Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4902 results about "Corrosive substance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A corrosive substance is one that will damage or destroy other substances with which it comes into contact by means of a chemical reaction.

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

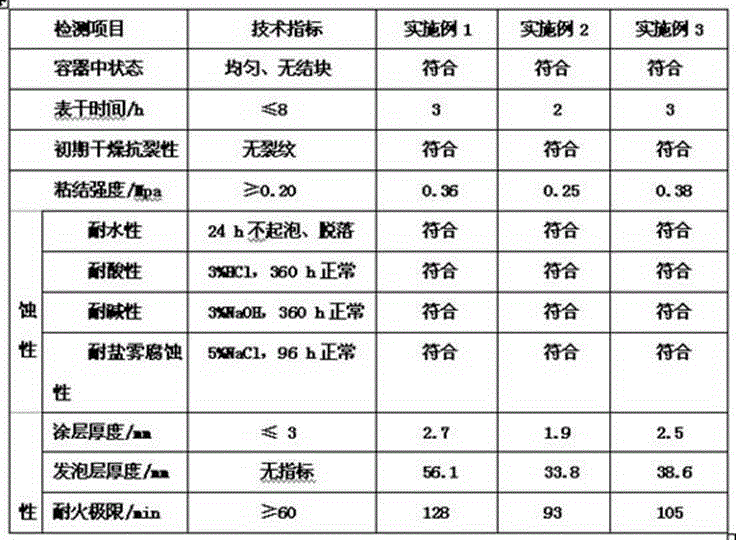

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

Corrosion resistant member

InactiveUS20070092696A1Loss of corrosion resistant capabilityUseful displayMolten spray coatingVacuum evaporation coatingCorrosion resistantCorrosive substance

When a corrosion resistant member is exposed to a chlorine-containing gas or plasma thereof and then to the ambient atmosphere, the member surface does not absorb moisture. The surface of the member to be exposed to a chlorine-containing gas or a plasma thereof does not form chloride particles of substrate material. After washing of the member with water, the wash water exhibits no corrosive nature to the substrate. The member is free of damages to the substrate and of a loss of corrosion resistant capability.

Owner:SHIN ETSU CHEM IND CO LTD

Method for chemical vapor deposition of silicon on to substrates for use in corrosive and vacuum environments

InactiveUS7070833B2Improve propertiesReduce outgassingPretreated surfacesSolid state diffusion coatingRoom temperatureSurface conditions

A method of passivating the surface of a substrate to protect the surface against corrosion, the surface effects on a vacuum environment, or both. The substrate surface is placed in a treatment environment and is first dehydrated and then the environment is evacuated. A silicon hydride gas is introduced into the treatment environment, which may be heated prior to the introduction of the gas. The substrate and silicon hydride gas contained therein are heated, if the treatment environment was not already heated prior to the introduction of the gas and pressurized to decompose the gas. A layer of silicon is deposited on the substrate surface. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the treatment environment. The substrate is then cooled and held at a cooled temperature to optimize surface conditions for subsequent depositions, and the treatment environment is purged with an inert gas to remove the silicon hydride gas. The substrate is cycled through the silicon depositing step until the surface of the substrate is covered with a layer of silicon. The treatment environment is then evacuated and the substrate cooled to room temperature.

Owner:SILCOTEK CORP

Composite flame retardant glass fibre reinforced nylon 66 insulating strip and preparation method thereof

The invention discloses a composite flame retardant glass fibre reinforced nylon 66 insulating strip. The insulating strip comprises the following components: nylon resin, glass fibre, inorganic packing, flexibilizer, coupling agent, dispersing lubricant, antioxidant, light stabilizer, heat stabilizer, composite flame retardant and master batch, wherein the composite flame retardant is a combination of nitrogen flame retardant and / or phosphorus flame retardant and / or nitrogen-phosphorus flame retardant and inorganic metal compound retardant. The invention also discloses a preparation method of the insulating strip. The product of the invention has no halogen, excellent mechanical property and stable dimension of sectional material, solves the problems of the prior art that the halogen-containing fire retardant product generates dense smoke and corrosive gas and has toxicity when used for antiflaming and reduces the secondary disaster caused by the problems; and the problems of the prior art that the dosage of the non-halogen flame retardant is too large and the compatibility is not good, are solved, the influence of using the flame retardant on the overall mechanical performance of the product is avoided, good antiflaming effect is obtained, and the product satisfies and expands the needs of customers and market.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

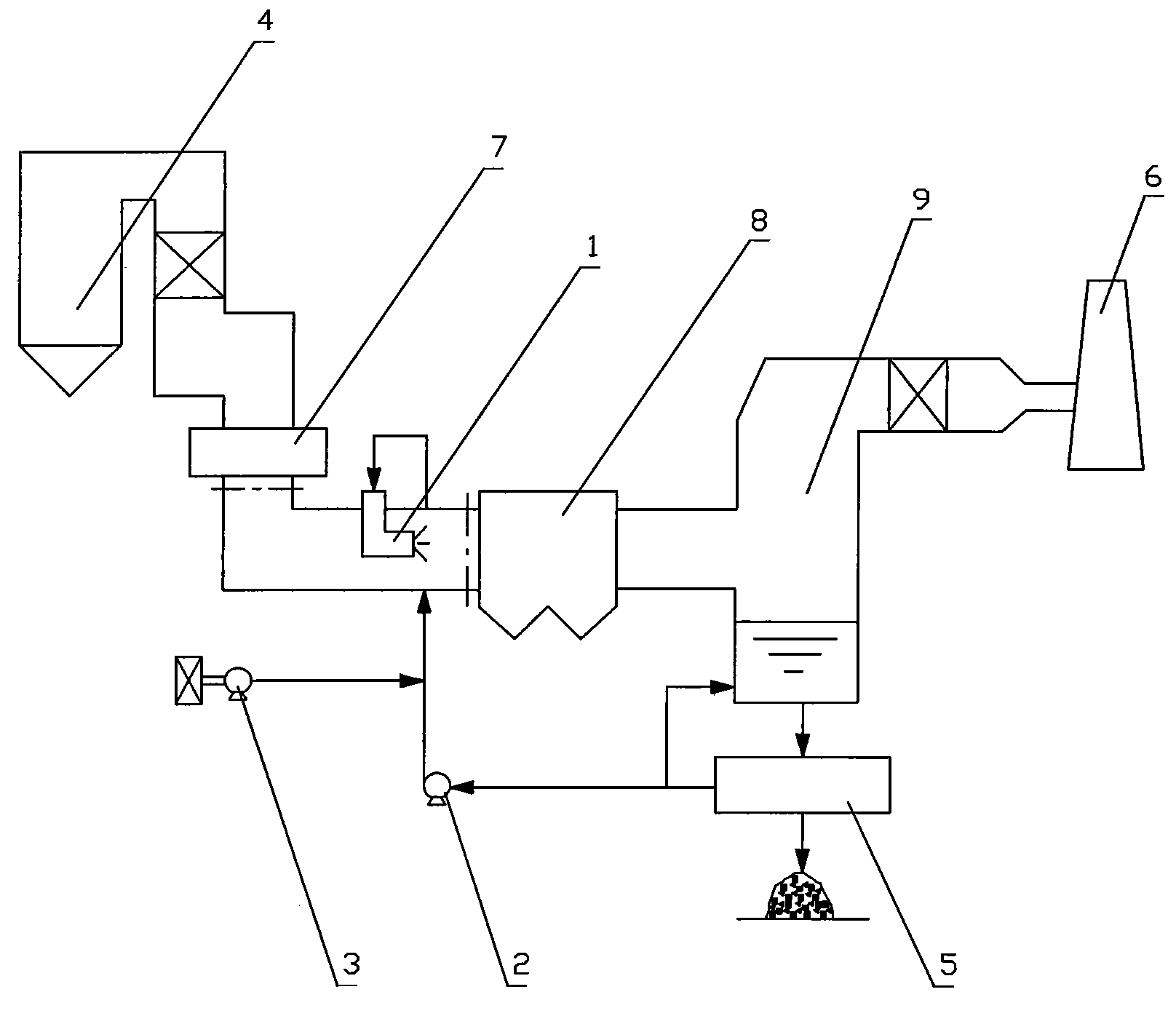

Spray evaporation treatment method of wet method flue gas desulfurization wastewater in thermal power station

ActiveCN101844819AOvercoming multiple configuration devicesSmall investmentDispersed particle separationWater/sewage treatmentEvaporationTreatment system

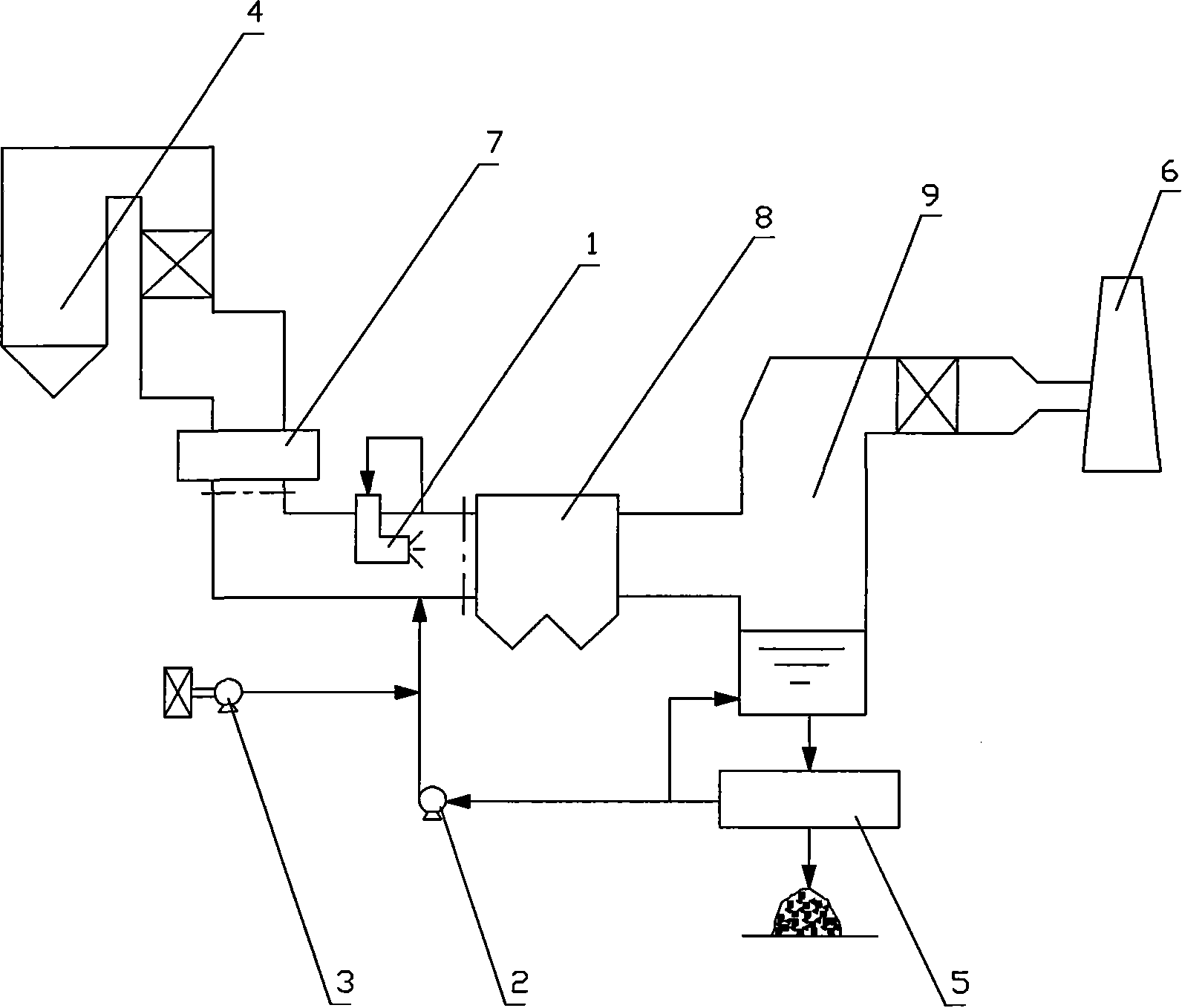

The invention discloses a spray evaporation treatment method of the wet method flue gas desulfurization wastewater in a thermal power station. In the method, an atomizing nozzle is arranged in the region with the temperature at 413-470 K and the flue gas speed of 5-11 m / s in a flue of the boiler tail part; desulfurization wastewater is pumped by utilizing a water pump, air is compressed by a compressor, and the pressure ratio of the compressed air to the desulfurization wastewater entering into the atomizing nozzle is 0.25-0.6; the speed of liquid droplets atomized by the atomizing nozzle is 50-80 m / s, and particle diameters of the liquid droplets are less than 50 mu m; and the liquid droplets are evaporated and then exhausted out of a chimney together with the flue gas. The invention can save chemical drugs utilized in the conventional wastewater treatment method; overcome the defects of many apparatuses, large investment, high running cost and heavy apparatus repair and maintenance load of a wastewater treatment system in the prior art, overcome the great corrosion influence of chlorine ions in water meta-acidity environment, reduce the specific resistance of ashes in a dust collector and improve the dust collector efficiency through increasing the flue gas humidity and properly lowering the flue gas temperature.

