Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15345 results about "Thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In thermodynamics, the thermal efficiency (ηₜₕ) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, a steam turbine or a steam engine, a boiler, furnace, or a refrigerator for example. For a heat engine, thermal efficiency is the fraction of the energy added by heat (primary energy) that is converted to net work output (secondary energy).

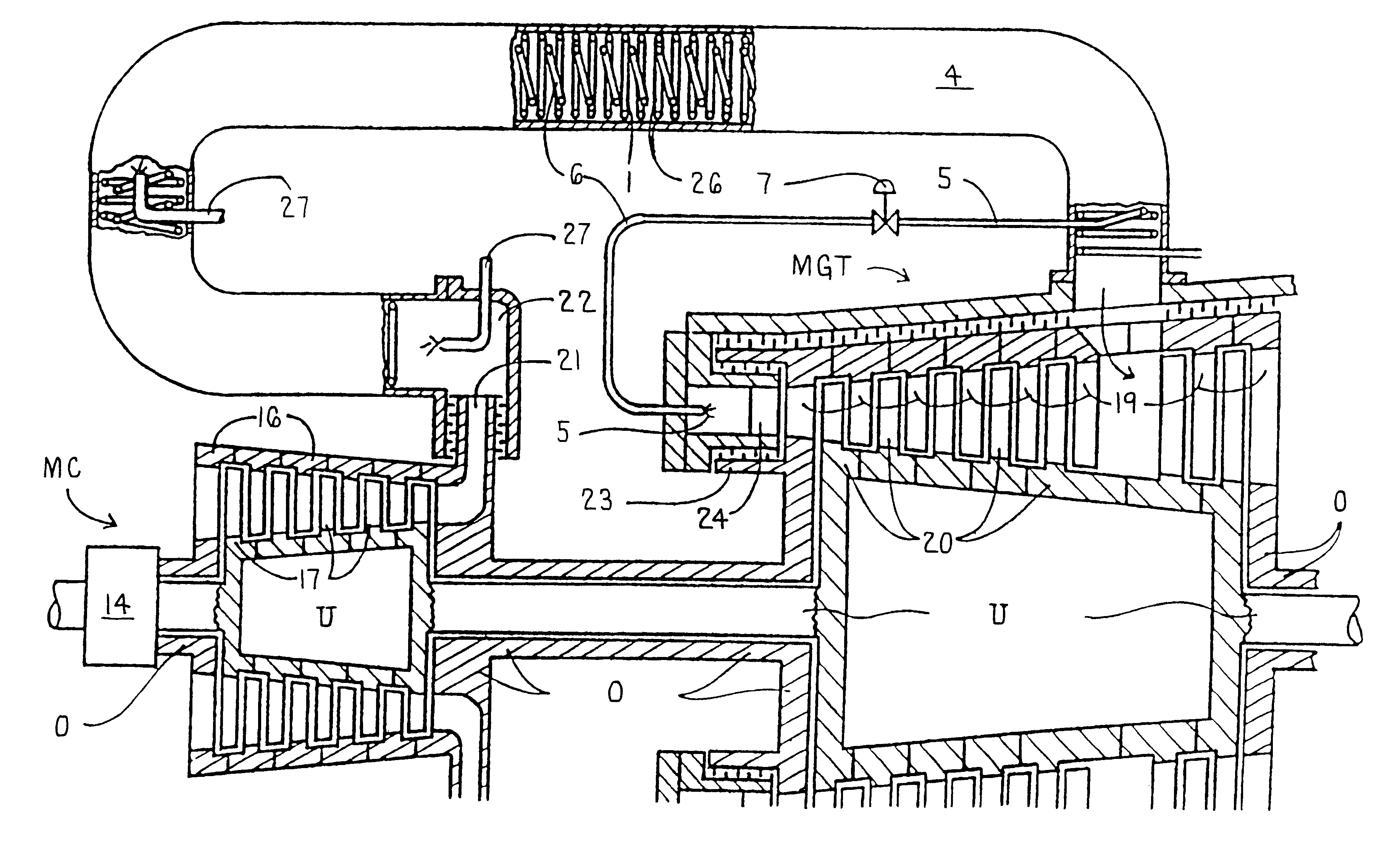

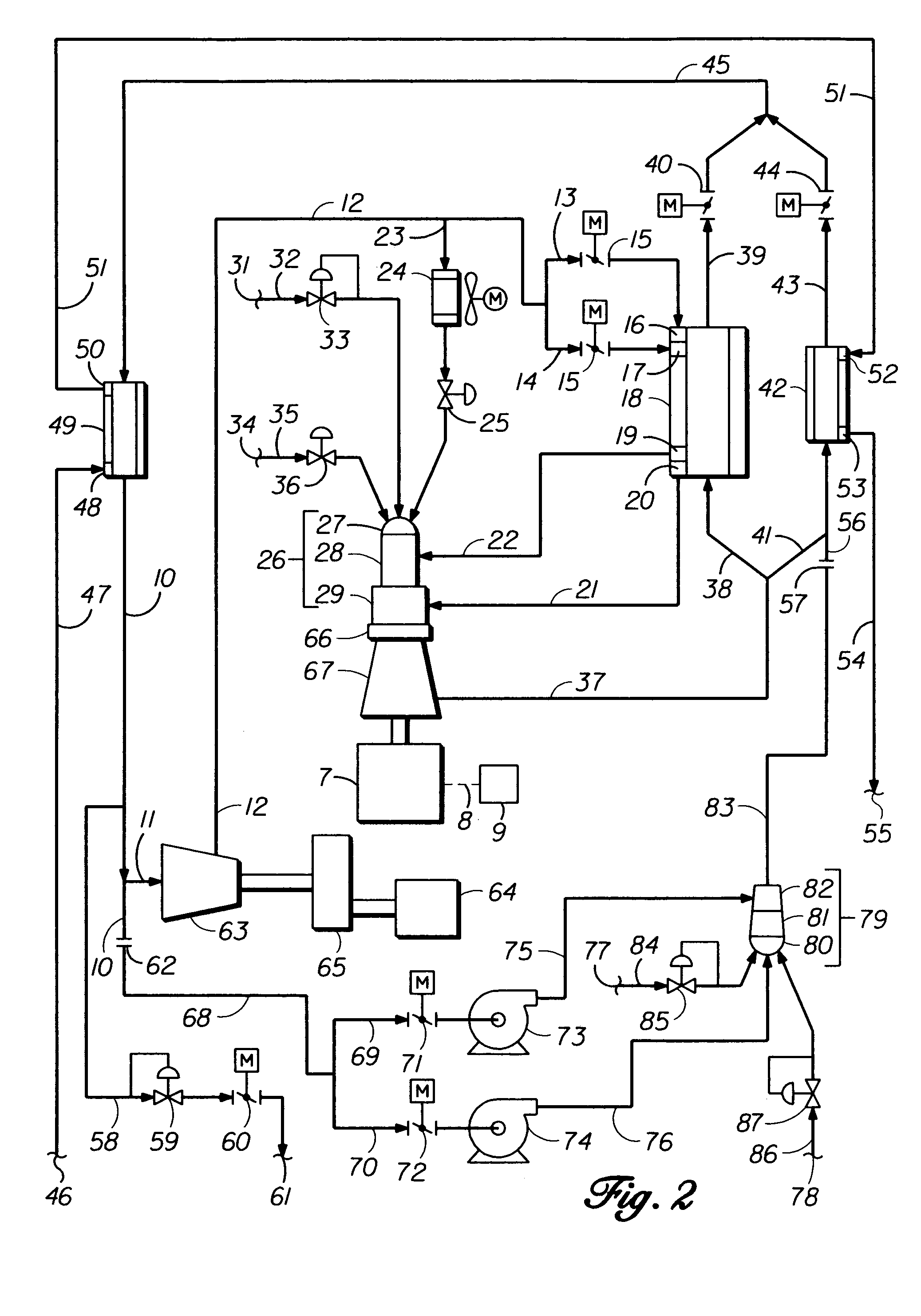

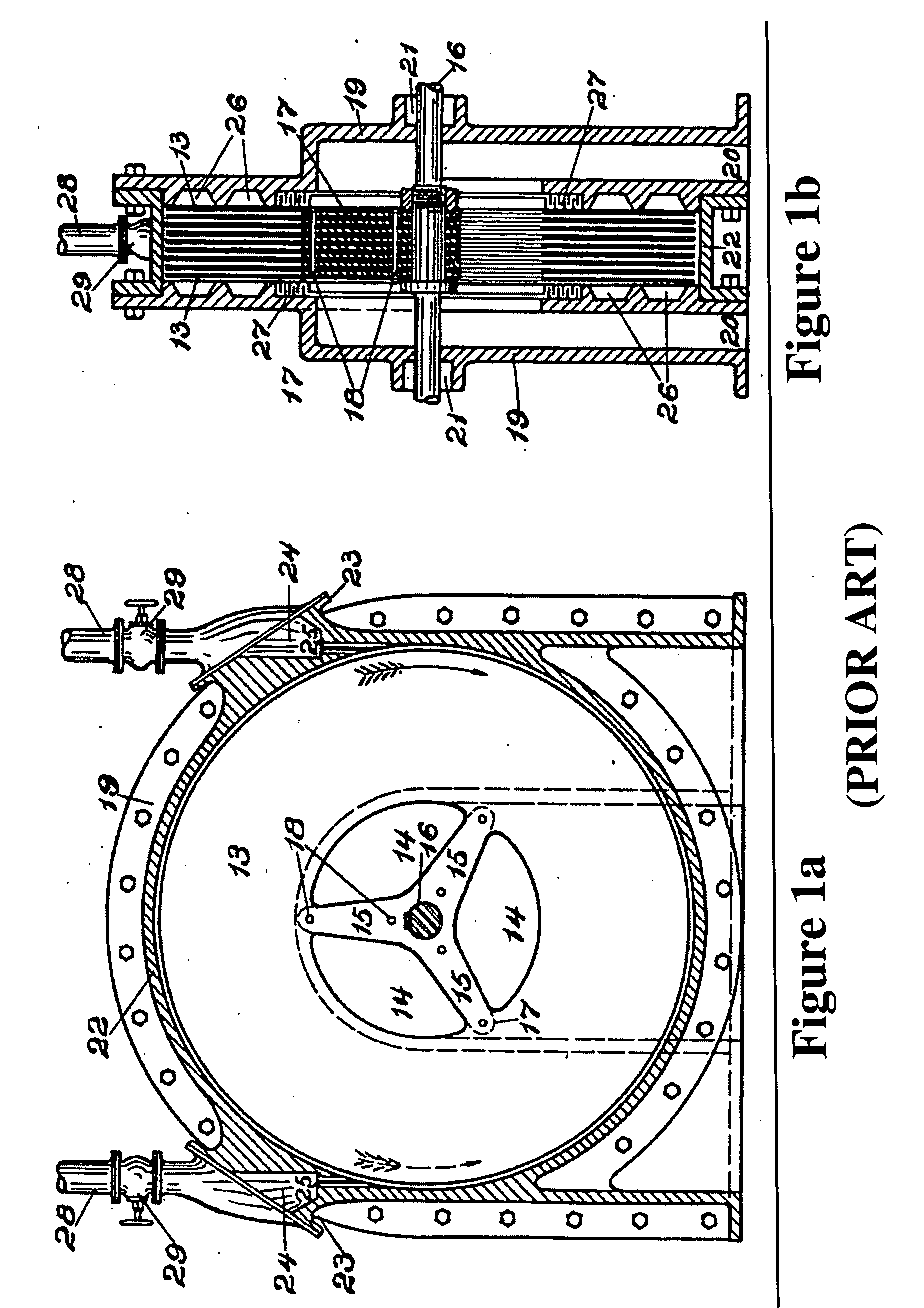

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

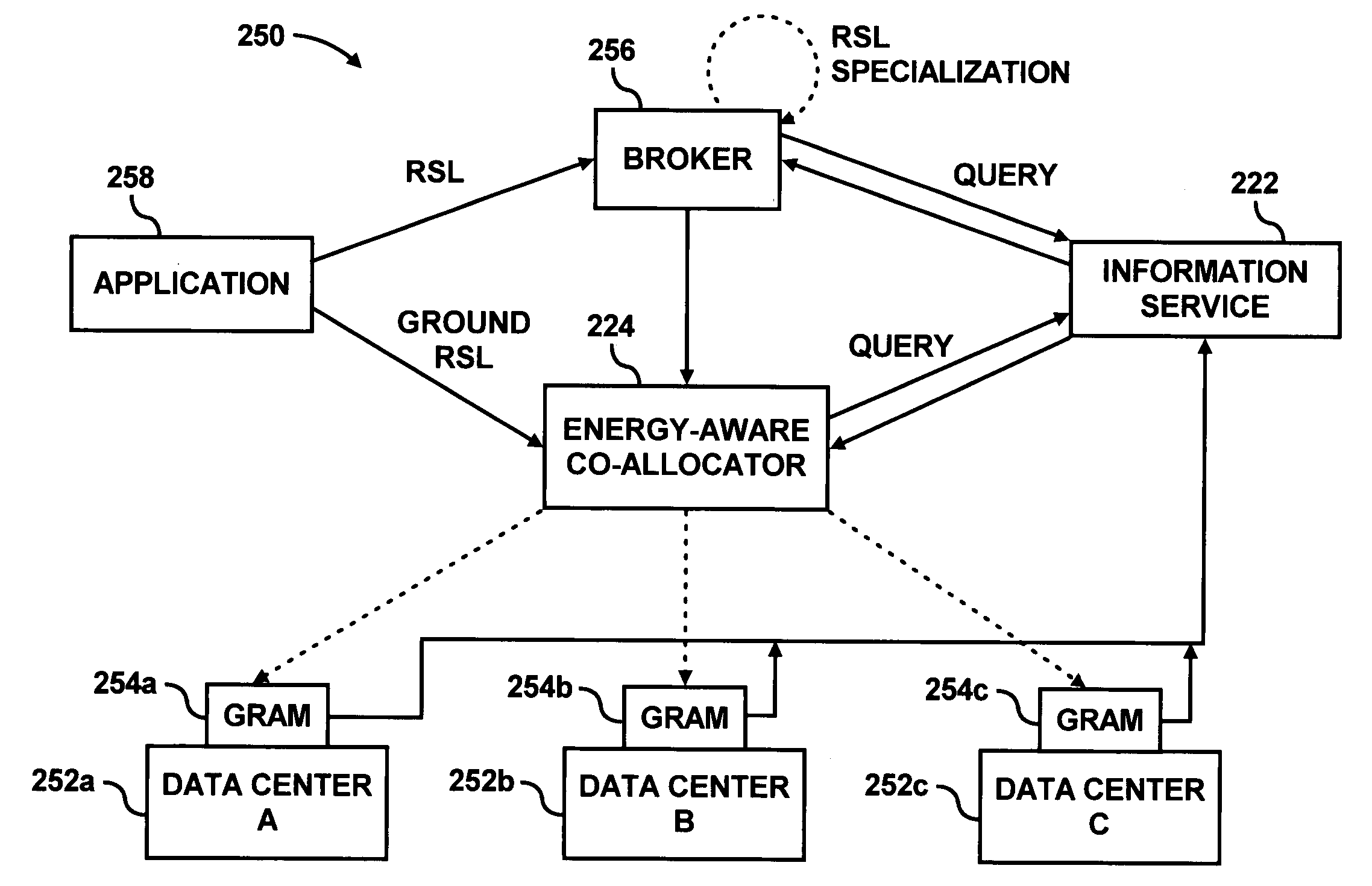

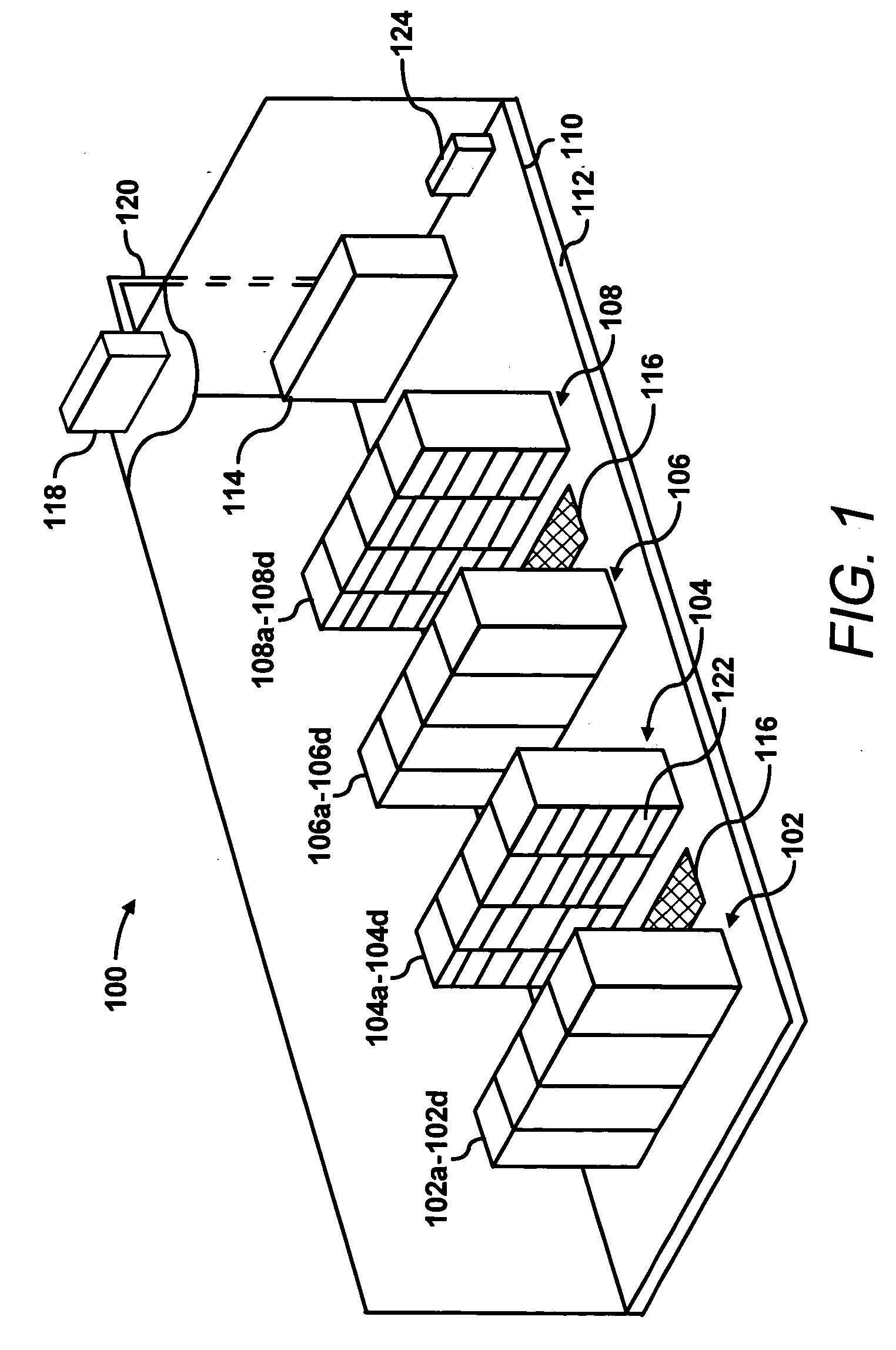

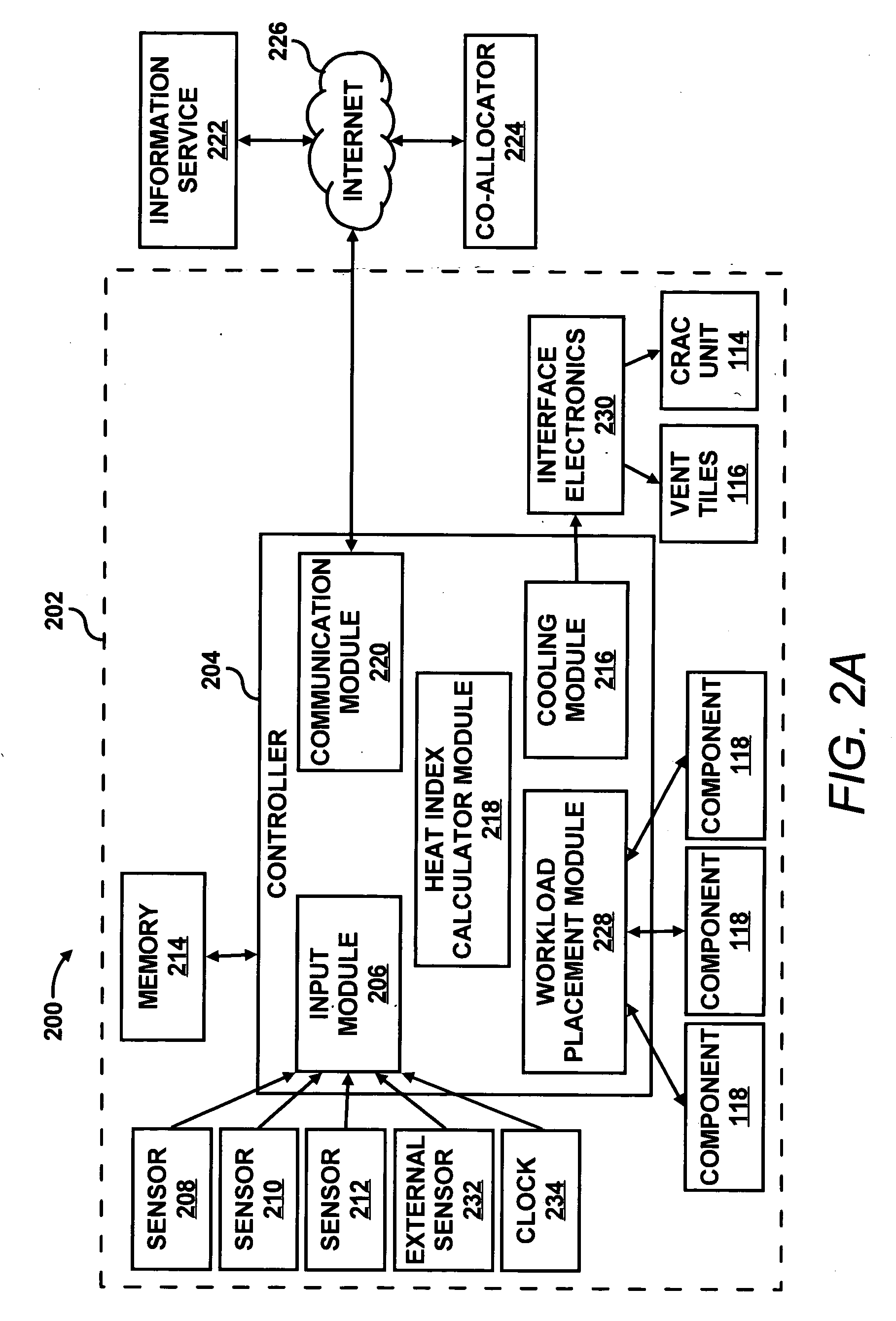

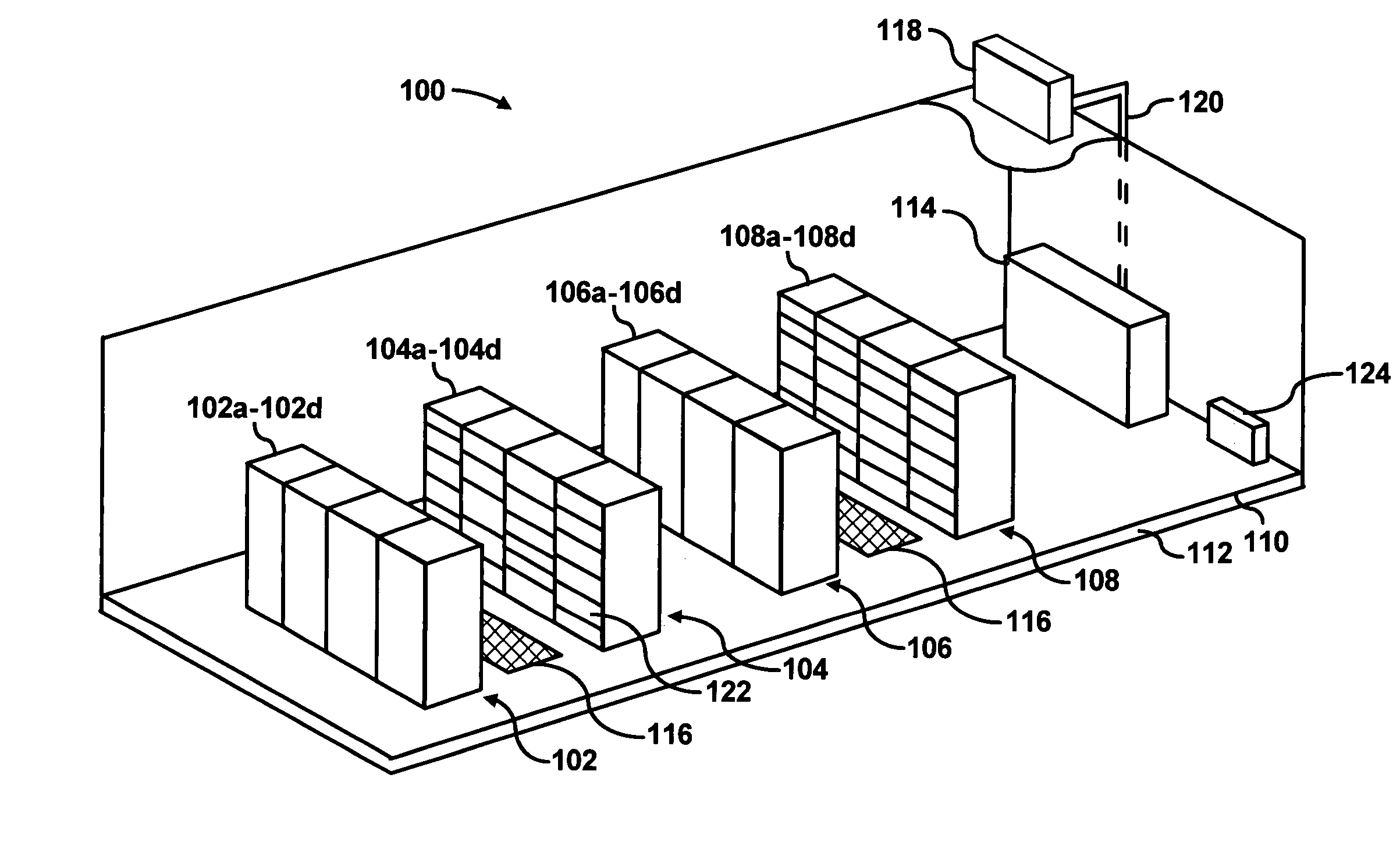

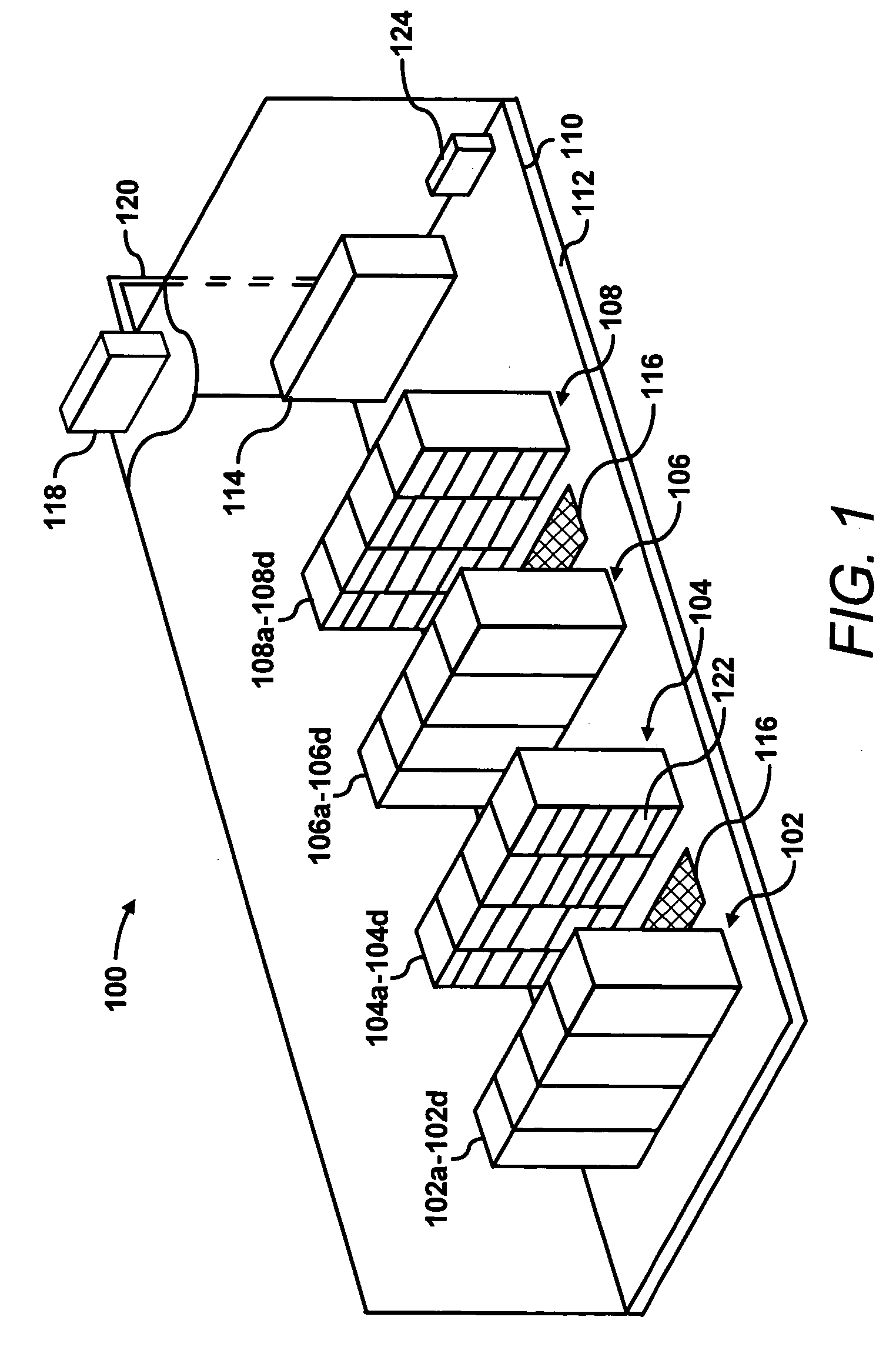

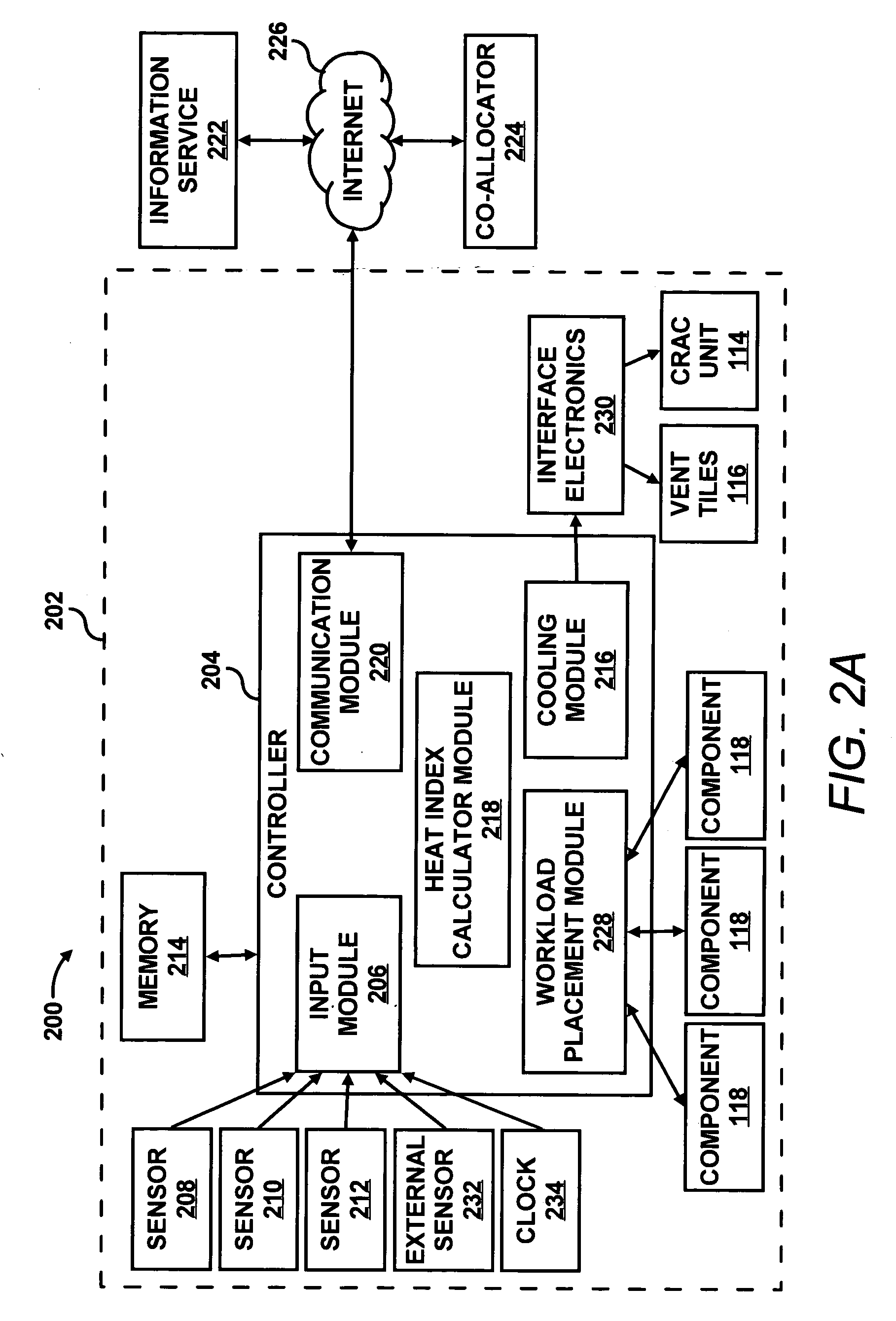

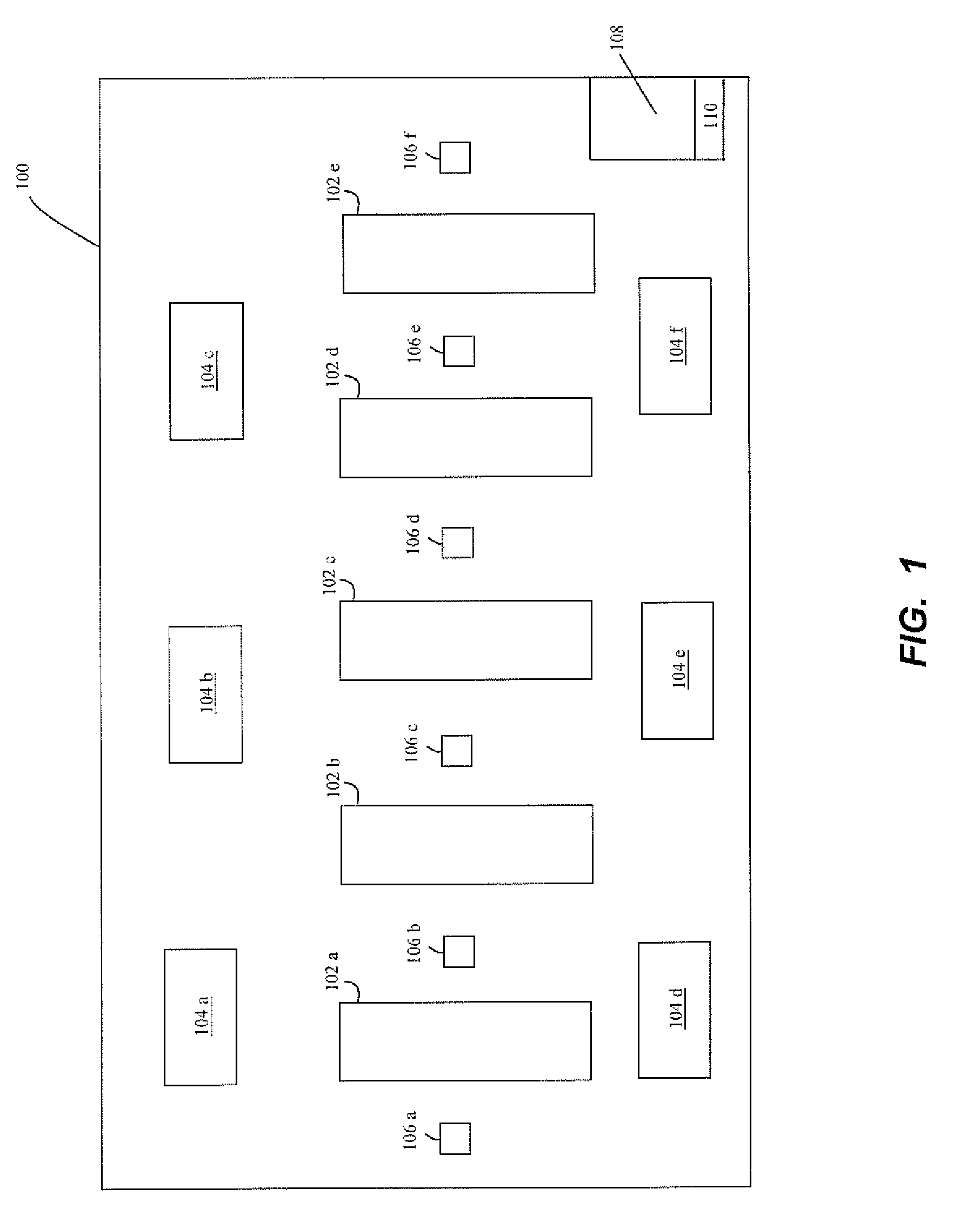

Workload placement among data centers based on thermal efficiency

A system for workload placement among data centers includes a plurality of grid resource allocation managers (GRAMs), wherein the GRAMs are configured to obtain information from the data centers. The system also includes an information service configured to receive information from the plurality of GRAMs and a broker configured to receive an application request and to determine resource requirements from the application request, wherein the broker is configured to determine which of the data centers contains adequate resources to perform the requested application. The system further includes a co-allocator configured to receive information pertaining to the data centers having the adequate resources, wherein the co-allocator is further configured to select one of the data centers to perform the requested application based upon energy efficiency characteristics of the data centers.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Workload placement among data centers based on thermal efficiency

