Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29330 results about "Waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility (or in thermodynamics lexicon a lower exergy or higher entropy) than the original energy source. Sources of waste heat include all manner of human activities, natural systems, and all organisms, for example, incandescent light bulbs get hot, a refrigerator warms the room air, an internal combustion engine generates high-temperature exhaust gases, and electronic components get warm when in operation.

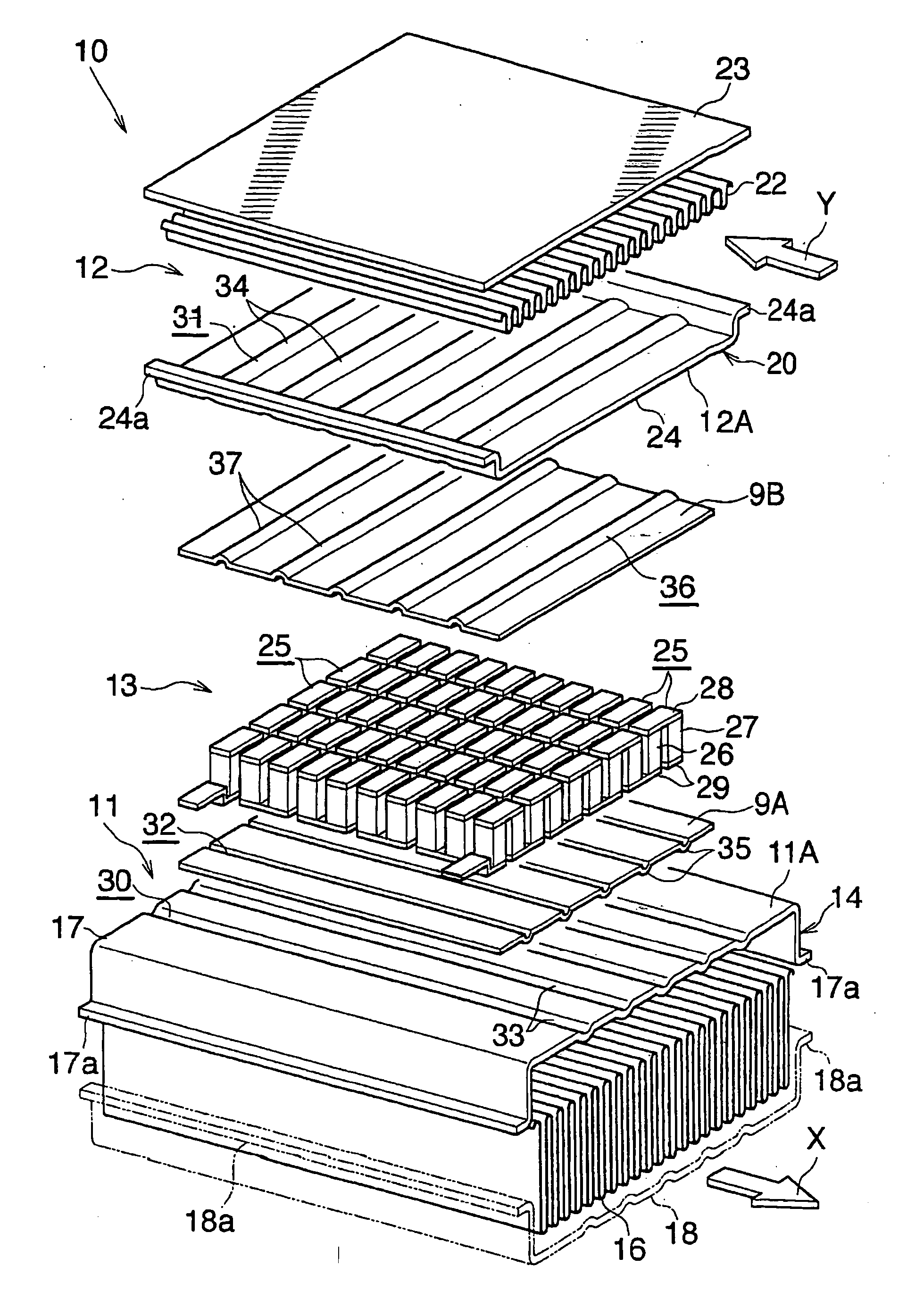

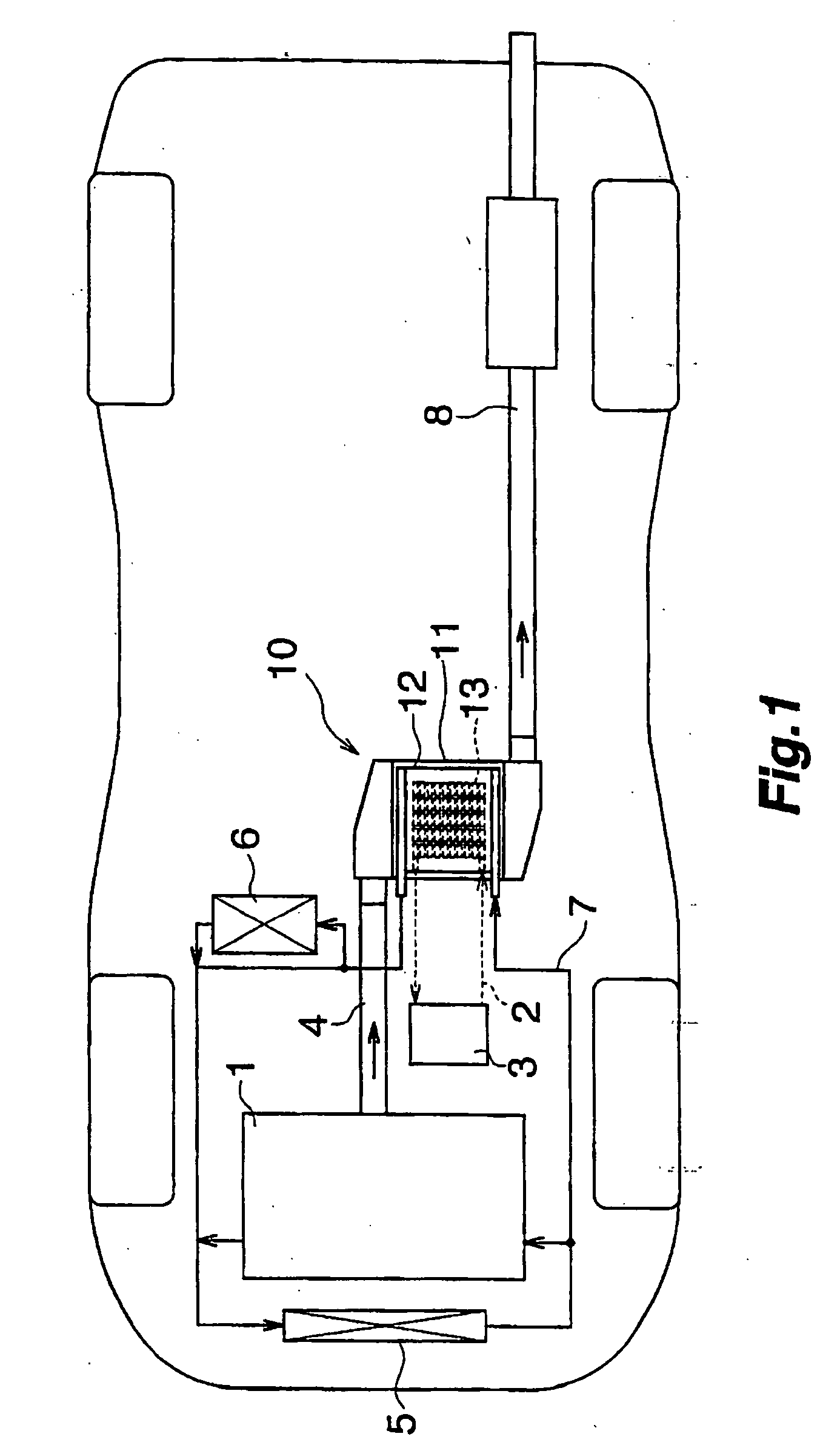

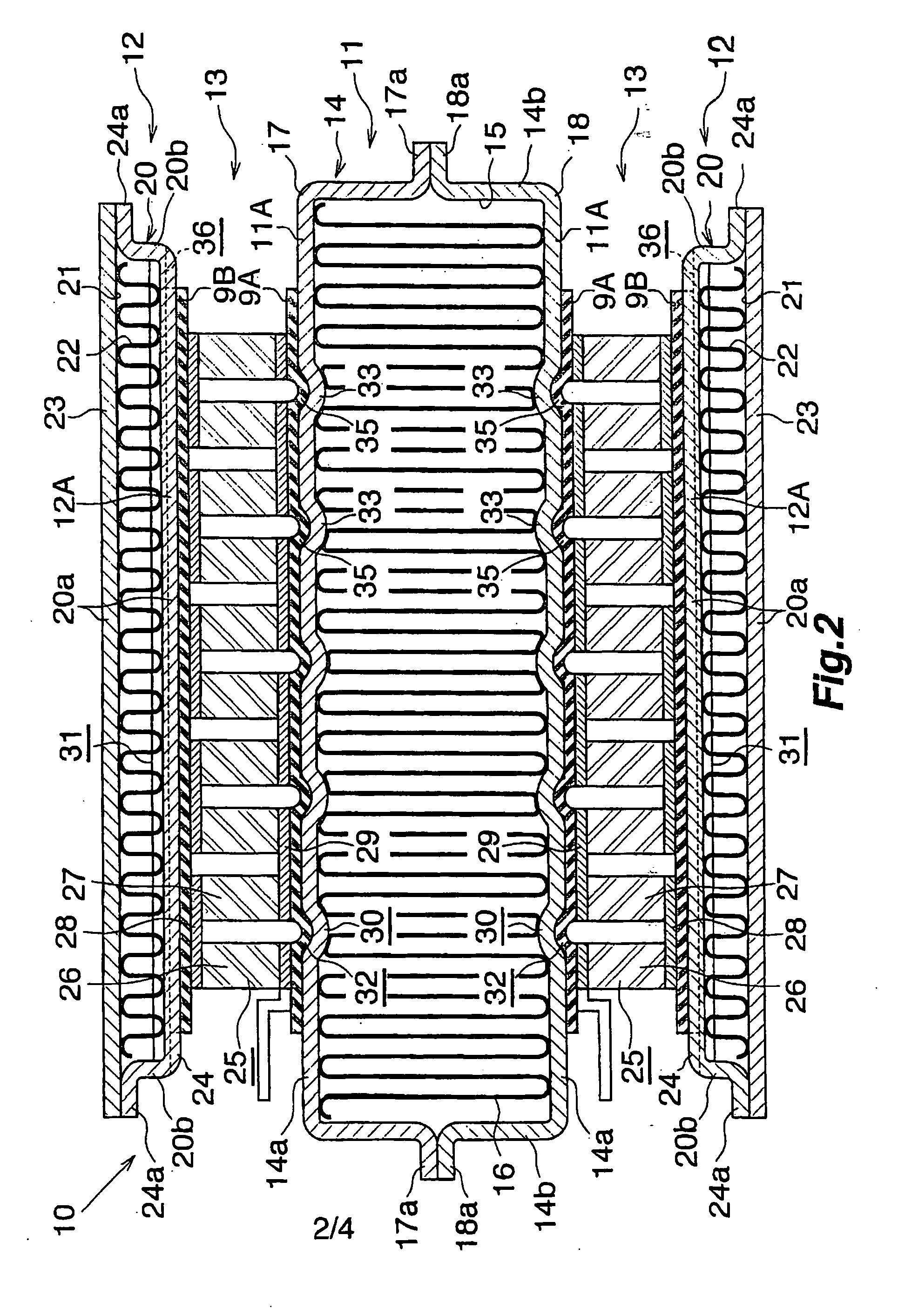

Waste heat recovery system and thermoelectric conversion system

InactiveUS20060157102A1Increase powerImprove efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectWaste heat recovery unitFuel cells

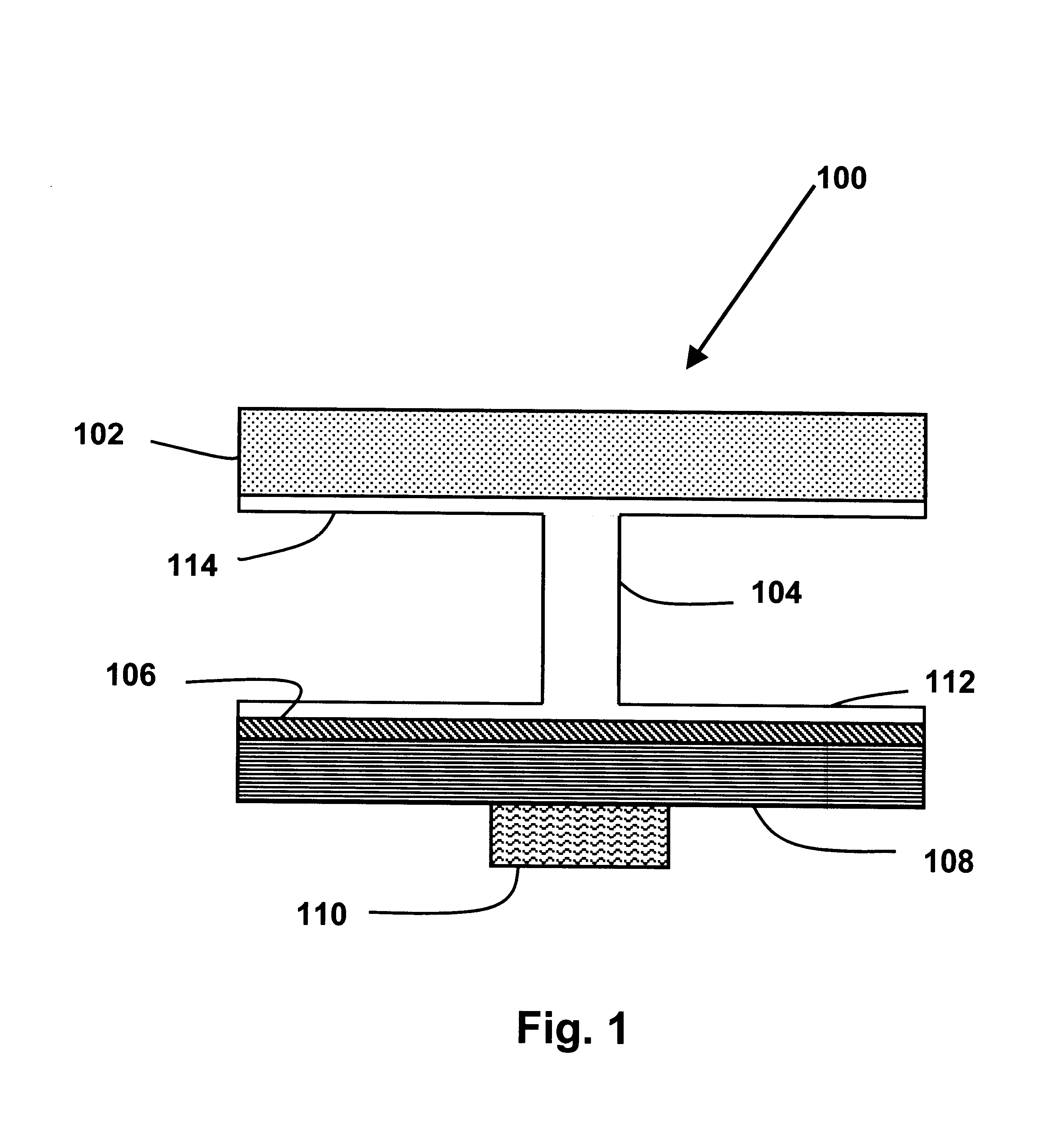

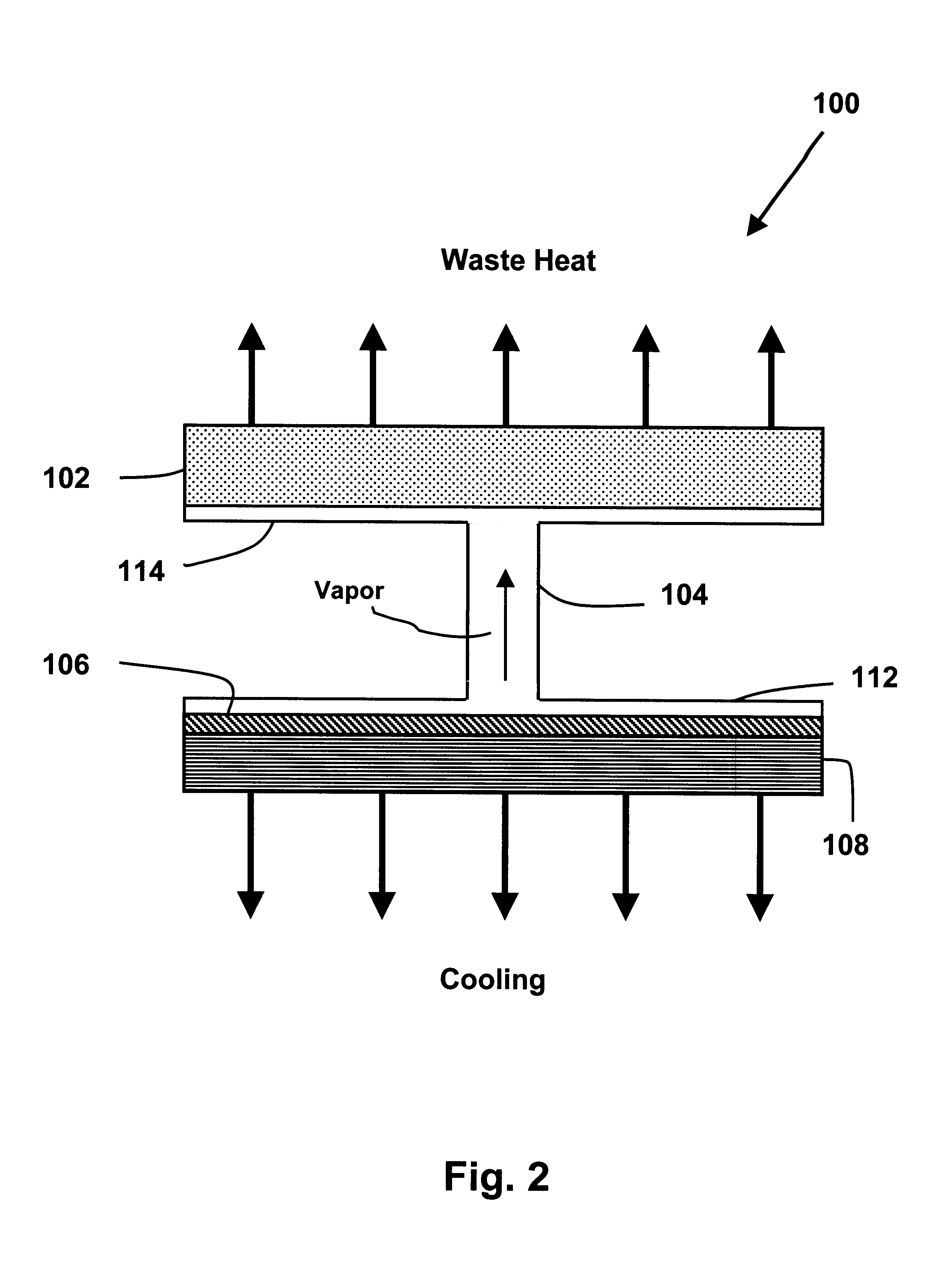

A waste heat recover system includes a mechanism for supplying power by use of a thermoelectric conversion unit, and a mechanism for utilizing heat released from the thermoelectric conversion unit. Heat released from the thermoelectric conversion unit is utilized for, for example, heating, defrosting, defogging, temperature keeping of fuel, temperature keeping of an internal combustion engine, and temperature keeping of a fuel cell. The waste heat recovery system is equipped in, for example, cars, incinerators, fuel cells, and industrial machinery.

Owner:SHOWA DENKO KK

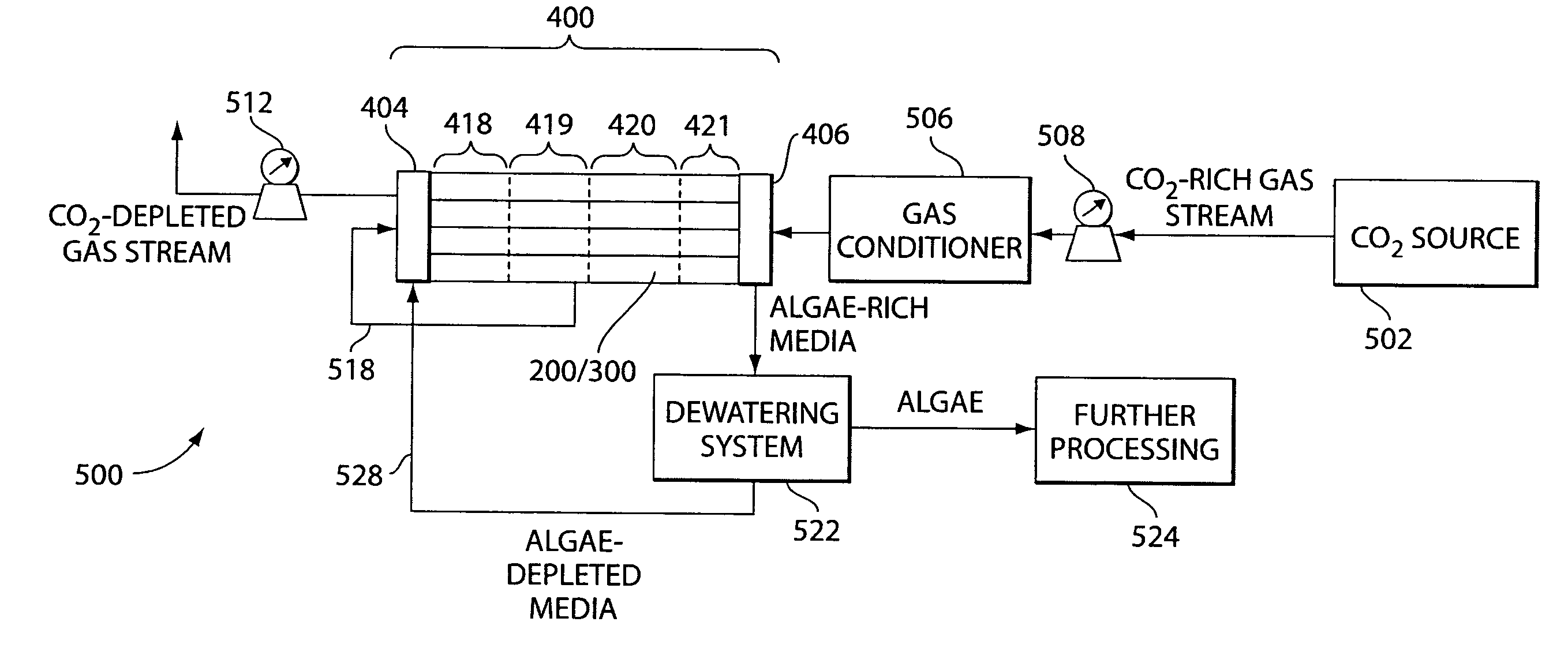

Integrated photobioreactor-based pollution mitigation and oil extraction processes and systems

InactiveUS20080009055A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

Integrated systems including a photobioreactor system designed to contain a liquid medium comprising at least one species of phototrophic organism therein, and a facility associated with extracting and / or processing oil extracted from mixtures of oil and solid material, such as an oil sands facility, are described. Processes for using a photobioreactor system as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a byproduct gas stream produced by an oil sands facility are also described. Examples of such pollutants that may be removed include compounds contained within combustion gases, e.g., CO2 and / or NOx. These pollutants processed with the photobioreactor system, and, in some embodiments, biomass produced with the photobioreactor system may be utilized to produce a fuel source (e.g., biodiesel) and cutting stock for further operation of or use in the oil sands facility. Such uses of certain embodiments can provide an efficient means for recycling carbon, thereby reducing CO2 emissions, fuel, and / or cutting stock requirements for a given quantum of energy produced. In addition, in some cases the photobioreactor can be integrated with a holding pond and waste heat from the oil extraction process can be used to maintain the photobioreactor temperature and / or provide energy for other processes. Accordingly, embodiments described herein can improve the overall environmental and economic profile of the oil sands facility.

Owner:GREENFUEL TECHNOLOGIES CORPORATION

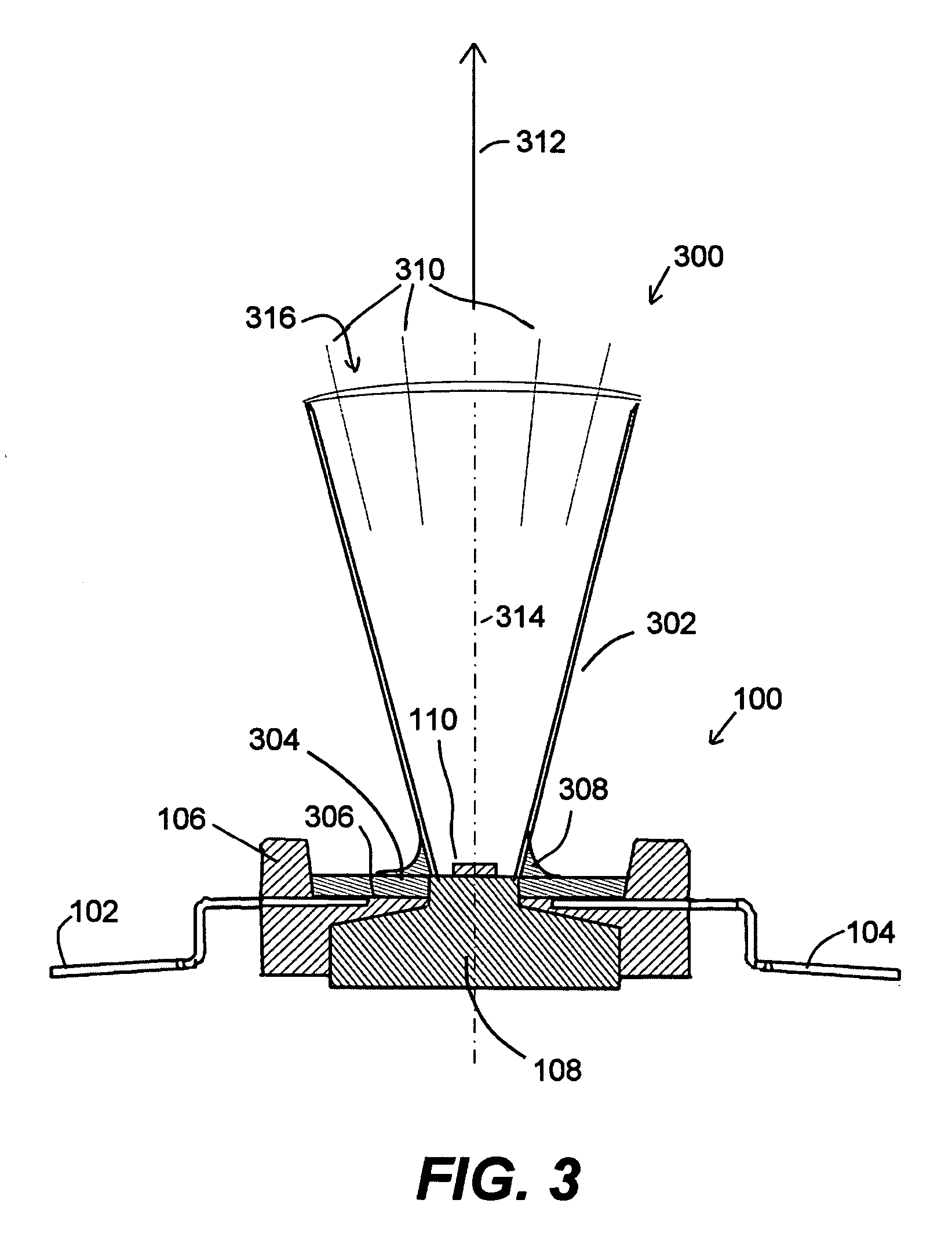

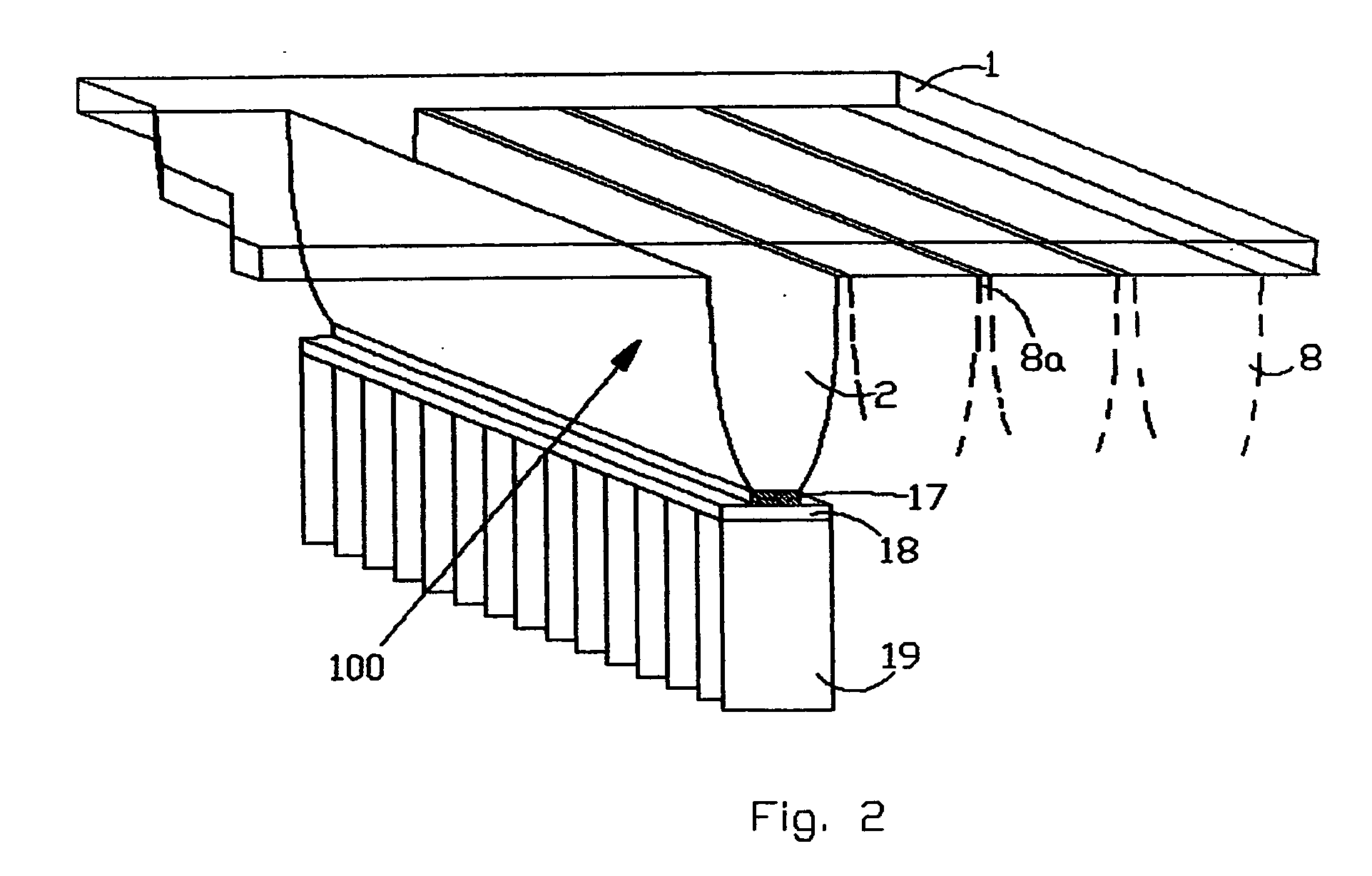

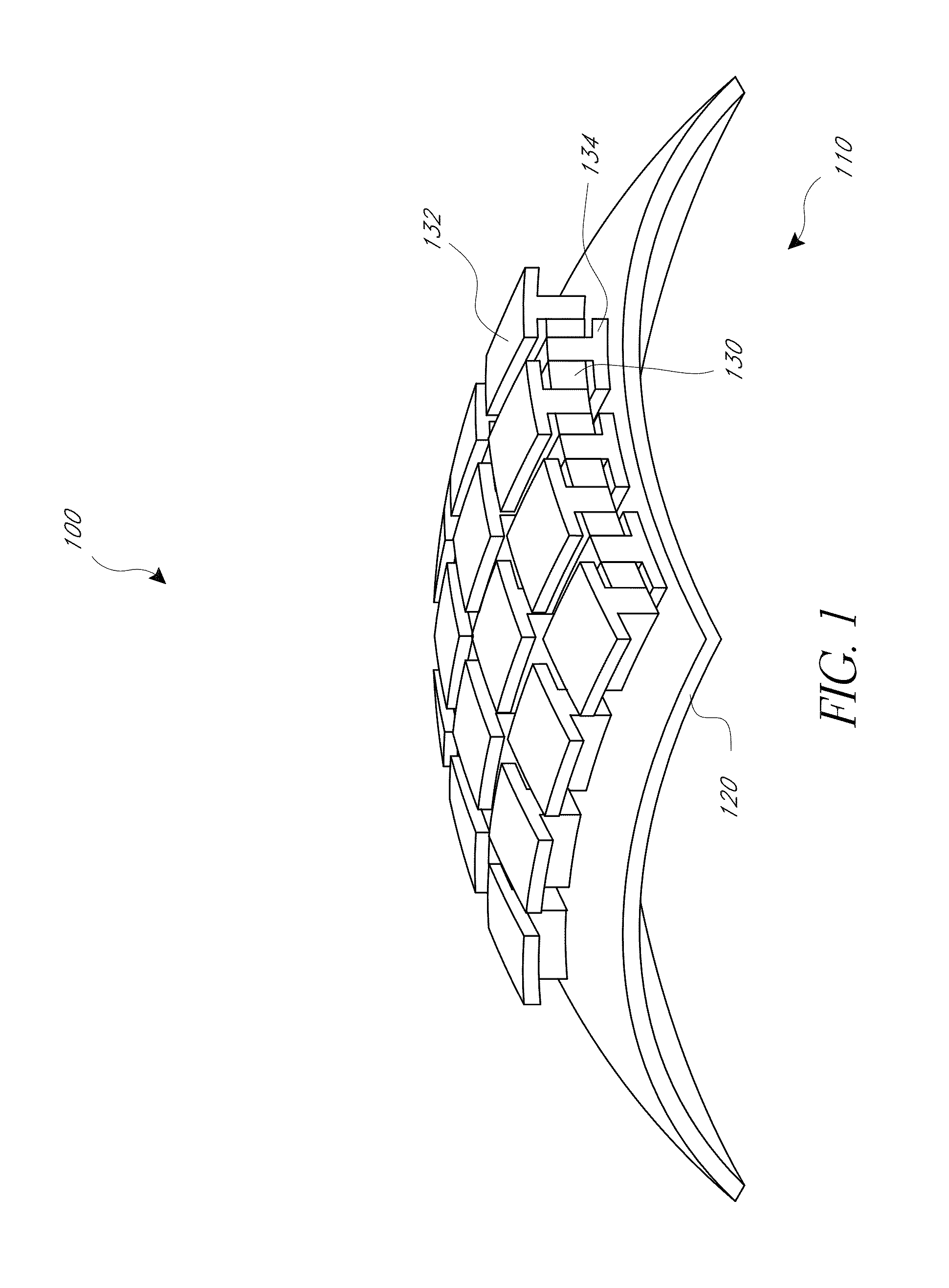

Light insertion and dispersion system

InactiveUS20050084229A1Prolong lifeImprove efficiencyMechanical apparatusCladded optical fibreLight guideOptoelectronics

A light source injects light into a translucent light guide, particularly using high-power LEDs. A core to the light guide contains a homogenous mixture of fluid and a light dispersing agent to effect scattering. Scattered light passes though the light guide and may be used for illumination. A high power LED is provided with a reflector and heat sink to disperse waste heat, increasing the efficiency and life of the LED.

Owner:BABBITT VICTOR +1

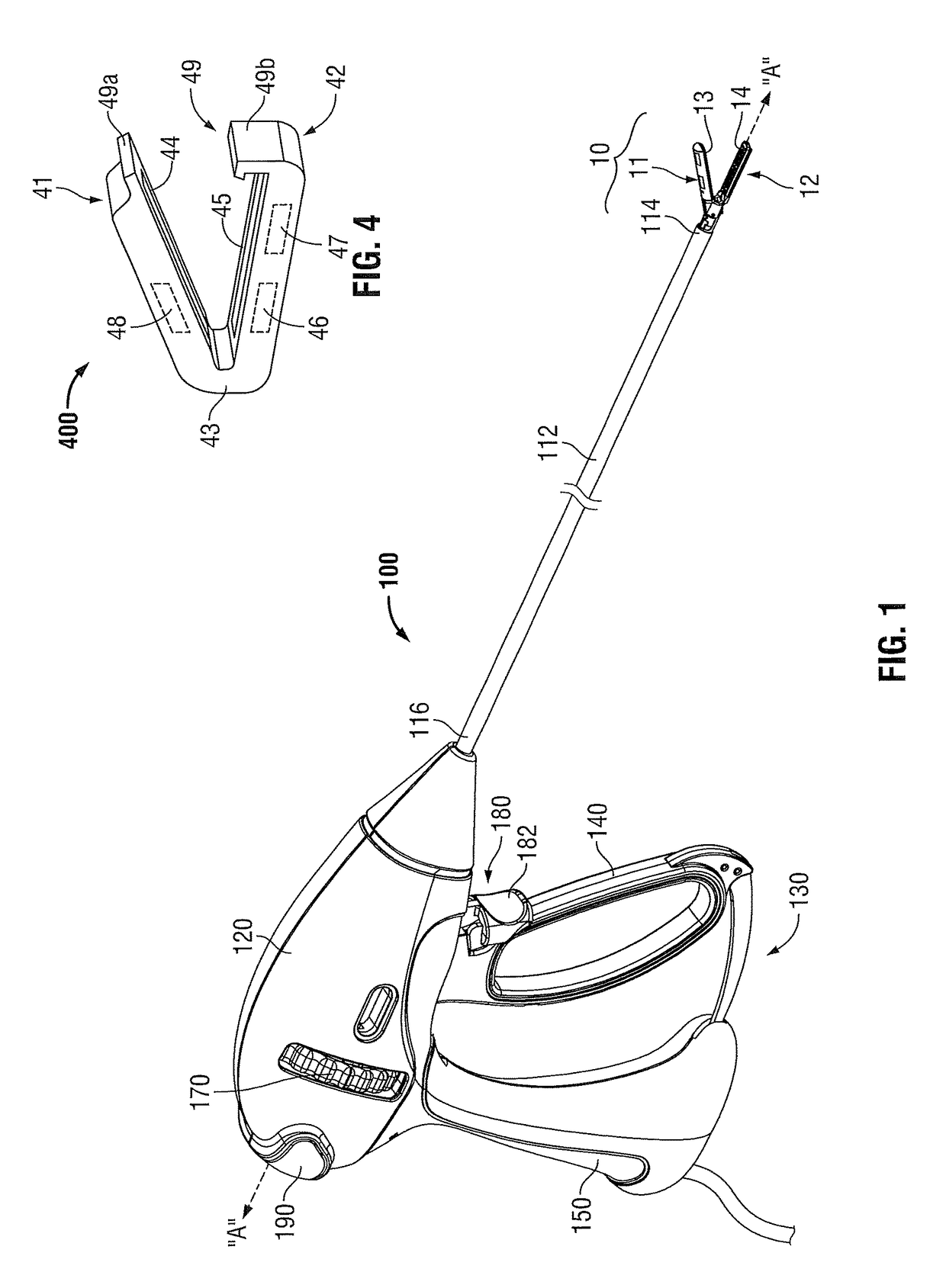

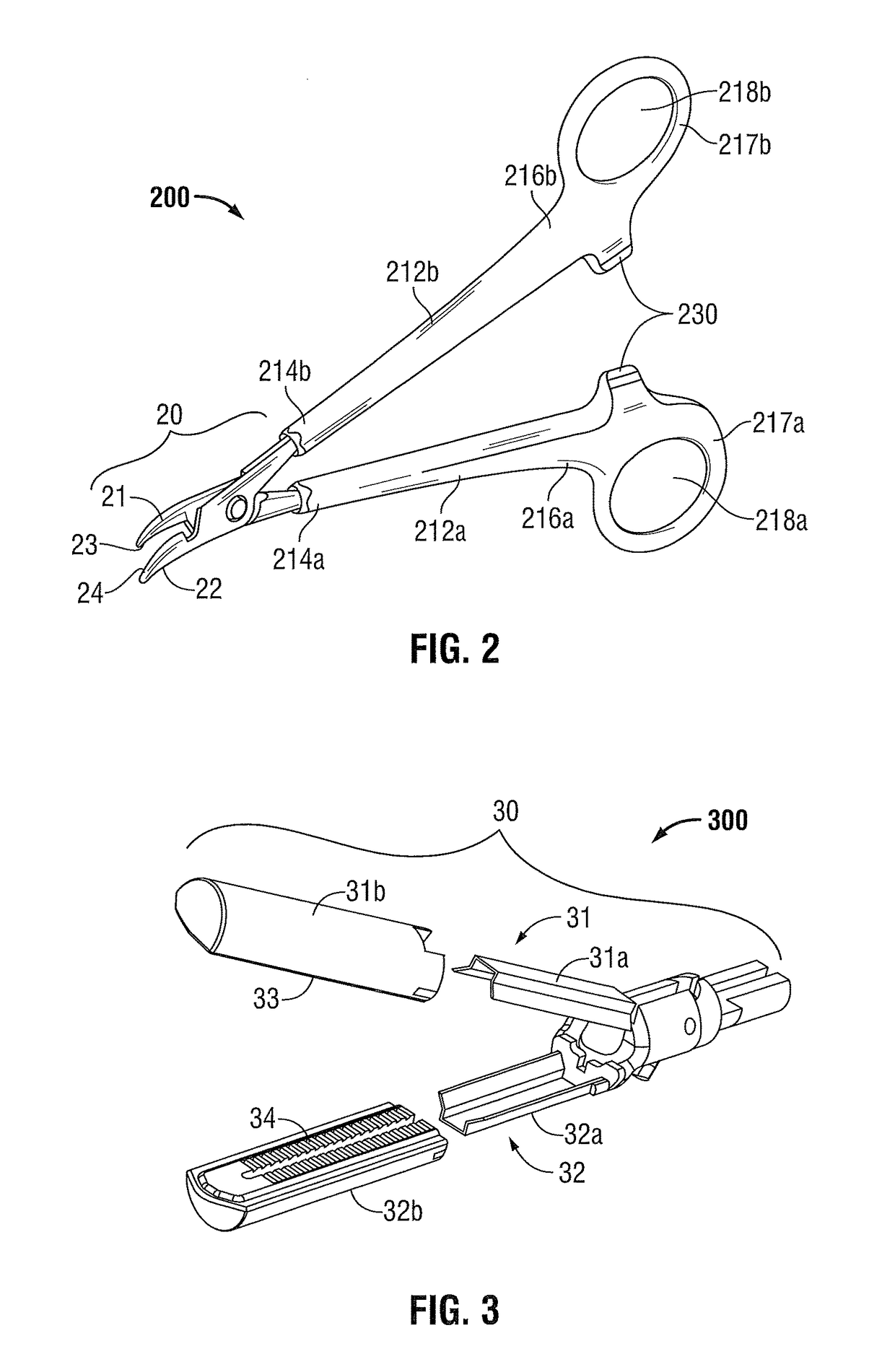

Energy-based medical devices

A medical device includes an energy-generating unit configured to produce energy for conduction through tissue to treat tissue. Waste heat produced by the energy-generating unit during energy production is conducted to tissue to facilitate treating tissue.

