Plasma processing apparatus and a plasma processing method

a processing apparatus and plasma technology, applied in the field of plasma processing apparatus and plasma processing method, can solve the problems of large etching speed of silicon (si) and small selection ratio, and achieve the effect of restrainting the fluctuation of etching characteristi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, a plasma processing apparatus and a plasma processing method representing one embodiment according to the present invention will be explained.

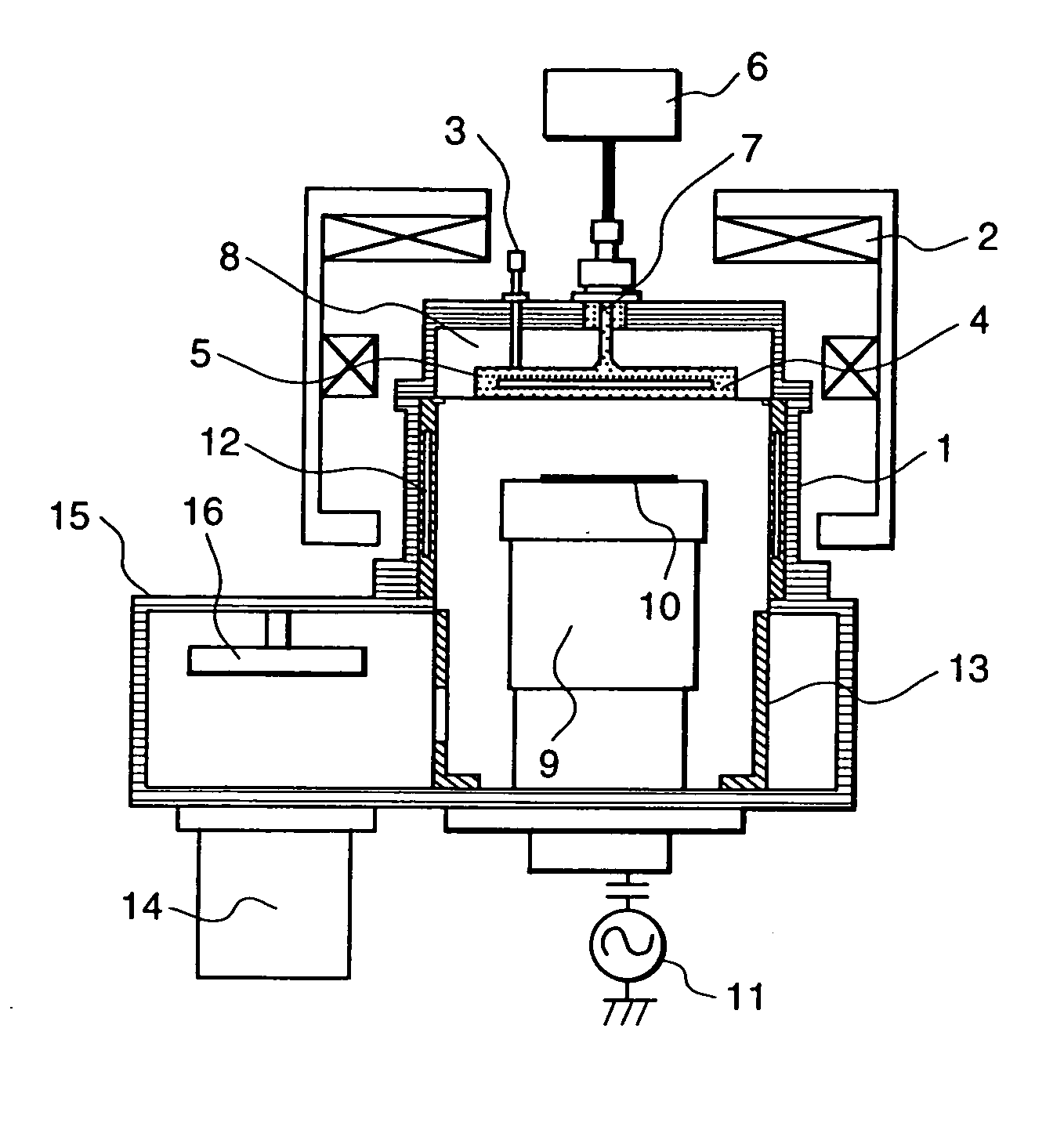

[0043]FIG. 1 is an example of a UHF type ECR plasma etching apparatus. At a peripheral portion of an etching chamber 1 (a vacuum processing chamber), which is operated as a vacuum vessel, a coil 2 is installed, and this coil 2 generates an electron cyclotron resonance (ECR) field. An etching gas is supplied from a gas supply pipe 3 and is introduced via a gas supply plate 4 to the etching chamber 1. The gas supply plate 4 is comprised of a plate made of silicon or a glass form carbon in which about 100 fine holes having a diameter of from 0.4 mm to 0.5 mm degree are provided.

[0044] At an upper portion of the gas supply plate 4, a disc-shaped antenna 5 is provided, and this antenna 5 radiates microwave energy in the UHF band. The microwave energy is supplied to the antenna 5 from a power supply 6 through an induction shaft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com