A system for workload placement among data centers includes a plurality of grid resource allocation managers (GRAMs), wherein the GRAMs are configured to obtain information from the data centers. The system also includes an information service configured to receive information from the plurality of GRAMs and a broker configured to receive an application request and to determine resource requirements from the application request, wherein the broker is configured to determine which of the data centers contains adequate resources to perform the requested application. The system further includes a co-allocator configured to receive information pertaining to the data centers having the adequate resources, wherein the co-allocator is further configured to select one of the data centers to perform the requested application based upon energy efficiency characteristics of the data centers.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

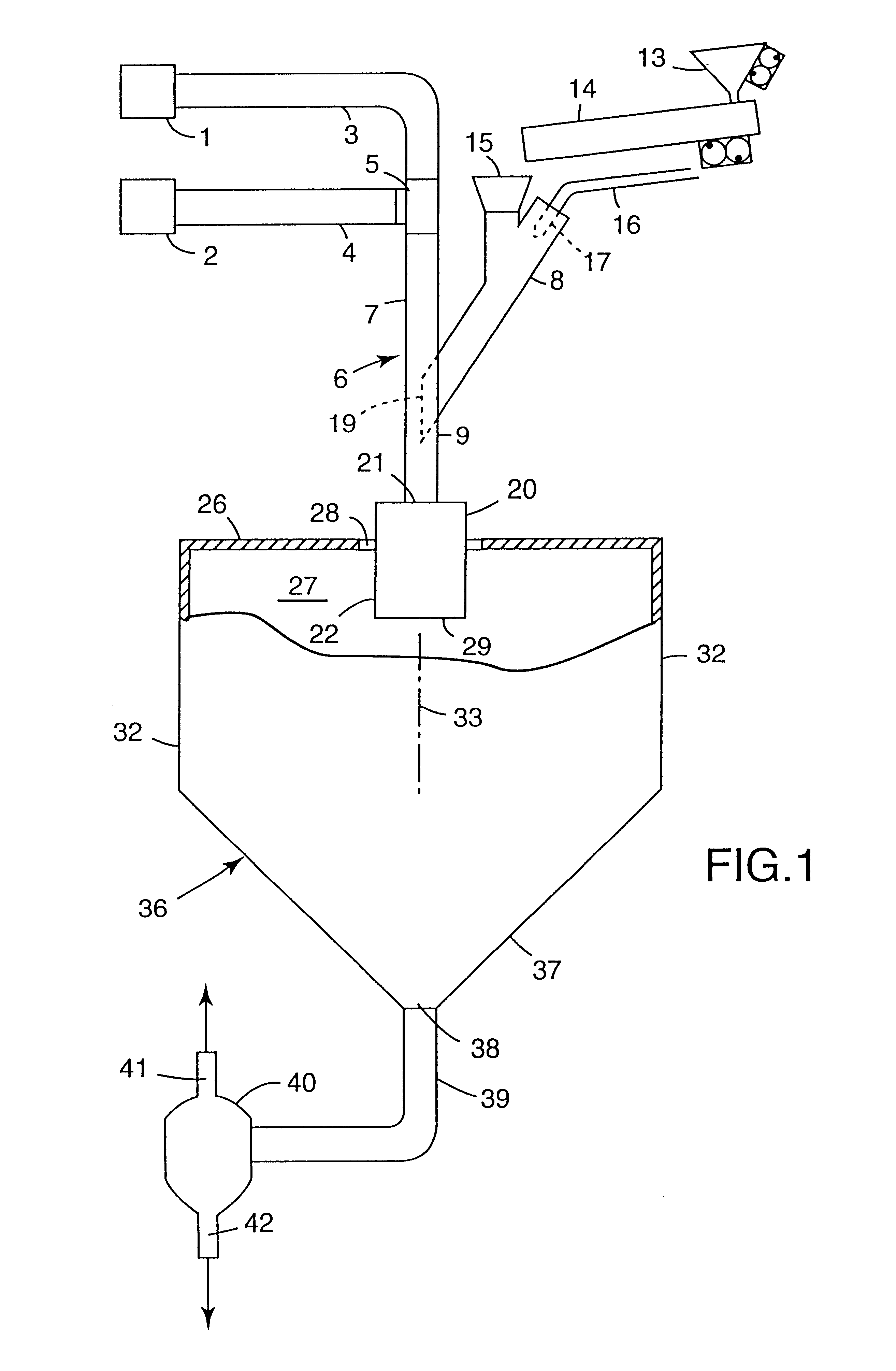

Fused glassy particulates obtained by flame fusion

InactiveUS6254981B1Efficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsParticulatesSuspended particles

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

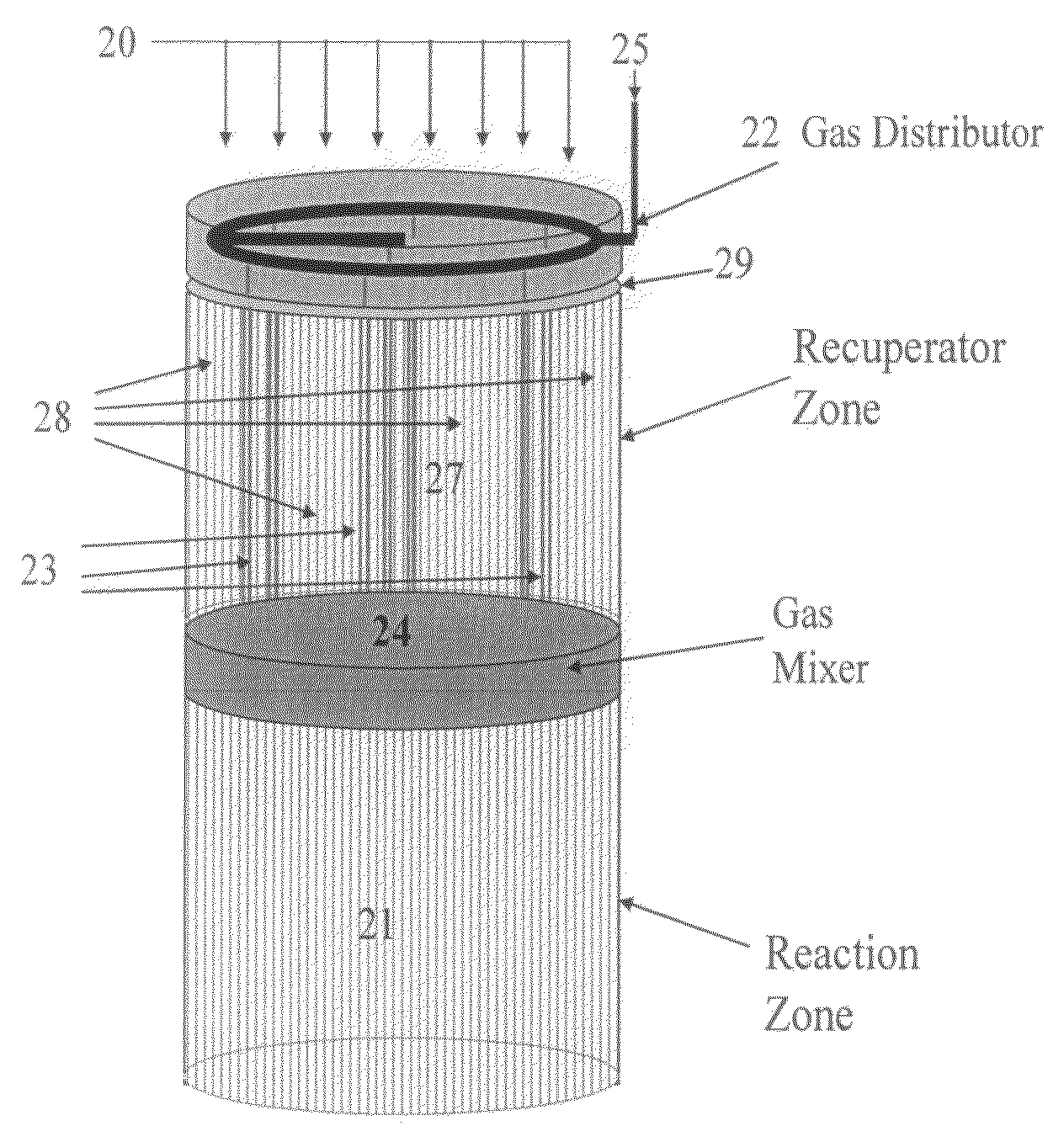

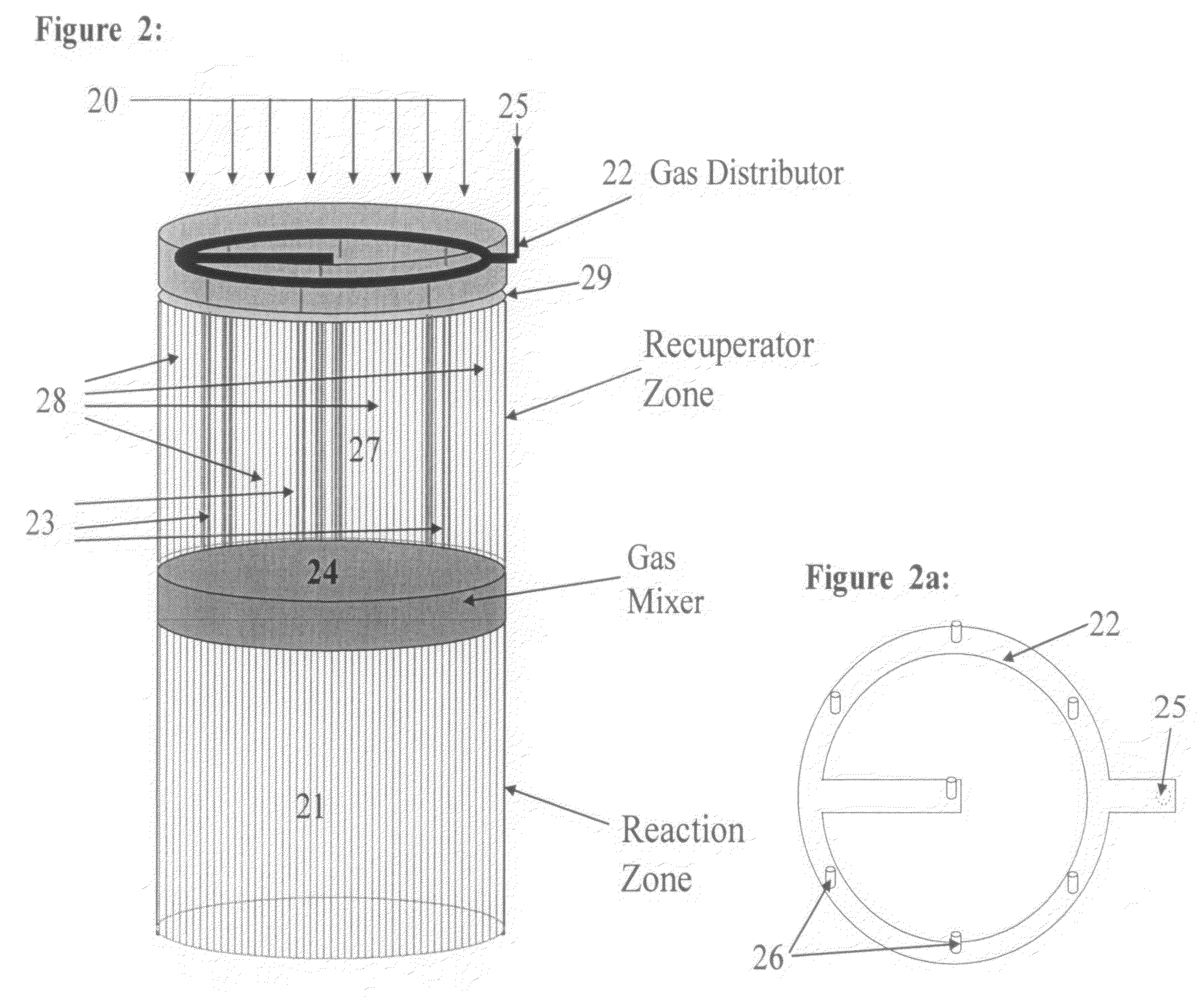

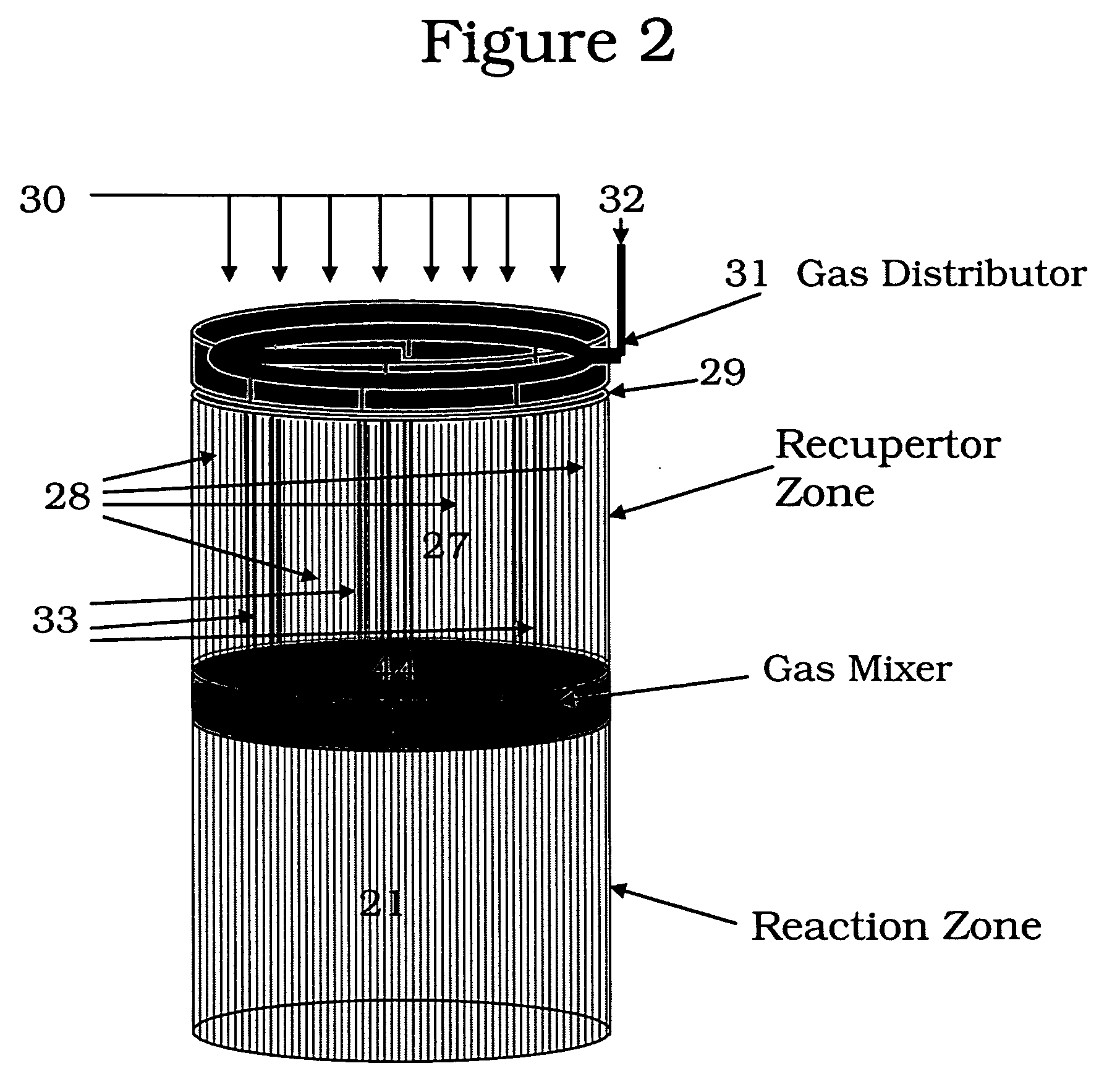

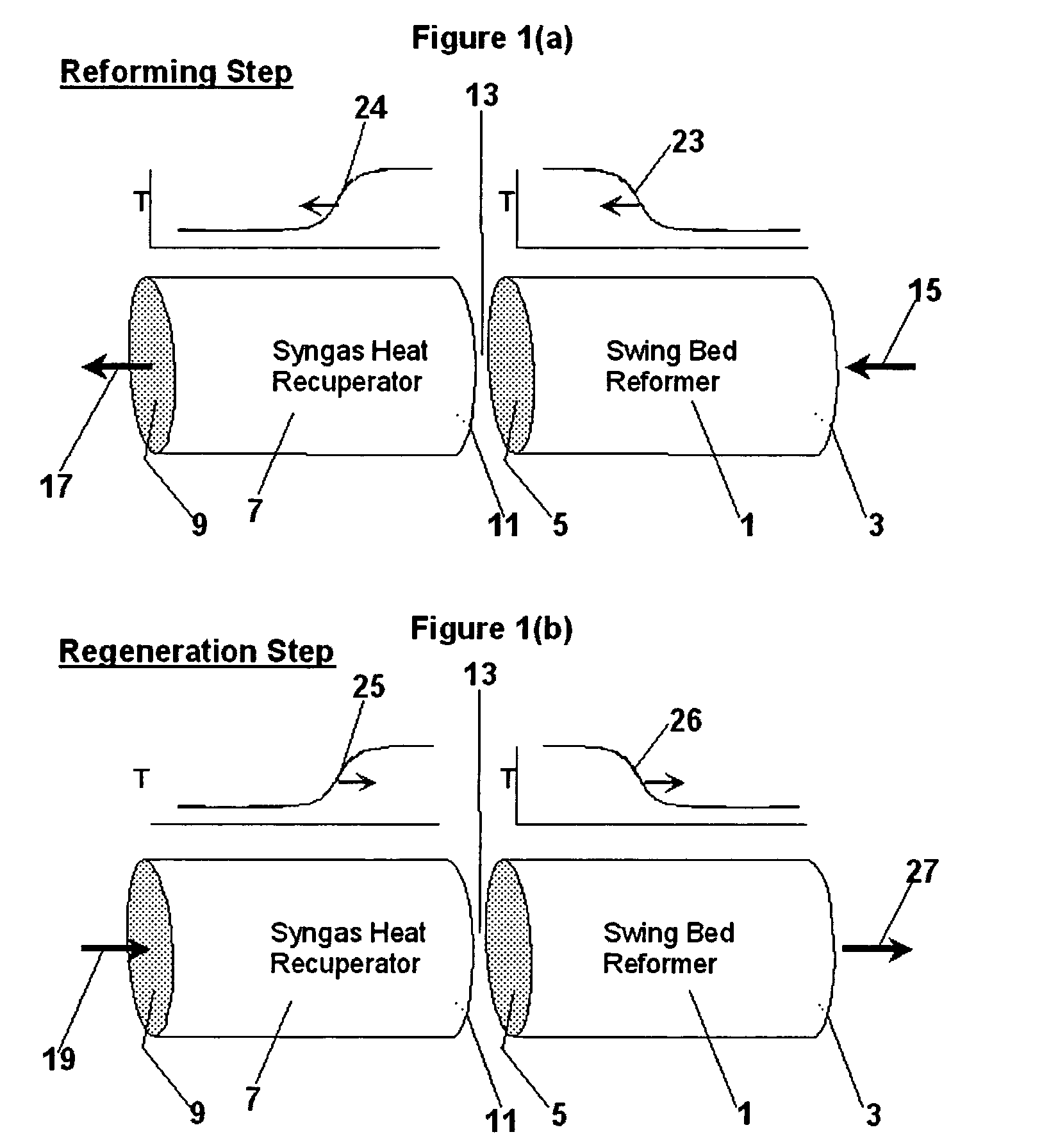

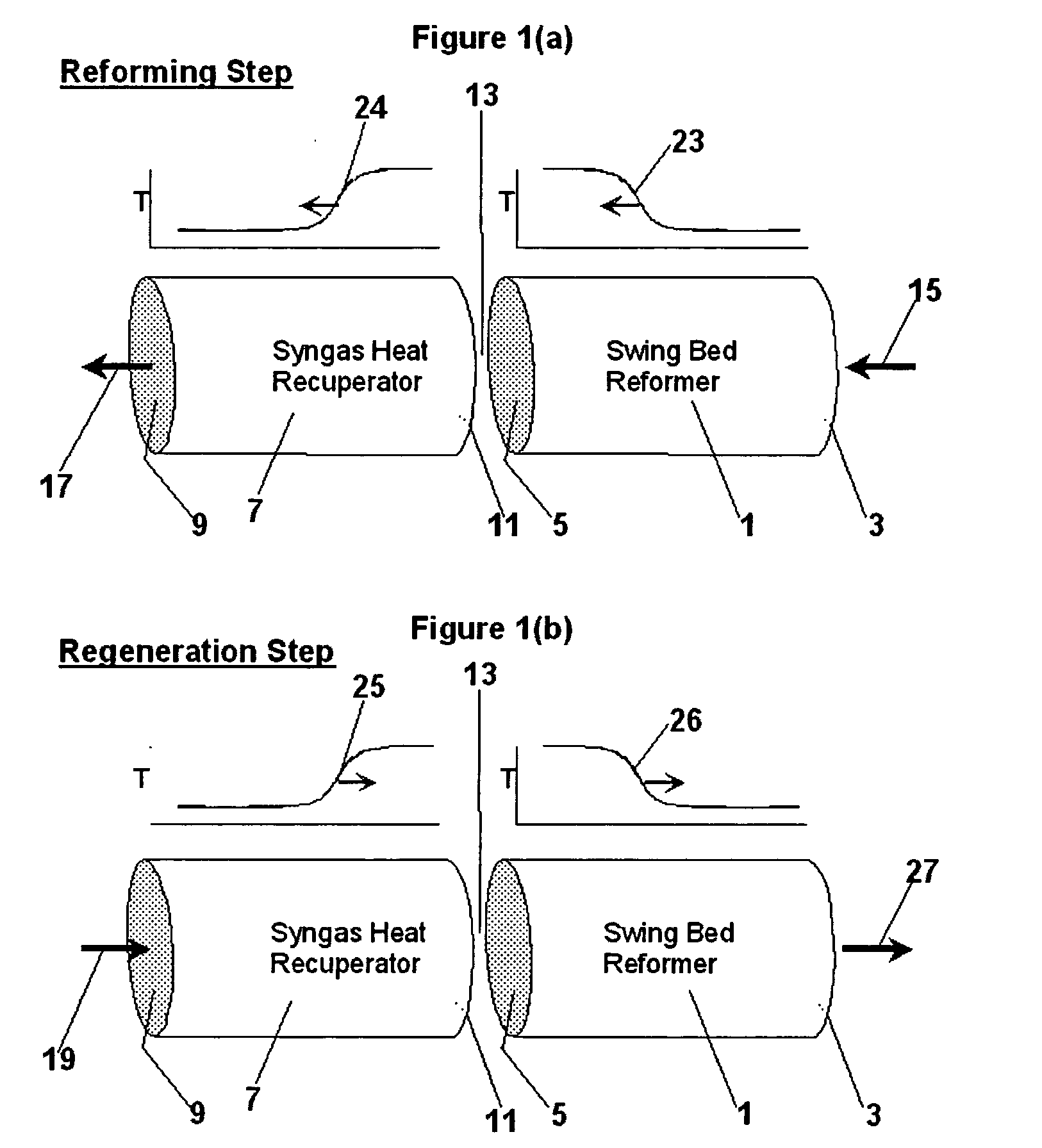

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

Power cogeneration system and apparatus means for improved high thermal efficiencies and ultra-low emissions

InactiveUS7124589B2Improve thermal efficiencyGas turbine plantsCombined combustion mitigationThermal energyCogeneration

A power cogeneration system employing a partially-open gaseous fluid cycle method and apparatus devices for oxy-fuel combustion conversion of a given hydrocarbon composition fuel's heat-value energy into mechanical or electrical power energy, and transferred useful heat energy, with accompanying large reductions of consumed fuel and undesirable exhaust emissions.

Owner:AES DEV CO

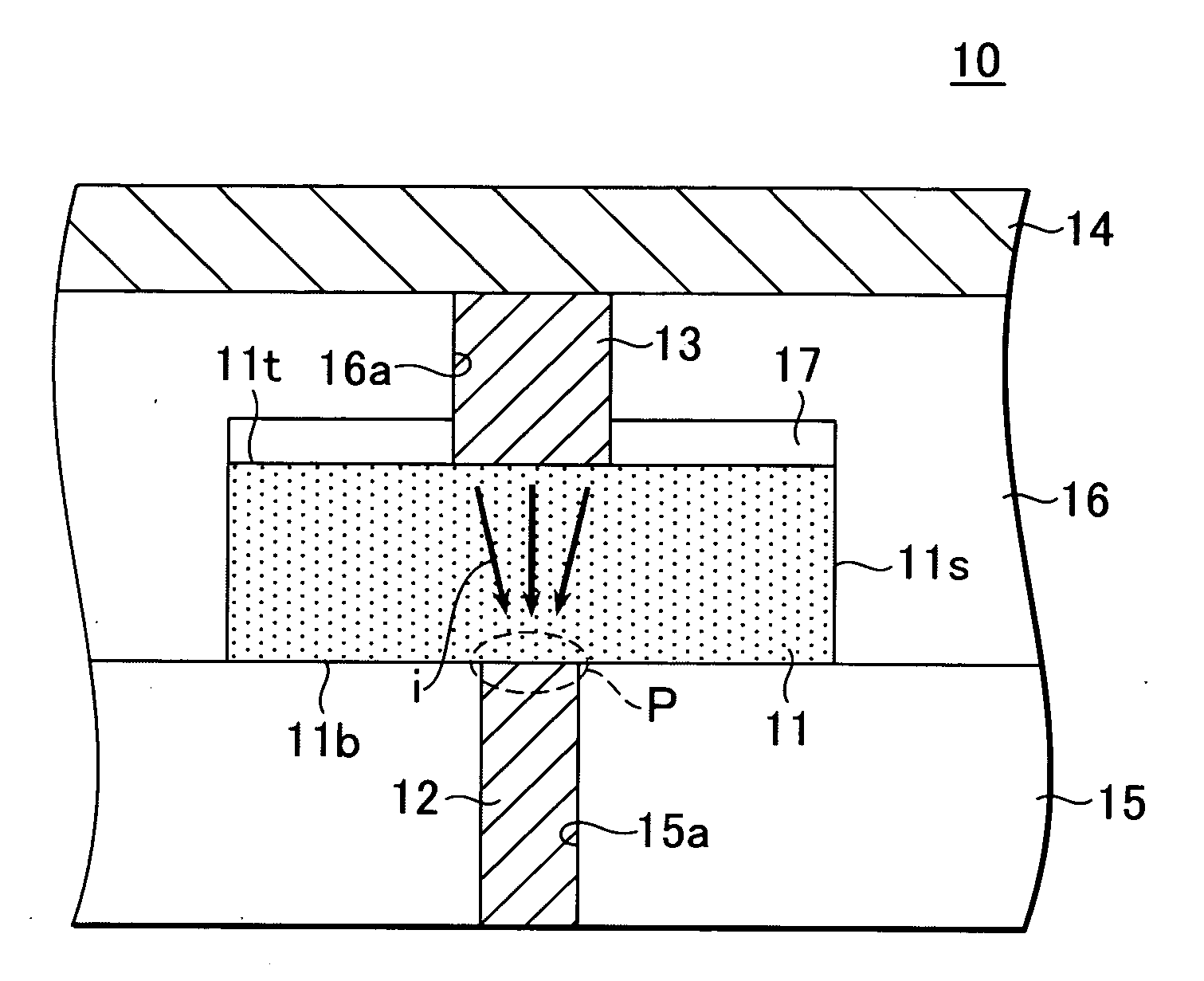

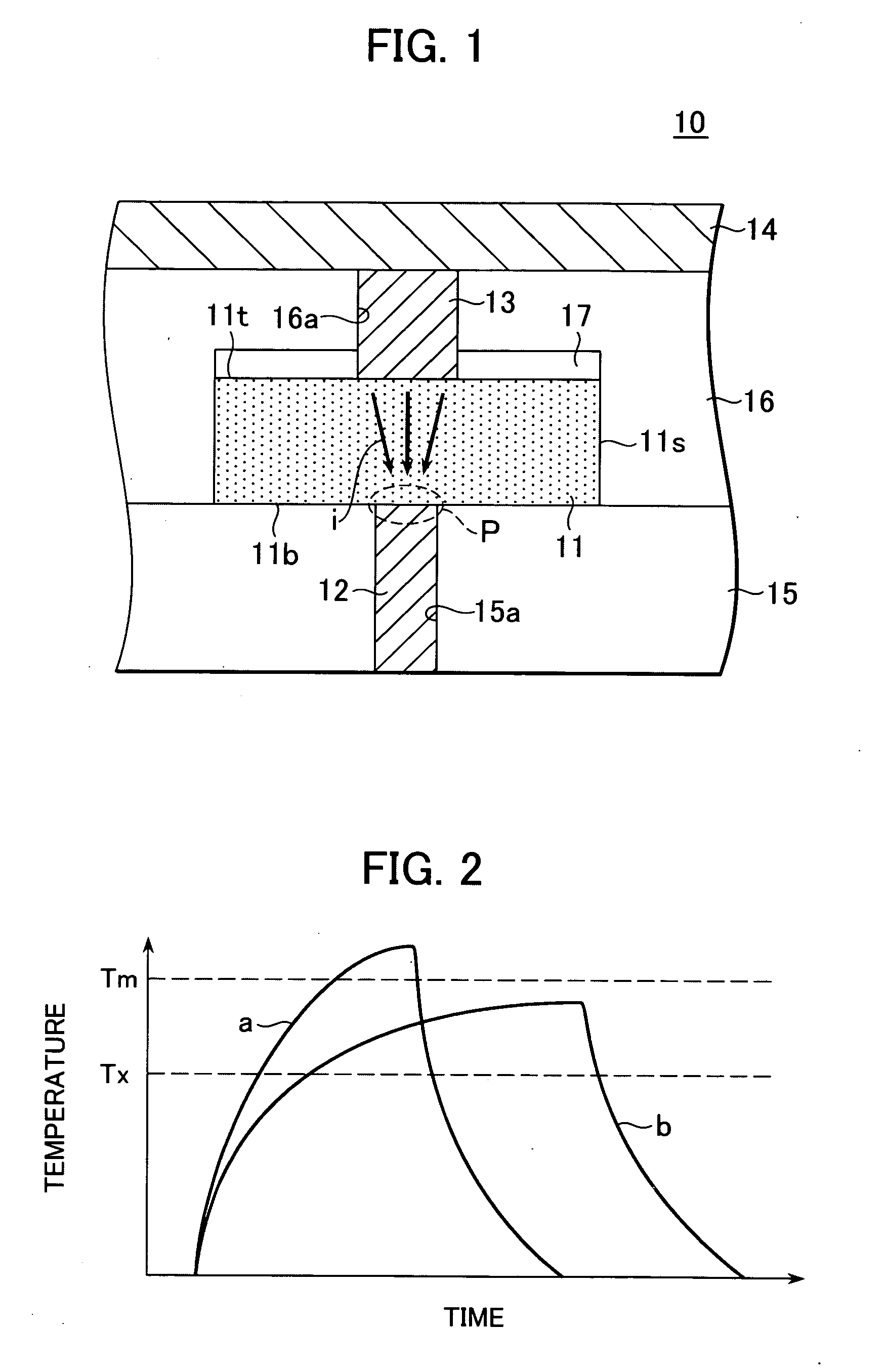

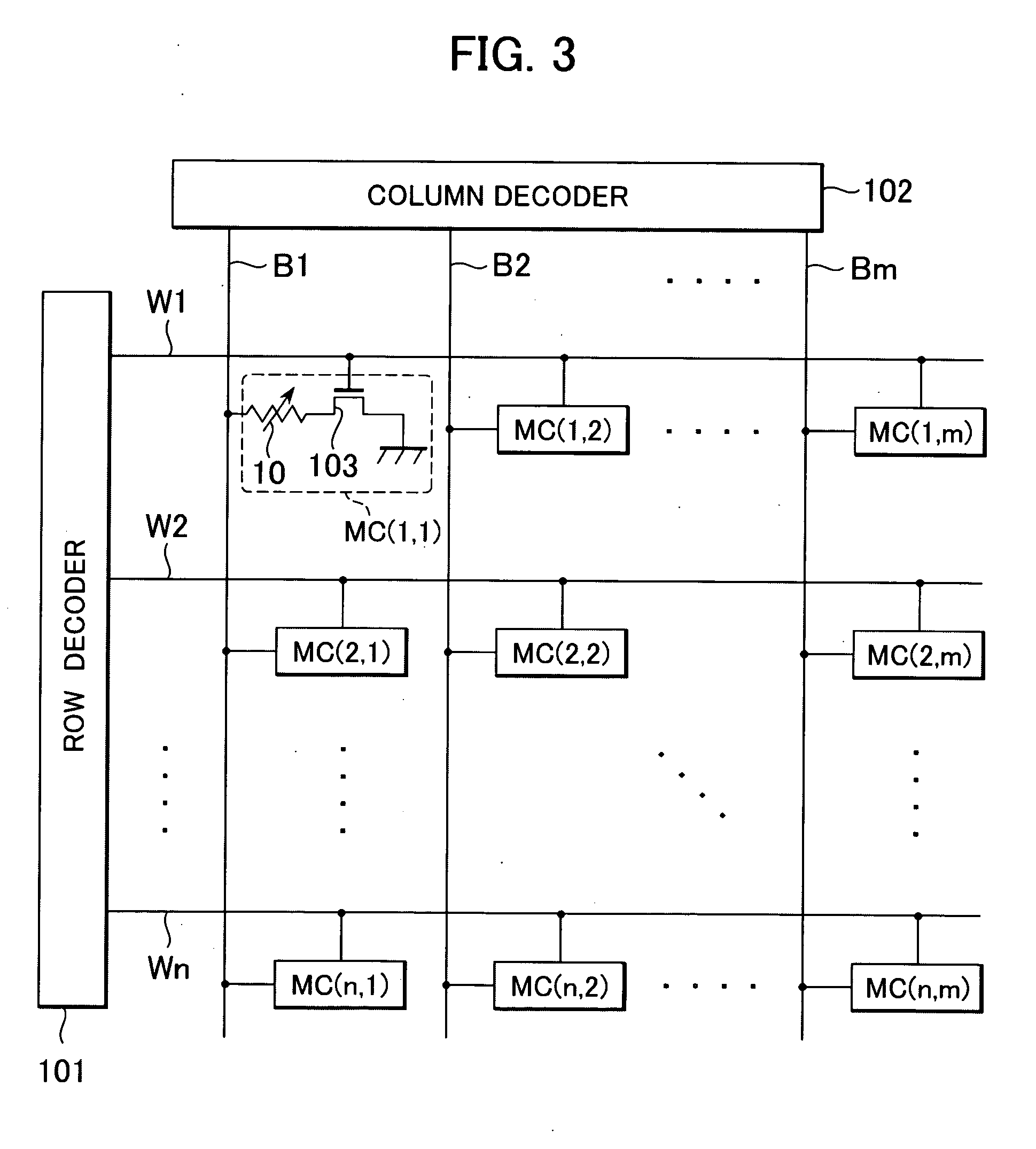

Electrically rewritable non-volatile memory element and method of manufacturing the same

InactiveUS20070063180A1Minimizing damageImprove thermal efficiencySolid-state devicesBulk negative resistance effect devicesEngineeringRecording layer

A non-volatile memory element includes a recording layer that includes a phase change material, a lower electrode provided in contact with the recording layer, an upper electrode provided in contact with a portion of the upper surface of the recording layer, a protective insulation film provided in contact with the other portion of the upper surface of the recording layer, and an interlayer insulation film provided on the protective insulation film. High thermal efficiency can thereby be obtained because the size of the area of contact between the recording layer and the upper electrode is reduced. Providing the protective insulation film between the interlayer insulation film and the upper surface of the recording layer makes it possible to reduce damage sustained by the recording layer during patterning of the recording layer or during formation of the through-hole for exposing a portion of the recording layer.