Owner:TYCO HEALTHCARE GRP LP

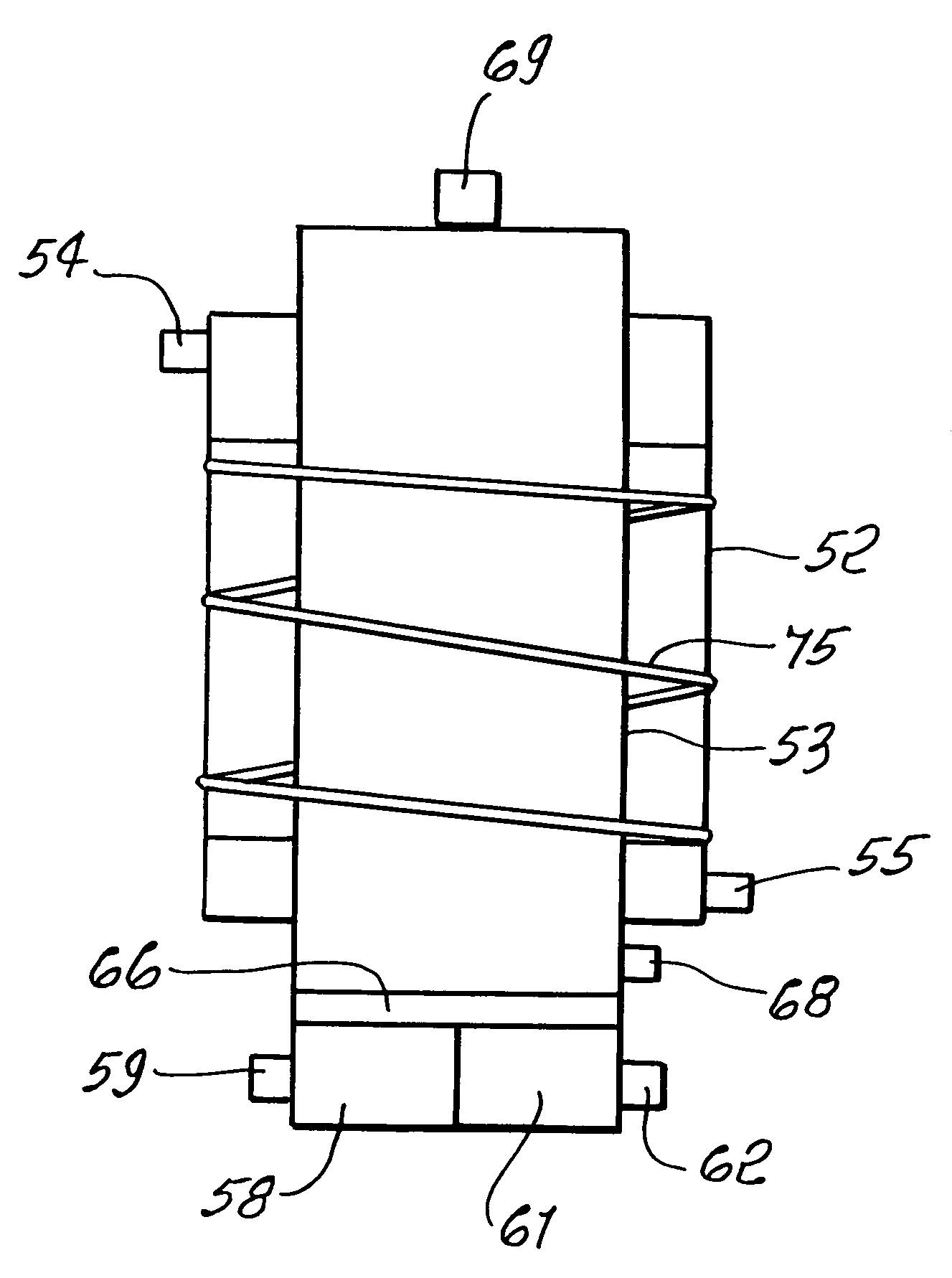

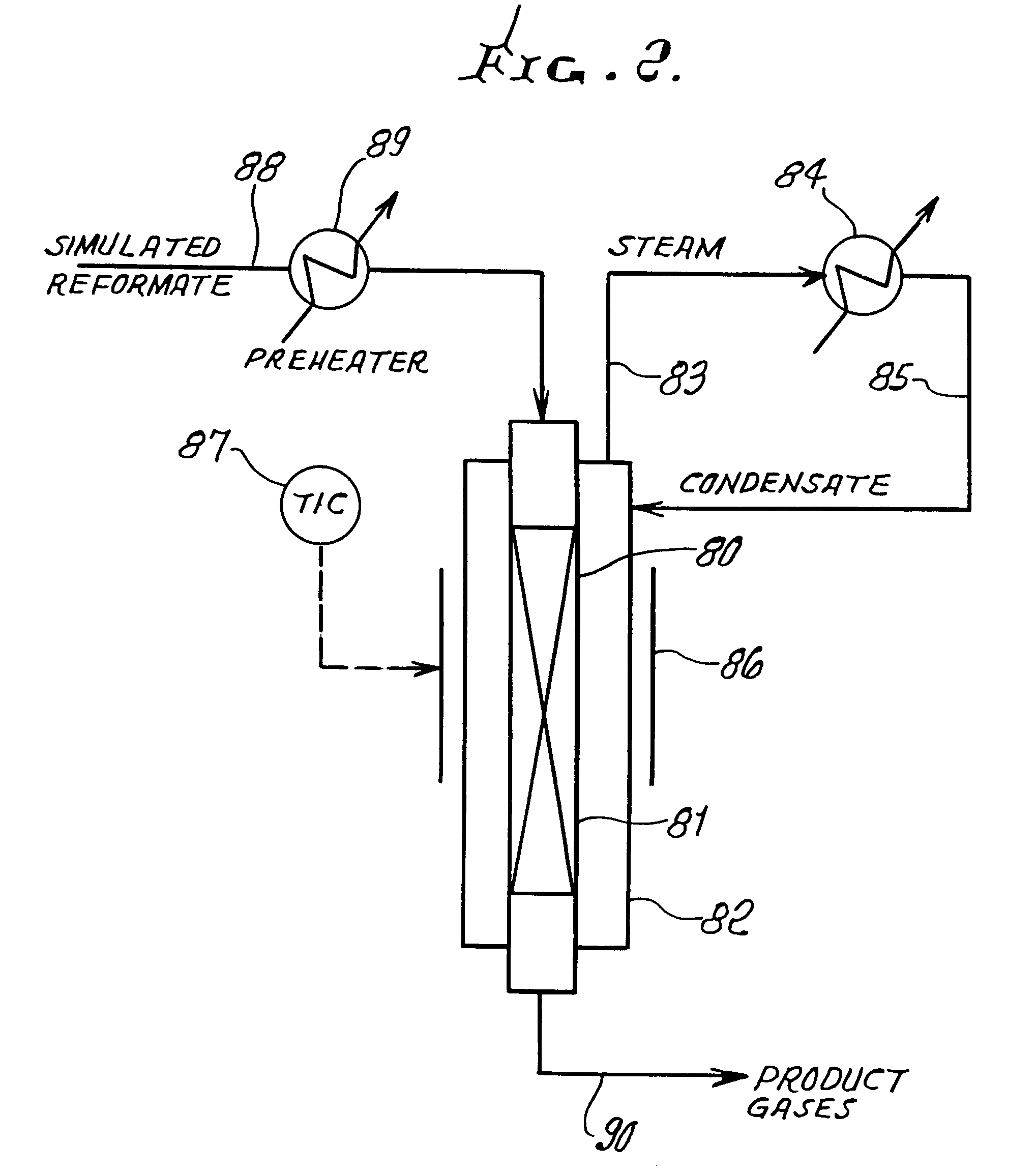

Thermally-integrated low temperature water-gas shift reactor apparatus and process

InactiveUS7074373B1Reduced toleranceExtended temperature rangeHydrogenPhysical/chemical process catalystsWater-gas shift reactionProduct gas

A thermally-integrated lower temperature water-gas shift reactor apparatus for converting carbon monoxide in the presence steam comprises a catalyst bed that is disposed within an outer region surrounding a waste heat recovery steam generator operating at a selected pressure corresponding to the optimum temperature for conducting the catalytic water-gas shift reaction and a process for useful recovery of the exothermic heat of reaction to generate steam that is used in a process for the conversion of hydrocarbon feedstock into useful gases such as hydrogen.

