Sintering furnace type cooling device

A technology of cooling device and mine furnace, which is applied to furnaces, furnace components, processing discharged materials, etc., can solve the problems of low waste heat utilization efficiency, fluctuation of waste heat parameters, and large cooling energy consumption, so as to reduce the amount of returned ore and ore particles. Uniform and stable temperature, the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

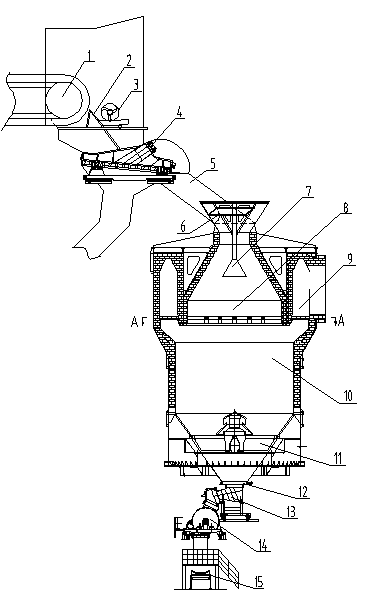

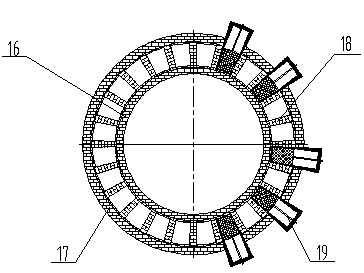

[0018] Such as figure 1 and figure 2 As shown, the sinter furnace type cooling device includes a sintering machine 1, a single roll crusher, a thermal vibrating screen 4, a chute 5, a material distribution device 7, a cooling furnace, an air distribution device 11, a discharge device and a belt conveyor 15. The outlet of the sintering machine 1 is provided with a single-roll crusher. The single-roll crusher includes a grate plate 2 and a crushing roller 3. The grate plate 2 is arranged obliquely, and the crushing roller 3 is vertically arranged directly above the grate plate 2; There is a thermal vibrating screen 4 arranged obliquely at the outlet; the thermal vibrating screen 4 is connected to the entrance of the chute 5, the outlet of the chute 5 is connected to the furnace mouth of the cooling furnace, the material distribution d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com