Owner:ELPIDA MEMORY INC

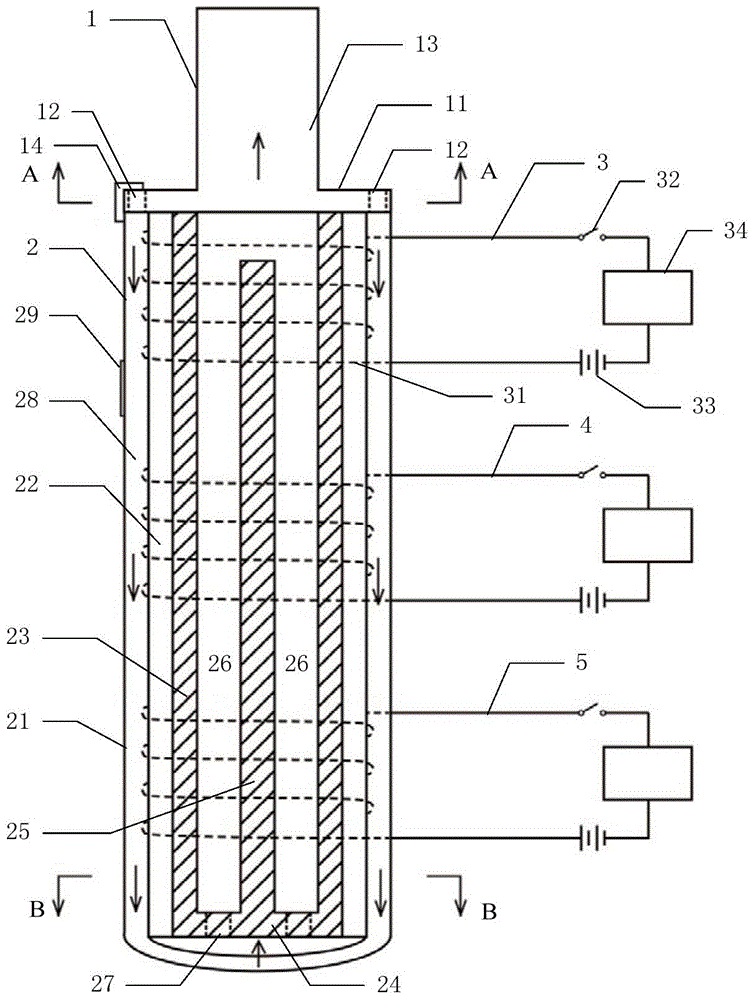

Tobacco suction system based on electromagnetic heating

The invention discloses a tobacco suction system based on electromagnetic heating. The tobacco suction system is characterized by comprising an end cover (1), a heater (2) and an electromagnetic induction system, wherein the end cover (1) is detachably connected to the heater (2); the end cover (1) comprises a circular cover (11) and a filter tip (13); the heater (2) comprises a shell (21), an inner container (23), a base plate (24) and a cylindrical iron core (25); the electromagnetic induction system comprises an induction coil for heating the inner container (23), the base plate (24) and the cylindrical iron core (25), and a temperature control circuit. By heating the inner container, the base plate and the cylindrical iron core through the electromagnetic induction system, the heating speed can be increased, the heat efficiency is high, and instant heating can be realized, thereby better meeting the requirement of good suction mouthfeel; due to the arrangement of the cylindrical iron core, tobacco products can be heated uniformly and fully, and waste caused by insufficient heating of the tobacco products can be avoided. The tobacco suction system is suitable to be popularized and applied.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

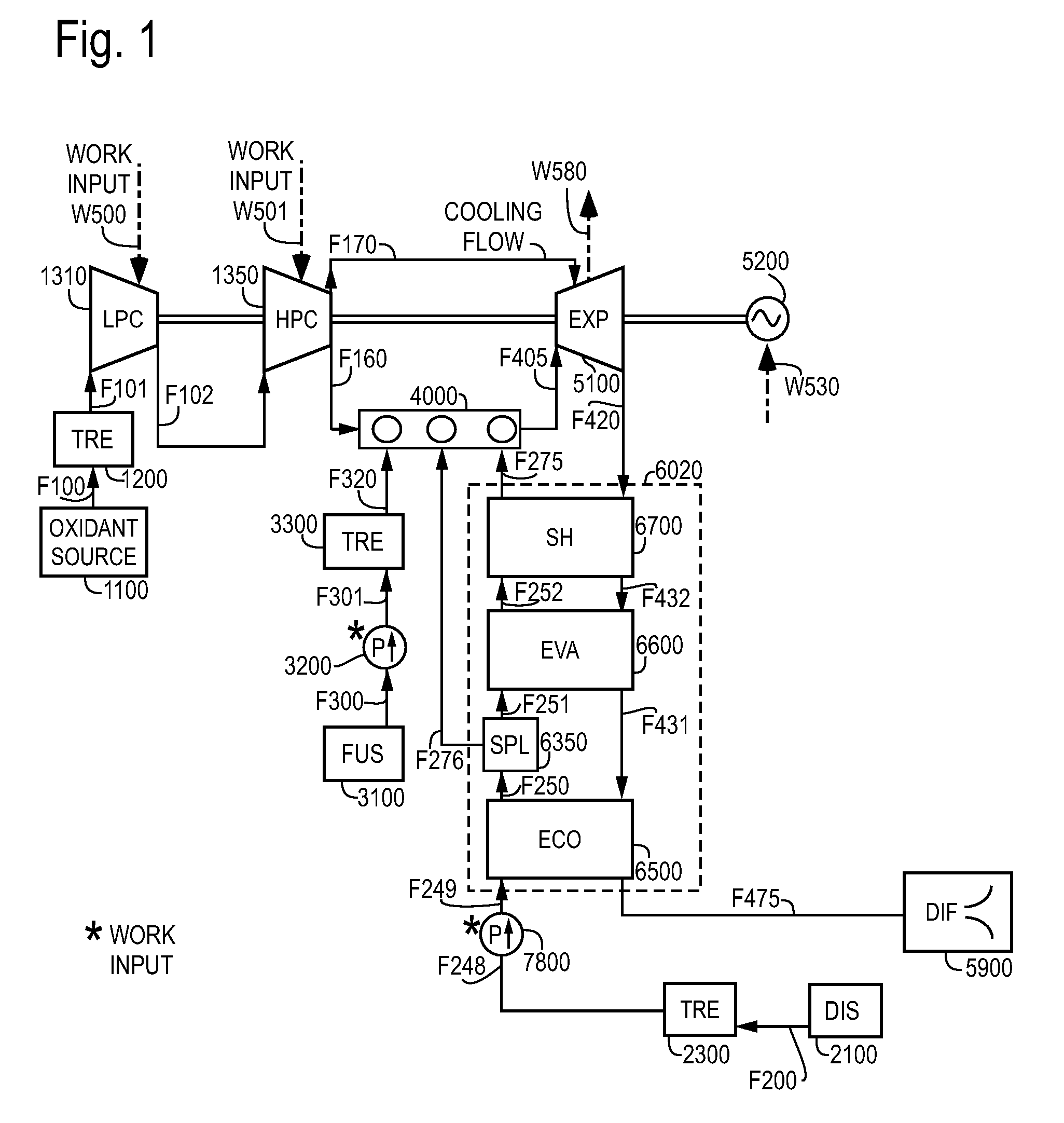

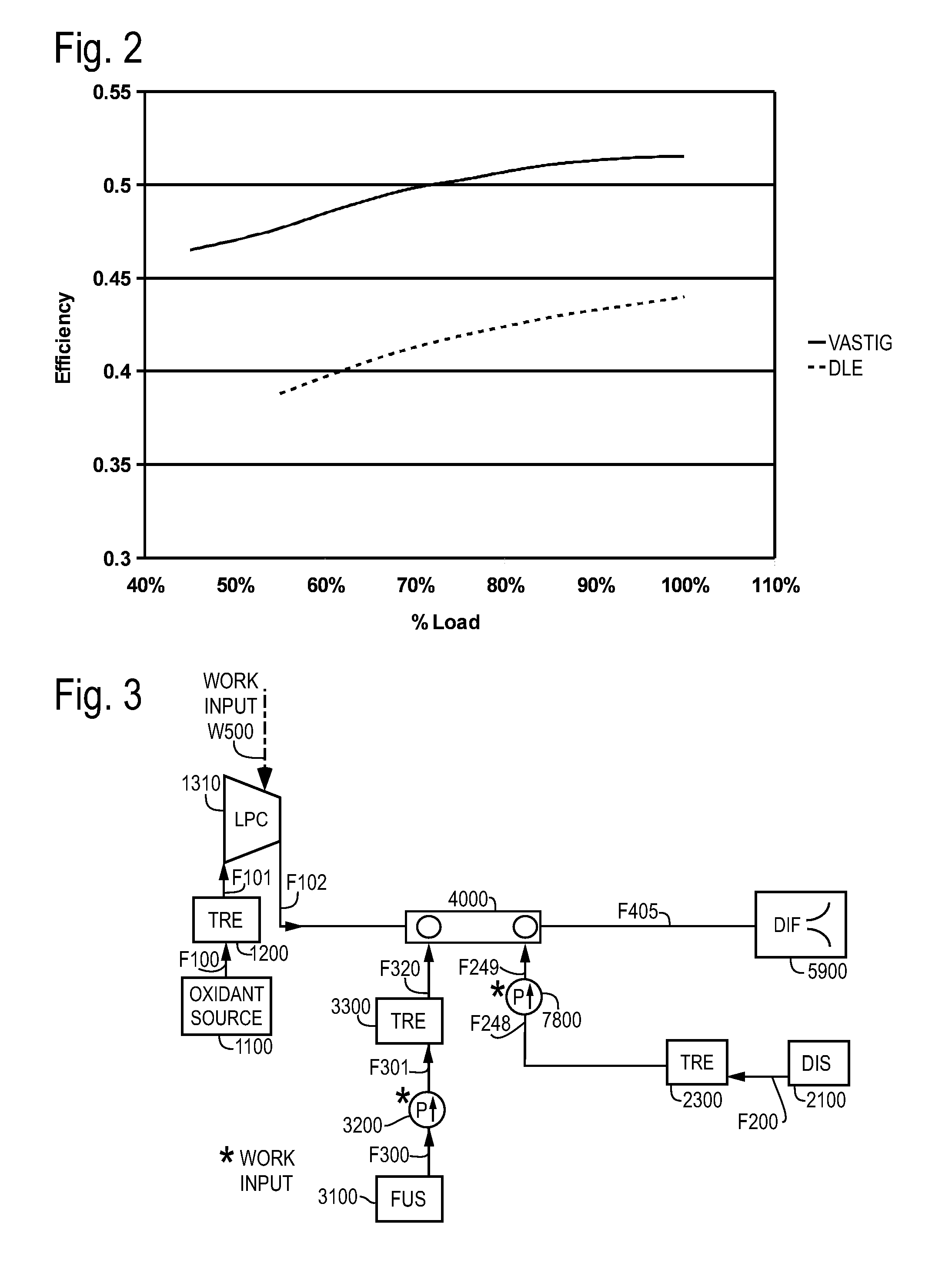

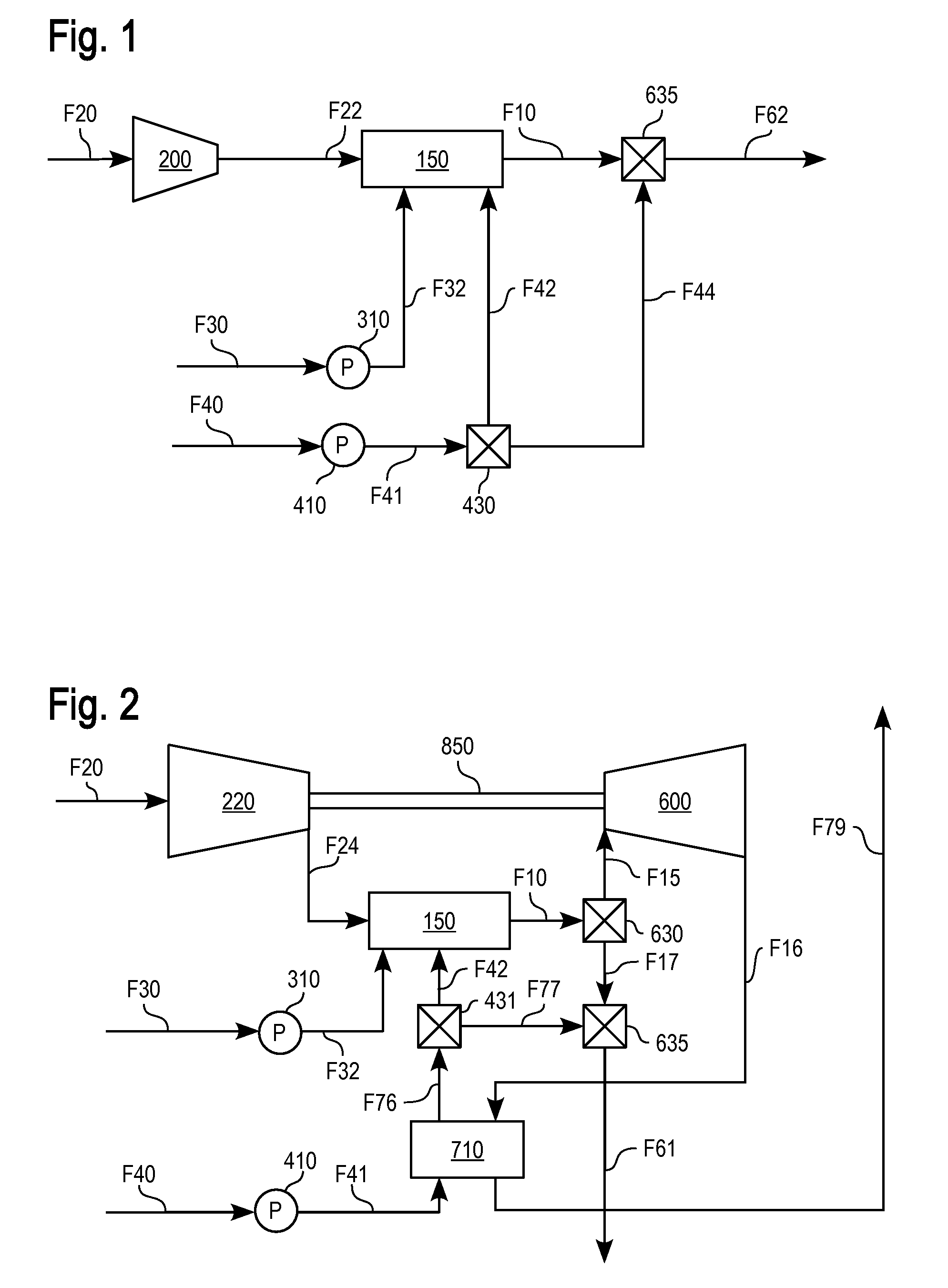

Partial load combustion cycles

ActiveUS20090064653A1Improve efficiencyReduced Power RequirementsGas turbine plantsVehicle heating/cooling devicesBrayton cycleCombustion

The part load method controls delivery of diluent fluid, fuel fluid, and oxidant fluid in thermodynamic cycles using diluent, to increase the Turbine Inlet Temperature (TIT) and thermal efficiency in part load operation above that obtained by relevant art part load operation of Brayton cycles, fogged Brayton cycles, or cycles operating with some steam delivery, or with maximum steam delivery. The part load method may control the TIT at the design level by controlling one or both of liquid and / or gaseous fluid water over a range from full load to less than 45% load. This extends operation to lower operating loads while providing higher efficiencies and lower operating costs using water, steam and / or CO2 as diluents, than in simple cycle operation.