Owner:HARVEST ENERGY TECH

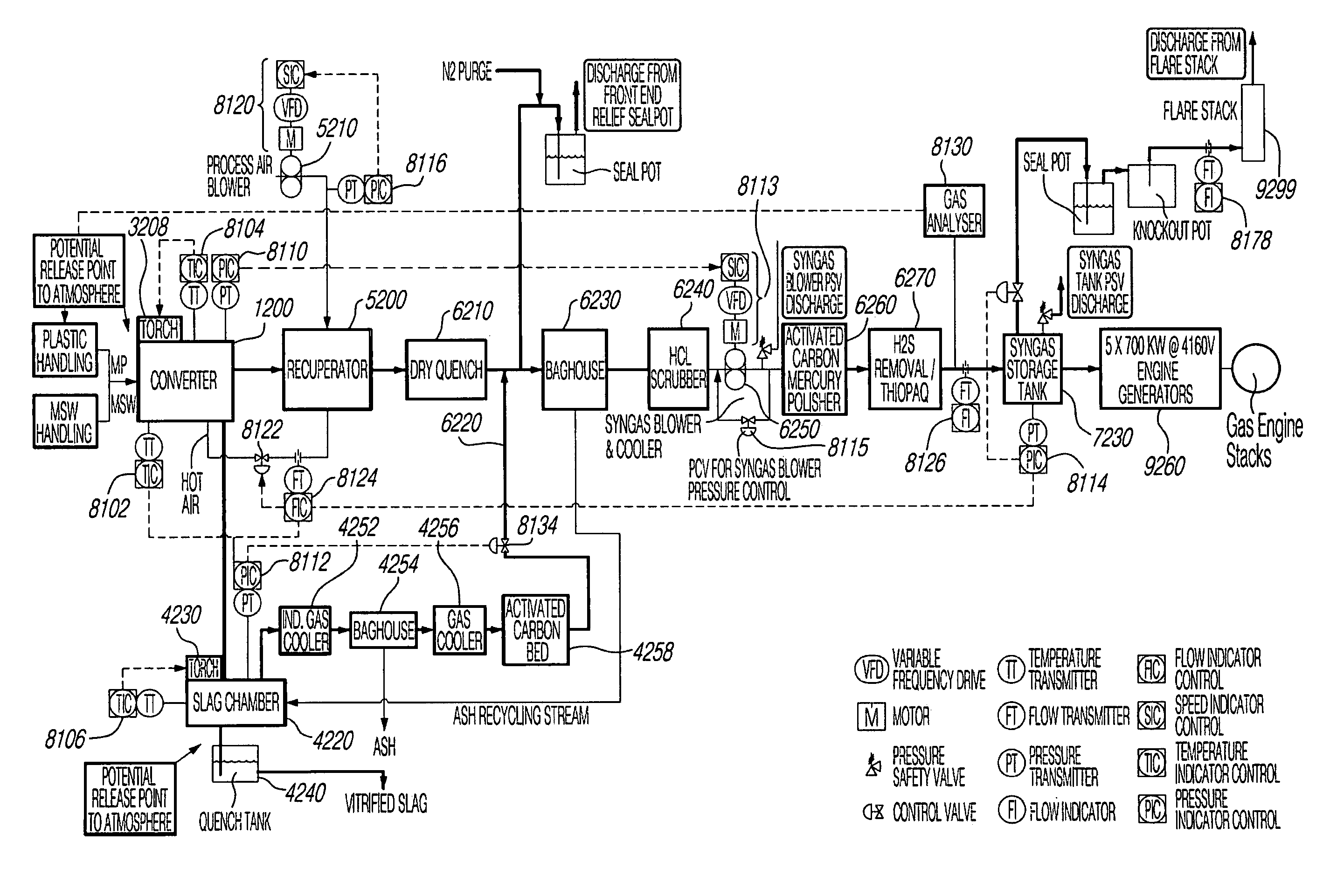

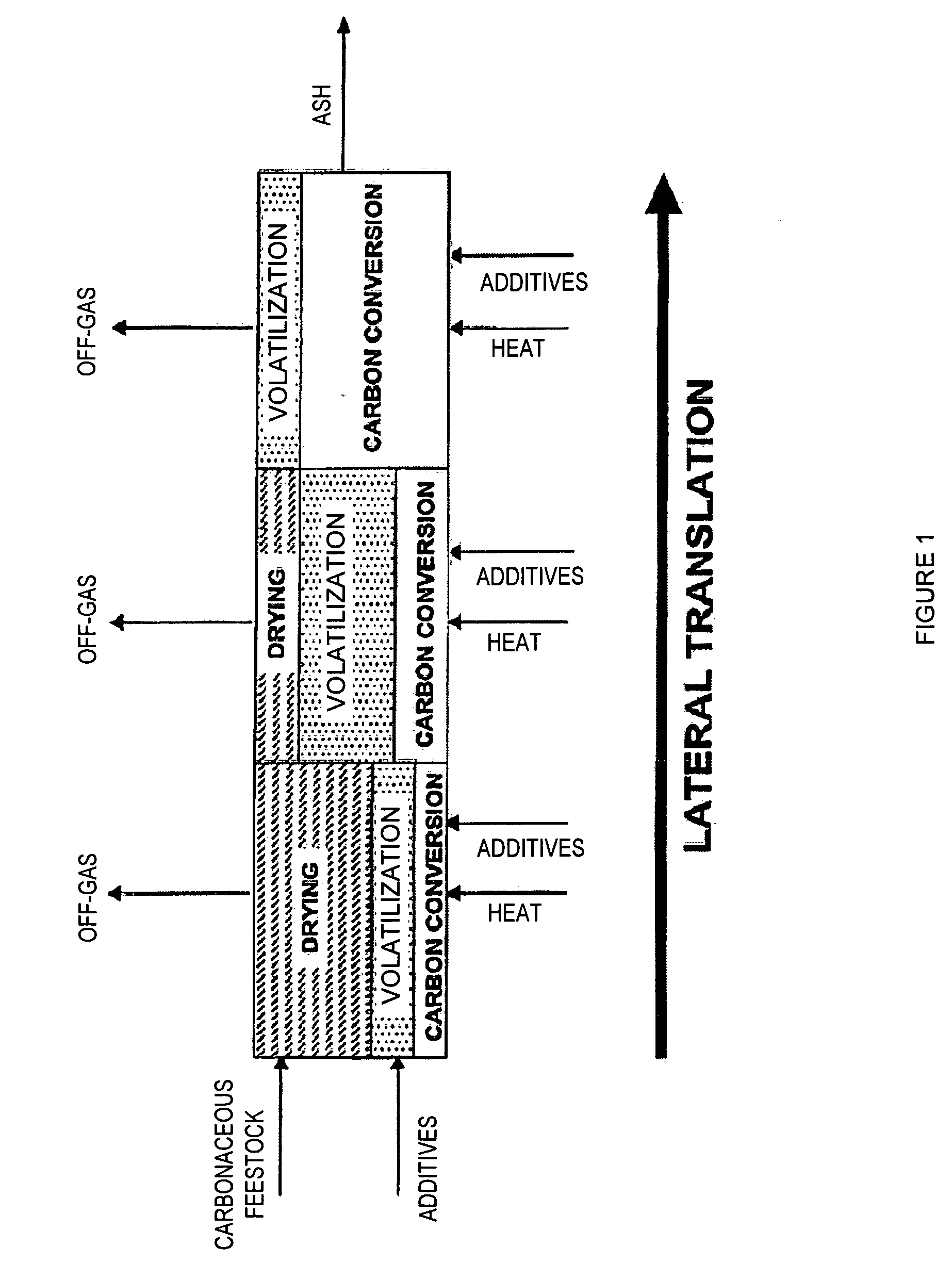

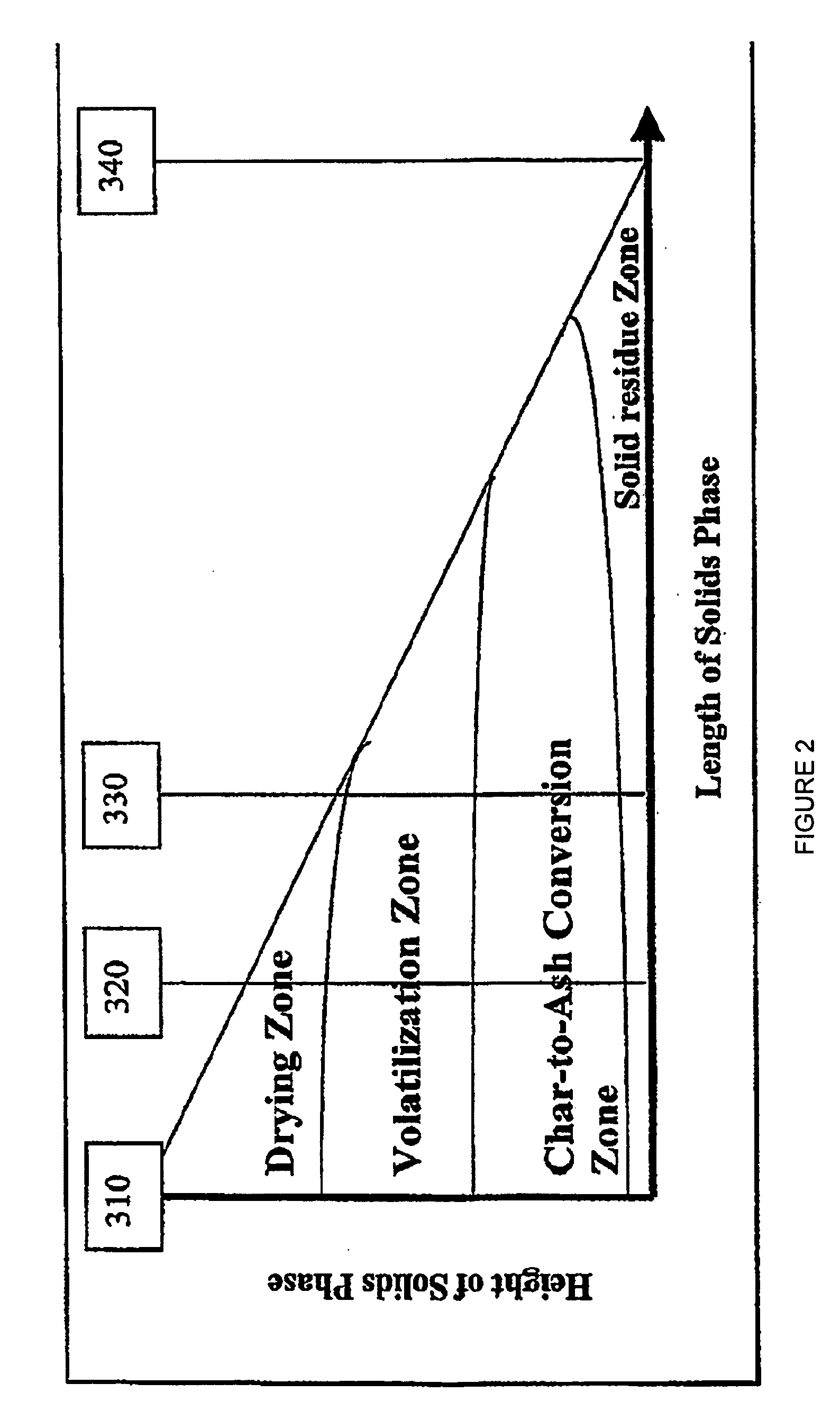

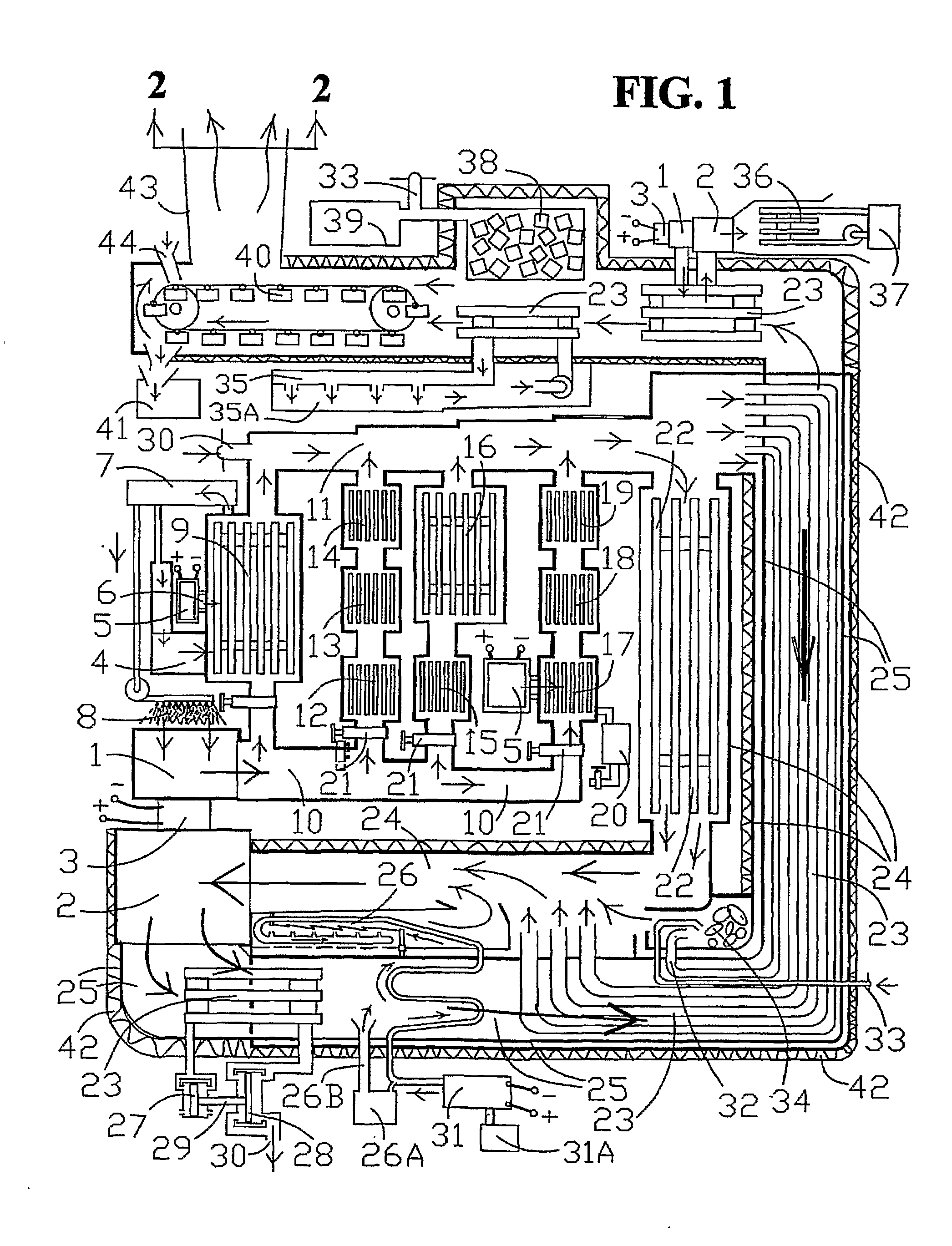

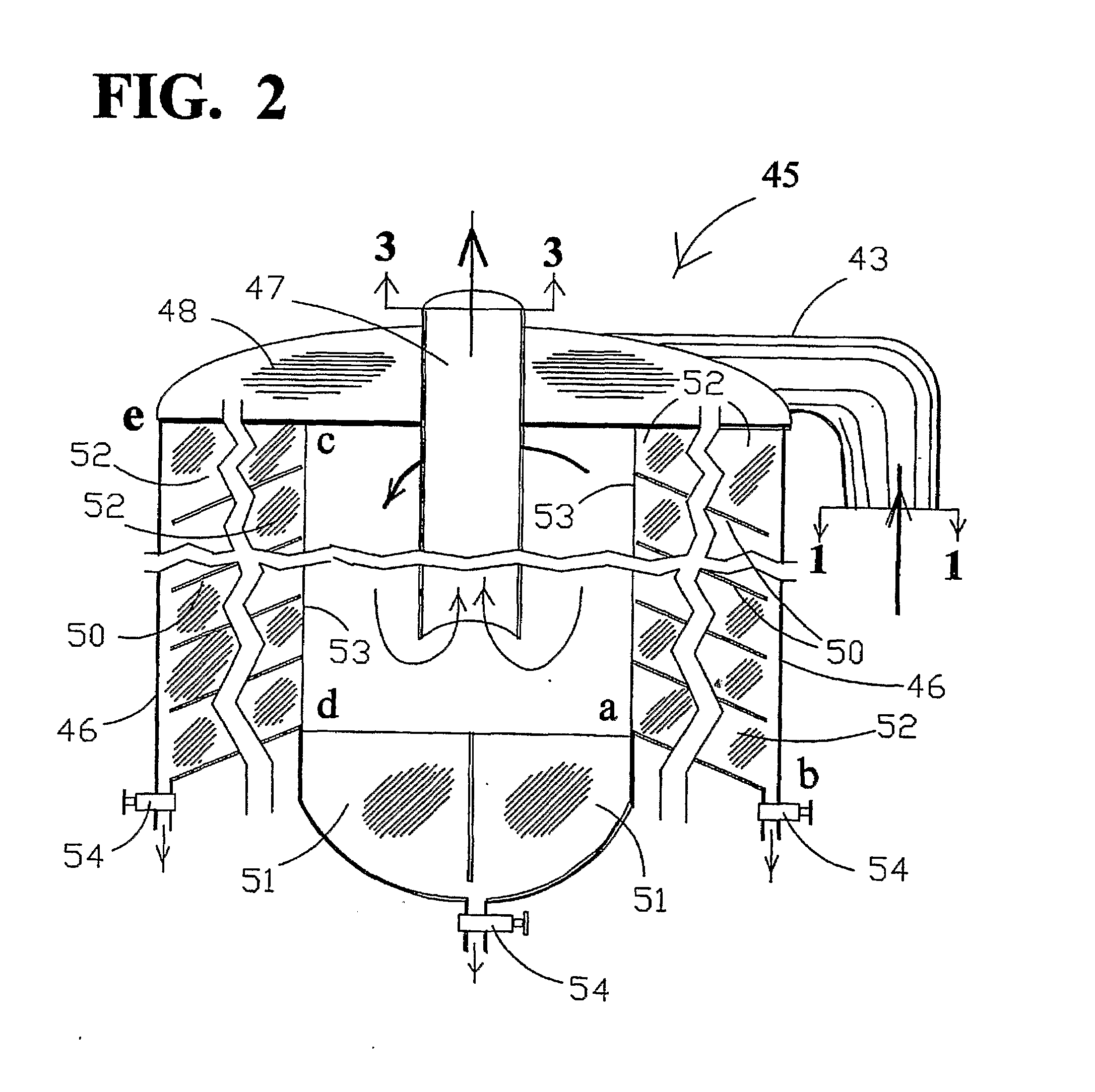

Low Temperature Gasification Facility with a Horizontally Oriented Gasifier

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

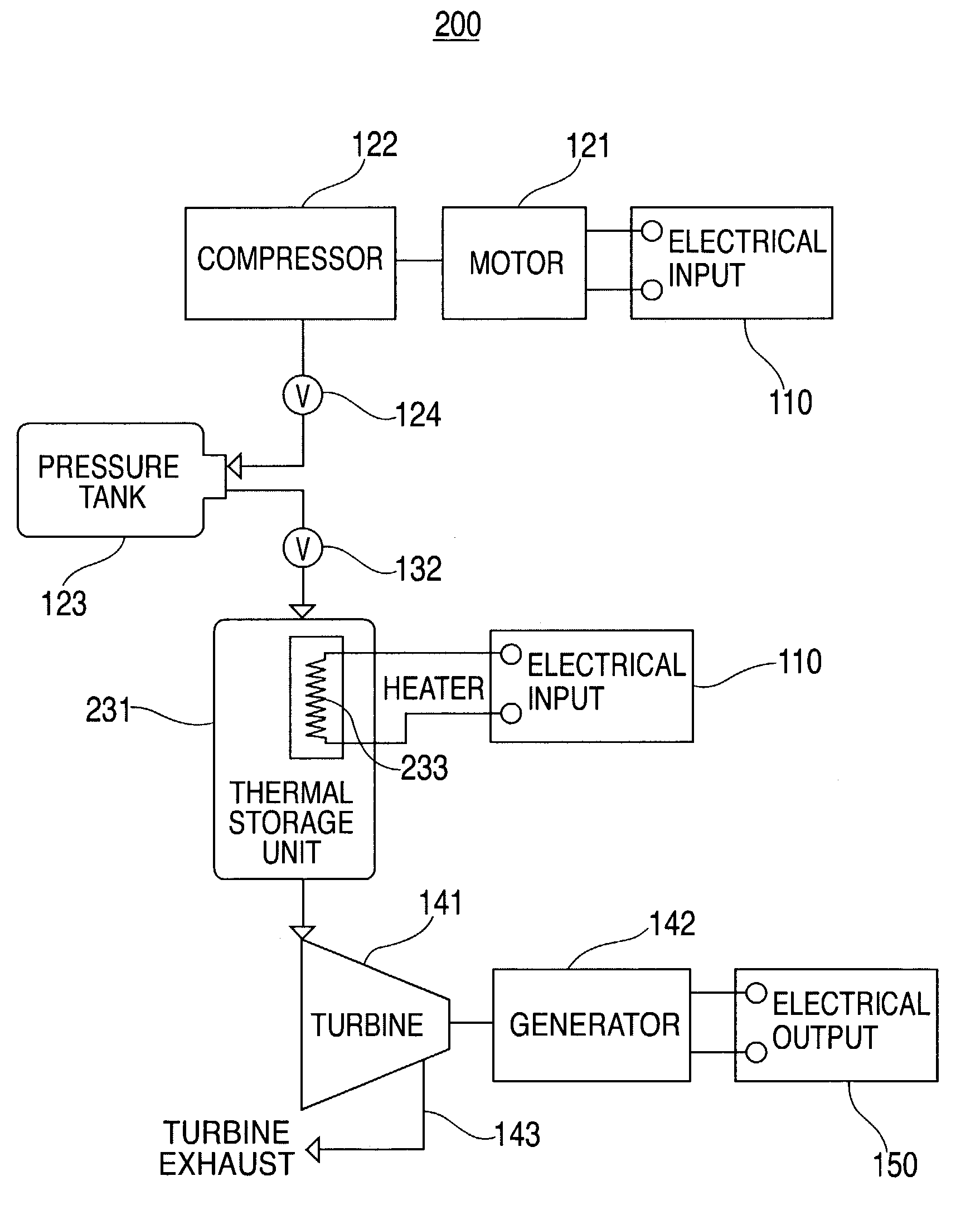

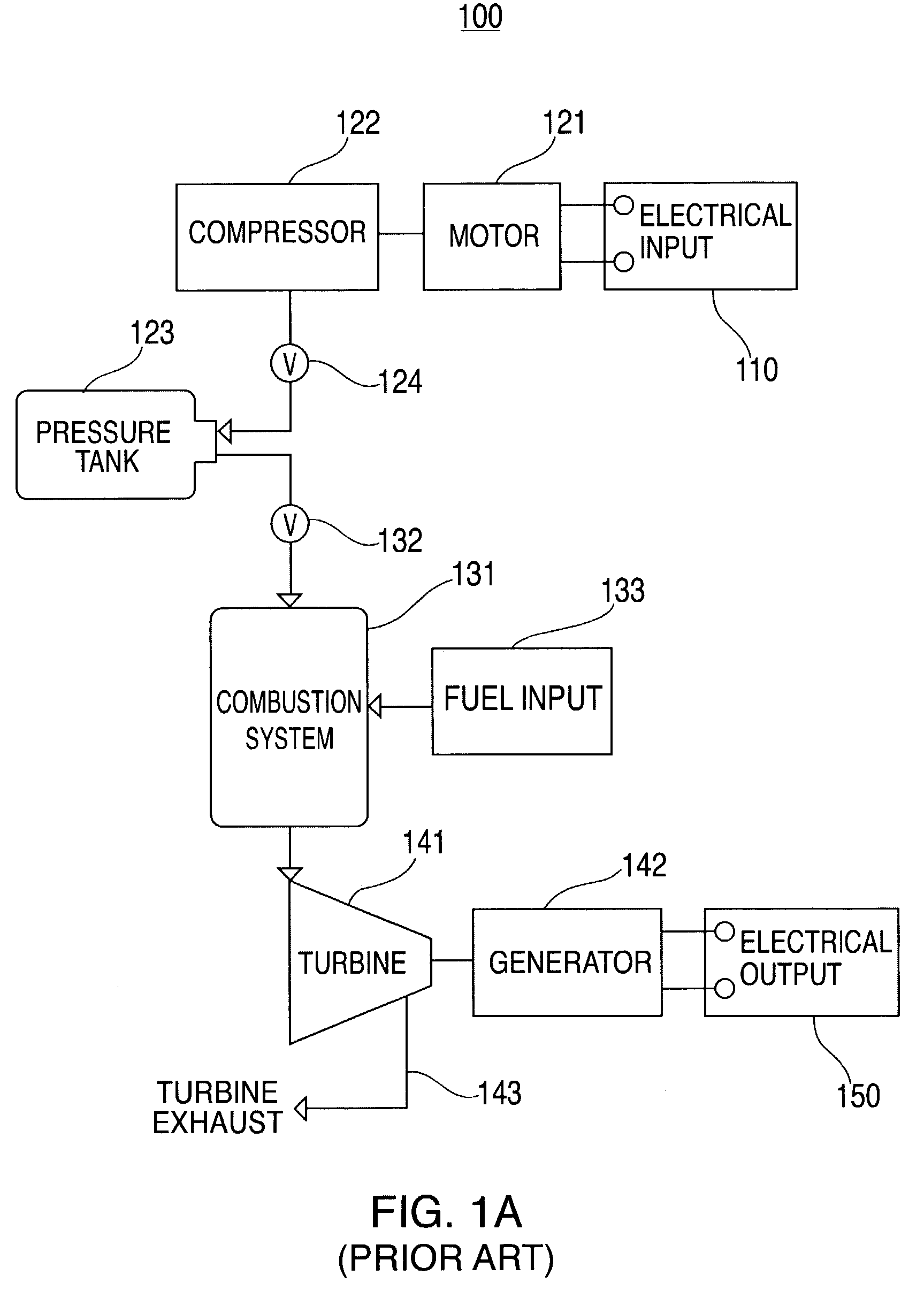

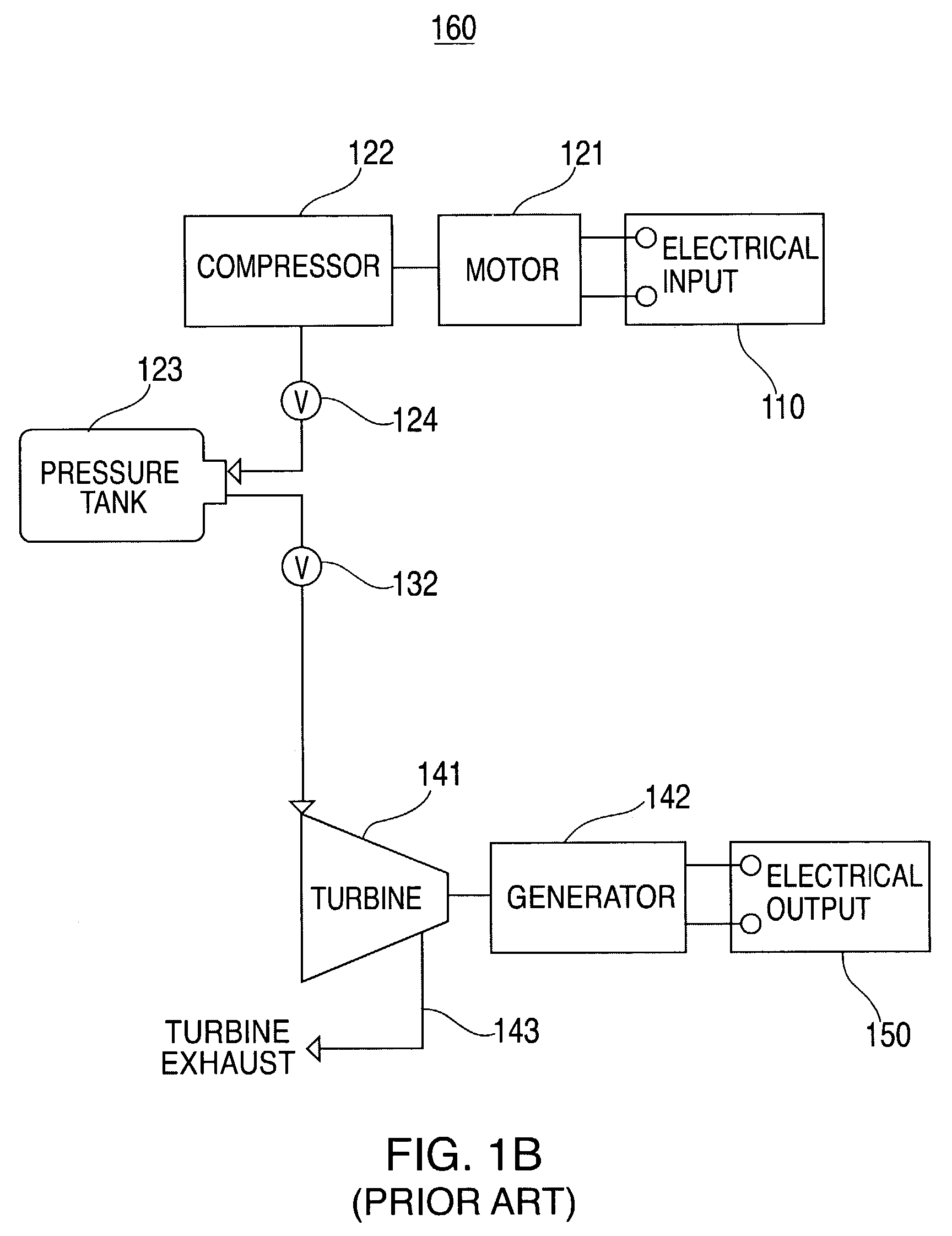

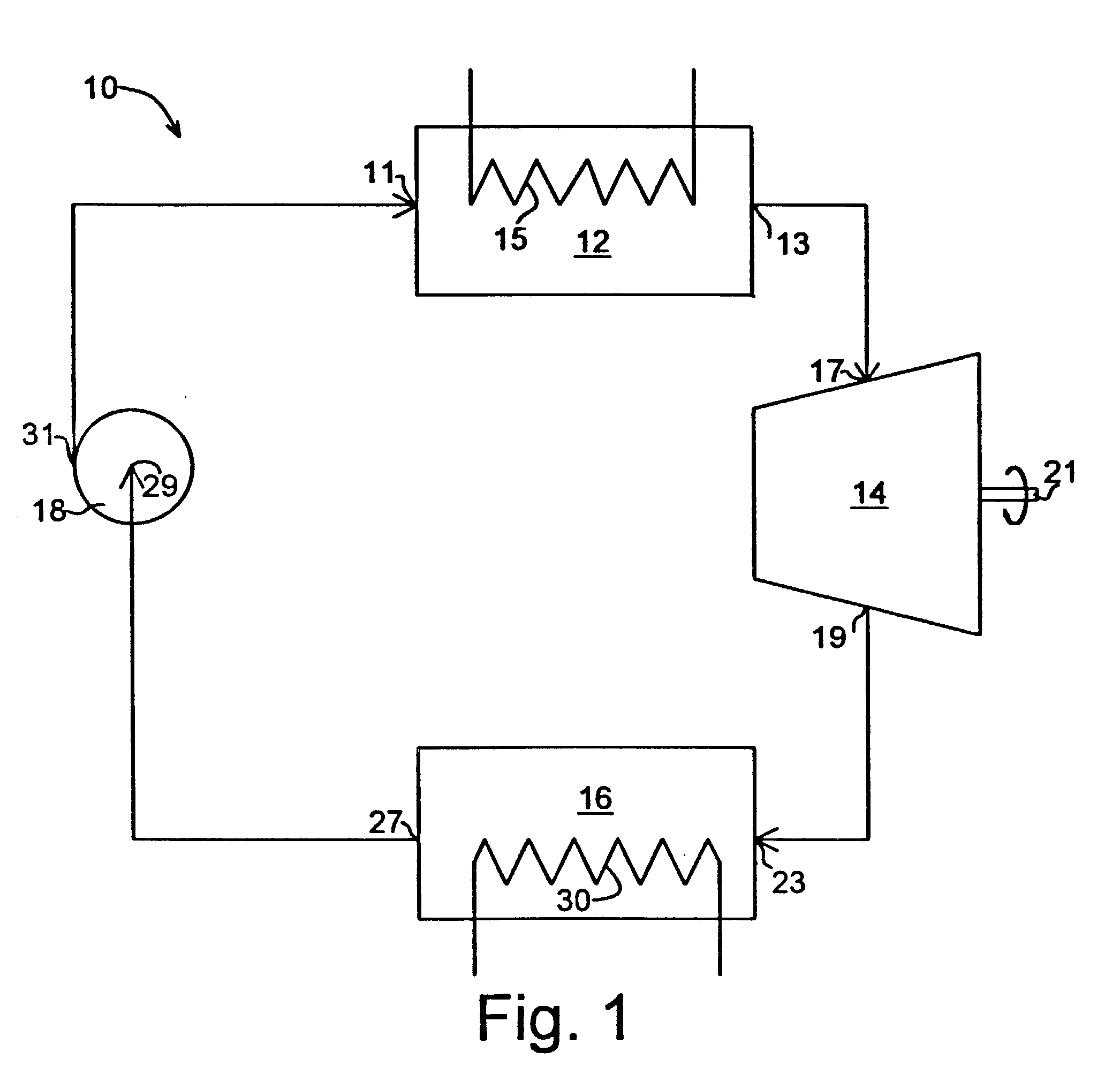

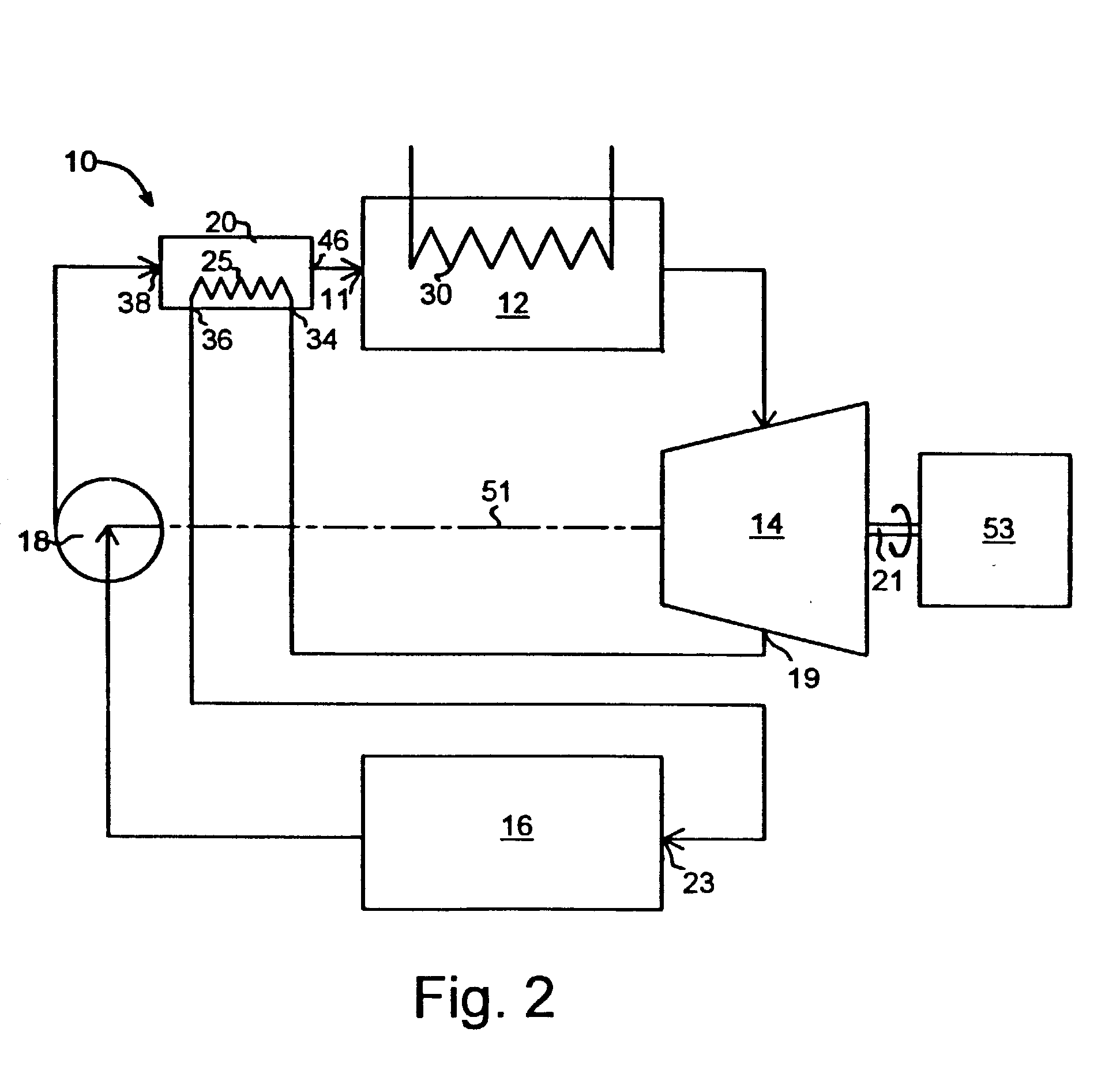

Thermal and compressed air storage system

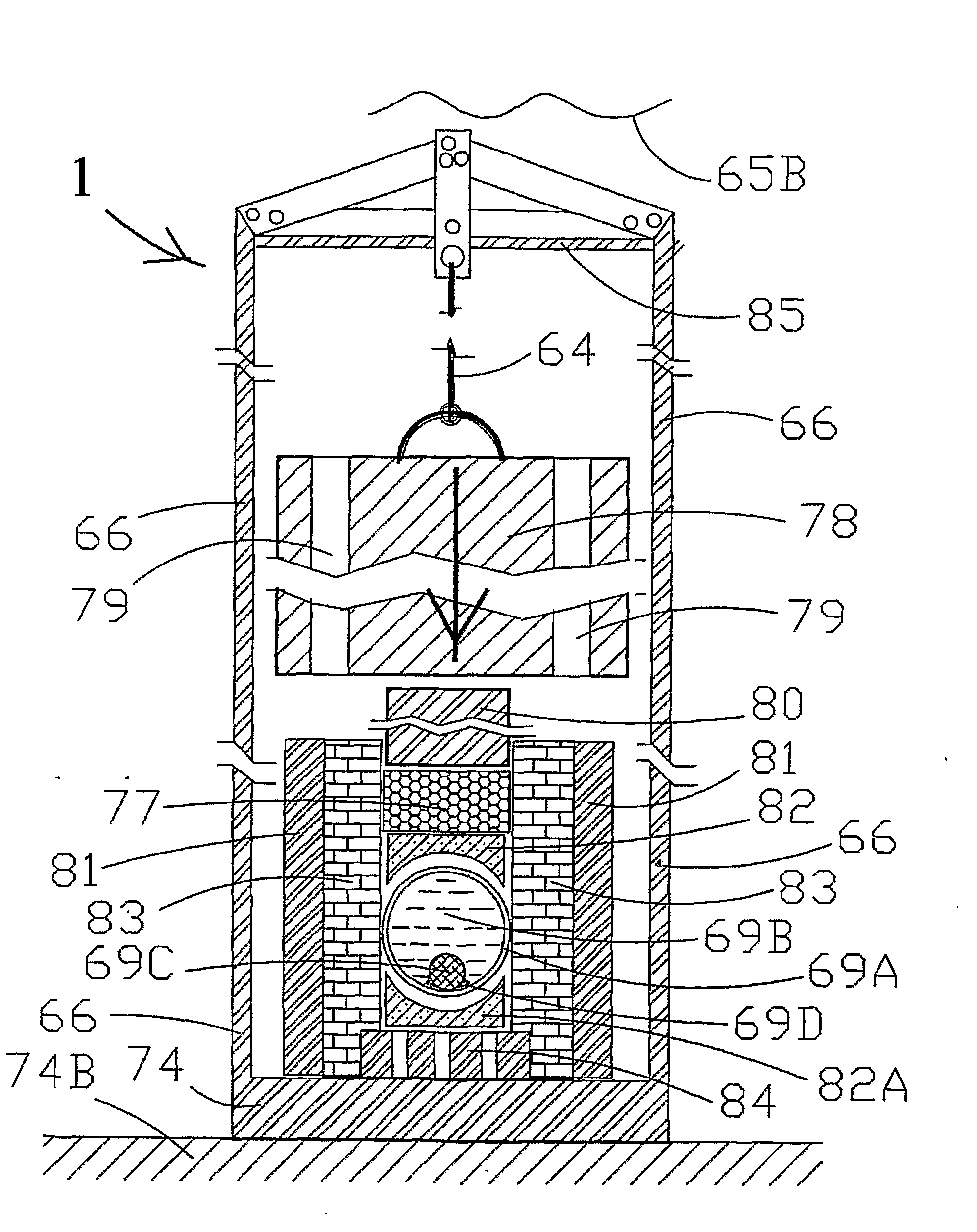

InactiveUS7086231B2Improve efficiencyReduced point source pollutionHeat storage plantsSteam accumulatorsEngineeringTurbine

Combined thermal and compressed air storage systems are provided that utilize an exhaustless heater, such as a thermal storage unit, to provide power with enhanced efficiency. Compressed air is heated by the thermal storage unit prior to entering a turbine, which powers an electrical generator. In various embodiments, ambient air temperature, turbine exhaust or other types of waste heat are used to preheat the compressed air prior to the compressed air entering the thermal storage unit, thereby further increasing system efficiency.

Owner:P10 IND INC

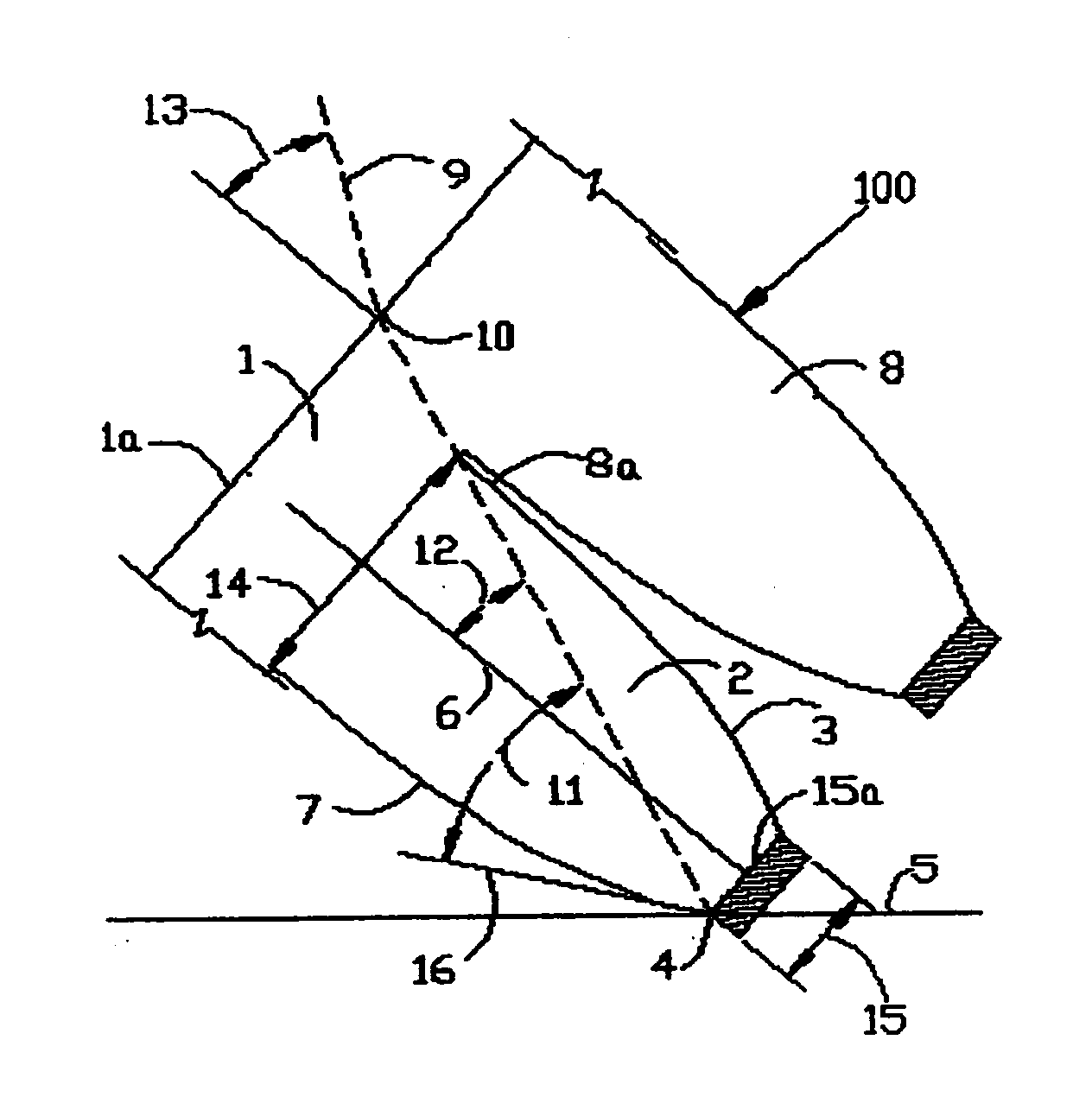

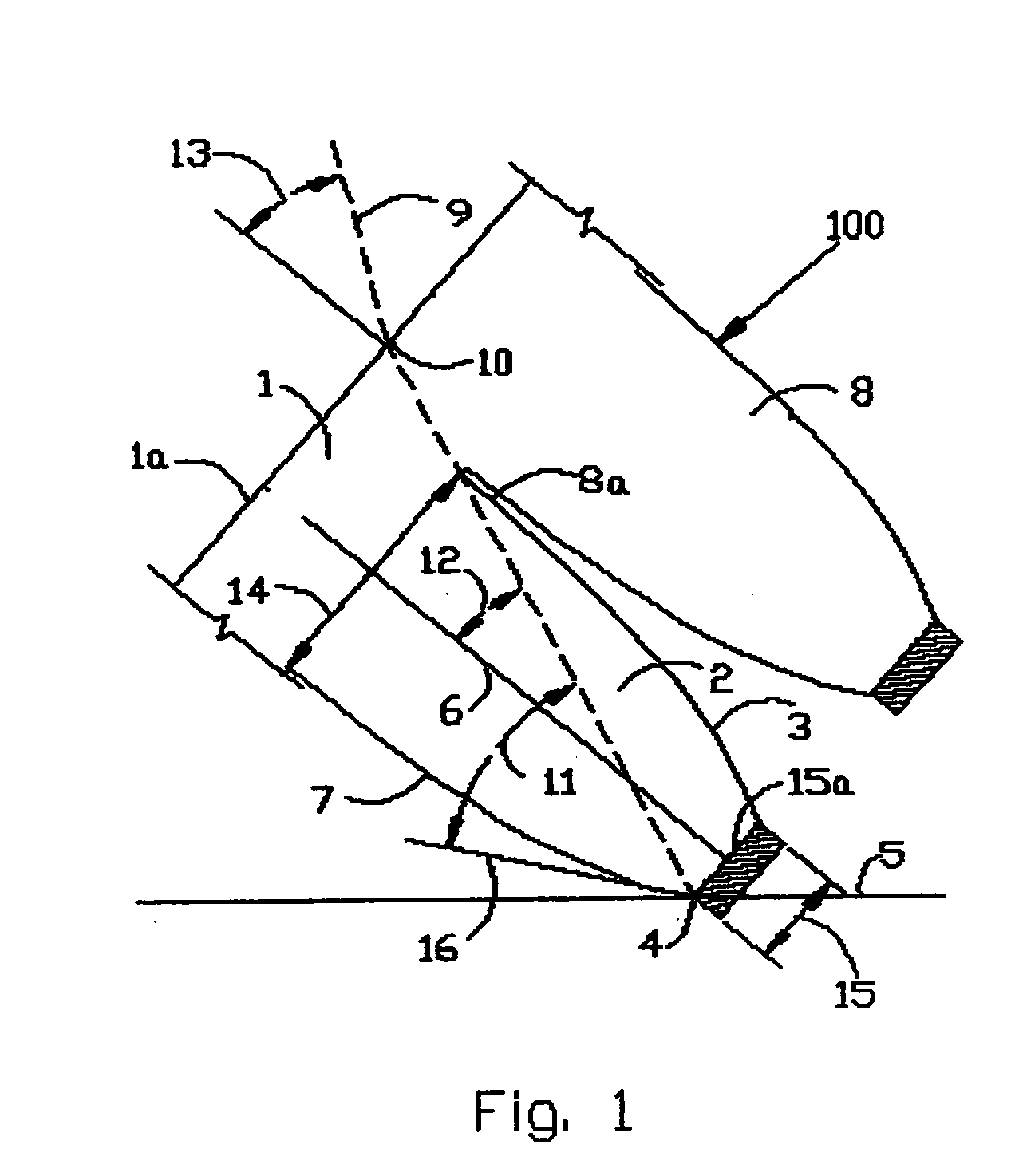

Concentrating solar roofing shingle

InactiveUS20050081909A1Reduce the amount requiredPrevent edgePhotovoltaic supportsSolar heating energyRoof tileEngineering

This invention describes a non-imaging, non-tracking, integrally-formed solar radiation concentrator that passively concentrates both diffuse and direct solar radiation onto photovoltaic cells to produce electricity, incorporating its features into a shingle-like element useful as a roofing material and in other structural applications. The substantially transparent, solar concentrating elements of the invention may also incorporate a system to remove waste energy in the form of heat that is not utilized in the generation of electricity. The invention further provides a thermal energy recovery system including a forced convection air system for removing waste heat from the concentrating shingle assembly and using it, if desired, for building space heat or domestic water heating.

Owner:STELLARIS

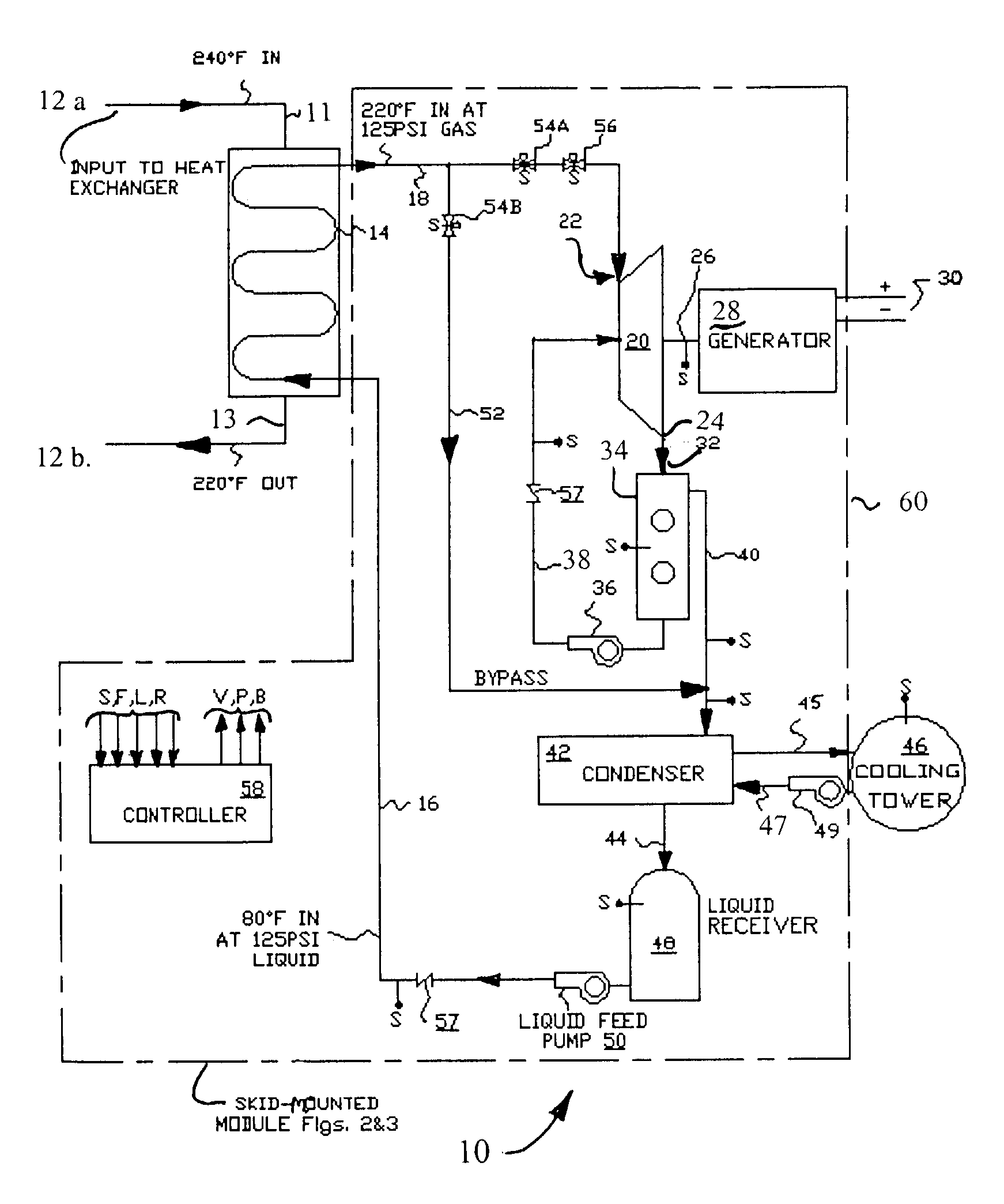

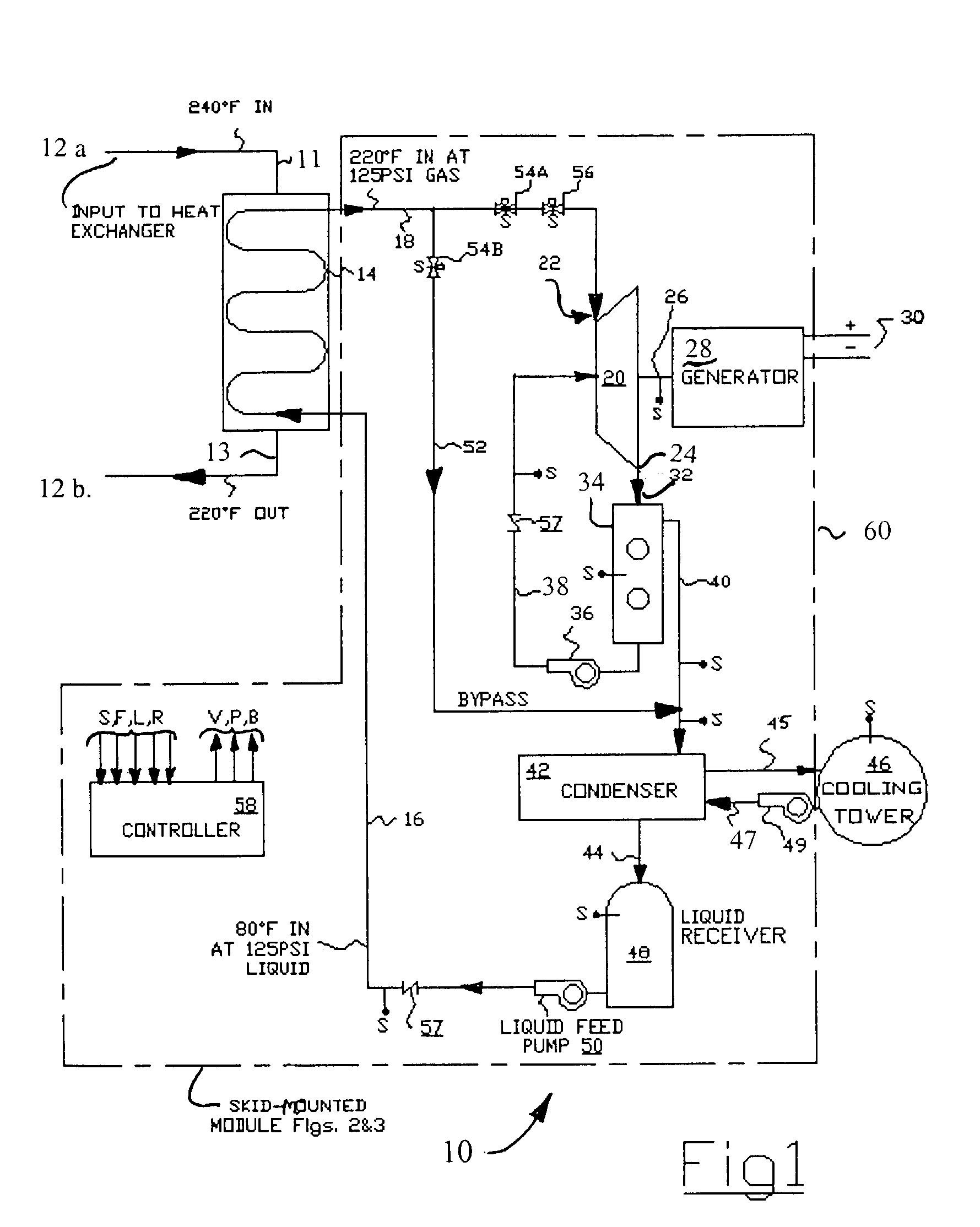

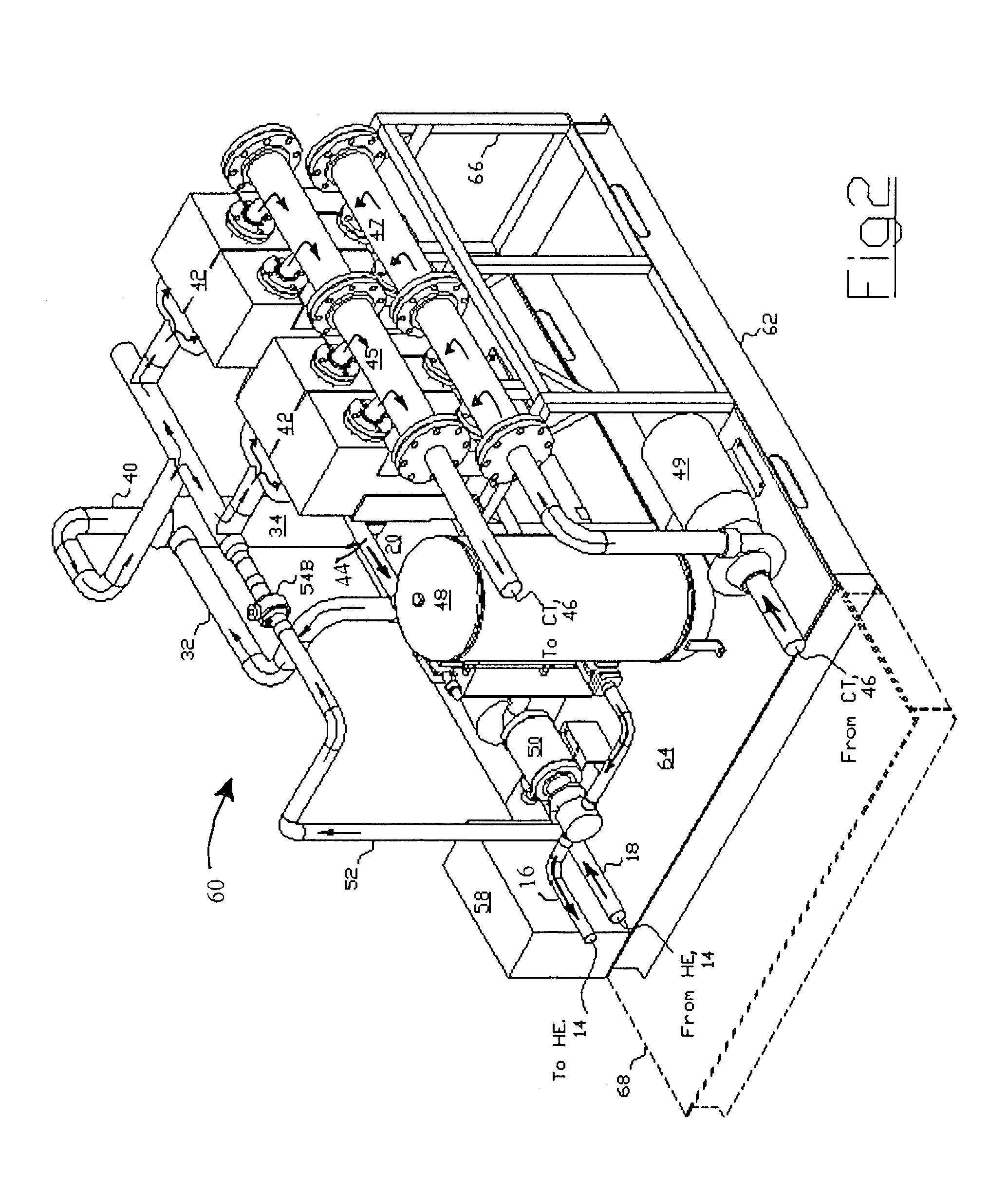

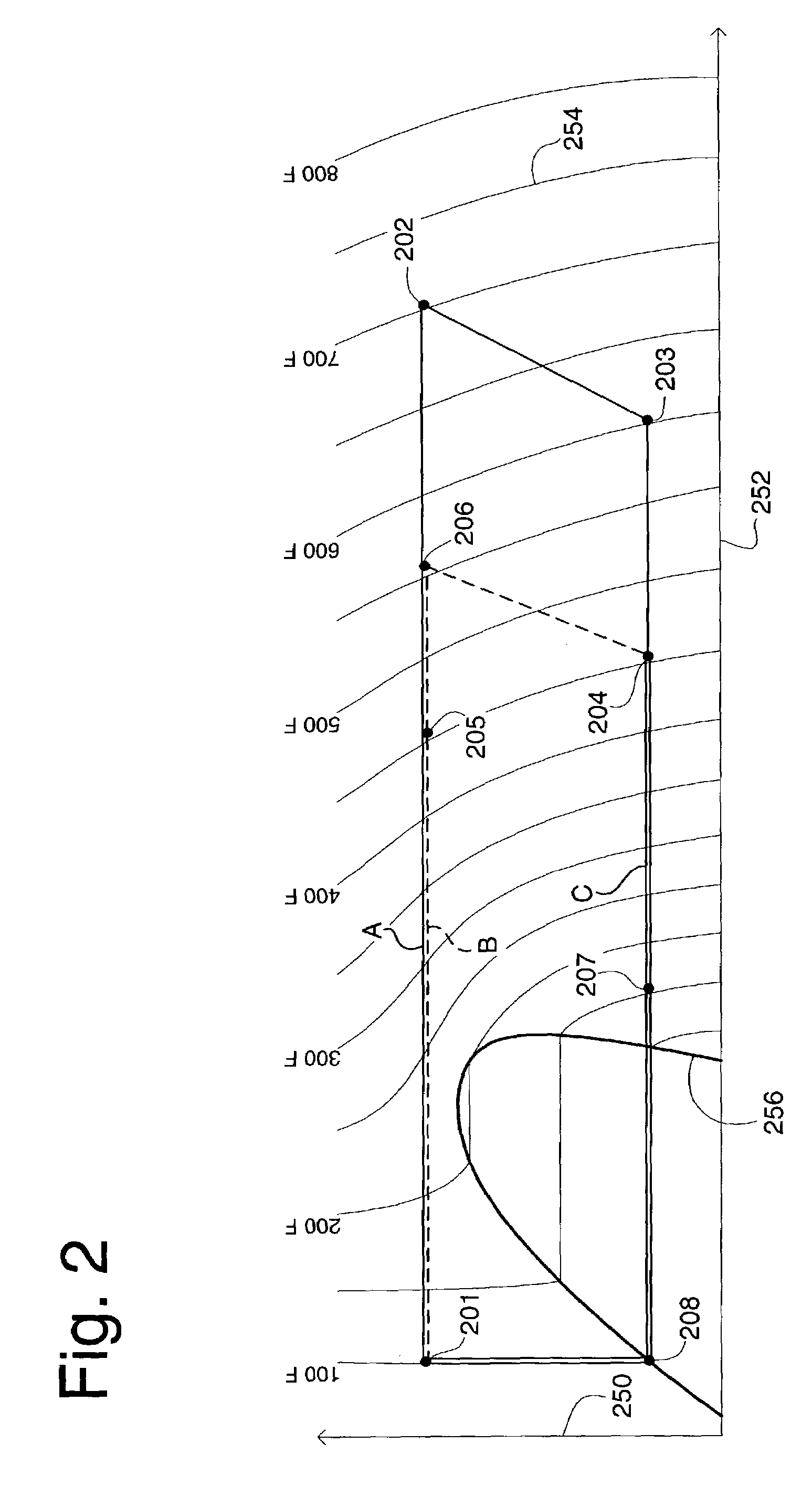

System and method for generation of electricity and power from waste heat and solar sources

InactiveUS6981377B2Conveniently skid-mountableEasy to installAuxillary drivesFrom solar energyThermal energyEngineering

Recovery of electric power from low-grade waste heat / solar energy, comprising a closed-cycle charged refrigerant loop. Pressurized refrigerant fluid is pumped at ambient temperature through a heat exchanger connected to a waste heat / solar source to extract heat energy during conversion to a high pressure gas. Heated / pressurized refrigerant gas is inlet into an expander to power an output shaft during the expansion of the fluid to a cooled gas at approximately 0 psig. Cooled gaseous refrigerant is condensed to a liquid at low pressure and ambient temperature, and recycled under pressure to the heat exchanger. The expander is a reverse-plumbed gas compressor; the pressurized, hot refrigerant gas is inlet at what is ordinarily its outlet, and the normal inlet becomes the expander end. The refrigerant gas mass flow pressure / temperature drop spins the expander shaft for direct mechanical power take-off, or coupling to a synchronous or inductive generator to produce electricity.

