Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

322 results about "Equivalence ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

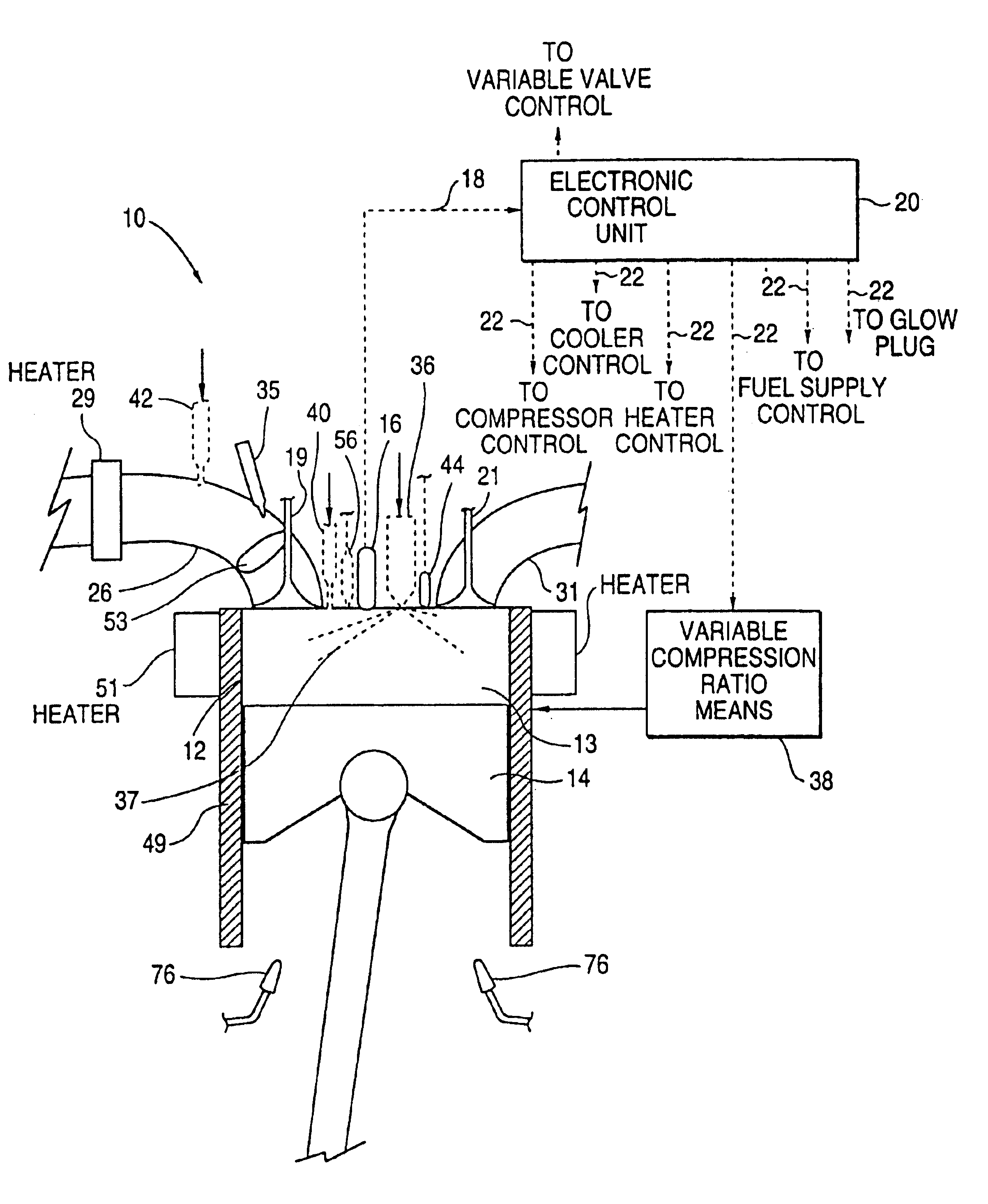

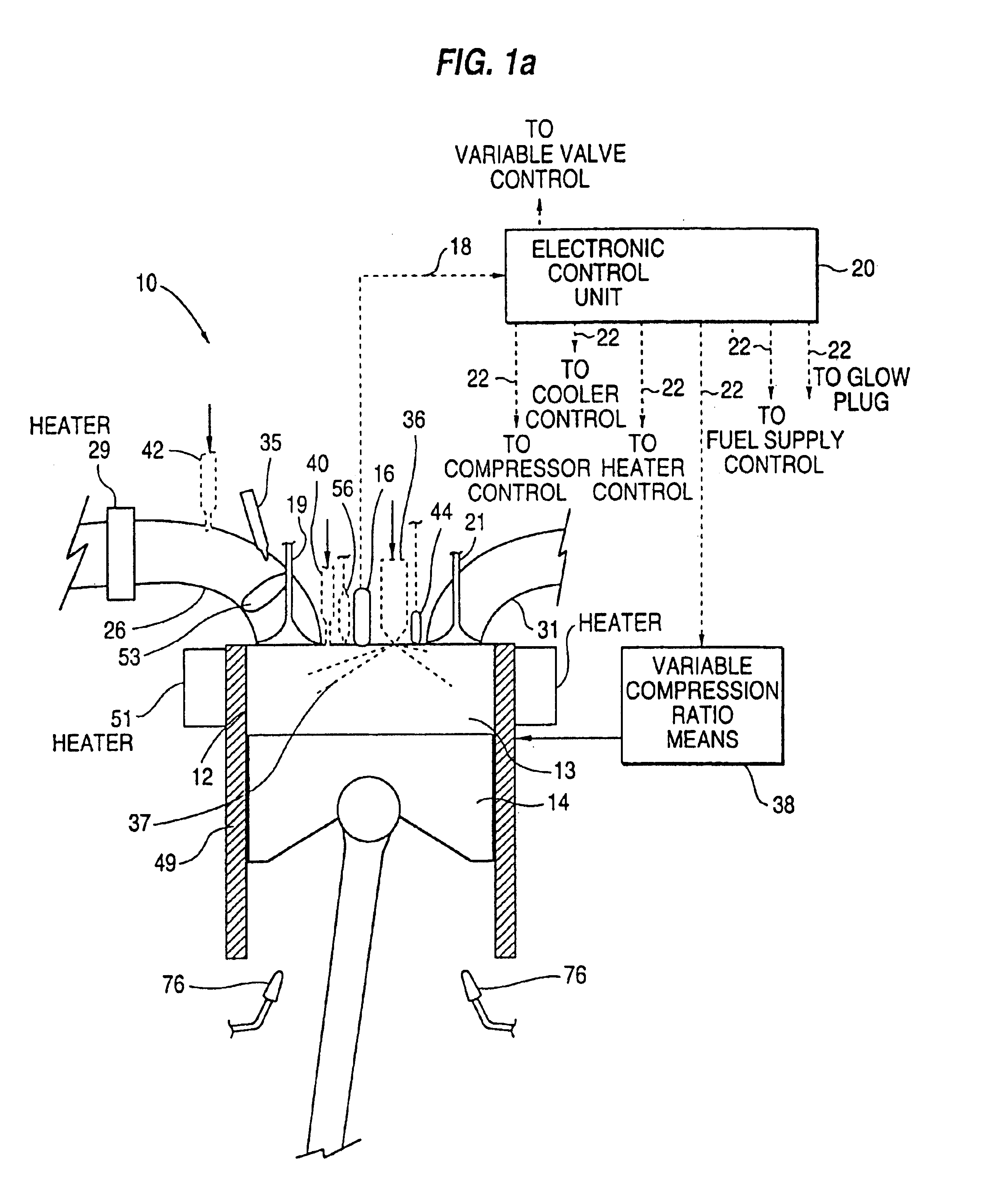

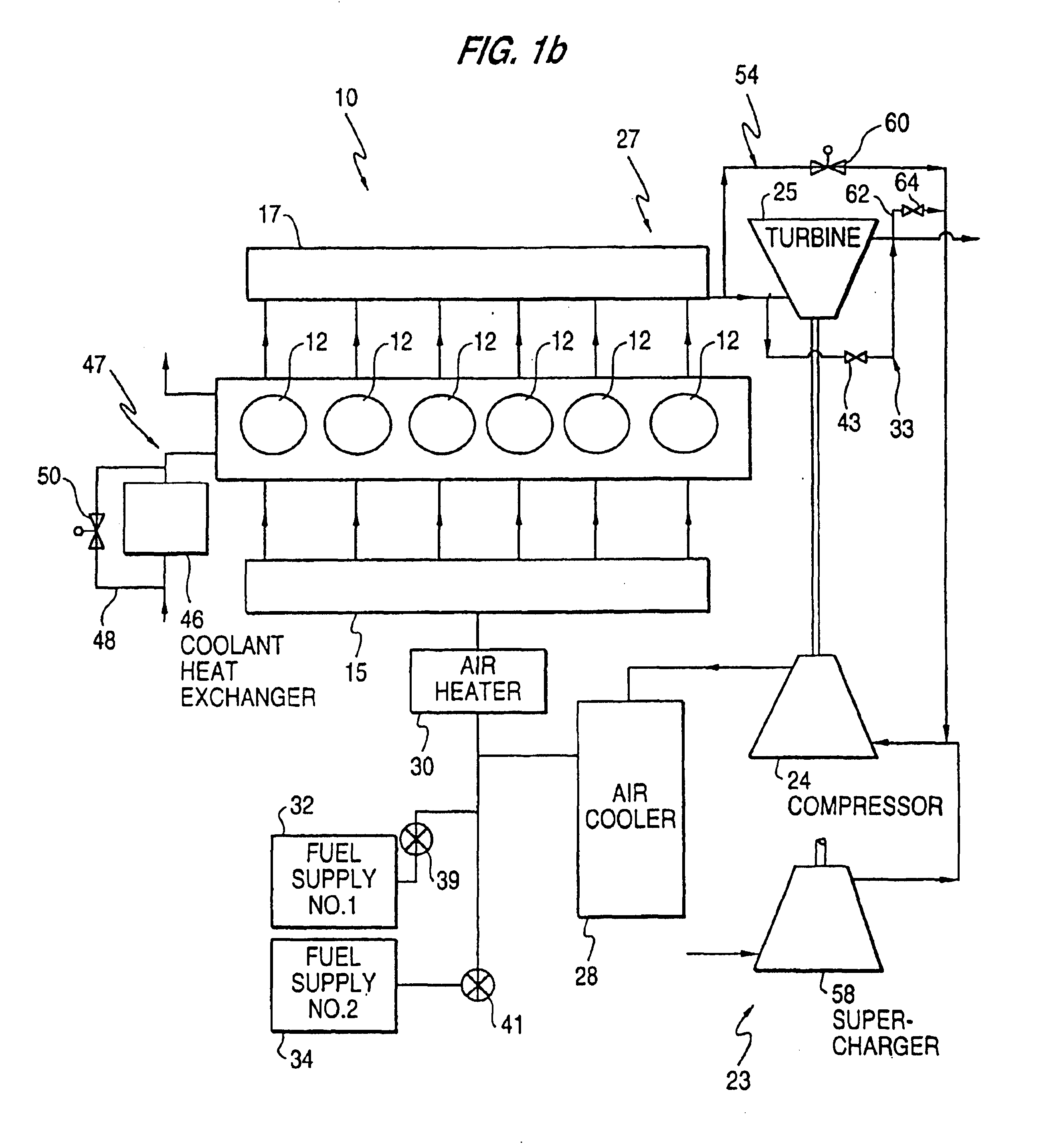

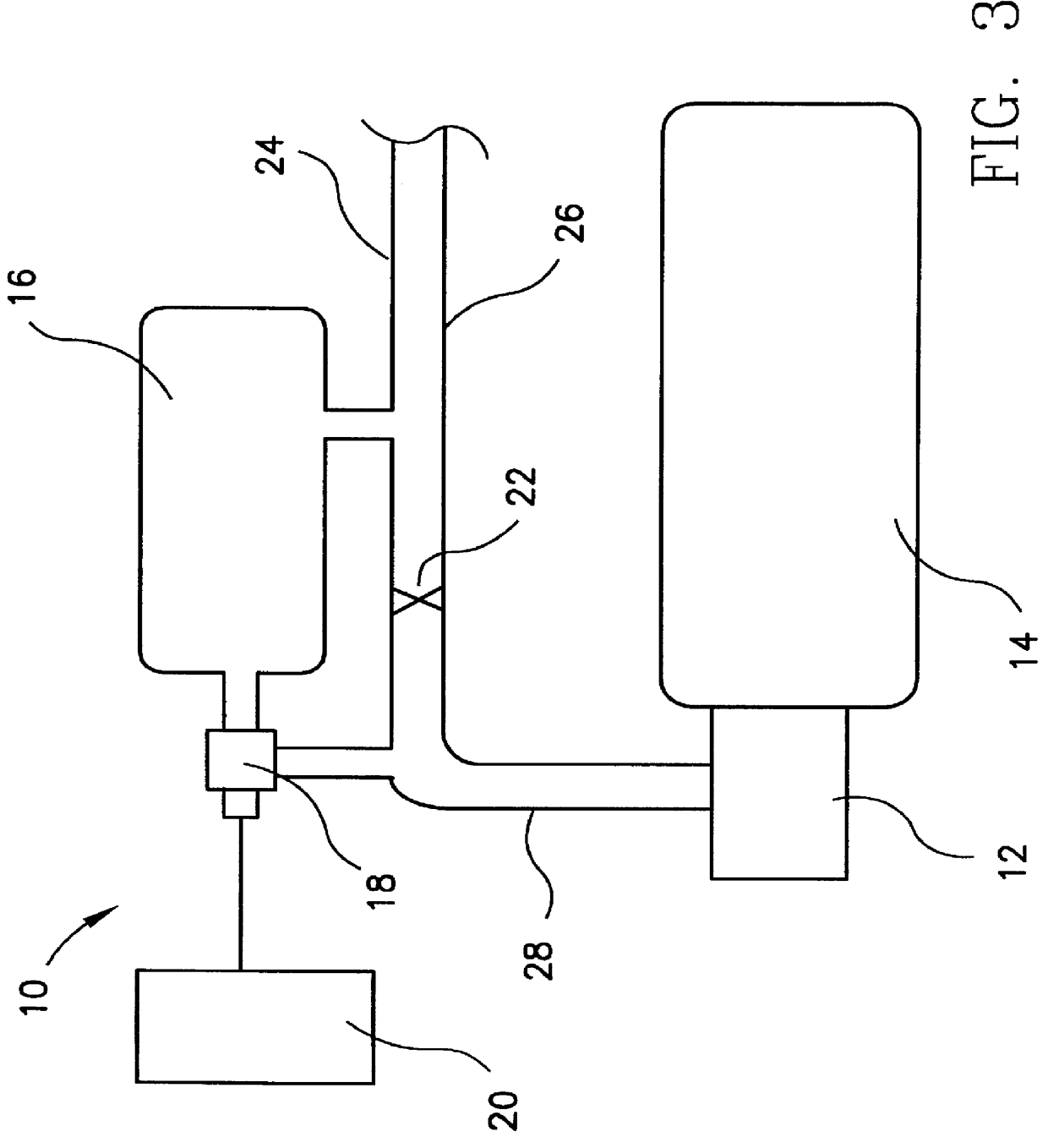

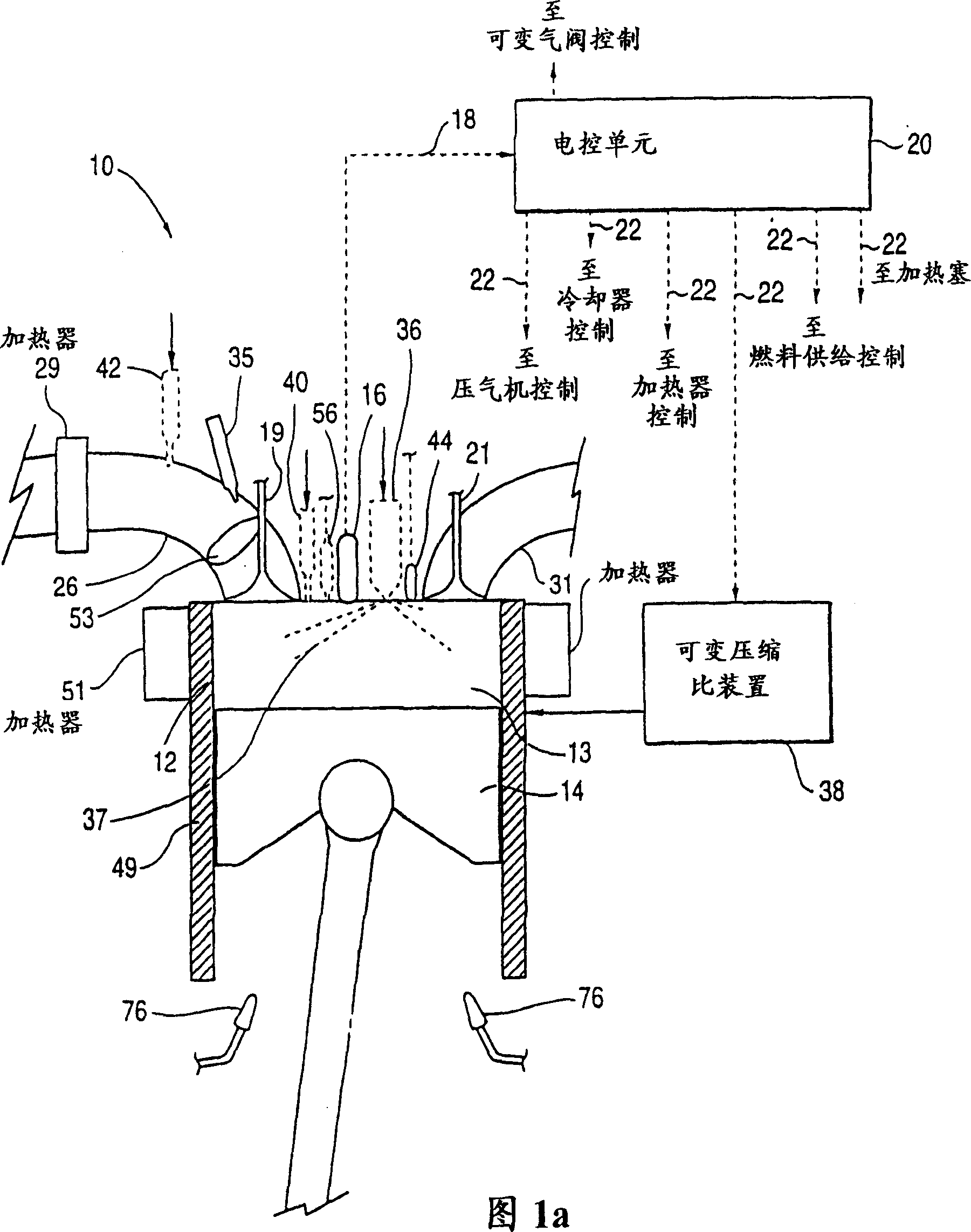

Premixed charge compression ignition engine with optimal combustion control

InactiveUS6915776B2Operate efficiently and effectivelyOvercome deficienciesElectrical controlNon-fuel substance addition to fuelCombustion noiseControl signal

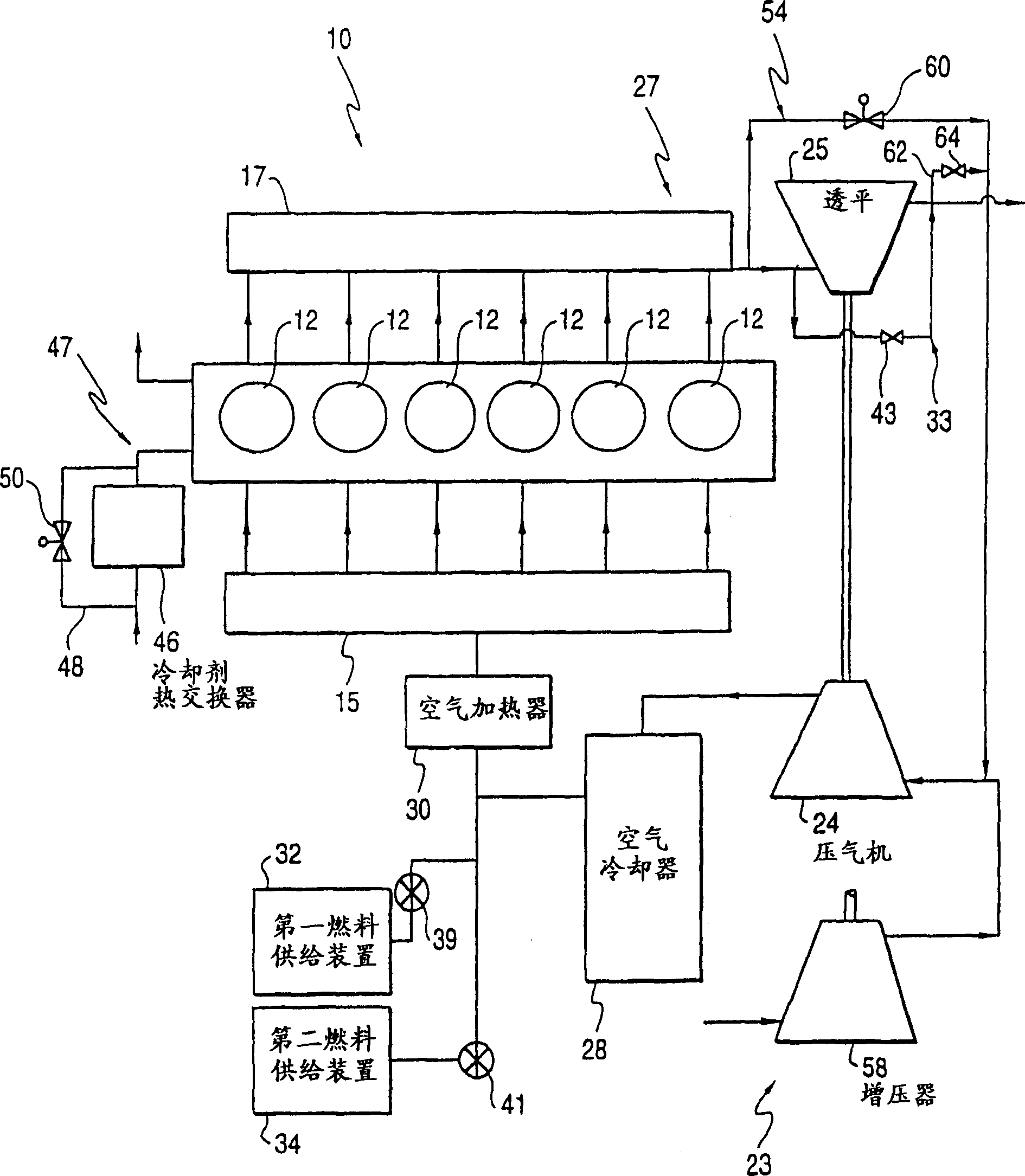

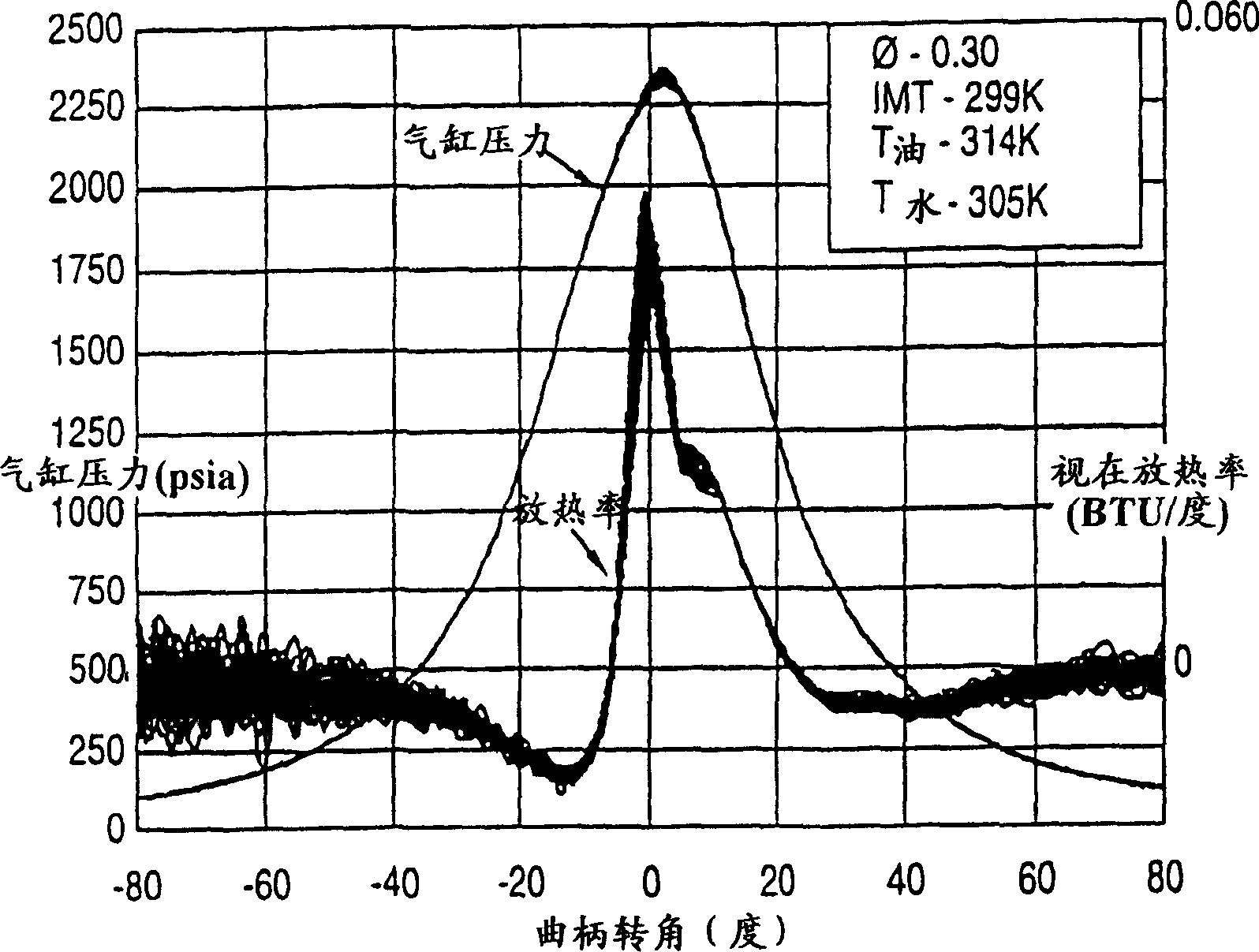

A premixed charge compression ignition engine, and a control system, is provided which effectively initiates combustion by compression ignition and maintains stable combustion while achieving extremely low nitrous oxide emissions, good overall efficiency and acceptable combustion noise and cylinder pressures. The present engine and control system effectively controls the combustion history, that is, the time at which combustion occurs, the rate of combustion, the duration of combustion and / or the completeness of combustion, by controlling the operation of certain control variables providing temperature control, pressure control, control of the mixture's autoignition properties and equivalence ratio control. The combustion control system provides active feedback control of the combustion event and includes a sensor, e.g. pressure sensor, for detecting an engine operating condition indicative of the combustion history, e.g. the start of combustion, and generating an associated engine operating condition signal. A processor receives the signal and generates control signals based on the engine operating condition signal for controlling various engine components to control the temperature, pressure, equivalence ratio and / or autoignition properties so as to variably control the combustion history of future combustion events to achieve stable, low emission combustion in each cylinder and combustion balancing between the cylinders.