Owner:VAST HLDG LLC

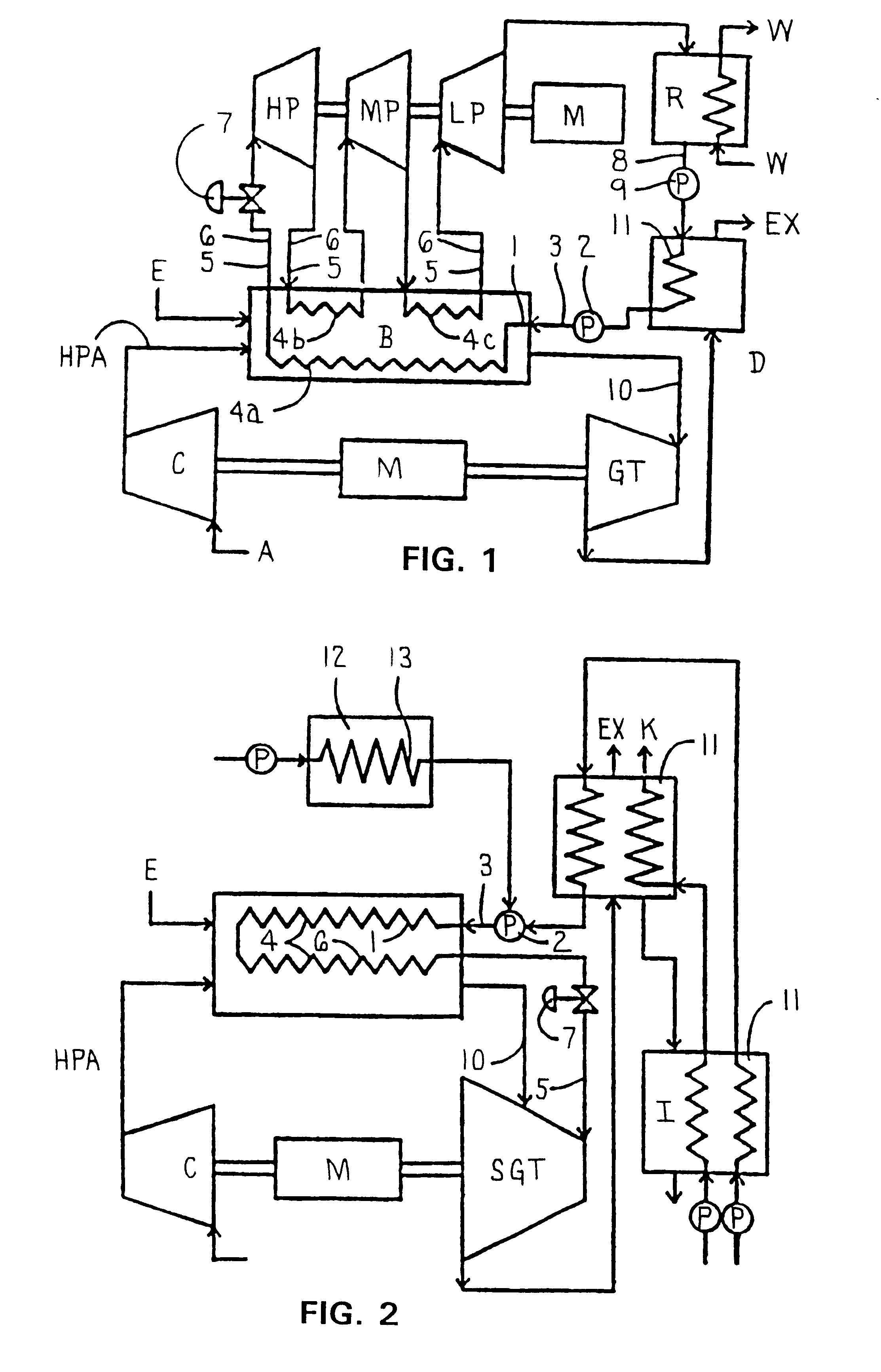

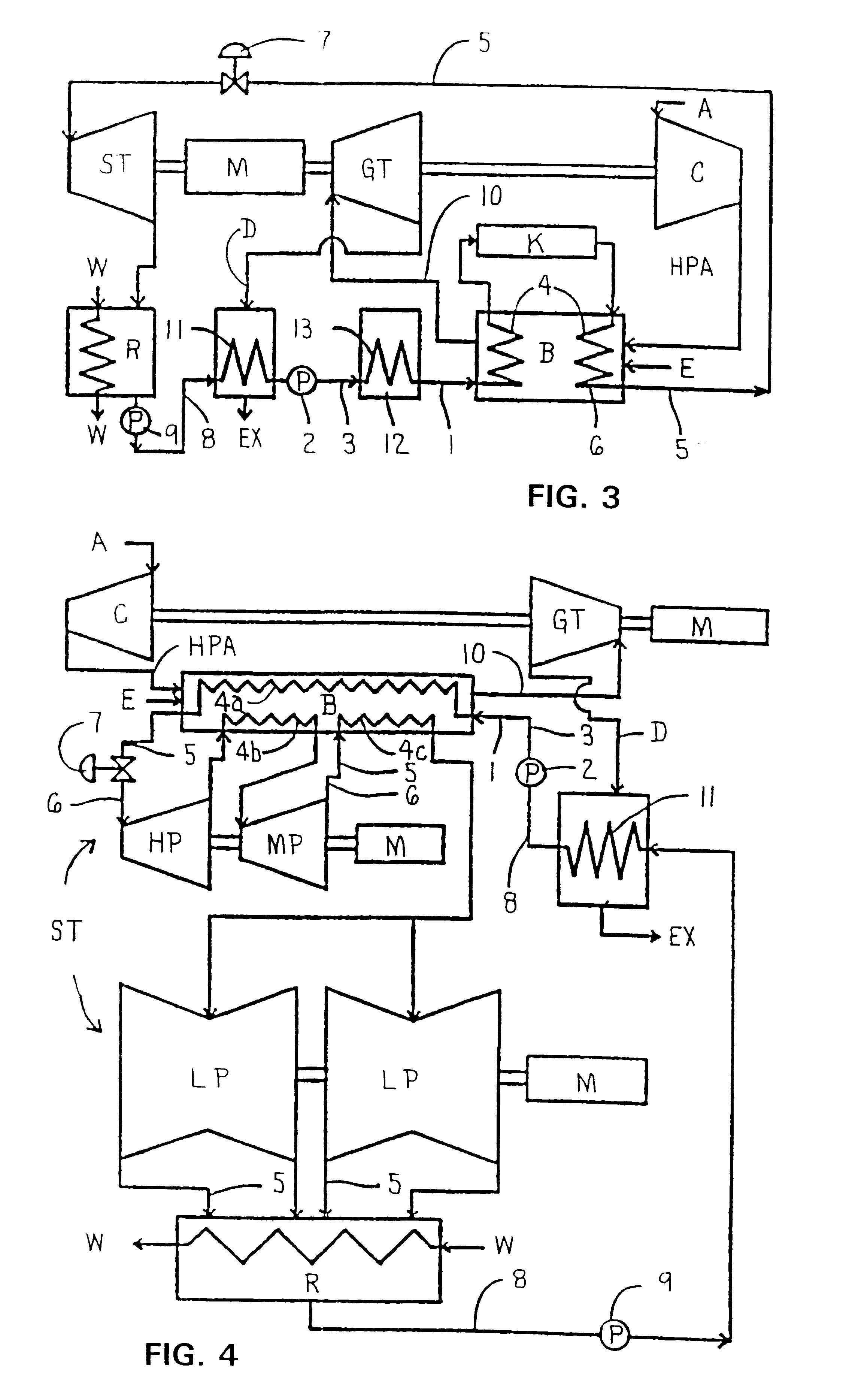

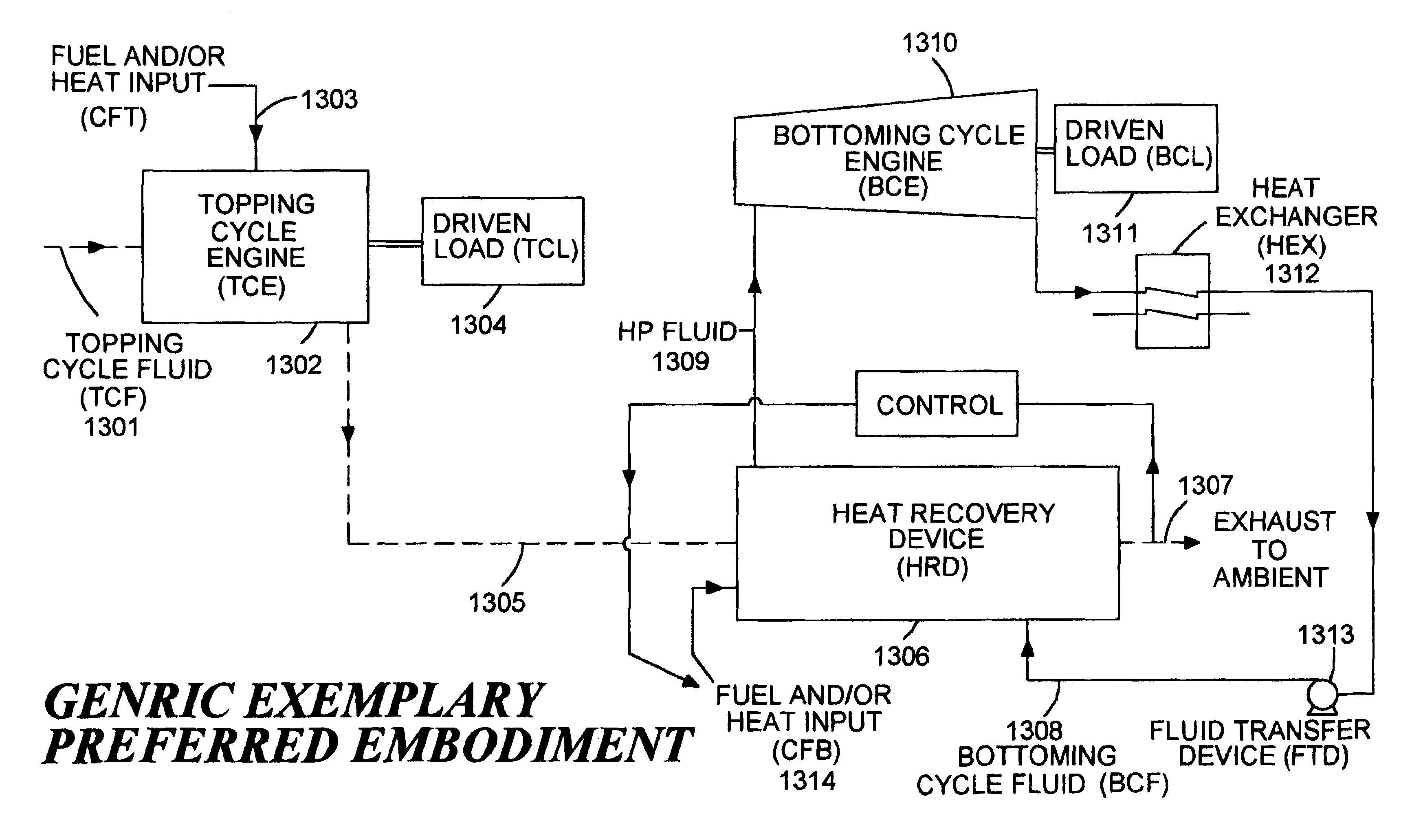

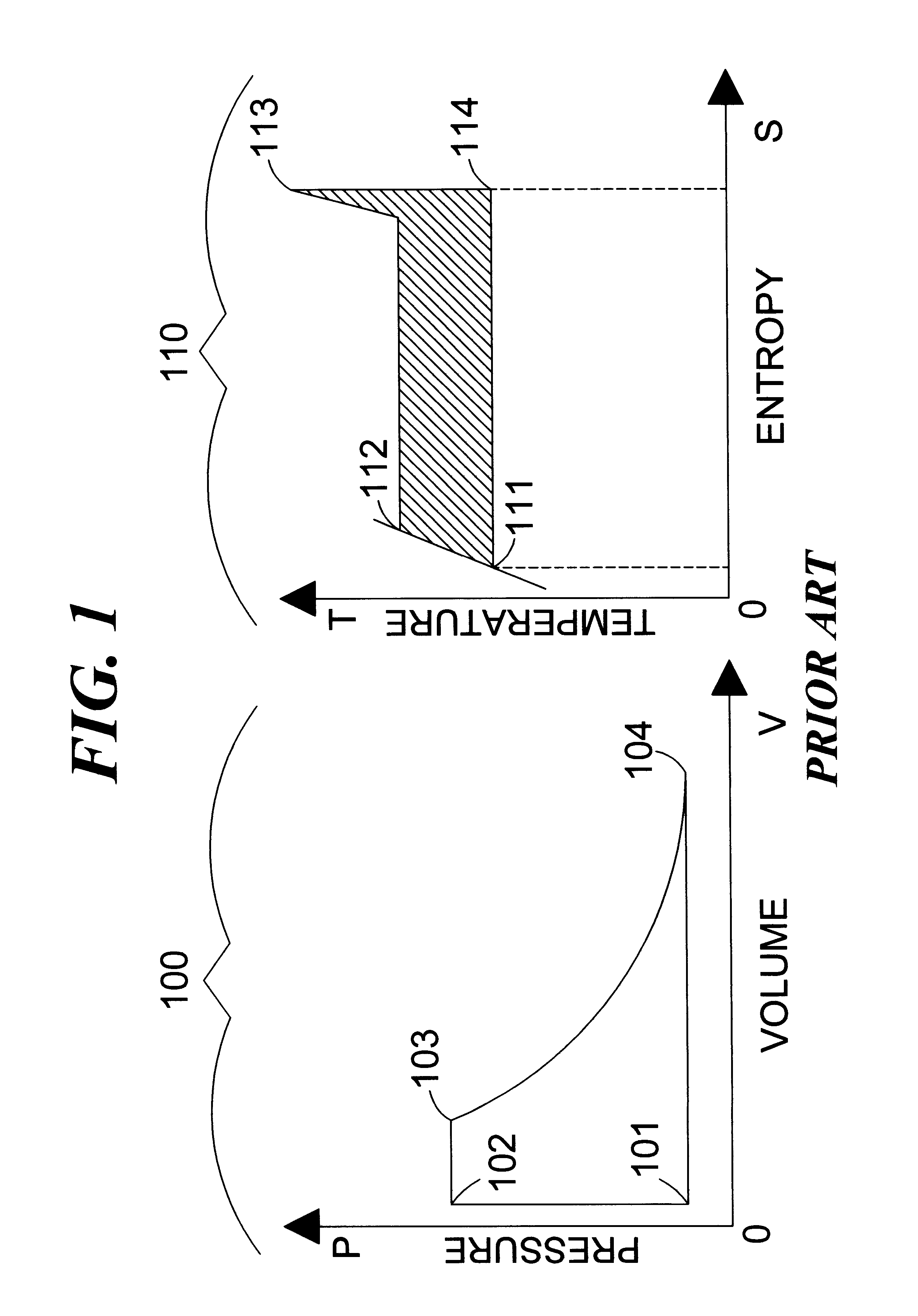

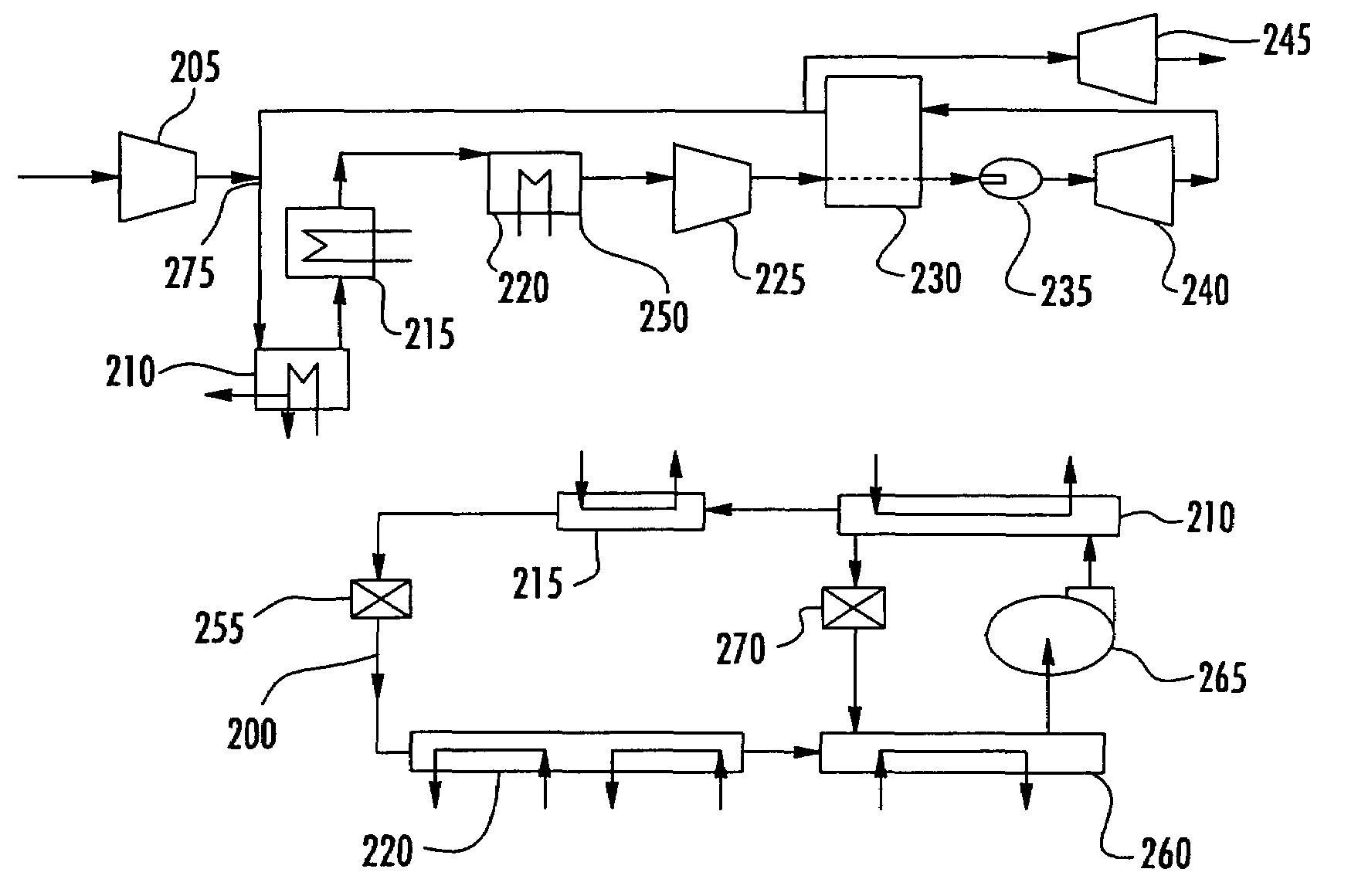

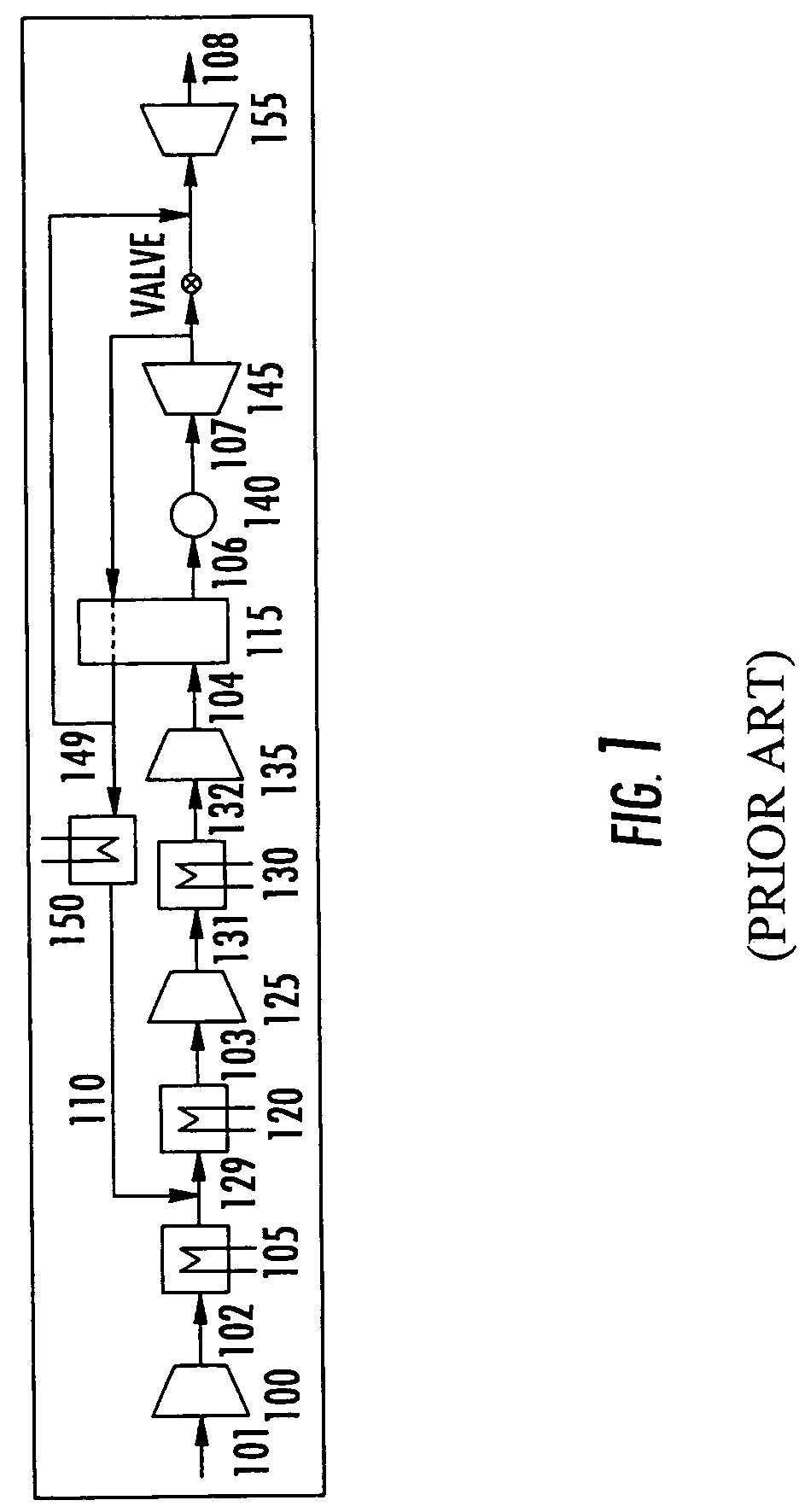

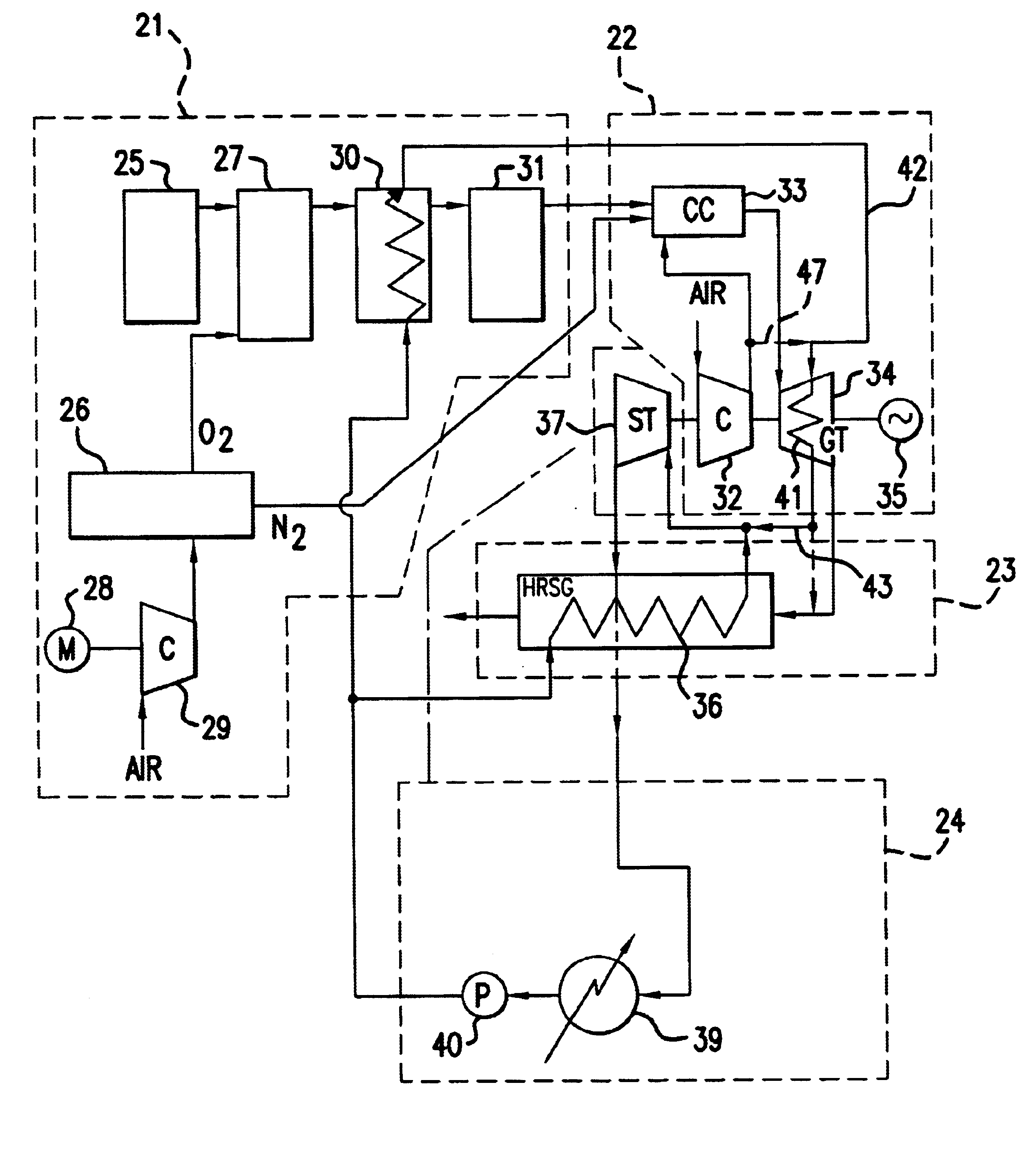

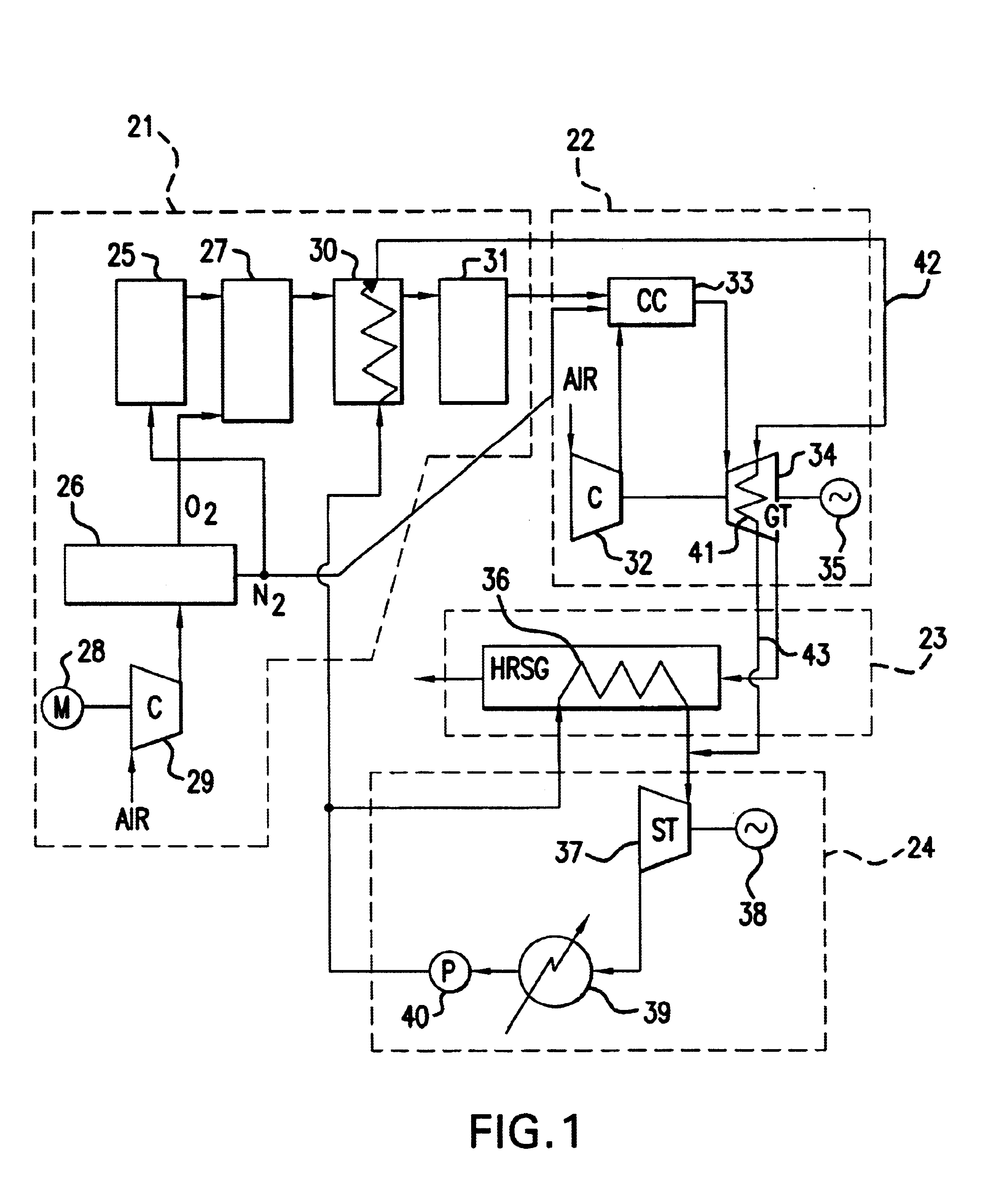

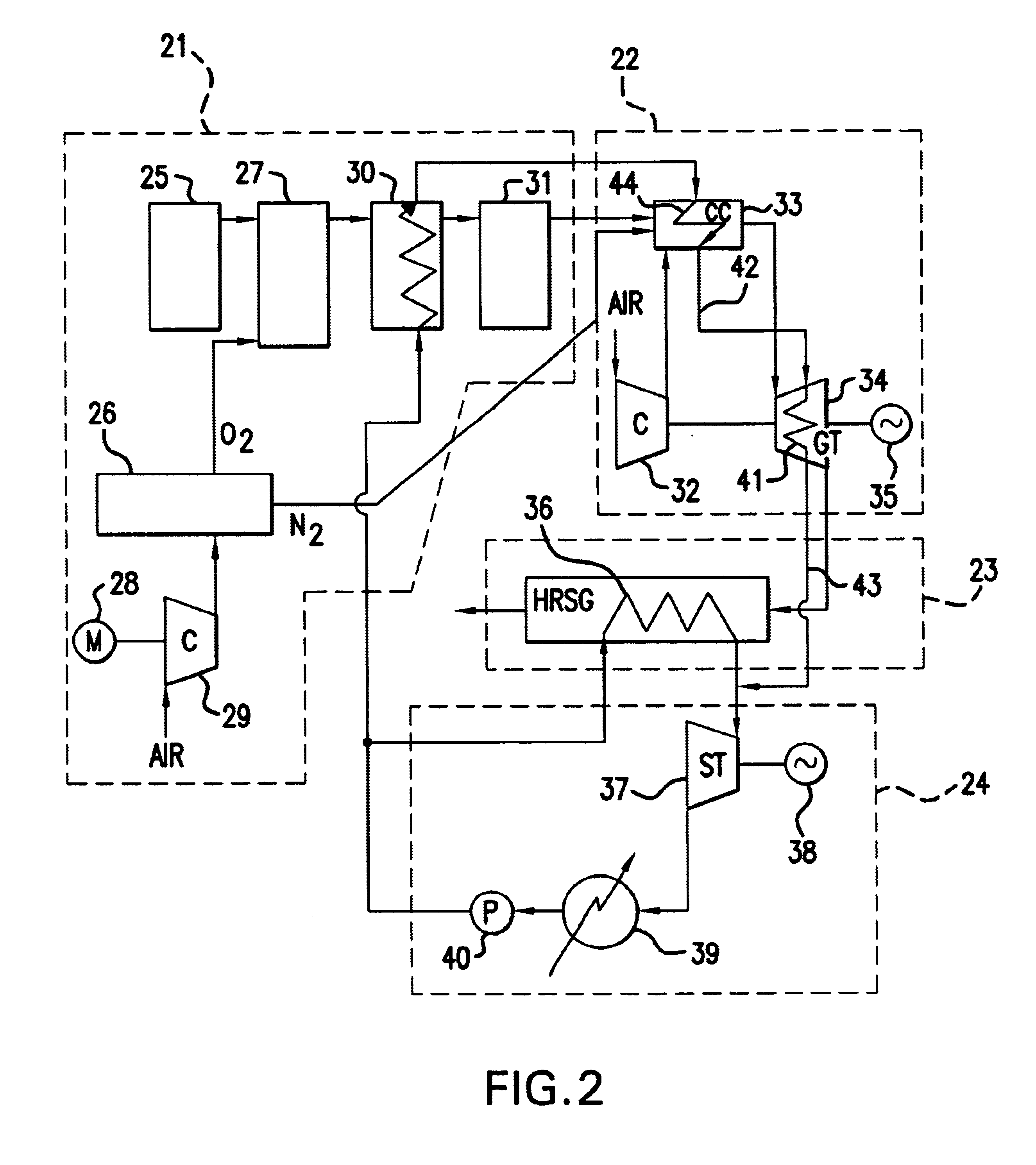

High power density combined cycle power plant

InactiveUS6230480B1Reduce installation costsService degradationEnergy industryGas turbine plantsPower stationCogeneration

A system and method for increasing the specific output of a combined cycle power plant and providing flexibility in the power plant rating, both without a commensurate increase in the plant heat rate, is disclosed. The present invention demonstrates that the process of upgrading thermal efficiencies of combined cycles can often be accomplished through the strategic use of additional fuel and / or heat input. In particular, gas turbines that exhaust into HRSGs, can be supplemental fired to obtain much higher steam turbine outputs and greater overall plant ratings, but without a penalty on efficiency. This system and method by in large defines a high efficiency combined cycle power plant that is predominantly a Rankine (bottoming) cycle. Exemplary embodiments of the present invention include a load driven by a topping cycle engine (TCE), powered by a topping cycle fluid (TCF) which exhausts into a heat recovery device (HRD). The HRD is fired with a supplementary fuel or provided an additional heat source to produce more energetic and / or a larger quantity of the bottoming cycle fluid (BCF) which is used to power a bottoming cycle engine, (BCE) which drives a load (potentially the same load as the topping cycle engine). Energy contained in either the TCF or BCF is used to power the TCE and BCE respectively, but these fluids, and / or their respective engine exhausts, may also be used to support a wide variety of cogeneration applications.

Owner:ROLLINS III WILLIAM SCOTT

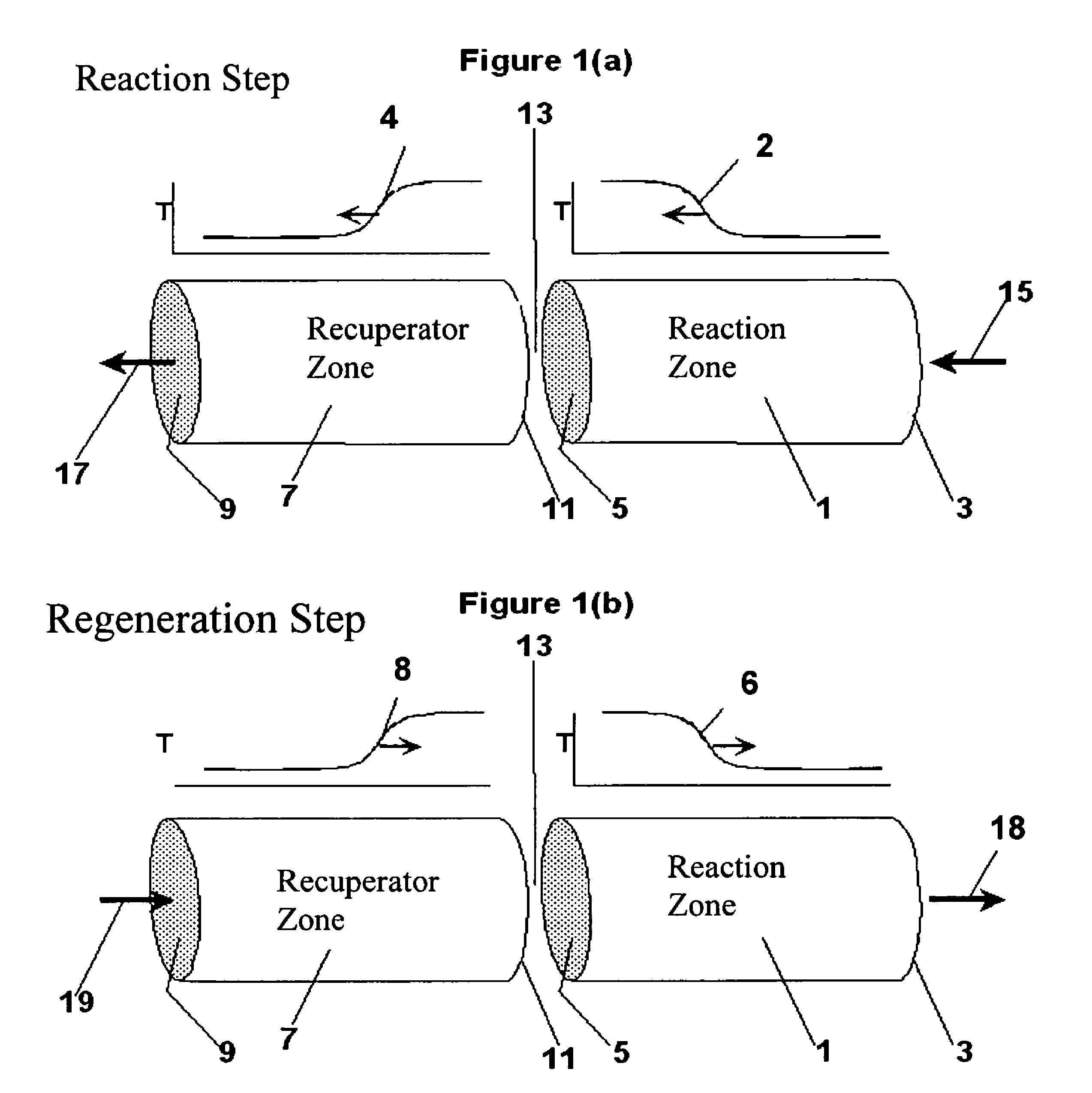

Controlled combustion for regenerative reactors

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

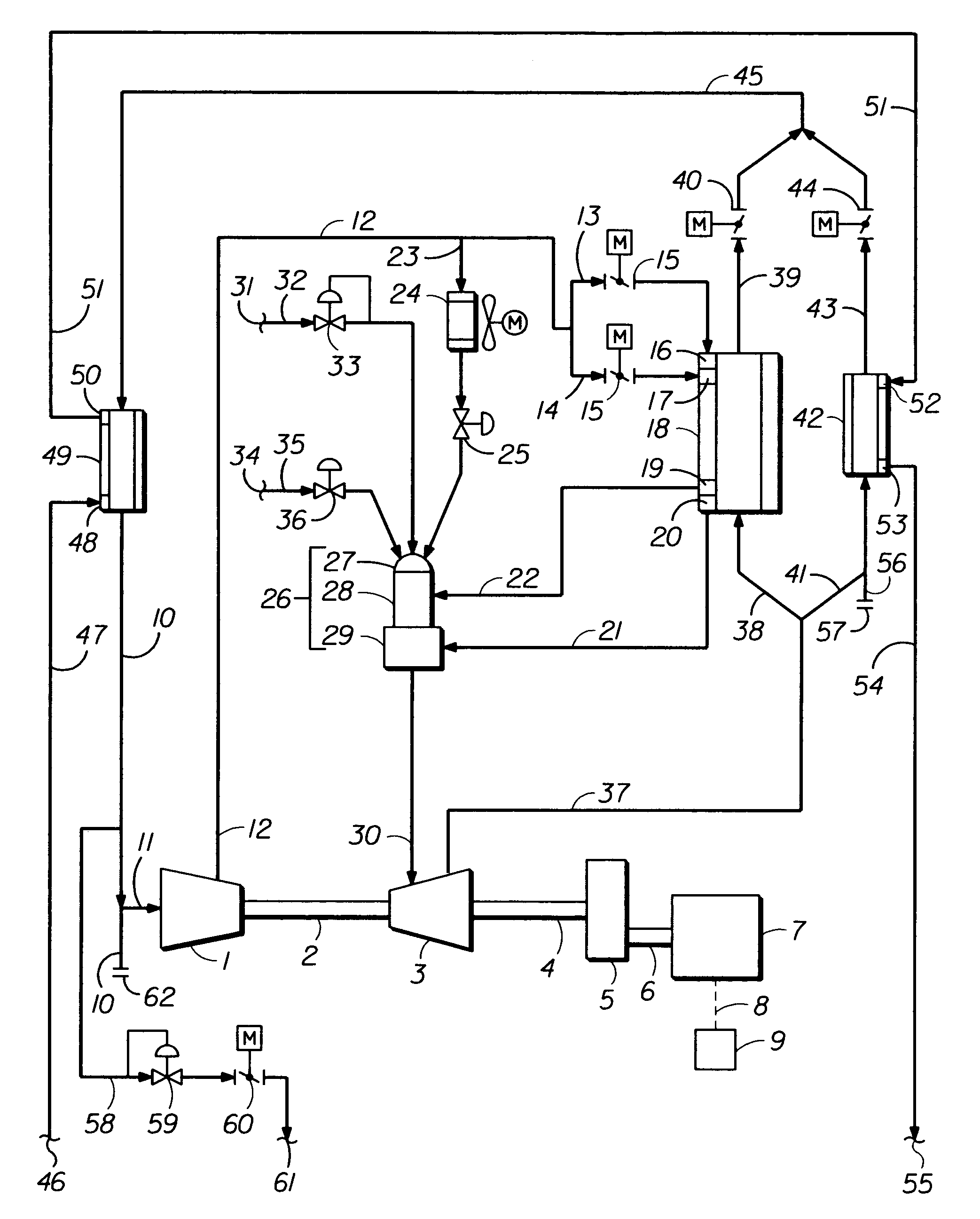

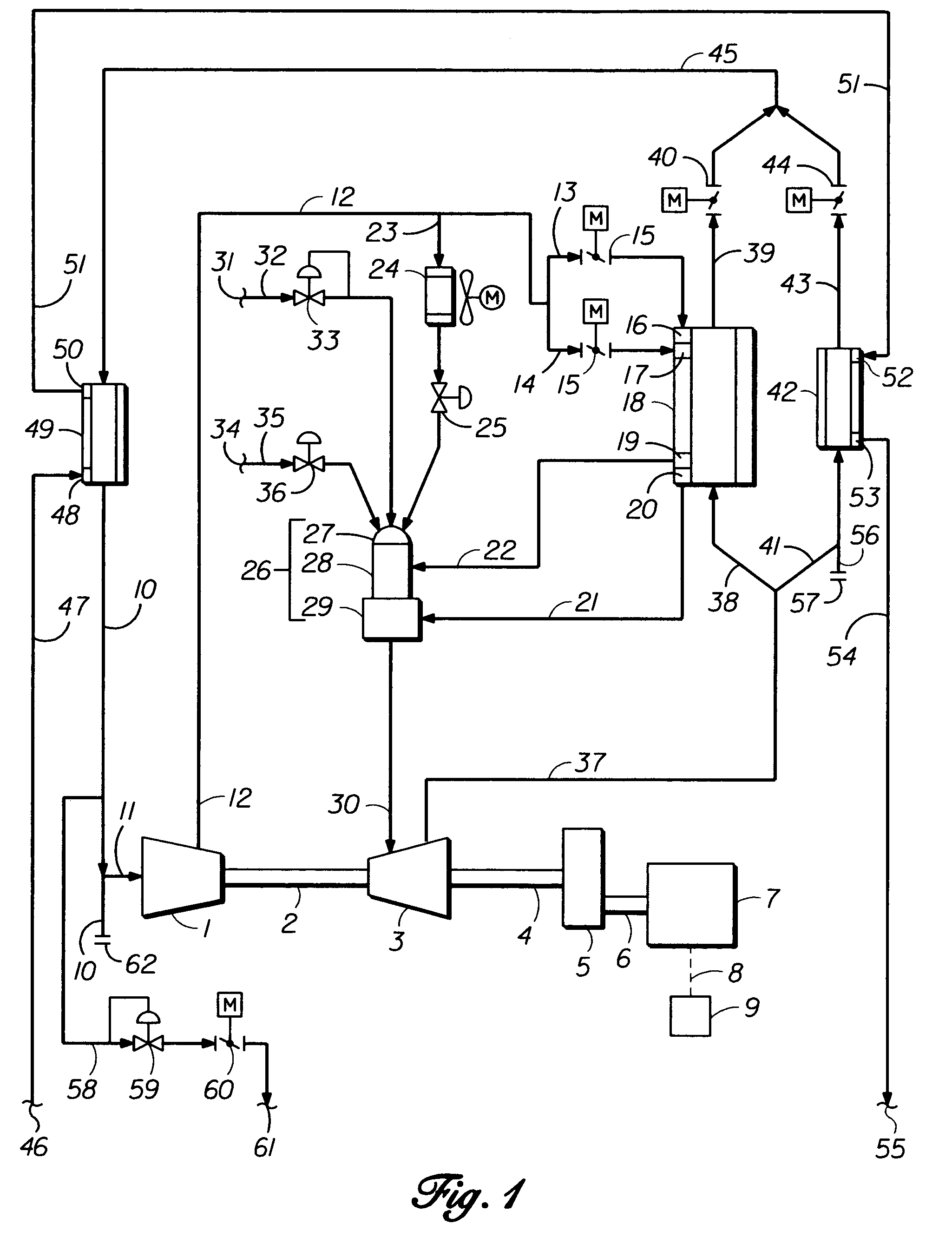

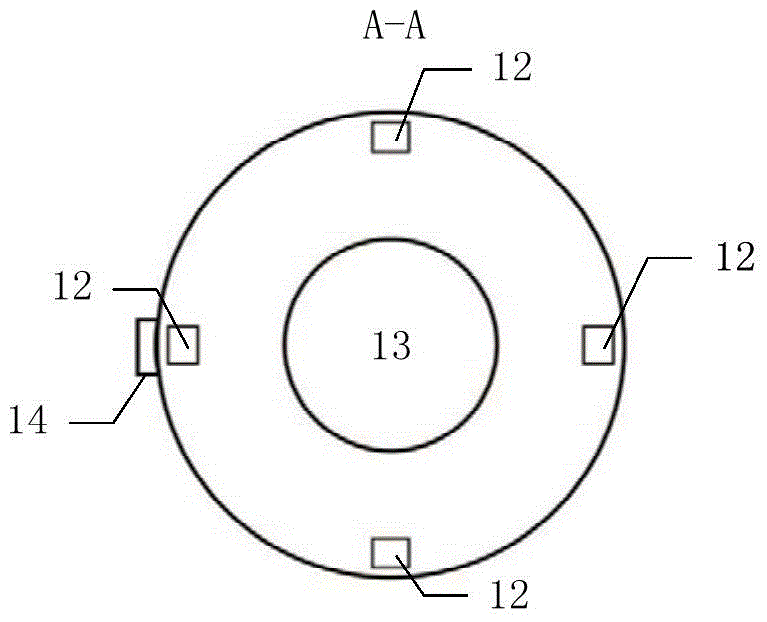

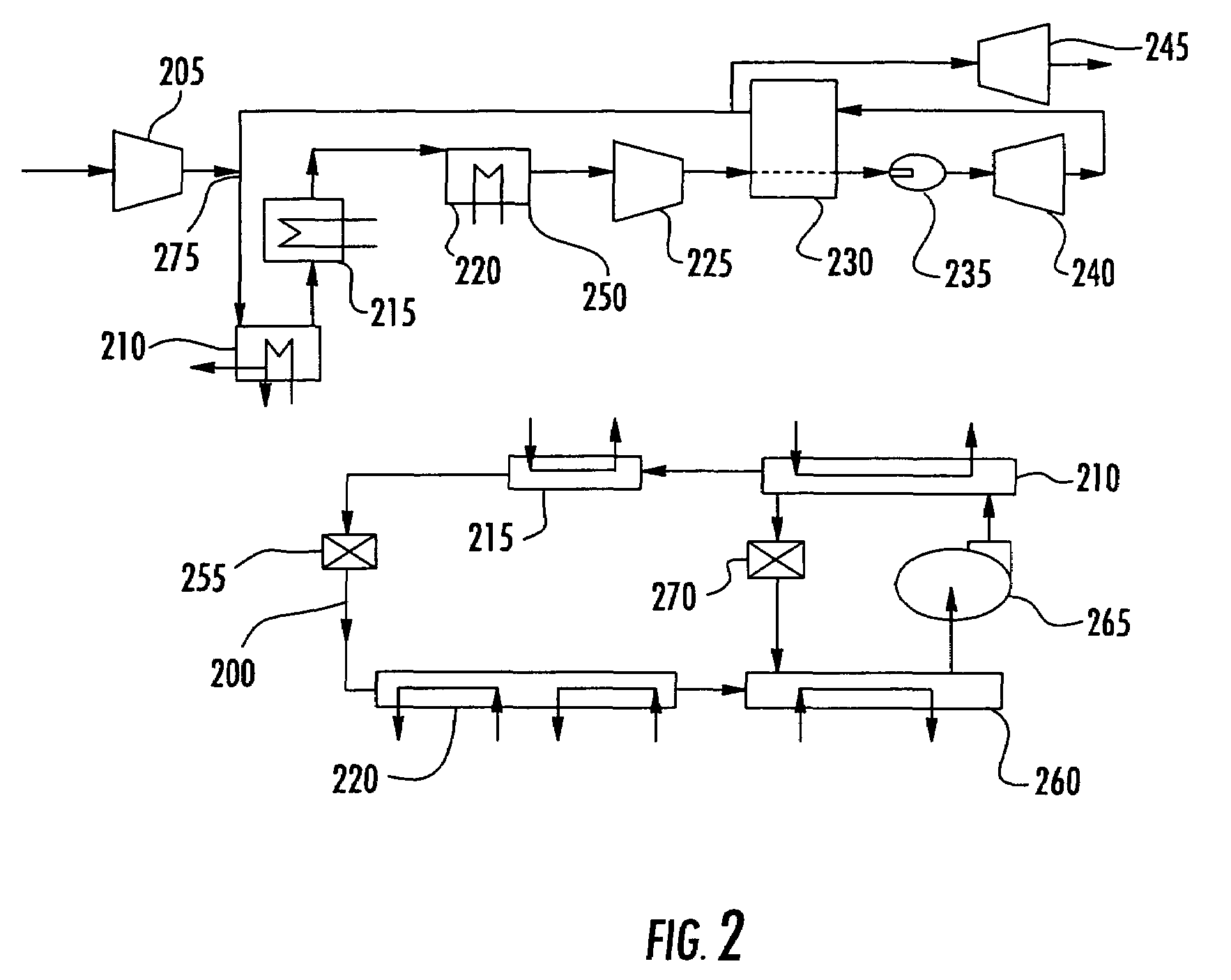

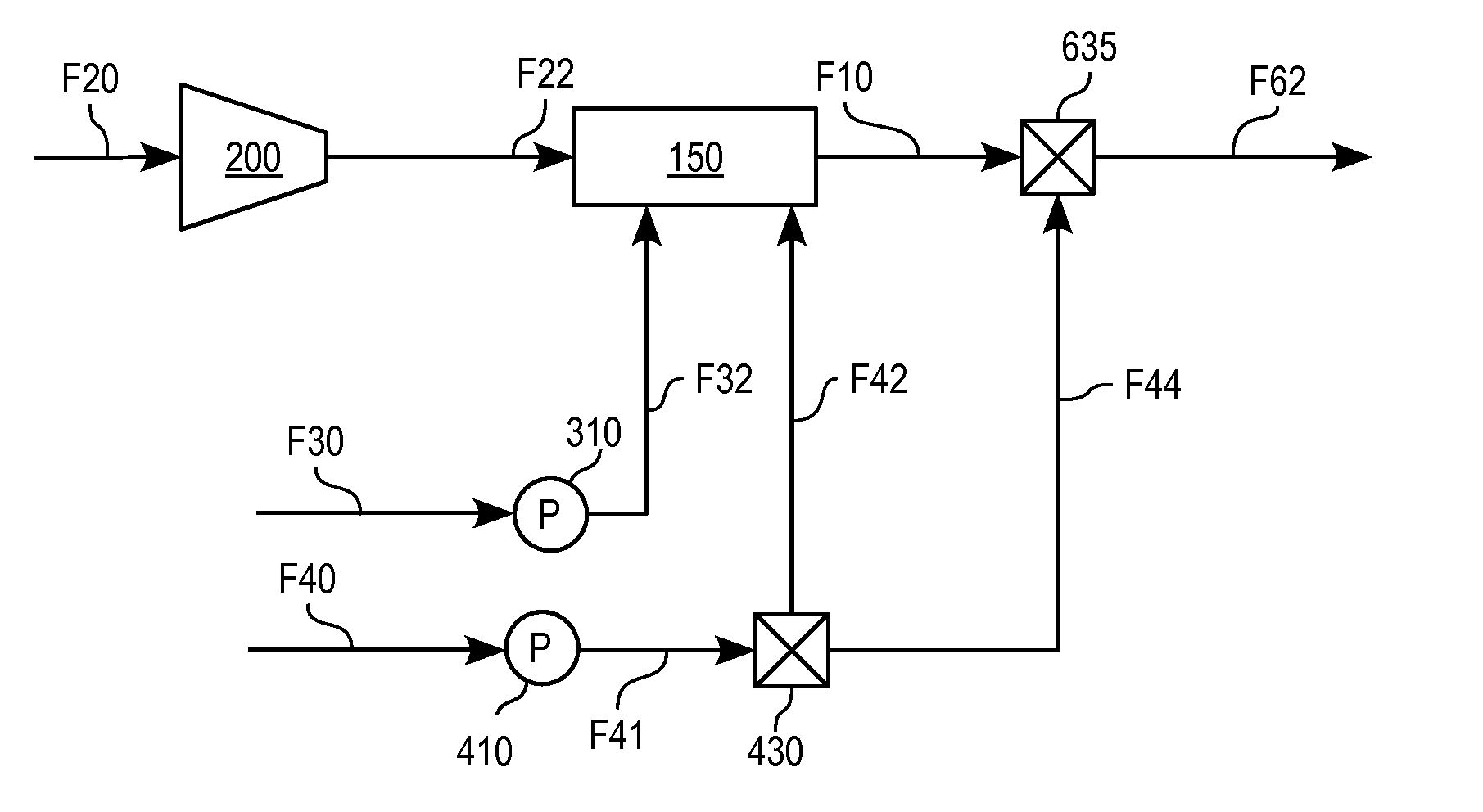

Combined cooling and power plant with water extraction

InactiveUS7472550B2Work lessImprove thermal efficiencyEngine fuctionsGas turbine plantsPower stationEngineering

A turbine engine system and a method for using the turbine engine system that includes at least one low-pressure compressor, at least one high-pressure compressor, at least one low-pressure turbine, and at least one high-pressure turbine. In addition, the turbine engine system includes an absorption refrigeration system that is used to pre-cool an air-gas mixture before it enters the high-pressure compressor. As such, the pre-cooled mixture is easier to compress, thereby increasing the thermal efficiency of the turbine engine. Additionally, the exhaust heat from the air-gas mixture that is pre-cooled may be used to drive the absorption refrigeration system. Lastly, water, may be extracted from the evaporator of the absorption refrigeration cycle.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