Owner:OUTFITTER ENERGY

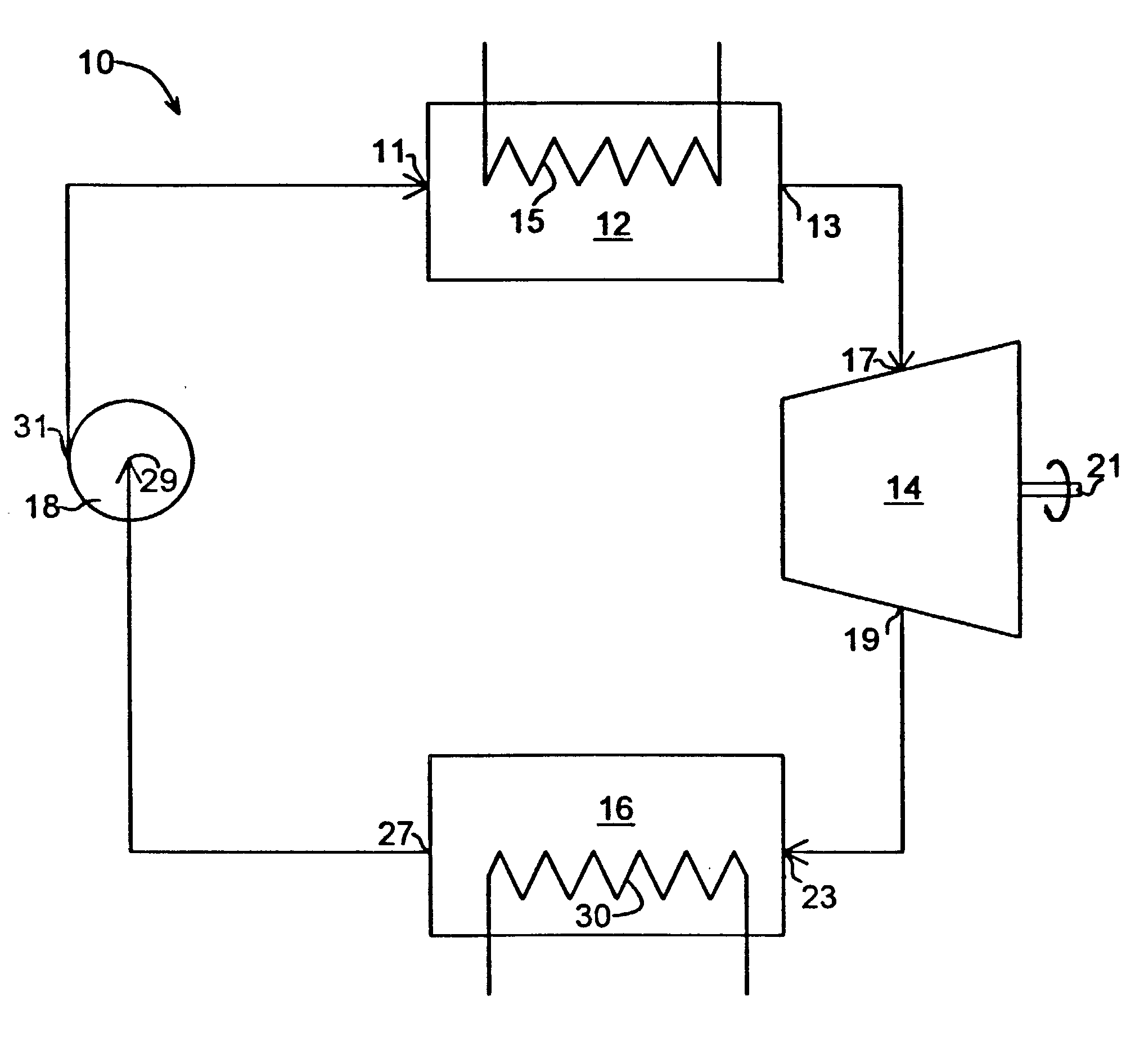

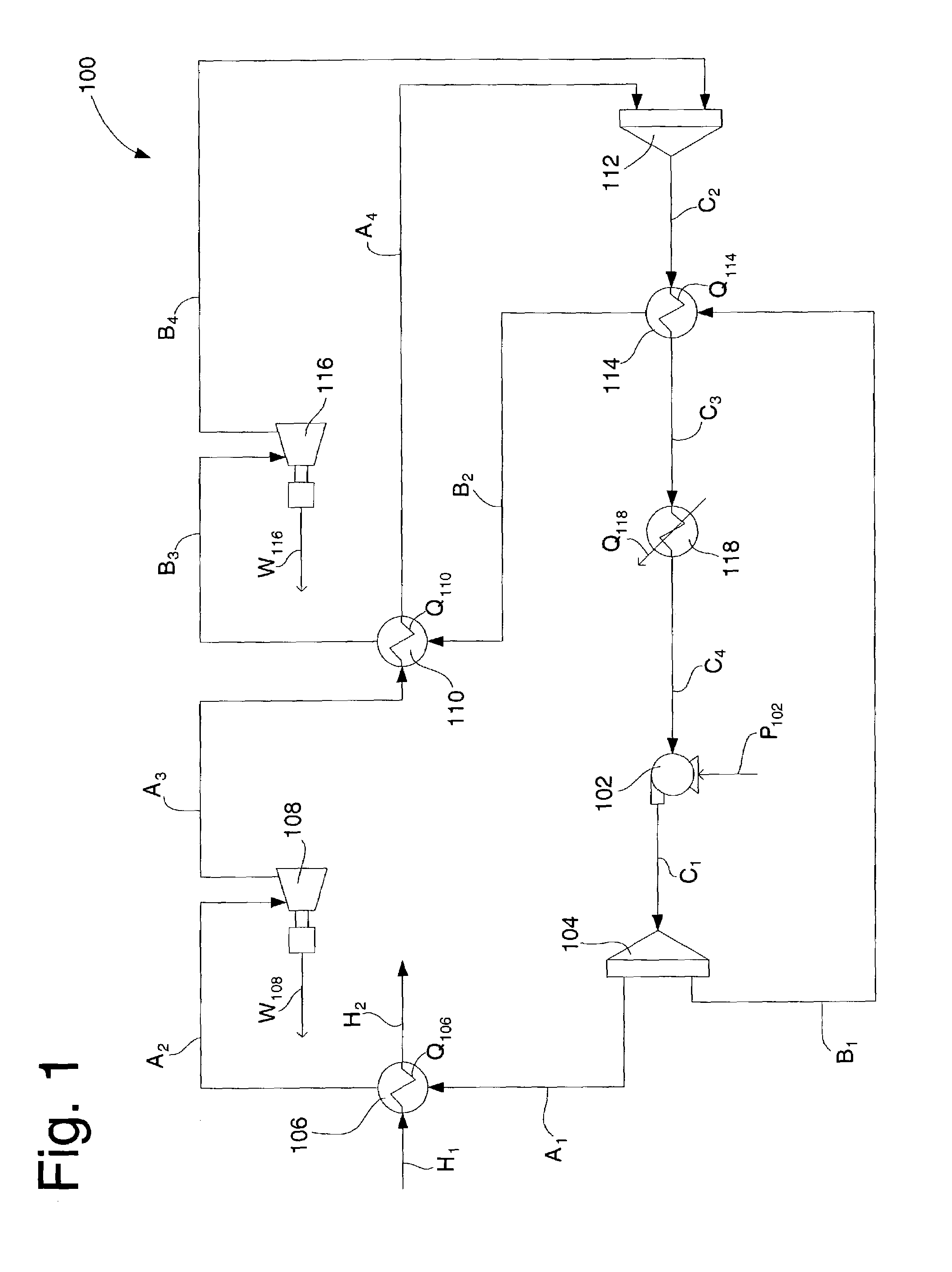

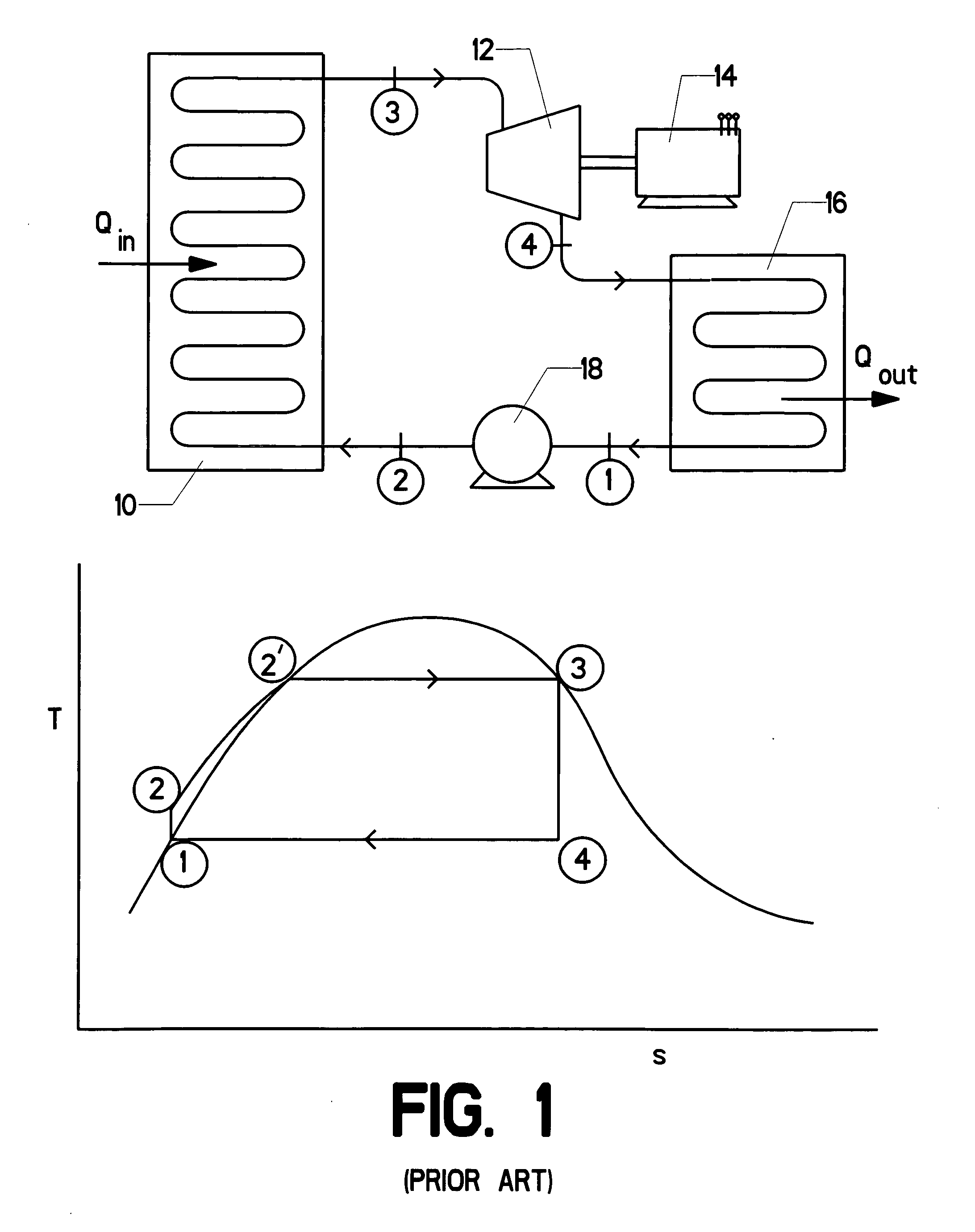

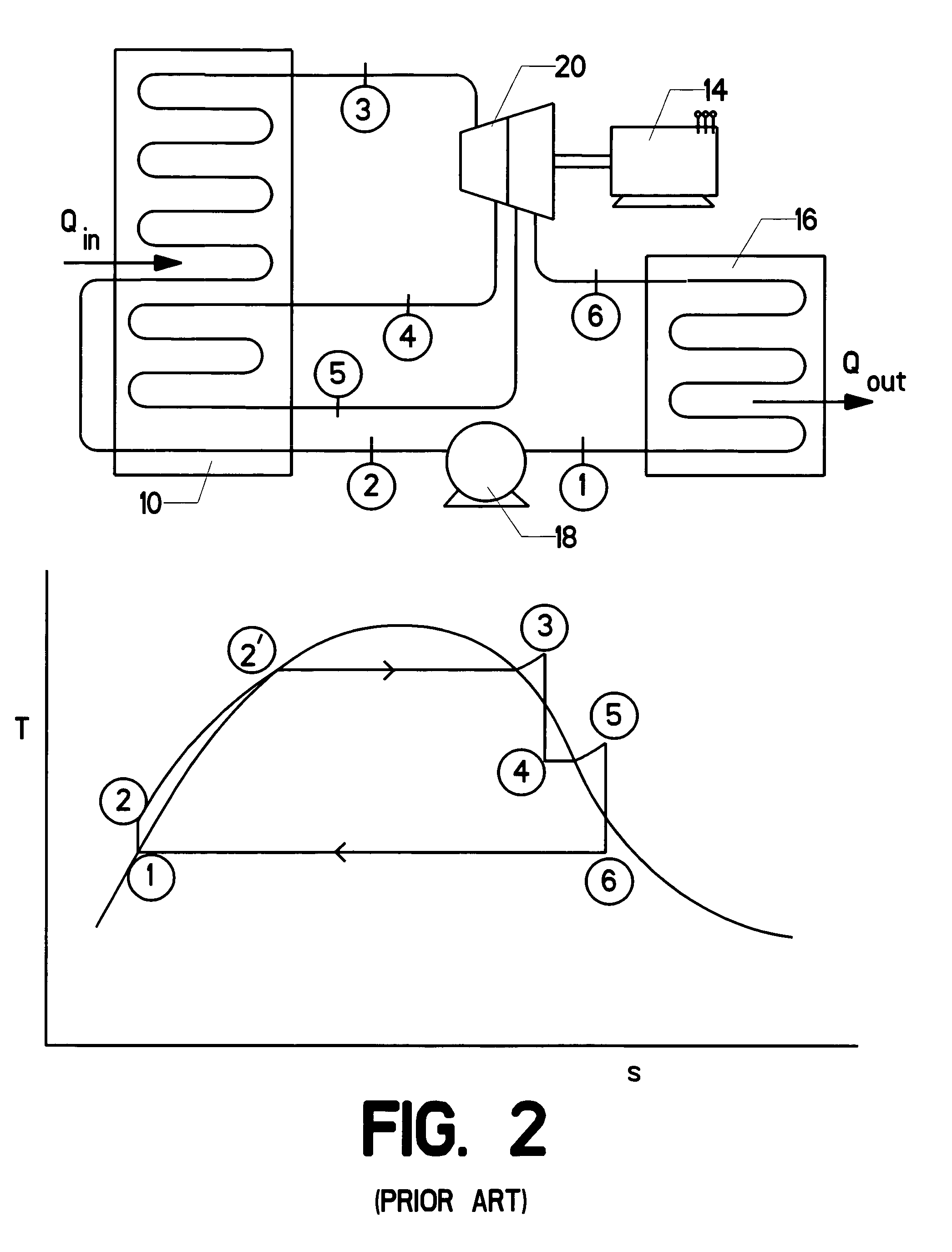

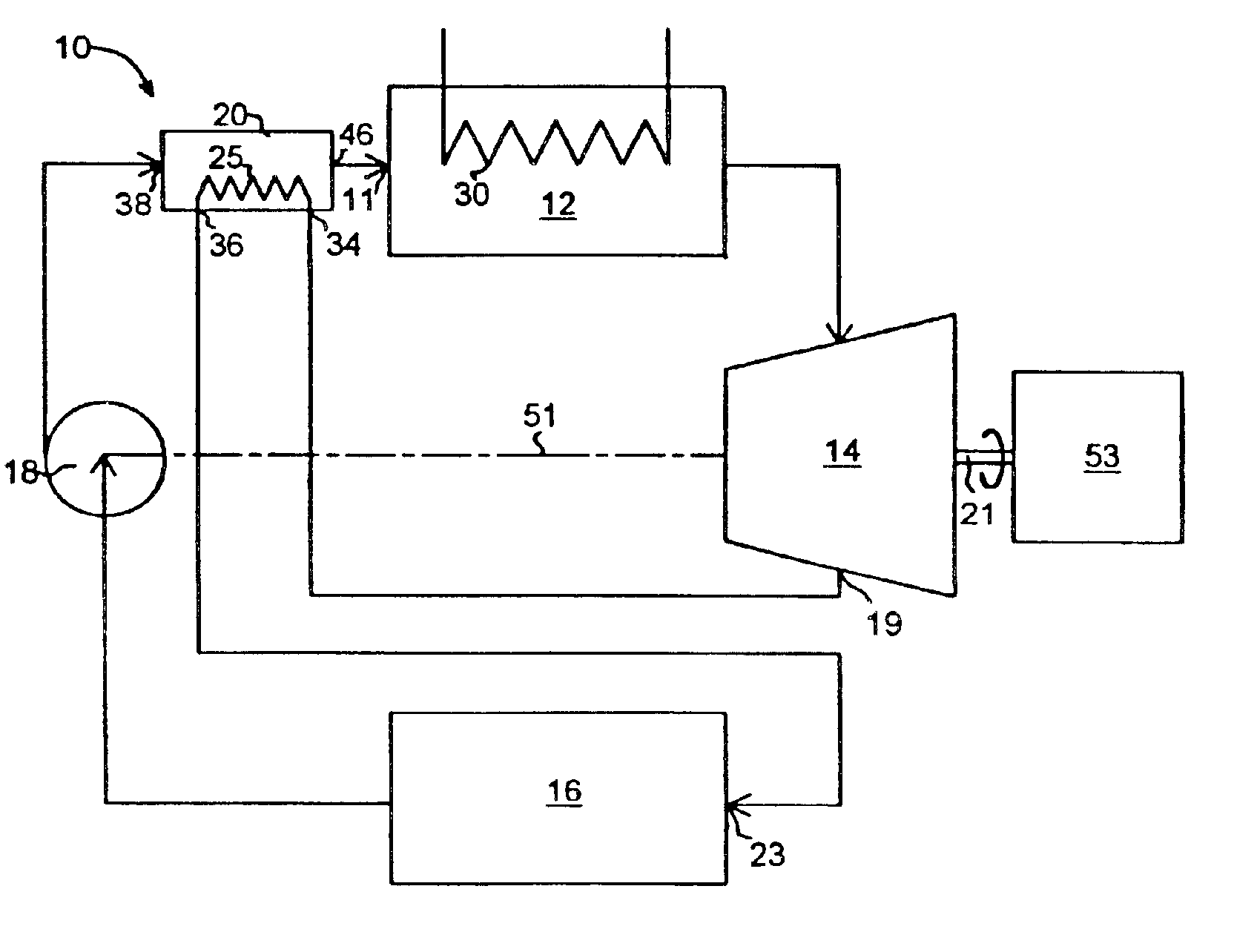

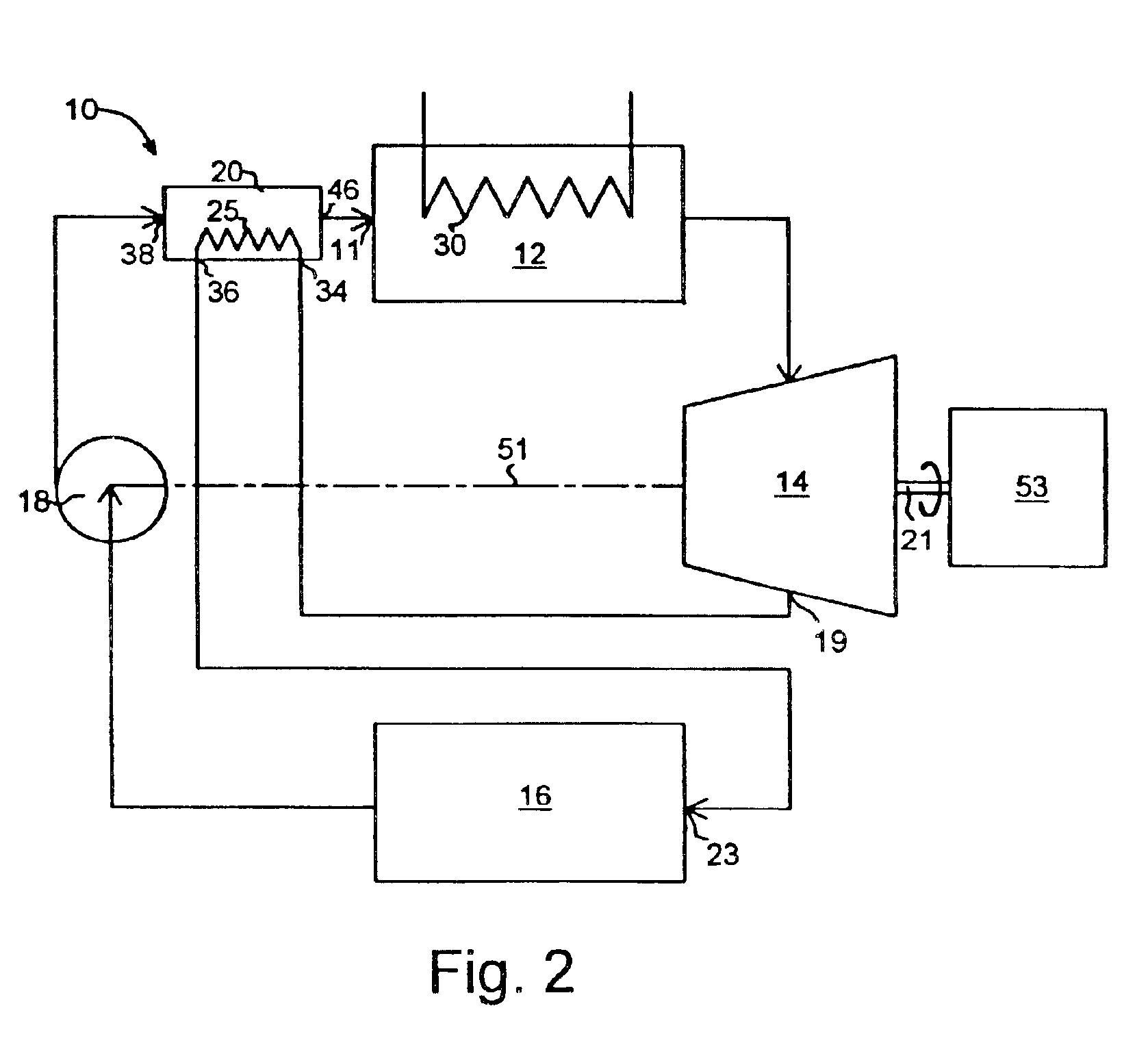

Heat engine

InactiveUS20030000213A1Easy to operateBoilers/analysersClimate change adaptationWorking fluidEngineering

A heat engine (10) achieves operational efficiencies by: 1) recovering waste heat from heat engine expander (14) to preheat heat-engine working fluid, 2) using super-heated working fluid from compressor (402) to pre-heat heat-engine working fluid, and 3) using reject heat from condenser (93) and absorber (95) to heat the heat-engine boiler (12). A dual heat-exchange generator (72) affords continuous operation by using gas-fired heat exchanger (212) to heat generator (72) when intermittent heat source (40), e.g., solar, is incapable of heating generator (72). The combination of heat engine (10) and absorption and compression heat transfer devices (60, 410) allows use of low-temperature heat sources such as solar, bio-mass, and waste heat to provide refrigeration, heating, work output including pumping and heating of subterranean water and electrical generation.

Owner:OHIO STATE INNOVATION FOUND

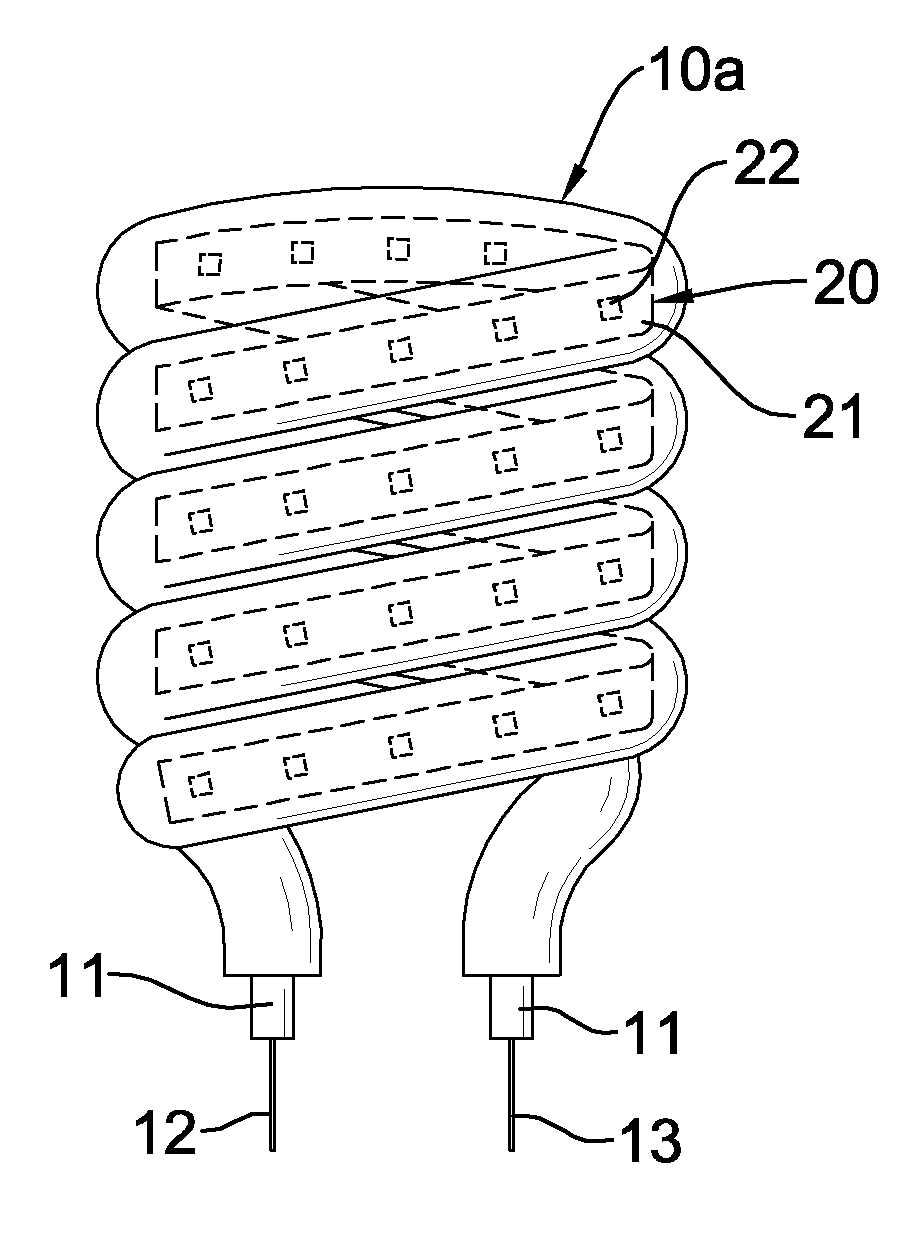

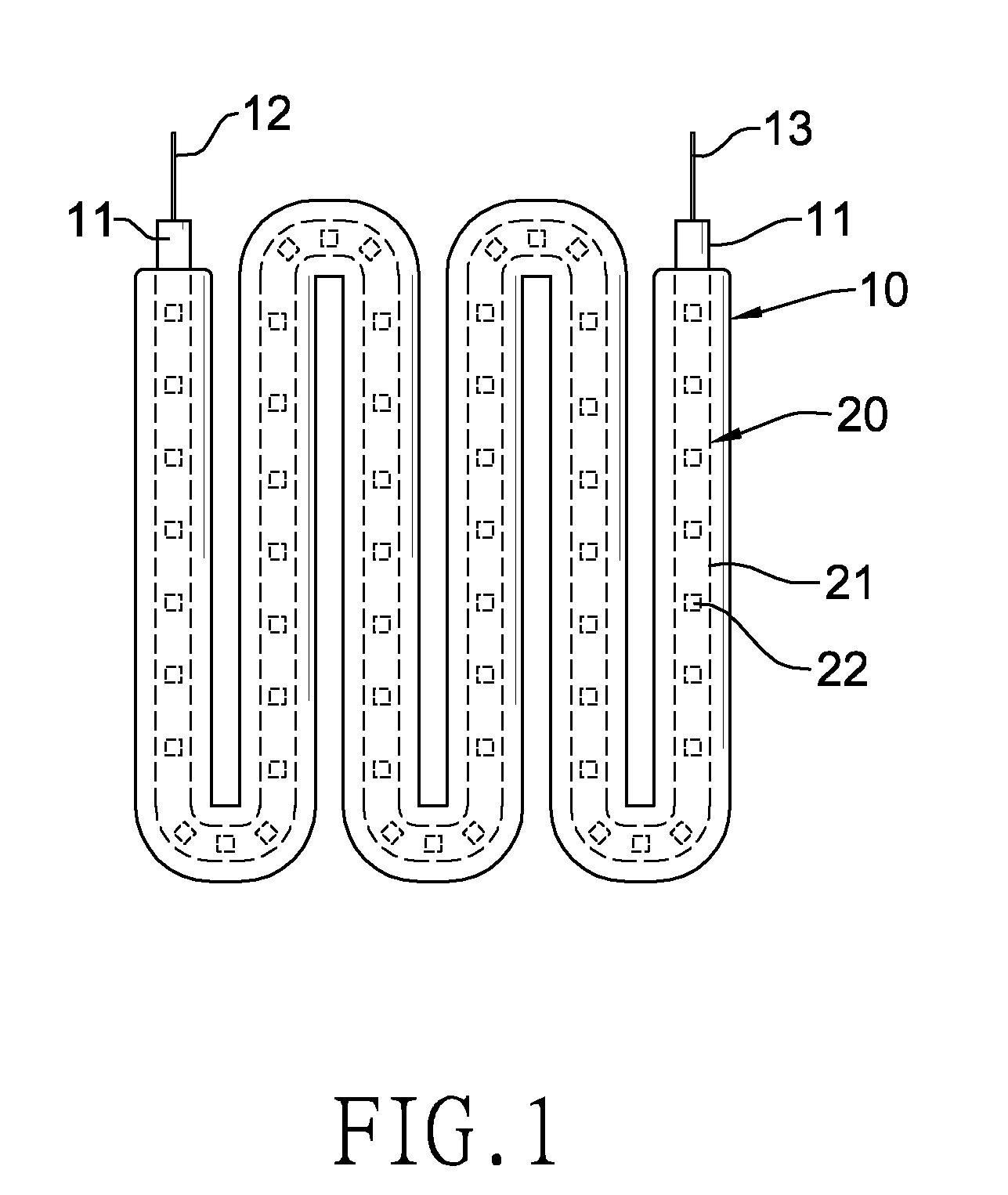

Bending LED bulb

ActiveUS20110050073A1Increase brightnessPoint-like light sourceElongate light sourcesEngineeringFlexible electronics

A bending LED bulb has a transparent bending tube and a flexible LED strip. The flexible LED strip has a flexible printed circuit board (PCB) and a plurality of LEDs mounted on the flexible PCB and is inserted and fixed in the transparent bending tube. As the LEDs are sequentially mounted on the flexible PCB, the LEDs are adjacent to a wall of the transparent bending tube, and are equally spaced. Accordingly, a lumen value of the bending LED bulb can be raised, and heat generated by the LEDs can be dissipated out through the wall of the transparent bending tube to avoid high temperature arising from accumulation of the waste heat.