Owner:CUMMINS INC

Oxidizing oxygen-fuel burner firing for reducing NOx emissions from high temperature furnaces

InactiveUS6171100B1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFurnace temperatureEquivalence ratio

Burner firing method and device are presented where an oxidizing oxygen-fuel burner is fired at an angle to the reducing air-fuel burner flame to reduce overall NOx emissions from high temperature furnaces. The oxidizing oxy-fuel burner stoichiometric equivalence ratio (oxygen / fuel) is maintained in the range of about 1.5 to about 12.5. The reducing air-fuel burner is fired at an equivalence ratio of 0.6 to 1.00 to reduce the availability of oxygen in the flame and reducing NOx emissions. The oxidizing flame from the oxy-fuel burner is oriented such that the oxidizing flame gas stream intersects the reducing air-fuel flame gas stream at or near the tail section of the air-fuel flame. The inventive methods improve furnace temperature control and thermal efficiency by eliminating some nitrogen and provide an effective burnout of CO and other hydrocarbons using the higher mixing ability of the oxidizing flame combustion products. The simultaneous air-fuel and oxy-fuel burner firing can reduce NOx emissions anywhere from 30% to 70% depending on the air-fuel burner stoichiometric ratio.

Owner:AIR LIQUIDE AMERICA INC +1

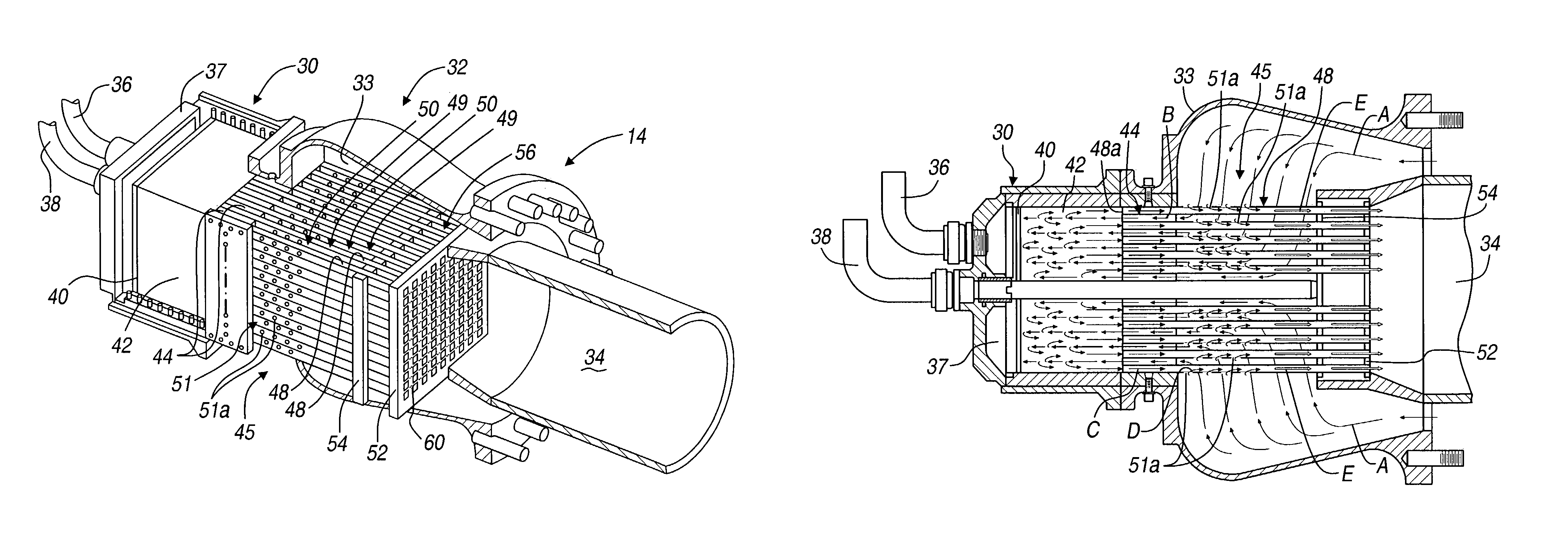

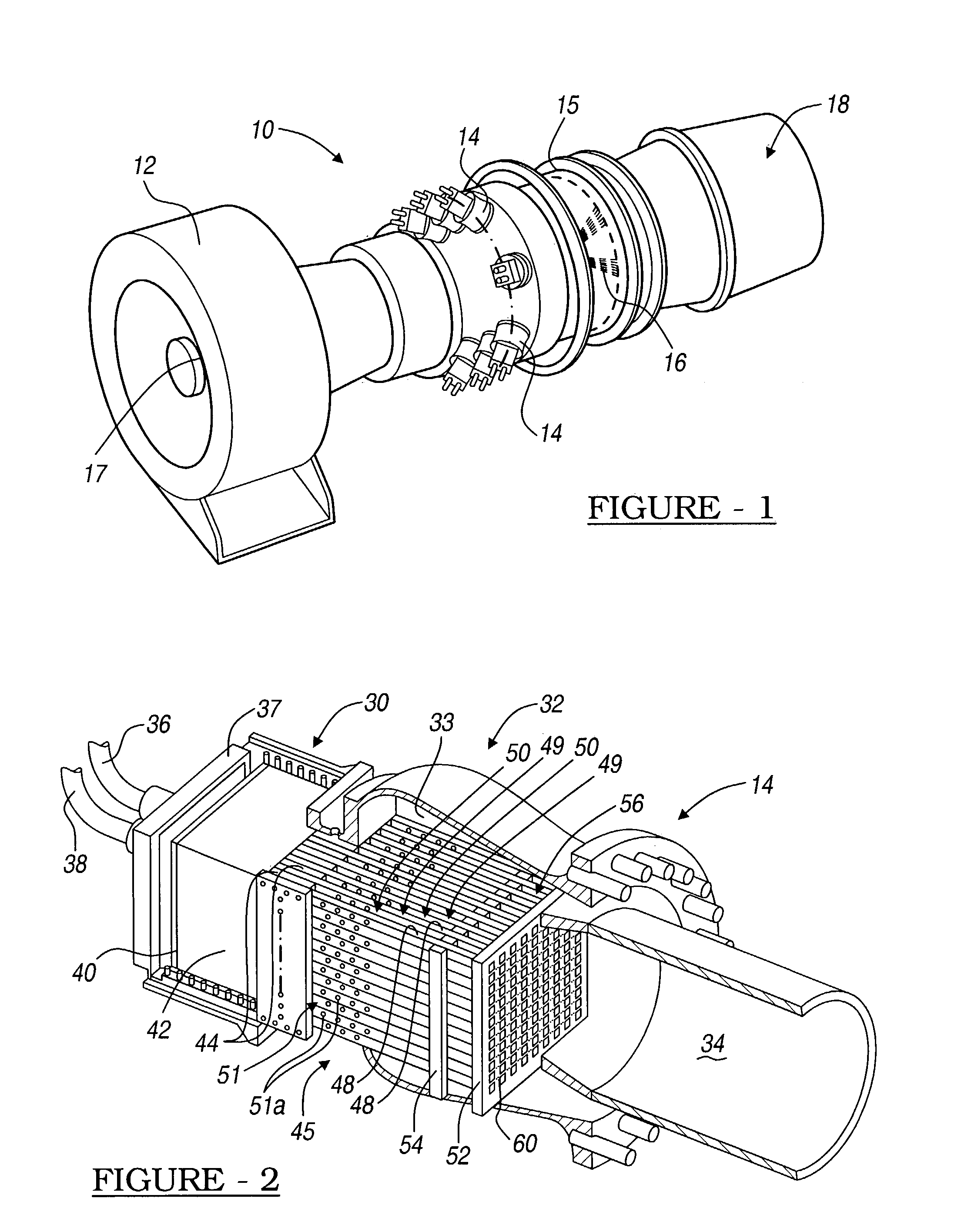

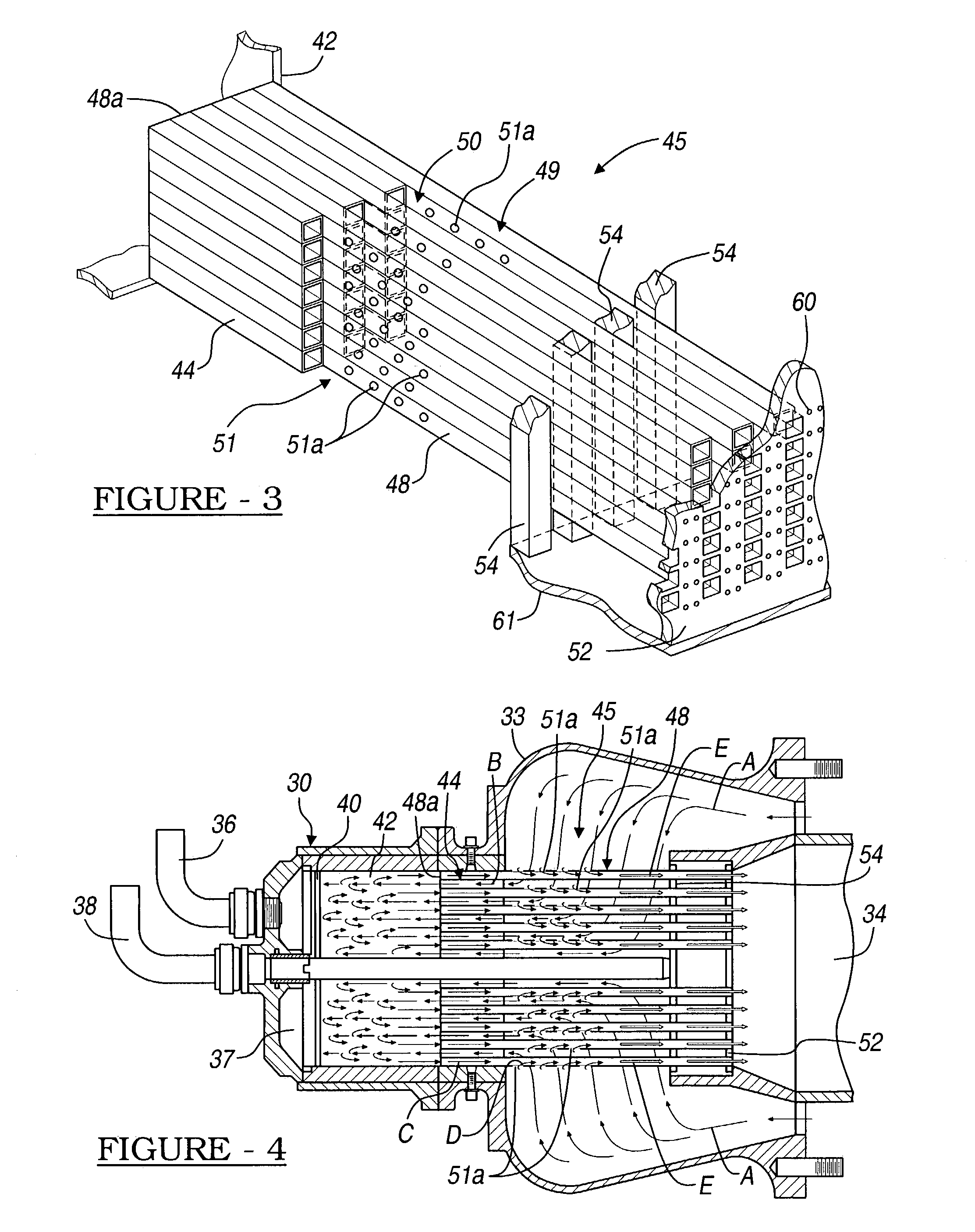

Apparatus and method for selecting a flow mixture

InactiveUS7007486B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCounter flowChemical species

A counter-flow system for use in a turbine for selecting various mixtures of fluids for use with the system. The system may be used for a combustor for a gas powered turbine which employs a heat exchanger to combust a fuel without the emission of undesired chemical species. A gas powered turbine requires expanding gases to power the turbine blades. Fuel is combusted to produce the required gases. An oxidizer is introduced into the counter-flow system in a first direction before a first portion of fuel is introduced into the oxidizer. The fuel and oxidizer mixture is then flowed through a second pathway wherein the fuel and oxidizer mixture obtains a selected amount of thermal energy. Moreover, in a second pathway an equivalence ratio of the fuel and oxidizer mixture may be altered from the original fuel and oxidizer mixture.

Owner:UNITED TECH CORP +1

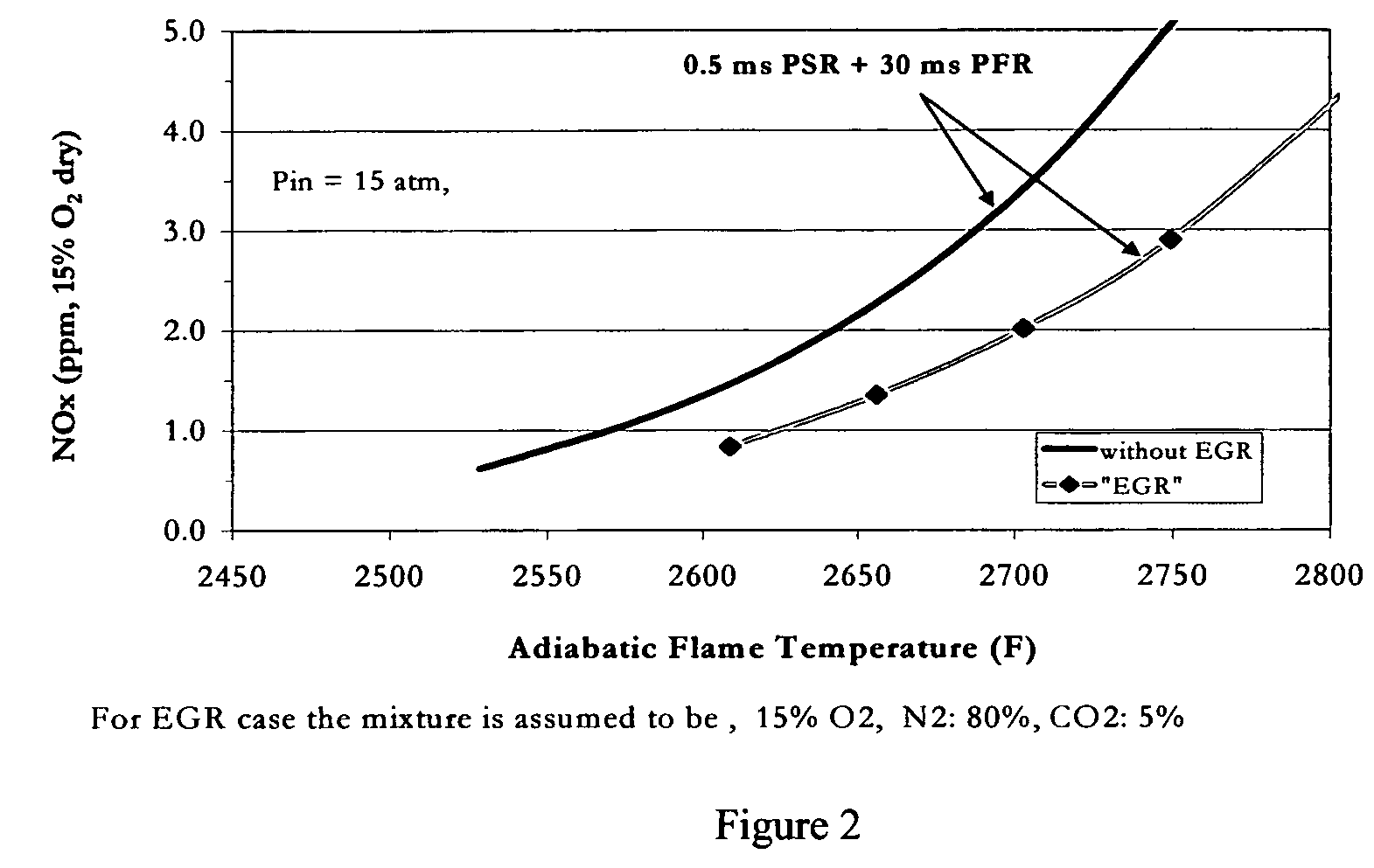

Method for obtaining ultra-low NOx emissions from gas turbines operating at high turbine inlet temperatures

ActiveUS7765810B2Improve combustion stabilityEasy to controlTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustion chamberEquivalence ratio

A method of lowered NOx combustion is taught wherein the kinetic rate of NOx formation is reduced for a given combustion temperature in a gas turbine combustor. A supply of fuel is provided along with a supply of ambient air in sufficient quantity to form a fuel / air mixture having an equivalence ratio greater than about 0.55 when mixed with the fuel. The fuel / air mixture is mixed with a supply of cooled combustion gases in sufficient quantity such that the oxygen content of the resulting air mixture is less than about 18 percent. The resulting air mixture is then passed into the combustor.

Owner:PRECISION COMBUSTION

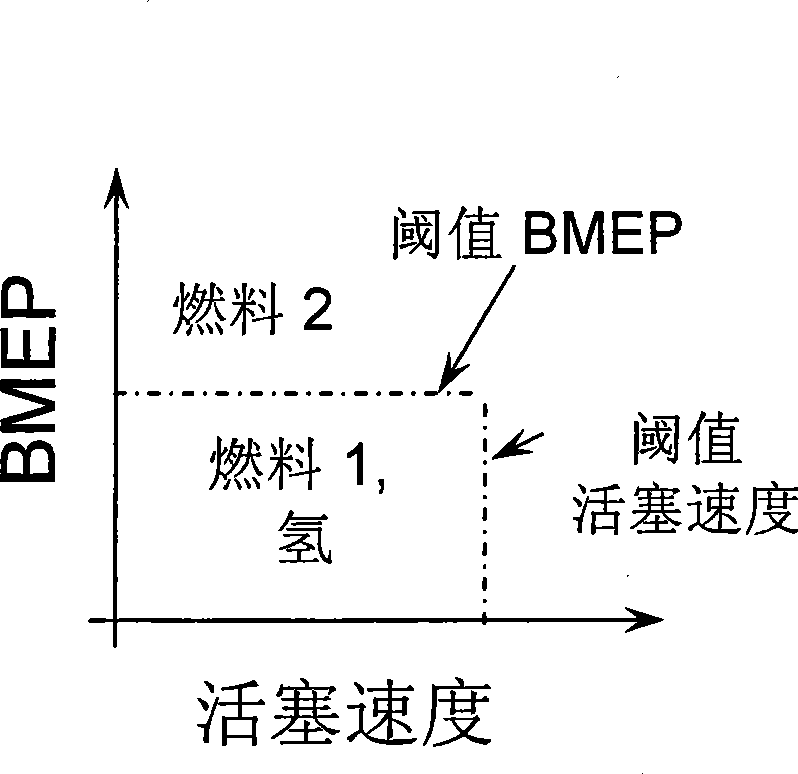

Bi-fuel Engine Using Hydrogen

InactiveUS20090071453A1Internal combustion piston enginesGaseous engine fuelsCombustion chamberEquivalence ratio

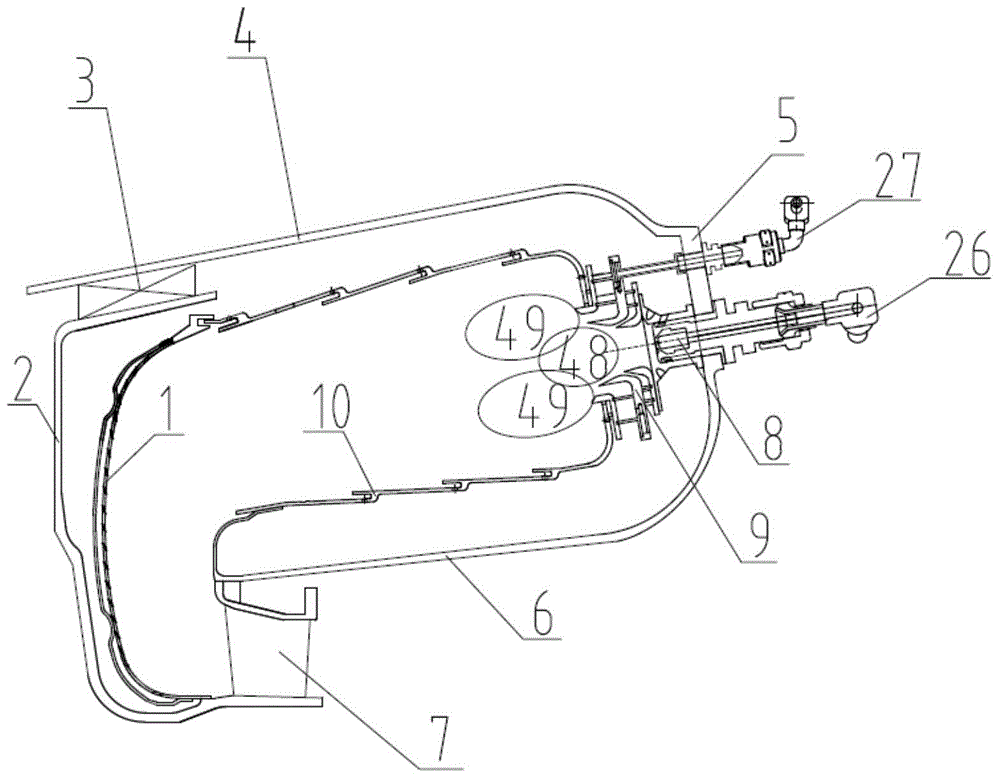

A method is disclosed for making a transition from fueling an engine with hydrogen to another fuel. That other fuel may be gasoline, a gasoline and alcohol mixture, or gaseous fuels, as examples. The other fuel has the capability of providing higher BMEP than the hydrogen because of better air utilization and because the other fuel occupies less volume of the combustion chamber. Because a desirable equivalence ratio to burn hydrogen is at 0.5 or less and a desirable equivalence ratio to burn other fuel is at 1.0, when a demand for BMEP that leads to a transition change from hydrogen fuel to the other fuel, the amount of air supplied to the engine is decreased to provide more torque and vice versa. During a transition in which liquid fuel supply is initiated, it may desirable to continue to provide some hydrogen, not leaner than 0.1 hydrogen equivalence ratio.