Owner:WUHAN TIANHE TECH

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20060079090A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

Nitrate molten salt heat transferring and reserving medium and preparation method and application thereof

InactiveCN102533226AWide operating temperature rangeImprove thermal stabilityHeat-exchange elementsDecompositionInstability

The invention discloses a nitrate molten salt heat transferring and reserving medium and a preparation method and application thereof. The nitrate molten salt heat transferring and reserving medium is prepared with 5 to 40 percent of potassium nitrate, 5 to 25 percent of sodium nitrate, and 10 to 70 percent of calcium nitrate. The melting point of the nitrate molten salt heat transferring and reserving medium can be as low as 120 DEG C, and the upper limit of temperature for use can reach 550 DEG C, the nitrate molten salt heat transferring and reserving medium has a wide temperature scope of application, can work normally at the temperature scope of 180 DEG C to 550 DEG C, and has good thermal stability; the shortcoming of high melting point of binary nitrate molten salt system can be overcome, and the problem of instability caused by easy oxidative decomposition at high temperature of NaNO2 in the Chinese patent 200110027954.1 and ternary nitrate salt system can be solved, and the problems of corrosion and cost increase caused by the existing LiNO3 in the Chinese patent 00111406.9 and the American patent US007588694B1 can also be solved.

Owner:SUN YAT SEN UNIV +1

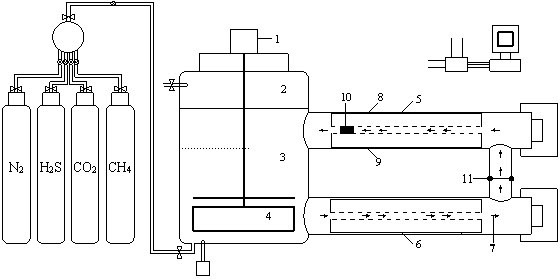

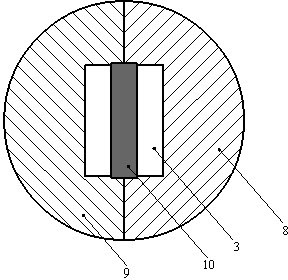

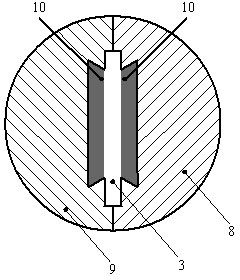

High-temperature high-pressure multiphase flow corrosion testing method and device

InactiveCN102654446AReliable corrosion resistanceReliable experimental methodWeather/light/corrosion resistanceSuspended particlesGas phase

The invention discloses a high-temperature high-pressure multiphase flow corrosion testing method and a high-temperature high-pressure multiphase flow corrosion testing device. The key points are as follows: under high temperature and high pressure conditions, circular flow of a gaseous-phase corrosive medium and a liquid-phase corrosive medium and thorough contact of the two mediums with the surface of a test sample are kept so that the mechanisms of corrosive actions of factors such as flow velocity, tube ponding, and deposited elemental sulphur can be simulated and researched; and the study on the influencing rules of gaseous-phase, liquid-phase, solid-phase and multiphase flows, suspension and suspended particles on the corrosion actions is also included. The testing method and the device are capable of realizing simulation of various corrosive working conditions: measuring the corrosion resistance of a metal material under various corrosive working conditions and in corrosive environments in high-temperature high pressure gaseous-phase, liquid-phase and multiphase flow states, and measuring the corrosion resistance and the corrosion rate of an oil sleeve in exploitation states such as water-carrying exploitation and water-gathered exploitation. Besides, the corrosion resistance of the metal material is comprehensively evaluated under the multiphase flow high-temperature high-pressure corrosion condition; and the preference of the metal material in a specific corrosive environment is realized according to testing results.