Owner:LIQUIDLEDS LIGHTING

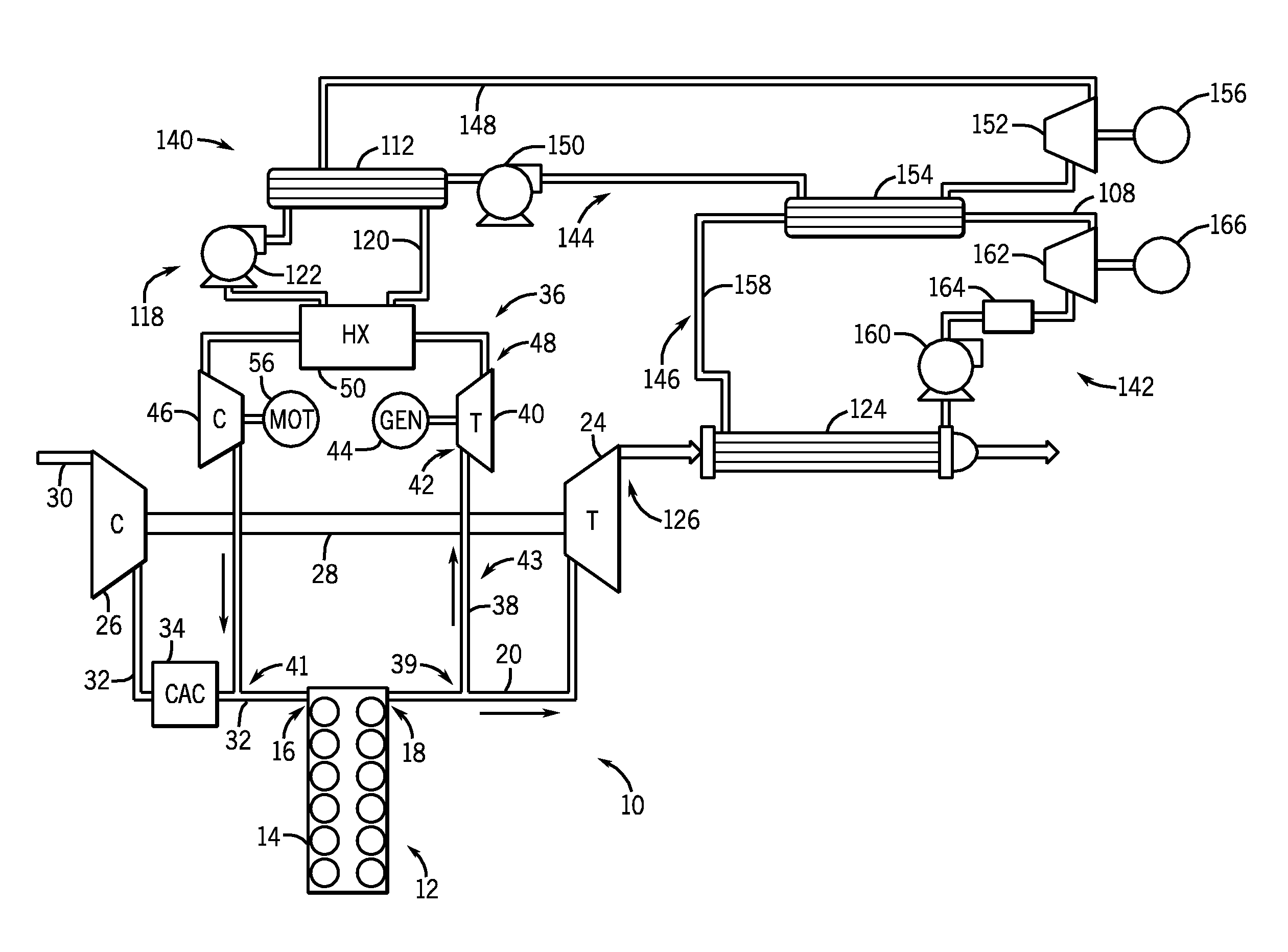

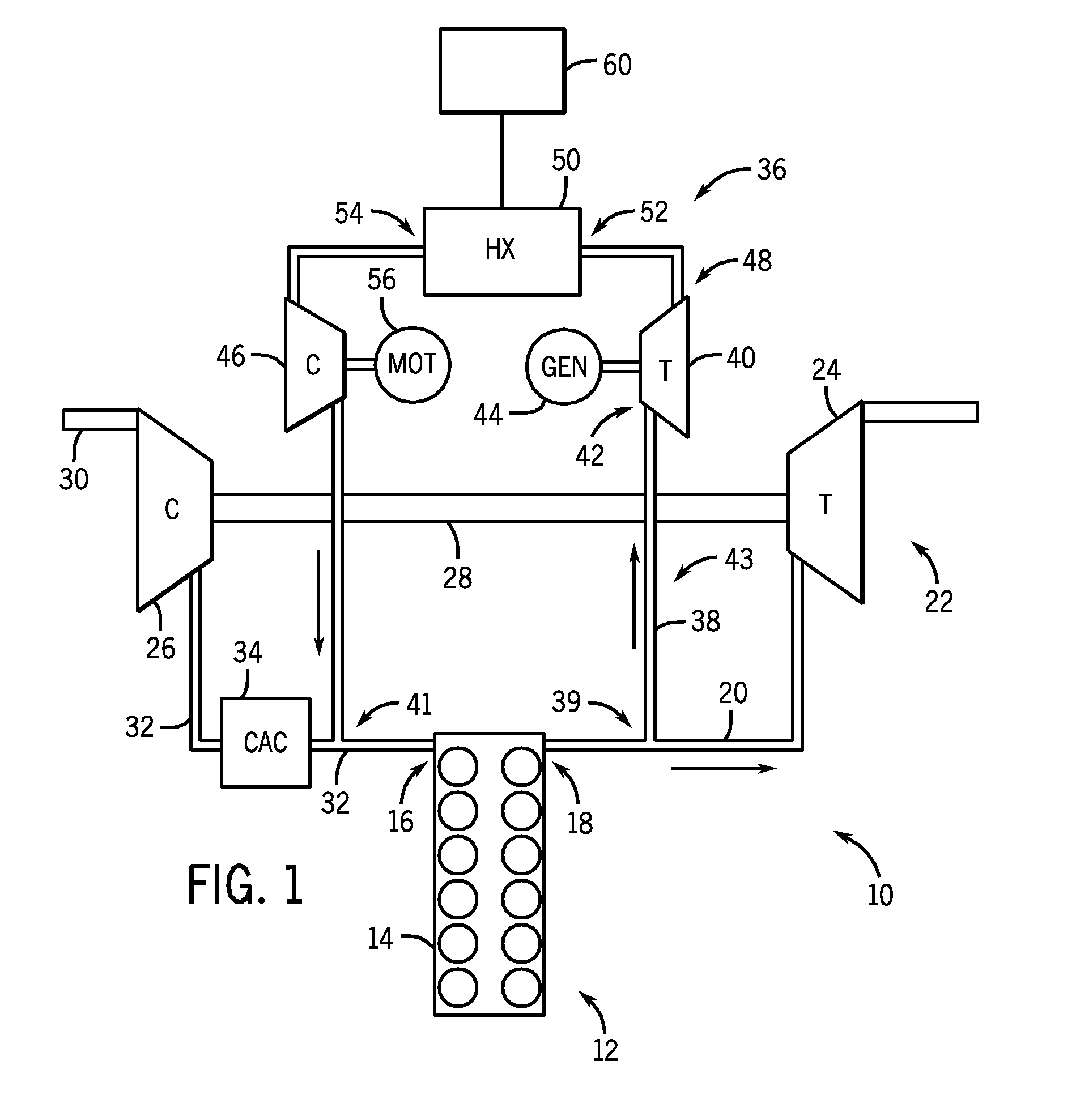

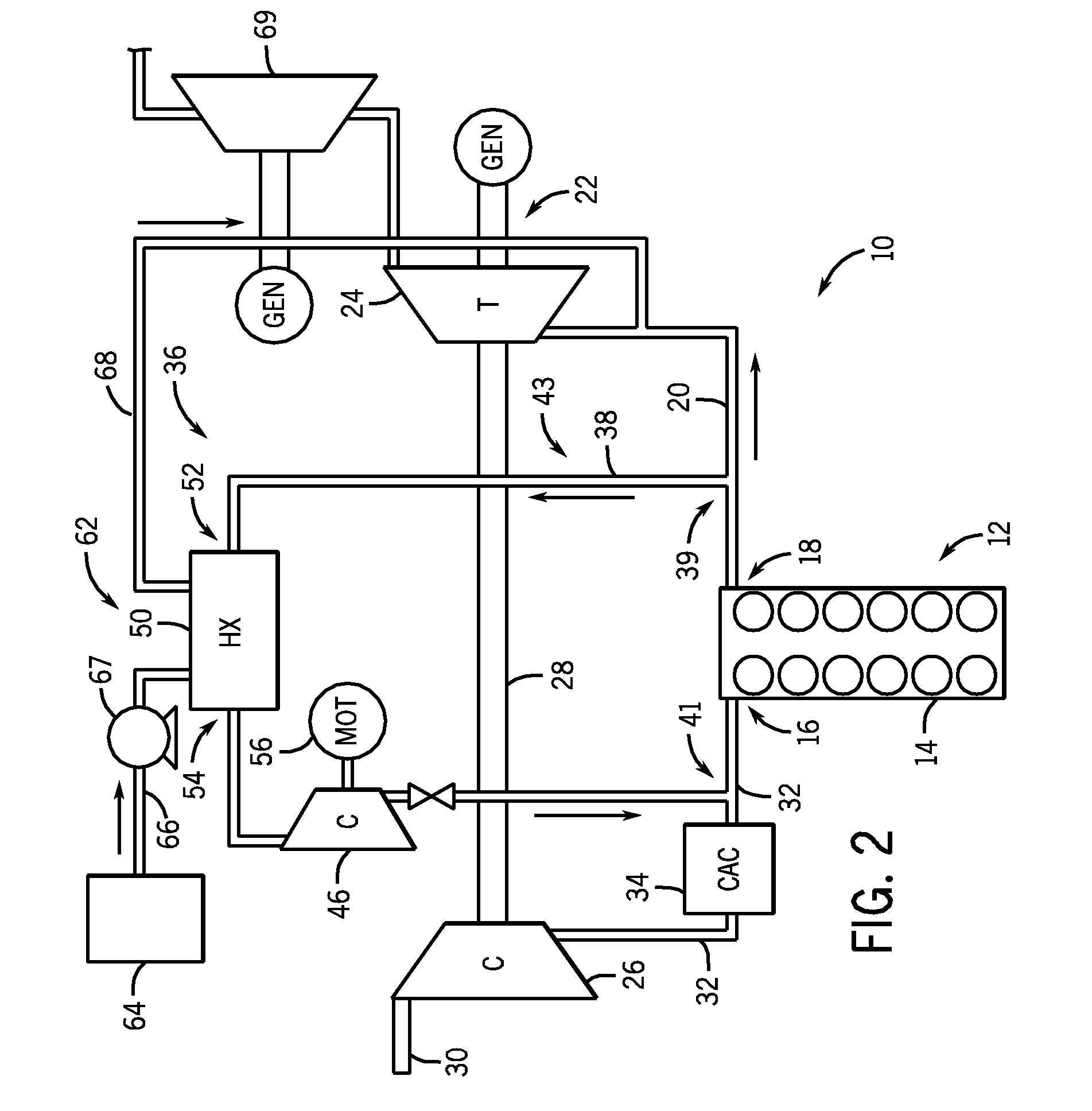

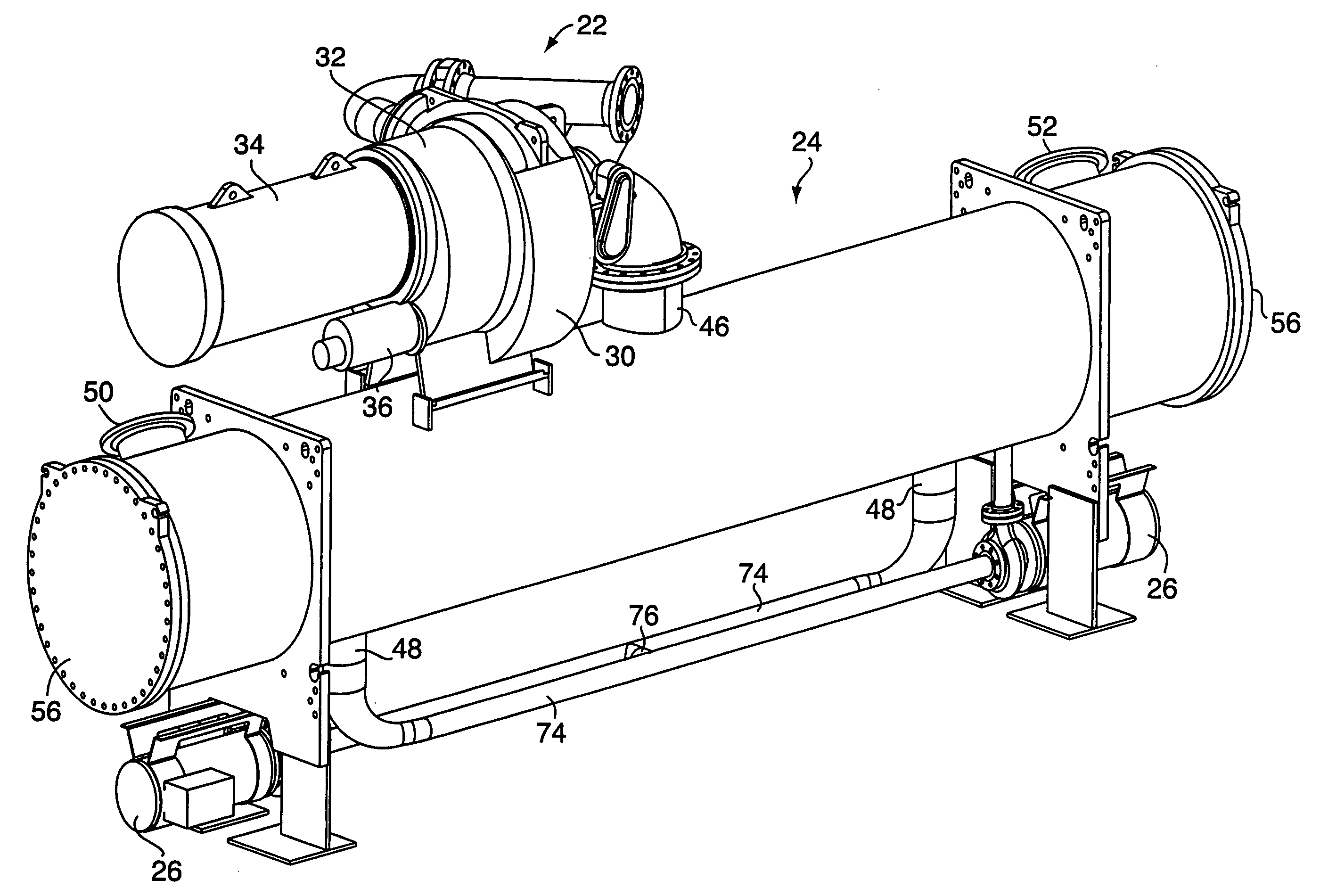

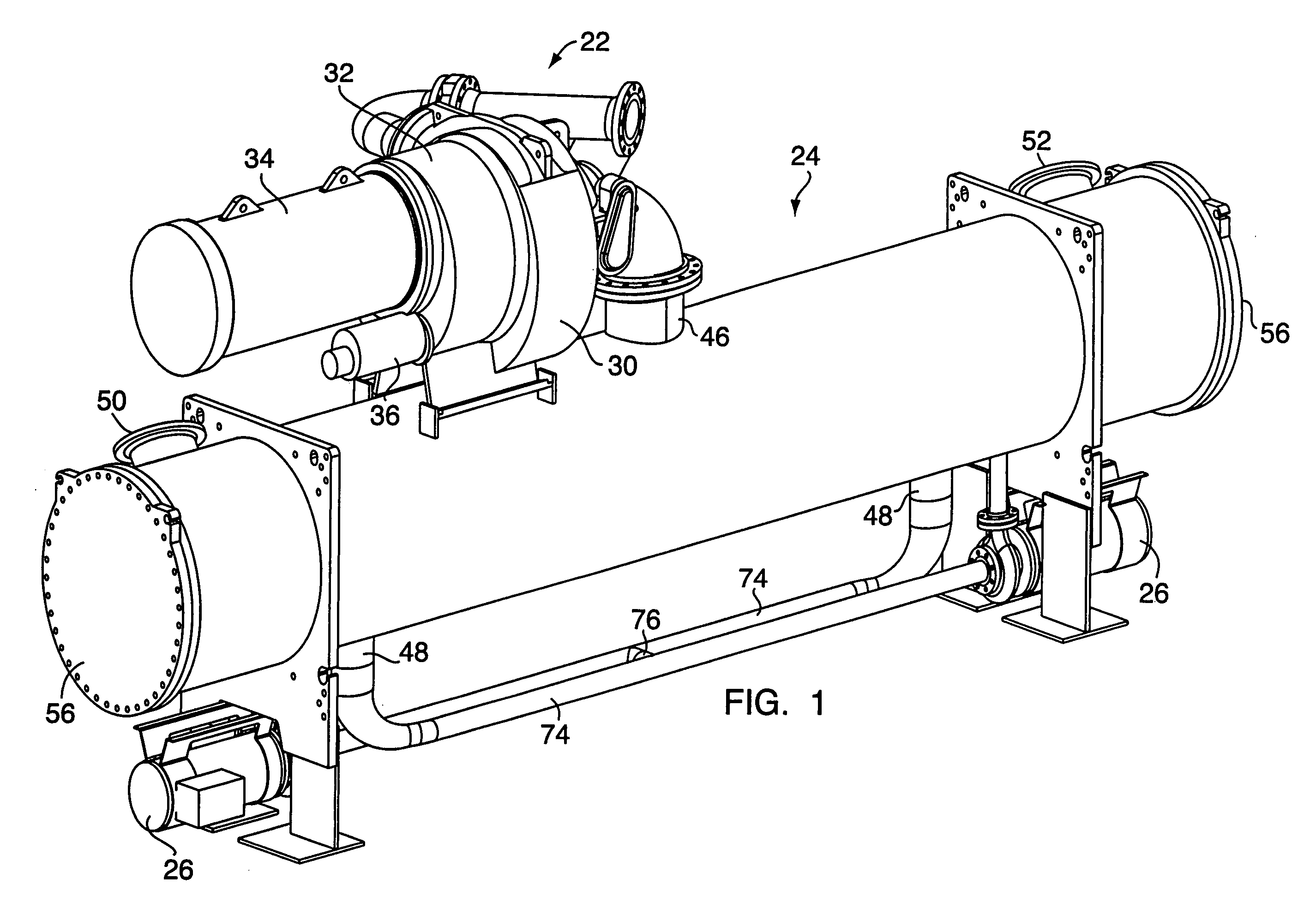

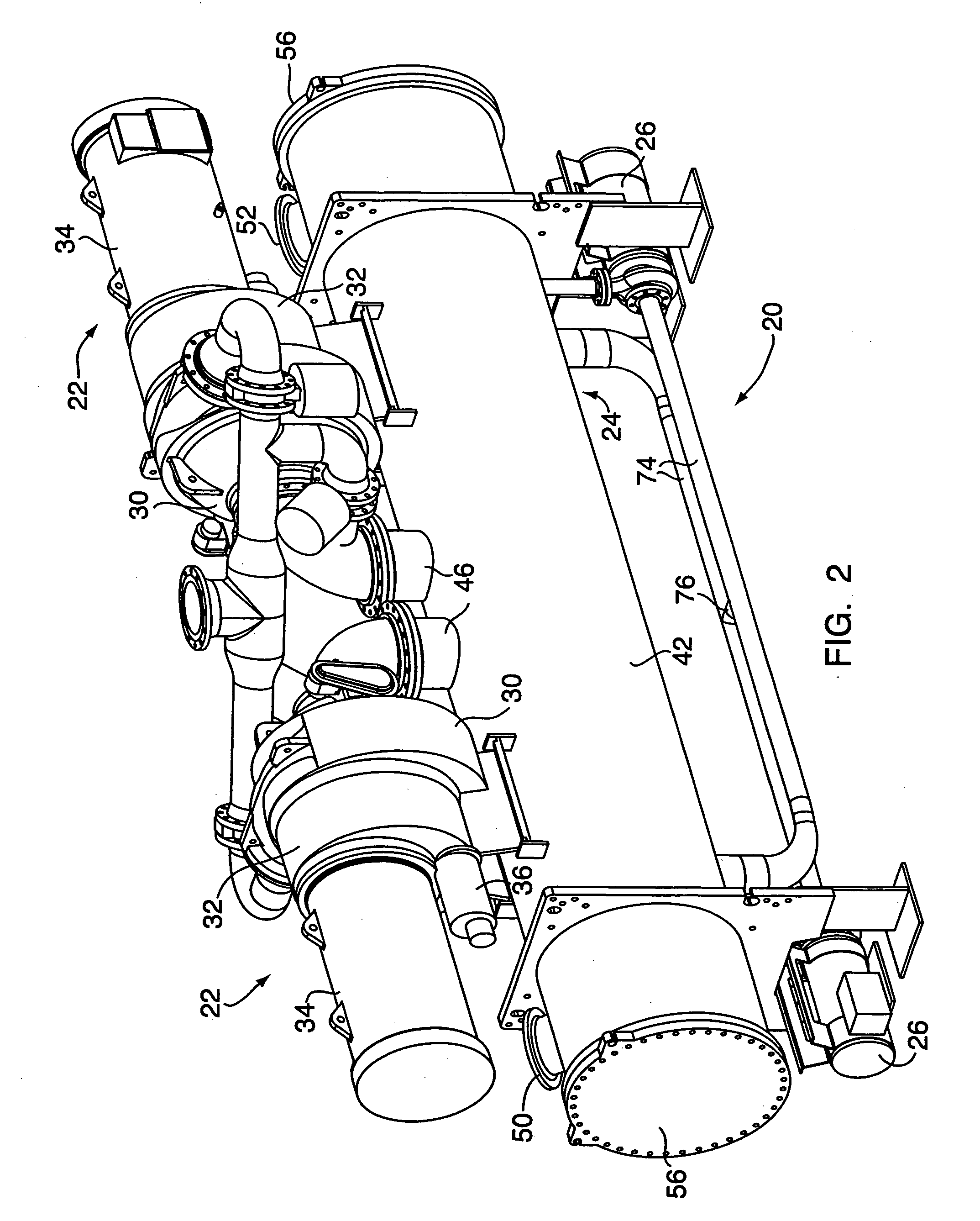

System and method for waste heat recovery in exhaust gas recirculation

InactiveUS20110209473A1Liquid degasificationInternal combustion piston enginesTurbochargerExhaust fumes

A system and method for waste heat recovery in exhaust gas recirculation is disclosed. The system includes an engine having an intake manifold and an exhaust manifold, an exhaust conduit connected to the exhaust manifold, and a turbocharger having a turbine and a compressor, the turbine being connected to the exhaust conduit to receive a portion of the exhaust gas from the exhaust manifold. The system also includes an EGR system connected to the exhaust conduit to receive a portion of the exhaust gas, with the EGR system including an EGR conduit that is connected to the exhaust conduit to receive a portion of the exhaust gas, a heat exchanger connected to the EGR conduit and being configured to extract heat from the exhaust gas, and a waste heat recovery system connected to the heat exchanger and configured to capture the heat extracted by the heat exchanger.

Owner:GENERAL ELECTRIC CO

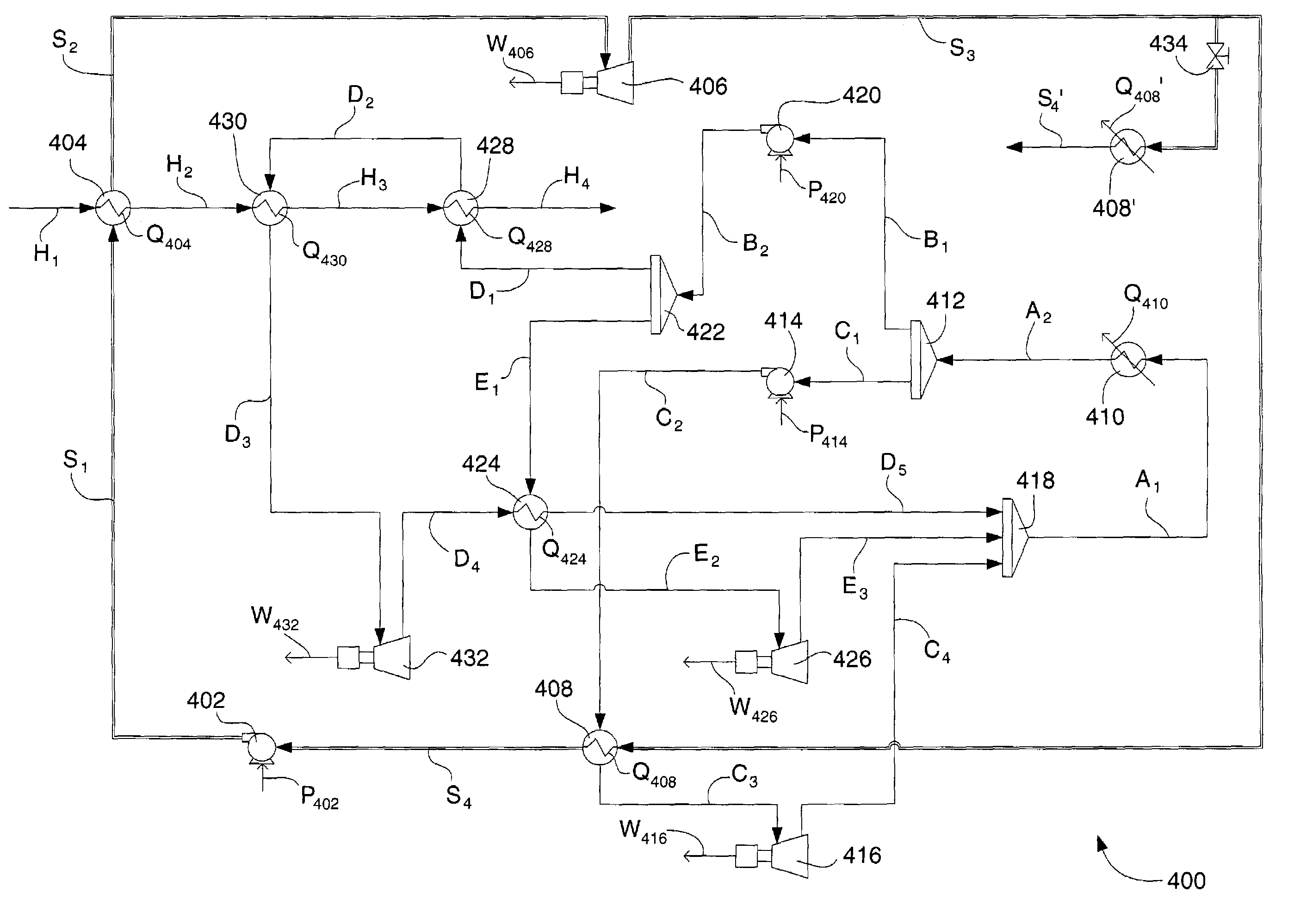

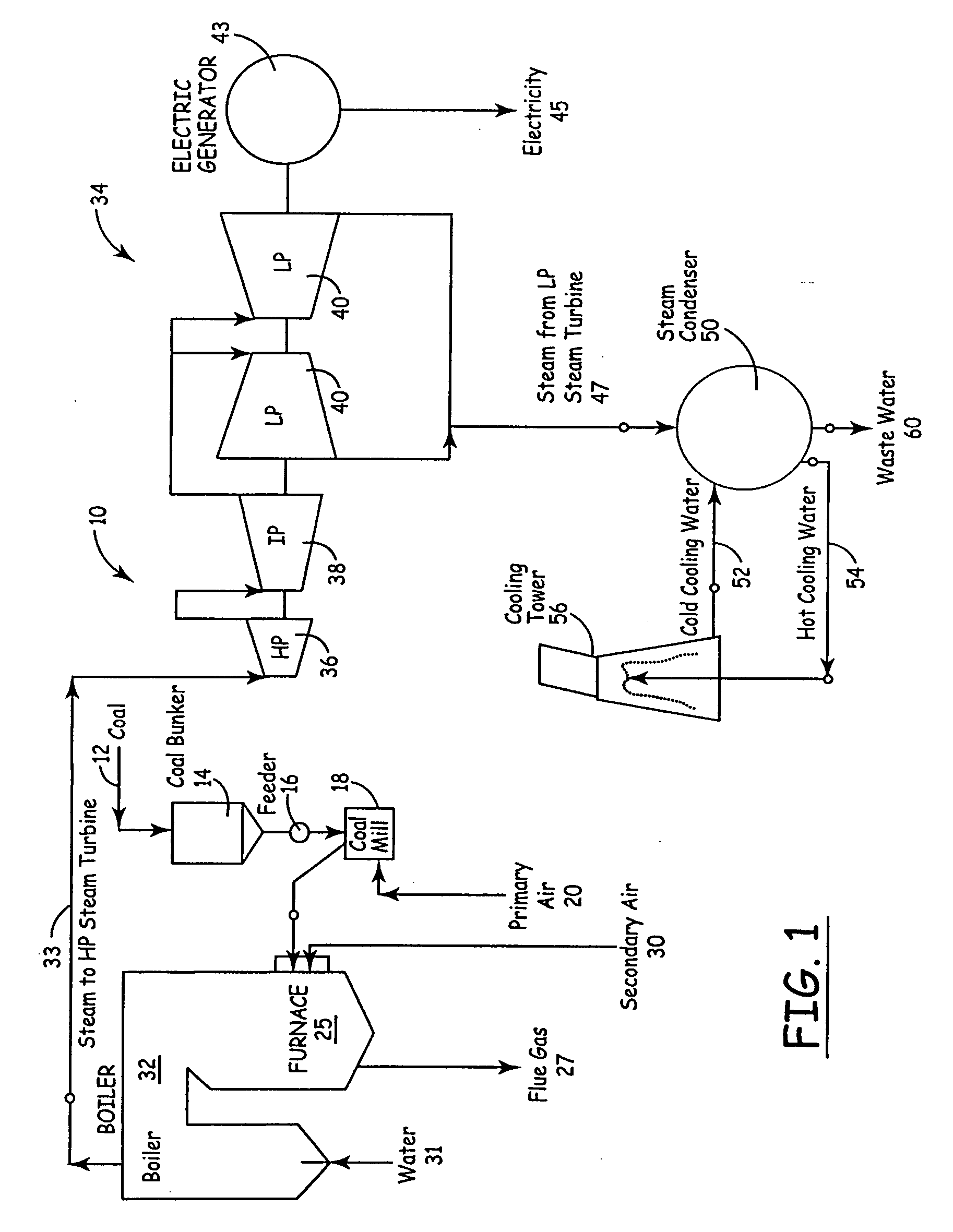

Cascading closed loop cycle power generation

InactiveUS7096665B2Improve power efficiencyIncrease pressureEnergy industrySteam accumulatorsLiquid propaneSteam condensation

Owner:UNIVERSAL TECH

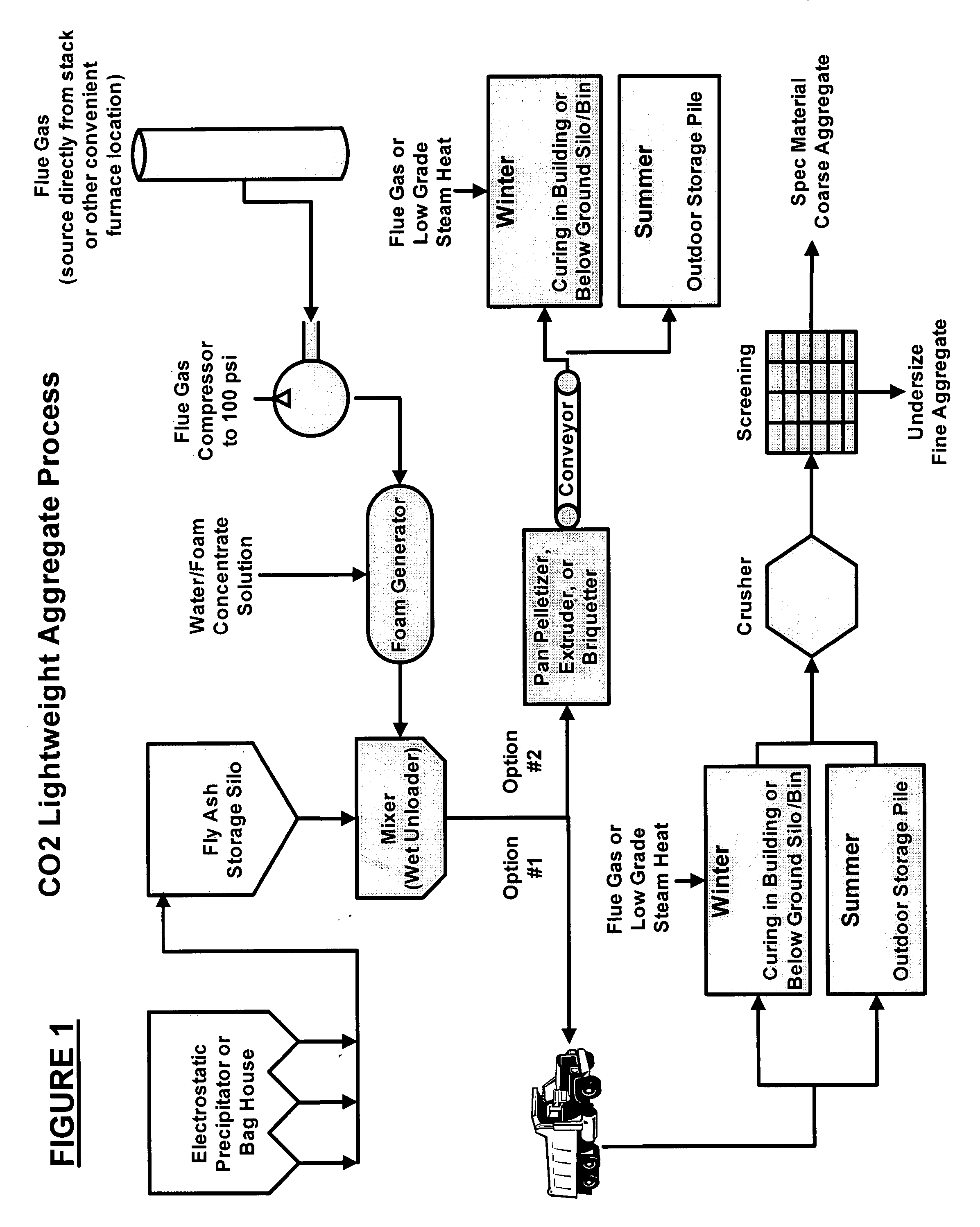

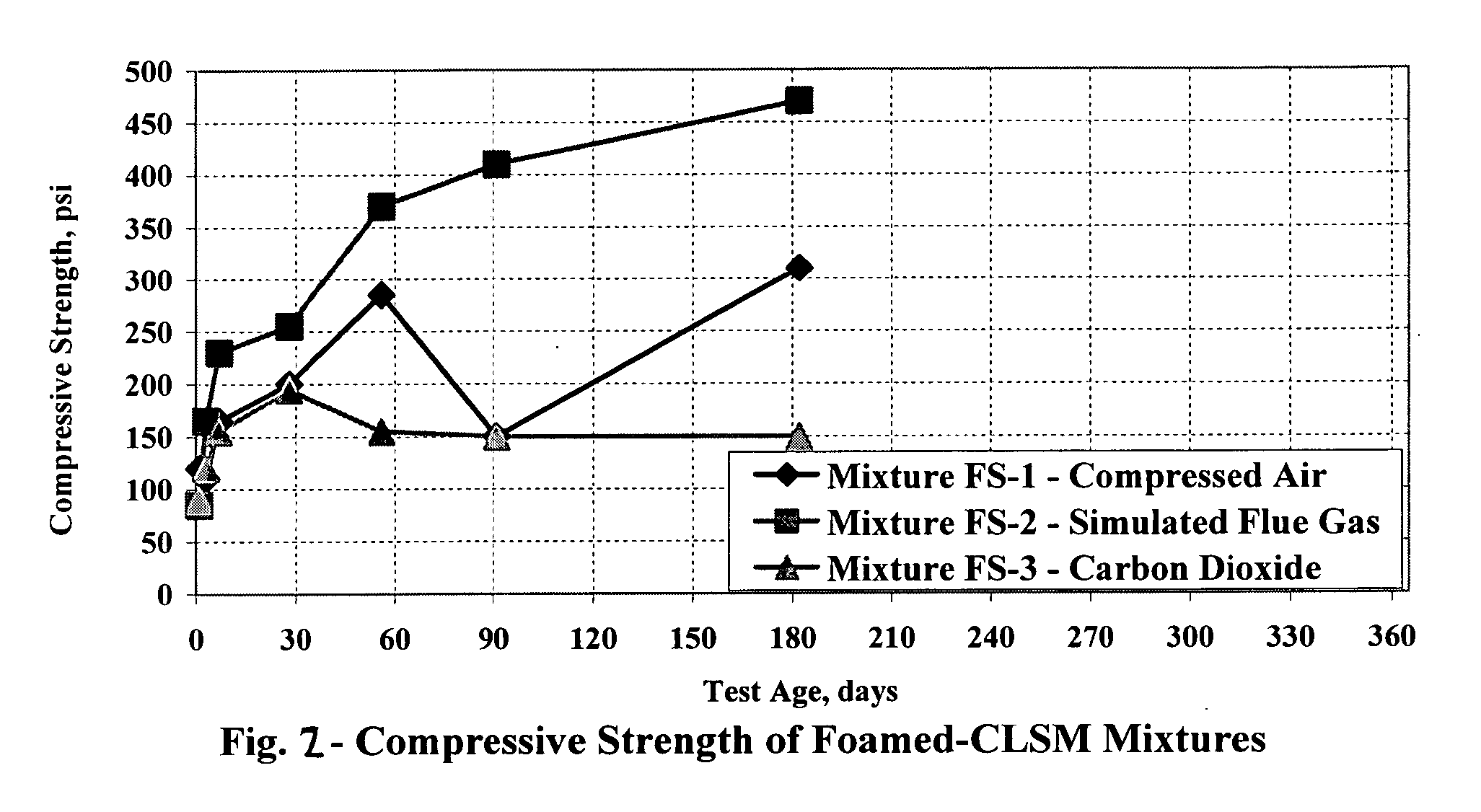

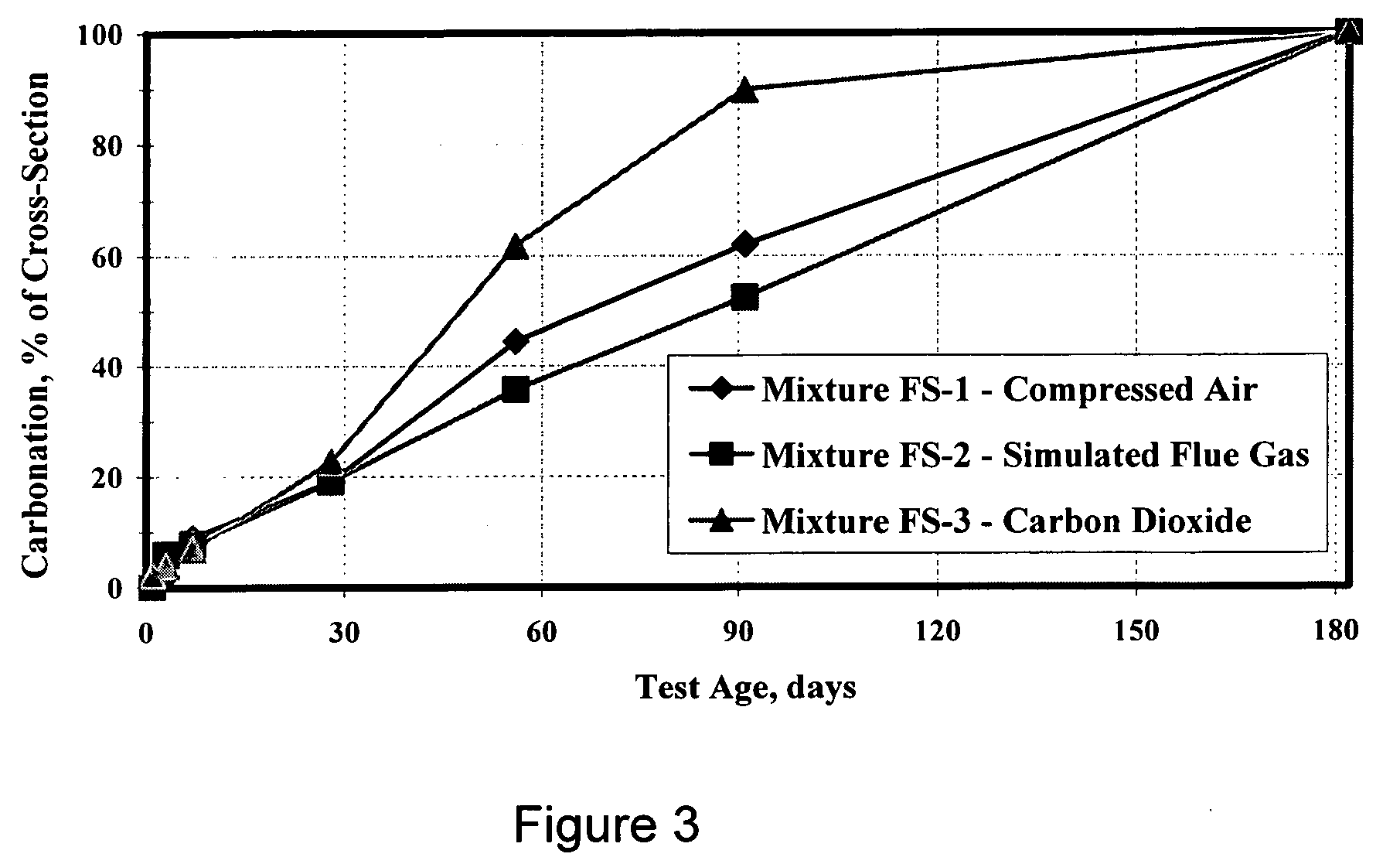

Carbon dioxide sequestration in foamed controlled low strength materials

InactiveUS20060185560A1Improve the environmentEasy to useProductsReagentsCombustion chamberMaterials science

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

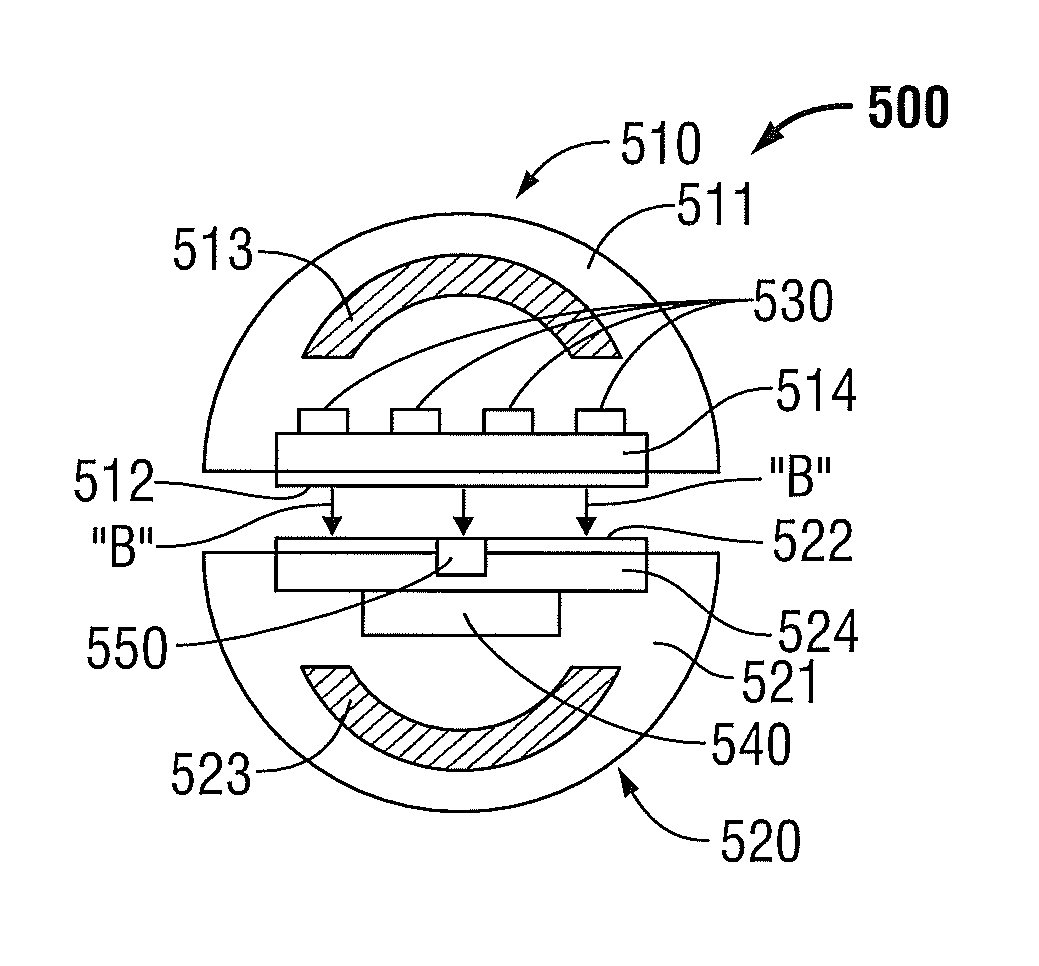

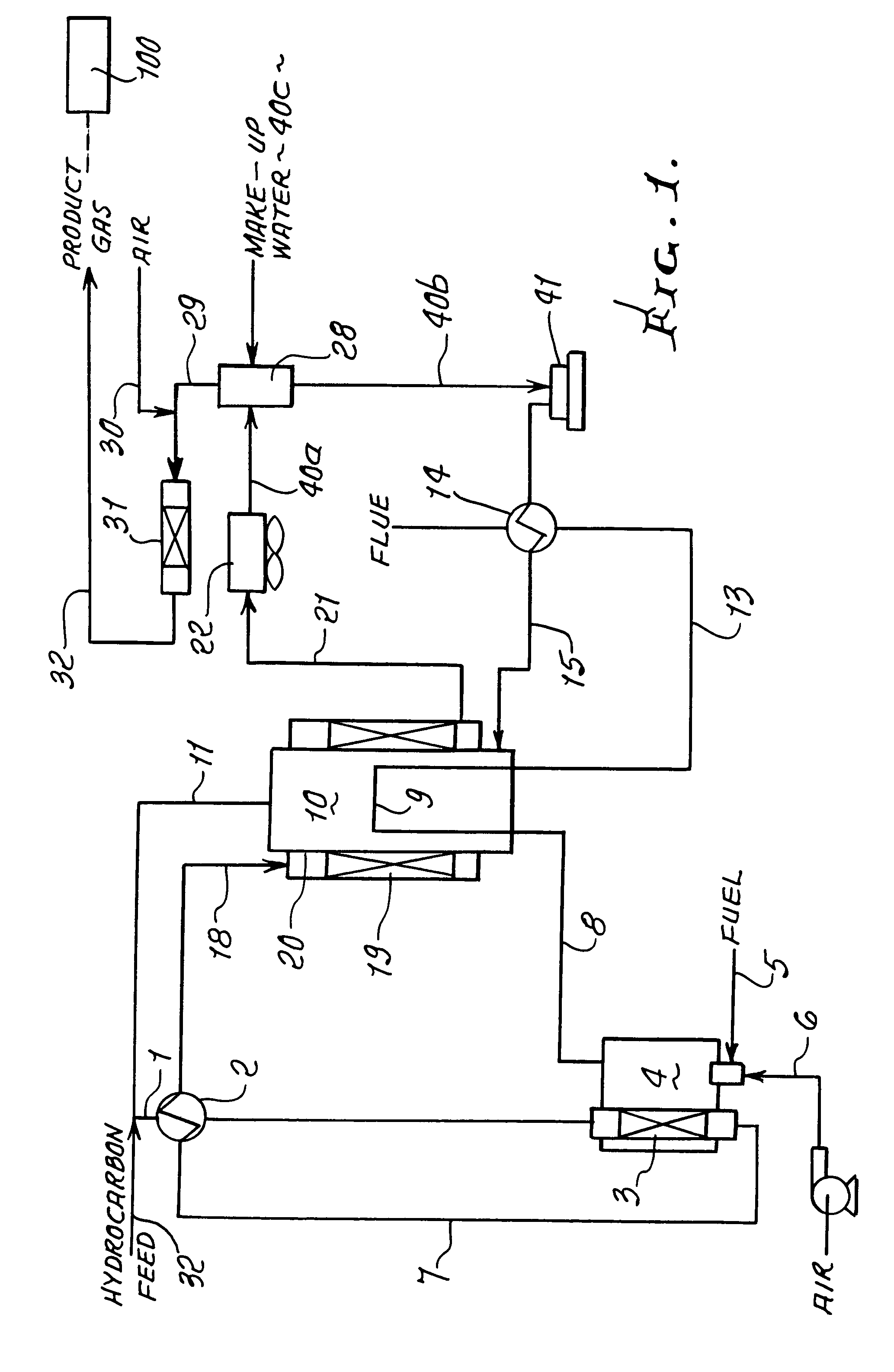

Systems and processes for providing hydrogen to fuel cells

InactiveUS20020098394A1Minimized in sizeMaximize energy efficiencyFuel cell auxillariesHydrogen/synthetic gas productionFuel cellsInternal combustion engine

A process and system for providing a hydrogen-containing gas stream to a fuel cell anode that includes providing a hydrogen-containing gas stream that includes carbon monoxide, introducing the hydrogen-containing gas stream into a pressure swing adsorption module that includes at least one carbon monoxide-selective adsorbent to produce a purified hydrogen-containing gas stream, and introducing the purified hydrogen-containing gas stream to the fuel cell anode. The pressure swing adsorption module can also include a second adsorbent and / or catalyst. Also disclosed is a fuel cell system coupled to an internal combustion engine and a fuel cell system that utilizes fuel cell waste heat for vaporizing a hydrocarbon / water mixture.