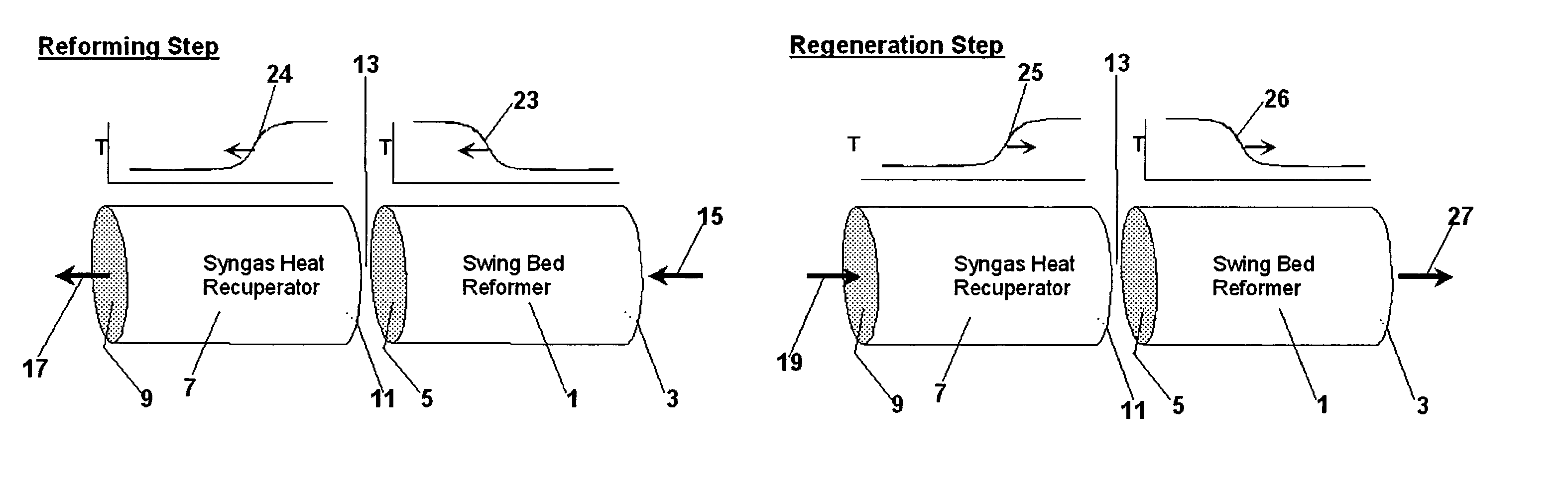

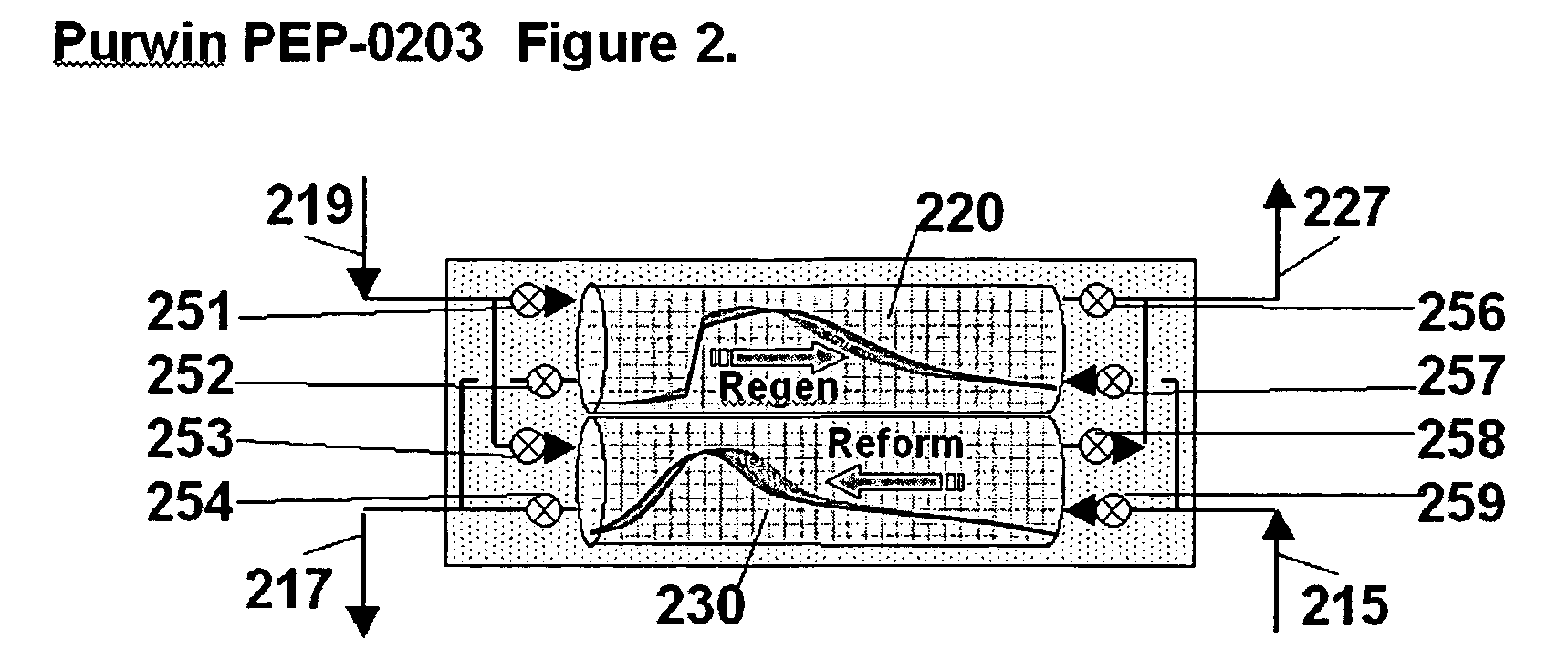

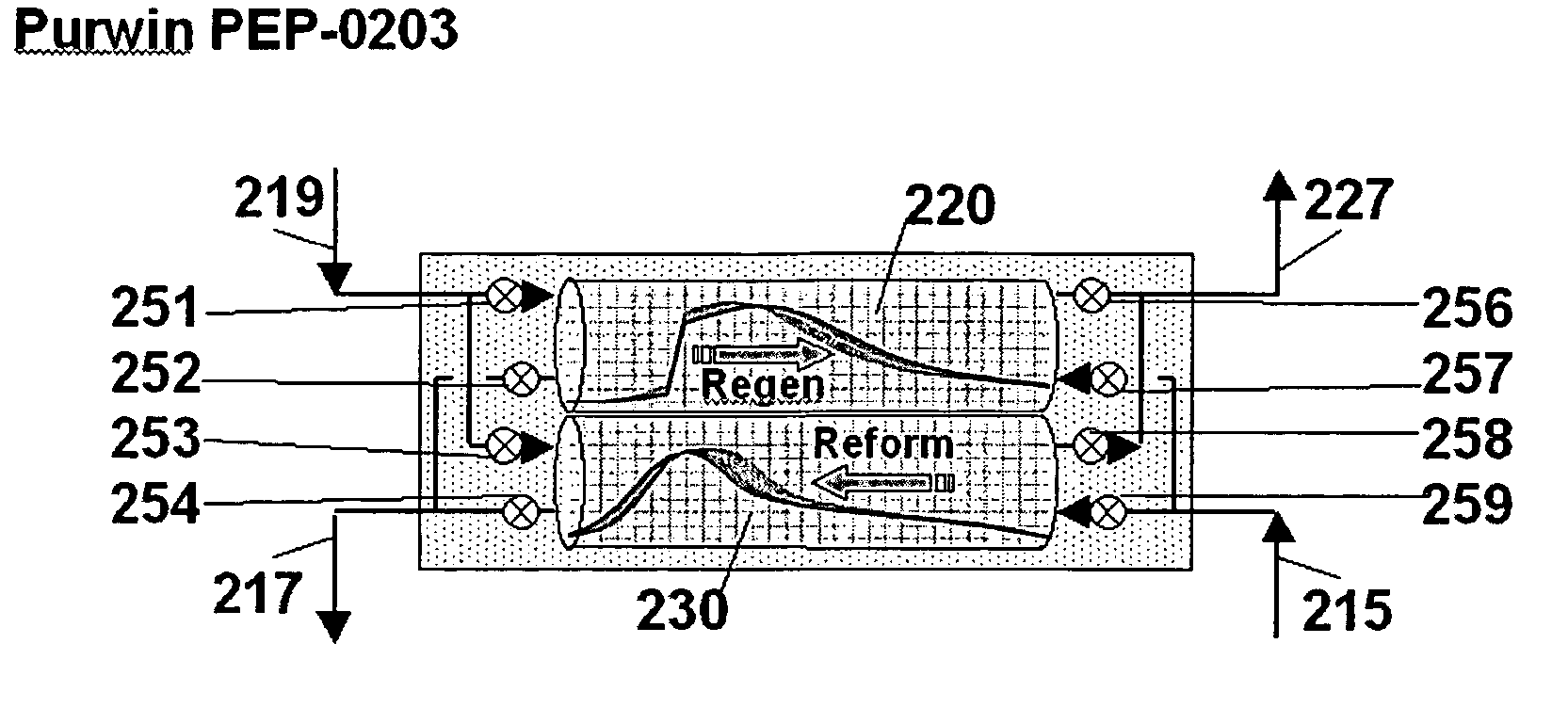

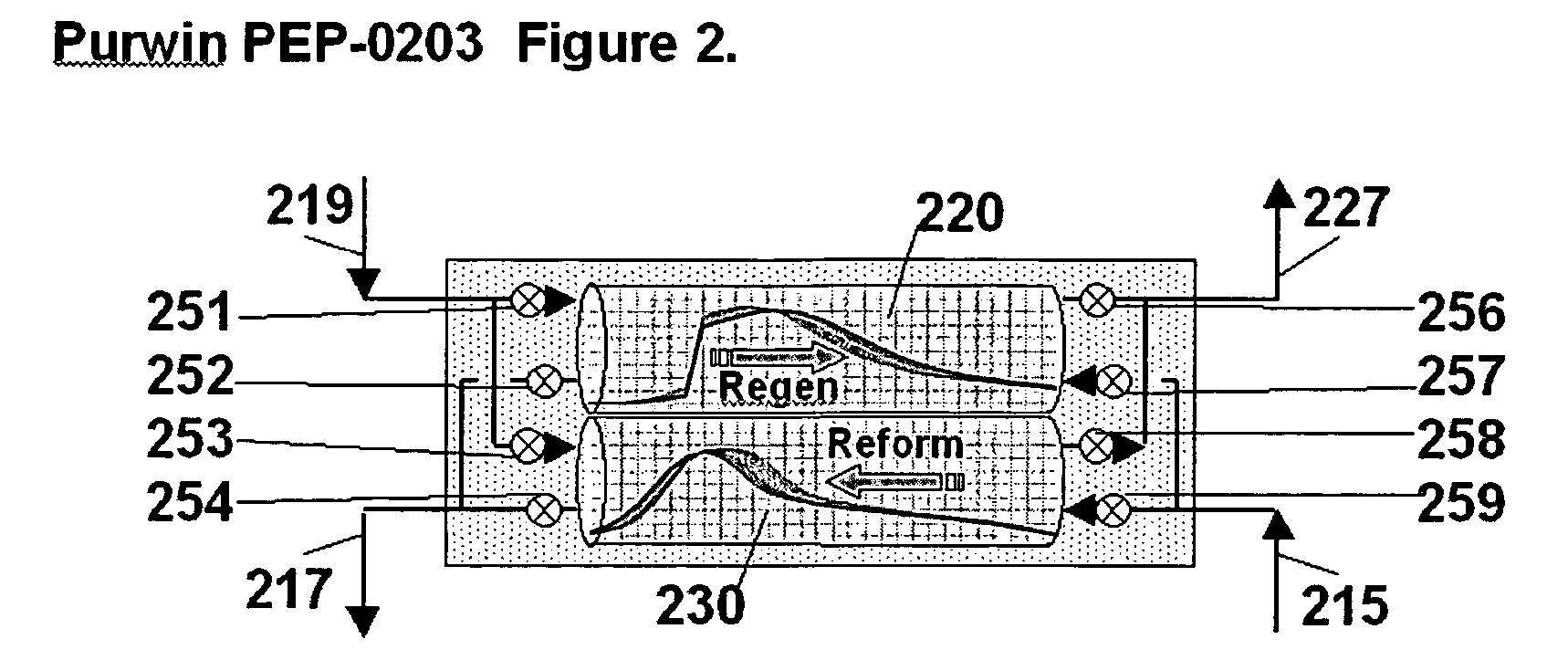

Pressure swing reforming for fuel cell systems

Owner:EXXON RES & ENG CO

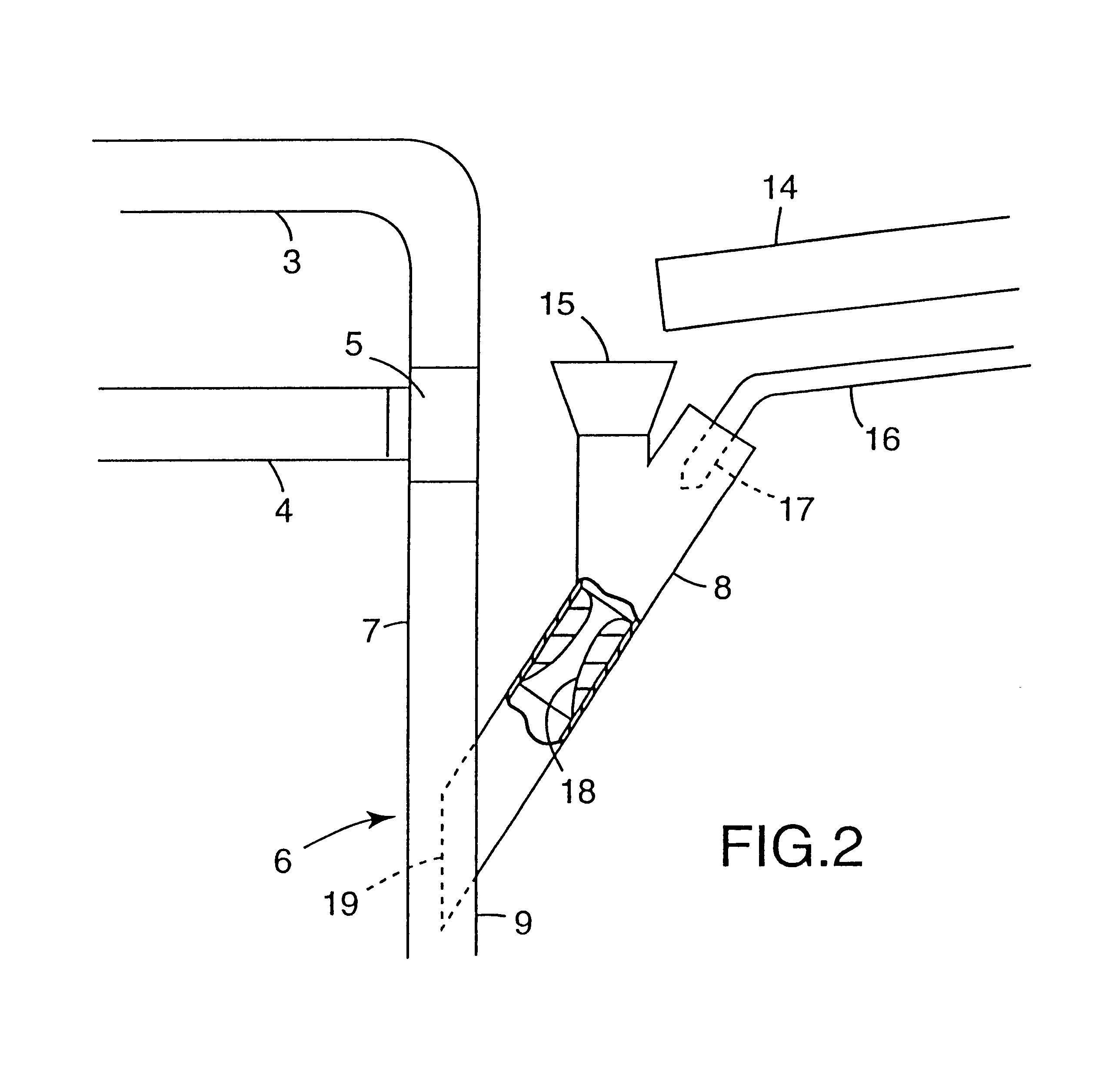

Oxidizing oxygen-fuel burner firing for reducing NOx emissions from high temperature furnaces

InactiveUS6171100B1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFurnace temperatureEquivalence ratio

Burner firing method and device are presented where an oxidizing oxygen-fuel burner is fired at an angle to the reducing air-fuel burner flame to reduce overall NOx emissions from high temperature furnaces. The oxidizing oxy-fuel burner stoichiometric equivalence ratio (oxygen / fuel) is maintained in the range of about 1.5 to about 12.5. The reducing air-fuel burner is fired at an equivalence ratio of 0.6 to 1.00 to reduce the availability of oxygen in the flame and reducing NOx emissions. The oxidizing flame from the oxy-fuel burner is oriented such that the oxidizing flame gas stream intersects the reducing air-fuel flame gas stream at or near the tail section of the air-fuel flame. The inventive methods improve furnace temperature control and thermal efficiency by eliminating some nitrogen and provide an effective burnout of CO and other hydrocarbons using the higher mixing ability of the oxidizing flame combustion products. The simultaneous air-fuel and oxy-fuel burner firing can reduce NOx emissions anywhere from 30% to 70% depending on the air-fuel burner stoichiometric ratio.

Owner:AIR LIQUIDE AMERICA INC +1

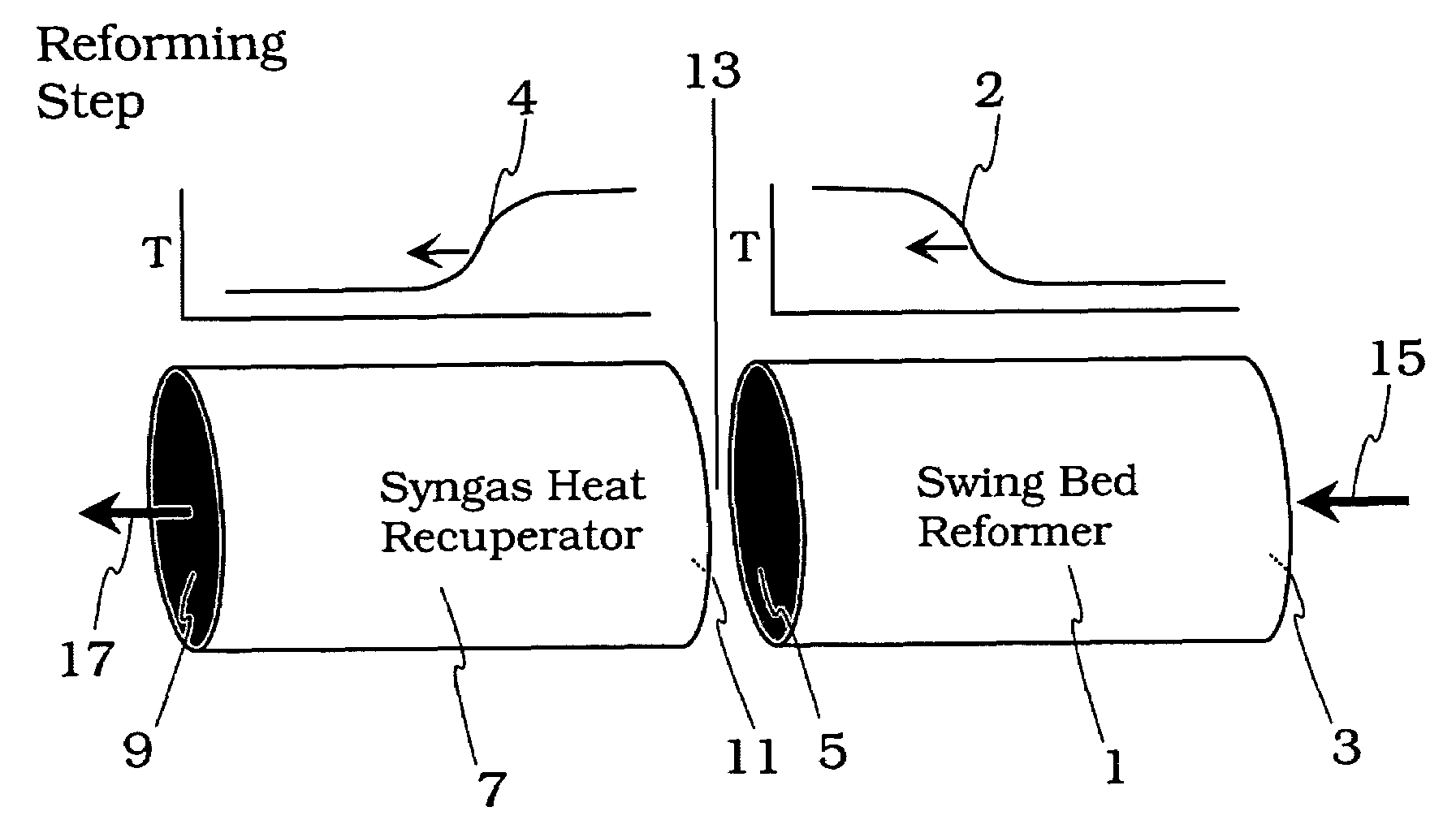

Pressure swing reforming for fuel cell systems

ActiveUS20040175326A1Efficient productionImprove permeabilityHydrogenChemical industrySyngasFuel cells

The present invention provides an improvement in the process of producing hydrogen from hydrocarbon-containing streams. A cyclic reforming process, referred to as pressure swing reforming, provides an efficient means for producing a hydrogen containing synthesis gas for fuel cell applications. Pressure swing reforming may be integrated with shift reactions, preferential oxidation, and membrane separation, achieving thermal and material efficiencies relative to conventional hydrogen production. In one embodiment, at least some synthesis gas which is first produced in the pressure swing reforming process is combusted with air to provide the heat for the regeneration step of the pressure swing reforming process.

Owner:EXXON RES & ENG CO

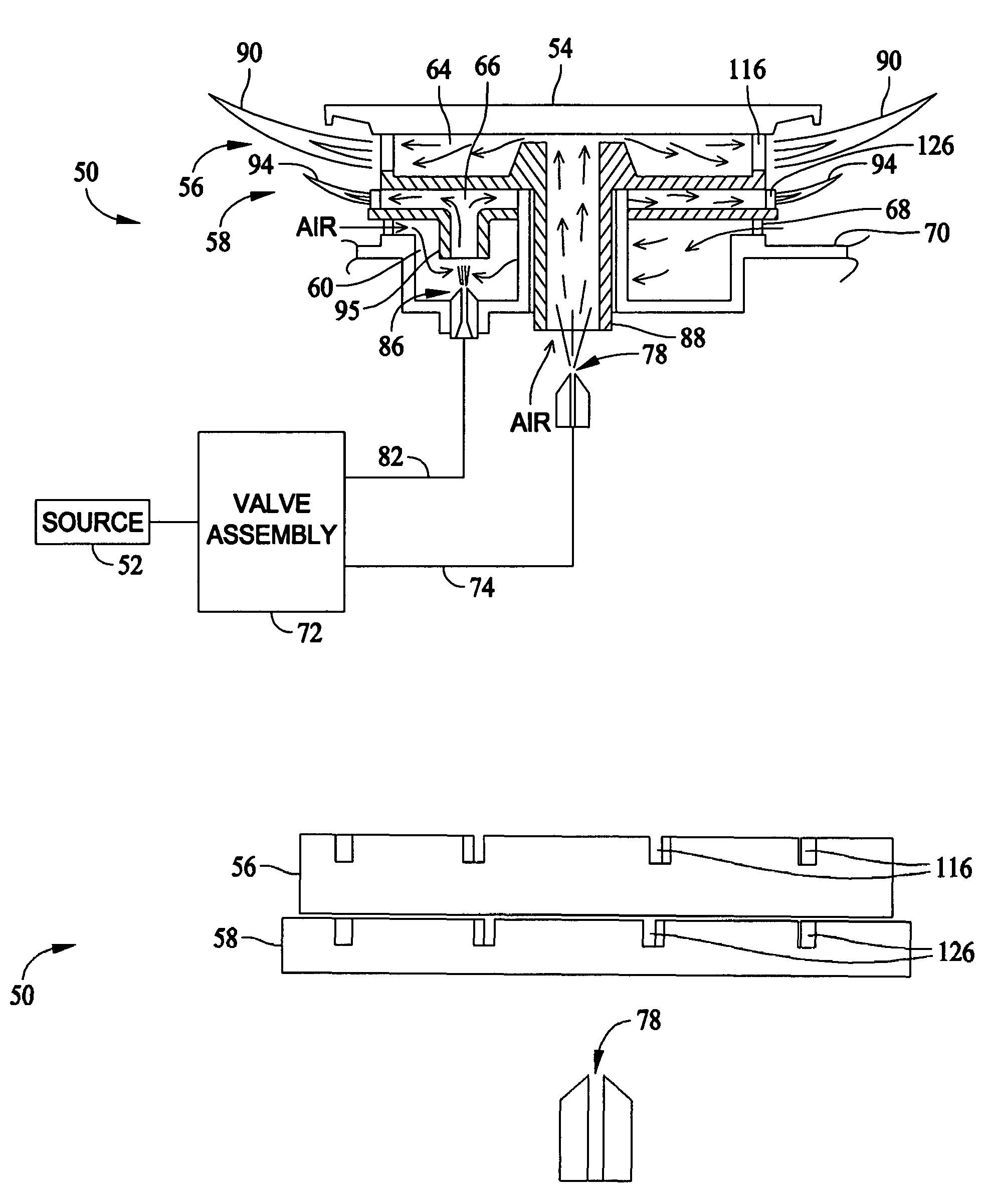

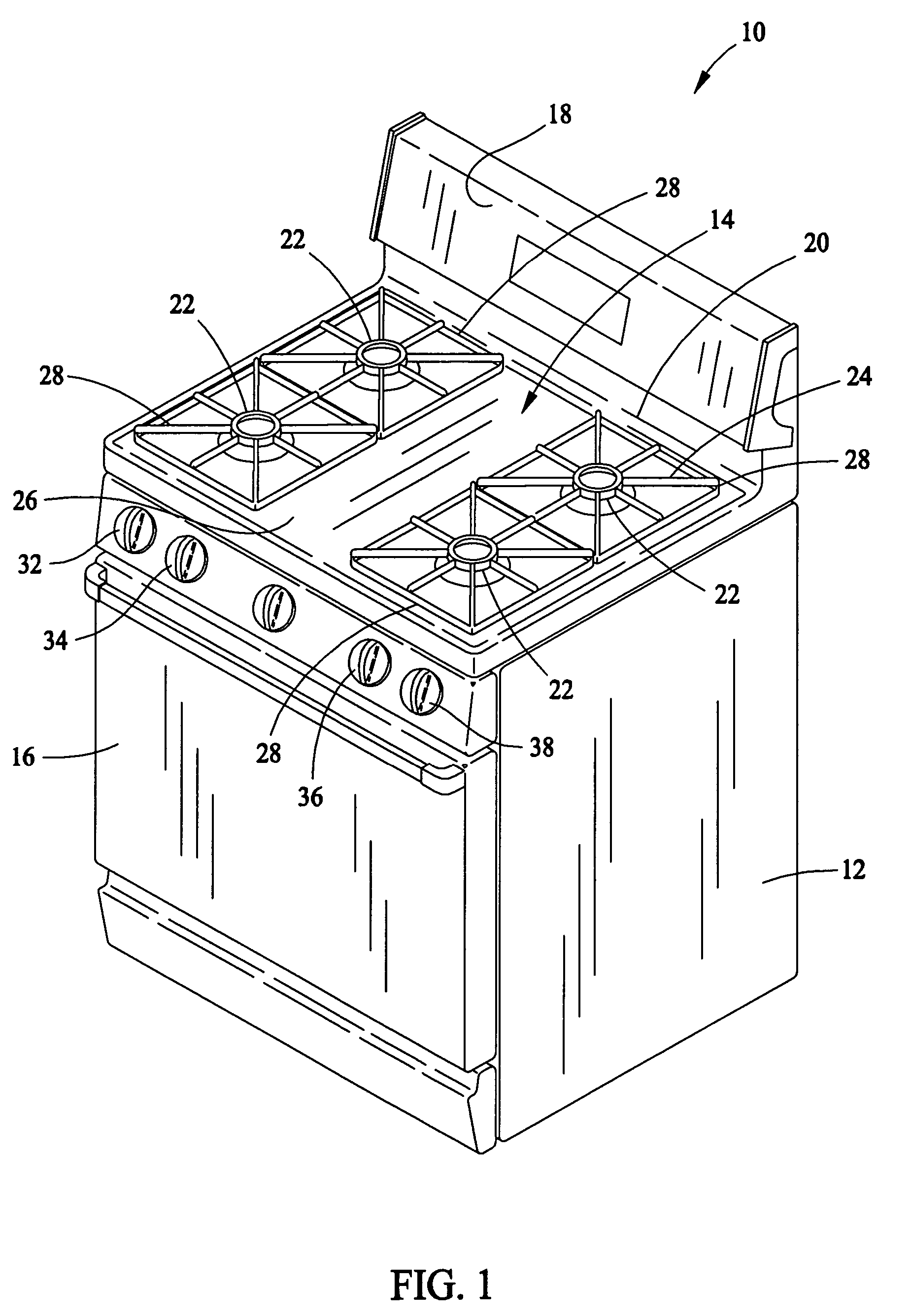

Dual stacked gas burner and a venturi for improving burner operation

ActiveUS7291009B2Amount of timeFacilitates simmeringDomestic stoves or rangesSpray nozzlesEngineeringThermal efficiency

A cooktop burner assembly is described. The cooktop burner assembly includes a main burner, and a simmer burner located below the main burner, where a diameter of the simmer burner is greater than a diameter of the main burner. The closer placement of the main burner to a cooking vessel placed on top of the cooktop burner assembly as compared to the placement of the simmer burner from the cooking vessel increases thermal efficiency. Moreover, the farther placement of the simmer burner from the cooking vessel facilitates simmering of items in the cooking vessel and the larger diameter of the simmer burner reduces a possibility of overheating the main burner and the cooking vessel.

Owner:HAIER US APPLIANCE SOLUTIONS INC

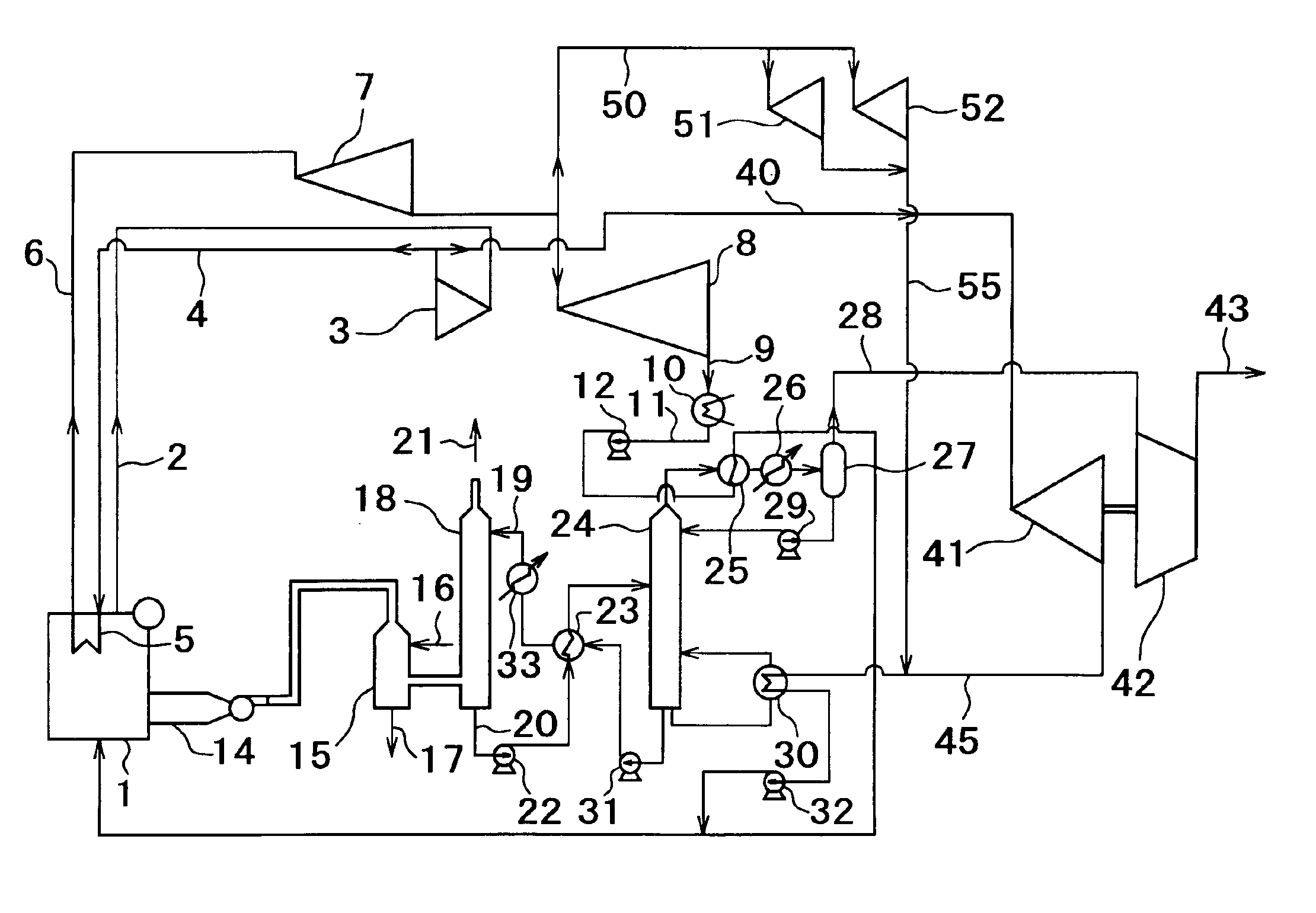

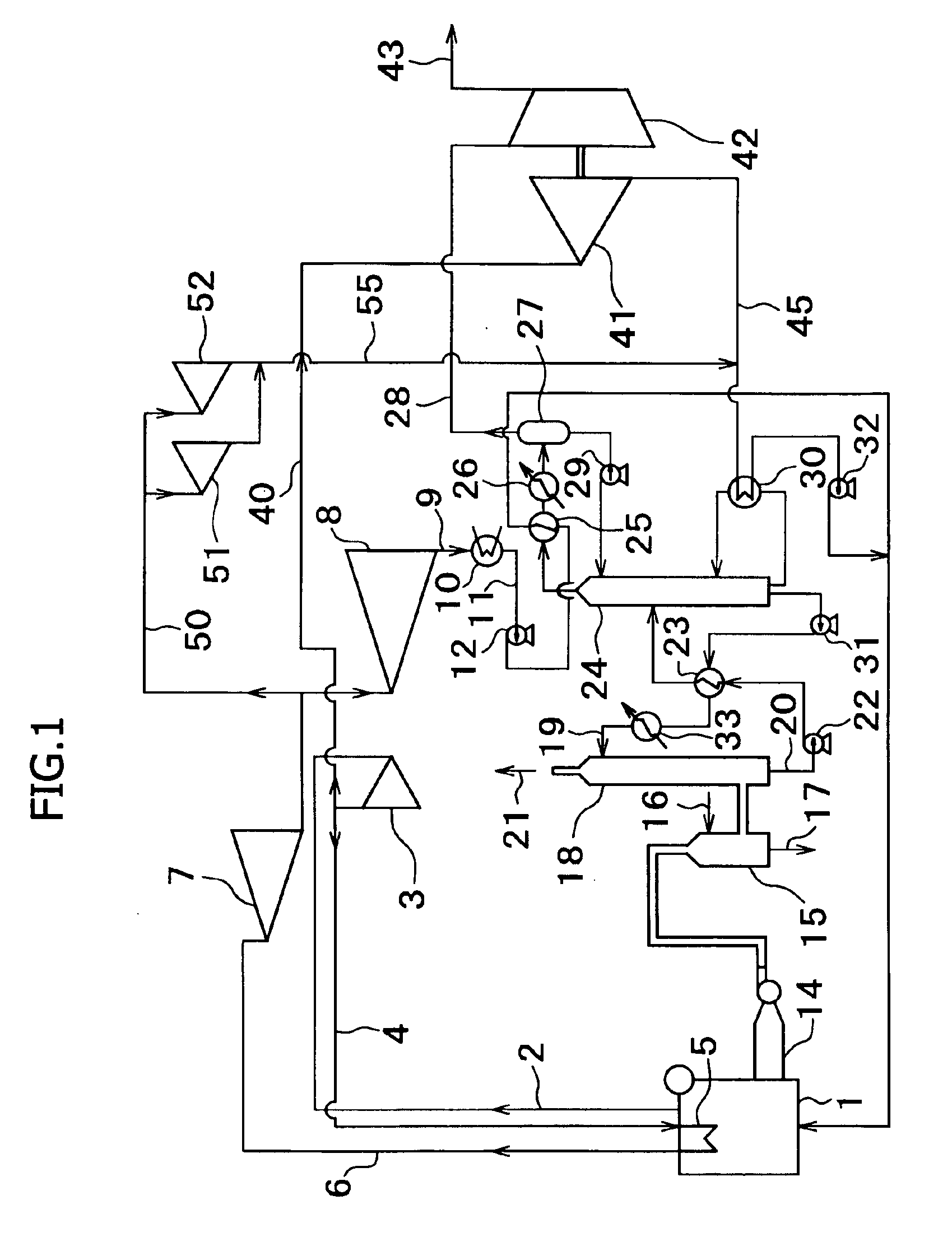

Method and system for recovering carbon dioxide

ActiveUS6883327B2High thermal efficiencyCarbon compoundsDispersed particle separationThermal energyCombustion