Owner:SOUTHWEST PETROLEUM UNIV

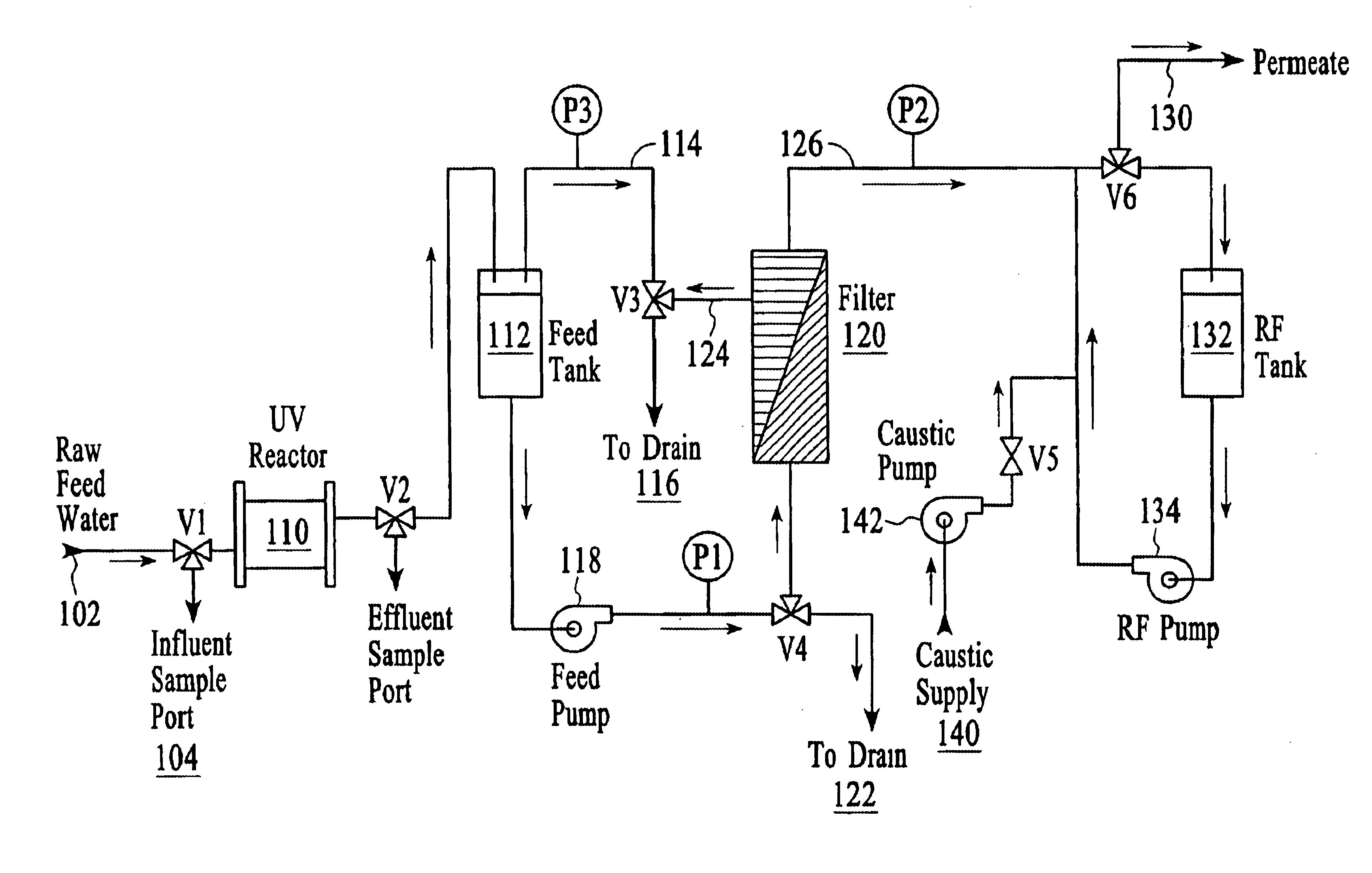

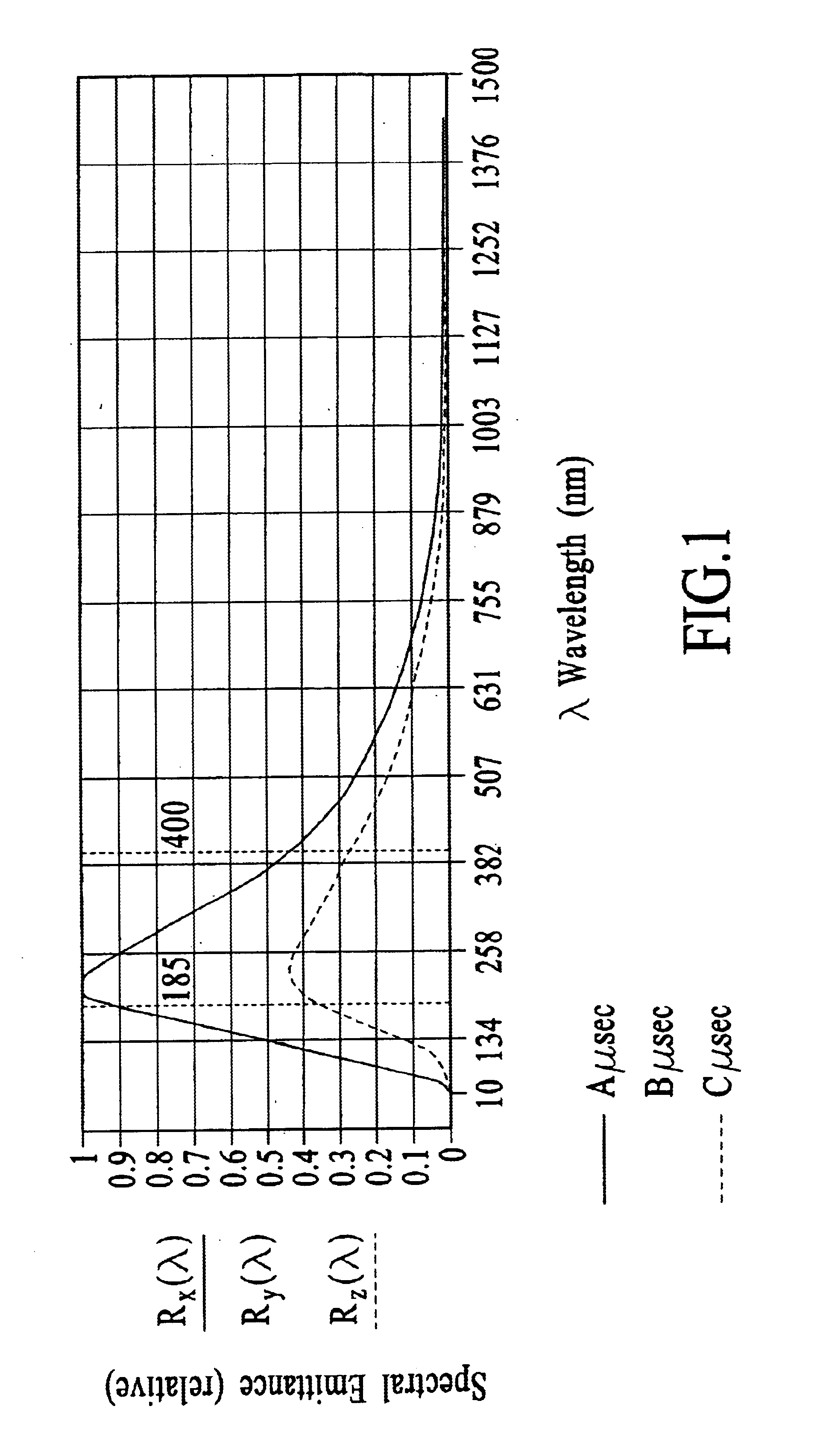

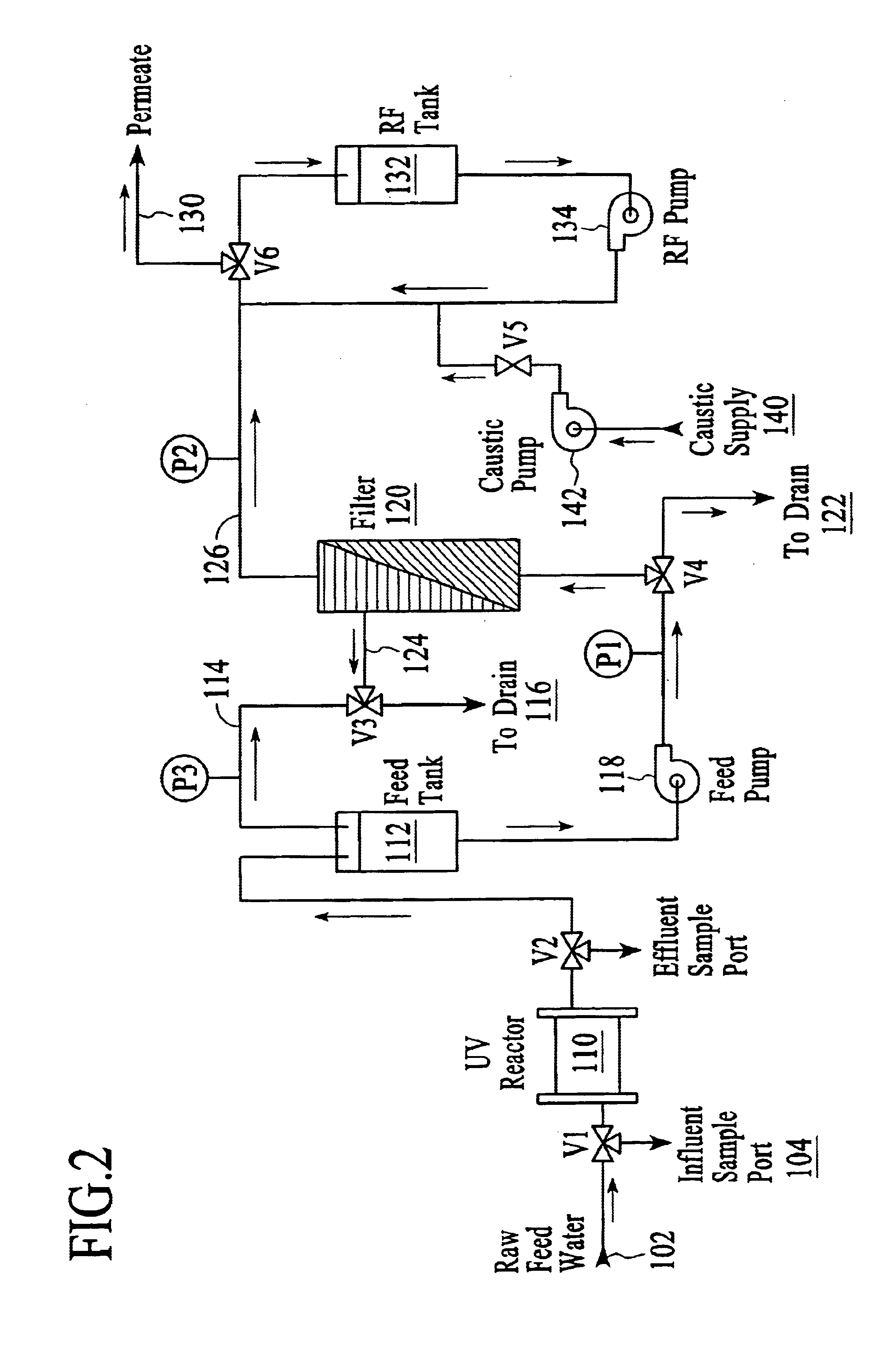

Pulsed blackbody radiation flux enhancement

A system and method for enhancing the flux and separation properties of water filtration membranes by oxidizing raw or processed water constituents with direct photolysis of the water matrix by pulsed blackbody UV, yielding ozone and hydrogen peroxide, hydroxyl radicals and other short lived oxidizing species. The result thereof, causing precipitation of inorganic molecules or organically complexed minerals, partial or complete mineralization of organic molecules and the deactivation or destruction of microbes including: virus, bacteria and protozoa. The system and method comprises a pulsed blackbody, deep-UV reactor having at least one treatment chamber, the reactor having a conveying assembly to convey the water to be treated into the chamber; a filter assembly to screen the UV treated water; a caustic supply means for the post-treatment of water; a recovering assembly recovering the permeate at an outlet of the filtration means. The effect of such UV water treatment is multifaceted. One aspect is the reduction of the transmembrane pressure (TMP), another is the reduction of duration of backwash and caustic cleaning cycles. Also, the oxidation of iron and manganese to insoluble compounds, without the addition of oxidizing agents, does not harm the membranes. Iron and manganese turn into hydroxide crystals trapped by the filtration membrane and separated from the permeate. These effects integrate to enhance the water flux through the filter membrane.

Owner:NEW STAR LASERS

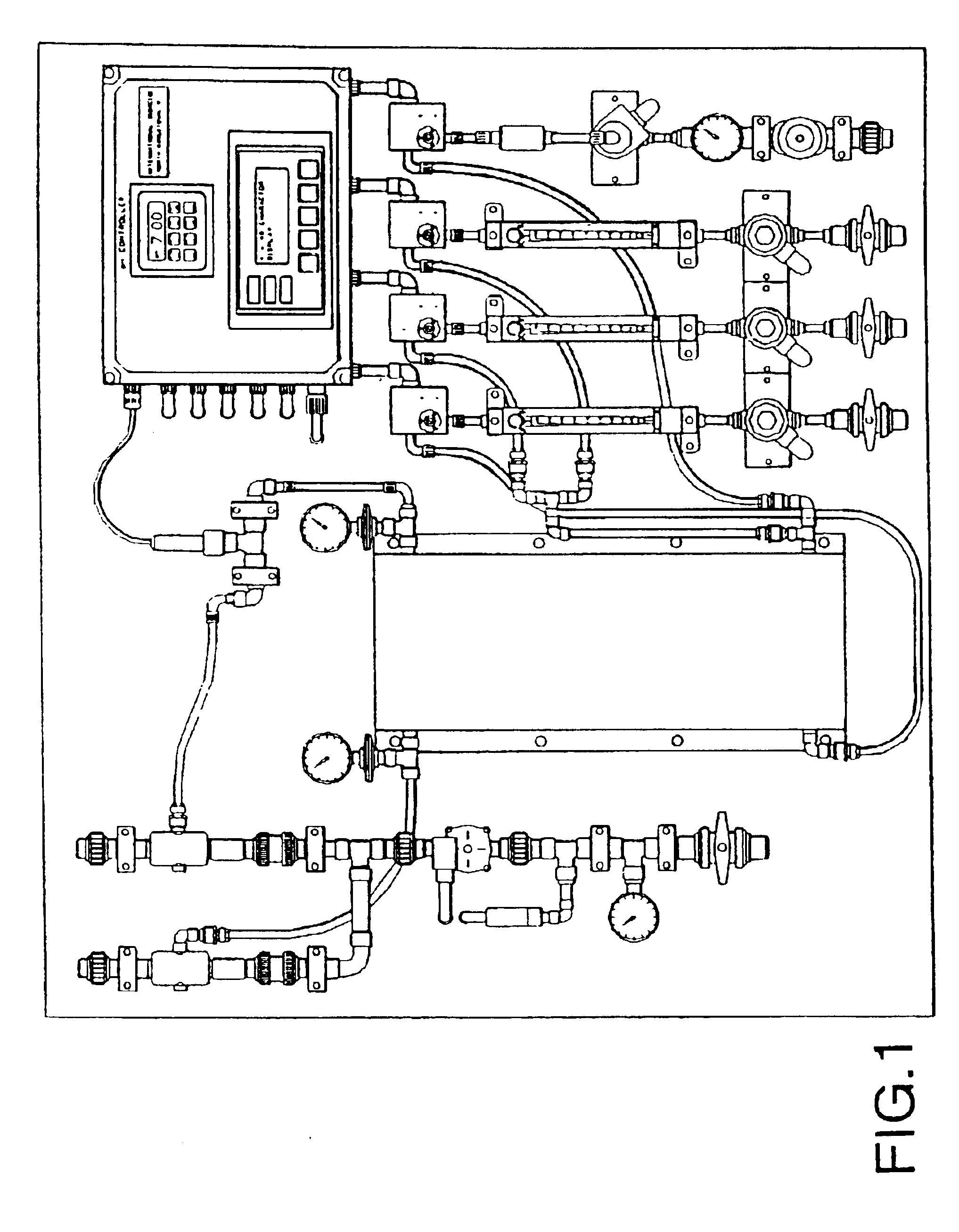

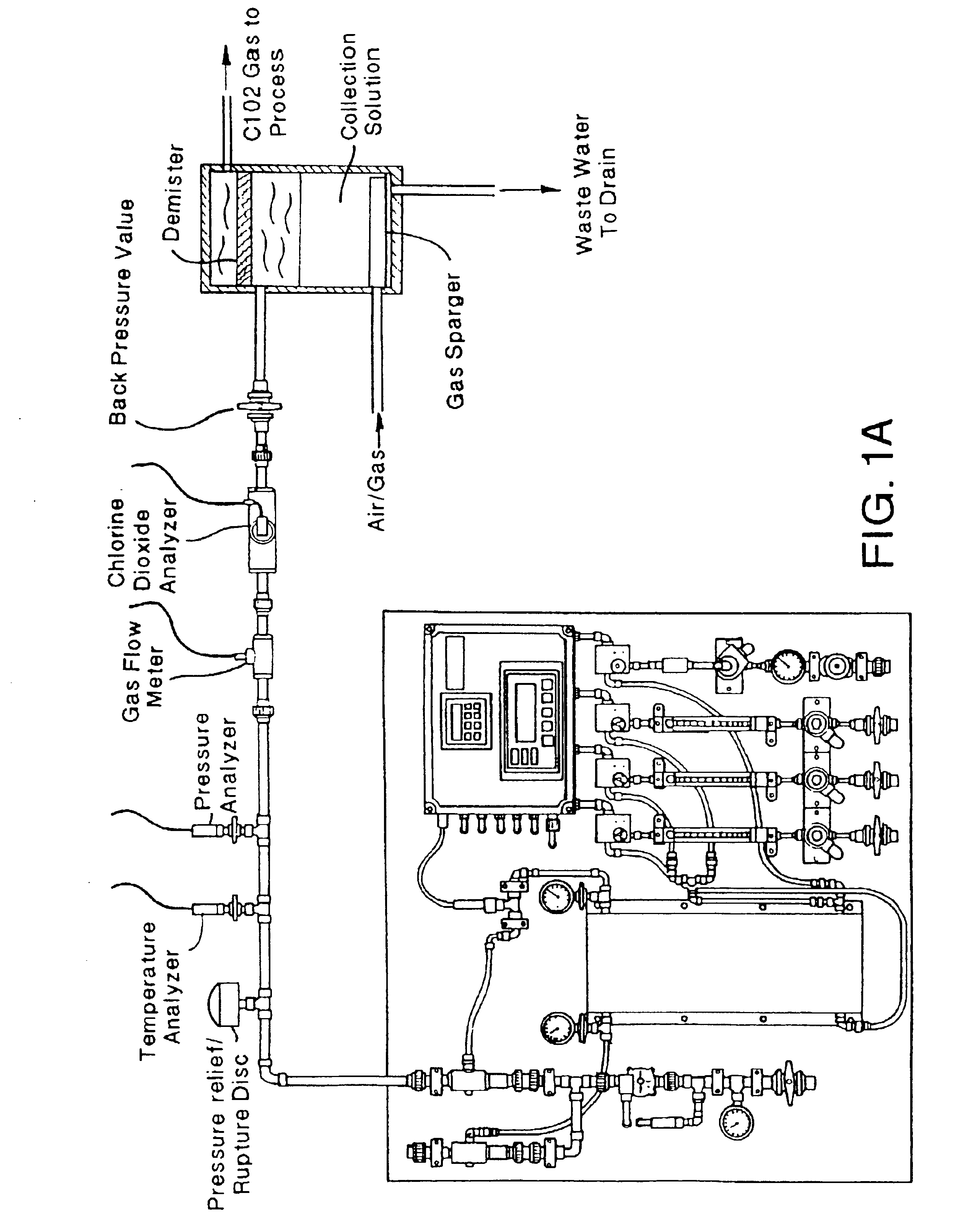

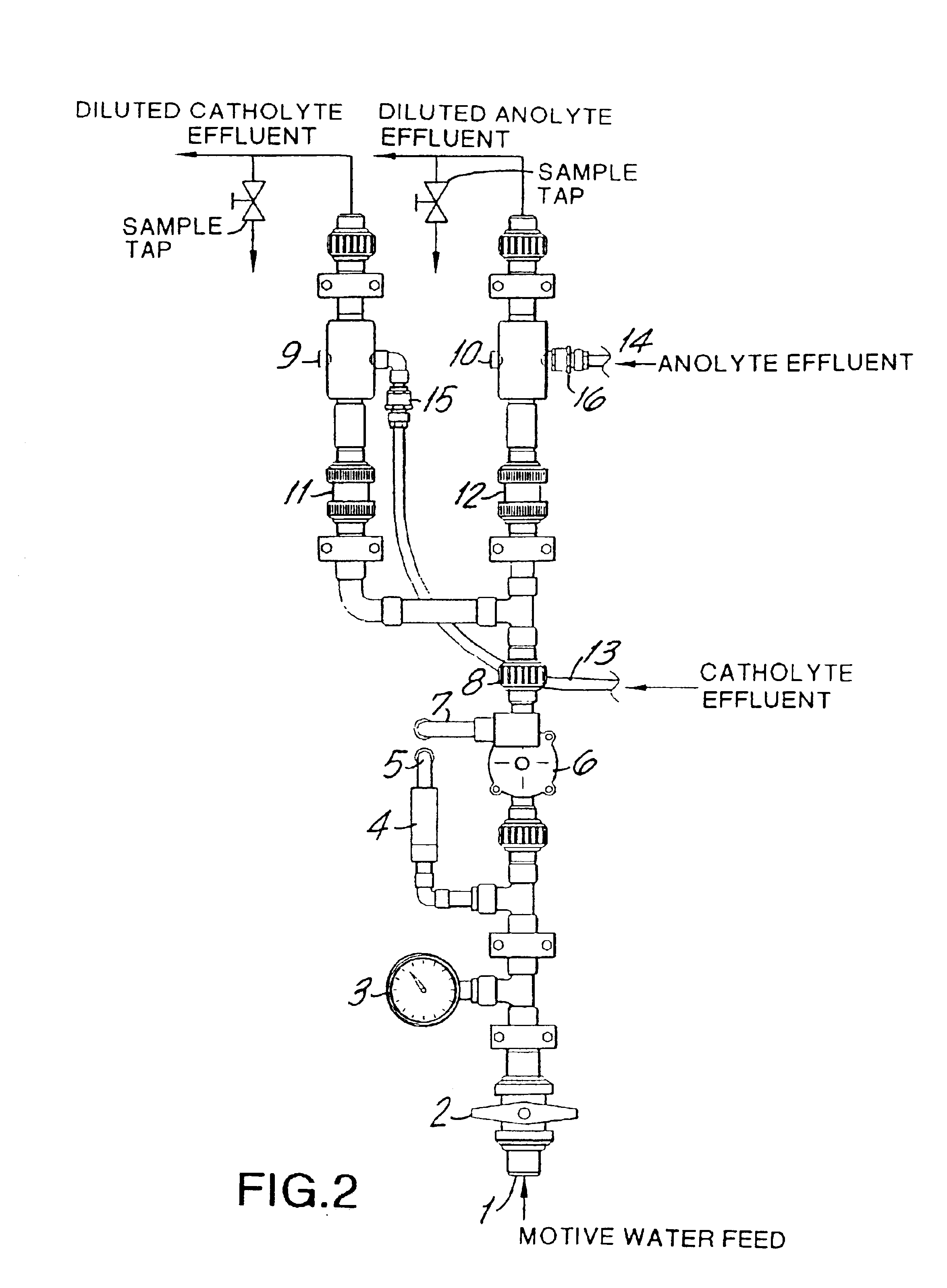

Generator for generating chlorine dioxide under vacuum eduction in a single pass

InactiveUS6881320B1Quickly and effectively evacuatesSecurity featureElectrolysis componentsAtomized substancesIon-exchange membranesChemistry

