Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

613 results about "Thermal circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

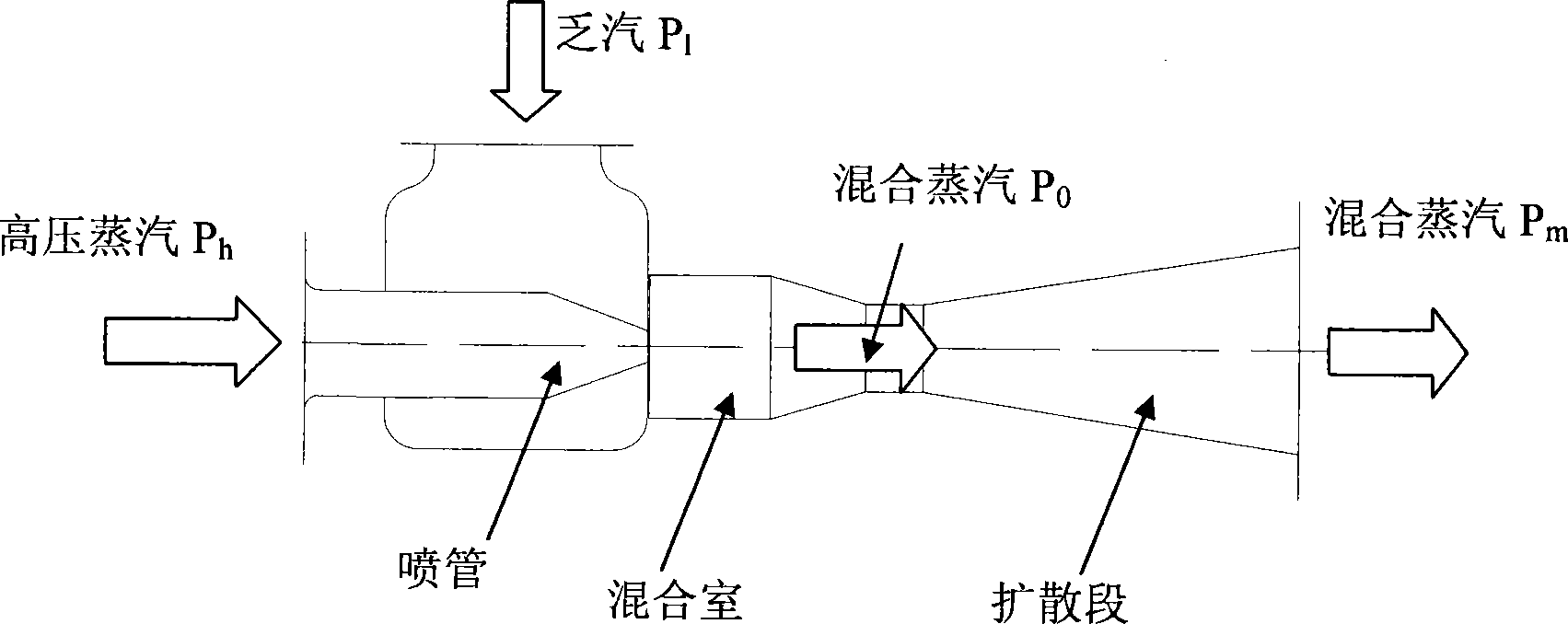

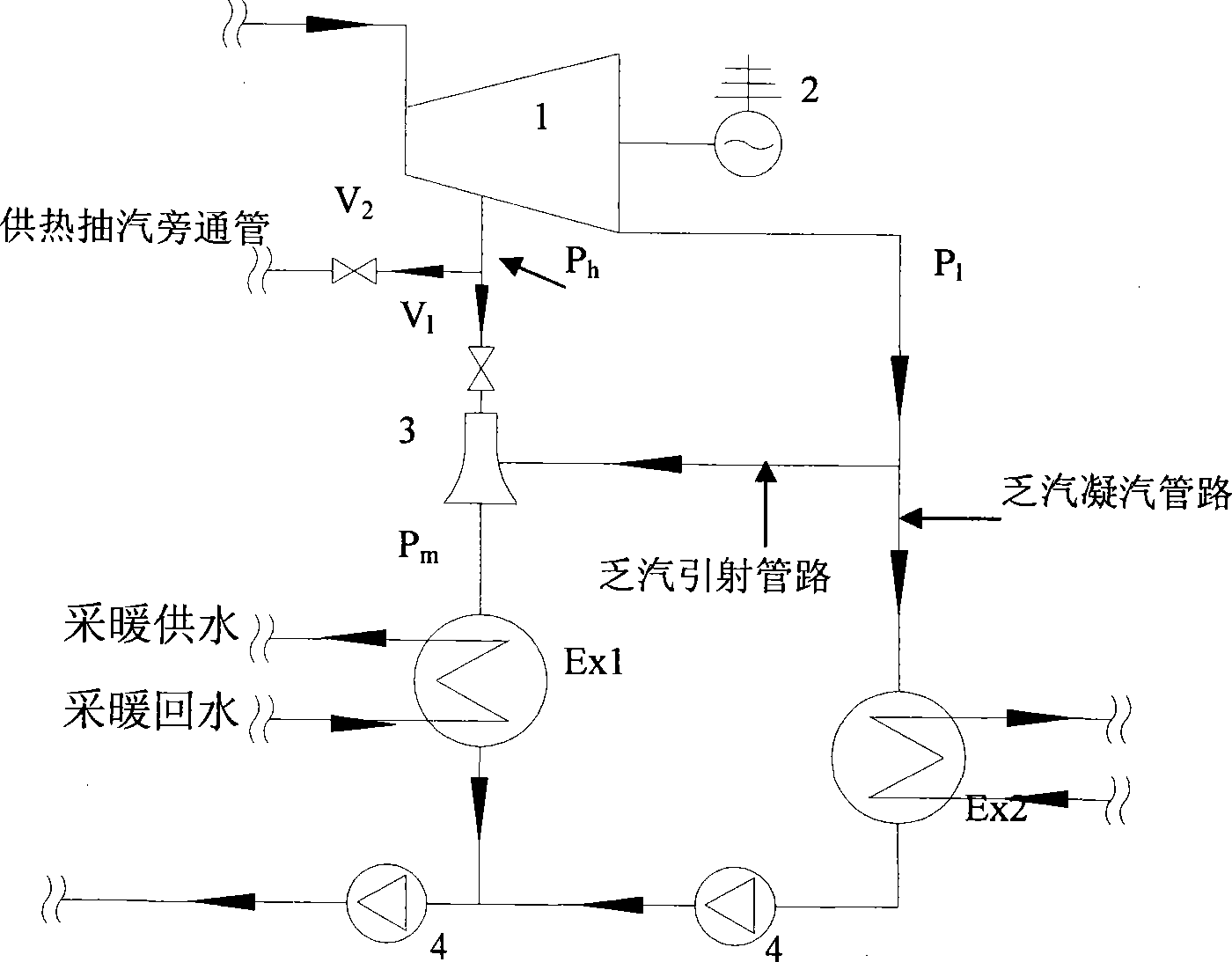

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

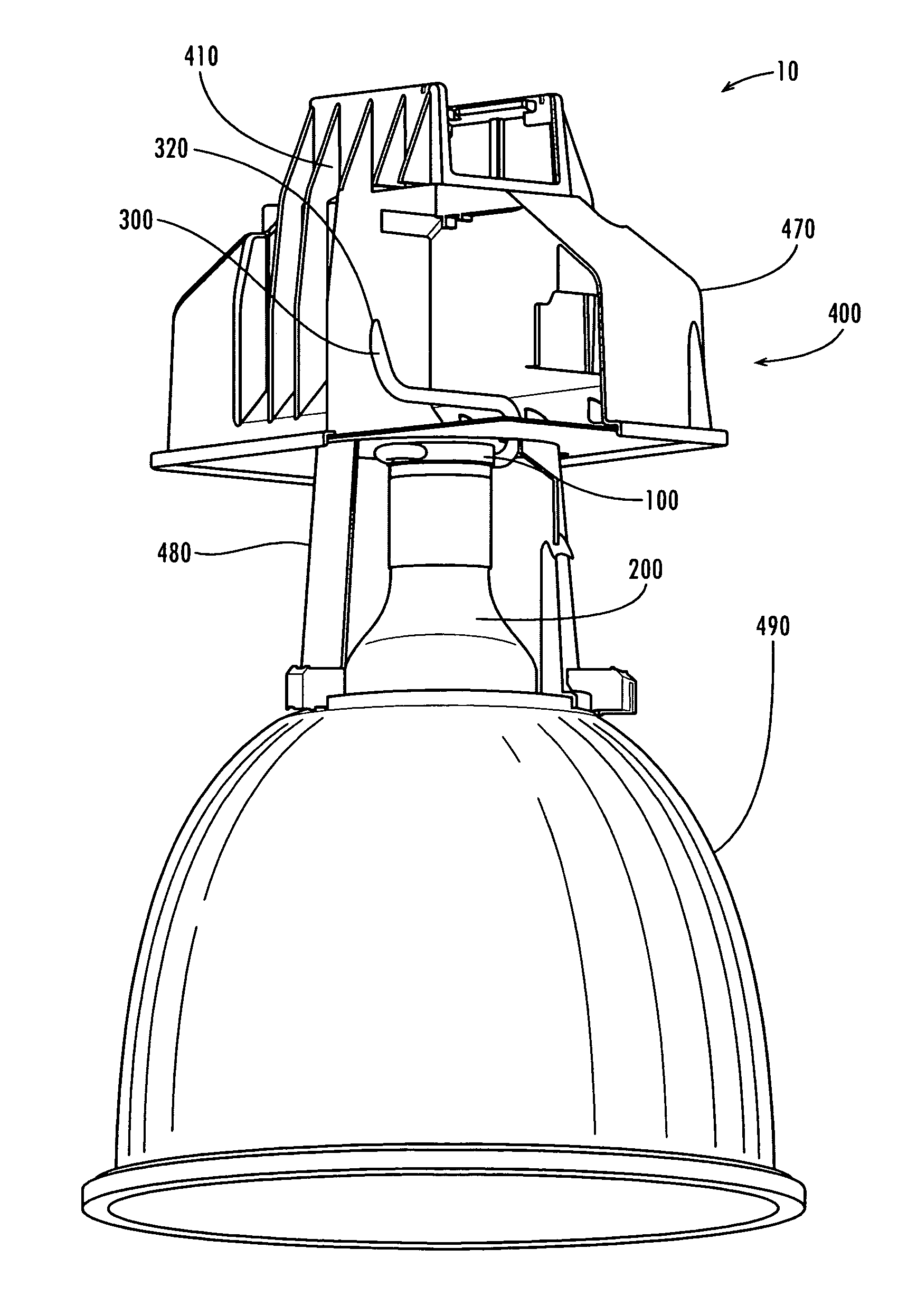

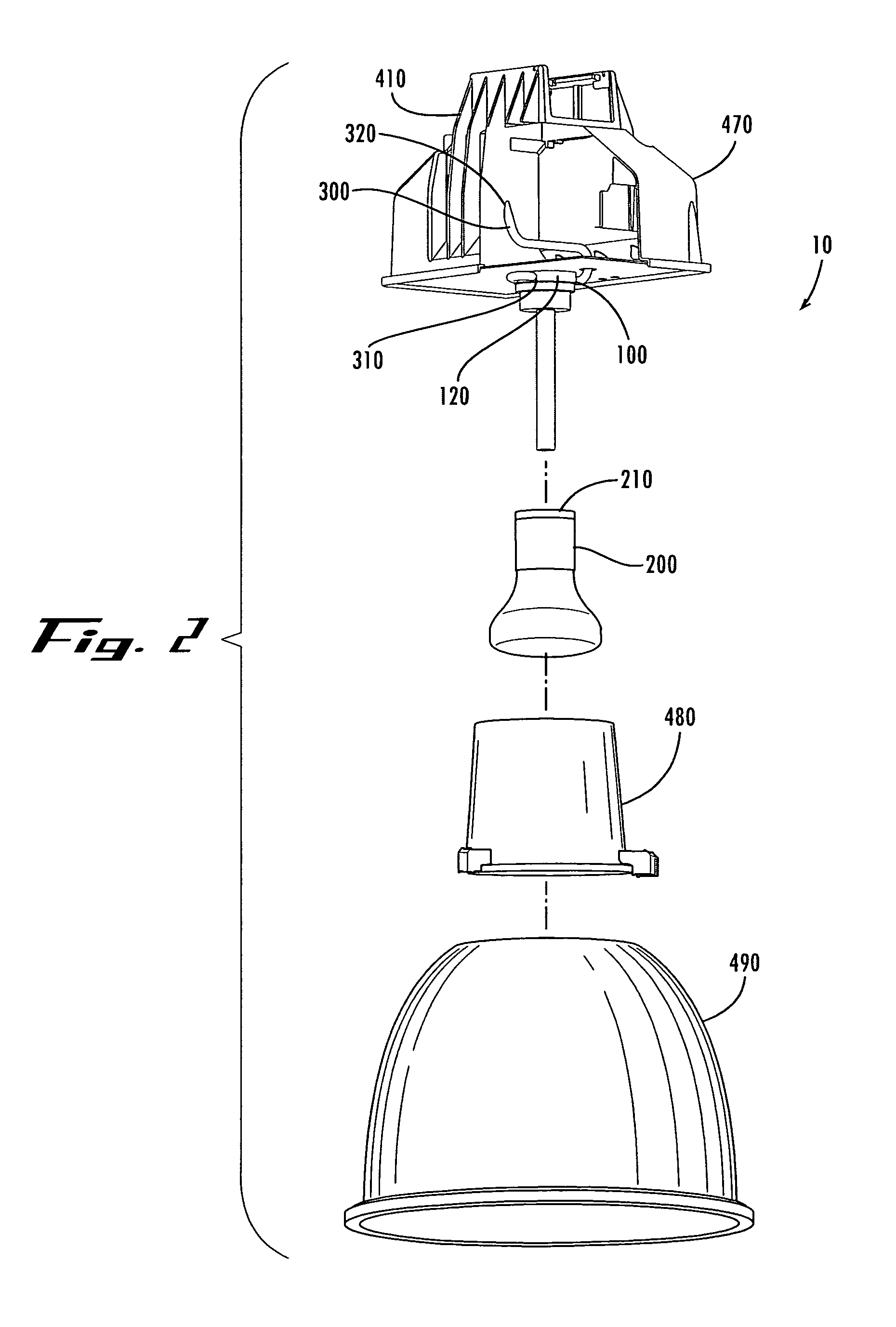

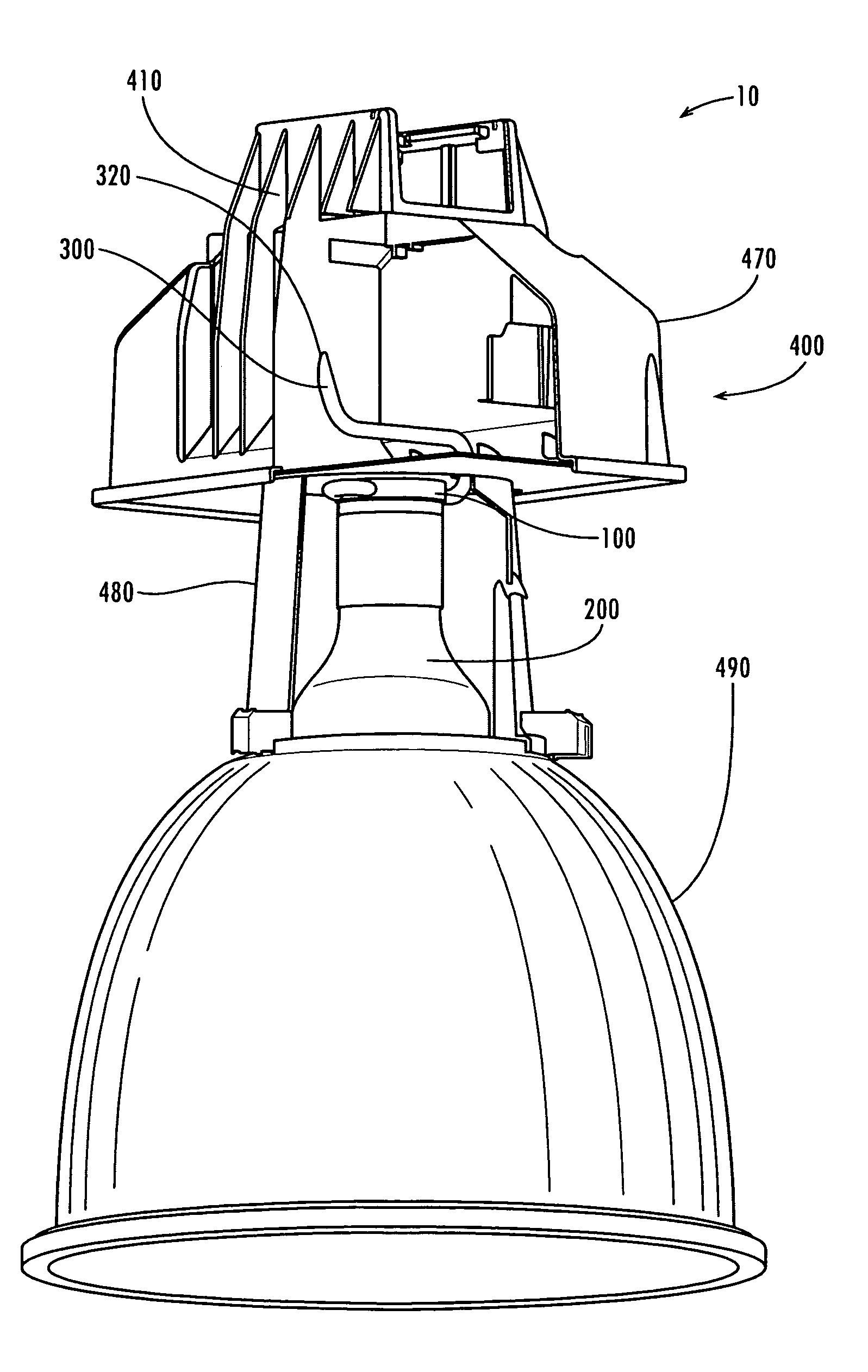

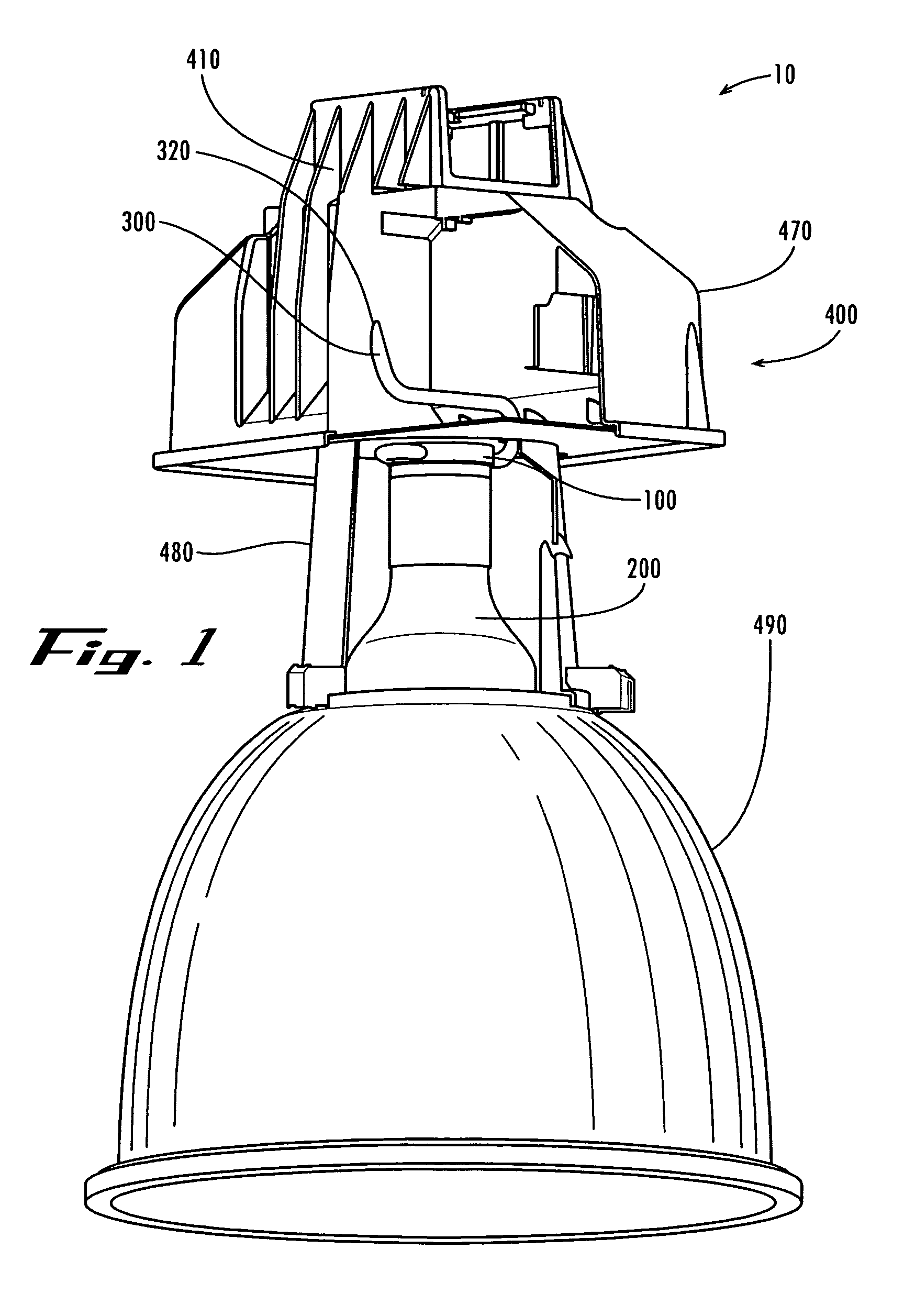

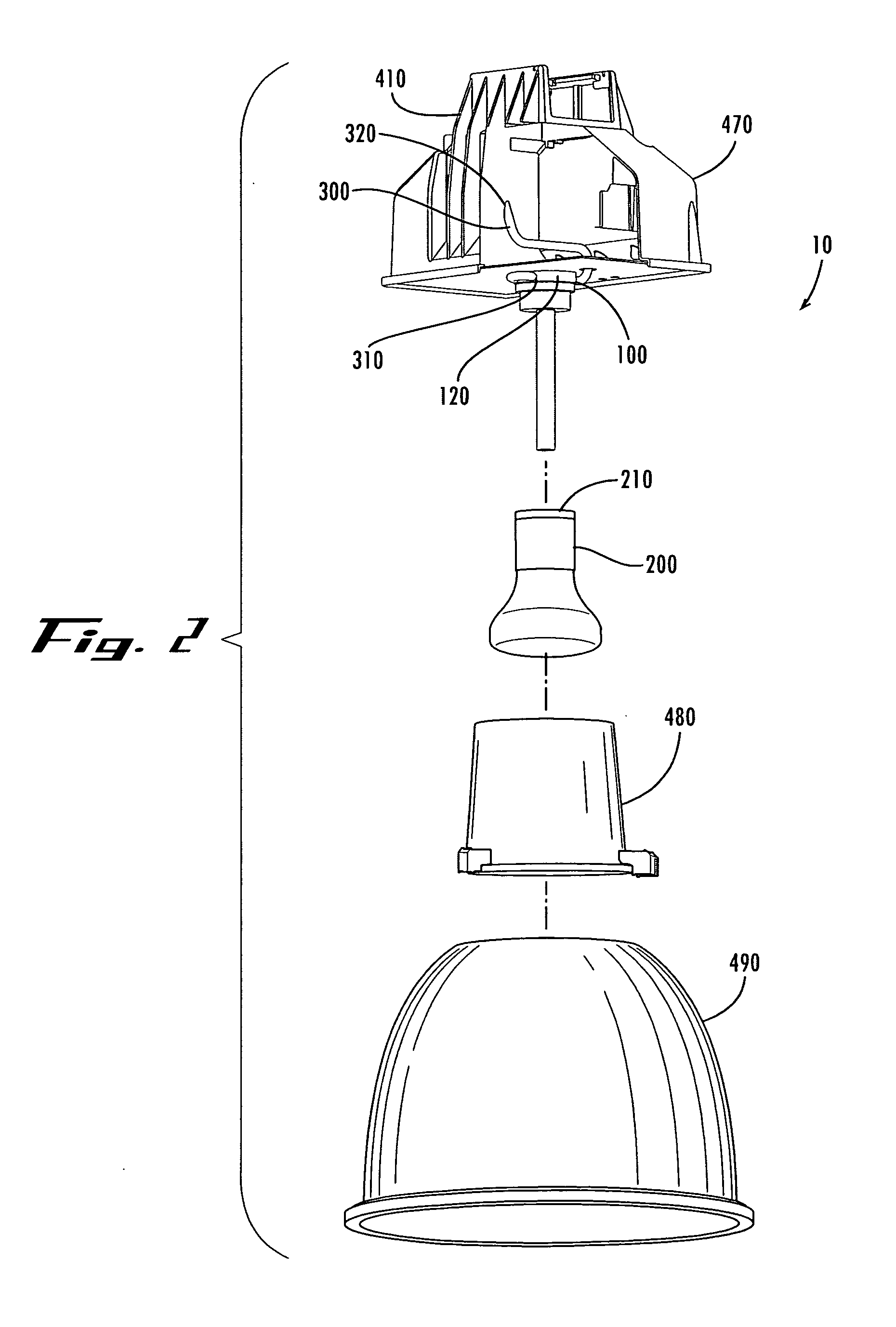

Lamp thermal management system

ActiveUS7438440B2Electric circuit arrangementsLighting heating/cooling arrangementsThermal management systemEngineering

The invention relates to a thermal management system for a lamp. The system comprises a lamp socket that comprises a socket body. The thermal assembly is in thermal communication with the socket body to form a thermal circuit between the lamp and the thermal assembly for dissipating heat generated by the lamp.

Owner:ABL IP HLDG

Lamp thermal management system

ActiveUS20070247853A1Electric circuit arrangementsLighting heating/cooling arrangementsThermal management systemEngineering

The invention relates to a thermal management system for a lamp. The system comprises a lamp socket that comprises a socket body. The thermal assembly is in thermal communication with the socket body to form a thermal circuit between the lamp and the thermal assembly for dissipating heat generated by the lamp.

Owner:ABL IP HLDG

Thermal management system

A thermal management system has a high temperature heat transfer circuit and a low temperature heat transfer circuit for modulating the temperature of heat-generating components having different operating temperatures. The heat transfer circuits are in flow communication and are interdependent so that a single circulating pump can be used to pump a liquid heat transfer medium through both circuits. One of the heat transfer circuits comprises a continuous loop and the other heat transfer circuit comprises an open loop having a first end and a second end at which it is in flow communication with the first heat transfer circuit. Each heat transfer circuit is provided with a heat exchanger to modulate temperature of the heat transfer medium.