Owner:FORD GLOBAL TECH LLC

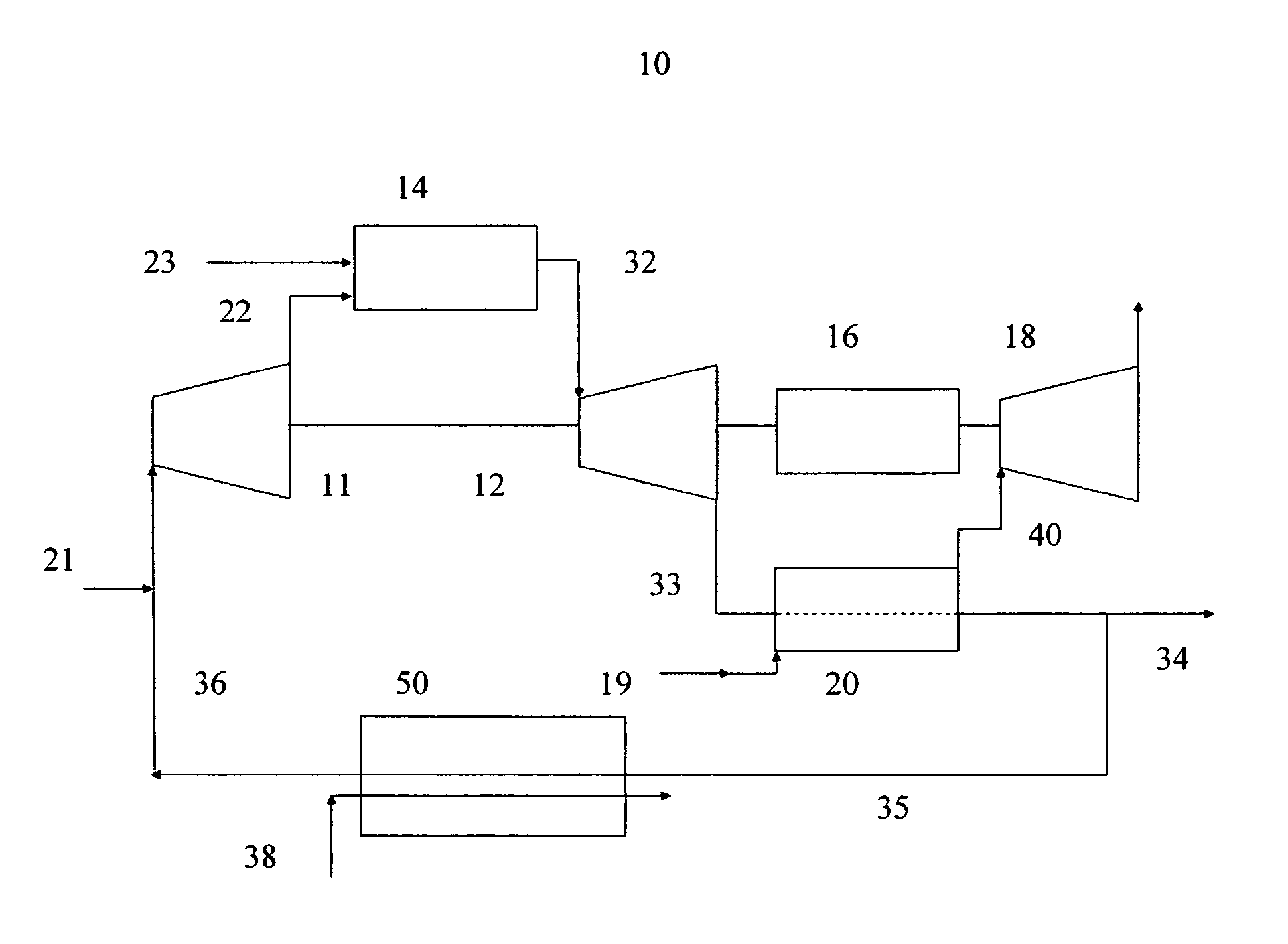

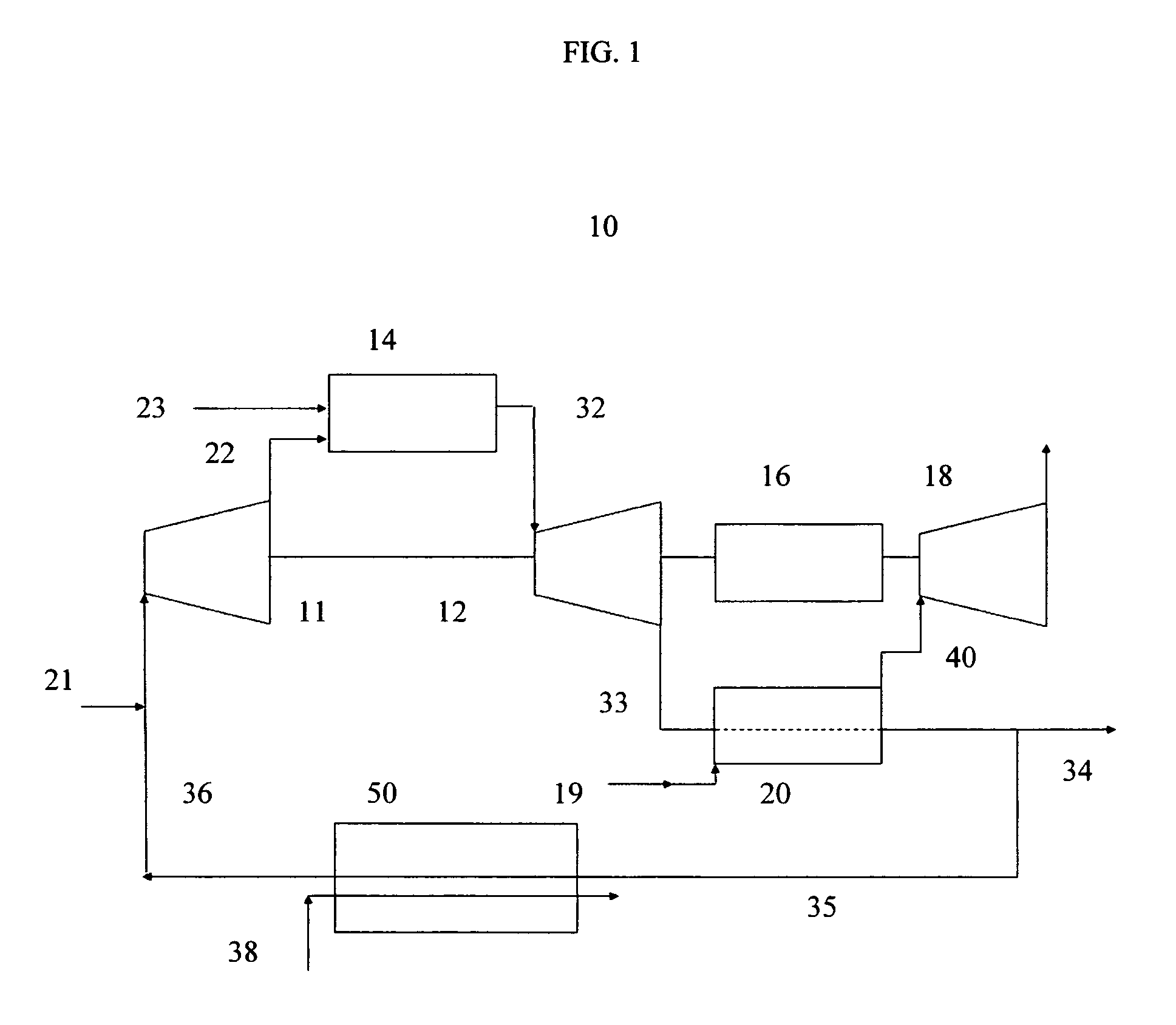

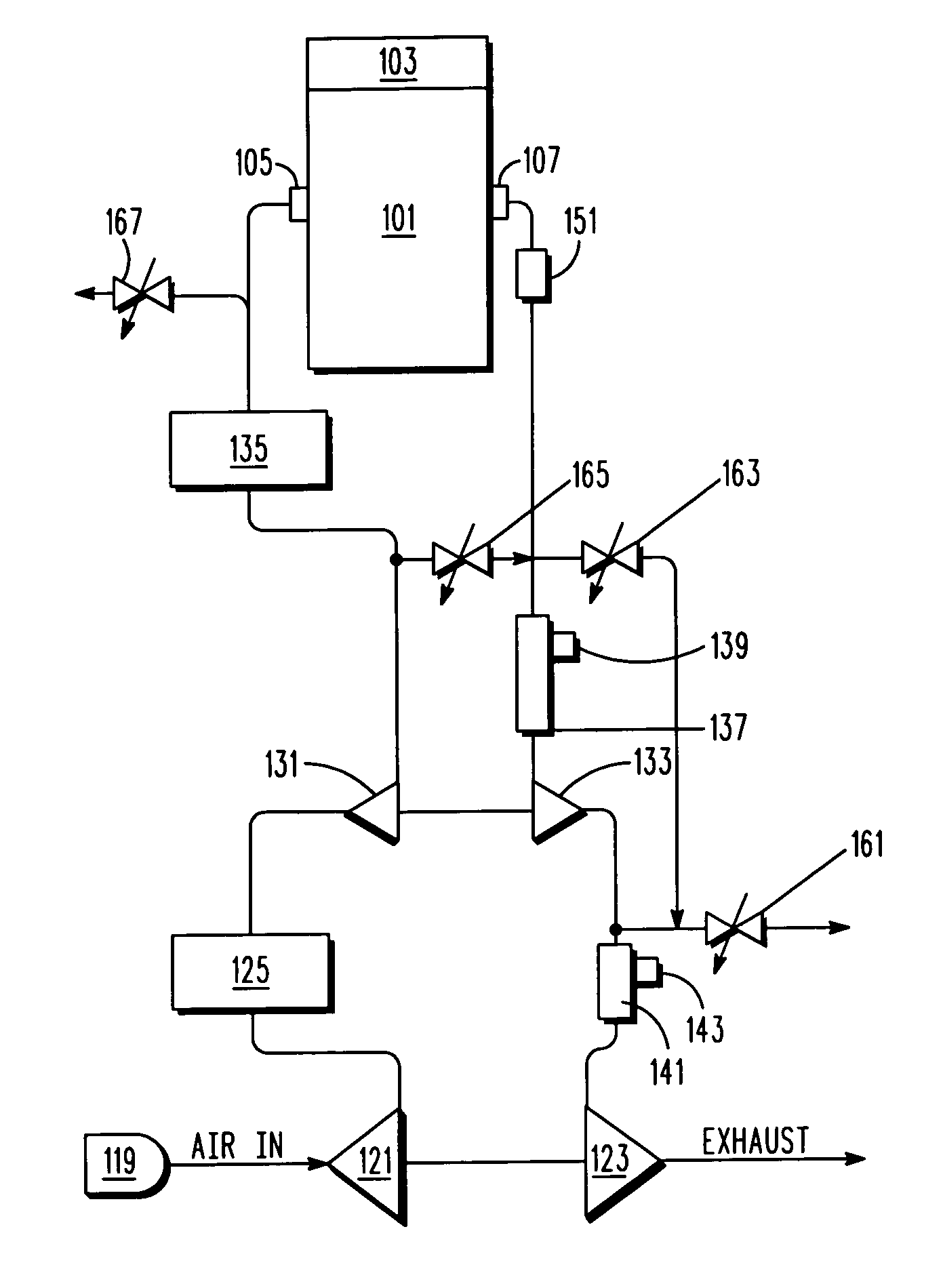

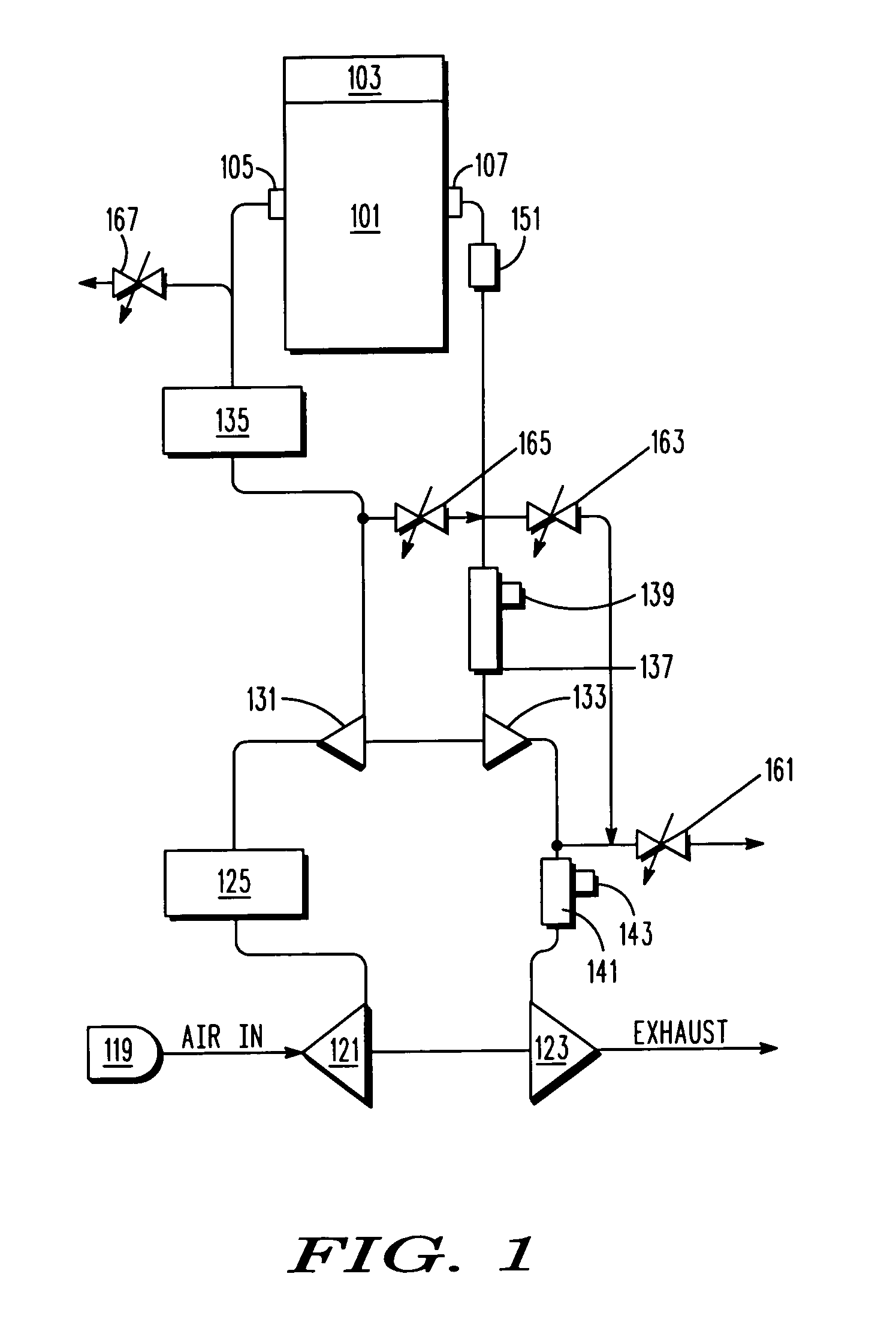

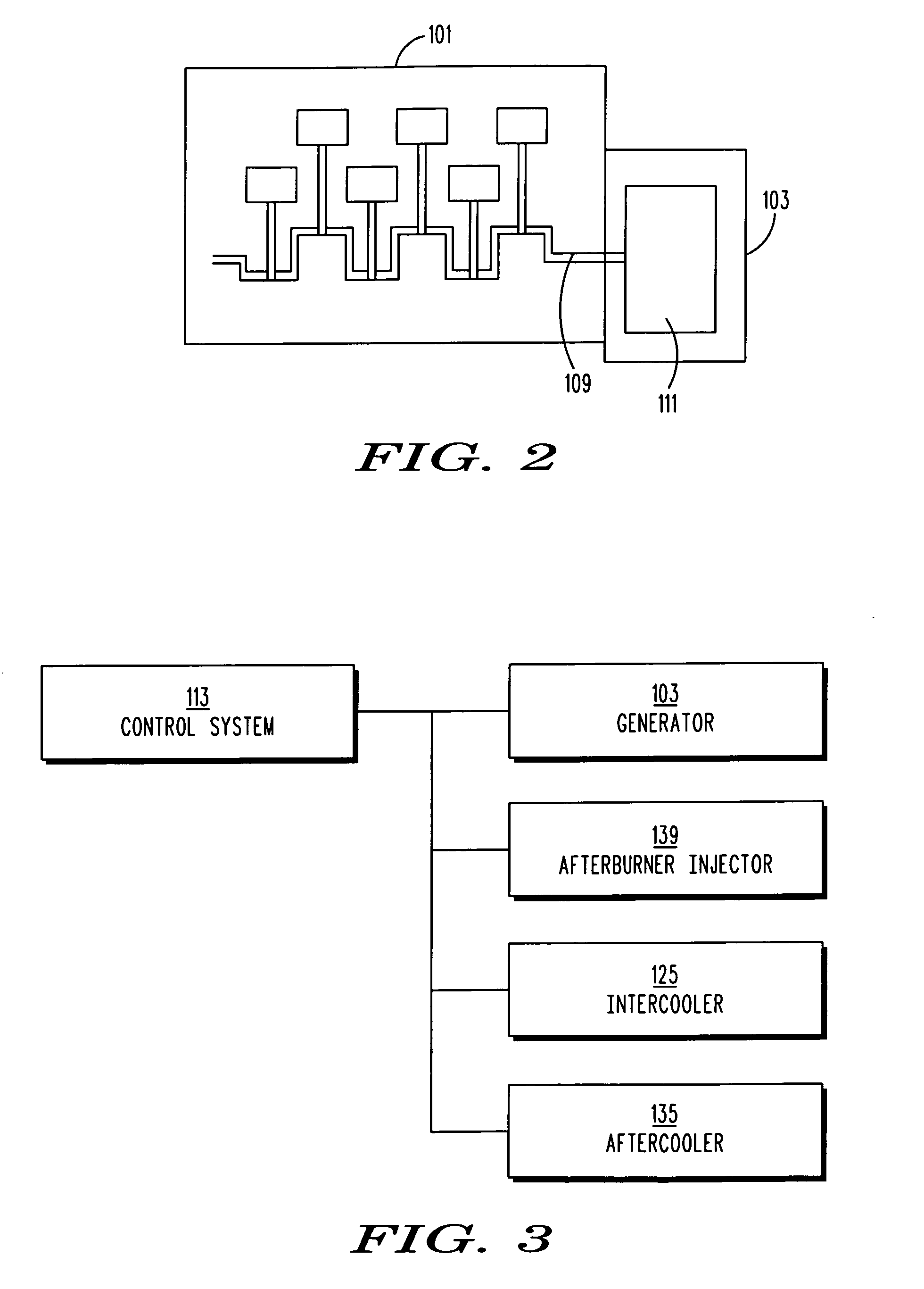

Powerplant and related control system and method

ActiveUS20100100300A1Efficient powerImprove reliabilityInternal combustion piston enginesDigital data processing detailsEquivalence ratioControl system

A hydrogen fueled powerplant including an internal combustion engine that drives a motor-generator, and has a two-stage turbocharger, for an aircraft. A control system controls the operation of the motor-generator to maintain the engine at a speed selected based on controlling the engine equivalence ratio. The control system controls an afterburner, an intercooler and an aftercooler to maximize powerplant efficiency. The afterburner also adds power to the turbochargers during high-altitude restarts. The turbochargers also include motor-generators that extract excess power from the exhaust.

Owner:AEROVIRONMENT INC

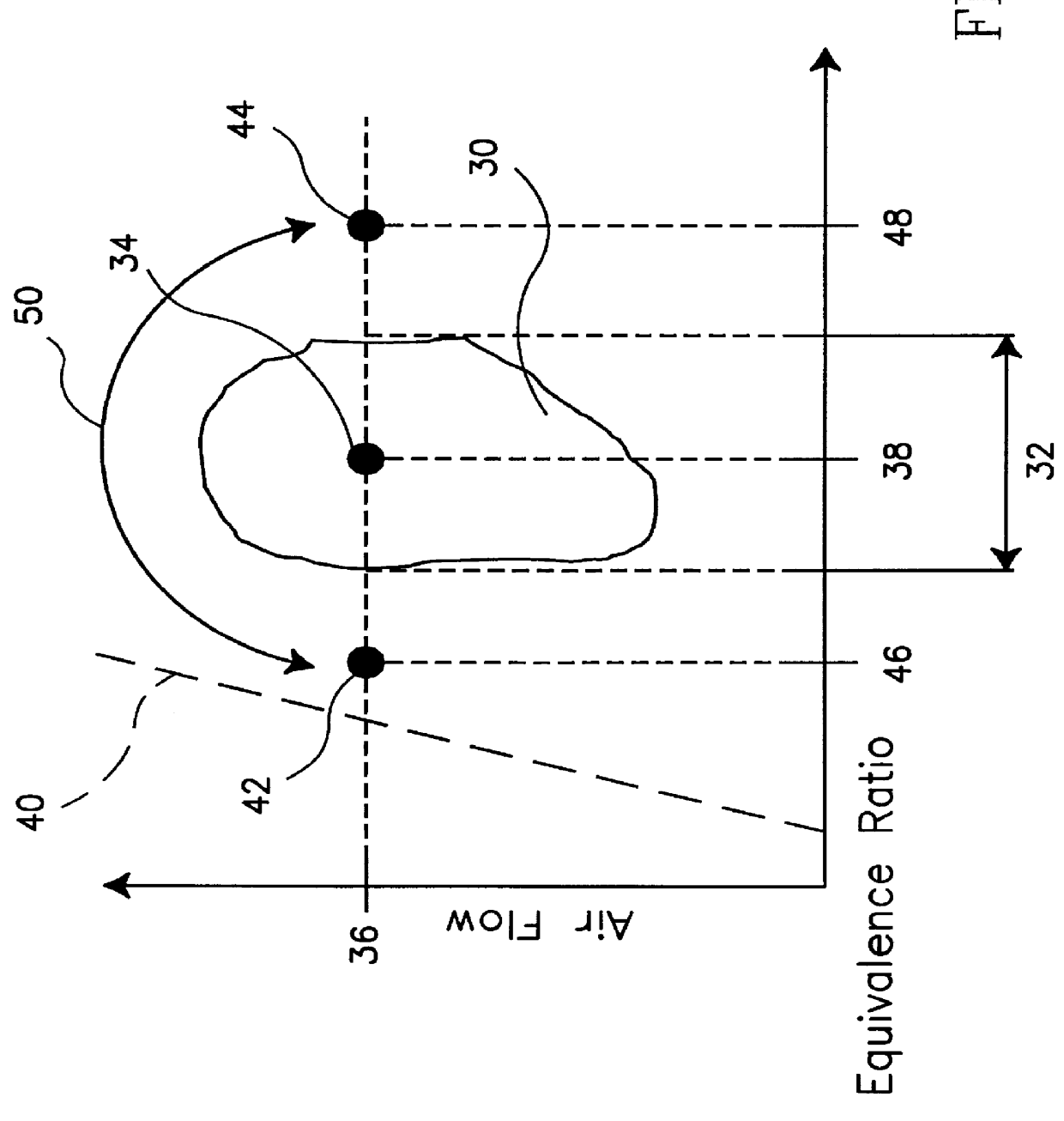

Engine combustion control via fuel reactivity stratification

ActiveUS20110192367A1High and low reactivityConvenience to workElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

A compression ignition engine uses two or more fuel charges having two or more reactivities to control the timing and duration of combustion. In a preferred implementation, a lower-reactivity fuel charge is injected or otherwise introduced into the combustion chamber, preferably sufficiently early that it becomes at least substantially homogeneously dispersed within the chamber before a subsequent injection is made. One or more subsequent injections of higher-reactivity fuel charges are then made, and these preferably distribute the higher-reactivity matter within the lower-reactivity chamber space such that combustion begins in the higher-reactivity regions, and with the lower-reactivity regions following thereafter. By appropriately choosing the reactivities of the charges, their relative amounts, and their timing, combustion can be tailored to achieve optimal power output (and thus fuel efficiency), at controlled temperatures (and thus controlled NOx), and with controlled equivalence ratios (and thus controlled soot).