Owner:AIR PROD & CHEM INC

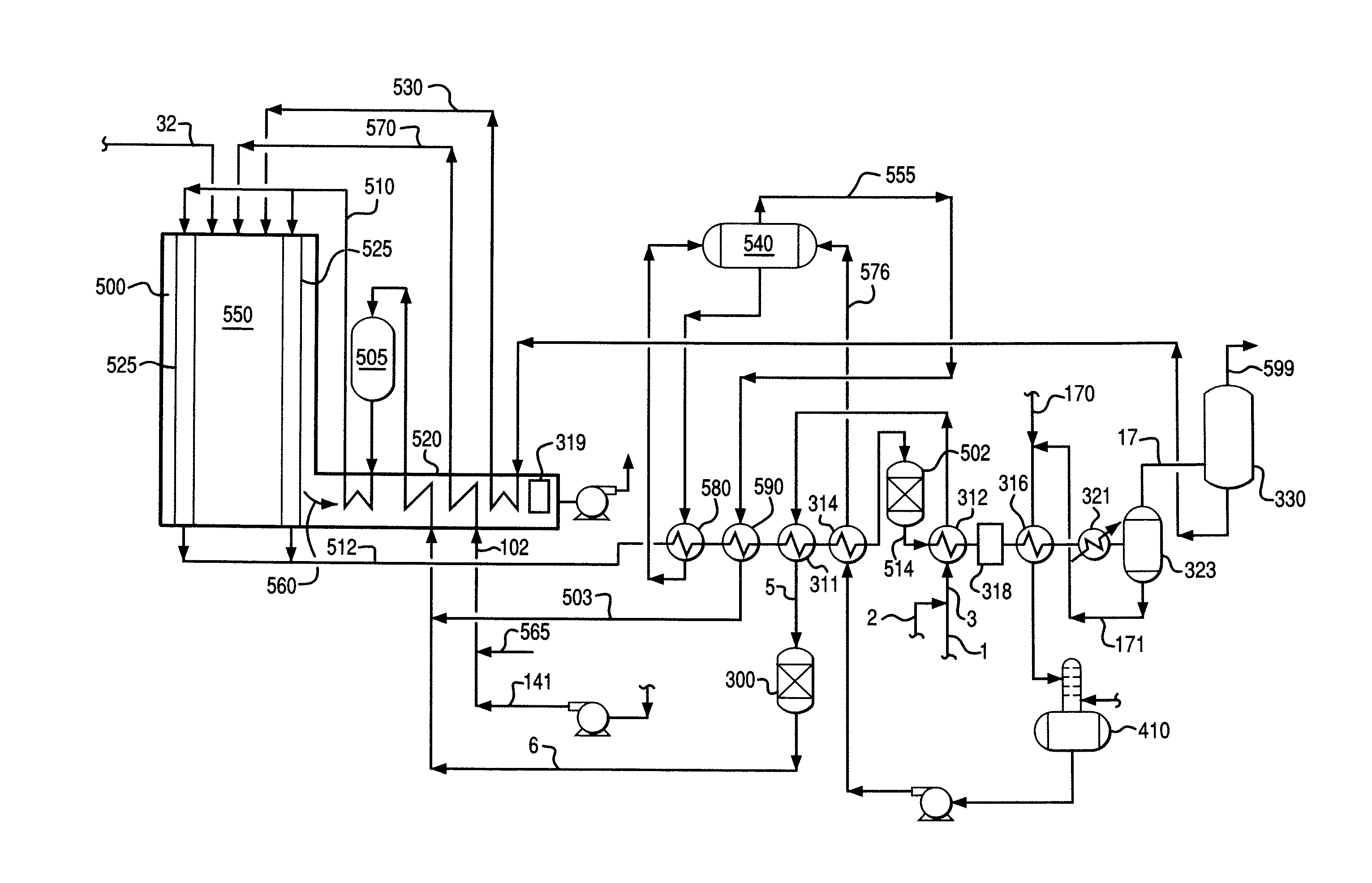

Steam-Hydrocarbon Reforming Method with Limited Steam Export

A method for generating hydrogen and / or synthesis gas in a production facility where little or no export steam is produced. Most or all of the high pressure steam produced from the waste heat from the process is used in the steam-hydrocarbon reformer with little or no steam export. The method uses oxygen enhanced combustion which may involve oxygen lancing and / or oxygen-enrichment. Plant efficiencies using the method and prior art-type methods are compared.

Owner:AIR PROD & CHEM INC

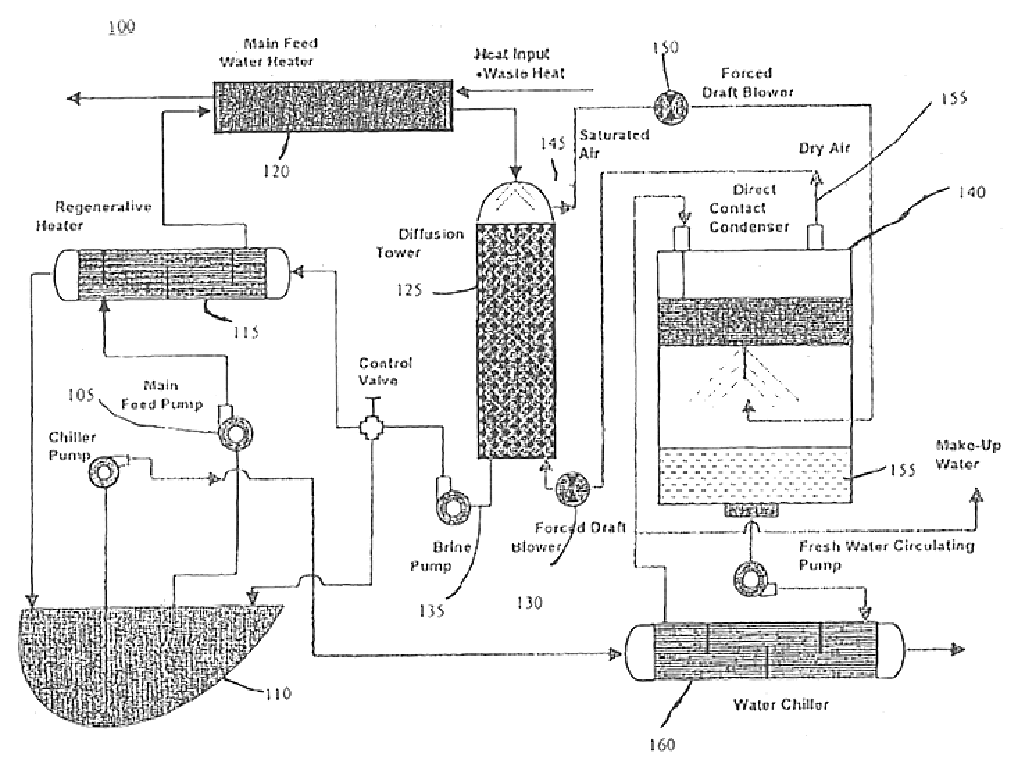

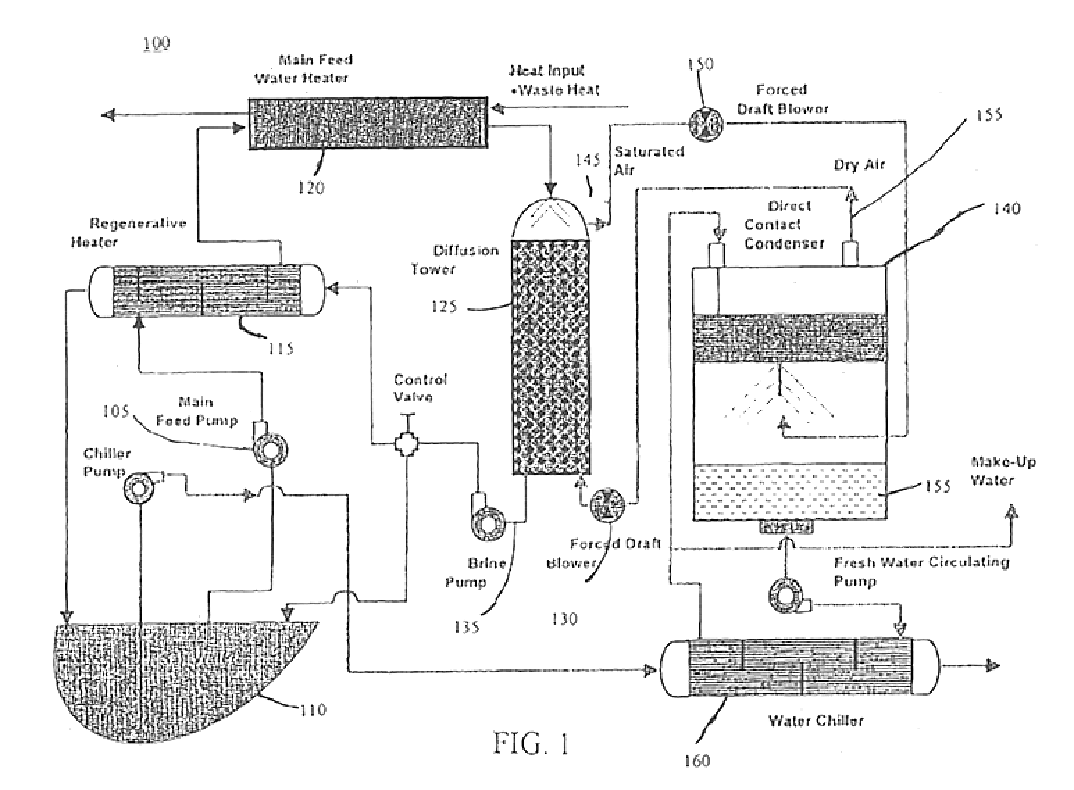

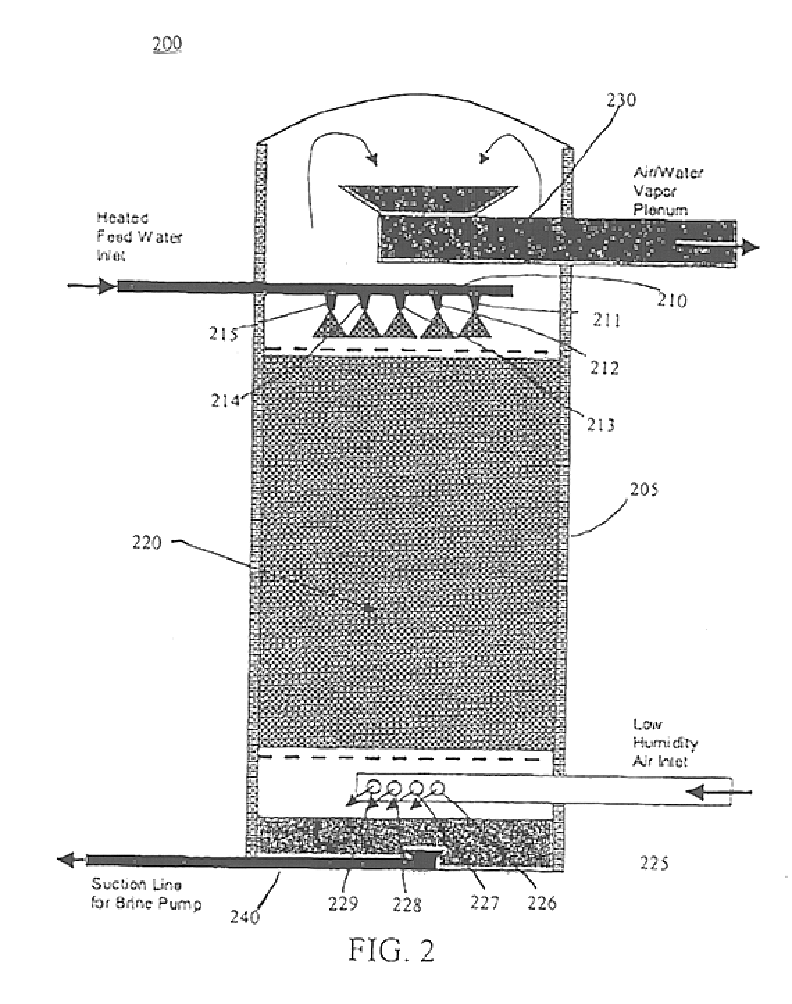

Diffusion driven desalination apparatus and process

A diffusion driven desalination apparatus and related method includes structure for receiving a heated water stream and creating at least one region having a thin film of water and structure for forcing a low humidity air stream over the thin film of water, wherein water from the thin film of water evaporates and diffuses into the air stream to create a humidified air stream. A diffusion tower including at least one plenum can be used to create and transfer the humidified air stream. At least one condenser, such as a direct contact condenser, condenses the humidified air stream, wherein purified water is produced. Waste heat from a power plant can be used to provide the heated water stream and power plants can use the waste heat generated to inexpensively provide purified water.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

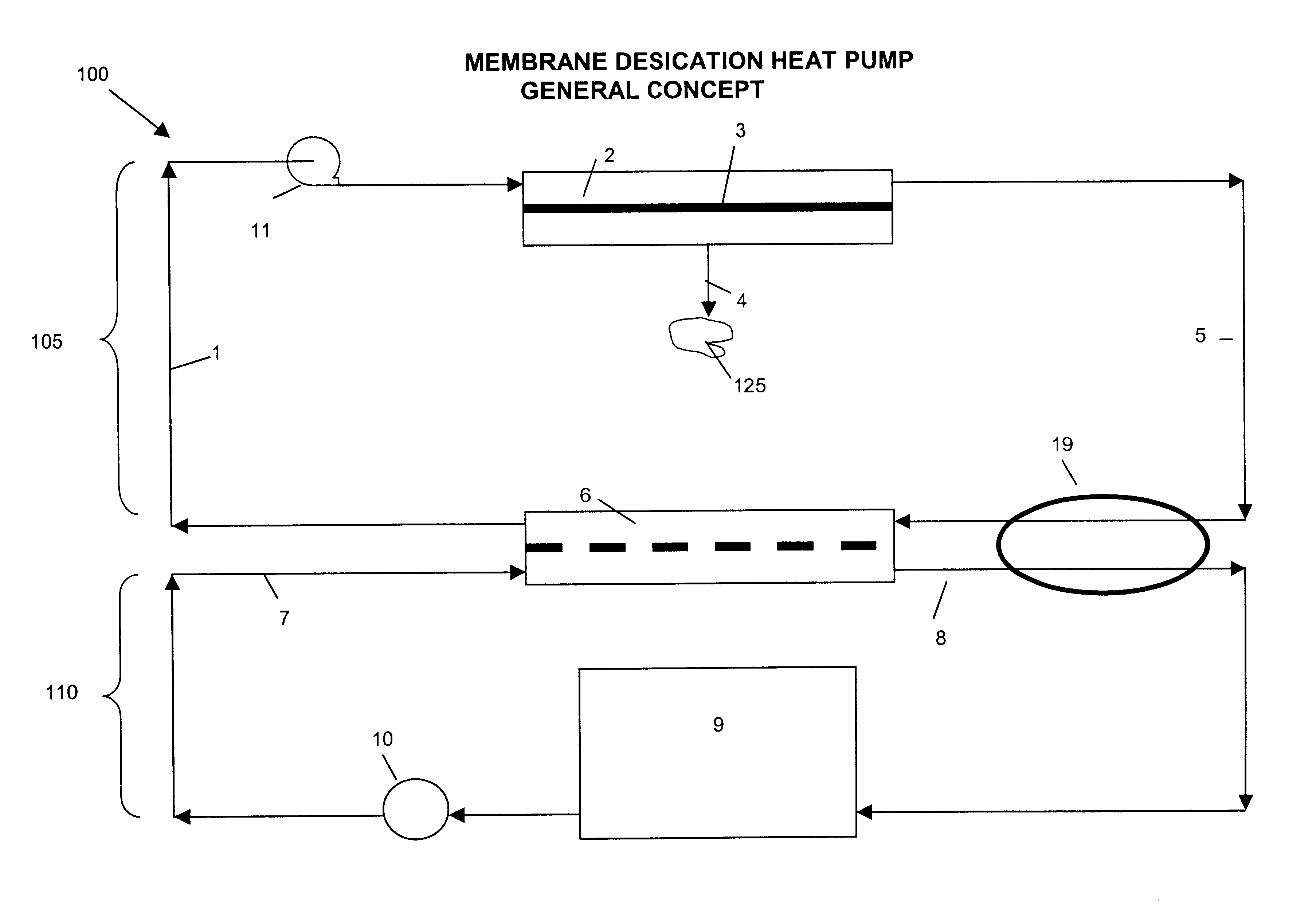

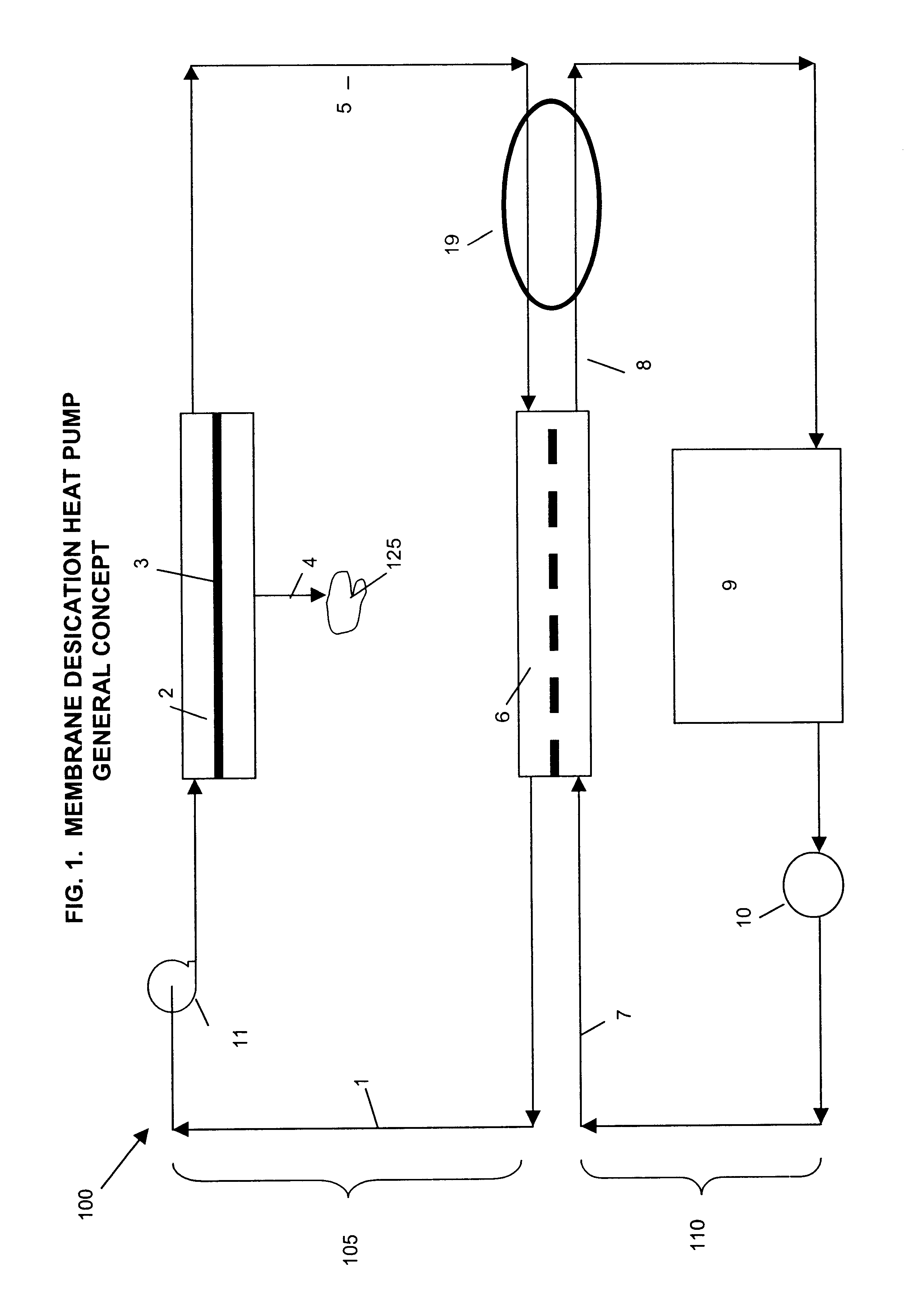

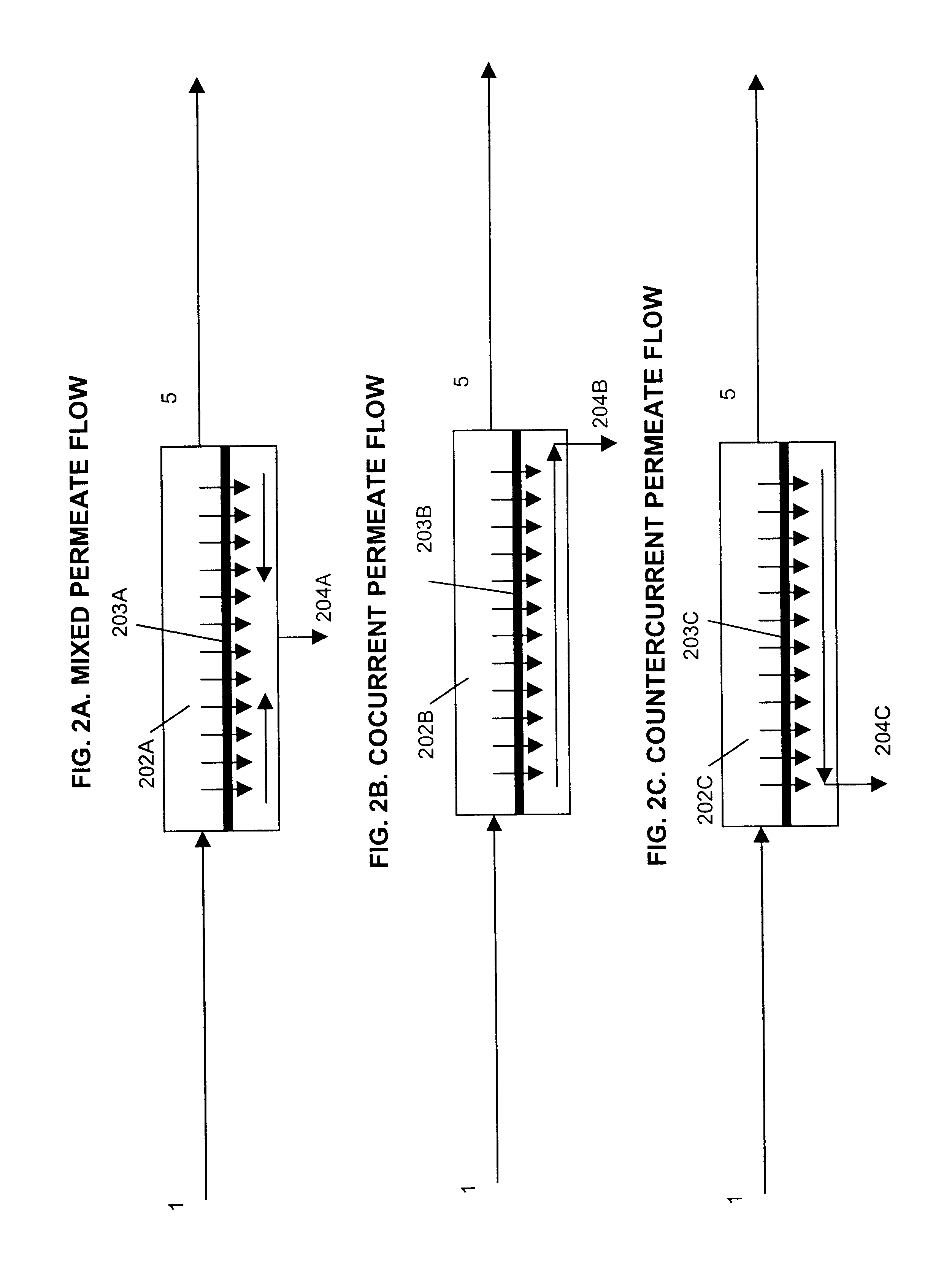

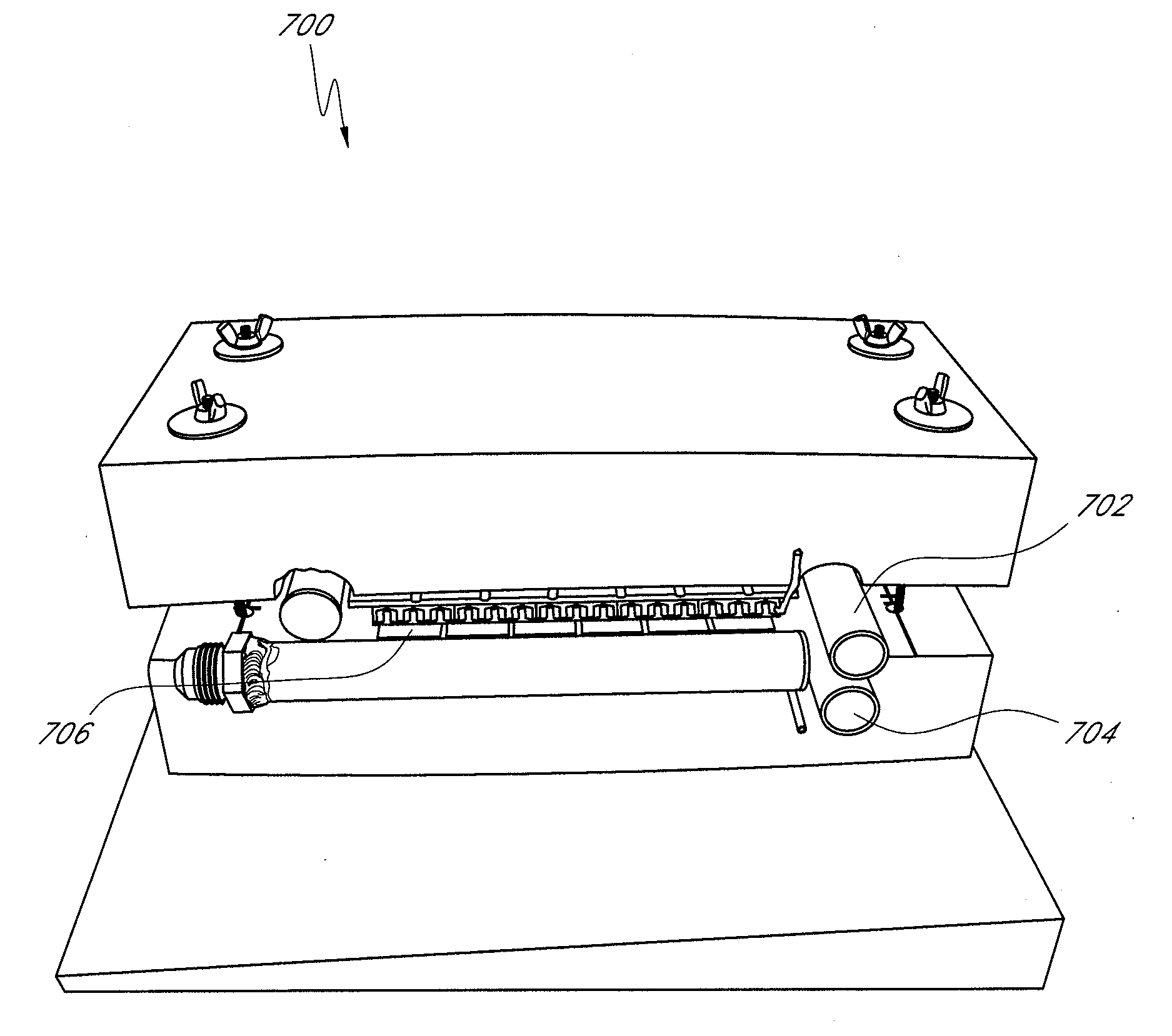

Membrane desiccation heat pump

InactiveUS6739142B2Great flexibility and controlReduce in quantityAir-treating devicesHeat pumpsThermal energyProcess engineering

Owner:KORIN AMOS

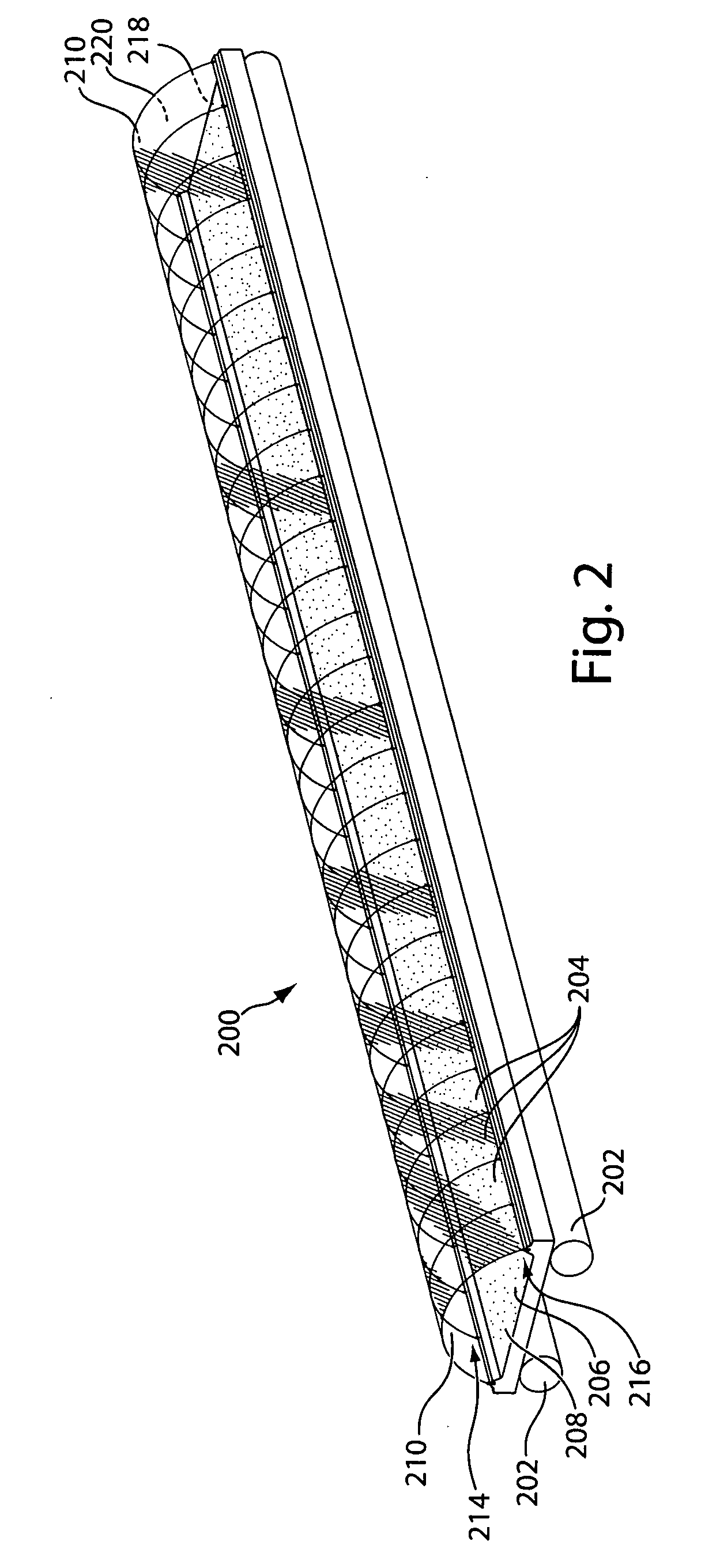

Thermoelectric-based power generation systems and methods

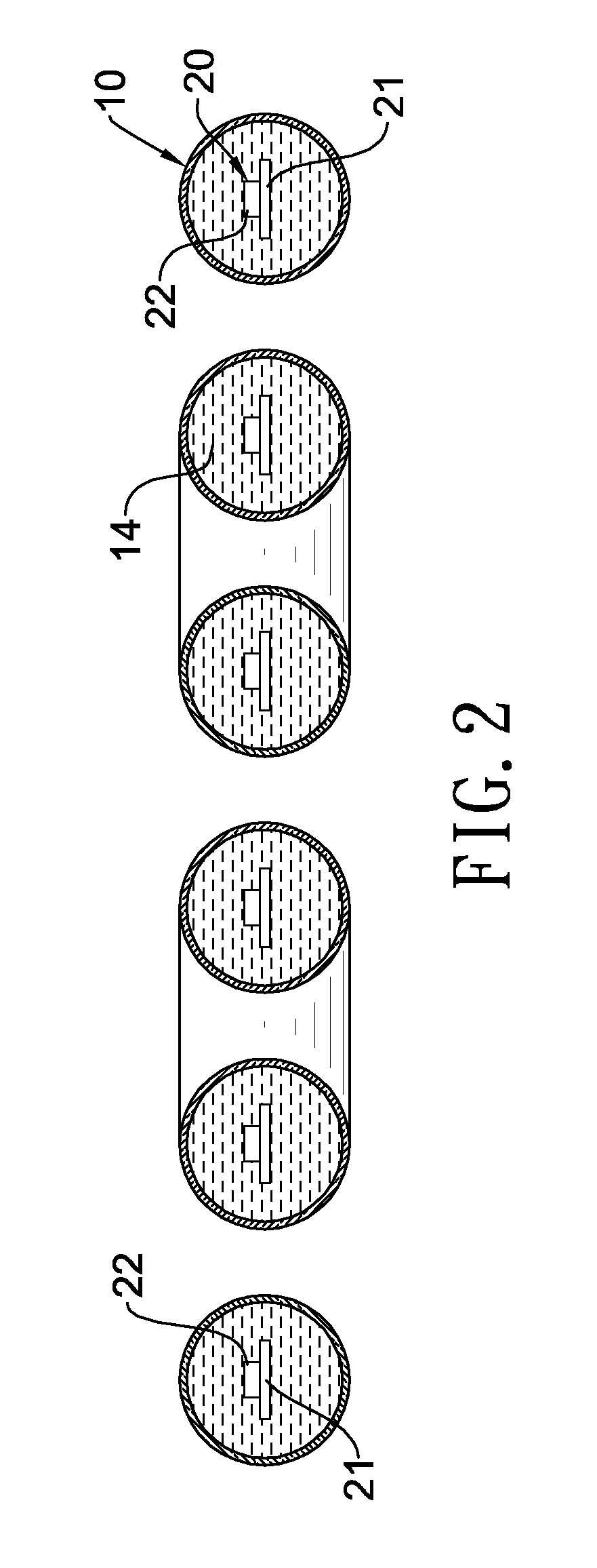

InactiveUS20110067742A1Lower overall pressure dropInternal combustion piston enginesRecuperative heat exchangersExhaust valveEngineering

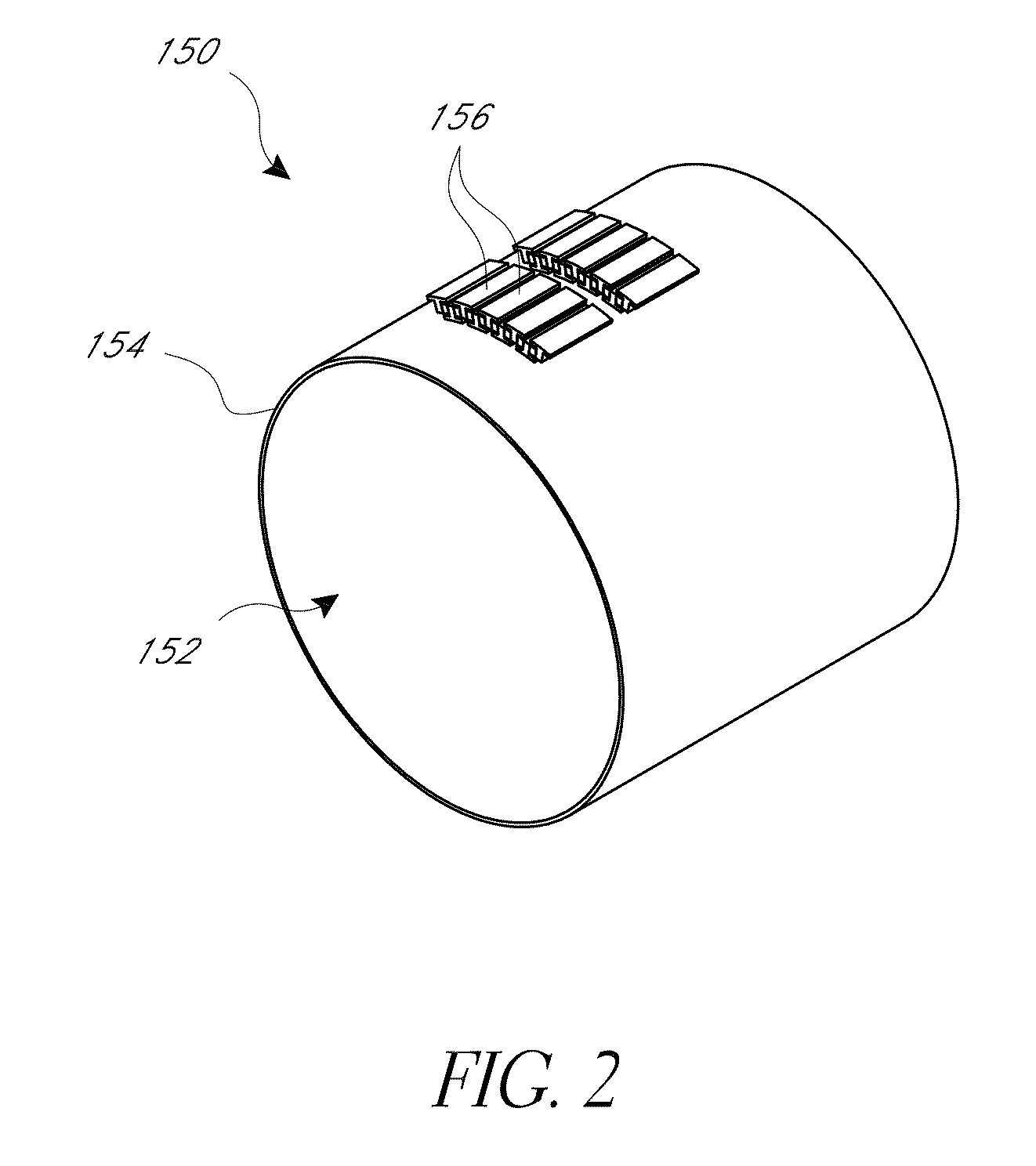

Some embodiments provide a waste heat recovery apparatus including an exhaust tube having a cylindrical outer shell configured to contain a flow of exhaust fluid; a first heat exchanger extending through a first region of the exhaust tube, the first heat exchanger in thermal communication with the cylindrical outer shell; a second region of the exhaust tube extending through the exhaust tube, the second region having a low exhaust fluid pressure drop; an exhaust valve operatively disposed within the second region and configured to allow exhaust fluid to flow through the second region only when a flow rate of the exhaust fluid becomes great enough to result in back pressure beyond an allowable limit; and a plurality of thermoelectric elements in thermal communication with an outer surface of the outer shell.

Owner:GENTHERM INC

Temperature-controlled shipping container and method for using same

InactiveUS6584797B1Container filling methodsDomestic refrigeratorsTemperature controlProcess engineering

A temperature-controlled container utilizing a sorption cooling unit to maintain the temperature within the container. The sorption cooling unit cools the interior of the container and rejects waste heat to the exterior. The sorption cooling unit provides a lightweight and low volume alternative to the traditional gel pack cooling systems that are commonly used in the modern shipping industry for shipping containers.

Owner:PELICAN NANOCOOL HLDG LLC

Heat Energy Recapture And Recycle And Its New Applications

InactiveUS20080155985A1Benefit maximizationReduce constructionReciprocating combination enginesEngine fuctionsFusion powerEngineering

A heat absorbing radiator and a gas turbine engine or a reciprocating piston engine are used to recapture and reconvert wasted heat energies into electric power and finally into hydrogen-deuterium fuel by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow to further drive the same engine. In order to capture fusion heat energy a hydrogen bomb is detonated in deep ocean to catch the flames by the water and the hot water energizes compressed air inside heat absorbing radiator pipes. In order to produce fusion energy an electric arc is passed thru / across liquid or gaseous deuterium by an electro-plasma torch and by a sparkplug in an internal combustion engine, or by detonating a dynamite inside liquid deuterium. Diamond is produced by placing carbon inside a hydrogen bomb which is then detonated in deepwater. Deuterium fusion flame is used first in smelting glass into large structural sizes before running an engine.