Owner:DANA CANADA CORP

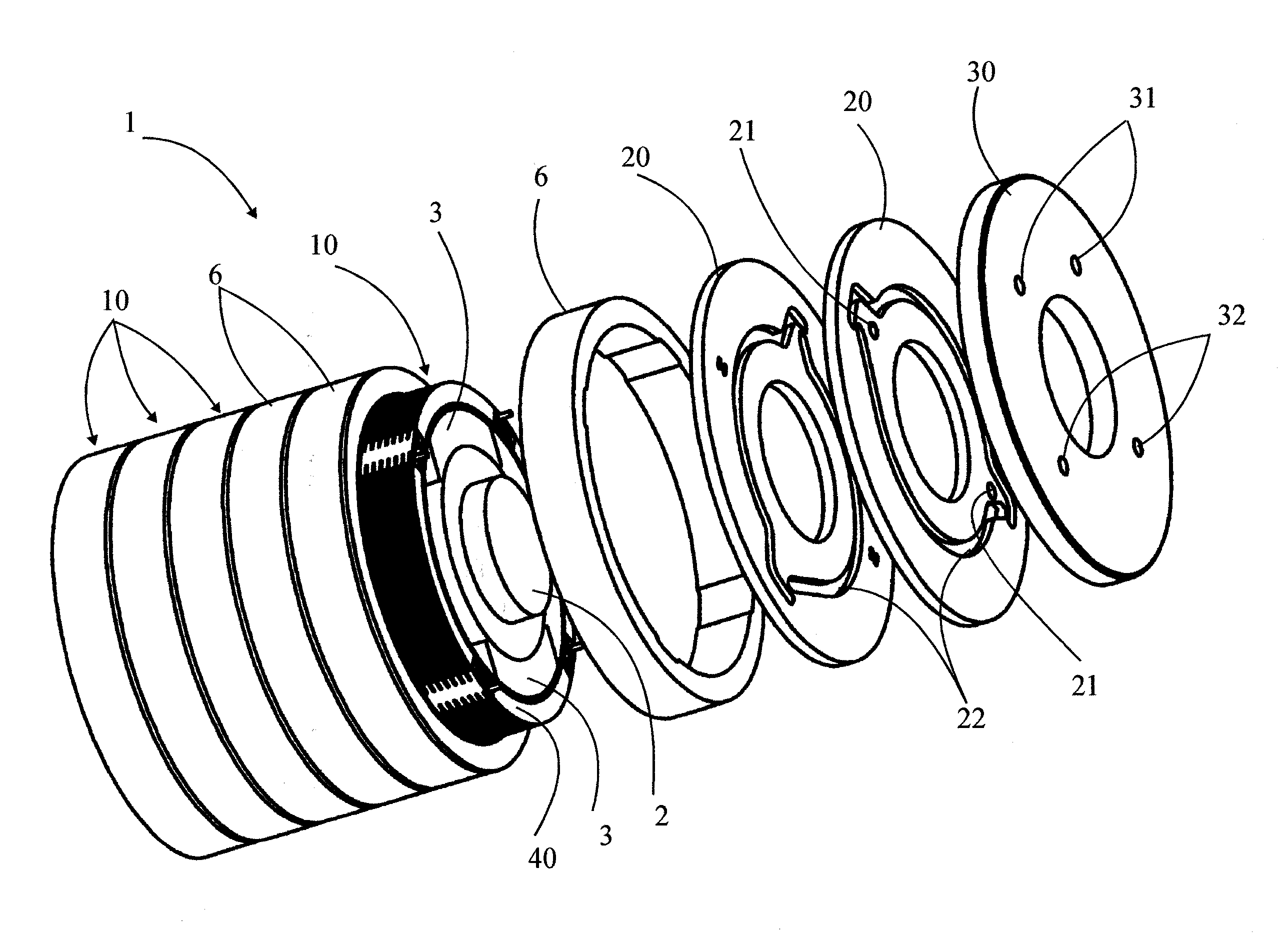

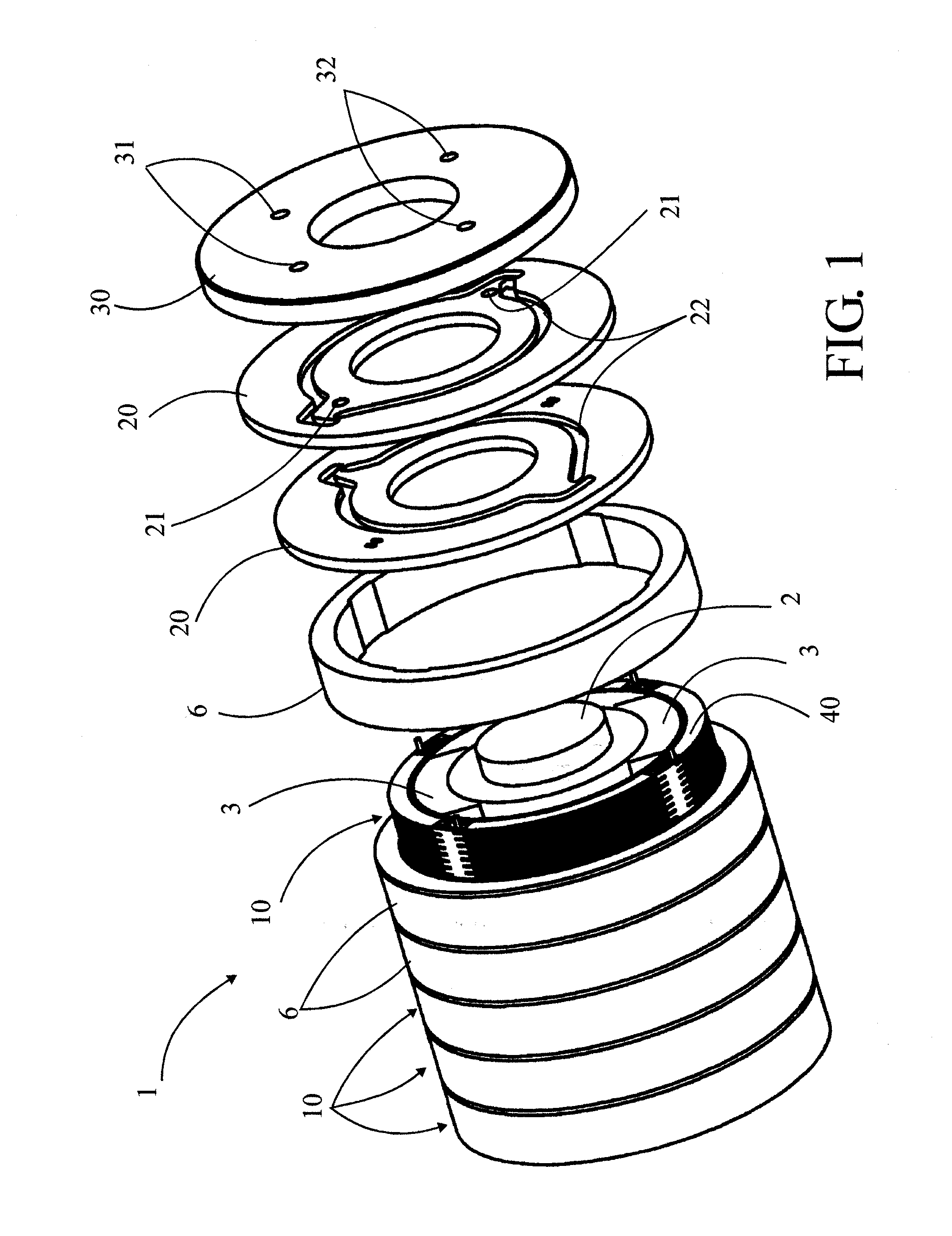

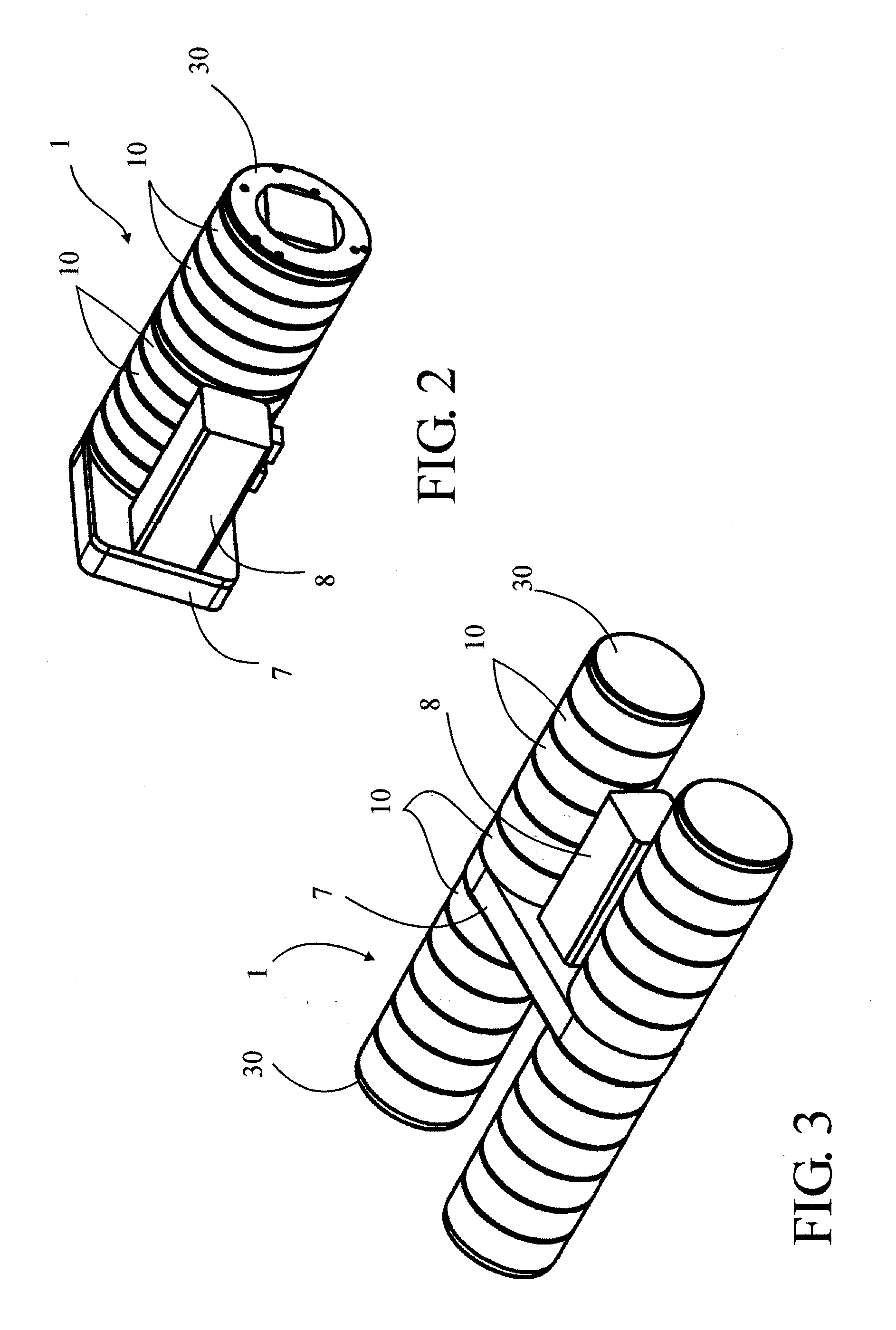

Magnetocaloric thermal generator

InactiveUS20090320499A1Maximal transfer coefficientImprove energy efficiencyEnergy efficient heating/coolingMachines using electric/magnetic effectsMagnetoEngineering

The present invention concerns a compact, multi-purpose magneto-calorific thermal generator of high thermal efficiency, having a maximal heat exchange coefficient, while being simple to industrialise in order to respond to a wide range of both industrial and domestic applications.The thermal generator (1) is characterised in that it comprises at least one thermal module (10) constituted from many thermal elements (40), stacked and arranged in order to delimit between each other channels for the circulation of heat transfer fluid, these channels being divided into hot channels in which the heat transfer fluid of the hot circuit flows and cold channels in which the heat transfer fluid of the cold circuit flows, the hot and cold channels being alternated between the said thermal elements (40) and in that the said thermal elements have fluid inlet and outlet orifices which communicate with each other so as to distribute the flow of heat transfer fluid of each hot and cold collector circuit respectively in the corresponding hot and cold channels.Applications: Heating, tempering, air conditioning or refrigeration in any industrial or domestic installation.

Owner:COOLTECH APPL S

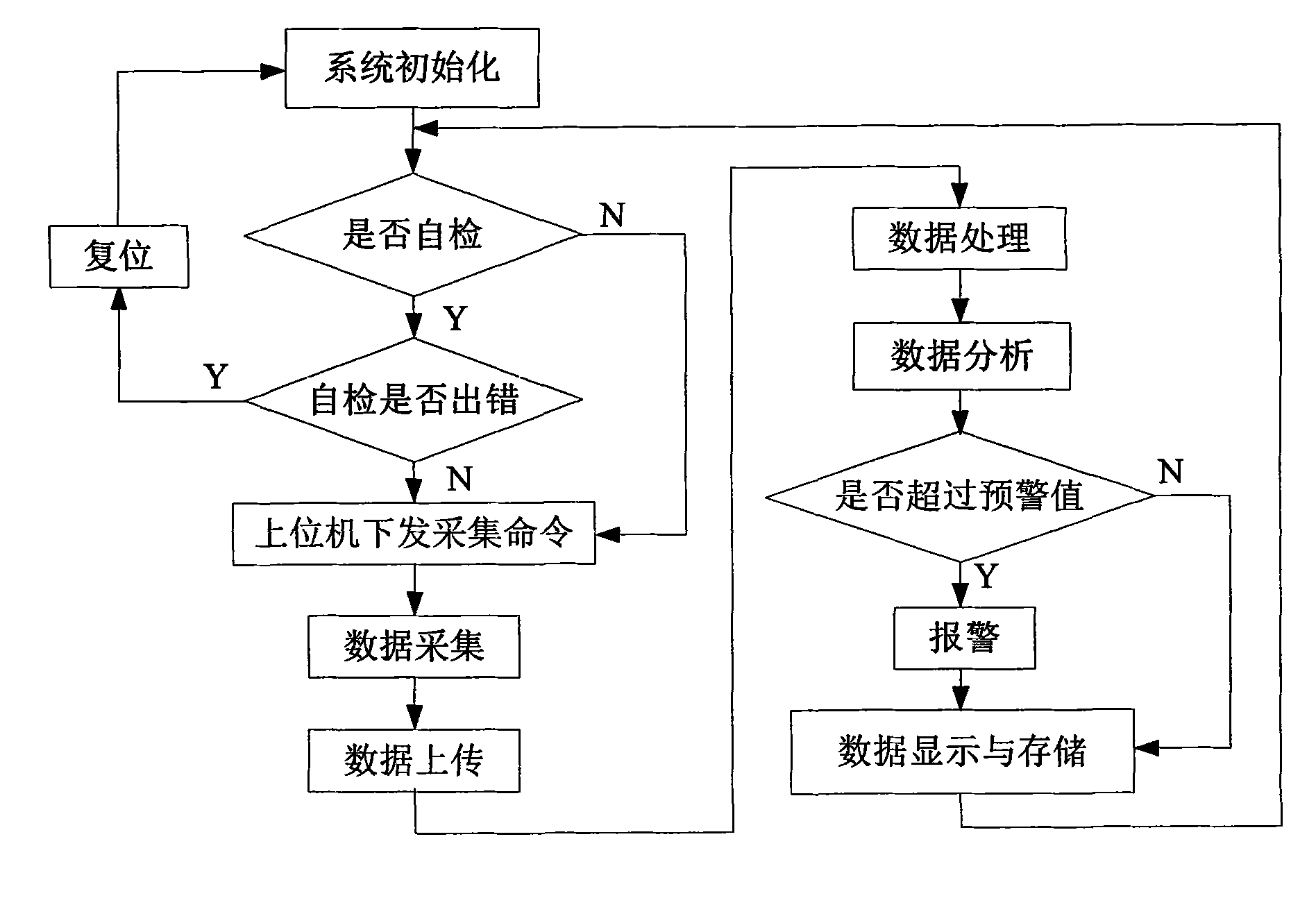

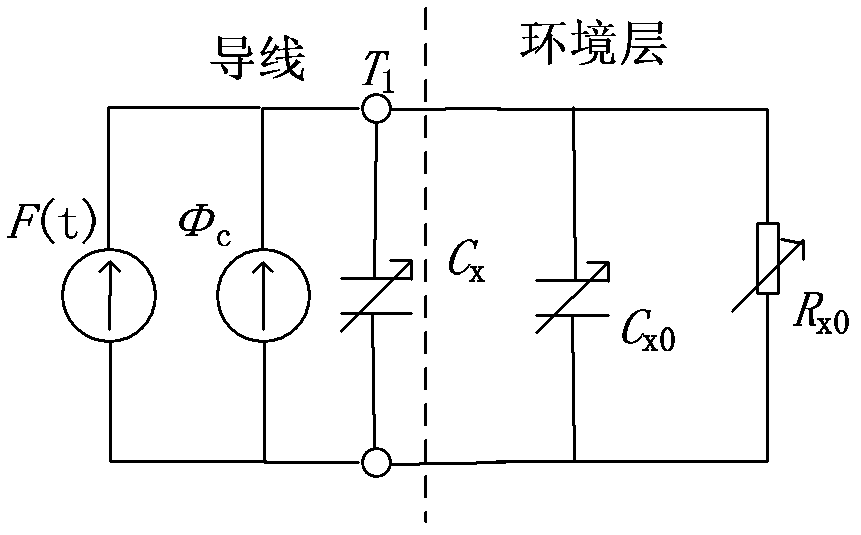

Cable connector fault diagnosing method

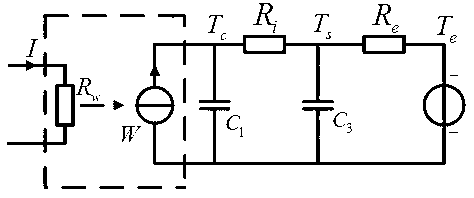

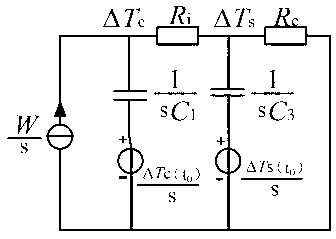

InactiveCN103323703AMeet the needs of online fault monitoringImprove stabilityElectrical testingThermometer applicationsTransient stateReduced model

The invention provides a cable connector fault diagnosing method. The cable connector fault diagnosing method comprises the steps that the temperature of the outer surface of a cable connector and the temperature of a monitoring point (located at the zero potential position of the outer surface of an aluminum protective sleeve or the outer surface of a prefabricated rubber insulating layer) inside the cable connector are monitored in real time; the linear least squares method is used for identifying relevant parameters of cable connector transient state thermal circuit models through the temperatures obtained through real-time monitoring in order to obtain the time constant tau of the first order transient state thermal circuit model and the steady state temperature rise coefficient k of the first order transient state thermal circuit model; and fault diagnose is conducted on the cable connector by the utilization of the identifying result. By means of the cable connector fault diagnosing method, the four common faults of the cable connector can be effectively diagnosed, the defect that in many quality evaluating theories of simplified models, cable heat capacity and the transient state process of cable connector temperature rise are not considered is overcome, the demand for on-line fault monitoring of the cable connector is met, and the stability of system running is improved.

Owner:WUHAN UNIV

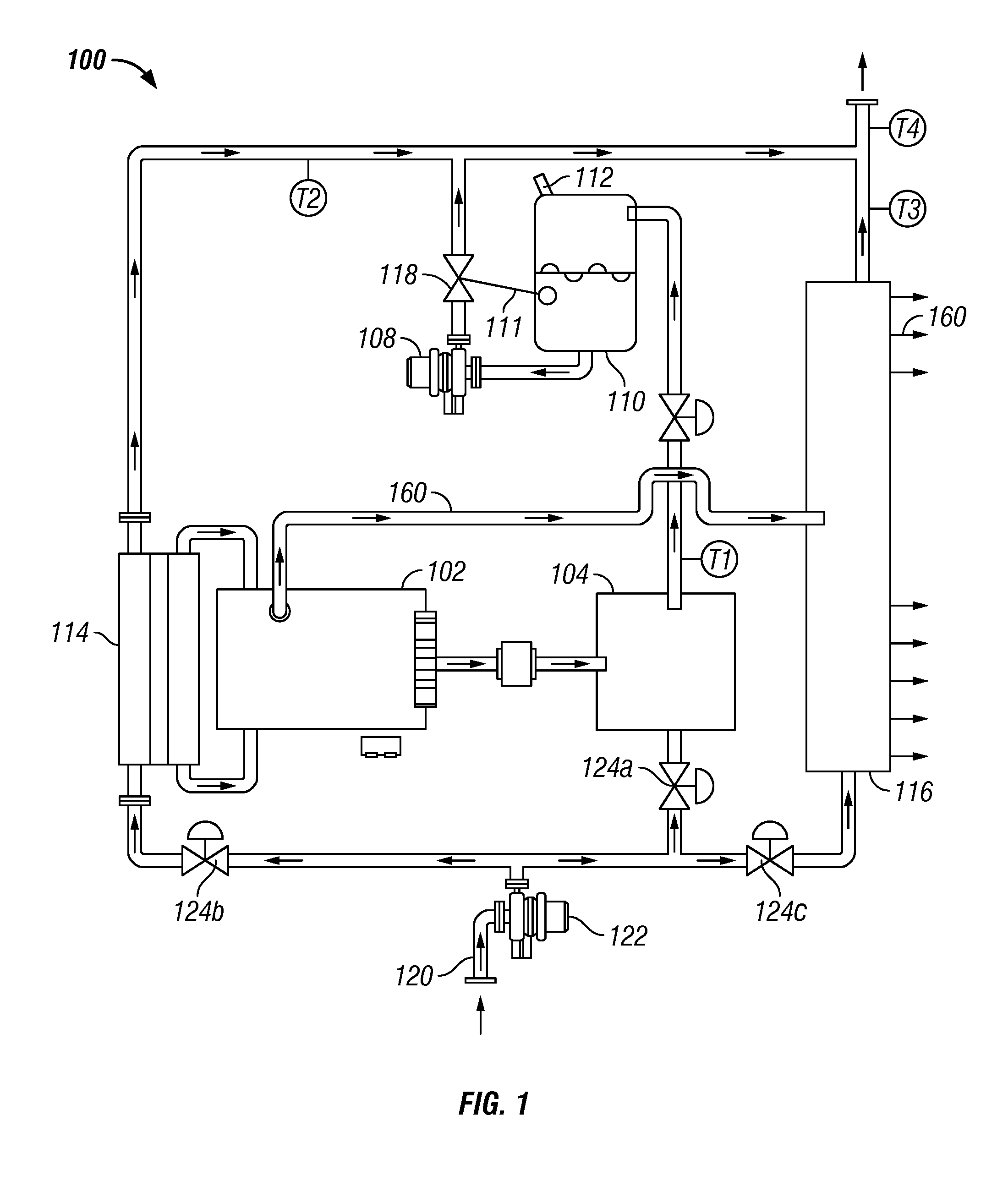

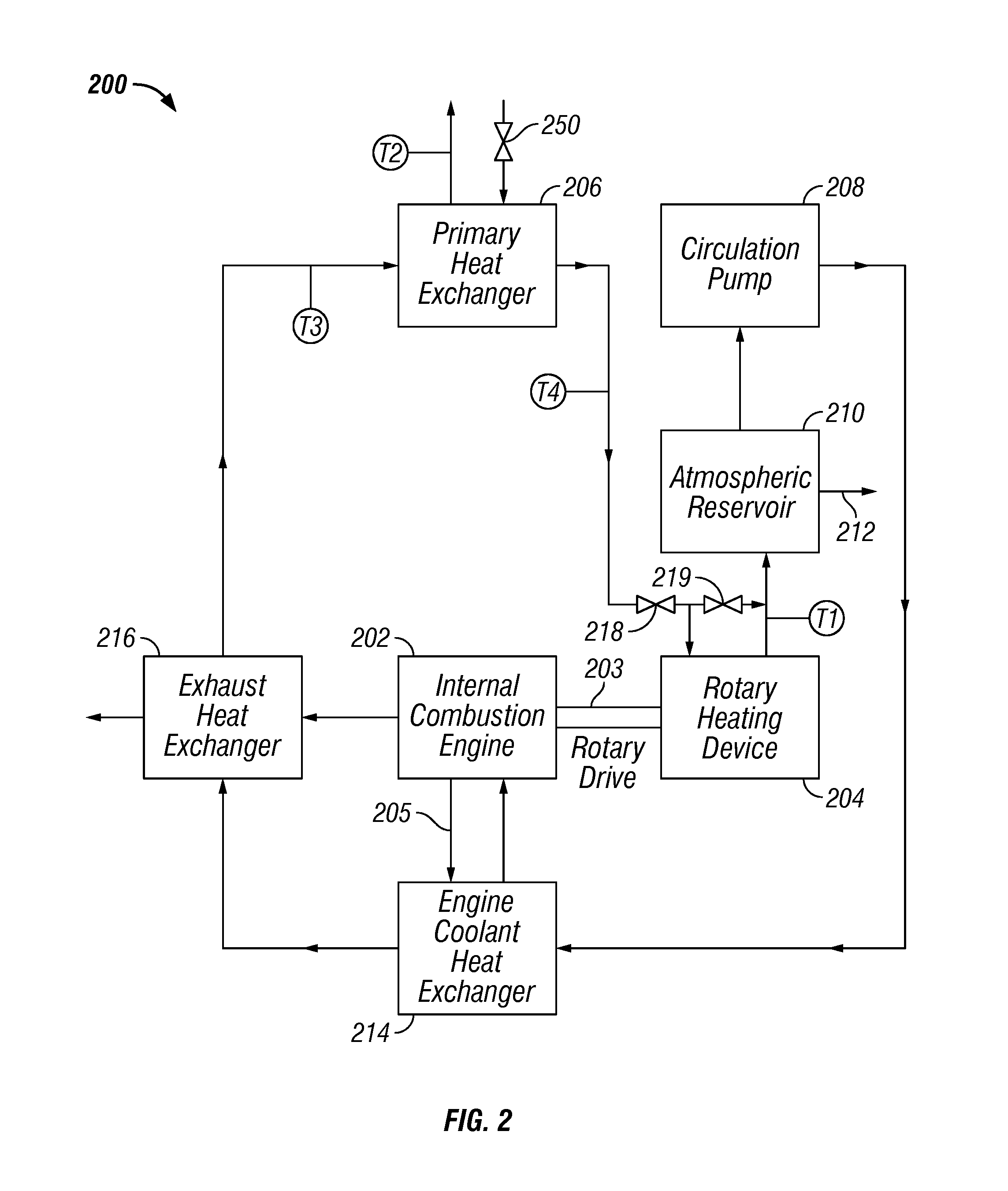

Methods and apparatuses for heating, concentrating and evaporating fluid

InactiveUS20100154395A1Steam generation using mechanical energyAir-treating devicesWater brakeClosed loop

Systems and methods are provided for heating a fluid comprising an opened-loop heating circuit or a closed-loop heating circuit both comprising a rotary heating device, such as a water brake, and a closed-loop direct-fired boiler heating circuit; and systems and methods for evaporating a fluid and systems and methods for concentrating a fluid based on these heating circuits.