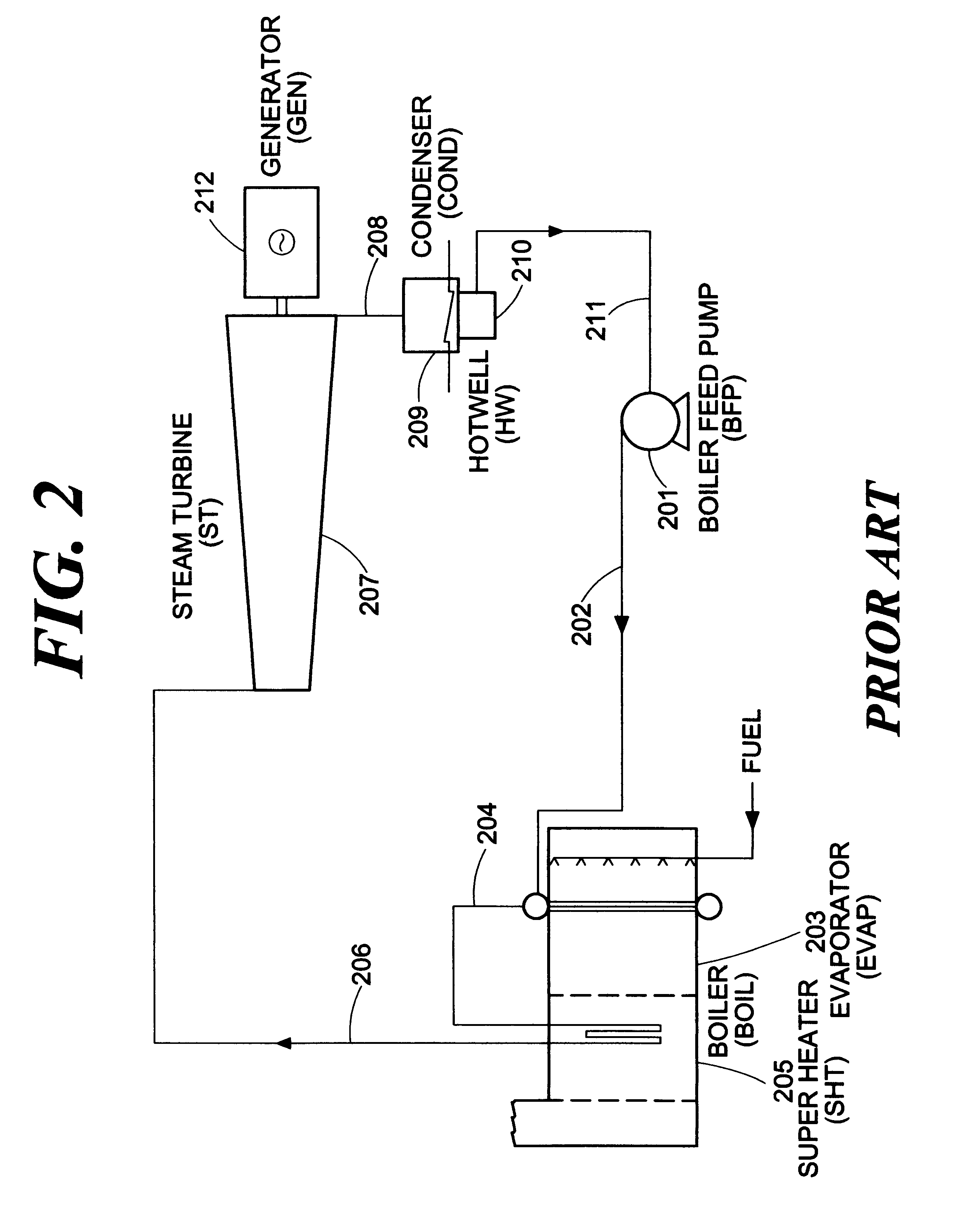

To provide a method for recovering carbon dioxide, in which thermal energy for regenerating a CO2 absorbing solution and power for compressing the recovered CO2 are supplied, and high thermal efficiency is achieved, and a system therefor. A system for recovering carbon dioxide including a high pressure turbine 3, an intermediate pressure turbine 7, and a low pressure turbine 8; a boiler 1 for generating steam for driving the turbines; an absorption tower 18 filled with a CO2 absorbing solution for absorbing and removing CO2 from combustion exhaust gas of the boiler; a regeneration tower 24 for regenerating the absorbing solution having absorbed CO2; a compressor 42 for compressing the removed CO2; a turbine 41 for a compressor, which is driven by some of the exhaust steam of the high pressure turbine; turbines 51 and 52 for auxiliary machinery, which are driven by some of the exhaust steam of the intermediate pressure turbine; and supply pipes 45 and 55 for supplying exhaust steam of the compressor turbine and the auxiliary machinery turbines to a reboiler 30 of the regeneration tower as a heating source.

Owner:MITSUBISHI HEAVY IND ENG LTD

Integrated coal gasification combined cycle power generator

Embodiments of the invention provide an IGCC which achieves improved plant thermal efficiency by using a cooling steam supply system that cools the high-temperature sections of the gas turbine 34. Embodiments of the invention further provide and IGCC in which the cooling steam recovery system recovers steam after cooling the gas-turbine high-temperature section and makes practical re-use of the energy and substances within the system. Therefore, embodiments of the invention can reduce or eliminate the degradation of certain equipment by cooling the high-temperature sections. Methods are provided for increasing the thermal efficiency o an IGCC.

Owner:KK TOSHIBA

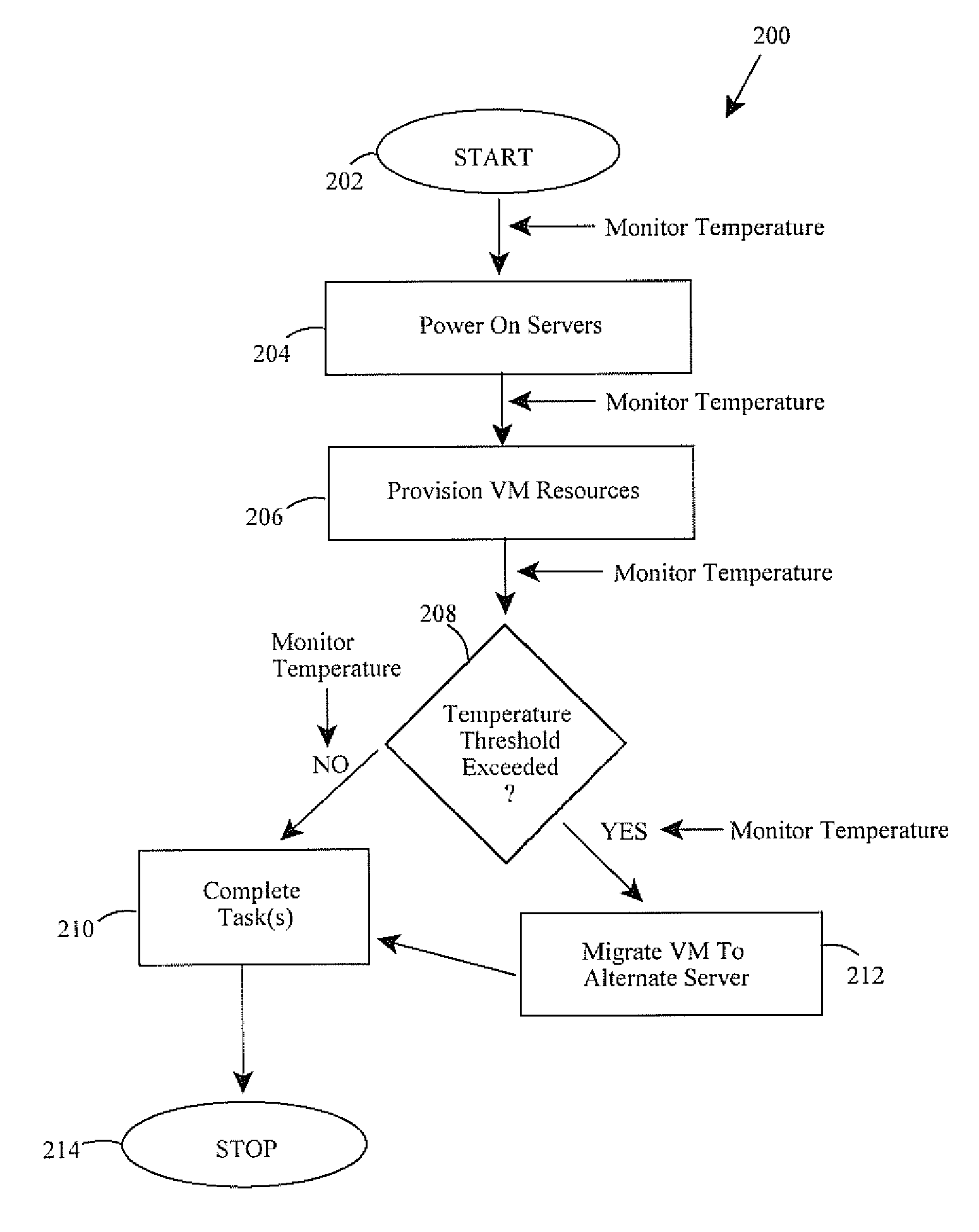

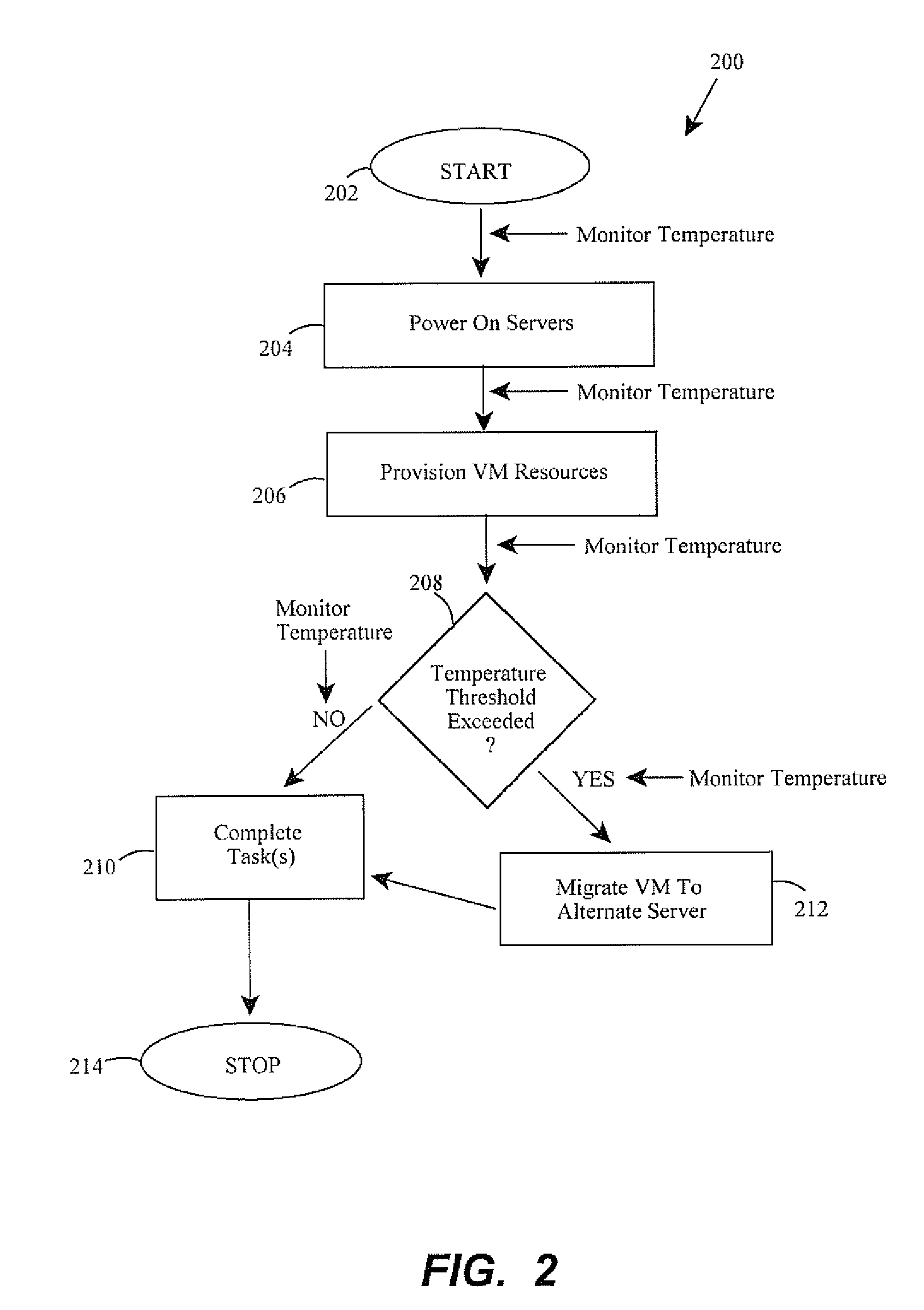

Dynamic thermal load balancing

ActiveUS20100217454A1Inhibit migrationImprove thermal efficiencyThermometer detailsTemperatue controlData centerComputerized system

A method for improving thermal efficiency in one or more data centers includes measuring a temperature at one or more computing devices having allocated thereto one or more computing workloads and determining whether the measured temperature exceeds a predetermined temperature threshold. If the predetermined temperature threshold is exceeded, sufficient computing workloads are migrated to one or more alternate computing devices to reduce the temperature at one or more of the computing devices to less than or equal to said predetermined temperature threshold. In accomplishing the method, there is provided a data orchestrator configured at least for receiving data concerning the measured temperature, determining whether the measured temperature exceeds the predetermined temperature threshold, and migrating one or more of the computing workloads to one or more alternate computing devices. Computer systems and computer programs available as a download or on a computer-readable medium for installation according to the invention are provided.

Owner:SUSE LLC

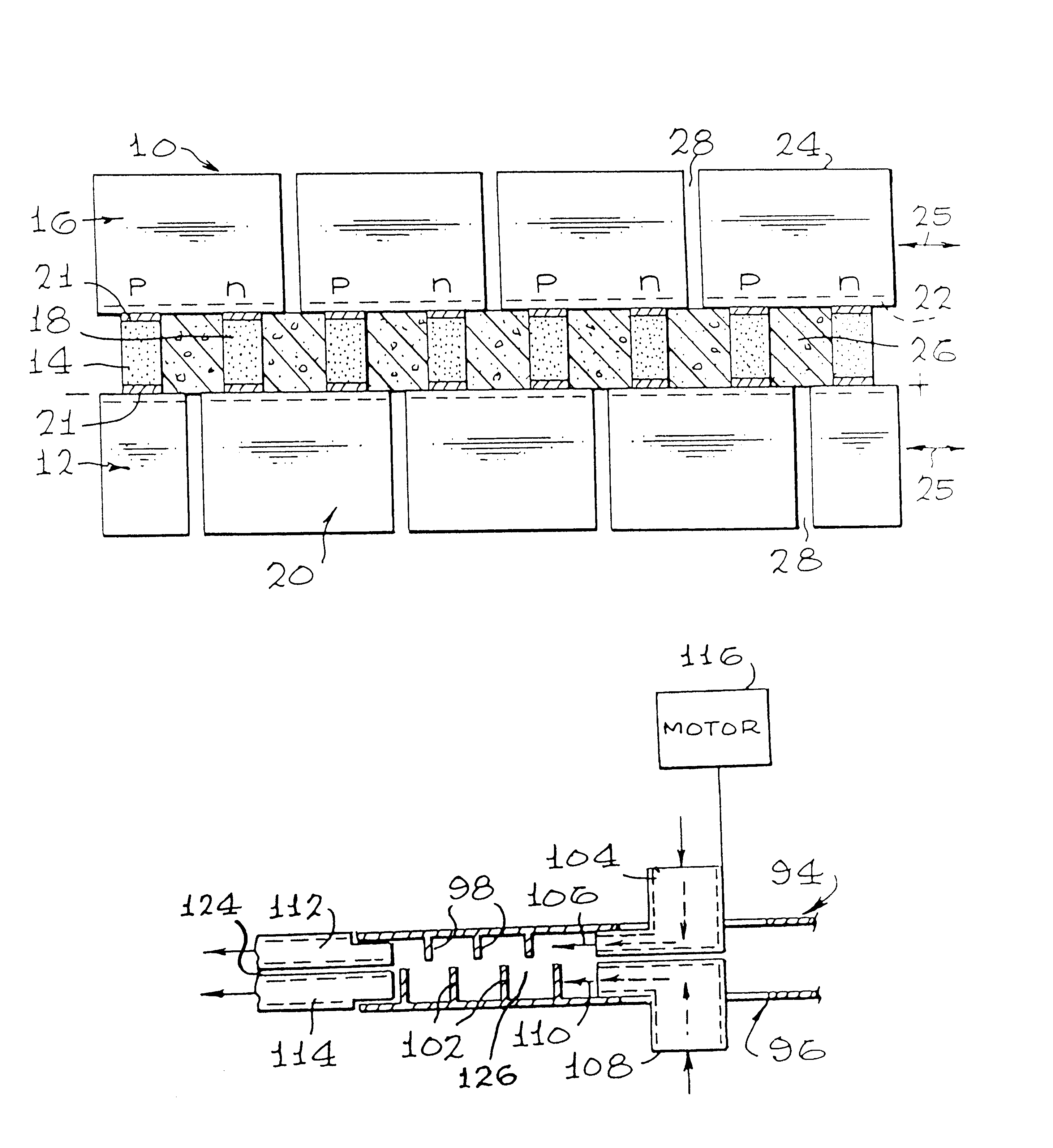

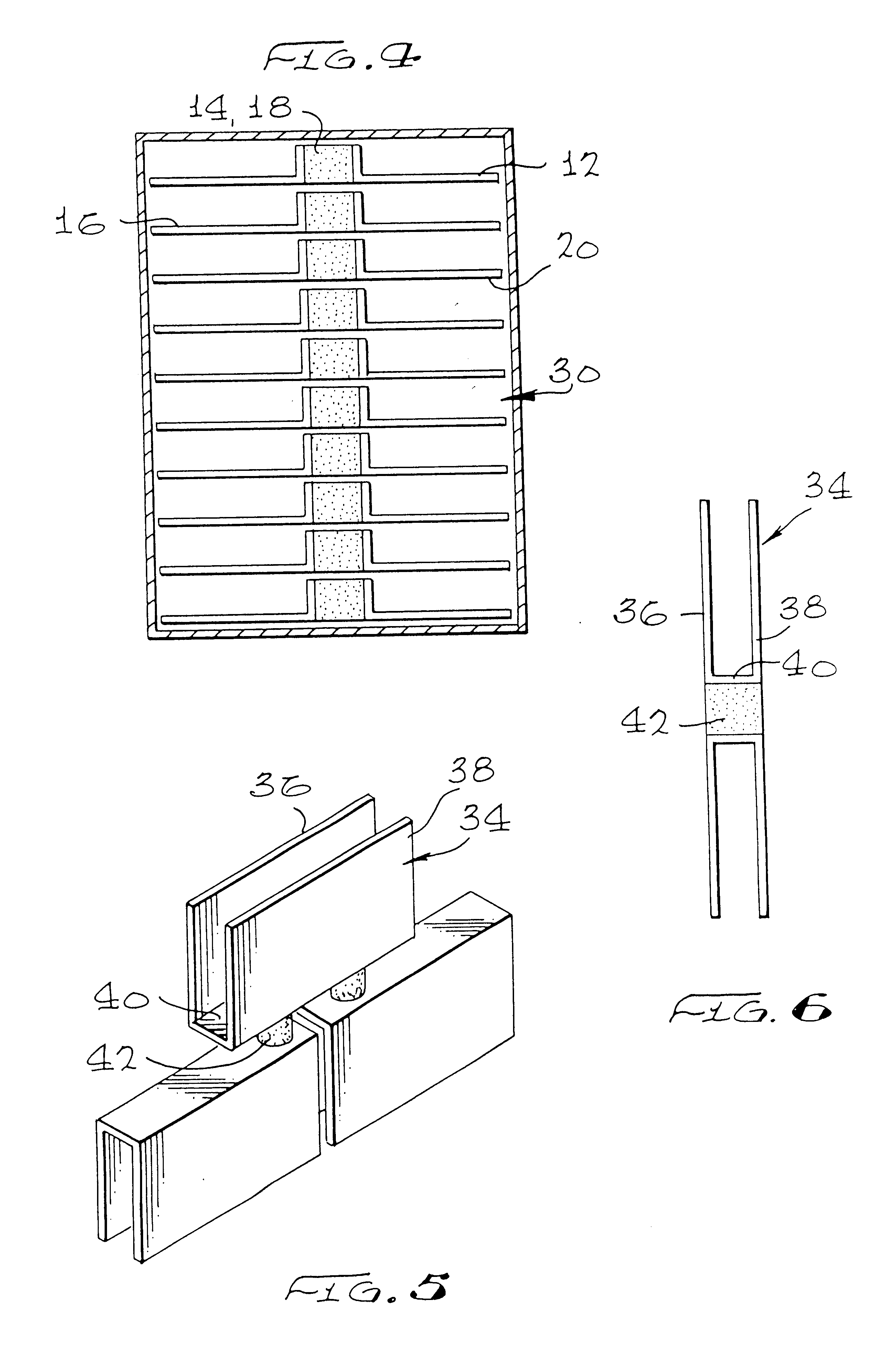

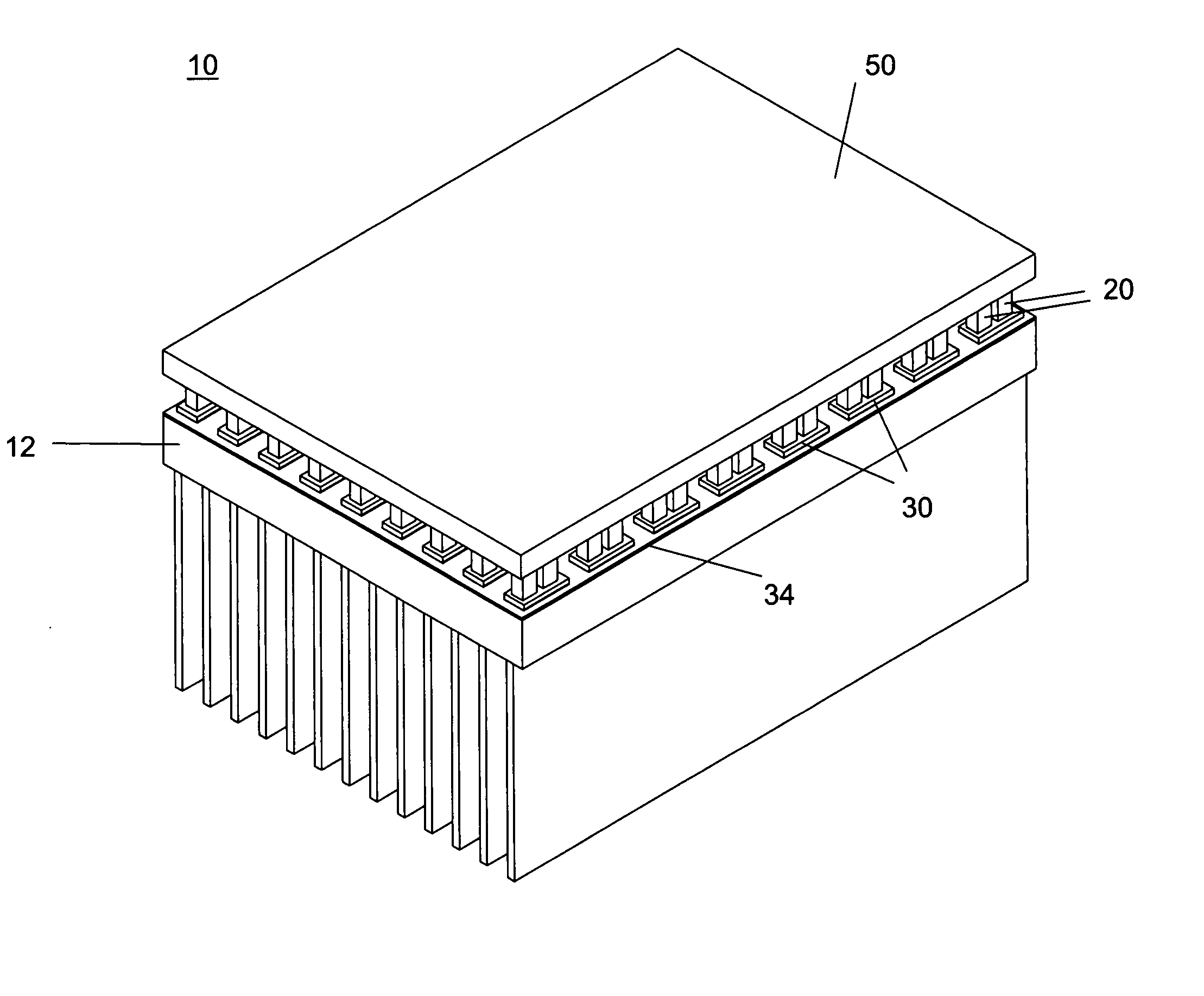

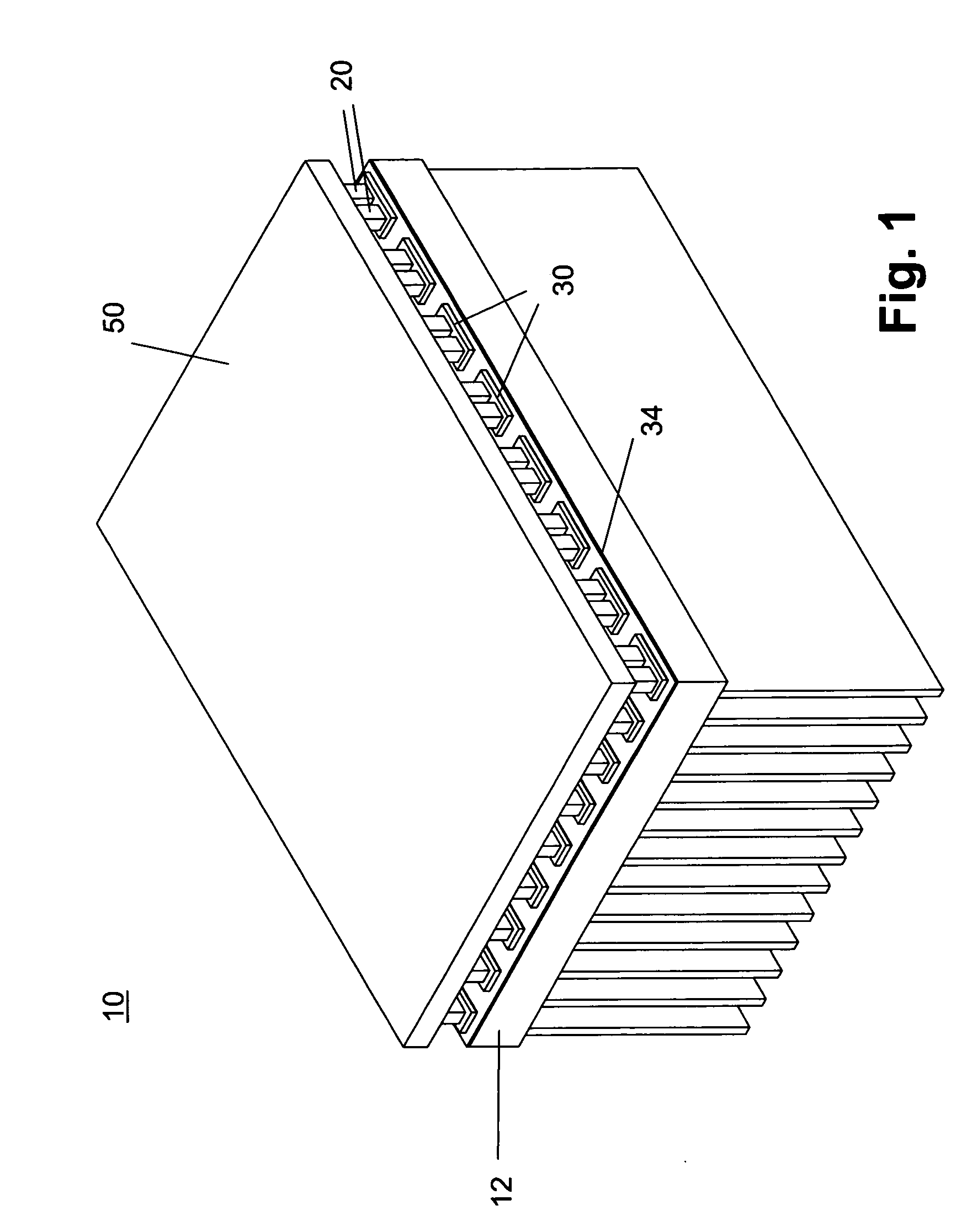

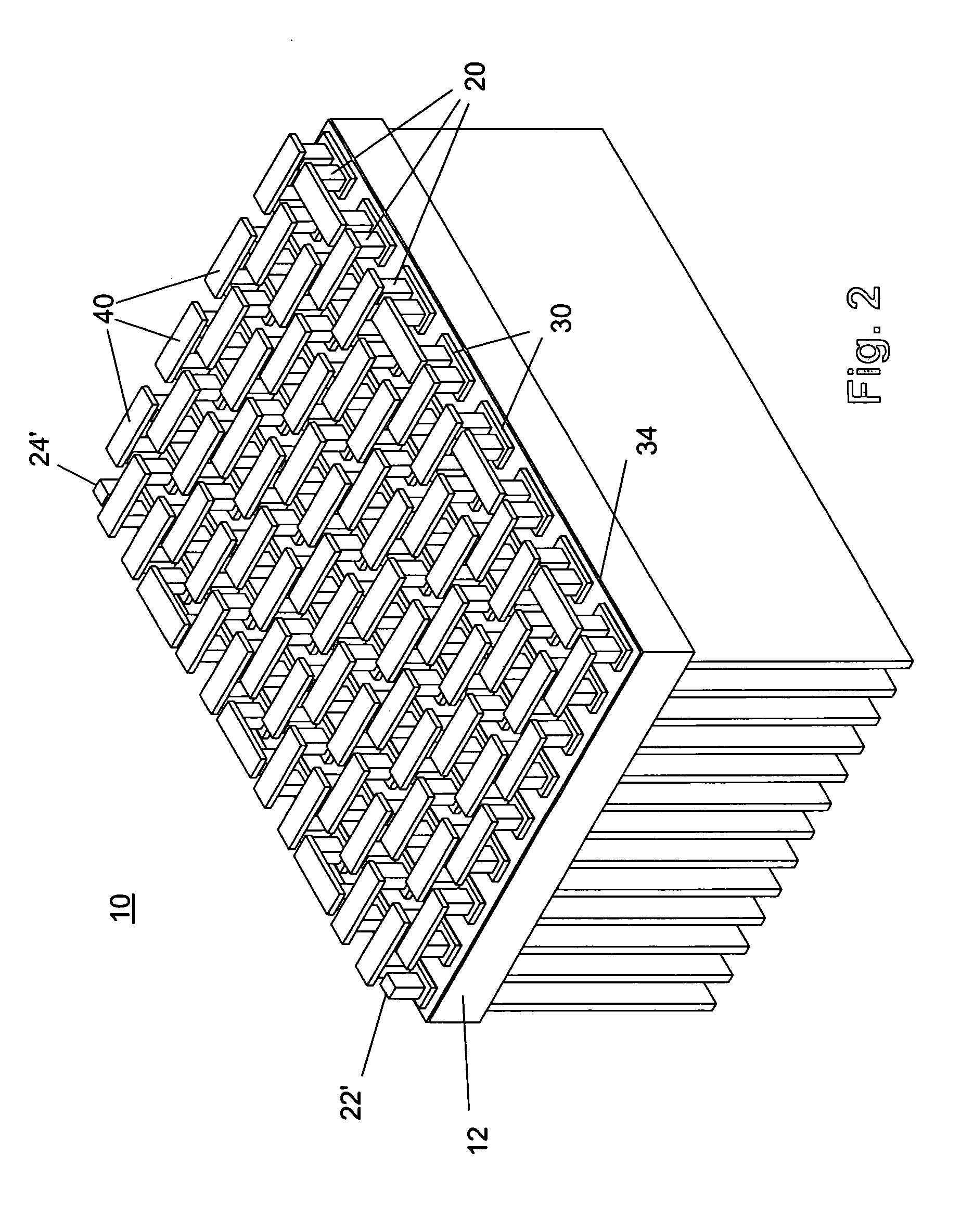

Modular thermoelectric couple and stack

InactiveUS6855880B2Produce undesirable thermal impedance losses during system operationReduce contractionThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsImpellerElectrical conductor

A thermoelectric semiconductor module (10) includes a plurality of semiconductor pellets (14, 18) having Peltier characteristics are mechanically interconnected and arranged in an electrical series circuit with heat transferring means (12, 16, 20) with all interconnections being directly made. The means (12, 16, 20) can be of platelike construction with an L-shaped cross-section or, alternatively, with a U-shaped cross-section. A large number of modules (10) can be arranged in a two-dimensional or three-dimensional stack (30) with adjacent lines or planes of modules electrically interrelated by end segment connectors (32). In a further version, one side of a modular plane has heat exchanger fins (44-50) while the other side is electrically connected by ceramic segments (58) with deposited conductors (56). In yet another version, the modules are mounted onto rotating discs (94, 96) so as to act as a fluid impeller moving therepast enhancing thermal efficiency.