Owner:WISCONSIN ALUMNI RES FOUND

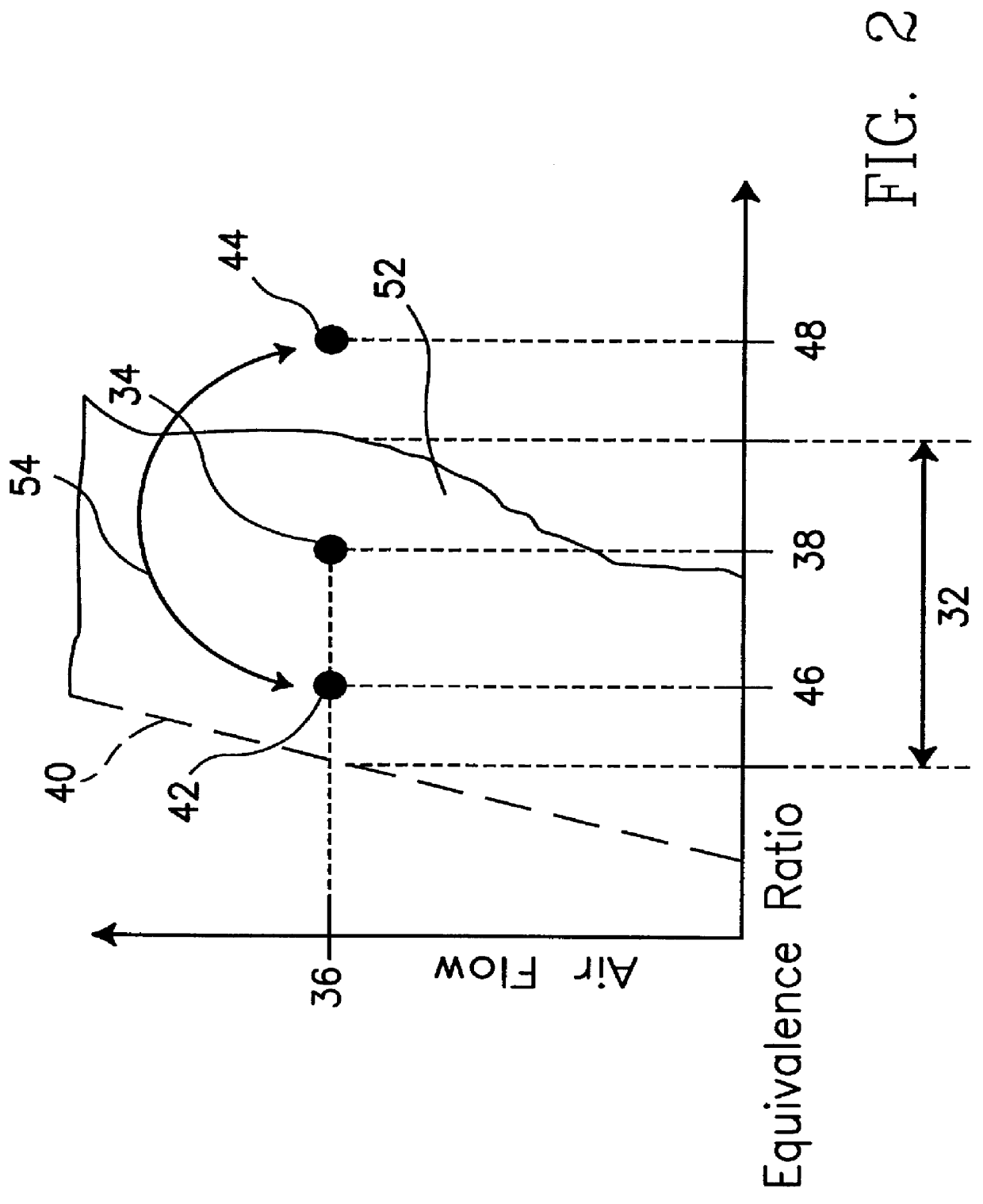

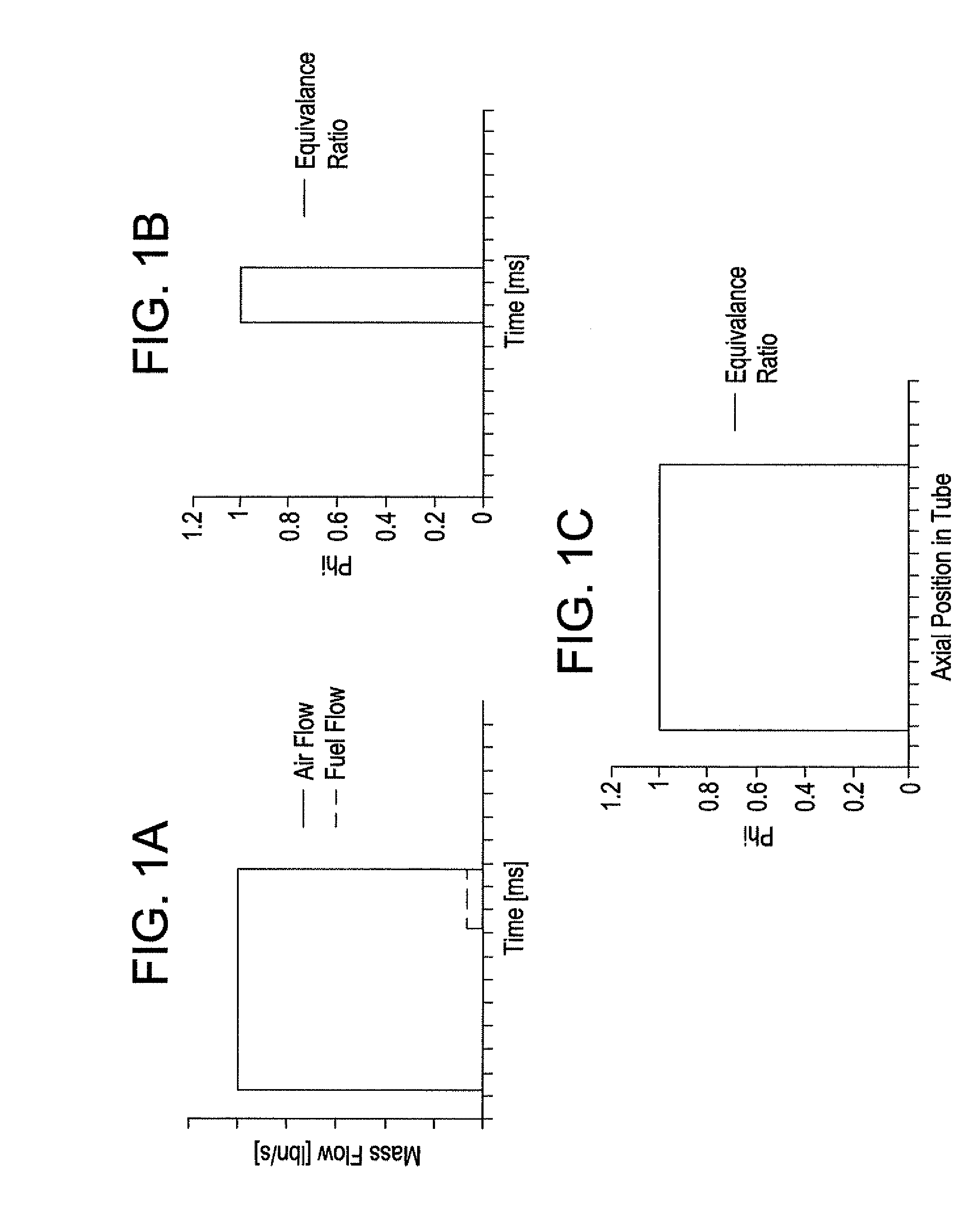

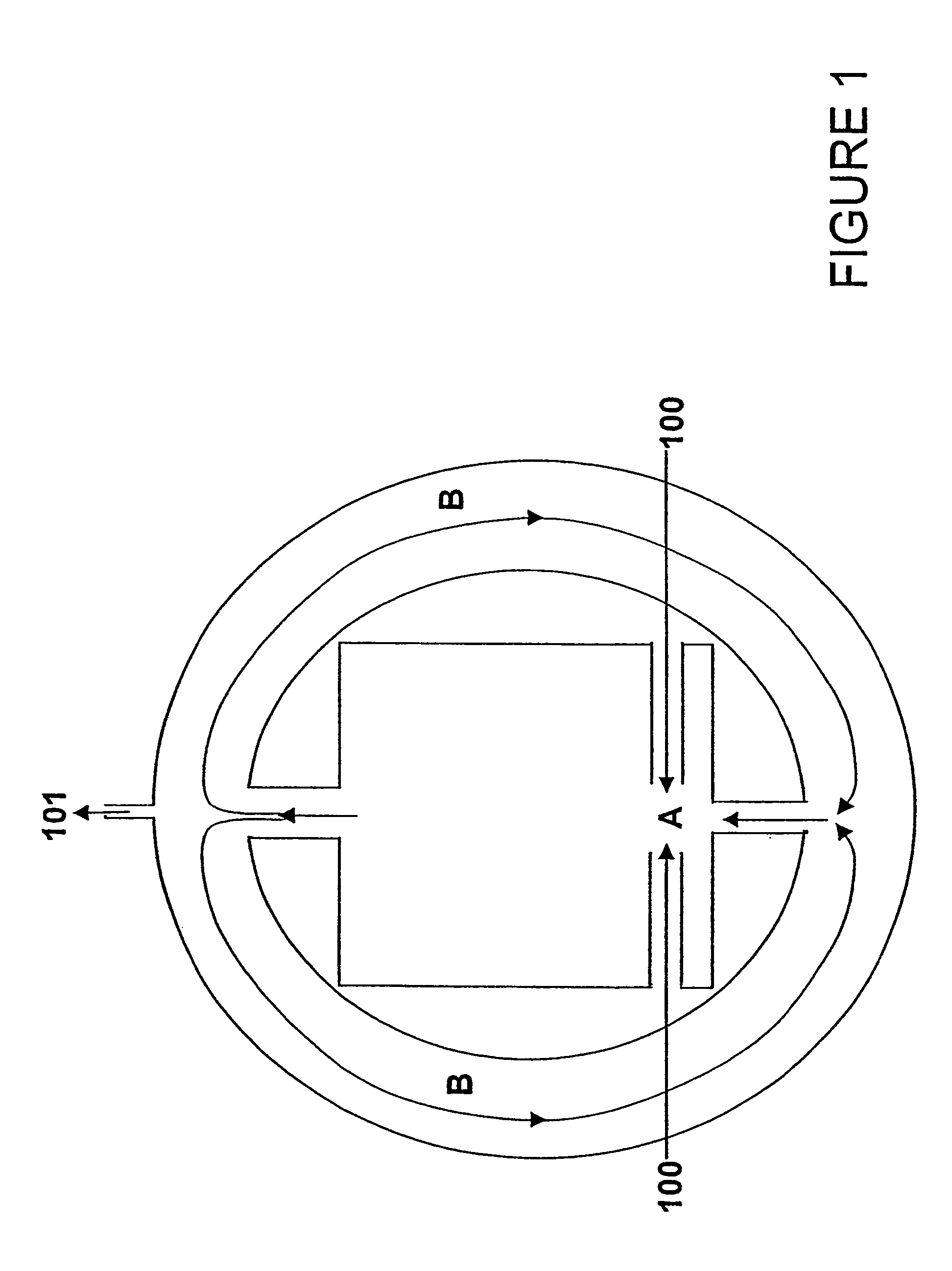

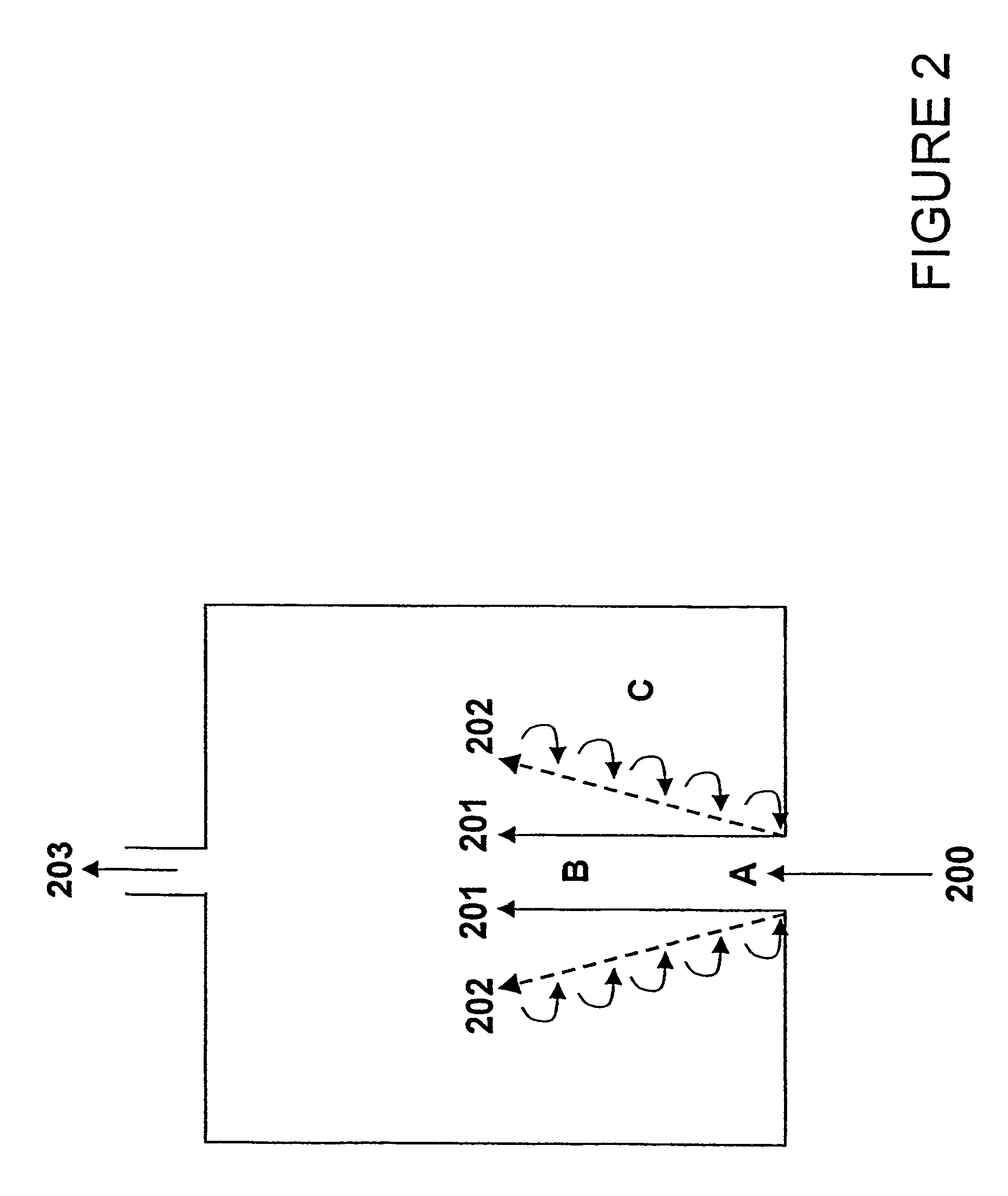

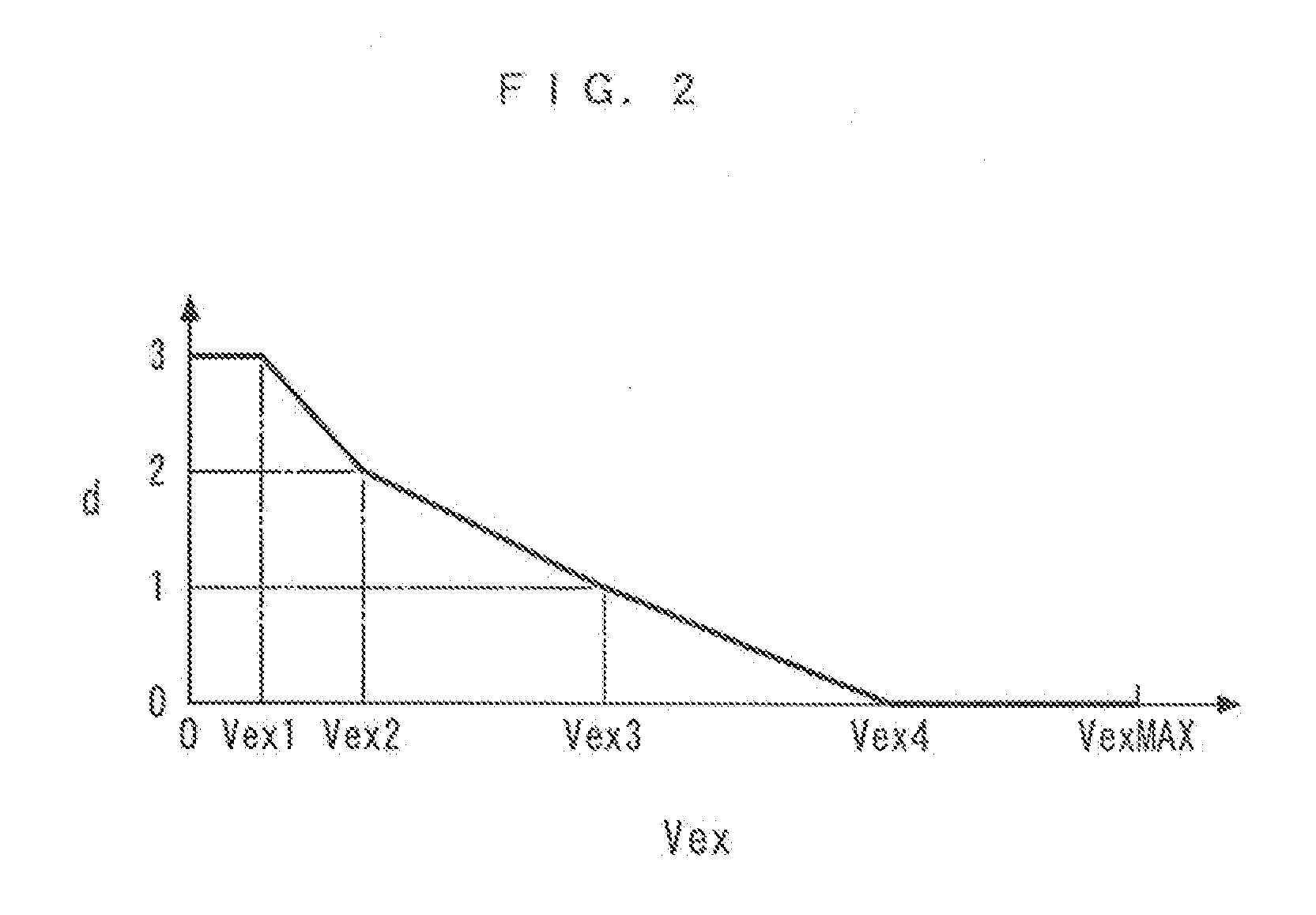

Periodic equivalence ratio modulation method and apparatus for controlling combustion instability

InactiveUS6059560AReduce pollutant emissionsReduce instabilityTurbine/propulsion fuel supply systemsPulsating combustionCombustion instabilityStable state

The periodic equivalence ratio modulation (PERM) method and apparatus significantly reduces and / or eliminates unstable conditions within a combustion chamber. The method involves modulating the equivalence ratio for the combustion device, such that the combustion device periodically operates outside of an identified unstable oscillation region. The equivalence ratio is modulated between preselected reference points, according to the shape of the oscillation region and operating parameters of the system. Preferably, the equivalence ratio is modulated from a first stable condition to a second stable condition, and, alternatively, the equivalence ratio is modulated from a stable condition to an unstable condition. The method is further applicable to multi-nozzle combustor designs, whereby individual nozzles are alternately modulated from stable to unstable conditions. Periodic equivalence ratio modulation (PERM) is accomplished by active control involving periodic, low frequency fuel modulation, whereby low frequency fuel pulses are injected into the main fuel delivery. Importantly, the fuel pulses are injected at a rate so as not to affect the desired time-average equivalence ratio for the combustion device.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