Owner:PHOENIX CALIENTE INC

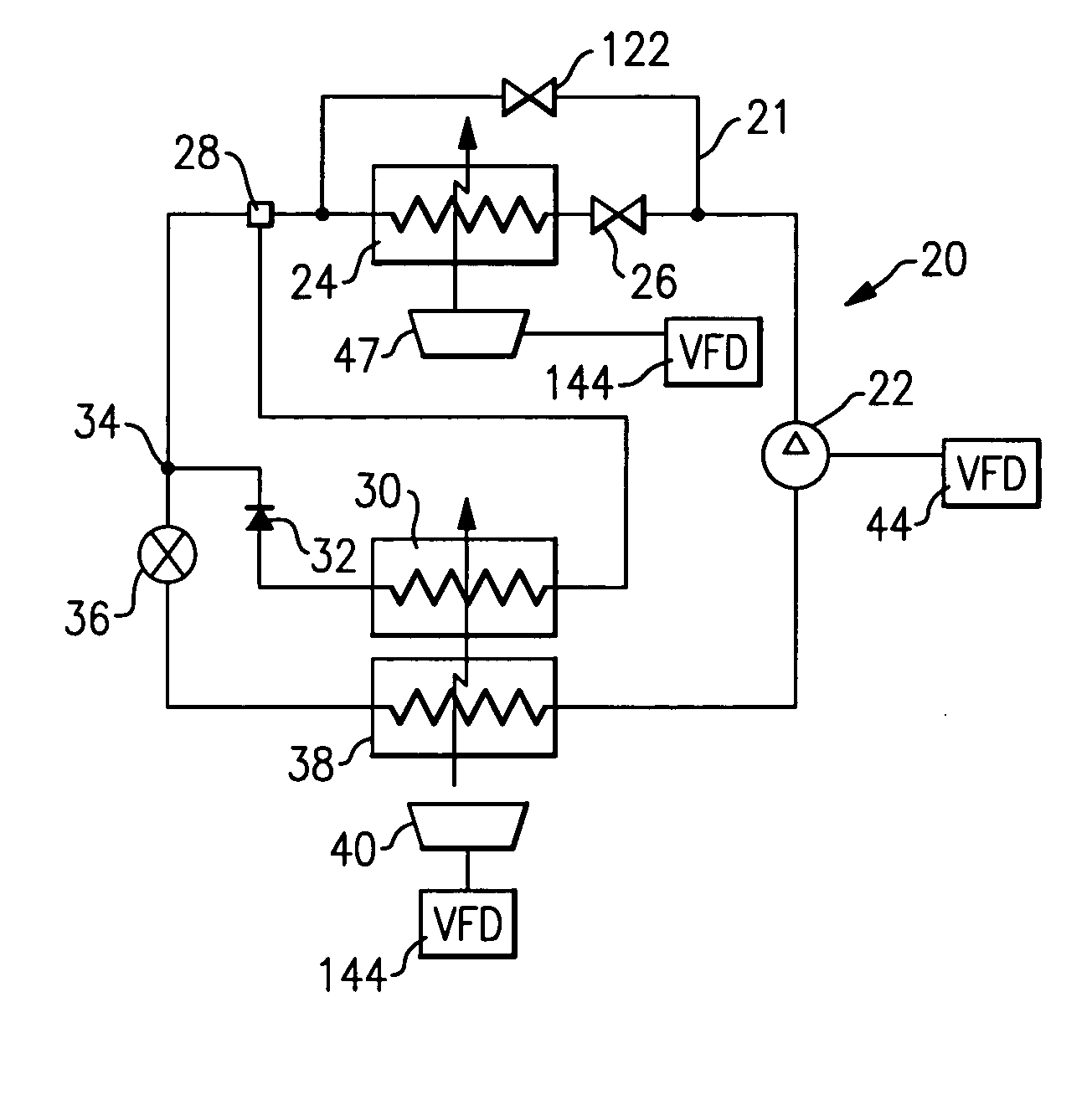

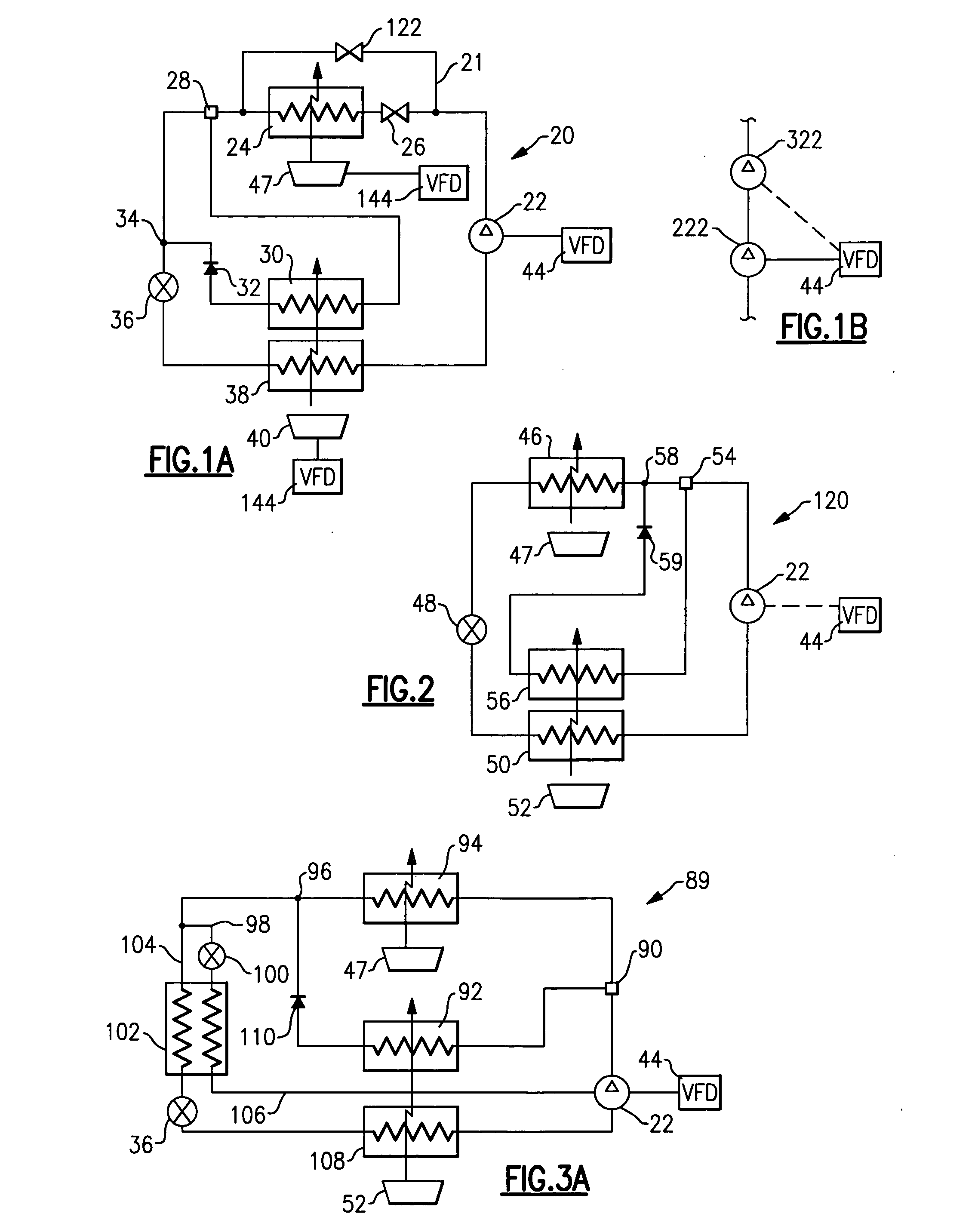

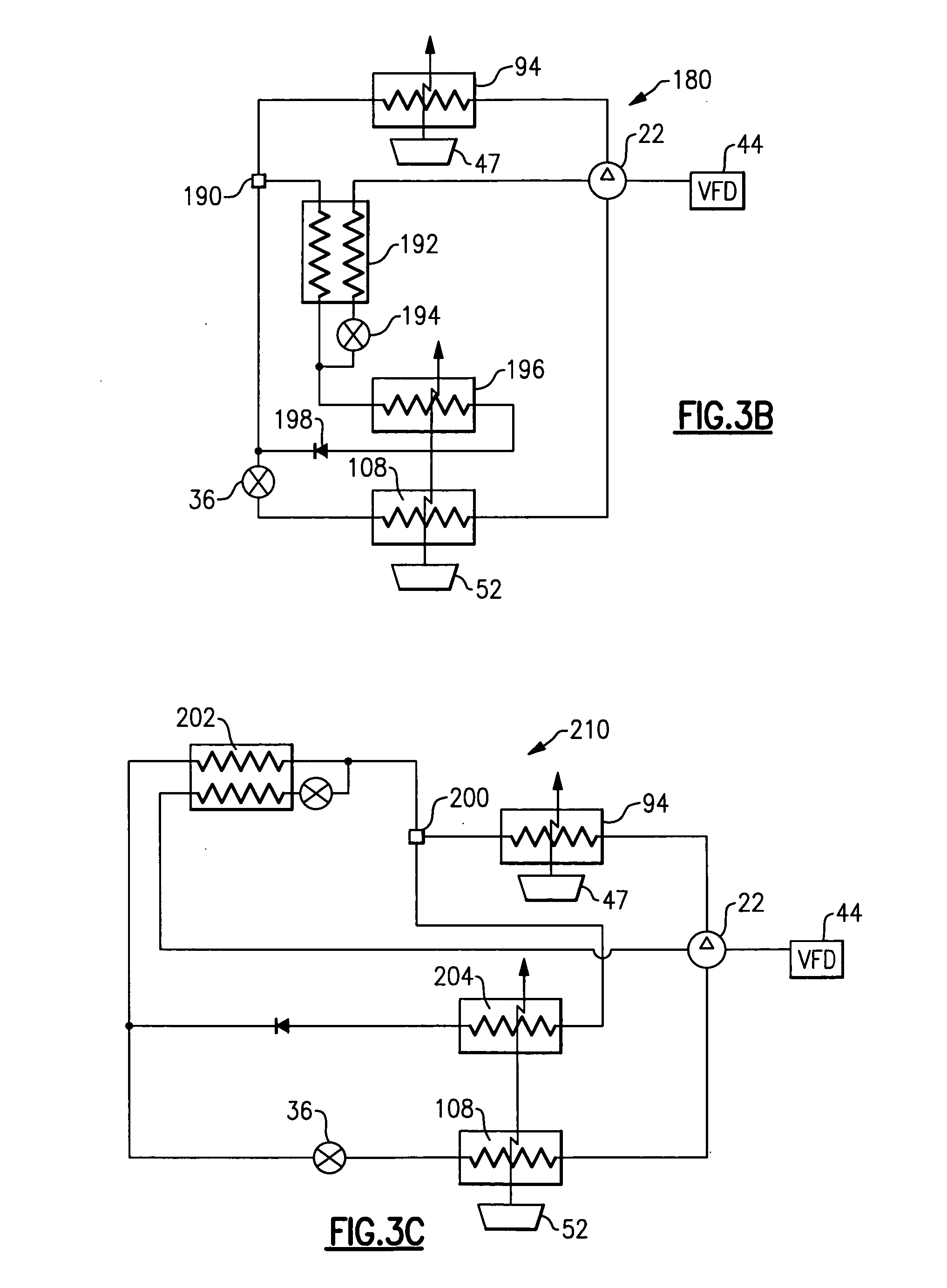

Refrigerant system with variable speed compressor and reheat function

InactiveUS20060225444A1Easy to control humidityIncrease flexibilityCompression machines with non-reversible cycleCompression machines with several condensersControl theoryRefrigerant

Refrigerant systems are provided with selectively operable components that allow variation in the capacity provided by the refrigerant system to achieve desired temperature and humidity levels. A reheat circuit is provided and an economizer circuit may also be added to the system. Typically, the reheat and economizer functions each provide a step change in the humidity control. A compressor having a variable speed drive is utilized. By providing the reheat / economizer functions along with the variable speed compressor, continuously adjustable humidity control is achieved

Owner:CARRIER CORP

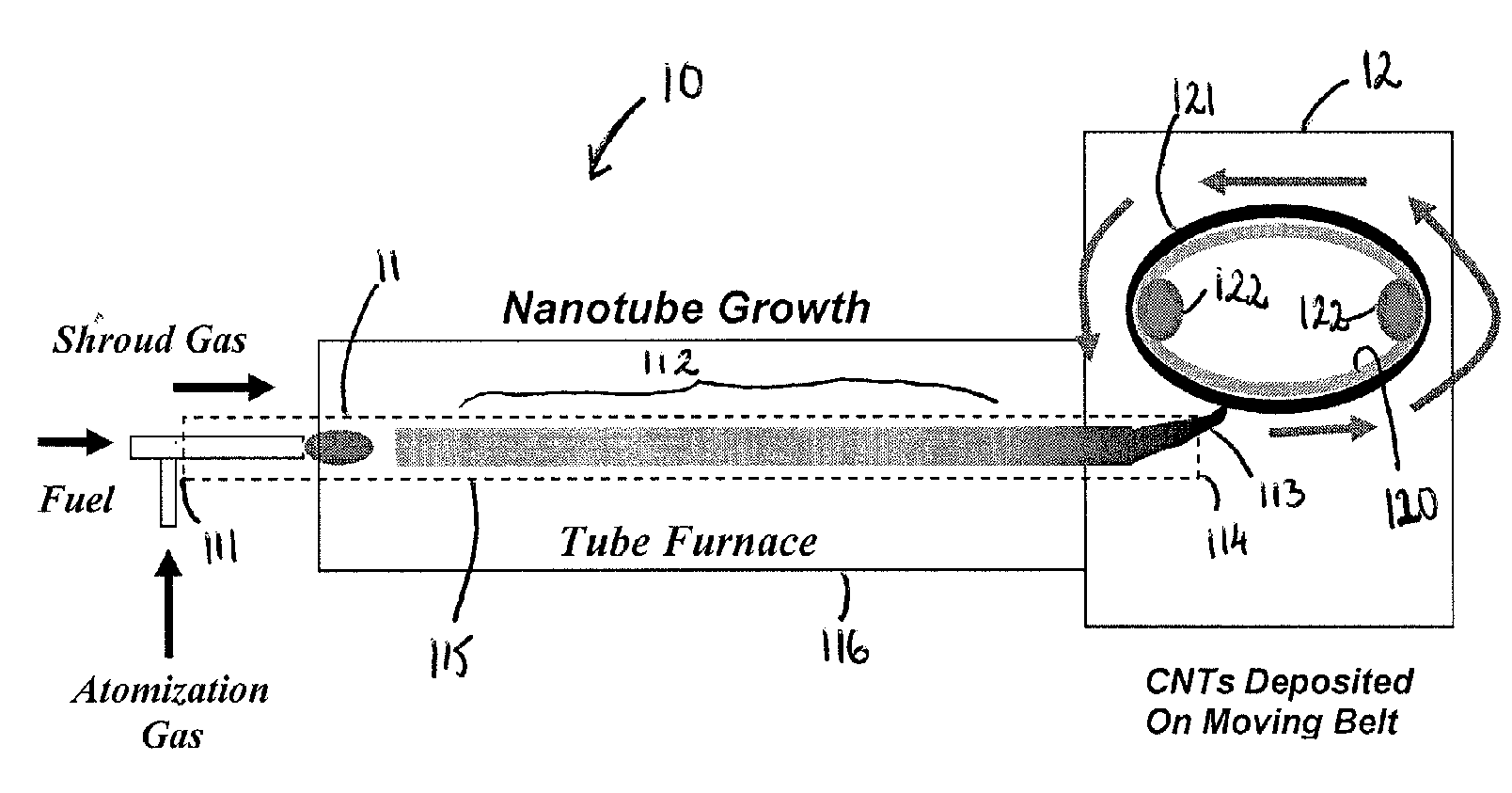

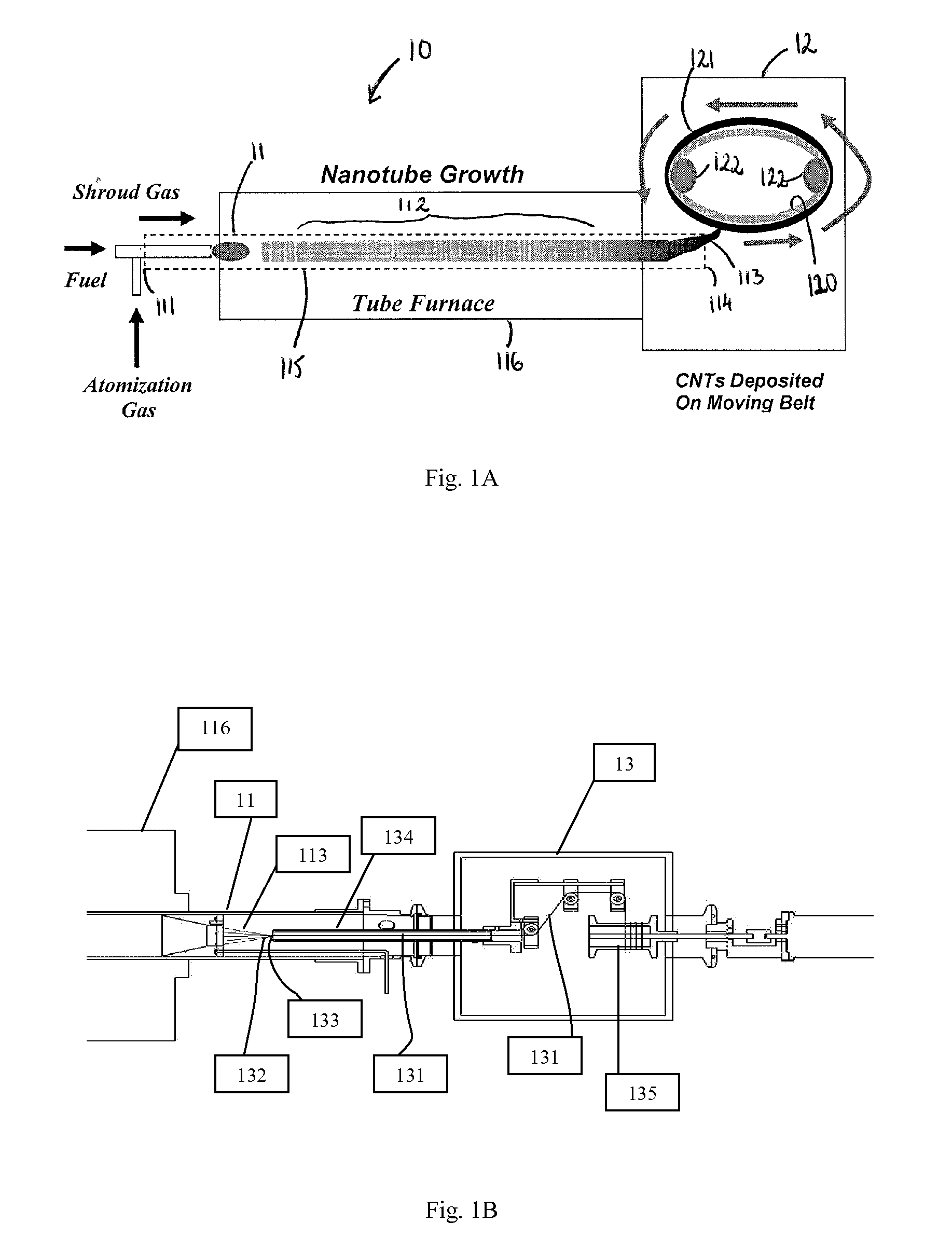

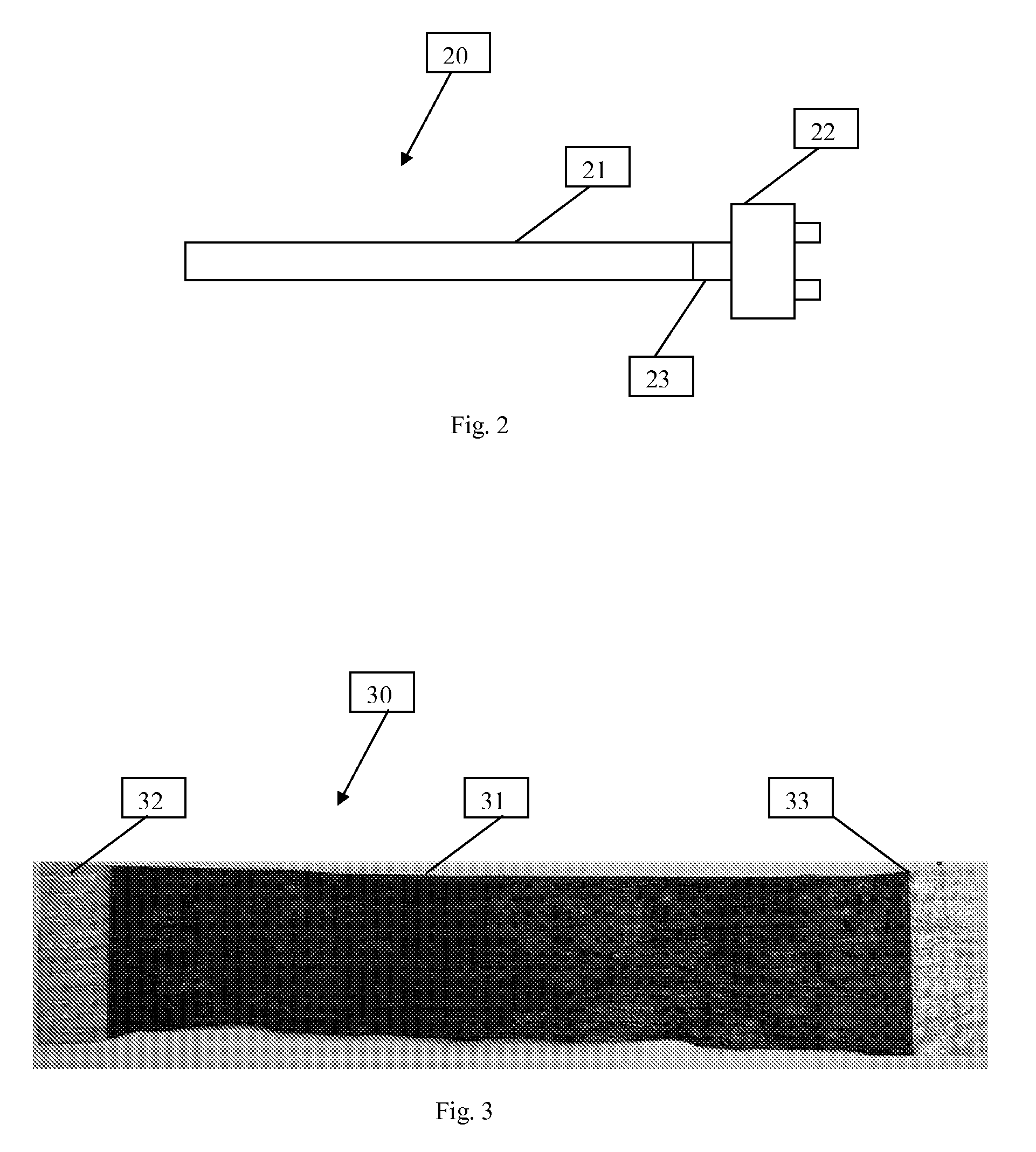

Electrically and Thermally Non-Metallic Conductive Nanostructure-Based Adapters

ActiveUS20090042455A1Low resistance couplingMaximizing numberApparatus for heat treatmentSoldered/welded conductive connectionsEngineeringNanostructure

A conductive adapter for carrying relatively high current from a source to an external circuit without degradation is provided. The adapter includes a conducting member made from a conductive nanostructure-based material and having opposing ends. The adapter can also include a connector portion positioned on one end of the conducting member for maximizing a number of conductive nanostructures within the conducting member in contact with connector portion, so as to enable efficient conduction between a nanoscale environment and a traditional electrical and / or thermal circuit system. The adapter can further include a coupling mechanism situated between the conducting member and the connector portion, to provide a substantially uniform contact between the conductive nanostructure-based material in the conducting member and the connector portion. A method for making such a conductive adapter is also provided.

Owner:NANCOMP TECHNOLOGIES INC

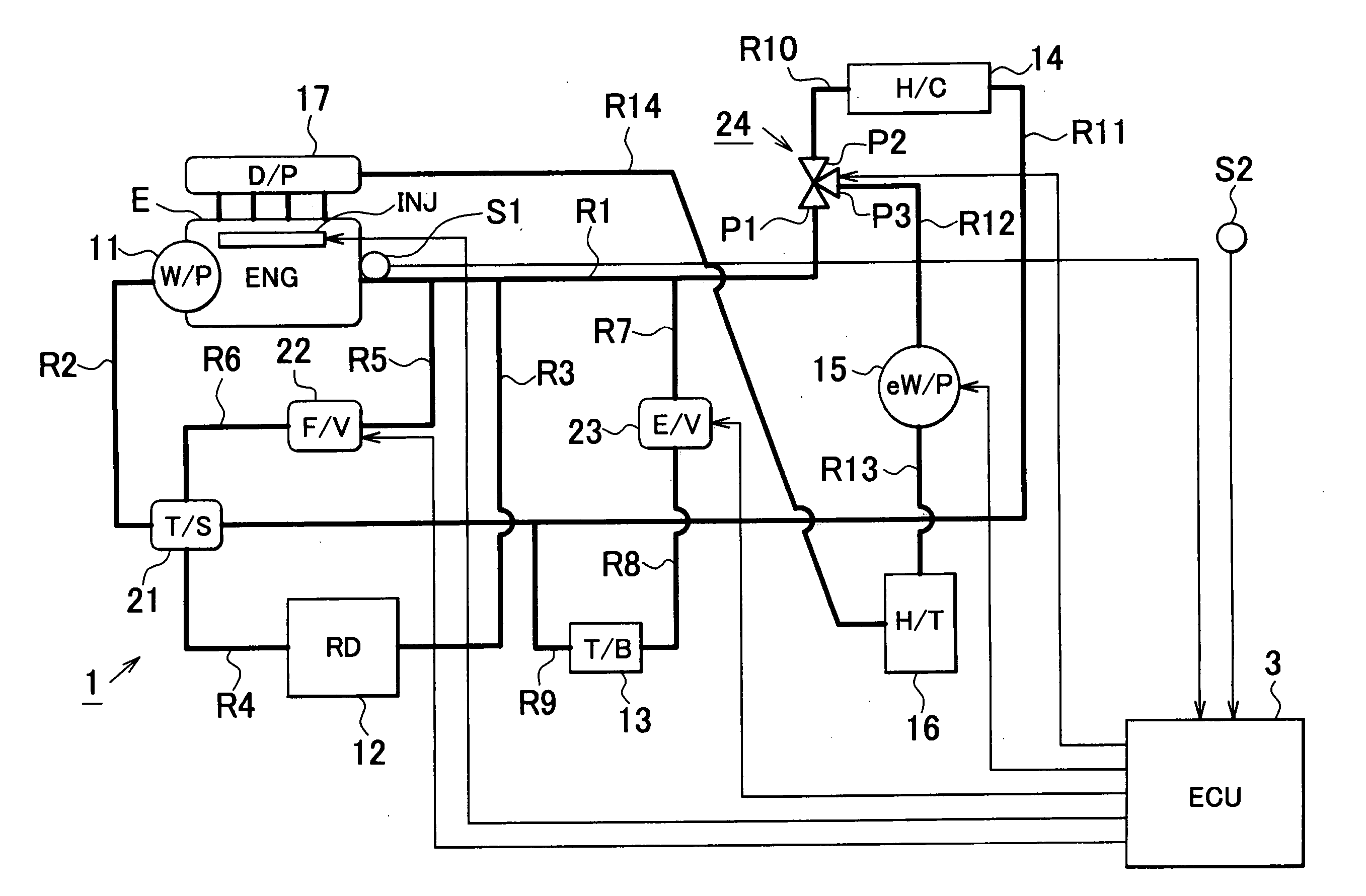

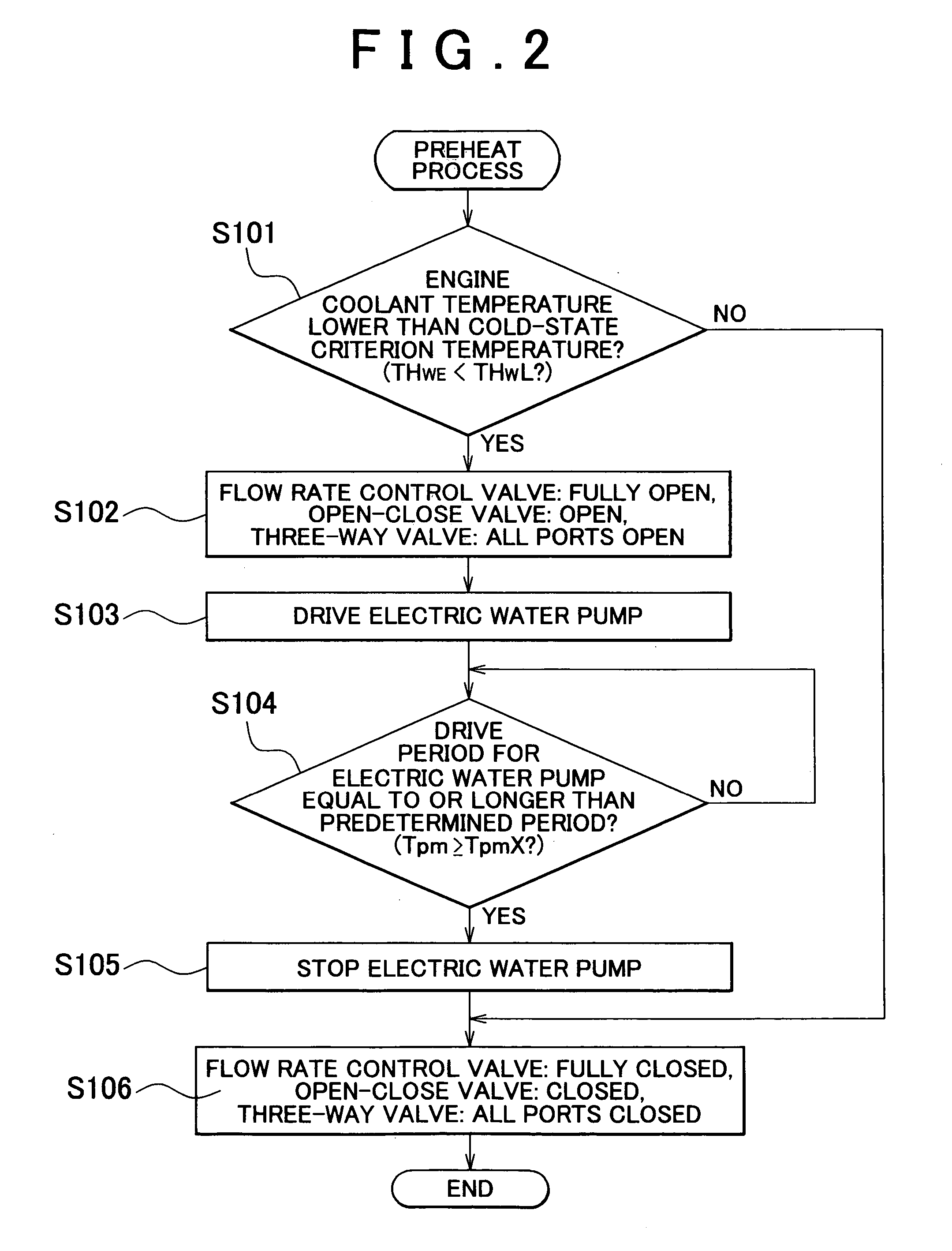

Engine cooling device and engine cooling method

The invention provides an engine cooling device capable of suitably promoting the warm-up of an engine. This engine cooling device comprises a cooling circuit and a heat-accumulating passage. The cooling circuit is composed of a radiator passage, a bypass passage, and a flow rate control value for controlling the flow rate of coolant flowing though the bypass passage. The heat-accumulating passage is provided with a heat-accumulating container, and constitutes a heat-accumulating circuit for causing coolant in the heat-accumulating container to circulate via the engine. The cooling device completes the heat-accumulating circuit by connecting the heat-accumulating passage to the cooling circuit to supply the cooling medium in the heat-accumulating container to the body of the engine, opens the flow rate control valve to increase a flow rate of cooling medium flowing though the bypass passage, then disconnects the heat-accumulating passage from the cooling circuit, and closes the flow rate control valve.

