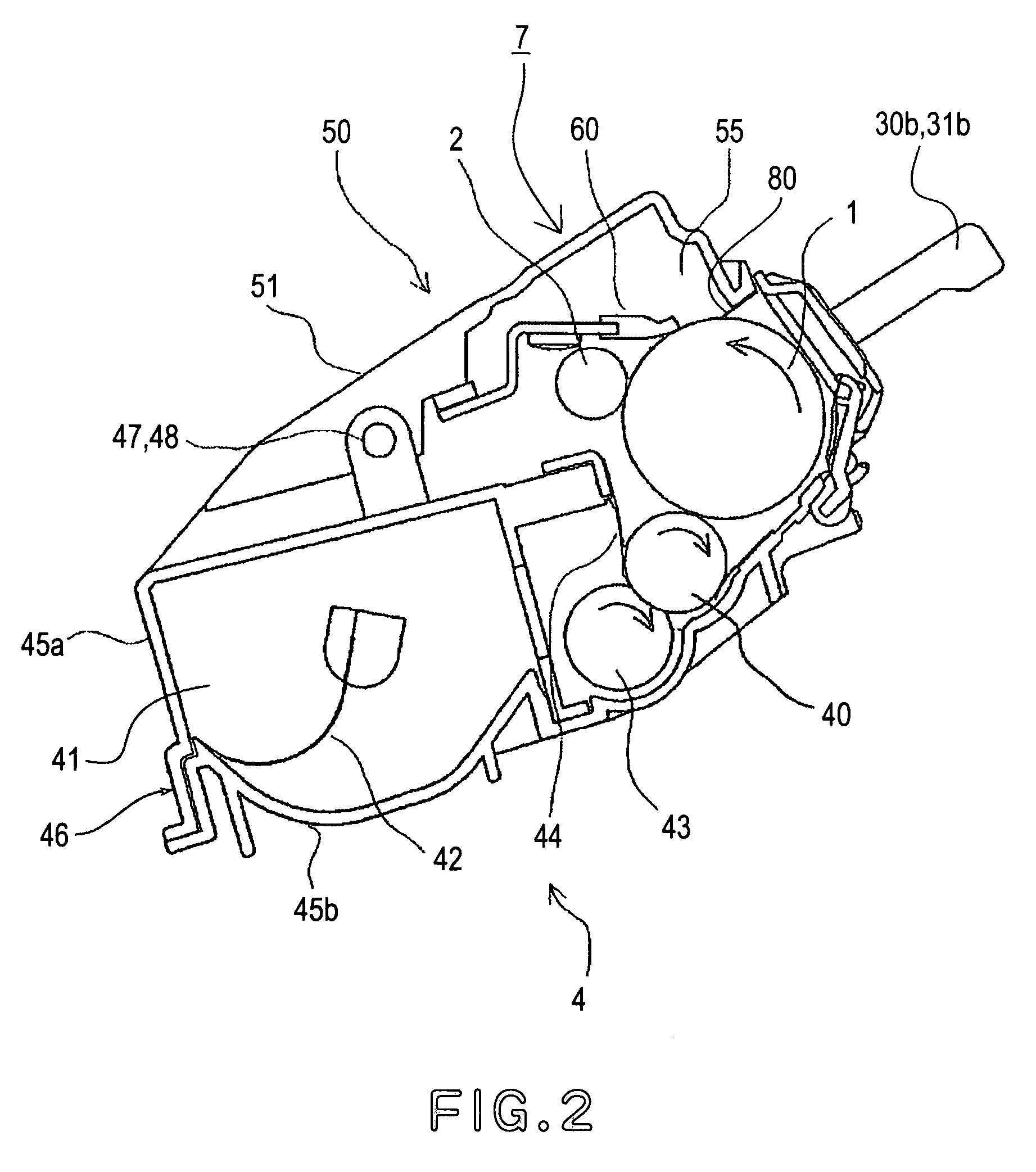

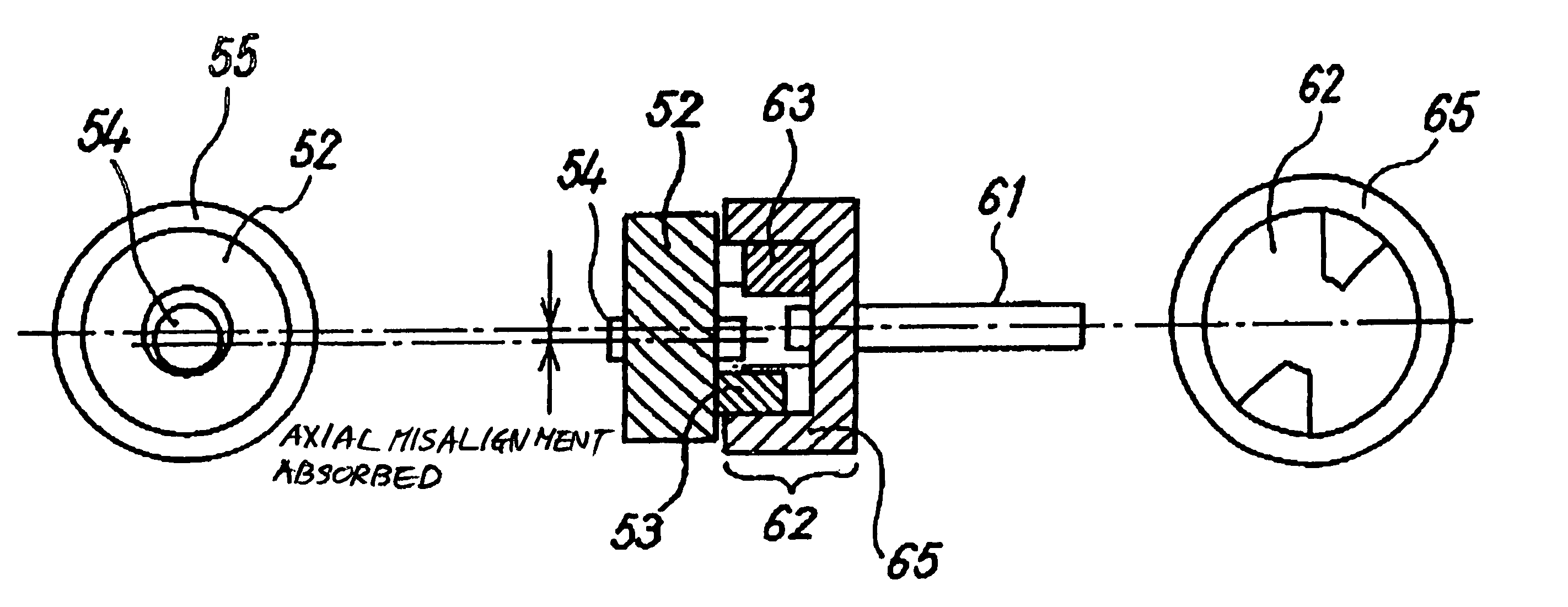

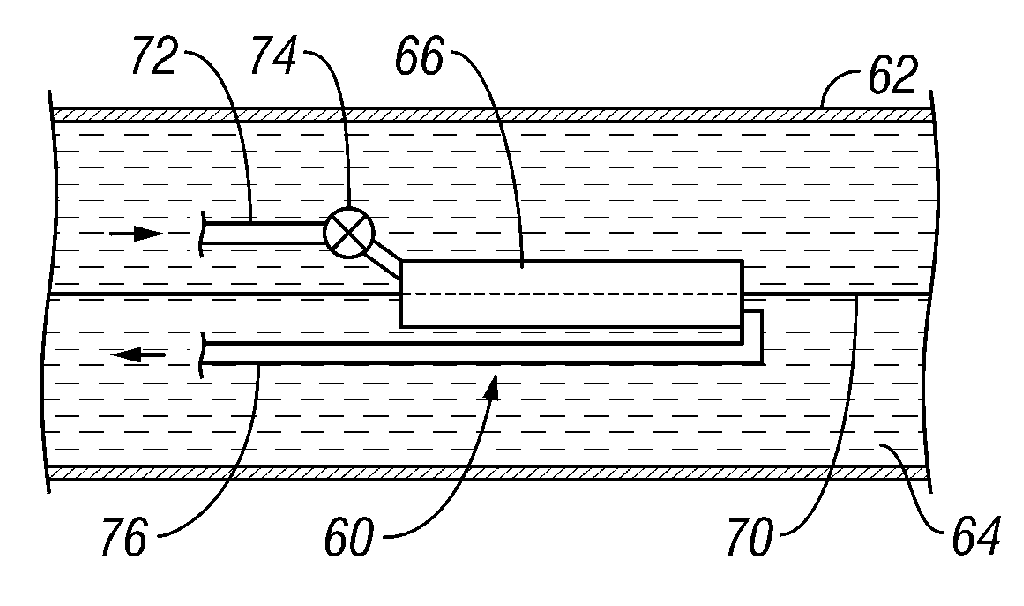

Electrophotographic photosensitive drum, process cartridge, and electrophotographic image forming apparatus

ActiveUS7209682B2Avoid volatilityCouplings for rigid shaftsElectrographic process apparatusPull forceEngineering

An electrophotographic photosensitive drum is for a process cartridge detachably mountable to a main assembly of an electrophotographic image forming apparatus. The main assembly includes a motor, and a gear having a non-circular twisted hole. The drum includes a cylinder having a non-circular twisted projection engageable with the hole to receive a driving force from the main assembly when the cartridge is mounted to the main assembly. A recess is formed in the projection and has a bottom portion and a side surface portion. When the projection receives a pulling force toward the hole by rotation of the gear with the projection and the hole being engaged with each other, the bottom portion contacts a spherical surface portion provided at a central portion of the hole, and the side surface portion contacts the spherical surface portion.

Owner:CANON KK

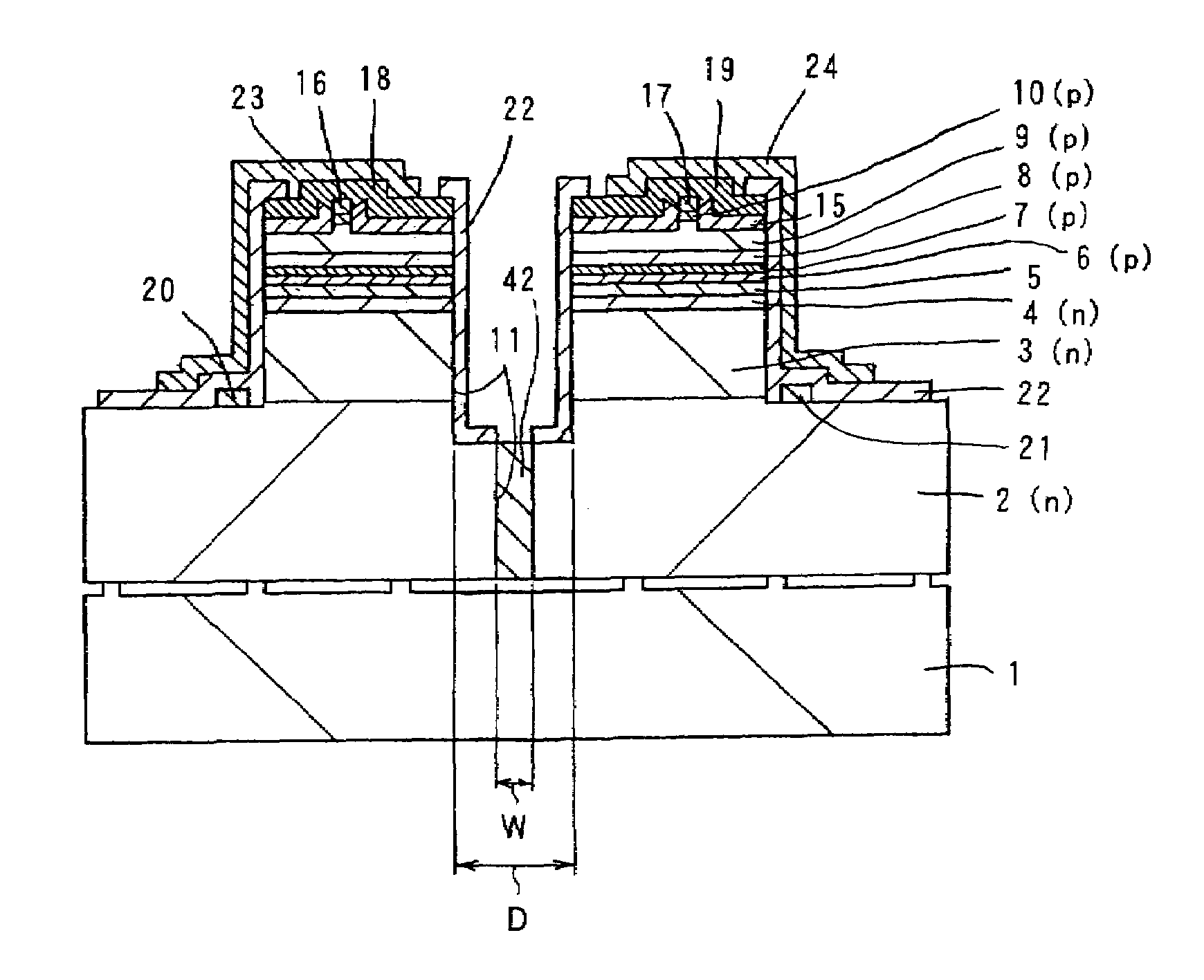

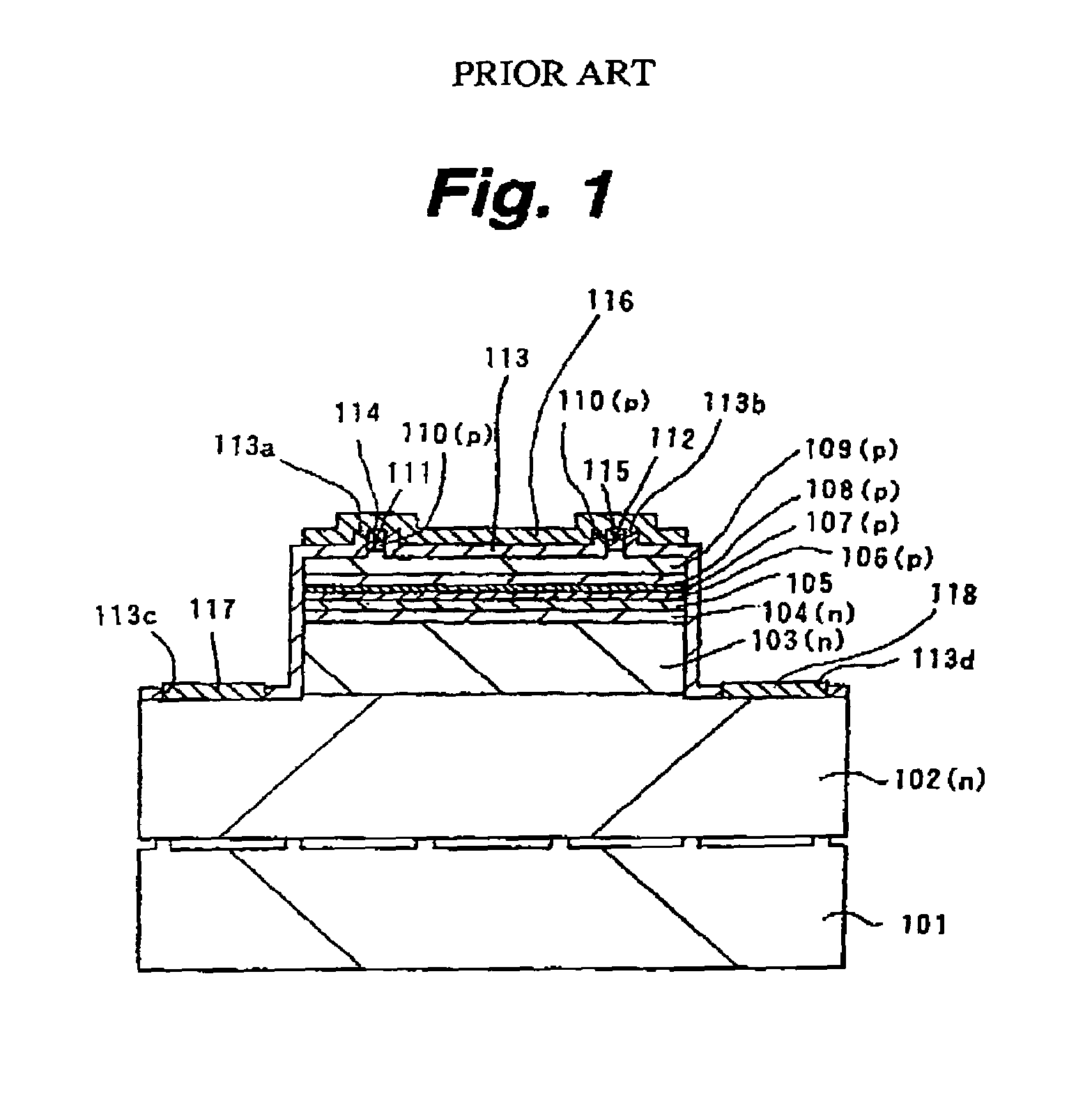

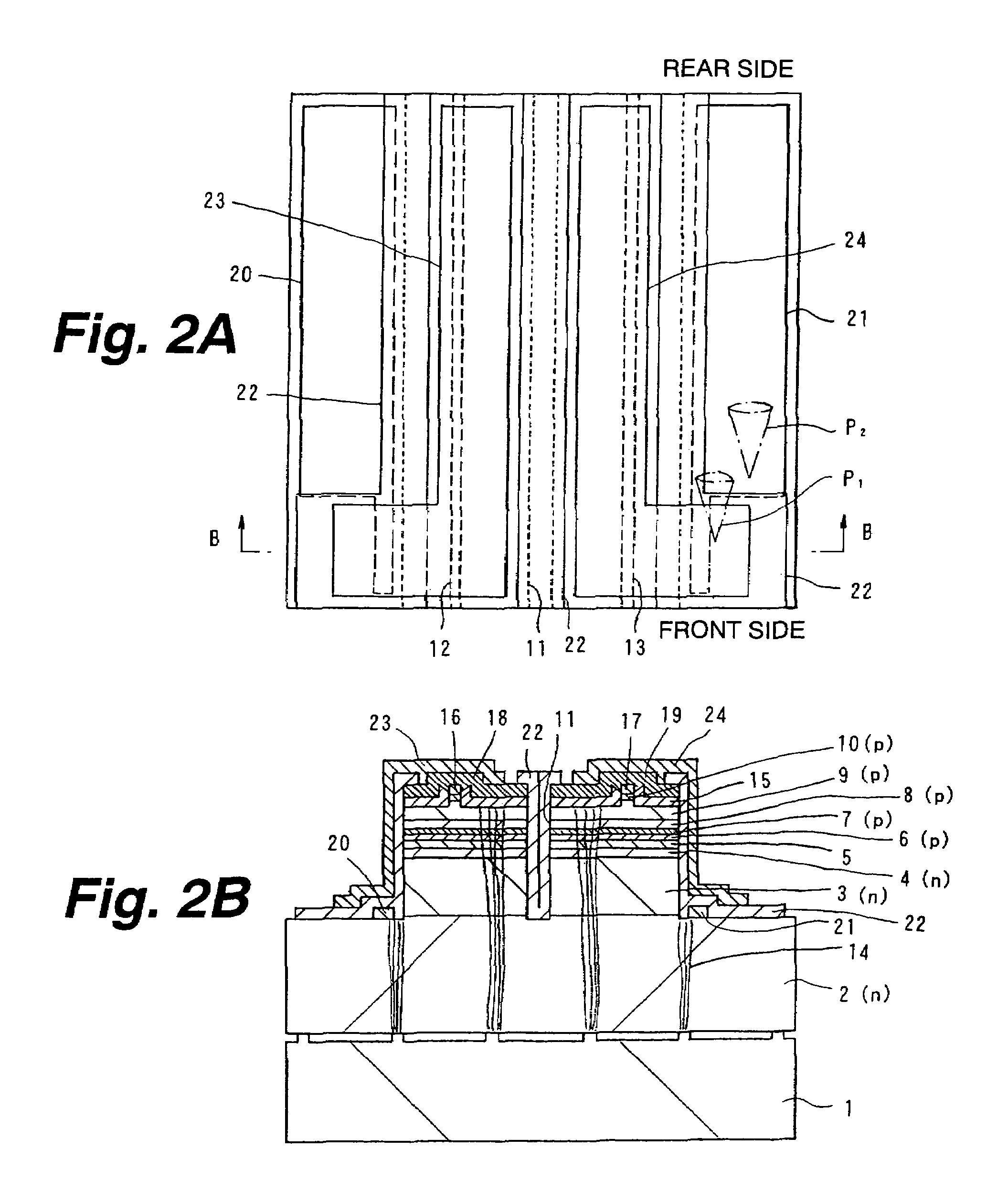

Multibeam semiconductor laser, semiconductor light-emitting device and semiconductor device

InactiveUS6995406B2Easy to checkReduce electrical and thermal cross talkOptical wave guidanceSemiconductor laser arrangementsLight emitting deviceNitride

In a multi-beam semiconductor laser including nitride III–V compound semiconductor layers stacked on one surface of a substrate of sapphire or other material to form laser structures, and including a plurality of anode electrodes and a plurality of cathode electrodes formed on the nitride III–V compound semiconductor layers, one of the anode electrodes is formed to bridge over one of the cathode electrodes via an insulating film, and another anode electrode is formed to bridge over another of the cathode electrodes via an insulating film.