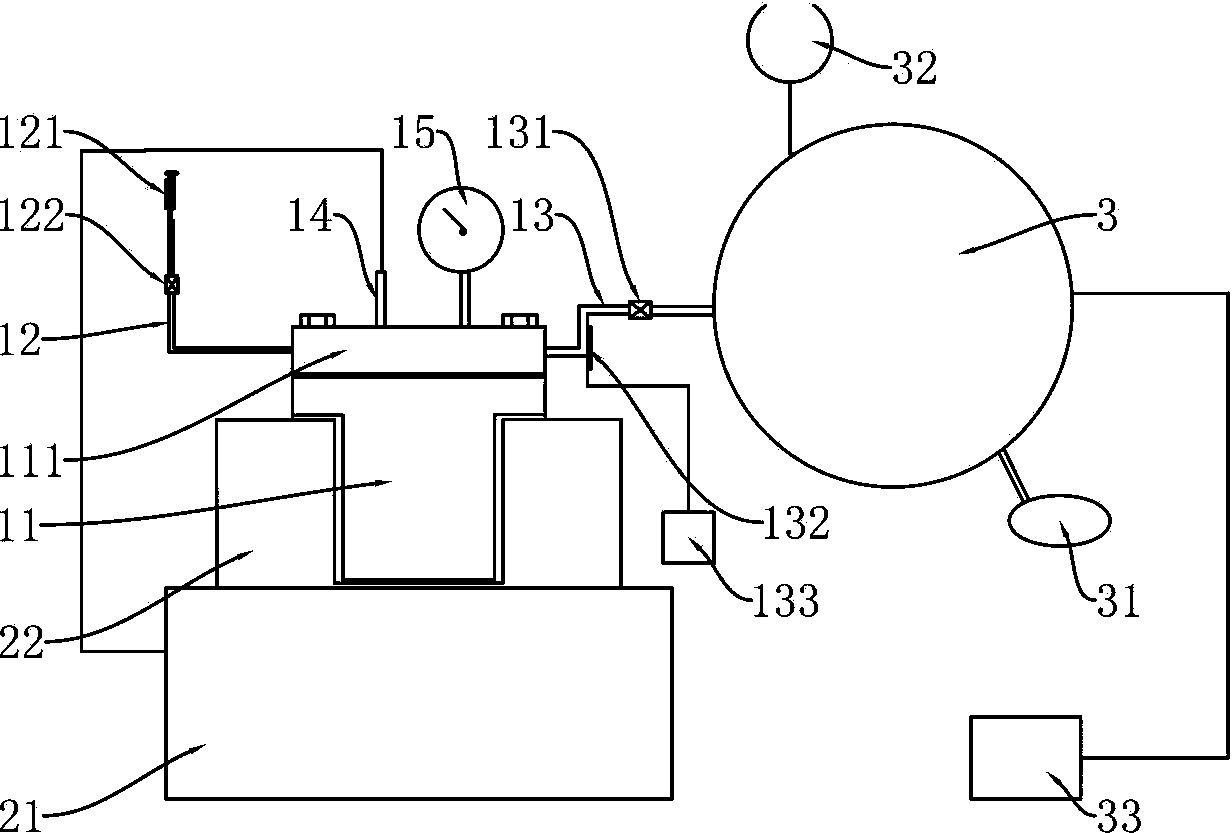

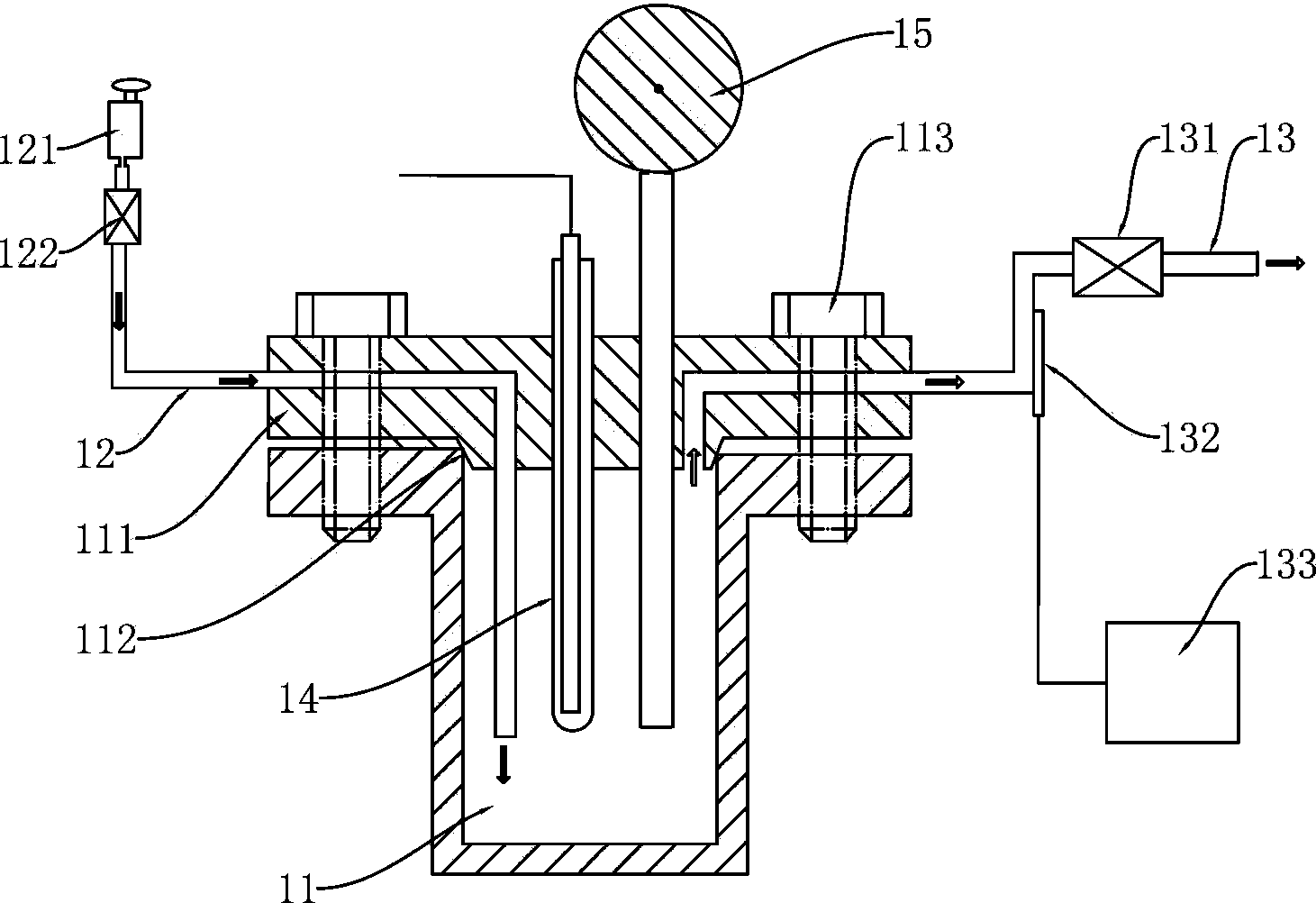

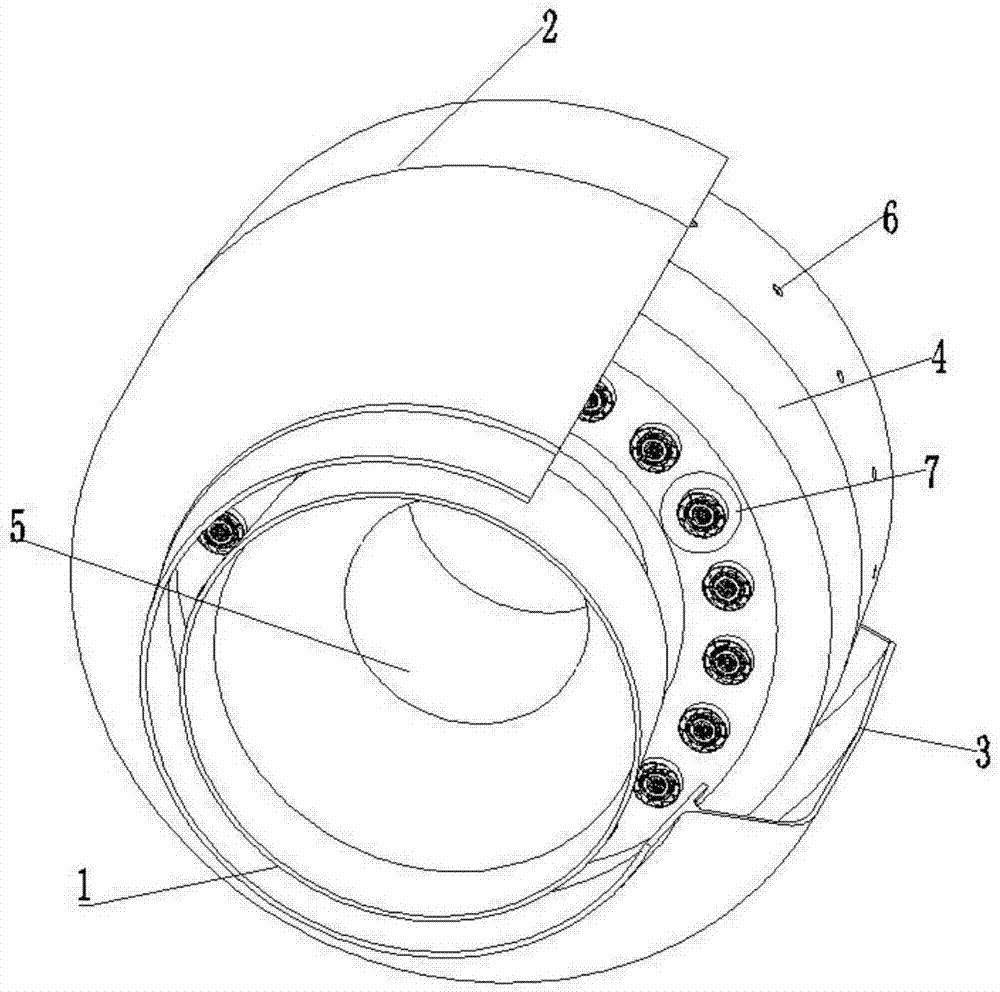

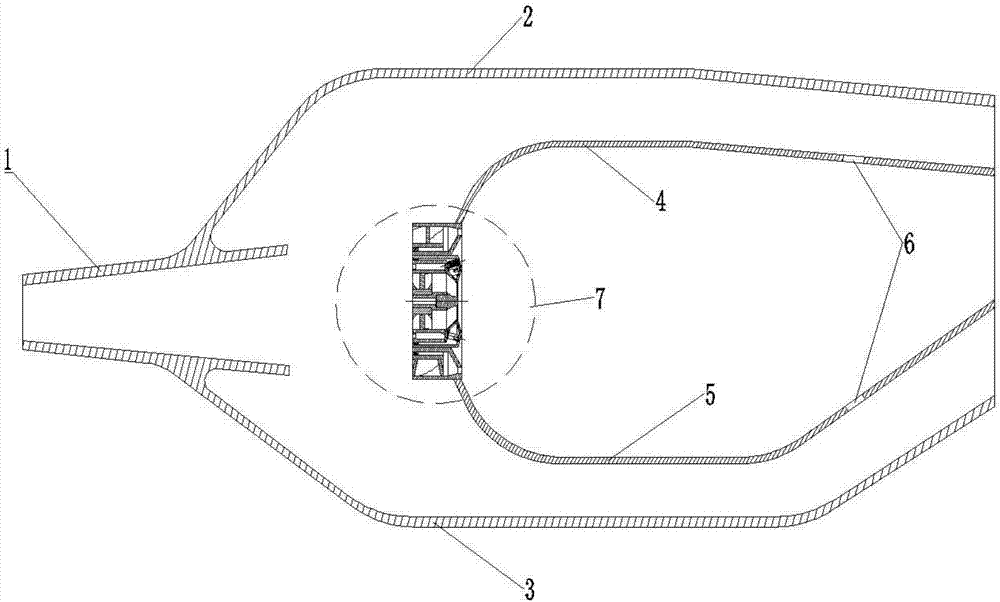

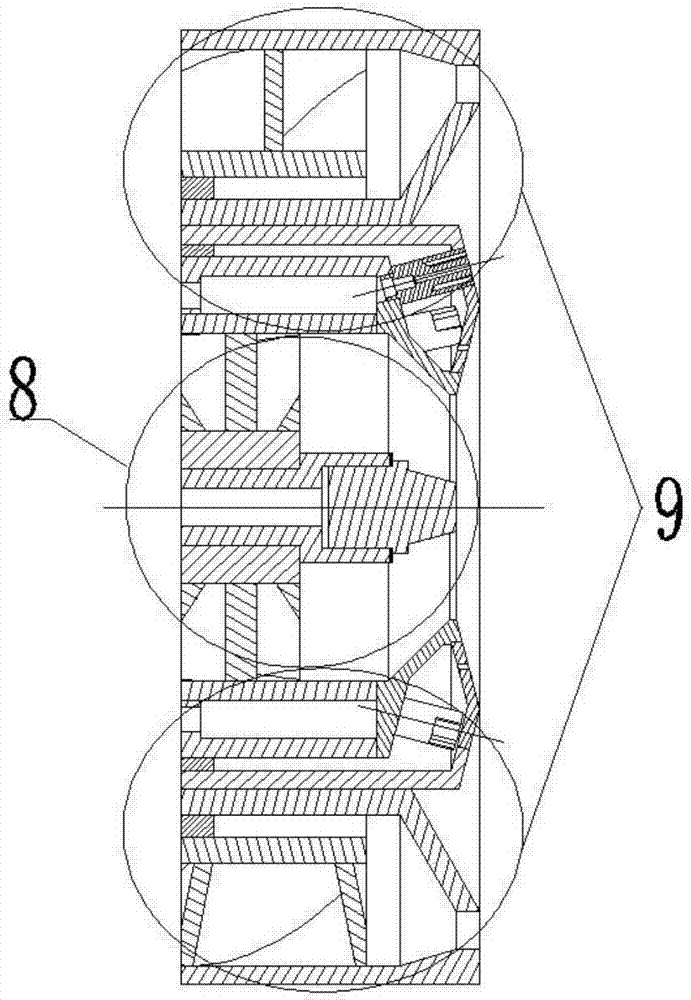

Constant volume combustion bomb and liquid fuel combustion performance testing method

InactiveCN104391074AEasy to operateEasy to controlChemical analysis using combustionEquivalence ratioCombustible gas

The invention discloses a constant volume combustion bomb and a liquid fuel combustion performance testing method. The constant volume combustion bomb comprises a combustion bomb, an evaporator, a heating device and a vacuum suction device, a discharge outlet of the evaporator is connected to the combustion bomb by a discharge pipe, and a flow control valve is installed on the discharge pipe. The liquid fuel combustion performance testing method realizes complete vaporization of liquid fuel, accurate calculation of the amount of fuel fed into the constant volume combustion bomb by a partial pressure method, and gas distribution by a high-precision electronic pressure gauge so that an air-fuel ratio of the combustible gas mixture in the constant volume combustion bomb is accurately controlled. The constant volume combustor can be operated conveniently and controlled accurately. The liquid fuel combustion performance testing method fully utilizes the existing equipment and realizes combustion of liquid fuel in the combustion bomb and accurate control of a combustible gas mixture equivalence ratio by reasonable use.

Owner:XIHUA UNIV

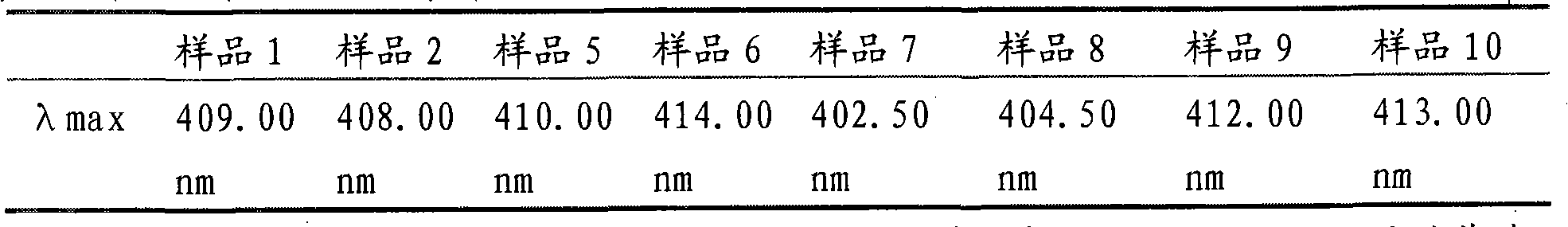

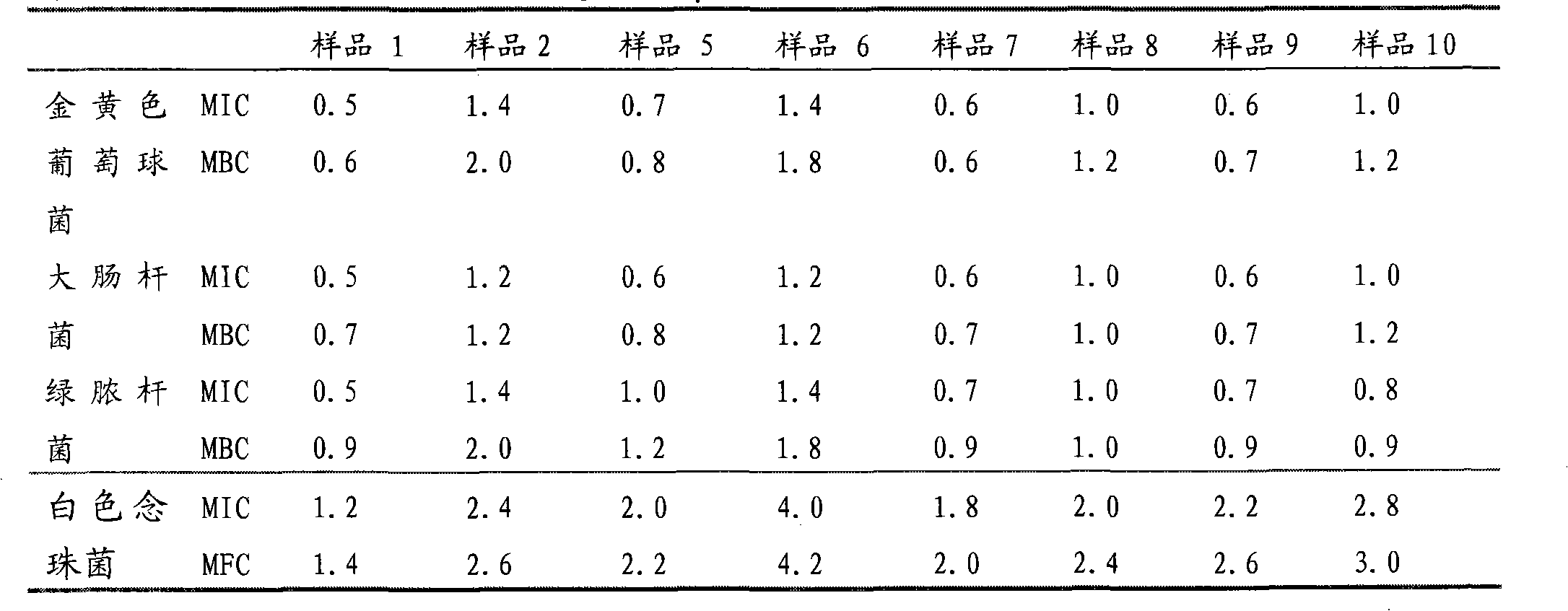

Preparation method and application of nanocomposite of silver, chitosan and/or derivative thereof

InactiveCN101618047AUniform particle sizeProtectiveAntibacterial agentsOrganic active ingredientsEquivalence ratioCervicitis

The invention discloses a nanocomposite of silver, chitosan and / or a chitosan derivative and a preparation method thereof. The preparation method comprises the steps of evenly mixing the chitosan and / or the chitosan derivative fine powder with silver nitrate fine powder and fully grinding for 1-3 hours with the weight proportion of the chitosan and / or the chitosan derivative to the silver nitrate of 100: 0.0005-0.5; adding a reducing agent with the reduction equivalence ratio of the reducing agent to the silver nitrate of 1: 1-2: 1 and fully grinding for 2-6 hours, thereby obtaining the nanocomposite of the silver, chitosan and / or the chitosan derivative with the silver particle size of 1-100nm. The nanocomposite has the effects of promoting wound healing, stopping bleeding, alleviating pain, anti-inflammation and sterilization, can be used for treating female vaginitis, cervicitis, cervical erosion, bedsores, skin ulcers, burns, scalds, trauma and other skin inflammation, tinea manus and pedis and the like, and can also be used for preparing a variety of trauma dressings, such as thin films, sponges, gynecological suppositories, patches and the like.

Owner:LIAOCHENG UNIV

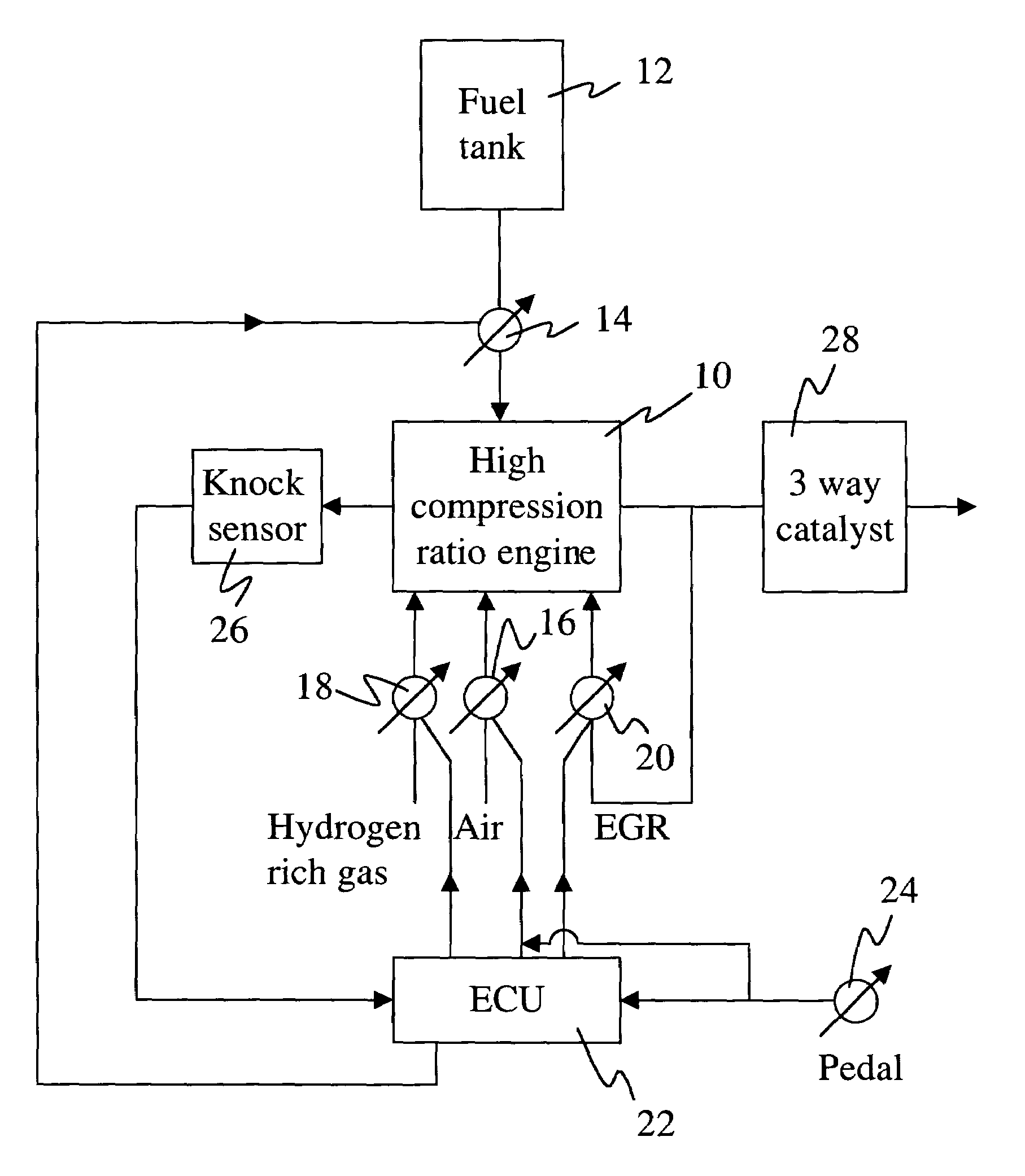

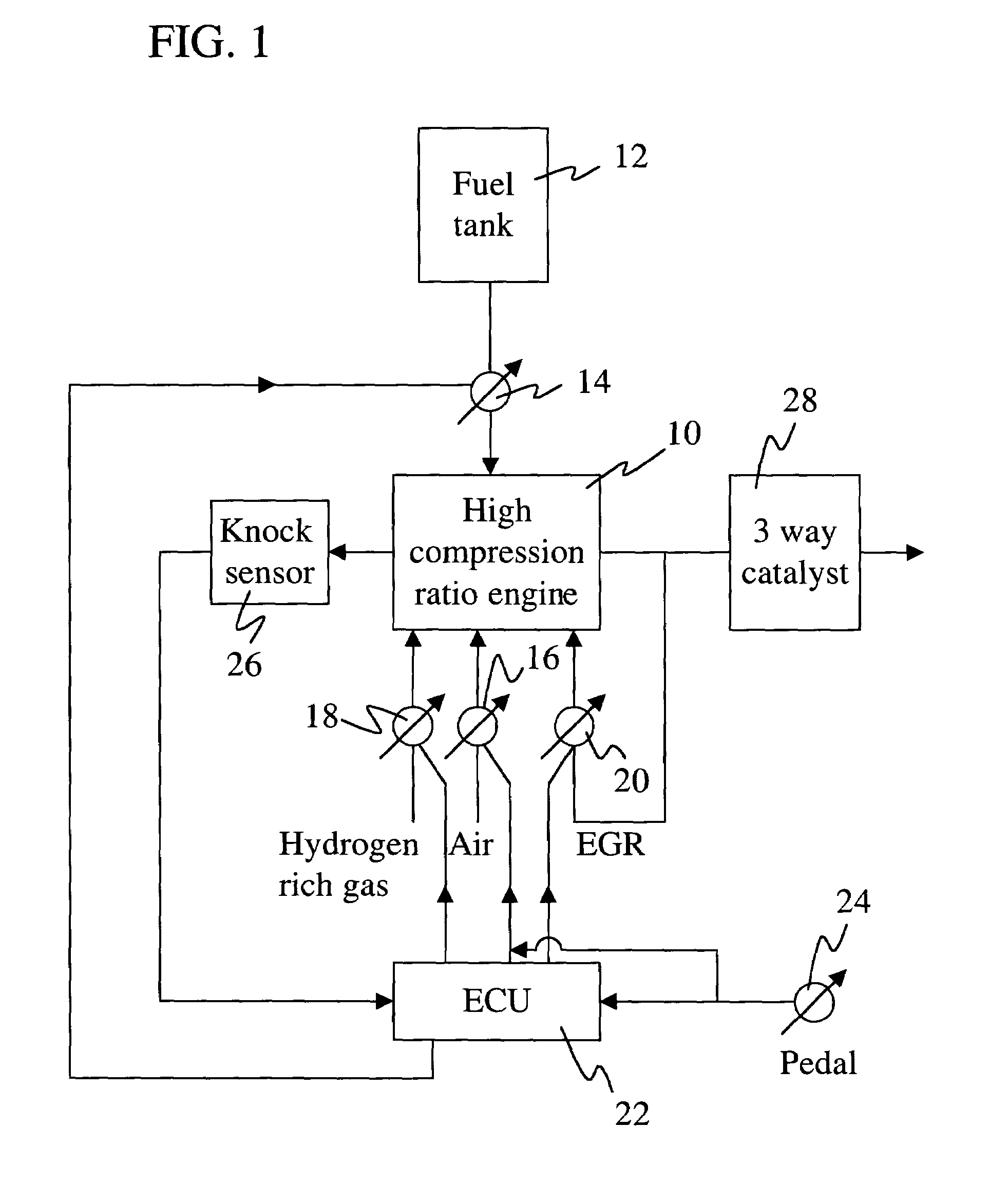

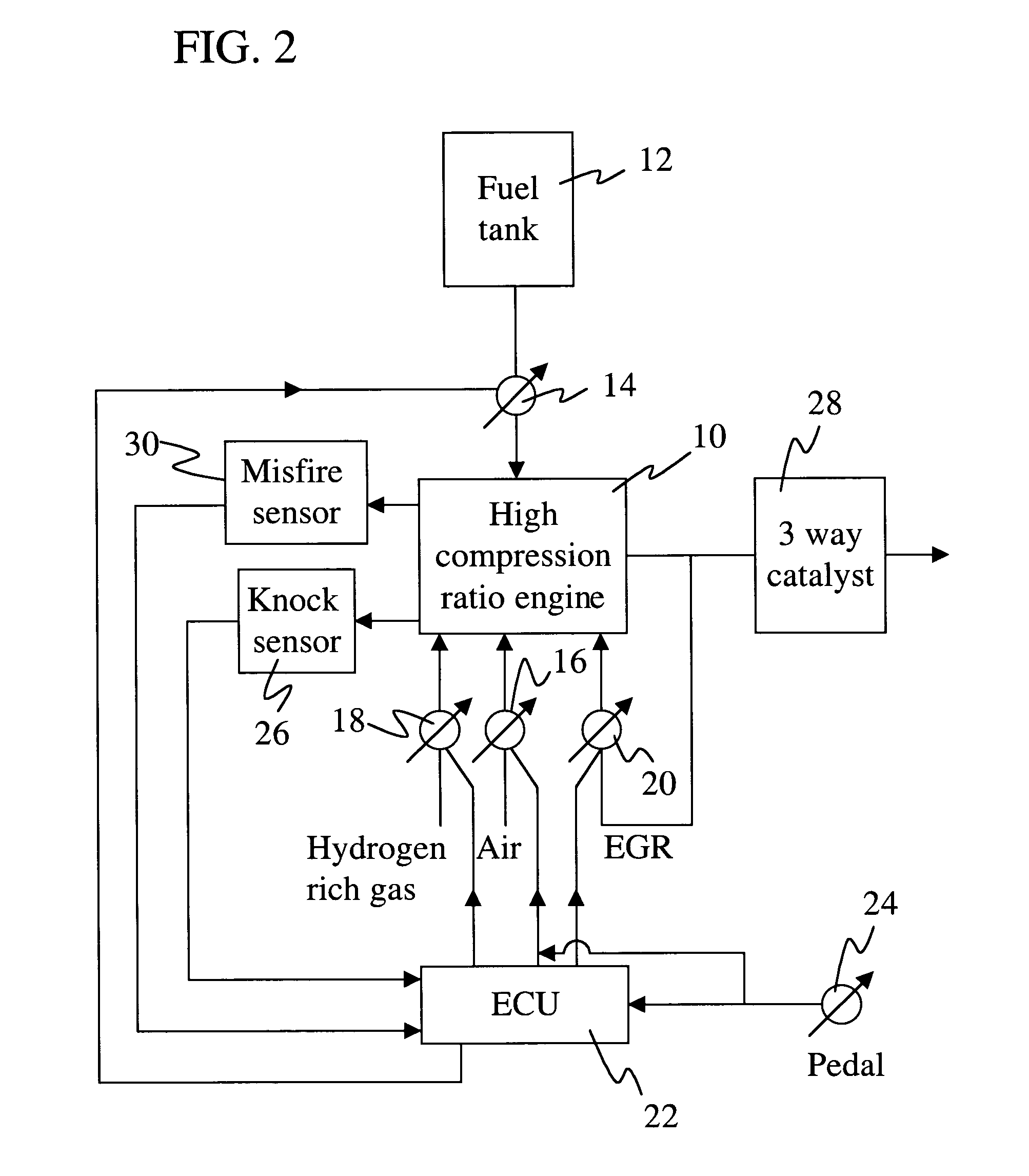

High compression ratio, hydrogen enhanced engine system

InactiveUS7028644B2Promote combustionAvoid knockingElectrical controlInternal combustion piston enginesHydrogenEngine efficiency

A hydrogen enhanced engine system using high compression ratio is optimized to minimize NOx emissions, exhaust aftertreatment catalyst requirements, hydrogen requirements, engine efficiency and cost. In one mode of operation the engine is operated very lean (equivalence ratio φ=0.4 to 0.7) at lower levels of power. Very lean operation reduces NOx to very low levels. A control system is used to increase equivalence ratio at increased torque or power requirements while avoiding the knock that would be produced by high compression ratio operation. The increased equivalence ratio reduces the amount of hydrogen required to extend the lean limit in order to avoid misfire and increases torque and power. The engine may be naturally aspirated, turbocharged, or supercharged.