A vacuum operated electrolytic generator can be used to produce a chlorine dioxide solution or a mist of chlorine dioxide from a buffered aqueous alkali metal chlorite solution in one pass through an electrolytic cell. The cell contains a high surface area anode, a corrosion-resistant highly conductive cathode, and a cation ion exchange membrane between the anode and cathode. An eductor is used on the anolyte effluent line to create a vacuum and draw the anolyte through the cell. Either motive water or a motive inert gas (such as air) is used in the eductor. Preferably, an eductor is used in the catholyte effluent line. An ascending anolyte effluent line with a non-corrosive check valve leads from the cell to the anode eductor. Sensors are used to monitor the composition of the anolyte effluent and / or the anolyte feed. The final product is a chlorine dioxide solution when water is used for the eduction. The final product is a mist consisting essentially of gaseous chlorine dioxide, an inert gas, and water vapor when an inert gas is used for the eduction. The mist is useful for application crop, soils, produce such as vegetables, fruit, and tobacco, fields, storage cellars, and the like.

Owner:INT DIOXCIDE

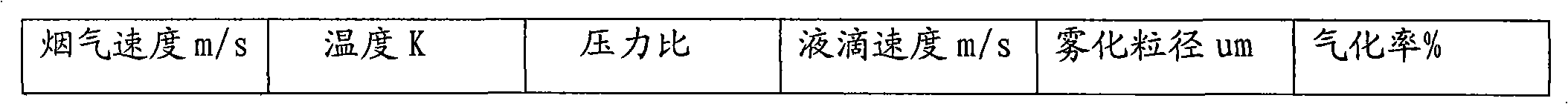

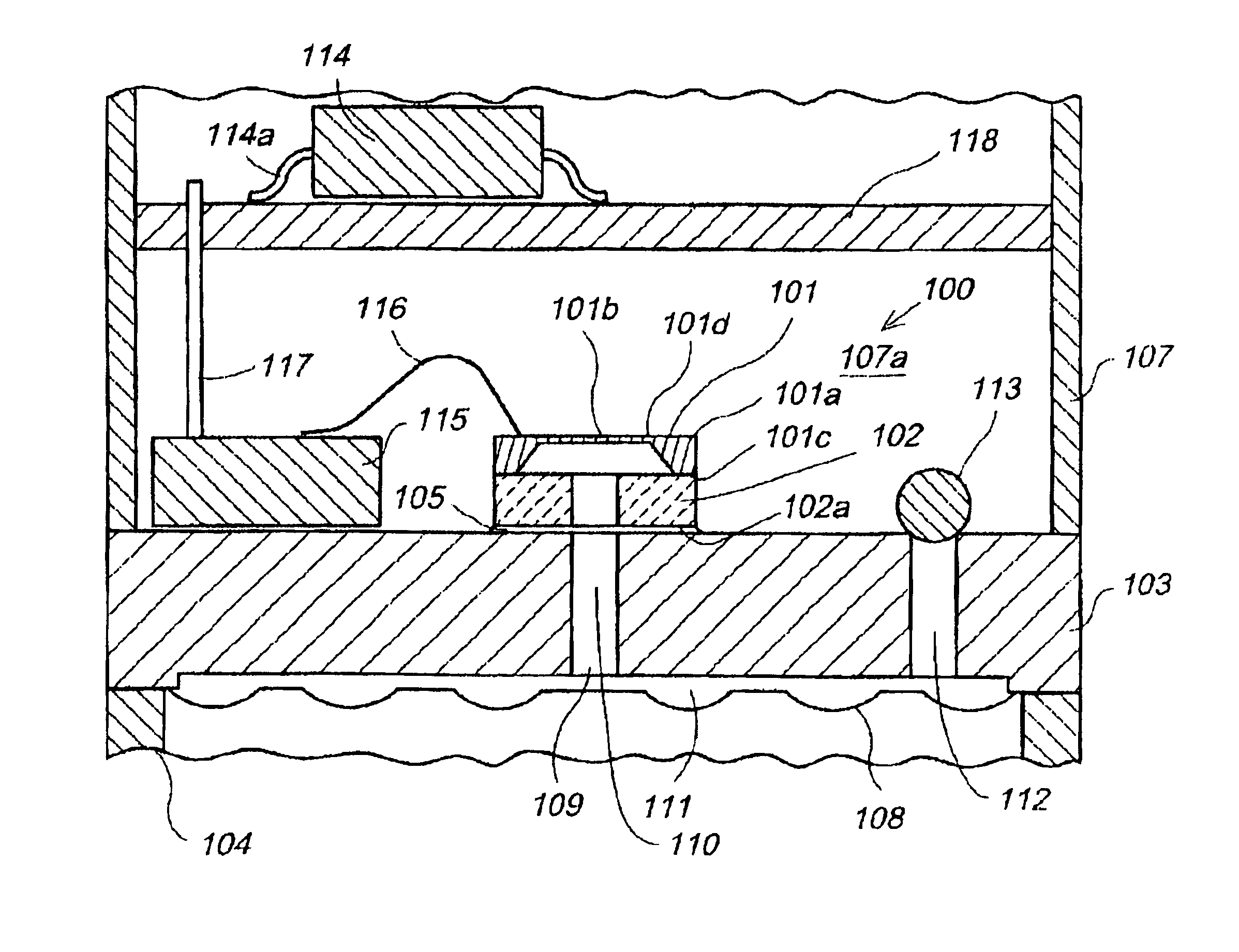

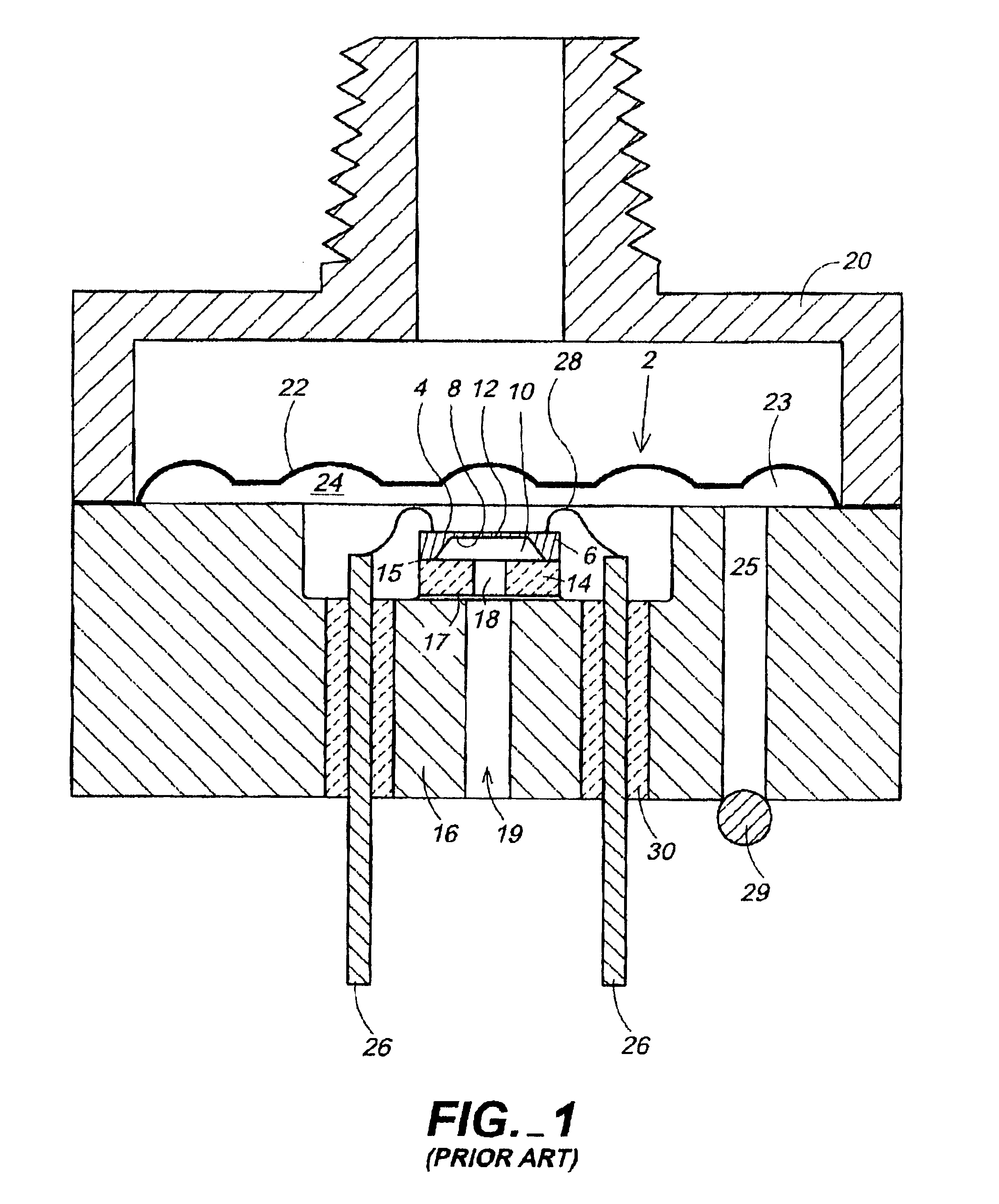

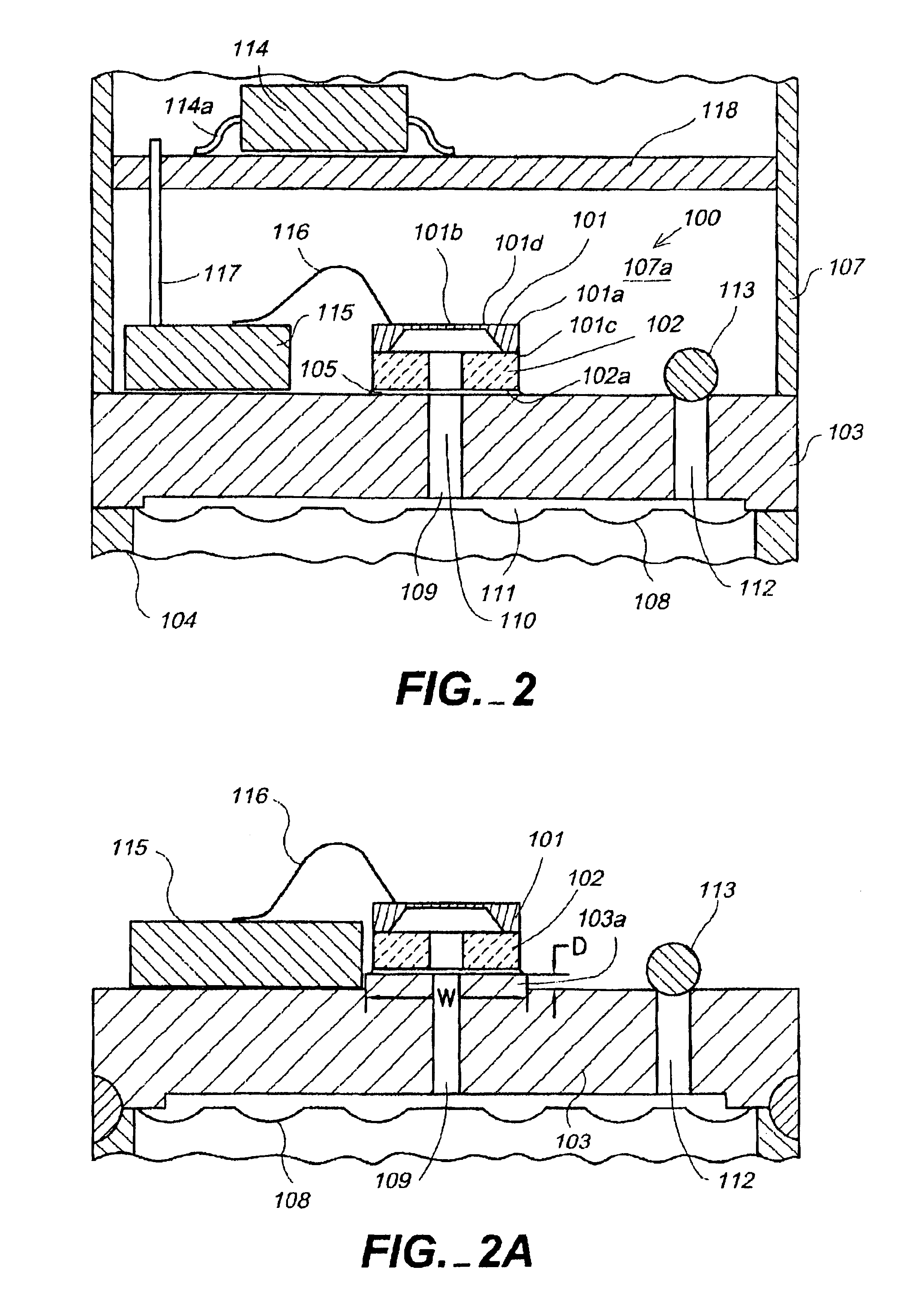

Isolation technique for pressure sensing structure

InactiveUS6938490B2Reduce oilLower the volumeFluid pressure measurement using elastically-deformable gaugesSolid-state devicesPressure senseIsolation techniques

An electronic pressure-sensing device is isolated from corrosive, conductive gasses and fluids by a corrosion resistant metal diaphragm welded to a pressure port. The pressure-sensing device is attached to a support structure with a hole that provides a path from the diaphragm area to the pressure-sensing device. A fill fluid is sealed behind the diaphragm and fills the hole through the support structure to the electronic pressure-sensing device. In this design, any hostile chemical applied is completely isolated from the electronic sensor and associated adhesive seals by the metal diaphragm.