Owner:LABRADOR GAUDENCIO AQUINO

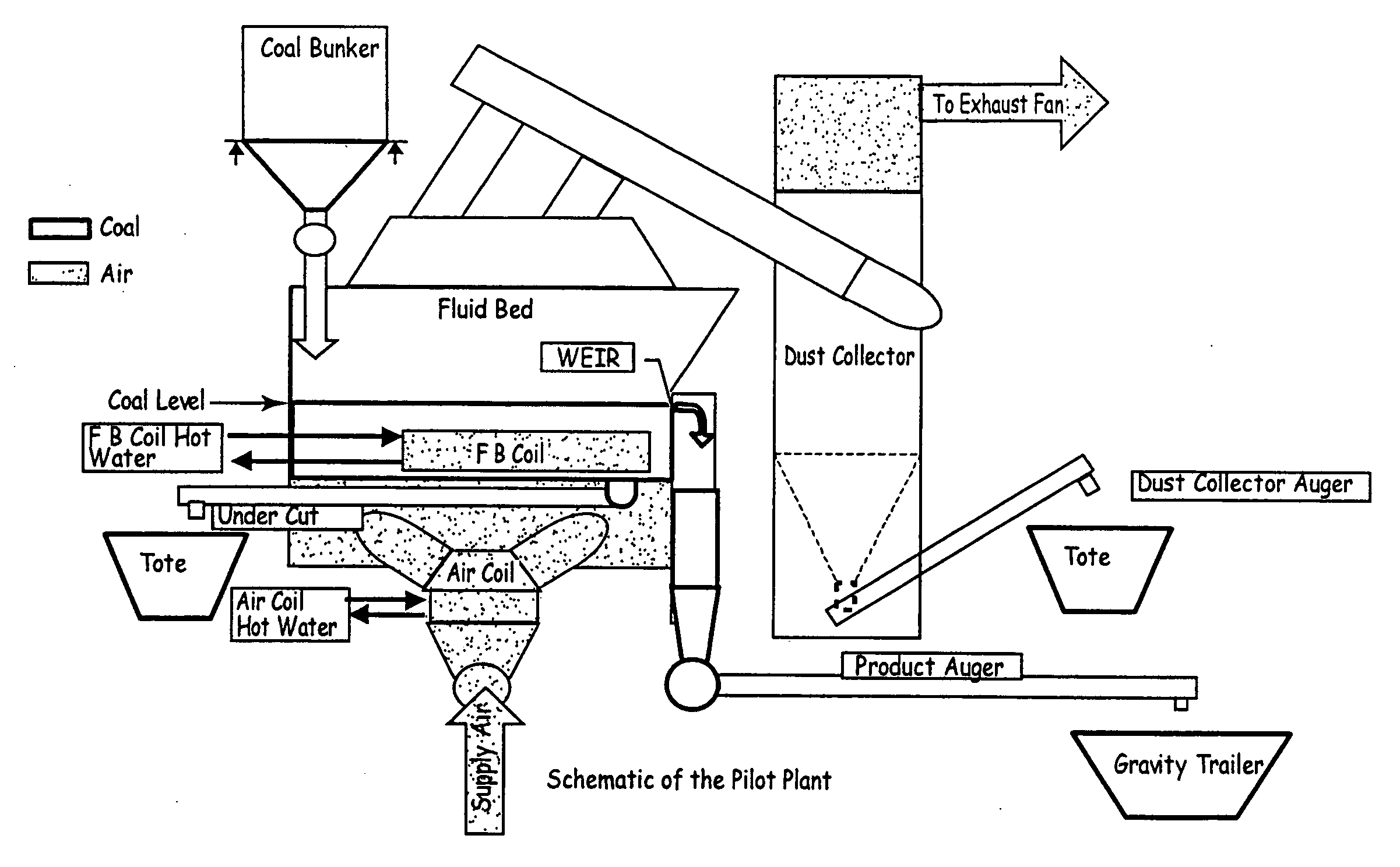

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

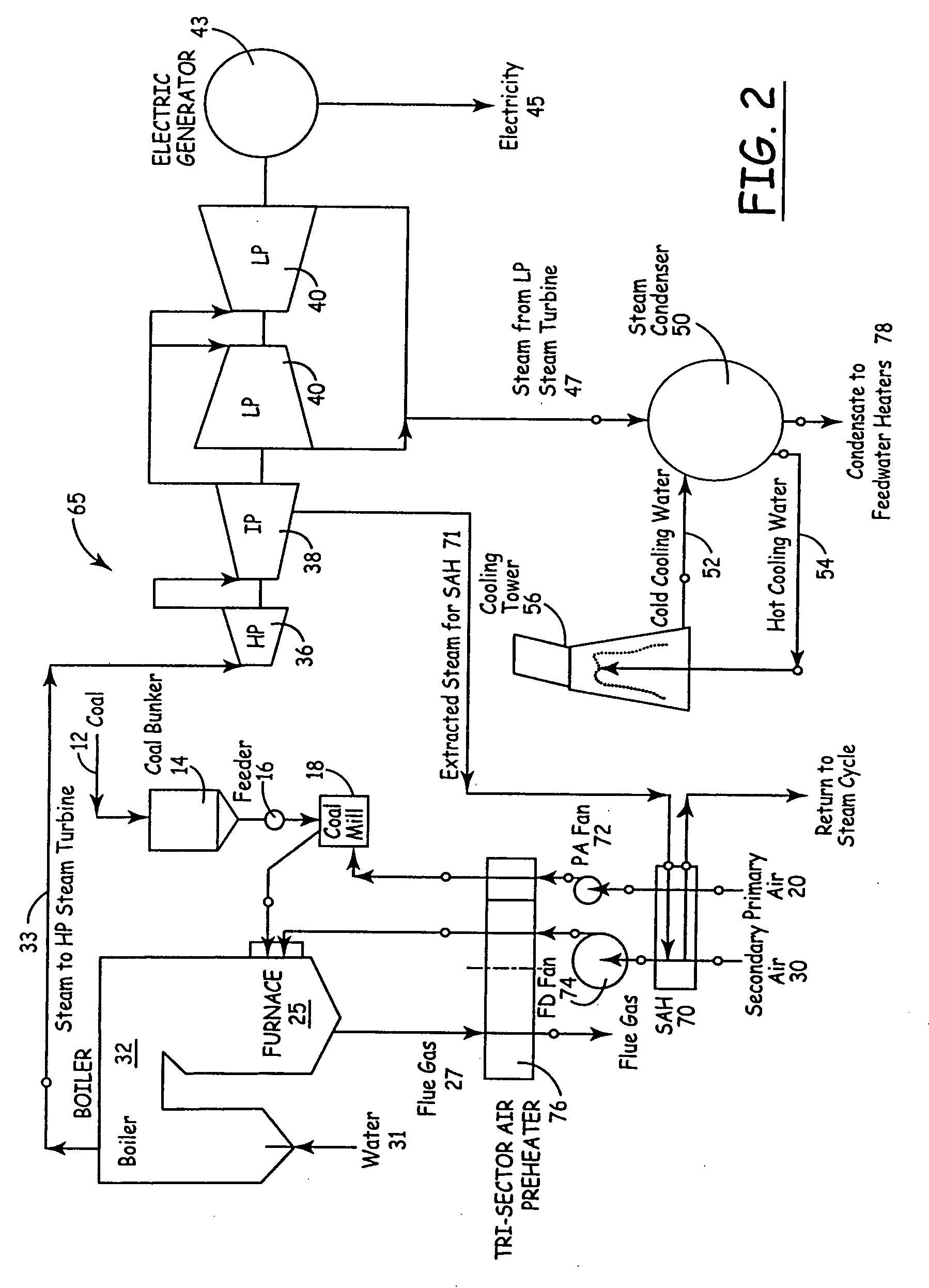

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

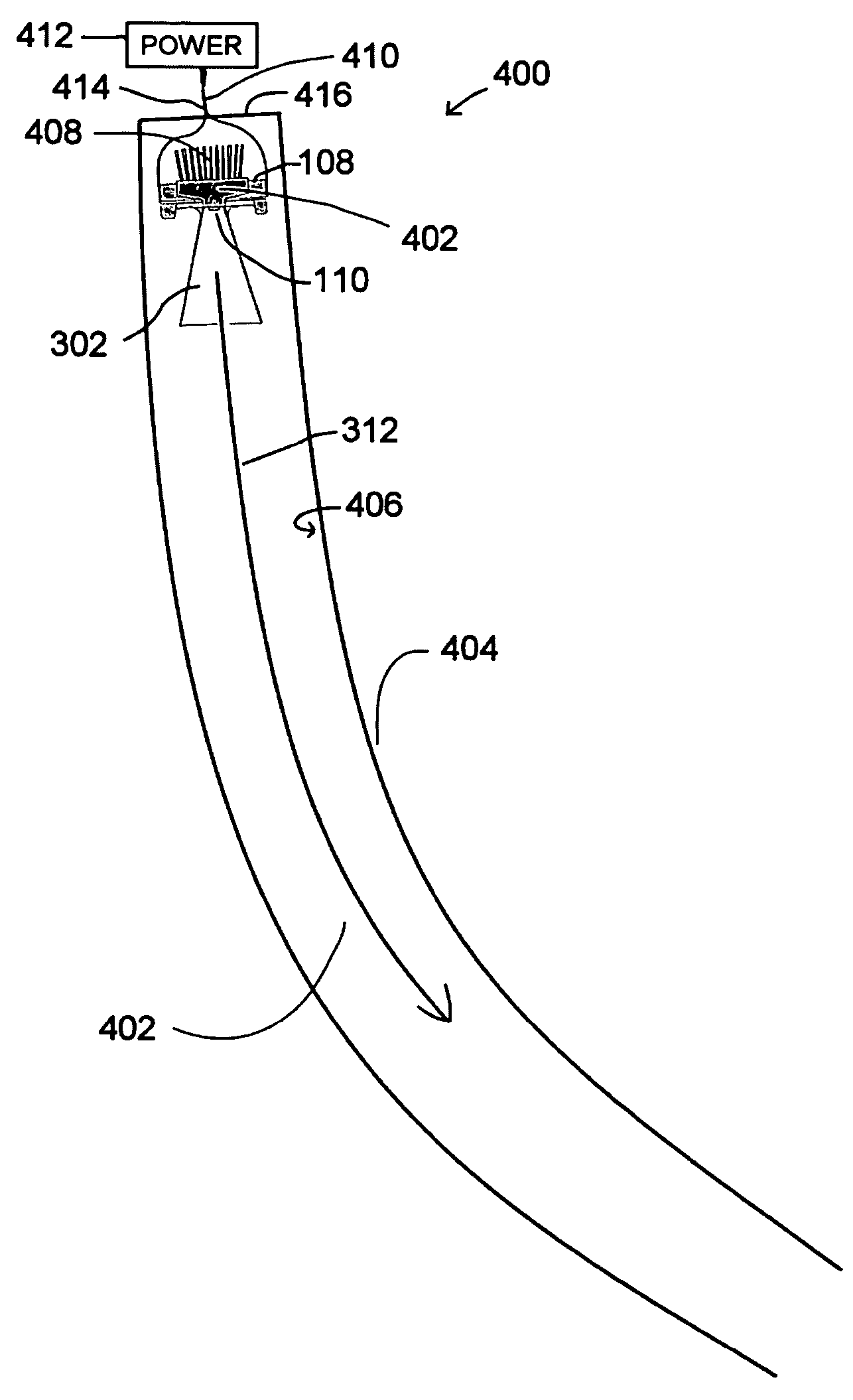

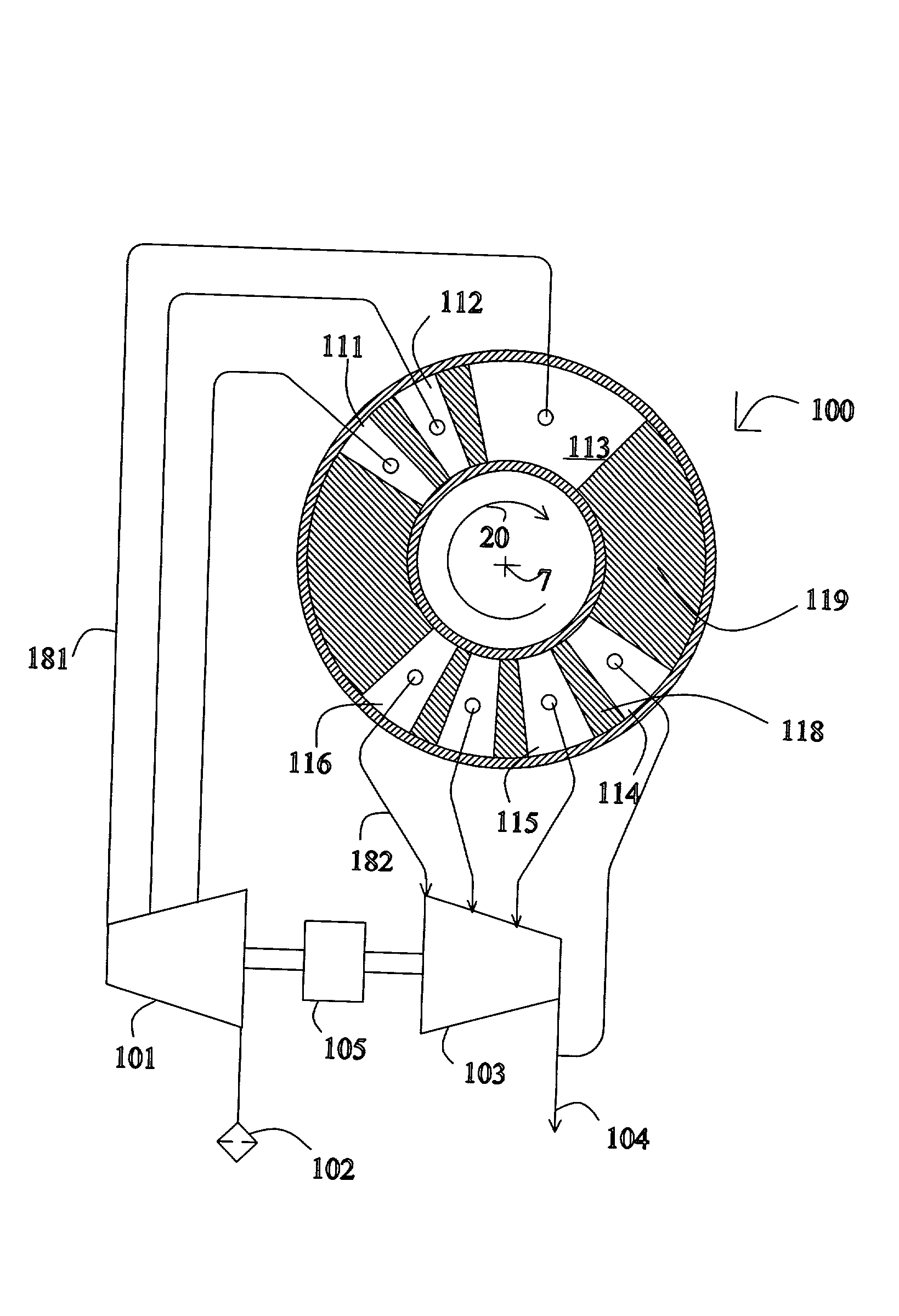

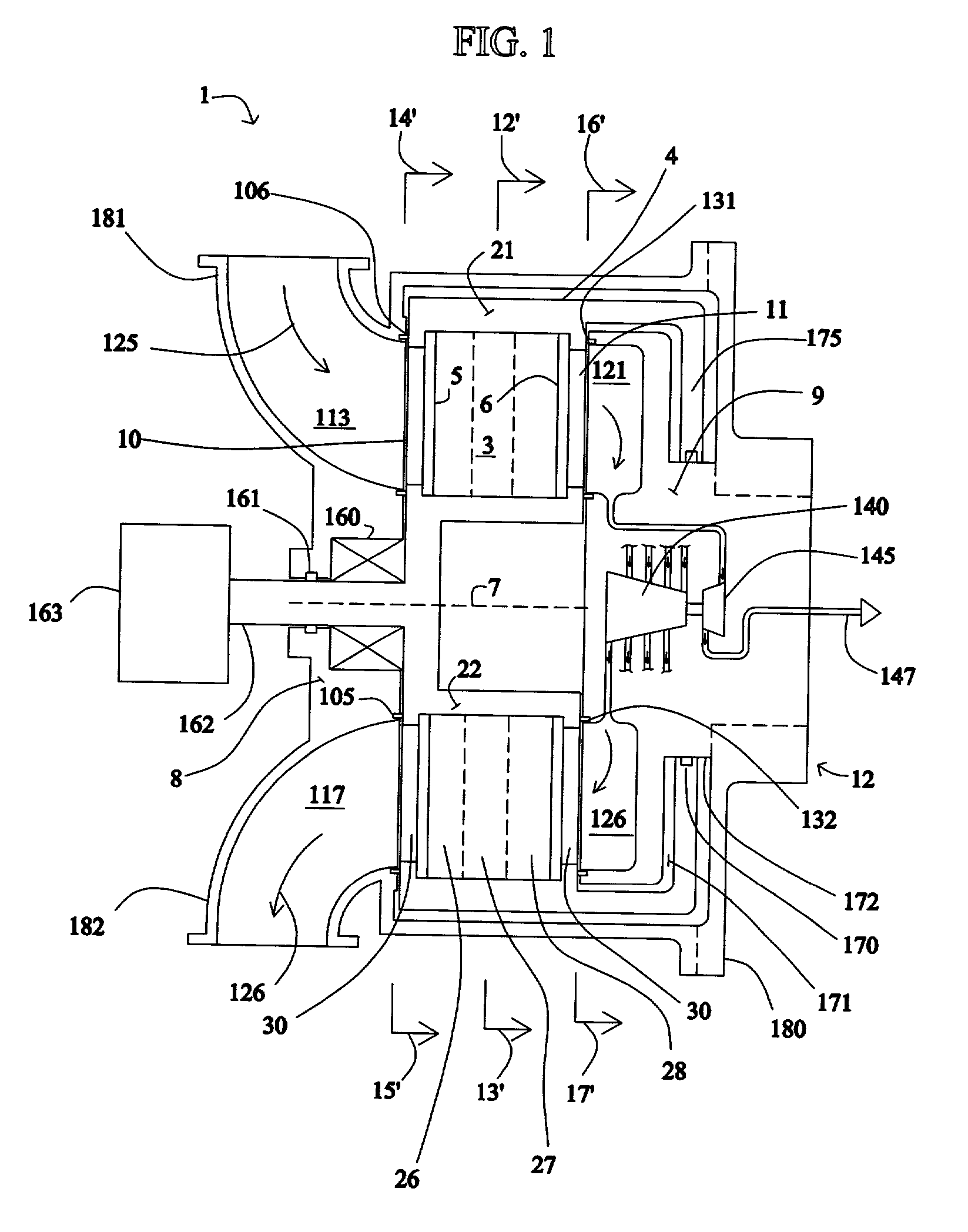

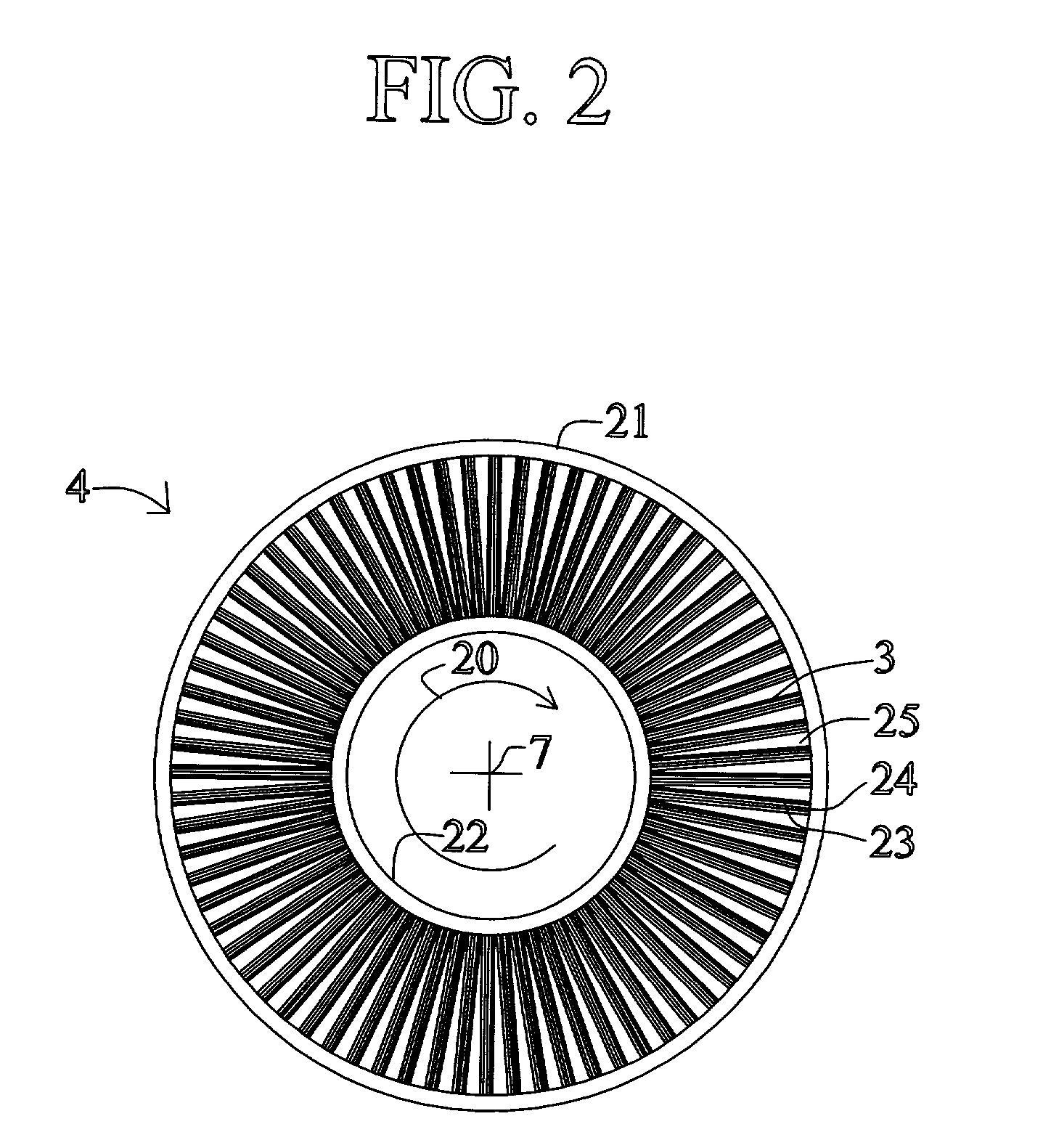

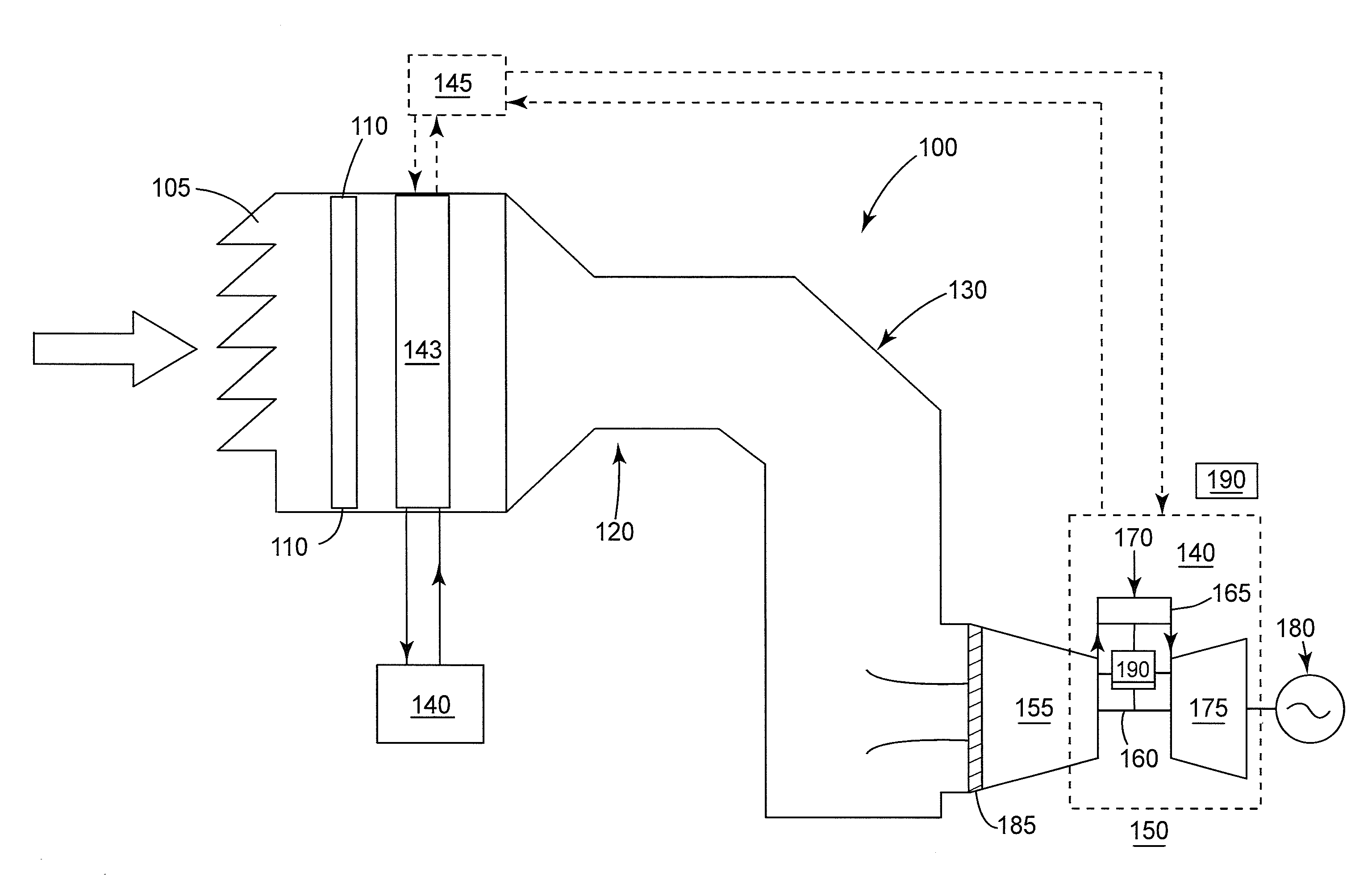

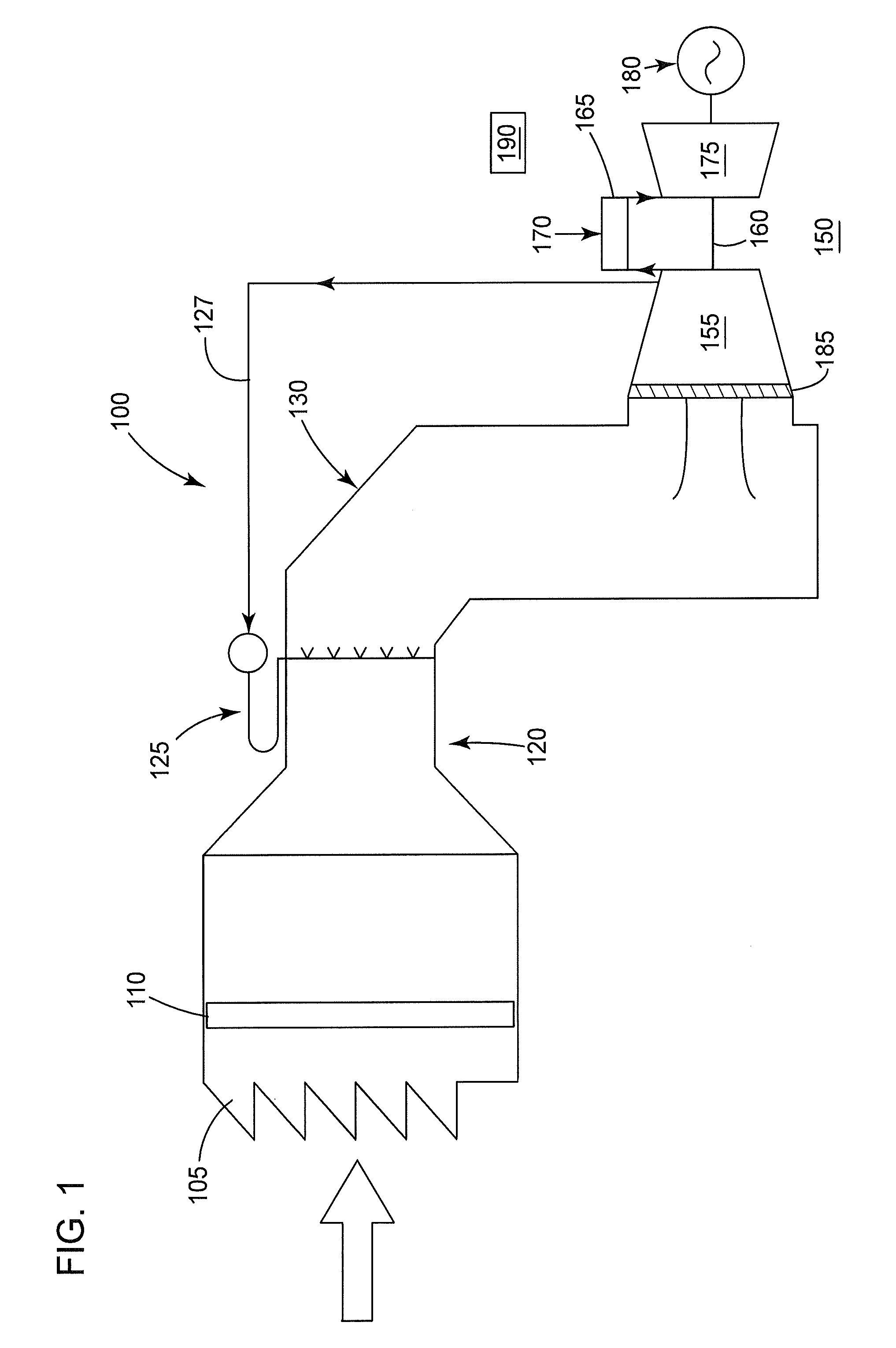

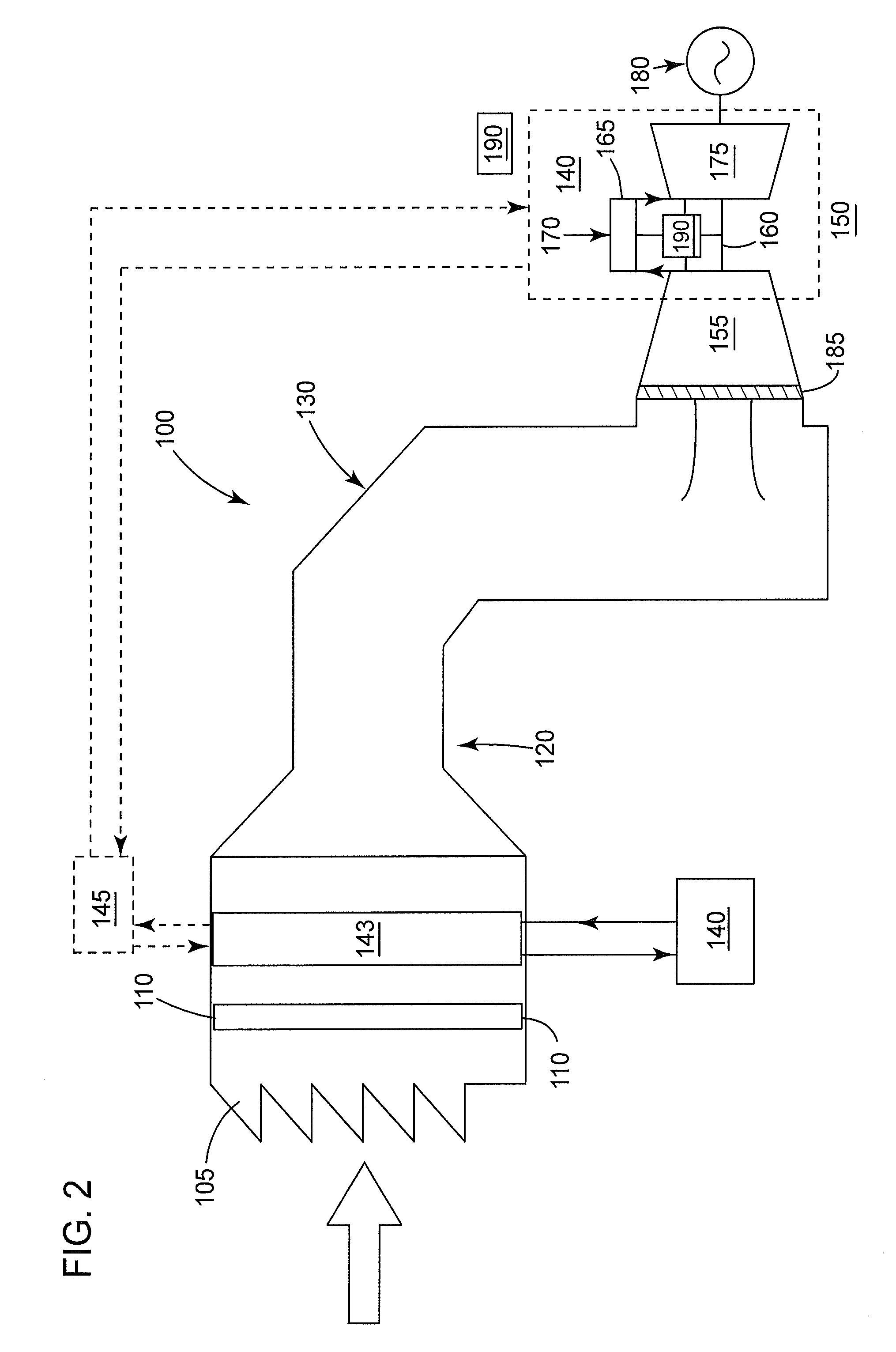

Rankine cycle heat recovery methods and devices

InactiveUS20090277400A1Minimize frictional lossIncrease speedLiquid coolingCoolant flow controlRecovery methodMagnetic bearing

An integrated expansion turbine / electrical generator assembly (collectively referred to as a “turbo-generator”) suitable for use in waste heat recovery and similar applications. The turbo-generator uses a common shaft mounting a one or more stage expansion turbine and a homopolar electrical generator. Magnetic levitating axial and thrust bearings are used to hold the common shaft in its proper position with a fixed housing. The magnetic bearings minimize frictional losses, allowing the common shaft to spin at a very high rotational velocity. Sensor rings continually monitor the common shaft's position. This information is used by control electronics to regulate the magnetic bearings in order to hold the rotating shaft's position. Electrical energy is extracted from the rotating shaft in the form of a direct current. Preferably integrated power-switching electronics are used to generate single or three-phase AC power, which can be phase-matched to an existing power grid or other application.