Owner:MASSACHUSETTS INST OF TECH

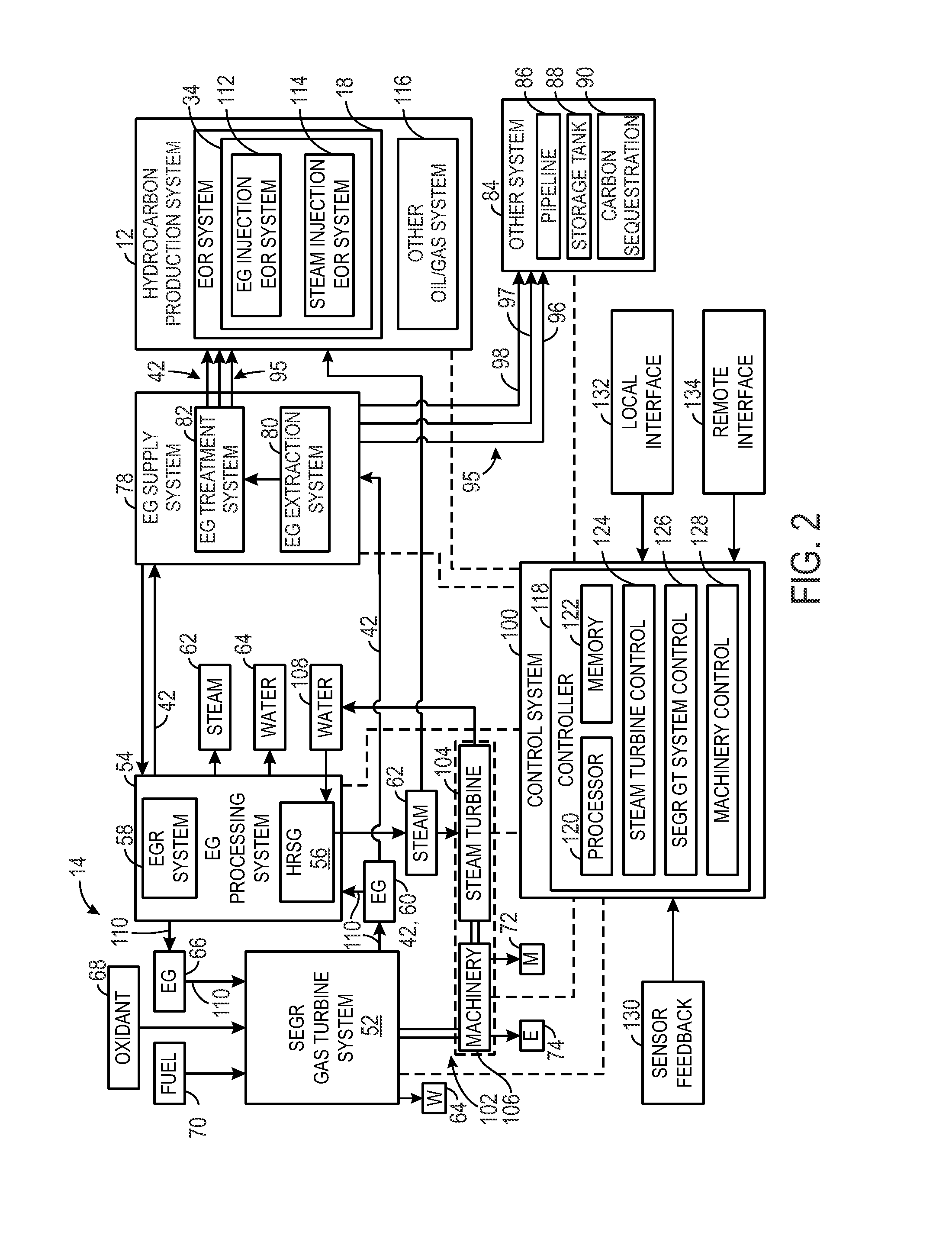

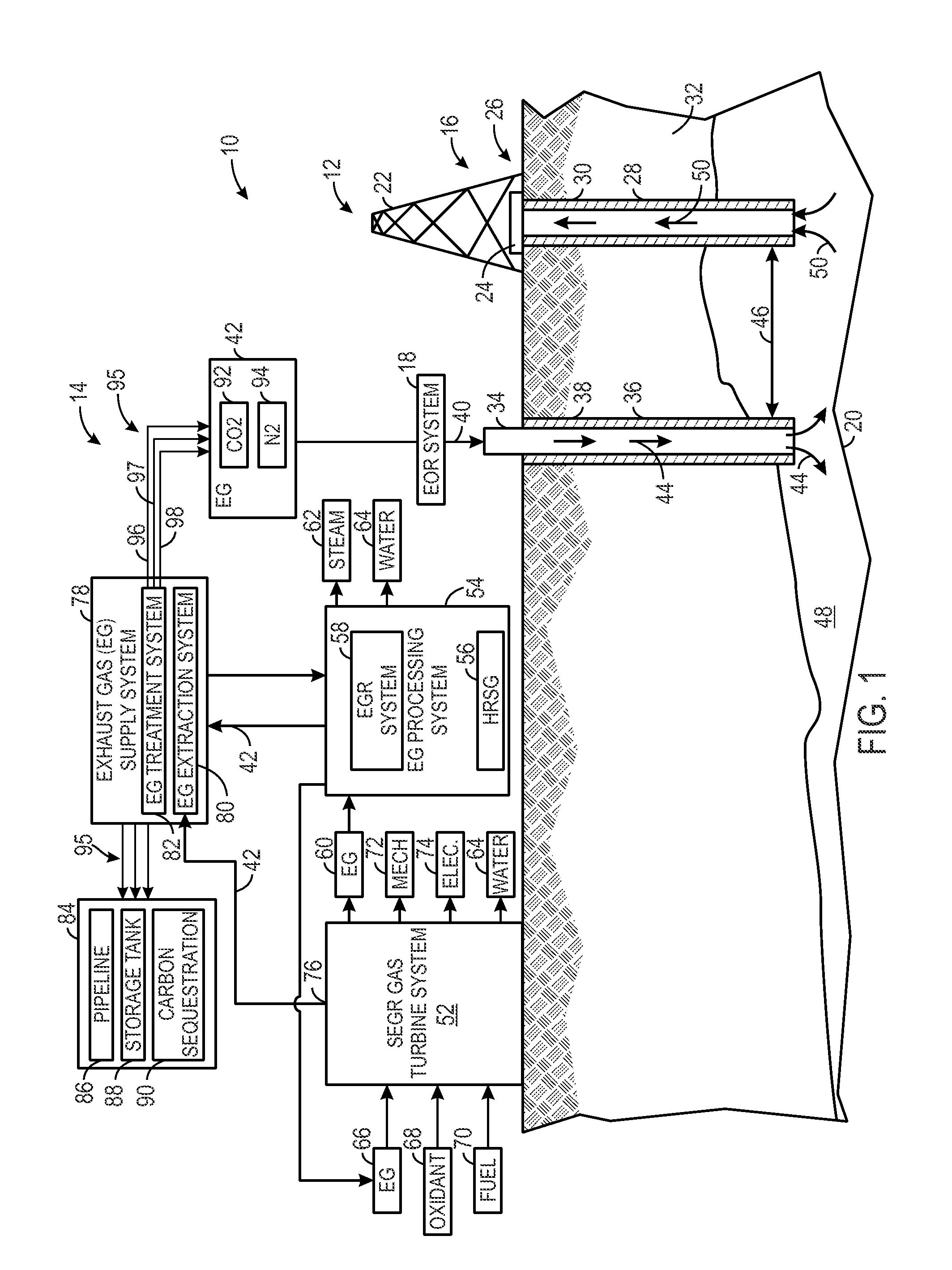

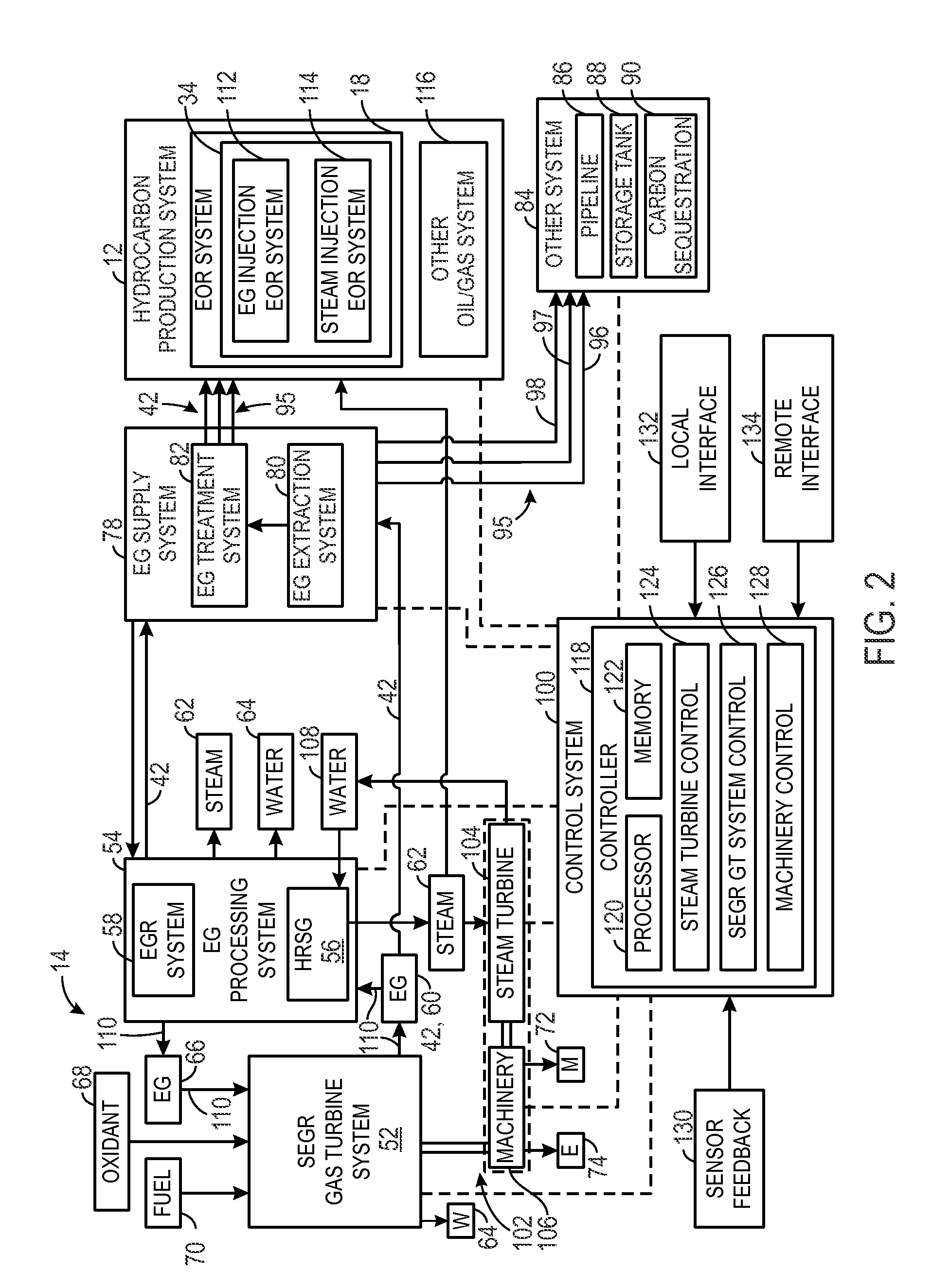

Stoichiometric combustion control for gas turbine system with exhaust gas recirculation

InactiveUS20140182298A1Gas turbine plantsTurbine/propulsion fuel controlGas turbinesEquivalence ratio

In one embodiment, a system includes at least one sensor configured to communicate a signal representative of a gas turbine operations. The system further includes a controller communicatively coupled to the sensor. The system additionally includes a stoichiometric model configured to receive one or more inputs representative of the gas turbine operations and a measured equivalence ratio, wherein the controller is configured to transform the signal into the one or more inputs and to use the stoichiometric model to derive an actuation signal based on a target equivalence ratio.

Owner:EXXONMOBIL UPSTREAM RES CO +1

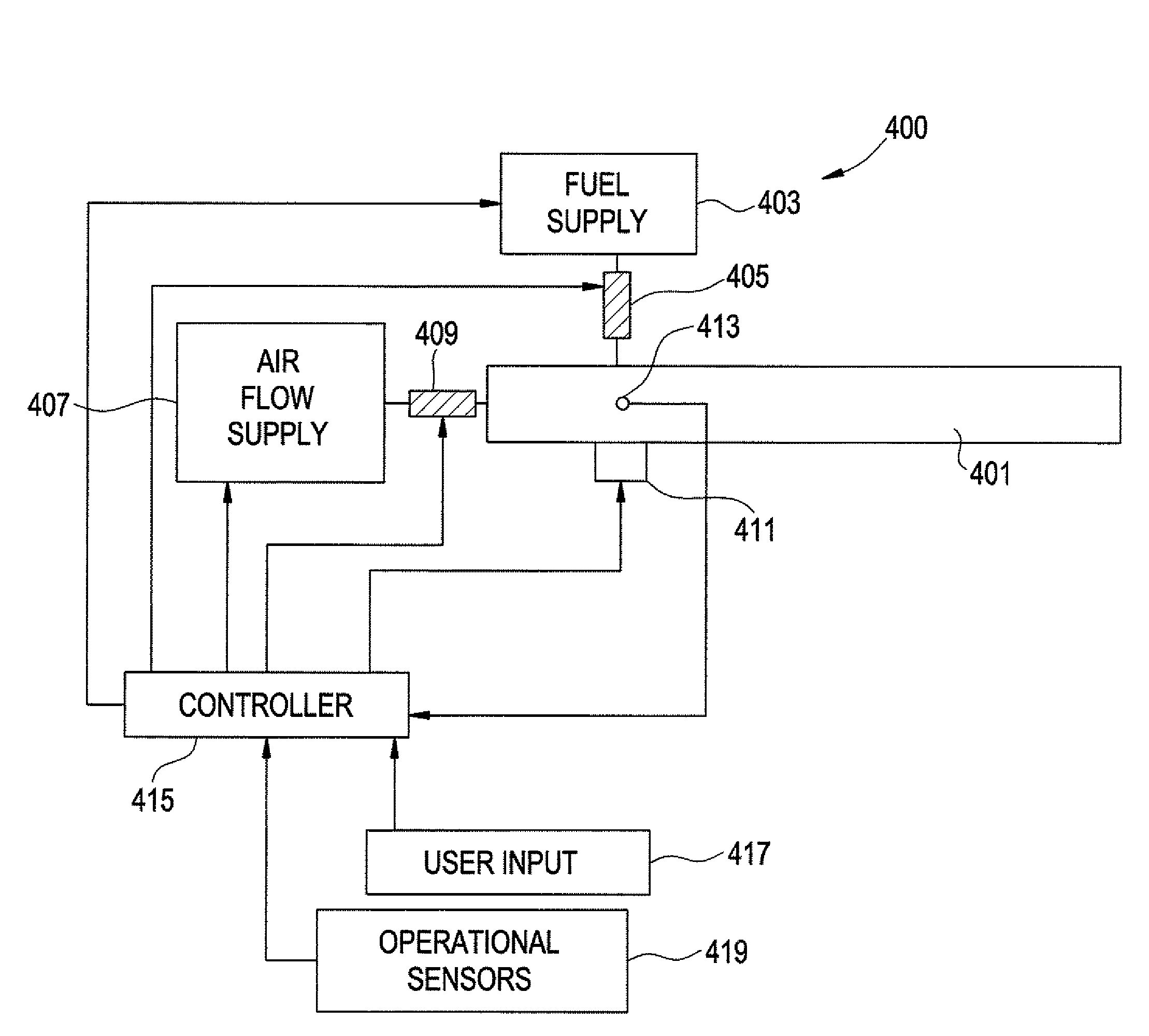

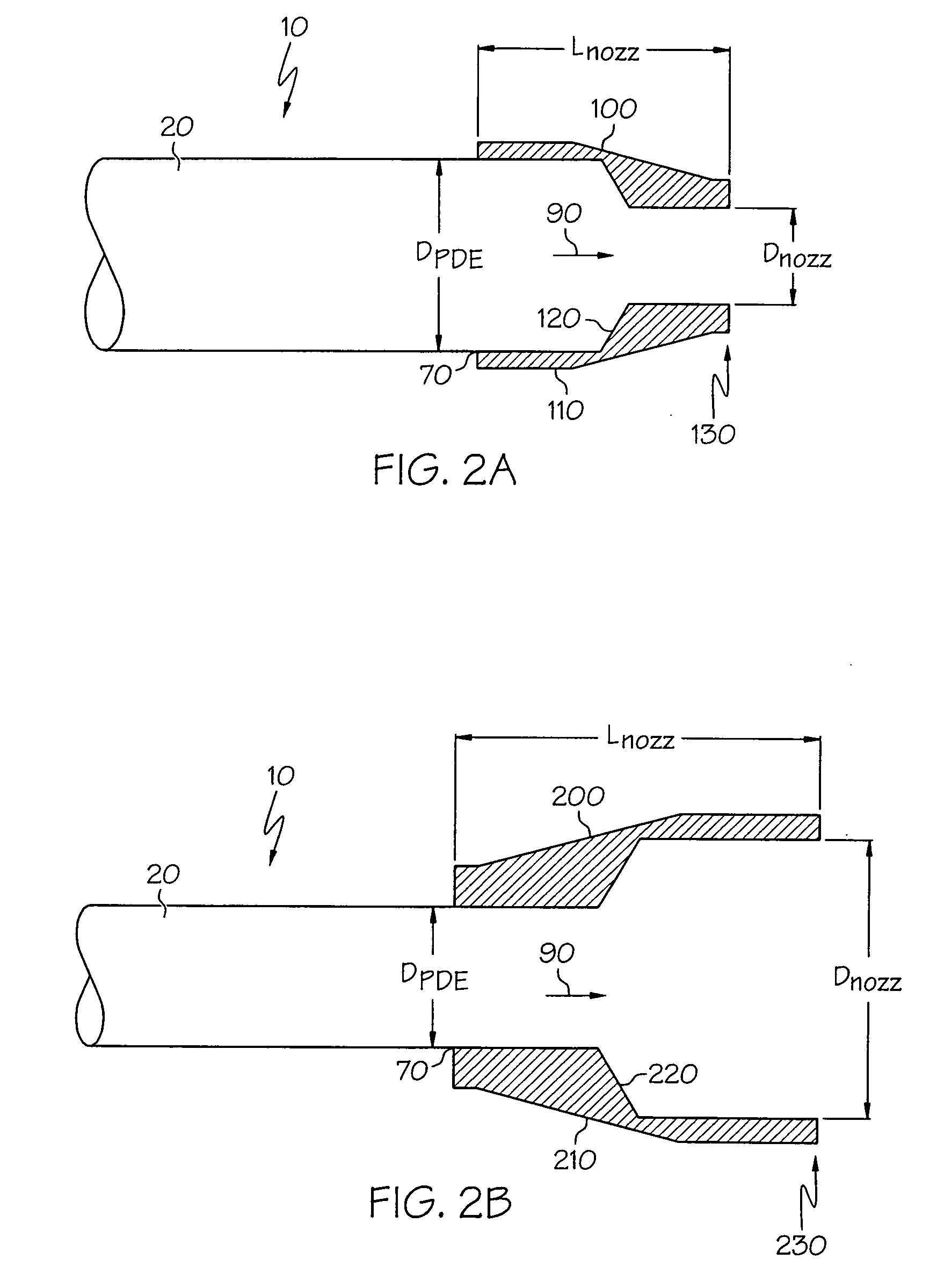

Method and apparatus for tailoring the equivalence ratio in a valved pulse detonation combustor

A pulse detonation combustor assembly contains at least one PDC tube, a mechanical air flow valve which directs an air flow into the PDC tube, where the mechanical air flow assembly changes a rate of the air flow into the PDC tube during a fill stage of the PDC tube. The assembly also contains a fuel flow control valve which directs fuel to the PDC tube and changes the rate of the fuel flow into PDC tube. By controlling the flow of the fuel and air into the PDC tube the equivalence ratio profile of the PDC tube can be tailored and controlled.

Owner:GENERAL ELECTRIC CO

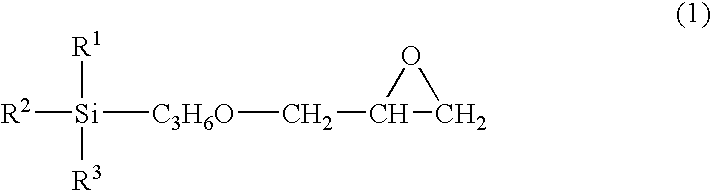

Clear coating composition, method of forming multilayer coating film and inmold decoration product

InactiveUS20060014024A1Design value is deterioratedBeautiful designSynthetic resin layered productsPolyurea/polyurethane coatingsClear LayerCorrosion reaction

It is an object of the present invention to provide a clear coating composition which inhibits a corrosion reaction by containing a rust preventive agent in a clear layer on a silver-plating layer and preventing a corrosive substance such as chlorine ion from contacting with the surface of the silver-plating layer, and develops beautiful silver-plating design for a long time, and an inmold decoration product comprising a silver-plating layer. A clear coating composition used in forming a multilayer coating film comprising a silver-plating layer, said multilayer coating film being obtainable by forming a base coating film layer, a silver-plating layer and a clear coating film layer in succession on a plastic substrate, wherein said clear coating composition is a two-package polyurethane coating composition comprising a main material containing acrylic polyol and a curing agent containing a polyisocyanate compound, the equivalence ratio of an NCO group in said polyisocyanate compound to an OH group in said acrylic polyol (NCO / OH) ranges from 0.8 / 1 to 1.2 / 1, and the clear coating composition contains a rust preventive agent in the proportions of 1.0 to 13.0 parts (on a basis of solids weight) with respect to 100 parts by weight of the total of the acrylic polyol and the rust preventive agent.

Owner:HONDA MOTOR CO LTD +1

System and method for reducing compression ignition engine emissions

InactiveUS7212908B2Improve efficiencyReduce formationElectrical controlInternal combustion piston enginesNitrogen oxidesEquivalence ratio

A method of reducing nitrogen oxides (NOx) and particulate matter (PM) in compression ignition engine emissions. The method includes monitoring at least one engine sensor that generates a signal in response to at least one engine operating condition, and adjusting at least one engine control parameter in response to the signal such that in-cylinder spacial distribution of equivalence ratio and temperature is substantially maintained to an operating region. The operating region corresponds to a set of equivalence ratio with respect to temperature values that are substantially outside regions supportive of NOx and PM formation. The temperature values are greater than 1650 K, and the equivalence ratio values are greater than 0.5.

Owner:DETROIT DIESEL CORP

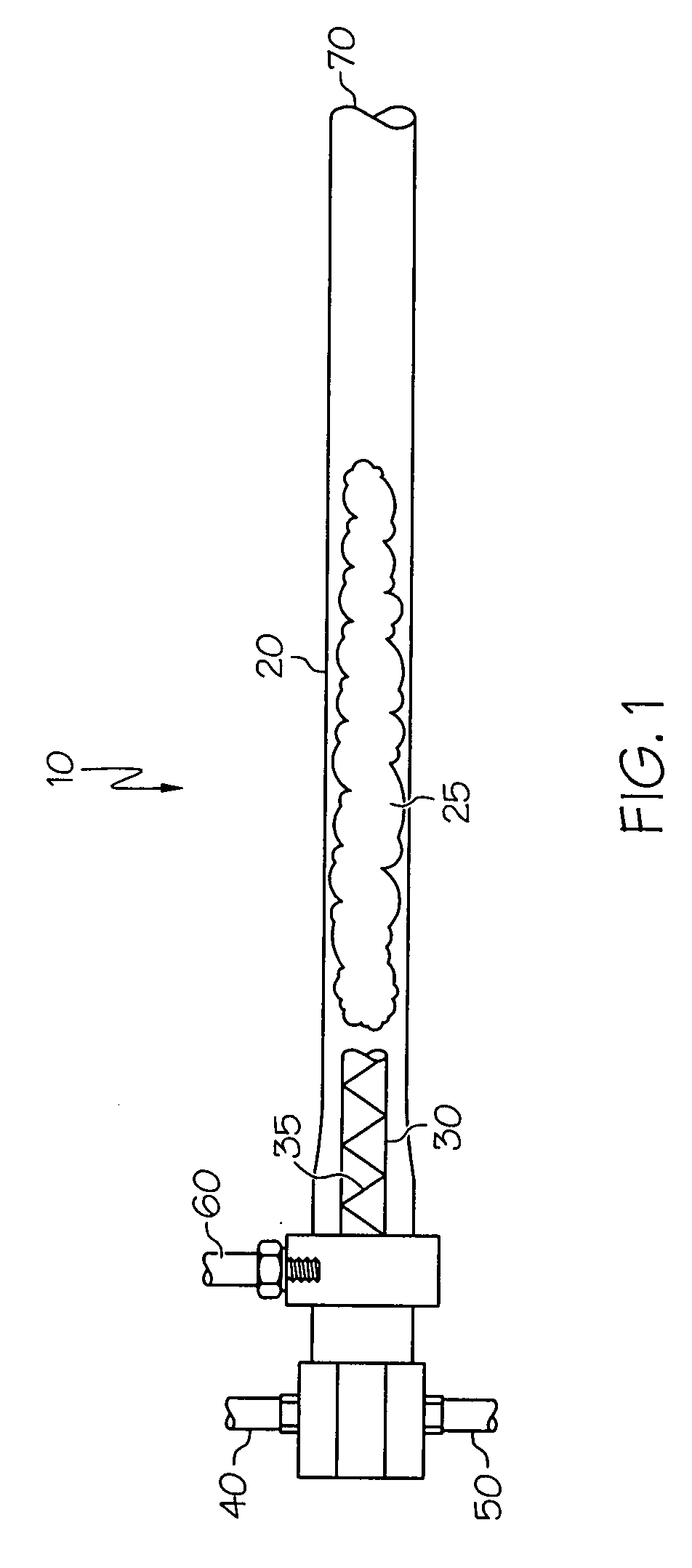

Performance improvements for pulse detonation engines

InactiveUS20090320446A1Reduce noiseImprove performanceEngine manufactureEngine fuctionsEquivalence ratioNoise reduction

A device and method for improving the performance of a pulse detonation engine. The device includes at least one of an exhaust structure and an ejector. The exhaust structure can be configured as a straight, converging or diverging nozzle device, and connected to the engine to control the flow of a primary fluid produced during a detonation reaction. The ejector is fluidly coupled to the engine, using the movement of the primary fluid to promote entrainment of a secondary fluid that can be mixed with the primary fluid. The secondary fluid can be used to increase the mass flow of the primary fluid to increase thrust, as well as be used to cool engine components. Device positioning, sizing, shaping and integration with other engine operating parameters, such as fill fraction, choice of fuel and equivalence ratio, can be used to improve engine performance. In addition to thrust augmentation and enhanced cooling, the disclosed device can be used for engine noise reduction.