Owner:SONY CORP

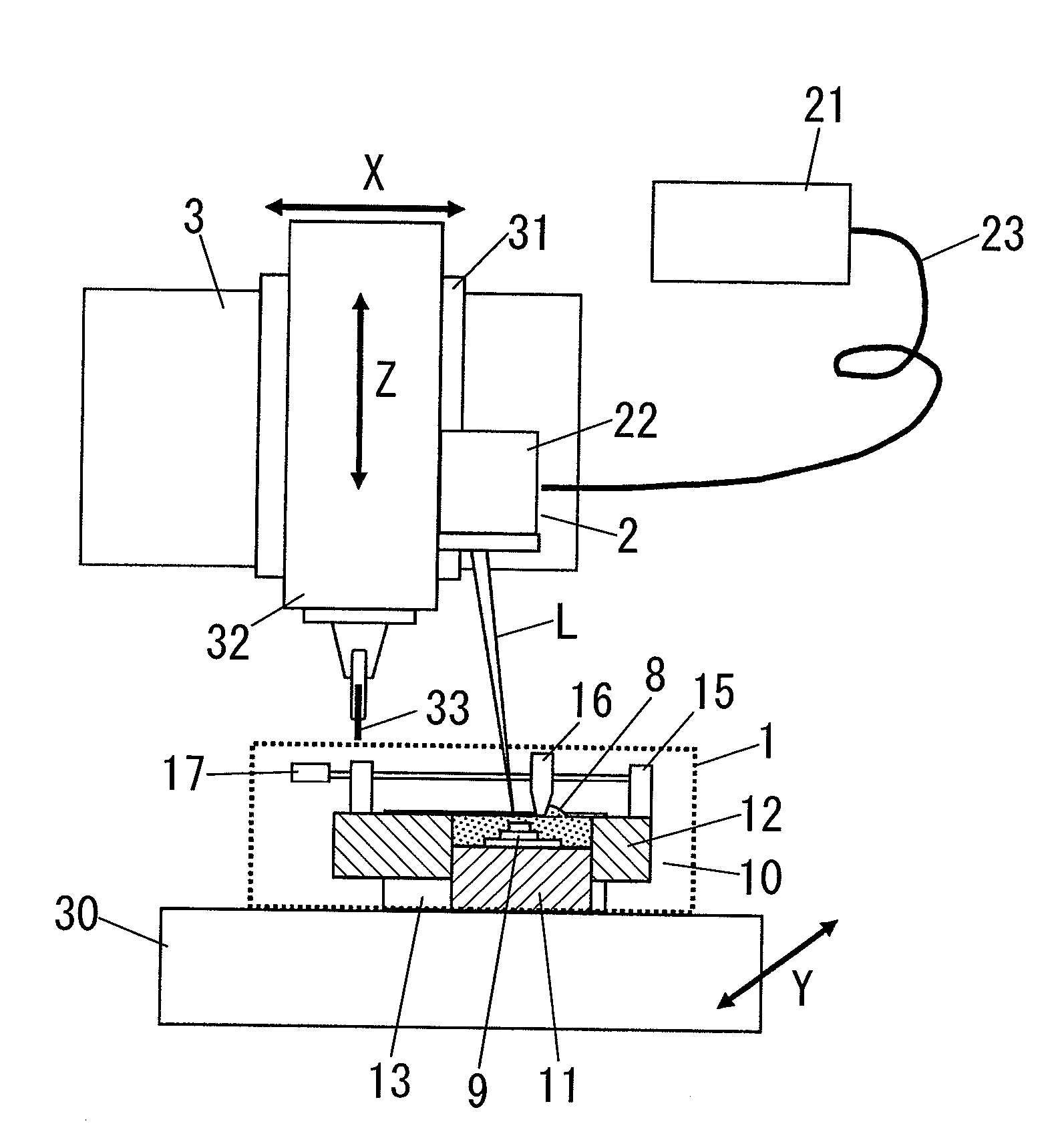

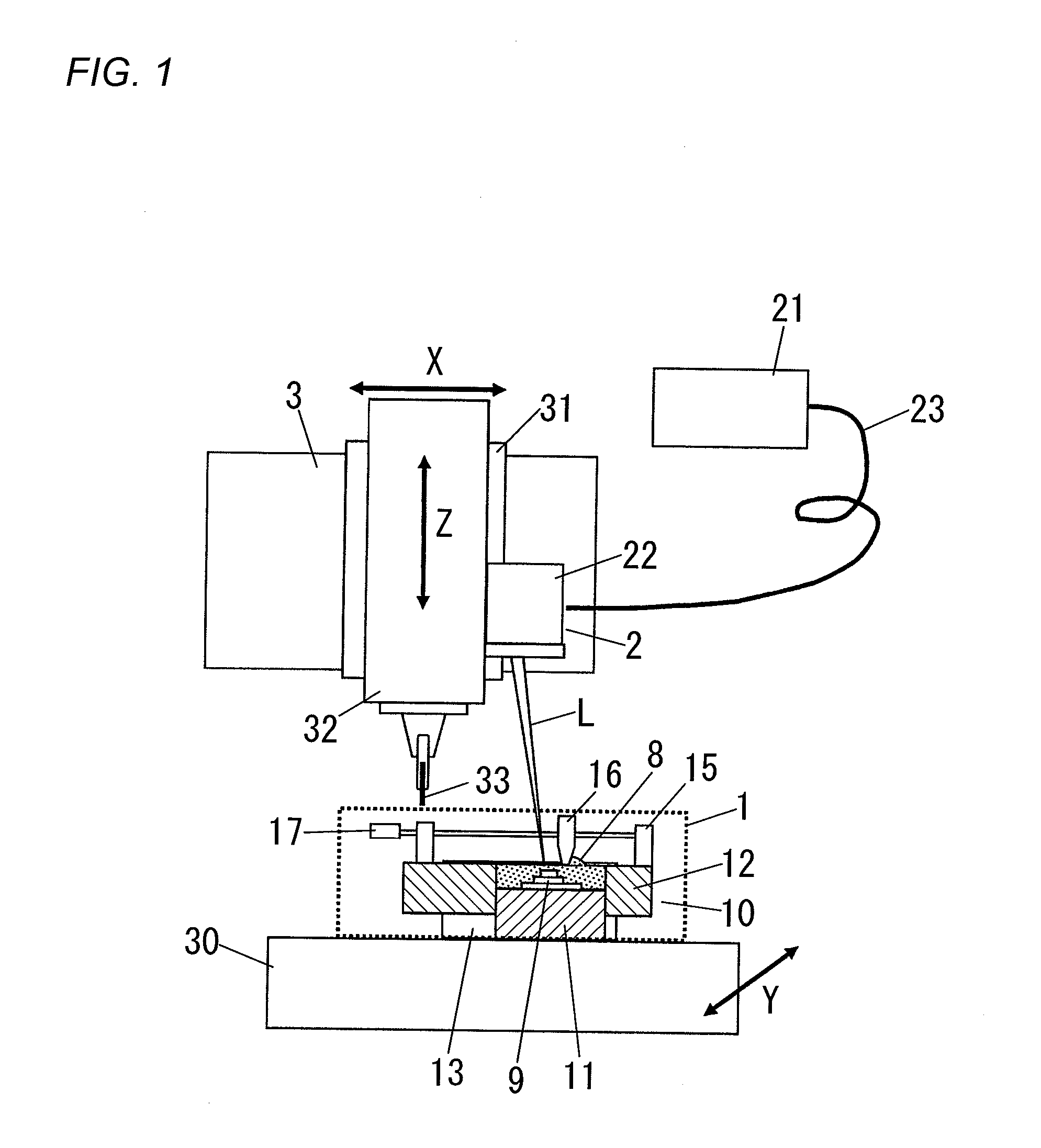

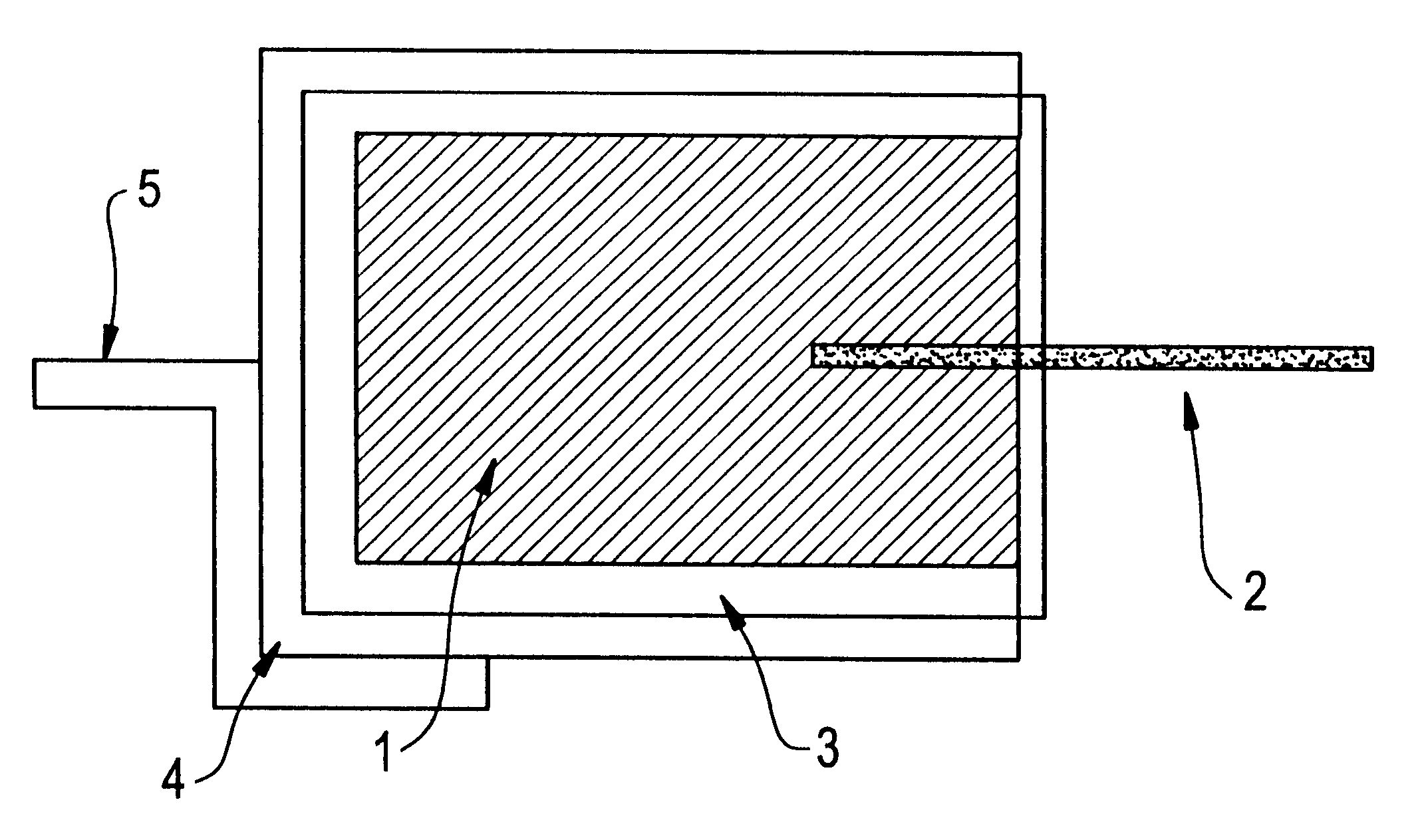

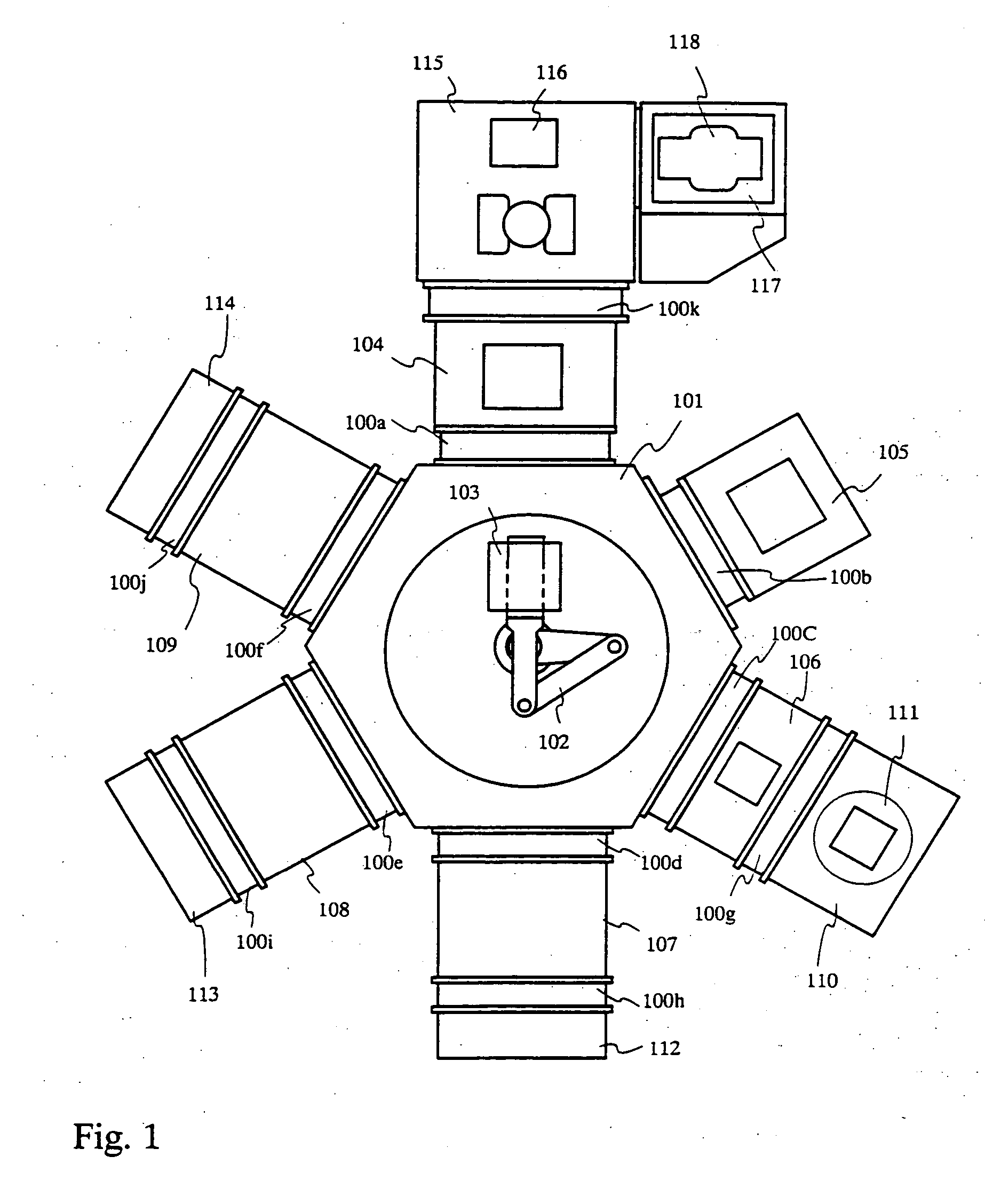

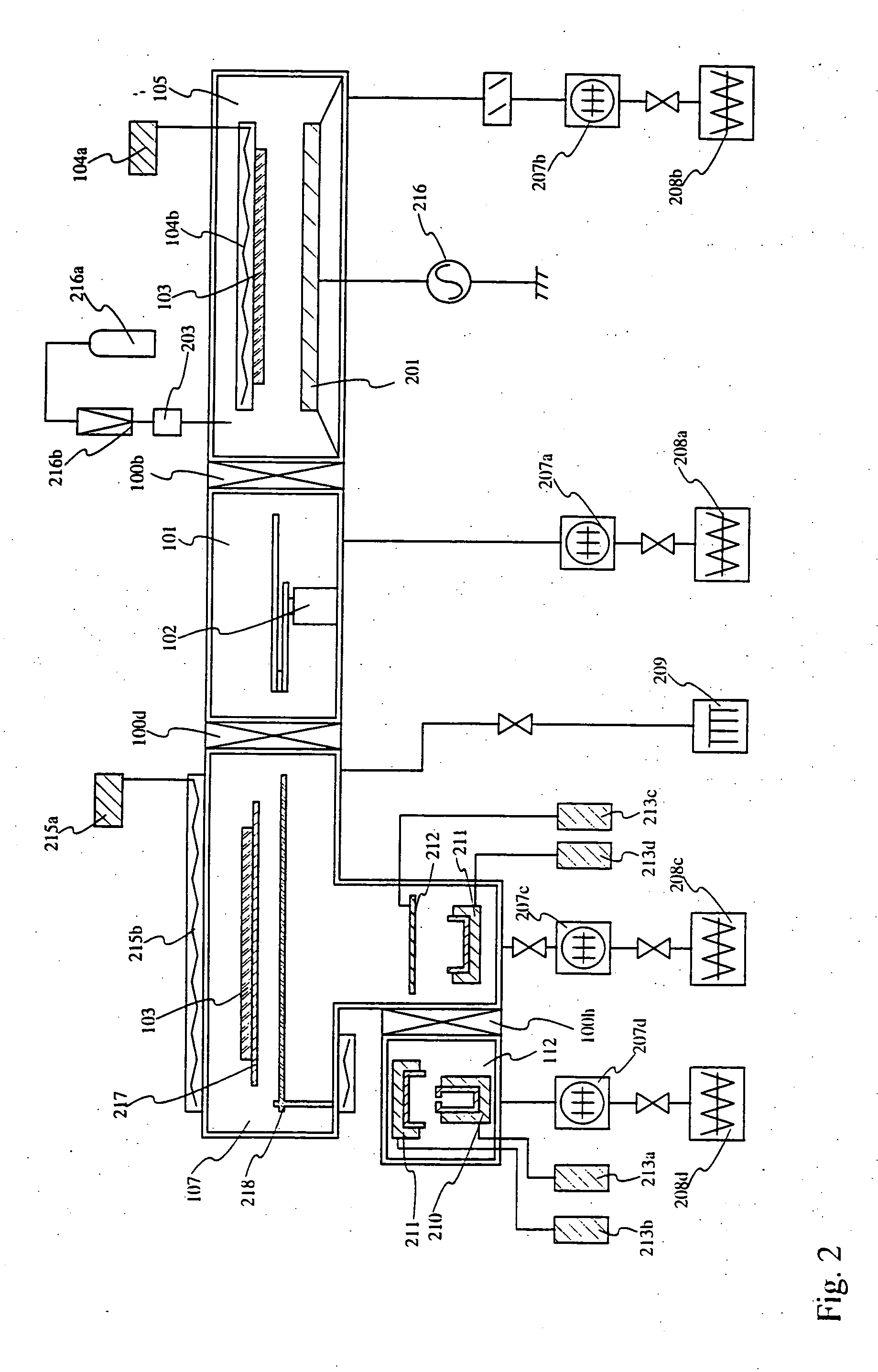

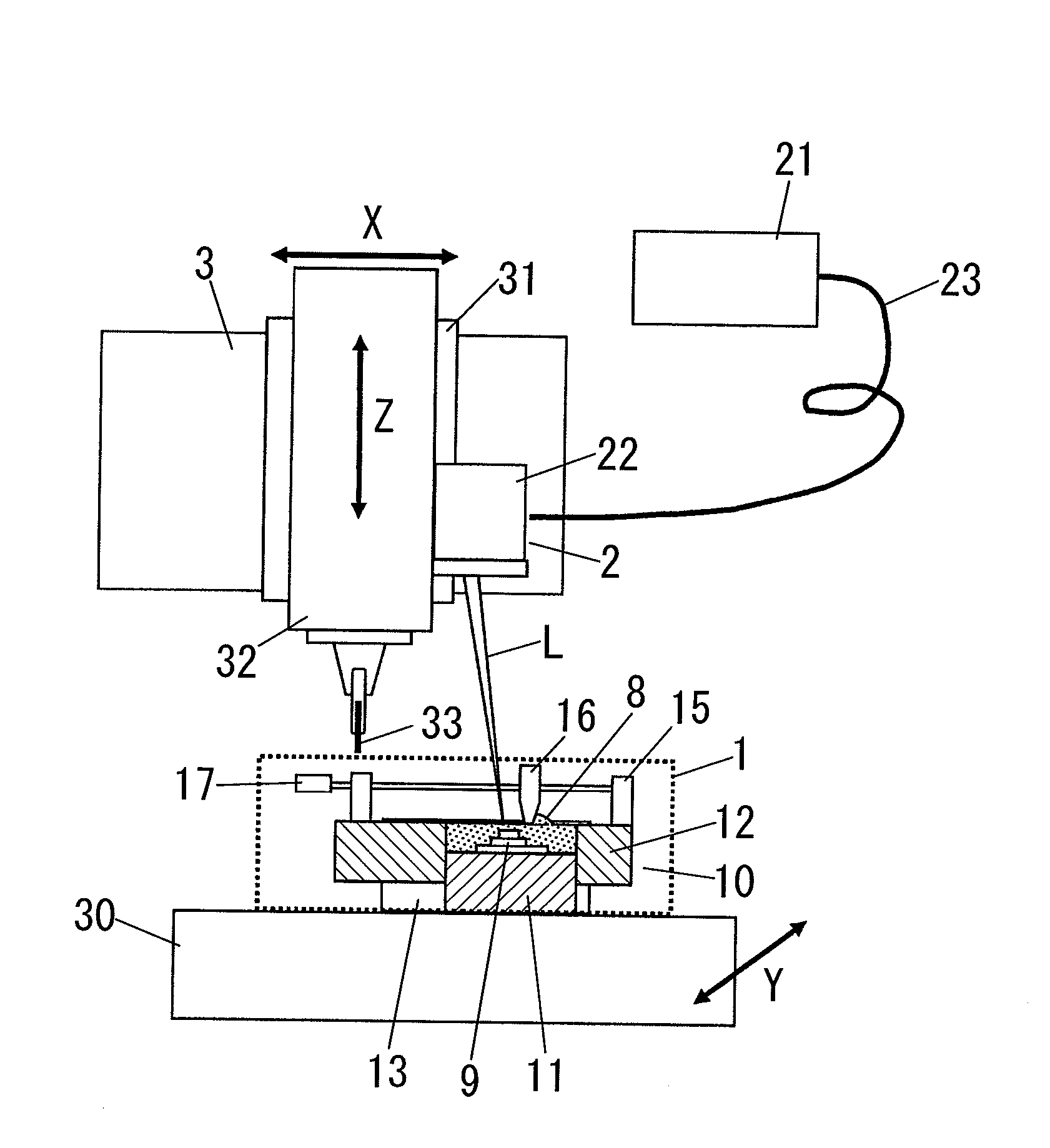

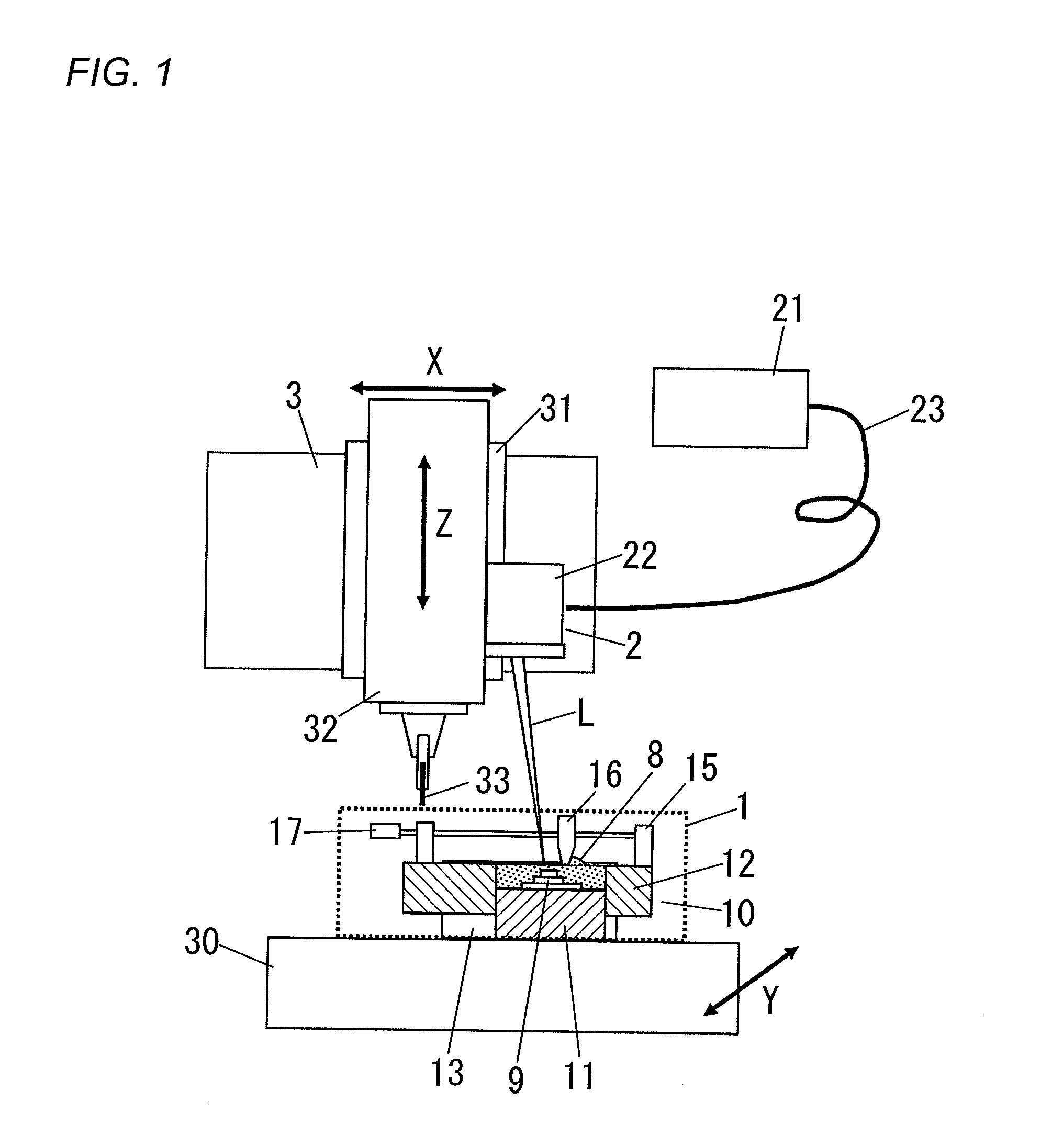

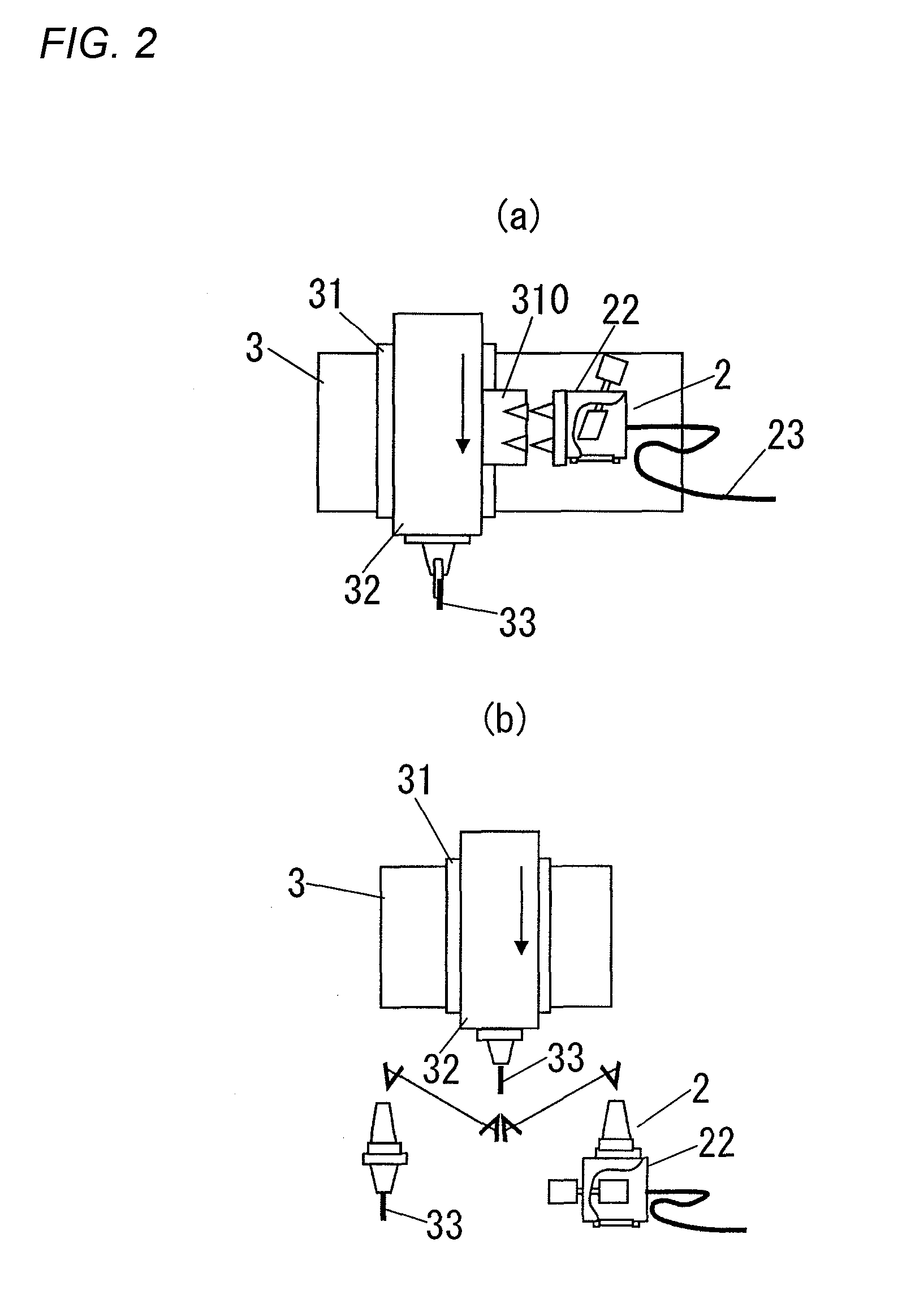

Lamination shaping apparatus

ActiveUS20100006228A1Easily fabricateAccuracy be degradeLiquid surface applicatorsMechanical working/deformationFixed positionEngineering

A lamination shaping apparatus has a powder layer preparing means and an optical unit which irradiates a light beam to an intended portion of a powder layer so as to sinter or melt for solidifying the portion into a cured layer. Preparation of the powder layer and curing of the cured layer are repeated to fabricate a three-dimensional object in which a plurality of the cured layers are laminated and integrated. The apparatus includes a fixed base carrying thereon the powder layer and the cured layer, an elevator frame surrounding a periphery of the fixed base, and driving means for driving the elevator frame to move vertically. The powder layer is formed within a space above the base and surrounded by an interior surface of the elevator fame such that the powder layer (cured layer) can be stacked on the base with the base being kept at a fixed position, thereby facilitating to fabricate a precisely shaped object.

Owner:MATSUSHITA ELECTRIC WORKS LTD

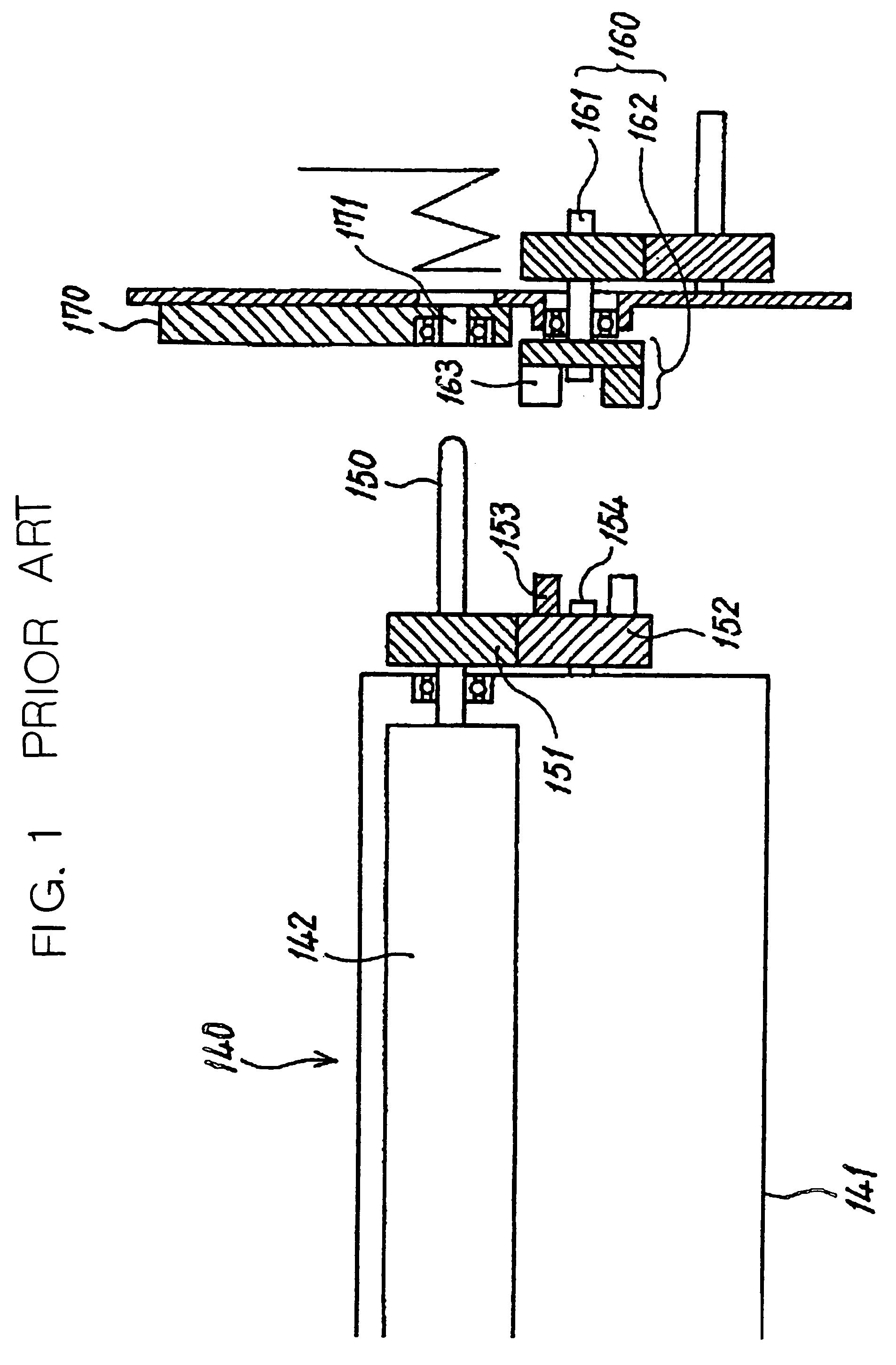

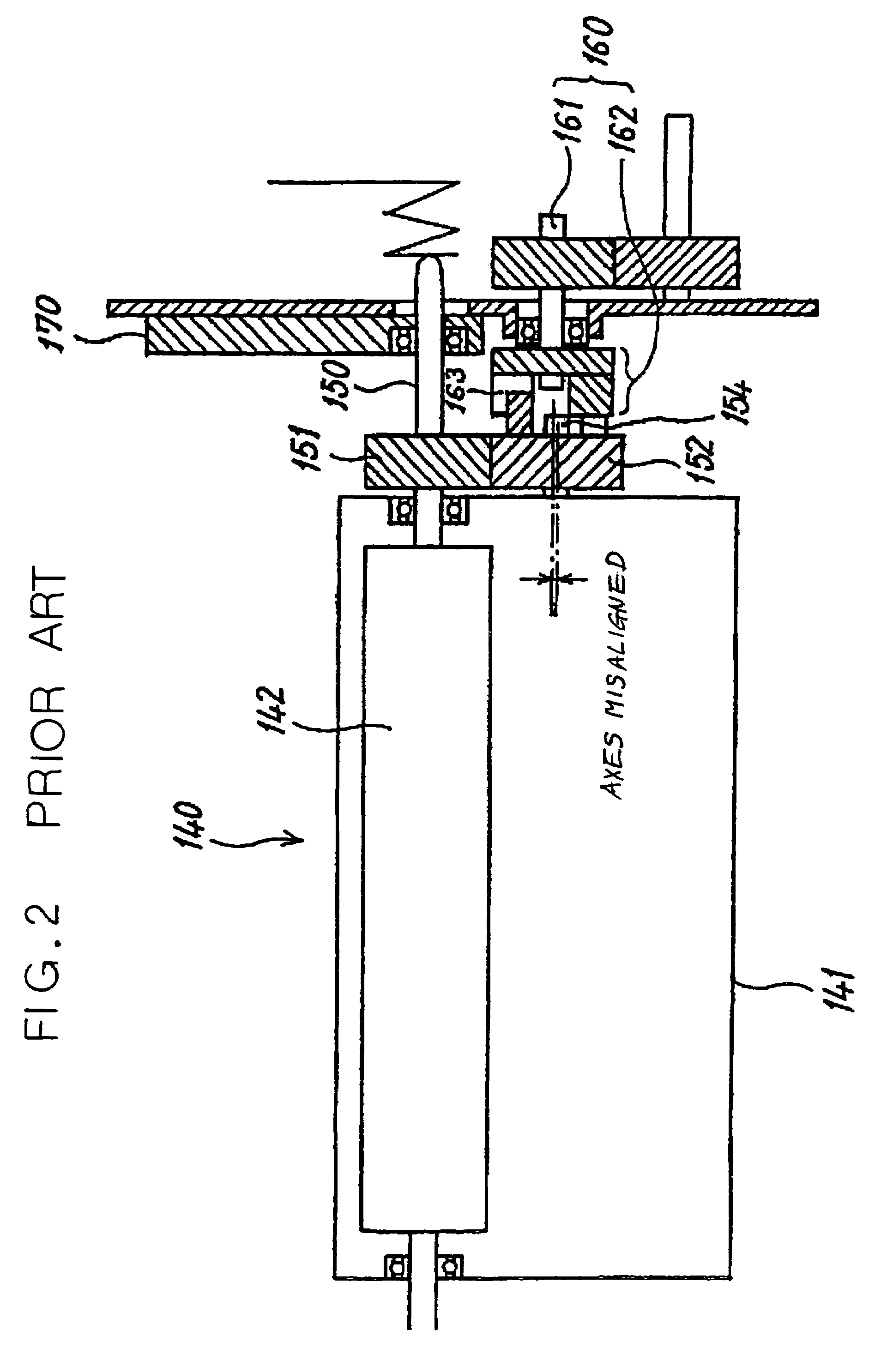

Image forming apparatus

An image forming apparatus whereby it is possible to prevent unevenness in developing density caused by misalignment between the central axes of a driven side rotational coupling section for rotating a developer carrier and a drive side rotational coupling section for transmitting rotational drive force to the driven side rotational coupling section. The driven side rotational coupling section is fixed and the position thereof can be corrected slightly, by engaging the driven side rotational coupling section with a drive side rotational coupling section. A transmission gear is provided which meshes with the driven side rotational coupling section and transmits rotational drive force used to move the surface of the developer carrier. By means of an axle provided on at least one end of the transmission gear engaging with a positioning member on the main body of the image forming apparatus, the developer carrier is positioned in the main body of the image forming apparatus.

Owner:RICOH KK

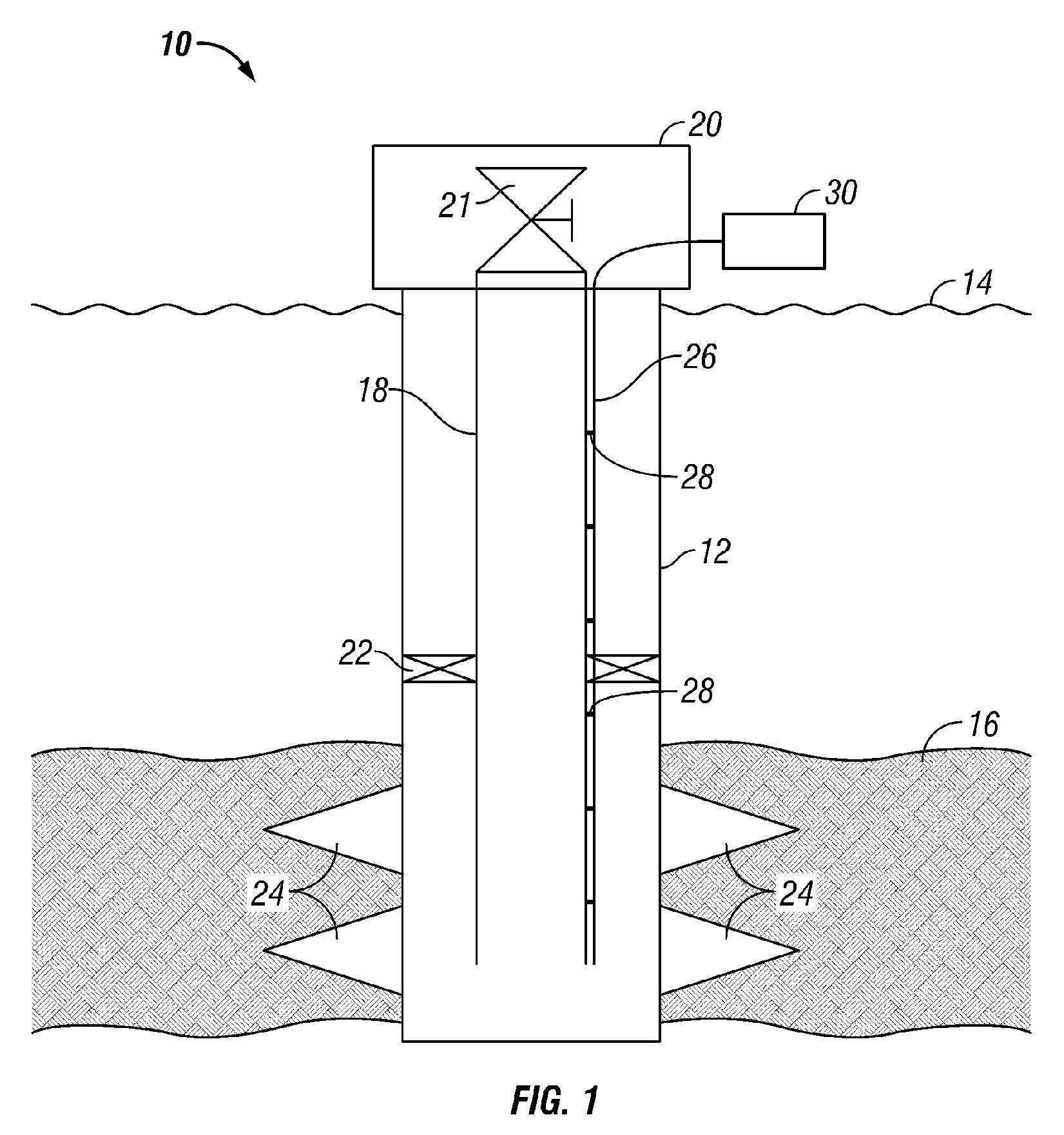

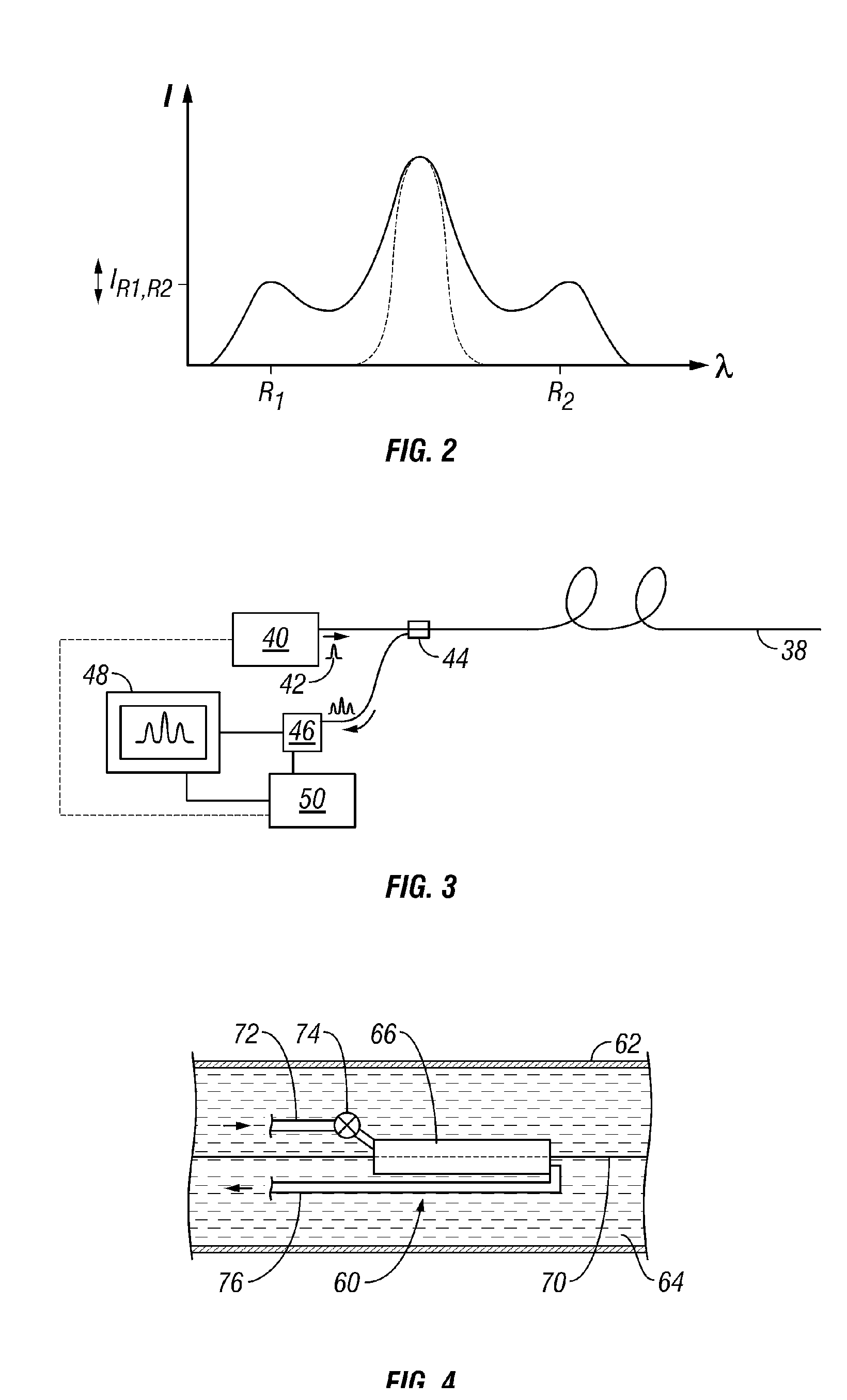

Method and Apparatus for Measuring Fluid Properties

InactiveUS20060010973A1Simple methodEnsure correct executionSurveyConstructionsThermal energyEngineering

A method of measuring fluid properties such as flow velocity, flow rate, and fluid composition comprises positioning a heat exchange element with a temperature sensor, such as an optical fiber temperature sensor, arranged centrally inside the element in thermal contact with a fluid of interest, heating or cooling the heat exchange element to cause a temperature difference and exchange of thermal energy between the element and the fluid, using the temperature sensor to measure the temperature of the heat exchange element during the exchange of thermal energy, and determining properties of the fluid from the temperature measurement. A second temperature sensor can be provided offset from the first sensor to provide additional measurements to improve accuracy, and a plurality of heat exchange elements with temperature sensors can be used together to determine fluid properties over a large region.