Owner:FEHER STEVE

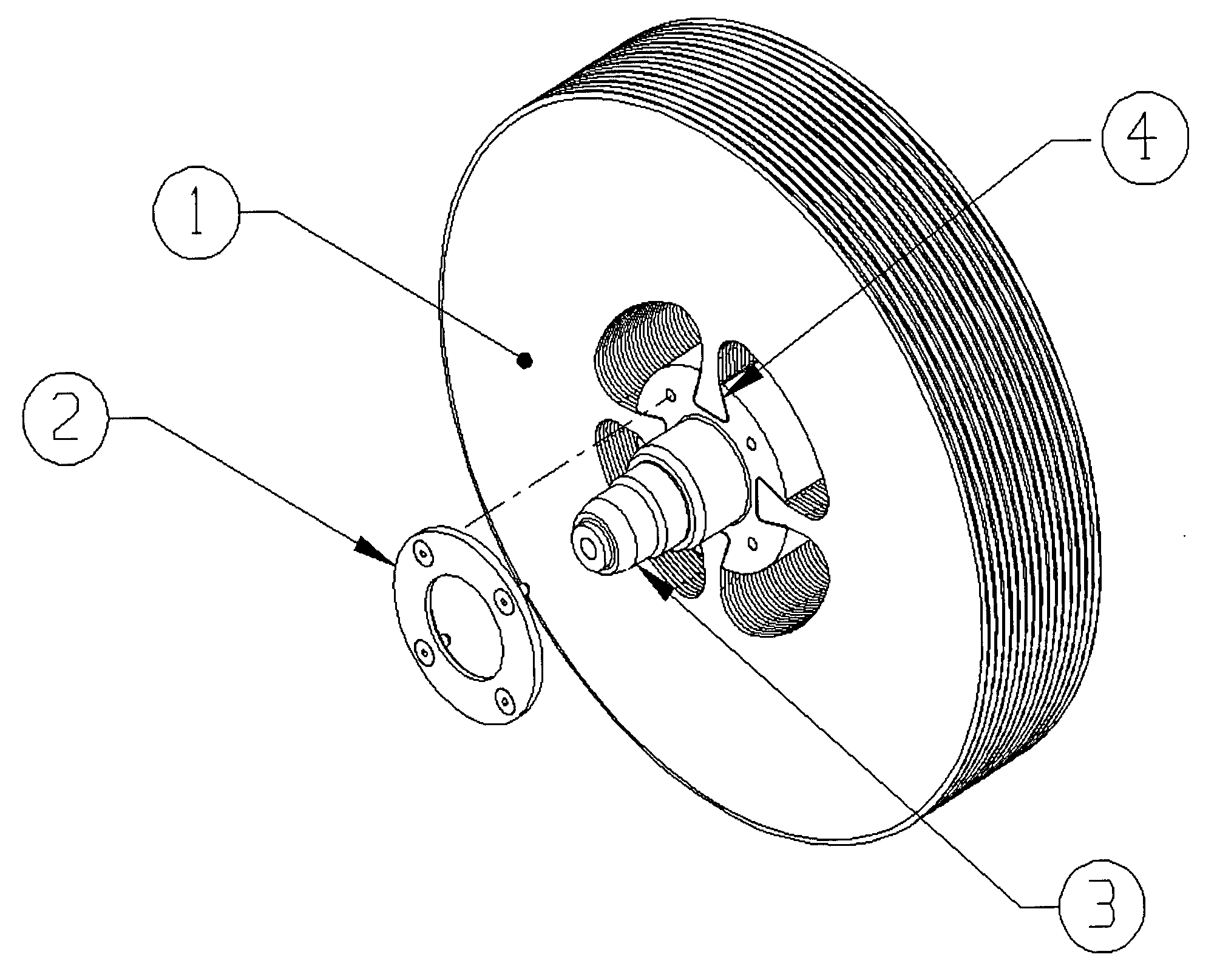

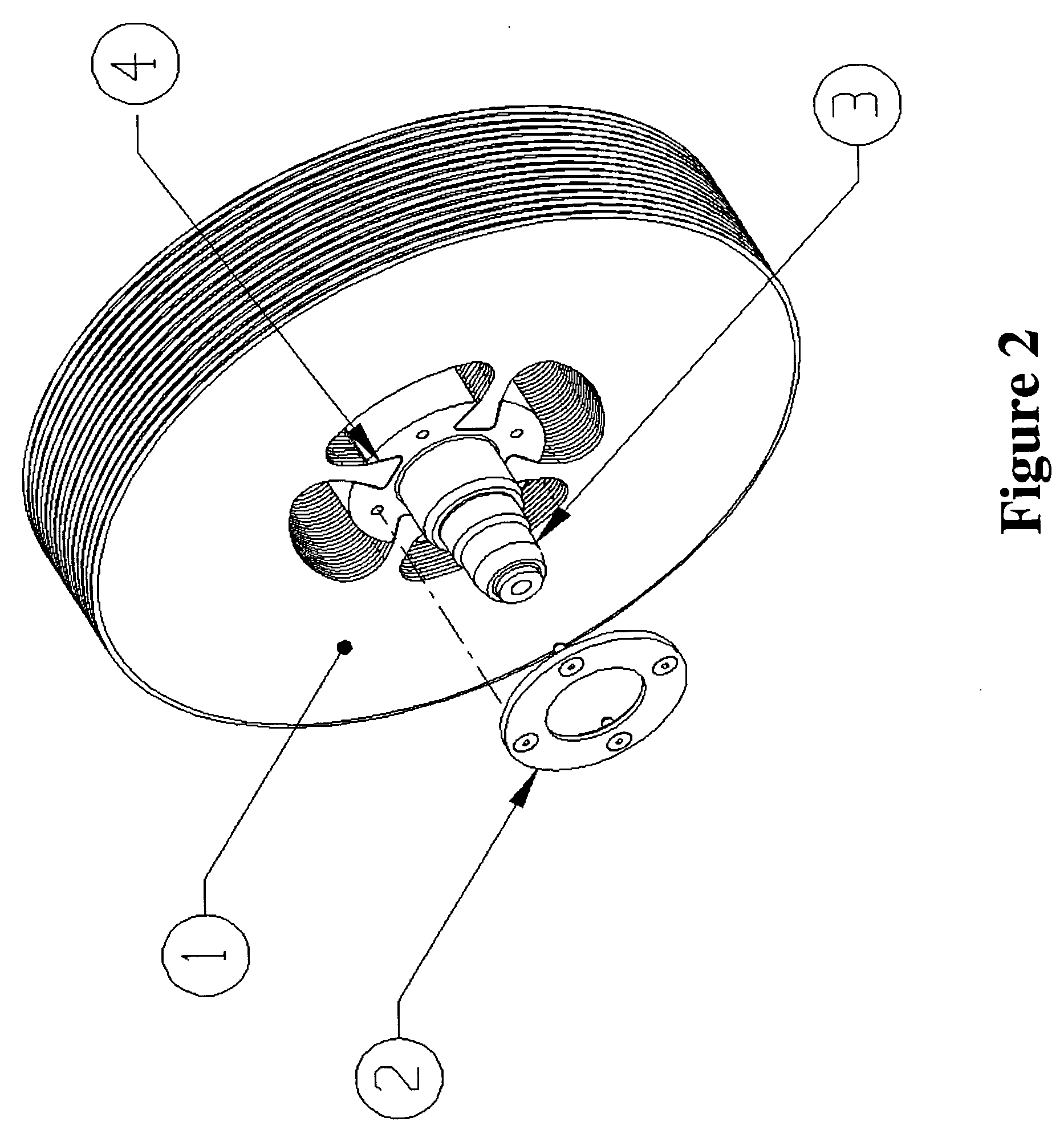

Method of and apparatus for a multi-stage boundary layer engine and process cell

InactiveUS20050169743A1Improve turbine efficiencyIncrease efficiency and reliability and flexibilityMaterial nanotechnologyInfluencers using Magnus effectCombustion chamberClosed loop

A multi-staged boundary layer engine and process cell, (based on the effect known as adhesion and viscosity) which achieves high thermal efficiencies and high mechanical power output for use in the power generation, geothermal, energy recovery, solar, transportation, hydrogen production, desalinating water and hydroelectric fields. The design is novel with a dovetail attachment of the disc packs, allowing lower stress and allowing the use of next generation materials such as ceramics, composites and nanocomposites to improve the maximum temperature and the maximum RPM of the engine, thereby producing more horsepower and torque. In addition, this invention includes multi-stage vacuum, an external combustion chamber and condenser stages to improve the vortex flow through the primary disc pack cell. This engine will also encompass a closed loop cycle for ultimate efficiencies. This invention will also include the use of catalysts and / or electrical polarities applied to the disc pack and the disc pack / casing respectively to achieve low NOx and also to achieve process cell capability for applications such as desalinization and hydrogen generation.

Owner:CENTRIPETAL DYNAMICS

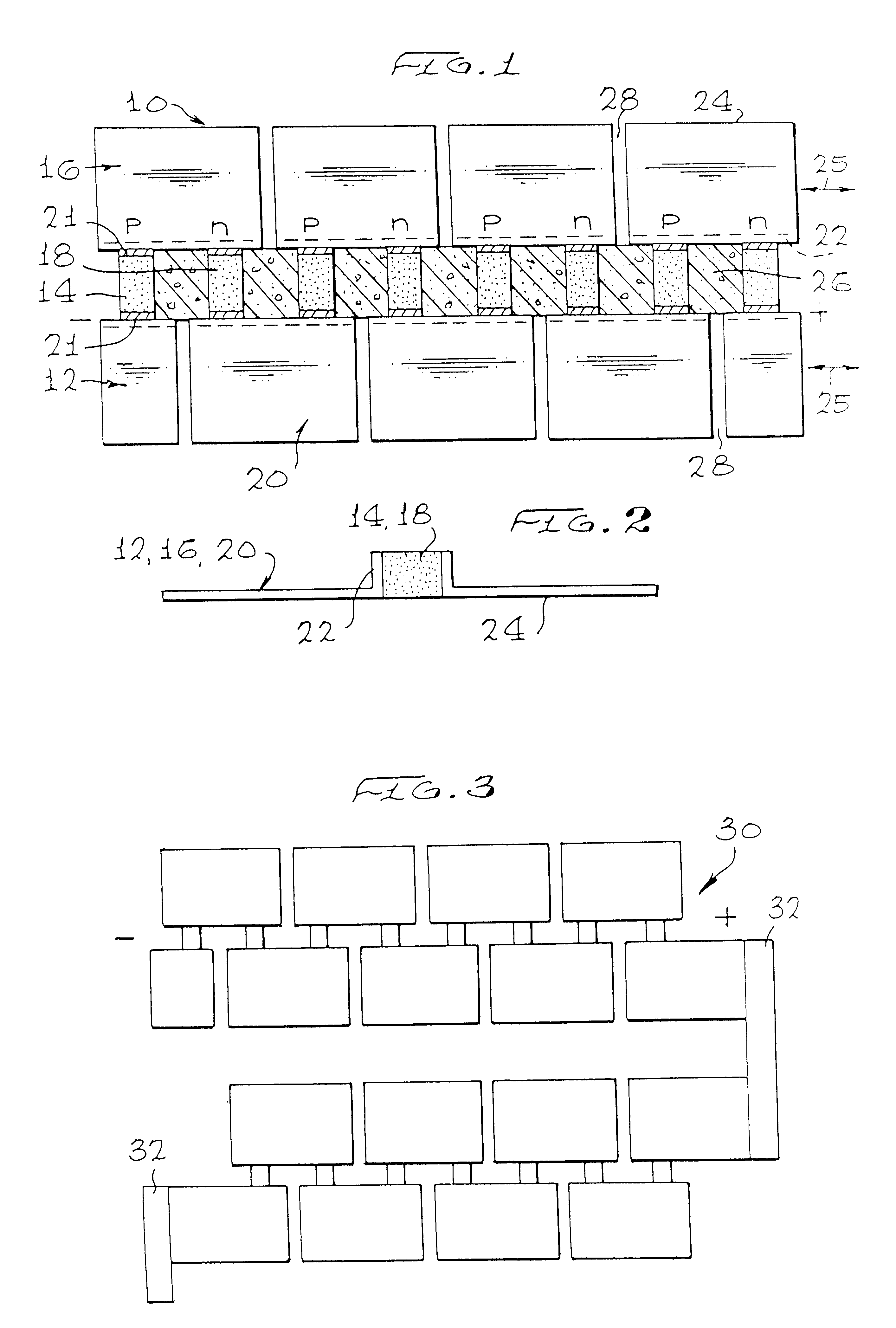

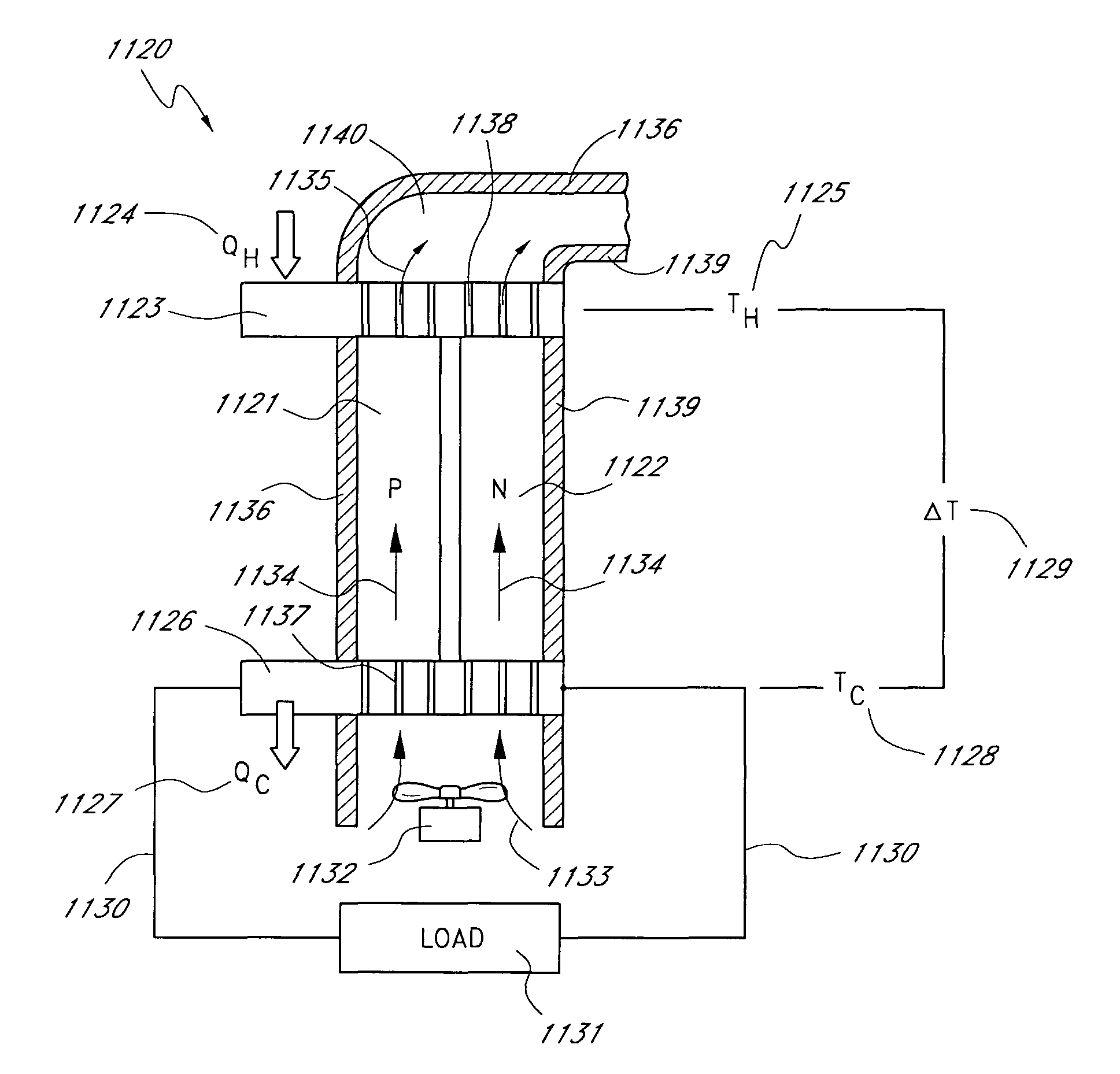

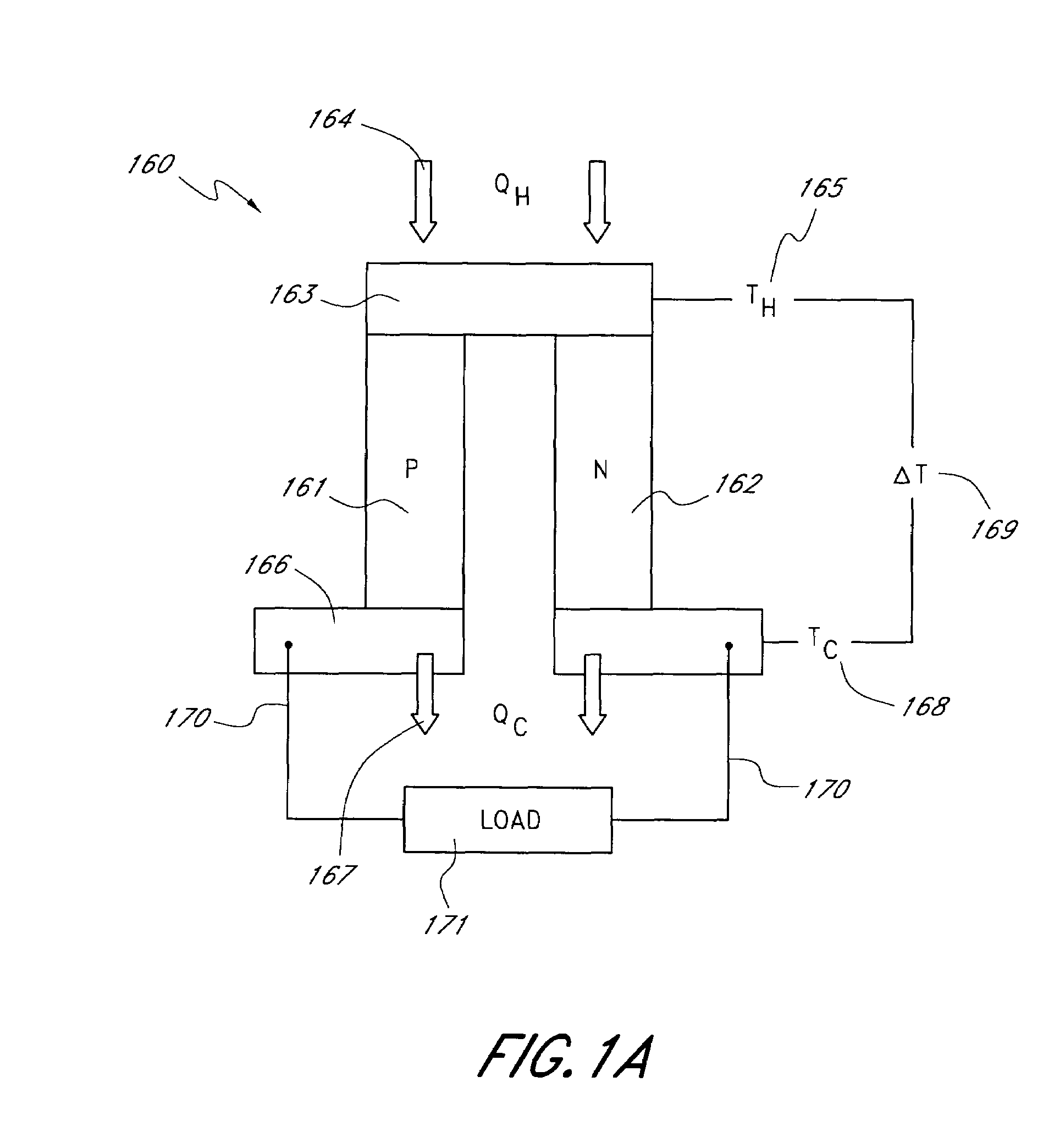

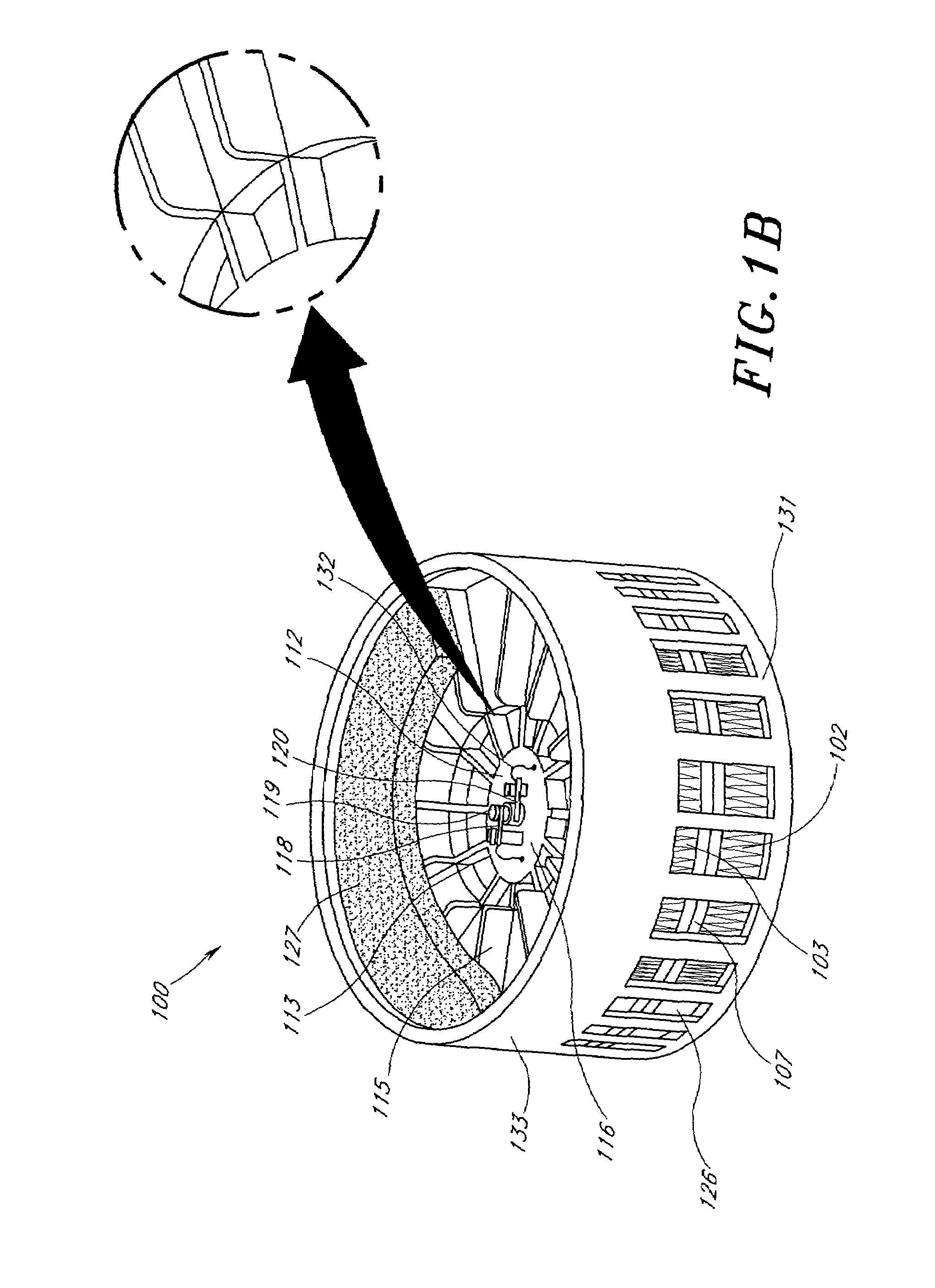

Thermoelectric power generation systems

InactiveUS7273981B2Renewed interestImprove power densityAir-treating devicesThermoelectric device with peltier/seeback effectEngineeringThermal efficiency

Representative configurations for improved thermoelectric power generation systems to improve and increase thermal efficiency are disclosed.

Owner:GENTHERM INC

Thermoelectric module with directly bonded heat exchanger

InactiveUS20050121065A1Improve thermal efficiencyReduce thermal resistanceThermoelectric device with peltier/seeback effectEngineeringThermoelectric element

A thermoelectric device with an improved thermal efficiency has an object to be heated or cooled having a surface, at least one electrically conductive lower pad bonded directly to the surface of the object using a thermally conductive dielectric material, at least one thermoelectric element coupled on one end to the electrically conductive pad, at least one electrically conductive upper pad coupled to an opposite end of the thermoelectric element, and electrical power connections coupled to the device.

Owner:FERROTEC USA CORP

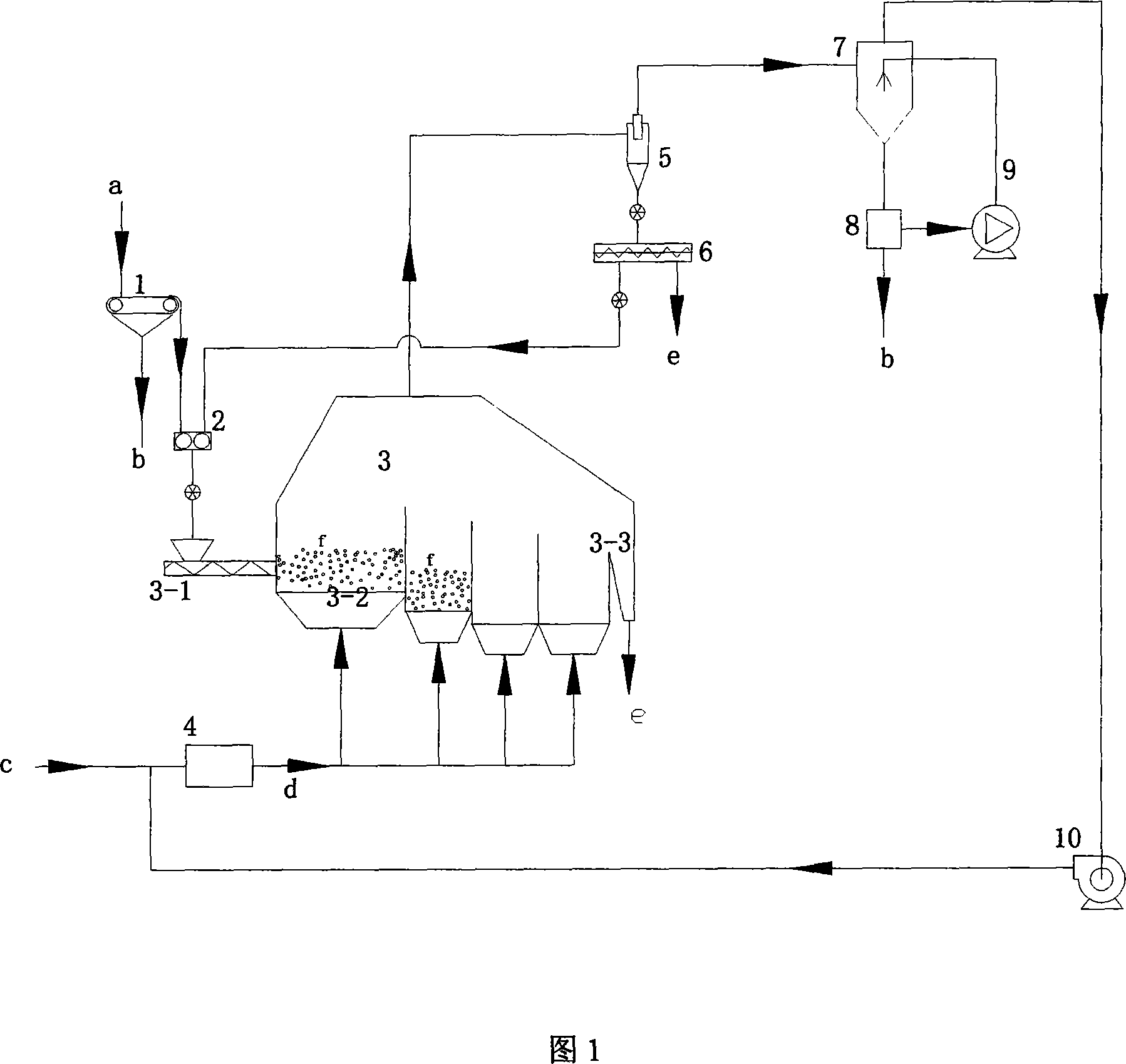

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

Heavy oil recovery with fluid water and carbon dioxide

ActiveUS20090071648A1Improves hydrocarbon extraction efficiencySpeed up the extraction processFluid removalFuel oilInjection well

Diluted wet combustion forms a hot process fluid or VASTgas comprising carbon dioxide (CO2) and fluid water which is delivered geologic formations and / or from surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. This may improve thermal efficiency and / or increases heat delivery for a given combustor or per capital investment. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

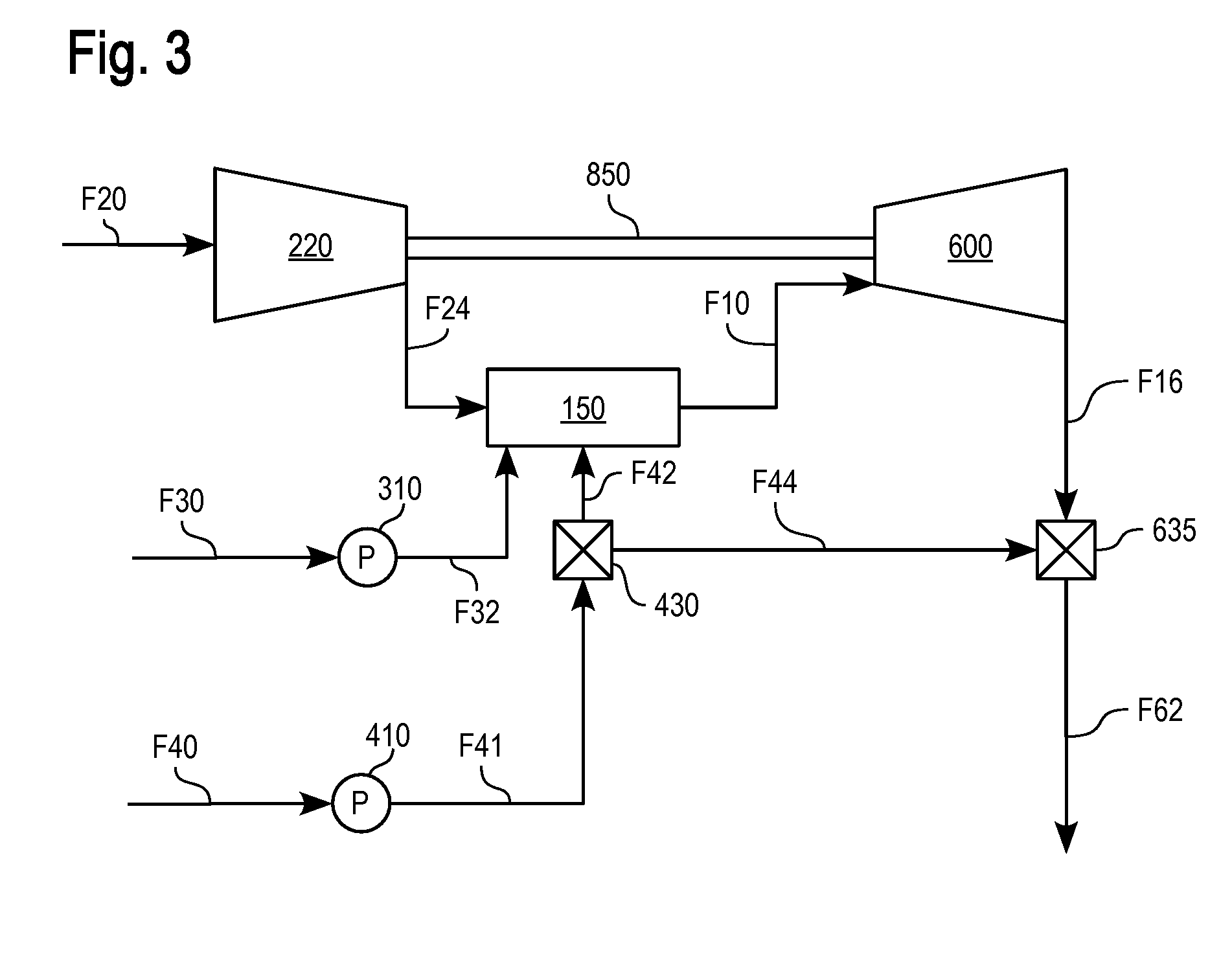

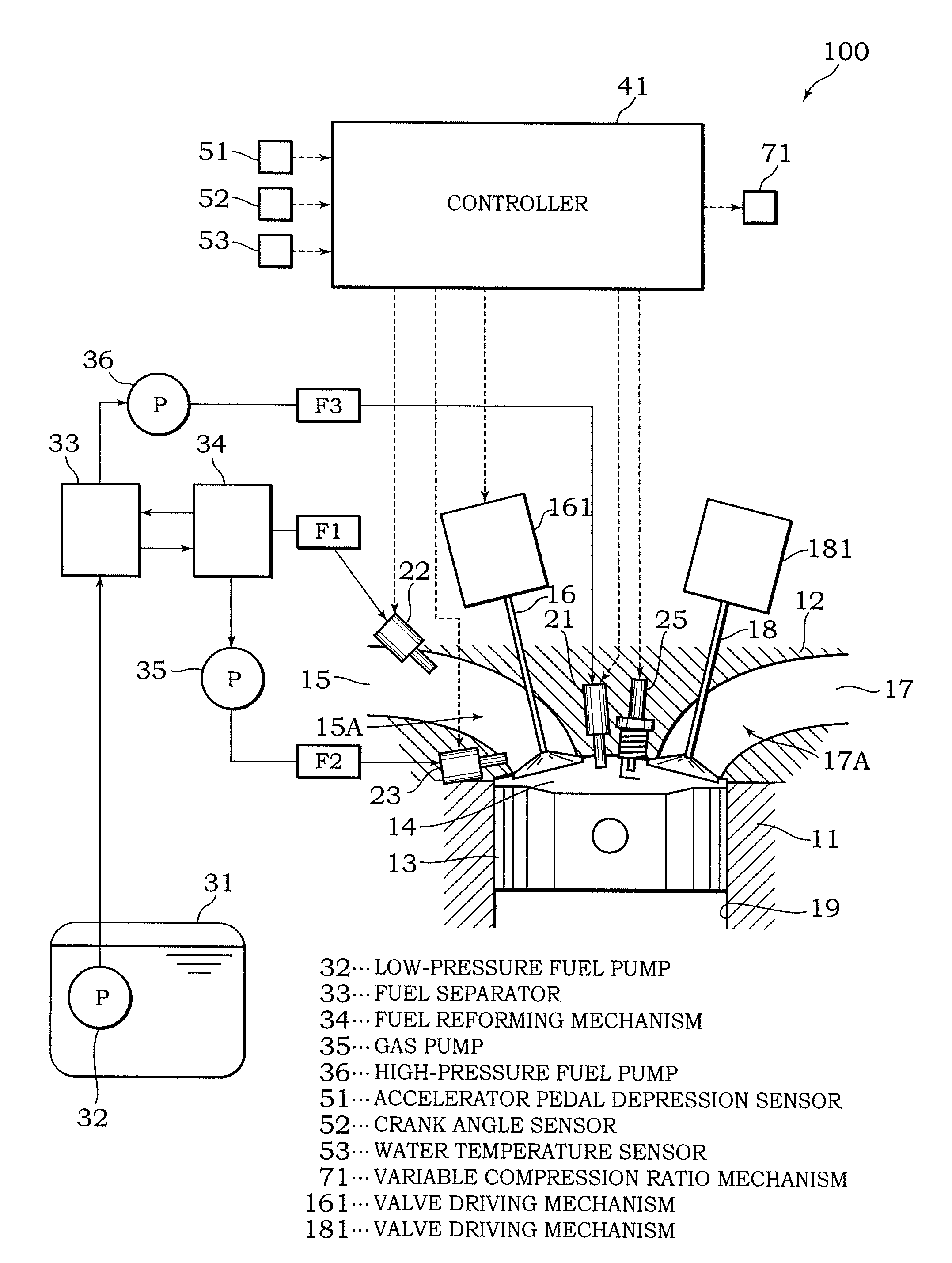

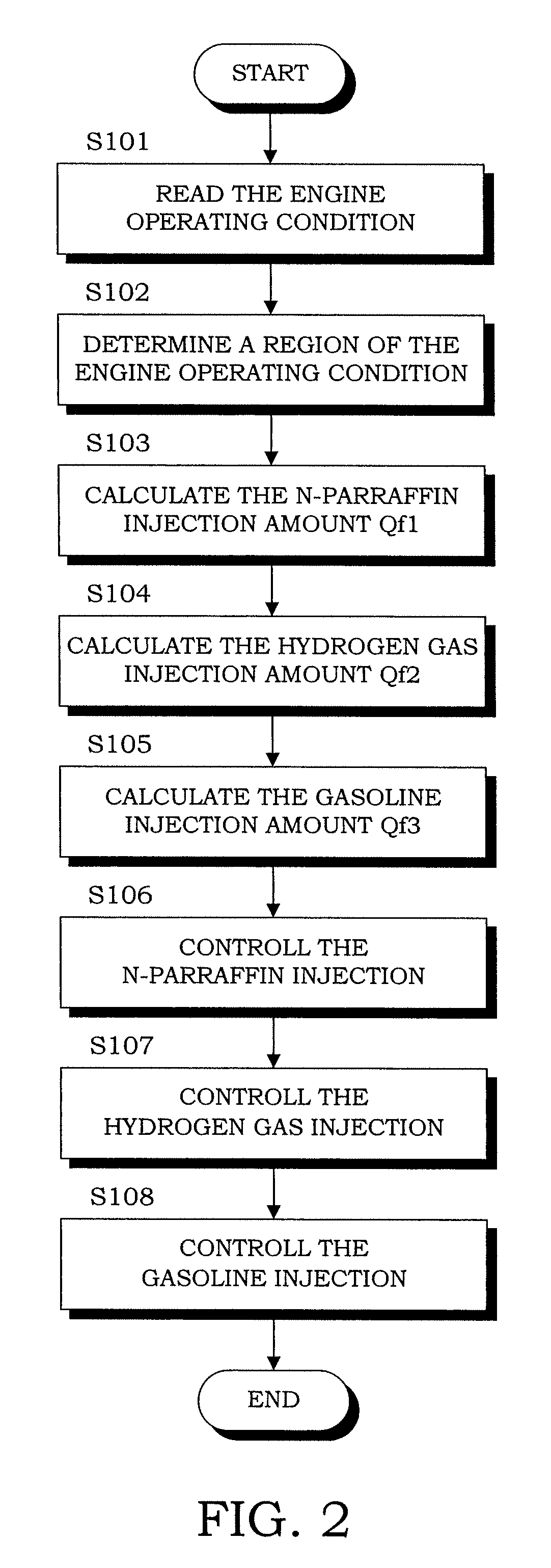

Internal combustion engine

InactiveUS20090043479A1High-temperature combustionIncrease temperatureElectrical controlInternal combustion piston enginesCombustion chamberFlame propagation

An internal combustion engine (100) comprises a fuel injection valve (21, 22) which supplies a first fuel having a higher self-ignitability than gasoline and a second fuel having a higher combustion speed than gasoline such that an air-fuel mixture containing the first fuel and the second fuel is formed in a combustion chamber (14), a spark plug (25) which ignites the air-fuel mixture, and a programmable controller (41) programmed to control supply proportions of the first fuel and the second fuel such that the ignited air-fuel mixture undergoes flame propagation combustion and then undergoes self-ignition combustion. Thus, a reduction in emissions can be achieved, and high thermal efficiency can be realized through the self-ignition combustion.