Owner:UNIVERSITY OF CINCINNATI

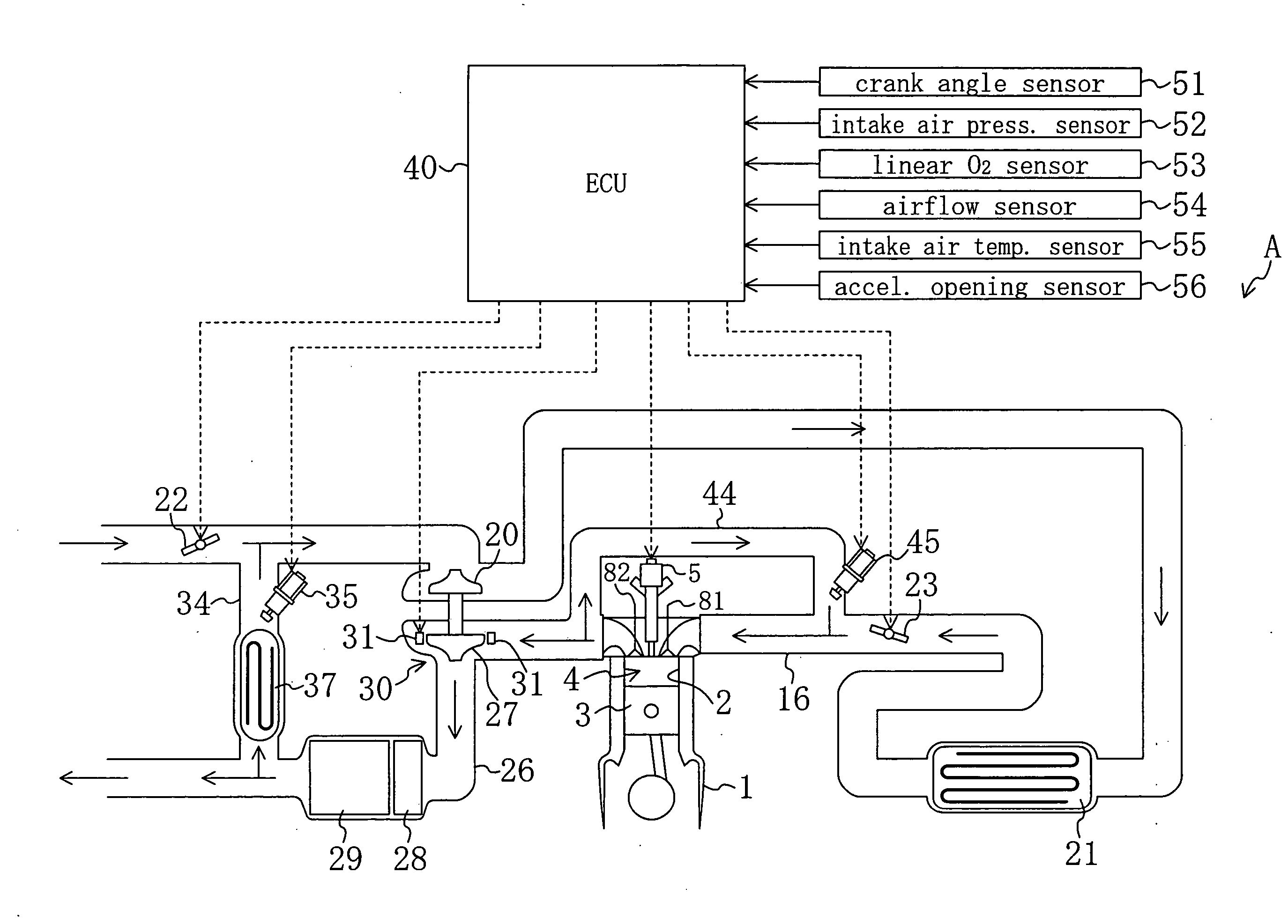

Engine exhaust gas purifier

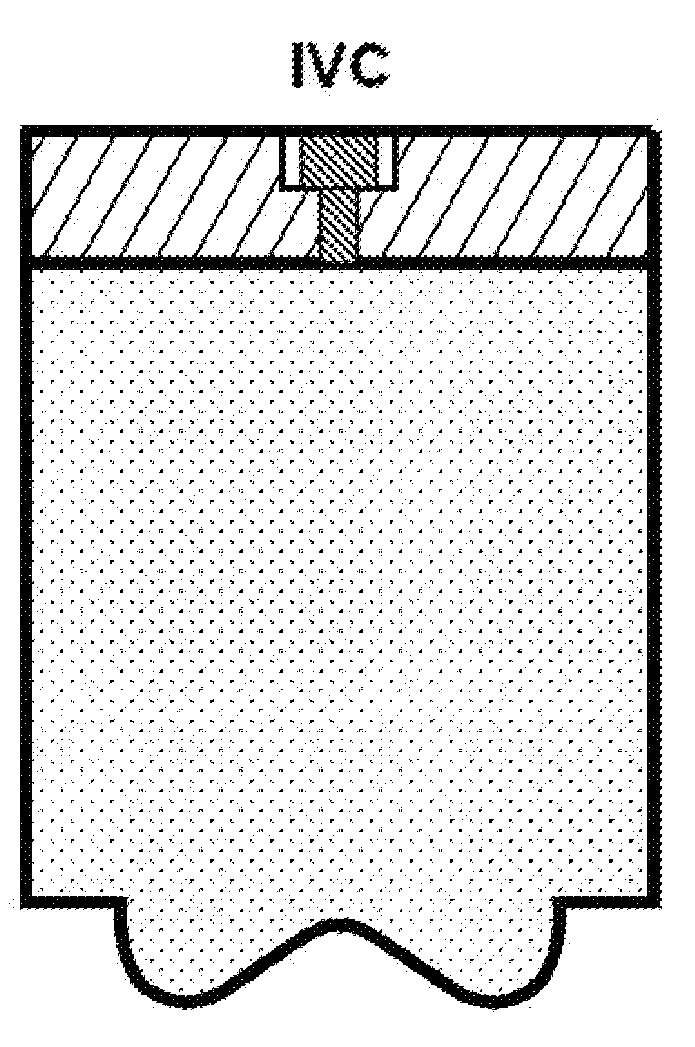

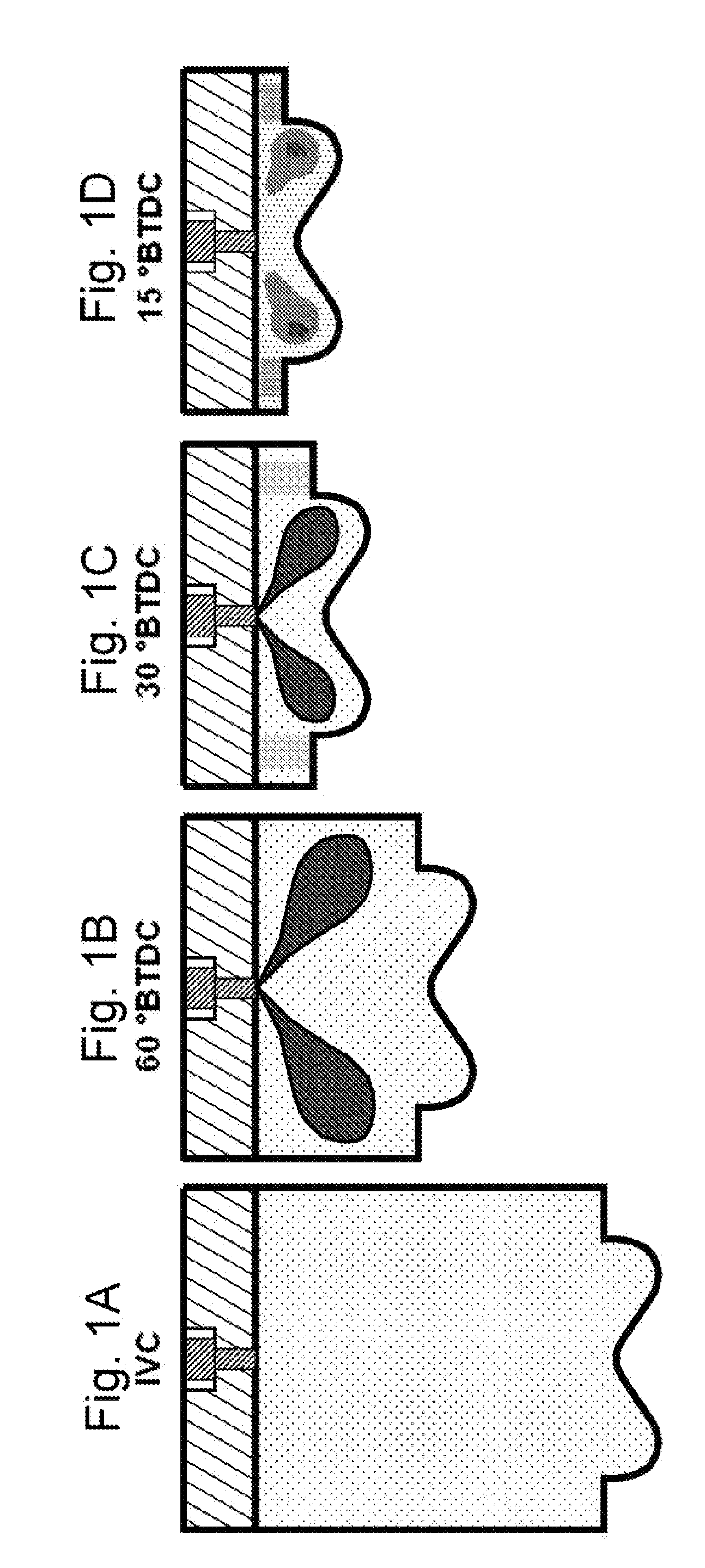

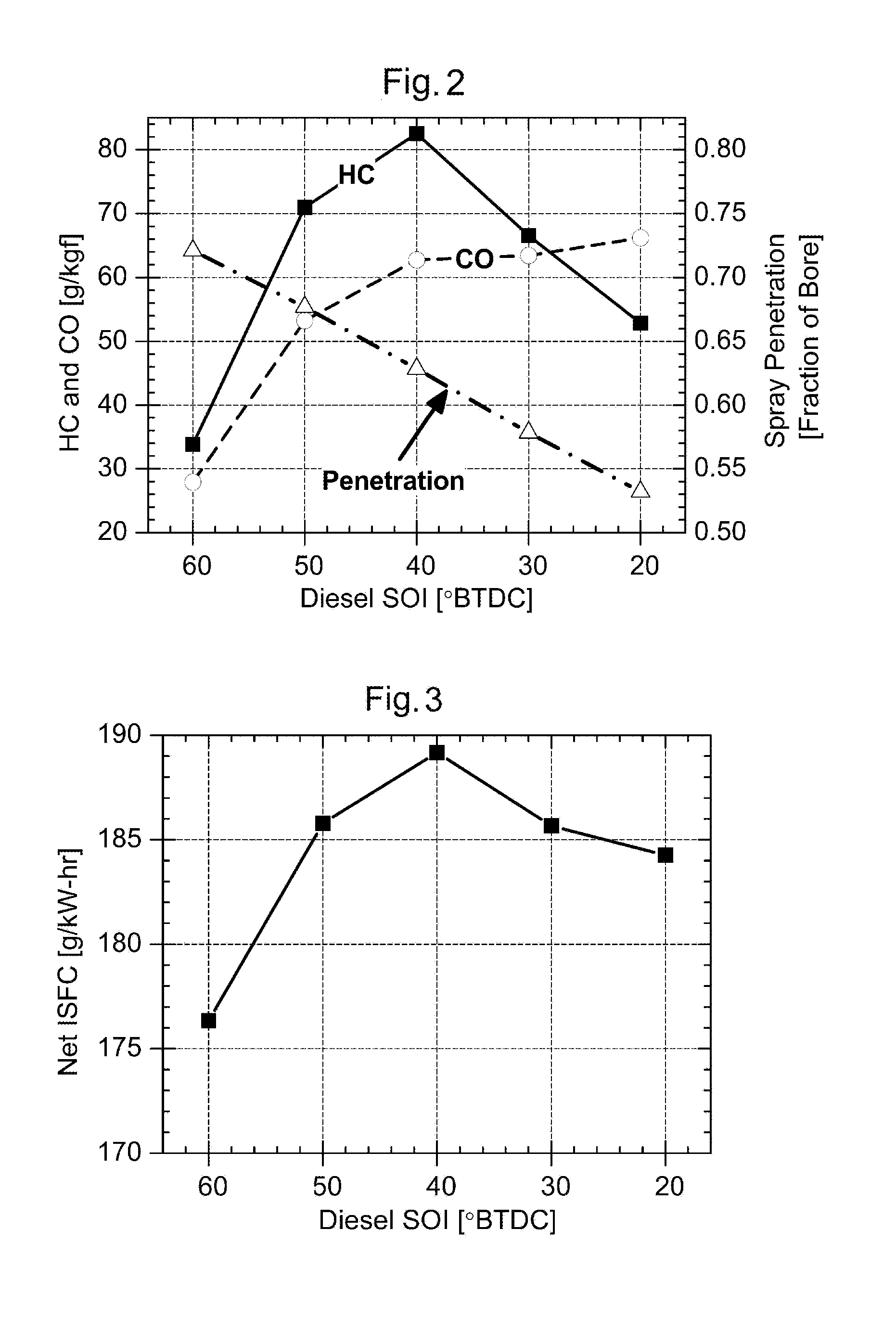

InactiveUS20080022972A1Inhibit productionEmission reductionElectrical controlNon-fuel substance addition to fuelCombustion chamberTop dead center

An engine exhaust gas purifier includes: an injection controller allowing a fuel injection valve to inject fuel near the top dead center on each compression stroke; an EGR amount controller for controlling the amount of exhaust gas recirculated into a combustion chamber; an excess air ratio controller for controlling the excess air ratio so that the local equivalence ratio in a late combustion stage is lower than the equivalence ratio at which soot is produced; and an intake air temperature controller for controlling the temperature of intake air after being mixed with exhaust gas. The intake air temperature controller controls the temperature of intake air within a temperature range lower than an upper temperature limit below which a predetermined ignition delay time can be secured and higher than a lower temperature limit above which the production of HC and CO can be avoided.

Owner:MAZDA MOTOR CORP

Premixed charge compression ignition engine with optimal combustion control

InactiveCN1624305AControl control systemEffective controlElectrical controlInternal combustion piston enginesTemperature controlActive feedback

The present invention provides a premixed charge compression ignition engine and control system (10), which can effectively trigger combustion and maintain stable combustion by means of compression ignition, while achieving extremely low nitrogen oxide emissions, good overall efficiency and Acceptable combustion noise and cylinder pressure. The engine and control system (10) of the present invention can effectively control the combustion process by controlling certain control variables of temperature control, pressure control, mixture self-ignitability control and equivalence ratio control, that is, the time of combustion initiation, the combustion rate , duration of combustion and / or completeness of combustion. The combustion control system (10) provides active feedback control of combustion and includes a sensor for detecting engine operating conditions representative of a combustion process, such as ignition of combustion, and generating a corresponding engine operating condition signal (18) , such as the pressure sensor (16).

Owner:CUMMINS INC

Low-emission reverse flow combustor adopting radial swirl injection and fuel oil grading schemes

Owner:中科航星科技有限公司

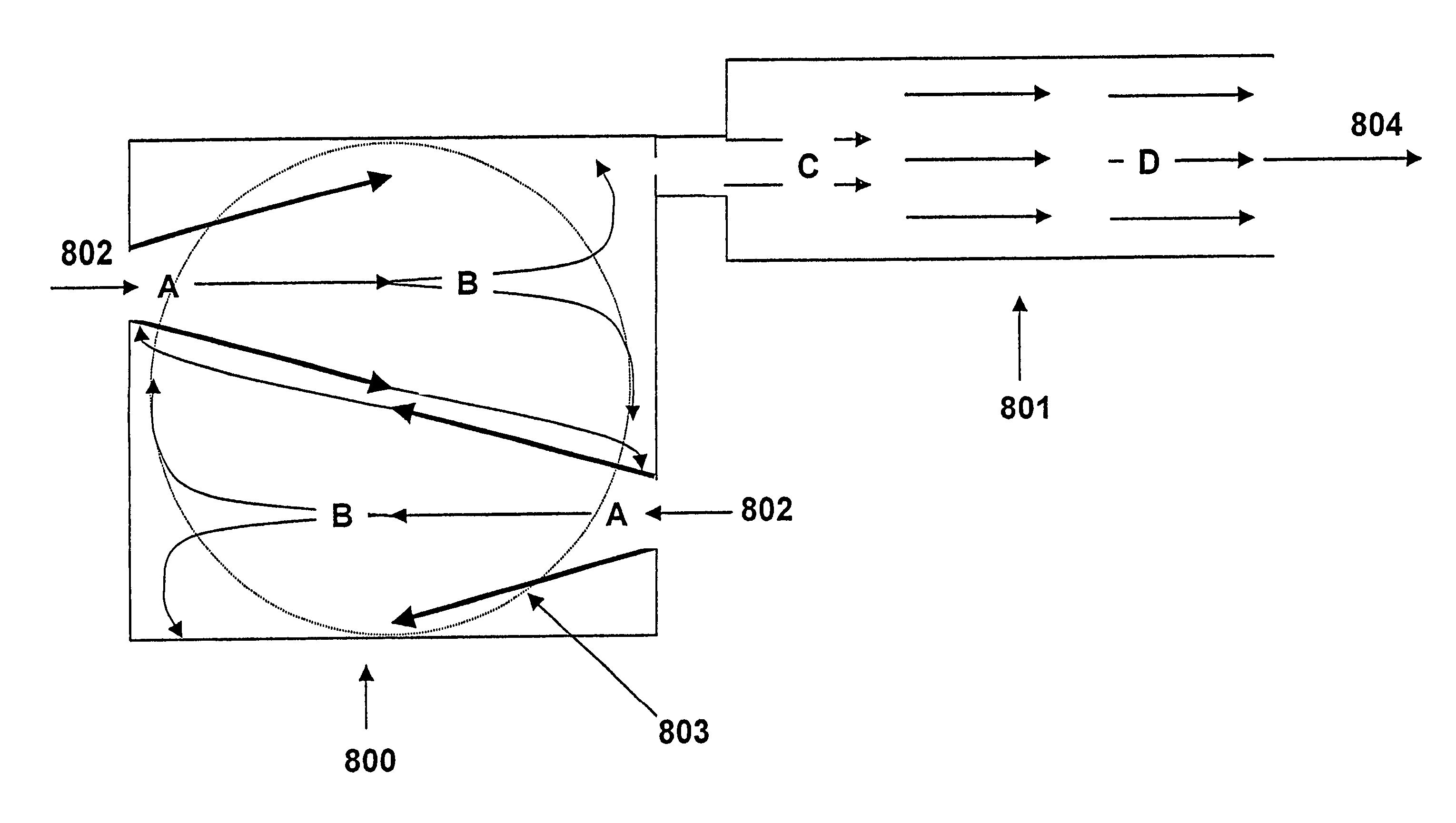

Method for combustion synthesis of fullerenes

ActiveUS7396520B2High yieldOvercome limitationsMaterial nanotechnologyFullerenesCombustionEquivalence ratio

A mod of combustion and a multi-component reactor to accomplish this mode of combustion are disclosed which produces fullerenes and fullerenic material by combustion. This mode consists of de-coupling an oxidation region of a flame from a post-flame region, thus giving greater control over operating parameters, such as equivalence ratio, temperature, and pressure; allows conditions of the operating parameters of the combustion reaction to be attained which would not be easily attained by conventional methods; and offers the ability to more easily stabilize the combustion reactions to allow for higher throughputs of fuel and oxidant. Several embodiments of a primary zone of a multicomponent reactor are also disclosed. Said primary zone serves as the oxidation region, operates on the principle of providing recycle to the reacting combustion mixture, and which may be operated as approximately a well-mixed reactor. A secondary zone is also disclosed which provides further residence time for reaction and the ability to control operating parameters, operates on the principle of minimizing recycle of the reacting combustion mixture. The secondary zone may be operated as approximately a plug-flow reactor. The primary and secondary zones may be operated in conjunction or either one alone.

Owner:NANO C INC

Bi-fuel engine using hydrogen

The invention relates to a bi-fuel engine using hydrogen. A method is disclosed for making a transition from fueling an engine with hydrogen to another fuel. That other fuel may be gasoline, a gasoline and alcohol mixture, or gaseous fuels, as examples. The other fuel has the capability of providing higher BMEP than the hydrogen because of better air utilization and because the other fuel occupies less volume of the combustion chamber. Because a desirable equivalence ratio to burn hydrogen is at 0.5 or less and a desirable equivalence ratio to burn other fuel is at 1.0, when a demand for BMEPthat leads to a transition change from hydrogen fuel to the other fuel, the amount of air supplied to the engine is decreased to provide more torque and vice versa. During a transition in which liquid fuel supply is initiated, it may desirable to continue to provide some hydrogen, not leaner than 0.1 hydrogen equivalence ratio.

Owner:FORD GLOBAL TECH LLC

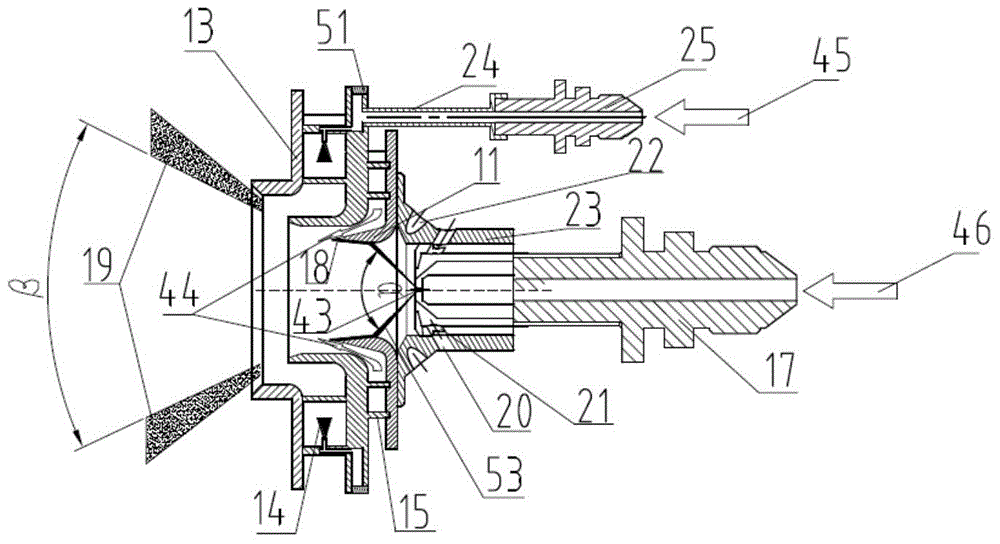

Lean oil direct injection and mixing low-pollution combustion chamber

ActiveCN107543201AGuarantee job stabilityReduce the temperatureContinuous combustion chamberSpontaneous combustionGasoline direct injection

The invention relates to a lean oil direct injection and mixing low-pollution combustion chamber. The lean oil direct injection and mixing low-pollution combustion chamber is composed of a diffuser, acombustion chamber outer case, a combustion chamber inner case, a combustion chamber head, a flame tube outer wall and a flame tube inner wall, wherein combustion air all enters a flame tube from thecombustion chamber head; the combustion chamber head is divided into an on-duty grade and a main combustion grade through a grading and partitioning combustion strategy; the on-duty grade and the main combustion grade both adopt a direct injection and mixing combustion method, the phenomena of spontaneous combustion and tempering are effectively avoided, and the risk of occurrence of oscillationcombustion is lowered; the lean oil direct injection and mixing low-pollution combustion chamber only works in an on-duty grade mode under an idling rating state, the designed partial equivalence ratio is higher, and the work stability of the combustion chamber is guaranteed; and with the increase of the work state of the combustion chamber, the main combustion grade is opened gradually, the maincombustion grade and the on-duty grade work simultaneously under a large state, the designed combustion area average equivalence ratio is lower, the average temperature of the combustion area is effectively lowered, and therefore the generation quantity of pollutants is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Transparent polyurethane coating composite and preparation method thereof

ActiveCN102604526AIncrease crosslink densityImprove mechanical propertiesPolyurea/polyurethane coatingsCarbon numberPolyester

The invention discloses a transparent polyurethane coating composite which is composed of a component A and a component B, wherein the component A is polyester polyol, and the component B is polyisocyanate. The transparent polyurethane coating composite is characterized in that polyester polyol comprises aliphatic and cycloaliphatic diacids with a carbon number of C6-C10; polyester polyol is prepared through carrying out condensation polymerization on one or more of aliphatic and cycloaliphatic dihydric alcohols with a carbon number of C2-C7 and one or more of aliphatic polyatomic alcohols with a carbon number of C2-C7, the molecular weight range of the polyester polyol is 500-5000, and the MWD (molecular weight distribution) of the polyester polyol is 1.1-2.1; the component B is polyisocyanate; and the equivalence ratio of reactive groups of polyisocyanate and polyester polyol is (1.1:1)-(2.5:1). The transparent polyurethane coating composite prepared by the method disclosed by the invention is good in impact property and weather resistance, the light transmittance is greater than or equal to 85.0%, and the impact strength is greater than or equal to 70%, and after the transparent polyurethane coating composite is subjected to QUV ultraviolet accelerated aging for a week, the appearance and light transmittance of a coating are not changed. The coating composite prepared by the method disclosed by the invention can be applied to the fields with higher requirements on the coating performance.