Owner:SCHLUMBERGER TECH CORP

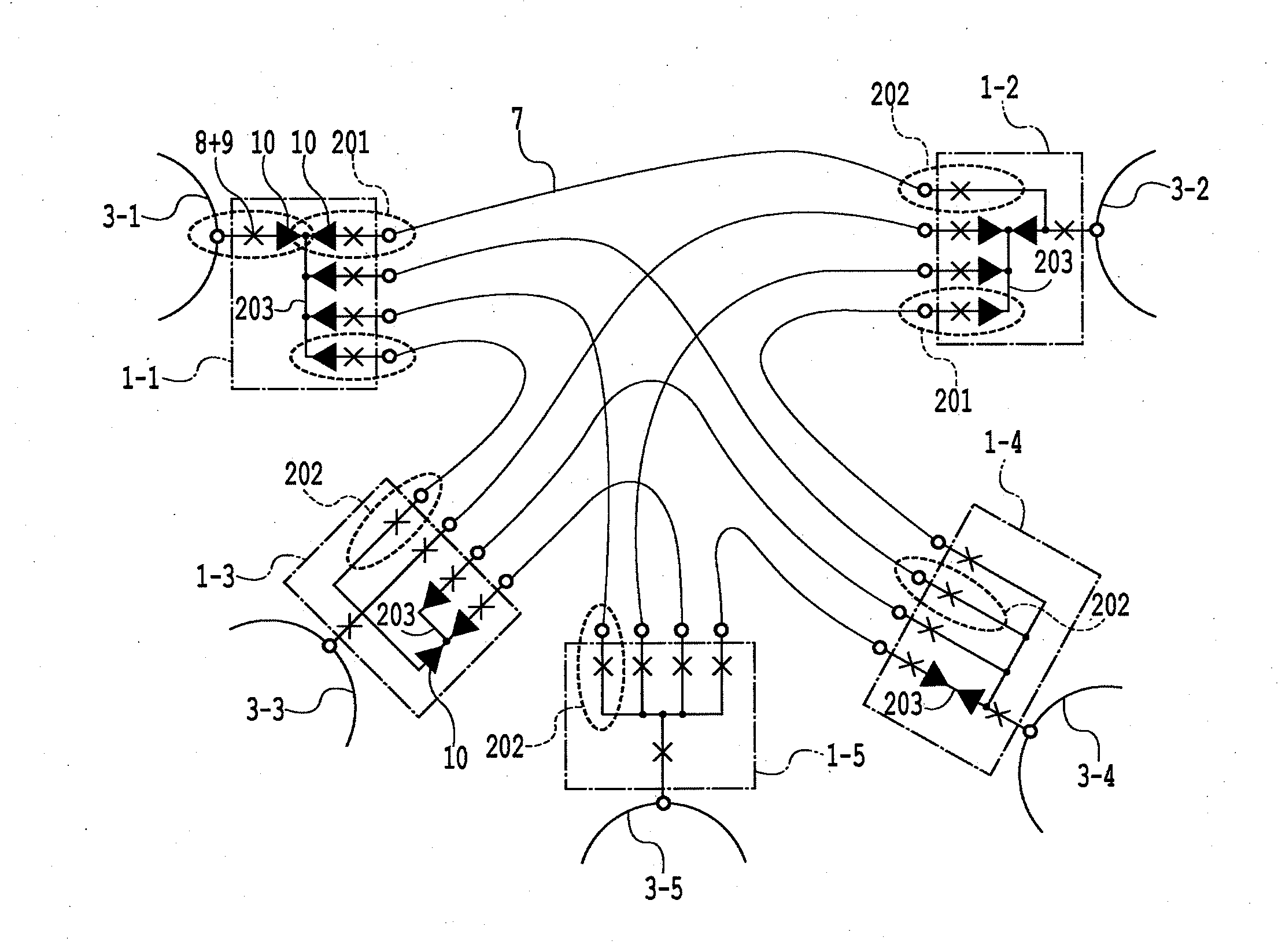

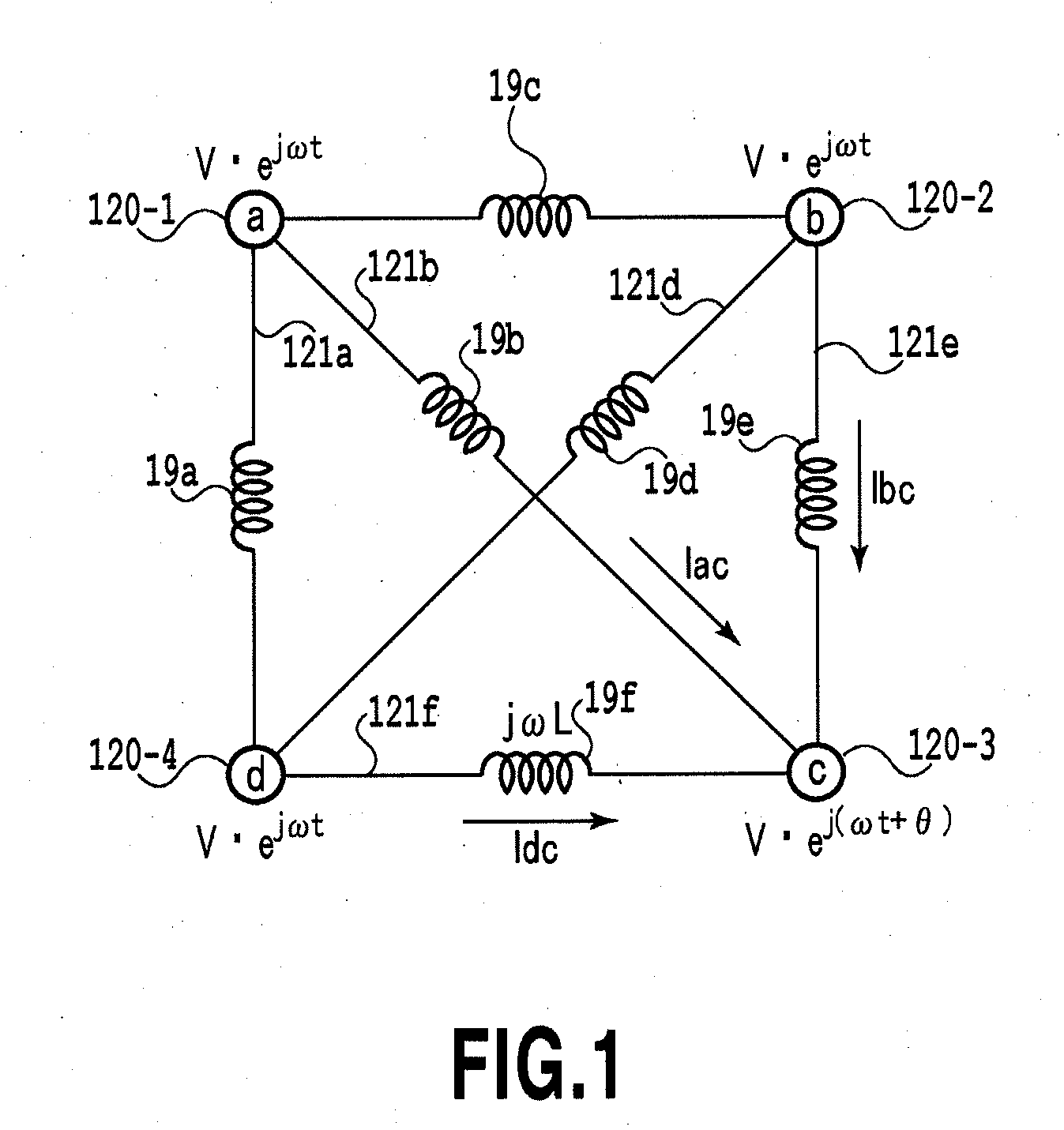

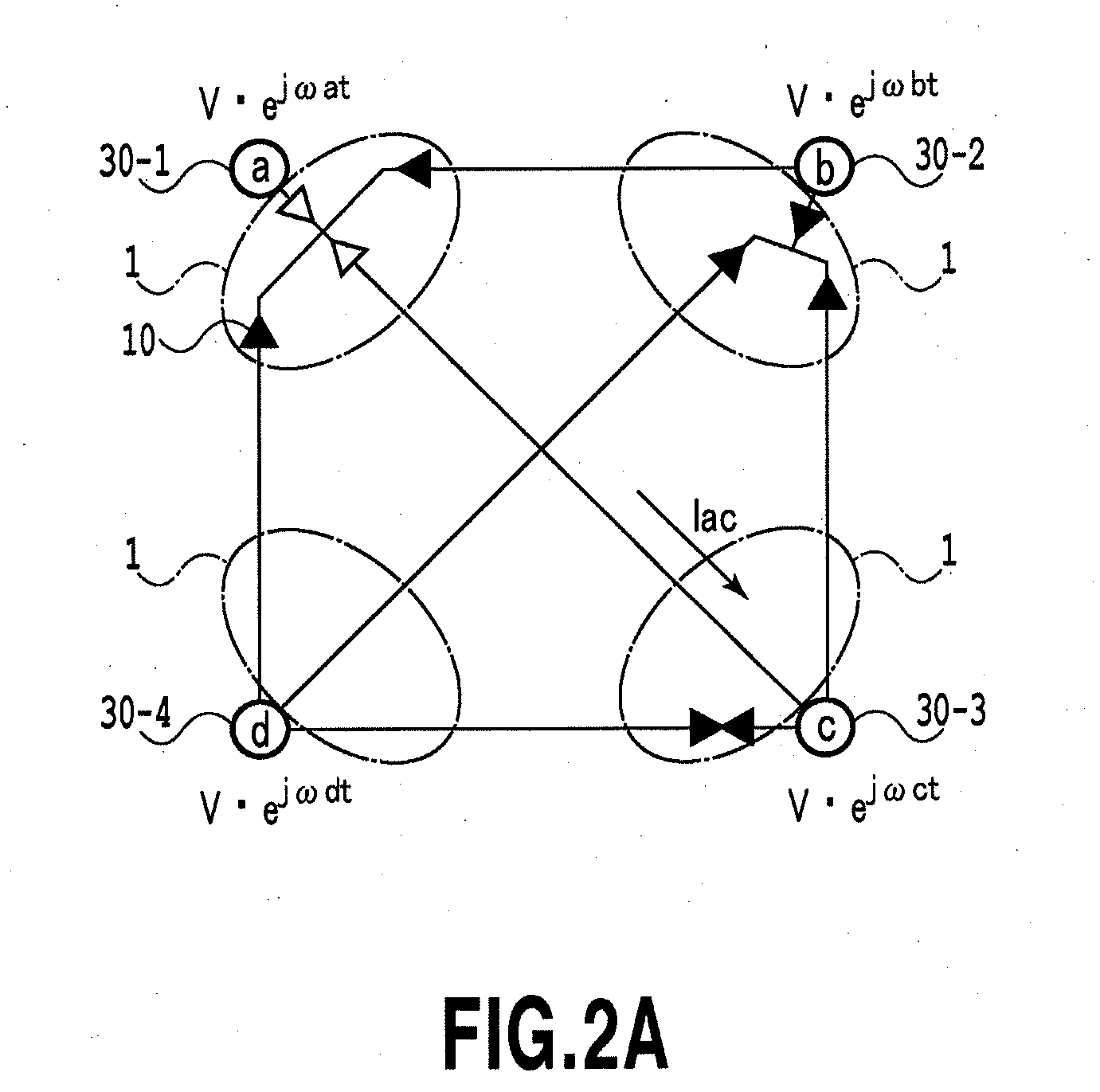

Multi-terminal power conversion device, multi-terminal power transfer device, and power network system

ActiveUS20120173035A1Reduce capacityIncrease volumeMechanical power/torque controlDc network circuit arrangementsNetworked systemTerminal equipment

The present invention provides a multi-terminal power conversion device, a multi-terminal power transfer device, and a power network system which allows an existing power grid to be divided into a plurality of power grids that can be interconnected together and operated stably via existing or new transmission lines. An inter-power grid asynchronous interconnection network system includes a multi-terminal power conversion device characterized by connecting together a plurality of asynchronous power grids including a bulk power grid and controlling power so that the sum of inflow power and outflow power is zero. An intra-power grid synchronous network system includes a power apparatus control terminal device with means for controlling power for a power apparatus installed in an autonomous power grid. A plurality of inter-power grid asynchronous interconnection network systems are connected to an intra-power grid synchronous network system to integrate the power control with communication control.

Owner:THE UNIV OF TOKYO

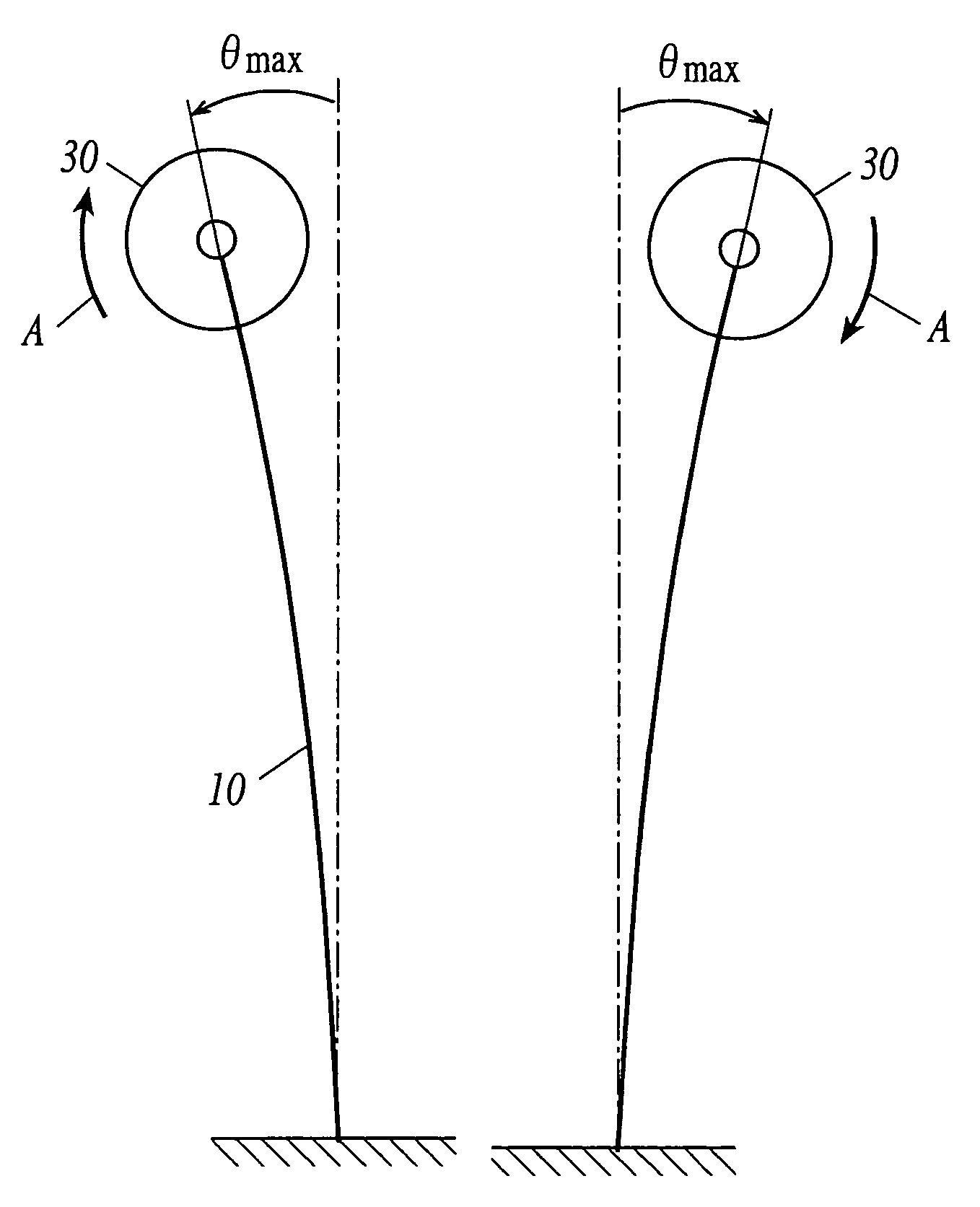

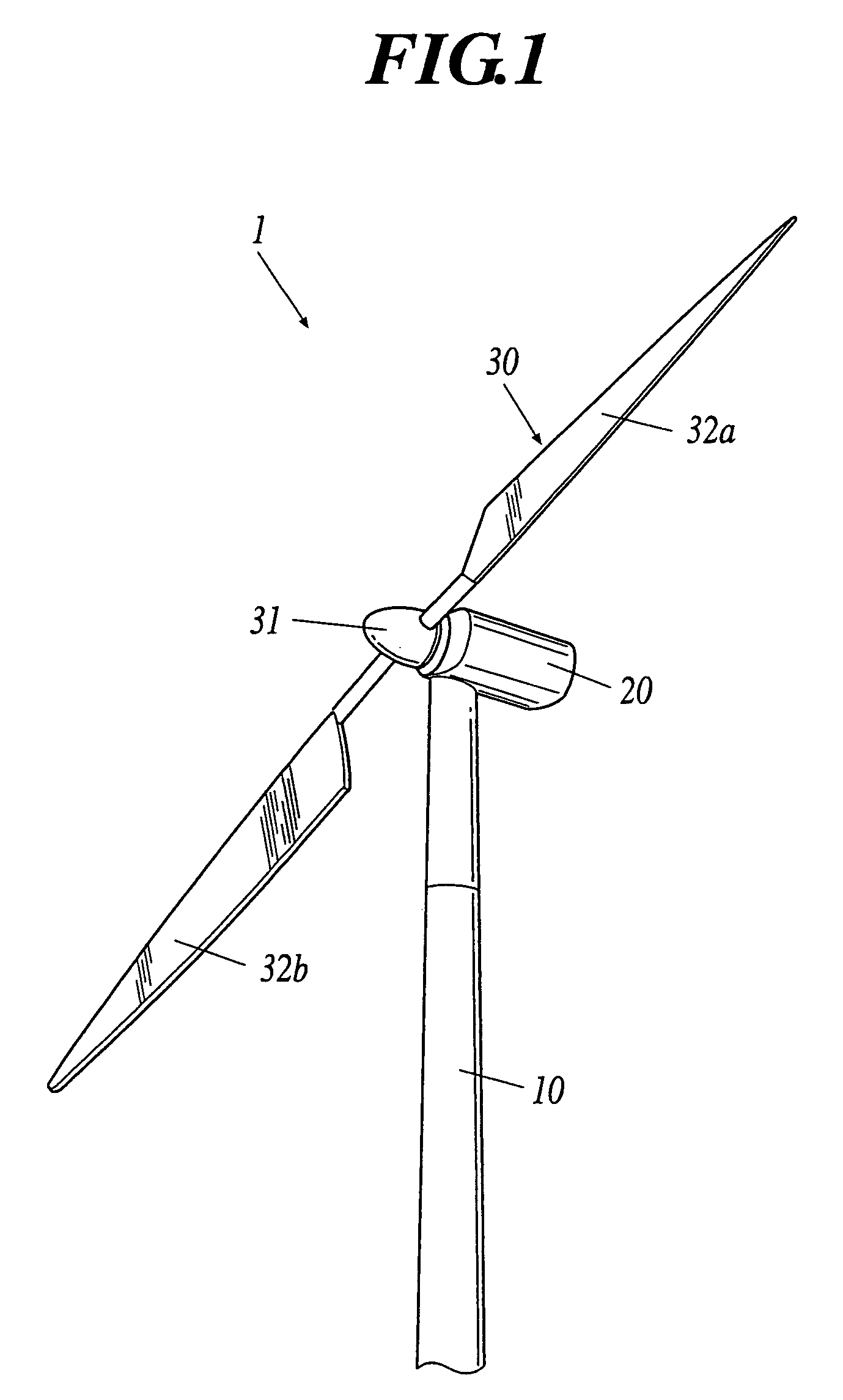

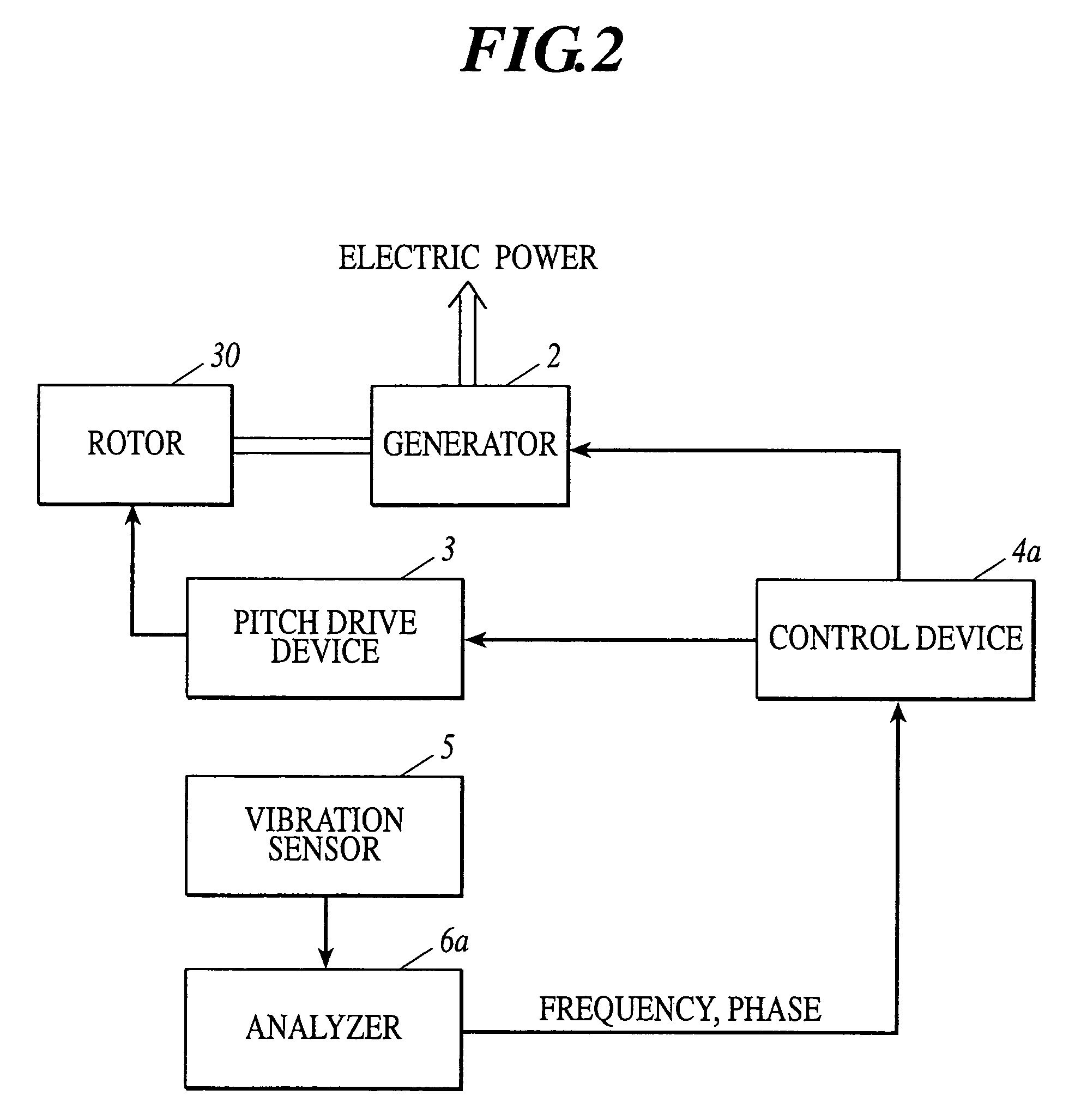

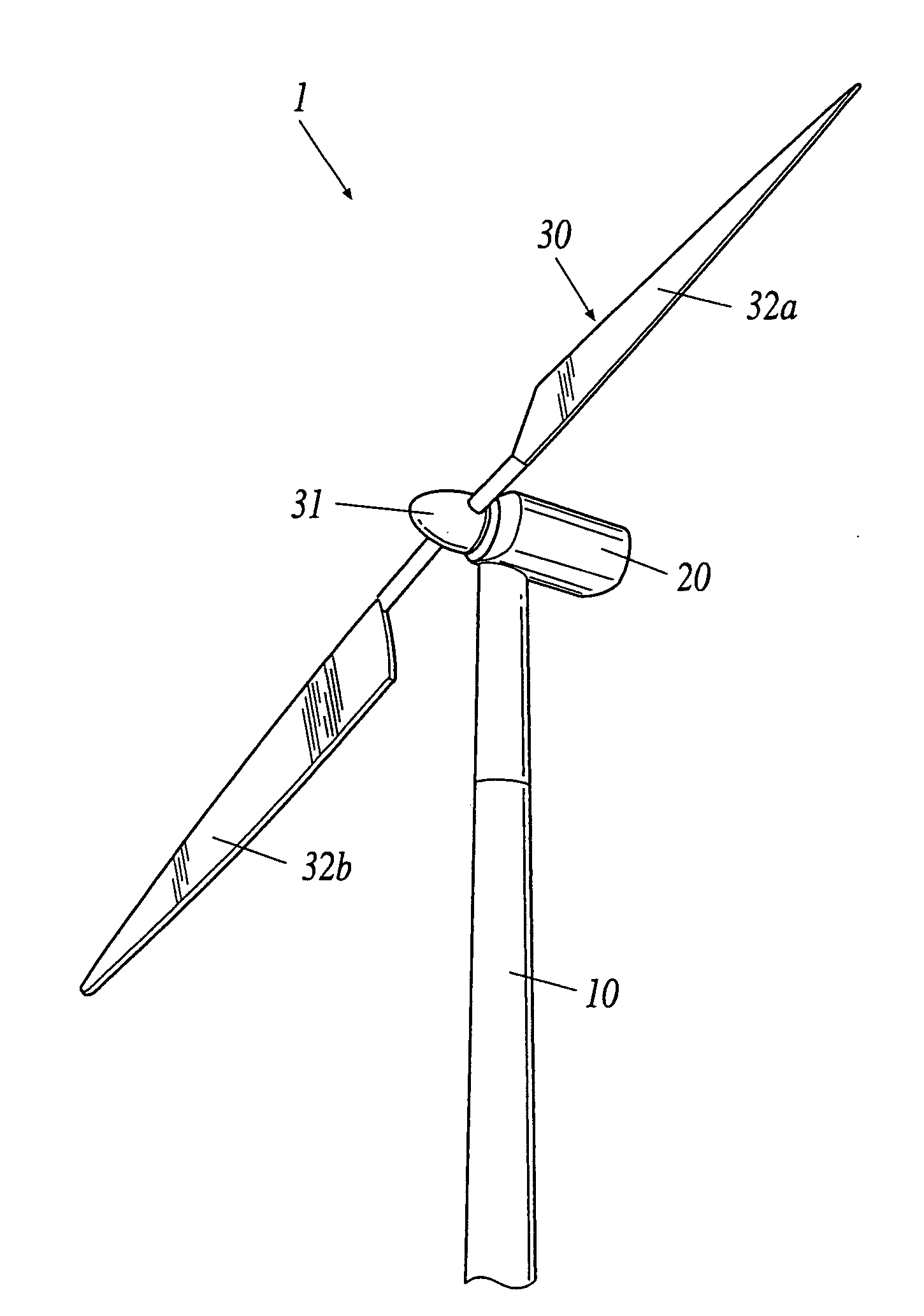

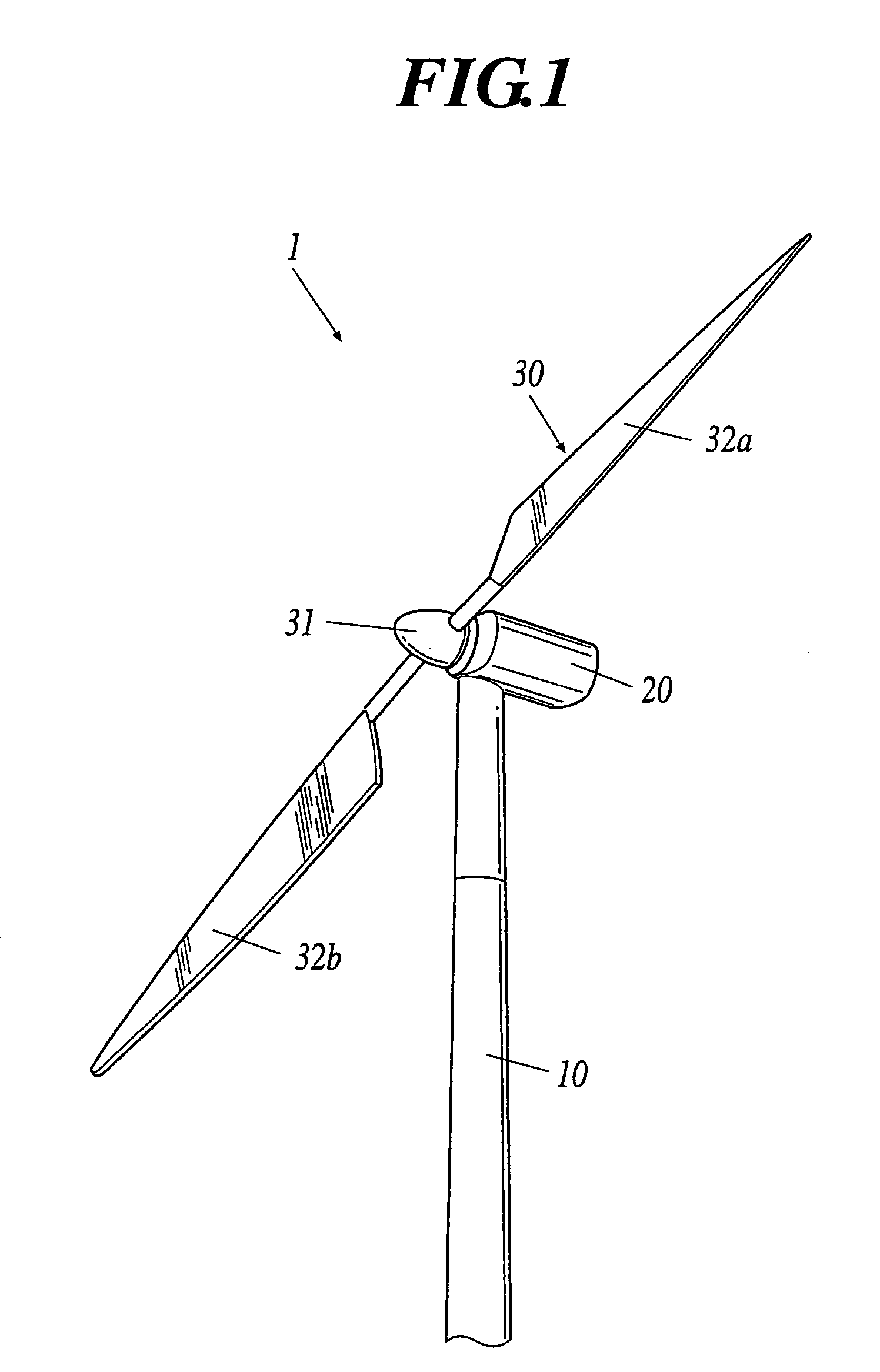

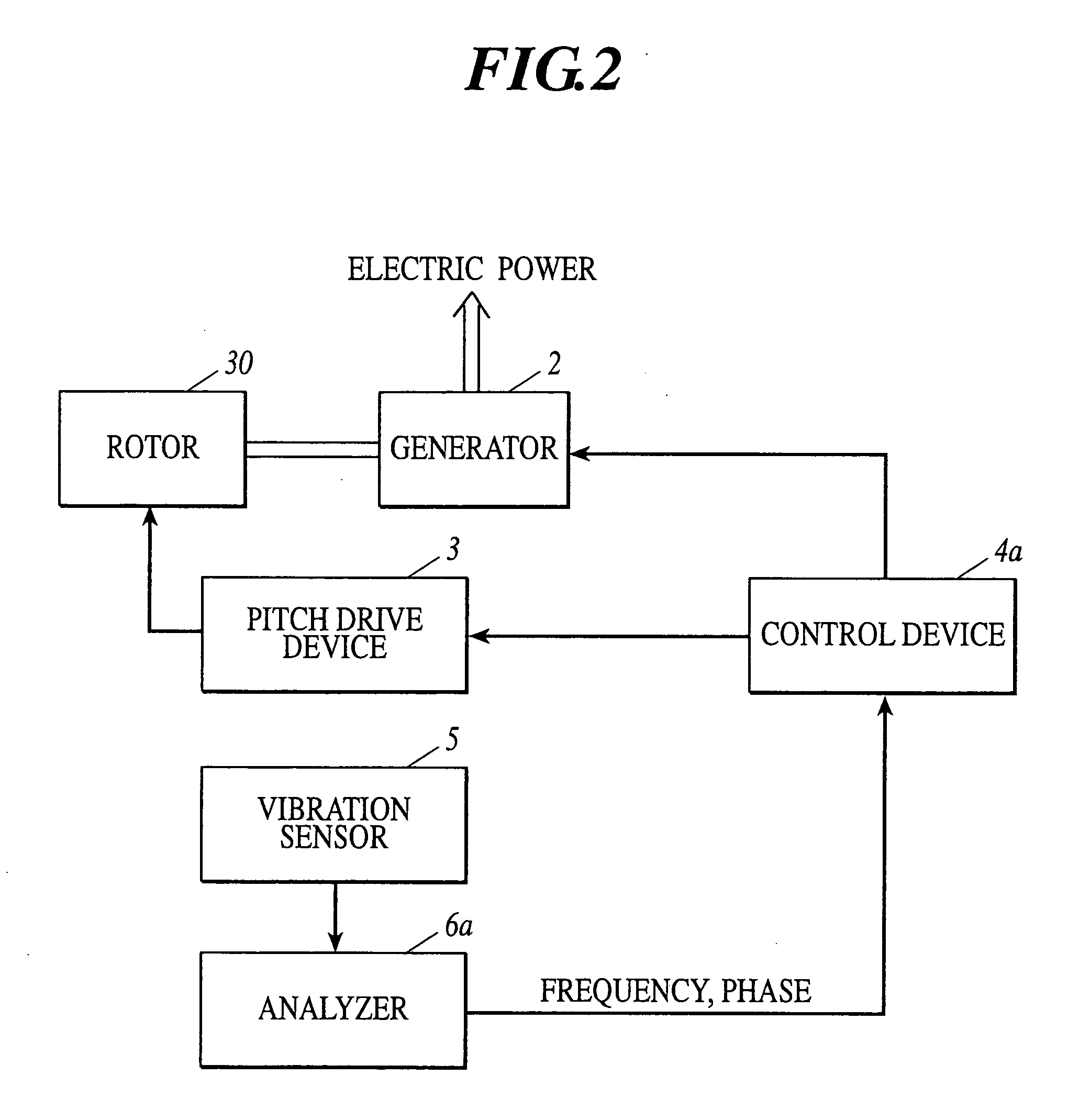

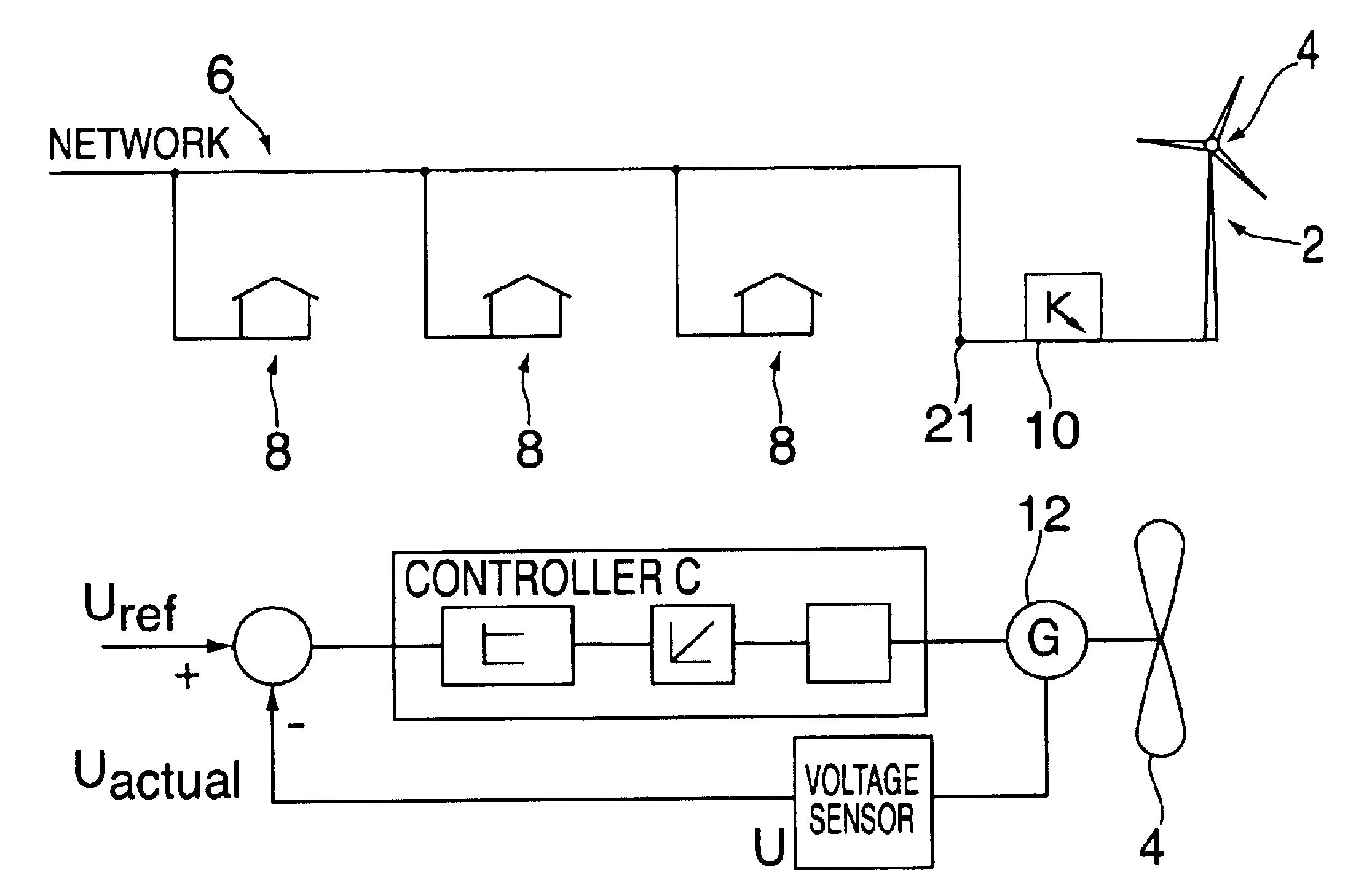

Wind turbine generator

ActiveUS7400055B2Suppress and prevent vibrationReduce vibrationWind motor controlEngine fuctionsRotational axisTower

A wind turbine generator includes: a tower; a rotor supported by the tower to rotate around a rotational axis which is not parallel with an axis direction of the tower by wind power; a generator driven by a rotational force of the rotor; a sensor that detects vibration component in a direction perpendicular to the rotational axis of the rotor; and a control device that controls the rotor so that fluctuation of the rotor is caused to suppress the vibration component.

Owner:HITACHI LTD

Solid electrolytic capacitor and manufacturing method thereof

InactiveUS6215652B1Avoid volatilityIncrease capacitanceLiquid electrolytic capacitorsFixed capacitor dielectricElectrolysisMetal powder

A solid electrolytic capacitor is here disclosed in which a dielectric layer formed on the surface of an anode obtained by molding and then sintering a niobium metal powder which includes a niobium oxide layer and a niobium nitride region, and a method for manufacturing the solid electrolytic capacitor is also disclosed.