Owner:NISSAN MOTOR CO LTD

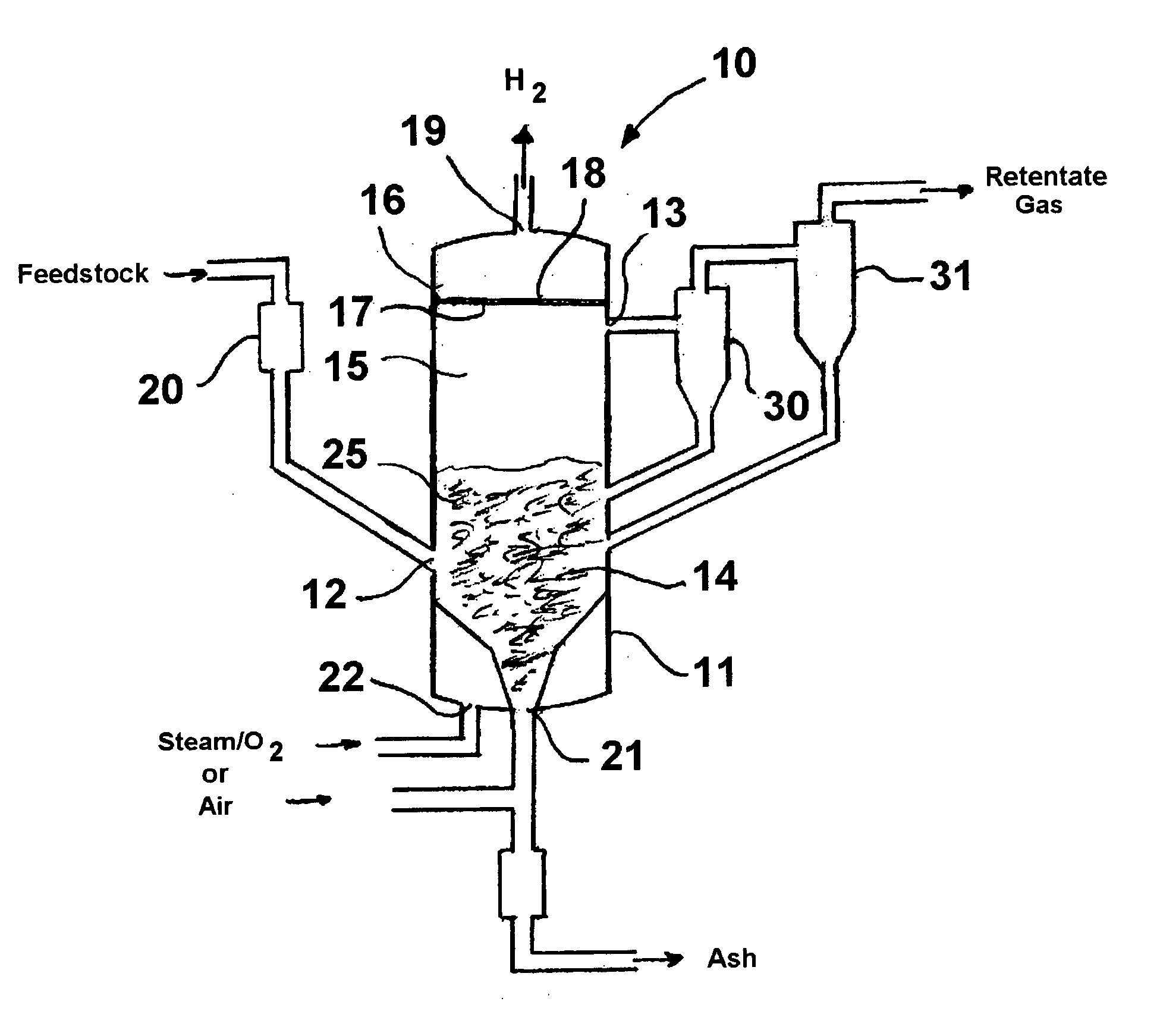

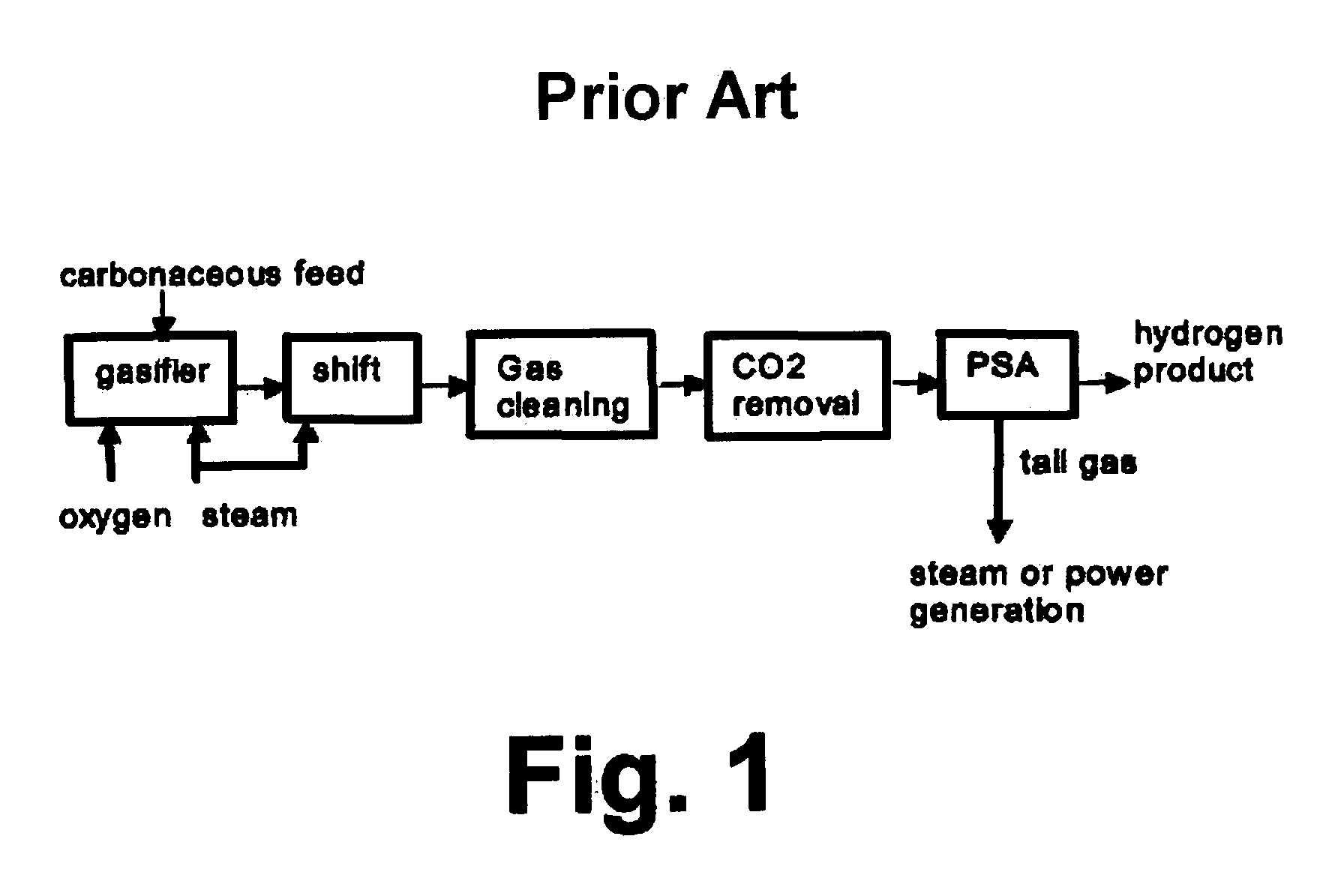

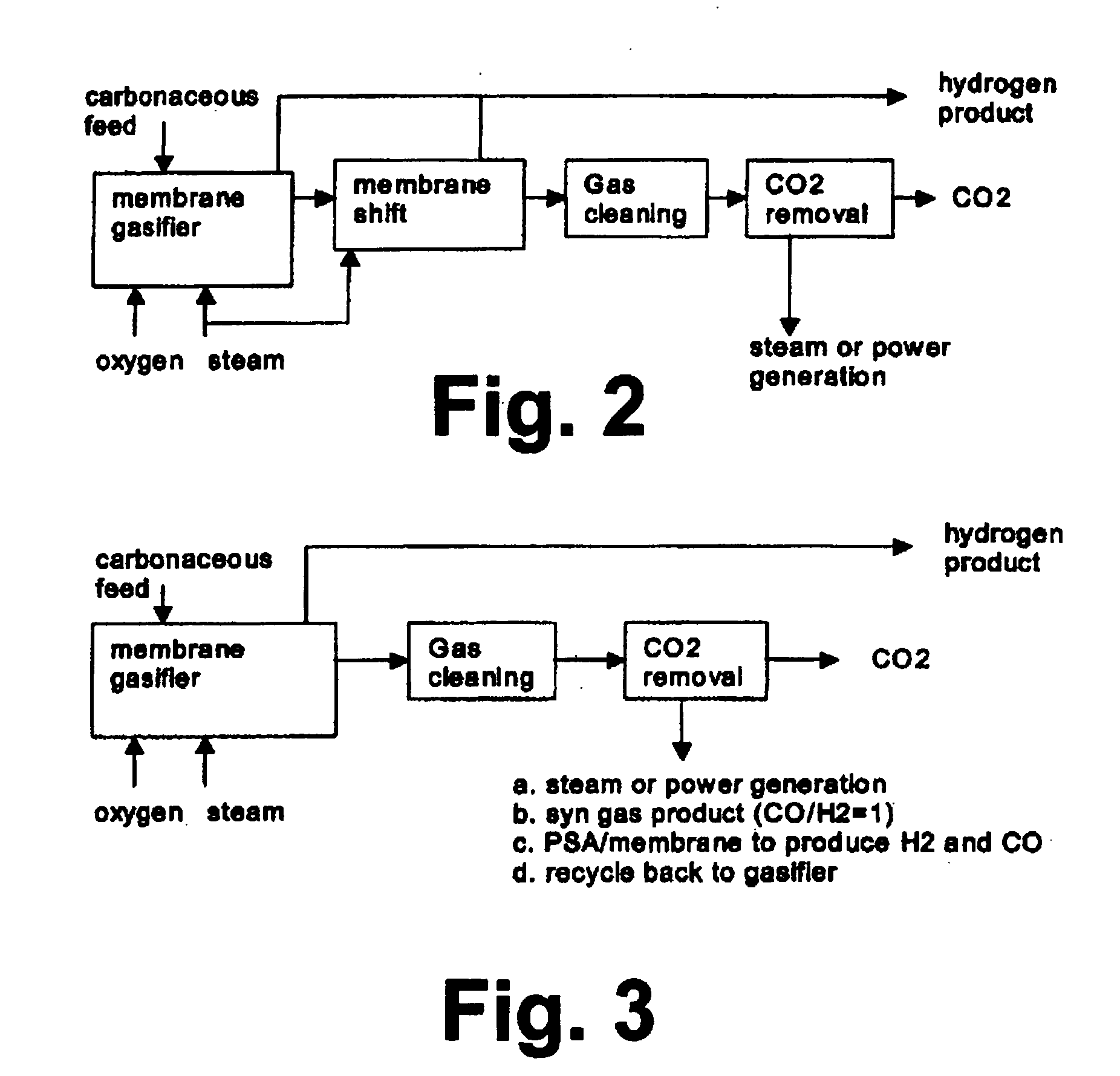

Hydrogen production process from carbonaceous materials using membrane gasifier

InactiveUS20050039400A1Improve thermal efficiencySmall sizeGasifier mechanical detailsHydrogen/synthetic gas productionPermeationThermal efficiency

A method and apparatus for producing hydrogen from carbonaceous materials using a hydrogen-selective permeation membrane incorporated into a carbonaceous material reactor, as a result of which, hydrogen production rate from the reactor is increased, downstream gas cleaning and purification units of conventional systems are eliminated or substantially reduced in size, and the thermal efficiency of producing hydrogen from carbon-containing materials is increased and its production cost is reduced.

Owner:GAS TECH INST

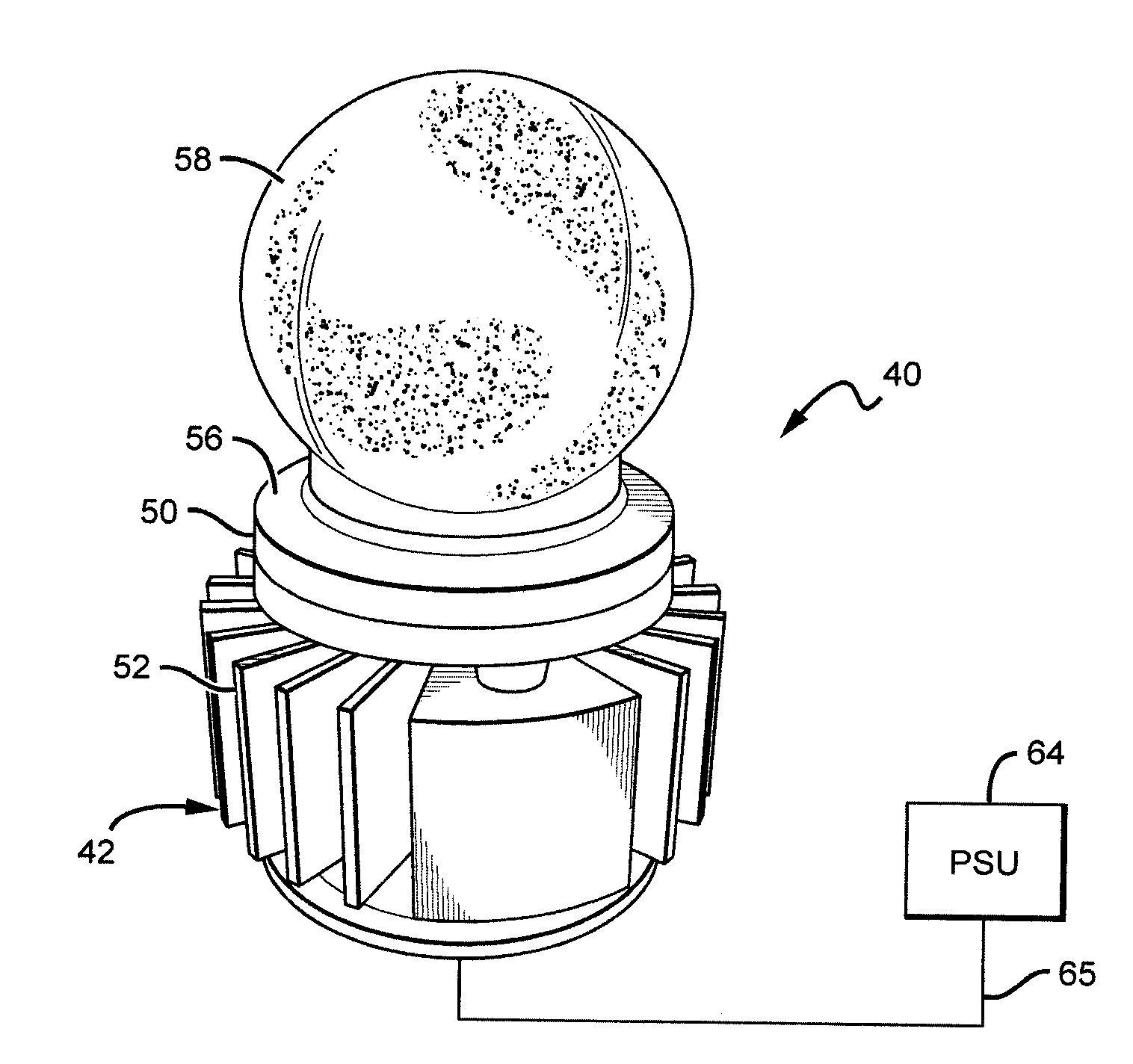

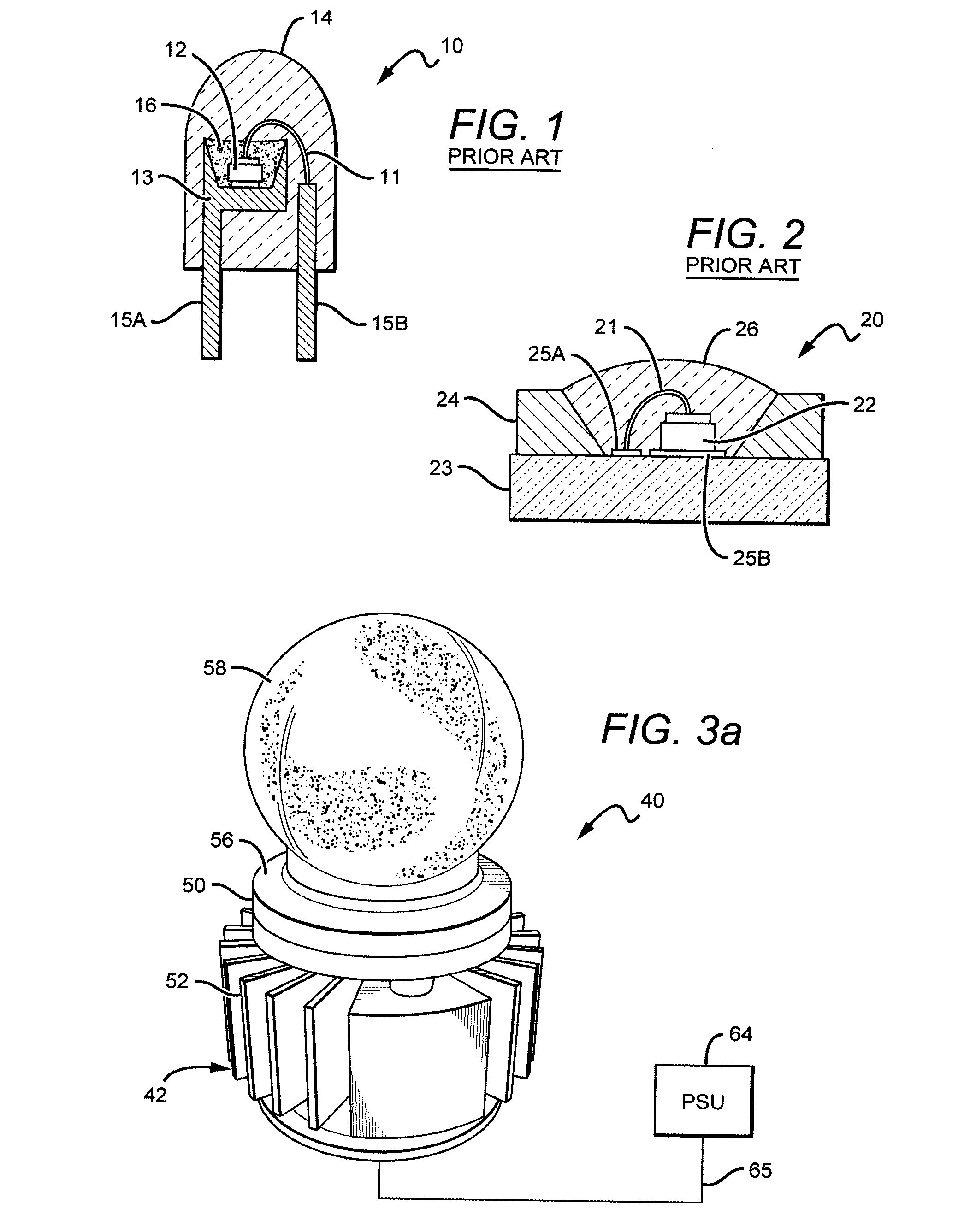

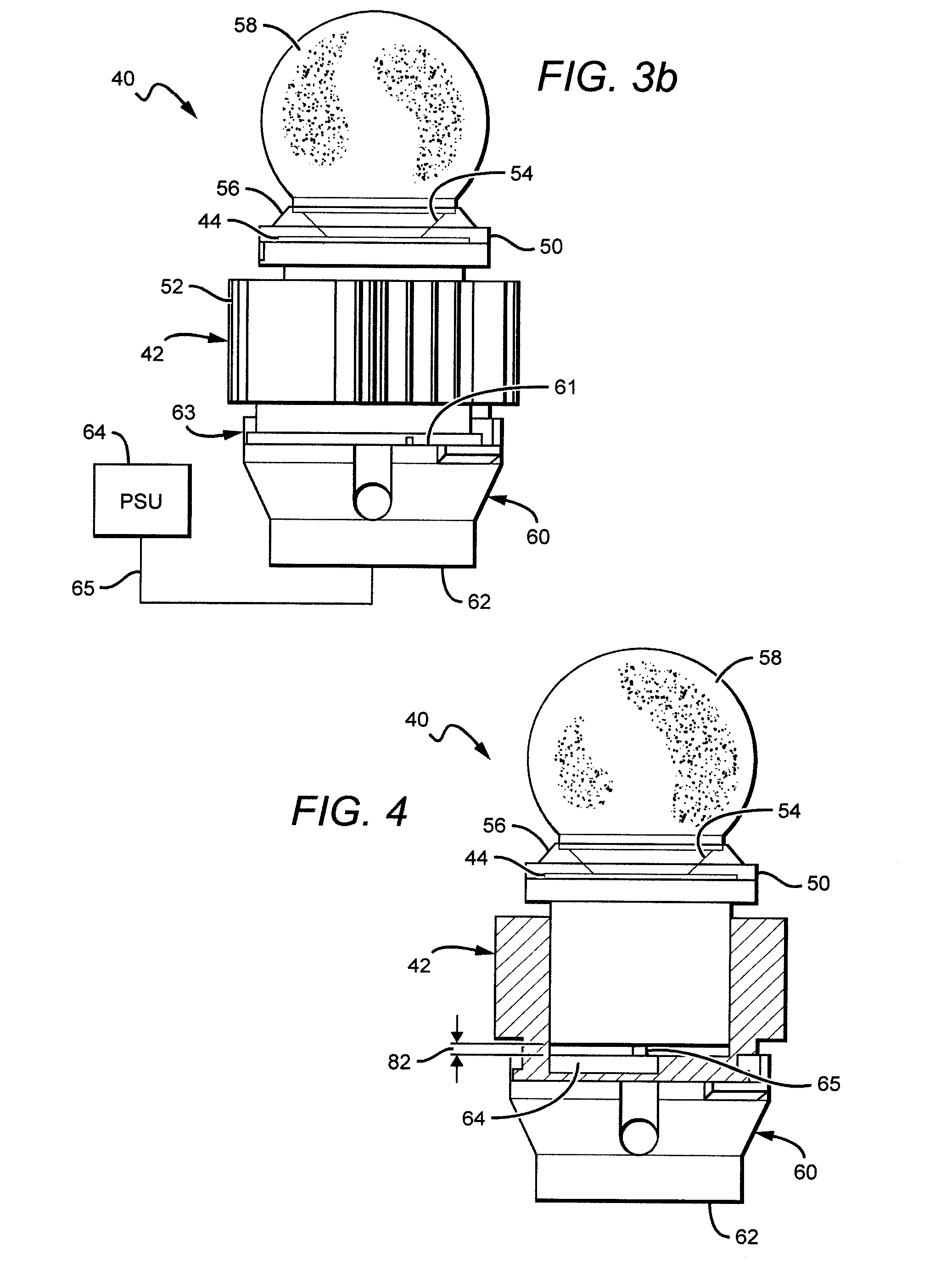

Compact high efficiency remote LED module

InactiveUS20130003346A1Small heat sinkFast heat conductionNon-electric lightingElectrical apparatusComputer moduleEngineering

Solid state modules and fixtures comprising different combinations and arrangements of a light source, one or more wavelength conversion materials, thermally conductive connection adapters allowing dissipation of heat outside of the module, and a remote power supply unit. This arrangement allows for greater thermal efficiency and reliability while employing solid state lighting and providing emission patterns that are equivalent with ENERGY STAR® standards. Some embodiments additionally place compensation circuits, previously included with power supply units, on the optical element itself, remote from the power supply unit. Various embodiments of the invention may be used to address many of the difficulties associated with utilizing efficient solid state light sources such as LEDs in the fabrication of lamps or bulbs suitable for direct replacement of traditional incandescent bulbs or fixtures using bulbs.

Owner:CREE INC

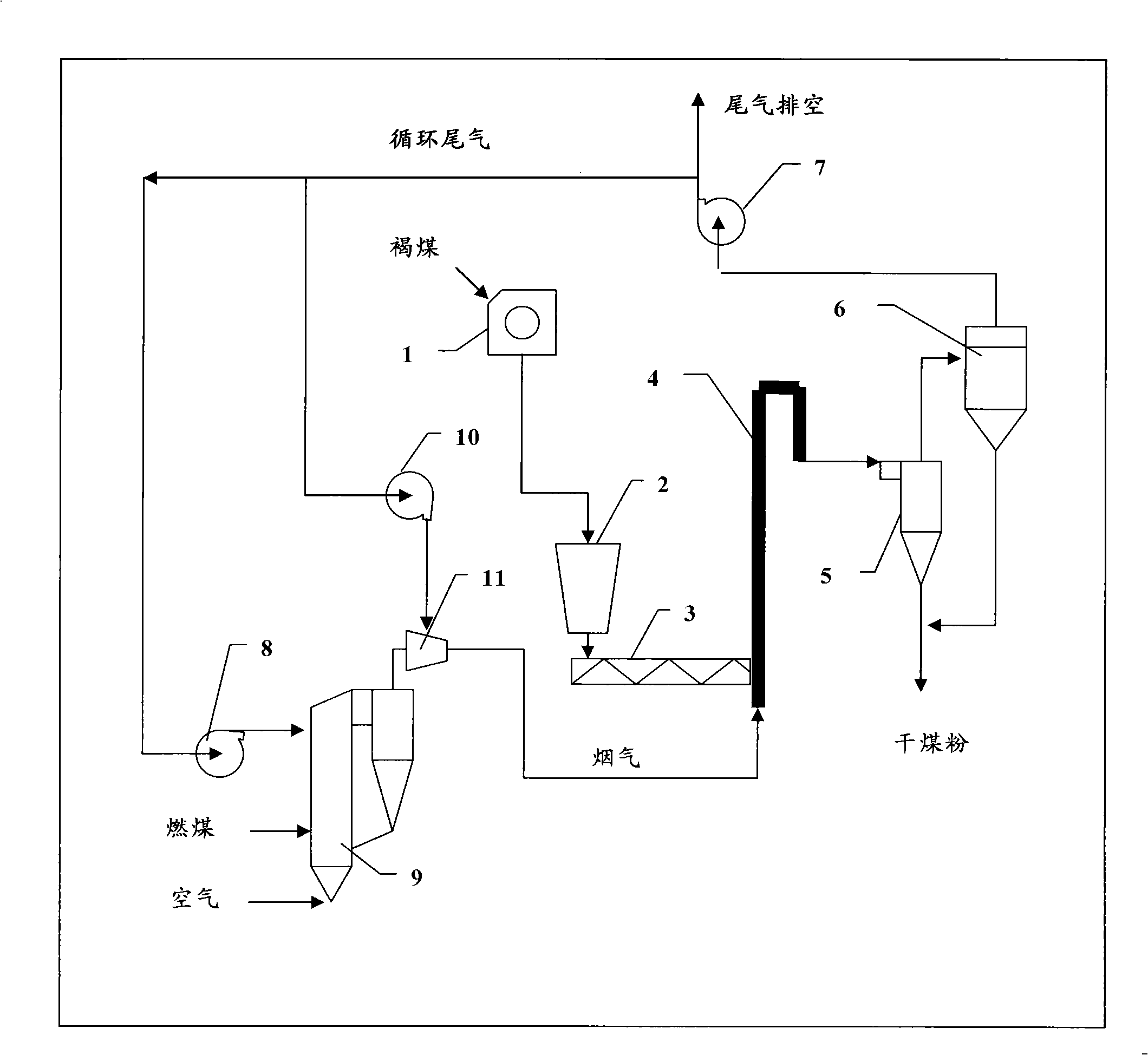

Low rank coal high temperature flue gas drying method and device

The invention relates to a method of high-temperature flue gas drying, which is particularly suitable for drying long flame coal, brown coal or other low rank coal. The coal-fired high-temperature flue gas is used to dry flammable and explosive coal types, such as brown coal in the direct contact method; therefore, the method has less gas exhaust, high thermal efficiency and high drying speed. The internal water content of the dried coal is obviously reduced, and the heating power of the dried coal is greatly increased. The invention also relates to the device using the method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

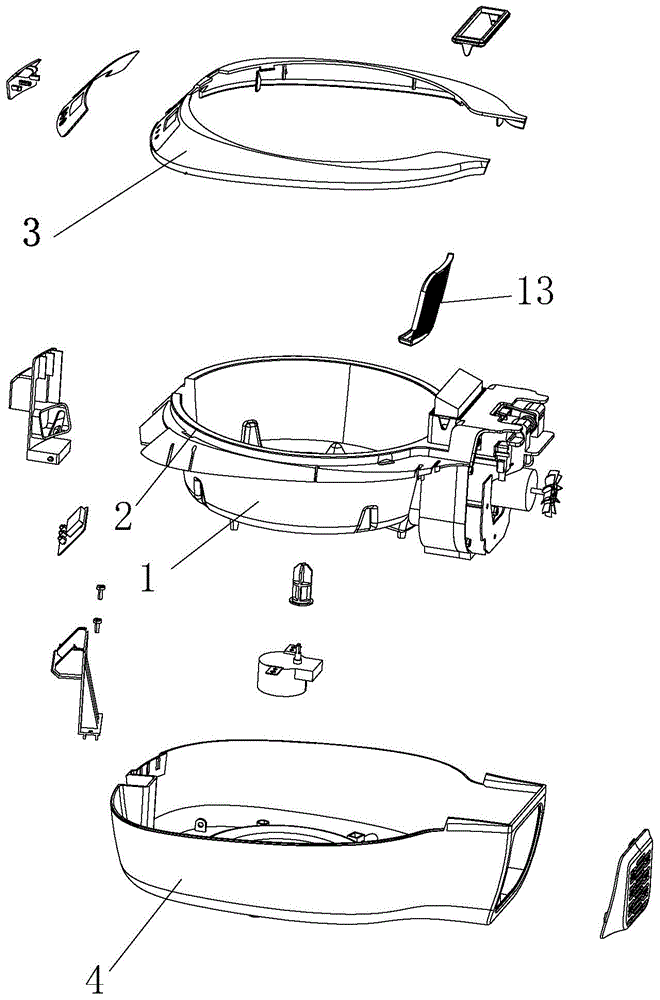

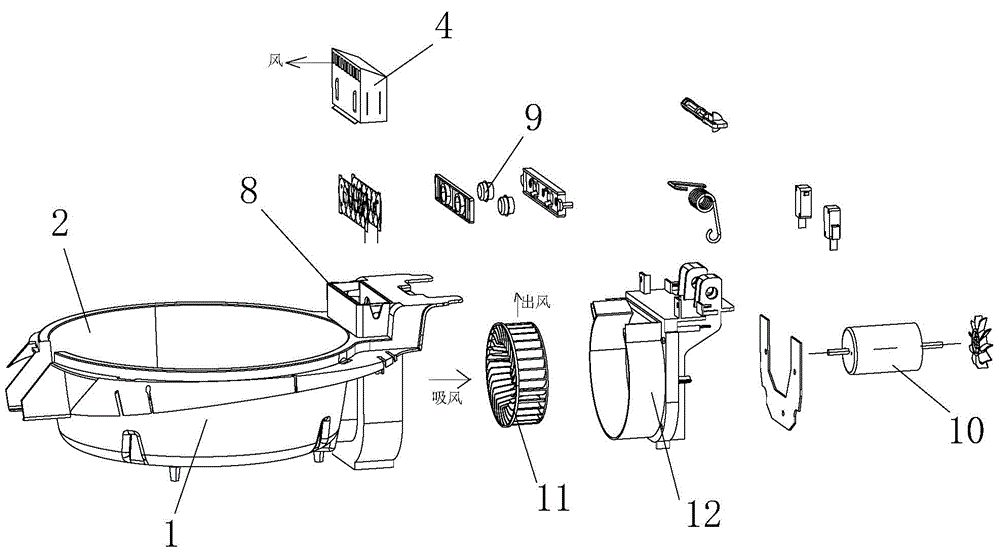

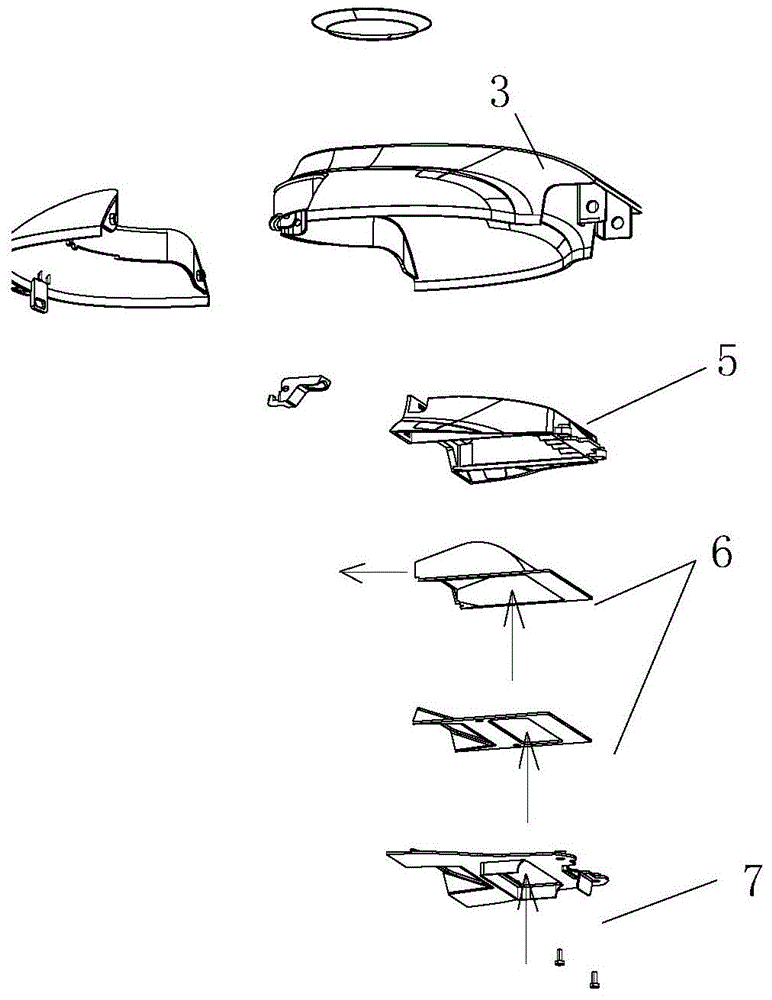

Air fryer

InactiveCN103908166AReduce power consumptionImprove thermal efficiencyRoasters/grillsHeating efficiencyThermal efficiency

Disclosed is an air fryer which comprises a fryer rack, a fryer body, a cover and a base. The fryer body is located in the fryer rack which is located in the base, and one end of the cover is hinged to the tail of the fryer rack while the other end of the cover is connected with the front of the fryer rack in an openable and closable manner. The air fryer further comprises a hot air circulation structure which comprises an axial flow fan, a wire heater and a hot air passage, the axial flow fan is mounted in the front of the fryer rack, an axial air suction opening of the axial flow fan is located in a hole between the fryer body and the fryer rack, a radial air outlet of the axial flow fan is communicated with an outlet at the bottom of the hot air passage which is disposed vertically and located in the cover, the outlet of the hot air passage is horizontal in direction and communicated with an inner cavity of the fryer body, and the wire heater is located in the hot air passage. The air fryer is capable of effectively lowering power consumption and high in heat efficiency.

Owner:ZHEJIANG WUYI WJL PLASTIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com