Owner:MEASUREMENT SPEC

Deicing compositions and methods of use

The invention provides a non-corrosive deicing composition containing a deicing component, a corrosion inhibitor and a protein solution having a pH adjusted to between about pH 5 and about pH 7. Optionally, the deicing composition contains a corrosion inhibitor as well. The invention also provides a method of removing snow and ice from a road surface by applying these deicing compositions to the ice or snow.

Owner:LEIST E GREG

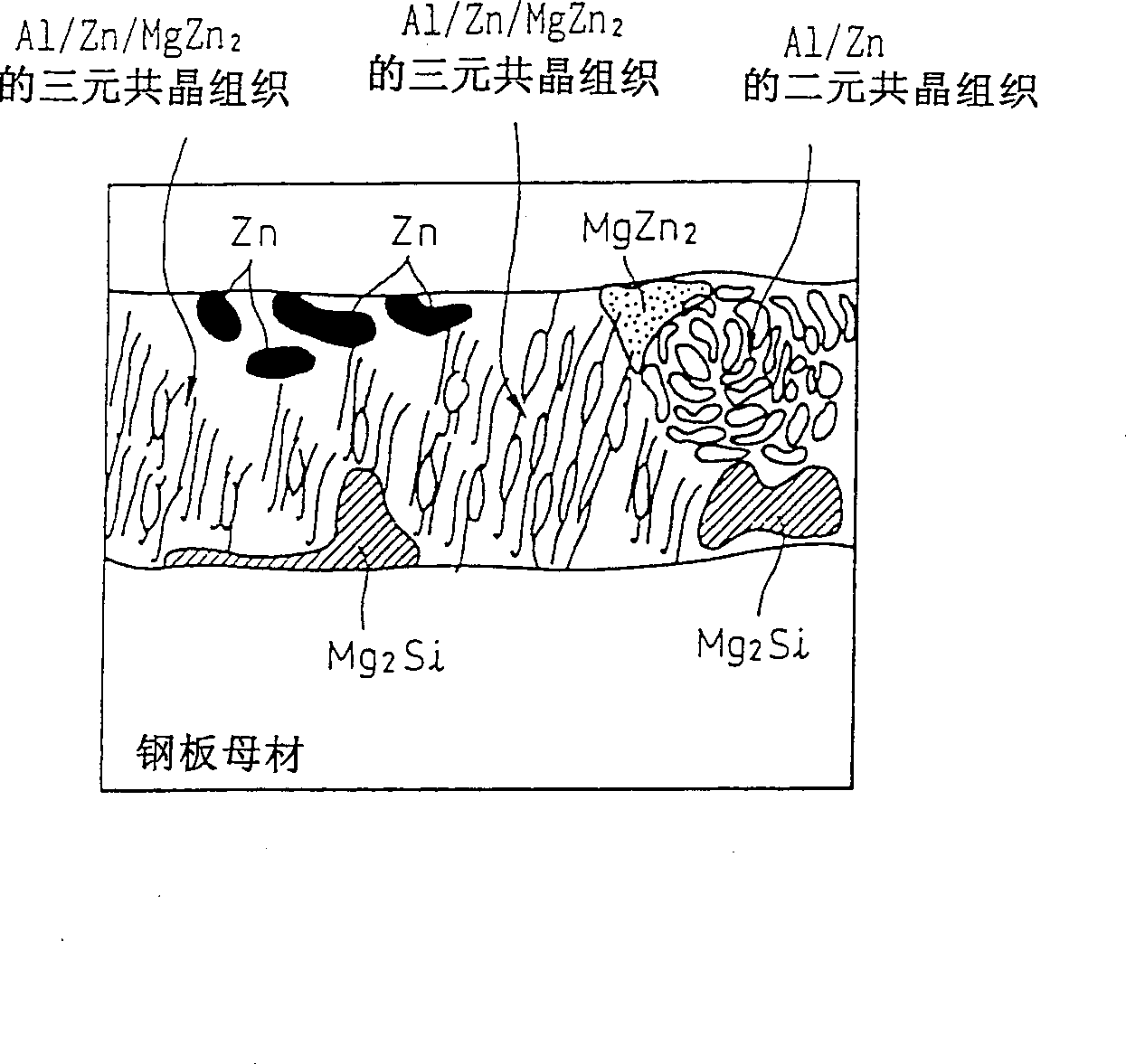

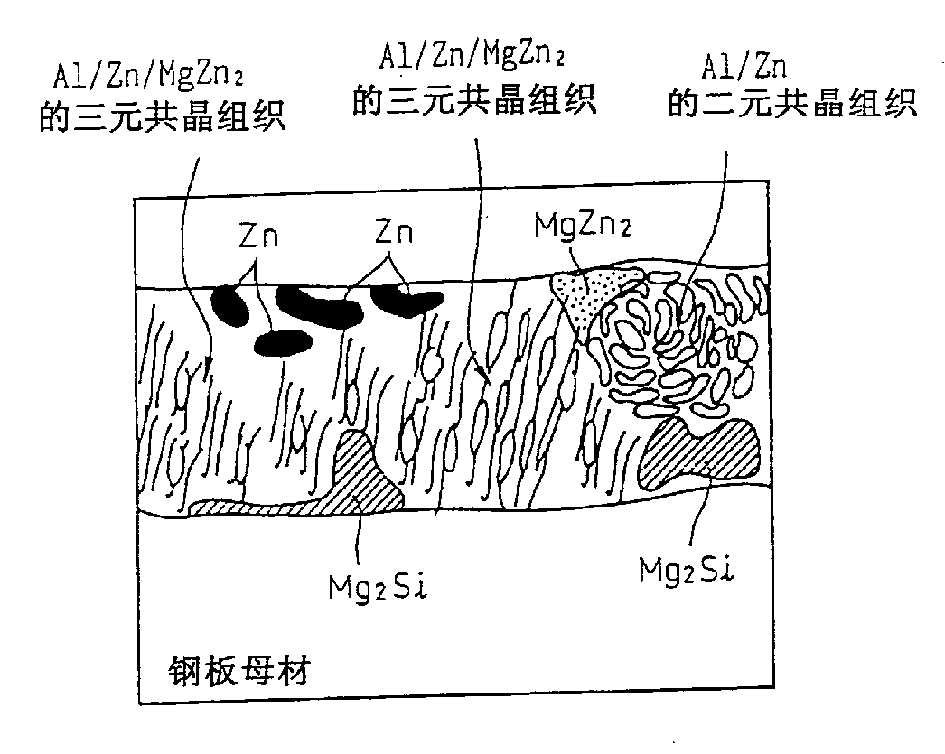

Plated steel product, plated steel sheet and precoated steel sheet having excellent resistance to corrosion

InactiveCN1342211AImprove adhesionImprove scratch resistanceHot-dipping/immersion processesLiquid surface applicatorsPhysical chemistryAlloy coating