Owner:TOKIN CORP

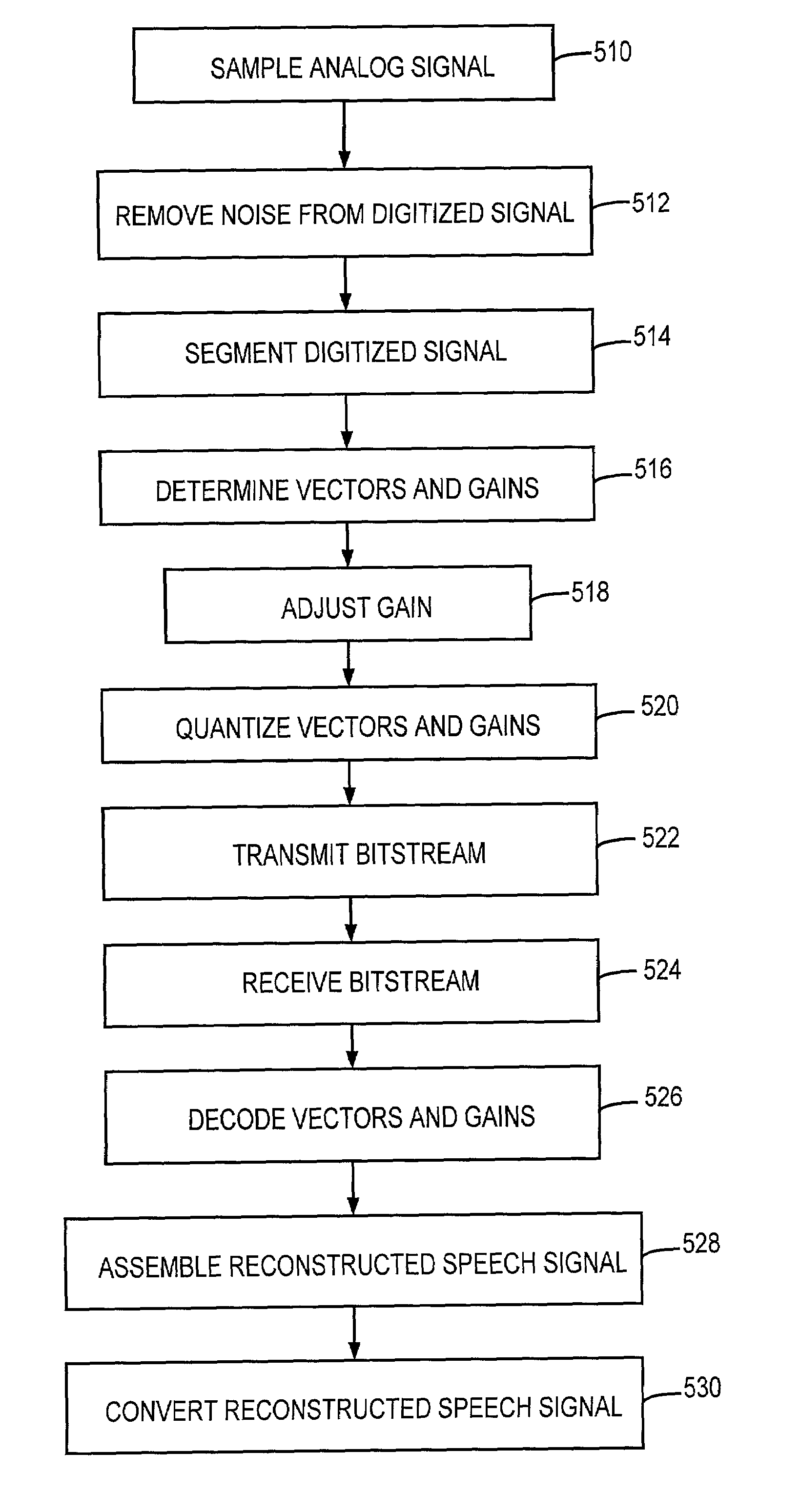

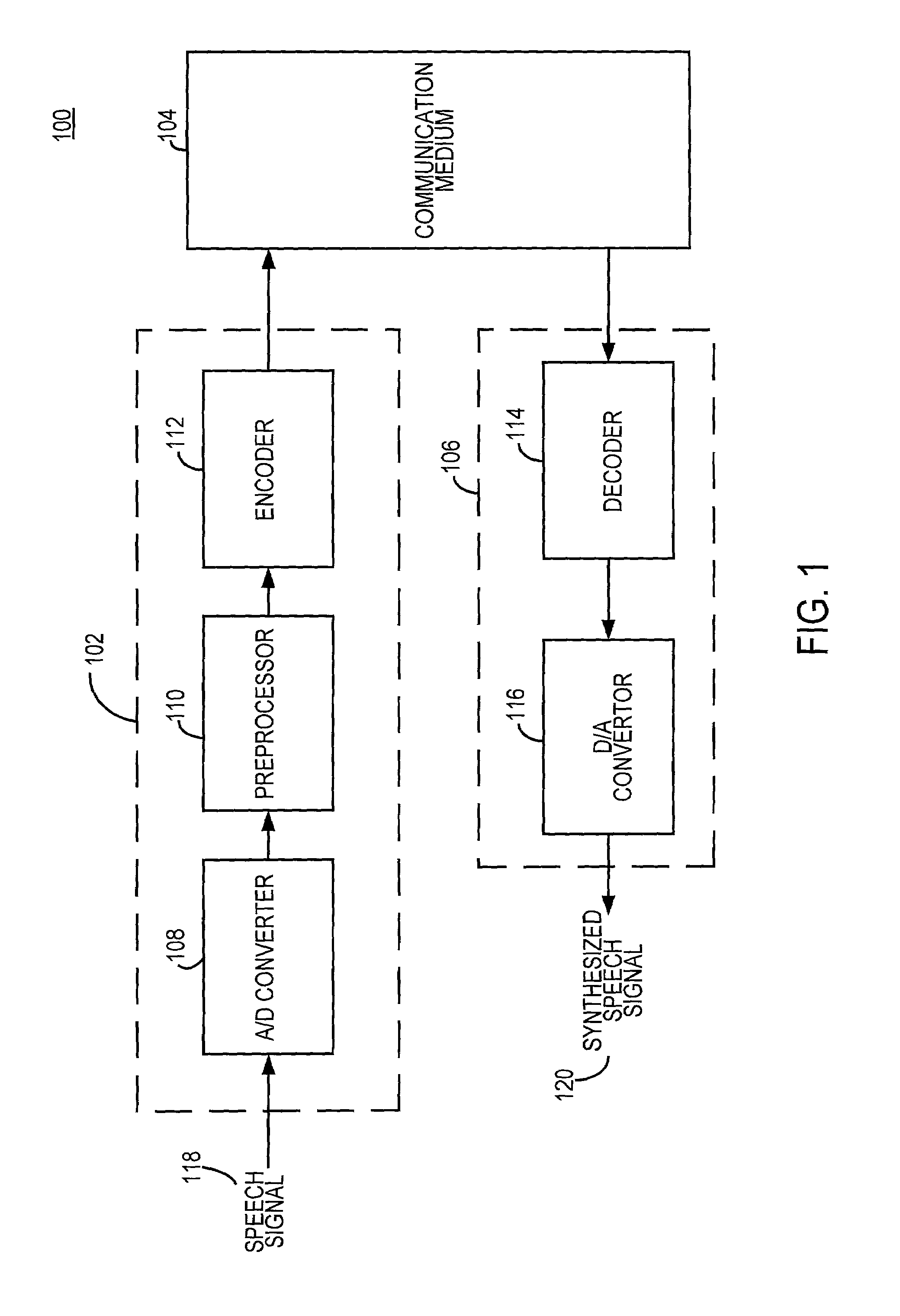

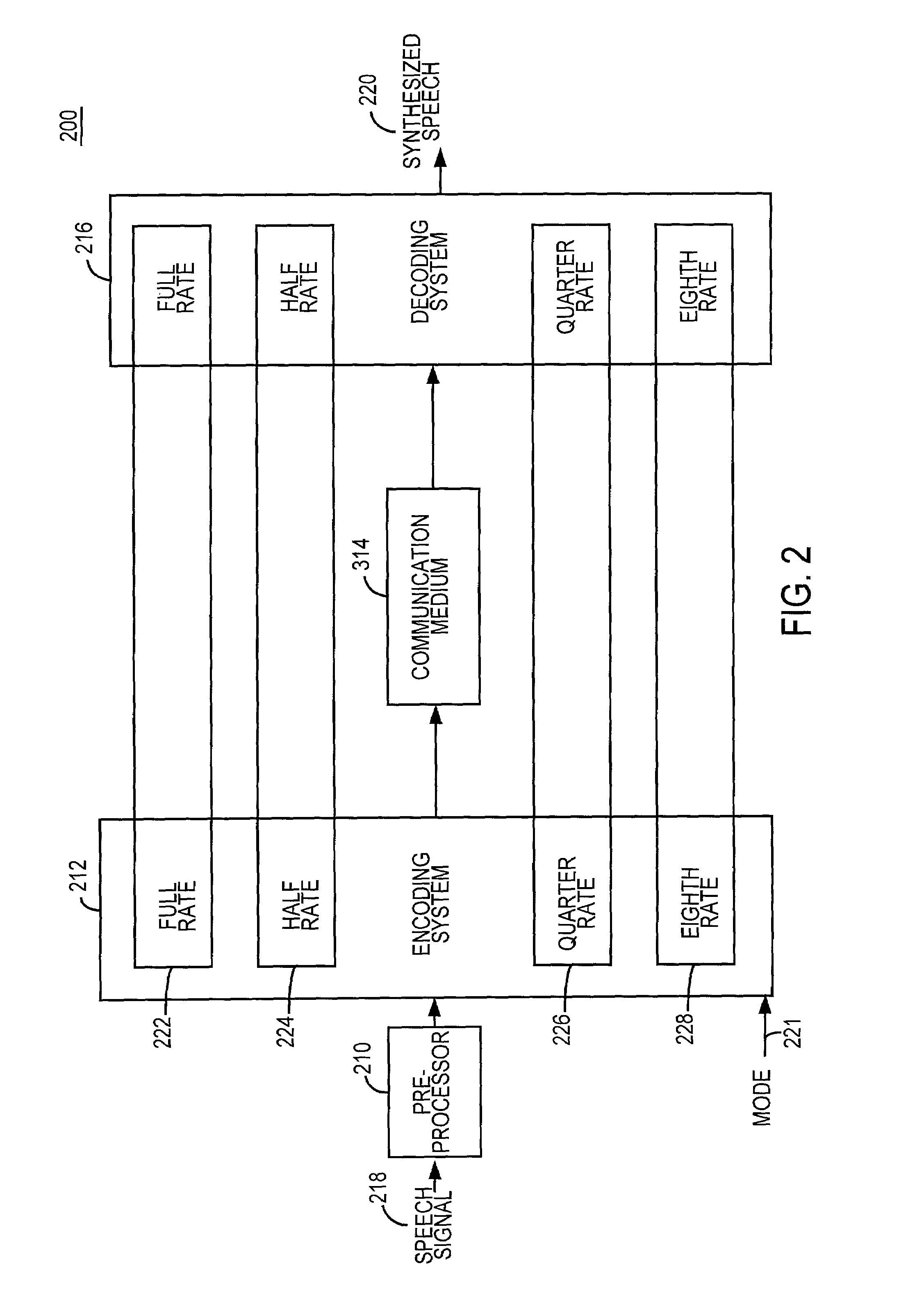

Speech coding system with time-domain noise attenuation

InactiveUS7020605B2Suppress noiseReduce background noiseSpeech analysisAnalog-to-digital converterBackground noise

A speech coding system is provided with time-domain noise attenuation. The speech coding system has an encoder operatively connected to a decoder via a communication medium. A preprocessor processes a digitized speech signal from an analog-to-digital converter. Speech coding systems are used to encode and decode a bitstream. Gains from the speech coding are adjusted by a gain factor Gf that provides time-domain background noise attenuation.

Owner:MACOM TECH SOLUTIONS HLDG INC +1

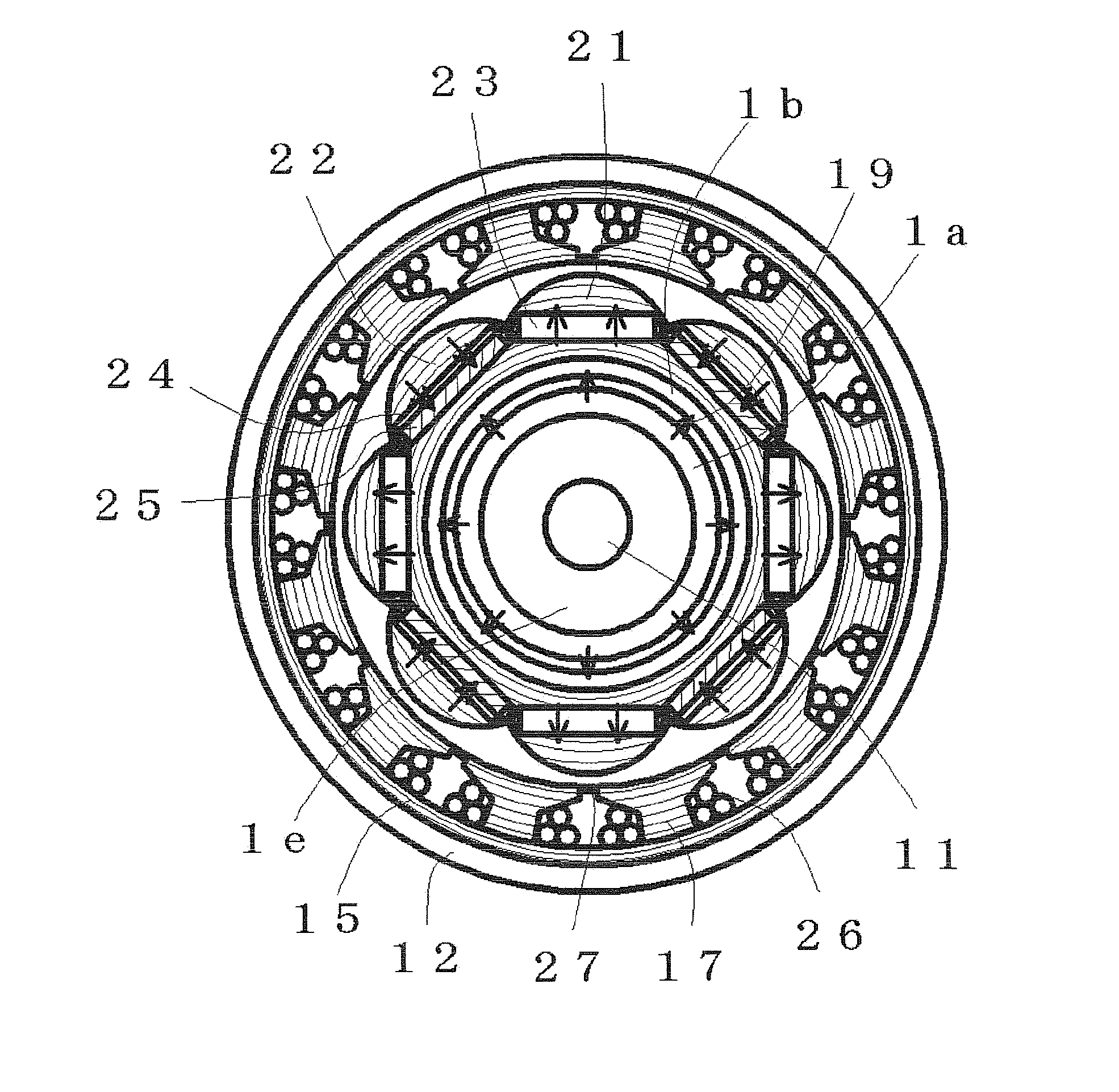

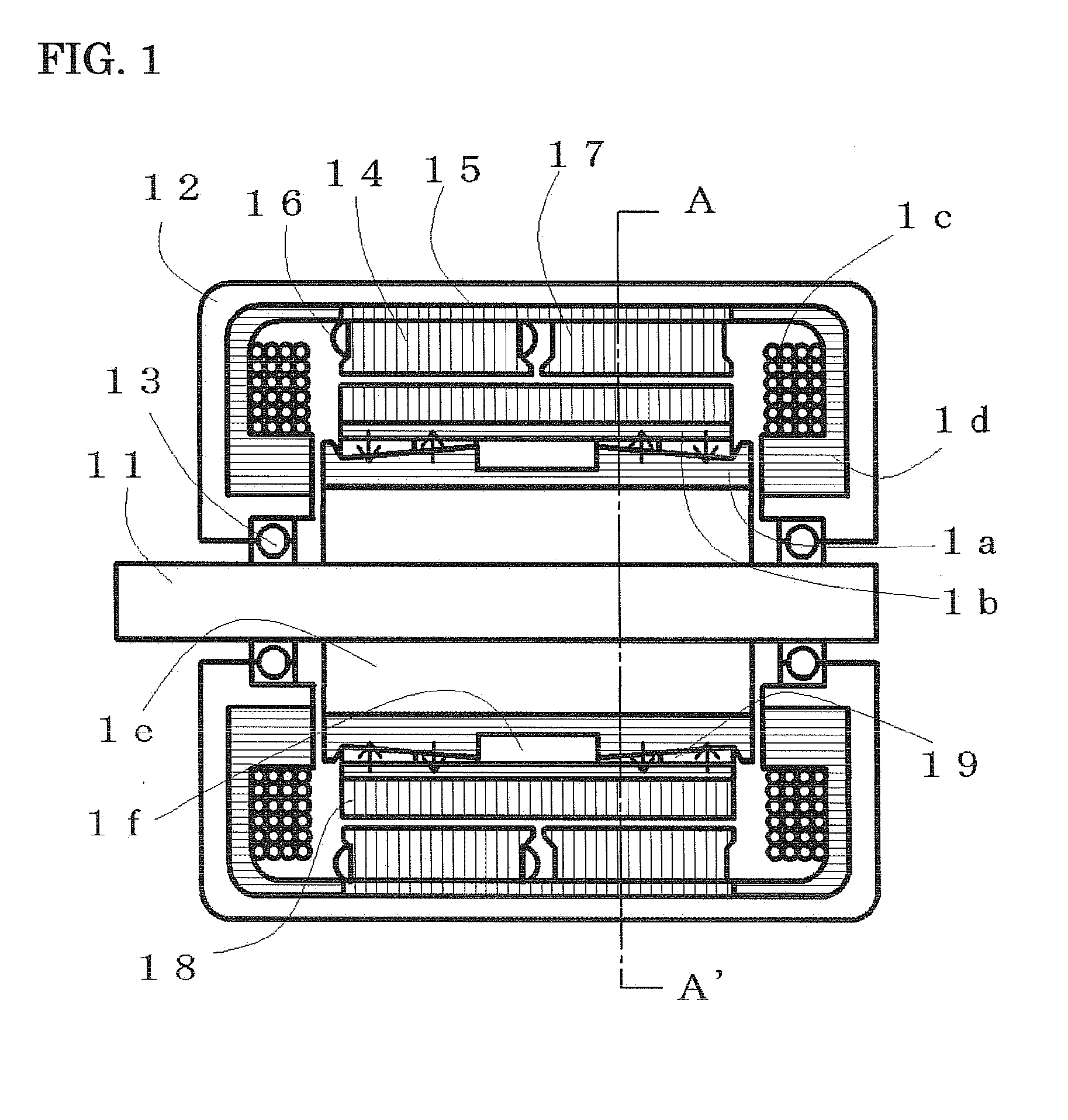

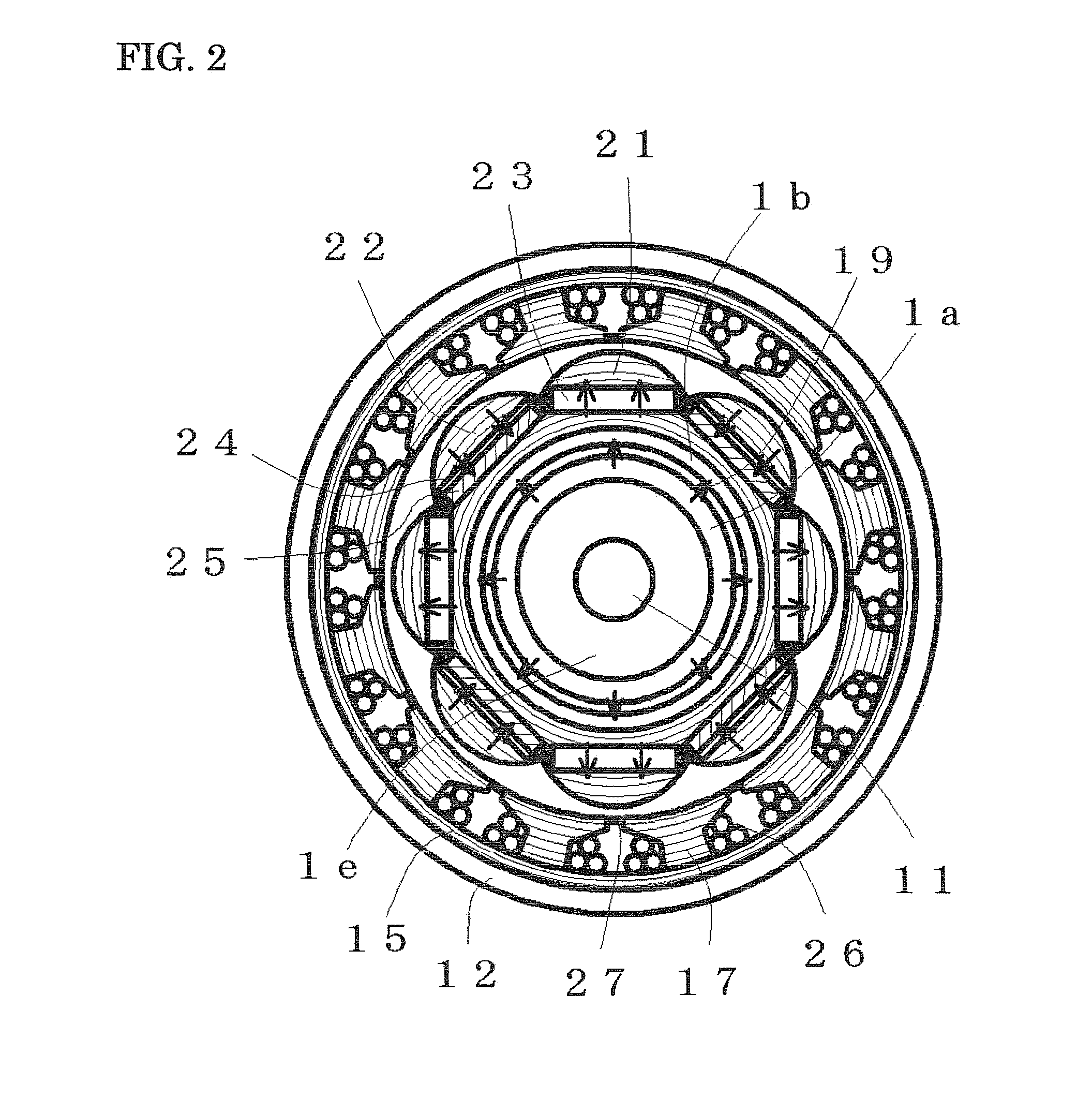

Magnetic flux controllable rotating electric machine system

InactiveUS20100213885A1Easily magnetizedIncreases amount of magnetic fluxSynchronous motors startersWindingsExcitation currentWave shape

In a magnet-exciting rotating electric machine system, a rotor surface has magnetic salient poles and island-shaped magnetic poles alternately in circumferential direction, and the island-shaped magnetic poles are constituted so that magnetic flux coming from an external source does not flow through. A magnetic excitation part magnetizes the island-shaped magnetic poles and the magnetic salient poles collectively in the same direction, and then control a flux amount flowing through an armature. The armature has armature coils that face the magnetic salient pole and the island-shaped magnetic pole simultaneously so that driving torque fluctuation or power generation voltage waveform distortion is controlled. The magnetic excitation part changes magnetization state of a field magnet irreversibly, or changes an excitation current to an excitation coil to control a flux crossing the armature.

Owner:KURA LAB

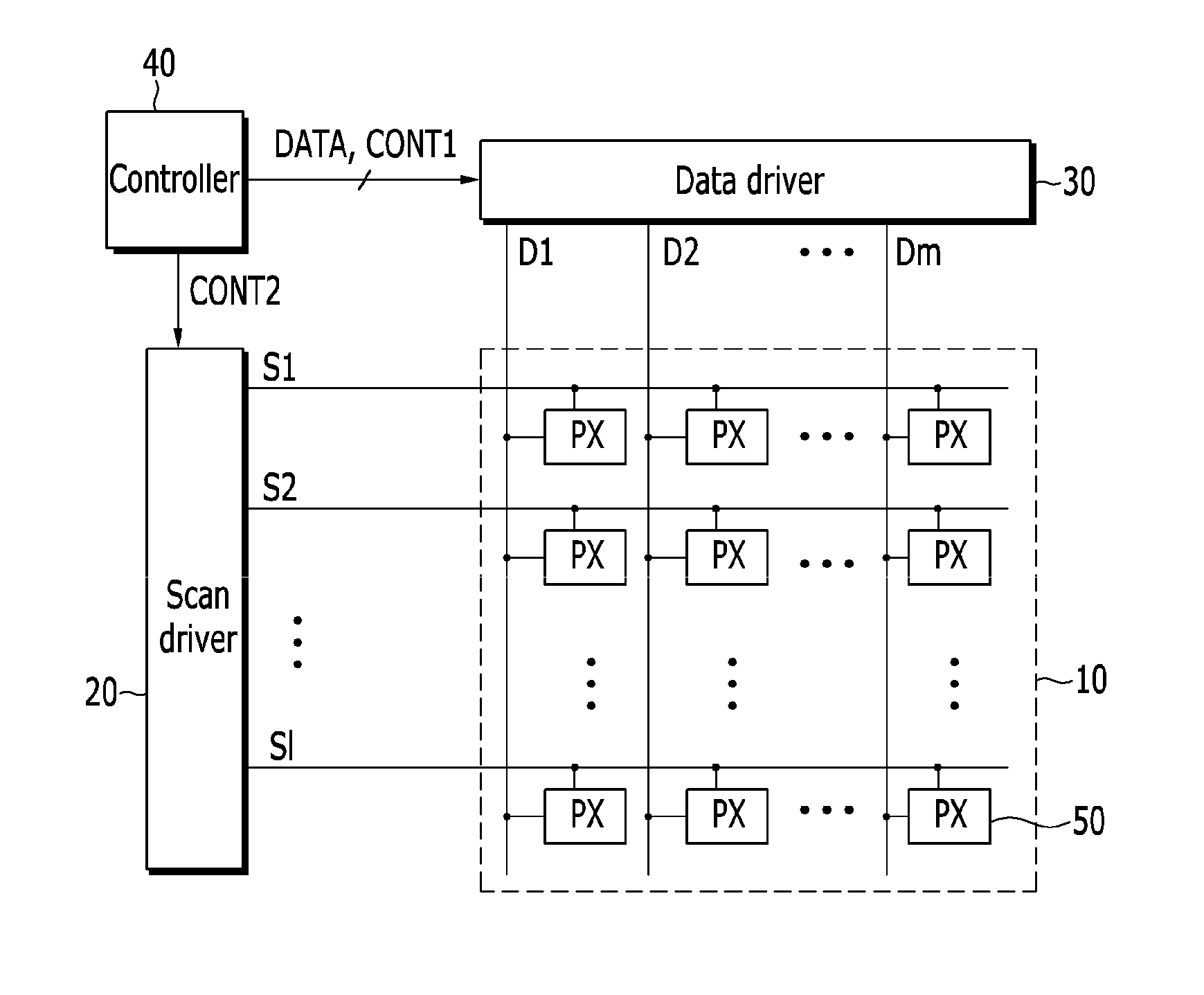

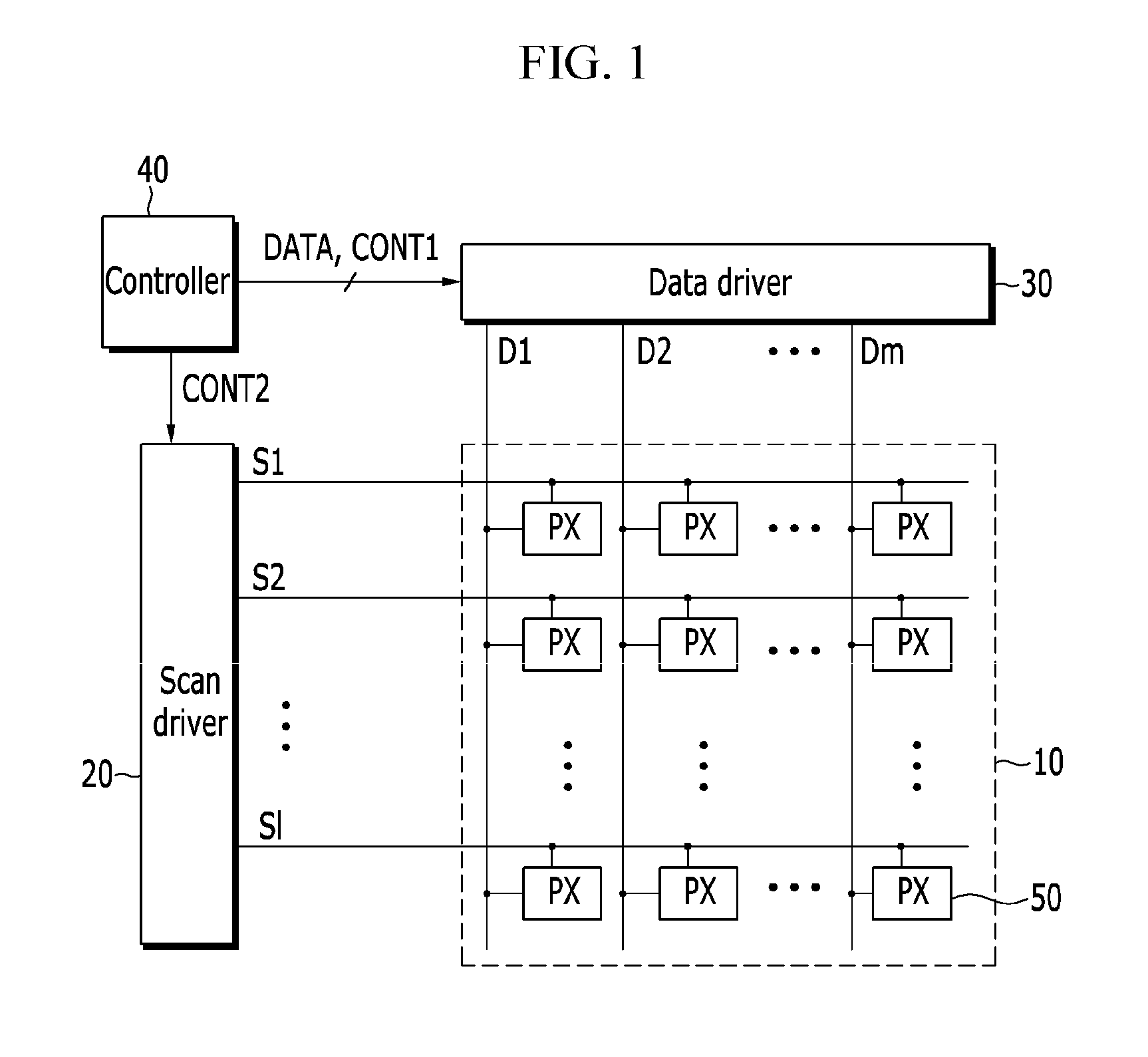

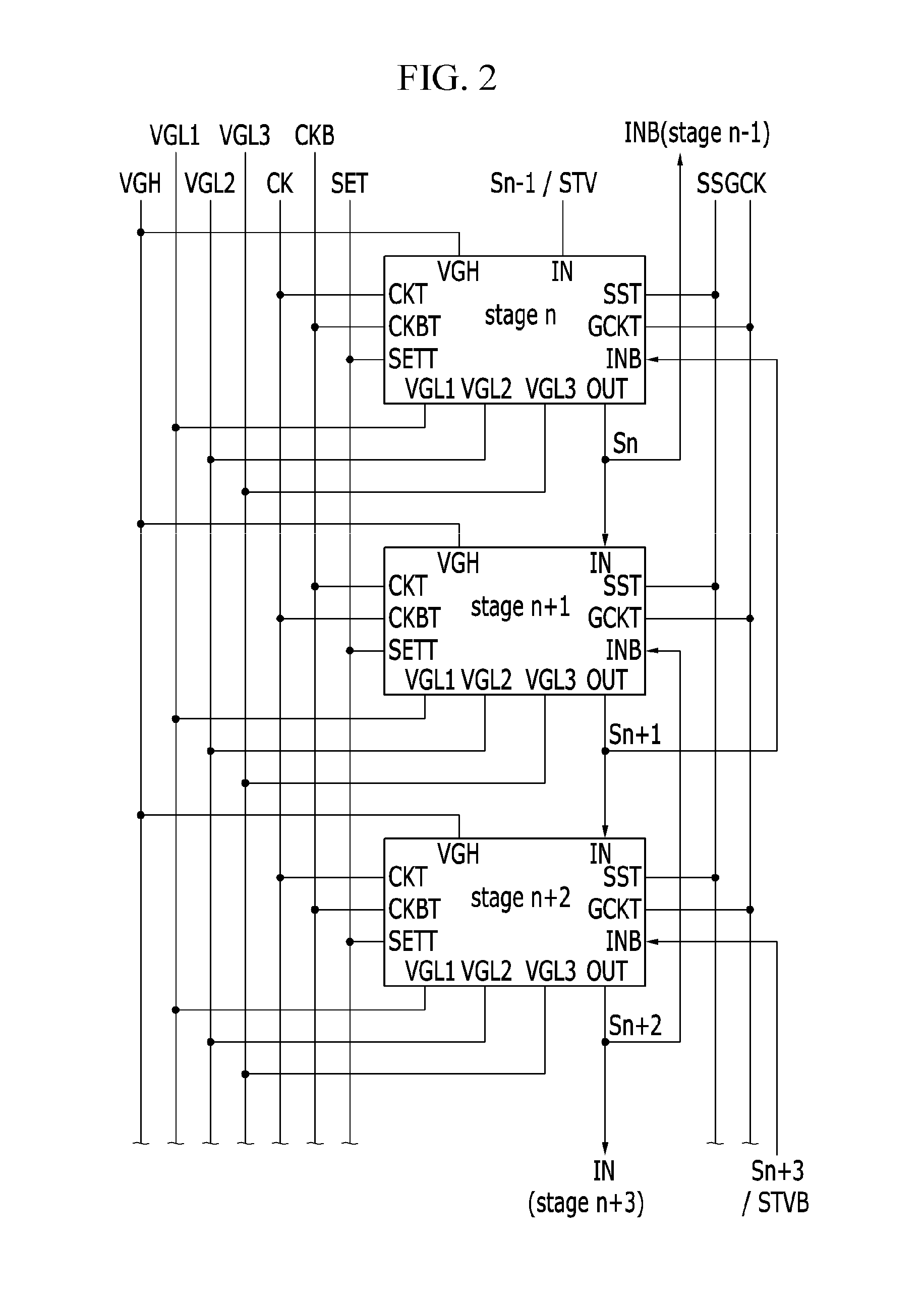

Scan driving device and display device including the same

ActiveUS20150015562A1Improve stress stabilityStably scan signalCathode-ray tube indicatorsDigital storageShift registerControl signal

A scan driving device includes shift registers, each including a first signal terminal to which a forward direction driving start signal is transferred, a second signal terminal to which a backward direction driving start signal is transferred, a clock signal terminal and a clock bar signal terminal to which a clock signal and a clock bar signal are applied, a sustain signal terminal to which a sustain signal is transferred, a control signal terminal to which a control signal is transferred, a gate clock signal terminal to which a gate clock signal is transferred, and an output signal terminal, where driving power source voltages including a high potential power source voltage and low potential power source voltages is applied to each shift register, and an application of the low potential power source voltages to each shift register is controlled based on the sustain signal.

Owner:SAMSUNG DISPLAY CO LTD

Wind turbine generator

ActiveUS20070176428A1Suppress and prevent vibrationReduce vibrationWind motor controlEngine fuctionsRotational axisTower

A wind turbine generator includes: a tower; a rotor supported by the tower to rotate around a rotational axis which is not parallel with an axis direction of the tower by wind power; a generator driven by a rotational force of the rotor; a sensor to detect vibration component in a direction perpendicular to the rotational axis of the rotor; and a control device to control the rotor so that fluctuation of the rotor is caused to suppress the vibration component.