Owner:GUANGDONG INST OF RARE METALS

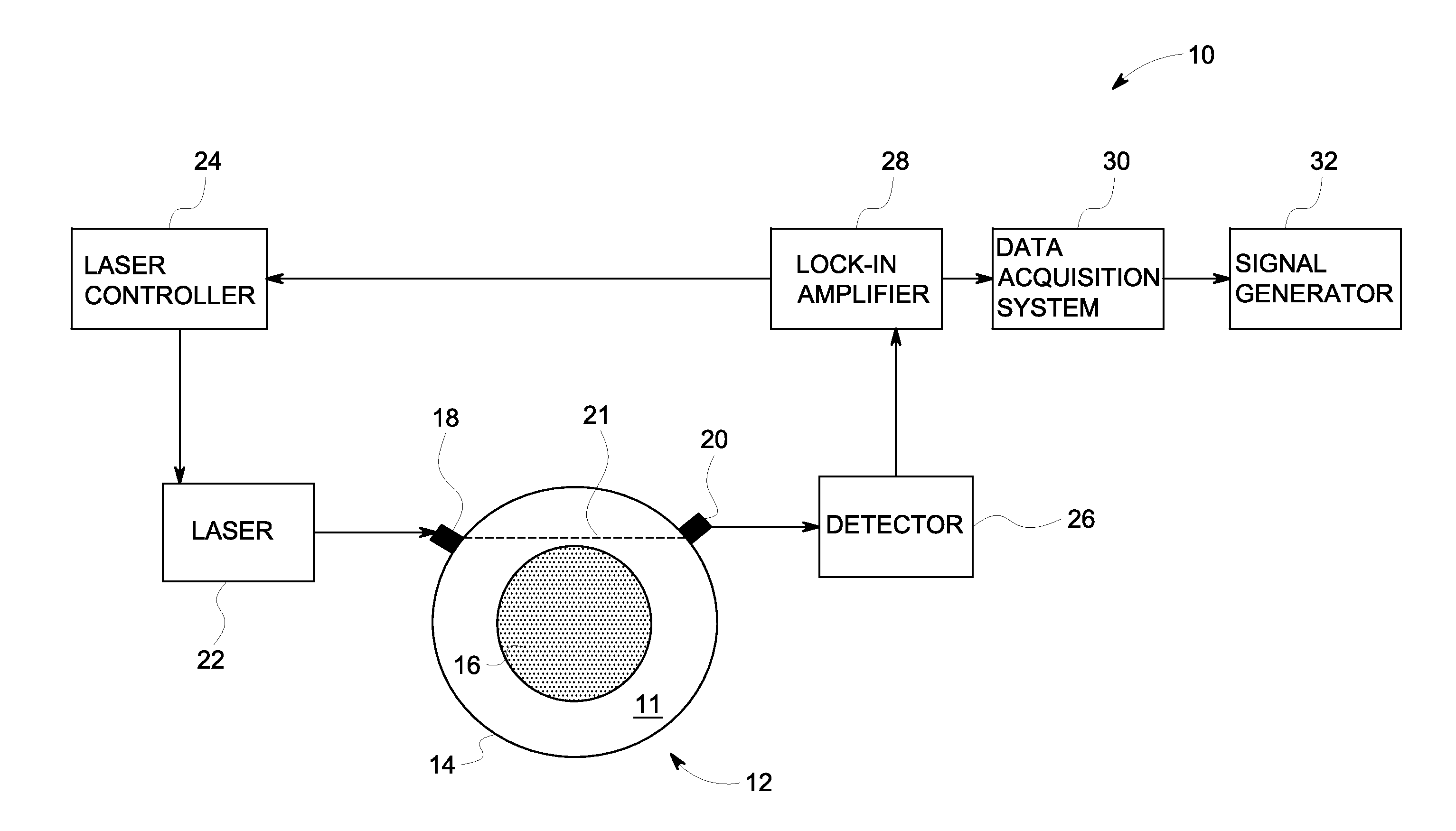

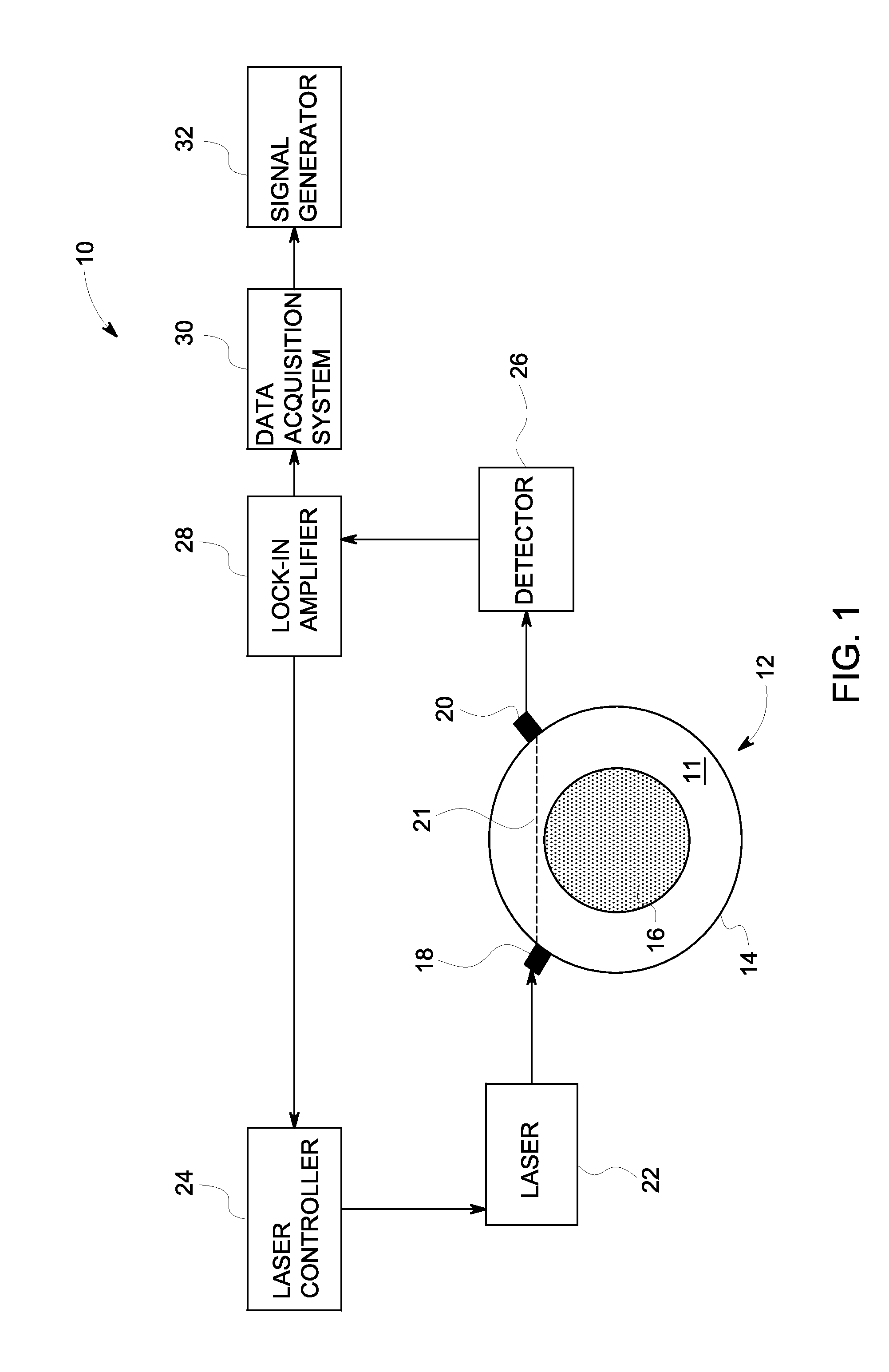

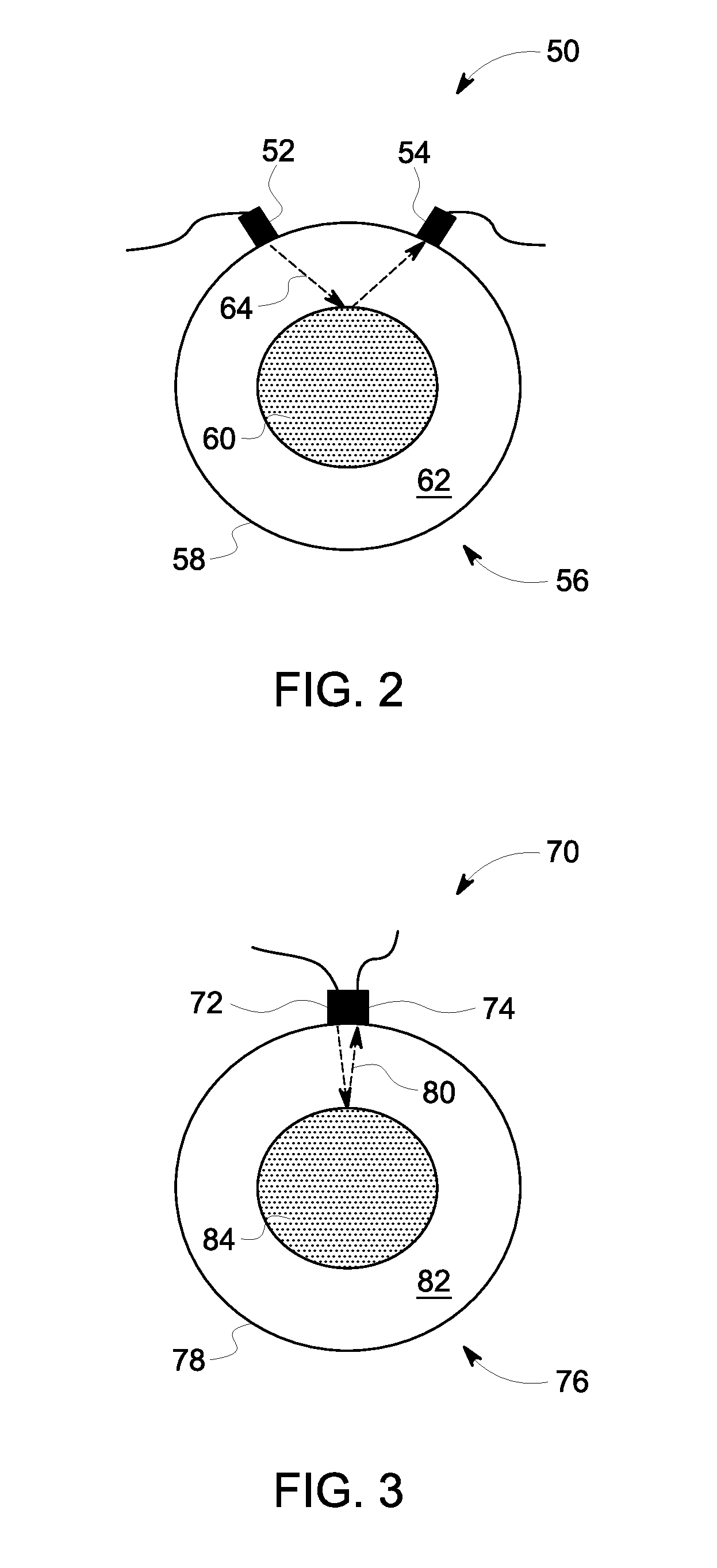

System and method for real-time measurement of equivalence ratio of gas fuel mixture

A real-time monitoring of an equivalence ratio of a gas-fuel mixture of a gas turbine engine is provided. The system includes multiple optical probes arranged on a plurality of fuel nozzles for transmitting laser beams directly through a gas-fuel mixture or indirectly by reflecting the laser beams from a surface of a centerbody or burner tube of the fuel nozzle. The system also includes one or more detectors to measure the transmitted laser beams from the multiple optical probes. Further, the system includes a data acquisition subsystem for acquiring and processing signals from the one or more detectors to determine the equivalence ratio of the gas-fuel mixture of the nozzle.

Owner:GENERAL ELECTRIC CO

System and method for a gas turbine engine

A system includes a gas turbine engine configured to combust an oxidant and a fuel to generate an exhaust gas, a catalyst bed configured to treat a portion of the exhaust gas from the gas turbine engine to generate a treated exhaust gas, a differential temperature monitor configured to monitor a differential temperature between a first temperature of the portion of exhaust gas upstream of the catalyst bed and a second temperature of the treated exhaust gas downstream of the catalyst bed, and an oxidant-to-fuel ratio system configured to adjust a parameter to maintain an efficacy of the catalyst bed based at least in part on the differential temperature in order to maintain a target equivalence ratio.

Owner:GENERAL ELECTRIC CO +1

Bi-component waterborne polyurethane coating composition

The invention relates to a bi-component waterborne polyurethane coating composition. The bi-component waterborne polyurethane coating composition comprises a component (a) and a component (b), wherein the component (a) comprises one or more polyol waterborne dispersions or waterborne emulsion, the content of hydroxy in the polyol is 0.5-5.5 wt.% based on the situation that the weight of the polyol is weighted by 100 wt.%, and the solid content of the polyol waterborne dispersion or the waterborne emulsion is 10-70 wt.% based on the situation that the total weight of the polyol waterborne dispersion or the waterborne emulsion is weighted by 100 wt.%; the component (b) comprises one or more hydrophilic modified isophorone diisocyanate polymers or prepolymers; due to the contents of the component (a) and the component (b), the equivalence ratio of an NCO group to the hydroxy in the bi-component waterborne polyurethane coating composition is 0.2:1 to 5:1. The bi-component waterborne polyurethane coating composition has high temperature yellowing resistance, and the chromatism value of a coating film prepared from the coating composition is less than 3.0 after the coating film is baked at the temperature of 150 DEG C for 1 day.

Owner:COVESTRO DEUTSCHLAND AG

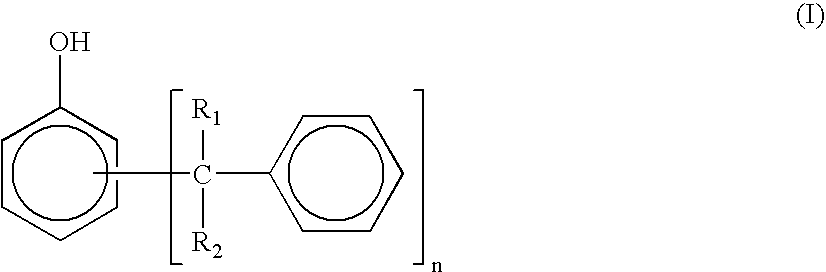

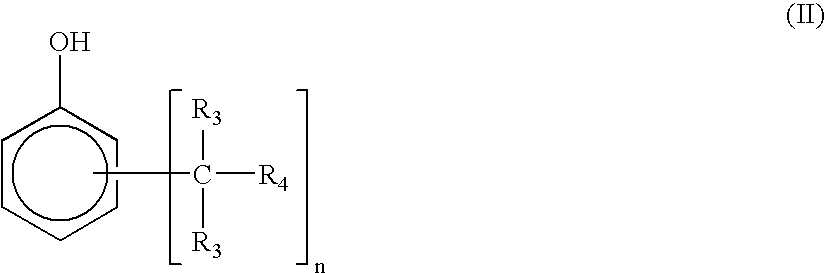

Thermosetting resin composition, and prepreg, metal-clad laminated board and printed wiring board using the same

InactiveUS20060099391A1Improve featuresPrinted circuitsThin material handlingEquivalence ratioCopper foil

The present invention provides a thermosetting resin composition superior with respect to all characteristics of dielectric characteristics, heat resistance, moisture resistance, electrolytic corrosion resistance, adhesiveness with a copper foil, chemical resistance and flame retardancy using a halogen-free flame retardant, its use, and for example, a prepreg, laminated board and printed wiring board. The present invention relates to: (1) a resin thermosetting resin composition comprising: (A) a phenol-modified cyanate ester oligomer obtained by reacting a cyanate compound (a) containing two or more cyanato groups in a single molecule, and (b) a phenol compound represented by the formula (I) and / or formula (II), such that a blending equivalence ratio of hydroxyl group (b) / cyanato group (a) is within a range of 0.01 to 0.3, and the monomer conversation rate of cyanate compound (a) containing two or more cyanato groups in a single molecule is 20 to 70%, (B) an epoxy resin containing two or more epoxy groups in a single molecule, and (C) at least one member selected from a metal salt of a di-substituted phosphinic acid and a phosphazene compound as a flame retardant; (2) a thermosetting resin composition comprising: components (A), (B), (C), (D) a silicone polymer containing at least one member of siloxane unit selected from a tri-functional siloxane unit represented by the formula: RSiO3 / 2 (wherein, R represents an organic group, and the R groups in the silicone polymer may be mutually the same or different) and a tetra-functional siloxane unit represented by the formula: SiO4 / 2, having a degree of polymerization of 7,000 or less, and having one or more functional groups on its terminals that react with hydroxyl groups, and (E) an organic filler; and, a prepreg obtained by using the same, and a metal-clad laminated board and printed wiring board obtained by using the same.

Owner:HITACHI CHEM CO LTD

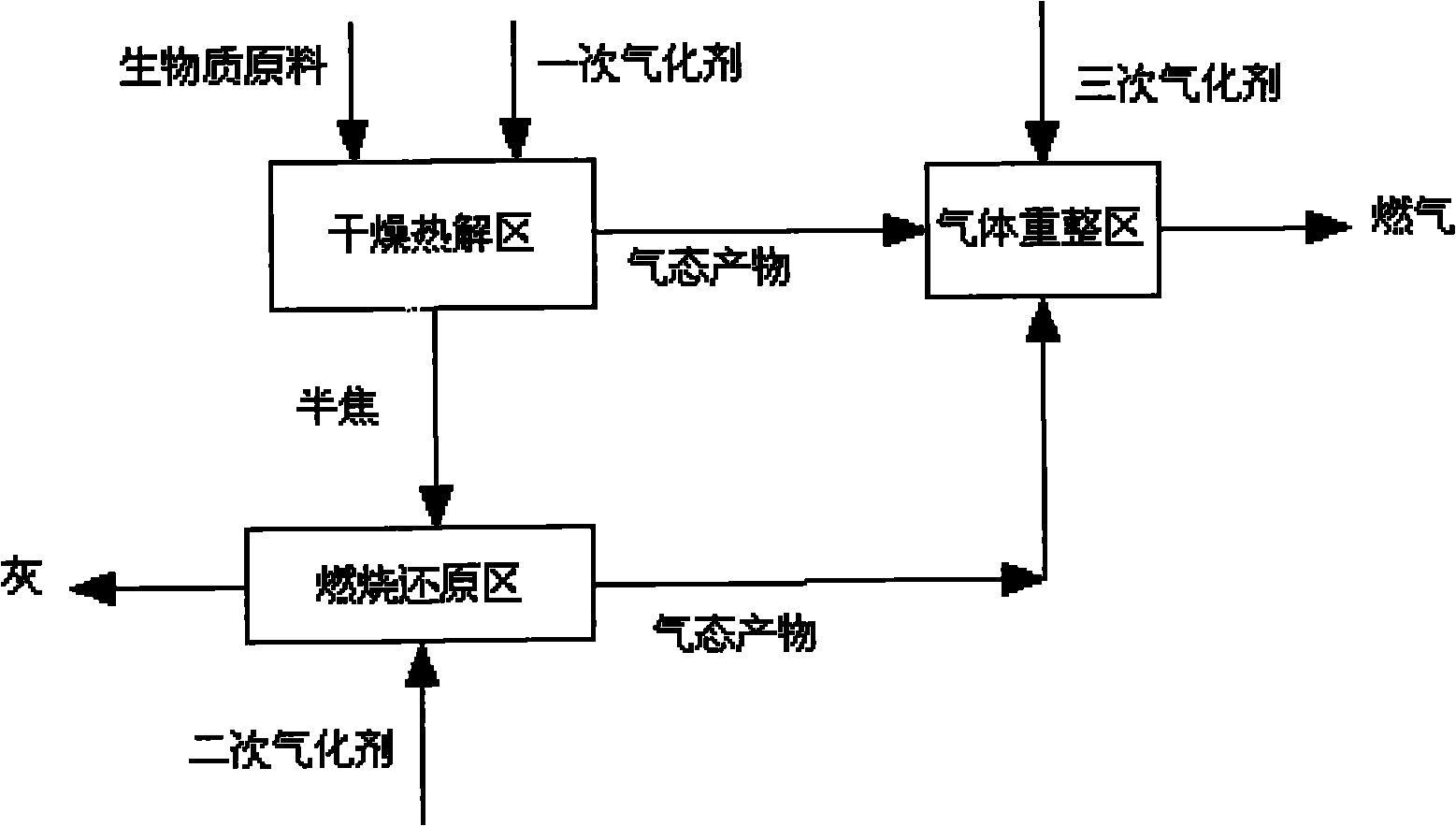

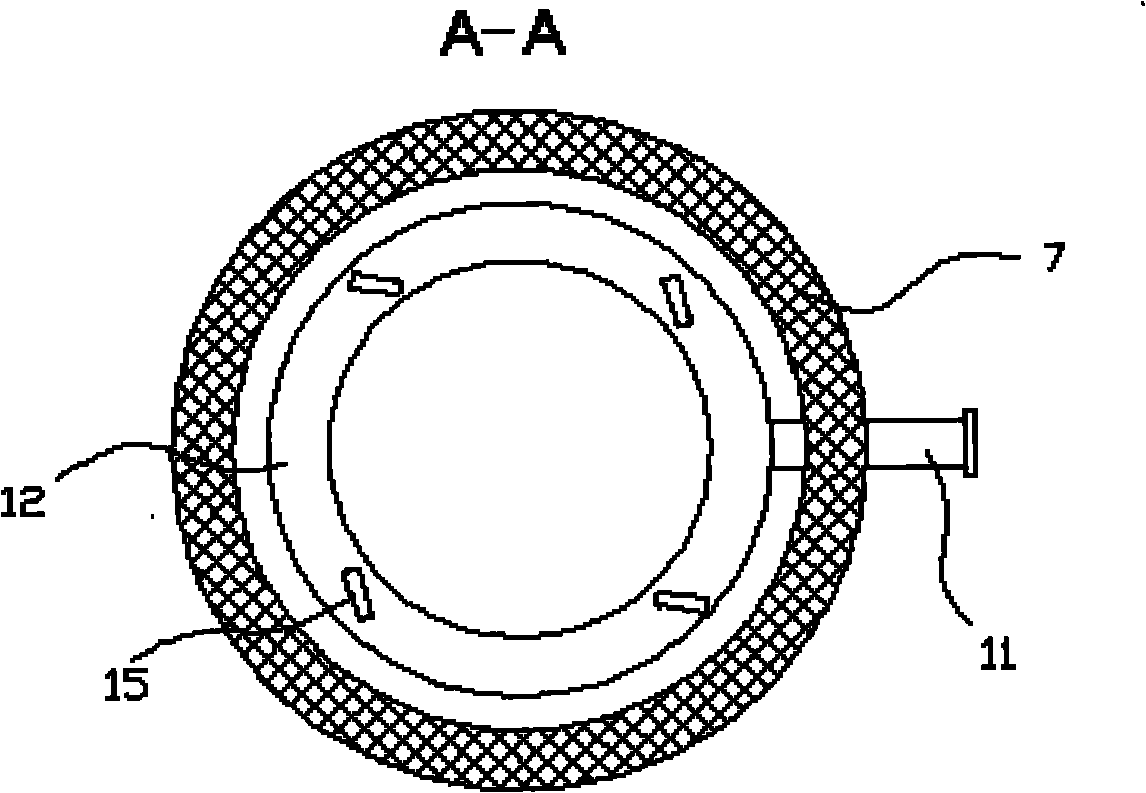

Biomass gasification method

ActiveCN101805638AReduce qualityAchieving directional gasificationCombustible gas productionCombustionMass ratio

The invention discloses a biomass gasification method. The method requires the steps of drying pyrolysis, combustion deoxidization and gas reforming in the gasification process to be relatively separated and continuously carried out in the same gasification furnace, simultaneously continuously gasification agent is introduced at three points in the whole gasification process and finally the cleanhigh quality product gas is obtained. In the invention, the equivalence ratio of the total gasification agent is 0.2-0.35, and the mass ratio of a first gasification agent, a second gasification agent and a third gasification agent is (0-0.8):(2-3.5):(0.7-1.5). The method controls the temperature and the reaction depth of each subarea in the furnace by controlling the mutual ratio of the biomass materials, the first gasification agent, the second gasification agent and the third gasification agent so as to control the quality of the final product gas. The obtained product gas can be used as the energy or the chemical engineering synthesis raw material gas. The method can generate clean product gas from the biomass, cannot generate secondary pollution and has high carbon conversion rate and simple implementation method.

Owner:山东山科环境资源有限公司

Control apparatus

A control apparatus which is capable of enhancing the accuracy of control of a controlled object having characteristics that dead time and response delay thereof vary. The control apparatus includes an ECU. The ECU calculates four predicted values as values of a controlled variable associated with respective times when four dead times elapse, respectively, calculates four weight function values associated with an exhaust gas volume, and calculates four products by multiplying the predicted values by the weight function values, respectively. The ECU sets the total sum of the four products as a predicted equivalent ratio and calculates an air-fuel ratio correction coefficient such that the predicted equivalent ratio becomes equal to a target equivalent ratio.

Owner:HONDA MOTOR CO LTD

Engine exhaust gas purifier

InactiveUS7426922B2Emission reductionImprove fuel economyElectrical controlInternal combustion piston enginesCombustion chamberTop dead center

An engine exhaust gas purifier includes: an injection controller allowing a fuel injection valve to inject fuel near the top dead center on each compression stroke; an EGR amount controller for controlling the amount of exhaust gas recirculated into a combustion chamber; an excess air ratio controller for controlling the excess air ratio so that the local equivalence ratio in a late combustion stage is lower than the equivalence ratio at which soot is produced; and an intake air temperature controller for controlling the temperature of intake air after being mixed with exhaust gas. The intake air temperature controller controls the temperature of intake air within a temperature range lower than an upper temperature limit below which a predetermined ignition delay time can be secured and higher than a lower temperature limit above which the production of HC and CO can be avoided.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com