Owner:TOYOTA JIDOSHA KK

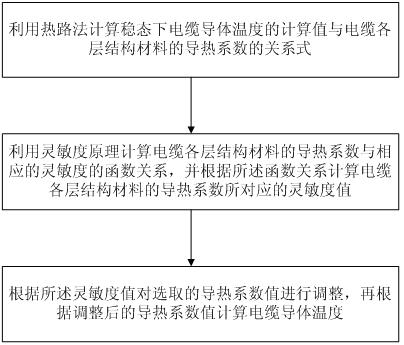

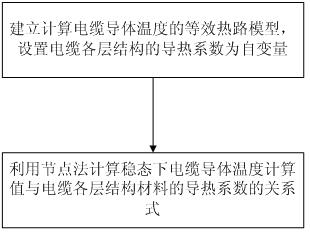

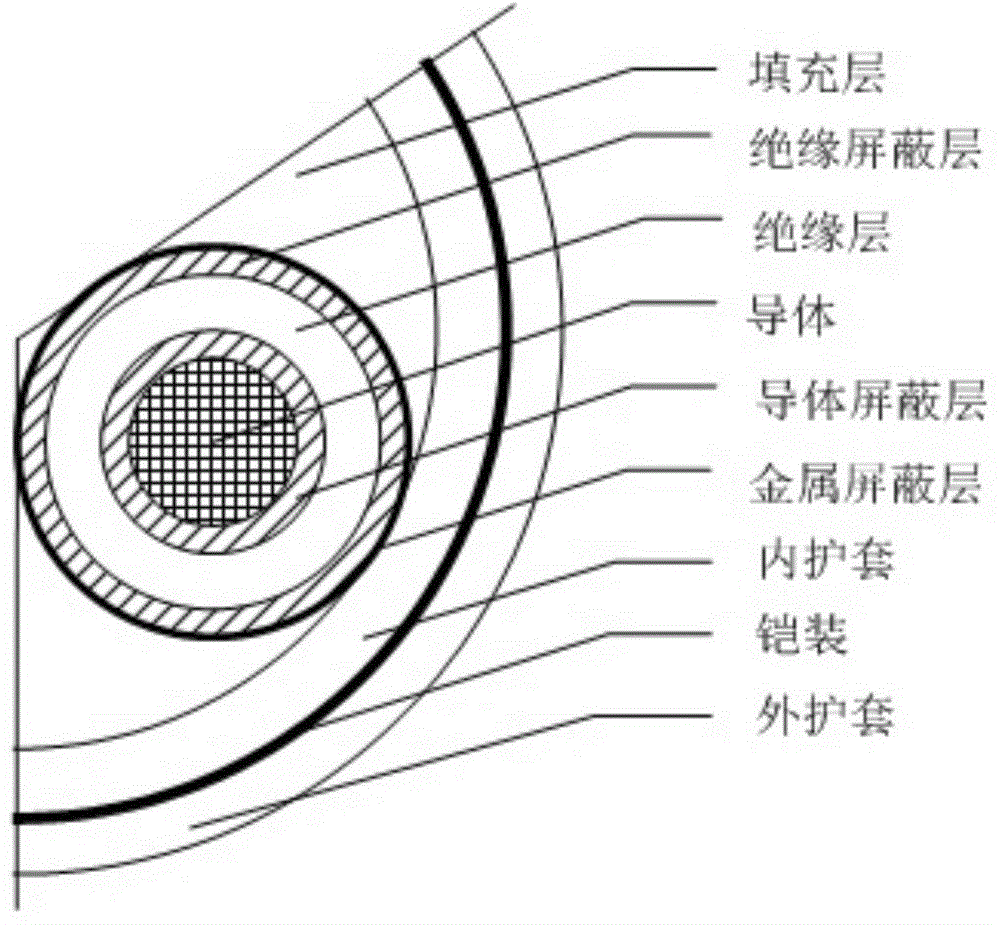

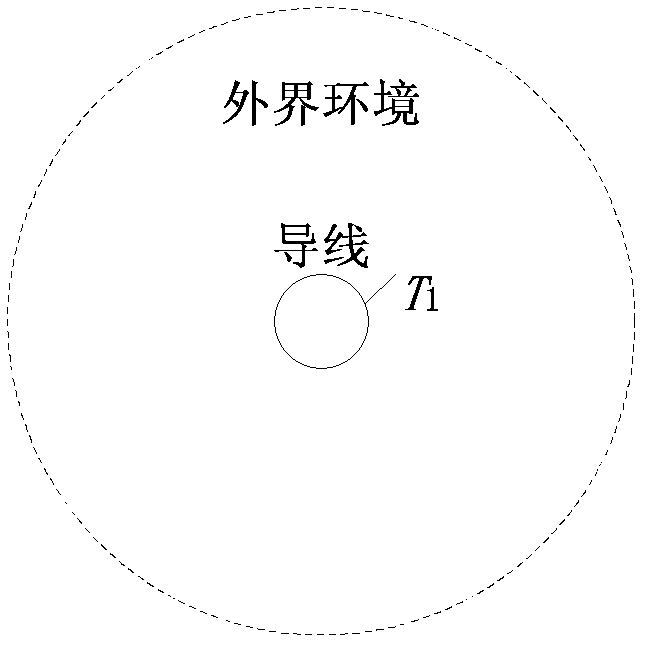

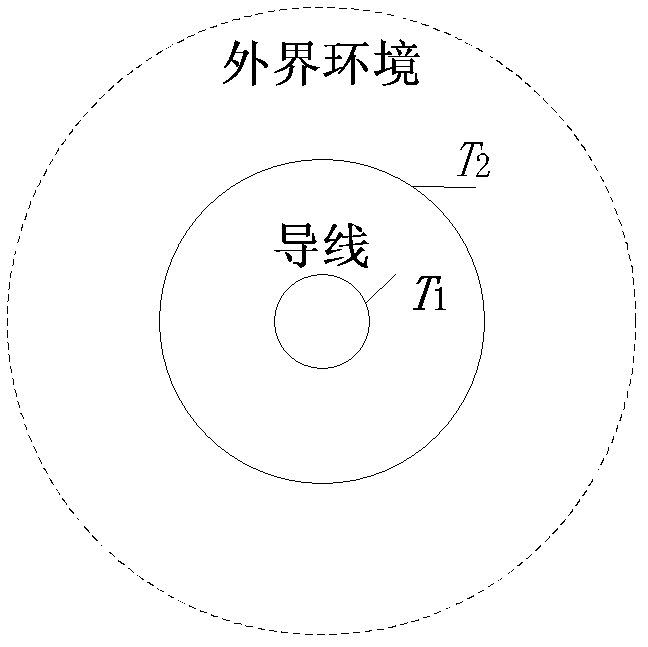

Method and device for calculating conductor temperature of cable

ActiveCN102323997AIncreased conveying capacity operationCalculation boostSpecial data processing applicationsCarrying capacityElectrical conductor

The invention discloses a method for calculating the conductor temperature of a cable. The method comprises the following steps: calculating a relation expression between a calculated value of the conductor temperature of the cable in a steady state and a heat-conductivity coefficient of a structural material of each layer of the cable by using a thermal-circuit method; calculating a functional relation between the heat-conductivity coefficient of the structural material of each layer of the cable and a corresponding sensitivity by using a sensitivity principle, and calculating the value of a sensitivity corresponding to the heat-conductivity coefficient of the structural material of each layer of the cable according to the functional relation; and adjusting the value of a selected heat-conductivity coefficient according to the value of the sensitivity, then calculating the conductor temperature of the cable according to the adjusted value of the heat-conductivity coefficient. The invention also provides a device for calculating the conductor temperature of the cable. By using the technology of the invention, the conductor temperature can be calculated accurately and the current-carrying capacity of the cable can be assessed accurately; and the calculated value of the conductor temperature of the cable is significantly improved on the basis of a calculated value stipulated in IEC (international electrotechnical commission) standards, thereby avoiding the occurrence of a problem that a result of the conductor temperature of the cable, calculated according to the IEC standards, has an excessive margin and a large error; and the method and device disclosed by the invention provide references for the real-time monitoring of the cable and the improvement of transmission capacity and operation of the cable.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

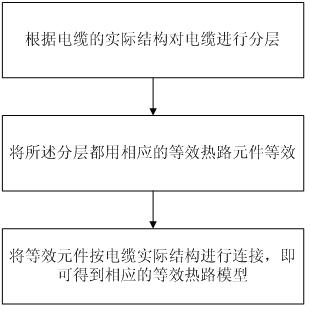

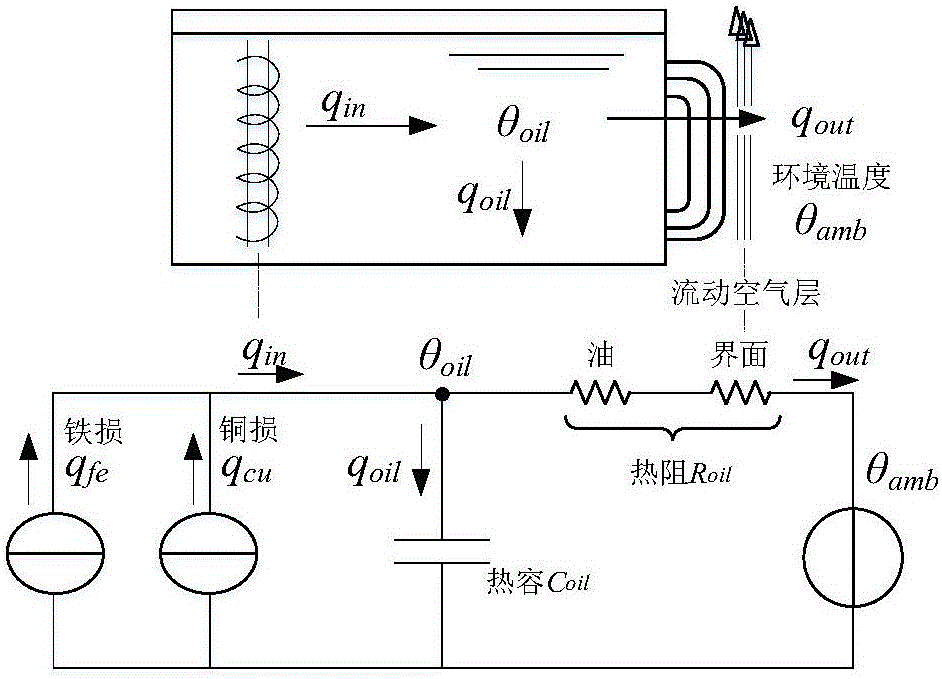

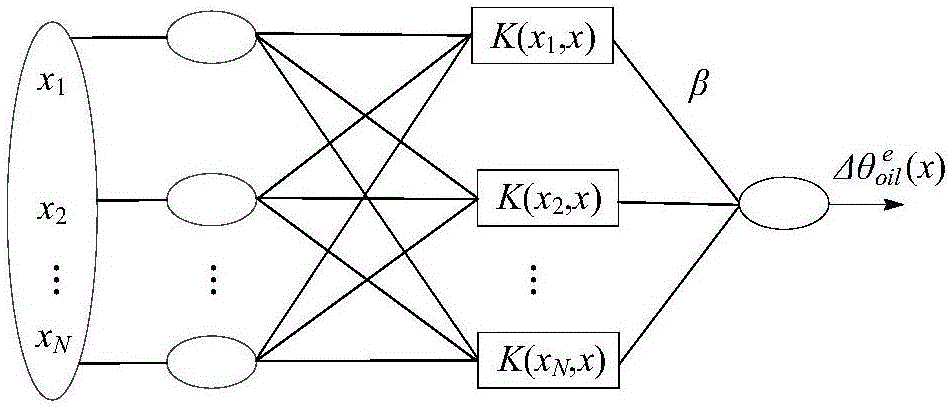

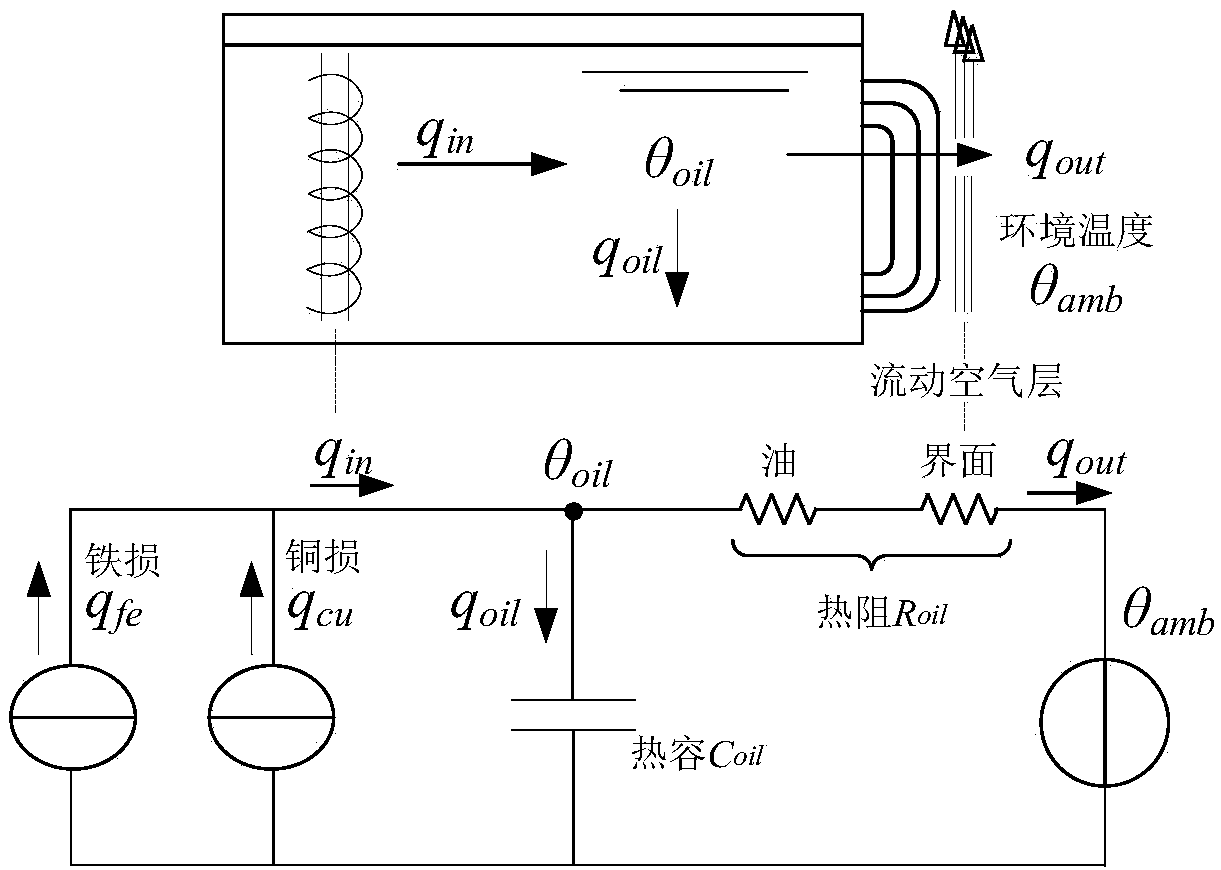

Predication method and device for top-oil temperature of transformer based on error predicting amendment

ActiveCN106055888AImprove accuracyGuide load operationCharacter and pattern recognitionSpecial data processing applicationsTransformerEngineering

The invention discloses a predication method and device for top-oil temperature of a transformer based on error predicting amendment, pertaining to the on-line monitoring field of the transformer. The method comprises following steps: obtaining a prediction dataset comprising load current and ambient environment of the transformer; using load current of the transformer at the current moment as input amount, utilizing a Susa thermal circuit model to predict top-oil temperature of the transformer in order to obtain top-oil temperature prediction value of the Susa thermal circuit model; normalizing top-oil temperature prediction value of the Susa thermal circuit model and the prediction dataset; using the normalized top-oil temperature prediction value of the Susa thermal circuit model and the prediction dataset as input amount and utilizing a GA-KEDLM model to make a regression forecast to obtain prediction errors; carry out anti-normalization operation on regression prediction errors; using prediction value of top-oil temperature of the Susa thermal circuit model before normalization to delete the regression prediction errors after anti-normalization operation in order to obtain top-oil temperature prediction value corrected by the transformer. The predication method and device for top-oil temperature of the transformer based on error predicting amendment are capable of accurately predicting top-oil temperature of the transformer.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

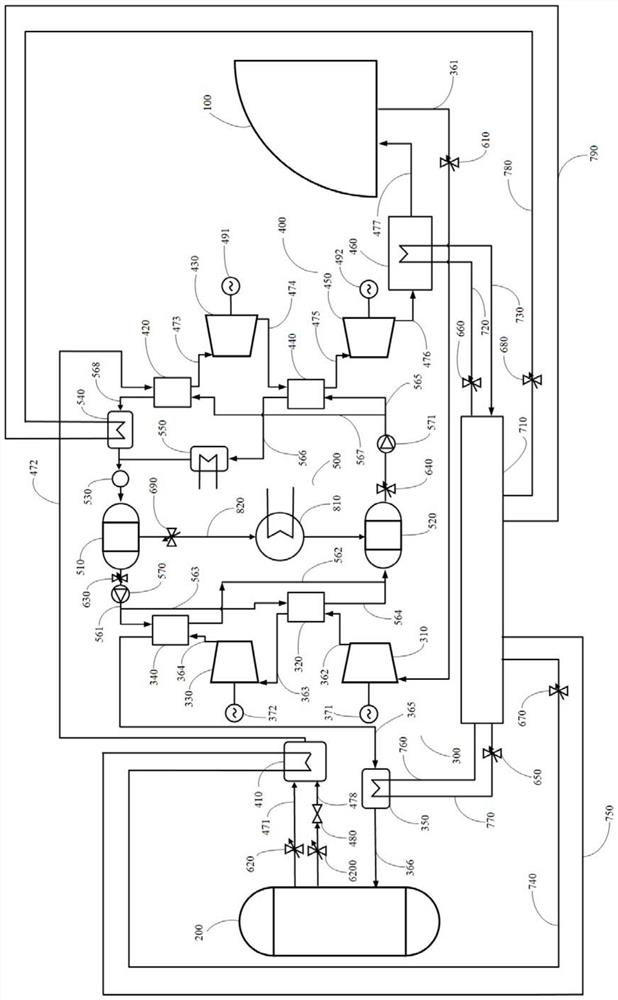

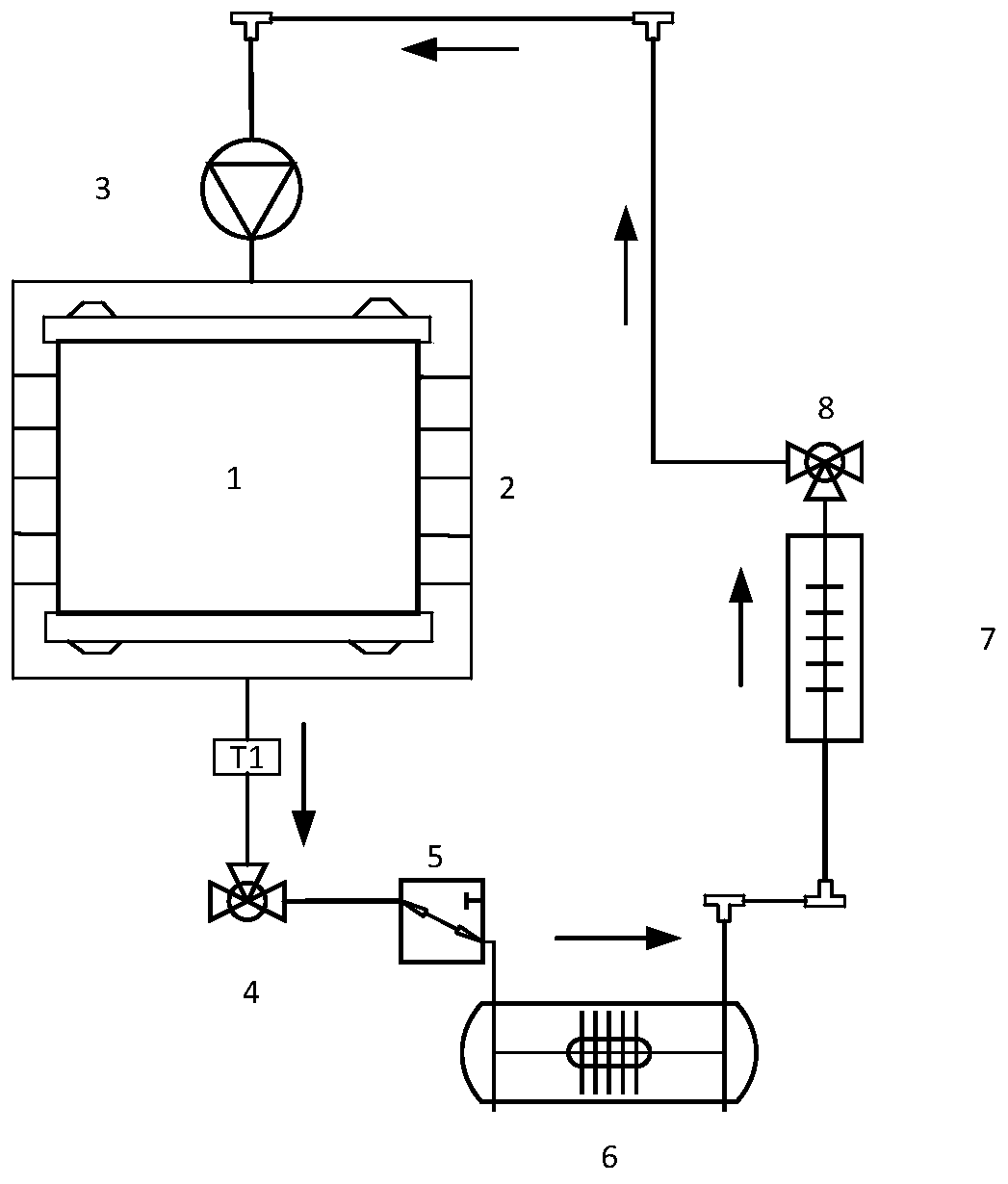

Multi-stage compression energy storage device and method based on gas-liquid phase transition of carbon dioxide

ActiveCN112985144BReduce wasteImprove energy utilizationSolar heating energyHeat storage plantsLiquid storage tankStorage tank

The invention relates to an energy storage device and method based on gas-liquid phase transition of carbon dioxide. The energy storage device based on the gas-liquid phase transition of carbon dioxide includes: a gas storage; a liquid storage tank; an energy storage component, which is arranged between the gas storage and the liquid storage tank, and the energy storage component includes a condenser and at least two compressed energy storage parts , the compression energy storage part includes a compressor and an energy storage heat exchanger; the energy release assembly is arranged between the gas storage and the liquid storage tank, and the energy release assembly includes an evaporator, an energy release cooler, and at least one expansion energy release part, The expansion energy release part includes the expander and the energy release heat exchanger; the heat exchange components include the cold storage tank, the heat storage tank and the heat recovery heat exchanger, and the cold storage tank and the heat storage tank are connected between the energy storage heat exchanger and the energy release heat exchanger. A heat exchange loop is formed between the heat exchangers, and the heat exchange medium can flow in the heat exchange loop; at least one of the condenser, energy release cooler, and heat recovery heat exchanger is connected to the evaporator. When energy is stored and released through the device, energy waste can be reduced and energy utilization rate can be improved.

Owner:EXA ENERGY TECH (SHENZHEN) CO LTD

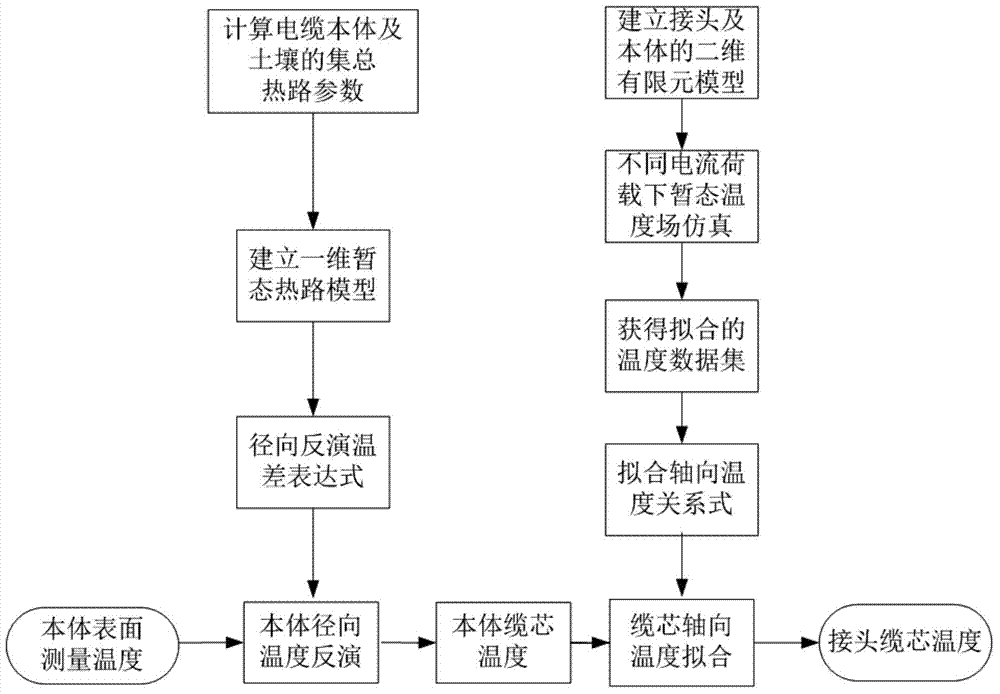

Cable-joint cable core temperature inversion method and system on basis of surface temperature of cable

ActiveCN104776938AAccurate temperatureGuaranteed safe operationThermometer detailsThermometer applicationsTransient stateCore temperature

The invention provides a cable-joint cable core temperature inversion method and a cable-joint cable core temperature inversion system on the basis of a surface temperature of a cable. The cable-joint cable core temperature inversion method comprises the following steps: S1, carrying out radial temperature inversion according to a cable one-dimensional transient thermal circuit model and a temperature of a surface temperature measured point of a cable body so as to obtain an inversion transient temperature of a cable core fit point; S2, constructing a cable two-dimensional temperature field simulation module by adopting a finite element temperature field simulation method and simulating transient temperatures of a cable core contact point and the cable core fit point under different loading currents and at different moments so as to obtain a transient temperature simulated data set; S3, using the transient temperature of the cable core contact point as an independent variable, using the transient temperature of the cable core fit point as a dependent variable and carrying out fitting on the transient temperature simulated data set so as to obtain a cable core axial temperature function; S4, combining the inversion transient temperature of the cable core fit point with the cable core axial temperature function to obtain a temperature of the cable core contact point. According to the invention, the accurate temperature of the cable core contact point can be obtained by utilizing the surface temperature of the cable body through inversion and fitting; the cable-joint cable core temperature inversion method and the cable-joint cable core temperature inversion system are simple, convenient and rapid.