Owner:HITACHI LTD

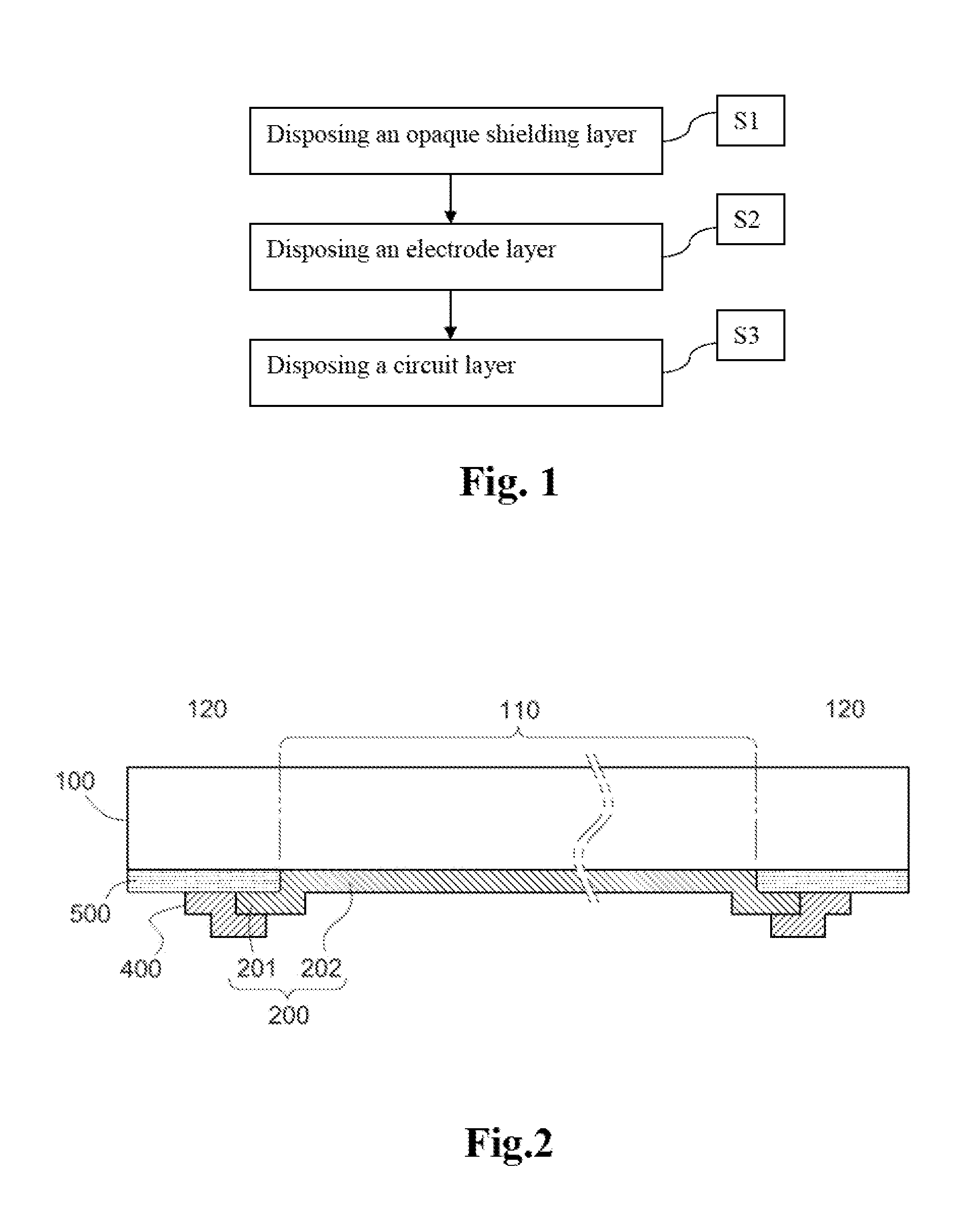

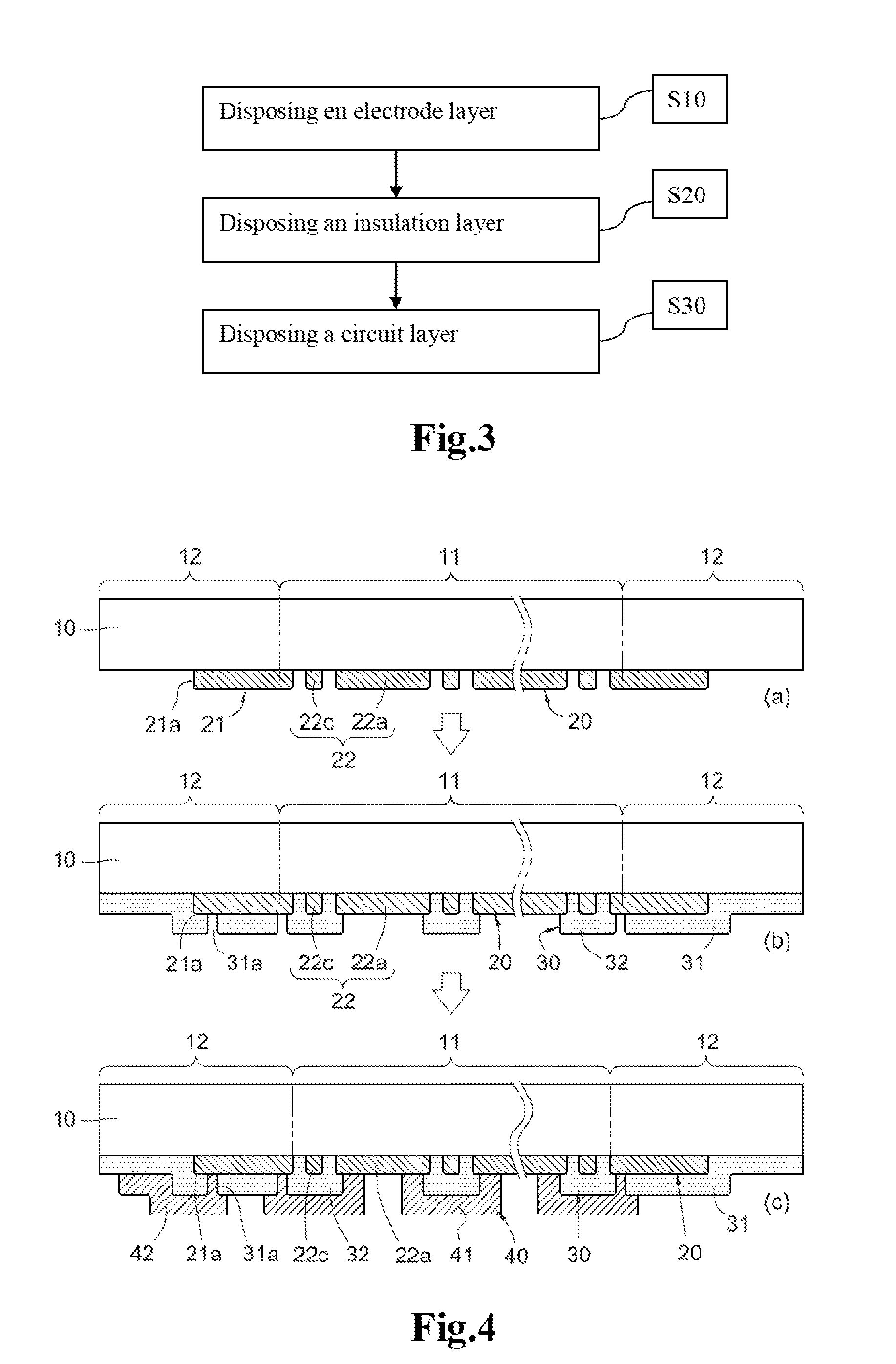

Touch panel and manufacturing method thereof

ActiveUS20130043068A1Avoiding fluctuation of resistance valueAvoid mutual conductionLiquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingInsulation layerHeight difference

The present disclosure provides a manufacturing method for a touch panel comprising: disposing an electrode layer extending from touch area of a substrate to periphery area of the substrate, wherein the periphery area surrounds the periphery of the touch area. The method further includes disposing an insulation layer in the periphery area of the substrate to form a shielding layer, making the shielding layer cover the overlapping electrode in the periphery area and making the electrode layer of the touch area and the overlapping electrode locate on the same layer of the substrate so as to avoid fluctuation of resistance value in the electrode layer due to height difference. Meanwhile, adopting the disposition method also maintains insulating performance of the shielding layer. The present disclosure also provides a touch panel made by the manufacturing method.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

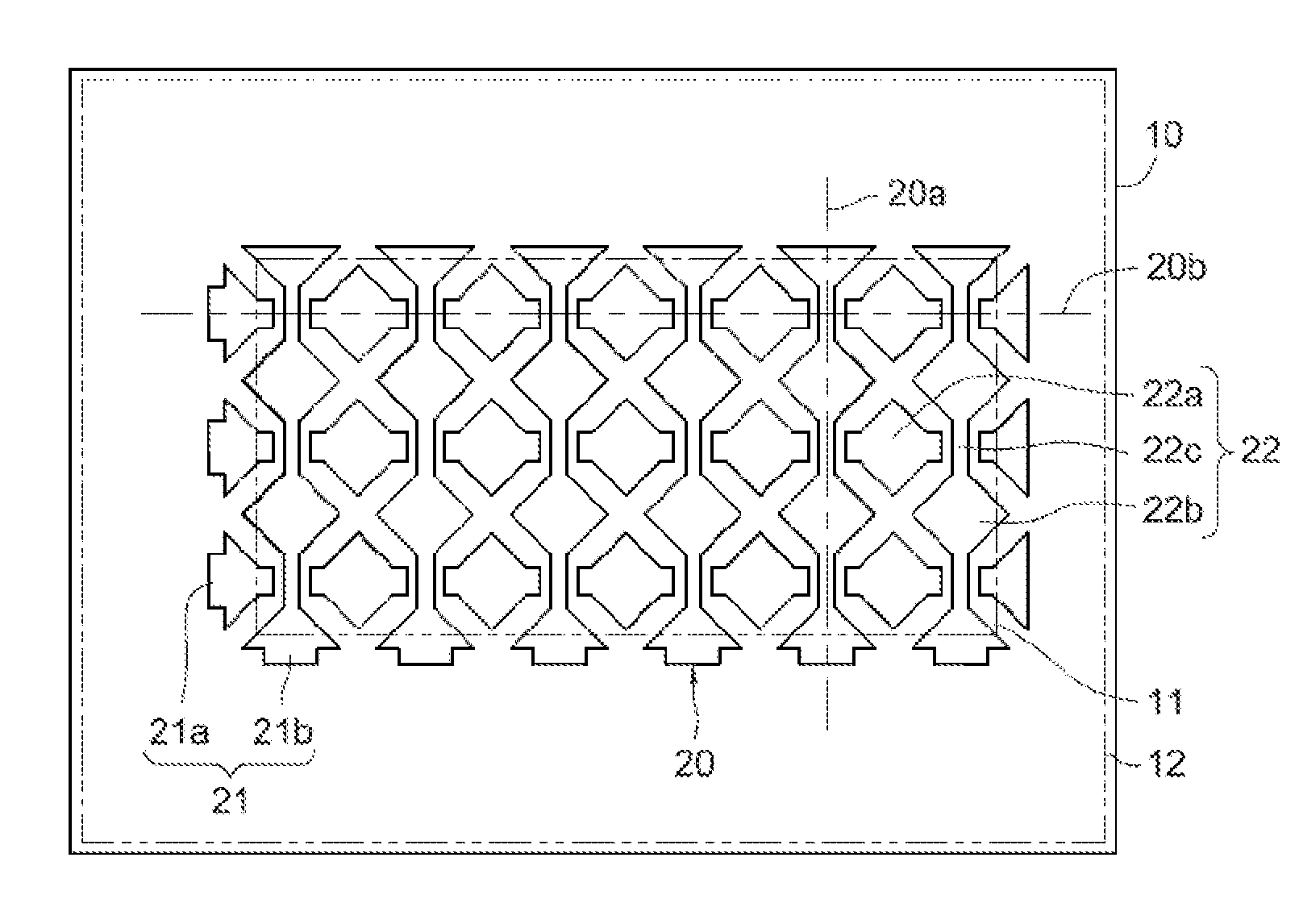

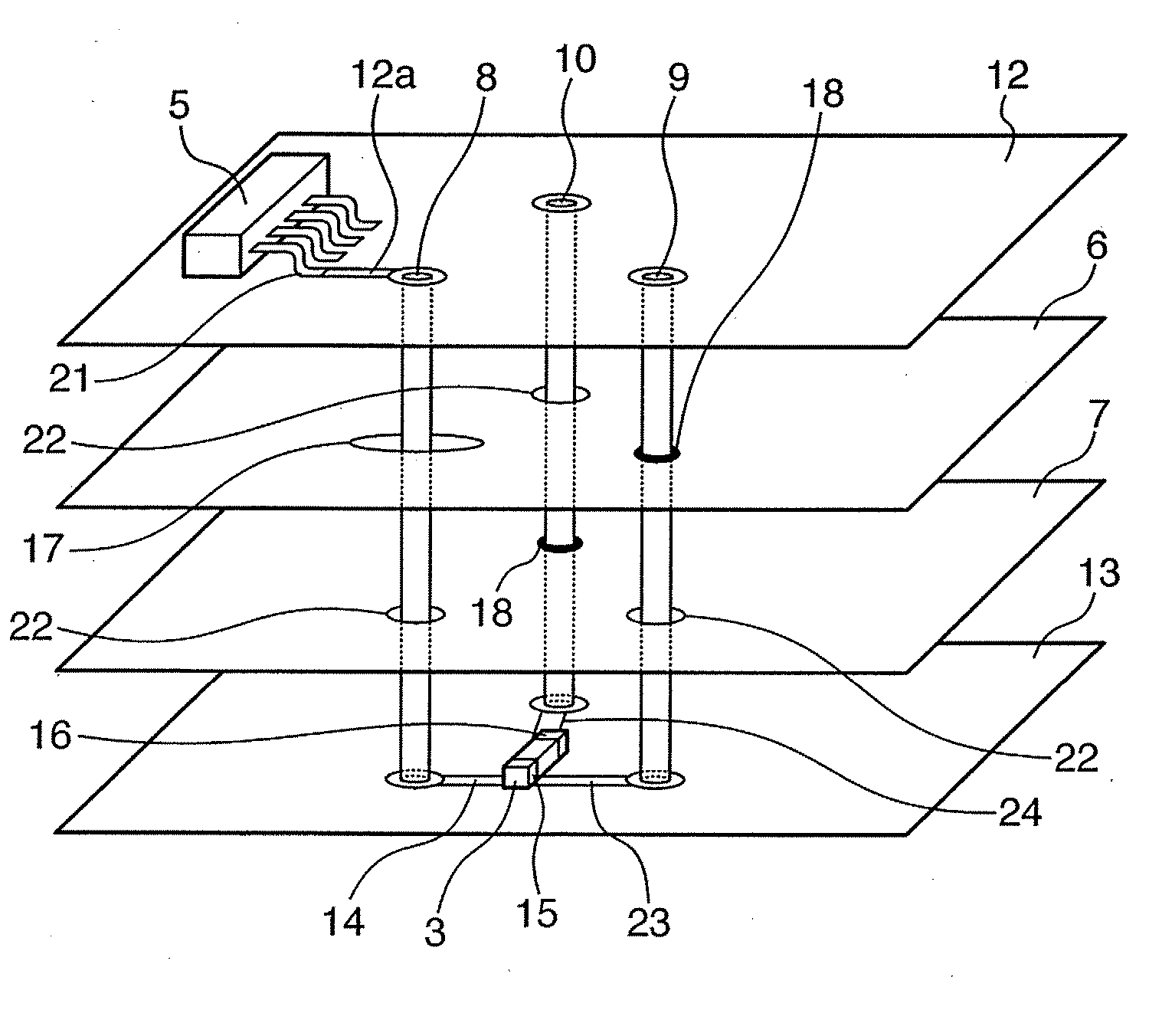

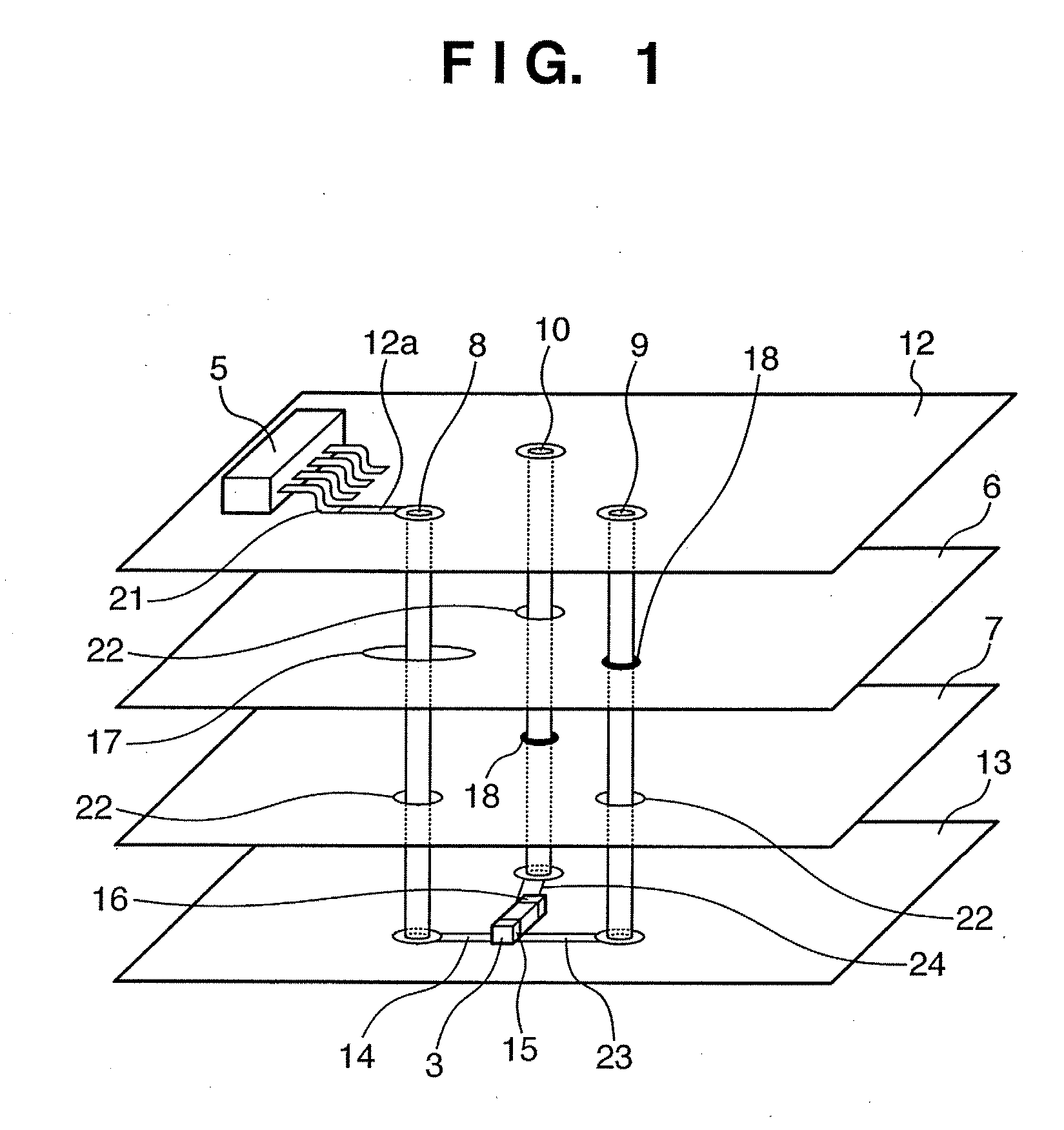

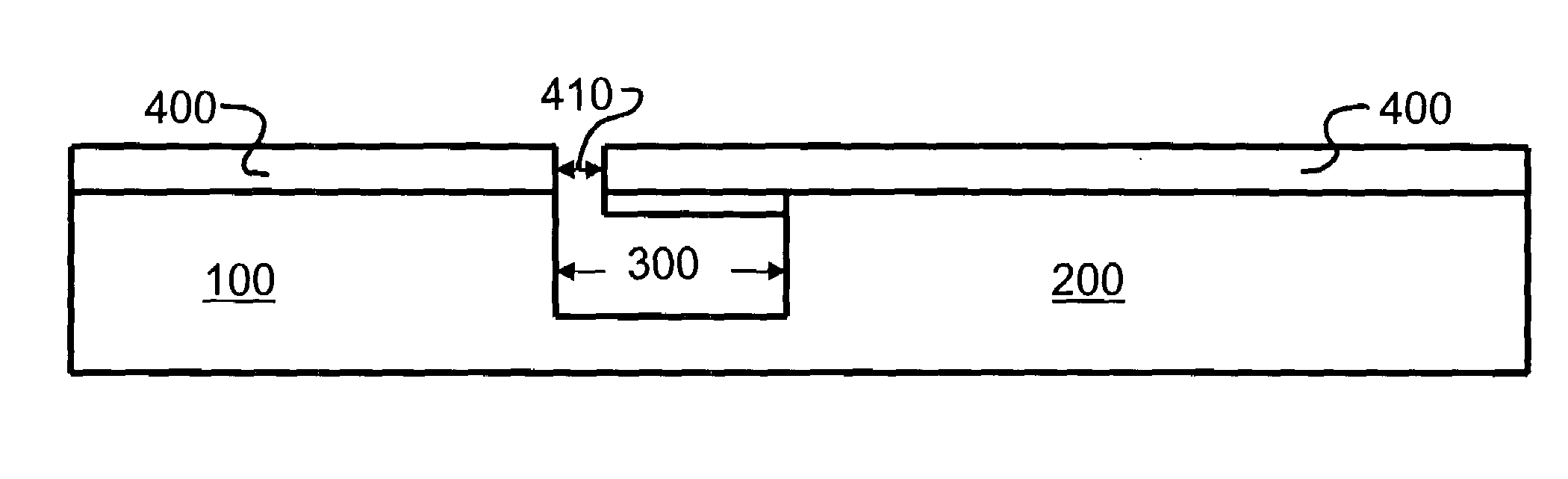

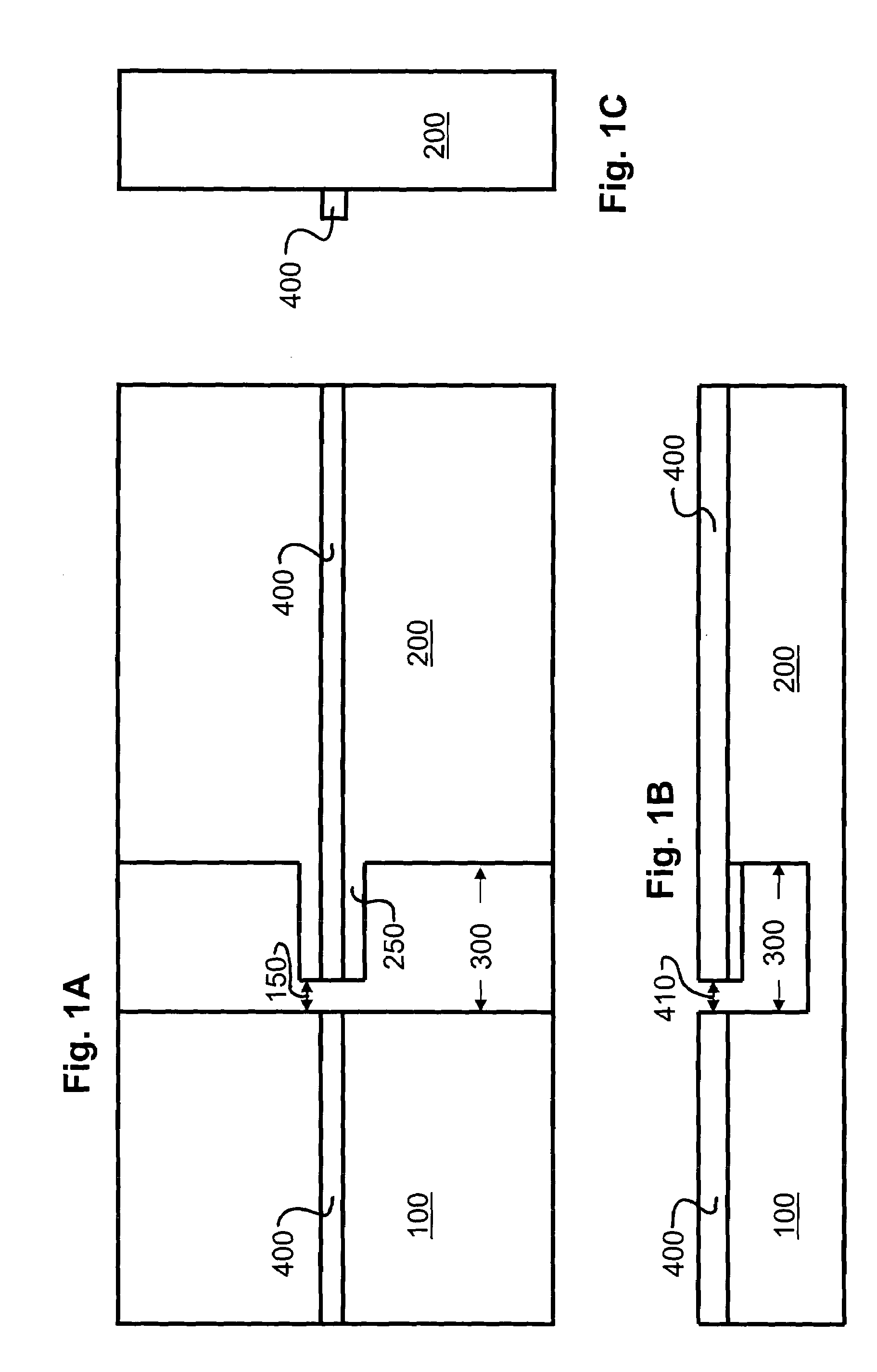

Multilayer print circuit board

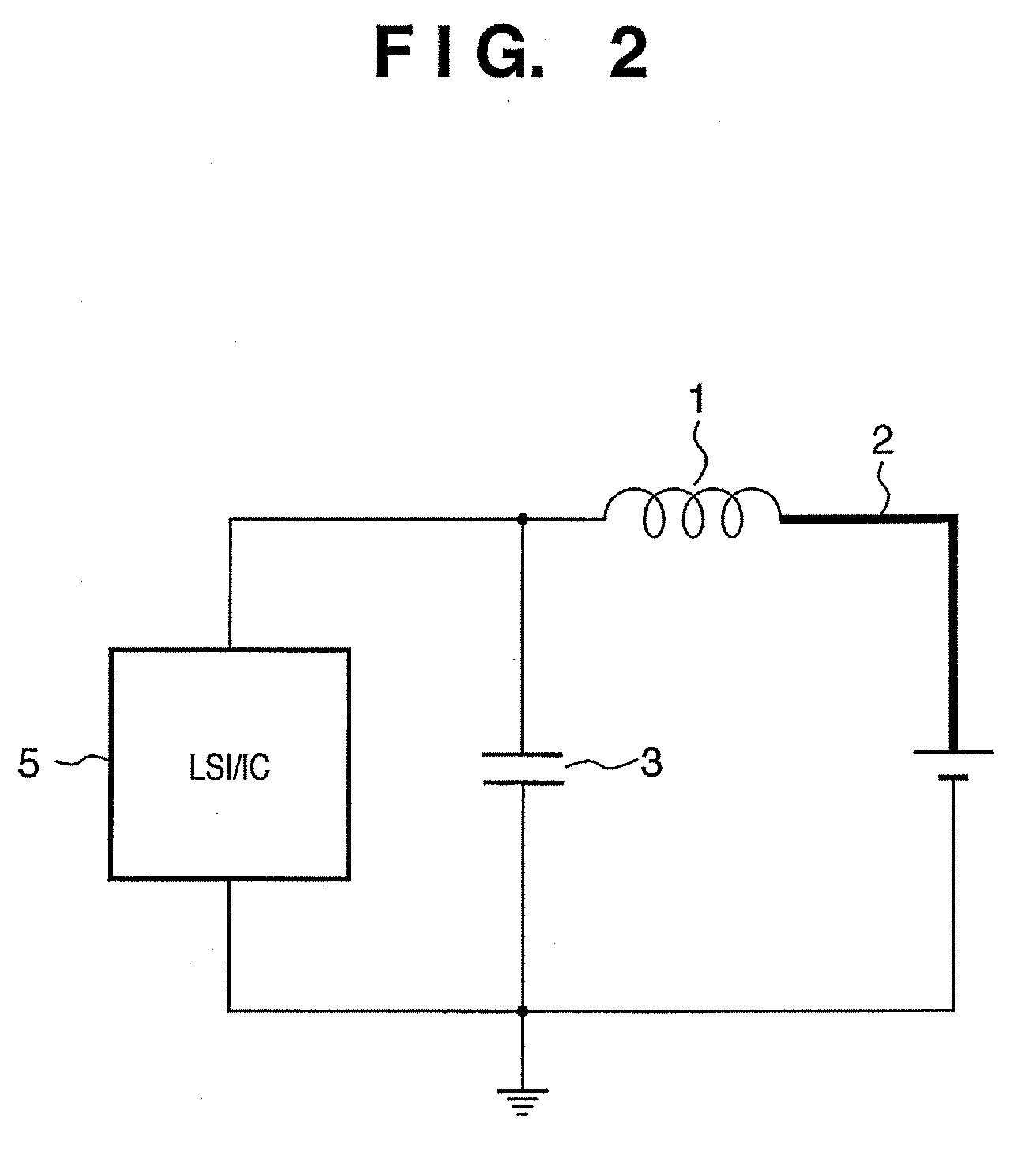

InactiveUS20070136618A1Avoid volatilityPrinted circuit assemblingMultiple-port networksCapacitanceSurface layer

This invention effectively prevents potential fluctuation in the power supply terminal of a semiconductor device, that is, noise from flowing out to a main power supply wiring. A multilayer print circuit board includes a first power supply via hole which connects to the power supply terminal of a semiconductor integrated circuit on a first surface layer and extends from the first surface layer to a second surface layer, a ground via hole which connects to a ground conductive layer, extends from the ground conductive layer to the second surface layer, and connects to the first power supply via hole on the second surface layer through a bypass capacitor, a first clearance hole which is formed in a power supply conductive layer, and a second clearance hole which is formed in the ground conductive layer. The first clearance hole is larger than the second clearance hole.

Owner:CANON KK

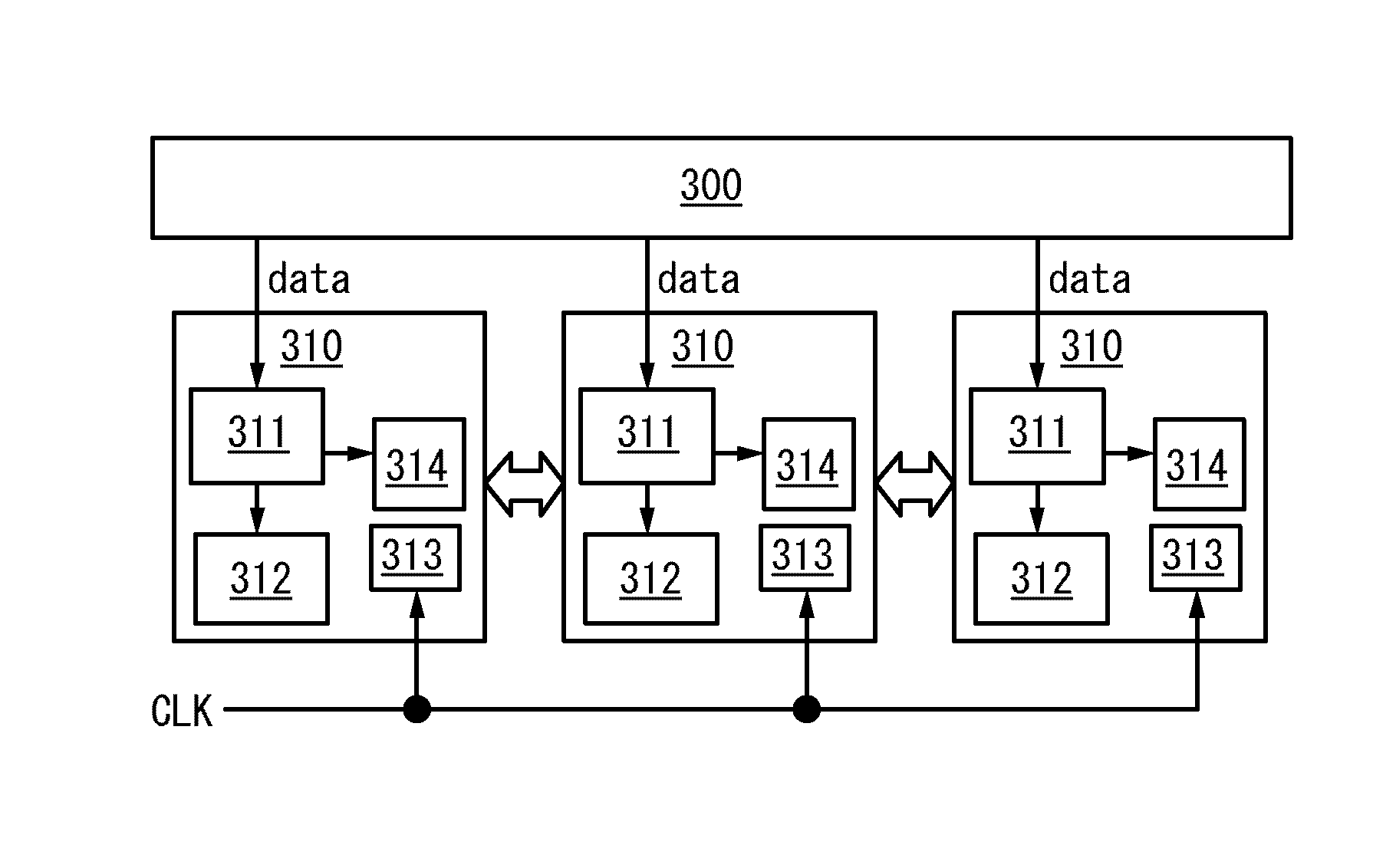

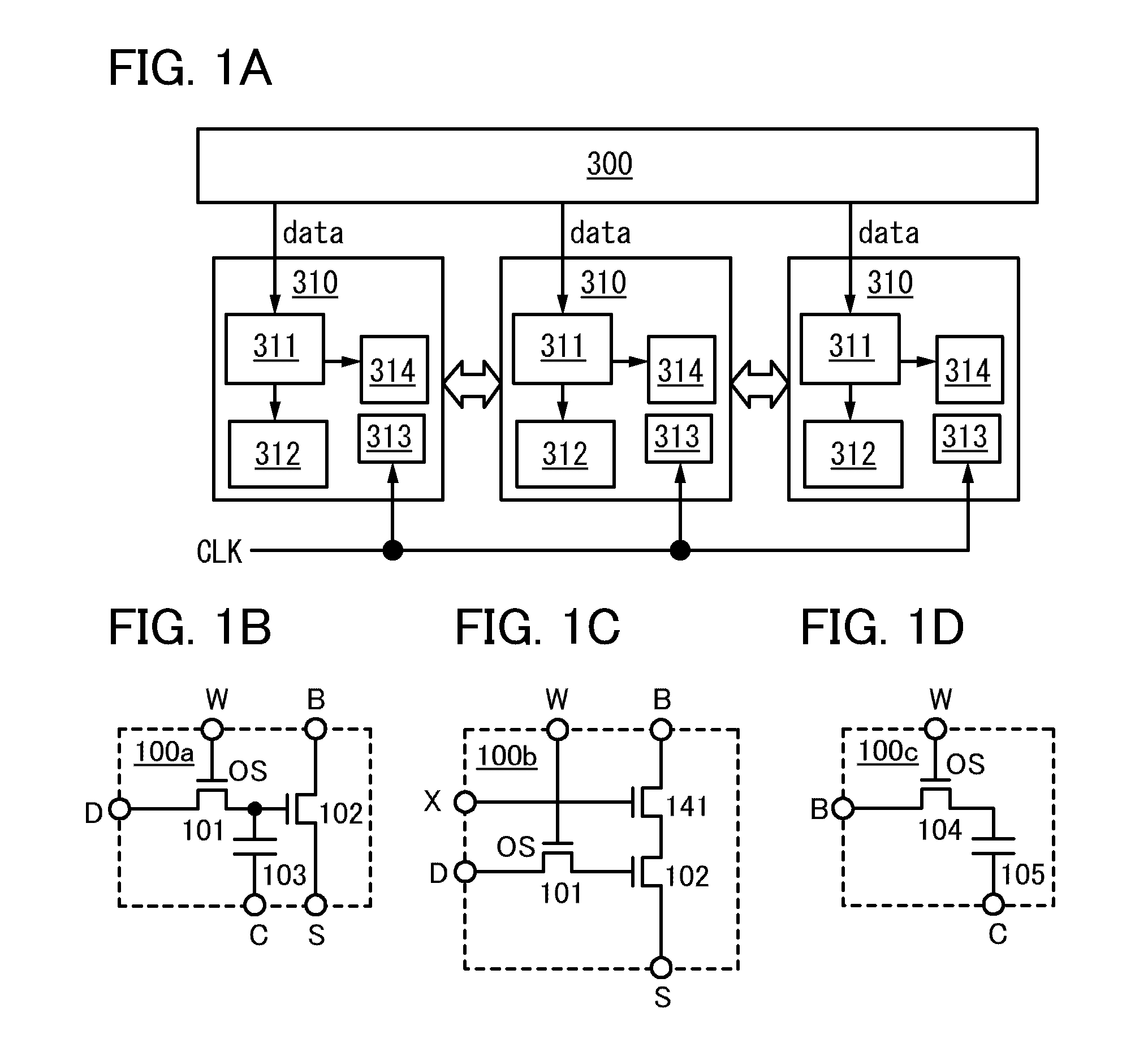

Programmable LSI

InactiveUS8675382B2Start fastIncrease speedDigital storageLogic circuitsElectricityComputer architecture