Owner:NIPPON STEEL CORP

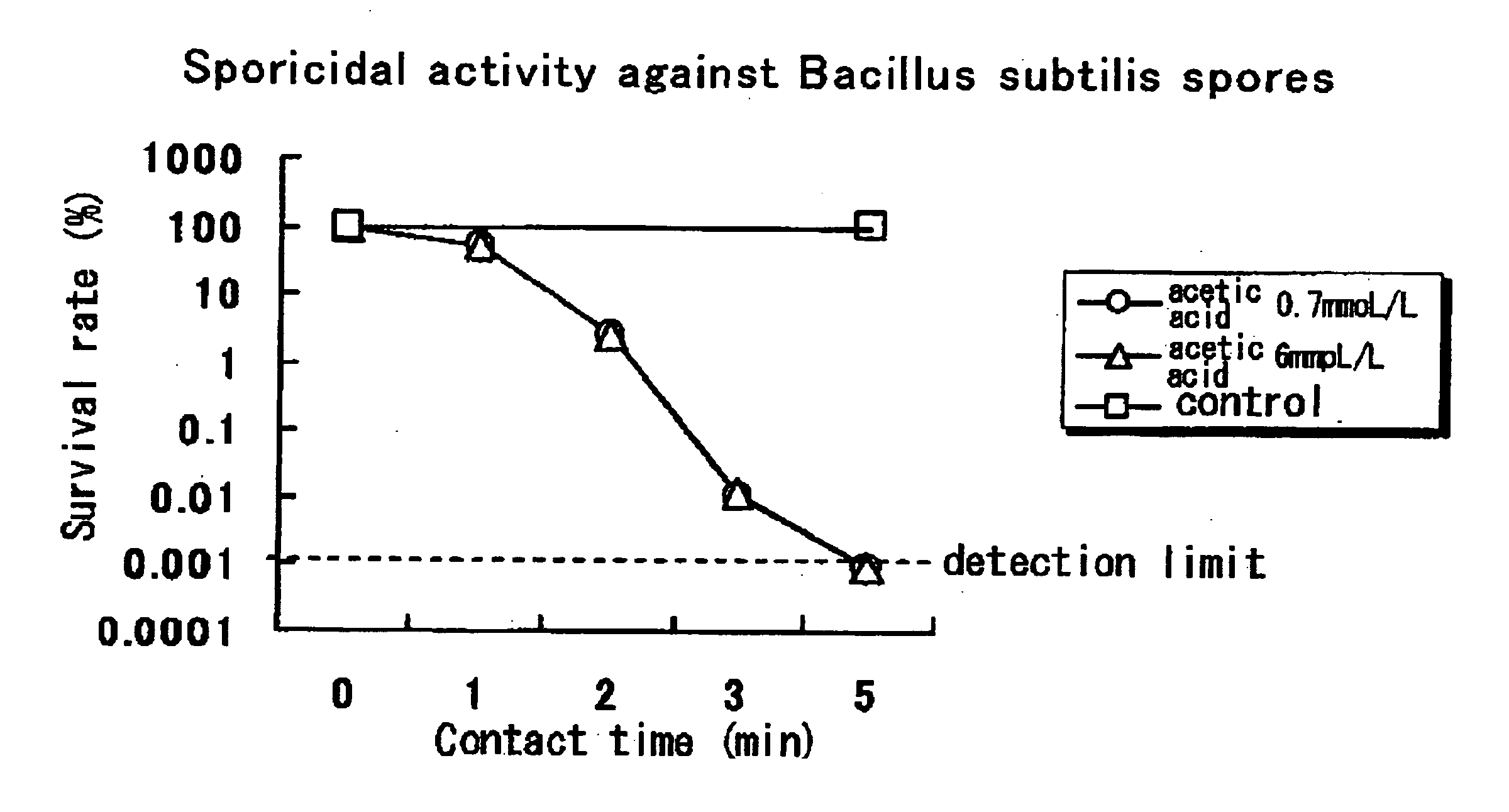

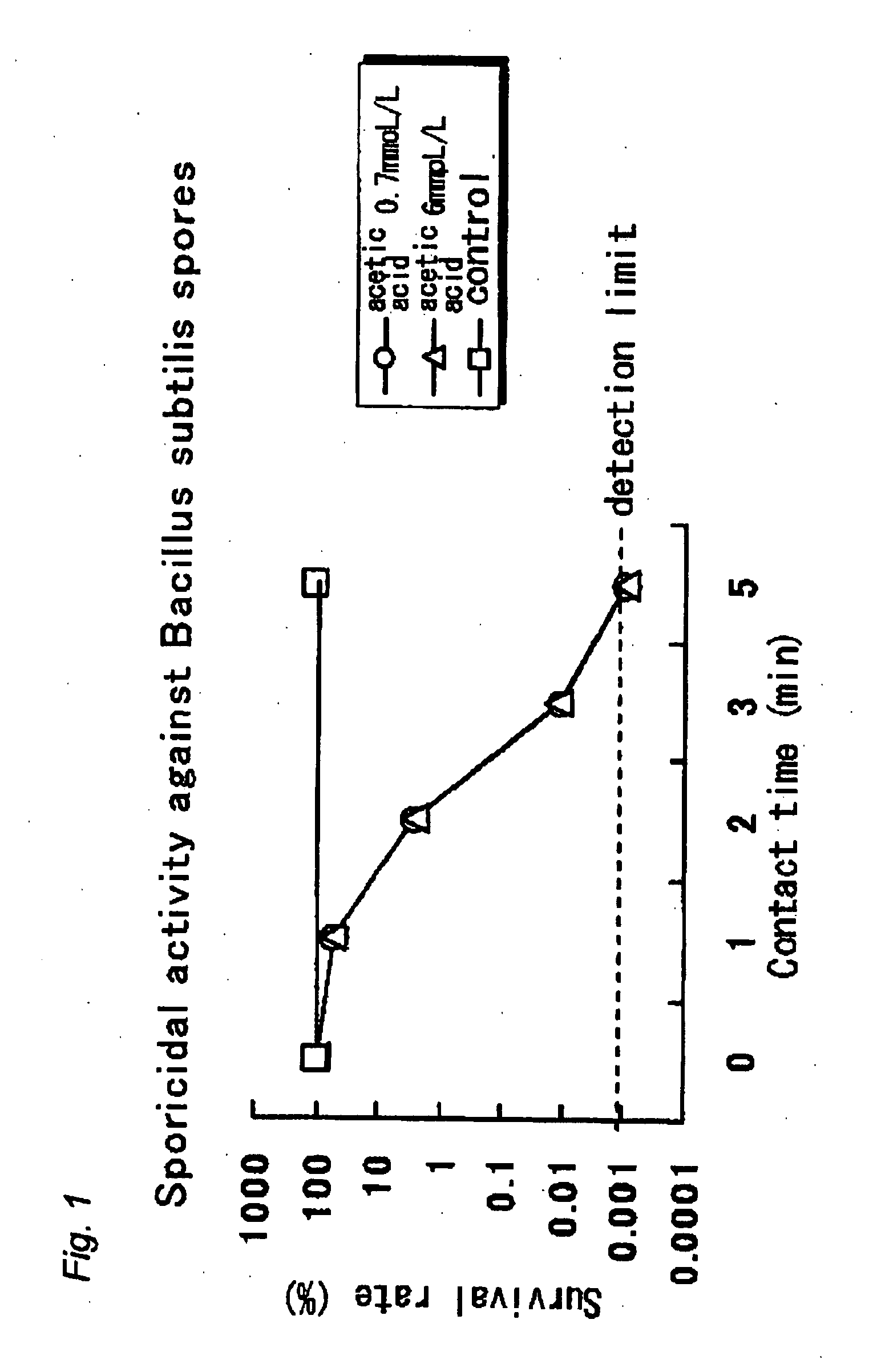

Hypochlorous Acid Based Sterilizing Composition

InactiveUS20080008621A1Easy to useLess corrosiveBiocideDead animal preservationReady to useBuffering agent

An object of the present invention is to provide a hypochlorous acid based sterilizing composition which is less corrosive to metal and a method for sterilizing a subject using the same. Provided by the present application is an aqueous sterilizing composition which comprises:(a) hypochlorous acid or at least one component which can release hypochlorous acid in water, and (b) a buffering agent; wherein the concentration of available chlorine in the composition upon use is 0.0001-12%. An electrolyzed water may be used instead of component (a). A method for sterilizing a subject using the aqueous sterilizing composition of the invention is also provided.

Owner:MARUISHI PHARMACEUTICAL CO LTD +1

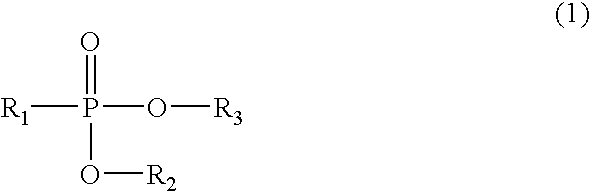

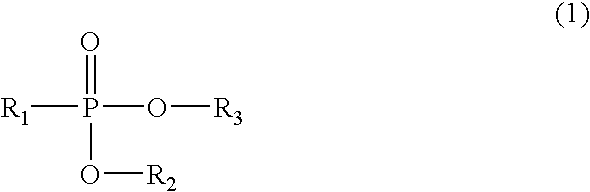

Lubricating oil compositions

ActiveUS20050143266A1Improve anti-wear performancePhosphorus reductionAdditivesBase-materialsPhosphoric Acid EstersCompound (substance)

A lubricating oil composition is disclosed which comprises a lubricating base oil, (A) at least one type of compound selected from specific phosphoric acid esters and salts thereof or in combination with (B) at least one type of compound selected from specific metal salts of specific phosphoric acid esters, with excellent oxidation stability, base number retention properties, anti-wear properties, extreme pressure properties and anti-corrosion properties and thus can be suitably used, in particular, as a lubricating oil for an internal combustion engine.

Owner:NIPPON OIL CORP

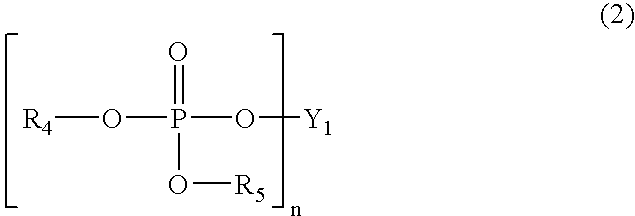

Solid energy saving screw cleaning agent

The invention provides a solid energy saving screw cleaning agent which can prepare non-corrosive and non-abrasive energy saving screw cleaning material. The raw material formula of the cleaning agent is as follows by weight percentage: 40-60% of matrix resin, 30%-40% of modified powder and 10-20% of auxiliary agent, and the sum of the weight percentage of all the components is 100%; the auxiliary agent is a cleaning surface, a surface active agent, a lubricating agent, a forming agent and a blowing activator; the raw material formula of the modified powder is as follows by weight percentage: 83-97% of inorganic powder, 2.0-8.0% of dispersing agent and 1.0-5.0% of coupling agent. According to the proportion of the formula, the matrix resin, the prepared modified powder, the cleaning agent, the surface active agent, the lubricating agent, the forming agent and the blowing activator are added into a high-speed mixer, and then are extruded and formed by an extruder to obtain the solid screen cleaning agent.

Owner:彭超

Environmental protection snow melt agent and preparation method thereof

ActiveCN1657586AGuaranteed to be environmentally friendlyEnsure biological sustainabilityOther chemical processesSnow meltingCorrosion

Owner:滁州市昌春木炭专业合作社 +1

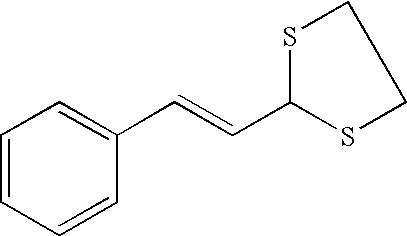

Thiol/aldehyde corrosion inhibitors

Methods of inhibiting corrosion comprising providing a corrosive environment; adding a corrosion inhibitor comprising a reaction product of a thiol compound and an aldehyde compound. Methods of acidizing a near well bore region of a subterranean formation comprising isolating a zone of interest along a well bore; and placing an acidizing solution in the zone of interest wherein the acidizing solution comprises an acid and a corrosion inhibiting compound comprising the reaction product of a thiol compound and an aldehyde compound.

Owner:HALLIBURTON ENERGY SERVICES INC

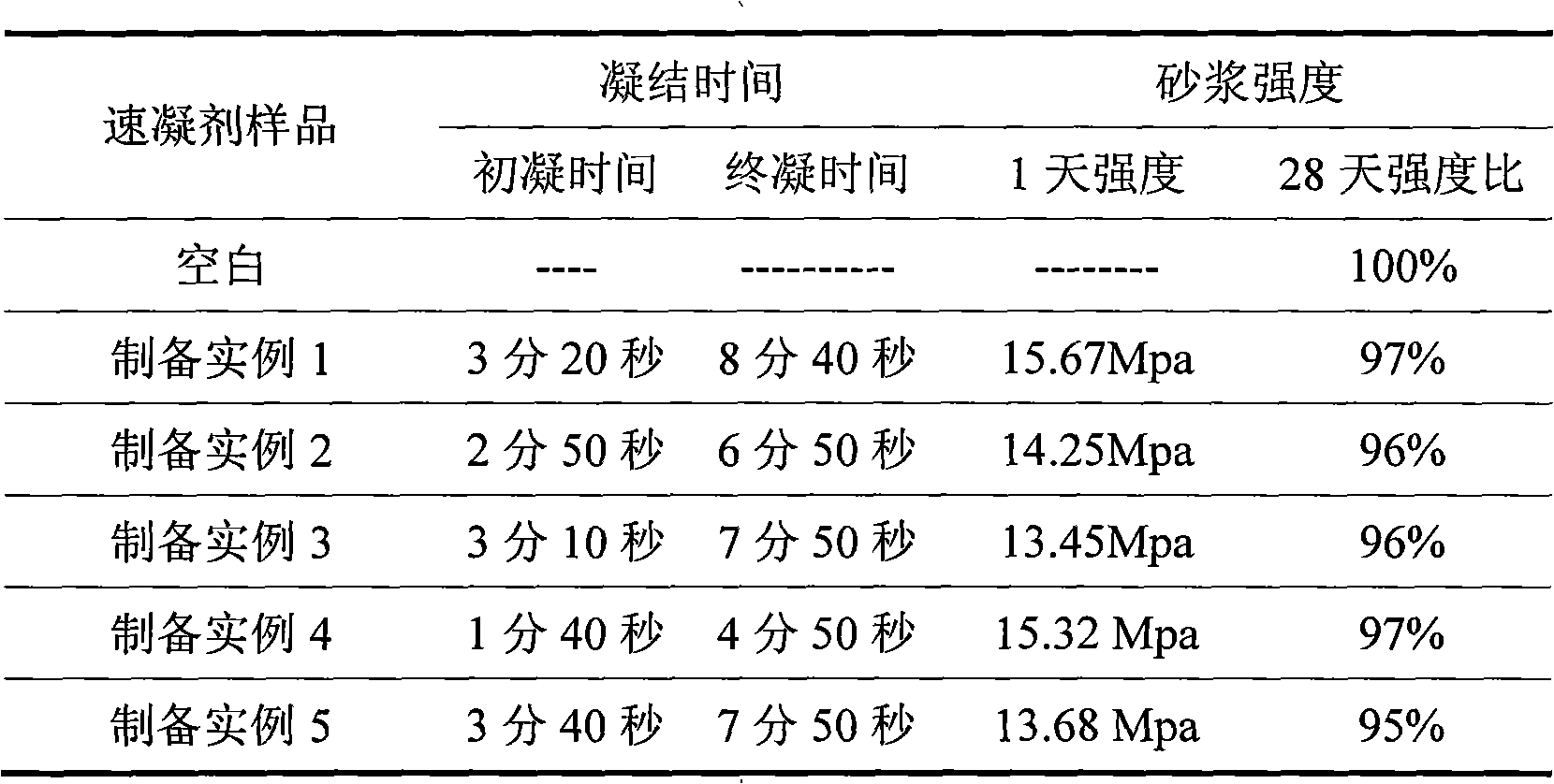

Alkali-free liquid setting accelerator

ActiveCN101648785ANo lossNo irritating smellUnderground chambersBuilding material handlingO-Phosphoric AcidSulfate radicals

The invention discloses an alkali-free liquid setting accelerator which is prepared from the following components by weight percent: 18-40% of hydroxycarboxylic acid, 1-5% of phosphoric acid, 15-30% of aluminium hydroxide, 0-5% of alkylol amine, 0.01-0.2% of defoaming agent and the balance water. The alkali-free liquid setting accelerator of invention does not contain alkali metal ions, sulfate ions and other corrosive materials, is safe to use and has no bad effect on the durability of sprayed concrete, thus being capable to be used in the construction of sprayed concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