Owner:WUHAN UNIV

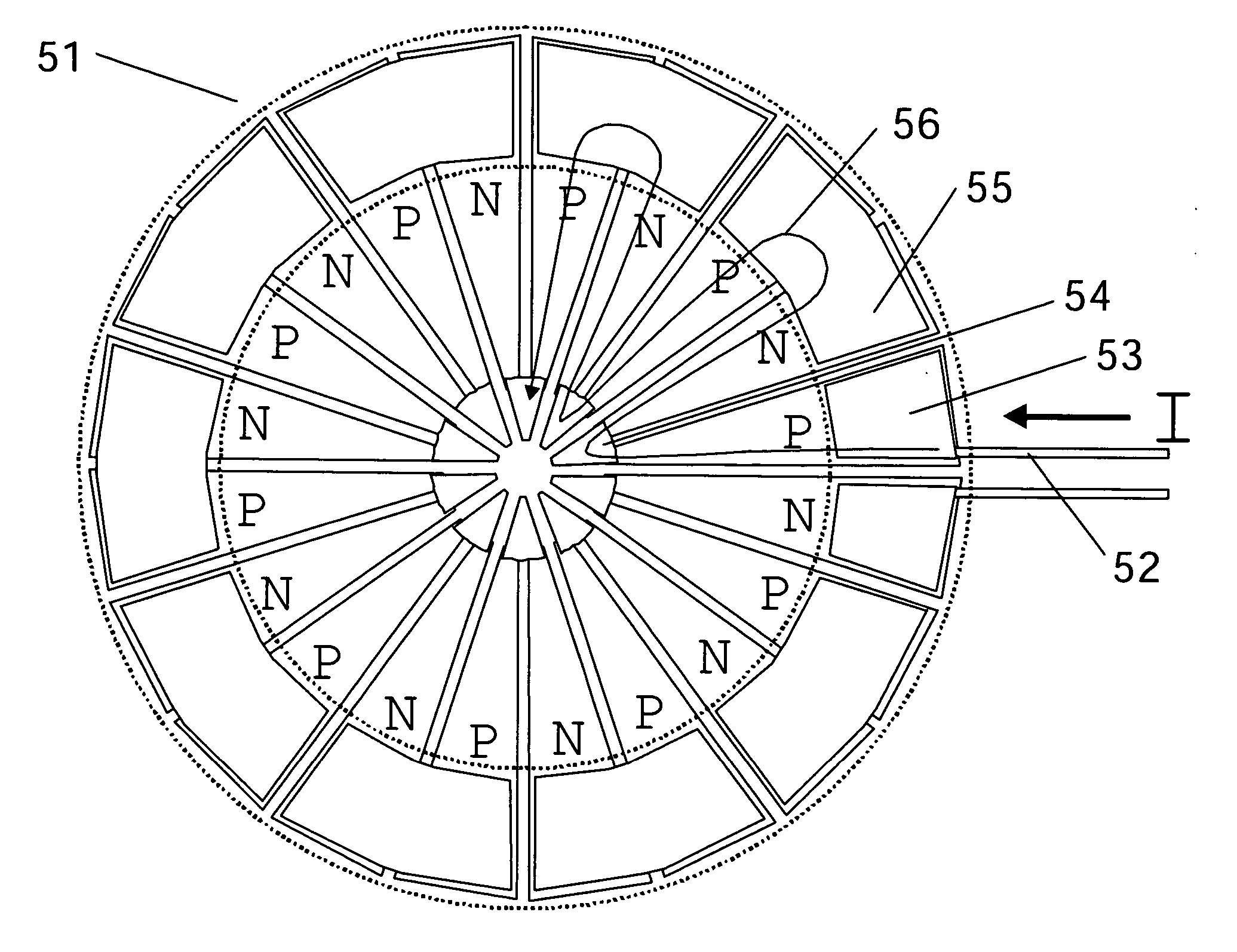

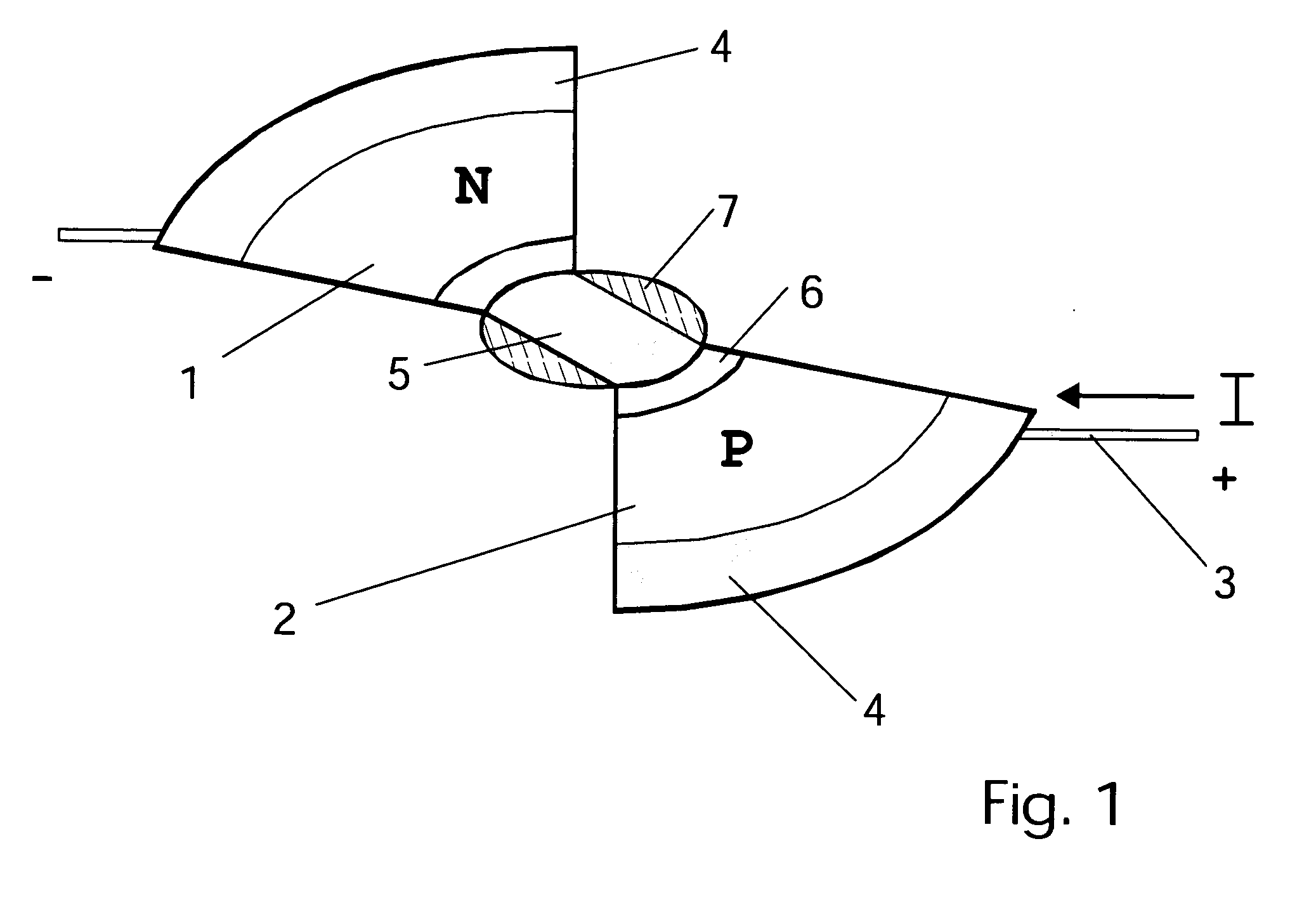

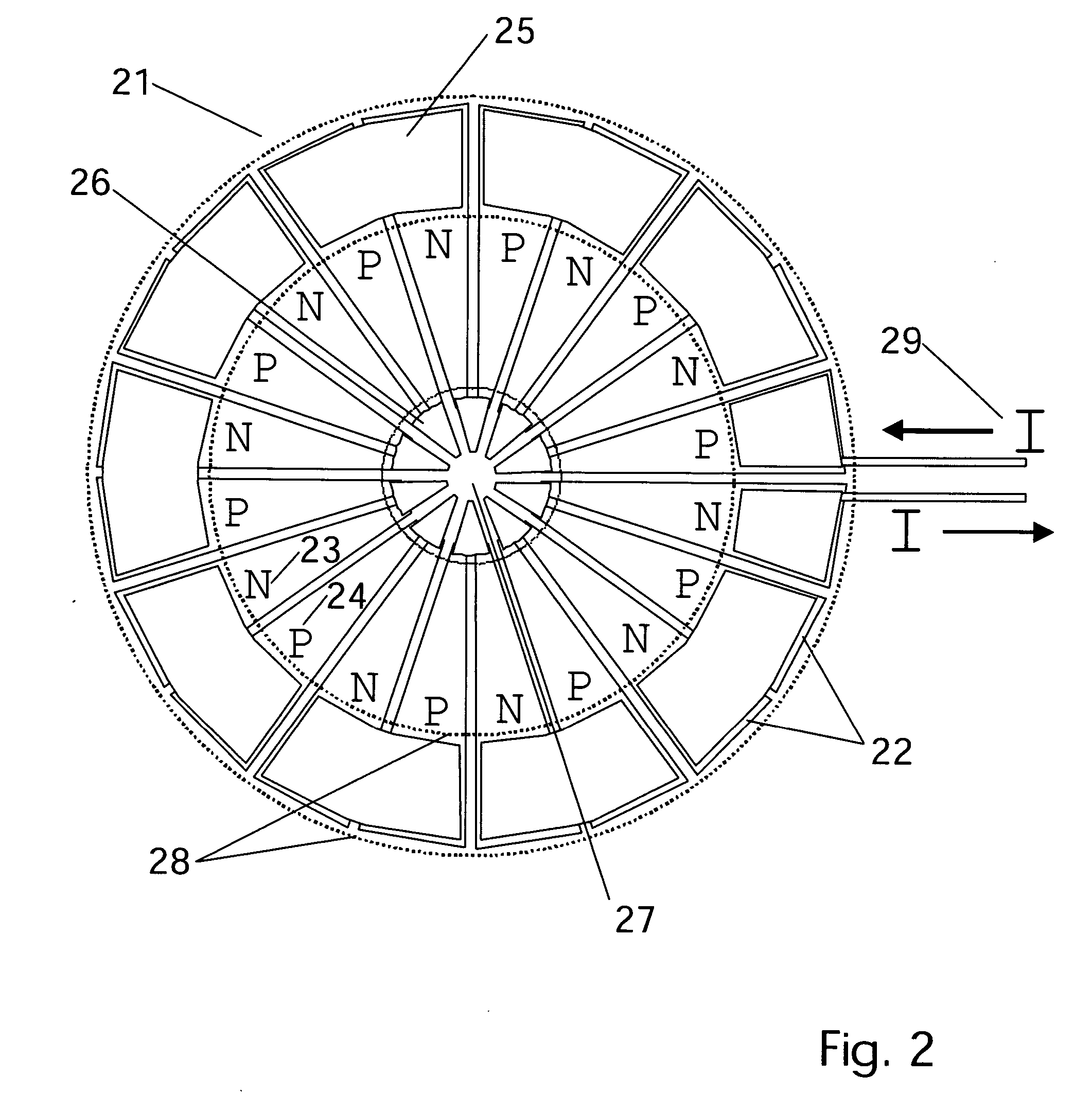

Peltier based heat transfer systems

InactiveUS20060179849A1Highly localized coolingImprove performanceThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsEngineeringElectron

Heat transfer systems are presented with improved heat dissipation schemes based upon an asymmetric arrangement of Peltier elements to form a hot side of greater area than the cold side. This permits greater heat dissipation at the hot side of the heat transfer device into a suitable heat sink. A substantially planar system of radial symmetry is the basis of a highly efficient heat spreading scheme. The ‘spokes’ of the system are pie-wedge shaped Peltier semiconductor elements having a small heat transfer junction at one end and large heat transfer junction at the other. In best versions, a concentric ring scheme has a cooled area at the center and a heat dump at the periphery. Semiconductor Peltier elements connect the two and provide a vehicle to carry heat radially away from a heat point source thermally coupled to the heat transfer system at an active area. These special arrangements are provided while still maintaining the necessary serial electronic circuit and parallel thermal circuit.

Owner:ACOL TECH

Method For Controlling An Electric Vehicle While Charging

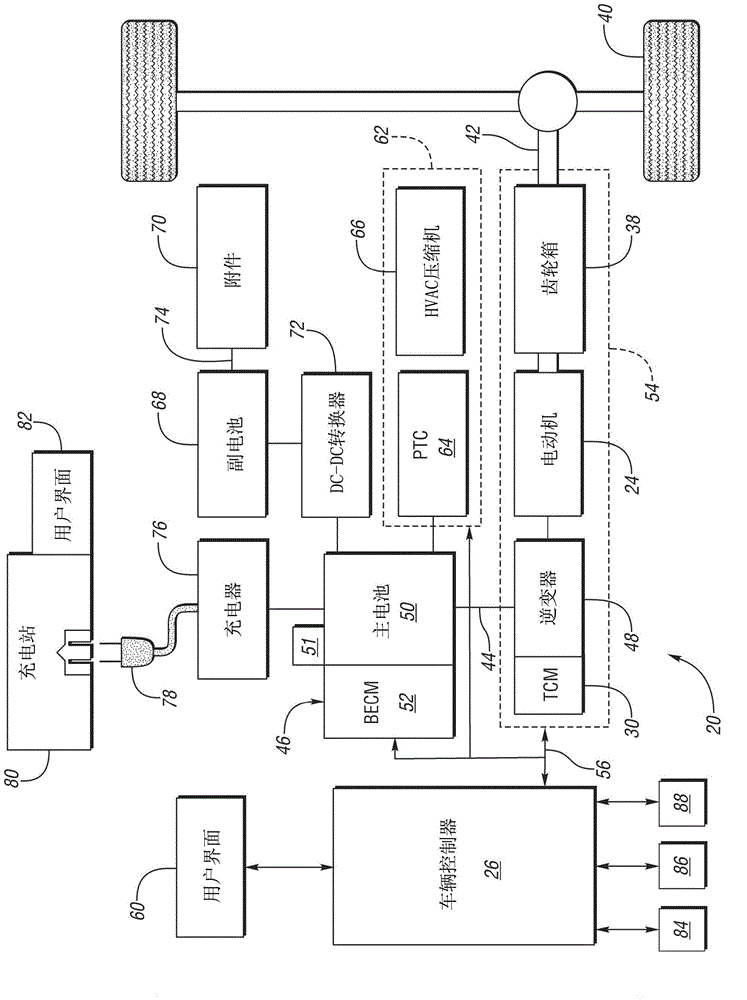

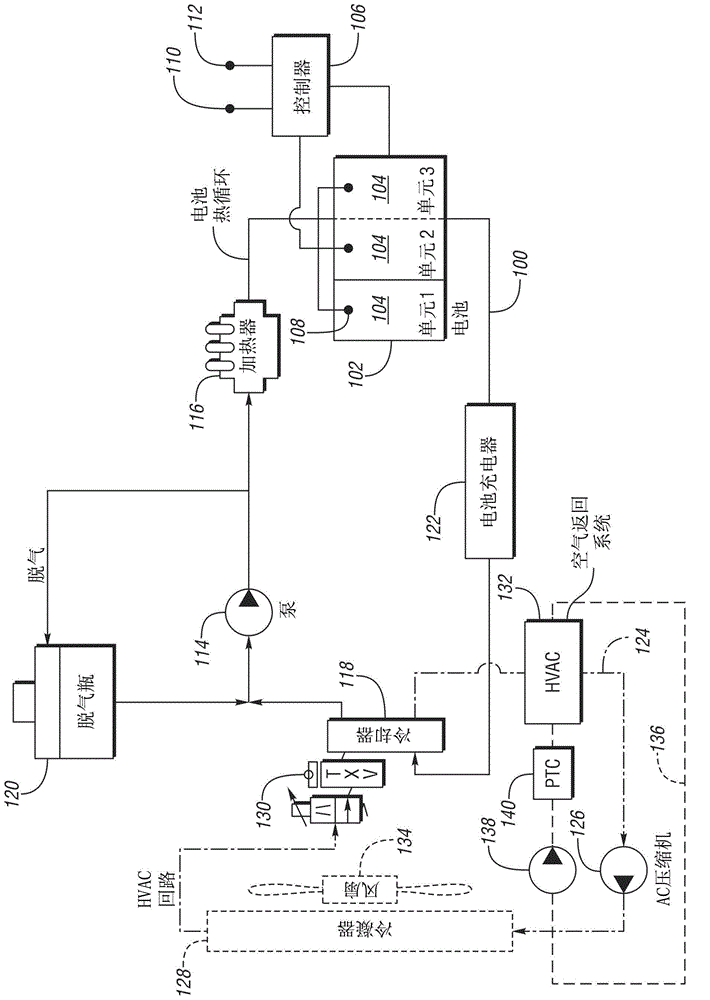

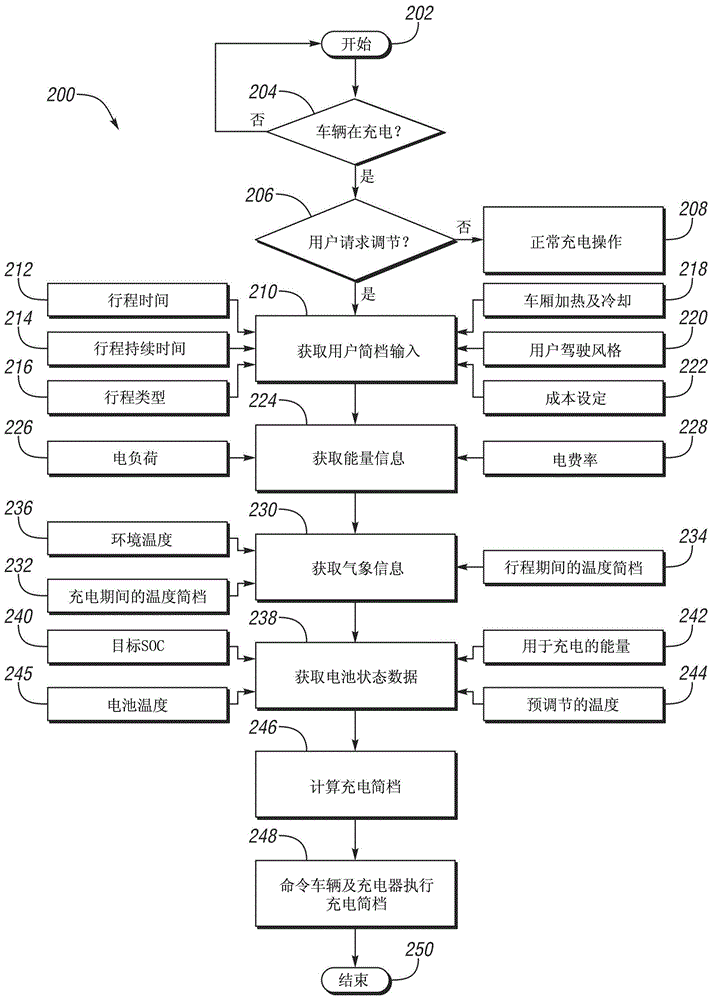

ActiveCN104044479AImprove energy efficiencyCharging stationsSecondary cellsUser inputElectrical battery

Provided is a method for controlling an electric vehicle while charging. An electric vehicle has a thermal circuit connected to a traction battery and a cabin climate system, a user interface, and a controller. The controller is configured to charge the traction battery to a target state of charge, condition the traction battery to a target battery temperature, and condition a vehicle cabin to a target cabin temperature based on a charging profile based on the user input in response to receiving a user input requesting vehicle conditioning from the user interface and the traction battery being connected to an external power source. A method for controlling an electric vehicle while connected to an external power source includes charging a traction battery to a target state of charge and conditioning the battery to a target temperature according to a charging profile based on a user initiated request for vehicle conditioning.