Owner:SEMICON ENERGY LAB CO LTD

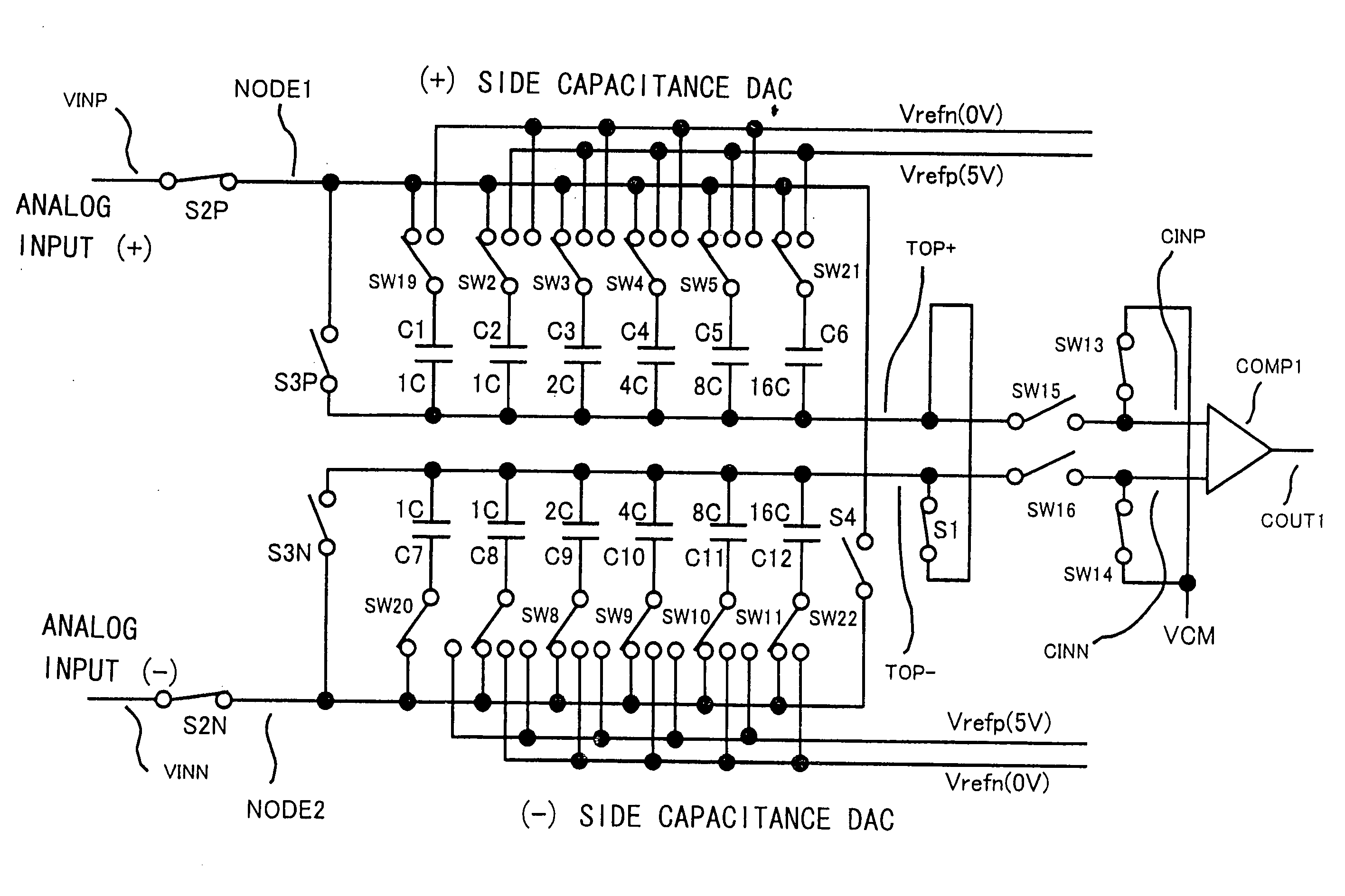

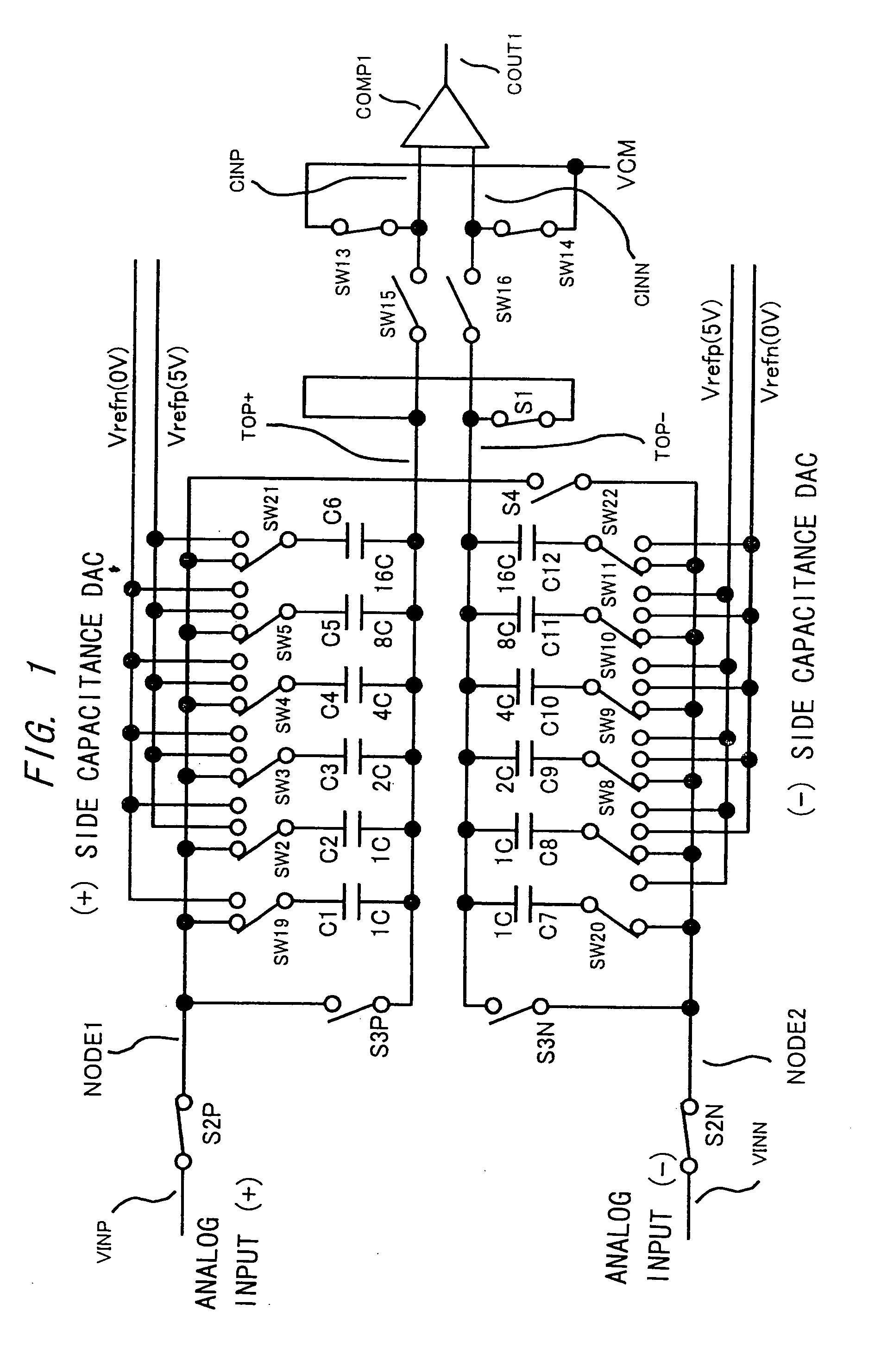

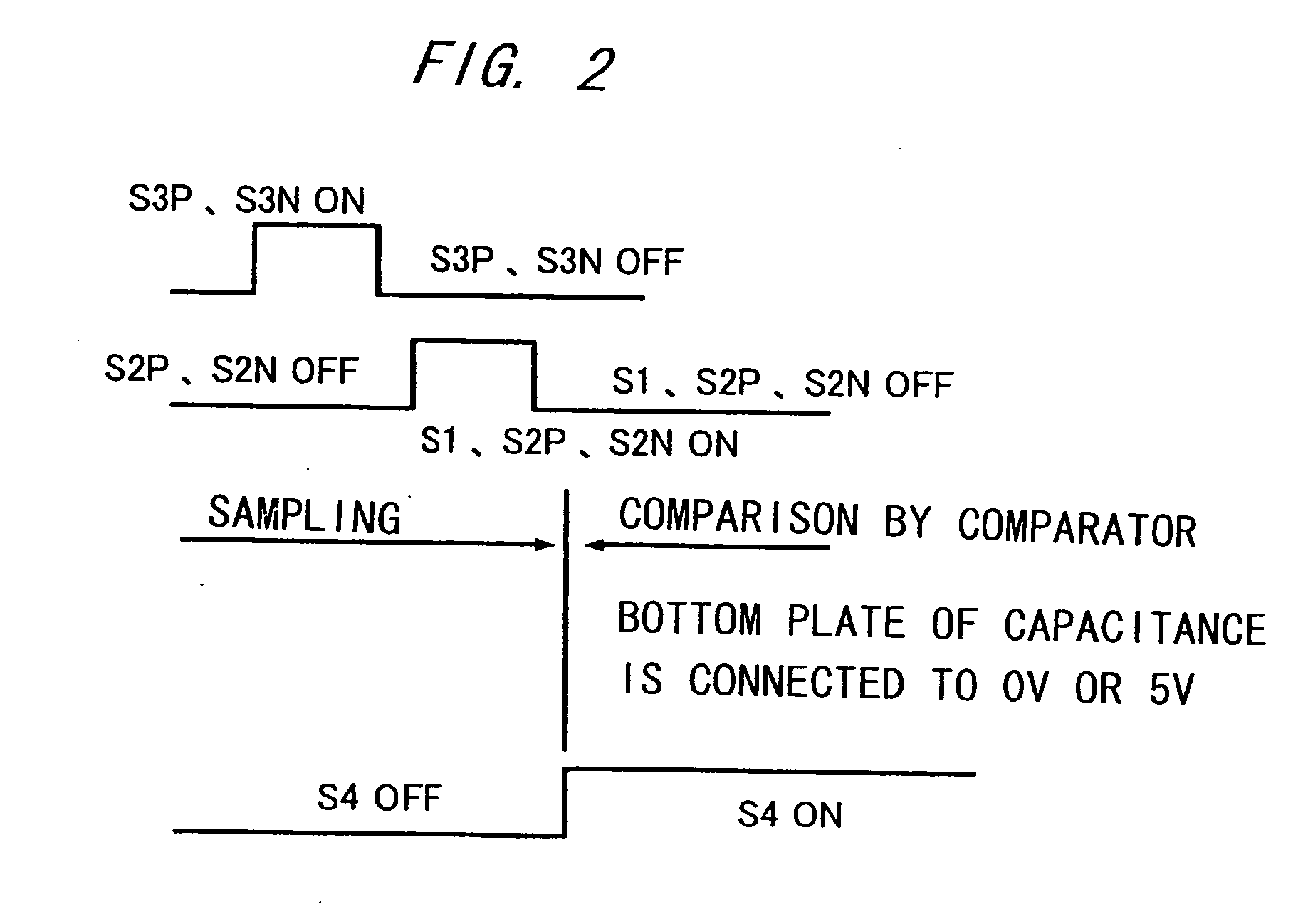

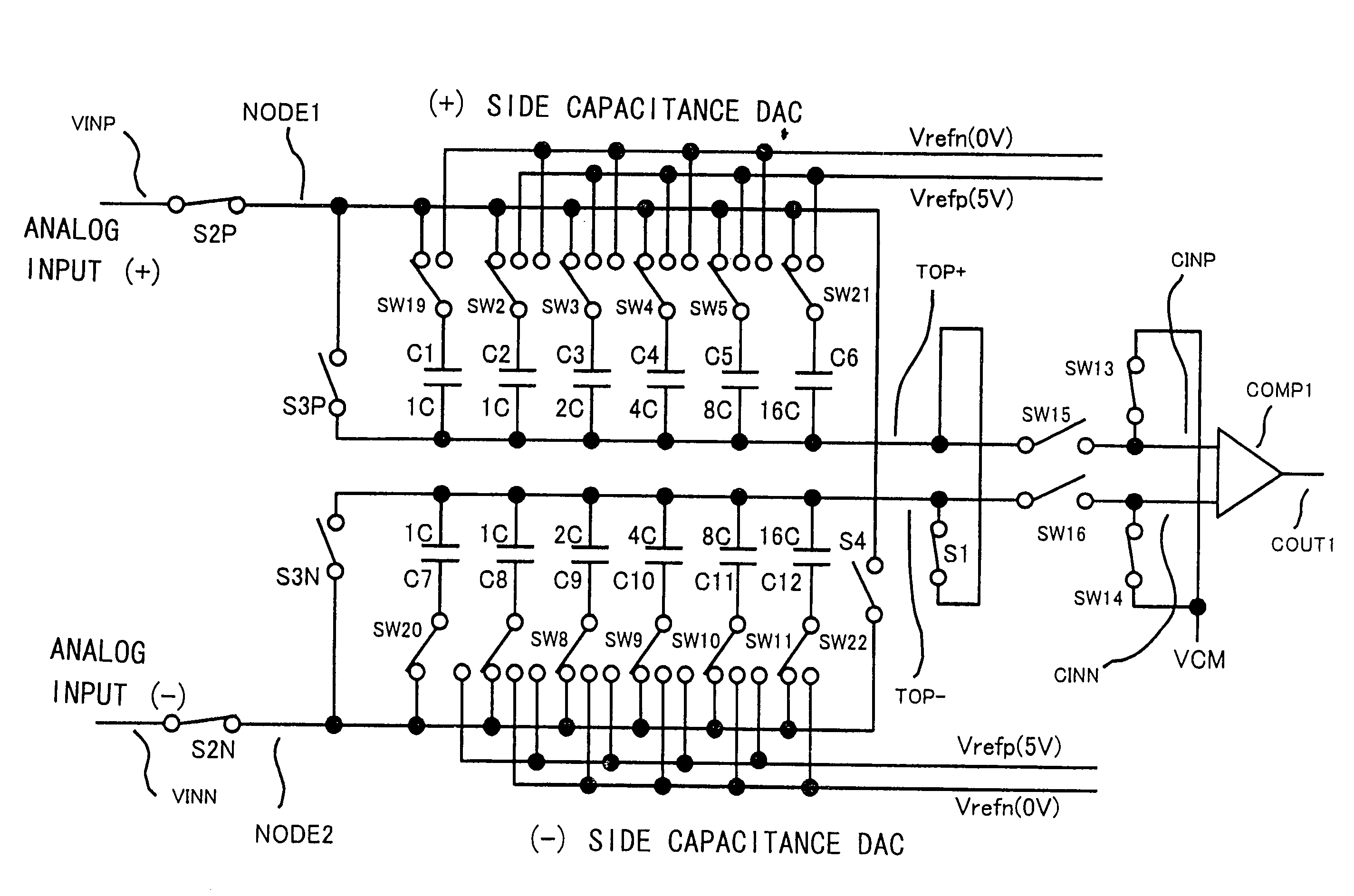

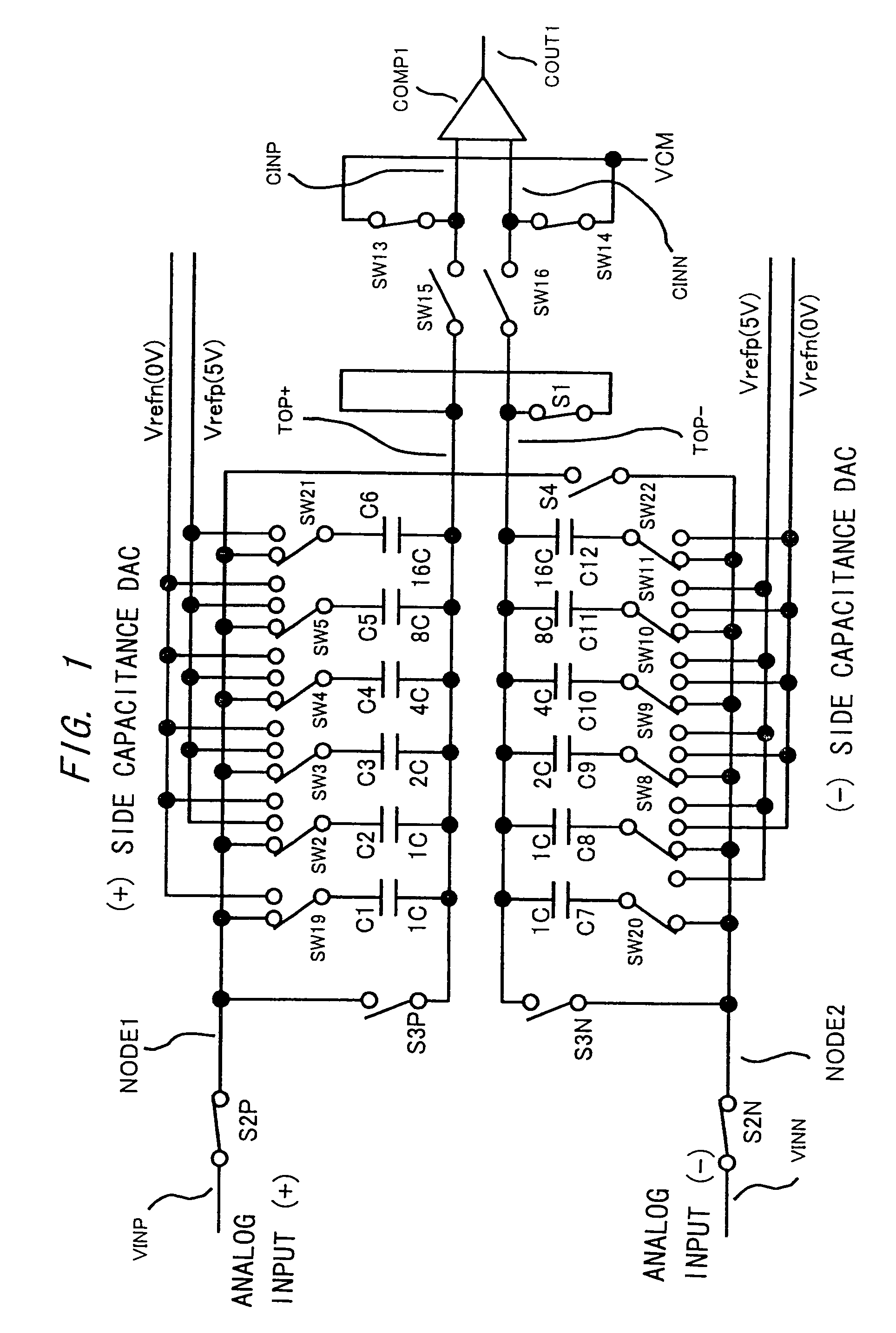

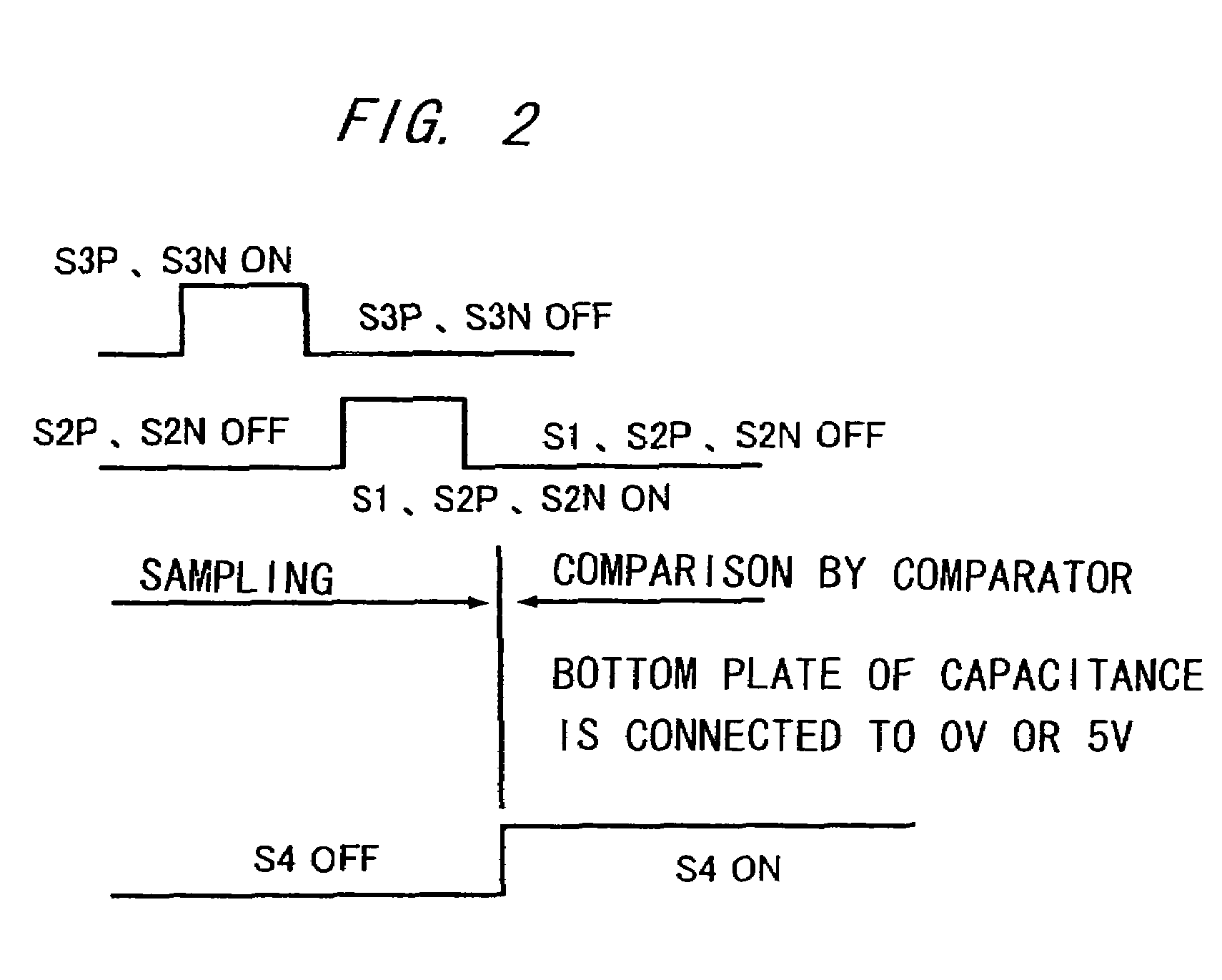

Analog-to-digital converter

InactiveUS20070115159A1Avoid volatilityOperating with small areaElectric signal transmission systemsAnalogue-digital convertersA d converterEngineering

Included are a first DAC taking in and retaining sample data of a first analog signal and generating a comparison signal serving as an object of comparison with the first analog signal, a second DAC taking in and retaining sample data of a second analog signal and generating a comparison signal as an object of comparison with the second analog signal, a first switch connecting the first digital-to-analog converter to an output side of a second digital converter in a openable / closable manner, a comparator comparing, when the first switch is opened, a differential value between the first analog signal and the second analog signal with a differential value between an output signal of the first DAC and an output signal of the second DAC, and an electric potential control circuit controlling fluctuations in electric potentials of a first analog terminal and a second analog terminal.

Owner:CYPRESS SEMICON CORP

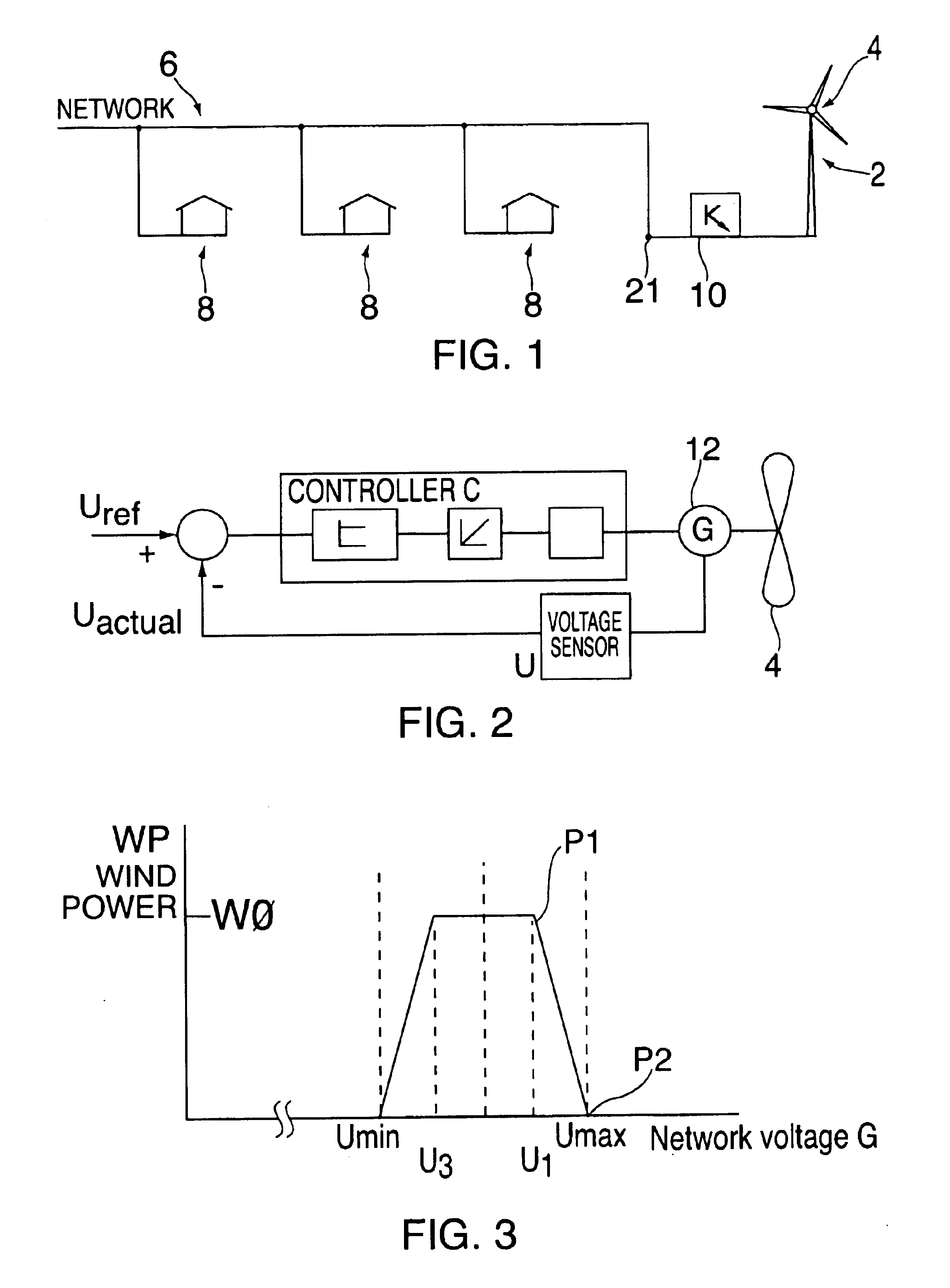

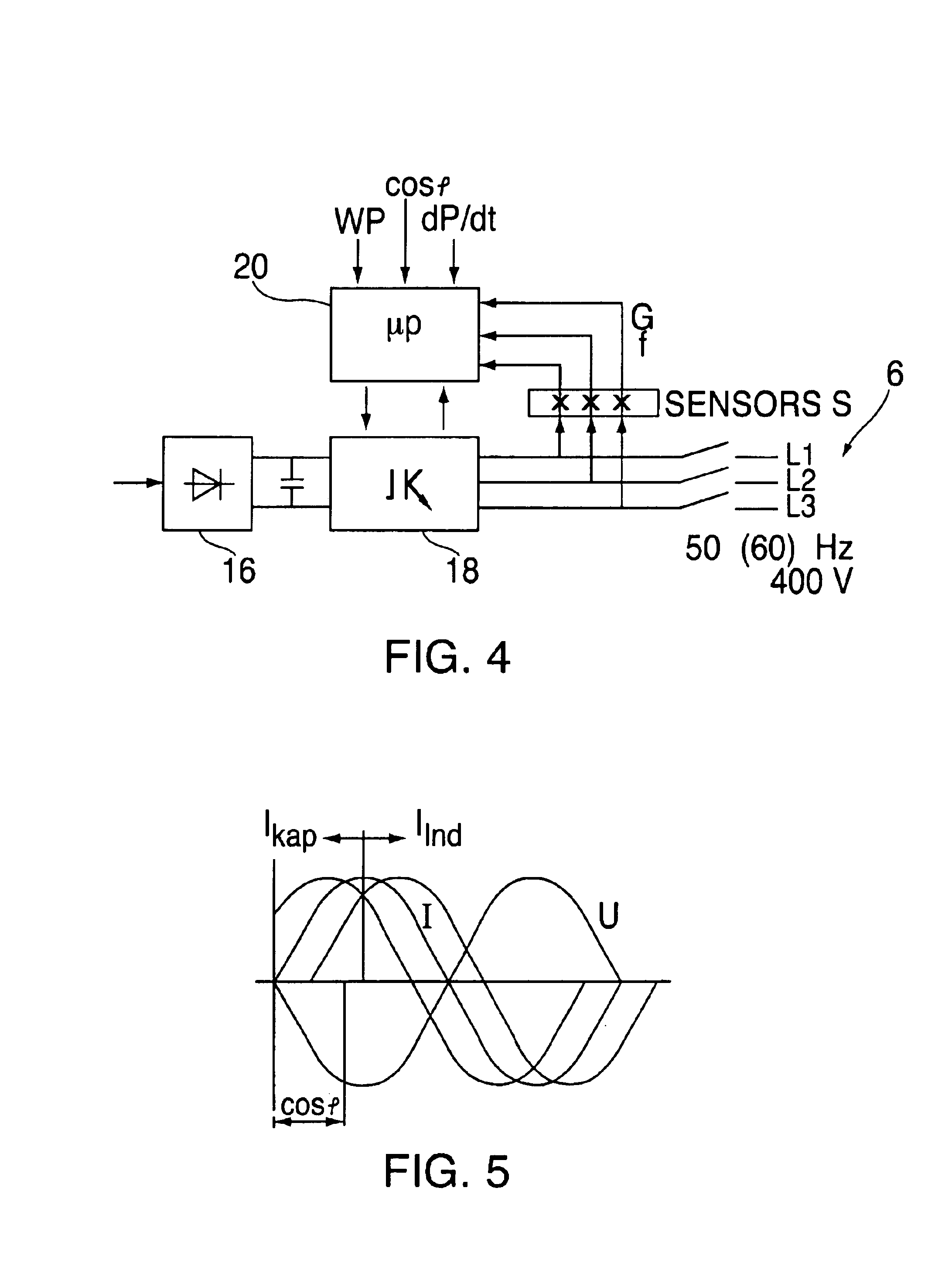

Method of operating a wind power installation and a wind power installation

InactiveUS6984898B2Avoid volatilityReduce voltageOptimise machine performanceWind motor controlPower gridElectric power

The present invention concerns a method of operating a wind power installation comprising an electric generator drivable by a rotor for outputting electrical power to an electrical consumer, in particular an electrical network.The invention further concerns a wind power installation comprising a rotor and an electric generator coupled to the rotor for outputting electric power to an electrical consumer, in particular an electrical network.The object of the present invention is to provide a method of operating a wind power installation, and a wind power installation, which avoid the disadvantages of the state of the art and in particular avoid voltage over-fluctuations at the consumer, in particular an electrical network, and unwanted shut-down of the wind power installation.In a method of the kind set forth in the opening part of this specification, that object is attained by the invention in that the power delivered to the network by the wind power generator is regulated in dependence on the applied network voltage of the power supply network.