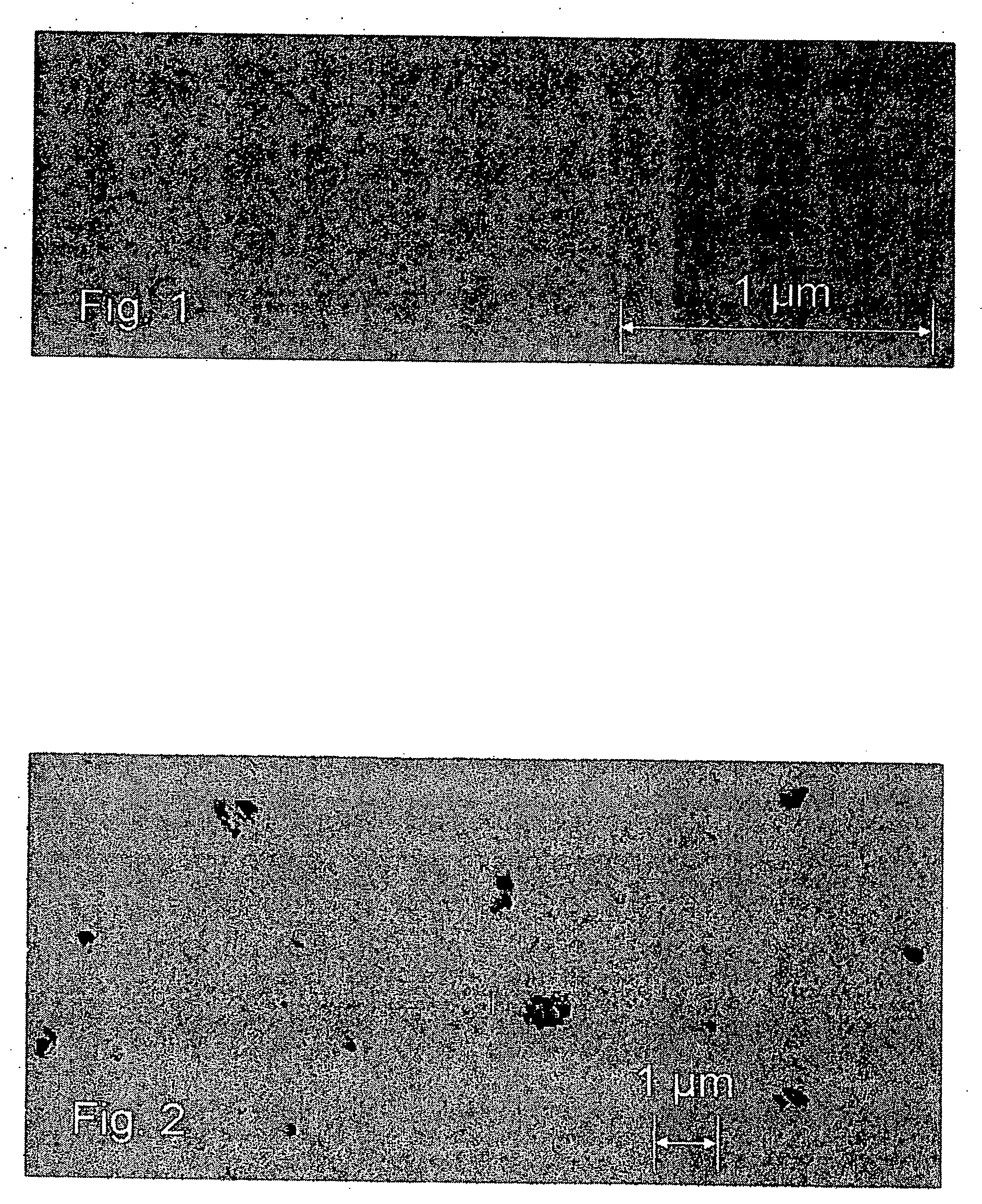

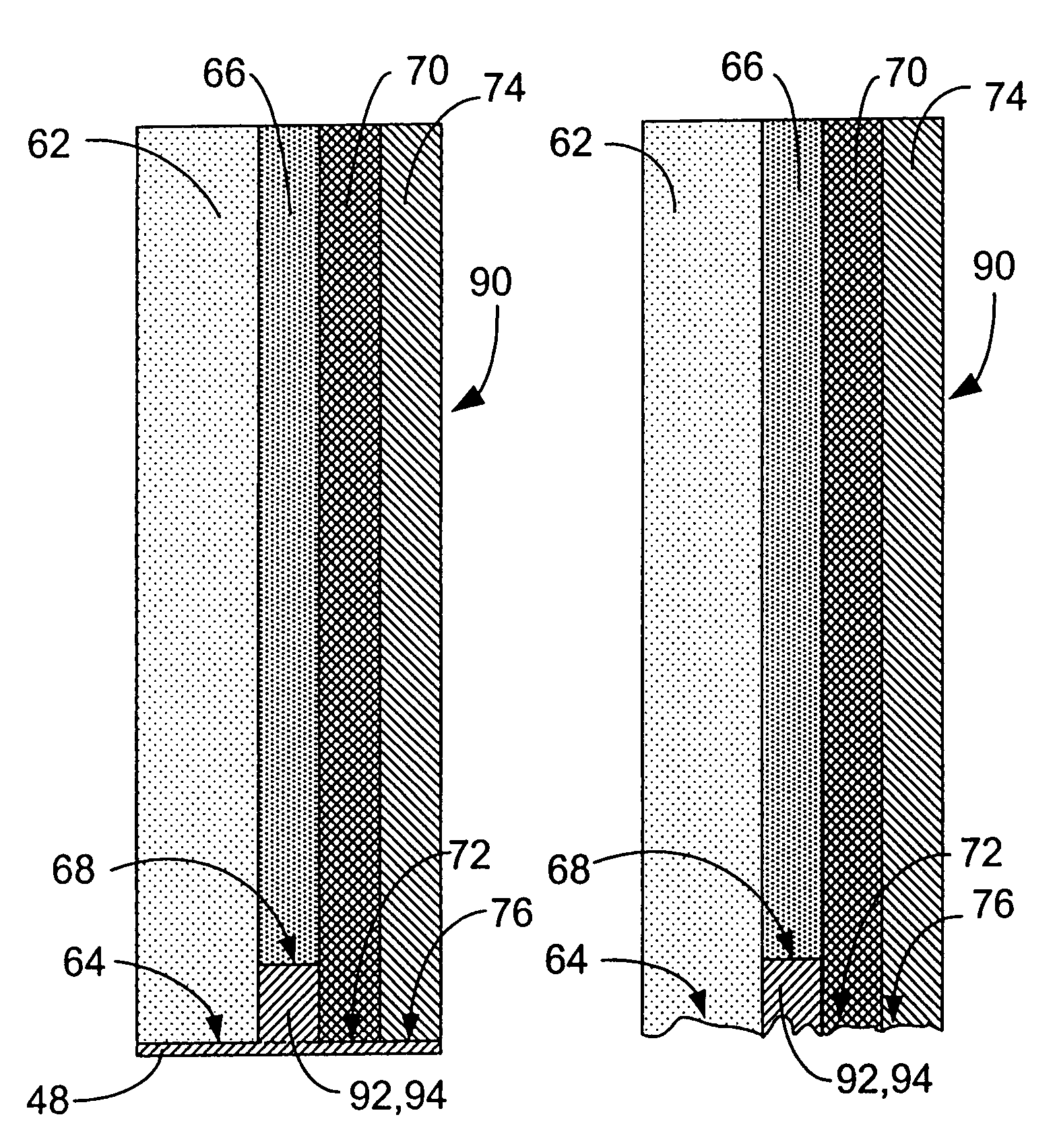

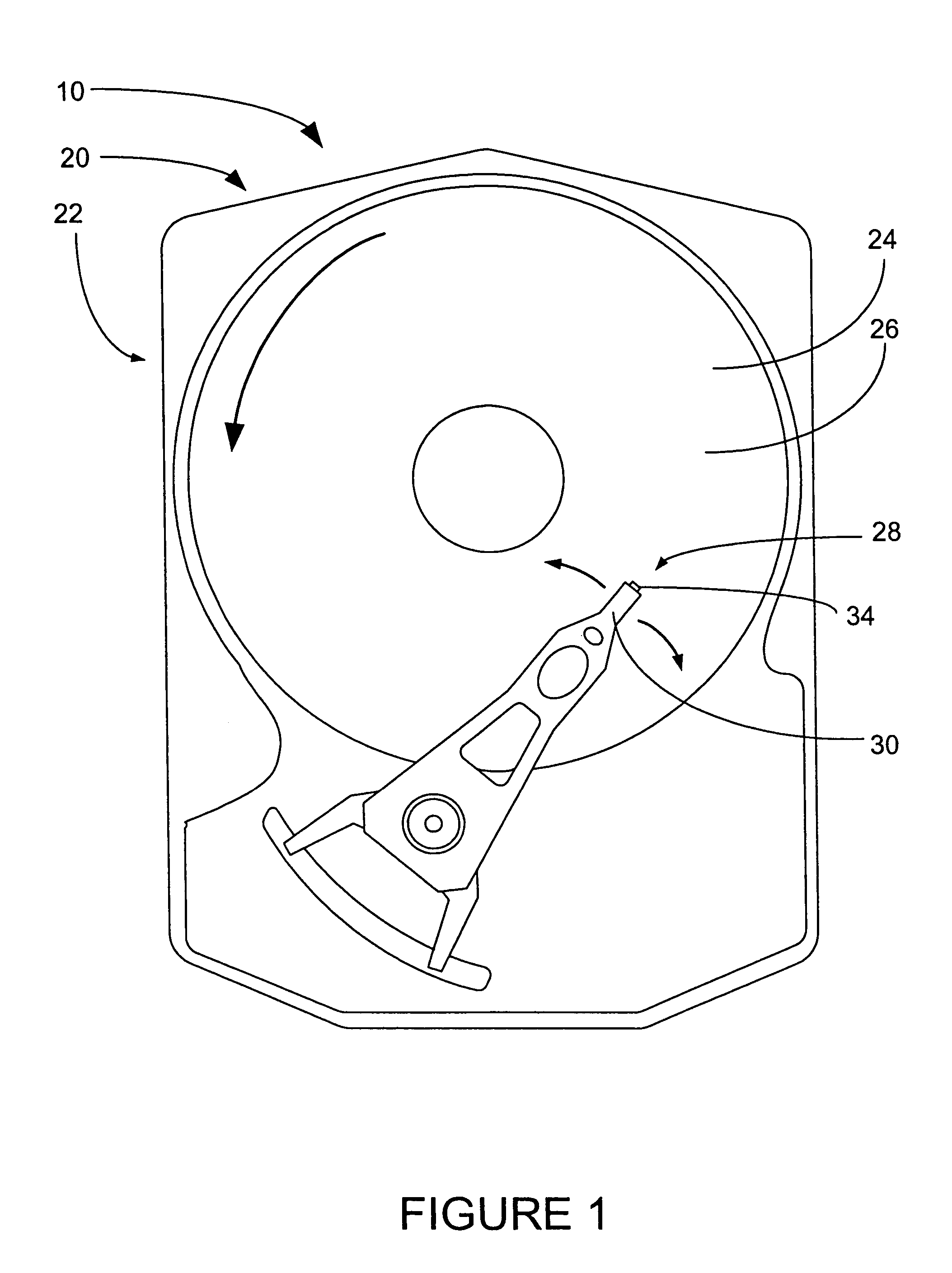

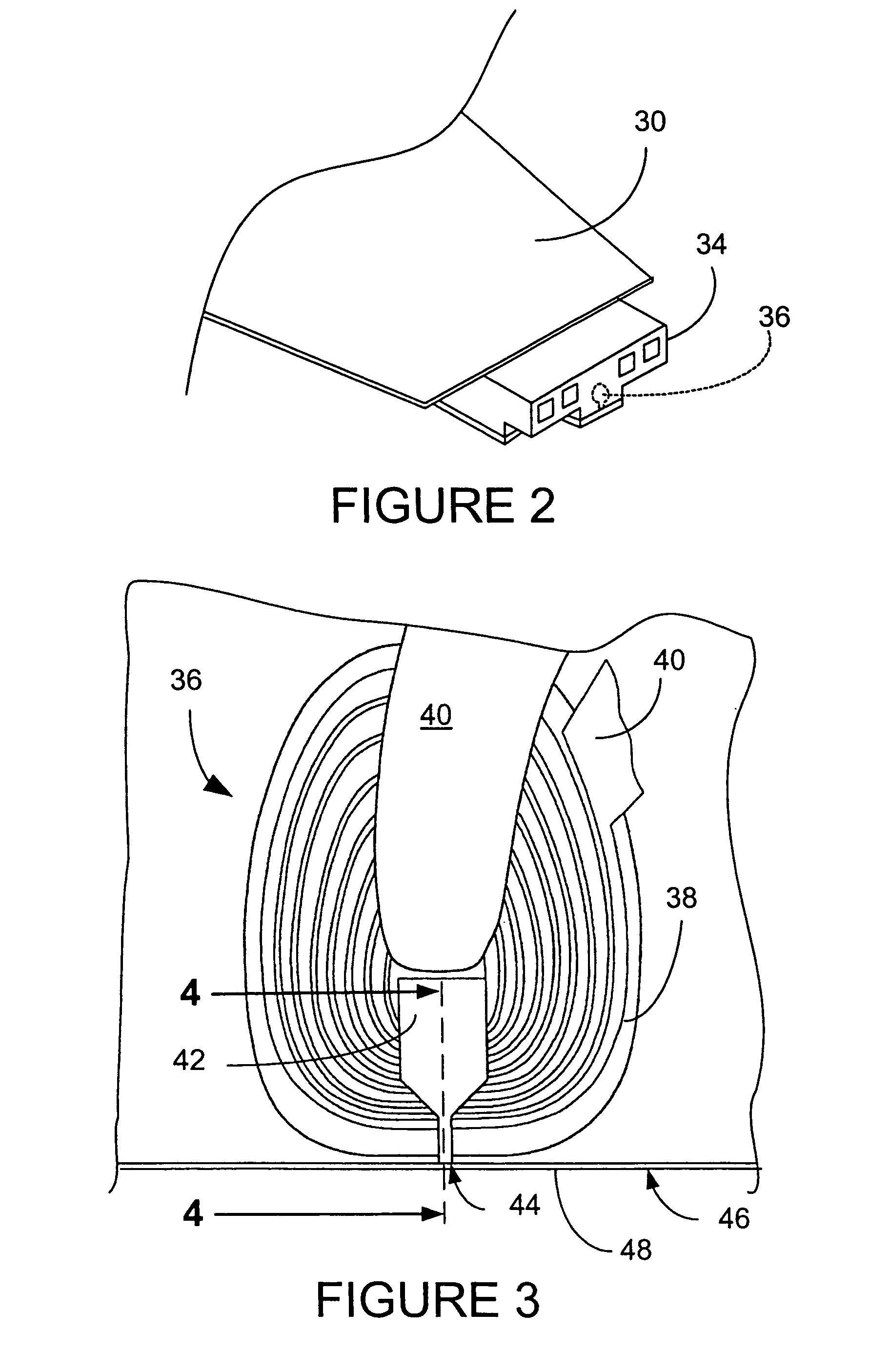

Process of making a non-corrosive GMR slider for proximity recording

InactiveUS7174622B2Fly height can be minimizedMinimise currentElectrical transducersNanomagnetismEngineeringNon magnetic

A method of fabrication of a slider includes forming a first ferromagnetic layer, a second ferromagnetic layer, and an antiferromagnetic layer and applying a layer of protective material to proximal ends of those layers that are proximal to the disk surface. The method further includes recessing a proximal end of a non-magnetic metal layer formed on the first ferromagnetic layer from the disk surface to form at least one recessed area. The method also includes filling the recessed area with protective material to a depth such that when the layer of protective material is worn from the ends of the first ferromagnetic layer, the second ferromagnetic layer, and the antiferromagnetic layer by burnishing of the ends by the disk surface, protective material still remains in the recessed area of the non-magnetic metal layer.