Owner:FORD GLOBAL TECH LLC

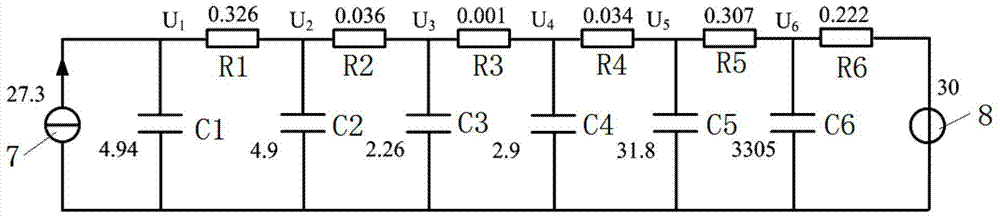

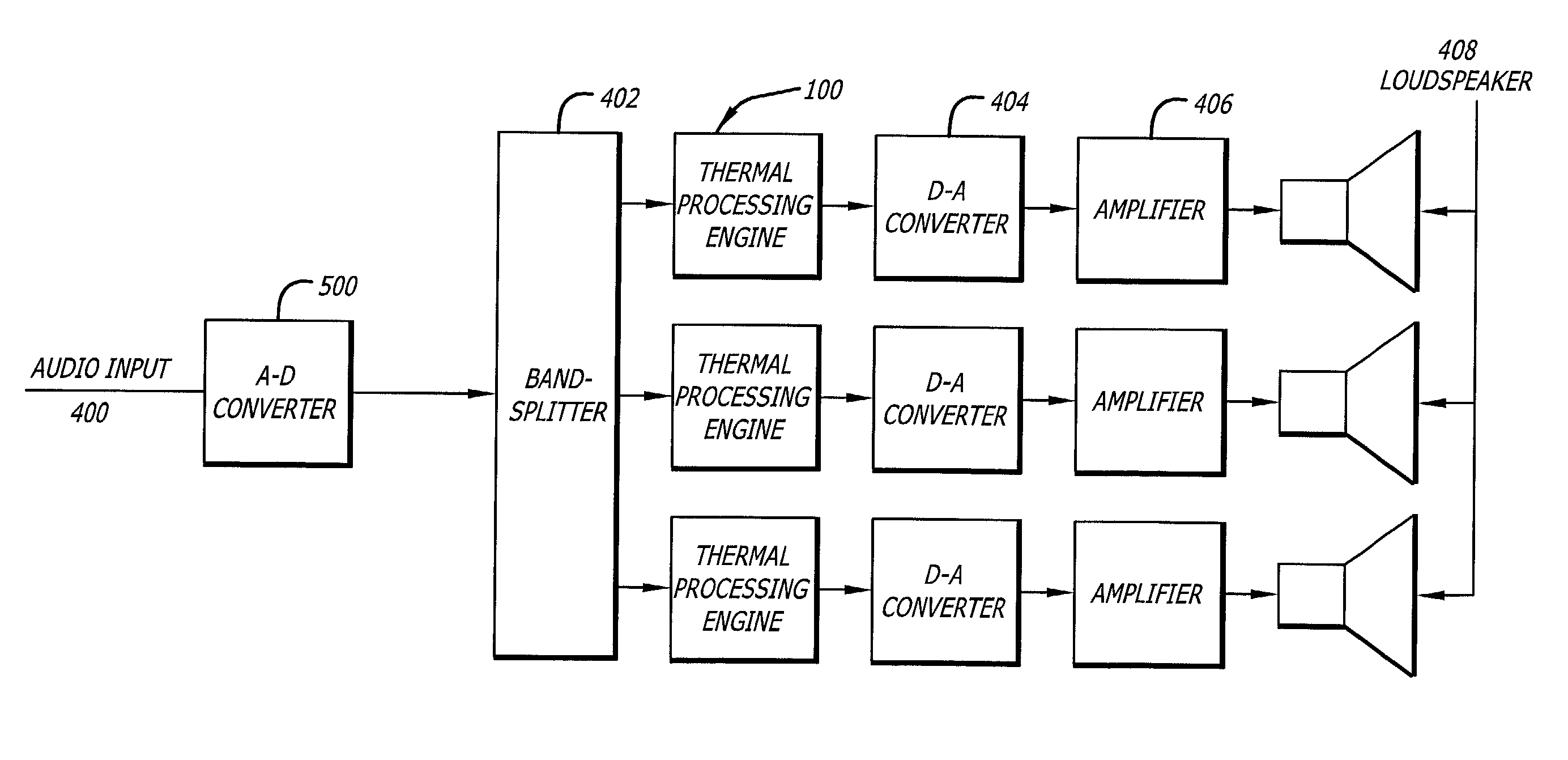

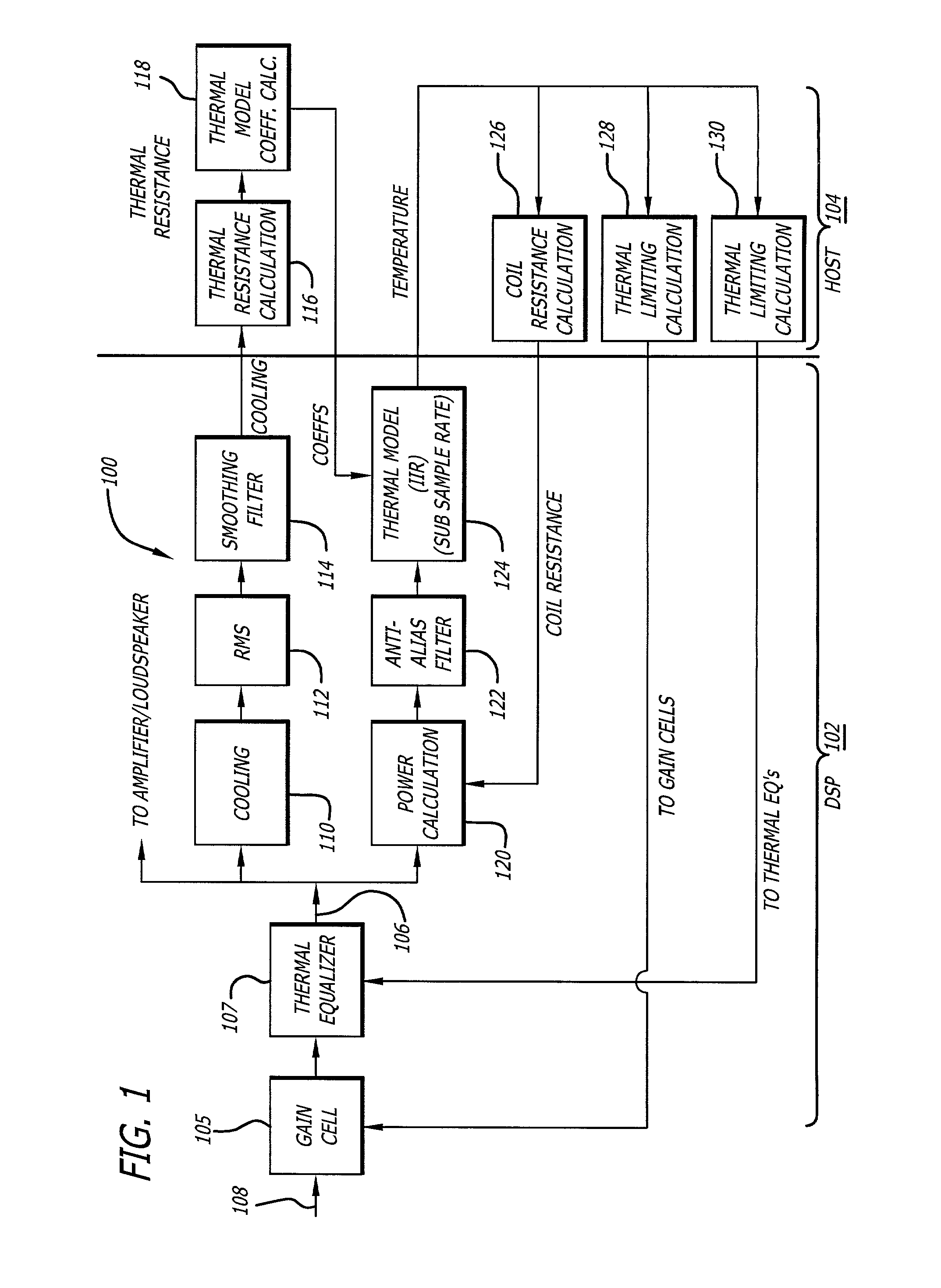

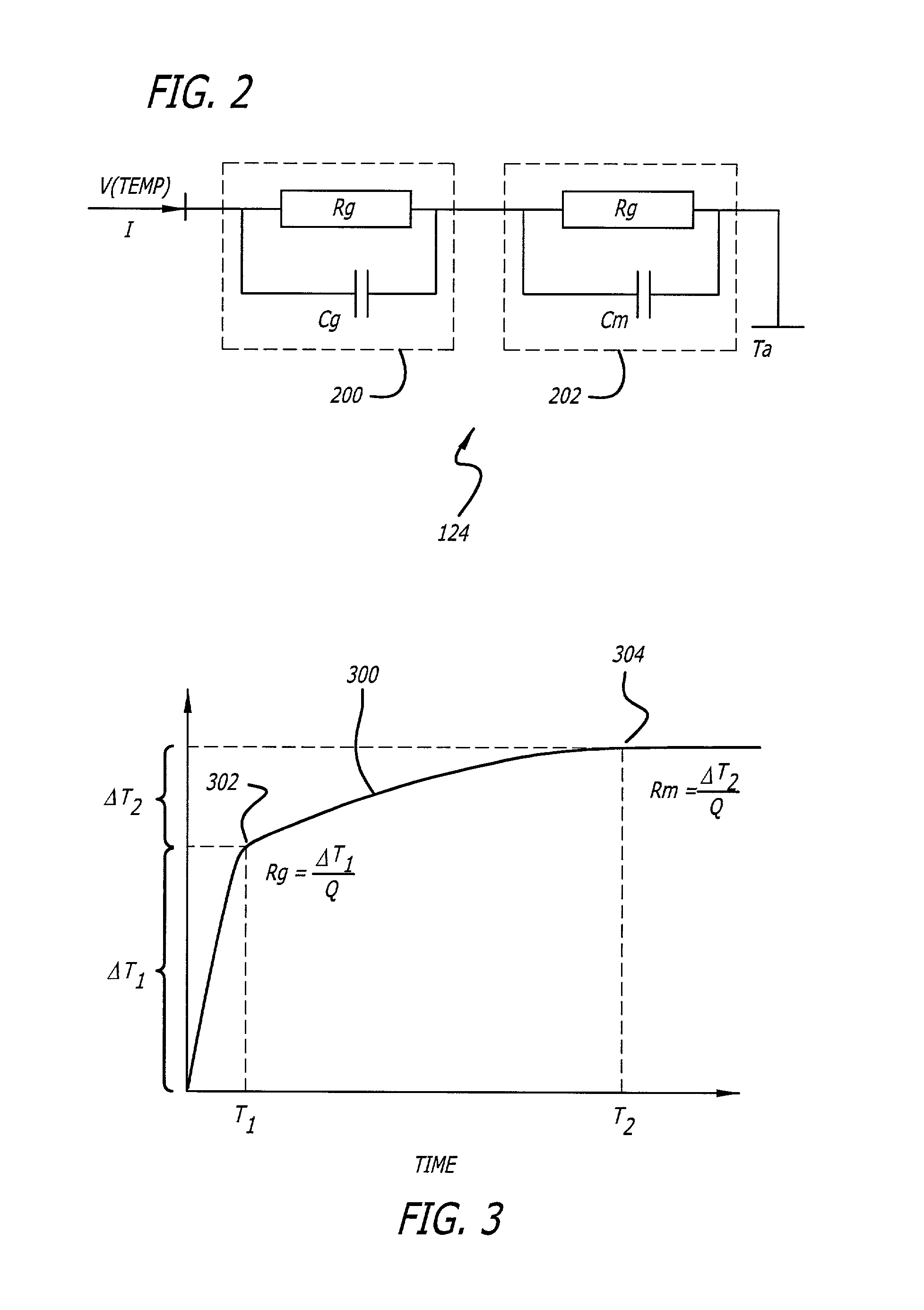

System for using digital signal processing to compensate for power compression of loudspeakers

ActiveUS7447318B2Reduction in voice coil thermal resistanceDegrade audio signalThermometers using electric/magnetic elementsUsing electrical meansDigital signal processingCooling effect

This invention provides a compensation system capable of compensating for power loss due to the power compression effects of the voice coil as the temperature of the voice coil increases. To compensate for the power compression effect, the invention predicts or estimates the temperature of the voice coil using a thermal-model, and adjusts the estimated temperature according to the cooling effect as the voice coil moves back and forth in the air gap. The thermal-model may be an equivalent electrical circuit that models the thermal circuit of a loudspeaker. With the input signal equating to the voltage delivered to the loudspeaker, the thermal-model estimates a temperature of the voice coil. The estimated temperature is then used to modify equalization parameters. To account for the cooling effect of the moving voice coil, the thermal resistance values may be modified dynamically, but since this cooling effect changes with frequency, a cooling equalization filter may be used to spectrally shape the cooling signal, whose RMS level may be used to modify the thermal resistance values. The invention may include a thermal limiter that determines whether the estimated voice coil temperature is below a predetermined maximum temperature to prevent overheating and possible destruction of the voice coil.

Owner:HARMAN INT IND INC

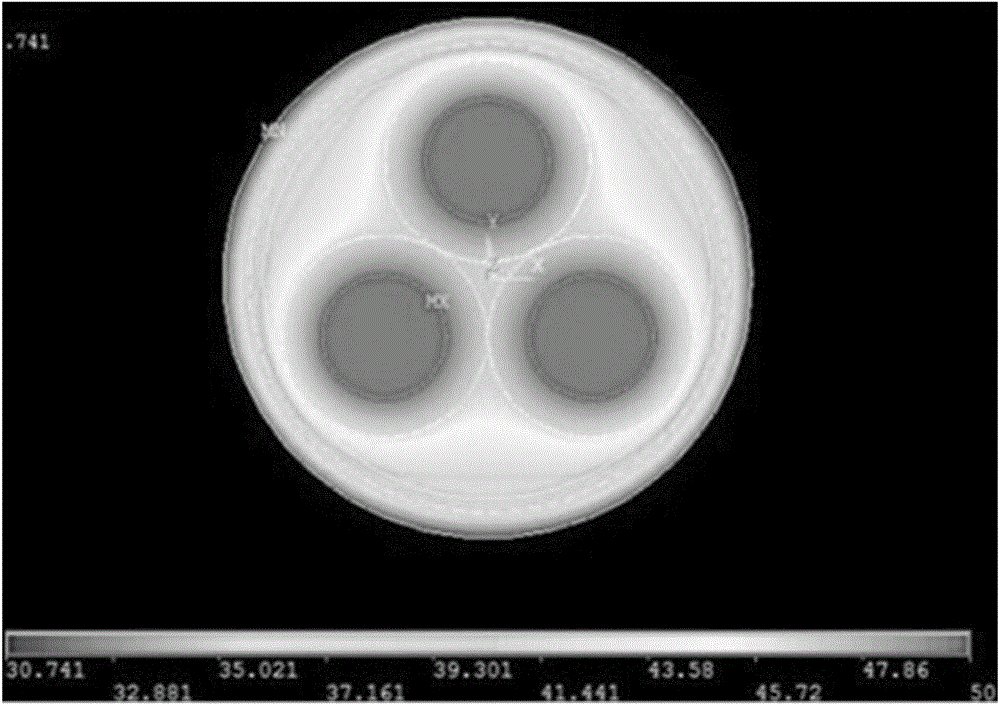

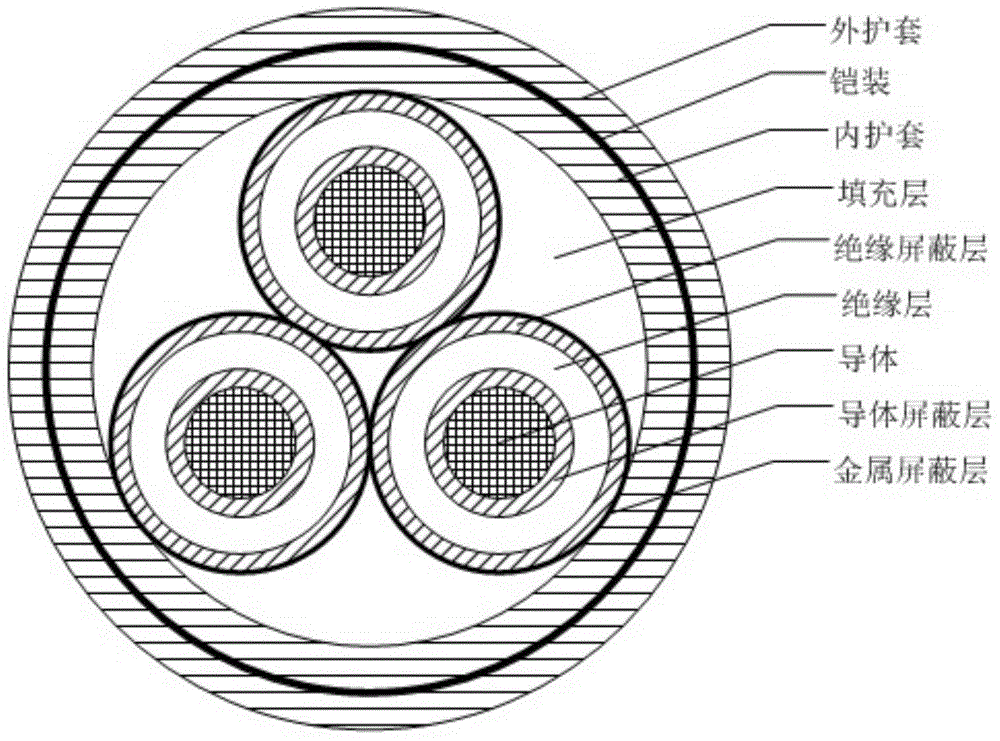

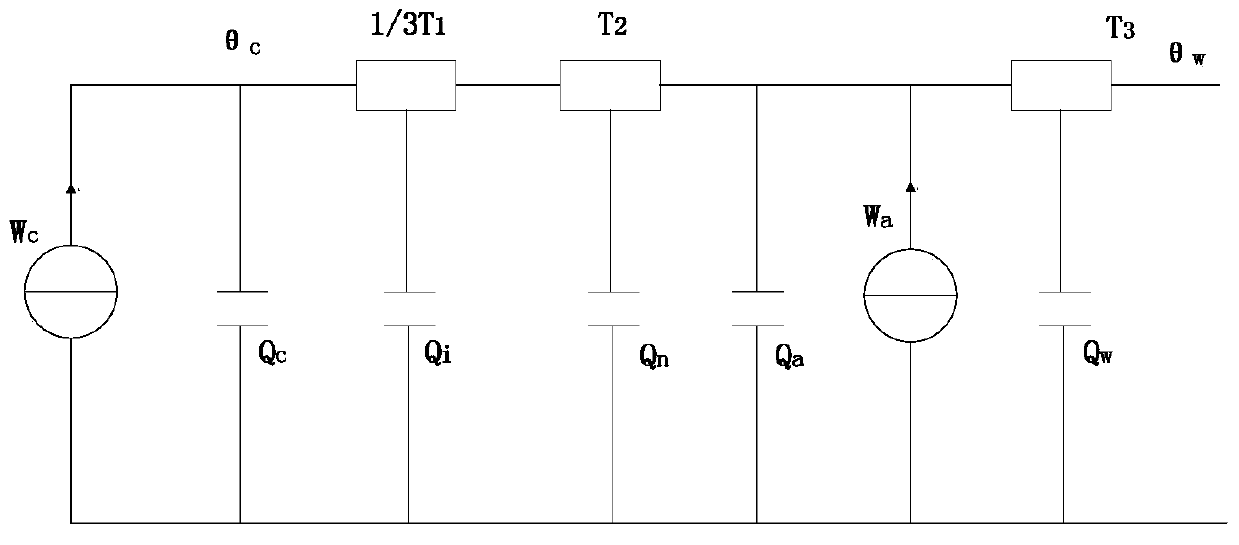

10kv three-core cable temperature field model establishing method

The invention discloses a 10kV three-core cable temperature field model establishing method. The method includes the steps that 1, thermal field simulation is conducted on a 10 kV three-core cable loaded with current through ANSYS simulation software, and a temperature field distribution diagram of a cable radial section is obtained; 2, the cable section is cut through a cutting method in cooperation with a cable symmetrical structure and the isotherm, the cable is equally cut into three parts according to three cable cores, and one of the three parts is selected to serve as the research object; 3, a steady state thermal circuit model is established for the selected one-third cable structure, and cable structure layers located on the isotherm on the same diagram serve as joints in the thermal circuit model; 4, the thermal resistance generated when heat flow flows through all layers of cable materials and the generated losses are determined; 5, the 10 kV three-core cable steady state thermal circuit model is established according to the temperature field distribution diagram of the 10 kV three-core cable, all the joints in the determined thermal circuit model, the heat resistance among all the joints and the losses of various materials. The established 10kV three-core cable steady state thermal circuit model can be used for numerical calculation.

Owner:SOUTH CHINA UNIV OF TECH

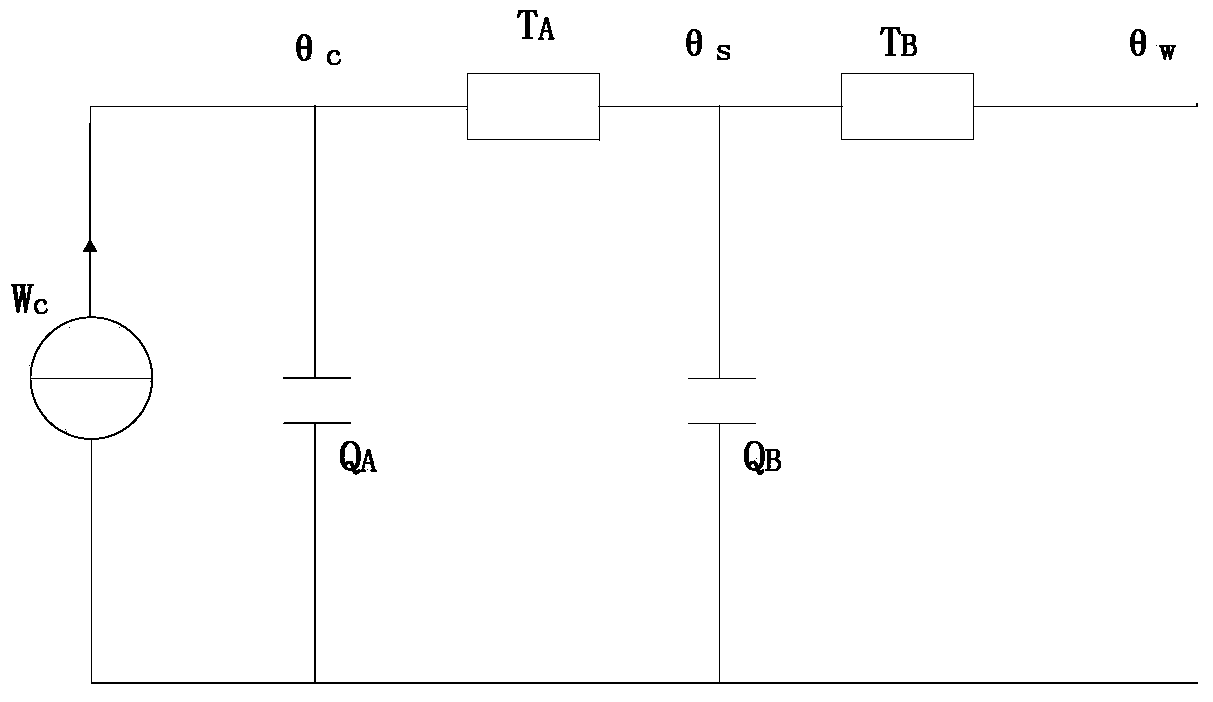

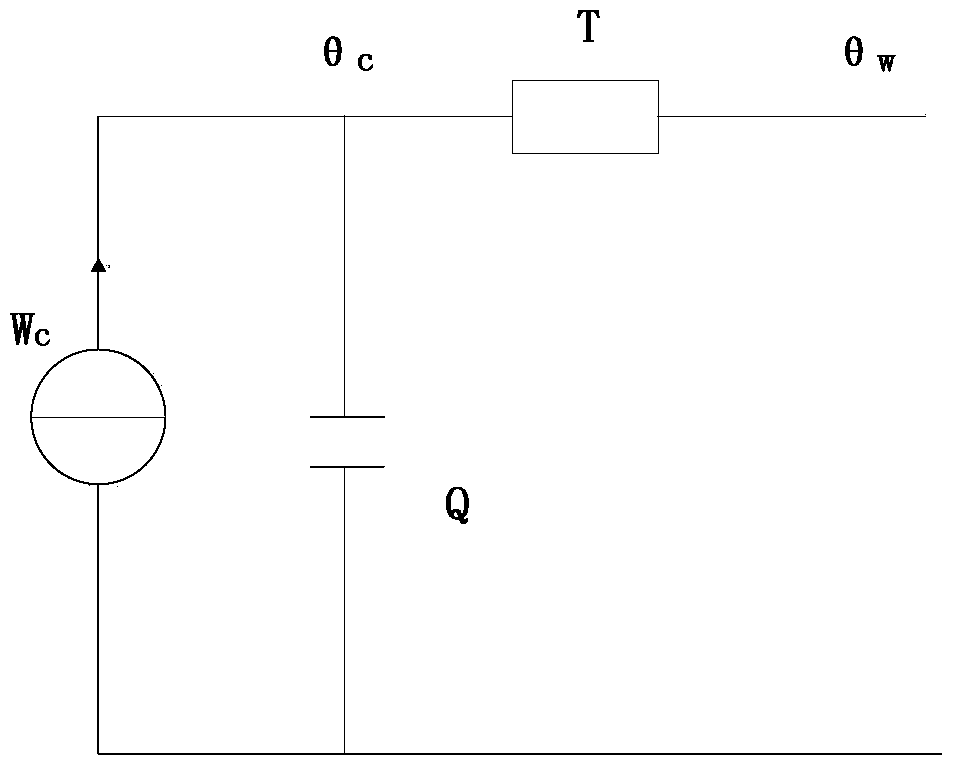

Method for calculating real-time conductor temperature of three-core cable

InactiveCN104198077AAvoid the effects of temperature calculationsSolve the technical problems of direct temperature measurementThermometers using electric/magnetic elementsUsing electrical meansCapacitanceTransient state

The invention discloses a method for calculating the real-time conductor temperature of a three-core cable. The method comprises the following steps of: (1) simplifying a complete transient-state thermal circuit model of the three-core cable into the simplest transient-state thermal circuit model only containing an equivalent thermal capacitance and an equivalent thermal resistance; (2) only considering current changes and skin temperature changes to obtain the relationship among the temperature of a conductor, a load current and a skin temperature, thus obtaining the temperature rise of the conductor caused by only considering current changes and skin temperature changes due to analogy on a first-order circuit transient response; (3) calculating the generated steady-state temperature rise and a temperature rise caused by medium losses according to a current at an initial time; (4) calculating a temperature rise caused by n times of currents and skin temperature changes in two hours (a cable thermal time constant) from the initial time; (5) summating the skin temperature at the initial time and all the temperature rises above to obtain the conductor temperature of the three-core cable currently.

Owner:SOUTH CHINA UNIV OF TECH

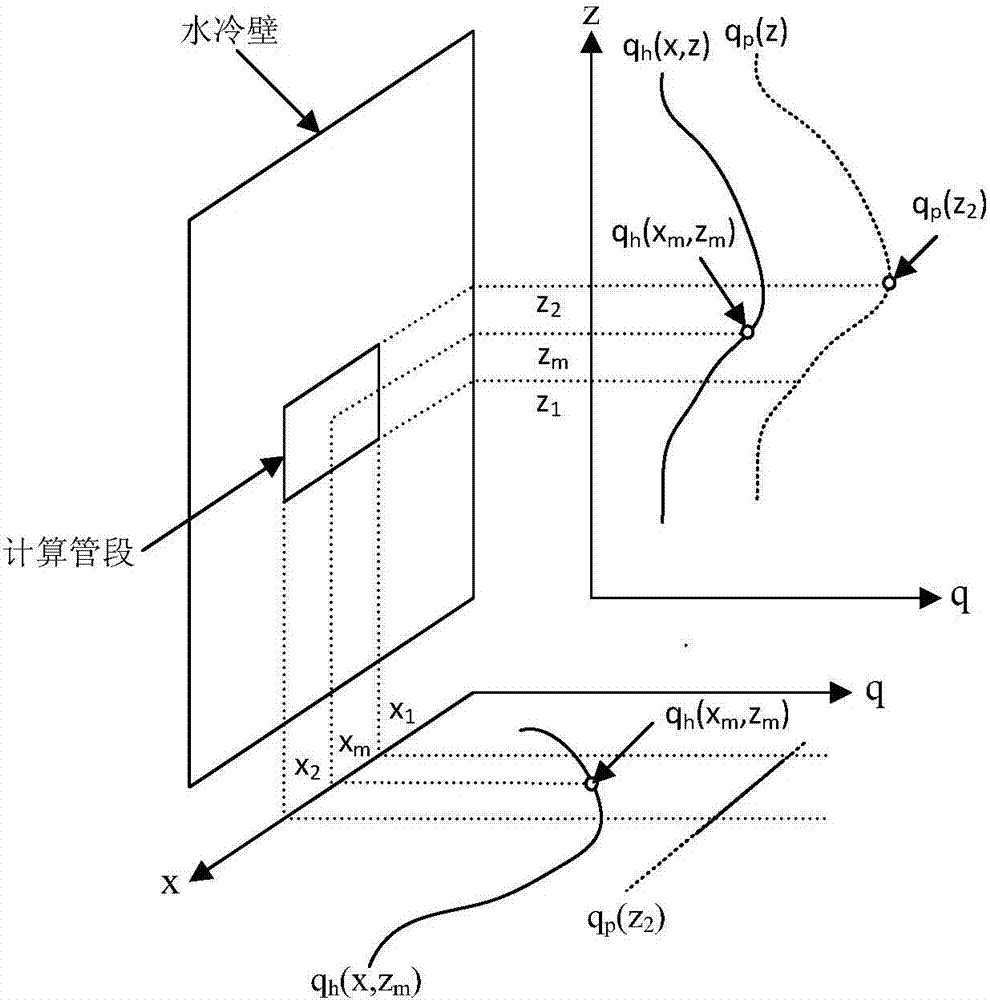

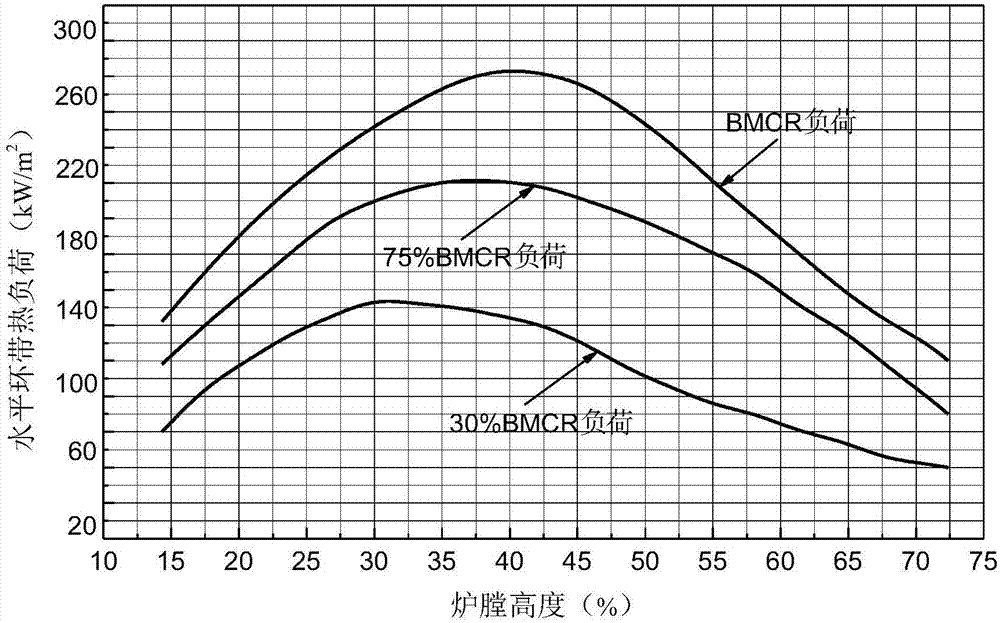

General hydrodynamic calculation method for ultra-supercritical boiler

ActiveCN106897547AFit closelyInformaticsSpecial data processing applicationsSupercritical steam generatorCombustion

The invention discloses a general hydrodynamic calculation method for an ultra-supercritical boiler, and provides a flow network system method consisting of a nonlinear model applied to a computer. The calculation method is suitable for hydrodynamic calculation and wall temperature safety analysis of the ultra-supercritical once-through boiler under various boiler overall arrangement forms, various pipe coil forms, various combustion technologies and various mass velocity combinations. The method comprises the steps of simplifying a water wall into a flow network system consisting of elements such as a connecting pipe loop, a heated loop, a pressure node and the like according to structure characteristics of the water wall and heat load distribution of a furnace chamber; and building the nonlinear calculation model of flow distribution according to a mass conservation equation, a momentum conservation equation and an energy conservation equation. Through direct solving of a nonlinear equation set, flow distribution and node pressure distribution in the heated loop and a connecting pipe are determined, and based on this, boiler water wall flow and metal wall temperature are subjected to safety check, so that guidance calculation can be performed for design and safety check of the boiler.

Owner:XI AN JIAOTONG UNIV +2

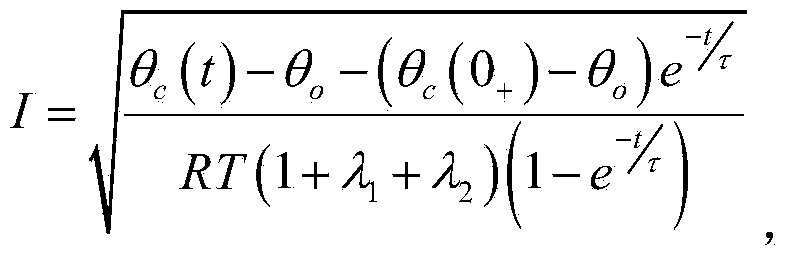

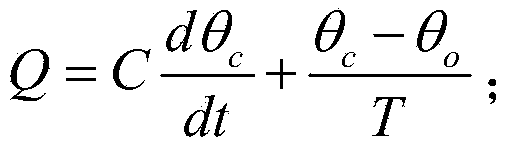

Method for calculating power cable real-time emergency carrying capacity

InactiveCN103439609AAvoid conservative operations such as power cutsReduce economyElectrical testingElectrical conductorLimit value

The invention discloses a method for calculating power cable real-time emergency carrying capacity. The method includes the steps of firstly, establishing a cable system transient state thermal circuit model; secondly, establishing a heat balance equation; thirdly, obtaining a general solution of the heat balance equation; fourthly, obtaining the expression of the temperature of a conductor according to the initial condition; fifthly, converting the expression of the temperature of the conductor into the expression of the real-time emergency carrying capacity; sixthly, measuring or calculating the environment temperature and the temperature of the conductor at the initial moment; seventhly, determining the time of the N-1 fault repairing period or the time of the peak electricity consumption period and the limit value of the temperature of the cable conductor; eighthly, calculating real-time emergency carrying capacity of a cable. The method has the advantages that the maximum carrying capacity, namely, the real-time emergency carrying capacity, which enables the temperature of the cable conductor to rise to the limit value in a certain period of time is calculated, the scientific and reasonable decision foundation is provided for power grid dispatch and power line repairing in the emergency situation, and the calculation can be easily and conveniently conducted.