Owner:WOBBEN ALOVS

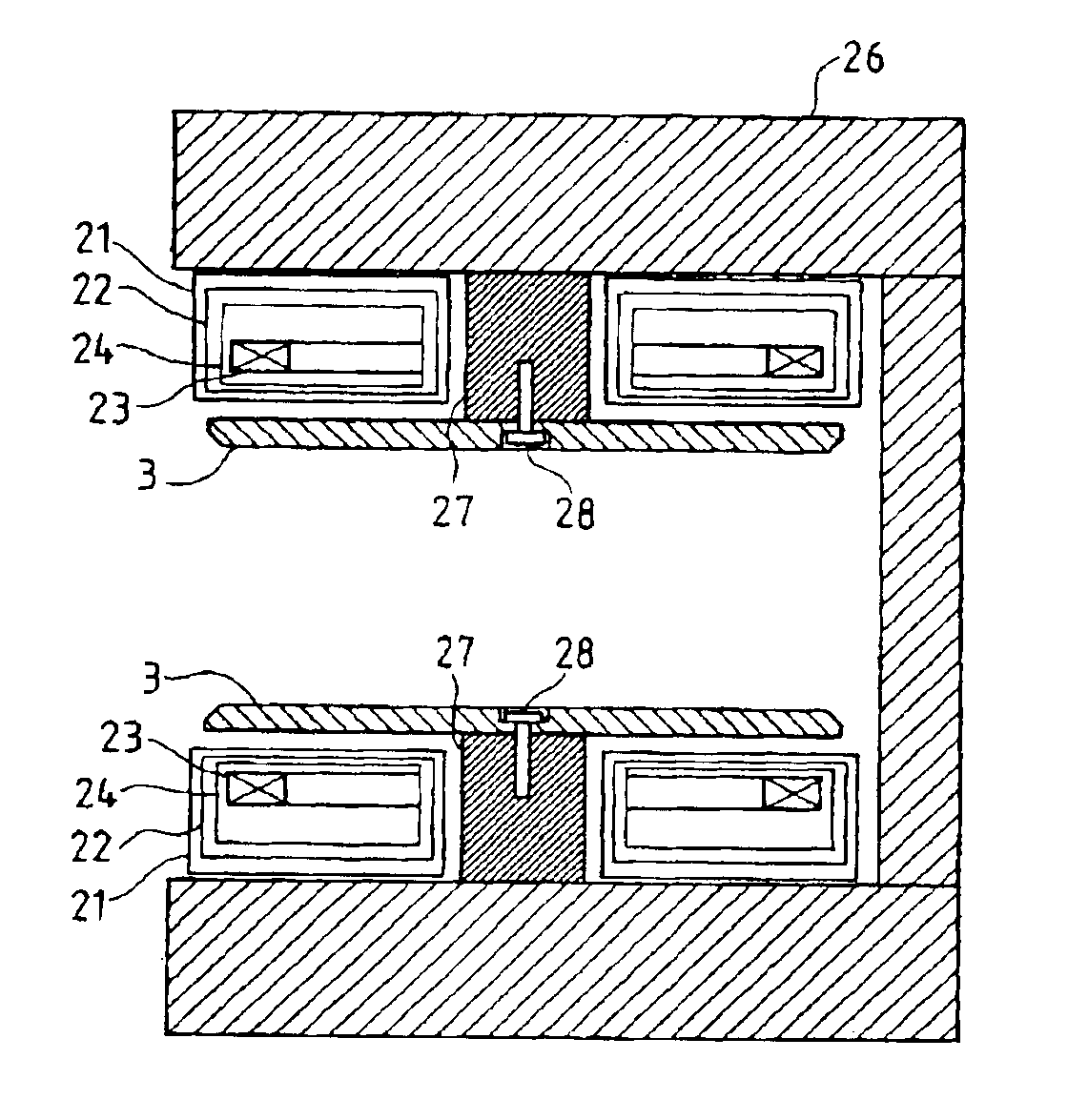

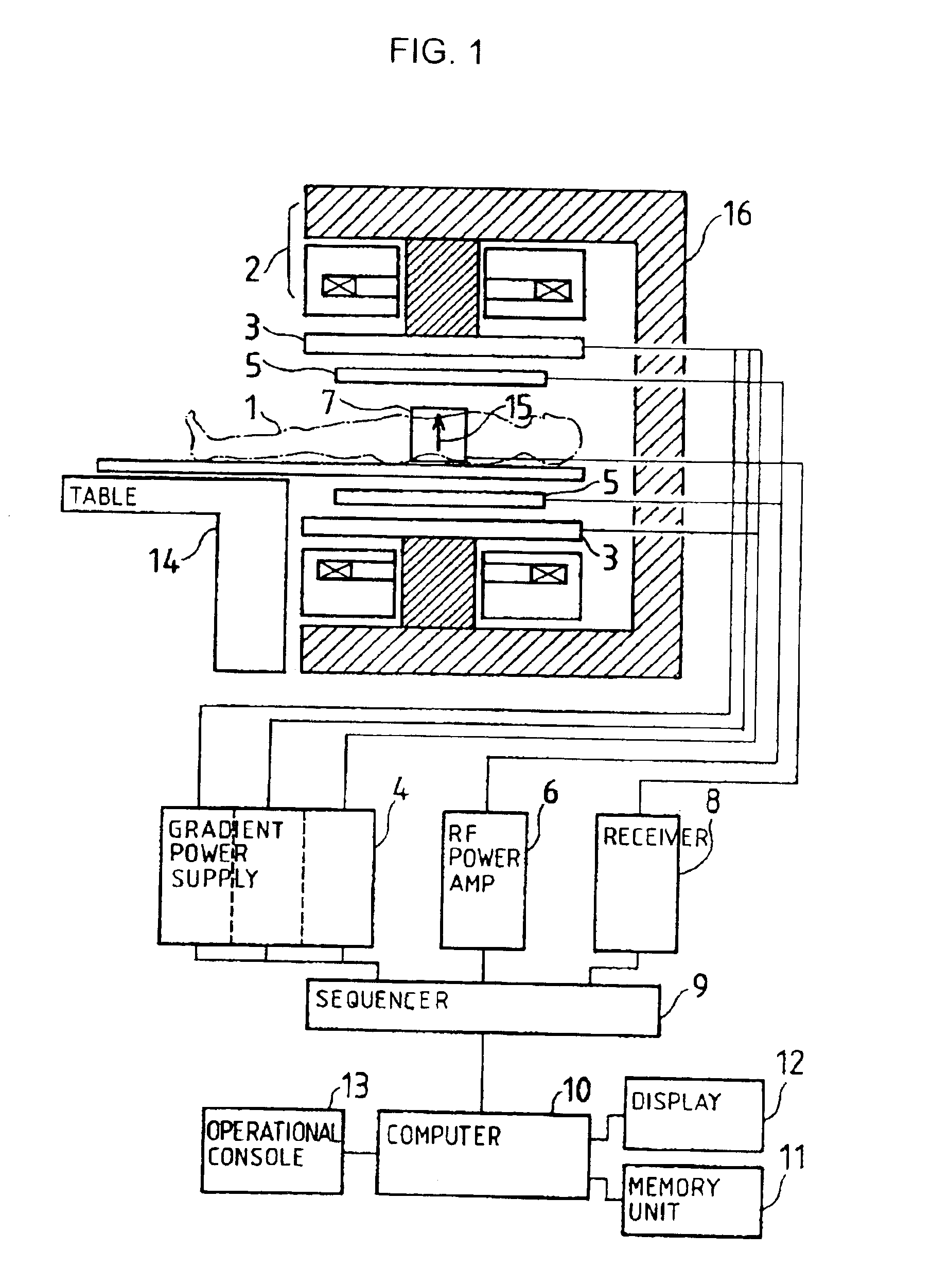

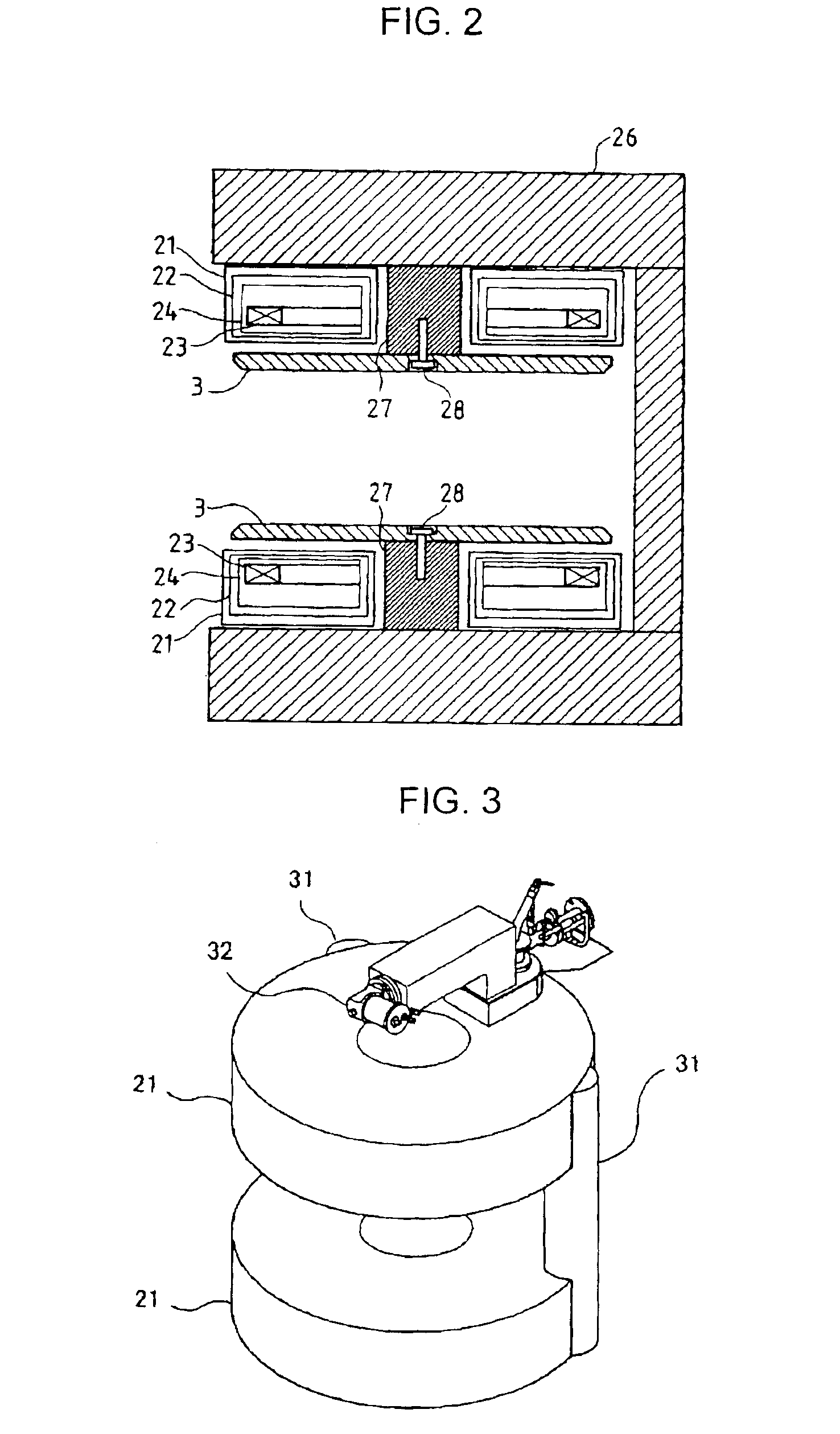

Magnetic resonance imaging device and gradient magnetic field coil used for it

InactiveUS6933722B2Reduce noiseReduce vibrationElectric/magnetic detectionMeasurements using magnetic resonanceEddy currentField coil

To reduce vibration and noise generated in supplying pulsatile current to the gradient magnetic field coil for driving that coil in a MRI apparatus, an active shielded gradient magnetic field coil is used, in which the gradient magnetic field coil is supported by and fixed to the static magnetic field generating magnet. The supporter for supporting this gradient magnetic field coil in non-contact does not prevent the interventional procedure performed by a doctor. Further, an eddy current generated on the surface of the static magnetic field generating magnet near the periphery of the gradient magnetic field coil, when supplying the pulsatile current to the gradient magnetic field coil, can be reduced.

Owner:HITACHI LTD

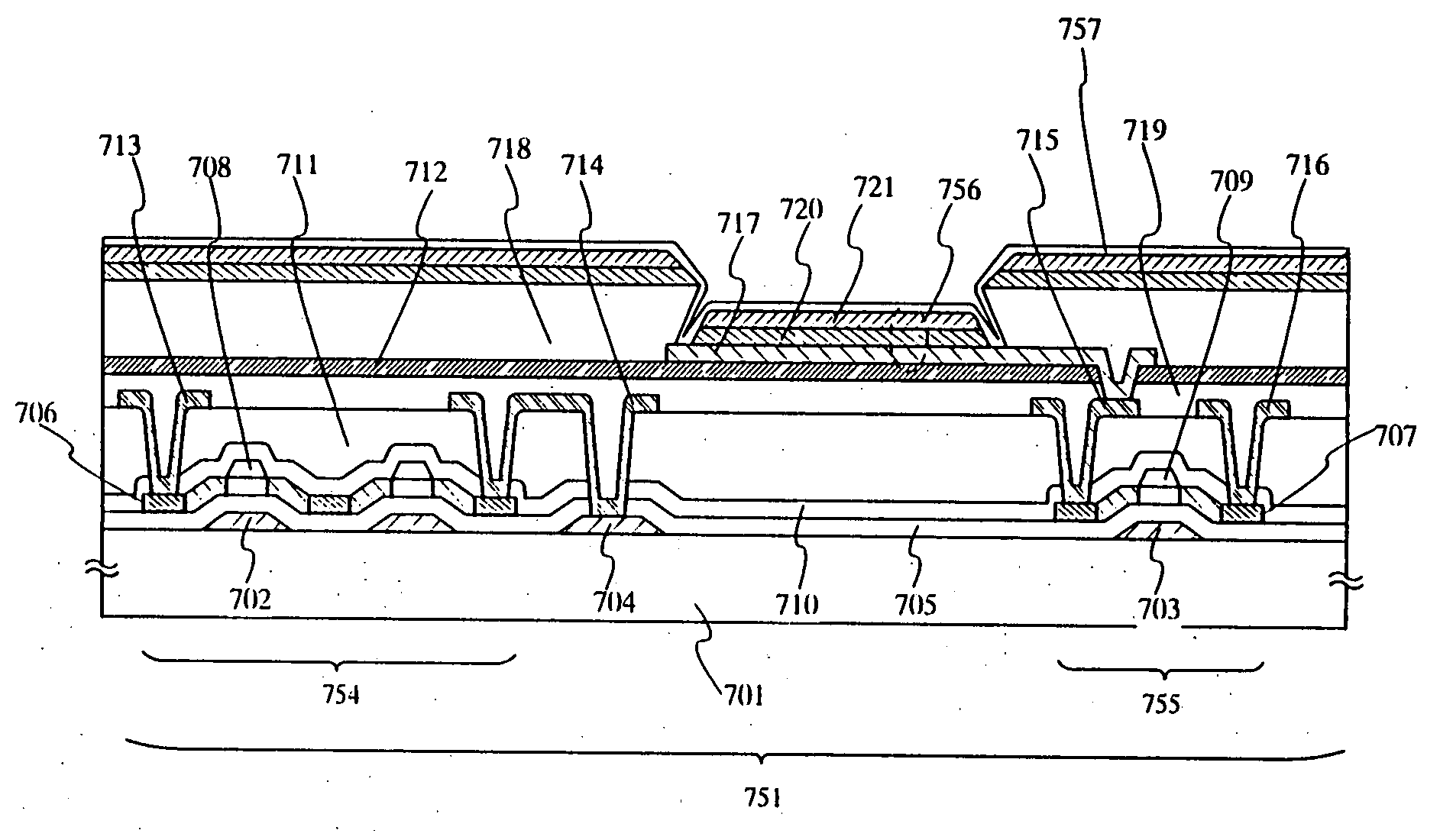

Light emitting device

InactiveUS20050093436A1Inhibit deteriorationImprove reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesSimple Organic CompoundsActive matrix

In an active matrix drive light emitting device, above a thin film transistor, a light emitting element having an anode, a layer comprised of an organic compound and a cathode containing an alkali metal is formed between a third insulating layer comprised of silicon nitride or silicon oxynitride and a fourth insulating layer containing carbon as its main constituent. The light emitting element is formed between partition layers that are formed of an insulating material and have an inverse tapered shape.

Owner:SEMICON ENERGY LAB CO LTD

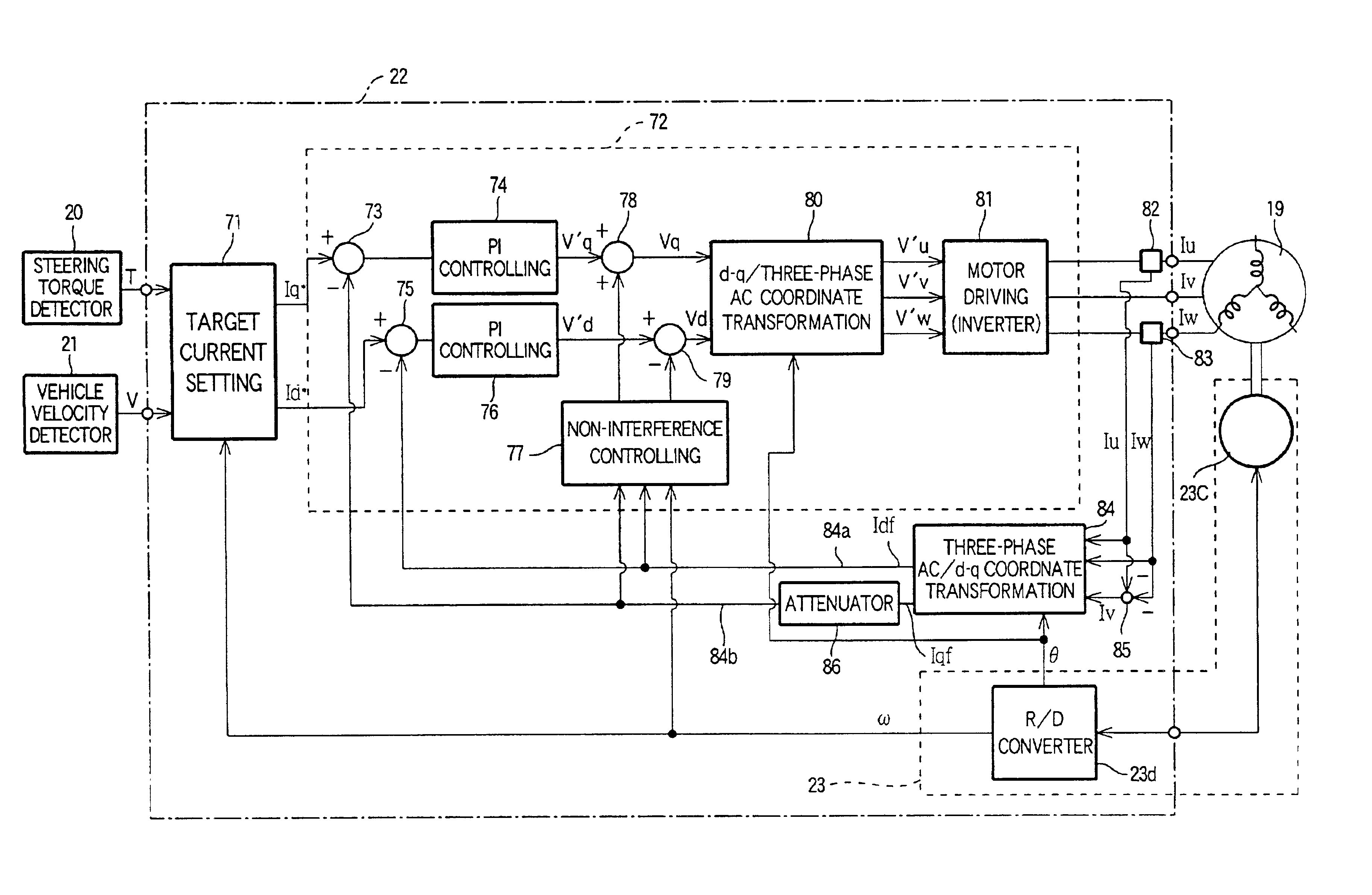

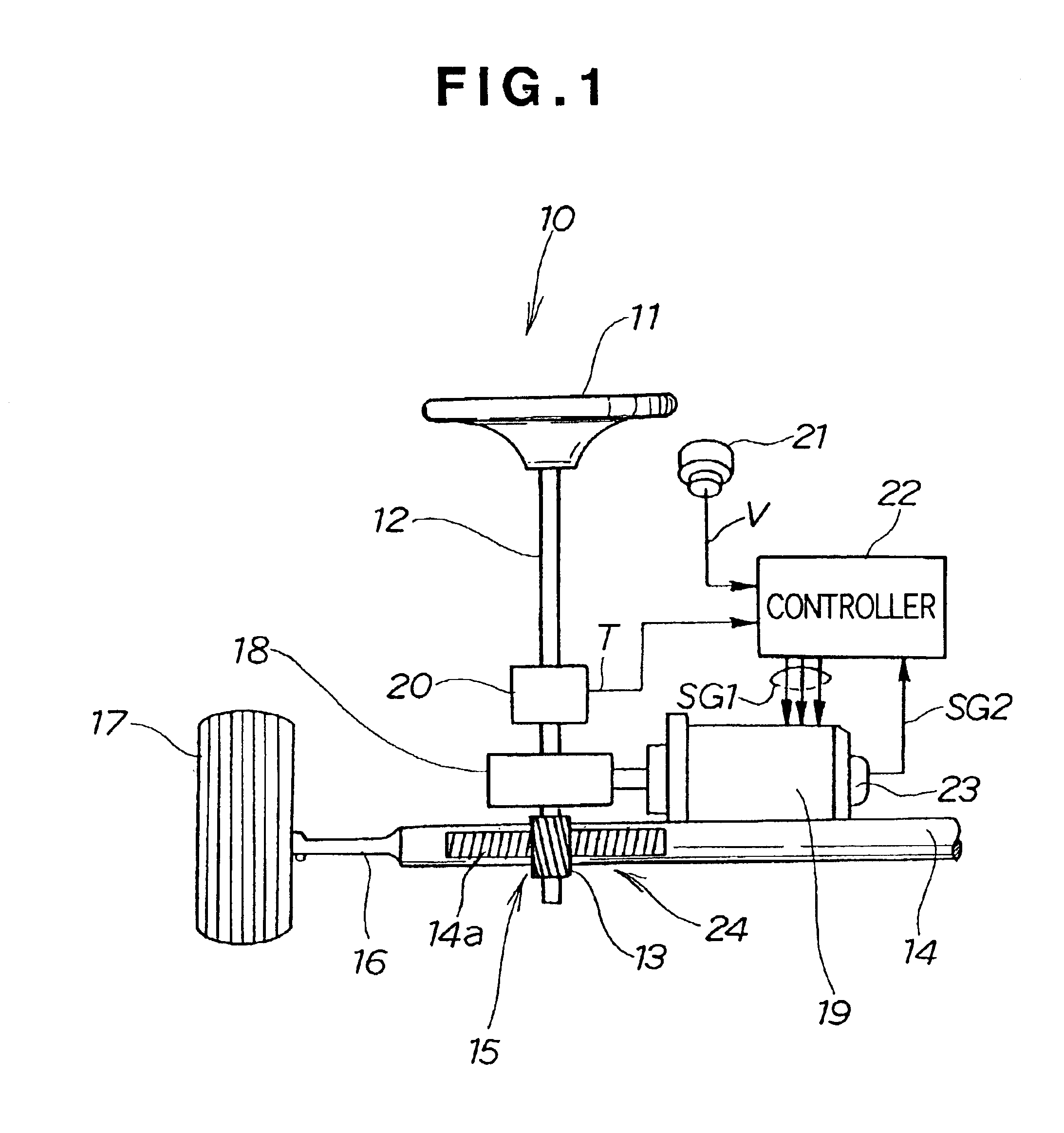

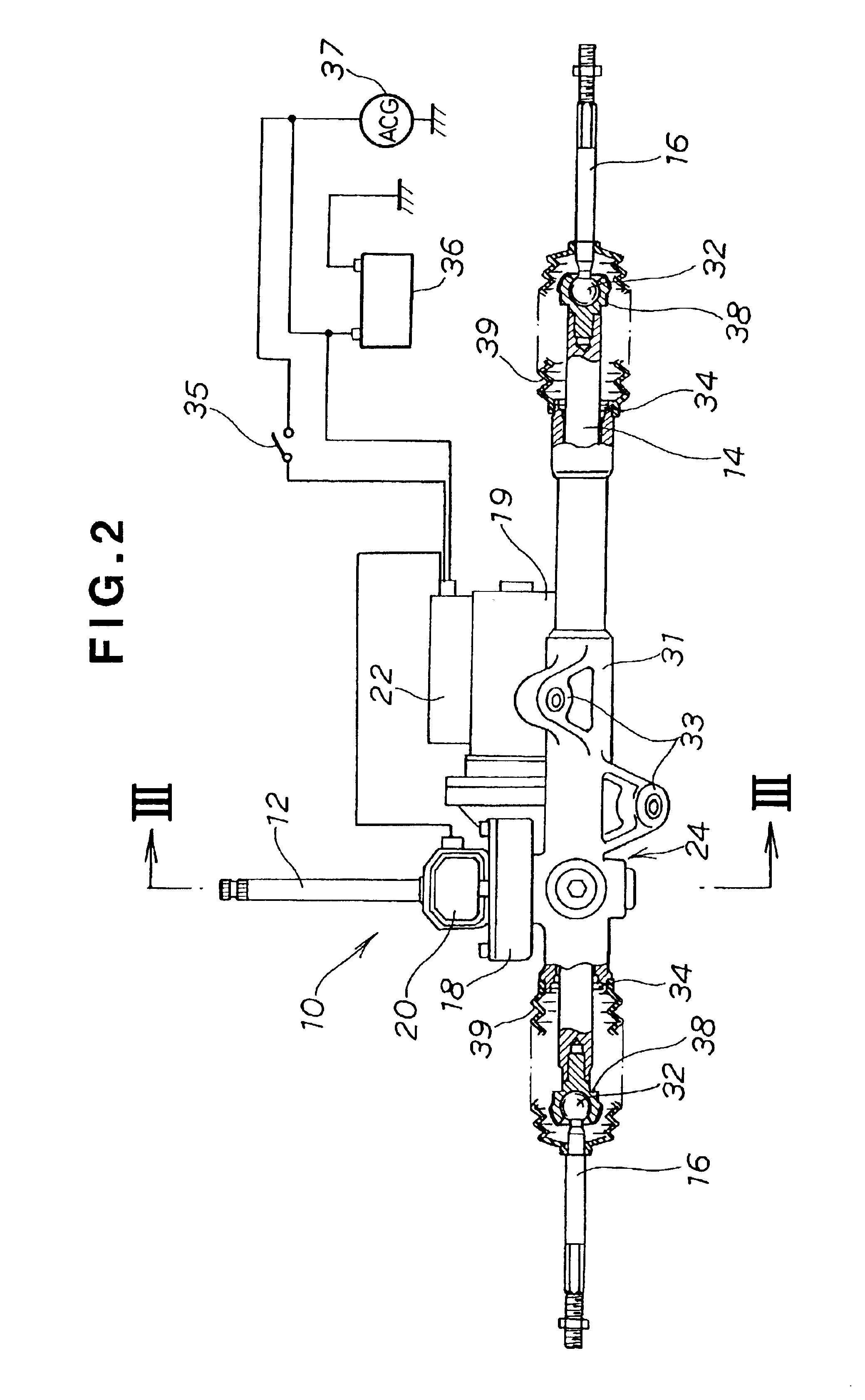

Electric power steering apparatus

InactiveUS6838844B2Avoid volatilitySmooth feeling of steeringSingle motor speed/torque controlDigital data processing detailsElectric power steeringBrushless motors

An electric power steering apparatus includes a steering torque detector, a brushless motor PWM-driven with a three-phase alternating motor current, a target current setting section for setting a d-axis target current value and a q-axis target current value, motor current detectors for detecting motor current values supplied to the brushless motor, a three-phase AC / d-q coordinate transformation circuit, a first deviation calculation circuit for calculating a deviation of a current value of a q-axis detection signal from the q-axis target current value, a second deviation calculation circuit for calculating a deviation of a direct current value a d-axis detection current signal from the d-axis target current, a motor control section for controlling driving of the brushless motor through a vector control process on the basis of deviation signals outputted from the first and second deviation calculation circuits, and an attenuation device provided in a feedback transmission path of the q-axis detection current signal for attenuating a high frequency noise mixed in the q-axis detection current signal.

Owner:HONDA MOTOR CO LTD

Lamination shaping apparatus

ActiveUS8070474B2Easy to makeAvoid volatilityLiquid surface applicatorsMechanical working/deformationLight beamEngineering

A lamination shaping apparatus has a powder layer preparing means and an optical unit which irradiates a light beam to an intended portion of a powder layer so as to sinter or melt for solidifying the portion into a cured layer. Preparation of the powder layer and curing of the cured layer are repeated to fabricate a three-dimensional object in which a plurality of the cured layers are laminated and integrated. The apparatus includes a fixed base carrying thereon the powder layer and the cured layer, an elevator frame surrounding a periphery of the fixed base, and driving means for driving the elevator frame to move vertically. The powder layer is formed within a space above the base and surrounded by an interior surface of the elevator fame such that the powder layer (cured layer) can be stacked on the base with the base being kept at a fixed position, thereby facilitating to fabricate a precisely shaped object.

Owner:MATSUSHITA ELECTRIC WORKS LTD

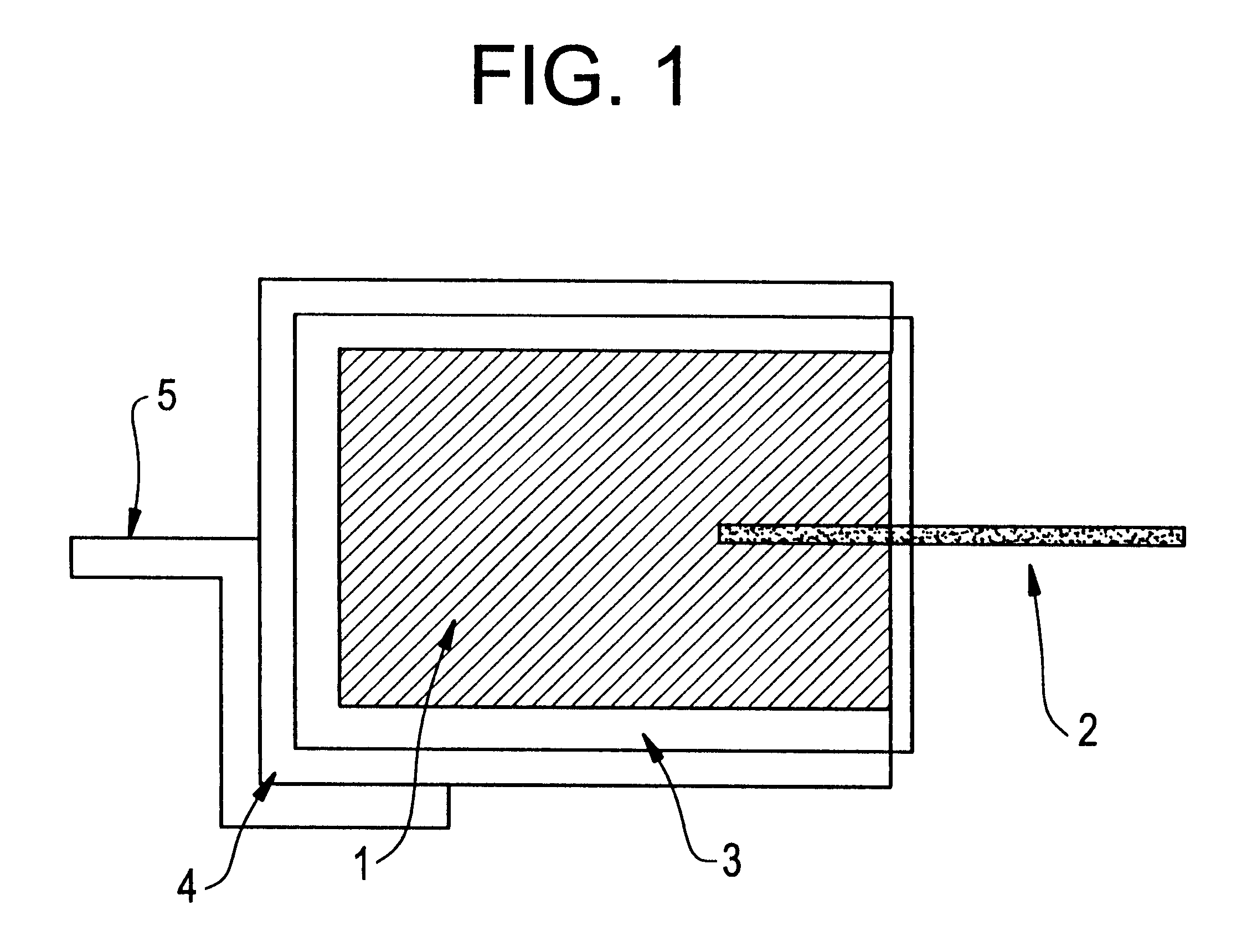

Molecular detection using an optical waveguide fixed to a cantilever

ActiveUS6987898B2Light couplingHigh light transmittanceForce measurement by measuring optical property variationMaterial analysis by optical meansCouplingWaveguide

The invention relates to devices and methods for detecting a ligand in a liquid, based on deflection of one or more microscopic cantilevers. Each cantilever has an optical waveguide fixed thereto or integral therewith. Deflection of the cantilever is detected by assessing coupling of light between the optical waveguide on the cantilever and an optical waveguide fixed distally thereto.

Owner:LUCENT TECH INC

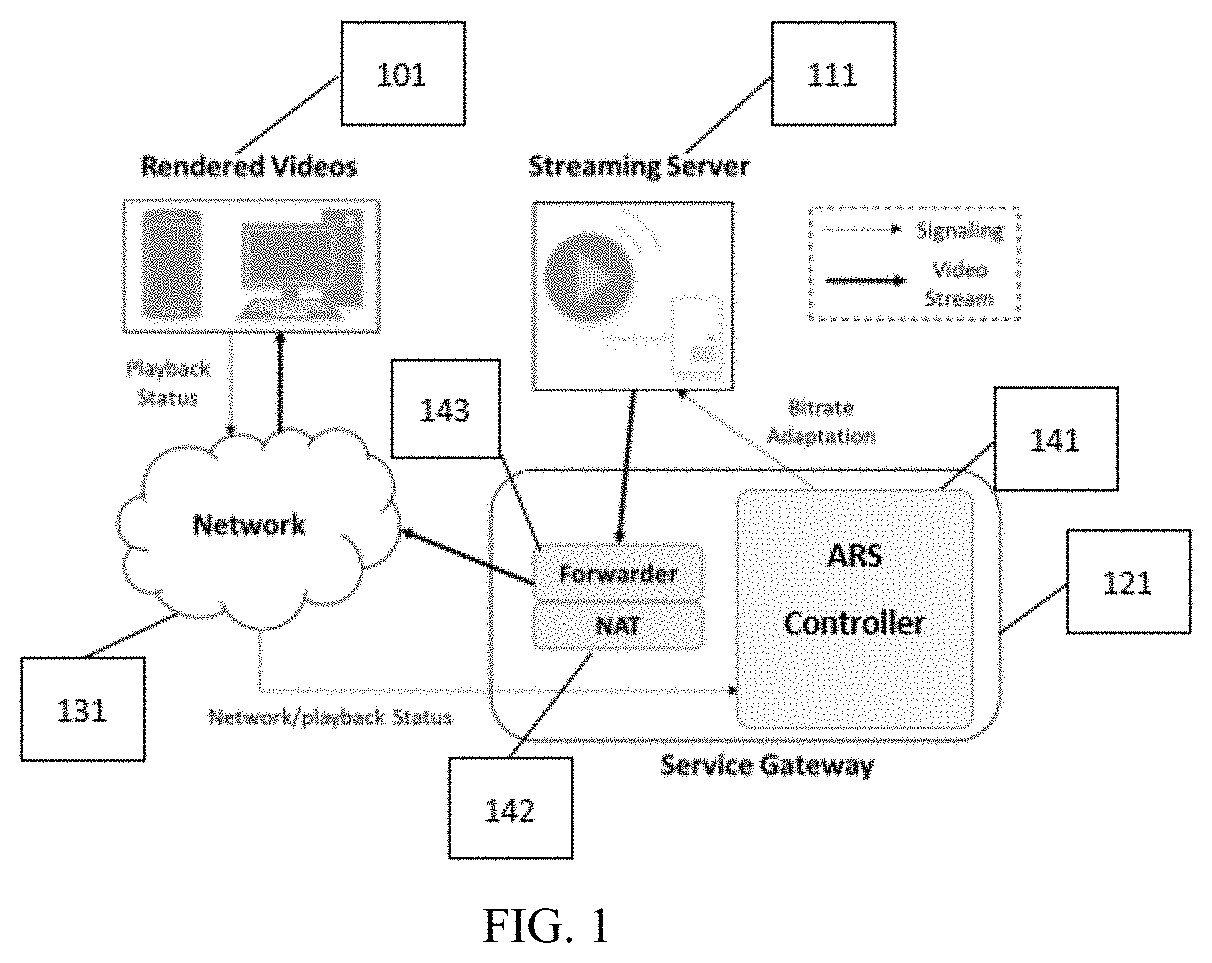

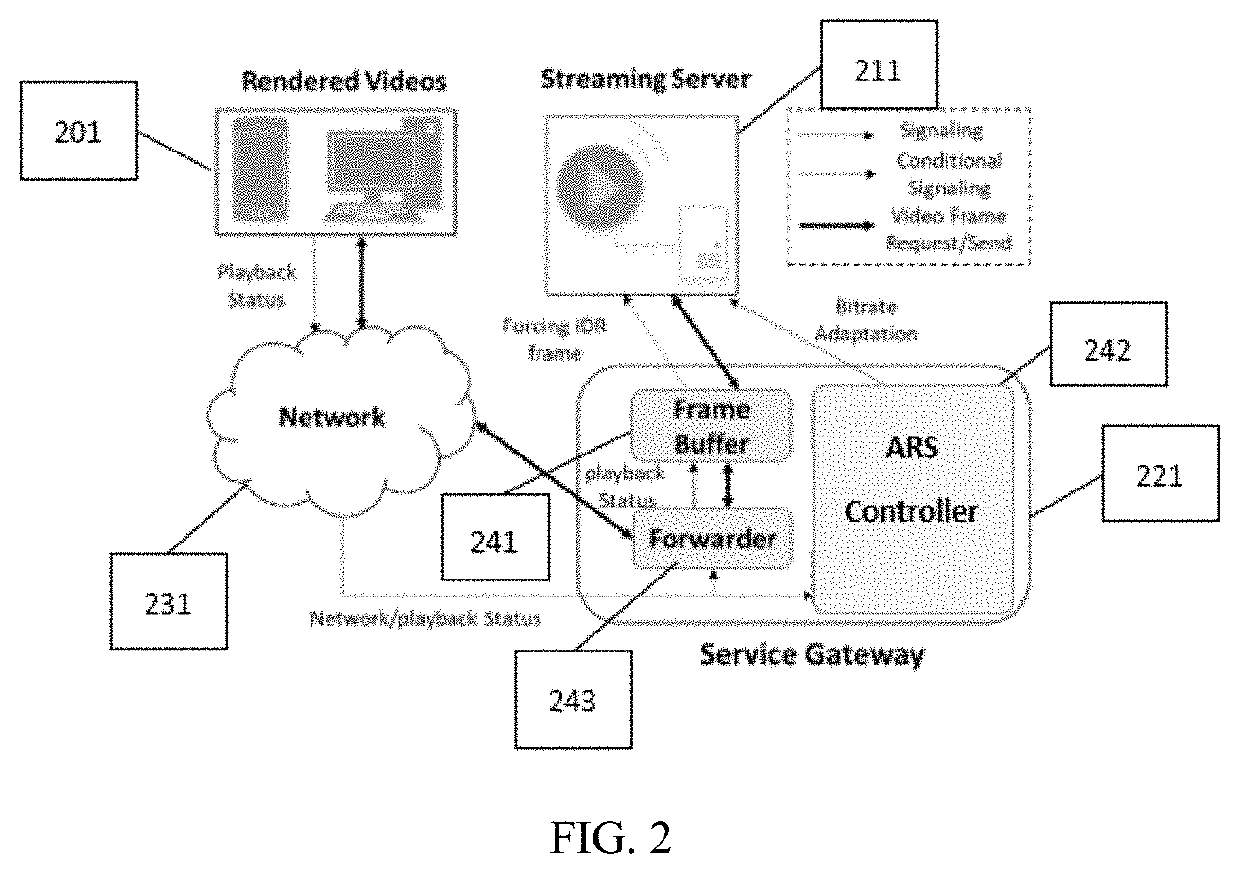

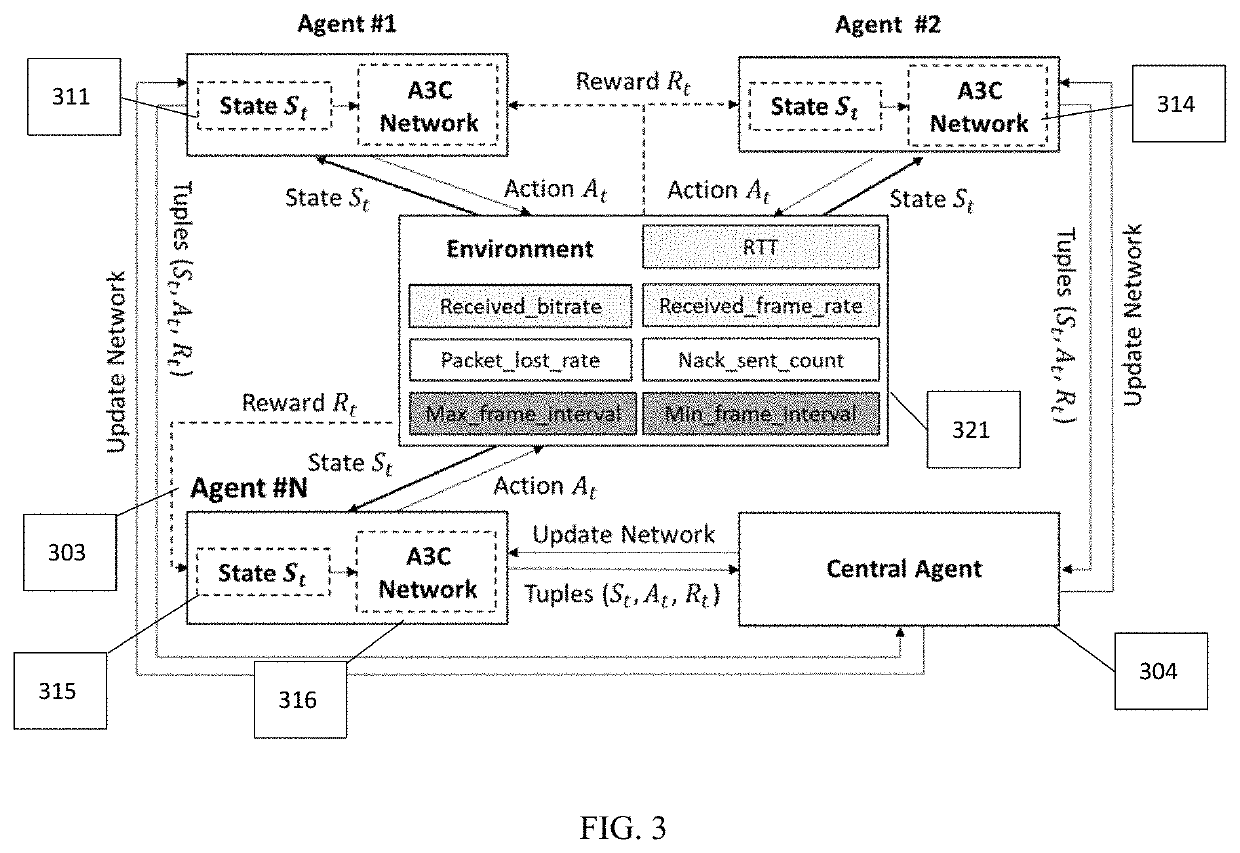

Methods and Apparatus for Learning Based Adaptive Real-time Streaming

InactiveUS20200162535A1Maximize video qualityMinimizing video freezing eventsMathematical modelsArtificial lifeSimulationOnline and offline

This invention discloses a deep reinforcement learning based adaptive bitrate selection method and system for real-time streaming, where deep reinforcement learning neural networks are utilized to receive states observations and make bitrate decisions. Simulation is constructed to provide network states including network QoS and playback status to agents and compute accumulated rewards according to the bitrate actions made by agents. ARS balances a variety of QoE goals to determine the accumulated rewards. ARS also enables multiple agents to be trained concurrently and conducts training process in a simulation environment to accelerate the training speed. In addition, ARS supports training ABR algorithm both online and offline.