Owner:WESTERN DIGITAL TECH INC

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

Electrically conductive element treated for use in a fuel cell

InactiveUS20050037212A1Final product manufacturePretreated surfacesElectrical resistance and conductanceProton exchange membrane fuel cell

The present invention provides an electrically conductive element for a proton exchange membrane fuel cell having low electrical contact resistance and high corrosion resistance. The conductive element comprises a corrosion susceptible metal substrate with a surface, which is preferably treated to activate the surface (i.e., to remove a passivation layer of oxides from the surface) with an acidic treatment solution. The treated surface is then overlaid with an electrically conductive, corrosion-resistant, protective coating to protect the substrate re-forming a passivation layer while exposed to the corrosive environment of the fuel cell. The present invention also provides methods of preparing an electrically conductive element to have low electrical contact resistance and high corrosion resistance.

Owner:GM GLOBAL TECH OPERATIONS LLC

Solution composition and method for electroless deposition of coatings free of alkali metals

InactiveUS6911067B2Low costImprove anti-corrosion performanceAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless depositionMaterials science

An electroless deposition solution of the invention for forming an alkali-metal-free coating on a substrate comprises a first-metal ion source for producing first-metal ions, a pH adjuster in the form of a hydroxide for adjusting the pH of the solution, a reducing agent, which reduces the first-metal ions into the first metal on the substrate, a complexing agent for keeping the first-metal ions in the solution, and a source of ions of a second element for generation of second-metal ions that improve the corrosion resistance of the aforementioned coating. The method of the invention consists of the following steps: preparing hydroxides of a metal such as Ni and Co by means of a complexing reaction, in which solutions of hydroxides of Ni and Co are obtained by displacing hydroxyl ions OH− beyond the external boundary of ligands of mono- or polydental complexants; preparing a complex composition based on a tungsten oxide WO3 or a phosphorous tungstic acid, such as H3[P(W3O10)4], as well as on the use of tungsten compounds for improving anti-corrosive properties of the deposited films; mixing the aforementioned solutions of salts of Co, Ni, or W and maintaining under a temperatures within the range of 20° C. to 100° C.; and carrying out deposition from the obtained mixed solution.

Owner:LAM RES CORP

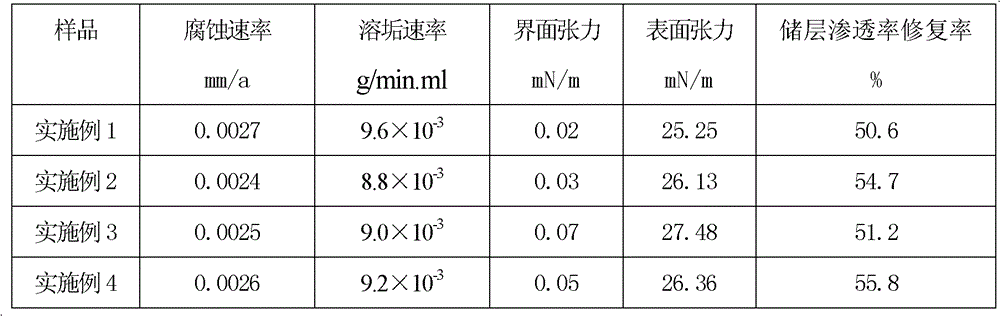

Blocking remover of gas well shaft

The invention relates to a blocking remover of a gas well shaft. The blocking remover comprises, by weight, 5-25% of an alcohol ether compound, 0.5-10% of a dispersant, 1-10% of a cleaning agent, and 0.5-5% of chelating agent, with the balance being a nitrogen-containing polar solvent, wherein the nitrogen-containing polar solvent is one selected from N,N dimethyl formamide, N,N dimethyl acetamide, and N-methyl pyrrolidone, the alcohol ether compound is one selected from glycol-ether, glycol-propyl ether, glycol-butyl ether, and diglycol-ether, the disperant whose micelle particle size is from 20nm to 100nm is a middle-phase microemulsion-type dispersant mixed by kerosene, water, a surfactant and a cosurfactant, the cleaning agent is one selected from allene diamine, acetonitrile and pentylamine, and the chelating agent is one selected from sodium citrate and EDTA. The blocking remover has the advantages that corrosivity is weak, that the speed of dissolving blockage is fast, that the product performance is stable in high temperatures, and that the blocking remover can reduce damages caused by water locking and fouling in areas close to gas wells, and can recover the permeability of storing layers.

Owner:PETROCHINA CO LTD

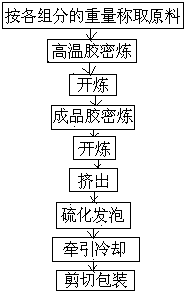

Environment-friendly rubber plastic heat-insulating material and its preparation method

The invention relates to an environment-friendly rubber plastic heat-insulating material and its preparation method, and the rubber plastic heat-insulating material is prepared from butyronitrile rubber (NBR), antimonous oxide (Sb2O3), zinc oxide, sulfur, dioctyl-phthalate (DOP), epoxidized soybean oil (ADDA), mercaptobenzothiazole (M), anti-aging agent (4020), antioxidant (AST-500), protective wax (HGB-3), ethylene-vinyl acetate copolymer (EVA), dicumyl peroxide (DCP crosslinking agent), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, foaming agent-dinitrosopentamethylene tetraamine (H), diphenylguanidine (D), pigment, anti-aging agent (RD), anti scorching agent (PVI), and the like. By limited use of raw materials containing chlorine ion components and cooperation of a new vulcanization foaming technology, environment-friendly and heat-insulating performances of the product can be stabilized, the prepared environment-friendly rubber plastic heat-insulating material has no corrosion performance in use, the material life is prolonged, metal pipes in refrigeration equipment can be effectively protected, and maximized performance of the product can be performed.

Owner:周良文

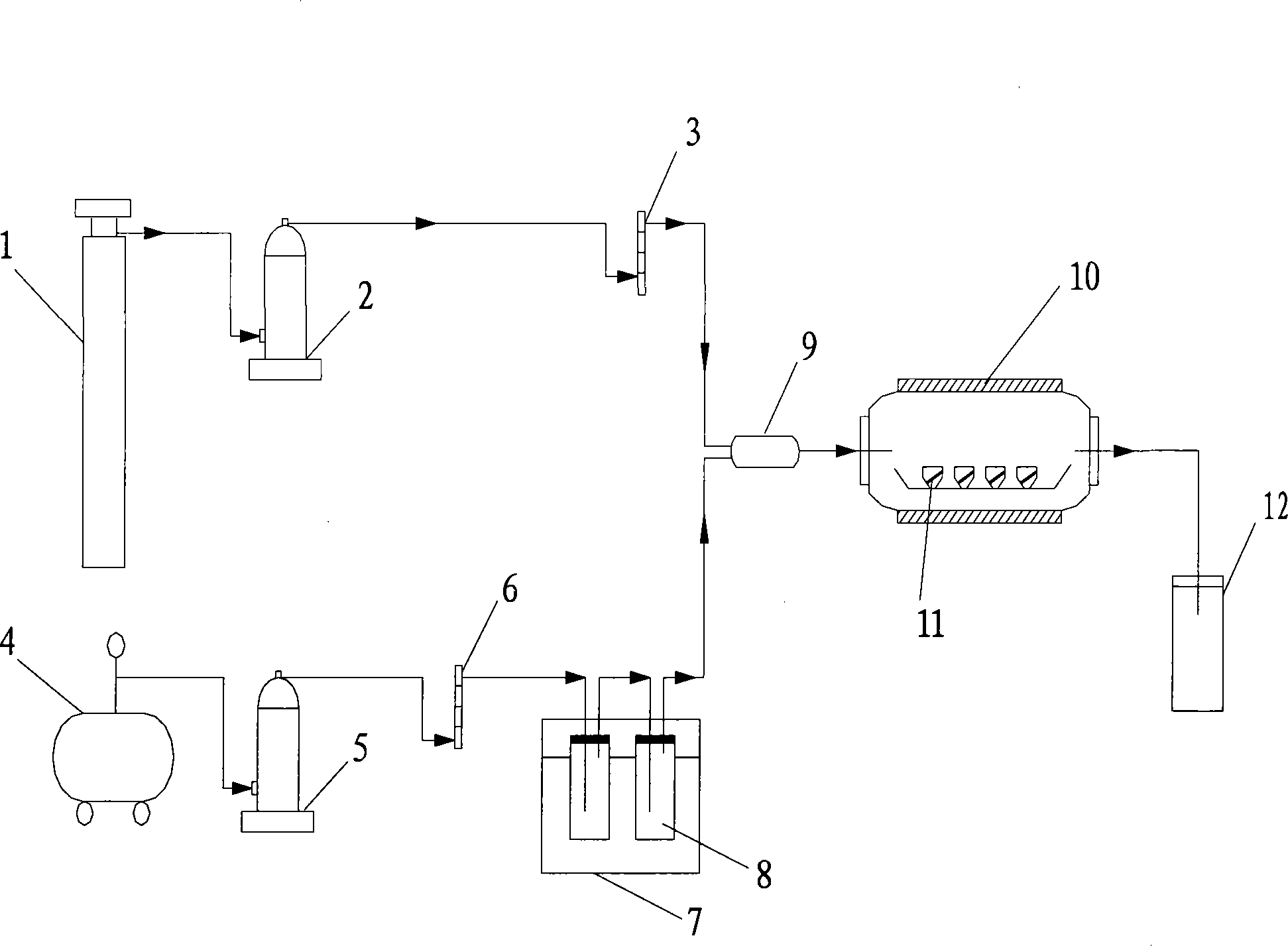

Apparatus and method for testing resistance dew-point corrosion of evaluating material

The present invention relates to a testing device and a testing method for evaluating the sulfuric acid dew point corrosion resistance quality of materials. The device adopts a structure that: an SO2 gas cylinder is connected with a drying tower and then is connected to a gas mixer through a flow meter; an air compressor passes through the drying tower, is connected with a bubbling bottle arranged in a constant temperature flume through the flow meter, and then is connected to the gas mixer; the mixer is serially connected with a heating furnace and a tail gas absorbing device; a ceramic crucible containing corrosion medium and a sample is placed inside the heating furnace 10. The device carries out evaluation through the weight change of the measured sample before and after an experiment, and the technical parameters during test are as follows: the air flow rate is 1000-2000 ml / min; the SO2 gas flow rate is 10-50 ml / min; the temperature of constant temperature water bath is controlled between 60 DEG C and 95 DEG C; the temperature of the heating furnace is controlled between 60 DEG C and 200 DEG C; the corrosion medium is concentrated sulfuric acid with the mass concentration of 80-90 percent; the experimental time is 24 hours.

Owner:EAST CHINA UNIV OF SCI & TECH

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

Sensor cable

InactiveUS6777947B2Leakage is detectedDetection of fluid at leakage pointMeasurement of fluid loss/gain rateElectricitySurface layer

A cable suitable for detecting the presence of corrosive liquids is disclosed. In an embodiment the cable includes two sensing wires wrapped around a core member, at least one of the sensing wires being surrounded by a non-conductive surface layer. In an alternate embodiment the cable includes two sensing wires wrapped around a core member, the sensing wires and core member being encapsulated by a non-conductive surface layer. Preferably, the cable includes insulating wires for detecting the location of a leak. When a corrosive liquid contacts the sensing wires of the cable an electrical connection is created between them.

Owner:NVENT SERVICES GMBH

Composition and method for surface treatment of oxidized metal

InactiveUS20050037935A1Surface-active detergent compositionsDetergent mixture composition preparationElectrical resistance and conductanceProton exchange membrane fuel cell

The present invention provides an electrically conductive element for a proton exchange membrane fuel cell having low electrical contact resistance and high corrosion resistance. The conductive element comprises a corrosion susceptible metal substrate with a surface, which is preferably treated to activate the surface (i.e. to remove a passivation layer of oxides from the surface) with an acidic treatment solution. The treated surface is then overlaid with an electrically conductive, corrosion-resistant, protective coating to protect the substrate re-forming a passivation layer while exposed to the corrosive environment of the fuel cell. The present invention also provides methods of preparing an electrically conductive element to have low electrical contact resistance and high corrosion resistance.

Owner:GENERAL MOTORS COMPANY

High-strength ceramsite proppant and preparation method thereof

The invention provides a high-strength ceramsite proppant and a process for preparation, wherein the agent comprises (by weight percentage) Al2O3 74-80%, SiO2 5.5-10.5%, TiO2 2.5-3.5%, Fe2O3 4-9%, other adjuvant 0-3%, the agent also contains SiO2, TiO2, Fe2O3, MnO2, K2O, Na2O, CaO, MgO. The preparation consists of mixing the components into mixed powder, rolling into balls through aerial fog, and finally obtaining the end product through high-sintering.

Owner:渑池县方圆陶粒砂厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com