Owner:SOUTH CHINA UNIV OF TECH

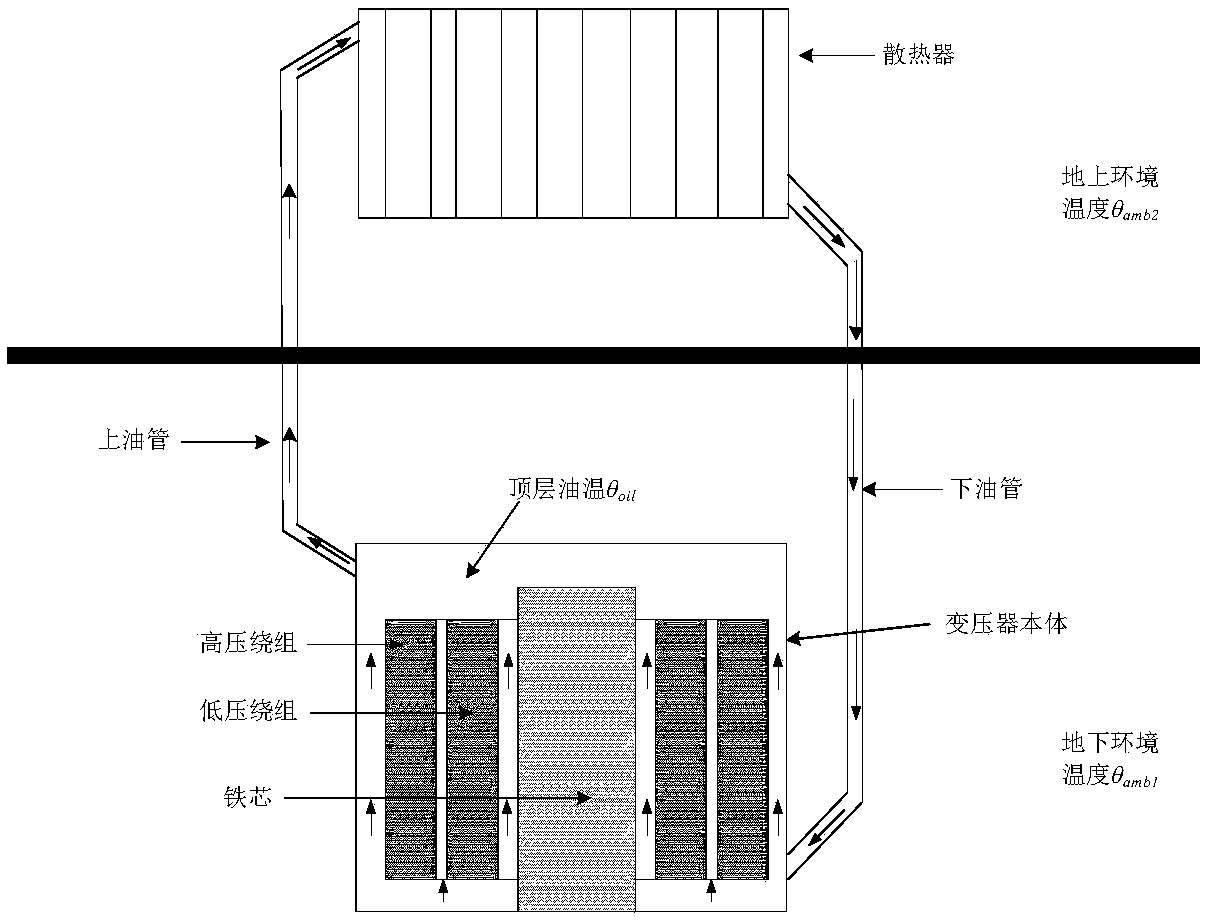

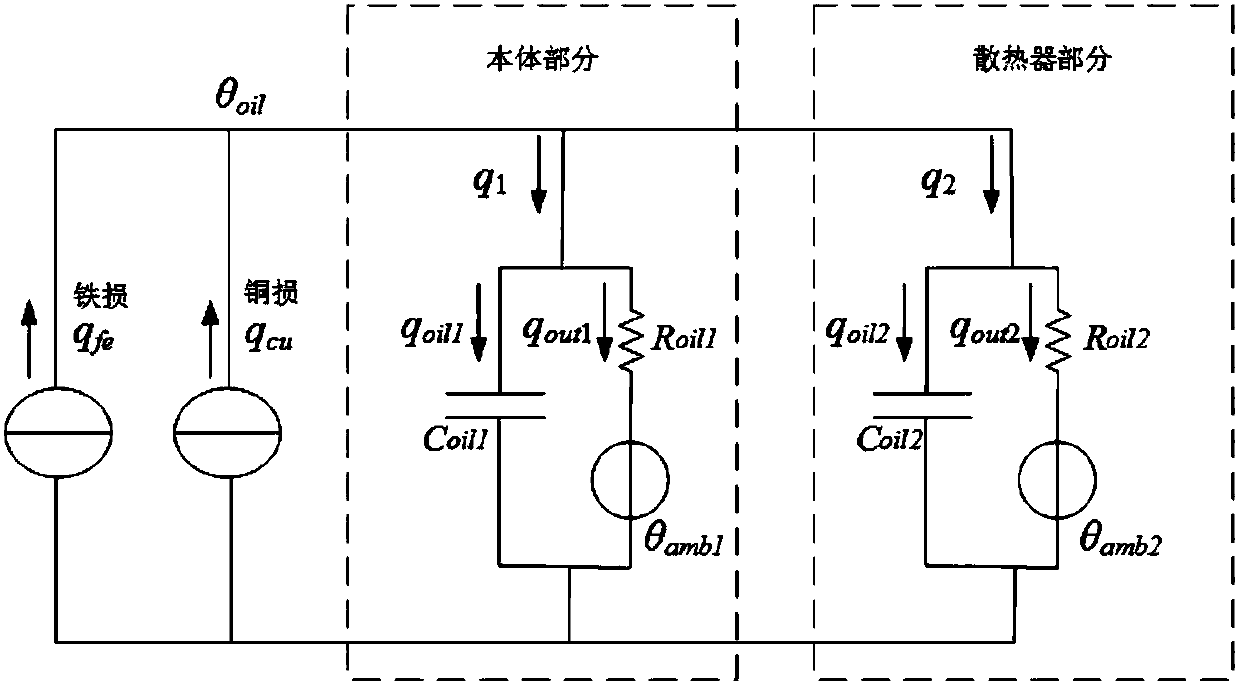

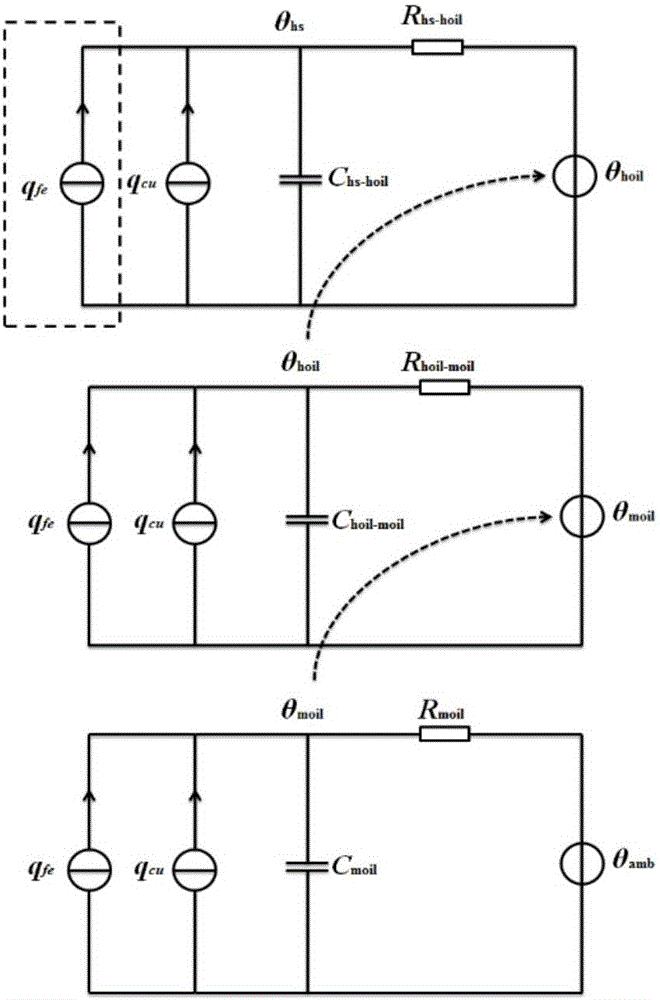

Method for calculating hotspot temperatures of split type cooling transformers in underground substations

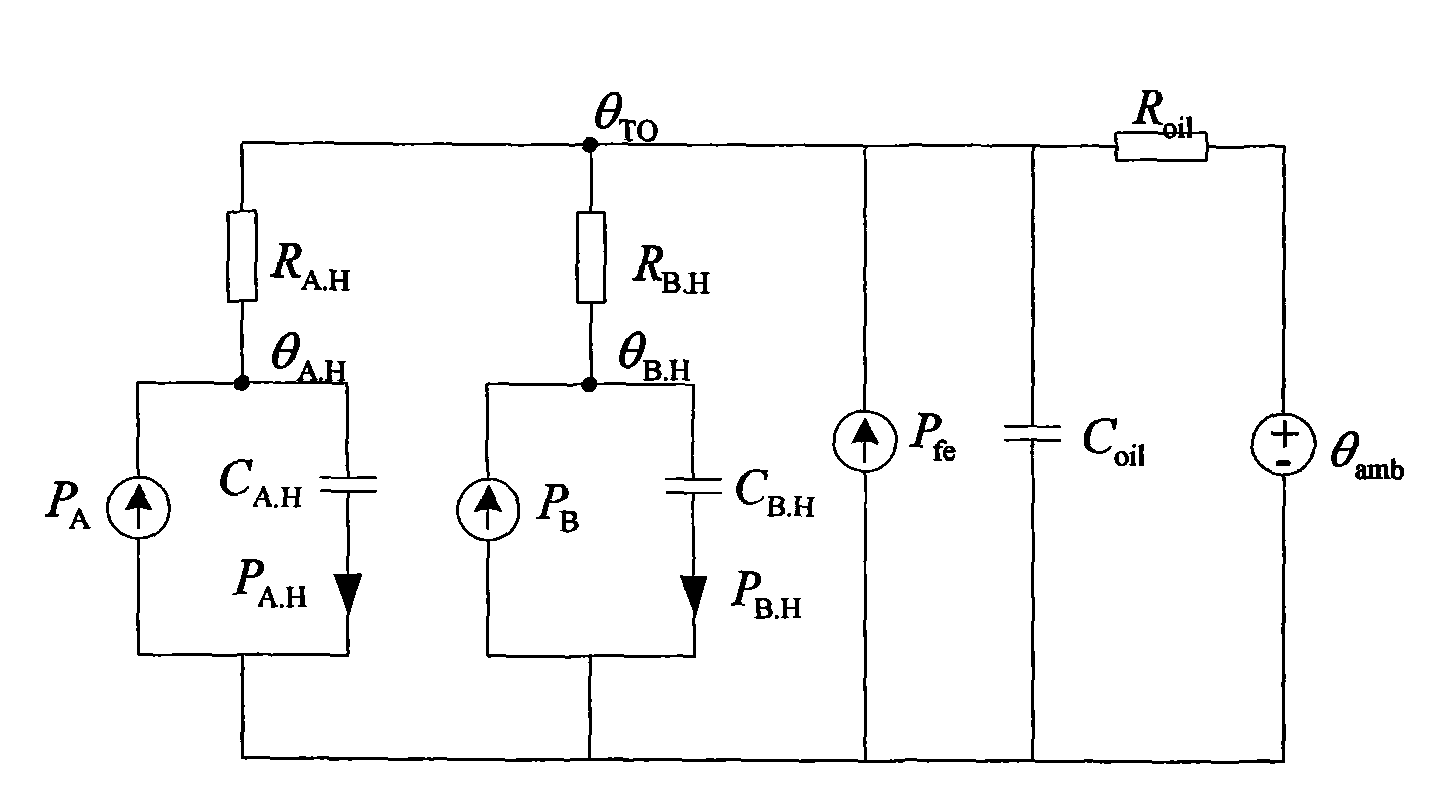

ActiveCN107066799AHigh precisionAccurately get the changing trendData processing applicationsSpecial data processing applicationsTransformerTemperature curve

The invention discloses a method for calculating hotspot temperatures of split type cooling transformers in underground substations. The method comprises the following steps of: obtaining equipment parameters of a split type cooling system transformer; carrying out a no-load test and a load test on the split type transformer and respectively carrying out measurements to obtain no-load loss and load loss of the transformer; carrying out a rated load temperature rise test to obtain rated top-layer oil temperature rise and winding temperature rise; establishing a split type transformer thermal circuit model on the basis of a thermoelectric equivalence theory, and optimizing the split type transformer thermal circuit model to obtain a transformer top-layer oil temperature thermal circuit model and a hotspot temperature model; and solving a thermal circuit differential equation by adoption of a four-order Ronge-Kutta method, and calculating a top-layer oil temperature time series and a hotspot temperature time series under a given load curve and a given environment temperature curve. According to the method disclosed by the invention, dynamic load capacity of the split type cooling transformers can be utilized more sufficiently to promote the good application of the transformers to online information monitoring.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

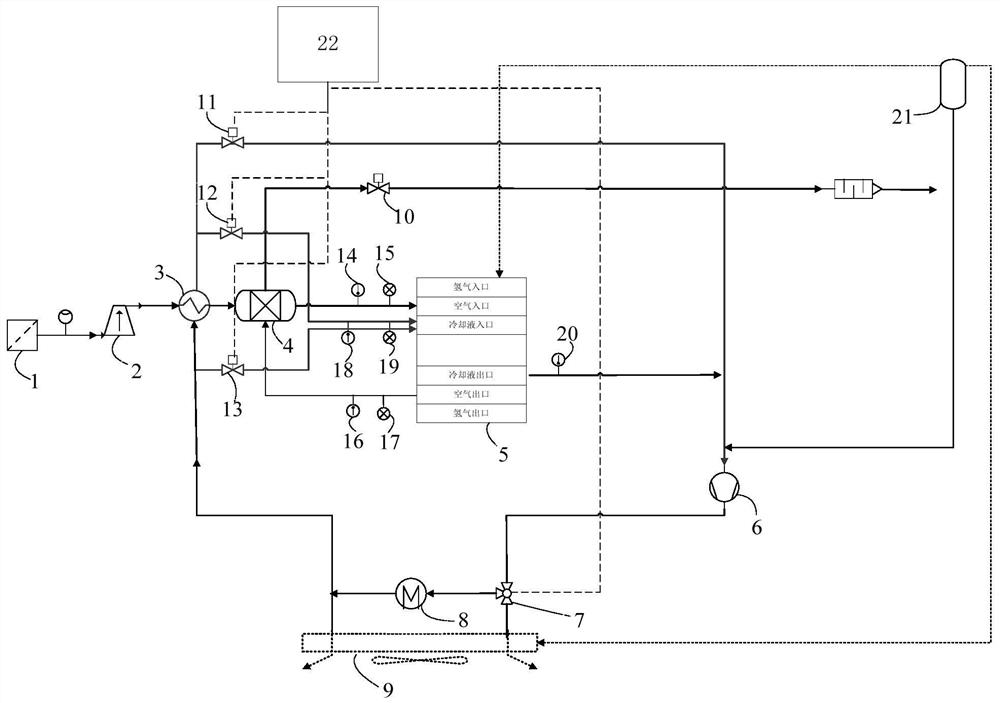

Automobile fuel cell cold start control system and method

ActiveCN112687910AStart fastFuel cell heat exchangeBattery/fuel cell control arrangementHumistorElectrical battery

The invention belongs to the technical field of vehicle battery heat dissipation, and discloses an automobile fuel cell cold start control system and method, and the system comprises an air compressor, an intercooler, a humidifier, a fuel cell stack, a water pump, a three-way control valve, a heater, a radiator, a throttle valve, a first valve, a second valve, a third valve, and a controller. An air heating path is formed by the air compressor, the intercooler, the humidifier, the fuel cell stack, the humidifier and the throttle valve; the water pump, three-way control valve, the heater, the intercooler, the second valve, the fuel cell stack, and the water pump form a cooling liquid heating loop; the water pump, the three-way valve, the radiator, the third valve, the fuel cell stack, and the water pump forms a first cooling liquid radiating loop; the water pump, the three-way control valve, the radiator, the first valve, and the water pump form a second cooling liquid radiating loop. Under a low-temperature condition, the fuel cell can be rapidly started under the low-temperature condition; under the condition of high temperature, the intercooler and the fuel cell stack are cooled by one radiator.

Owner:CHINA FIRST AUTOMOBILE

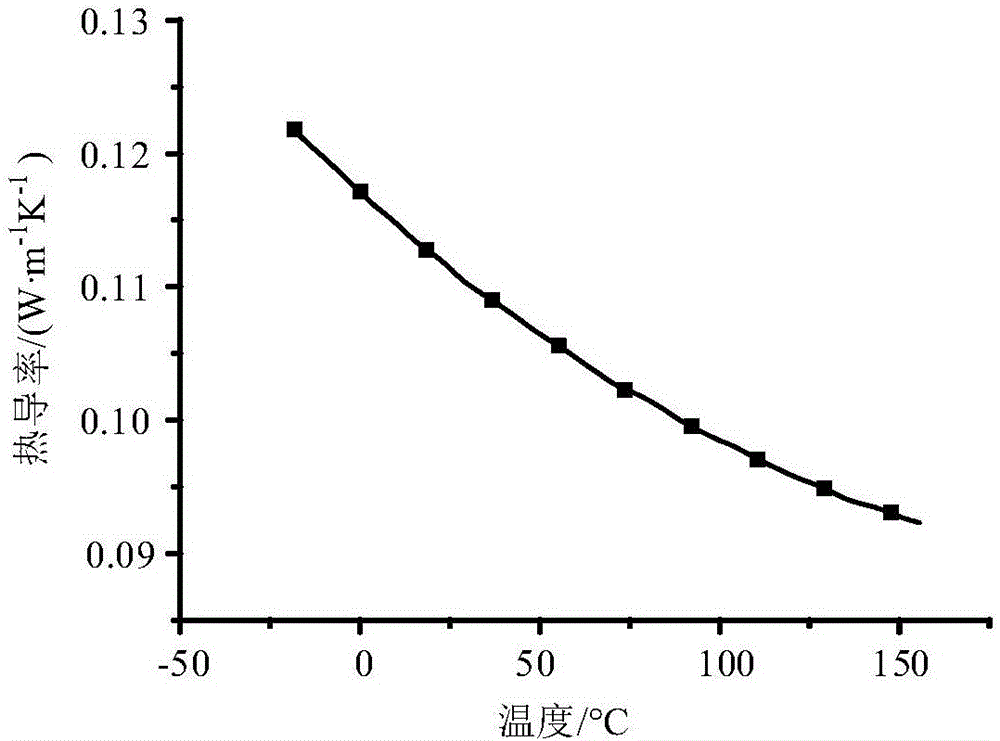

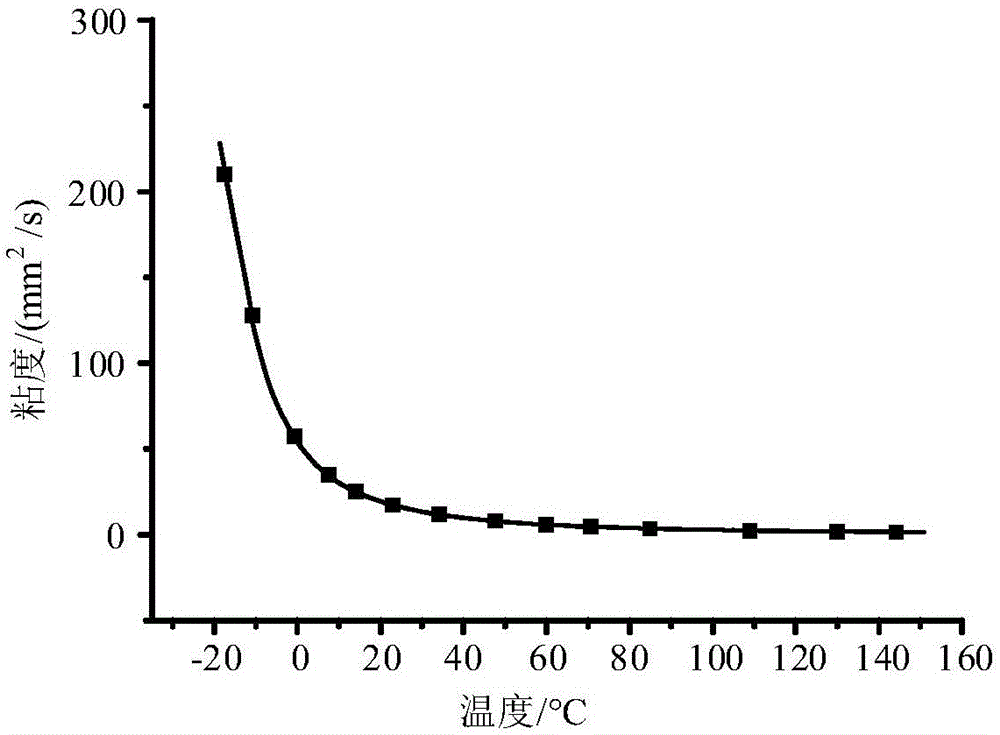

Method for predicting hot-spot temperature of transformer winding under low temperature

ActiveCN106595884AImprove forecast accuracyMake up for the lack of accurate calculationThermometers using electric/magnetic elementsUsing electrical meansPredictive methodsEconomic benefits

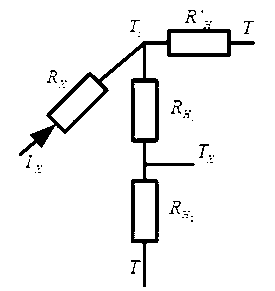

The invention discloses a method for predicting the hot-spot temperature of a transformer winding under low temperature, and the method comprises the steps: firstly building an improved three-thermal-circuit model; carrying out the correction of the improved three-thermal-circuit model in different oil flow cooling modes; comparing a temperature rise value, detected by a temperature measurement sensor, of transformer oil with a temperature value calculated through the corrected three-thermal-circuit model, and correcting a transformer thermal circuit model approaching to the reality; calculating the mean oil temperature of a transformer based on environment temperature through the transformer thermal circuit model approaching to the reality, enabling the mean oil temperature of the transformer to serve as the reference temperature of central oil temperature of the improved three-thermal-circuit model, calculating the top oil temperature of the model, and finally calculating the hot-spot temperature value of the transformer winding. According to the invention, the method is simple in design, is easy to implement, is easy to popularize and implement, provides a basis for the checking of the capability of a transformer for resisting a short-circuit fault, improves the operation safety and stability of the transformer, and is better in economic benefits.

Owner:STATE GRID EAST INNER MONGOLIA ELECTRIC POWER CO LTD MAINTENANCE BRANCH +3

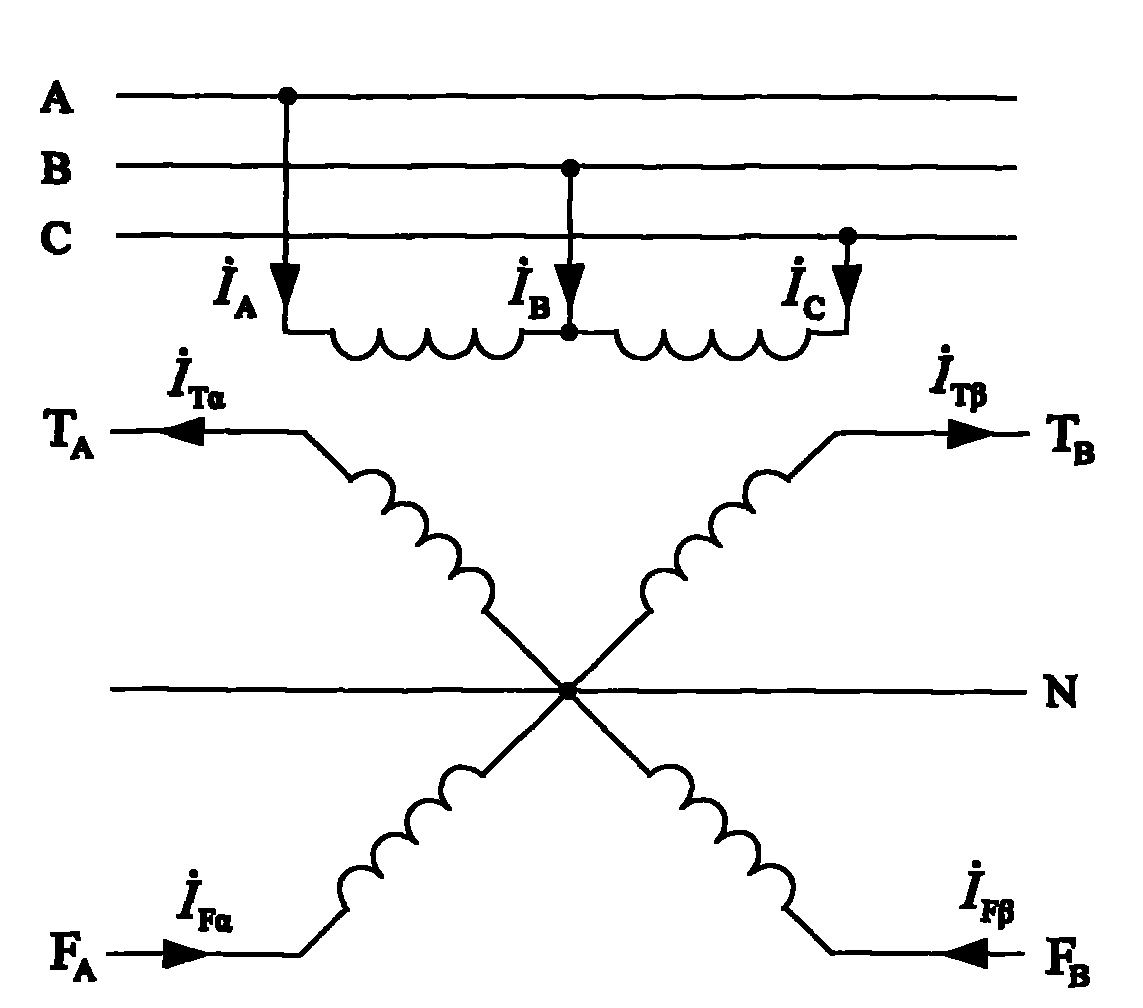

Internal temperature rise on-line monitoring method of traction transformer of V/X connection

InactiveCN102087321ALower performance requirementsImprove calculation accuracyElectrical testingDistribution transformerComputer performance

The invention discloses an internal temperature on-line monitoring method of a traction transformer of V / X connection. The method comprises the following steps of: (1) acquiring the basic parameters of the transformer; (2) monitoring the current of a traction winding, the current of a positive feed winding and the temperature of top oil of the transformer on line and uploading the monitored data to an upper computer; and (3) calculating the on-line monitored data by utilizing an internal temperature rise calculating formula established on the basis of an internal temperature rise thermal circuit model of the traction transformer of V / X connection to obtain the internal temperature rise condition during the running of the traction transformer of V / X connection. The invention particularly aims at the traction transformers of V / X connection, which are widely applied to heavy haul railways and high speed railways in China at present, has the advantages of simple system structure, less data required to be monitored, easy monitoring, simple data processing process and lower requirement for computer performance; and an ordinary industrial personal computer can meet the requirement for operation, thus the calculating precision is higher.