Owner:MA ZHAN +2

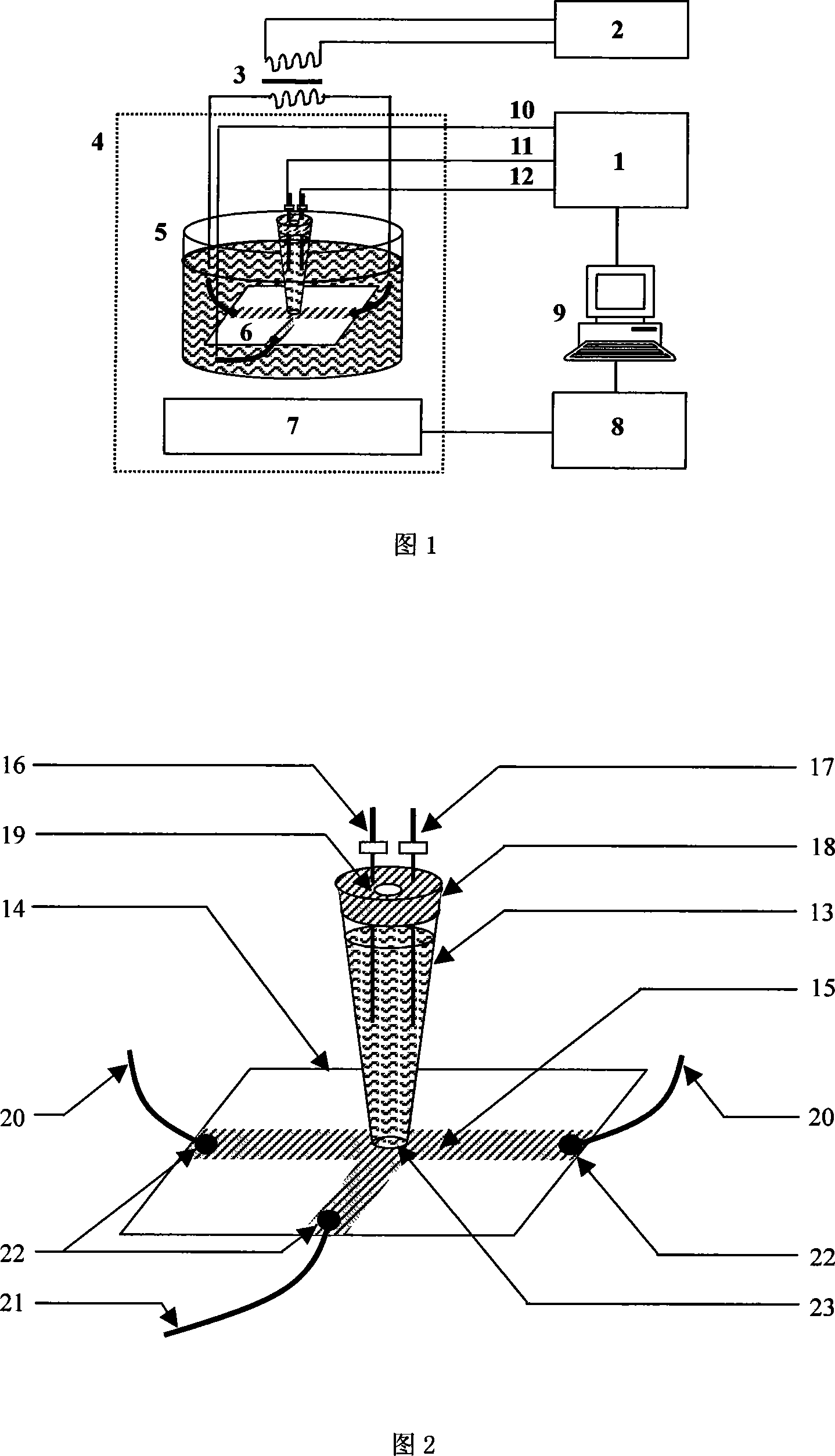

Heat controlled electric pole electrogenerated chemiluminescence testing apparatus and testing-pool preparation method

InactiveCN101162199AReduce dosageImprove collection efficiencyAnalysis by electrical excitationMaterial electrochemical variablesElectrochemiluminescenceEngineering

The invention provides a detection device of thermal control electrode electrochemiluminescence, which is characterized in that the detection device comprises a detection cell and an electrical heating system. The electrical heating system is connected with working electrodes of the detection cell, the working electrodes are conducting glass electrodes with indium-tin oxide (ITO) coating; the detection cell is a three-electrode system, the three electrodes are respectively connected with an electrochemical workstation which is connected with a computer; the detection cell is provided with a photomultiplier at the lower part; the photomultiplier is connected to a feeble light detector which is connected to the computer; the photomultiplier and the detection cell are both arranged in a dark box. The invention is simple to manufacture and convenient to use. The system is stable and is of low cost, which can facilitate in heating the working electrodes. The integrated thermal control ITO electrode electrochemiluminescence detection system has good sensitivity and repeatability on the detection of amines.

Owner:FUZHOU UNIV

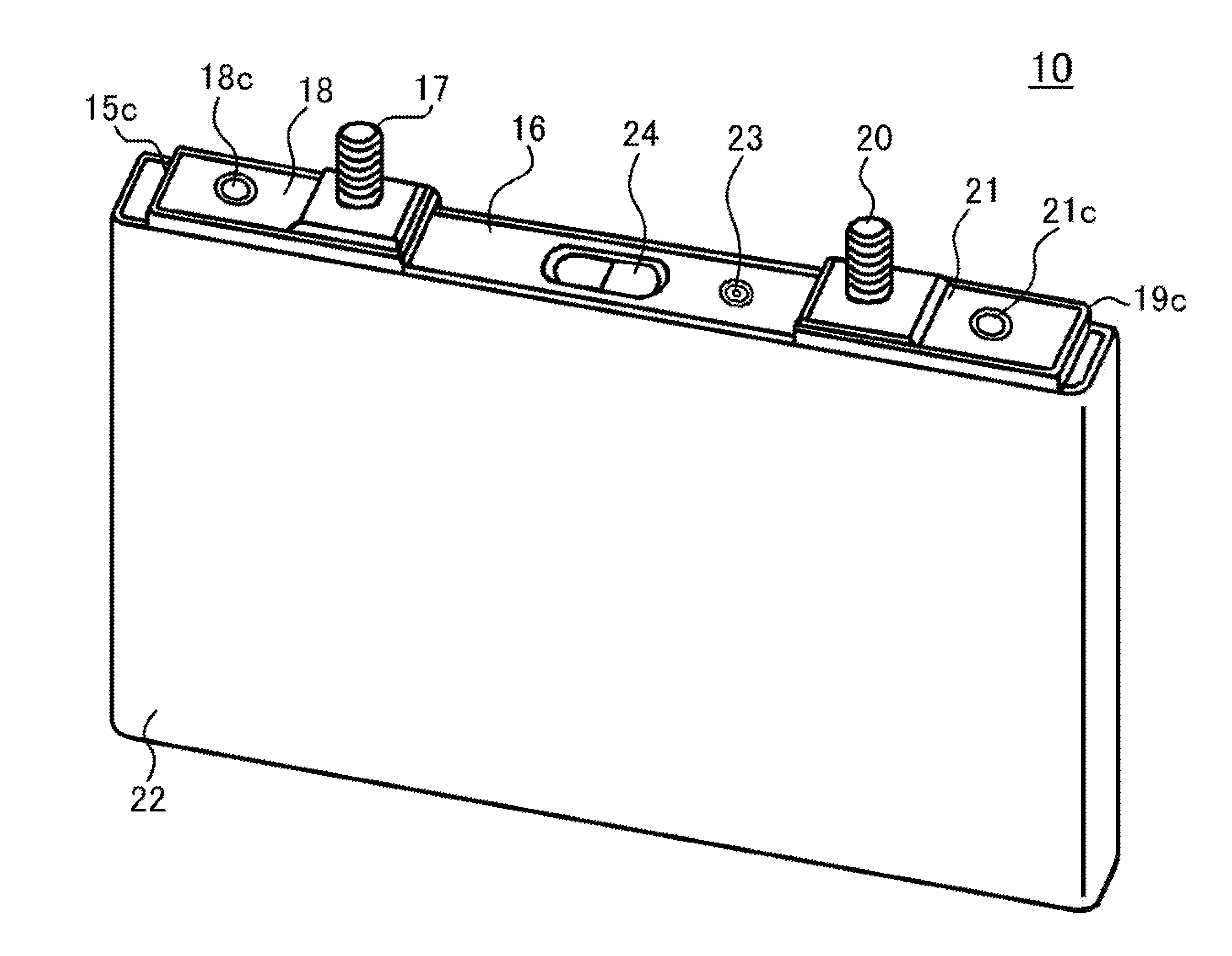

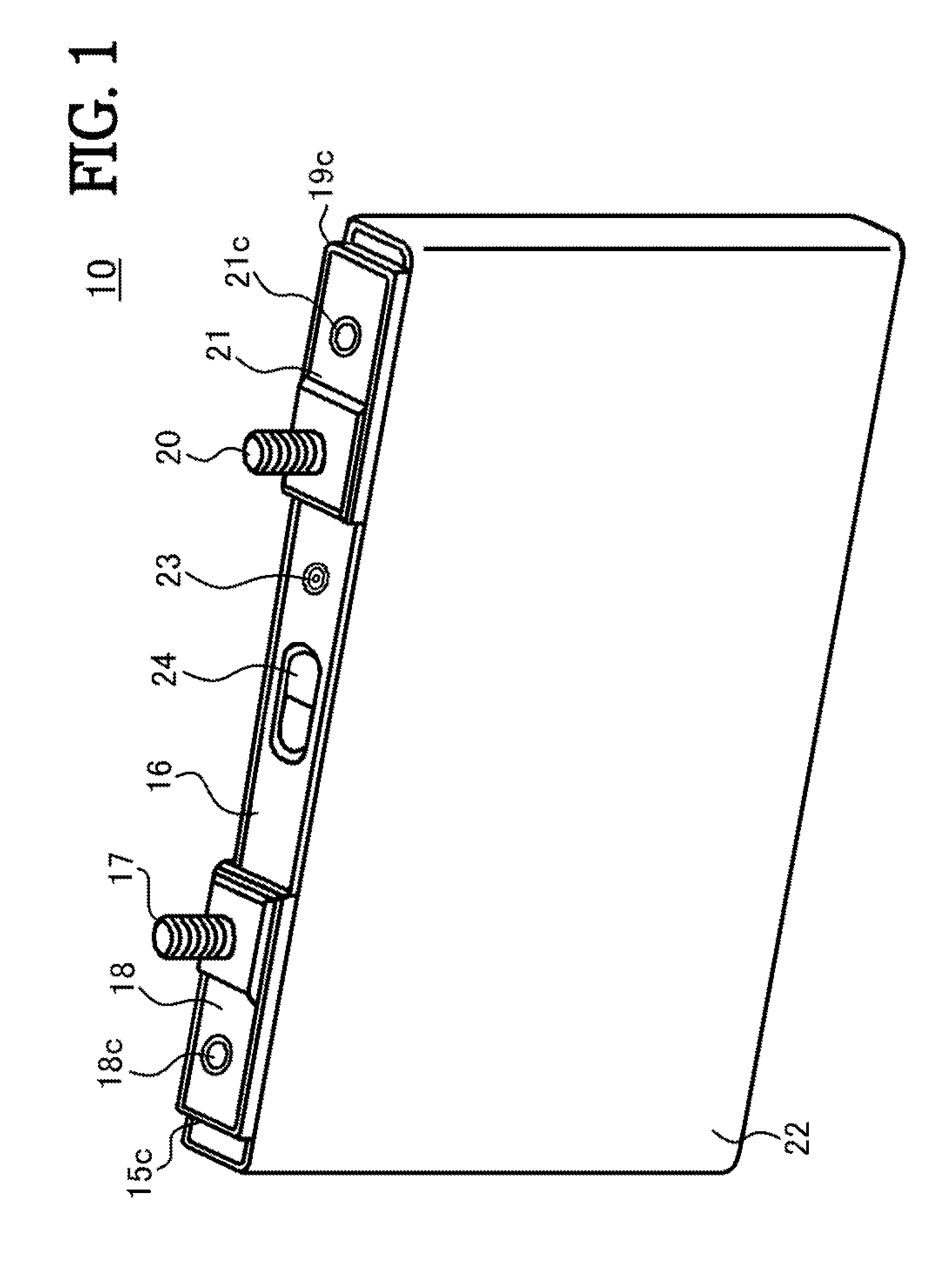

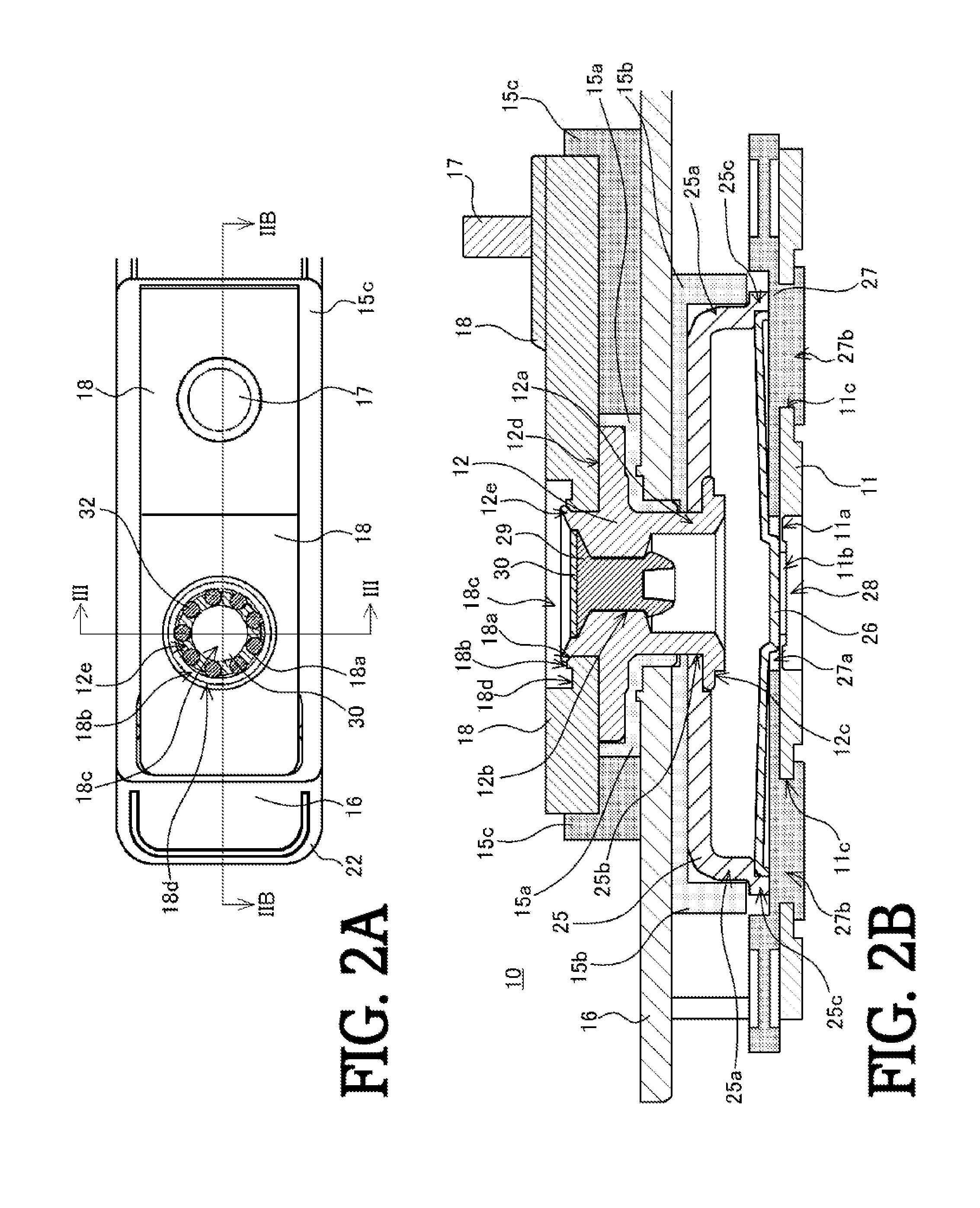

Prismatic secondary battery

ActiveUS20130224536A1Large capacityImprove output performanceSmall-sized cells cases/jacketsElectrical resistance and conductanceInternal resistance

A groove is formed in a ring shape and a ring-shaped convexity is formed on the periphery of a through-hole of a positive electrode terminal plate. An upper end side of a crimping part of a positive electrode exterior terminal is inserted through the through-hole of the positive electrode terminal plate and crimped, and welded spots are formed by irradiation with high-energy beams between a distal end side of the crimping part and the convexity. The mechanical and electrical connection of an exterior terminal and a terminal plate to the crimping part through welding with high-energy beams makes it possible to provide a prismatic secondary battery of enhanced reliability in which cracking is less likely to occur in the welded spots, the coupling strength between the exterior terminal and the terminal plate is increased, and fluctuations in the internal resistance are curbed.

Owner:SANYO ELECTRIC CO LTD

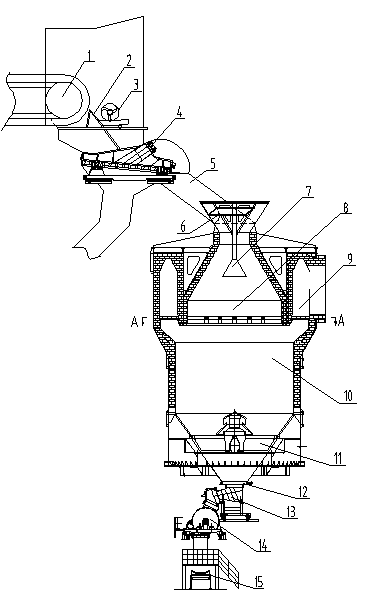

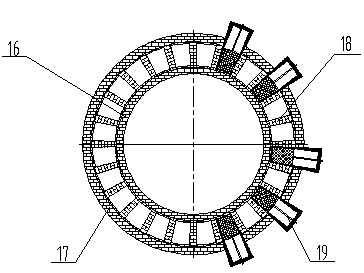

Sintering furnace type cooling device

ActiveCN103234359AReduce height differenceImprove qualityHandling discharged materialThermal energyFlue gas

A sintering furnace type cooling device relates to the technology field of sintering cooling devices. An outlet of a sintering machine is provided with a single roll crusher; an outlet of the single roll crusher is provided with a hot sinter screen; the hot sinter screen is connected with an inlet of a chute; an outlet of the chute is connected with a furnace opening of a cooling furnace; a distributing device is arranged inside the furnace opening of the cooling furnace; a ventilation device is arranged at the bottom of the cooling furnace; a discharging device is connected under the ventilation device; a belt conveyer is arranged under the discharging device; the cooling furnace comprises a pre-store area which is arranged on the upper portion, a cooling area which is arranged on the lower portion and an annular flue area which is arranged on the periphery of the pre-store area; radial supporting columns which are integrally and radially distributed are arranged at the bottom of the annular flue area; a high-temperature flue gas adjustment plate is coated on two adjacent radial supporting columns; and the high-temperature flue gas adjustment plate is capable of sliding along a diametrical direction of the annular flue. The sintering furnace type cooling device has the advantages of effectively overcoming the defects that an existing sintering cooling system is serious in air infiltration and low in waste heat utilization rate, achieving efficient heat replacement, improving the temperature of the flue gas and reducing energy consumption in cooling.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Analog-to-digital converter

InactiveUS7233273B2Low costReduce power consumptionElectric signal transmission systemsAnalogue-digital convertersDigital down converterControl circuit

Included are a first unit including a DAC which generates a comparison signal serving as an object of comparison with the first analog signal, taking in and retaining the first analog signal, a second unit including a DAC which generates a comparison signal serving as an object of comparison with the first analog signal, taking in and retaining the second analog signal, a first switch connecting the first unit to an output side of the second unit, a comparator comparing a differential value between the first analog signal and the second analog signal with a differential value between the comparison signal of the first DAC and an output signal of the second DAC, and an electric potential control circuit controlling fluctuations in electric potentials of the first analog terminal and the second analog terminal.

Owner:CYPRESS SEMICON CORP

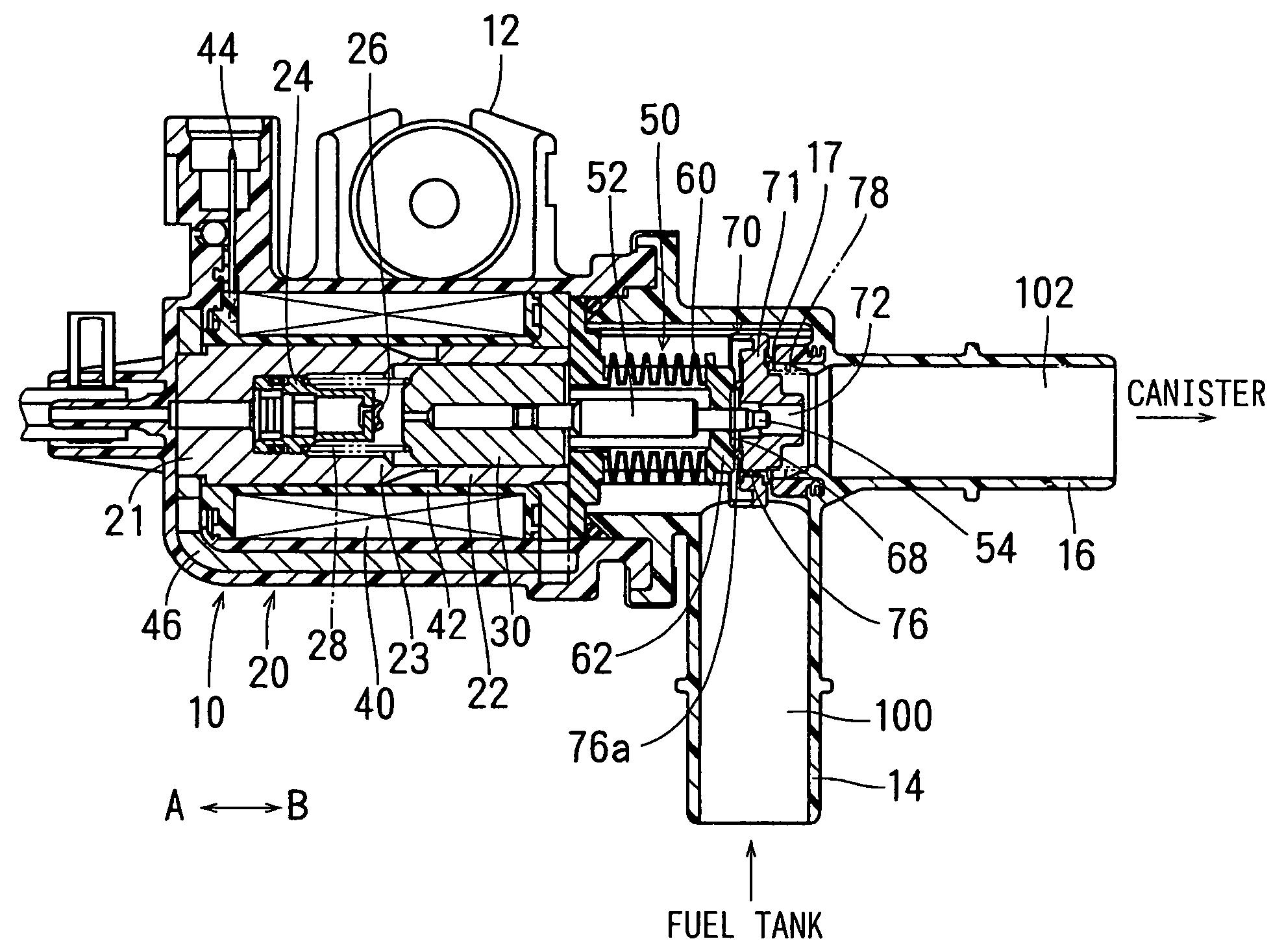

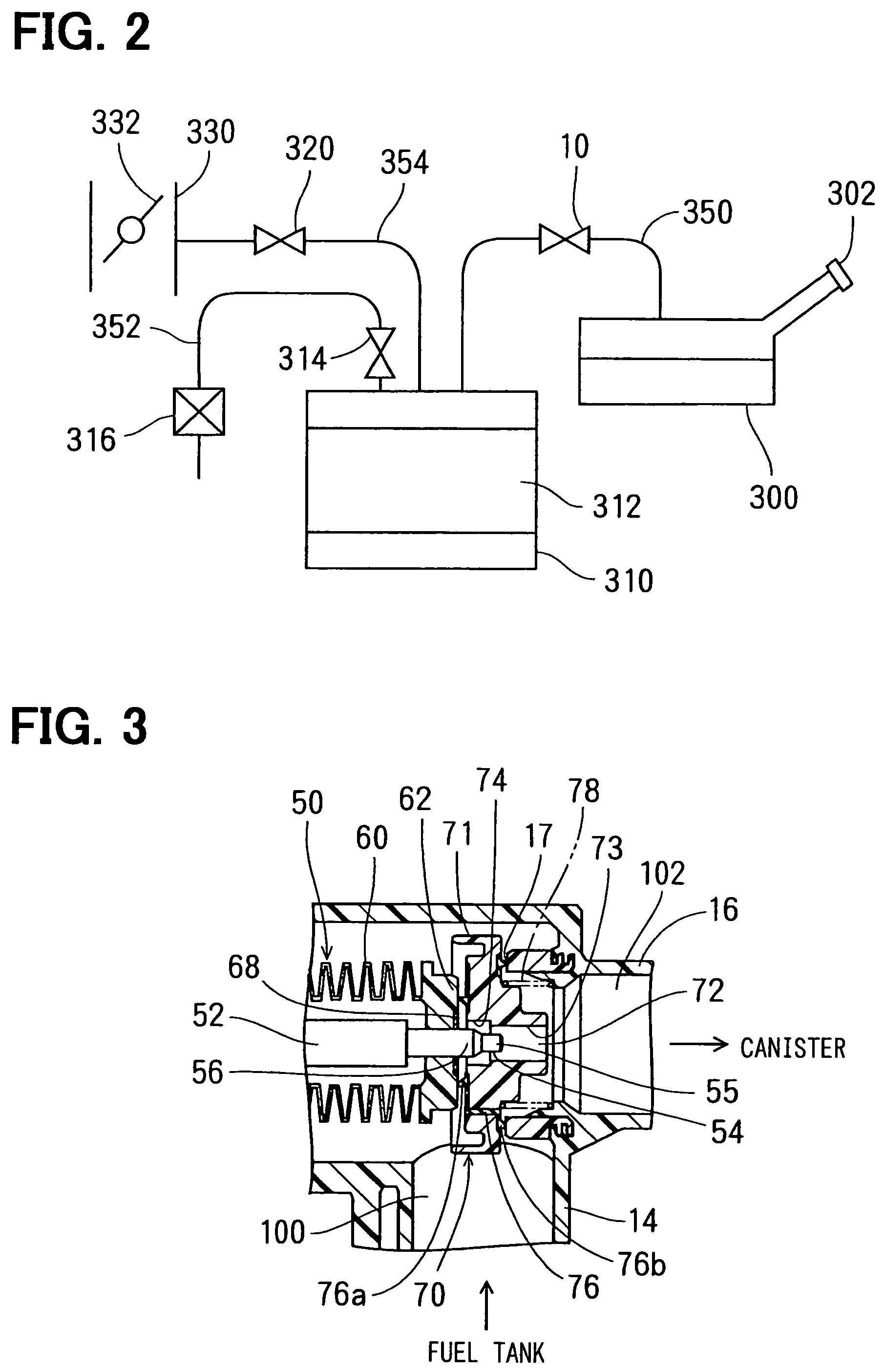

Electromagnetic valve and vapor fuel treating system applying the same

ActiveUS7270310B2Increase the areaAvoid flowDiaphragm valvesOperating means/releasing devices for valvesSolenoid valveFuel treatment

A first connecting pipe of an electromagnetic valve connects with the fuel tank, and a second connecting pipe connects with a canister. A spring urges a moving core and a first valve body in a closing direction of a electromagnetic valve. A shaft of the first valve body includes a fluid-amount controlling portion on the top. The fluid-amount controlling portion is inserted to the communicating passage while a contact member of bellows seats on a convex of a rubber member, and is tapered in an inserted direction. When a coil is energized, the first valve body is lifted in the direction in which the fluid-amount controlling portion retracts from the communicating passage.

Owner:DENSO CORP

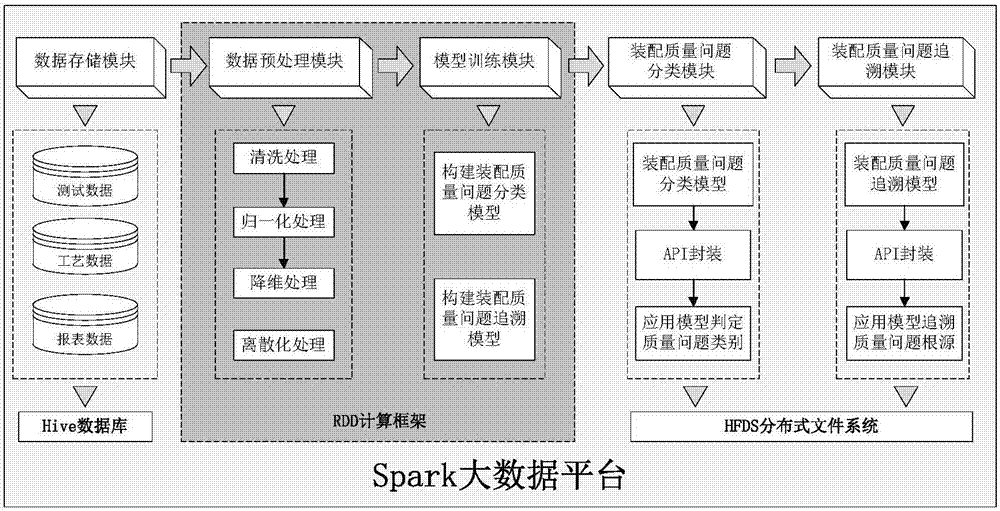

Circuit breaker assembly quality problem tracing system and method based on large data analysis

InactiveCN107451666AEnsure safetySolve intractableCharacter and pattern recognitionResourcesComputer scienceData pre-processing

The invention discloses a circuit breaker assembly quality problem tracing system and method based on large data analysis. The problem that an ancillary system cannot meet the requirement of massive data analysis in a circuit breaker assembly production process is solved. The new idea of quality circuit breaker assembly quality problem tracing is provided from the aspect of data mining. The method comprises the steps that Spark is used to build a large data analysis platform; data preprocessing is carried out in combination with business; K-Means is used to build an assembly quality problem classification model based on distance; an Apriori association rule algorithm is used to build an influential factor analysis model; and assembly quality problem tracing is realized. The assembly quality problem classification model completes the deficiencies of mechanism classification or experience classification from the aspect of data characteristics. According to the invention, the system and method are capable of storing and analyzing massive data, have the advantages of high-performance redundancy, real-time and efficient data analysis and storage, are used for circuit breaker assembly quality problem tracing, and provide suggestions and references for circuit breaker assembly quality production.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com