Owner:DANFOSS AS

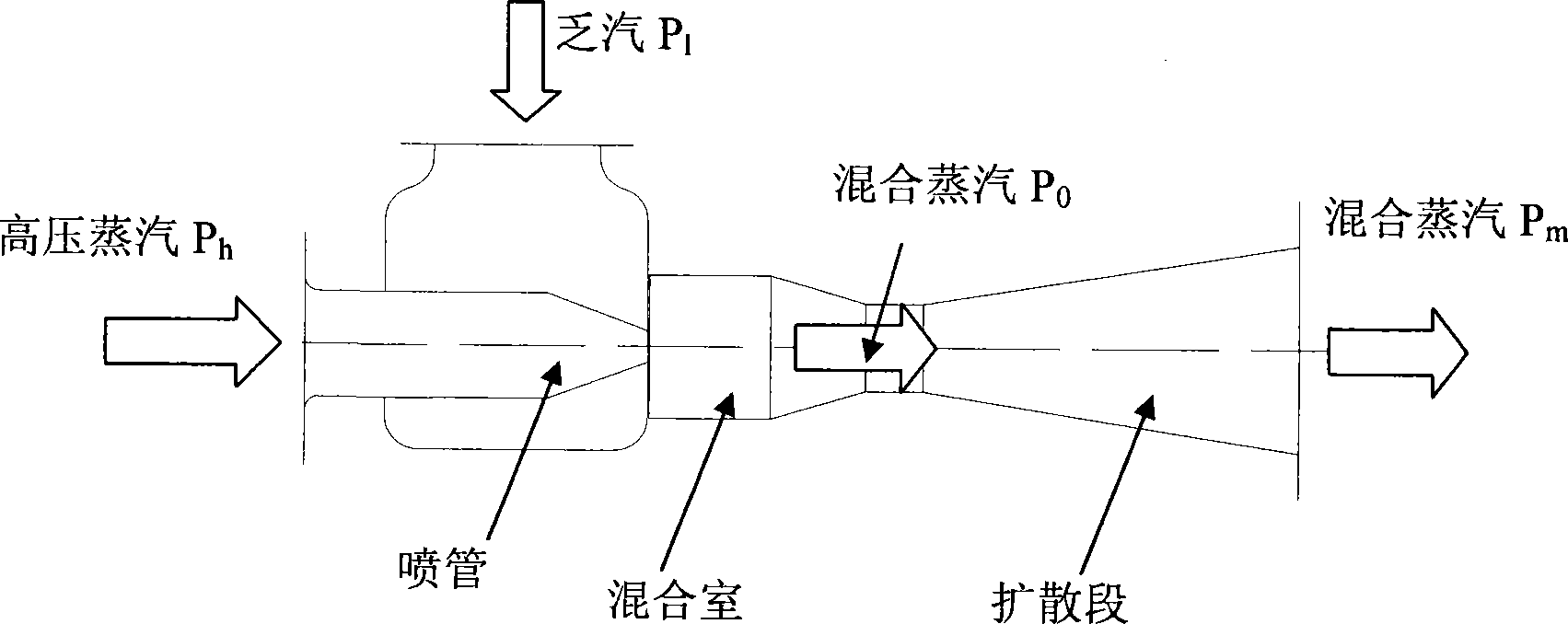

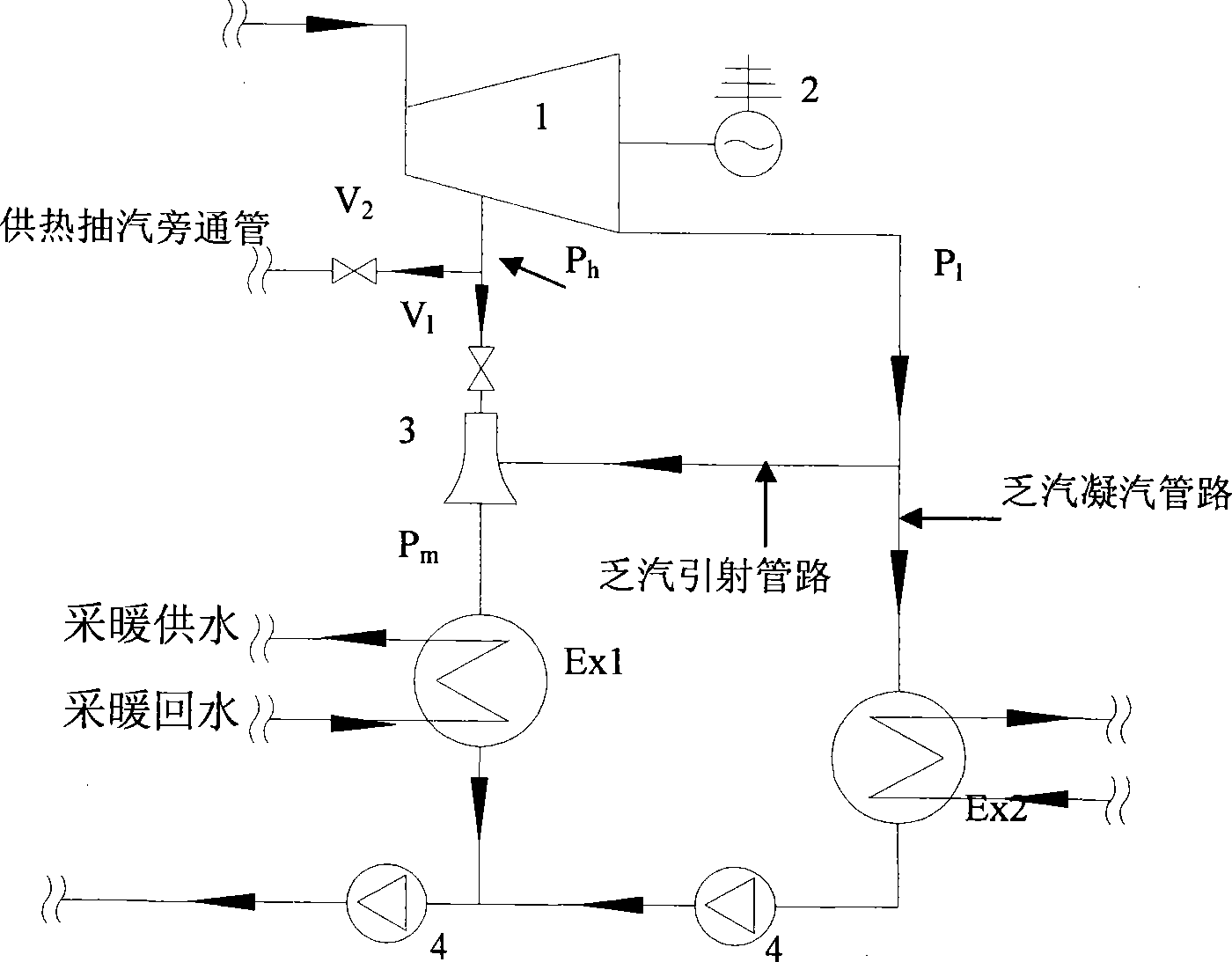

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

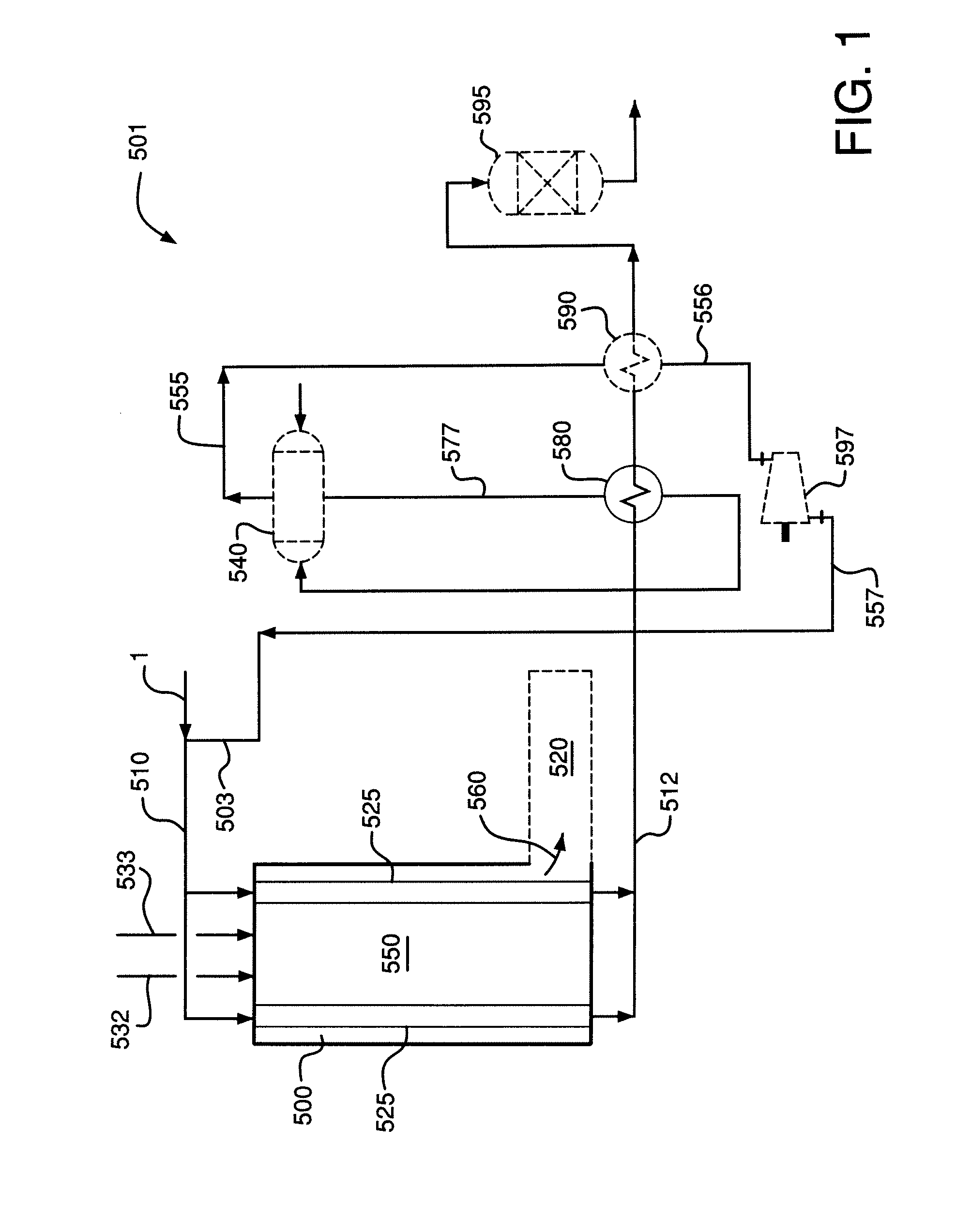

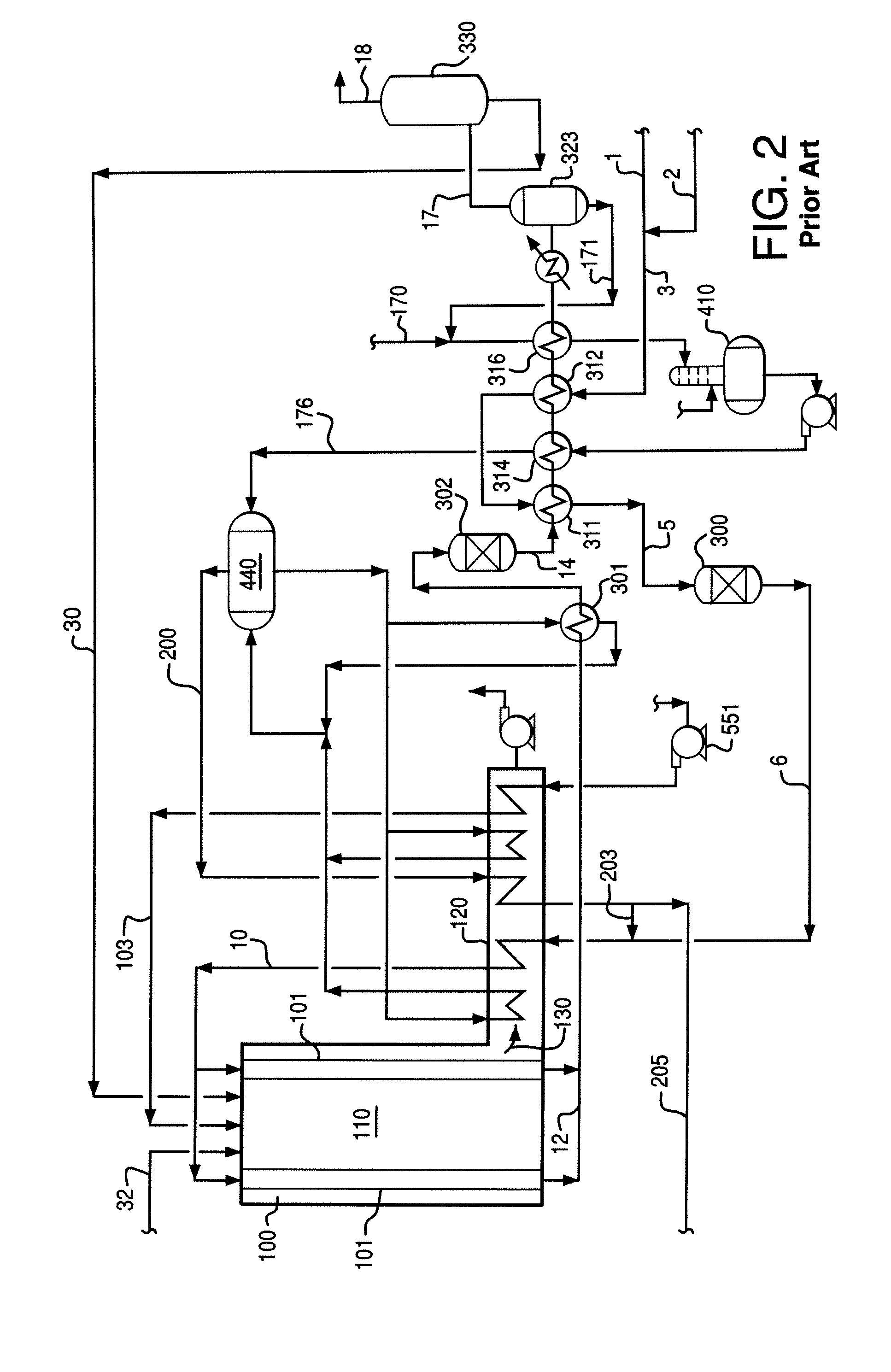

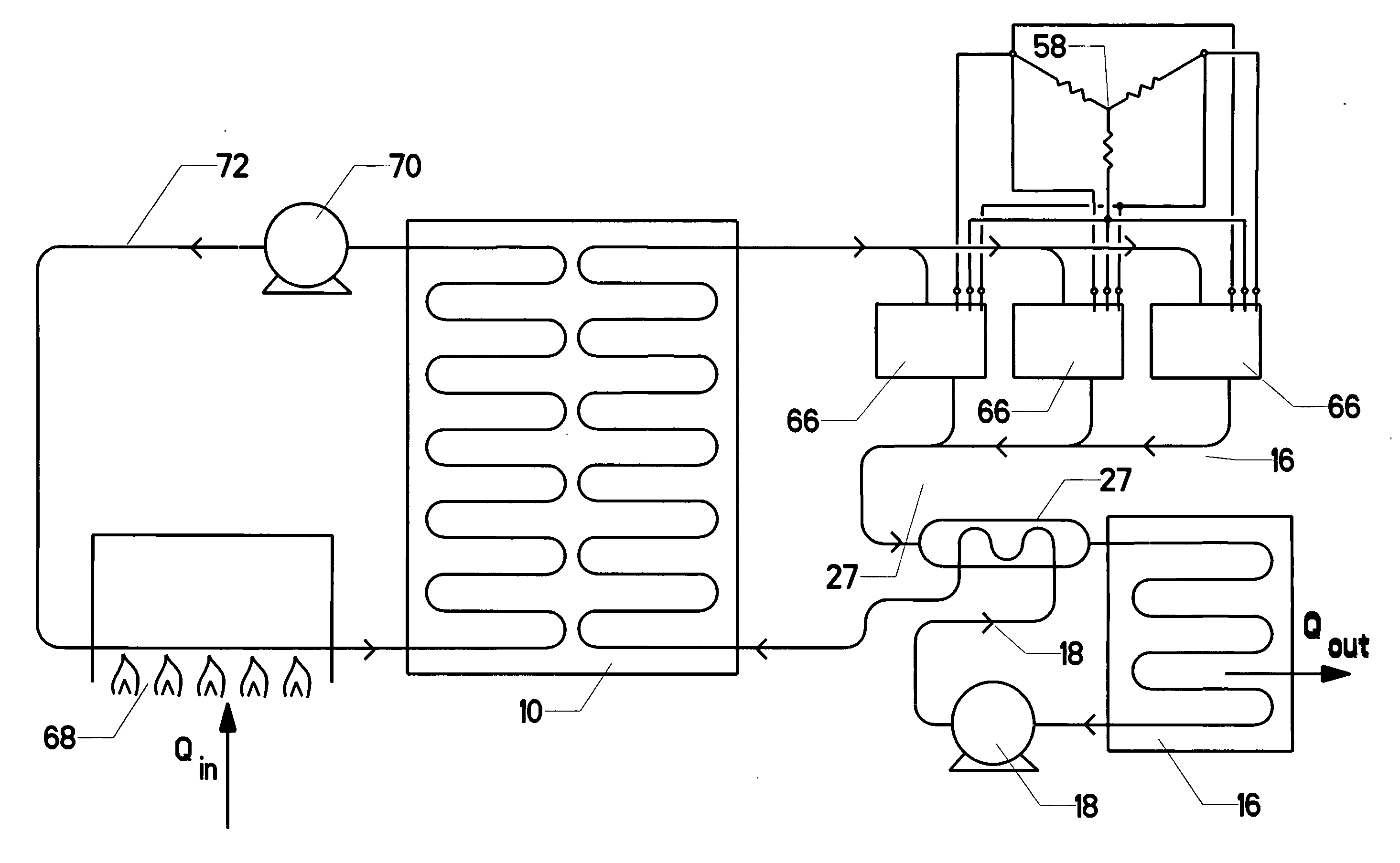

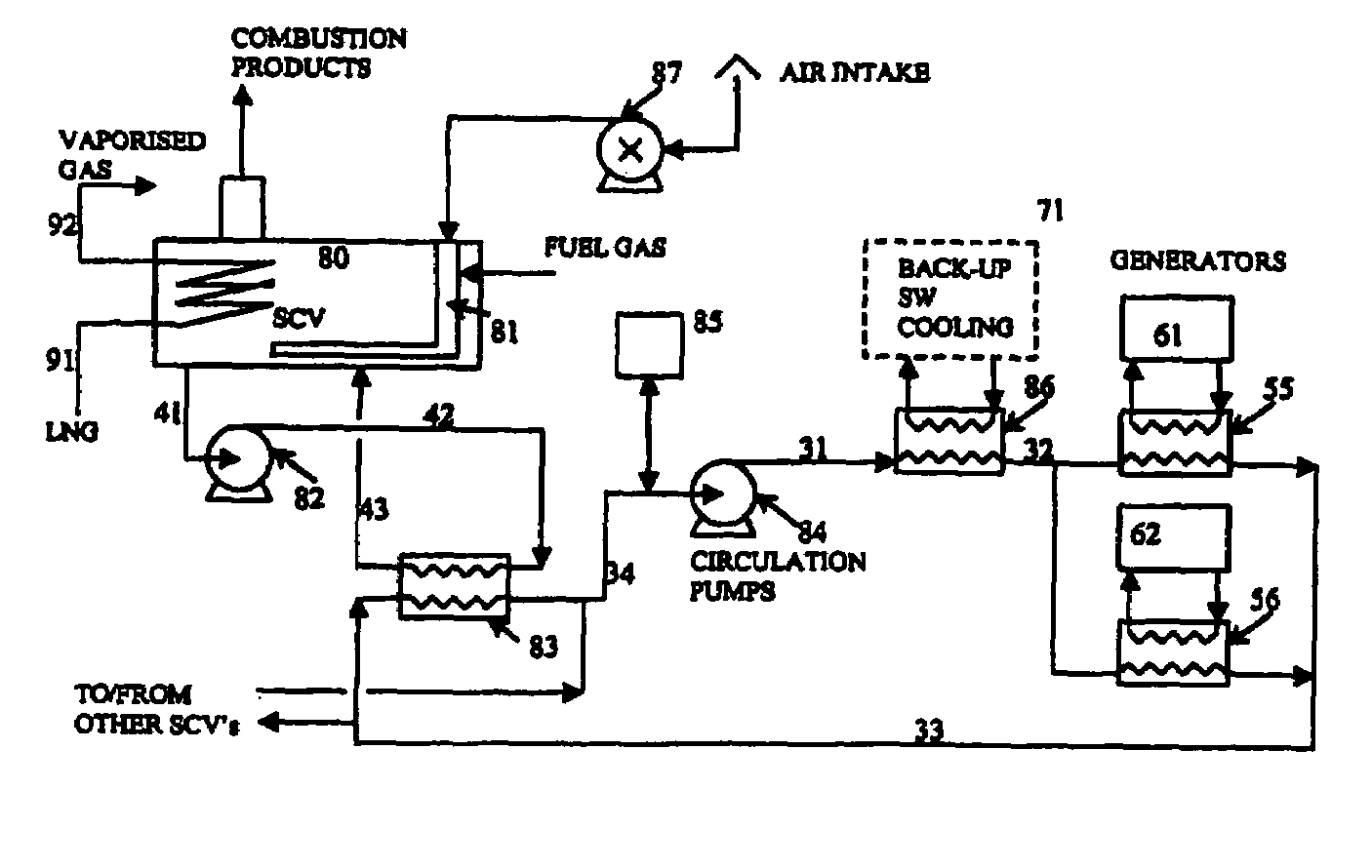

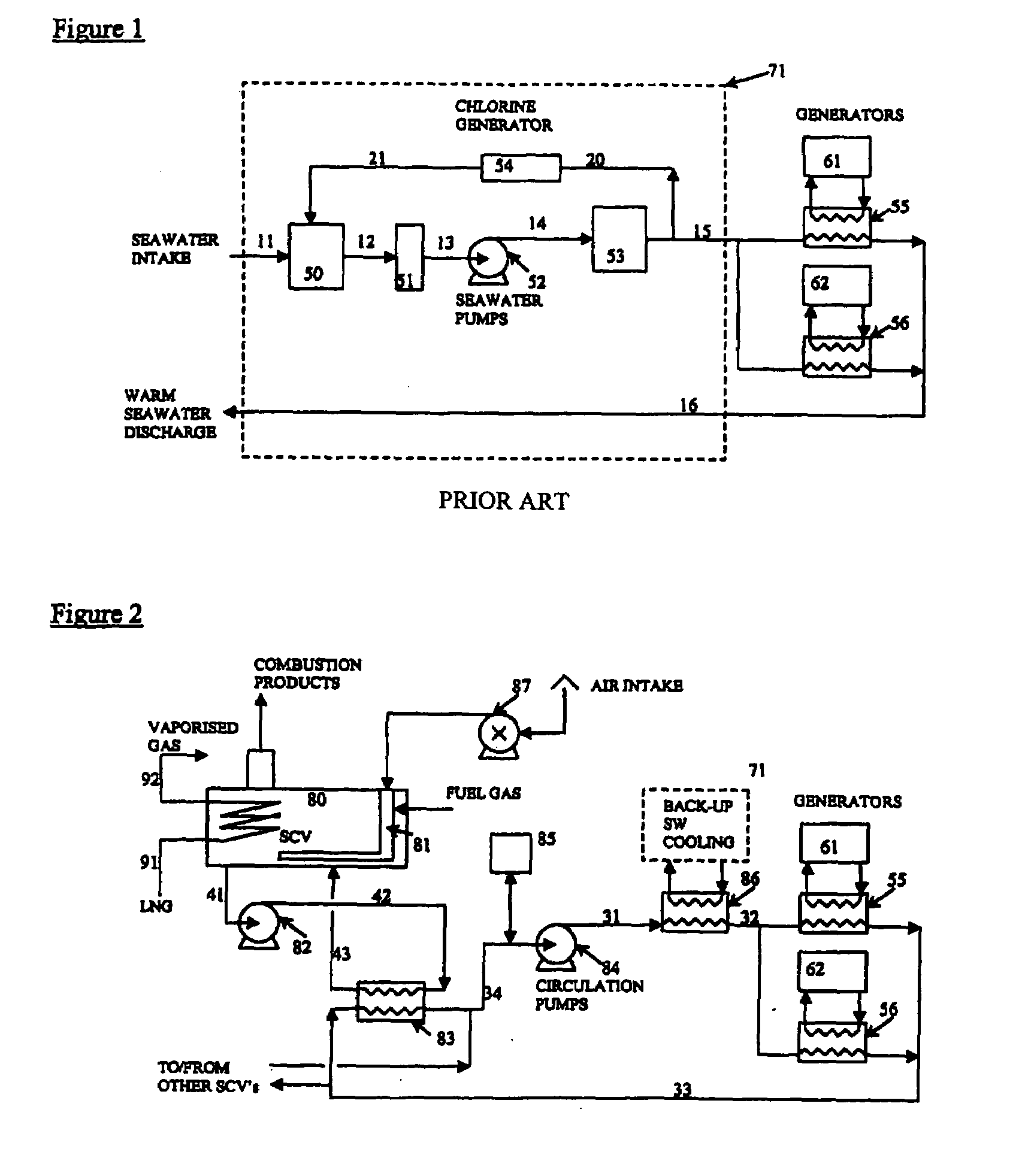

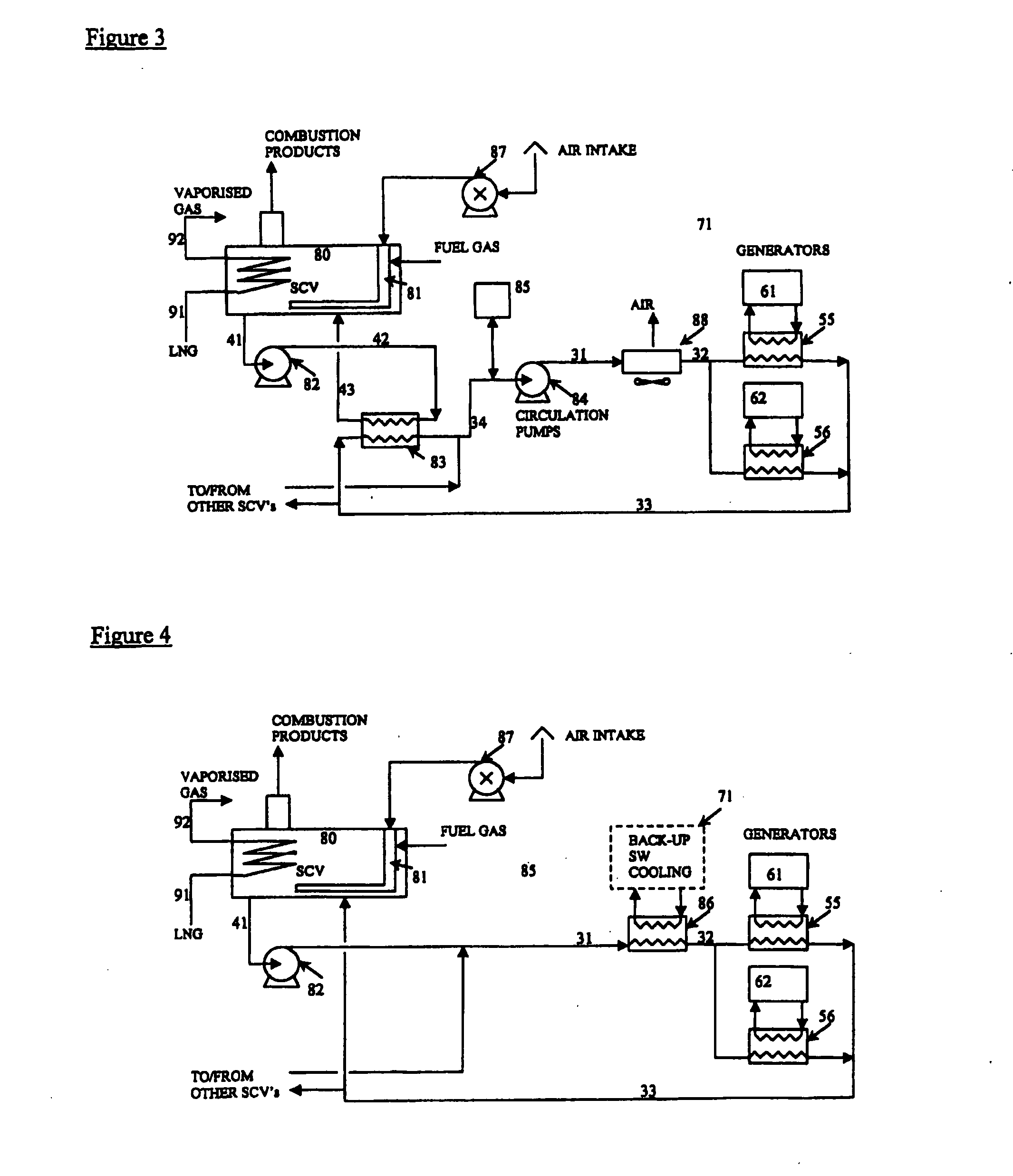

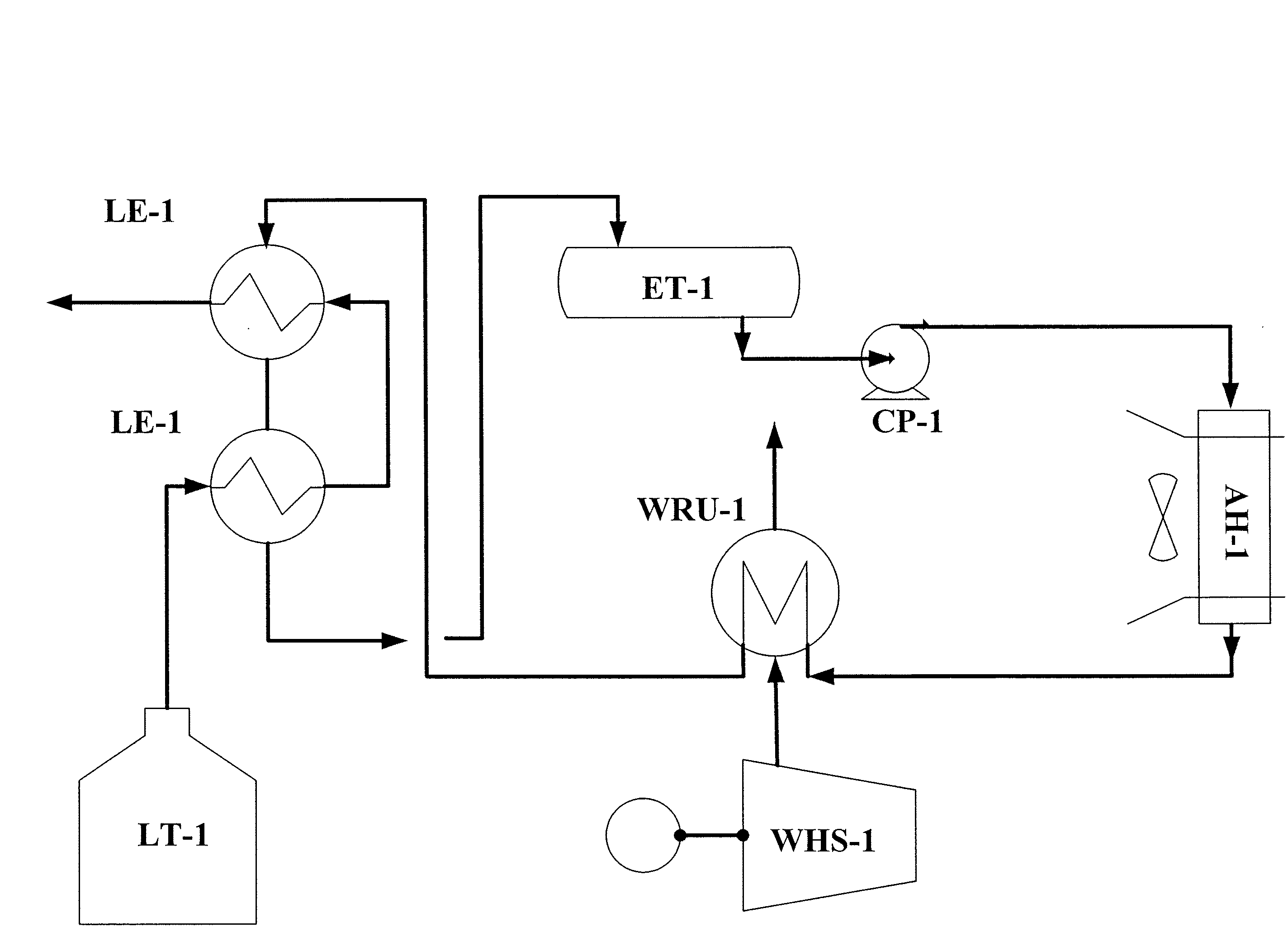

Heat recovery system

InactiveUS20080047280A1Easy to replenishReduce and even eliminateGas handling/storage effectsFluid transferredClosed loopEngineering

A heat recovery system comprising: an LNG warmer; at least one item of equipment requiring cooling and thereby generating waste heat; a heat exchanger arranged to provide heat exchange between the LNG warmer and the waste heat, whereby said waste heat can be used to provide warming for the LNG; wherein said heat exchanger is a closed loop heat exchange means, whereby the heat exchange fluids in said heat exchanger are substantially retained within the heat exchanger during operation of the system. This enables the system to be operated offshore without needing to use the surrounding seawater to provide cooling for the waste heat from the equipment.

Owner:BHP BILLITON INNOVATION PTY LTD

Method and apparatus for power generation using waste heat

InactiveUS20060112693A1High densityReduce flowSteam generation heating methodsSteam usePower stationEngineering

According to the present invention, a method and apparatus for generating power aboard a marine vessel is provided. The method comprises the steps of: (a) providing a Rankine Cycle device that includes at least one of each of an evaporator, a turbo-generator that includes a turbine coupled with an electrical generator, a condenser, and a refrigerant feed pump; (b) disposing the one or more evaporators within an exhaust duct of a power plant of the marine vessel; (c) operating the power plant; and (d) selectively pumping refrigerant through the Rankine Cycle device, wherein refrigerant exiting the evaporator powers the turbine, which in turn powers the generator to produce power.

Owner:CARRIER CORP

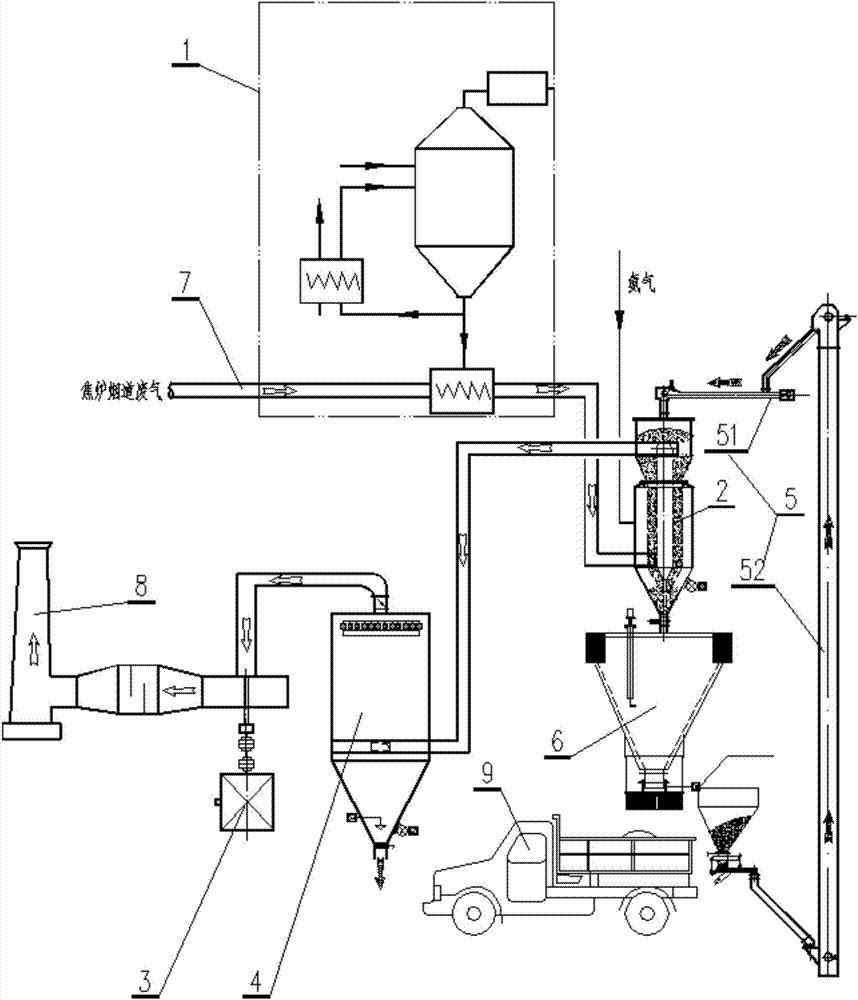

Coke oven flue gas waste heat utilization and purification method

ActiveCN103877856AReduce consumptionEfficient governanceDispersed particle separationPurification methodsCoking plant

The invention relates to the technical field of coke oven flue gas integrated utilization and pollution treatment and in particular relates to a coke oven flue gas waste heat utilization and purification method. The method is characterized in that flue gas waste heat is recovered by utilizing a flue gas waste heat recovery device, the temperature of the flue waste gas is reduced, and integrated desulfurization and denitration of the flue waste gas is realized by utilizing the activated adsorption capacity and low-temperature denitration catalytic capability of the coke. Compared with an existing process, the method has the beneficial effects that the flue waste gas desulfurization and denitration is performed under low-temperature working conditions, an additional heating system is not needed, and the energy consumption is reduced. In order to realize the desulfurization and denitration under low-temperature working conditions, the flue waste gas is cooled through the waste heat recovery device, so that the waste heat of the flue waste gas is fully utilized. The coke serves as a main catalyst for desulfurization and denitration and comes from a coking plant, the source is sufficient, and waste loss is avoided. The method disclosed by the invention can be widely applied to pollution treatment and integrated utilization of coke oven heated flue waste gas in coking production enterprises.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

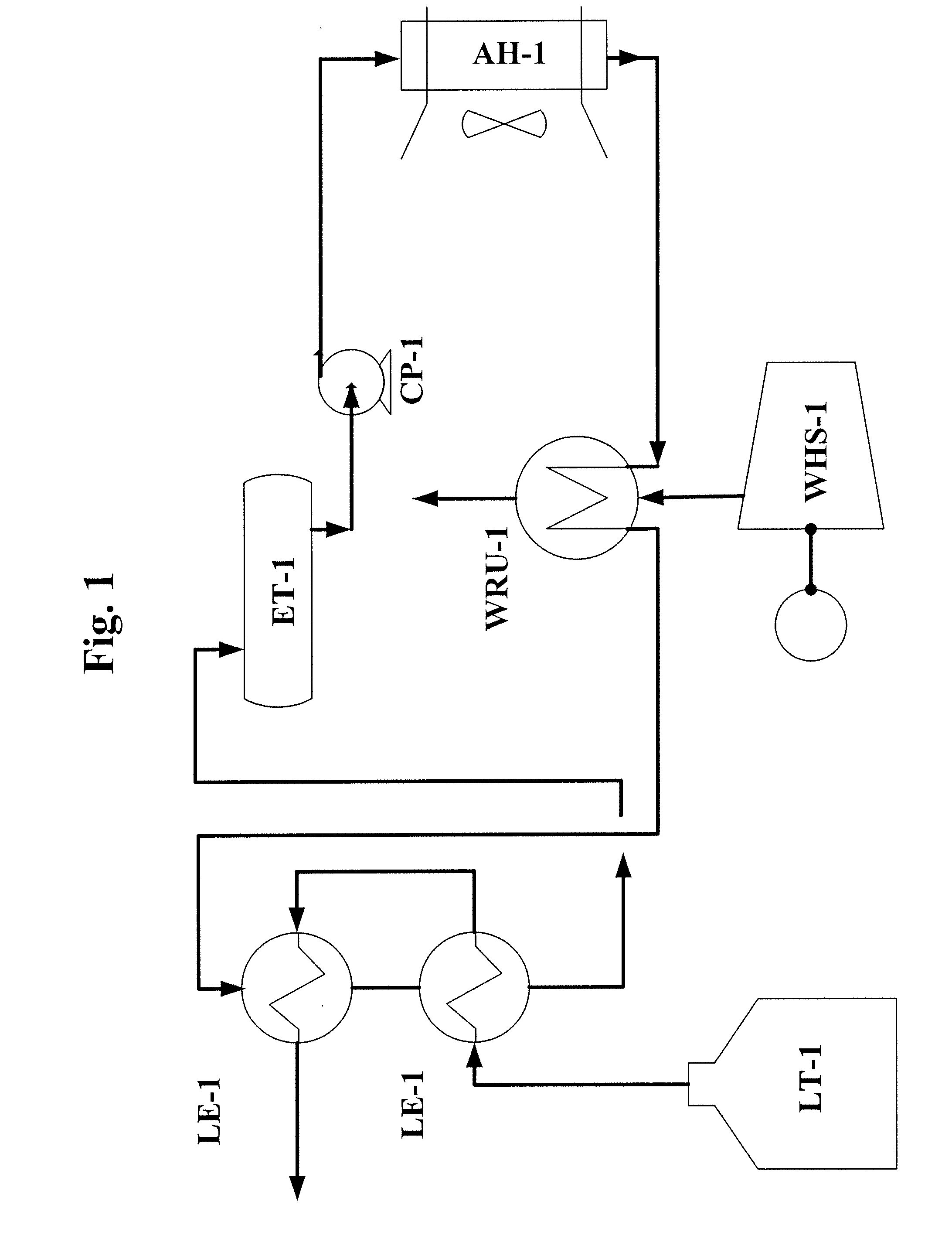

Ecological Liquefied Natural Gas (LNG) Vaporizer System

InactiveUS20080178611A1Gas handling applicationsGas handling/storage effectsProcess engineeringAmbient air

An approach is provided for vaporizing liquefied natural gas (LNG). A system utilizing closed circulation of a heat transfer medium heated by ambient air and waste heat from a waste heat source vaporizes the LNG.

Owner:AMEC FOSTER WHEELER USA CORP

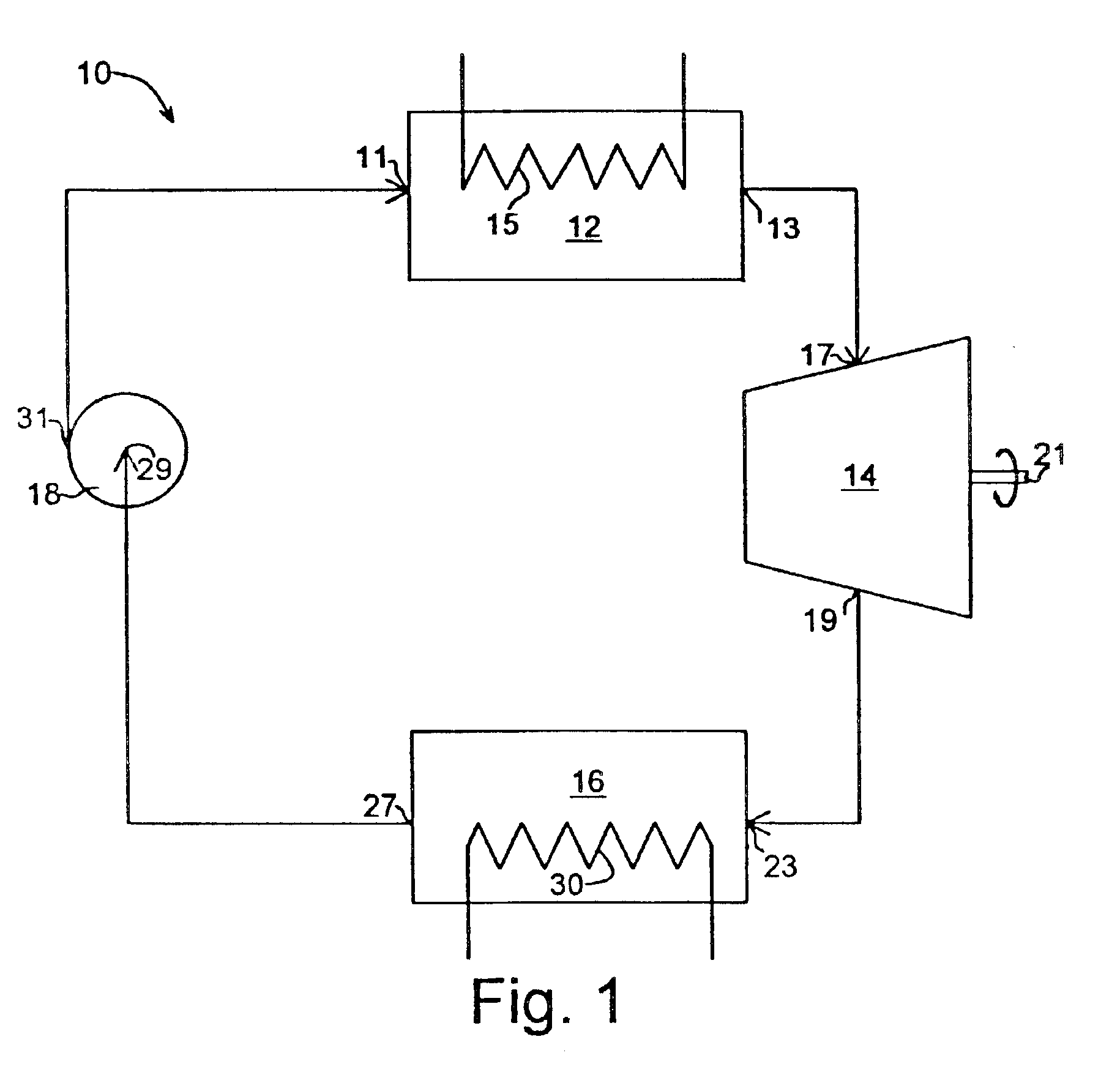

Heat engine

InactiveUS7062913B2Improve efficiencyBoilers/analysersClimate change adaptationWorking fluidEngineering

Owner:OHIO STATE INNOVATION FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com