Owner:SOUTHWEST JIAOTONG UNIV

Steady state thermal circuit model-based method and device for determining permissible current of overhead conductor

The invention discloses a steady state thermal circuit model-based method and device for determining a permissible current of an overhead conductor. The method comprises the steps of: firstly, loading a current to the overhead conductor, after the temperature of the conductor is stabilized, measuring the temperature of the conductor and an environment temperature of an environment where the conductor is in; according to the two temperatures, by adopting a special formula, sequentially calculating an AC resistance and an environment thermal resistance, and the maximum permissible current when the temperature of the conductor reaches 70 DEG C under the current outside environment; and comparing the current current and the maximum permissible current to carry out corresponding compatibility on the overhead conductor, and providing basis for load transfer, scheduling plan and the like, wherein the formula for calculating the environment thermal resistance and the maximum permissible current is based on a steady state thermal circuit model, the maximum permissible current can be obtained through measuring the temperature of the conductor and the environment temperature of the environment where the conductor is in and through simple calculation, and proved by experiments, result errors are in a permissible range.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +1

Fuel cell thermal management system with phase change heat storage and preheating functions

ActiveCN111463453AImprove cold start speedReduce consumptionFuel cell heat exchangeMotive system fuel cellsFuel cellsEngineering

The invention discloses a fuel cell thermal management system with phase change heat storage and preheating functions. The fuel cell thermal management system comprises a heat pipe heat exchange part,a liquid path preheating loop, a liquid path heating loop, a gas path preheating loop and a gas path heating loop, wherein the heat pipe heat exchange part is embedded into a heat pipe in a polar plate to exchange heat with an external liquid path, a first phase-change heat exchanger is connected with a liquid path, a second phase-change heat exchanger is simultaneously connected with a gas pathand the liquid path, the liquid path preheating loop heats the liquid path through the first phase change heat exchanger, the gas path preheating loop heats the gas path through the second phase change heat exchanger to jointly preheat a fuel cell, waste heat of a fuel cell in the liquid path heating loop accumulates heat for the phase change heat exchanger or heats a lithium battery and a passenger compartment, the gas path heating loop indirectly heats inlet gas through cooling liquid. The fuel cell thermal management system is advantaged in that the waste heat of the fuel cell can be storedin the phase change heat exchanger and used for preheating the fuel cell through a liquid path and a gas path or for heat preservation of the fuel cell, in addition, the waste heat of the fuel cell can heat intake air, a lithium battery or a passenger compartment, and the energy utilization rate is increased.

Owner:JILIN UNIV

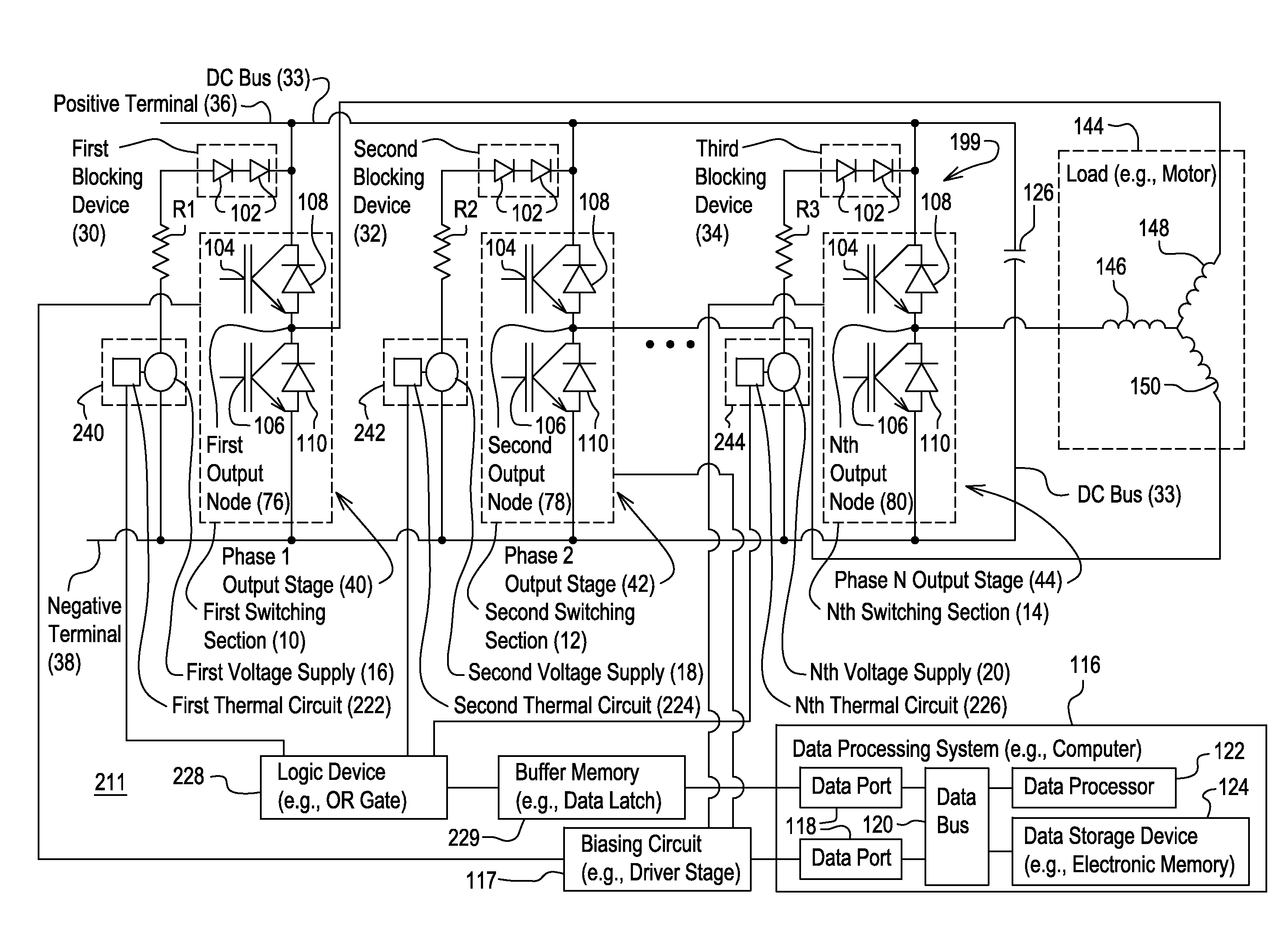

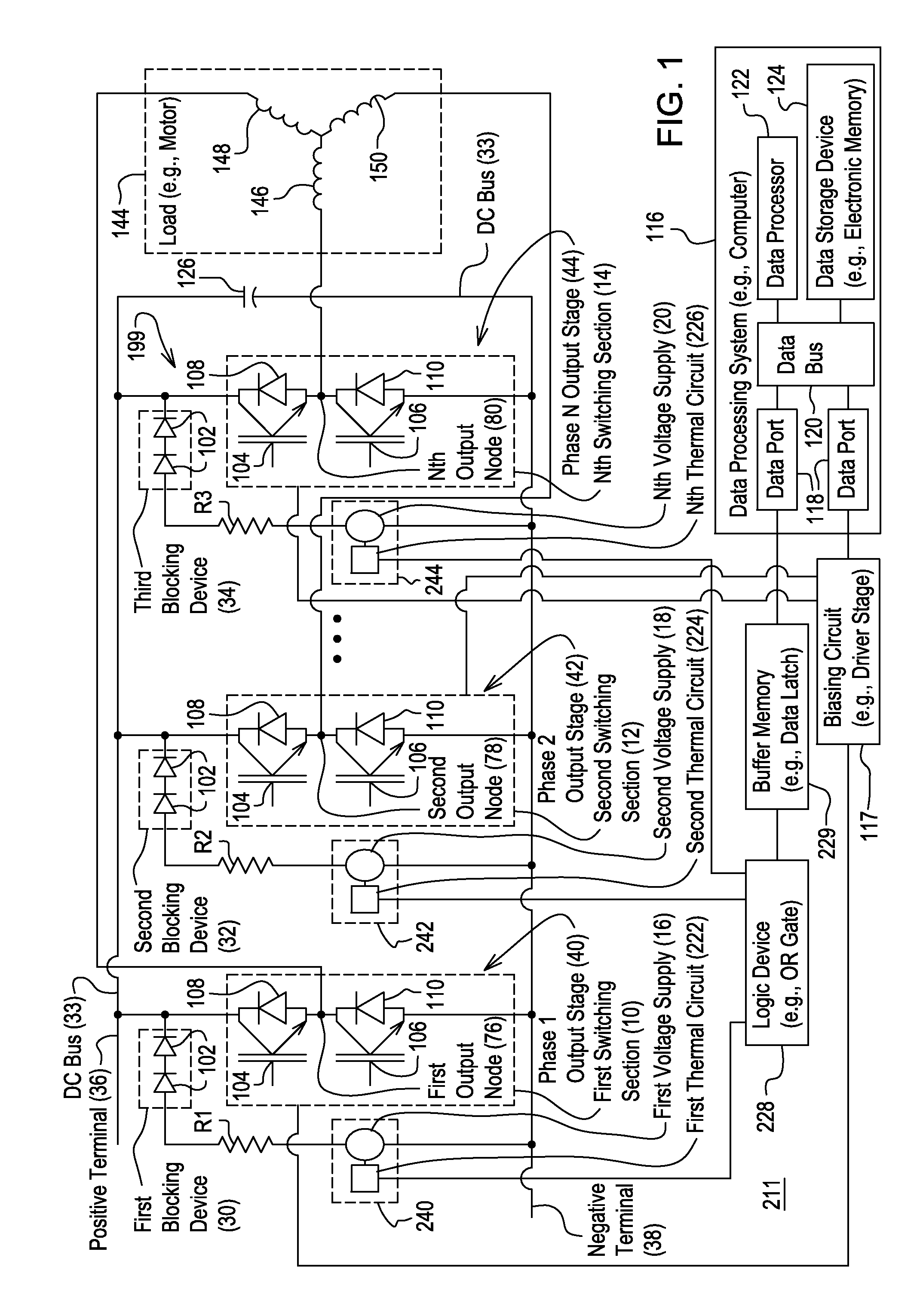

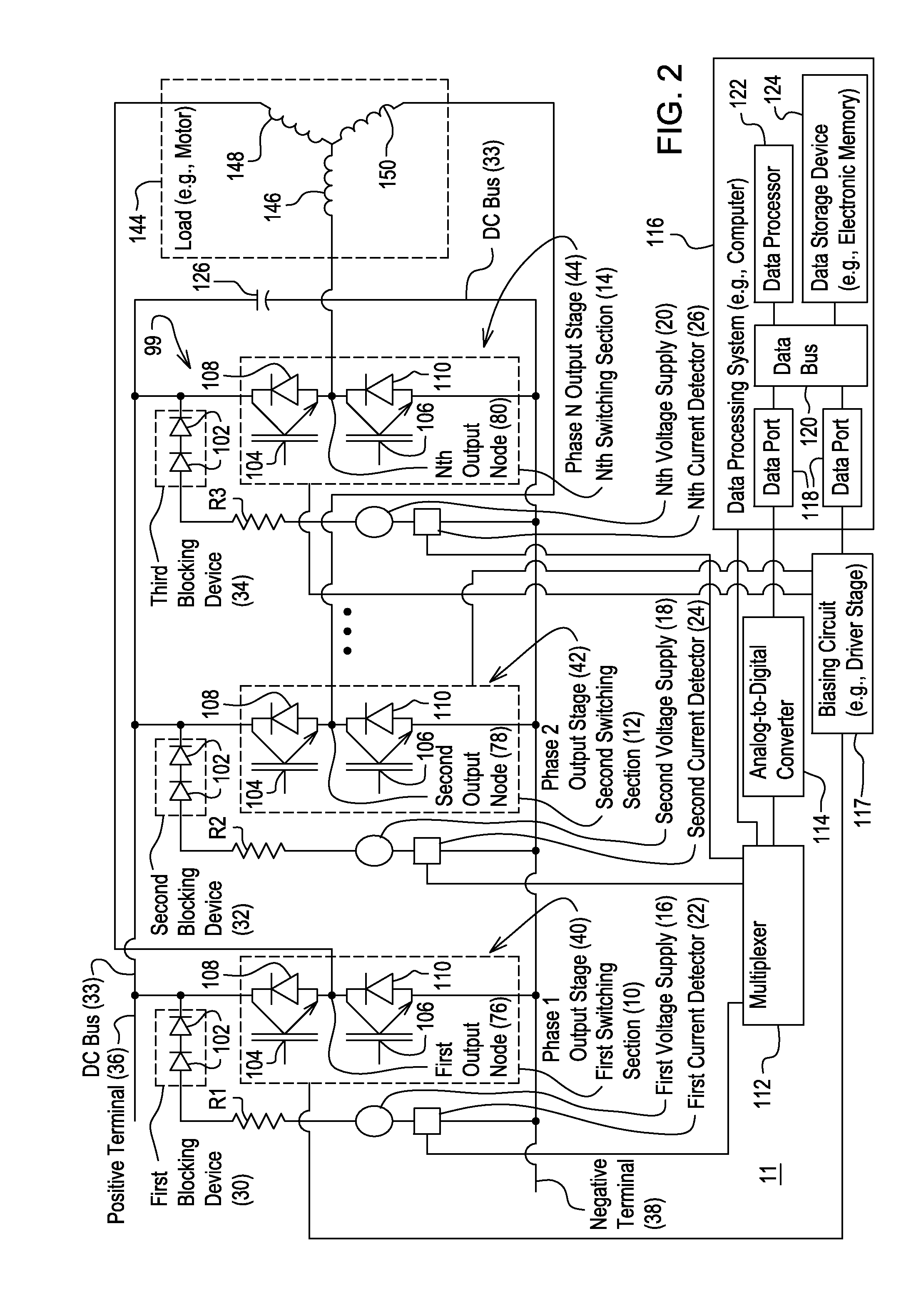

System for detecting a short circuit associated with a direct current bus

The system comprises a direct current bus having a positive terminal and a negative terminal. A first switching transistor and a second switching transistor have their respective switched terminals connected in series with respect to each other between the positive terminal and the negative terminal. A primary supply is arranged to generating a test voltage that is lower than an operational voltage of the direct current bus. The test voltage is applied between the positive terminal and the negative terminal of the direct current bus. A primary thermal circuit is associated with the supply for detecting whether the supply exceeds an operational temperature threshold. The thermal circuit provides a signal or logic level state indicative of a detected short circuit in the direct current bus if the primary supply exceeds the operational temperature threshold.

Owner:DEERE & CO

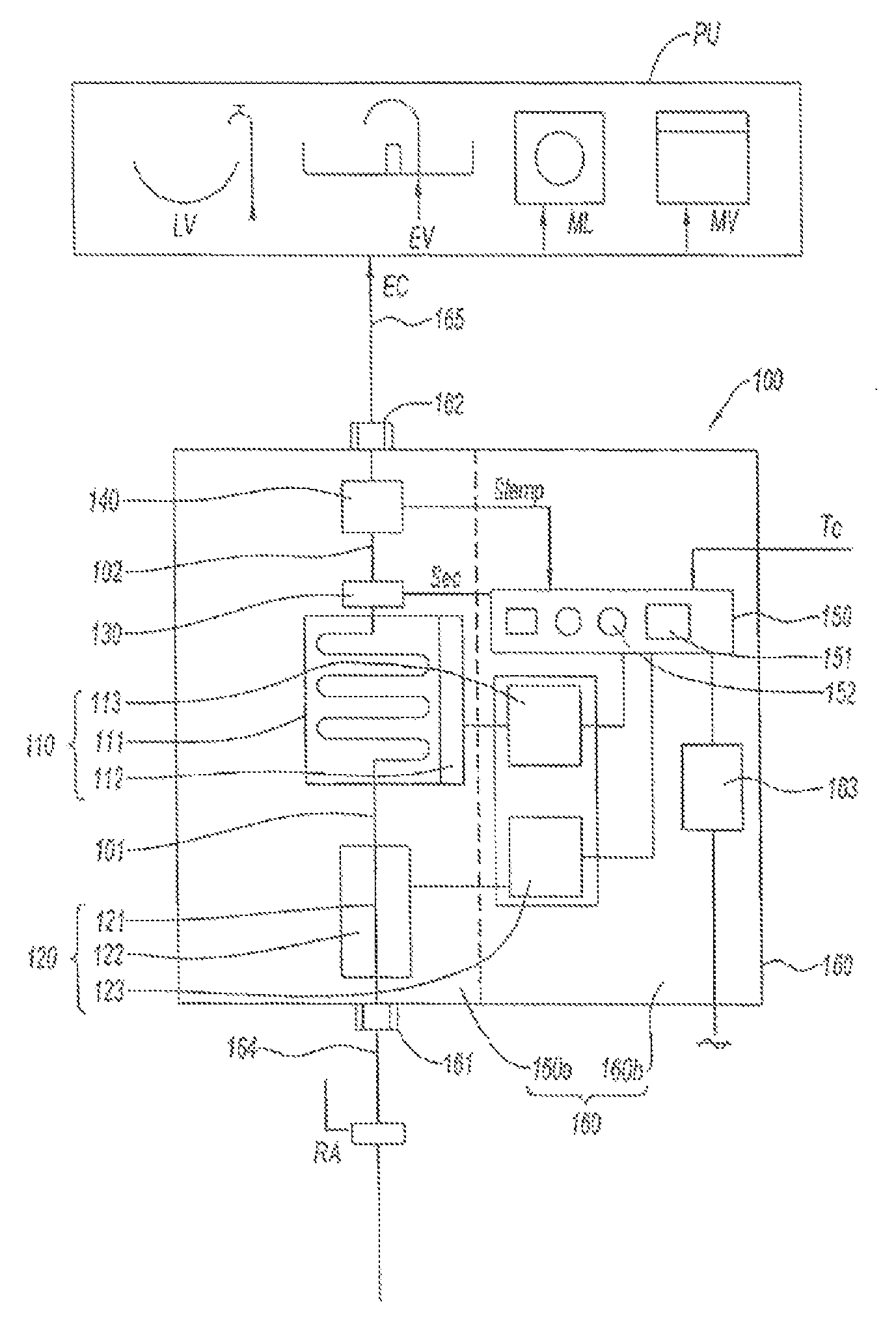

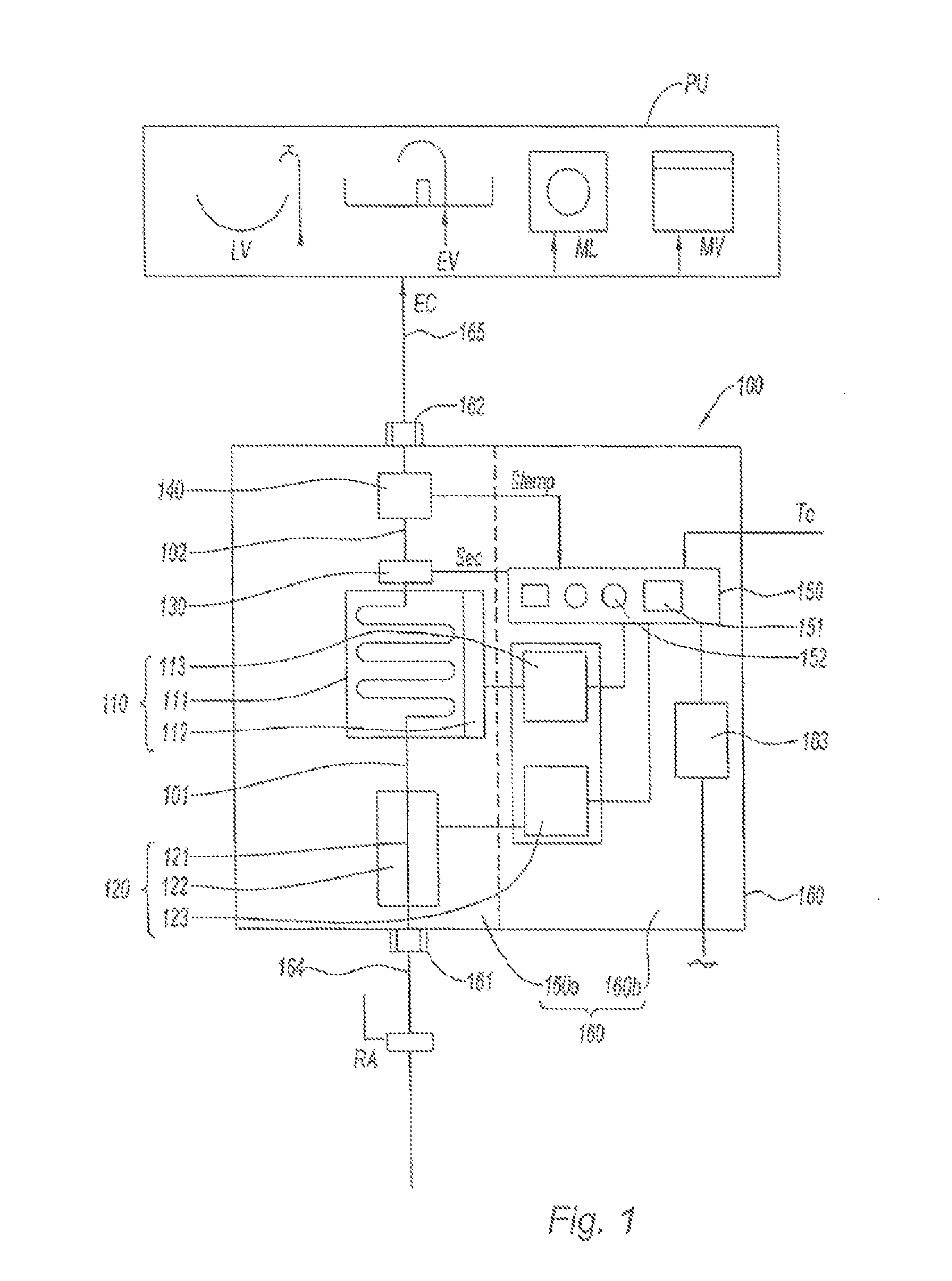

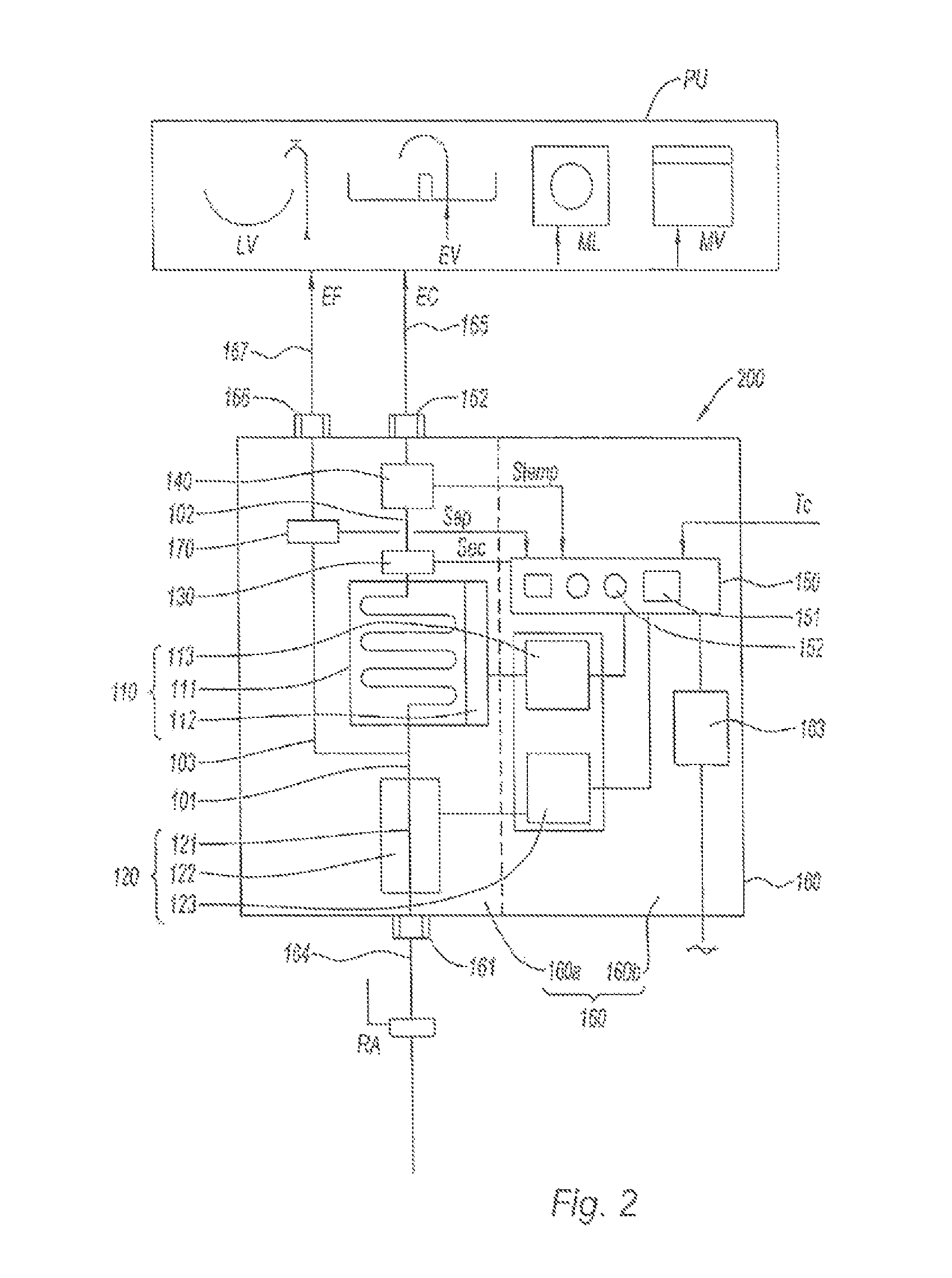

Apparatus for instantly preparing hot water

InactiveUS9163855B2Coil arrangementsWater/sewage treatment by magnetic/electric fieldsEngineeringThermal water

The invention relates to an apparatus including an induction device (110) for heating water in a channel and supplied by a high-frequency generator (113), and an electromagnetic scale-preventative device (120) upstream from the heating circuit (110) and powered by a frequency generator (113). A channel sensor (130) detects a request for water and a control circuit (150) receives the water request signal (Sec) from the sensor (130) so as to control the operation of the heating circuit (110) and of the scale-preventative device (120), adjusting the power thereof in order to adjust the temperature and to stop the operation thereof.

Owner:AKEL DOMINIQUE

IGBT junction temperature thermal calculation method under fault current

InactiveCN108680847AOptimize thermal designHigh precisionIndividual semiconductor device testingVoltage dropJunction temperature

An IGBT junction temperature thermal calculation method under a fault current relates to a thermal calculation method, and aims to solve the technical problems that an existing method cannot effectively reflect the transient junction temperature of each chip in an IGBT module; the method comprises the following steps: 1, calculating power module loss according to circuit state information and a loss parameter, fitting a manual curve of the IGBT module so as to obtain a conduction voltage drop, an IGBT open loss and a shut down loss, and using an instantaneous power consumption integration in aperiod to represent the loss; 2, obtaining a power device peak junction temperature calculation method under a burst pulse power according to an IGBT peak junction temperature calculation method under a short power pulse, inputting IGBT module thermal property parameters, using the physical parameter of a related layer to simulate a thermal response curve in operation, and building a module system thermal circuit module; 3, determining the IGBT module temperature. The IGBT junction temperature thermal calculation method is reasonable in design, high in precision, and accurate in prediction results.

Owner:ZHOUSHAN ELECTRIC POWER SUPPLY COMPANY OF STATE GRID ZHEJIANG ELECTRIC POWER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com